Patents

Literature

845 results about "PRESSURE FEET" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

To Measure: When presser foot is down, measure the distance from the bottom of the pressure foot to the screw-hole that holds the foot onto the presser bar. A high shank machine measures approximately 1 1/4" from the presser foot screw to the bottom of the foot.

Pressure foot clamping apparatus and methods

ActiveUS20060124691A1Avoid paddingWelding/cutting auxillary devicesAuxillary welding devicesSpot weldingPRESSURE FEET

The present invention is directed to apparatus and methods for clamping and controlling flash around a manufacturing tool engaging a workpiece and preventing fill within he workpiece. In one embodiment, a clamp for securing a workpiece during a manufacturing operation includes a housing and a foot biased away from the housing, the foot defining an opening through which a manufacturing tool may pass to engage the workpiece. In another embodiment, the manufacturing tool is a rotating or counter-rotating shoulder friction stir spot welding tool. In accordance with other aspects of the invention, the foot defines at least one recess for holding flashing.

Owner:THE BOEING CO

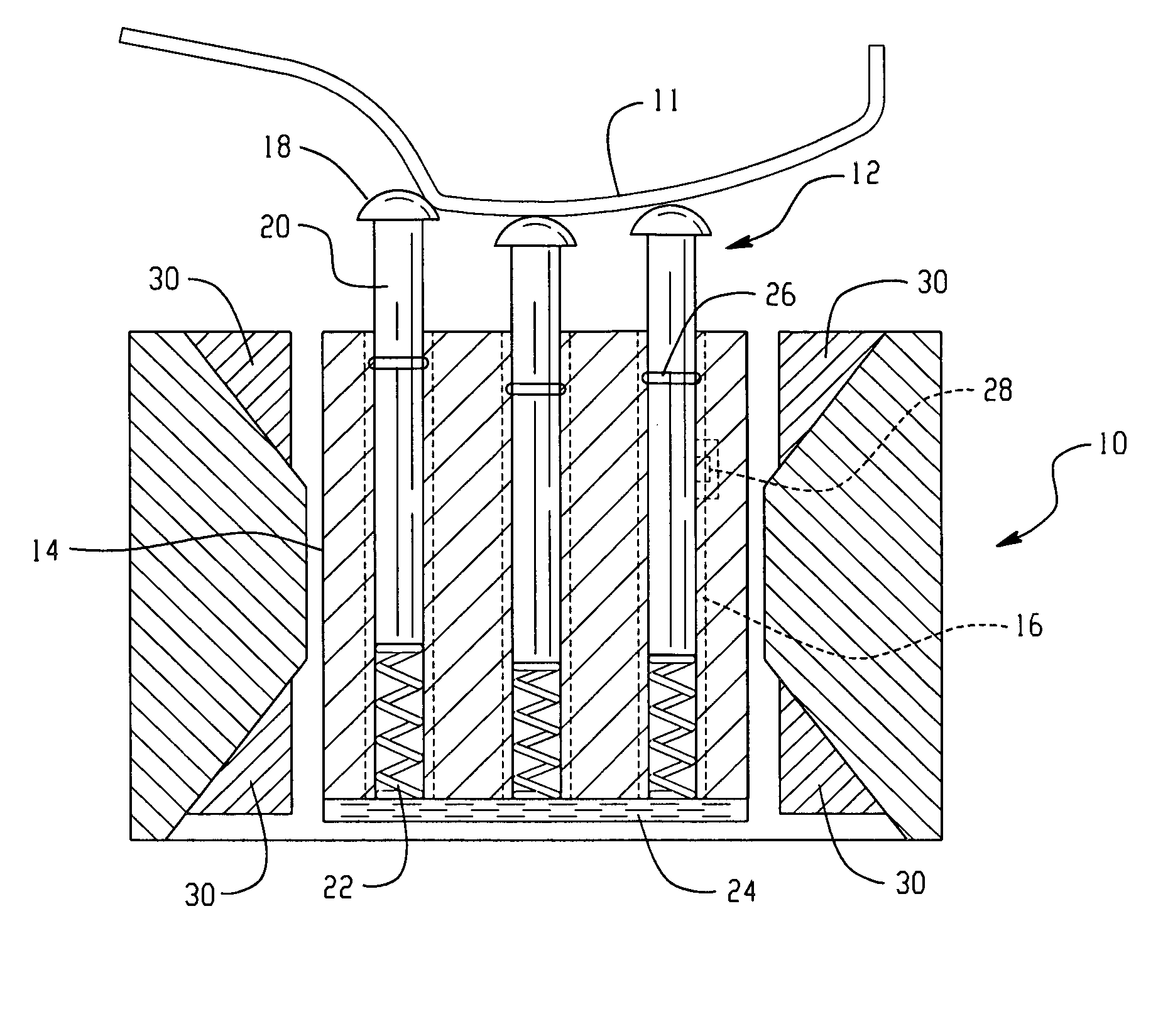

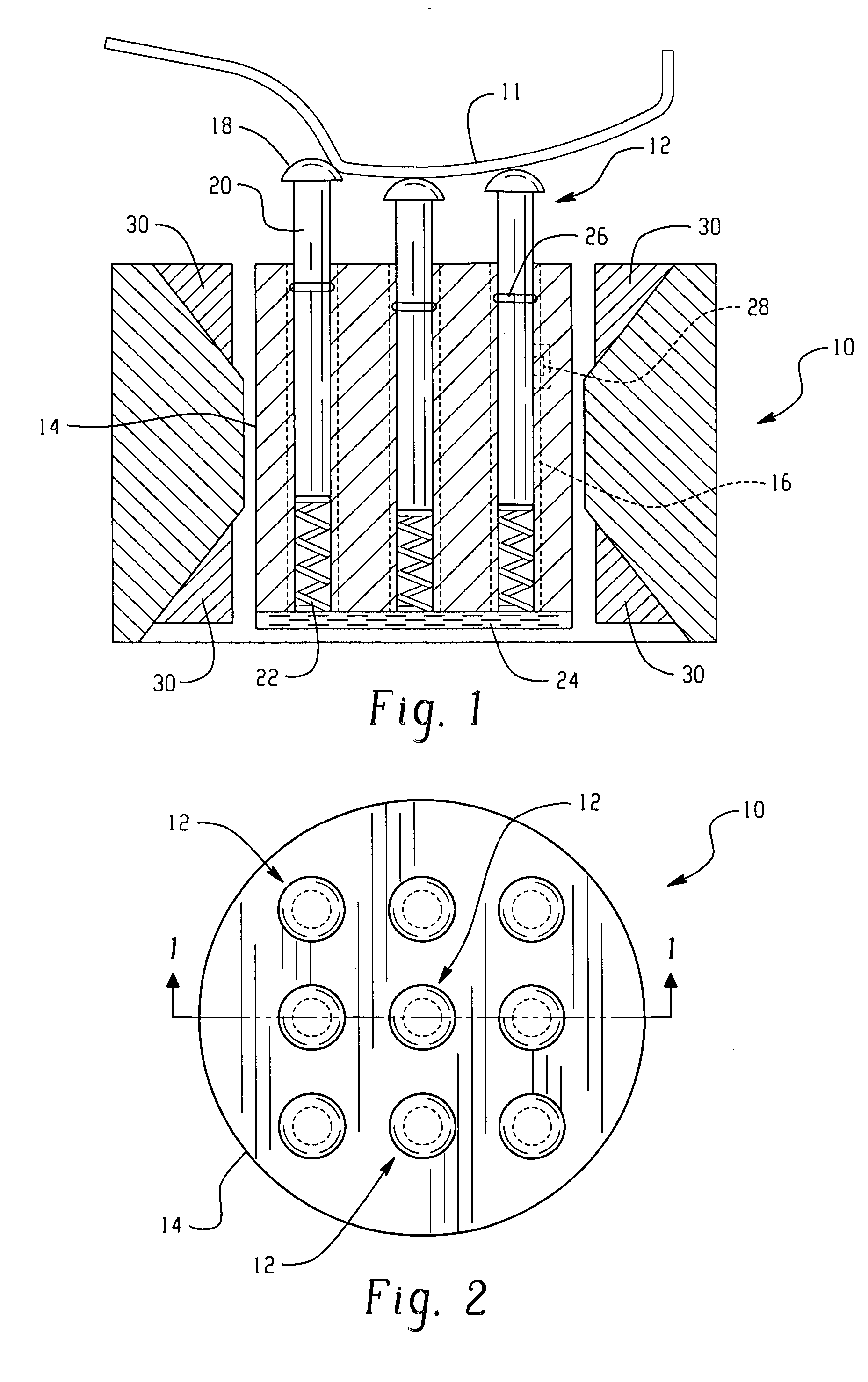

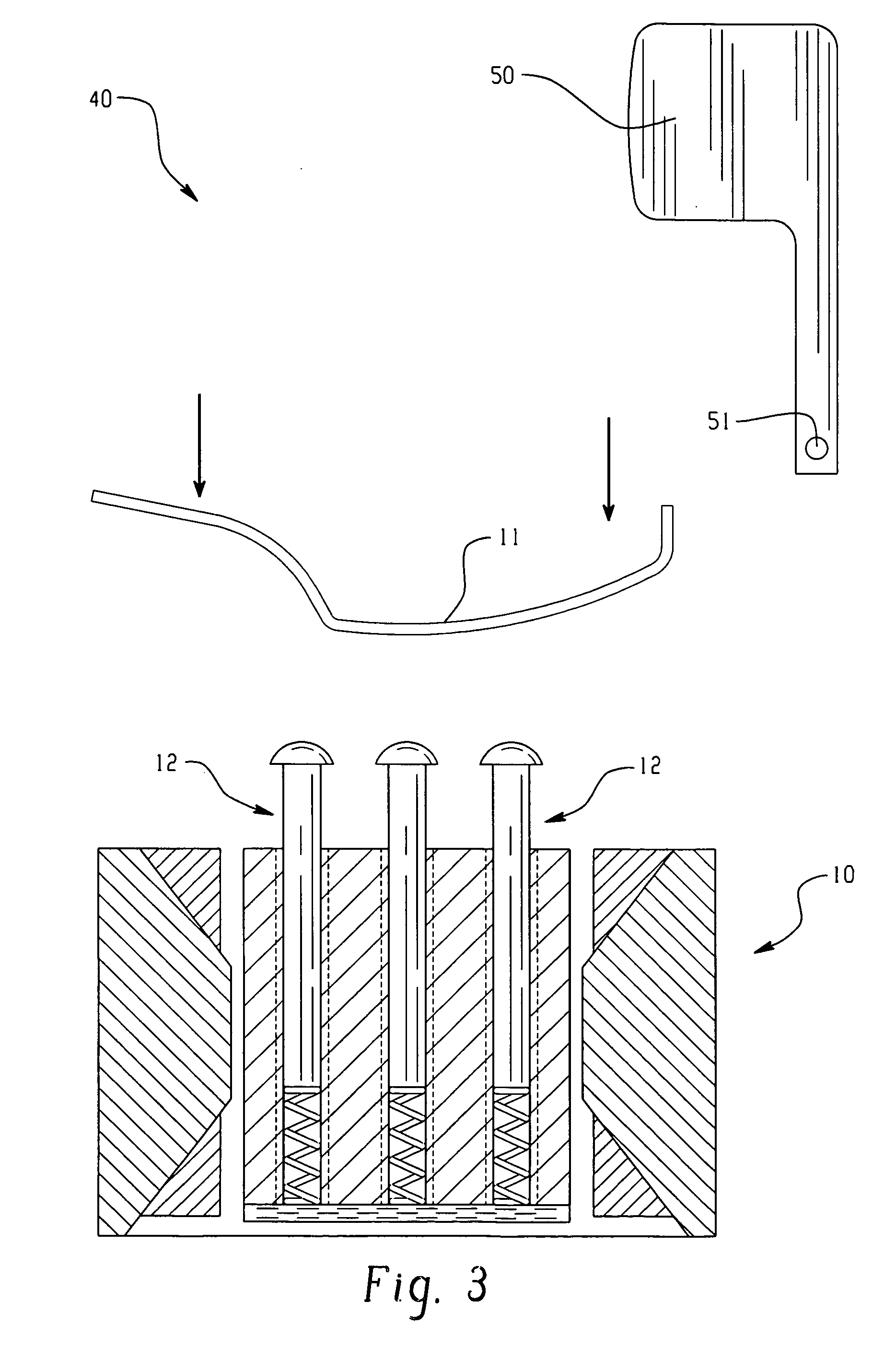

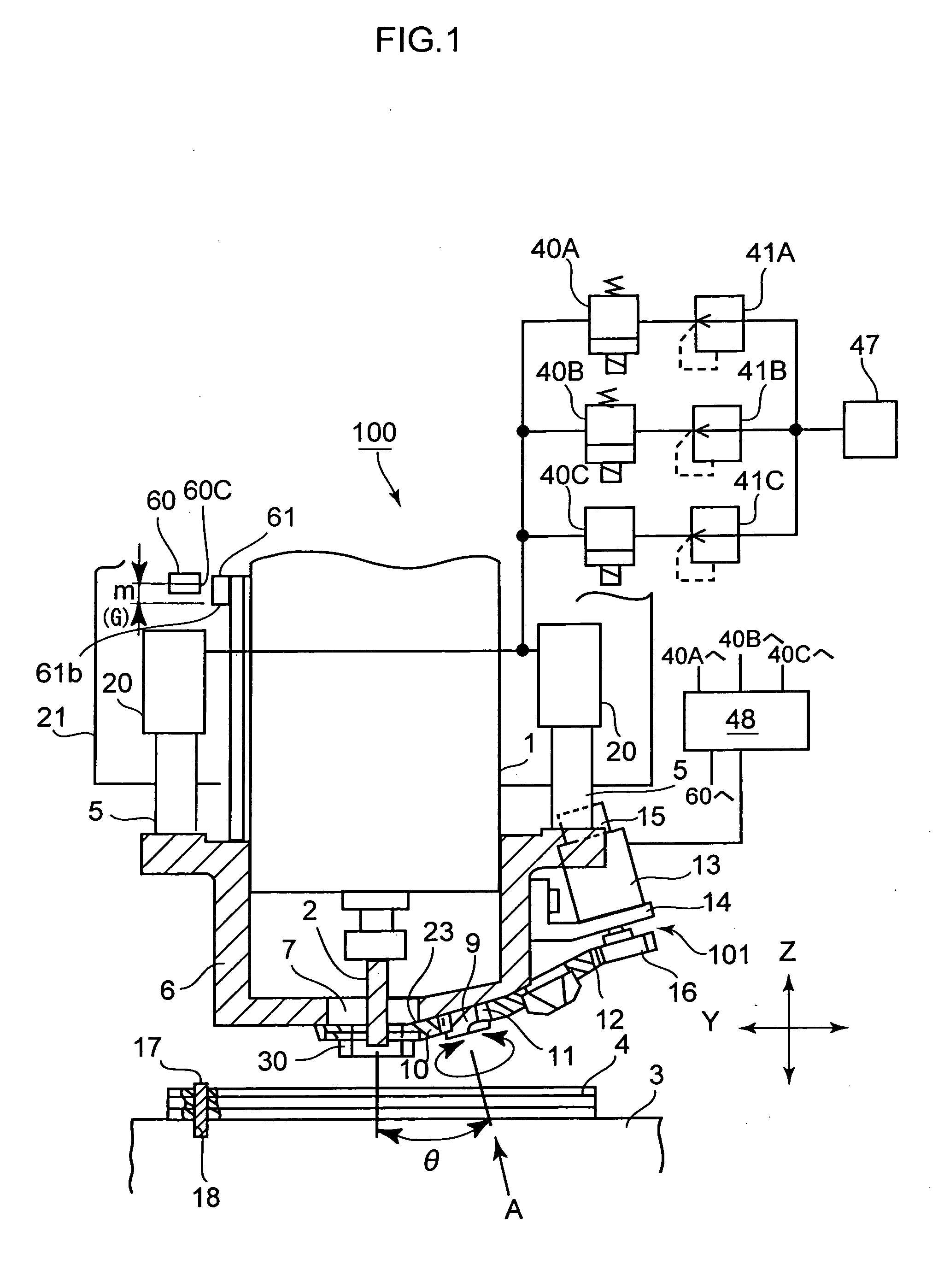

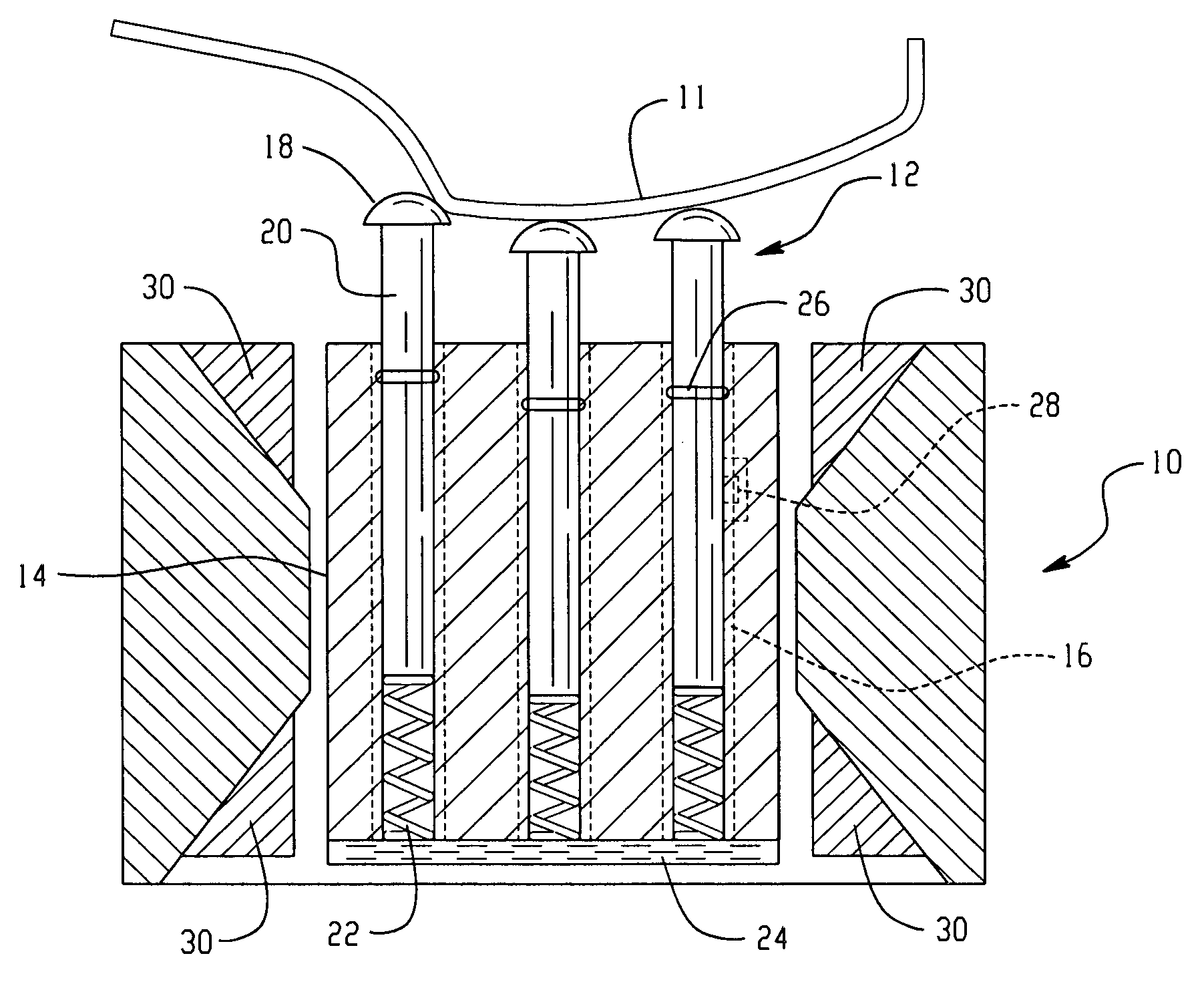

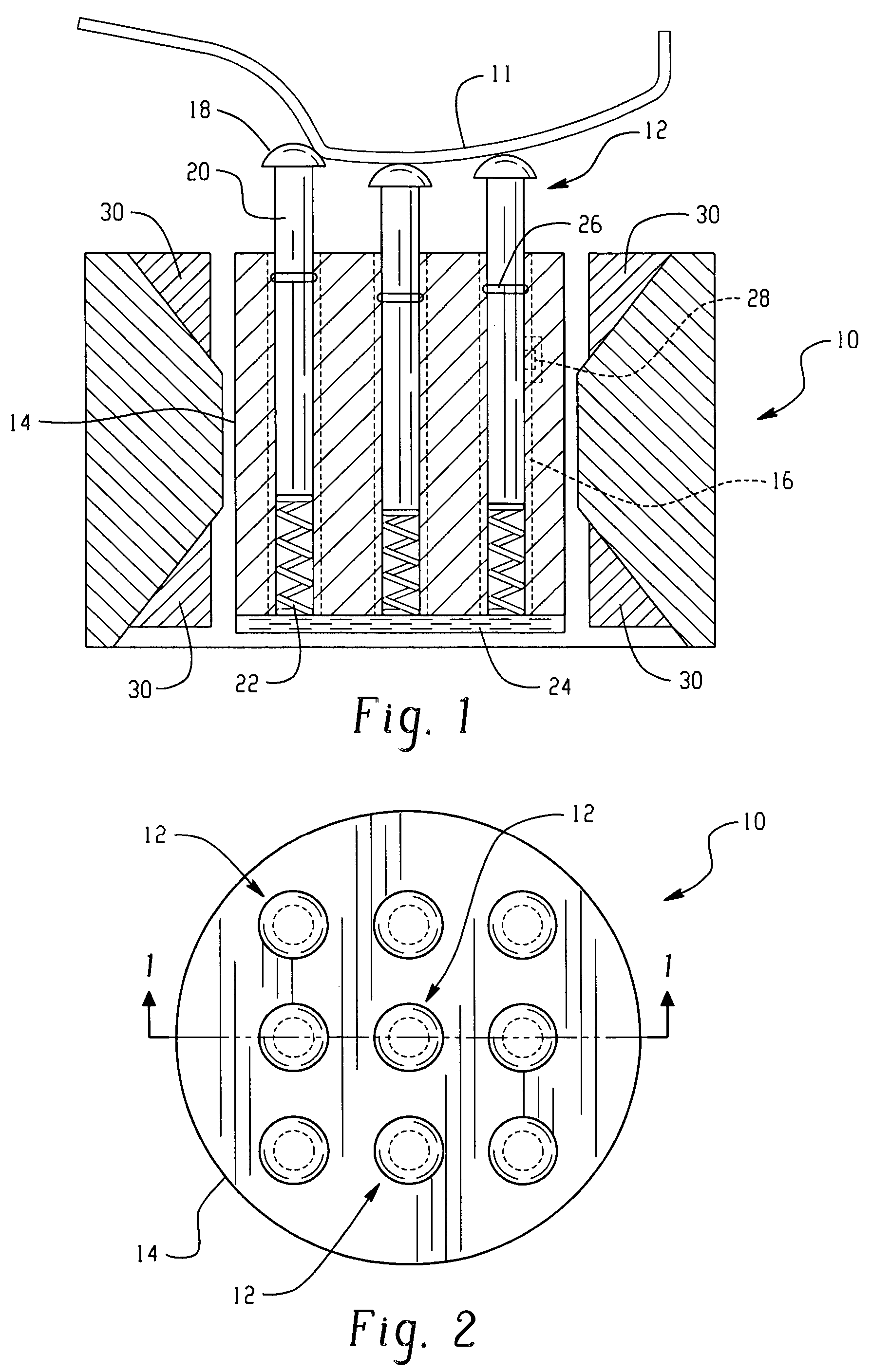

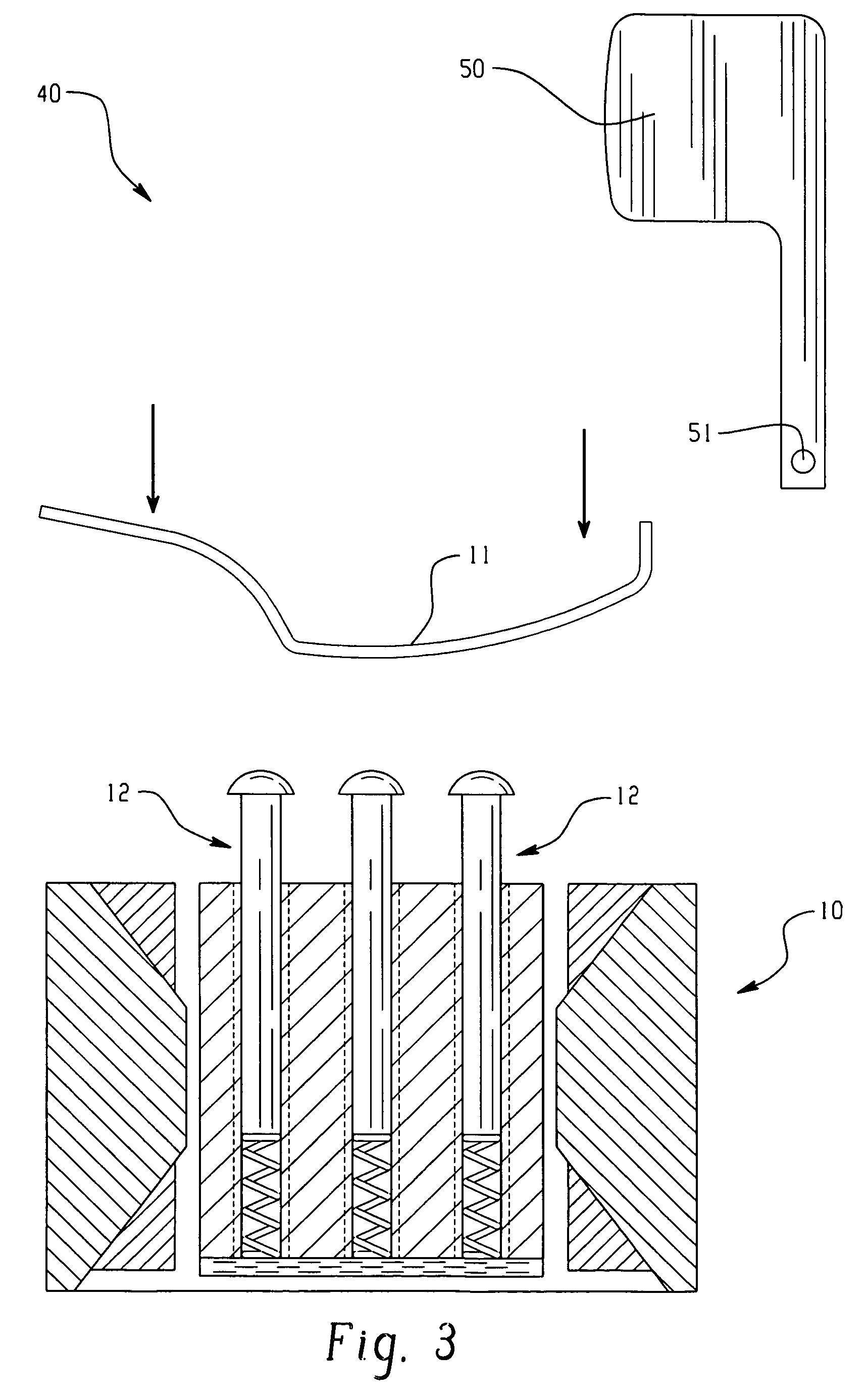

Magnetorheological reconfigurable clamp for a flexible manufacturing system

InactiveUS20050269758A1Welding/cutting auxillary devicesWork holdersFlexible manufacturing systemMagnetorheological fluid

A reconfigurable clamp for a flexible manufacturing system comprises a body portion, a plurality of pins slidably engaged within sleeves formed in the body portion, a compression spring attached to each shaft of the plurality of pins, a reservoir comprising a magnetorheological fluid in operative communication with the plurality of pins, and an electromagnet in operative communication with the magnetorheological fluid, wherein the electromagnet selectively increases a yield stress property of the magnetorheological fluid; and a matching pressure foot.

Owner:GM GLOBAL TECH OPERATIONS LLC

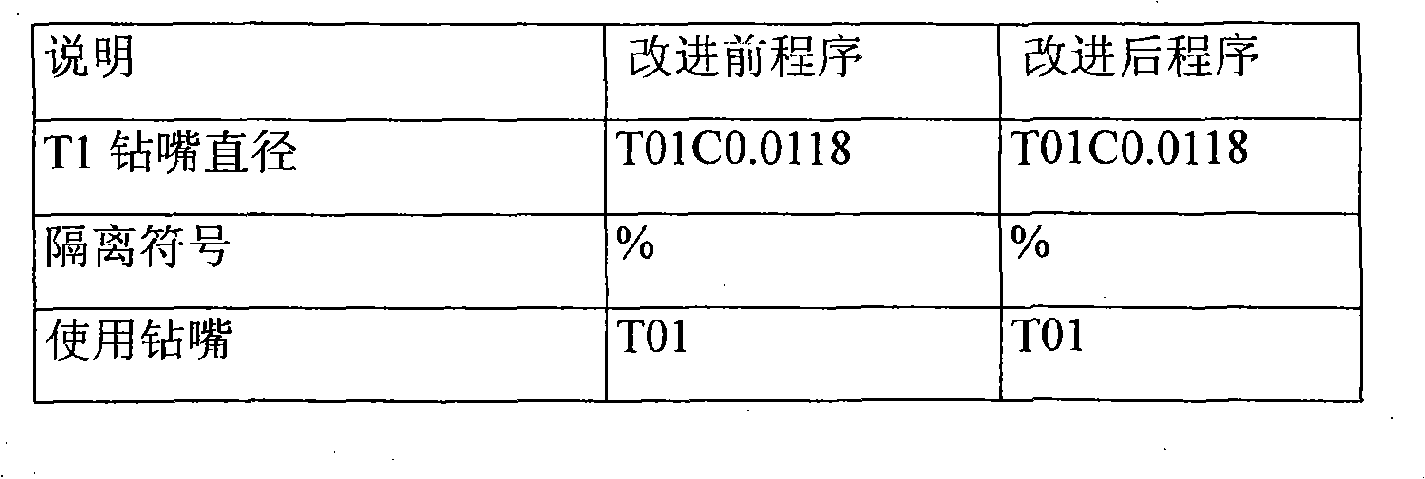

Small-aperture high-density drilling method of printed circuit board

InactiveCN101537505AIncrease working edge lengthReduce the spindle dynamic yaw valuePrinted circuit manufactureHigh densityEngineering

The invention aims at the technical state of the prior printed circuit board drilling method to provide a mechanically drilling method of a high-density and small-aperture multilayer printed circuit board, which improves the drilling machine yield and has good drilling quality by improving drilling parameters. The method mainly comprises the following steps of adjusting zero-position, setting drilling parameters, drilling positioning holes, installing bearing plate, substrate and aluminum sheet, drilling, grinding raw edges, blowing holes and inspecting, wherein the drilling order is set by a leap-frog method with coordinate hole space not smaller than 4 mm; the hole position requirements are converted into a PCB drilling program by CAM, the original hole positions are arranged in sequence, and the drilling sequence is deigned according to the standard of the coordinate hole space not smaller than 4 mm; the pressure foot gasket of a main shaft of a drilling machine is a soft plastic pressure foot gasket; and the bit is a UC-type bit with good chip removal effect, and the total thickness of the drilled substrate is up to 4.5 to 4.8 mm.

