Patents

Literature

320results about How to "Avoid padding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

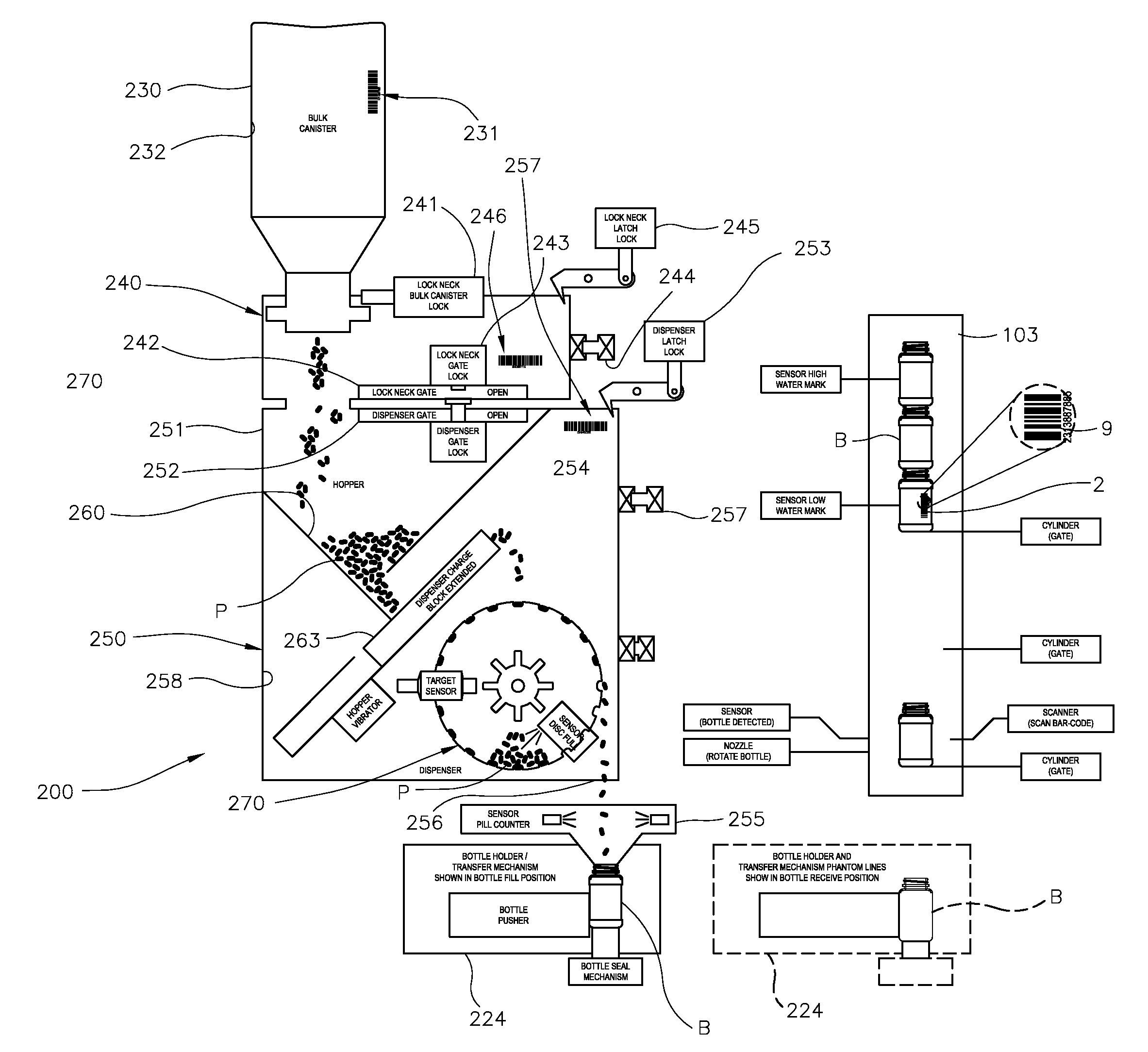

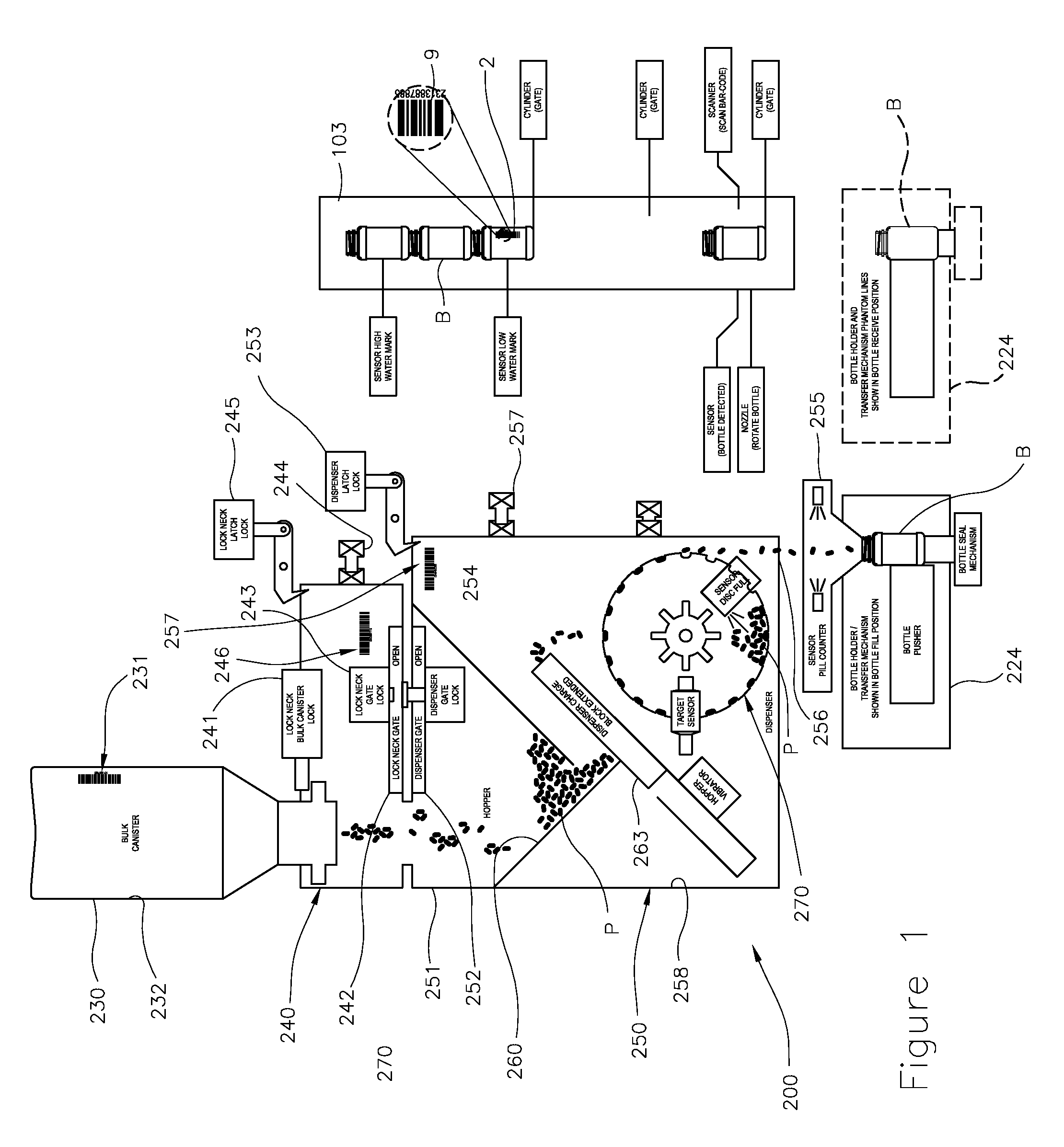

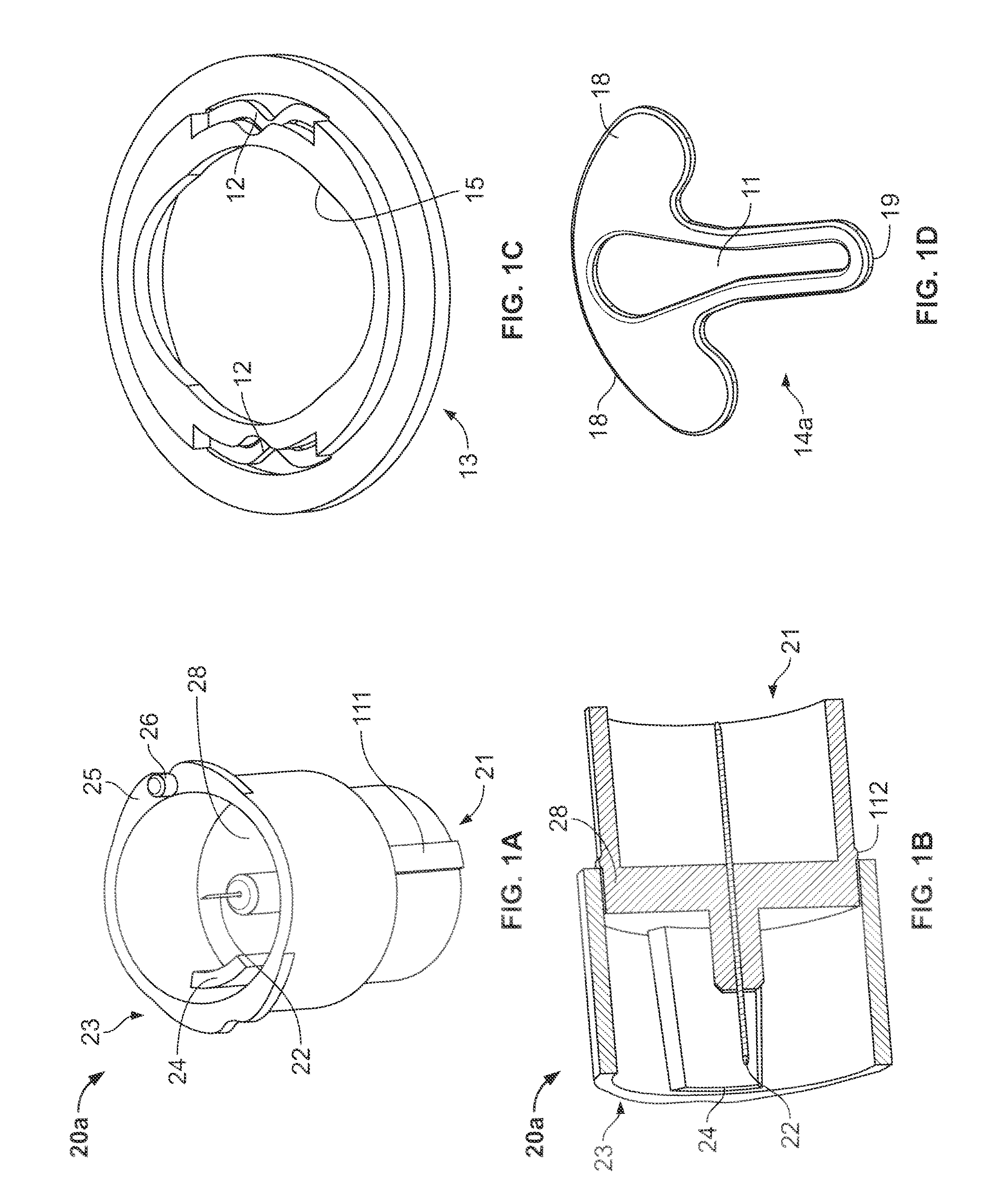

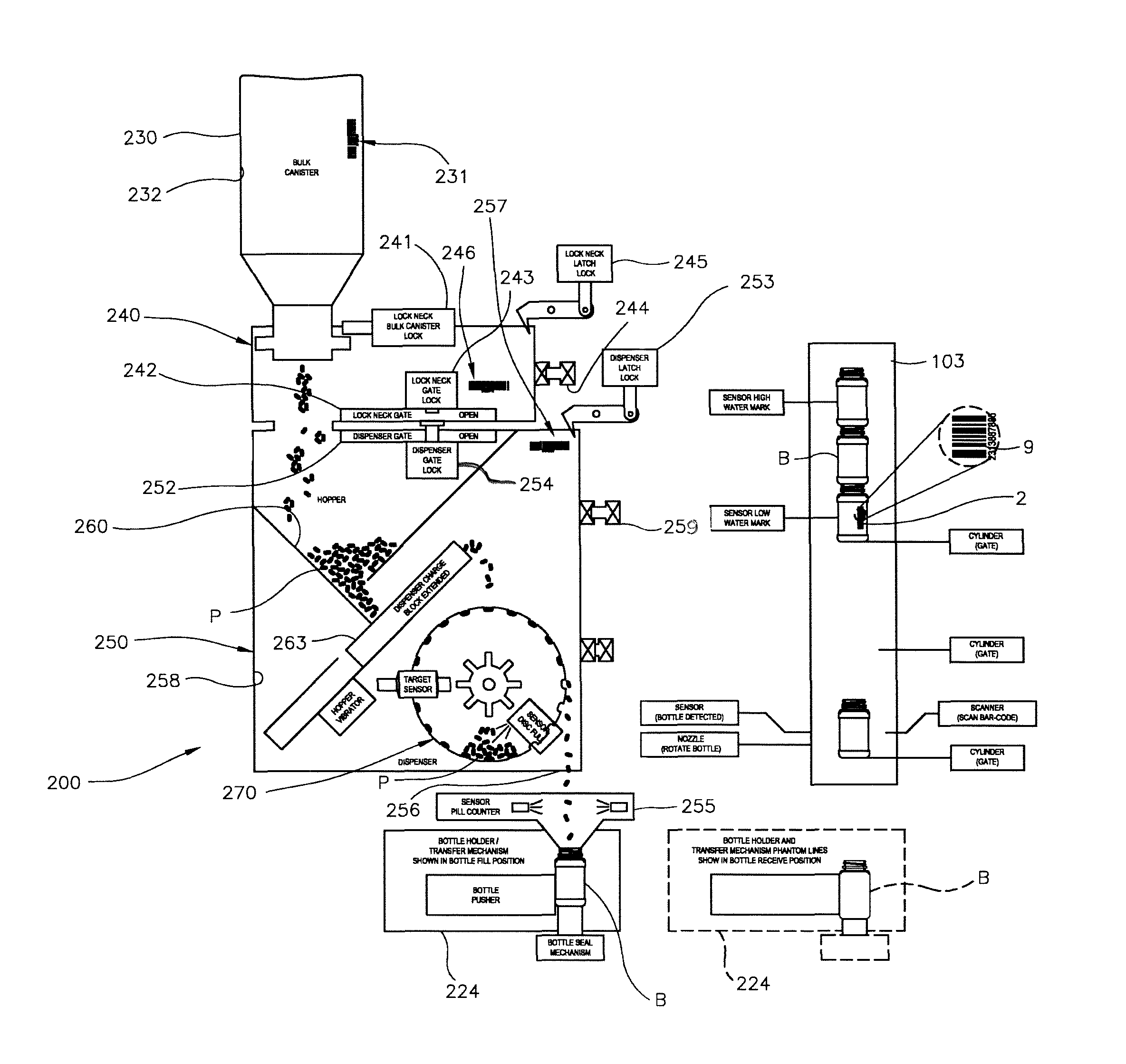

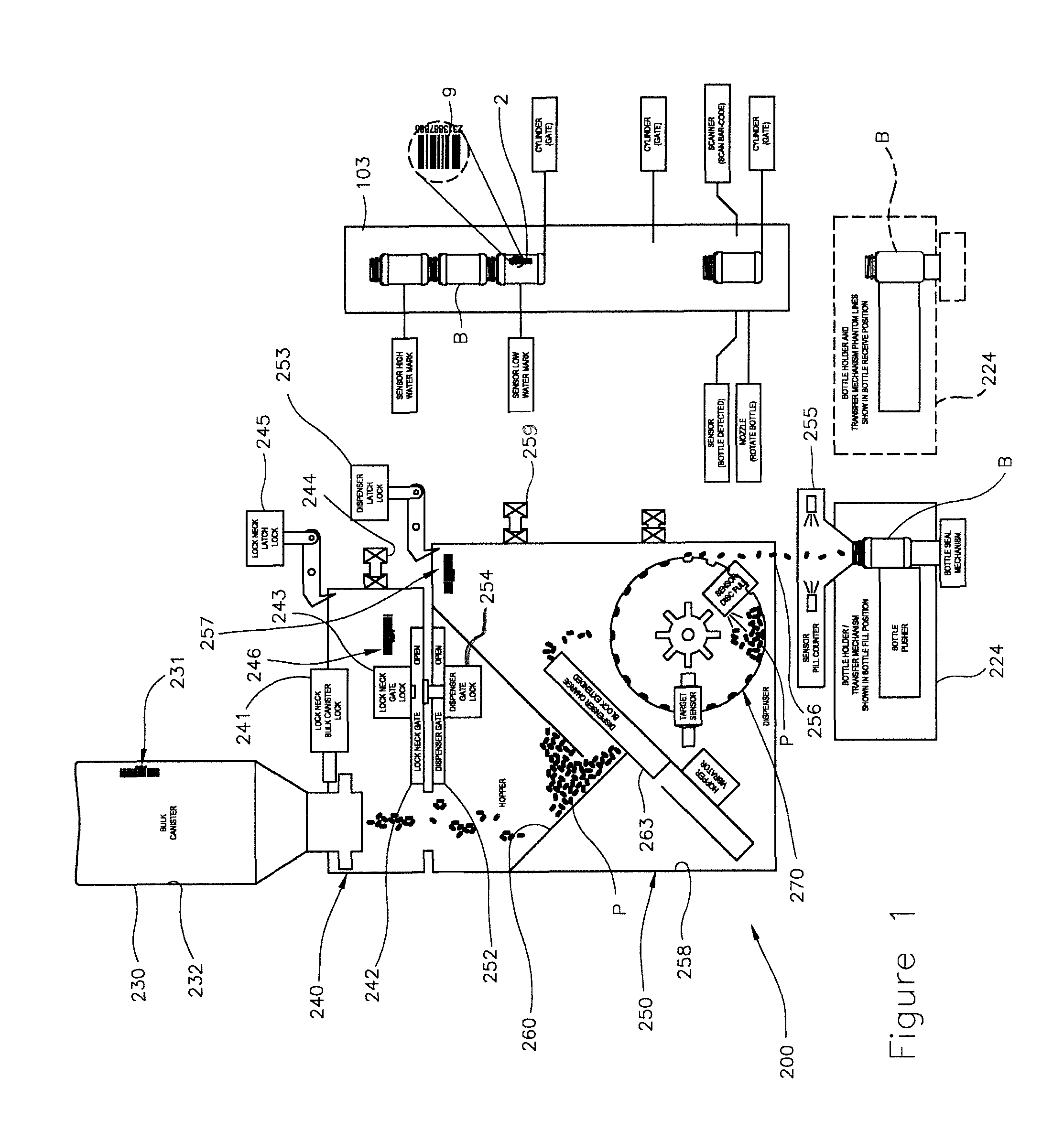

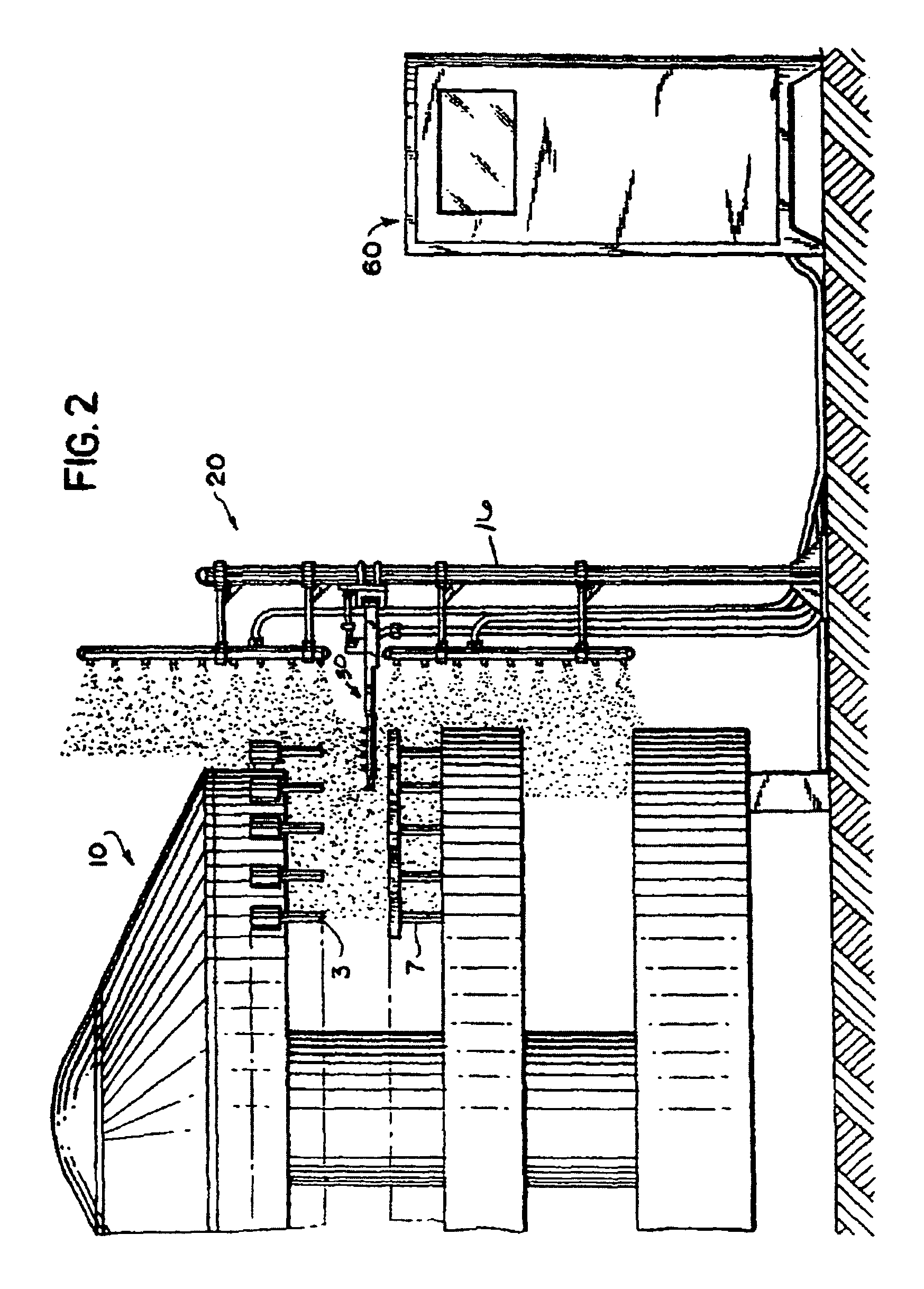

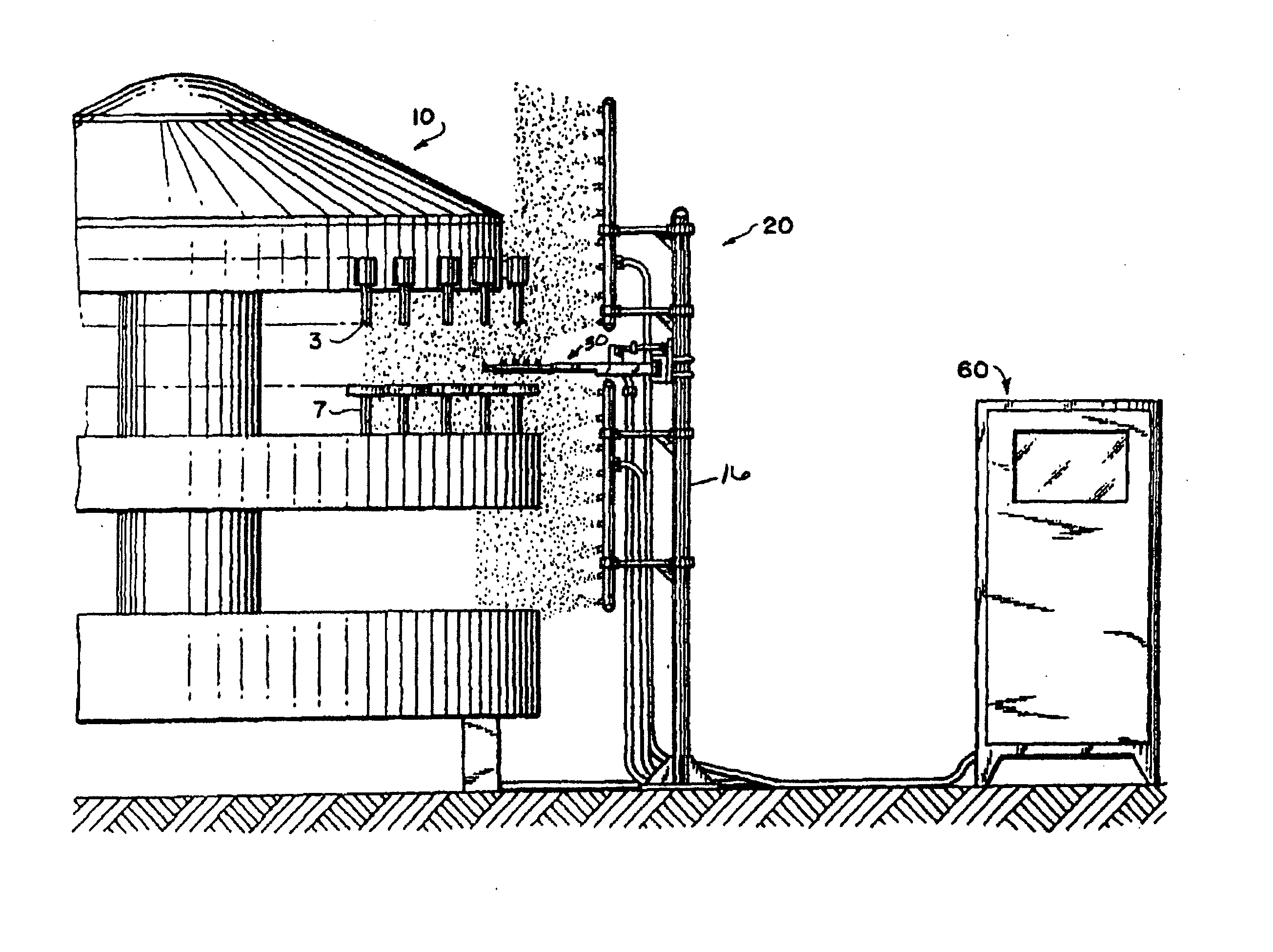

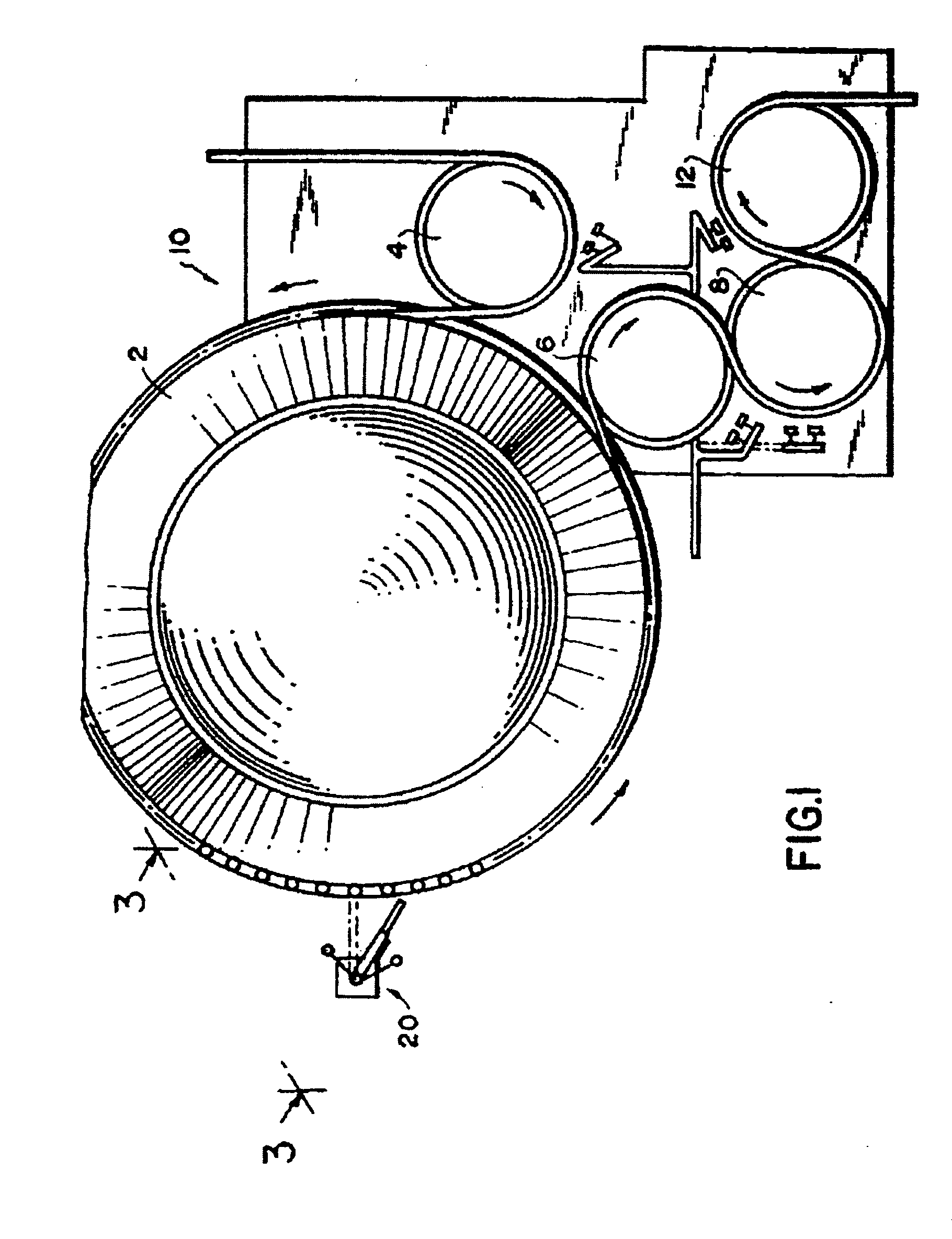

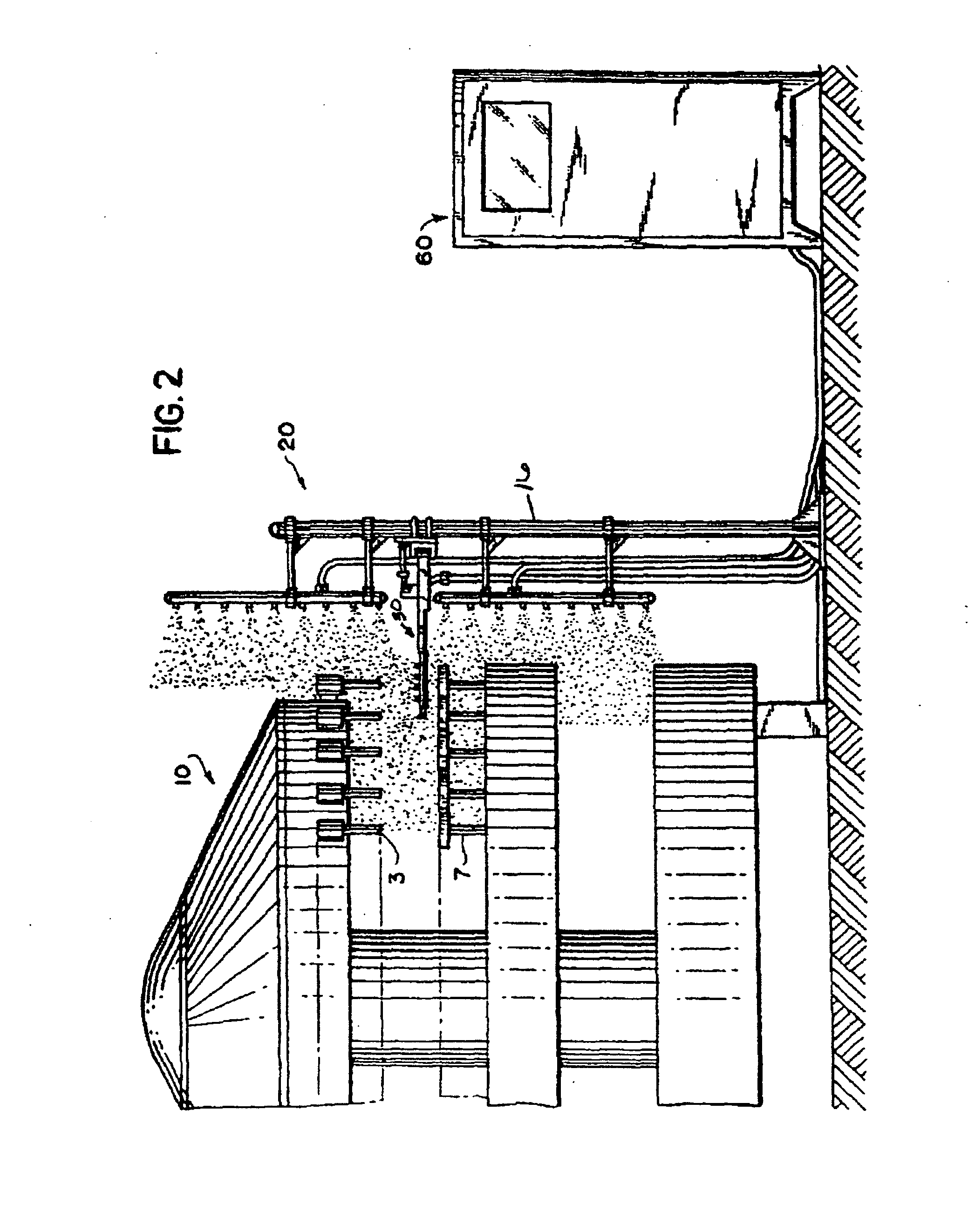

Automated precision small object counting and dispensing system and method

ActiveUS20090218363A1Prevent overflowAccurate countSmall article dispensingCoin-freed apparatus detailsMechanical engineeringDrug packaging

A small object dispenser adapted to receive a canister of objects such as pills, the canister being coupled atop it through a secure, bar-code matched gate operated by a central controller. A hopper below the gate directs smaller quantities of objects into a charge block adapted to measure out a select number of objects into an angularly disposed, circular counter where they accumulate atop a movable plate forming the bottom of the counter. The plate bears slots around its perimeter adjacent the cylindrical walls of the counter. As the central controller operates a servo motor to rotate the plate in measured increments, it urges a precise count of objects from the bottom of the counter to a port through which they fall one at a time into a receptacle such as a prescription bottle. Orientation means on the interior of the walls orient objects so that only a single object may fall into each slot, thereby preventing overfilling. A separate sensor counts the objects as they fall to verify quantity and guard against underfilling due to empty slots.

