Patents

Literature

4146 results about "Aluminium powder" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

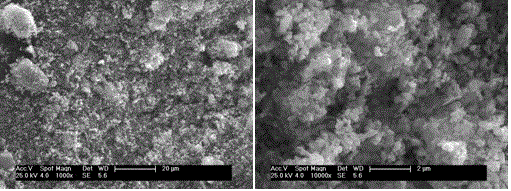

Aluminum powder is powdered aluminum. This was originally produced by mechanical means using a stamp mill to create flakes. Subsequently, a process of spraying molten aluminum to create a powder of droplets was developed by E. J. Hall in the 1920s. The resulting powder might then be processed further in a ball mill to flatten it into flakes for use as a coating or pigment. Aluminum powder is non-toxic and is not harmful unless injected directly in a major blood vessel such as the aorta. Aluminum powder, if breathed in, is not particularly harmful and will only cause minor irritation. The melting point of aluminum powder is 660 °C.

Preparing method of coated aluminium powder pigment

InactiveCN1986648AGood storage stabilityEasy to usePigment treatment with organosilicon compoundsWater bathsAlcohol

The present invention is coated aluminum powder pigment and its preparation process. The coated aluminum powder pigment is prepared through the following steps: mixing aluminum powder pigment with alcohol solvent; adding organosiloxane, water and acid catalyst, and heating in water bath to react to obtain organosiloxane coated aluminum powder pigment; heating the reaction system to 65-120 deg.c, adding polymer monomer and initiator to react to obtain organosiloxane and polymer coated aluminum powder pigment; and cooling, filtering, washing and drying to obtain the coated aluminum powder pigment product. The coated aluminum powder pigment with two coating layers has excellent metal luster and high acid and alkali resistance, and is suitable for water paint.

Owner:SOUTH CHINA UNIV OF TECH

Wear-resistant sintered aluminum alloy with high strength and manufacturing method thereof

Disclosed is a wear-resistant sintered aluminum alloy with high strength and a manufacturing method thereof. The sintered aluminum alloy contains, by mass: 3.0-10% zinc; 0.5-5.0% magnesium; 0.5-5.0% copper; 0.1-10% hard particles; impurities; and aluminum. The metallographic structure has an aluminum alloy matrix in which the hard particles dispersed; and an intermetallic compound phase being dispersedly precipitated in the aluminum alloy matrix. Using an aluminum powder, a hard particles powder and other powders, a compact is formed and sintered at 580-610 degrees C., then cooled and subjected to heat treatment at a temperature of 460-490 degrees C., including water-quenching and aging at 110-200 degrees C.

Owner:ICHIKAWA JUNICHI +1

Watery zinc-aluminium heavy-duty coating in compounding squama shape and preparation method thereof

InactiveCN101525505AAchieve complete chrome-freeImprove bindingAnti-corrosive paintsPotassium hydroxideHeavy duty

The invention relates to a watery zinc-aluminium heavy-duty coating in a compounding squama shape and a preparation method thereof. The watery zinc-aluminium heavy-duty coating belongs to a bi-component coating and is prepared from organic-inorganic modified base stock and pigment according to a certain proportion by weight, wherein the organic-inorganic modified base stock contains silica sol, potassium hydroxide, silicone-acrylate emulsion, a pigment dispersing agent, a film forming addition agent and an antifoaming agent, and the balance is deionized water or distilled water; the pigment comprises squama-shaped zinc powder and squama-shaped aluminium powder; and the weight ratio of the organic-inorganic modified base stock to the pigment is 5: 1-2. The watery zinc-aluminium heavy-duty coating contains no chrome, can be solidified at the normal temperature, has environmental protection and low energy consumption and can be used for preparing thin coatings with high corrosion resistance, and the like.

Owner:HOHAI UNIV +1

Thermocured, heat conductive and heat radiating paint for LED lamp and preparation method thereof

InactiveCN103555094AExtended service lifeImprove fullnessPolyurea/polyurethane coatingsEthyl acetateColor changes

A thermocured, heat conductive and heat radiating paint for an LED lamp is prepared by the following raw materials by weight: 40-45 parts of polyacrylic resin, 5-8 parts of polyurethane resin, 4-6 parts of polyacrylamide, 6-8 parts of isophorone diamine IPDA, 20-24 parts of xylene, 2-3 parts of silane coupling agent KH550, 1-2 parts of aluminium powder, 8-12 parts of ethyl acetate, 2-4 parts of benzyltrimethylammonium tribromide, 10-12 parts of aluminium nitride, 2-3 parts of beryllia, and 4-5 parts of film forming auxiliary agent. Aluminium nitride powder, the beryllia and the aluminium powder are added, so as that the paint has high heat conduction rate and good heat radiation effect, and can be long-term used under 200 DEG C without change of mechanical property; polyacrylic resin is used, so as that the paint has advantages of excellent fullness, glossiness, hardness, solvent resistance and weatherability, without color change and brightness reversion when high temperature baked; and the paint has advantages of large adhesion stress, not-easy shedding, aging resistance and long usage life.

Owner:天长市天泰光电科技有限公司

Apparatus and method for penetrating oilbearing sandy formations, reducing skin damage and reducing hydrocarbon viscosity

InactiveUS20050115448A1Excessive heatingMinimal damageExplosive chargesAmmunition projectilesPorosityPolyester

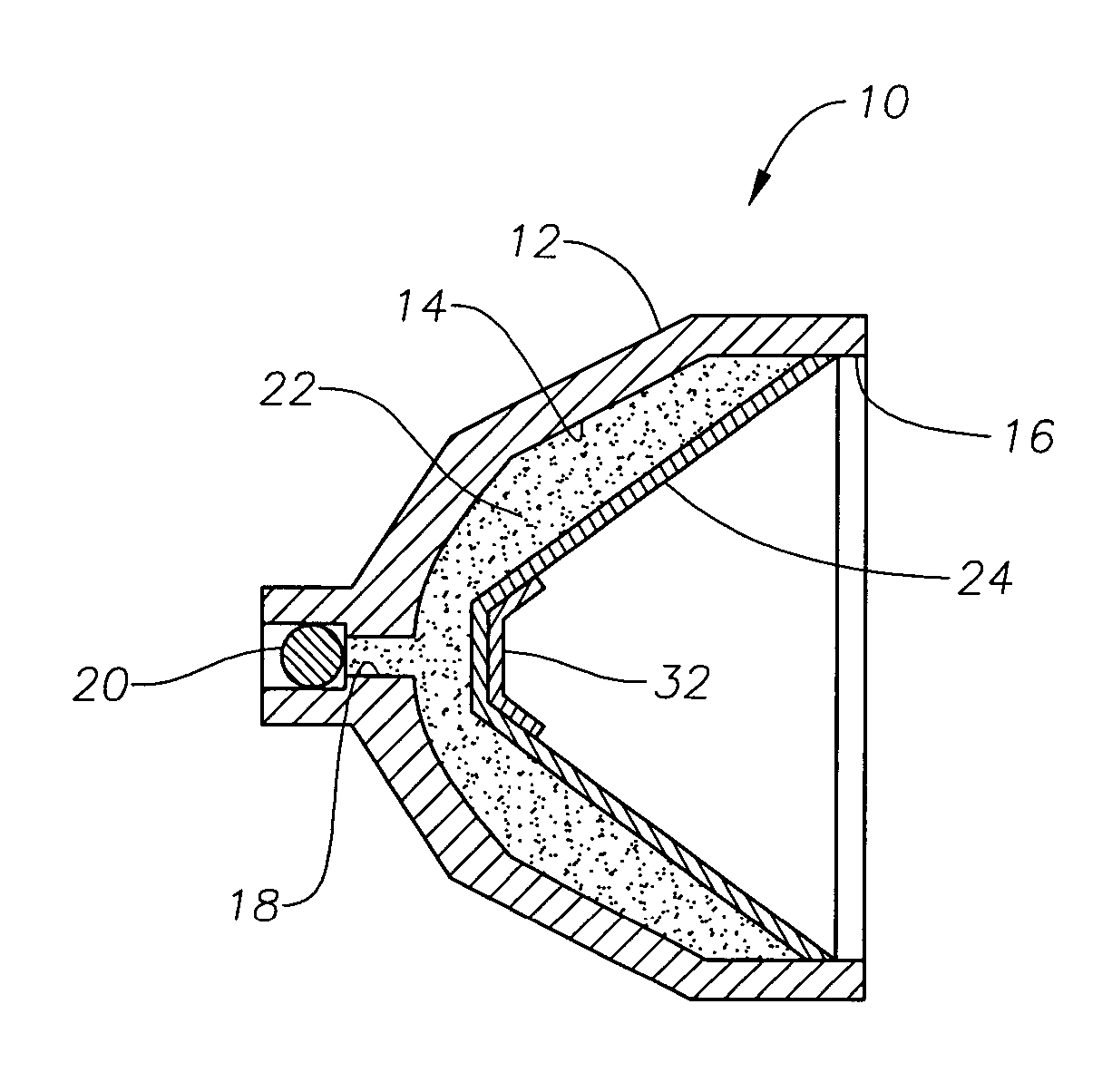

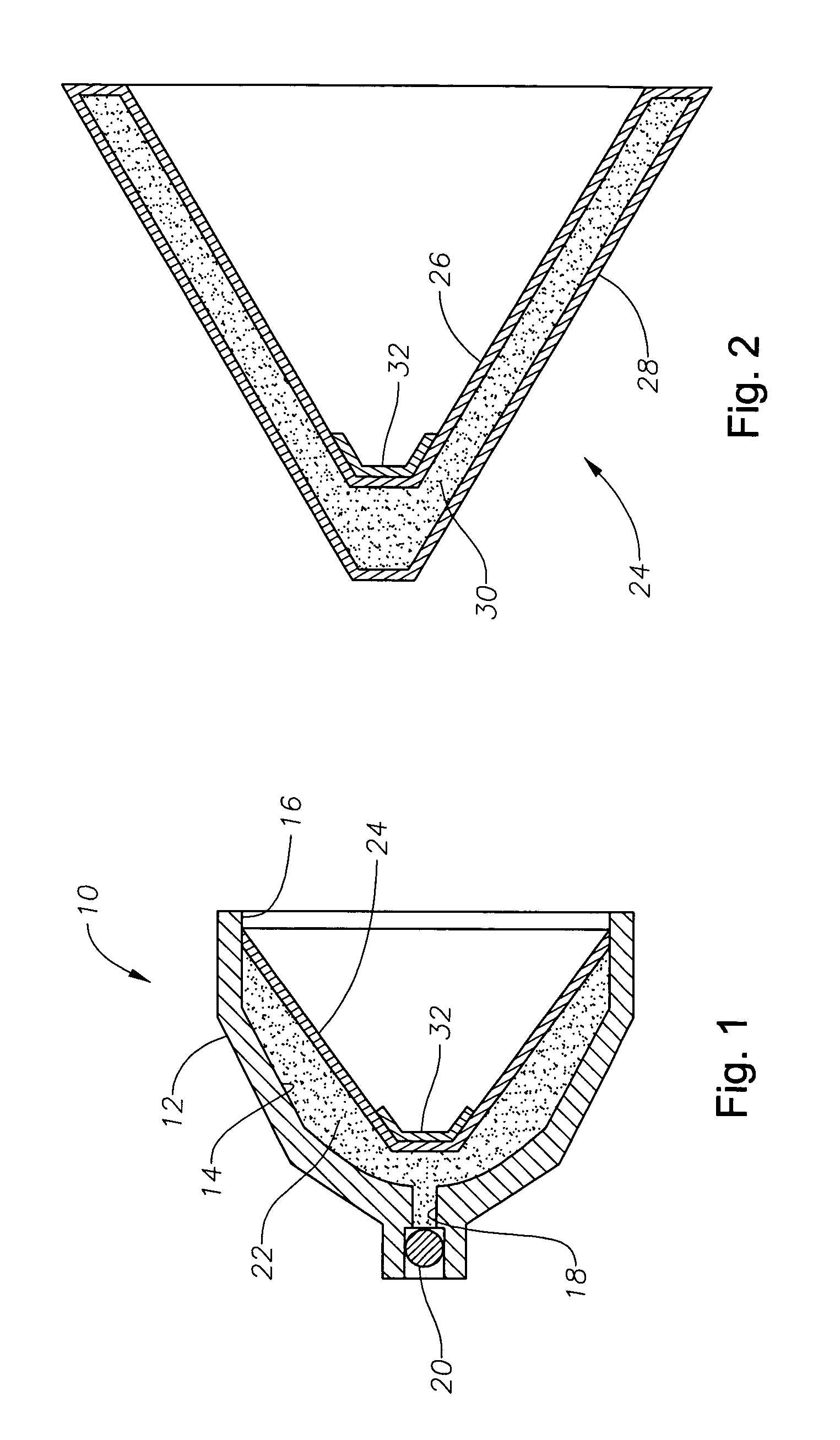

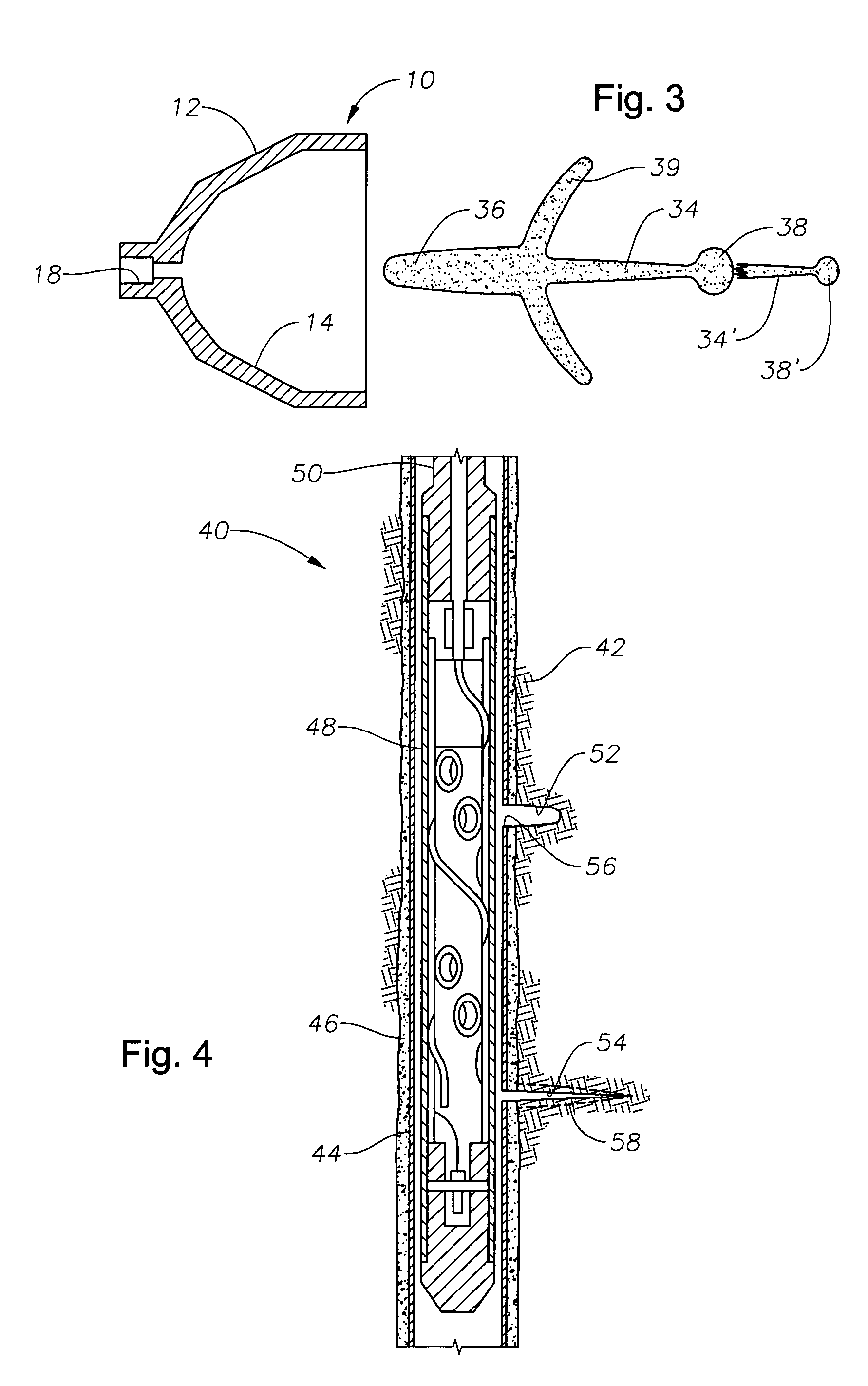

A shaped charge and a method of using such to provide for large and effective perforations in oil bearing sandy formations while causing minimal disturbance to the formation porosity is described. This shaped charge uses a low-density liner having a filler material that is enclosed by outer walls made, preferably, of plastic or polyester. The filler material is preferably a powdered metal or a granulated substance, which is left largely unconsolidated. The preferred filler material is aluminum powder, or aluminum particles, that are coated with an oxidizing substance, such as TEFLON®, permitting a secondary detonation reaction inside the formation following jet penetration. The filled liner is also provided with a metal cap to aid penetration of the gun scallops, the surrounding borehole casing and the cement sheath. The metal cap forms the leading portion of the jet, during detonation. The remaining portion of the jet is formed from the low-density filler material, thereby resulting in a more particulated jet. The jet results in less compression around the perforation tunnel and less skin damage to the proximal end of the perforation tunnel.

