Self-piercing frictional rivet welding connecting device

A riveted welding connection and self-piercing technology, applied in welding equipment, non-electric welding equipment, manufacturing tools, etc., can solve the problems of difficult deformation of high-strength steel self-piercing riveting, low friction spot welding efficiency, and reduced feed resistance. Riveting force and requirements for equipment rigidity, the effect of improving connection efficiency and joint strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

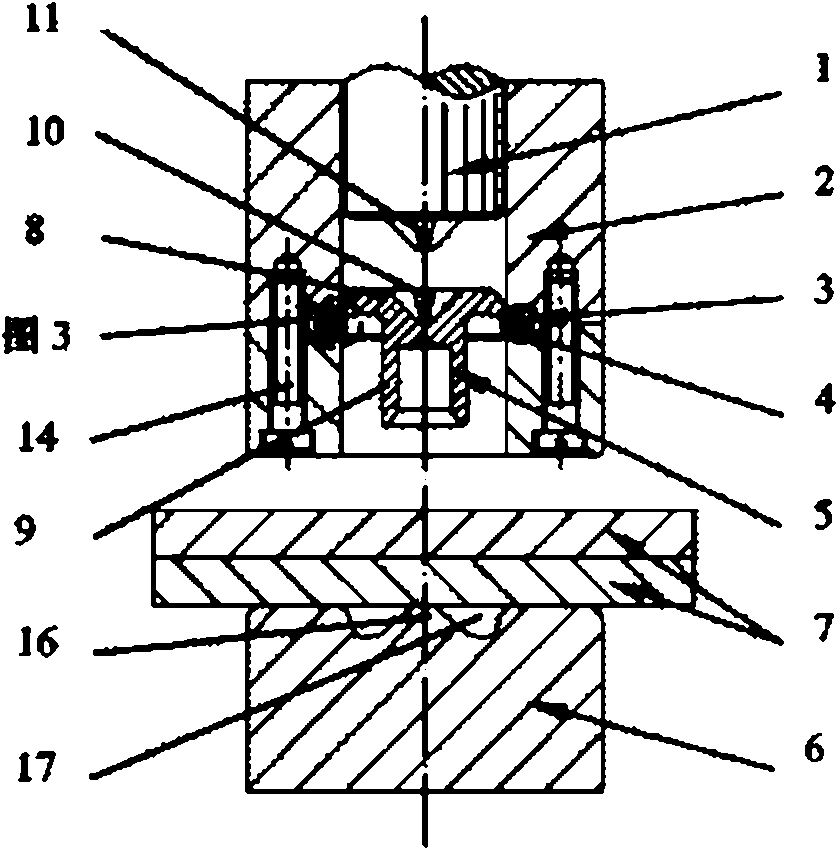

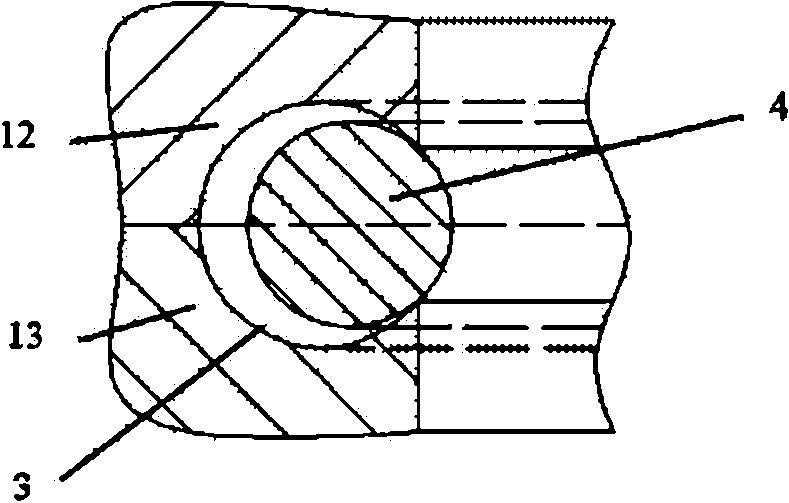

[0023] like figure 1 As shown, this embodiment includes: a driving pin 1, a blank holder 2, an annular guide groove 3, an annular positioning spring 4, a semi-tubular rivet 5, a die 6 and a plate 7, wherein: the blank holder 2 is sleeved to drive Needle 1, a semi-hollow rivet 5 is provided under the driving pin 1, an annular guide groove 3 is provided on the inner wall of the blank holder 2, an annular positioning spring 4 is arranged in the annular guide groove 3, and the semi-hollow rivet 5 is positioned on the annular positioning spring 4 Above, the die 6 is set under the semi-tubular rivet 5 , and the plate 7 is set on the die 6 .

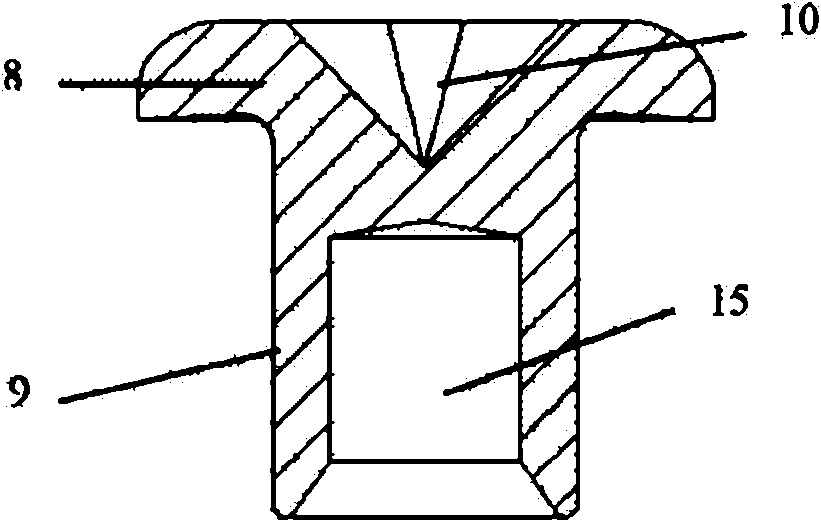

[0024] like figure 2 As shown, the semi-tubular rivet 5 includes: a rivet head 8 and a rivet leg 9, wherein: the center of the rivet head 8 is provided with a groove 10, the rivet head 8 is fixedly provided with a rivet leg 9, and the diameter of the rivet head 8 is larger than that of the rivet leg 9 path.

[0025] The shape of the rivet h...

Embodiment 2

[0043] The plate 7 in this implementation is: strong steel DP780 + aluminum alloy AA6061-T6, that is, the high-strength steel is on the top and the aluminum alloy is on the bottom; the thickness of the plate is matched: 1.4mm+2mm;

[0044] Process parameters: the rotation speed of the driving pin 1 and the rivet meshing stage is 90r / min, the feeding speed of the driving pin 1 is 30mm / s; Hold for 40ms after the stroke ends.

[0045] Other implementation modes of this embodiment are the same as Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com