Patents

Literature

181results about How to "Reduce connection strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

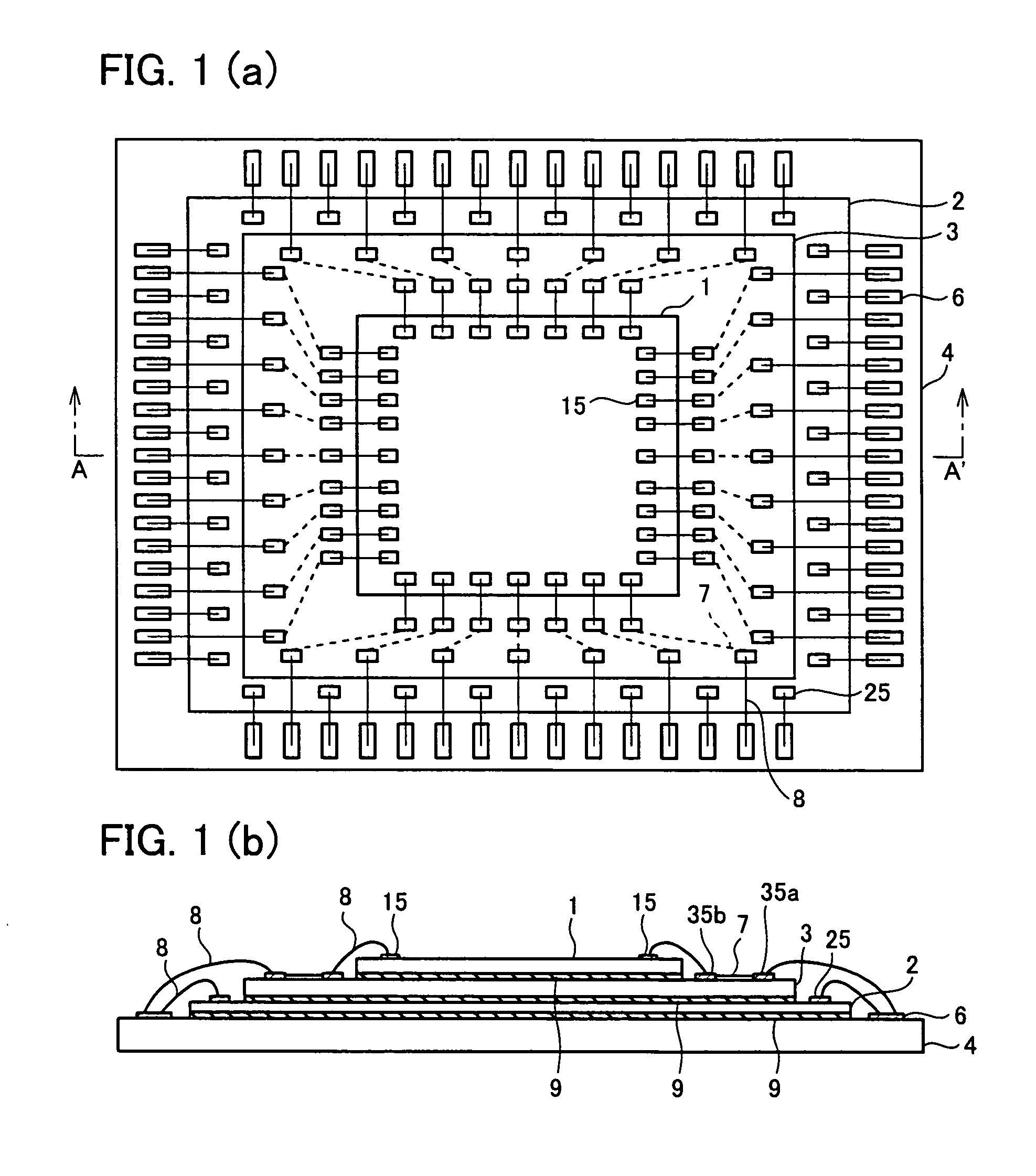

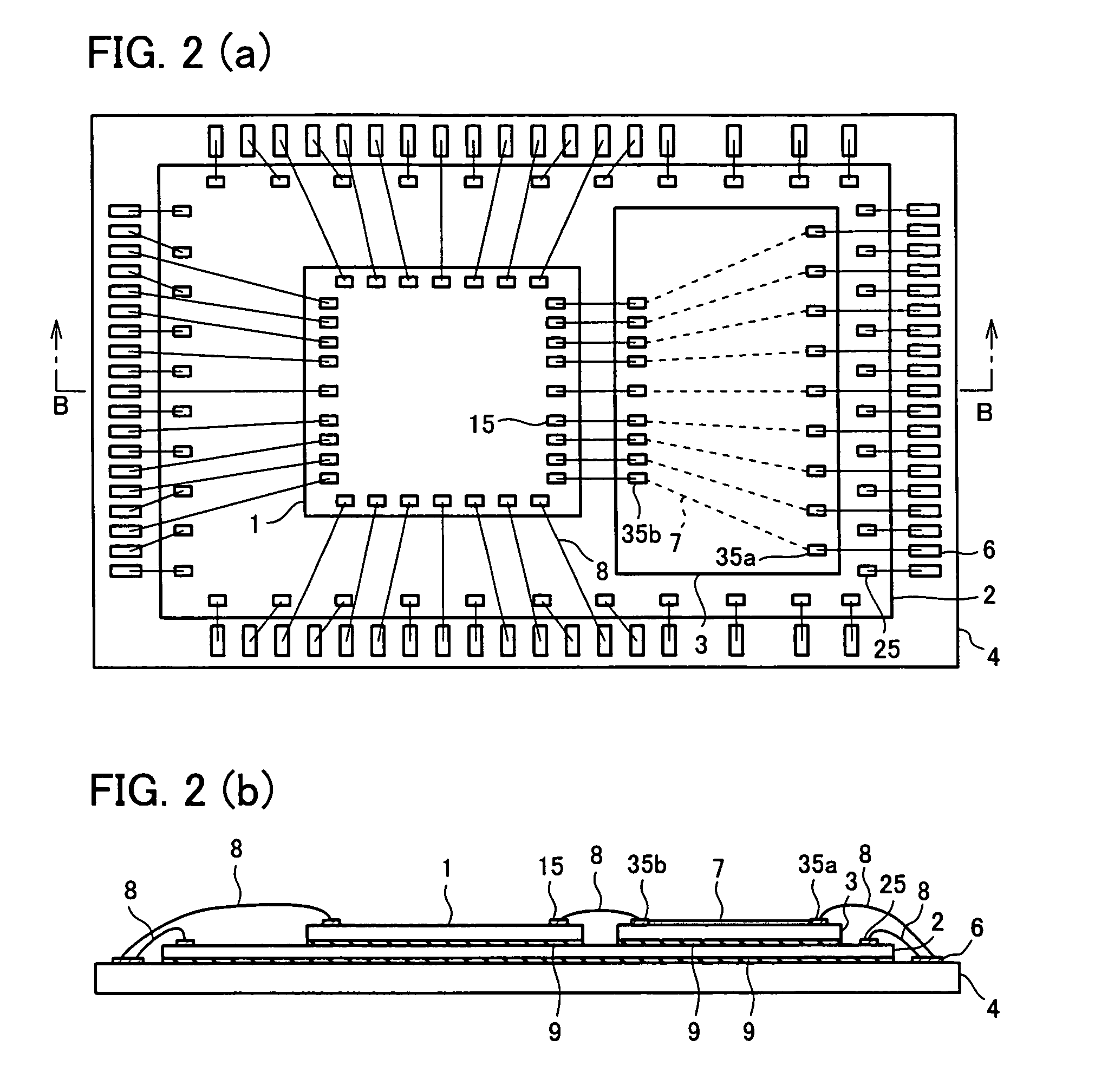

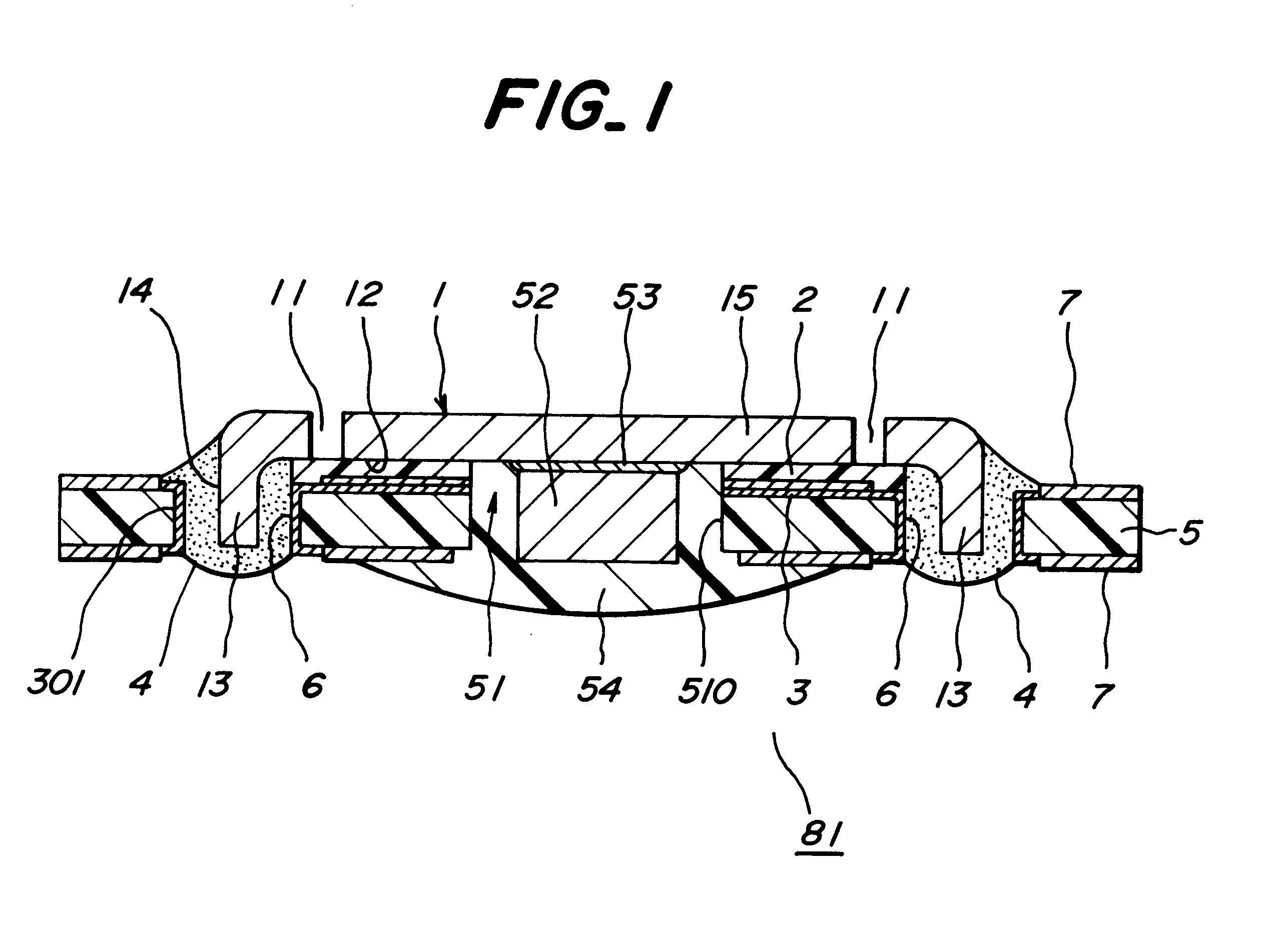

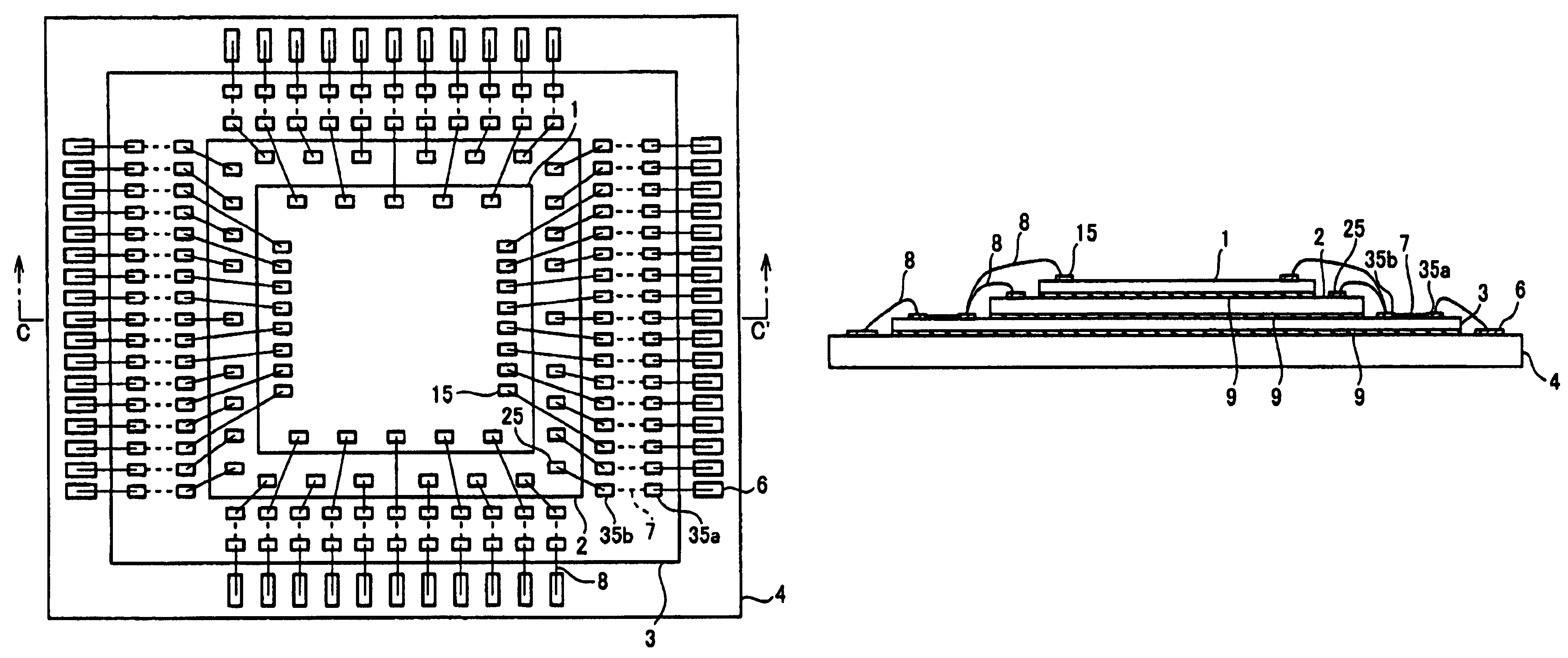

Semiconductor device

ActiveUS6979905B2Prevents wire bonding strengthInhibition strengthSemiconductor/solid-state device detailsSolid-state devicesElectric propertiesEngineering

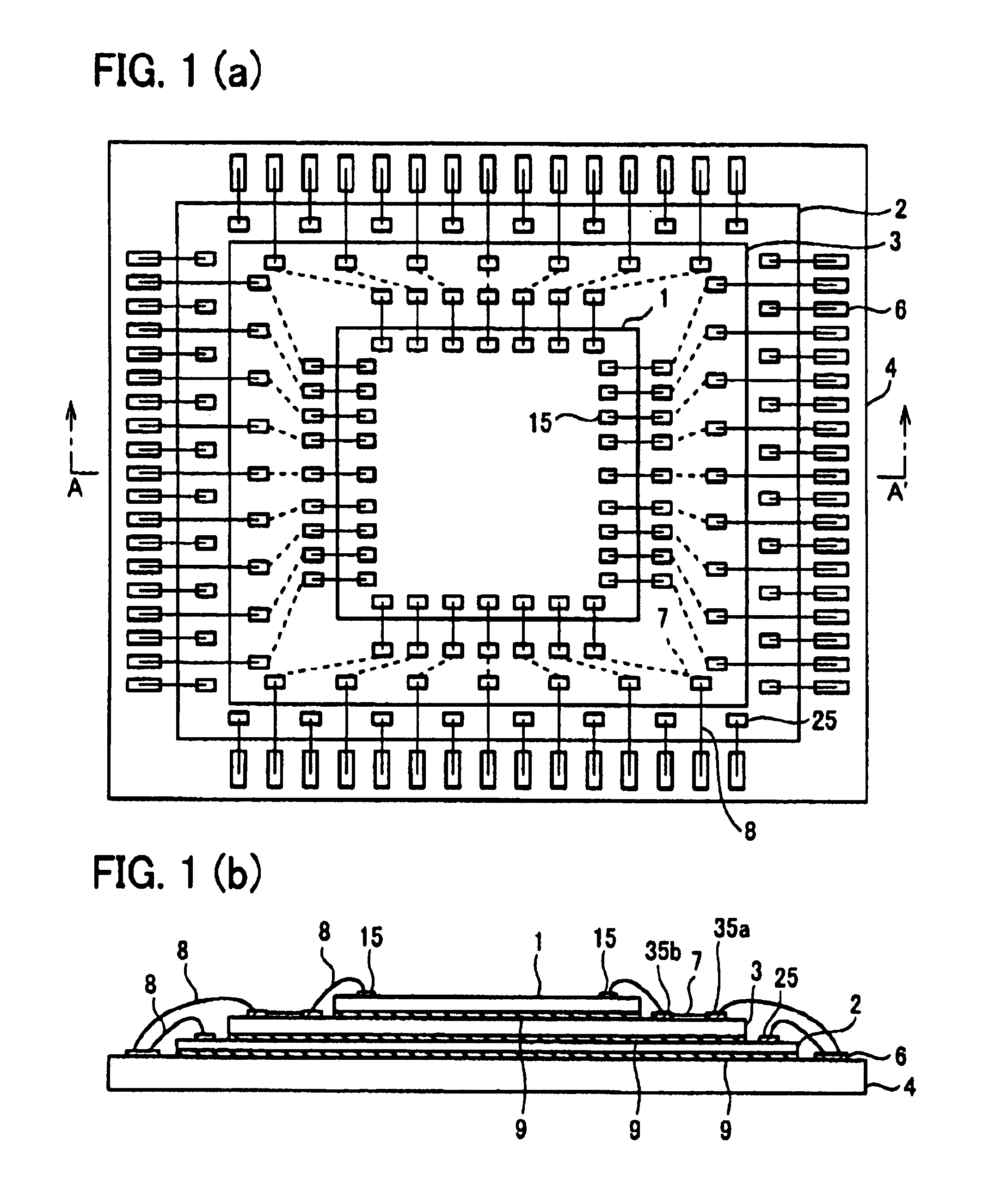

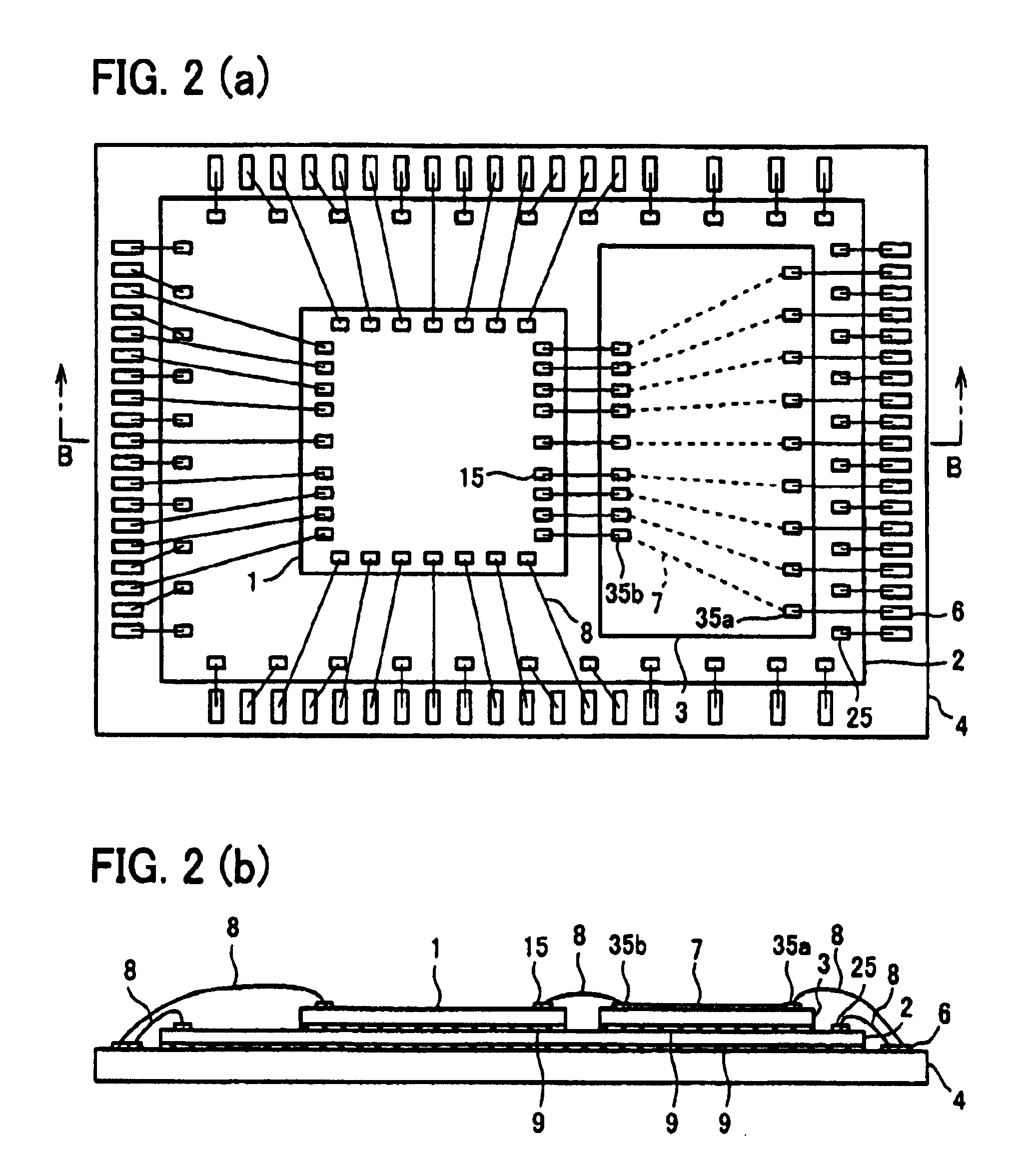

In a semiconductor device in which a semiconductor chip is stacked on a substrate, an interposer chip having wirings is provided under the semiconductor chip. A bonding pad of the semiconductor chip is electrically connected to a bonding terminal provided on the substrate via the interposer chip by wire bonding. The interposer chip prevents a semiconductor element formed in the semiconductor chip from deteriorating in terms of an electric property and from being physically damaged. Further, the wire bonding strength does not drop. Moreover, it is possible to form a fine wiring pitch for relaying a wire-bonding wire.

Owner:SHARP KK

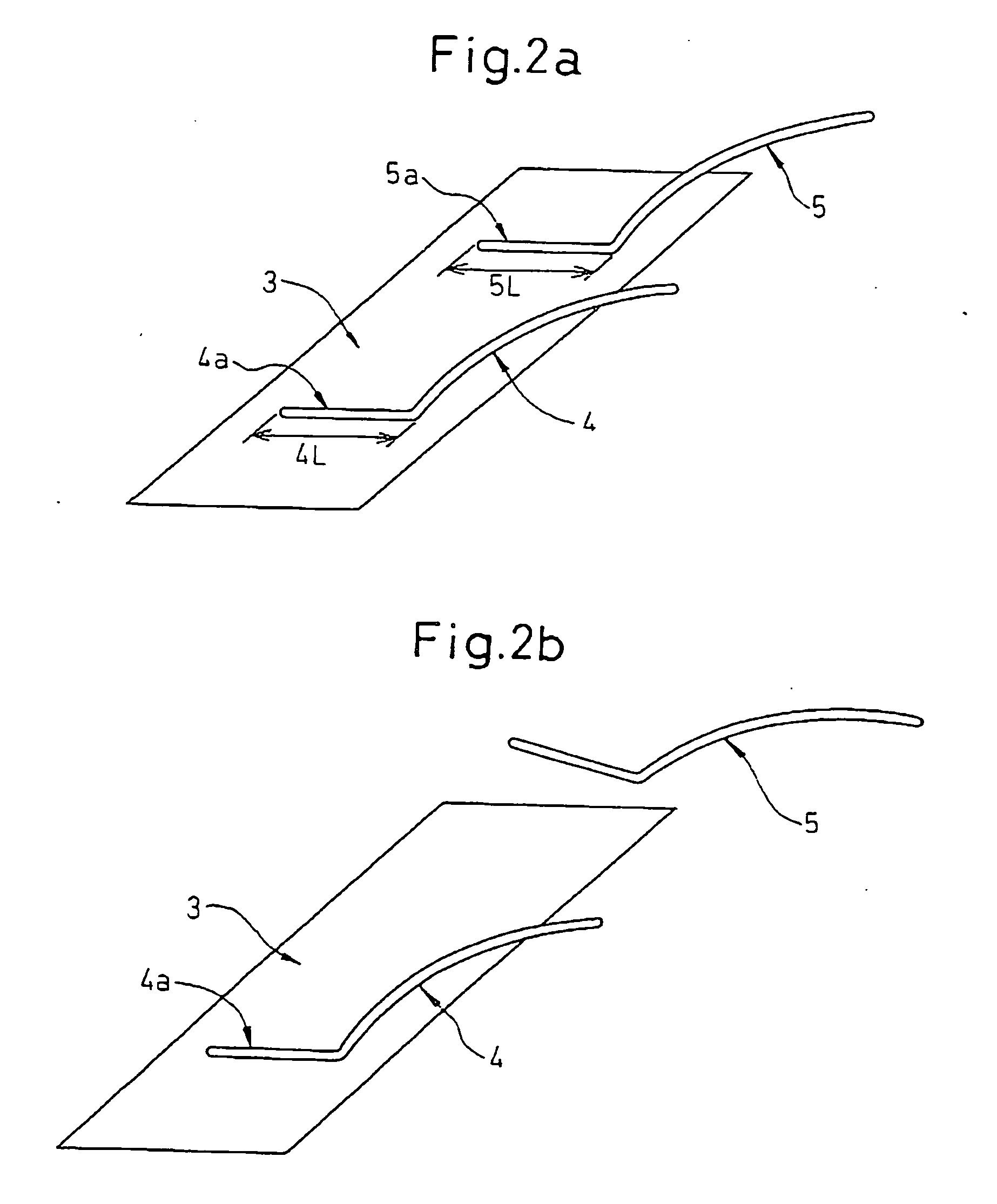

Electronic component mounting base board having heat slug with slits and projections

InactiveUS6232558B1Avoid it happening againAvoid warpingPrinted circuit assemblingSemiconductor/solid-state device detailsHeat sinkElectrical conductor

An electronic component mounting base board has an insulating substrate provided with a conductor circuit and a mount portion for an electronic component, and a heat slug adhered to the insulating substrate, wherein the heat slug is comprised of a flat main body and a projection portion extending vertically from a side face of the main body, and provided with a slit deforming portion absorbing deformation of the insulating substrate.

