Resistance spot welding electrode and manufacturing method thereof

A resistance spot welding and electrode technology, applied in resistance welding equipment, electrode features, welding equipment and other directions, can solve problems affecting the connection strength of aluminum alloy plates/steel plates, etc., to improve the connection strength of joints, the preparation method is simple and convenient, and the connection strength is improved. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

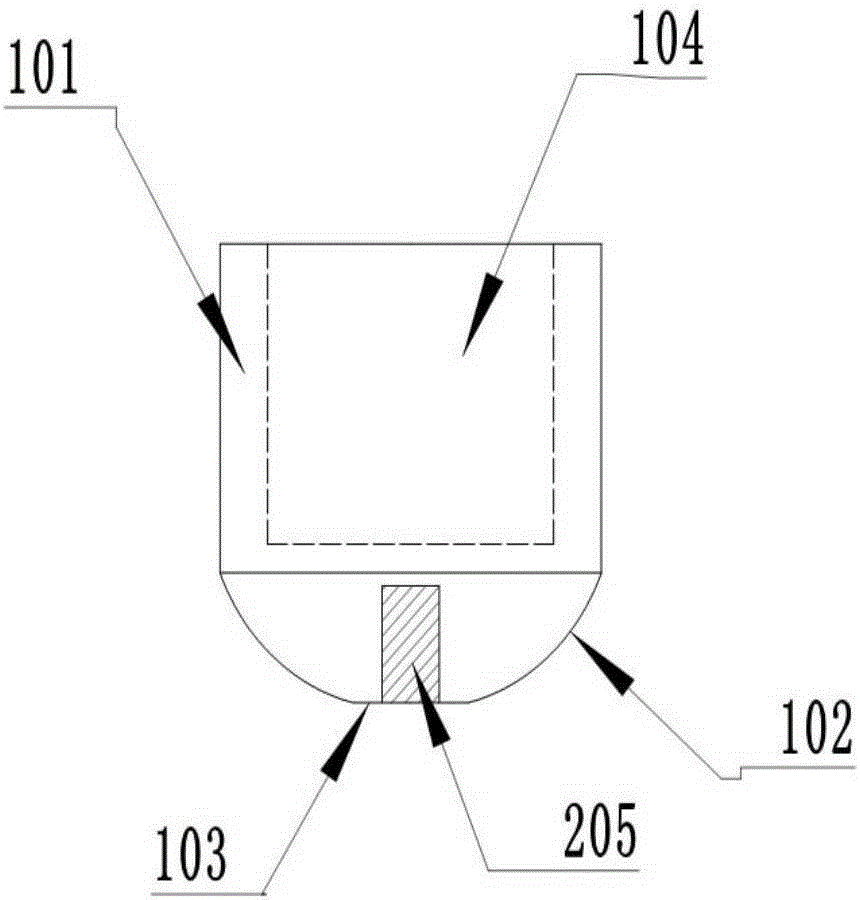

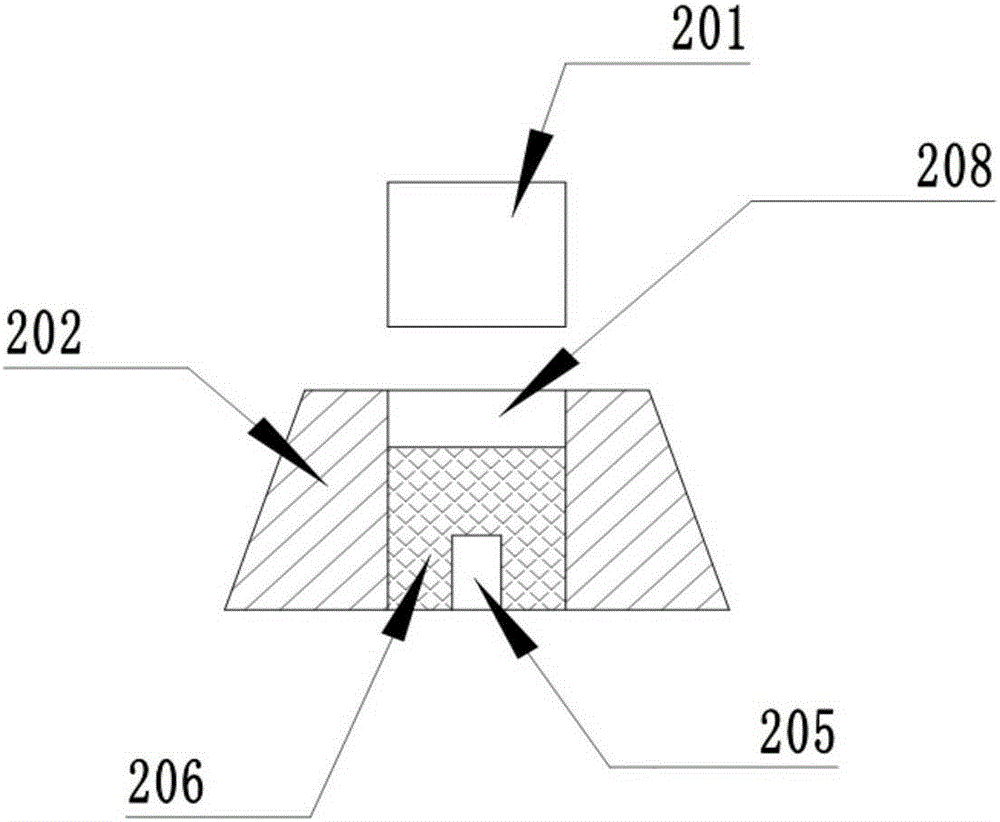

[0029] The resistance spot welding electrode of the present embodiment, as figure 1 As shown, including the first conductor and the second conductor 205, the material of the first conductor is red copper, the material of the second conductor 205 is molybdenum, the total height of the resistance spot welding electrode is 20mm, the first conductor upper part 101 is a cylinder, the diameter 20mm, 15mm high, the first conductor lower part 102 is a circular frustum whose diameter gradually decreases from top to bottom, with a height of 5mm, the diameter of the lower end surface 103 of the first conductor is 6mm, and the upper end surface of the first conductor is provided with a cooling groove 104, so The cooling tank body is cylindrical, with a diameter of 10 mm and a height of 10 mm, used to receive the cooling water of the spot welding equipment to cool the spot welding electrodes; the lower end surface 103 of the first conductor is provided with a shape matching the second condu...

Embodiment 2

