Patents

Literature

535 results about "Clay brick" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Clay brick is a very popular building material used in the construction of residential, commercial, and industrial structures. Although refinements have been made in the brick manufacturing process, it remains largely unchanged from the manufacture of the earliest bricks, estimated to be around 10,000 years ago in the Middle East.

Method and a system for handling processed wet clay bricks

InactiveUS20130181370A1Control movementDischarging arrangementAuxillary shaping apparatusEngineeringClay brick

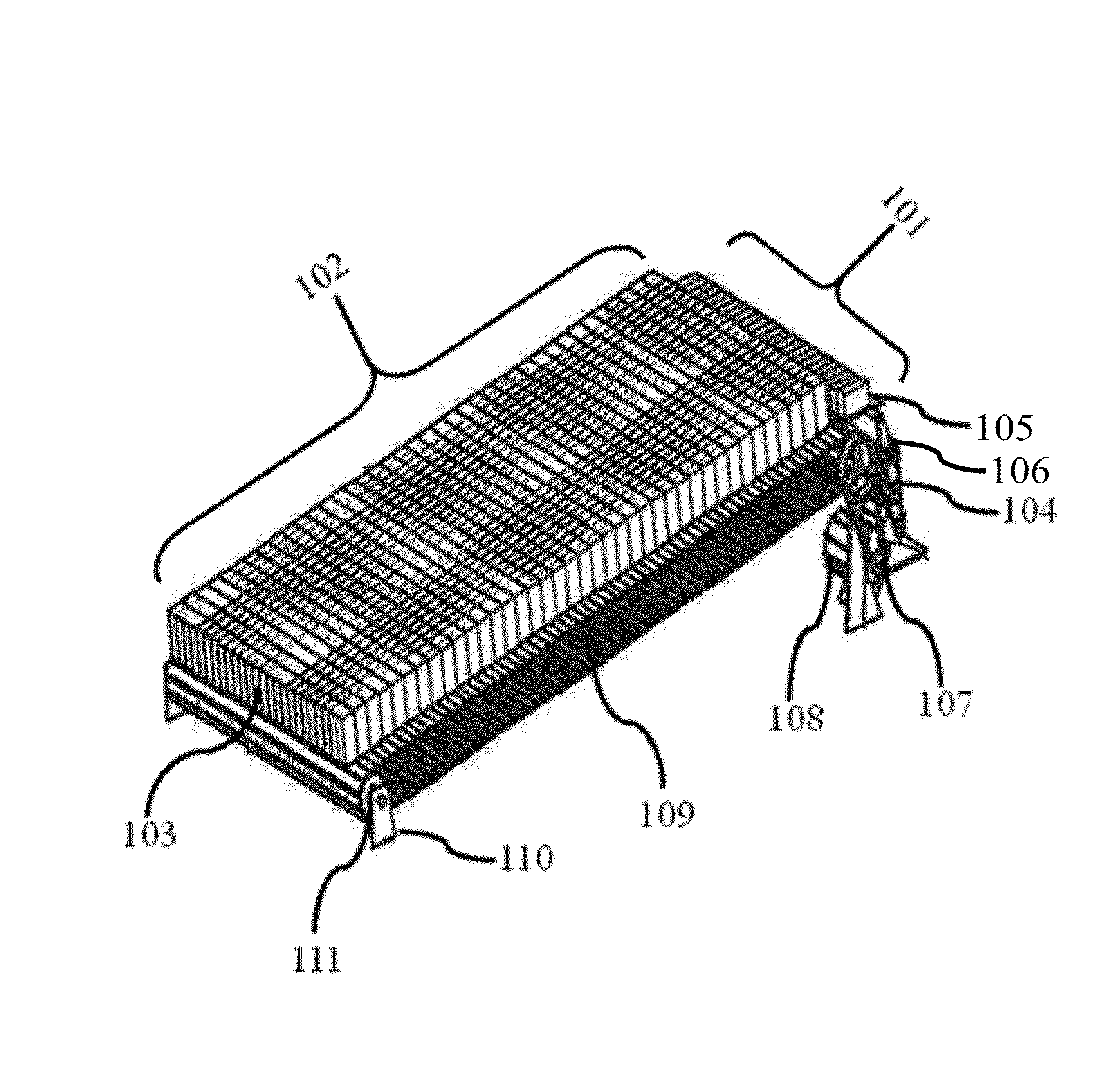

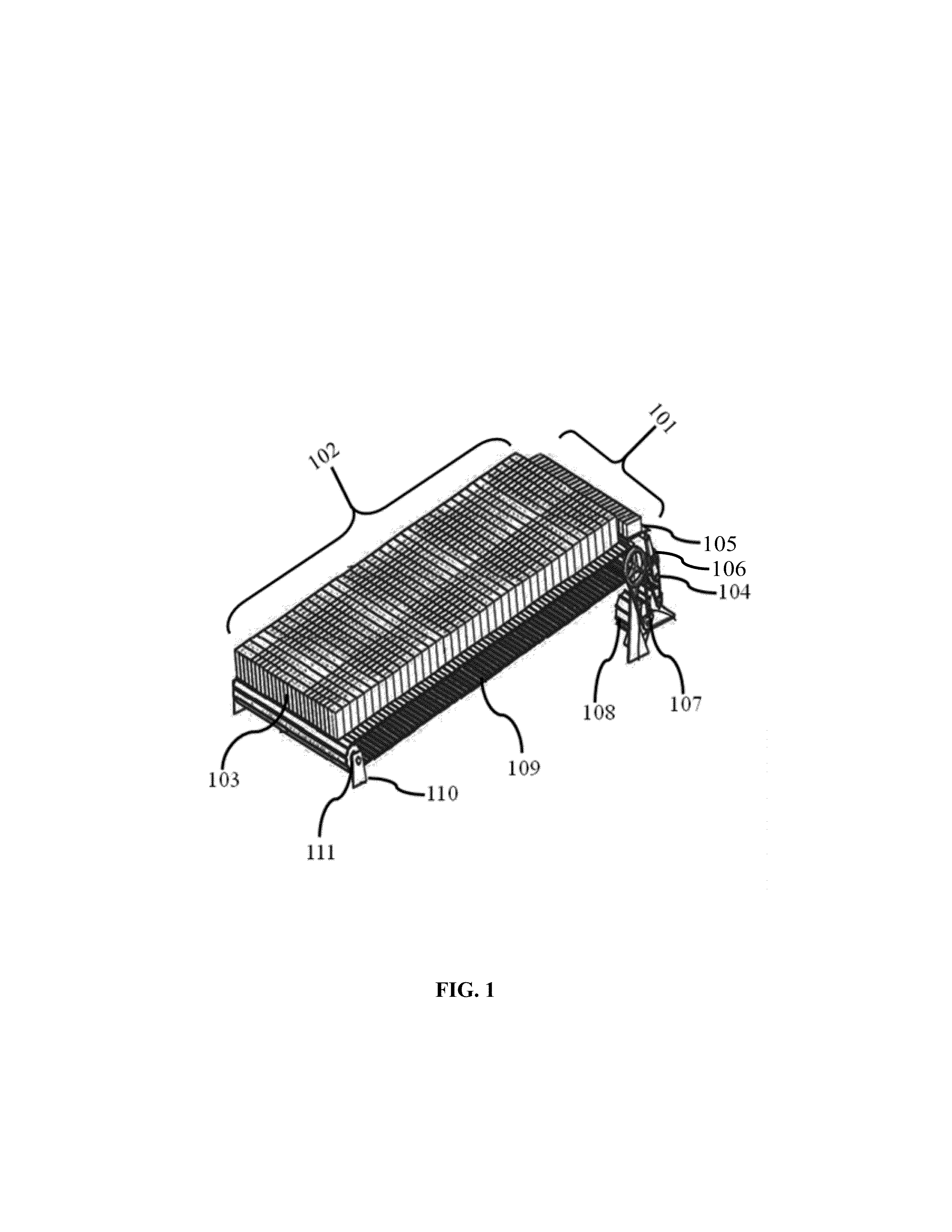

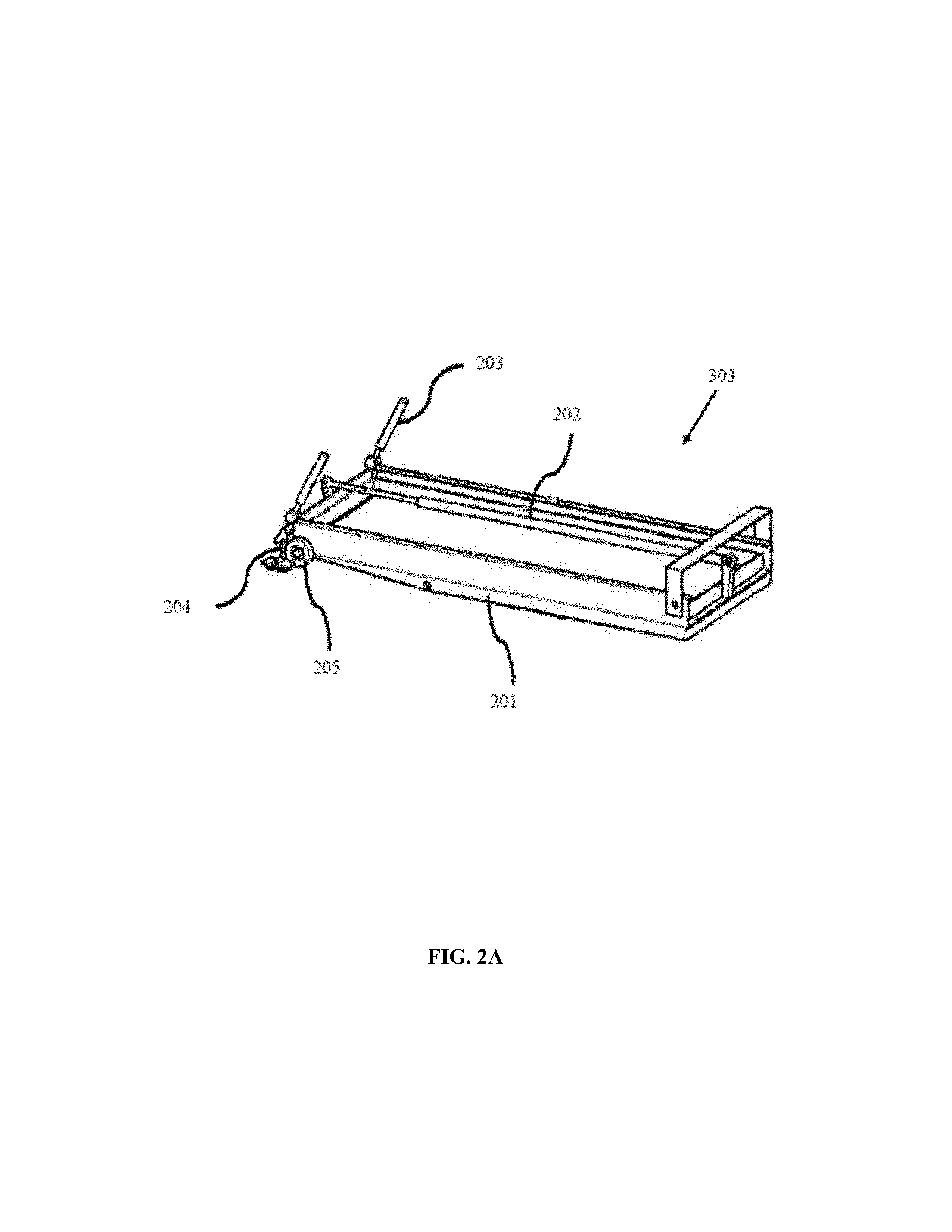

The various embodiments herein provide a method and system for handling wet clay bricks. The wet clay bricks are sectioned on the section table. The sectioned wet clay bricks are erected by an erect maker machine. The erect maker machine is connected to a stock maker machine to store a preset number of wet clay bricks. The wet clay bricks are loaded from the stock maker machine to an automatic loading and unloading tools, which is fixed to a shifting machine. The wet clay bricks are shifted through shifting vehicle to sunshiny locations and the wet clay bricks are unloaded to the ground from the shifting vehicle. Thus the embodiments herein provides a simple way to erect, load and unload wet clay bricks in a cost effective manner and also reduces the number of workers.