Owner:NANJING ELEC & ELTEK ELECTRON

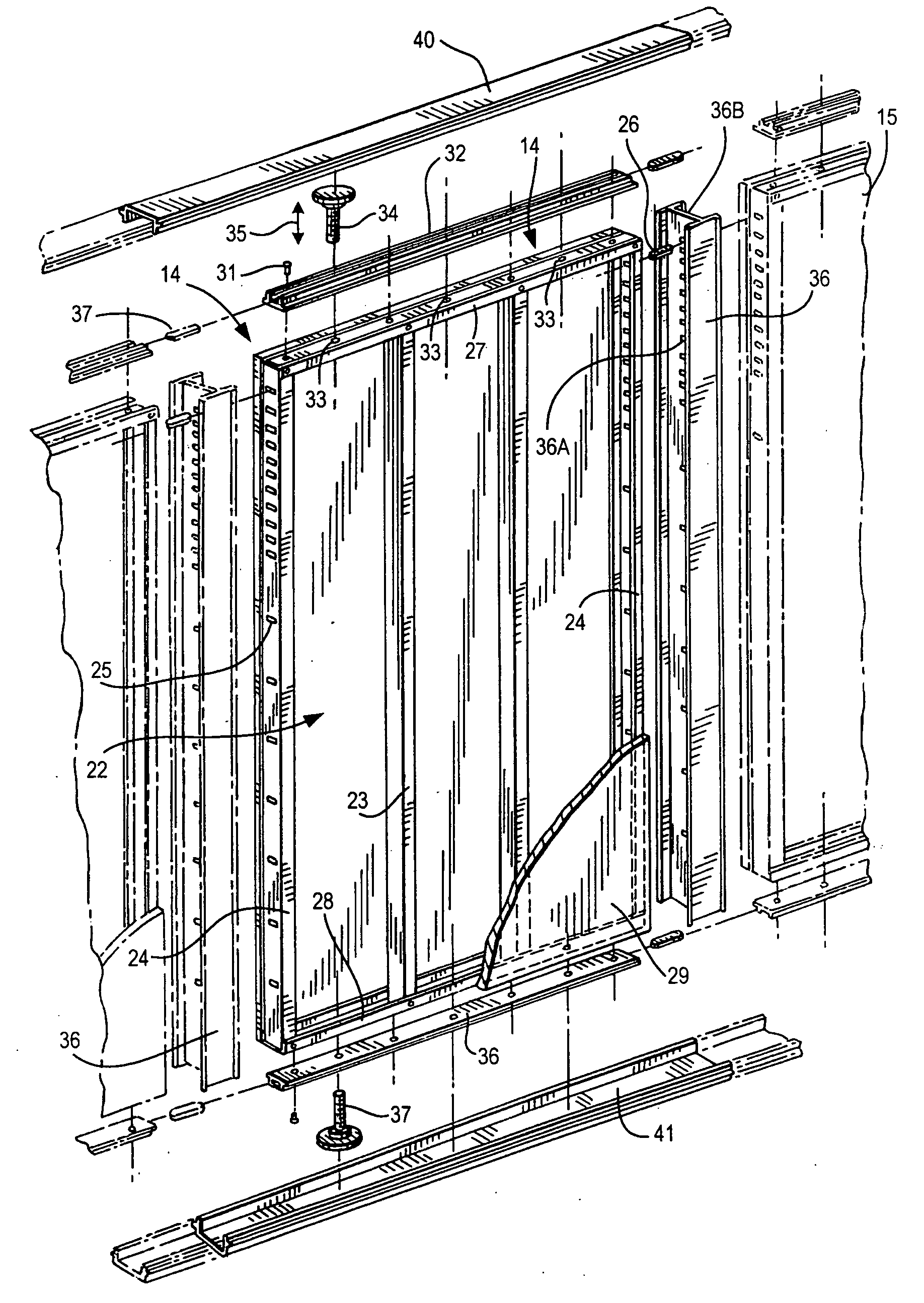

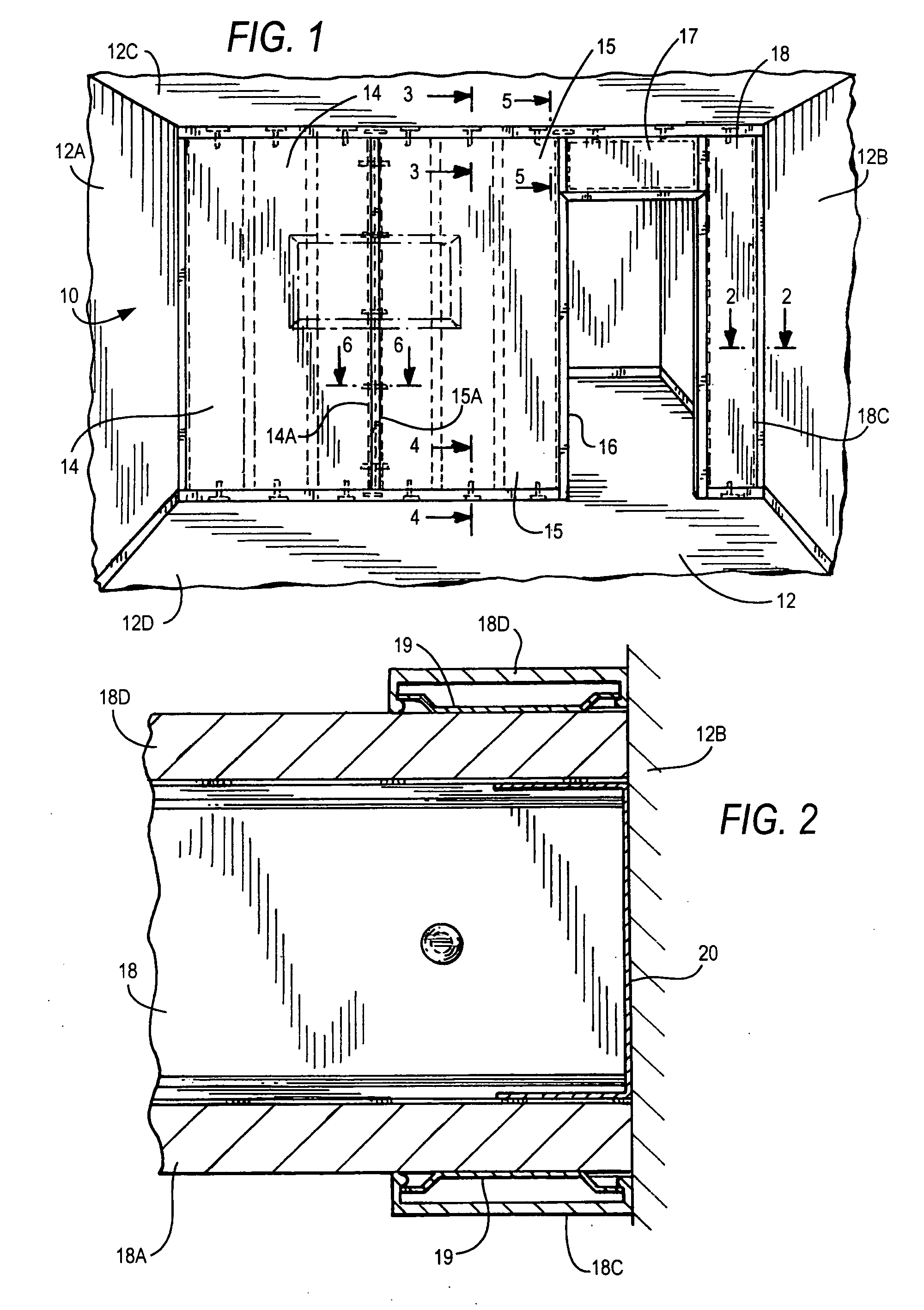

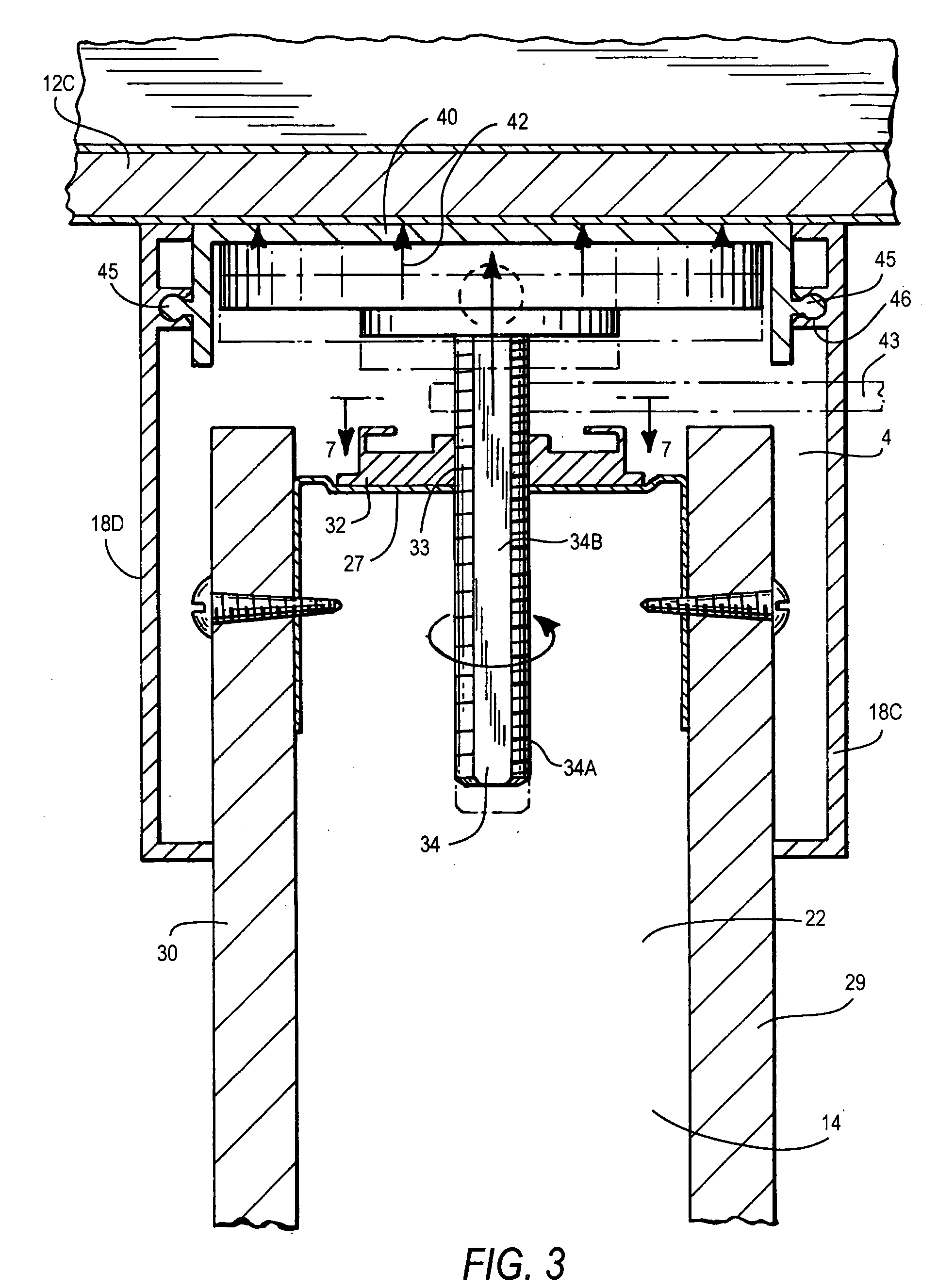

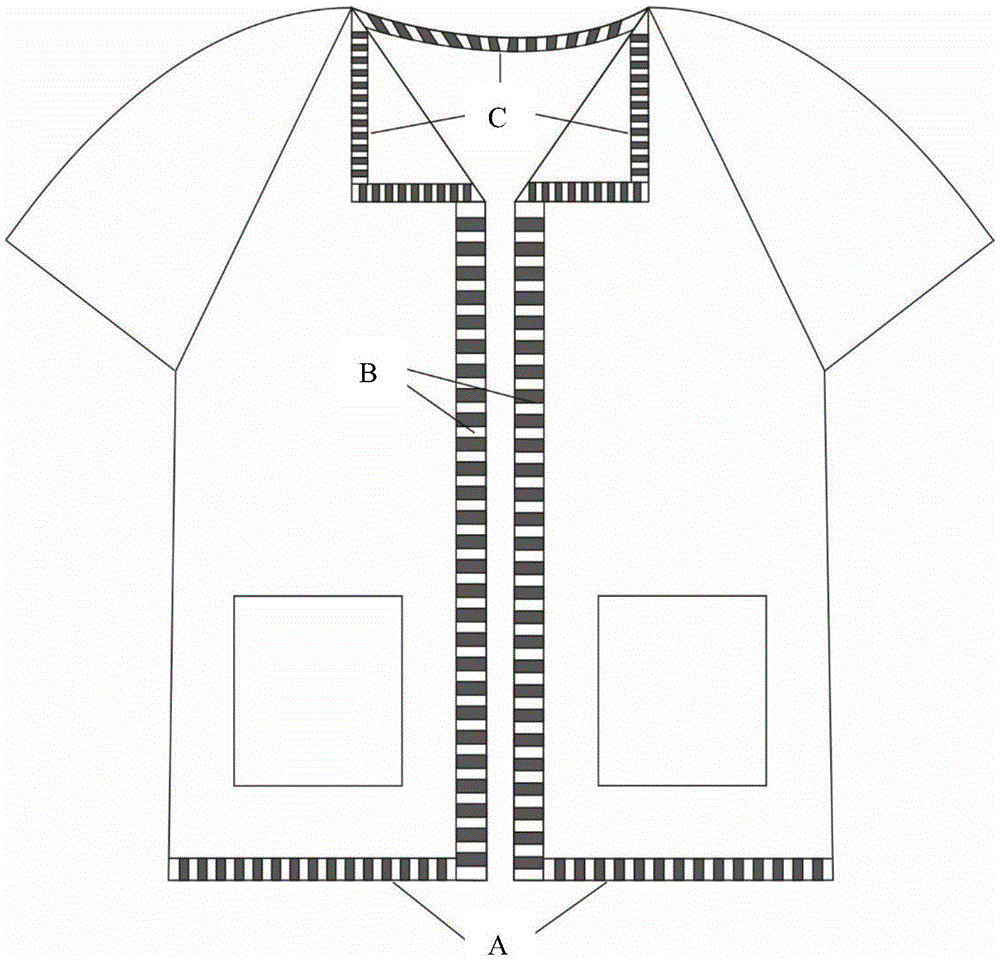

Temporary movable/removable compression partition wall system

InactiveUS20080209827A1Easy and quick connectionNot to damageShutters/ movable grillesWallsStructural engineeringPRESSURE FEET

A temporary movable / removable compression partition wall system for partitioning a room includes a wall component and spaced-apart pressure feet at the top of the wall for pressing against a track positioned between the top of the wall and the ceiling and additional spaced-apart pressure feet at the bottom of the wall for pressing against a track positioned between the bottom of the wall and the floor. This wall is temporarily, securely and rigidly positionable at a selected location in a room and subsequently removable with substantially no damage to the ceiling, floor or walls.

Owner:WEBB SCOTT T

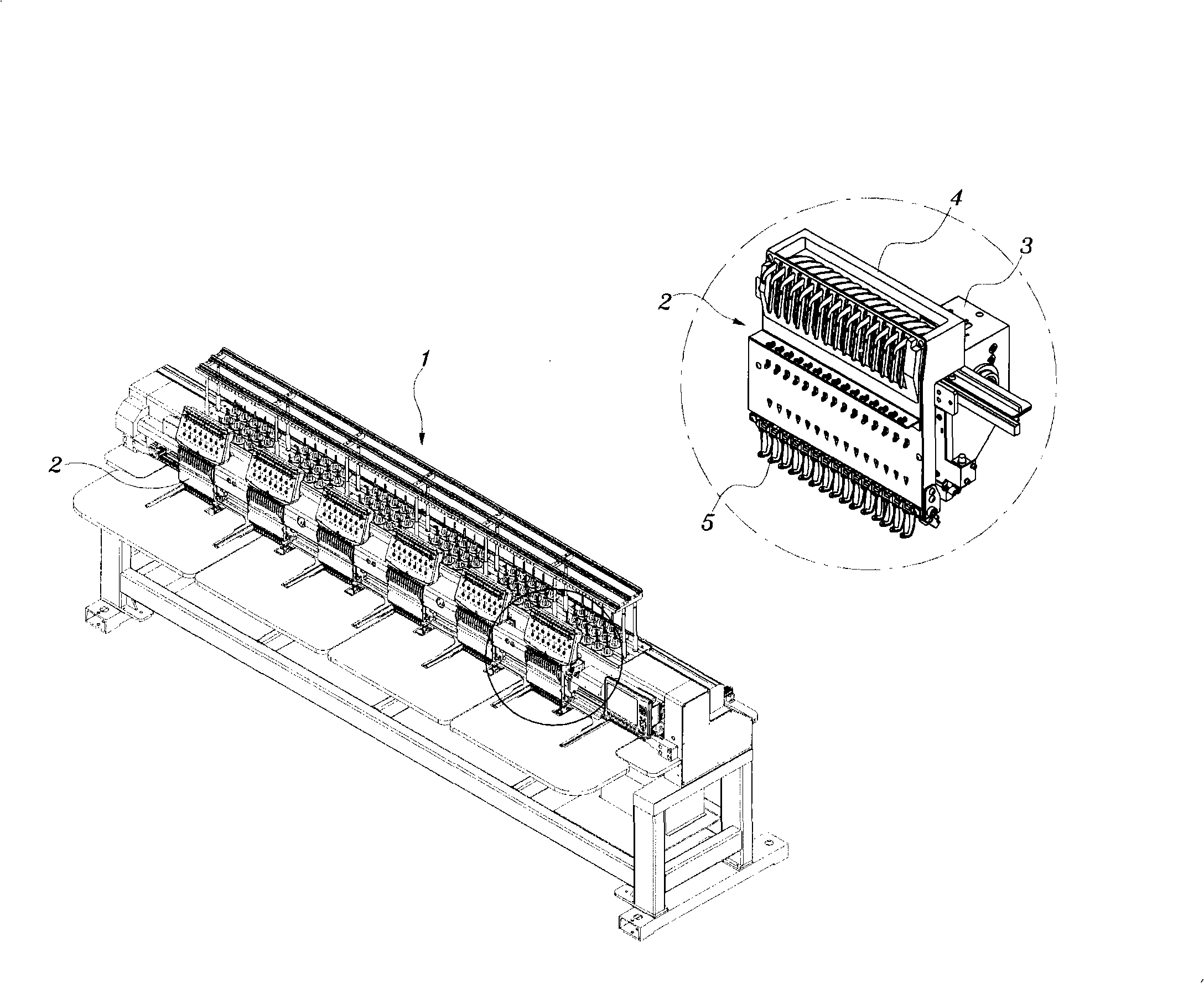

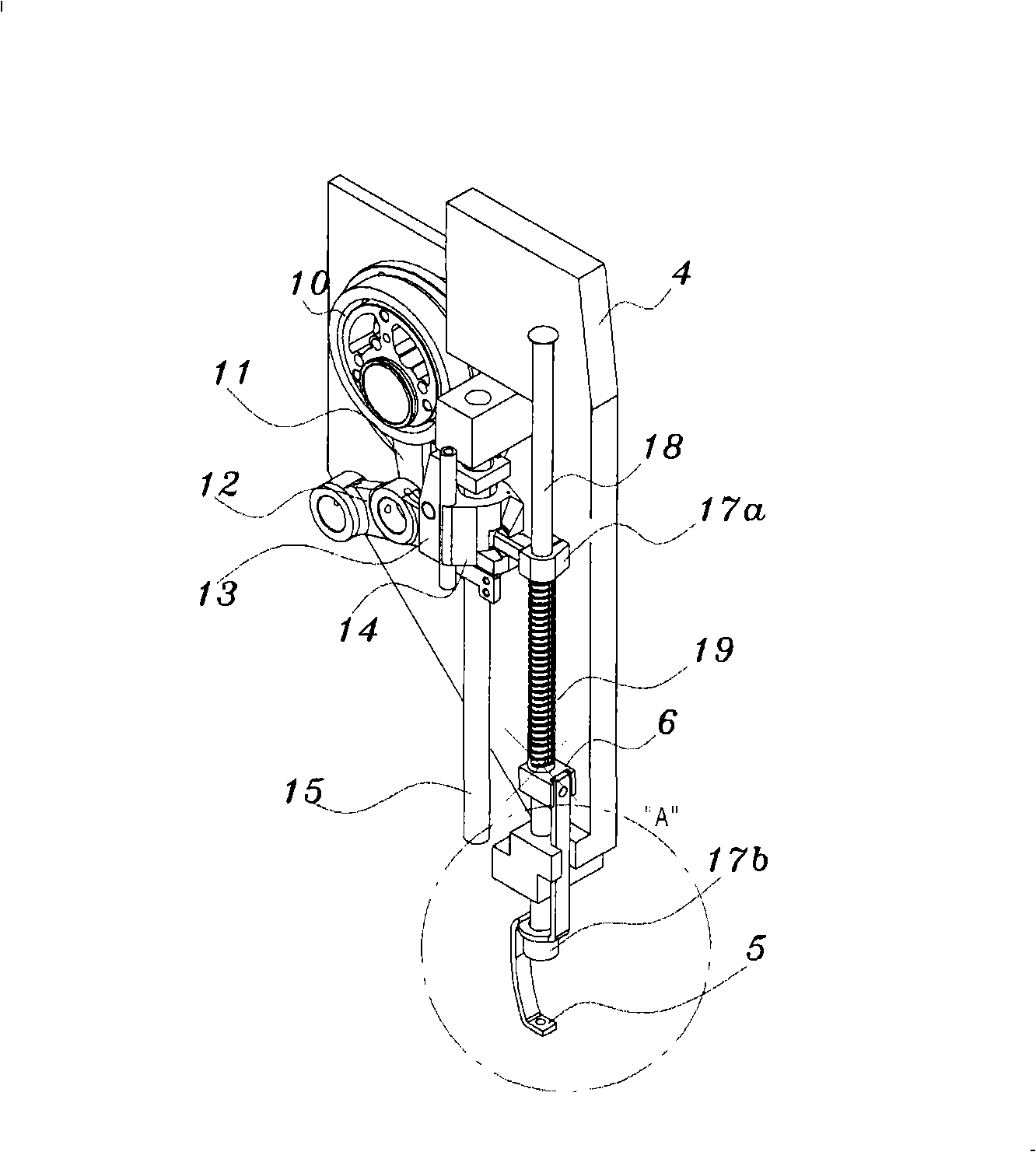

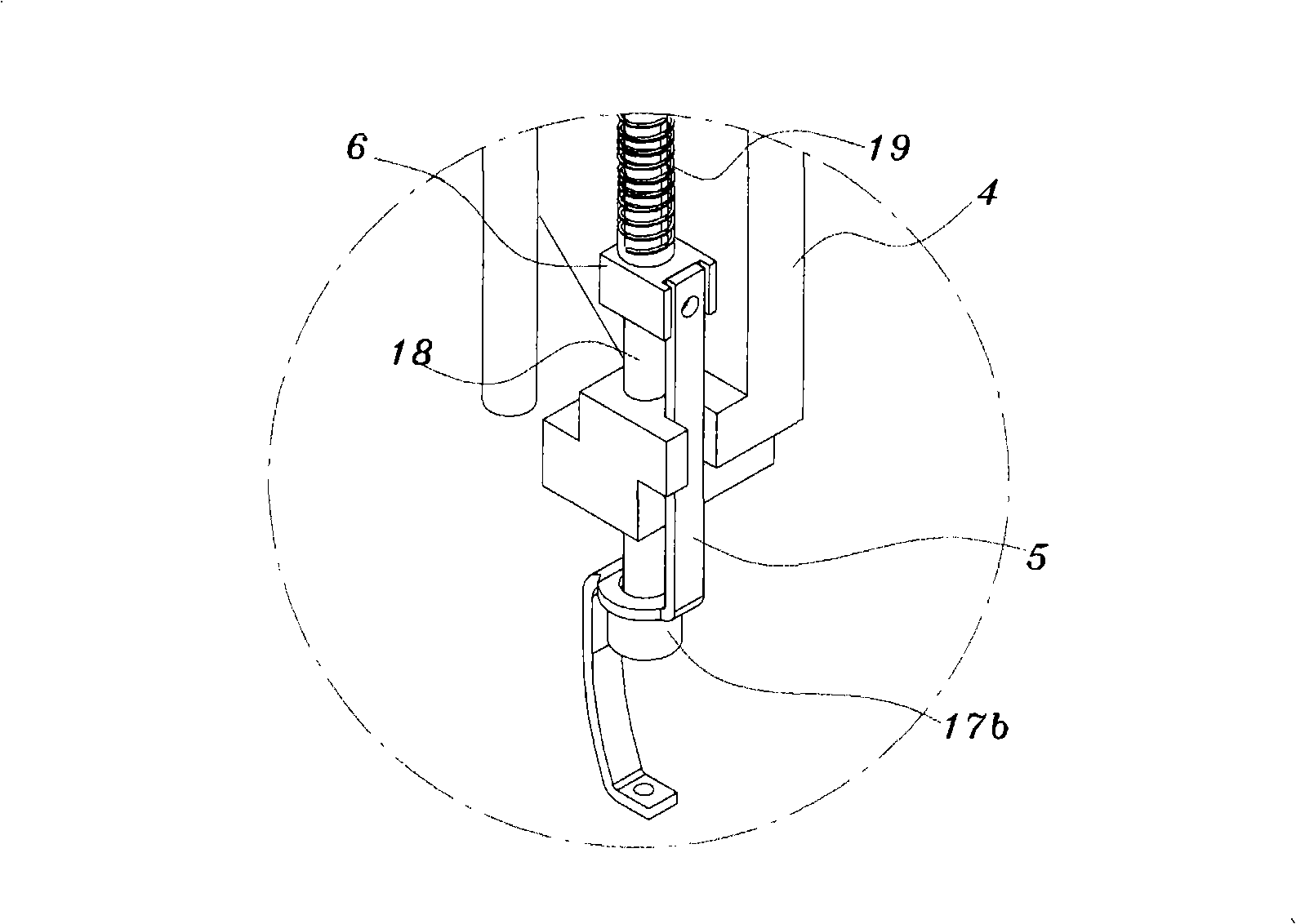

Embroidery machine

InactiveCN101260601AChange itineraryProgramme-controlled sewing machinesPressersEngineeringPRESSURE FEET

An embroidery machine includes a sewing arm having an upper shaft for providing a driving force, a needle bar support case, which is assembled to a front portion of the sewing arm so as to be laterally movable, a needle bar provided in a needle bar support case, the needle bar having a needle at a lower end thereof and vertically carrying the needle using a rotation driving force of the upper shaft, and a presser foot, which is provided in the needle bar support case so as to be vertically movable, characterized in that each of the needle bar and the presser foot is operated by an individual drive mechanism. The presser foot is separately driven by its own drive source, independent of the drive source of the needle bar.

Owner:SUSR PRECISION CO LTD

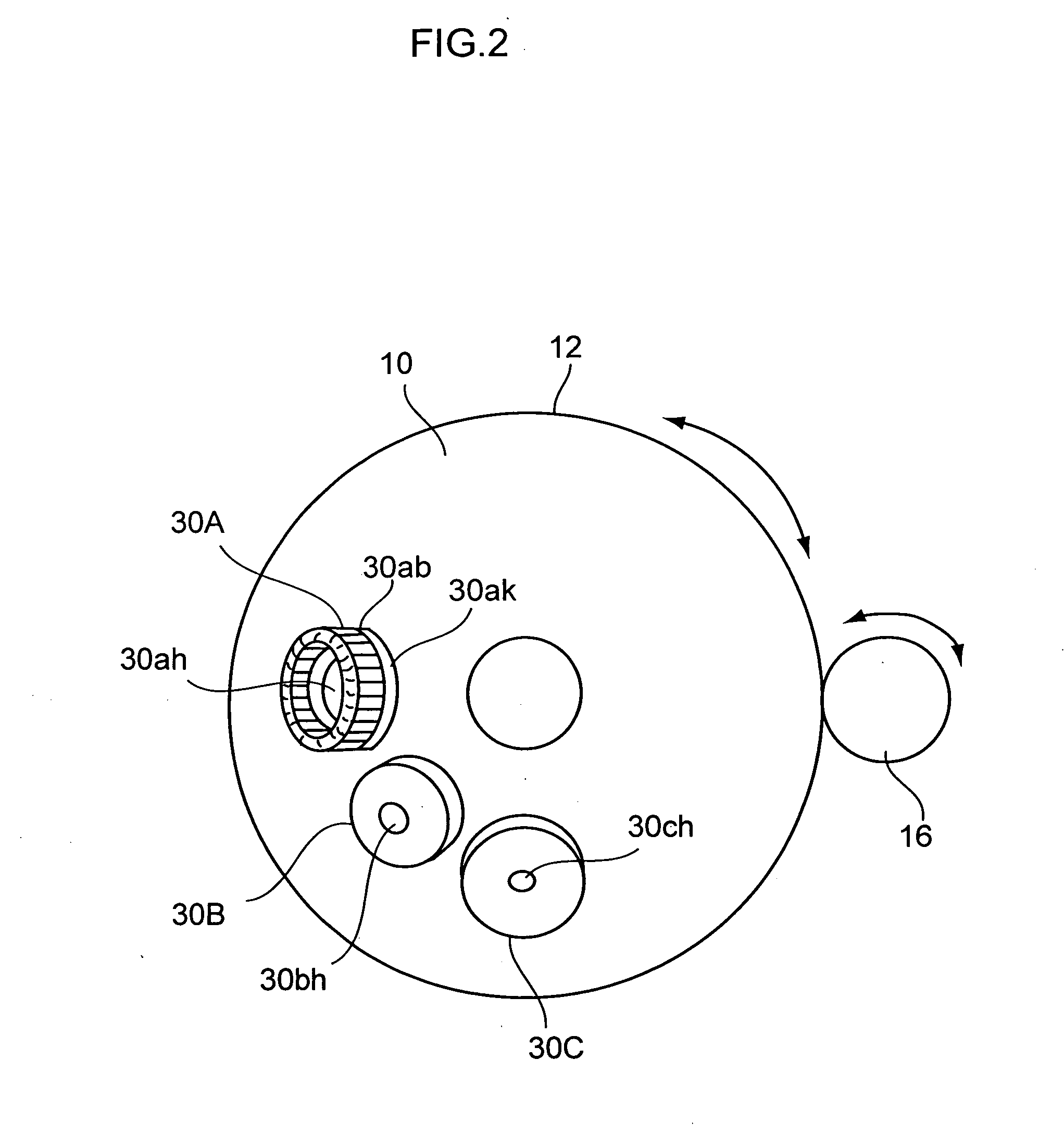

Printed circuit board machinging apparatus

InactiveUS20080292416A1CapableEfficient and accurateDrilling/boring measurement devicesThread cutting feeding devicesEngineeringPrinted circuit board

A printed circuit board machining apparatus includes a spindle that holds a tool for machining a printed circuit board and a pressure unit for pressing the printed circuit board to a table in machining the printed circuit board. The pressure unit includes a pressure foot movable up an down along the spindle, a rotating member having a plurality of pressure pieces through which a through hole for passing the tool is formed and provided so as to select one among the plurality of pressure pieces, a motor for moving the rotating member, cylinders and electromagnetic valves for moving the pressure foot up and down and a control section for controlling the cylinders and electromagnetic valves. The control section rotates the motor so as to select the pressure piece and controls the cylinders and the electromagnetic valves to change force for pressing the printed circuit board.