Owner:IBIDEN CO LTD +1

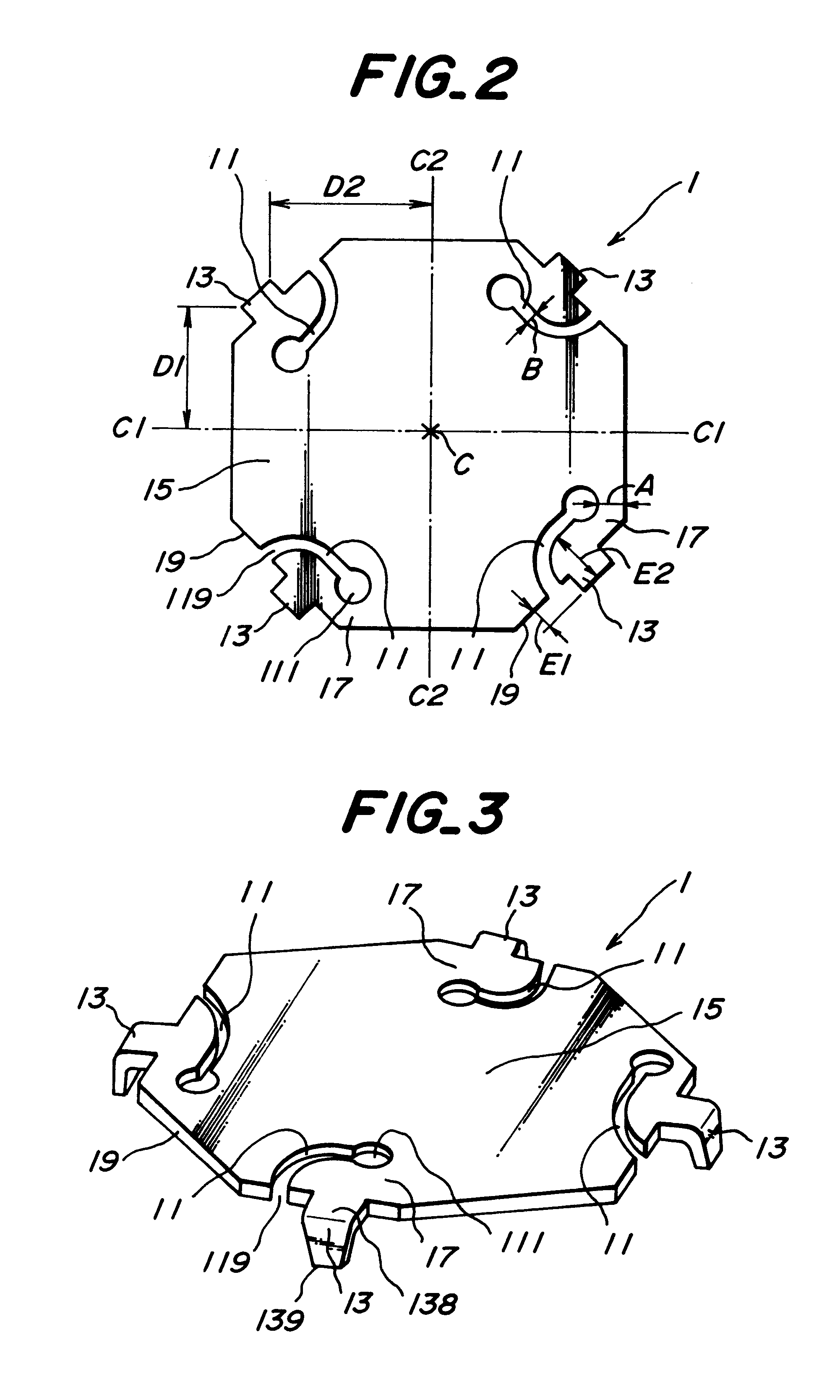

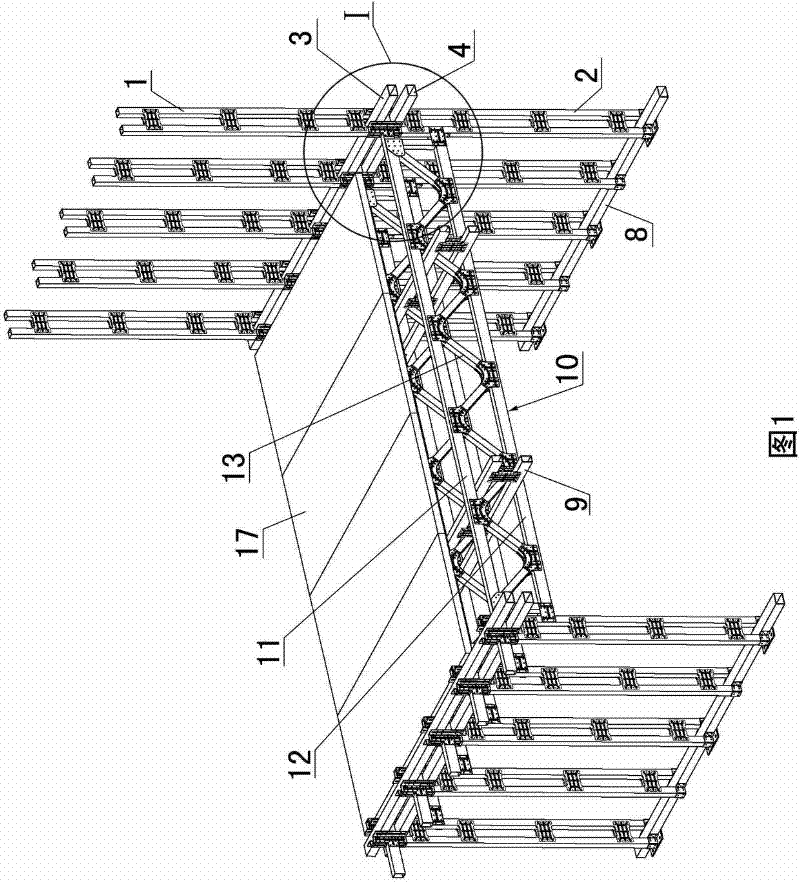

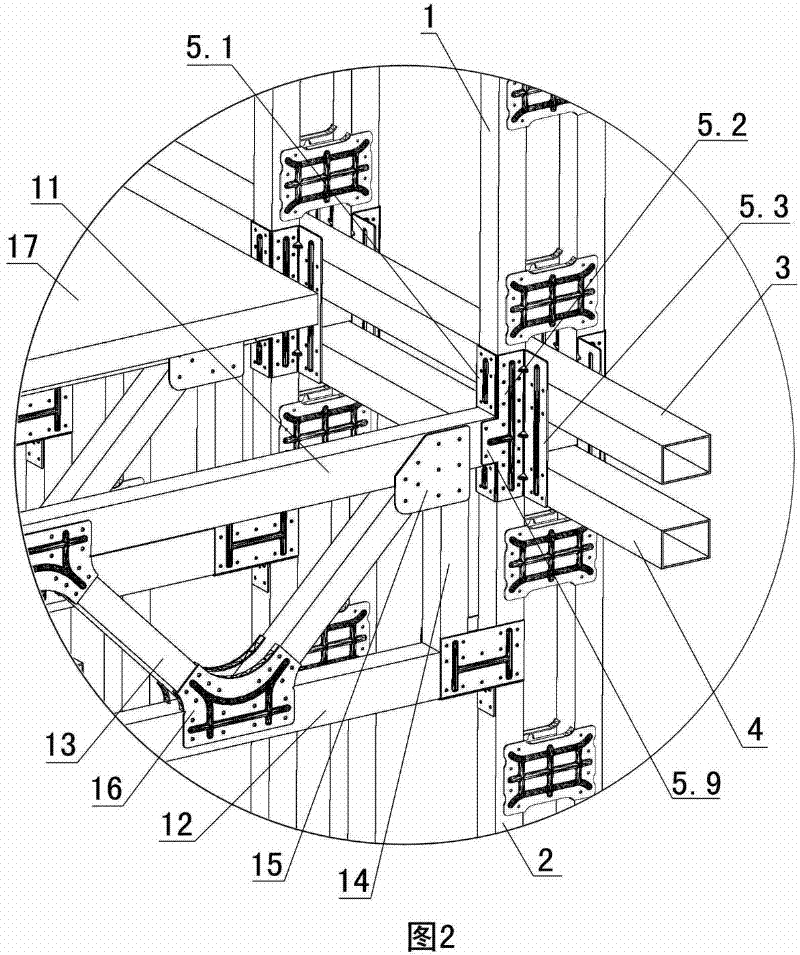

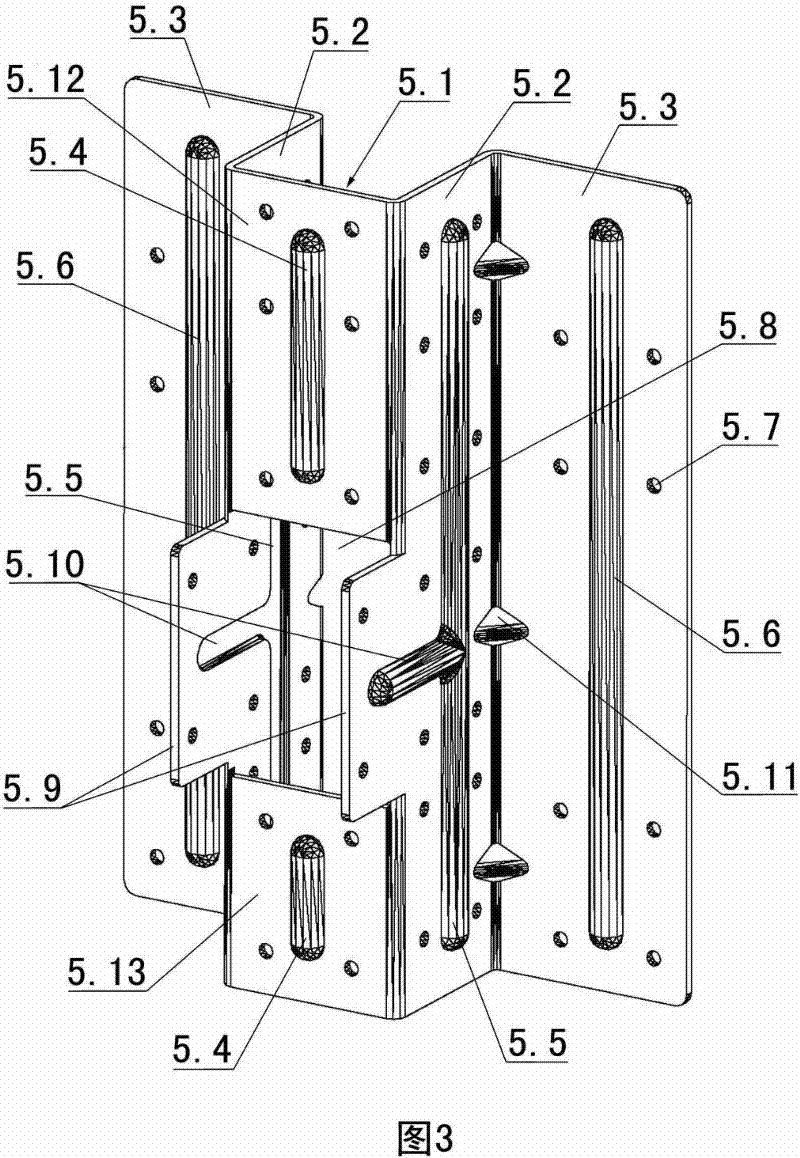

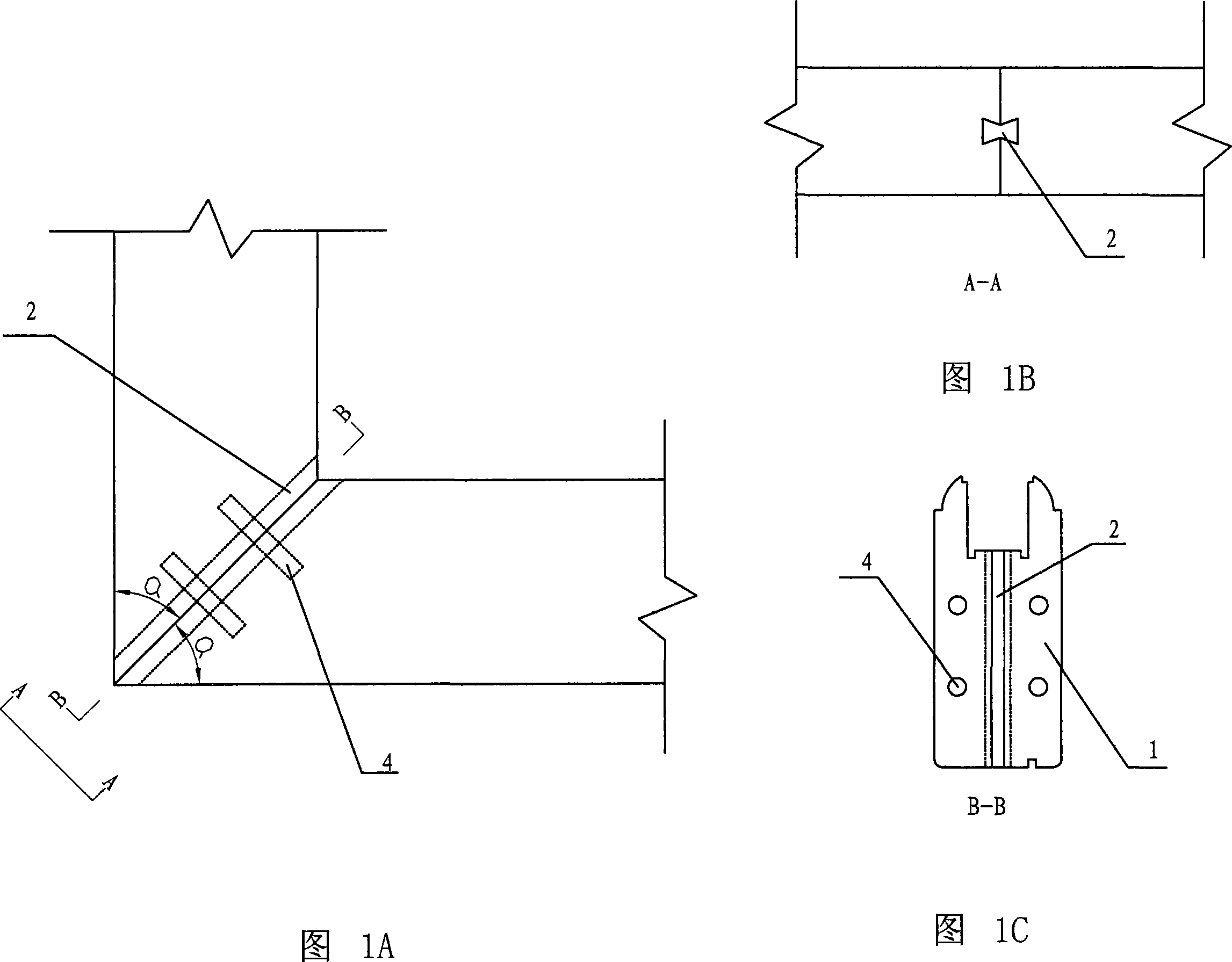

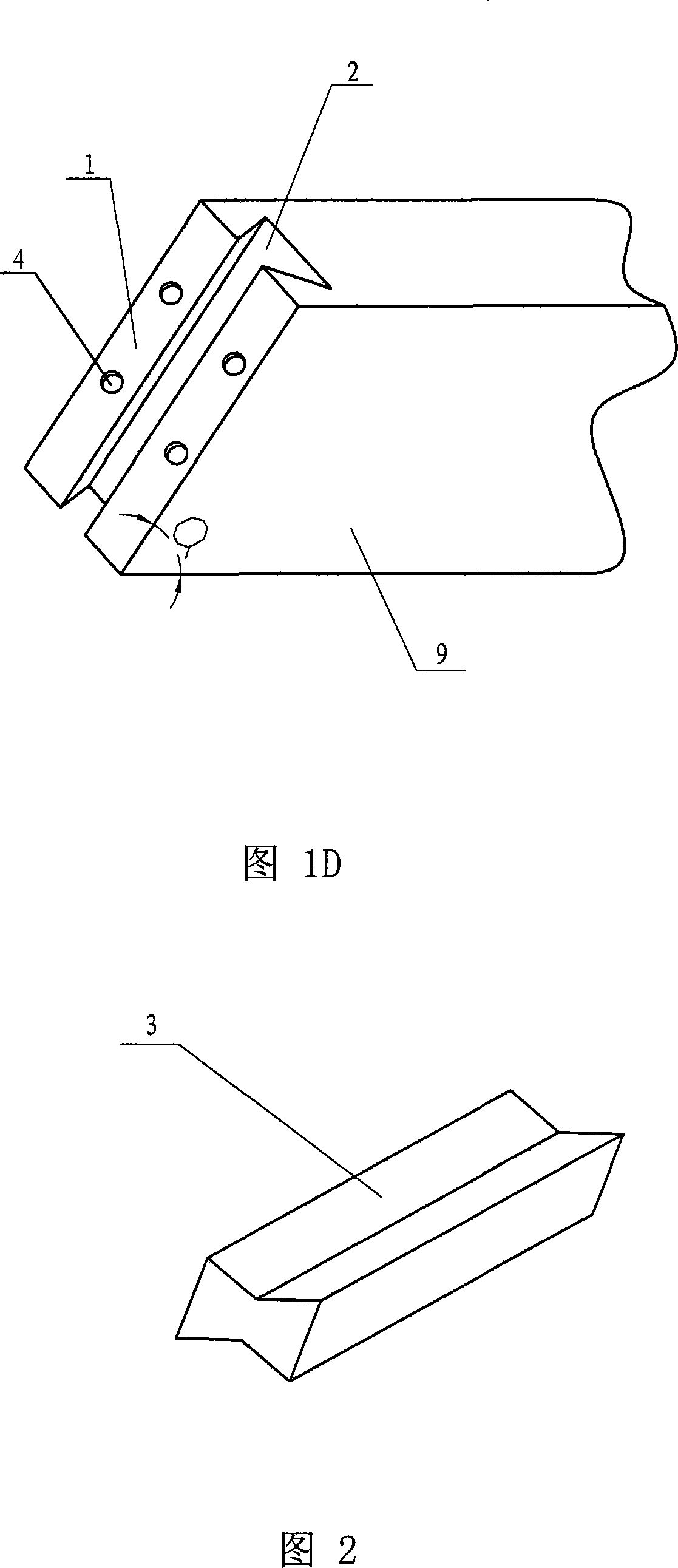

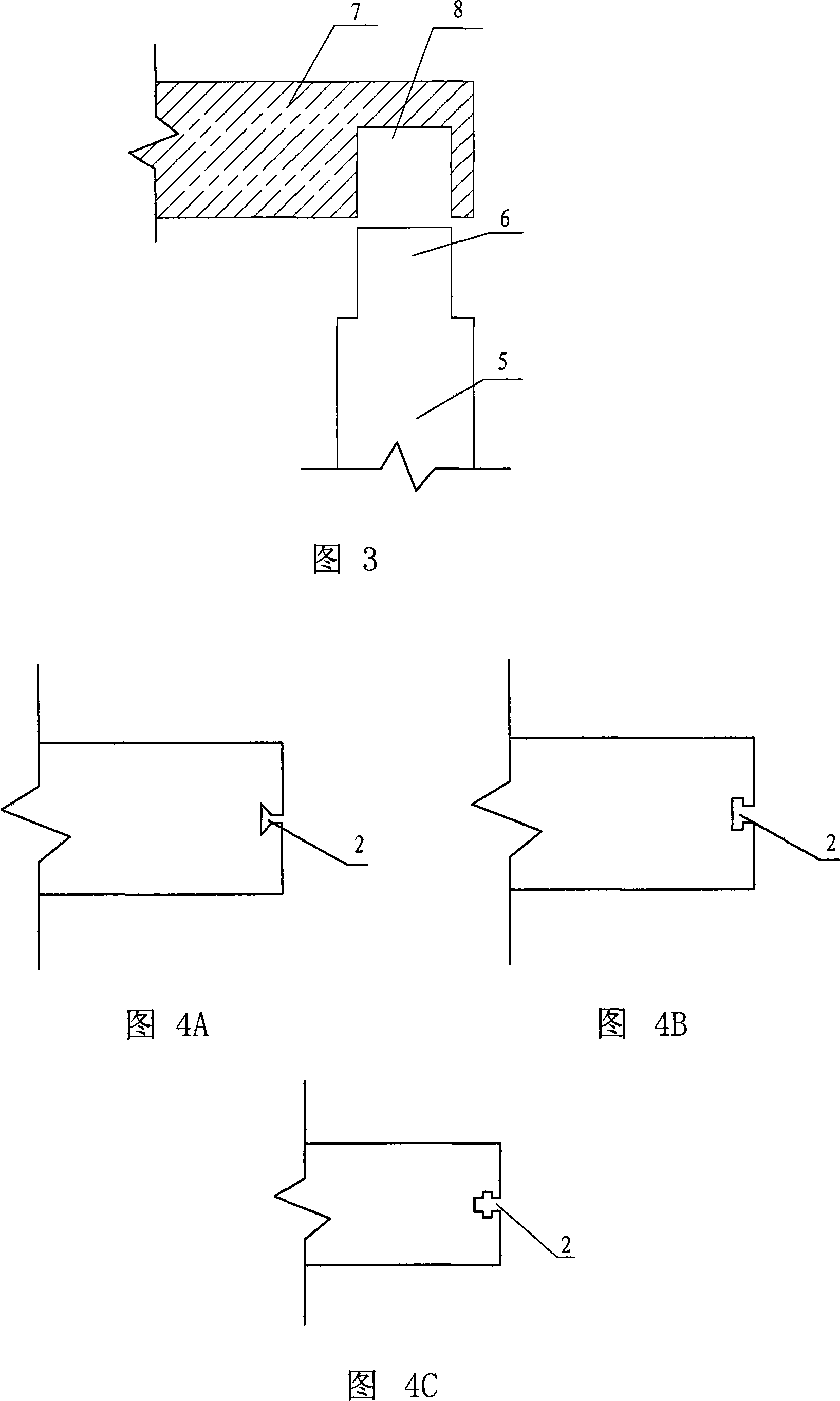

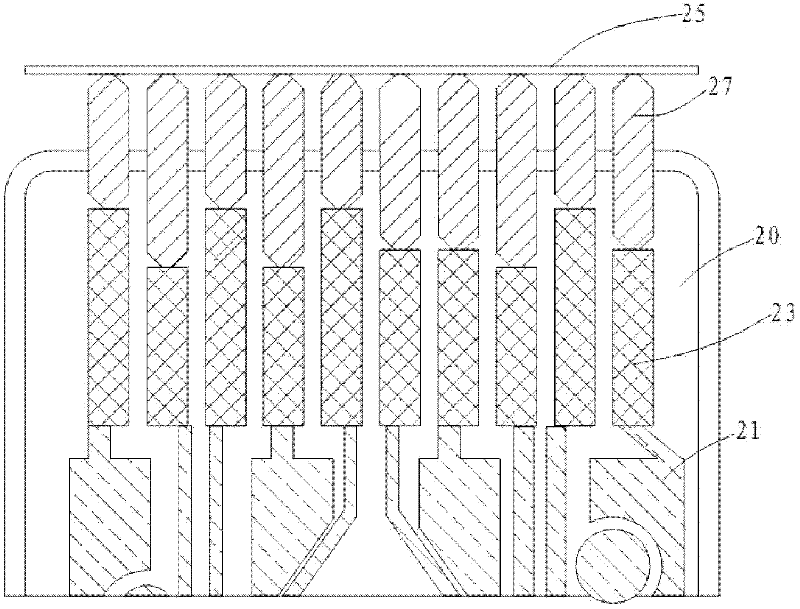

Truss combined beam and upper and layer connected light steel structure and construction method thereof

InactiveCN102359180ATroubleshoot simultaneous connectionsSolve the shortcomings that the pressure is not easy to meet the force requirementsGirdersJoistsRear quarterKeel

The invention discloses a truss combined beam and upper and layer connected light steel structure and a construction method thereof. The light steel structure comprises upper wall sheet columns distributed at intervals, lower wall sheet columns distributed at intervals, upper wall sheet column lower connecting pipes connected among the lower parts of the upper wall sheet columns, lower wall sheet column upper connecting pipes connected among the upper parts of the lower wall sheet columns, and truss combined beams connected between the upper wall sheet columns and the lower wall sheet columns through upper and lower connectors, wherein the upper and lower connectors are beam passing buckles, the web plates of the beam passing buckles consist of upper web plates and lower web plates, a square connecting port is formed between the upper web plates and the lower web plates, upper chord member connecting plates are extended from the left and right sides of the square connecting ports, and the upper chord member connecting plates and side plates of the beam passing buckles are positioned in the same plane. Through the light steel structure, the structural stability of a light steel keel house system is enhanced, and the floor surface beams, the connecting pipes and the floor panels do not easily vibrate.

Owner:筑巢(北京)科技有限公司

Method for manufacturing wooden sash section bar and method for assembling wooden window and door by using the same

InactiveCN101117874AImprove connection strengthReduce connection strengthCorner/edge jointsWindow/door framesEngineeringBuilding construction

A manufacturing method for assembling wood and door frame section material in field comprises the following steps: firstly, the wood is cut as per specified size and section shape; secondly, after cut, combination surfaces are formed on both ends of the wood, a key channel is formed at the combination surface, after the key channel is assembled into a frame parallel to the wood door section material and extended at the plane where is located and arranged between two surfaces of the frame, after the wood door and the window section material are matched at the corresponding combination surfaces, a pin key lock is used to fix with the adaptive key channel shapes; thirdly, surface treatment is done for wood of all the formed combination surfaces and key channels to be applicable for the wood door and the window section material for assembly at the construction site. The present invention is applicable for the manufacturing method for the wood door and the window section material in field and the method for assembling the wood door and the window with the section material for on-site arrangement. Structural strength of tenon is high, thus not damaging the surface of the section material and keeping the door and the window nice.

Owner:北京市木材厂有限责任公司

Resistance spot welding electrode and manufacturing method thereof

ActiveCN105234544ASolve thin and discontinuous problemsImprove connection strengthElectrode featuresWelding/soldering/cutting articlesElectrical resistance and conductanceElectrical conductor

The invention relates to a resistance spot welding electrode and a manufacturing method thereof, and belongs to the technical field of resistance spot welding. The resistance spot welding electrode comprises a first conductor and a second conductor. A groove matched with the second conductor in appearance is formed in the lower end face of the first conductor. The second conductor is inlaid in the groove. The lower end face of the second conductor is flush with the lower end face of the first conductor. The electrical resistivity of the second conductor is larger than the electrical resistivity of the first conductor. A cooling groove is formed in the upper end face of the first conductor. When the resistance spot welding electrode is used for welding, the connection strength between metal plates can be improved; the manufacturing method is simple and convenient, and the manufactured resistance spot welding electrode is firm in combination, good in performance and high in strength.

Owner:HENAN UNIV OF SCI & TECH

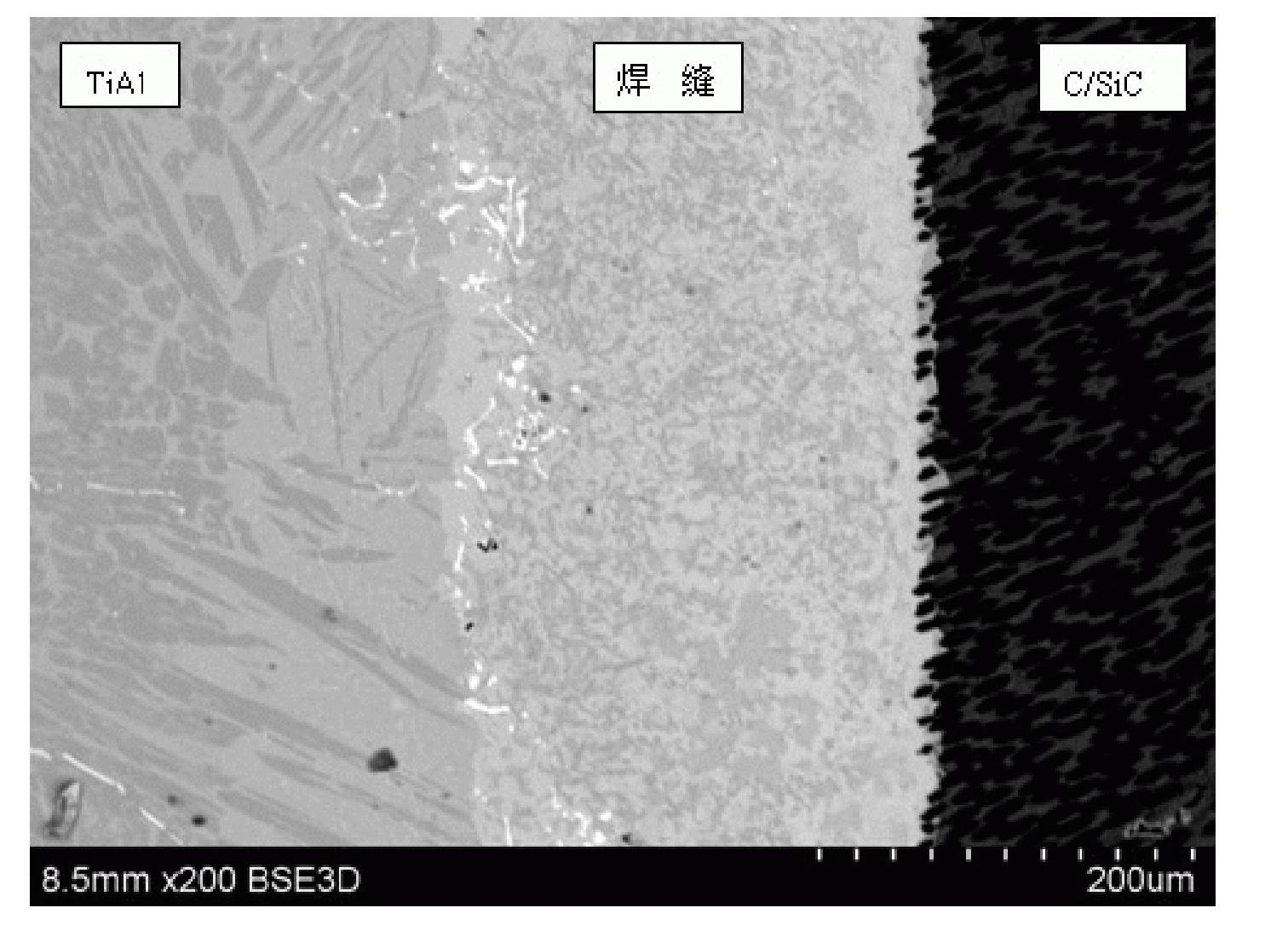

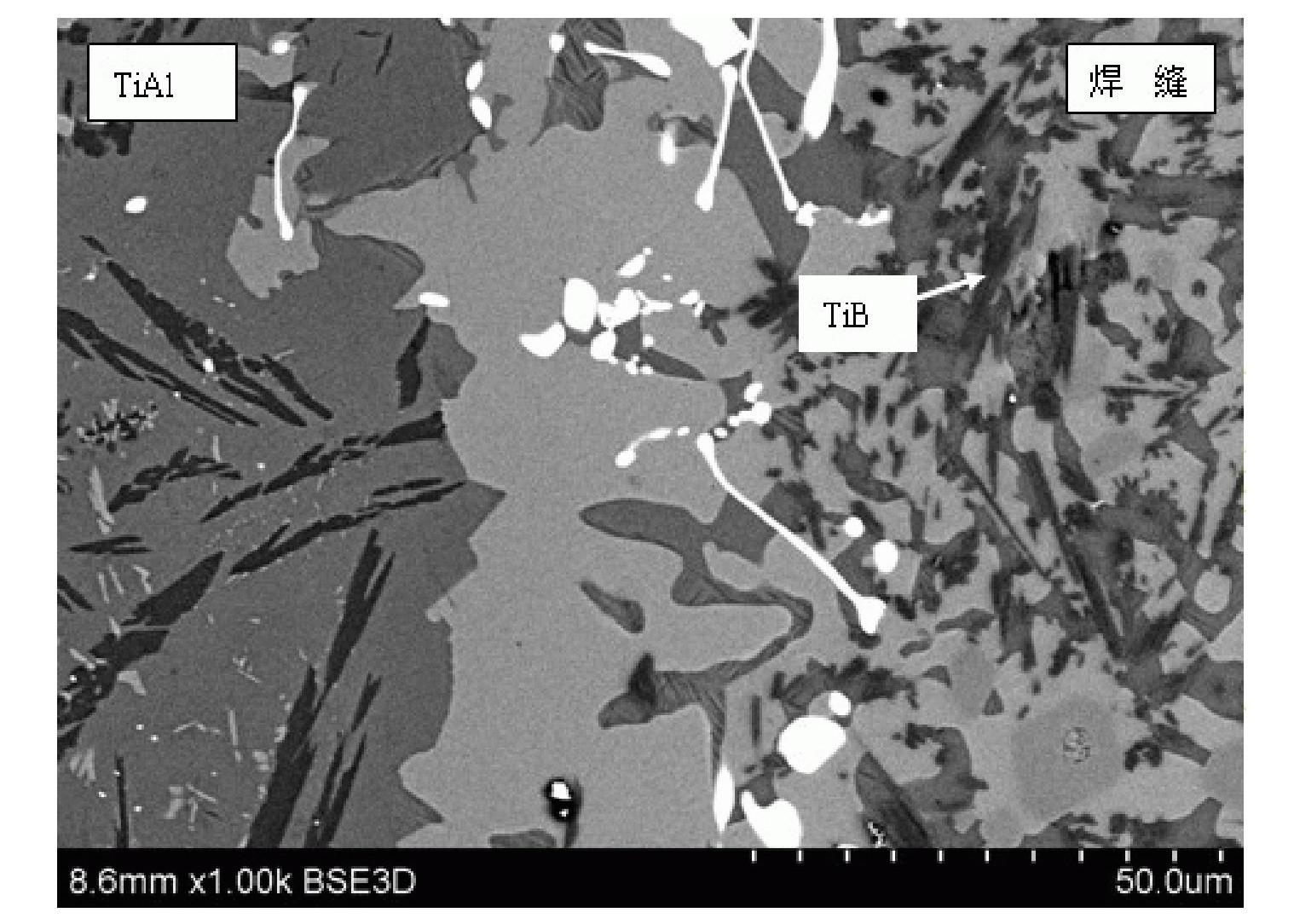

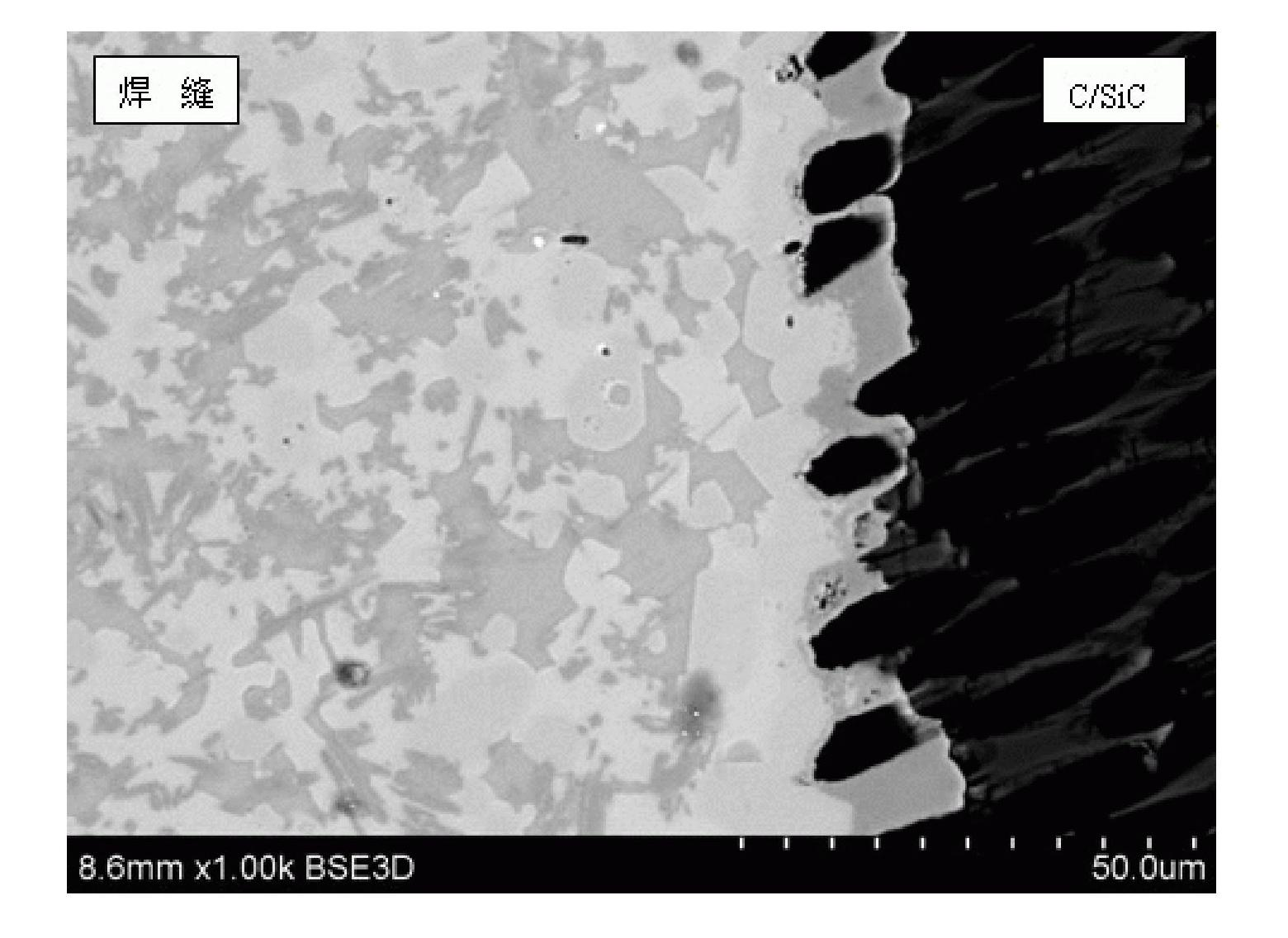

Solder for welding carbon/silicon carbide ceramic matrix composite material and titanium-aluminum-based alloy and soldering method

The invention discloses a solder for welding a carbon / silicon carbide ceramic matrix composite material and a titanium-aluminum-based alloy and a soldering method, relating to solders and soldering methods thereof. By the invention, the problems that the using temperature of the welding joint of the conventional silver-based solder for welding composite materials and titanium alloys is low and the process of a traditional method for indirectly soldering the carbon / silicon carbide ceramic matrix composite materials and metals is complex. The solder comprises titanium material powder, nickel powder and boron powder. The method comprises the following steps of: performing ball milling on the solder, preparing the solder into paste, coating the paste on a joint face to be welded of the carbon / silicon carbide ceramic matrix composite material and the titanium-aluminum-based alloy, putting a piece to be welded into a vacuum heating furnace, heating and preserving heat to complete the welding. The joint welded by the invention has a shearing strength of 40-105MPa at the room temperature, a shearing strength of 30-70MPa at 600 DEG C and the using temperature of not less than 600 DEG C, the soldering process is simple, and the welding efficiency is high. The solder can be used for the welding the carbon / silicon carbide ceramic matrix composite material and the titanium-aluminum-based alloy or a titanium-aluminum-based alloy piece.

