Patents

Literature

8584 results about "Spot welding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Resistance spot welding (RSW) is a process in which contacting metal surface points are joined by the heat obtained from resistance to electric current. It is a subset of electric resistance welding. Work-pieces are held together under pressure exerted by electrodes. Typically the sheets are in the 0.5 to 3 mm (0.020 to 0.118 in) thickness range. The process uses two shaped copper alloy electrodes to concentrate welding current into a small "spot" and to simultaneously clamp the sheets together. Forcing a large current through the spot will melt the metal and form the weld. The attractive feature of spot welding is that a lot of energy can be delivered to the spot in a very short time (approximately 10–100 milliseconds). That permits the welding to occur without excessive heating of the remainder of the sheet.

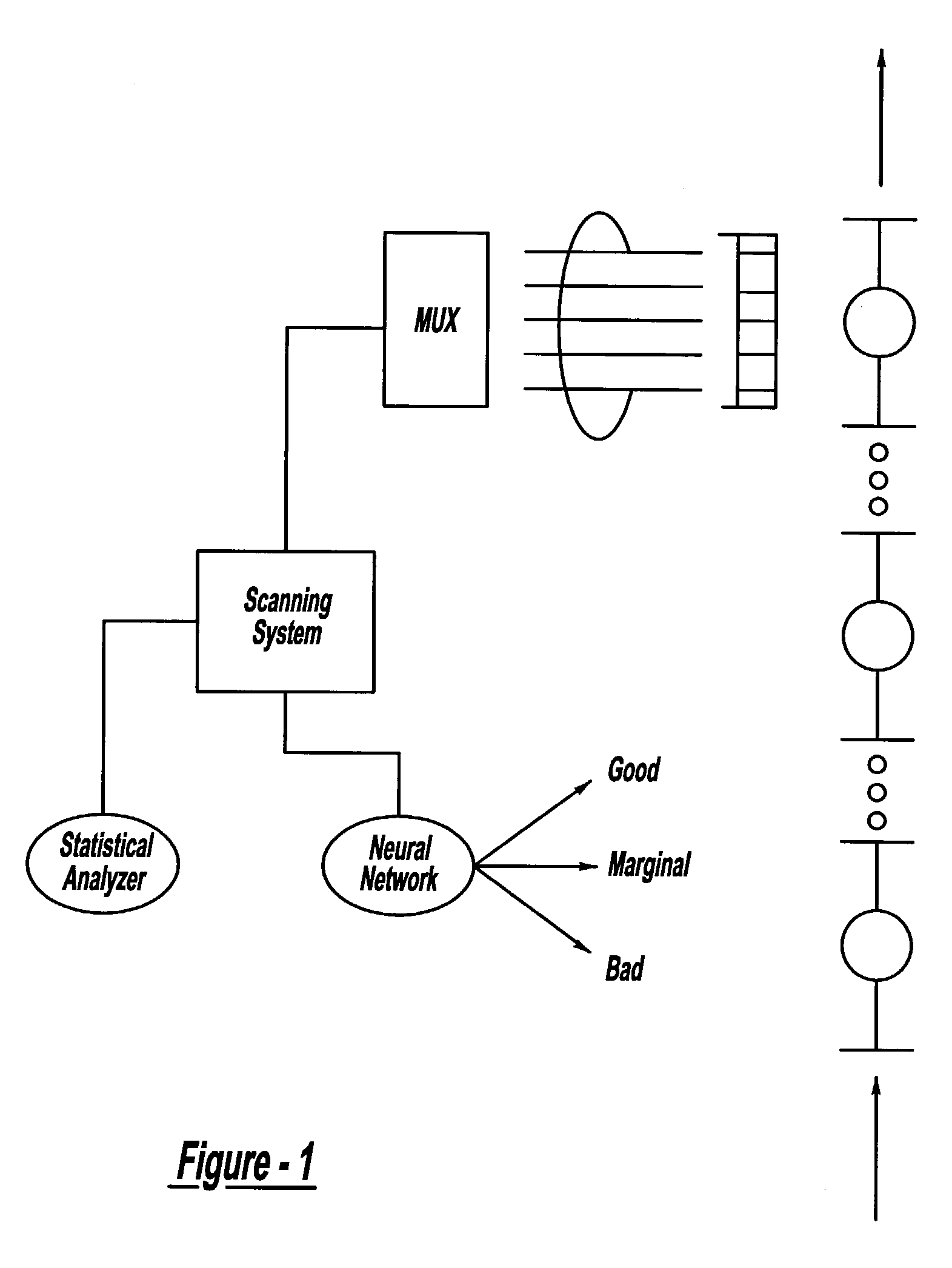

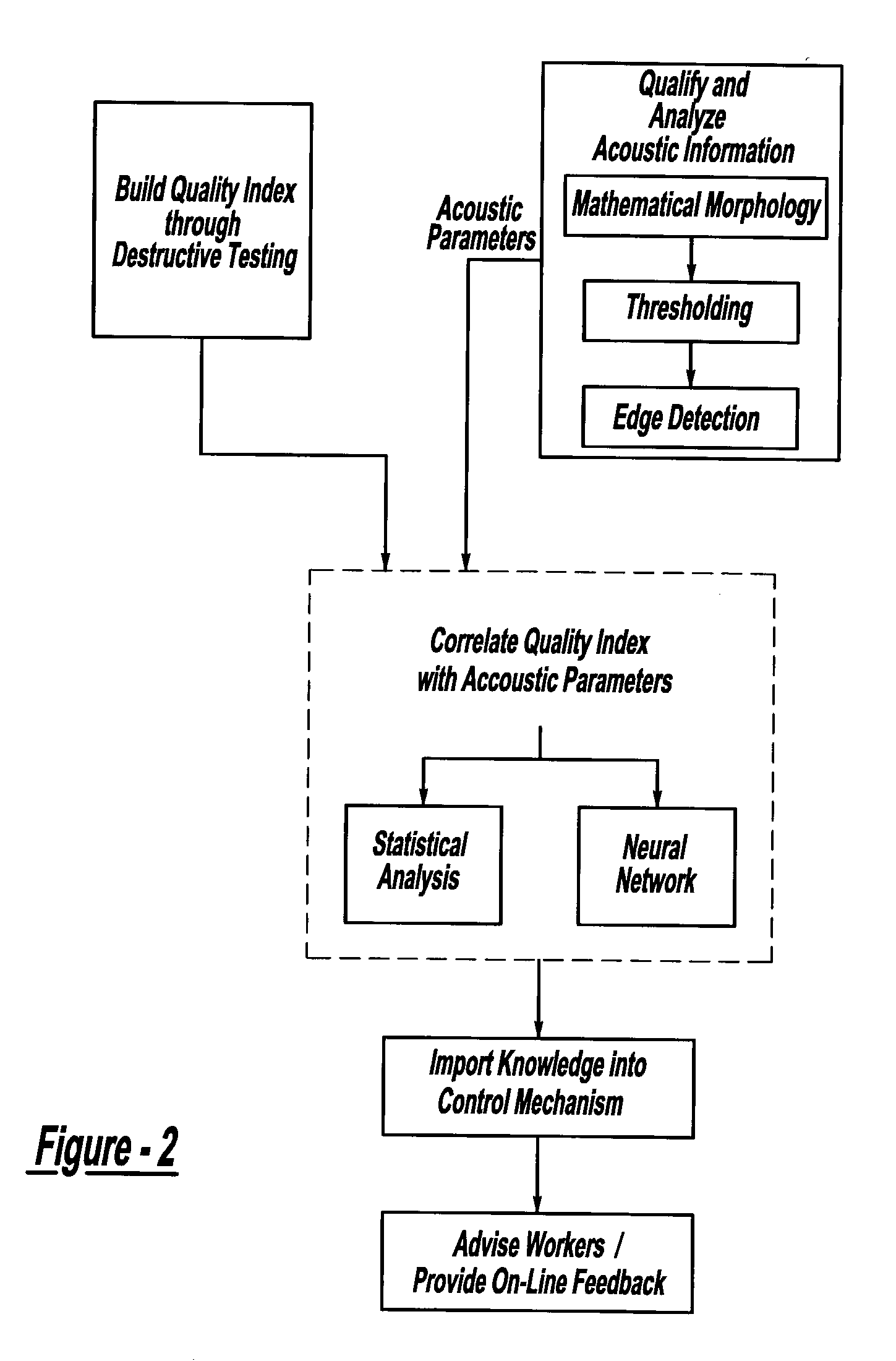

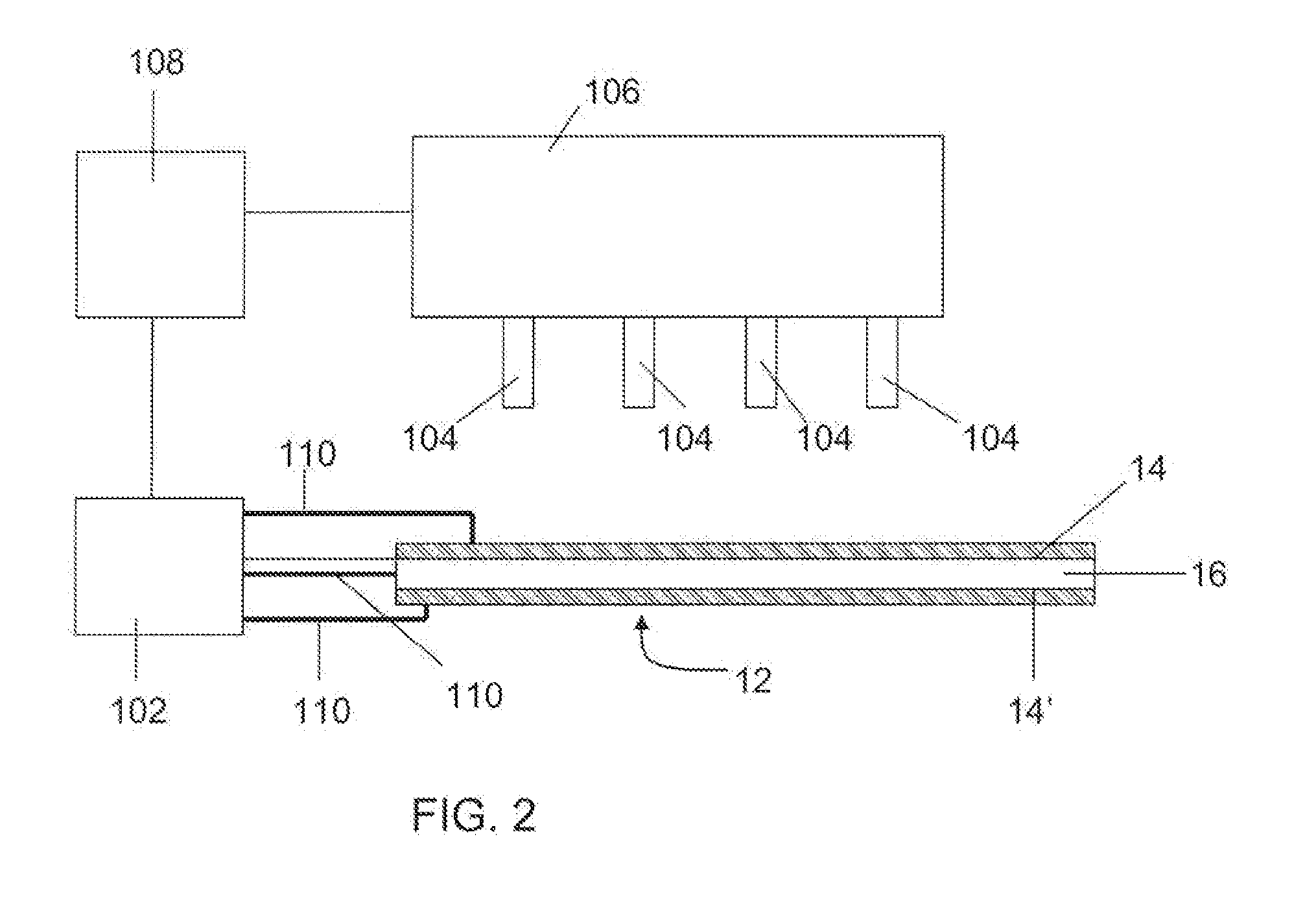

Method And System For Assessing Quality Of Spot Welds

InactiveUS20070038400A1Reduce in quantityReduce manufacturing costMultiple-port networksMagnetic property measurementsDigital dataSonification

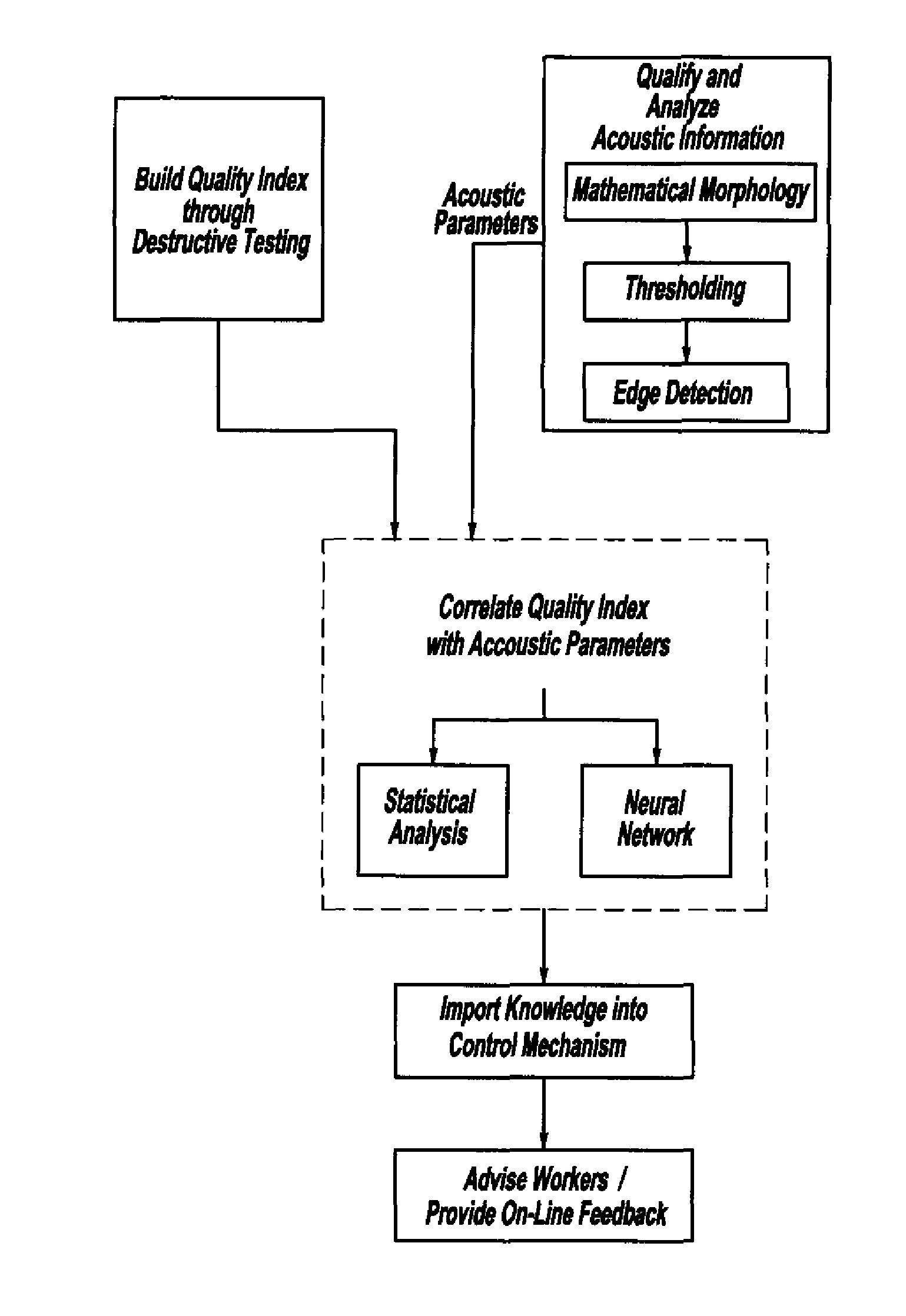

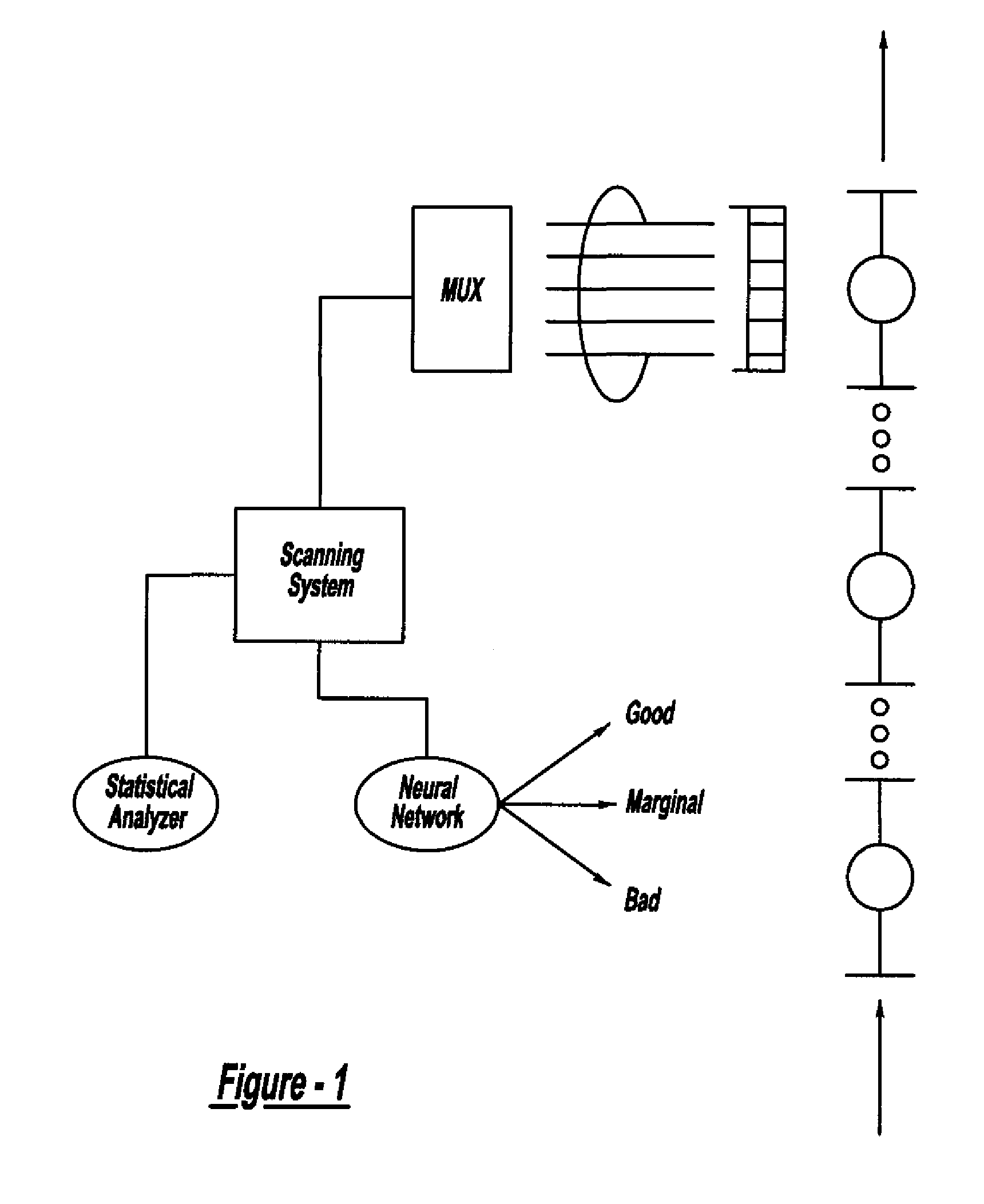

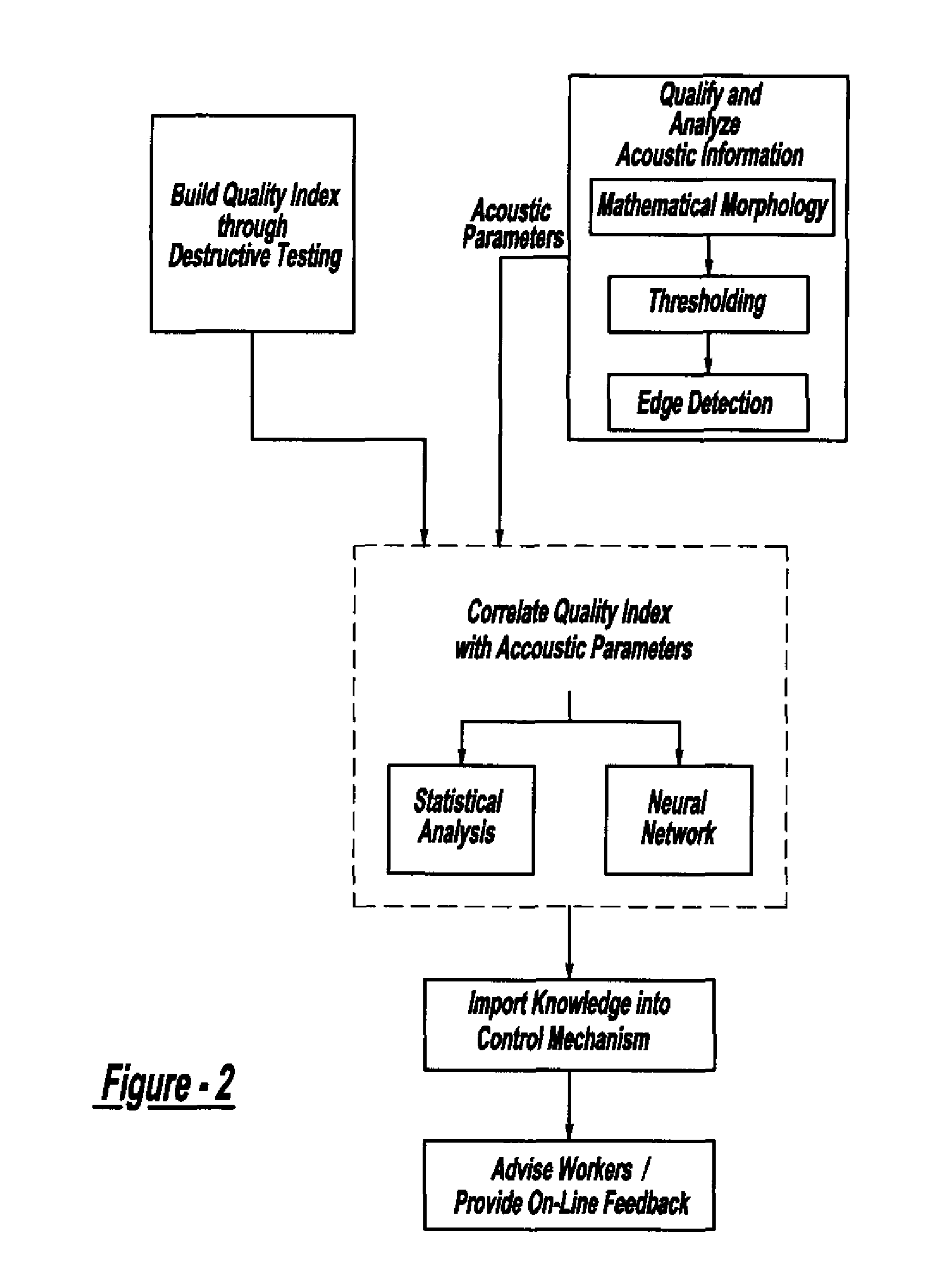

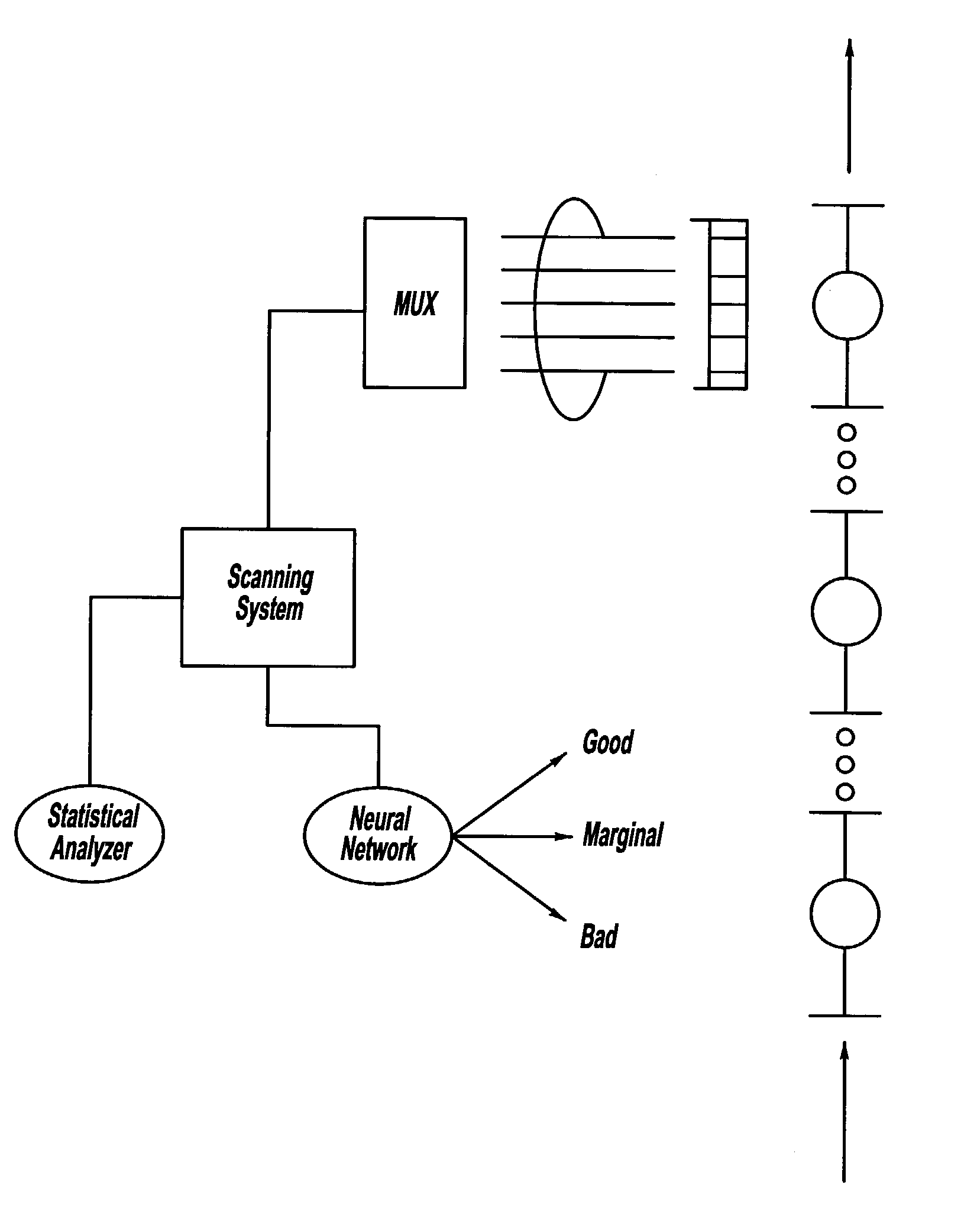

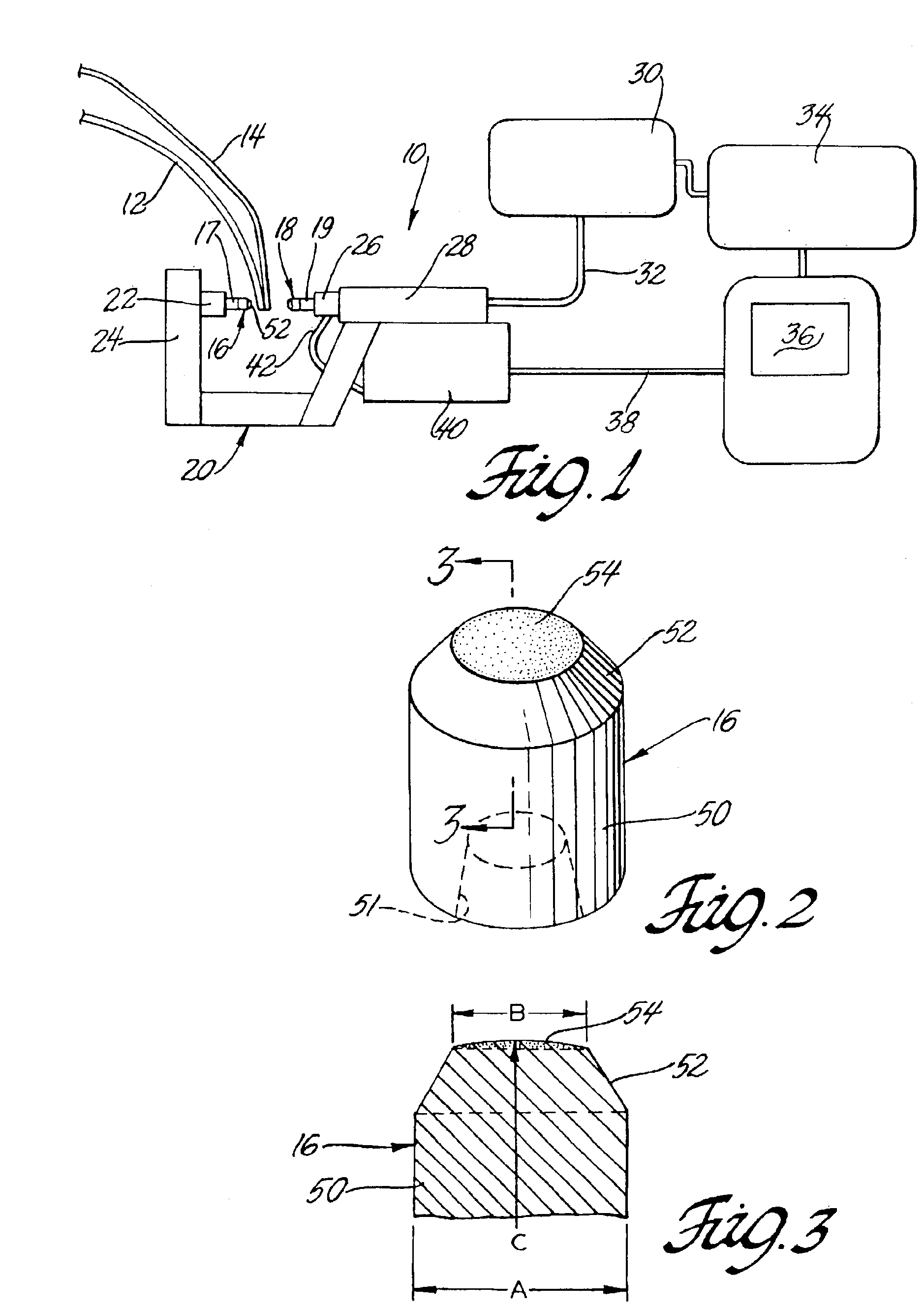

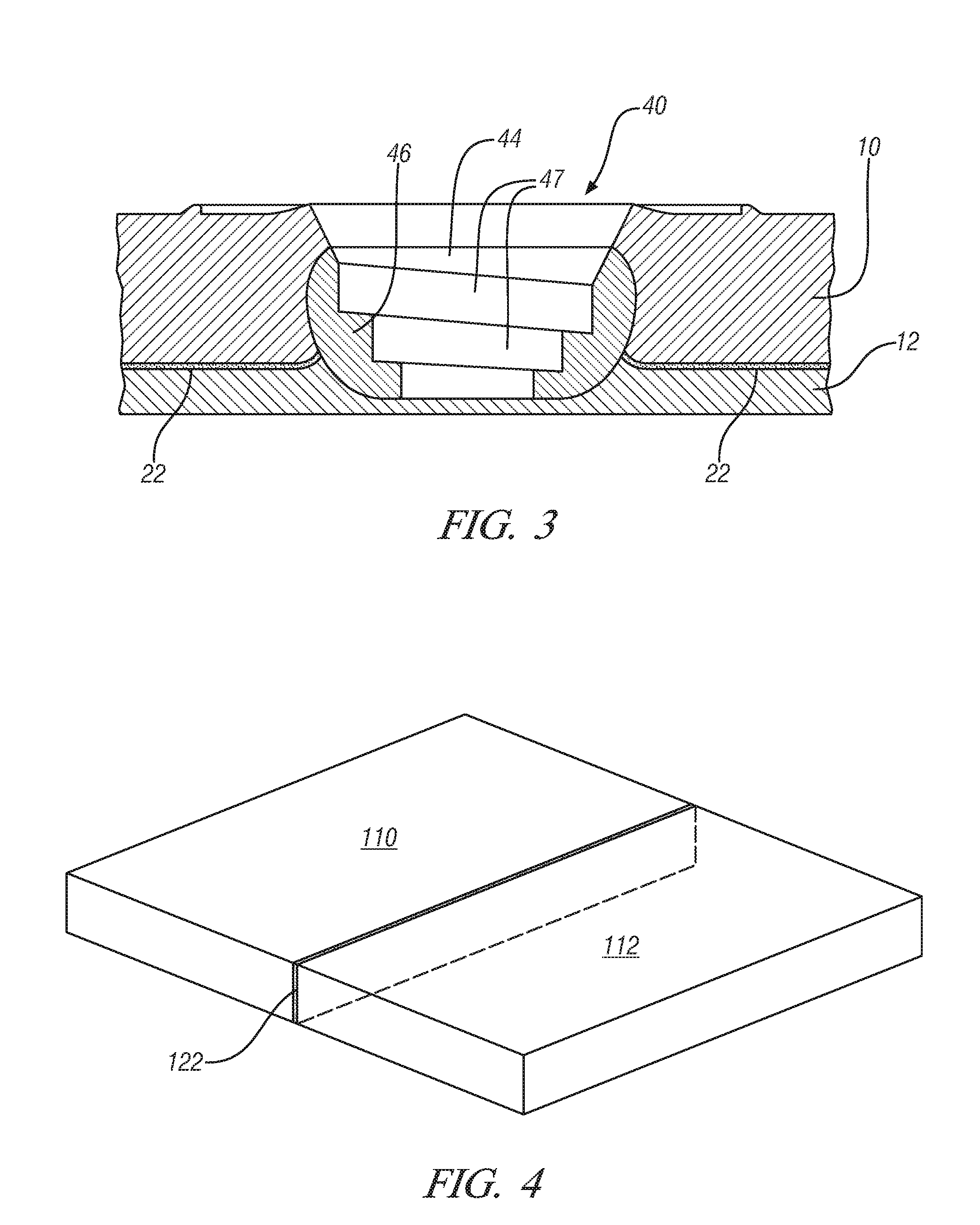

A system and method for assessing the quality of spot weld joints between pieces of metal includes an ultrasound transducer probing a spot weld joint. The ultrasound transducer transmits ultrasonic radiation into the spot weld joint, receives corresponding echoes, and transforms the echoes into electrical signals. An image reconstructor connected to the ultrasound transducer transforms the electrical signals into numerical data representing an ultrasound image. A neural network connected to the image reconstructor analyzes the numerical data and an output system presents information representing the quality of the spot weld joint. The system is trained to assess the quality of spot weld joints by scanning a spot weld joint with an ultrasound transducer to produce the data set representing the joint; then physically deconstructing the joint to assess the joint quality.

Owner:FCA US

Method and system for assessing quality of spot welds

ActiveUS7132617B2Reduce in quantityReduce manufacturing costAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalDigital dataElectricity

A system and method for assessing the quality of spot weld joints between pieces of metal includes an ultrasound transducer probing a spot weld joint. The ultrasound transducer transmits ultrasonic radiation into the spot weld joint, receives corresponding echoes, and transforms the echoes into electrical signals. An image reconstructor connected to the ultrasound transducer transforms the electrical signals into numerical data representing an ultrasound image. A neural network connected to the image reconstructor analyzes the numerical data and an output system presents information representing the quality of the spot weld joint. The system is trained to assess the quality of spot weld joints by scanning a spot weld joint with an ultrasound transducer to produce the data set representing the joint; then physically deconstructing the joint to assess the joint quality.

