Patents

Literature

1612results about "Programme-controlled sewing machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

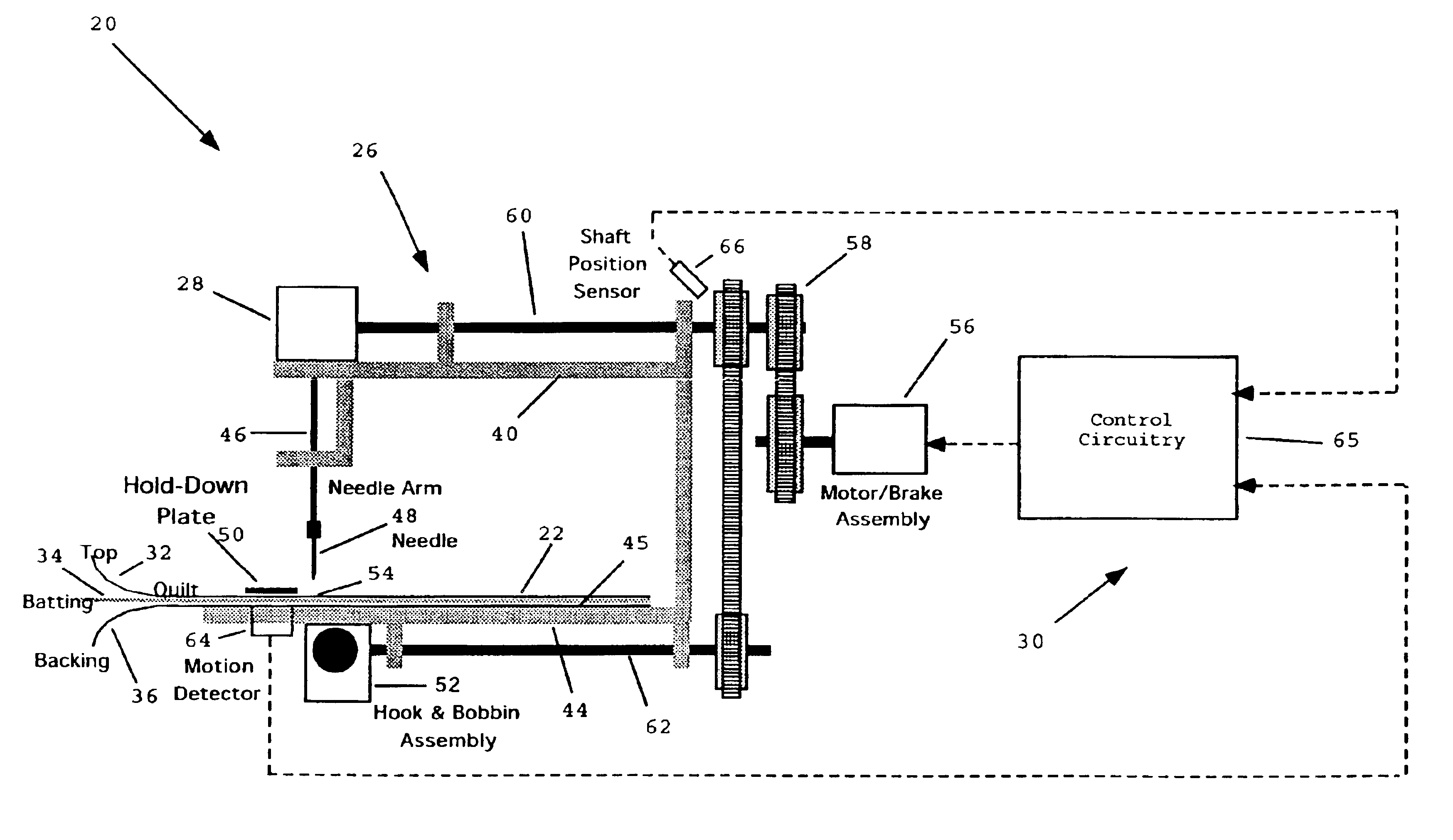

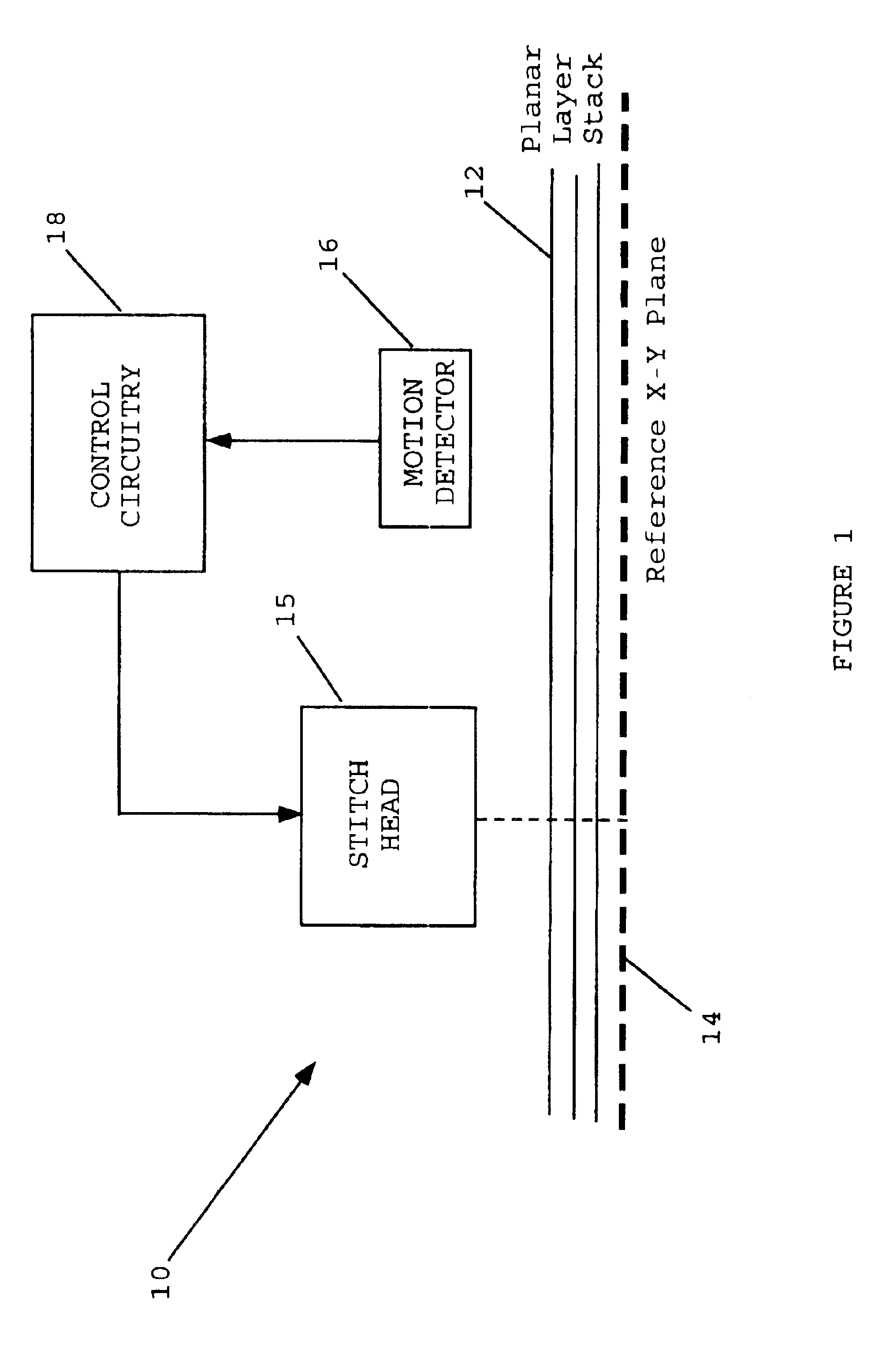

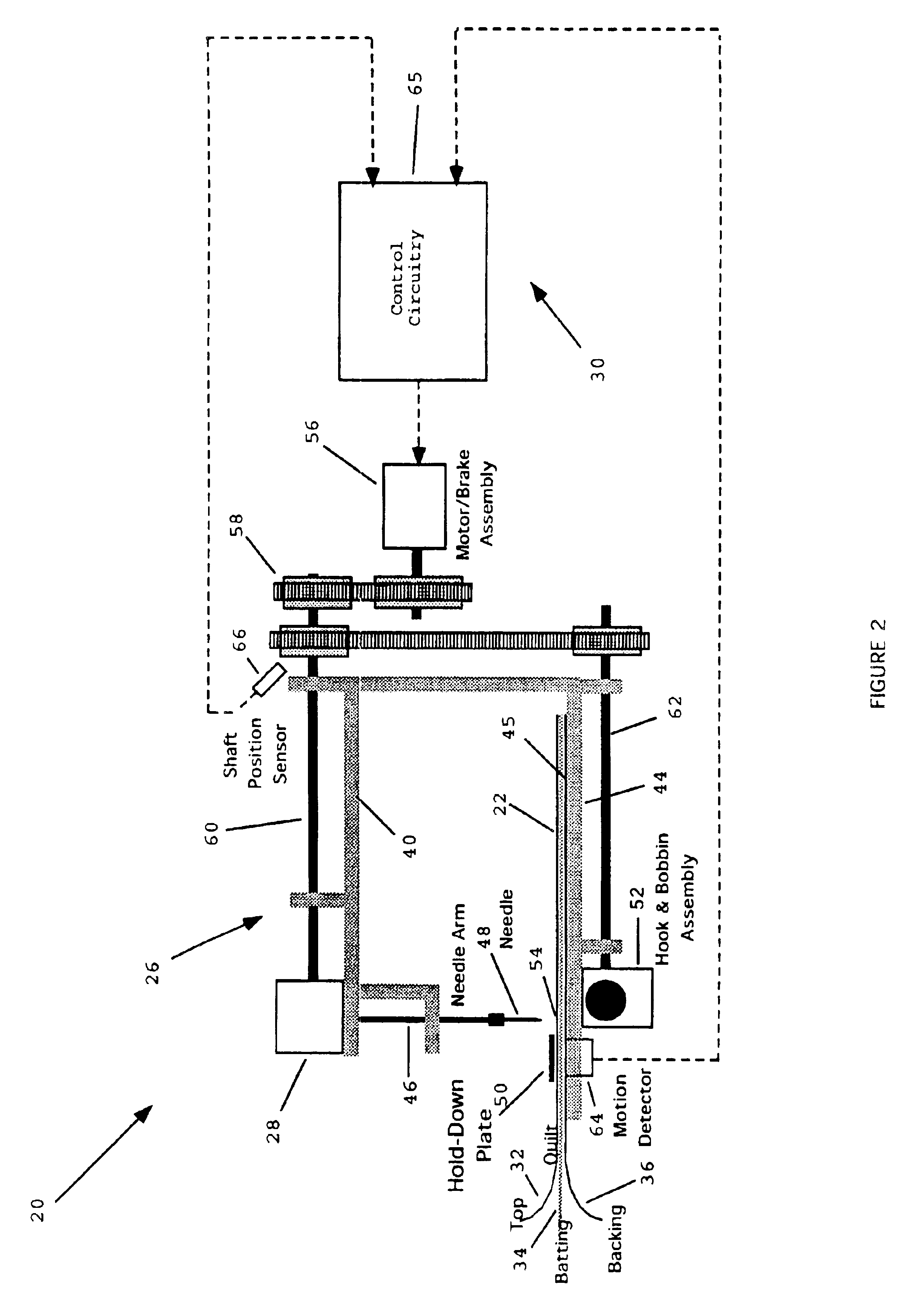

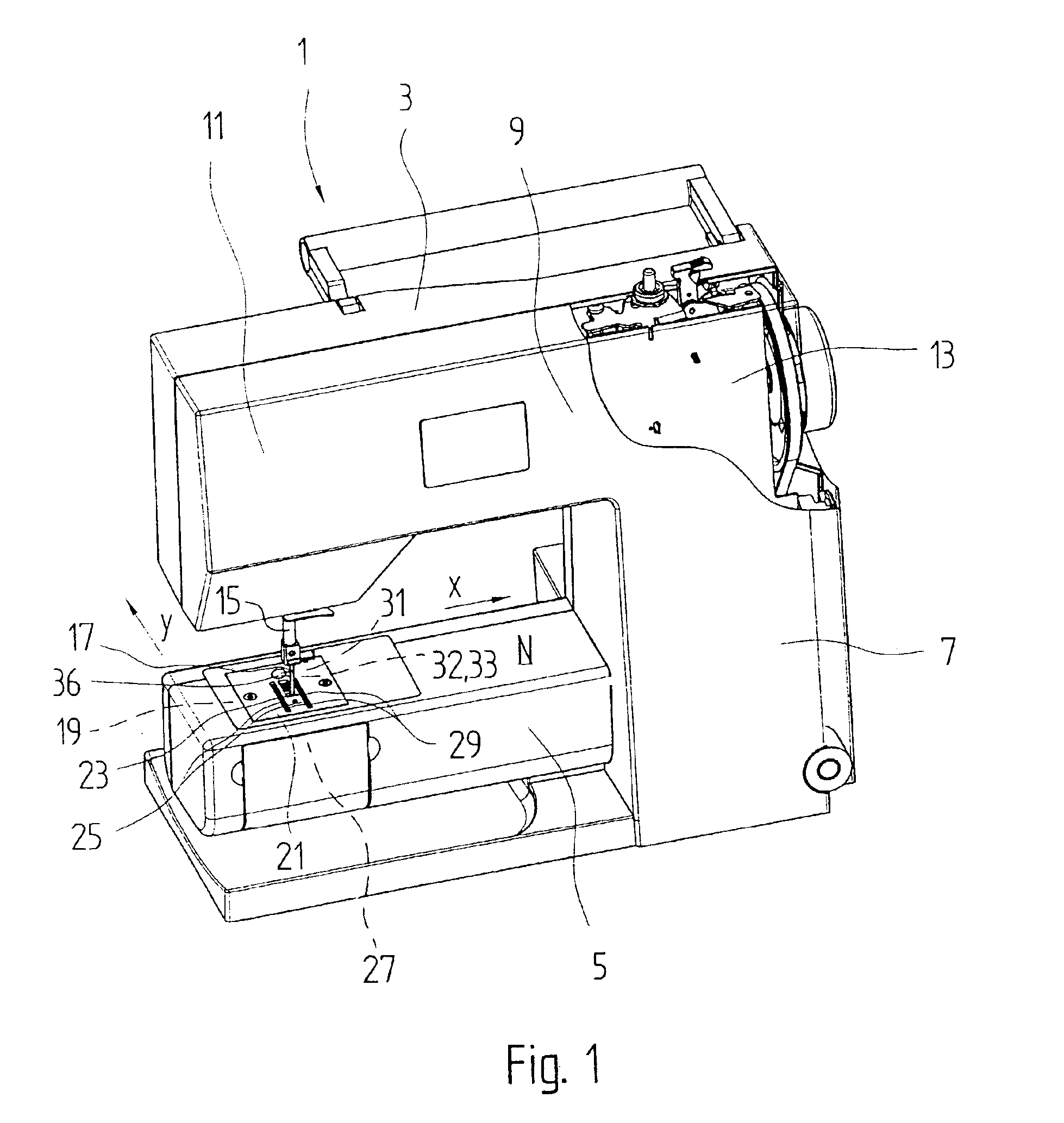

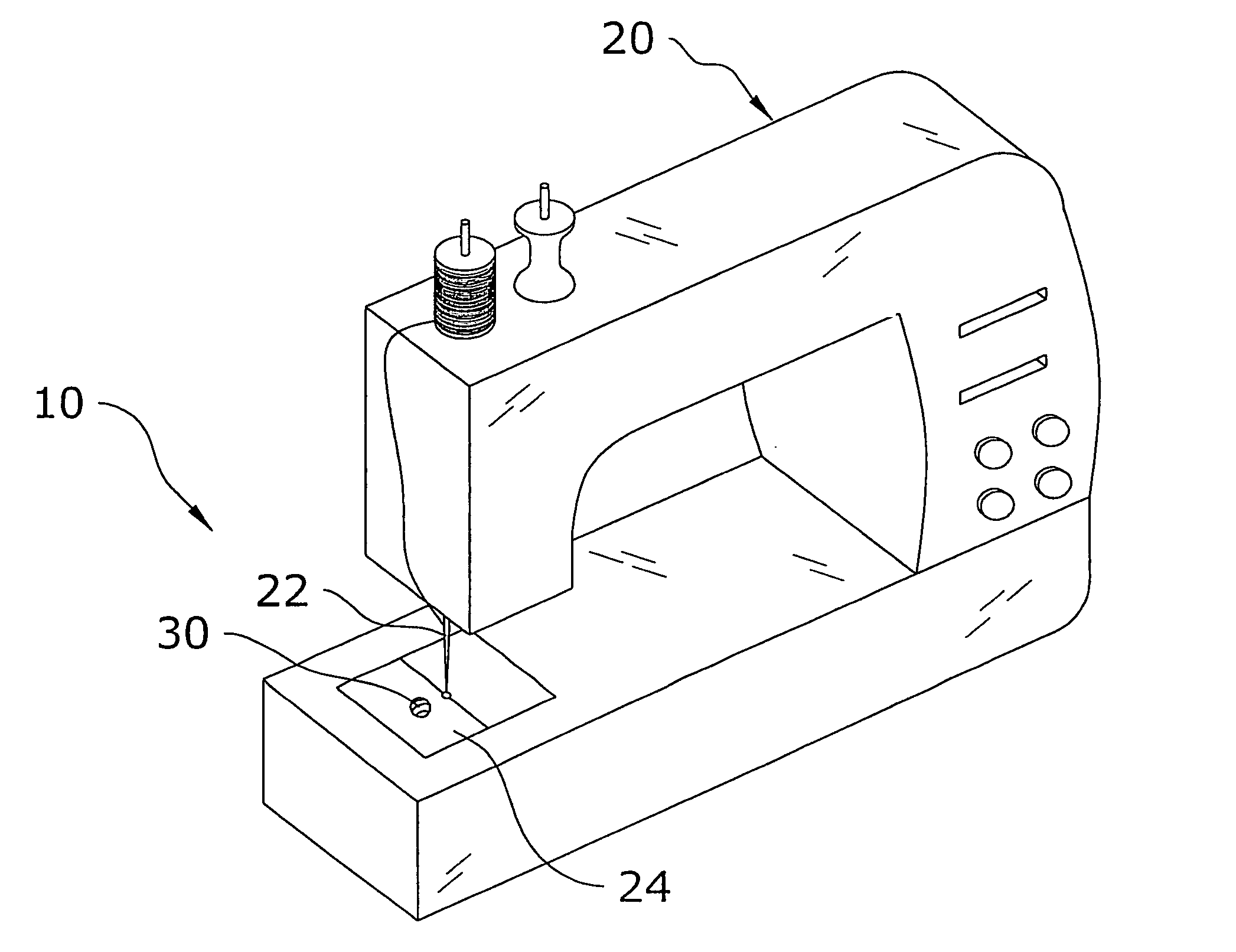

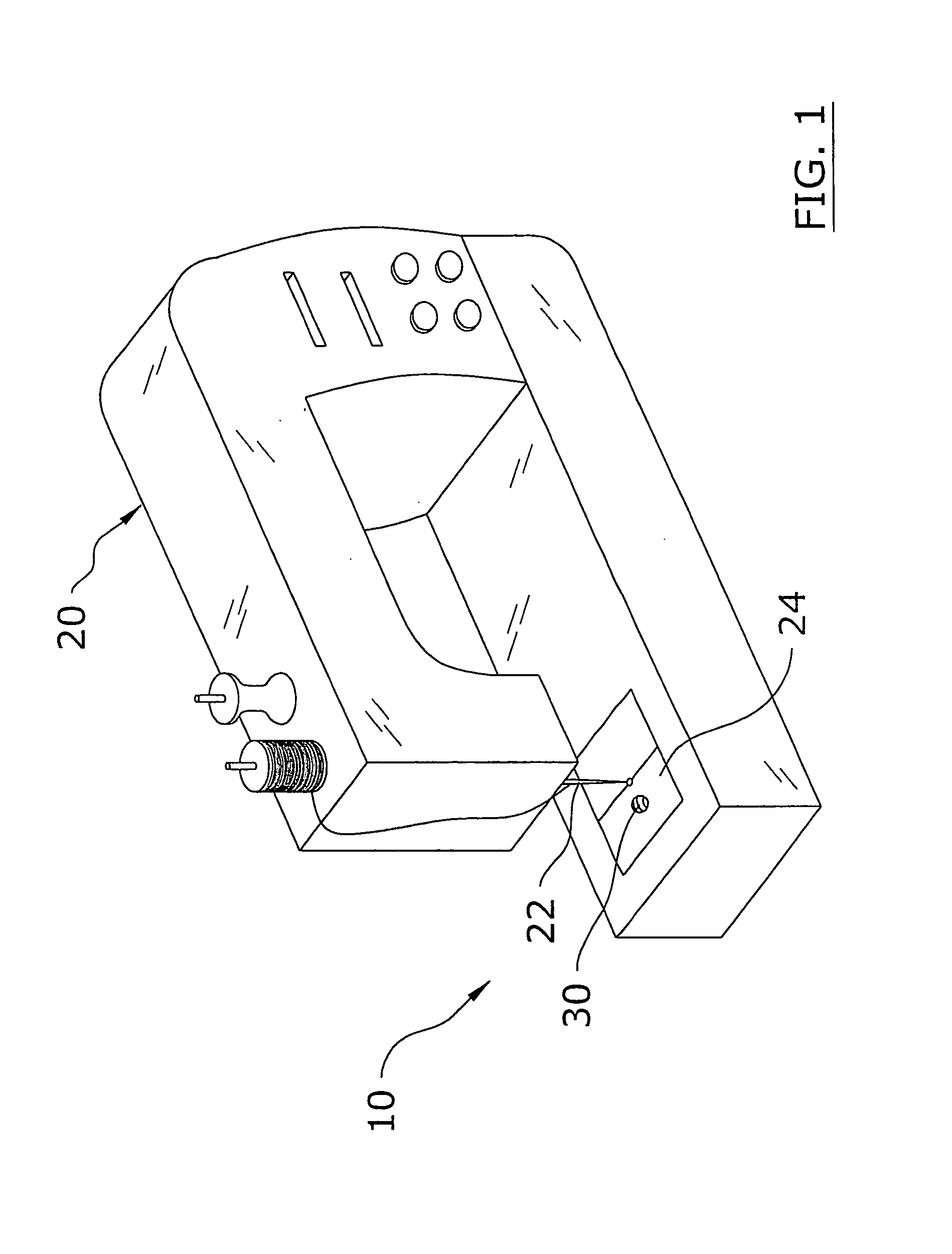

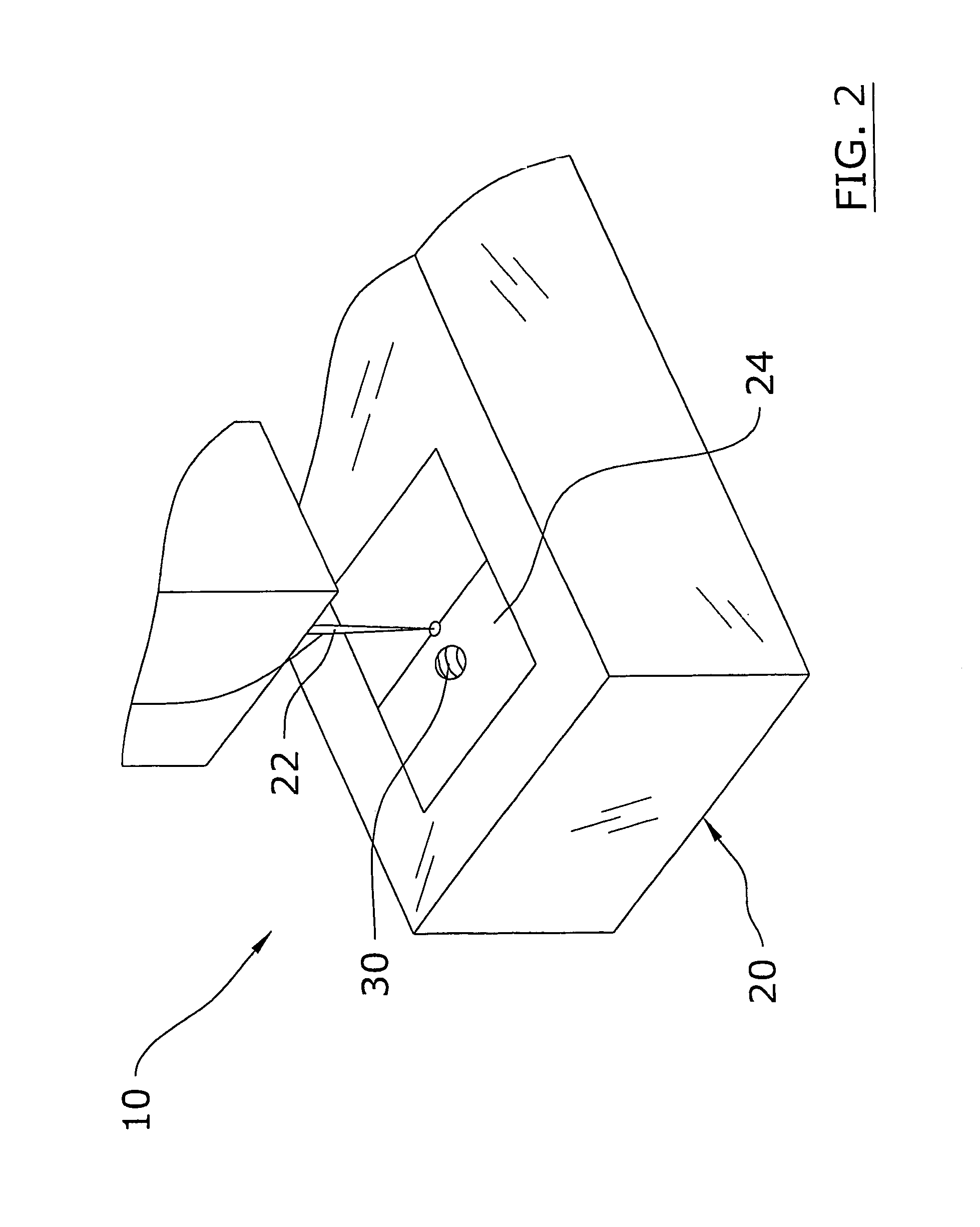

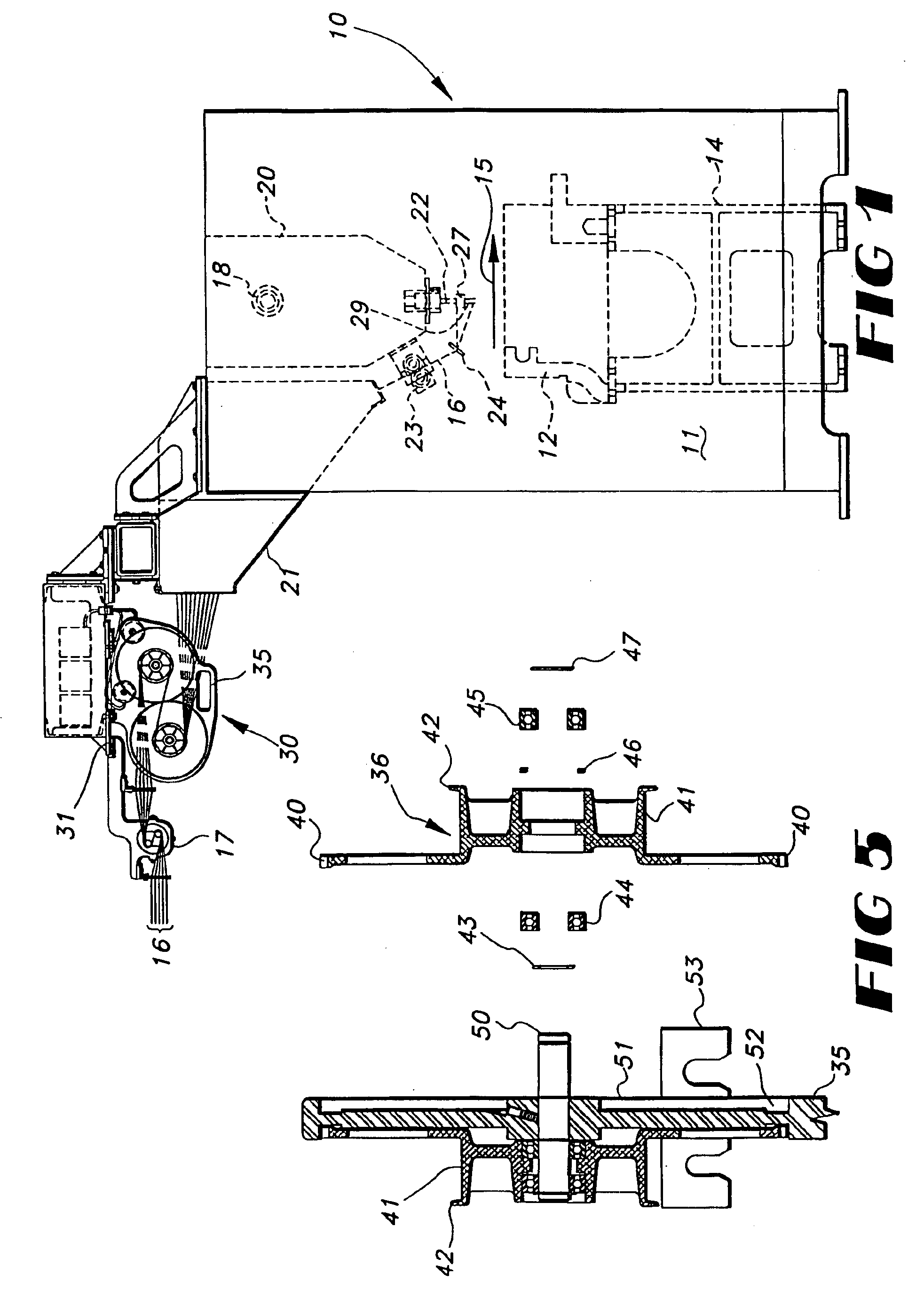

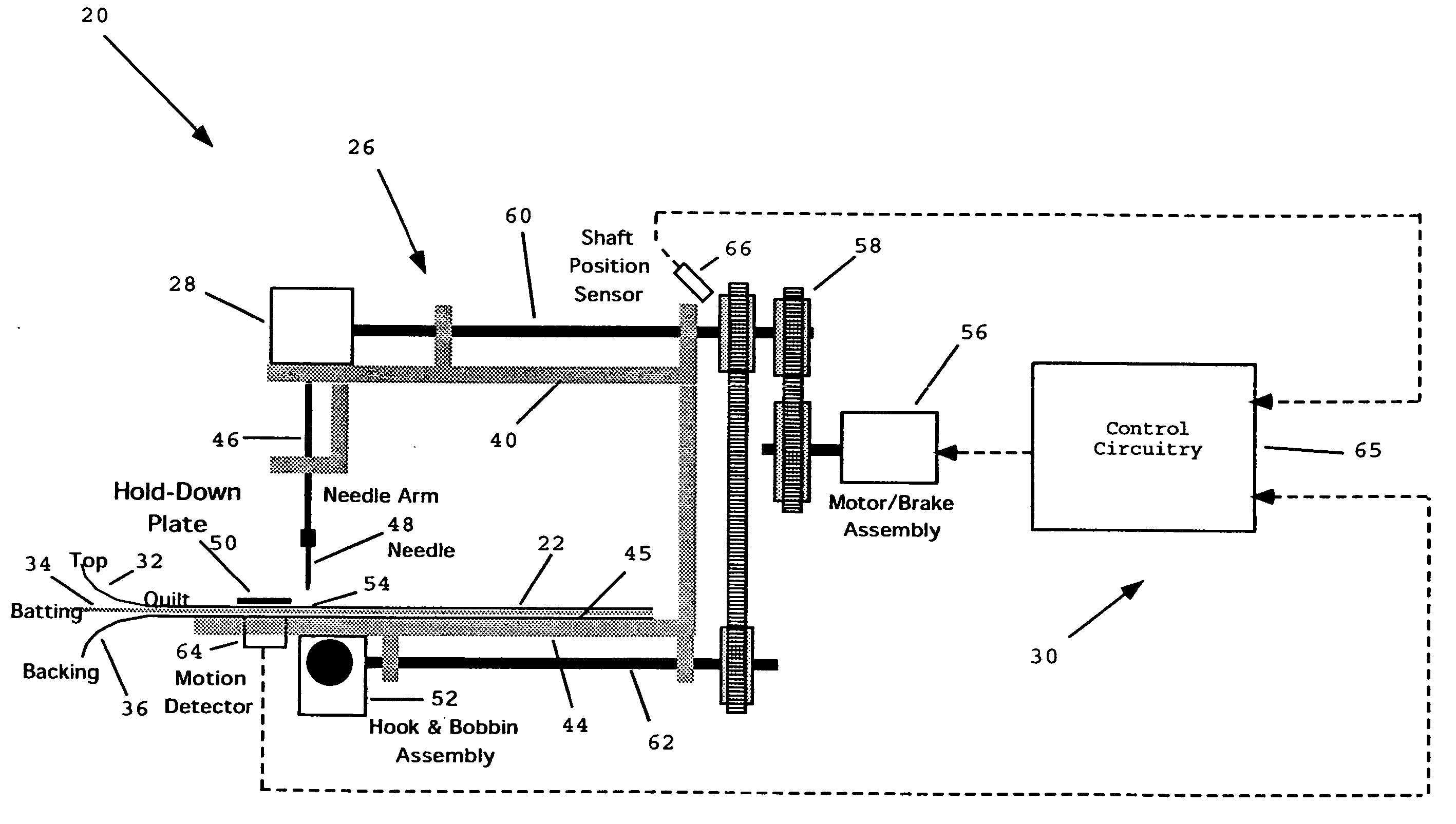

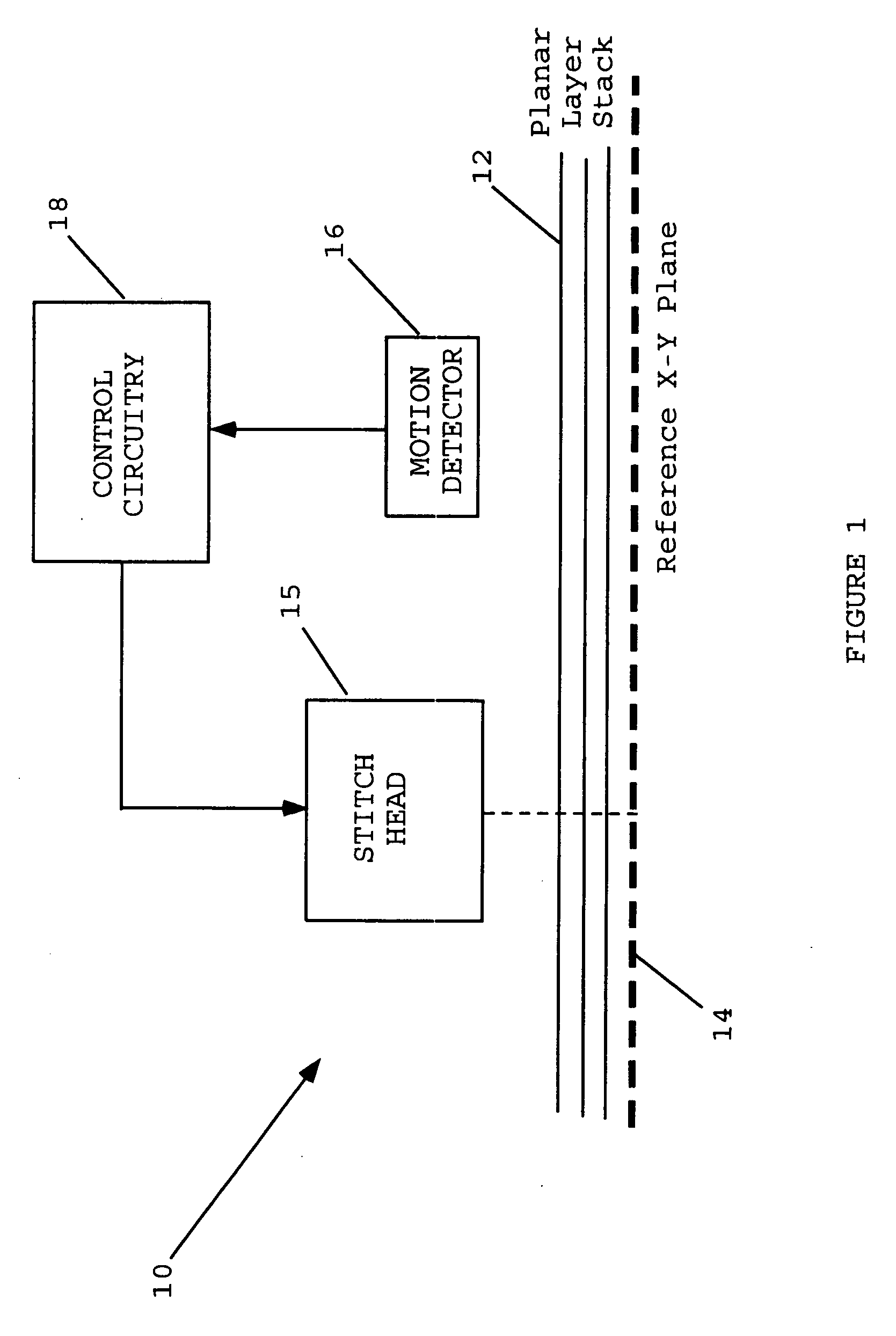

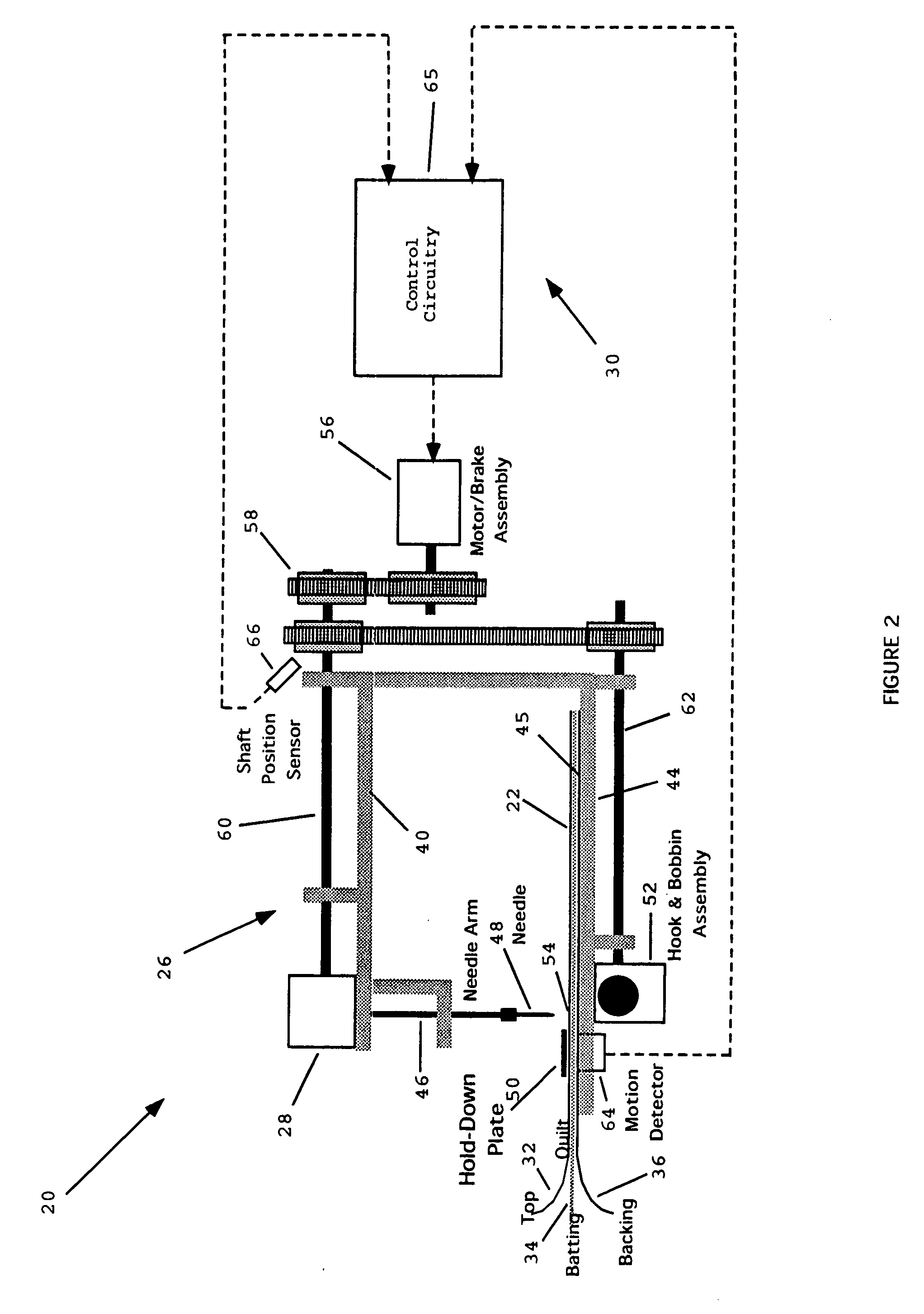

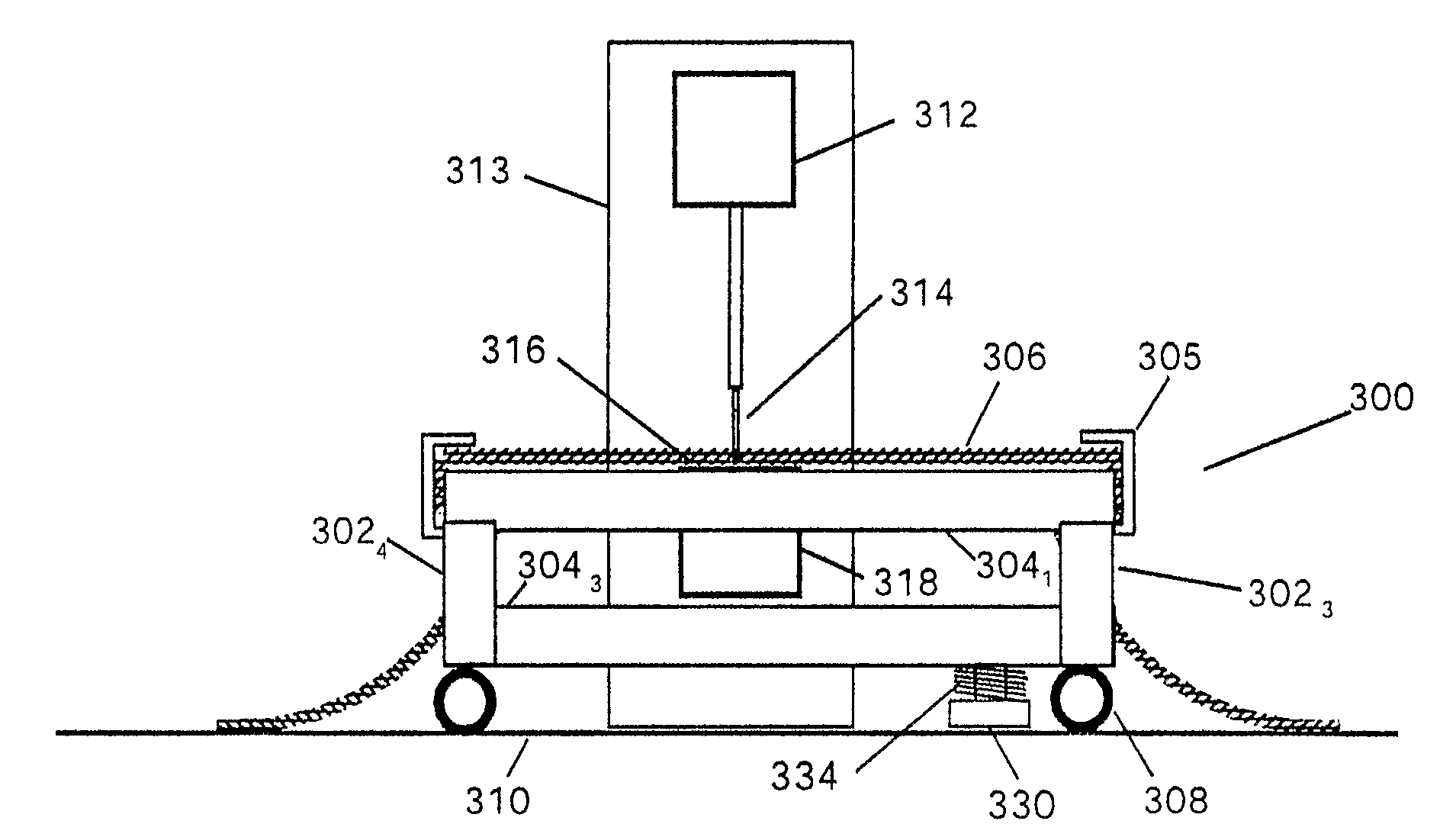

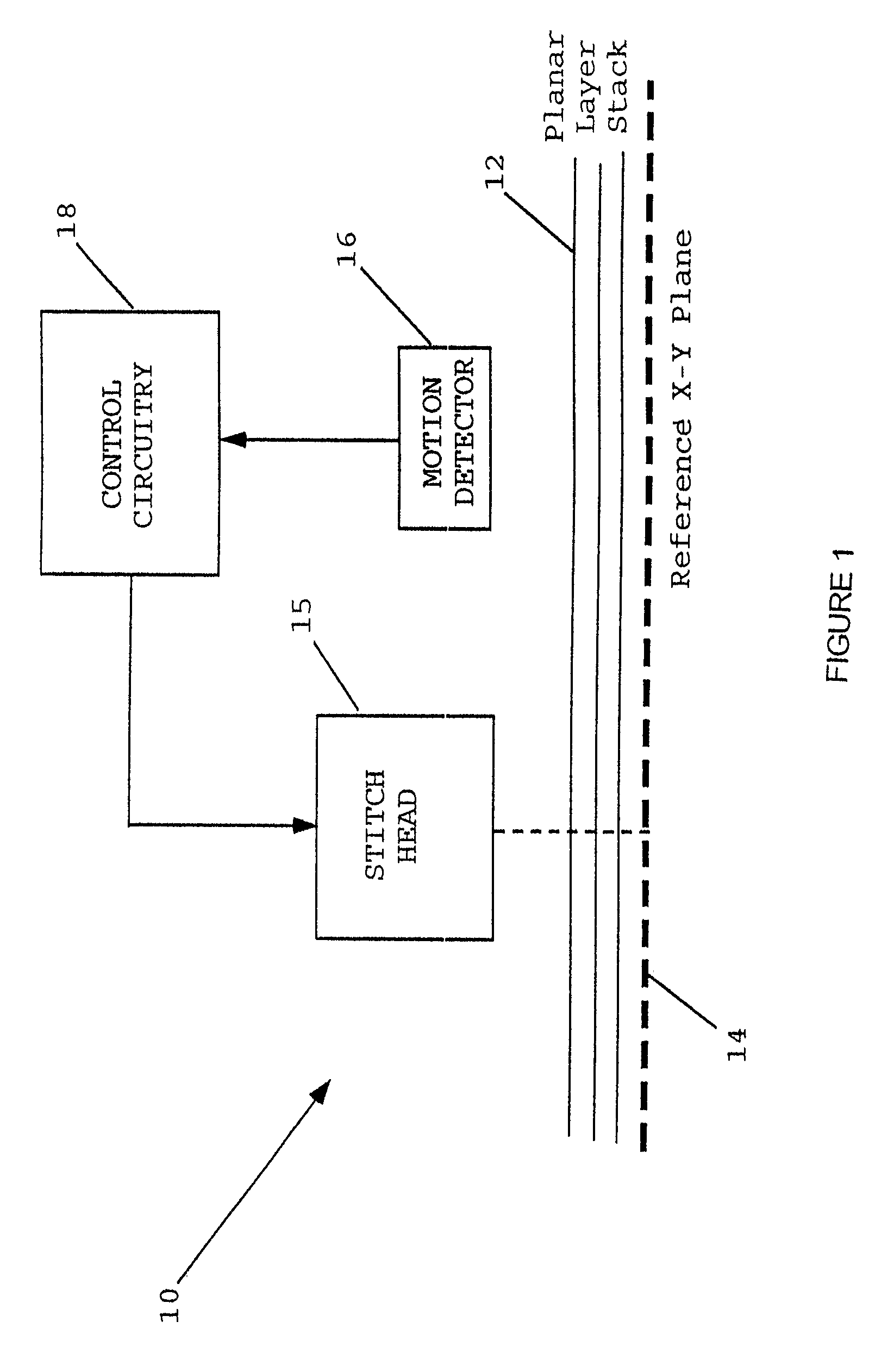

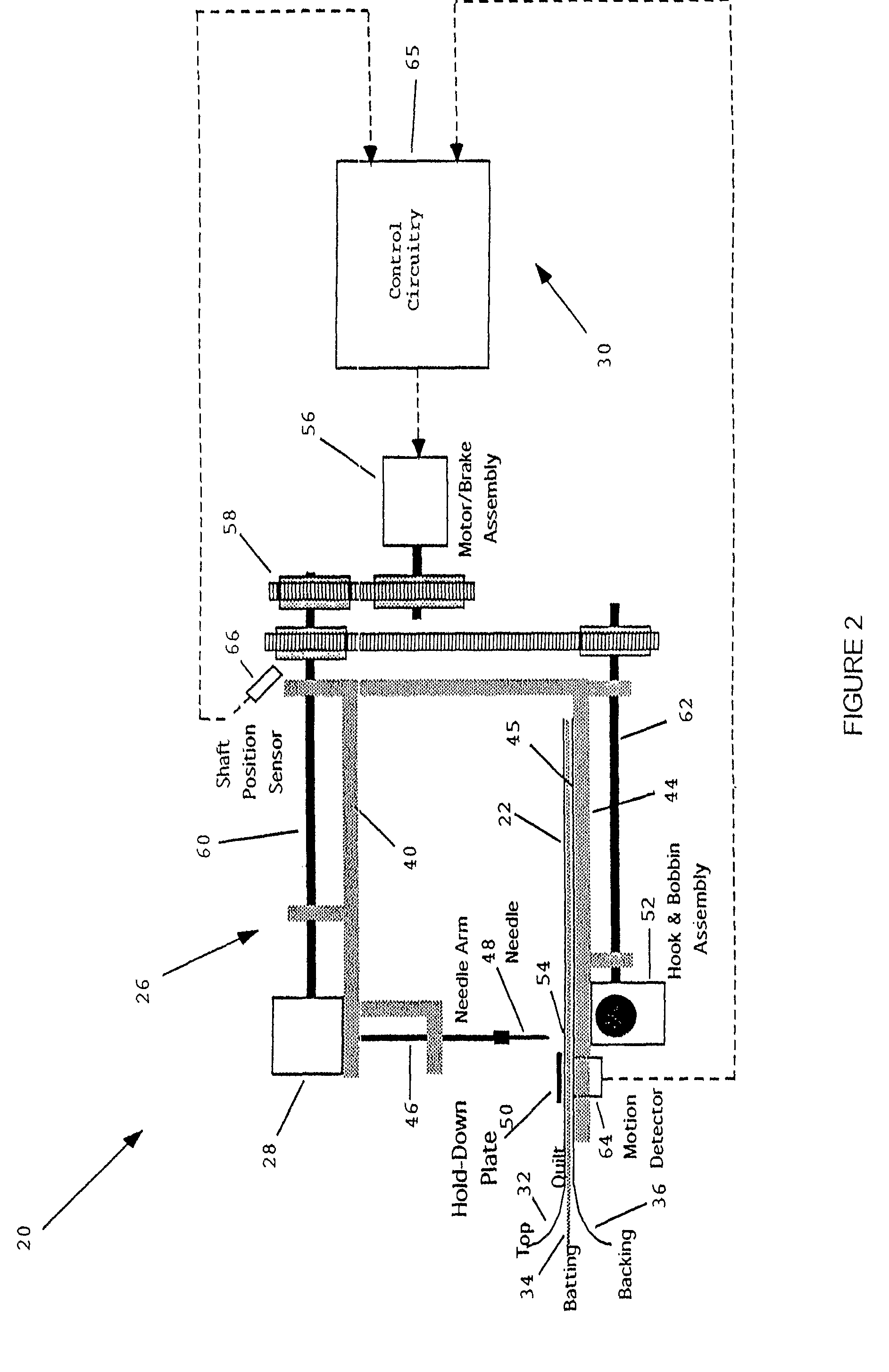

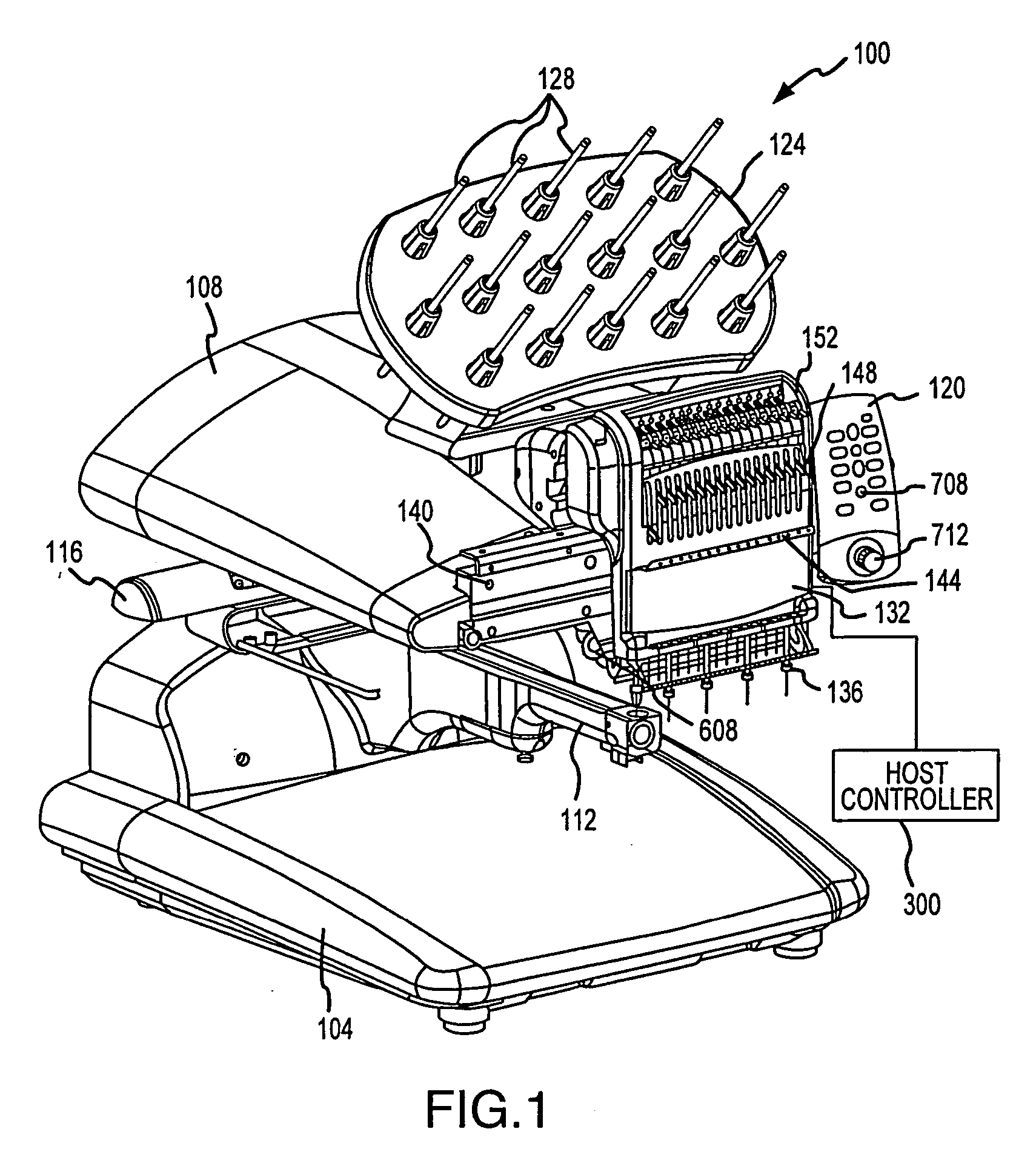

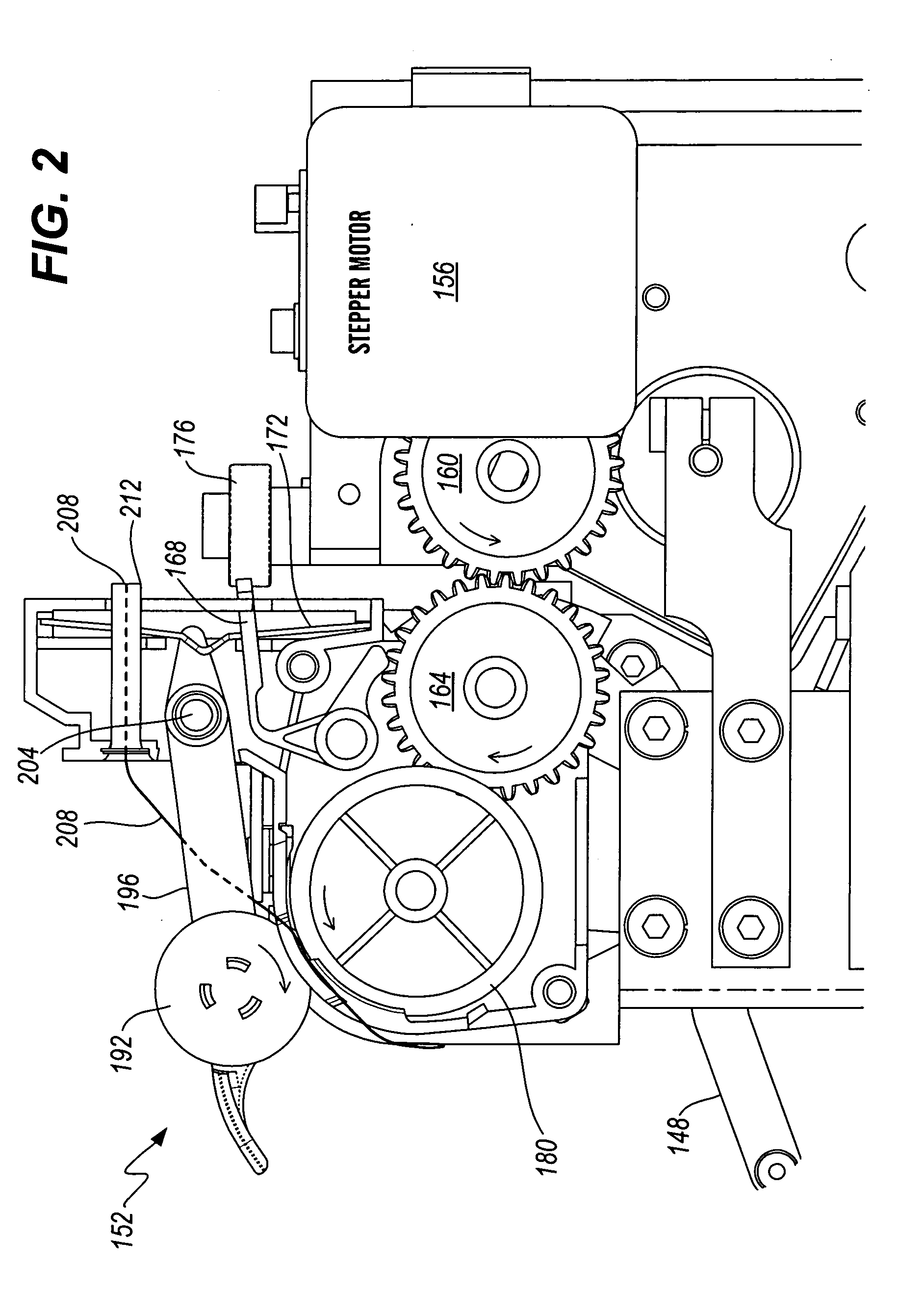

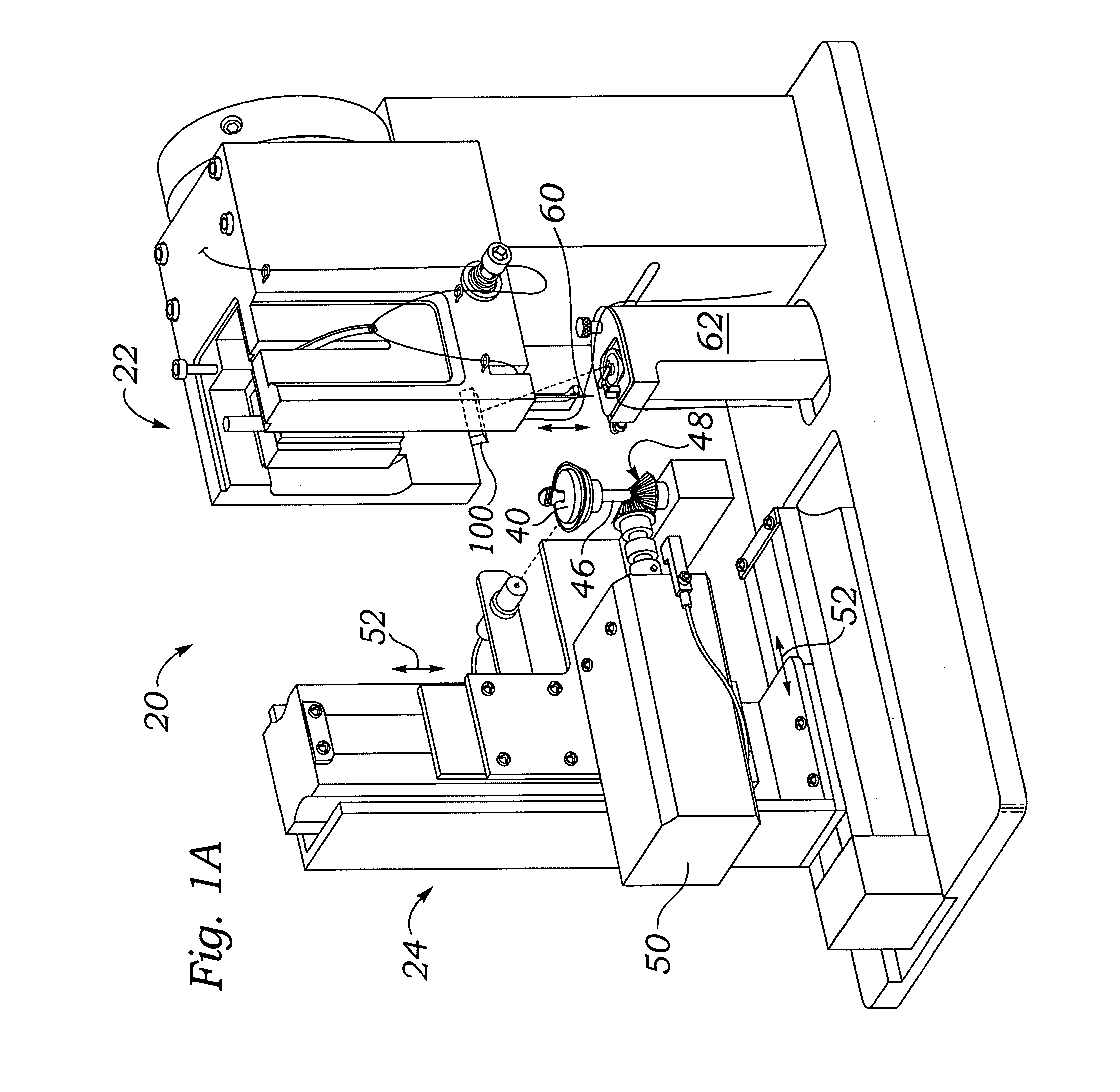

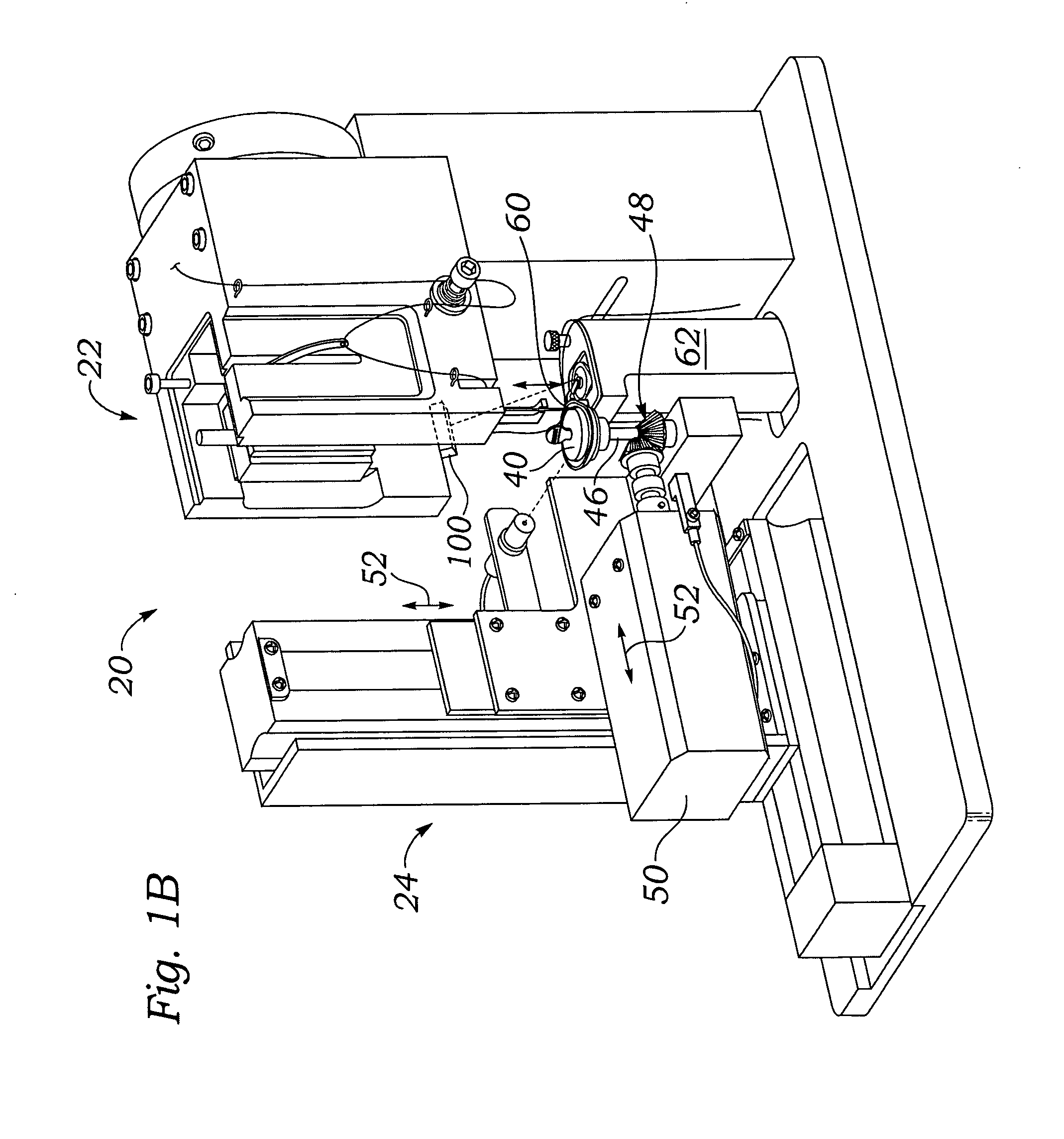

Quilting method and apparatus

ActiveUS6883446B2Easy to produceProgramme-controlled sewing machinesSewing-machine control devicesMotion detectorEngineering

A quilting apparatus for enabling a user to freely move a stack of fabric layers across a planar bed relative to an actuatable stitch head. The apparatus includes a motion detector which detects the movement of the stack and controls the actuation of the stitch head. Consequently, the apparatus functions to synchronize