Owner:HARBIN INST OF TECH

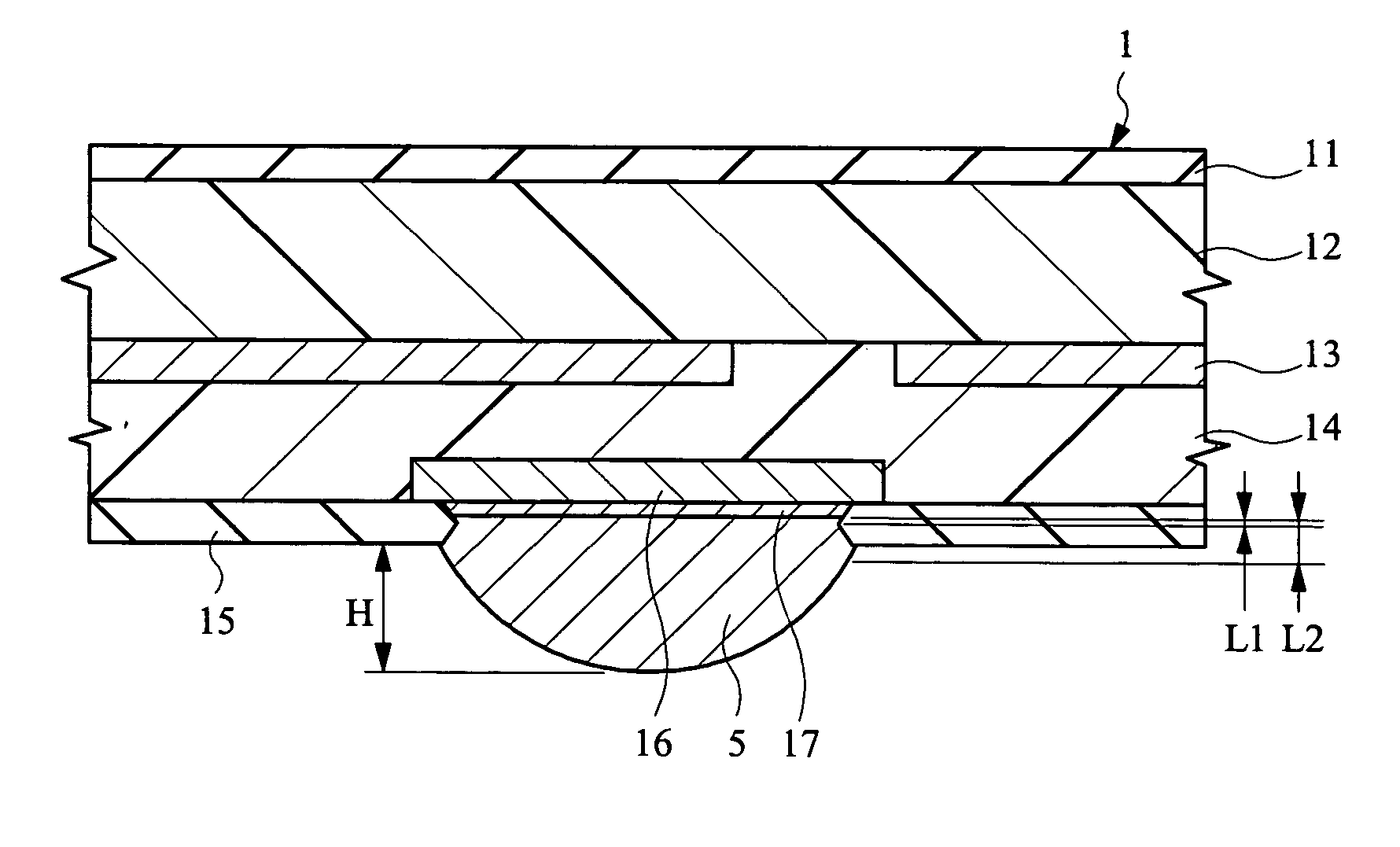

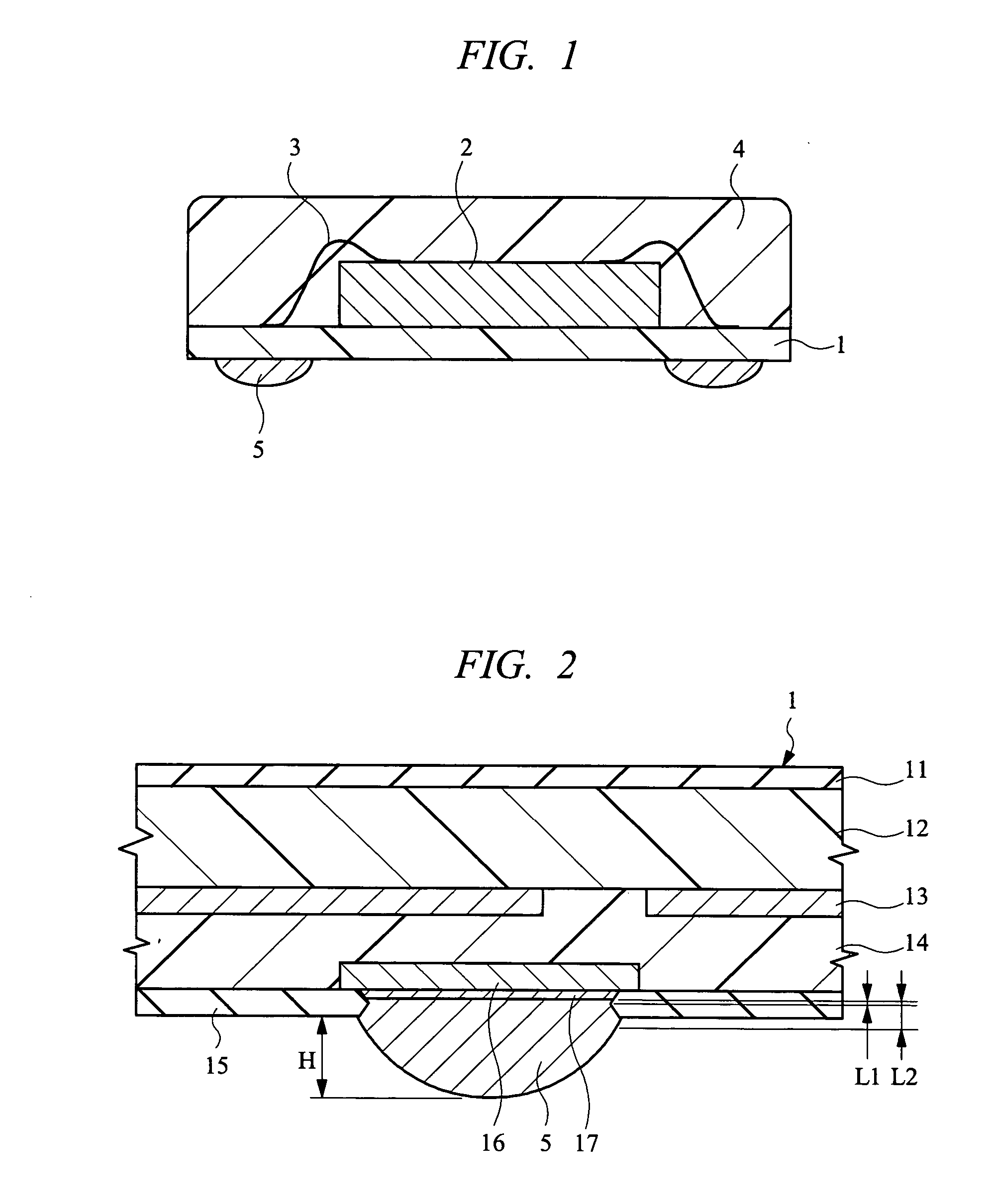

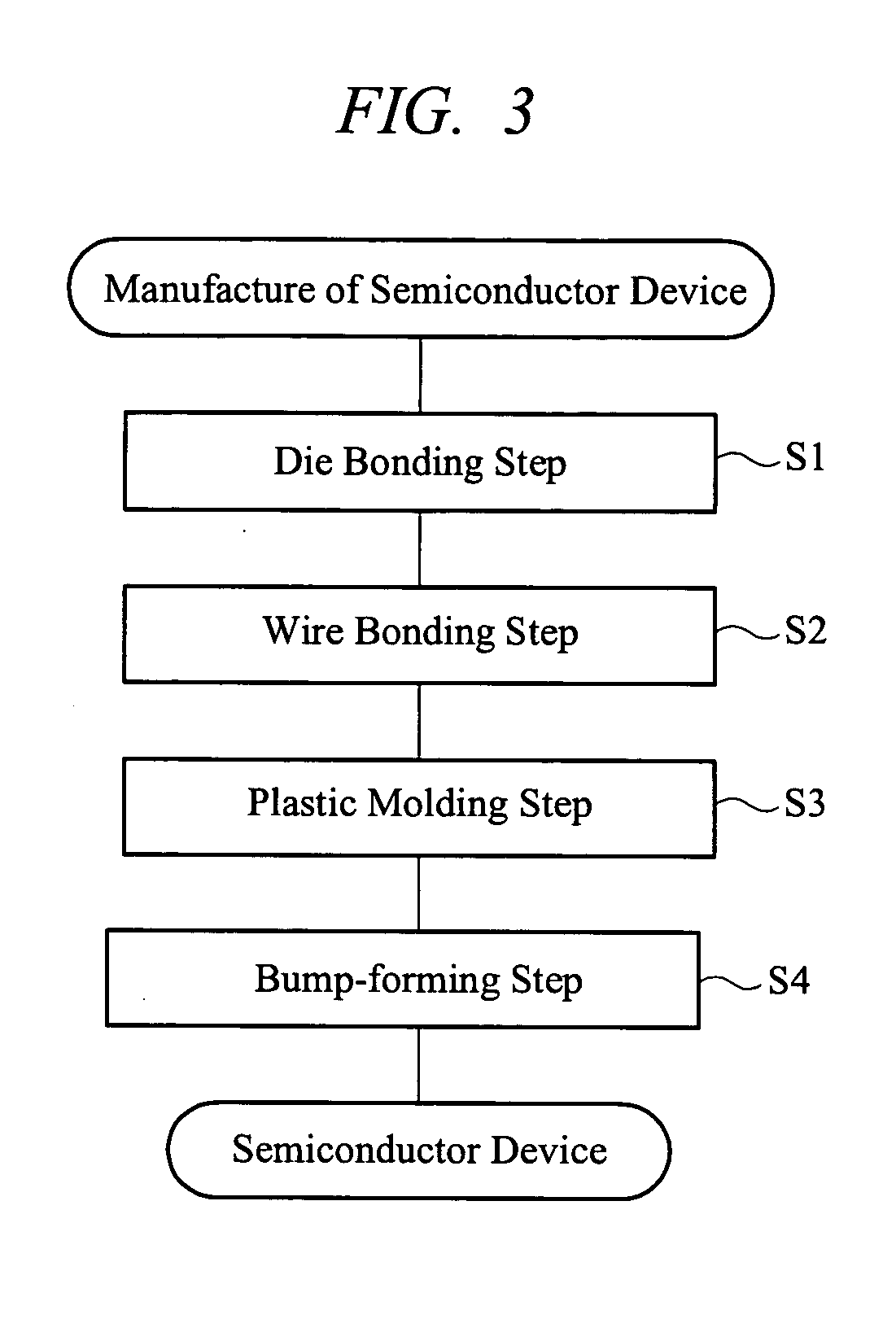

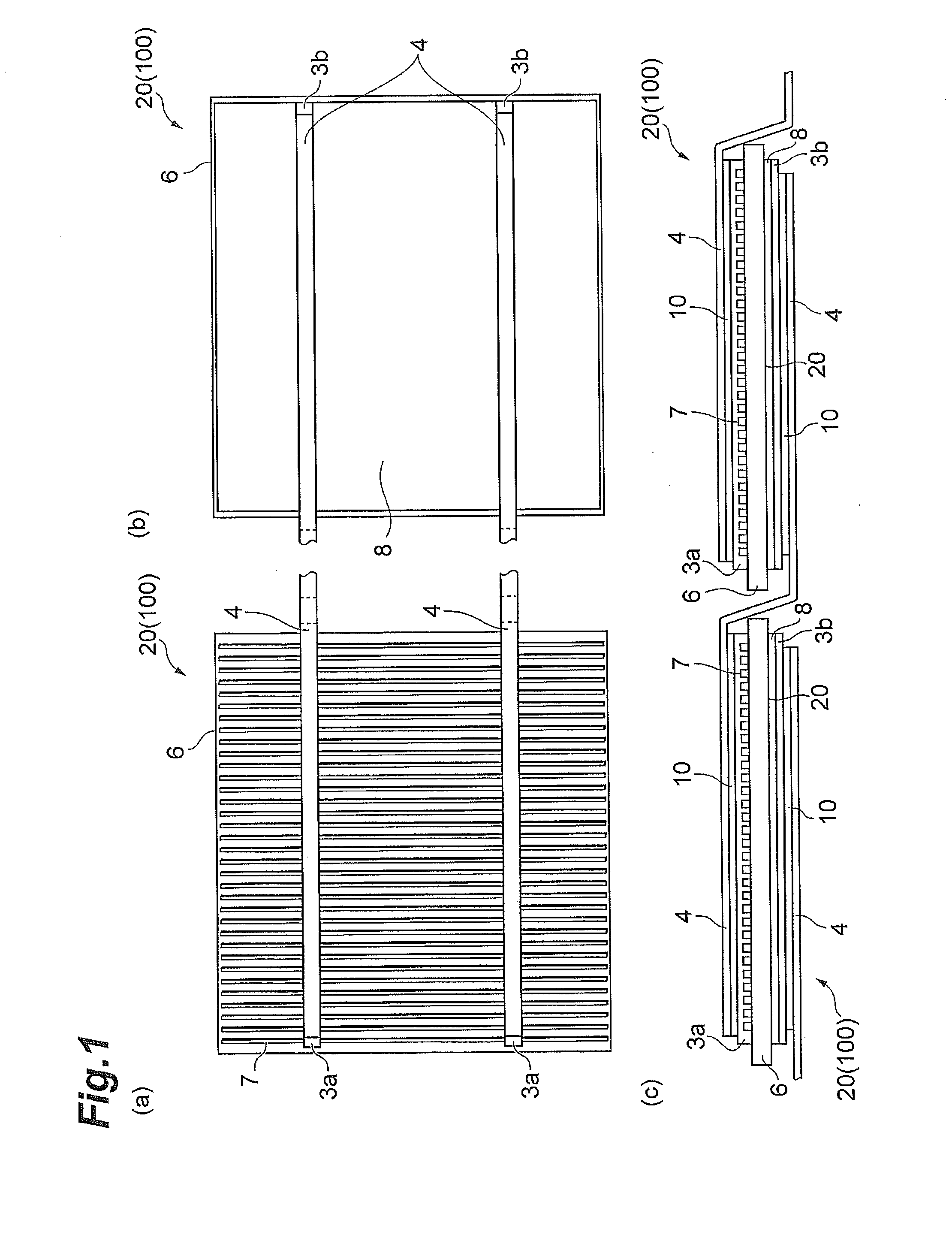

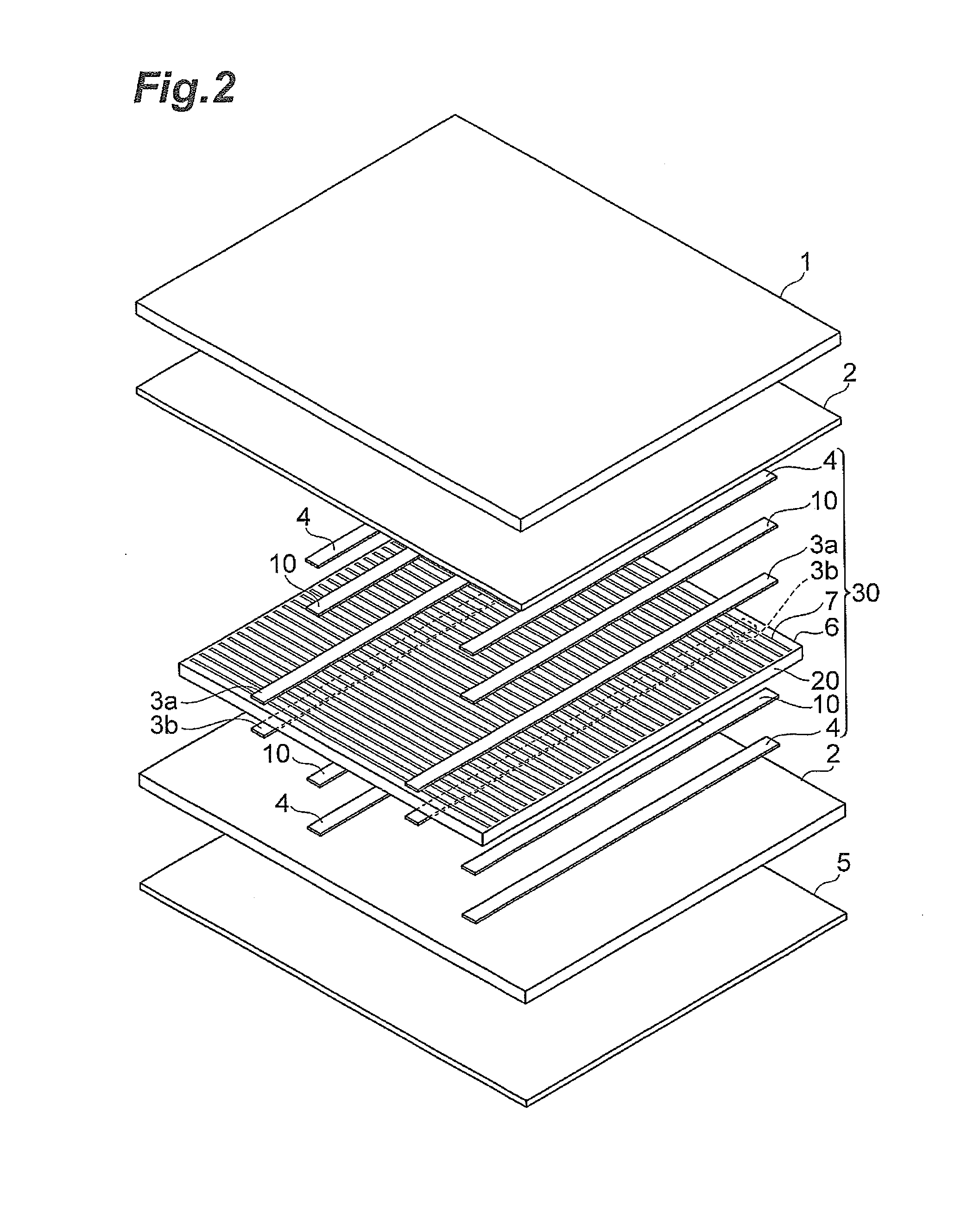

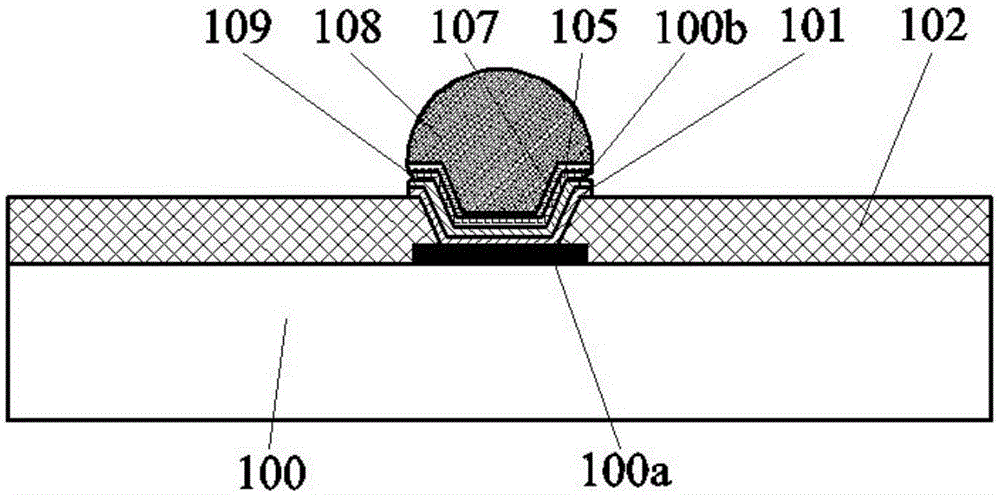

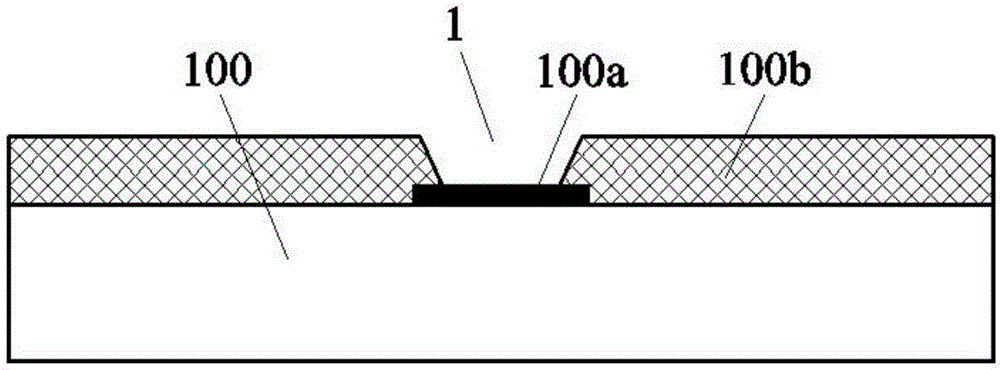

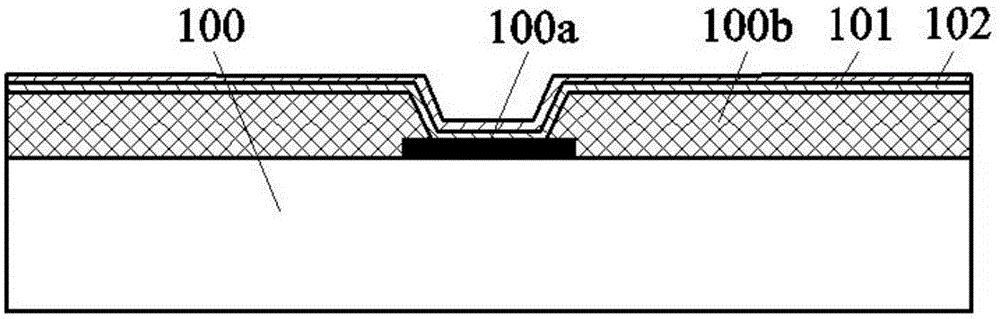

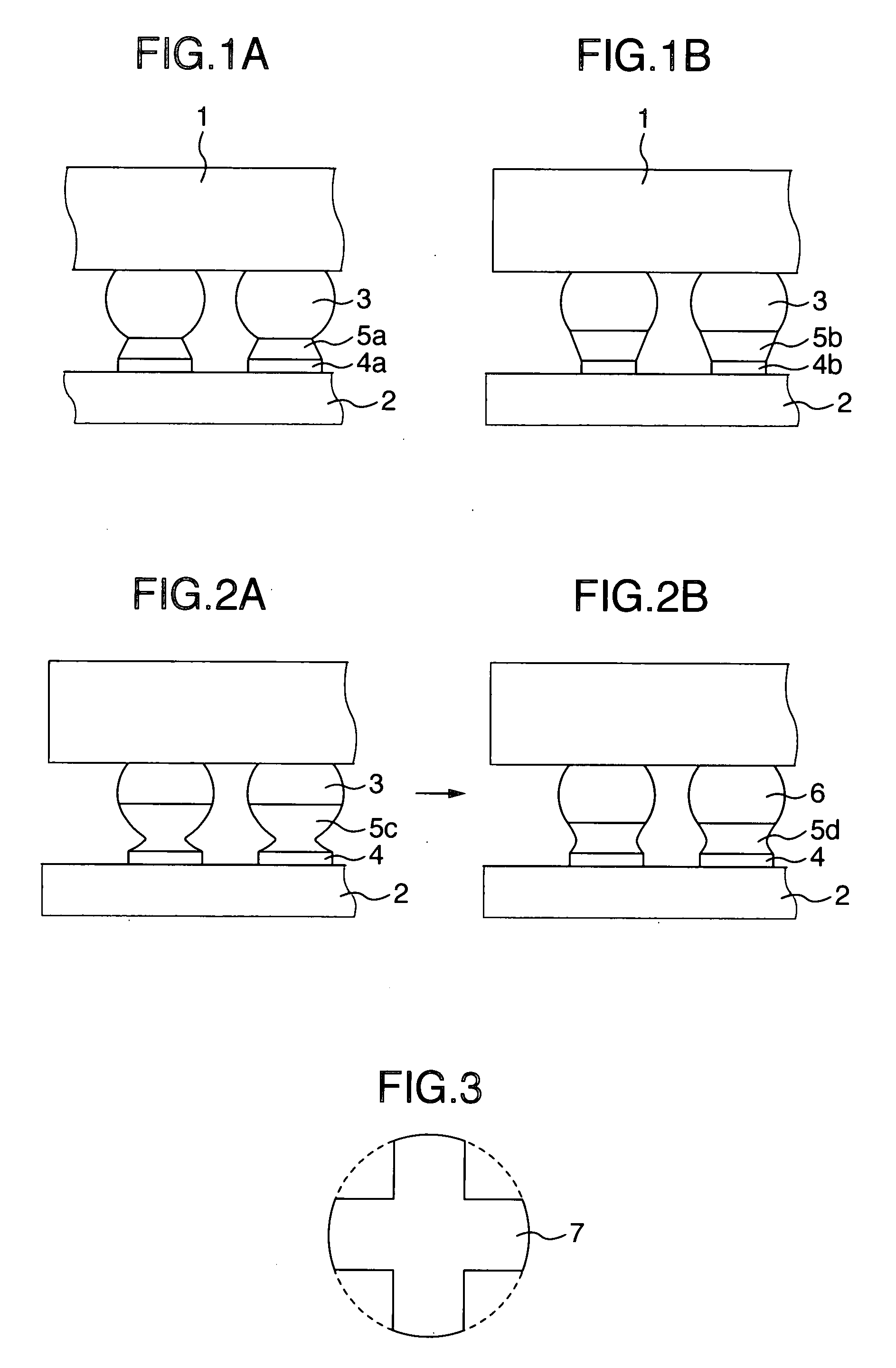

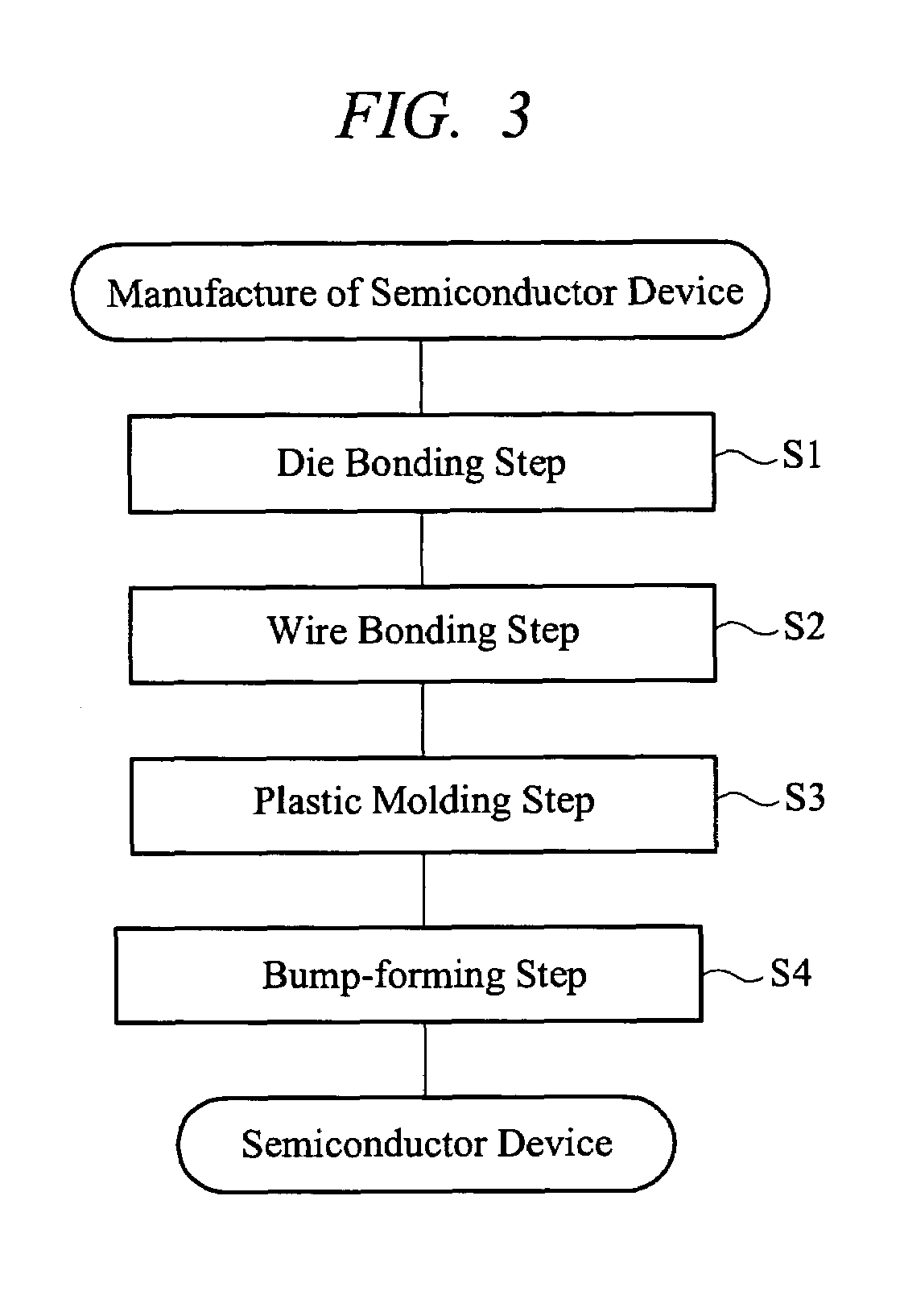

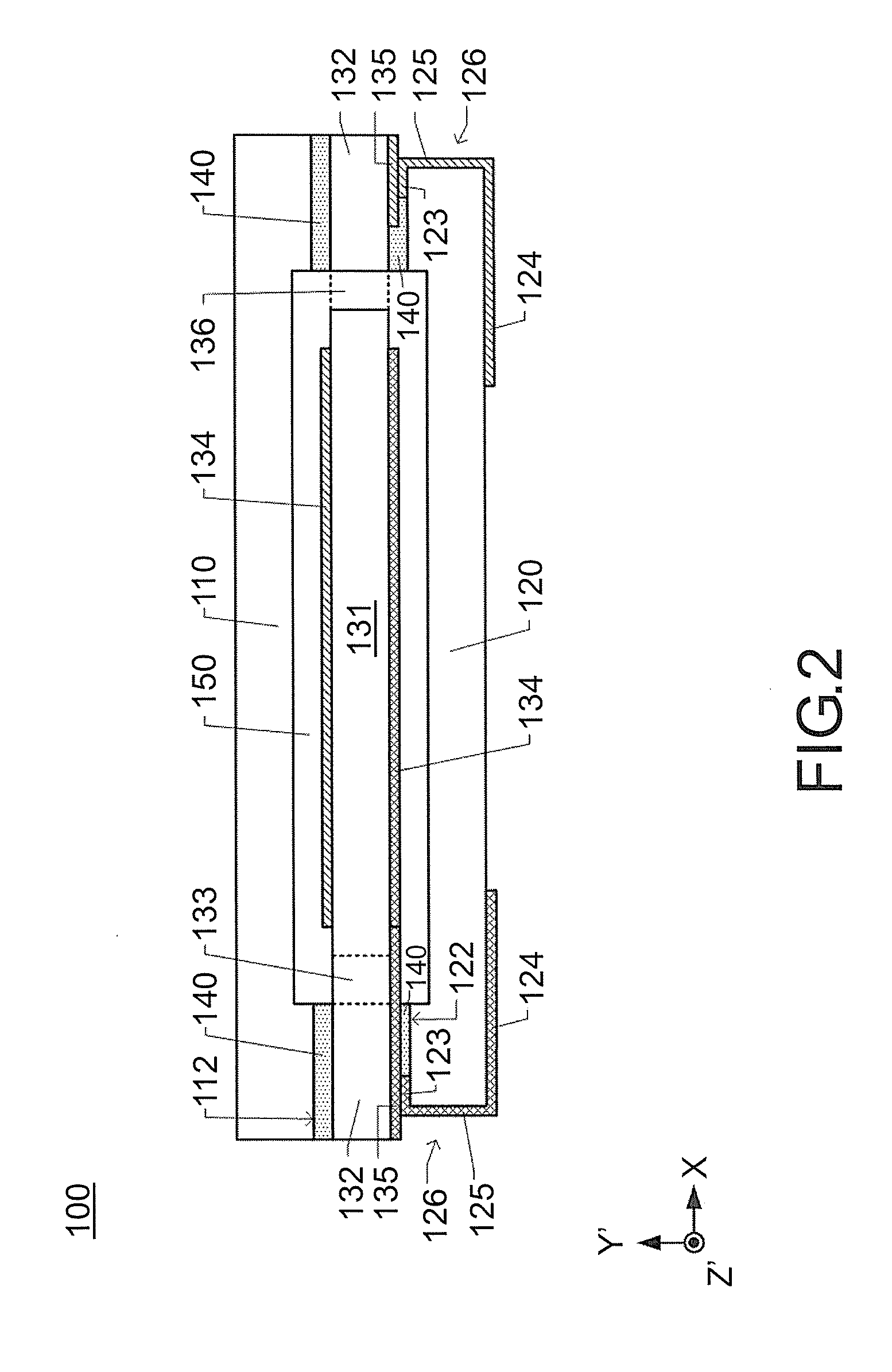

Semiconductor device and manufacturing method thereof

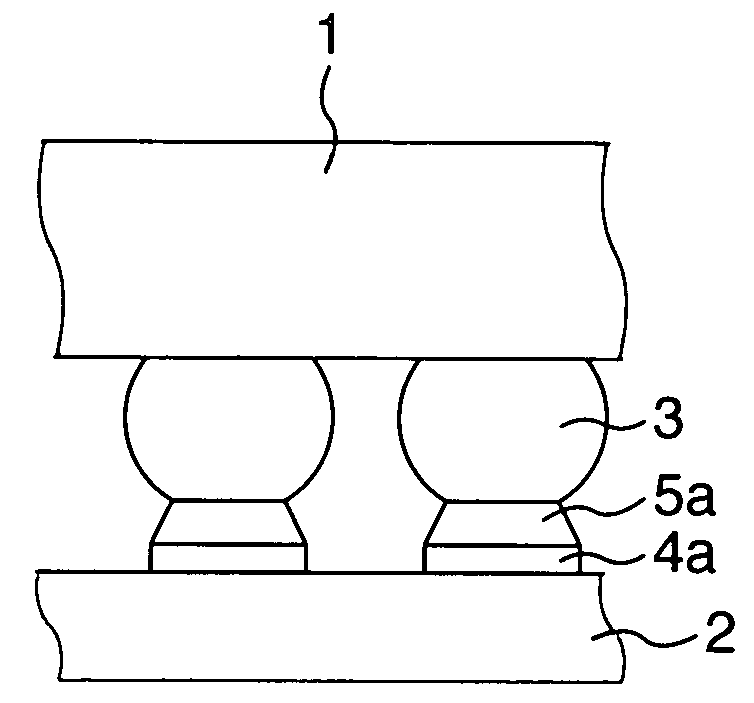

InactiveUS20060151877A1Inhibit reduction of strengthImprove thermal fatigue lifePrinted circuit assemblingSemiconductor/solid-state device detailsDevice materialCombined use

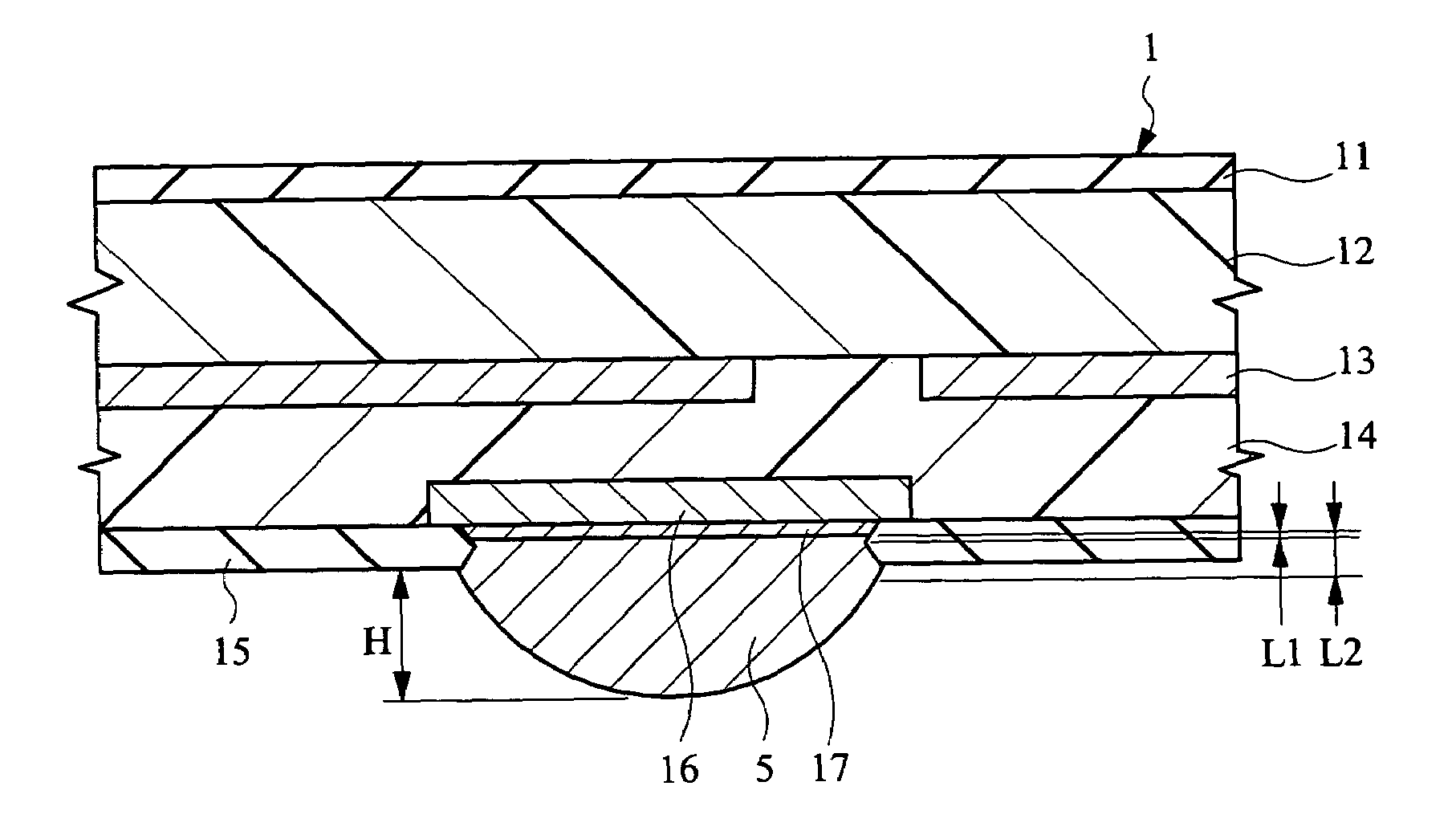

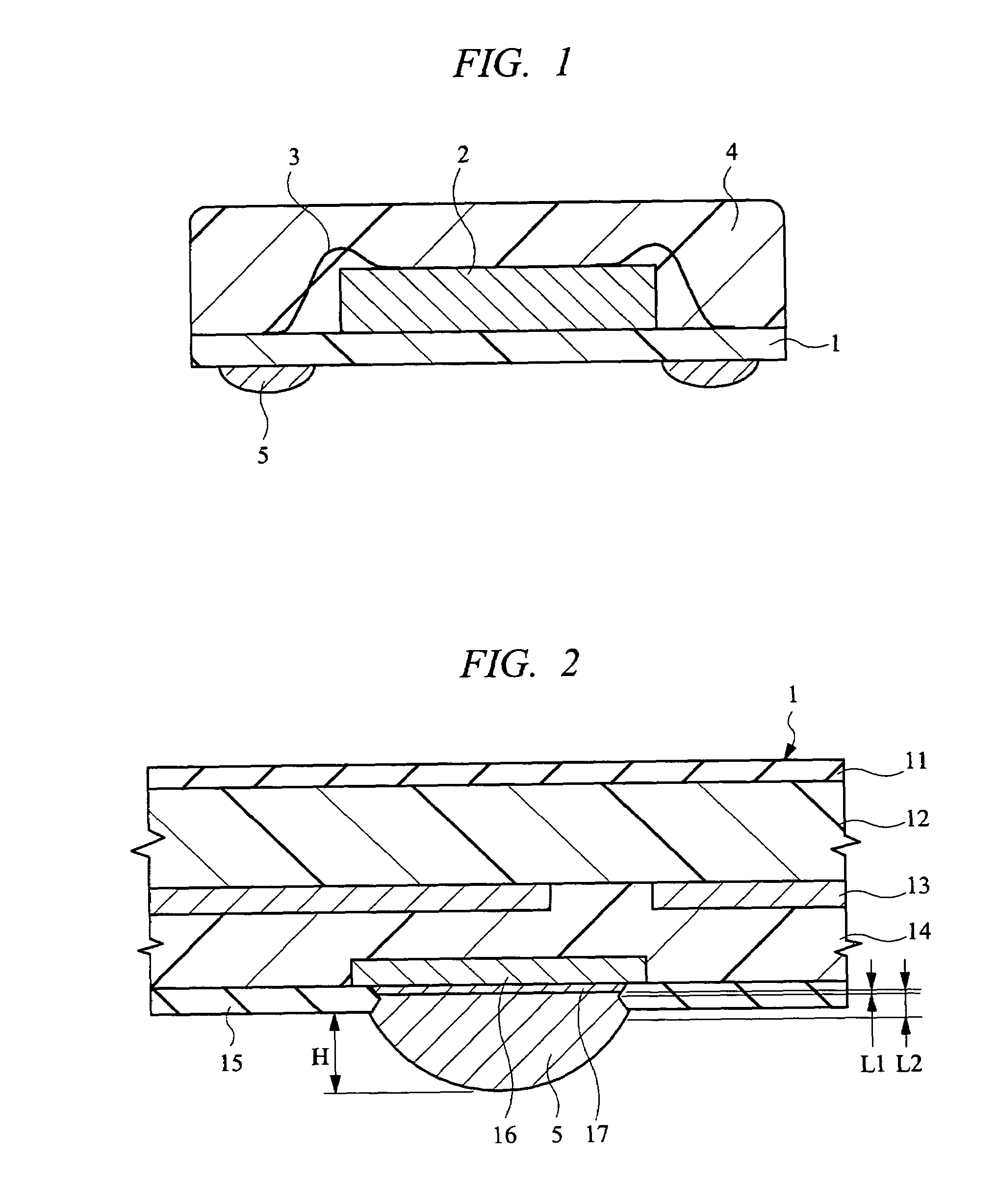

In order to inhibit the connection failure due to the degradation of the connection interface strength of the electrode pad and the warp thereof in the semiconductor device having an electrode pad, a metal layer formed on the electrode pad, and a metal bump formed on the metal layer, in the present invention, gold (Au) is contained in the metal layer, the metal bump is made of solder mainly made of Sn and designed to have an average height H of 100 μm or less per unit area in the electrode pad, and the concentration of Au of the metal layer dissolved in the solder is set to 1.3×10−3 (Vol %) or less. More preferably, the metal bump contains palladium (Pd), and the solder coating for forming the metal bump on the electrode pad is performed by using the dipping and the paste printing in combination.

