Patents

Literature

2236 results about "Bronze" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bronze is an alloy consisting primarily of copper, commonly with about 12–12.5% tin and often with the addition of other metals (such as aluminium, manganese, nickel or zinc) and sometimes non-metals or metalloids such as arsenic, phosphorus or silicon. These additions produce a range of alloys that may be harder than copper alone, or have other useful properties, such as stiffness, ductility, or machinability.

Composite material containing tungsten and bronze

High-density composite materials comprising tungsten and bronze are useful as lead replacements in the production of ammunition, weights and other high density articles. The composition of the composite, articles manufactured using the composite, and a process for making the composite are disclosed.

Owner:ELLIOTT CARTRIDGE COMPANY (CANADA) LTD

Lead free reduced ricochet limited penetration projectile

A frangible projectile with a specific gravity similar to a lead projectile. The projectile comprises 34-94%, by weight, binder. The binder comprises poly ether block amide resin. The projectile further comprises 6-66%, by weight, ballast. The ballast comprises at least one member selected from a group consisting of tungsten, tungsten carbide, molybdenum, tantalum, ferro-tungsten, copper, bismuth, iron, steel, brass, aluminum bronze, beryllium copper, tin, aluminum, titanium, zinc, nickel silver alloy, cupronickel and nickel. The projectile can be prepared with a particularly preferred specific gravity of 5-14 and more preferably 11-11.5.

Owner:ACCUTEC USA

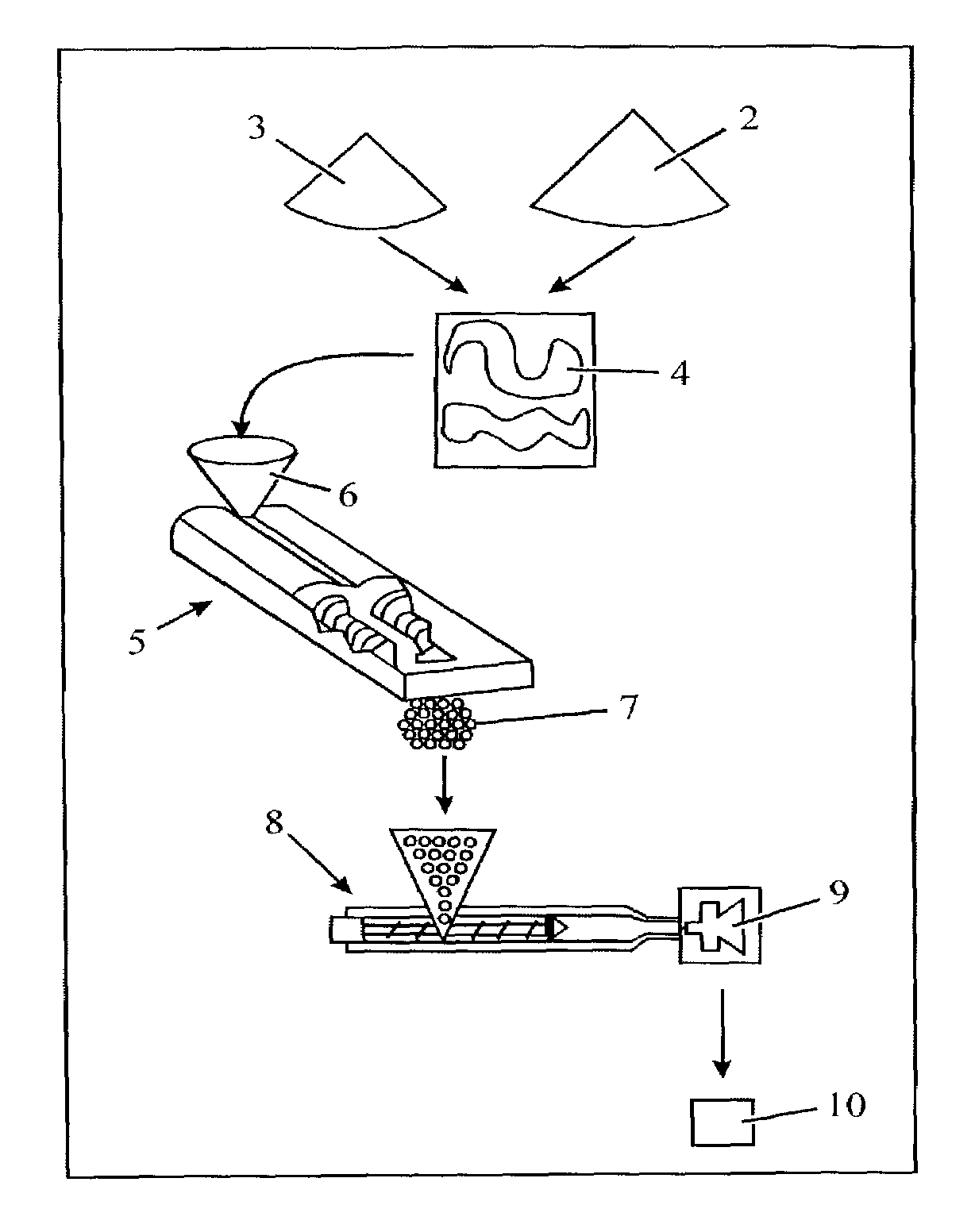

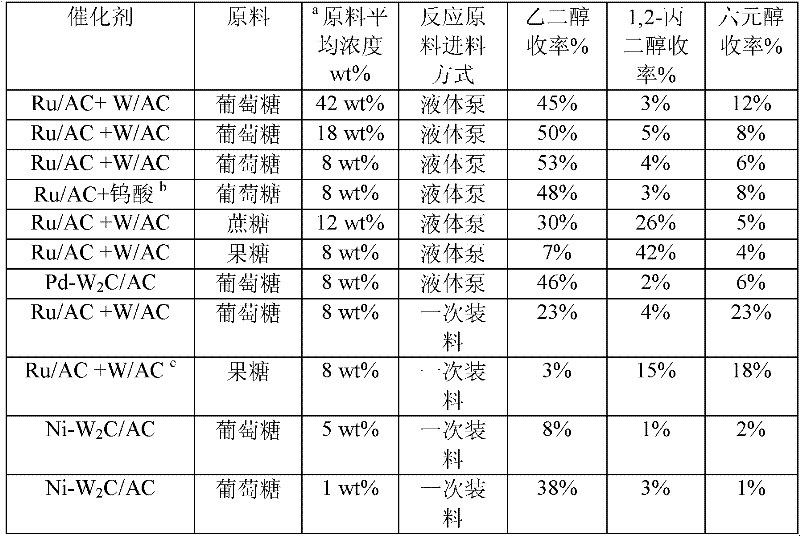

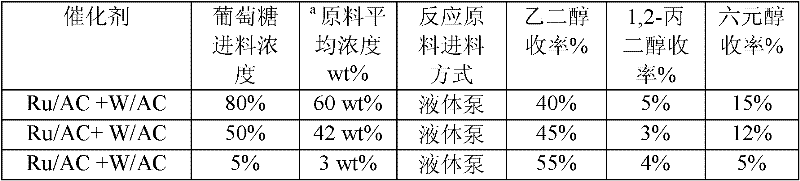

Method for preparing ethylene glycol and 1,2-propylene glycol by using saccharide solution

ActiveCN102675045AIncrease concentrationReduce distillation energy consumptionOrganic compound preparationHydroxy compound preparationHydrogen pressurePolyethylene glycol

The invention provides a method for preparing ethylene glycol and 1,2-propylene glycol by using a high-concentration saccharide solution. Reaction raw materials comprise cane sugar, glucose, fructose, fructosan, xylose, soluble lower polyxylose and soluble starch. According to the method, high-concentration saccharide is used as a reaction raw material, and a high-pressure pump feeding mode is used in a reaction process which is performed in a high-pressure reaction kettle; iron, cobalt, nickel, ruthenium, rhodium, palladium, iridium and platinum which serve as transition metal in eighth, ninth and tenth groups are used as hydrogenation active ingredients; the hydrogenation active ingredients form a composite catalyst together with metal tungsten, tungsten carbide, tungsten nitride, tungsten phosphide, tungsten oxide, tungsten sulfide, tungsten chloride, tungsten hydroxide, tungsten bronze, tungstic acid, tungstate, metatungstic acid, metatungstate, paratungstic acid, paratungstate, peroxotungstic acid, peroxotungstate and tungsten-containing heteropolyacid which serve as catalytic active ingredients; and the high-concentration saccharide solution can be efficiently prepared into the ethylene glycol and the propylene glycol at high selectivity and high yield in a one-step catalytic conversion process under the hydrothermal condition that the temperature is 120 to 300 DEG C and the hydrogen pressure is 1 to 13MPa. By the method, the problem of coking of the high-concentration saccharide in the catalytic conversion process can be effectively solved, and high-concentration ethylene glycol and propylene glycol can be prepared by the high-concentration saccharide.

Owner:中科柏易金(郑州)新能源科技有限责任公司

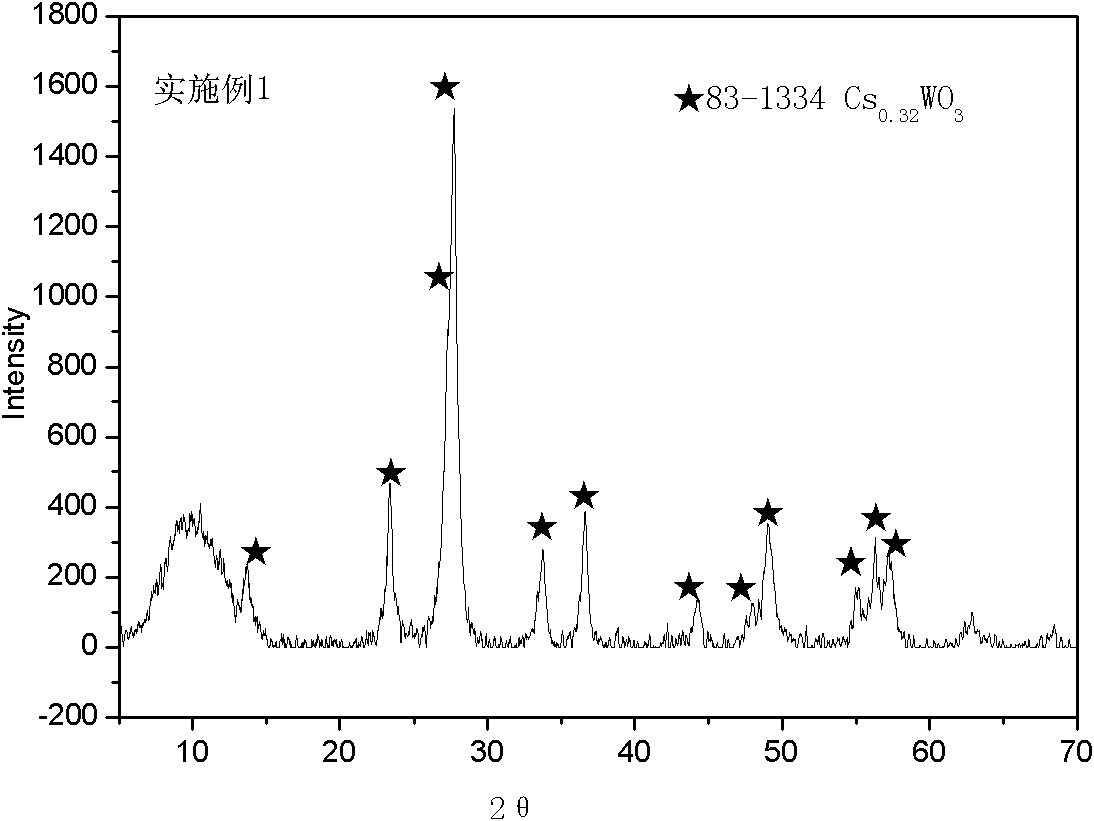

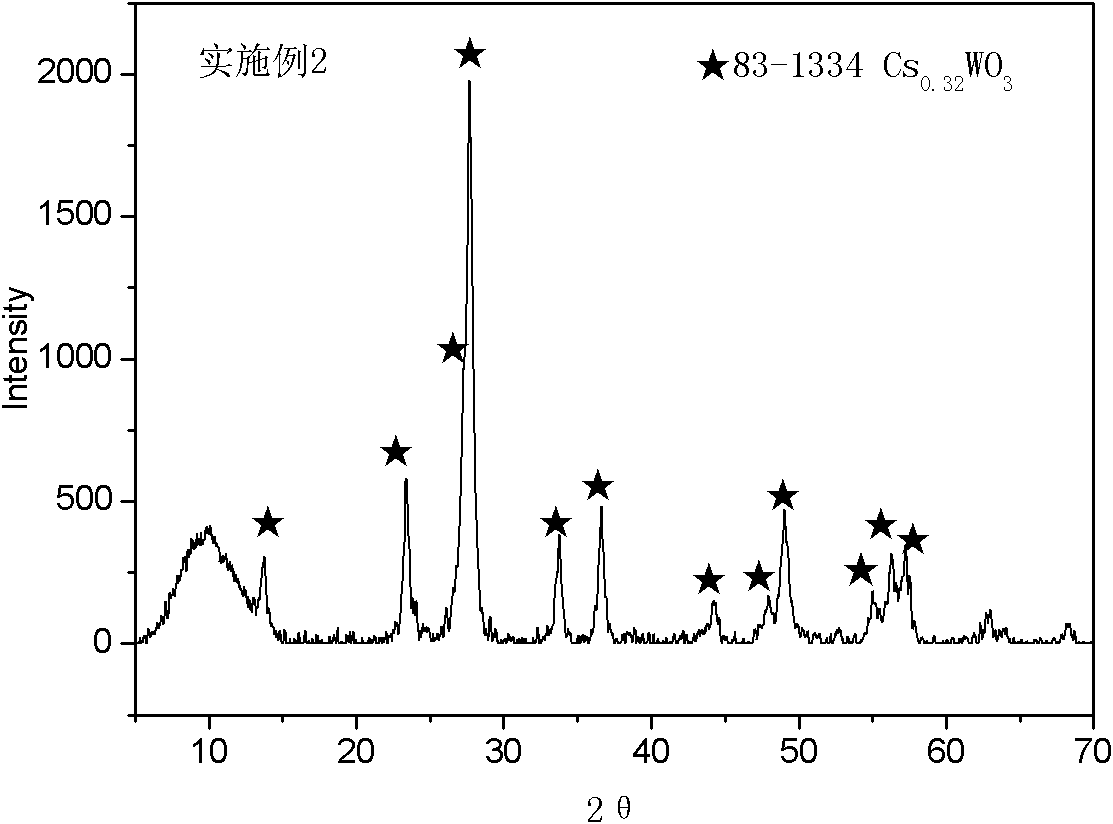

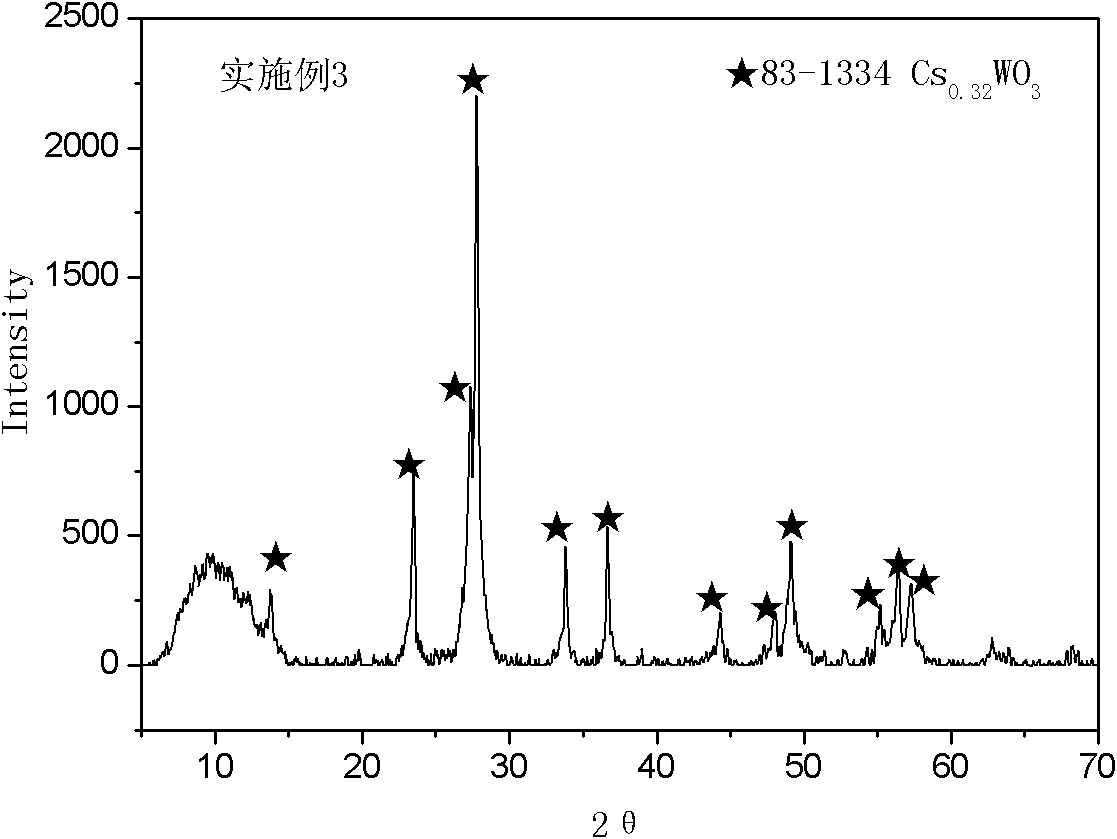

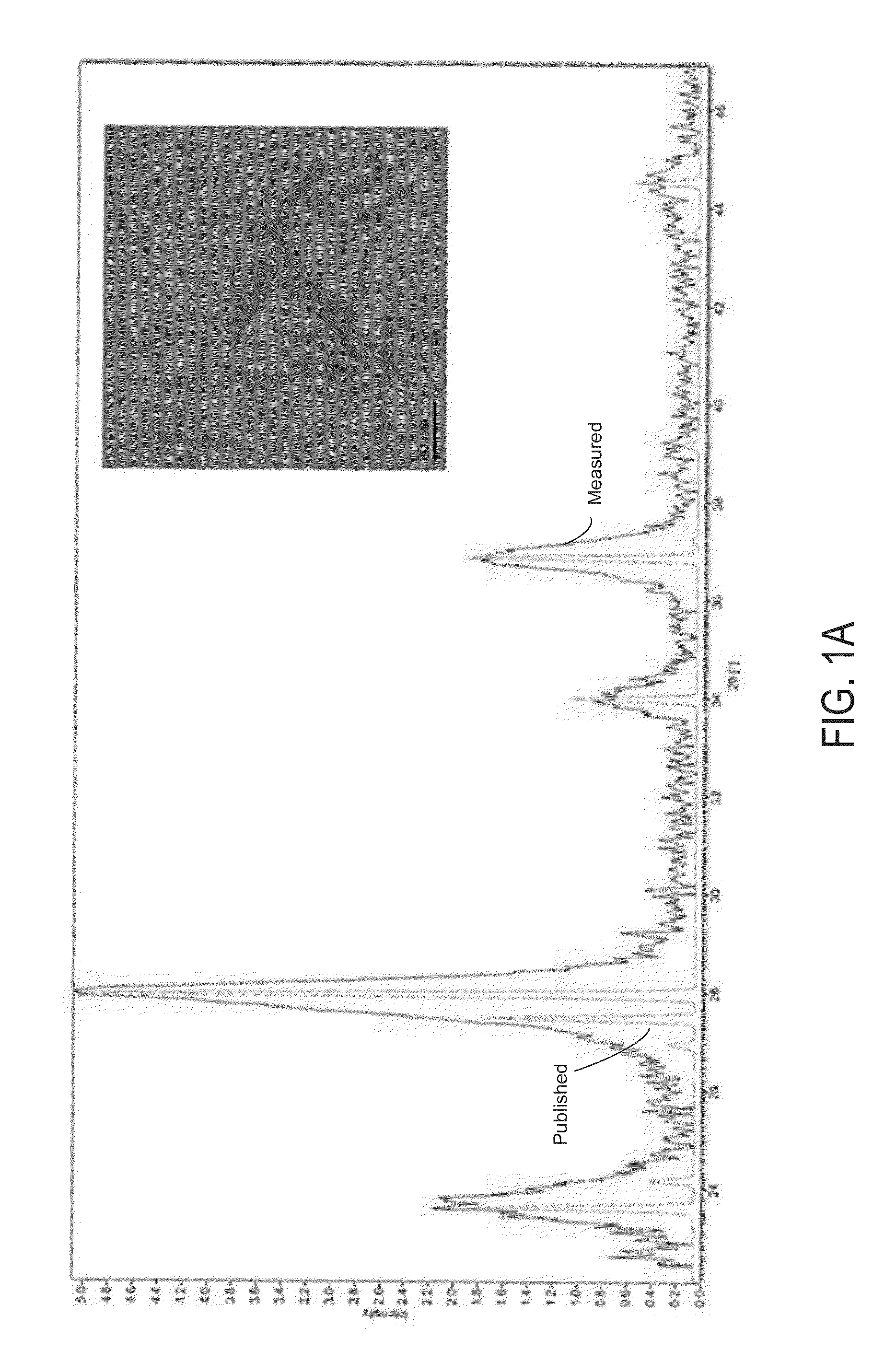

Cesium tungsten bronze powder and preparation method thereof

InactiveCN102320662AOptimal Control StructureReduce manufacturing costTungsten compoundsGranularitySolvent

The invention relates to cesium tungsten bronze powder and a preparation method thereof. The method comprises the following steps that: 1, precursor solution with tungstic acid, cesium carbonate and reducing substances is prepared according to a Cs / W mole ratio of 0.01 to 0.35 / 1, and the solvents are water or a mixture formed by ethanol and the water according to a volume ratio of 1 / 4 to 4 / 1; and 2, the precursor solution takes reaction for 1 to 3d under the condition of 180 to 200 DEG C in an autoclave, and the cesium tungsten bronze powder is obtained after the obtained precipitates are treated. The powder has the crystalline phase composition of Cs0.2WO3 or Cs0.32WO3, the size of the powder particle is 100 to 1300nm, and the specific surface area is 7 to 50m<2> / g. The synthetic process has the advantages that raw materials are cheap and mild, the operation is easy, the production cost can be reduced, in addition, the low-temperature (lower than or equal to 20 DEG C) synthesis is adopted, and the process is suitable for production and practical application. In addition, the product purposes are wide.

Owner:DALIAN POLYTECHNIC UNIVERSITY

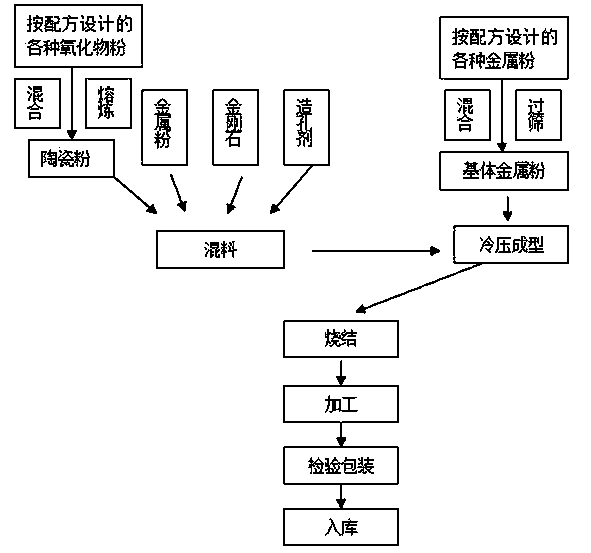

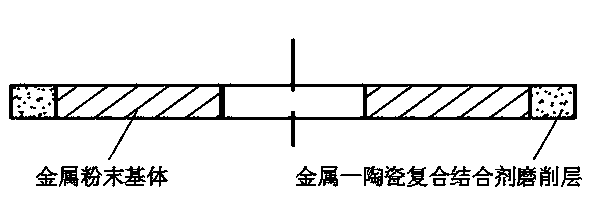

Metal ceramic combination binding agent and combination binding agent diamond wheel

ActiveCN103831740AGood self-sharpeningImprove sharpnessAbrasion apparatusGrinding devicesNumerical controlSilicon dioxide

The invention belongs to the field of diamond wheels and particularly relates to a metal ceramic combination binding agent and a combination binding agent diamond wheel. The metal ceramic combination binding agent is composed of, by weight, 60%-80% of 663 bronze powder and 20%-40% of ceramic powder. The ceramic powder is homemade and composed of, by weight, 45%-60% of silicon dioxide, 20%-30% of boric oxide, 10%-15% of potassium oxide, 5%-10% of magnesium oxide and 2%-5% of calcium oxide. The combination binding agent diamond wheel is composed of, by volume, 25%-40%of diamond abrasive, 55%-75% of combination binding agent and 2%-3% of pore forming agent. When the diamond wheel made of the metal ceramic combination binding agent is applied to a five-axis cnc machine tool, the good sharpness and the good self-sharpening performance of a ceramic binding agent are kept and the advantages of high rigidity and the good shape-maintaining performance of a metal binding agene are obtained. The comprehensive processing efficiency is improved by 100% to 150%.