Owner:OWEN OIL TOOLS

Paste for forming solar battery electrode

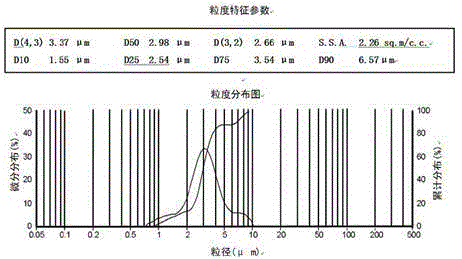

InactiveCN101609847AConversion efficiency is not affectedConversion efficiency impactFinal product manufactureNon-conductive material with dispersed conductive materialElectrical resistance and conductanceBack surface field

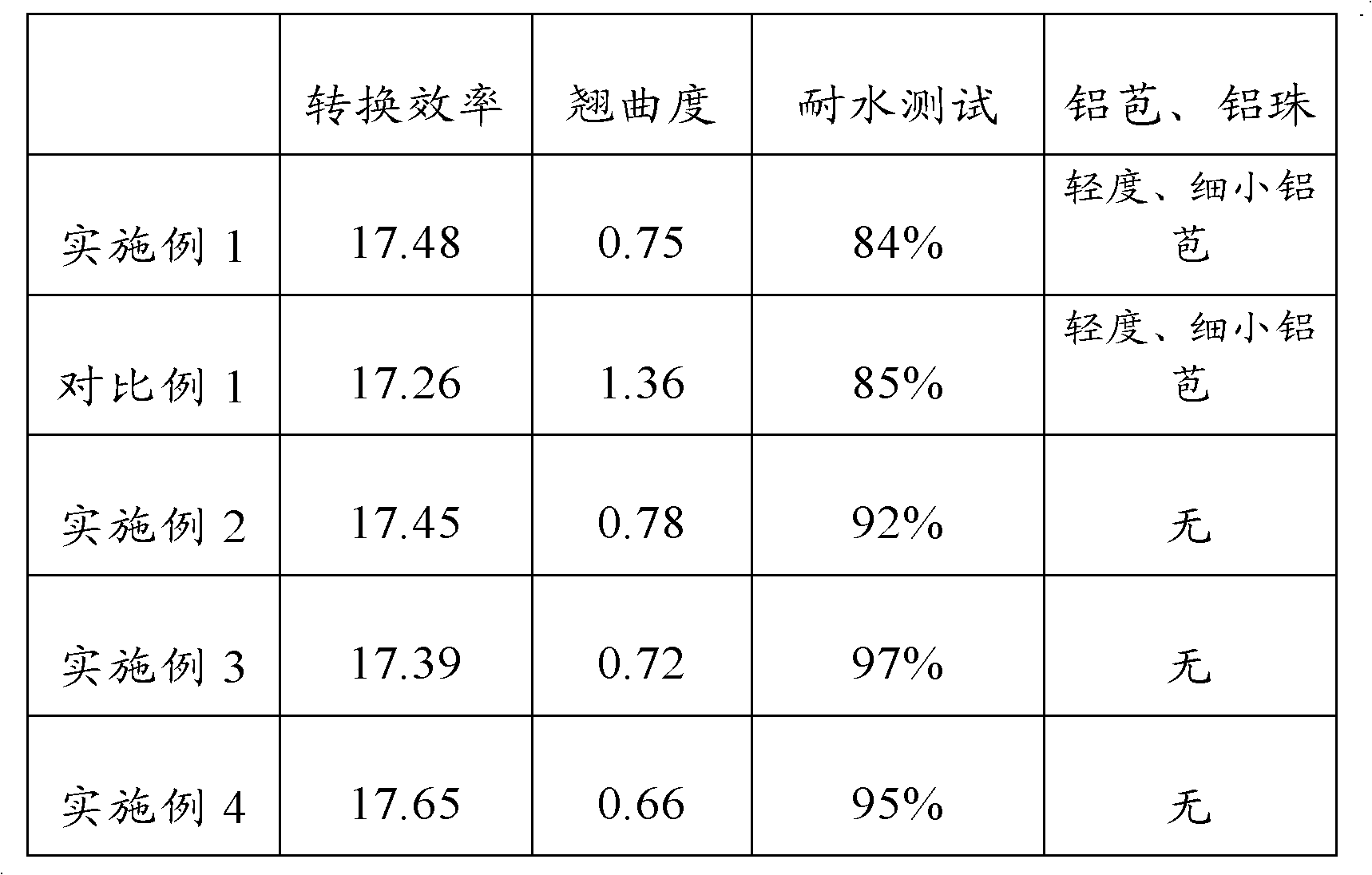

The invention discloses paste for forming solar battery electrode, which comprises the following components by mass percent: 65 to 75 percent of aluminum powder, 20 to 30 percent of organic carrier, 0.2 to 6 percent of inorganic glass powder and 0.5 to 1 percent of functional additive. The aluminum powder comprises at least two types, the average particle diameter of one type of the aluminum powder is smaller than 2 micro meters and the mass of the type of the aluminum powder is 1 to 10 percent of that of the aluminum powder. The paste can form back surface field effect required by a solar battery with a silicon substrate, and has the advantages that the electrical conductivity is good, the contact resistance is low, the adhering to the silicon substrate is firm, the silicon substrate is slightly bent, and the open-circuit voltage of the solar battery and the photoelectric conversion efficiency are high.

Owner:RES INST OF XIAN JIAOTONG UNIV & SUZHOU

Back surface field aluminium paste for solar cells

ActiveCN102097154AReduce warpageNon-conductive material with dispersed conductive materialSemiconductor devicesAdhesiveBack surface field

The invention relates to a back surface field aluminium paste for solar cells. The aluminium paste comprises the following components in parts by weight: 65-80 parts of aluminium powder, 1-5 parts of inorganic adhesive, 10-30 parts of organic carrier and 1-2 parts of modifier. Sintered films with lower warpage can be obtained through the back surface field aluminium paste.

Owner:长沙族兴新材料股份有限公司

A kind of aqueous chrome-free dacromet coating solution and preparation method thereof

ActiveCN102277022ANo pollution in the processWon't happenAnti-corrosive paintsChromium freeWater based

The invention discloses water-based chrome-free Dacromet coating solution. The coating solution is environment-friendly, is free of environmental pollution and simultaneously has good corrosion and weather resistance. The coating solution comprises components A, components B, a component C and components D, wherein the components A include 18-24% of zinc powder, 2-5% of aluminium powder, 28-34% of wetting and dispersing agent, 1-3% of passivator, 1-3% of corrosion inhibitor and water by mass; the components B include 5-12% of film-forming agent, 0.1-0.5% of forming auxiliaries and water by mass; the component C is 5-12% of film-forming auxiliary by mass; the components D include the balance of thickener and water; and the total mass percent of water is 18-27%.

Owner:朱承飞

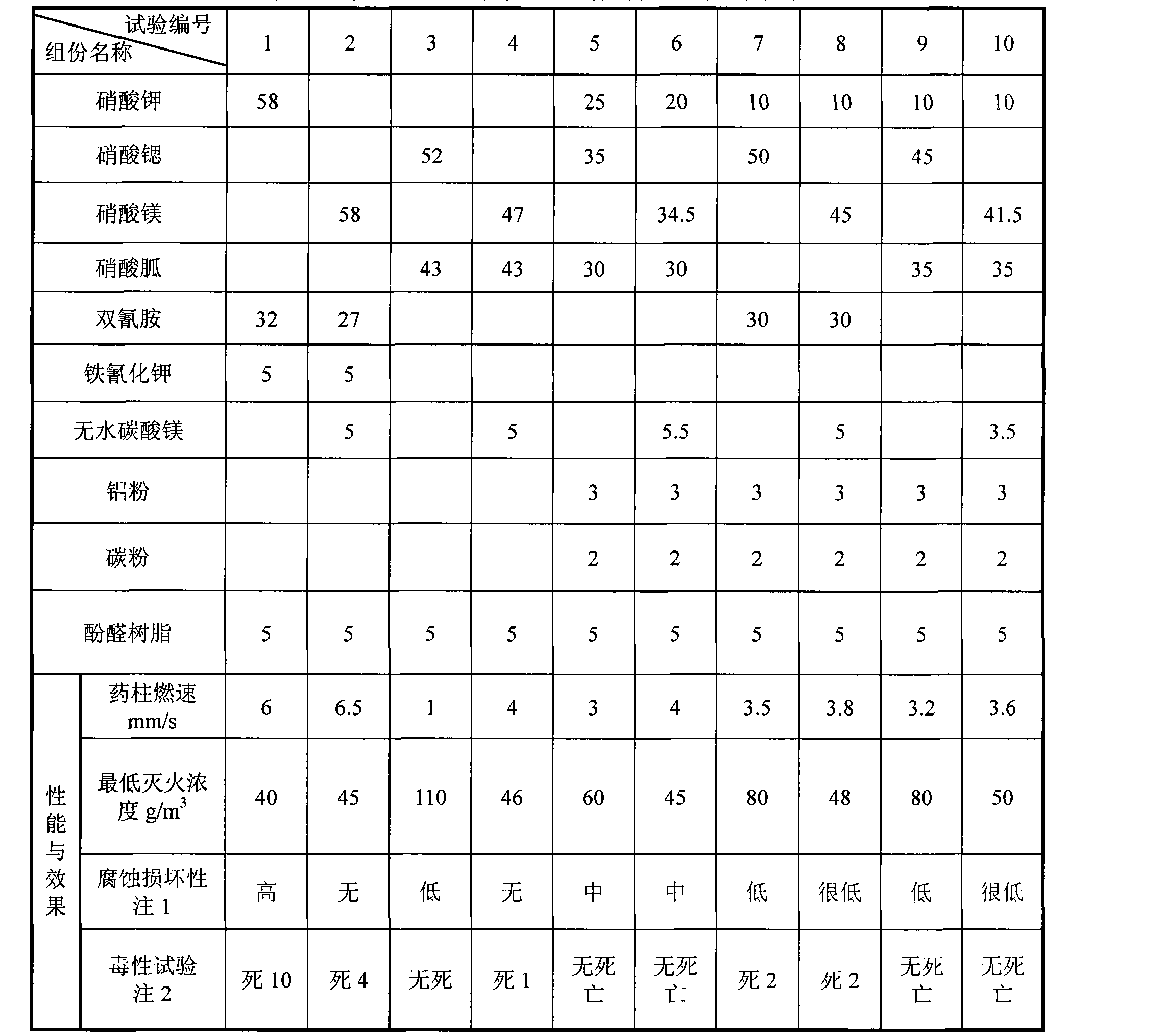

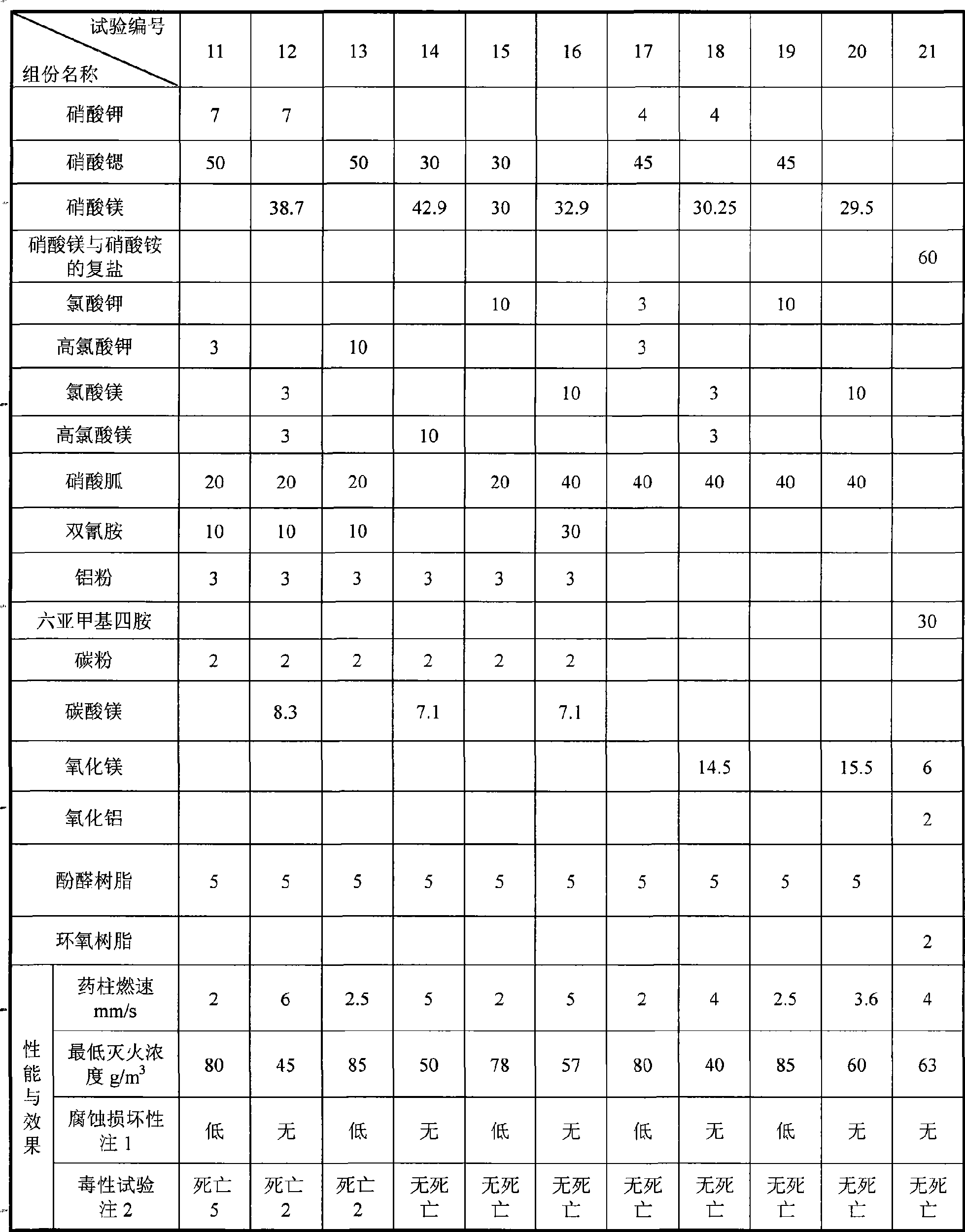

Extinguishment combination with hot gas sol

The invention provides ''a hot aerosol fire-extinguishing composition'' and relates to an oxidative magnesium salt hot aerosol fire-extinguishing composition represented by anhydrous magnesium nitrate. The composition is characterized in that the composition can be magnesium nitrate, magnesium carbonate, or other magnesium salt, and can also be a compound of magnesium nitrate, or other magnesium salt with potassium nitrate, strontium nitrate, or other potassium salt or strontium salt; a reducer can be one of or the combination of a plurality of ammonium carbamidine, dicyandiamide, red prussiate of potash, formamine, triazole, and tetrazole; a capability improver can be magnesium carbonate, manganous carbonate, aluminium powder, powdered carbon, magnesium hydrate, metal oxide, etc.; and the bond adopts phenolic resin, etc. The preparation of the magnesium salt comprises the continuous steps: medium temperature and low pressure dehydration, spray under the protection of nitrogen-oxygen flow or ultrafine grinding of grinded colloid, and microencapsulated hydrophobic treatment, etc. Compared with the prior art, the fire-extinguishing composition has the advantages of low price, extensive source, fire-extinguishing capability of K-type composition, and low causticity and toxicity of the ultimate product of combustion.