Owner:RAFIE HOSSEIN

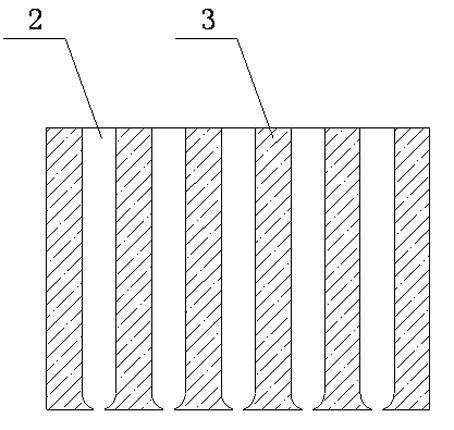

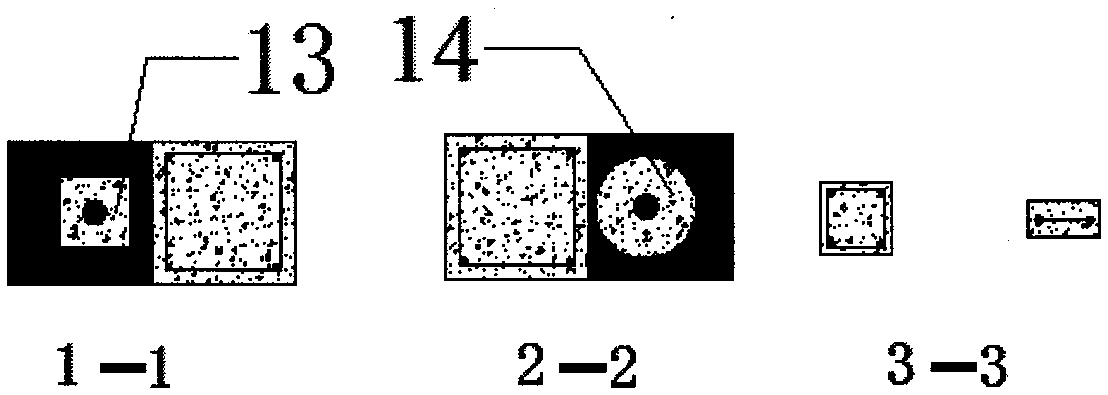

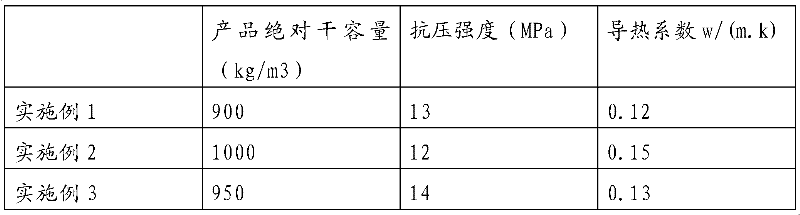

Light fly ash multi-row hole self-thermal insulation building block

InactiveCN102320799AIncrease thermal resistanceReduce usageClimate change adaptationPassive housesSlagAdhesive

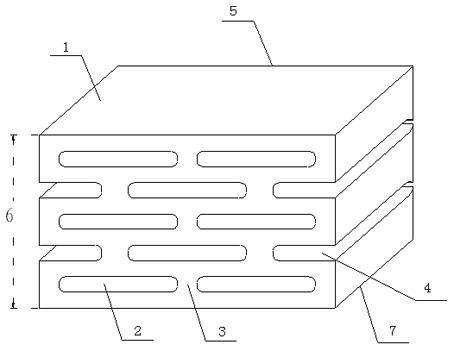

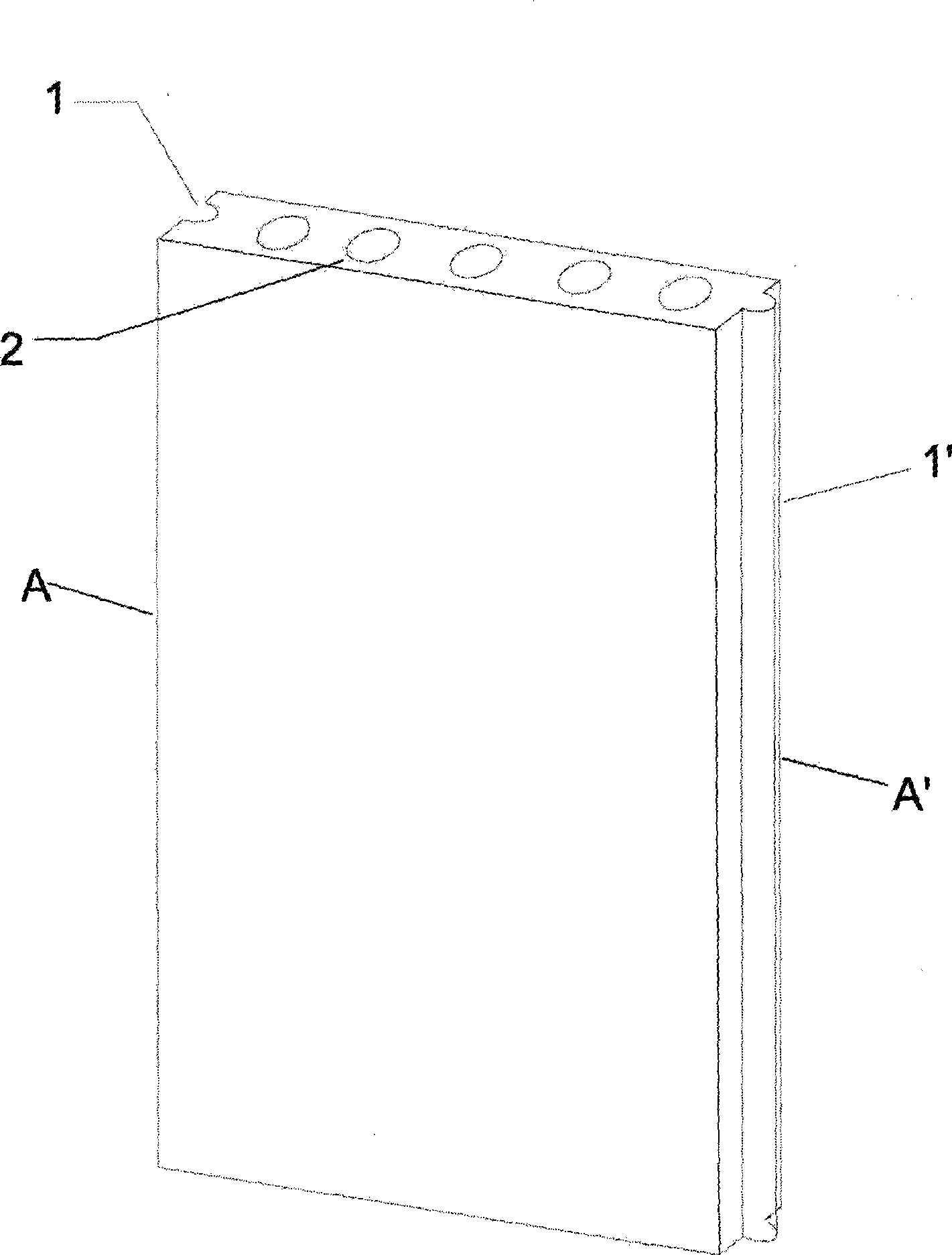

The invention relates to a building material, and particularly relates to a light fly ash multi-row hole self-thermal insulation building block. The technical scheme is that: according to the light fly ash multi-row hole self-thermal insulation building block, through holes are uniformly distributed on a cuboid light fly ash building block. The light fly ash building block is prepared by adopting portland cement as a gelling material, adopting fly ash, crude ash, ceramsite or slag, pumice, perlite or vermiculite, sawdust, polyphenyl particles, building adhesives, humectants and additives as filling materials, diluting and dissolving the mixture with water, mixing, stirring, extruding, and curing; the cross sections of the through holes are rectangular, and the arrangement form of the through holes is multi-section, multi-layer, parallel, and interactive. With the combination of the structure of the multi-row hole self-thermal insulation building block and the light composite fly ash material, the performance of the building block such as heat preservation, light weight, thermal insulation, sound insulation, fire prevention, durability, and the like is greatly improved; traditional clay bricks, aerated blocks and traditional outer wall insulation methods are substituted; and national requirements for building energy saving are fully met.

Owner:王长河

Autoclaved aerated concrete building block and manufacturing method thereof

InactiveCN101172819AHigh strengthSolid waste managementCeramicwareAluminium powderUltimate tensile strength

The invention relates to an autoclaved aerated concrete block and the manufacturing method thereof. According to the weight share, the autoclaved aerated concrete block contains the main raw materials as follows: 65 to 70 parts of fly ash, 18 to 22 parts of lime, 6 to 9 parts of cement, 2.5 to 3.5 parts of gypsum, 7 to 805 parts of aluminium powder and 64 to 70 parts of water, wherein, the fly ash is dry powder fly ash. The manufacturing method of the autoclaved aerated concrete block includes the following steps: putting the materials for mixing, teeming, stopping to conserve, cutting and then autoclaving, then the finished product is obtained, wherein, autoclaving is processed in an autoclave, and the autoclaving is divided into the steps of vacuumizing, pressurizing, stabilizing the pressure and releasing the pressure. The autoclaved aerated concrete block adopting the manufacturing method above has high strength and can completely replace the solid clay brick to be used in the places which have high strength requirements for walling material, such as external wall bearing wall, etc.