Owner:江苏赛扬精工科技有限责任公司

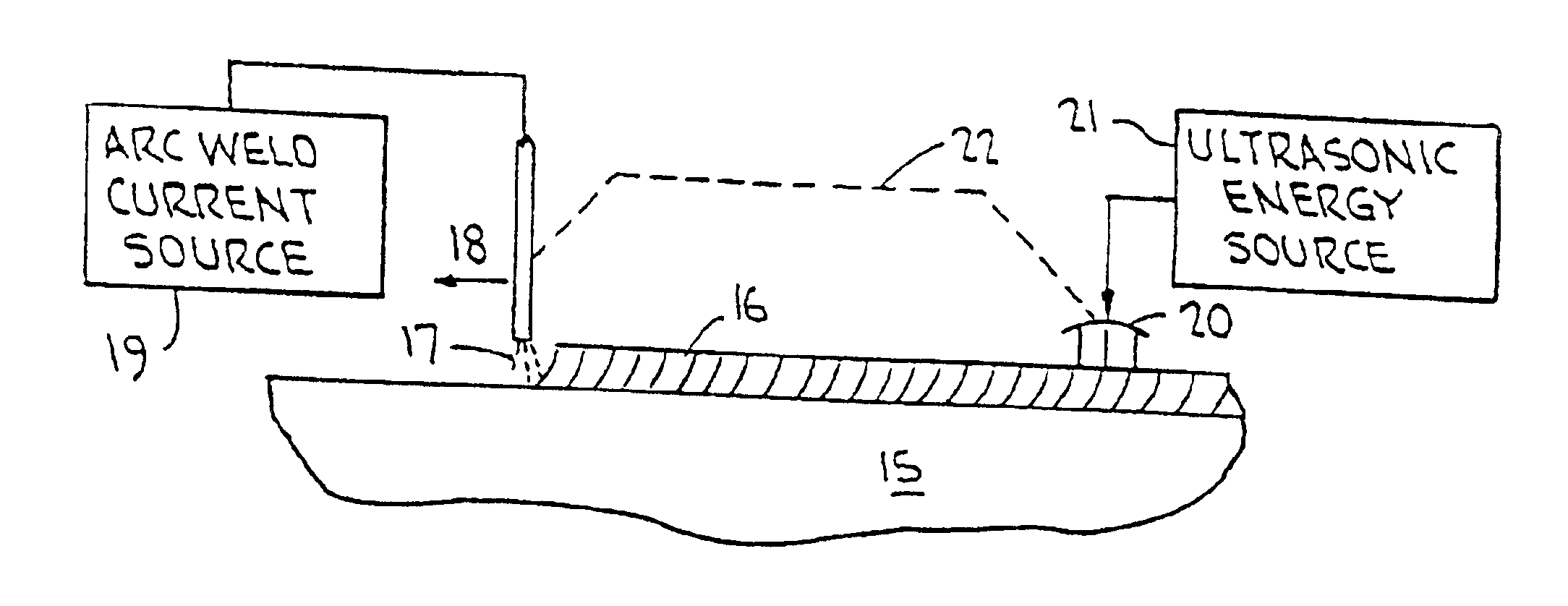

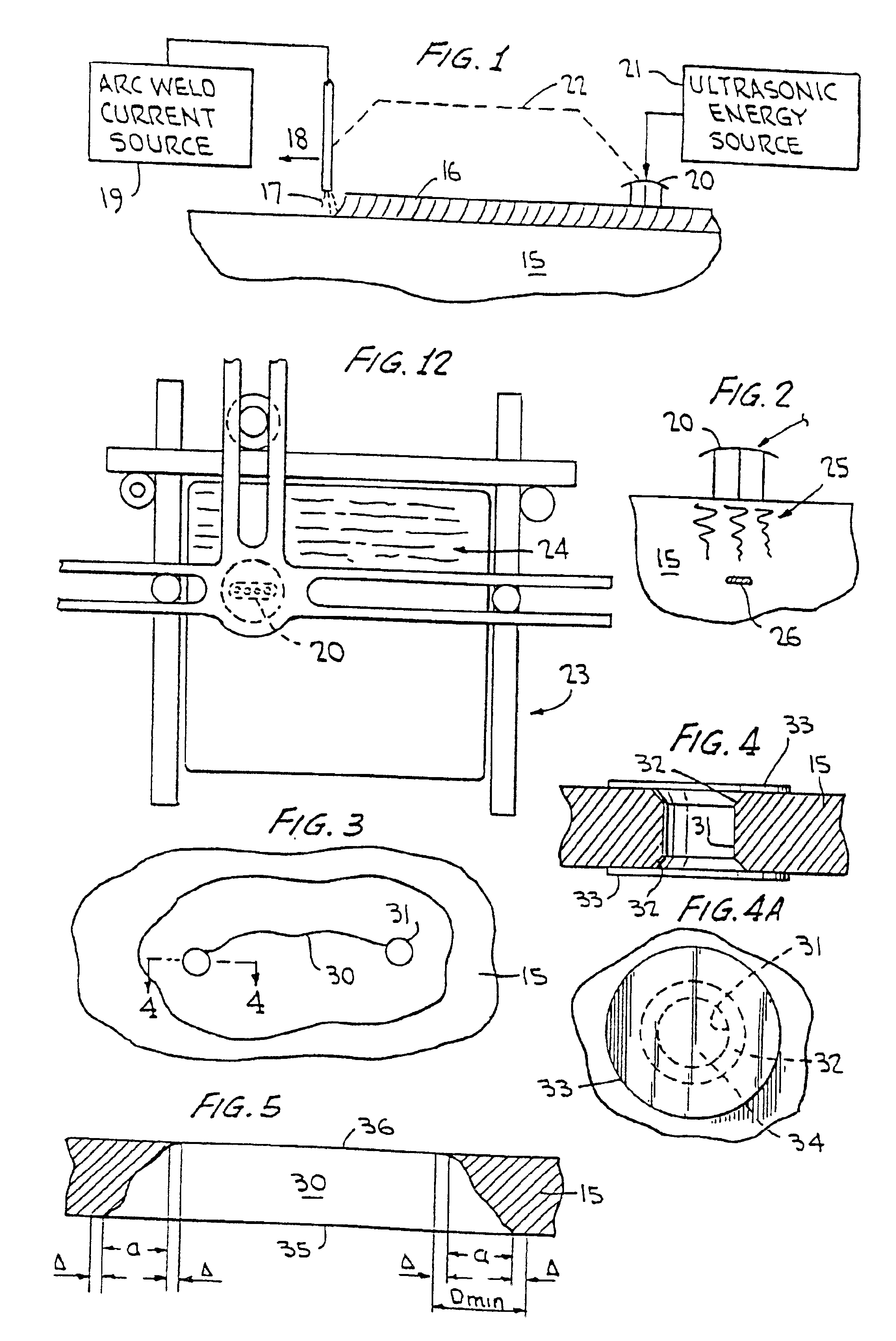

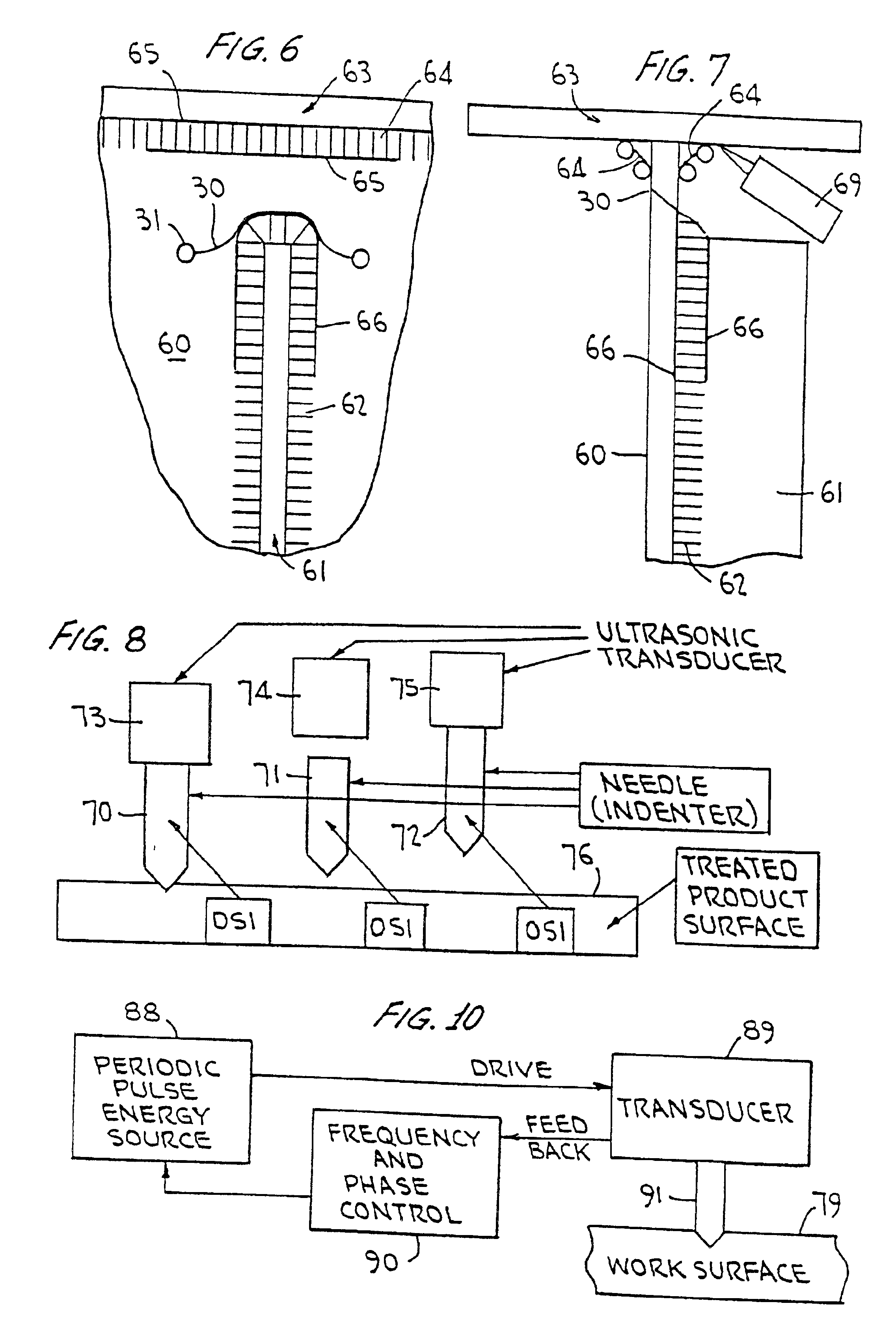

Ultrasonic impact methods for treatment of welded structures

InactiveUS6843957B2Improve corrosion fatigue strengthIncreased durabilityBlast furnace detailsHigh frequency current welding apparatusUltrasonic sensorEngineering

This invention provides methods of treatment for work products of materials such as steel, bronze, plastic, etc. and particularly welded steel bodies by pulse impact energy, preferably ultrasonic, to relax fatigue and aging and extend expectant life. The treatment may occur (a) at original production, (b) during the active life period for maintenance or (c) after failure in a repair stage. The ultrasonic treatment improves the work product strength. In welded products residual stress patterns near the weld sites are relaxed and micro-stress defects such as voids and unusual grain boundaries are reduced. The basic method steps are non-destructive in nature, inducing interior pulse compression waves with ultrasonic transducers and accessory tools impacting an external product surface with enough impulse energy to heat and temporarily plasticize the metal interior and relax stresses. The nature of the work product interior structure being treated is determined by sensing the mechanical movement at the impact surface of the work body to produce feedback frequency and phase signals responsive to input impact signals. These signals automatically conform driving pulse energy frequency and phase to the input transducers to match the mechanical resonance frequency of the working transducers and increase efficiency of energy transfer. Such feedback signals also are available for automated procedures which can improve product quality and consistency.

Owner:PROGRESS RAIL SERVICES

Friction material

InactiveUS20050004258A1Good brake feelingImprove effectivenessBraking element arrangementsOther chemical processesMohs scale of mineral hardnessHardness

A friction material is made by molding and curing a composition containing a fibrous base that includes stainless steel fibers but not other steel fibers, a binder, and a friction modifier that includes at least two types of hard particles having a large Mohs hardness, bronze powder and a specific amount of tin sulfide. The friction material has a excellent balance of properties, including a high strain linearity that provides a excellent brake feel, a high torque linearity and a excellent effectiveness, and also minimizes disc rotor attack, disc pad wear and metal pickup. Such friction materials are particularly suitable for automotive applications, such as disc pads.

Owner:NISSHINBO INDDUSTRIES

Methods for preparing ethylene glycol from polyhydroxy compounds

ActiveUS20120172633A1High yieldHigh selectivityOxygen-containing compound preparationOrganic compound preparationHydrogen pressureHeteropoly acid

This invention provides methods for producing ethylene glycol from polyhydroxy compounds such as cellulose, starch, hemicellulose, glucose, sucrose, fructose, fructan, xylose and soluble xylooligosaccharides. The methods uses polyhydroxy compounds as the reactant, a composite catalyst having active components comprising one or more transition metals of Groups 8, 9, or 10, including iron, cobalt, nickel, ruthenium, rhodium, palladium, iridium, and platinum, as well as tungsten oxide, tungsten sulfide, tungsten hydroxide, tungsten chloride, tungsten bronze oxide, tungsten acid, tungstate, metatungstate acid, metatungstate, paratungstate acid, paratungstate, peroxotungstic acid, pertungstate, heteropoly acid containing tungsten. Reacting at a temperature of 120-300° C. and a hydrogen pressure of 1-13 MPa under hydrothermal conditions to accomplish one-step catalytic conversion. It realizes efficient, highly selective, high yield preparation of ethylene glycol and propylene glycol from polyhydroxy compounds. The advantage of processes disclosed in this invention include renewable raw material and high atom economy. At the same time, compared with other technologies that converts biomass raw materials into polyols, methods disclosed herein enjoy advantages including simple reaction process, high yield of targeted products, as well as easy preparation and low cost for the catalysts.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