Owner:SHAANXI J&R FIRE FIGHTING CO LTD

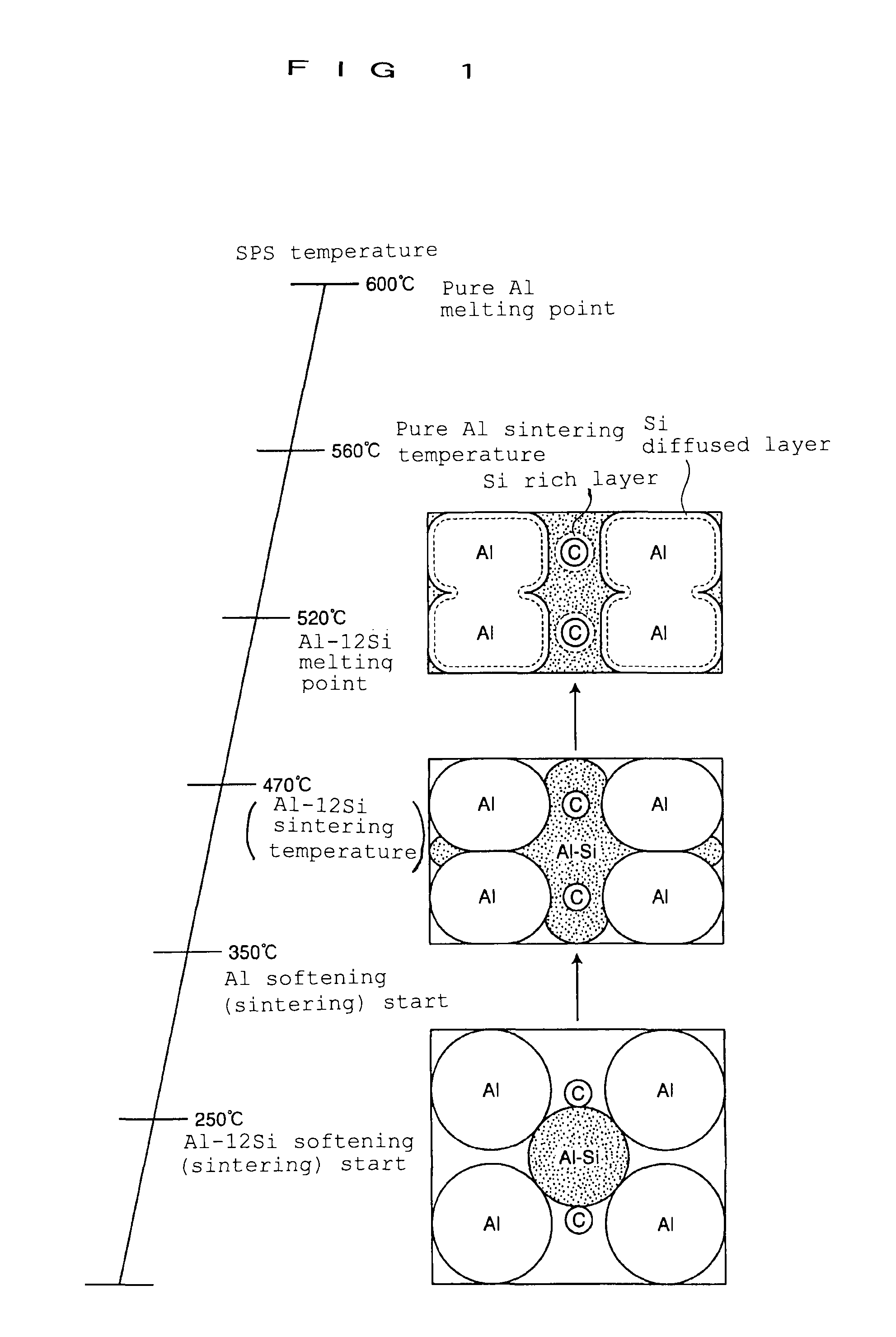

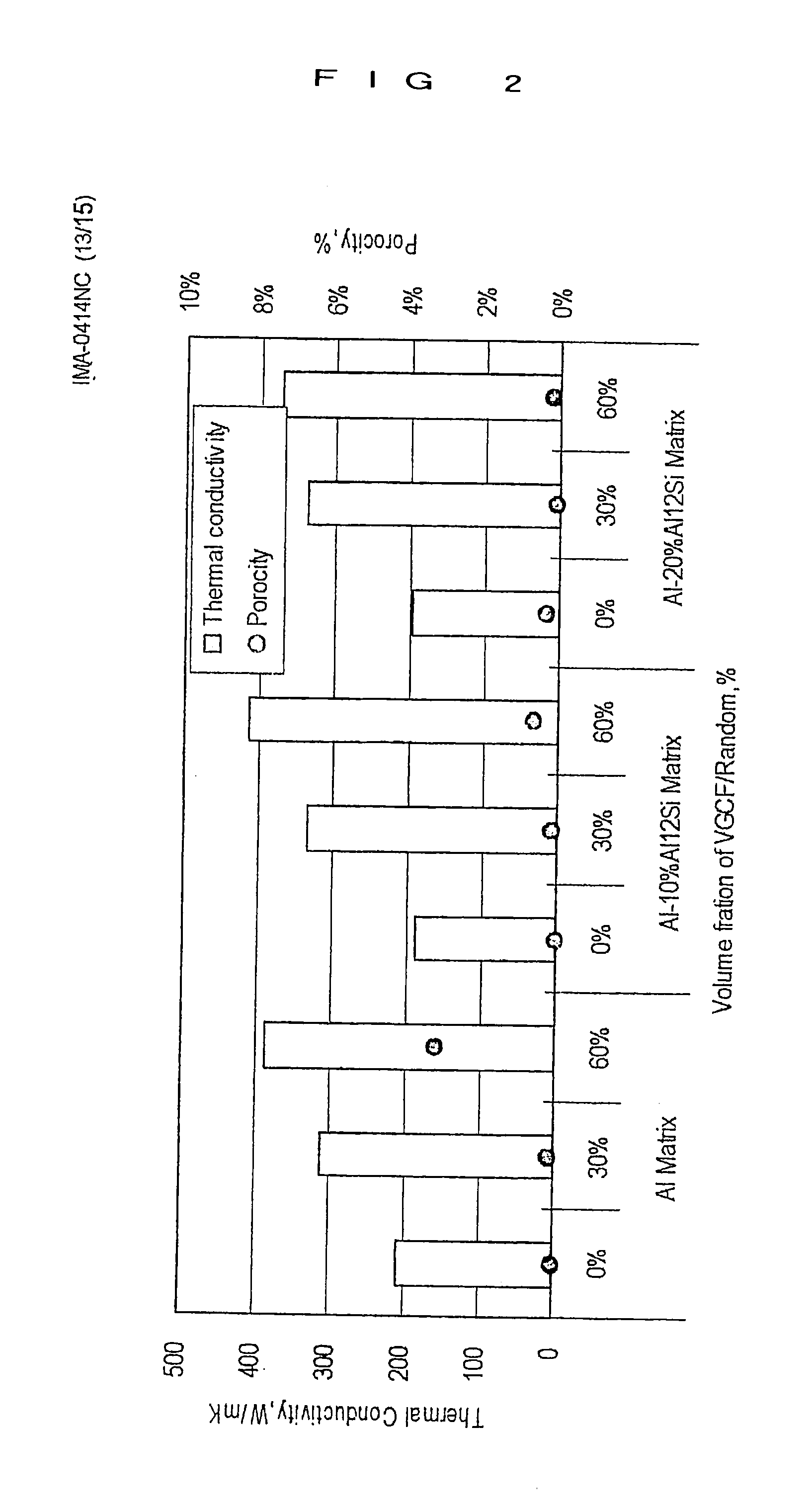

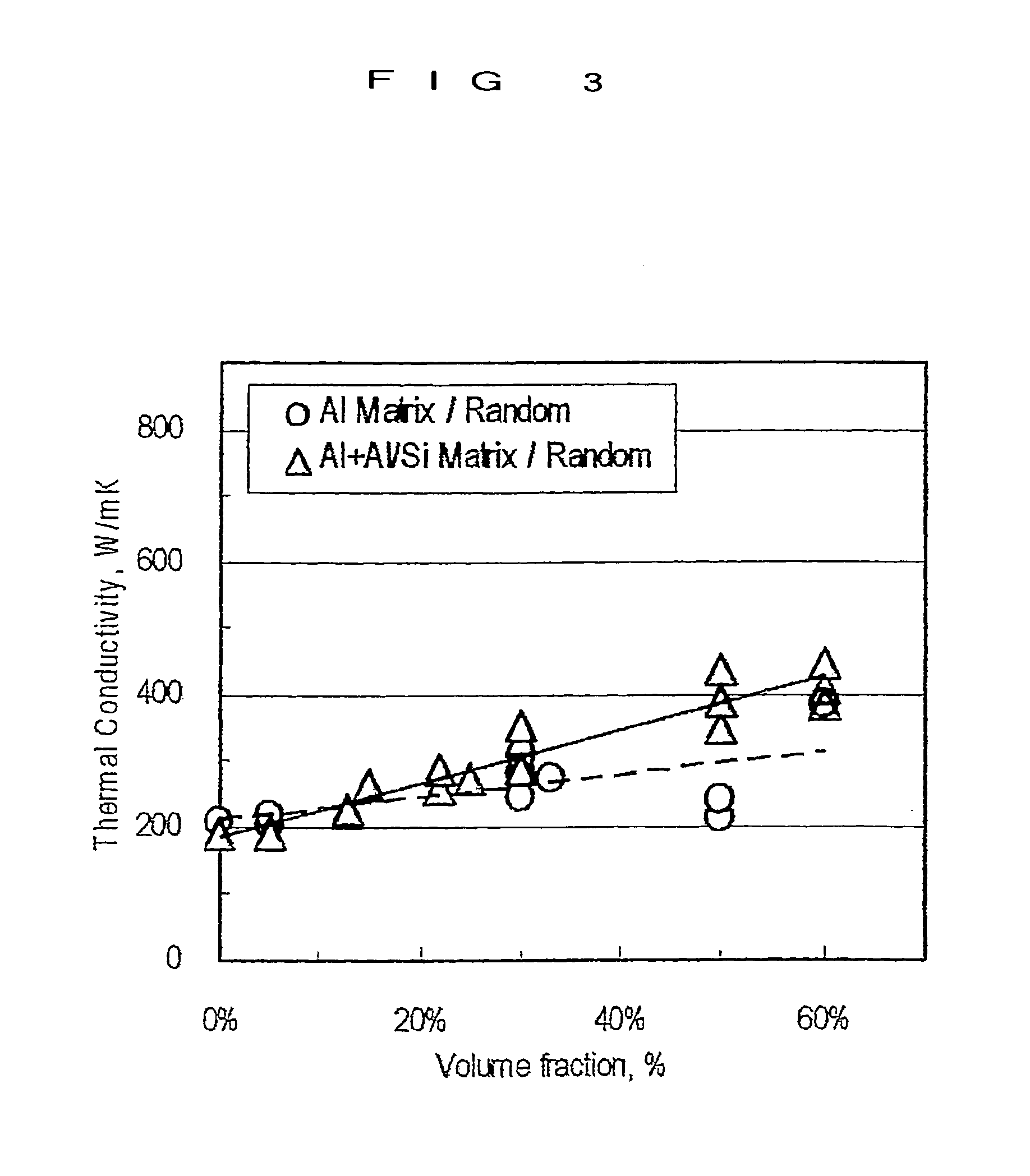

Highly heat-conductive composite material

InactiveUS8163060B2Improve the heating effectIncrease resistanceSingle layer grapheneAluminium powderAlloy

The heat conductivity of an aluminum composite material containing a fibrous carbon material is enhanced. In order to realize this, a spark plasma sintered body having a fibrous carbon material compounded in a metal matrix powder of aluminum or the like is fabricated. At the time of fabrication, an aluminum powder serving as a matrix mother material is compounded with an Al alloy powder such as an Al-12Si powder having a melting point lower than the sintering temperature of the mother material. During the process of sintering the aluminum powder, the Al alloy powder is melted, whereby the heat conductivity between the aluminum powder particles and between the aluminum powder particle and the fibrous carbon material is improved.

Owner:SUMITOMO PRECISION PROD CO LTD +1

Leadless electronic slurry composition for solar silicon photovoltaic cell and preparation method thereof

InactiveCN101345263AHigh electrical conductivityRefined nanocrystalline structureFinal product manufactureSemiconductor devicesAdhesiveSlurry

The invention discloses a compounding and a preparation method for lead-free electronic slurry used for a solar silicon photocell; according to the mass percentage, the slurry is obtained by preparing 70 to 75 percent of aluminium powders, 20 to 25 percent of organic adhesive, 1 to 5 percent of inorganic glass powders and 1 to 5 percent of additives; the aluminium powder is ball-shaped aluminium powder with the surface covered by an aluminium nitride protection layer, with the purity not less than 99.9 percent and the average grain size of 2 to 6 microns; simultaneously, organic adhesives consisting of ethyl cellulose, resin, hexadecanol, diethyleneglycol monomethyl ether, diethyleneglycol monobutyl ether, terpineol and n-butyl alcohol are added into the aluminium powder; the inorganic glass powder is silicon dioxide, boracic acid, alumina, antimony oxide and zirconia; the additive consists of Span and pump oil. The product prepared by the method of the invention has no dust generation or aluminium peeling phenomenon and achieves the requirement of no lead and environmental protection.