Owner:RENESAS ELECTRONICS CORP

Preparation method of Ti-6Al-4V alloy welding wire suitable for repair welding of titanium alloy casting

ActiveCN106041369ARealize mass productionMeet performance requirementsWelding/cutting media/materialsSoldering mediaTi 6al 4vStress relief

The invention relates to a preparation method of a Ti-6Al-4V alloy welding wire suitable for repair welding of a titanium alloy casting and belongs to the technical field of nonferrous metal material preparation. The preparation method comprises the steps that S1, alloy welding wire raw materials are mixed and pressed into electrodes, and an alloy cast ingot is formed through smelting; S2, homogenizing annealing is conducted; S3, billet forging is conducted; S4, forging is conducted, and flaw detection is conducted through ultrasonic waves; S5, large deformation is conducted once, rolling is conducted twice, and heating and heat preservation are conducted; S6, hot drawing and finishing rolling are conducted, and surface treatment is conducted; S7, temperature-control hot drawing is conducted; S8, annealing is conducted after cold drawing; and S9, sliding block straightening is conducted, straightening and cutting-off are conducted, and a finished product is obtained through stress relief annealing and polishing. The preparation method has the beneficial effects that nonuniformity, caused by quenching, of alloy components and structures in the caisting process is eliminated; and the contaminated surfaces of wire materials are removed in a centerless grinding mechanical mode, surface impurities are removed, further corrosion of the surfaces of the wire materials is prevented during subsequent storage, and the quality of the wire materials is stabilized and improved easily.

Owner:DALIAN SUNNY TITANIUM IND

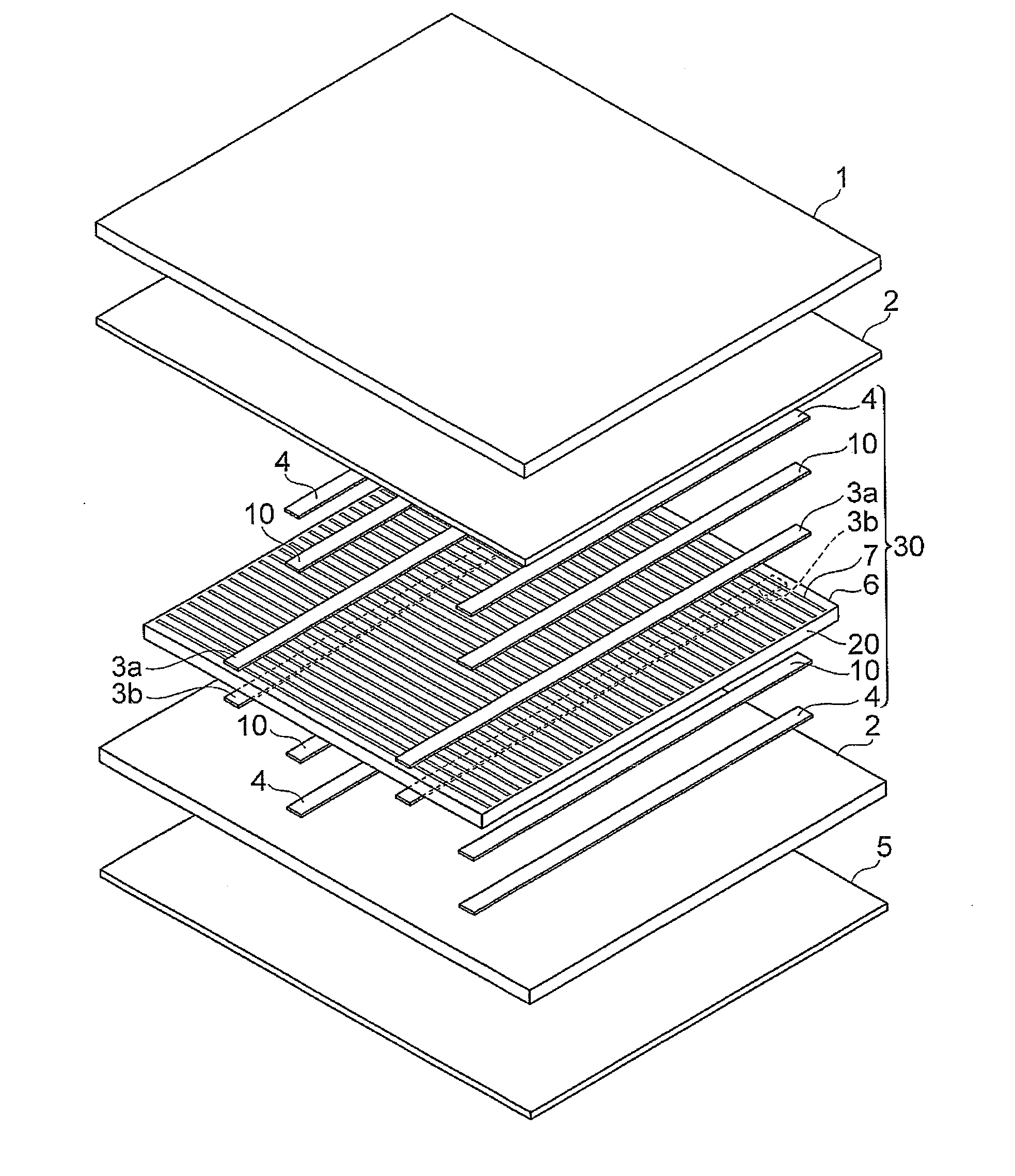

Electrically conductive adhesive composition, connection structure, solar battery module, and method for producing same

ActiveUS20150255633A1Improve connection reliabilityImprove connection strengthConductive materialSemiconductor/solid-state device manufacturingCationic polymerizationSolar battery

An electrically conductive adhesive composition comprising electrically conductive particles containing a metal of which melting point is 220° C. or less, a thermosetting resin, and a thermal cationic polymerization initiator.

Owner:RESONAC CORP

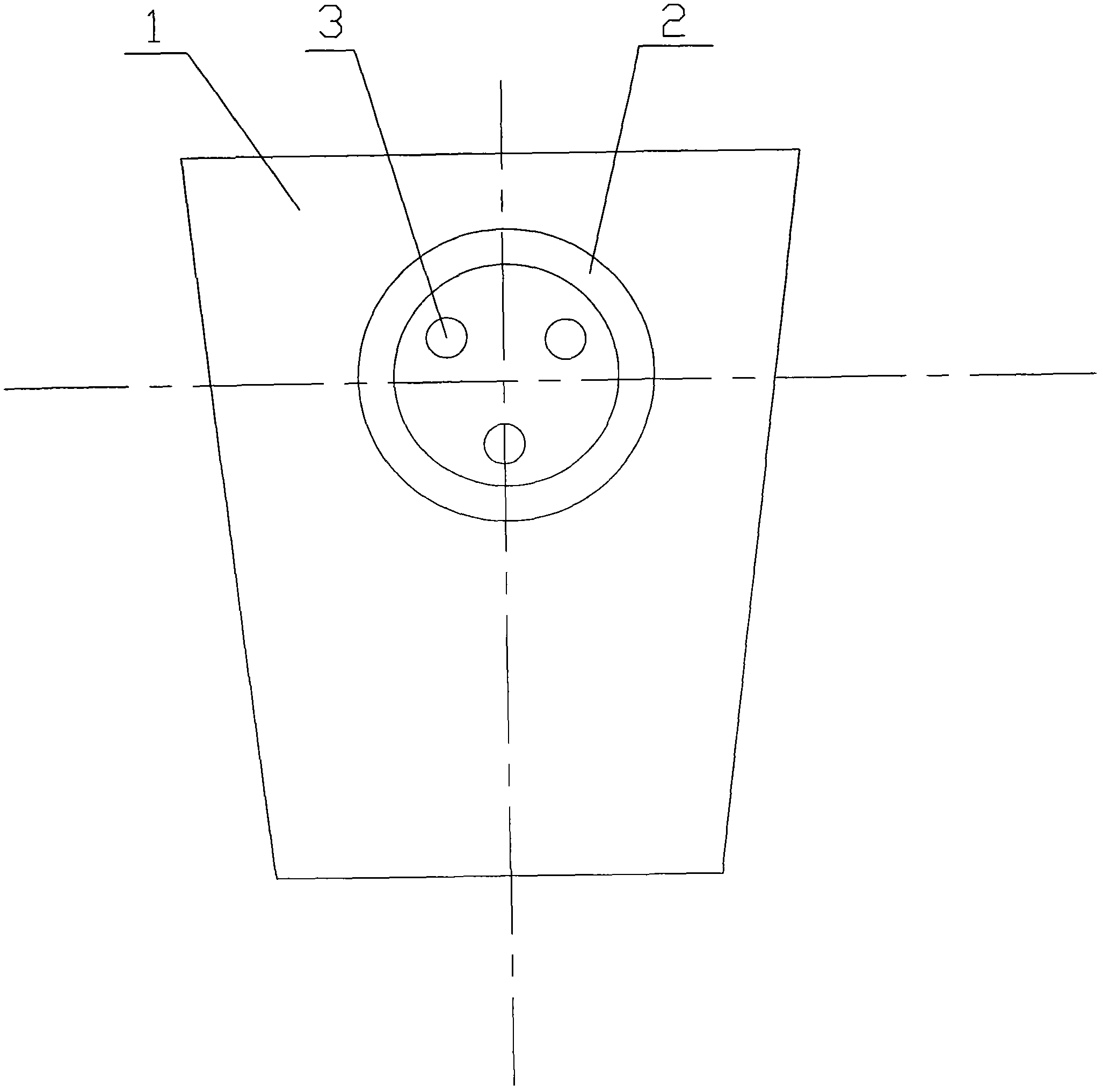

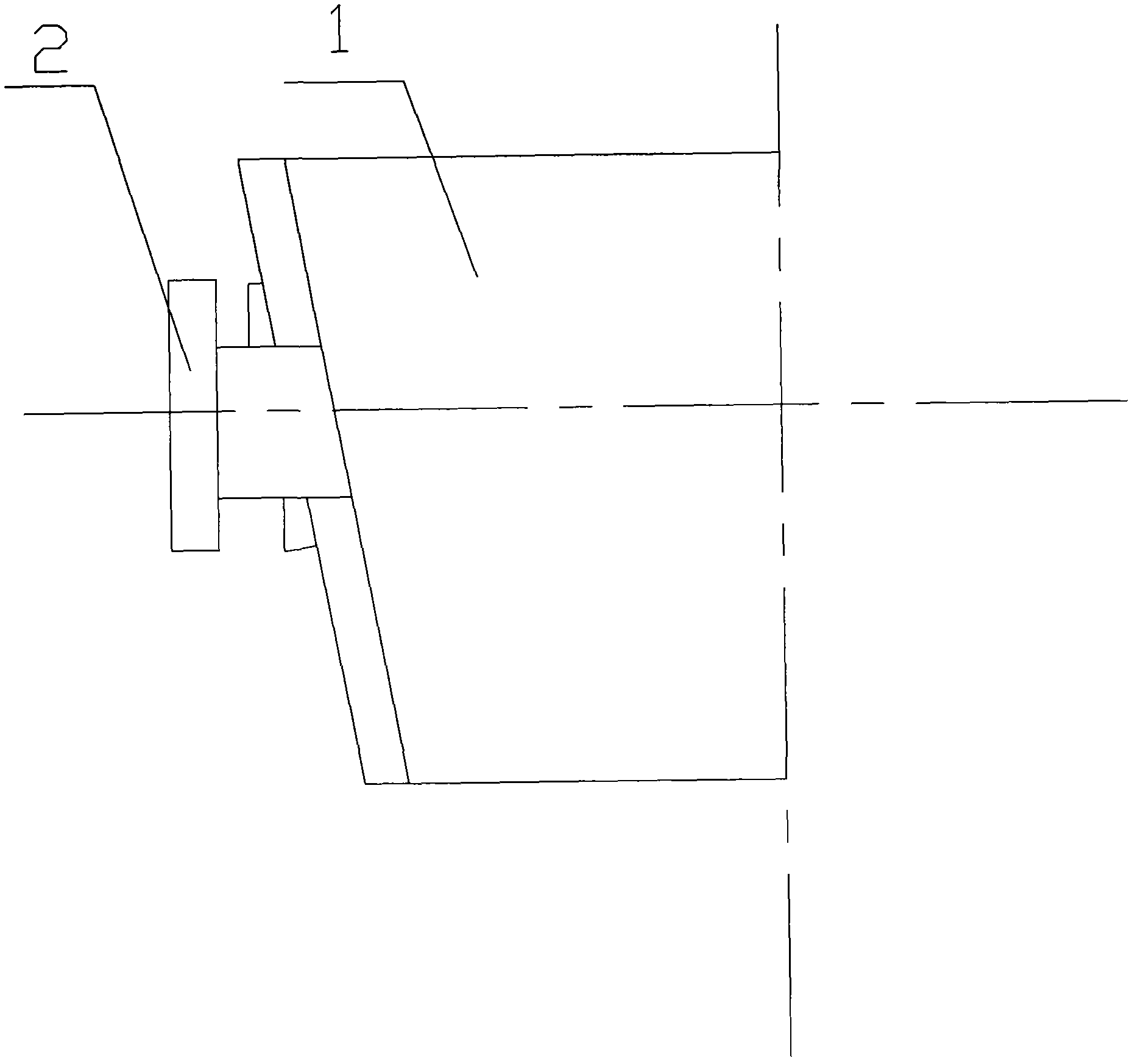

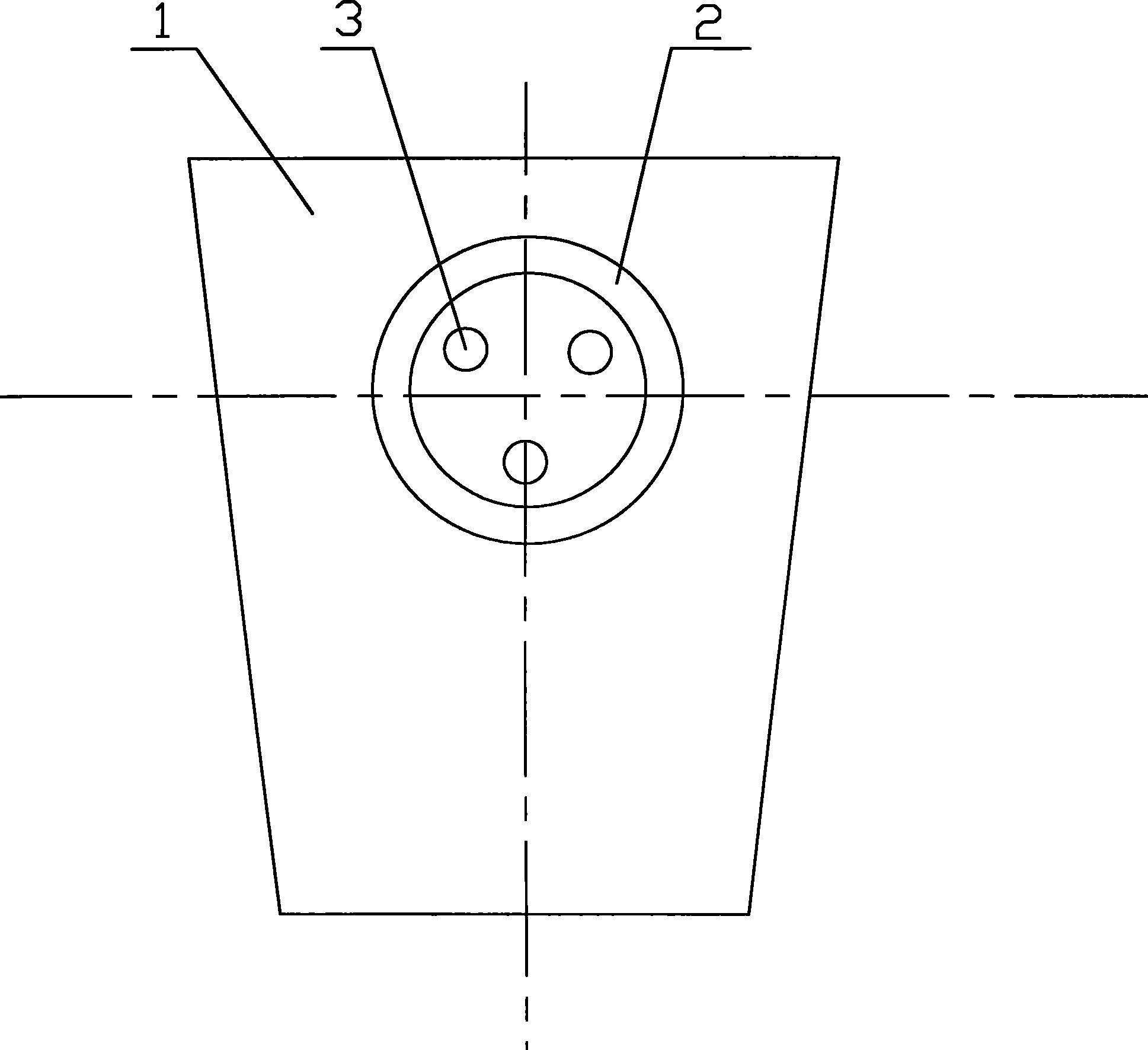

Sprinkler head cover and a sprinkler head

InactiveUS7543654B2Improve adhesionReduce connection strengthWatering devicesSpray nozzlesAlloyLow melting point

A sprinkler head cover including a housing adapted to be attached to a sprinkler head which is connected to a water supply piping and in which, in the case of fire, a valve disposed inside the sprinkler head is opened to allow a fire-extinguishing liquid in the water supply piping to be dispersed. A cover plate is adapted to cover the sprinkler head so that the sprinkler head cannot be seen from outside, and a mount is installed in the housing and has a hole inside thereof. The cover plate and the mount are connected to each other by a low melting point alloy melted out from the hole, and a heat collector of the sprinkler head has a structure for allowing the heat collector to come into contact with the cover plate.

Owner:SENJU SPRINKLER

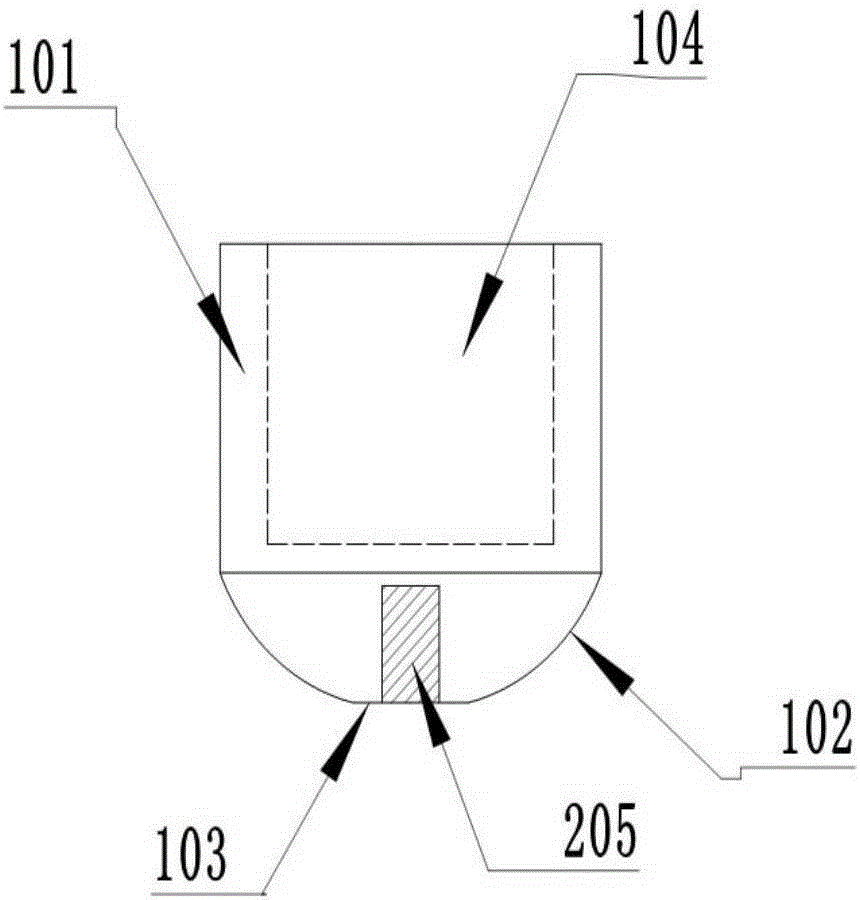

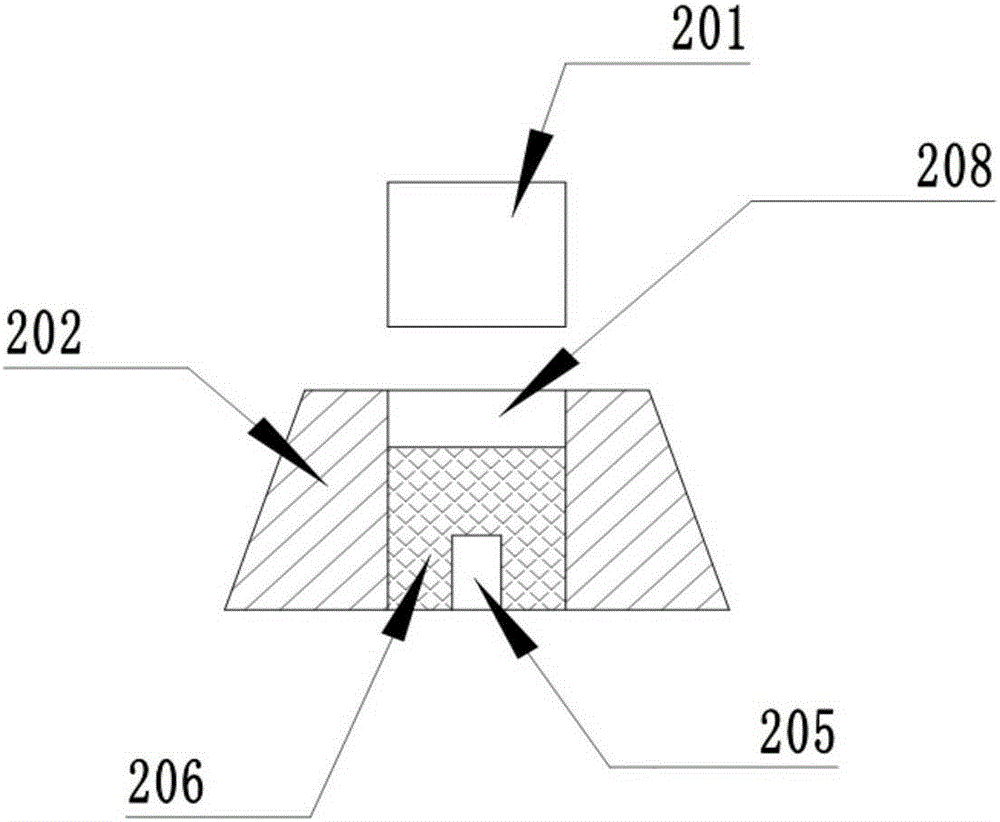

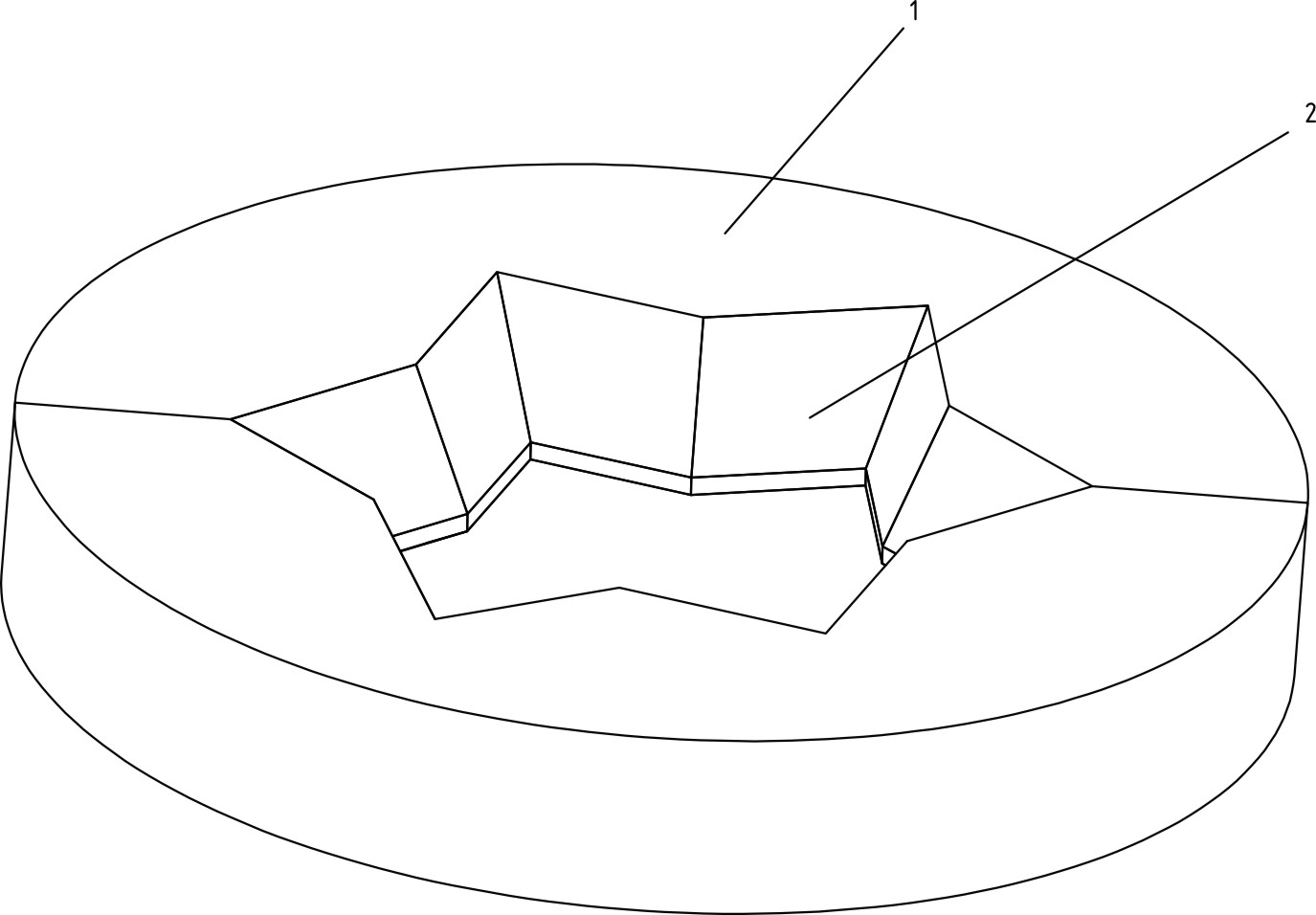

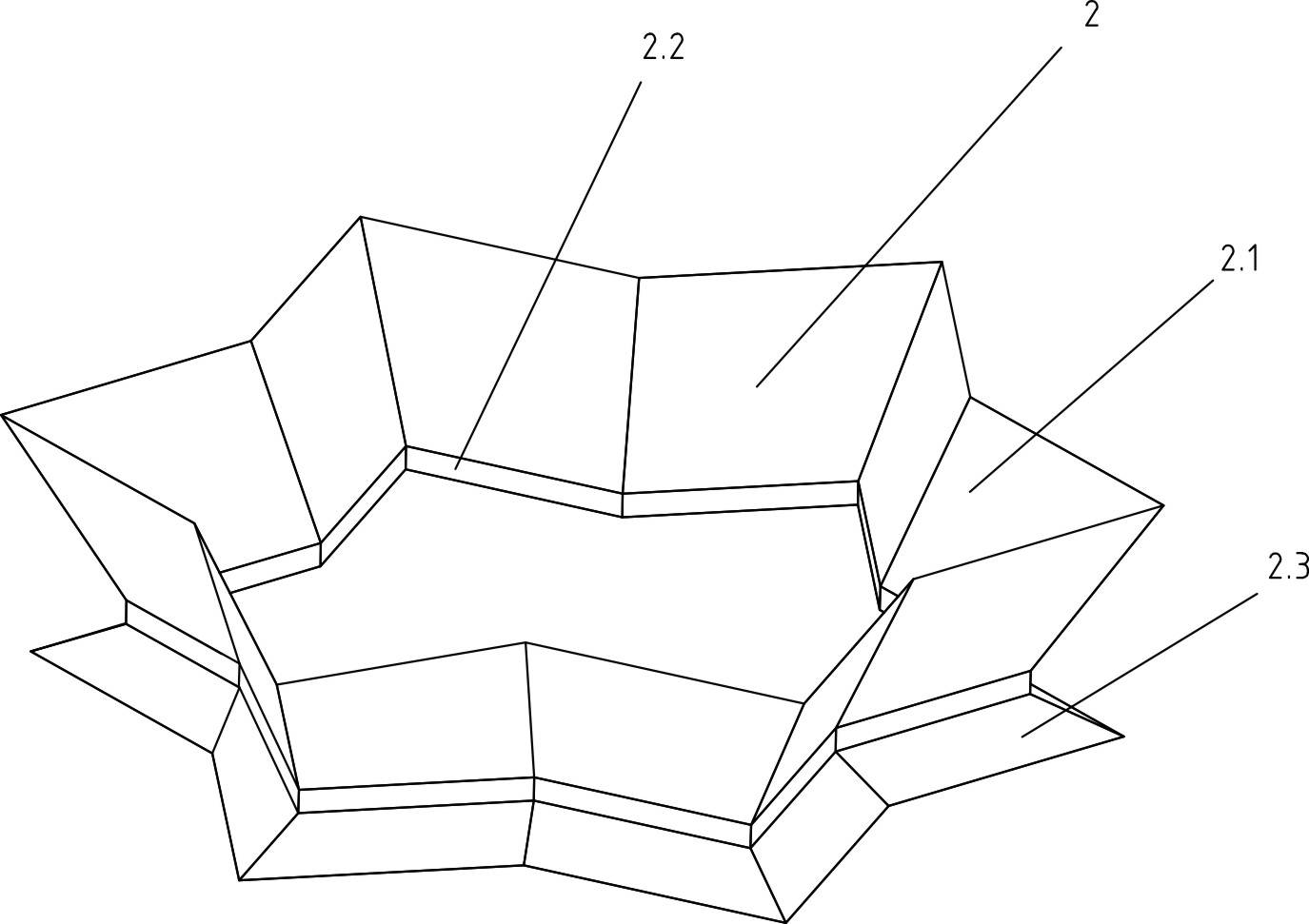

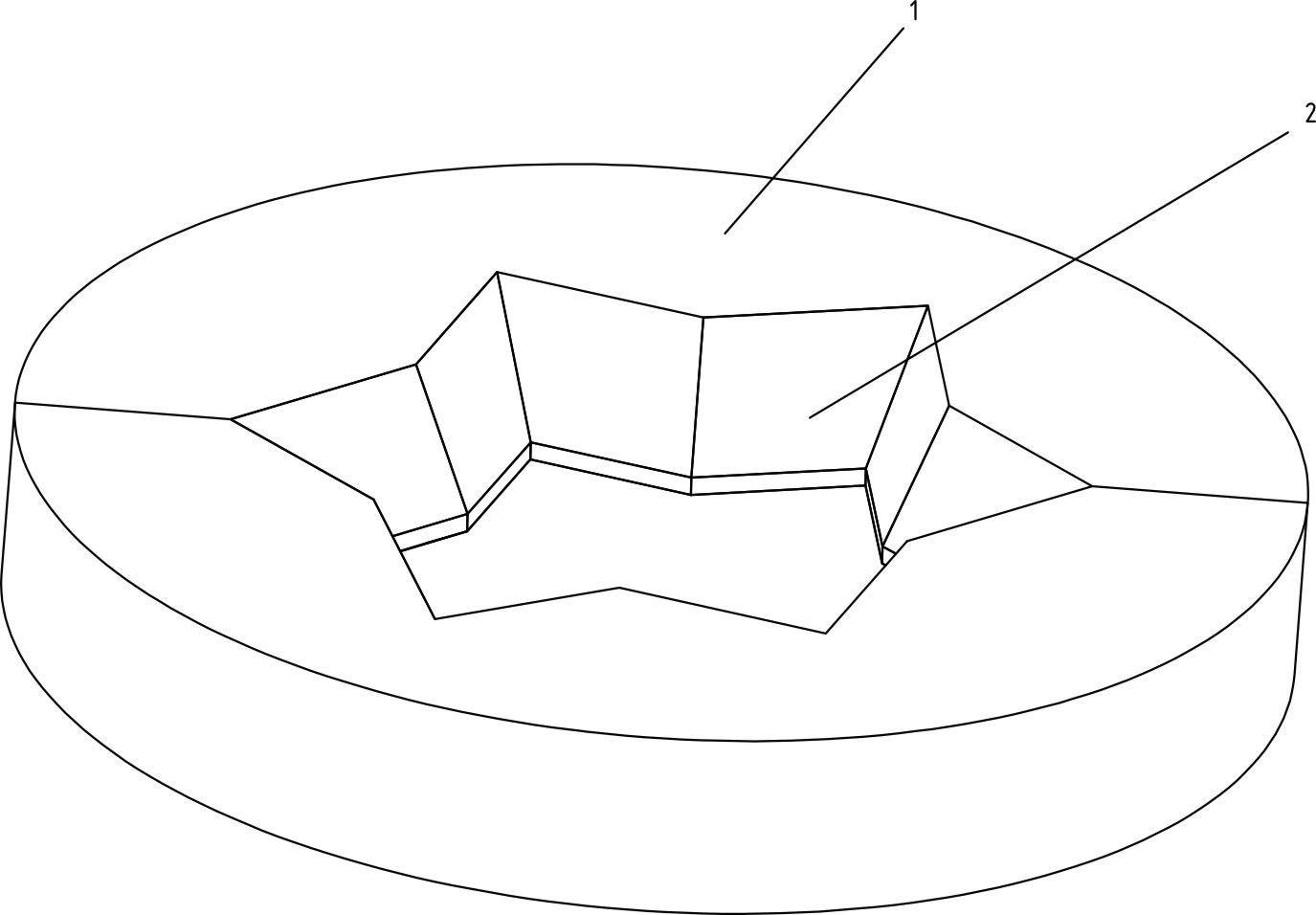

Feeder head knock-off core

ActiveCN102328030AResolve separation difficultiesReduce connection strengthFoundry mouldsFoundry coresUltimate tensile strengthMaterials science

The invention relates to the cast field, in particular relates to a knock-off core between a cast cavity and a feeder head. The feeder head knock-off core solves the technical problems that a cast feeder head and a cast main body in the existing feeder head knock-off core have high connection strength, the cast feeder head is hard to separate from the cast main body, and the separation work of the cast feeder head and the cast main body has high strength in the prior art. The invention provides a feeder head knock-off core, wherein the cast feeder head and the cast main body have low connection strength, the cast feeder head is easy to separate from the cast main body, the separation work strength of the cast feeder head and the cast main body is low, and the processing work load after the casting of the cast main body is low. The feeder head knock-off core provided by the invention comprises a knock-off core main body on which a liquid communicating hole for communicating upper and lower surfaces of the knock-off core is arranged; the liquid communicating hole comprises an upper liquid communicating hole and a lower communicating hole; and cross section outlines of the upper and lower communicating holes are in four-pointed star shape or five-pointed star shape or six-pointed star shape, and a lower opening of the upper liquid communicating hole is congruent to a small opening of the lower communicating hole.