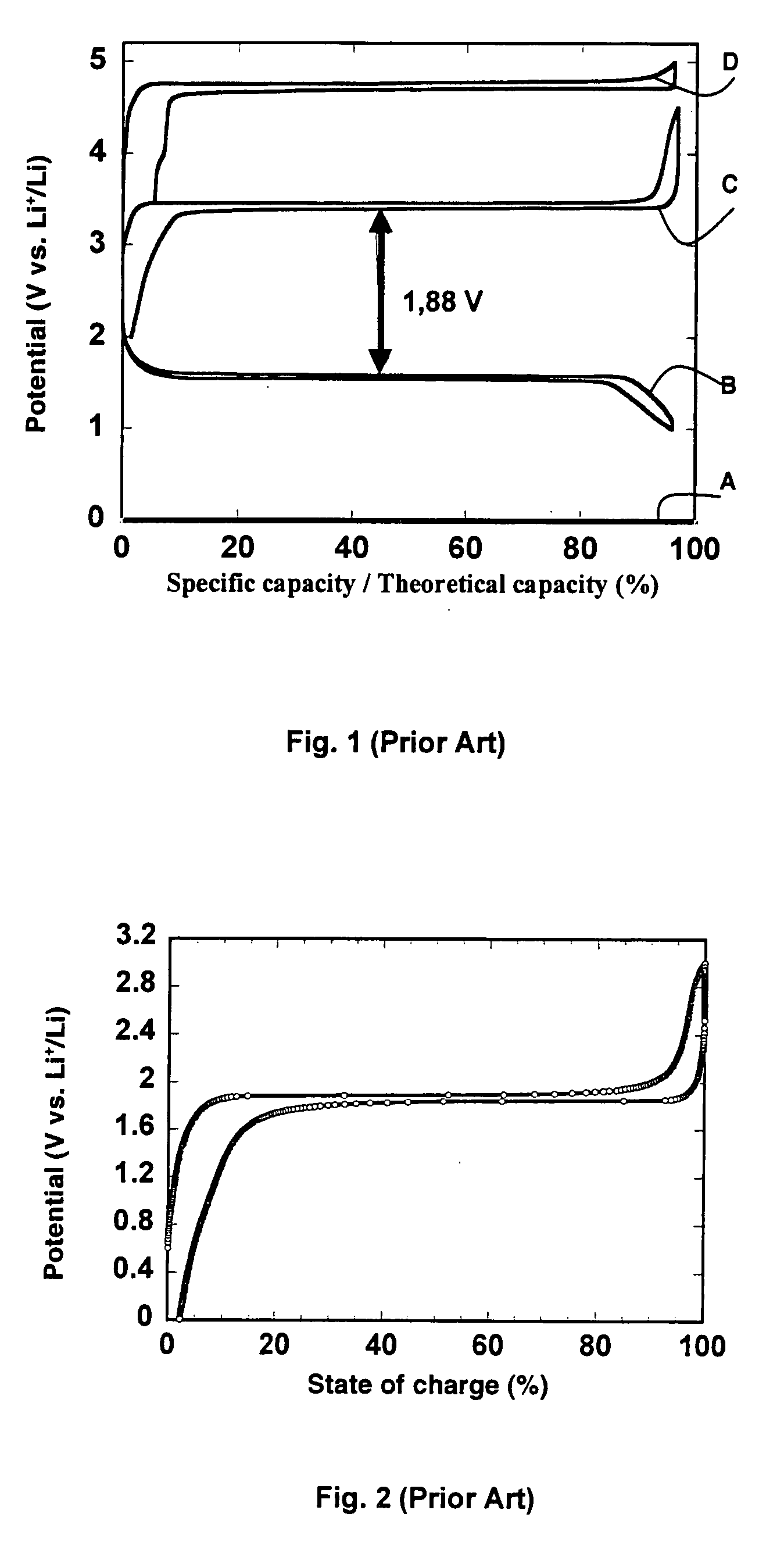

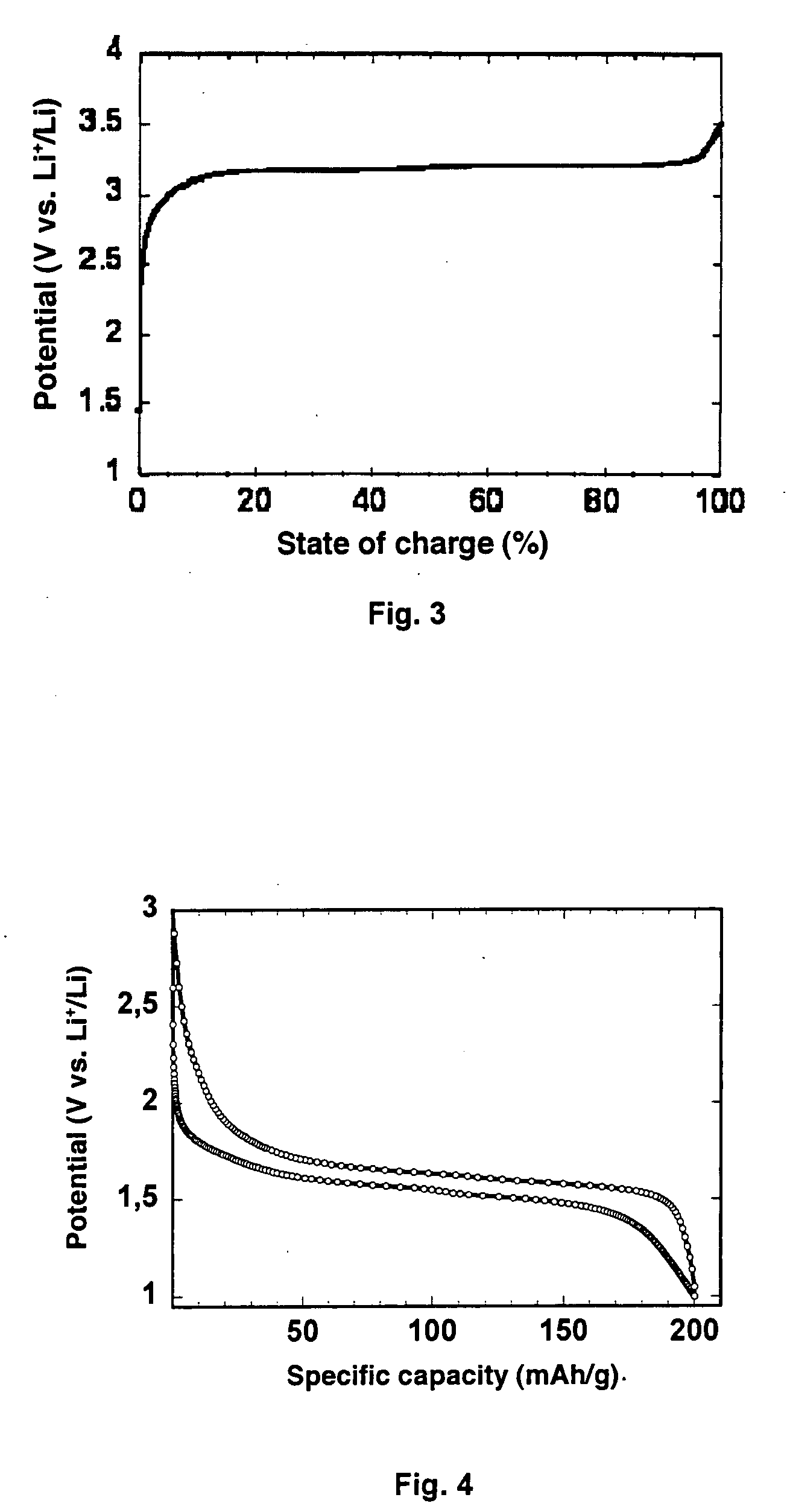

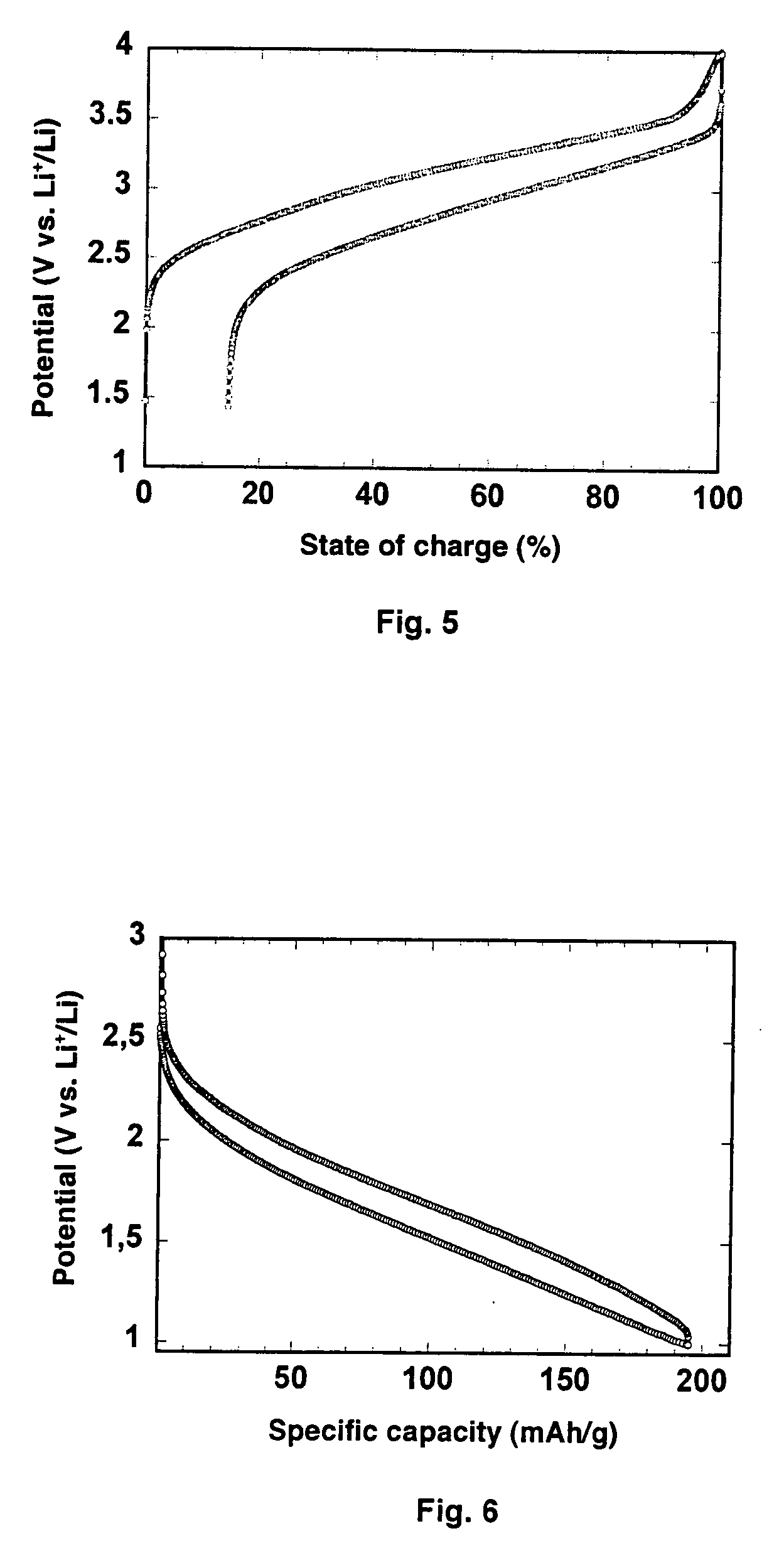

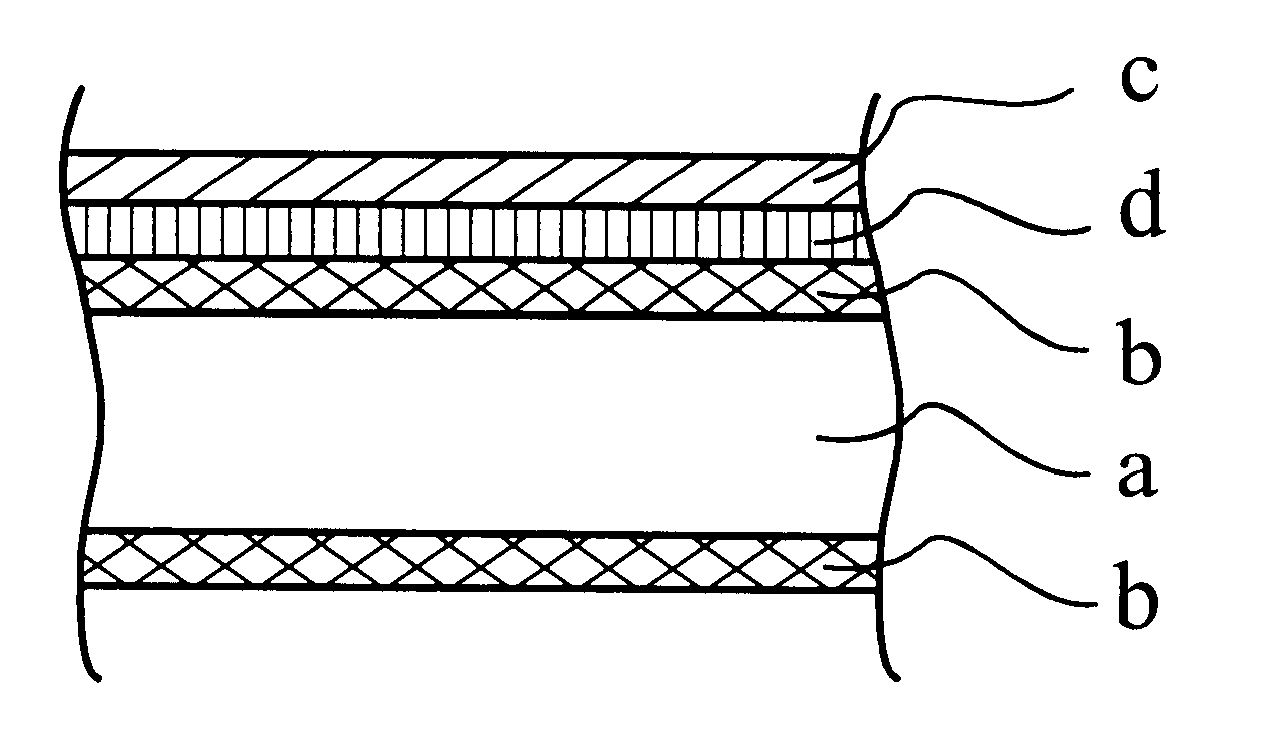

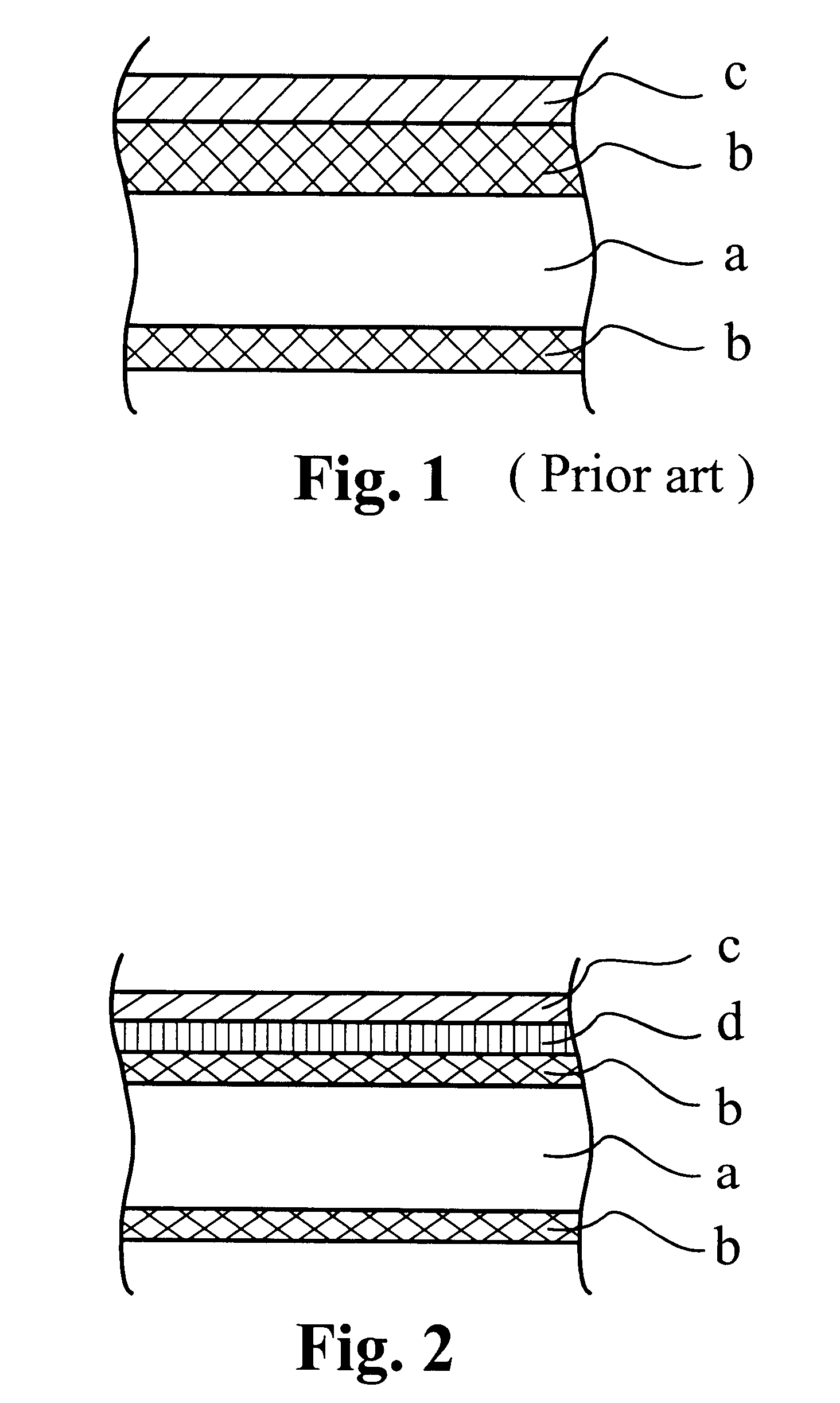

Lithium-ion storage battery comprising TiO2-B as negative electrode active material

InactiveUS20070292760A1Easy to checkLarge energy is requiredSecondary cellsNon-aqueous electrolyte accumulator electrodesLithiumState of charge

The state of charge of a Li-Ion storage battery comprising a positive electrode active material presenting a constant lithium insertion / extraction potential over most of the capacity operating range and titanium oxide TiO2 of bronze type structure as negative electrode active material can be easily monitored by simple reading of the operating voltage. The positive electrode active material is selected among LiNi0.5Mn1.5O4 and derivatives thereof.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