Owner:NANTONG UNIVERSITY

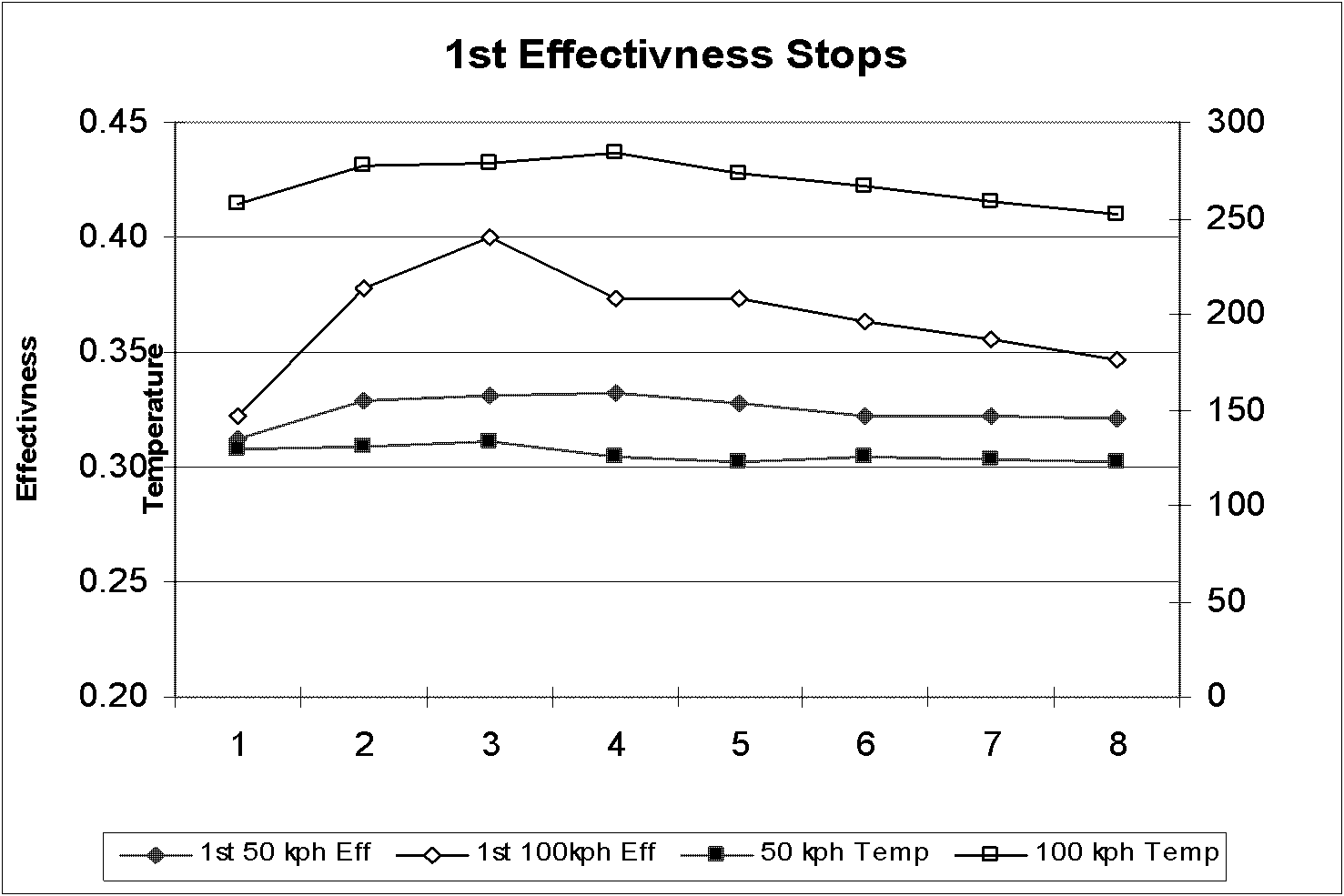

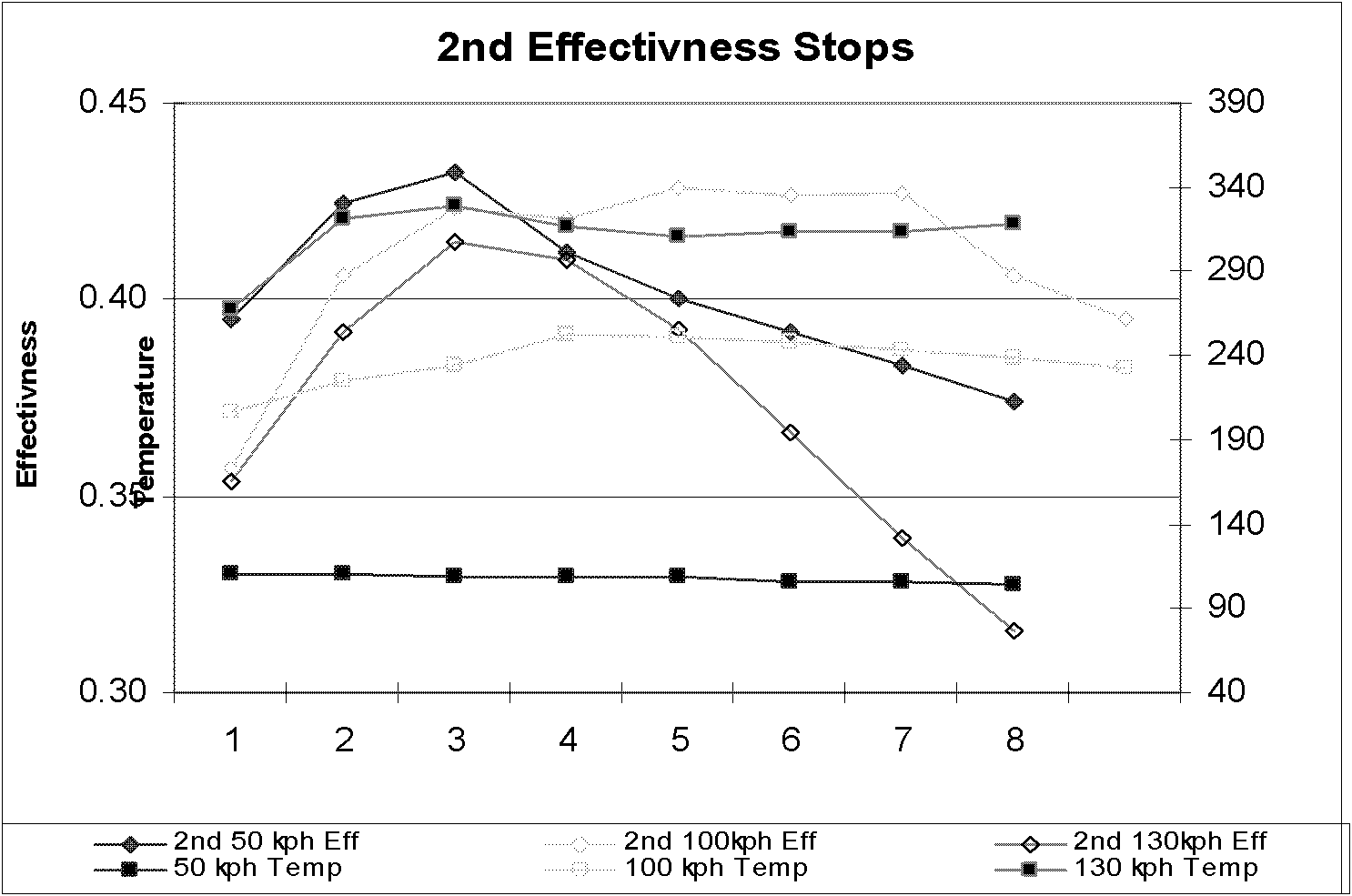

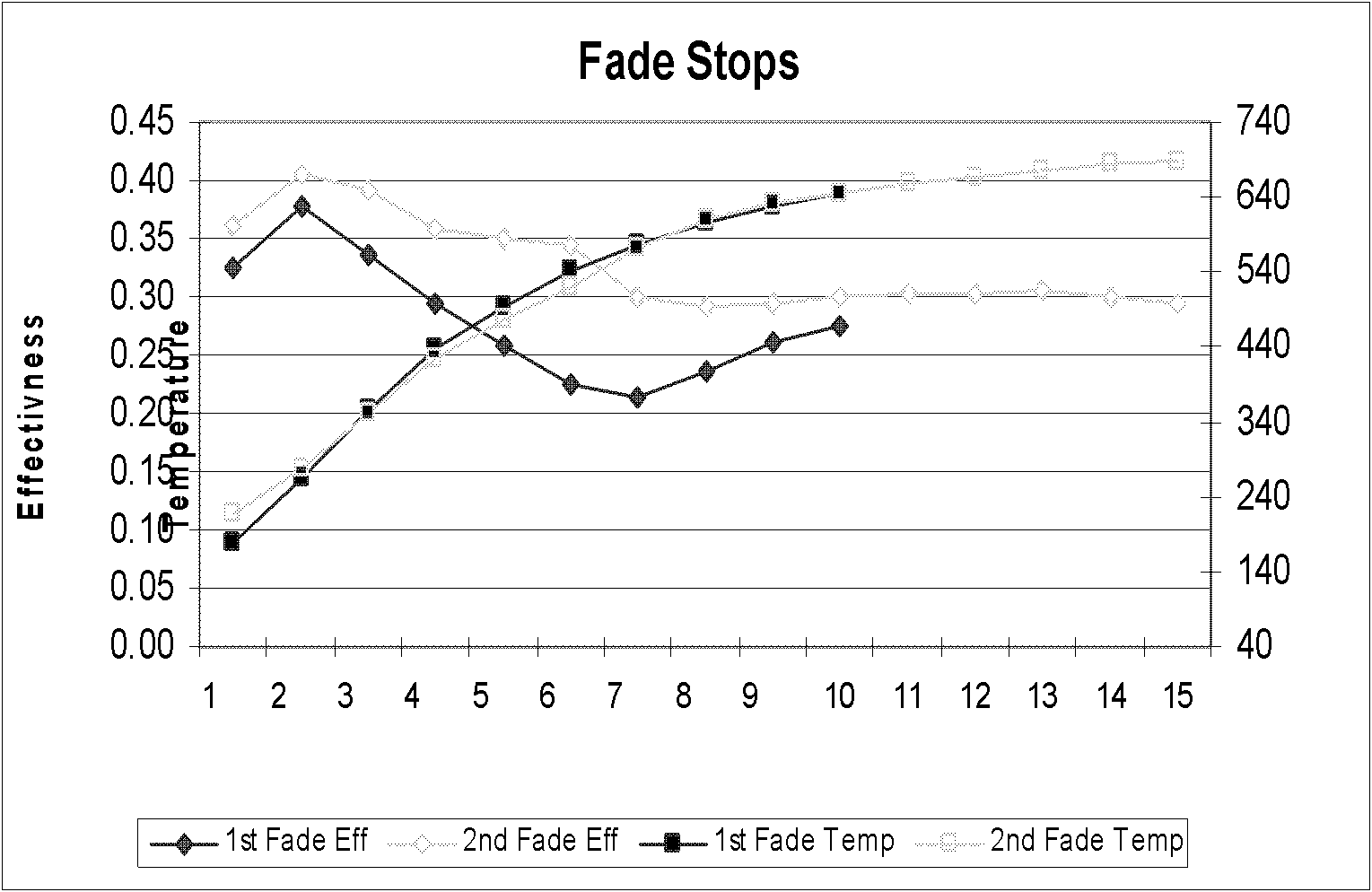

Copper-free ceramic friction material with little falling ash and preparation method thereof

InactiveCN101823856AAvoid secondary pollutionMeet the requirements of environmental protectionBraking membersFriction liningAdhesiveAramid

The invention discloses a copper-free ceramic friction material with little falling ash and a preparation method thereof. The copper-free ceramic friction material with little falling ash is prepared by mixing, shaping and thermally processing the following raw materials in percentage by weight: 5 to 14 percent of adhesive, 20 to 45 percent of reinforcing material, 10 to 40 percent of ceramic material, 10 to 18 percent of lubricant and the balance of filler, wherein nitrile rubber modified phenolic resin and nitrile rubber powder are used as the adhesive; the reinforcing material is one or a mixture of more of aramid fiber, carbon fiber, steel fiber, foam iron powder and aluminum oxide fiber; the ceramic material is one or a combination of more of molybdenum disulfide, magnesium oxide andferrous disulphide; the lubricant is the mixture of graphite and mica; and the filler is the mixture of composite filler, barite, friction powder and aluminum powder. The material has high friction performance, low brake noise and high heat fading resistance, and particularly shows high performance in aspects of wear resistance, long life and great reduction in the falling ash of a wheel hub; therefore, the material can meet both the requirement of a modern automobile braking system on operating conditions and the requirement on economy and environment friendliness when an automobile is used.

Owner:HUNAN BOYUN AUTOMOBILE BRAKE MATERIALS +1

Method for comprehensive harmless recovery and utilization of waste lithium ion power battery

ActiveCN105428745AReduce wasteEasy to keepWaste accumulators reclaimingBattery recyclingPower batteryElectrical battery

The present invention relates to a method for comprehensive harmless recovery and utilization of a waste lithium ion power battery. The method comprises the following steps: disassembling a waste battery pack, and measuring and collecting good battery cells to re-combine the good batteries for gradient utilization; sufficiently discharging defective waste lithium ion power battery cells, and disassembling the power battery cells in an oxygen-isolated environment; performing heat treatment on a fetched core pack in a heating furnace, and collecting a distilled solvent by means of condensation; disassembling the core pack from which the solvent is distilled off to obtain a membrane material, a positive electrode plate and a negative electrode plate; placing the positive electrode plate and the negative electrode plate in a rotary kiln of 200-600 DEG C to be subjected to heat treatment; sorting electrode plates, which have been subjected to the heat treatment, by using a pulverizer and a powder sorter separately, so as to obtain an aluminum powder, a copper powder, a waste positive electrode powder and a waste negative electrode powder; and repairing the positive electrode powder and the negative electrode powder separately. According to the method provided by the present invention, a fully-dry closed-circuit recovery process is adopted, thereby achieving the harmless recovery and utilization of the waste lithium ion power battery.