Owner:HITACHI SEIKO LTD

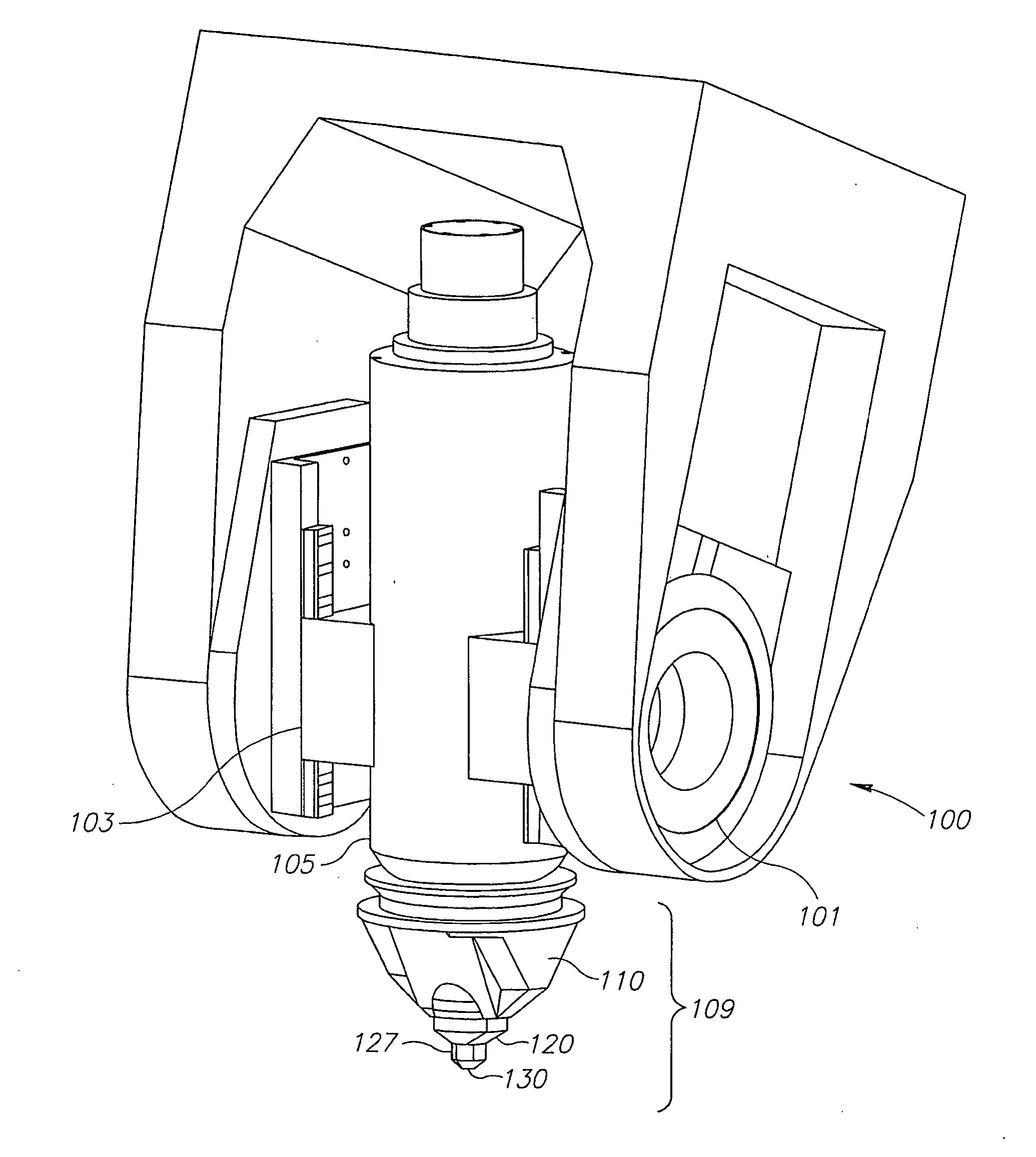

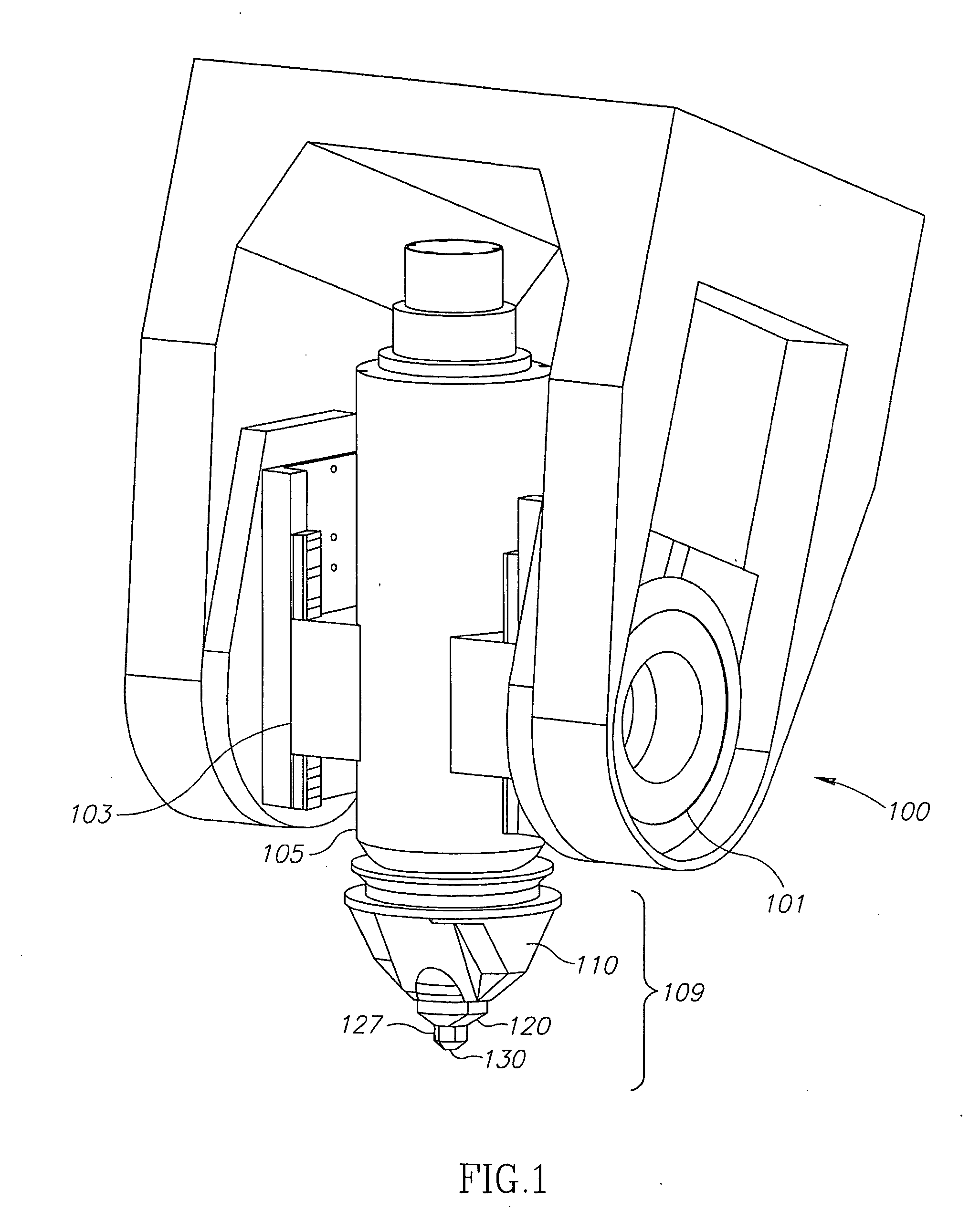

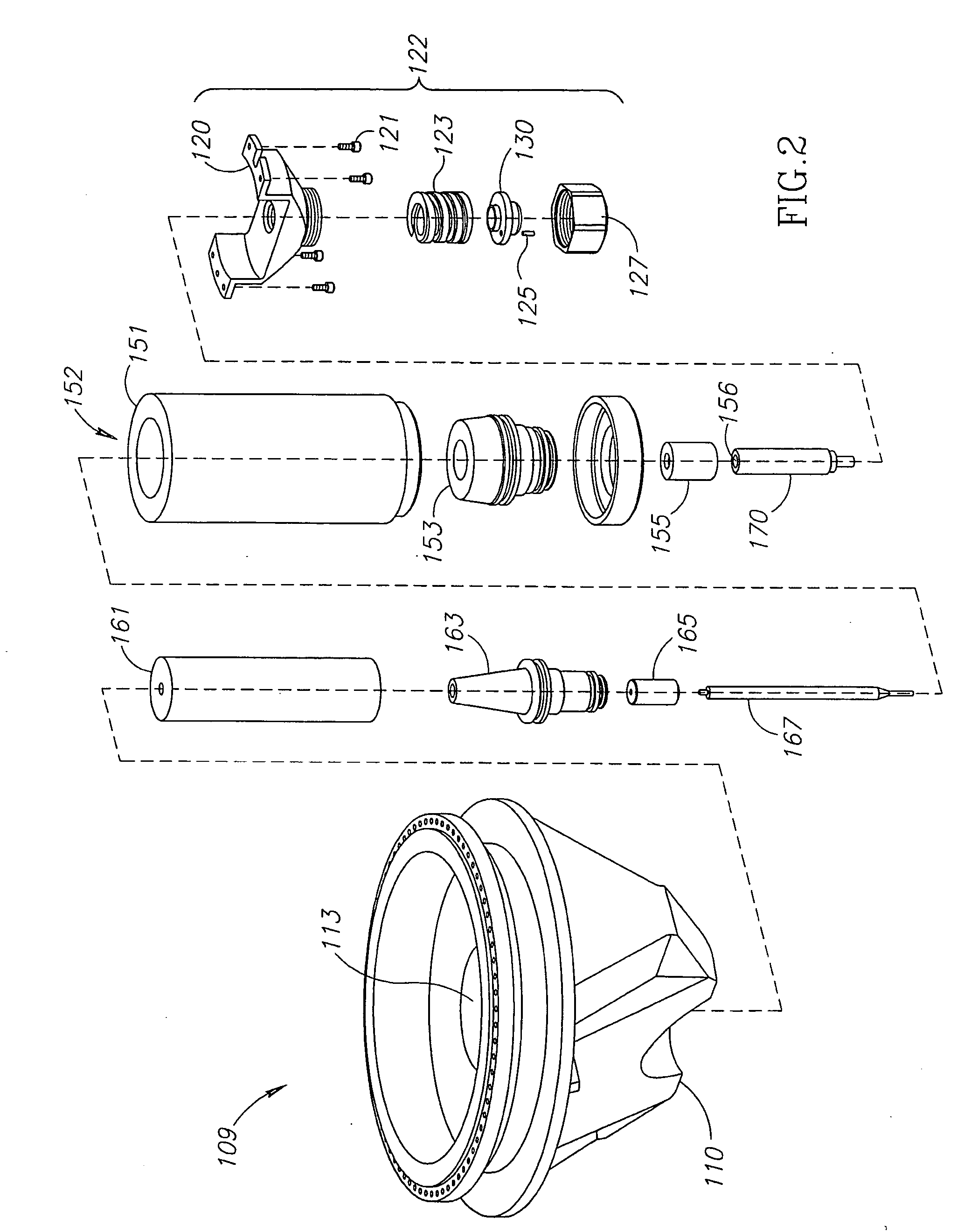

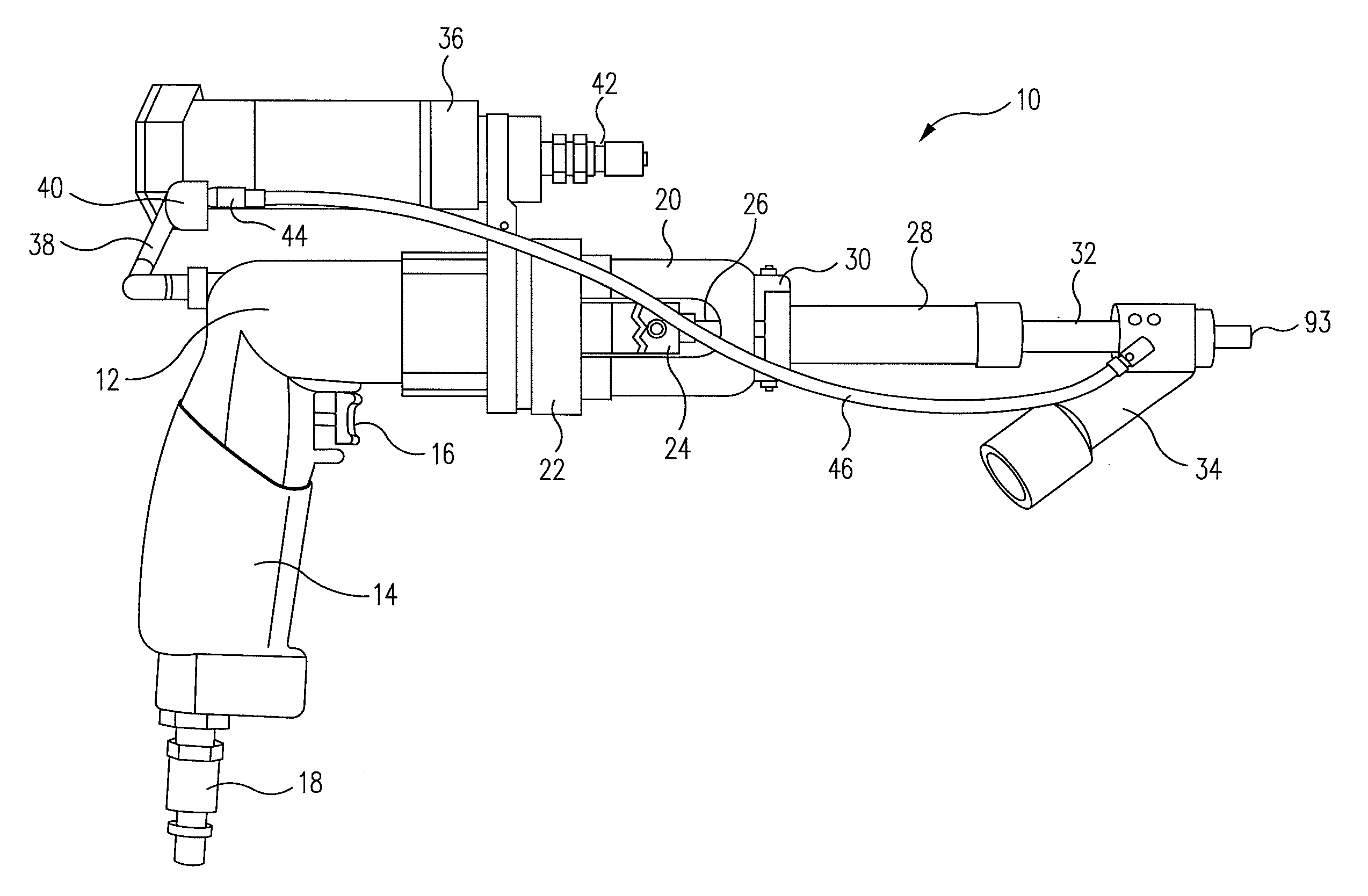

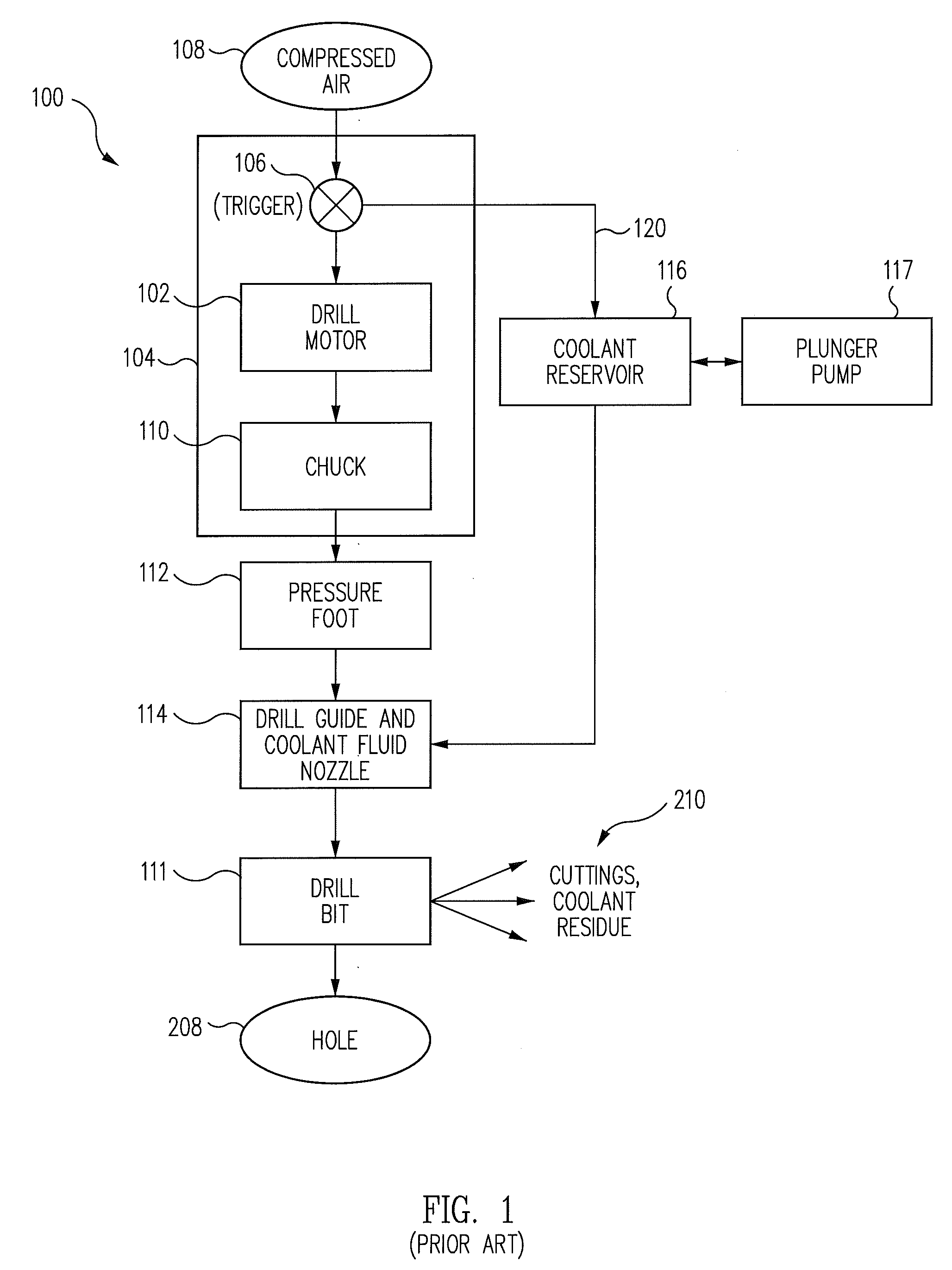

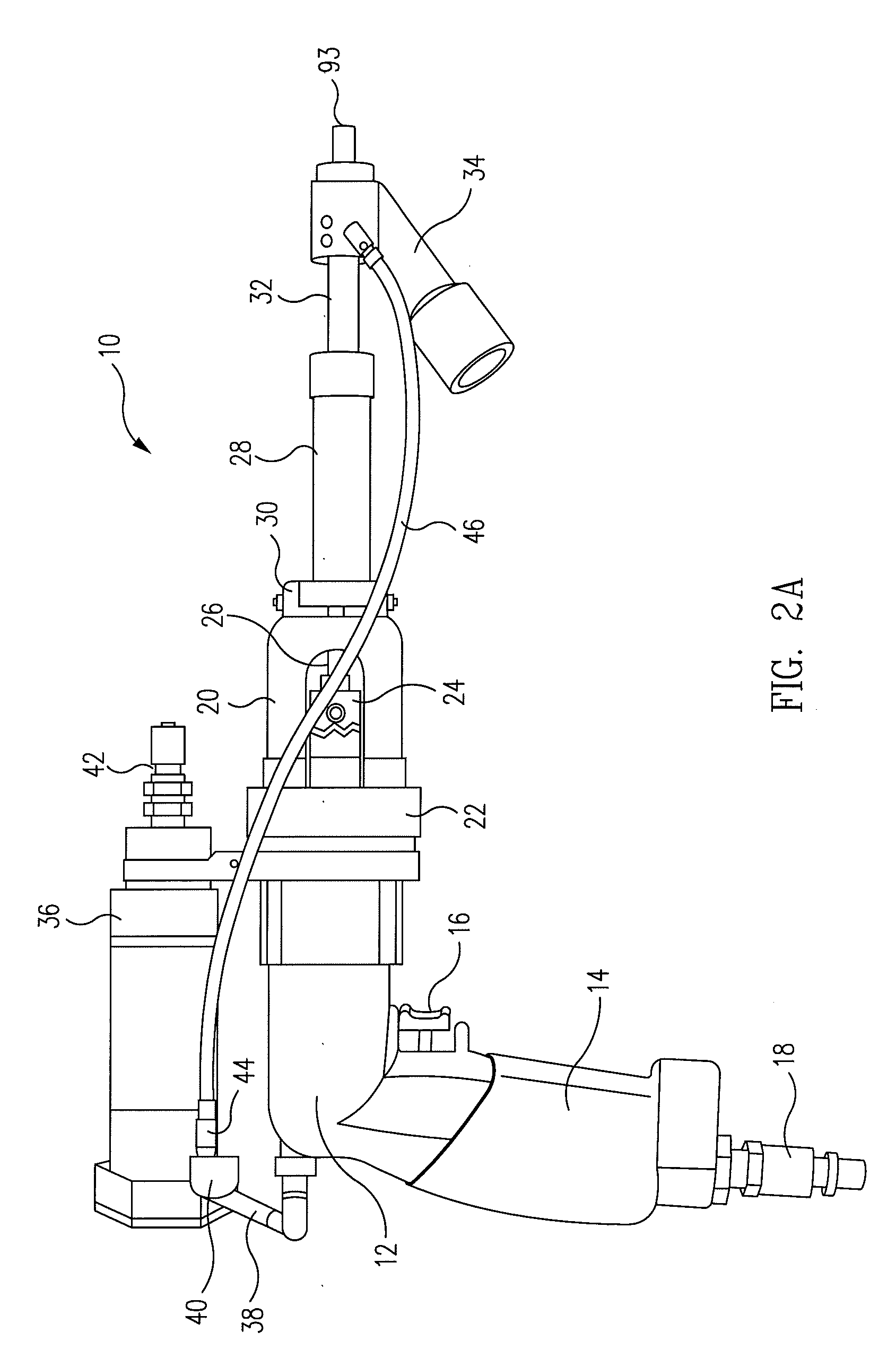

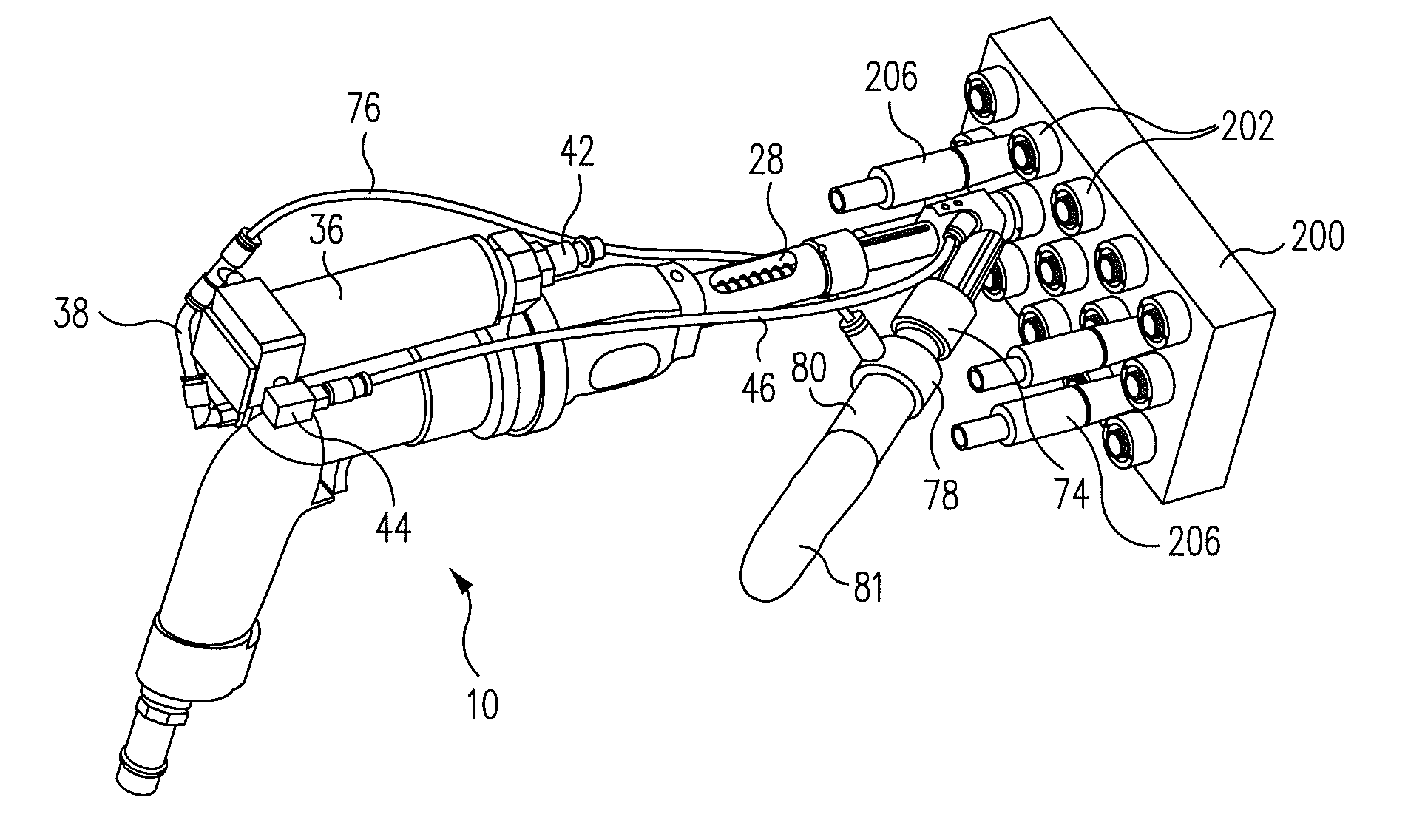

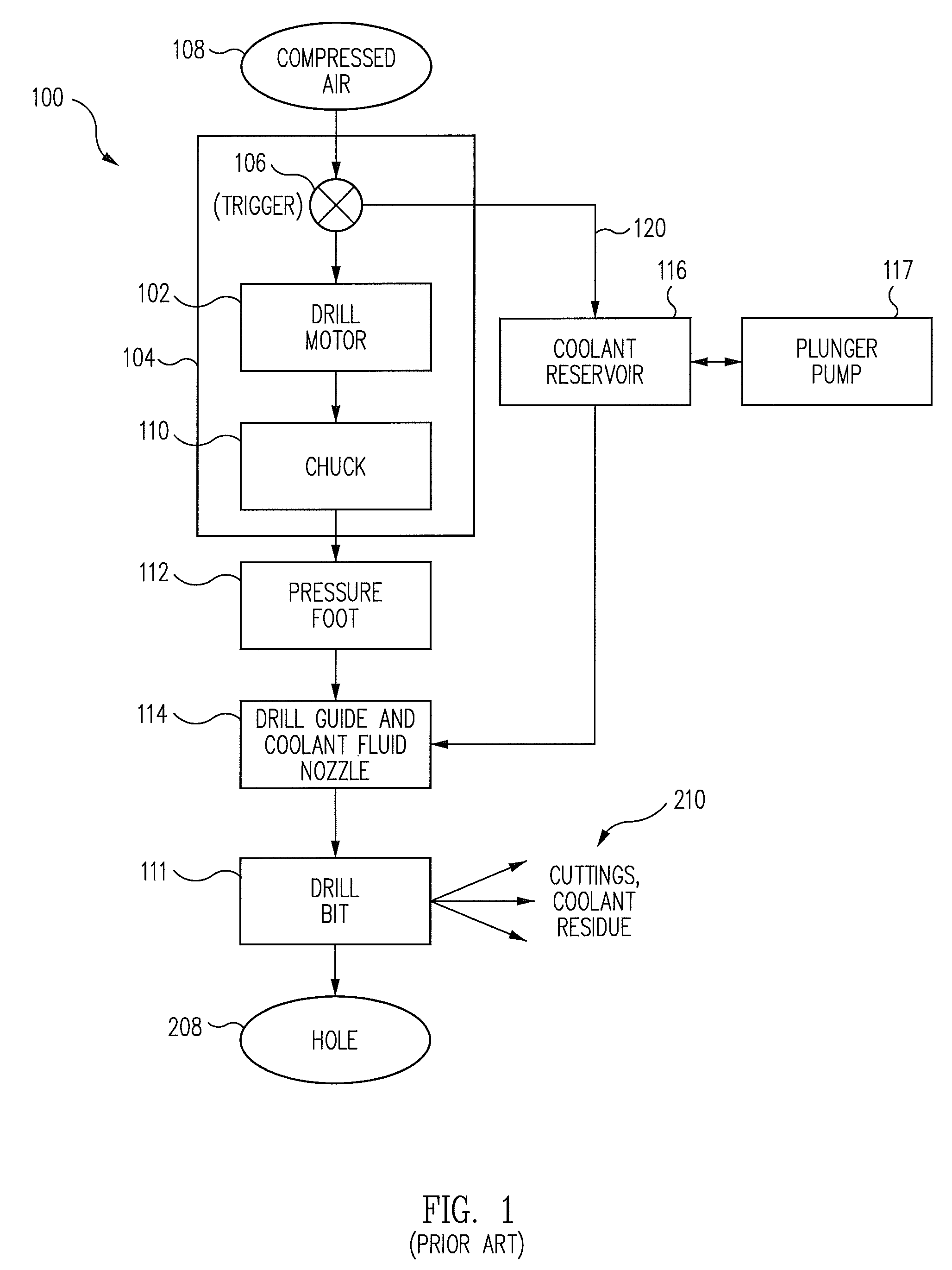

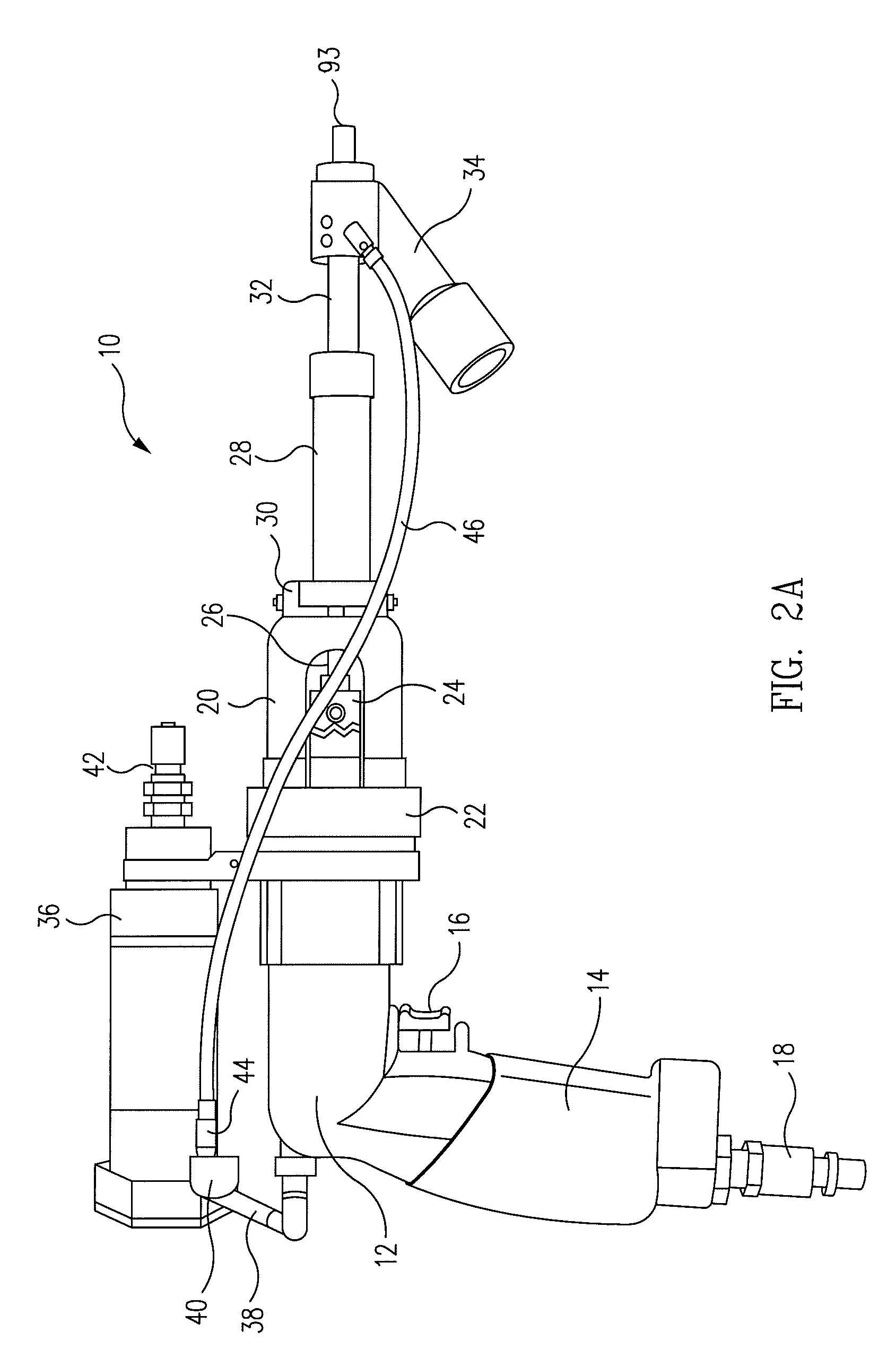

High speed hand drill with swiveling pressure foot and integrated vacuum pickup and coolant delivery duct

ActiveUS20090214307A1Improve tool ergonomicsImproved drill guideDrilling/boring measurement devicesThread cutting feeding devicesHand heldEngineering

A high speed handheld power drill includes a housing with a motor, a chuck rotationally driven by the motor, and a drill bit clamped in the chuck. A pressure foot is mounted on the housing for coaxial rotation about the drill bit and lockable in a selectable angular position relative to the housing. A drill guide is slidably disposed within the pressure foot at an outer end thereof and biased for coaxial sliding movement between the drill bit and pressure foot. A vacuum cuttings pickup and coolant fluid delivery tool is coupled to the drill guide and arranged to deliver coolant fluid to the drill bit and to remove drill cuttings and coolant fluid and vapor therefrom during drilling. A coolant fluid reservoir is coupled to the drill motor housing and adapted to deliver selectably metered amounts of coolant fluid to the cuttings pickup and coolant delivery tool during drilling.

Owner:THE BOEING CO

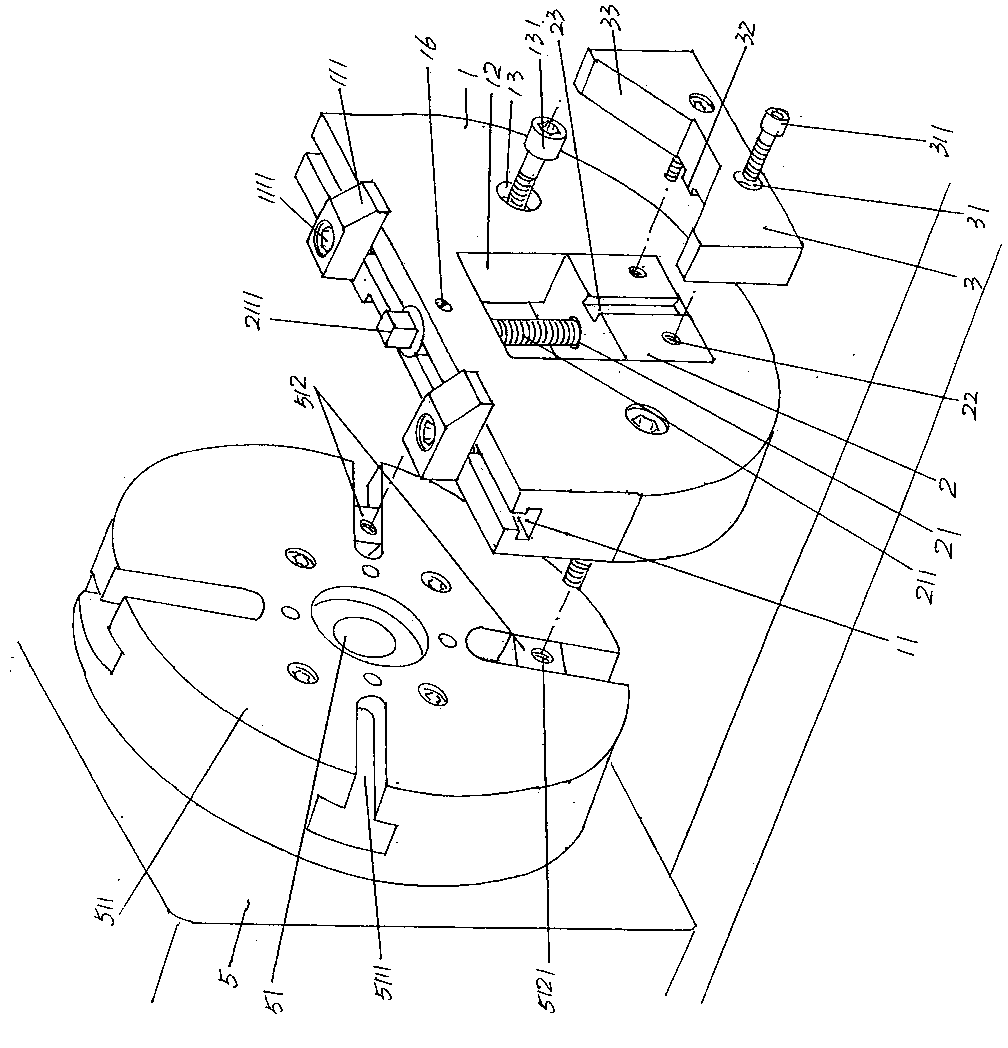

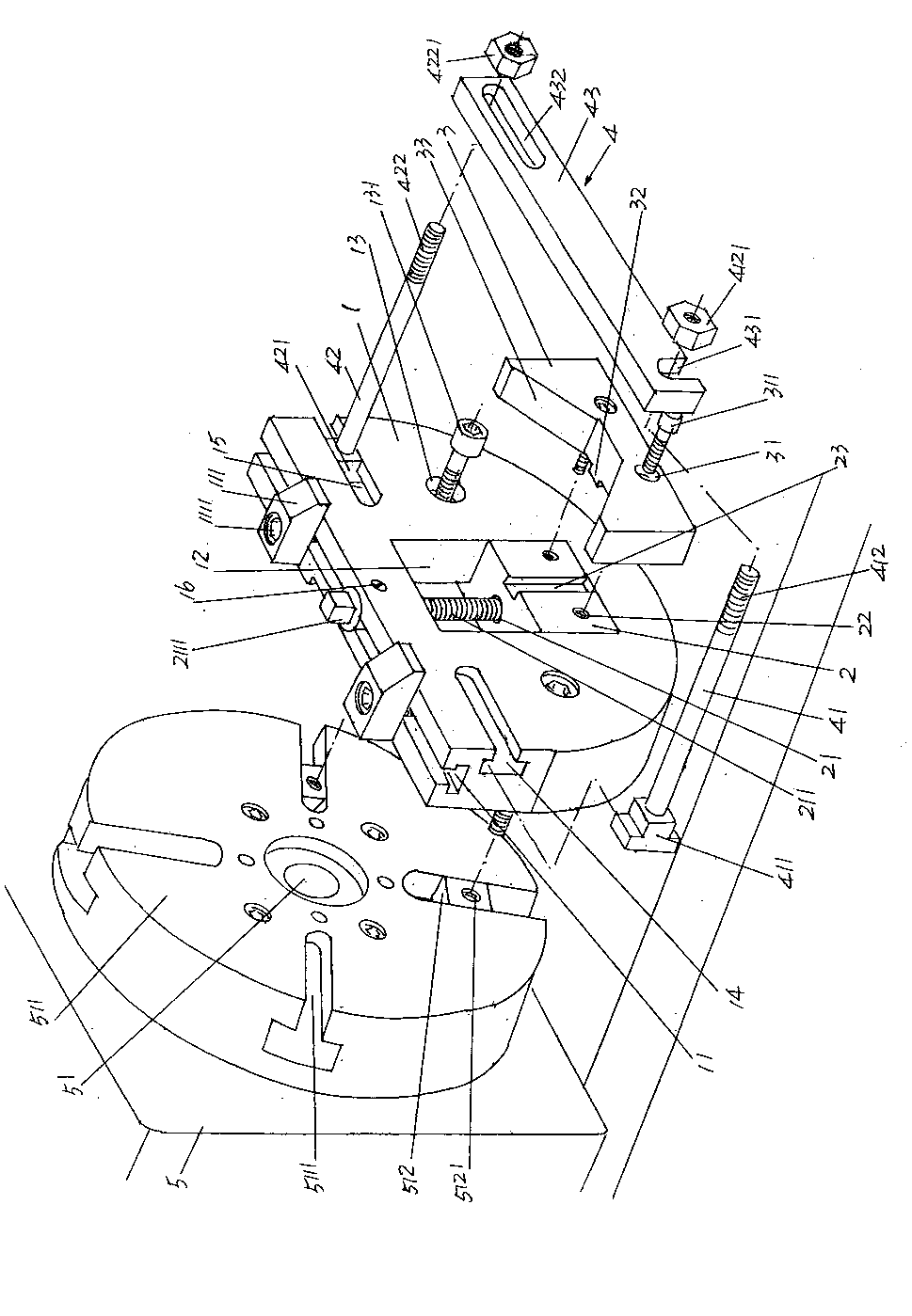

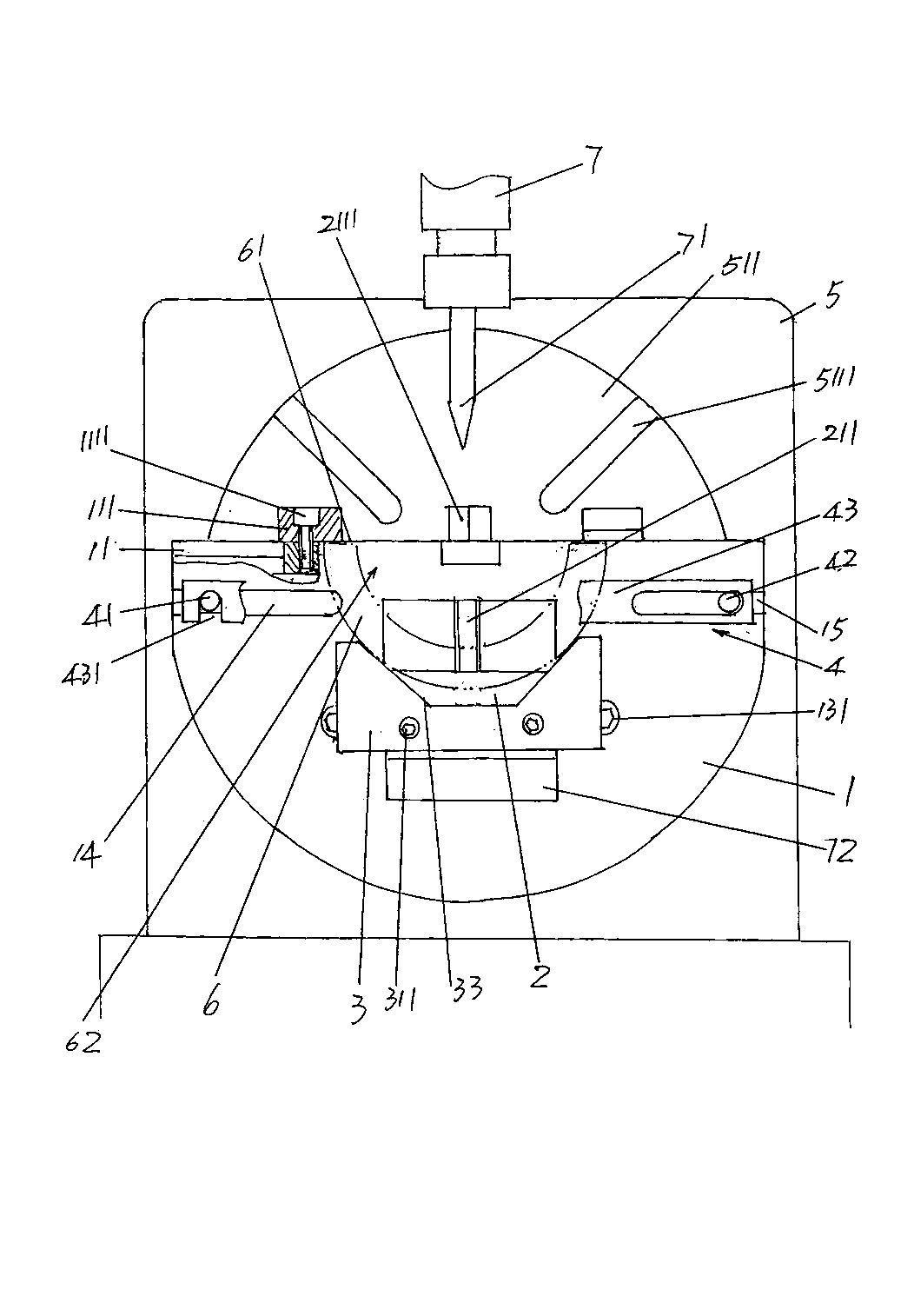

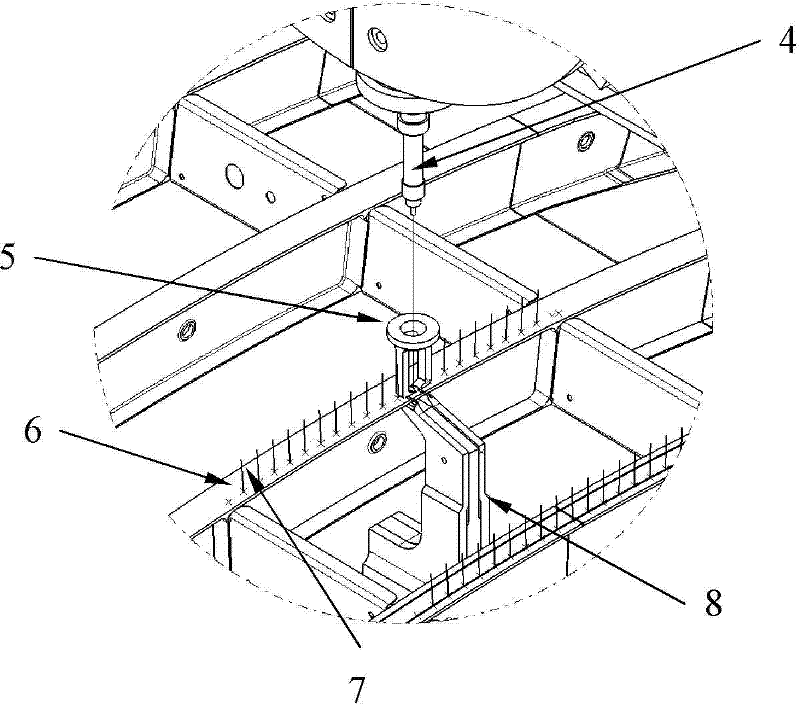

Fixture structure for glass mould machining

ActiveCN102837213AQuality assuranceGuarantee efficiencyPositioning apparatusMetal-working holdersEngineeringMachining

The invention belongs to the field of a tool fixture and provides a fixture structure for glass mould machining. The fixture structure comprises a base seat, a pressure foot slide groove is arranged on the surface of one side of the base seat along the length direction of the surface, pressure feet are arranged on the pressure foot slide groove in a matched mode, a supporting mould block fixing seat and a supporting mould block slide cavity are arranged on the base seat, and the positions on the base seat where the supporting mould block fixing seat and the supporting mould block slide cavity are arranged correspond to the lower portion of the center position of the length direction of the pressure foot slide groove; the supporting mould block fixing seat is matched with the supporting mould block slide cavity, a supporting mould block fixing seat nut is arranged on the supporting mould block fixing seat in matched mode, the supporting mould block fixing seat nut is connected with one end of a lifting screw rod of the supporting mould block fixing seat, and the other end of the lifting screw rod of the supporting mould block fixing seat is arranged on the pressure foot slide groove in a supporting mode; a supporting mould block is fixed with one side of the supporting mould block fixing seat, one end of each pressure feet stretches out the surface of one side of the base seat, wherein the end and the surface both face towards the supporting mould block. The fixture structure for the glass mould machining has the advantages that the fixture structure breaks away from a traditional electric spark mode that flower engraving machining is used for a cavity of the glass mould, the flower engraving quality and efficiency are ensured, and the operation is convenient and fast.

