Differential cloth feeding sewing machine

A sewing machine and cloth feeding mechanism technology, applied in the direction of cloth feeding mechanism, sewing machine components, sewing machine casings, etc., can solve problems such as reducing the quality of sewn products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

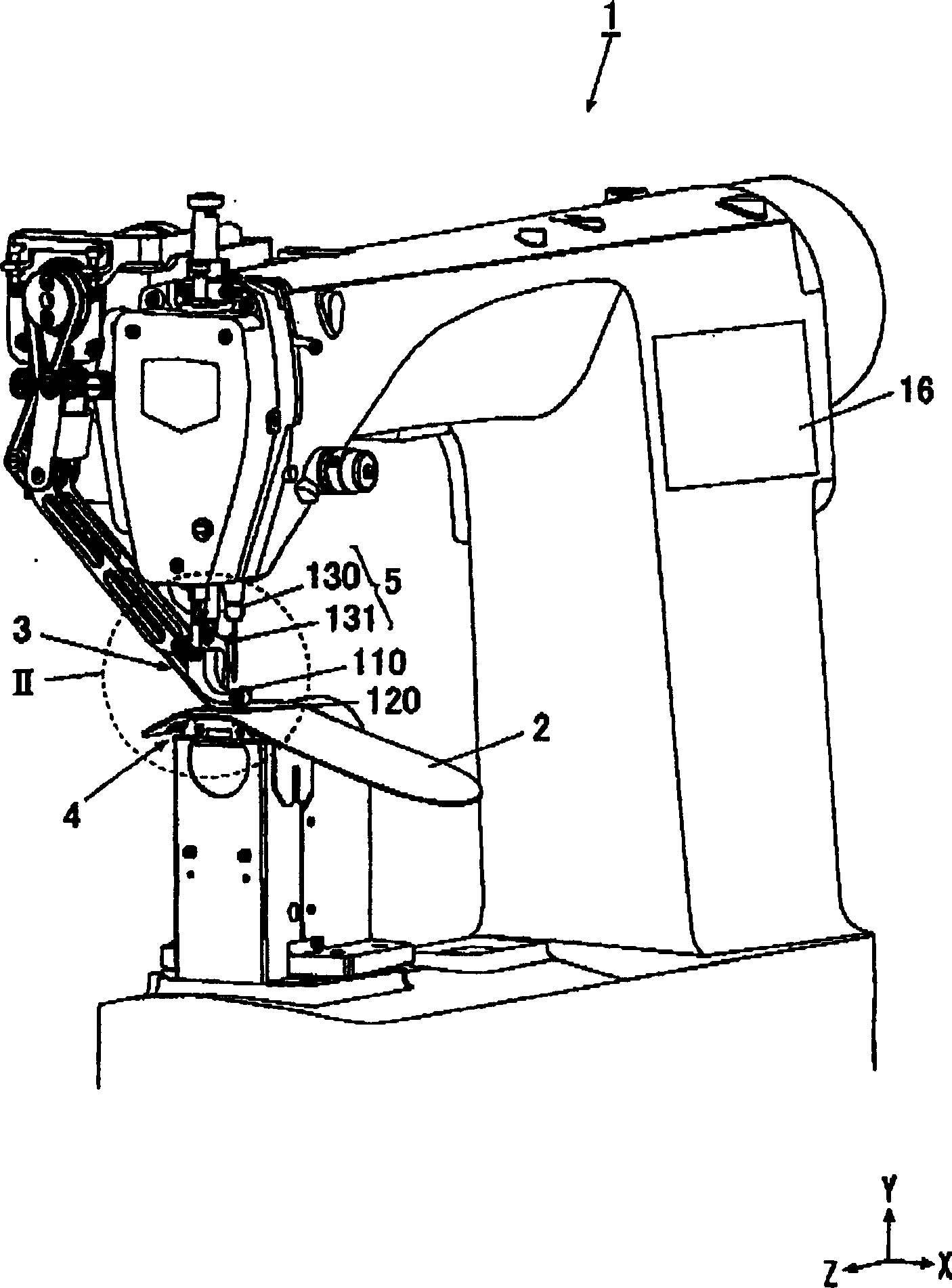

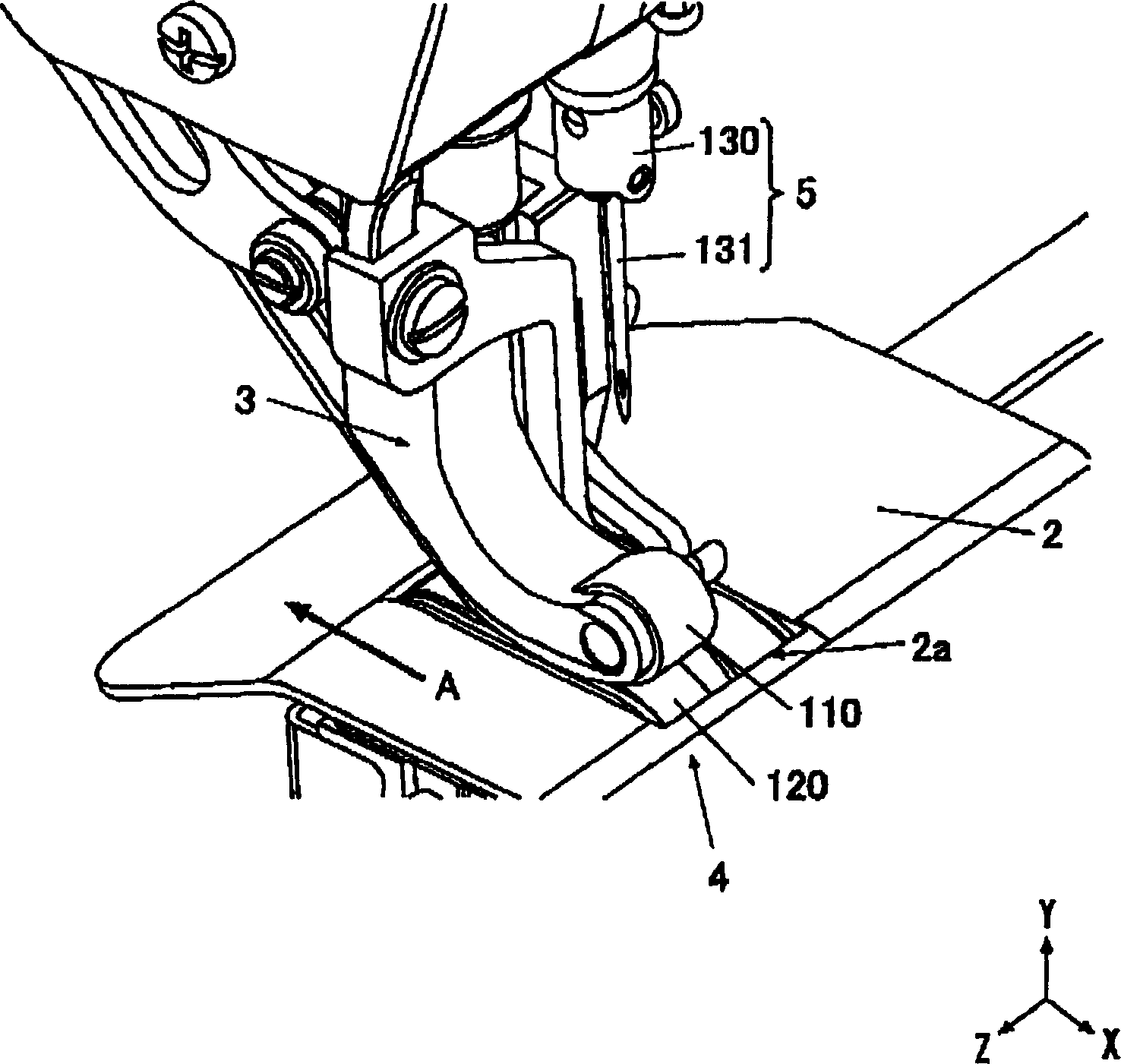

[0048] The differential feed sewing machine 1 of this embodiment is a sewing machine that sews while shirring by setting a difference in feed amount of the upper cloth and the lower cloth to be sewn. Sewing of the cloth for the sleeves of the cloth to the front and back of the body as the lower cloth, etc.

[0049] At this time, the direction in which the sewing machine needle 131 described later moves up and down is defined as the Y-axis direction (up-and-down direction), and a direction perpendicular thereto is defined as the X-axis direction (front-rear direction). The direction in which both directions are perpendicular is defined as the Z-axis direction (left-right direction).

[0050] The differential feed sewing machine 1, such as figure 1 , figure 2 As shown, it has: a needle plate 2 that carries the upper and lower fabrics for sewing, an upper cloth feeding mechanism part 3 that feeds the upper cloth on the needle plate 2 at a predetermined cloth feeding amount, an...

Embodiment 2

[0118] Next, Embodiment 2 of the differential feed sewing machine of the present invention will be described. In addition, the same code|symbol is attached|subjected to the same part as Example 1, and only a different part is demonstrated.