Owner:TENSION INT

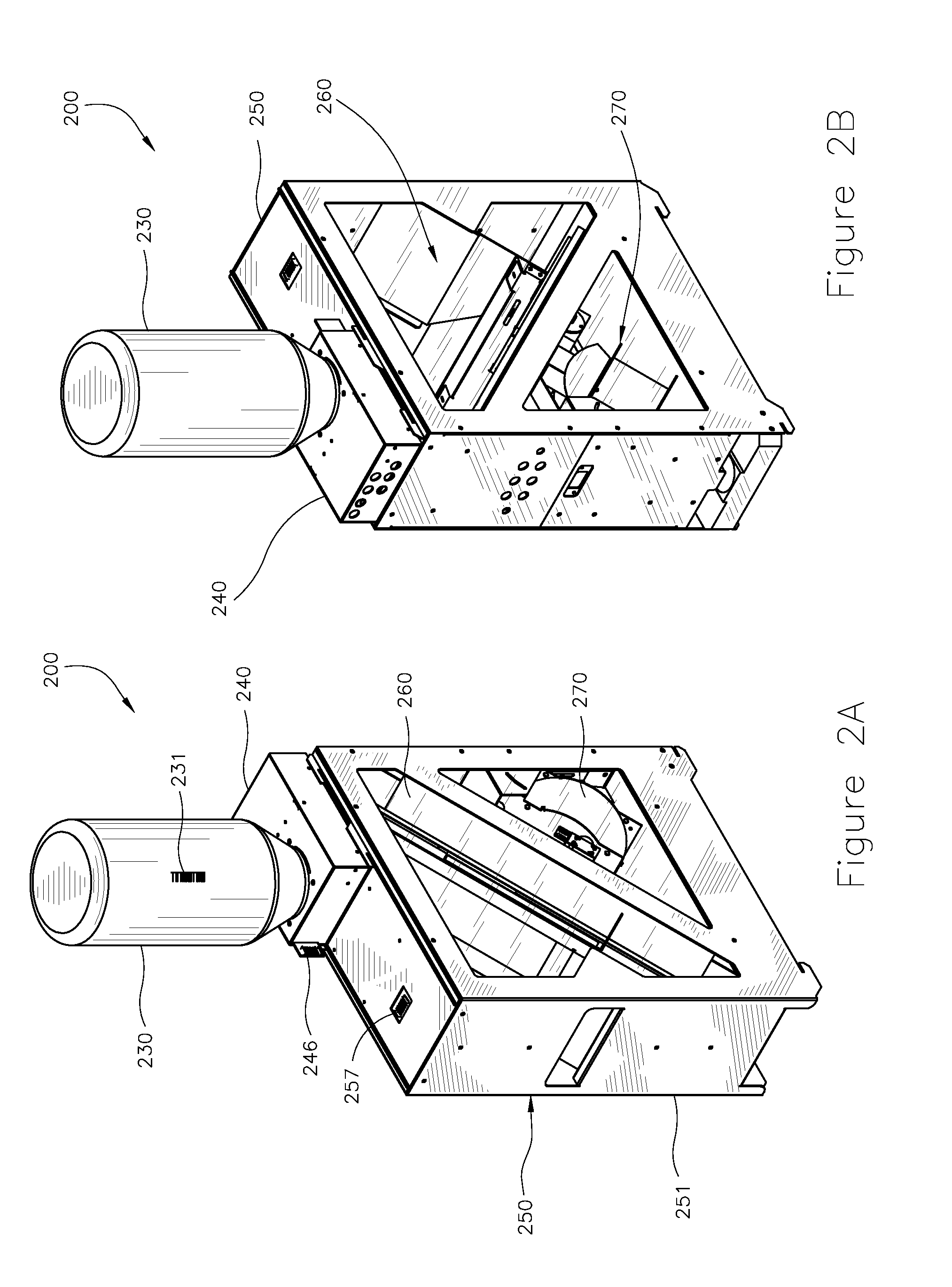

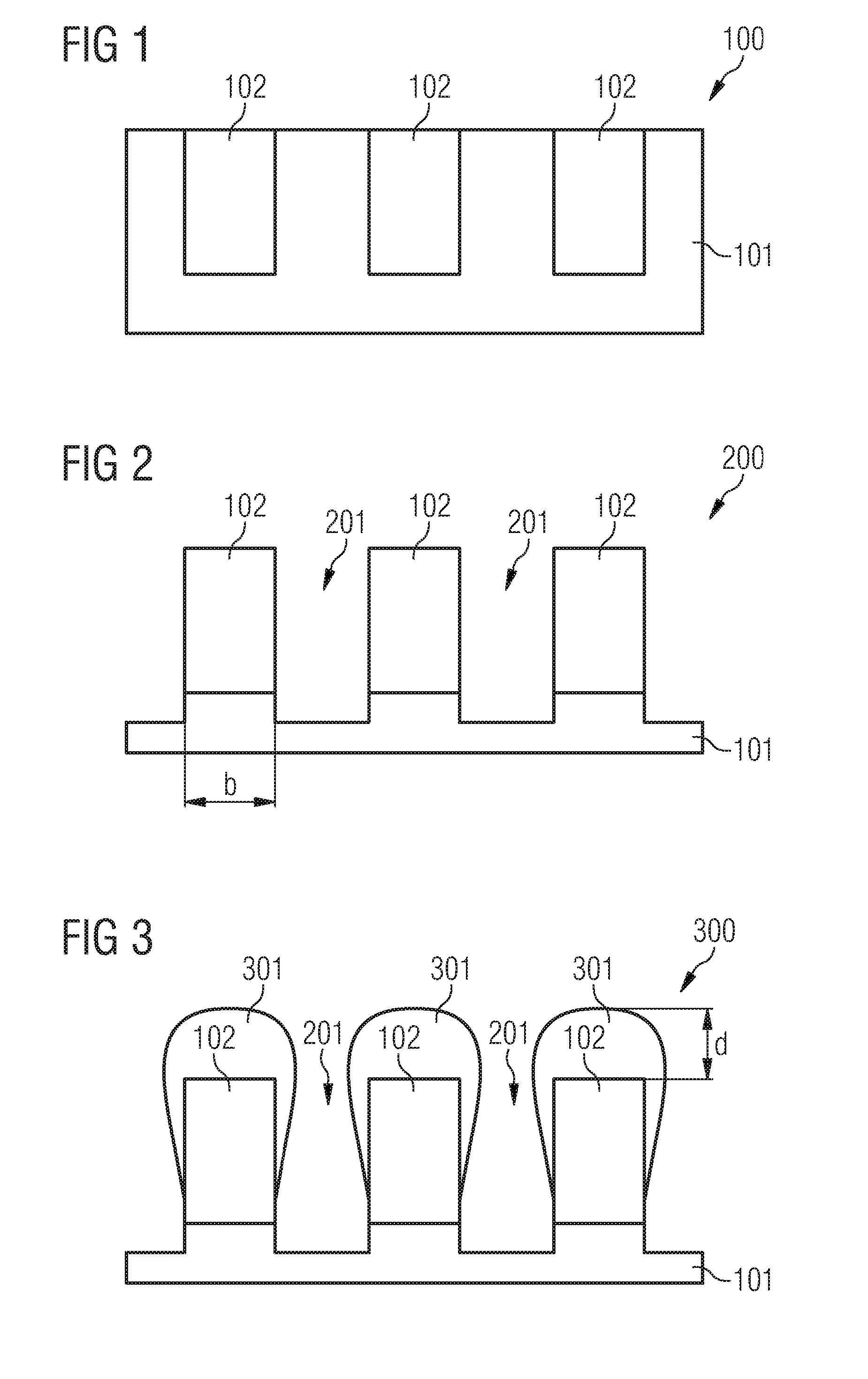

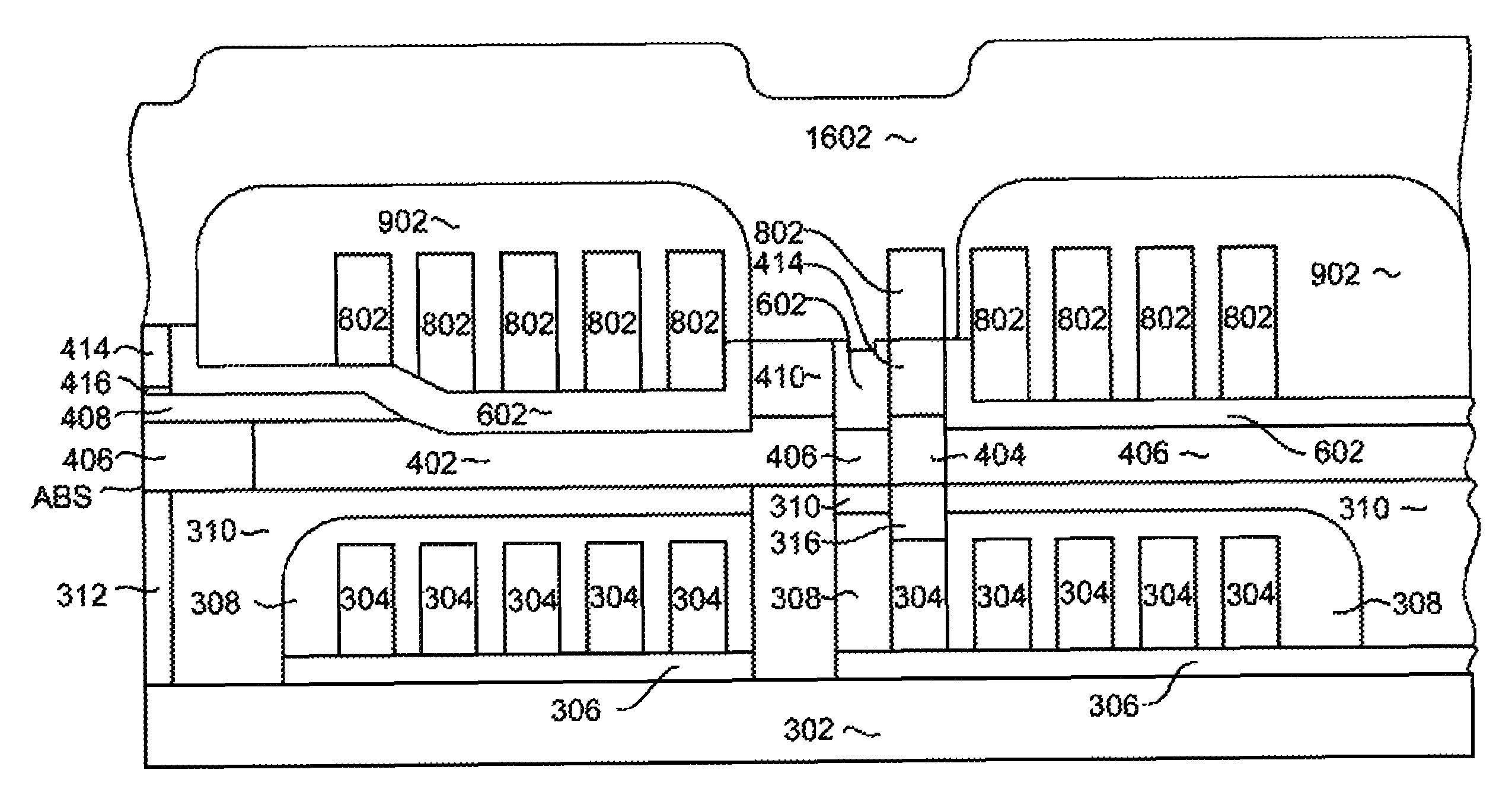

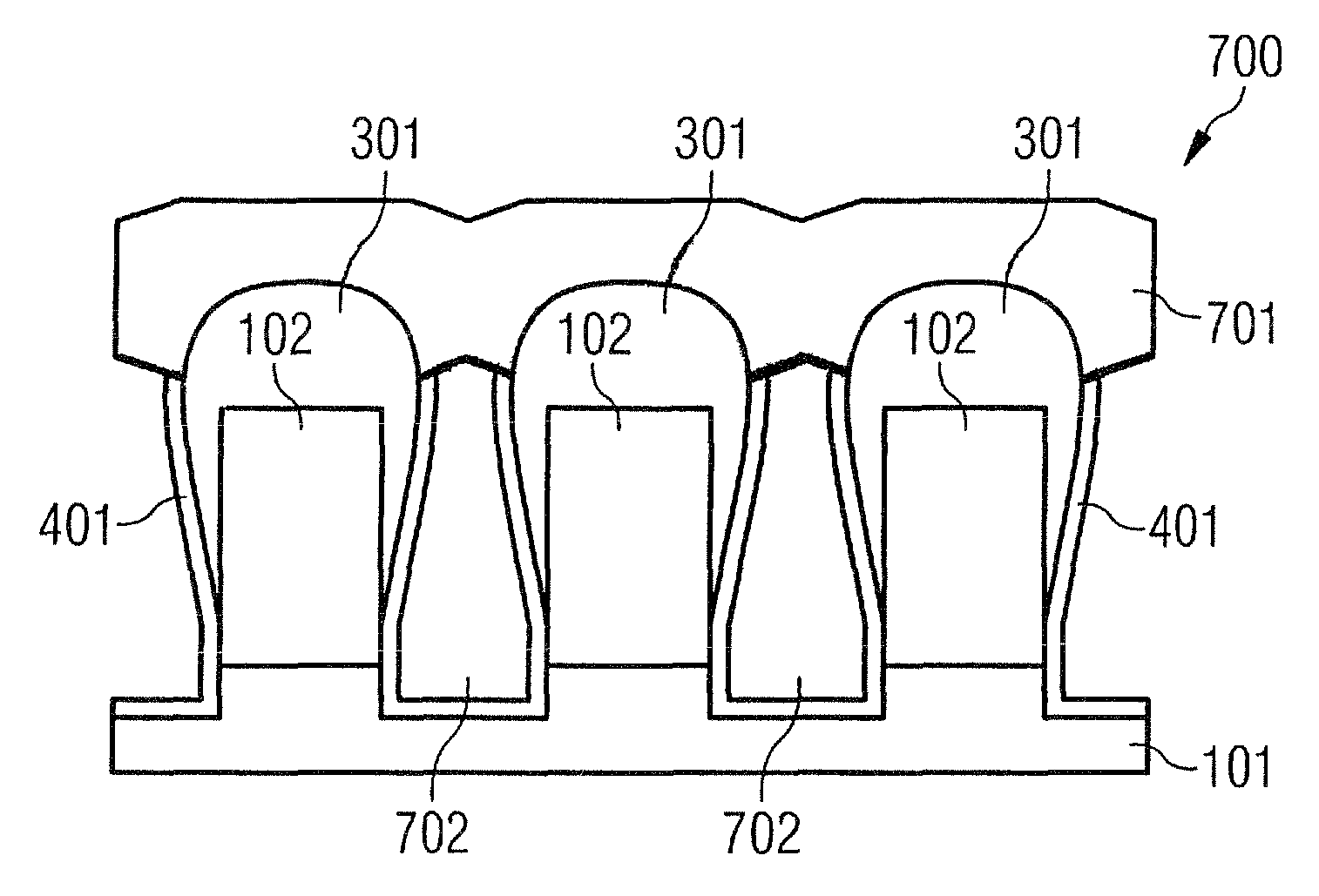

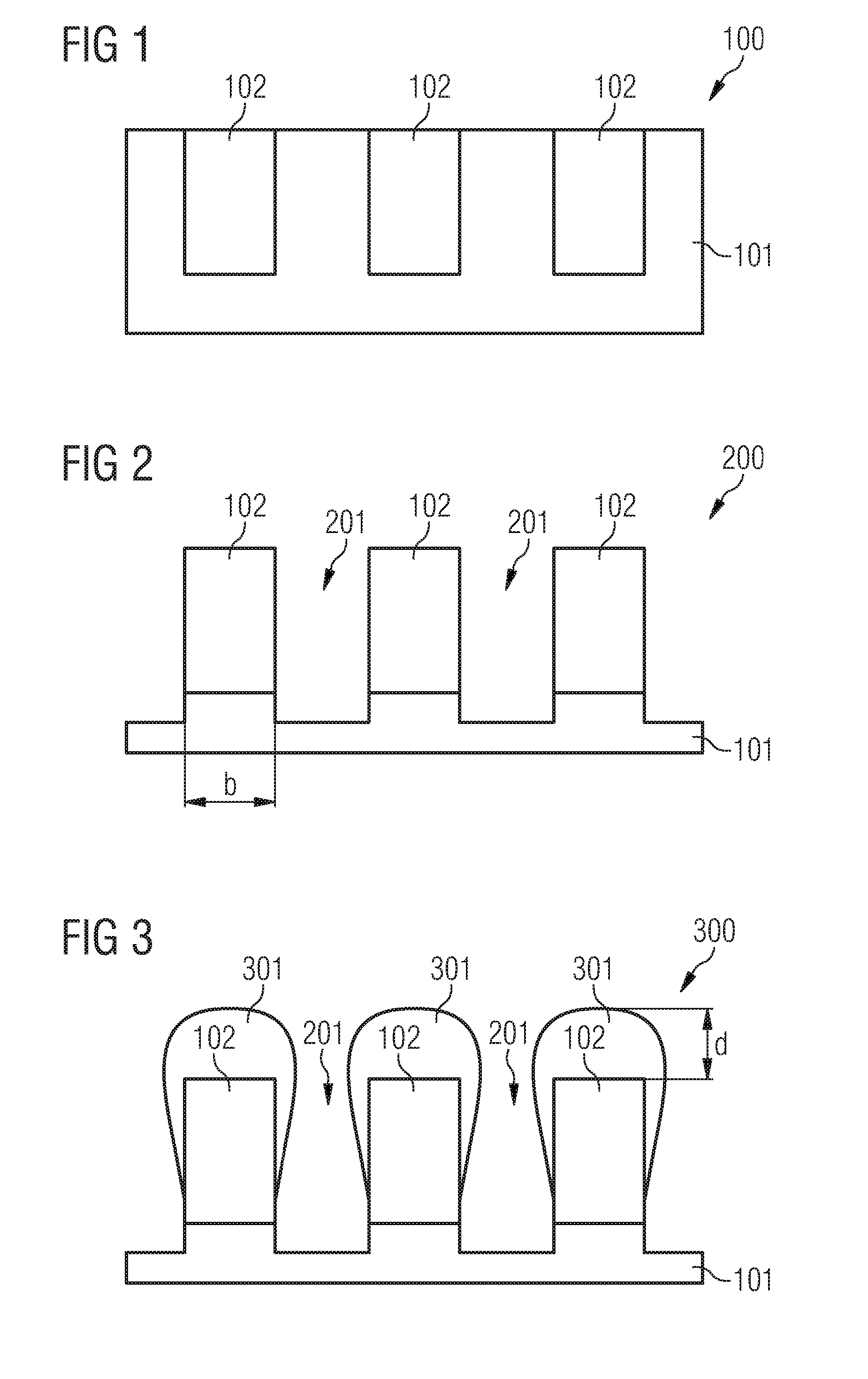

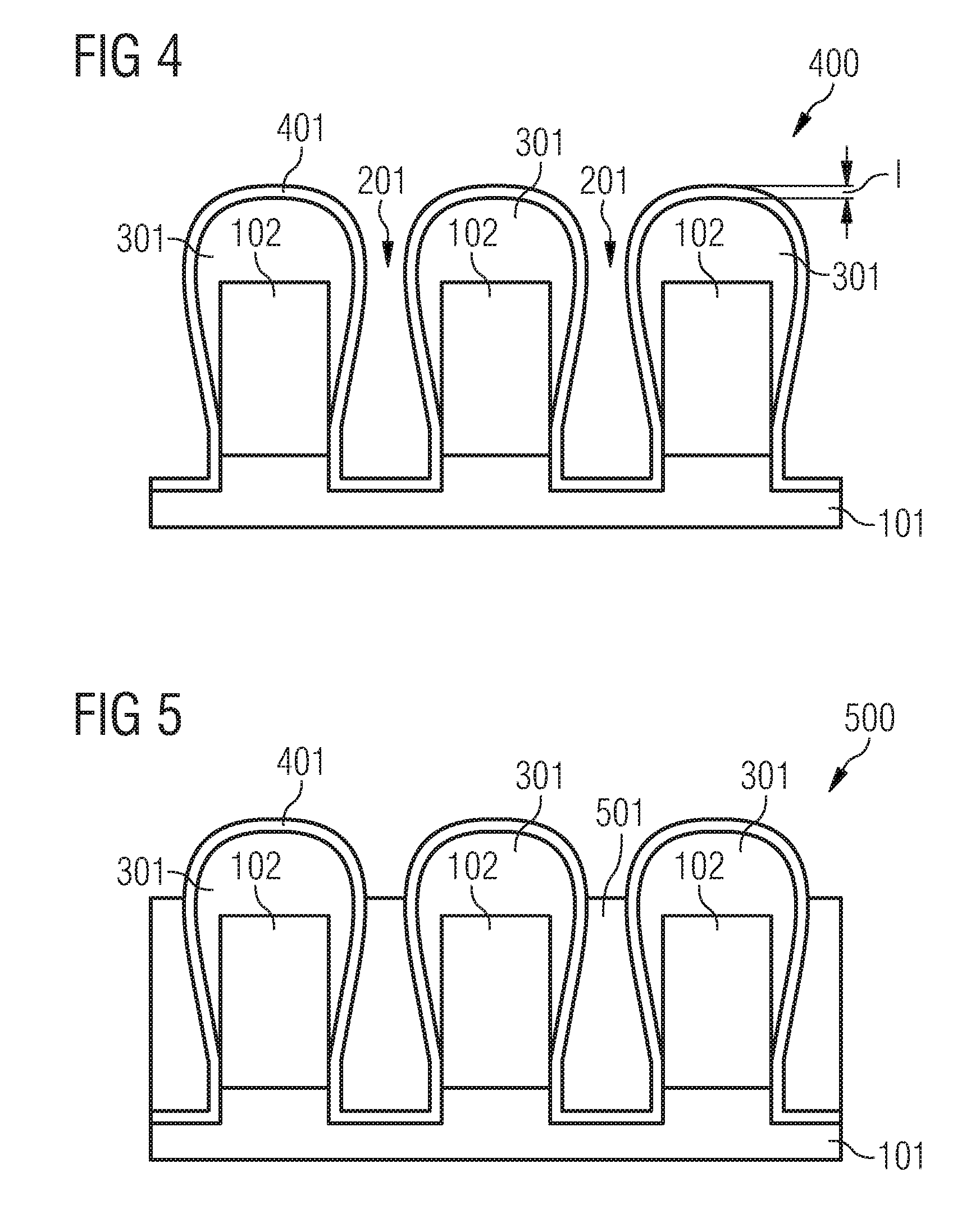

Method for manufacturing a layer arrangement and layer arrangement

InactiveUS20070246831A1Excellent dielectric propertiesAvoid paddingSemiconductor/solid-state device detailsSolid-state devicesElectrically conductive

In a method for manufacturing a layer arrangement, a plurality of electrically conductive structures are embedded in a substrate. Material of the substrate is removed at least between adjacent electrically conductive structures. An interlayer is formed on at least one portion of sidewalls of each of the electrically conductive structures. A first layer is formed on the interlayer where an upper partial region of the interlayer remaining free of a covering with the first layer. An electrically insulating second layer is formed selectively on that partial region of the interlayer which is free of the first layer, in such a way that the electrically insulating second layer bridges adjacent electrically conductive structures such that air gaps are formed between adjacent electrically conductive structures.

Owner:INFINEON TECH AG

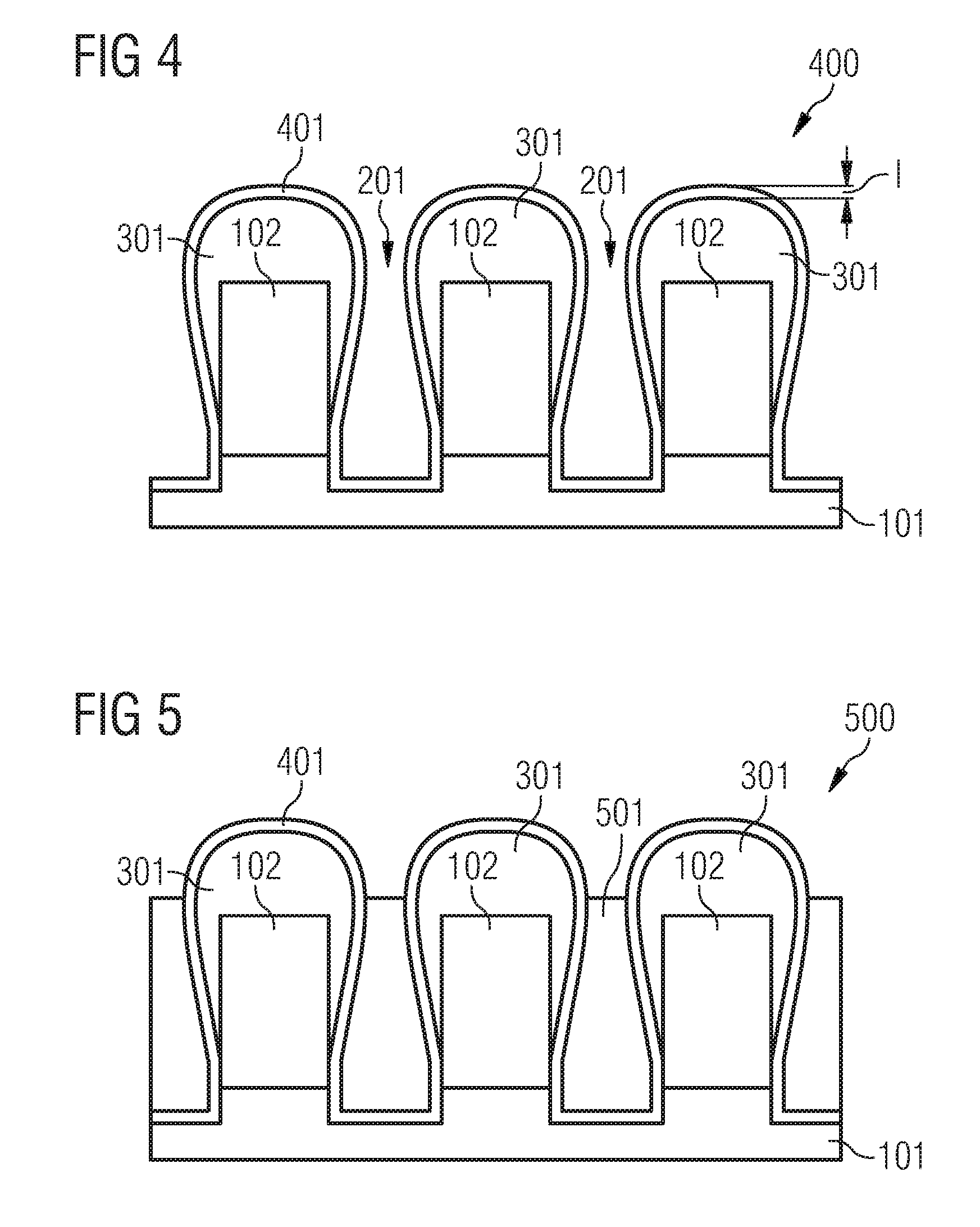

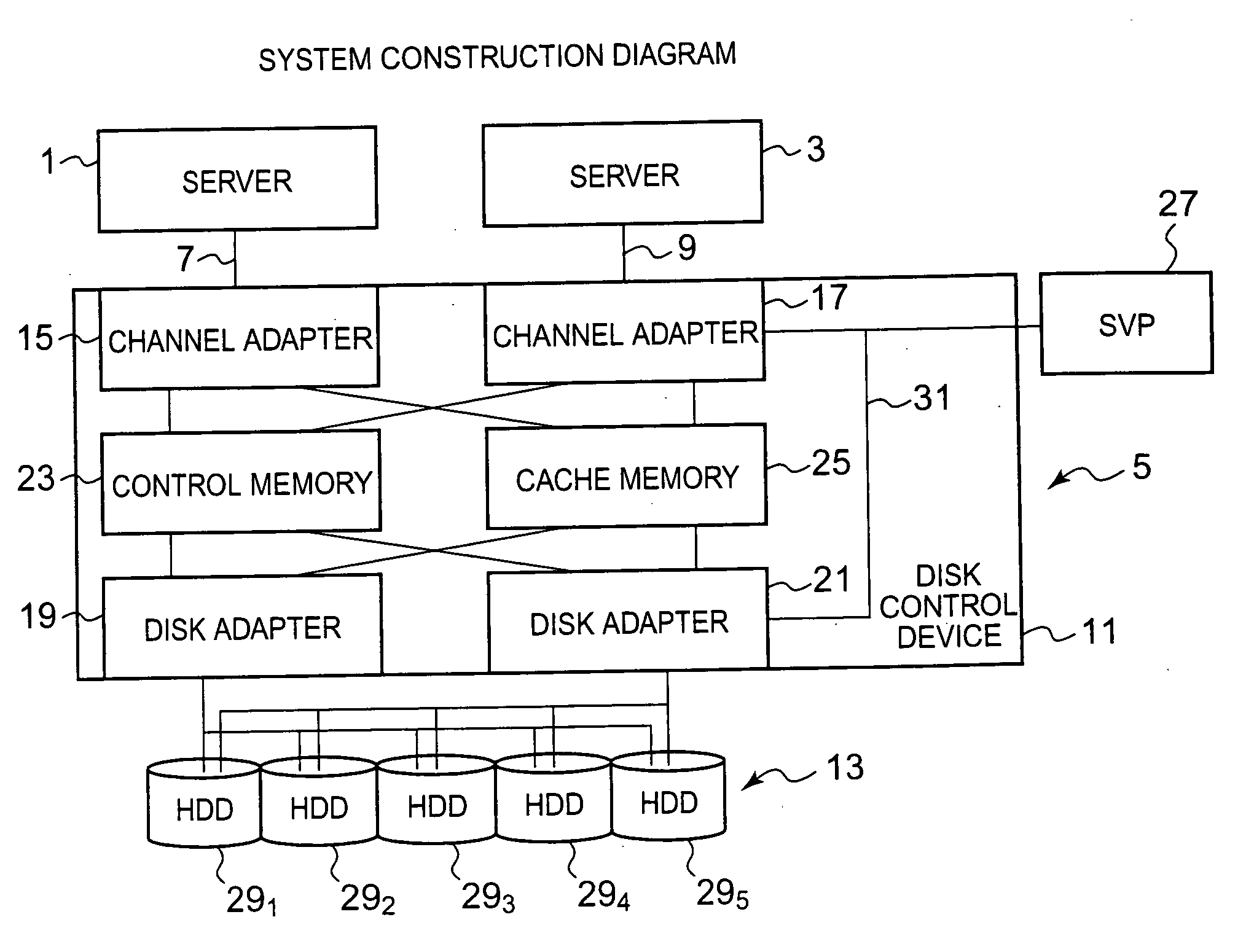

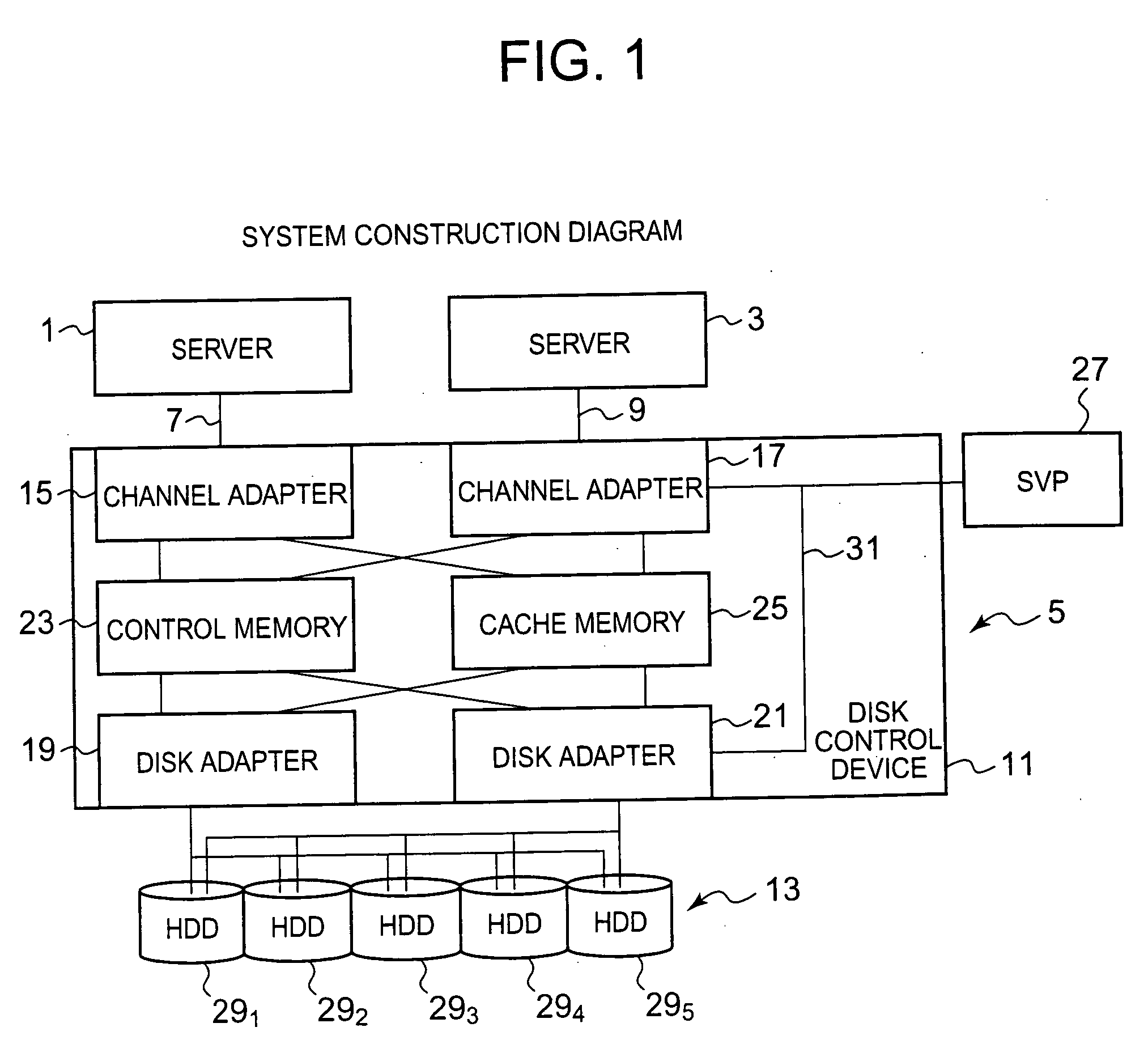

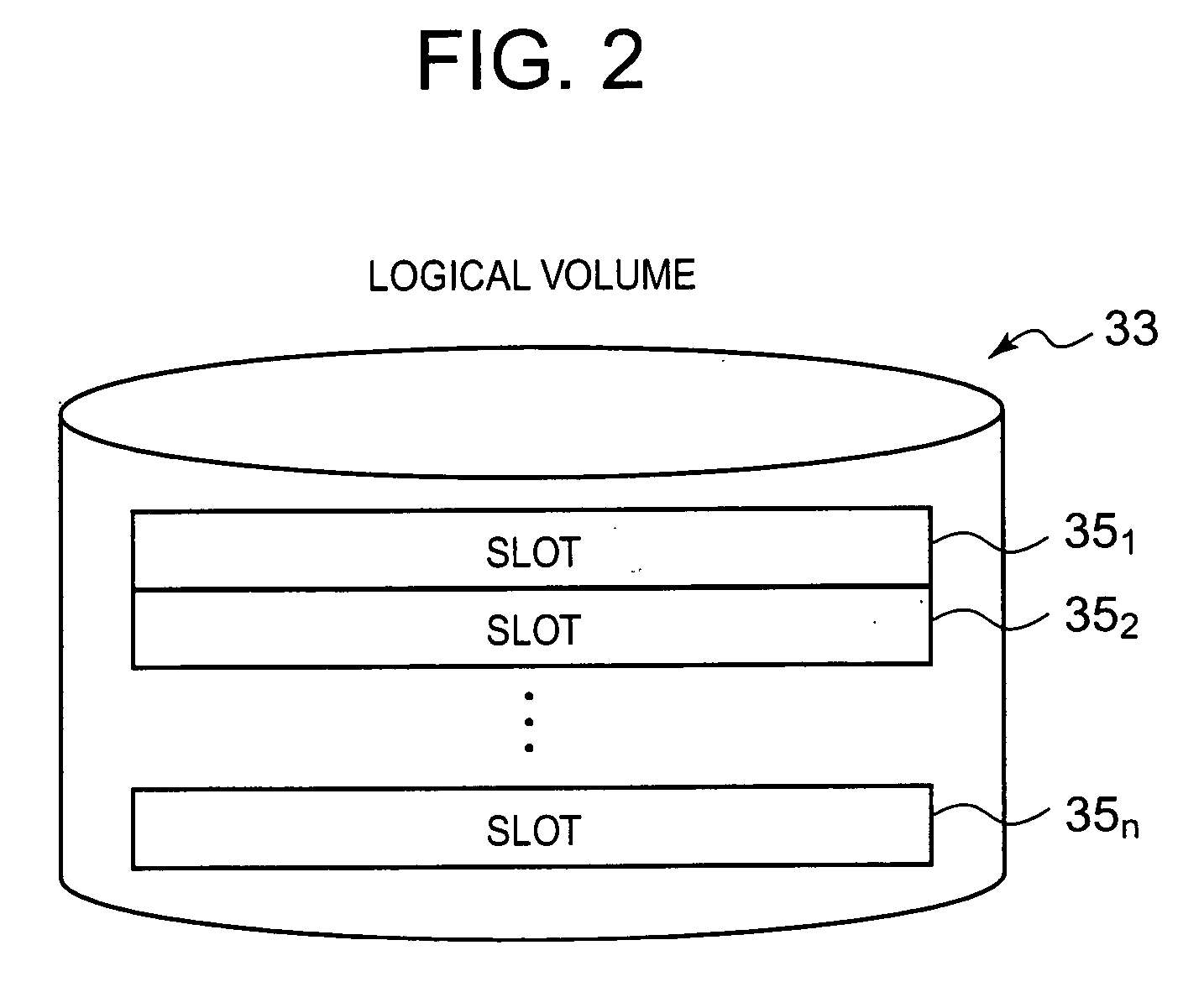

Storage system and snapshot data preparation method in storage system

InactiveUS20060136771A1Avoid paddingNon-redundant fault processingInput/output processes for data processingData preparationArtificial intelligence

The present invention is devised so that snapshot data preparation processing does not end abnormally as a result of the pool region becoming full with saved data from the primary logical volume during snapshot data preparation. When the CHA receives a snapshot data preparation request, the CHA checks whether or not update information is present in the logical volume that is the object of this data preparation. If such information is present (YES in S51), a check is made from the number of slots in the in the volume control information and the updating amount count value in the update information in order to ascertain whether or not the proportion of the updating amount relative to the number of slots is equal to or greater than the threshold value in the threshold value control information (S52). If this proportion is equal to or greater than the threshold value (YES in S52), the update information is initialized (S53), and physical snapshot control is started (S54). If such is not the case (NO in S52), the update information is initialized (S55), and logical snapshot control is started (S56).