Owner:CHANGSHU JIANHUA MOLD TECH

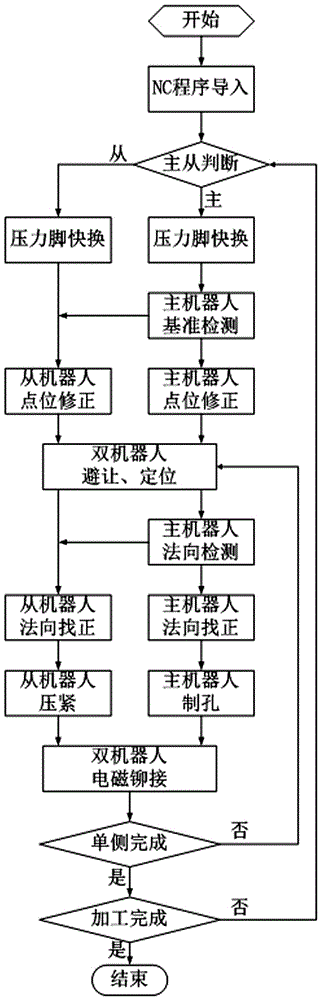

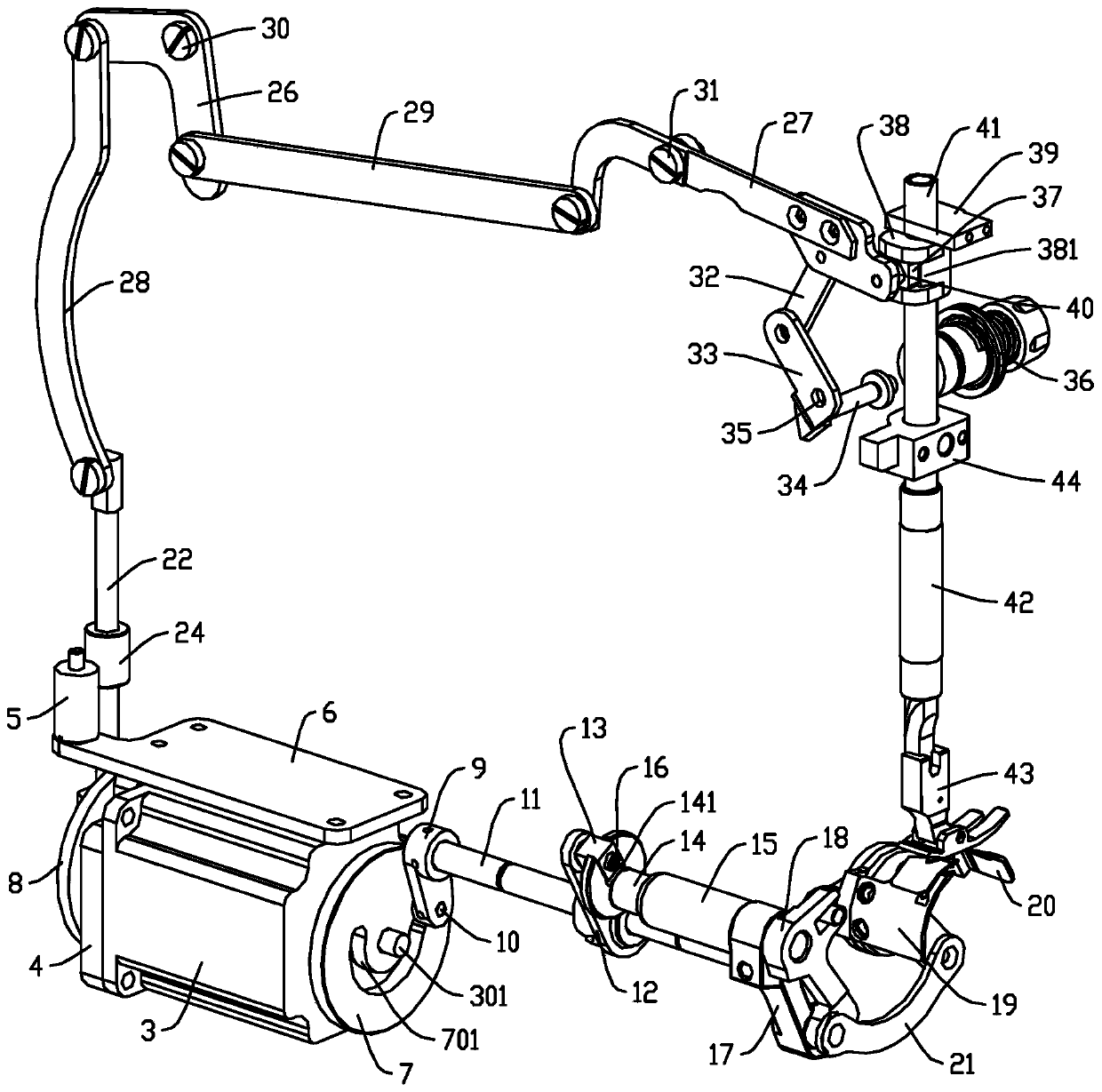

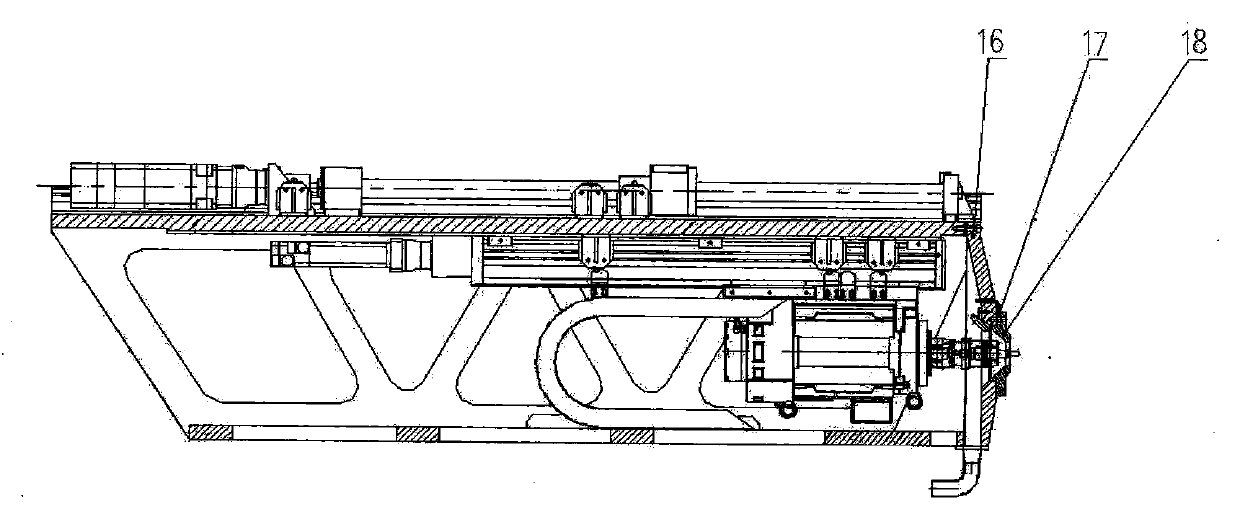

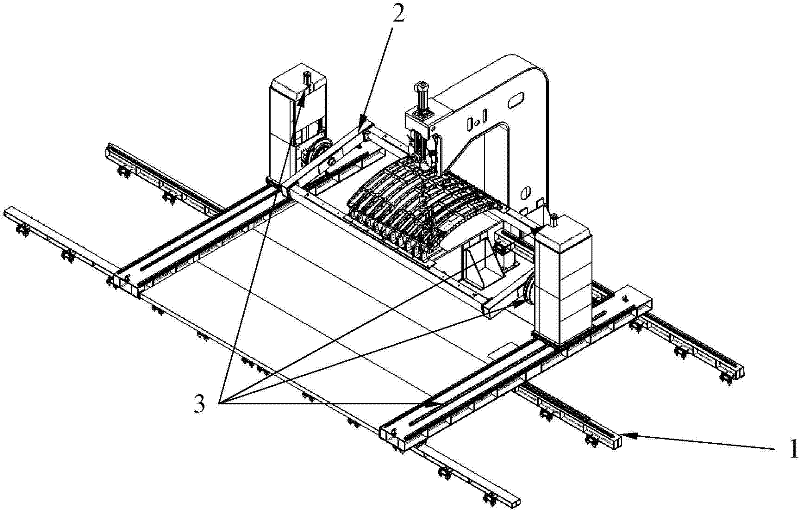

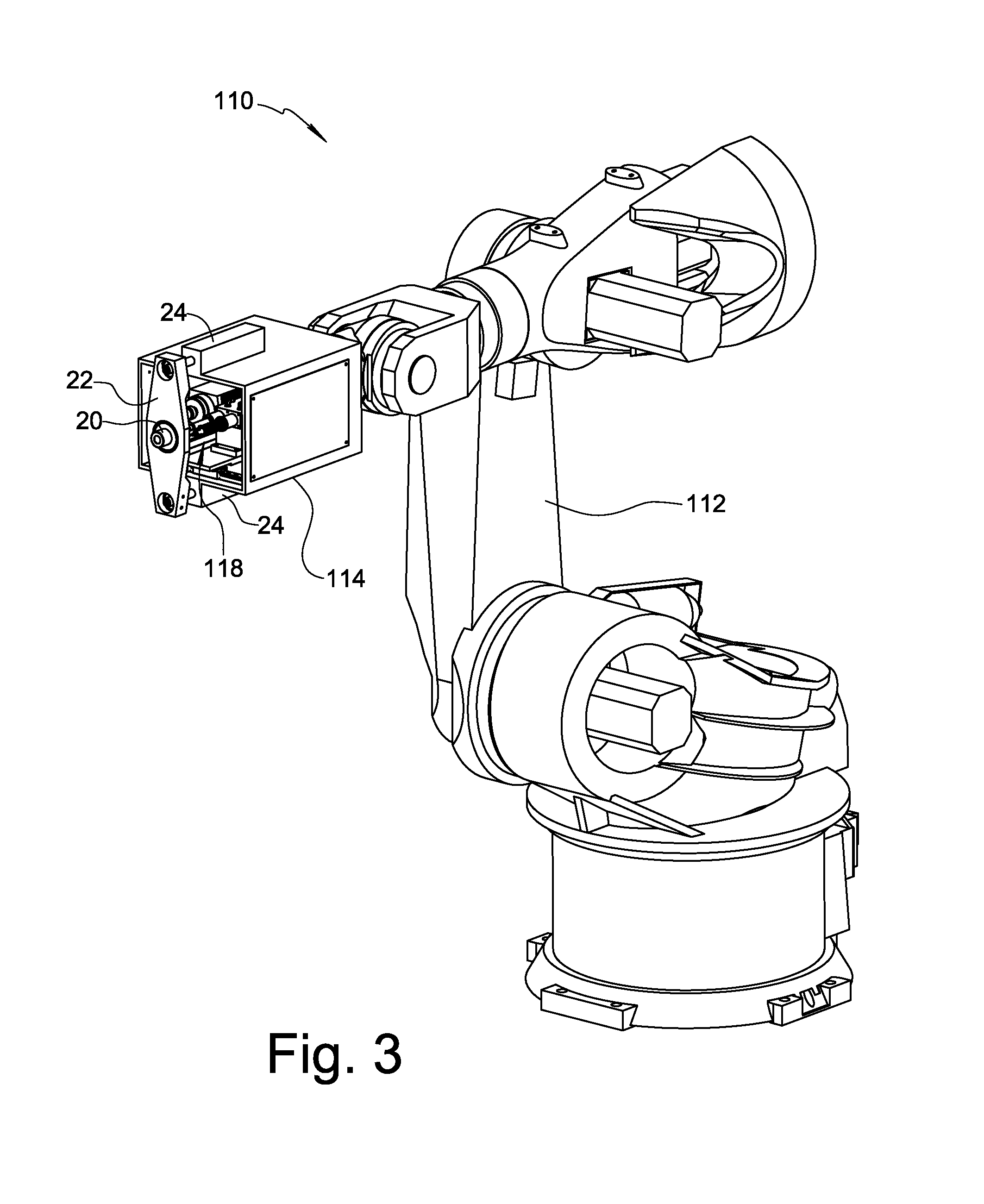

Intelligent flexible production line with double robot cooperative automatic assembling and operation method for same

The invention discloses an intelligent flexible production line with double robot cooperative automatic assembling and operation method for the same. The production line comprises an industrial control computer, a double track moving platform, double industrial robots, a control cabinet, a nail feeding system, a vacuum chip absorbing device, a knife trying station and a flexible tool. With a double-robot cooperative drilling-riveting work mode, the double-robot systems are distributed on two sides of a product, and information is detected by one-side robot to achieve robot pose correction; master-slave distribution of the robots can be dynamically realized during the work; pressure feet can be quickly exchanged upon master-slave switch; a master robot drills and conduct front compression and a slave robot compresses on the back surface of the product; and at last after drilling completion, electromagnetic riveting can be conducted to the double robots. Double-robot cooperative drilling-riveting work can be conducted with high intelligent degree; double-sized drilling and single-sided riveting operations can be completed; burrs can be prevented; and the intelligent flexible production line with double robot cooperative automatic assembling possesses high riveting quality, wide processing range, high flexibility and is suitable for various products.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