Owner:SUZHOU JINTONG NEW TYPE BUILDING MATERIAL

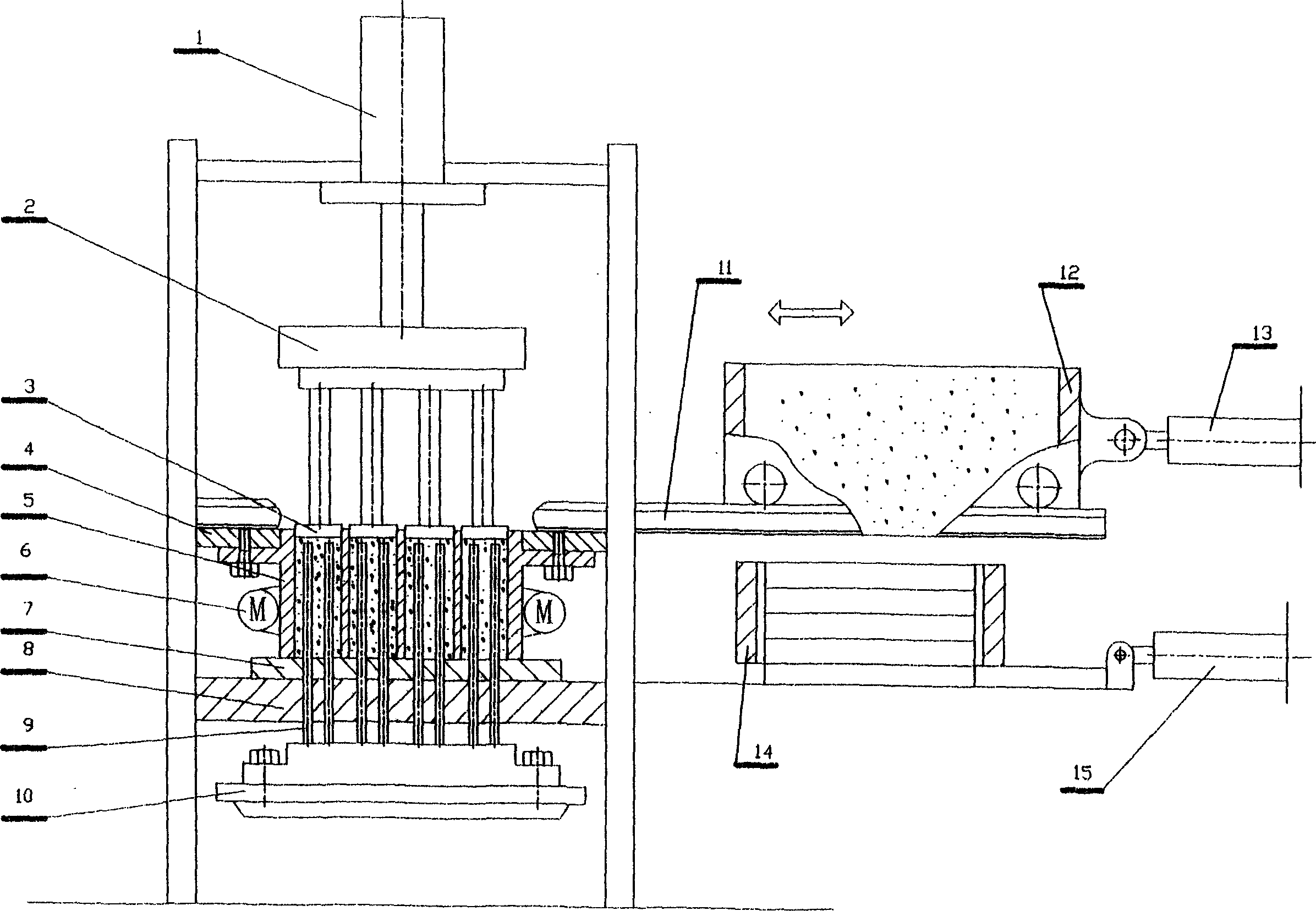

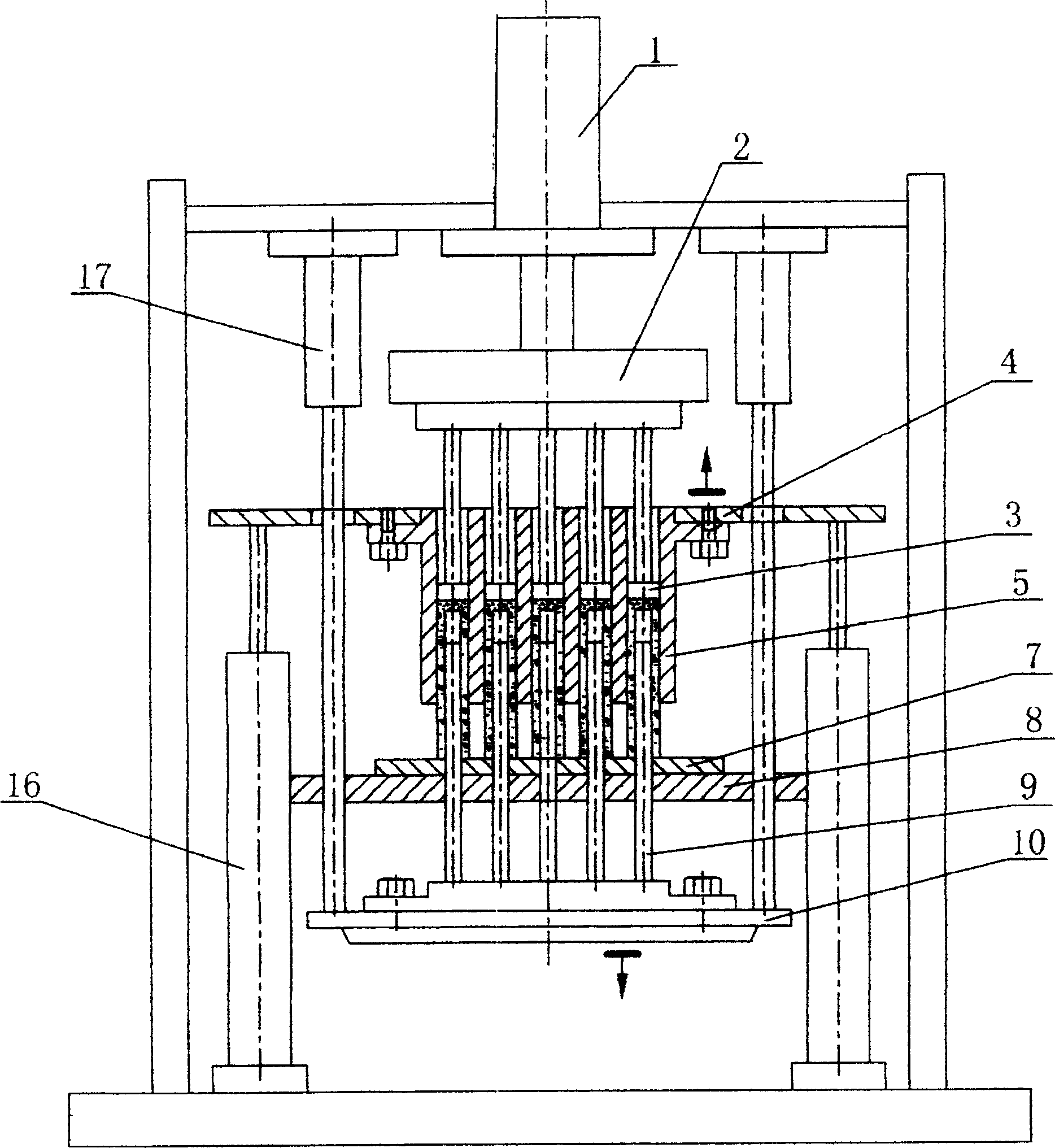

Automatic shaping method and equipment for load-bearing hollow brick

InactiveCN1657251ALiberate labor intensitySpeed up the flowDischarging arrangementMouldsBrickEngineering

A method for automatically shaping the load-bearing hollow brick includes such steps as preparing concrete, stirring, filling in mould, inserting core mould while vibrating, hydraulic pressing, and demoulding. Its apparatus is composed of electric power control box, control mechanism, motor, concrete preparing system, shaping system, feeding unit, and discharging unit.

Owner:广西金瓯建材机械有限公司

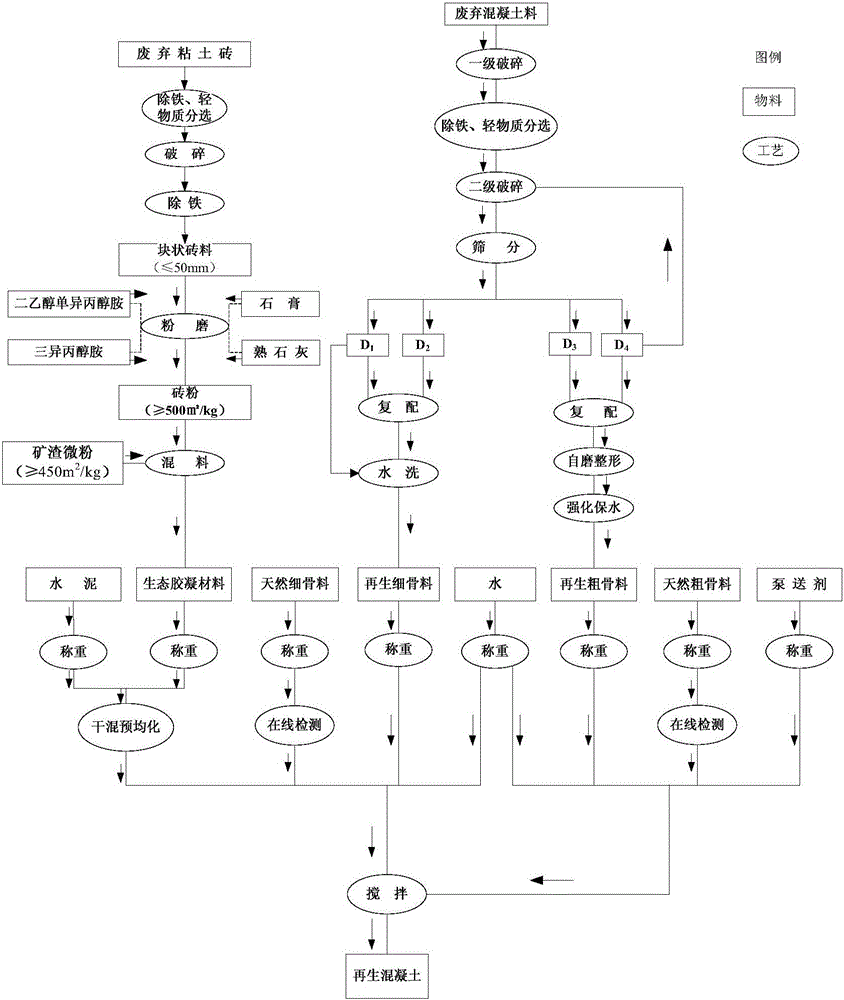

Production technology of ecological concrete

InactiveCN105948545AEfficient use ofAchieve recyclingSolid waste managementClinker productionSlurryUltimate tensile strength

The invention discloses a production technology of ecological concrete. The production technology comprises the steps of preparing an ecological cementing material by using construction waste clay bricks, and preparing recycled aggregate by using construction waste concrete; uniformly mixing cement and the ecological cementing material, then adding part of water, natural fine aggregate and recycled fine aggregate, stirring to form slurry, then adding natural coarse aggregate, recycled coarse aggregate, the rest water and a pumping aid, and stirring to prepare C30-C40 strength grade ecological concrete. By adopting the production technology of the ecological concrete, provided by the invention, useful components of construction waste are effectively used, the waste is turned into wealth, resources are saved, and the recycling of the construction waste resources is realized; the prepared ecological concrete is comparative with normal concrete in performance, is low in production cost, and can be largely applied to general construction engineering.

Owner:GANSU DELONG ECOLOGICAL BUILDING MATERIAL CO LTD

Stone powder sludge sintering brick and method for making the same

InactiveCN101081732AHigh strengthImprove performanceCeramic materials productionClaywaresAdobeAdhesive

The present invention discloses one kind of stone powder sludge sintering brick and its production process. The stone powder sludge sintering brick is produced with stone powder sludge from stone material producing process as main material, sludge from river, lake or sea, building waste clay or clay as adhesive, slag, coal slack, fly ash or coal as inner material, and through crushing, stirring, forming adobe, drying, roasting and other steps. The present invention has the features of waste utilization, environment friendship, saving in soil, low power consumption, high compression strength, etc. It may be used in replacing sintered clay brick.

Owner:林建国

Grey brick mechanically manufactured from lime sludge and construction wastes and method for manufacturing same

The invention discloses a gray brick mechanically manufactured from lime sludge and construction wastes and a method for manufacturing the same. The materials for mechanically manufacturing the gray brick comprise the following raw materials in portion by weight: 1,015 to 1,135 portions of construction waste crushed materials, 240 to 290 portions of cement, 810 to 1,010 portions of lime sludge, 60 to 75 portions of gray lime, and 100 to 125 portions of water, wherein the particle size of the construction waste crushed materials is less than 15 millimeters. If necessary, less than 20 portions of fly ash and proper amount of activating agent can be added to the materials. The method for mechanically manufacturing gray brick comprises the following steps: firstly, crushing the construction wastes; secondly, mixing the construction waste crushed materials with the other materials according to the proportions; and thirdly, pressing the mixture by adopting a mechanical method so as to produce the gray brick of the invention. The gray brick and the method for manufacturing the same recycle the sludge and the construction wastes in a reducing, harmless and resource-utilizing mode, and solve the problem that substituting materials and products are hard to find after clay bricks are forbidden to use and the problem of gray brick sources for civilian constructions.

Owner:梁林华 +1

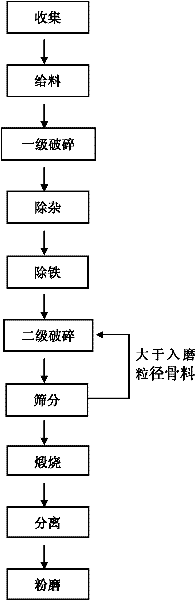

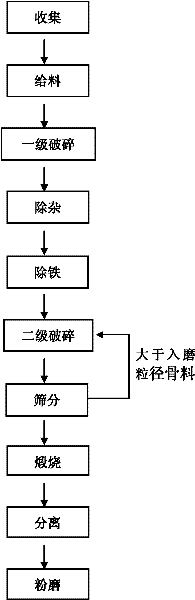

Method for recycling waste clay

InactiveCN102218435AGive full play to the role of materialImprove grindabilityConstruction waste recoverySolid waste disposalLitterIron removal

The invention provides a method for recycling waste clay, which comprises the following steps of: removing impurities from construction waste materials through treatment processes such as crushing, impurity removal, iron removal, sieving and the like, and preparing the materials into a recycled aggregate meeting the requirement of grinding equipment on particle size; burning up combustibles in the recycled aggregate through a calcining process to reduce ignition loss and water content; separating a concrete component from a clay brick component in the recycled aggregate; and grinding the clay brick component to obtain regenerated powder. By the method, waste clay brick resources can be fully utilized by a simple process; moreover, the regenerated clay powder obtained in the production has good performance, wide application range and high added value.

Owner:上海德滨环保科技有限公司

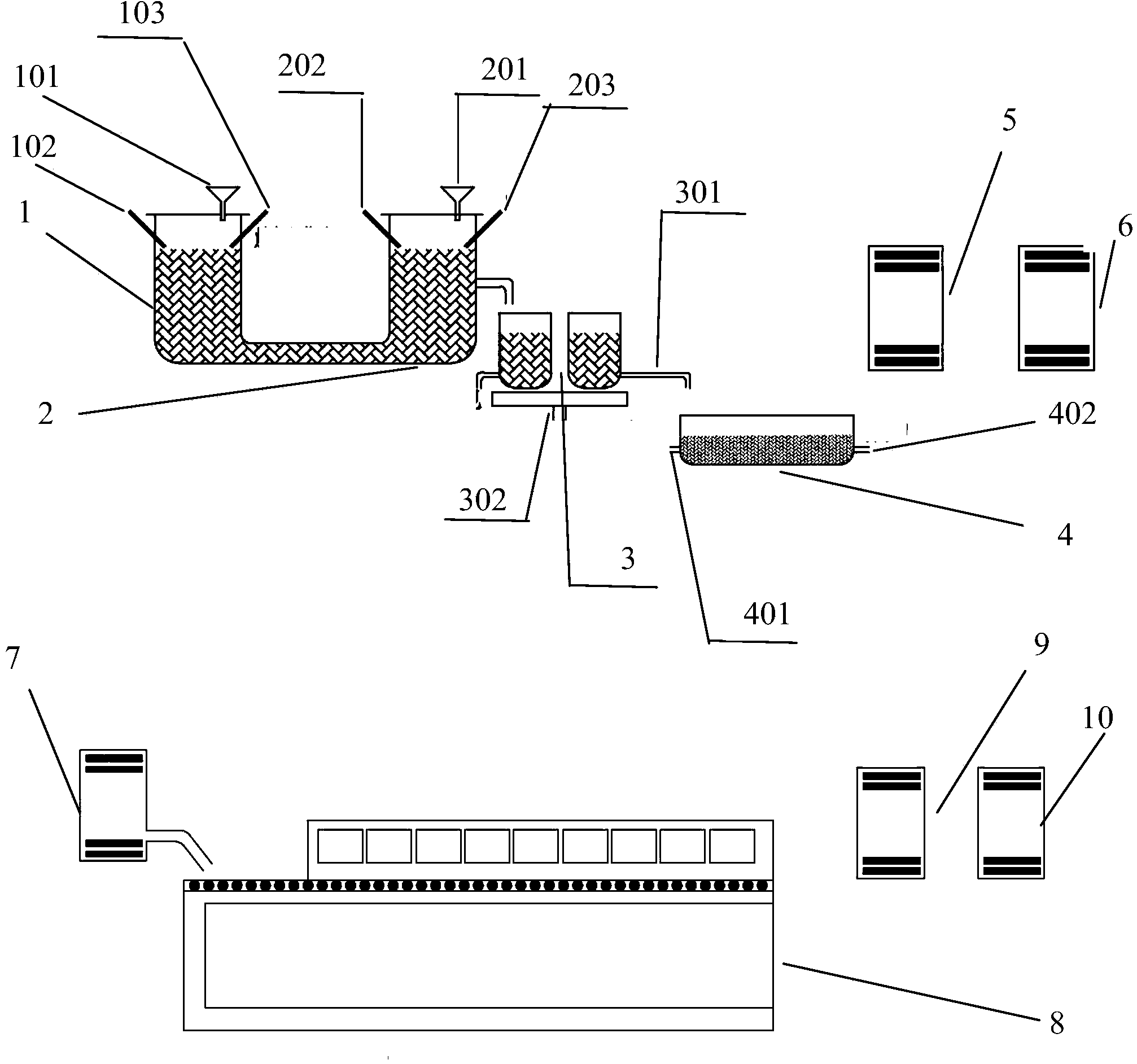

Powder ash air-entrained concrete building block and preparation method thereof

InactiveCN101913902ALose weightSmall sizeSolid waste managementCeramic shaping apparatusFire protectionEnergy consumption