Owner:HITACHI LTD

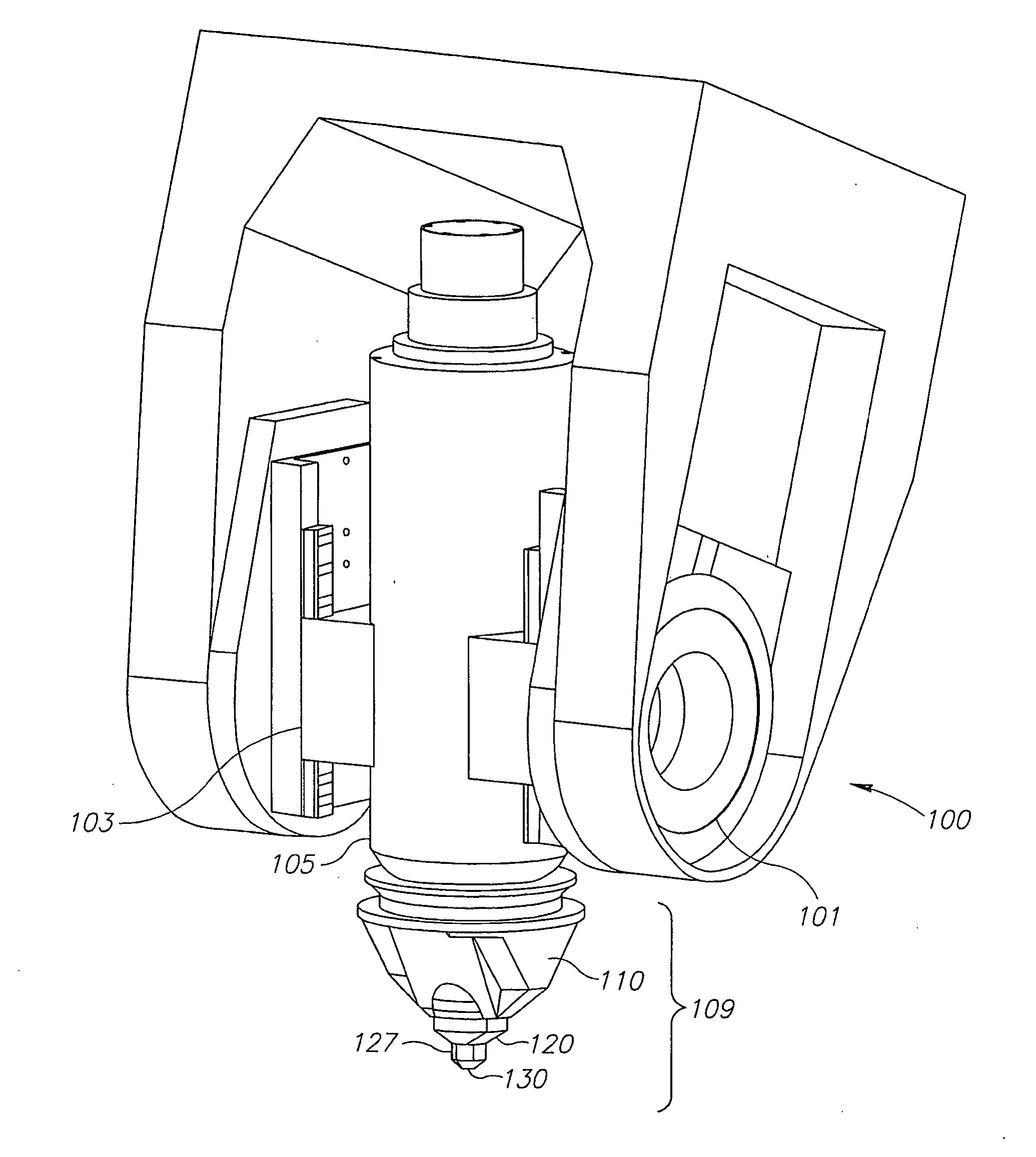

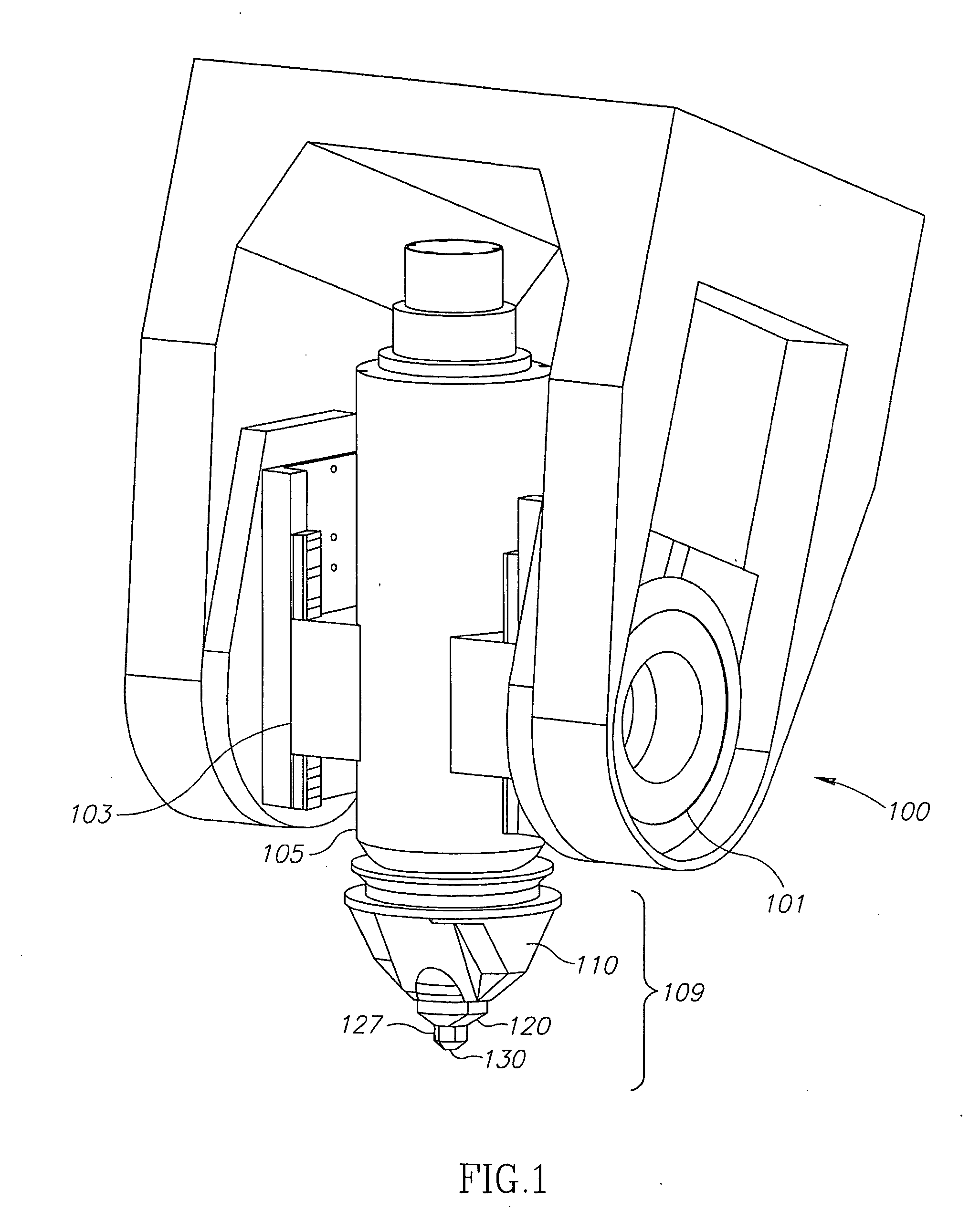

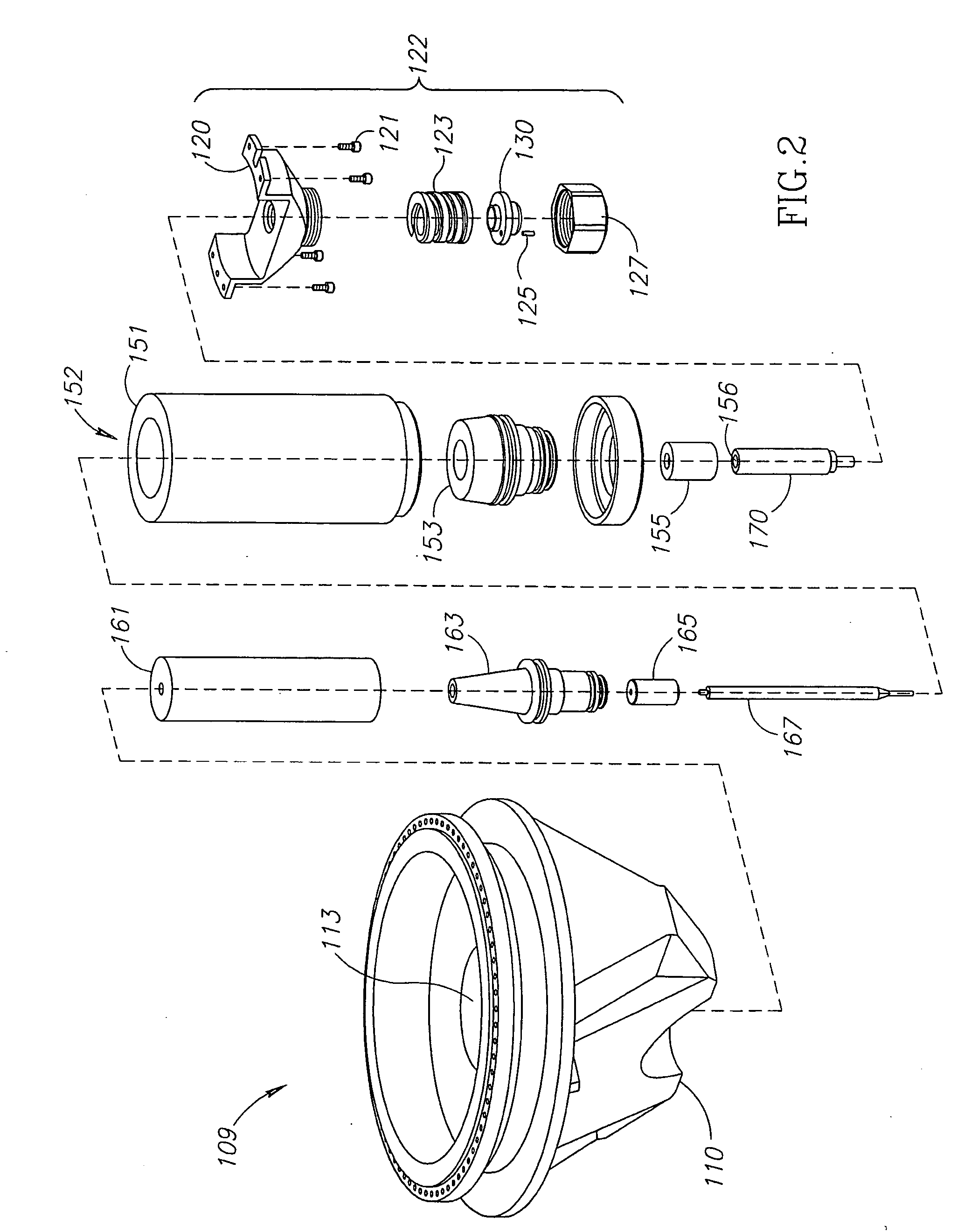

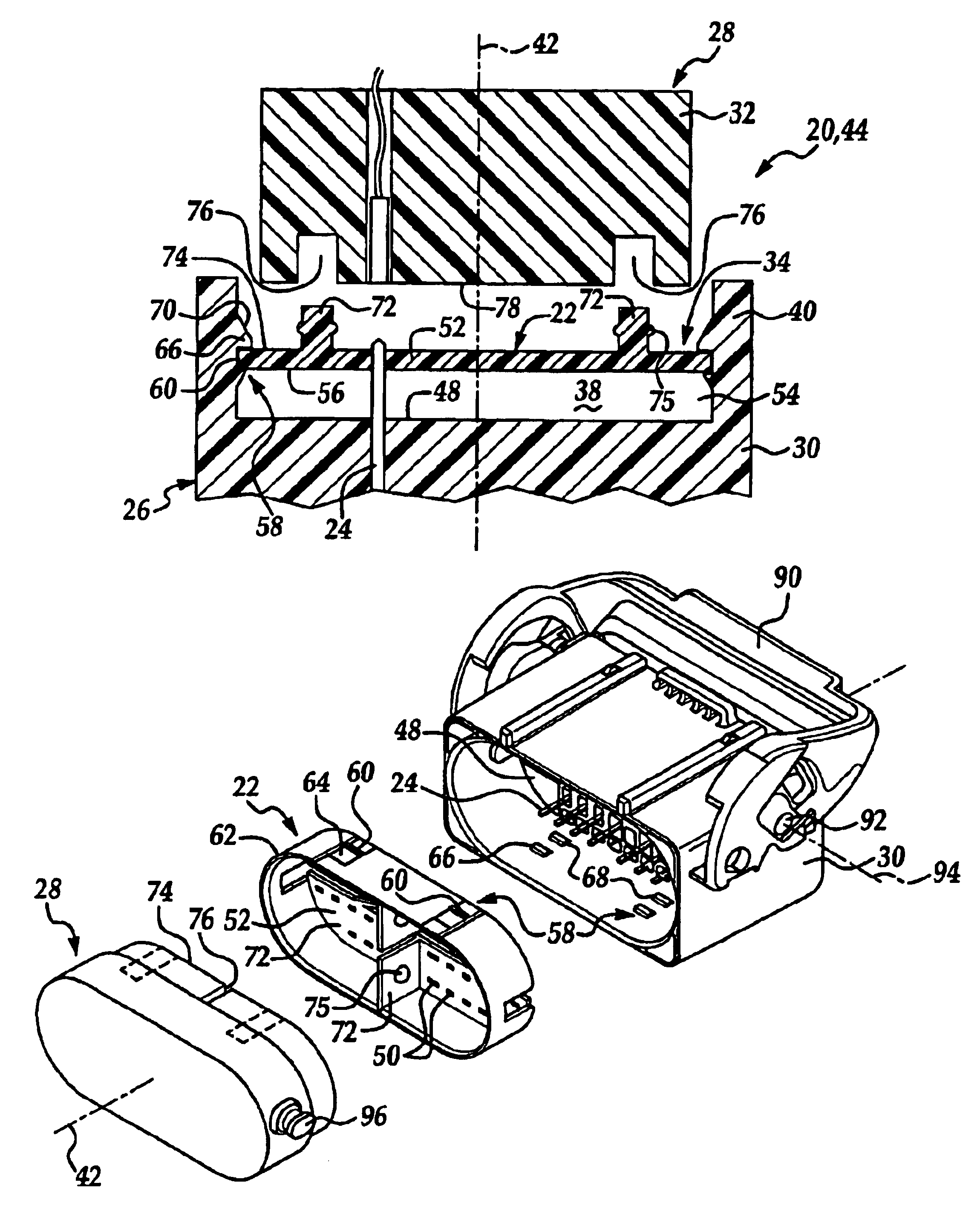

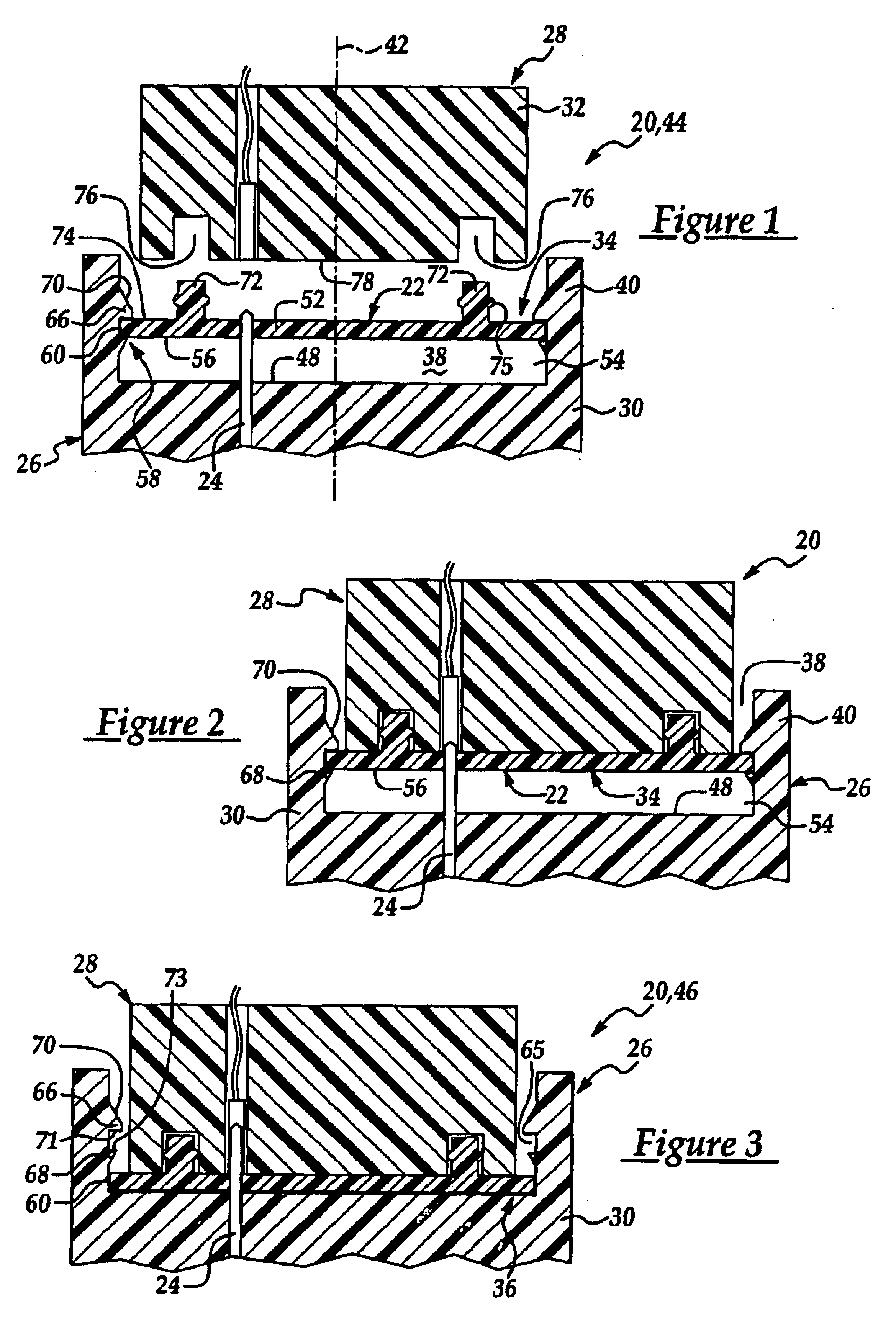

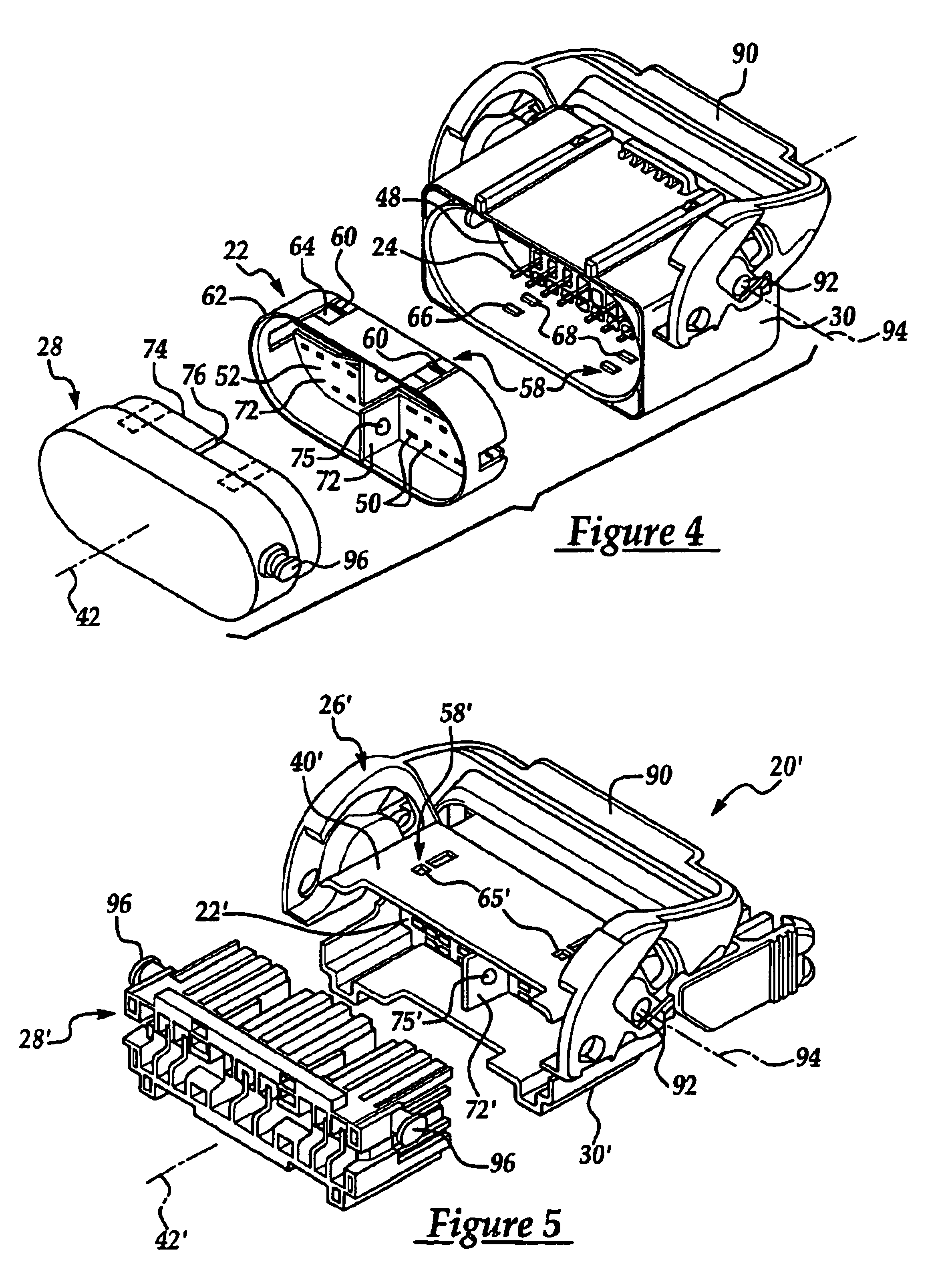

Pressure foot clamping apparatus and methods

ActiveUS20060124691A1Avoid paddingWelding/cutting auxillary devicesAuxillary welding devicesSpot weldingPRESSURE FEET

The present invention is directed to apparatus and methods for clamping and controlling flash around a manufacturing tool engaging a workpiece and preventing fill within he workpiece. In one embodiment, a clamp for securing a workpiece during a manufacturing operation includes a housing and a foot biased away from the housing, the foot defining an opening through which a manufacturing tool may pass to engage the workpiece. In another embodiment, the manufacturing tool is a rotating or counter-rotating shoulder friction stir spot welding tool. In accordance with other aspects of the invention, the foot defines at least one recess for holding flashing.

Owner:THE BOEING CO

Electrical connector assembly

InactiveUS6846191B2Robust and low costRepeatably reusableEngagement/disengagement of coupling partsIncorrect coupling preventionEngineeringElectrical connector

An electrical connector assembly has a male connector which mates to a female connector thereby electrically engaging male terminal blades, locked to a male connector body, to female terminals locked to a female connector body. The blade of each male terminal project into a blind bore defined by a shroud of the male connector body. Prior to mating of the electrical connector assembly, a retractable terminal blade stabilizer is snap fitted into a blade alignment position with the male connector via a dual fastening feature constructed and arranged between the male connector body and the stabilizer, which prevents withdrawal of the stabilizer from the male connector and restricts further insertion of the stabilizer into the blind bore. When the stabilizer is in the blade alignment position, the tips of the blades are disposed within respective apertures of the stabilizer and aligned to their respective female terminals and the remaining portion of the blades are shielded and thus protected from possible damage. During mating of the electrical connector assembly, the female connector body is press fitted to an axial projecting member of the stabilizer, prior to the stabilizer moving out of the alignment position.

Owner:DELPHI TECH INC

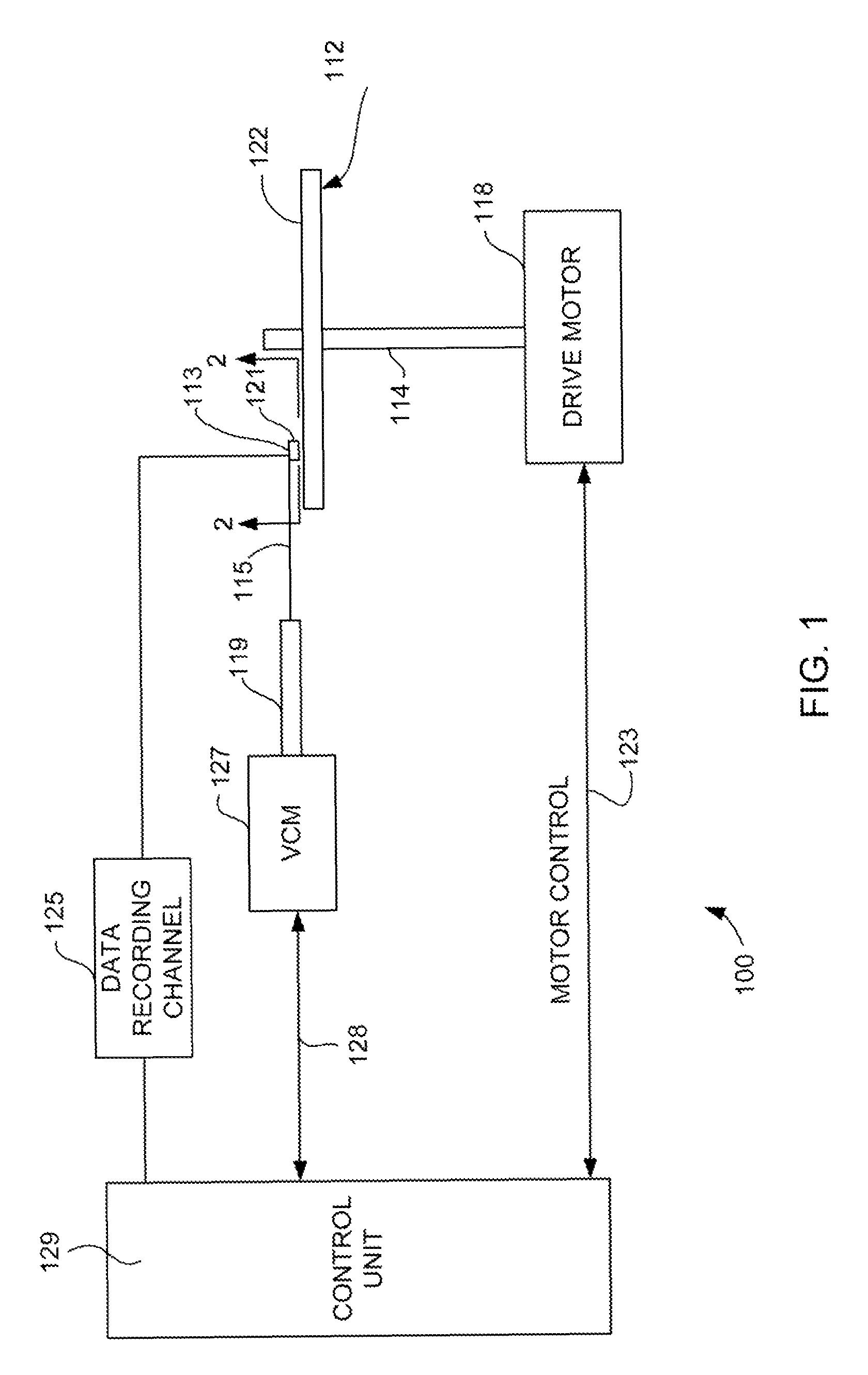

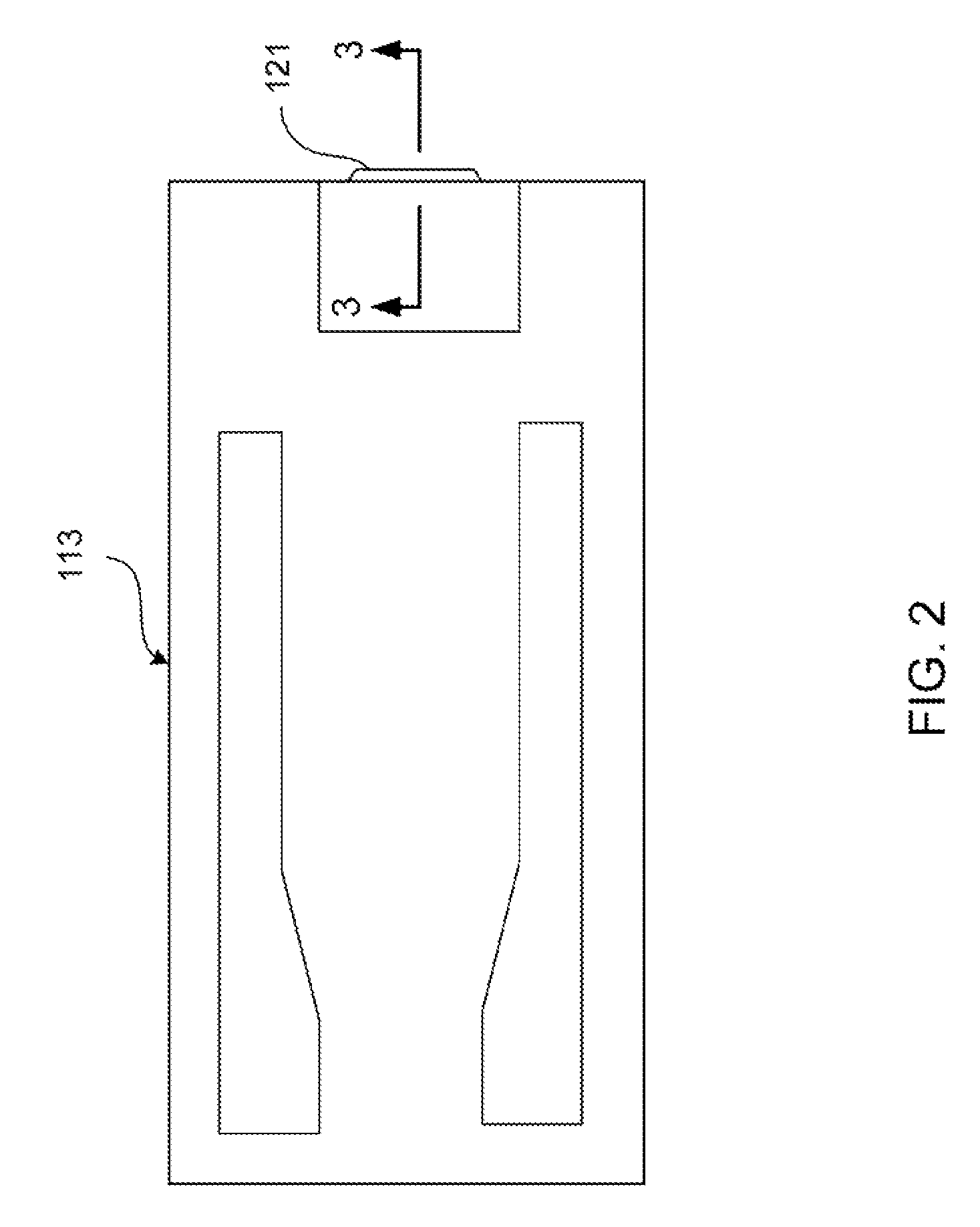

Method of manufacturing a magnetic write head for perpendicular magnetic recording

InactiveUS7963024B2Avoid the needReduce manufacturing stepsManufacture head surfaceElectrical transducersEngineeringNon magnetic

Owner:WESTERN DIGITAL TECH INC

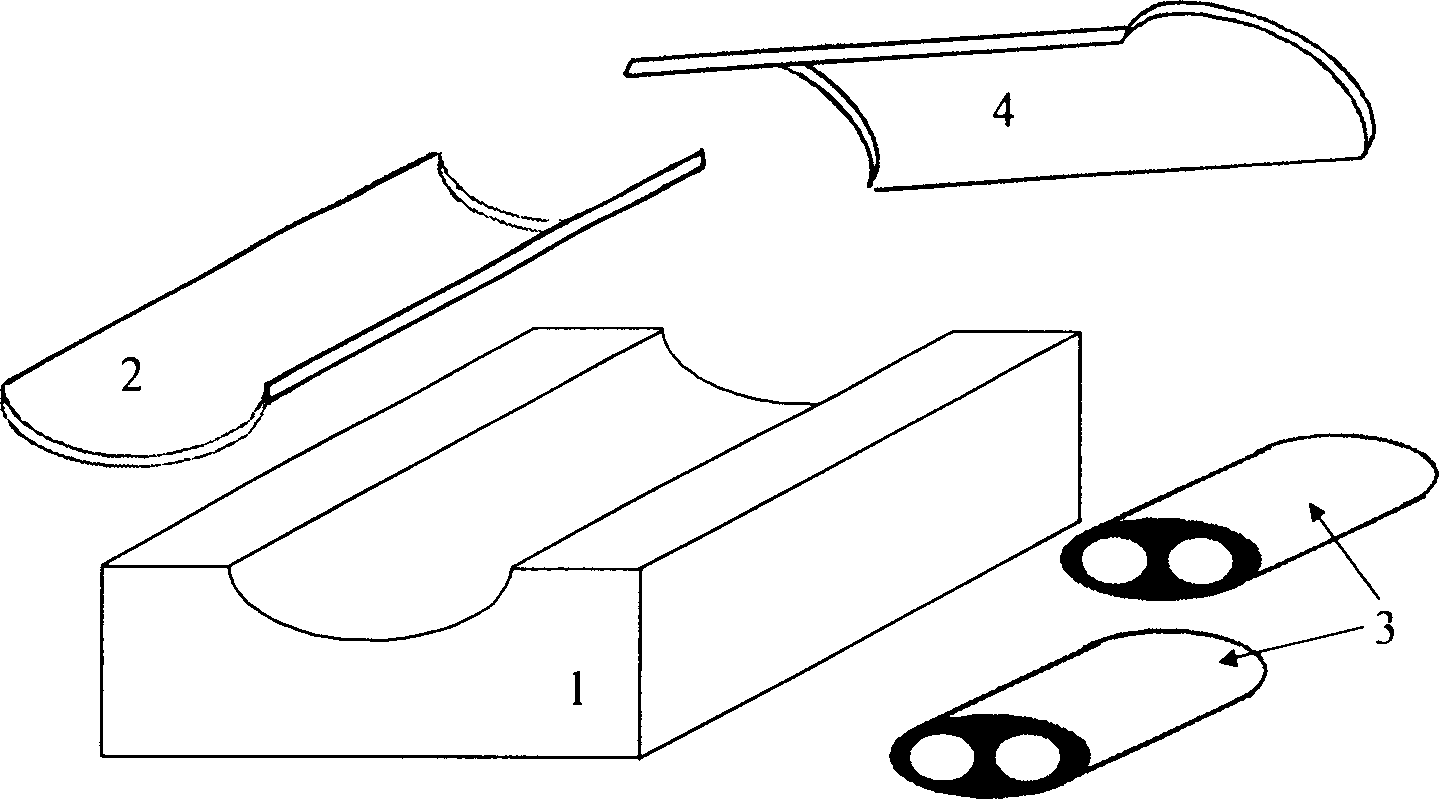

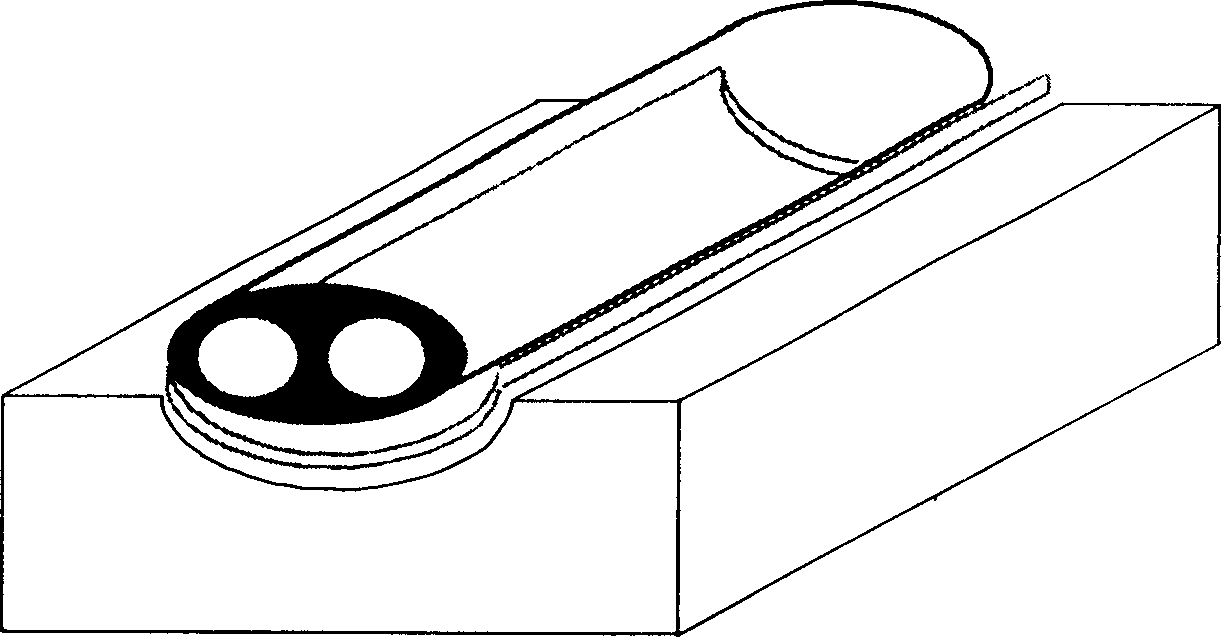

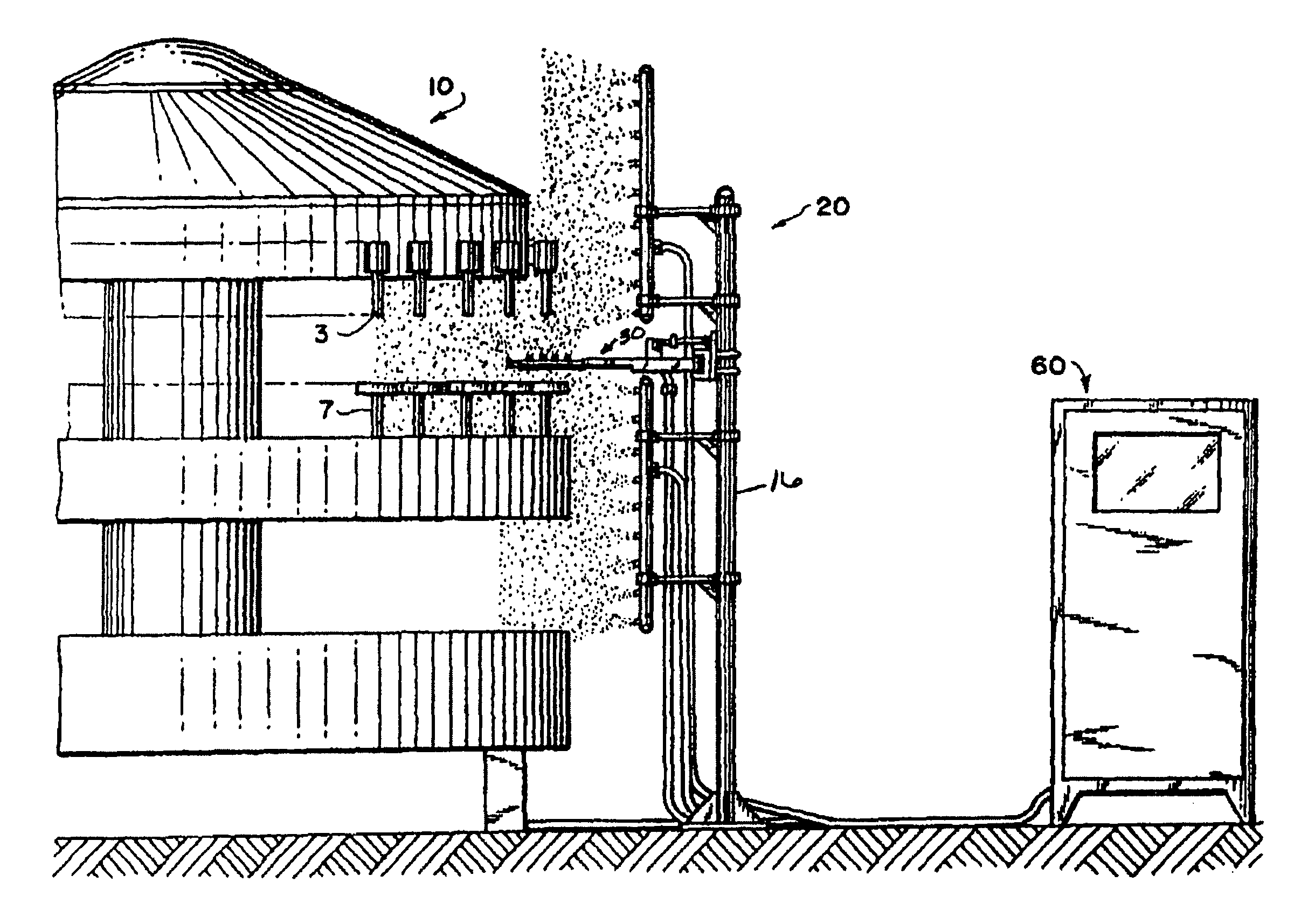

Large pneumatic equipment blades made of composite material and production thereof

A big-scale composite wind turbine blade characterized by once molding with entwined fiber as the strengthened materials and its fabricating method. The blade is composed by enhanced fiber, resin base, keel and couplings. The glue dipped fiber is put in a stair way in the lower blade mold, whereon the keels conjunct to each other and the keel on the rear part of the blade conjunct to the coupling. The cross section of the keels is similar to that of the blade. Correspondingly another layer of the glue dipped fiber is put in a stair way in the upper blade mold. The two parts of the blade mold are closed, sealed, vacuumed, injected into resin, heated to solidify and removed in steps to get the wind turbine blade.

Owner:TONGJI UNIV

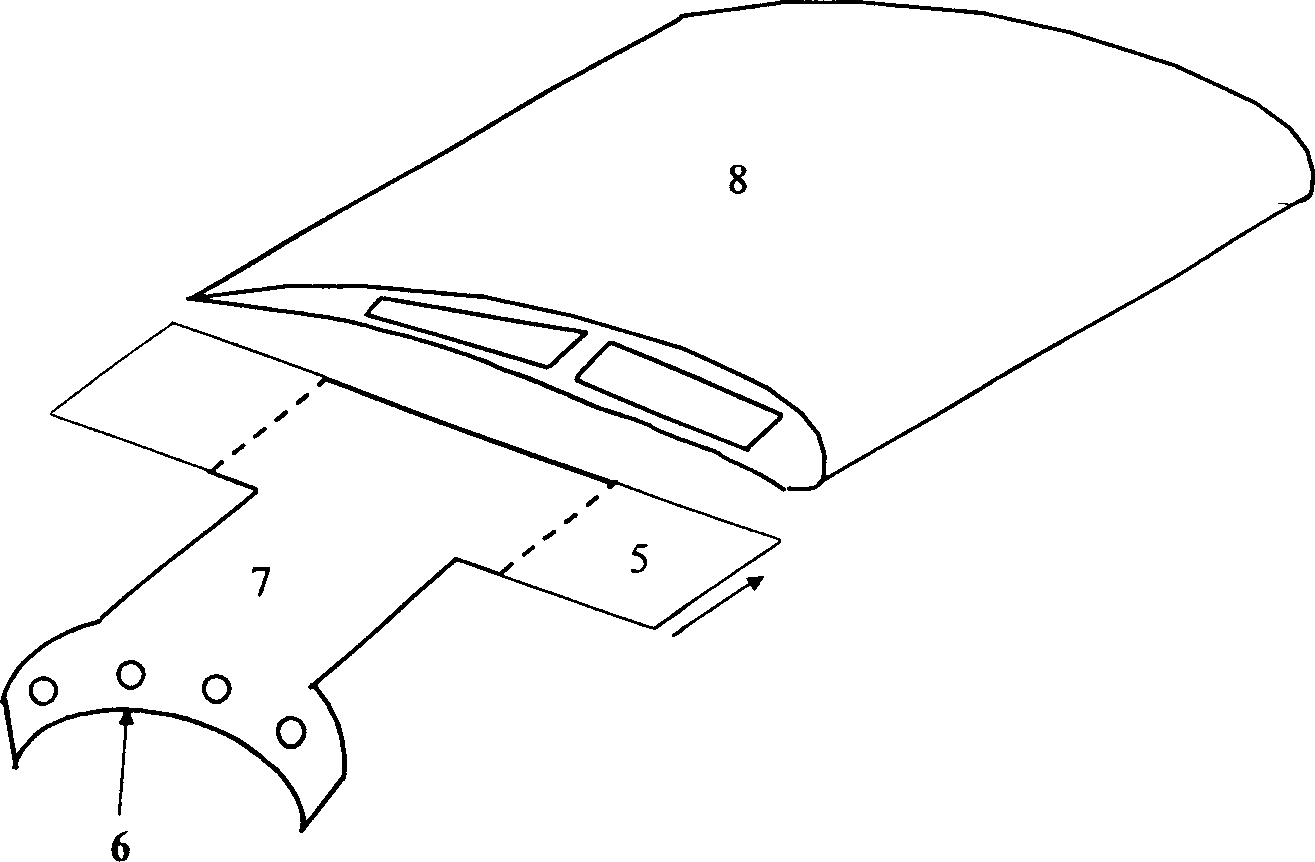

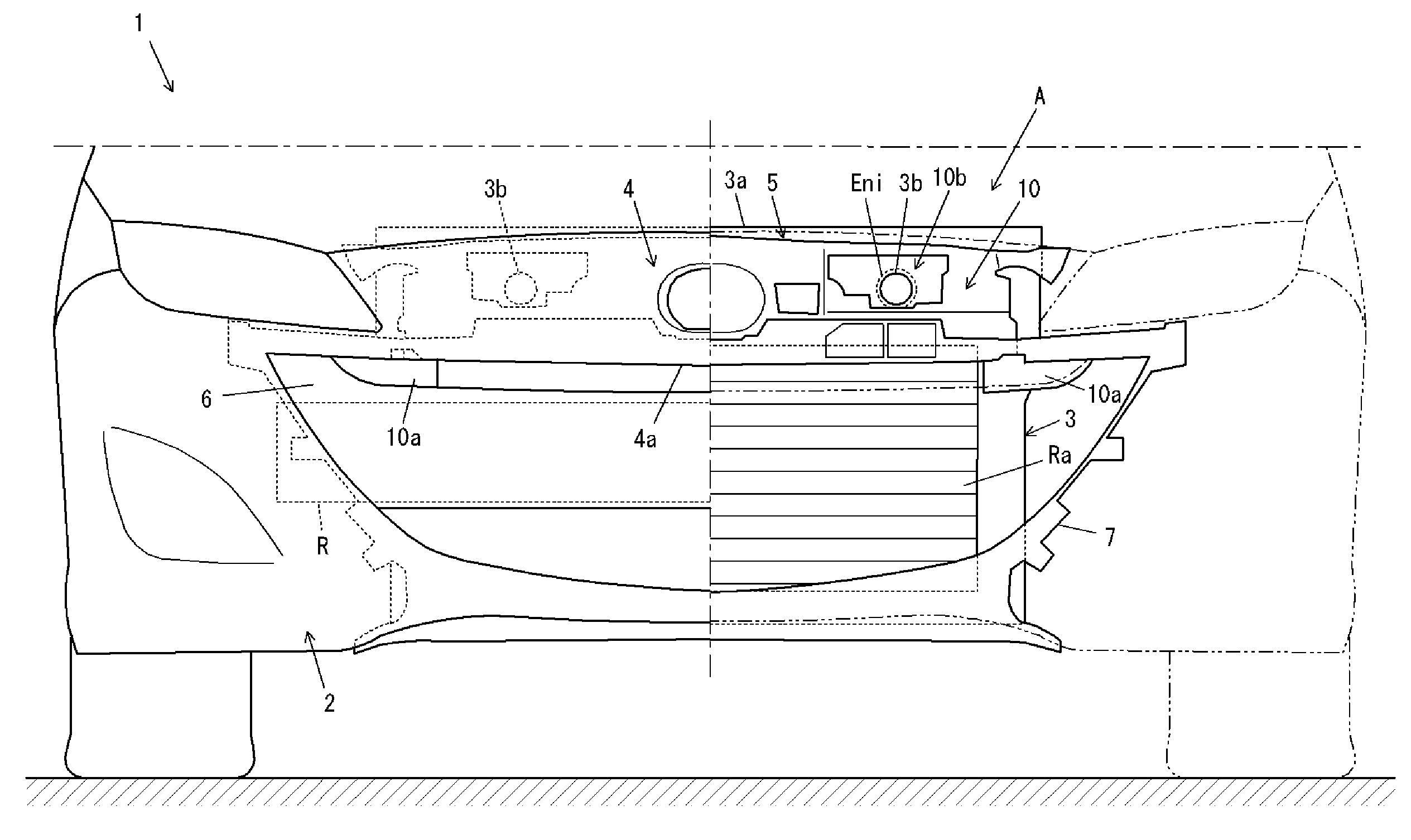

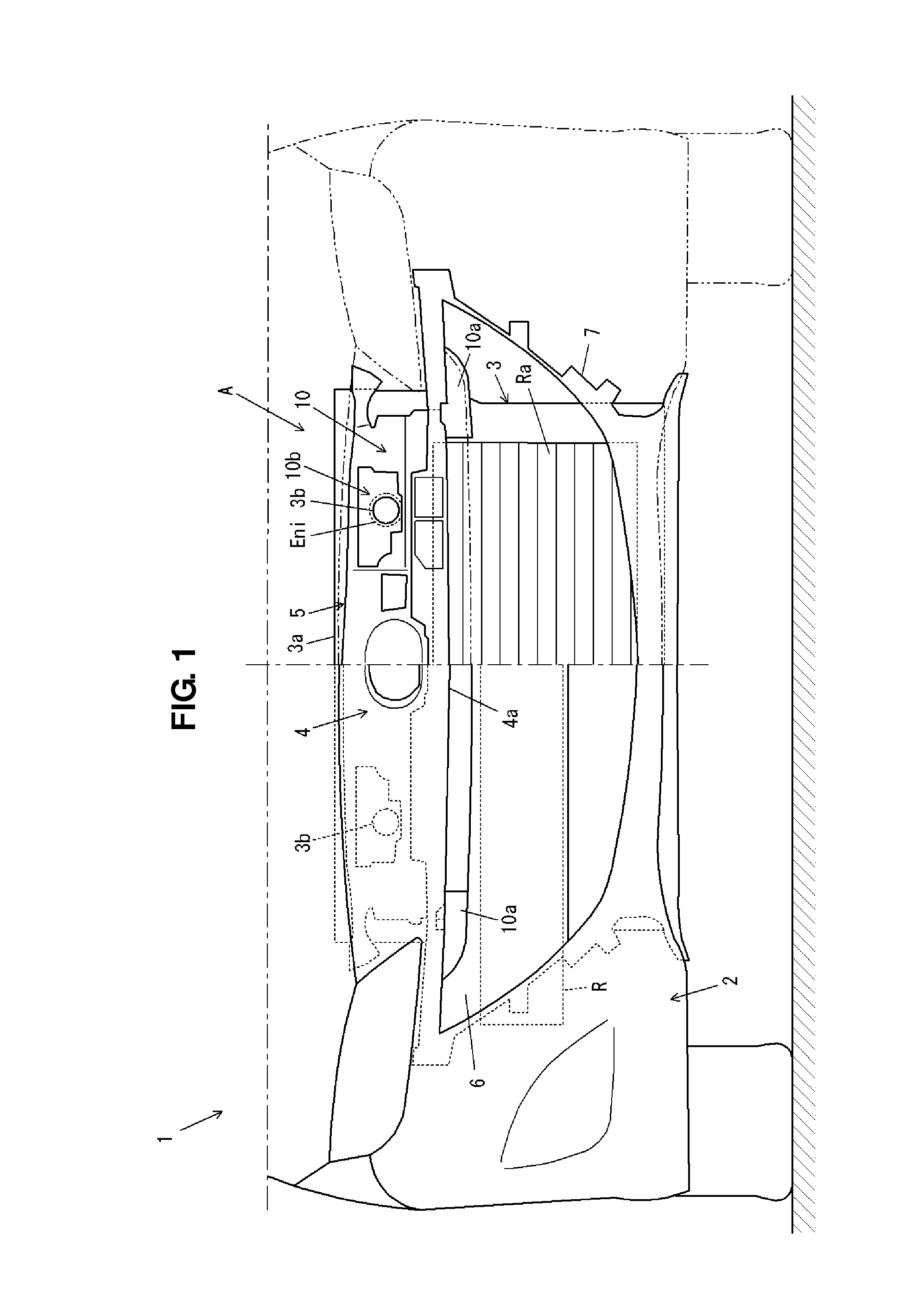

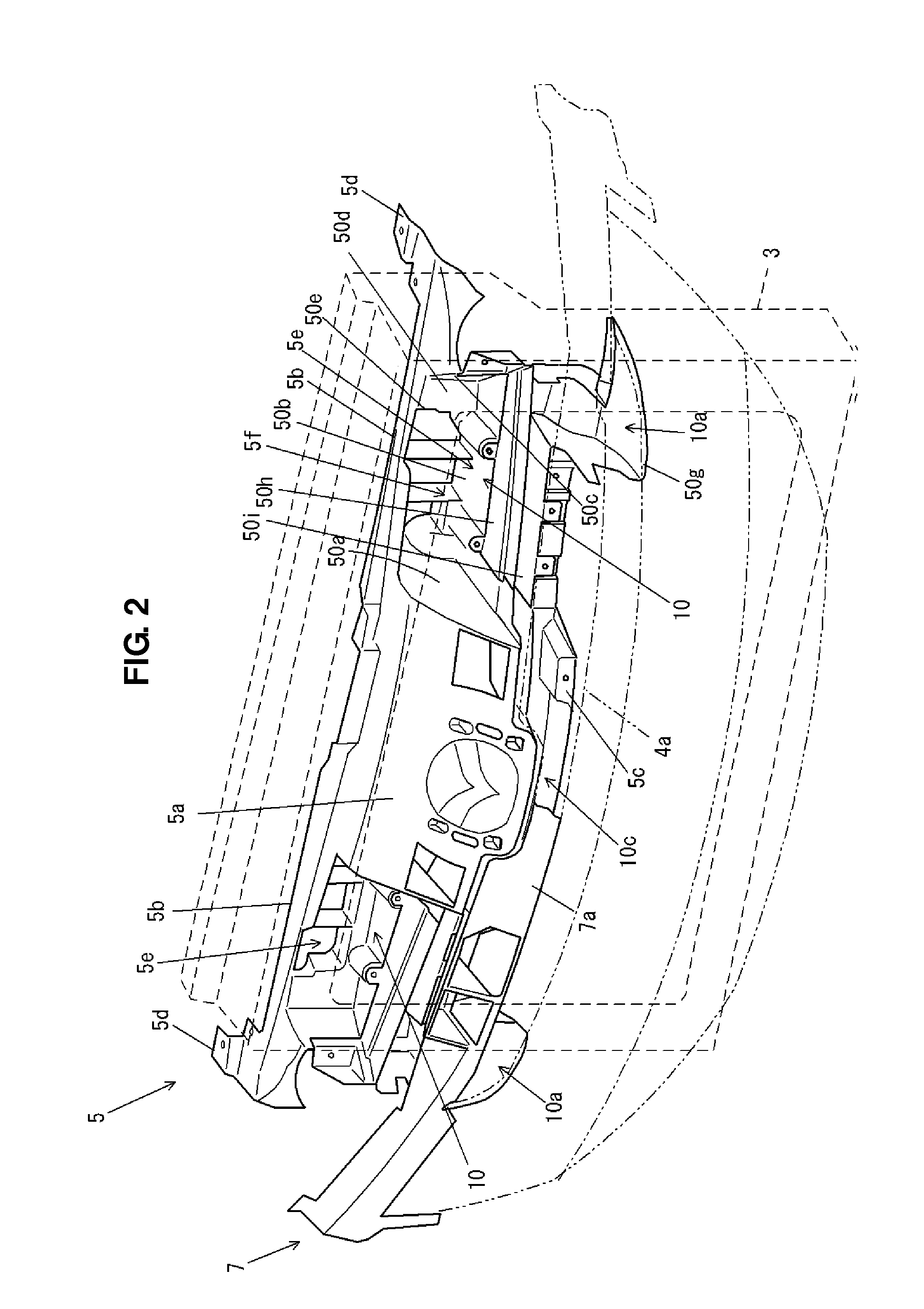

Engine intake passage structure of front vehicle body

InactiveUS20100032220A1Reduce riskAvoid paddingMachines/enginesAir cleaners for fuelAutomotive engineering