Owner:ZHEJIANG WUJING MACHINE MFG +1

Novel wafer level tin solder micro bump manufacturing method

InactiveCN105140140AAvoid over etchingImprove reliabilitySolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor chipCopper

The invention provides a novel wafer level tin solder micro bump manufacturing method, and belongs to the field of semiconductor chip packaging. Photoresist of which the opening is formed through exposure development is utilized to act as a mask film firstly. A copper layer, a barrier layer and solder alloy are electroplated on an under bump metal layer in turn, and the solder alloy is enabled to completely wrap a copper layer-barrier layer of the bottom part. Then tin solder micro bumps are formed via a method of backflow and then photoresist removing. Finally the micro bumps act as an etching mask film and a wet etching technology is adopted to remove the excess under bump metal layer. Excessive etching of electroplating copper of a bump layer in isotropic etching of the under bump metal layer can be avoided, and bridging caused by collapsing of backflow of the micro bumps can be avoided so that reliability of the micro bumps and packaging products can be enhanced.

Owner:BEIJING UNIV OF TECH

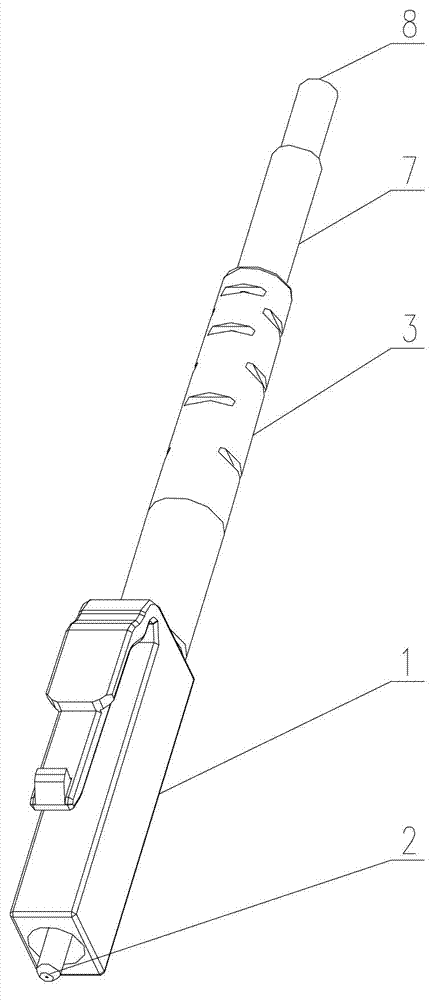

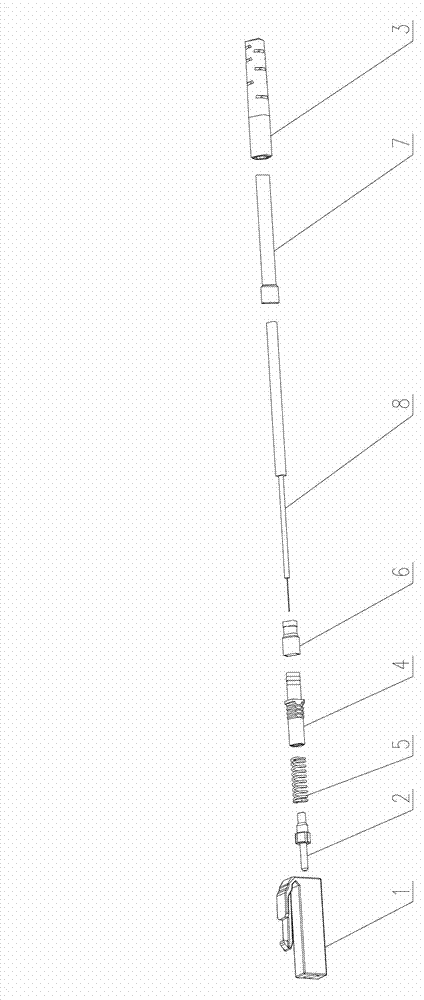

Optical fiber accessing plug with integrated housing

ActiveCN102854579AReduce connection strengthSimple structureCoupling light guidesEngineeringUltimate tensile strength

The invention discloses an optical fiber accessing plug with an integrated housing. The optical fiber accessing plug with the integrated housing comprises a housing, an inserting core subassembly connected with optical fiber and a tail protecting bush, wherein the inserting core subassembly comprises a ceramic inserting core and a ceramic inserting core tailstock fixed with the ceramic inserting core; the housing adopts an integrated cavity structure; a through hole is arranged at the front end of the housing, and a tail pipe is inserted into the tail part of the housing; the ceramic inserting core penetrates through the through hole; the front part of the tail pipe is in interference fitting with the internal wall of the housing through a backstopping barb on the external wall thereof; the tail protecting bush is connected with the back part of the tail pipe; and a spring used for providing fitting force for a plug in butting is arranged in an internal chamber of the housing between the ceramic inserting core tailstock and the tail pipe. According to the optical fiber accessing plug with the integrated housing provided by the invention, the housing adopts the integrated cavity structure and is composed of two parts compared with an existing plug, which is simpler in structure, and is more convenient and quicker in the producing and assembling processes; and the problem that the connection strength between parts of the structure comprising two parts is reduced during mutually plugging process can be avoided.

Owner:SUS TELECOMM

Wire-connecting device

ActiveCN1941507AReduce connection strengthReduce in quantityConnections effected by permanent deformationCable junctionsEngineeringElectrical conductor

A wire-connecting device including a joint terminal for connecting an inner conductor of a coaxial cable and a core wire of an electric wire, and a heat-shrinkable member for covering at least the joint terminal and a cut edge of a braided wire of the coaxial cable exposed at the joint terminal.

Owner:YAZAKI CORP

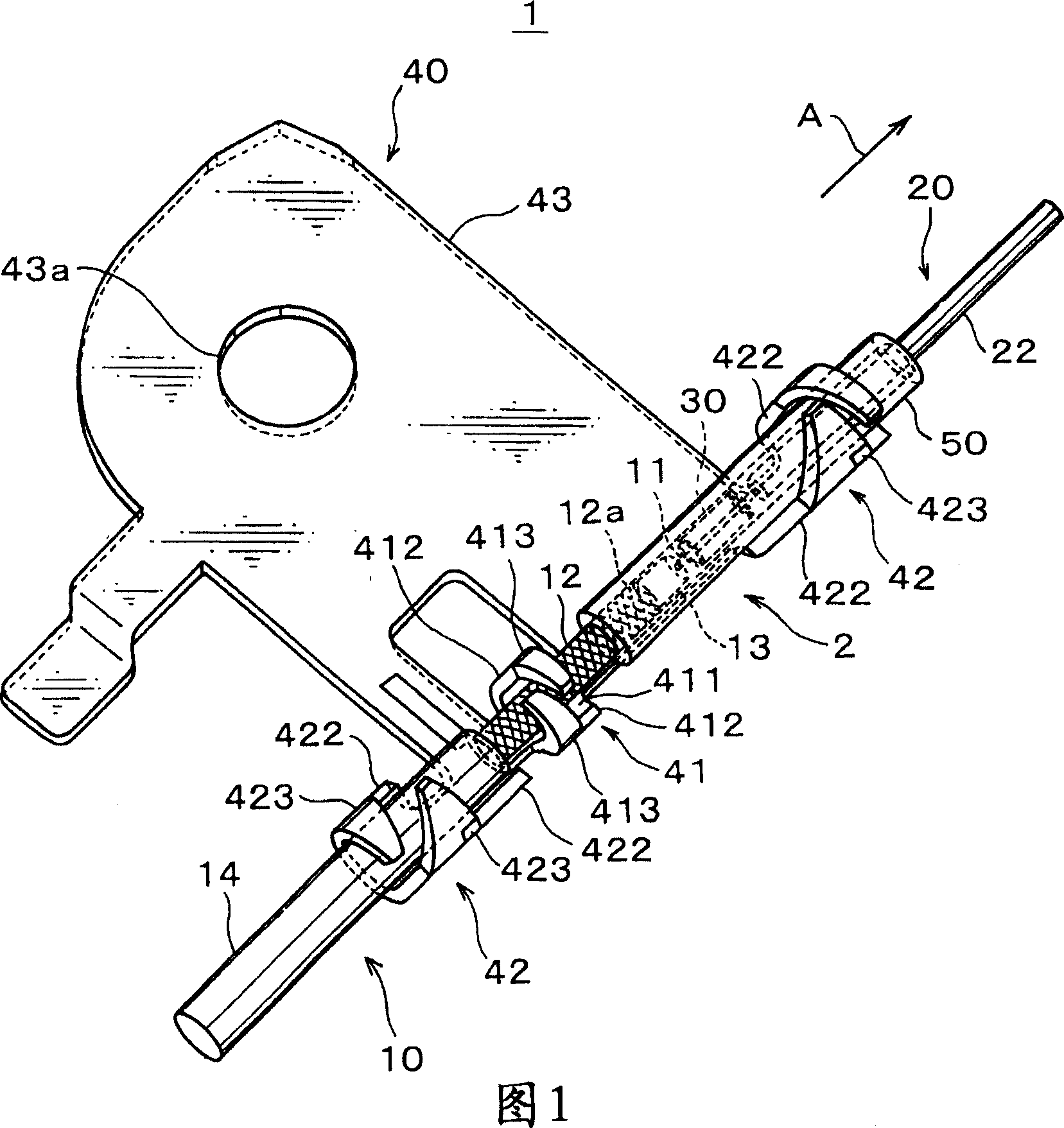

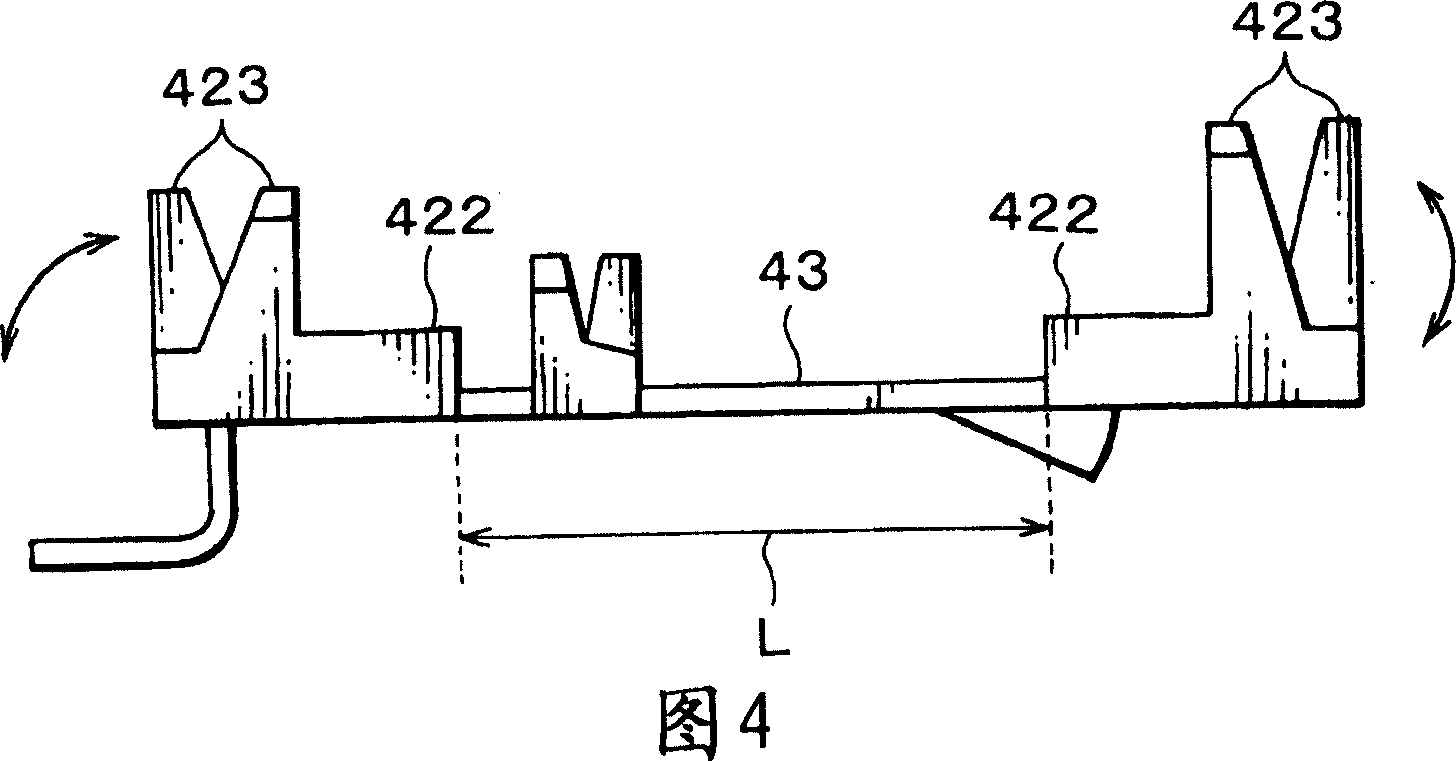

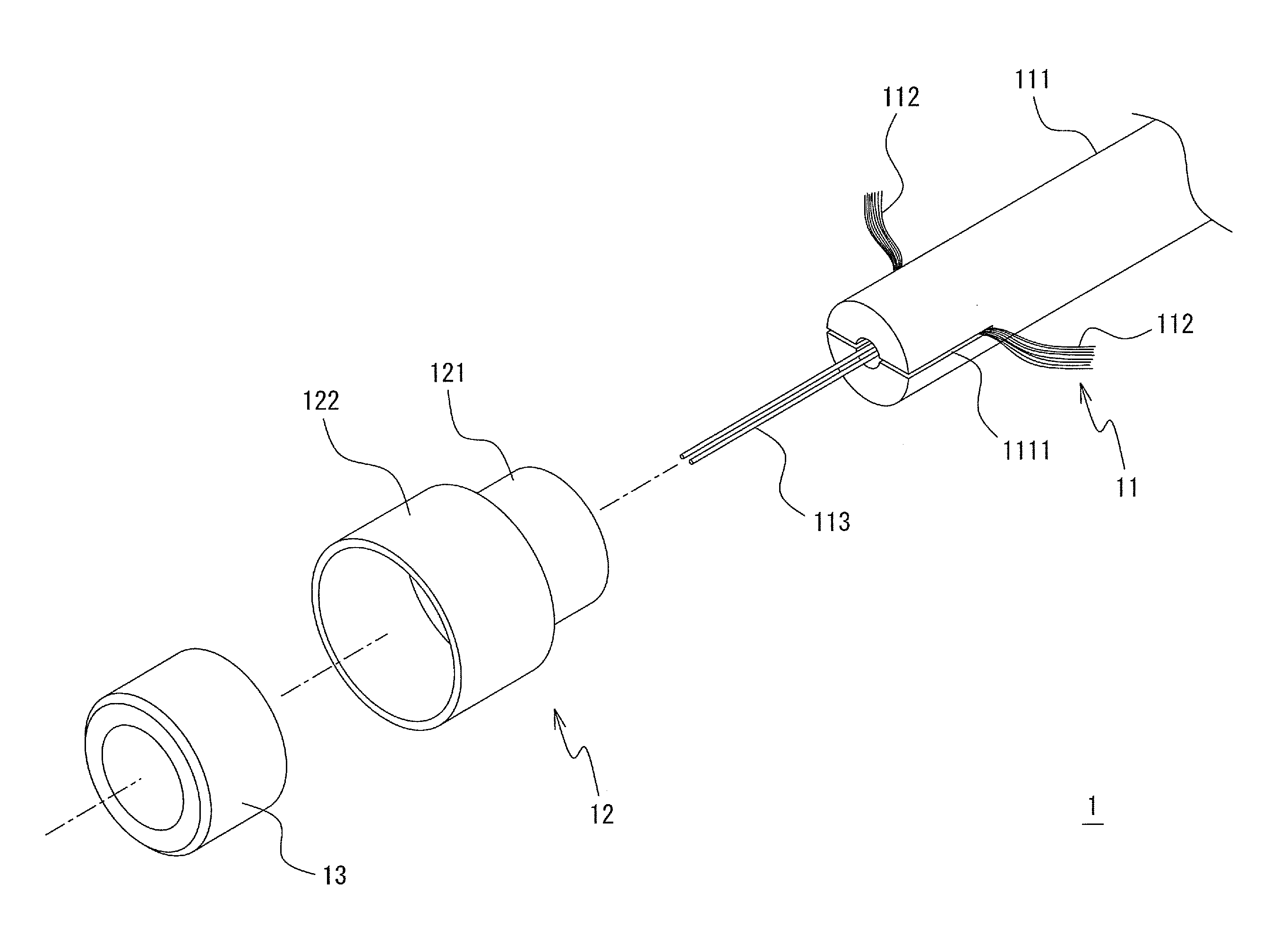

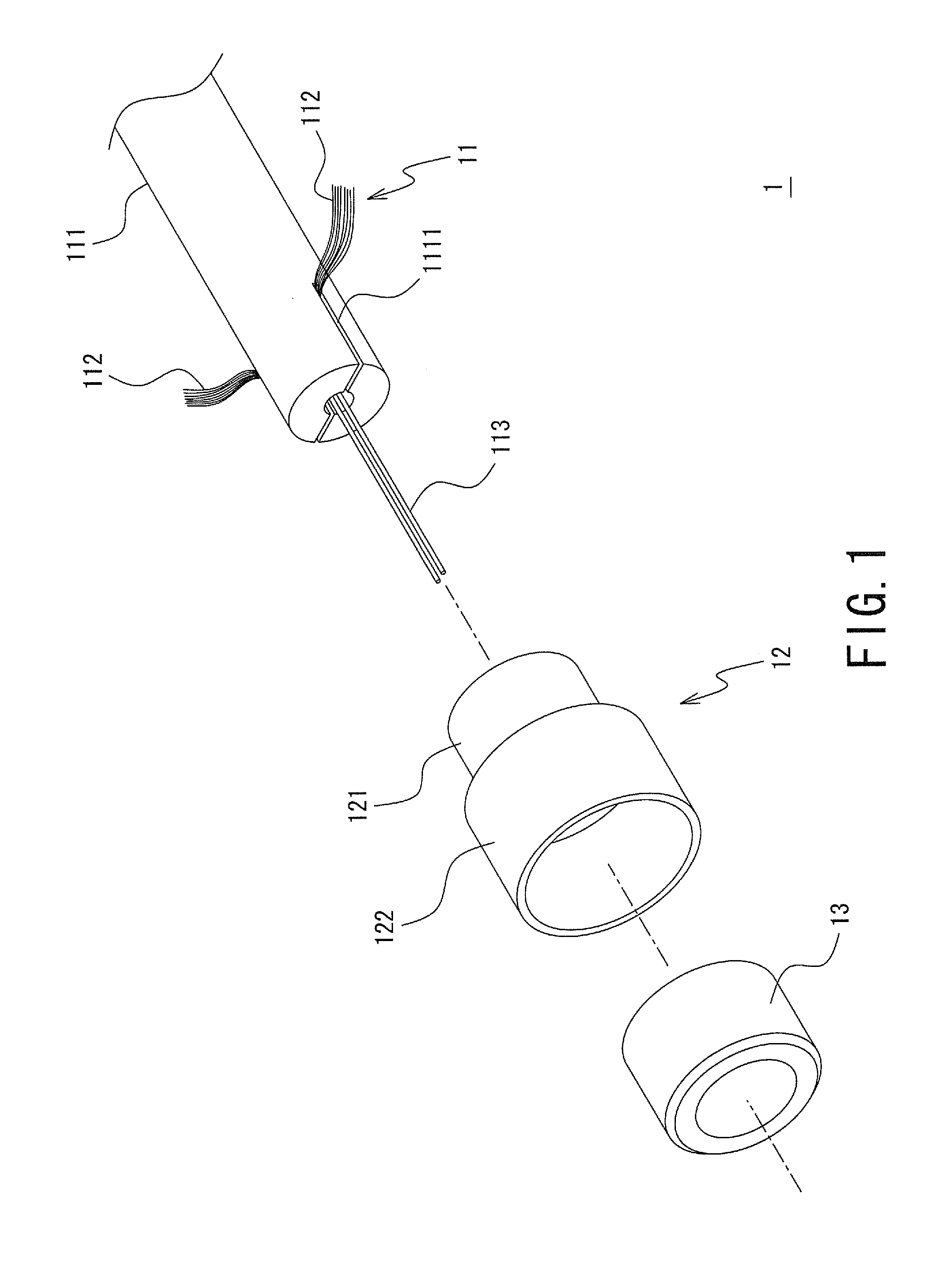

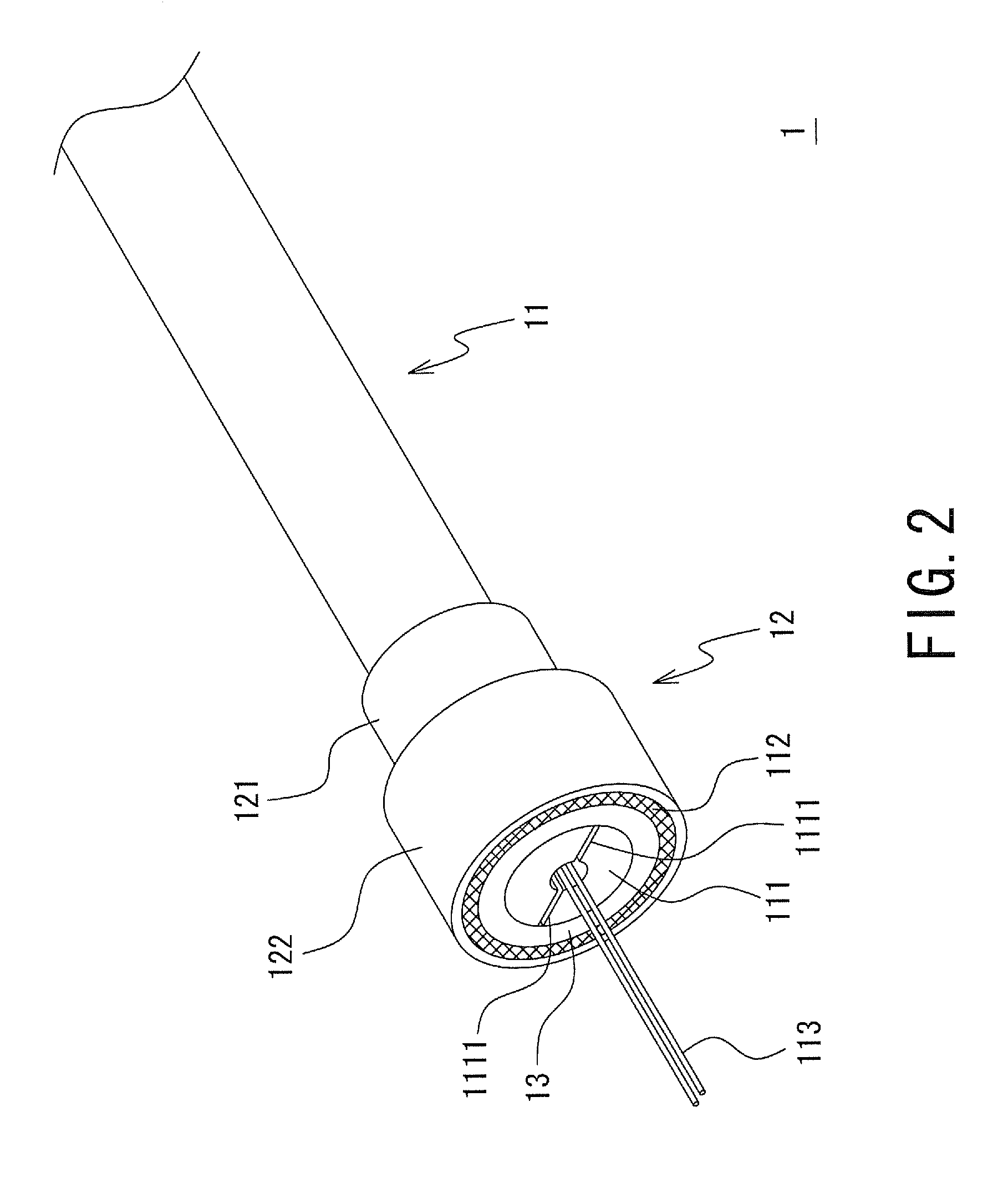

Fiber-optic cable with fitting

ActiveUS20130094814A1Improve the fixing strengthMinimize movementCoupling light guidesFibre mechanical structuresFiberEngineering

A fiber-optic cable with a fitting capable of increasing connection strength between a fiber-optic cable and an optical connector, which includes a fiber-optic cable including a sheath and a tensile member, an inner ring mounted on a circumference of the sheath from a position where the tensile member is drawn out of the sheath through a slit to a front end of the sheath, and a fitting mounted on the circumference and including a first portion mounted from the position where the tensile member is drawn out of the sheath to a position of the sheath on a side opposite to the ring side, and a second portion mounted while covering a circumference of the ring, wherein the first portion connects with the sheath, and the end portion of the tensile member is sandwiched by the ring and the second portion.

Owner:AUTONETWORKS TECH LTD +2

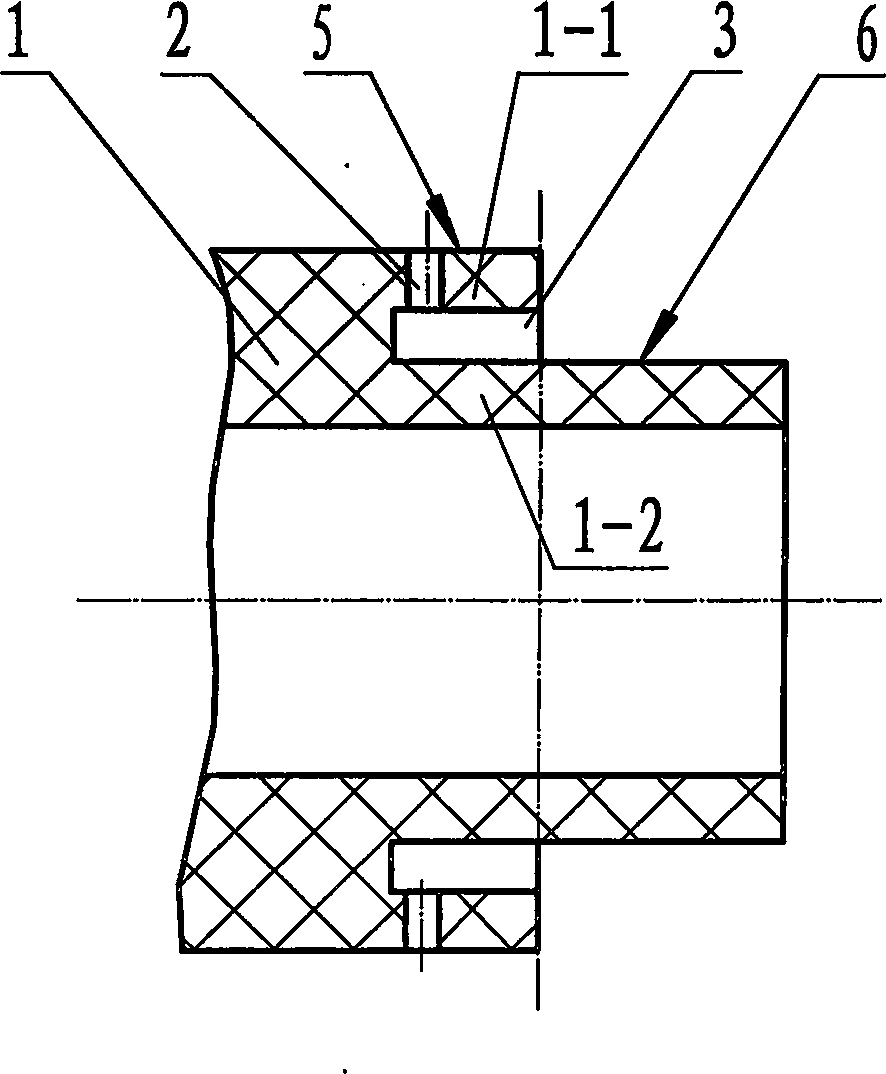

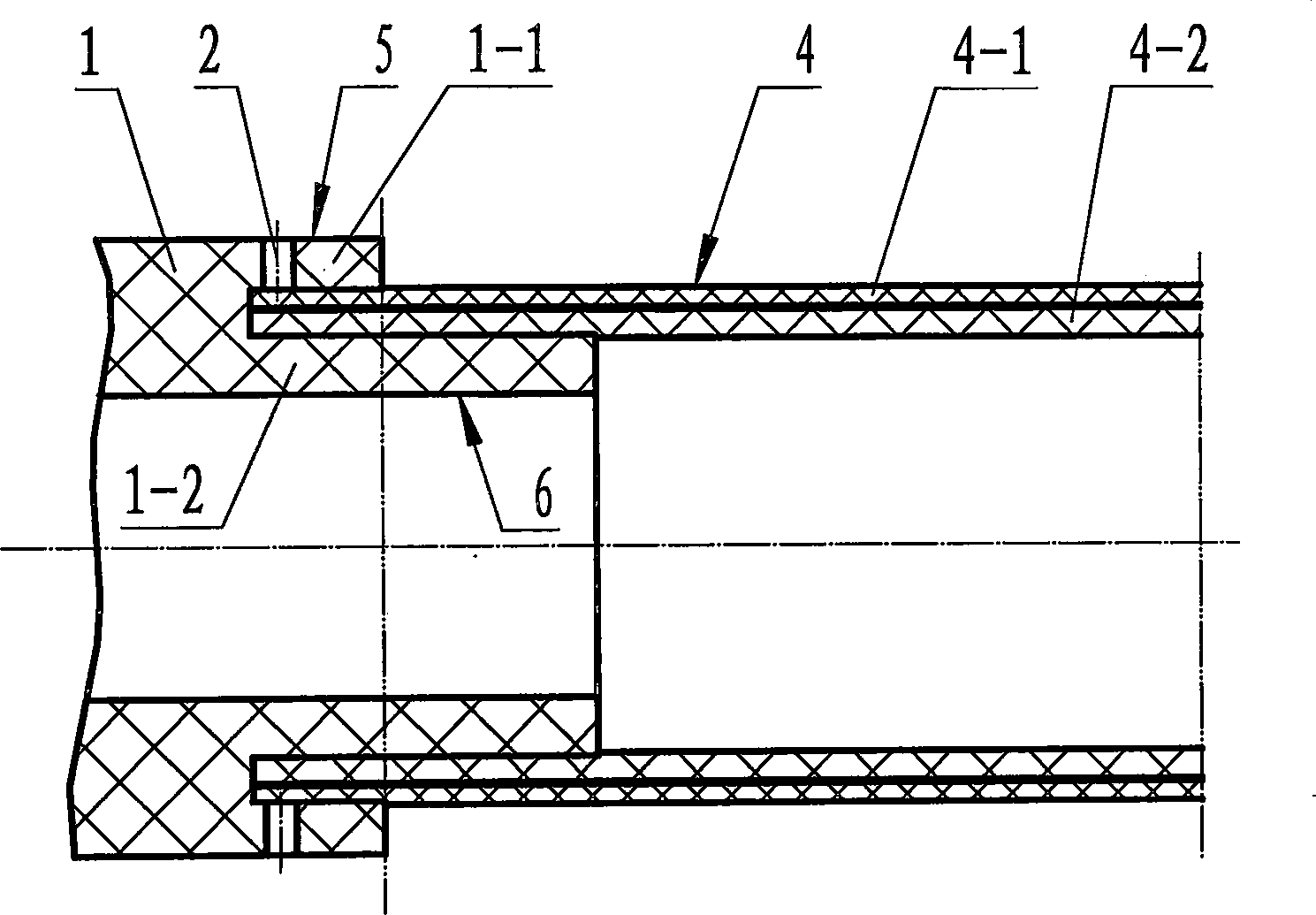

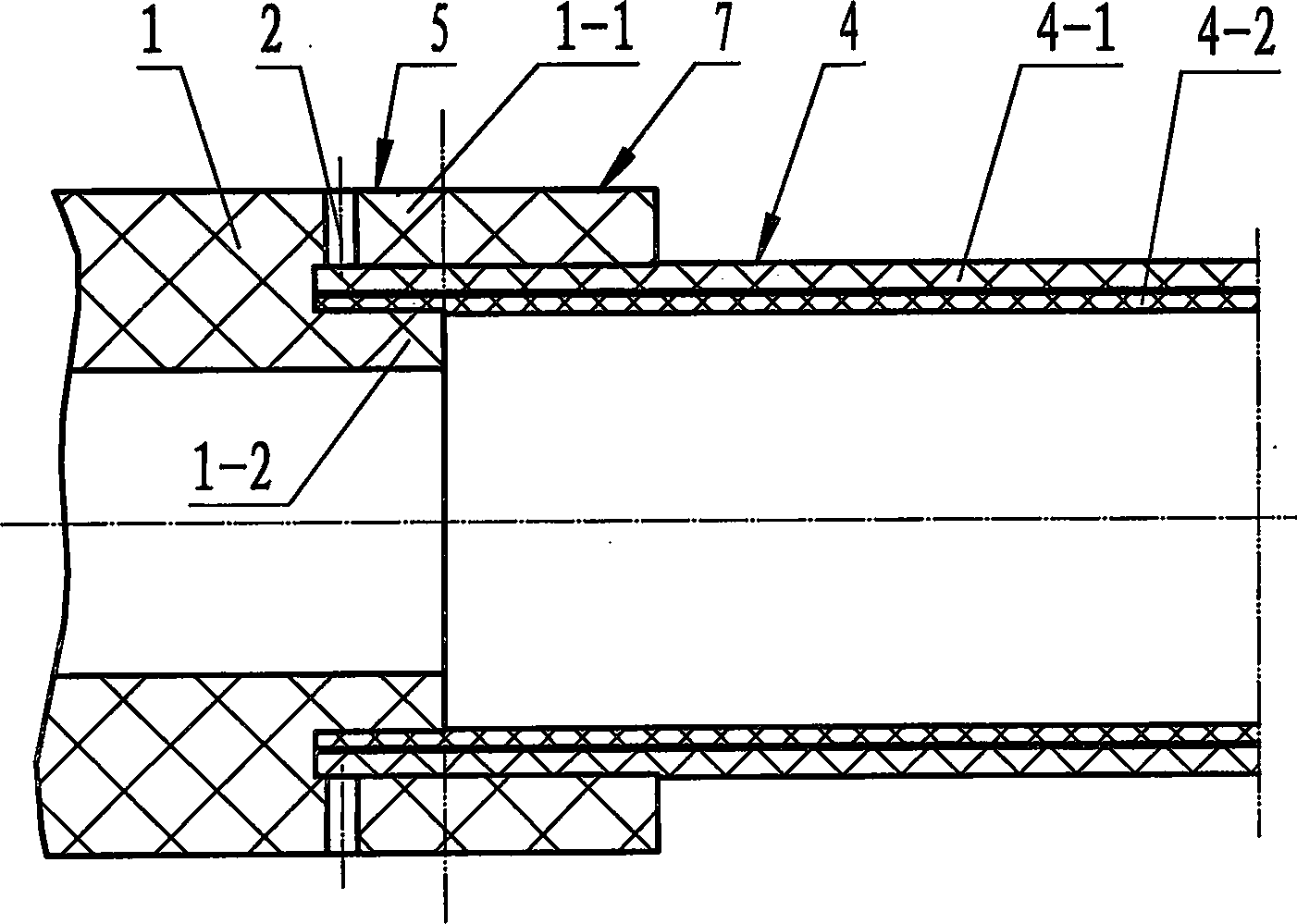

Socket pipe piece of heat melted connection

ActiveCN1873283ATightly boundImprove bending resistancePipe connection arrangementsPipe fittingHot melt

The present invention discloses a hot-melt connecting spigot-and-socket pipe fitting for aluminium plastics composite pipe. At least one end of said pipe fitting possesses adjacent spigot-and-socket part and internal layer connecting part, the rear portion of said spigot-and-socket part is equipped with an exhaust viewing hole, and the internal and external layer hot-melt connections of said joint are not identical in length, so that said invention can completely solve the exhaust problem produced when the aluminium plastics composite pipe and spigot-and-socket pipe fitting are hot-melt connected.