the delivery of stitch strokes by the head with the manually controlled movement of the quilt material stack. This frees the user to move the stack over a wide range of speeds, to start or stop movement at will, and to guide the stack in any direction across the planar bed.

Owner:BERNINA SEWING MACHINE

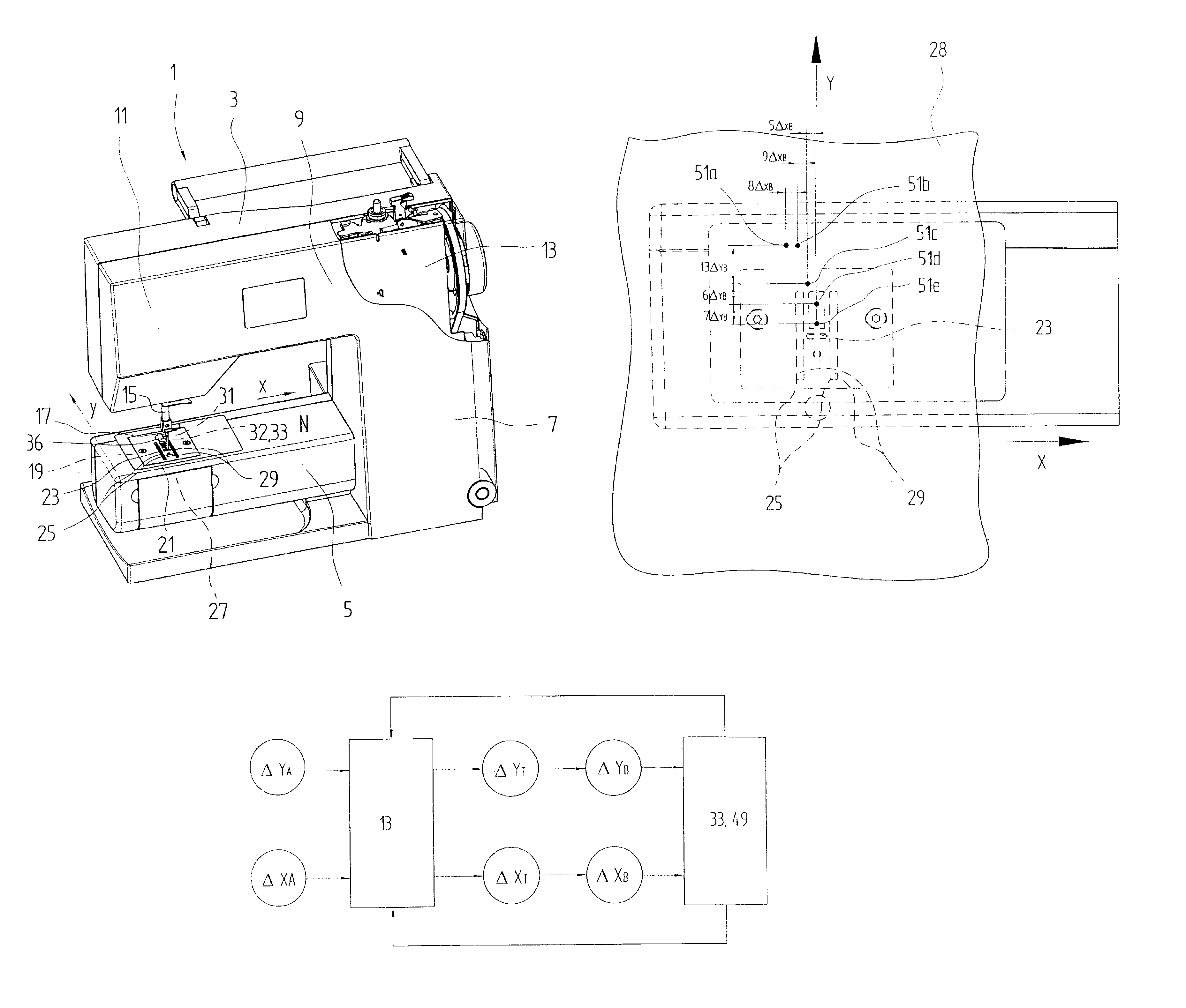

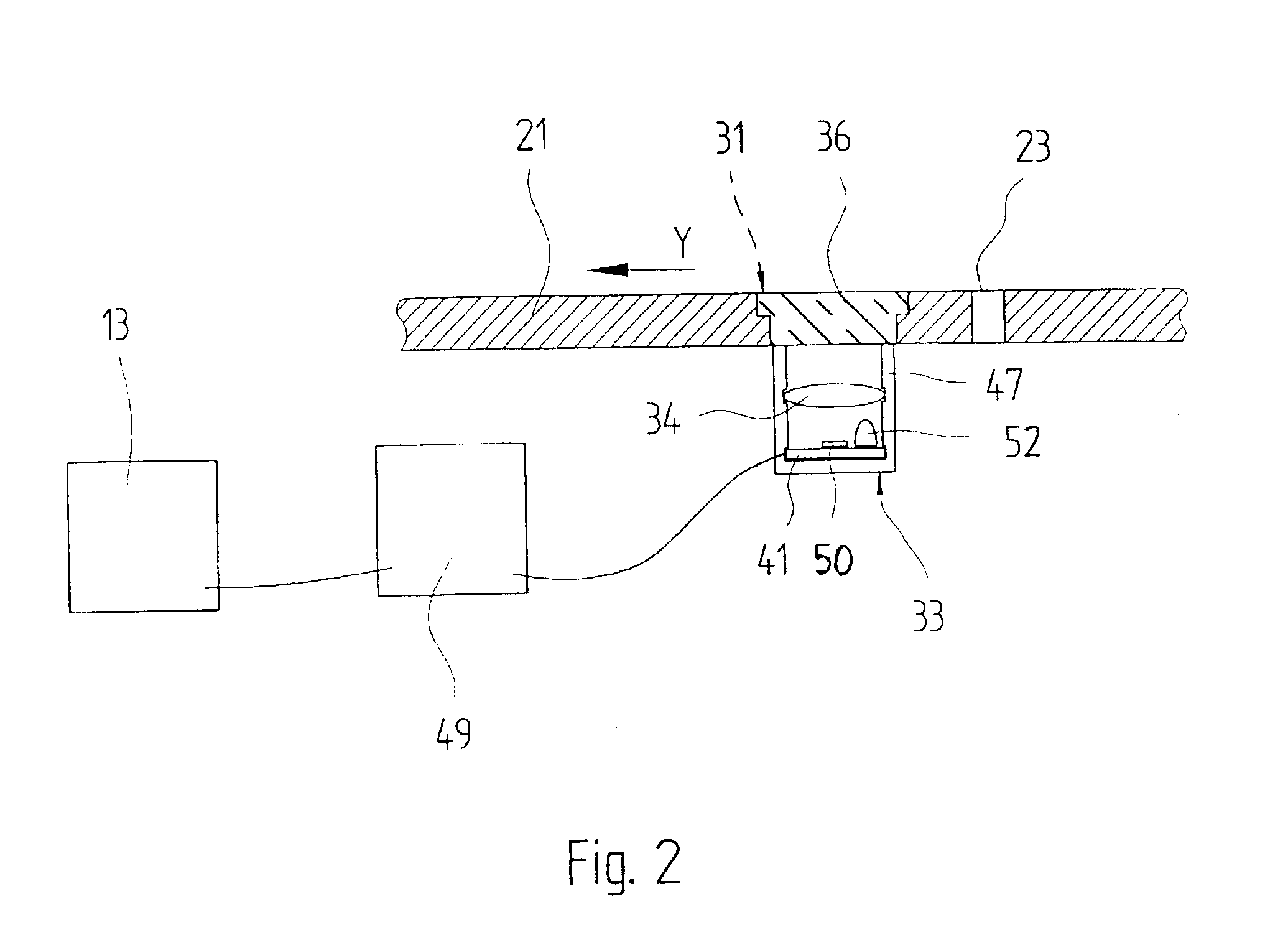

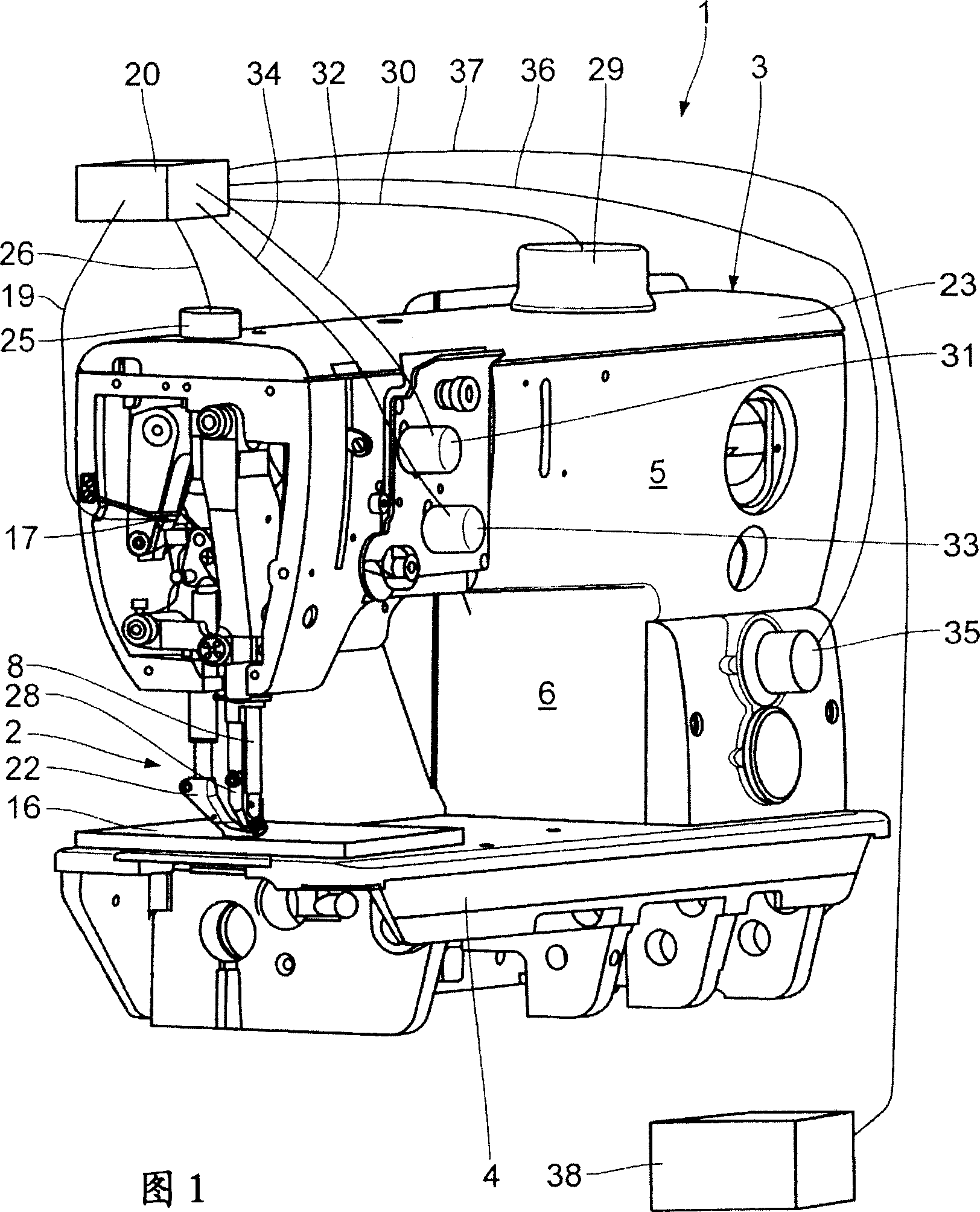

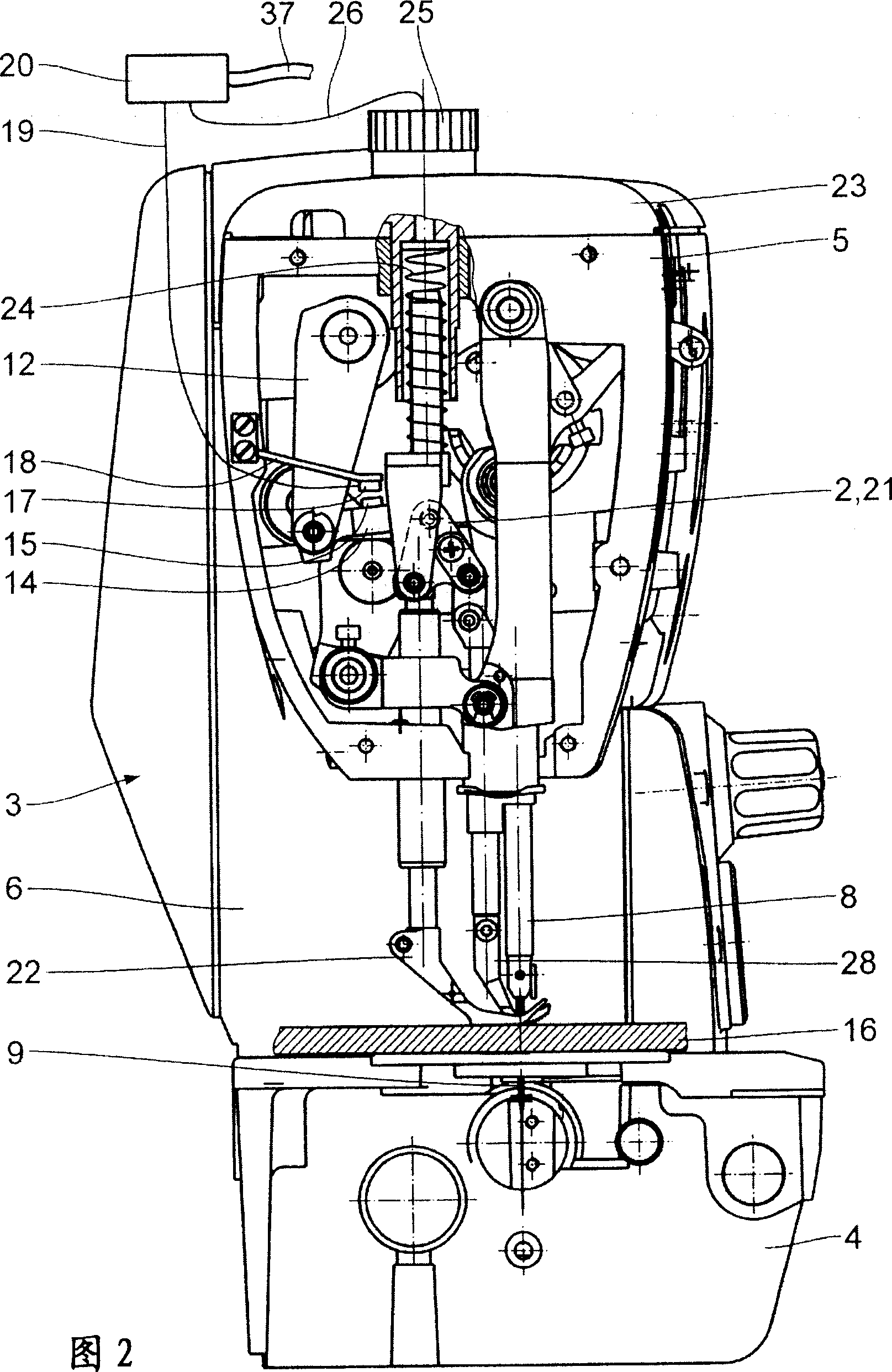

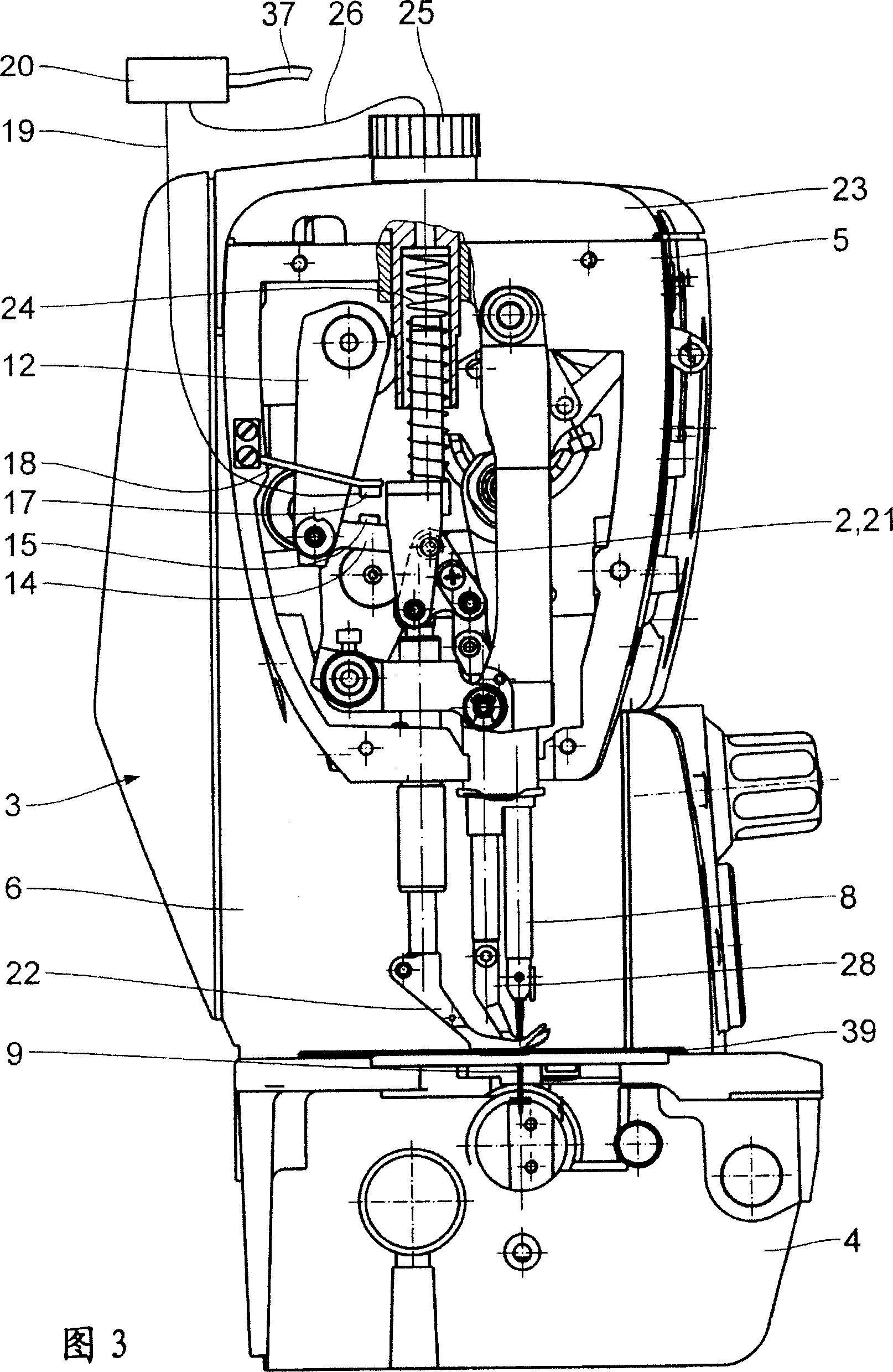

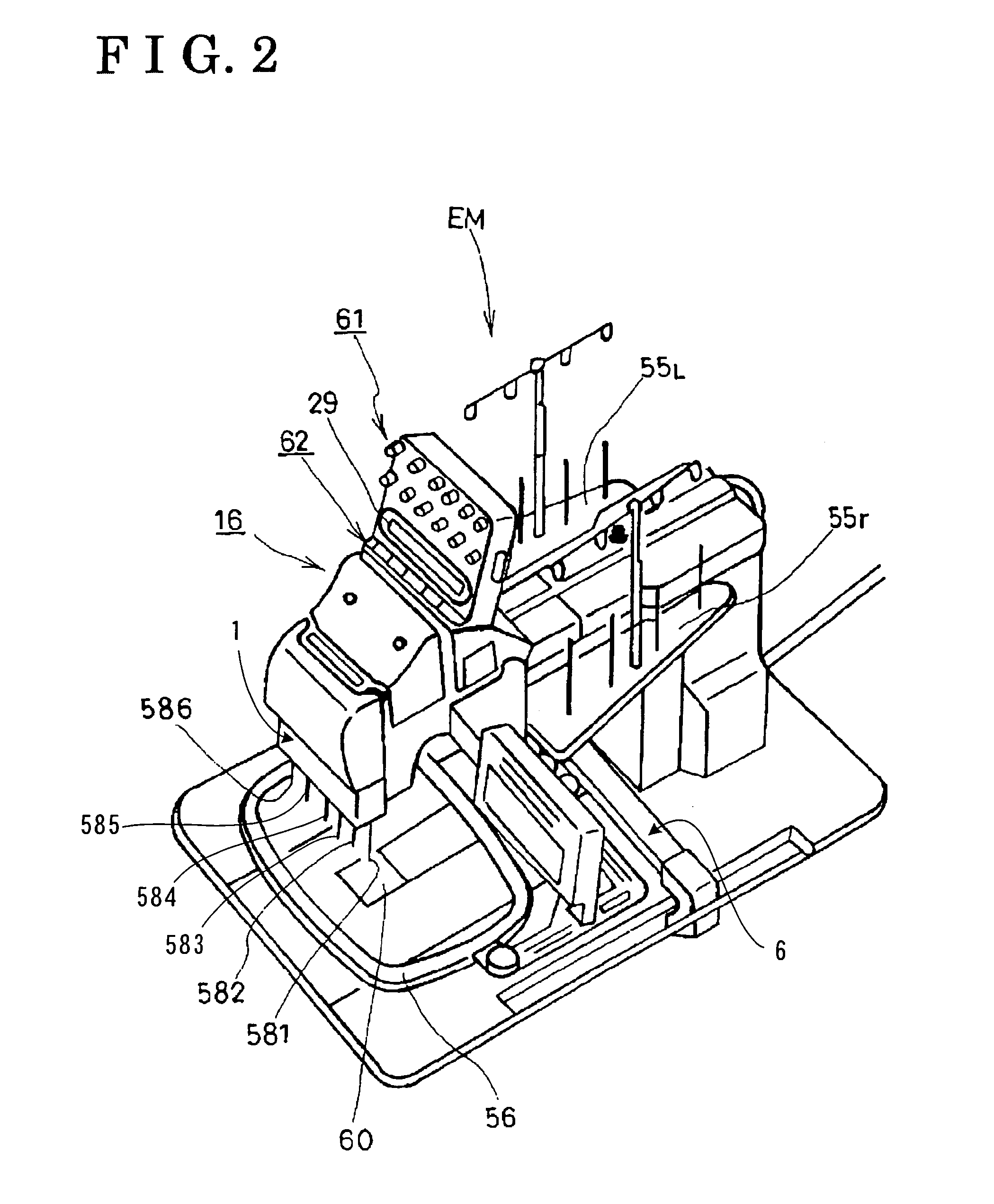

Method and device for regulating material transport in a sewing or embroidery machine

InactiveUS6871606B2Quickly and accurately calculated and compensatedImprove scanning rateProgramme-controlled sewing machinesWork-feeding meansMaterial transportMotion sensors

A method and device for regulating the transport of material in a sewing or embroidery machine (1) that uses information from a position or movement sensor (33) located underneath the throat plate (21). The controls for the sewing machine (1) calculate deviations of the actual feeding increments of the article to be sewn from the corresponding target values from the periodically read sensor signals. With this information, the feeding increments are regulated in such a way that the deviations are cancelled out by averaging.