Owner:MAZDA MOTOR CORP

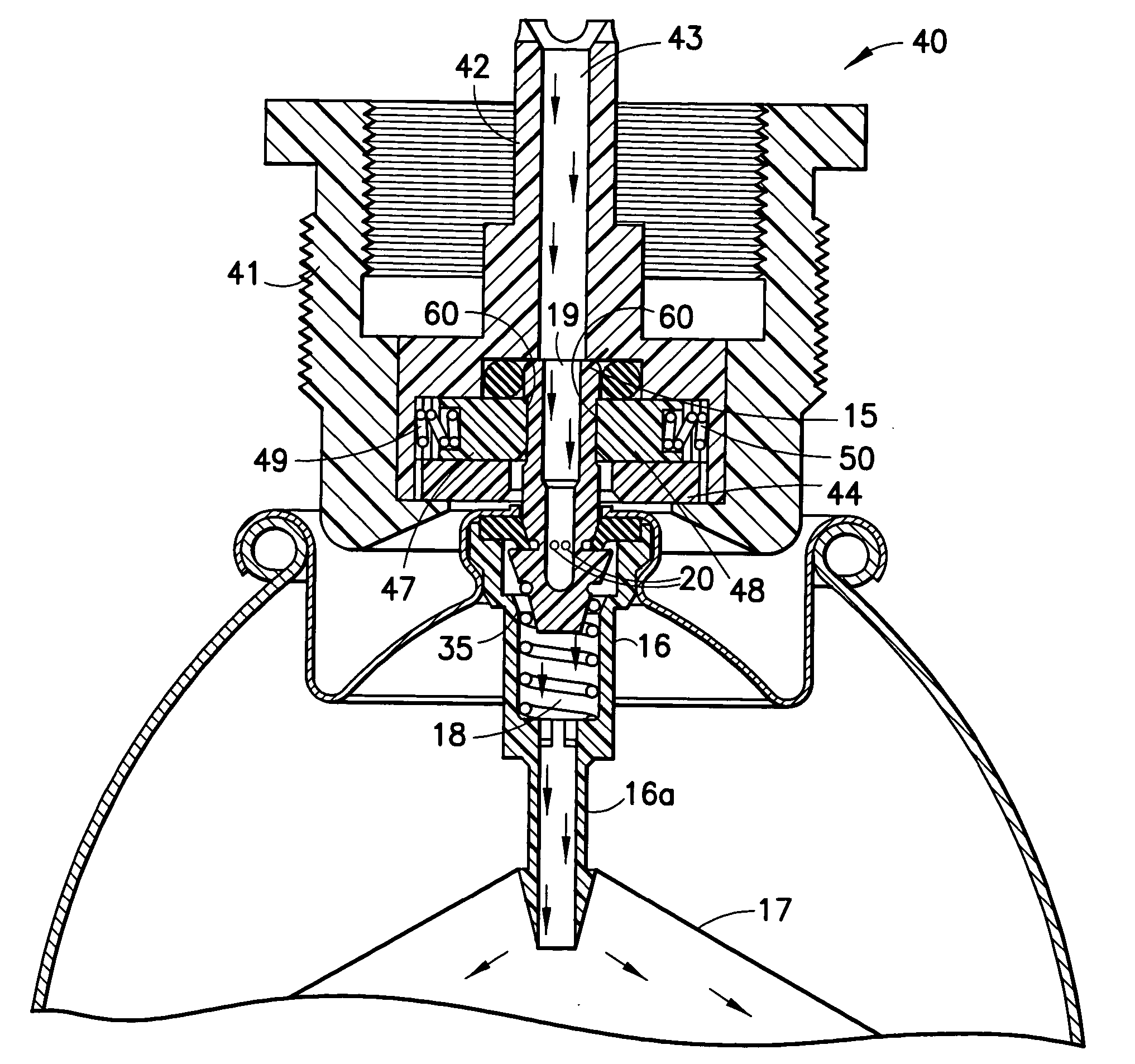

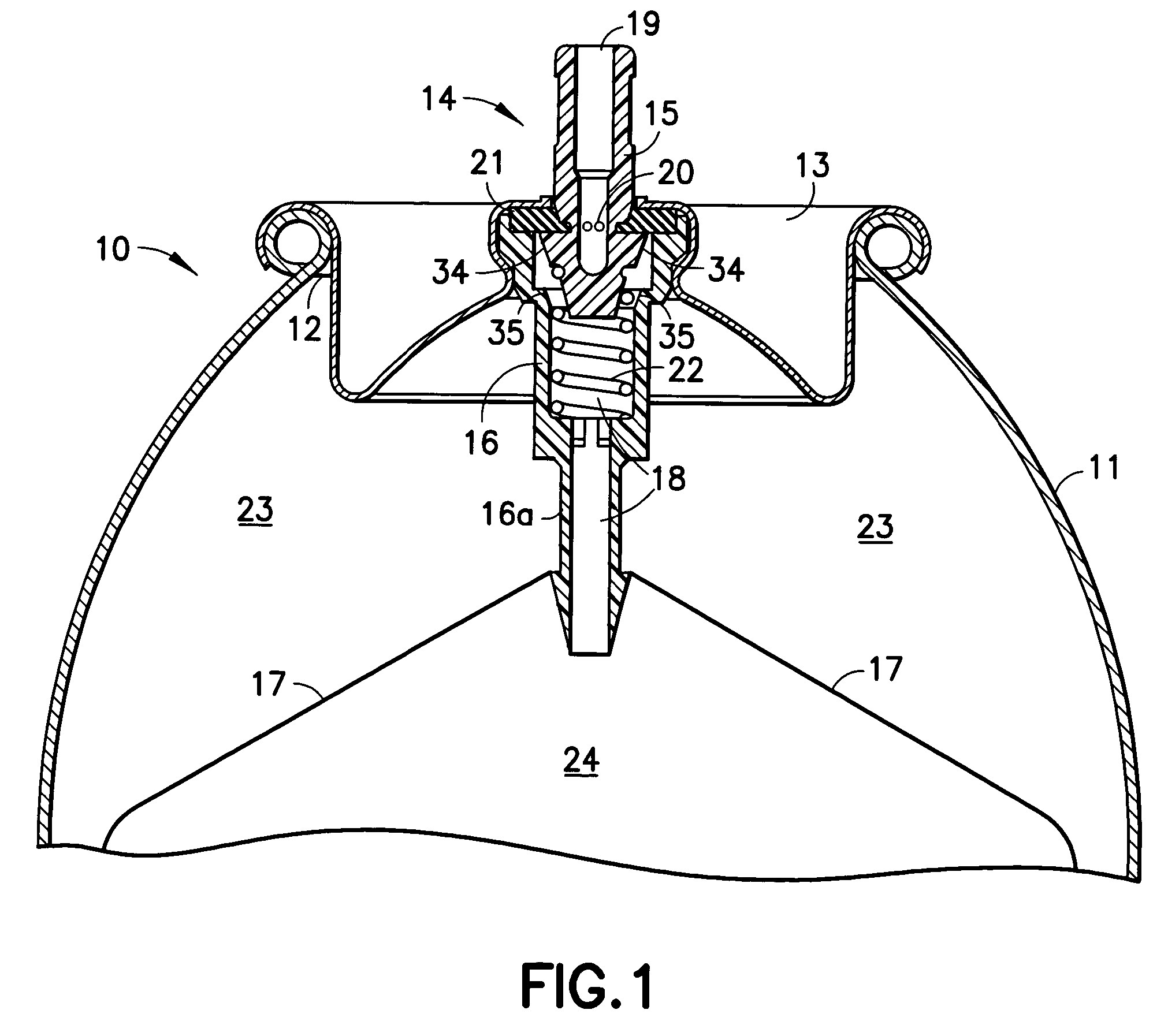

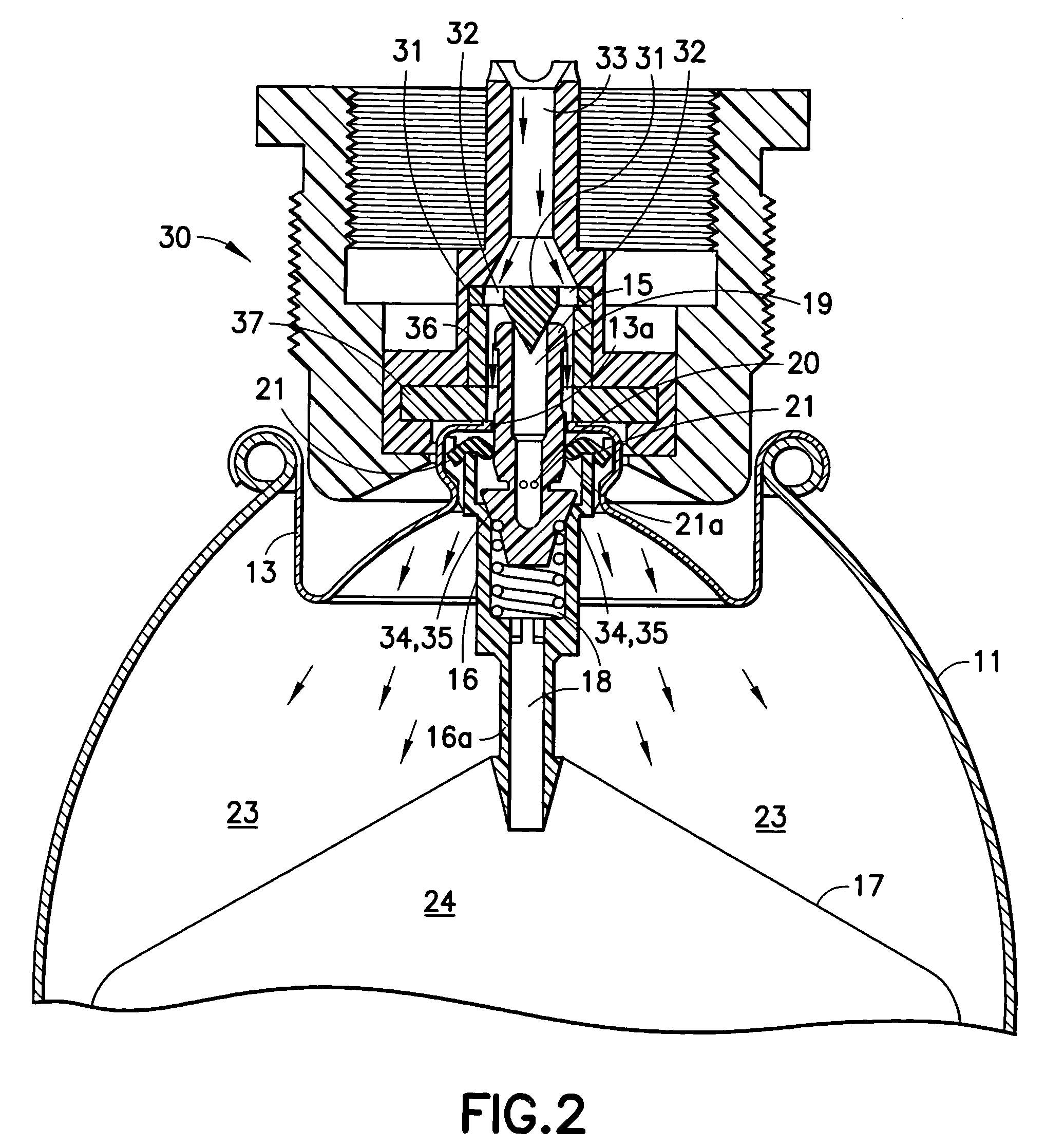

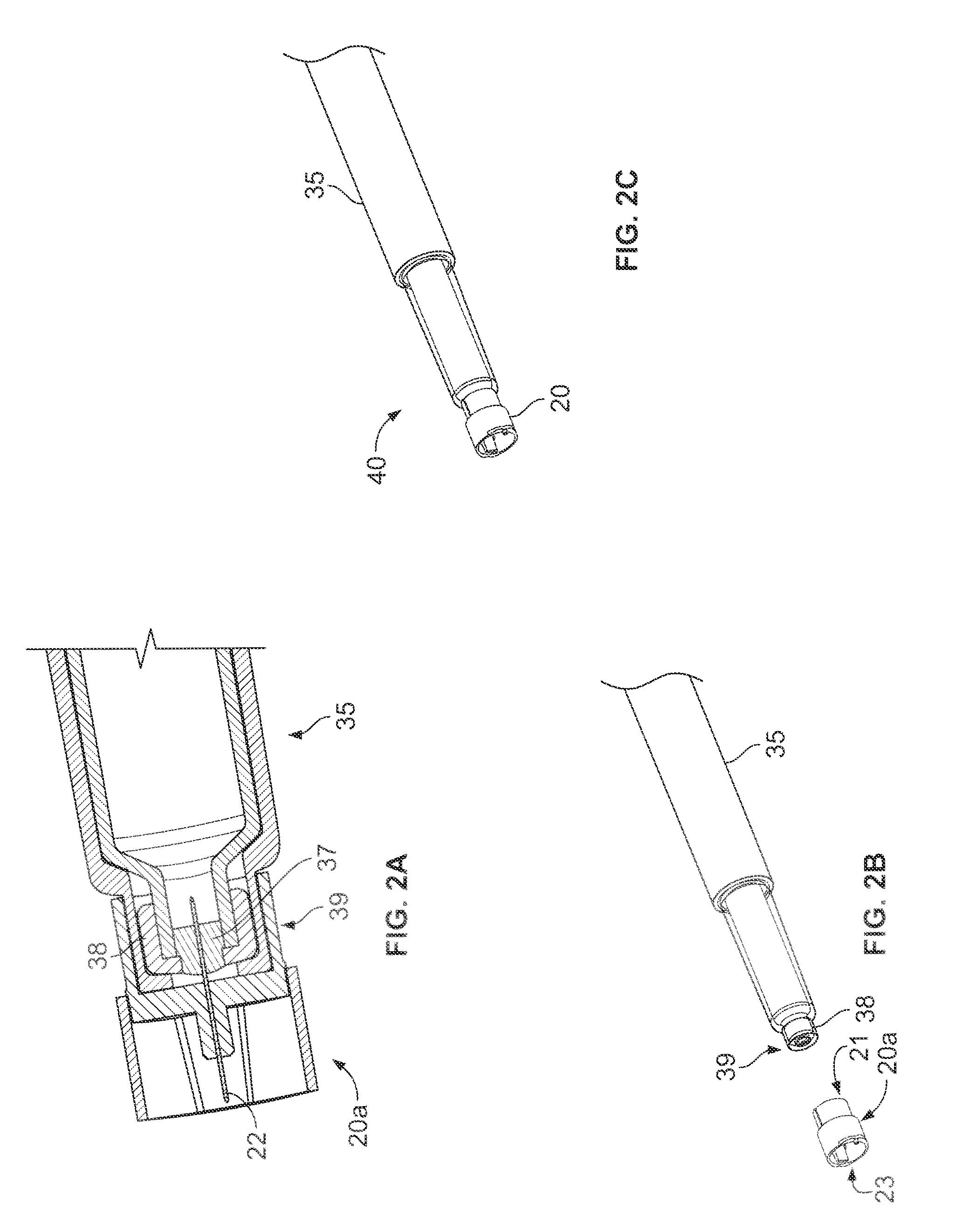

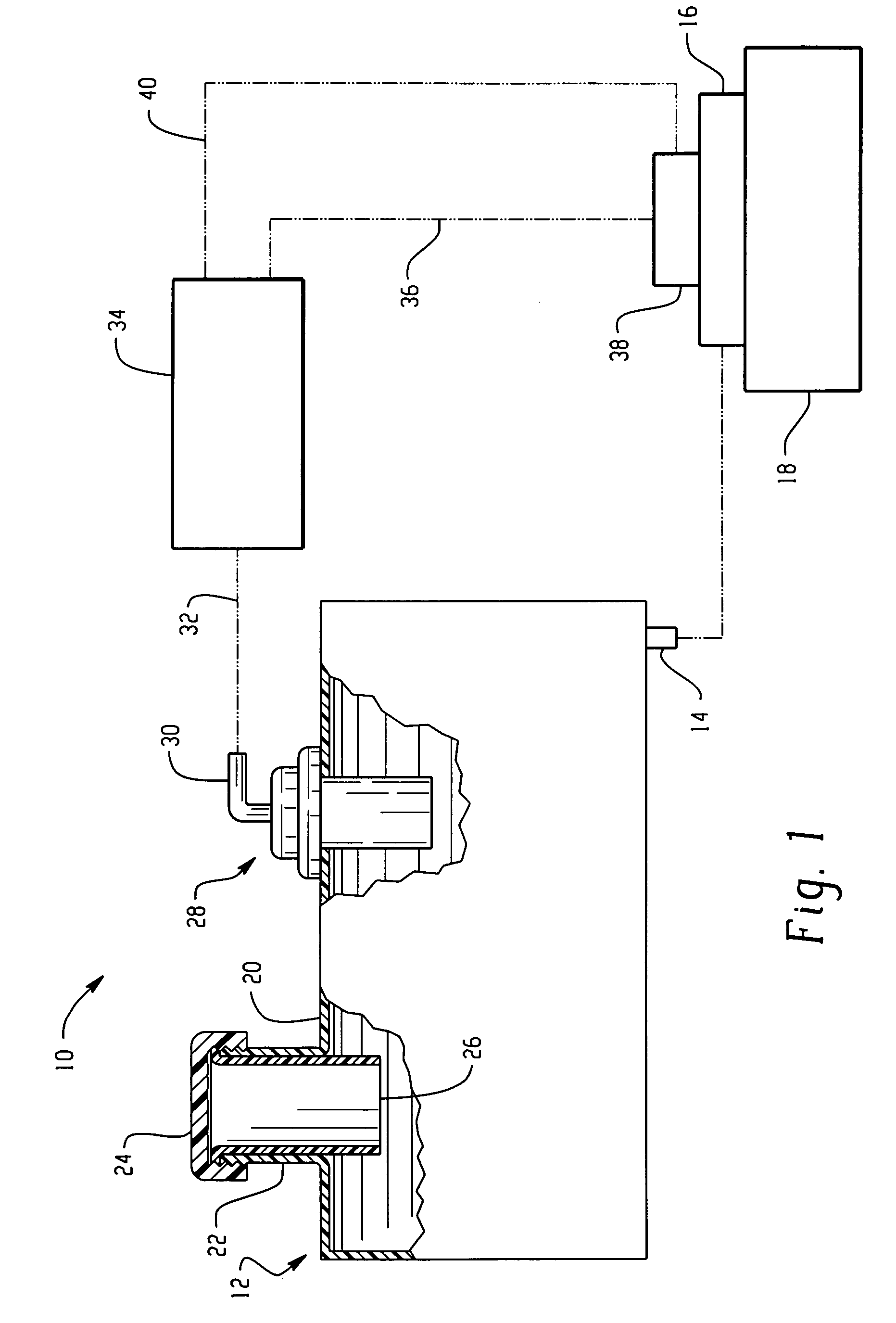

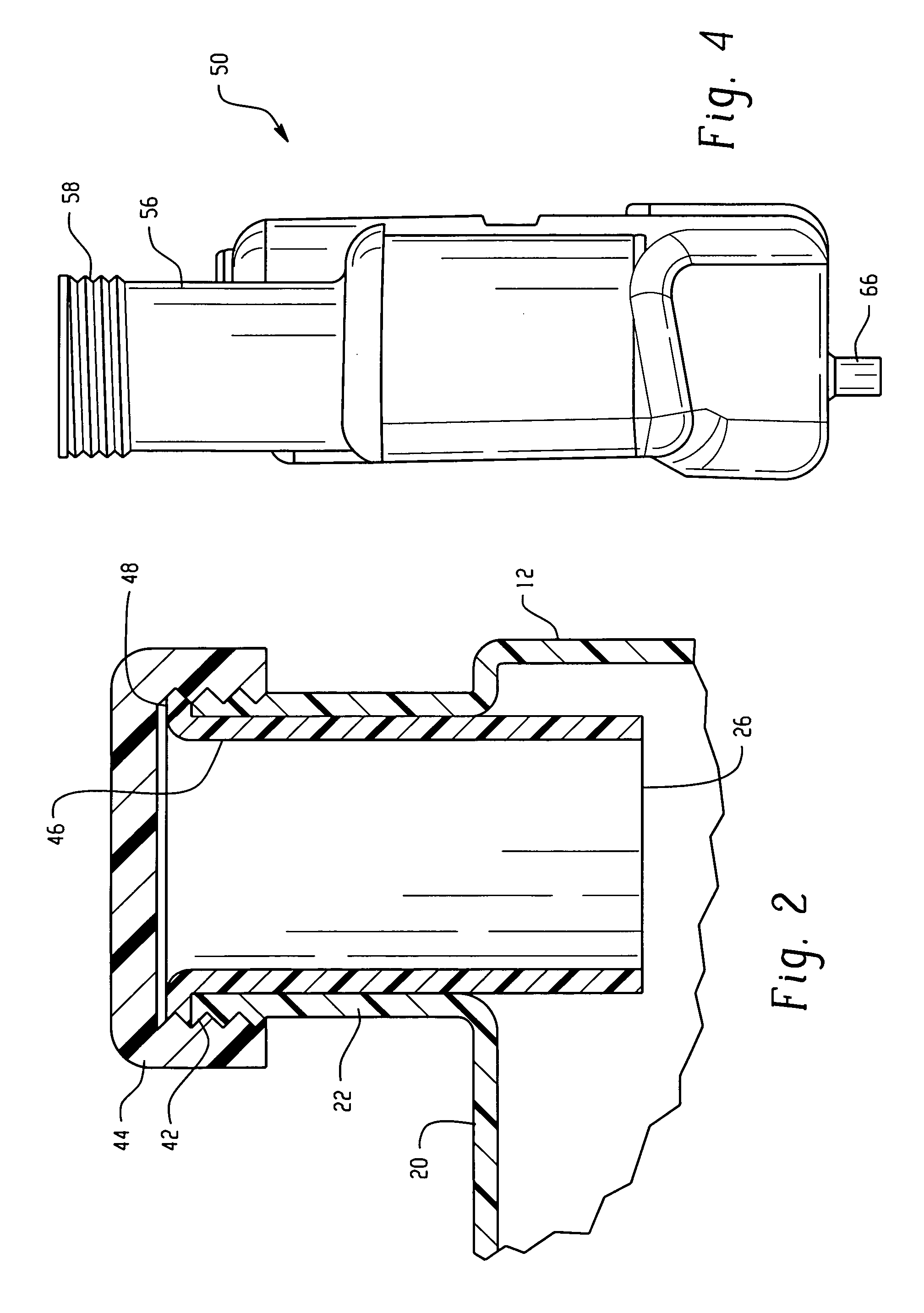

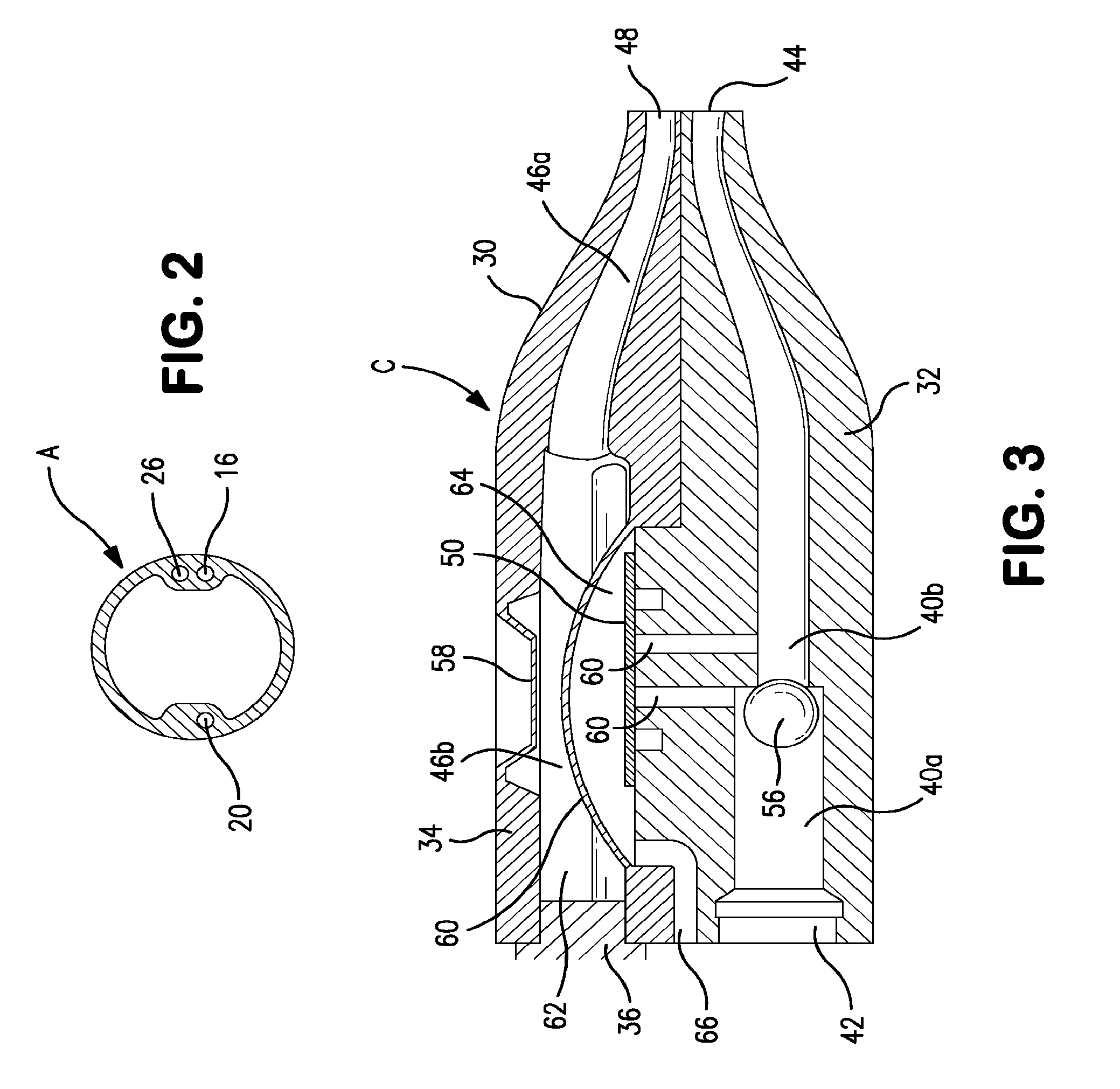

Means and method for filling bag-on-valve aerosol barrier packs

InactiveUS20050005995A1Prevent exitMaintain positionSolid materialLiquid dispensingEngineeringValve stem

A bag-on-valve aerosol valve system in a container. Propellant is pressure filled around the valve stem, outwardly over the stem gasket and down into the container space outside the bag. Product is filled through the valve stem into the bag. The valve stem has an exterior intermediate frusto-conical annular surface and the valve housing has an interior frusto-conical annular surface, with both surfaces engaging in annular sealing contact to block propellant access to the bag when the valve stem is deeply depressed to a first predetermined position for propellant pressure filling. A stem exterior surface indent interacts with radially-biased spring-loaded slides to lock the stem in a second less depressed predetermined position for product filling through the stem down into the bag. The propellant and product may be pressure filled in either order using essentially conventional pressure filing equipment, after the valve is mounted on the container and the bag is mounted on the valve.

Owner:PRECISION VALVE CORP

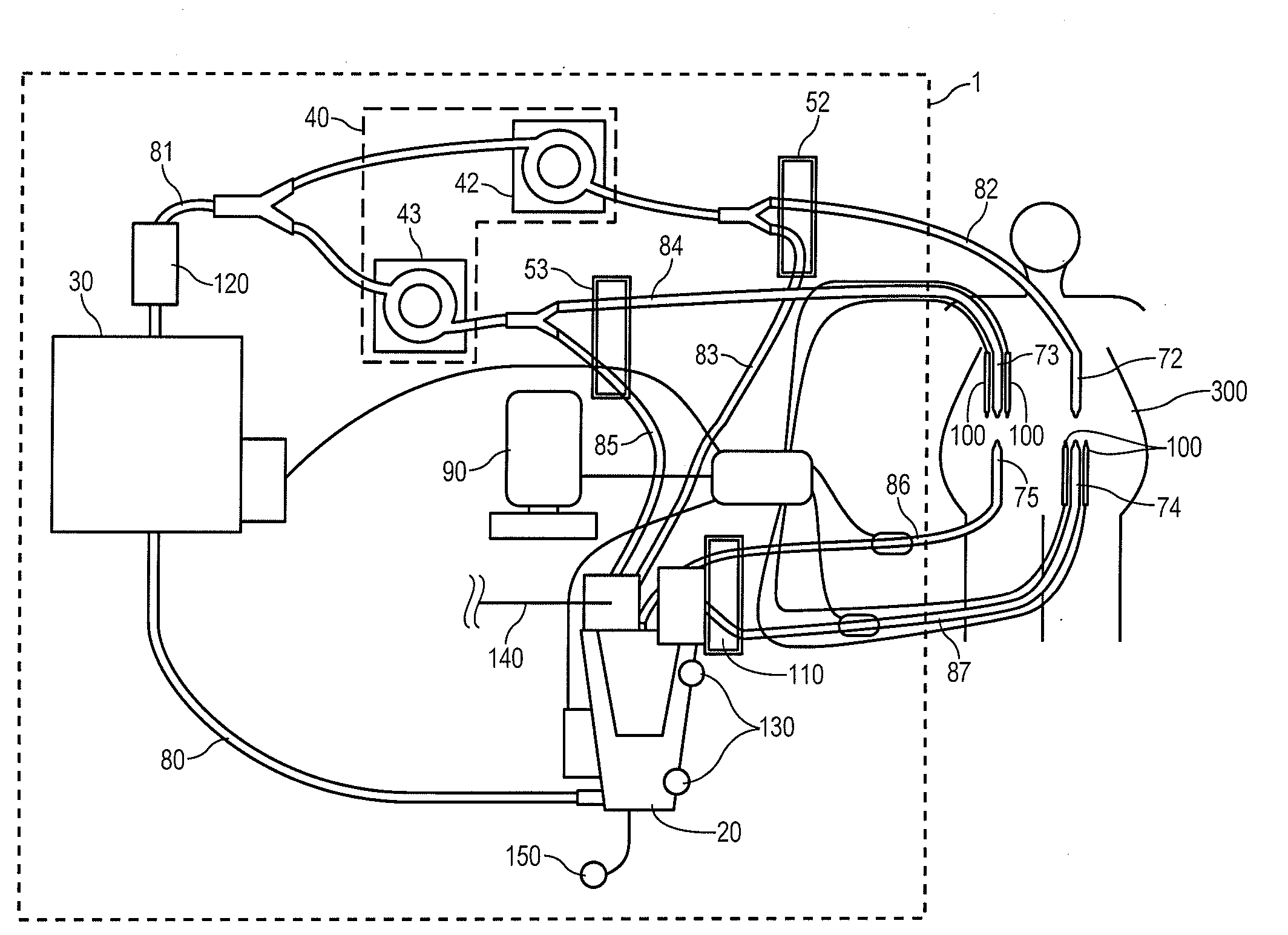

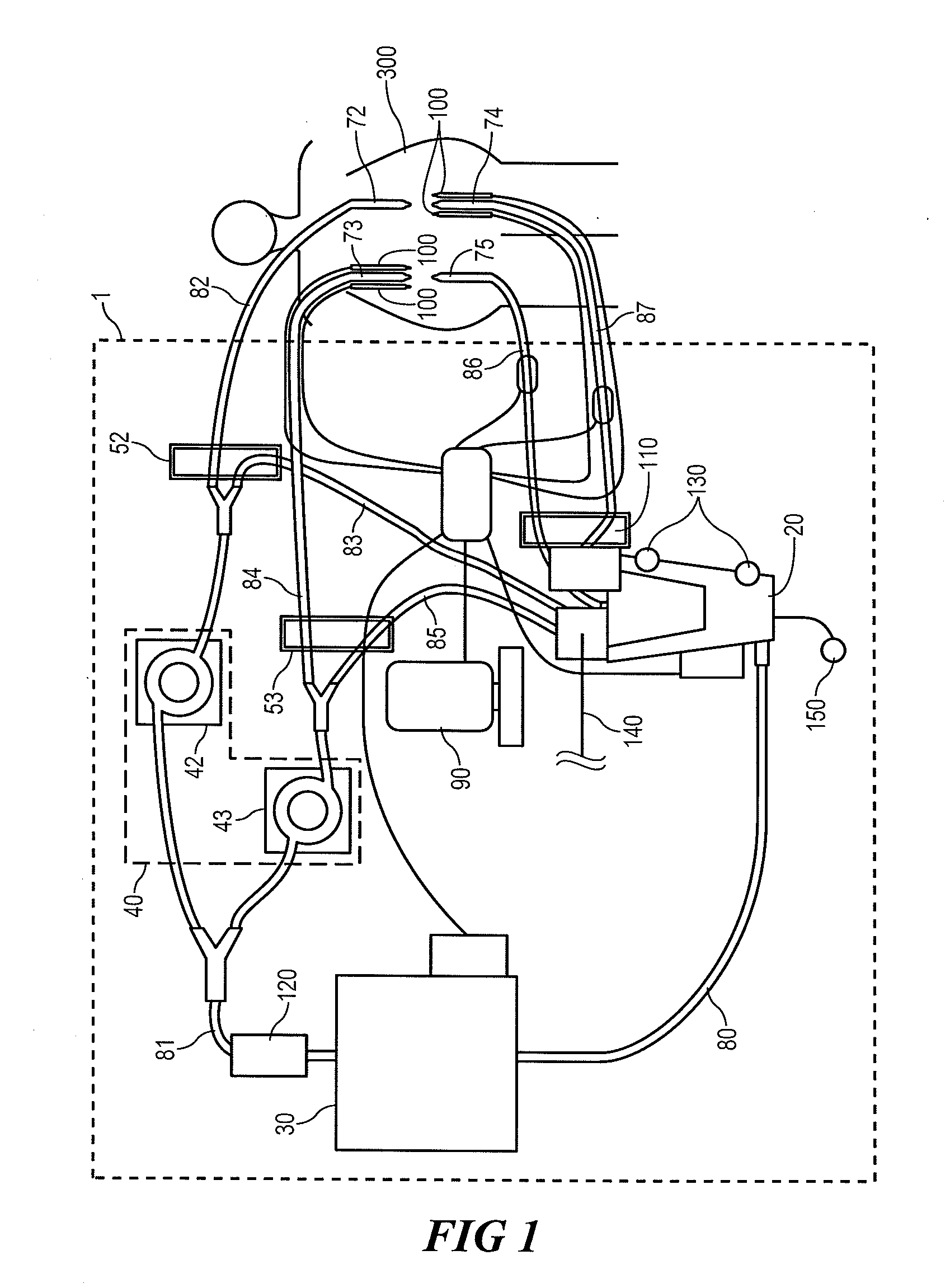

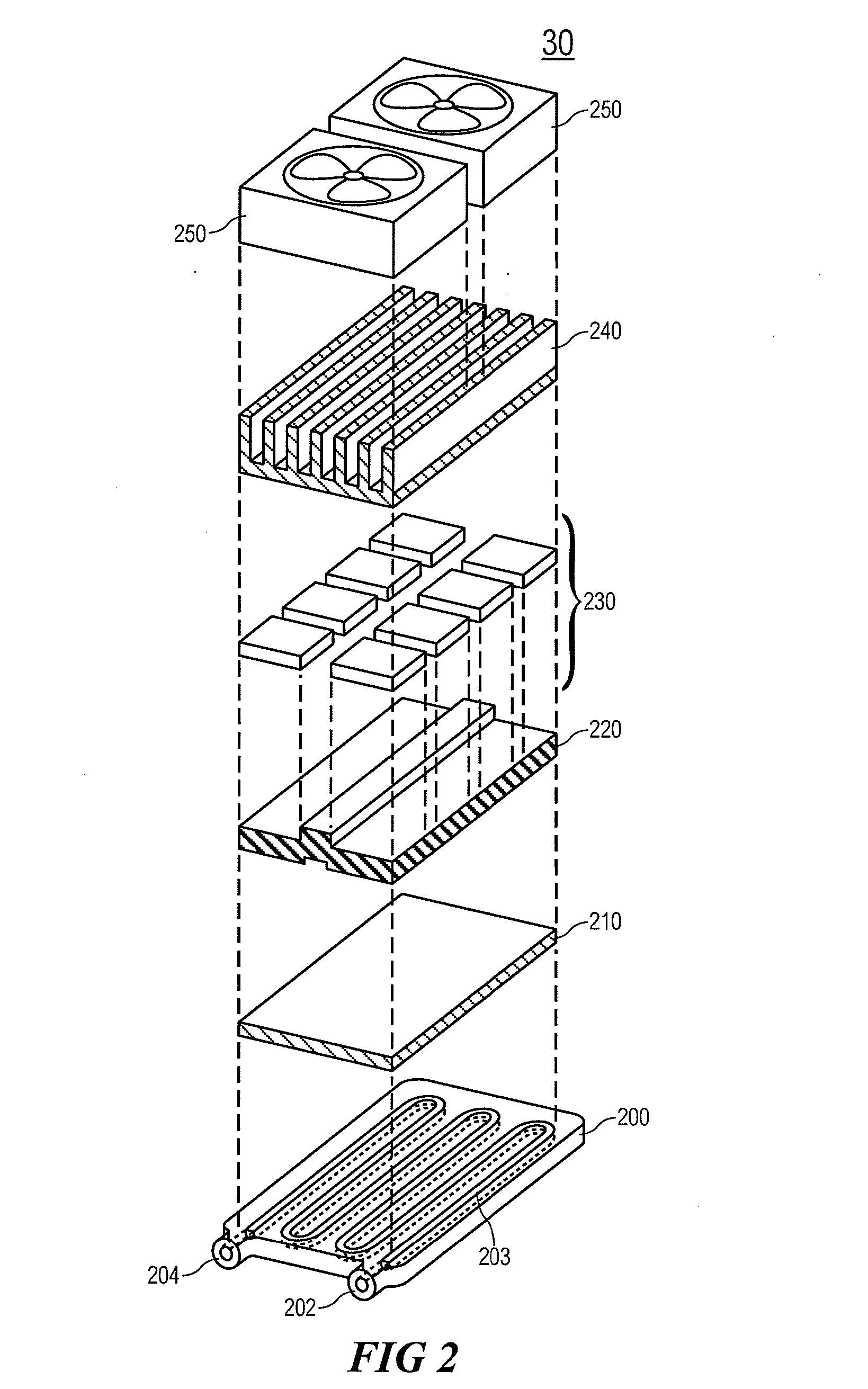

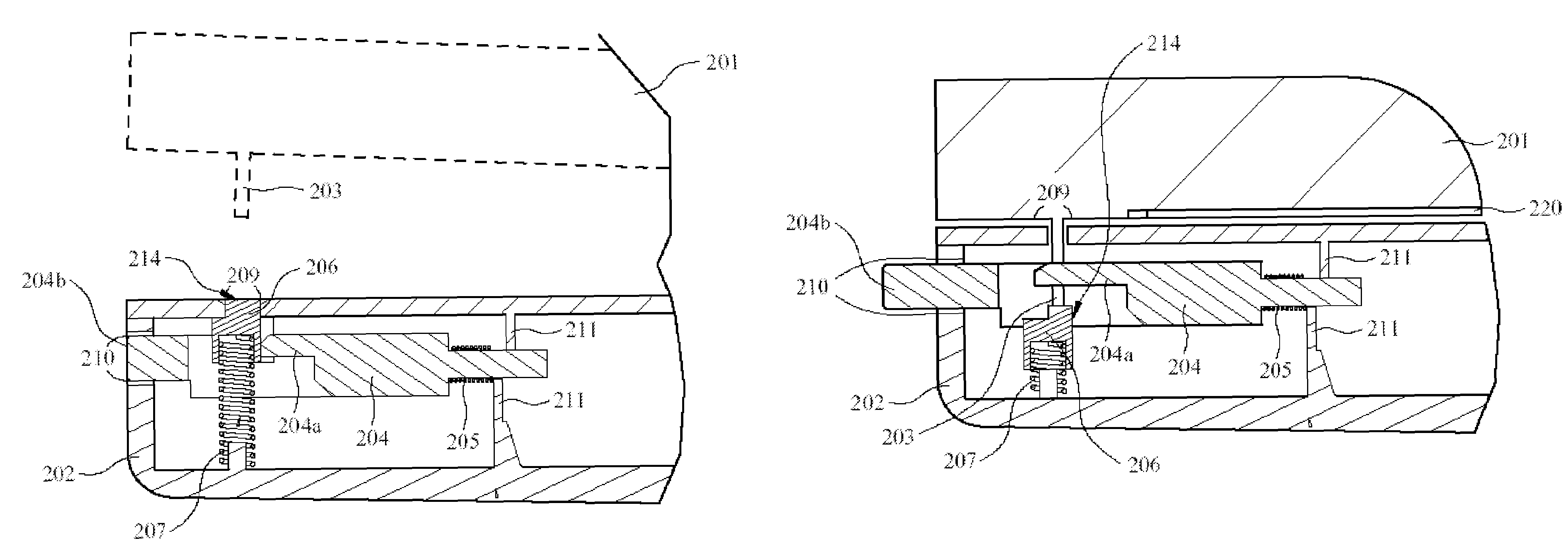

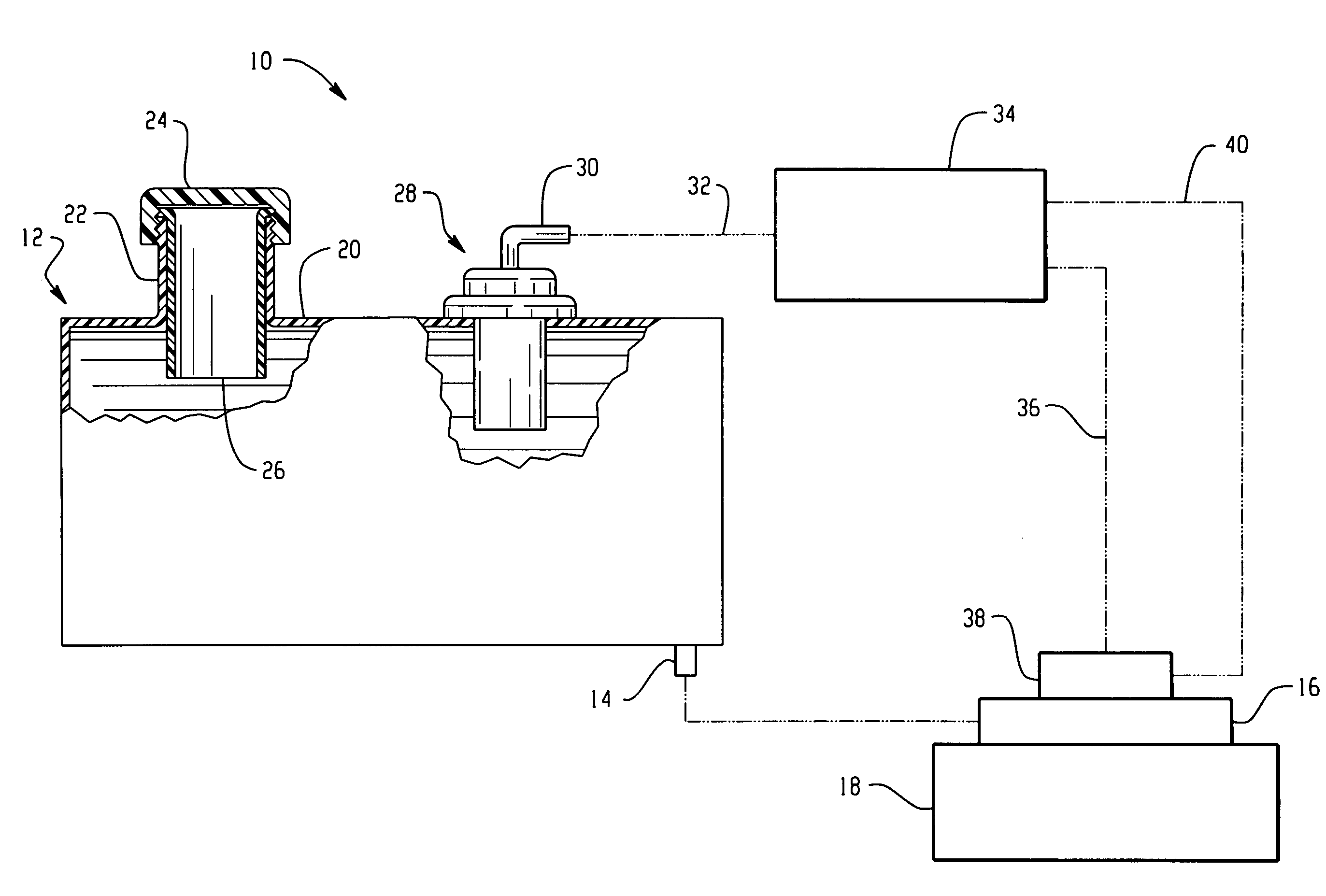

System For Chemohyperthermia Treatment

InactiveUS20080097562A1Easy to controlSmall weightCatheterIntravenous devicesGuide tubeHeating system

The present invention provides a system for chemohyperthermia treatment. The chemohyperthermia treatment system comprises a reservoir for storing fluid; a heating / cooling system coupled to the reservoir so that the fluid can be transferred from the reservoir to the heating system, wherein the heating / cooling system comprises a heating / cooling exchange module having a channel within which the fluid can flow; and a plurality of peltier modules coupled to the heating / cooling module, wherein the plurality of peltier modules heat up the fluid flowing through the channel, and wherein in the cooling mode, the plurality of peltier modules cool the fluid flowing through the channel; a pumping means coupled to the heating / cooling system, wherein the pumping means pump the perfusion fluid from the reservoir to the heating / cooling system, thereby allowing the heating / cooling system to change the temperature of the fluid; at least one inflow catheter coupled to the pumping means, wherein the at least one inflow catheter delivers the heated / cooled fluid to an object; and at least one outflow catheter coupled to the reservoir, wherein the at least one outflow catheter drains the fluid from the object to the reservoir.