Owner:FCA US

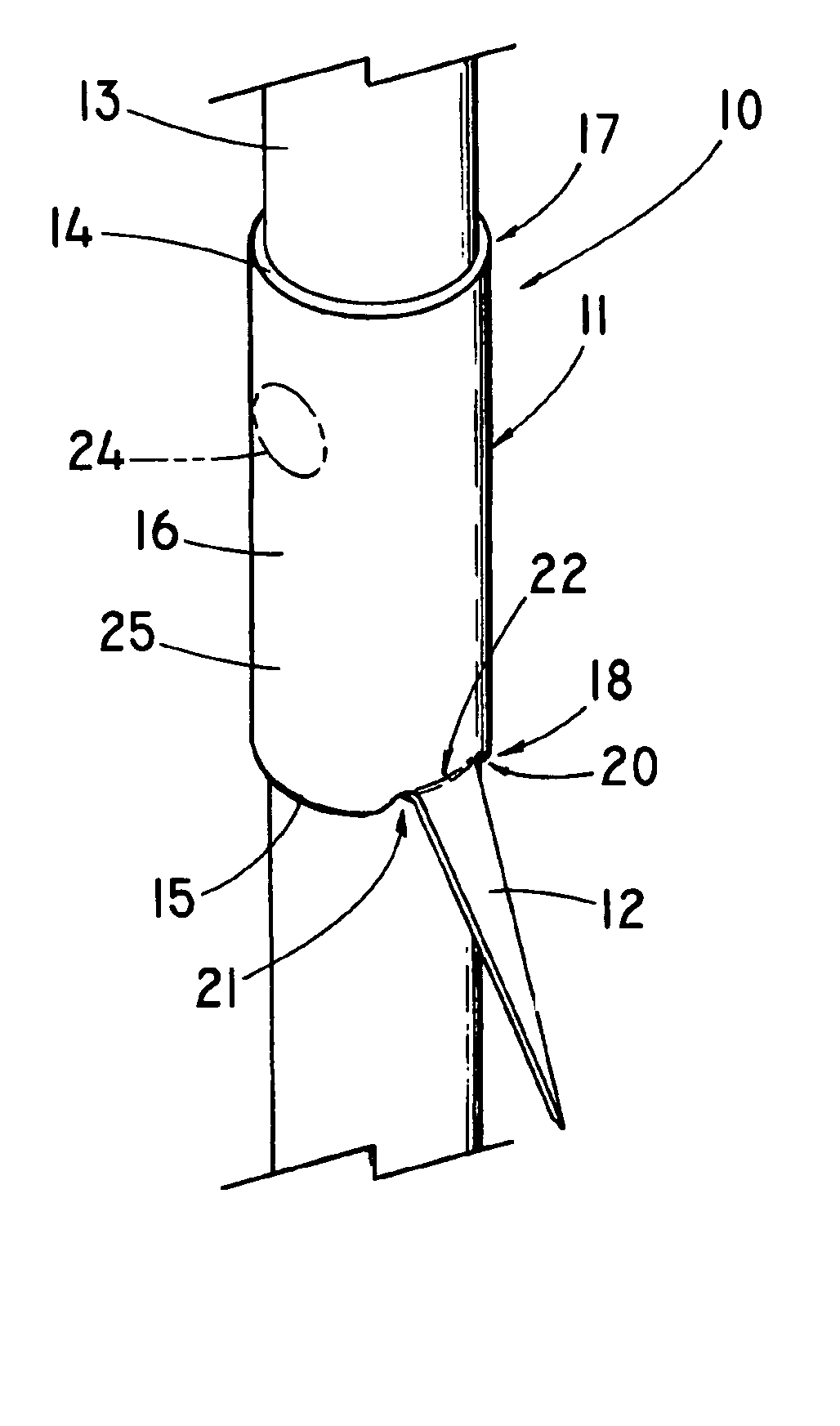

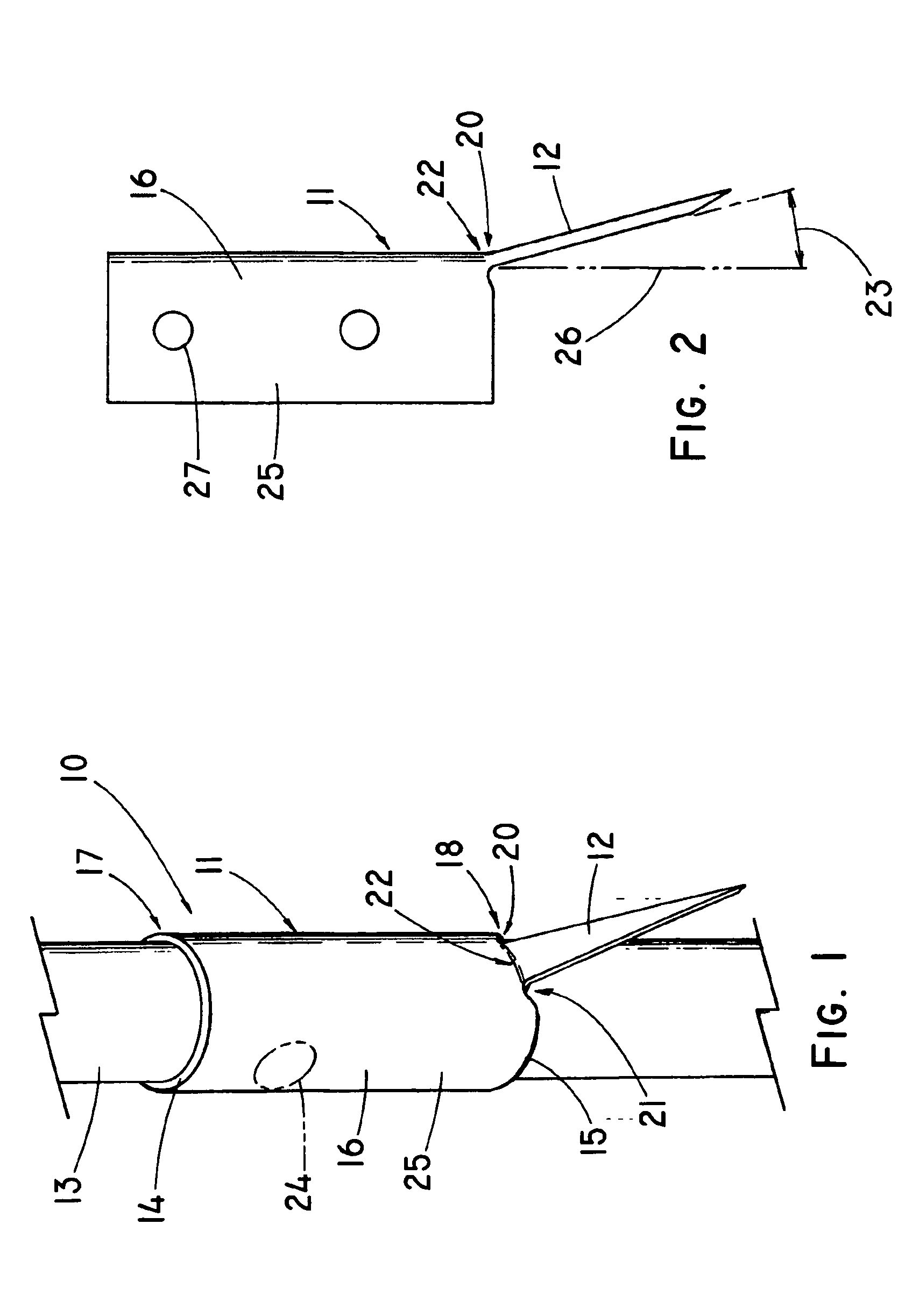

Anchoring barb for attachment to a medical prosthesis

ActiveUS20050240259A1Limited extentLimit longitudinal movementStentsBlood vesselsThin layerSpot welding

Disclosed is an anchoring element for an implantable prosthesis that includes a barb, wherein the anchoring element, which includes a basal portion, comprises a thin layer of material, such as a cannula or sheet of metal, that extends or wraps at least partially around the strut of the prosthesis to which it is attached. The barb is configured to extend outward from the basal portion to penetrate adjacent tissue. The anchoring element is either permanently affixed to the strut, such as by laser or spot welding, crimping, or some other method of bonding, or allowed to slide longitudinally over the strut between two points or stops in order to relieve any excessive loads placed upon the barb that could cause fracture. The anchoring element and strut may be configured to limit axial rotation of the barb, while still allowing longitudinal movement. In another embodiment, the slidable anchoring element may be manipulated following initial deployment to reorient the barb toward the implantation site.

Owner:COOK MEDICAL TECH LLC

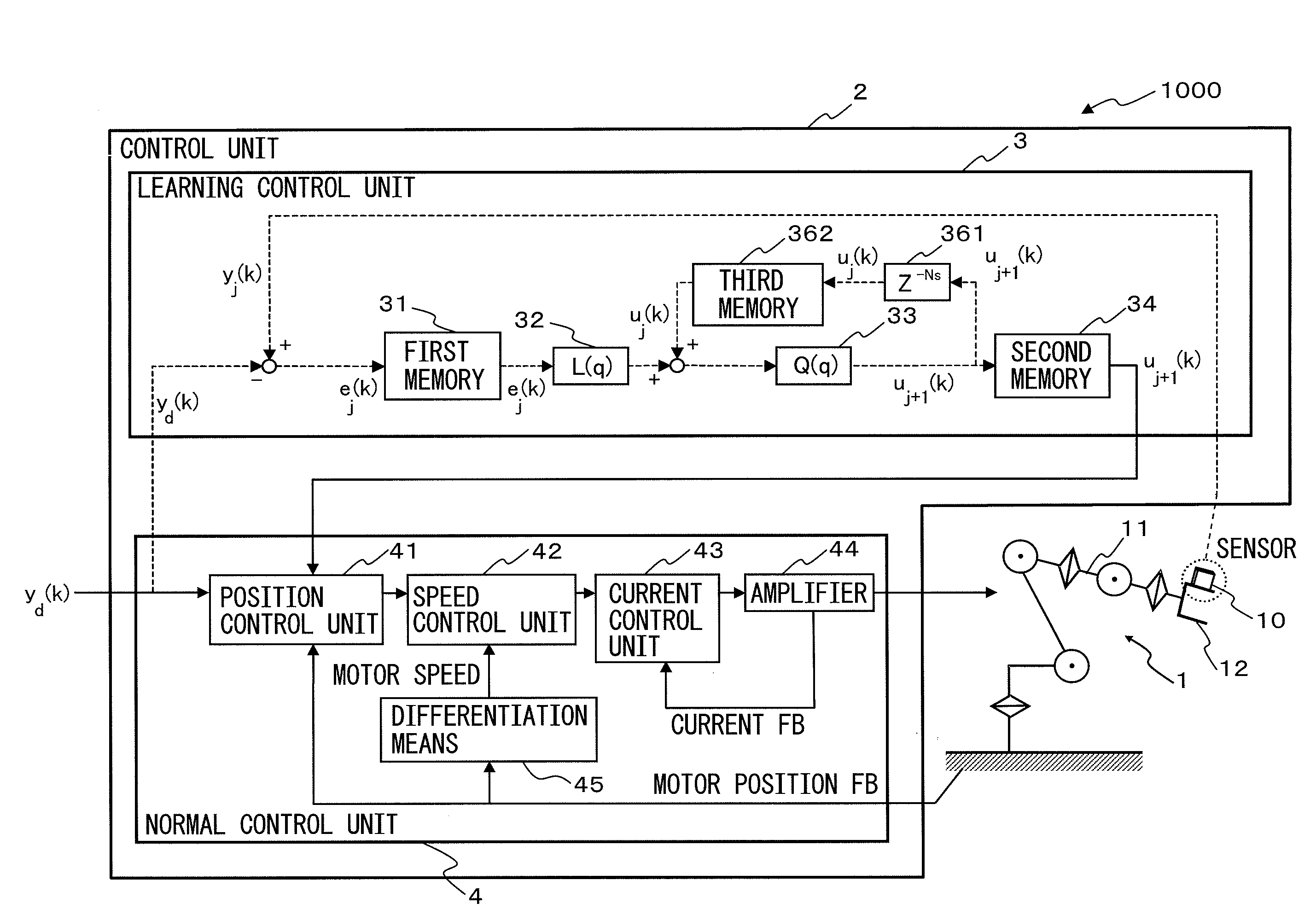

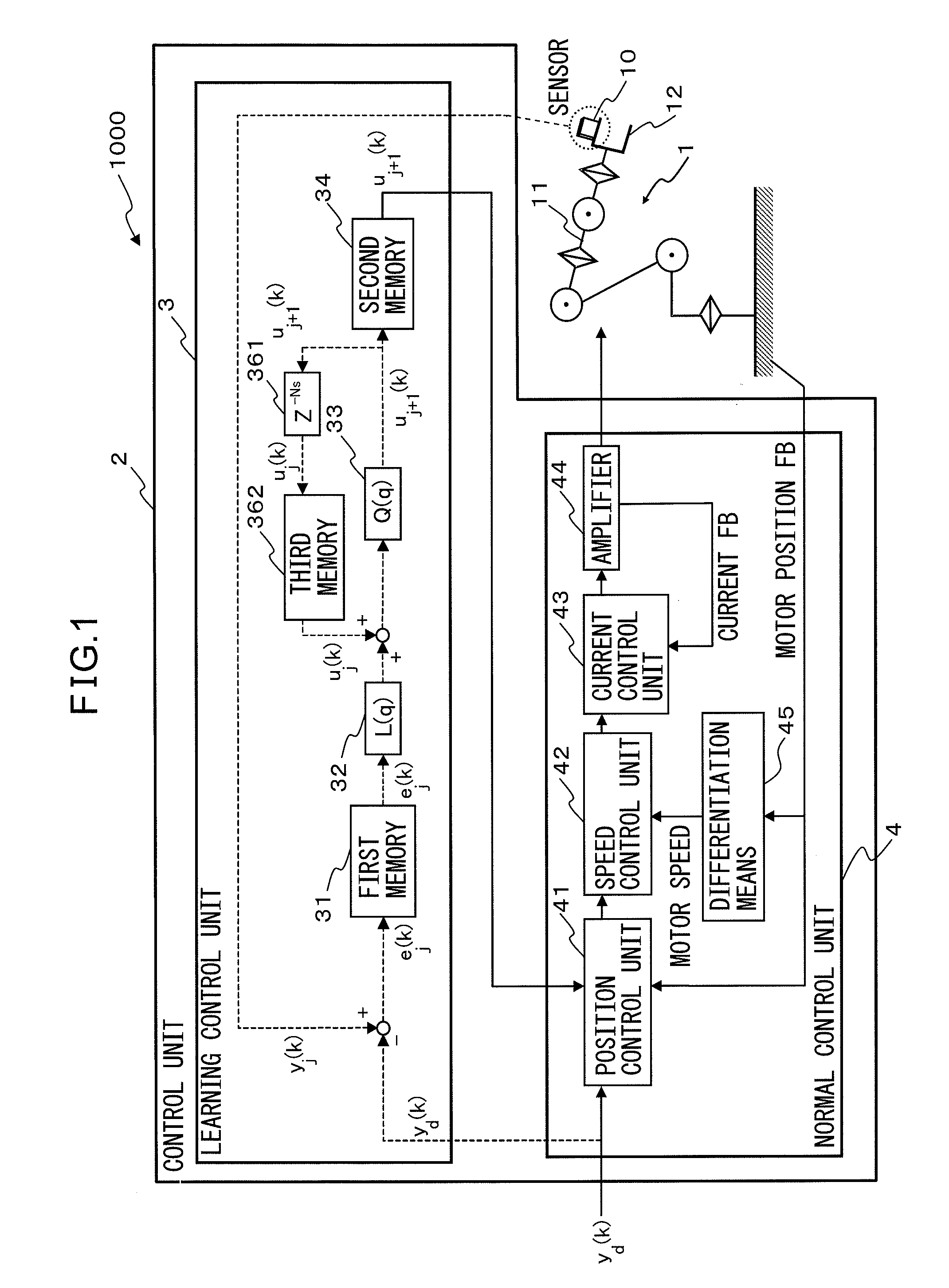

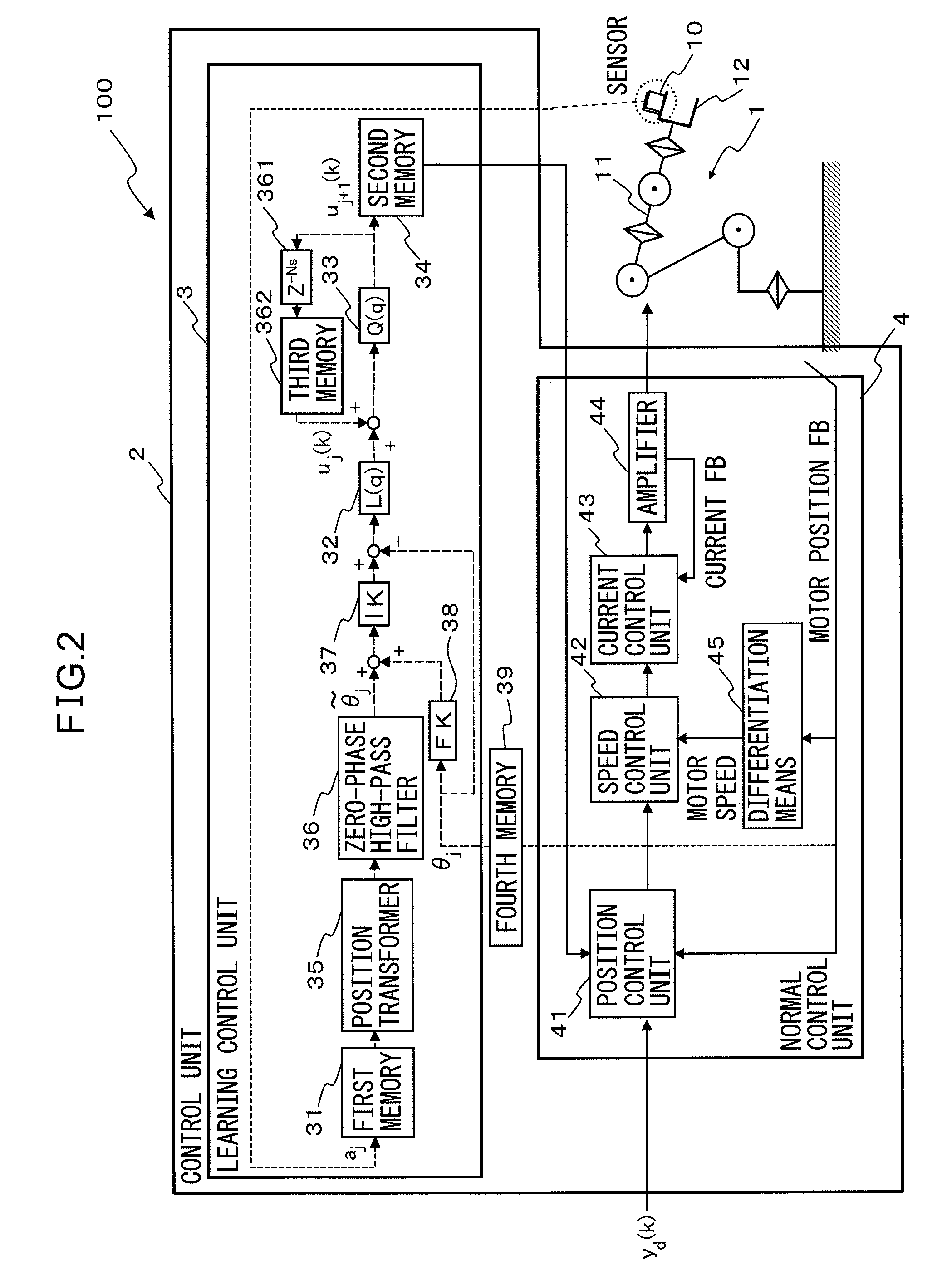

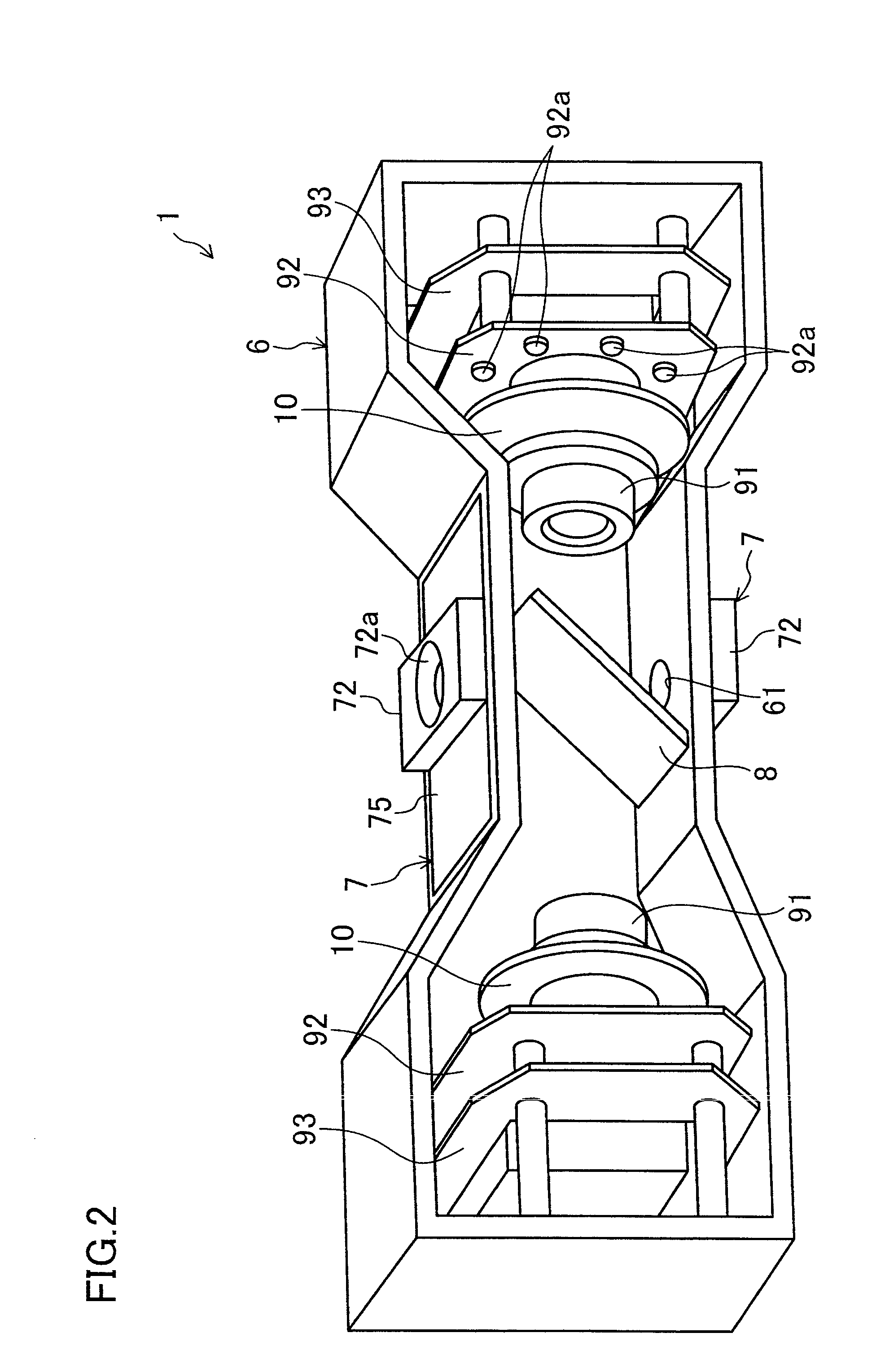

Robot and spot welding robot with learning control function

ActiveUS20120296471A1Improve accuracyImprove securityProgramme-controlled manipulatorComputer controlControl objectiveNormal control

A robot (100) has a robot mechanism unit (1) having a sensor (10) and a control unit (2), and the control unit (2) includes a normal control unit (4) that controls the operation of the robot mechanism unit, and a learning control unit (3) that, when the robot mechanism unit (1) is operated by a speed command that is given by multiplying a teaching speed designated in a task program by a speed change ratio, performs learning to calculate, from a detection result by the sensor (10), a learning correction amount for making the trajectory or position of the control target in the robot mechanism unit (1) approach the target trajectory or target position, or for reducing the vibration of the control target, and performs processes so that the control target position of the robot mechanism unit (1) moves along a fixed trajectory regardless of the speed change ratio.