Owner:北京赛德美资源再利用研究院有限公司

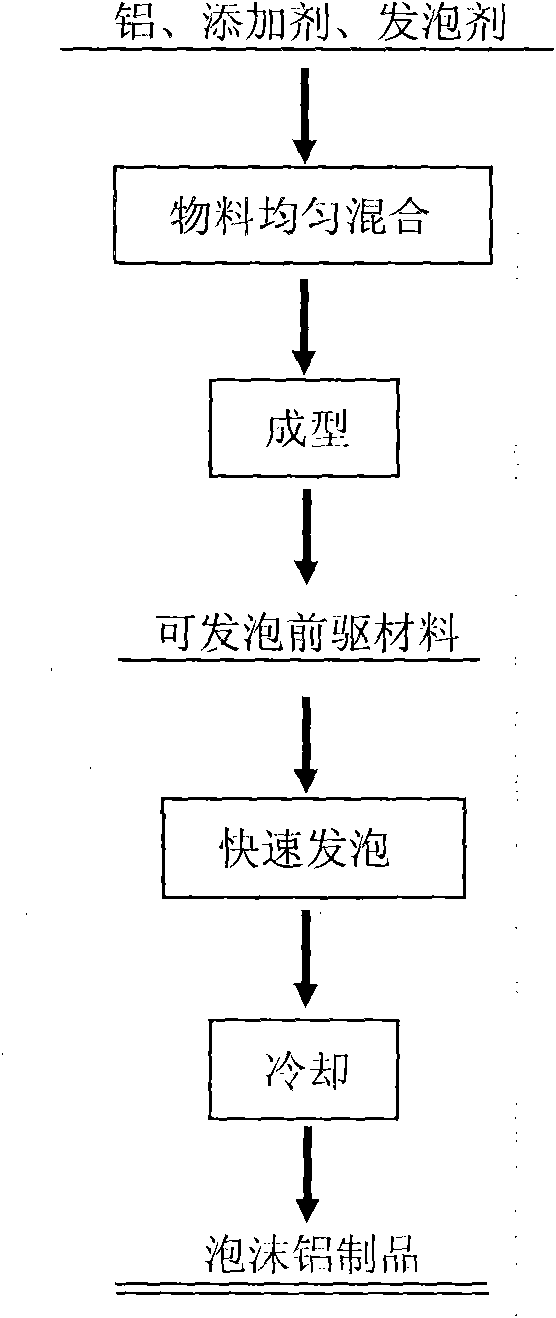

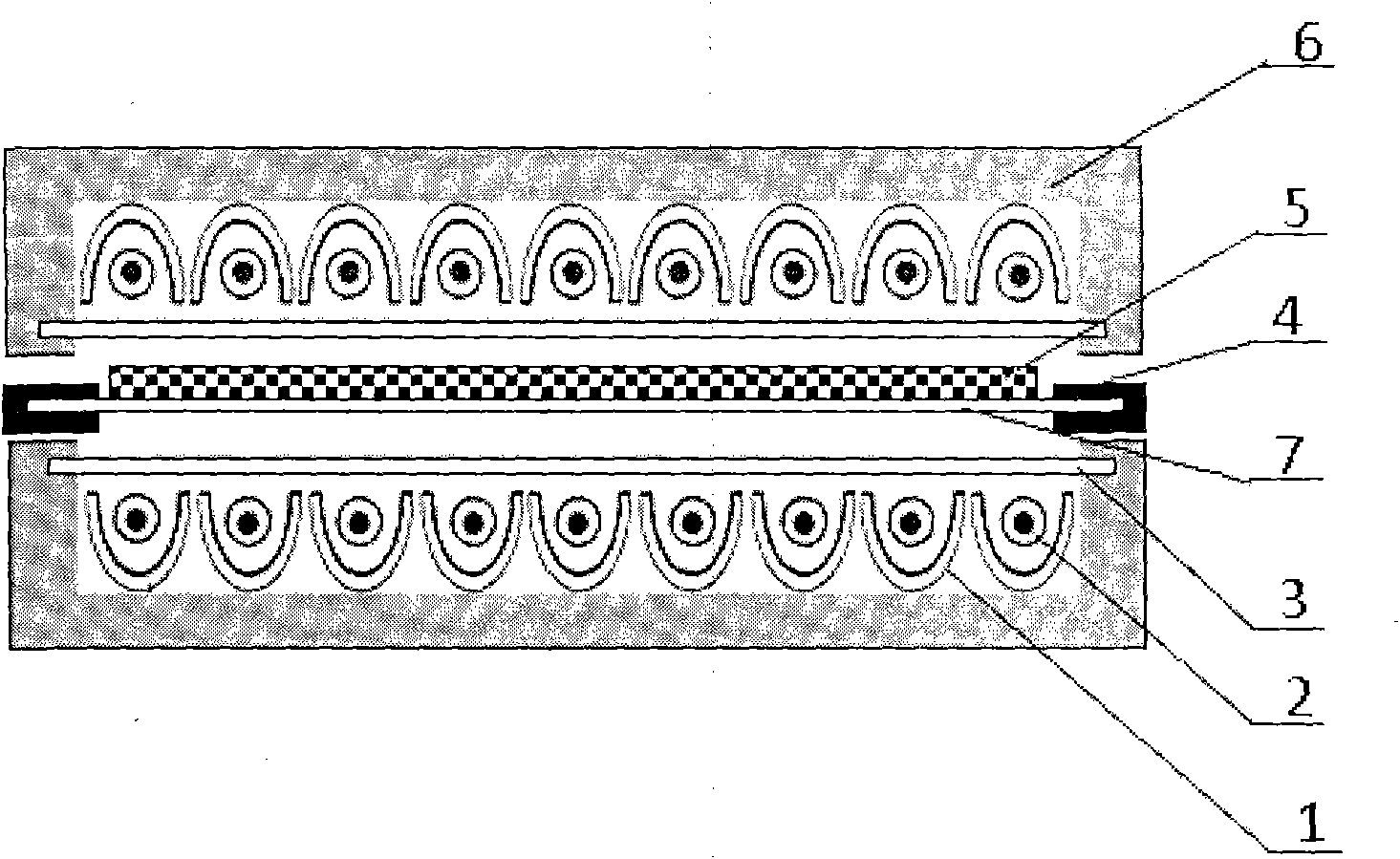

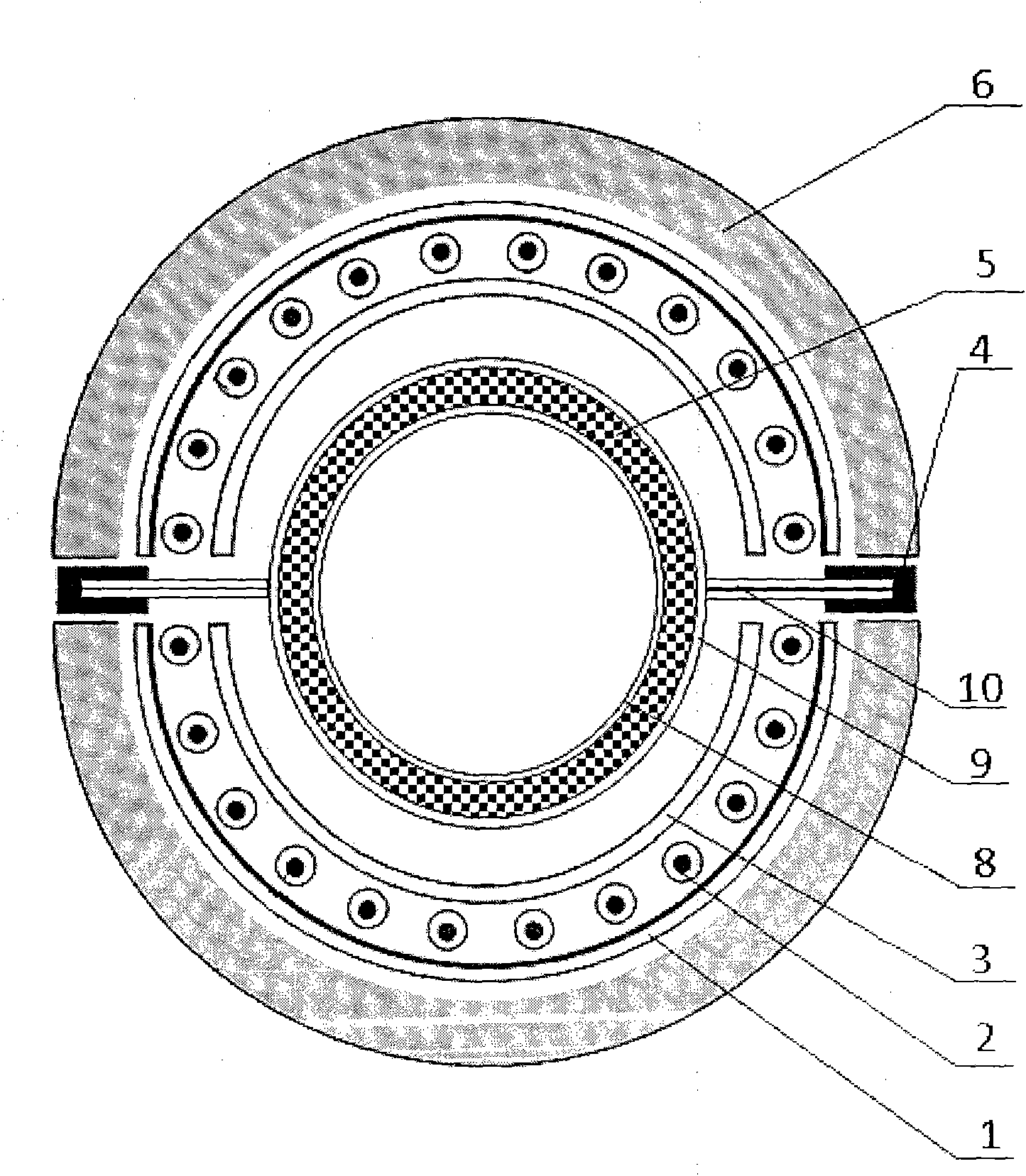

Preparation method and device of metal foam material

The invention discloses a preparation method and a device of a metal foam material. The preparation method comprises the following steps: mixing 93-99 wt% of aluminium matrix, 0.5-5 wt% of additive and 0.5-2 wt% of foaming agent uniformly to form a shaped foamable precursor material, putting the foamable precursor material in a foaming furnace with infrared heating to foam the foamable precursor material fast under infrared radiation, then taking the foam material out from the foaming furnace and cooling, wherein, the aluminium matrix is pure aluminium, aluminium powder or aluminium alloy, the foaming agent is titanium hydride, zirconium hydride, or calcium carbonate, and the additive is calcium, carborundum powder, or alumina powder. The device is a foaming furnace with infrared heating,has the advantages of fast foaming the precursor material, eliminating the hole gradient, easily controlling the foaming and cooling process, making the product have reproducibility and maneuverability, and improving cellular uniformity. According to the invention, metal foam sandwich panels can be prepared directly, and the mechanical properties of the aluminium-based foam material are improved.

Owner:NORTHEASTERN UNIV

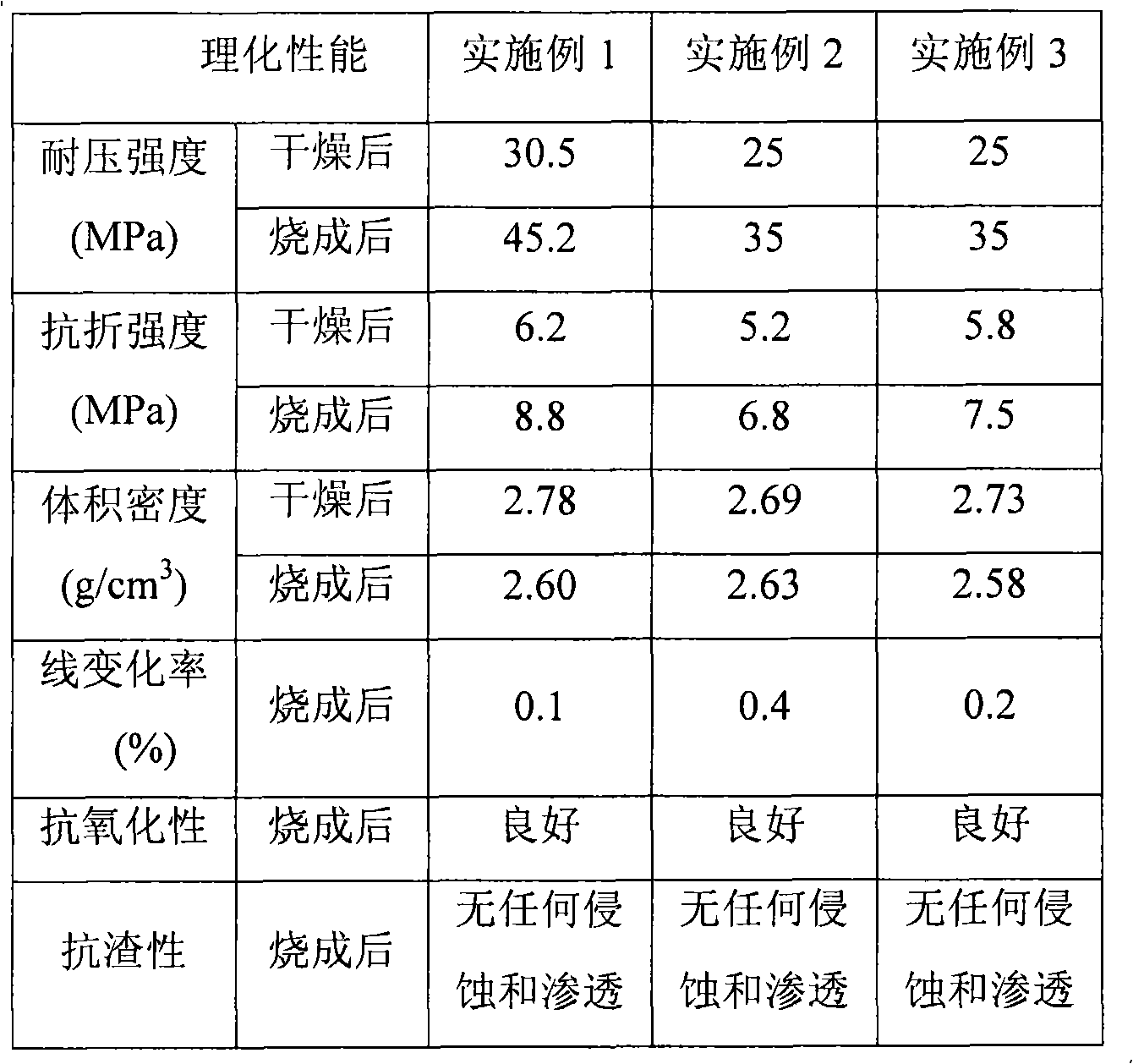

Unsteamed concrete air-filled insulating brick produced from building waste, and production method thereof

InactiveCN102617076AReduce encroachmentReduce pollutionSolid waste managementCeramicwareCelluloseBrick

The invention relates to an unsteamed concrete air-filled insulating brick produced from building waste, and a production method of the insulating brick. The insulating brick is prepared from the raw materials in parts by weight: 30-40 parts of cement, 20-30 parts of aggregate, 8-10 parts of CaO, 3-5 parts of CaSO4, 3-5 parts of carbamide, 3-5 parts of polyvinyl alcohol, 5-10 parts of cellulose hydroxypropyl methyl, 3-5 parts of calcium formate, 5-10 parts of foaming agent and 40-60 parts of external water, wherein cement contains one or more than two of common silicate, high-alumina cement, fly ash cement, alumina cement and aluminate cement; the aggregate is building waste with the particle size being less than or equal to 5mm; and the foaming agent contains one or more than two of aluminium powder, aluminium powder paste, hydrogen peroxide and sodium hydrogen carbonate. The unsteamedconcrete insulating brick is prepared by material preparing, mixing, injection molding and curing. Therefore, the land occupation and the living environmental pollution caused by the building waste can be effectively reduced, and the produced unsteamed concrete air-filled insulating brick has the advantages of good heat insulation effect, light weight, good sound insulation effect and high strength, and can be nailed and sawed; and the construction intensity can be reduced.

Owner:ANSHAN QUANYIJU ENVIRONMENTAL PROTECTION BUILDINGMATERIAL

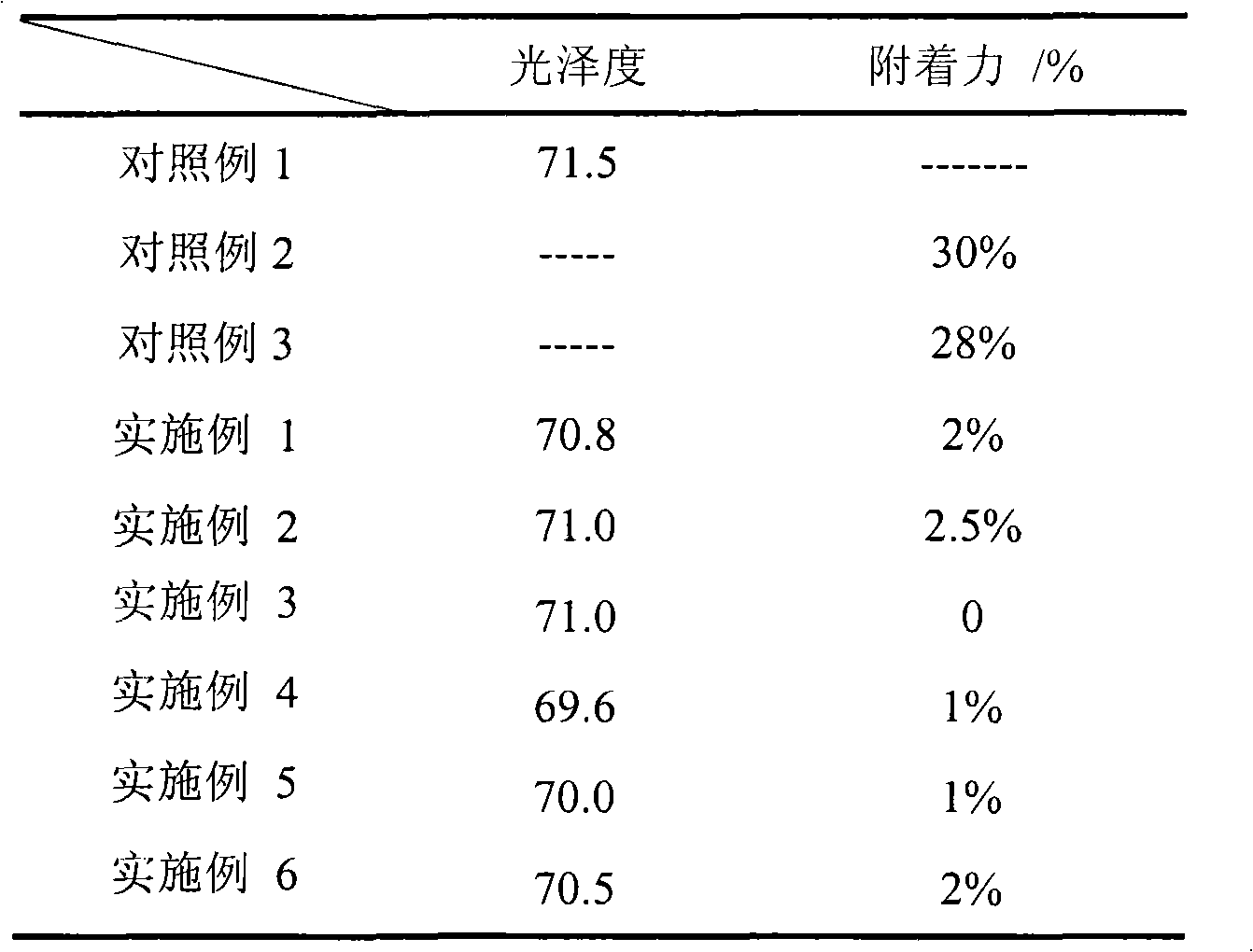

Colored aluminum pigment with high color depth and preparation method thereof

InactiveCN101445675AGood acid and alkali resistanceColorfulInorganic pigment treatmentMetallic aluminumKetone solvents

The invention relates to a colored aluminum pigment with high color depth and a preparation method thereof. The colored aluminum pigment is obtained by depositing a layer of silicon dioxide on a flaky metallic aluminum sheet substrate and then depositing one or more layers of metal oxide on the surface of the silicon dioxide, and the colored aluminum pigment exists in the form of dry powder. The preparation method comprises the following steps: a. stirring to disperse commercially available aluminum pigment slurry in alcohol, alcohol ether or a ketone solvent; b. regulating the temperature to 30-80 DEG C, respectively adding tetraethoxysilane and aqueous solution to the dispersed aluminum pigment slurry with the mol ratio of the tetraethylorthosilicate to the water ranging from 1:0.5 to 1:20, adding a catalyst such as ethylenediamine solution or aqueous ammonia, and obtaining aqueous aluminum pigment slurry by vacuum filtration and washing after the reaction; and c. cladding the aqueous aluminum pigment slurry obtained in the step b with the hydrated metal oxide on the powdered aluminum surface in a liquid phase. The preparation method help prepare the colored aluminum pigment with diversified colors and high color depth without reducing brightness of the original aluminum pigment slurry.