Owner:DYAMED BIOTECH PTE

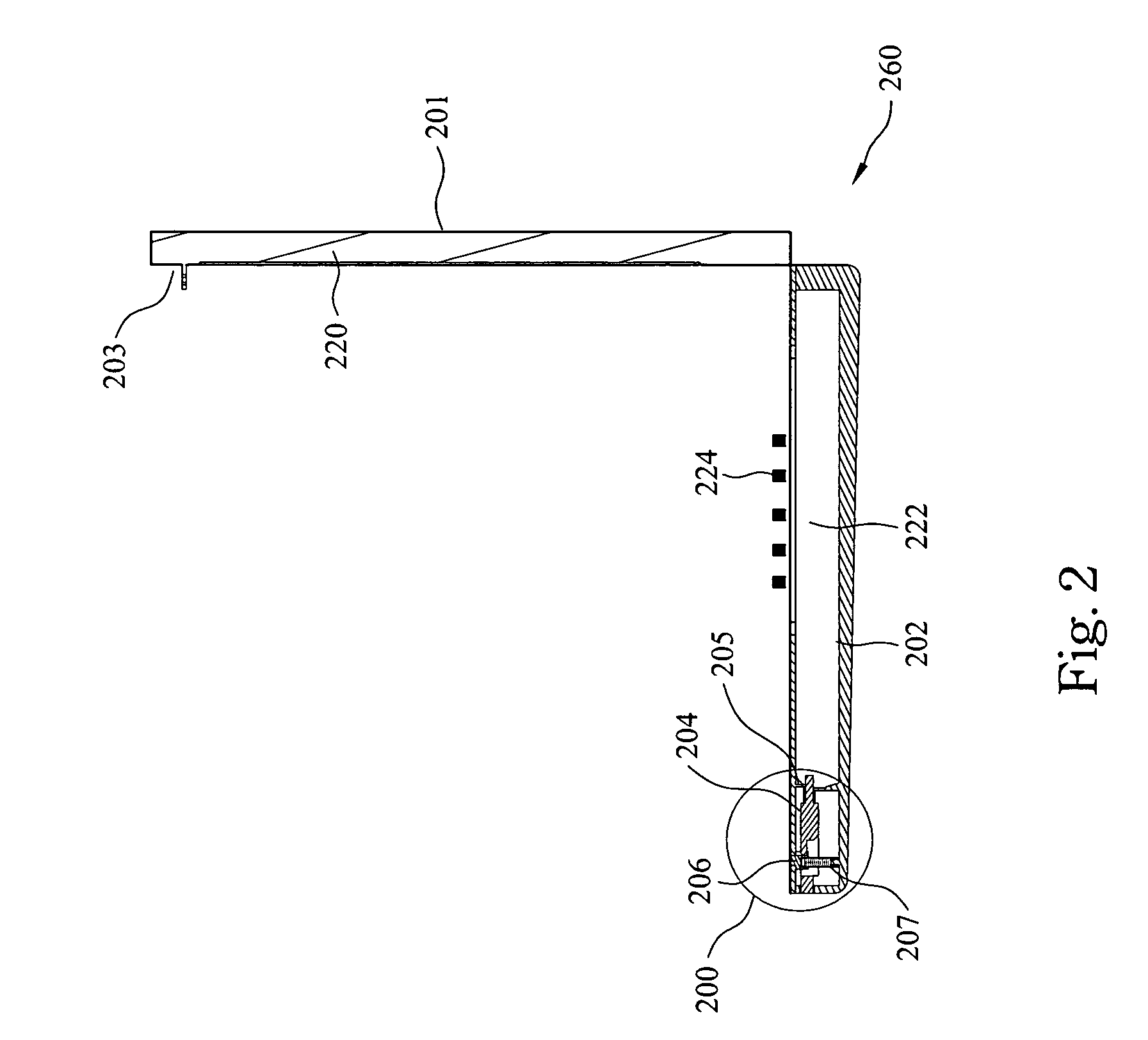

Case structure of portable electronic device

ActiveUS7420799B2Avoid paddingEasy to liftWing fastenersDetails for portable computersMechanical engineeringElectronic equipment

A case structure of an electronic device comprises a first shell, a second shell, a first engagement element, a second engagement element, a first spring element, a second spring element and a plug element. The first engagement element protrudes from the first shell. The second shell having a first penetrating opening allows the first engagement element to pass through. The second engagement element having a button portion passes through a second penetrating opening of the second shell. The second engagement element is driven by the button portion and the first spring element to control the second engagement element and the first engagement element to engage or disengage from each other. The plug element located in the second shell is pushed for filling in the first penetrating opening by the second spring element.

Owner:ASUSTEK COMPUTER INC

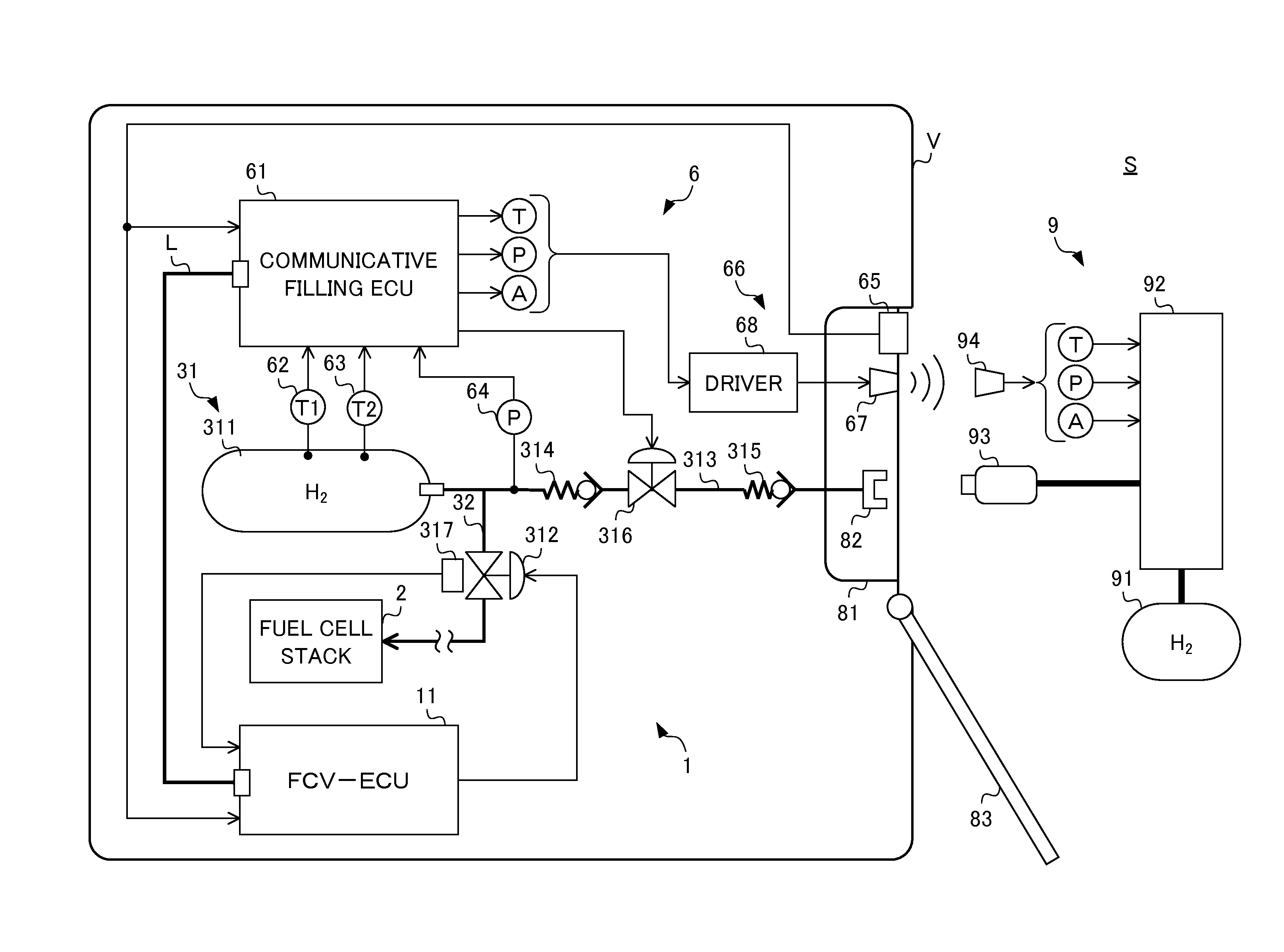

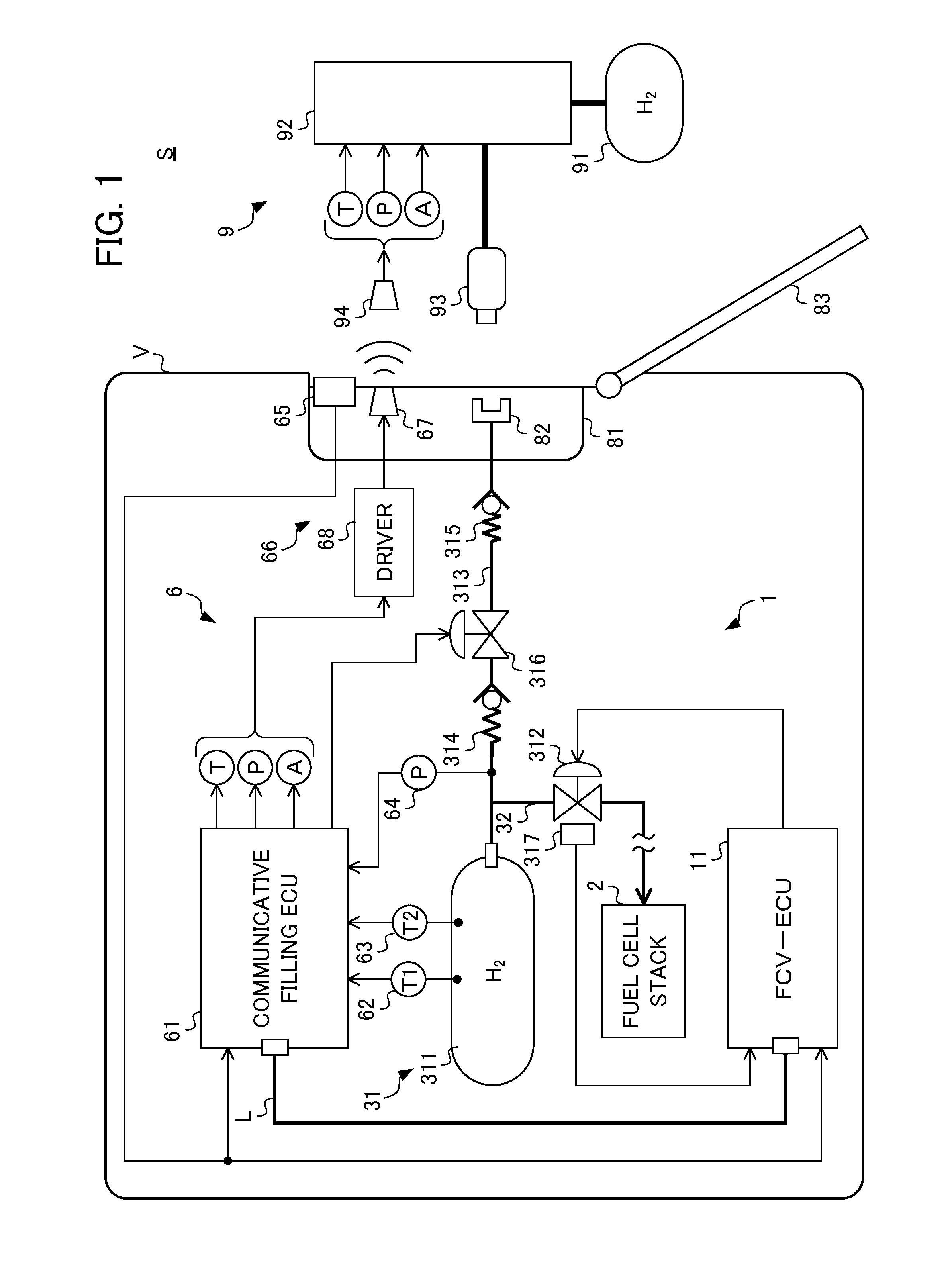

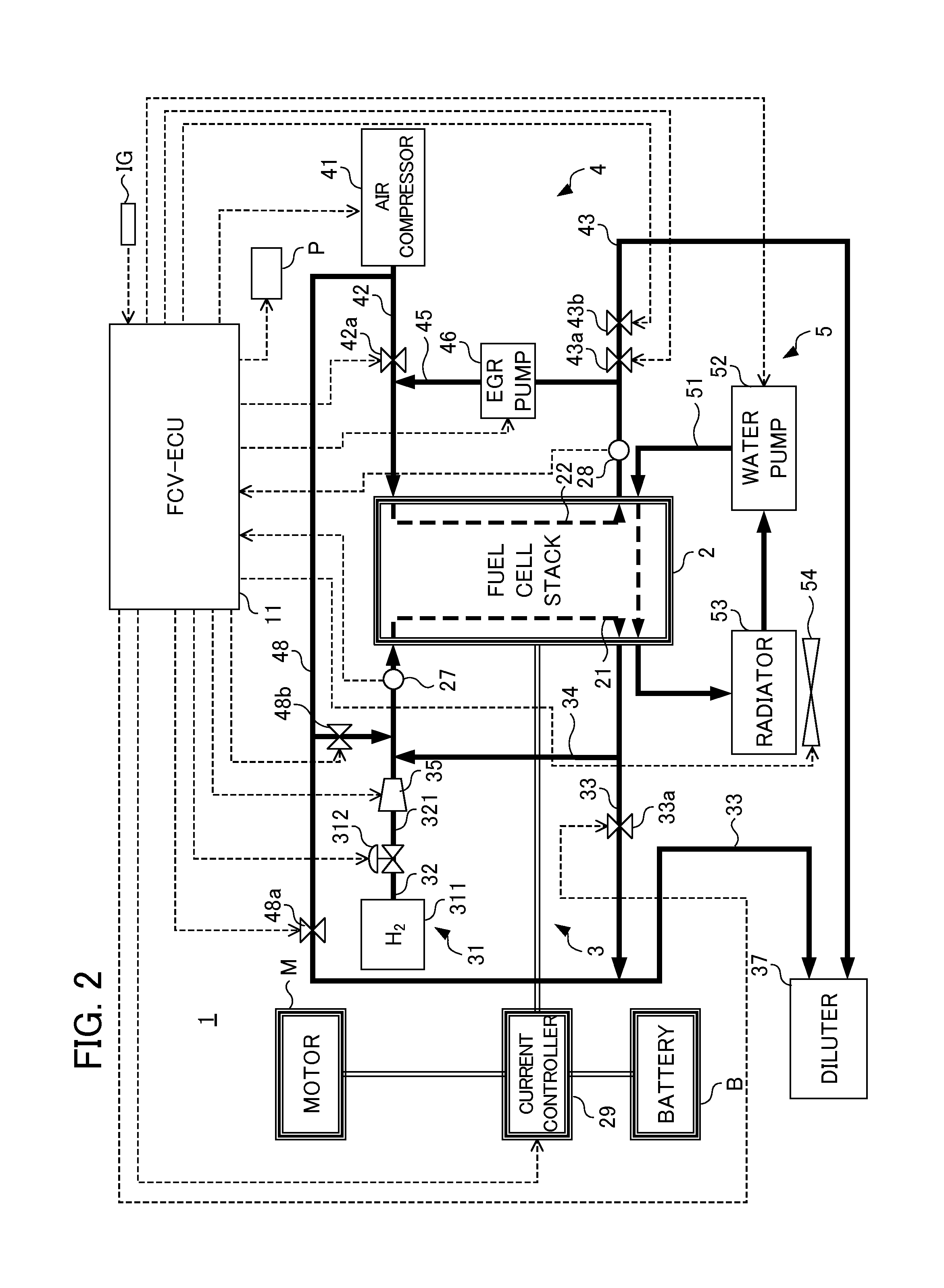

Fuel cell vehicle and moving body

ActiveUS20140295305A1Reduce electric power consumptionRaise convenienceReactant parameters controlPower to auxillary motorsAutomotive engineeringHydrogen tank

A data signal accurately reflecting the actual state of a storage vessel is sent to a station side. A fuel cell system (1) includes a hydrogen supply line (32) that connects a tank main body (311) and a fuel cell stack (2), and a main stop valve provided to the hydrogen supply line (32). A communicative filling system (6) generates a data signal based on the state of a hydrogen tank (31), and sends the generated data signal to a station (9). A vehicle (V) includes an FCV-ECU (11) that assumes processing related to control of the fuel cell system (1), and a communicative filling ECU (61) that assumes processing related to control of the communicative filling system (6). Then, the communicative filling ECU inhibits start of communication with the station (9) at least when determined that a main stop valve (312) is in a completely closed state.

Owner:HONDA MOTOR CO LTD

Hanger

InactiveUS7097144B2Strong attractive forceIncrease air circulationApparel holdersPicture framesEngineeringClothes hanger

A hanger includes a hanger body having a prescribed external peripheral shape on which clothing is hung up. A first magnet is arranged in a projecting manner on a rear side of the hanger body for attaching the hanger to a prescribed suspending place.

Owner:KOHNO TATSUYUKI

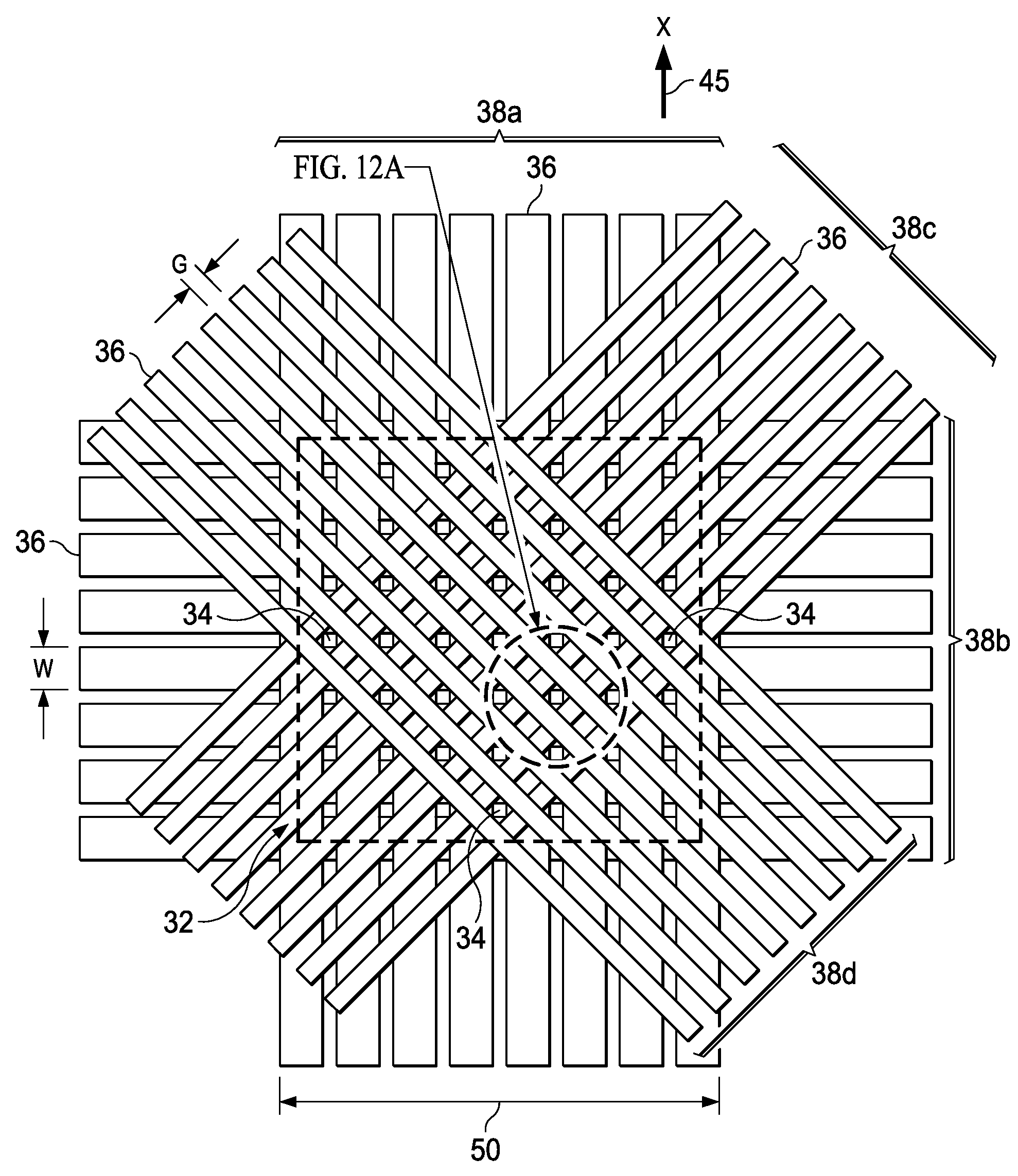

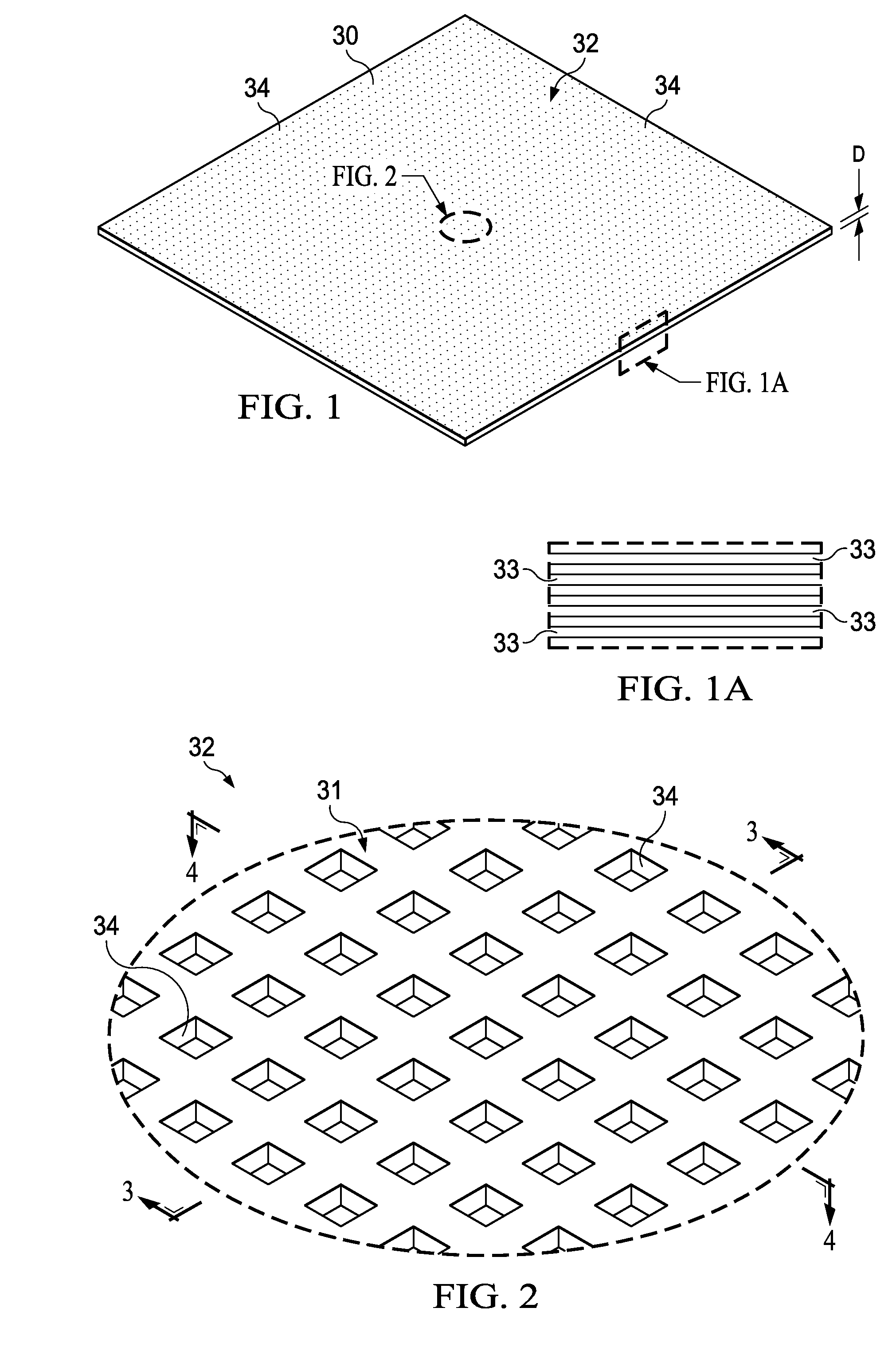

Composite Laminates Having Hole Patterns Produced by Controlled Fiber Placement

InactiveUS20150030803A1Improve acoustic propertiesSolve low usageLaminationLamination apparatusComposite laminatesFiber orientation

A composite laminate has a pattern of holes therein. The holes are formed by laying down plies of unidirectional pre-preg material having varying fiber orientations. The tows are spaced apart and located to form holes through the laminate.

Owner:THE BOEING CO

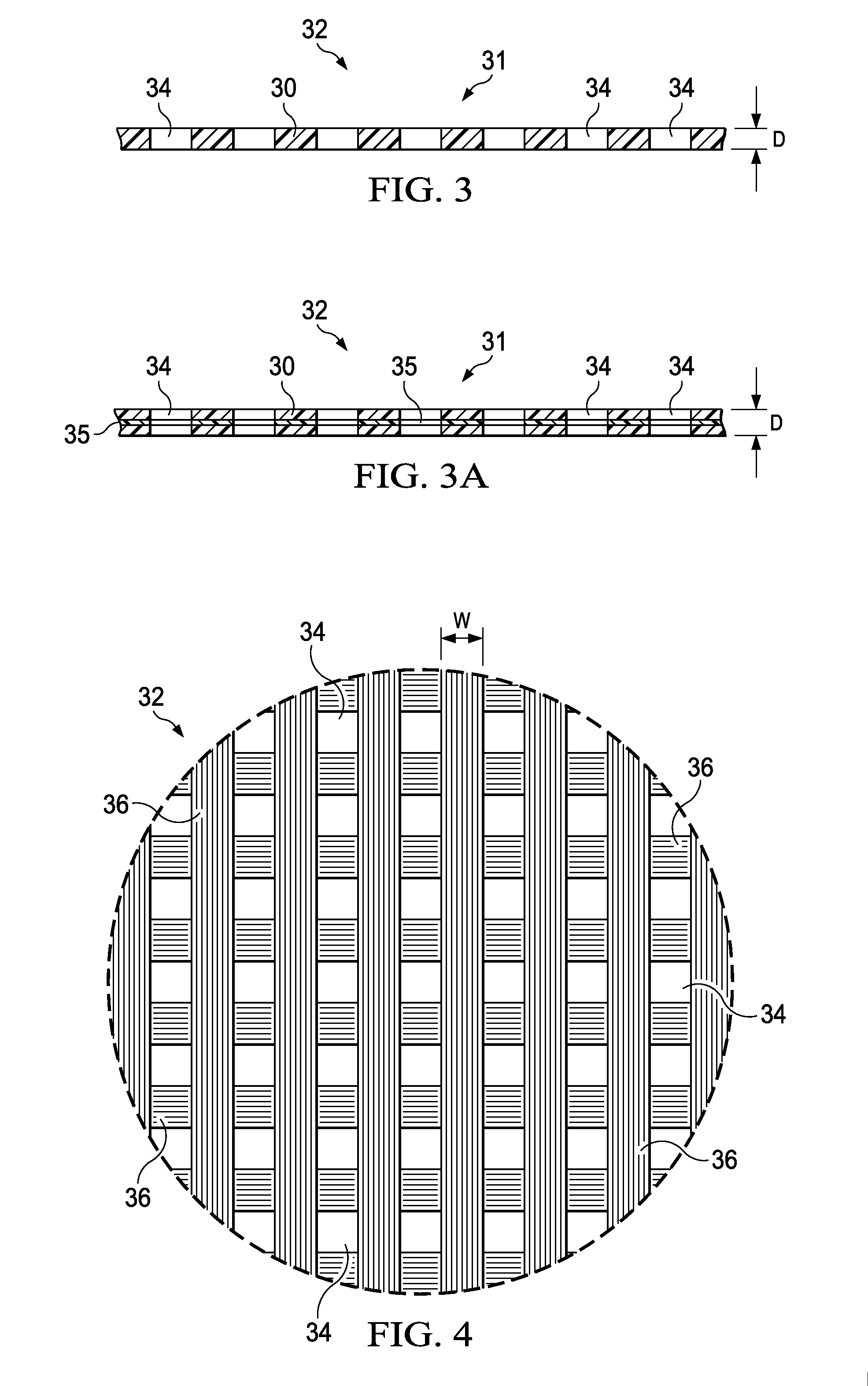

Medicine delivery device with restricted access filling port

A disposable patch pump may be provided with a filling adapter, to ensure filling by an authorized user. The adapter mates with the pump and a source of medicament, such as an insulin vial, to prevent filling the pump directly with a conventional syringe. The adapter and / or pump filling port may be configured with a frangible element, to limit the system to single use.

Owner:CEQUR SA

Automated precision small object counting and dispensing system and method

ActiveUS8392020B2Accurate countAvoid mistakesSmall article dispensingCoin-freed apparatus detailsBarcodeMechanical engineering

Owner:TENSION INT

Method for manufacturing a layer arrangement and layer arrangement

InactiveUS7807563B2Avoid paddingReduce parasitic capacitanceSemiconductor/solid-state device detailsSolid-state devicesElectrically conductive

In a method for manufacturing a layer arrangement, a plurality of electrically conductive structures are embedded in a substrate. Material of the substrate is removed at least between adjacent electrically conductive structures. An interlayer is formed on at least one portion of sidewalls of each of the electrically conductive structures. A first layer is formed on the interlayer where an upper partial region of the interlayer remaining free of a covering with the first layer. An electrically insulating second layer is formed selectively on that partial region of the interlayer which is free of the first layer, in such a way that the electrically insulating second layer bridges adjacent electrically conductive structures such that air gaps are formed between adjacent electrically conductive structures.

Owner:INFINEON TECH AG

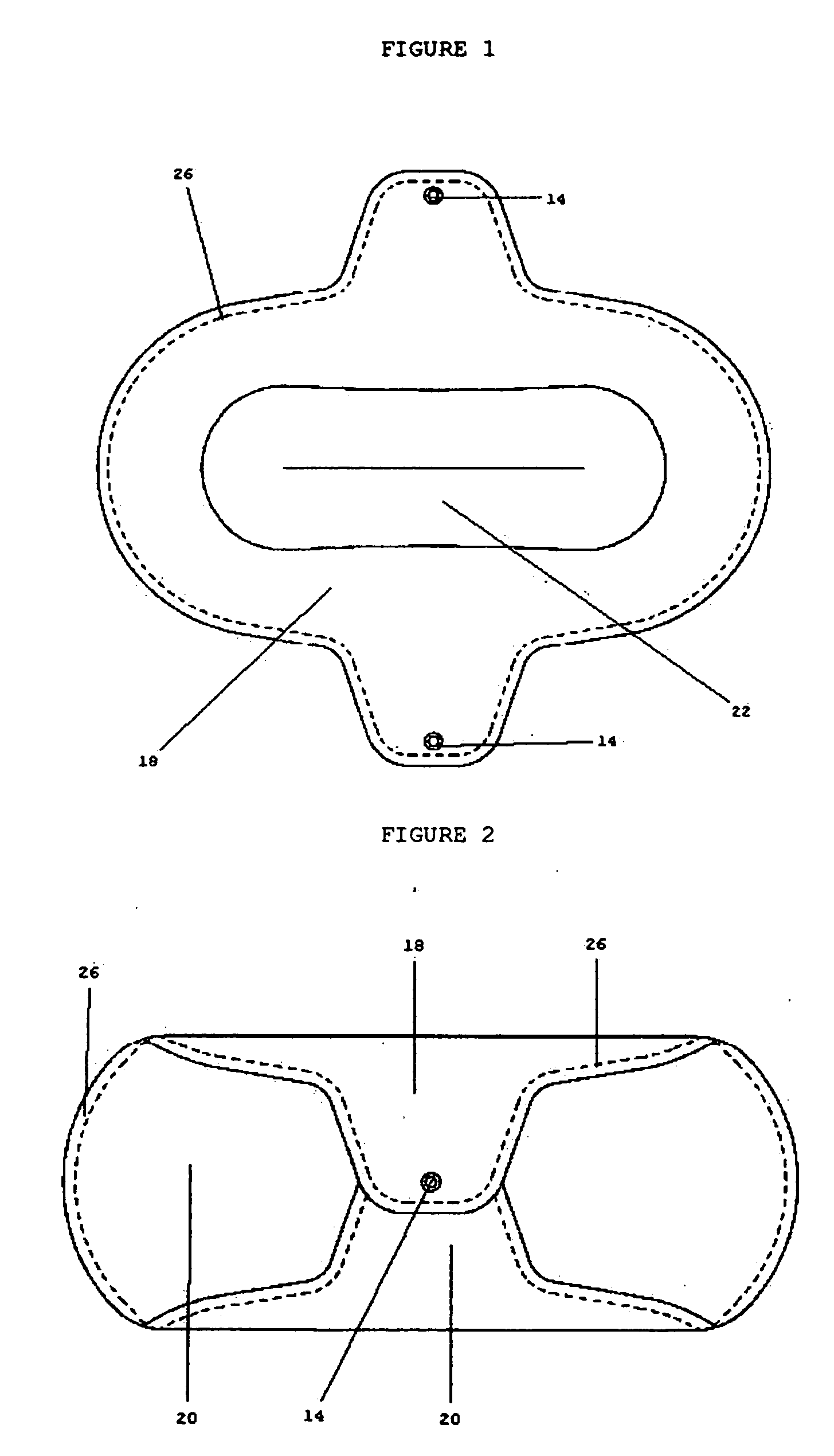

Cloth menstrual pad with hemp core

InactiveUS20060224136A1Easy to usePrevent leakageSanitary towelsBaby linensCloth menstrual padEngineering

Owner:MARTINEZ CHRISTINA MARIE GABBARD

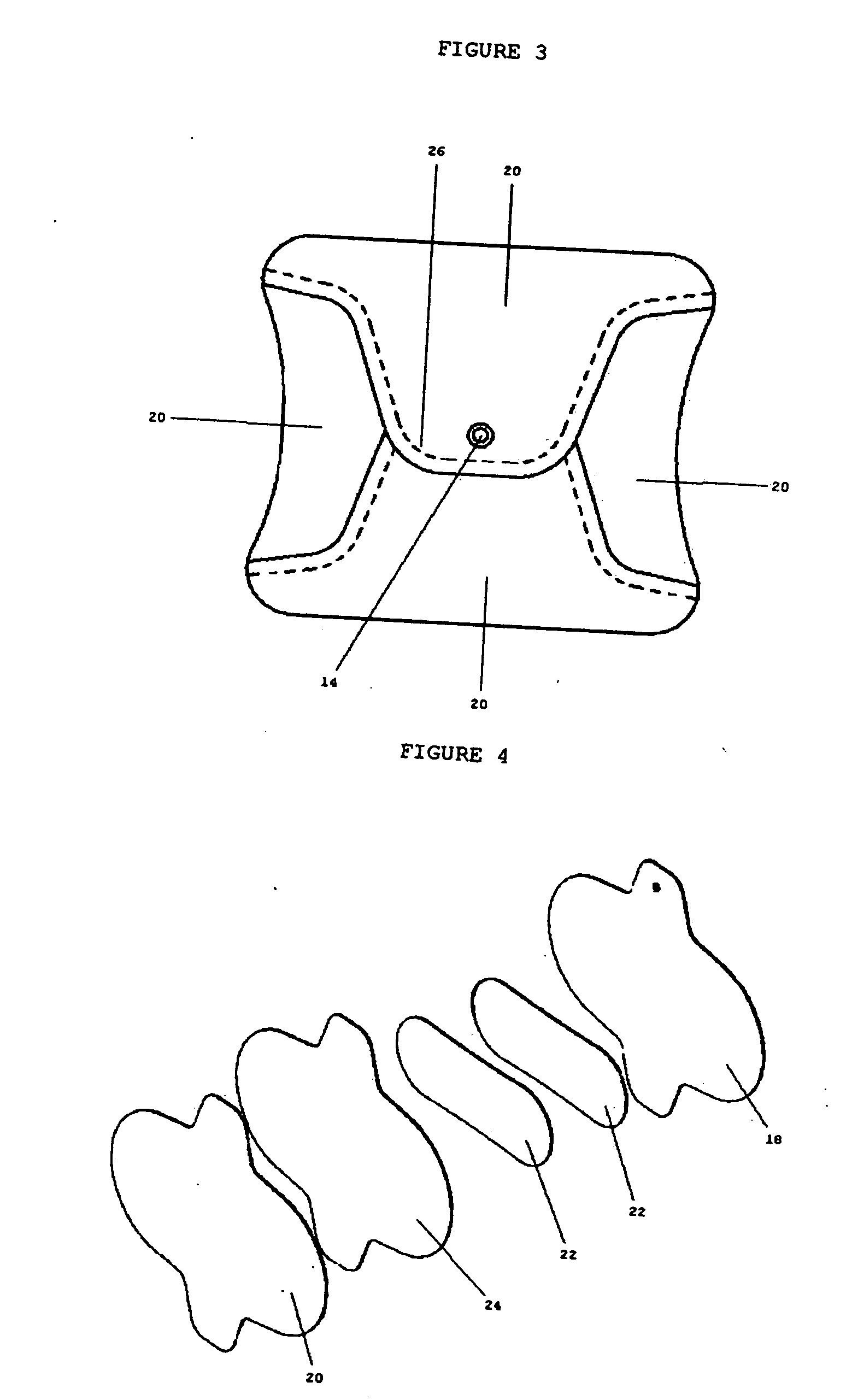

Cleaning system for a filling machine

An automatic cleaning apparatus and / or method for periodically cleaning a filling machine during a filling cycle without the need for human interaction to initiate the cleaning process. In some embodiments, a controller automatically initiates a cleaning sequence at predetermined intervals. The predetermined intervals can be a time interval, such as every thirty minutes for example, or based upon filling characteristics, such as after a predetermined number of containers are filled or a predetermined amount of product has flowed through the filling machine. In some embodiments, the controller performs many operations during the cleaning process. For example, the controller can prevent containers from entering the filling machine and control the operation of a cleaning manifold. Upon completion of the cleaning operation, the controller waits a predetermined period while filing operations commence before automatically initiating the next cleaning operation.

Owner:JOHNSONDIVERSEY INC

Cleaning system for a filling machine

InactiveUS20060185755A1Avoid paddingLiquid fillingSolid materialHuman interactionMechanical engineering

An automatic cleaning apparatus and / or method for periodically cleaning a filling machine during a filling cycle without the need for human interaction to initiate the cleaning process. In some embodiments, a controller automatically initiates a cleaning sequence at predetermined intervals. The predetermined intervals can be a time interval, such as every thirty minutes for example, or based upon filling characteristics, such as after a predetermined number of containers are filled or a predetermined amount of product has flowed through the filling machine. In some embodiments, the controller performs many operations during the cleaning process. For example, the controller can prevent containers from entering the filling machine and control the operation of a cleaning manifold. Upon completion of the cleaning operation, the controller waits a predetermined period while filing operations commence before automatically initiating the next cleaning operation.

Owner:JOHNSONDIVERSEY INC

System and method for controlling fuel vapor emission in a small engine

ActiveUS7225795B2Avoid paddingNon-fuel substance addition to fuelWing accessoriesAtmospheric airPolyamide

A small engine fuel system has a tank with an integrally formed filler tube having the lower end located at a level below the upper portion of the tank wall which is formed of vapor impermeable material which may include HDPE interspersed with EVOH or polyamide. In one exemplary embodiment the filler neck is disposed in a depression in the upper portion of the tank wall; and in another exemplary embodiment the filler tube has an insert which extends into the tank to a position below the upper portion of the tank wall to form a vapor space. The tank includes a fill limiting vapor vent / tipping valve with its outlet connected to a storage canister which outputs to the engine and which has an atmospheric air vent.