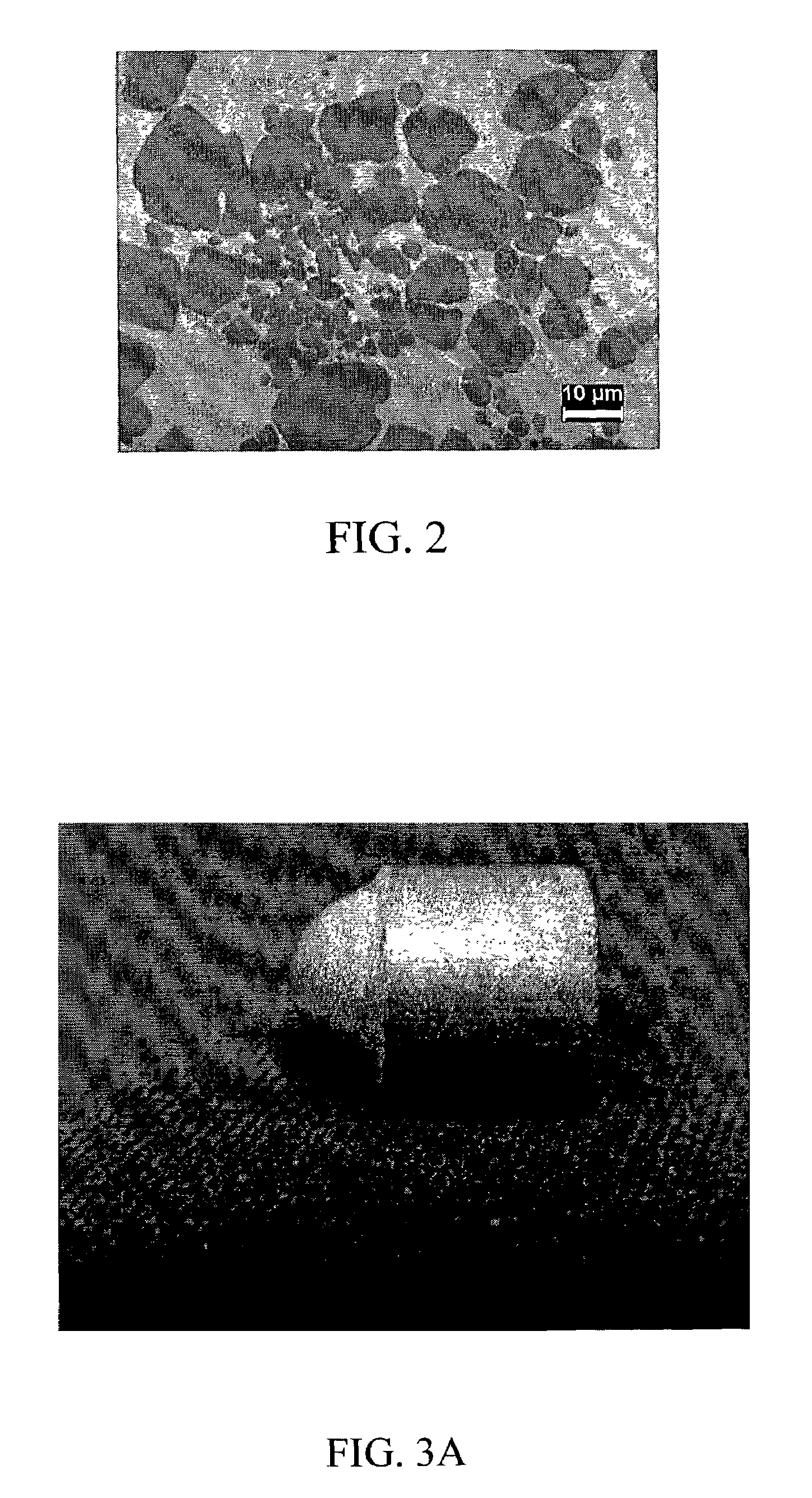

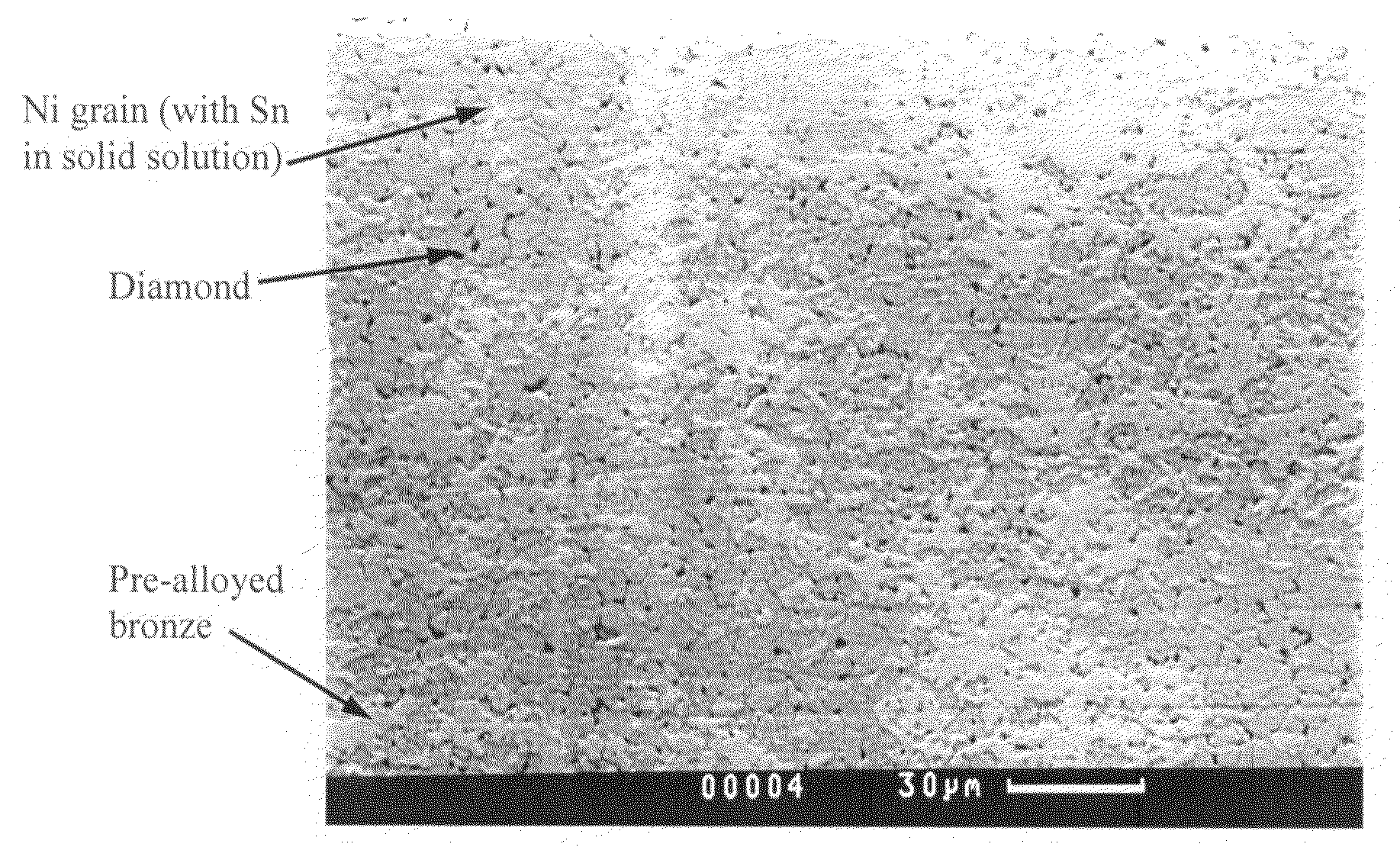

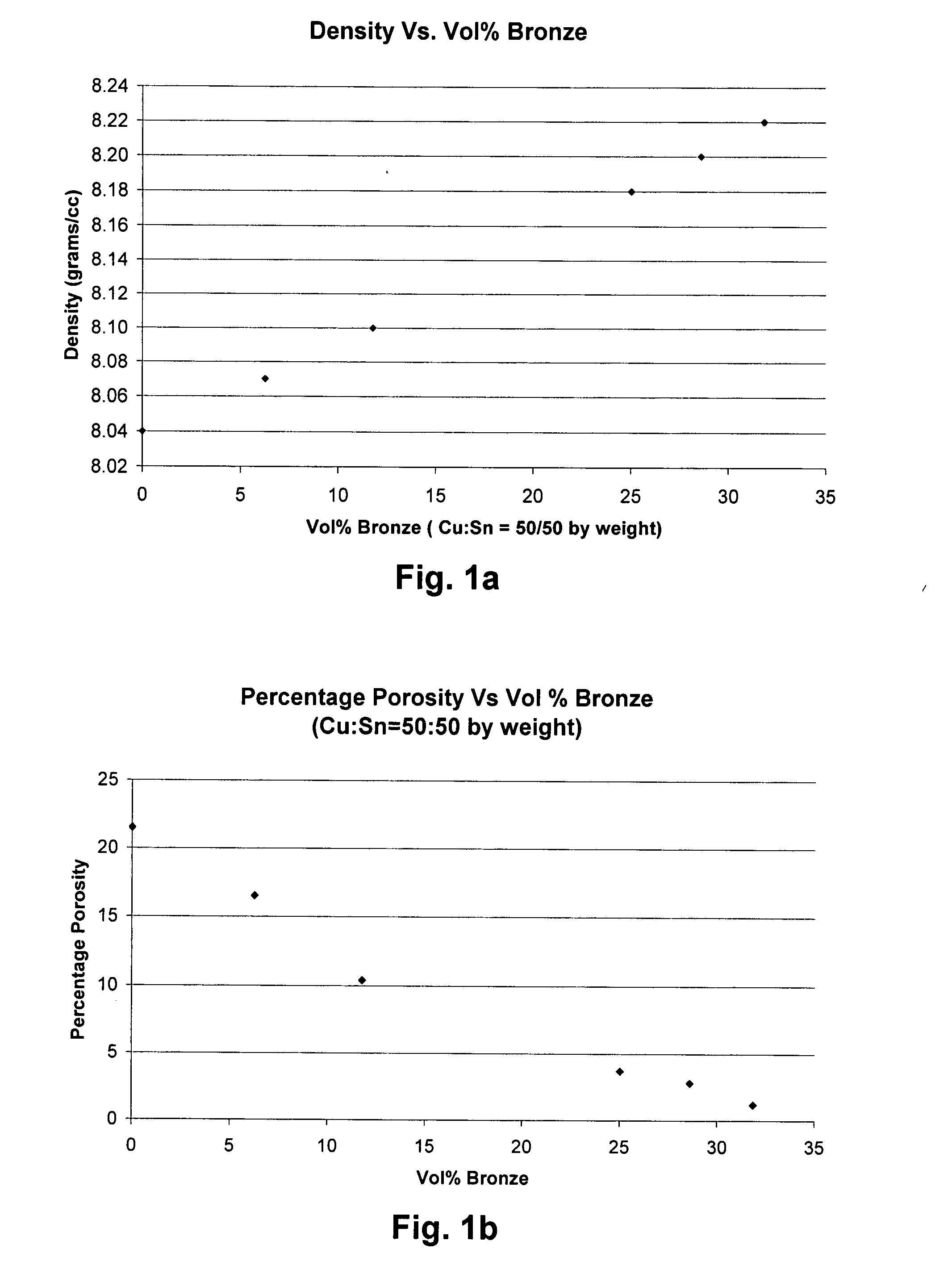

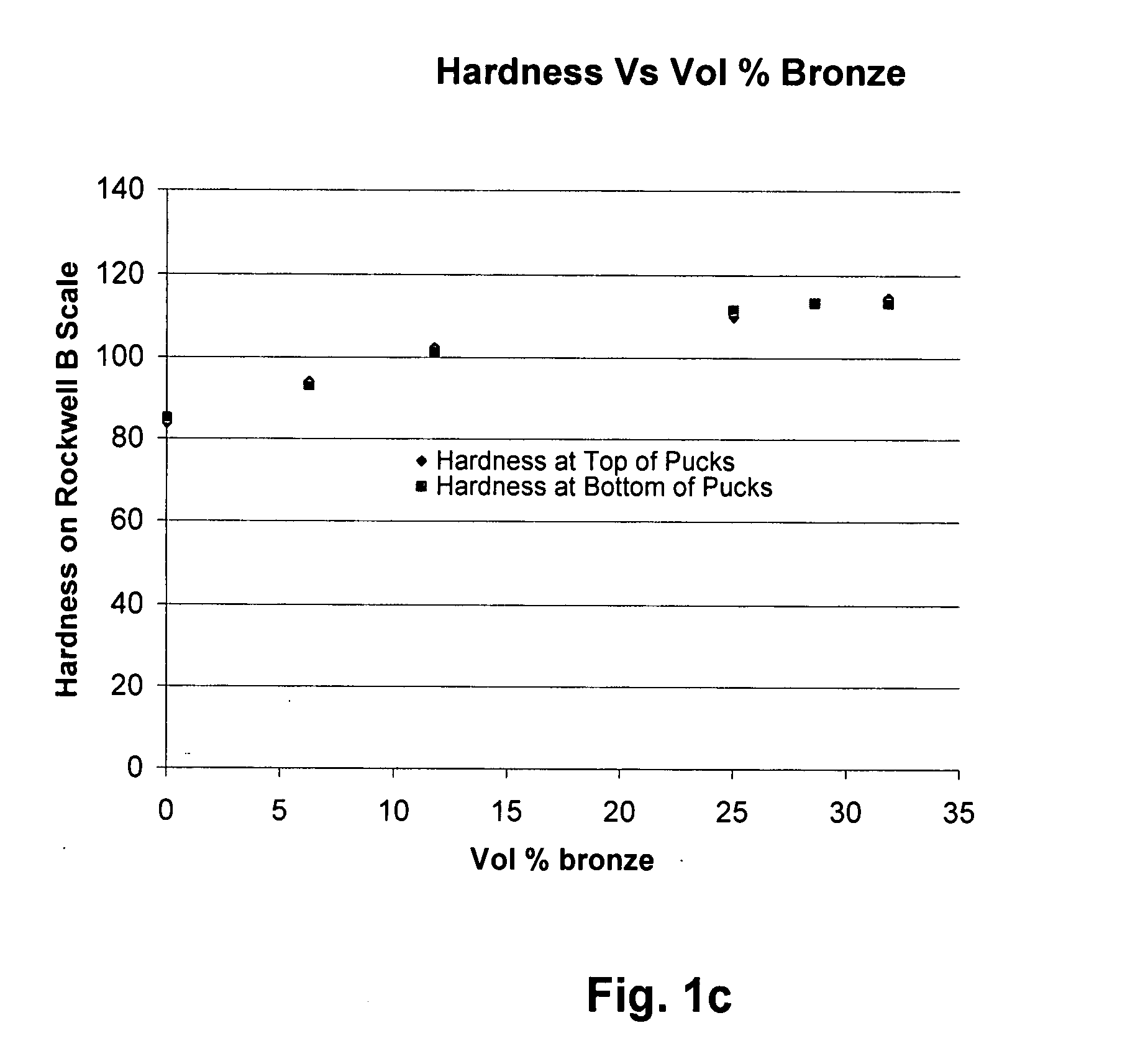

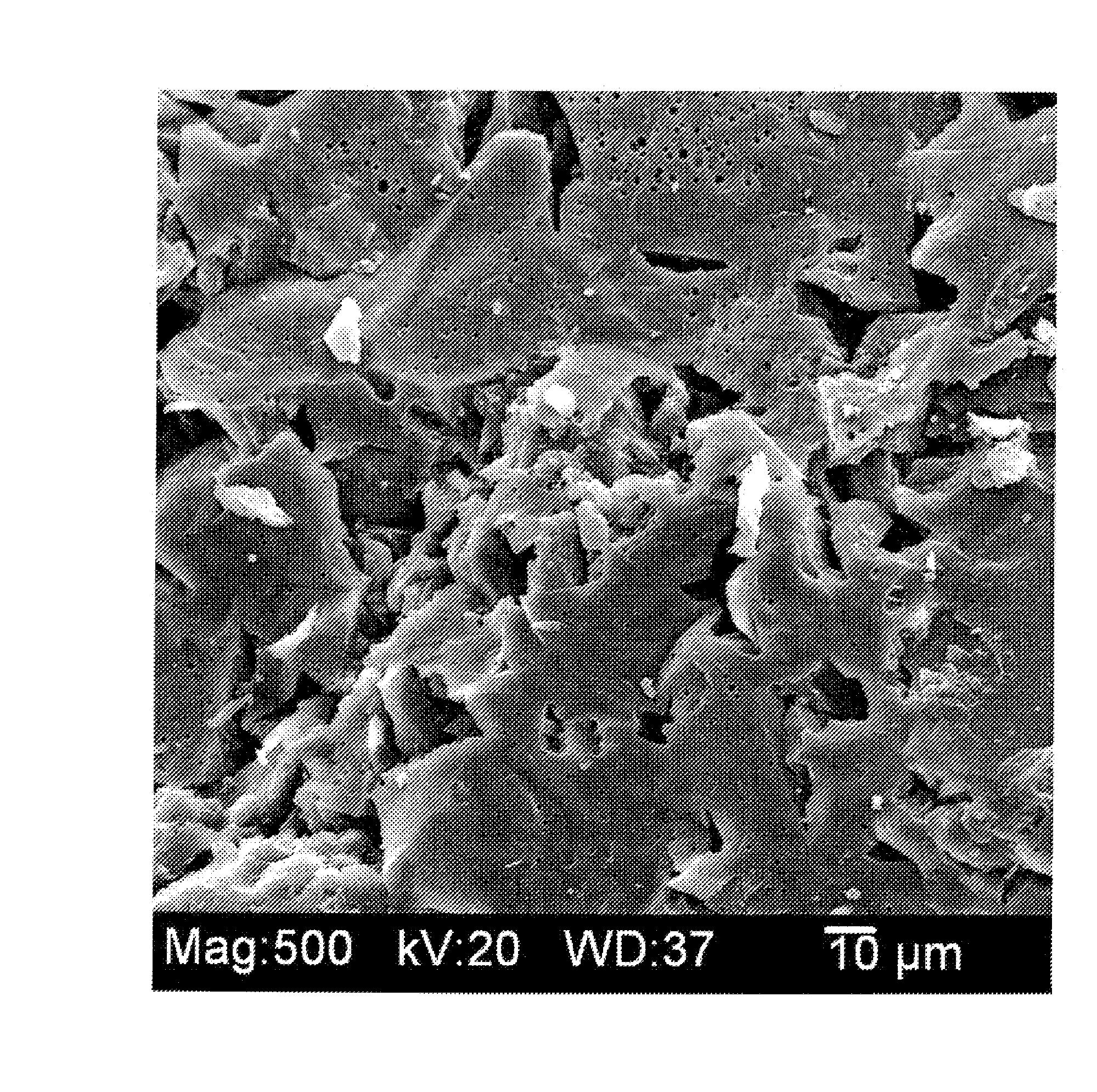

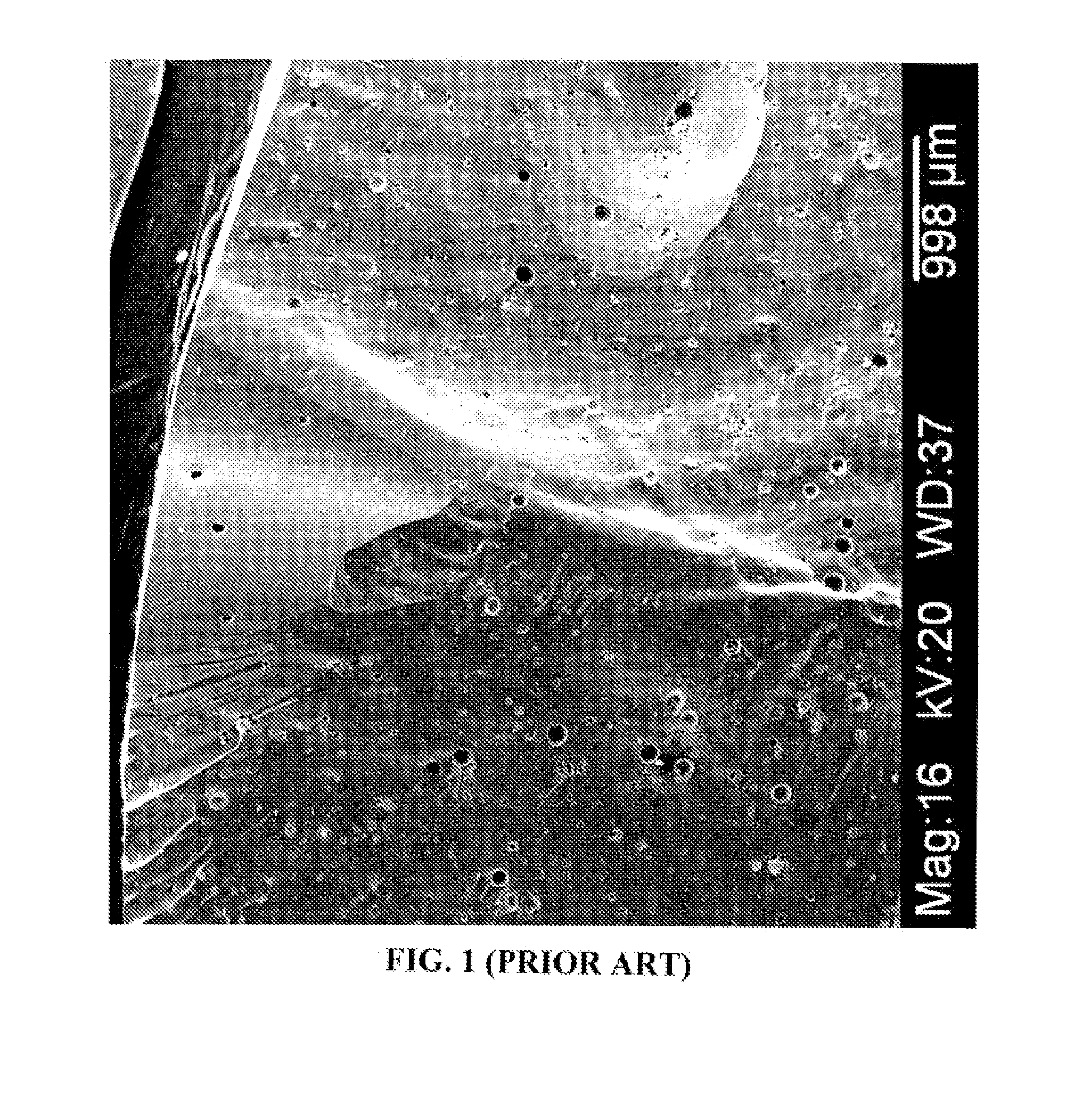

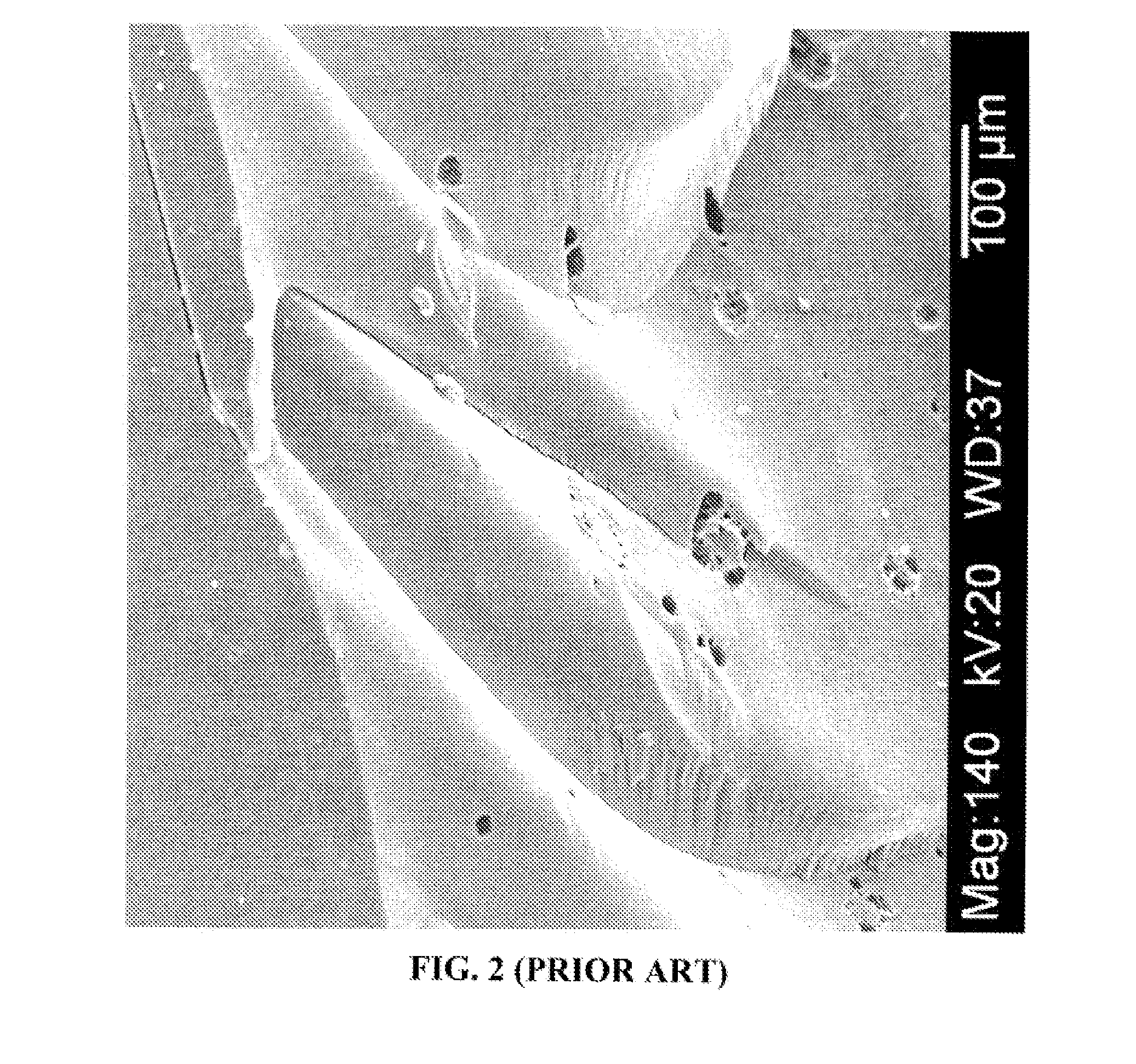

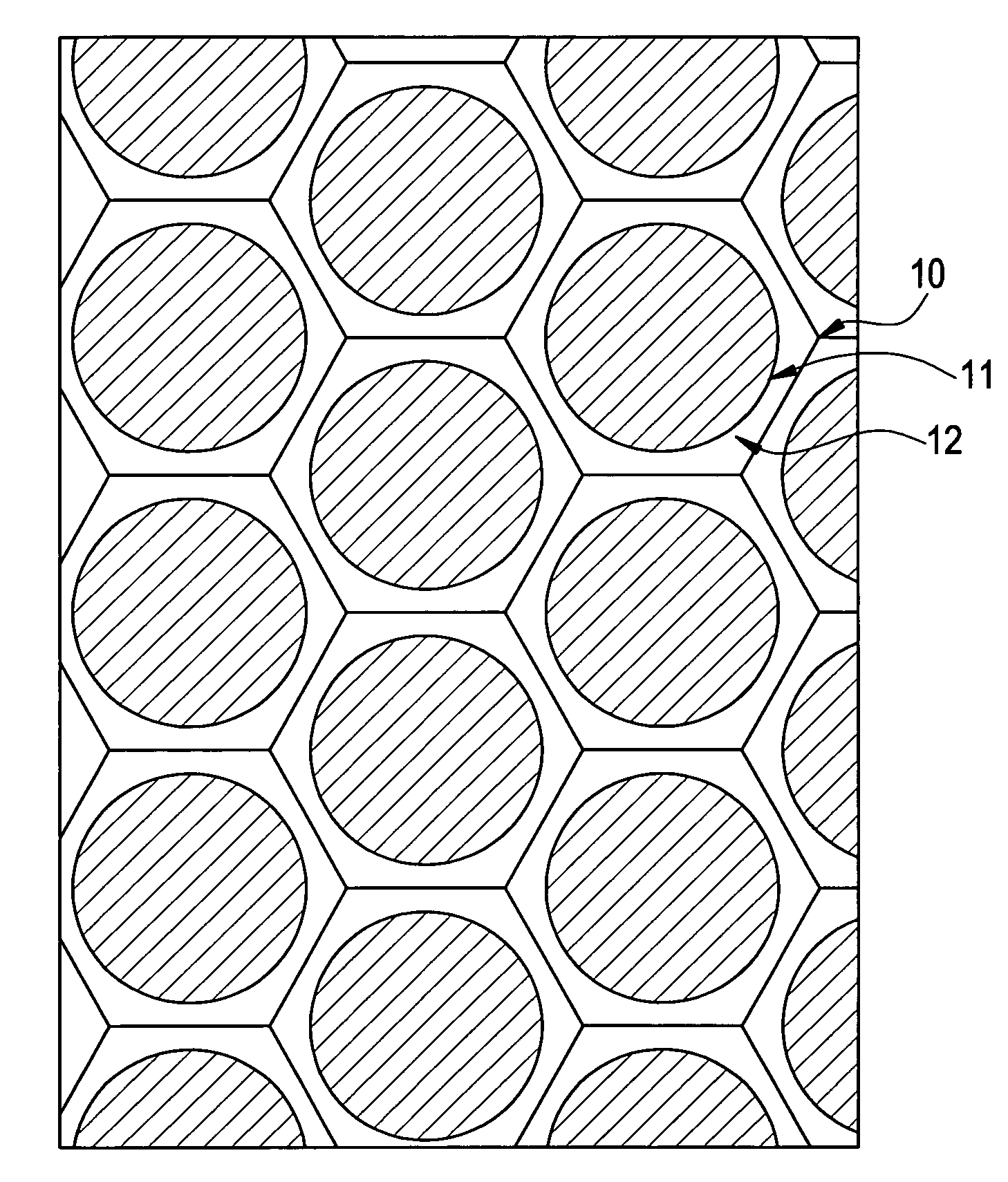

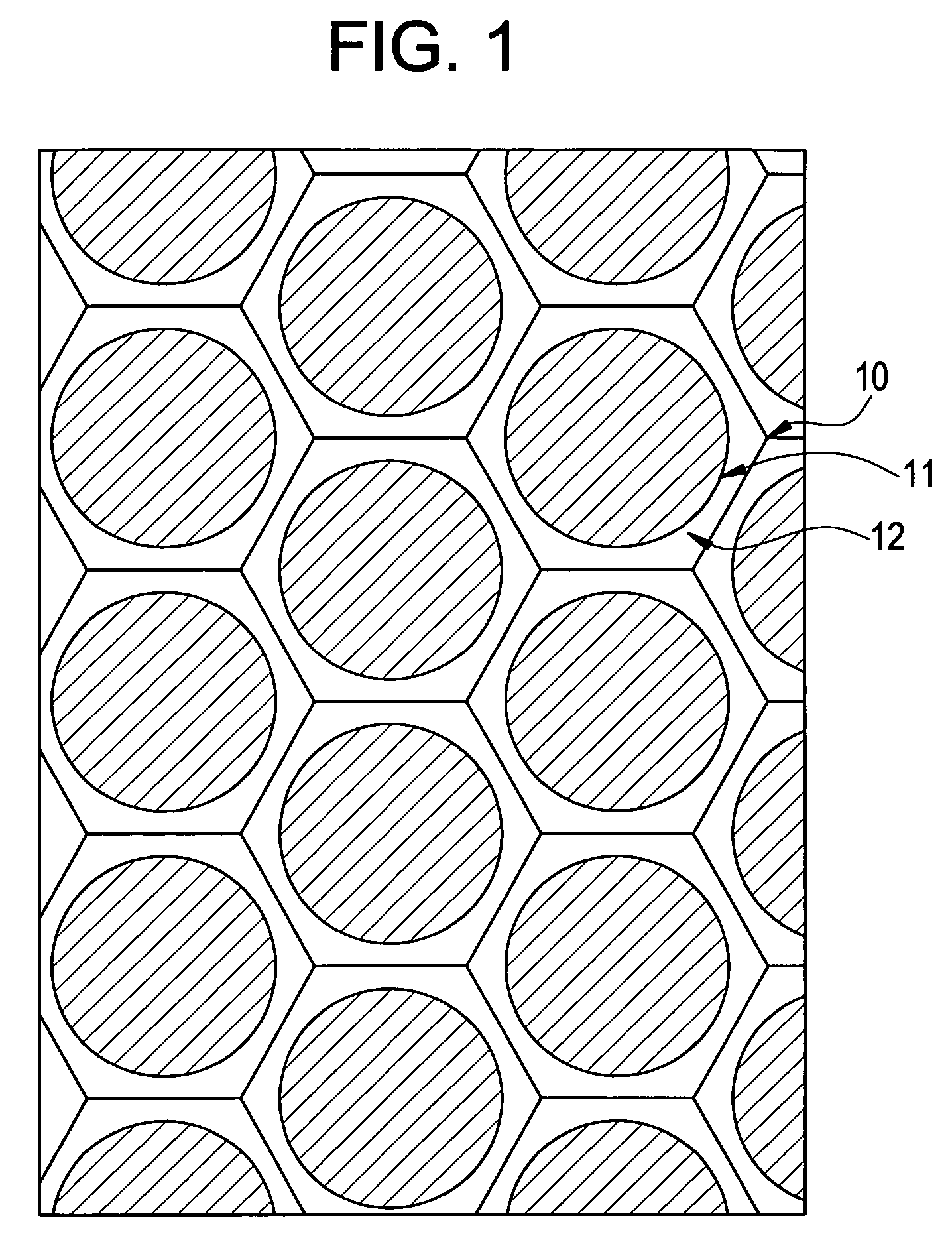

Abrasive processing of hard and /or brittle materials

ActiveUS20090084042A1Slow feed ratePigmenting treatmentOther chemical processesManufacturing technologyTitanium carbide

Abrasive articles possessing a highly open (porous) structure and uniform abrasive grit distribution are disclosed. The abrasive articles are fabricated using a metal matrix (e.g., fine nickel, tin, bronze and abrasives). The open structure is controlled with a porosity scheme, including interconnected porosity (e.g., formed by leaching of dispersoid), closed porosity (e.g., induced by adding a hollow micro-spheres and / or sacrificial pore-forming additives), and / or intrinsic porosity (e.g., controlled via matrix component selection to provide desired densification). In some cases, manufacturing process temperatures for achieving near full density of metal bond with fillers and abrasives, are below the melting point of the filler used, although sacrificial fillers may be used as well. The resulting abrasive articles are useful in high performance cutting and grinding operations, such as back-grinding silicon, alumina titanium carbide, and silicon carbide wafers to very fine surface finish values. Techniques of use and manufacture are also disclosed.

Owner:SAINT GOBAIN ABRASIVES INC +1

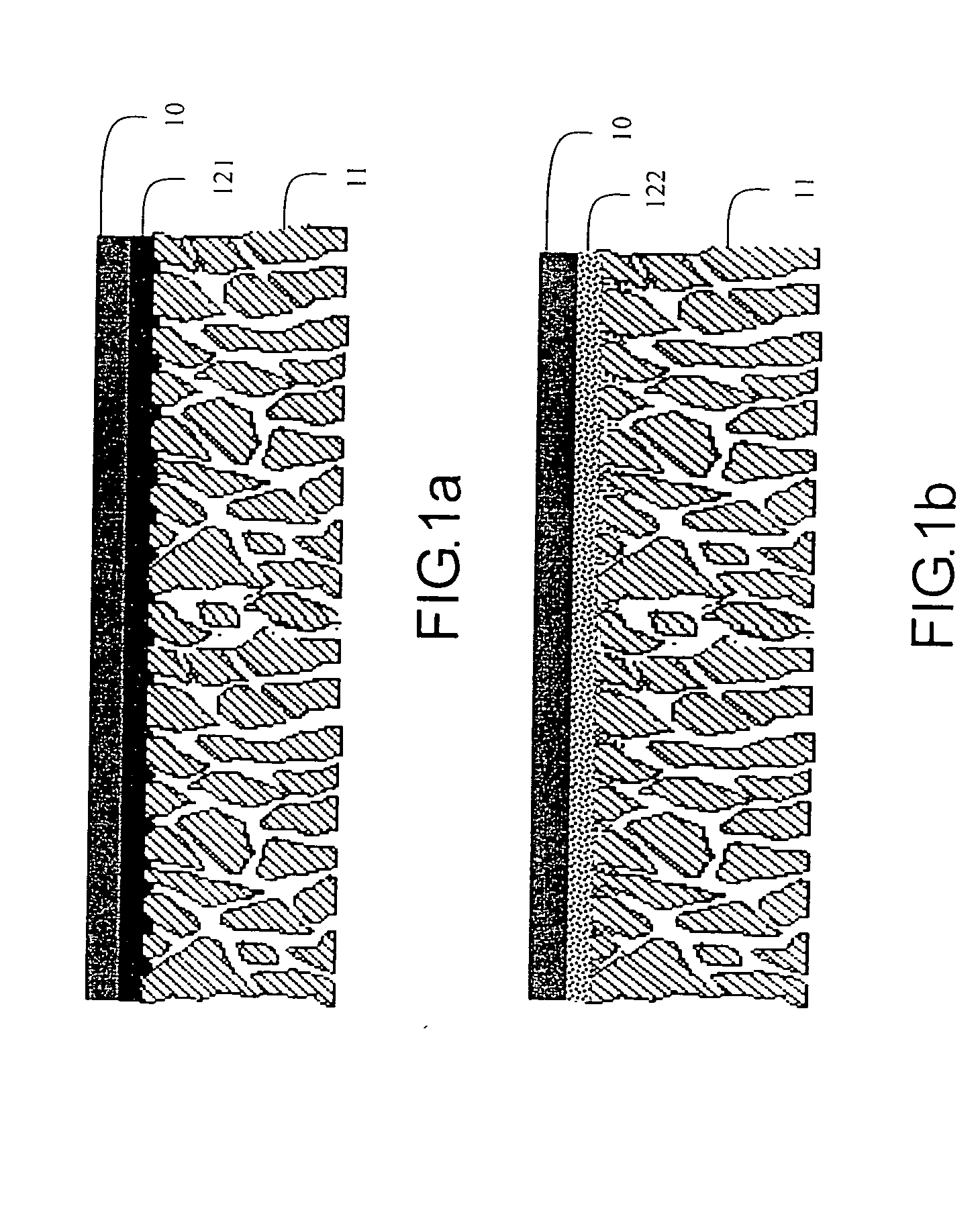

Oil/gas separation membrane, its use in gas sensor and process for producing the same

InactiveUS20050086998A1Losing mechanical propertyLosing permeation efficiencyPreparing sample for investigationFuel testingAdhesiveHexafluoropropylene

An oil gas separation membrane combines a gas permeable yet oil and temperature resistant bulk polymer membrane such as poly(tetrafluoroethylene) and poly(tetrafluoroethylene-co-hexafluoropropylene); a porous metal support such as sintered metal frit disk made with stainless steel, bronze or nickel; and an highly gas permeable adhesive that bonds firmly the bulk polymer membrane and the metal frit surface together. The adhesive is either a homogenous polymer that has desirable gas permeability, or a coalescent porous polymer particulates network. A gas sensor employing the oil gas separation membrane for detecting and monitoring fault gases of oil filled electrical equipment requires no mechanical wearing or moving part such as pump and valve and the gas sensor is operated normally under various temperature and pressure conditions.

Owner:ASENSOR TECH

Method of manufacturing an assembly of brazed dissimilar metal components

InactiveUS6503640B2Improve abilitiesHigh strengthBuilding componentsElectron beam welding apparatusTitanium coatingSS - Stainless steel

Owner:DANA CANADA CORP

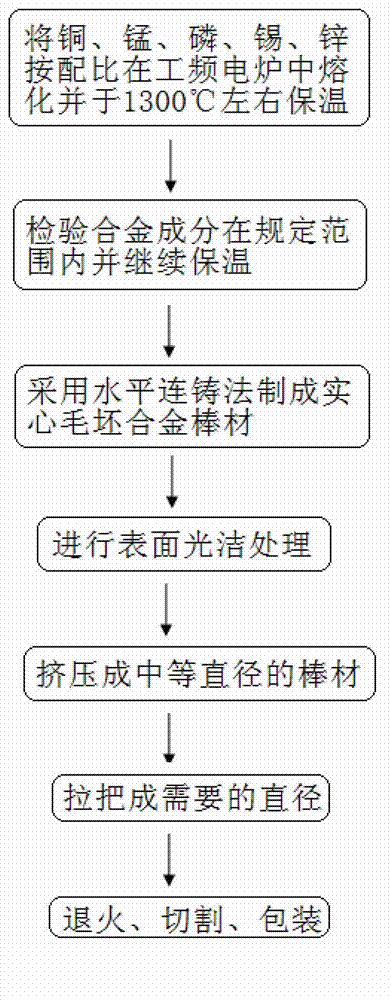

Novel lead-free environment-friendly high-strength wear-resistant copper-base alloy bar and preparation method thereof

The invention relates to a novel lead-free environment-friendly high-strength wear-resistant copper-base alloy bar which is prepared from the following components in percentage by weight: 1-3% of manganese, 2-4% of tin, 0.01-0.5% of phosphorus, 1.5-4.5% of zinc and the balance of copper. The metallic element manganese is used instead of lead; the manganese, zinc, tin, phosphorus and copper are mixed proportionally, extruded by an extruding machine at proper temperature, and drawn by a drawing machine to obtain the alloy bar; the alloy bar has wear resistance in the traditional copper-lead-bronze alloy, can be used for hot working, and has better workability than the copper-lead-bronze alloy; the alloy bar provided by the invention is free of lead, thereby avoiding the environmental pollution caused by the use of lead and being beneficial to environmental protection; and thus, the novel lead-free environment-friendly high-strength wear-resistant copper-base alloy bar provided by the invention can completely substitute the traditional copper-lead-bronze alloy.