[0036] The resistance spot welding electrode of the present embodiment comprises a first conductor and a second conductor, the material of the first conductor is chrome bronze, the material of the second conductor is tungsten, the total height of the resistance spot welding electrode is 25mm, and the first conductor top is A cylinder with a diameter of 25mm and a height of 18mm. The lower part of the first conductor is a circular frustum whose diameter gradually decreases from top to bottom, with a height of 7mm. The diameter of the lower end surface of the first conductor is 8mm; the upper end surface of the first conductor is provided with a cooling groove. The cooling tank body is cylindrical, with a diameter of 15mm and a height of 15mm, used to receive the cooling water of the spot welding equipment, and to cool the spot welding electrodes with resistance; the lower end surface of the first conductor is provided with a concave hole matching the shape of the second conductor...

Embodiment 3

[0043] The resistance spot welding electrode of this embodiment includes a first conductor and a second conductor. The material of the first conductor is a mixture of red copper and chromium-zirconium-copper whose mass ratio is copper: chromium-zirconium-copper=1:1. The material of the second conductor is Tungsten, the total height of the resistance spot welding electrode is 22mm, the upper part of the first conductor is a cylinder with a diameter of 22mm and a height of 17mm, the lower part of the first conductor is a circular frustum whose diameter gradually decreases, with a height of 5mm, and the diameter of the lower end surface of the first conductor is 7mm; the upper end surface of the first conductor is provided with a cooling groove, the body of the cooling groove is cylindrical, with a diameter of 13mm and a height of 13mm, and is used to receive the cooling water of the spot welding equipment to cool the spot welding electrodes; The lower end surface is provided with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com