Owner:EATON INTELLIGENT POWER LTD

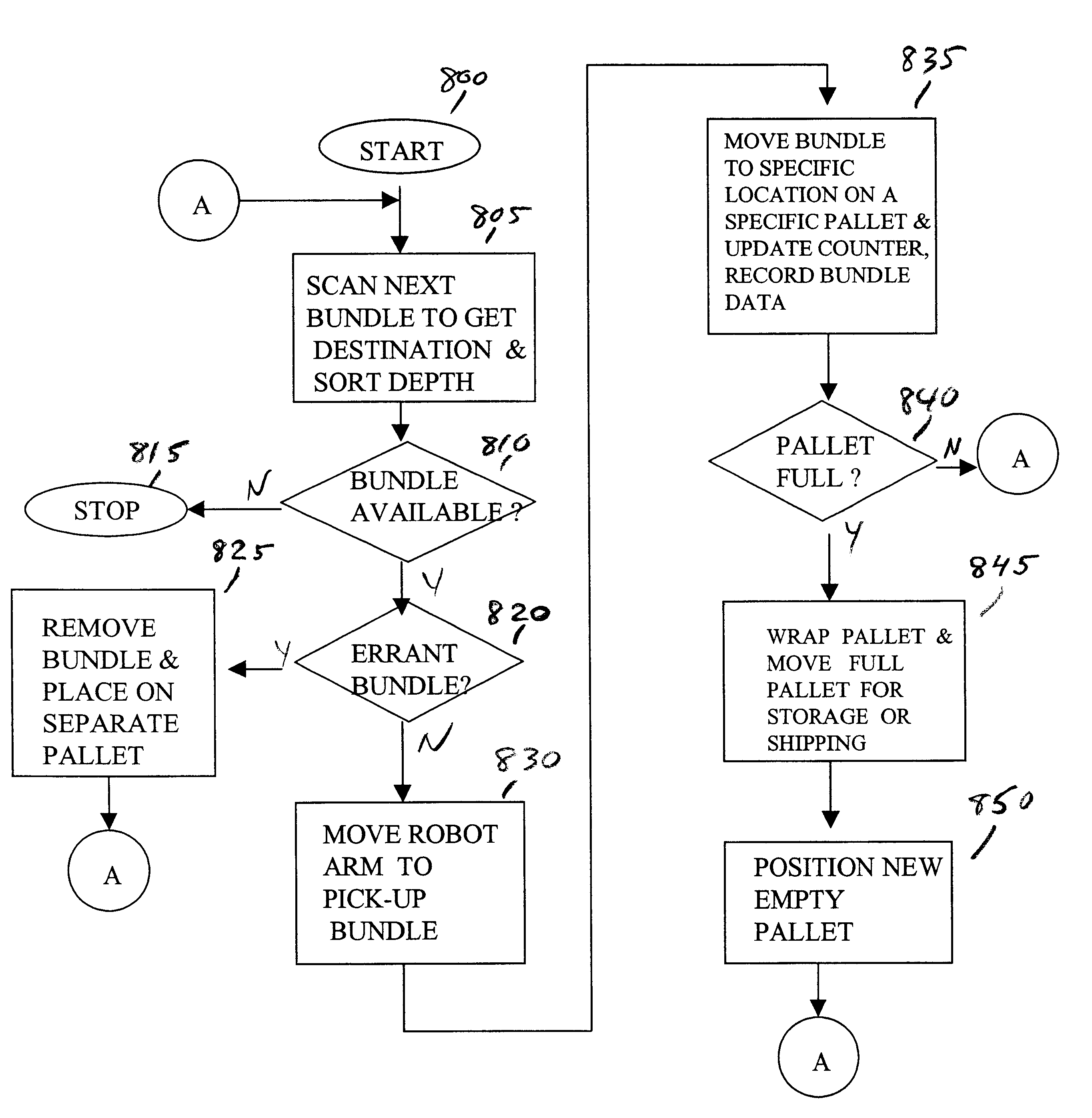

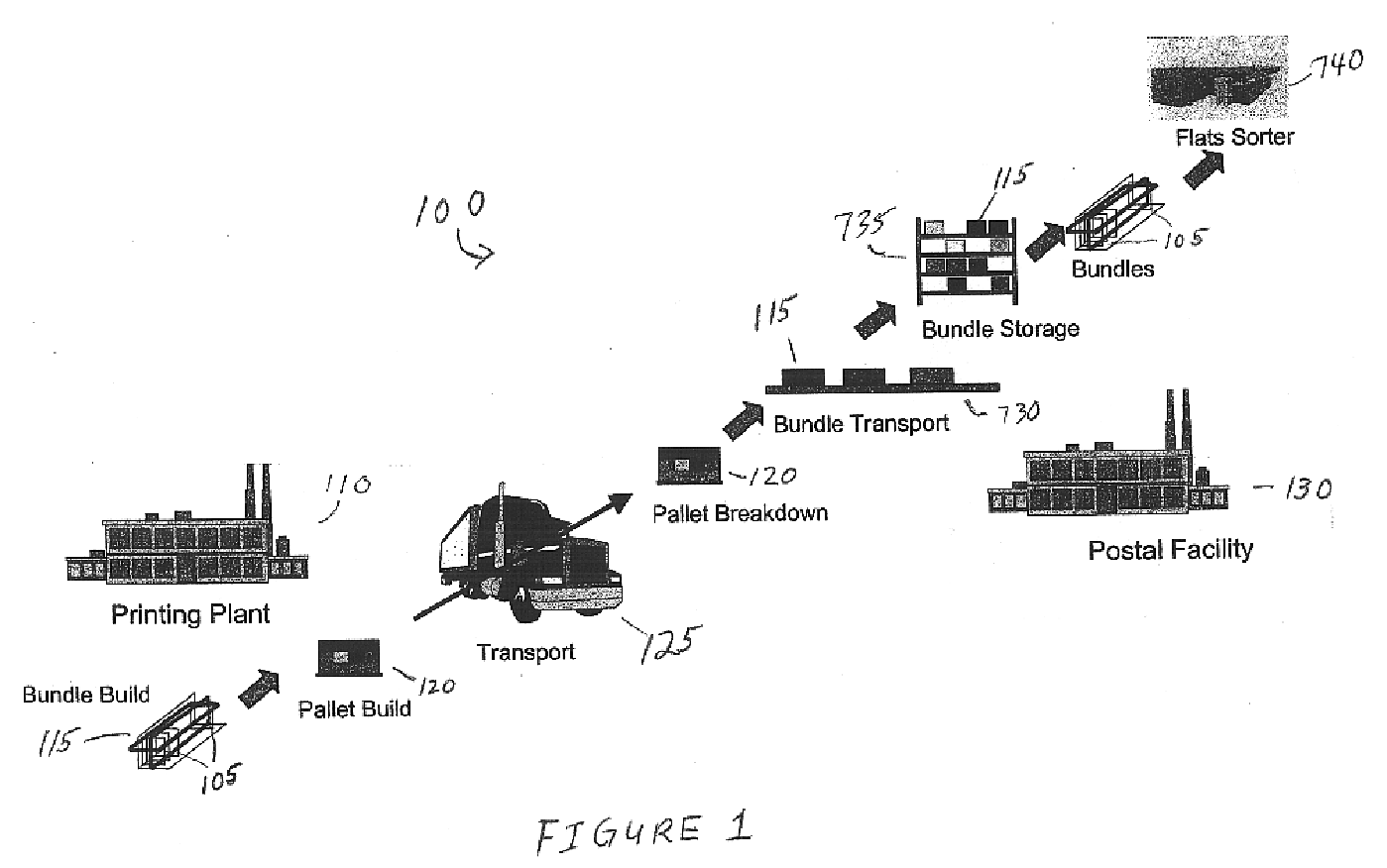

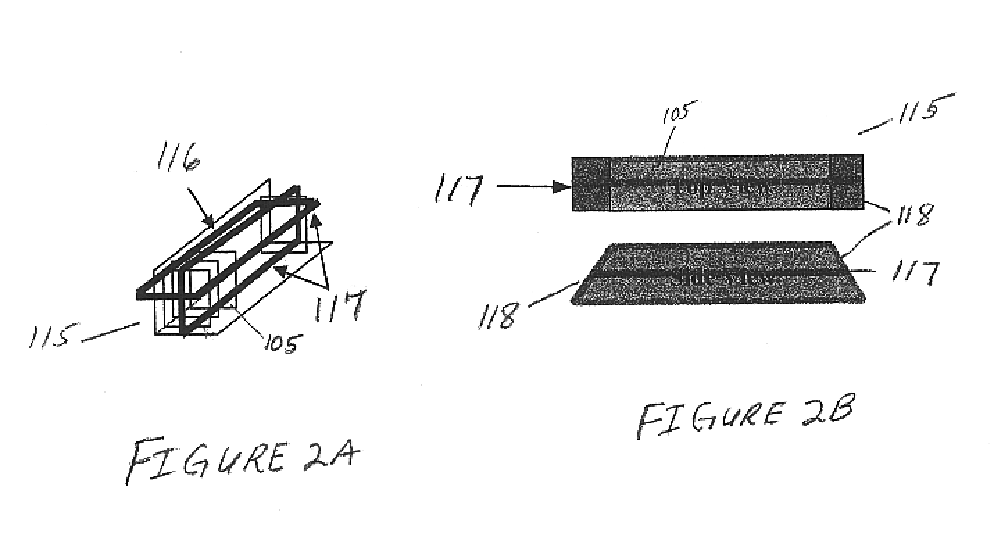

Flats bundle processing system

A processing system for automating the packaging, packing, unpacking, transfer / short term storage and loading of flats mail into flats sorters for sortation is disclosed. This involves bundling flats mail into bundles or logs and creating pallets for transporting in a standardized manner at mailer facilities such as publishers so that the sort depth and final destination of the bundle contents are preserved and used throughout its journey through postal facilities. Sort depth and destination bar coding is placed on each bundle. An automated method for palletizing involves creating a stack of bundles on a pallet in a predetermined sequence so that sorting processes in the postal facility become more efficient. Once the pallets are received at the postal facilities, the pallets are broken down in a pre-determined sequence in accordance with the sequence of original creation. The bundles are scanned into the sorter processes of the postal facility where the scanned information concerning destination codes and sort depth facilitates or eliminates routing and sorting within the postal facility, thereby reducing overhead and costs. A system to create pallets using both robotic and conveyor mechanisms is disclosed.

Owner:LOCKHEED MARTIN CORP

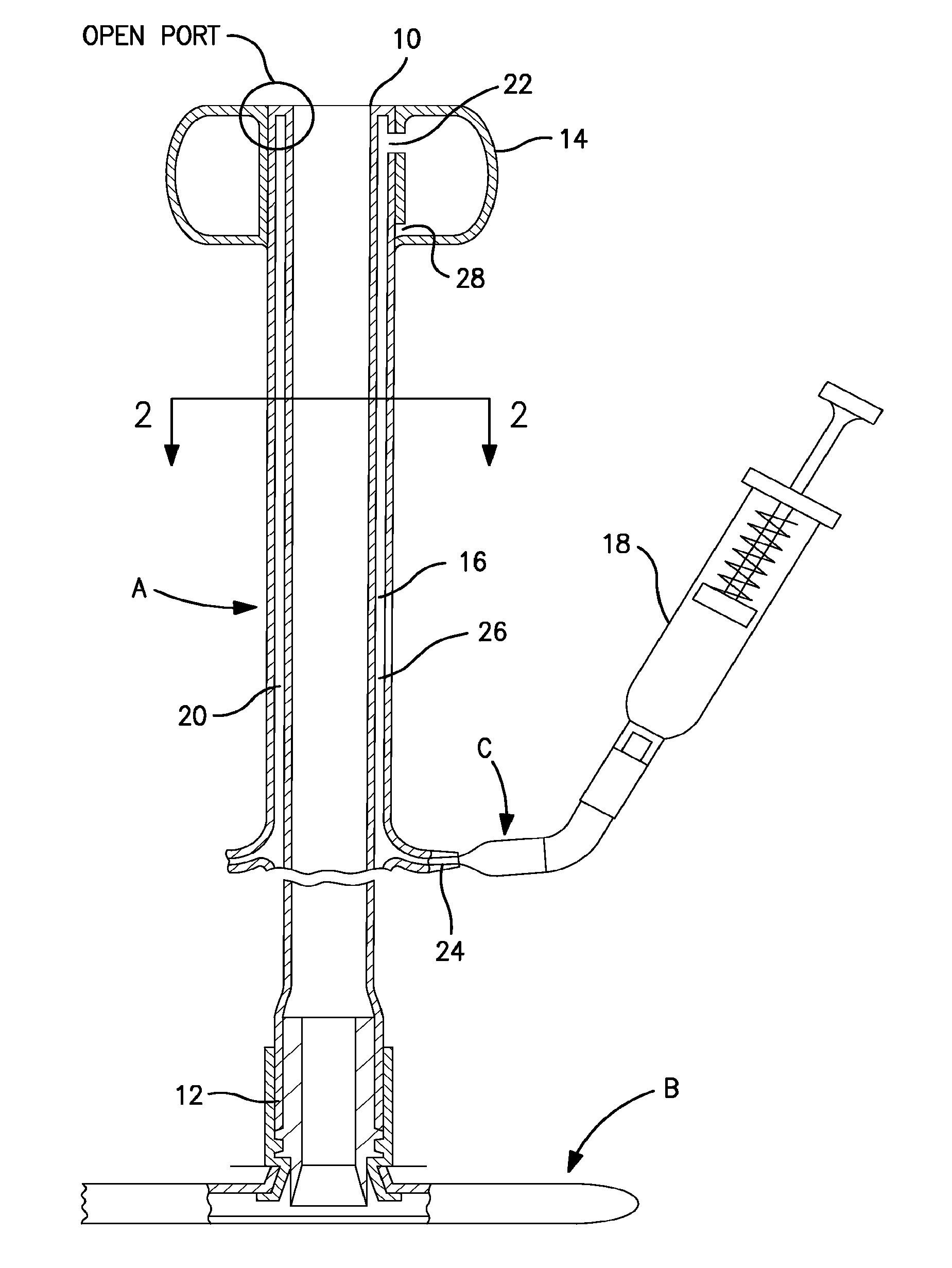

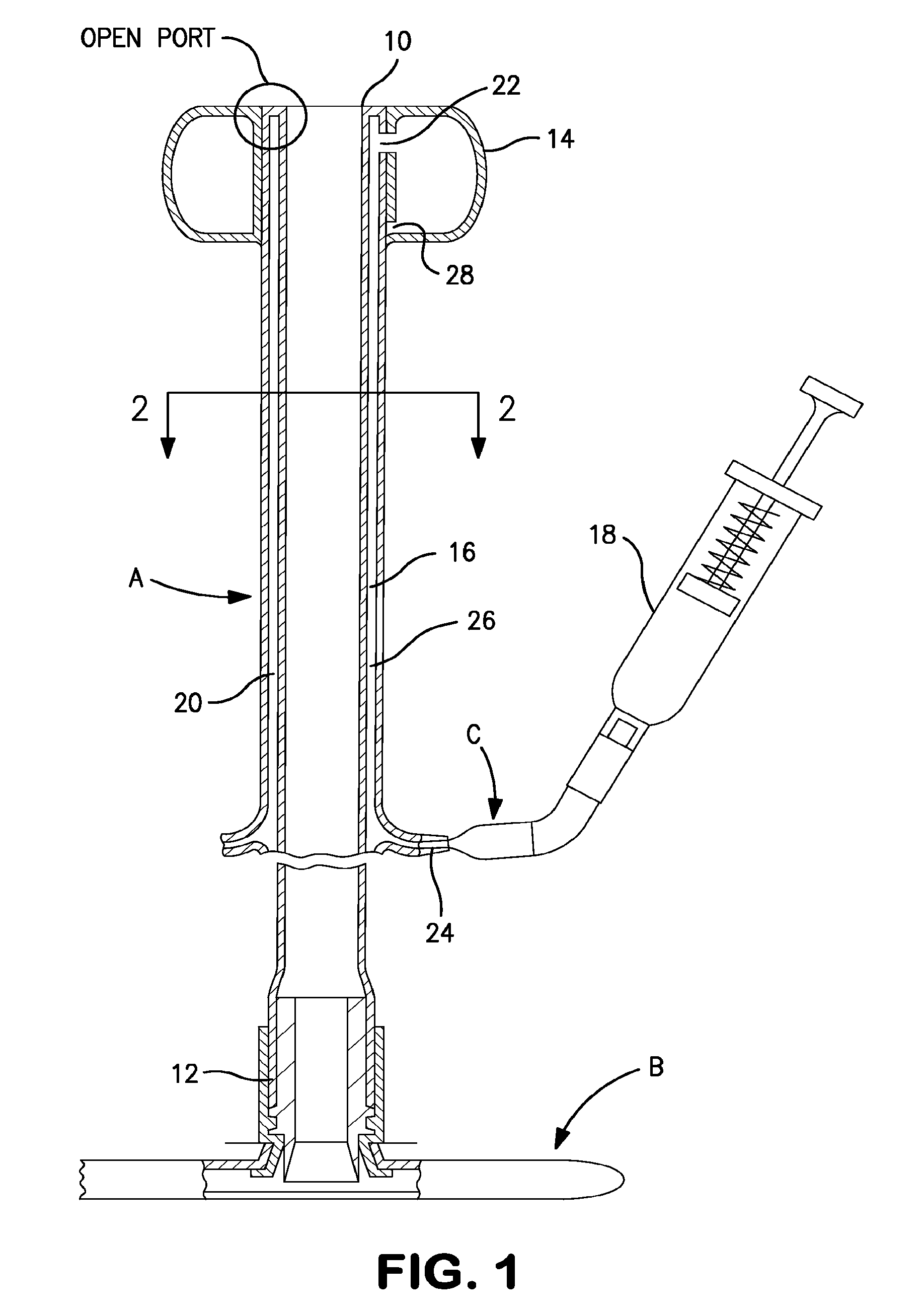

Apparatus for preventing over inflation of the retention balloon in medical catheters and airway devices

ActiveUS8888739B2Preventing inflationAvoid enteringTracheal tubesBalloon catheterMedicineBiomedical engineering

The body has a fluid inlet port for receiving pressurized fluid and a fluid outlet port connected to the retention balloon. A first passage connects the fluid inlet port and the fluid outlet port. A second passage in the body is connected to the balloon fluid return path and is at the pressure of the retention balloon. A valve prevents fluid flow through the first passage when actuated. The valve includes a pressure-responsive member movable to a position to obstruct fluid flow in response to fluid pressure in the second passage exceeding the predetermined level. Flexible means such as a membrane defines a normally open portion of the first fluid passage, which is closed by the moveable means bearing on the membrane when pressure exceeding the predetermined level actuates the valve.

Owner:CONVATEC TECH INC

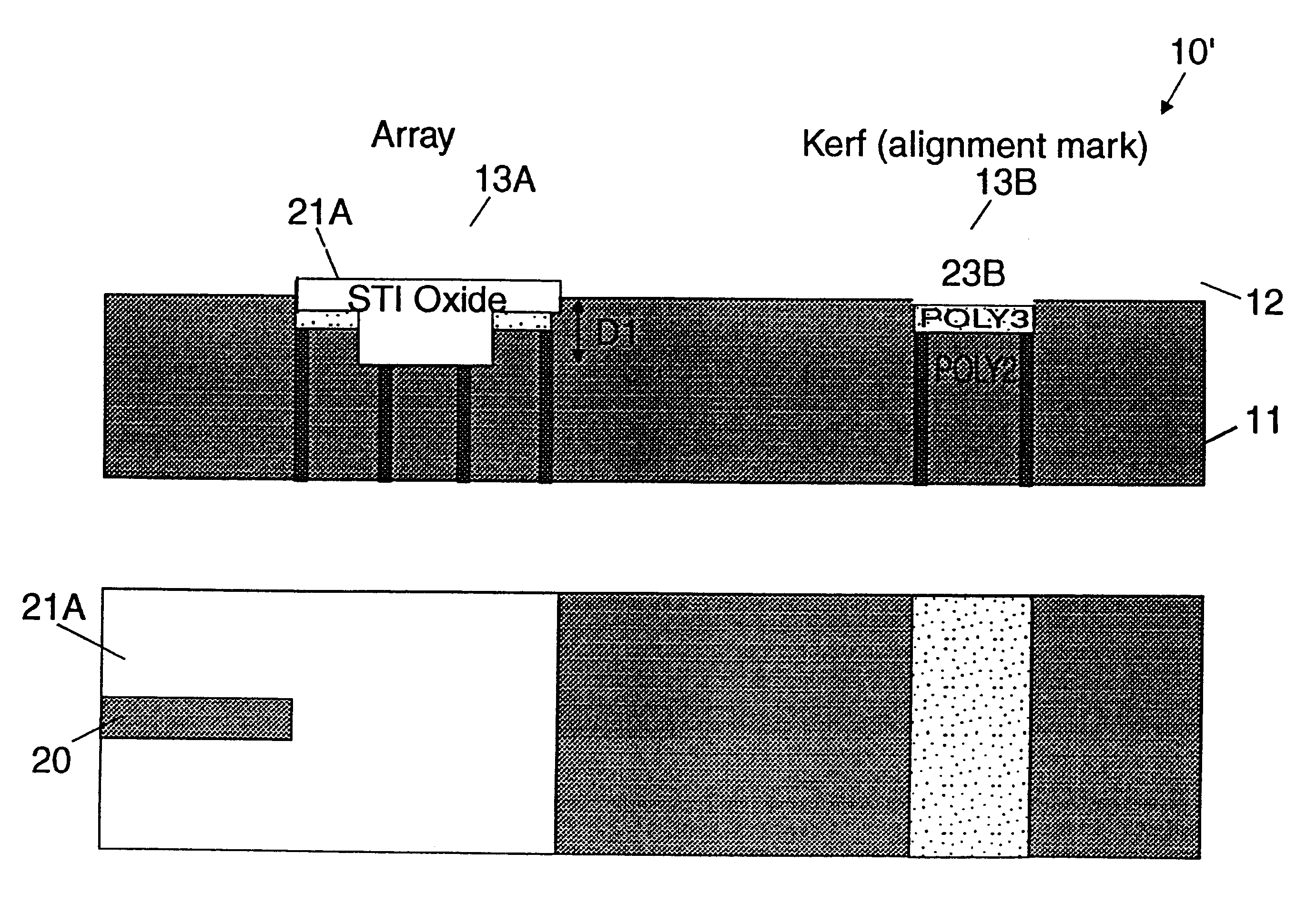

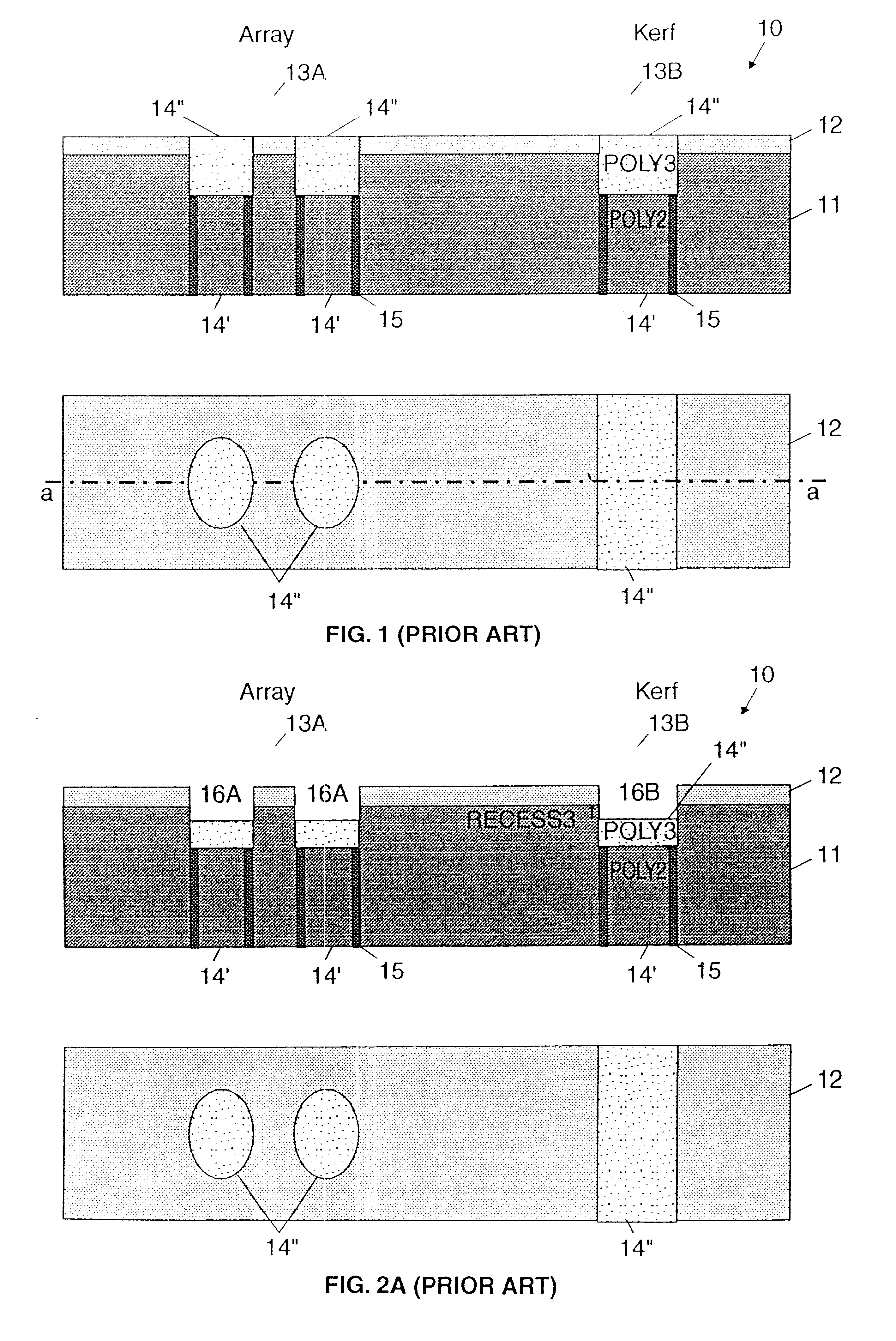

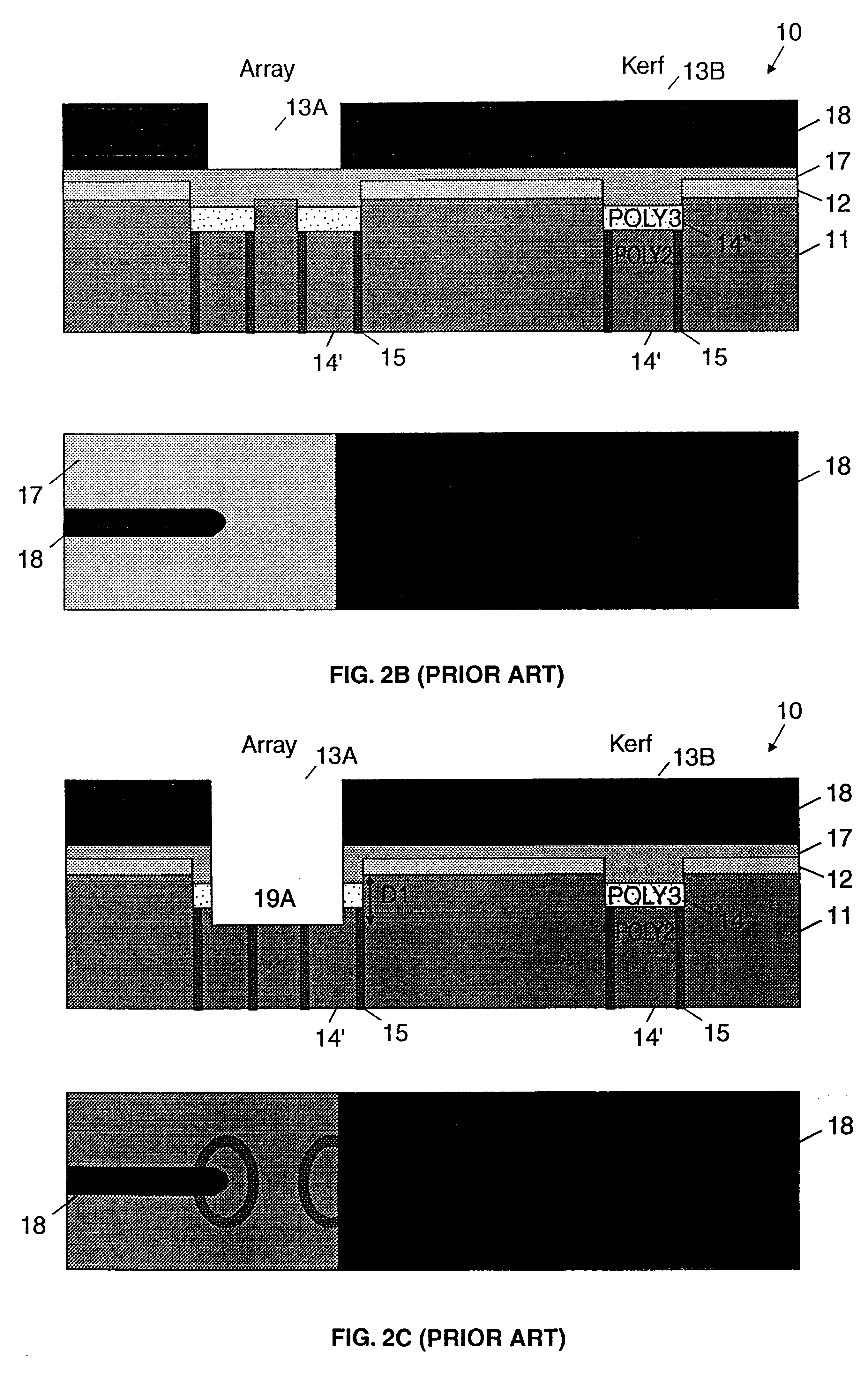

Method of forming STI oxide regions and alignment marks in a semiconductor structure with one masking step

InactiveUS6417072B2Increase capacitySimple processSemiconductor/solid-state device manufacturingResistSemiconductor structure

The method of the present invention applies to any semiconductor structure provided with polysilicon filled deep trenches formed in a silicon substrate coated by a Si3N4 pad layer both in the "array" and "kerf" areas. First, a photoresist mask is formed onto the structure and patterned to expose the deep trenches only in the "array" areas. Deep trenches are then anisotropically dry etched to create recesses having a determined depth. Next, the photoresist mask is removed only in the "array" areas. A step of anisotropic dry etching is now performed to extend said recesses down to the desired depth to create the shallow isolation trenches. The photoresist mask is totally removed. A layer of oxide (STI oxide) is conformally deposited by LPCVD onto the structure to fill said shallow isolation trenches in excess. The structure is planarized to create the STI oxide regions and expose deep trenches in the "kerf" areas. The polysilicon in these deep trenches is partially or totally removed by etching. Finally, the Si3N4 pad layer is eliminated, creating recesses that will be used as alignment marks for the subsequent photolithography steps. If the polysilicon is not etched, the above method will produce polysilicon bumps instead that can be used for the same purpose.

Owner:IBM CORP

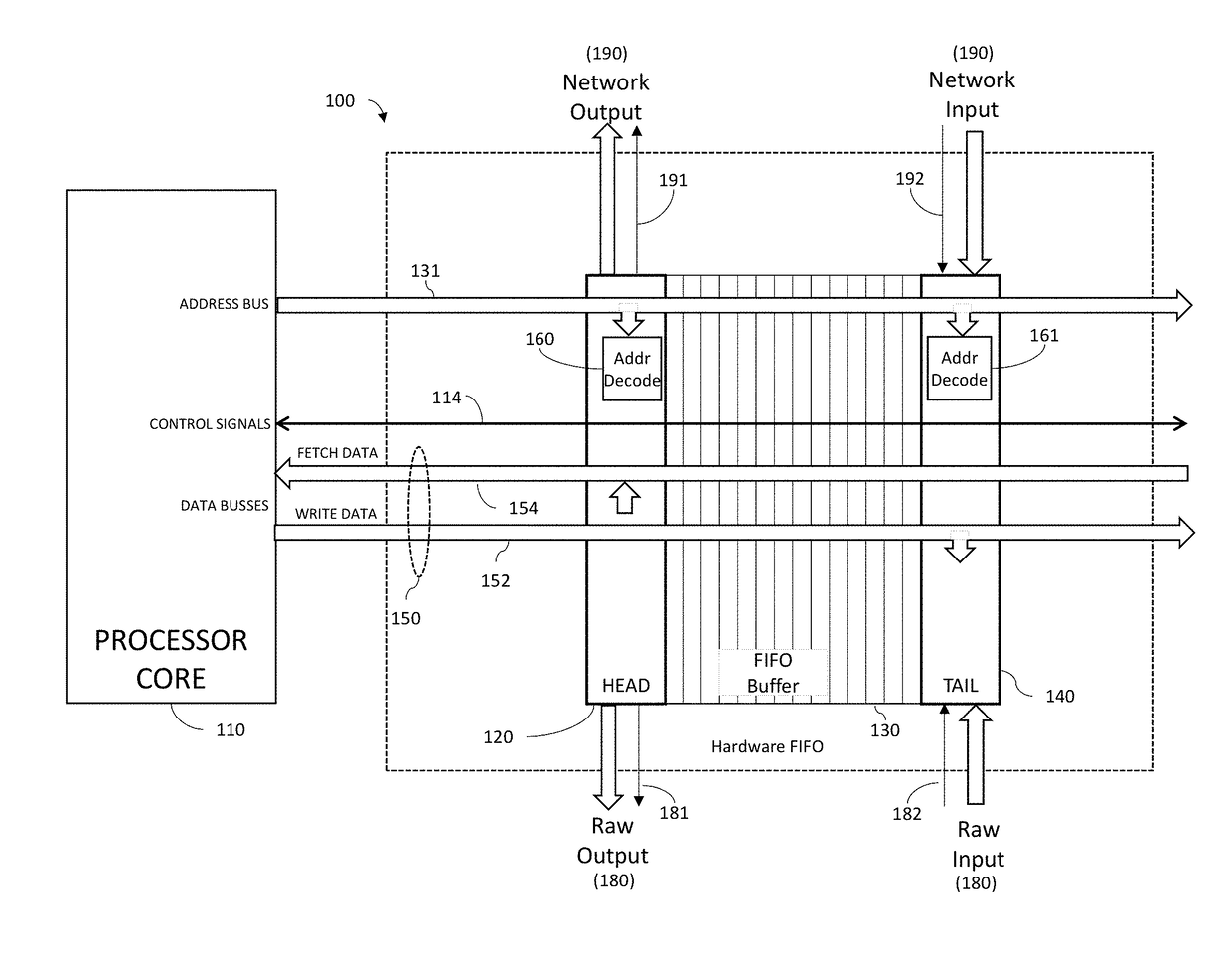

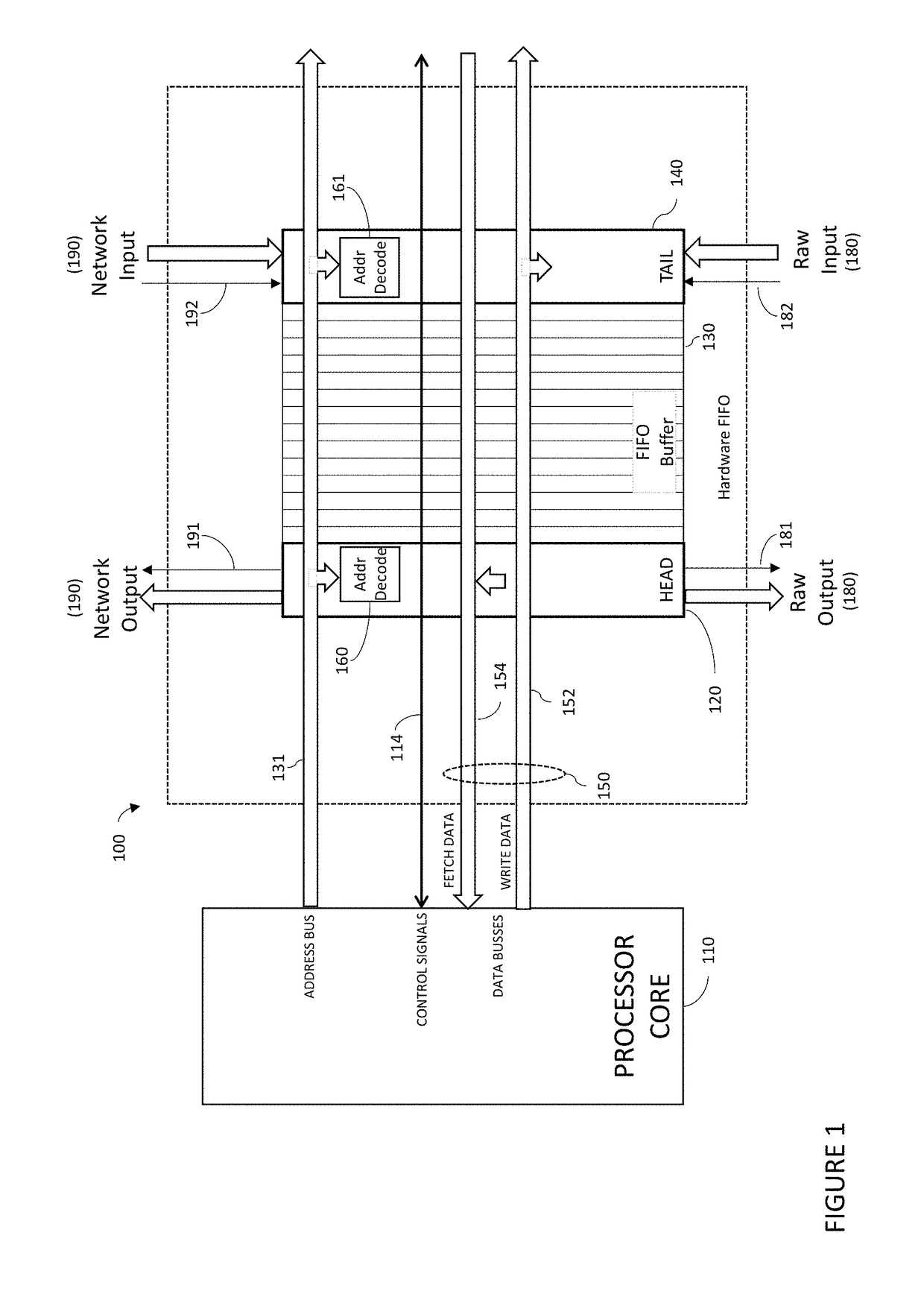

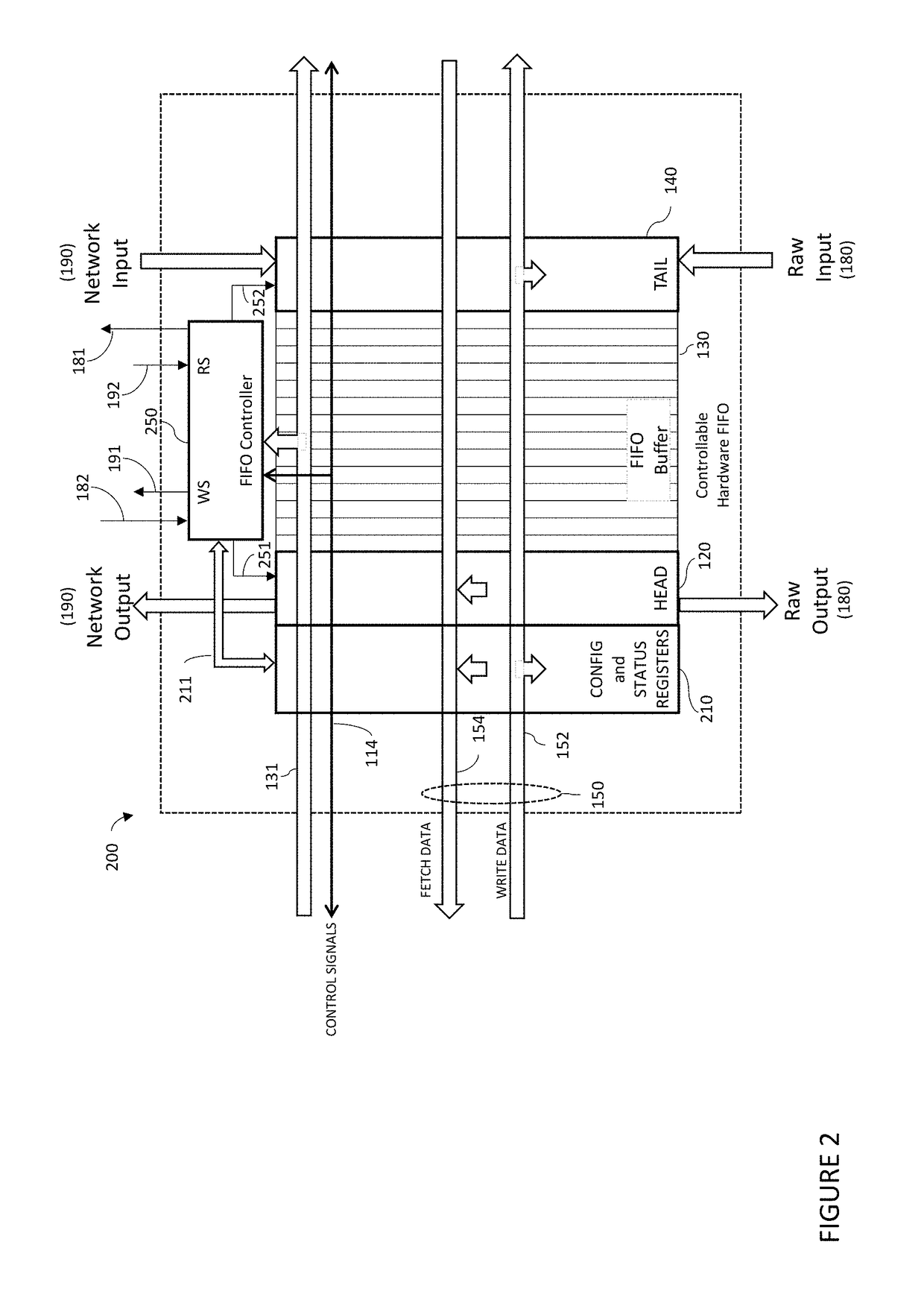

Systems and method for mapping fifos to processor address space

ActiveUS20180137075A1Efficiently manipulate incoming and outgoing dataIncrease capacityEngine sealsBearing componentsOriginal dataMemory map

An apparatus for a microprocessor computer system and method for configuring the same where said microprocessor computer system comprises a processor core and at least one hardware buffer FIFO with memory-mapped head and tail that handles data movement among the processor cores, networks, raw data input and outputs, and memory. The method for configuring said microprocessor computer system comprises utilizing a FIFO auxiliary processor to process said data traversing said hardware FIFO; utilizing said hardware FIFOs to efficiently pipe data through functional blocks; and utilizing a FIFO controller to perform DMA operations that include non-unit-stride access patterns and transfers among processor cores, networks, raw data input and outputs, memory, and other memory-mapped hardware FIFOs.