Owner:SUZHOU TIANJIAN METAL NEW MATERIAL

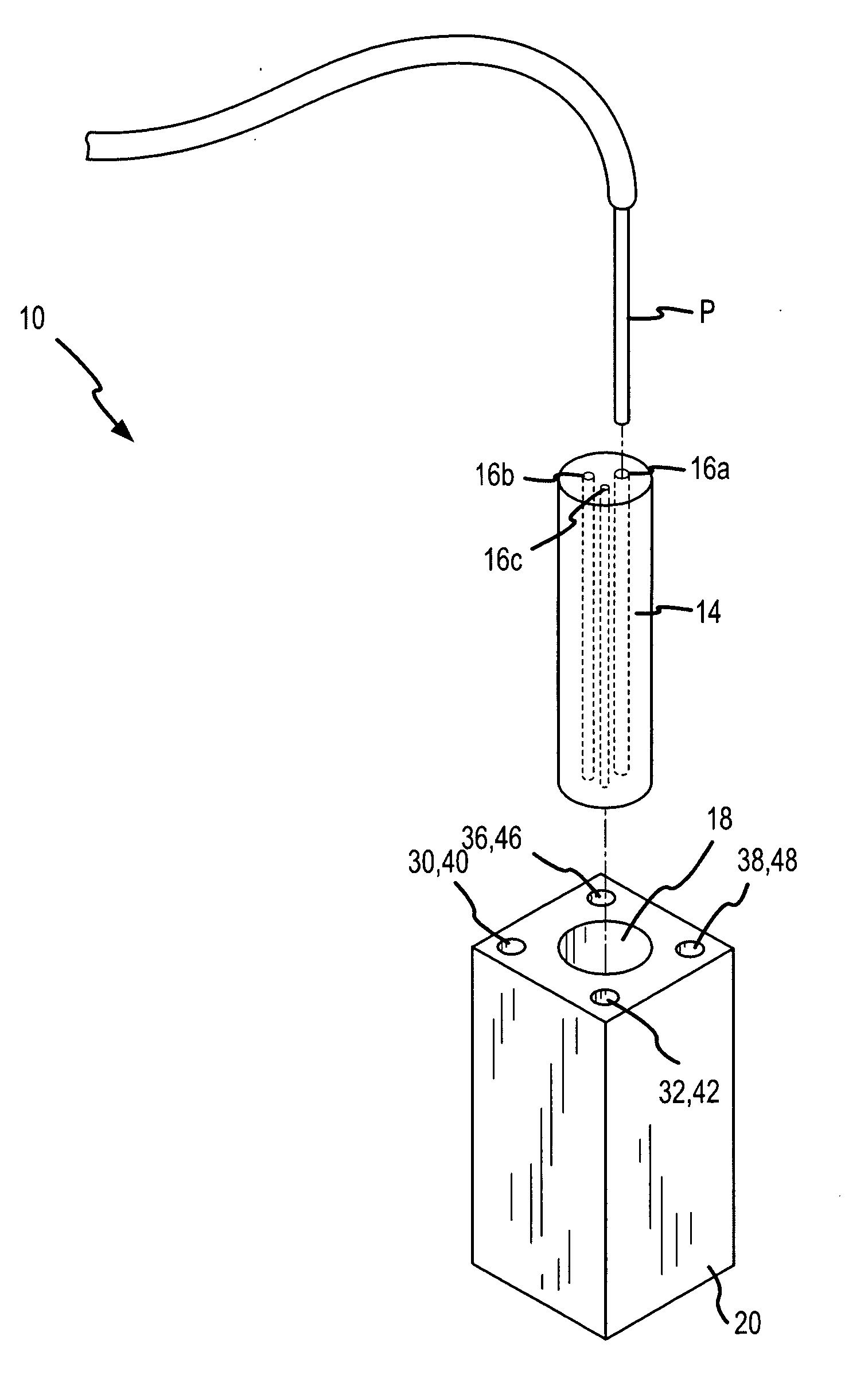

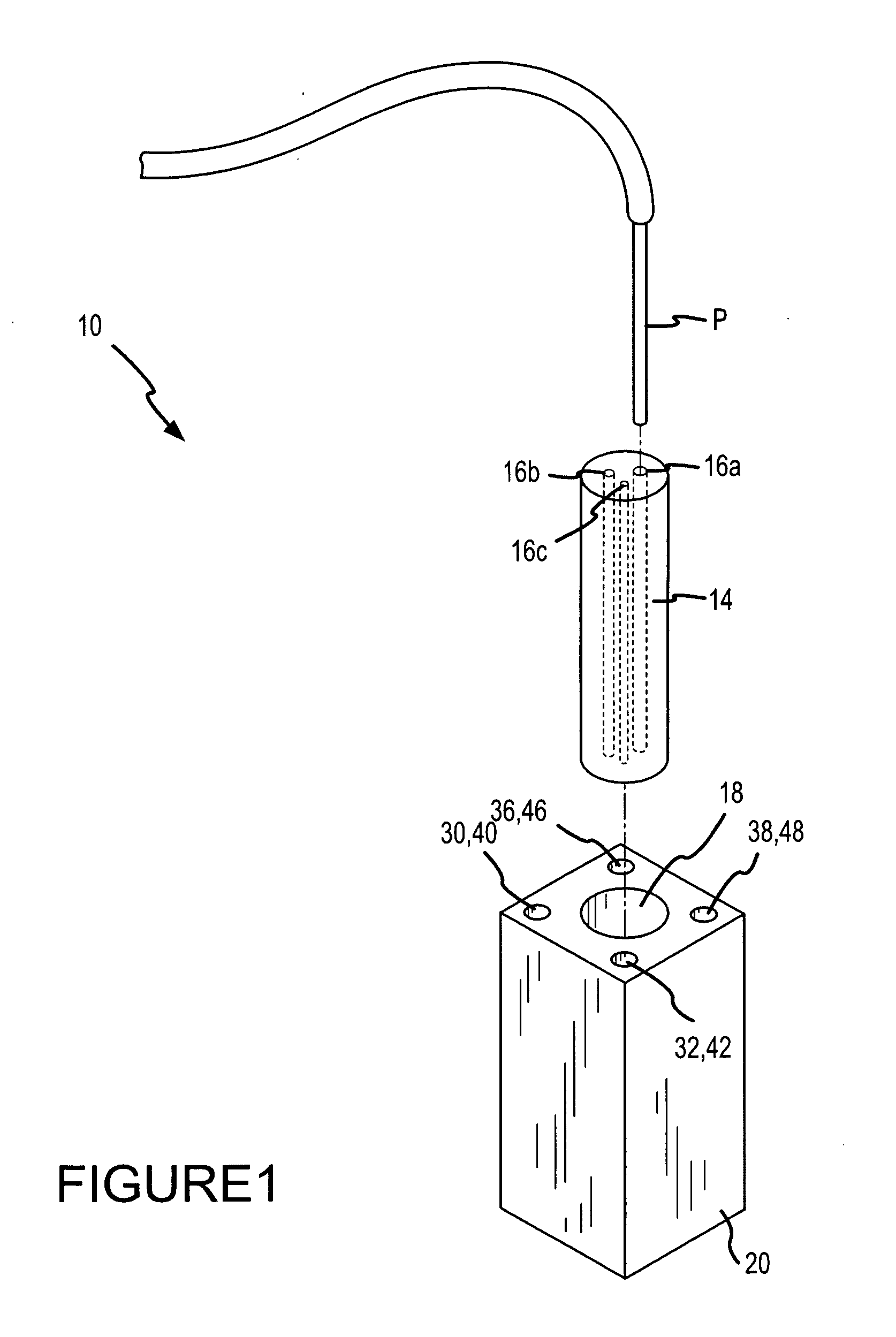

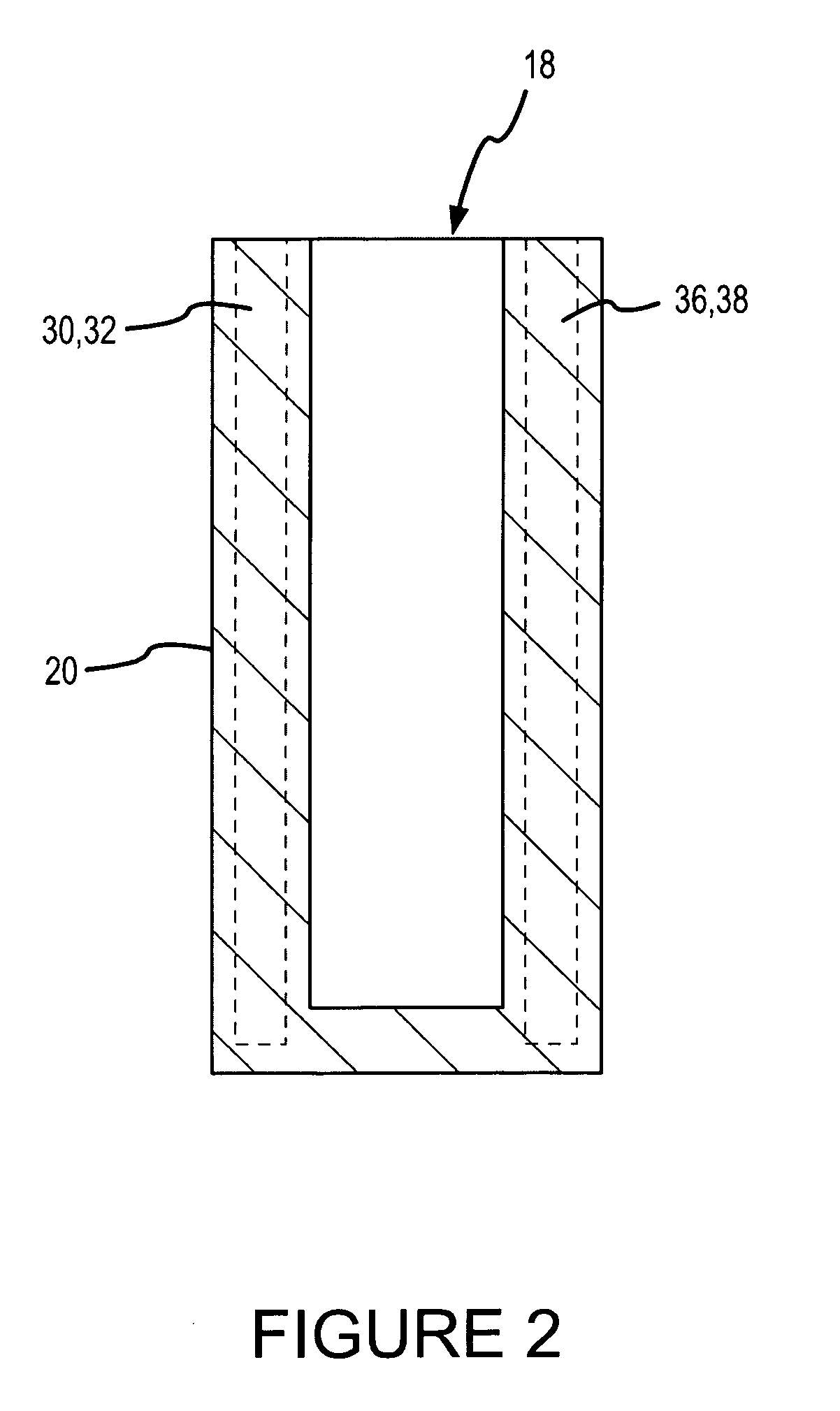

Insert and/or calibrator block formed of aluminum-bronze alloy, temperature calibration device using same, and methods of use

InactiveUS20070291814A1Reduce environmental degradationThermometer testing/calibrationCalorimeterAlloyBronze

Inserts and / or calibrator blocks formed of aluminum-bronze alloys resistant to environmental degradation, temperature calibration devices employing such inserts and calibrator blocks, and methods of using such devices and structures are disclosed. An insert and / or calibrator block for use with a temperature calibration device may be formed of an aluminum-bronze alloy having a composition selected to reduce environmental degradation thereof during use.