Owner:WENZHOU YOUNGBIO CHEM

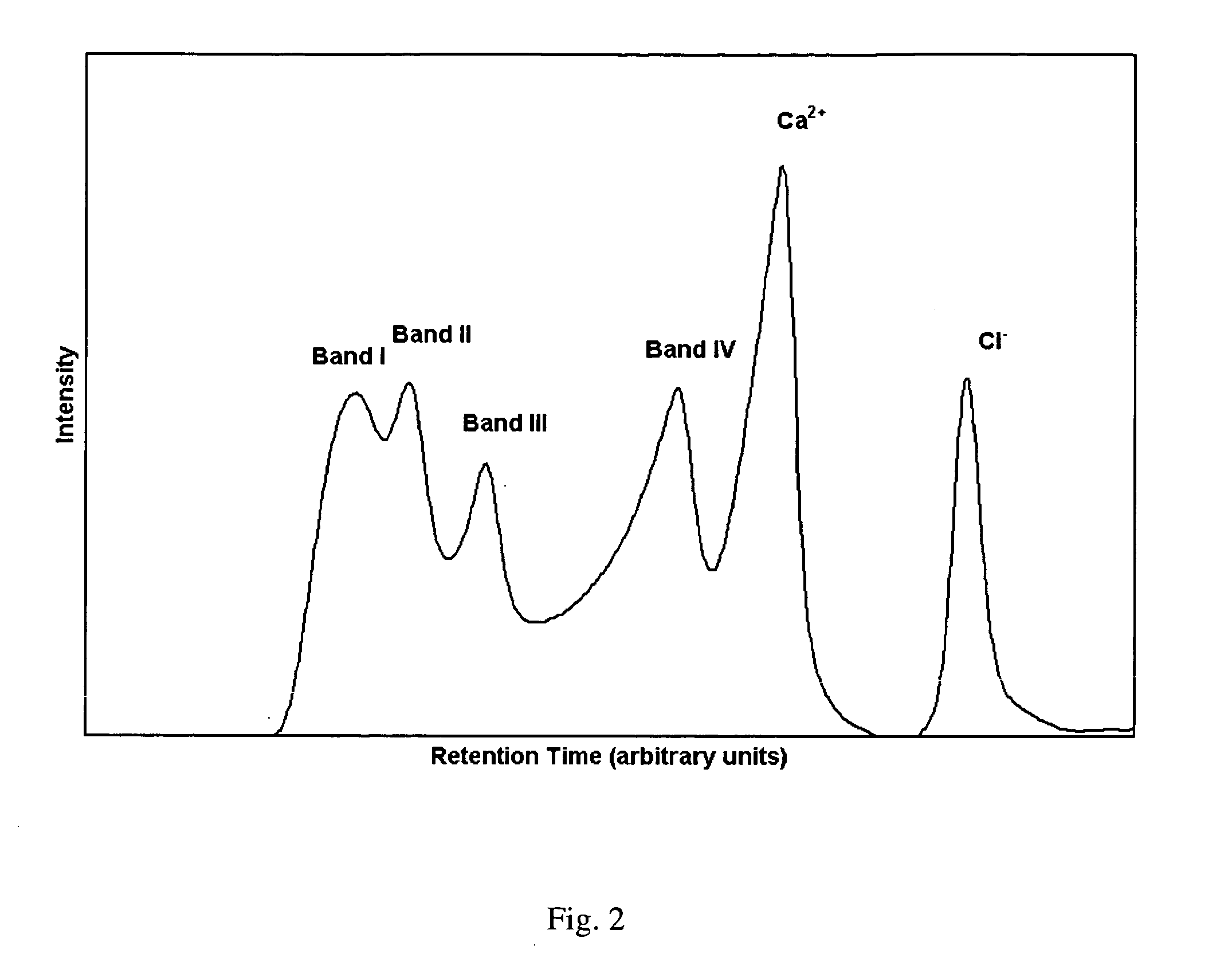

Polyaluminum calcium hydroxychlorides and methods of making the same

InactiveUS20080131354A1Improve efficiencyReduce sludge generationCosmetic preparationsChloride preparationAluminum hydrateHigh pressure

A process is provided for the preparation of a novel polyaluminum calcium hydroxychloride composition of enhanced efficiency for water treatment, paper sizing, and antiperspirant applications. The polyaluminum calcium hydroxychloride compositions are prepared via the acidification of higher basicity reaction products to form mid-to-high basicity final products. Two methods are provided for the preparation of higher basicity products, contemplated in the first, and an aqueous acid solution, such as hydrochloric acid, aluminum chloride, or a mixture thereof, is mixed with a strong alkaline calcium salt such as calcium oxide or calcium carbonate and aluminum powder at temperatures greater than 60° C. In a second method, bauxite, aluminum hydrate, or aluminum metal, and calcium aluminate are mixed with hydrochloric acid and are reacted at high temperatures and / or elevated pressures for a certain period of time whereby, when the reaction is complete, the mixtures are filtered to obtain clear solutions. The final PAC-Ca solutions may be dried to powder to have a wide range of basicities from about 40% to about 80%. At lower basicities, the polyaluminum calcium hydroxychloride sales are used preferably as antiperspirants, while at higher basicities, the solutions are used preferably as water treatment chemicals.