The invention discloses a powder ash air-entrained concrete building block and a preparation method thereof. The powder ash air-entrained concrete building block is prepared by adding water to 100-200kg of cement, 350-380kg of lime, 1350-1550kg of powder ash, 1.4-1.5kg of aluminite powder and 0.195-0.205kg of foam stabilizers. The preparation method comprises the following steps of raw material preparation, metering, stirring, pouring in a mould, standing for procuring, demoulding, swinging to cutting parts for cutting, steaming and curing in a reactor and finished product warehousing. The building block has the advantages of light weight, good heat insulation, machinability, convenient construction, wide source of raw materials, high production efficiency, low production energy consumption and good fire protection and sound insulation, wherein the dry volume density of the building block is 500-700kg / m3 and amounts to one third of a clay brick; as a large quantity of air holes and micro holes are arranged inside the building block, the building block has favorable heat insulation; as coarse aggregates are not used, the building block has favorable machinability, can be sawn, dug,drilled and nailed and bonded by bonding materials, thereby providing beneficial conditions for building construction; and the building block belongs to a green environmental-protection product.

Owner:舟山市宇锦新型墙体材料有限公司

Modified building residue baking-free brick

InactiveCN105110720AEfficient use ofMore consumptionSolid waste managementCompressive strengthUltimate tensile strength

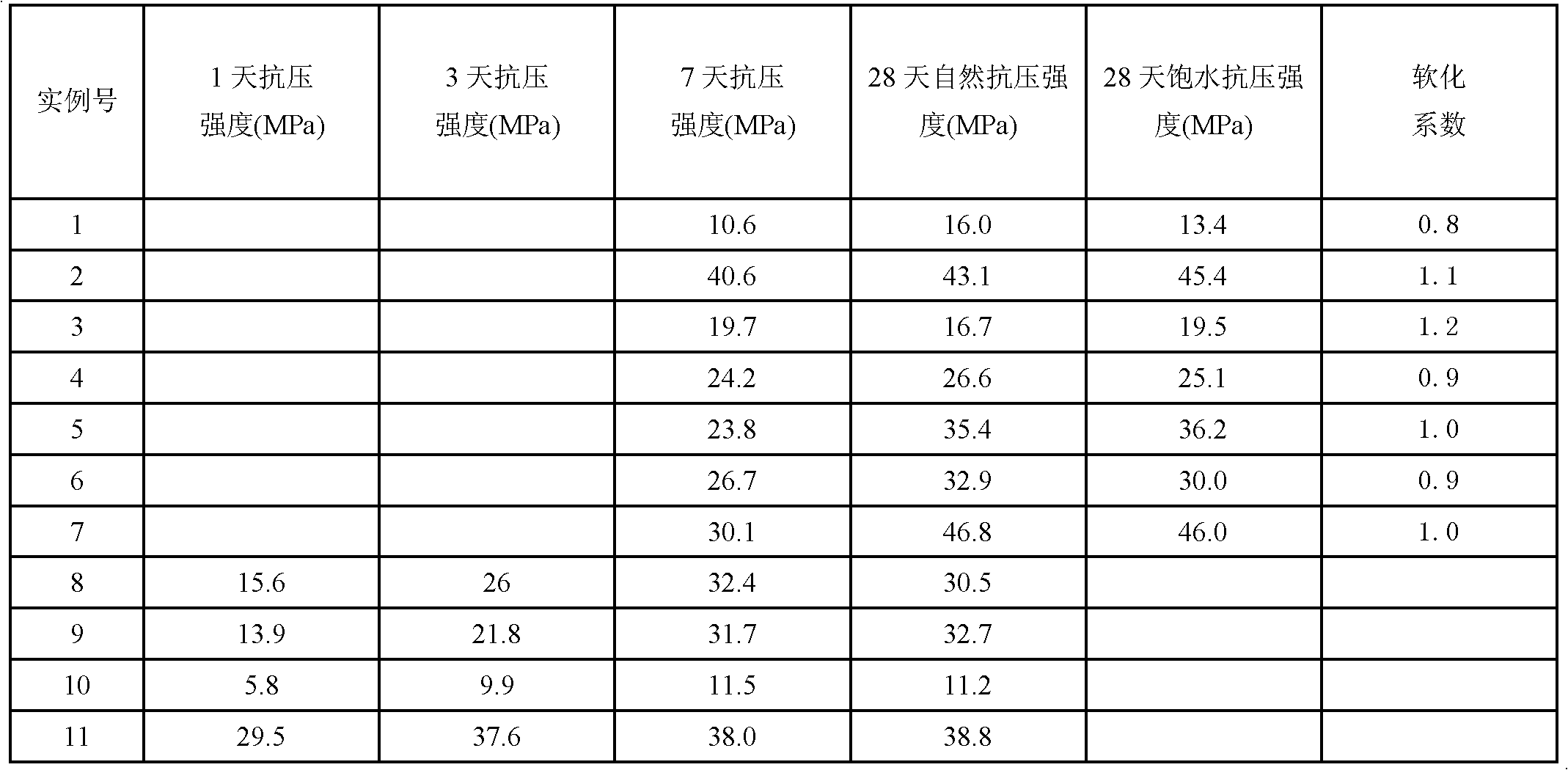

The invention discloses a modified building residue baking-free brick. The modified building residue baking-free brick is prepared from, by mass, 65 to 75% of building residue, 10 to 15% of sand, 5 to 15% of cement, and 2 to 5% of industrial lime. The modified building residue baking-free brick is prepared via following steps: 1) building residue generated in subway construction processes is subjected to simple ball milling so as to obtain building residue powder; 2) the ingredients above are weighed according to the ratio above, and water-solid ratio is controlled to be 0.20 to 0.24; 3) cement, lime, gypsum, and sand are uniformly mixed with the building residue powder, water is added for uniform mixing, an obtained mixed material is subjected to extrusion forming, and curing under natural conditions for 3 to 7 days, is delivered into a drying oven, and is dried to be constant in weight at 40 to 60 DEG C so as to obtain the modified building residue baking-free brick. The modified building residue baking-free brick is cheap; a large amount of building residue can be recycled; environmental pollution and soil waste are reduced; compressive strength is high; water resistance is excellent; the modified building residue baking-free brick is capable of satisfying performance requirements of building bricks, and can be used for replacing sintering clay bricks.

Owner:TIANJIN CHENGJIAN UNIV

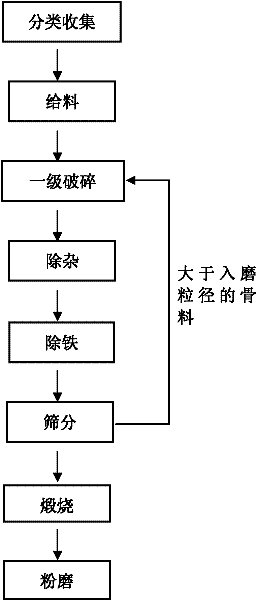

Method for preparing active admixture for concrete and cement by building waste

A method for preparing an active admixture for concrete and cement by building wastes is characterized in that the components comprises 60-70% of building wastes, 10-50% of blast furnace water quenching slag, 5-20% of fly ash, 5-10% of limestone, 3-5% of quicklime, 3-5% of gypsum, 3-5% of alkaline residues, and 1-3% of poly alkanolamine additives; the method comprises the following steps: sortingbuilding wastes to obtain broken sintered clay bricks and tiles to be used, performing crushing, iron removal, and drying, proportionally adding blast furnace water quenching slag, fly ash, limestone, quicklime, gypsum, alkaline residues, and poly alkanolamine additives, grinding and uniformly stirring. The invention solves the problems of resource optimization and cyclic utilization of building wastes, and is widely applicable to full, high-efficient, and reasonable utilization and processing of building wastes.

Owner:QINGDAO JIANYIXIN MATERIAL TECH

Barium residue coal ash building block and production method thereof

InactiveCN102531500AReduce pollutionRealize comprehensive utilizationSolid waste managementSodium sulfateWaste material

The invention discloses a barium residue coal ash building block and a productbulion method thereof. The barium residue coal ash building block is made in the manner that barium residue, coal ash, cement, water and an additive that is used for eliminating the toxicity of barium residue are taken as raw materials, and the raw materials are processed through metering, stirring and blending, compression moulding and stacking and maintaining; and the additive adopts soluble sulfate and slightly soluble sulfate. Desulfurized gypsum is used as the additive used for eliminating the toxicity of barium residue, and the raw material formula of the barium residue coal ash building block includes, by the mass proportion, 50 cement, 450 mountain sand, 400 barium residue, 100 coal ash, 50 desulfurized gypsum and appropriate amount of water; and sodium sulfate is used as the additive for eliminating the toxicity of barium residue, and the raw material formula of the barium residue coal ash building block includes, by the mass proportion, 50 cement, 500 mountain sand, 400 barium residue, 100 coal ash, 6 sodium sulfate and appropriate amount of water. According to the invention, the pollution to the environment from barium residue is reduced; clay bricks are replaced with waste materials to achieve waste material utilization, which meets the requirement of developing recycling economy; and the building block cost is lowered. The invention is suitable for building material producing enterprises discharging barium residue.

Owner:ANSHUN HUAYANG NEW BUILDING MATERIALS

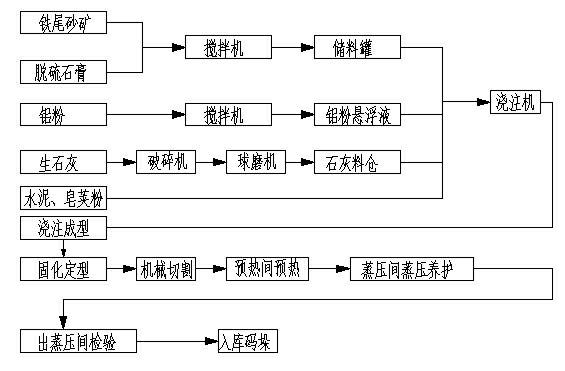

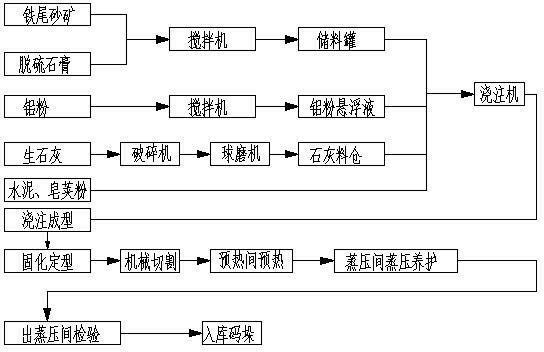

Production method for iron tailing sand aerated concrete building block

InactiveCN102603358AWide variety of sourcesEasy dischargeSolid waste managementCeramicwareThermal insulationWater vapor permeability

The invention discloses a production method for an aerated concrete building block, in particular to a production method for an iron tailing sand aerated concrete building block. The production method for an iron tailing sand aerated concrete building block comprises the following steps of: preparing iron tailing mortar material, wherein the concentration of added desulfurized gypsum is 50-60%; preparing aluminum powder solution of which the concentration is 20-25%; burdening at the following mass ratio: 81.54% of iron tailing mortar, 10.58% of lime powder, 5.88% of cement, 1% of Chinese honey locust powder and 1% of aluminum powder solution; and pouring, procuring, demoulding, cutting for shaping, and steaming for curing. The production method for the iron tailing sand aerated concrete building block has the outstanding characteristics that the abandoned iron tailing sand serves as main raw material for production, and the production method has the advantages of wide raw material resource, high waste use ratio and low production cost and is easy to popularize and apply. Because the product weight is low, the iron tailing sand aerated concrete building block is suitable for the filling wall of a high-rise building and the load bearing wall of a low-rise building; because the iron tailing sand aerated concrete building block has good thermal-insulation performance, the thickness of the wall body can be reduced; because the iron tailing sand aerated concrete building block has good water vapor permeability, moisture on the wall body is easy to discharge; and the iron tailing sand aerated concrete building block has high strength which is equivalent to the compressive strength of No.125 clay bricks and limesand bricks.