Owner:FANUC LTD

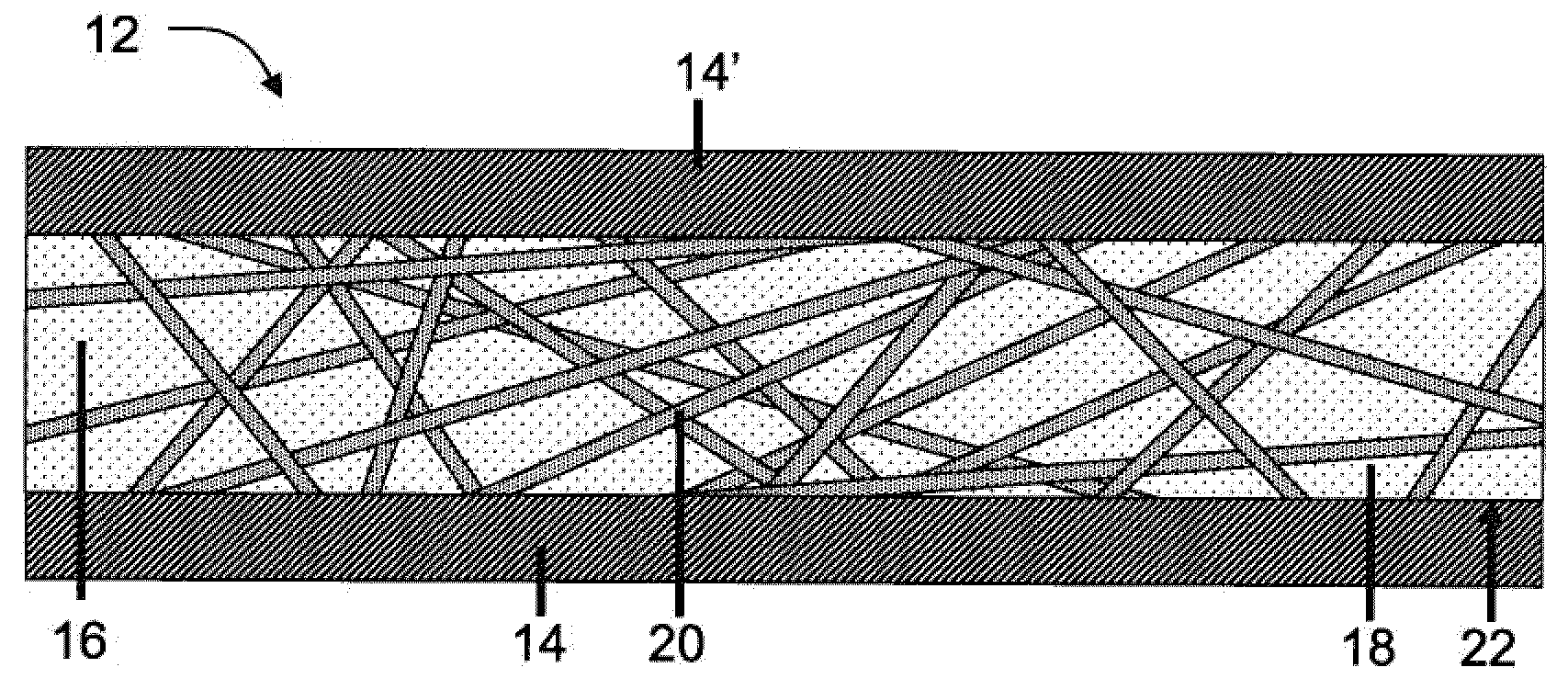

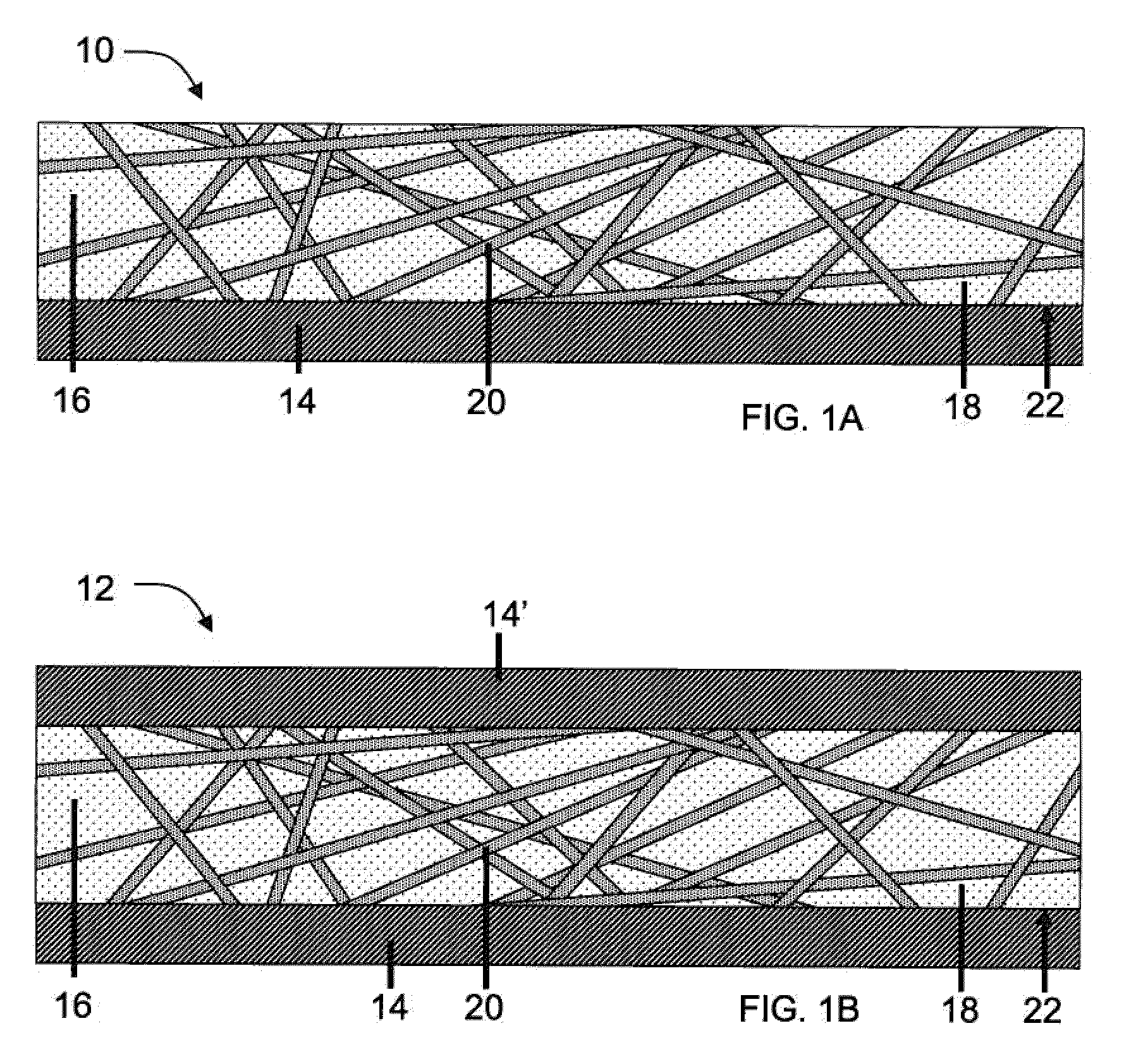

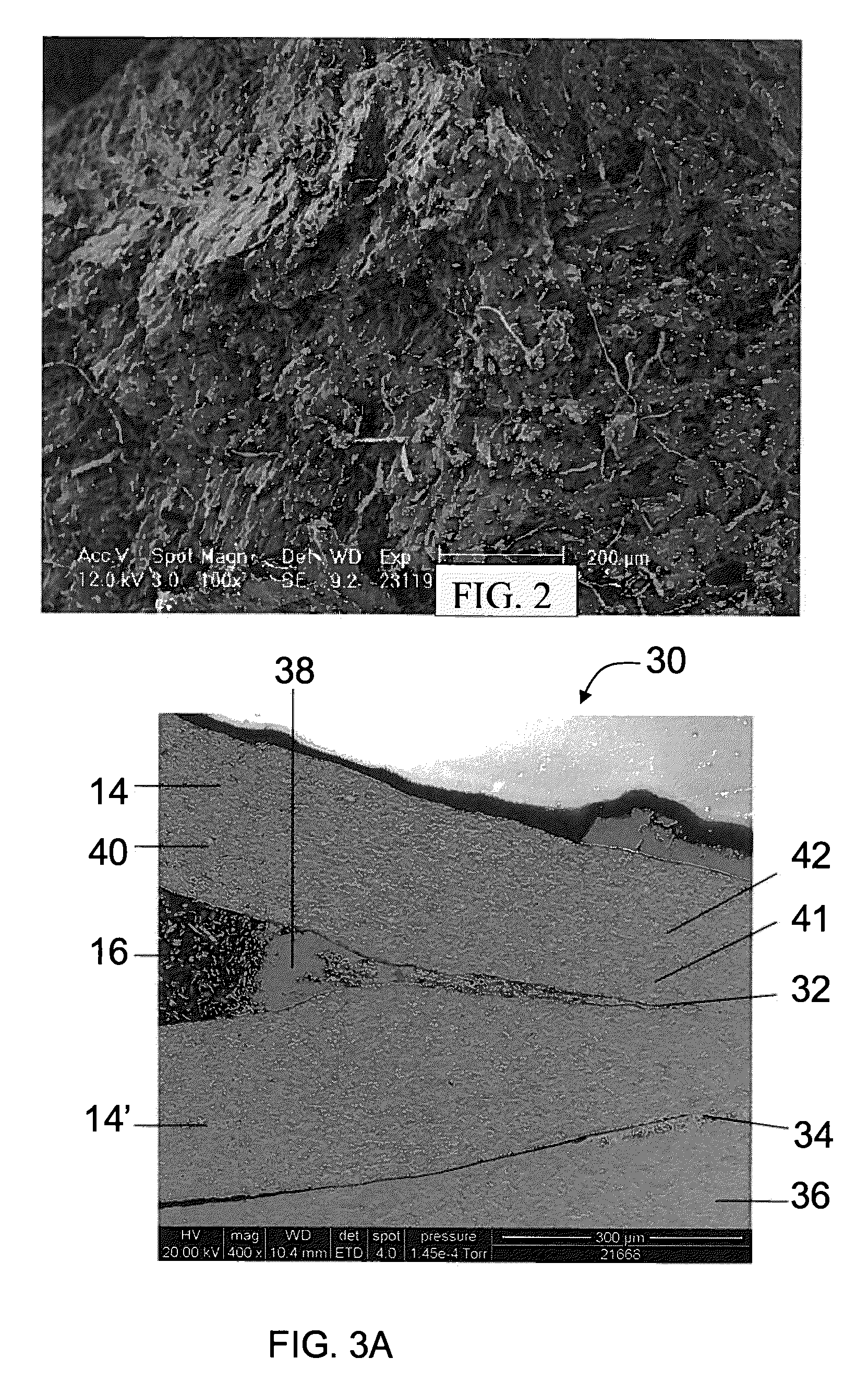

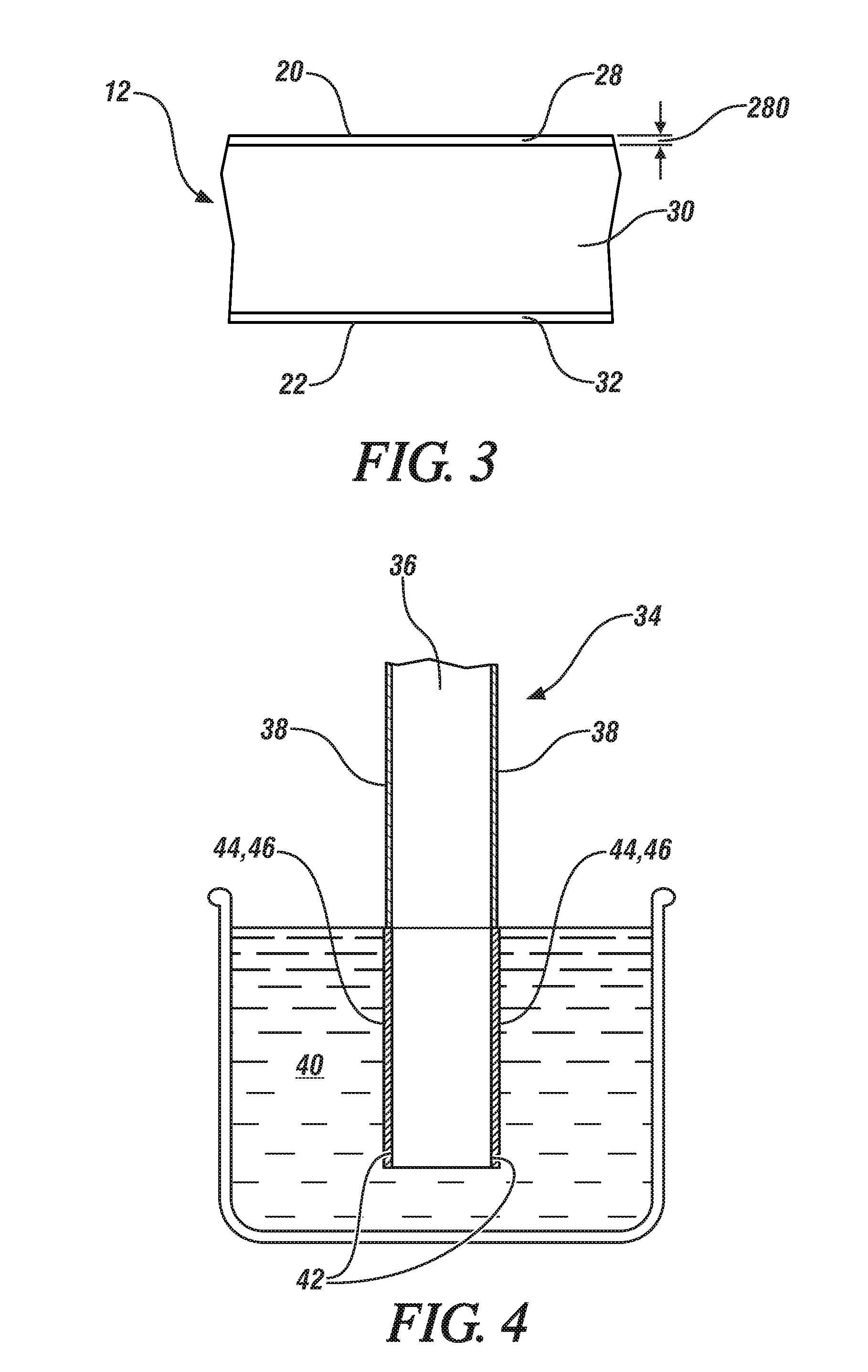

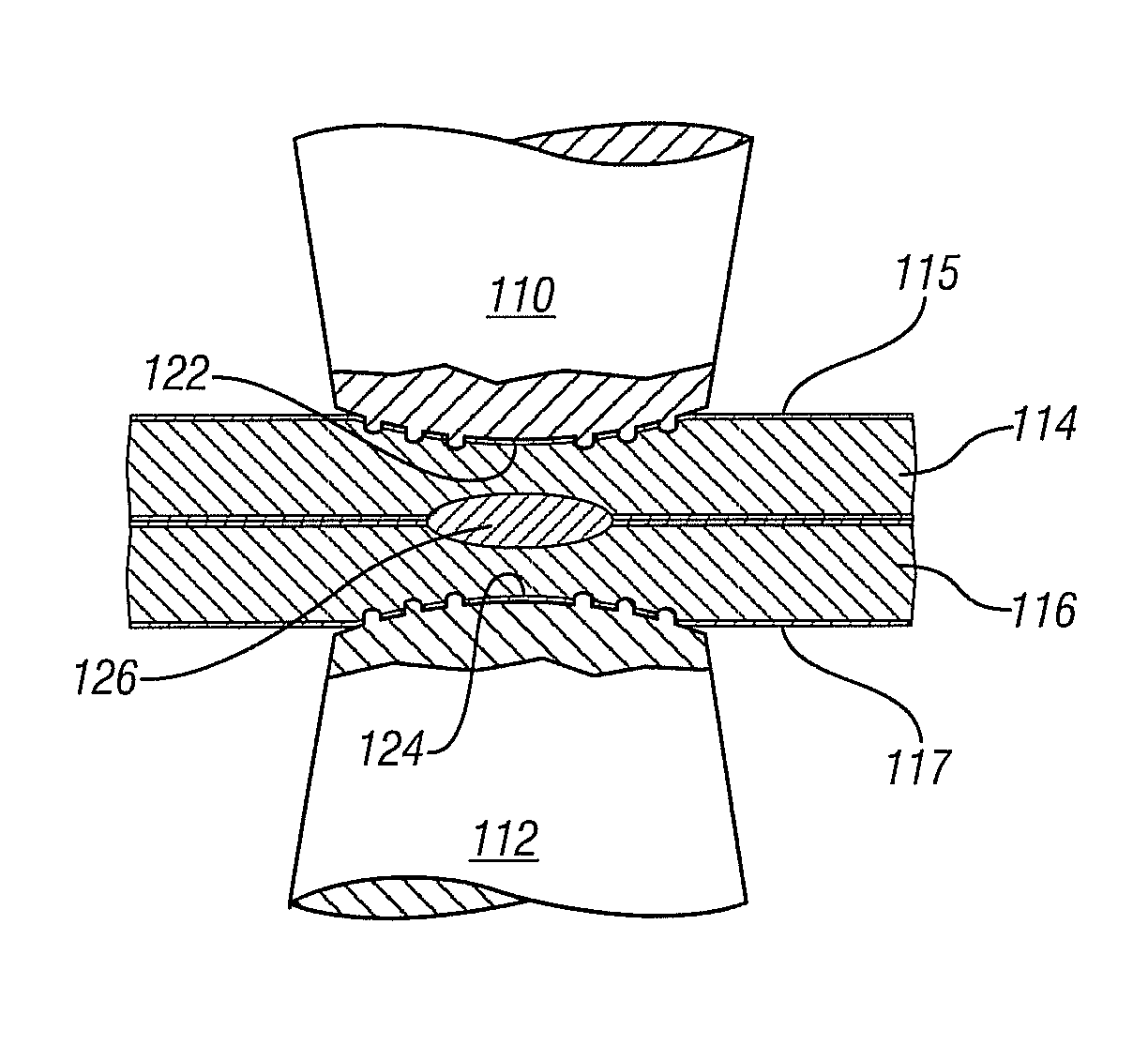

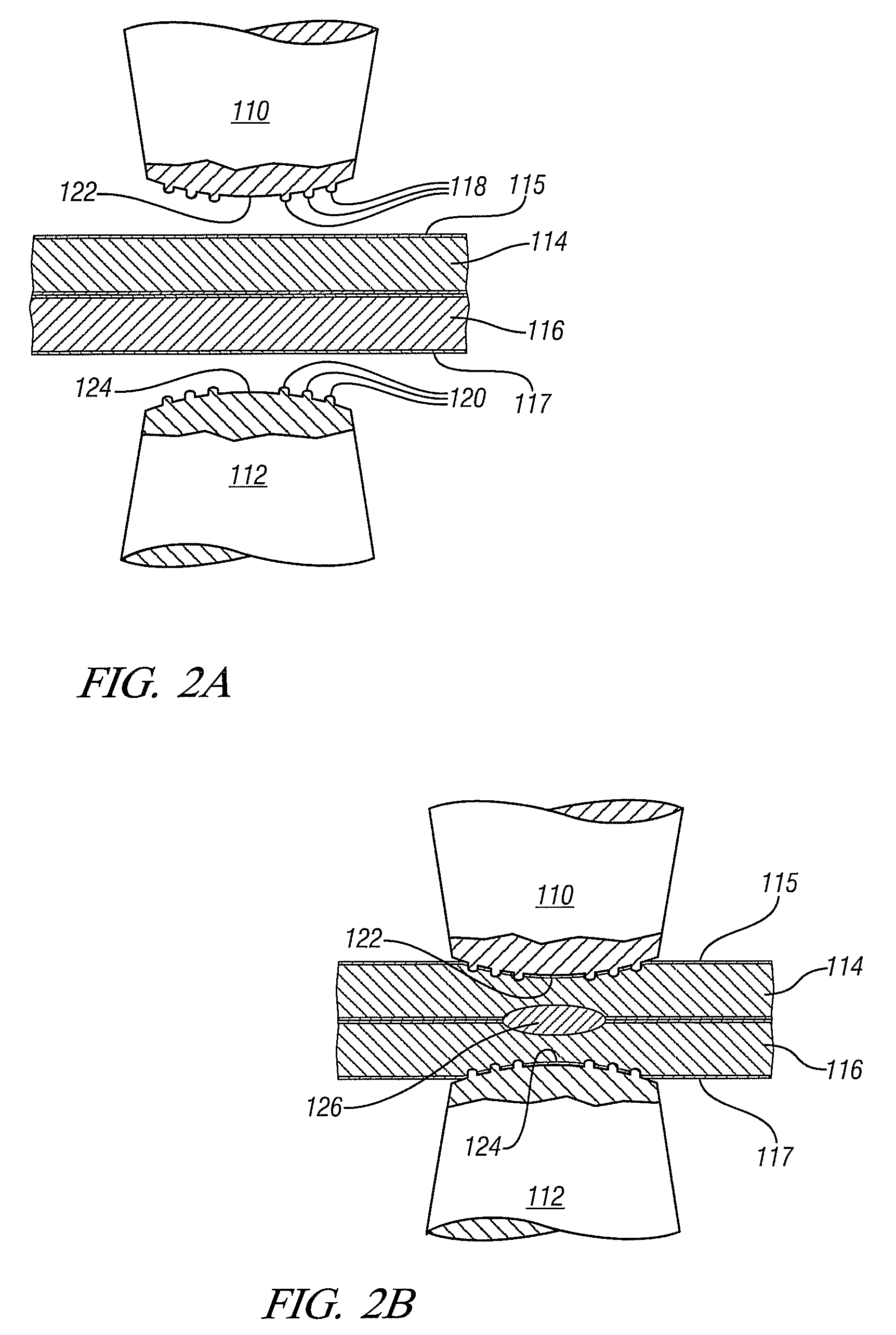

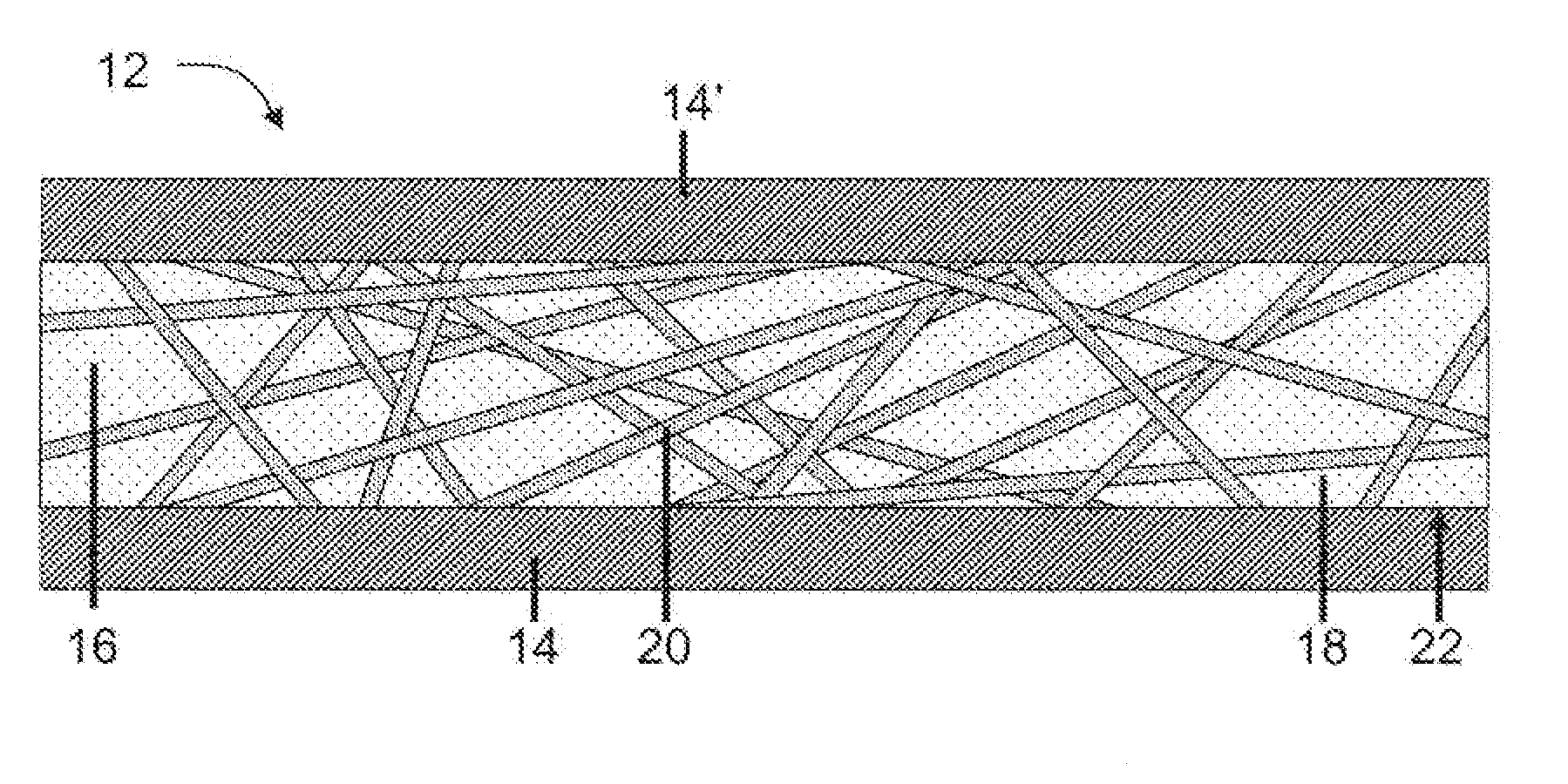

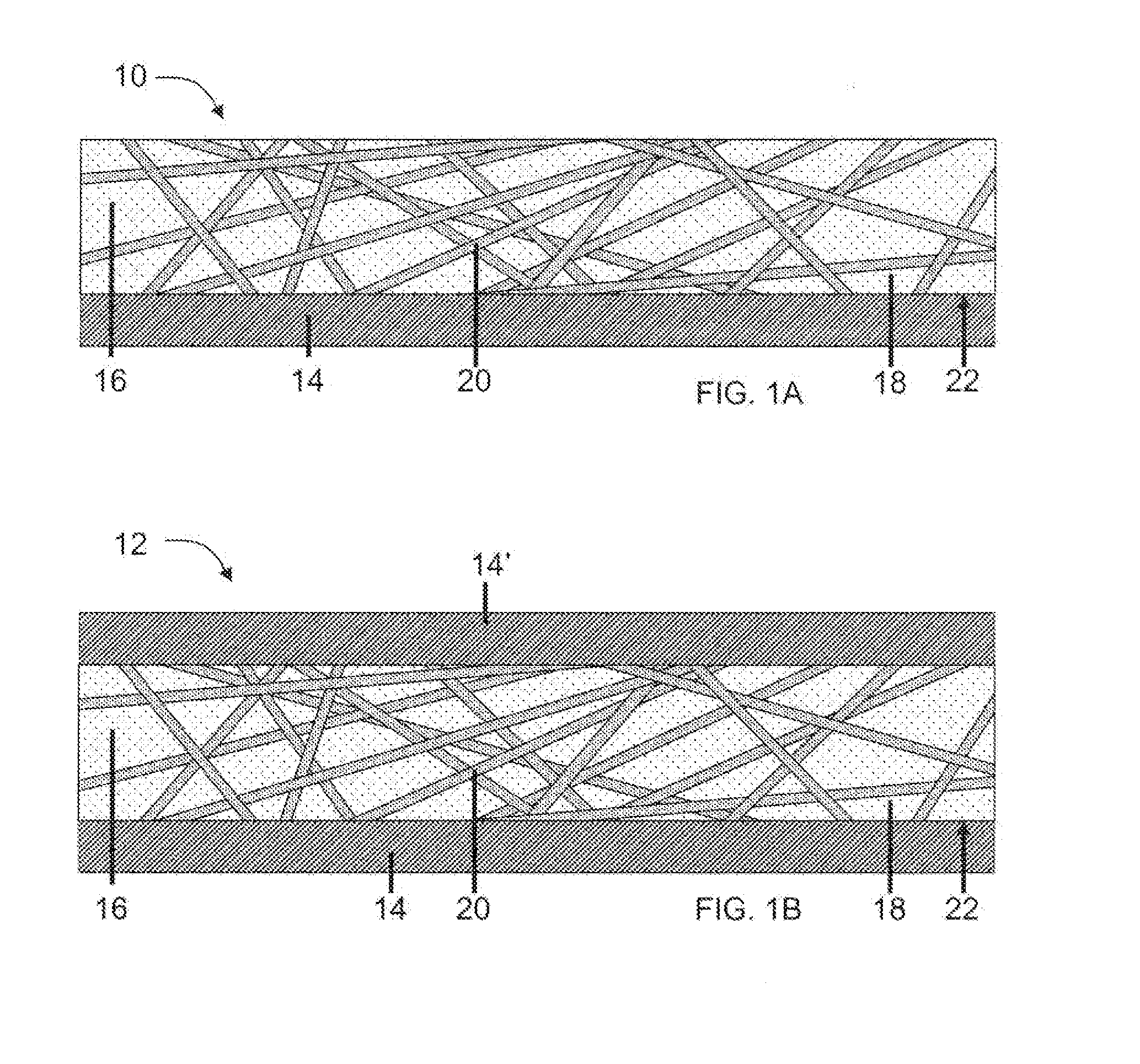

Formable light weight composites

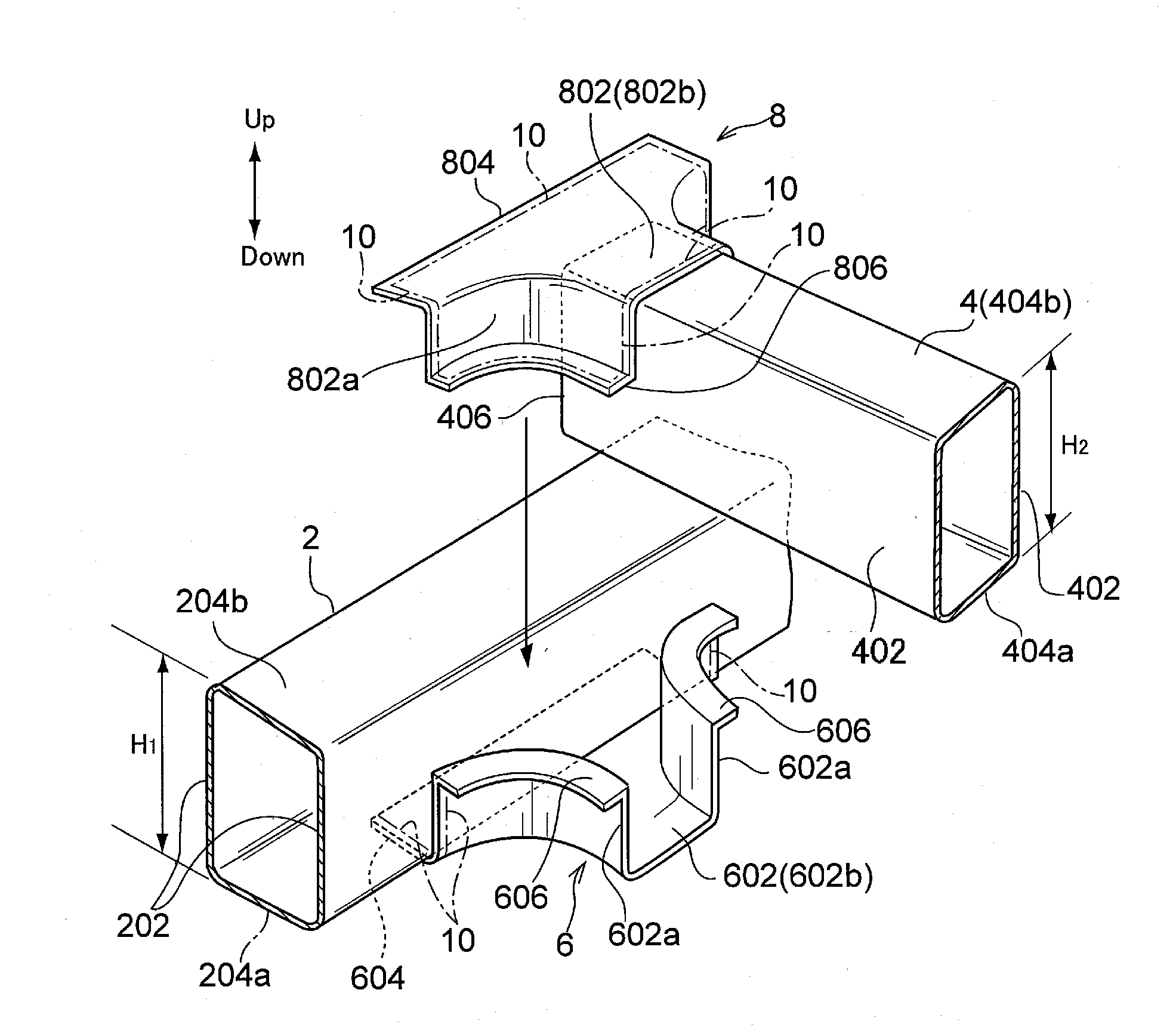

ActiveUS20100040902A1Synthetic resin layered productsLaminationElectrical resistance and conductanceMetal fibers

The present invention relates to light weight composite materials which comprise a metallic layer and a polymeric layer, the polymeric layer containing a filled thermoplastic polymer which includes a thermoplastic polymer and a metallic fiber. The composite materials of the present invention may be formed using conventional stamping equipment at ambient temperatures. Composite materials of the present invention may also be capable of being welded to other metal materials using a resistance welding process such as resistance spot welding.

Owner:PRODIVE RES

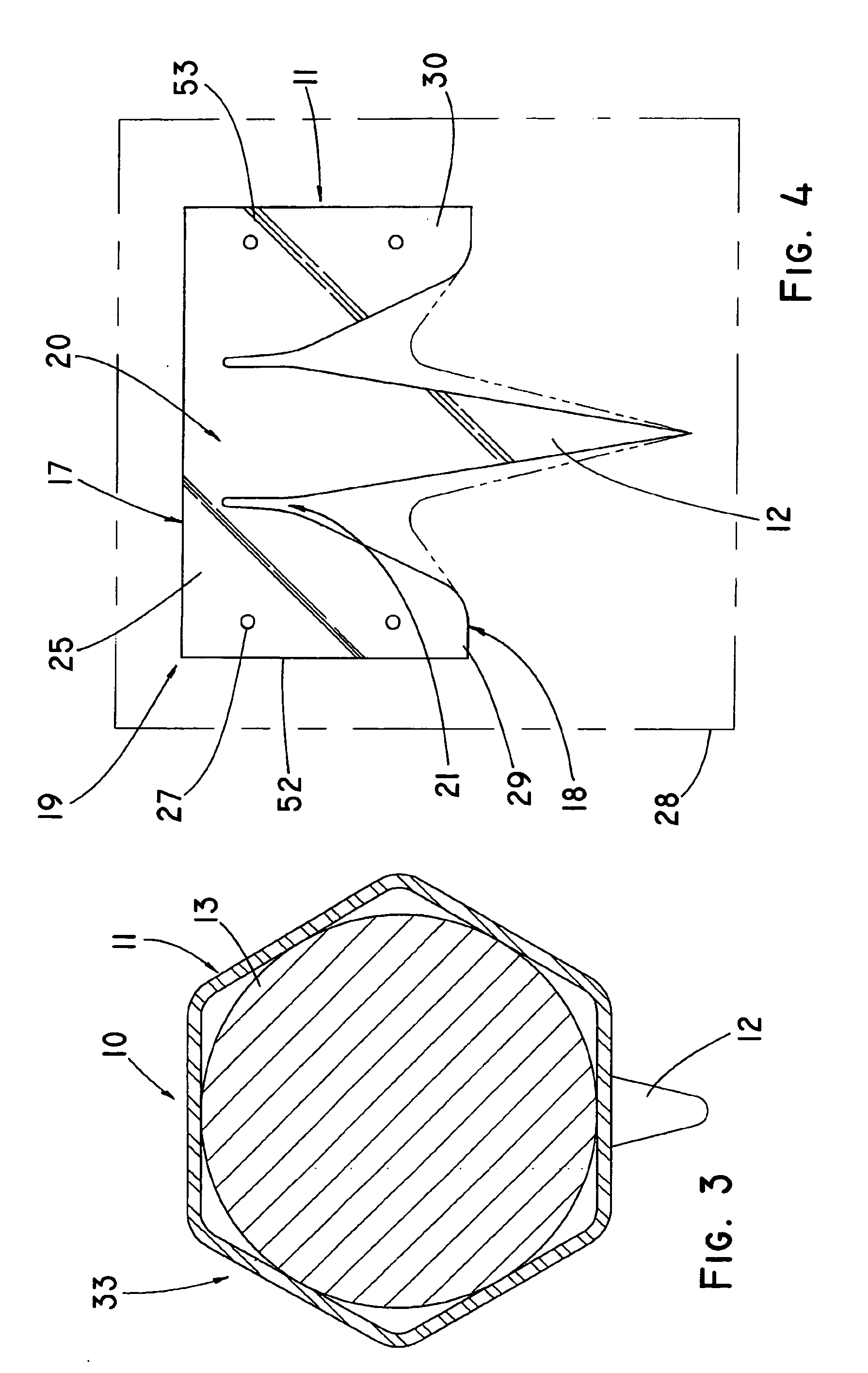

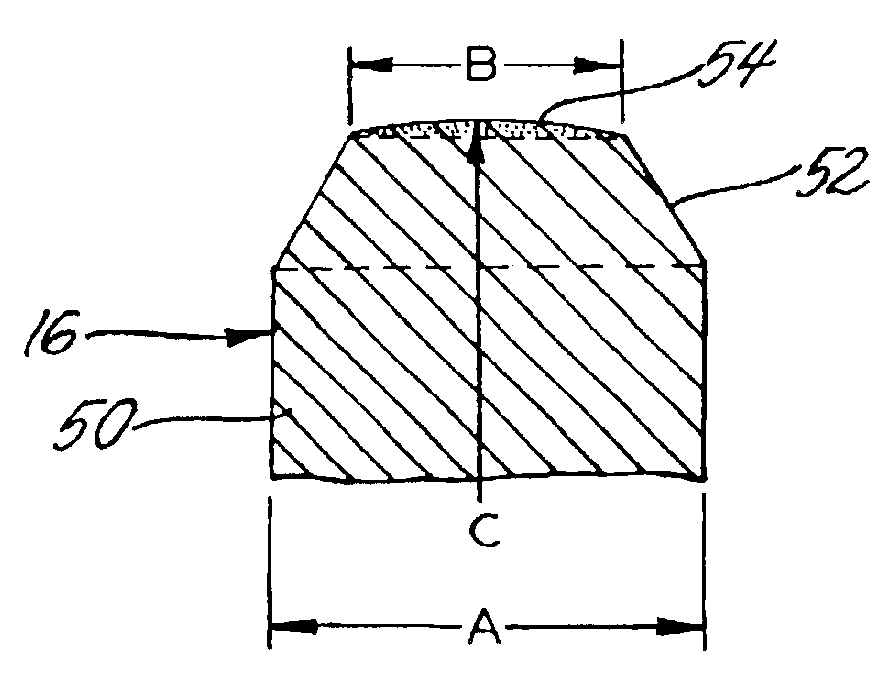

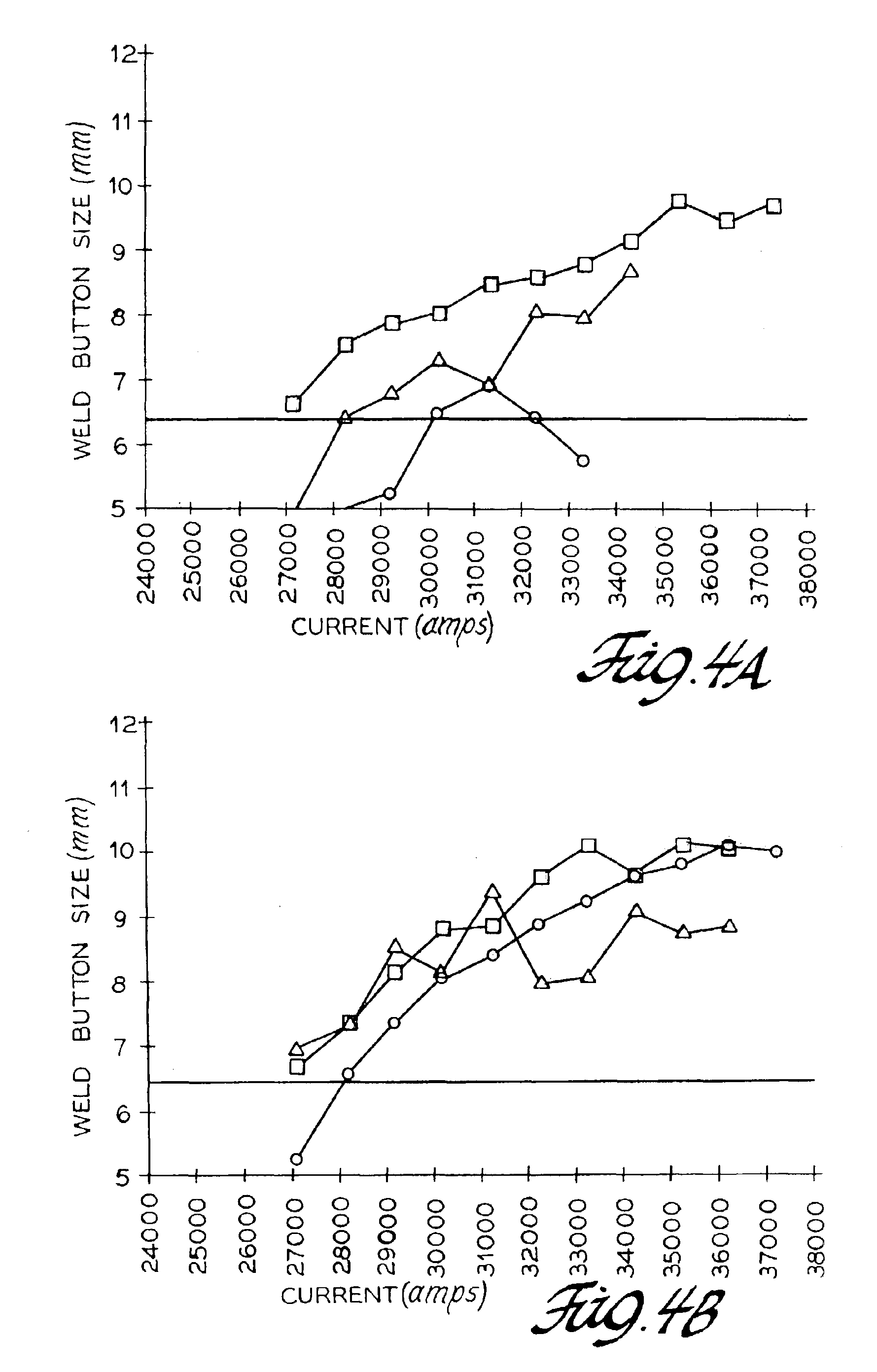

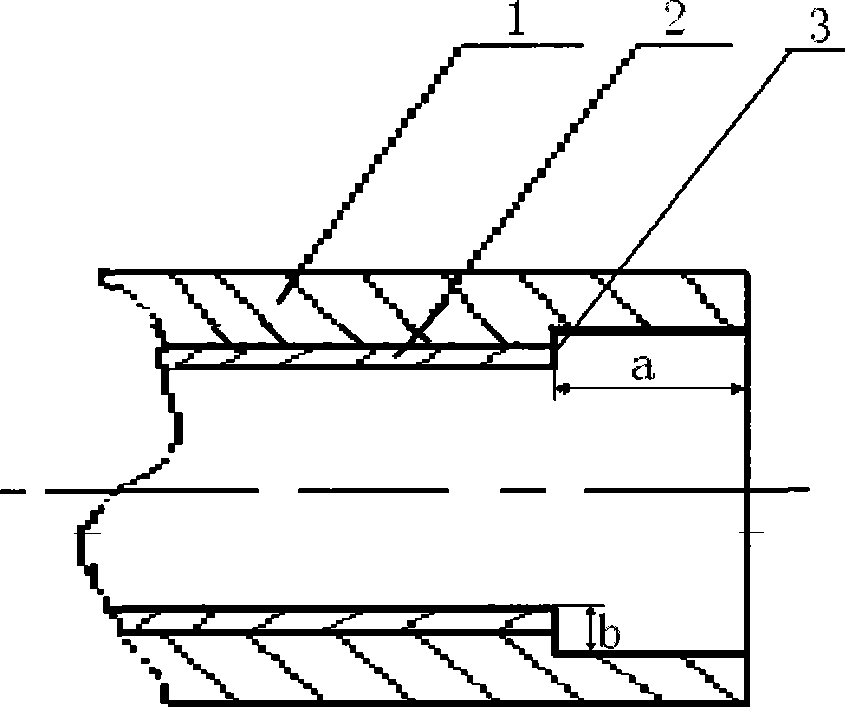

Welding electrode for aluminum sheets

InactiveUS6861609B2Good welding performanceCurvature of the face is more pronouncedOhmic-resistance electrodesPressure electrodesEngineeringAlloy

A design of copper welding electrode is disclosed. The electrode can be used in successive spot welding operations on assembled aluminum alloy sheet parts of widely varying thicknesses, e.g., from 0.9 to 4+ mm. The electrode has a round body terminating in a truncated cone with a crowned face. The face has a diameter of about eleven millimeters up to the diameter of the body and the radius of the crowned face is about twenty to thirty millimeters. The dimensions and shape of the electrode provide robust welding performances despite varying part thicknesses and off angle electrode positioning, and the textured surface provides good electrical contact.

Owner:GM GLOBAL TECH OPERATIONS LLC

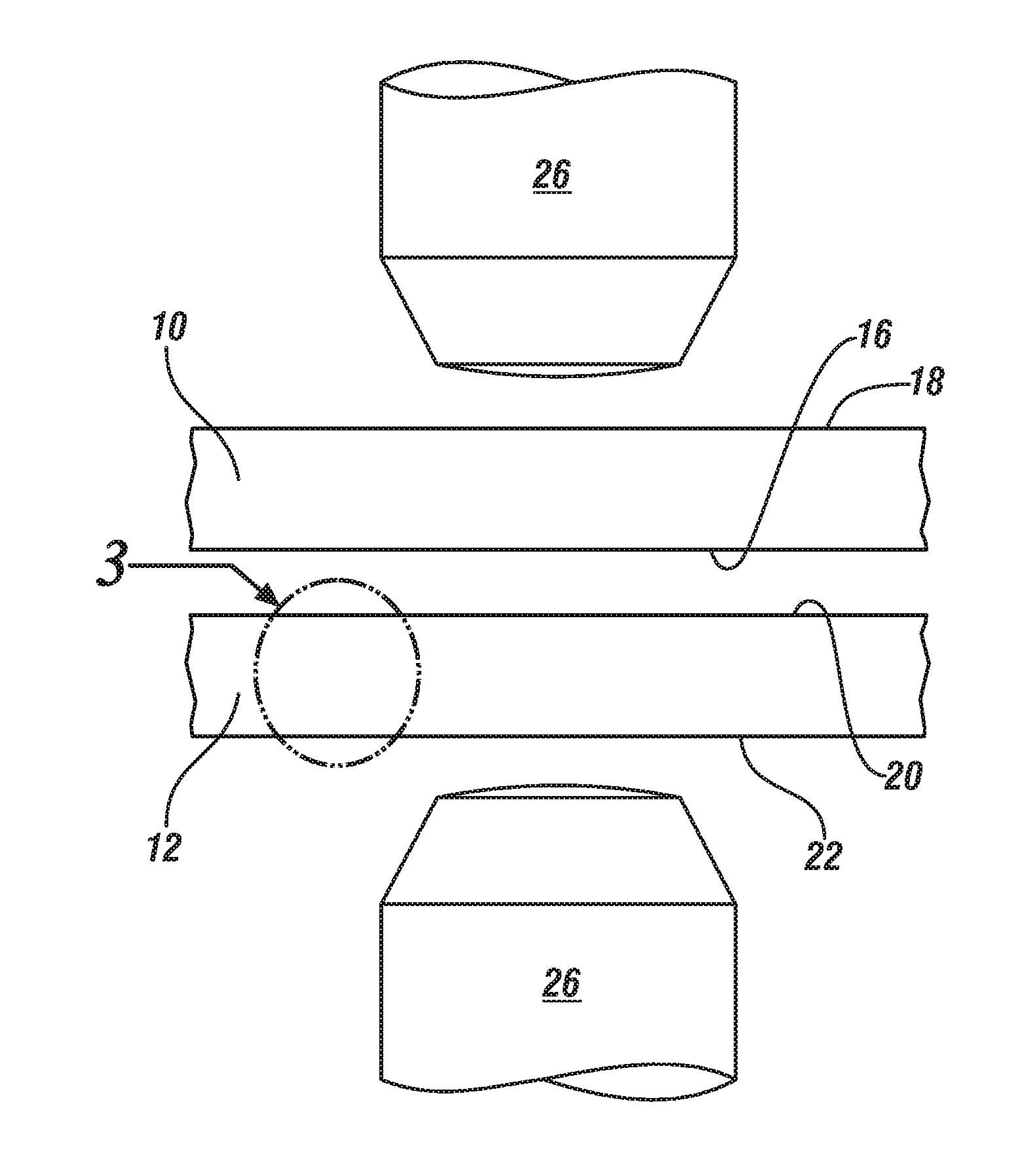

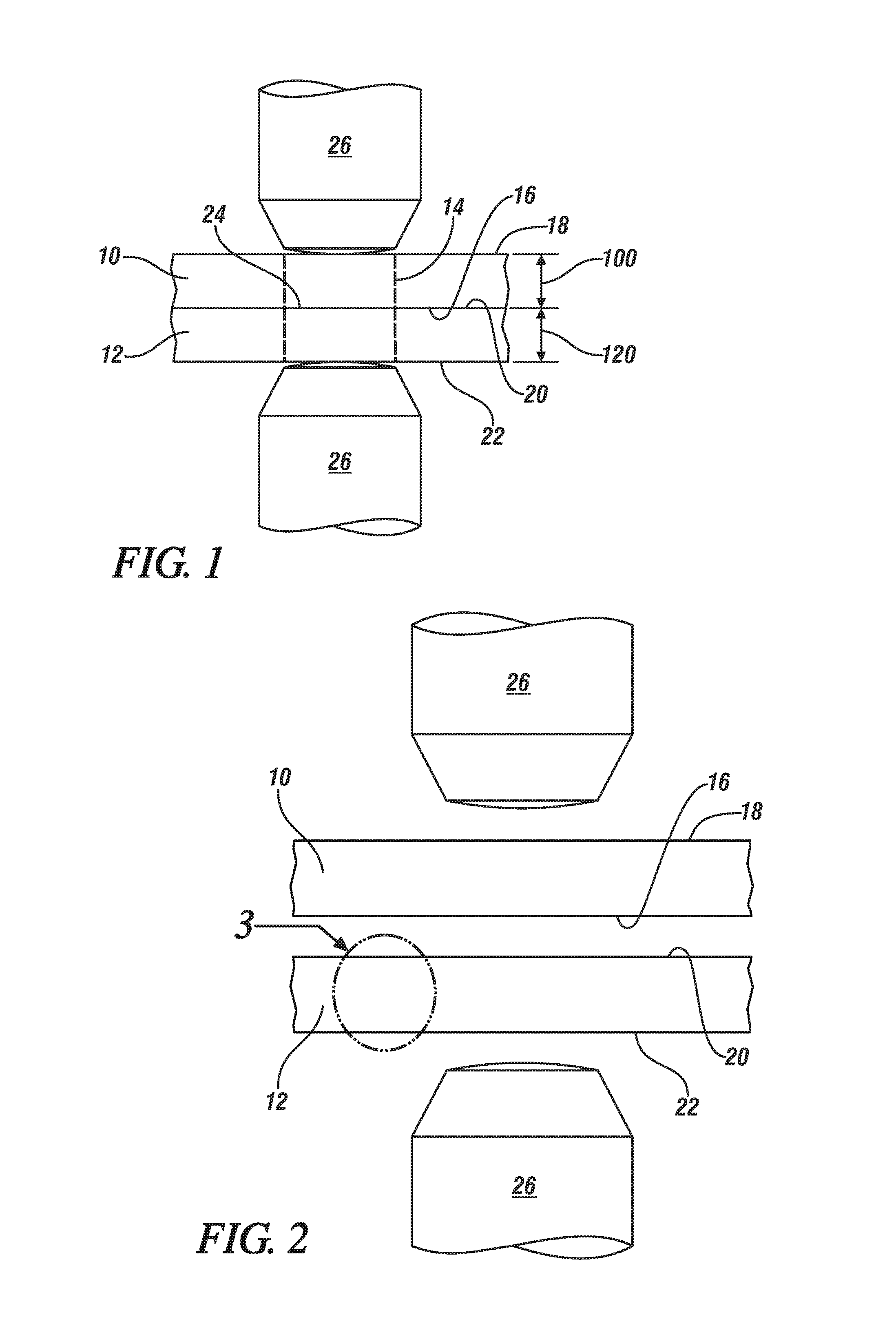

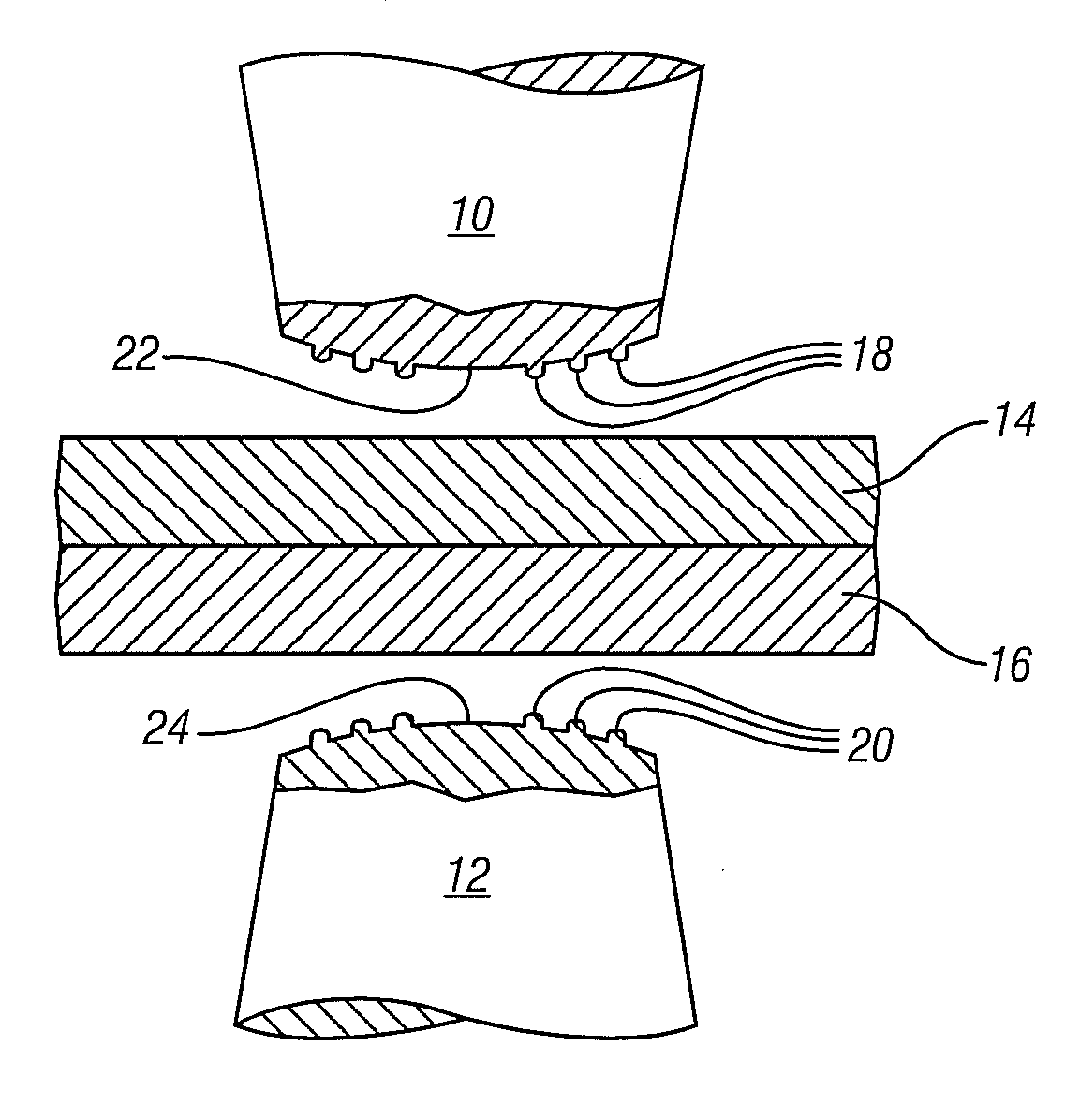

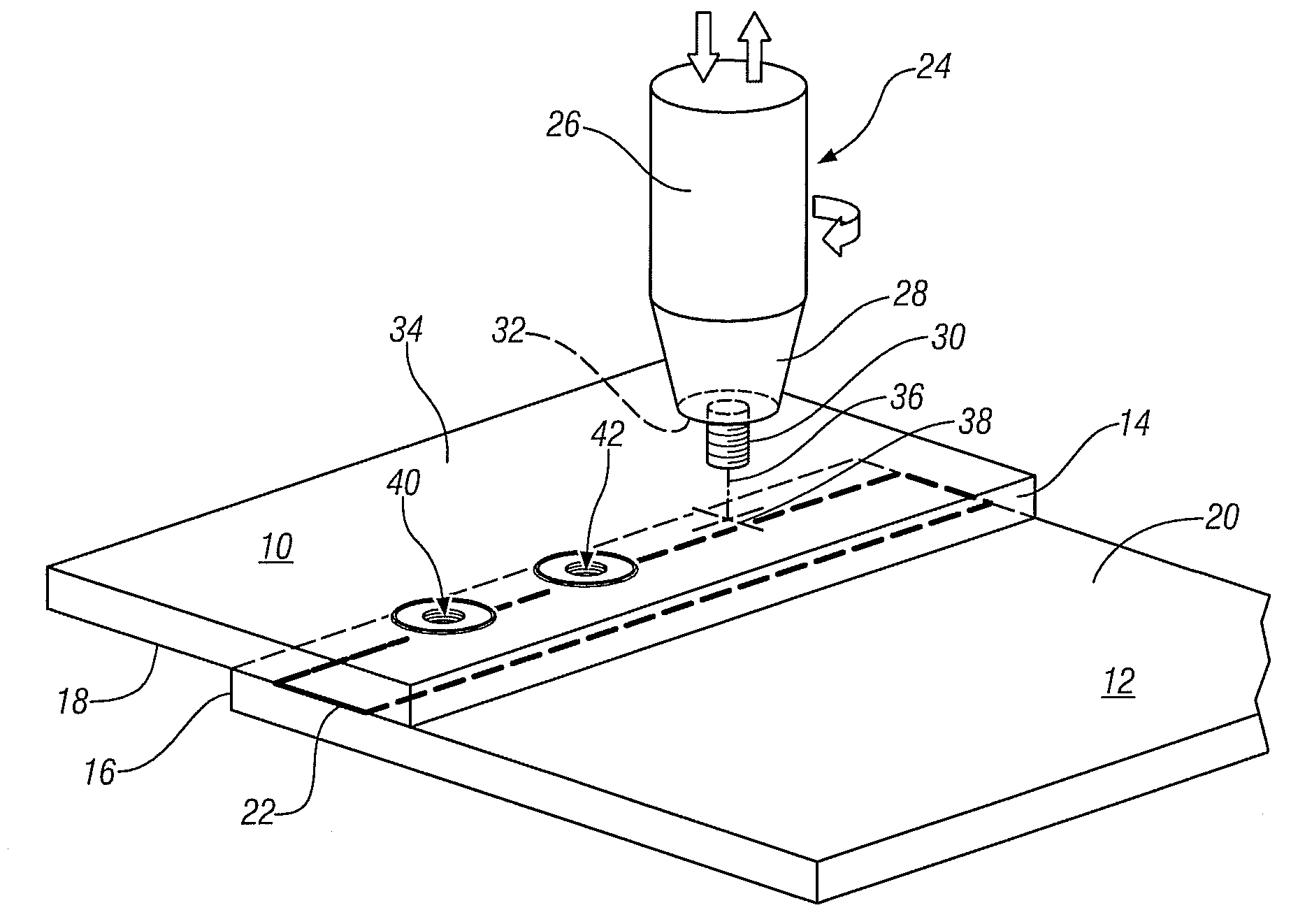

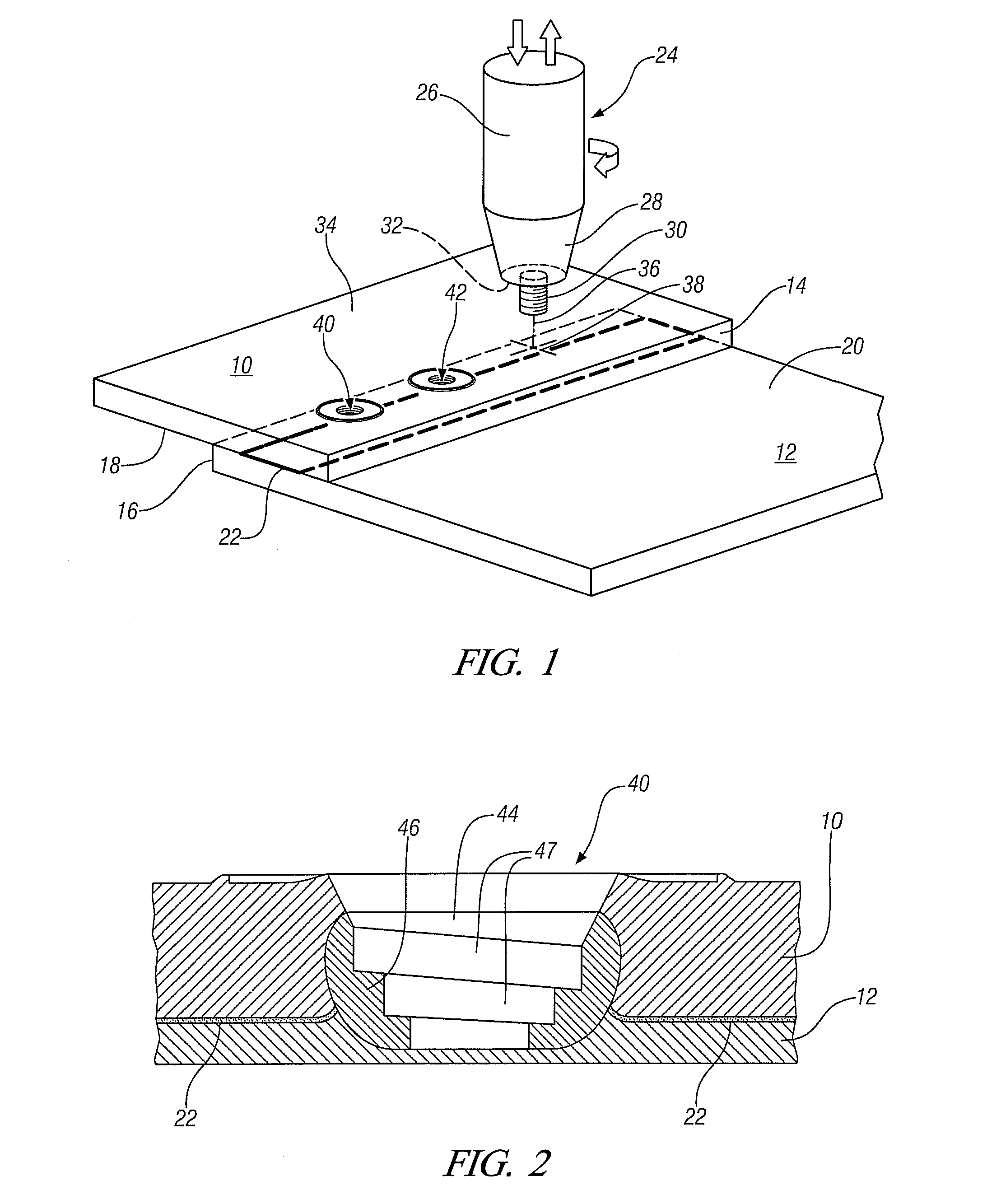

Resistance spot welding of steel to pre-coated aluminum

ActiveUS20140360986A1Low melting pointImprove the immunityWelding/soldering/cutting articlesResistance welding apparatusTitanium zirconiumConversion coating