Owner:GENERAL CHEM LLC

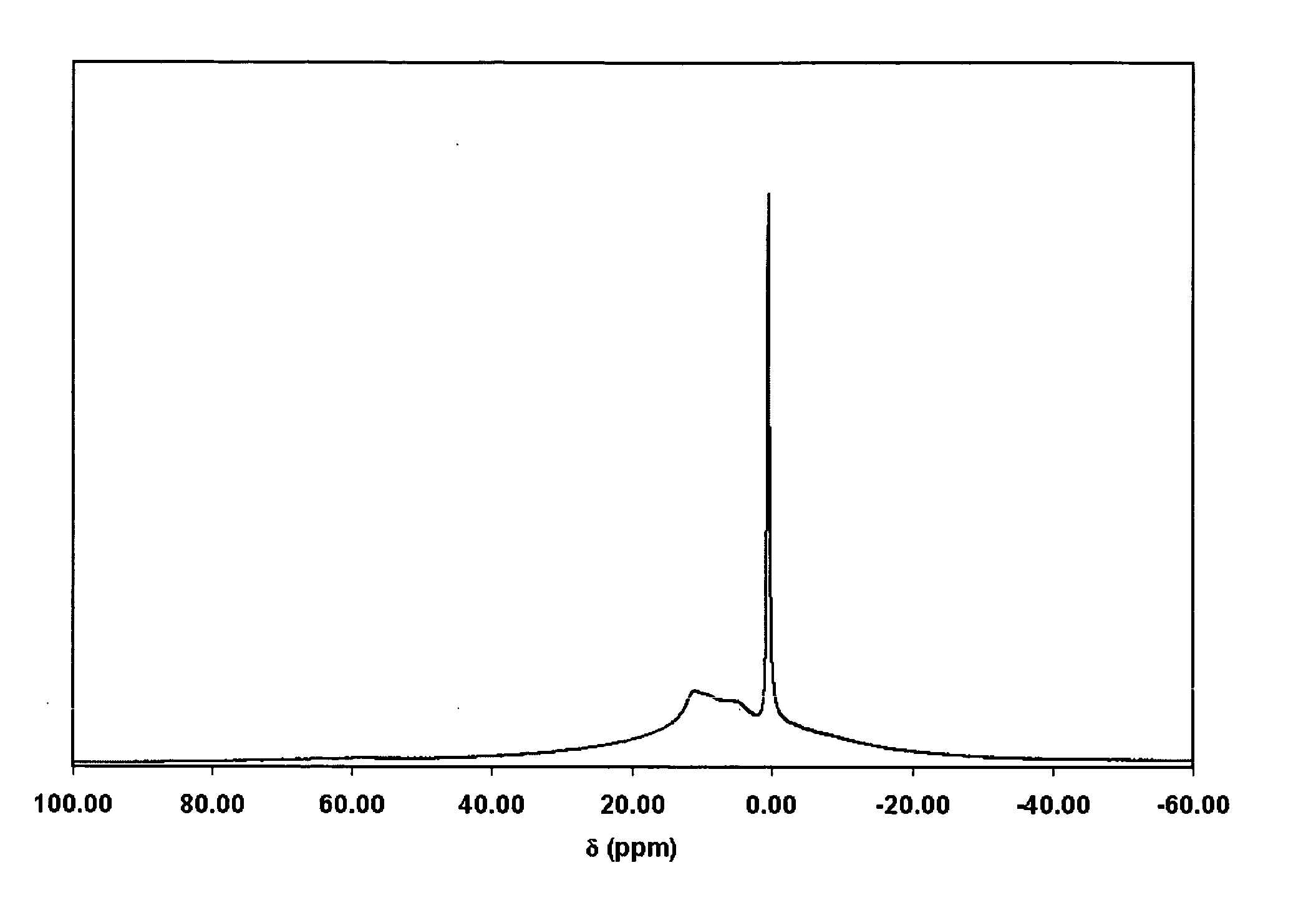

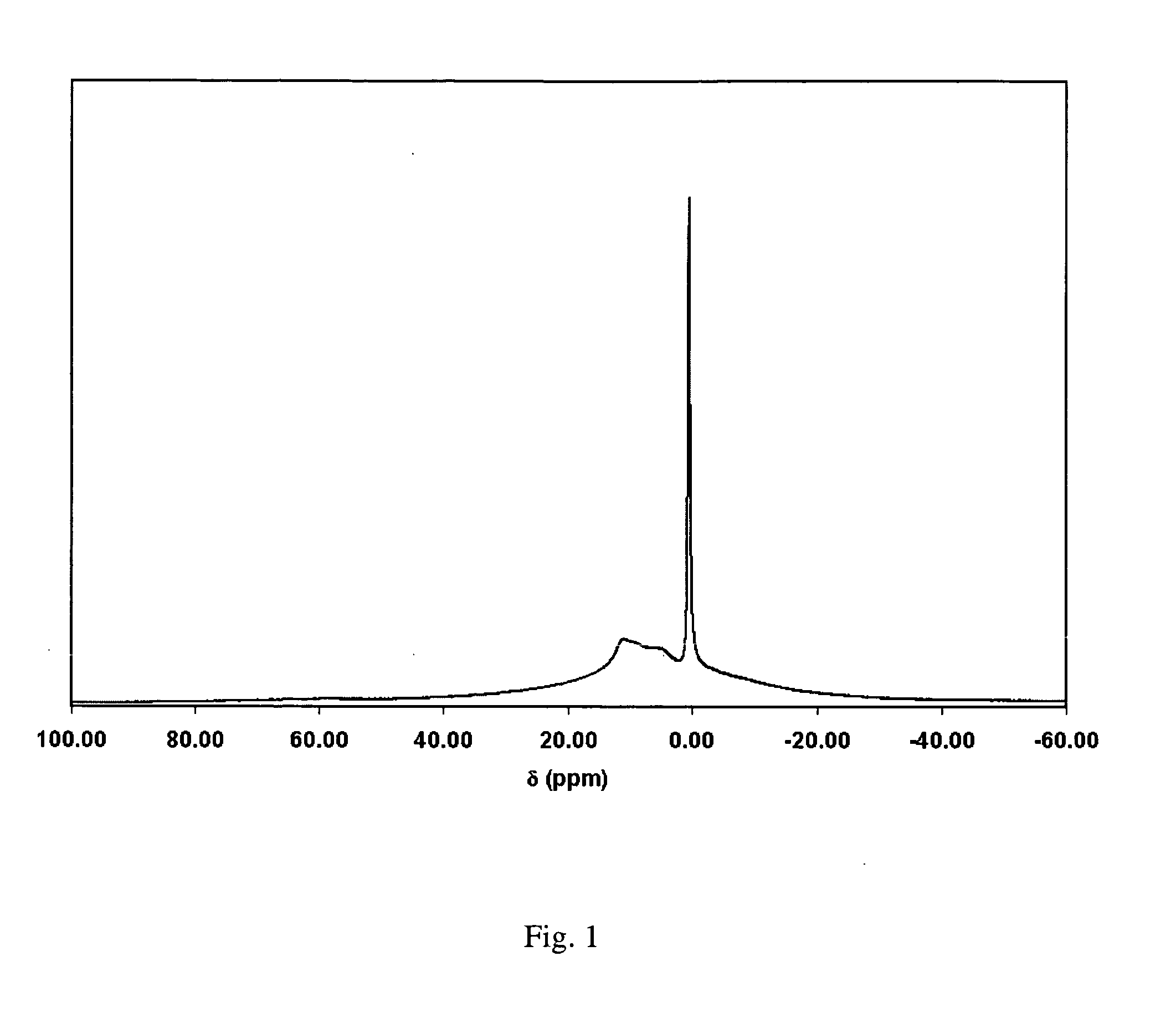

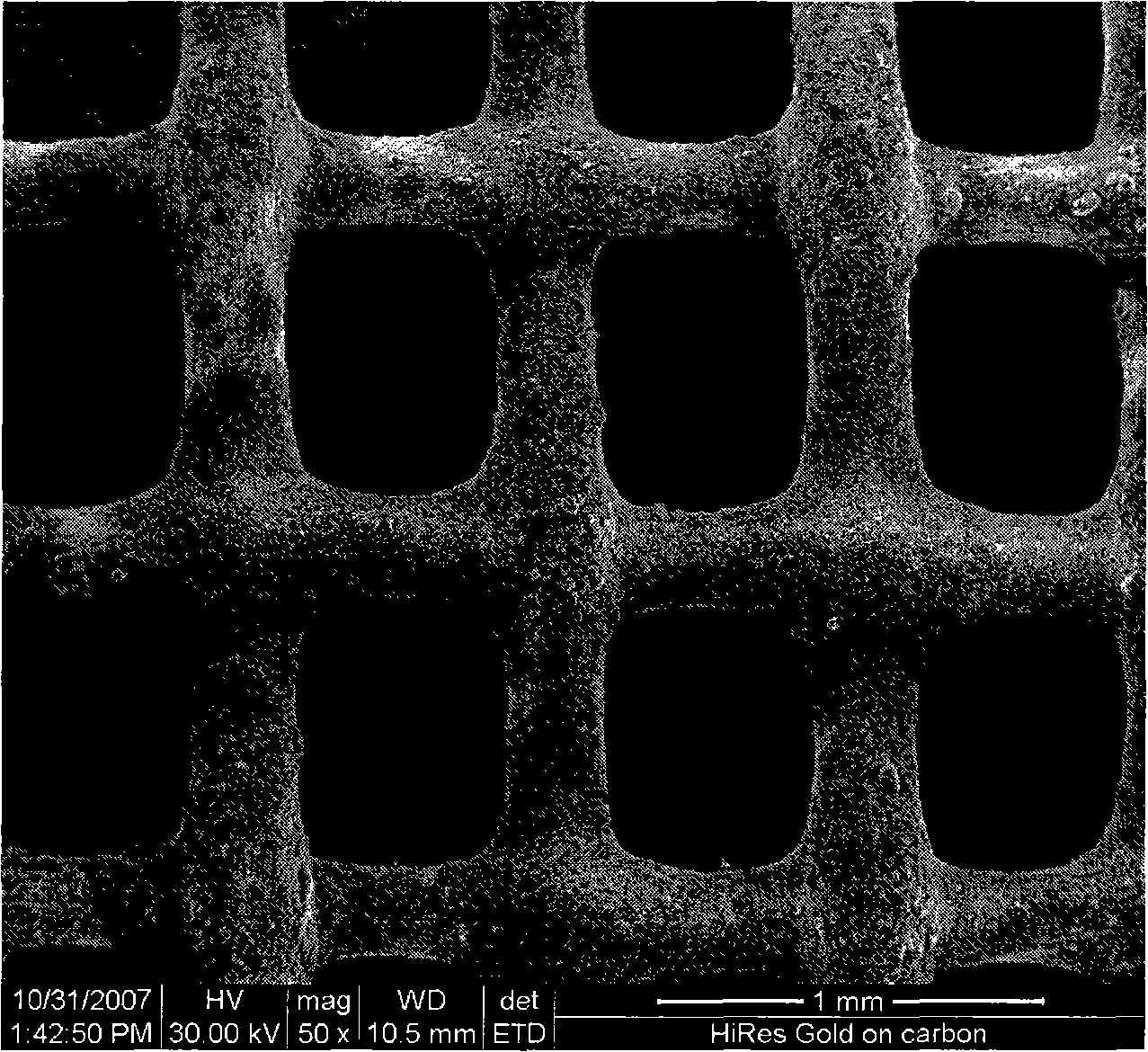

Method for covering aluminum oxide coating on honeycomb shaped wire mesh carrier

InactiveCN101274291AStrong adhesionNo crackCatalyst carriersCatalyst activation/preparationHoneycomb likeThermal shock

The invention discloses a method for coating an alumina coating layer on a faviform metal wire mesh carrier, which belongs to the technical field of the preparation of the coating layers of metal carriers, and is characterized in that after the faviform metal wire mesh carrier is molded, a pretreatment is implemented on the metal surface, and then the faviform metal wire mesh carrier is soaked in a sizing agent that contains Gamma-Al2O3 powder and aluminum powder, the Gamma-Al2O3 powder and the aluminum powder are sedimentated on the surface of the faviform metal wire mesh carrier through the electrolytic deposition method, and finally the faviform metal wire mesh carrier coated with the coating layer is roasted, wherein, the faviform metal wire mesh carrier takes the material of a stainless metal wire mesh that contains aluminum, the coating layer is distributed evenly on the surface of the faviform metal wire mesh carrier and does not chap, the thickness of the coating layer is 30 to 80Mum; the addition of the aluminum powder improves the thermal shock resistance and the mechanical vibration resistance of the coating layer, as well as the conglutination degree between the coating layer and the faviform metal wire mesh. The method for coating the alumina coating layer on the faviform metal wire mesh carrier of the invention has the advantages that the method is applicable to the preparation of the coating layers of the catalyst carriers which are used in the gas-solid catalytic reactions that are related to the environmental protection field such as the fields of the tail gas burning of motor vehicles and fixed sources and catalytic burning.

Owner:DALIAN UNIV OF TECH

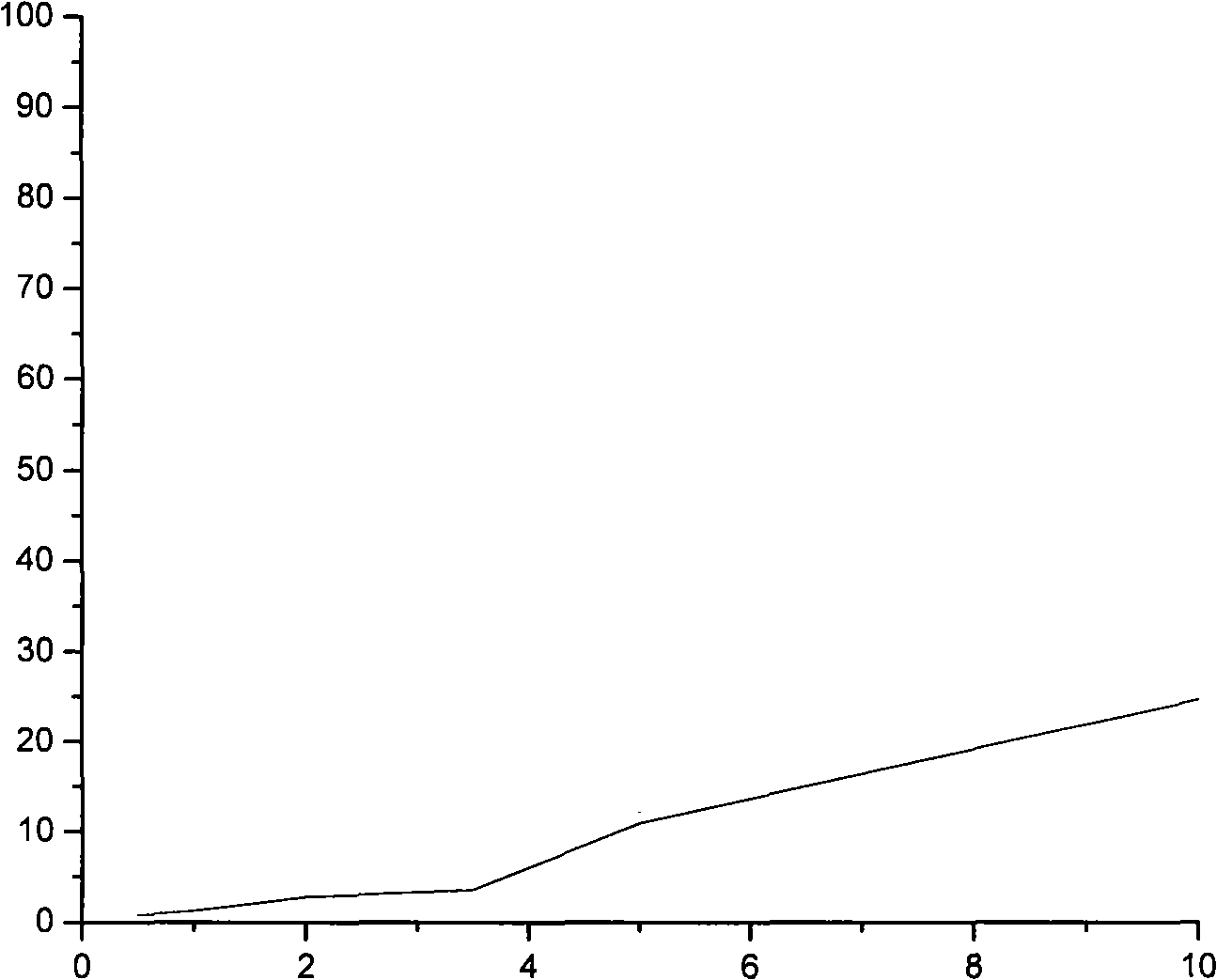

Organic-inorganic hybrid nanometer film coating aluminum powder pigment and preparation method and application thereof

InactiveCN101580653AGood acid and alkali resistance and water resistanceGood metallic lusterCoatingsPigment treatment with organosilicon compoundsDouble bondChemistry

The invention discloses organic-inorganic hybrid nanometer film coating aluminum powder pigment and a preparation method and application thereof. The preparation method comprises the followings steps: by utilizing organic-inorganic hybrid technology and taking aluminum powder pigment as nuclear, firstly performing free radical polymerization on polymerisable carbon-carbon double bond reaction monomers and polymerisable carbon-carbon double bond organosiloxane; and bonding the obtained polymer and ethyl orthosilicate with the surface of the aluminum powder pigment in a hydrolysis mode, and further coating a layer of organic-inorganic hybrid nanometer film on the surface of the aluminum powder. On the basis of maintaining the lustrousness of the aluminum powder, the prepared organic-inorganic hybrid nanometer film coating aluminum powder pigment has excellent compatibility with resin and good acid and alkaline resistance properties, simultaneously well solves the problem of 'powder falling' when the conventional aluminum powder and single-layer or two-layer costing aluminum powder pigment are applied to metallic coatings, and provides a foundation for applying modified aluminum powder pigment and developing high performance metallic coatings.

Owner:SOUTH CHINA UNIV OF TECH

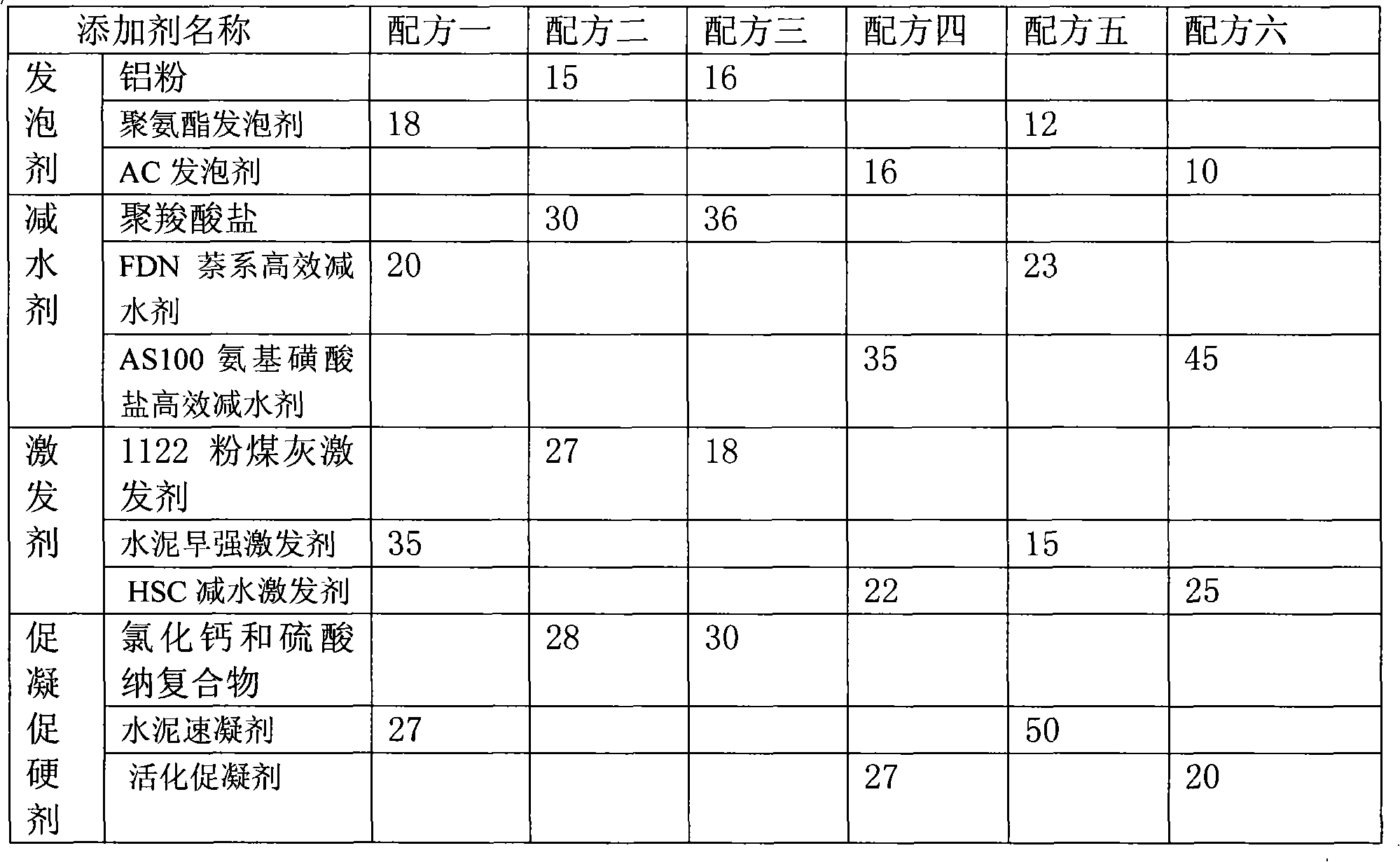

Haydite aerated concrete block and method for manufacturing same

InactiveCN101306934AImprove performanceIntegrity guaranteedSolid waste managementCeramic shaping plantsBrickSlag

The invention discloses a formula of a ceramic aggregate aerated concrete brick and a method for making the concrete brick. The compositions in portion by weight of the concrete brick are: 12 to 26 portions of cement, 26 to 46 portions of fly ash, 16 to 28 portions of ceramic aggregate, 2 to 6 portions of slag, 2 to 6 portions of cinder, 16 to 26 portions of water and 2 portions of addition agent, wherein the concrete matters in percentage by weight of the addition agent are: 10 to 18 percent of aluminum powder (a foaming agent), 20 to 45 percent of polycarboxylate (a water reducing agent), 15 to 35 percent of 1122 fly ash excitant and 20 to 50 percent of coagulant hardening accelerator in which calcium chloride and sodium sulfate compounds respectively occupies 50 percent. The concrete steps for making the ceramic aggregate aerated concrete brick are as follows: raw materials are weighed; the weighed raw materials are placed in a stirring machine to carry out stirring and mixing in advance; an addition agent is added in the stirring machine to carry out full stirring; a brick die is prepared, and stirred raw materials are cast in the brick die; initial set and forming are carried out; stripping is carried out; a water-proofing agent is sprinkled on a stripped brick; and natural curing is carried out. Moreover, the obtained brick has light dead weight, low density, high strength, low water absorption rate and excellent sound insulation performance and heat-shielding performance.

Owner:胡宗芳 +1

Method for producing air entrapping building block by utilizing ardealite

InactiveCN101648403AReduce secondary pollutionLow costSolid waste managementMixing operation control apparatusMass ratioSlag

The invention provides a method for producing an air entrapping building block by utilizing ardealite, comprising the following processing steps: mixing materials according to the following mass ratio: 50-70 percent of ardealite, 10-15 percent of cement, 15-25 percent of yellow phosphorus slag and 5-10 percent of lime, then adding water according to 85-100 percent of the mass of the mixture, adding aluminium powder according to 0.04-0.06 percent of the mass of the mixture and adding an auxiliary agent according to 0.5-0.8 percent of the mass of the mixture, and then mixing to prepare a sizingagent; and finally obtaining the air entrapping building block through foaming, standing and steam curing. The air entrapping building block has the advantages of stable physical properties, light weight, good heat-insulation property, high waste use ratio, simple process, low cost, environmental protection, natural resource saving and the like, and can be used as non-load bearing partitions of urban high-rise buildings and as heat-insulation building blocks of low-temperature warehouses, heat-insulation warehouses and cold storage warehouses of industrial equipment.