Owner:ZUNHUA HAIXIANG NEW BUILDING MATERIAL

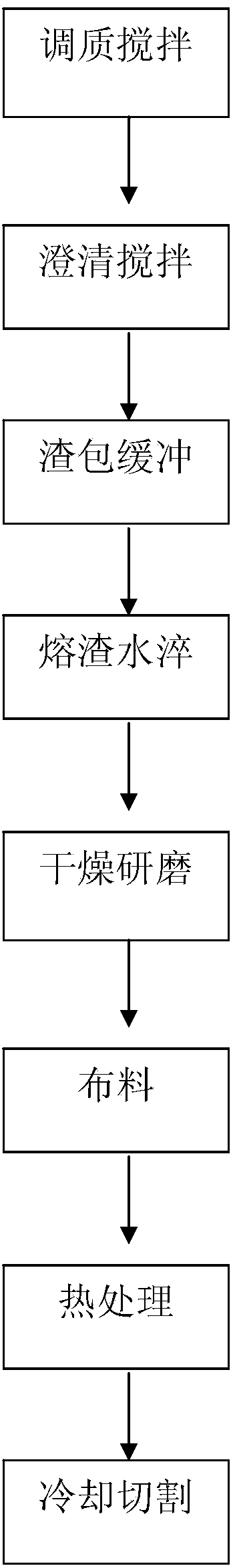

Method for using blast furnace slag to produce micro-crystalline light brick

The invention discloses a method for using blast furnace slag to produce a micro-crystalline light brick. The light brick uses the blast furnace slag as main raw material. The method for using the blast furnace slag to produce the micro-crystalline light brick includes that tempering and clearing the blast furnace slag to obtain slag with qualified ingredients, feeding to a water quenching pool to form micro-crystalline particles through water quenching, grinding and sieving the micro-crystalline particles to obtain micro-crystalline particles with proper granularity, uniformly mixing with foaming agent, putting the mixture in a casting mould, and sintering to form the micro-crystalline light brick with uniform air bubbles and stable ingredients. Compared with the traditional clay brick, the micro-crystalline light brick has lower density and higher intensity, so that the micro-crystalline light brick has better bearing ability, and moreover, the micro-crystalline light brick has good heat preservation effect and sound insulation effect due to the uniform air hole structure, so that the micro-crystalline light brick can replace the clay brick or ordinary light brick in a certain degree to serve as novel building material.

Owner:江西璞晶新材料股份有限公司

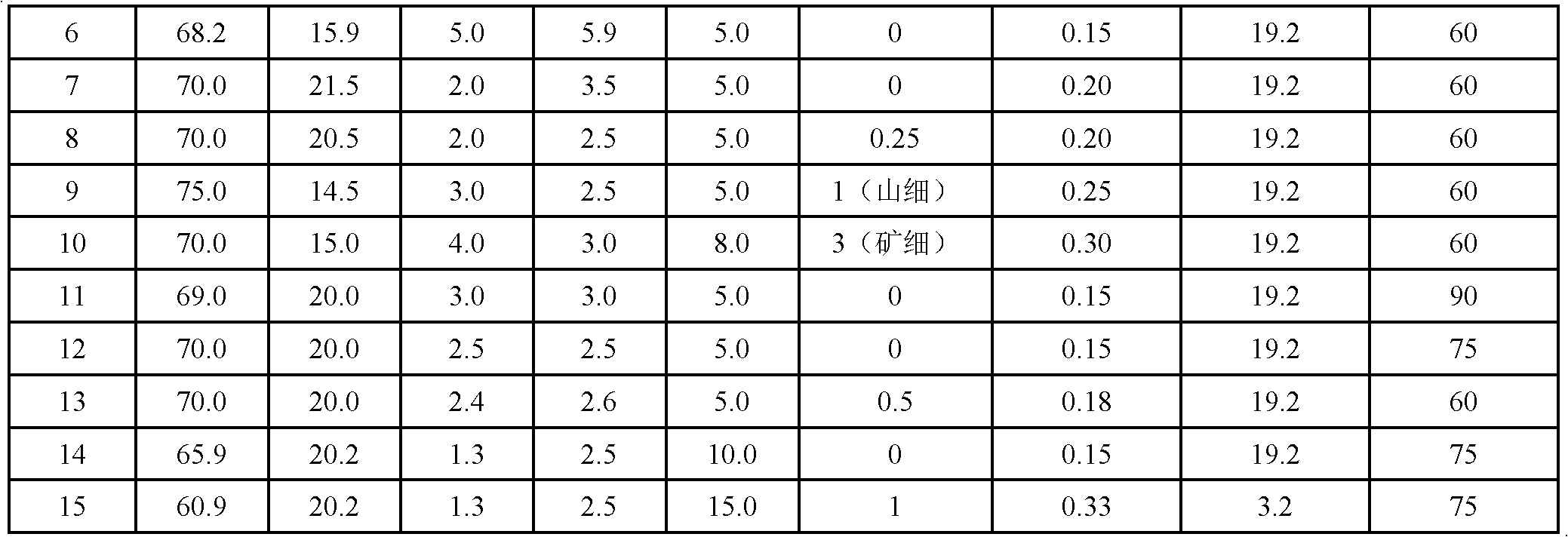

Novel lightweight mullite brick and fabrication method thereof

The invention discloses a novel lightweight mullite brick and a fabrication method thereof. According to the fabrication method, partial high-strength lightweight mullite aggregate, composite organic pore forming material and a high-polymer bonding agent are added to mullite which is used as a main raw material. The novel lightweight mullite brick has a lower heat conductivity coefficient, high compressive strength, high service temperature and certain erosion resistance, and can be extensively applied to parts of various sets of thermal equipment, which are not in direct contact with melt and materials. The novel lightweight mullite brick can replace a heavyweight high-alumina brick and a clay brick to be used as a working layer at some parts of various sets of thermal equipment, the deadweight of the thermal equipment can be reduced by more than 20%, and energy can be saved by above 25%.

Owner:郑州瑞泰耐火科技有限公司

Tuff, tuff lava sintered brick and preparation method thereof

The invention discloses a tuff and tuff lava sintered brick and a preparation method thereof. The tuff and tuff lava are used as main materials combined with the weathered soils of the tuff and the tuff lava, or silts from rivers, lakes and seas or building waste soils or clays as adhesives, or slag or coal gangues or fly ashes or coals are also used as internal fuels. The tuff and tuff lava sintered bricks are prepared by the procedures of crushing, stirring, blank forming, drying and roasting, etc. The preparation method is characterized by utilizing industrial wastes, environmental protection, saving soil and energy, improving the compressive strength and thermal insulation performance of bricks, and the like, and the tuff and tuff lava sintered bricks conform to the national standards of sintering porous bricks, hollow bricks and road bricks. The tuff and tuff lava sintered brick has the advantages of high strength, heat preservation, convenience for preparation and construction, and the like, and is another new product replacing clay brick after the nation prohibits clay brick usage.

Owner:林建国

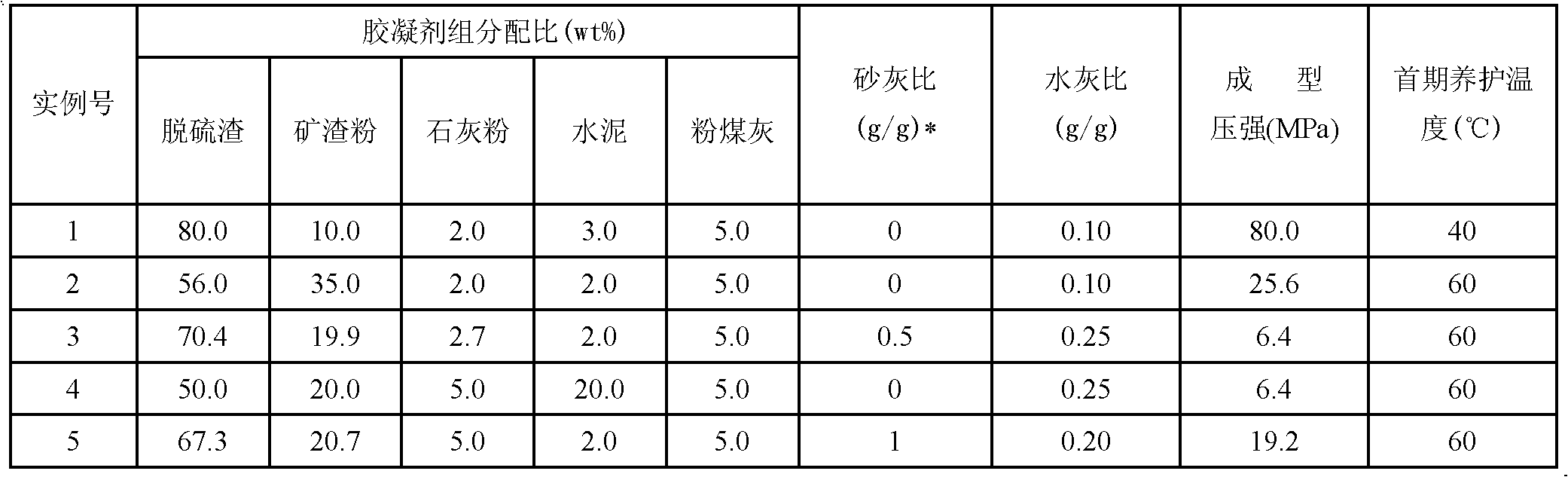

Method of preparing baking-free load-bearing bricks through steam curing of semidry desulfurization residues

The invention discloses a method of preparing baking-free load-bearing bricks through steam curing of semidry desulfurization residues, belonging to the technical fields of environmental engineering and preparation of construction material. According to the invention, a gelling agent is prepared from semidry desulfurization slag and multi-component powder and is uniformly mixed with inert sandy aggregate in a mixer, water accounting for 10 to 46% of the mass of solid powder is added and uniformly mixed with the solid powder, an obtained mixture undergoes pressure forming and demolding so as to obtain green bricks, and the green bricks are subjected to steam curing at a temperature of 40 to 90 DEG C for 1 to 7 d so as to obtain baking-free bricks with sufficient strength; the baking-free bricks can meet different strength requirements for load-bearing bricks of a model number in a range of MU10 to MU30, have excellent water resistance and can be used as exterior wall tiles. According to the invention, the problem that comprehensive utilization of semidry desulfurization gypsum is not easy due to complex composition of the semidry desulfurization gypsum is overcome; effective usage of solid waste in production of the baking-free bricks which cost less than conventional sintered clay bricks do has great significance to energy conservation and environmental protection.

Owner:HUNAN UNIV OF SCI & TECH

Sludge environmental protection block

The invention discloses a sludge environmental protection block and relates to a building block. Present blocks are clay or cement and bath brick. Chamotte brick needs a lot of clay. A lot of fine fields will be destroyed, cement-bath brick will destroy massif and river, and disasters are brought to humans. Therefore, both clay and sand should not be used as a brick-making material. Furtherly, a lot of sludge left after sewage treatment is not effectively utilized. The invention provides the environmental protection block with sludge used as a raw material. The formula of the environmental protection block contains: by weight, 18-25 parts of portland cement, 0.5-1.5 parts of expanded perlite, 25-35 parts of sludge, 8-12 parts of pulverized limestone, 30-40 parts of small broken stone, 5-12 parts of building garbage, 0.5-1 part of foamed plastic fragments and 1-3 parts of industrial fiber. The invention relates to the green industry for environmental protection, and has beneficial effects of excellent product performance, multi-purposes, simple manufacturing industry, energy conservation, low cost and the like.