Owner:RIFENG ENTERPRISE GRP CO LTD

Integrated forming manufacturing method of I-shaped beam made from composite material

The invention discloses an integrated forming manufacturing method of an I-shaped beam made from a composite material. The method comprises the following steps: I, preparing a die; II, clipping, impregnating and overlaying fiber cloth; III, laminating the fiber cloth in the die; IV, hot-pressing and curing the laminated fiber cloth through a hot-press and the die; and V, opening the die. The method provided by the invention has the following advantages that material damage caused by punching connection and low connecting strength between a flange and a web caused by gluing connection are overcome when the flange and the web of the split type I-shaped beam made from the composite material obtained by existing manufacturing method are combined and connected, and the integral strength of the I-shaped beam made from the composite material is improved.

Owner:CHONGQING UNIV

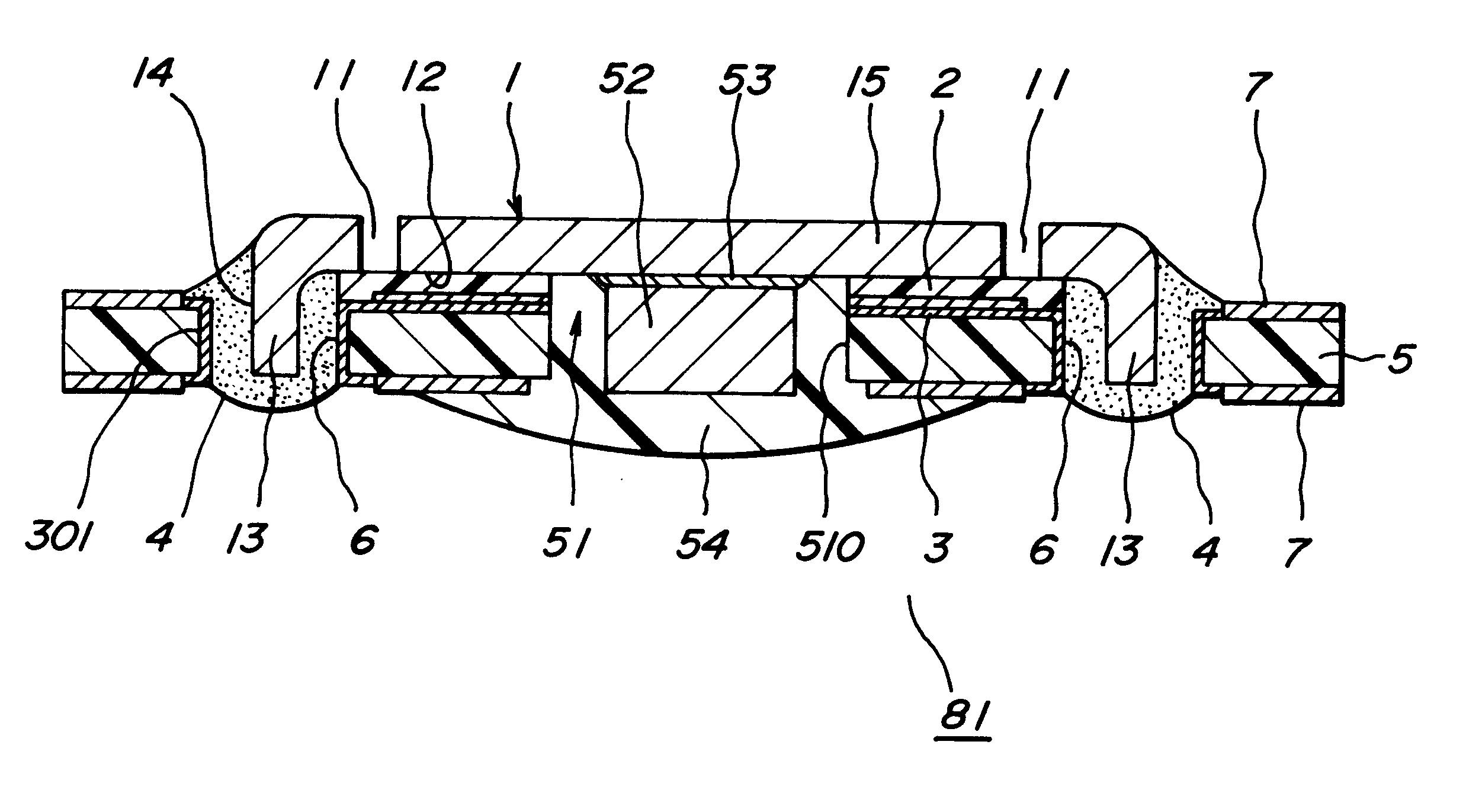

Coupling structure of sheath structure and coupling method thereof

ActiveUS20160165665A1Tentative attachmentImprove workabilityThermometer detailsContact member assembly/disassemblyElectricityCoupling

To provide a sheath structure assembly coupling structure and a sheath structure assembly coupling method, with which excellent workability and a reduction in costs can be achieved; a reduction in the strength of the connection portion or in the electrical connection can be prevented and a uniform and excellent electrical connection, can be achieved; with which excellent durability is maintained for a long period even in the usage environment in which a great force such a tension or the like continuously acts; and with which break or a reduction in insulating performance can be avoided.

Owner:NORITAKE KENSUKE +1

Mounting structure

InactiveUS20080062665A1Supply amount is increasedReduce connection strengthPrinted circuit assemblingFinal product manufactureEngineering

There is proposed a mounting structure including a plurality of components each having a plurality of solder bumps, a substrate having a plurality of lands, and a solder connecting portion for connecting the solder bump and the land, wherein the land provided in an outer peripheral portion of the substrate is smaller than that of the land in a central portion of the substrate.