Owner:JOHN FLUKE MFG CO INC

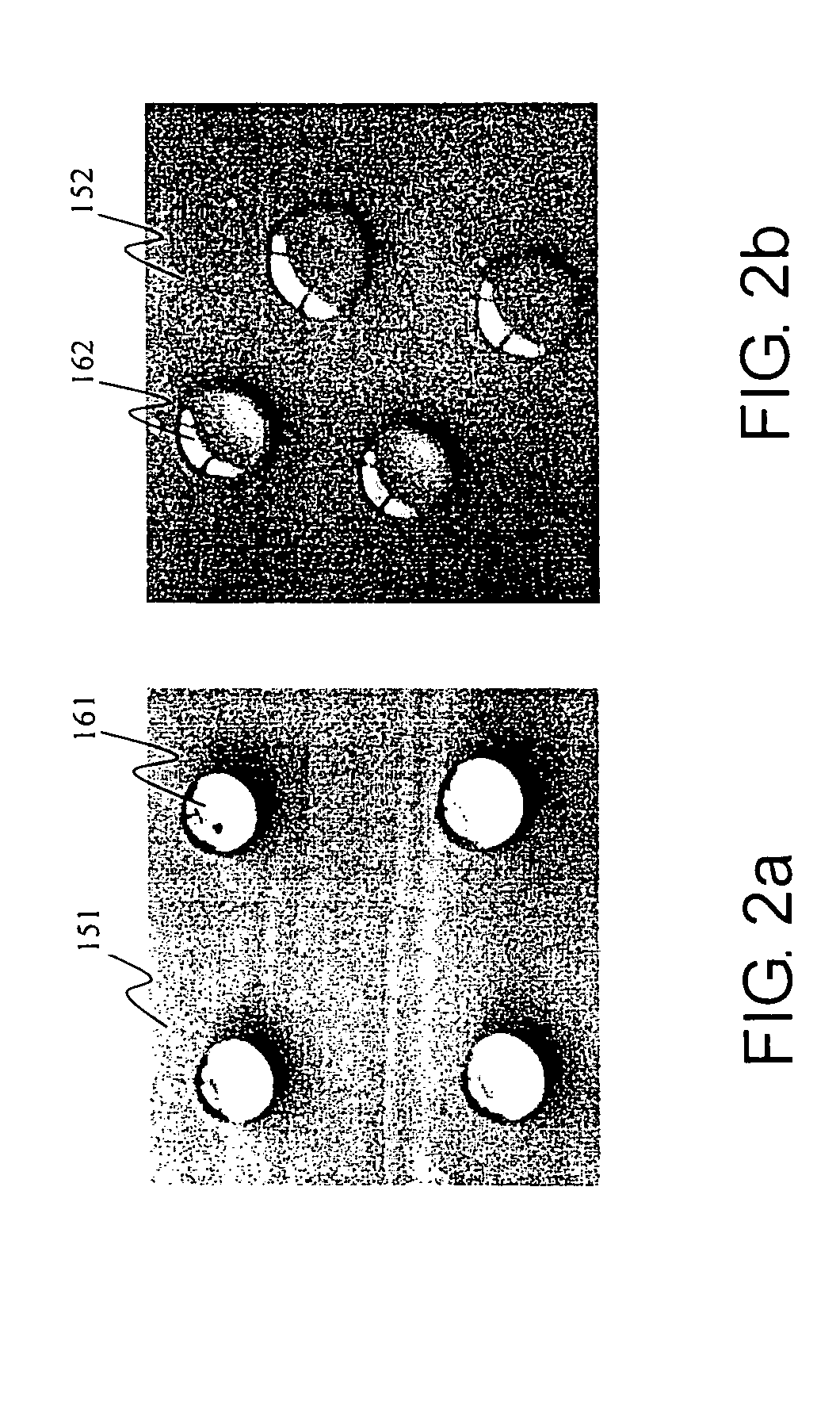

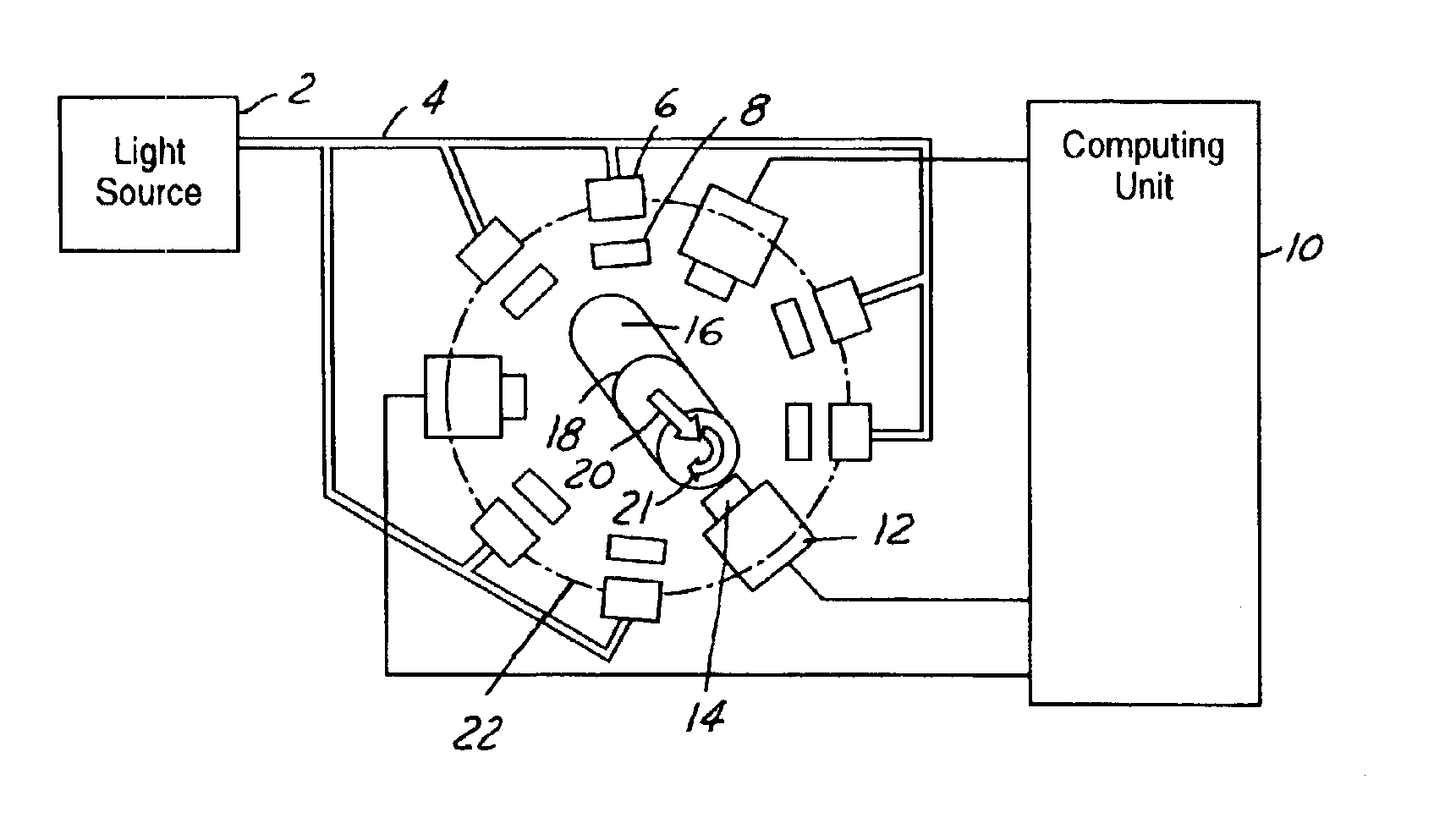

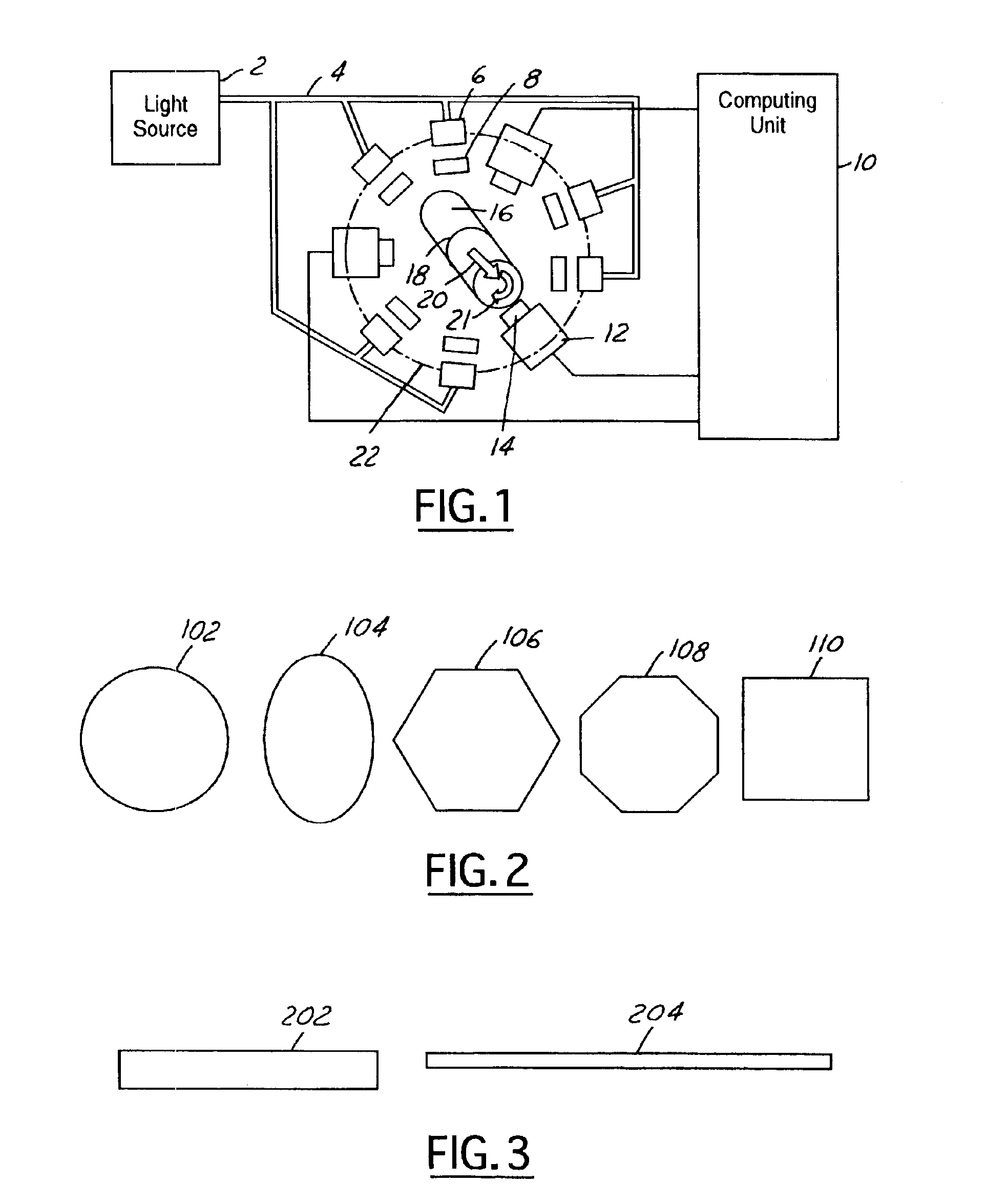

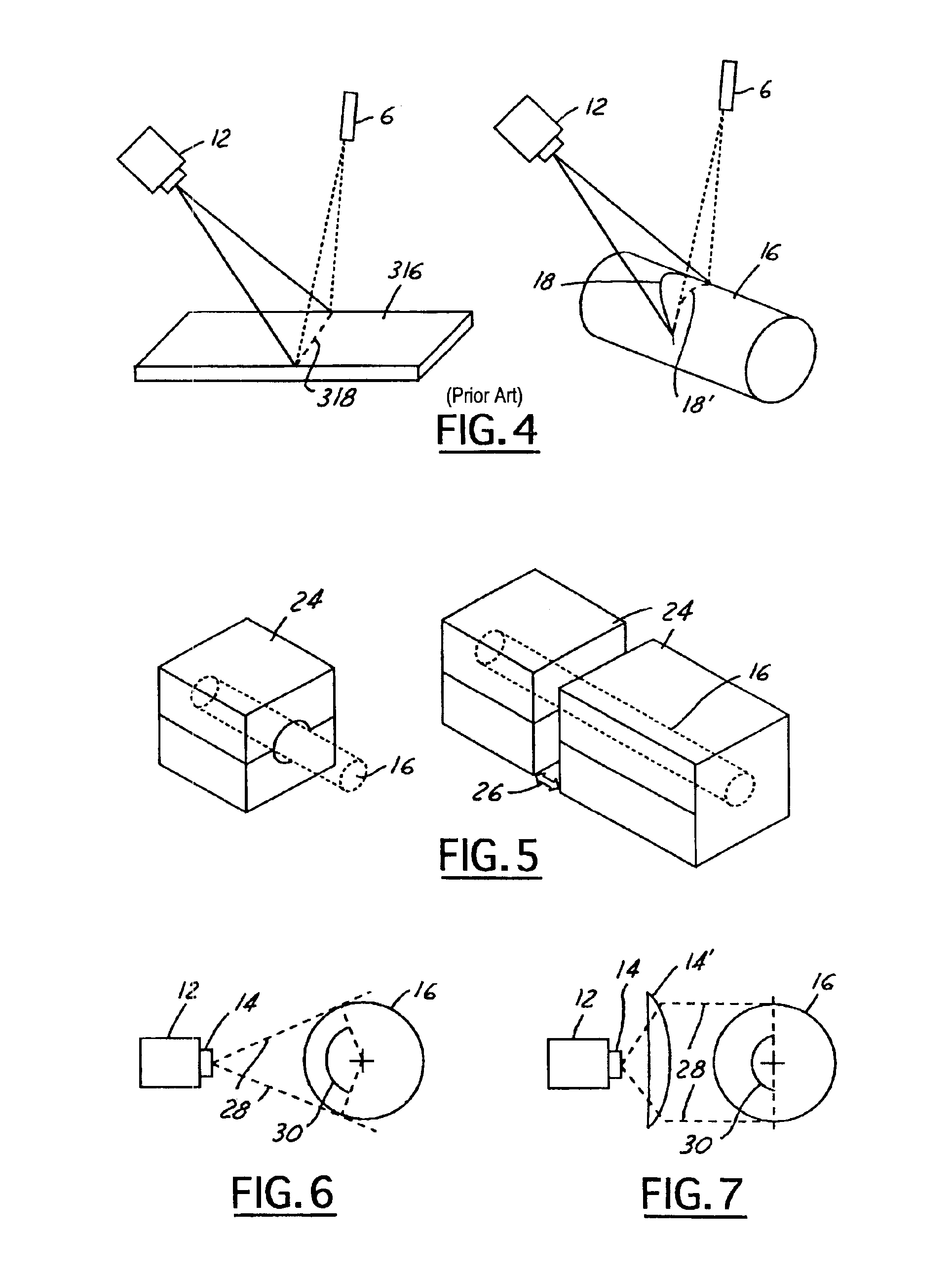

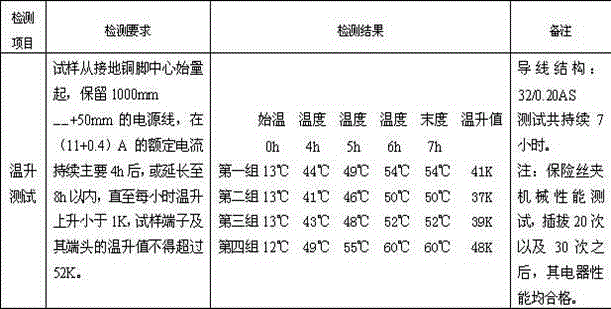

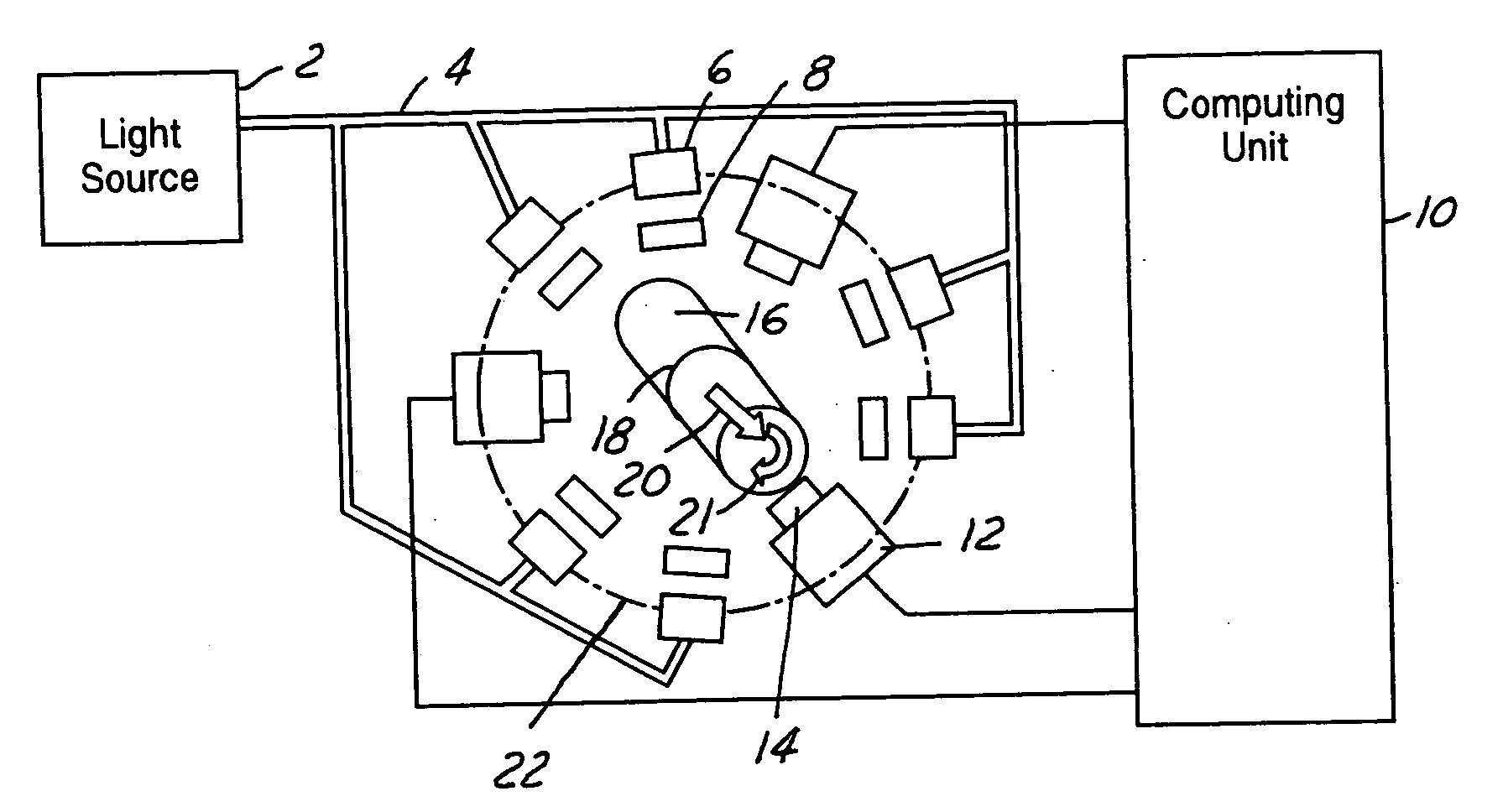

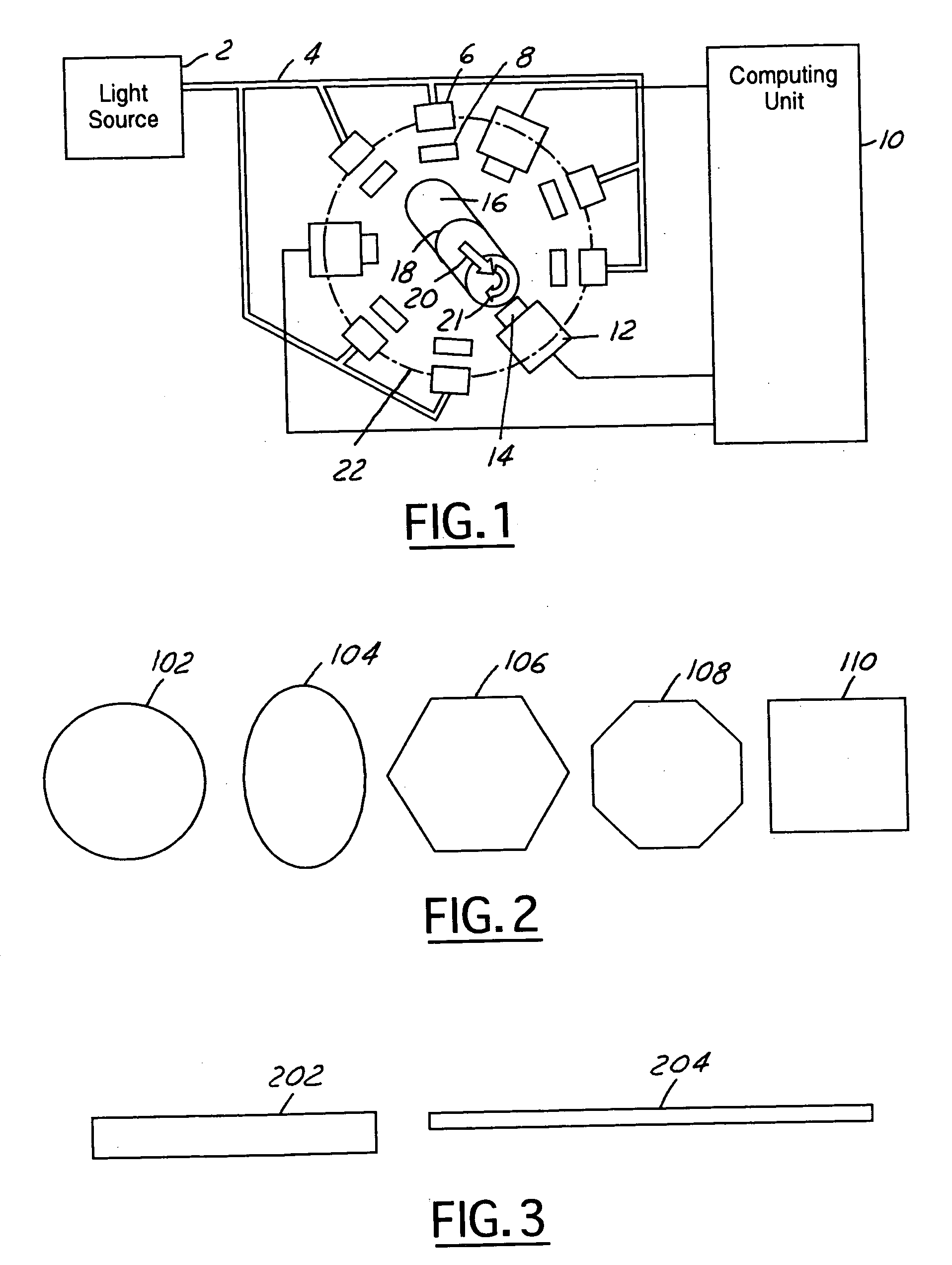

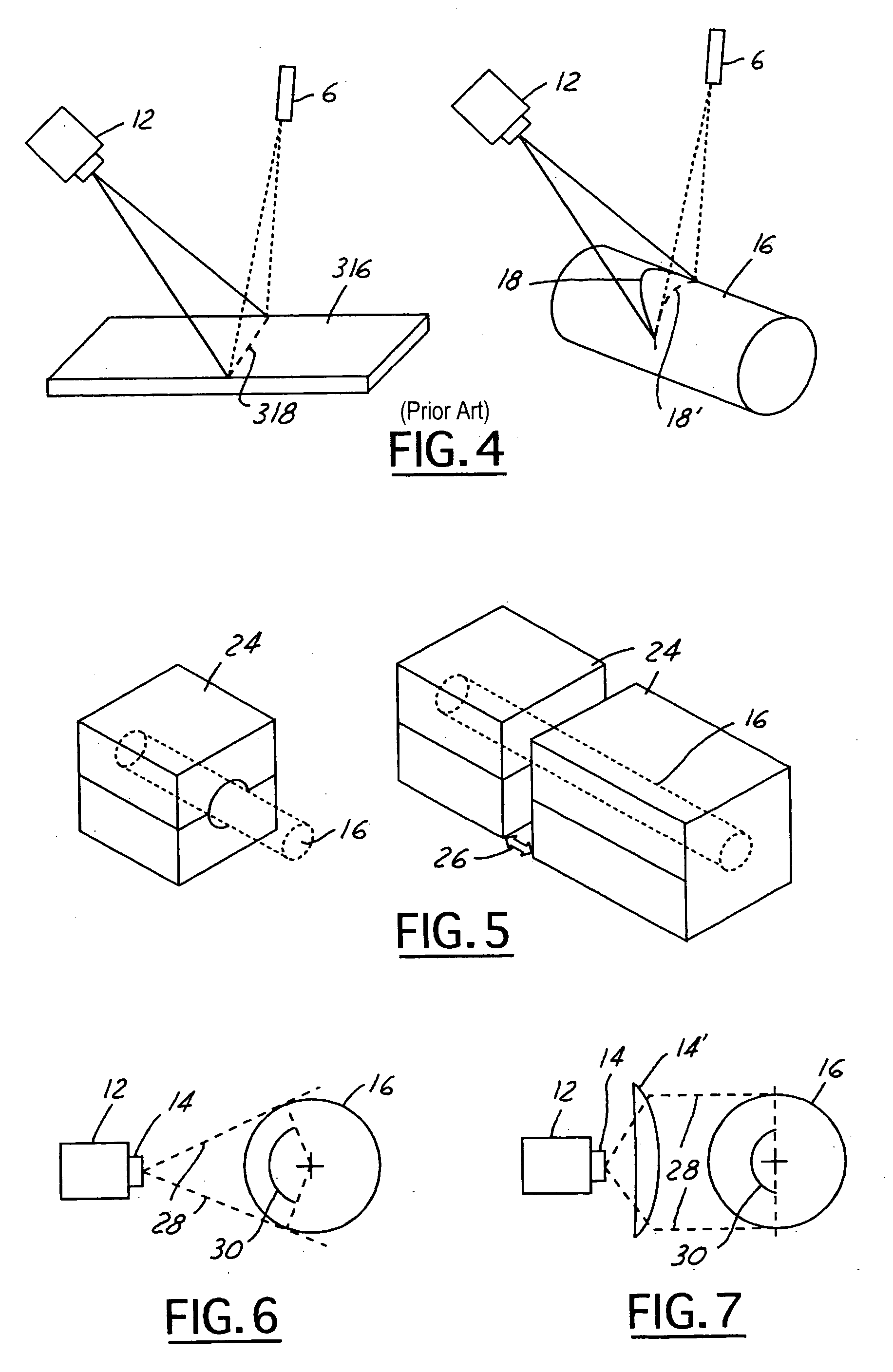

Apparatus and method for detecting surface defects on a workpiece such as a rolled/drawn metal bar

ActiveUS6950546B2Efficiently employedIncrease the working distanceCharacter and pattern recognitionColor synchronisationNon destructiveEngineering

The present invention is directed to solving the problems associated with the detection of surface defects on metal bars as well as the problems associated with applying metal flat inspection systems to metal bars for non-destructive surface defects detection. A specially designed imaging system, which is comprised of a computing unit, line lights and high data rate line scan cameras, is developed for the aforementioned purpose. The target application is the metal bars (1) that have a circumference / cross-section-area ratio equal to or smaller than 4.25 when the cross section area is unity for the given shape, (2) whose cross-sections are round, oval, or in the shape of a polygon, and (3) are manufactured by mechanically cross-section reduction processes. The said metal can be steel, stainless steel, aluminum, copper, bronze, titanium, nickel, and so forth, and / or their alloys. The said metal bars can be at the temperature when they are being manufactured.

