Haydite aerated concrete block and method for manufacturing same

A technology of aerated concrete and ceramsite, which is applied in the field of building wall materials, can solve the problems of insufficient heat insulation, sound insulation, moisture resistance, etc., can not be used as external wall wall materials, waste land resources, etc. The effect of mixing time, shortening the time of initial setting and forming, and reducing the water absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0032] Each formulation is an example.

[0033] Each embodiment makes block by following formula

[0034] Table II:

[0035] Raw material name

recipe one

recipe two

Recipe three

Recipe four

Recipe five

Recipe six

27

30

28

25

22

25

fly ash

38

35

40

36

38

35

Ceramsite

20

25

20

24

25

25

8

4

5

6

7

5

5

4

5

7

6

8

Additives

2

2

2

2

2

2

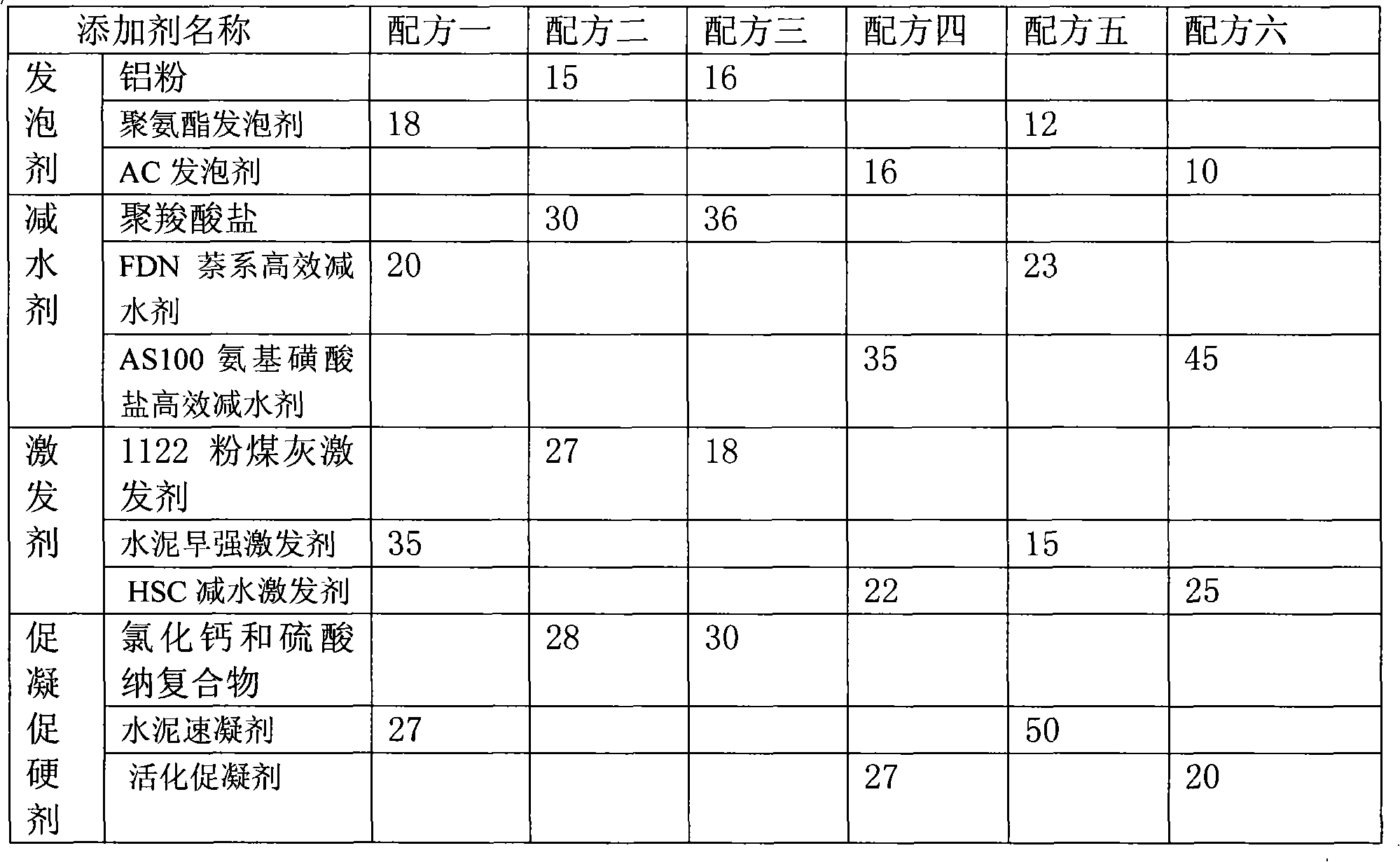

[0036] Additives in Table 2 mainly refer to the following substances: foaming agent, water reducer, activator, coagulation and hardening accelerator.

[0037] Each formula in following table three corresponds to each formula in above-mentioned table two, with 2 parts of additives in the formula of table two being 100%, the percentage by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com