Owner:HITACHI LTD

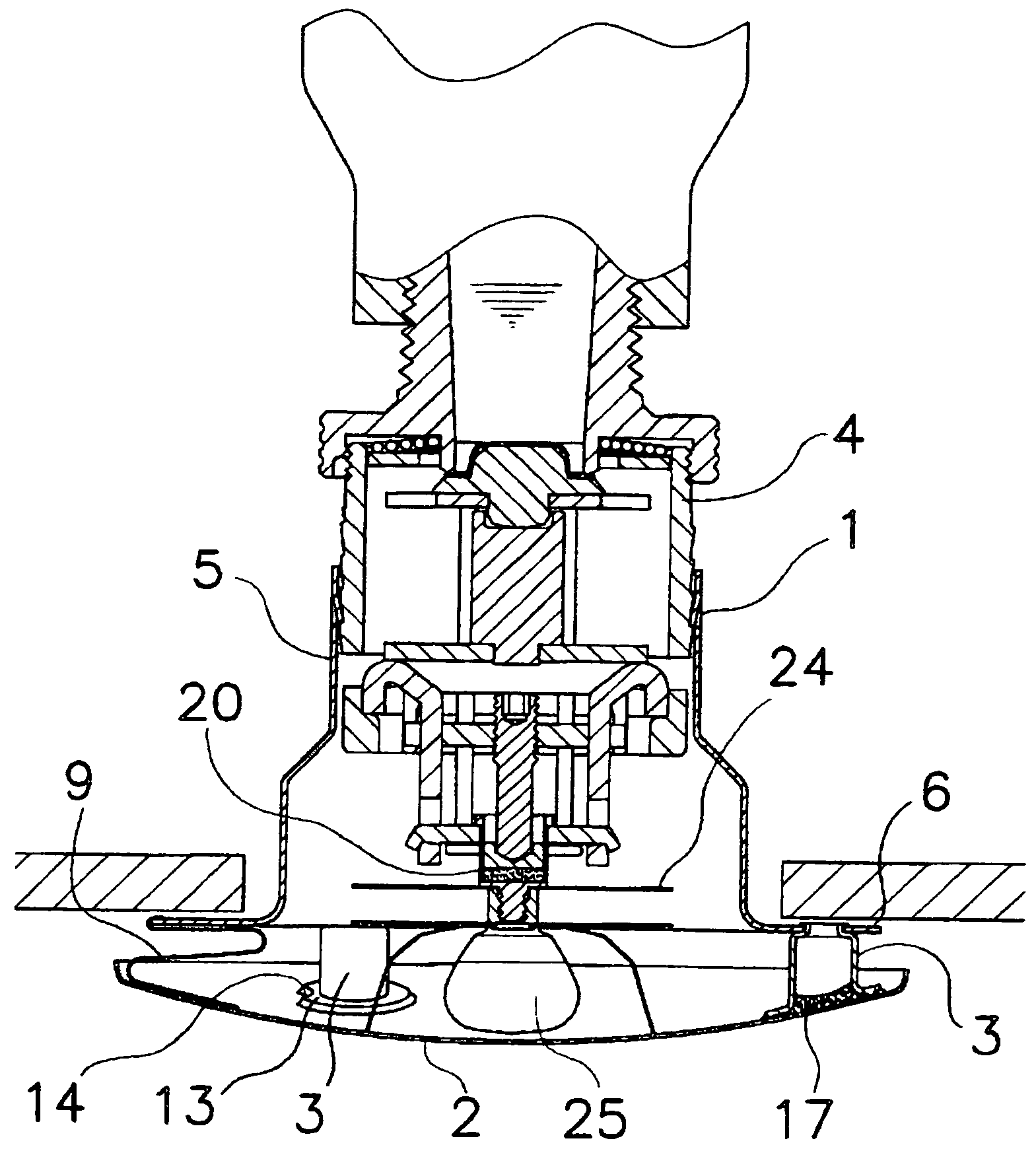

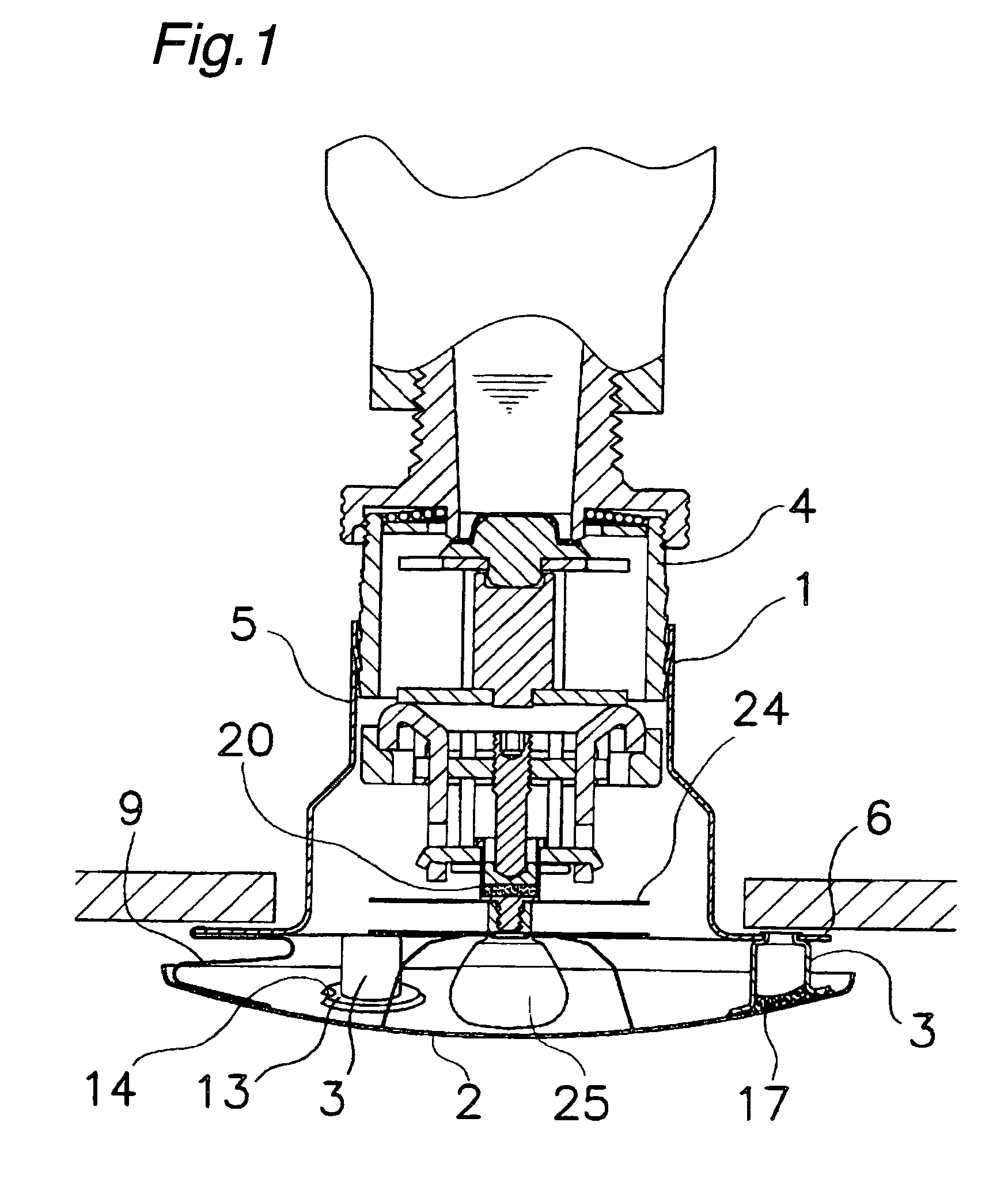

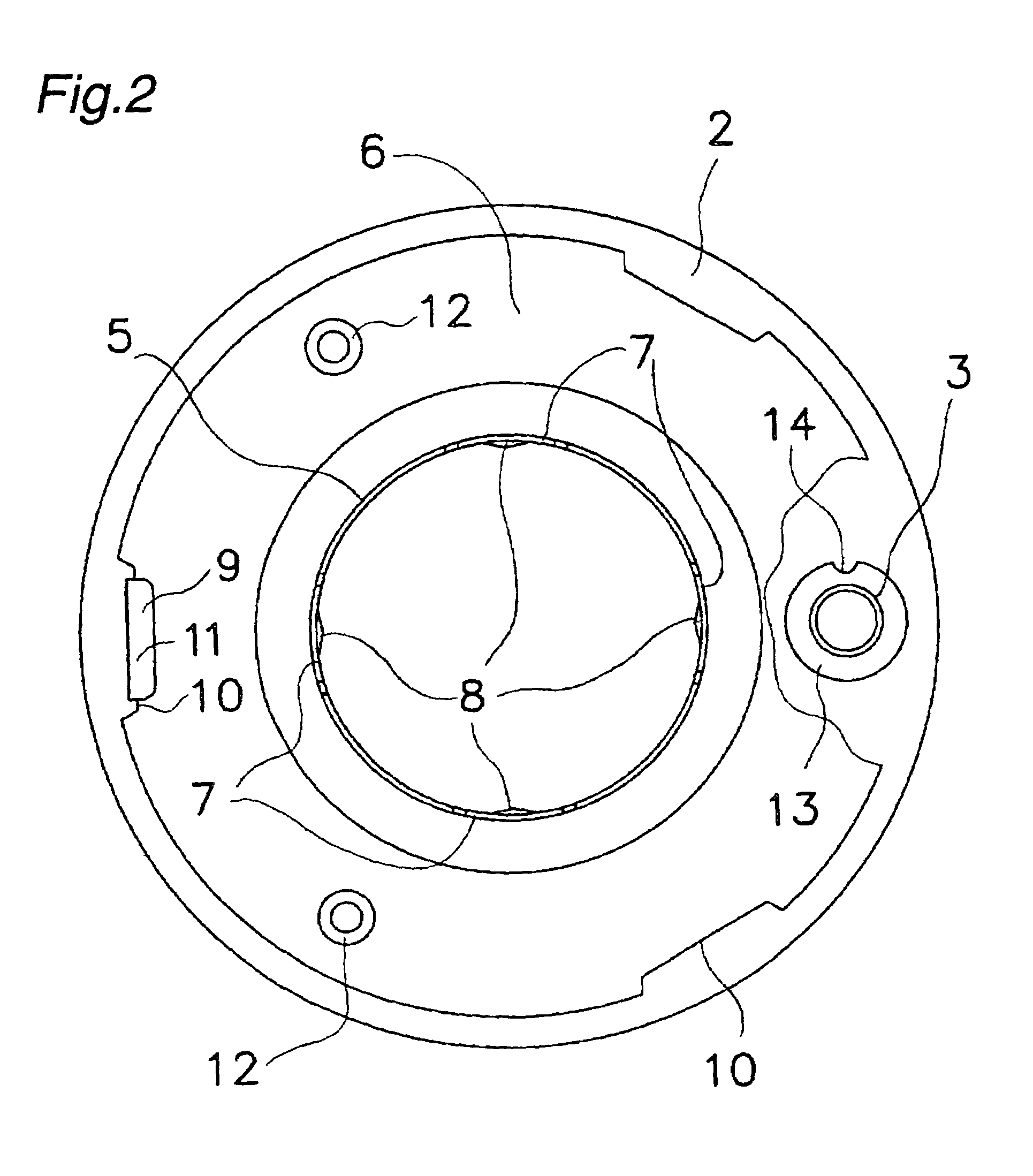

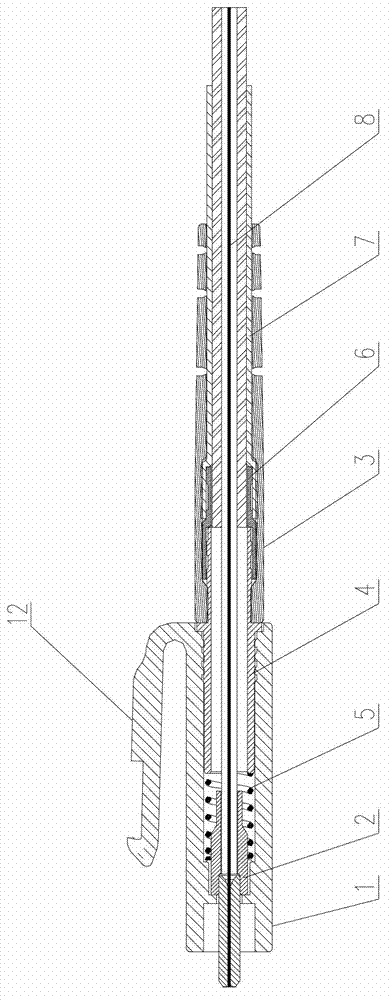

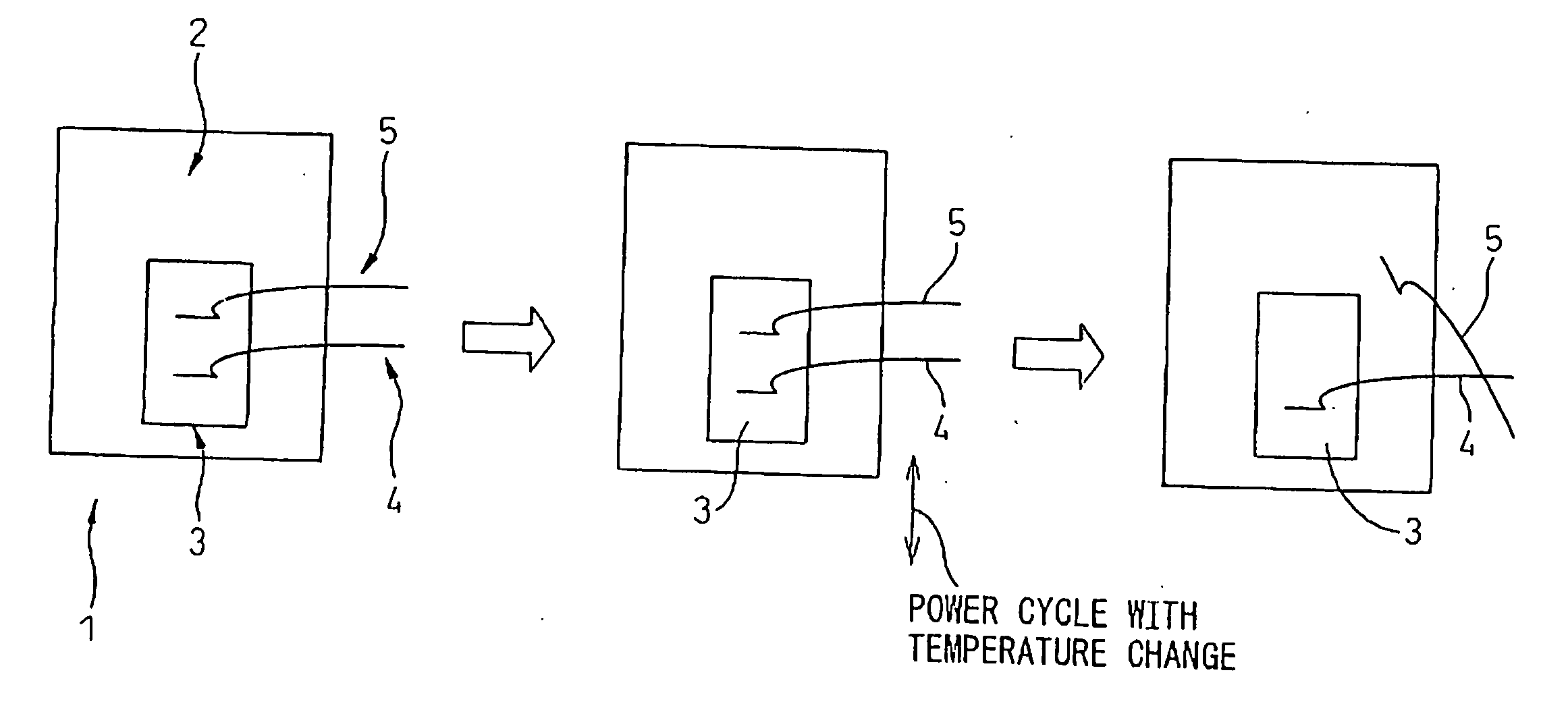

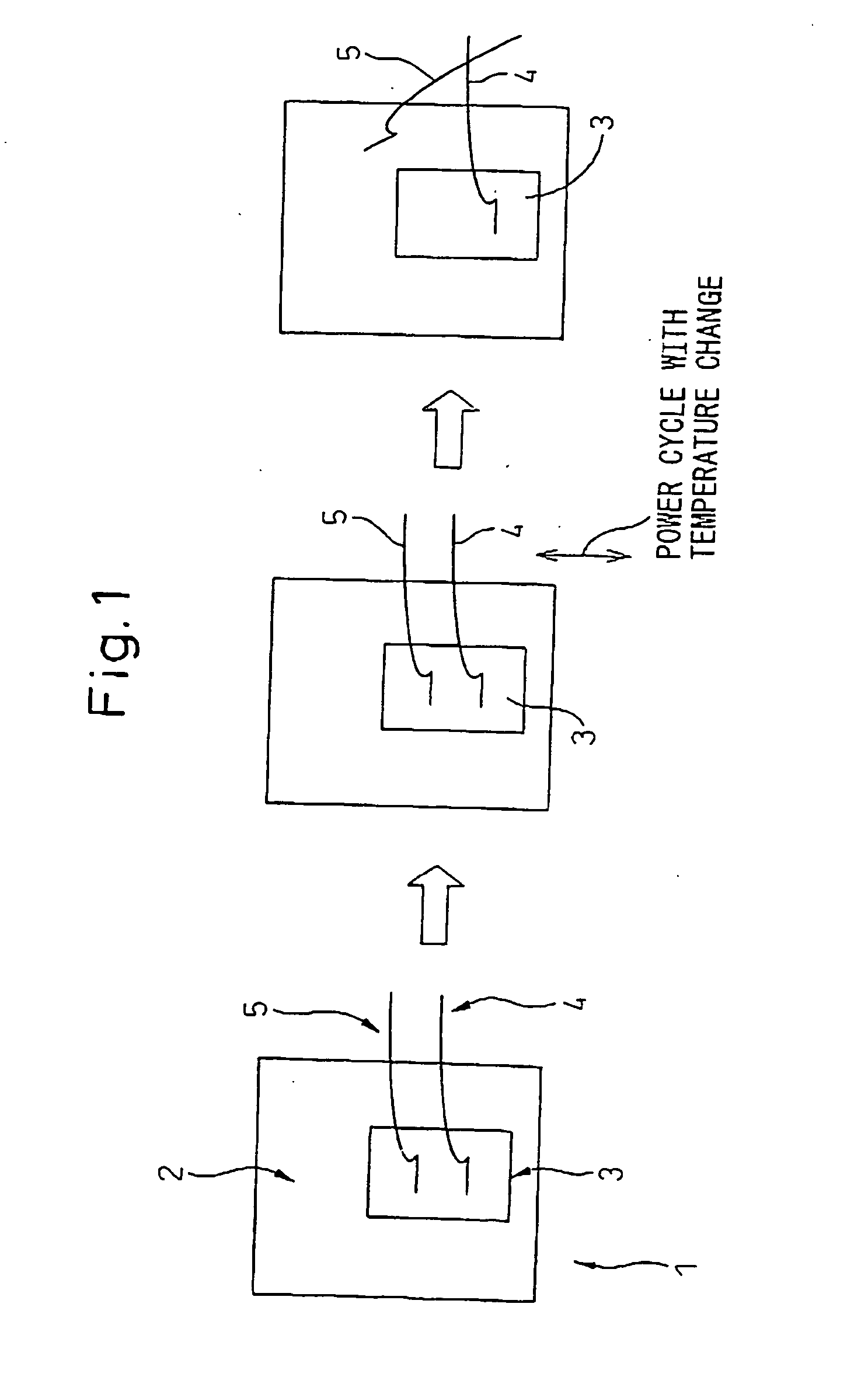

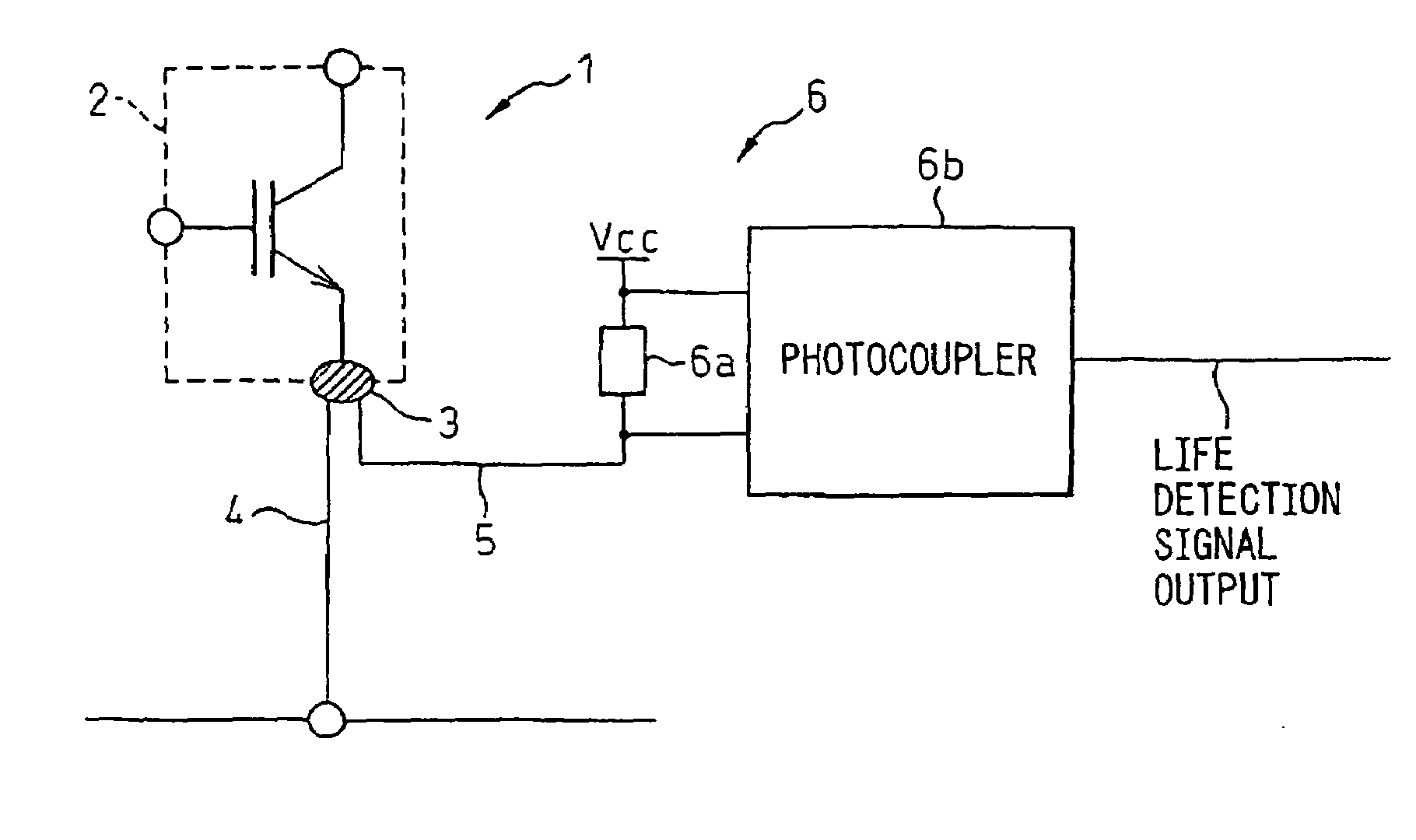

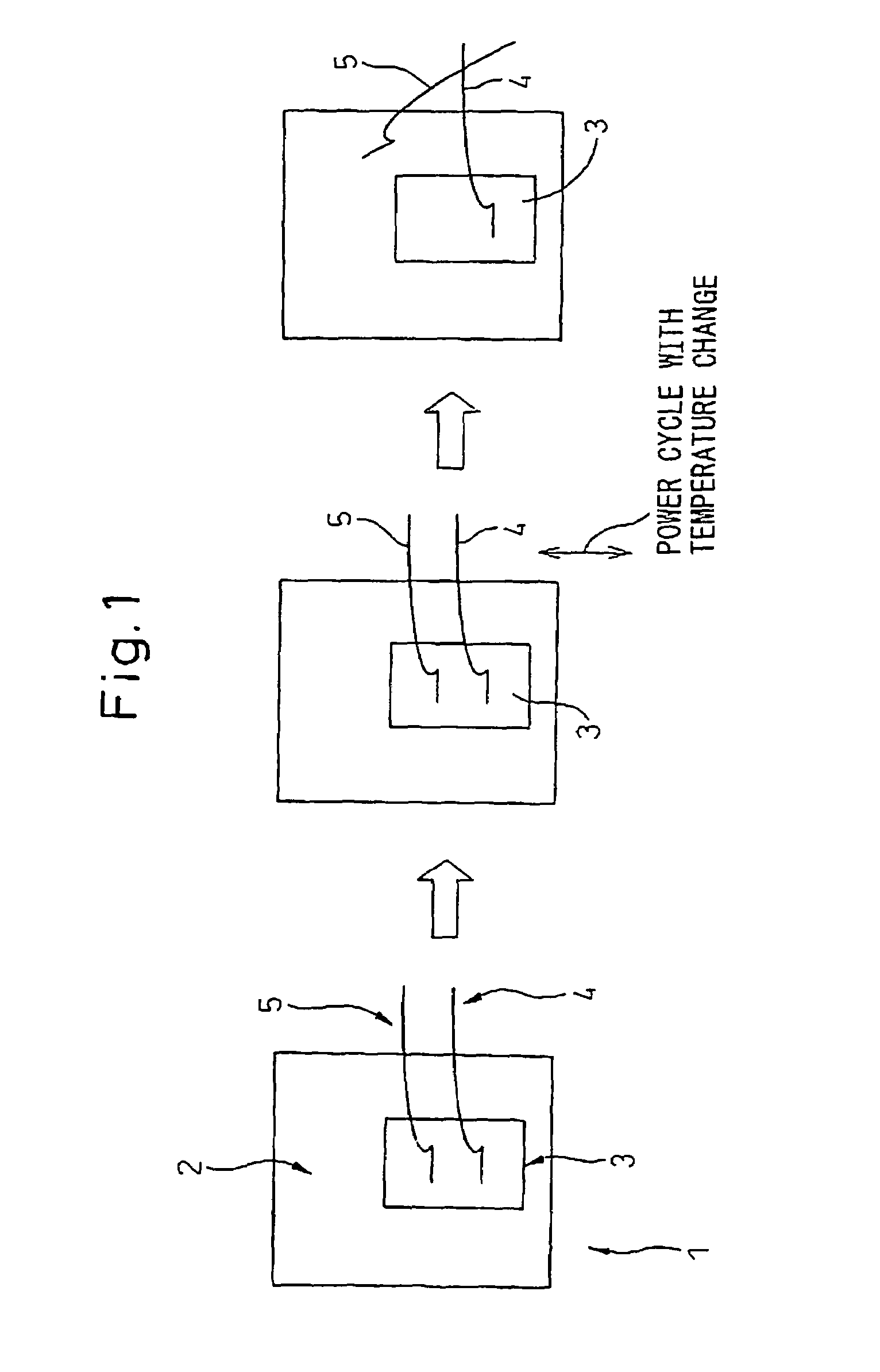

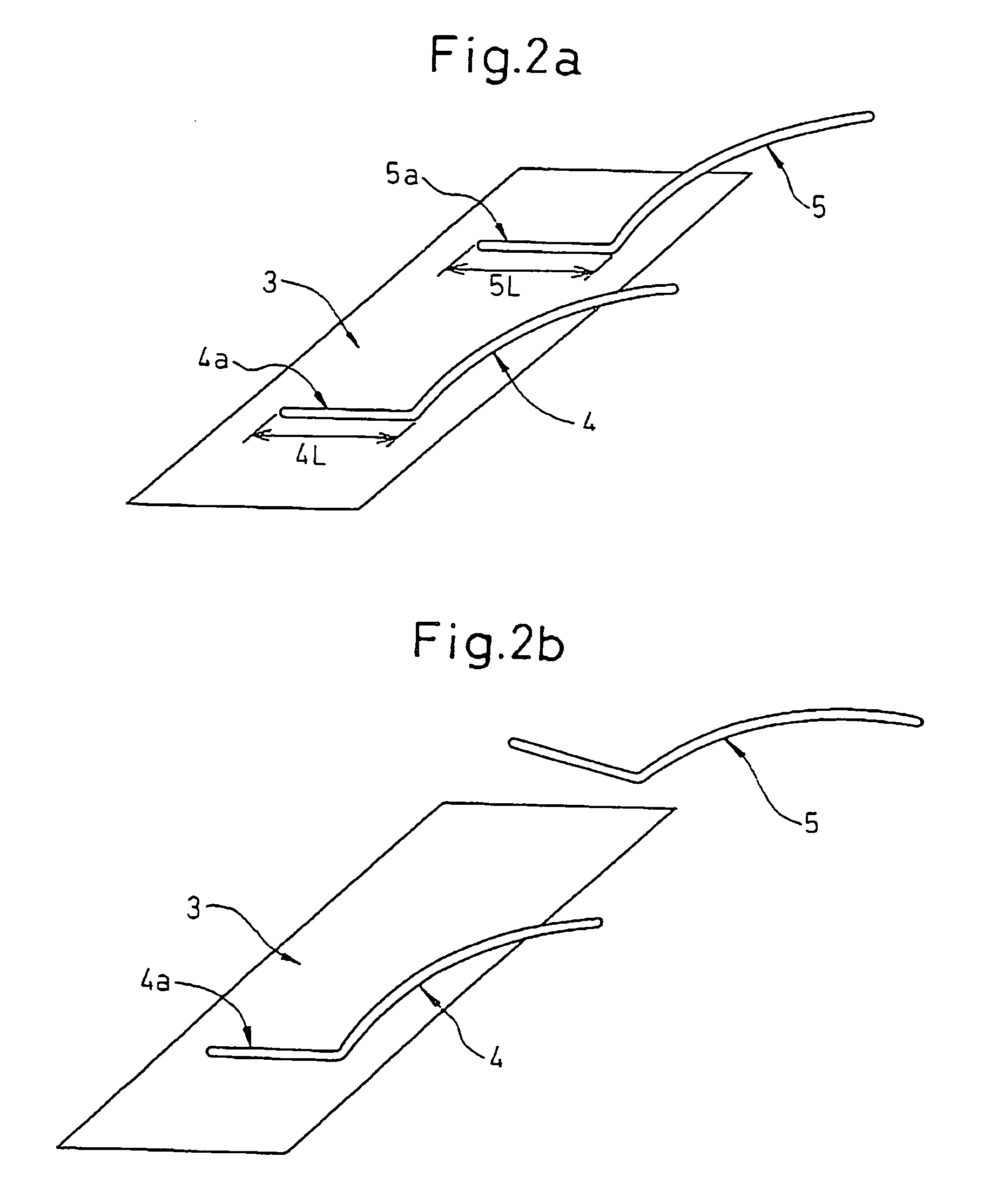

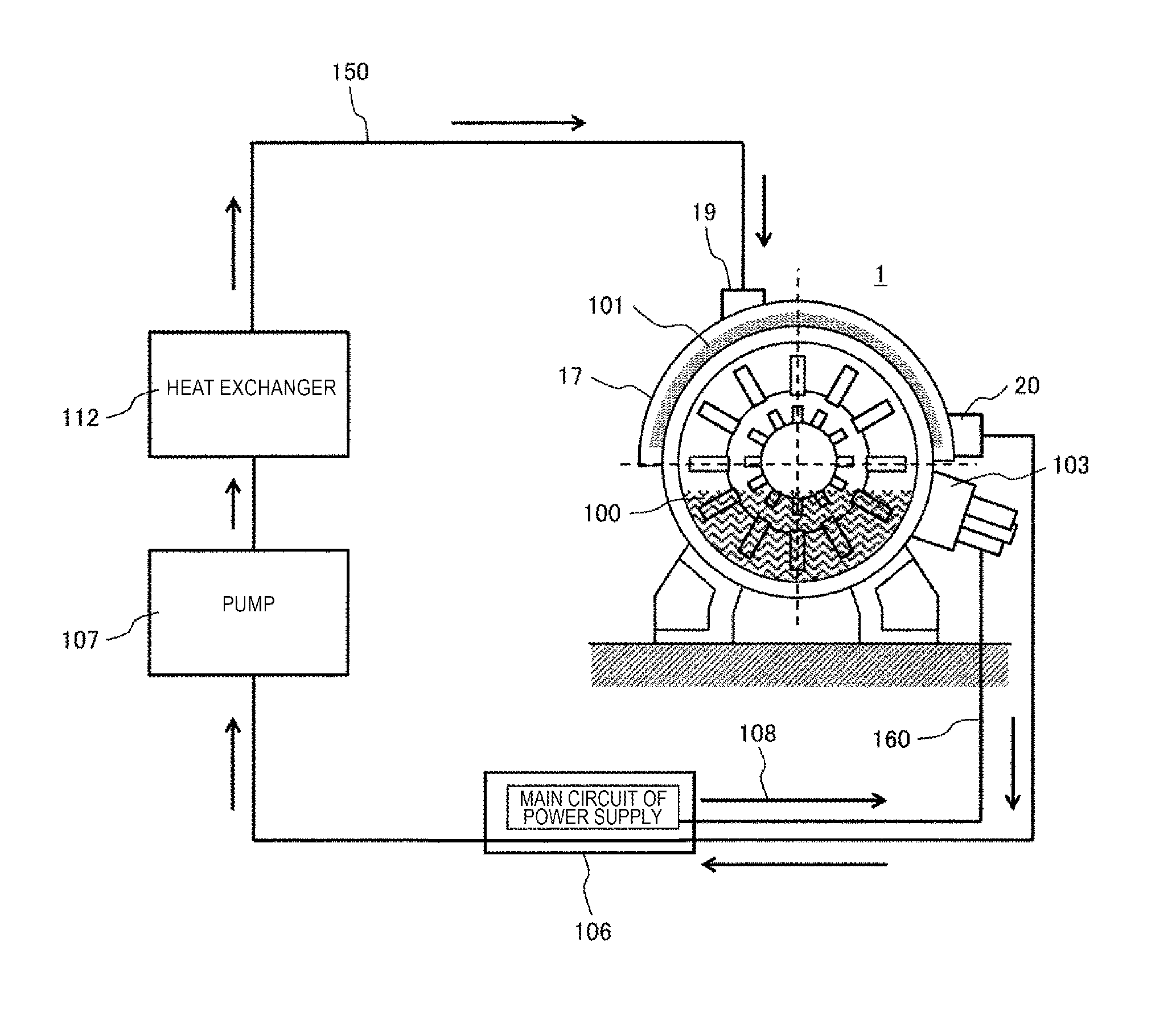

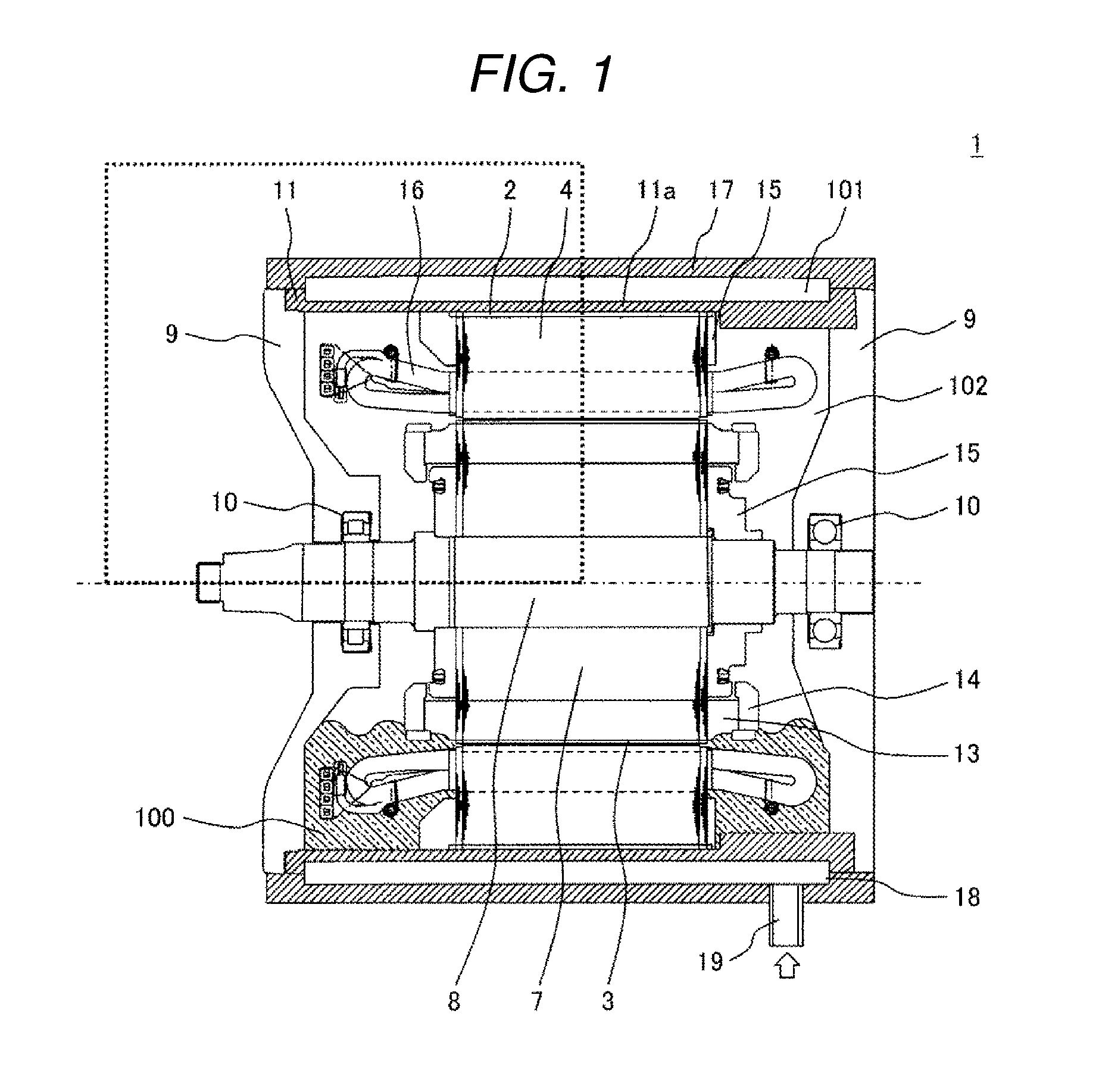

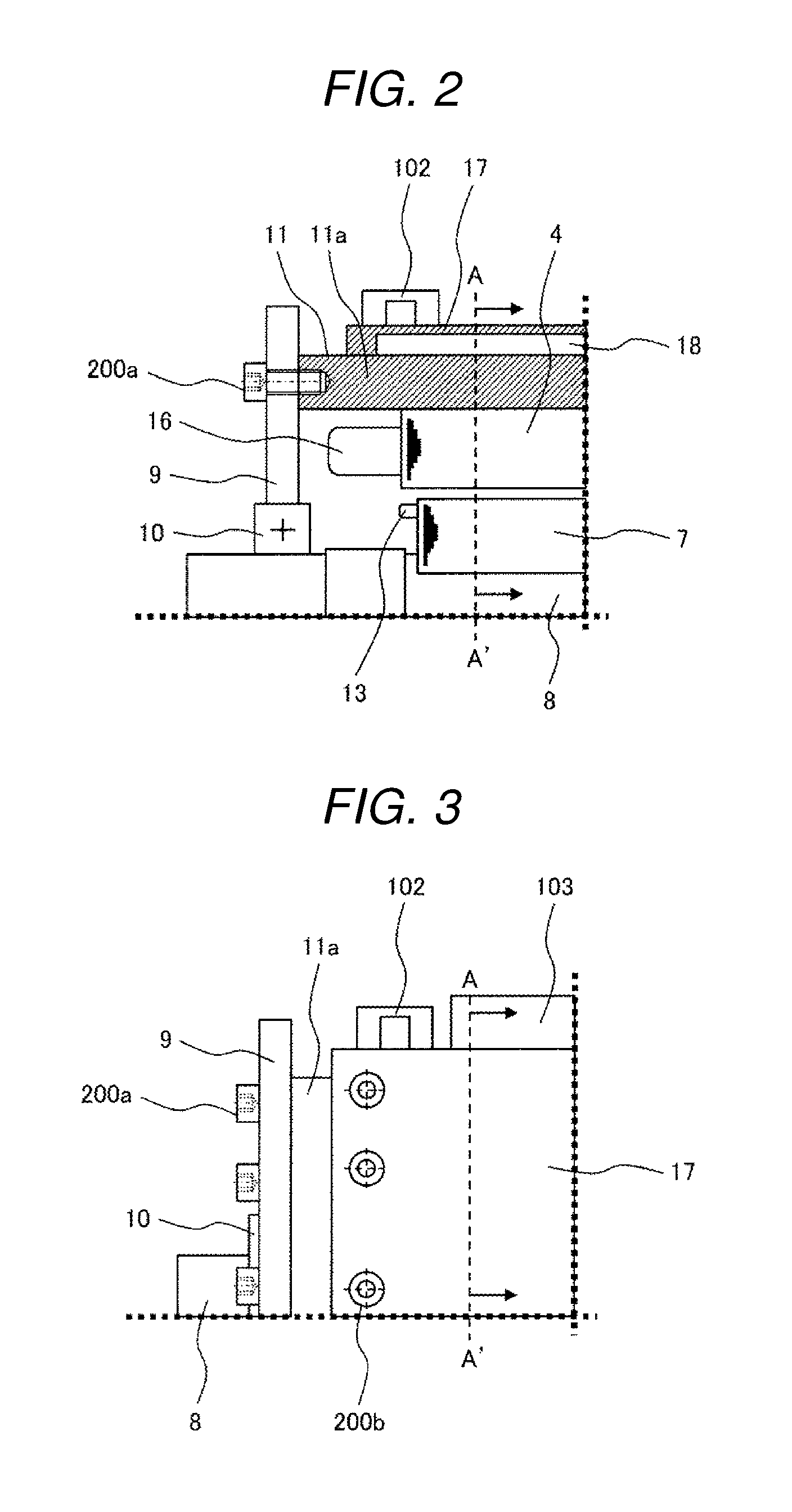

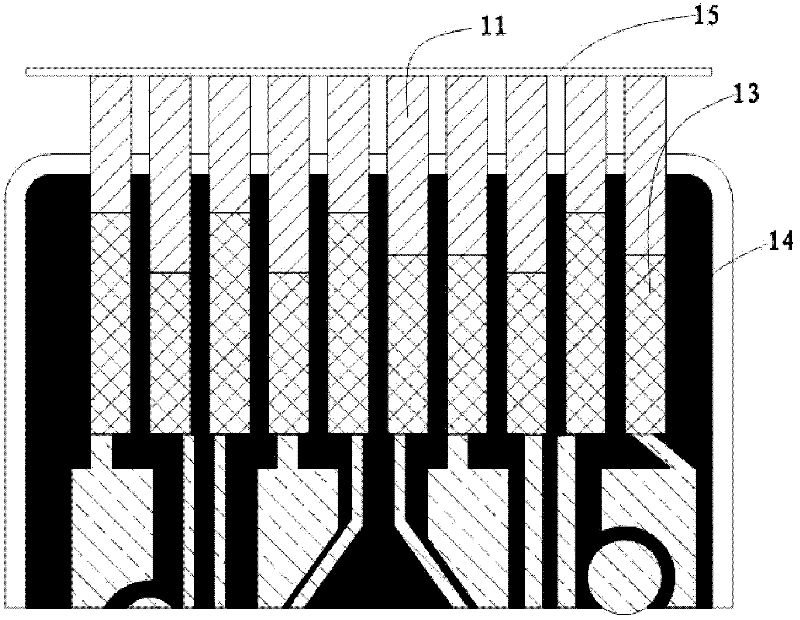

Motor driving system having power semiconductor module life detection function

InactiveUS20050212549A1Operation failureReduce connection strengthDC motor speed/torque controlElectronic circuit testingMotor driveSemiconductor chip

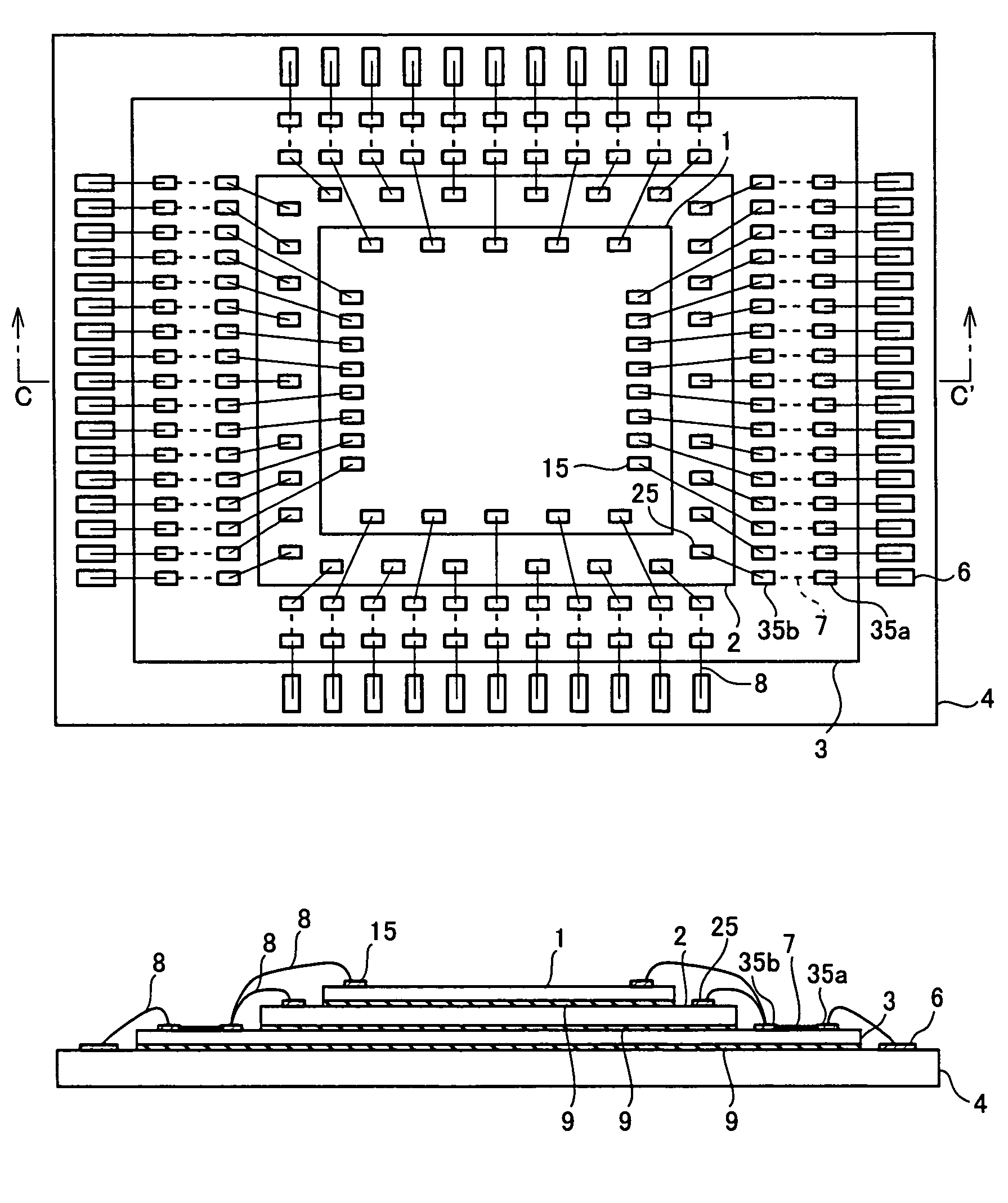

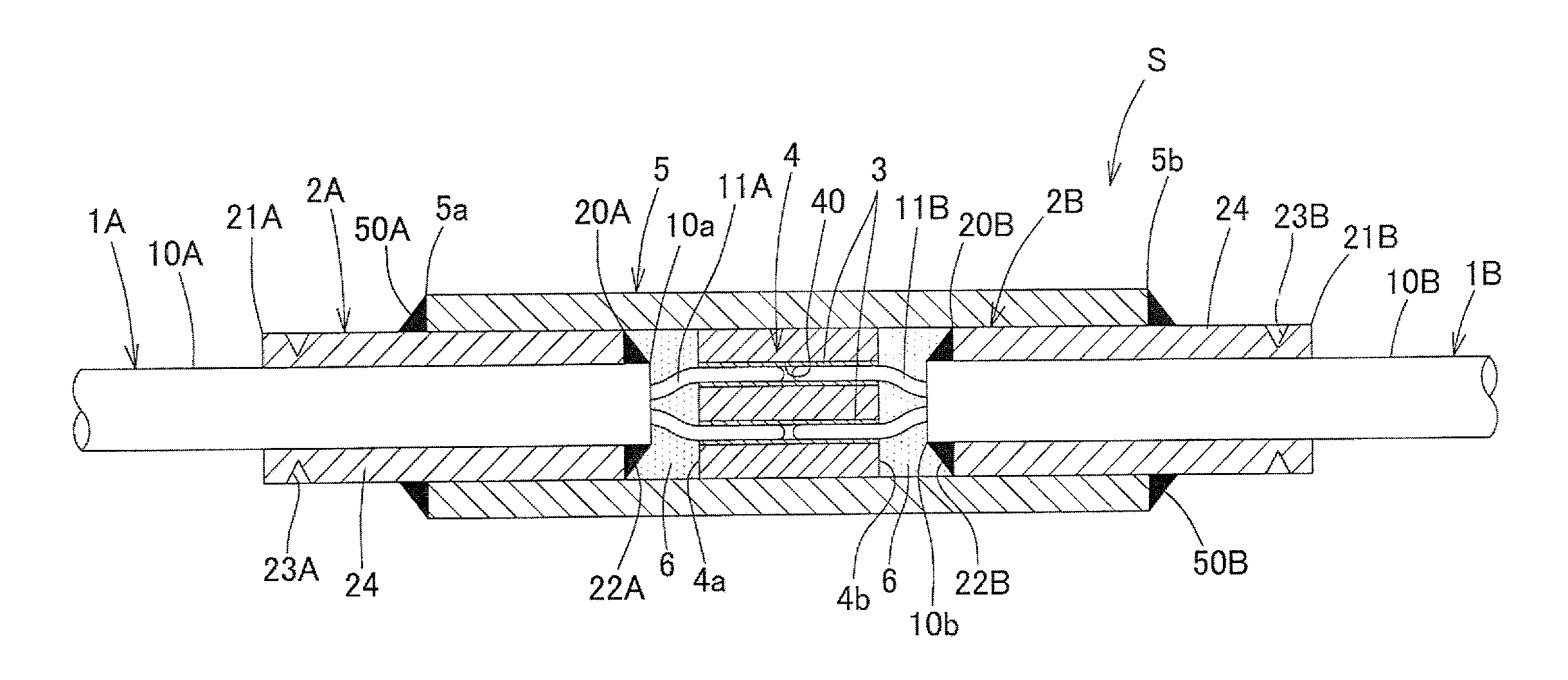

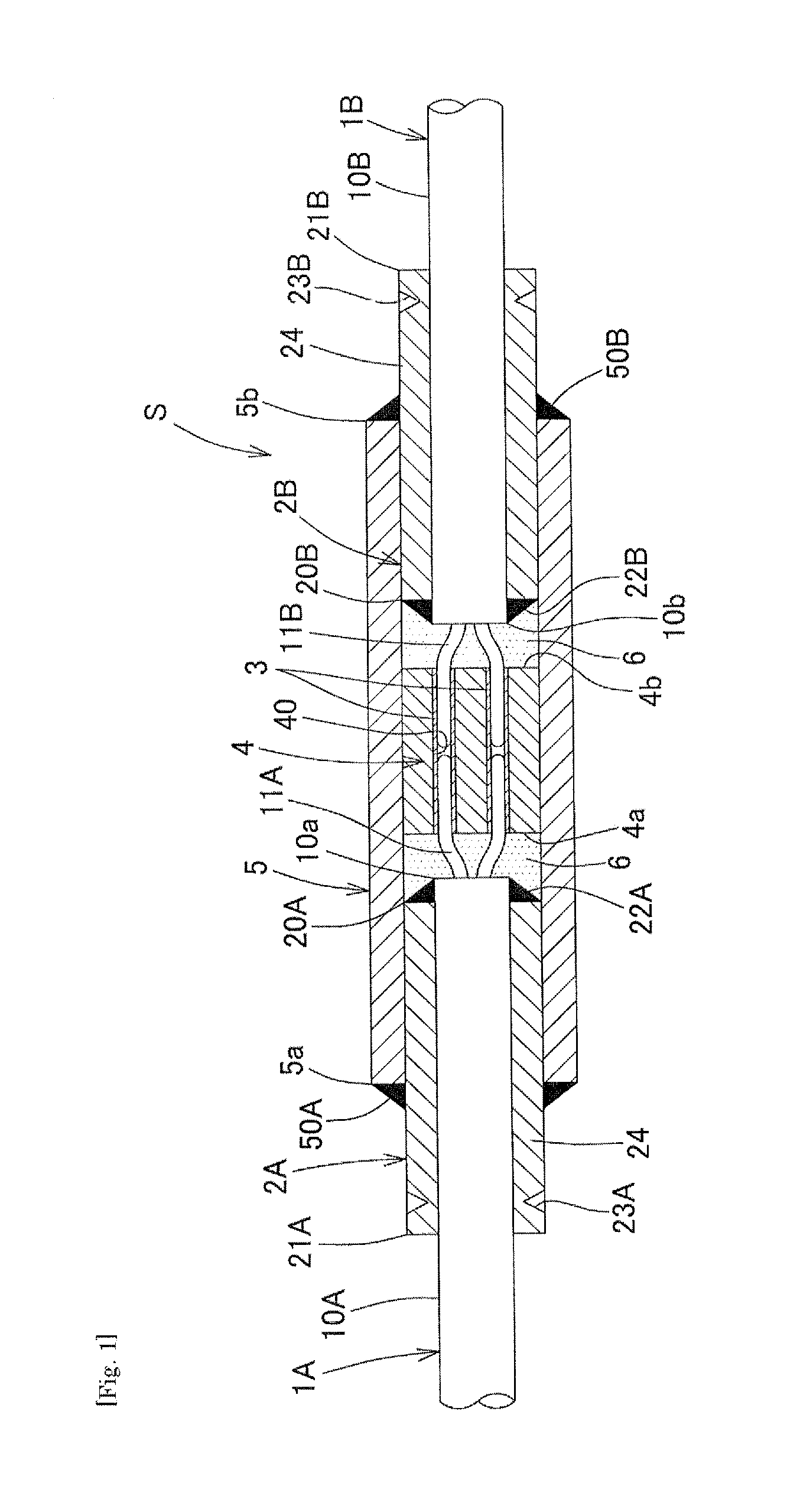

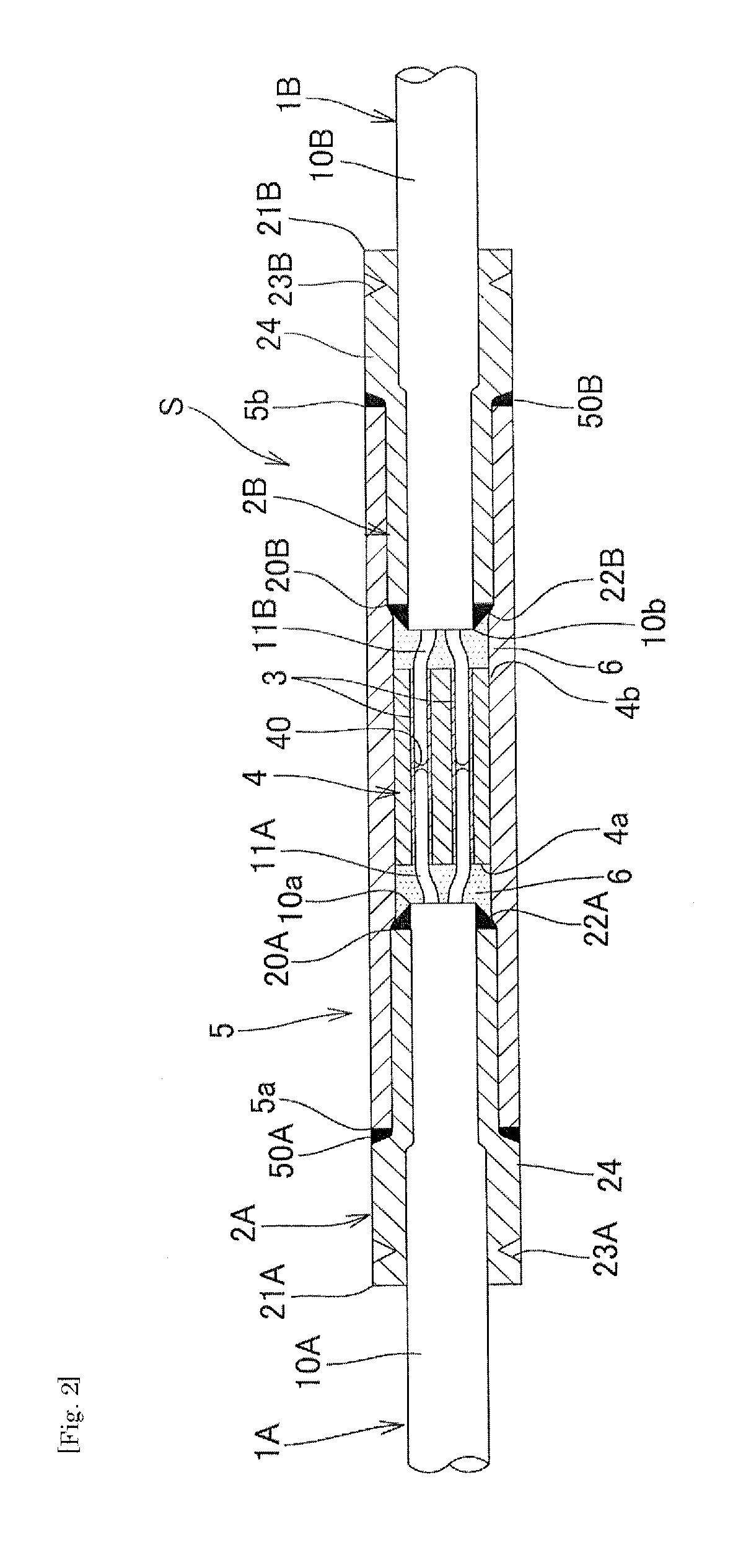

In the motor driving system, a unit to predict the separation of the wire is built into the power semiconductor module thereby to predict that the time of separation of the wire is approaching before the actual separation of the wire. Thus, the time to replace the power semiconductor module used for power devices such as the motor driving system is clarified to prevent an operation failure of the motor driving system from occurring. The power semiconductor module (1) has a power semiconductor chip (2) mounted thereon, and the power semiconductor chip (2) includes a main circuit wire (4) and a dummy wire (5) connected to the electrode (3) of the power semiconductor. The dummy wire is set to a lower connection strength than the main circuit wire.

Owner:FANUC LTD

Motor driving system having power semiconductor module life detection function

InactiveUS7098683B2Operation failureReduce connection strengthDC motor speed/torque controlElectronic circuit testingMotor driveSemiconductor chip

In the motor driving system, a unit to predict the separation of the wire is built into the power semiconductor module thereby to predict that the time of separation of the wire is approaching before the actual separation of the wire. Thus, the time to replace the power semiconductor module used for power devices such as the motor driving system is clarified to prevent an operation failure of the motor driving system from occurring. The power semiconductor module (1) has a power semiconductor chip (2) mounted thereon, and the power semiconductor chip (2) includes a main circuit wire (4) and a dummy wire (5) connected to the electrode (3) of the power semiconductor. The dummy wire is set to a lower connection strength than the main circuit wire.

Owner:FANUC LTD

Semiconductor device

ActiveUSRE41826E1Inhibition strengthShorten the line lengthSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipEngineering

In a semiconductor device in which a semiconductor chip is stacked on a substrate, an interposer chip having wirings is provided under the semiconductor chip. A bonding pad of the semiconductor chip is electrically connected to a bonding terminal provided on the substrate via the interposer chip by wire bonding. The interposer chip prevents a semiconductor element formed in the semiconductor chip from deteriorating in terms of an electric property and from being physically damaged. Further, the wire bonding strength does not drop. Moreover, it is possible to form a fine wiring pitch for relaying a wire-bonding wire.

Owner:III HLDG 12 LLC

Semiconductor device having a particular electrode structure

InactiveUS7211892B2Reduced inhibitory strengthImprove thermal fatigue lifePrinted circuit assemblingSemiconductor/solid-state device detailsMetallurgyPalladium

Owner:RENESAS ELECTRONICS CORP

Process method for replacing trunnion of ladle

InactiveCN101992375AImprove the heating effectImprove cooling effectMelt-holding vesselsMetal working apparatusMachine partsHigh pressure oxygen

The invention discloses a method for replacing a trunnion of a ladle, which comprises the following steps: cutting of part, which extends out of the ladle, of the trunnion of the ladle; planning the weld joint at the connected part of the trunnion and the ladle; heating the end face of the trunnion with acetylene flame to melt the end face of the trunnion; blowing oxygen to a molten point by using a high-pressure oxygen lance till a hole is blown; cooling the part of the trunnion and creating a gap between the trunnion and the ladle body; and striking the trunnion, and separating the trunnion from the ladle body. The invention provides a process method for separating the ladle body of the ladle from the trunnion conveniently and quickly, which is a more advanced clearance fit machine part maintenance and detachment technique and has a high utilization value in metallurgical machine industry.