Owner:GOVERNMENT OF THE UNITED STATES AS REPRESENTED BY THE SEC OF THE AIR FORCE

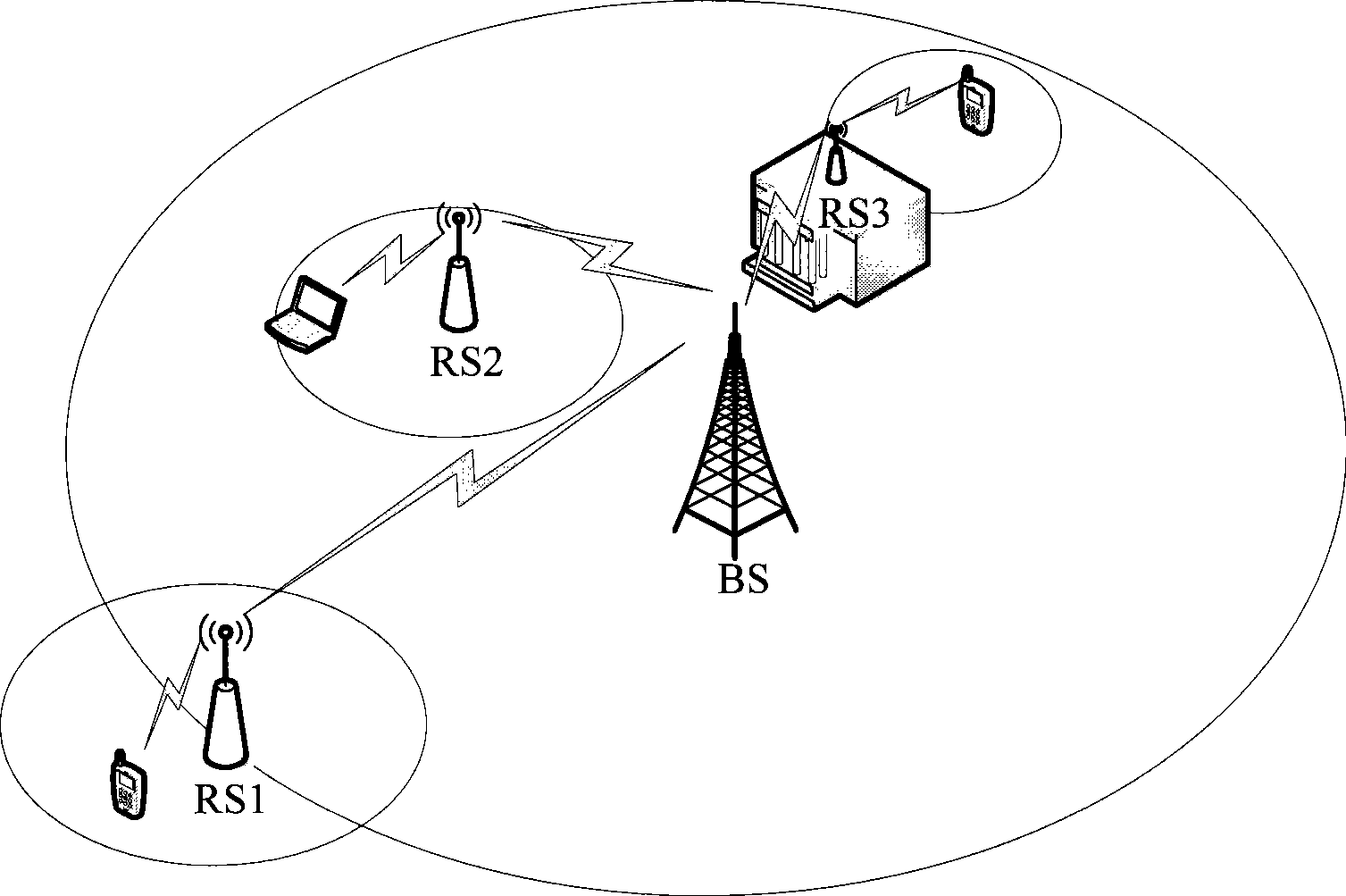

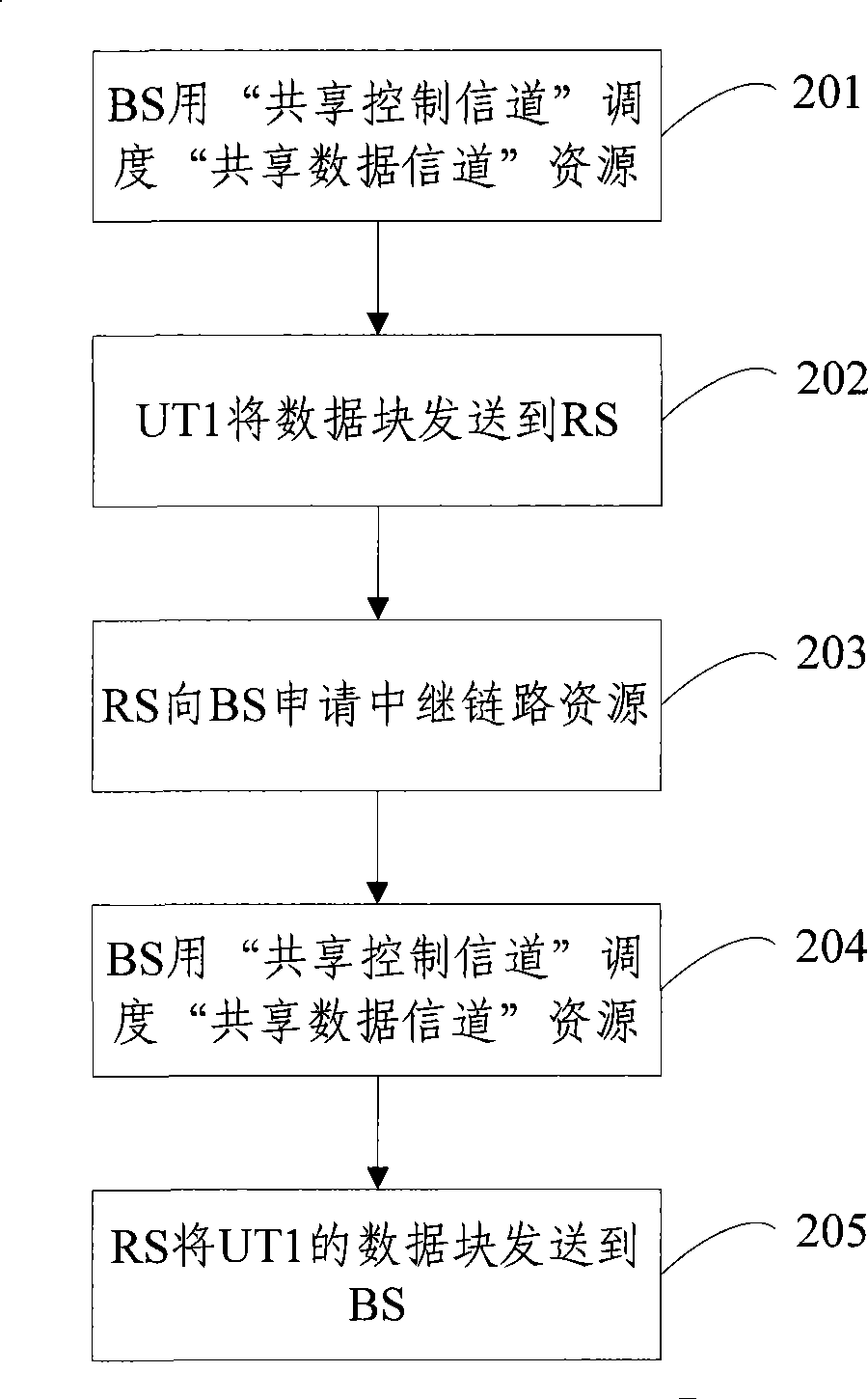

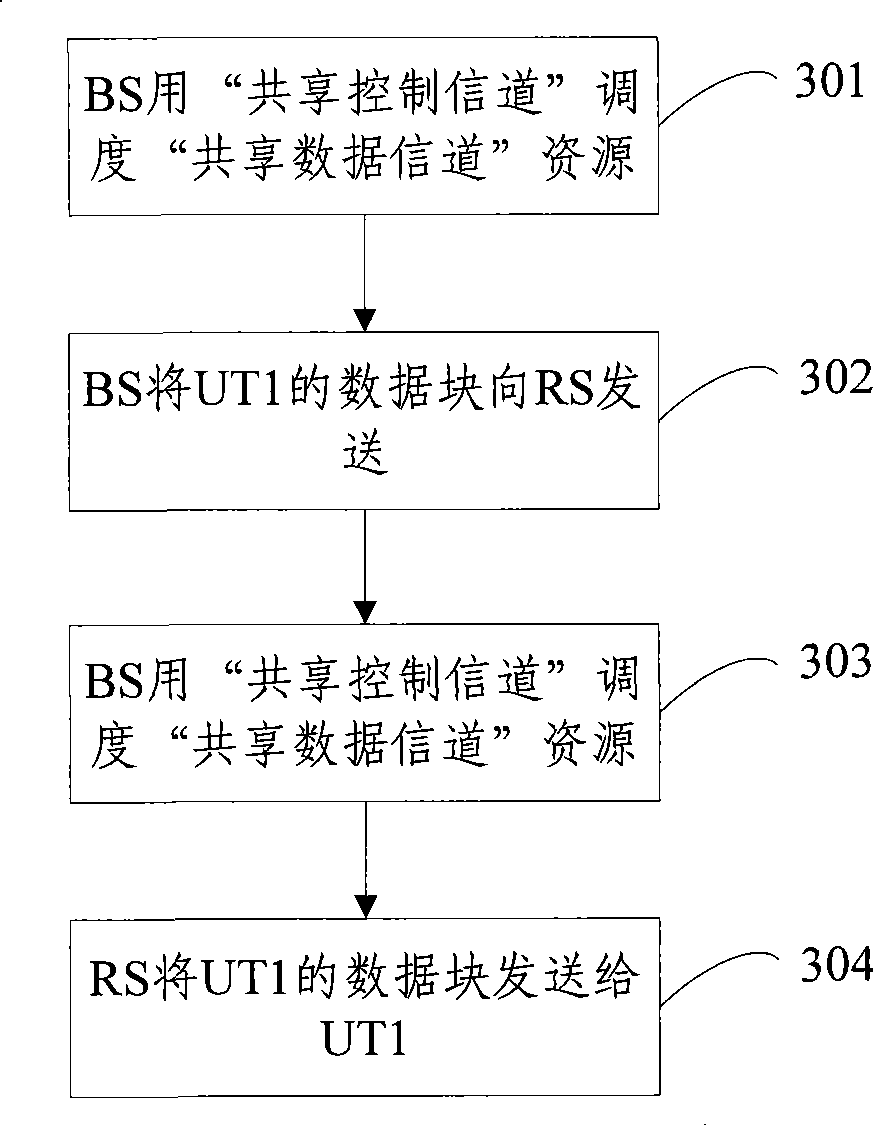

Method, relay and base station for data transmission on relay link

The invention discloses a method for performing data transmission on a relay link, namely, sending nodes connect the data block with the same sending time and the same receiving node at the next jumping destination in series, and transmit to the receiving node for one time. Meanwhile, the invention also discloses a base station and a relay for realizing the method. According to the method, the base station and the relay of the invention, resource waste caused by using a plurality of signallings when single transmission on the data of each terminal is adopted in the prior art is overcome, meanwhile, excessive filling on the residual parts of the physical resource blocks is avoided, thereby greatly increasing open efficiency, saving open resource.

Owner:DATANG MOBILE COMM EQUIP CO LTD

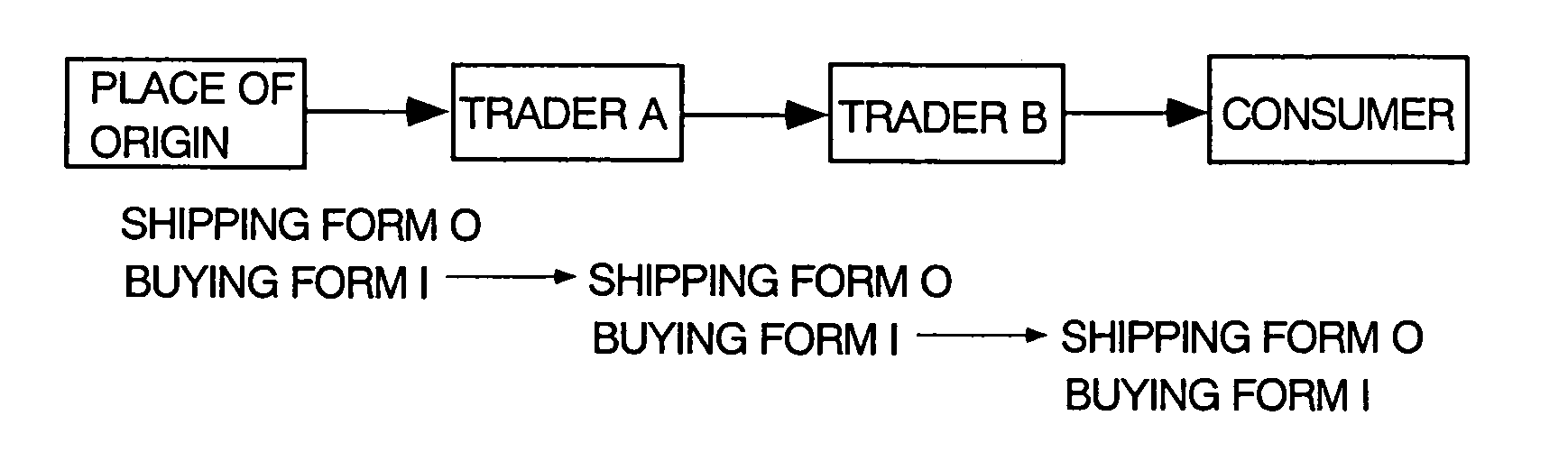

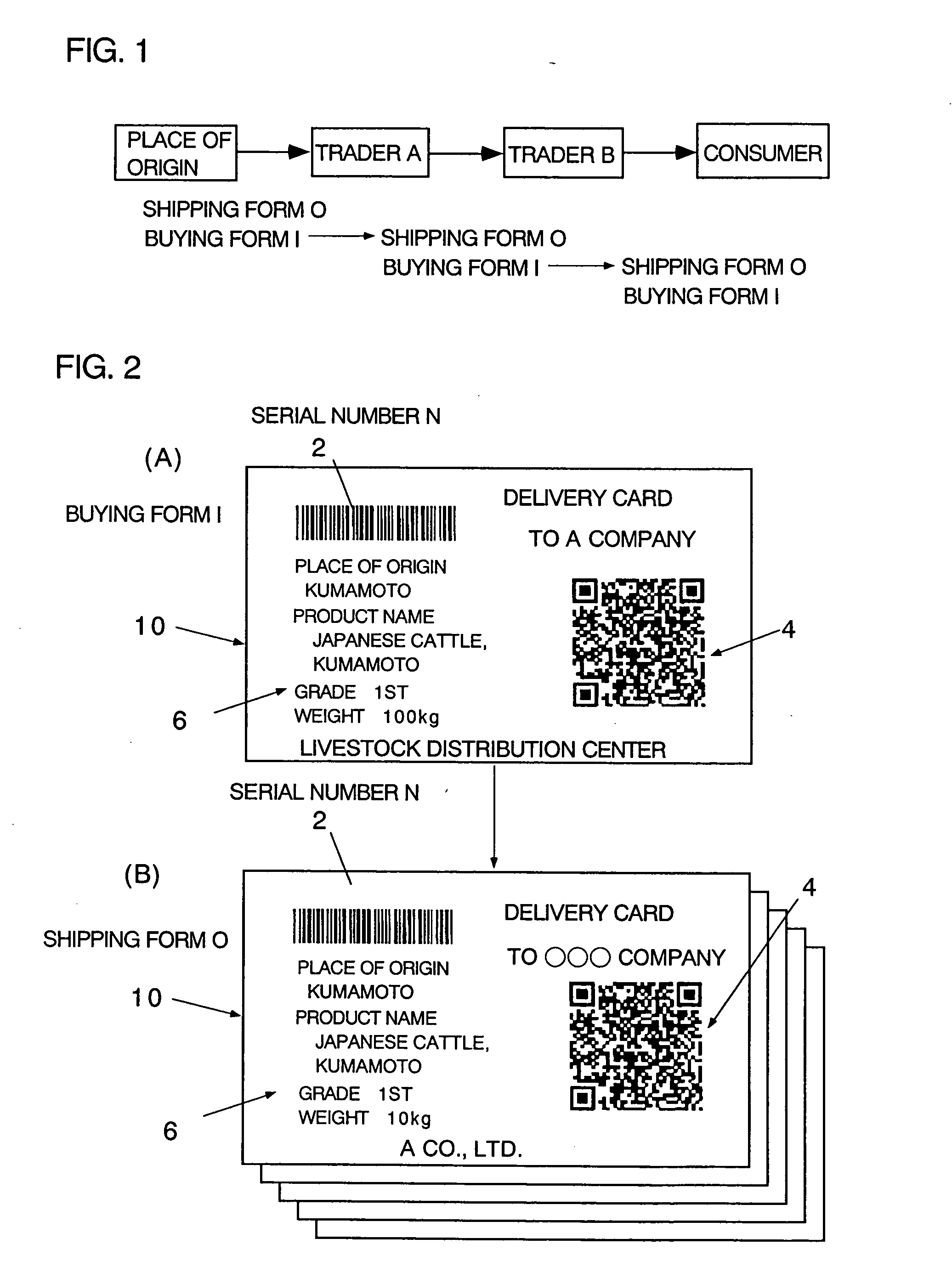

Method for preventing false indication in commodity distribution and label write device having false alteration prevention function used for the same

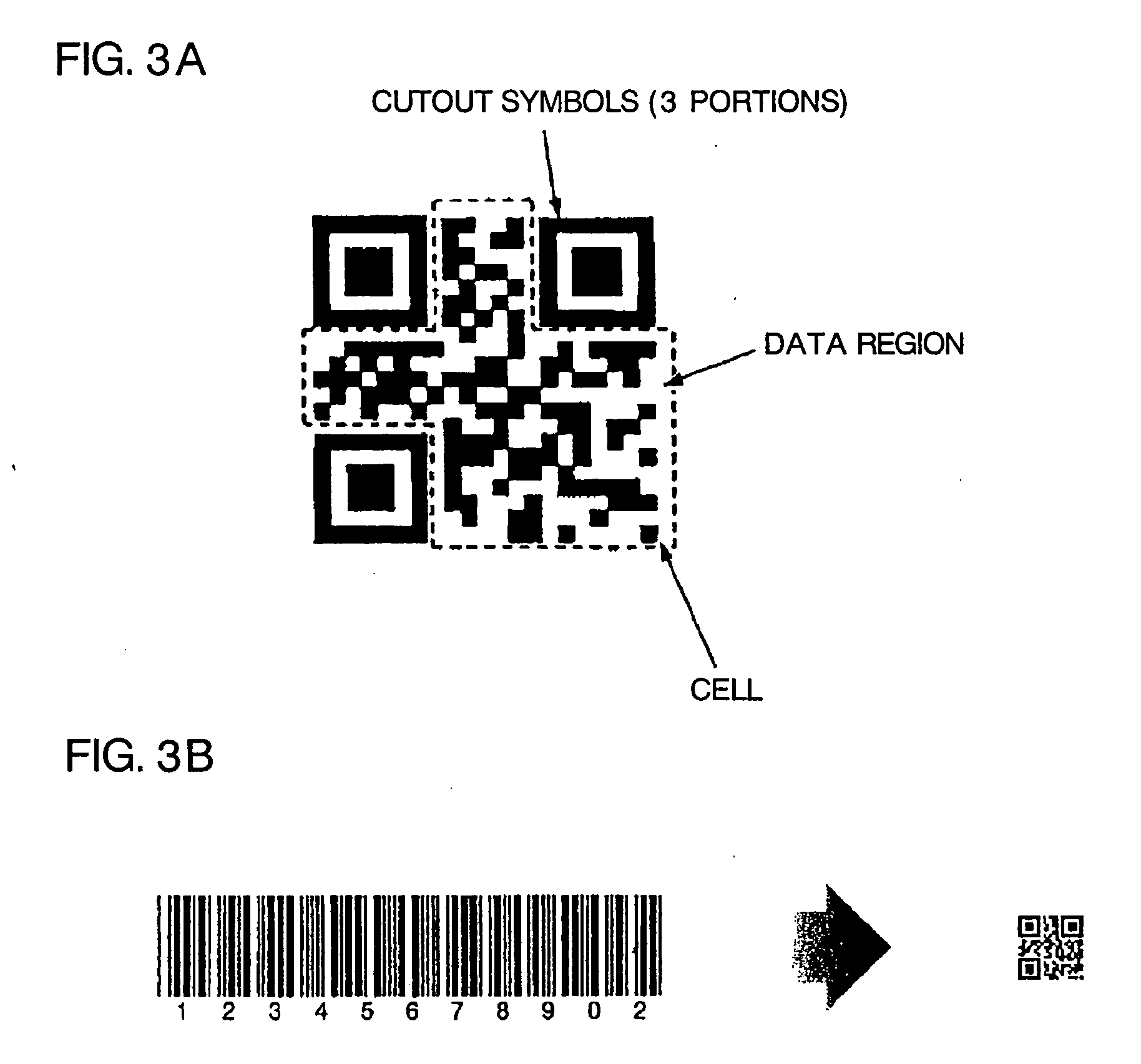

InactiveUS20050288938A1Secure traceabilityDouble useStampsPaper-money testing devicesBarcodeComputer science

Rewritable labels 10 capable of erasing and writing information are used as a buying form I and shipping form O incapable of being falsified. Each rewritable label has a barcode 2 in which a serial number N is written in a mode incapable of being erased, and an erasable two-dimensional code 4 for writing commodity information. In the two-dimensional code 4 of the buying form I, supplier's commodity information and the serial number N of the buying form I are written in a mode incapable of being falsified. In the two-dimensional code 4 of the shipping form O, at least some of contents of the two-dimensional code 4 of the buying form I, new commodity information, and the serial number N of the shipping form O are written in a mode incapable of being falsified.

Owner:RIKEN +1

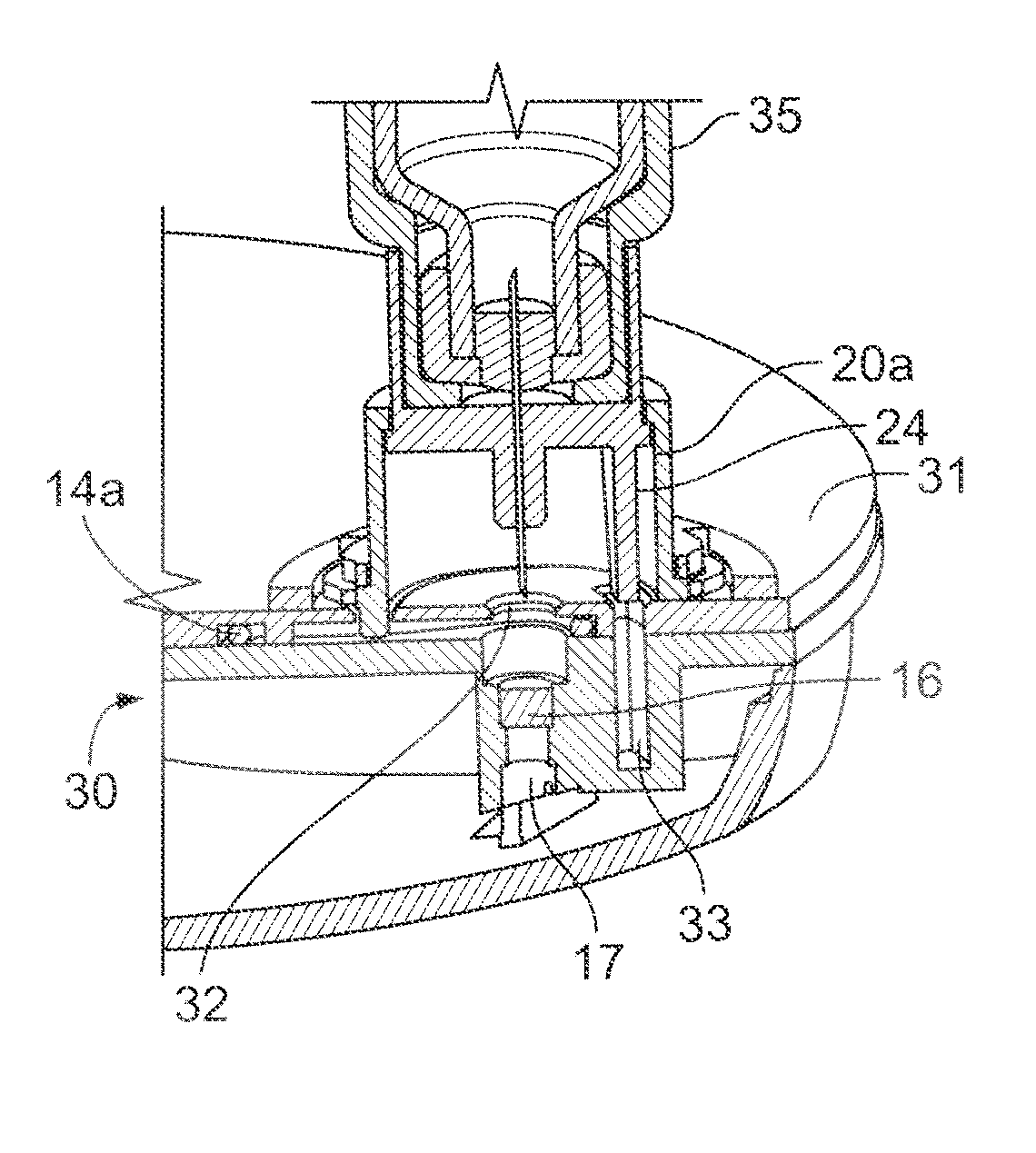

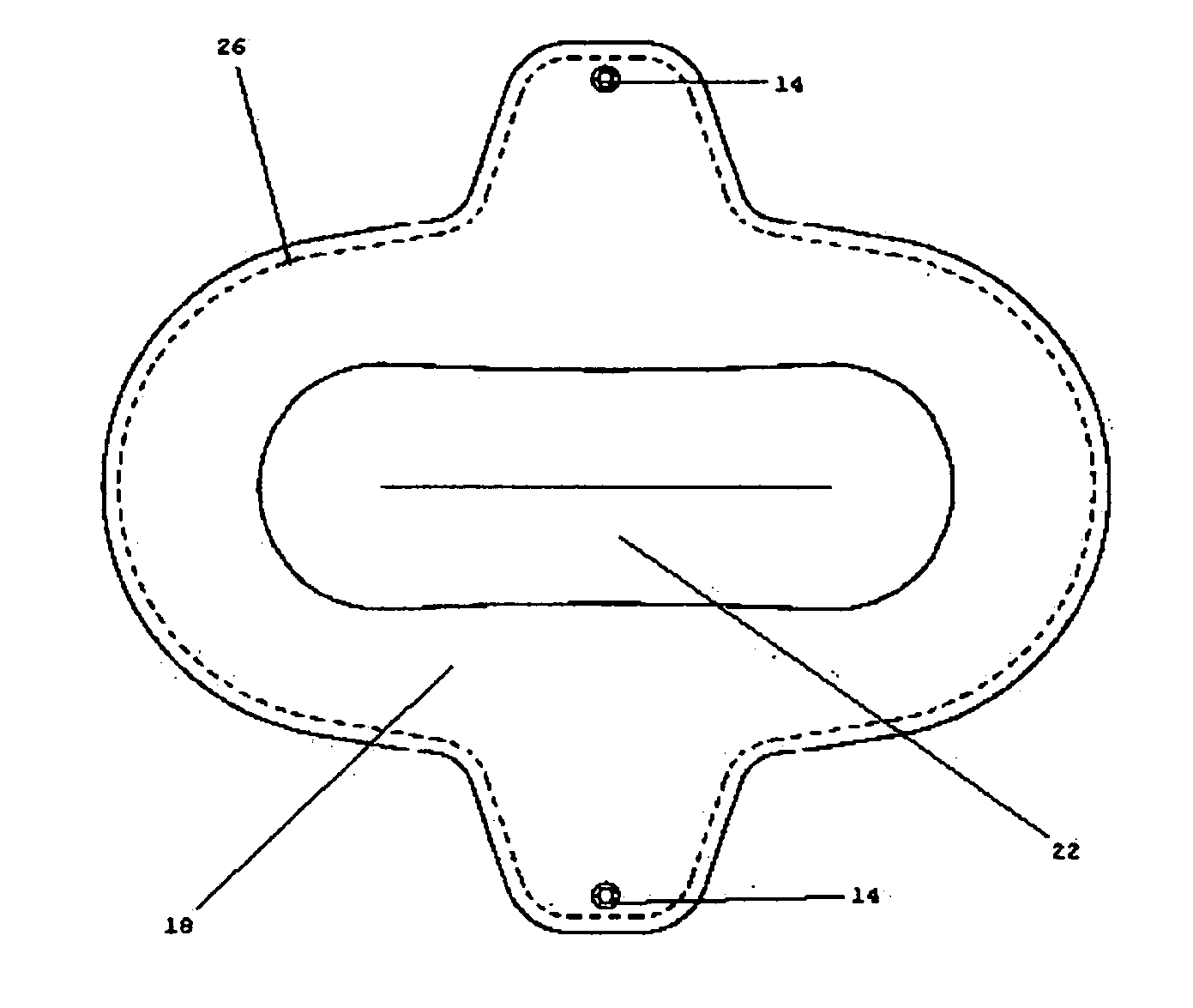

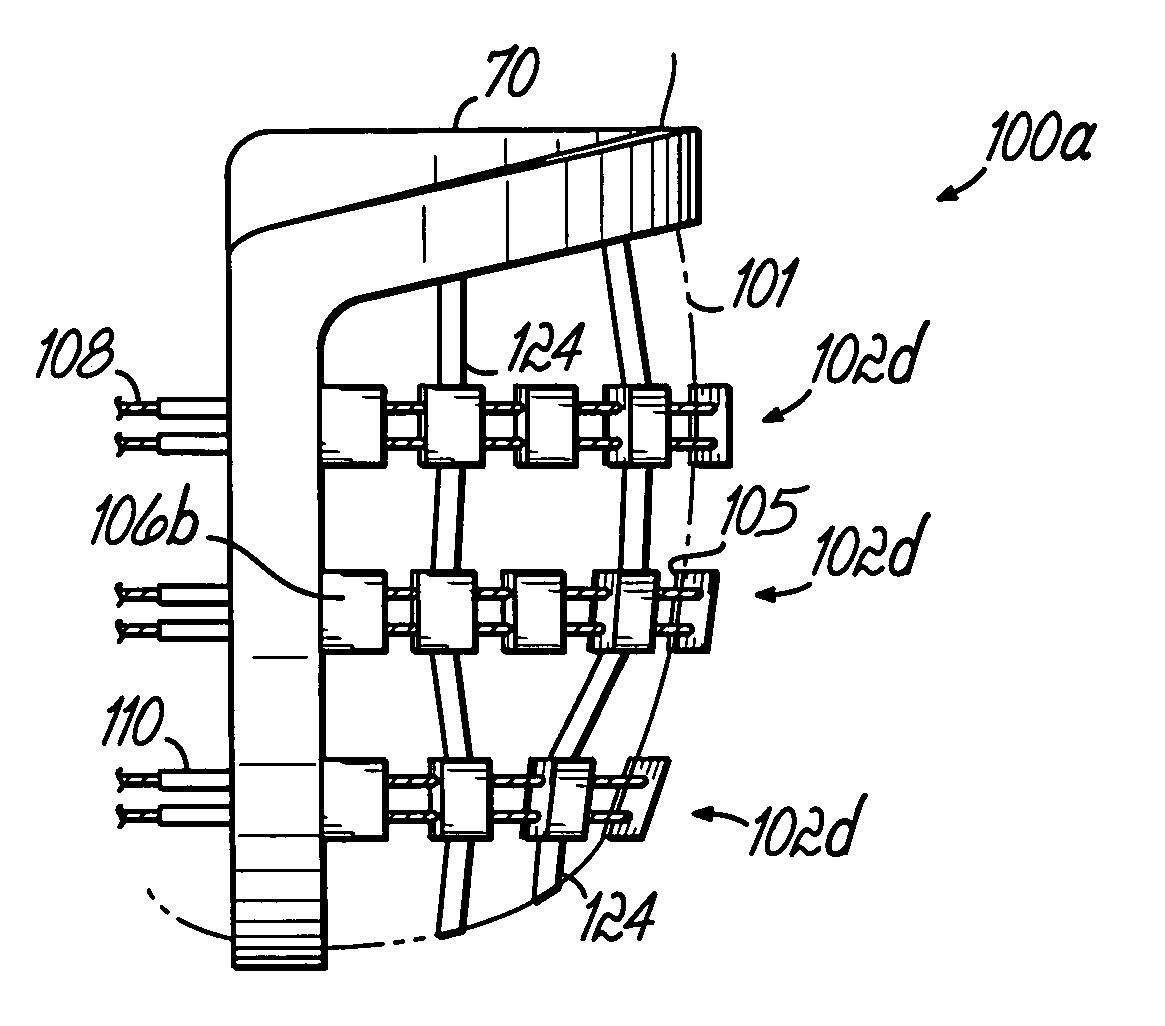

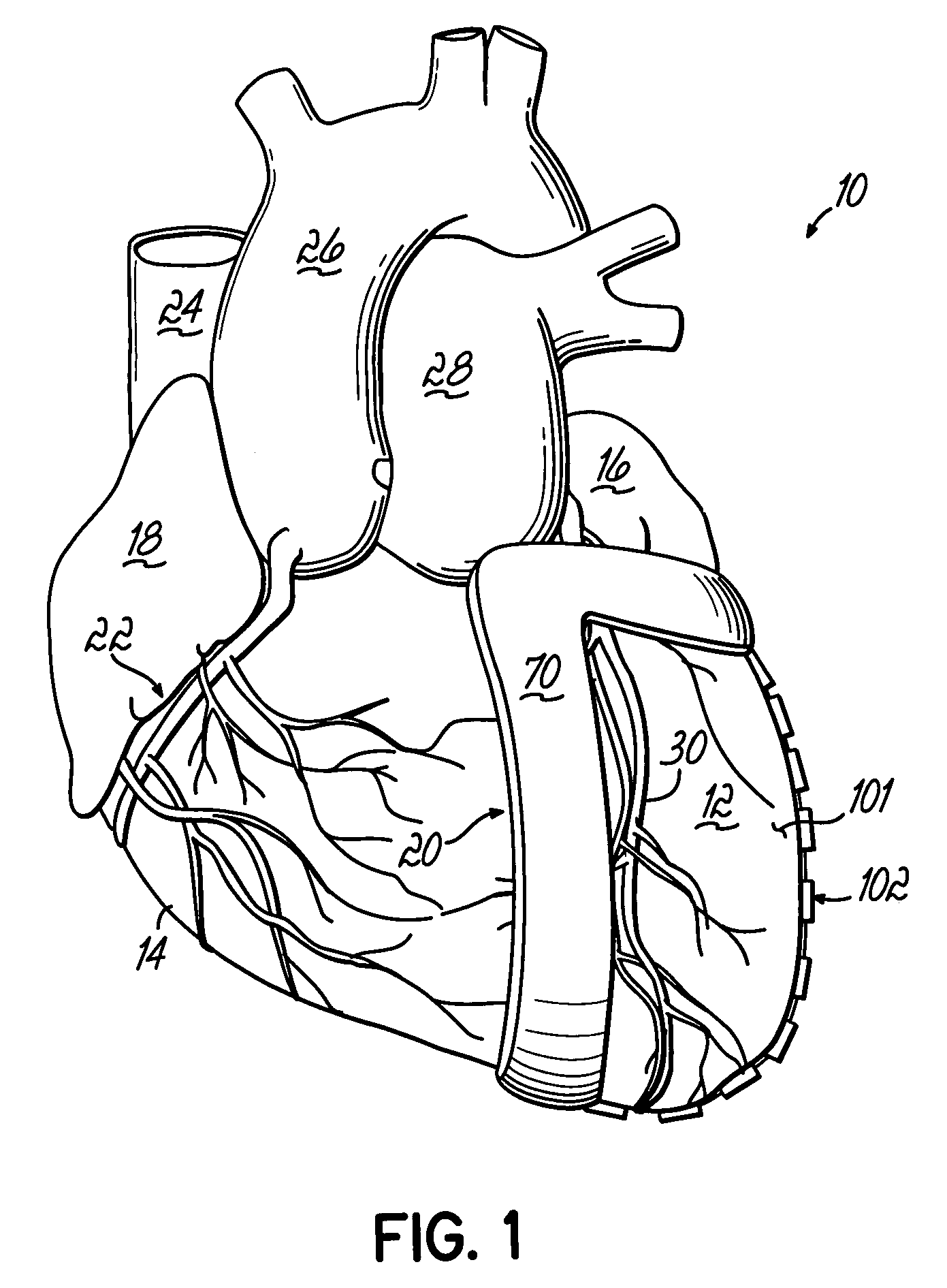

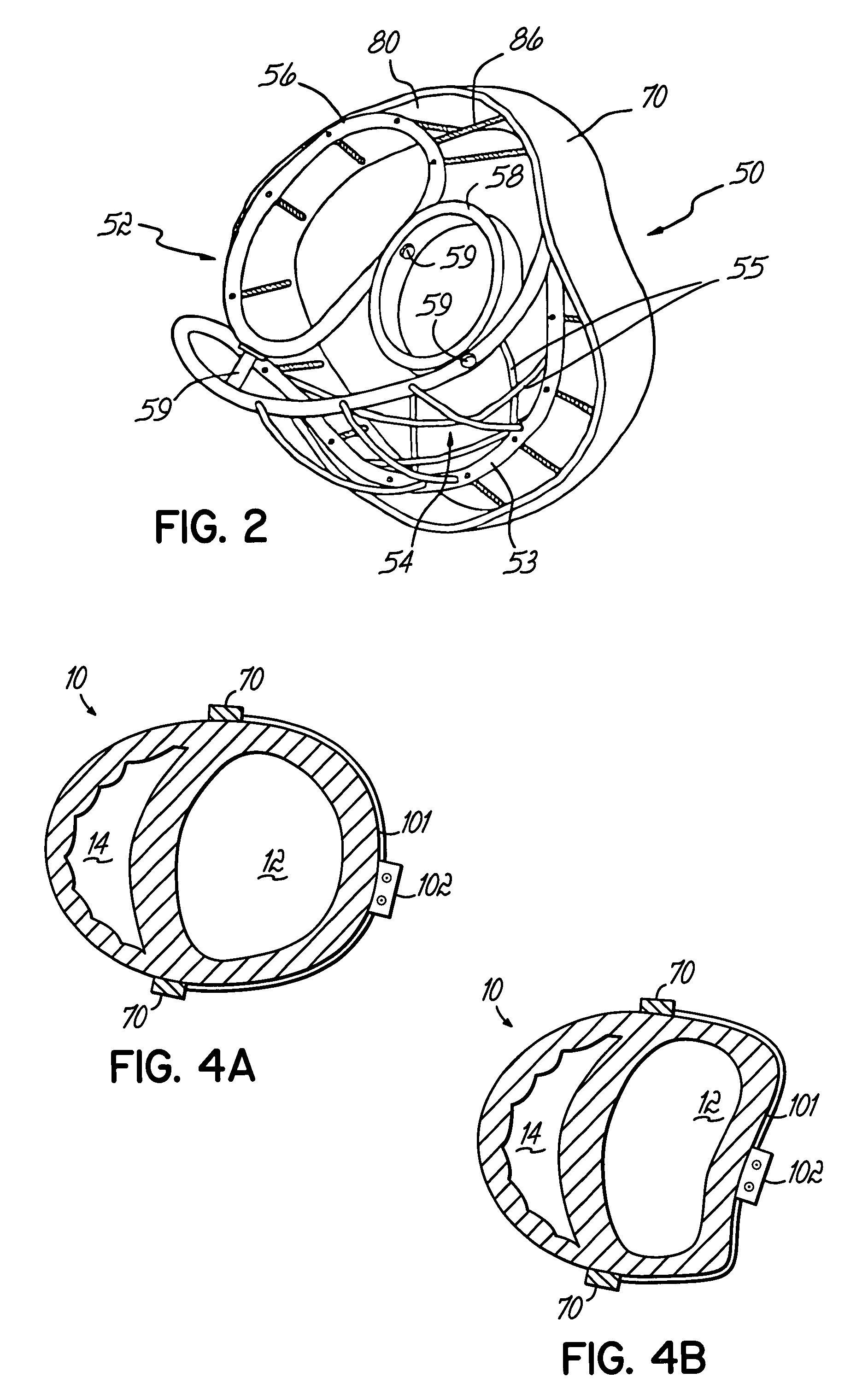

Heart wall actuation device for the natural heart

InactiveUS7361191B2Maintain abilityLower the volumeHeart valvesIntravenous devicesHeart wallEngineering

An actuation system for assisting the operation of the natural heart comprises a framework for interfacing with a natural heart, through the wall of the heart, which includes an internal framework element configured to be positioned within the interior volume of a heart and an external framework element configured to be positioned proximate an exterior surface of the heart. The internal framework is flexibly suspended with respect to the external frame. An actuator system is coupled to the framework and configured to engage an exterior surface of the heart. The actuator system comprises an actuator band extending along a portion of a heart wall exterior surface. The actuator band is selectively movable between an actuated state and a relaxed state and is operable, when in the actuated state, to assume a predetermined shape and thereby indent a portion of the heart wall to effect a reduction in the volume of the heart. A drive apparatus is coupled to the actuator band and is operable for selectively moving the actuator band between the relaxed and actuated states to achieve the desired assistance of the natural heart.