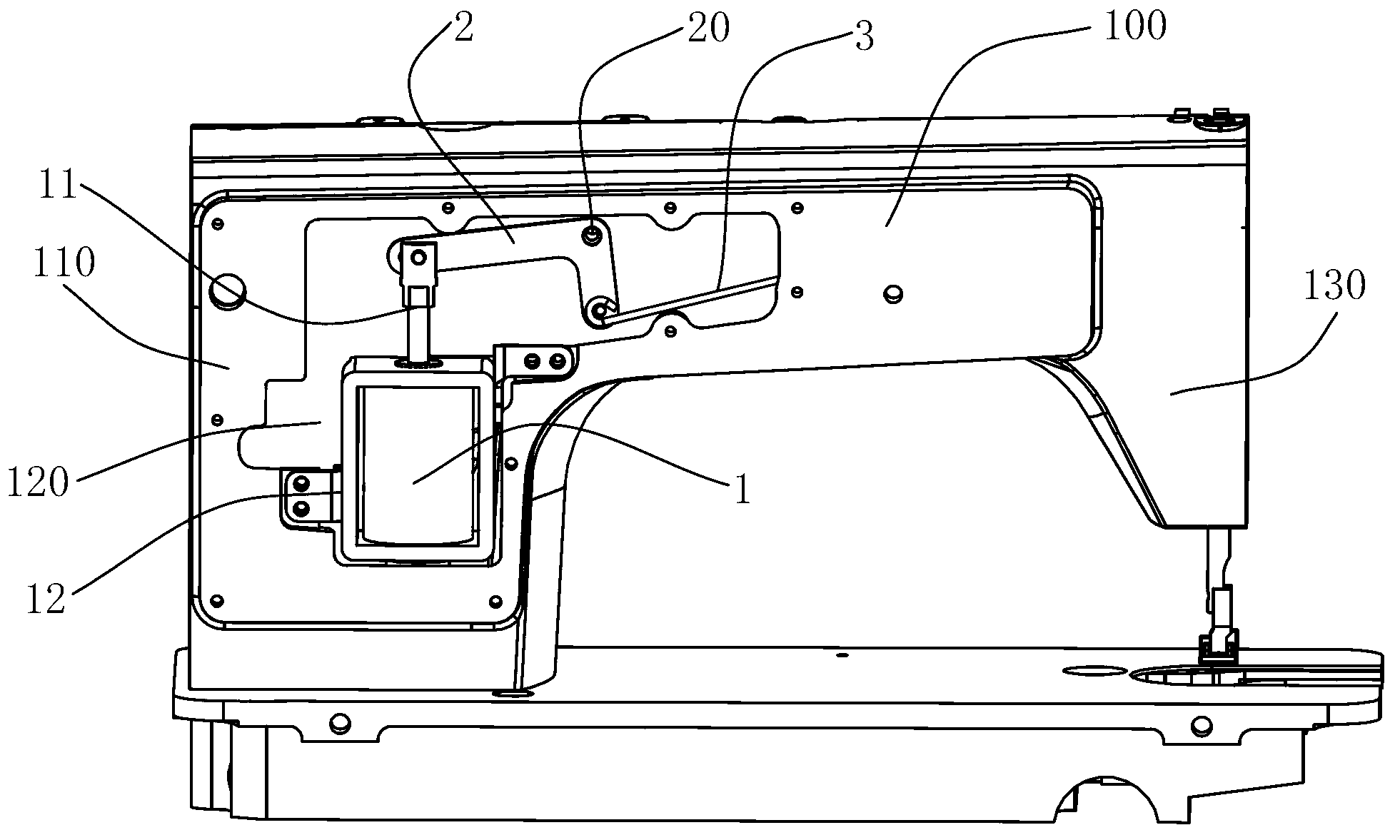

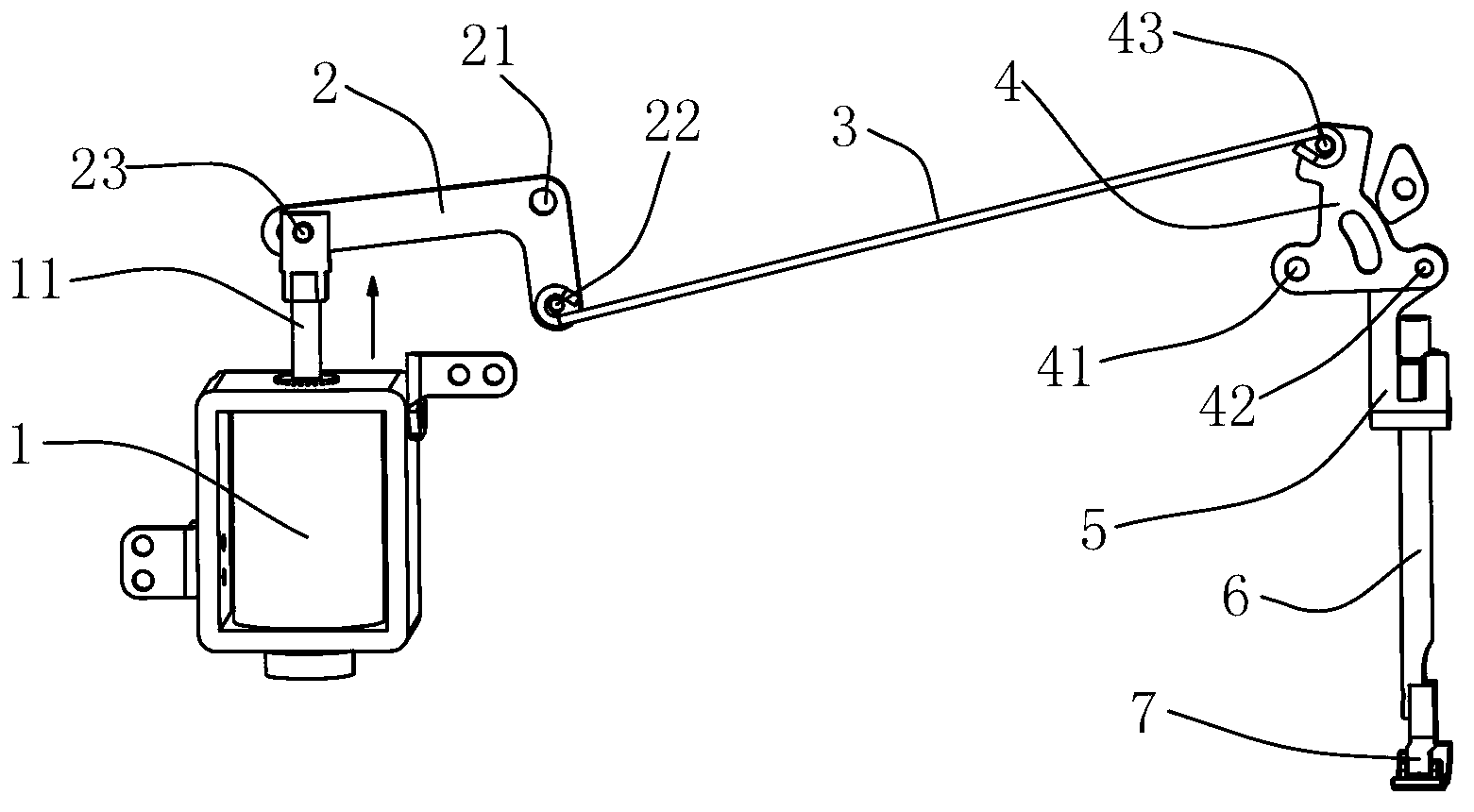

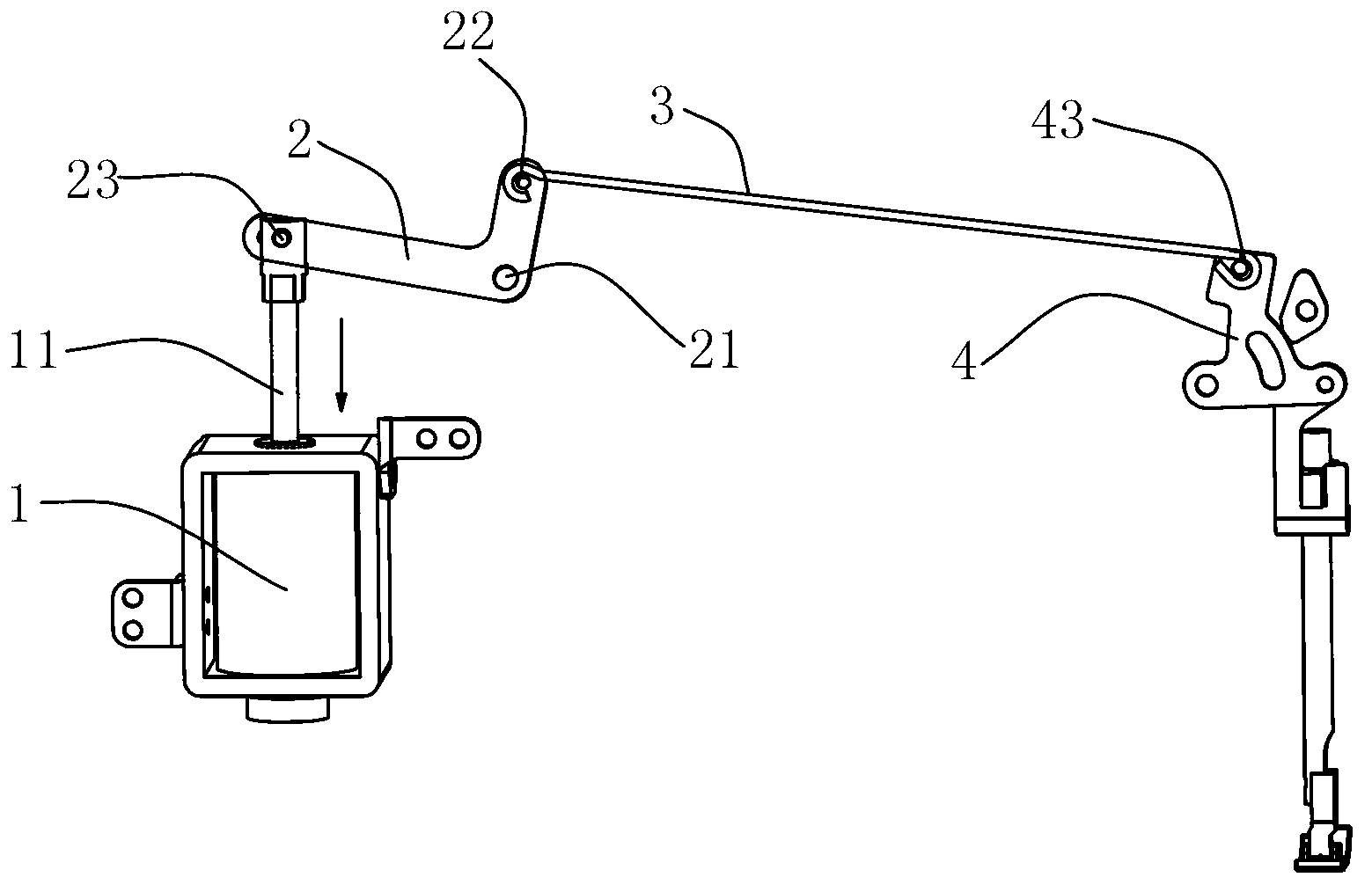

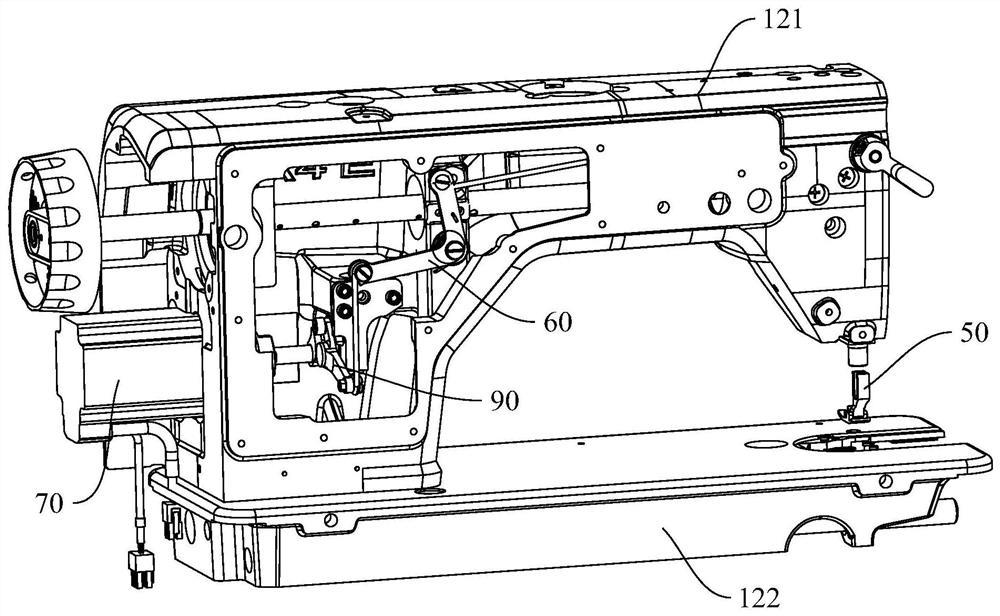

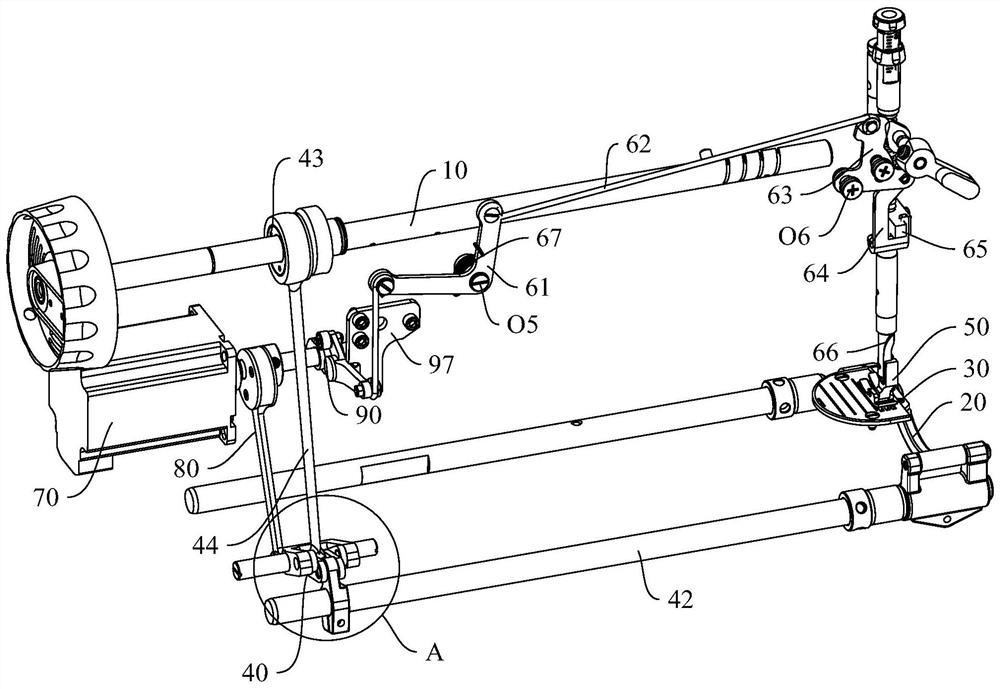

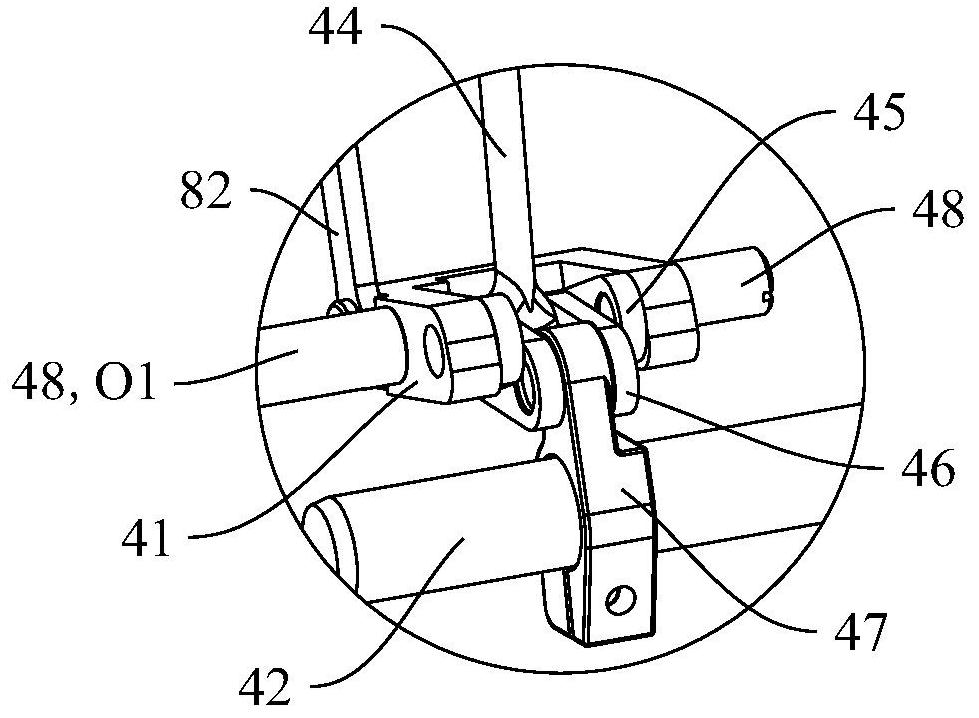

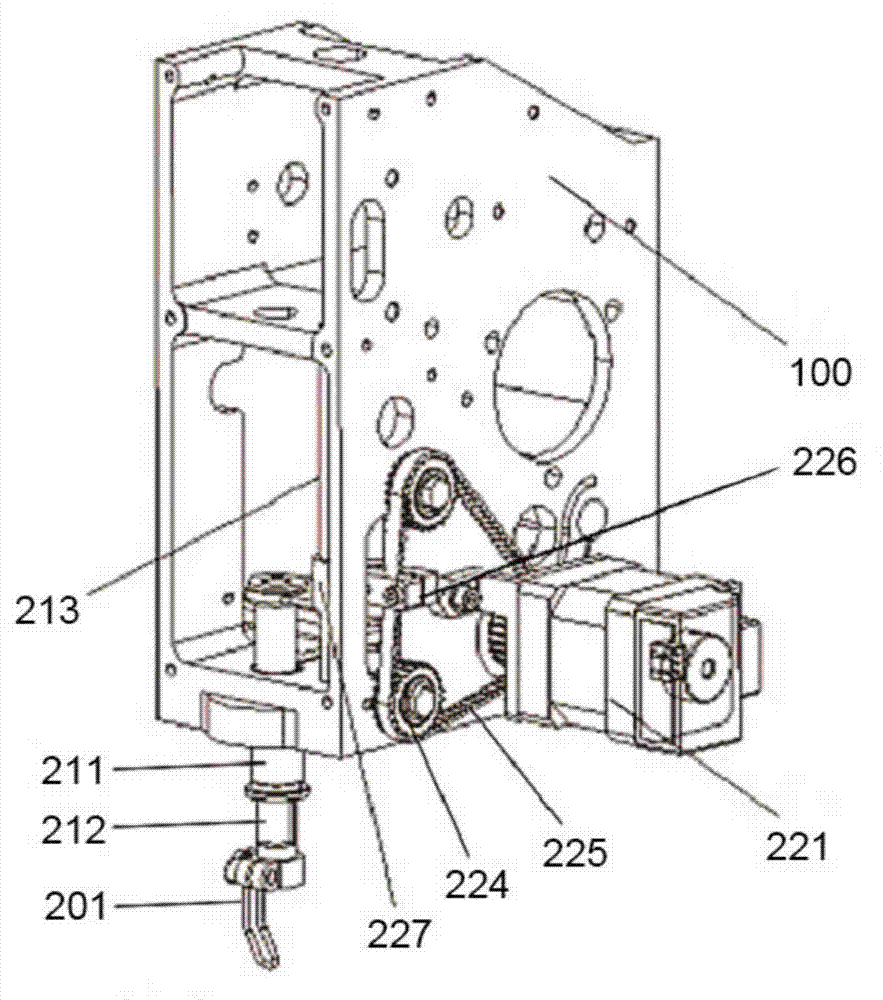

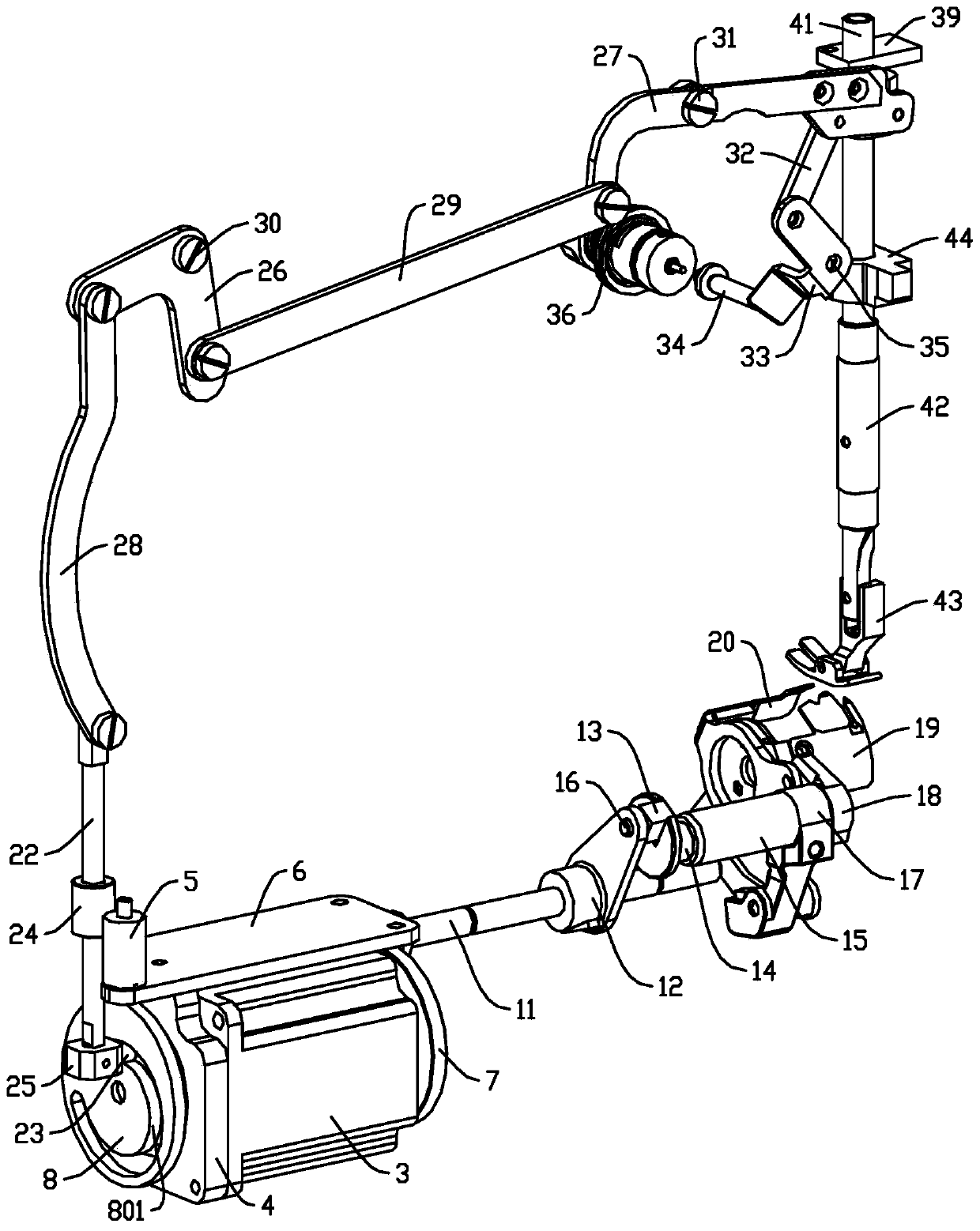

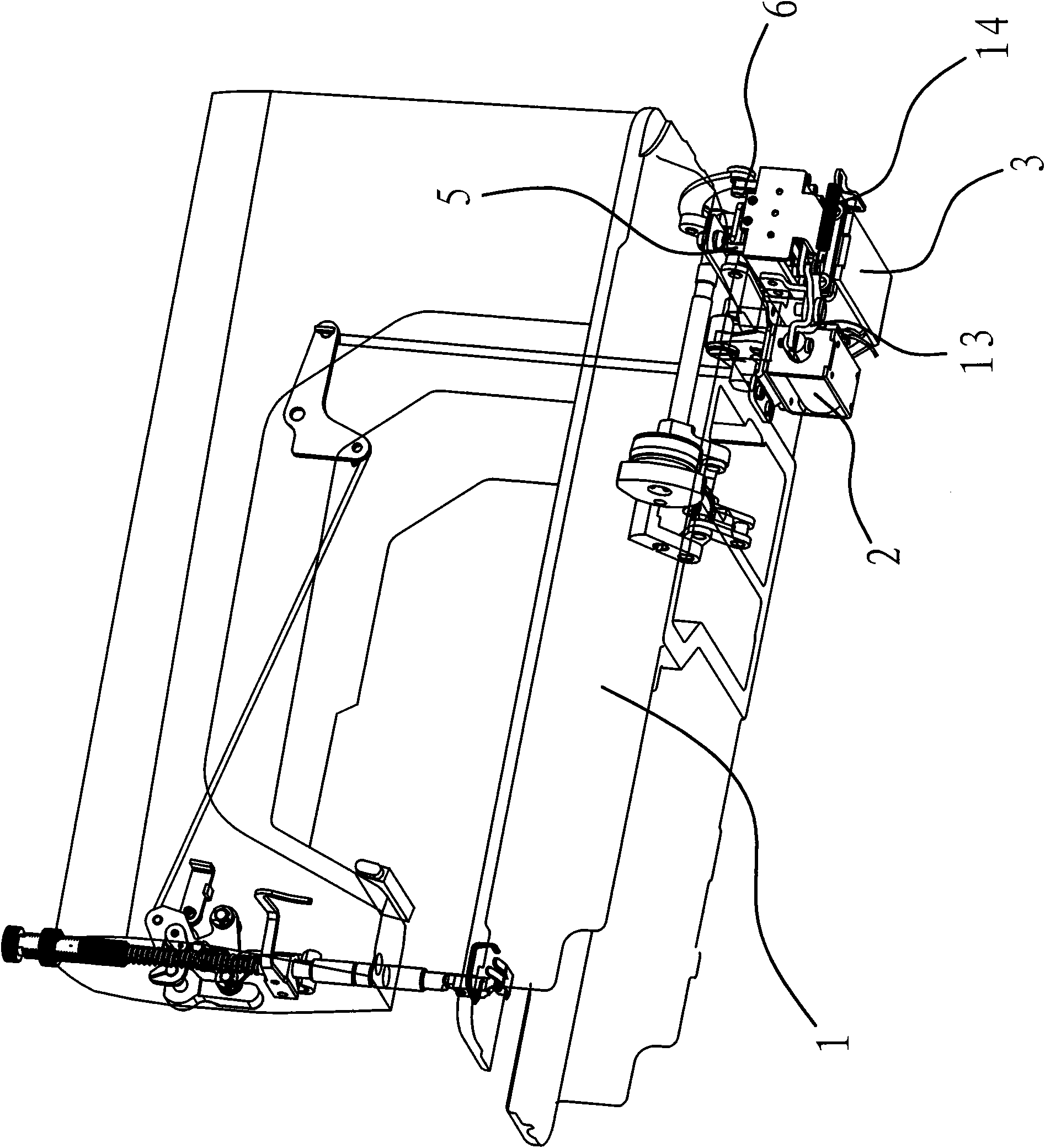

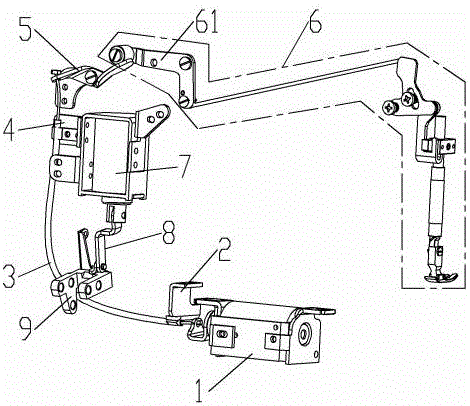

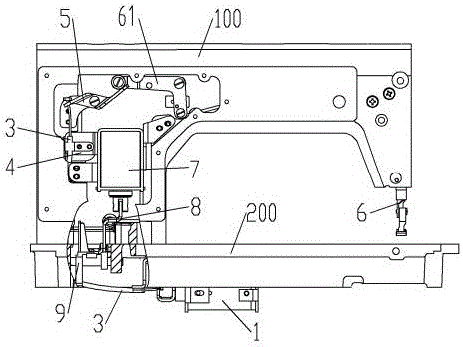

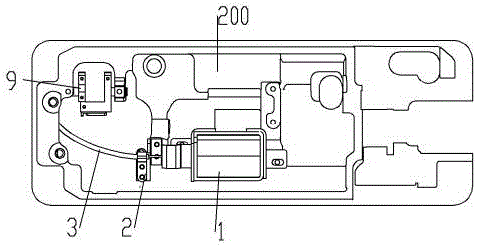

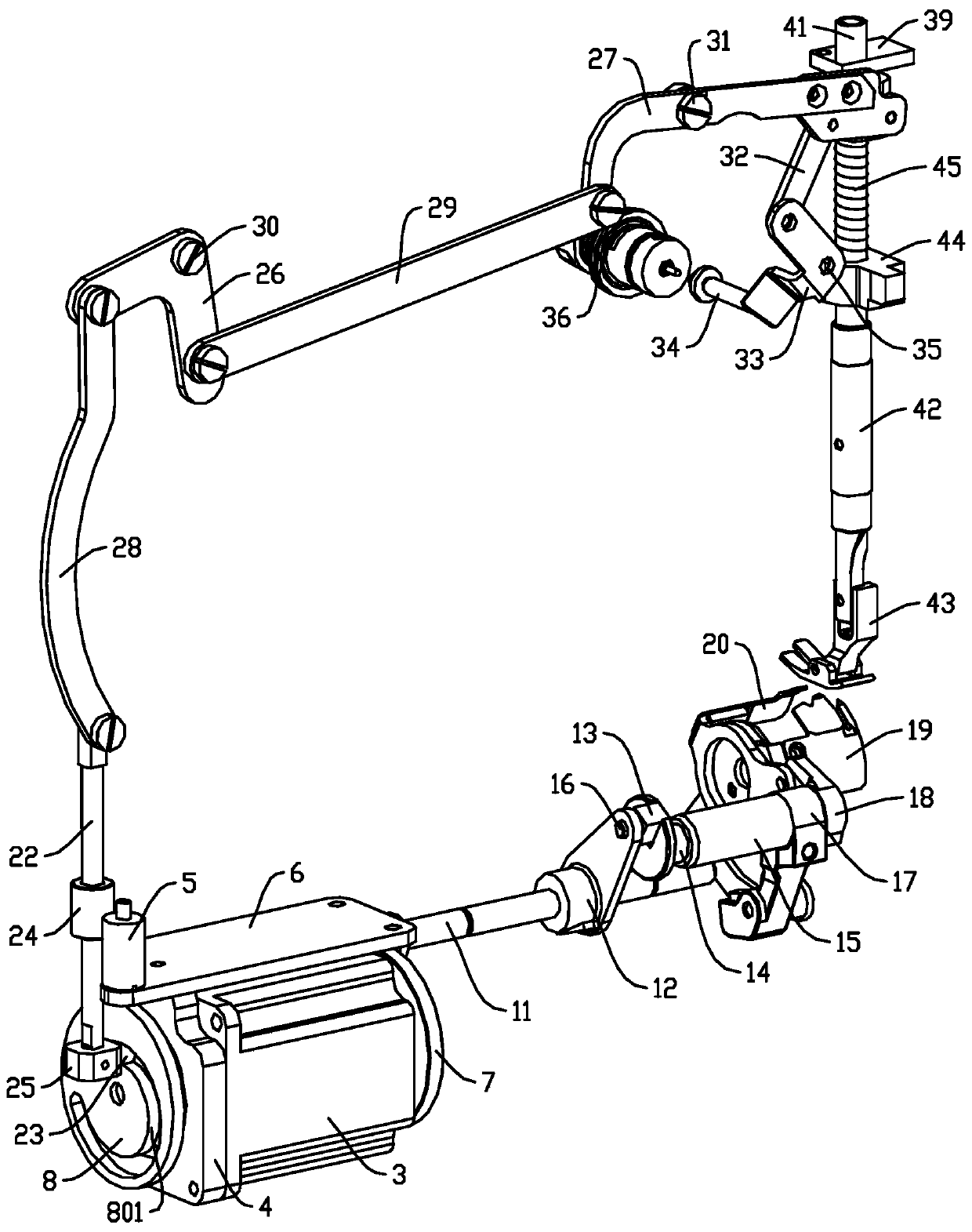

Built-in type automatic pressure foot lifting mechanism of sewing machine

The invention discloses a built-in type automatic pressure foot lifting mechanism of a sewing machine. The built-in type automatic pressure foot lifting mechanism comprises a housing, a linear driver, a back lever, a front lever and a pull rod, wherein the housing comprises an upright column part; a cavity is formed in the upright column part; the linear driver is fixedly mounted in the cavity and comprises a drag rod which is capable of linearly moving in a reciprocating manner; a back pin hole of the back lever is hinged with one end part of the drag rod, a first front pin hole of the back lever is rotationally connected onto the housing through a pin shaft, and the distance from the back pin hole to the first front pin hole is greater than the distance from a second front pin hole to the first front pin hole; the front lever comprises three pin holes, the first pin hole is rotationally connected onto the housing through a pin shaft, and the second pin hole is hinged with a pressure foot lifting plate; and the back end of the pull rod is hinged with the second front pin hole of the back lever, and the front end of the pull rod is hinged with the third pin hole of the front lever. According to the built-in type automatic pressure foot lifting mechanism, the linear driver is arranged in the housing, so the structure of the whole mechanism is more compact, the appearance of the mechanism is more attractive, and vibration and noise produced when the automatic pressure foot lifting device works are also reduced.

Owner:JACK SEWING MASCH CO LTD

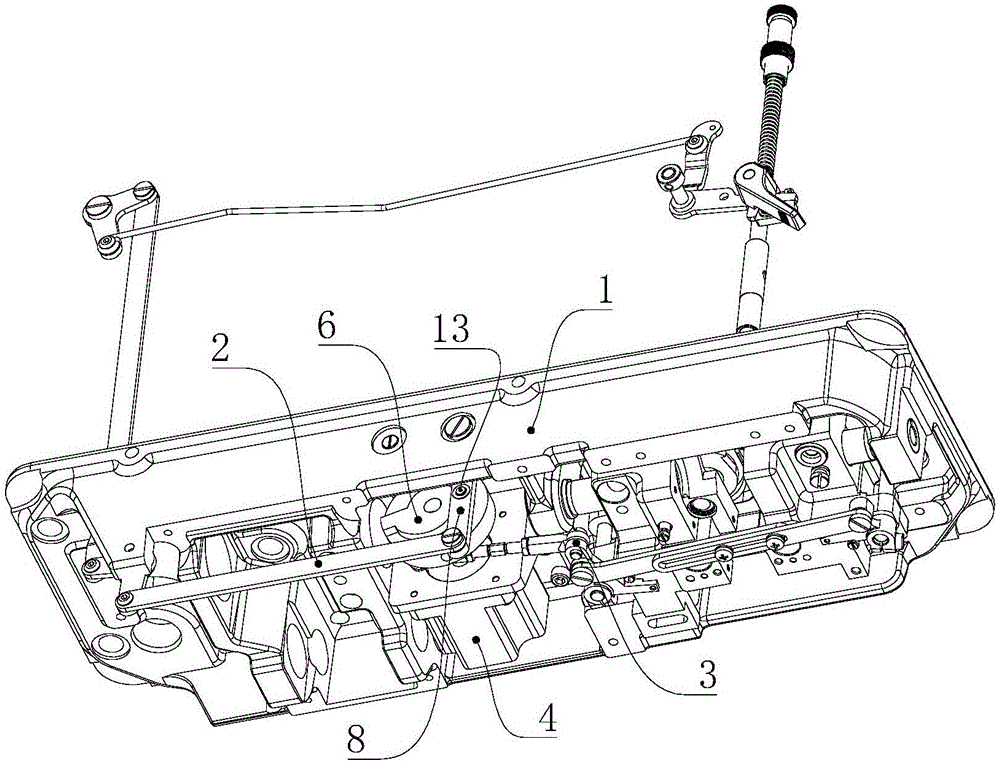

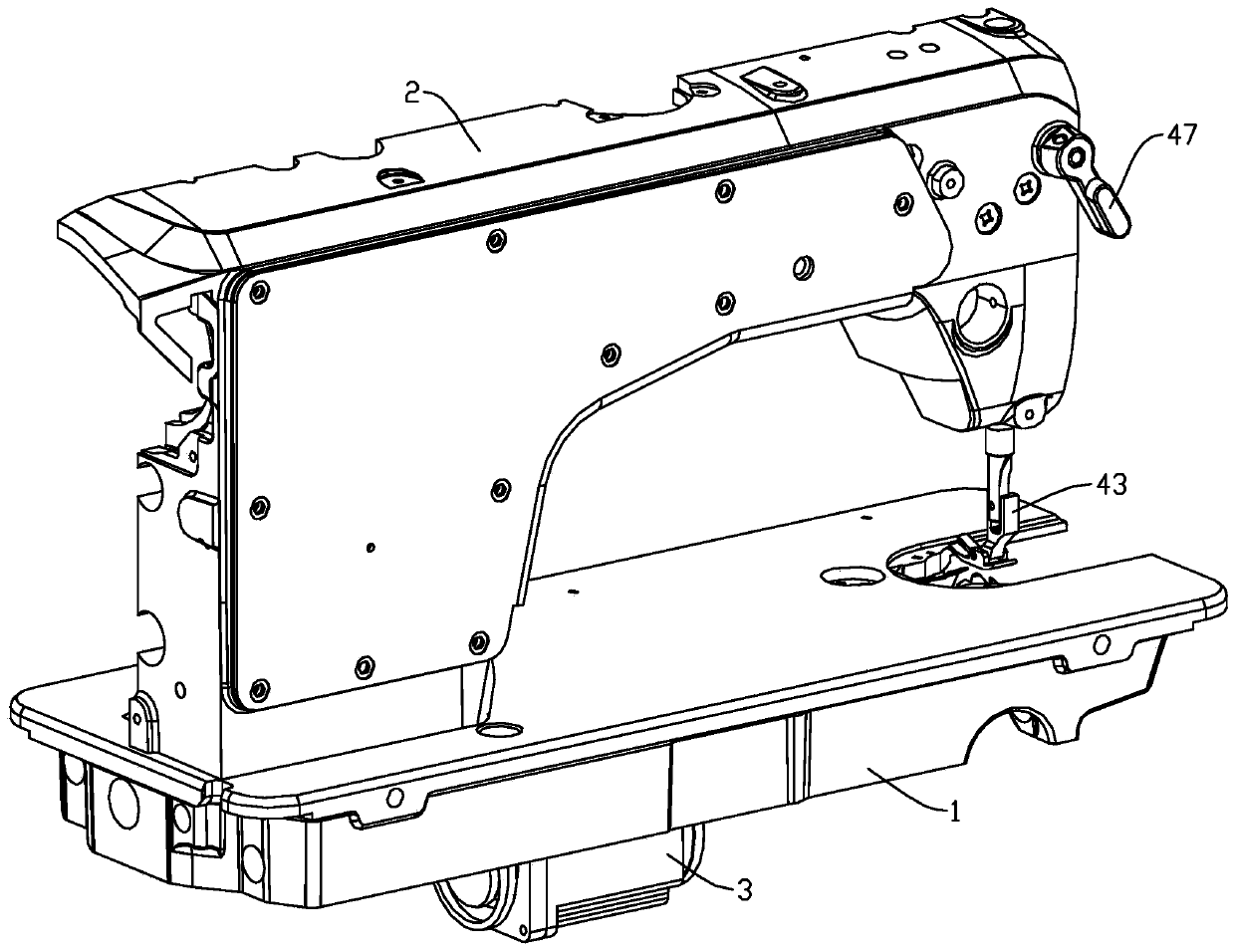

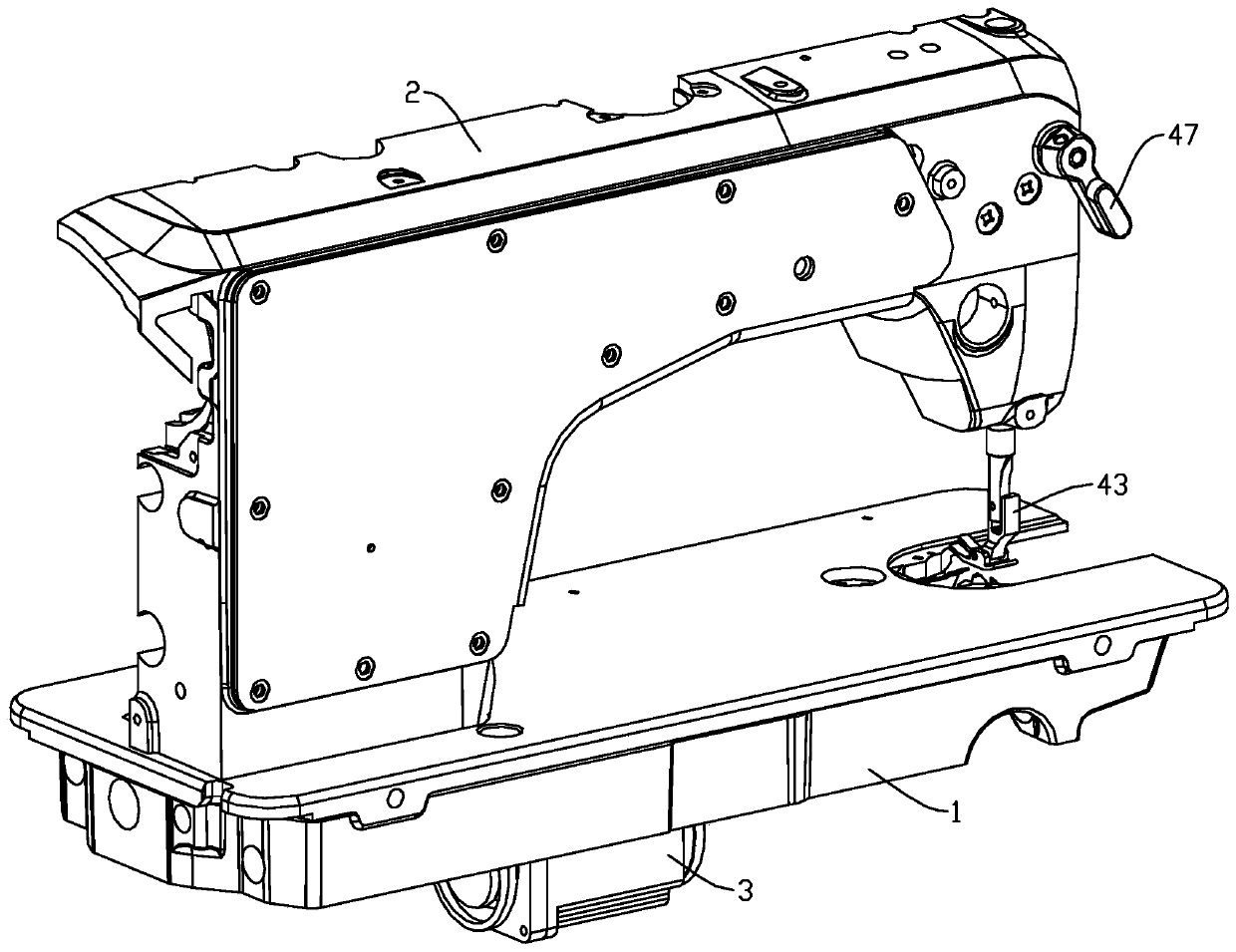

Sewing machine

ActiveCN111648053AAvoid collisionCompact structureWork-feeding meansPressersElectric machineryEngineering

The invention provides a sewing machine. The sewing machine comprises a main shaft, a material feeding mechanism, a presser foot lifting mechanism, a driving motor, a needle pitch adjusting power transmission mechanism and a presser foot lifting transmission mechanism, wherein the material feeding mechanism is provided with a material feeding swinging seat; the needle pitch adjusting power transmission mechanism enables power transmission to continuously exist between the driving motor and the material feeding swinging seat; a collision avoidance structure is arranged in the presser foot lifting transmission mechanism; a corner of an output shaft of the driving motor is provided with a needle pitch active adjusting area and a presser foot lifting area; when the output shaft of the drivingmotor operates within the needle pitch active adjusting area, the sewing machine is provided with effective needle pitch; the collision avoidance structure enables no power transmission to exist between the driving motor and a presser foot lifting mechanism; when the output shaft of the driving motor operates within the presser foot lifting area, the presser foot lifting transmission mechanism enables power transmission to exist between the driving motor and the presser foot lifting mechanism; and the absolute value of a needle pitch corresponding to an angle of the material feeding swinging seat is not larger than a maximum absolute value of the effective needle pitch. According to the sewing machine, timely response, suspended seam and very good needle pitch adjusting stability of the needle pitch adjusting mechanism are realized.

Owner:JACK SEWING MASCH CO LTD

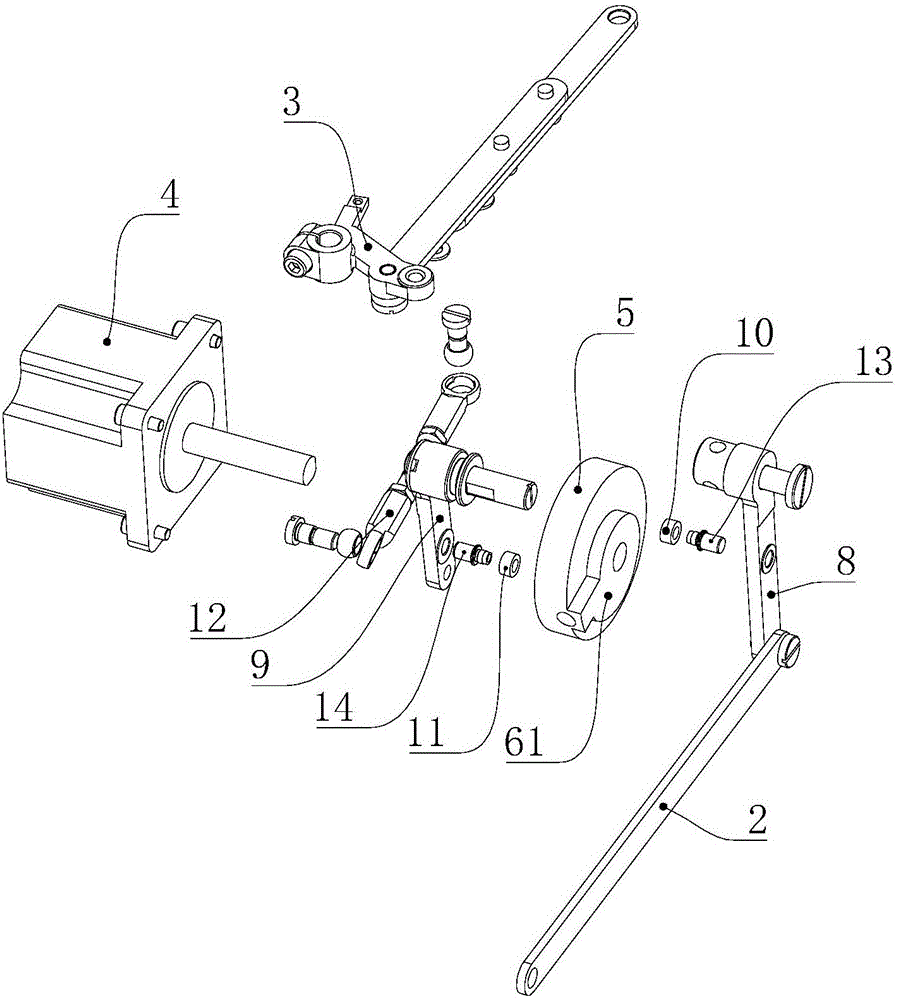

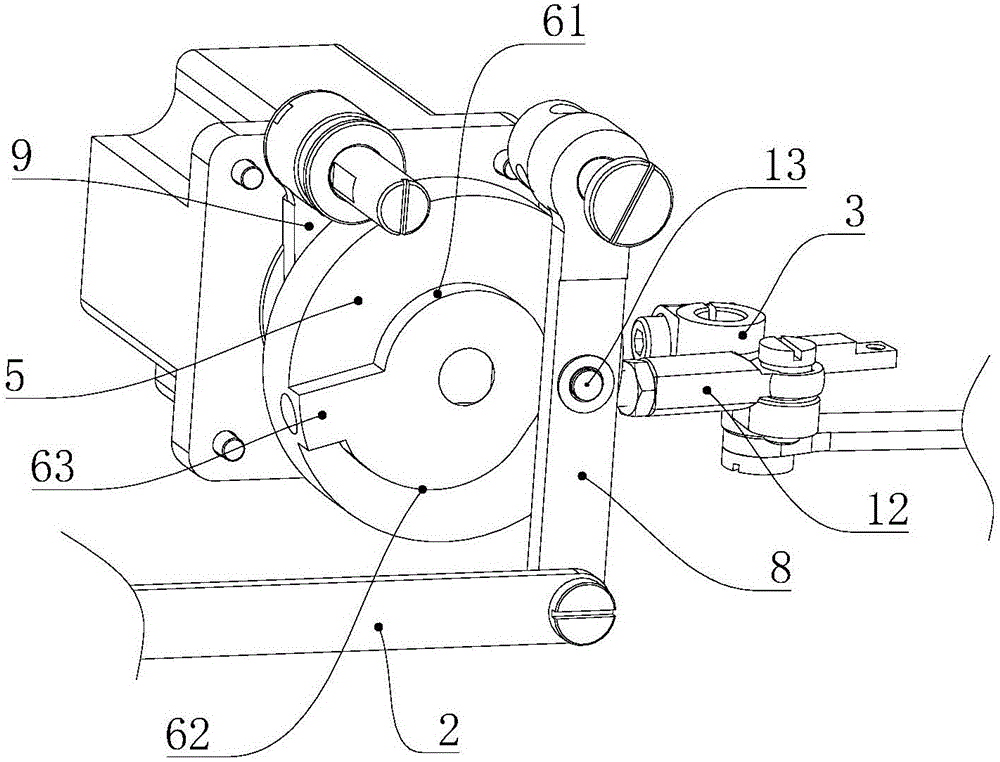

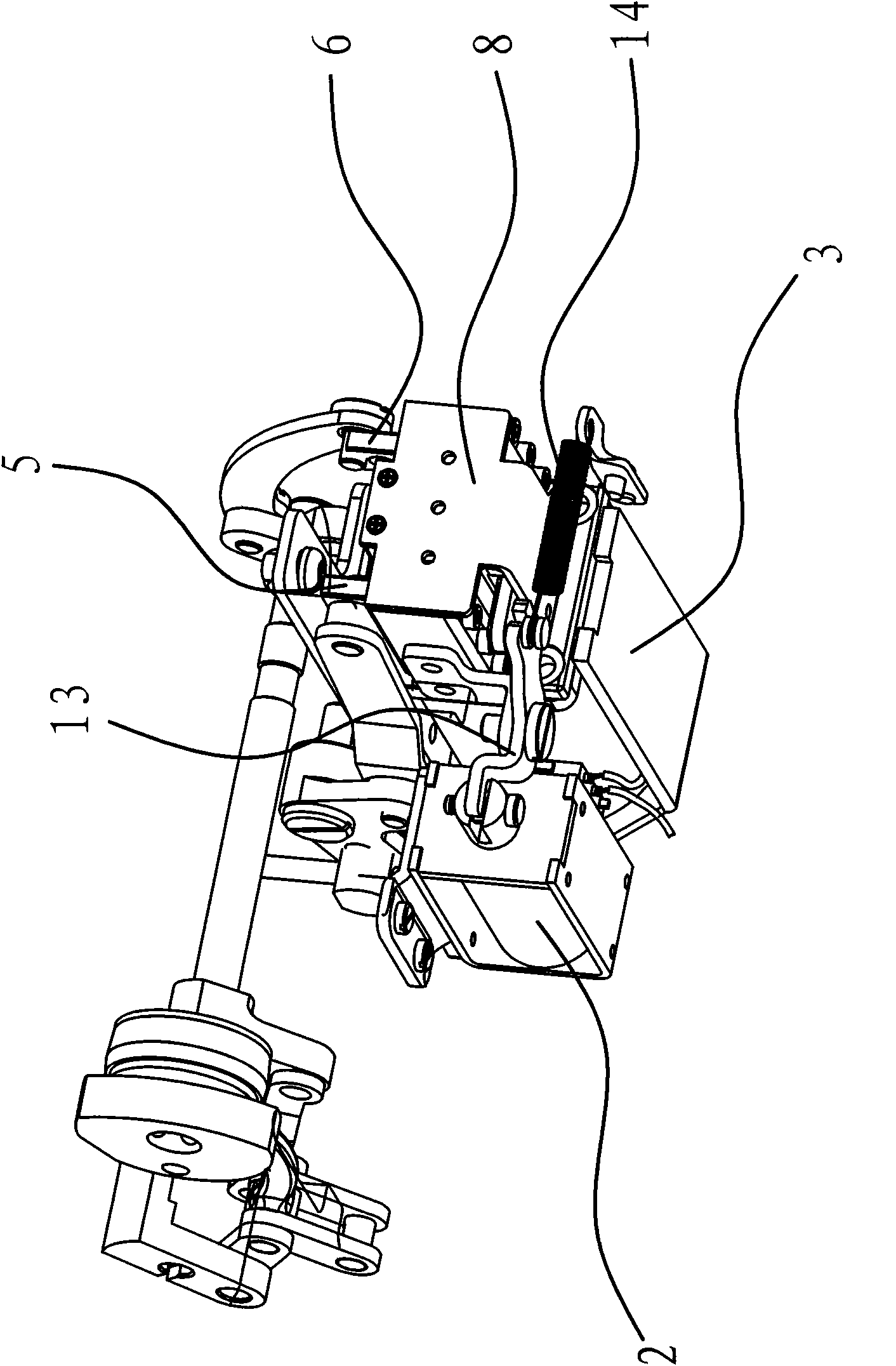

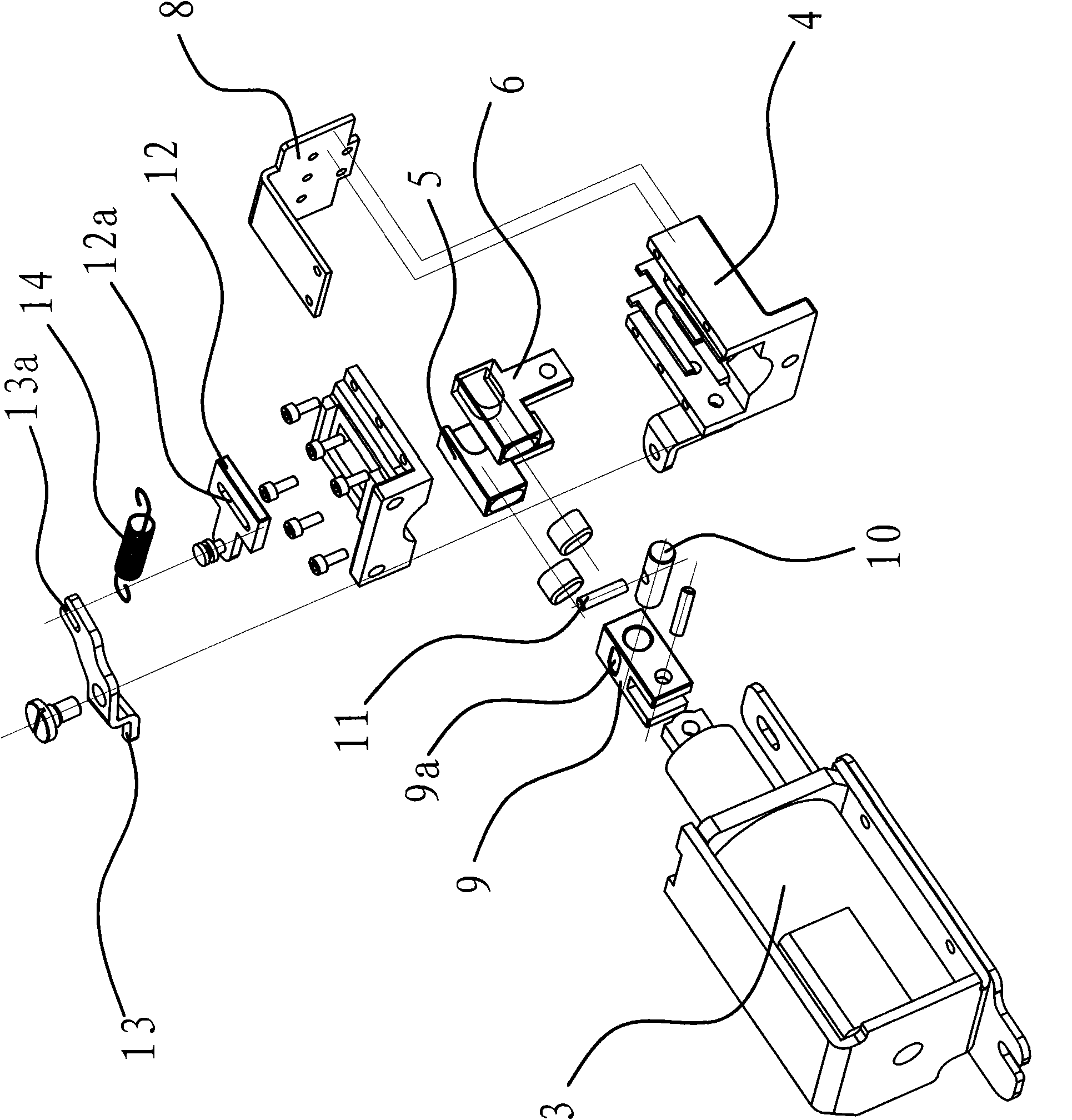

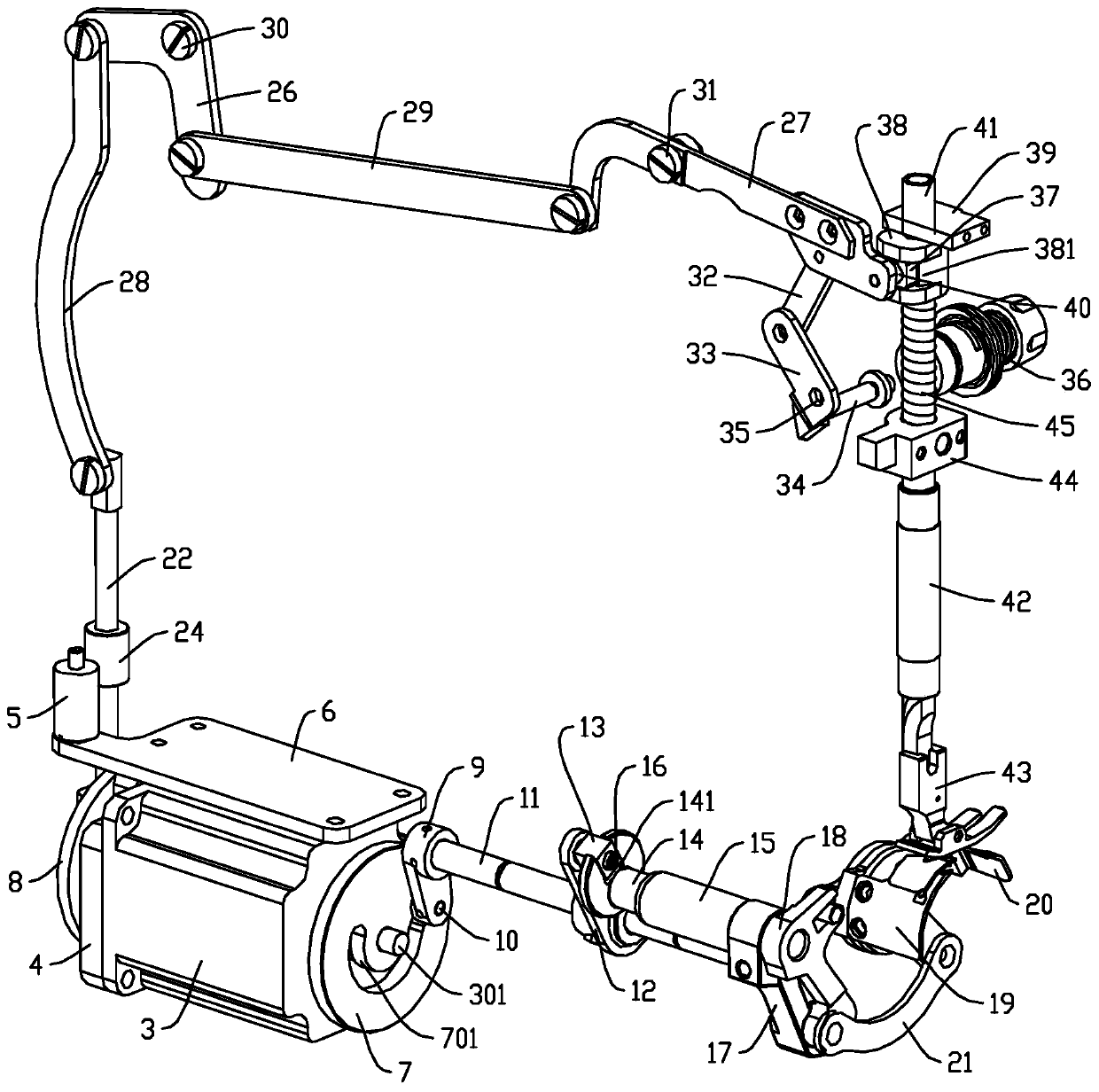

Driving device for automatic thread trimming and automatic presser foot lifting

ActiveCN106012323ACompact structureSame rotation speedNeedle severing devicesPressersMotor driveEngineering

The invention belongs to the technical field of sewing machines, and particularly discloses a driving device for automatic thread trimming and automatic presser foot lifting. The driving device is simple in structure and capable of guaranteeing stable operation of a sewing machine. The driving device comprises a presser foot lifting transmission rod, a thread trimming transmission rod, a stepping motor, a cam body arranged on the stepping motor, a pressure foot lifting connecting rod and a thread trimming connecting rod. The cam body is provided with a pressure foot lifting driving cam surface and a thread trimming driving cam surface, both of which comprise a base circle surface and a lift curved surface. The other end of the pressure foot lifting connecting rod is hinged to one end of the pressure foot lifting transmission rod, and the pressure foot lifting connecting rod is provided with a first driven pin. The thread trimming transmission rod is hinged to the other end of the thread trimming connecting rod, and the thread trimming connecting rod is provided with a second driven pin. When the stepping motor drives the cam body to rotate clockwise by a certain angle, one driven pin enters the lift curved surfaces from the base circle surfaces, and the other driven pin slides on the base circle surfaces; when the stepping motor drives the cam body to rotate anticlockwise, one driven pin slides on the base circle surfaces, and the other driven pin enters the lift curved surfaces from the base circle surfaces.