Owner:LAIWU IRON & STEEL GRP

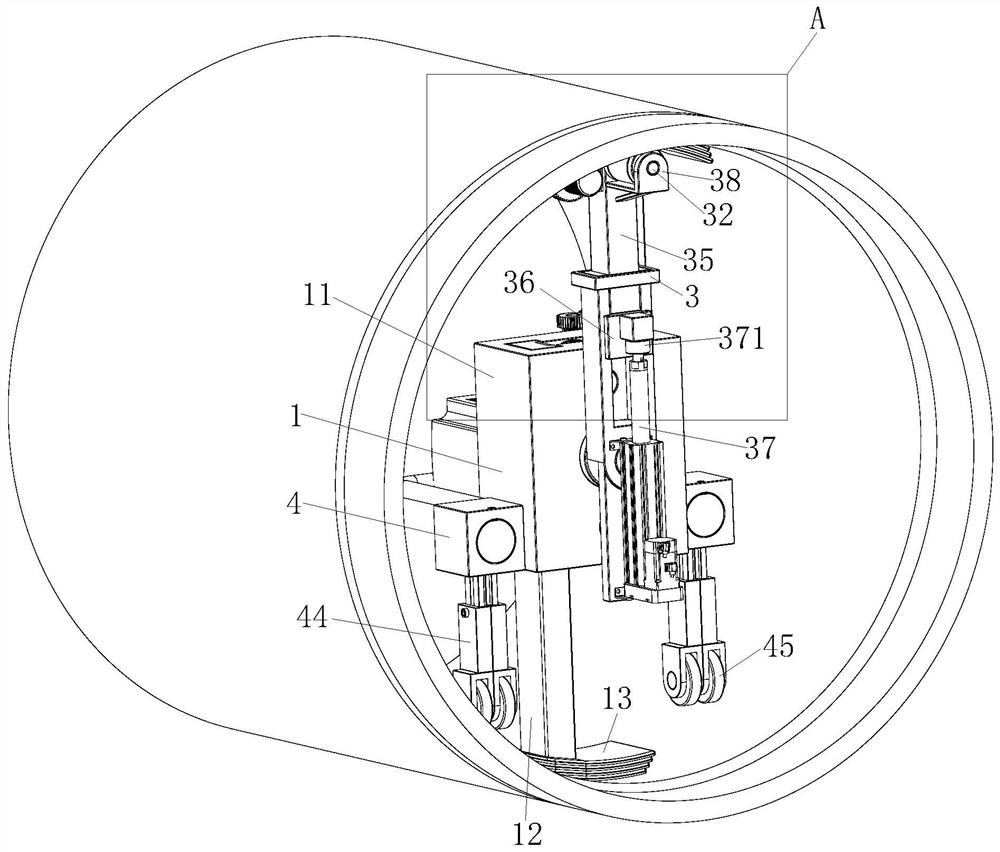

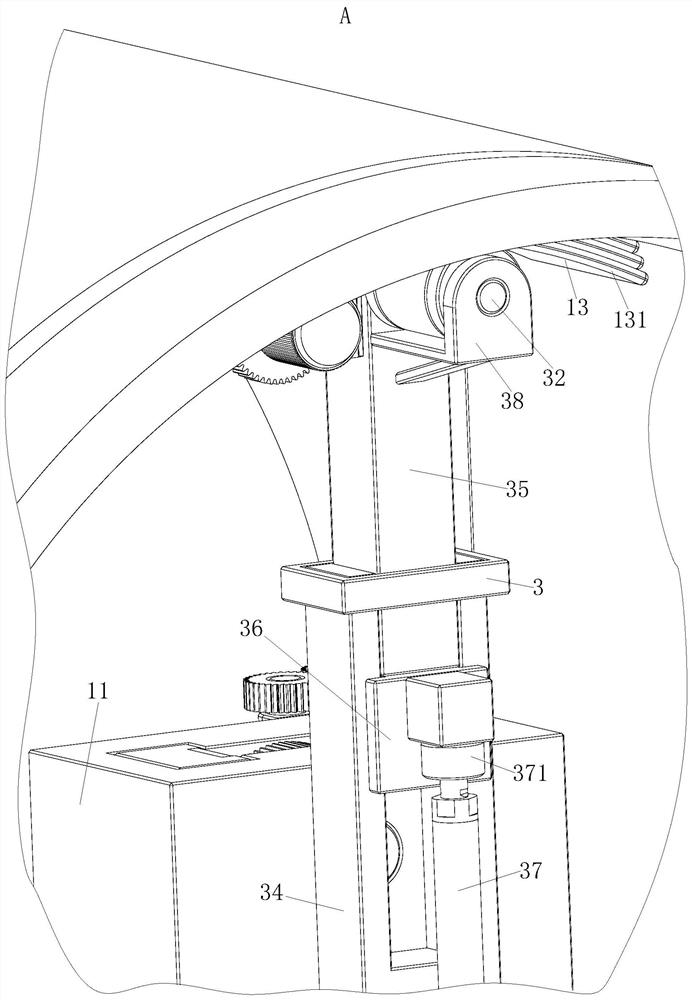

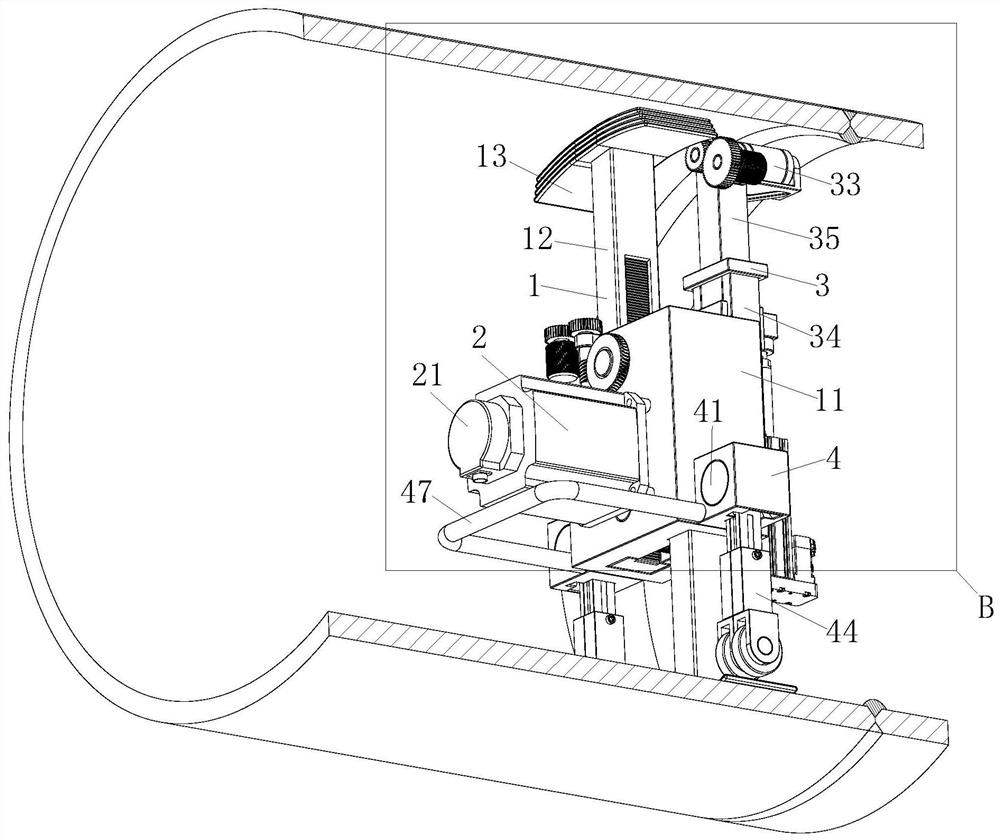

Large steel pipe inner opening welding seam polishing machine

InactiveCN113579892AQuality improvementReduce connection strengthEdge grinding machinesGrinding carriagesPolishingWeld seam

The invention belongs to the technical field of steel pipe machining equipment, and particularly relates to a large steel pipe inner opening welding seam polishing machine. The large steel pipe inner opening welding seam polishing machine comprises a tensioning component, a rotating component and a polishing component. According to the large steel pipe inner opening welding seam polishing machine, after the polishing machine is fixed into a large steel pipe through the tensioning component, the rotating component drives the polishing component to rotate, the polishing component rotates around the axis of the large steel pipe, then the polishing component polishes away redundant metal at the weld joint while rotating, so that the surplus height of the weld joint meets the technical requirement; the polishing machine solves the problems that the conventional polishing mostly adopts manual polishing, the welding seam polishing degree cannot be controlled, and excessive local polishing and insufficient local polishing are easily caused; moreover, the polishing machine avoids the situation that the welding seam strength is reduced due to excessive local polishing, further guarantees the welding seam strength, and avoids the situation that the welding seam is too large in local surplus reinforcement due to insufficient local polishing, therefore, the frictional resistance of the medium during flowing is reduced, and the conveying energy consumption is reduced; and manual polishing is not needed, so that the physical strength expenditure of people is saved, and the labor cost is further saved.

Owner:刘良霞

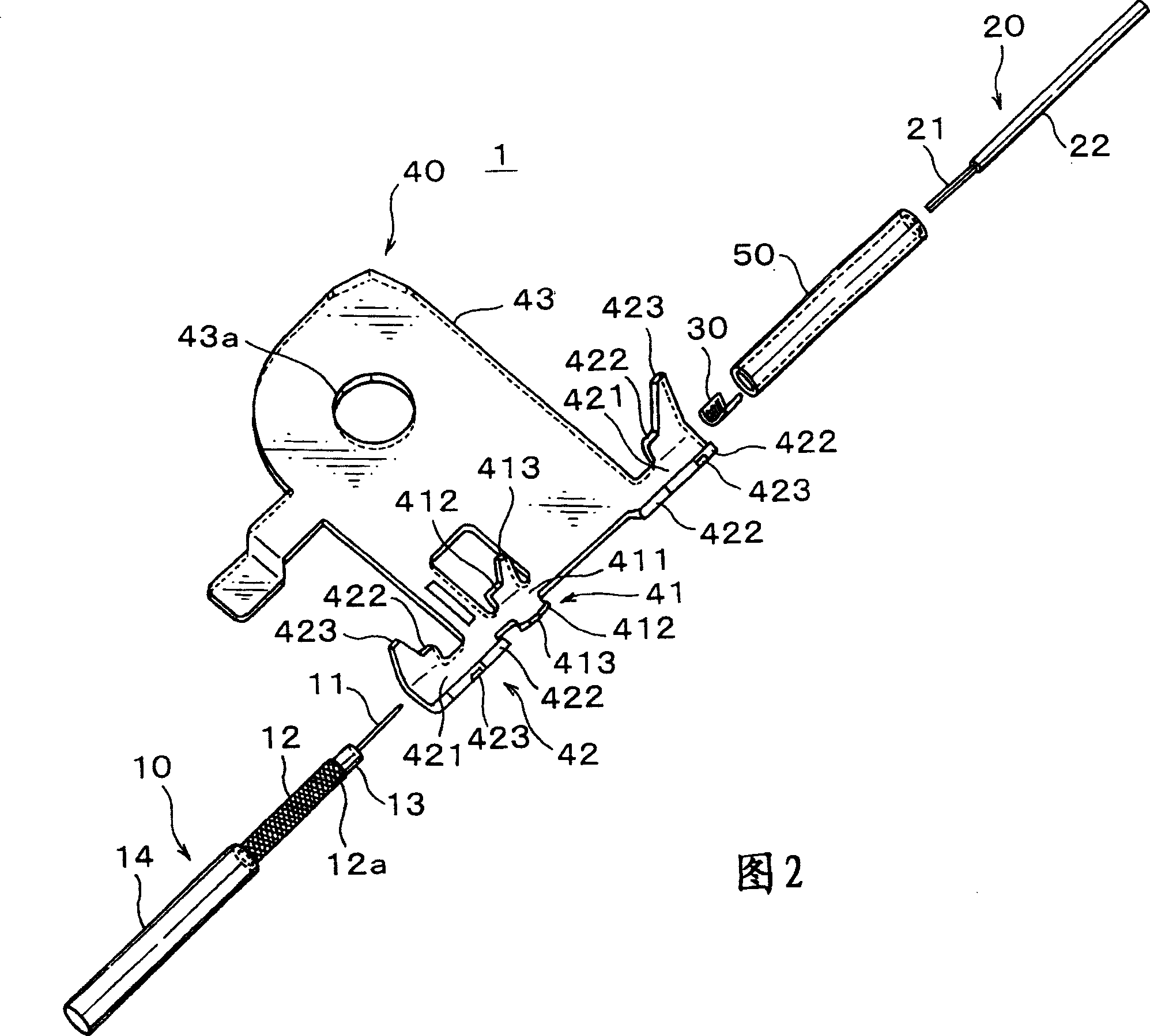

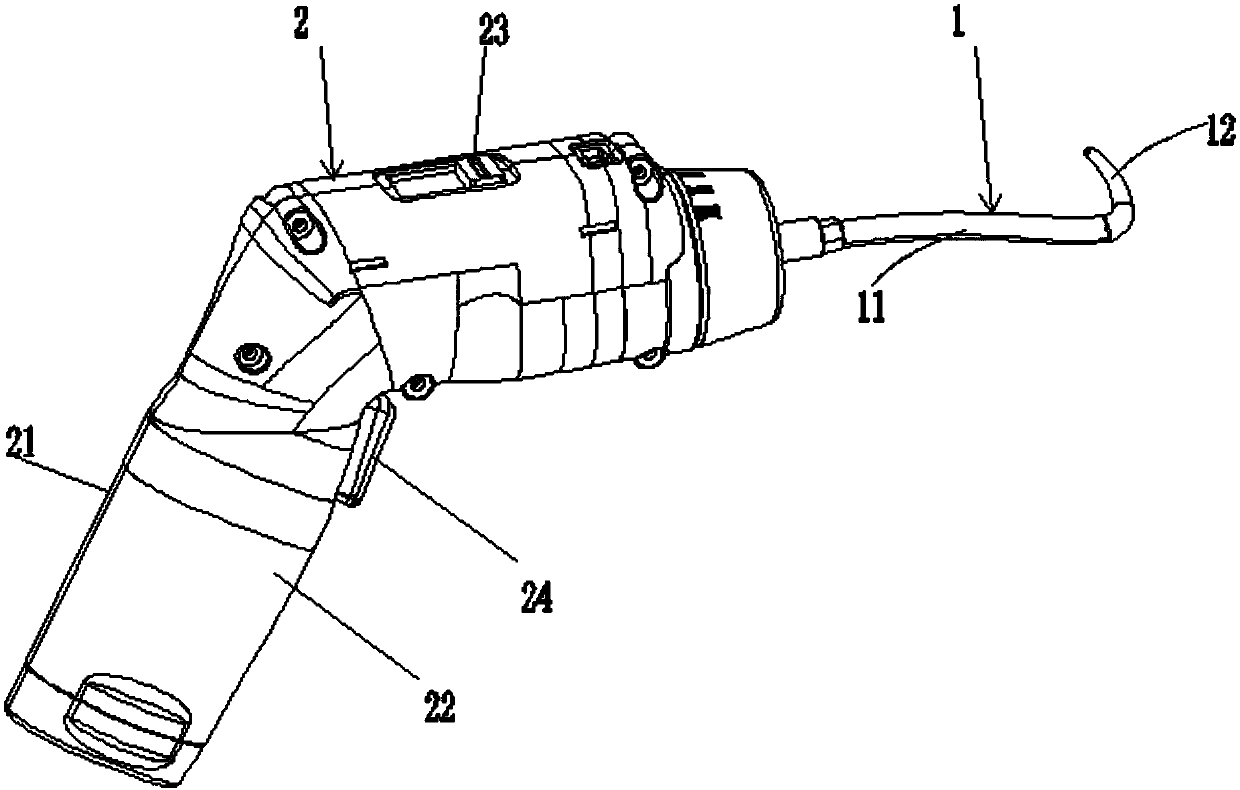

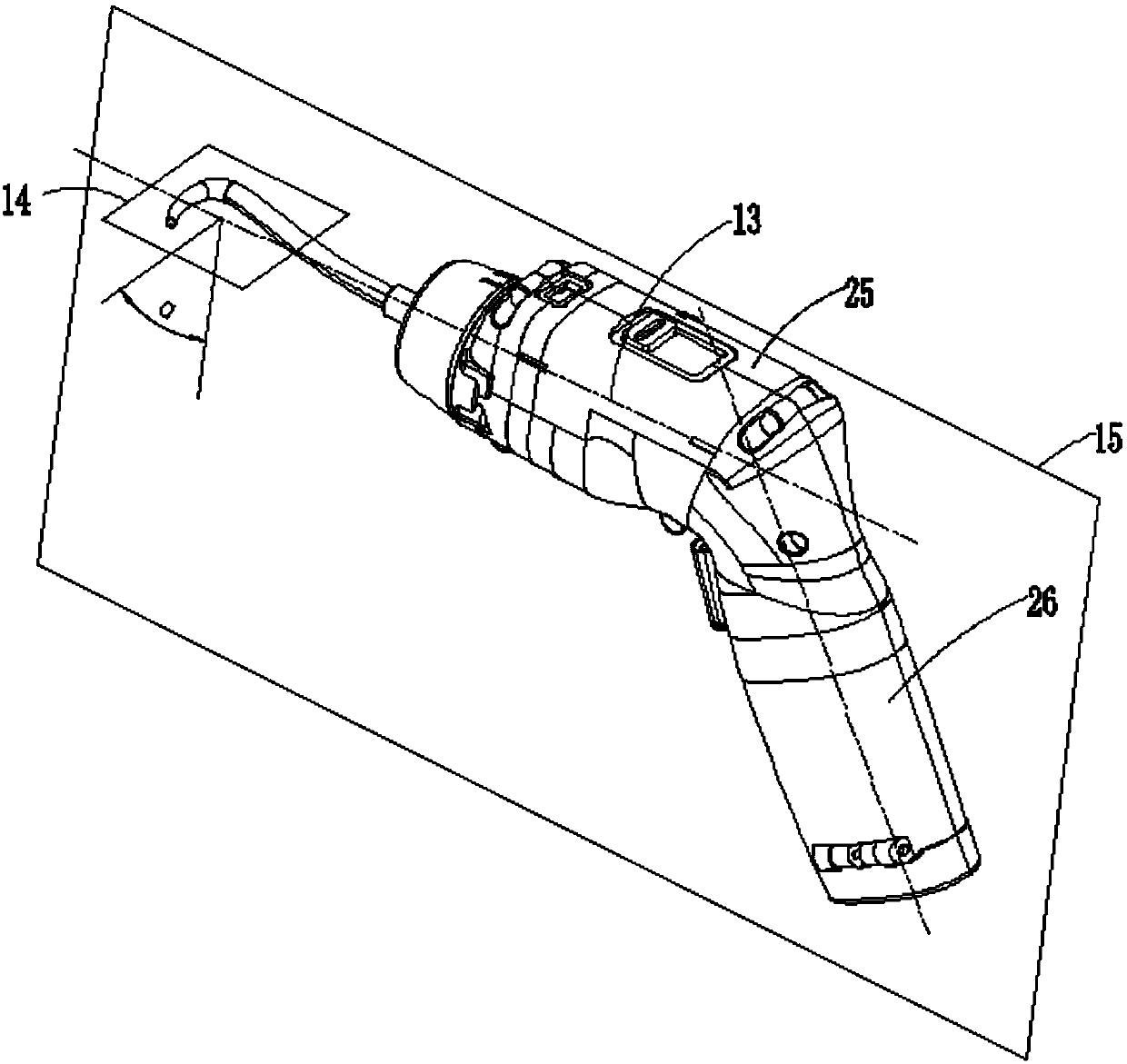

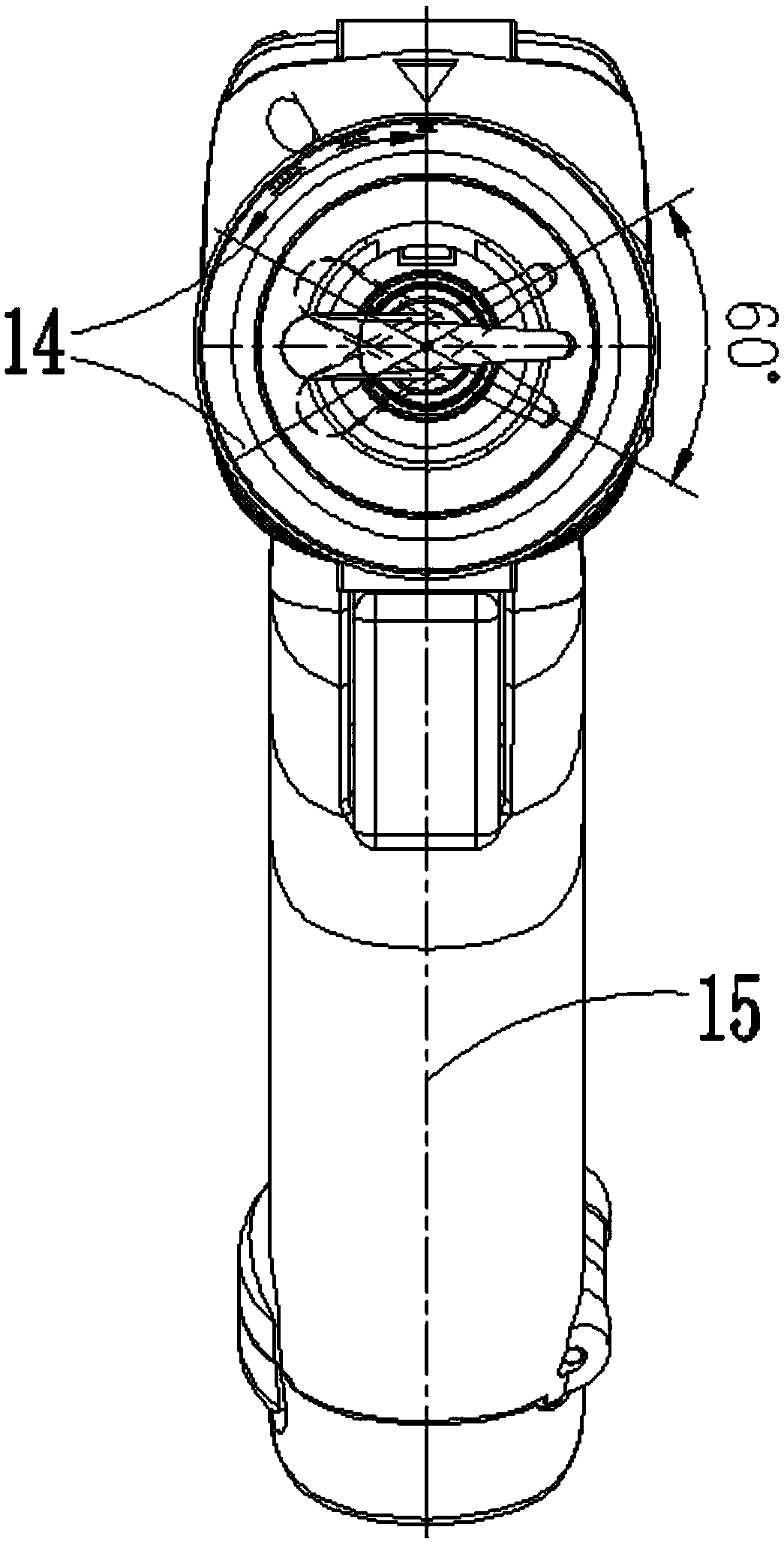

Steel bar binding machine

PendingCN111140017ACompact structureReduce weightBuilding material handlingSteel barMechanical engineering

The invention discloses a steel bar binding machine. The steel bar binding machine comprises a shell, a working head, a power mechanism, a signal acquisition unit and a control unit, wherein the working head is used for twisting joint of steel wires, and the working head comprises a body part extending out of the shell in a first extending direction and a working part arranged at the end, far awayfrom the shell, of the body part; the working part has a second extending direction different from the first extending direction, and the body part defines a first axis in the first extending direction; the power mechanism is used for driving the working head to rotate around the first axis; the signal acquisition unit is used for acquiring a signal representing the twisting joint state of the steel wires; and the control unit is electrically connected with the power mechanism and the signal acquisition unit, and the control unit is used for controlling the working head to stop rotating underthe condition that the signal acquisition unit acquires a signal indicating that the steel wires finish twisting joint. With the steel bar binding machine, the operation convenience can be improved and the working condition adaptability is higher.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

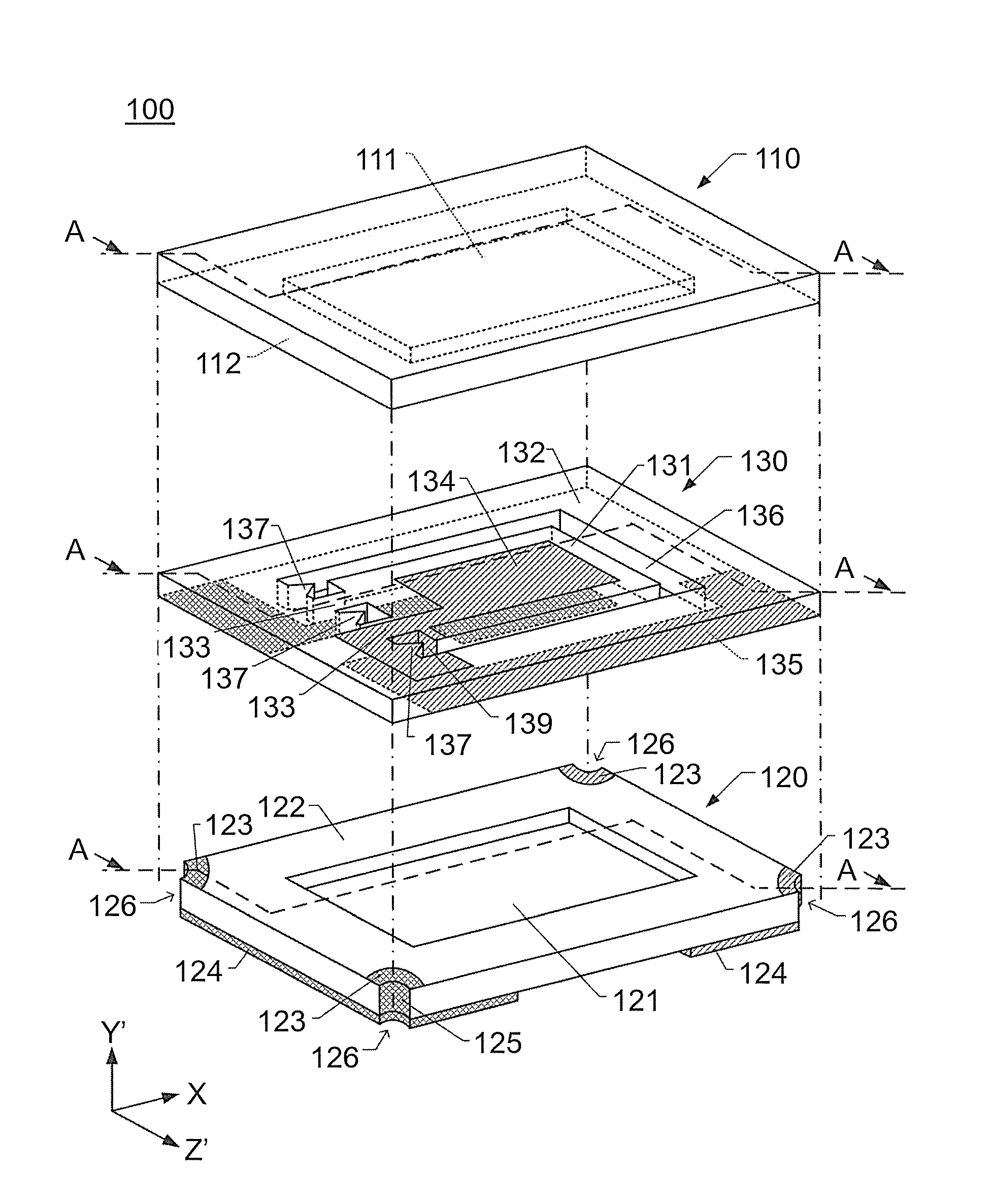

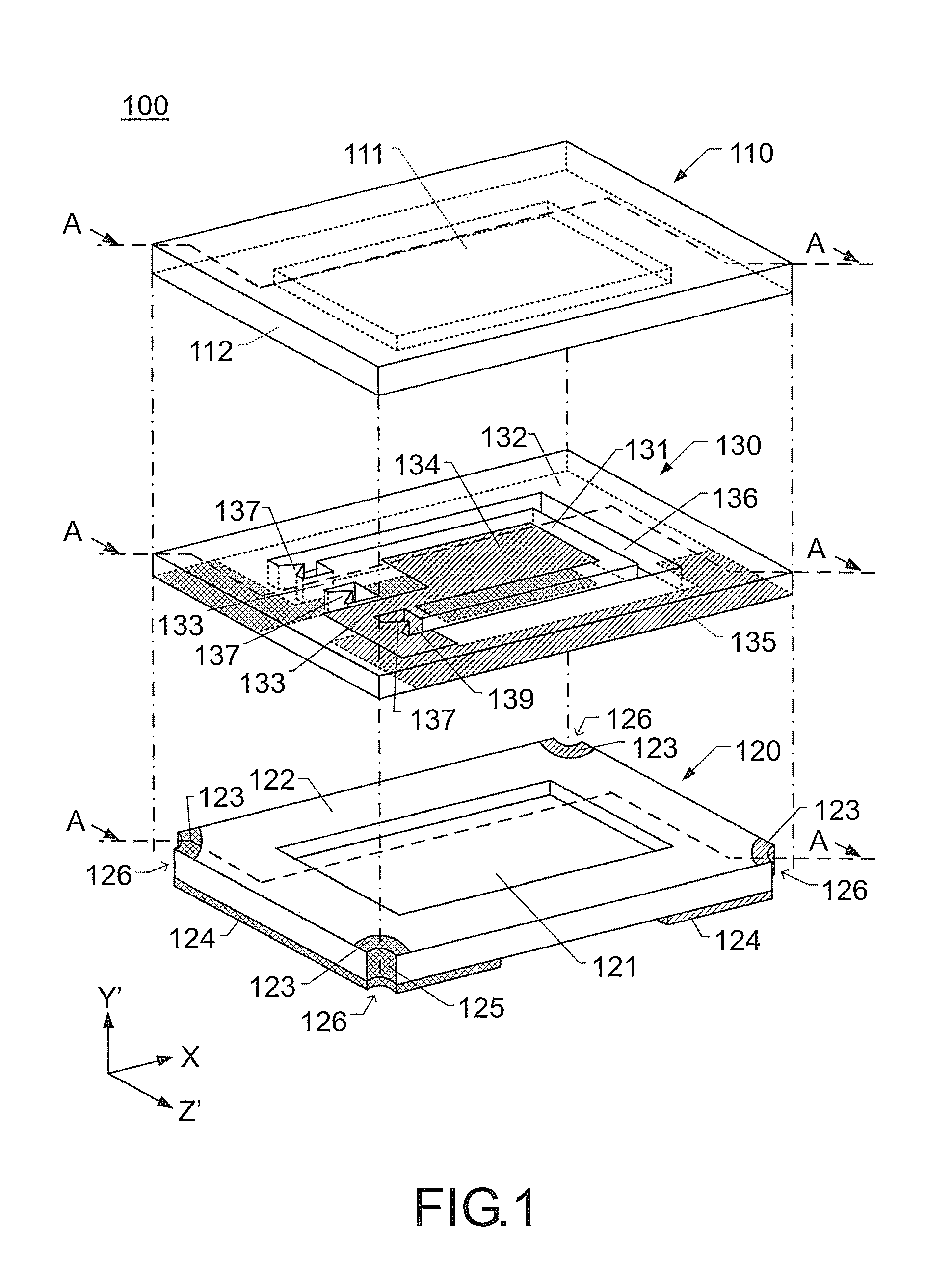

Piezoelectric vibrating piece and piezoelectric device

InactiveUS20130320809A1Reduced impact resistanceReduce connection strengthPiezoelectric/electrostriction/magnetostriction machinesImpedence networksEngineeringMechanical engineering

A piezoelectric vibrating piece includes a rectangular vibrator, a framing portion, a connecting portion, and a protrusion. The rectangular vibrator vibrates at a predetermined vibration frequency. The framing portion surrounds a peripheral area of the vibrator. The framing portion includes an inner side surface facing the vibrator. The connecting portion connects the vibrator and the framing portion. The protrusion protrudes to the vibrator side. The protrusion is formed on at least one of the inner side surface facing a side of the vibrator where the connecting portion is connected and the inner side surface adjacent to the connecting portion.

Owner:NIHON DEMPA KOGYO CO LTD

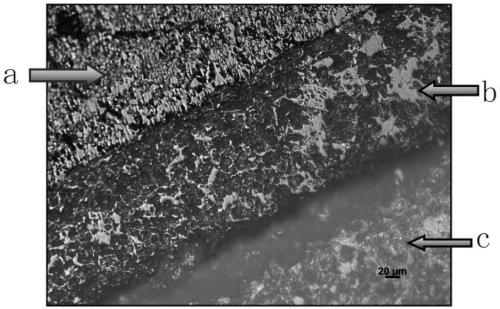

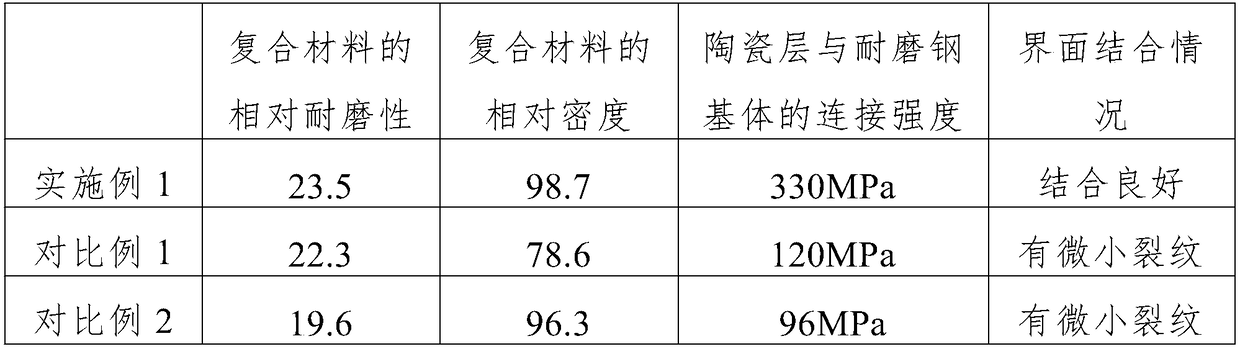

Alumina ceramic-wear resistant steel composite material and preparation method thereof

The invention provides an alumina ceramic-wear resistant steel composite material which comprises a wear resistant steel matrix, a ceramic layer and an enamel layer; and the enamel layer is arranged between the wear resistant steel matrix and the ceramic layer. The invention also provides a preparation method of the alumina ceramic-wear resistant steel composite material. The preparation method comprises the following steps of performing decarburization treatment on the wear resistant steel matrix to obtain the wear resistant steel matrix, preparing enamel powder and ceramic particle, then sequentially putting the materials in a lapping tool, and performing bi-directional compression and normal pressure sintering to obtain the alumina ceramic-wear resistant steel composite material. For the alumina ceramic-wear resistant steel composite material provided by the invention, the enamel layer can wet the ceramic layer and can improve the wettability with the wear resistant steel matrix toform chemical bond bonding; a part of the enamel powder is charged in pores of the ceramic layer, so that bubbles are difficultly formed between the wear resistant steel matrix and the enamel layer; and TiO2-x and CuO in the ceramic layer can lower the sintering temperature as sintering aids, prevent the wear resistant steel matrix from oxidizing, improves the preparation efficiency and lowers thepreparation cost.

Owner:JIAMUSI UNIVERSITY

Rotating electrical machine and cooling system of rotating electrical machine

InactiveUS20160380504A1Reduce weight and sizeWeight increaseCooling/ventillation arrangementSupports/enclosures/casingsElectric machineryMiniaturization

A rotating electrical machine includes a housing having an approximately cylindrical shape; a stator and a rotor that are accommodated in the housing; and a cooling frame that is provided on an outer circumferential surface of the housing and circulates a first liquid refrigerant, in which the cooling frame has a partially cylindrical shape. By setting the cooling frame to have the partially cylindrical shape, it is possible to obtain cooling structure capable of obtaining a reduction in size and weight while securing the strength.

Owner:HITACHI LTD

Manufacturing process for circuit board with long and short gold fingers

InactiveCN102510680AReduced physical connection structure areaSimple processElectrical connection printed elementsPrinted element electric connection formationElectric propertiesElectricity

The invention relates to a manufacturing process for a circuit board with long and short gold fingers, which comprises the following steps: supplying a base plate; arranging a plurality of gold finger patterns on the surface of the base plate; arranging a gold-plated lead with tip structures on the surface of the base plate; correspondingly and electrically connecting the tip structures of the gold-plated lead with the gold finger patterns; performing gold-plating treatment on the gold finger patterns so as to form the gold fingers; and tearing off and removing the gold-plated lead, thereby separating the tip structures of the gold-plated lead from the gold fingers. According to the manufacturing process for the circuit board provided by the invention, the tip structures are arranged at the end parts of the gold-plated lead, so that the gold-plated lead and the gold fingers are electrically connected while an area of a physical connecting structure between the gold-plated lead and the gold fingers is greatly reduced. When a test is finished, an operator can easily remove the gold-plated lead in the manner of pulling and tearing by hand, and the gold-plated lead is prevented from being remained, so that the change in electric properties of the gold fingers caused by the remained gold-plated lead is avoided, the short circuit risk is eliminated and the reliability of products is increased.

Owner:SHENZHEN WUZHU TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com