Owner:KUNMING UNIV OF SCI & TECH

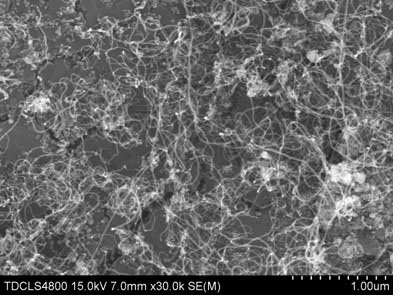

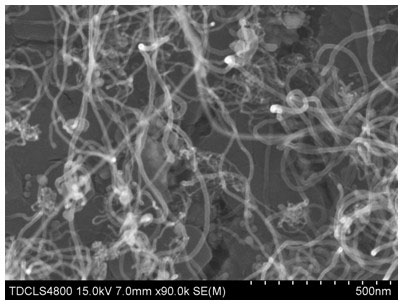

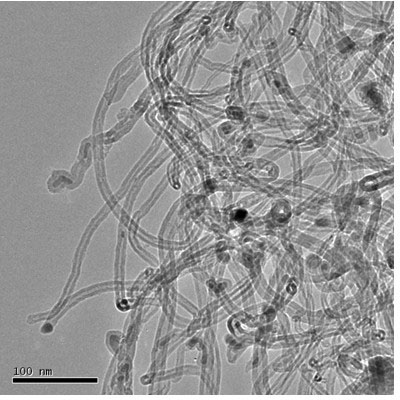

Method for preparing carbon nanotube reinforced aluminum-based composite material

InactiveCN102424919AImprove mechanical propertiesEnhanced interface bindingCarbon nanotubeAluminum substrate

The invention relates to a method for preparing a carbon nanotube reinforced aluminum-based composite material and belongs to a technique for preparing aluminum-based composite materials. The method comprises: preparing composite powder in which carbon nanotubes are uniformly distributed on the surface of aluminum powder by using cobalt as a catalyst and by using a chemical vapor deposition process; allowing the carbon nanotubes to reach deep parts of the aluminum powder substrate by using a ball milling process; densifying the composite powder by a pressing and sintering process or hot pressing process to obtain a blocky material; and obtaining the carbon nanotube reinforced aluminum-based composite material through hot extrusion forming. The method has the advantages that: the aluminum particle bridging function of carbon nanotubes is fully played, and the interface combination between carbon nanotubes and the aluminum substrate is strengthened; and the ball milling time is relatively short, so the damage to the structure of carbon nanotubes in a ball milling process is avoided. The composite material prepared by the method has a much higher mechanical property than that of pure aluminum substrate and thus, has a bright industrial application prospect.

Owner:TIANJIN UNIV

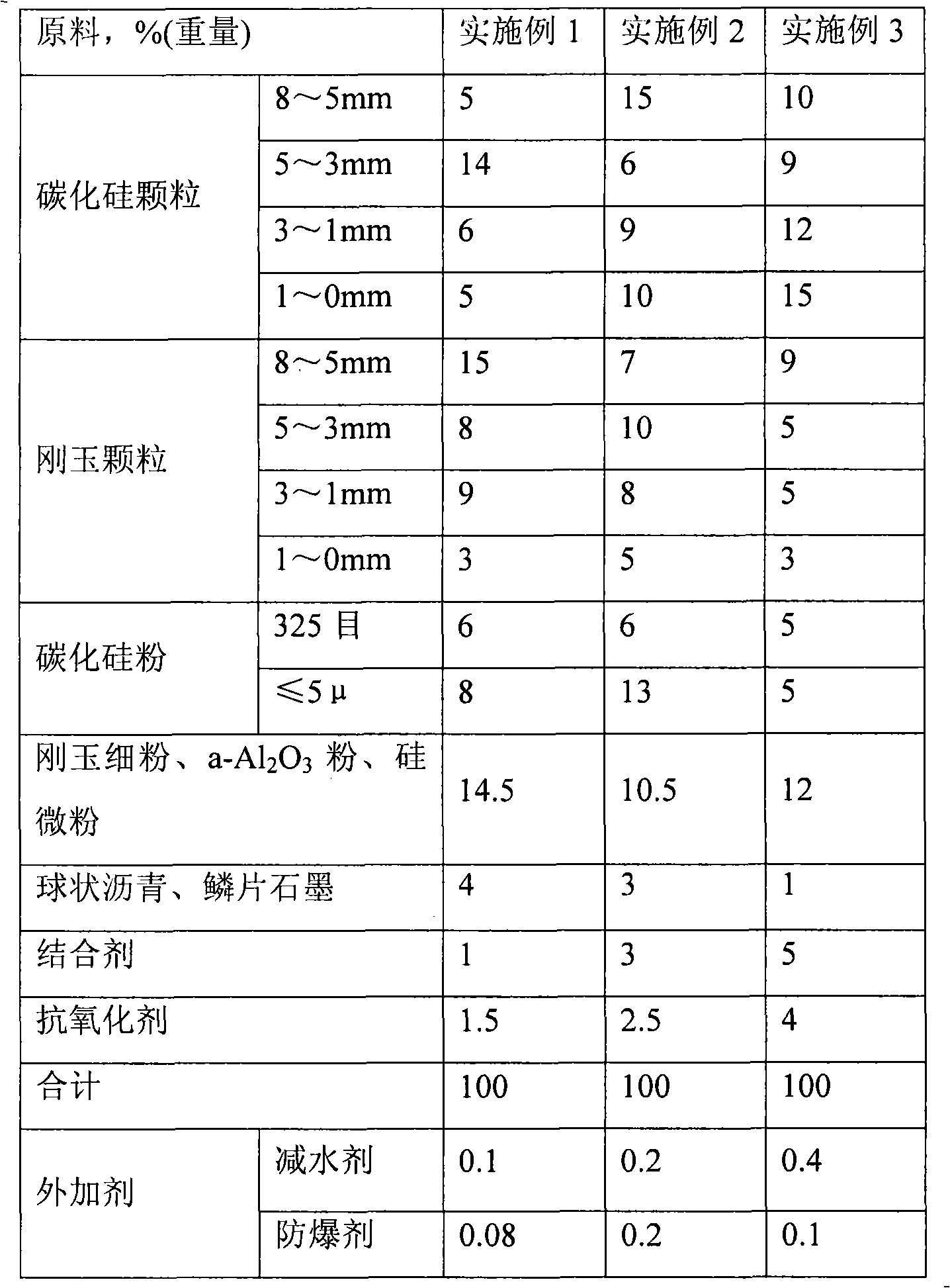

Preparation method of Al2O3-SiC-C castable material for slag line of main trough of blast furnace

The invention relates to an Al2O3-SiC-C castable material for a slag line of a main trough of a large blast furnace and a preparation method thereof. The castable material comprises an aggregate, a matrix, a bonding agent, an antioxidant and an admixture; wherein, the aggregate comprises corundum grains and carborundum grains; the matrix comprises ball pitch, flake graphite, corundum fine powder, a-Al2O3 ultrafine powder, silicon powder and carborundum ultrafine powder; the bonding agent is aluminate cement; the antioxidant is a compound of aluminium powder and silicon powder; the admixture comprises a water reducing agent and a detonation suppressor. The castable material is prepared by the steps of mixing various raw materials evenly, adding water, stirring, casting molding, maintaining and drying. The castable material has strong anti-slag corrosion and anti-scour capabilities, good high temperature resistance, abrasion resistance and thermal shock resistance, slight reheating change and long service life.

Owner:BEIJING TONGDA REFRACTORY TECH CO LTD

Lead-free aluminum paste for solar battery

InactiveCN101789456AMeet environmental protection requirementsStrong adhesionFinal product manufactureNon-conductive material with dispersed conductive materialAluminium powderSolar battery

The invention provides a lead-free aluminum paste for a solar battery, which is mainly used for producing a conductive electrode for a solar battery. The lead-free aluminum paste mainly comprises the following components by weight percent: 70 to 80 percent of aluminum powder, 19 to 30 percent of organic bond, 0.1 to 5 percent of inorganic glass powder and 0.1 to 2 percent of a first additive. The organic bond comprises the following components by weight percent: 40 to 60 percent of terpineol, 1 to 5 percent of ethylcellulose, 1 to 5 percent of lecithin and 20 to 50 percent of a second additive. The lead-free aluminum paste for the solar battery mainly solves the technical problems that the existing aluminum paste for the solar battery has poor electrical conductivity and low photoelectric conversion efficiency. The lead-free aluminum paste has the advantages of good electric conductivity, high photoelectric conversion efficiency and the like.

Owner:西安宏星电子浆料科技股份有限公司

Modified nano mineral powder-containing aerated brick

The invention discloses a modified nano mineral powder-containing aerated brick. The aerated brick is prepared from the following raw materials by the conventional process for preparing the aerated brick: 25 to 30 weight parts of carbide slag, 5 to 10 weight pars of cement, 10 to 15 weight parts of quick lime, 5 to 10 weight parts of modified nano mineral powder, 5 to 10 weight parts of shell powder, 3 to 5 weight parts of gypsum, 0.05 to 0.1 weight part of aluminum powder, 0.002 to 0.008 weight part of lauryl sodium sulfate, 0.03 to 0.08 weight part of tea seed cake powder, 0.3 to 0.5 weight part of soda ash, 0.5 to 0.8 weight part of expanded vermiculite powder, 0.3 to 0.5 weight part of zinc stearate, 0.01 to 0.03 weight part of aluminum hydroxide, 0.05 to 0.1 weight part of sodium diacetate and an appropriate amount of water. By adding the nano mineral powder, the volume weight of the brick, and the energy consumption are reduced; the brick is high in thermal insulation performance and sound insulation performance; compared with the conventional aerated brick, the aerated brick has the advantages that the thermal insulation performance and the sound insulation performance are improved obviously; the raw materials are mixed according to an optimized formula; and the intensity and the freezing resistance of the brick are improved obviously.

Owner:广东合盛建筑工程有限公司

Acetylene sludge aerated concrete block and preparation method thereof

ActiveCN102875070ALow bulk densityGood heat insulationSolid waste managementCeramicwareSODIUM METAPHOSPHATEParaffin wax

The invention provides an acetylene sludge aerated concrete block, which is prepared by processing the following raw materials in part by weight: 20-30 parts of acetylene sludge, 25-30 parts of coal ash, 5-10 parts of cement, 4-6 parts of modified attapulgite, 5-10 parts of water treatment sludge, 5-10 parts of soda residue, 5-10 parts of light calcium powder, 10-15 parts of lime, triethanolamine, 4-5 parts of gypse, 0.02-0.08 part of aluminium powder, oxidized paraffin wax soap, 0.01-0.02 part of calcium bicarbonate, 2-3 parts of chelky slag, 1-2 parts of lignocellulose, 0.3-0.5 part of water glass, 0.03-0.05 part of borax, 1-2 parts of sodium hexametaphosphate, 1-2 parts of hydroxy propyl methyl cellulose sodium and 1-2 parts of superfine polyvinyl alcohol, wherein the weight of the triethanolamine is 0.1-0.3 percent of that of the lime, and the weight of the oxidized paraffin wax soap is 3-5 percent of that of the aluminium powder. According to the invention, the acetylene sludge is added into the raw materials of the aerated concrete block, and meanwhile other conventional additives and modified nano additives are added; the aerated concrete block is prepared by adopting a proper technology and is low in cost and good in performance; the circulating economy effect of changing waste into valuable is realized; the pollution is reduced; and the prepared aerated concrete block has the characteristics of light volume weight, high thermal insulation performance, good sound absorption effect and high strength and can be used for non-bearing or bearing wall bodies.

Owner:广东合盛建筑工程有限公司

Autoclaved aerated concrete building block and manufacturing method thereof

InactiveCN101172819AHigh strengthSolid waste managementCeramicwareAluminium powderUltimate tensile strength

The invention relates to an autoclaved aerated concrete block and the manufacturing method thereof. According to the weight share, the autoclaved aerated concrete block contains the main raw materials as follows: 65 to 70 parts of fly ash, 18 to 22 parts of lime, 6 to 9 parts of cement, 2.5 to 3.5 parts of gypsum, 7 to 805 parts of aluminium powder and 64 to 70 parts of water, wherein, the fly ash is dry powder fly ash. The manufacturing method of the autoclaved aerated concrete block includes the following steps: putting the materials for mixing, teeming, stopping to conserve, cutting and then autoclaving, then the finished product is obtained, wherein, autoclaving is processed in an autoclave, and the autoclaving is divided into the steps of vacuumizing, pressurizing, stabilizing the pressure and releasing the pressure. The autoclaved aerated concrete block adopting the manufacturing method above has high strength and can completely replace the solid clay brick to be used in the places which have high strength requirements for walling material, such as external wall bearing wall, etc.

Owner:SUZHOU JINTONG NEW TYPE BUILDING MATERIAL

Lead-free Al-back-surface-field (BSF) paste for crystalline silicon solar battery and preparation method thereof

ActiveCN101582462AReduce warpageGood dispersionFinal product manufactureMetal/alloy conductorsScreen printingOhmic contact

The invention provides a lead-free Al-back-surface-field (BSF) paste for a crystalline silicon solar battery and a preparation method thereof. The paste is made of 72-82 parts of aluminium powder, 0.1-2 parts of zirconia powder, 0.1-5 parts of inorganic bonding agent, 15-25 parts of organic bonding agent and 1-3 parts of auxiliary agent. After being processed by screen painting and sintering, the paste forms Al-BSF on a silicon chip, the BSF and the silicon chip form good ohmic contact and have good adhesive attraction; an aluminum film does not fall off, the battery has high transfer efficiency, and a battery piece has low warpage.

Owner:GUANGZHOU RUXING TECH DEV +1

Fire-extinguishing aerosol without toxicity and corrosion for electric appliance

InactiveCN1386554AAvoid corrosionWon't happenFire extinguisherHazardous substancePotassium ferrocyanide

A fire-extinguishing aerosol not generating harmful substance for electric equipment (computer, communication equipment, electric generator, etc) is prepared from oxidant (strontium nitrate or strontium nitrate / potassium nitrate), reducer (guanidine nitrate or dicyandiamide) and modifier (potassium ferrocyanide, aluminium powder, carbon powder and phenolic resin). After it is ignited by sensor, alot of fire-extinguishing particles are generated to cover on the object to be protected while the inert gas is generated for extinguishing fire.

Owner:SHAANXI J&R FIRE FIGHTING CO LTD

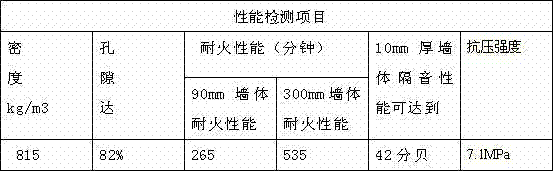

Flux-free aluminium alloy additive agent and preparation method

The invention belongs to the field of nonferrous metal aluminum alloy processing and relates to a flux-free aluminum alloy additive and a preparation method thereof. The additive is formed by pressing metal powder and aluminum powder, and the compositions in weight percentage of the additive are 70 to 95 percent of the metal powder and 5 to 30 percent of the aluminum powder, wherein the metal powder in the additive is one type or a plurality of types among iron, manganese, copper, titanium, chromium and nickel. The performance of the metal powder and the aluminum powder meets the demands that: firstly, the purity of the metal powder is not less than 98 percent, and the average mean diameter of the powder is between 0.01 and 0.5 millimeter; and secondly, the purity of the aluminum powder is not less than 95 percent, and the average mean diameter of the powder is between 0.01 and 0.5 millimeter. The preparation method is to uniformly mix the metal powder and the aluminum powder, to press the mixture into blocks by a press machine, and to perform hermetical package. The preparation method has the advantages of simple addition means, quick melting under the condition of normal aluminum alloy casting temperature, high extraction yield, stable content, easy control, no flux contained, incapability of exhausting fluorine-containing pollutant, and improvement of the purity of fused masses.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com