Owner:ZHEJIANG DUMA SEWING MACHINE

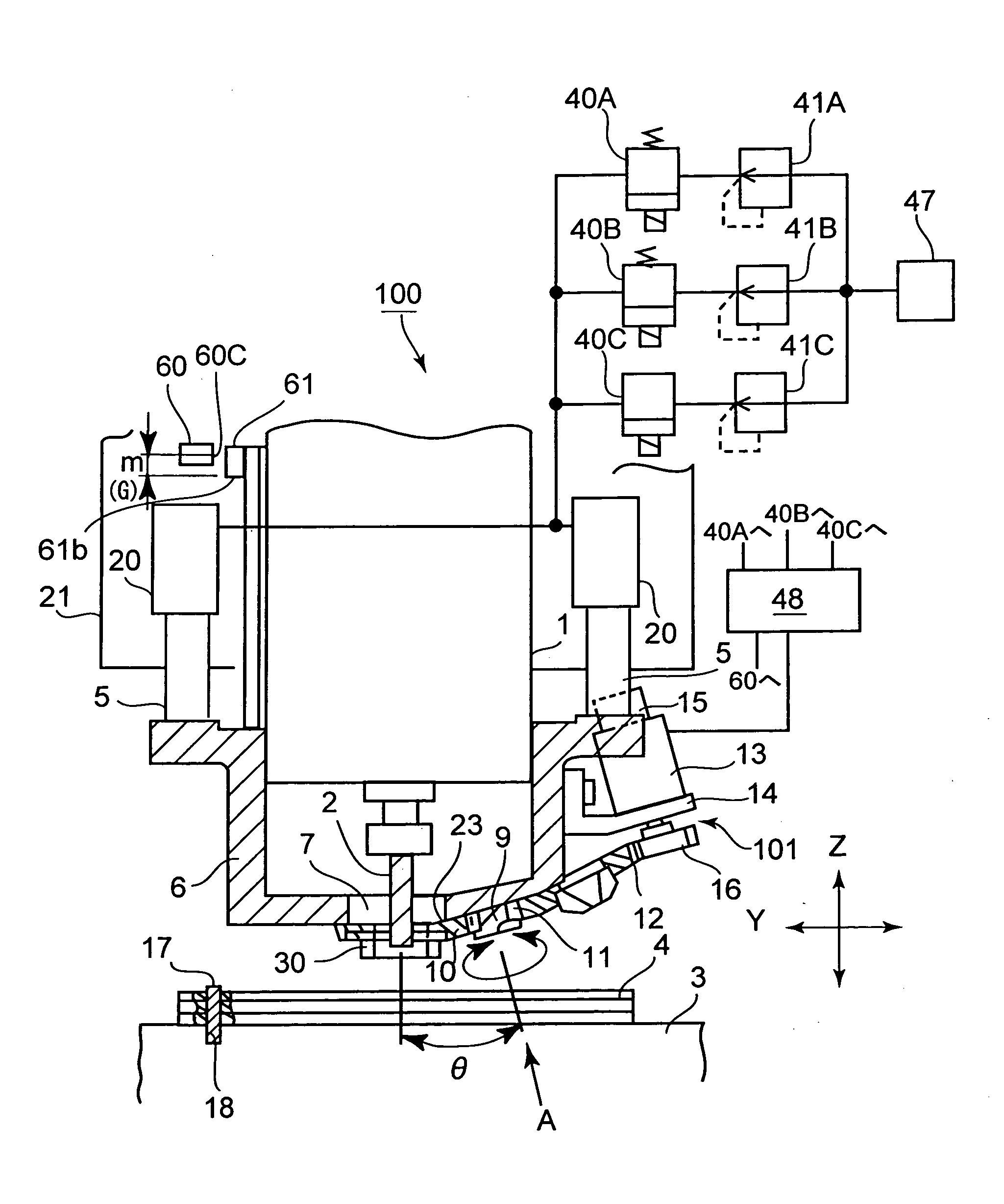

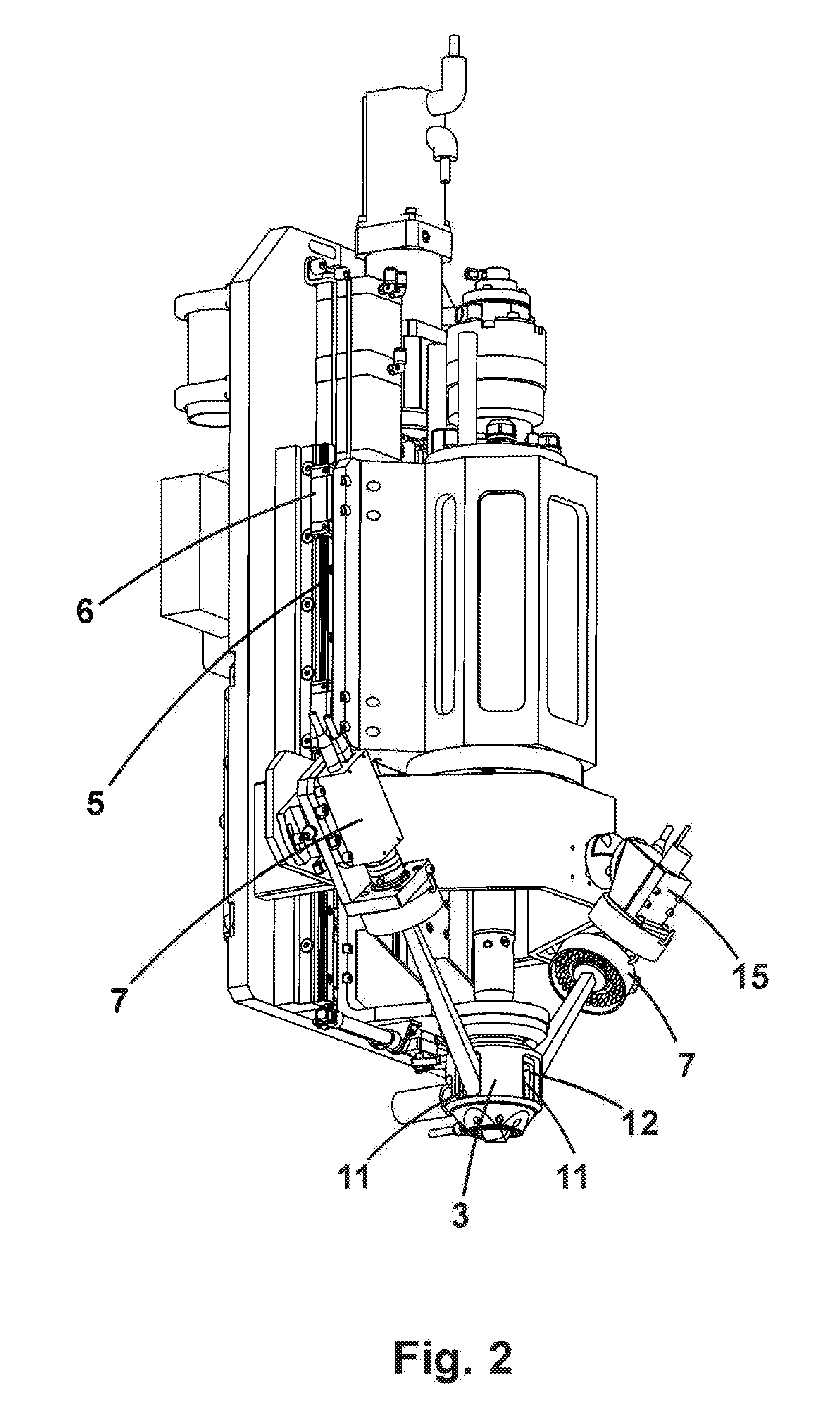

Head and automated mechanized method with vision

ActiveUS20160082598A1Great preload forceEfficient process parameterProgramme controlProgramme-controlled manipulatorParallel kinematicsSources of error

An automated machining head with vision and procedure includes a pressure foot provided with side windows with the capacity to open and close, encasing the machining tool, associated with a vertical movement device provided with mechanical locking, vision equipment connected to a computer and a communications module. The main advantage is endowing an anthropomorphic robot, originally designed for the car industry and with relatively low accuracy, with a notably higher machining accuracy, equivalent to equipment of a much greater accuracy or to parallel kinematic-type robots, also compensating, in real-time and in a continuous manner, for off-centring and loss of perpendicularity by the pressure foot, which are common in conventional heads and are a source of errors and inaccuracy.

Owner:LOXIN 2002

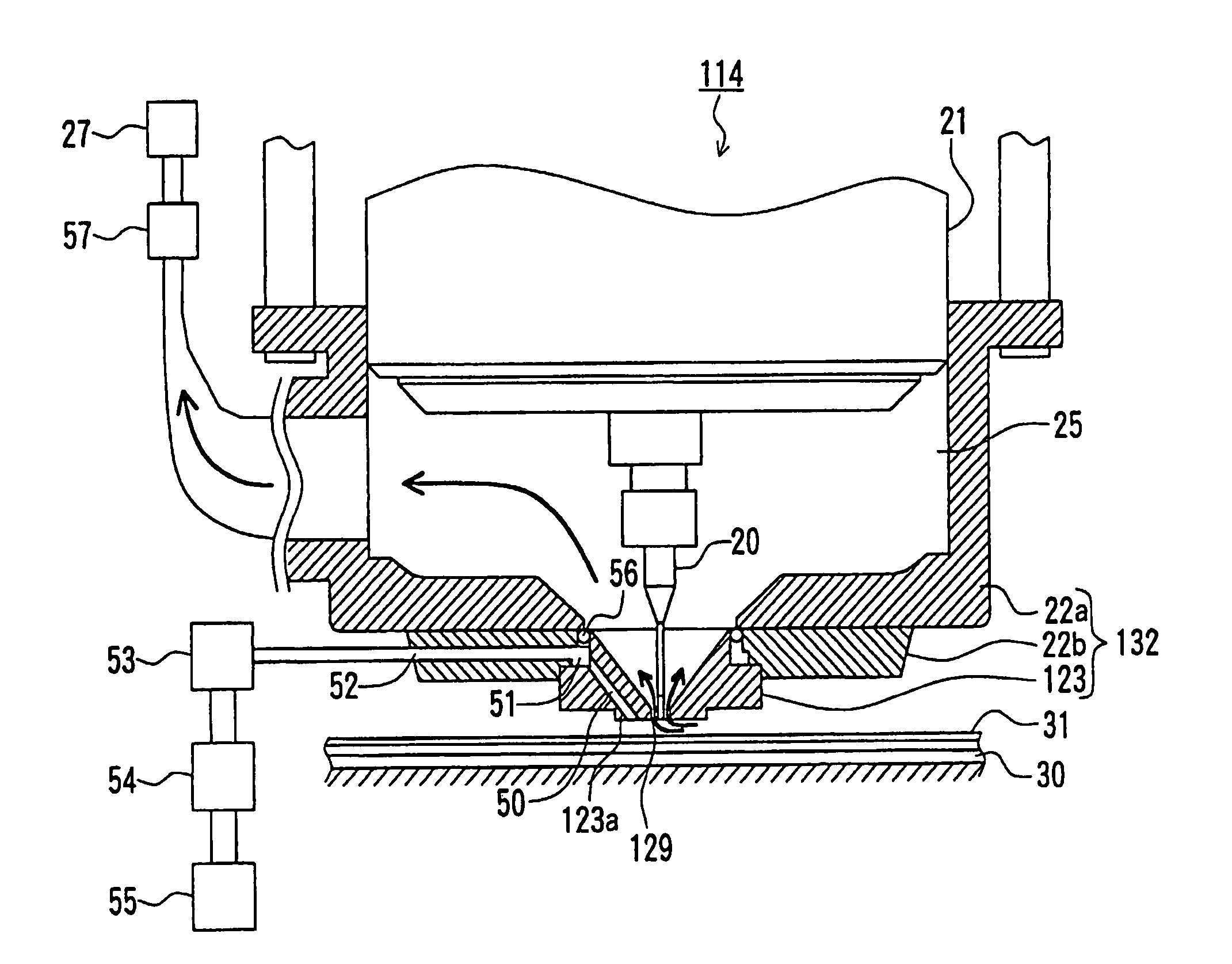

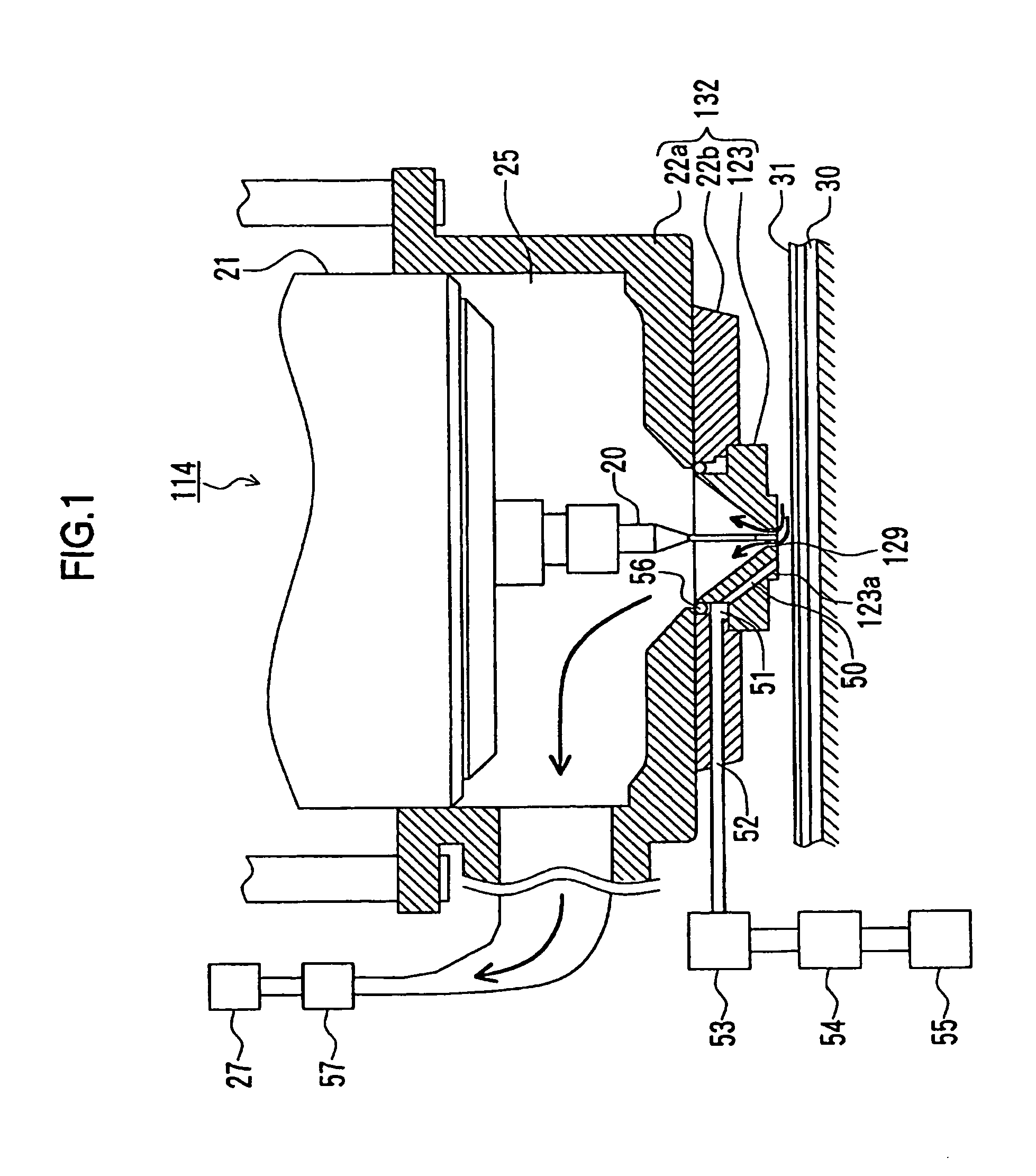

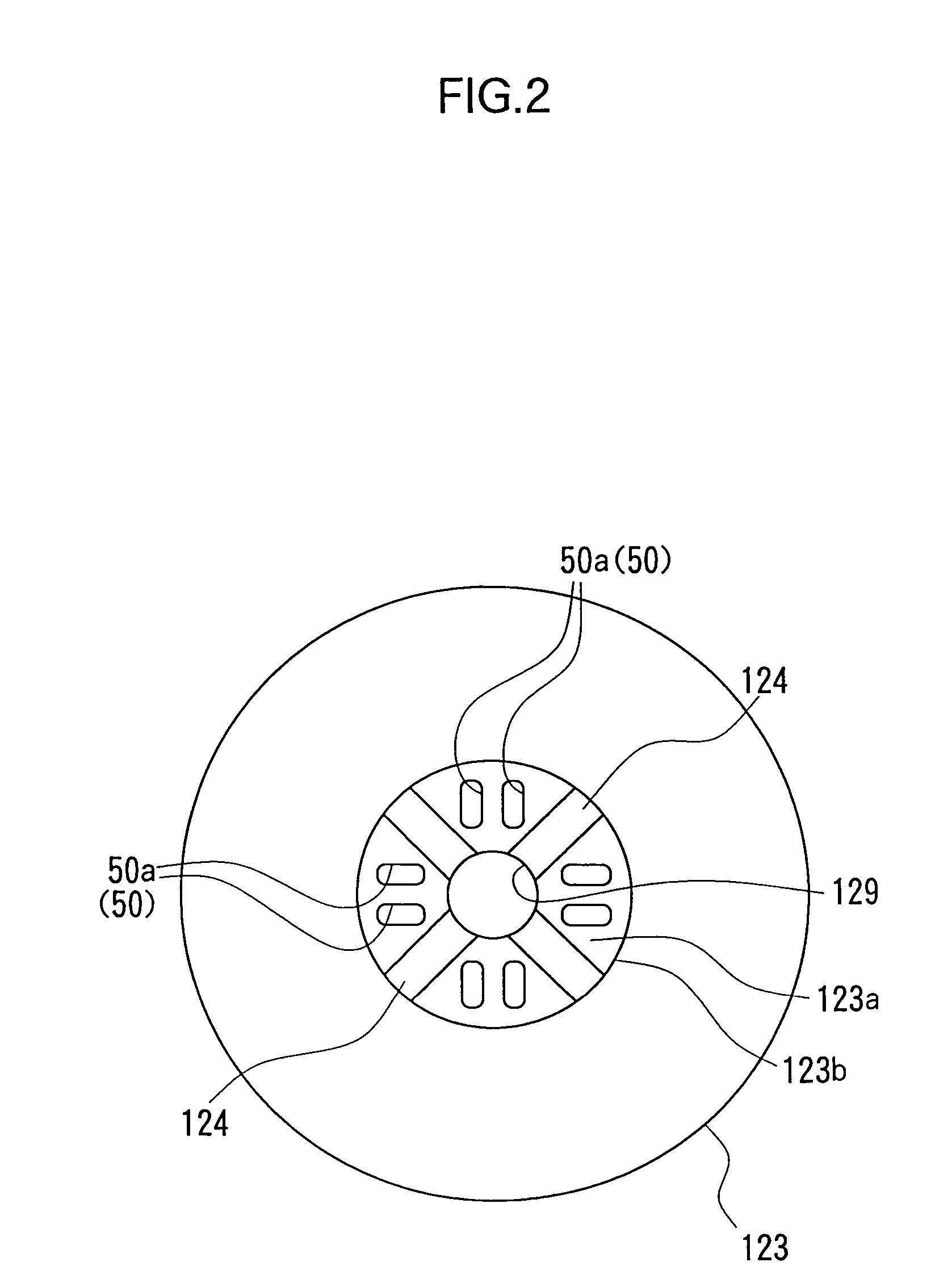

Printed board machining apparatus

ActiveUS7134817B2Improve accuracyIncrease or decrease pressureDrilling/boring measurement devicesThread cutting feeding devicesEngineeringMachining

There is provided a printed board machining apparatus that is capable of improving machining efficiency without hampering machining accuracy. The printed board machining apparatus includes a pressure foot which is provided with a port whose one end is opened at a lower surface of the pressure foot facing a stiffening plate, and whose other end is connected to a compressed gas source to blow out gas from the port at a pressure which does not interfere with the pressure foot pressurizing the stiffening plate and printed boards in machining the printed boards. It is noted that the gas is blown out during a period of time at least when the pressure foot and the stiffening plate are moving relatively in the horizontal direction.

Owner:HITACHI SEIKO LTD

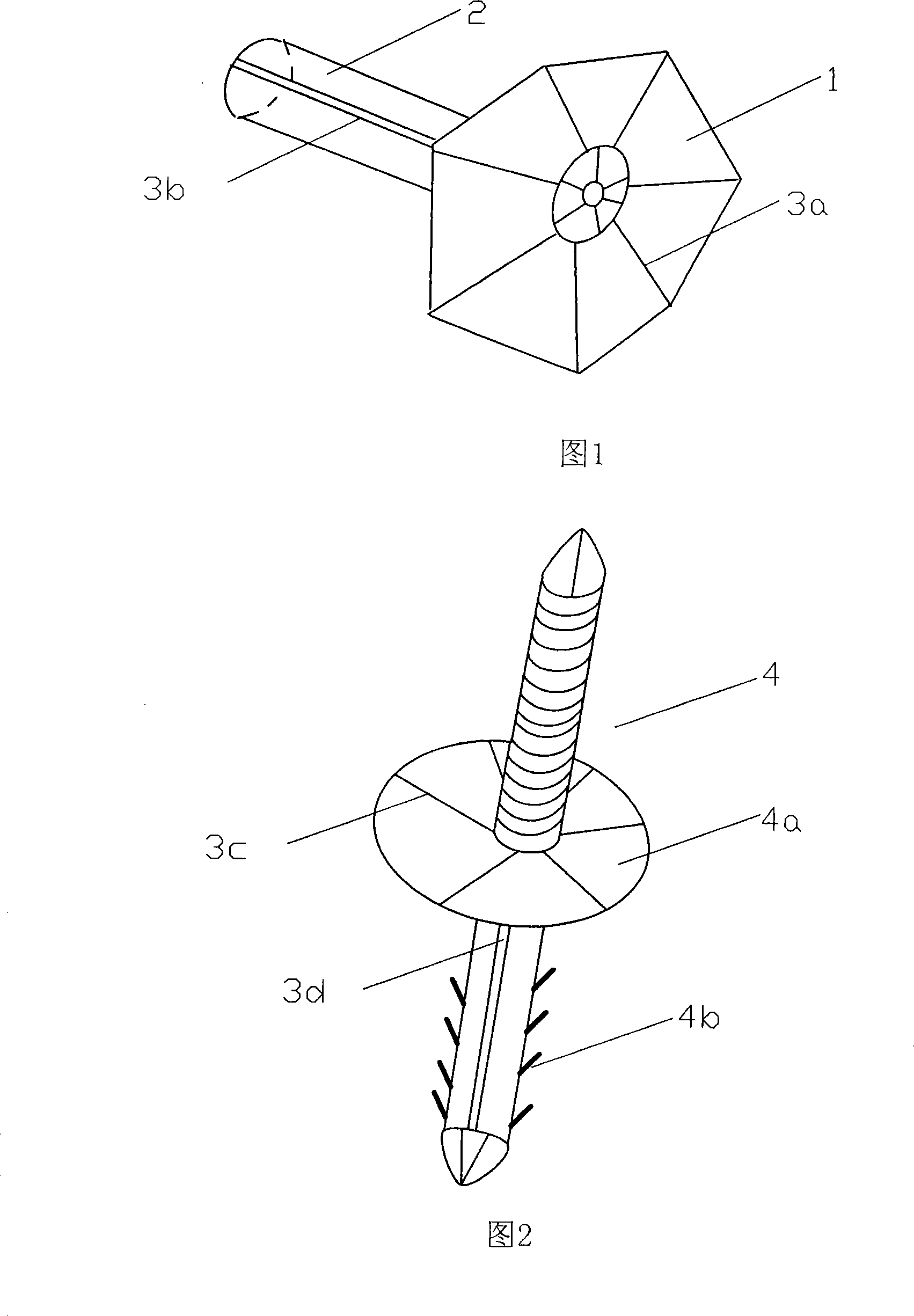

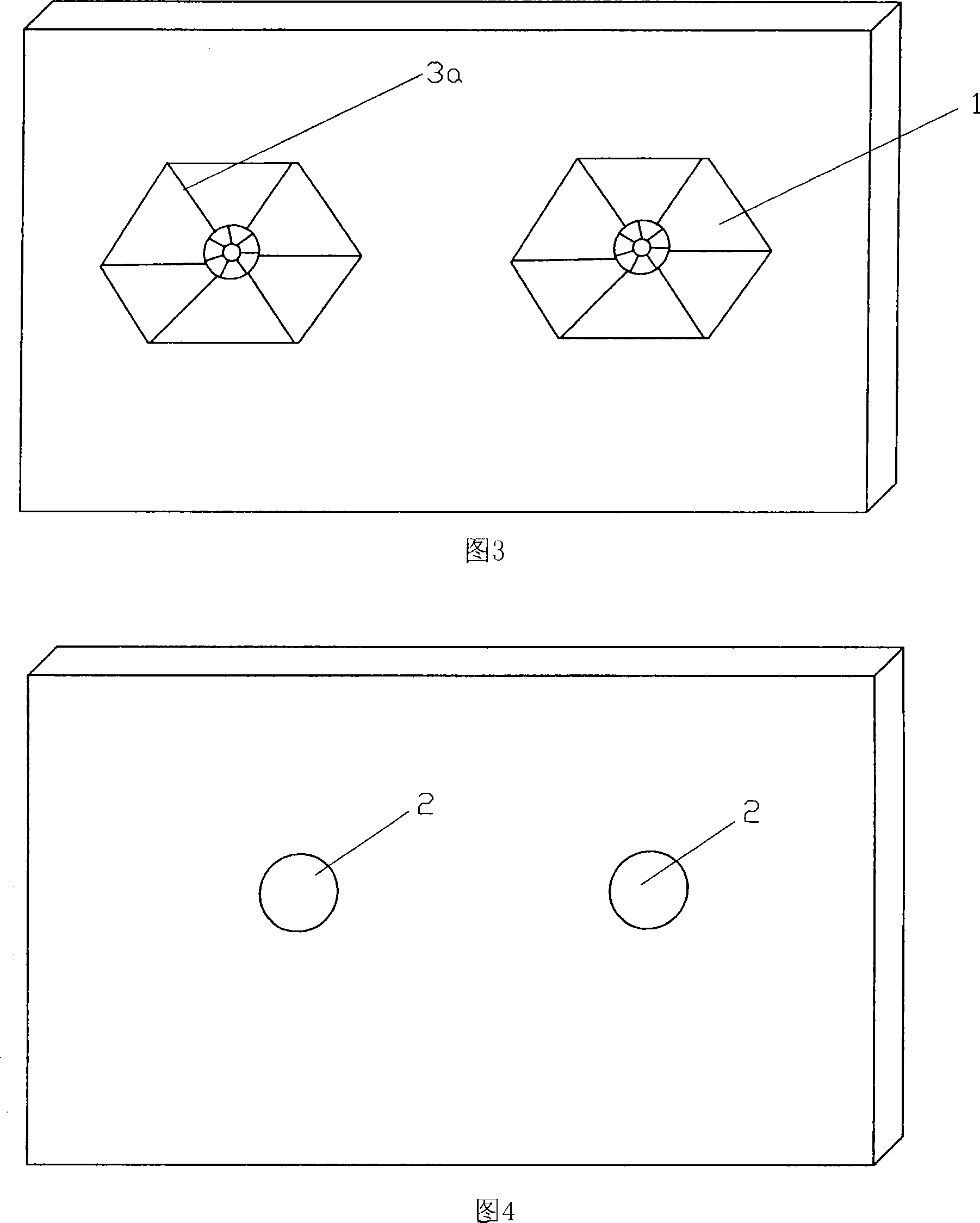

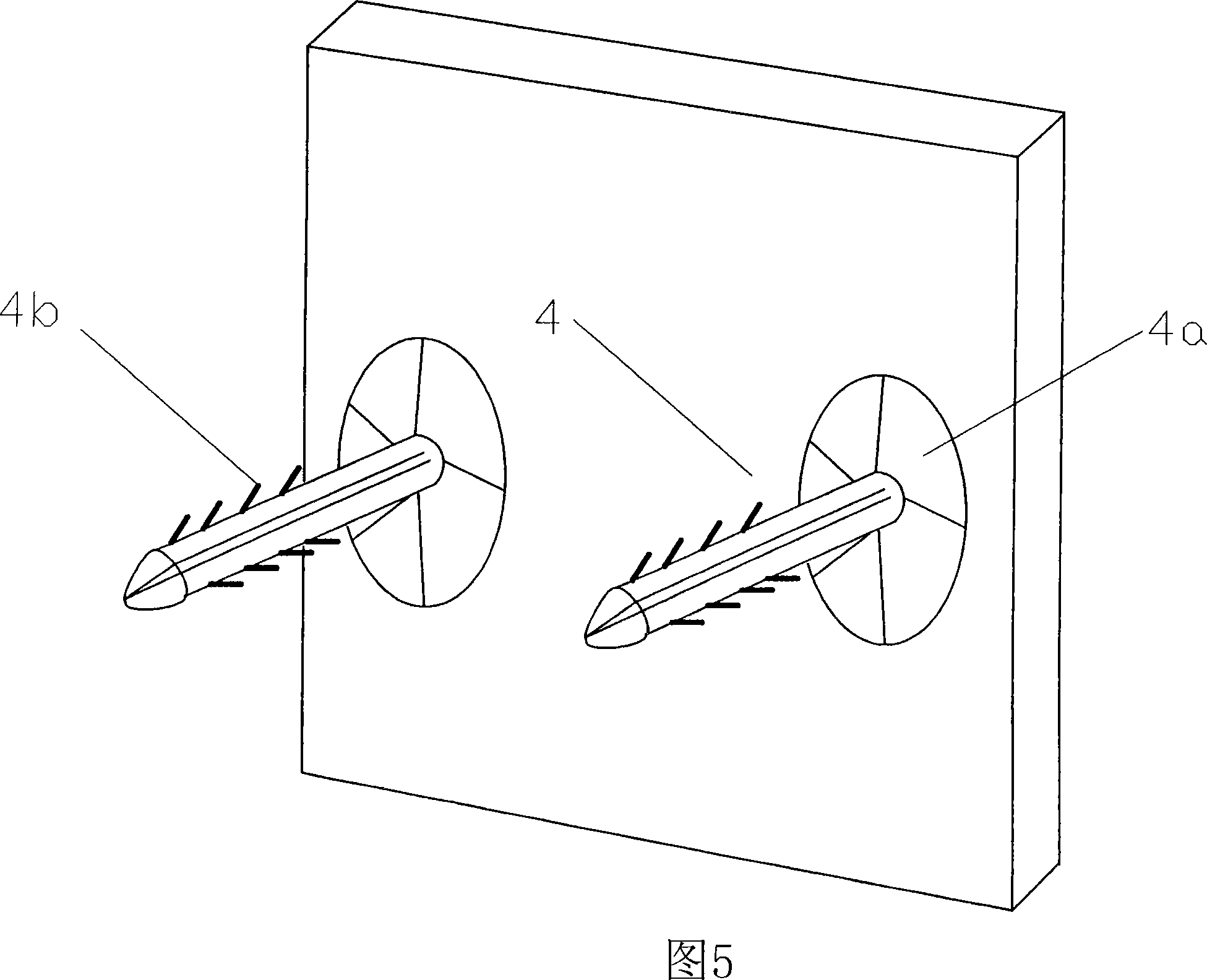

External wall heat insulation decorative board concealed anchor bolt and integral quick-mounting board for external wall heat insulation and decoration

The invention discloses an invisible anchor bolt of an external wall insulating decoration plate and an external wall insulating decoration integration packaged plate. The invisible anchor bolt comprises an inner tabletting with a column-shaped presser foot and a fastener, and the inner tabletting is embedded and inserted in a heat-insulating board, the pressure foot is an inner screw thread, one end of the fastener with an outer screw thread is connected with the pressure foot, and the outer wall of the other end is provided with a barb which is inserted in a mounting hole of the wall body, and the waist portion is provided with an outer tabletting which is vertical with the fastener, when the fastener is tightly screwed on the pressure foot, the outer tabletting is tightly clung on the surface of the packaged plate. The external wall insulating decoration integration packaged plate comprises a heated board whose inner surface is tightly clung on the wall body, and an alkali-fast break fiber web checked cloth layer and a decoration layer which are adhered on the outer surface of the plate one by one, the inner tabletting with the pressure foot are embedded into the heated board, and the surface of the pressure foot and the inner tabletting are all fell into the heated board, and the pressure foot is provided with an inner screw thread which is connected with the fastener. The invention has the advantages of simple structure, beauty and firmness, convenient transporting, and fast assemblage, which achieves a possibility of the industrialized production of external wall insulating decoration packaged plate.

Owner:合肥乐千年涂料有限公司

Method for full-needle knitting of fully-formed sweater on double-needle-bar flat knitting machine

The invention discloses a method for full-needle knitting of a fully-formed sweater on a double-needle-bar flat knitting machine. The sweater is knitted on the double-needle bar computerized flat knitting machine with high-position rollers or pressure feet, a front needle bar or a rear needle bar of the computerized flat knitting machine is in full-needle needle withdrawing in the knitting process, a local knitting technology is adopted, knitting is conducted in the transverse direction of the sweater, knitting needles can achieve full-needle needle withdrawing in the knitting process, and fabric is compact. In the knitting process, due to the fact that only one needle bar is used for cut piece knitting, pockets and other parts can be knitted for the fully-formed sweater, multi-needle bar transfer can be conducted, and pattern design is achieved.

Owner:无锡太平针织有限公司

Locking mechanisms for a retractable tarpaulin system

ActiveUS20070035153A1Easy to operate manuallySuperstructure subunitsLoad coveringLocking mechanismEngineering

Locking systems are provided for a retractable cover system mounted on the bed of a flat bed trailer or similar structure. The cover system includes a bow arrangement for supporting a flexible cover or tarpaulin with a front and a rear bow structure. A front locking mechanism includes a plurality of self-latching latch mechanism mounted within a hollow beam of a bulkhead mounted on the bed. Hasps are mounted to the front bow structure and aligned to activate and engage the latch mechanisms. A rear locking mechanism includes a telescoping mechanism mounted with the rear bow structure. The telescoping mechanism includes a pressure foot that engages a reaction plate mounted to the bed. The pressure foot and reaction plate define complementary features that allow the foot to engage the reaction plate at multiple positions prior to extension of the telescoping mechanism.

Owner:AERO INDS

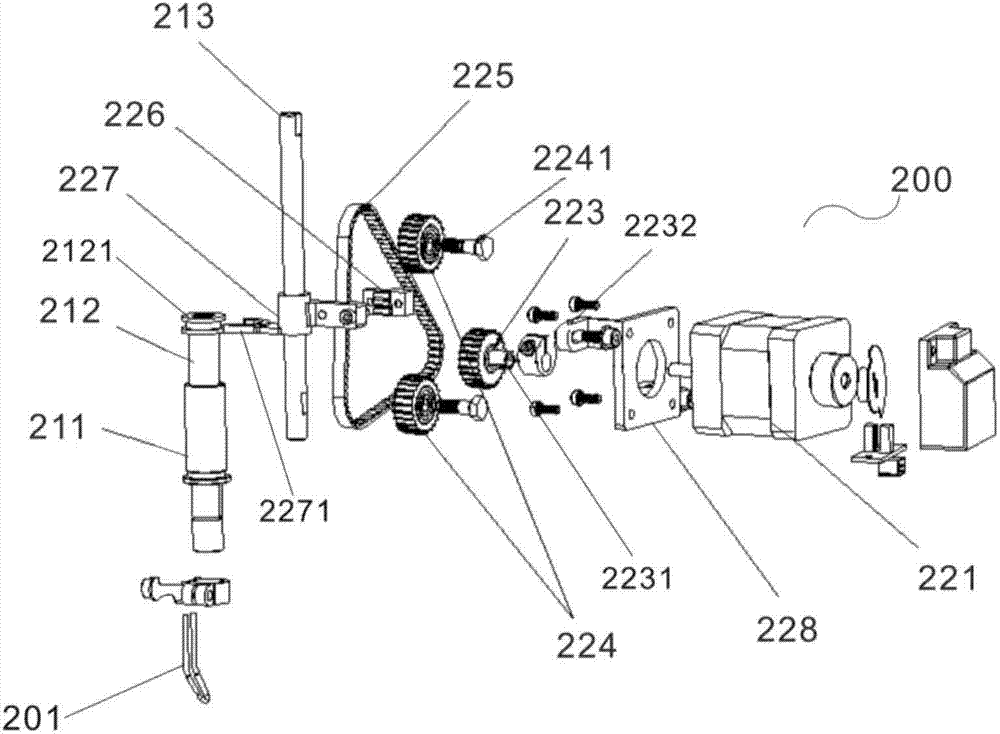

Independent taping embroidery device and embroidery machine comprising same

The invention provides an independent taping embroidery device and an embroidery machine comprising same. The independent taping embroidery device comprises an enclosure, a pressure foot mechanism arranged on the enclosure, an embroidery trajectory tracking mechanism, a cording embroidery mechanism and a needle bar driving mechanism, wherein the pressure foot mechanism comprises a pressure foot, a pressure foot transmission component and a pressure foot driving component; the embroidery trajectory tracking mechanism comprises a trajectory tracking driving component and a trajectory tracking transmission component, and the cording embroidery mechanism comprises a sliding bar, a cording embroidery driving component, a lifting ring component and a pendulum plate component, wherein the needle bar driving mechanism drives a needle bar to move up and down by a spindle of the embroidery machine, and the pressure foot mechanism, the embroidery trajectory tracking mechanism and the cording embroidery mechanism are respectively driven by stepping motors which are installed at corresponding positions on the enclosure and drive corresponding synchronous belts. Compared with the prior art, the invention can realize automatic switching of various working modes, and has the obvious advantages and positive effects such as simple and compact structure, convenience in installation and maintenance, more functions and wide application.