Owner:周中德

Treatment method for recycling waste red mud residues

InactiveCN101773925ASolve processing problemsThe processing method is scientific and reasonableAluminium compoundsConstruction materialTunnel kilnRed mud

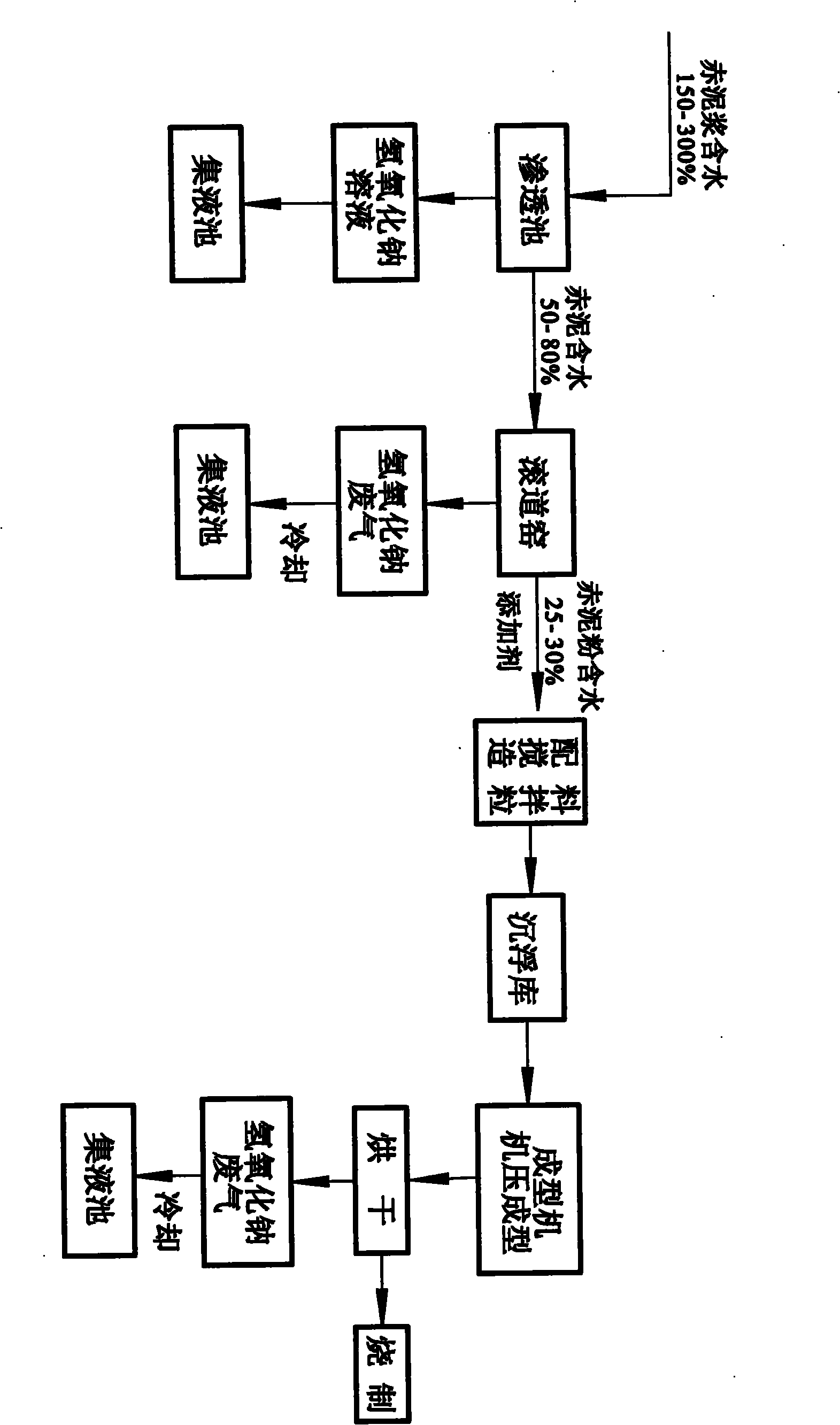

The invention discloses a treatment method for recycling waste red mud residues. The treatment method comprises the following steps of: firstly, injecting red mud slurry with a water content of 150-300 percent into an infiltration pond for primary dewatering, and after dewatering, obtaining red mud and a sodium hydroxide solution; injecting the sodium hydroxide solution into a liquid collection pond and returning to an aluminum oxide plant for recycling; sending the primarily dewatered red mud into roller kiln for drying to obtain red mud powder; adding an additive to the red mud powder, uniformly stirring and granulating; sinking and floating a mixture material after granulating and then sending the mixture material into a molding machine for pressing and molding into brick blanks; and pouring the brick blanks into a tunnel kiln to dry and burn into clay bricks. Material inlets of the roller kiln and the tunnel kiln are additionally and respectively provided with a waste gas recovery device for collecting waste sodium hydroxide gas generated during drying, and the sodium hydroxide solution is obtained through cooling, injected into the liquid collection pond and returned to the aluminum oxide plant for recycling. The method can greatly improve the utilization rate of the red mud, maximally utilize the red mud and change wastes into values. The invention has scientific treatment method, environmental protection and no three waste discharges.

Owner:李志奇

Lightweight refractory for glass smelting kiln

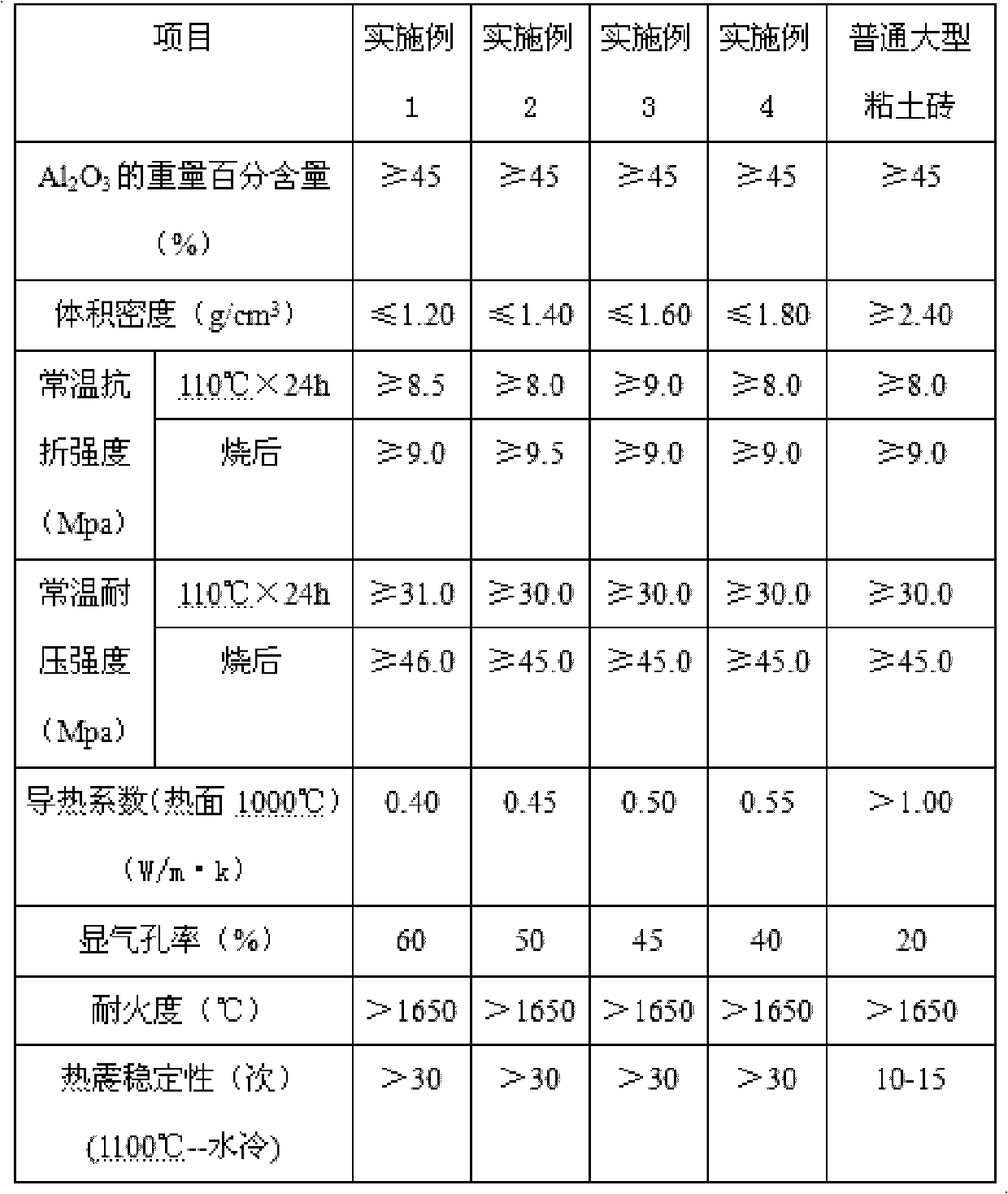

The invention discloses a lightweight refractory for a glass smelting kiln. The lightweight refractory is prepared from the following raw materials in percentage by weight: 40-60% of micropored lightweight mullite aggregates, 5-15% of high-temperature cement, 5-10% of silica powder, 6-18% of high-alumina powder, 4-12% of clay powder, 2-8% of expansion agents and 0.1-0.3% of water reducing agent. The lightweight refractory has the advantages of small proportion, light weight, high strength, good thermal shock resistance, high refractoriness (higher than 1650 DEG C), low thermal conductivity and the like. Being used for the glass smelting kiln instead of the common large clay brick materials, the lightweight refractory can greatly reduce the weight of the kiln by 30-60% and reduce the heat capacity and has good thermal shock resistance, thus greatly improving the service life of the kiln; meanwhile, the lightweight refractory has low coefficient of heat conductivity, good heat insulation effect and little heat loss, saves the cost, obviously improves the heat utilization efficiency and saves the energy.

Owner:HENAN ZHONGYUAN SPECIAL REFRACTORY

Low-cost fire-resistant pouring material and method for making same

The present invention discloses a fireproof pouring material with low cost, which takes the low-grade fireproof waste material residue such as waste clay brick, waste wonderstone brick and waste aluminum brick and so on as the raw materials, water glass as the binding agent, fluoriin sodium silicate as the accelerating agent. By using of pouring material, the fireproof precast block can be prepared. The fireproof pouring materials can be used in the heat stove bushing including metallurgy residue pot separated container, middle enveloping level and heat stove bushing and so on. The fireproof pouring material is not only with high refractoriness and large intension, but also can decrease the cost of the residue pot. The present invention plays very importance to saving fireproof material resource, decreasing the discharge of the fireproof material after being used, improving the environment and circulating the economy and so on.