Owner:UNIVERSITY OF CINCINNATI

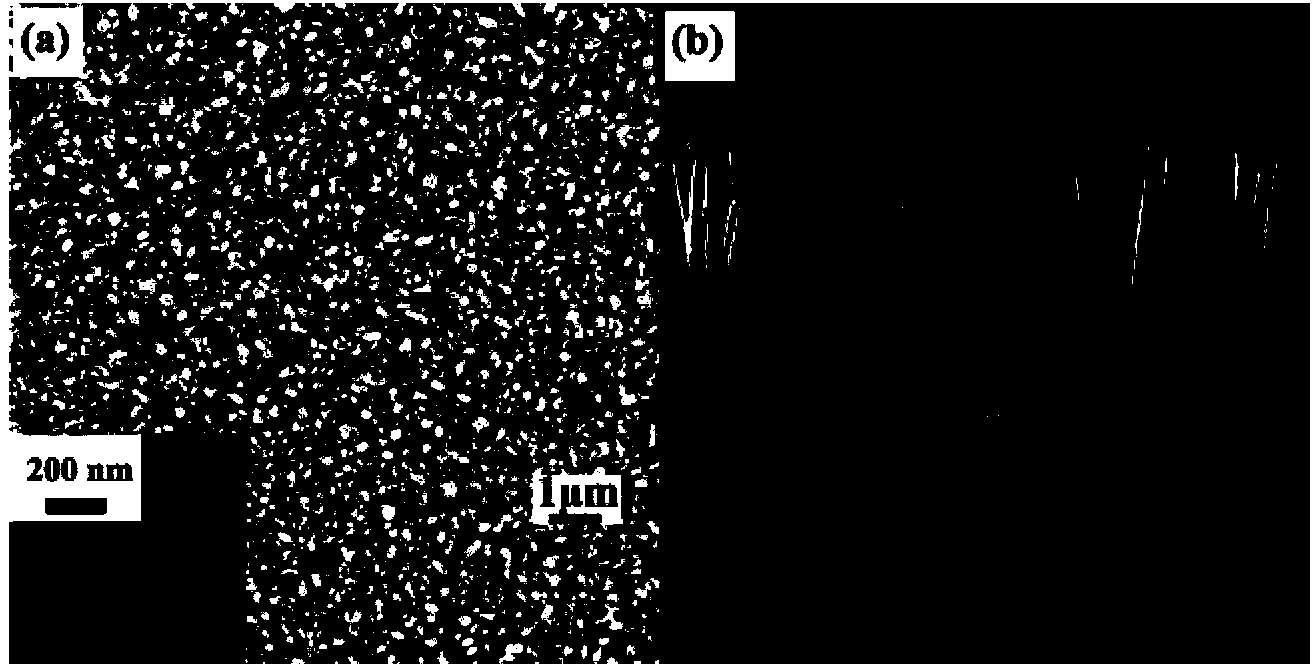

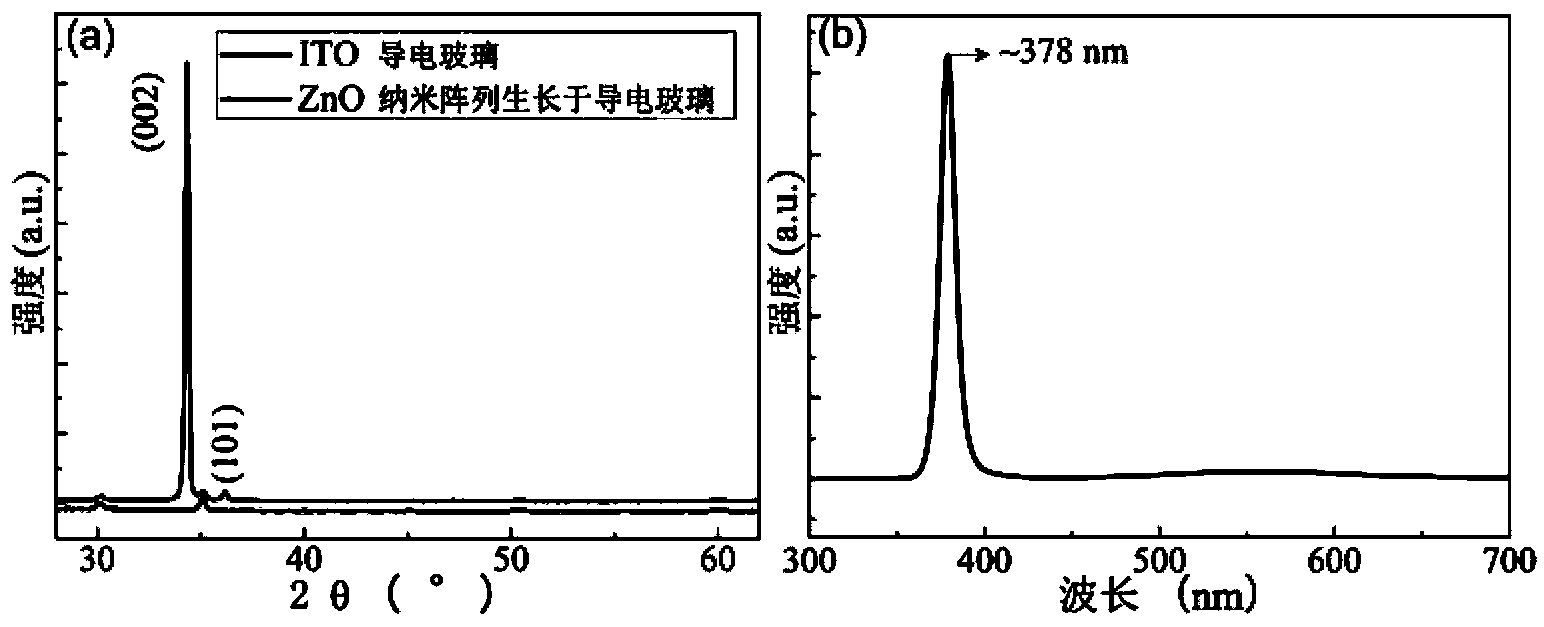

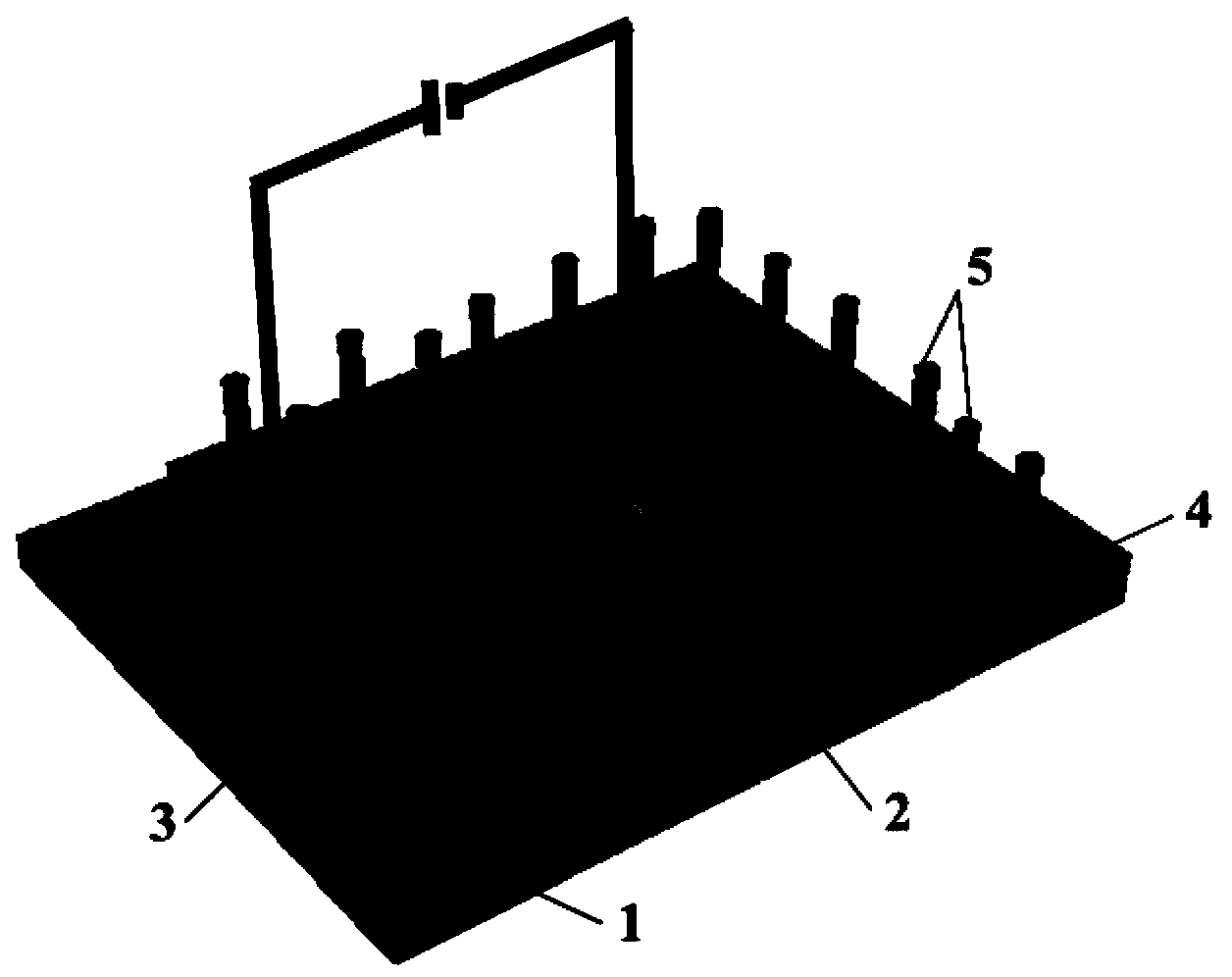

ZnO nanometer array ultraviolet detector and manufacturing method thereof

ActiveCN103441154ASimplify the build processImprove collection efficiencyFinal product manufactureSemiconductor devicesUltraviolet detectorsThin membrane

The invention discloses a ZnO nanometer array ultraviolet detector and a manufacturing method of the ZnO nanometer array ultraviolet detector. The structure of the ultraviolet detector is of a metal-semiconductor-metal contact type. The ultraviolet detector sequentially comprises a substrate of ITO conductive glass or FTO conductive glass, a ZnO film, an electrode at the other end and a ZnO nanometer array from bottom to top. The substrate is an electrode at one end; the ZnO film covers the substrate, the electrode at the other end is located in the middle position of the ZnO film, and the ZnO nanometer array is arranged on the periphery of the electrode at the other end; the area of the electrode at the other end is 10%-12% of the total area of the substrate. The manufacturing method comprises the following steps: firstly, performing sputtering on the substrate through magnetic control to produce a layer of ZnO film, secondly, installing electrodes on the ZnO film and leading out one end of a wire, thirdly, covering the electrodes with PDMS protection layers, fourthly, developing the ZnO nanometer array through a hydrothermal method, finally, scraping off part of ZnO at the edge on one side of a sample so that the substrate of the conductive glass can be exposed, and leading out the other end of the wire. Thus, the ultraviolet detector is obtained. The ultraviolet detector and the manufacturing method of the ultraviolet detector have the advantages of being simple in manufacturing process, easy to operate, low in cost, high in device sensitivity, stable in performance and the like.

Owner:UNIV OF SCI & TECH BEIJING

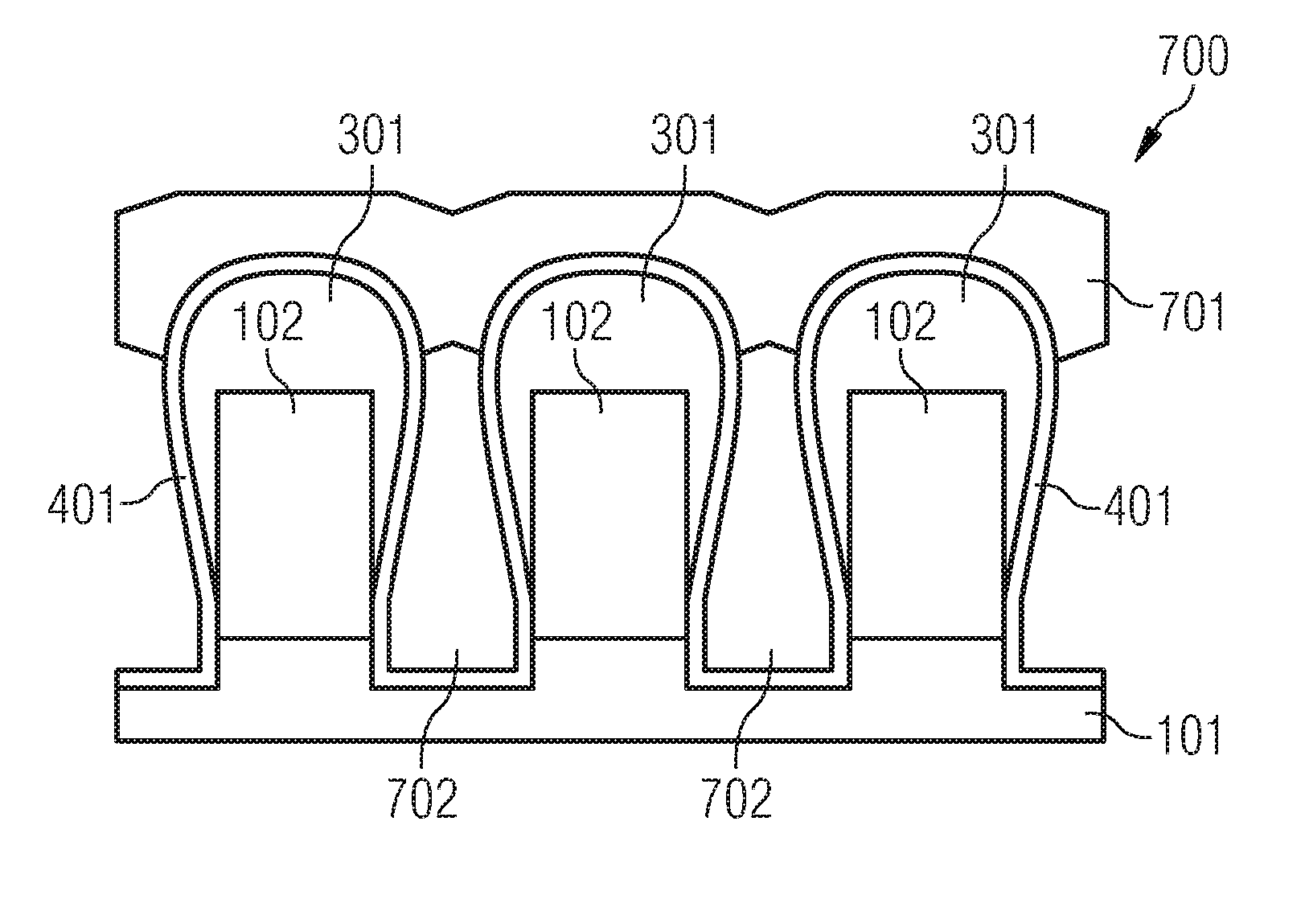

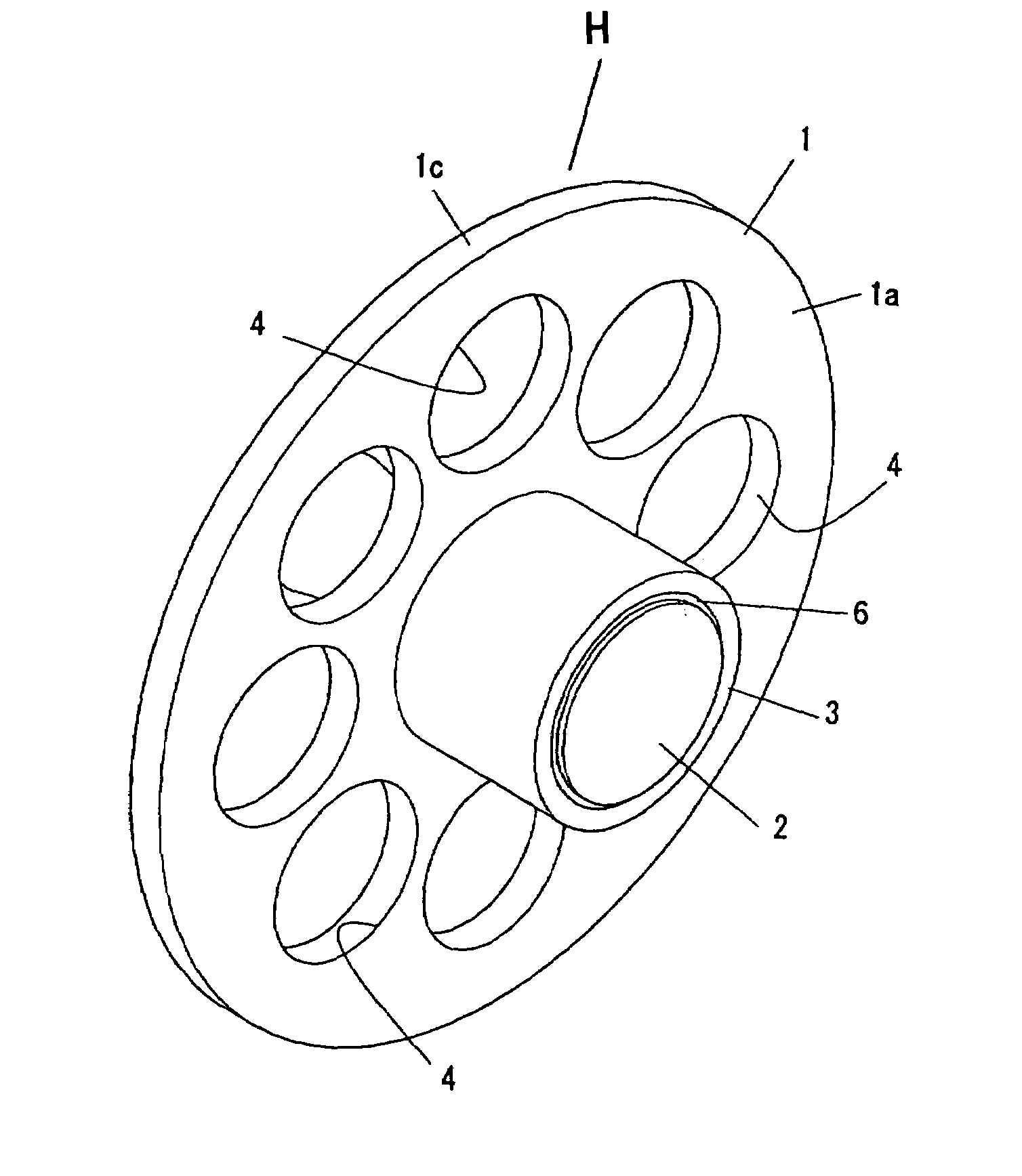

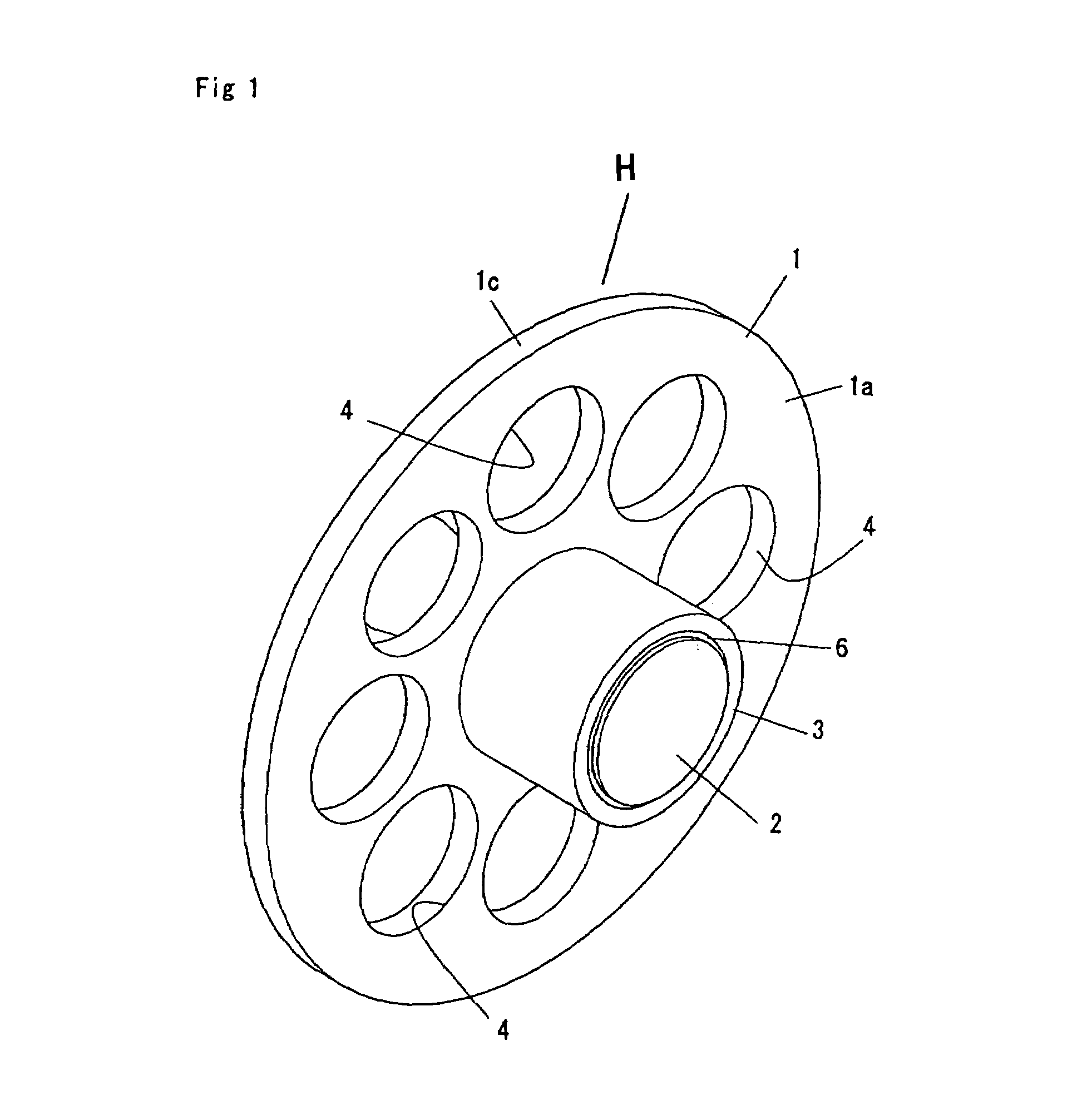

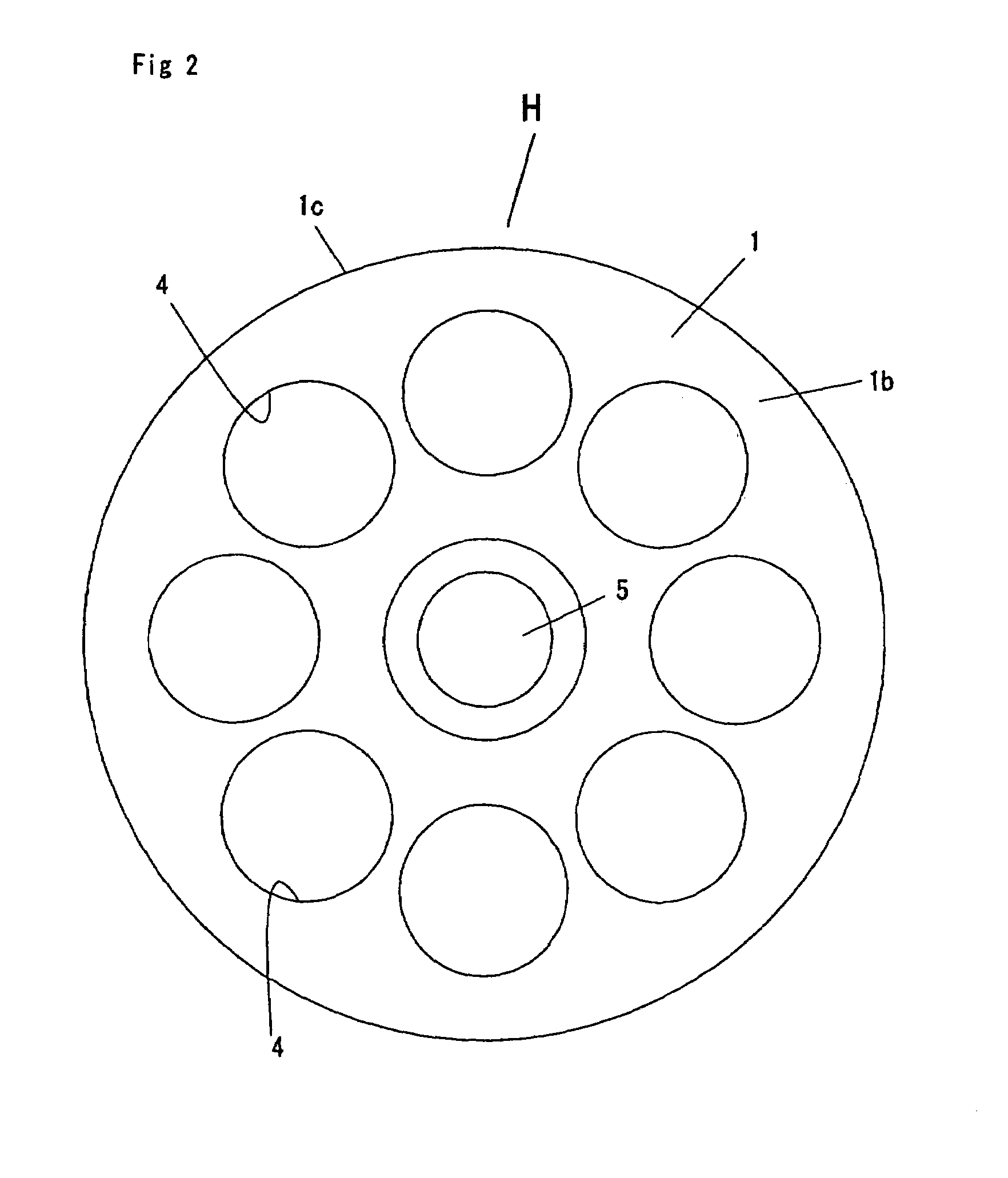

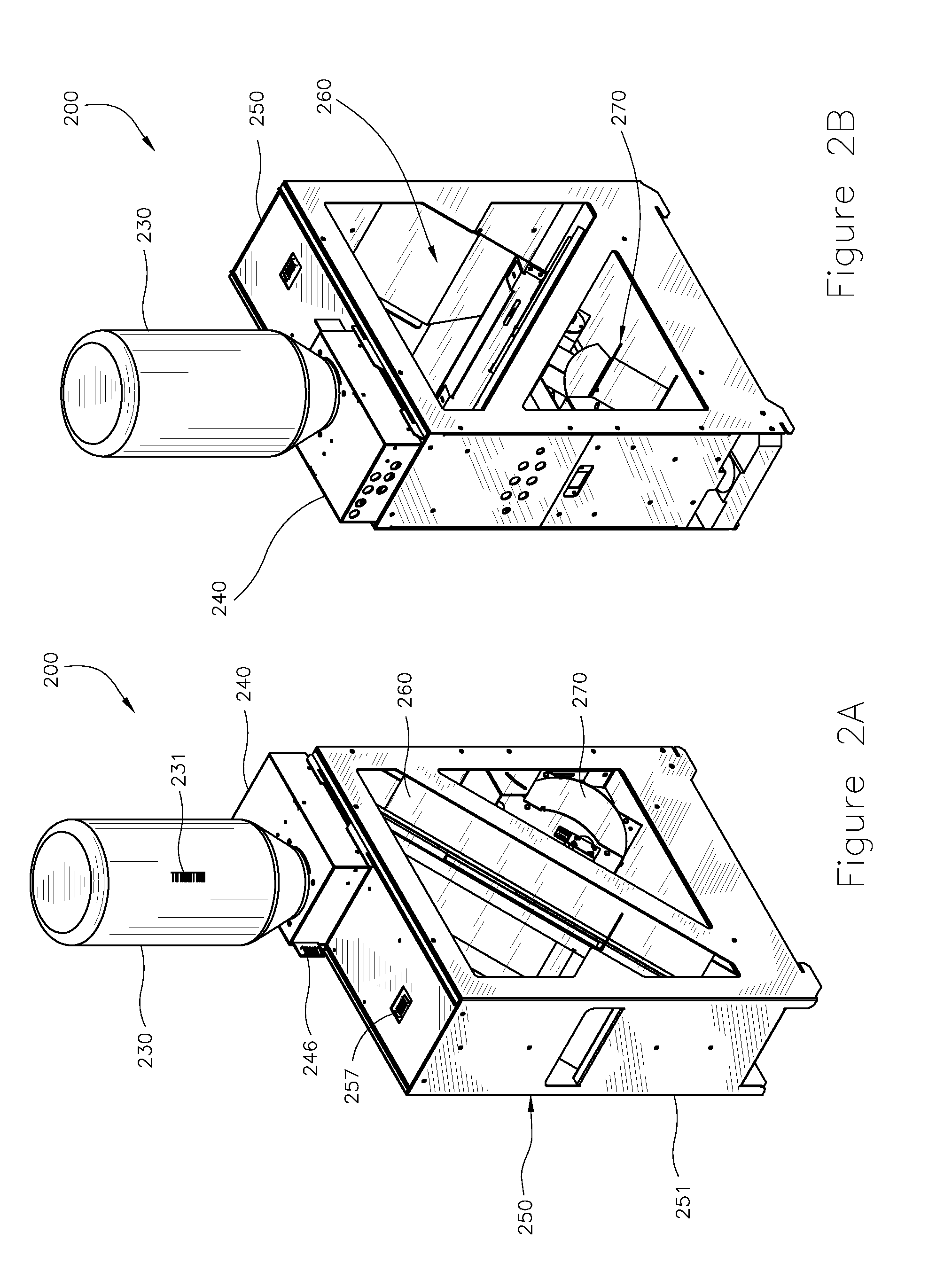

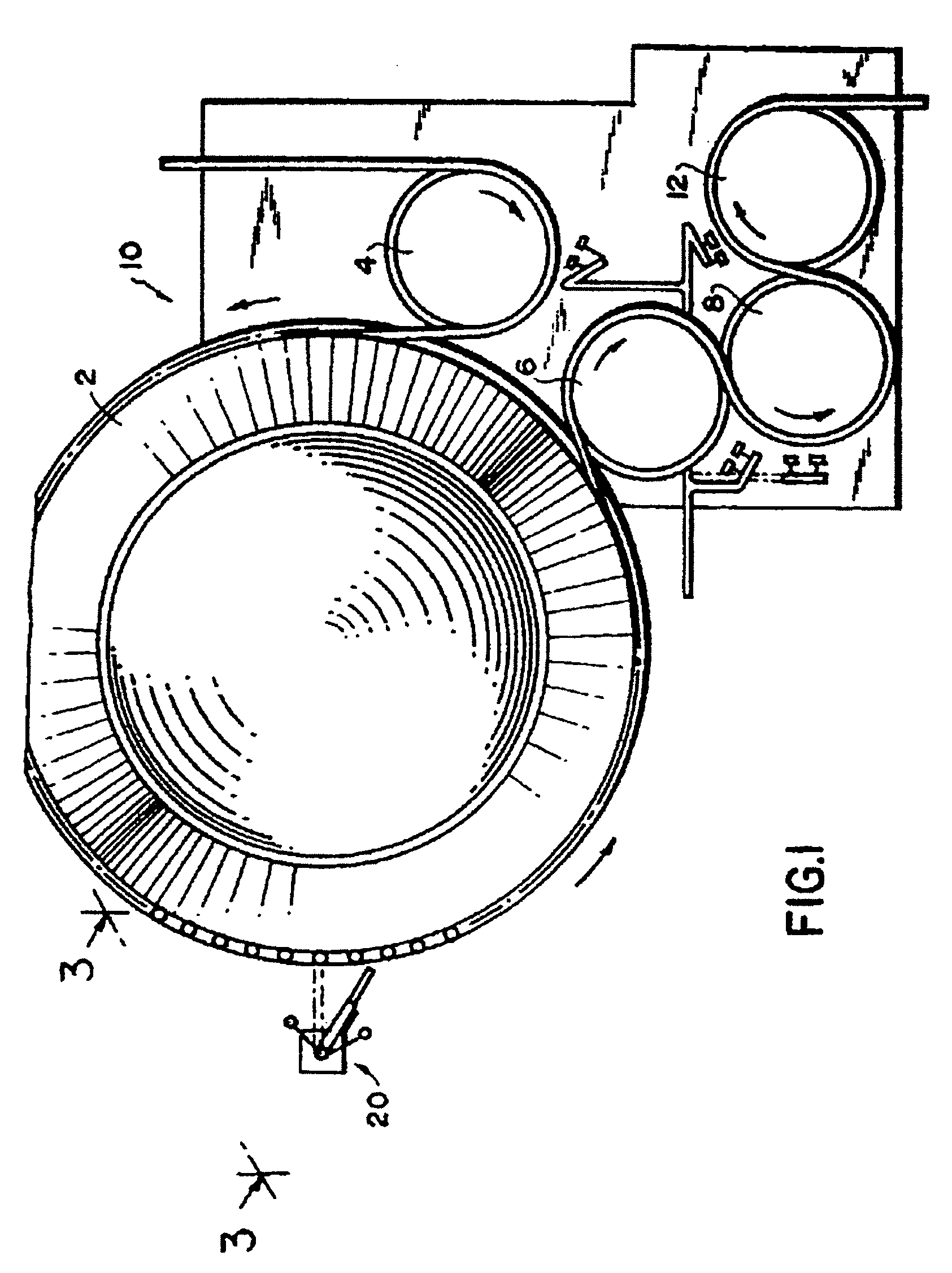

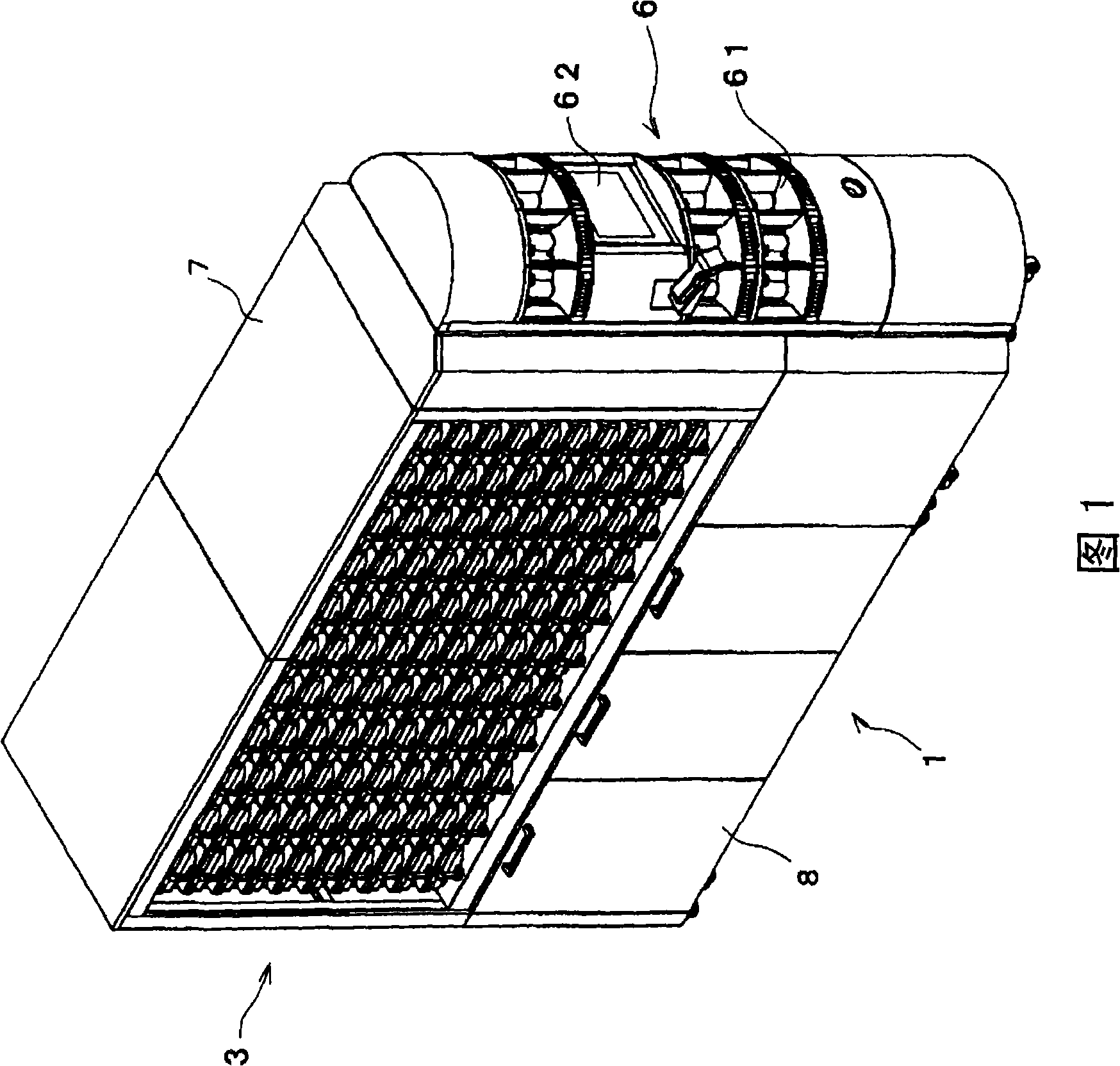

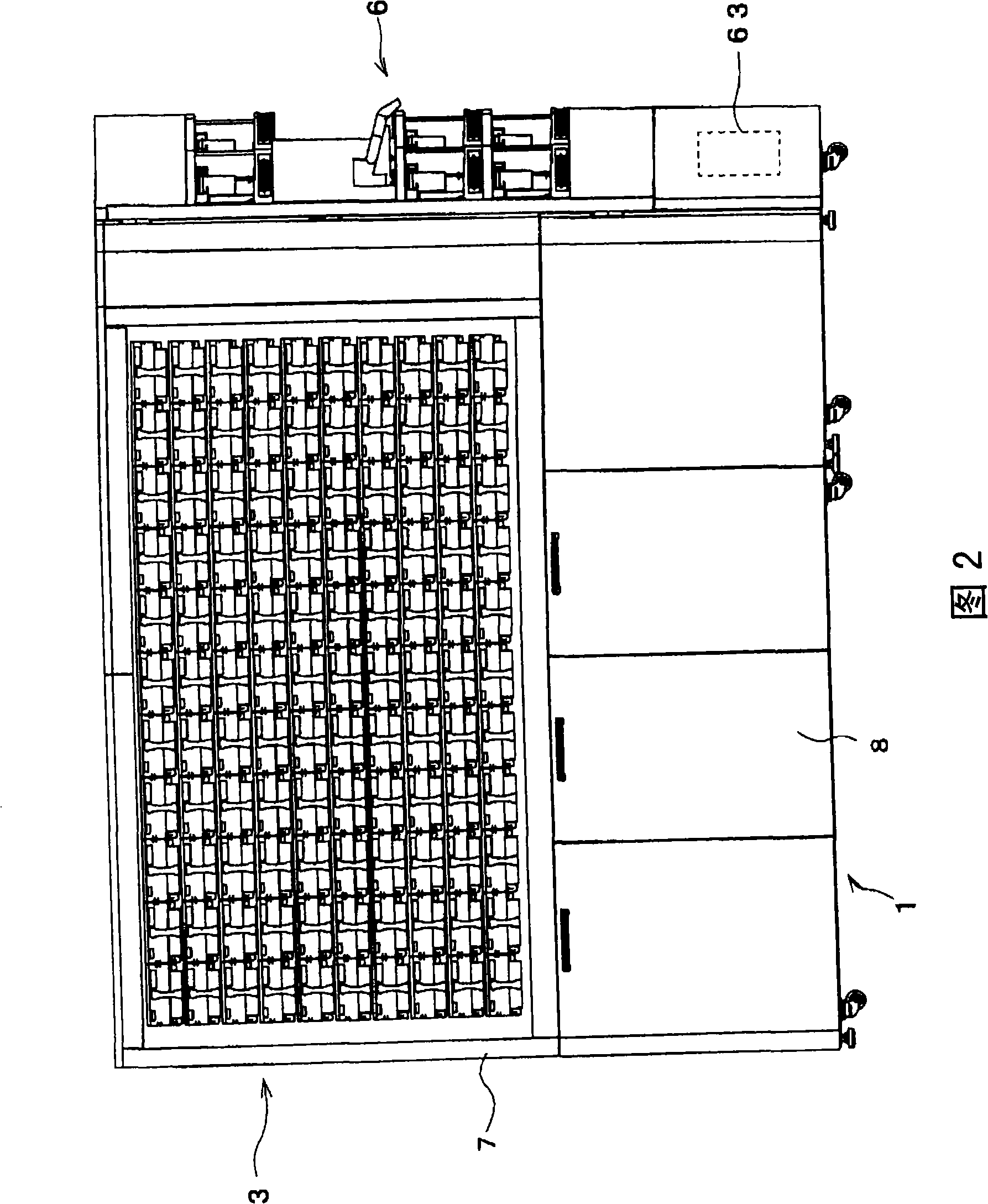

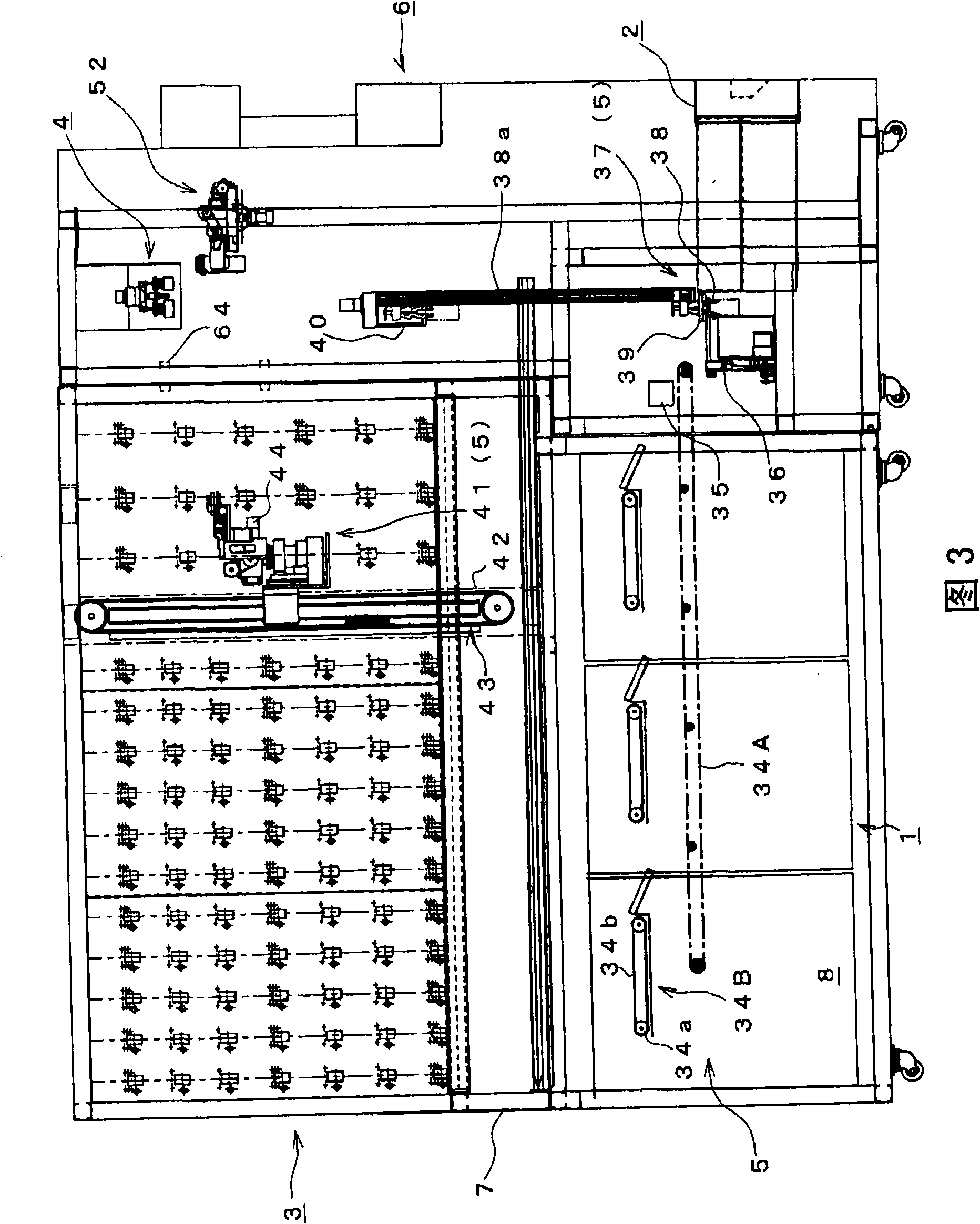

Tablet filling apparatus

InactiveCN101257882AAvoid paddingInappropriate situations to prevent overflowPharmaceutical product form changeSolid materialEngineeringFill device

The present invention provides a tablet filling device for supplying a vial container of desired size certainly with no mistake comprising a plurality of containing means (8) containing vial containers (9) by size, a means (8a) for taking out a vial container (9) from the containing means (8) based on prescription data, means (34, 37, 41, 52) for carrying a vial container (9) taken out by the container take out means (8a), a means (11) for providing a table to a vial container (9) carried by the carrying means (52), a means (107) for collecting a vial container (9) in the middle of carriage by the carrying means (34), a means (100) provided on the carrying passage of the carrying means (34) and detecting the size of a carried vial container (9), and a control means (63) for judging (S6) whether the size of a vial container (9) selected based on the prescription data matches the size of a vial container (9) detected by the container size detection means (100) and collecting (S7) the carried vial container (9) by the container collection means (107) if they do not match each other.

Owner:YUYAMA MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com