Resistance spot welding of a steel workpiece to an aluminum or an aluminum alloy workpiece can be facilitated by replacing the refractory aluminum oxide-based layer(s) on at least the faying surface of the aluminum or aluminum alloy workpiece with a protective coating that is more conducive to the spot welding process. The protective coating may be a metallic coating or a metal oxide conversion coating. In a preferred embodiment, the protective coating is a coating of zinc, tin, or an oxide of titanium, zirconium, chromium, or silicon.

Owner:GM GLOBAL TECH OPERATIONS LLC

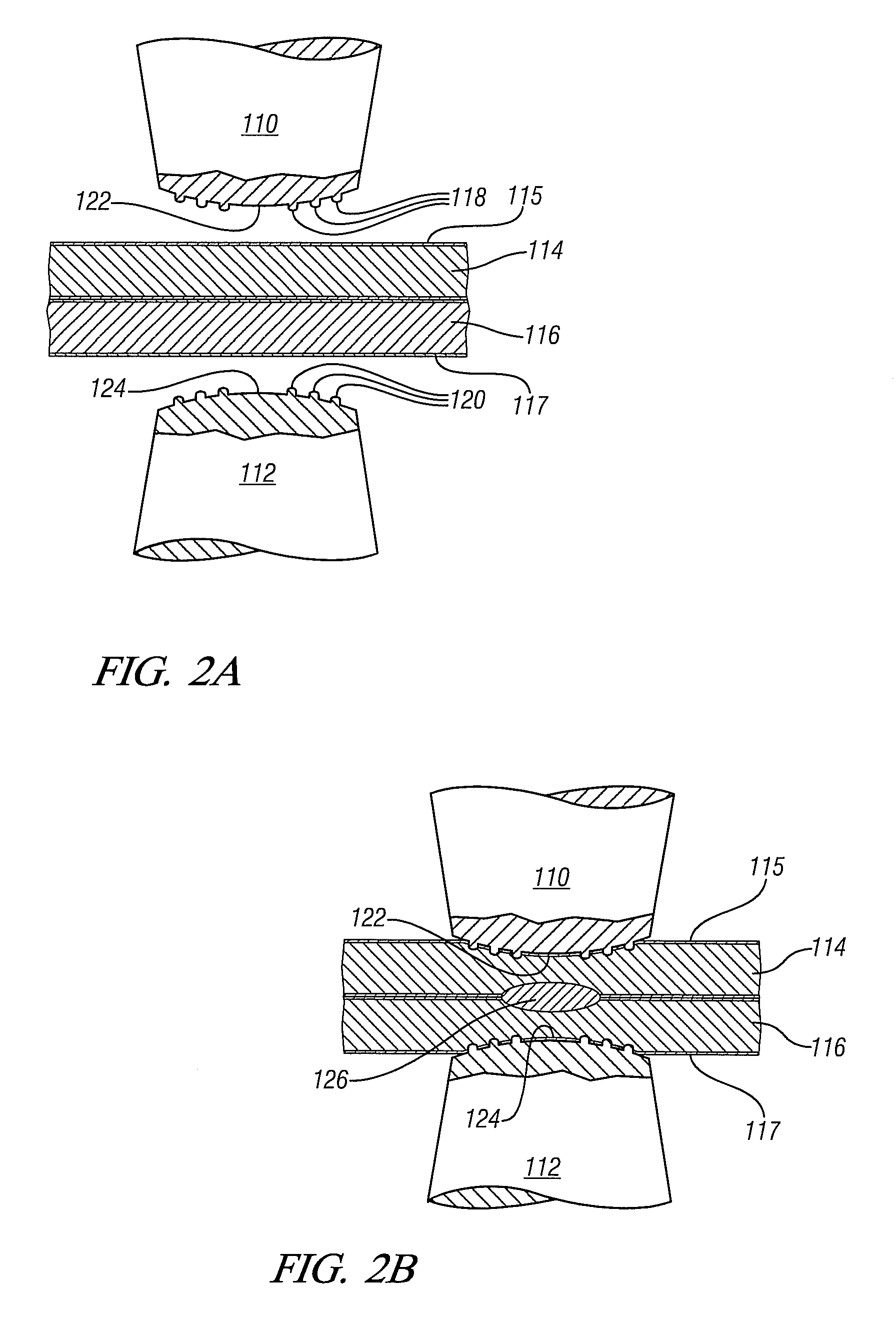

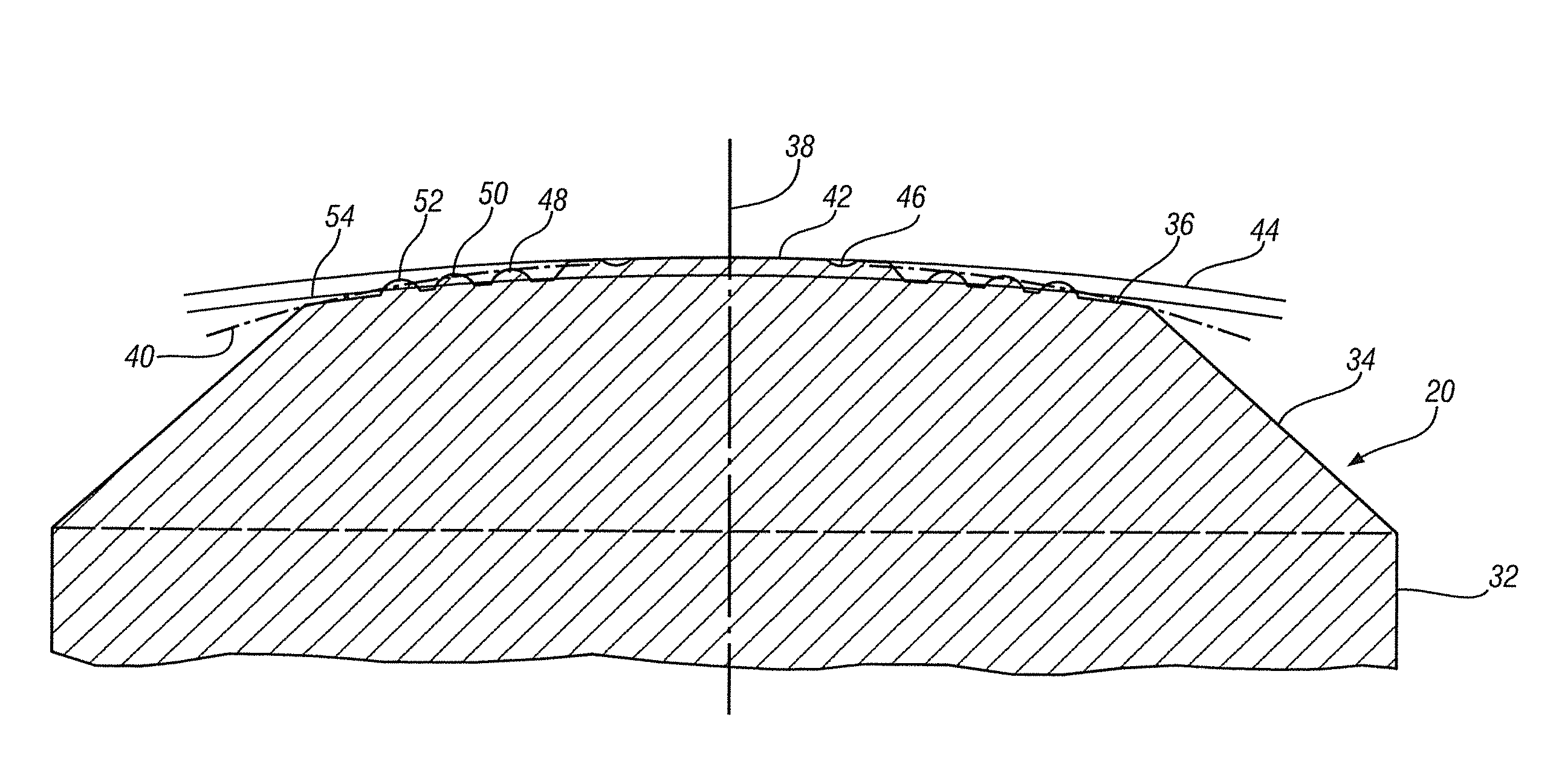

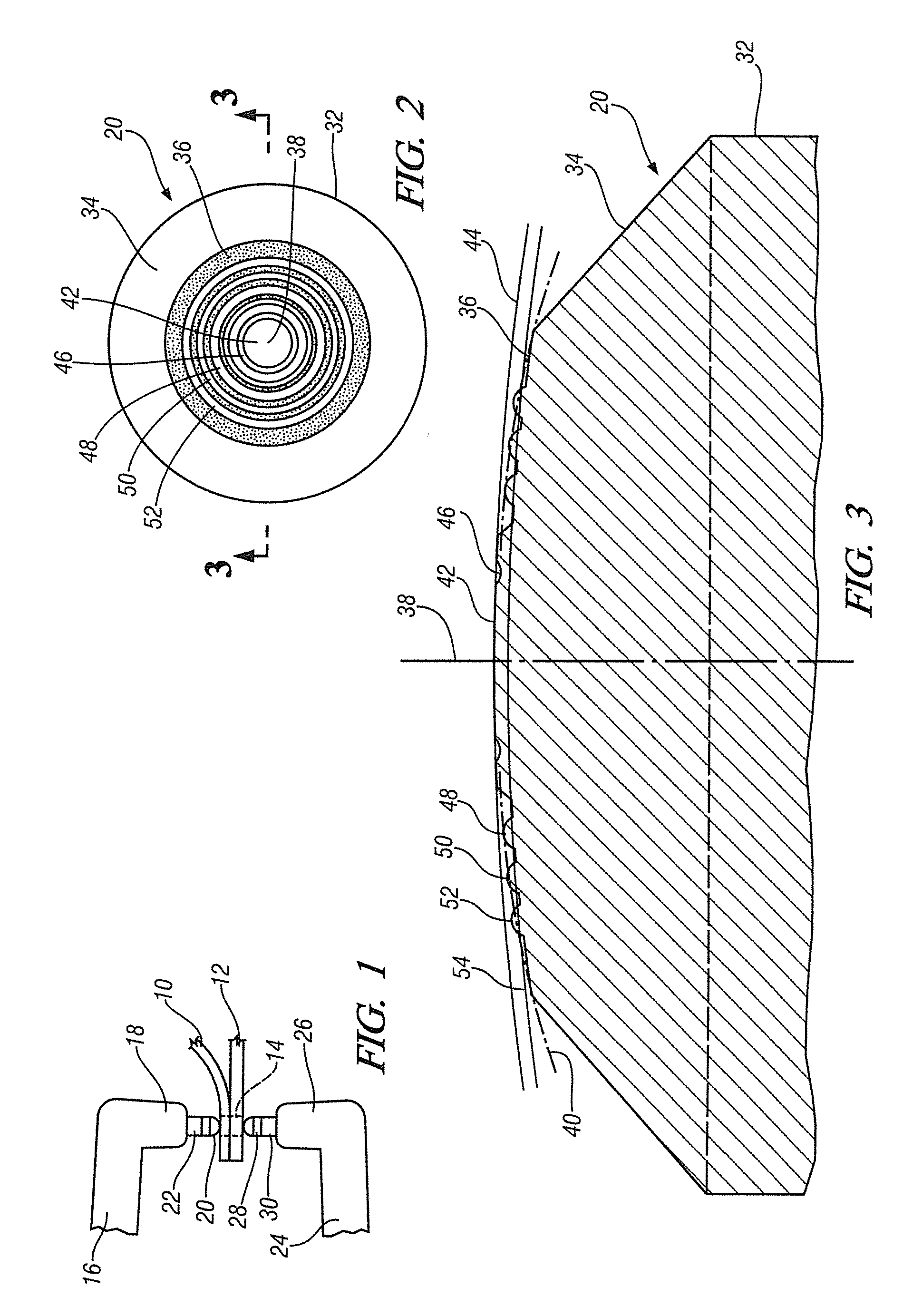

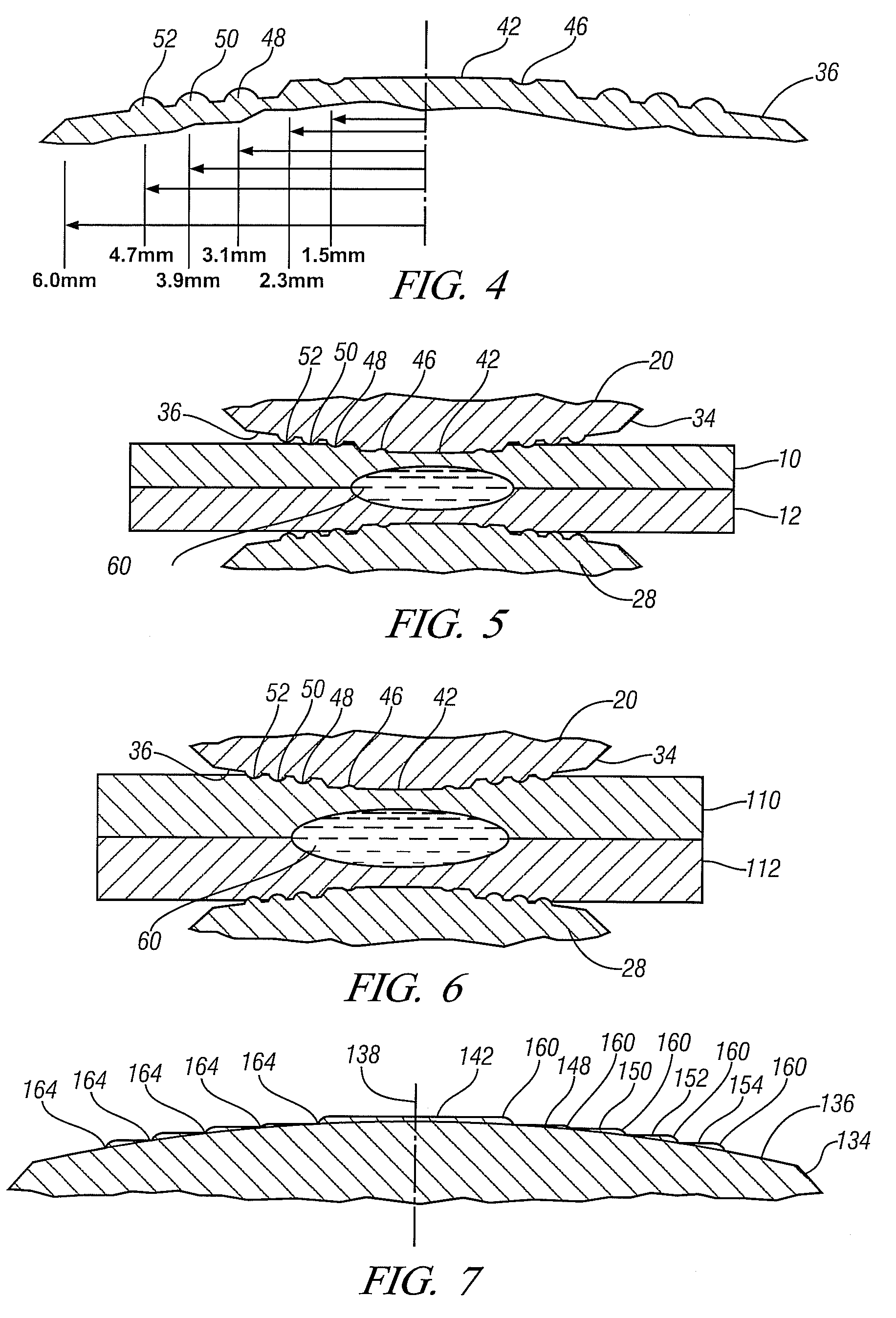

Weld electrode for attractive weld appearance

ActiveUS20090255908A1High thermal and electrical resistivityHigh melting pointPressure electrodesSheet steelSpot welding

Weld faces of electrodes for resistance spot welding are formed with a suitable area of protrusions and / or intrusions. The size, shape, and elevation or depths of the protrusions or intrusions are determined for the formation of suitable spot welds in and between metal workpieces such as aluminum or steel panels for vehicle bodies. The protrusions or intrusions are also conceived and used to form an image on at least a visible surface of the welded article to produce an attractive appearance on the surface of the welded sheet.