Owner:BAOSHAN IRON & STEEL CO LTD

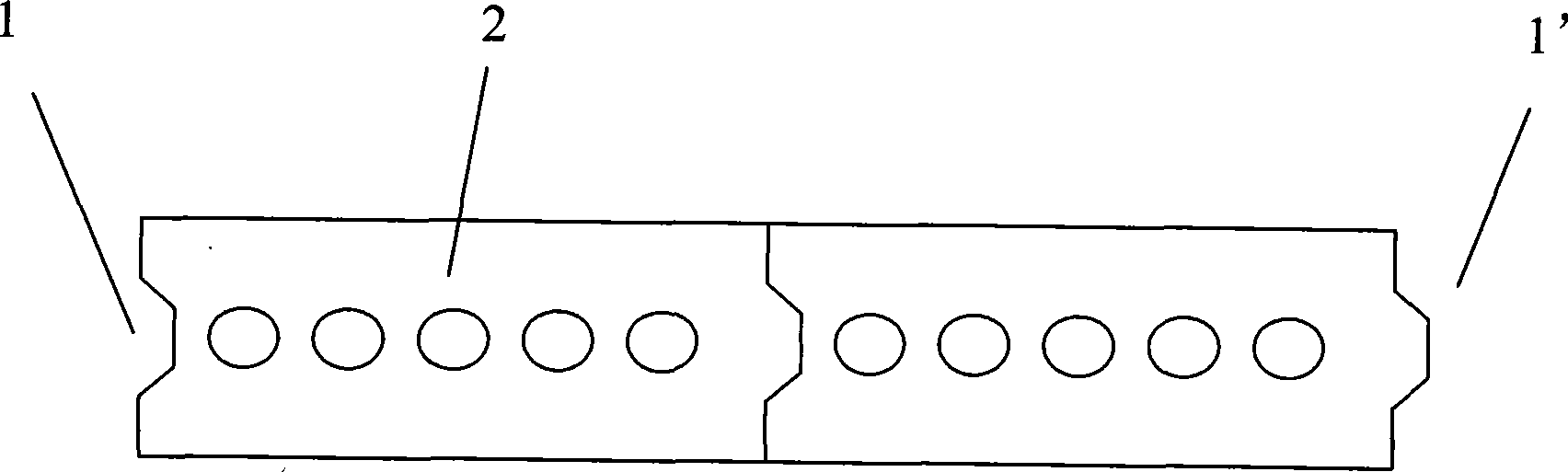

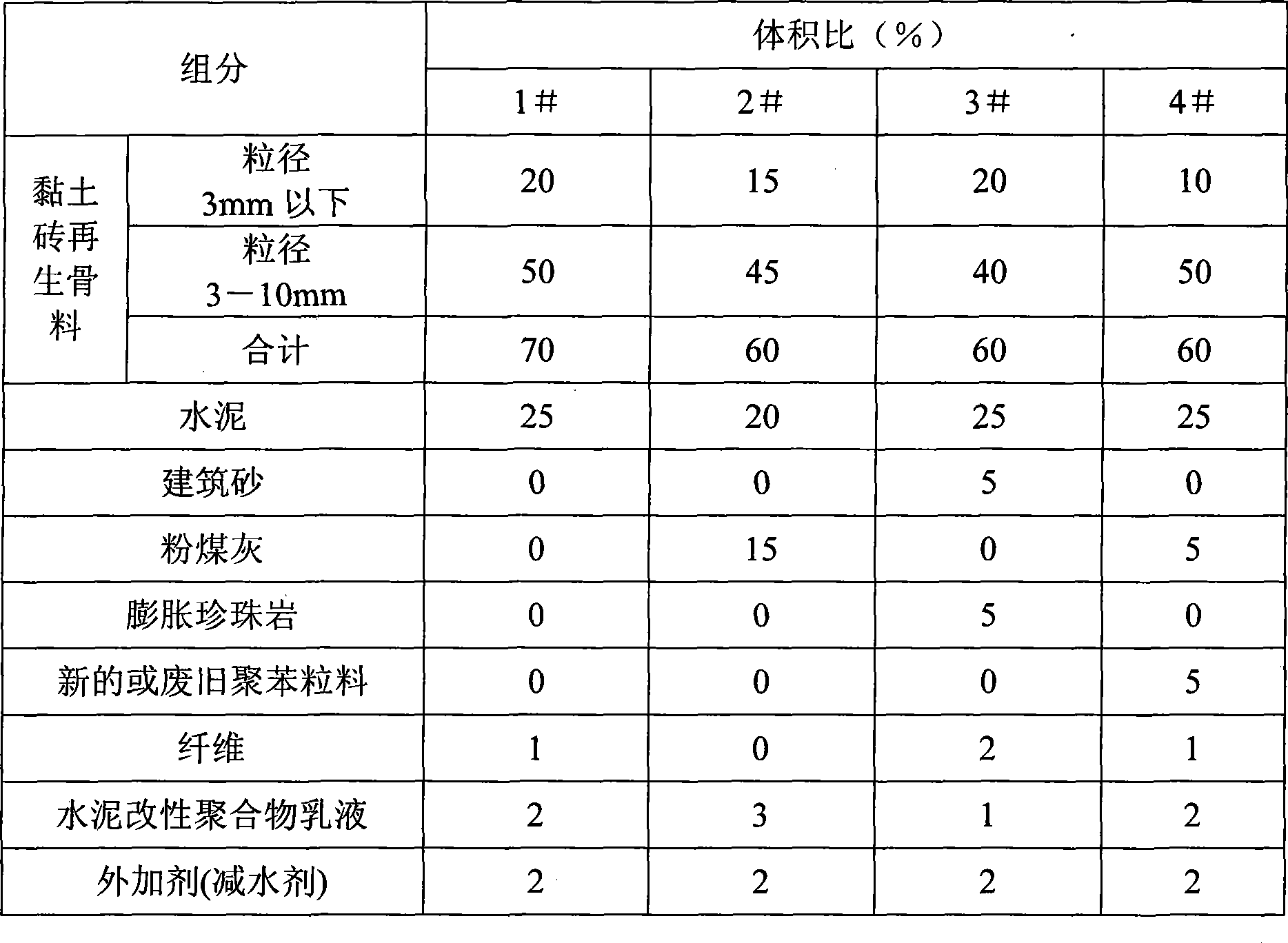

Clay brick recycled aggregate concrete partition slat

InactiveCN101456702AModerate densityHigh strengthSolid waste managementCrazingStructural engineering

The invention discloses a clay brick regenerative aggregate concrete partition lath. The partition lath is manufactured by the following components by volume percentage: 60 to 70 percent of clay brick regenerative aggregate, 20 to 25 percent of cement, 0 to 5 percent of building sand, 0 to 15 percent of coal ash, 0 to 5 percent of expanded perlite, 0 to 5 percent of new or waste polyphenyl granules, 0 to 2 percent of fibers, 1 to 3 percent of cement modified polymer emulsion, and 2 percent of additive. The invention also discloses a method for manufacturing the clay brick regenerative aggregate concrete partition lath. The clay brick regenerative aggregate concrete partition lath has proper density, excellent performances on strength, shrinkage value, sound insulation and the like, is favorable for controlling crack on wall surfaces, has manpower tolerable range on installation construction of the lath, and realizes high added value utilization of building waste.

Owner:上海德滨环保科技有限公司

Polyethylene cable material and preparation method thereof

InactiveCN103351518AImprove mechanical propertiesHigh temperature resistantPlastic/resin/waxes insulatorsInsulated cablesMonoglycerideSlag

The invention provides a polyethylene cable material and a preparation method thereof. The coating is characterized by comprising the following raw materials by weight parts: 45-50 parts of linear low-density polyethylene, 2-3 parts of PPS, 4-5 parts of stearic acid monoglyceride, 1-2 parts of nano-clay brick slag powder, 16-19 parts of general purpose polystyrene, 2-3 parts of polyisobutylene, 1-2 parts of ABS high crumb rubber, 4-5 parts of microcrystalline wax, 3-4 parts of rapeseed oil, 32-35 parts of sepiolite powder, 23-26 parts of vermiculite powder, 12-14 parts of celestine powder, 1-2 parts of magnesium oxide, 1-2 parts of zinc oxide, 2-3 parts of zinc stearate, 1-2 parts of an accelerator TETD, 3-5 parts of methyl trimethoxy silane, 2-3 parts of vinyltriethoxysilane, 2-3 parts of ethyl acrylate, 8-10 parts of high wear resistant carbon black N 330 and 6-8 parts of modified diatomite. The cable material provided by the invention is high in mechanical property, high temperature resistance, high in flame retardant, and low-smoke and nontoxic during combustion.

Owner:ANHUI TIANXING OPTICAL FIBER COMM EQUIP

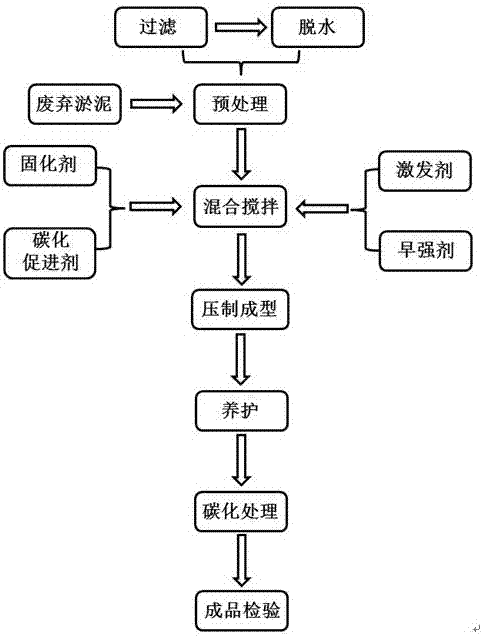

Novel carbonized baking-free brick prepared through marine waste silt and preparation method of brick

ActiveCN107337414AMeet strength requirementsLight in massSolid waste managementCeramic shaping apparatusCarbonizationHigh pressure

The invention provides a method for preparing a novel carbonized baking-free brick prepared through marine waste silt. The method comprises the steps that a curing agent, a carbonization accelerator, excitant and an early strength agent are added in the marine waste silt, and a green brick is prepared; the prepared green brick is delivered into a high pressure steamer to be subjected to steam curing, and the green brick is taken out to be put in the air to be subjected to natural curing; the green brick obtained after natural curing is conducted is put in a carbonation tank with the temperature ranging from 20 DEG C to 40 DEG C to be carbonized, and the carbonized baking-free brick is obtained. The novel carbonized baking-free brick has the significant advantages of being high in degree of automation, stable in product performance, good in mechanical property, low in cost, high in yield, friendly to environment and the like, the novel carbonized baking-free brick can completely or partially replace a traditional solid clay brick, and a wide market prospect is achieved.

Owner:WUHAN UNIV

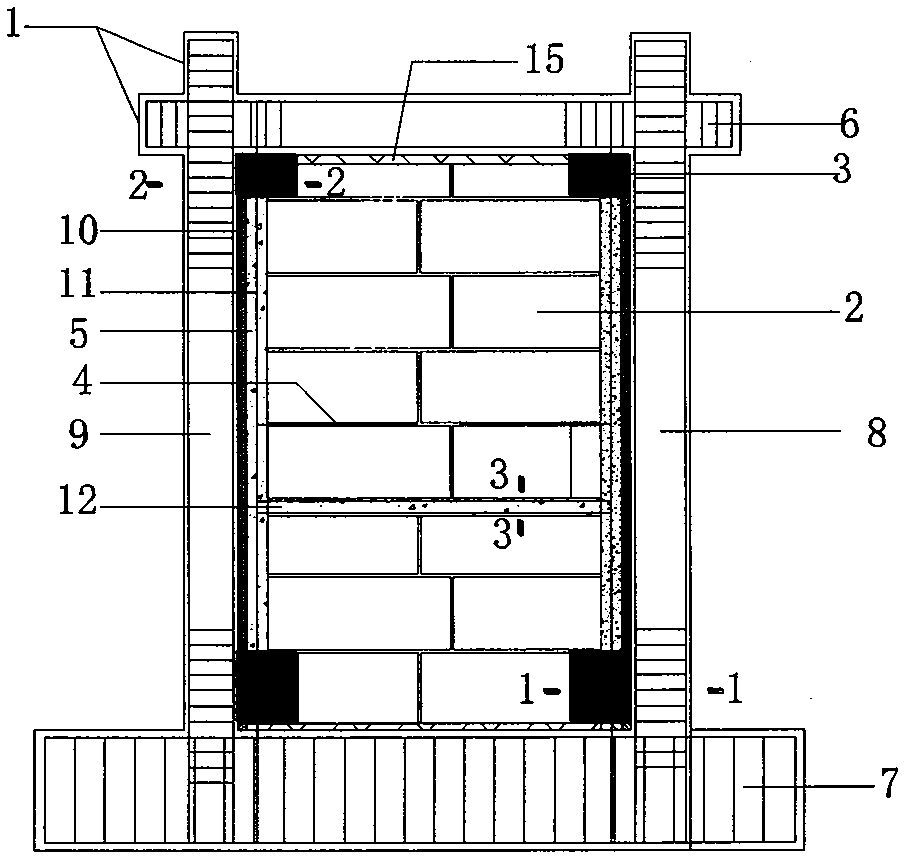

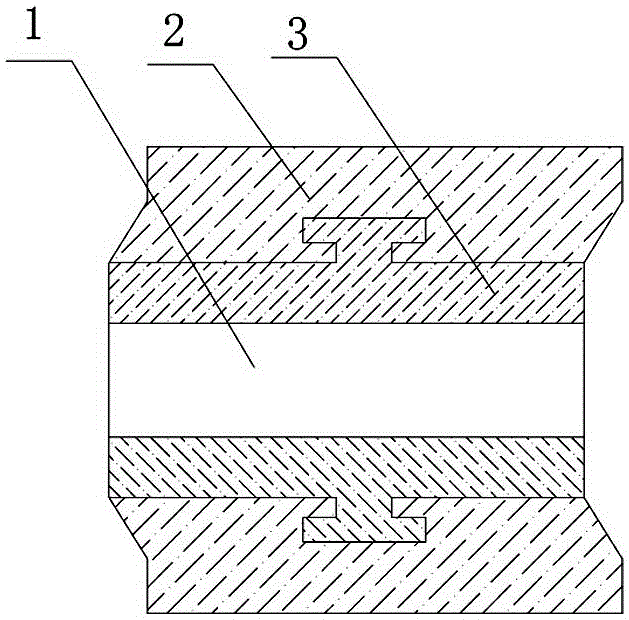

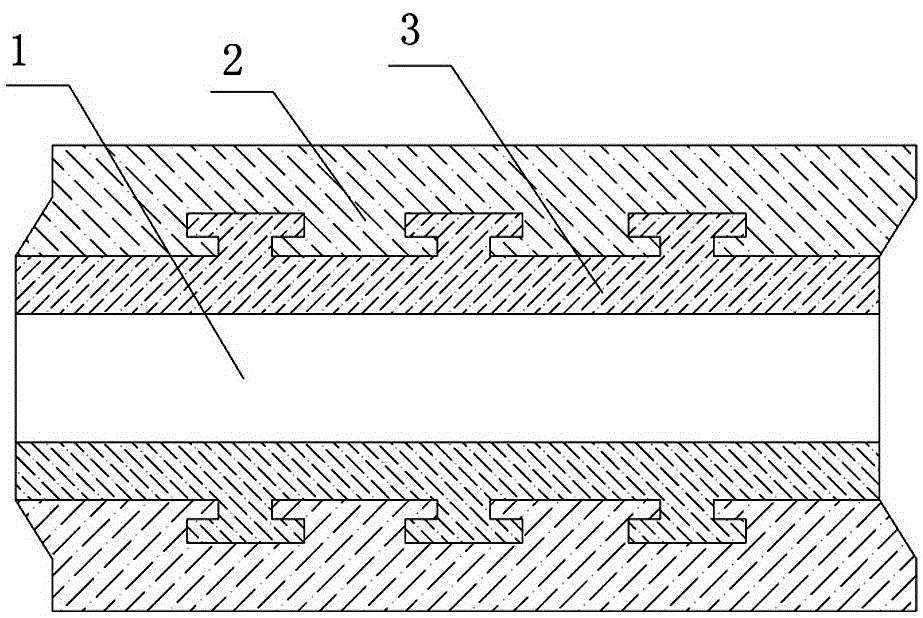

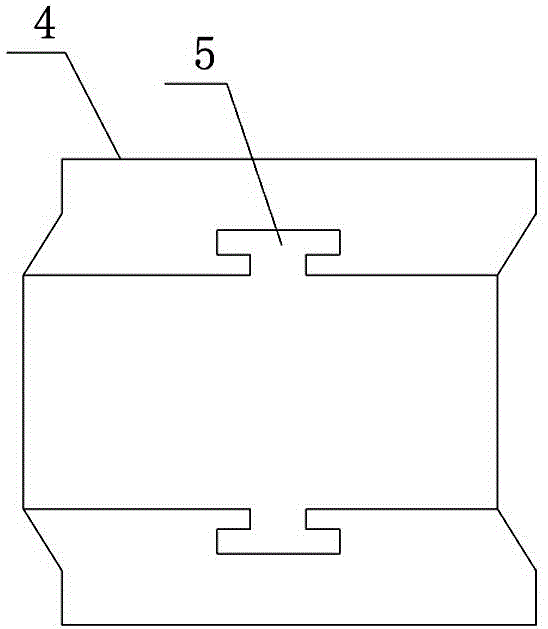

Deformation-controllable frame filling wall and construction method thereof

InactiveCN105507454AReduce earthquake forceProtection securityWallsShock proofingRebarDeformation control

The invention discloses a deformation-controllable frame filling wall which is mainly composed of a frame 1, a filling wall 2, deformation control parts 3, horizontal tie bars 4, restraint columns 5 and horizontal connection beams 12. The deformation-controllable frame filling wall is characterized in that the frame 1 is composed of a frame upper beam 6, a frame lower beam 7, a frame left column 8 and a frame right column 9, the filling wall 2 is a brickwork filling wall which is built by bricks (clay bricks and hollow bricks) or concrete building blocks, the deformation control parts 3 are arranged at positions where four corners of the filling wall contact with joints of the frame, the filling wall 2 is connected with the frame left column 8 and the frame left column 9 through a flexible material 10, and connected with the frame upper beam 6 and the frame lower beam 7 through an elastic connection material 15, the restraint columns 5 are arranged at positions where the filling wall 2 is connected with the flexible material 10, and the horizontal tie bars 4 which are arranged in the height direction of the filling wall are connected with the restraint columns. When the height of the filling wall is large, horizontal tie beams 12 can be arranged in the filling wall, and two ends of the horizontal tie beams 12 are connected with the restraint columns 5.