Owner:FRITZ GEGAUF AKTIENGES BERNINA NAHMASCHFAB

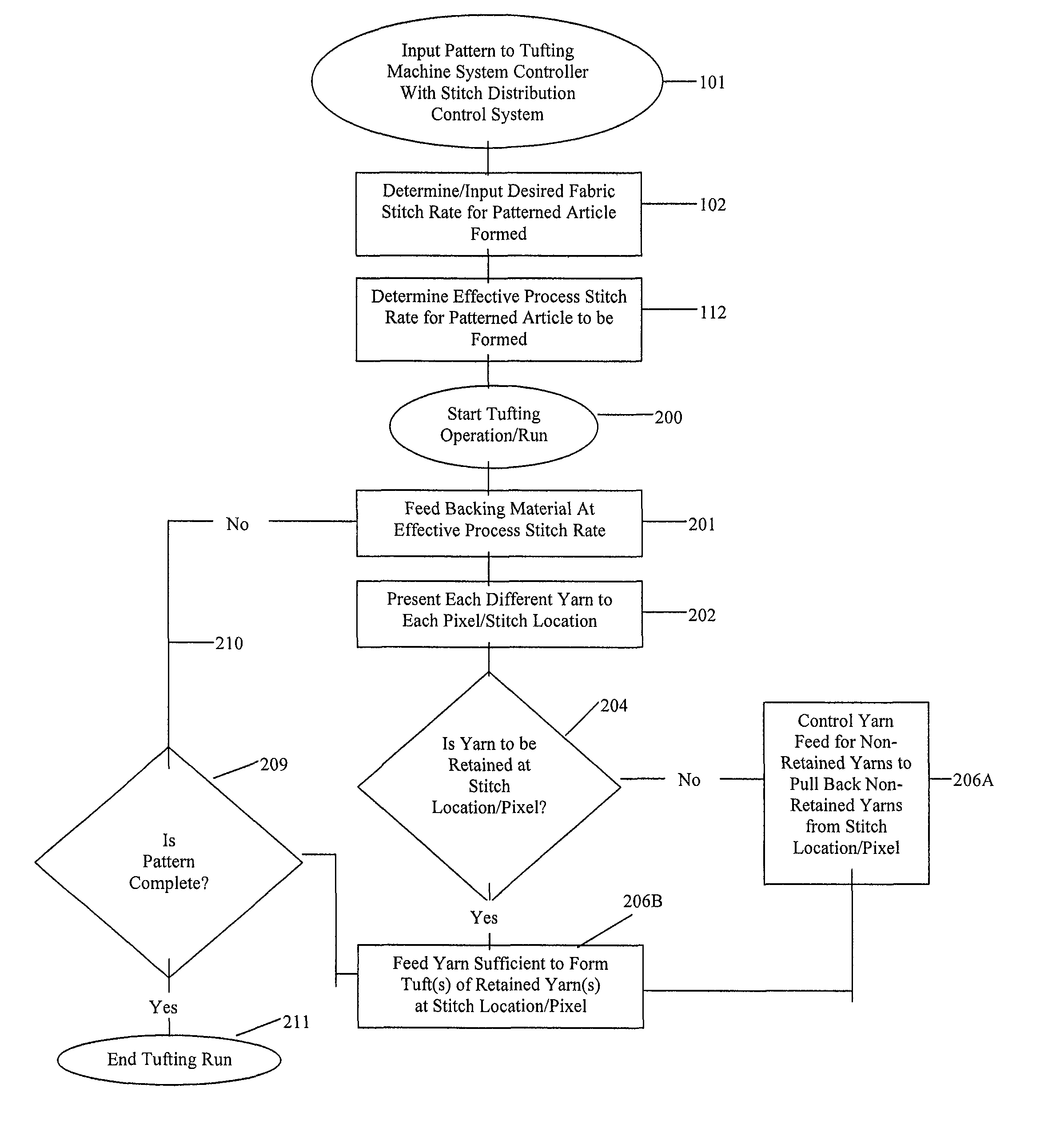

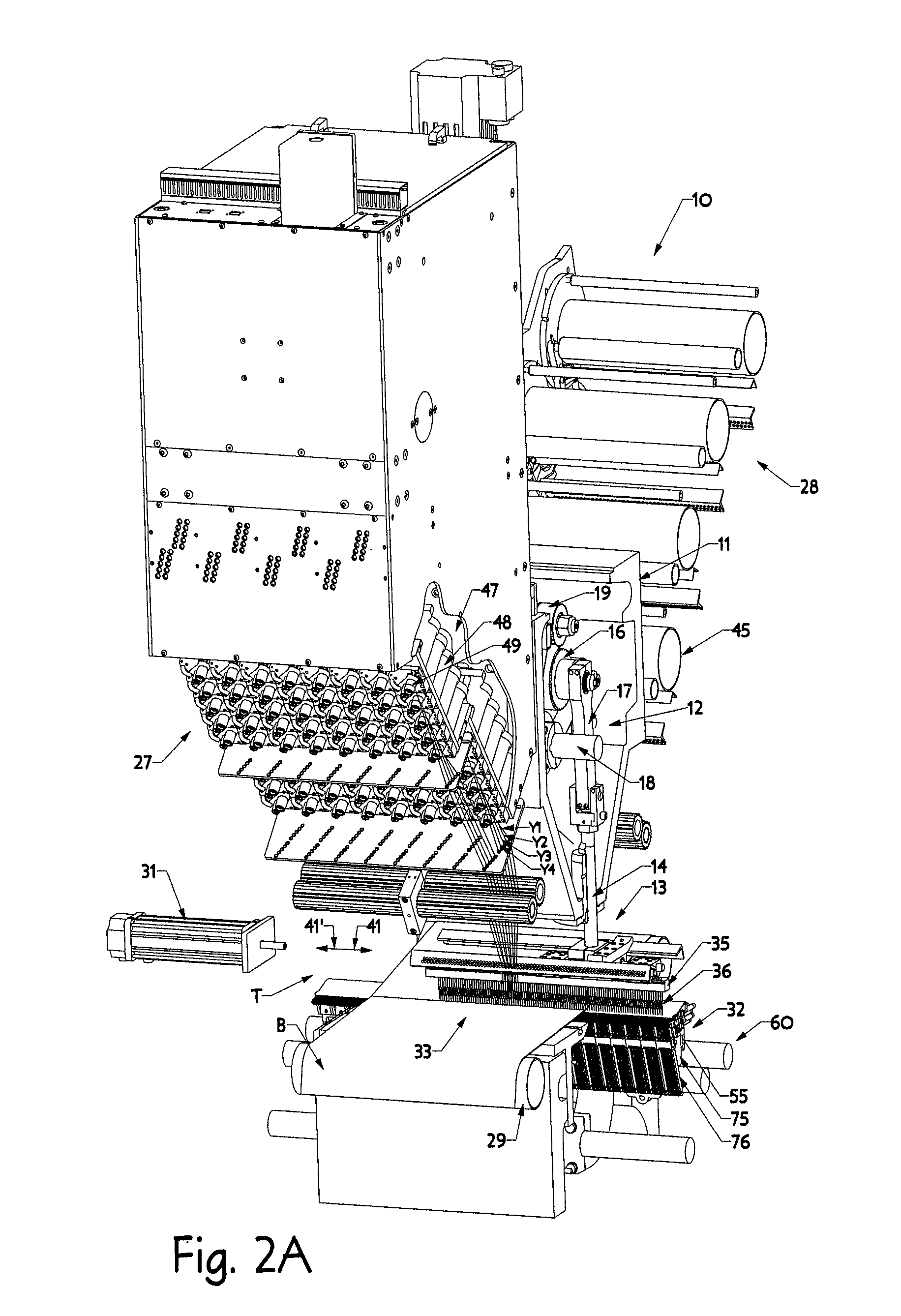

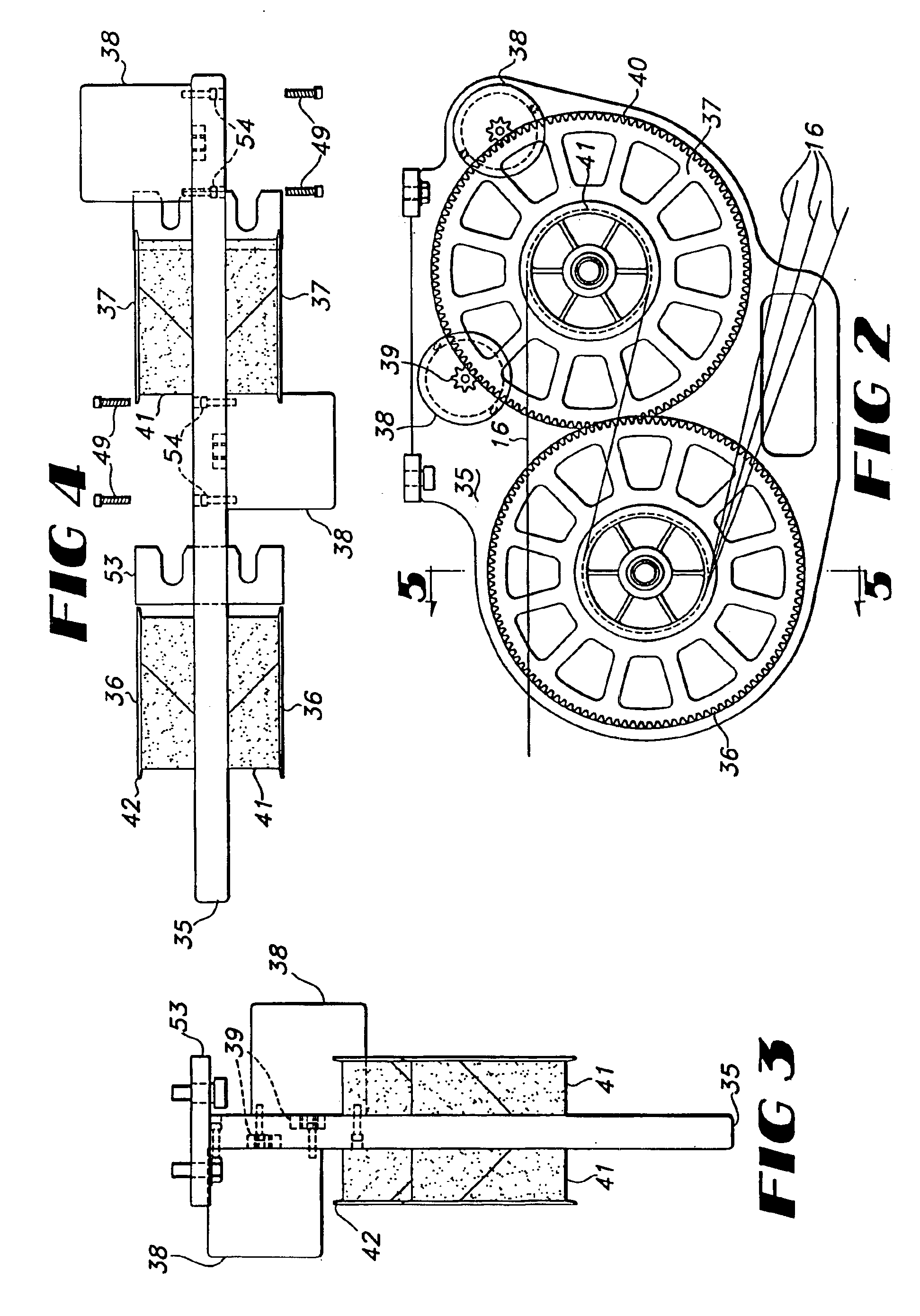

Stitch distribution control system for tufting machines

ActiveUS8359989B2High selectivityEnable formationProgramme-controlled sewing machinesTufting apparatusYarnDistribution control

Owner:CARD MONROE

Optical stitch regulator system

InactiveUS6959657B1Effective supervisionProgramme-controlled sewing machinesSewing-machine casingsEngineeringControl unit

An optical stitch regulator system for efficiently regulating the stitch length and stitch frequency of a sewing machine. The optical stitch regulator system includes at least one optical sensor within or external of the sewing platform of a sewing machine for sensing the motion of the fabric being sewn. The motion data is communicated to a control unit which communicates with the sewing machine for controlling the stitch length and frequency.

Owner:DUVAL RICHARD J

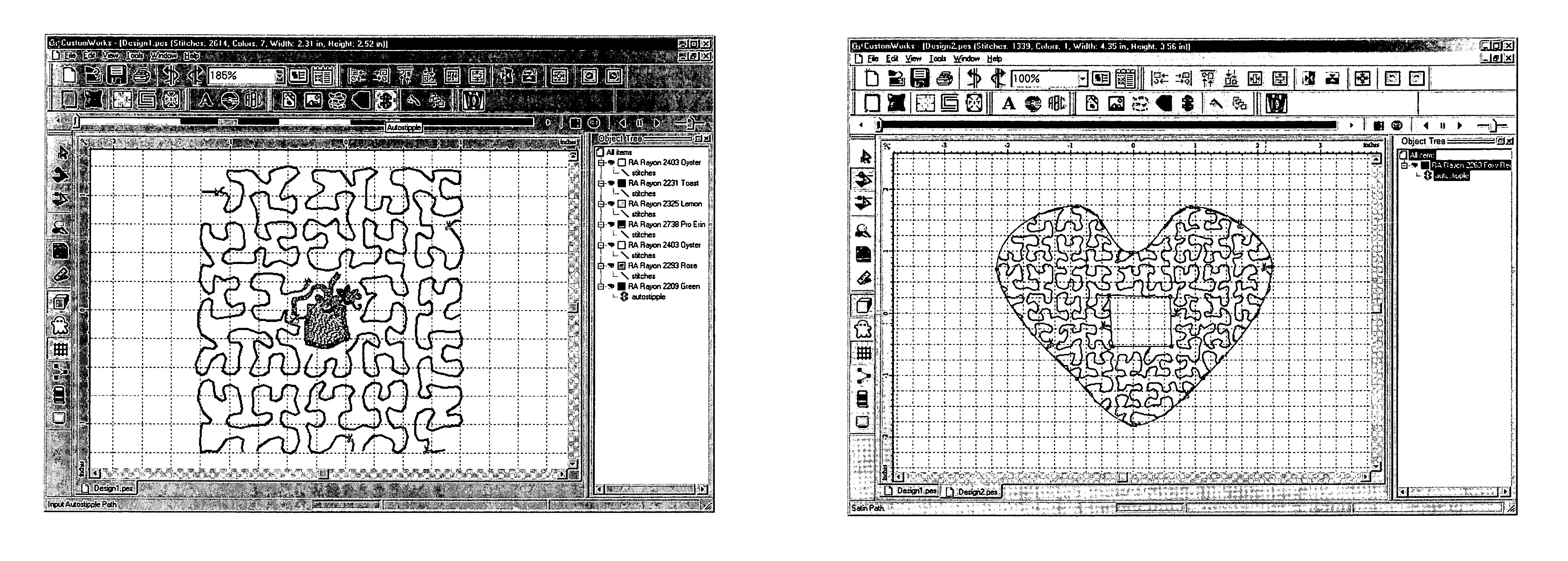

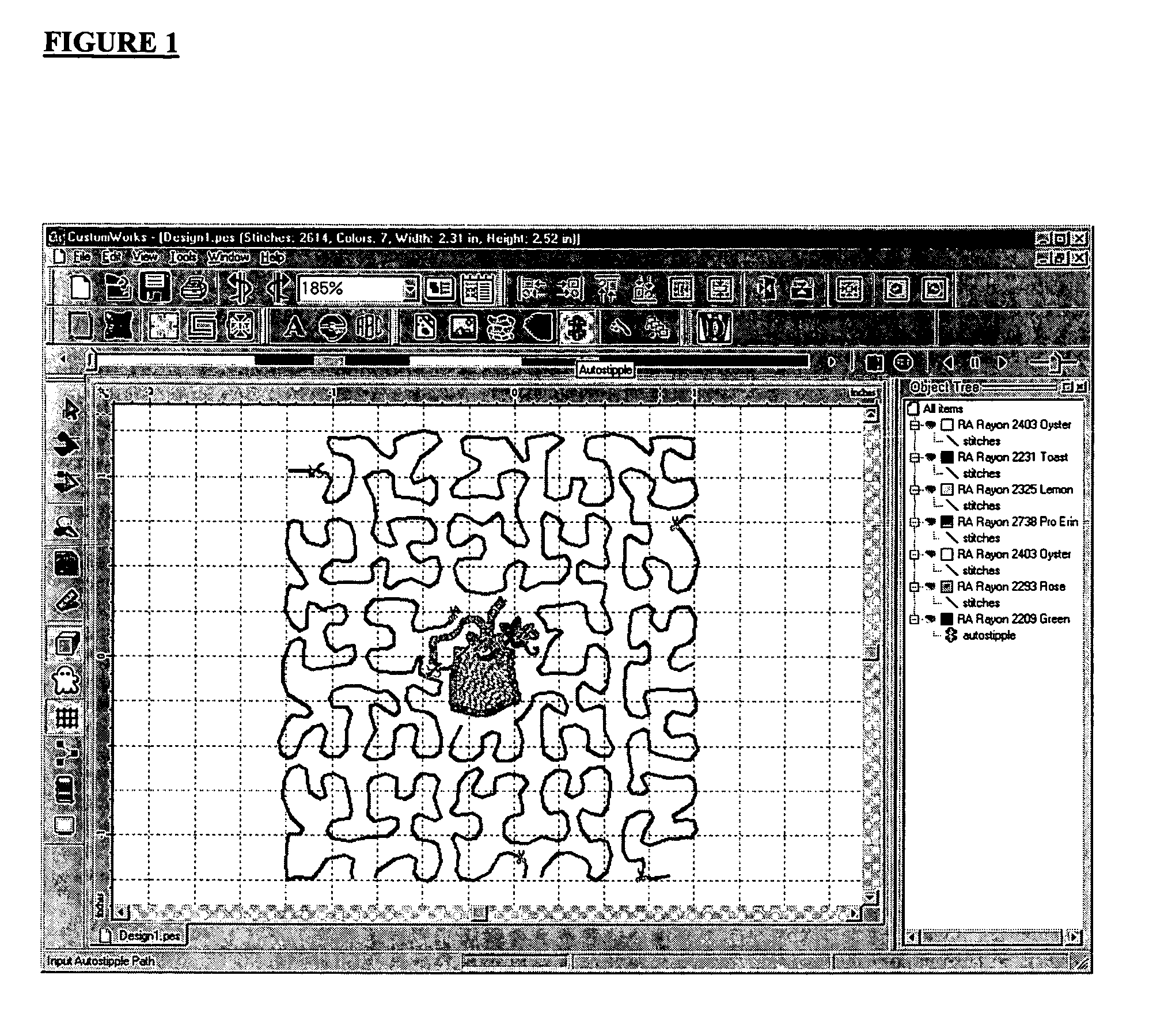

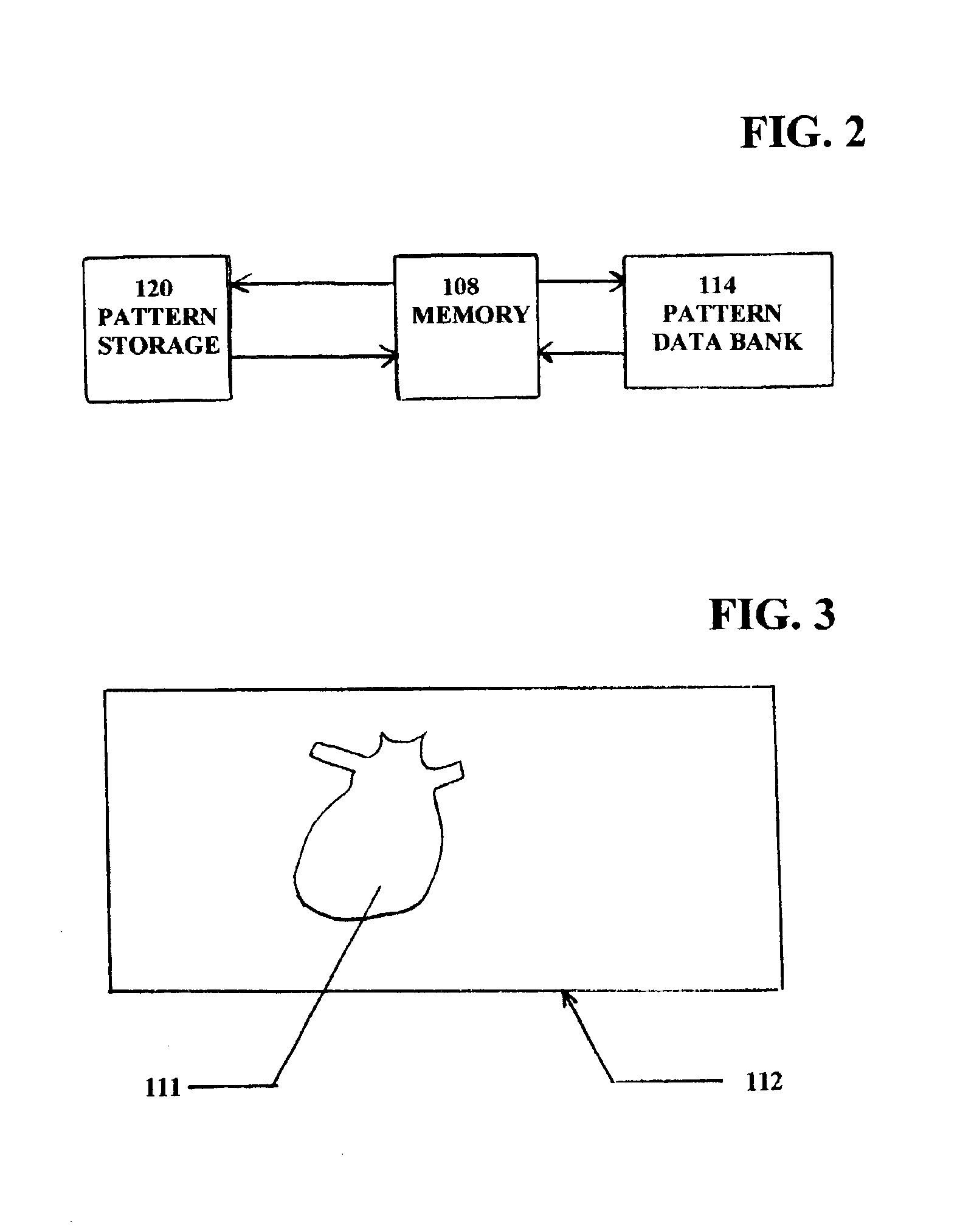

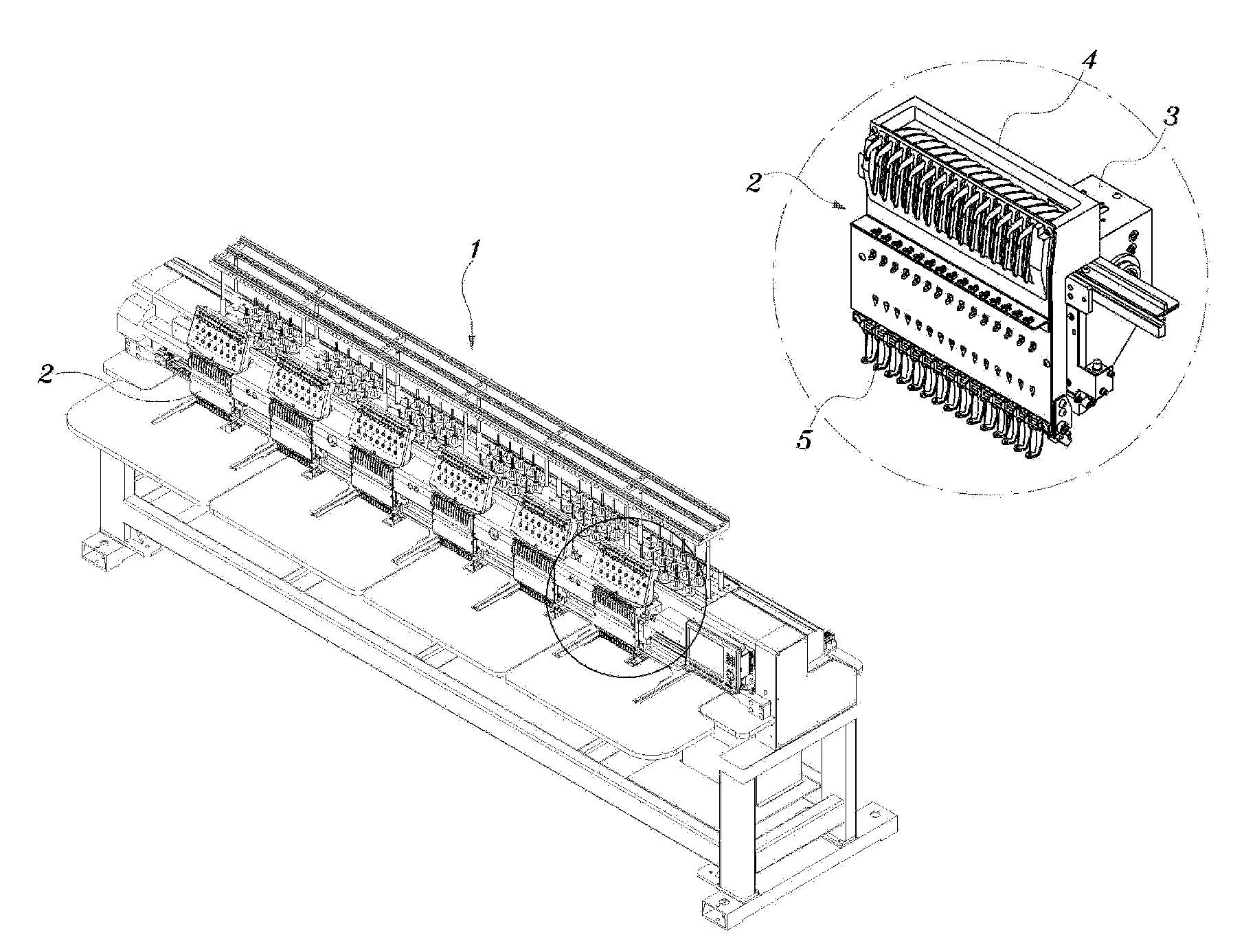

Method and system for automatically deriving stippling stitch designs in embroidery patterns

ActiveUS6968255B1Accurate and convenient to useProgramme-controlled sewing machinesSpecial data processing applicationsData formatComputer science

The invention pertains to a method of applying a stippling stitch design to an area defining an asymmetrical polygon in a coordinate planar display format, involving: defining a pathway, which may be based on a fractal design, within a geometrically symmetrical boundary, the pathway comprising a single non-intersecting line; conforming the pathway to an asymmetrical polygon area substantially disposed within the geometrically symmetrical boundary; deriving a plurality of coordinate points representative of the pathway; and passing the points to a data storage medium in a pre-determined embroidery data format.

Owner:TAJIMA SOFTWARE SOLUTIONS INC

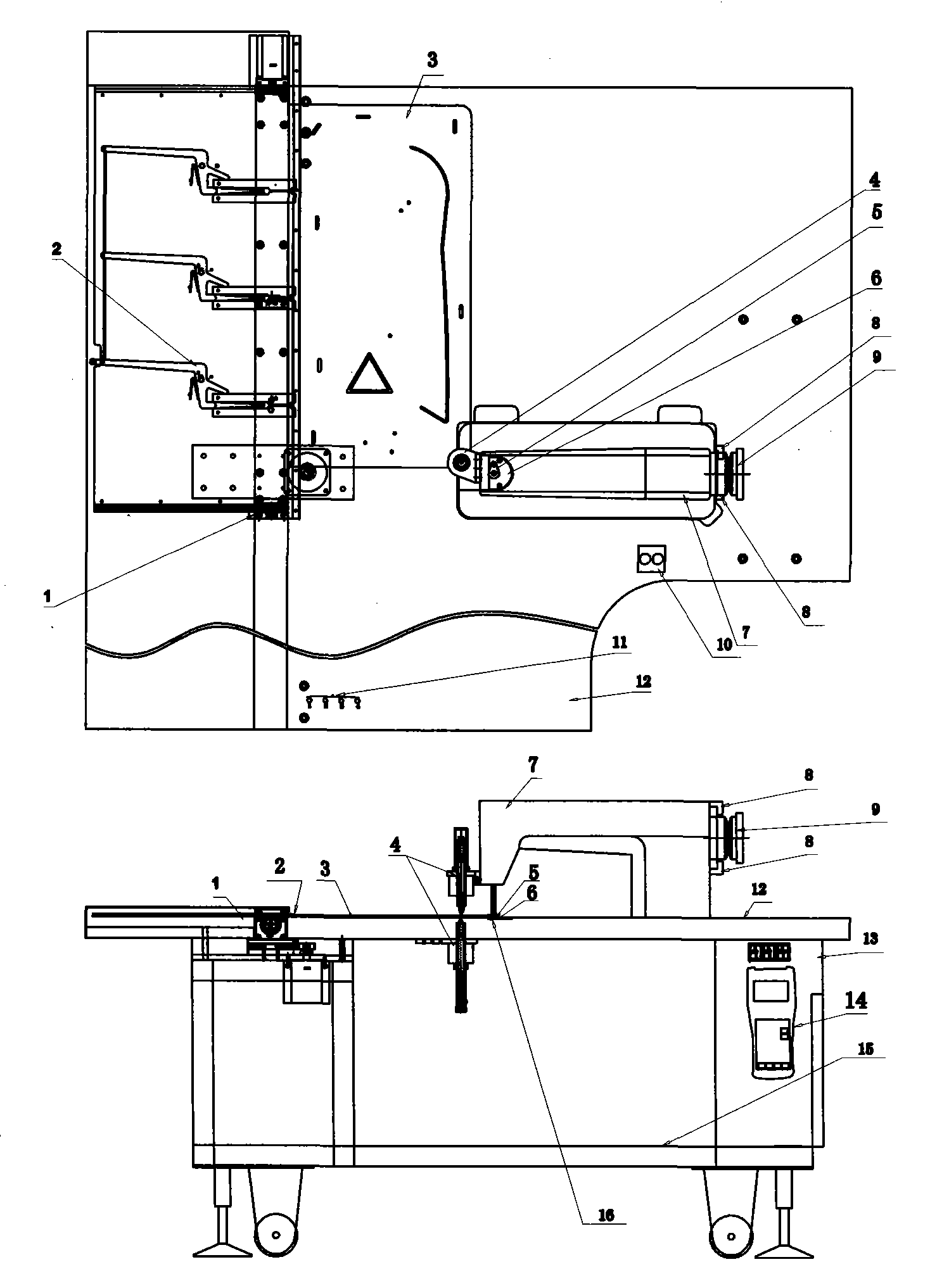

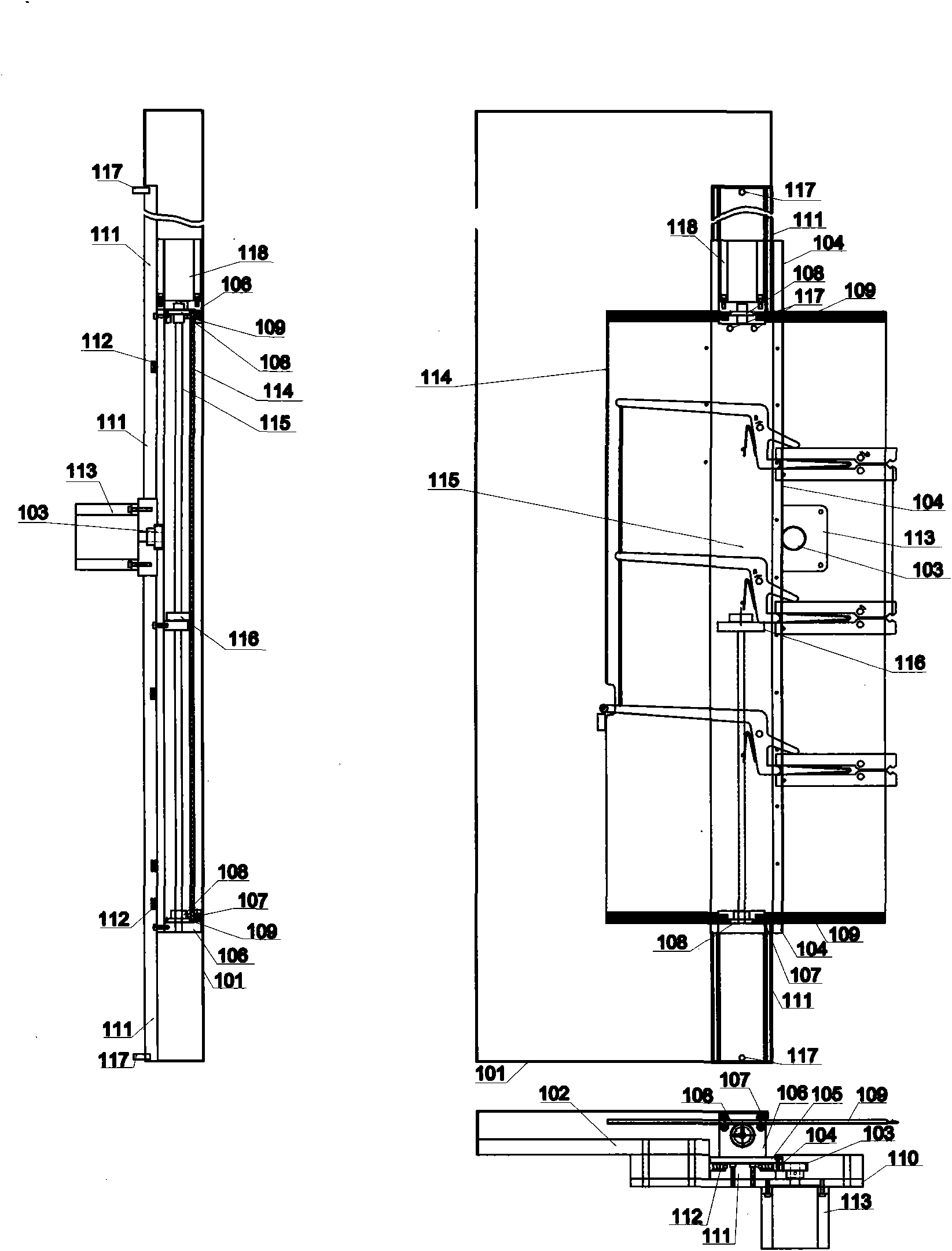

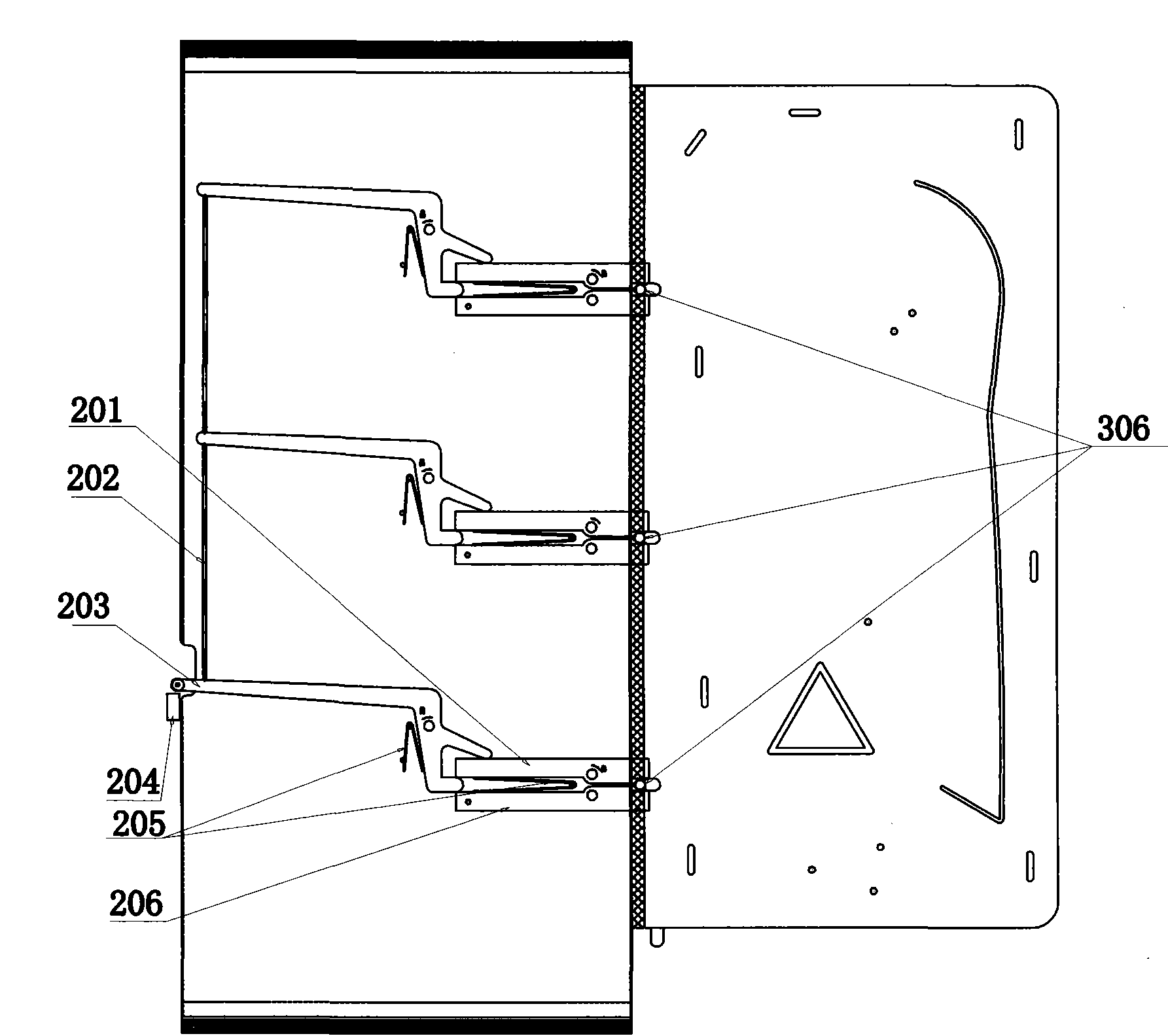

Multifunctional digital control sewing machine for feeding by clamping cloth sheets through template

InactiveCN101775712ALow costSimple structureProgramme-controlled sewing machinesControl systemElectric control

The invention discloses a multifunctional digital control sewing machine for feeding by clamping cloth sheets through a template, which comprises X and Y moving devices, a template automatic clamping mechanism device, a sewing template, a stippling marking device, a rotary core sleeve need board device, a sewing operation wood table board, a Z axial rotary speed regulation device, an electric cabinet, an electric control system and a sewing digital control programming system, a simply-modified common computer flat sewing machine head (7), a control system and a stander (15). The multifunctional digital control sewing machine for feeding by clamping the cloth sheets through the template has the advantages of low cost, simple structure, simple operation, and greatly improved production efficiency and product quality.