Owner:GM GLOBAL TECH OPERATIONS LLC

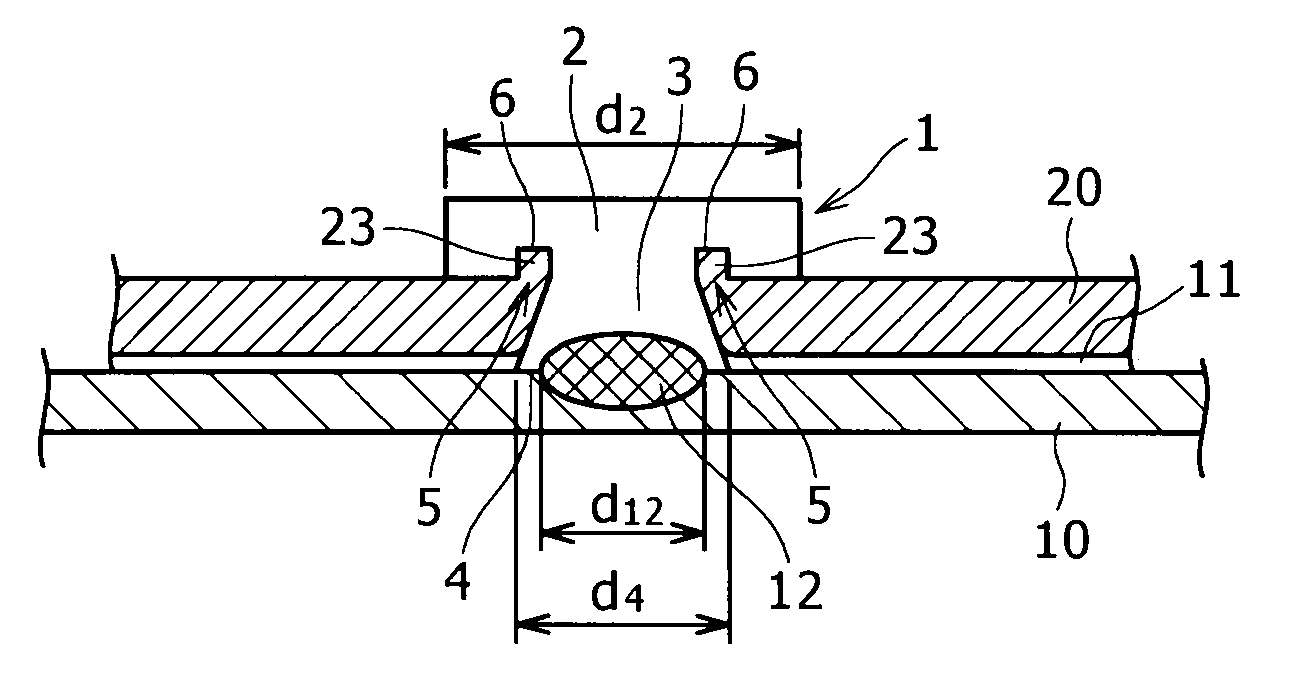

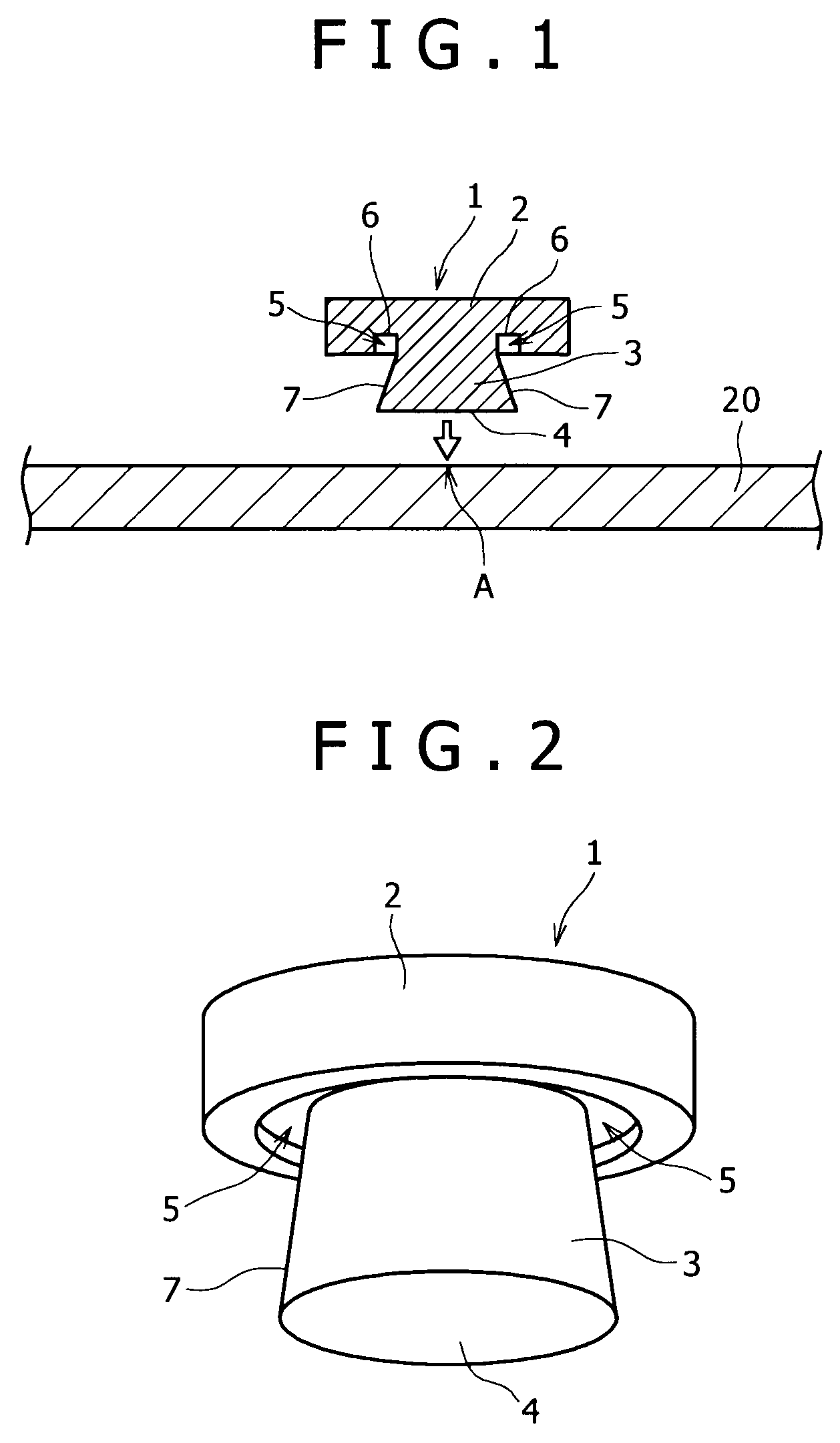

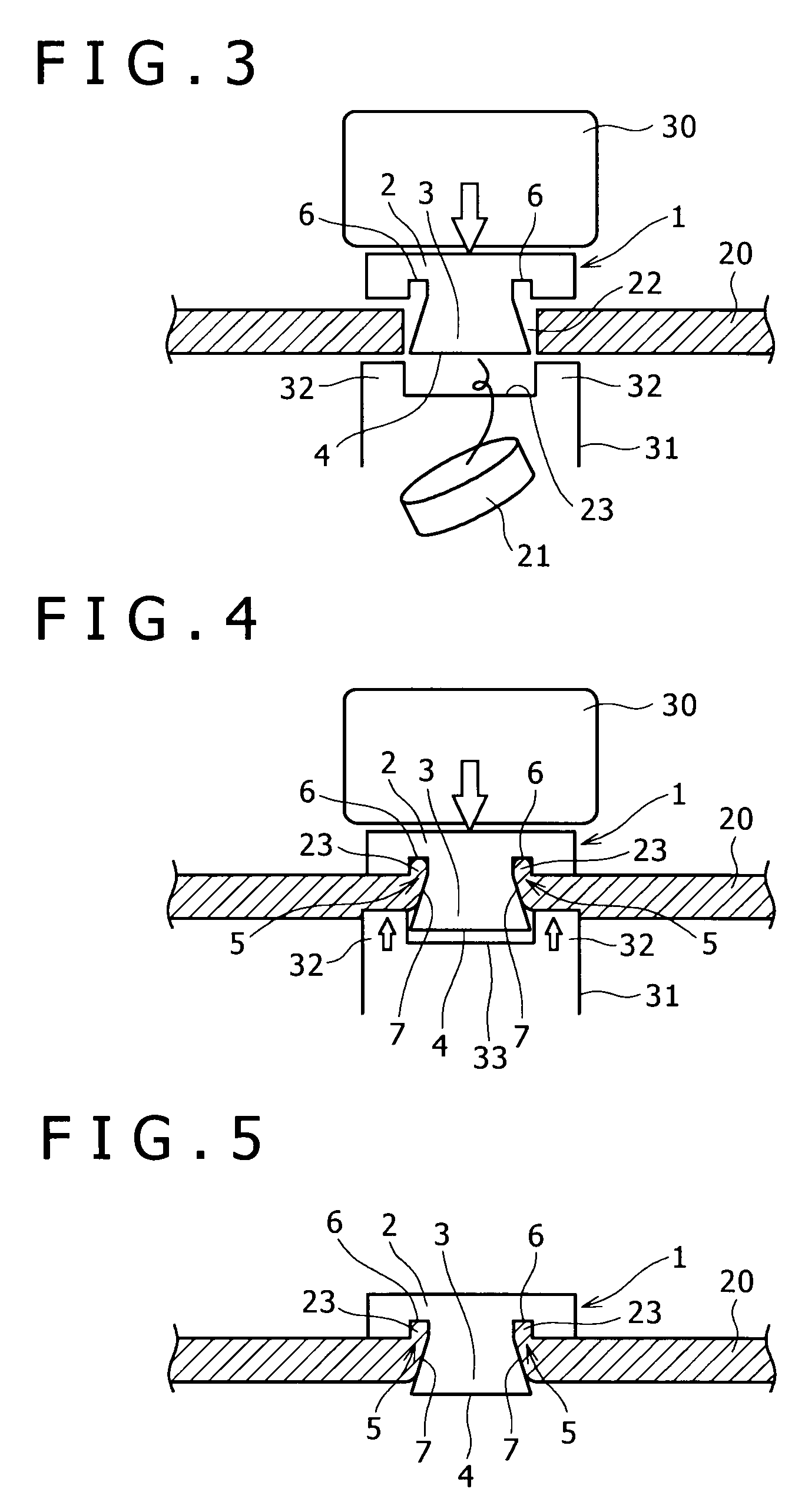

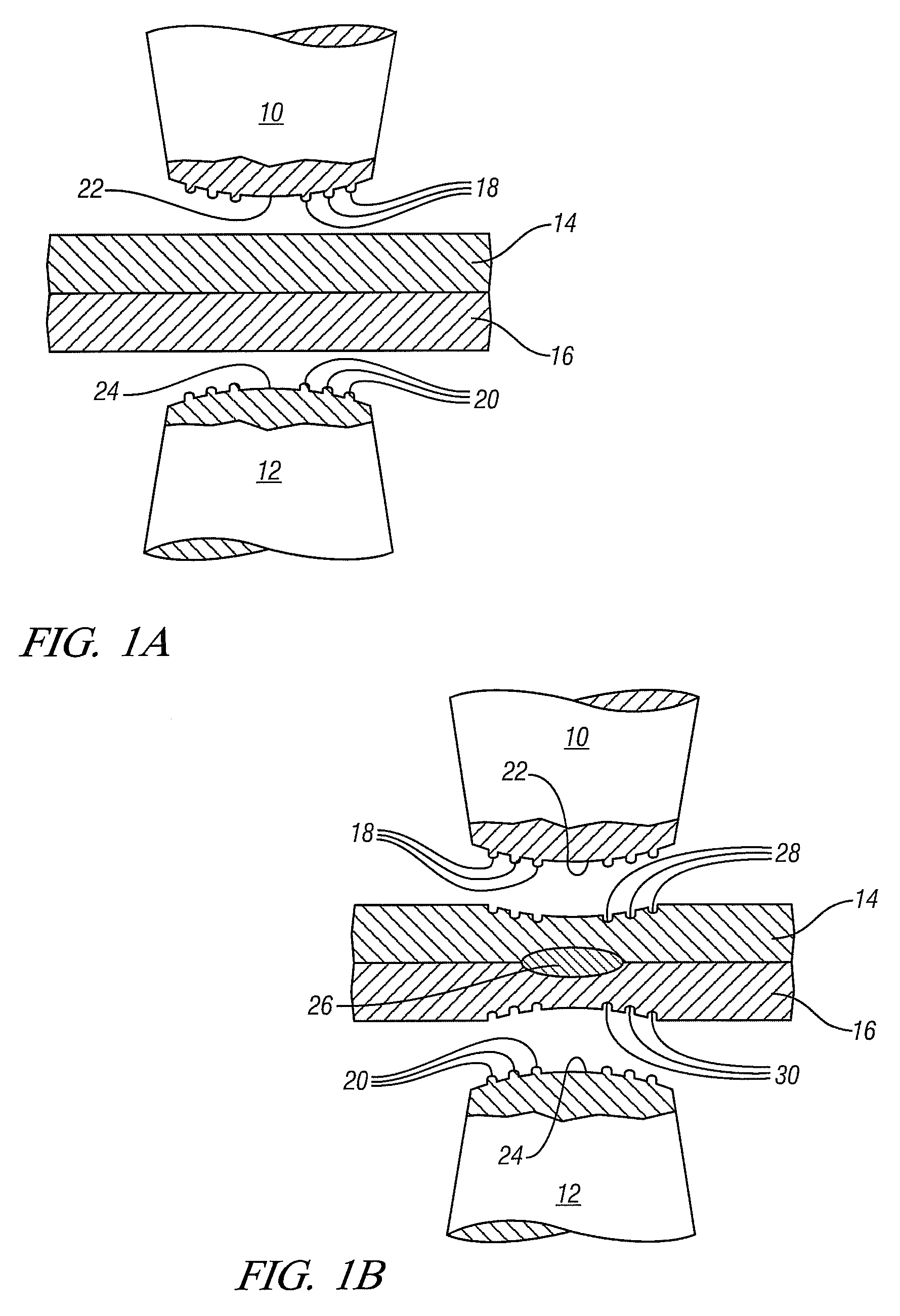

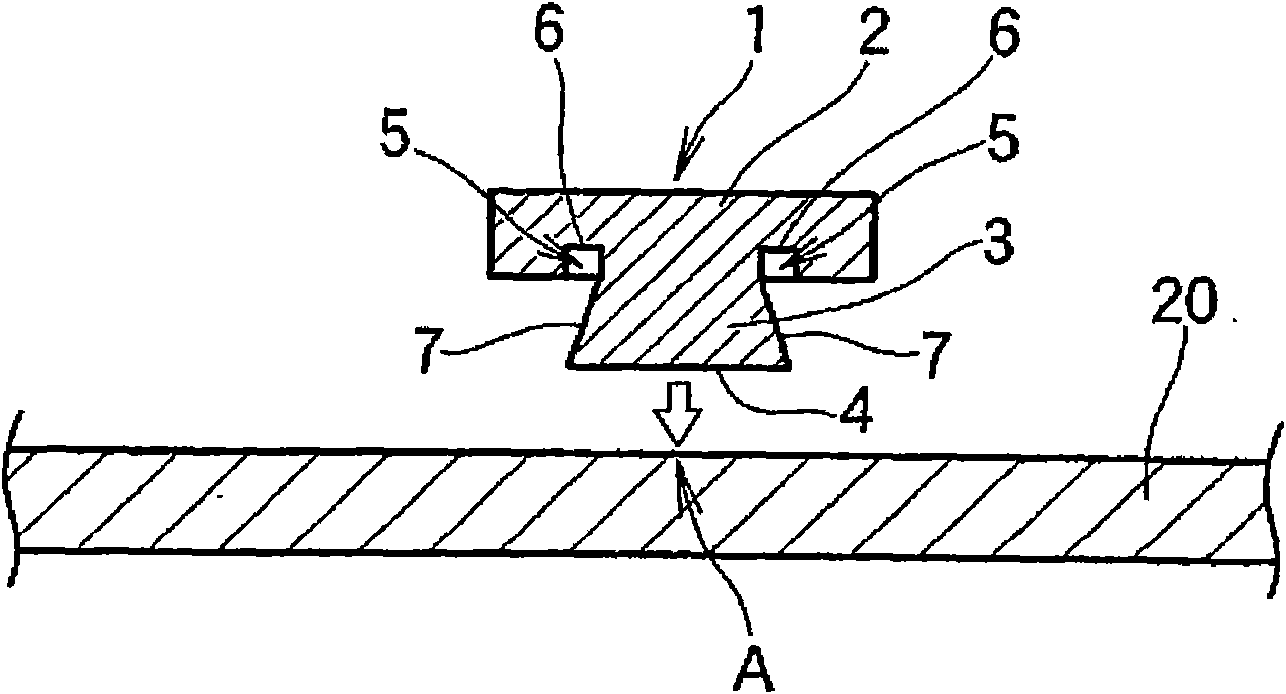

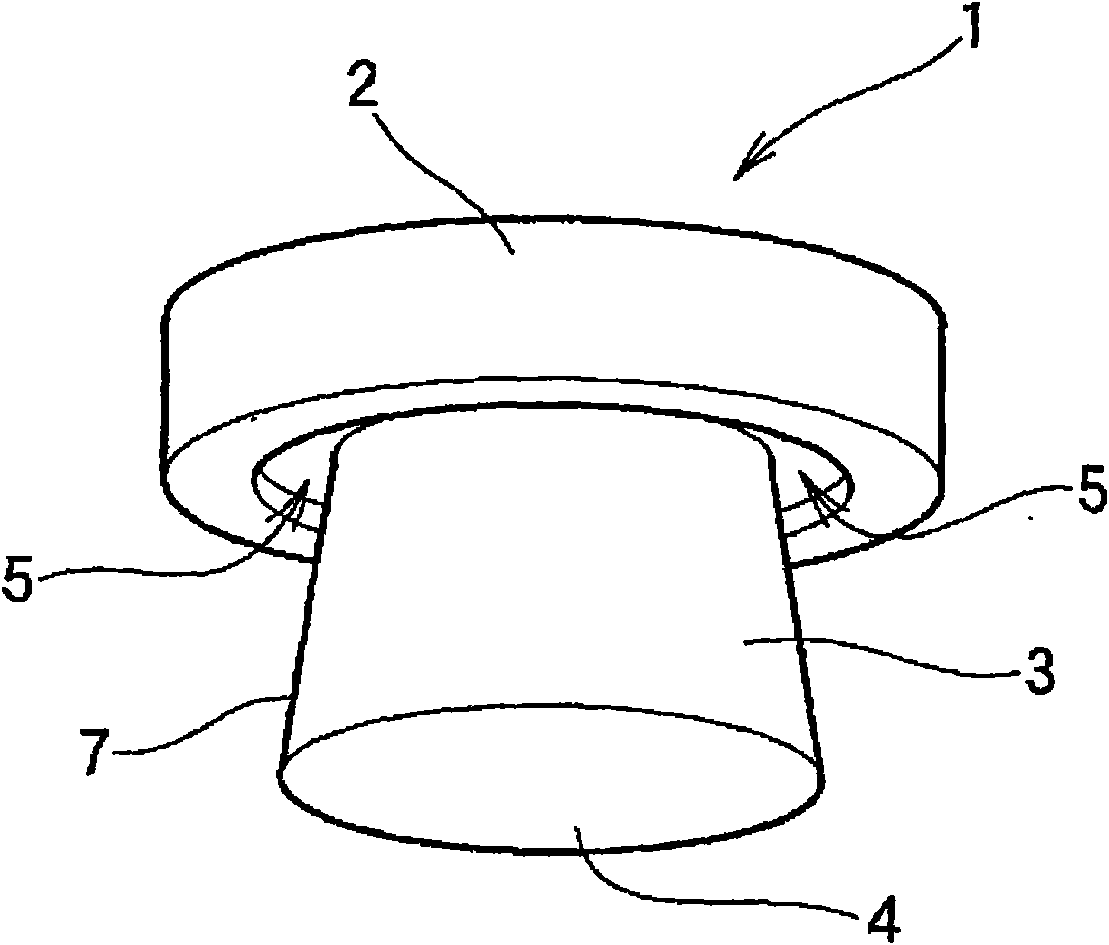

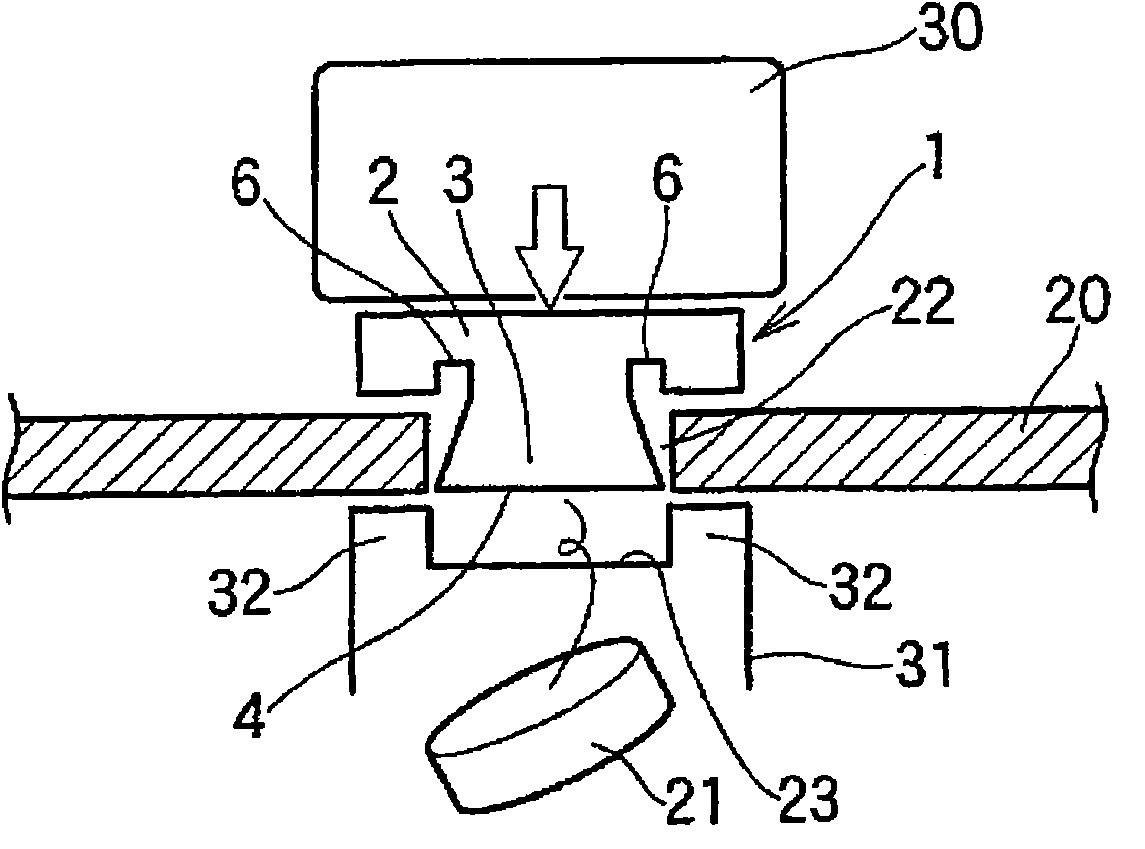

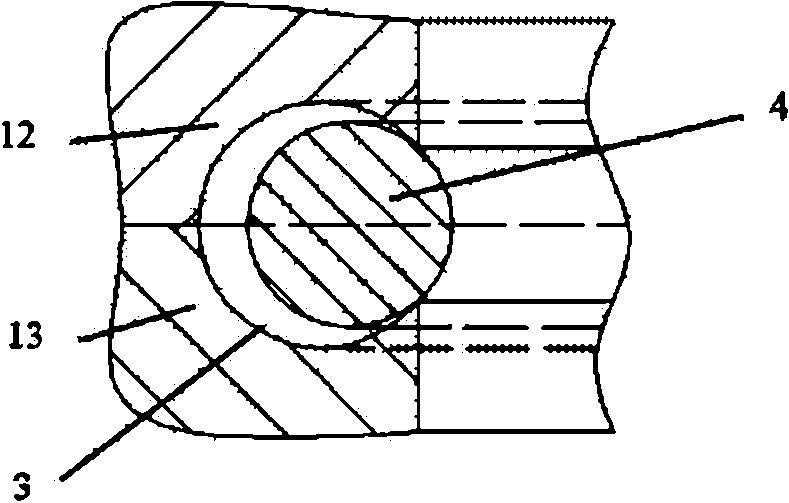

Method for joining dissimilar metals of steel product and light metal product with each other

InactiveUS20090294410A1Overcome limitationsImprove joint strengthShrinkage connectionsSheet joiningSpot weldingUltimate tensile strength

There is provided method for joining dissimilar metals of a steel product and a light metal product with each other, wherein the light metal product and a rivet made of an iron-base metal are connected with each other beforehand in a previous process preceding spot welding, and subsequently, the rivet and the steel product are spot welded with each other. Then, a cavity for use in clinching the light metal product is formed, and upon the stem of the rivet is embedded into the light metal product to penetrate therethrough, light metal is caused to undergo plastic flow into the cavity of the rivet, for clinching the light metal product to be thereby clinched with the rivet whereupon spot welding for forming a weld nugget only within the scope of an interface between the stem of the rivet, and the steel product is carried out. Thus, the present invention can implement the spot welding between iron—iron similar metals, without a constraint on, and a problem with conditions applicable to the spot welding and a high joint strength can be obtained owing to the synergistic effect of the spot welding and connection by clinching of the aluminum alloy product with the iron-base rivet, added thereto.

Owner:KOBE STEEL LTD

Weld electrode for attractive weld appearance

ActiveUS8222560B2High thermal and electrical resistivityHigh melting pointOhmic-resistance electrodesPressure electrodesSpot weldingVisible surface

Weld faces of electrodes for resistance spot welding are formed with a suitable area of protrusions and / or intrusions. The size, shape, and elevation or depths of the protrusions or intrusions are determined for the formation of suitable spot welds in and between metal workpieces such as aluminum or steel panels for vehicle bodies. The protrusions or intrusions are also conceived and used to form an image on at least a visible surface of the welded article to produce an attractive appearance on the surface of the welded sheet.

Owner:GM GLOBAL TECH OPERATIONS LLC

Coating material for protecting metals, especially steel, from corrosion and/or scaling, method for coating metals and metal element

InactiveCN101360796AVarious usabilityImprove conductivityPretreated surfacesAnti-corrosive paintsAfter treatmentSpot welding

The invention surprisingly finds that when a suitable binder including a suitable filler is used during the high temperature treatment of a curing process, the coating materials of the invention change in such a manner that electrically conducting reactive layers are formed that allow welding and especially spot welding together with the metal substrate even after treatment at temperatures of more than 800 DEG C.

Owner:NANOX

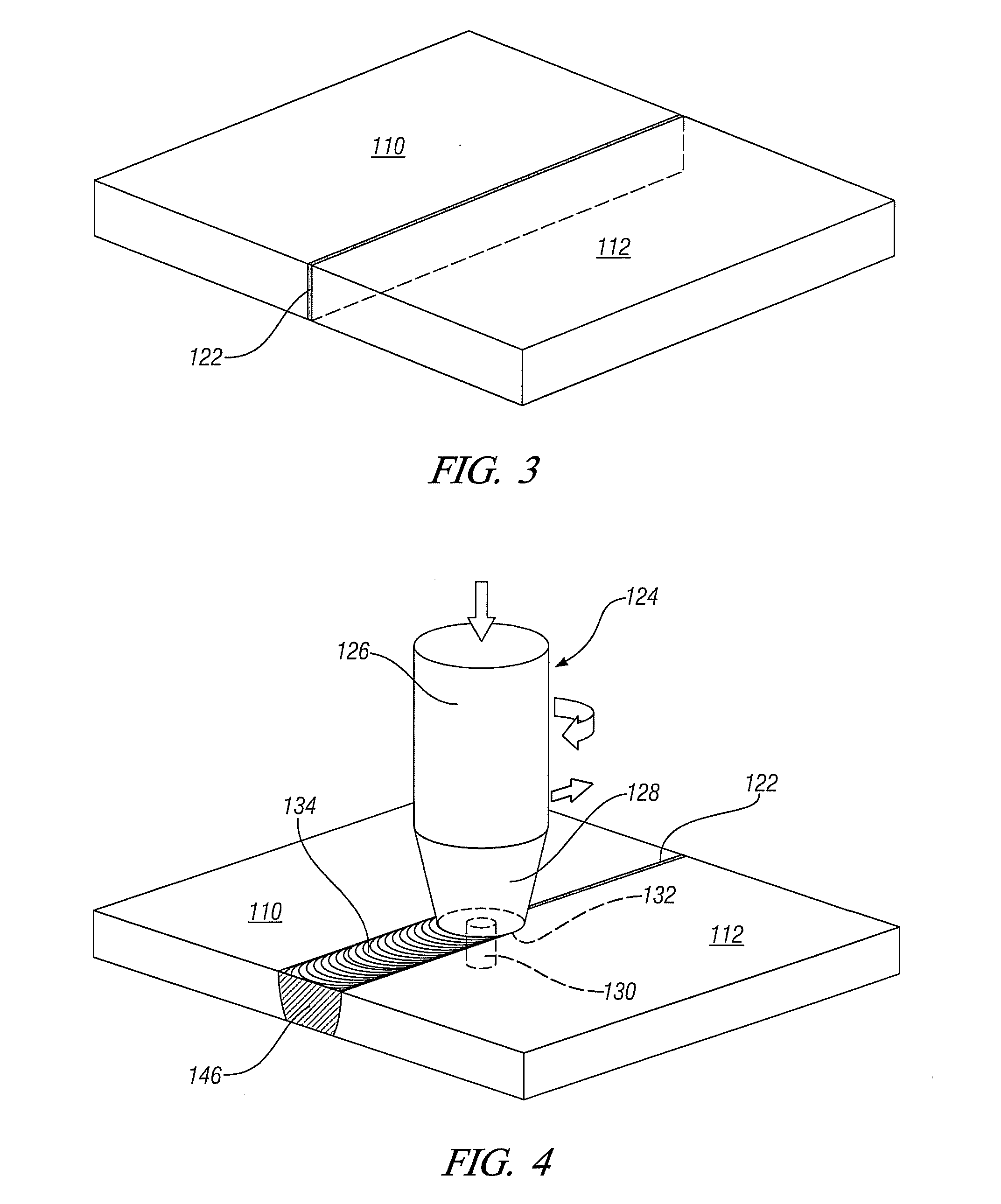

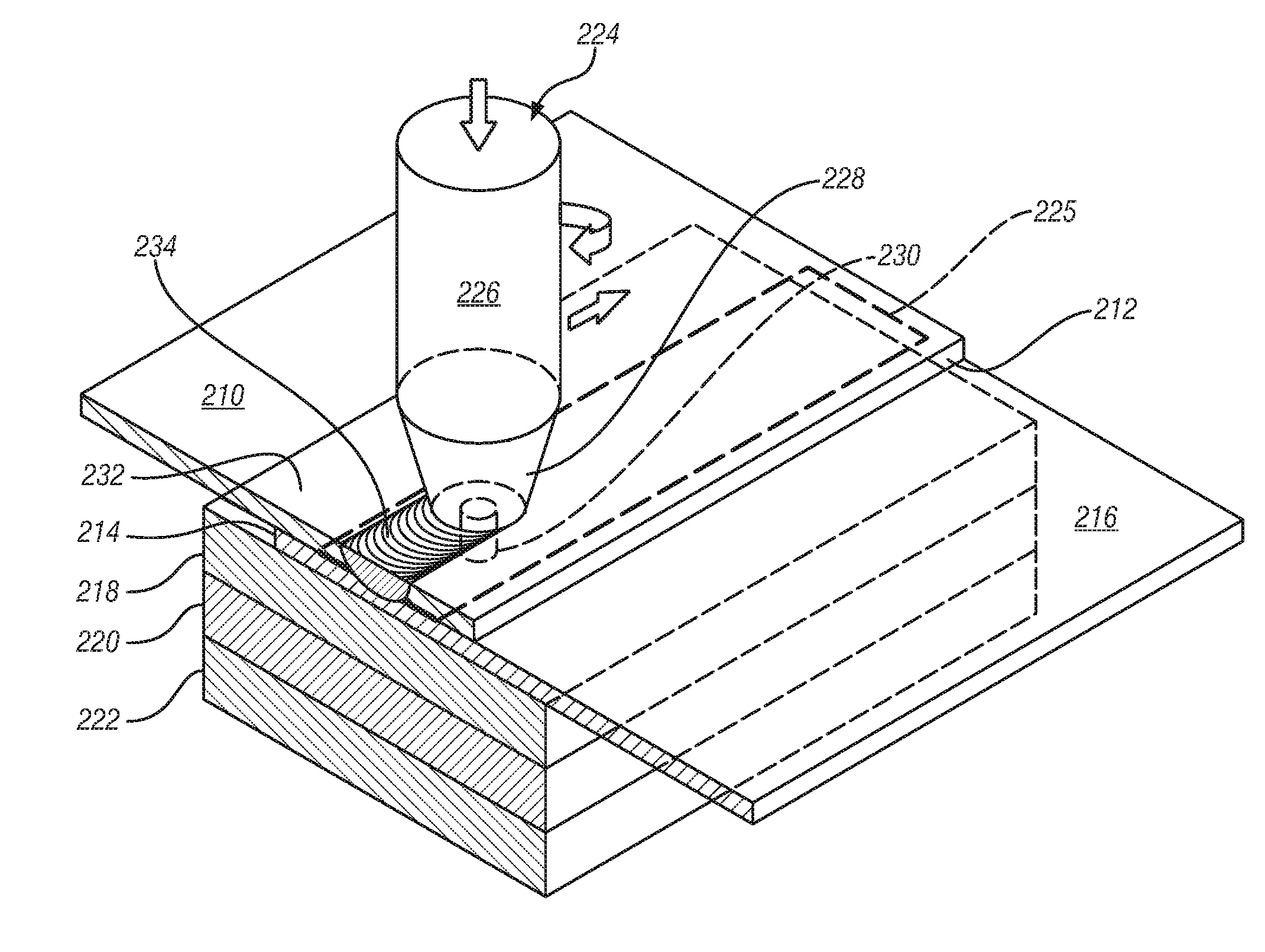

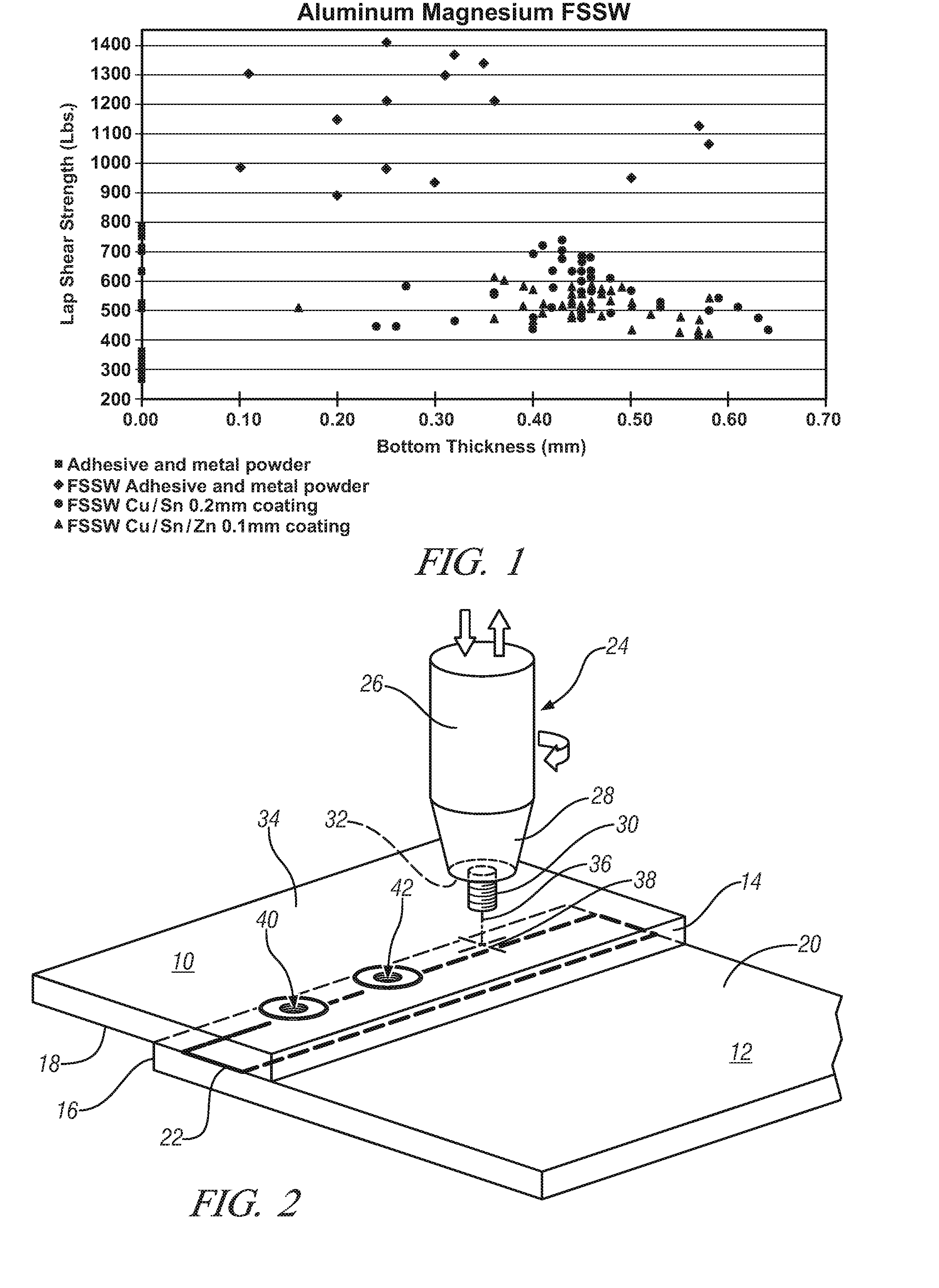

Friction stir welding of dissimilar metals

InactiveUS20100089977A1Improve mechanical propertiesHigh viscosityWelding/soldering/cutting articlesNon-electric welding apparatusFriction stir weldingTin

When a friction stir weld tool penetrates the interface of two workpieces of dissimilar metal alloy materials, the resultant weld of the different alloy materials may produce a weak weld joint. Such weak joints are often experienced, for example, when attempting to form spot welds or other friction stir welds between a magnesium alloy sheet or strip and an aluminum alloy sheet or strip. It is discovered that suitable coating compositions placed at the interface of assembled workpieces can alter the composition of the friction stir weld material and strengthen the resulting bond. In the example of friction stir welds between magnesium alloy and aluminum alloy workpieces, it is found that combinations of copper, tin, and zinc, and other powders can strengthen the magnesium-containing and aluminum-containing friction stir weld material.

Owner:GM GLOBAL TECH OPERATIONS LLC

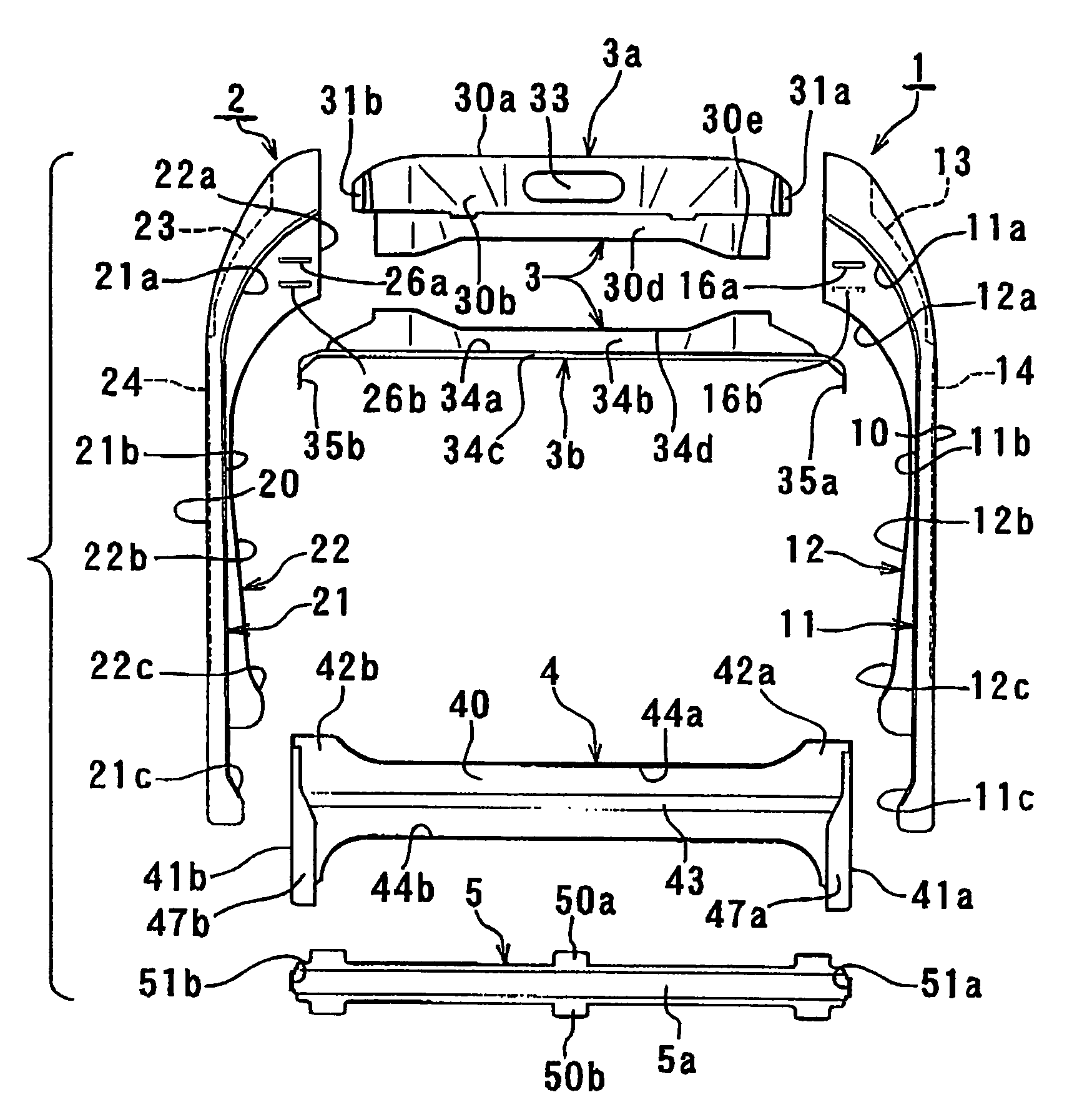

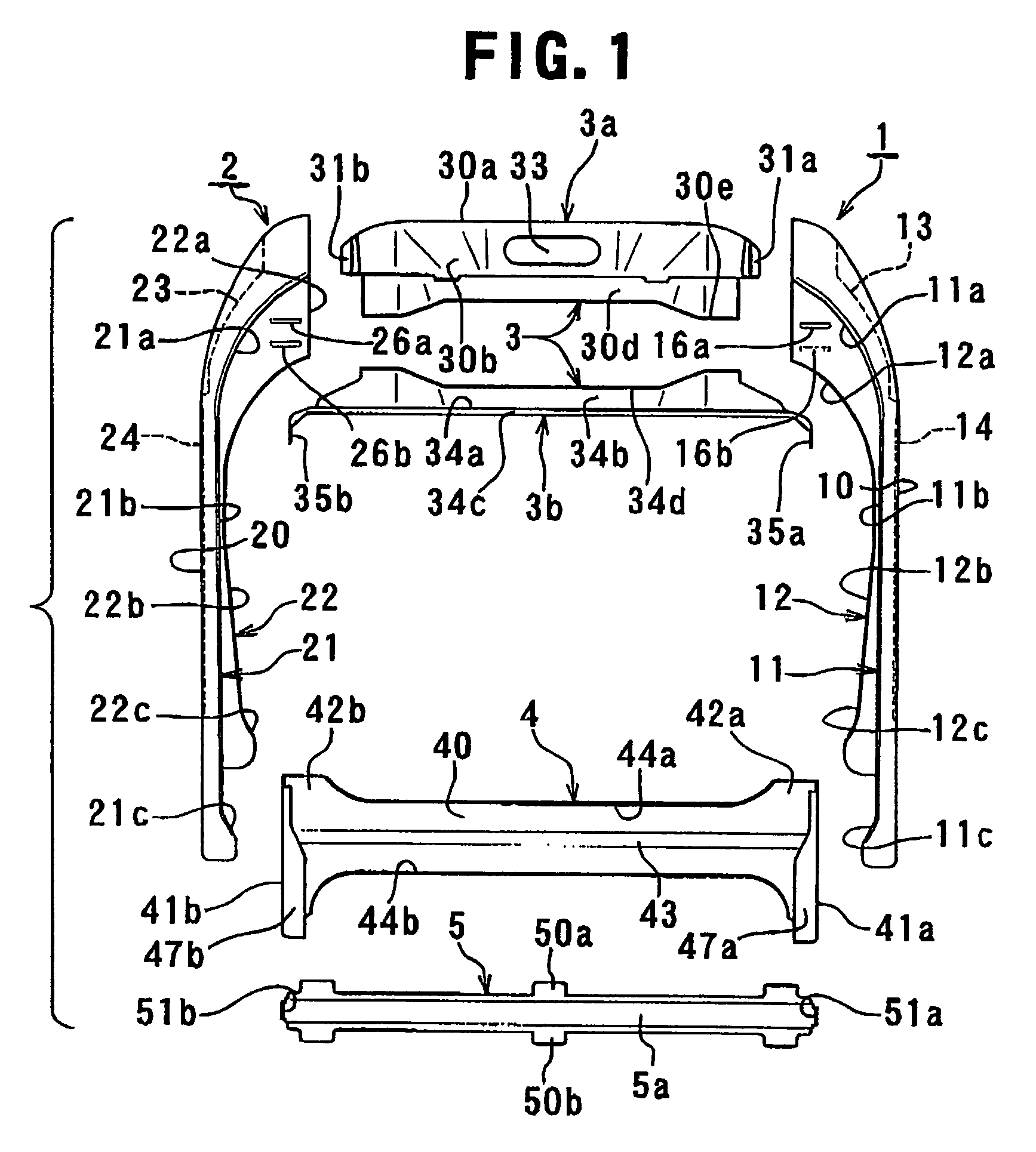

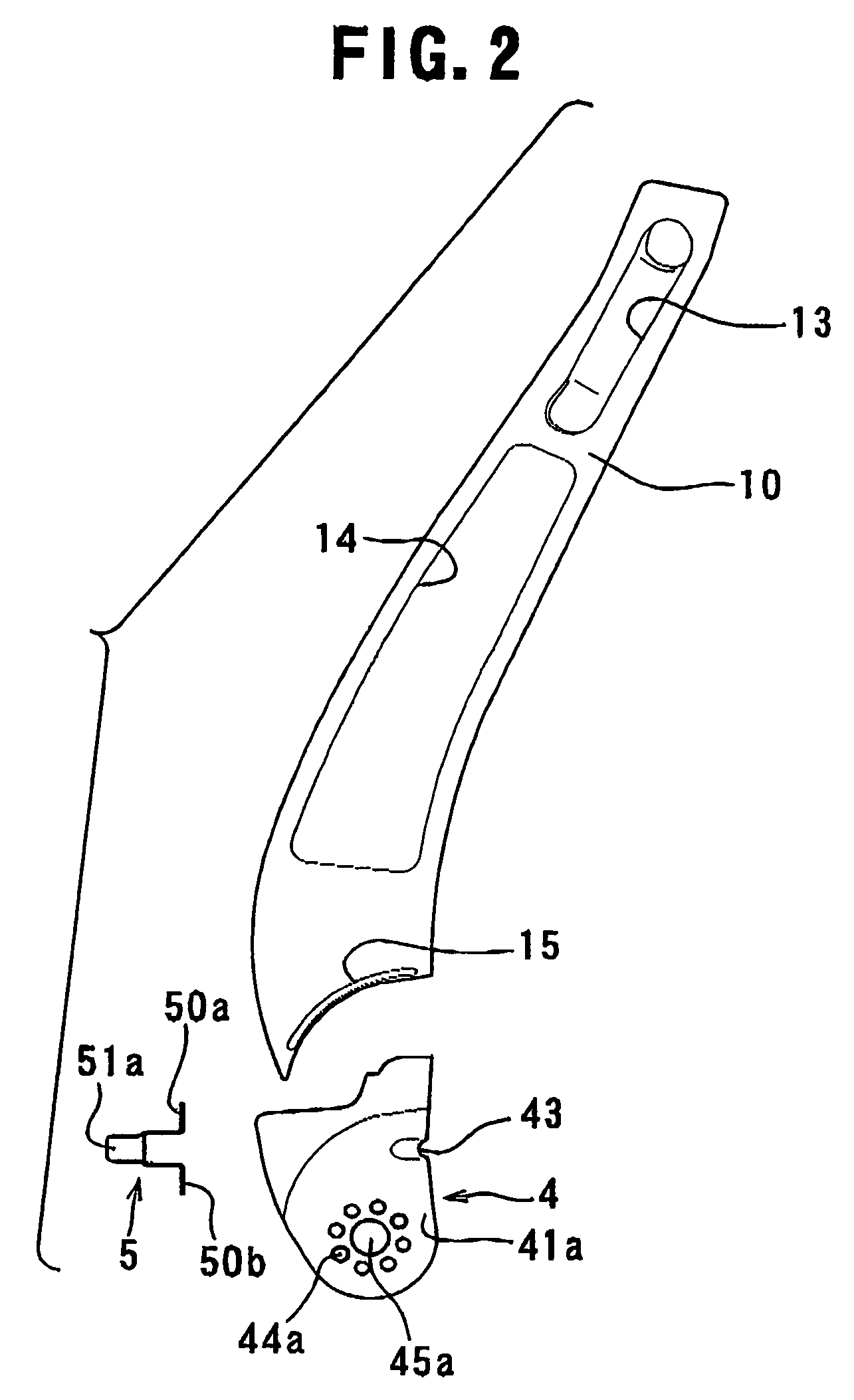

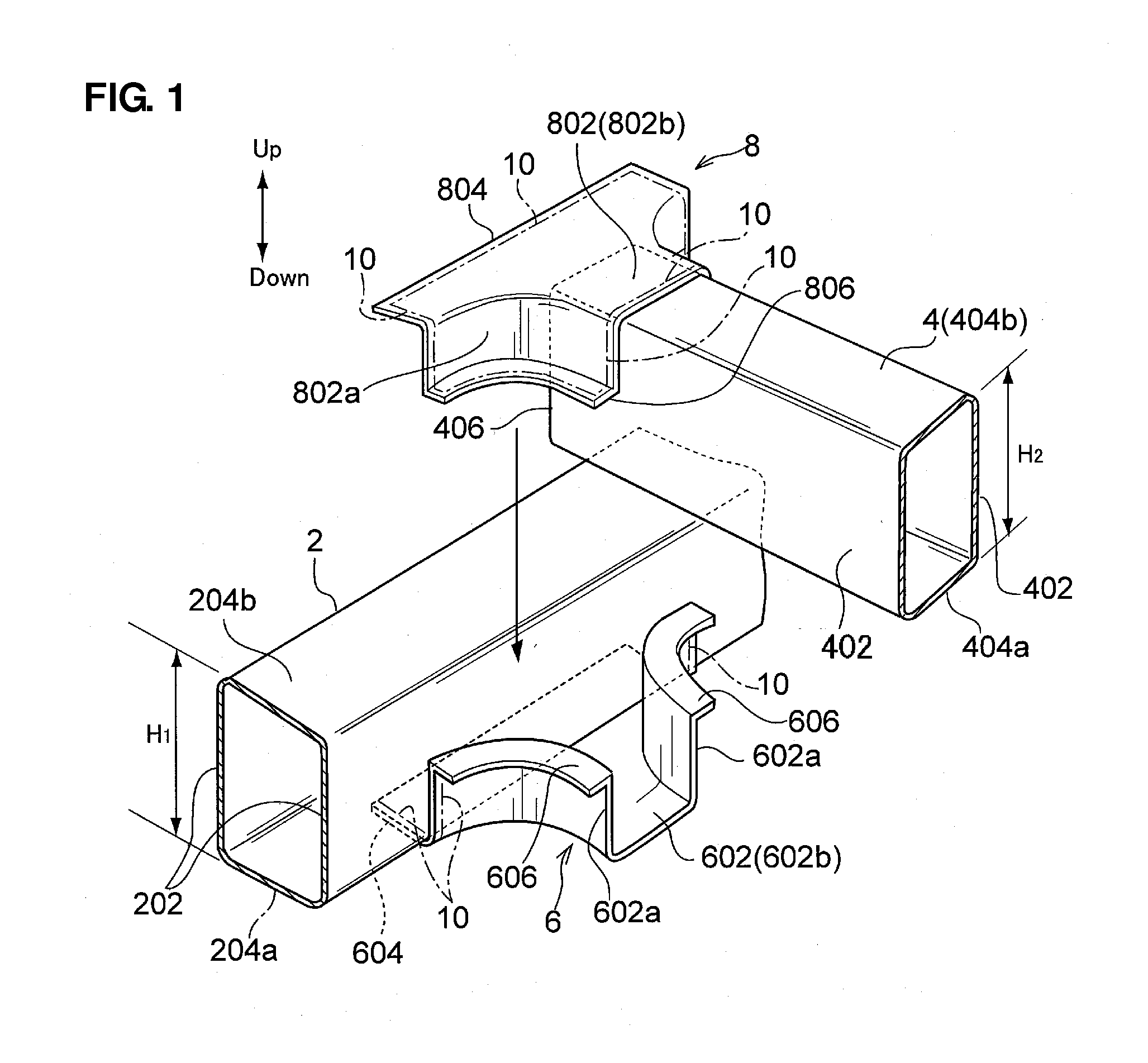

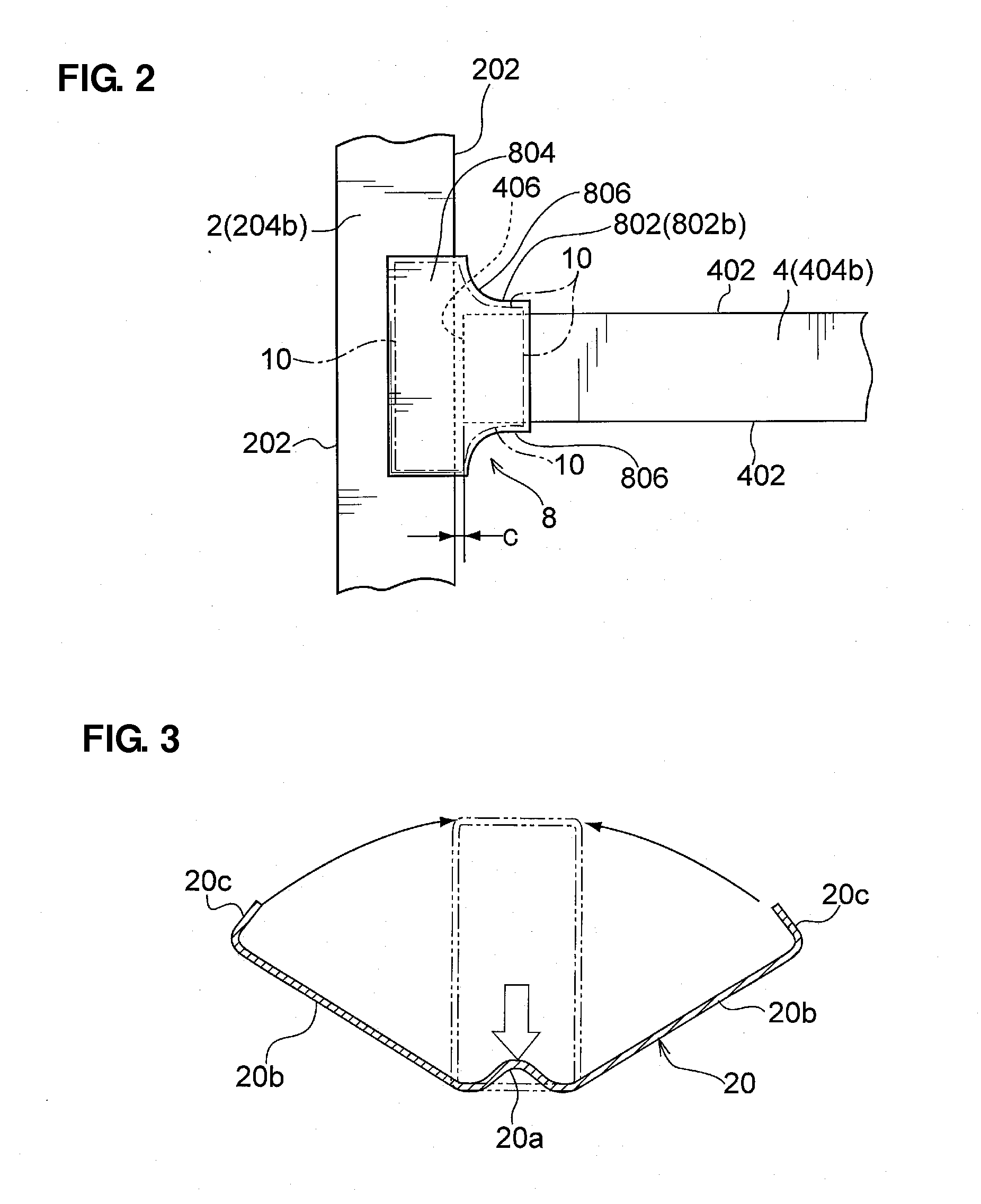

Seat back frame for vehicle seat

A seat back frame for a vehicle seat includes first and second side members spaced apart from each other, each of the first and second side members being made of ultra-high tensile strength steel, the first side member having a first longitudinal body of a substantially U-shape in cross-section, the first longitudinal body comprising a pair of first spaced apart flange sections and a first main plate section interconnecting the first spaced apart flange sections, the first side member having a first upper region and a first lower region, the second side member having a second longitudinal body of a substantially U-shape in cross-section, the second longitudinal body comprising a pair of second spaced apart flange sections and a second main plate section interconnecting the second spaced apart flange sections, the second side member having a second upper region and a second lower region, an upper member arranged between the first and second upper regions of the first and second side members, the upper member being made of ultra-high tensile strength steel, the upper member having first and second end portions, the upper member being mounted, by spot-welding, to the first and second upper regions of the first and second side members with the first and second end portions thereof being fitted in the first and second side members, and a lower member arranged between the first and second lower regions of the first and second side members, the lower member being made of ultra-high tensile strength steel, the lower member having third and fourth end portions, and the lower member being mounted, by spot-welding, to the first and second lower regions of the first and second side members with the third and fourth end portions thereof being fitted in the first and second side members.