Owner:INST OF ENG MECHANICS CHINA EARTHQUAKE ADMINISTRATION

Super strengthen adhesives for adhering ceramic tile of wall and floor

The invention relates to a wall and floor tile paving ultrastrong adhesive, composed of cement, yellow sand, limestone powder, sulphoaluminate sweller, fibrin and polyvinyl acetate emulsion powder, and it can completely efficiently paving the wall surfaces and top surfaces of buildings, improving the binding strength of ceramic wall tiles and natural and man-made stone materials to the bases by a large margin, and it has high press-cut-binding strength, water resistance, high temperature resistance and good freeze-thaw resistance, and can be cold-placed and has long regulating time, and low shrinkage. It is applied to pasting the decorative materials, such as ceramic wall and floor tiles or marble, granite, man-made stone materials, etc on the surfaces of clay brick, cement mortar, cement and concrete and concrete bricks.

Owner:TONGJI UNIV

Ceramsite heat insulation brick and preparation method thereof

The invention relates to a building material and a preparation process thereof, and in particular relates to a heat insulation brick containing ceramsites and a preparation method thereof. The technical scheme of the invention is as follows: a ceramsite heat insulation brick is provided. The ceramsite heat insulation brick comprises the following raw material in parts by weight: 20-40 parts of ceramsite, 20-40 parts of steel furnace slag, 5-10 parts of fluorite tailings, 8-9 parts of coal ash, 5-10 parts of white mud and 1-3 parts of activating agent. The ceramsite heat insulation brick has the beneficial effects that 1, if the brick disclosed by the invention is used in a building to build a wall body, the self-weight of the building is reduced by about 30% as compared with the traditional clay brick, basic building cost of a foundation is reduced, and project cost is reduced; 2, compression strength is high; 3, heat insulation, heat isolation and sound isolation properties are good;4, the brick has fire-resistant and seismic performance and is good in durability; and 5, the brick does not crack and is good in frost resisting property. The heat insulation brick is strong in practicability when in use; and because the heat insulation brick is light and high in strength, construction efficiency is high, and the heat insulation brick is suitable for various building structures.

Owner:赵汝雄

Clay-corundum mullite composite runner brick, and production method thereof

The invention discloses a clay-corundum mullite composite runner brick. The clay-corundum mullite composite runner brick comprises a brick base body provided with a molten steel runner; the surface of the molten steel runner is combined with a working layer so as to improve washing resistance and erosion resistance of the clay-corundum mullite composite runner brick; the bonding surface of the brick base body with the working layer is designed to be a staggered slot structure; cheap flint clay, clay raw material, and pyrophyllite raw material are taken as the main materials of an outer layer of the brick base body; tabular corundum, electro-fused white corundum, electro-fused mullite, and sintered alpha-Al2O3 micro powder are taken as the main materials of the working layer; the thickness of the brick base layer and the thickness of the working layer can be adjusted based on the kind of alloy steel to be smelted. In production, a clay brick base body green body and a corundum mullite working layer self-flowing material are prepared respectively; a mould is delivered into the clay brick base body green body, and the gaps between the mould and the clay brick base body green body are filled with the corundum mullite working layer self-flowing material; and at last, the clay-corundum mullite composite runner brick is obtained via roasting and sintering at 1350 to 1400 DEG C. The clay-corundum mullite composite runner brick is low in cost, and high in thermal insulation performance and molten steel washing erosion resistance; and the market competitive advantages are obvious.

Owner:济源市耐火炉业有限公司

Light fireproof thermal insulating mortar with cement base

InactiveCN1559967AImprove fire performanceImprove thermal insulation performanceSolid waste managementRebarFire resistance

The invention relates to a cement-based light fireproof heat-preserving mortar, composed of ordinary portland cement, powder coal ashes, expanded perlite, fibrin, and sodium lauryl benzene sulfonate. It can efficiently construct thermal insulating layers on wall surfaces and top surfaces of buildings, thus improving the heat-preserving and -insulating property of buildings, reducing the energy consumption for heating in the northern winter and temperature drop in the southern summer. It has characters of low density, high temperature resistance, incombustibility, good fire resistance, and use safety. It is applied to the construction of thermal insulating layers of walls and roofs of reinforced concrete, concrete, clay brick, metal, etc, and also applied to the construction of thermal insulating layers of bathrooms, basements, refrigeratories, etc.

Owner:TONGJI UNIV

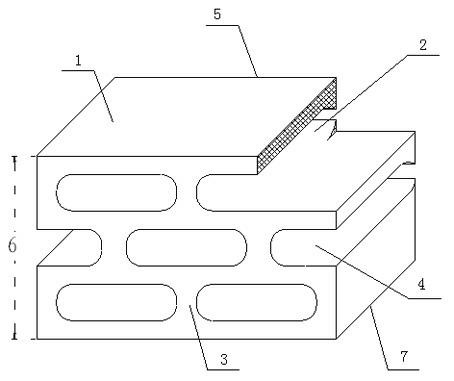

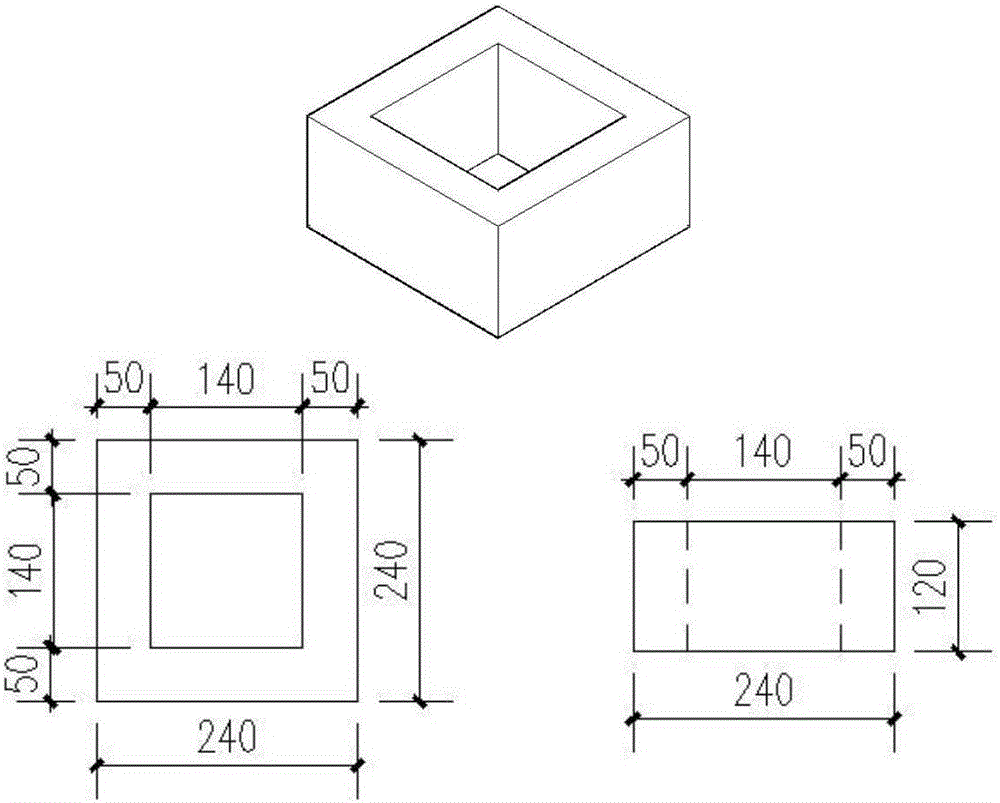

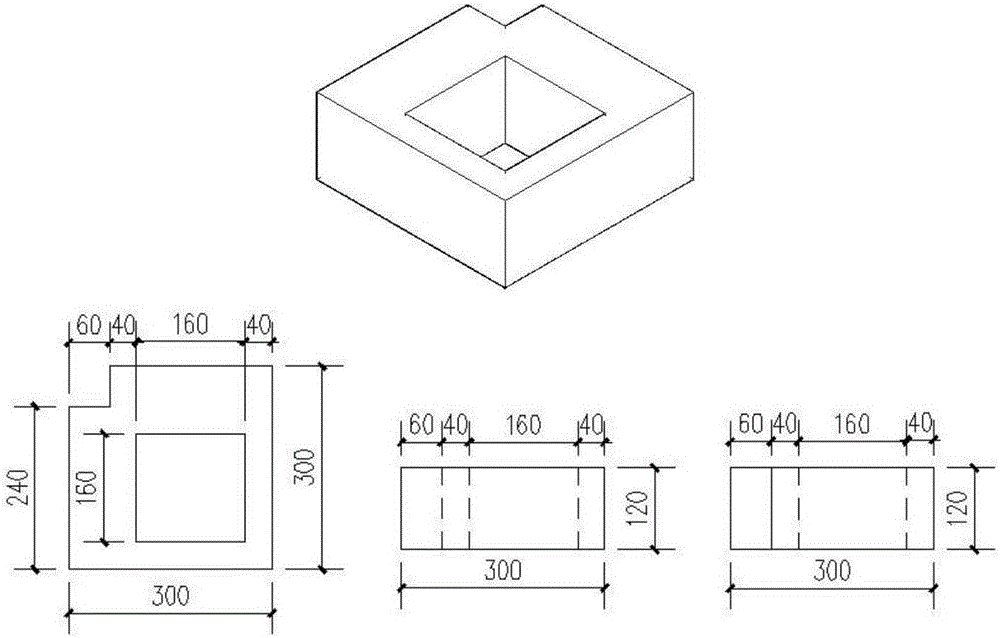

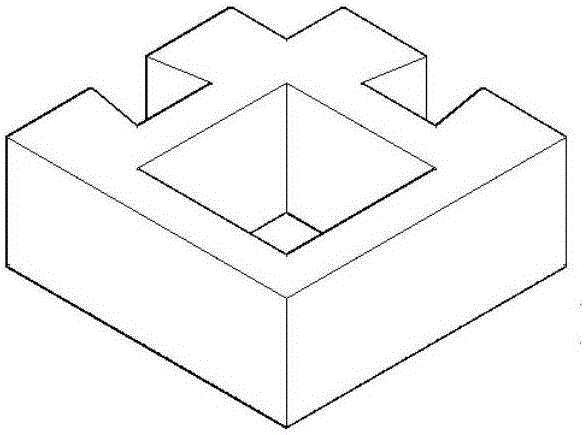

Rural masonry structure assembled integral type ring beam-constructional column combination technology

The invention discloses a rural masonry structure assembled integral type ring beam-constructional column combination technology. The technology comprises the steps that (1) ring beam blocks, tenon blocks, constructional column blocks not containing horse tooth troughs, constructional column blocks containing horse tooth troughs and constructional column blocks containing mortises are prefabricated; (2) when a wall is built with bricks, the constructional column blocks not containing horse tooth troughs, the constructional column blocks containing the horse tooth troughs and the wall are assembled and built with the bricks in a staggered mode, and assembled type hollow prefabricated construction columns are formed; (3) after masonry, steel reinforcement cages are put into center holes, and assembled integral type constructional columns are formed by concrete pouring; and (4) the constructional column blocks containing the mortises and the prefabricated ring beam blocks are connected, through long ribs with the diameter greater than or equal to 10 mm are distributed in reserved stirrups of the upper portions of the prefabricated ring beam blocks and are connected with the steel reinforcement cages of the constructional columns, clay bricks are laid on the two sides of the upper portions of the prefabricated blocks, concrete is poured, assembled integral type ring beams are formed, and an assembled integral type ring beam-constructional column house is formed through sequential masonry. The rural masonry structure assembled integral type ring beam-constructional column combination technology advantageously achieves industrial production, standard construction and environmental protection of masonry structures, improves the anti-seismic performance of rural masonry structure houses, and ensures the life and property security of people.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com