Owner:苏运松

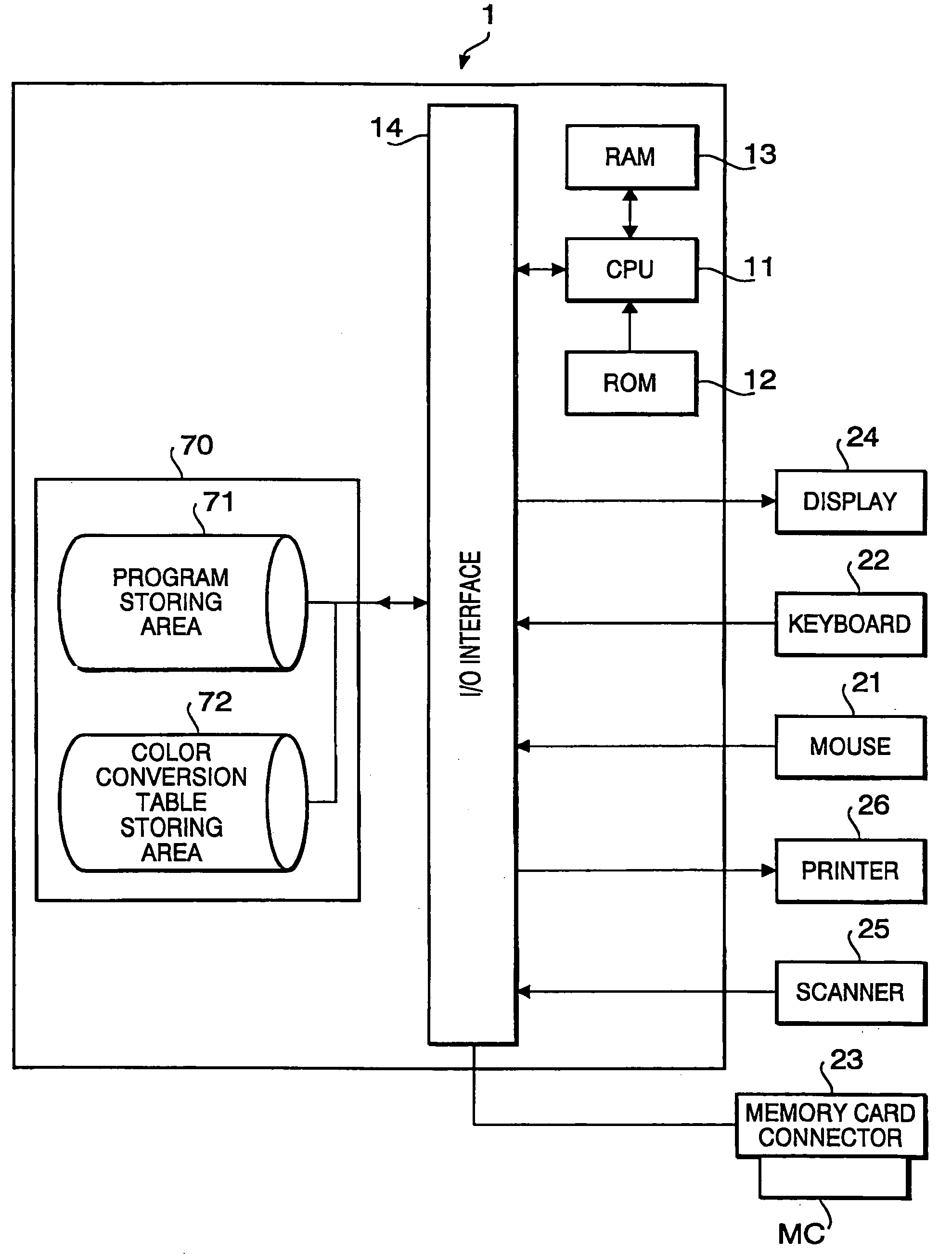

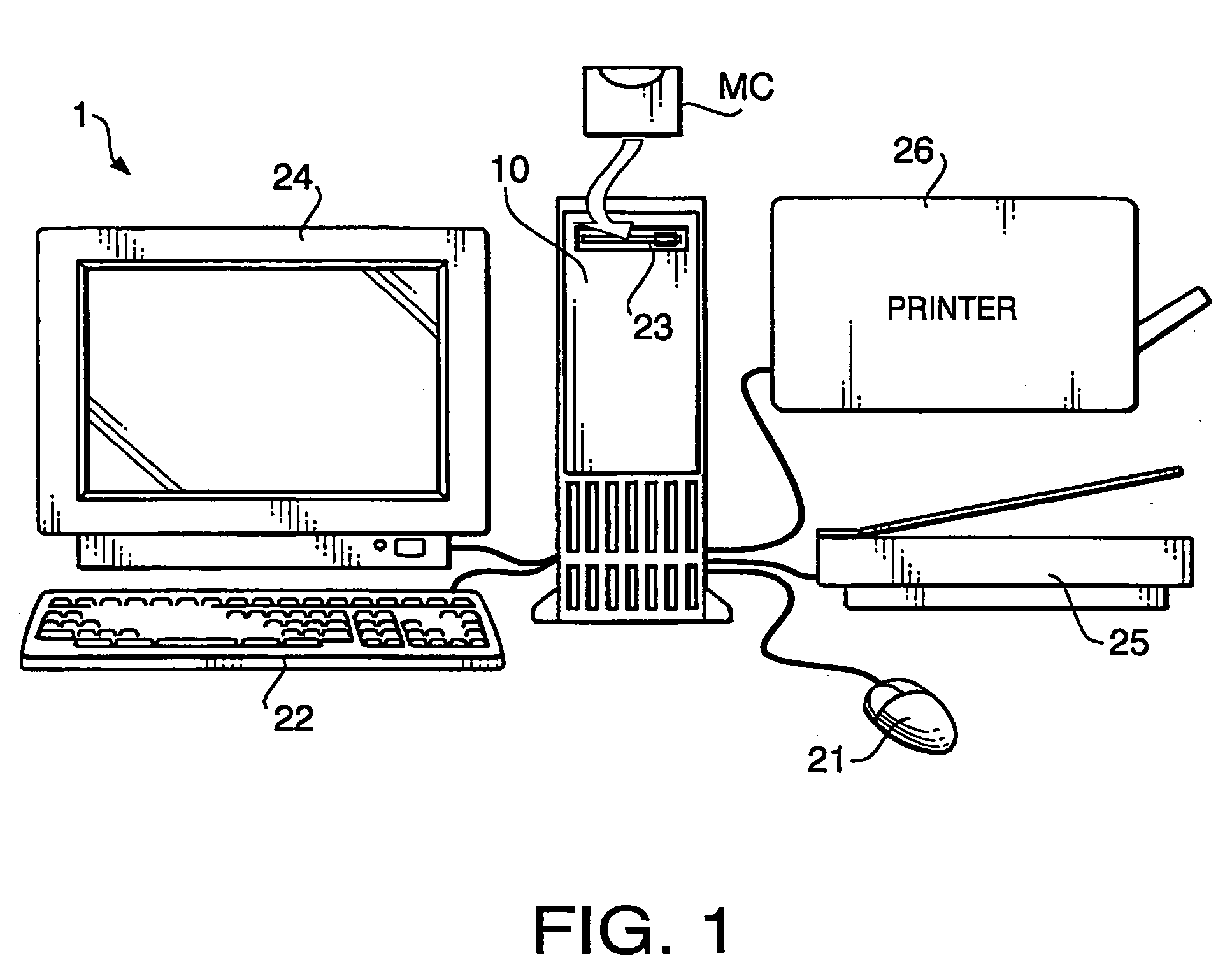

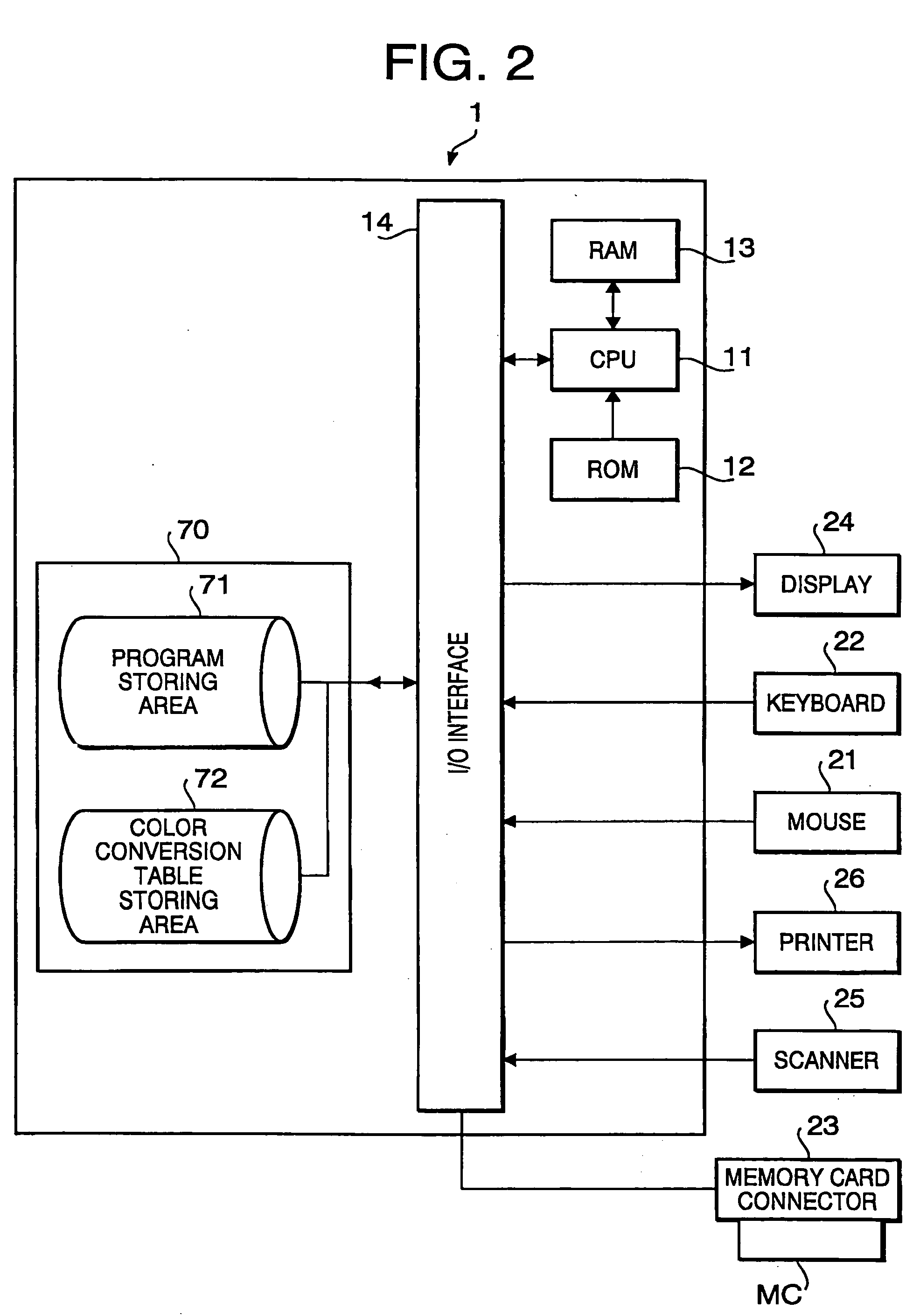

Image editing device and print/embroidery data creating device

ActiveUS20050182508A1Ink ejection amount can be controlledDifferent permeability characteristicProgramme-controlled sewing machinesAutomatic machinesComputer printingImage editing

A print / embroidery data creating device is provided with a usable color designating system, an output information setting system, a pixel examining system, an area setting system that sets a pixel area determined to correspond to the usable color as a usable color area and sets an area which does not correspond to the usable color area as a print area, an embroidery data creating system. The usable color area is output with the size set by the output information setting system at the position set by the output information setting system by the embroidering machine, and a print data creating system that creates print data such that a pixel area set as the print area by the area setting system is output as printed area with a color corresponding to the pixel color, the print area being output with the size set by the output information setting system at the position set by the output information setting system by the printer.

Owner:BROTHER KOGYO KK

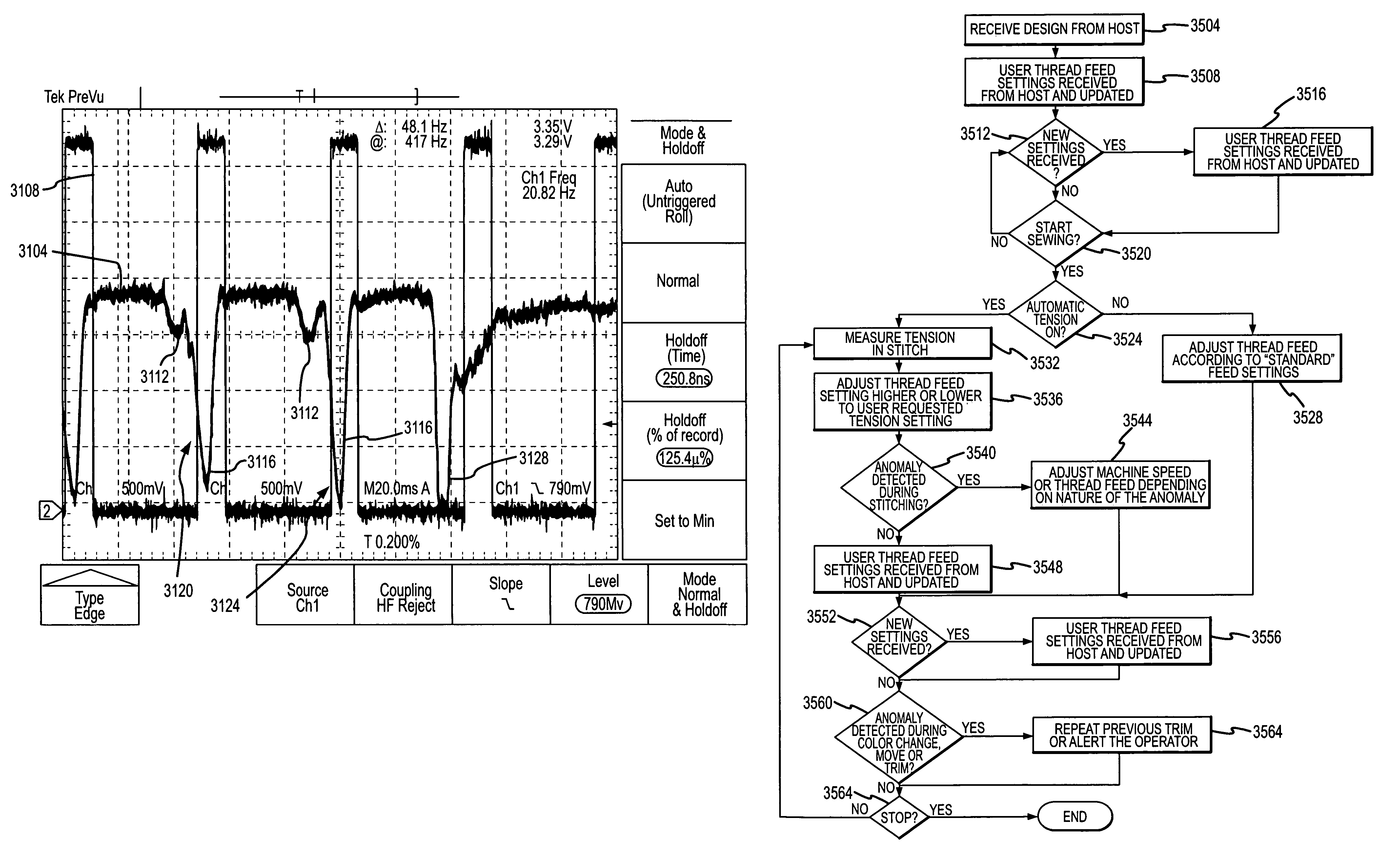

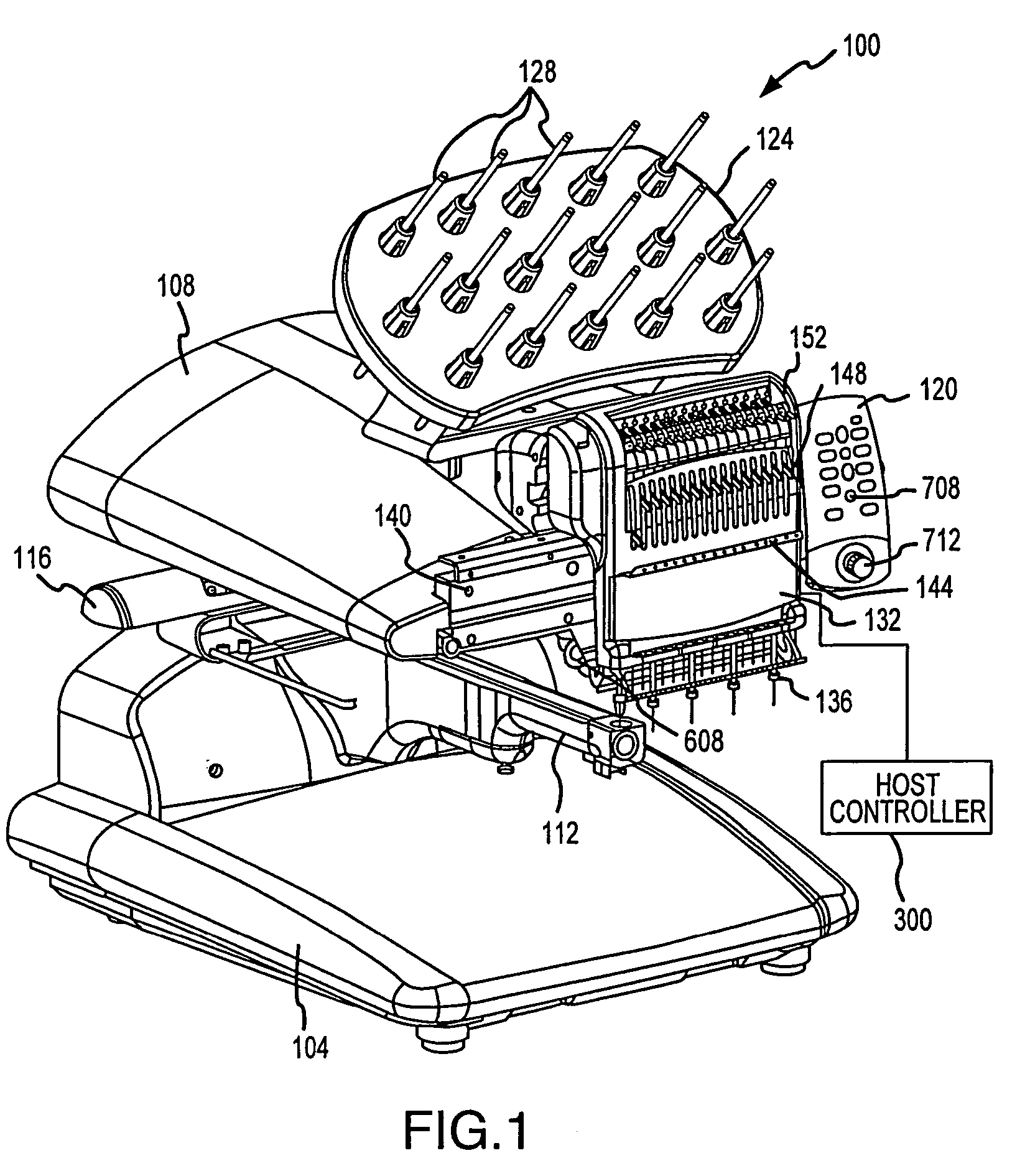

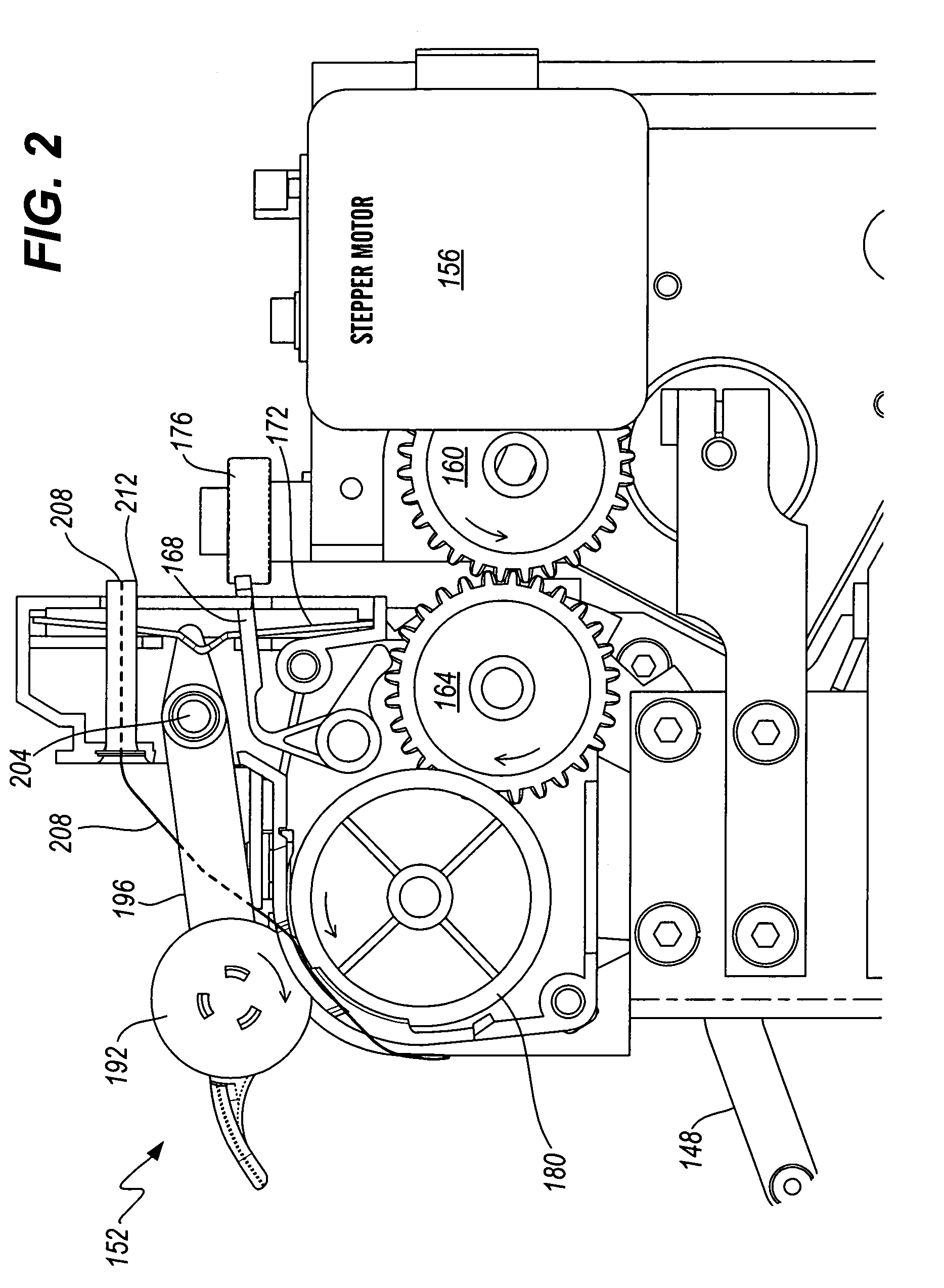

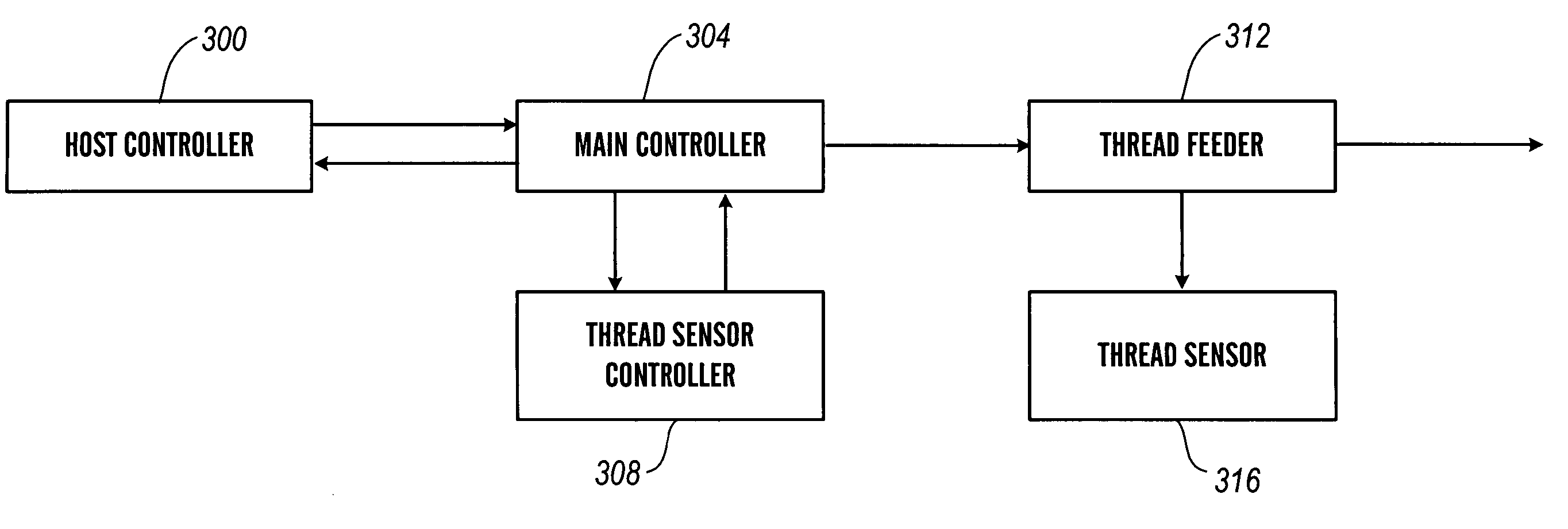

Computerized stitching including embroidering

InactiveUS7308333B2Easy to controlProgramme-controlled sewing machinesPressersAnomaly detectionRemedial action

A stitching apparatus with thread tension control is provided. Tension in a thread is monitored during stitching apparatus operations, and remedial action is taken in response to the detection of an anomaly in the thread tension profile. The remedial action can include altering a feed rate of the thread in order to adjust the thread tension, and / or repeating a previous operation. Anomaly detection can be performed with respect to stitching or sewing operations, and also with respect to trim operations performed in connection with moving between elements and / or thread color changes.

Owner:MELCO INT

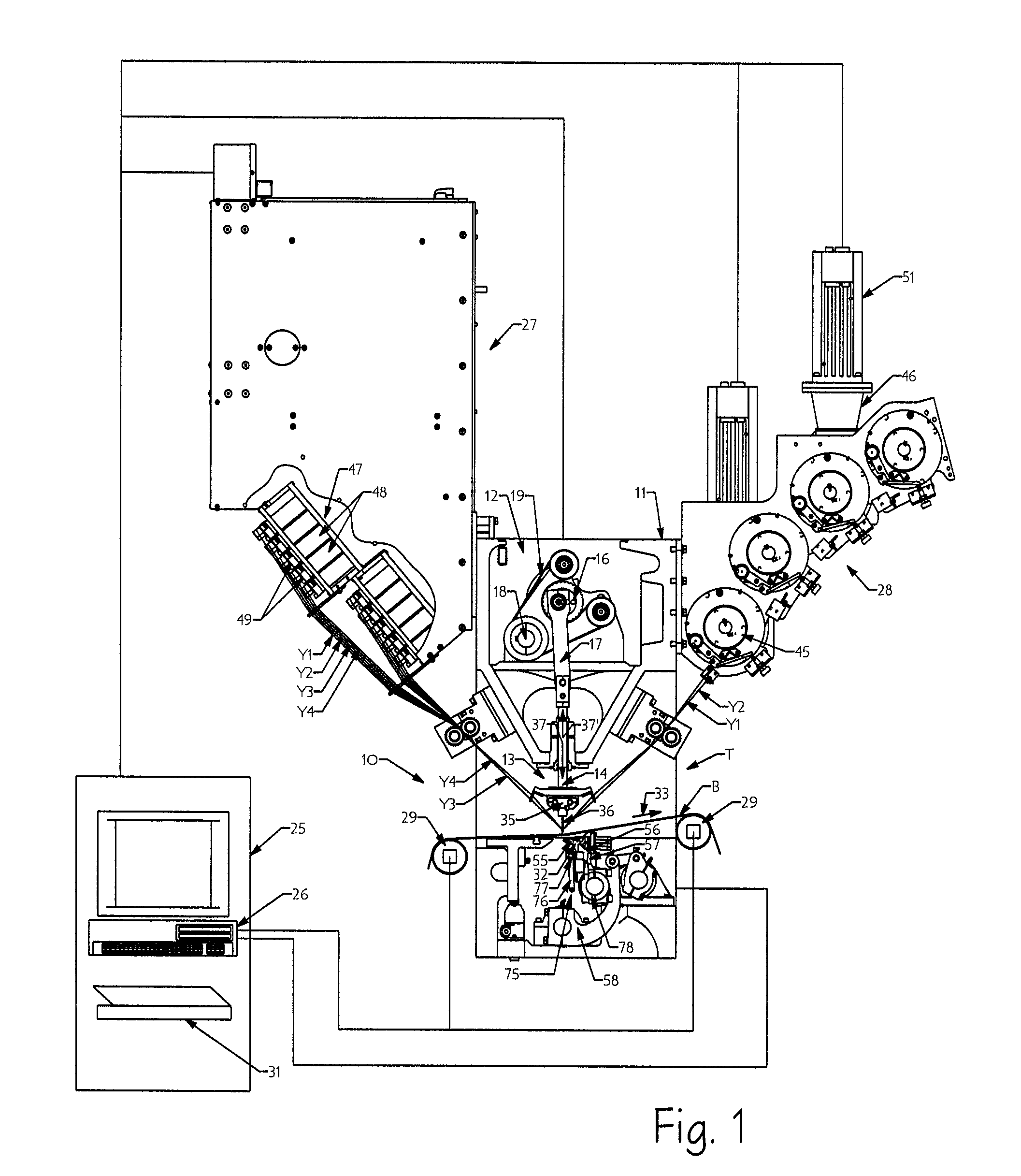

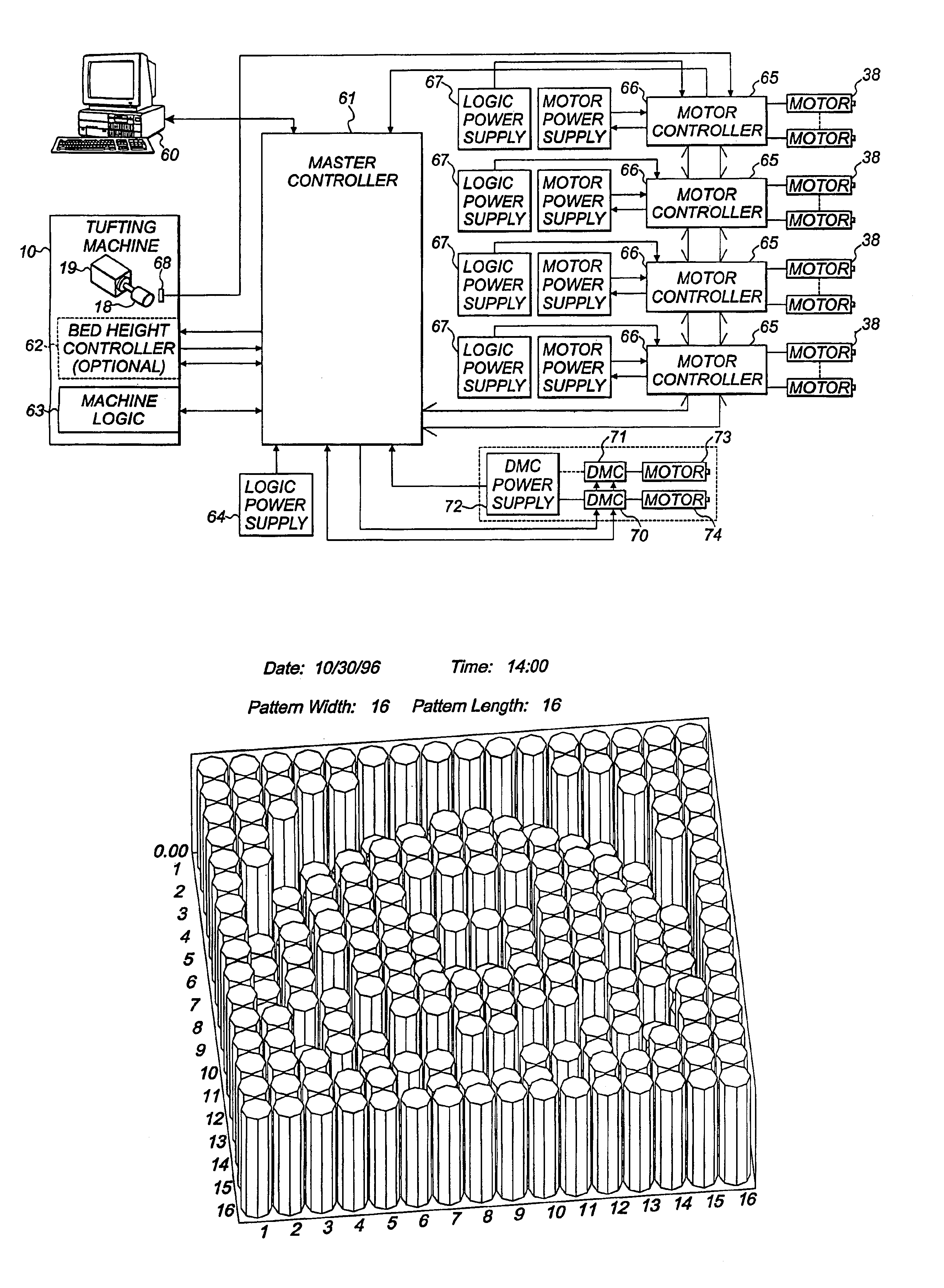

Servo motor driven scroll pattern attachments for tufting machine with computerized design system and methods of tufting

InactiveUS6877449B2Minimize the differenceEliminate needProgramme-controlled sewing machinesTufting apparatusYarnMotor drive

Owner:TUFTCO

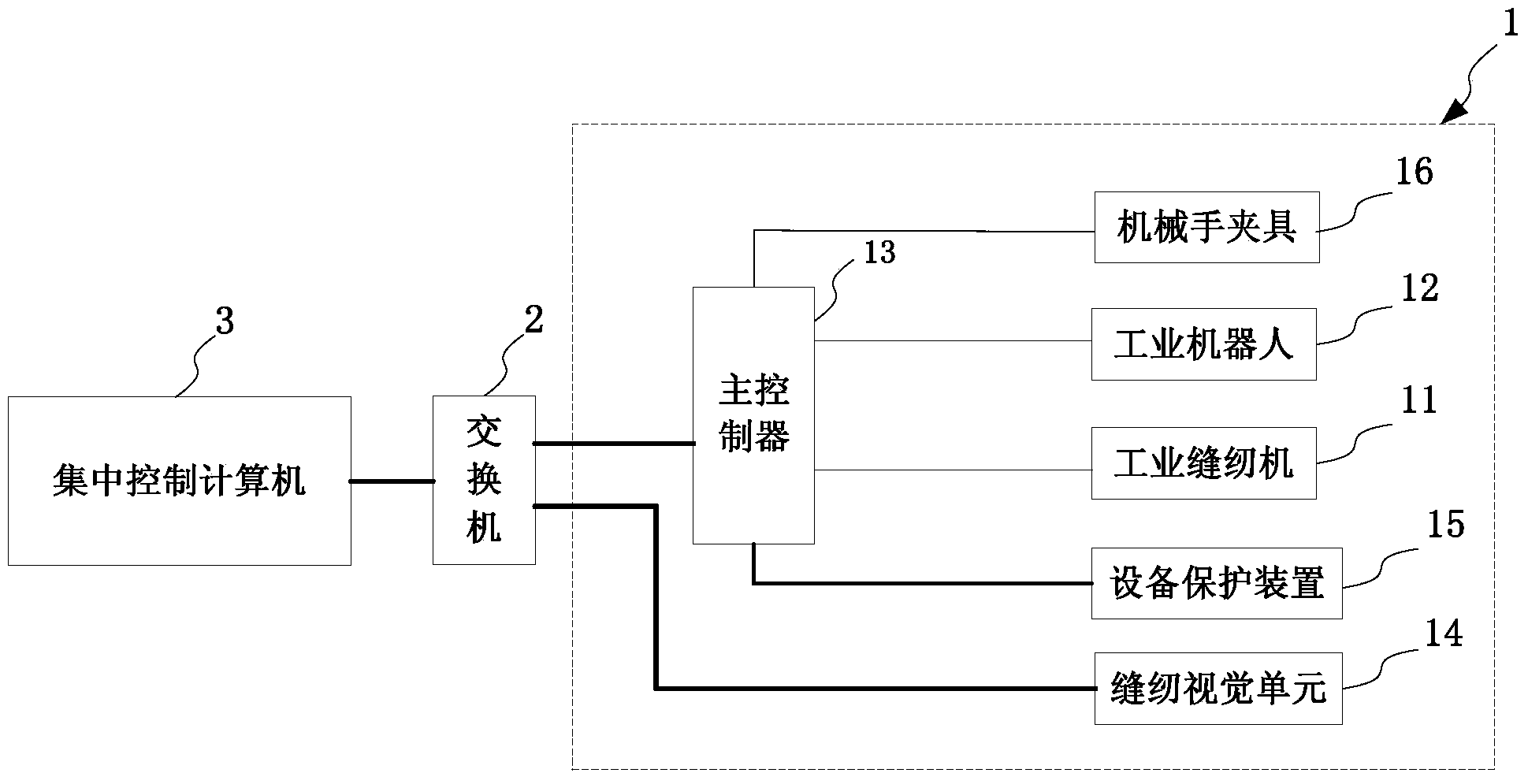

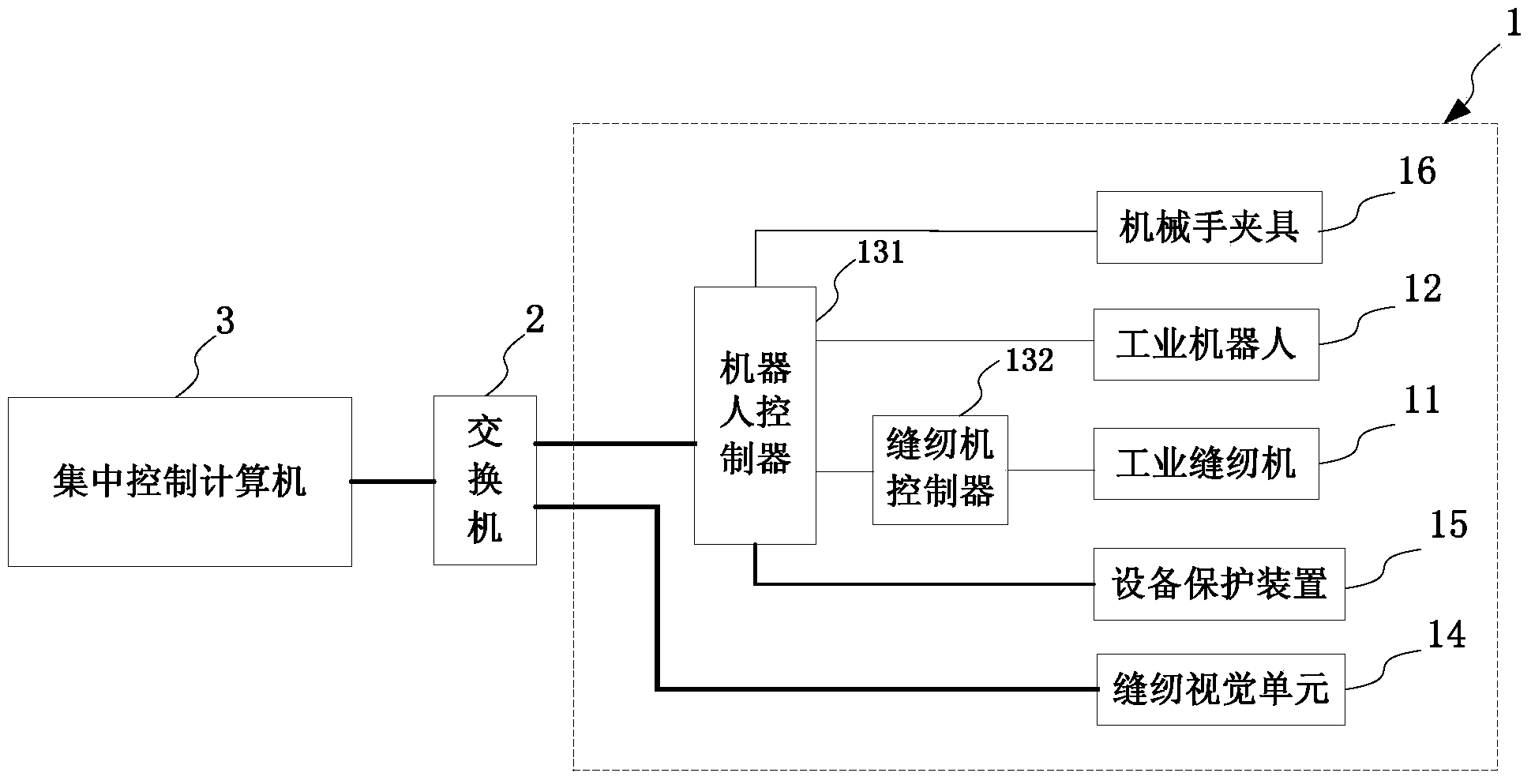

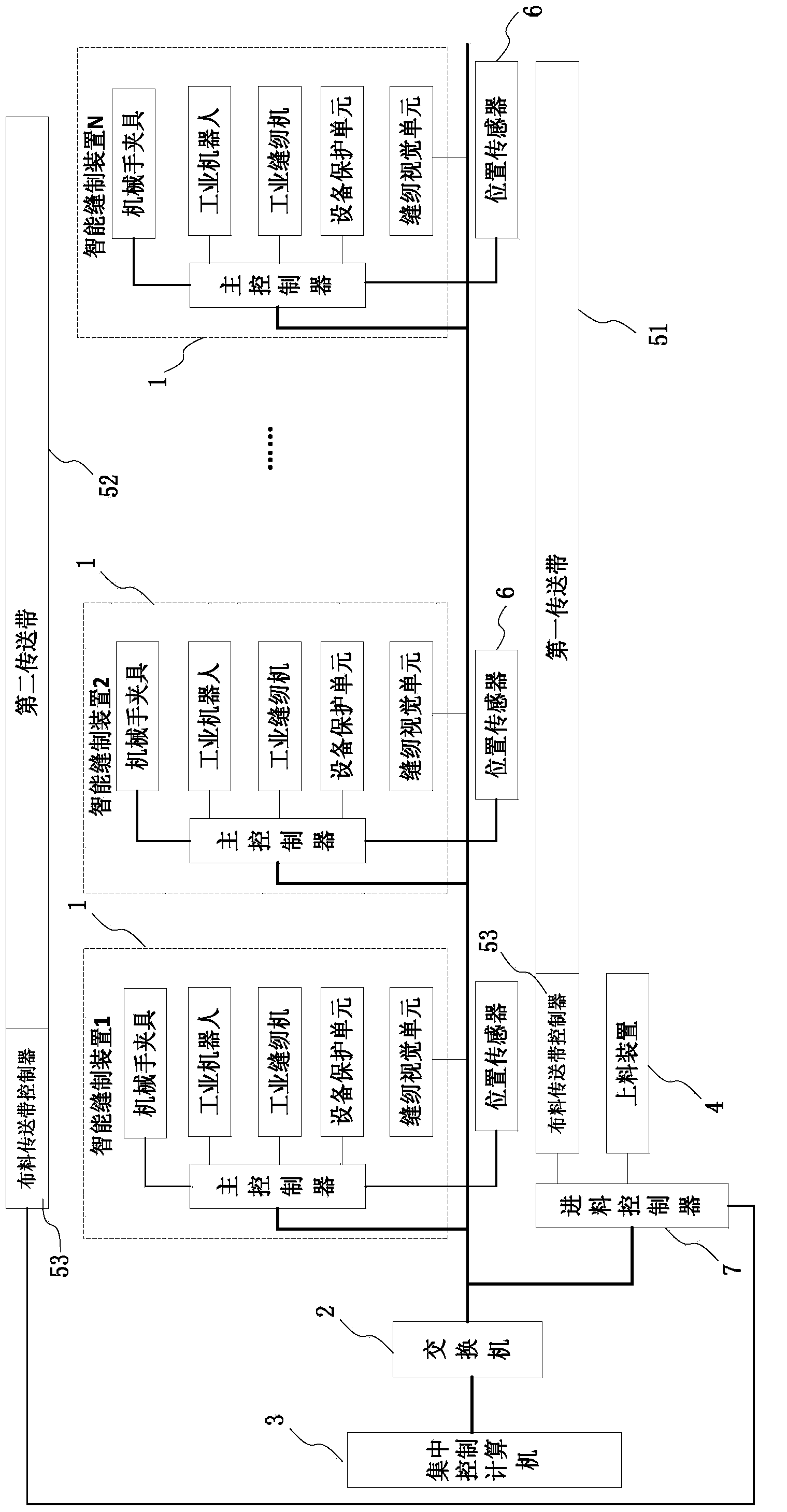

Intelligent sewing device and system

ActiveCN104018297ASewing precisionImprove work efficiencyProgramme-controlled sewing machinesSewing-machine control devicesHuman–computer interactionManipulator

The invention provides an intelligent sewing device and system. The device comprises an industrial sewing machine for sewing cloth, a mechanical arm clamp, an industrial robot, a main controller and a sewing vision unit. The industrial robot operates the mechanical arm clamp for sewing matching. The industrial sewing machine, the mechanical arm clamp, an equipment protecting device and the industrial robot are connected through the main controller which then carries out control. The sewing vision unit is used for shooting sewing workbench images and obtaining cloth images. The system comprises a plurality of intelligent sewing devices, main controllers, exchangers, feeding controllers, loading devices, feeding devices and centralized control computers. The main controllers and the exchangers are in communication connection with the intelligent sewing devices. The feeding controllers are in communication connection to the exchangers. The loading devices are connected with the feeding controllers. The feeding devices are used for placing of cloth by the loading devices and conveying the cloth to the intelligent sewing devices. The centralized control computers are in communication connection with operation man-machine interaction platforms of the exchangers. Through the system, automatic loading, feeding and sewing are achieved, during a sewing process, the cloth can be used for locating or correcting an algorithm, sewing is accurate, and working efficiency and product yield are greatly improved.