Owner:TS TECH CO LTD

Method for joining dissimilar metals of steel product and light metal product

InactiveCN101590598AOvercome limitationsRemove constraintsShrinkage connectionsSheet joiningMetallic materialsSpot welding

There is provided method for joining dissimilar metals of a steel product and a light metal product with each other, wherein the light metal product and a rivet made of an iron-base metal are connected with each other beforehand in a previous process preceding spot welding, and subsequently, the rivet and the steel product are spot welded with each other. Then, a cavity for use in clinching the light metal product is formed, and upon the stem of the rivet is embedded into the light metal product to penetrate therethrough, light metal is caused to undergo plastic flow into the cavity of the rivet, for clinching the light metal product to be thereby clinched with the rivet whereupon spot welding for forming a weld nugget only within the scope of an interface between the stem of the rivet, and the steel product is carried out. Thus, the present invention can implement the spot welding between iron-iron similar metals, without a constraint on, and a problem with conditions applicable to the spot welding and a high joint strength can be obtained owing to the synergistic effect of the spot welding and connection by clinching of the aluminum alloy product with the iron-base rivet, added thereto.

Owner:KOBE STEEL LTD

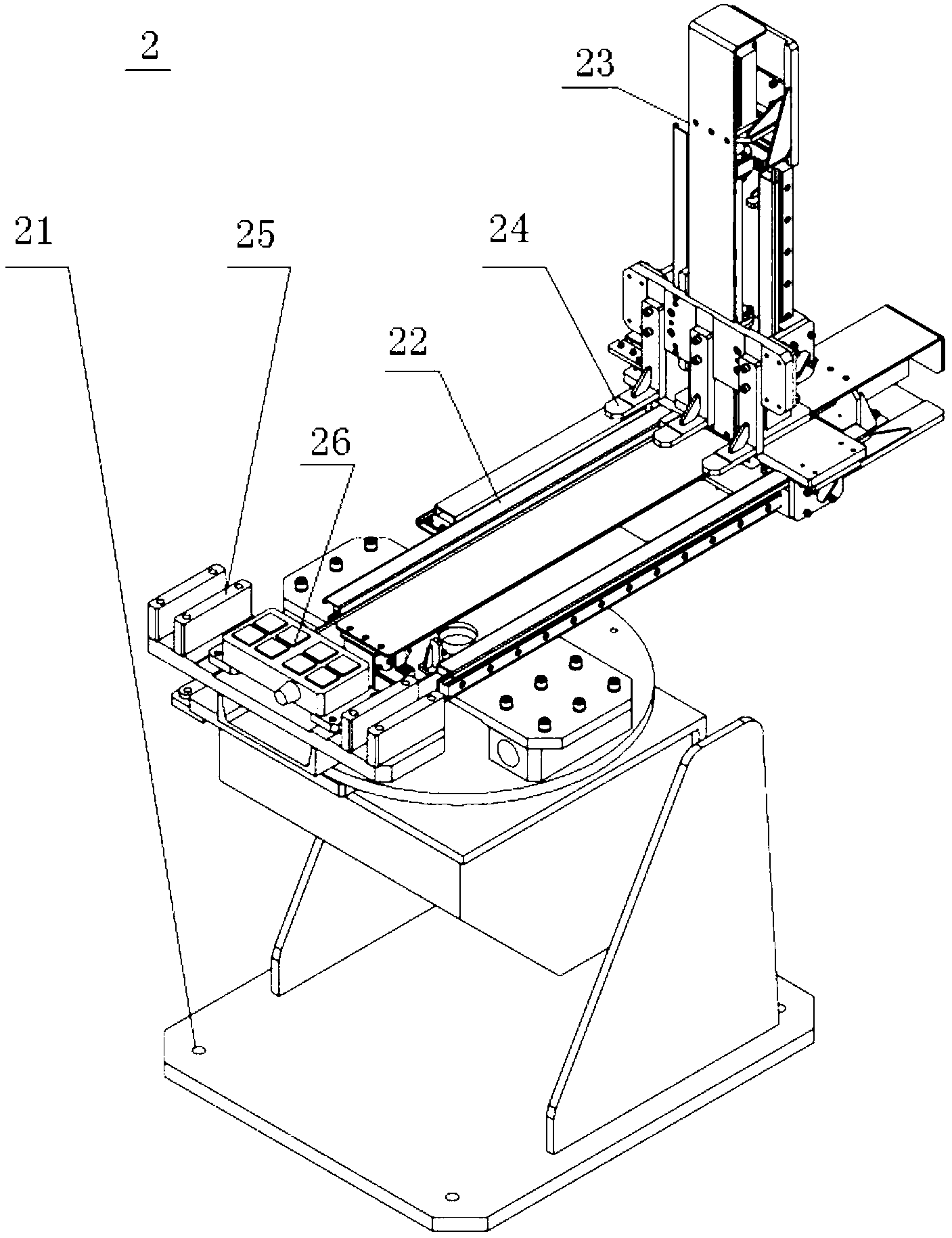

Self-piercing frictional rivet welding connecting device

InactiveCN101817142AHigh elongationImprove connection efficiencyOther manufacturing equipments/toolsNon-electric welding apparatusEngineeringAlloy

The invention relates to a self-piercing frictional rivet welding connecting device which belongs to the technical field of rivet welding. The device comprises a driving needle, a blank holder, an annular guide slot, an annular positioning spring, a semi-tubular rivet and a female die, wherein the driving needle is sleeved in the blank holder; the semi-tubular rivet is positioned below the driving needle; the annular guide slot is formed in the blank holder; the annular positioning spring is arranged in the annular guide slot; the semi-tubular rivet is positioned on the annular positioning spring; and the female die is arranged below the semi-tubular rivet. The high-strength steels are softened by using the friction heat generated by speedily rotating the rivet so the percentage of elongation of the high-strength steel is increased, the riveting force and the rigid requirement on equipment are reduced, the joint efficiency of friction stir spot welding is improved, the technical shrinkage pool is eliminated, the joint strength is efficiently increased, the mechanical-solid phase double joint is realized and the static and dynamic mechanical properties of the joint are greatly improved. The connecting device of the invention is applied to the connection between the light alloy and the high-strength steel and is also applied to the connection between the different light alloys and between different high-strength steels.

Owner:SHANGHAI JIAO TONG UNIV +1

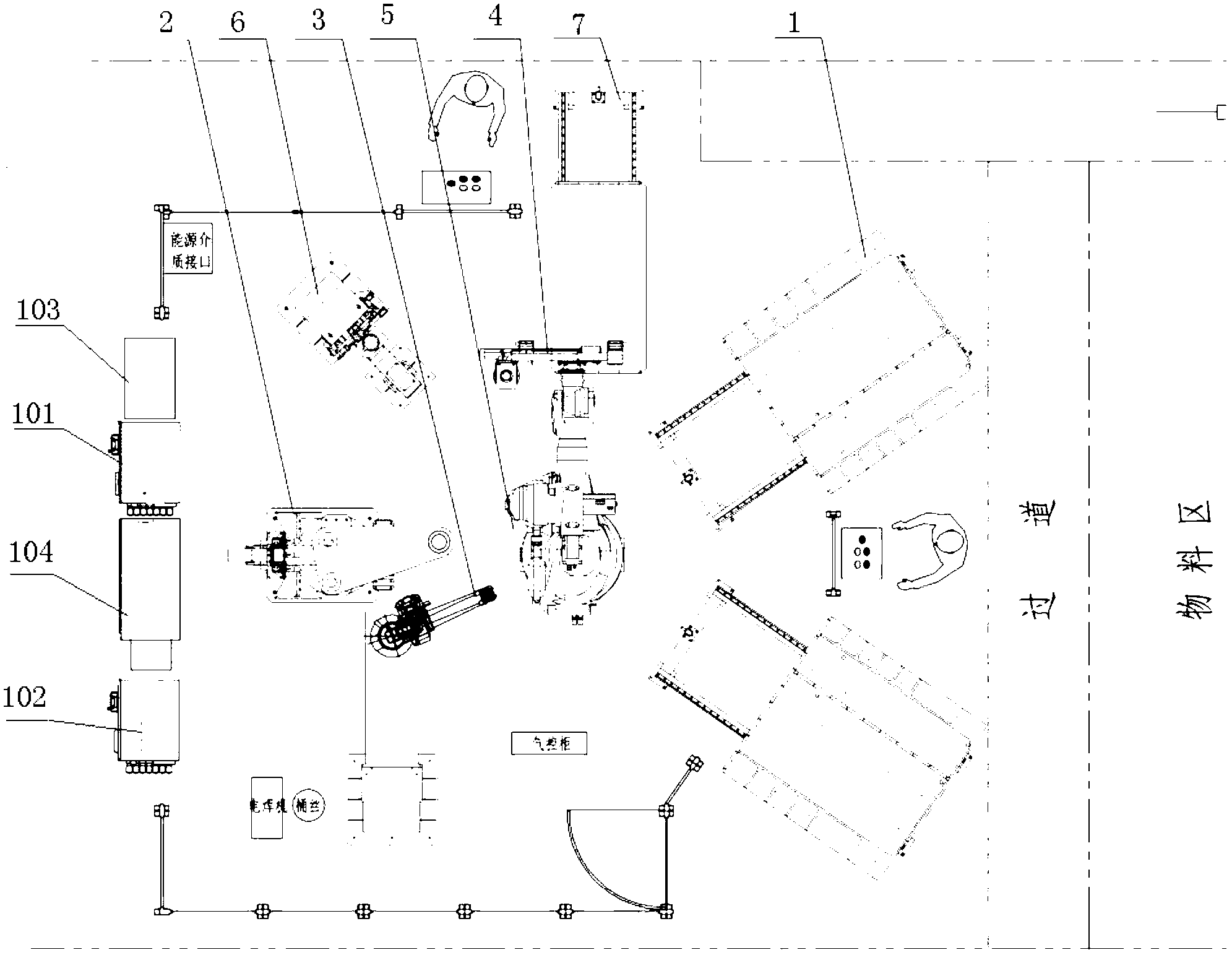

Automatic assembling and welding system based on three-dimensional laser vision

ActiveCN102837103AHigh precisionWelding/cutting auxillary devicesAuxillary welding devicesControl systemControl engineering

The invention discloses an automatic assembling and welding system based on three-dimensional laser vision, which comprises a loading station, a spot welding station, a welding robot, a turnover station, an unloading station, a transfer station, a transfer robot, a control system and an electric system, wherein the control system comprises a welding robot control cabinet for controlling the welding robot, and a transfer robot control cabinet for controlling the transfer robot, and the welding robot control cabinet and the transfer robot control cabinet can communicate with a three-dimensional vision system. By adopting the automatic assembling and welding system based on three-dimensional laser vision disclosed by the invention, high-precision automatic assembling of work pieces can be realized, so that a guarantee is provided for automatic welding of the work pieces.

Owner:CHANGSHA CTR ROBOTICS

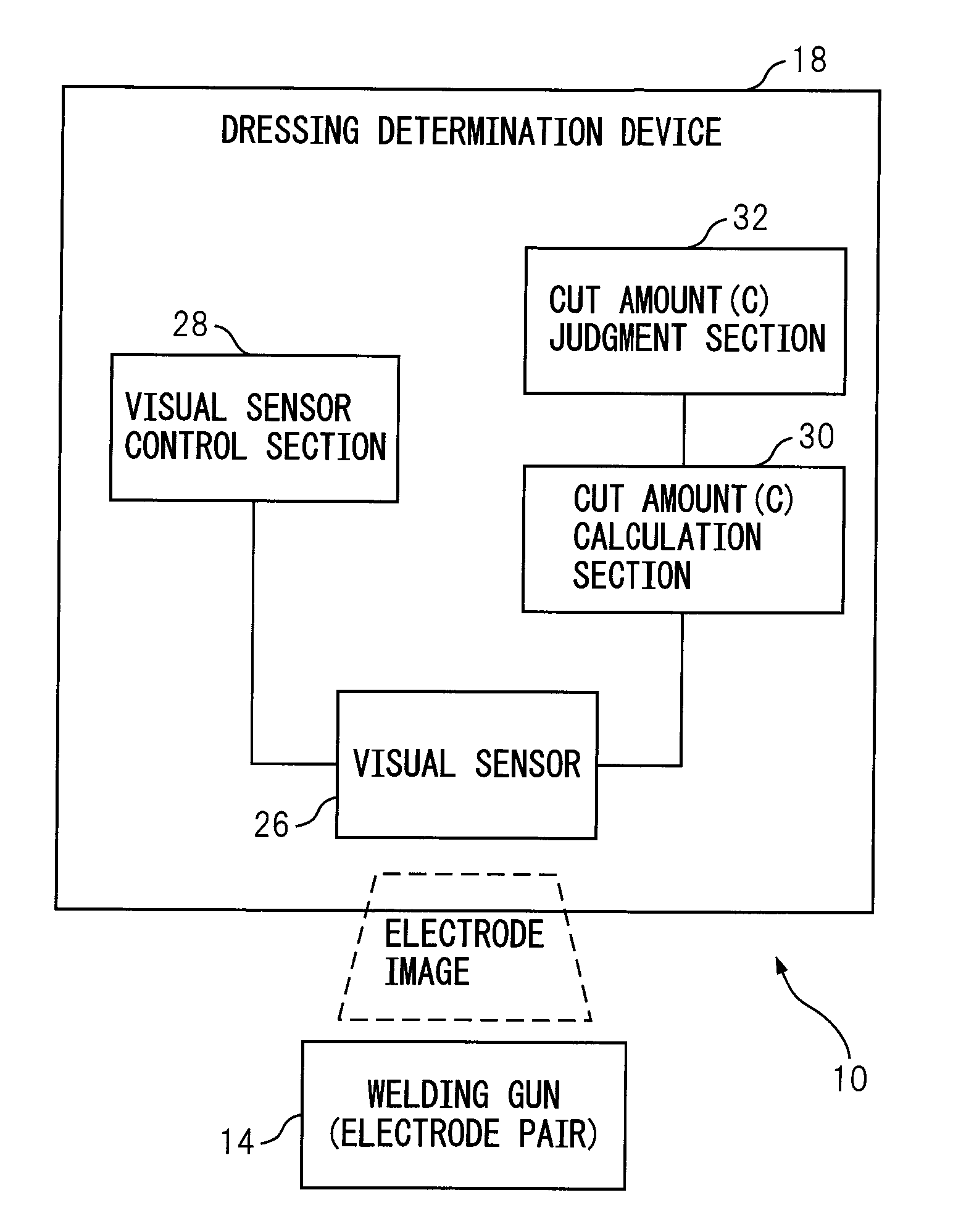

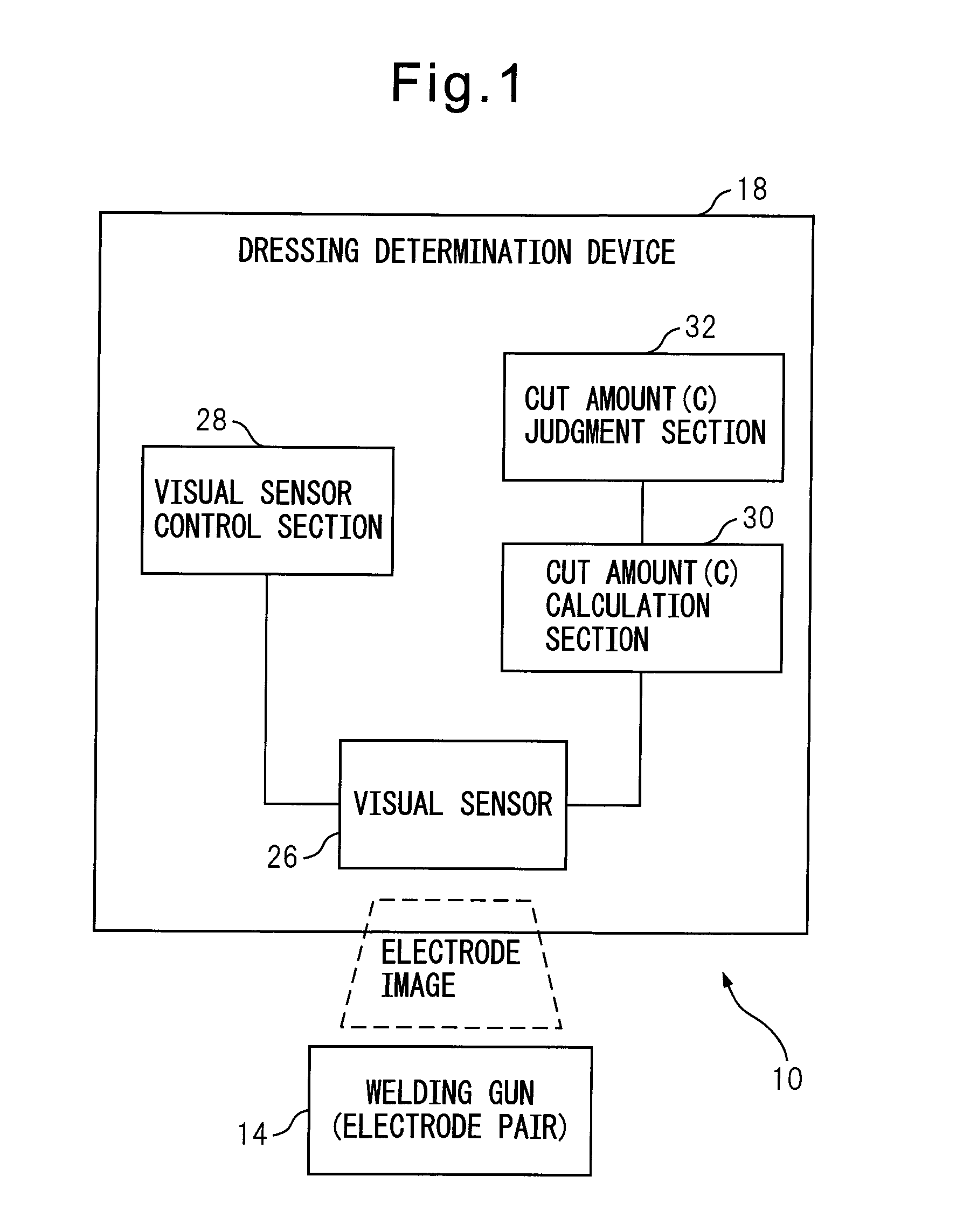

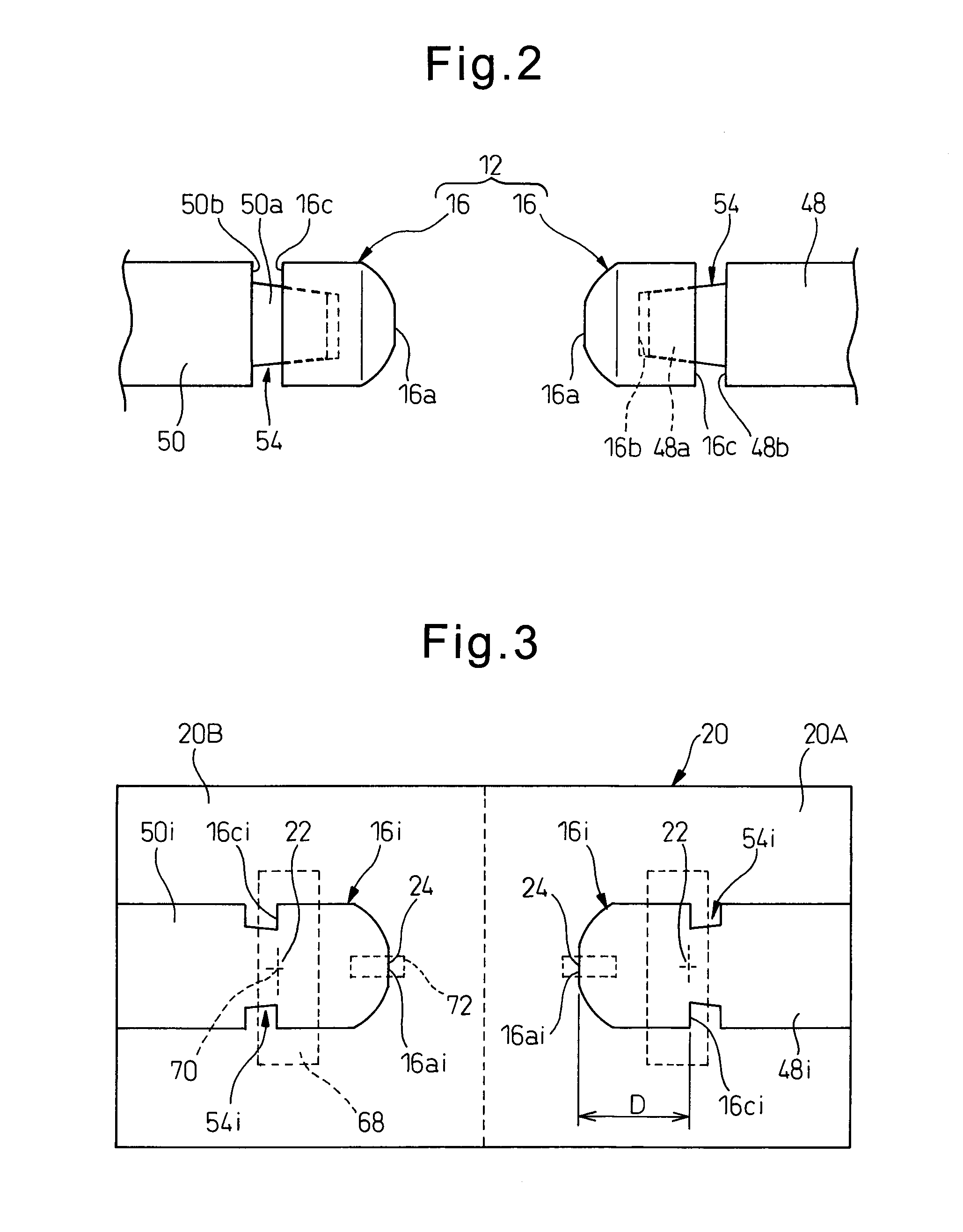

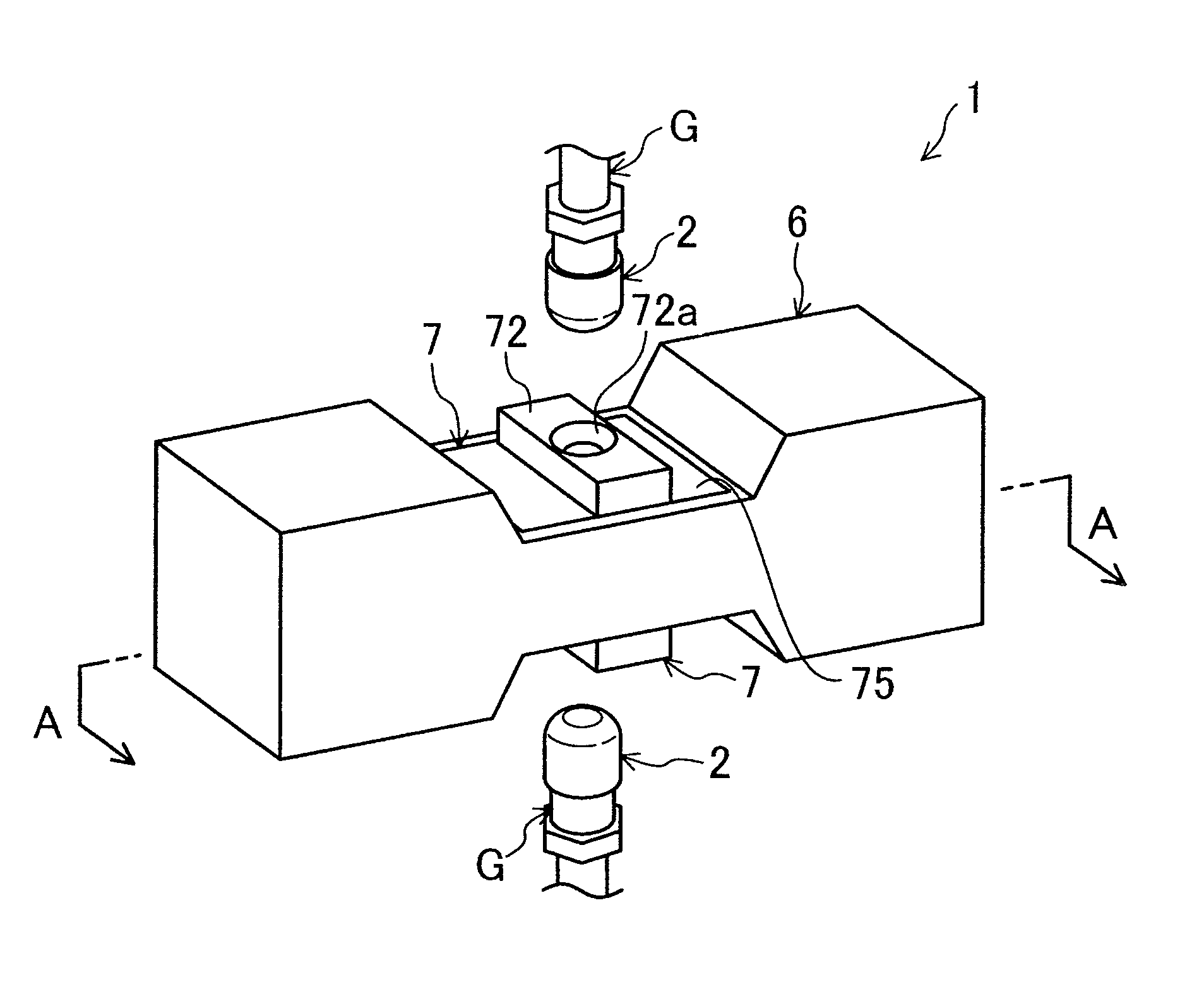

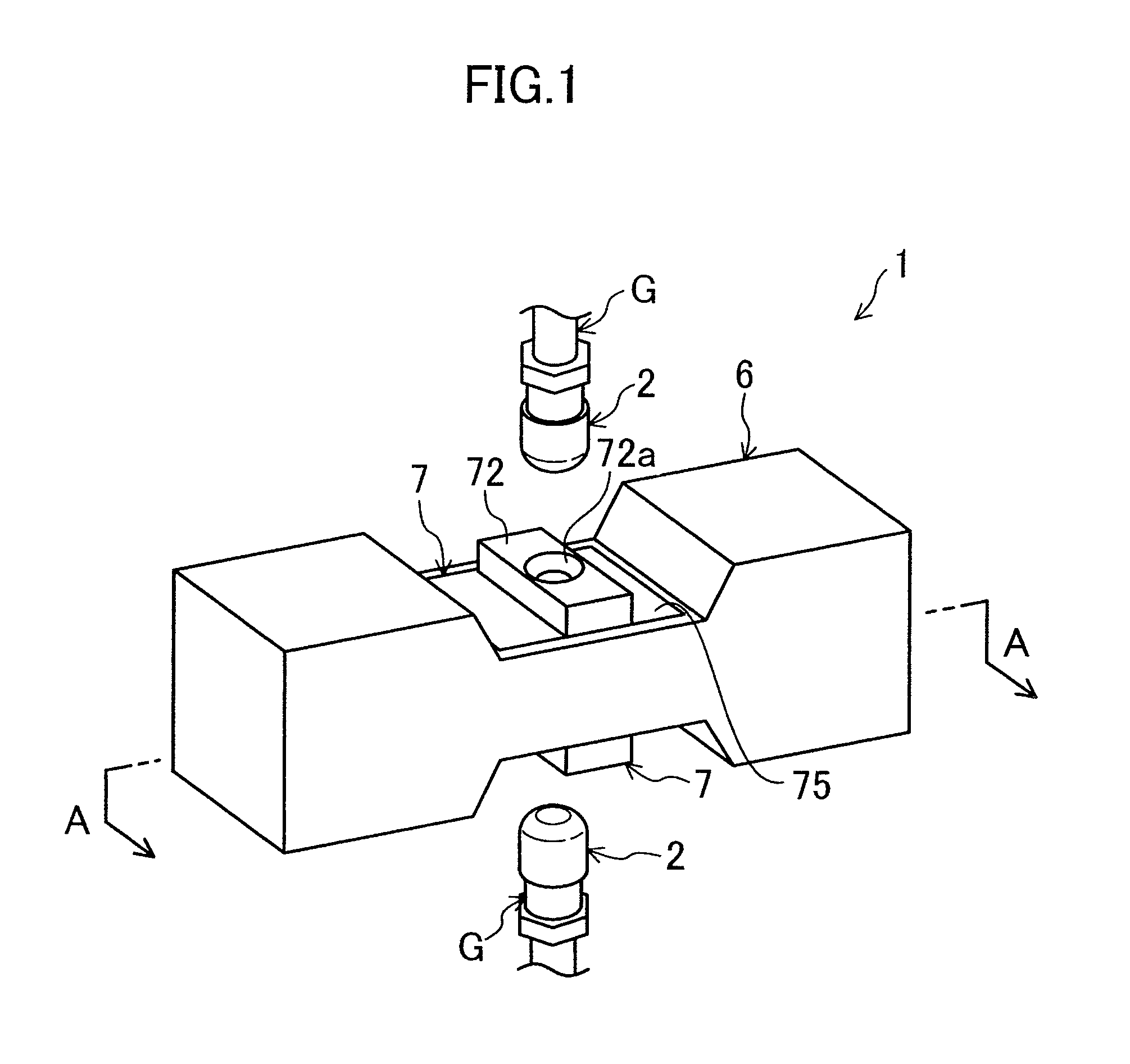

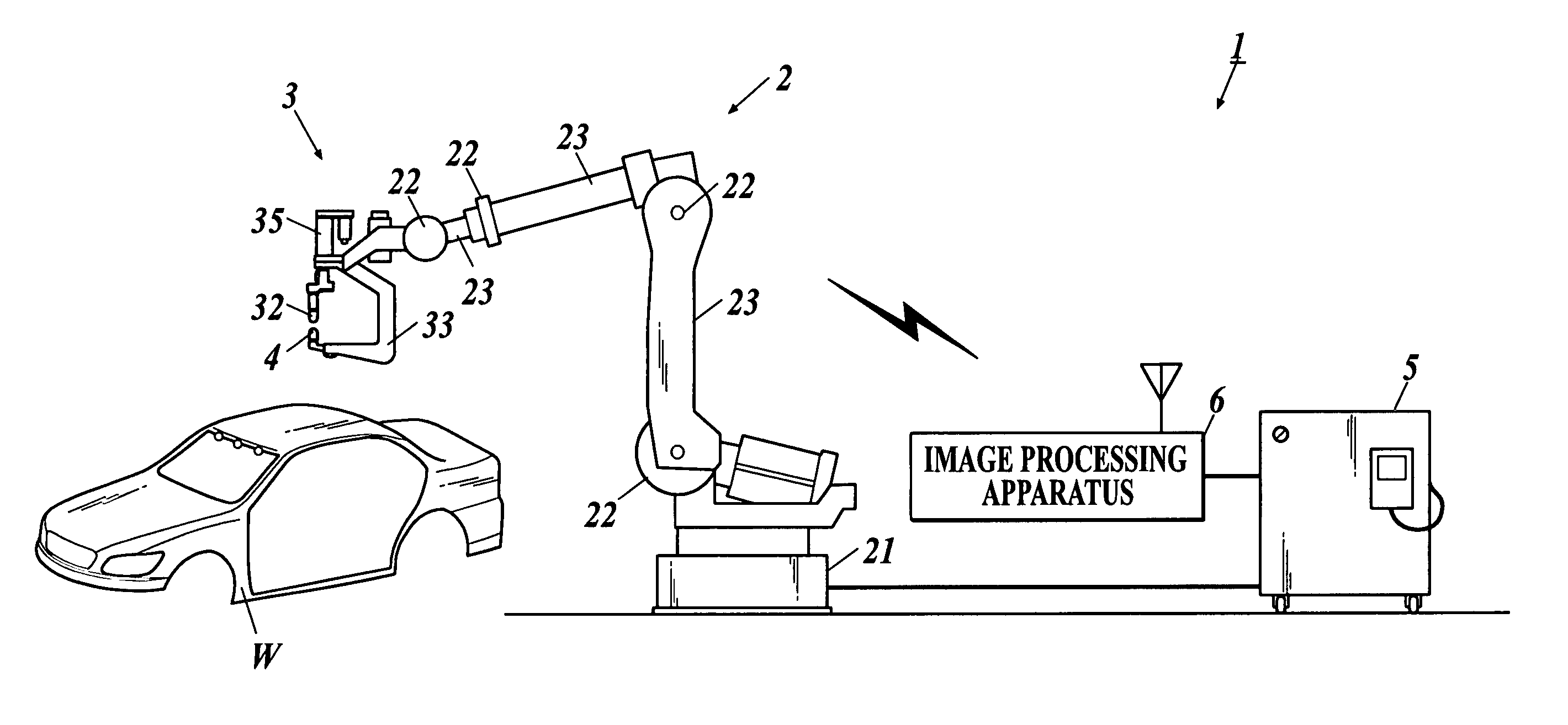

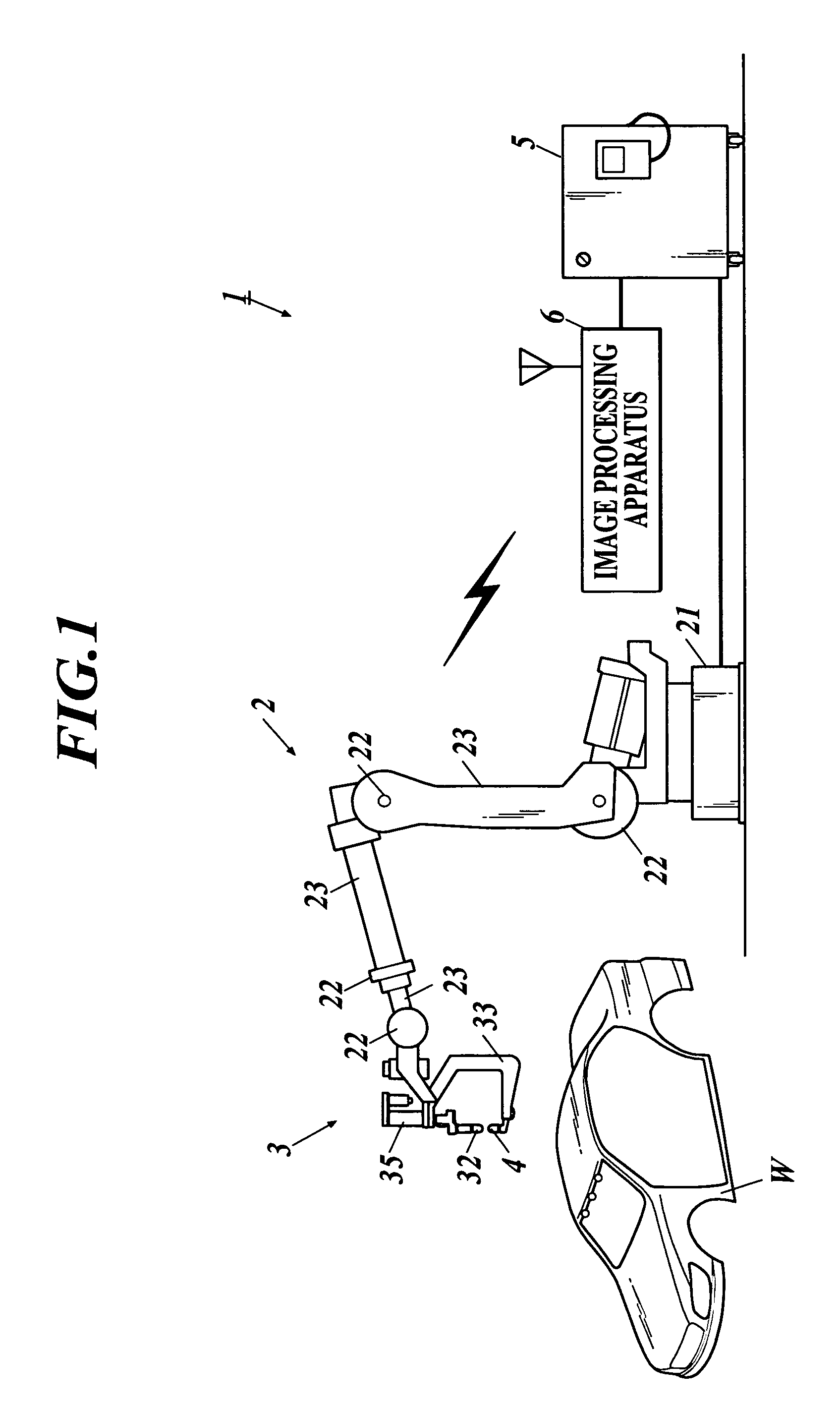

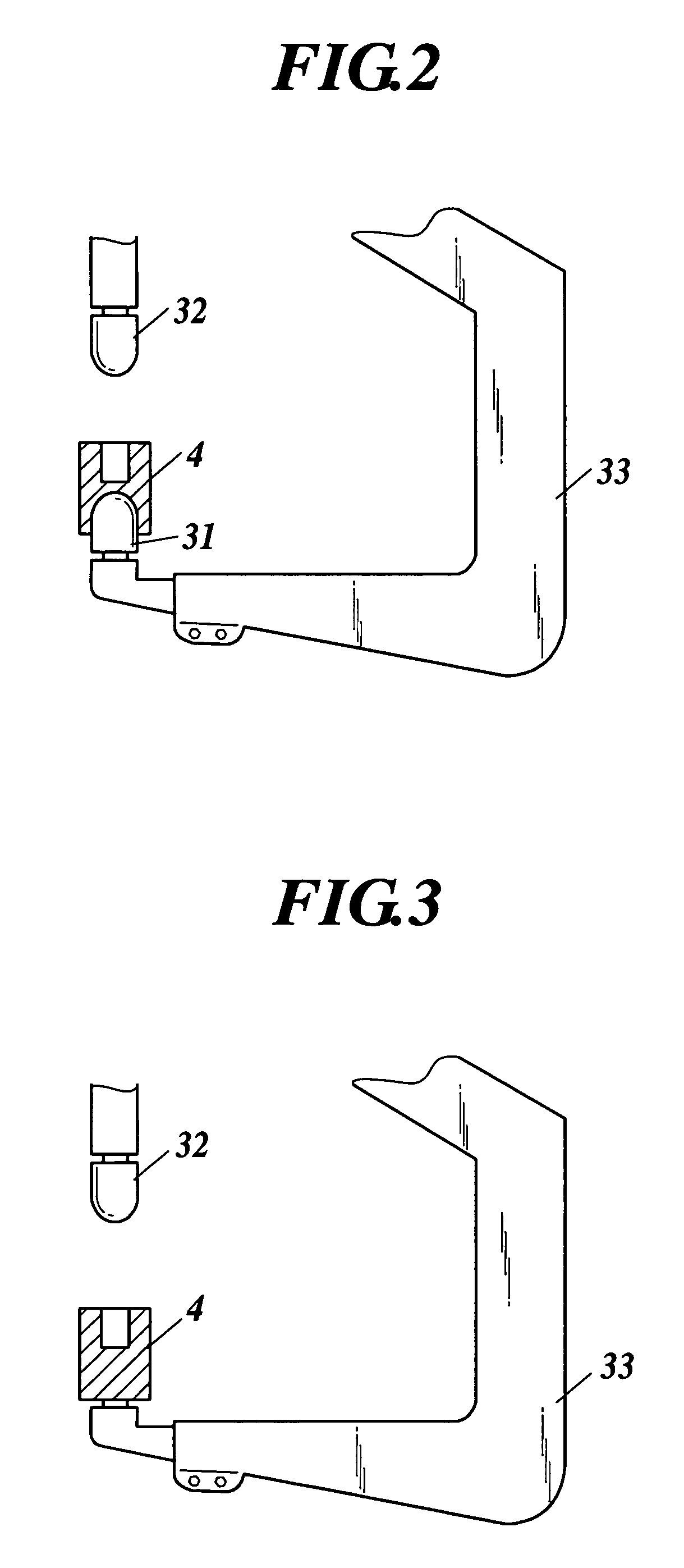

Spot welding system and dressing determination method

ActiveUS20110240605A1Easy to operateAccurate judgmentElectrode supporting devicesElectrode maintenanceImaging processingEngineering

A spot welding system including a welding gun with an openable / closable electrode pair; and a dressing determination device determining a quality of a shaping process applied to an electrode of the electrode pair. The dressing determination device includes a visual sensor obtaining an image of the electrode, identifying a base and a tip of the electrode on the image and measuring a distance between the base and the tip on the image, by image processing; a visual sensor control section allowing the visual sensor to measure the distance immediately before and after the shaping process is performed; a cut amount calculation section calculating a difference between the distances measured by the visual sensor immediately before and after the shaping process is performed, as a cut amount of the electrode; and a cut amount judgment section judging whether the calculated cut amount is within a predetermined acceptable range.