Owner:WENZHOU OULUOHUA INDAL

Thread trimming/loosening foot-lifting/pressing device for sewing machine, and sewing machine

ActiveCN110923967ASignificant progressSimple structureNeedle severing devicesPressersDrive wheelCrank

Owner:浙江杰克智能缝制科技有限公司

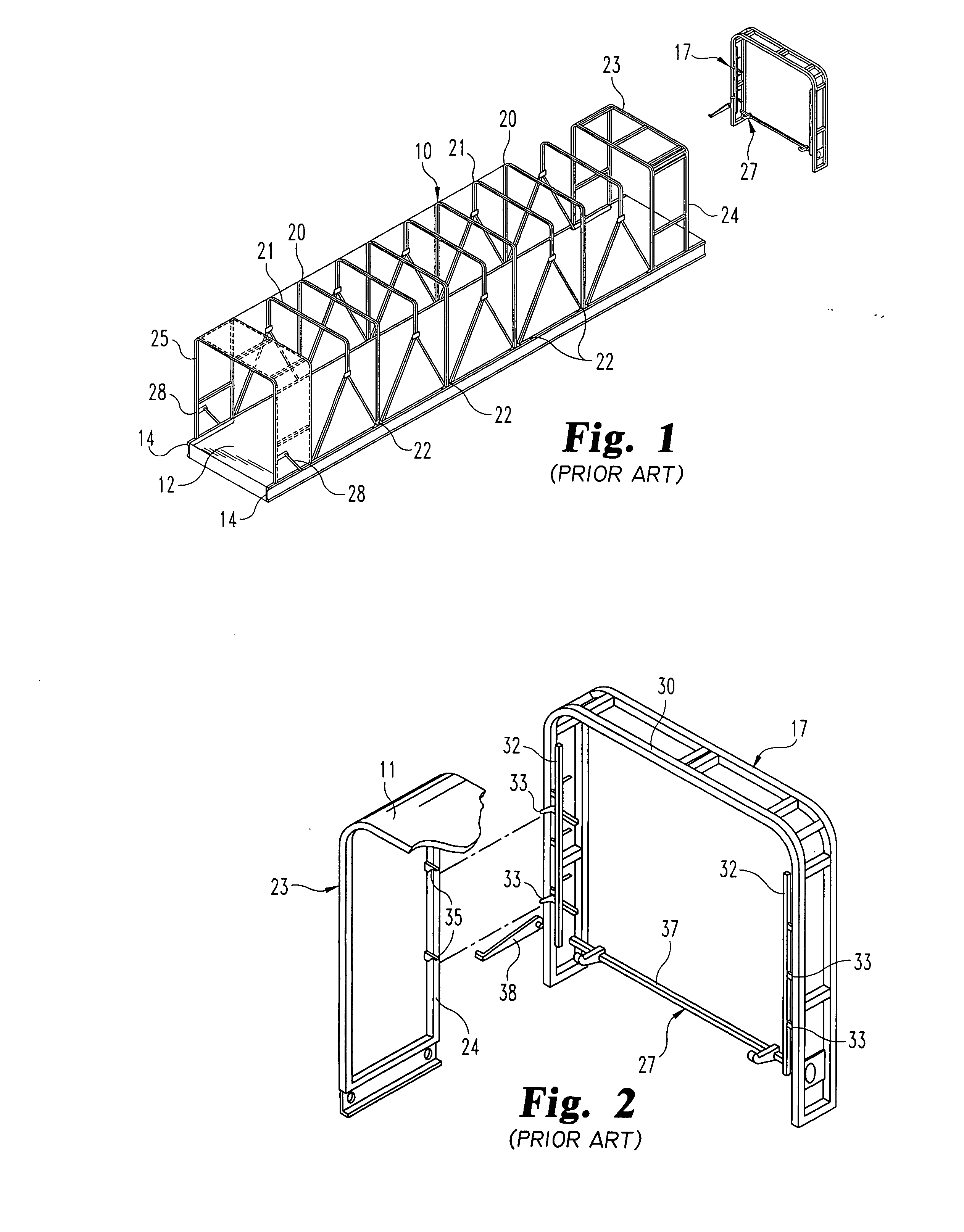

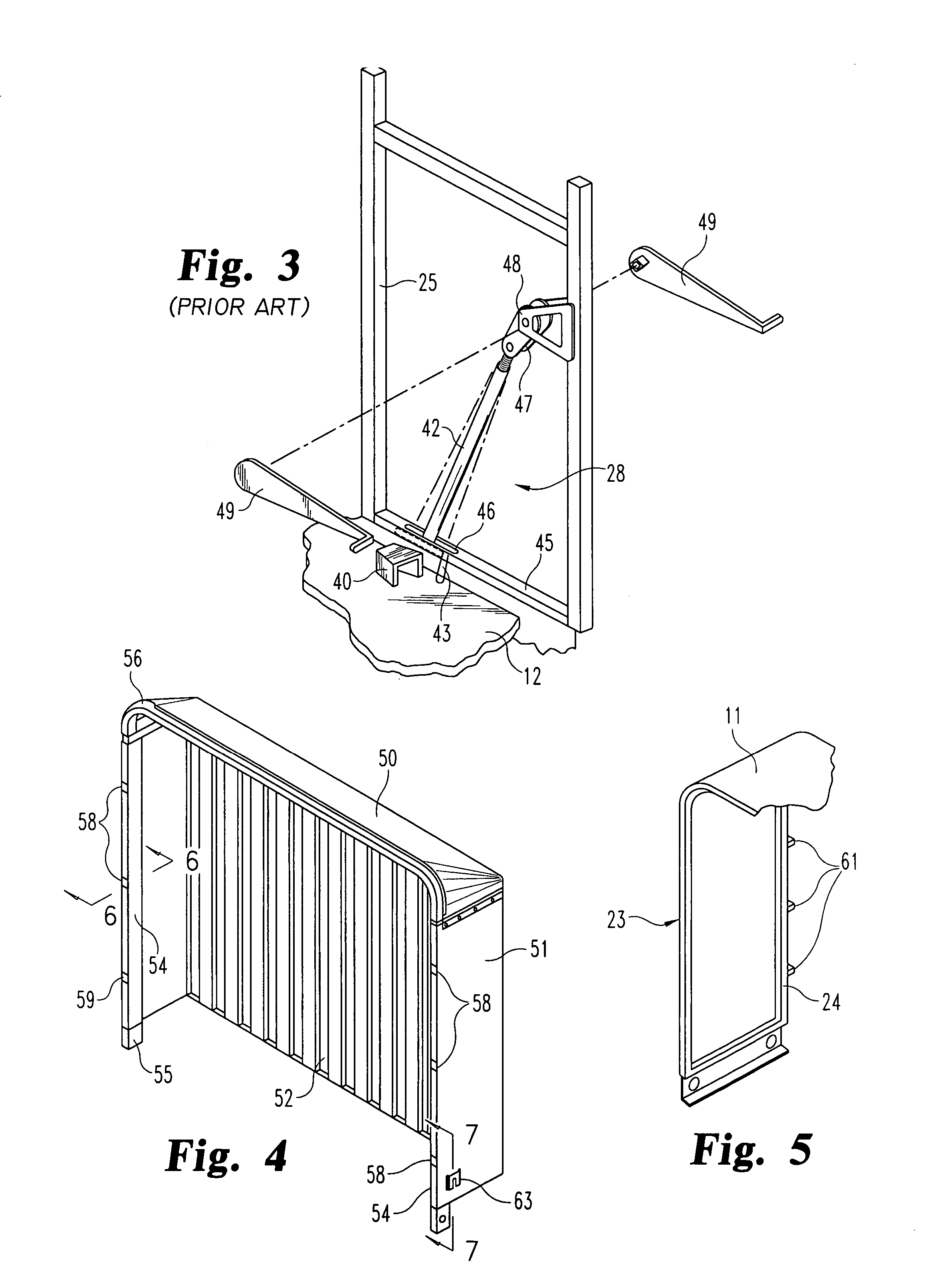

Magnetorheological reconfigurable clamp for a flexible manufacturing system

InactiveUS7204481B2Welding/cutting auxillary devicesWork holdersFlexible manufacturing systemMagnetorheological fluid

A reconfigurable clamp for a flexible manufacturing system comprises a body portion, a plurality of pins slidably engaged within sleeves formed in the body portion, a compression spring attached to each shaft of the plurality of pins, a reservoir comprising a magnetorheological fluid in operative communication with the plurality of pins, and an electromagnet in operative communication with the magnetorheological fluid, wherein the electromagnet selectively increases a yield stress property of the magnetorheological fluid; and a matching pressure foot.

Owner:GM GLOBAL TECH OPERATIONS LLC

Pressure foot lifting and inverted material feeding device of sewing machine

The invention provides a pressure foot lifting and inverted material feeding device of a sewing machine, belonging to the mechanical technical field. The pressure foot lifting and inverted material feeding device solves the technical problems of complex structure, high producing cost and the like existing in the existing sewing machine. The pressure foot lifting and inverted material feeding device of the sewing machine is arranged on a baseboard of the sewing machine and comprises a control mechanism, a power part and a clutch mechanism which are connected with the baseboard of the sewing machine, wherein the clutch mechanism has two power output ends; the control mechanism is connected with the clutch mechanism; the control mechanism can cause one of the power output ends to be connected with the power section; one of the power output ends is connected with an inverted material feeding mechanism of the sewing machine, and the other power output end is connected with a pressure foot lifting mechanism of the sewing machine. The device has compact structure, beautiful appearance, simple structure design, and reduces the cost of the sewing machine.

Owner:ZHEJIANG ZOJE SEWING MACHINE

Automatic presser foot lifting and backward and forward sewing device of sewing machine and sewing machine

InactiveCN105821597ASimple and compact structureEasy to install and maintainPressersSewing-machine control devicesEngineeringSewing machine

The invention discloses an automatic presser foot lifting and backward and forward sewing device of a sewing machine. The automatic presser foot lifting and backward and forward sewing device comprises a presser foot lifting driver. A first straight rod of the presser foot lifting driver is connected with one end of a pull rope of a pull rope assembly, and the other end of the pull rope is connected with one end of a swing rod. The other end of the swing rod is in contact with one end of a presser foot lifting rear lever which can swing around the lever axis. A presser foot lifting mechanism is connected with the other end of the presser foot lifting rear lever and can be driven to act through swing of the presser foot lifting rear lever. The automatic presser foot lifting and backward and forward sewing device further comprises a backward and forward sewing driver. A second straight rod of the backward and forward sewing driver is connected with one end of a pull rod, and a swing plate seat is connected with the other end of the pull rod. Backward and forward sewing action can be achieved through swing of the swing plate seat. The automatic presser foot lifting and backward and forward sewing device is simple and compact in structure, convenient to install and maintain, low in manufacturing cost and capable of being in comprehensive application with a traditional presser foot lifting and backward and forward sewing mode. The invention further discloses the sewing machine with the automatic presser foot lifting and backward and forward sewing device.

Owner:ZHEJIANG MAQI SEWING MACHINE

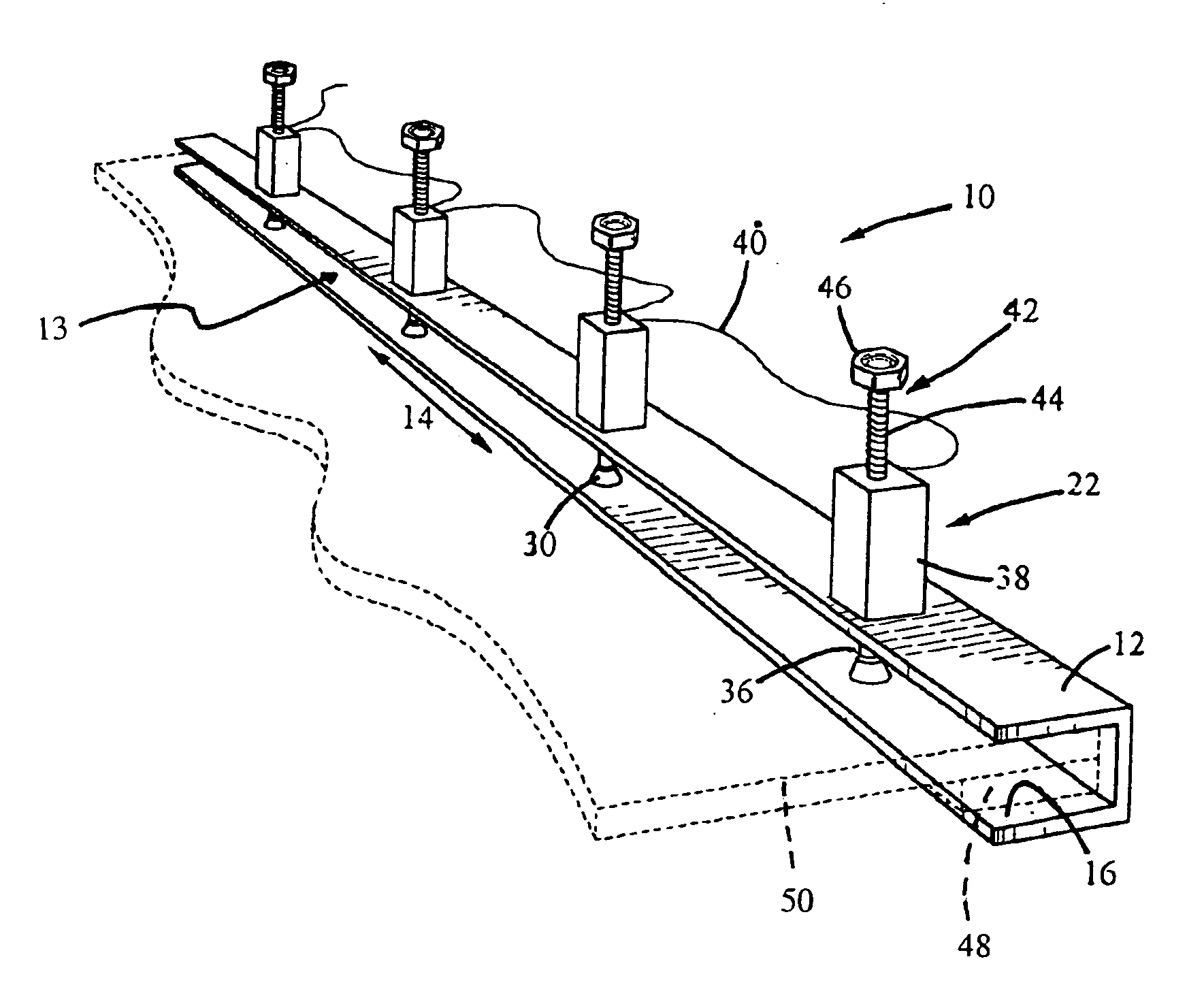

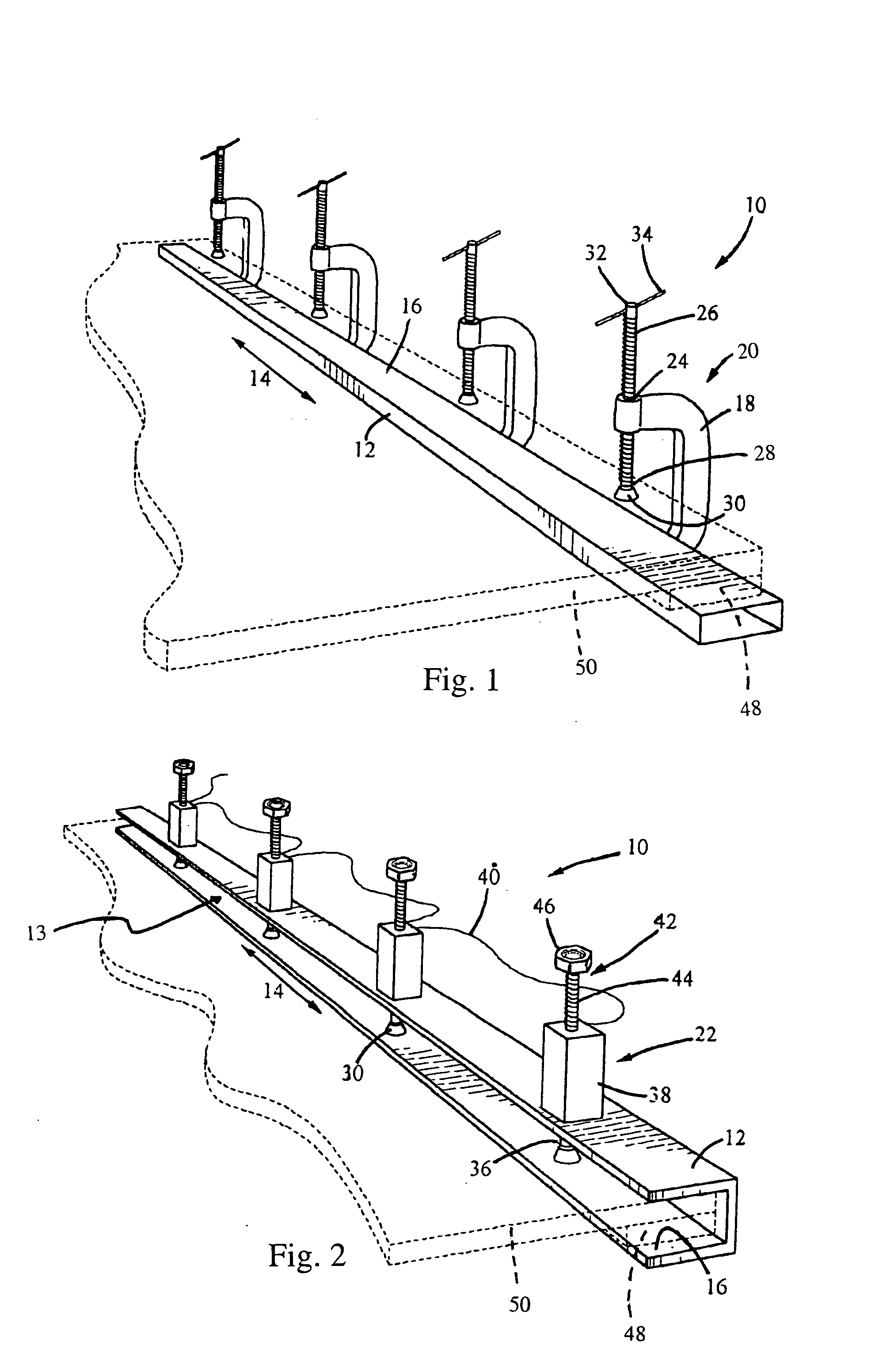

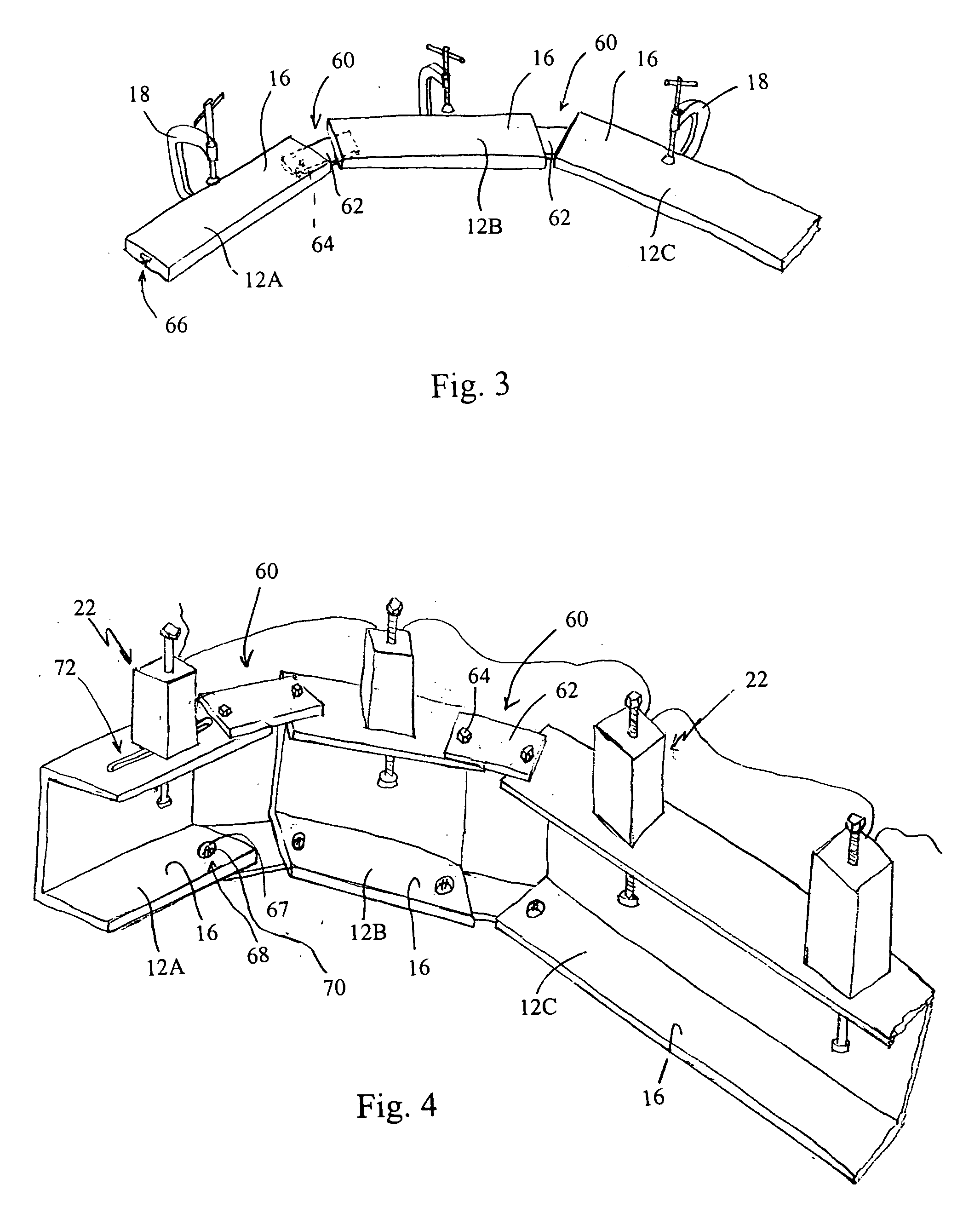

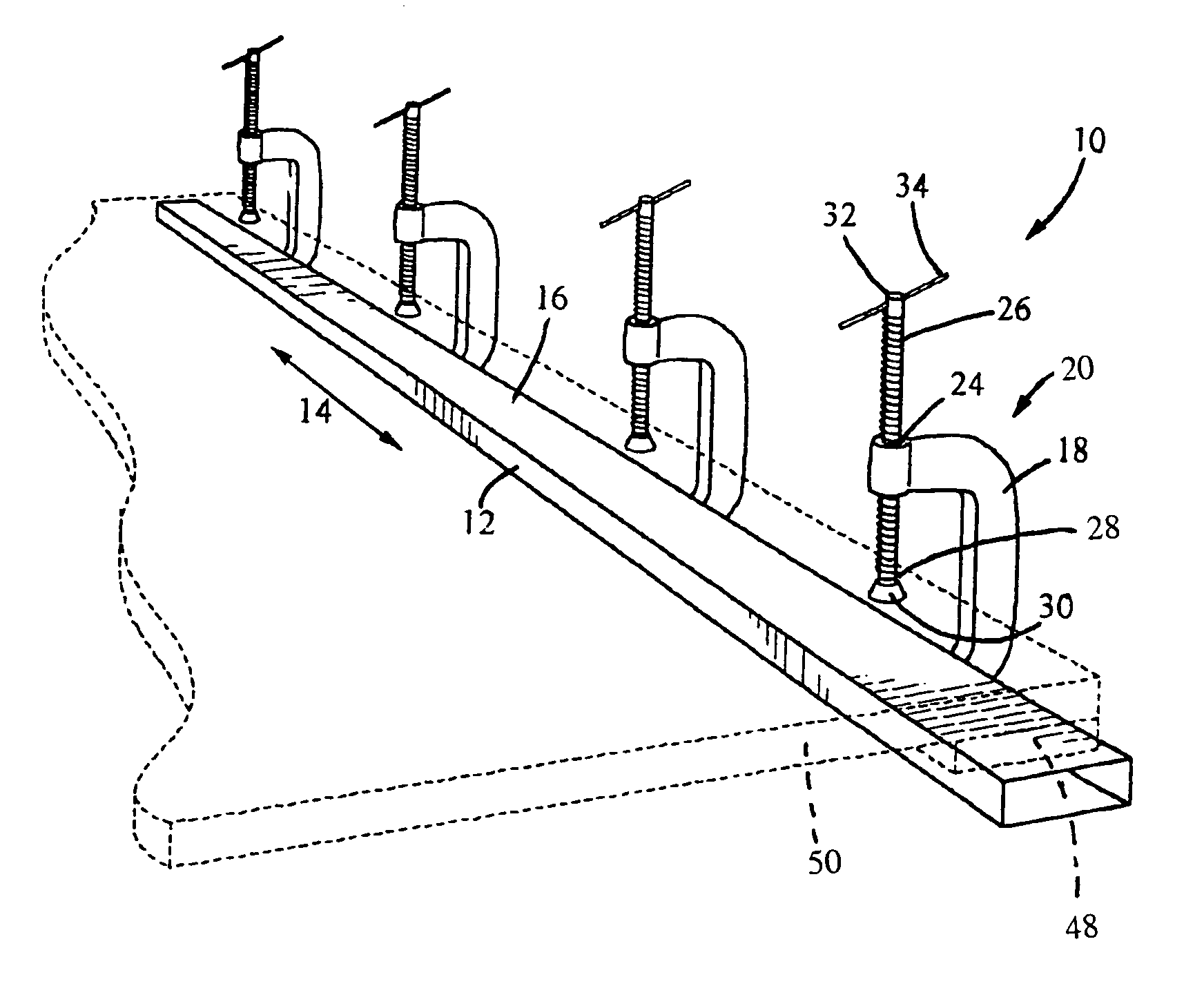

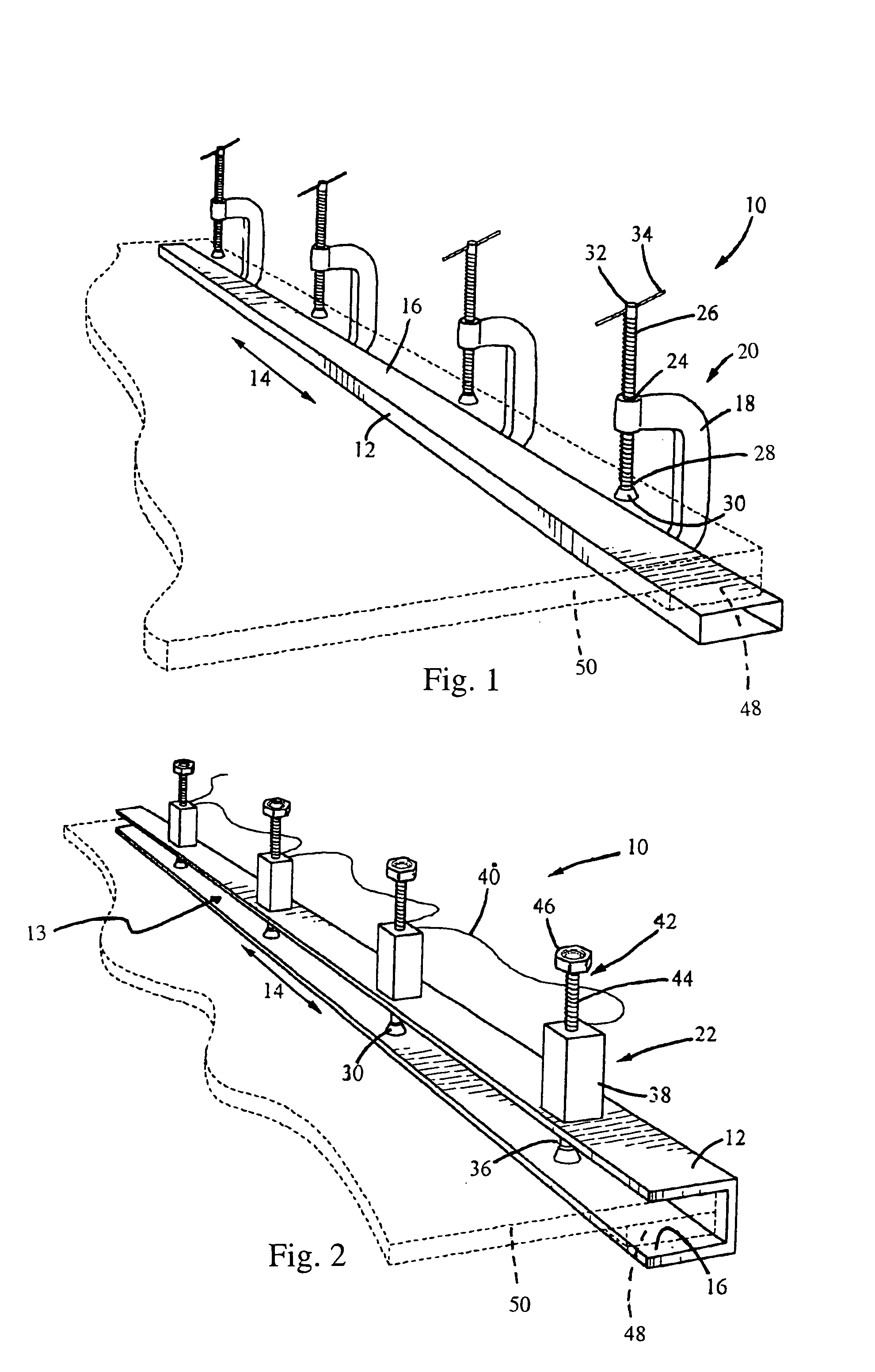

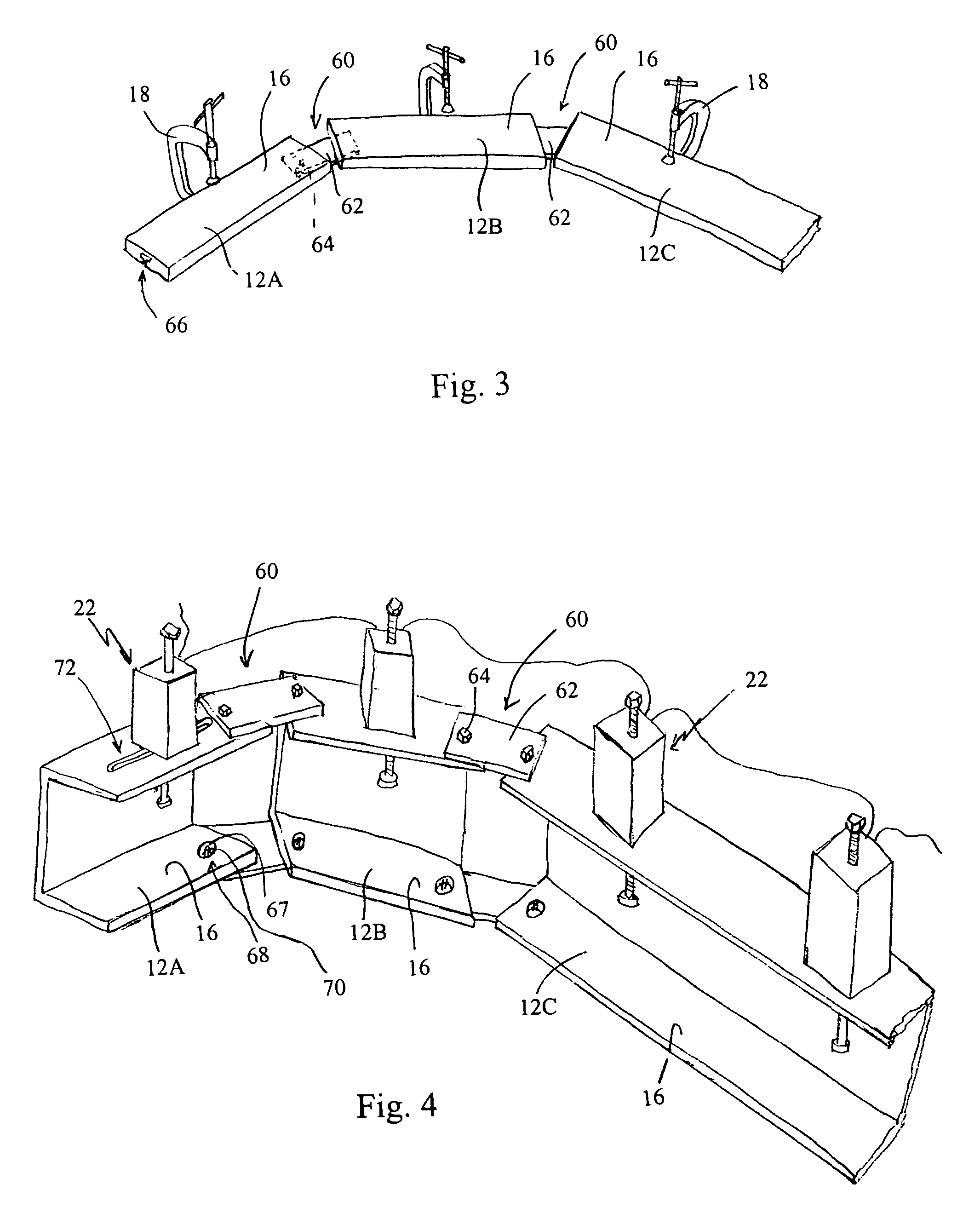

Sheet material clamp

InactiveUS20050001369A1Apply evenlyEfficiently and quickly applyCandle holdersLighting support devicesBiomedical engineeringPRESSURE FEET

A sheet material clamp having a rigid clamp base of a pre-selected length. The rigid clamp base has a clamping surface and at least two clamping apparatus attached to the clamping base for applying clamping pressure through a pressure foot toward the clamping surface. The apparatus for applying clamping pressure are spaced along the length of the clamp base so that clamping pressure can be applied evenly along the edge of the sheet material being clamped.

Owner:CROSS CHRISTOPHER TODD

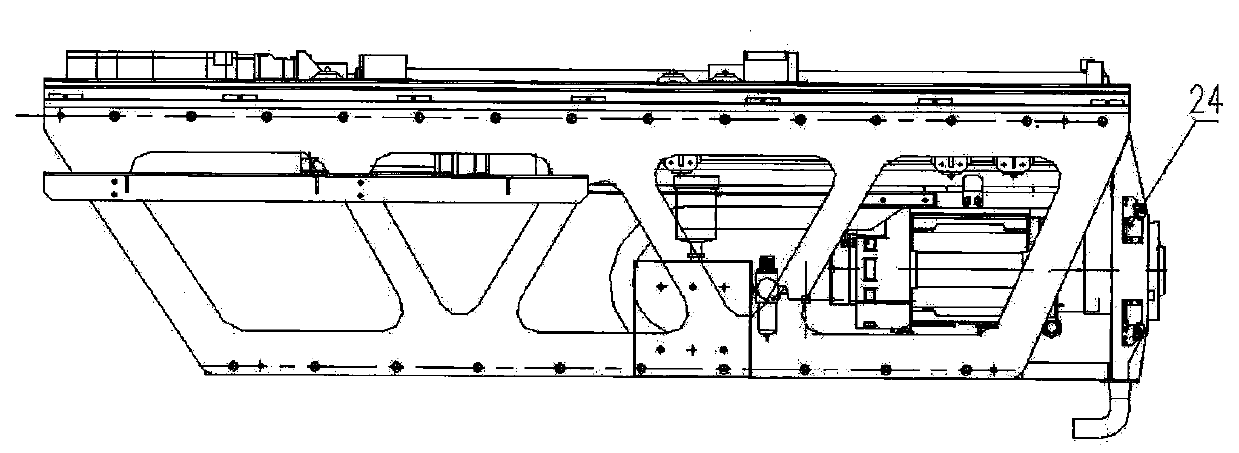

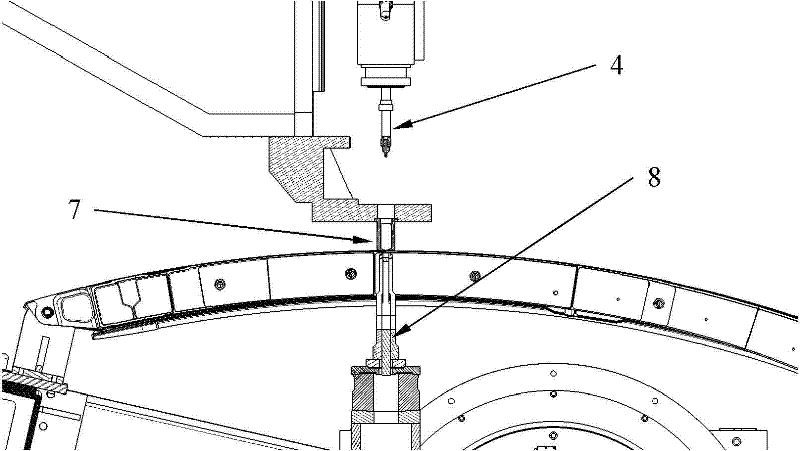

Automatic hole forming equipment and hole forming method for composite airfoil components

ActiveCN103722207AAvoid splittingImprove work efficiencyMetal working apparatusBoring/drilling machinesFour quadrantsLaser ranging

The invention relates to automatic hole forming equipment for composite airfoil components. The automatic hole forming equipment is five-axis linkage numerically controlled equipment, and comprises a main rack, a B-axis support, an A-axis rotary table, a Z-axis subassembly, a Y-axis drag chain, a Z-axis drag chain, a scrap suction device, a knife lubricating system and an oil pump of the lubricating system, wherein a spindle is arranged on the Z-axis subassembly; a component knife which can be used for drilling holes, reaming holes and reaming pits is hydraulically clamped on the spindle; four laser distance measuring sensors are symmetrically arranged at ends of the Z-axis subassembly and are distributed on four quadrants; a pressure foot support is arranged below the Z-axis subassembly; and pressure feet are arranged on the periphery of a center hole of the pressure foot support, and are provided with pressure foot sensors. By using the automatic hole forming equipment and the hole forming method, the clamping and positioning precision is high, the accuracy of formed holes is high, and damage to composites in a hole forming process is reduced, so that the quality of a product is improved while the work efficiency is improved.