Owner:JACK SEWING MASCH CO LTD

Quilting method and apparatus

ActiveUS20050016428A1Easy to produceProgramme-controlled sewing machinesSewing-machine control devicesMotion detectorEngineering

A quilting apparatus for enabling a user to freely move a stack of fabric layers across a planar bed relative to an actuatable stitch head. The apparatus includes a motion detector which detects the movement of the stack and controls the actuation of the stitch head. Consequently, the apparatus functions to synchronize the delivery of stitch strokes by the head with the manually controlled movement of the quilt material stack. This frees the user to move the stack over a wide range of speeds, to start or stop movement at will, and to guide the stack in any direction across the planar bed.

Owner:BERNINA SEWING MACHINE

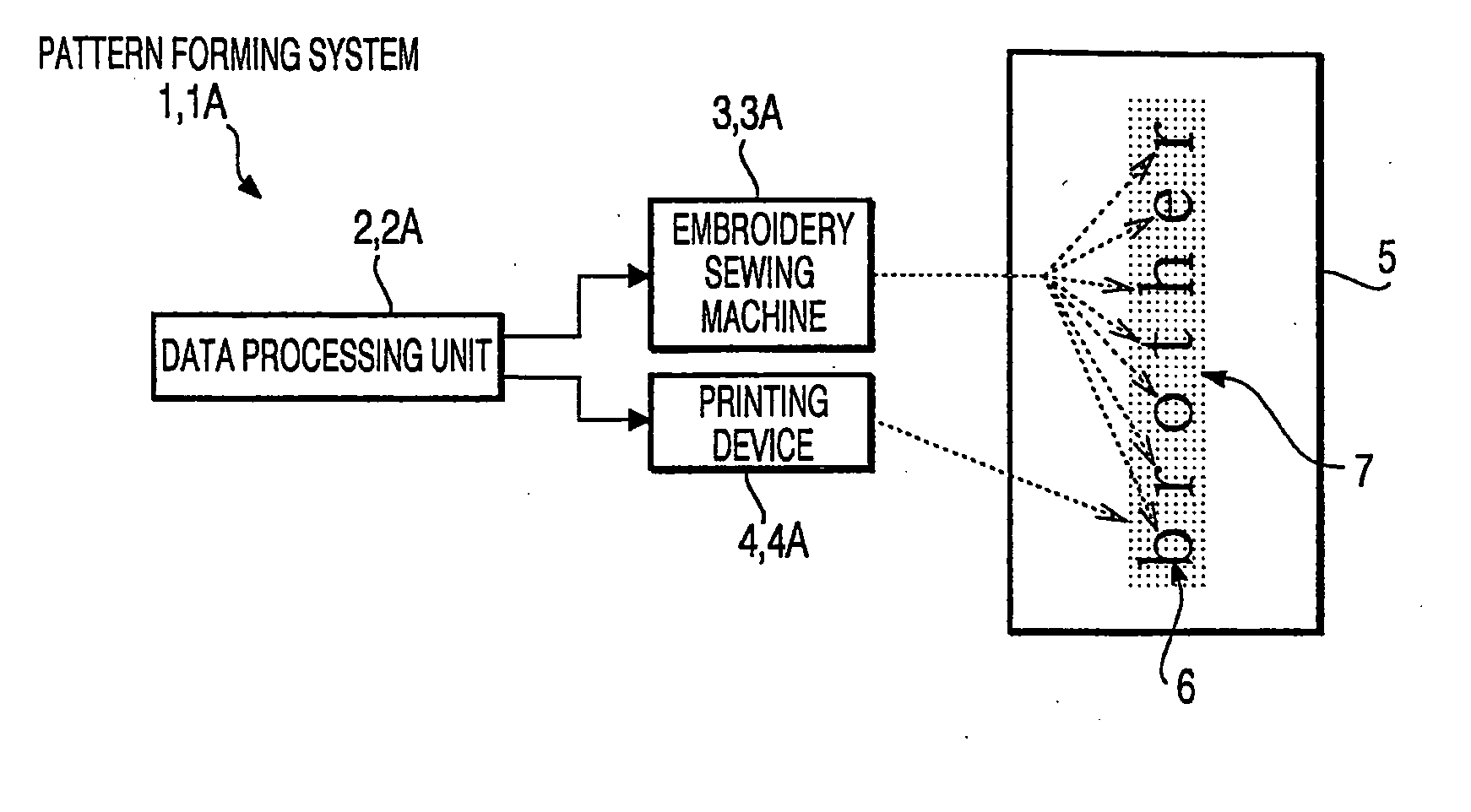

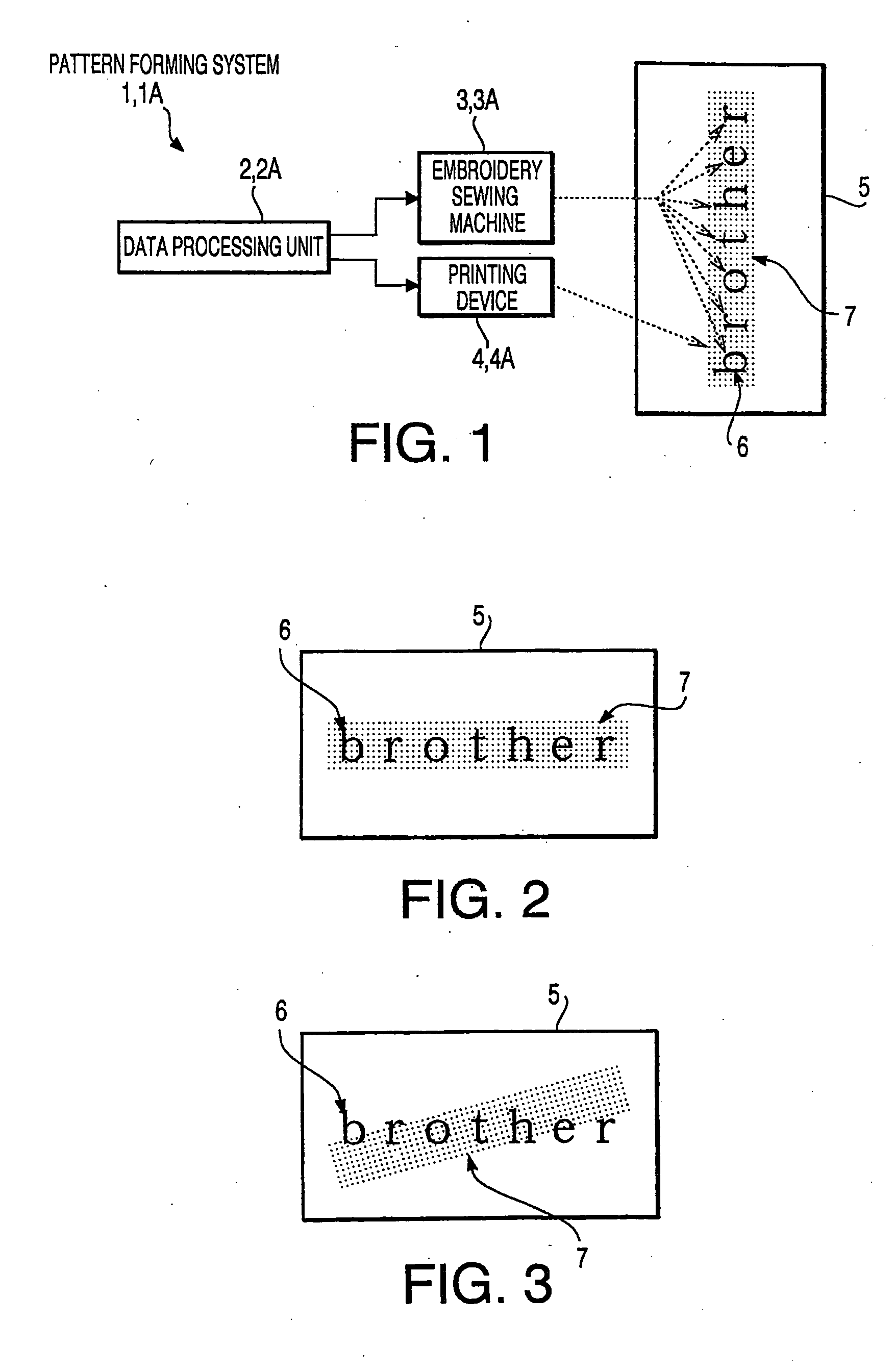

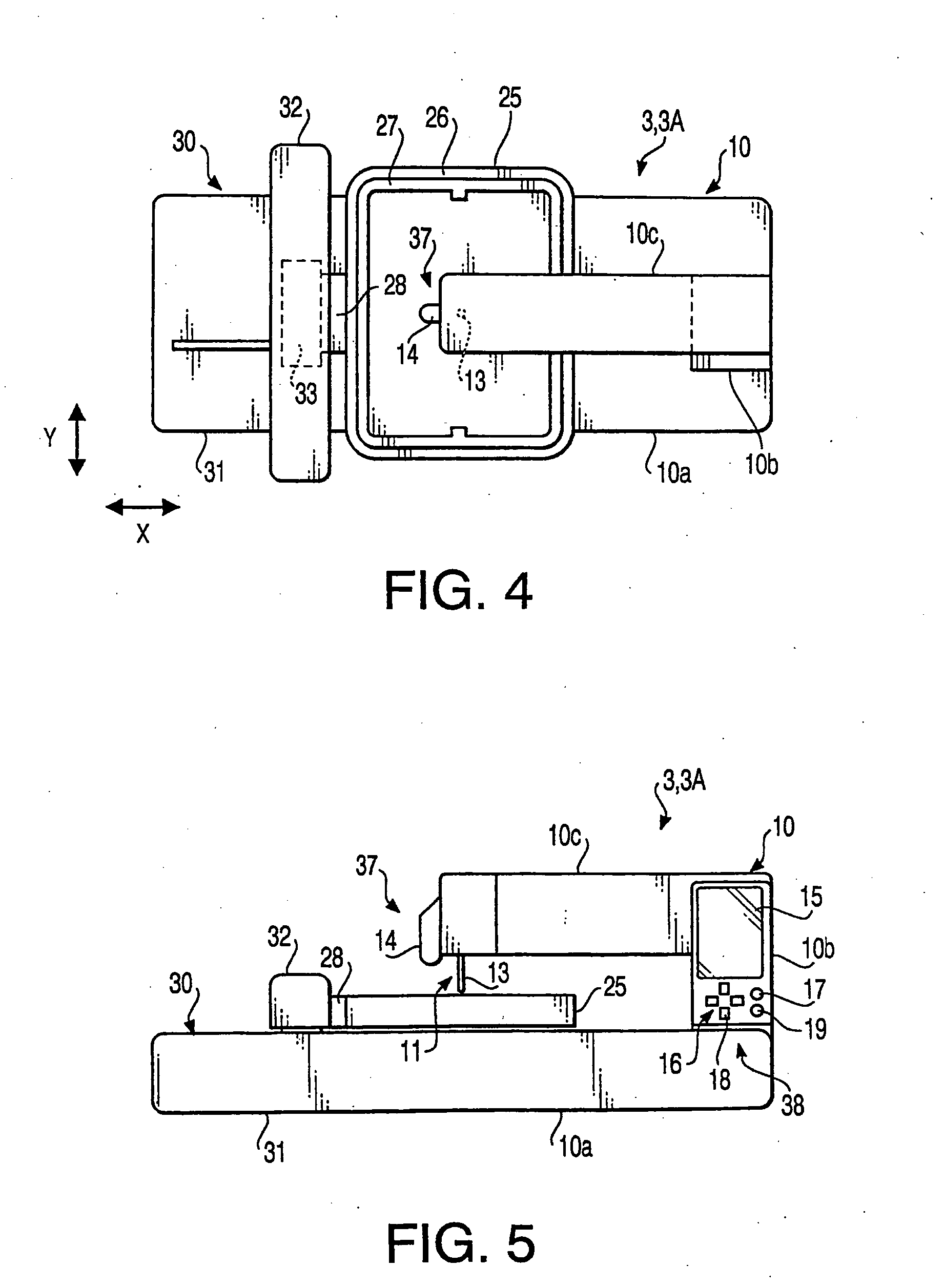

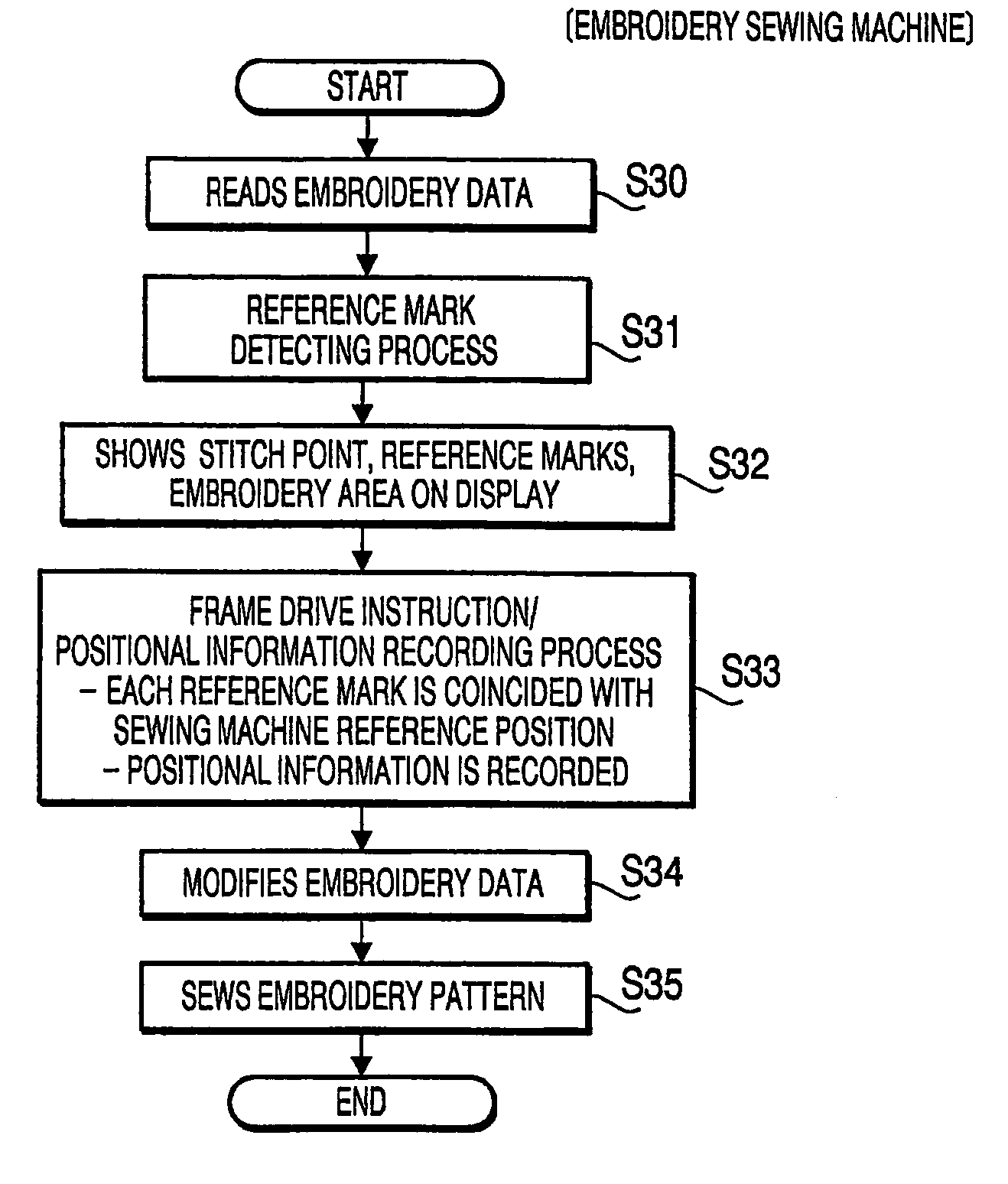

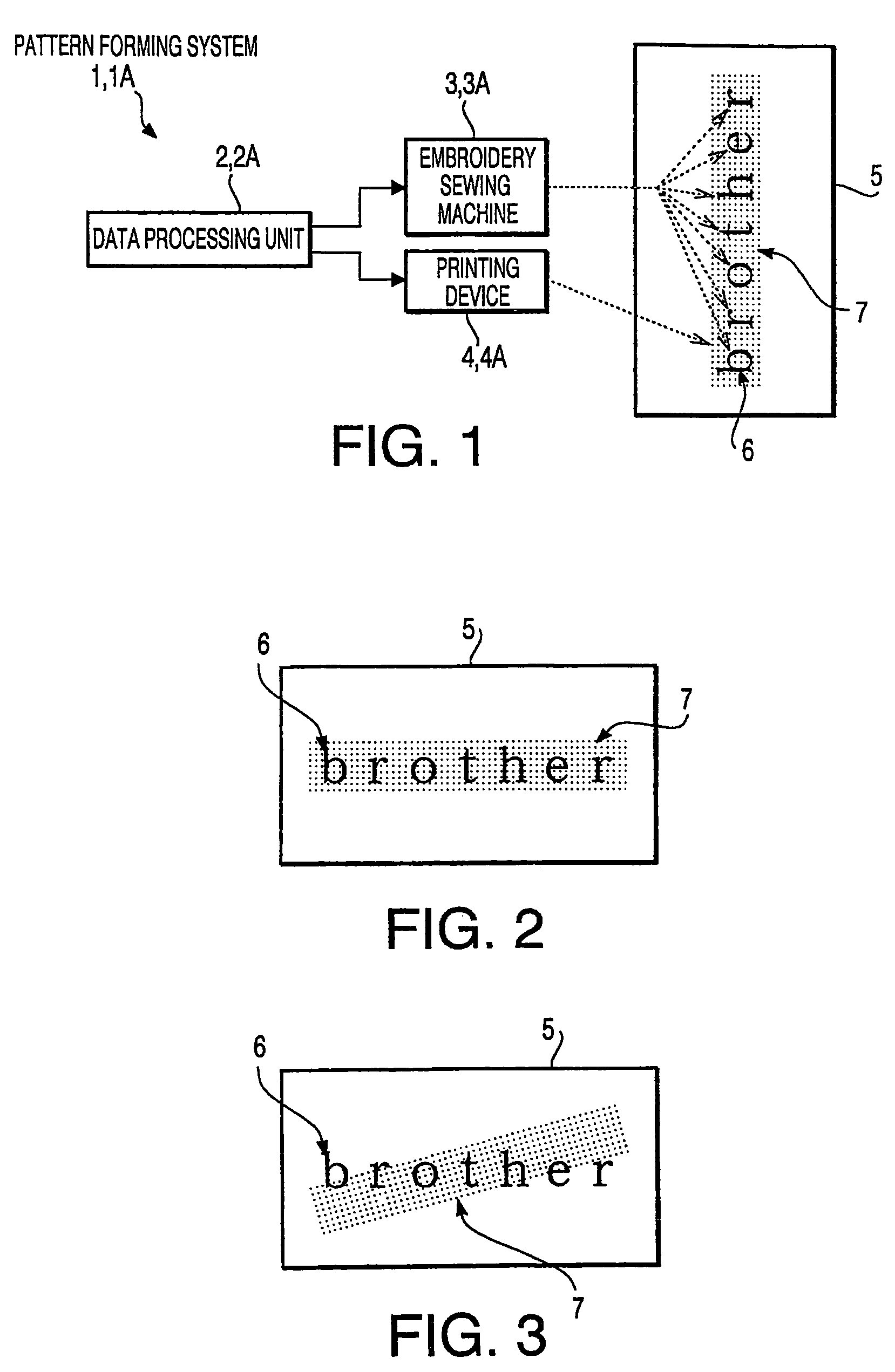

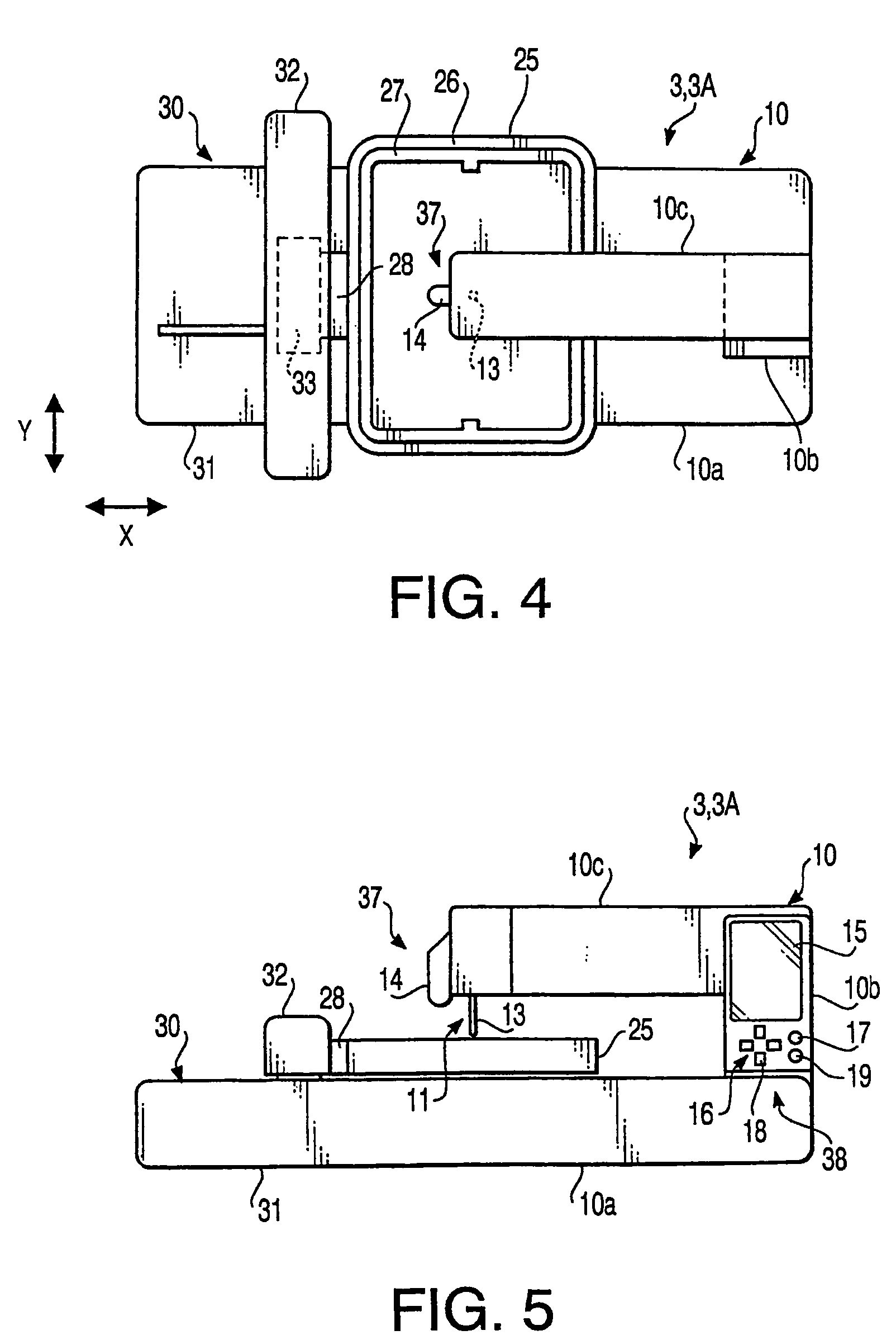

Data processing unit and pattern forming method

ActiveUS20060096510A1Quality improvementProgramme-controlled sewing machinesDigital differential analysersComputer graphics (images)Imaging data

A printing and embroidering system having a positional data appending system that is adapted to append positional data indicating positions of a first image and a second image with respect to each other to first image data representing the first image to be formed by one of printing and embroidering and second image data representing the second image to be formed by the other one of printing and embroidering, a first image forming unit with a first fabric holding member, which is adapted to form the first image based on the first image data on a fabric being held by the first fabric holding member, and a second image forming unit with a second fabric holding member, which is adapted to form the second image based on the fabric being held by the second fabric holding member, wherein the first image forming unit is provided with a mark forming system, which is adapted to form a predetermined mark represented by the positional data on the fabric, and wherein the second image forming system is provided with a misalignment eliciting system, which is adapted to elicit a misalignment between a position of the predetermined mark formed on the fabric held by the second fabric holding member and a position represented by the positional data appended to the second image data prior to forming the second image.

Owner:BROTHER KOGYO KK

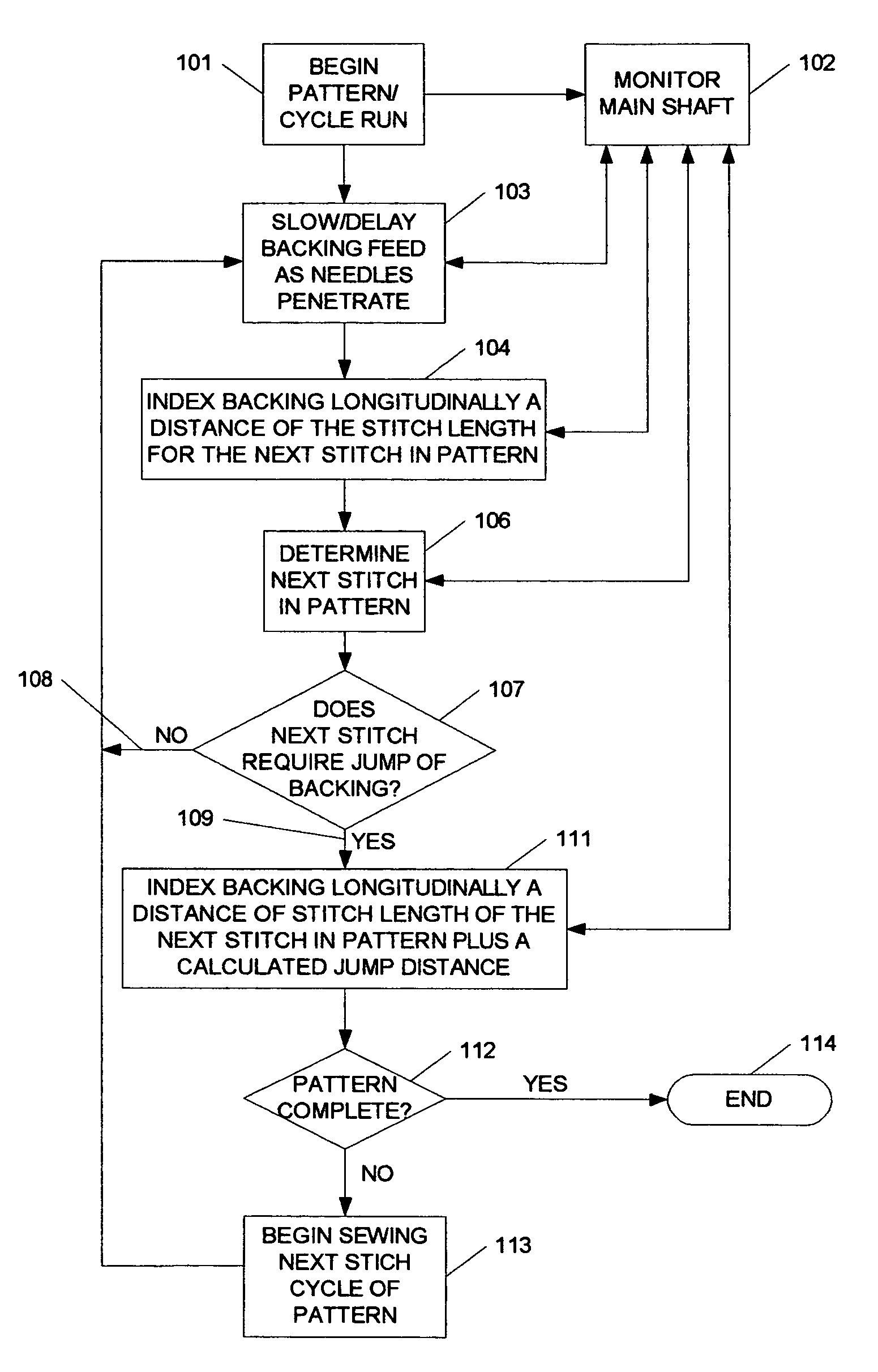

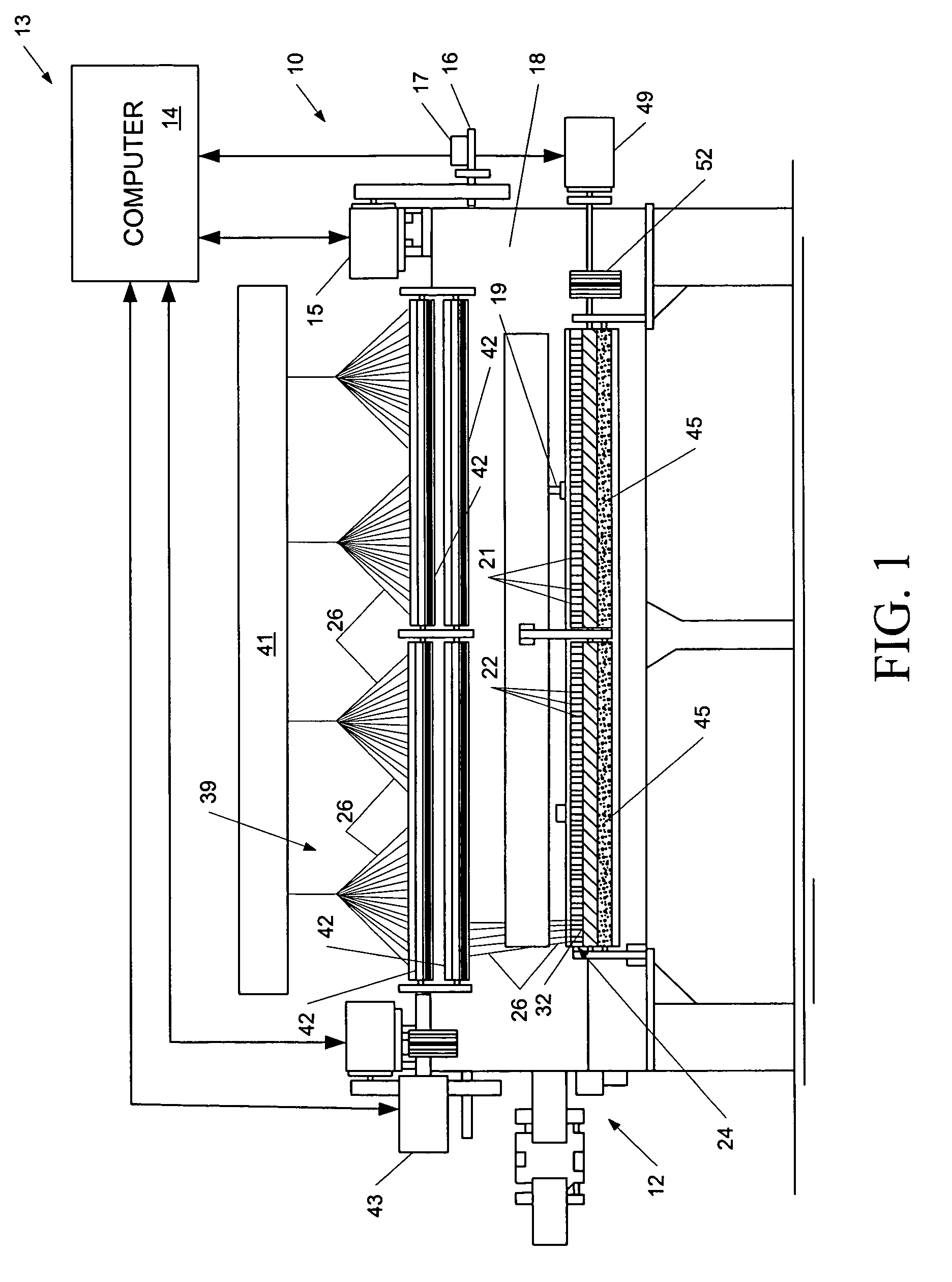

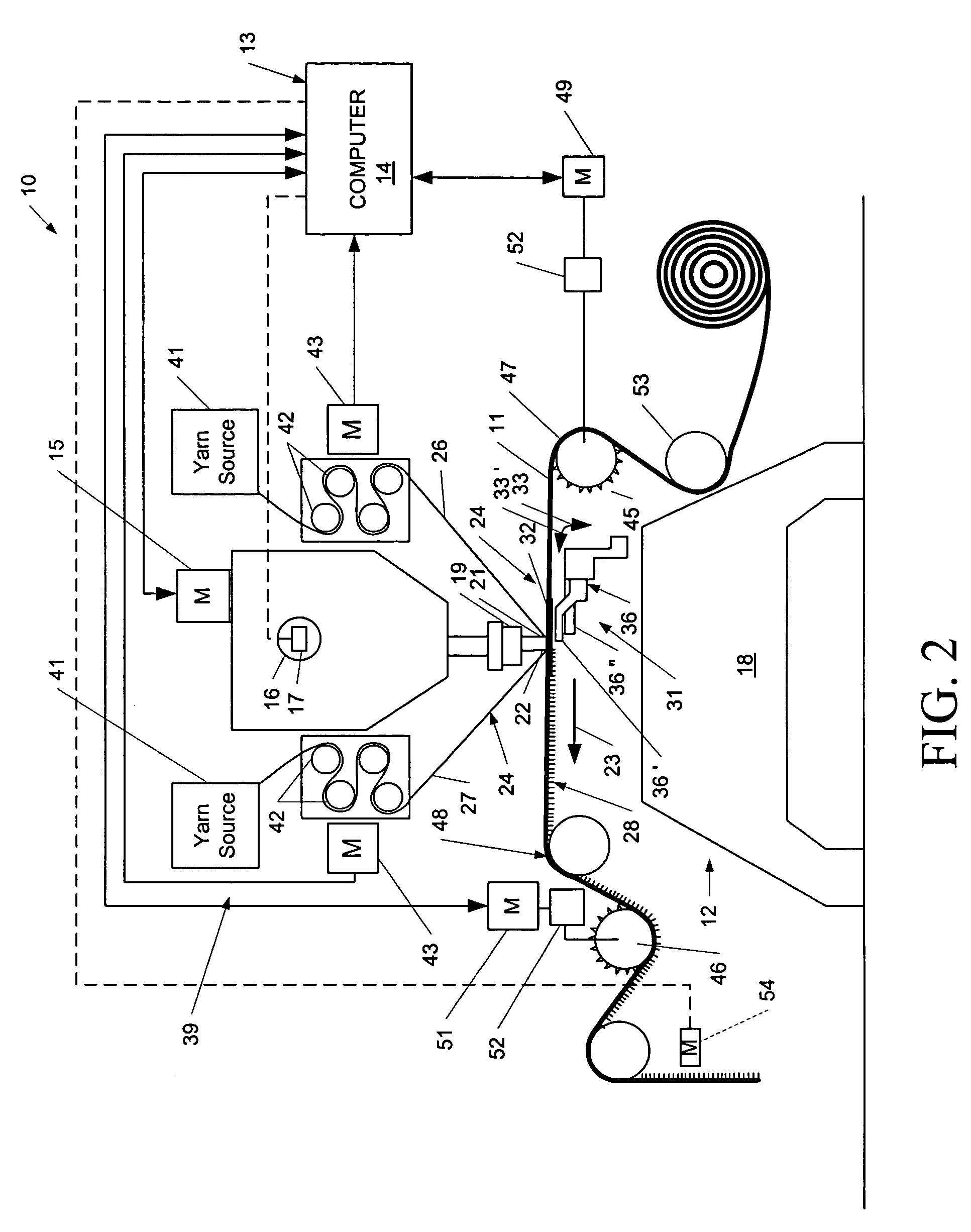

System and method for control of the backing feed for a tufting machine

ActiveUS7717051B1Further pattern effectsProgramme-controlled sewing machinesTufting apparatusMechanical engineeringTufting