Owner:FANUC LTD

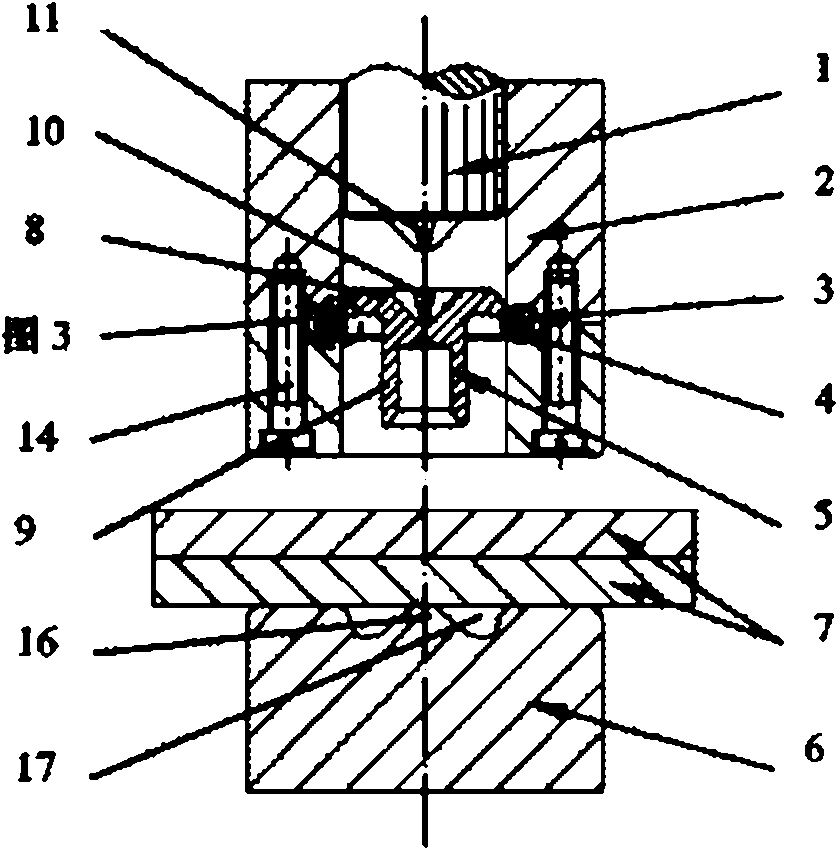

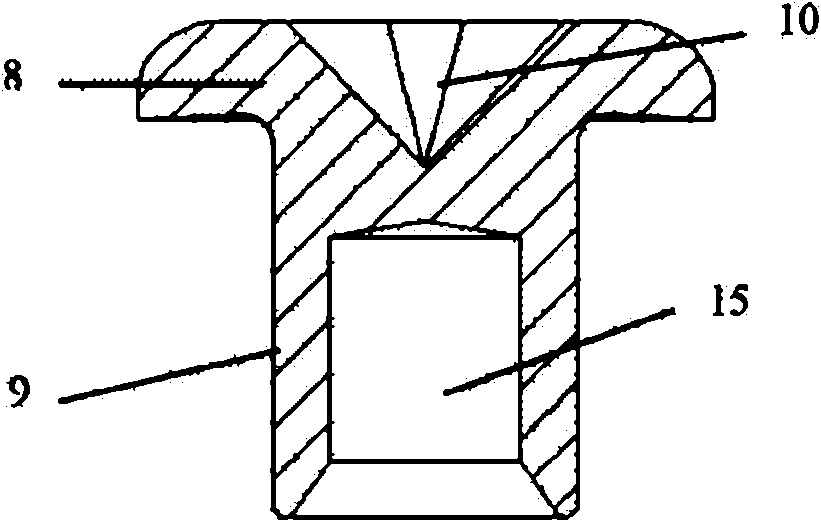

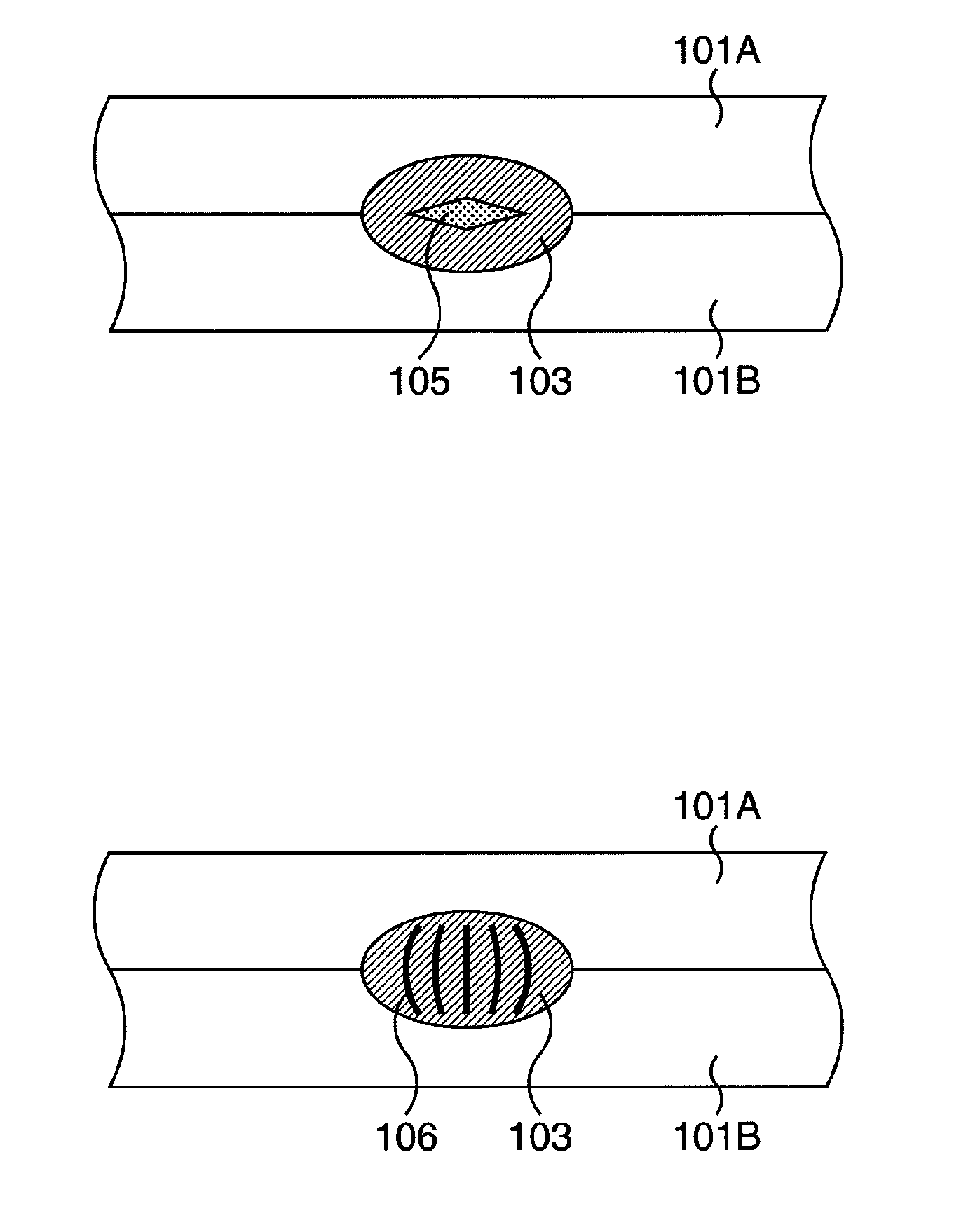

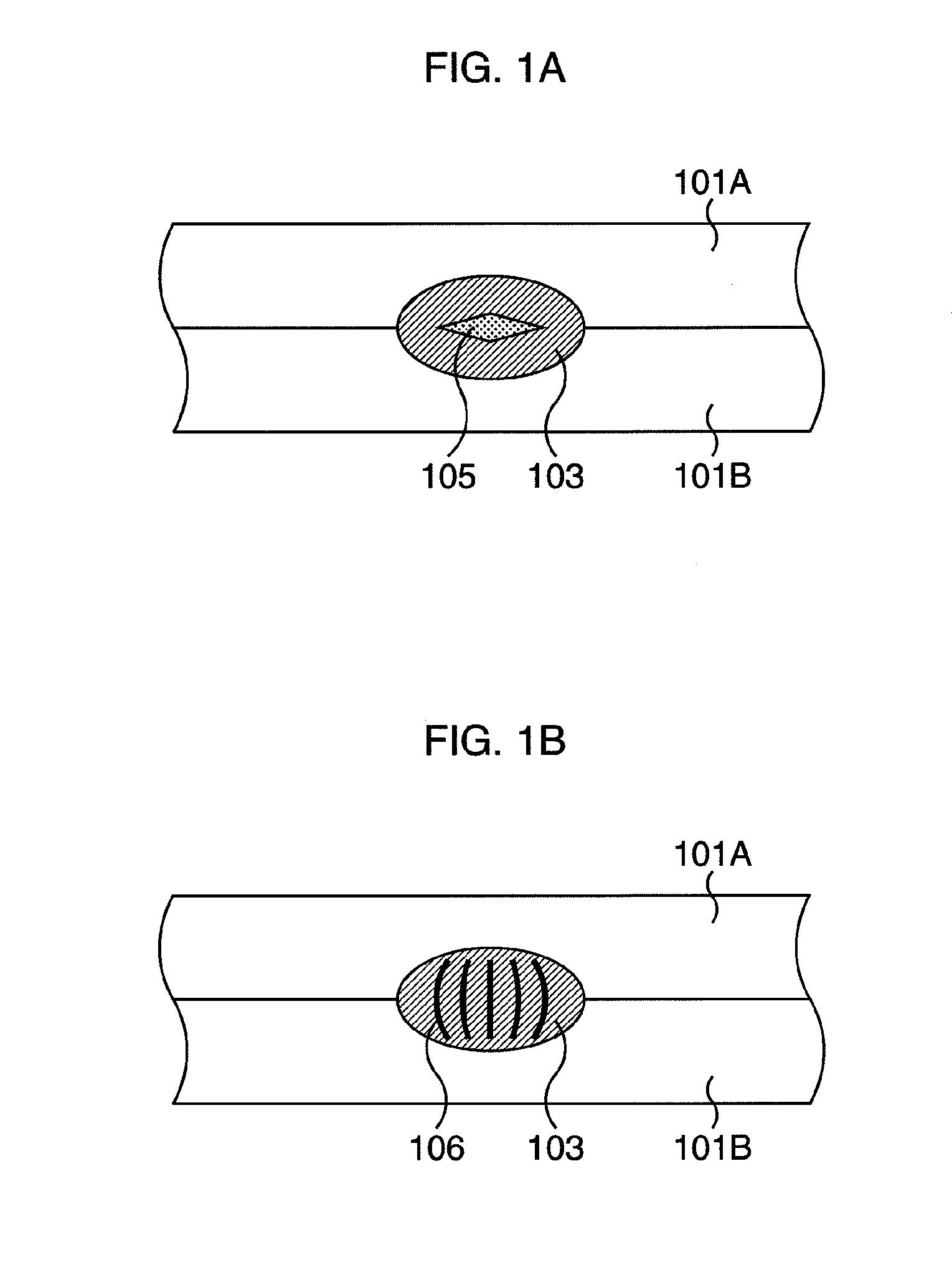

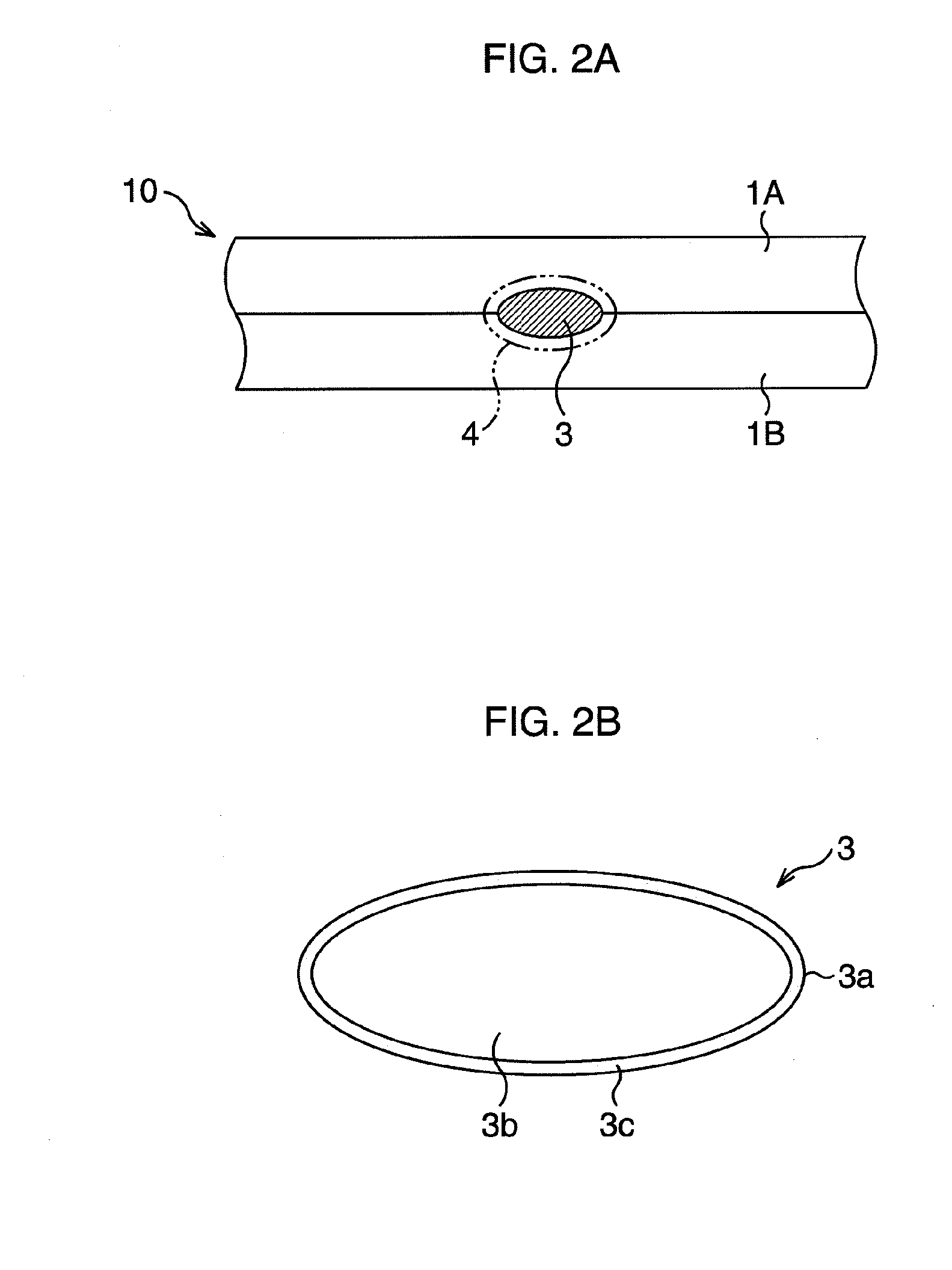

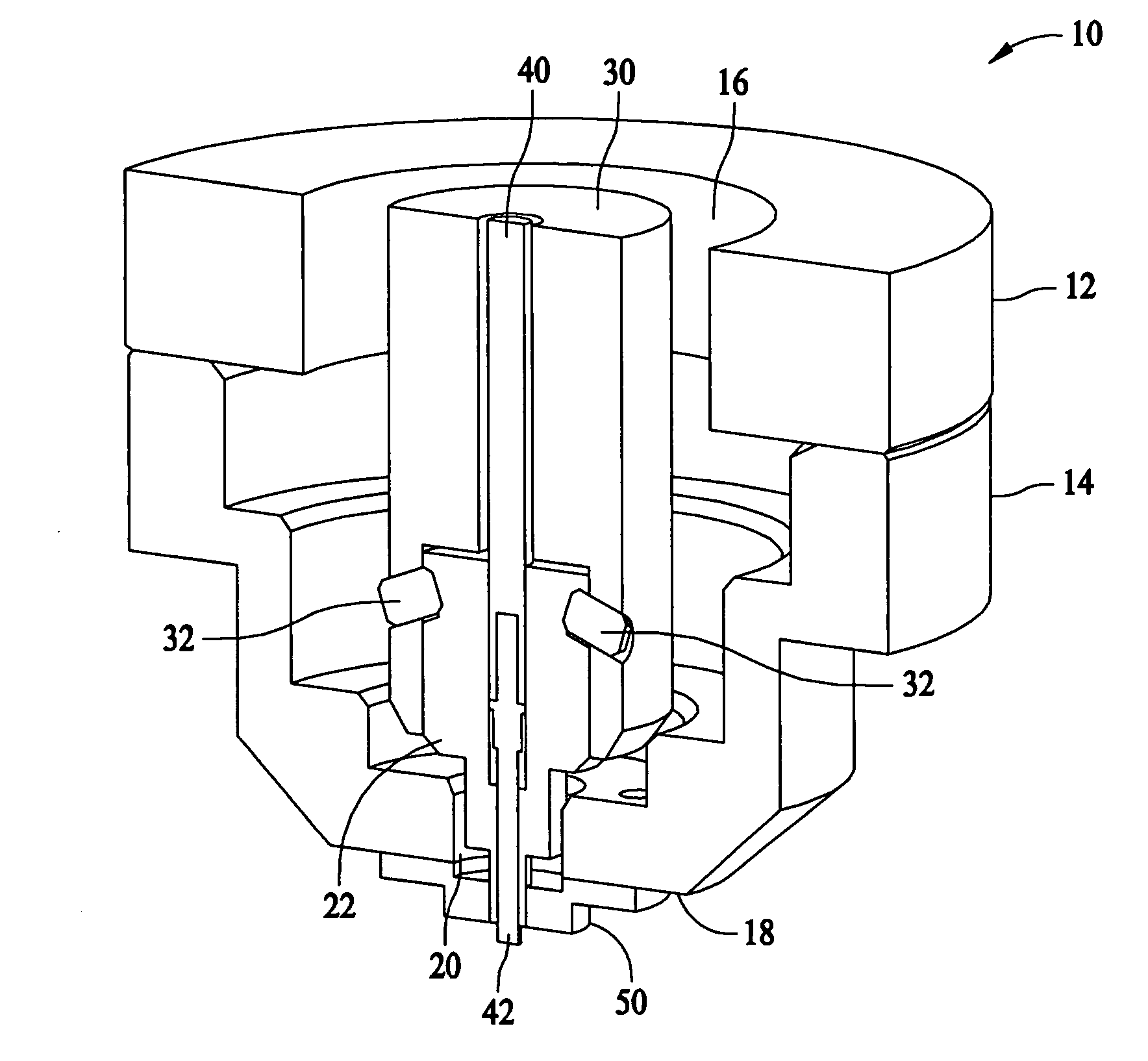

Spot welded joint and spot welding method

ActiveUS20120141829A1Improve machinabilityImprove reliabilityArc welding apparatusWelding/soldering/cutting articlesNumber densityCarbide

Provided is a spot welded joint (10) which includes at least one thin steel plate with a tensile strength of 750 MPa to 1850 MPa and a carbon equivalent Ceq of equal to or more than 0.22 mass % to 0.55 mass % and in which a nugget (3) is formed in an interface of the thin steel plates (1A, 1B). In a nugget outer layer zone, a microstructure consists of a dendrite structure in which an average value of arm intervals is equal to or less than 12 μm, an average grain diameter of carbides contained in the microstructure is 5 nm to 100 nm, and a number density of carbides is equal to or more than 2×106 / mm2.

Owner:NIPPON STEEL CORP

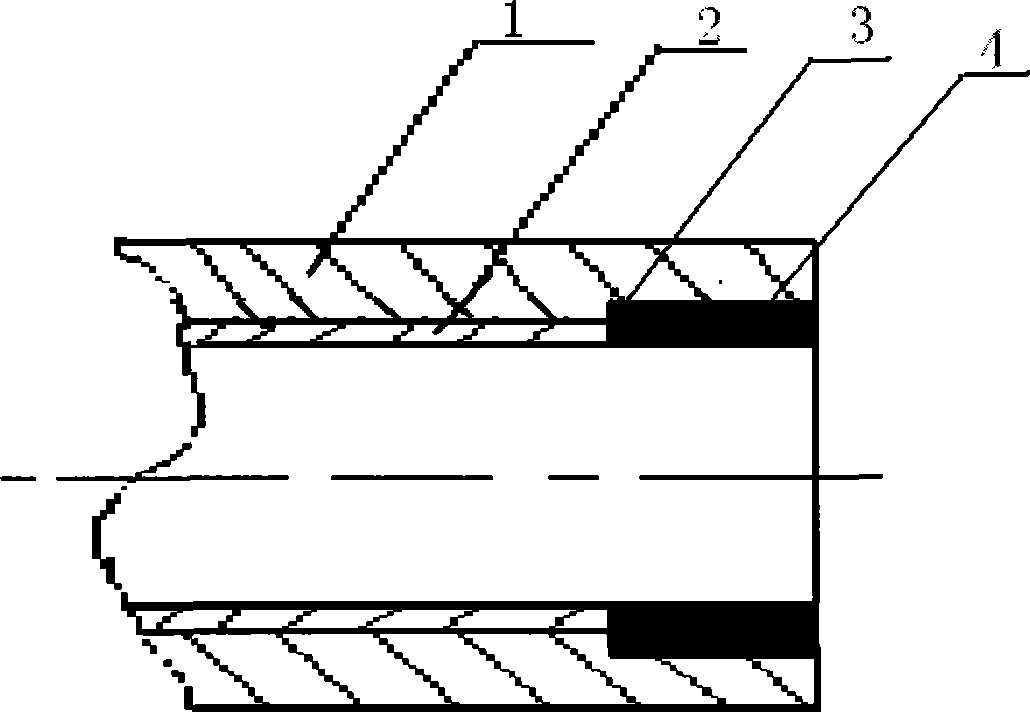

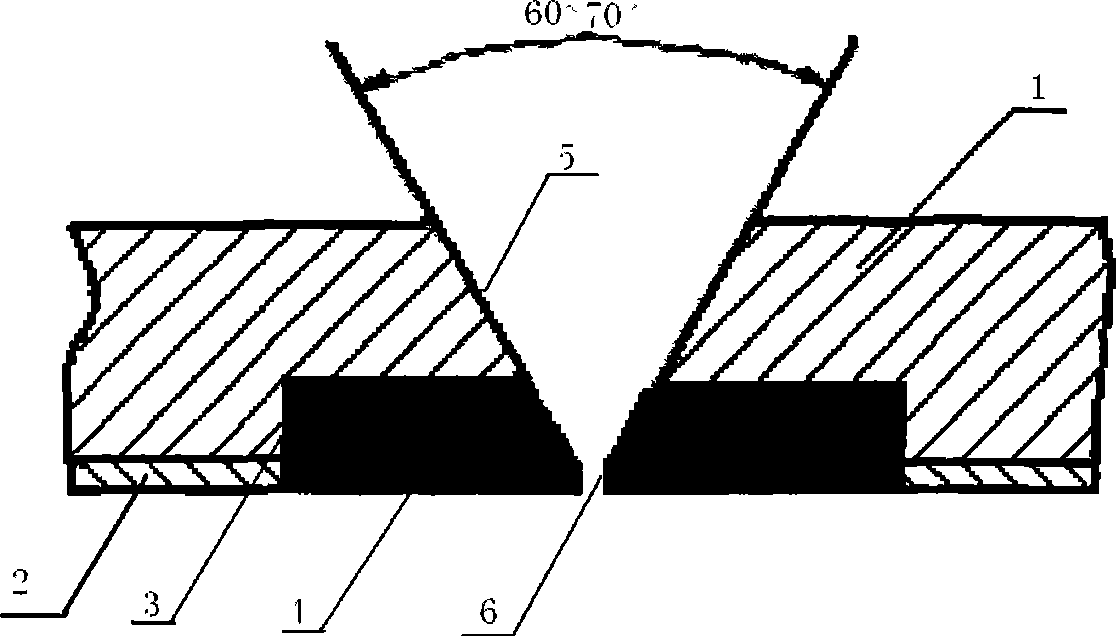

Method for welding thin layer iron nickel base alloy carbon steel composite tube

ActiveCN101462193AIncrease the effective thicknessHigh strengthArc welding apparatusWelding/cutting media/materialsAlloyWeld seam

The invention relates to a method for welding a carbon steel composite pipe of a thin iron-nickel-based alloy. The method comprises: processing a step on the end part of the composite pipe; adopting the surfacing of argon arc welding on the surface of the step and trimming the surfacing layer; processing a groove; adopting tungsten electrode argon arc welding to carry out three-point positioning of spot welding evenly around a welding seam, and adopting the tungsten electrode argon arc welding to carry out back welding on the root; and adopting manual electric arc welding to carry out filling welding and overlay welding on the upper part of a second layer of back welding. The chemical compositions of a welding material by weight percentage: 0.02 to 0.1 percent of C, 0.2 to 1.0 percent of Si, 1.0 to 2.2 percent of Mn, 20.0 to 31.5 percent of Cr, 40.0 to 60.0 percent of Ni, 8.0 to 14.5 percent of Mo, 0.5 to 2.5 percent of Cu, 0 to 5.0 percent of Co, 0.3 to 4.2 percent of Nb, and the balance being Fe. The welding seam has the characteristics of no sensitivity to offset, favorable corrosion resistance, high strength and favorable plastic toughness.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Electrode inspection apparatus for spot welding

ActiveUS8953033B2Ensure correct executionReduce the ratioColor television detailsClosed circuit television systemsProduction lineEngineering

Owner:KEYLEX CORP

Electrode for spot welding

ActiveUS8525066B2Readily re-shapedOhmic-resistance electrodesWelding/cutting media/materialsSheet steelSpot welding

Owner:GM GLOBAL TECH OPERATIONS LLC

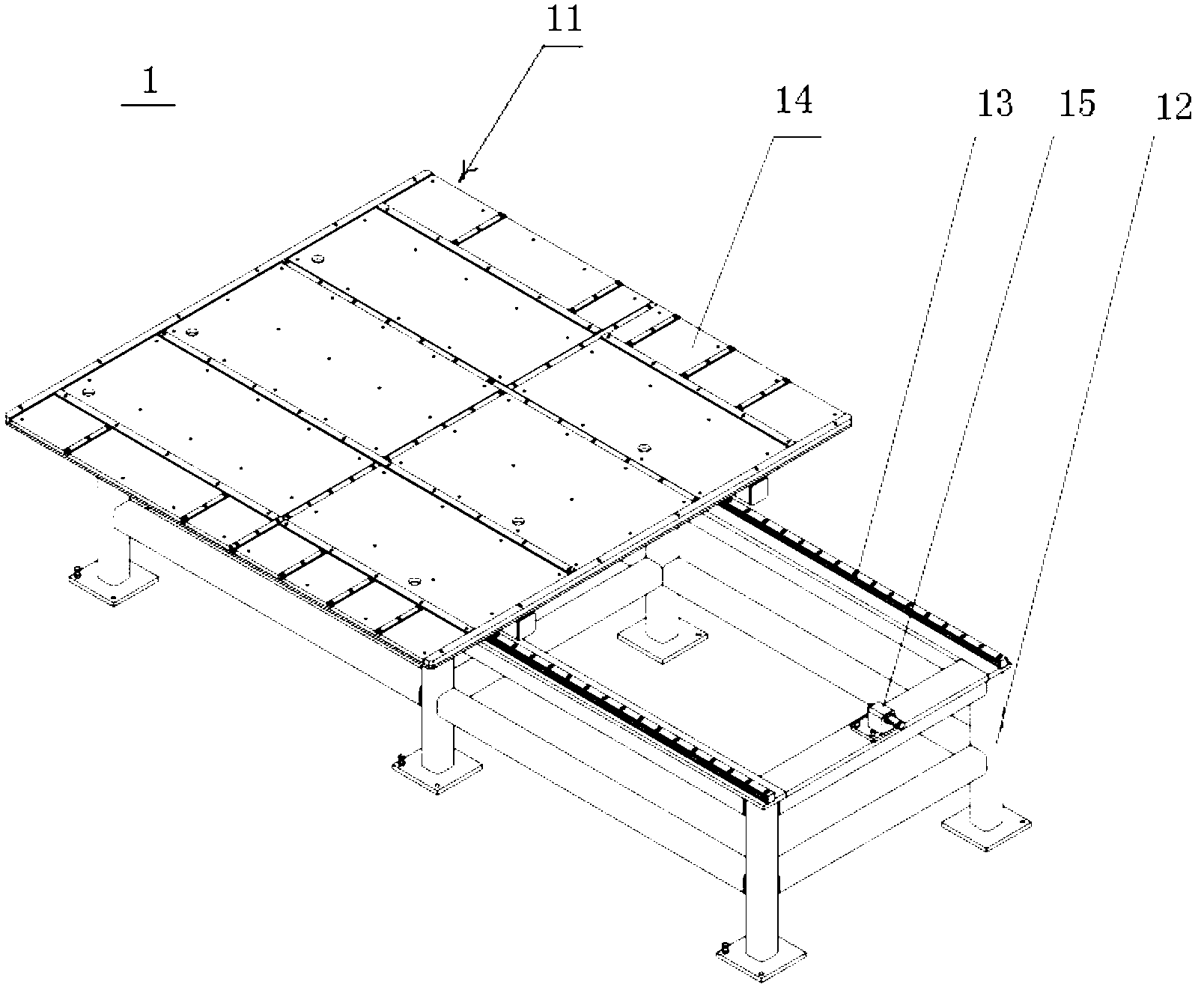

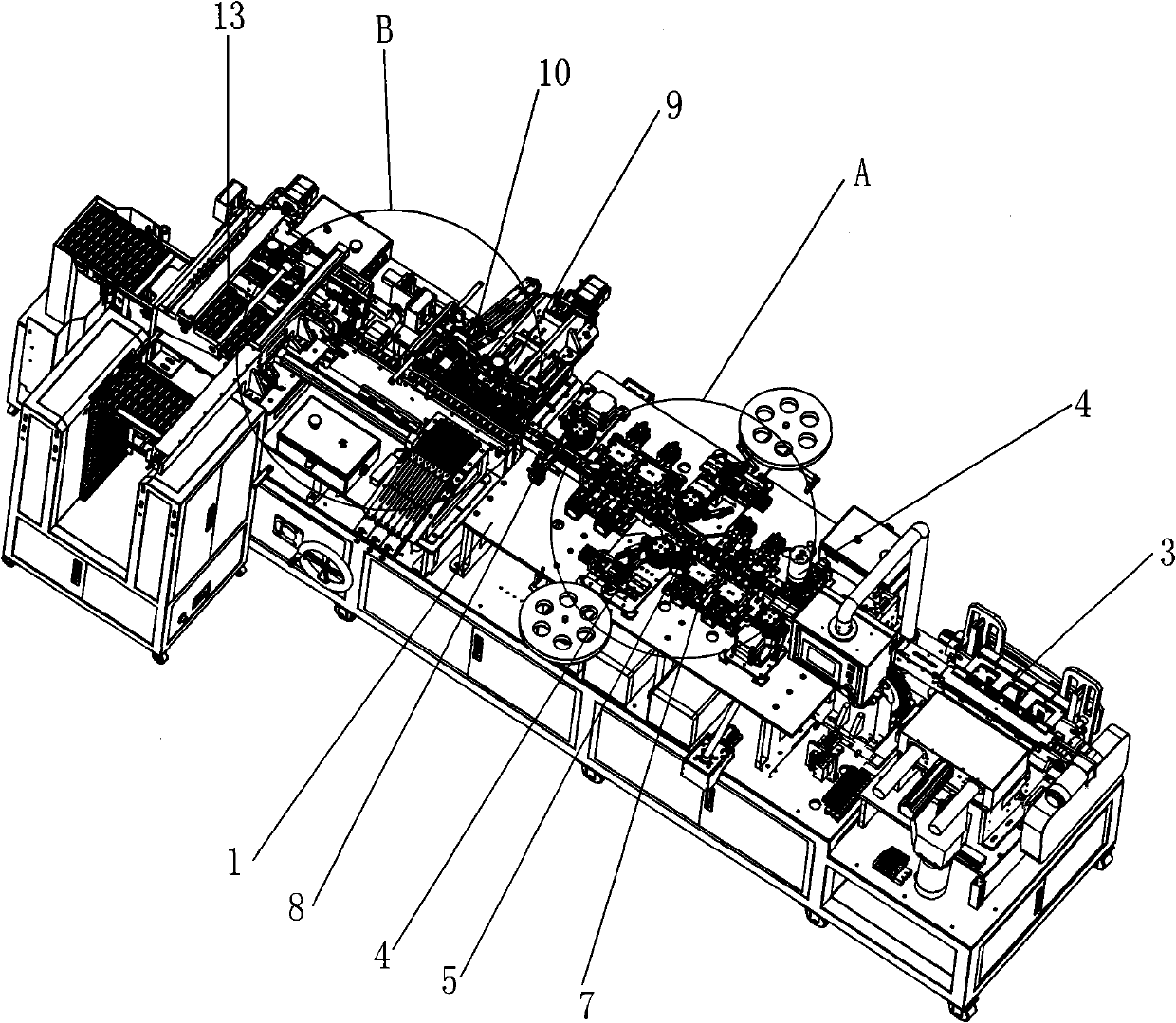

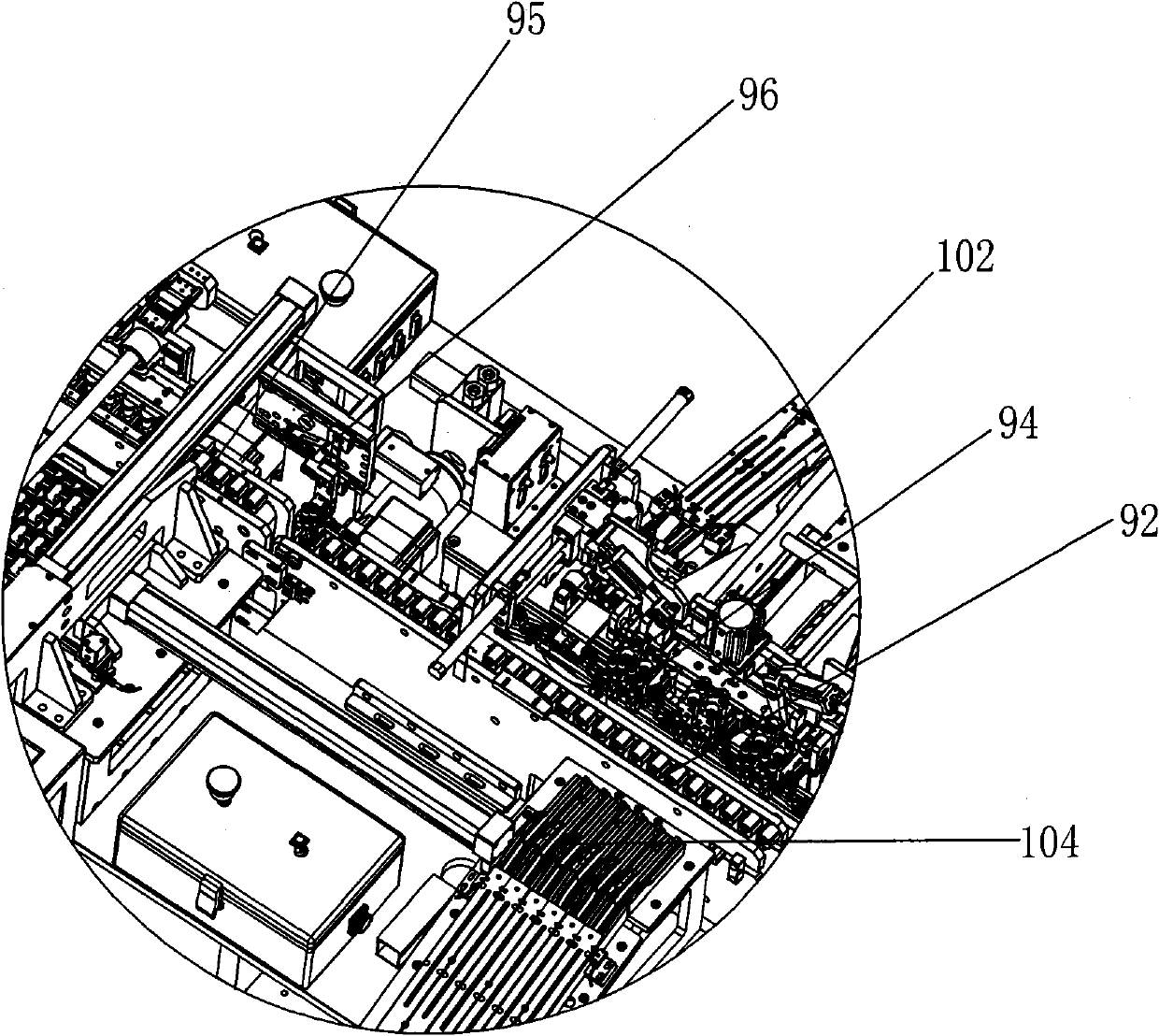

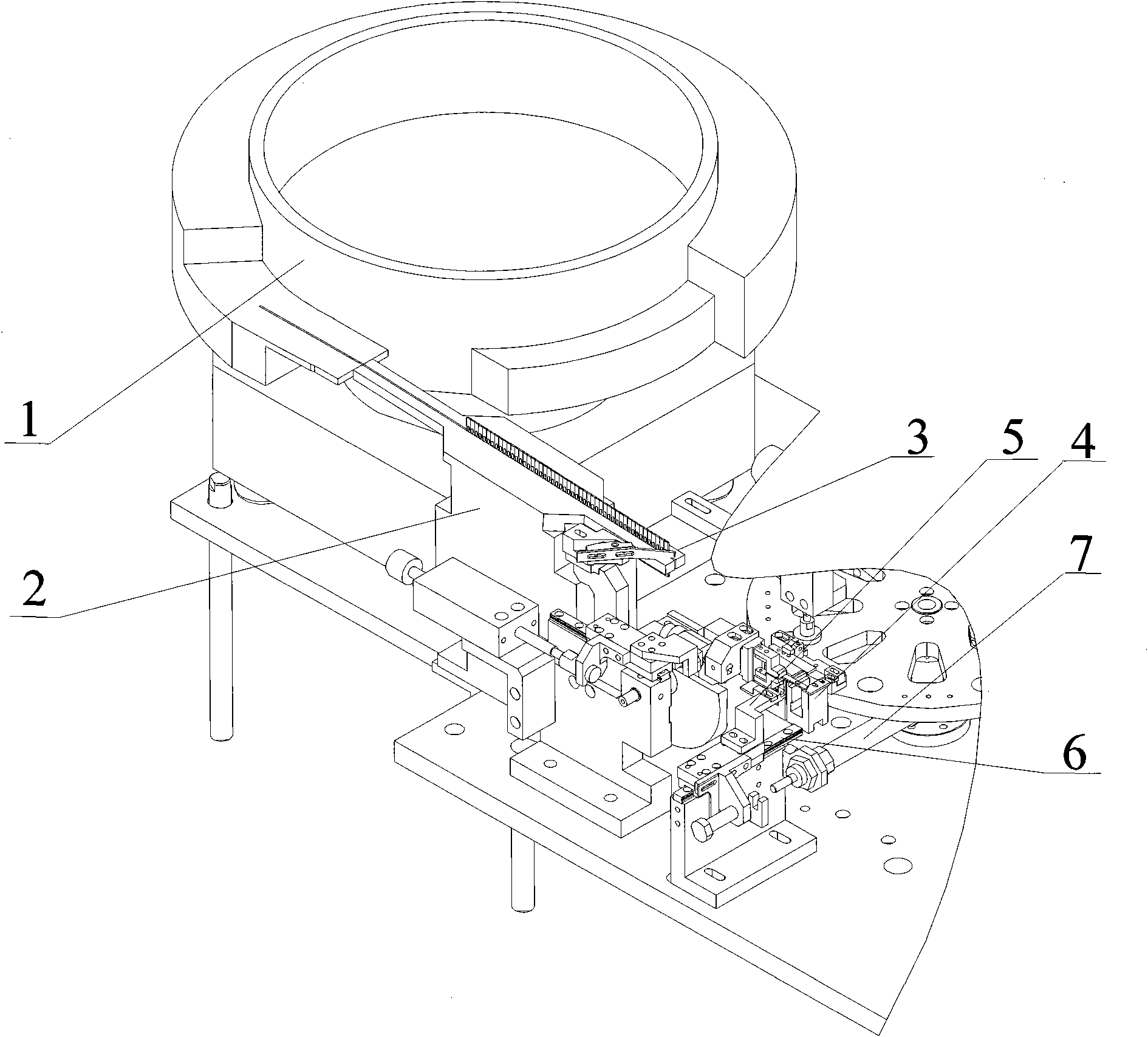

Automatic spot welding equipment

ActiveCN101992341AQuality improvementImprove quality and efficiencyResistance welding apparatusHigh volume manufacturingElectrical control

The invention relates to automatic spot welding equipment which comprises a stand and a workbench arranged on the stand, wherein the workbench is provided with a battery feed mechanism, a steel band feed mechanism, a transfer mechanism, a welding tab cut-off mechanism, a welding mechanism and a good product blanking mechanism, wherein the battery feed mechanism and the steel band feed mechanism are respectively used for feeding a battery and a steel band connected with a welding tab into a welding station; the transfer mechanism is used for bearing and transferring the battery; the welding tab cut-off mechanism is used for cutting off the welding tab on the steel band; the welding mechanism is used for welding the welding tab to the anode end and the cathode end of the battery; the transfer mechanism is provided with a battery clamping seat used for clamping the battery, and an elastic piece inwards pressing the battery is arranged on the battery clamping seat; and the mechanisms are connected with a master control circuit. In the invention, the structural design of the equipment is reasonable, and the automatic feeding, the welding and the property detecting of the battery and the steel band are realized by adopting electrical control, thus the equipment has the advantages of high feed speed, high welding precision and good welded product quality, improves the quality and the production efficiency of the welded product, reduces the labor intensity of workers, saves the production cost and is particularly suitable for producing batteries welded with welding tabs in batches, thereby improving market competitive force of enterprises.