Owner:SHENYANG AIRCRAFT CORP

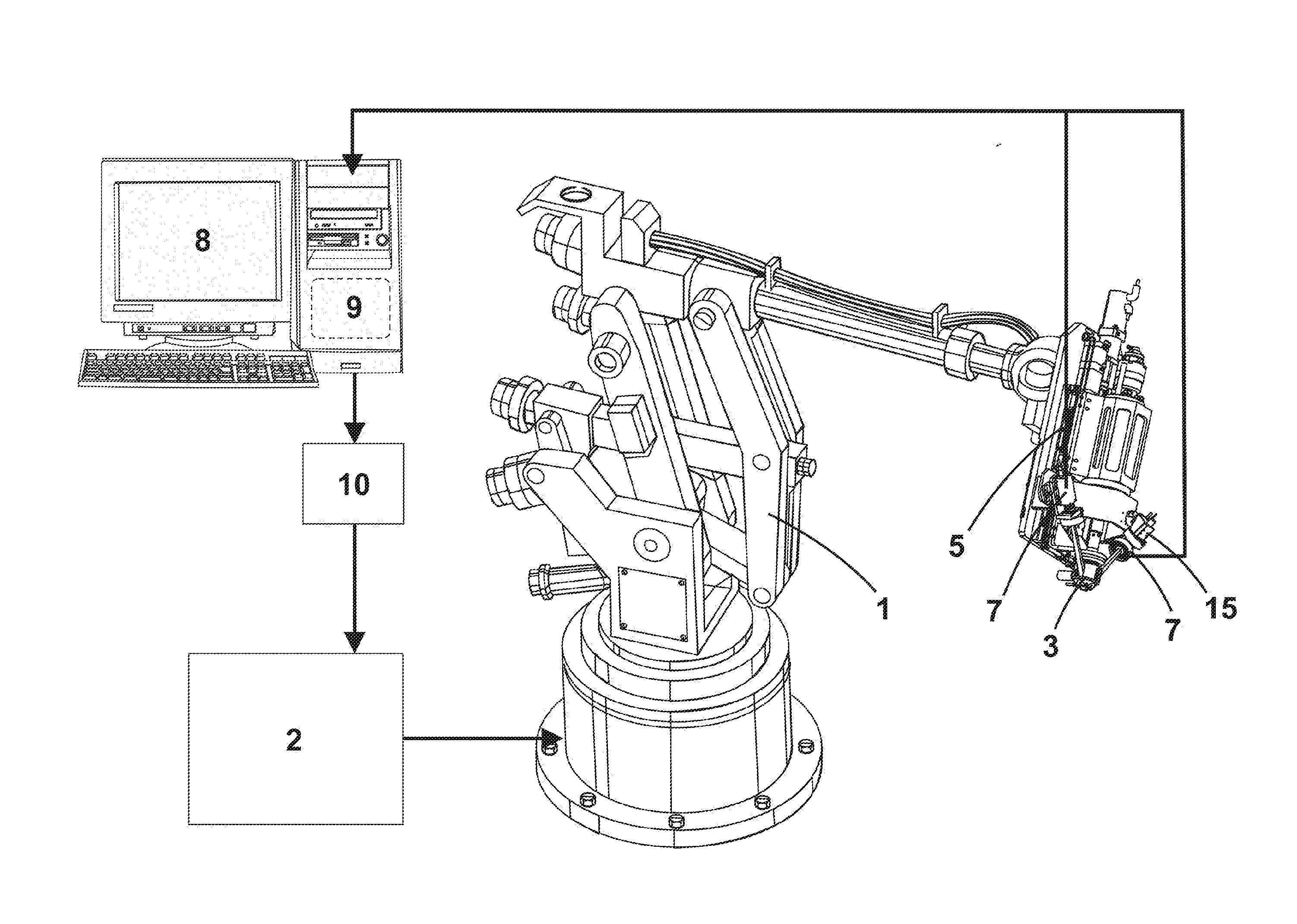

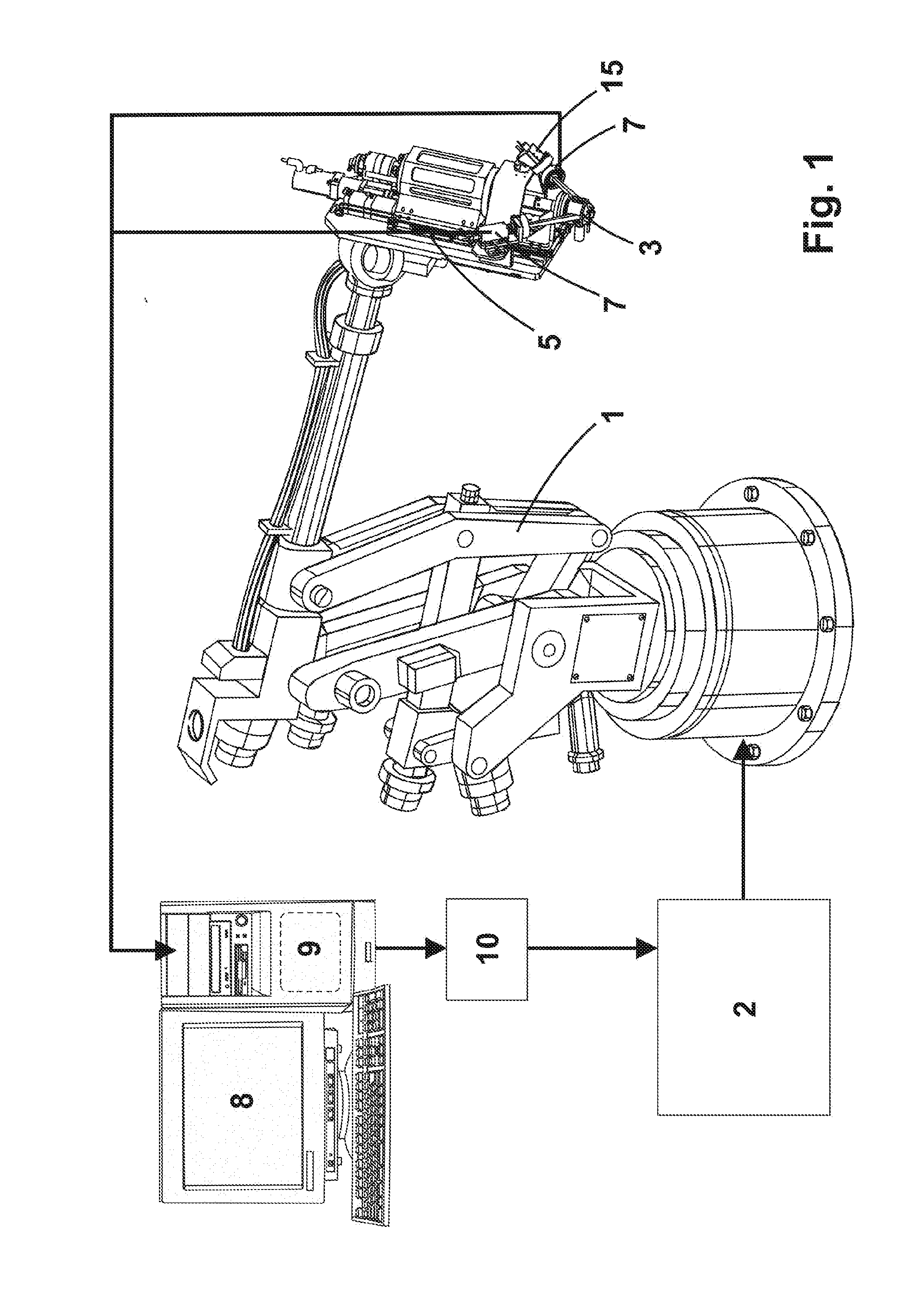

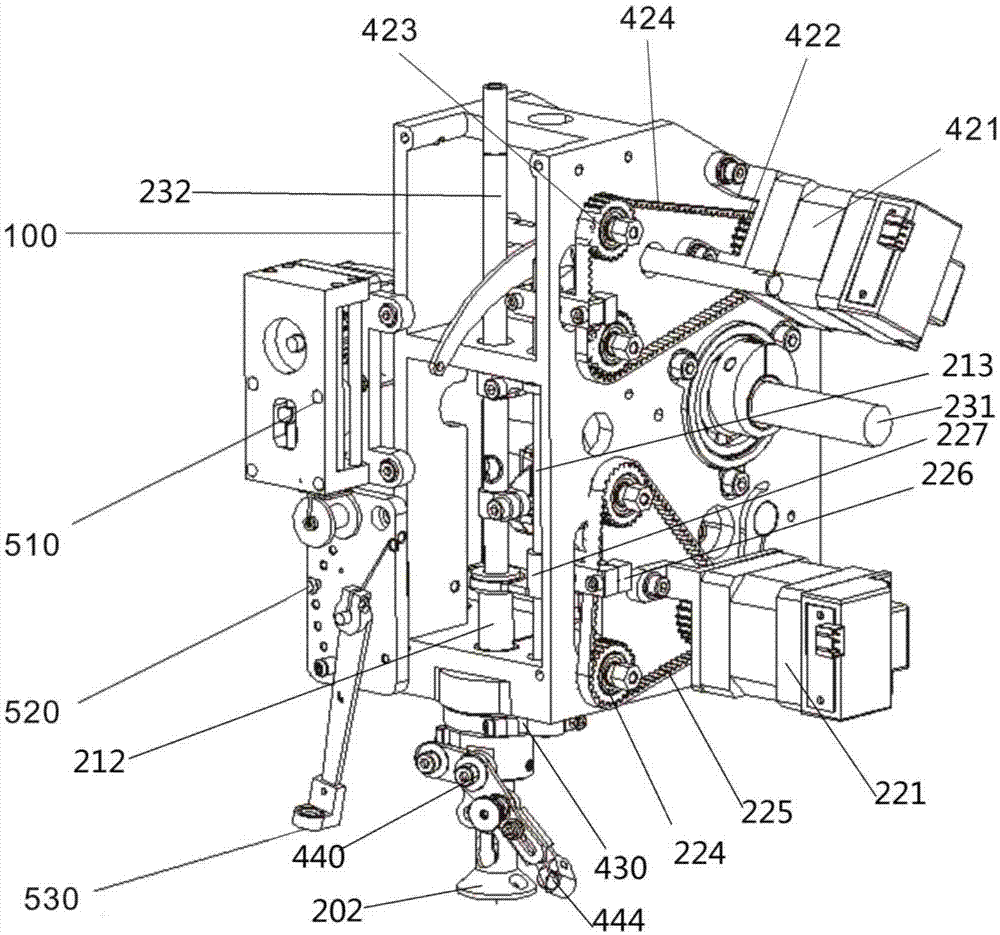

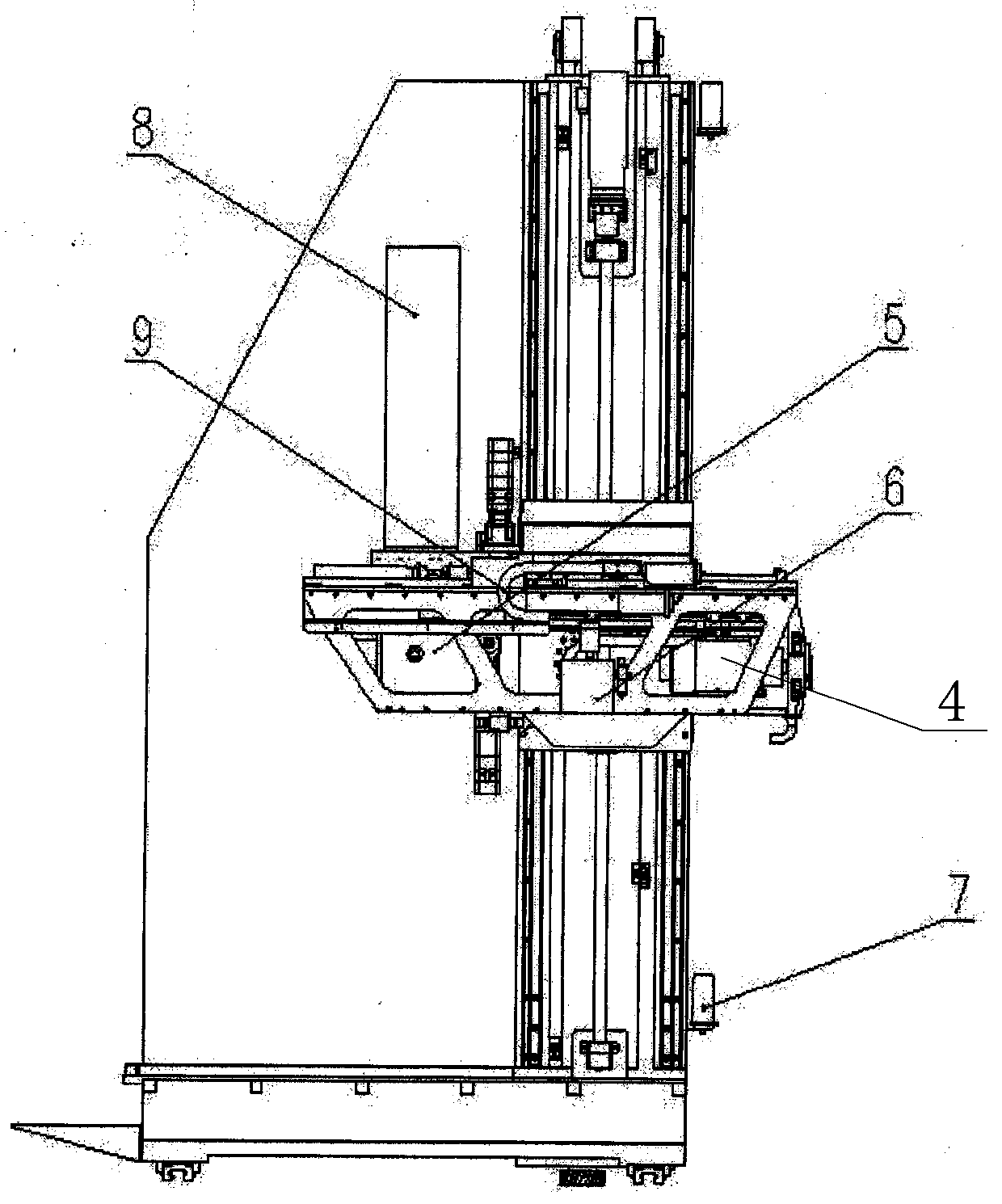

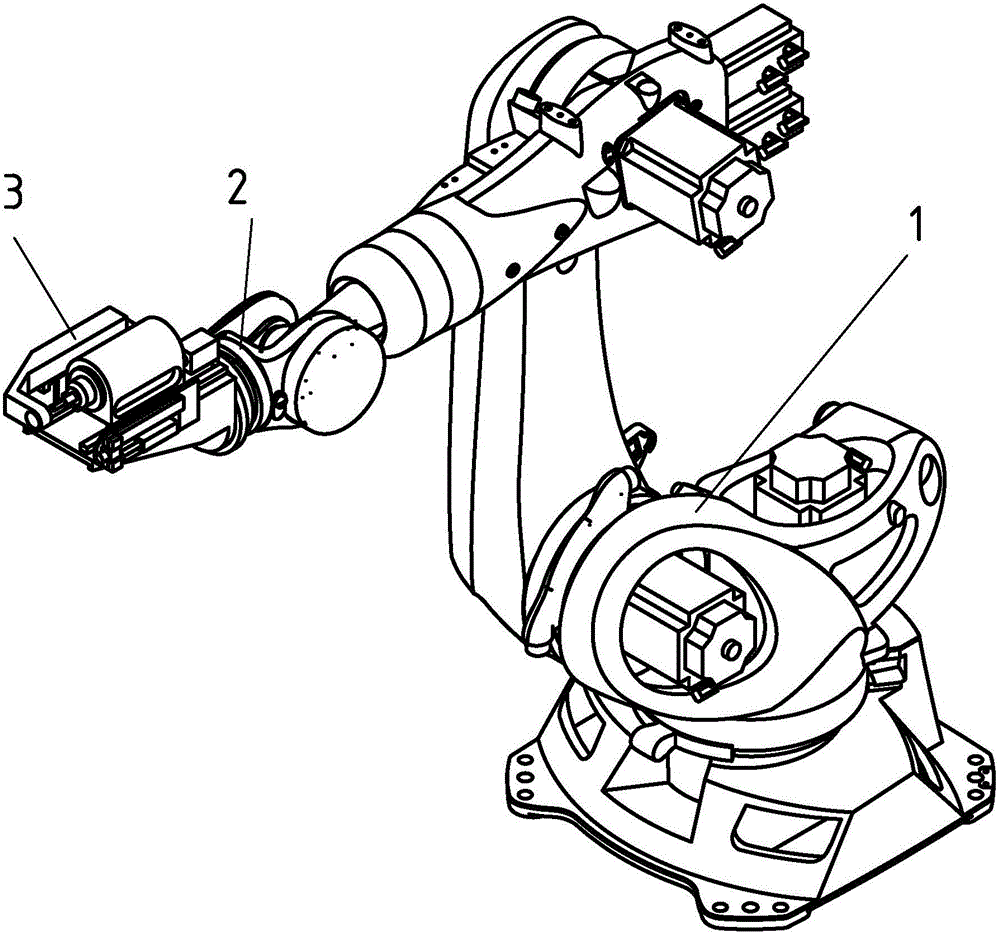

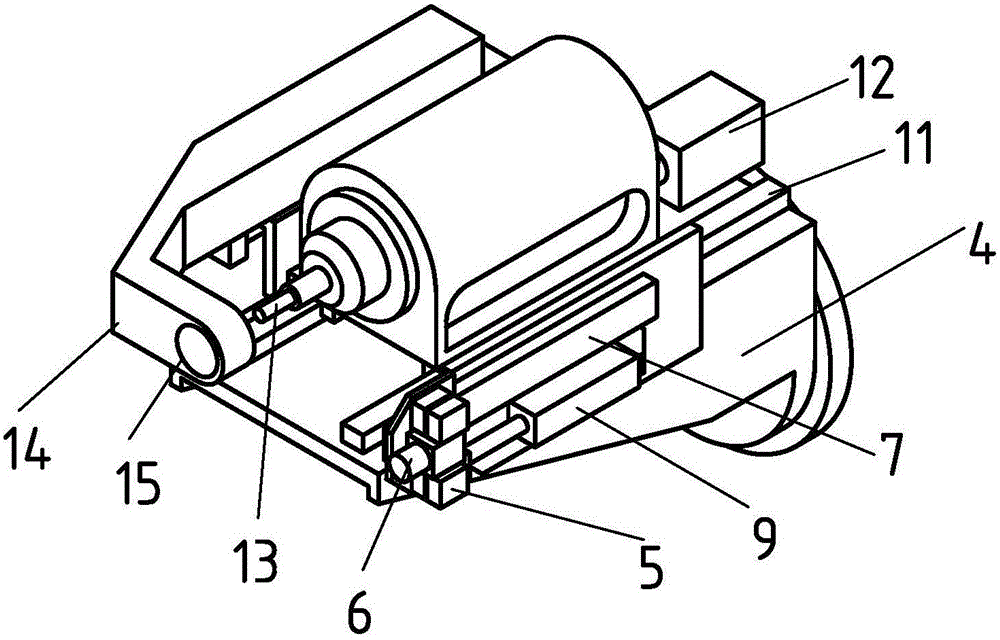

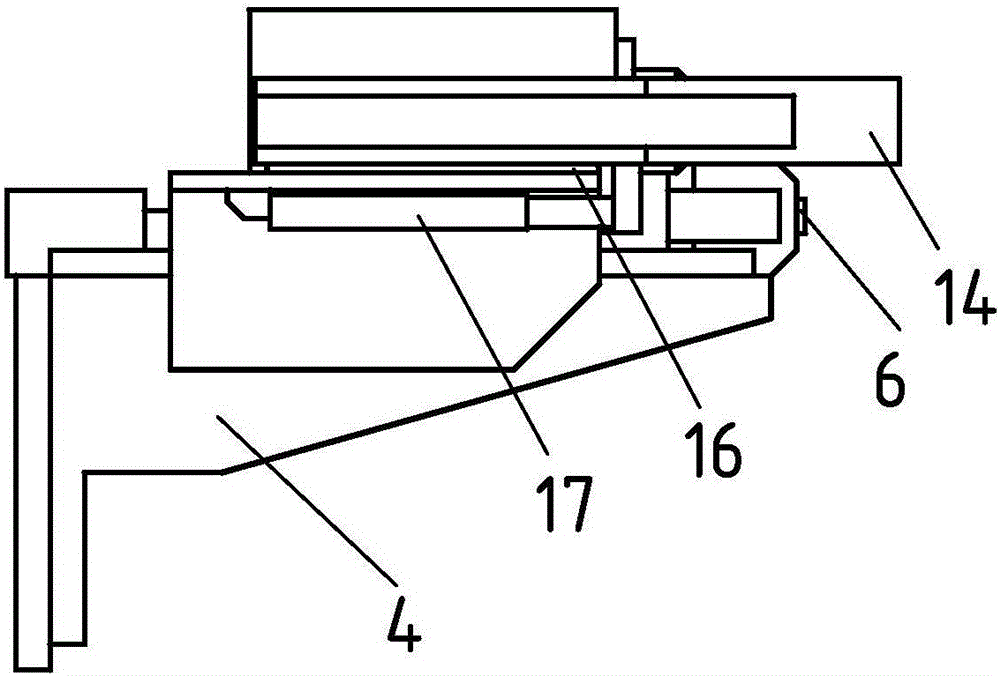

Automatic hole making device of robot and machining method

ActiveCN106041955AHigh positioning accuracyImprove processing efficiencyOther manufacturing equipments/toolsManipulatorRobotic armRotational degrees of freedom

The invention discloses an automatic hole making device of a robot and a machining method. The hole making device comprises a six-shaft series-connection mechanical arm, a mechanical arm tail end rotating mechanism and an automatic hole making tail end executor; the six-shaft series-connection mechanical arm is connected with the automatic hole making tail end executor through the mechanical arm tail end rotating mechanism; and the automatic hole making tail end executor comprises an automatic positioning alignment module, a hole making module, a pressure foot module and a rack. The automatic hole making device of the robot has an automatic positioning alignment function, is high in hole making positioning precision, can achieve automatic hole making in cooperation with a mechanical arm and is high in machining efficiency. According to the automatic hole making device of the robot, conversion of different stations is achieved through the rotating freedom degree of the mechanical arm tail end rotating mechanism, and the device structure is simplified. The automatic hole making device of the robot can be additionally provided with other functional modules, is good in development performance, can integrate functional modules for riveting, hole making precision and quality detection and the like, adapts to different requirements and achieves various functions.

Owner:DALIAN UNIV OF TECH

Sheet material clamp

InactiveUS7055787B2Apply evenlyEfficiently and quickly applyCandle holdersLighting support devicesEngineeringBiomedical engineering

A sheet material clamp having a rigid clamp base of a pre-selected length. The rigid clamp base has a clamping surface and at least two clamping apparatus attached to the clamping base for applying clamping pressure through a pressure foot toward the clamping surface. The apparatus for applying clamping pressure are spaced along the length of the clamp base so that clamping pressure can be applied evenly along the edge of the sheet material being clamped.

Owner:CROSS CHRISTOPHER TODD

Space orientation computing method for numerical control bracket

InactiveCN102566439AWork quicklyContinuous operationSimulator controlSpatial positioningComputer science

The invention relates to a space orientation computing method for a numerical control bracket, which comprises the following steps of: 1, processing three-dimensional digital analogy of each part; 2, defining a fixed mechanism and a moving mechanism in each digital analogy; 3, setting a drive command for a multiple axis movements of a numerical control bracket; 4, simulating whether each axis movement accords with an actual condition; 5, correcting a movement zero point of the digital analogy of the numerical control bracket; 6, enabling a spindle axes of an automatic drilling and riveting machine to be coincident with a normal line of a riveting point and the riveting point to be coincident with the center of a pressure foot bush; 7, refreshing the digital analogy; 8, figuring out data of five axes of the numerical digital bracket and data of a lifting position and a rotating angle of a lower riveting head under the condition of automatic drilling and riveting on any point on the surface of an airplane; 9, carrying out collision checking and batch output on space orientation data; and 10, carrying out numerical control programming to ensure that the automatic drilling and riveting machine continuously operates. According to the space orientation computing method, the numerical control system can automatically operate according to the space orientation data, and the airplane on the numerical control bracket meets the working requirements of the automatic drilling and riveting machine on the space.

Owner:AVIC SAC COMML AIRCRAFT

Thread trimming, thread loosening, presser foot lifting and presser foot pressure adjusting device of sewing machine and sewing machine

ActiveCN110983644ASimple structureCompact structureNeedle severing devicesSewing-machine control devicesCrankEngineering

The invention relates to the technical field of sewing machines, in particular to a thread trimming, thread loosening, presser foot lifting and presser foot pressure adjusting device of a sewing machine and the sewing machine comprising the device. The device comprises a power piece, a cam structure, a thread trimming driving crank connected with a thread trimming mechanism and an ejector rod connected with a thread loosening mechanism, a presser foot lifting mechanism and a presser foot pressure adjusting mechanism, a first transmission pin on the thread trimming driving crank is matched witha first driving contour face of the cam structure, and the first driving contour face is provided with a thread trimming driving section for driving the thread trimming mechanism to execute thread trimming action; and a second transmission pin on the ejector rod is matched with a second driving contour face of the cam structure, and the second driving contour face is provided with a thread loosening driving section for driving the thread loosening mechanism to execute thread loosening action, a presser foot lifting driving section for driving the presser foot lifting mechanism to execute presser foot lifting action and a presser foot pressure adjusting driving section for driving the presser foot pressure adjusting mechanism to execute presser foot pressure adjusting action. The four functions of thread trimming, thread loosening, presser foot lifting and presser foot pressure adjusting are achieved through the driving of one power piece.

Owner:JACK SEWING MASCH CO LTD

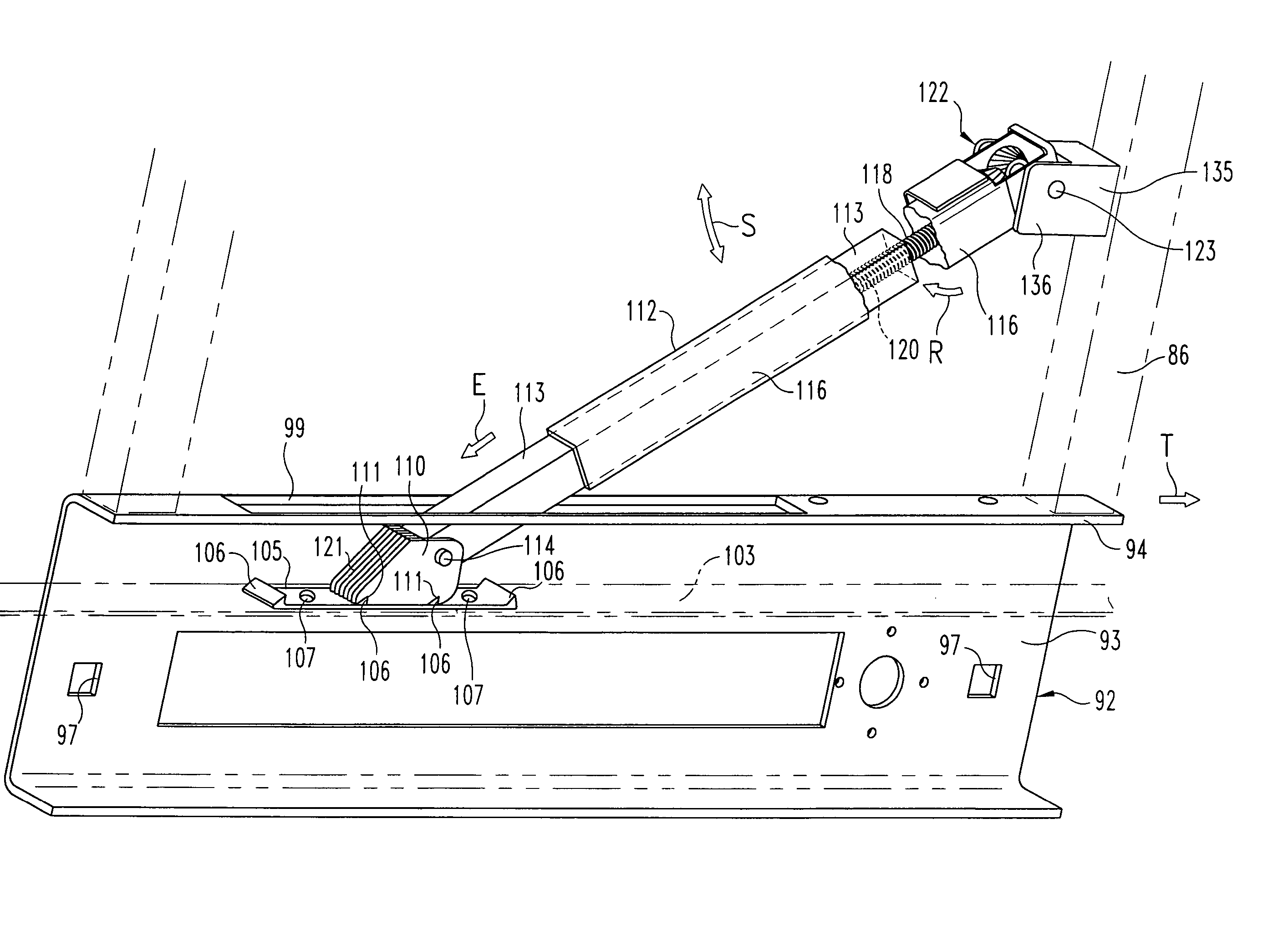

High speed hand drill with swiveling pressure foot and integrated vacuum pickup and coolant delivery duct

ActiveUS8337124B2Improve tool ergonomicsImproved drill guideDrilling/boring measurement devicesThread cutting feeding devicesEngineeringDrill cuttings

A high speed handheld power drill includes a housing with a motor, a chuck rotationally driven by the motor, and a drill bit clamped in the chuck. A pressure foot is mounted on the housing for coaxial rotation about the drill bit and lockable in a selectable angular position relative to the housing. A drill guide is slidably disposed within the pressure foot at an outer end thereof and biased for coaxial sliding movement between the drill bit and pressure foot. A vacuum cuttings pickup and coolant fluid delivery tool is coupled to the drill guide and arranged to deliver coolant fluid to the drill bit and to remove drill cuttings and coolant fluid and vapor therefrom during drilling. A coolant fluid reservoir is coupled to the drill motor housing and adapted to deliver selectably metered amounts of coolant fluid to the cuttings pickup and coolant delivery tool during drilling.

Owner:THE BOEING CO

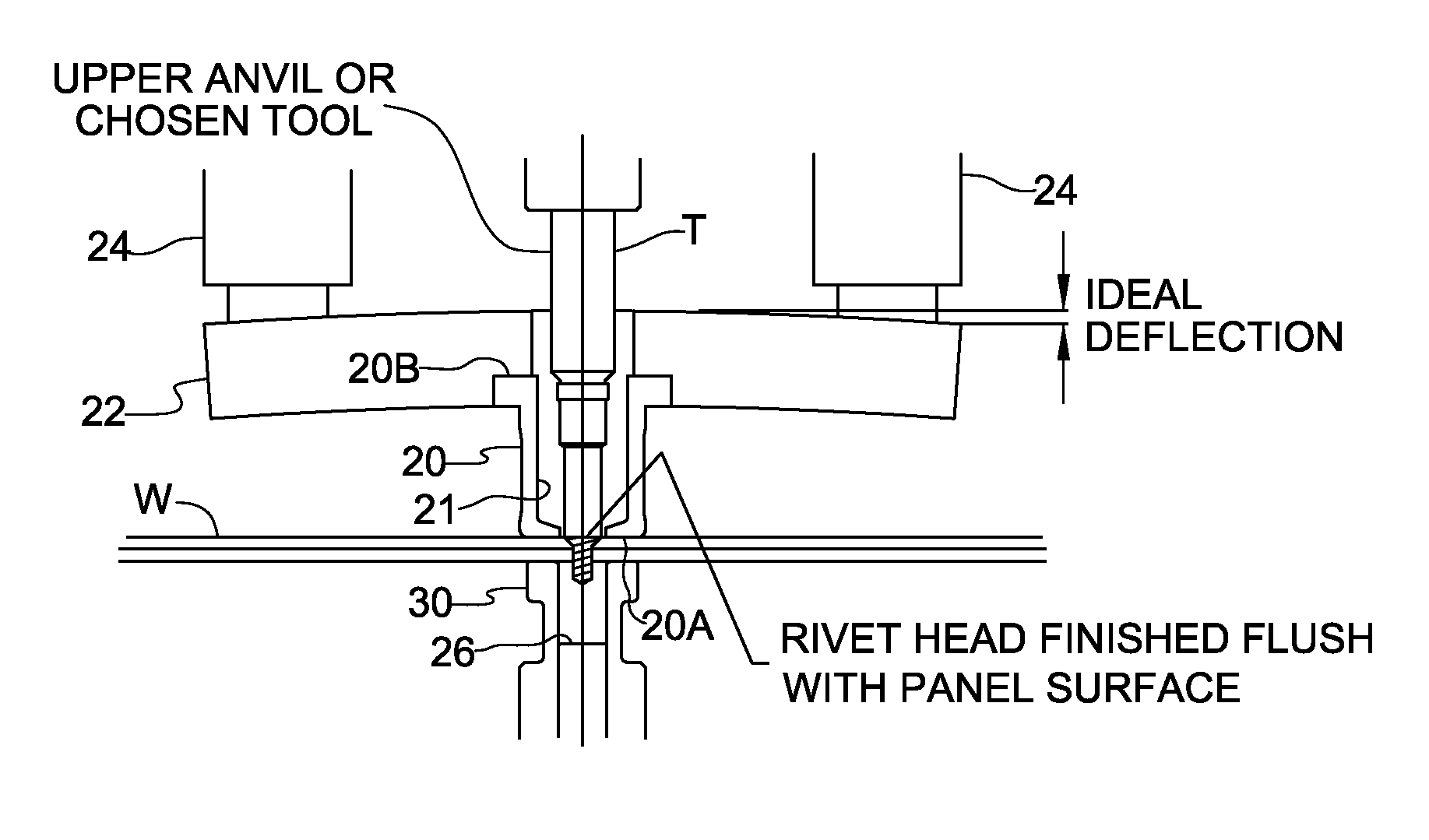

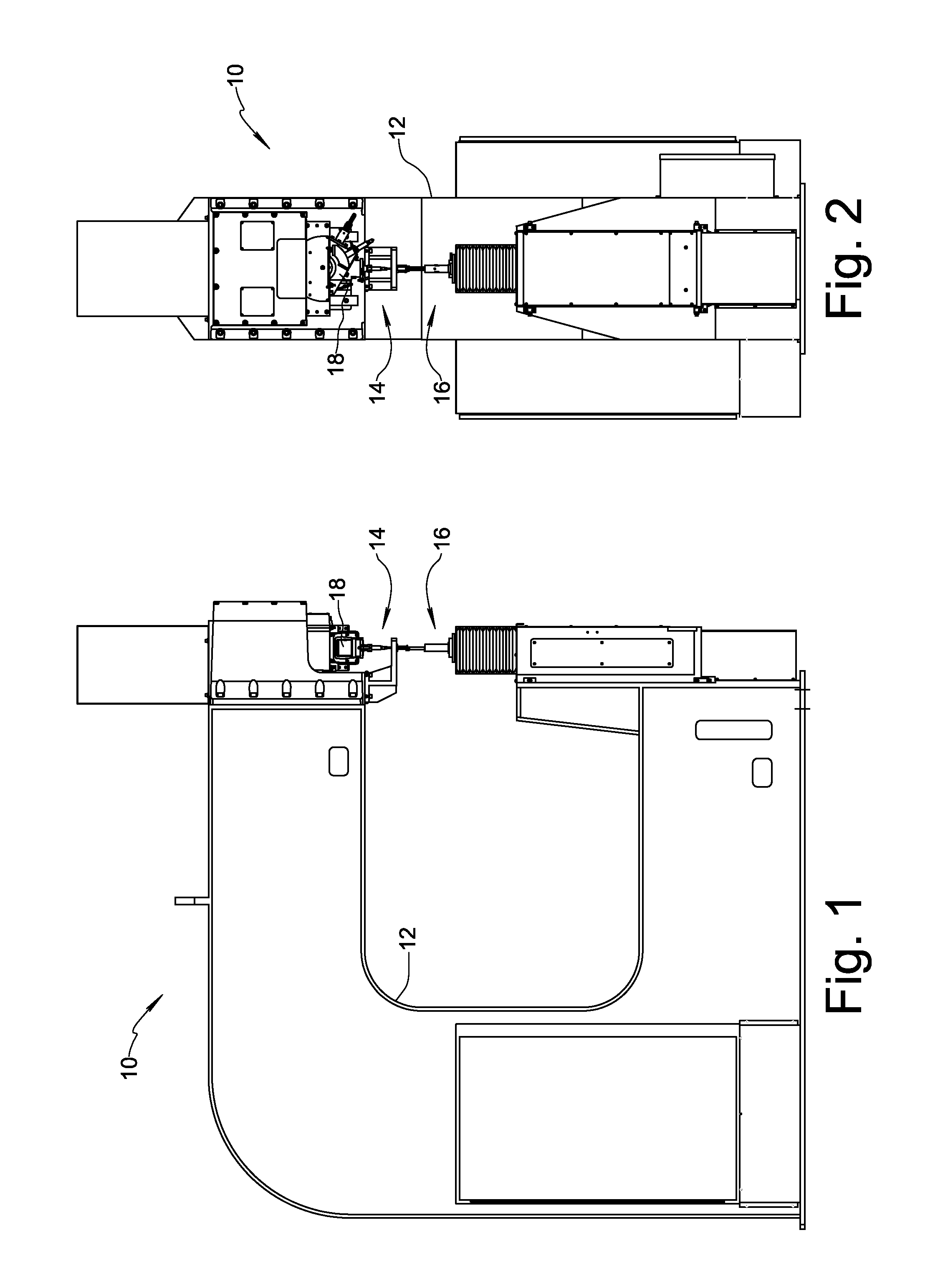

Apparatus and method for improving safety and quality of automatic riveting operations

An automatic riveting apparatus is improved by providing at least one sensor on a pressure foot plate or at an interface between the pressure foot plate and a pressure foot bushing of the apparatus for generating a signal indicative of force transmitted between the pressure foot plate and the pressure foot bushing. For example, the at least one sensor may include a strain gauge or other type of sensor for measuring deflection of the pressure foot plate, or it may include load cell(s) for measuring force at the interface between the pressure foot plate and the pressure foot bushing. A control system of the apparatus may be configured to execute one or more control functions based on a value of the sensor signal or signals. The control functions may adjust machine operation commands or trigger a safety mode based at least in part on the sensor signal.

Owner:GEN ELECTRO MECHANICAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com