Owner:CARD MONROE

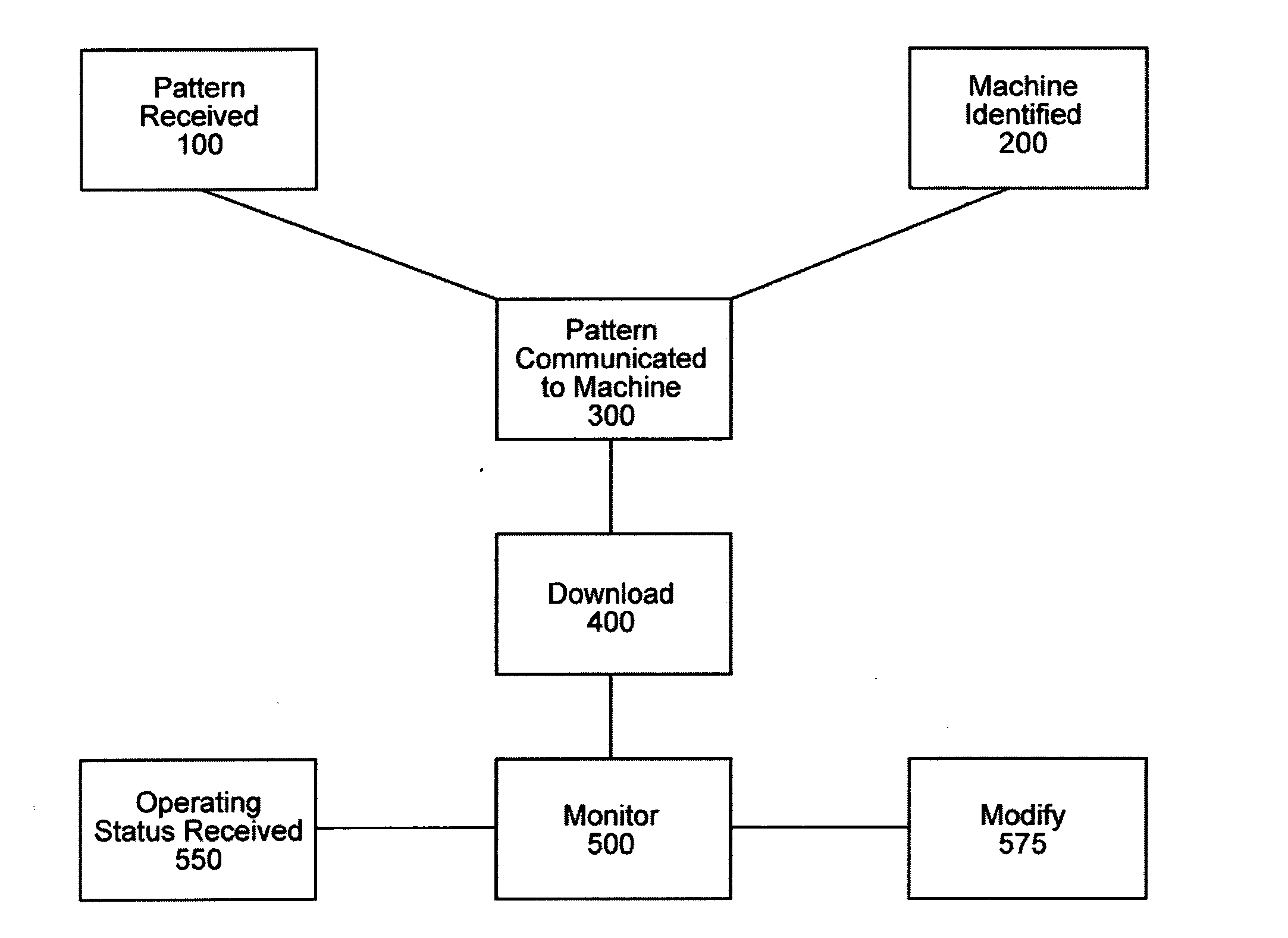

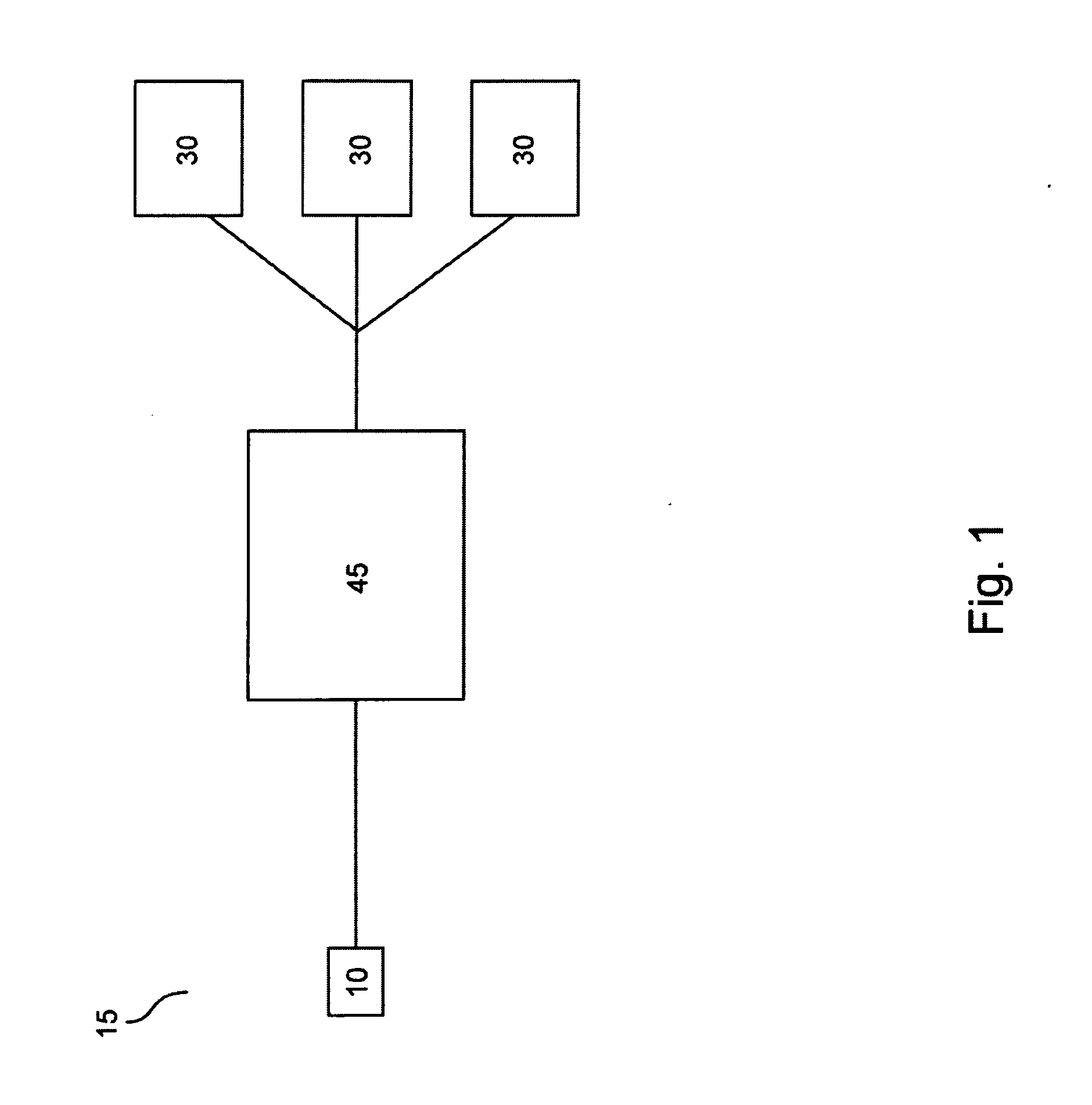

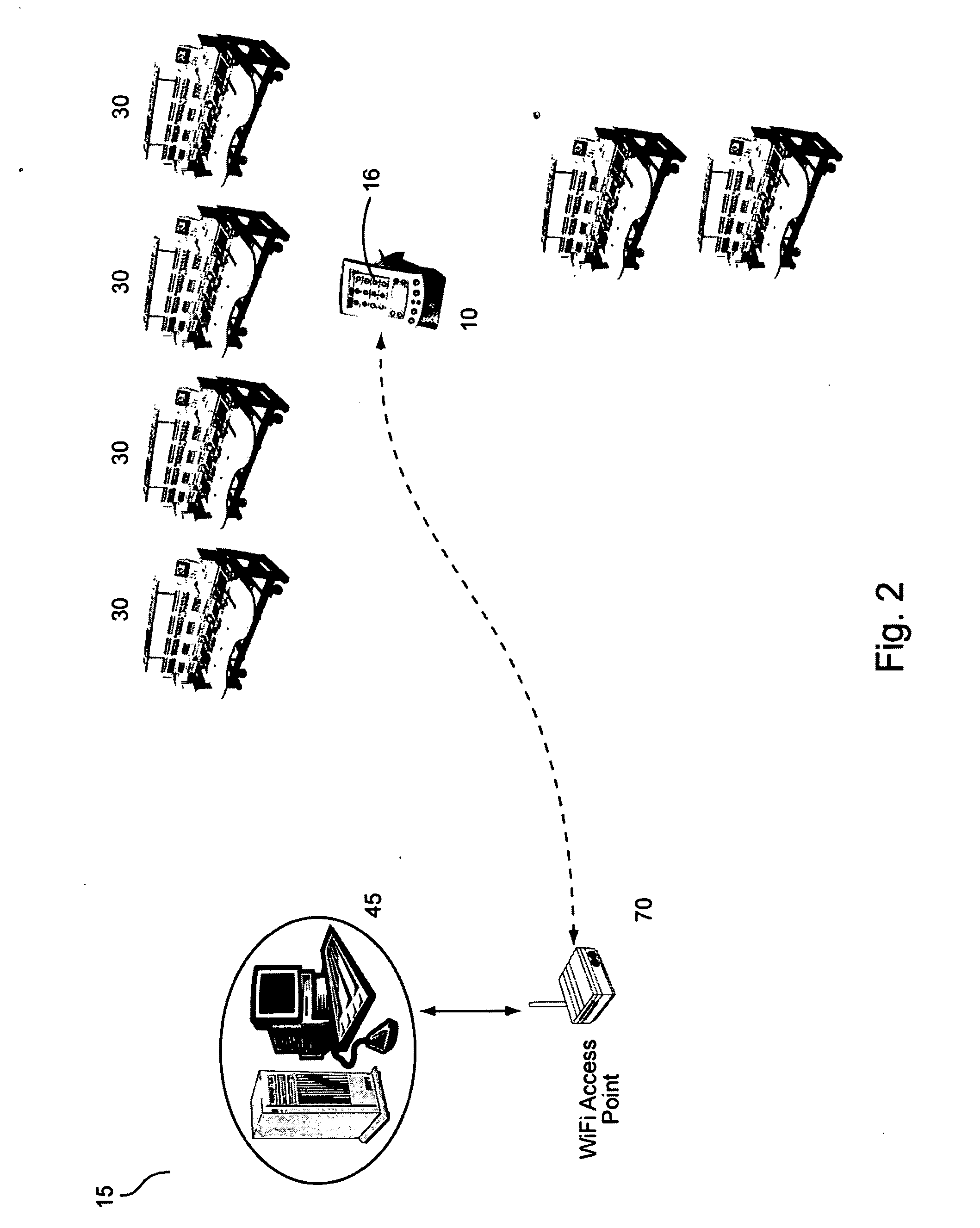

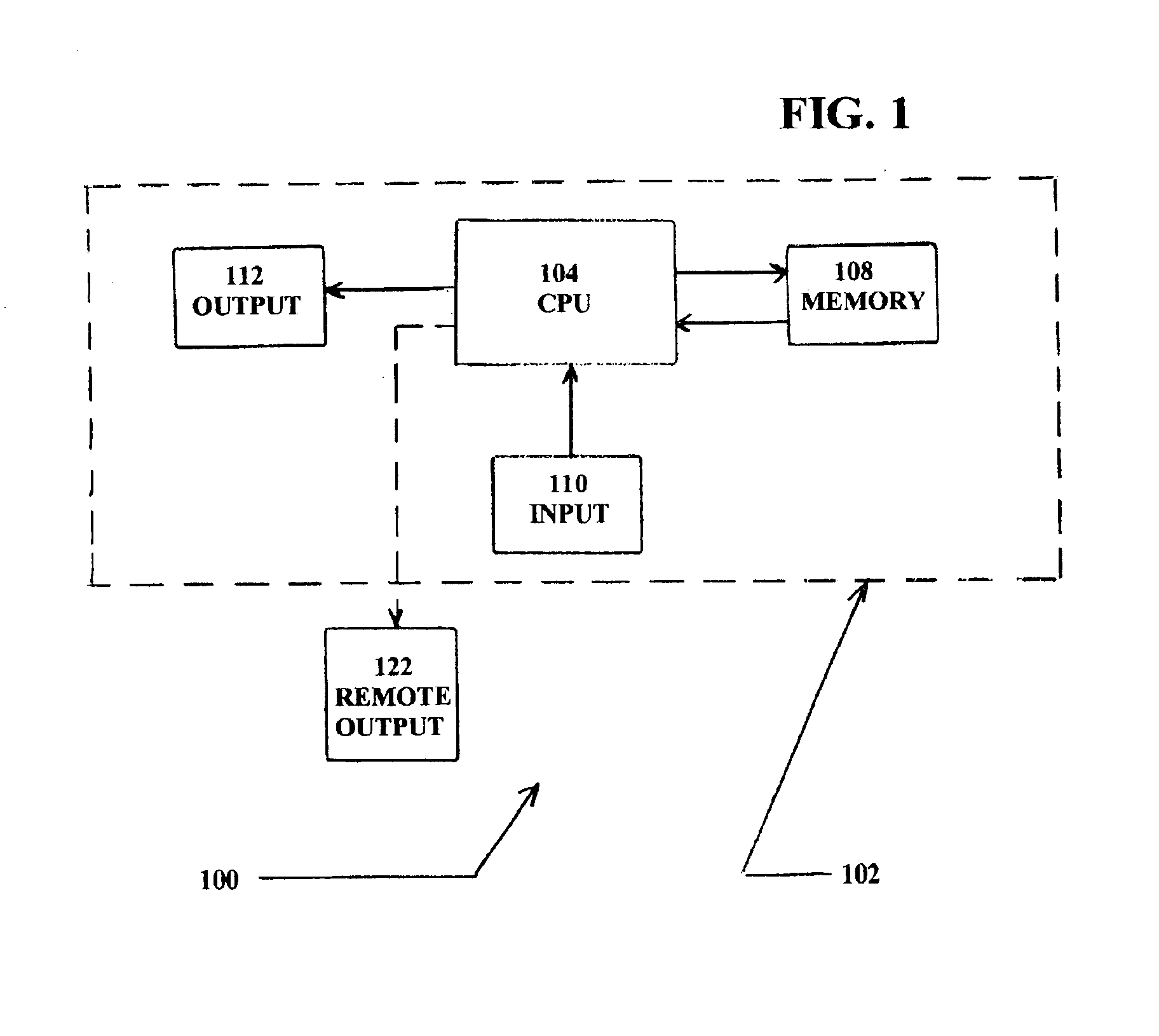

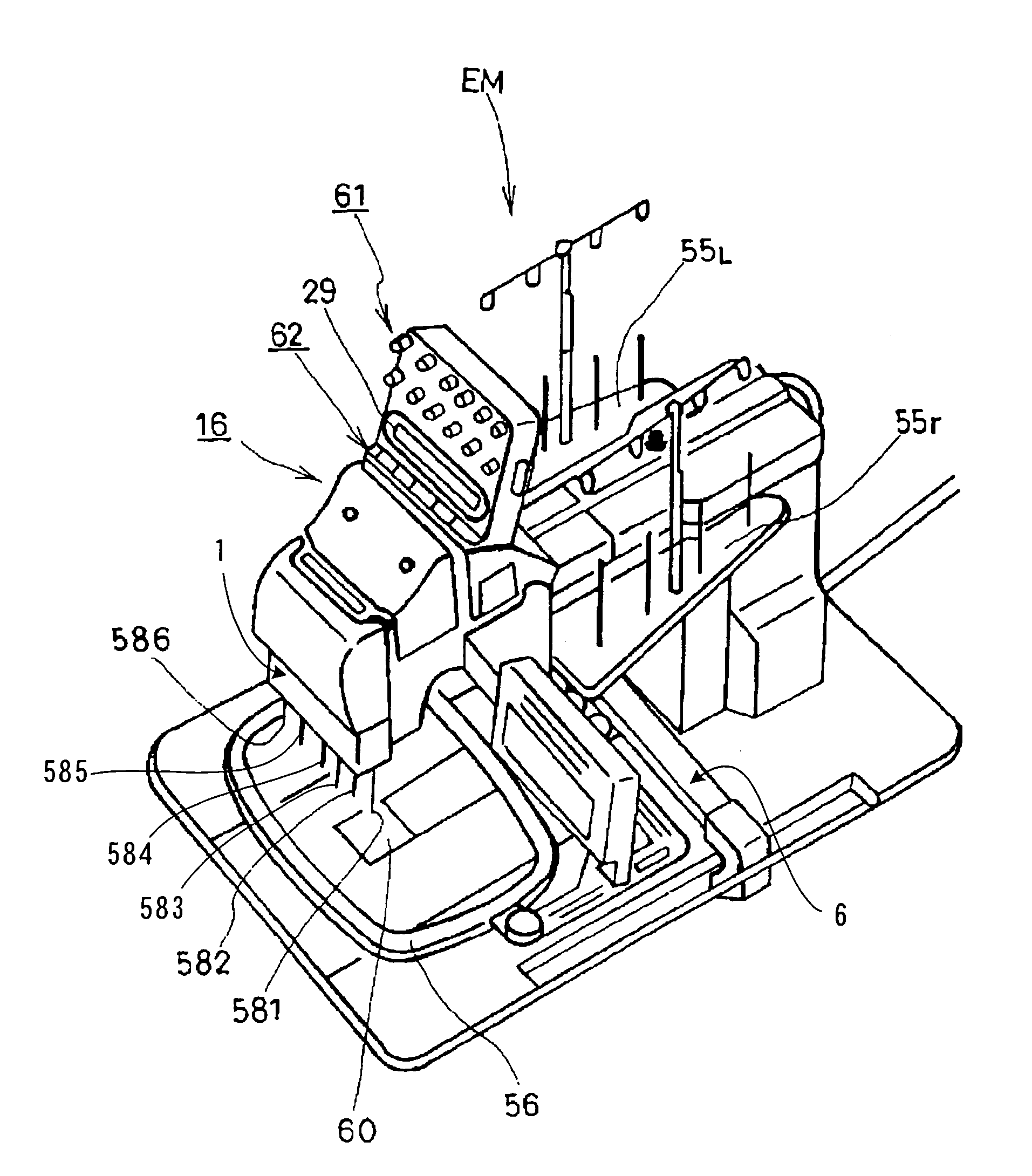

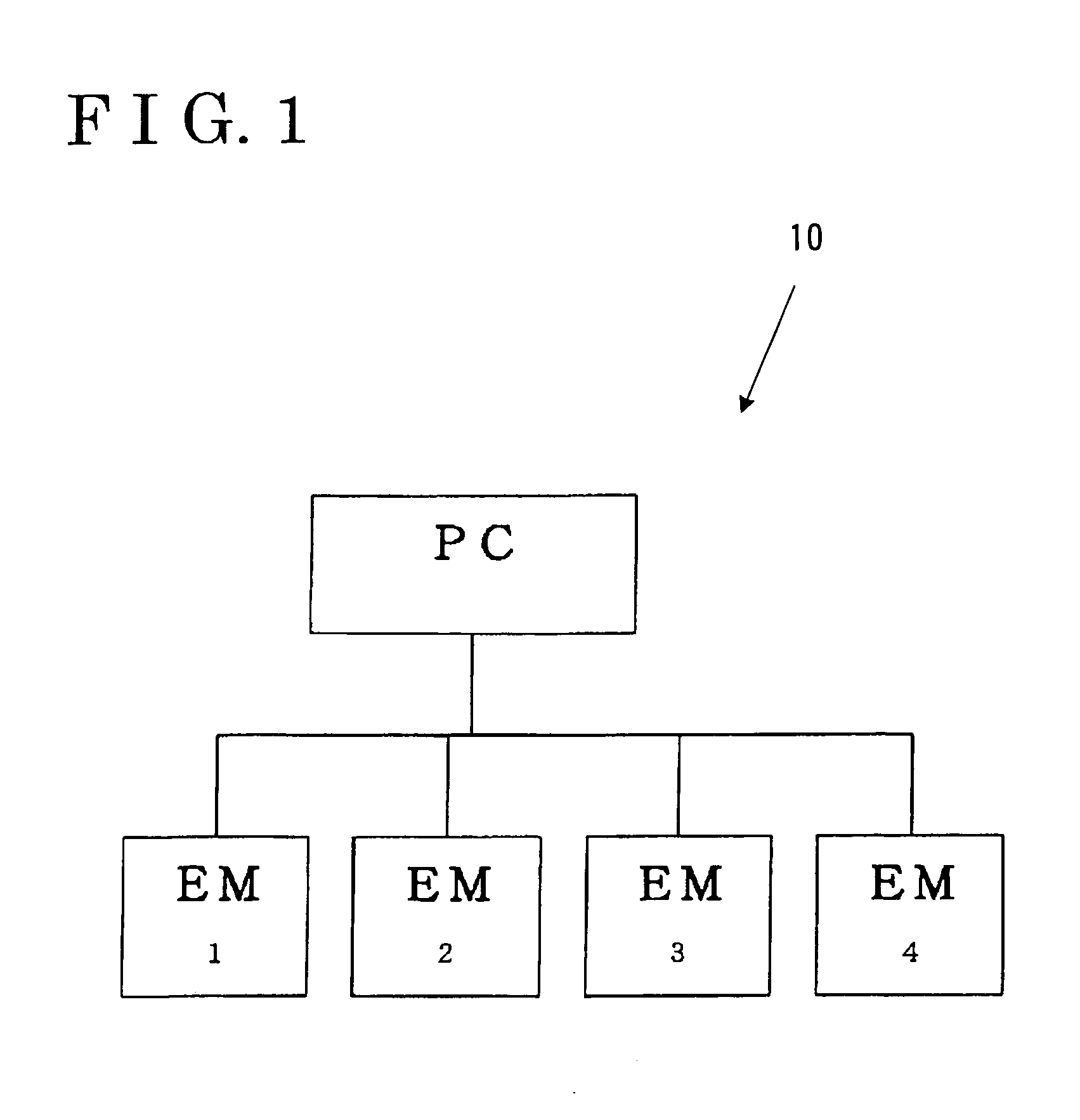

Embroidery network control system and method

InactiveUS20050060058A1Easy to operateExpand accessProgramme-controlled sewing machinesSpecial data processing applicationsGraphicsGraphical user interface

A method and system of remotely communicating embroidery pattern data to embroidery machines involving providing an embroidery pattern in response to a pattern selection input from a remote user at a local node, the input communicated through a communications connection between the local node and a server, receiving an identification address for an embroidery machine, communicating the embroidery pattern to the embroidery machine for application of the embroidery pattern to a work piece. The system includes a server having circuitry for receiving wireless electronic communications, a local node having a graphical user interface for receiving input from a remote user, the local node in wireless electronic communication with the server, a database of electronically encoded data, the data comprising embroidery patterns, the database in communication with the server, and responsive to the local node input, to retrieve embroidery patterns and to display the embroidery patterns through the server to the remote user, and an embroidery machine in communication with the server, the embroidery machine receiving embroidery patterns from the database through the server.

Owner:CAMERON MARION +7

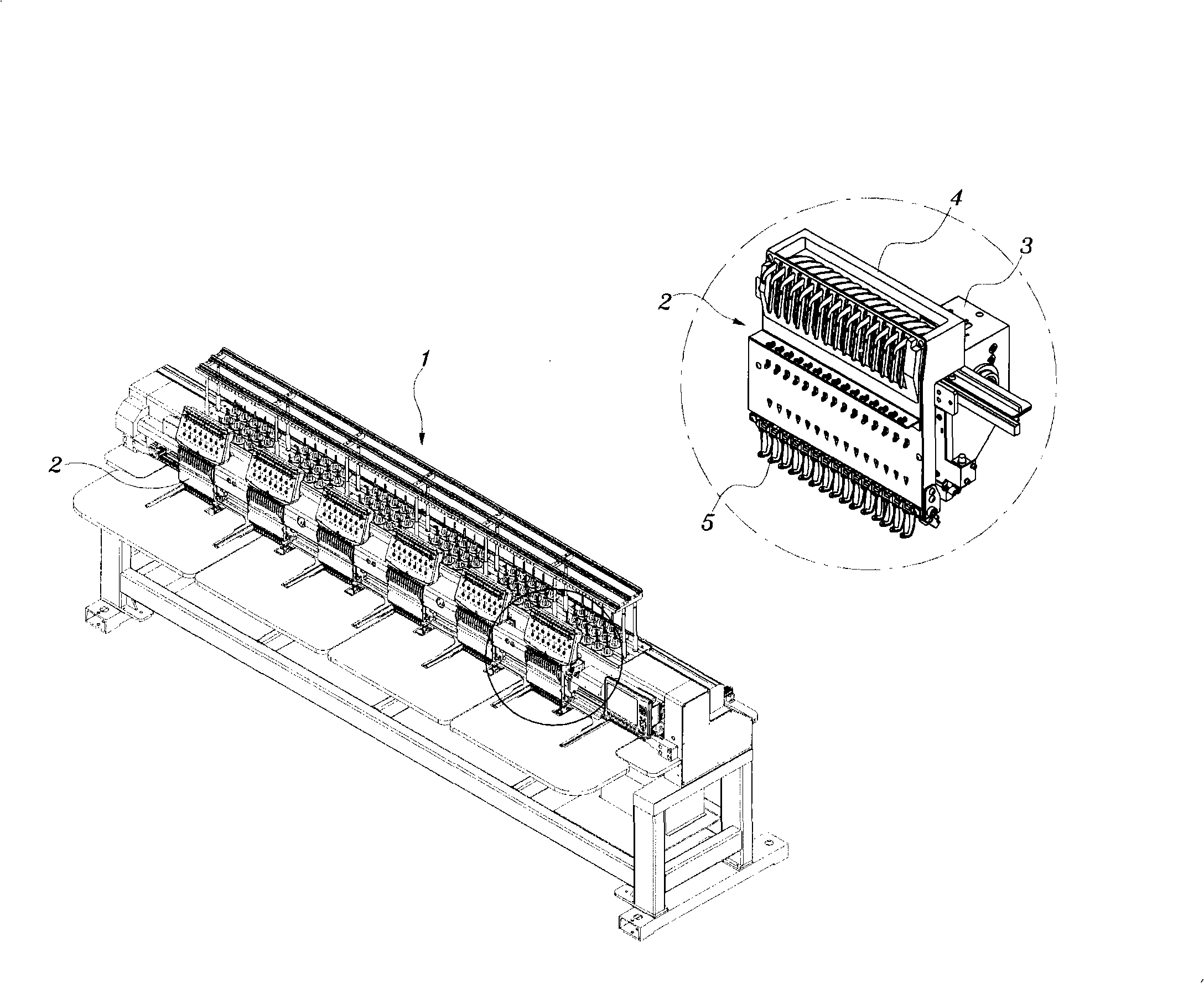

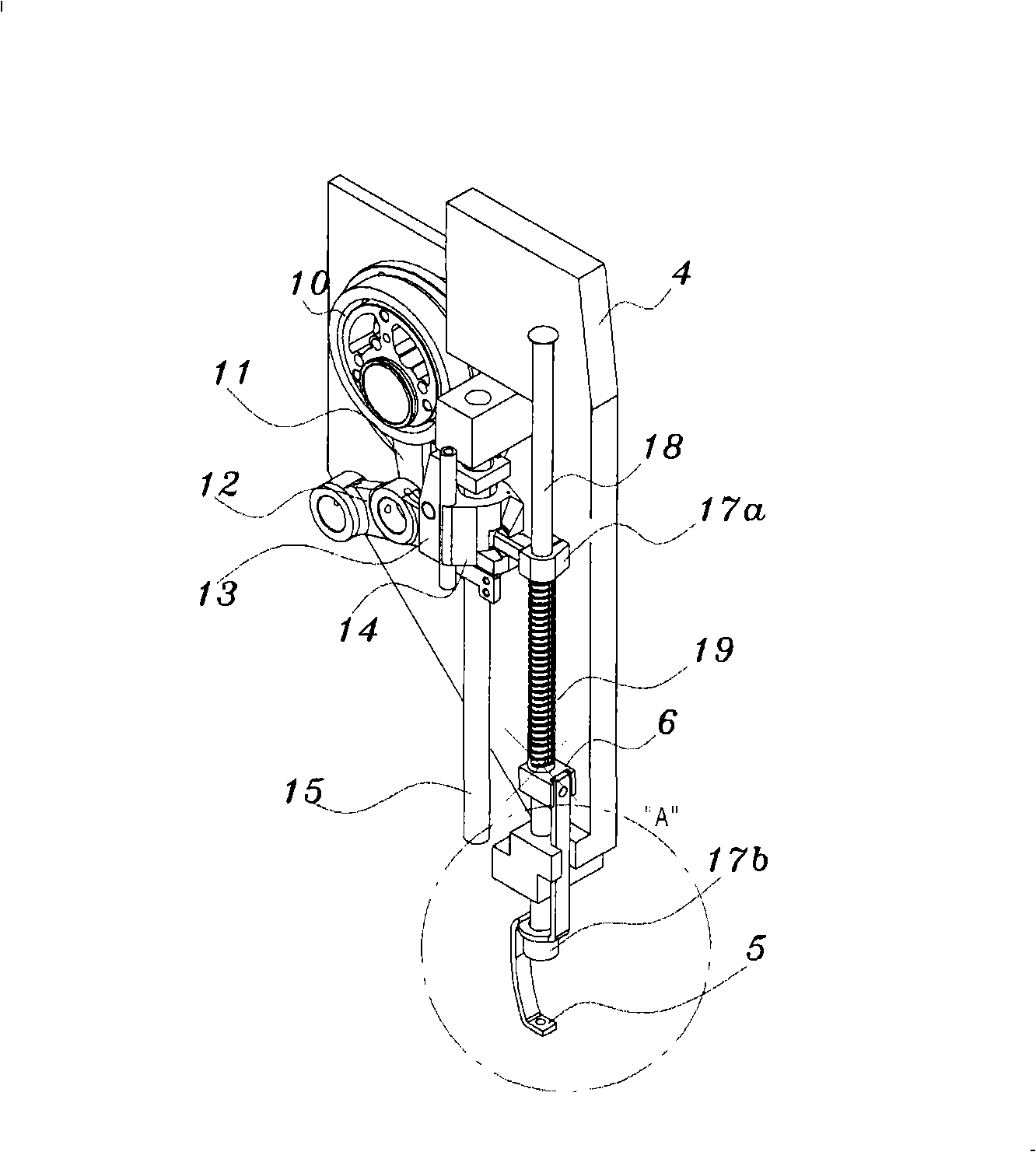

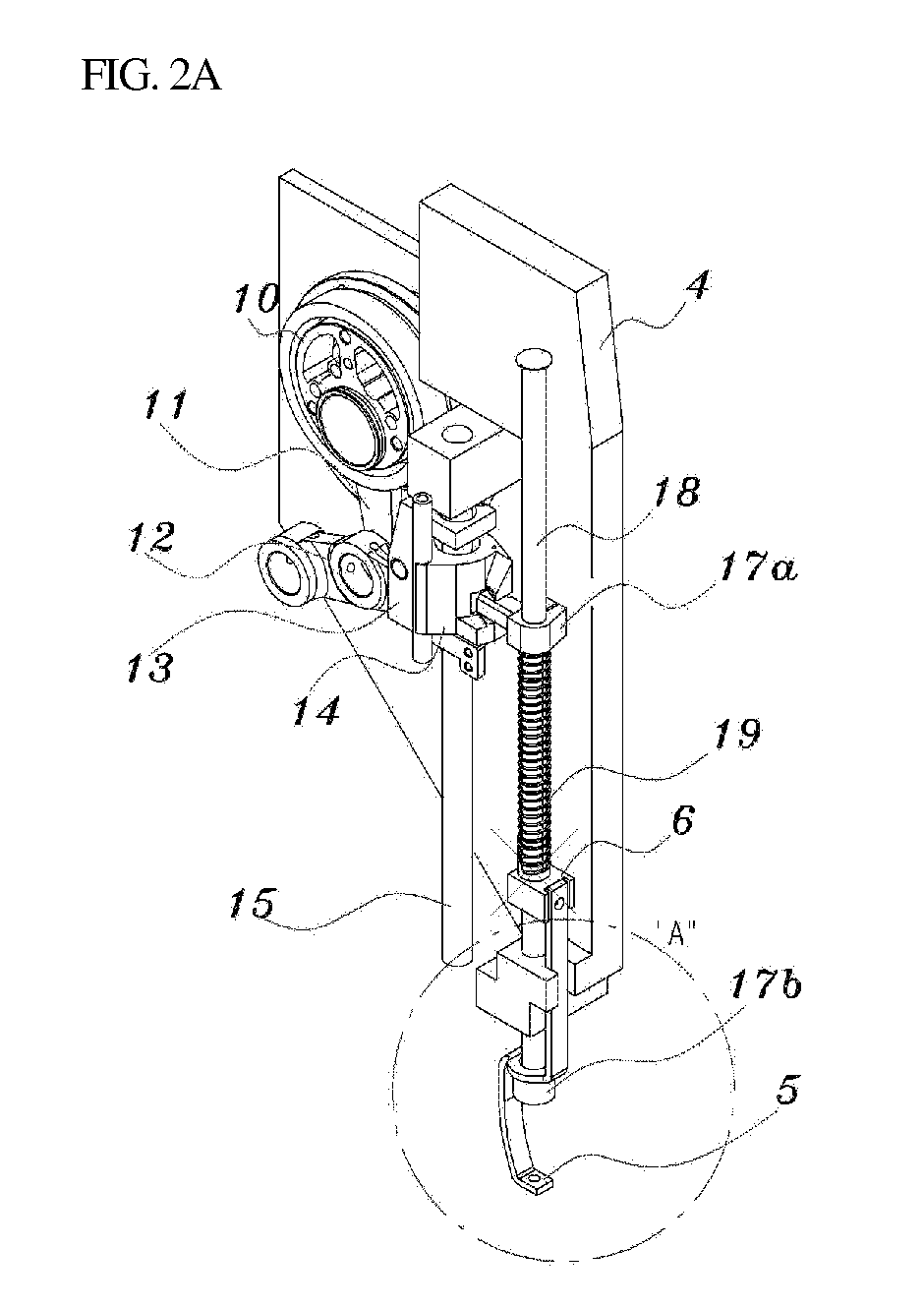

Embroidery machine

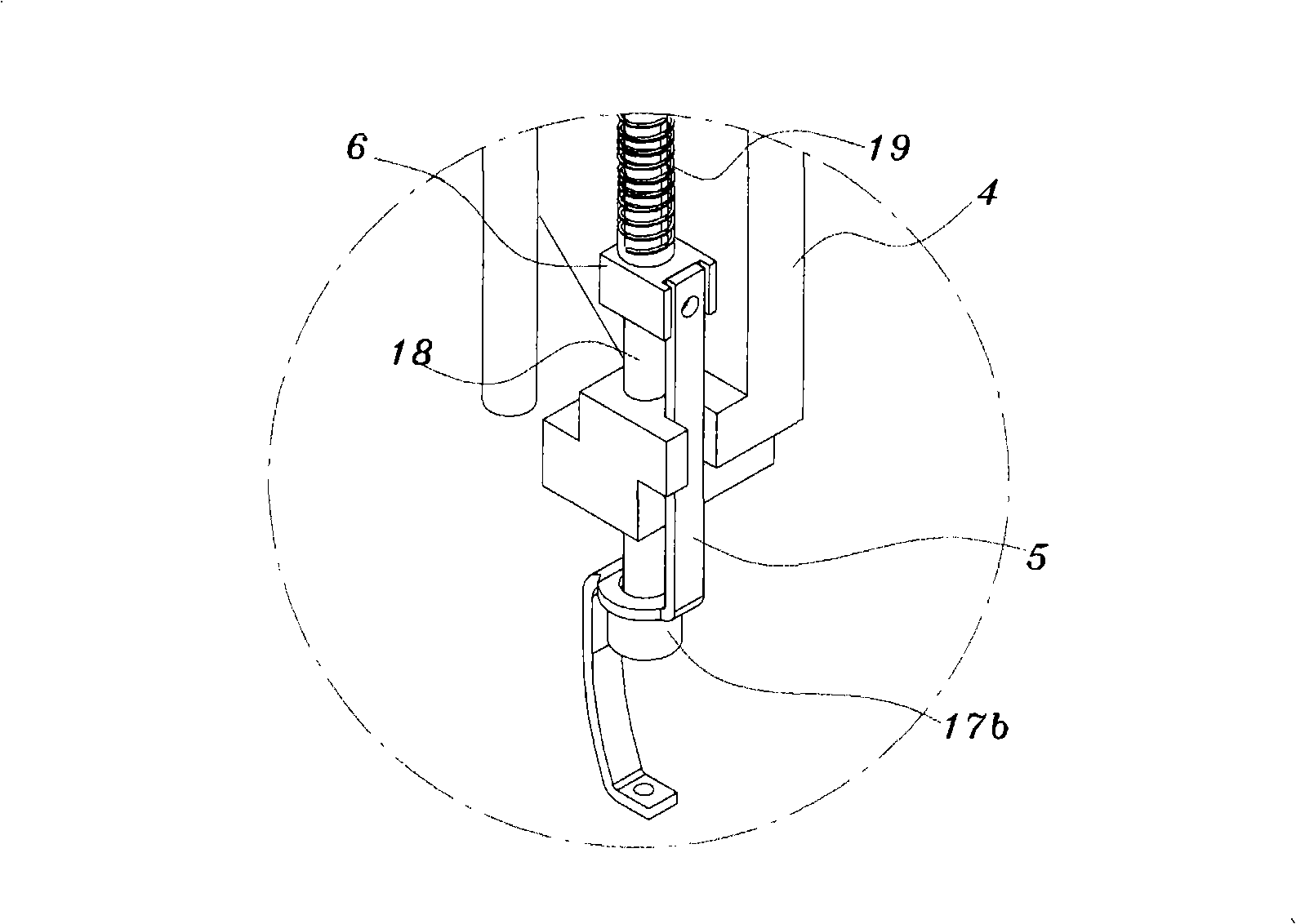

InactiveCN101260601AChange itineraryProgramme-controlled sewing machinesPressersEngineeringPRESSURE FEET

An embroidery machine includes a sewing arm having an upper shaft for providing a driving force, a needle bar support case, which is assembled to a front portion of the sewing arm so as to be laterally movable, a needle bar provided in a needle bar support case, the needle bar having a needle at a lower end thereof and vertically carrying the needle using a rotation driving force of the upper shaft, and a presser foot, which is provided in the needle bar support case so as to be vertically movable, characterized in that each of the needle bar and the presser foot is operated by an individual drive mechanism. The presser foot is separately driven by its own drive source, independent of the drive source of the needle bar.

Owner:SUSR PRECISION CO LTD

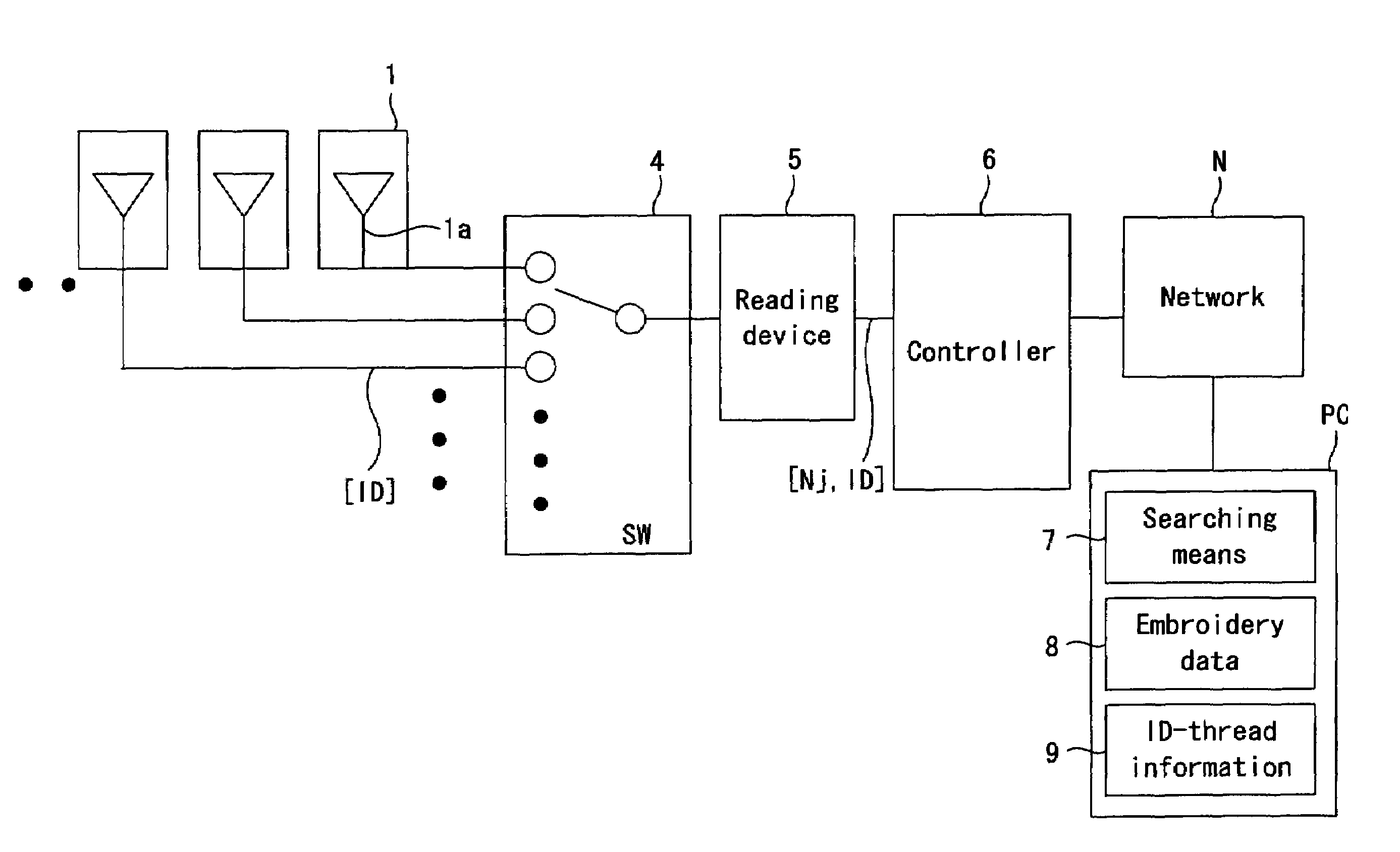

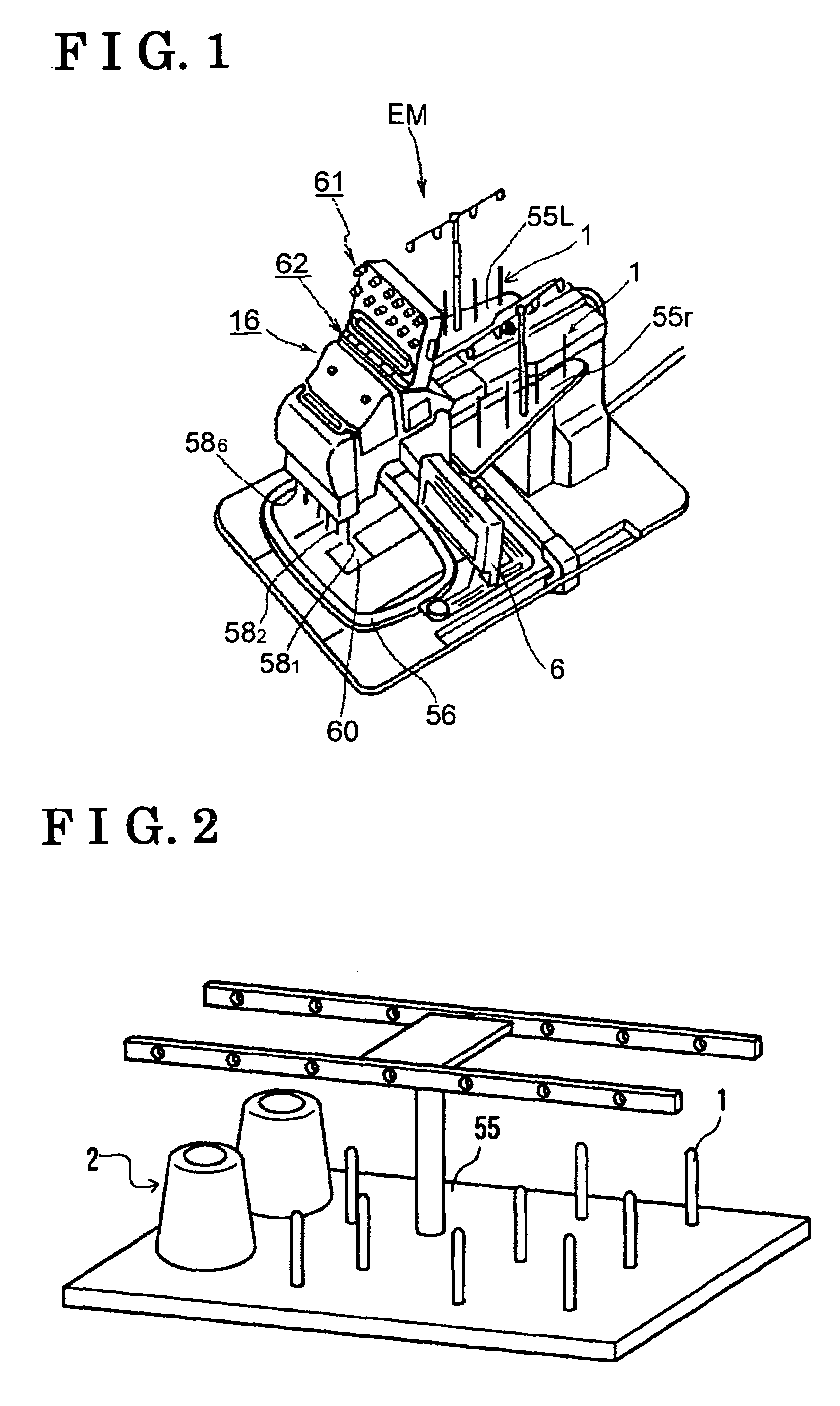

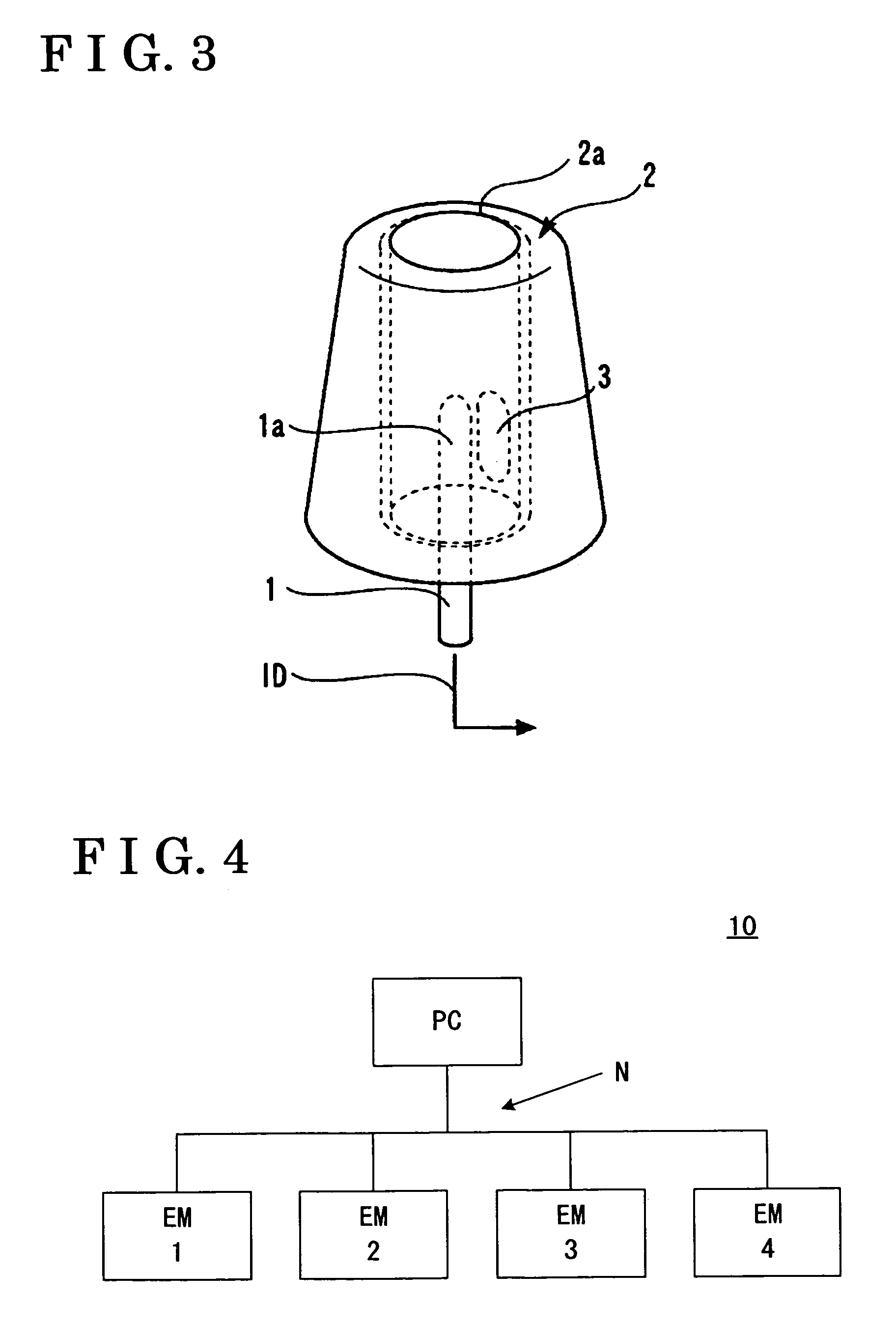

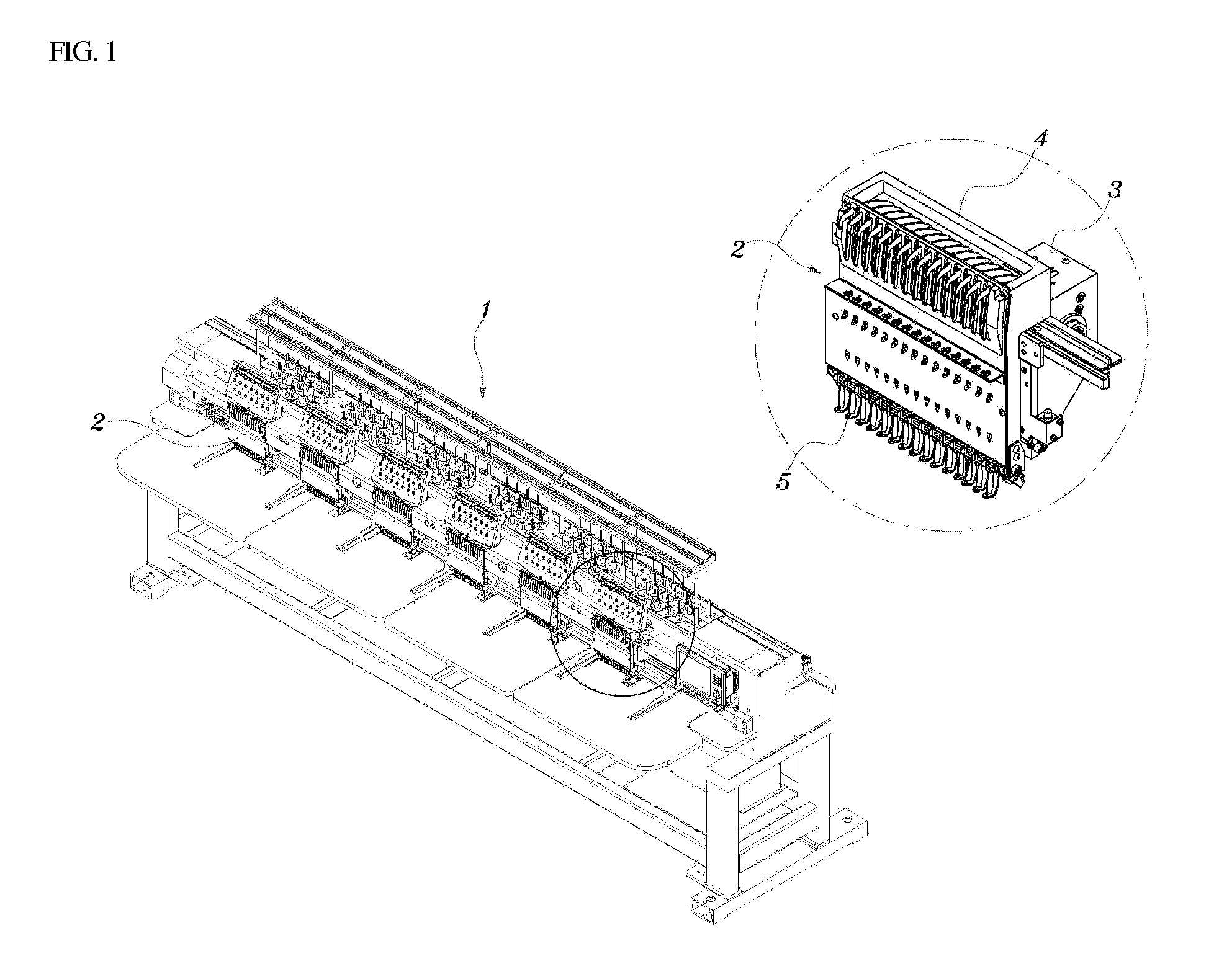

Embroidery machine and embroidery system

An embroidery machine includes a plurality of thread reel stand bars, a plurality of thread reels installed to the thread reel stand bars, respectively, a plurality of needles to which threads are supplied from the respective thread reels, at least two of the needles being selected to operate, on the basis of an embroidery data, in order for forming a stitch pattern of multiple colors, a wireless tag attached to each of the thread reels an having information related to the thread wound therearound, and a receiving device, for reading the information in the wireless tag, provided at each of the thread reel stand.