Owner:OG TECH INC

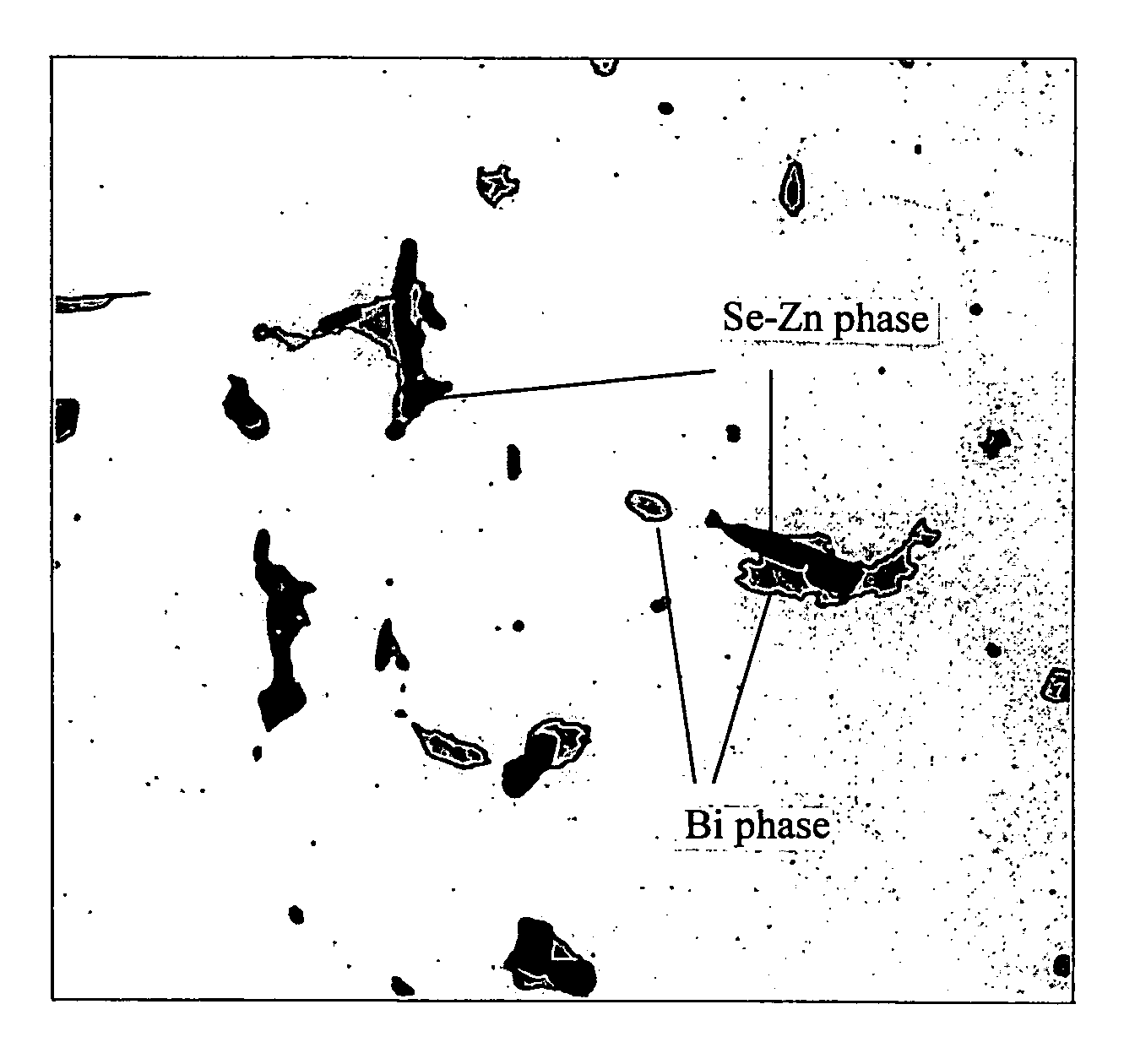

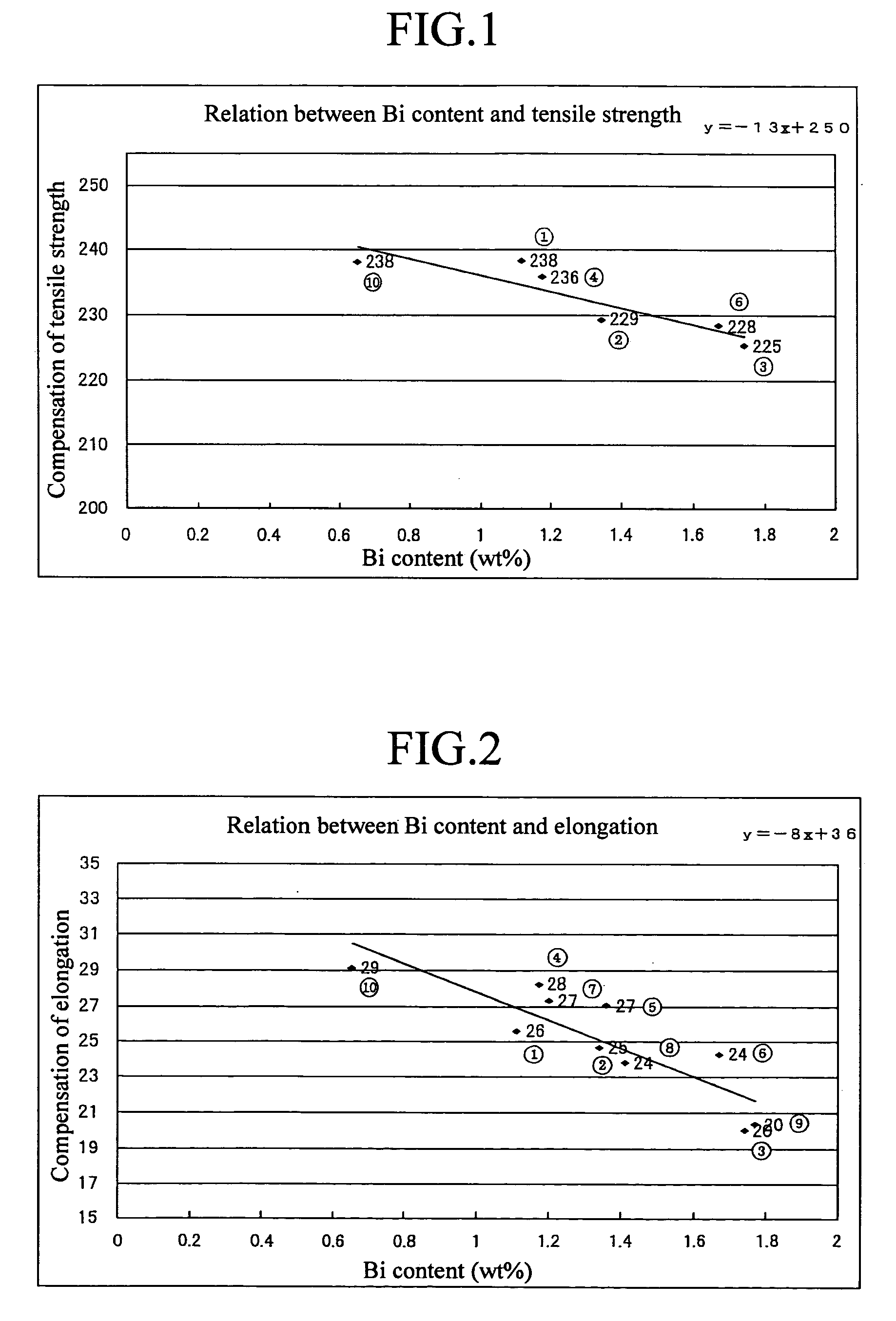

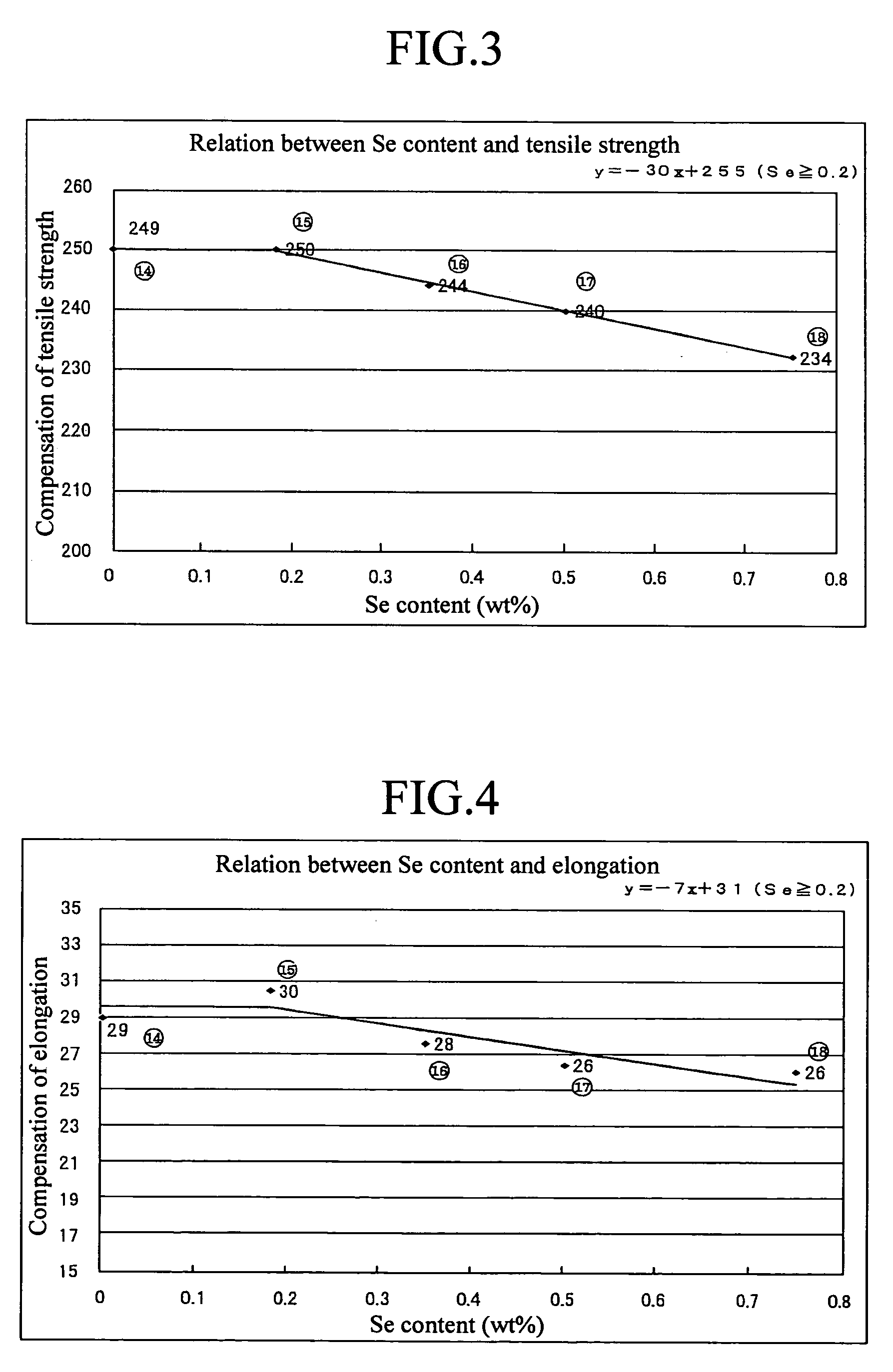

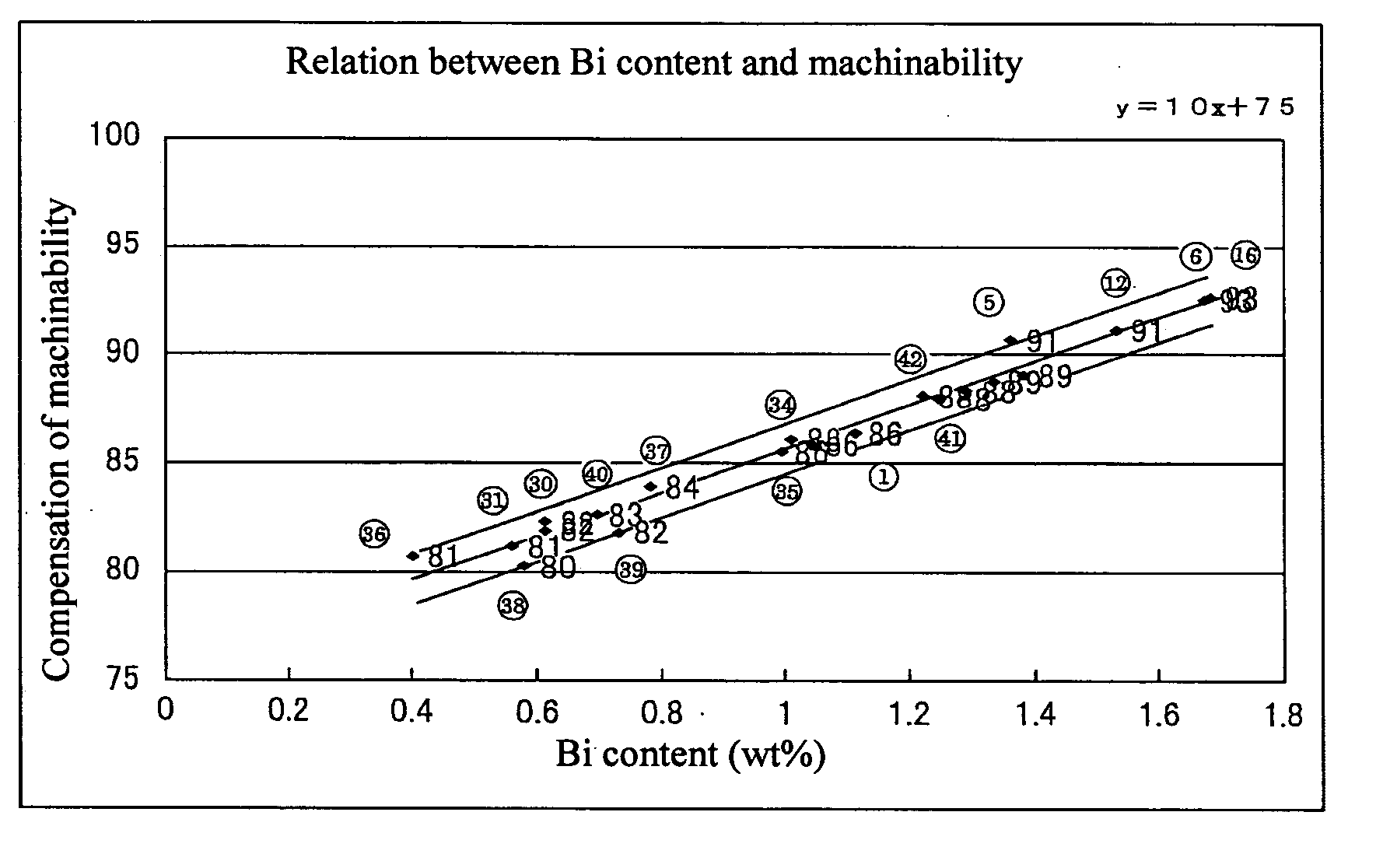

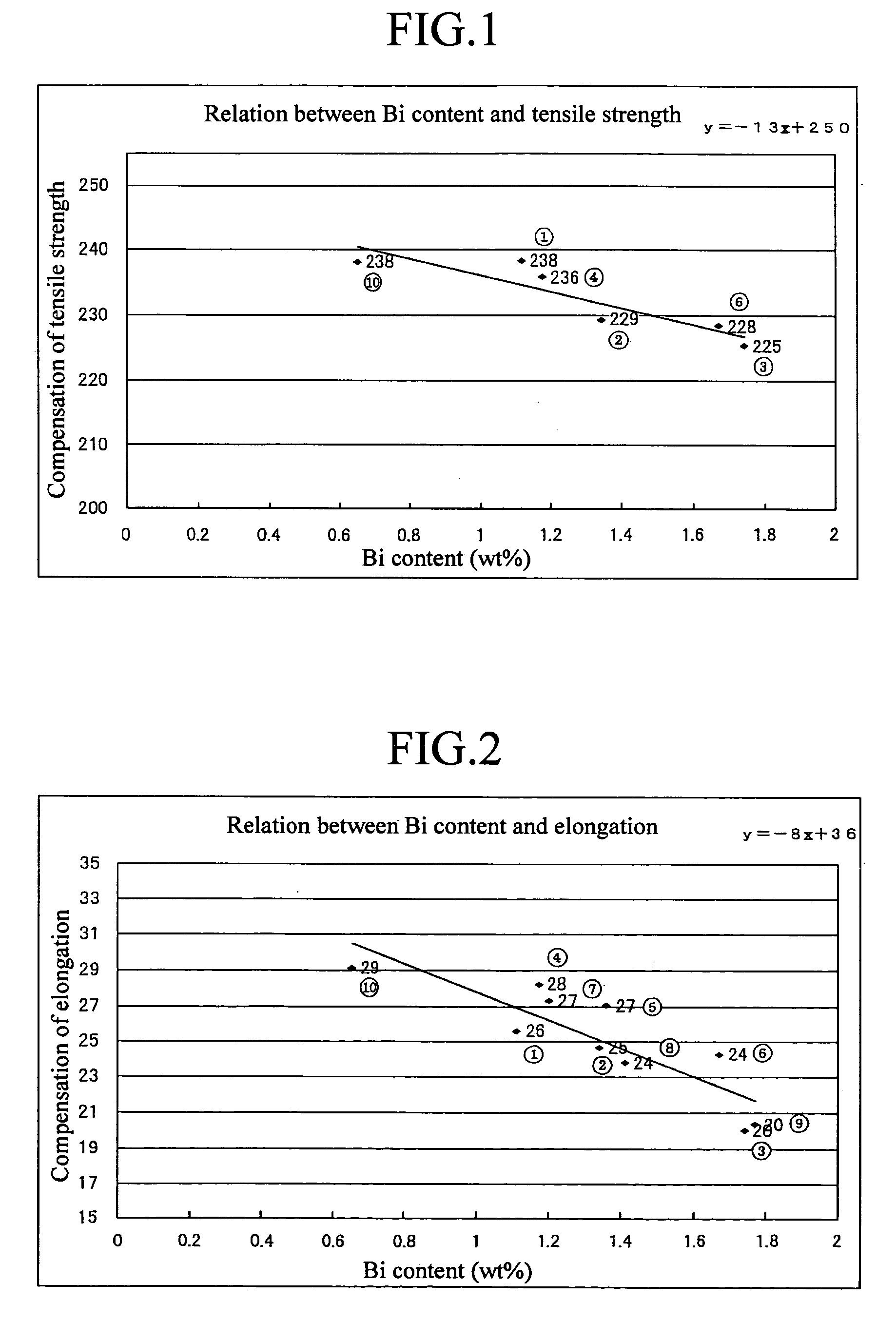

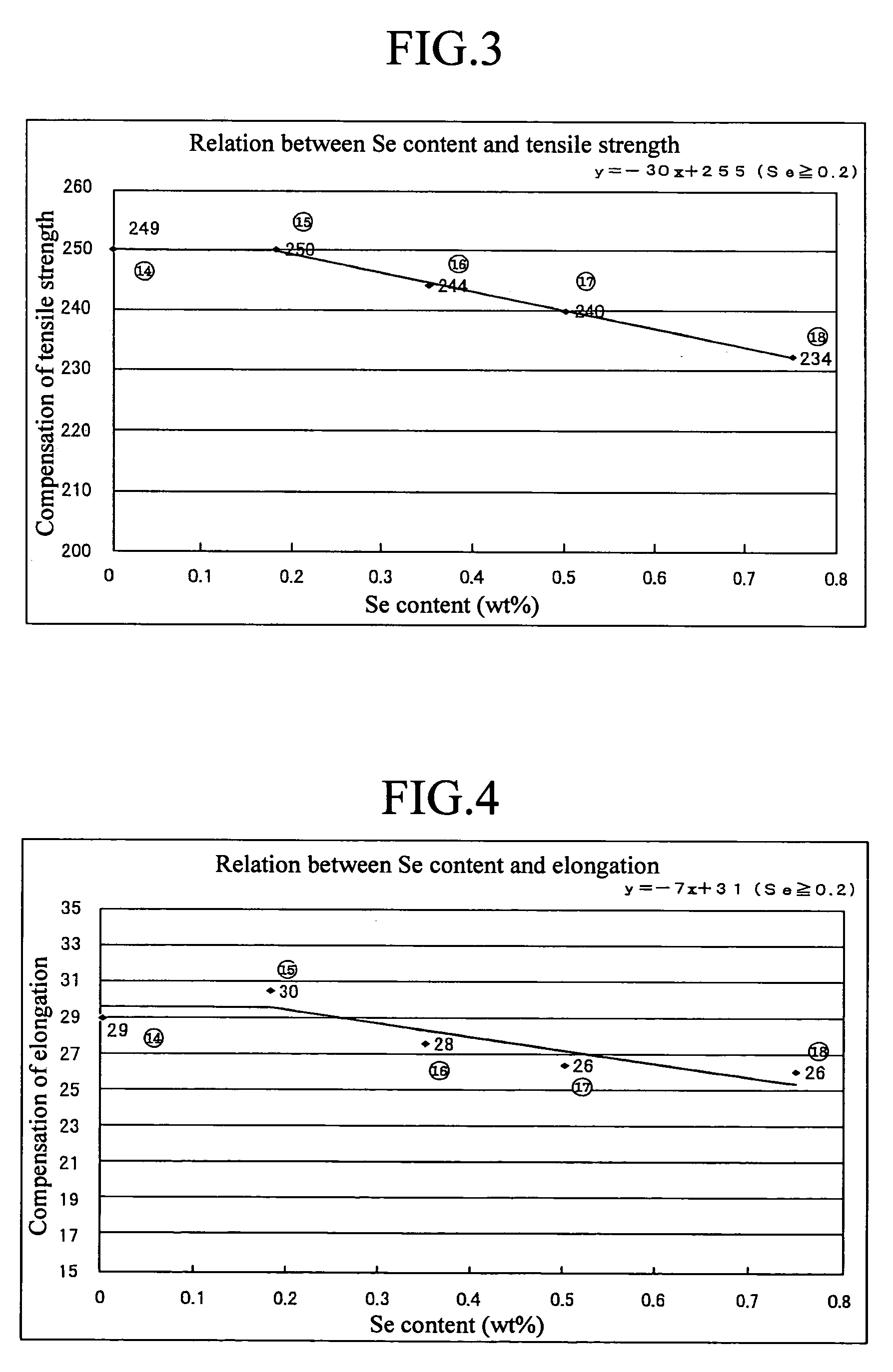

Copper base alloy, and cast ingot and parts to be contacted with liquid

By exactly comprehending the true properties of the rare elements (such as Bi and Se) which are alternative components for Pb, the alloy is enabled to secure machinability equal to the bronze alloy (CAC406) generally used hitherto and acquire mechanical properties at least equal to the CAC406 as well in spite of a decrease in the content of the rare elements (such as Bi and Se) in the alloy. Further, it is possible to suppress the occurrence of casting defects by elucidating the unresolved influence of the decrease of the alternative components (such as Bi and Se) for Pb on the wholesomeness of a casting. Moreover, it is possible, by decreasing the rare elements, to produce a copper-based alloy containing rare elements at a low cost and to provide a cast ingot and a liquid-contacting part each using the alloy. The copper-based alloy, and the cast ingot and liquid-contacting part each using the alloy individually contain at least 2.8 to 5.0 wt % of Sn, 0.4 to 3.0 wt % of Bi and satisfying 0<Se≦0.35 wt % to enable securing prescribed machinability and wholesomeness of a casting and exalt mechanical properties thereof.

Owner:KITZ CORP

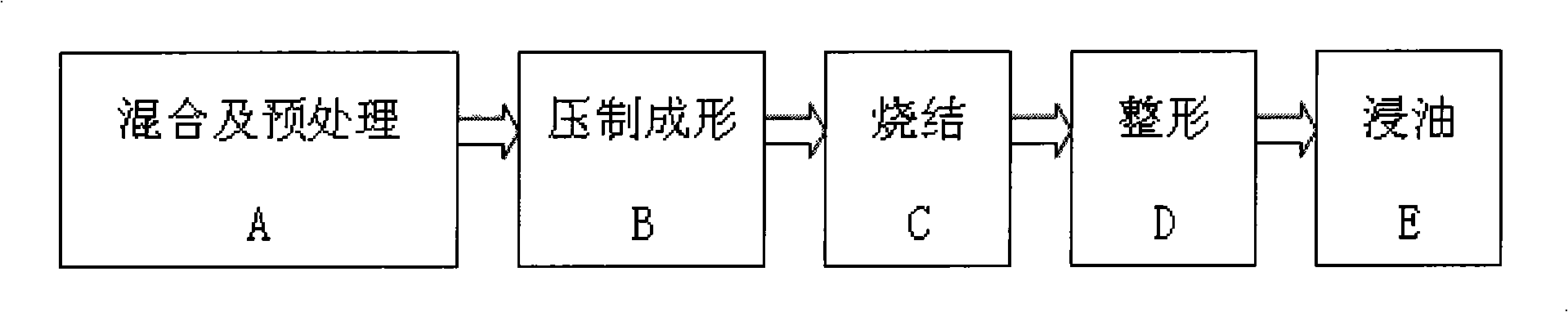

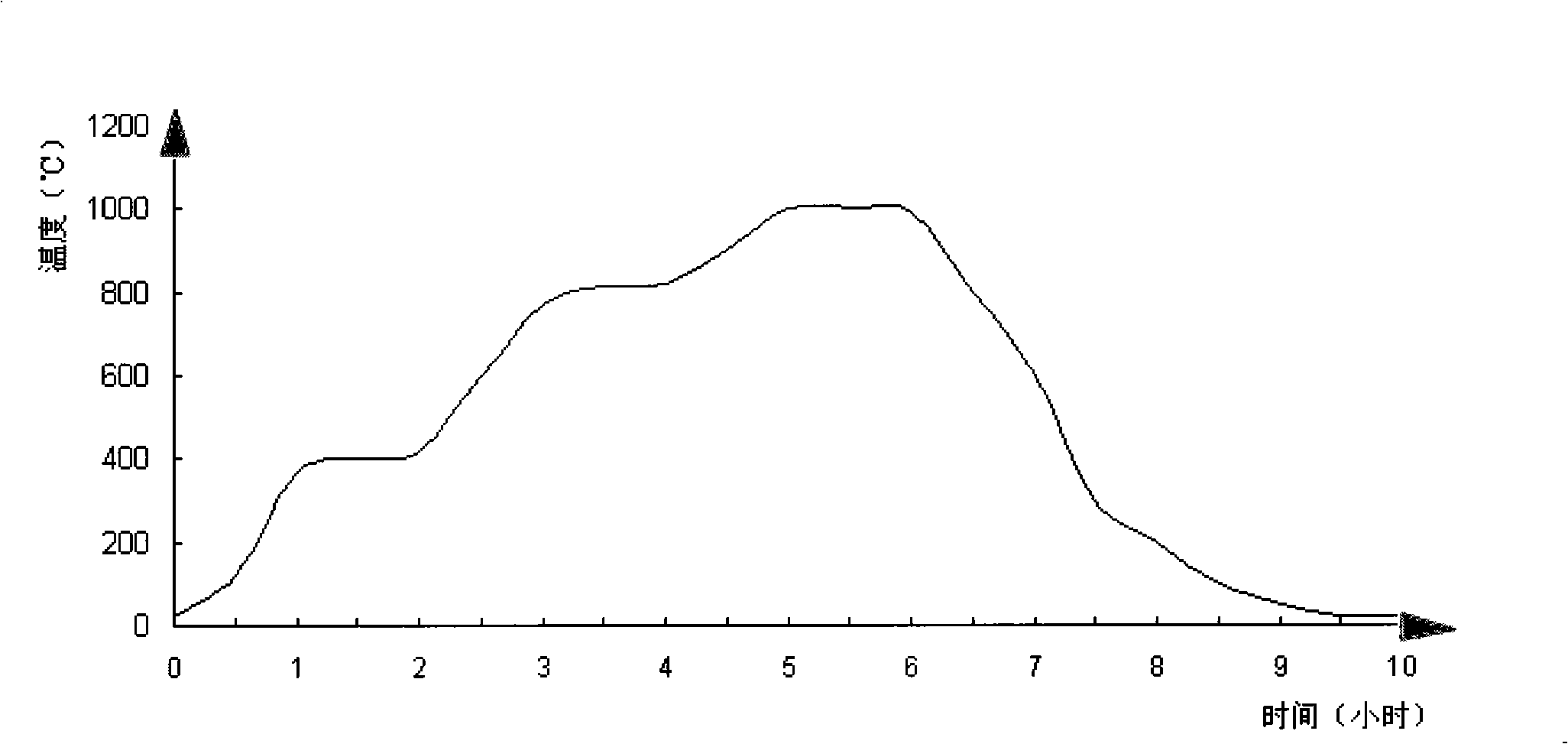

Powder metallurgy rare earth copper coated ferroalloy oil-retaining bearing and manufacturing method thereof

InactiveCN101407889AMeet environmental protection requirementsExtended service lifeTurbinesOther manufacturing equipments/toolsManufacturing cost reductionRare earth

The invention discloses a powder metallurgy rare-earth copper-clad iron alloy oil-impregnated bearing and a manufacturing method thereof. Accounted by percentage, the bearing consists of the following compositions by percentage: 18 to 22 percent of Cu, 0.2 to 1.0 percent of graphite, 0.3 to 0.8 percent of La or Ce and the residual quantity of Fe and unavoidable impurities. The bearing is made by the procedures of mixing, low temperature diffusion treatment, pressing, sintering and the like of a mixture formed by copper-clad iron powder, powder of the element La or Ce and the residual quantity of Fe and unavoidable impurities according to certain mixture ratios. The bearing uses the iron powder for substituting most of the copper powder to reduce the manufacturing cost; lead is not contained in the bearing, which meets the requirement of environmental protection; the rare earth is adopted as a catalyst for causing the copper-clad iron powder to be easily combined with other powder, and the alloy is uniformly distributed, which is beneficial for the refinement of alloy grains and leads thin through holes to be formed in the sintering body with hole connection efficiency being more than 95 percent. The mechanical property of the bearing is better than technical standards of oil-impregnated bearings sintered by copper-clad iron powder and 6-6-3 bronze powder.

Owner:JIANGSU YINGQIU GRP CO LTD

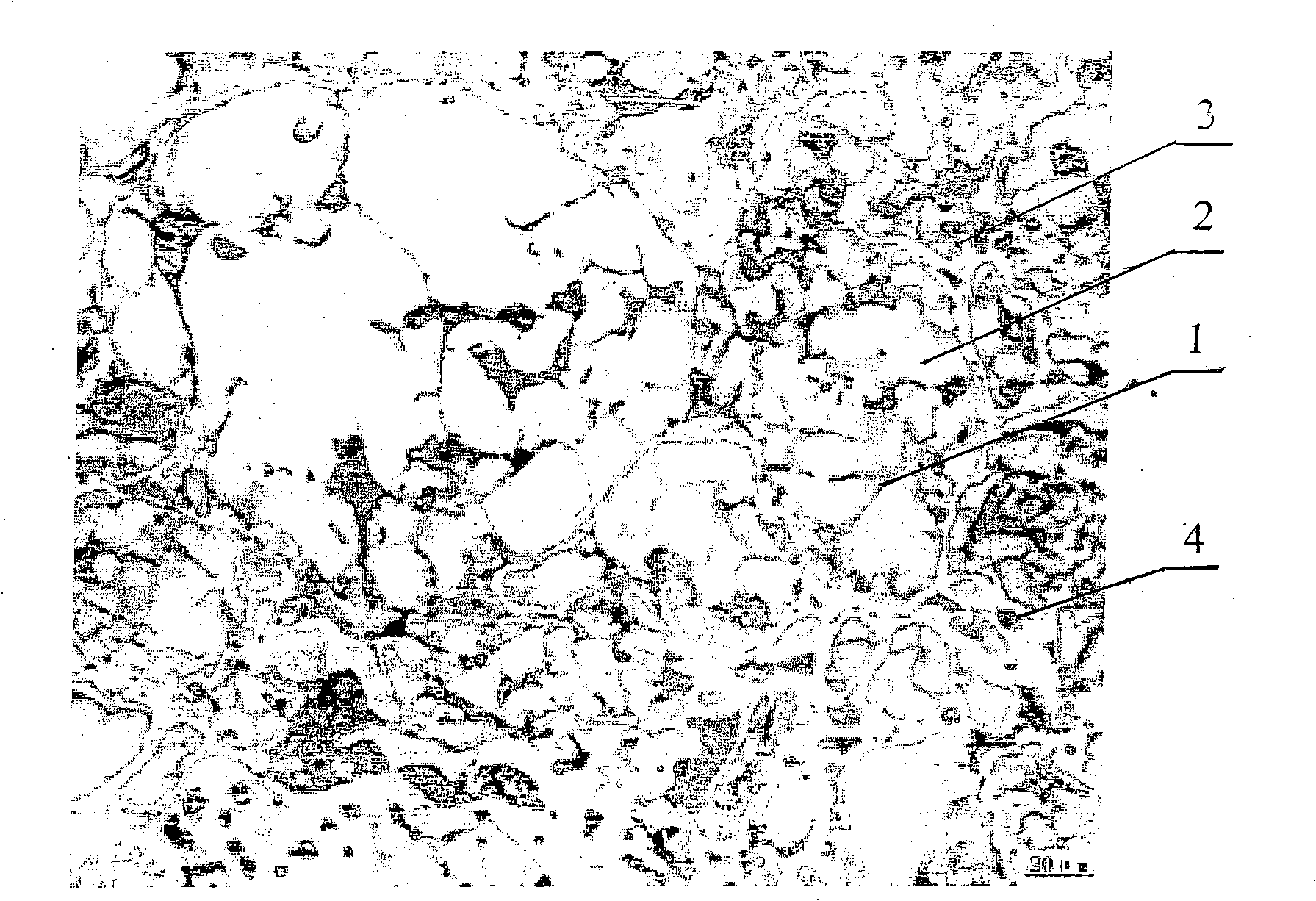

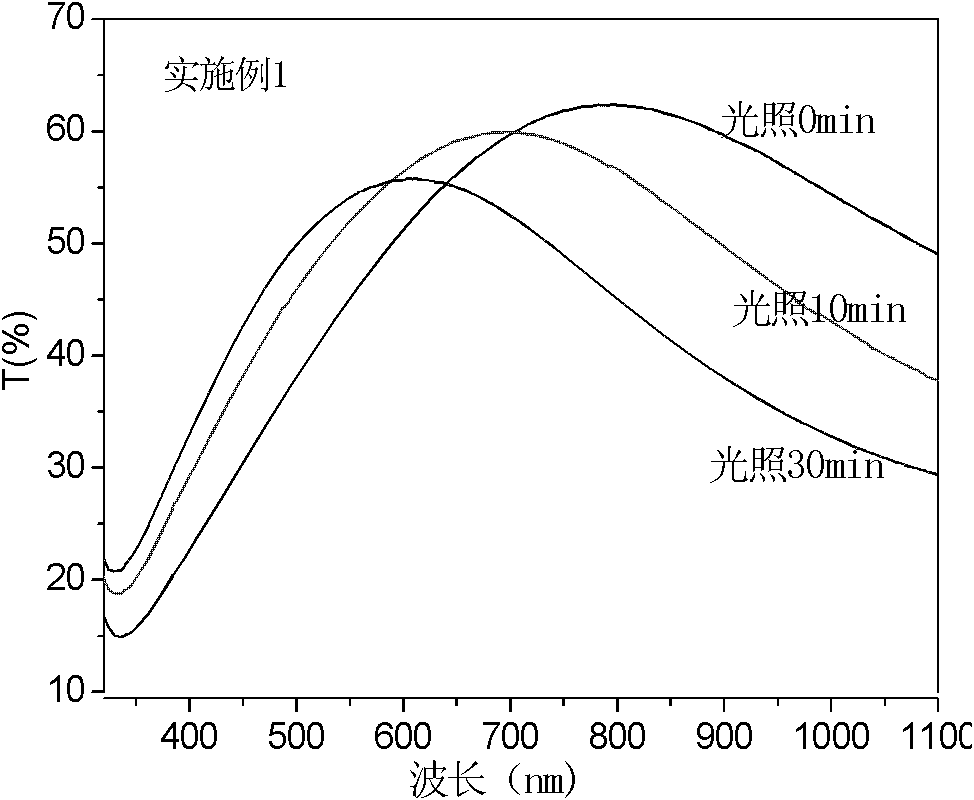

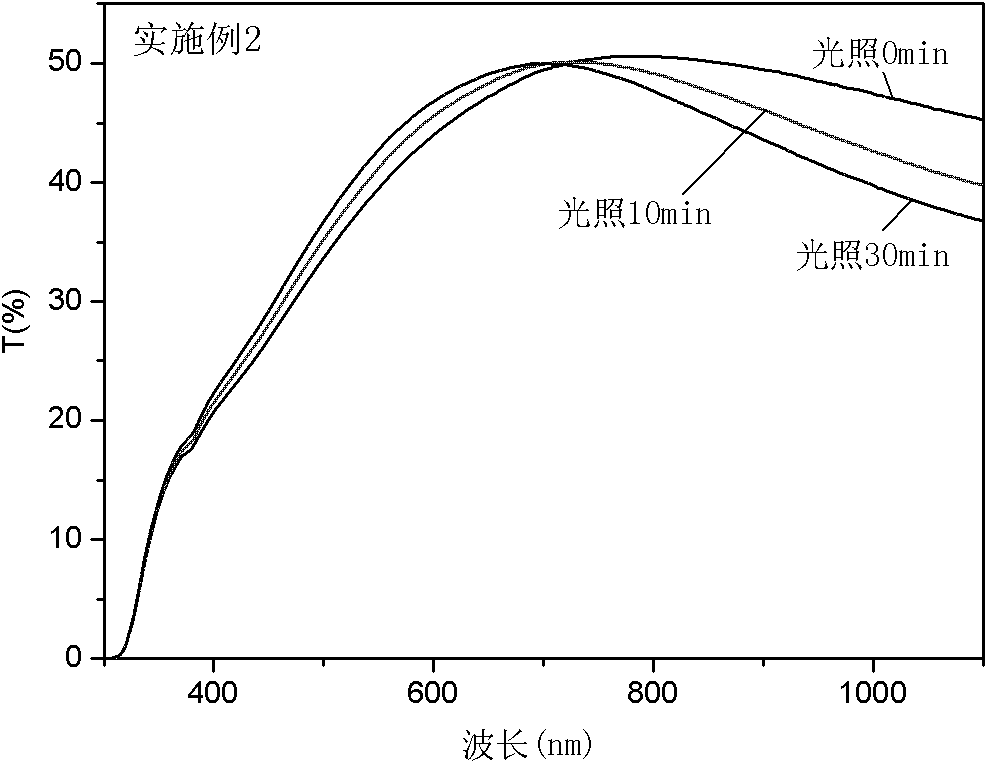

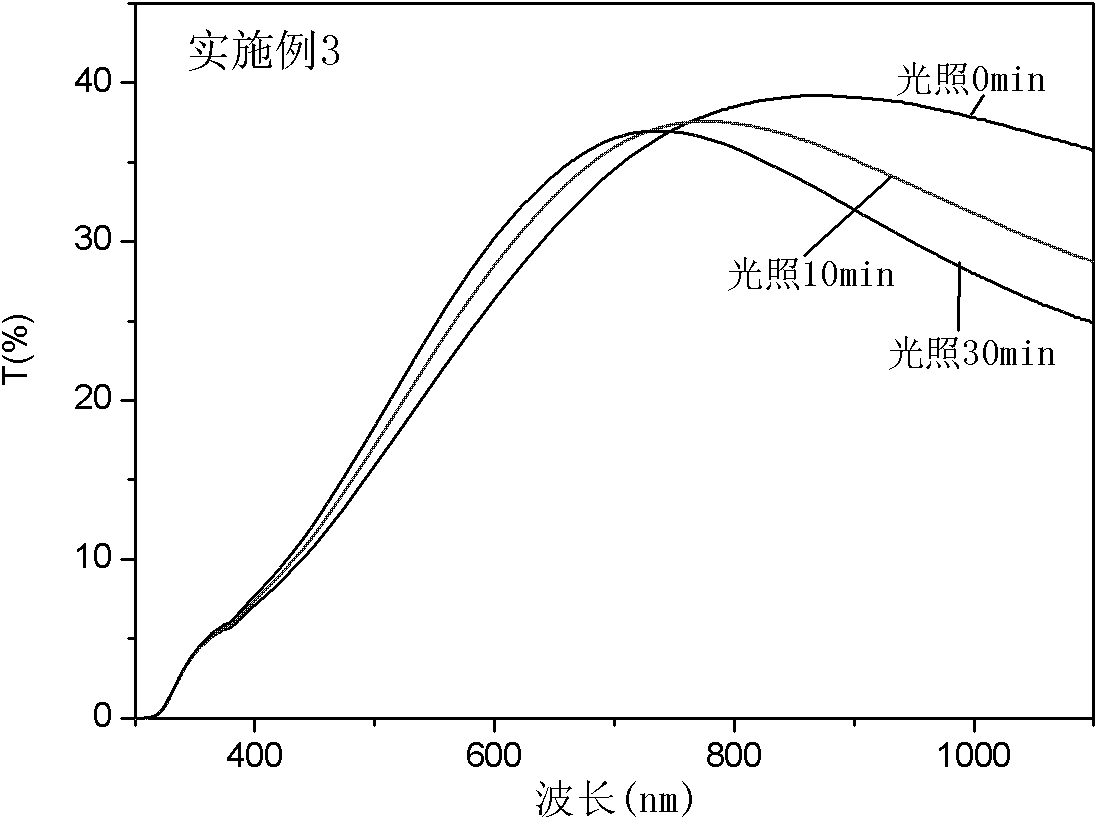

A kind of glass transparent thermal insulation coating and preparation method thereof

A glass transparent heat-insulating coating and its preparation method, the coating contains cesium tungsten bronze powder with a general formula of Cs0.1-3.5WO3, the crystal phase composition of the powder is Cs0.2WO3 or Cs0.32WO3, the powder The particle size is 100-1300nm, and the specific surface area is 7-50m2 / g. The glass transparent heat-insulating coating of the present invention has the functions of visible light transmission and near-infrared shielding, and has the function of light self-regulation, that is, with the extension of light intensity and light time, the effects of visible light transmission and near-infrared shielding will be further enhanced , so it is especially suitable for preparing transparent thermal insulation film on the surface of glass. It is an intelligent transparent thermal insulation coating for glass and has broad application prospects in the fields of thermal insulation of architectural window glass and automotive glass. The coating has simple components and is suitable for large-scale industrial production and practical application.

