Novel carbonized baking-free brick prepared through marine waste silt and preparation method of brick

A technology of burning-free bricks and silt, which is applied in the manufacture of tools, ceramic molding machines, solid waste management, etc., can solve the problems that the compressive strength cannot be less than 8MPa, and it is difficult to meet the industrial application requirements of burning-free and pressure-free silt bricks, so as to achieve energy saving Remarkable effect, reduction of greenhouse effect, effect of shortening brick-making cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

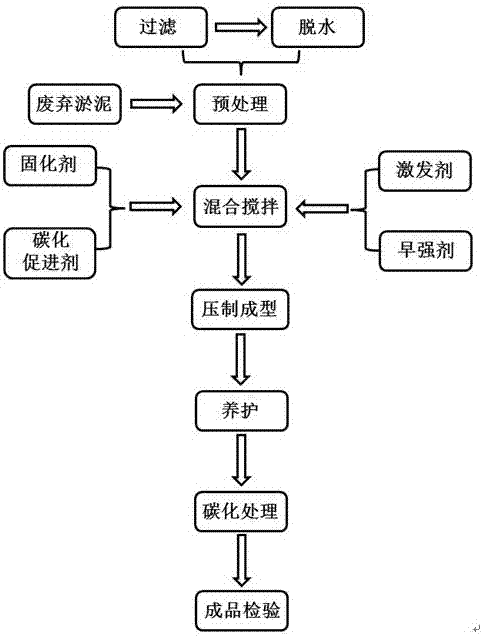

[0041] The present invention provides a method for preparing novel carbonized non-burning bricks by using marine waste silt, comprising the following steps:

[0042] (1) Pretreatment: filter the waste marine silt to remove large-grained stones, aquatic plants and other debris in the silt, and then centrifugally dehydrate the filtered silt to reduce the moisture content to 45-75%;

[0043] (2) Mixing and stirring: put 30 parts of waste sludge (excluding the dry weight of water), 10 parts of quicklime, 5 parts of activated magnesium oxide, 10 parts of slag, 30 parts of fly ash, and 15 parts of sand into the Mix and stir in the mixer for 5 minutes to ensure that the mixture is uniform;

[0044] (3) Compression forming: the mixture obtained in step (2) is put into a mould, and it is compressed and formed under a pressure of 20-35MPa by a hydraulic automatic forming machine to obtain adobe;

[0045] (4) Curing: send the adobe made in step (3) to a high-pressure steam engine for 10...

Embodiment 2

[0050] In Example 2, a method for preparing a new type of carbonized unburned brick by using marine waste sludge is the same as the preparation method in Example 1.

[0051] Wherein, the parts by weight of each raw material in step (2) are: 60 parts of waste sludge (dry weight excluding moisture), 5 parts of quicklime, 5 parts of slag, 20 parts of fly ash, 5 parts of sand, and 1 part of water glass , 2 parts of sodium hydroxide, 2 parts of powdered calcium formate.

[0052] The new carbonized burnt-free brick obtained in Example 2 was tested, and its strength value was 35MPa, and its durability was good, which could effectively replace the existing solid clay brick.

Embodiment 3

[0054] In Example 3, a method for preparing a novel carbonized non-burning brick by using marine waste sludge is the same as the preparation method in Example 1.

[0055] Wherein, the parts by weight of each raw material in the step (2) are respectively: 40 parts of waste sludge, 5 parts of cement, 5 parts of quicklime, 5 parts of active magnesium oxide, 5 parts of slag, 30 parts of fly ash, 7 parts of sand, water glass 1 part, 1 part sodium hydroxide, 1 part powdered calcium formate.

[0056] The new carbonized unburned brick obtained in Example 3 was tested, and its strength value was 25MPa, and its durability was good, which can effectively replace the existing solid clay brick.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intensity value | aaaaa | aaaaa |

| Intensity value | aaaaa | aaaaa |

| Intensity value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com