Owner:AISIN SEIKI KK

Data processing unit and pattern forming method

ActiveUS7854207B2Quality improvementProgramme-controlled sewing machinesDigital differential analysersComputer graphics (images)Computer science

A printing and embroidering system having a positional data appending system that is adapted to append positional data indicating positions of a first image and a second image with respect to each other to first image data representing the first image to be formed by one of printing and embroidering and second image data representing the second image to be formed by the other one of printing and embroidering, a first image forming unit with a first fabric holding member, which is adapted to form the first image based on the first image data on a fabric being held by the first fabric holding member, and a second image forming unit with a second fabric holding member, which is adapted to form the second image based on the fabric being held by the second fabric holding member, wherein the first image forming unit is provided with a mark forming system, which is adapted to form a predetermined mark represented by the positional data on the fabric, and wherein the second image forming system is provided with a misalignment eliciting system, which is adapted to elicit a misalignment between a position of the predetermined mark formed on the fabric held by the second fabric holding member and a position represented by the positional data appended to the second image data prior to forming the second image.

Owner:BROTHER KOGYO KK

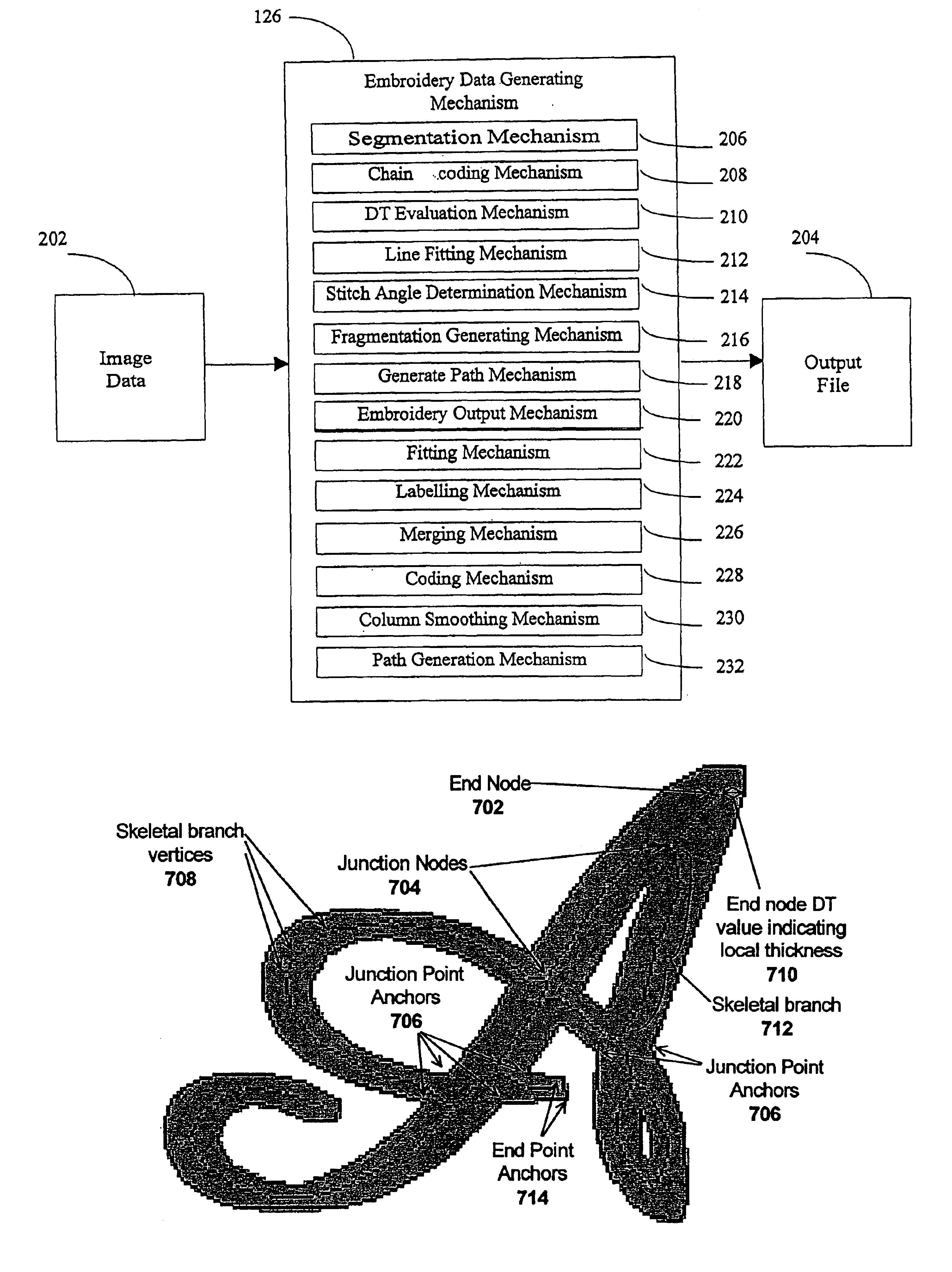

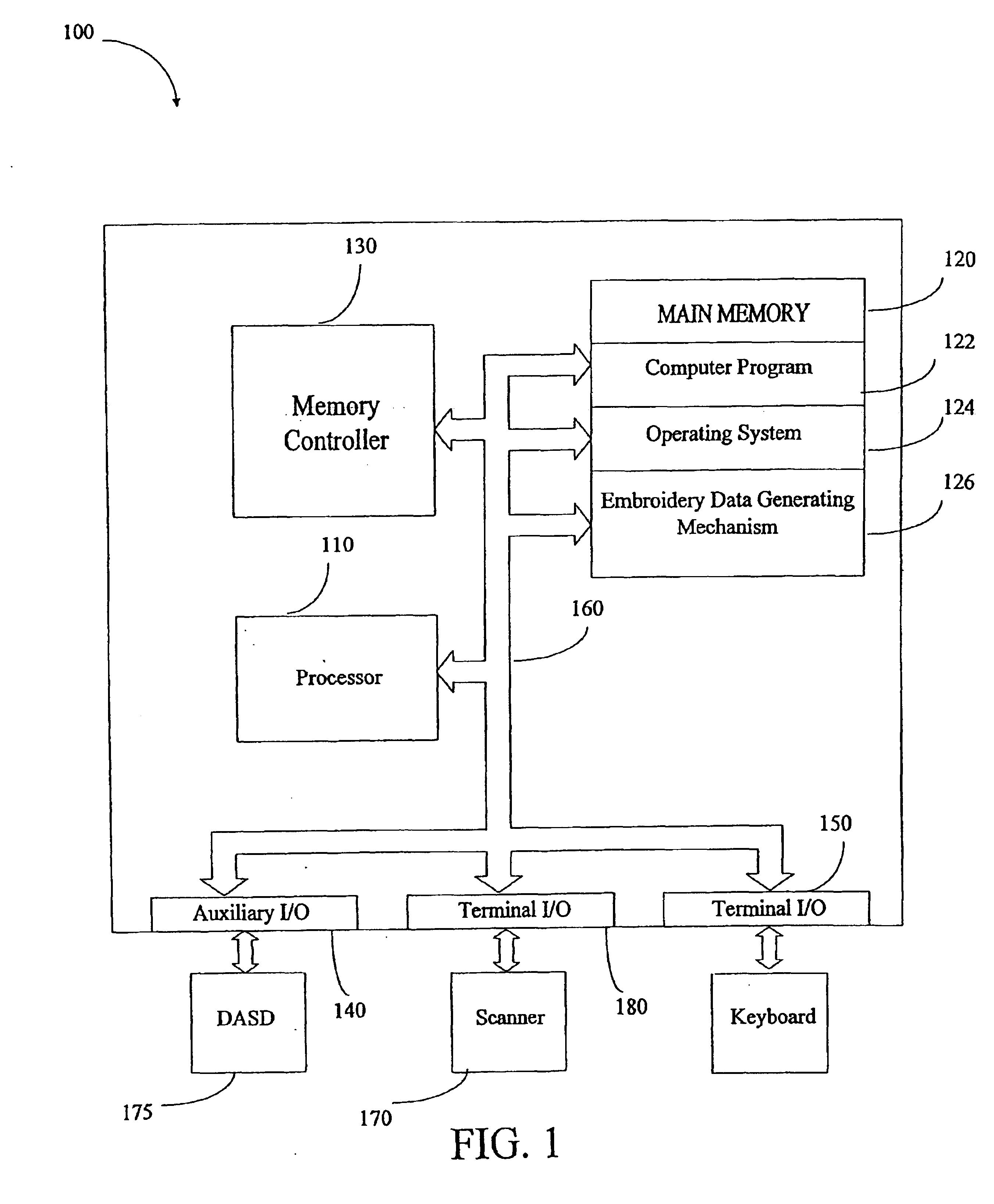

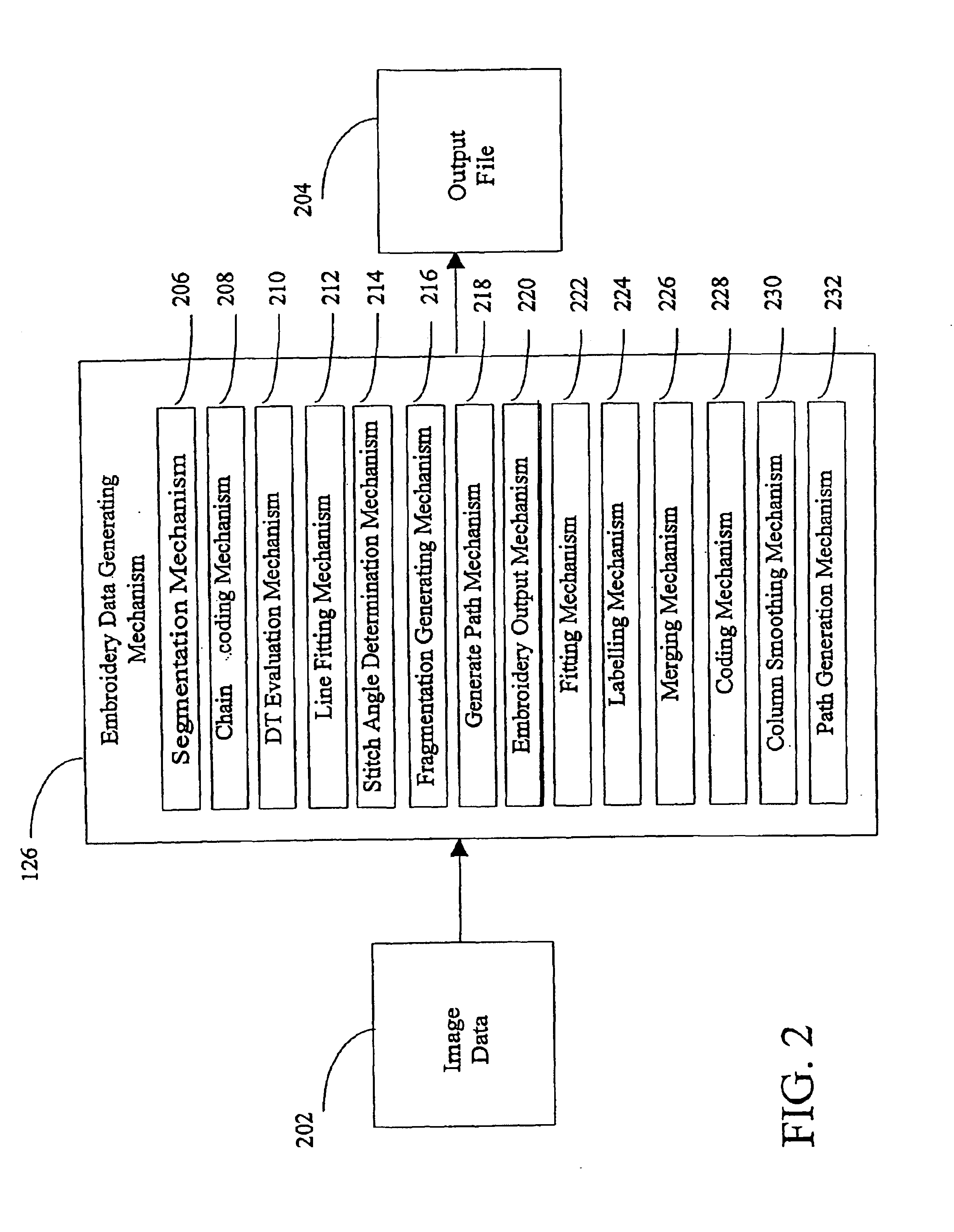

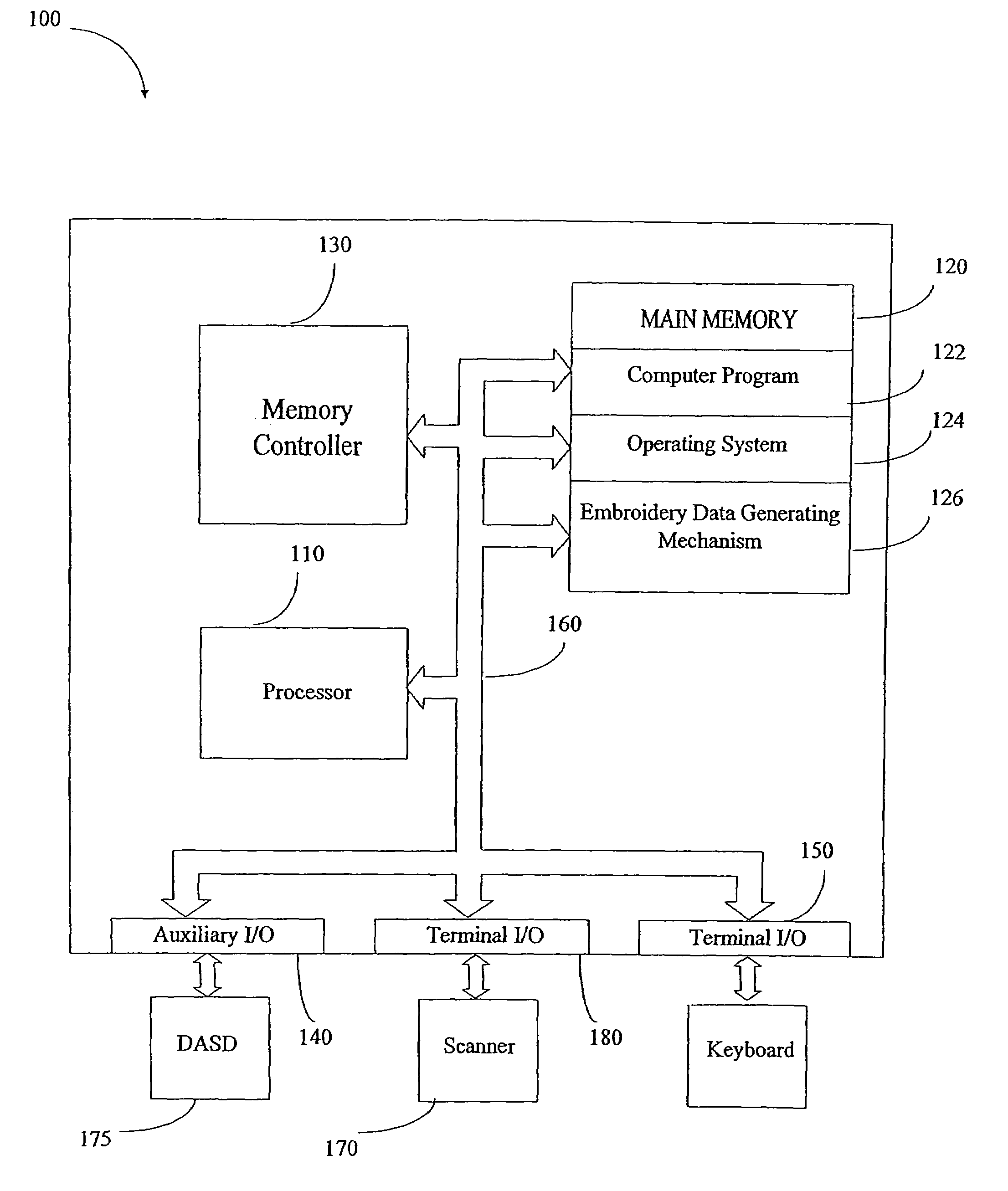

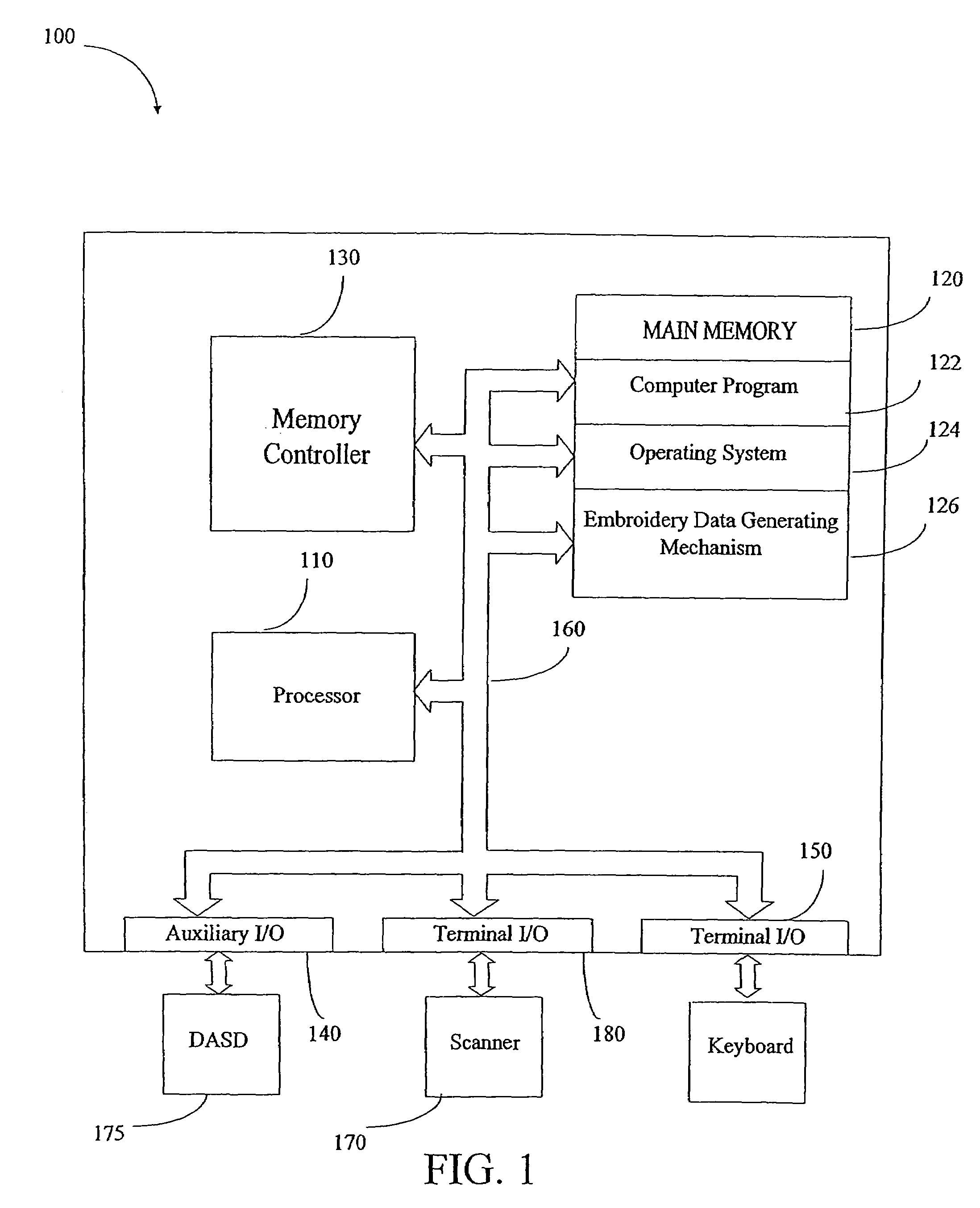

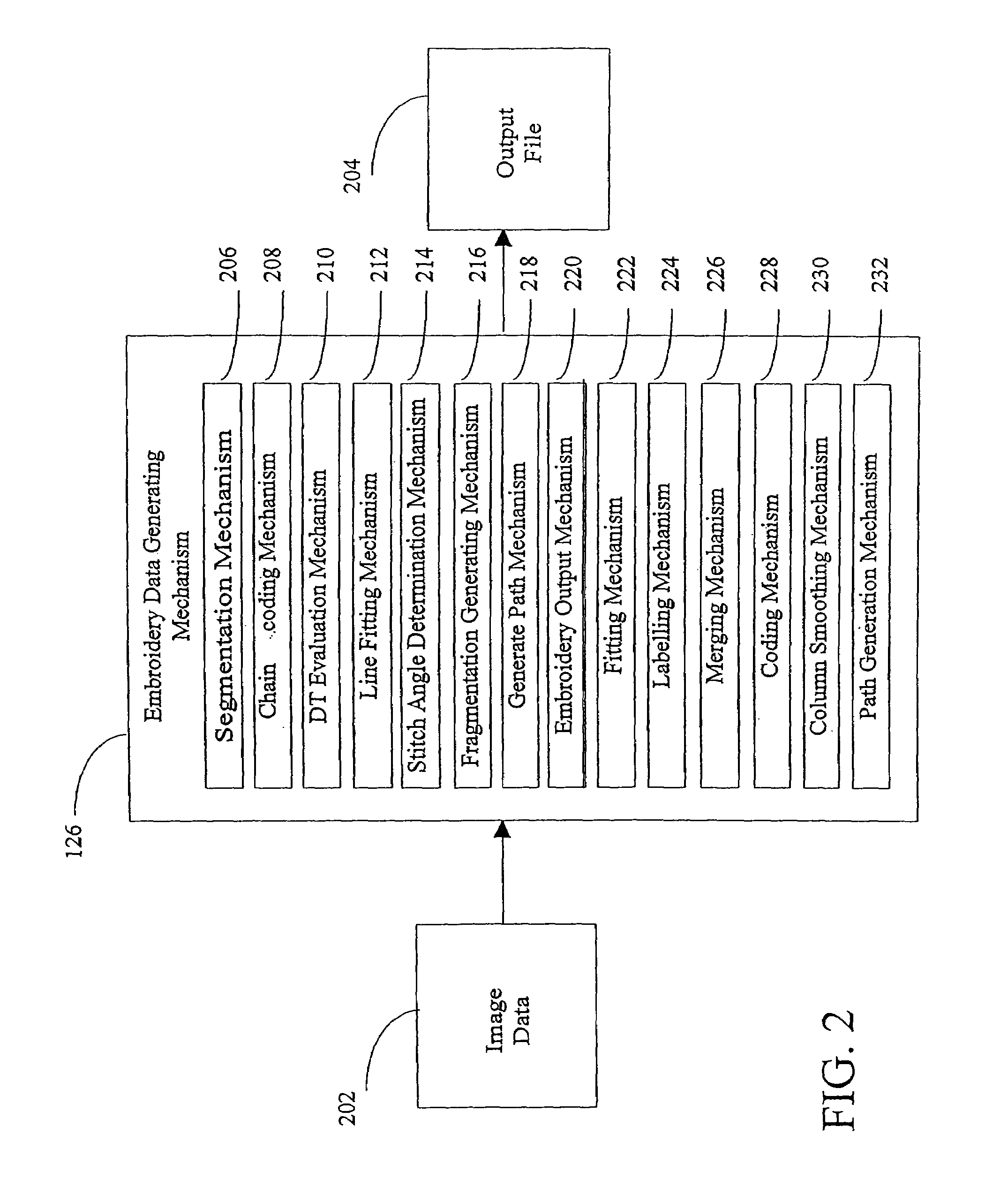

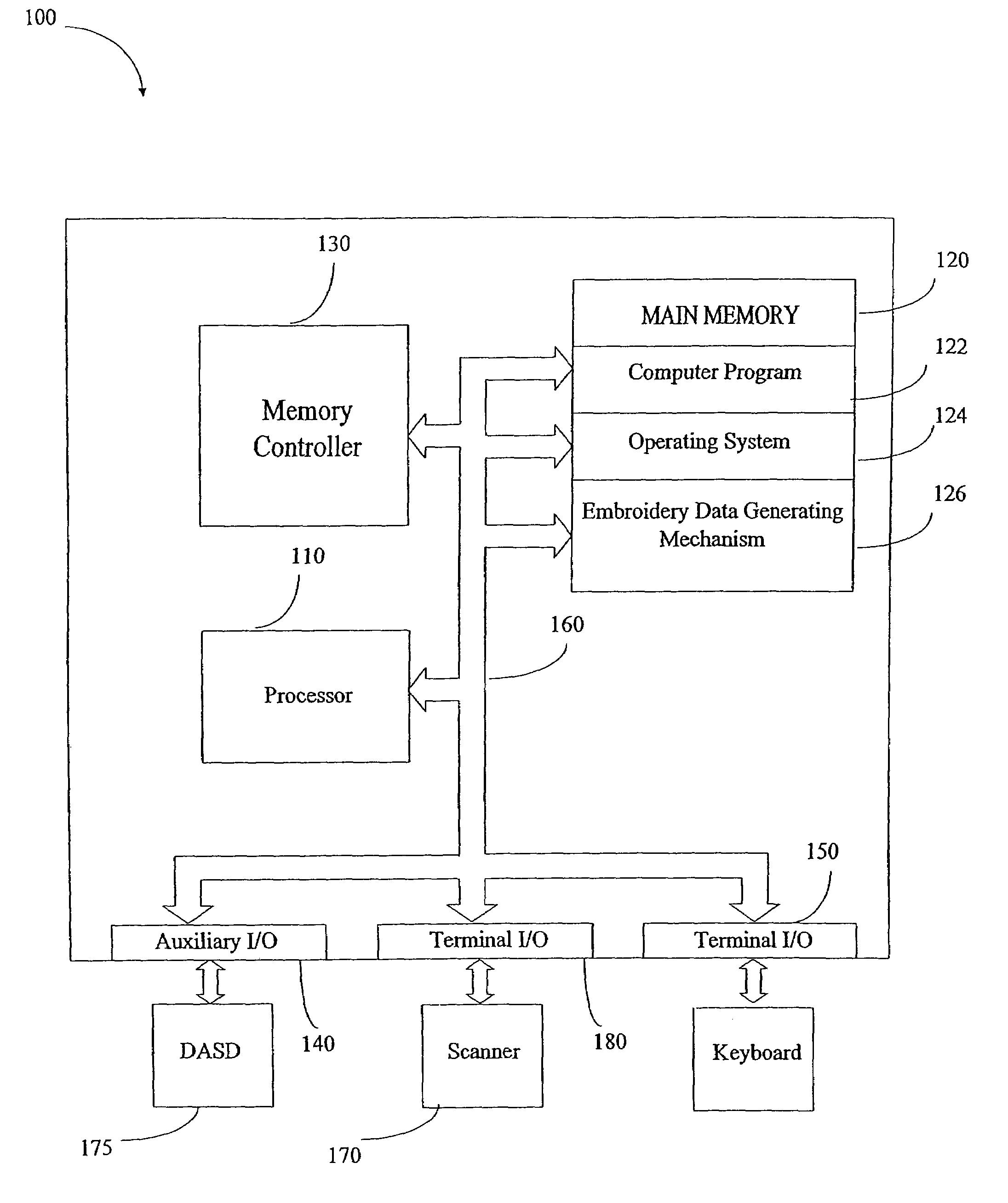

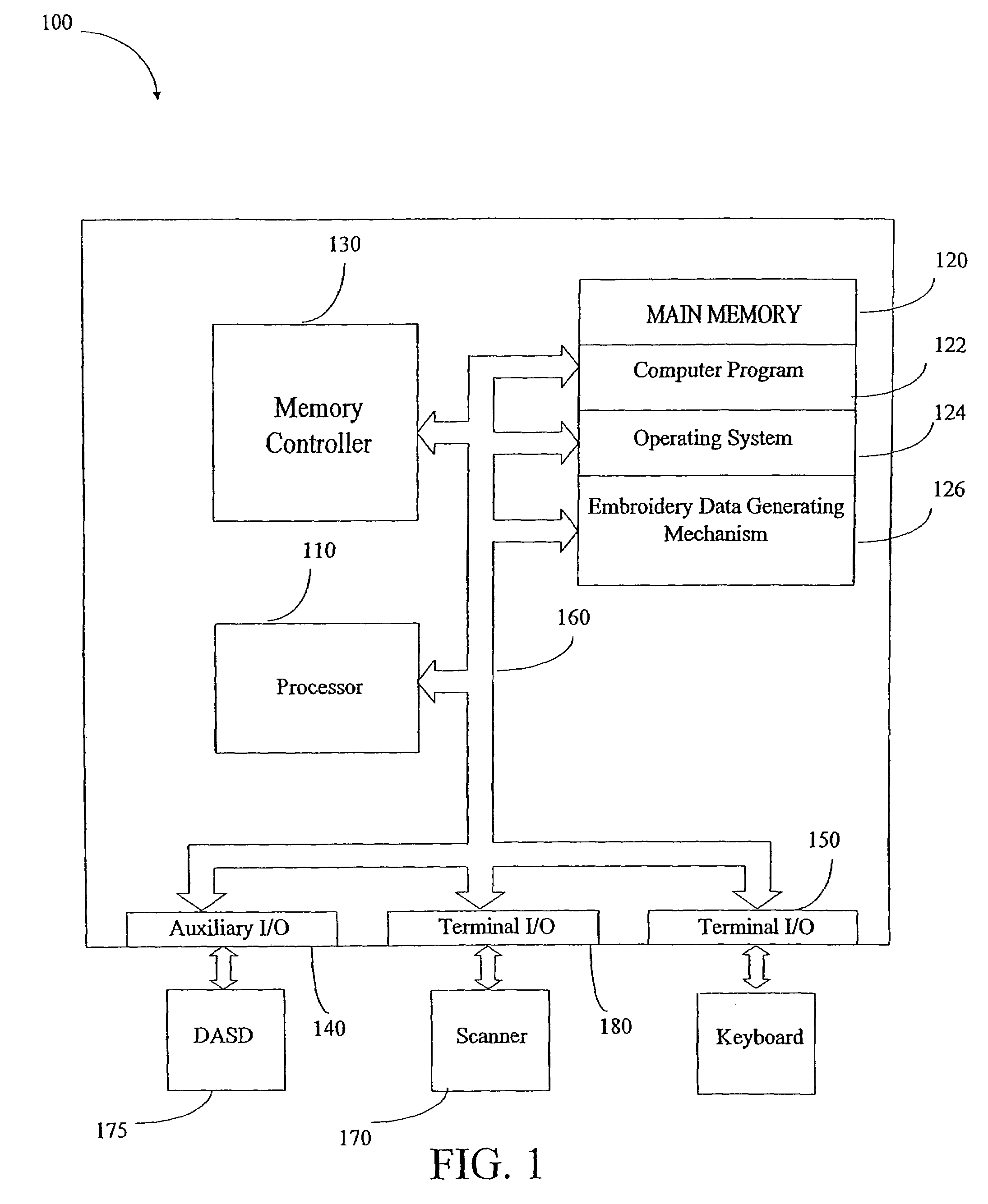

Automatically generating embroidery designs from a scanned image

InactiveUS6947808B2Automatically and efficiently generates accurate embroidery design dataEfficient and accurateProgramme-controlled sewing machinesTotal factory controlData fileComputer science

A method and system are disclosed for automatically generating embroidery designs from a scanned image. An embroidery data generating mechanism generates accurate embroidery designs. The embroidery data generating mechanism first reads an image data file, which contains bitmapping information generated from a software scanning tool, the information being related to an embroidery pattern that has been scanned. The scanned pattern is broken up into pixels, each pixel in the scanned image having a bitmap associated with the color of the pattern. Each unique color in the scanned pattern has its own unique bitmap. The embroidery generating mechanism also includes a segmentation mechanism and a chain-encoding mechanism which perform operations to enhance the quality of the bitmapped information and to separate regions of the scanned image into objects. A distance transform evaluation mechanism classifies each object as being either a thick object or a thin, predominantly regular object. Additional mechanisms further interpret the objects into entities such as regular and singular regions and compute optimum sewing paths for embroidery data generation.

Owner:CIMPRESS SCHWEIZ

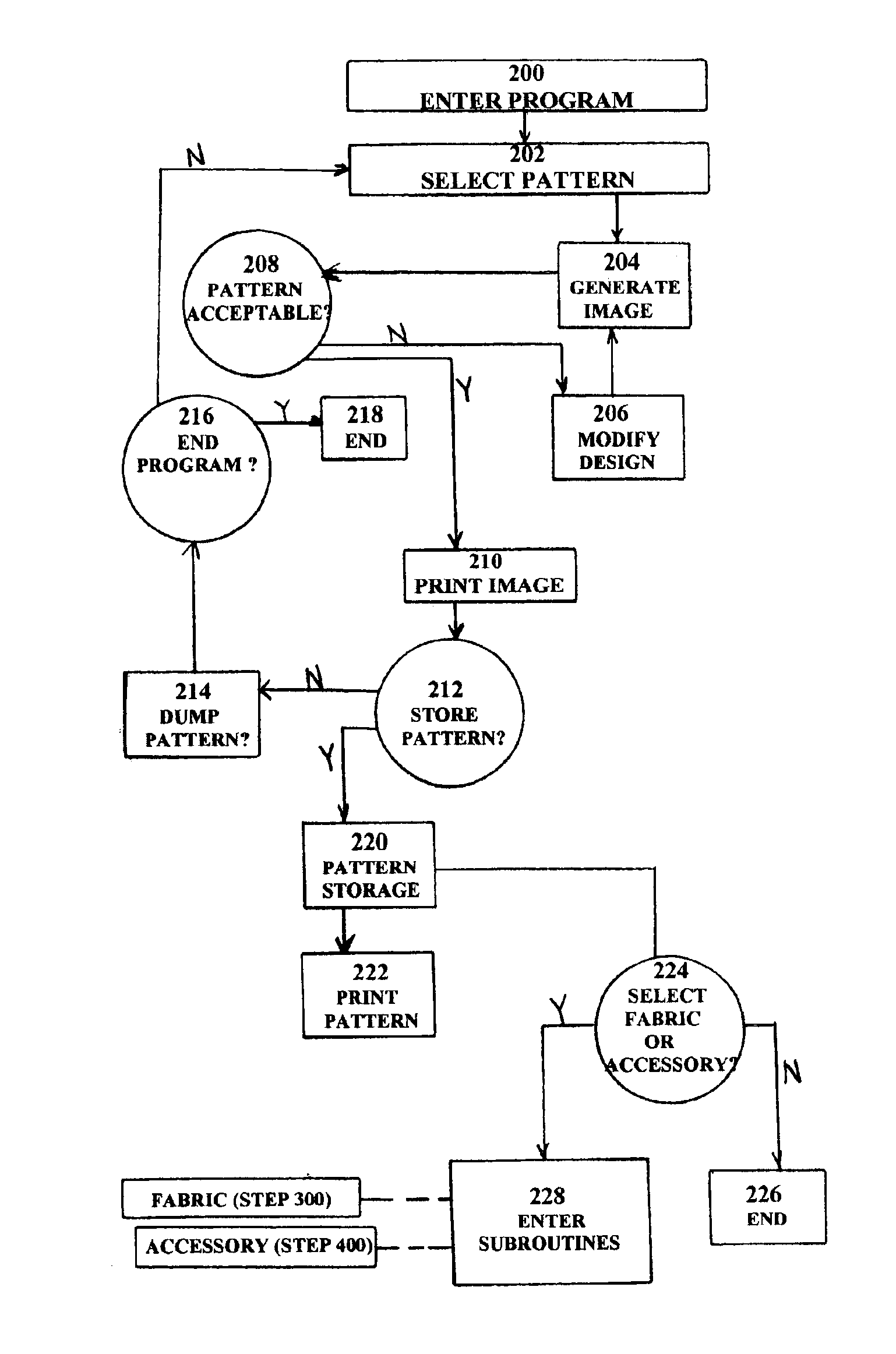

Method and apparatus for producing a sewing pattern

InactiveUS6859679B1Programme-controlled sewing machinesAnalogue computers for control systemsEngineering

Owner:SMITH ALEXANDRA K +1

Embroidery Machine

An embroidery machine includes a sewing arm having an upper shaft for providing a driving force, a needle bar support case, which is assembled to a front portion of the sewing arm so as to be laterally movable, a needle bar provided in a needle bar support case, the needle bar having a needle at a lower end thereof and vertically carrying the needle using a rotation driving force of the upper shaft, and a presser foot, which is provided in the needle bar support case so as to be vertically movable, characterized in that each of the needle bar and the presser foot is operated by an individual drive mechanism. The presser foot is separately driven by its own drive source, independent of the drive source of the needle bar.

Owner:SUSR PRECISION CO LTD

Quilting method and apparatus using frame with motion detector

Owner:KOERNER RALPH J

Computerized stitching including embroidering

InactiveUS20060064195A1Easy to controlProgramme-controlled sewing machinesPressersAnomaly detectionRemedial action

A stitching apparatus with thread tension control is provided. Tension in a thread is monitored during stitching apparatus operations, and remedial action is taken in response to the detection of an anomaly in the thread tension profile. The remedial action can include altering a feed rate of the thread in order to adjust the thread tension, and / or repeating a previous operation. Anomaly detection can be performed with respect to stitching or sewing operations, and also with respect to trim operations performed in connection with moving between elements and / or thread color changes.

Owner:MELCO INT

Sewing machine

InactiveCN1891887AReduce setup timeAvoid misadjustmentProgramme-controlled sewing machinesWork-feeding meansControl systemEngineering

The invention provided a sewing machine, improved to automatically switch the sewing machine to the thickness of cloth. This sewing machine includes: a housing having a base plate; a top arm; and a strut for integrating the base plate with the top arm. A metallic presser presses a cloth piece near a stitch forming position. The metallic presser driven by a movable rod is capable of moving between the lift position for releasing the cloth piece and the pressing position for the cloth piece to be pressed. When the metallic presser moves between these positions, the distance of at least one movable rod part from a reference structure fixed to the housing stably changes. The position sensor detects the position of the metallic presser in the pressing position. A control system makes signal connection thereto. The system sets an adjustment variable for the sewing machine depending upon the output value of the position sensor. As a result, the obtained sewing machine automatically performs switching to the thickness of variable cloth piece.