Owner:GUANGDONG LYRIC ROBOT INTELLIGENT AUTOMATION CO LTD

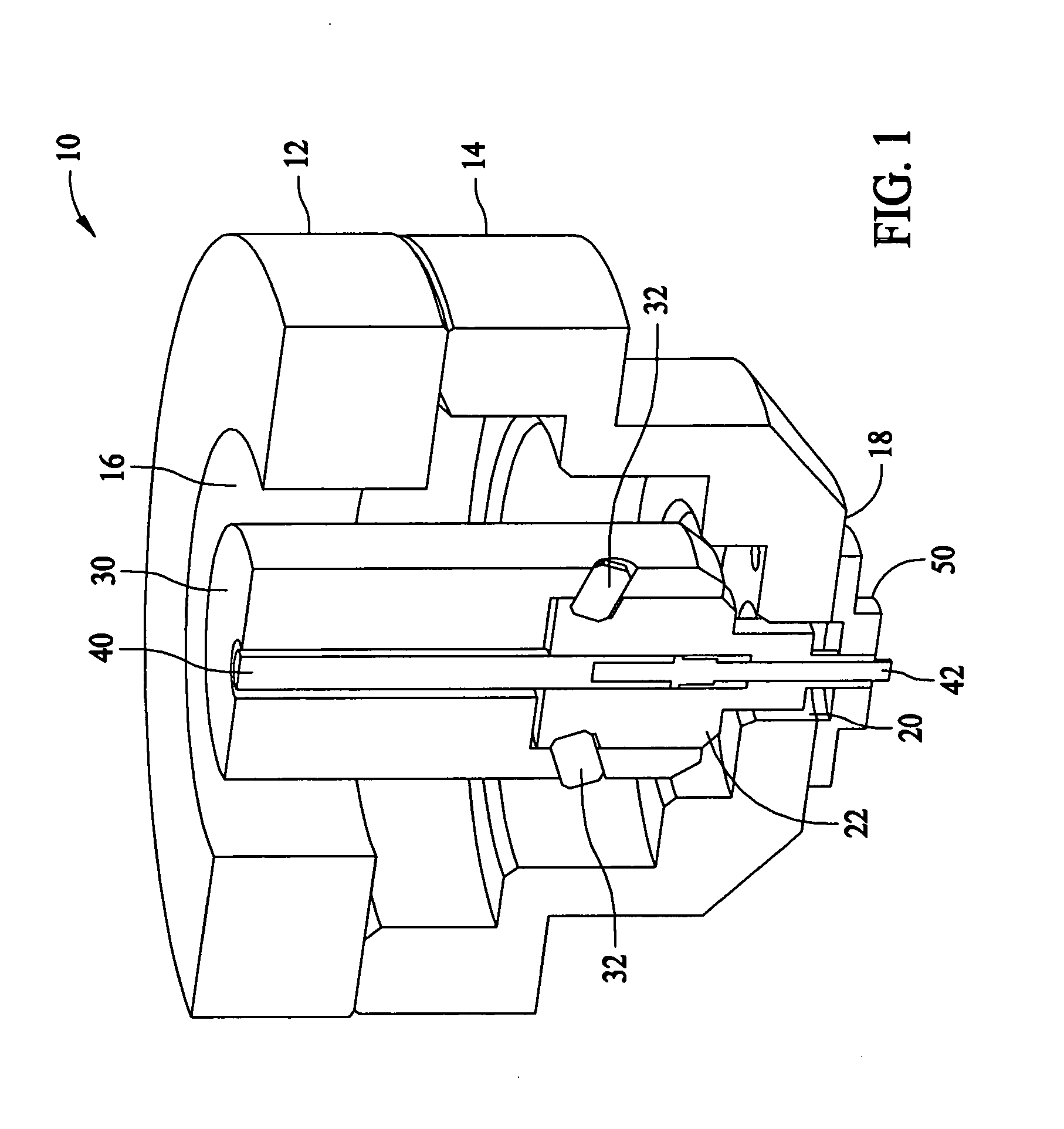

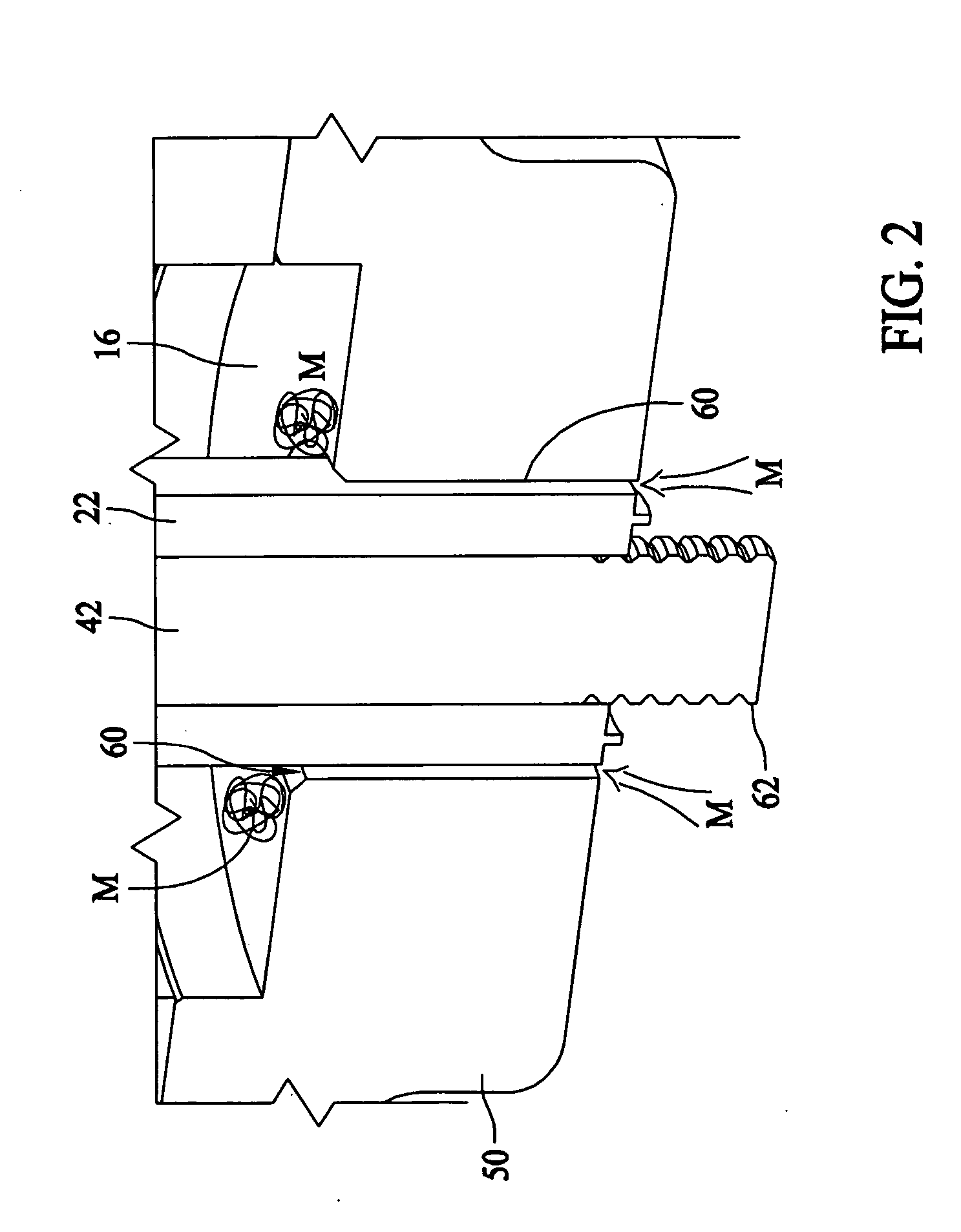

Methods and apparatus for retractable pin friction stir welding and spot welding

ActiveUS20070152015A1Welding/cutting auxillary devicesAuxillary welding devicesEngineeringSpot welding

An apparatus for friction stir welding is described that includes a stationary assembly having a bore therethrough, the bore having an inner diameter, and a rotational assembly having a welding end. At least the welding end of the rotational assembly extends through the bore. A portion of the rotational assembly is adjacent the inner diameter of the bore. At least one of the adjacent portion of the rotational assembly and the inner diameter of the stationary assembly are configured such that rotation of the rotational assembly will cause plasticized material from a welding process that has entered an area between the adjacent portion and the inner diameter to move towards a welding zone located proximate the welding end.

Owner:THE BOEING CO

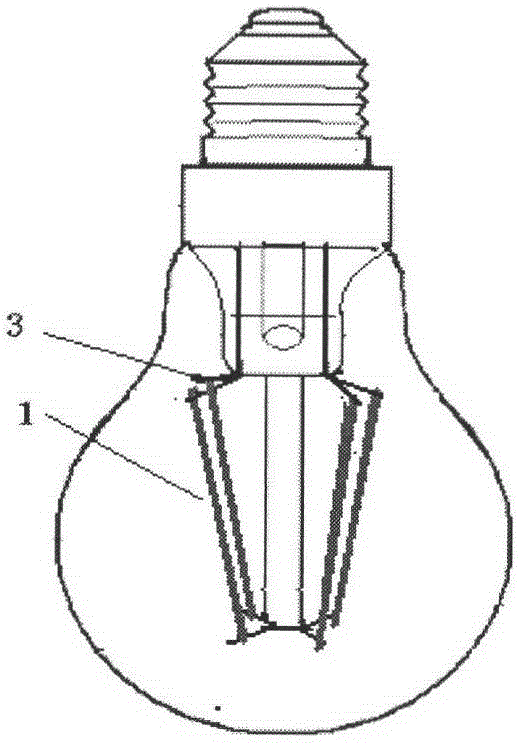

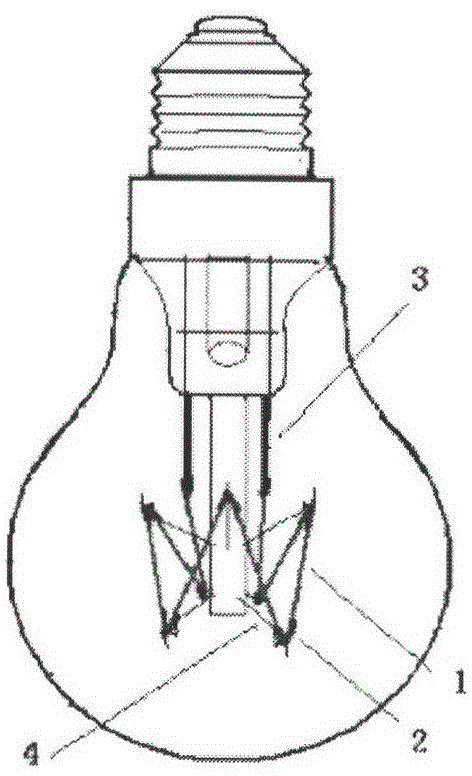

Connection and installation method for LED filaments

ActiveCN105371243AReduce damage rateReduce stressPoint-like light sourceLight fasteningsElectrical polarityEngineering

The invention provides a connection and installation method for LED filaments. The connection and installation method is used for assembling wicks in filament type LED bulbs. As the difference from the prior art of welding the lead-out ends of the LED filaments to a guide wire of a glass core column through a spot welding method, the electrode lead-out ends of the LED filaments are connected through elastic metal thin wire spiral parts, and therefore the LED filaments are connected in series one by one in an end-to-end manner according to the polarity to form a multi-joint LED filament series-connection system which can be bent. Then, the metal thin wire spiral parts at the head lead-out end and the tail lead-out end of the filament series-connection system are clamped on and fixed to corresponding core column side rod guide wires, and the metal thin wire spiral parts between the adjacent filaments are placed on corresponding filament hooks on the core column one by one so that the filaments can be arranged in order. By means of the connection and installation method, the defects that in the prior art, due to spot welding, the production efficiency is low, the finished product rate is low, and filament stress is large are overcome, and the production efficiency of filament type LED bulbs can be easily improved and the finished product rate of the filament type LED bulbs can be easily increased.

Owner:厦门银旭工贸有限公司

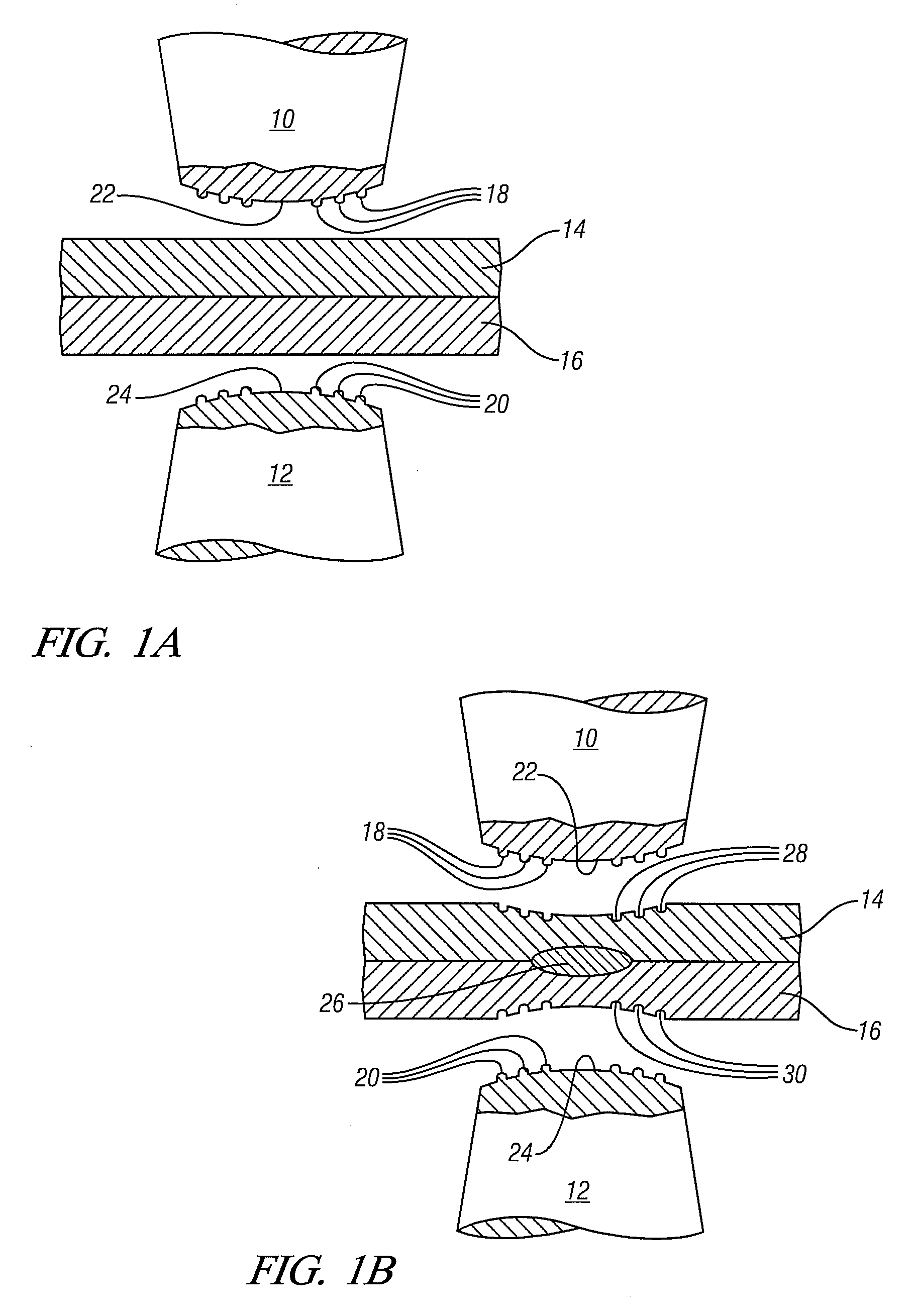

Formable light weight composite material systems and methods

ActiveUS20110200816A1Attractive performance characteristicHigh strengthConductive materialSoldering apparatusElectrical resistance and conductancePolymer science

The present invention relates to filled polymeric materials including a polymer and a mass of metallic fibers distributed within the polymer, and to light weight composites which comprise at least a pair of metallic layers and a polymeric layer interposed between the pair of metallic layers, the polymeric layer containing the filled polymeric material. The composite materials of the present invention may be formed using conventional stamping equipment at ambient temperatures. Composite materials of the present invention may also be capable of being welded to other metal materials using a resistance welding process such as resistance spot welding. Preferred composite materials include one or any combination of the following features: metallic fibers that are ribbon fibers; a polymer selected from a polyolefin, a polyamide, or a combination thereof; or a metallic layer (e.g., one or both of the pair of metallic layers) having a surface facing the filled polymeric material that is untreated.

Owner:PRODIVE RES

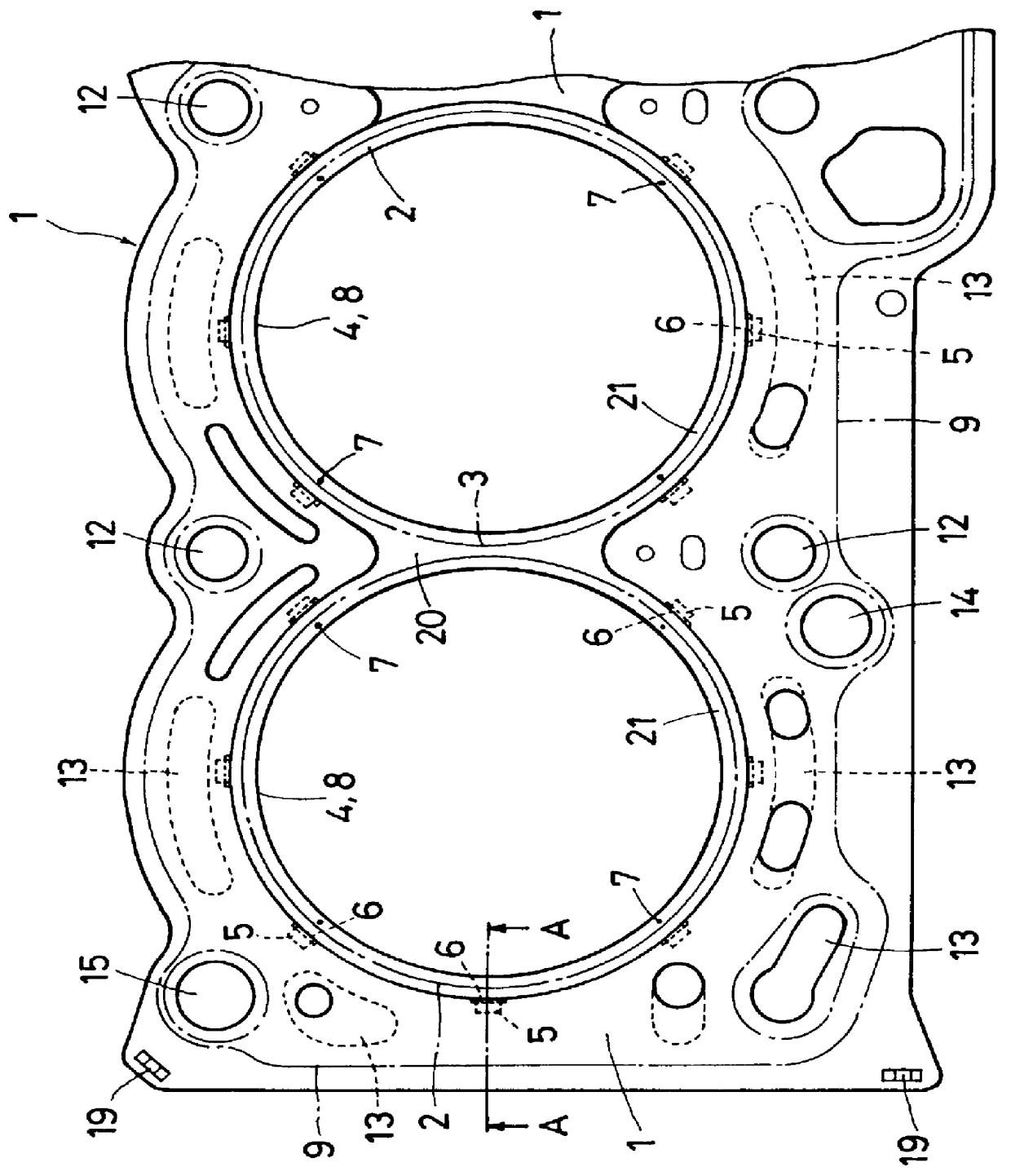

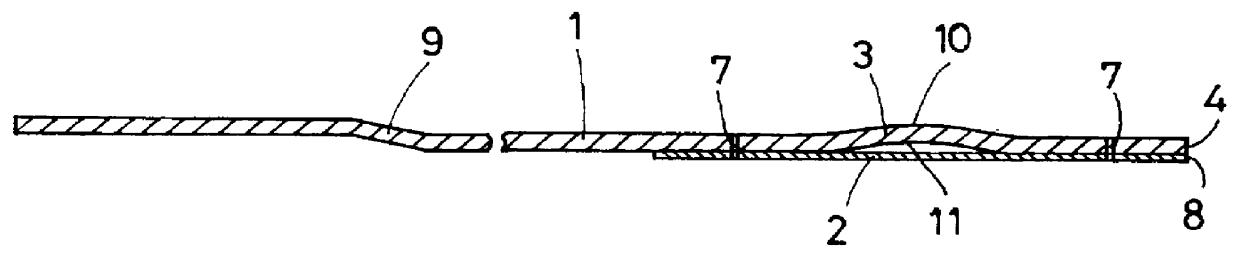

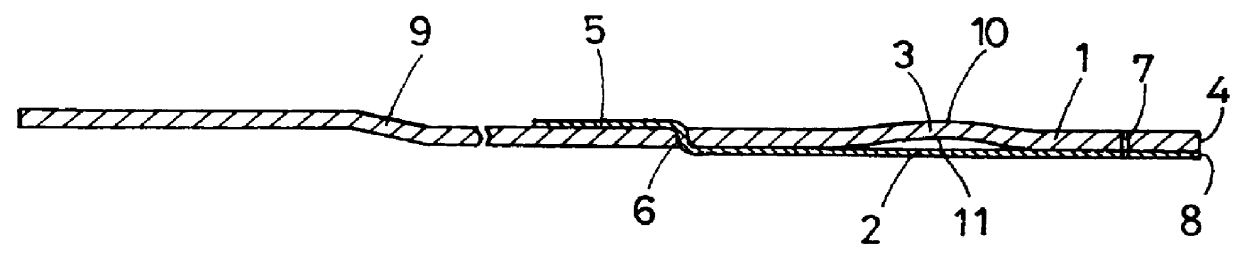

Metal gasket

InactiveUS6027124AImprove sealingImprove balanceEngine sealsSealing arrangements for enginesThin metalCombustion chamber

A metal gasket in which a thin metal plate for reinforcing the beads of an elastic metal plate is laminated on bead regions only of the elastic metal plate, whereby a stable sealing performance is secured for a long period of time. This metal gasket comprises a thin metal plate provided with beads extending around the circumferences of parallel arranged combustion chamber holes, and an elastic metal plate having combustion chamber holes and extending with a predetermined width and laminated on the portions of the thin metal plate which are around the combustion chamber holes so as to be opposed to valley portions of the beads. The thickness of the thin metal plate is set smaller than that of the elastic metal plate. The thin metal plate is fixed to the elastic metal plate with locking portions formed at the outer circumference of the former engaged with slits formed in the regions of the latter which are on the outer sides of the beads, the thin metal plate being combined with the elastic metal plate at joint portions thereof by spot welding or laser welding.

Owner:NIPPON GASKET CO LTD

Welding teaching point correction system and calibration method

InactiveUS20070075048A1Improve calibration accuracyEnsure correct executionProgramme controlProgramme-controlled manipulatorImaging processingSimulation

Disclosed is a welding teaching point correction system, including: a robot; a spot welding gun comprising two welding tips provided to be opposed to each other; an imaging apparatus to image a welding point of a workpiece, the imaging apparatus being provided detachably to or exchangeably with at least one of the two welding tips; an operation control unit to control the robot and the spot welding gun in accordance with an teaching program to teach welding operation to the robot and the spot welding gun; an image processing unit to acquire positional information of the welding point of the workpiece in the image; and a program correction unit to correct an teaching point for the robot in the teaching program in a plurality of directions based on the positional information of the welding point of the workpiece in the image acquired by the image processing unit.

Owner:NACHI-FUJIKOSHI

Friction stir welding of dissimilar metals

InactiveUS20100089976A1Improve adhesionImprove joint strengthWelding/cutting media/materialsWelding/soldering/cutting articlesAdhesiveMaterials science

When a friction stir weld tool penetrates the interface of two workpieces of dissimilar metal alloy materials, the resultant weld of the different alloy materials may produce a weak weld joint. Such weak joints are often experienced, for example, when attempting to form spot welds or other friction stir welds between a magnesium alloy sheet or strip and an aluminum alloy sheet or strip. It is discovered that suitable coating compositions including an adhesive placed at the interface of assembled workpieces can alter the composition of the friction stir weld material and strengthen the resulting bond. In the example of friction stir welds between magnesium alloy and aluminum alloy workpieces, it is found that combinations of an adhesive with copper, tin, zinc, and / or other powders can strengthen the magnesium-containing and aluminum-containing friction stir weld material.

Owner:GM GLOBAL TECH OPERATIONS LLC

Connection structure and assembly method of tube-shaped frames

InactiveUS20100244497A1Accurate connectionEnsures rigiditySuspensionsVehicle seatsEngineeringSpot welding

A first split-bracket is joined to a first tube-shaped frame by lazar welding. A second split-bracket is joined to an end portion of a second tube-shaped frame by the lazar wielding. The second tube-shaped frame equipped with the second split-bracket is assembled to the first tube-shaped frame equipped with the first split-bracket. A second flange of the first split-bracket and a second flange of the second split-bracket are joined temporarily by spot welding. The second flange of the first split-bracket and the second flange of the second split-bracket are joined by continuous welding with lazar welding. Accordingly, the tube-shaped frames can be connected properly without forming any hole at a wall of the tube-shaped frame, ensuring the rigidity of the connection portion of the tube-shaped frames.

Owner:MAZDA MOTOR CORP

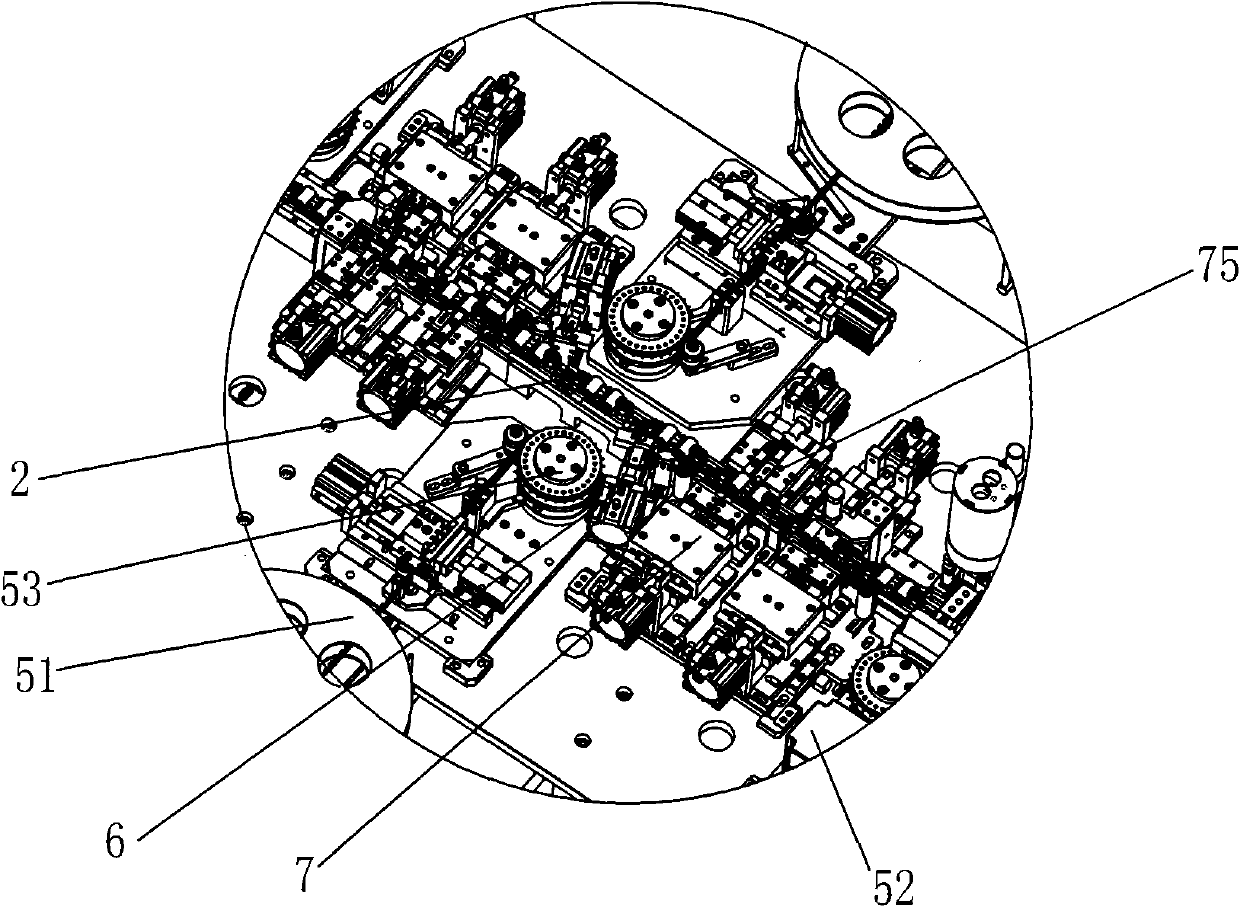

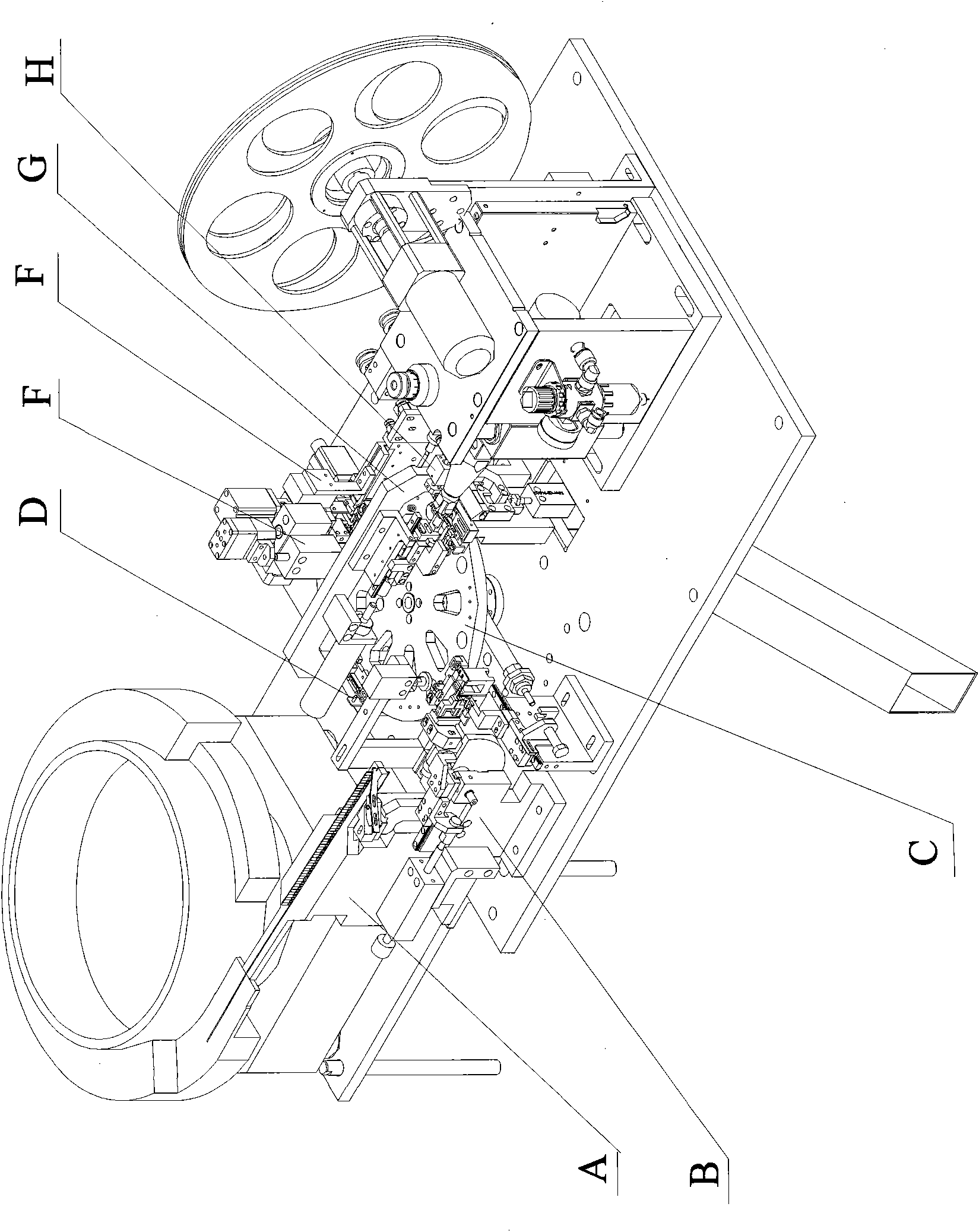

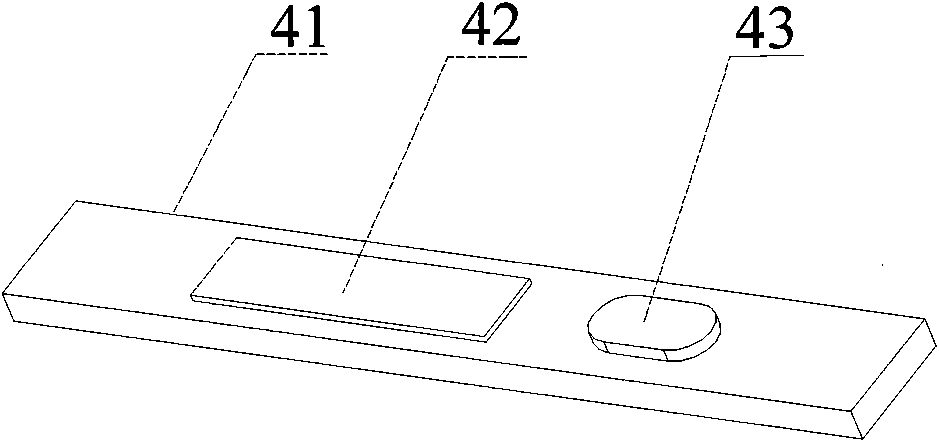

Automatic welding machine of aluminum-nickel compound piece of lithium ion battery cover plate

ActiveCN101913029AChange choresSave human effortWelding apparatusAutomatic controlUltrasonic welding

The invention provides an automatic welding machine of an aluminum-nickel compound piece of a lithium ion battery cover plate, consisting of a feeding mechanism A, a feeding turnover mechanism B, a turnplate mechanism C, a detection mechanism D, a nickel piece feeding mechanism E, a spot-welding machine F, an ultrasonic welding mechanism G, a banking mechanism H and an automatic control mechanism, wherein the feeding mechanism A, the feeding turnover mechanism B, the turnplate mechanism C and the detection mechanism D are arranged on the tabletop of the automatic welding machine; the nickel piece feeding mechanism E, the spot-welding machine F, the ultesonic welding mechanism G and the banking mechanism H are arranged on the turnplate mechanism C; the aluminum-nickel compound piece is placed on the lithium ion battery cover plate through the feeding mechanism A, the feeding turnover mechanism B, the turnplate mechanism C, the detection mechanism D and the nickel piece feeding mechanism E; and the lithium ion battery cover plate is automatically welded with the aluminum-nickel compound piece through the spot-welding machine F, the ultrasonic welding mechanism G and the banking mechanism H. The invention ensures that the whole process flow realizes the automation, changes the traditional mode for manually finishing miscellaneous work, librates the large amount of labor force, greatly improves the work conditions, greatly increases the yield, greatly reduces the manufacturing cost and simultaneously and effectively ensures the quality of products.

Owner:HUNAN HUAHUI NEW ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com