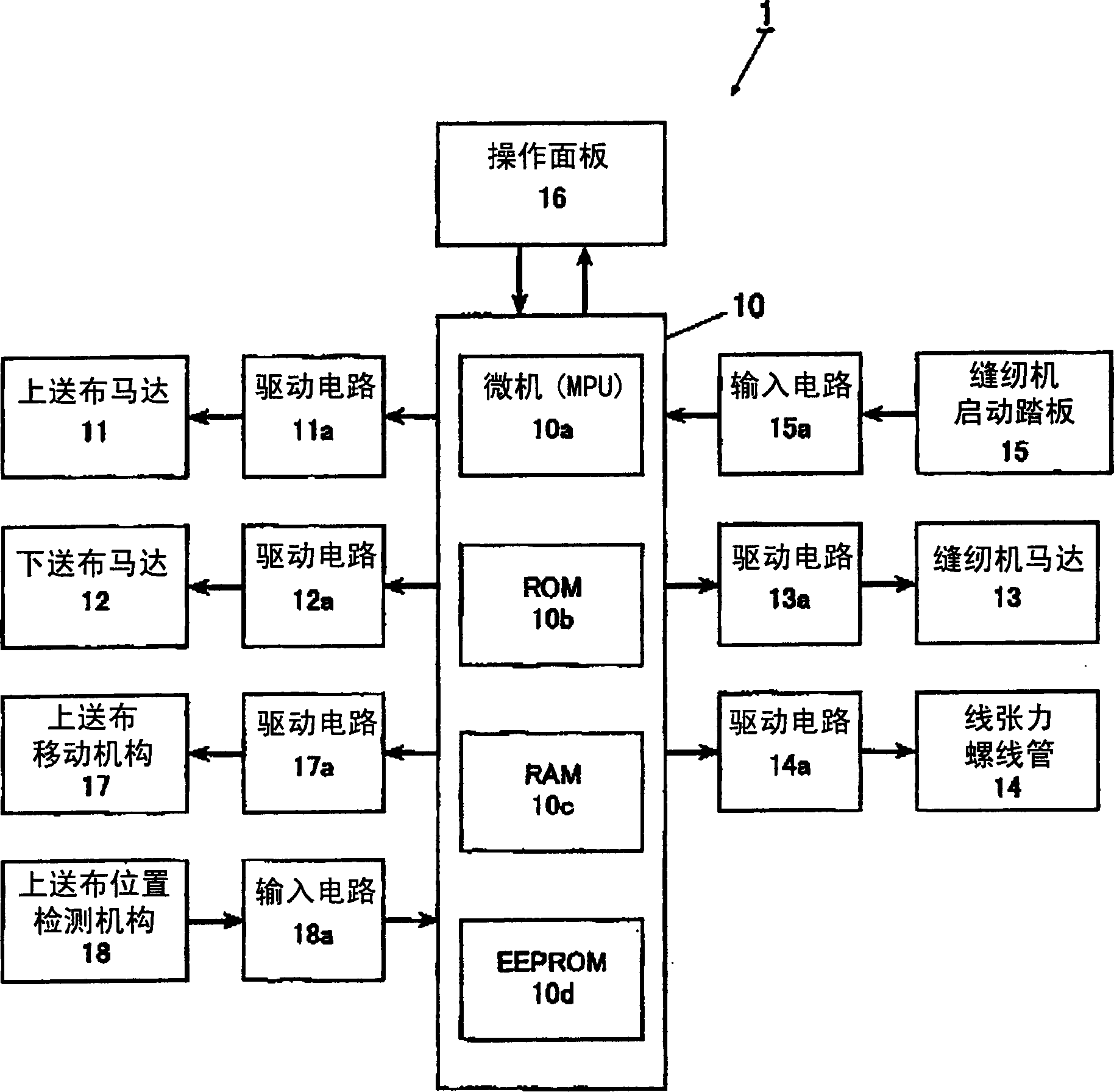

[0119] The operation panel 16 of the differential feed sewing machine 1 may include a differential amount setting key (not shown) as a set value setting key functioning as a part of the set value setting mechanism.

[0120] And, on the operation panel 16, the cloth feeding amount per stitch of feeding the upper cloth (that is, the upper cloth feeding mechanism Part 3 conveys the upper cloth amount for one stitch of upper cloth), and the differential amount data of the portion that exceeds the lower cloth amount as the difference is input. The input differential amount data is output to the control unit 10 and stored in the EEPROM 10d.

[0121] The control unit 10 functions as a part of the bottom feed amount setting mechanism, and can co...

Embodiment 3

[0130] Next, Embodiment 3 of the differential feed sewing machine of the present invention will be described. In addition, the same code|symbol is attached|subjected to the same part as Example 1, and only a different part is demonstrated.

[0131] The operation panel 16 of the differential feed sewing machine 1 may include a proportional value setting key (not shown) as a set value setting key functioning as a part of the set value setting mechanism.

[0132] And, on the operation panel 16, through the proportional value setting key not shown in figure that functions as a part of the setting value setting mechanism, it is possible to perform the operation relative to the feeding amount setting mechanism (operation panel 16, control unit). 10) Input the proportional value data of the differential amount of the set bottom feeding amount. The input differential amount proportional value data is output to the control unit 10 and stored in the EEPROM 10d.

[0133] The control un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com