Owner:DURKOPP ADLER AG

Automatically generating embroidery designs from a scanned image

InactiveUS7016756B2Automatically and efficiently generates accurate embroidery design dataEfficient and accurateProgramme-controlled sewing machinesTotal factory controlData fileComputer vision

A method and system are disclosed for automatically generating embroidery designs from a scanned image. An embroidery data generating mechanism generates accurate embroidery designs. The embroidery data generating mechanism first reads an image data file, which contains bitmapping information generated from a software scanning tool, the information being related to an embroidery pattern that has been scanned. The scanned pattern is broken up into pixels, each pixel in the scanned image having a bitmap associated with the color of the pattern. Each unique color in the scanned pattern has its own unique bitmap. The embroidery generating mechanism also includes a segmentation mechanism and a chain-encoding mechanism which perform operations to enhance the quality of the bitmapped information and to separate regions of the scanned image into objects. A distance transform evaluation mechanism classifies each object as being either a thick object or a thin, predominantly regular object. Additional mechanisms further interpret the objects into entities such as regular and singular regions and compute optimum sewing paths for embroidery data generation.

Owner:CIMPRESS SCHWEIZ

Automatically generating embroidery designs from a scanned image

InactiveUS7016757B2Automatically and efficiently generates accurate embroidery design dataEfficient and accurateProgramme-controlled sewing machinesTotal factory controlData fileSoftware

A method and system are disclosed for automatically generating embroidery designs from a scanned image. An embroidery data generating mechanism generates accurate embroidery designs. The embroidery data generating mechanism first reads an image data file, which contains bitmapping information generated from a software scanning tool, the information being related to an embroidery pattern that has been scanned. The scanned pattern is broken up into pixels, each pixel in the scanned image having a bitmap associated with the color of the pattern. Each unique color in the scanned pattern has its own unique bitmap. The embroidery generating mechanism also includes a segmentation mechanism and a chain-encoding mechanism which perform operations to enhance the quality of the bitmapped information and to separate regions of the scanned image into objects. A distance transform evaluation mechanism classifies each object as being either a thick object or a thin, predominantly regular object. Additional mechanisms further interpret the objects into entities such as regular and singular regions and compute optimum sewing paths for embroidery data generation.

Owner:CIMPRESS SCHWEIZ

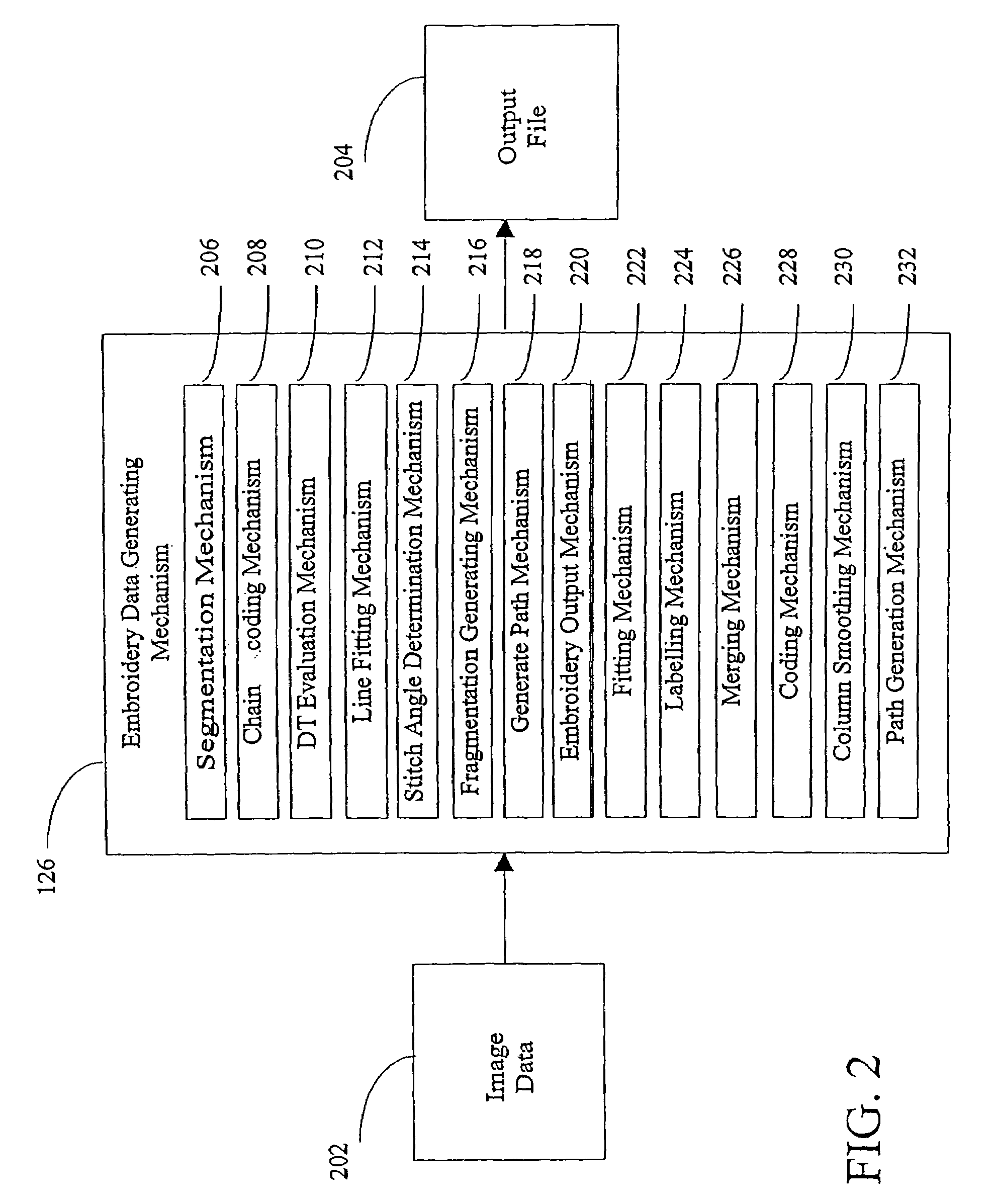

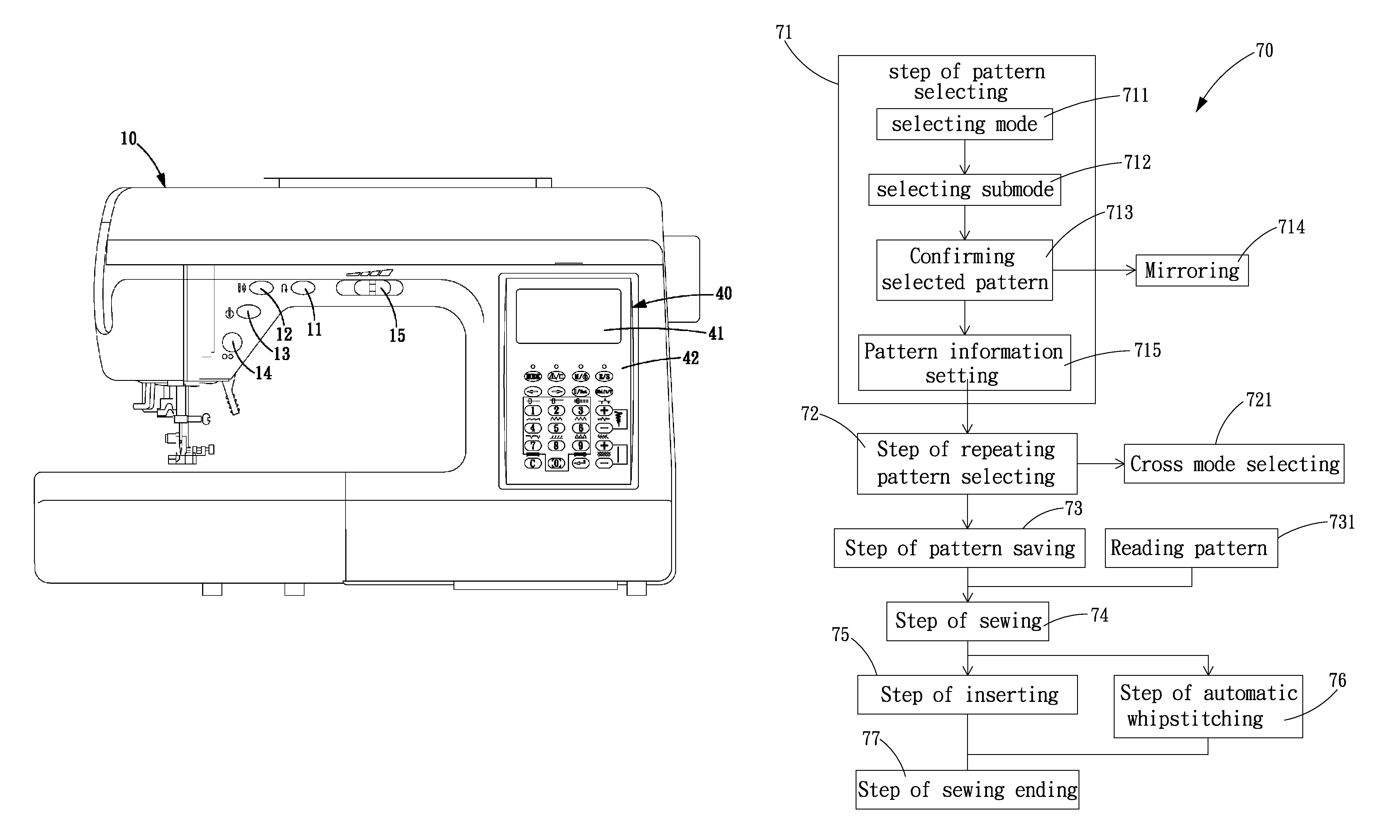

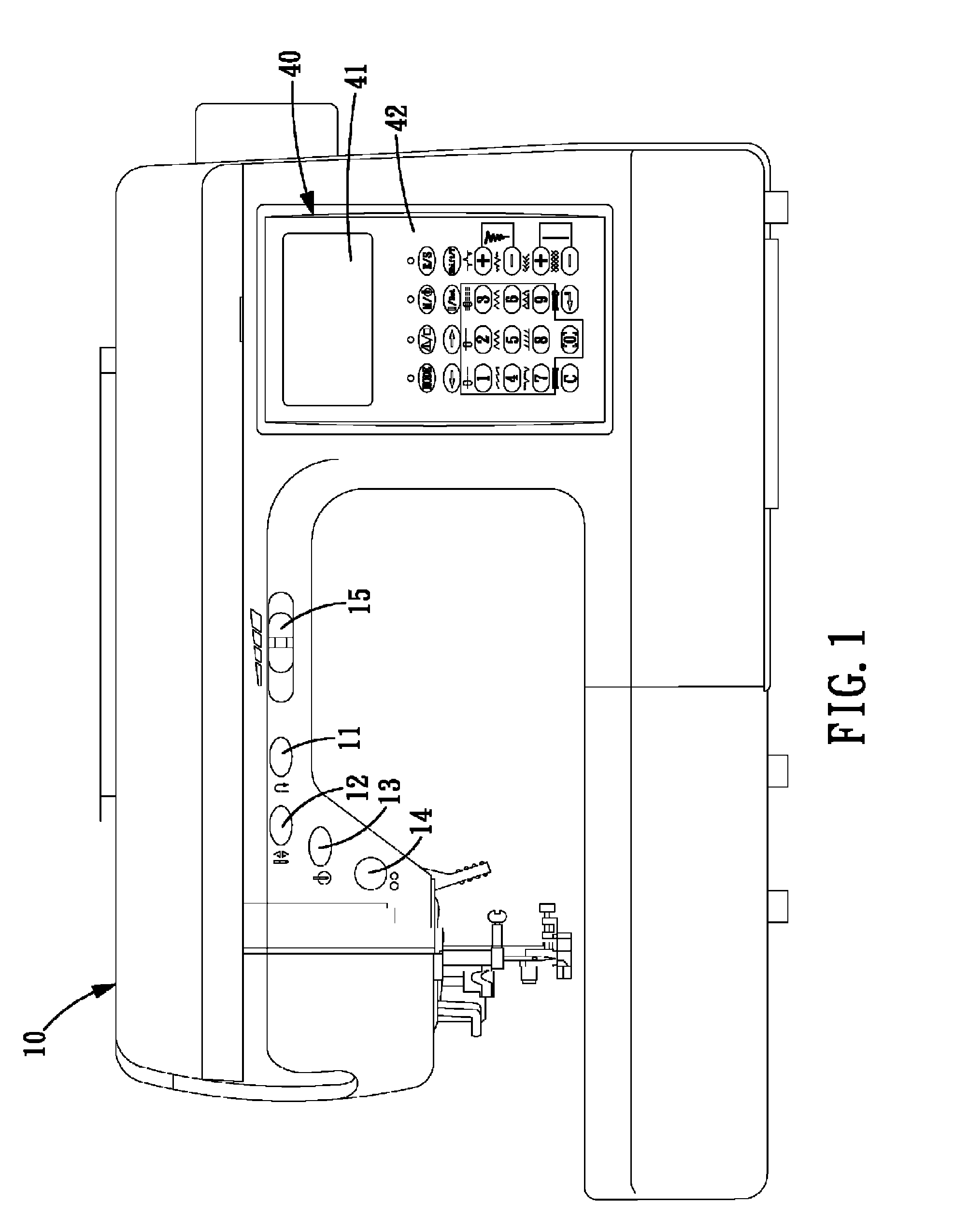

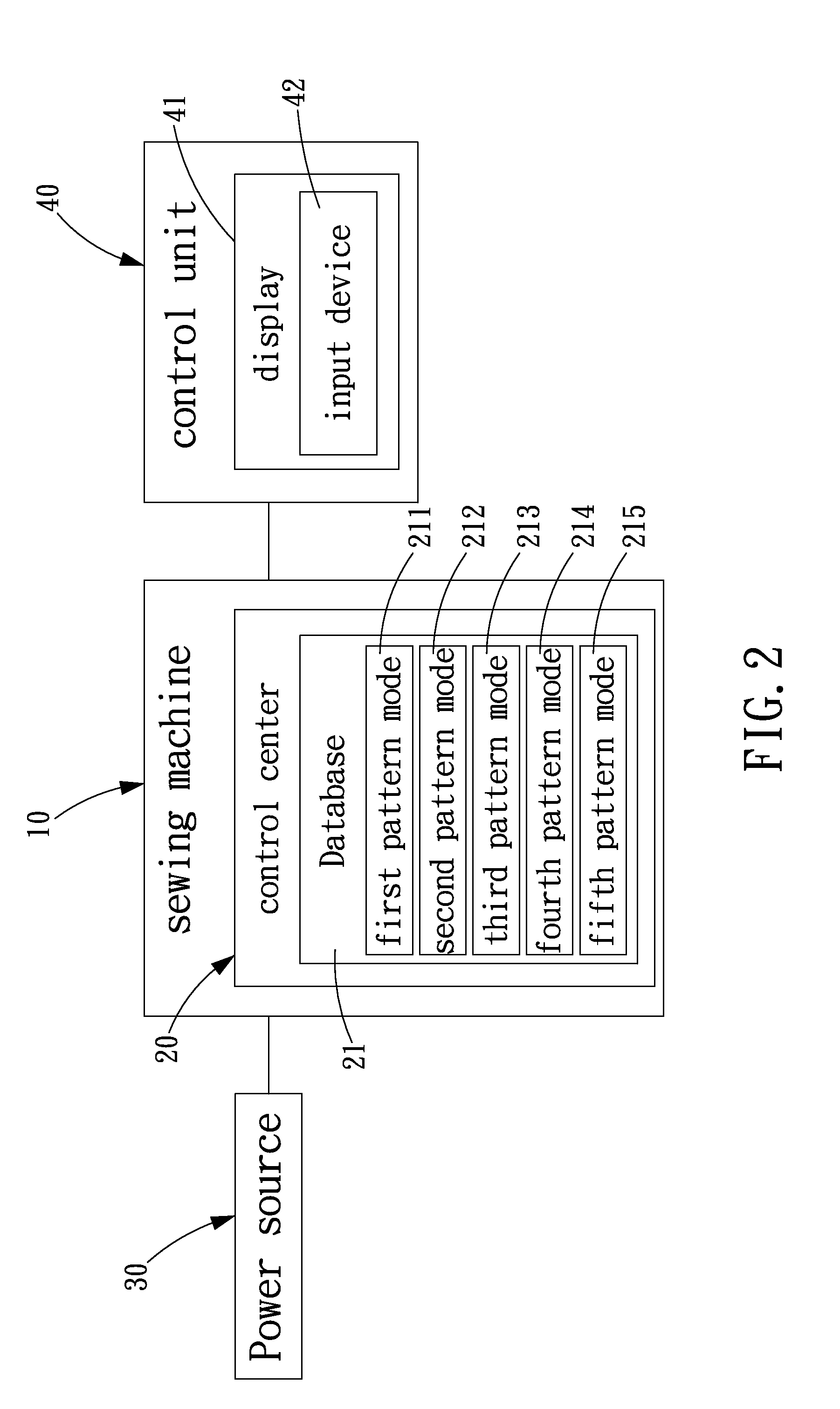

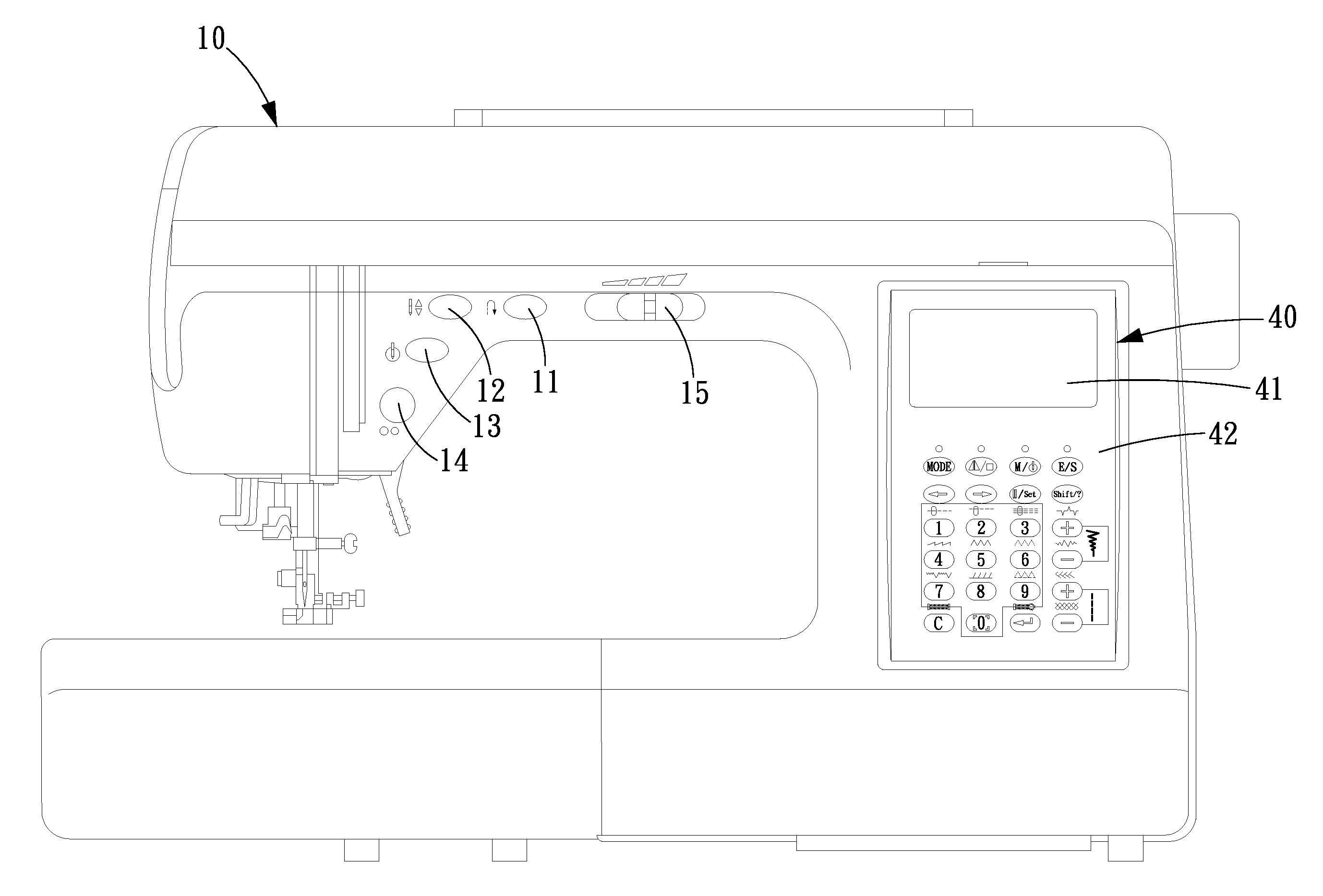

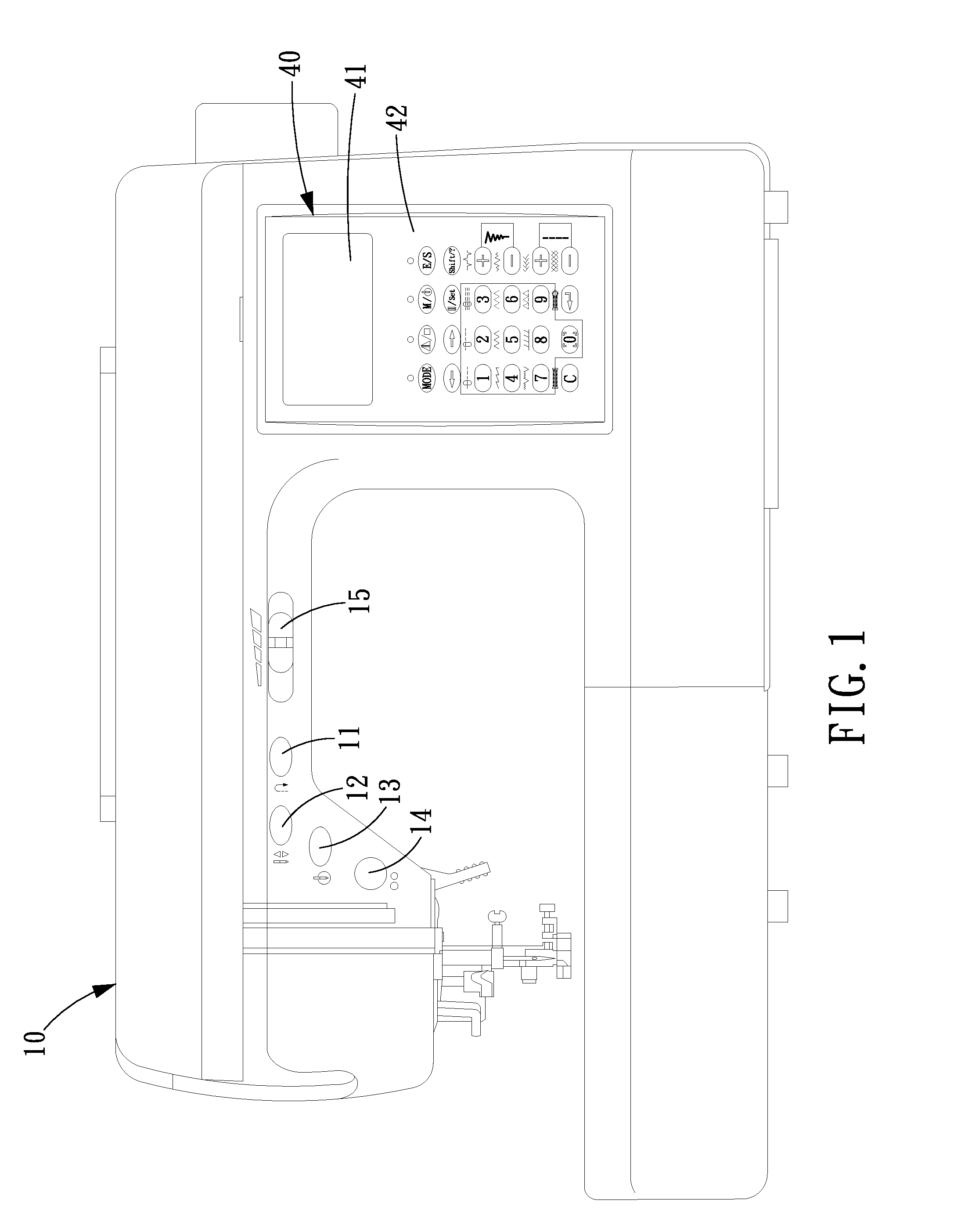

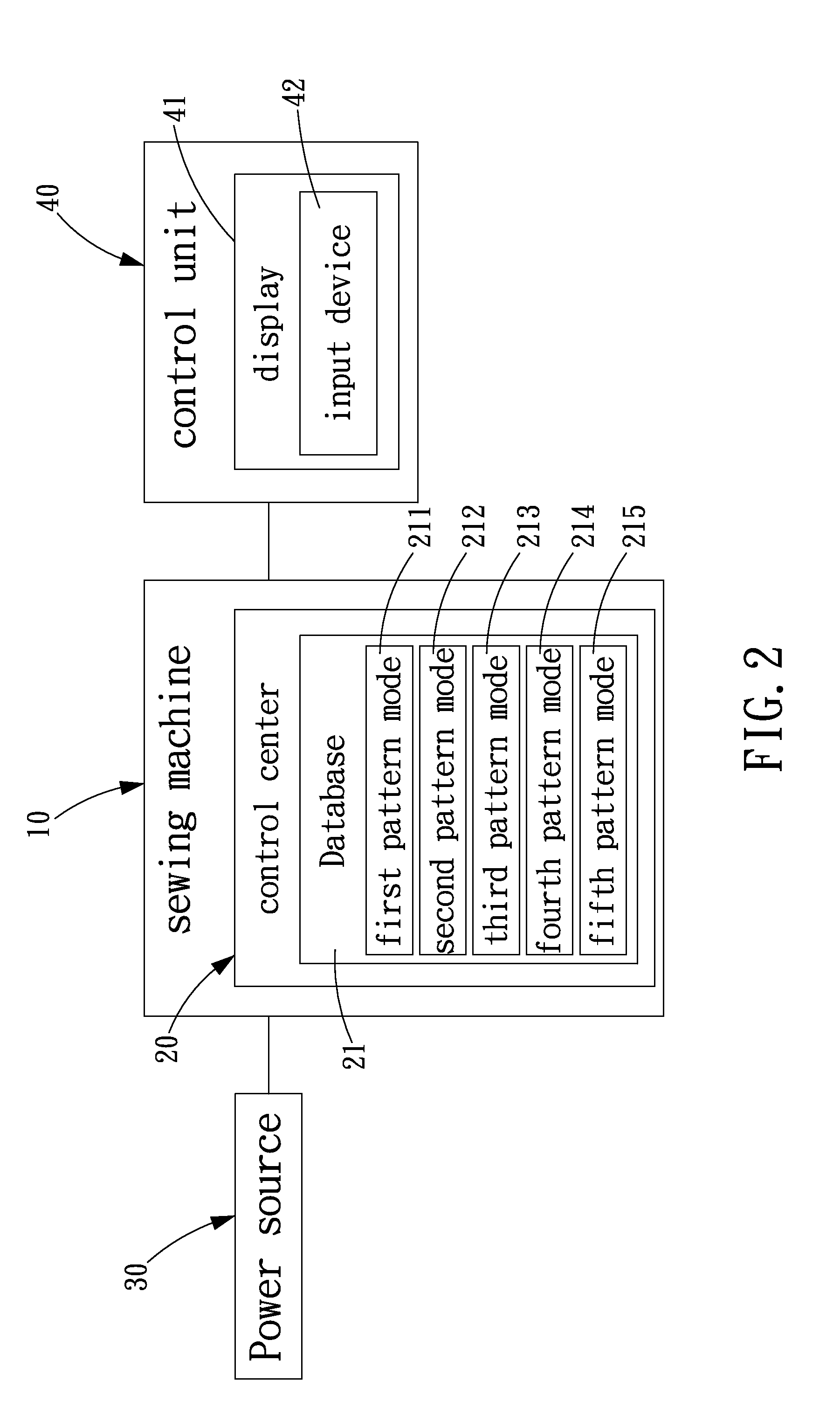

Method and device for controlling sewing patterns of a sewing machine

InactiveUS8763545B2Better satisfy userProgramme-controlled sewing machinesAutomatic machinesEngineeringSewing machine

A method and device for controlling sewing patterns of a sewing machine allows the user to edit the patterns or pattern strings saved in the database, and to mirror the patterns, or control the respective data of sewing. The sewing pattern can be easily and freely edited, and the information of all the sewing operations is clearly displayed on the display.

Owner:TSENG HSIEN CHANG

Embroidering system

An embroidering system includes at least one embroidering machine having plural needles supplied with threads having different colors, and a control device for transmitting an embroidery data to the at least one embroidering machine so as to selectively drive the plural needles. The embroidery data is generated and memorized in the control device prior to being transmitted to the at least one embroidering machine. The embroidery data is corrected as required. It is preferable that the embroidery data is corrected as the basis for needle numbers for the respective needles and the colors of the threads supplied to the respective needles.

Owner:AISIN SEIKI KK

Method and device for controlling sewing patterns of a sewing machine

InactiveUS20130125803A1Better satisfy userProgramme-controlled sewing machinesAutomatic machinesEngineeringSewing machine

A method and device for controlling sewing patterns of a sewing machine allows the user to edit the patterns or pattern strings saved in the database, and to mirror the patterns, or control the respective data of sewing. The sewing pattern can be easily and freely edited, and the information of all the sewing operations is clearly displayed on the display.

Owner:TSENG HSIEN CHANG

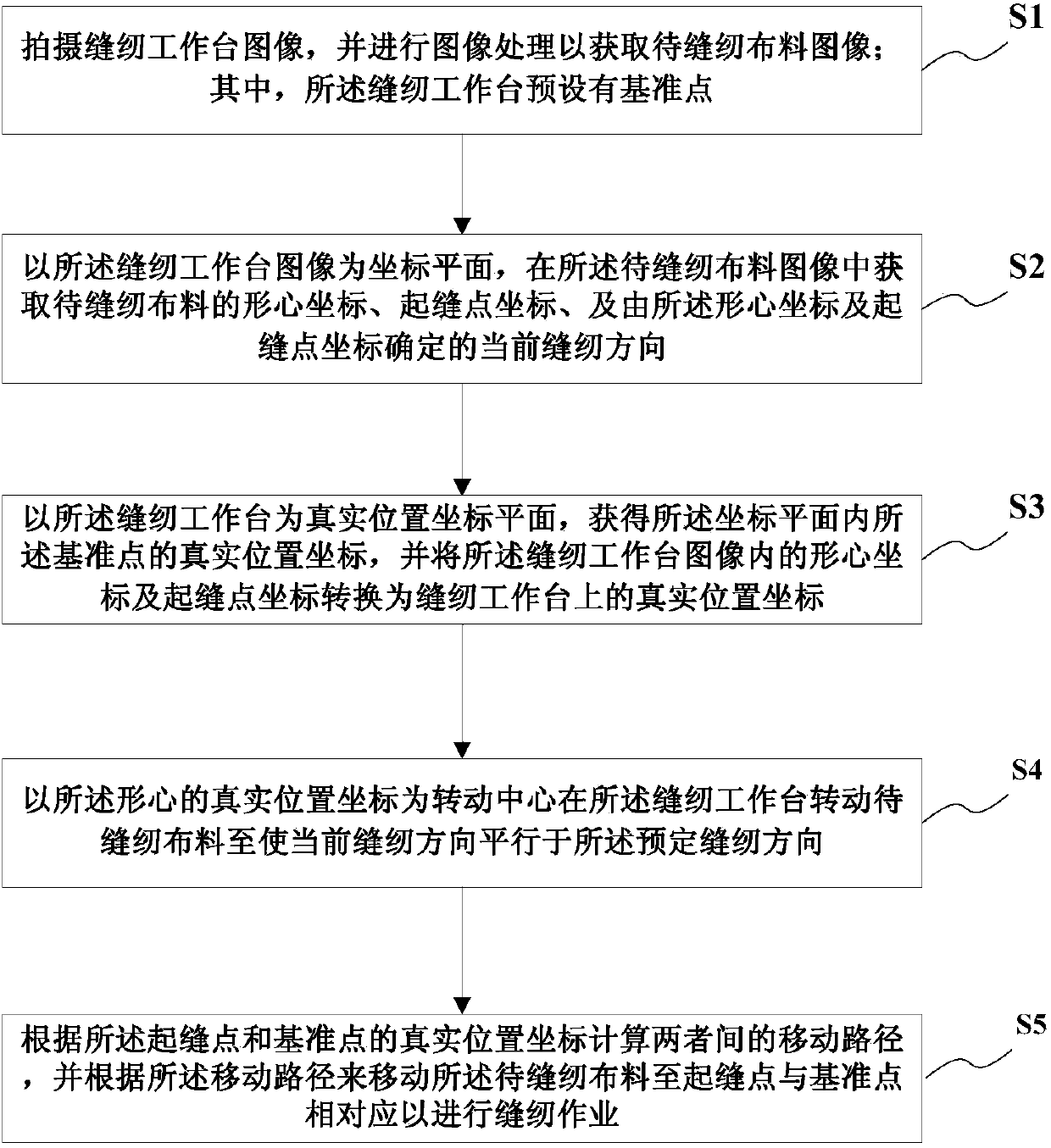

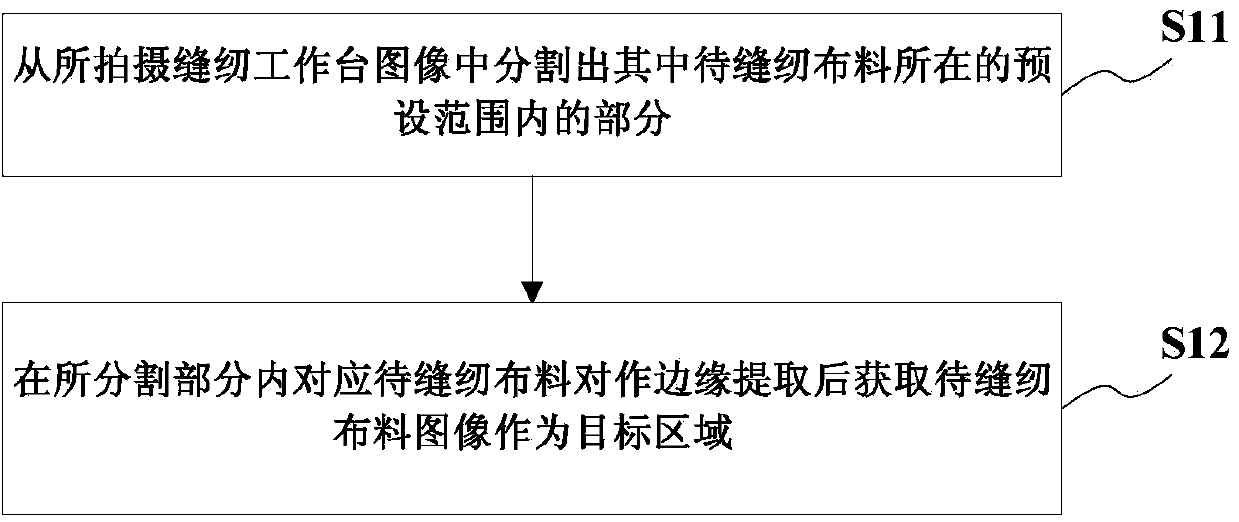

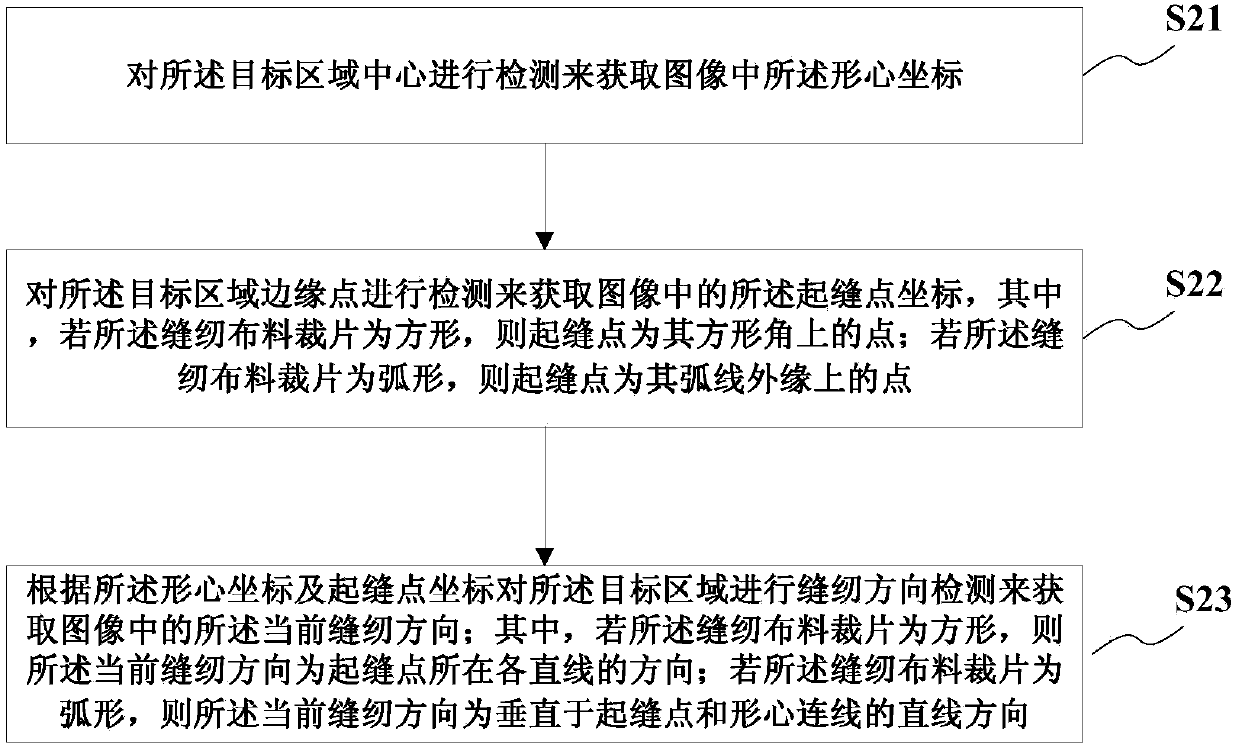

Visual positioning method and system for sewing

ActiveCN104005180ASolve the problem of poor positioning of automatic sewingProgramme-controlled sewing machinesImaging processingEngineering

The invention provides a visual positioning method and system for sewing. An image of a cloth material to be sewn is obtained by shooting and processing an image of a sewing workbench, a datum point is preset on the sewing workbench, and centroid coordinates, sewing starting point coordinates and the current sewing direction of the cloth material to be sewn are obtained in the image of the cloth material to be sewn with the image of the sewing workbench as a coordinate plane; true position coordinates of the datum point in the coordinate plane are obtained with the sewing workbench as a true position coordinate plane, and the centroid coordinates and the sewing starting point coordinates in the image of the sewing workbench are converted into true position coordinates of the sewing workbench; the cloth material to be sewn is rotated to the current sewing direction parallel to the preset sewing direction with true position coordinates of the centroid as the rotating center; the moving distance between the sewing starting point and the datum point is calculated, and the cloth material to be sewn is moved to the sewing starting point corresponding to the datum point for sewing work according to the moving distance. Since visual image processing is used for positioning, the problem that existing automatic sewing is poor in positioning is well solved.

Owner:JACK SEWING MASCH CO LTD

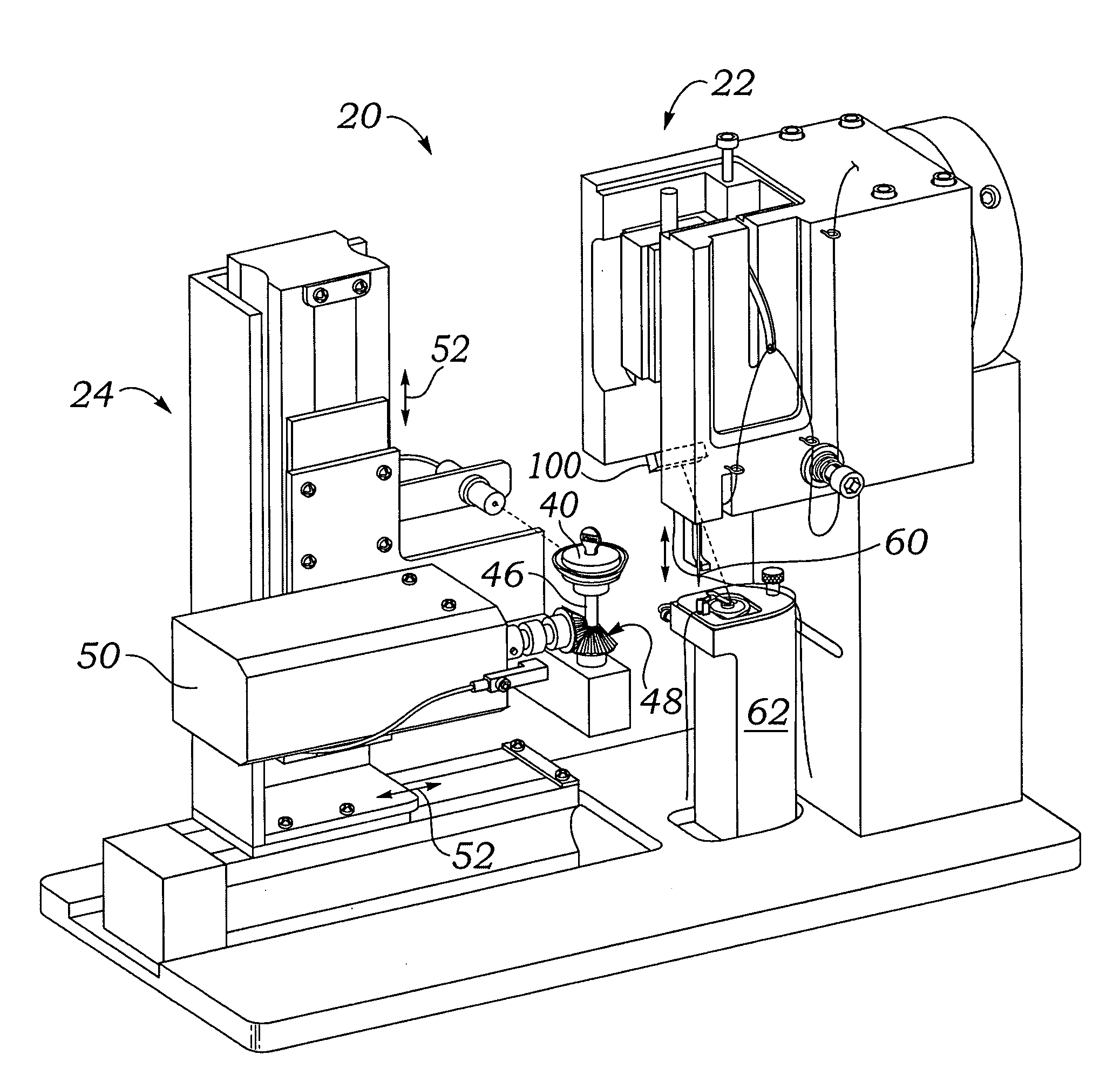

Automated surgical implant sewing system and method

ActiveUS20080035038A1Increase productionAccurate placementProgramme-controlled sewing machinesHeart valvesBobbinProsthetic heart

A system and method for assembling a prosthetic heart valve, including a procedure for sewing fabric around a heart valve support stent. The system includes a support stent handling component that works in conjunction with a sewing machine component. The sewing machine has a bobbin, and the system includes a non-contact sensor to monitor the passage of a needle thread loop over the bobbin. The sensor may be a monitoring laser, and a controlling processor receives information therefrom for 100% real-time inspection of each stitch. The occurrence of an unsuccessful stitch may prompt the processor to repeat the stitch at a slower speed. The automation of the fabric sewing procedure greatly enhances manufacturing throughput and reduces ergonomic strain on workers.

Owner:EDWARDS LIFESCIENCES CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com