Owner:DALIAN POLYTECHNIC UNIVERSITY

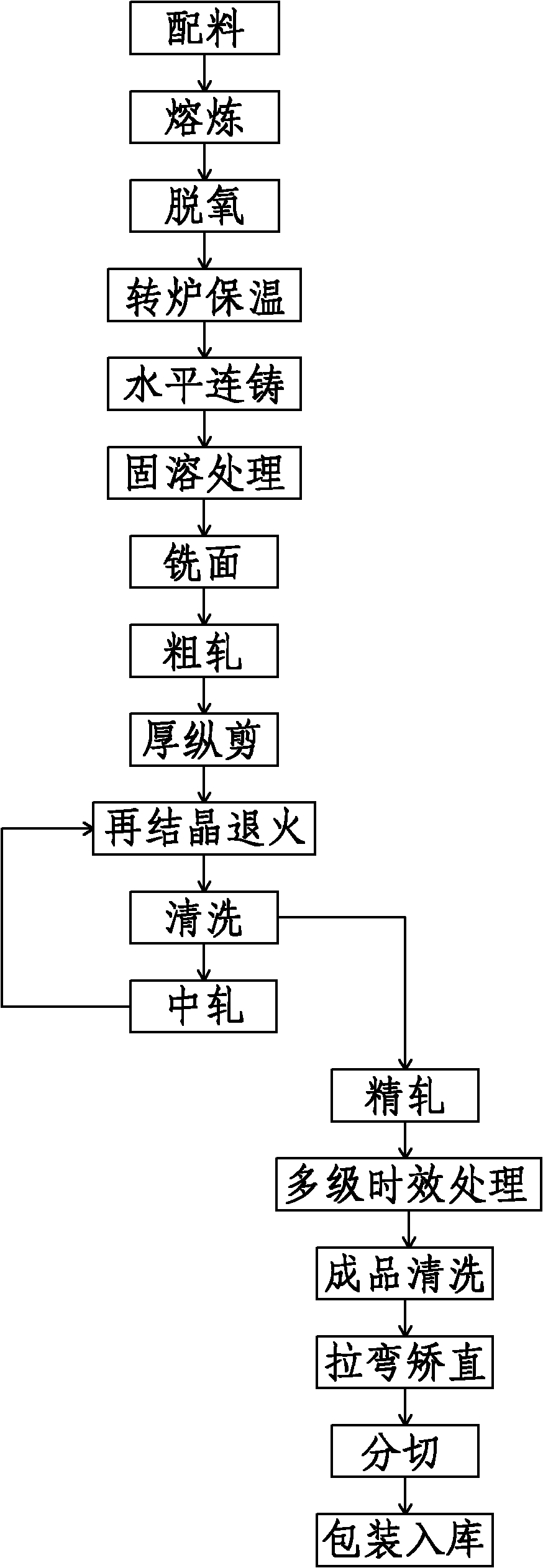

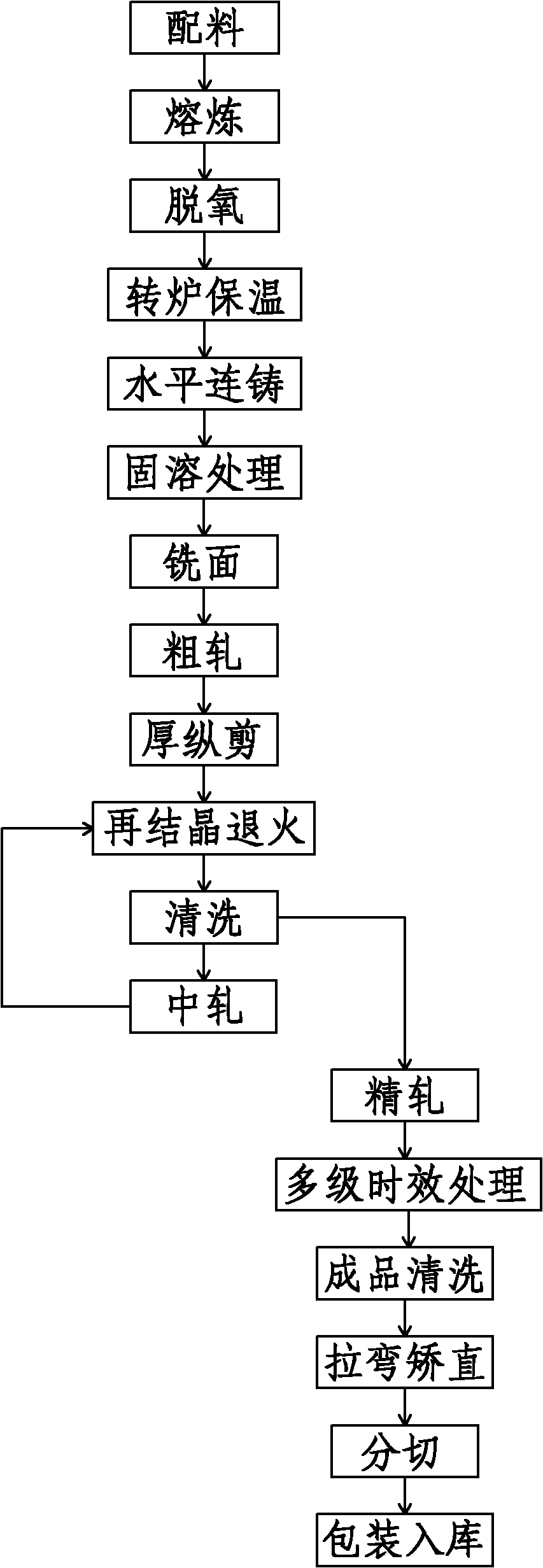

Formula of copper nickel tin alloy strip and production process

The invention discloses a formula of a copper nickel tin alloy strip and a production process. The formula of the alloy strip comprises the following components in percentage by weight: 19.0 to 21.0 percent of Ni, 4.0 to 6.0 percent of Sn, 0.01 to 0.05 percent of Zr and the balance of Cu. The production process comprises the following steps of: proportioning, smelting, bath analysis, deoxidation, converter heat preservation, horizontal continuous casting, solution treatment, surface milling, rough rolling, thickness longitudinal shearing, strong convection bright annealing, cleaning, precision rolling, multistage ageing, bending, straightening and slitting. The production process has no pollution, the production flow is short, the alloy strip blank has small specification size and high quality, cold rolling is directly performed, a hot rolling process is saved, and the production efficiency is improved; the obtained copper nickel tin alloy has the properties of high strength, high elongation, high hardness, high elasticity, stress corrosion resistance and the like, the performance of the copper nickel tin alloy is close to that of beryllium bronze, and the copper nickel tin alloy can partially replace the beryllium bronze to manufacture elastic elements.

Owner:江苏富威科技股份有限公司

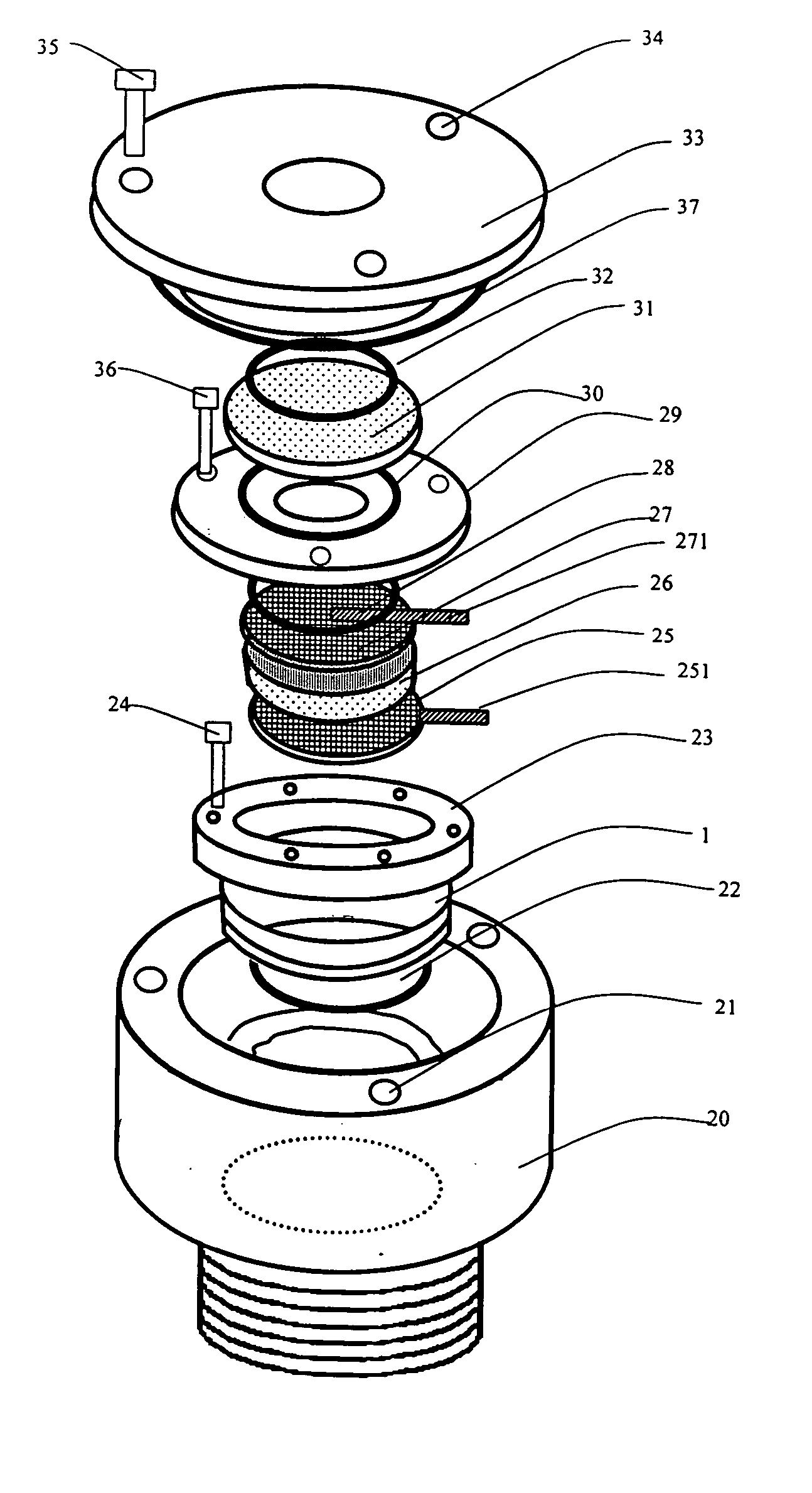

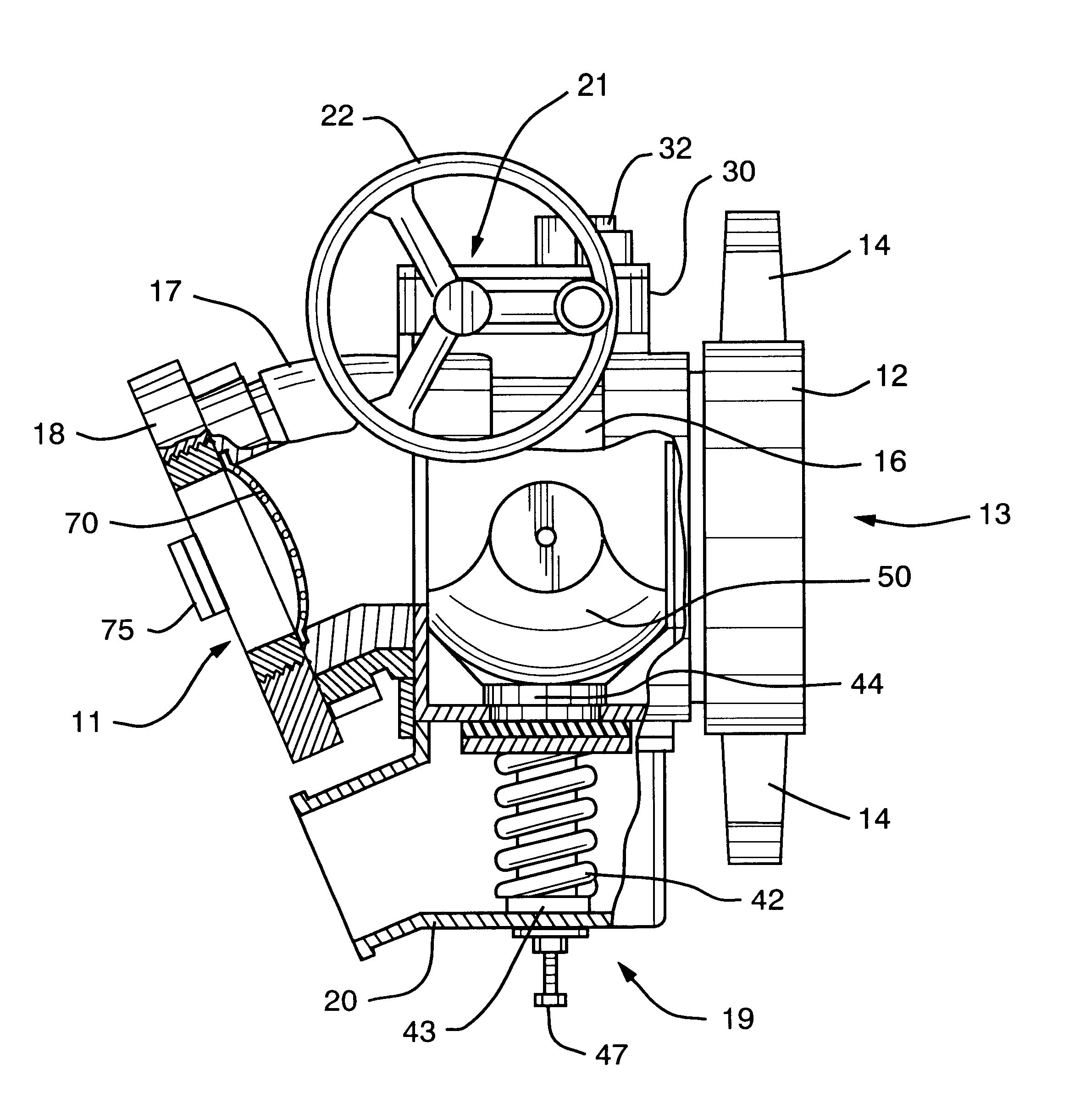

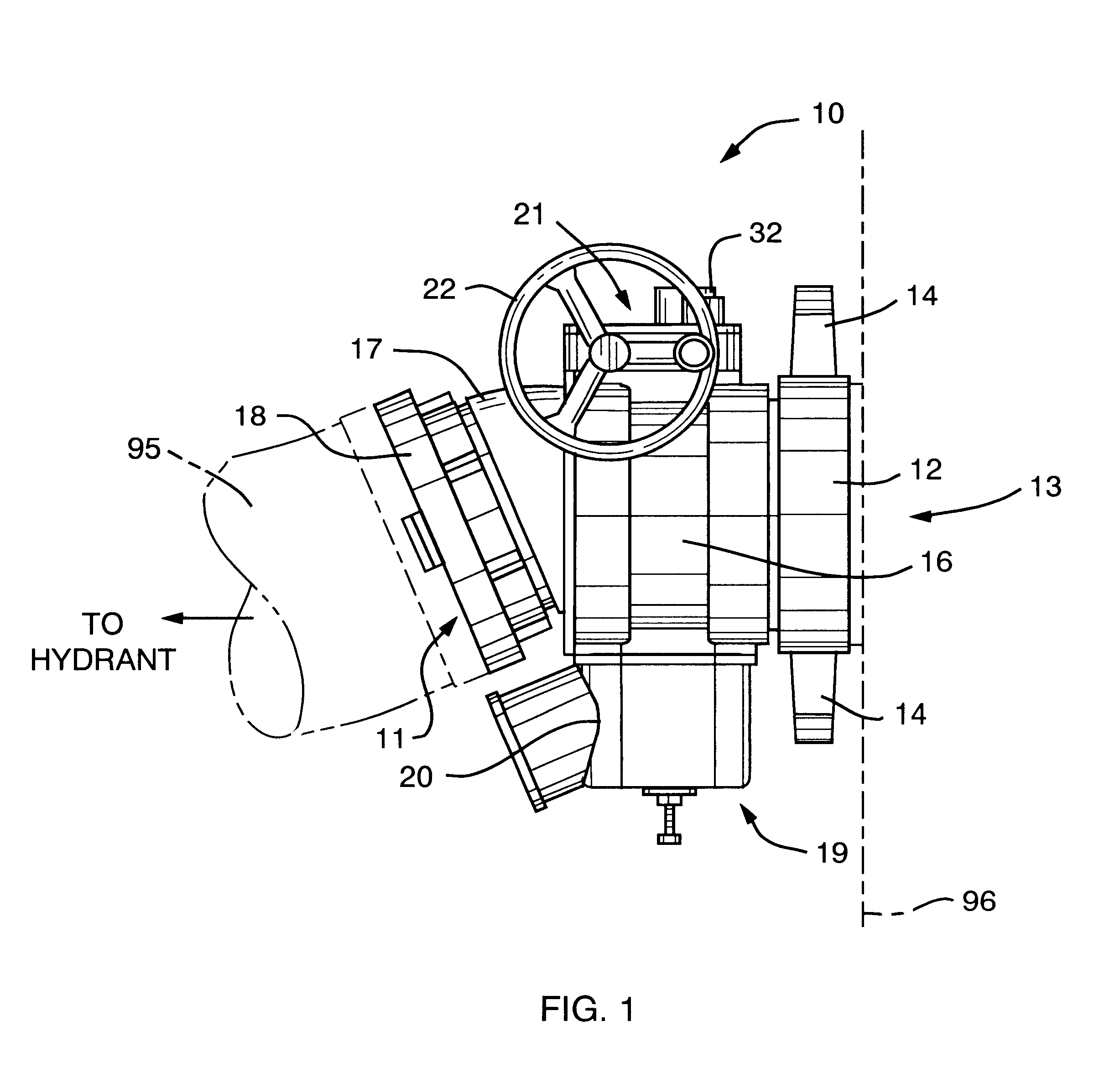

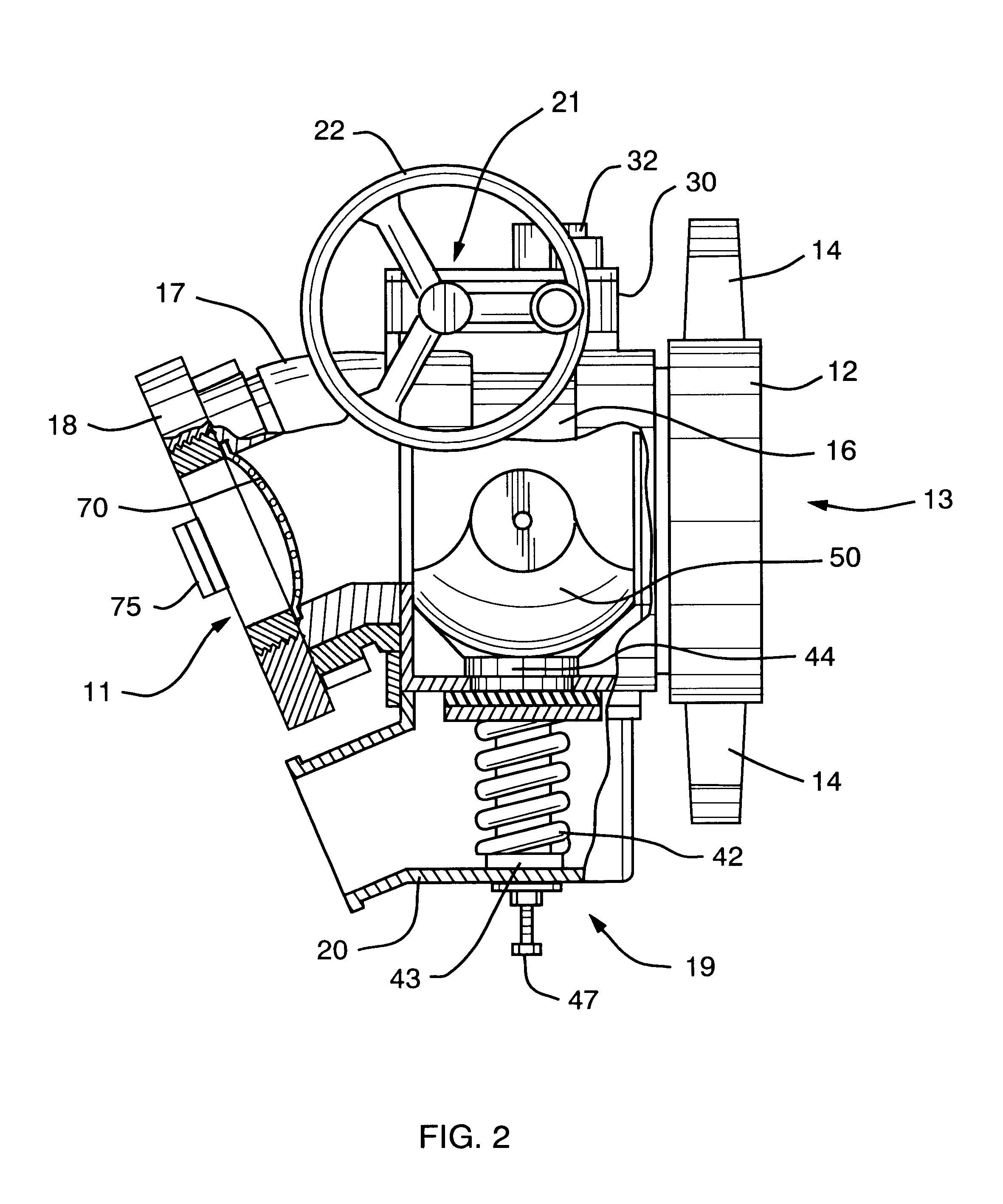

Dry sectional gate relief valve

An intake relief valve comprises a bronze sectional gate positioned within the valve chamber adjacent to an outlet section of the valve. A quick attachment coupler of the valve connects the outlet section typically to a pumper fire truck, and a hose from a hydrant or draft source connects to an opposite inlet section of the valve. When the valve is closed and the hose is disconnected from the valve with the valve connected to the pumper fire truck, there is no water remaining in the valve chamber. Any residual water is released by a pit drainage outlet on the bottom wall of the valve. Not having water stored in the valve eliminates corrosion problems within the valve, when the valve is connected to the pumper fire truck.

Owner:TASK FORCE TIPS

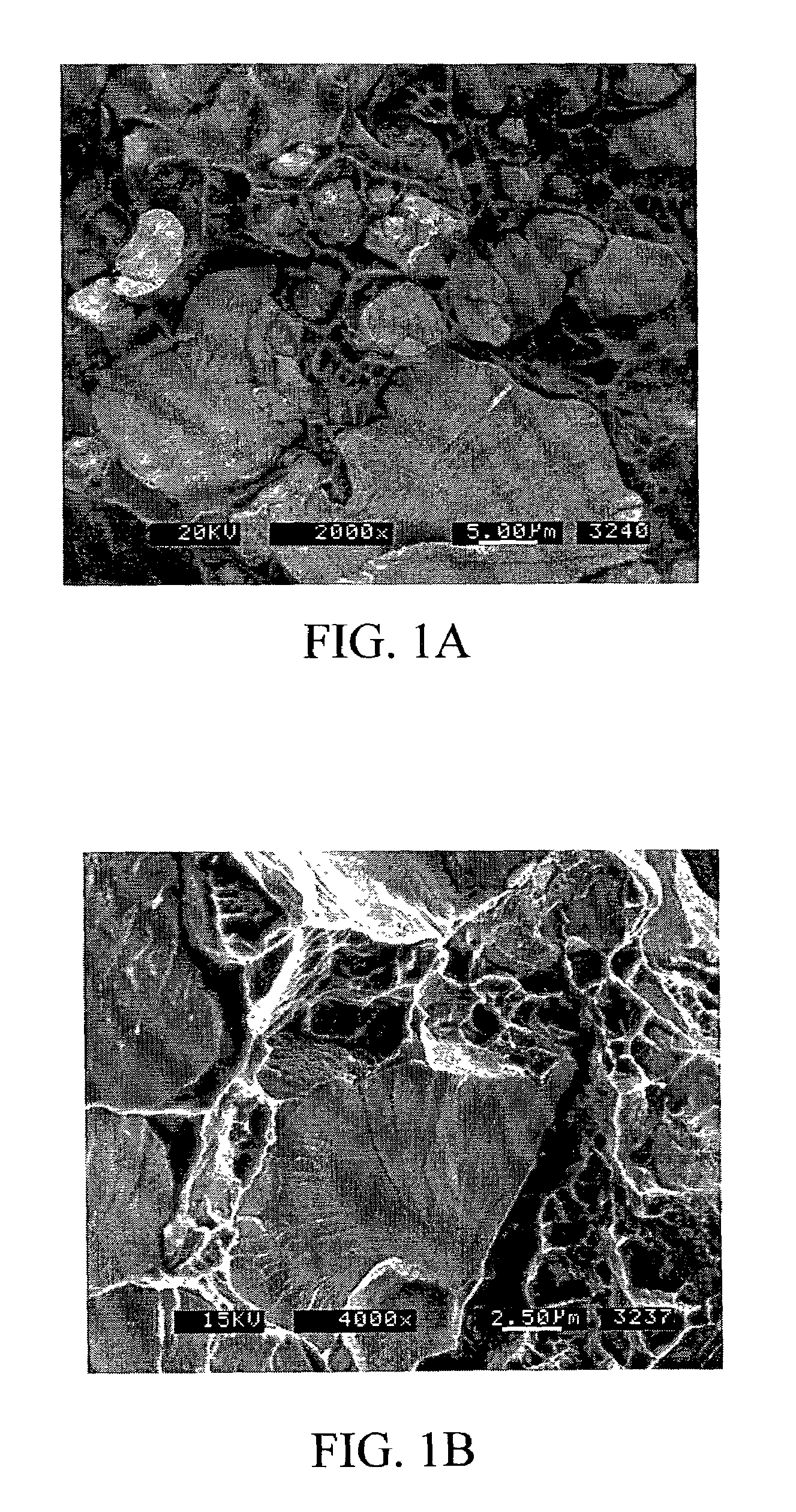

Biphasic nanoporous vitreous carbon material and method of making the same

A biphasic nanoporous vitreous carbon material with a cementitious morphology characterized by presence of non-round porosity, having superior hardness and tribological properties, as useful for high wear-force applications. The biphasic nanoporous vitreous carbon material is produced by firing, under inert atmosphere, of particulate vitrified carbon in a composition containing (i) a precursor resin that is curable and pyrolyzable to form vitreous carbon and, optionally, (ii) addition of one or more of the following: solid lubricant, such as graphite, boron nitride, or molybdenum disulfide; a heat-resistant fiber reinforcement, such as copper, bronze, iron alloy, graphite, alumina, silica, or silicon carbide; or one or more substances to improve electrical conductivity, such as dendritic copper powder, copper “felt” or graphite flake, to produce a superior vitreous carbon that is useful alone or as a continuous phase in reinforced composites, in relation to conventional glassy carbon materials.

Owner:CARBON CERAMICS CO LLC

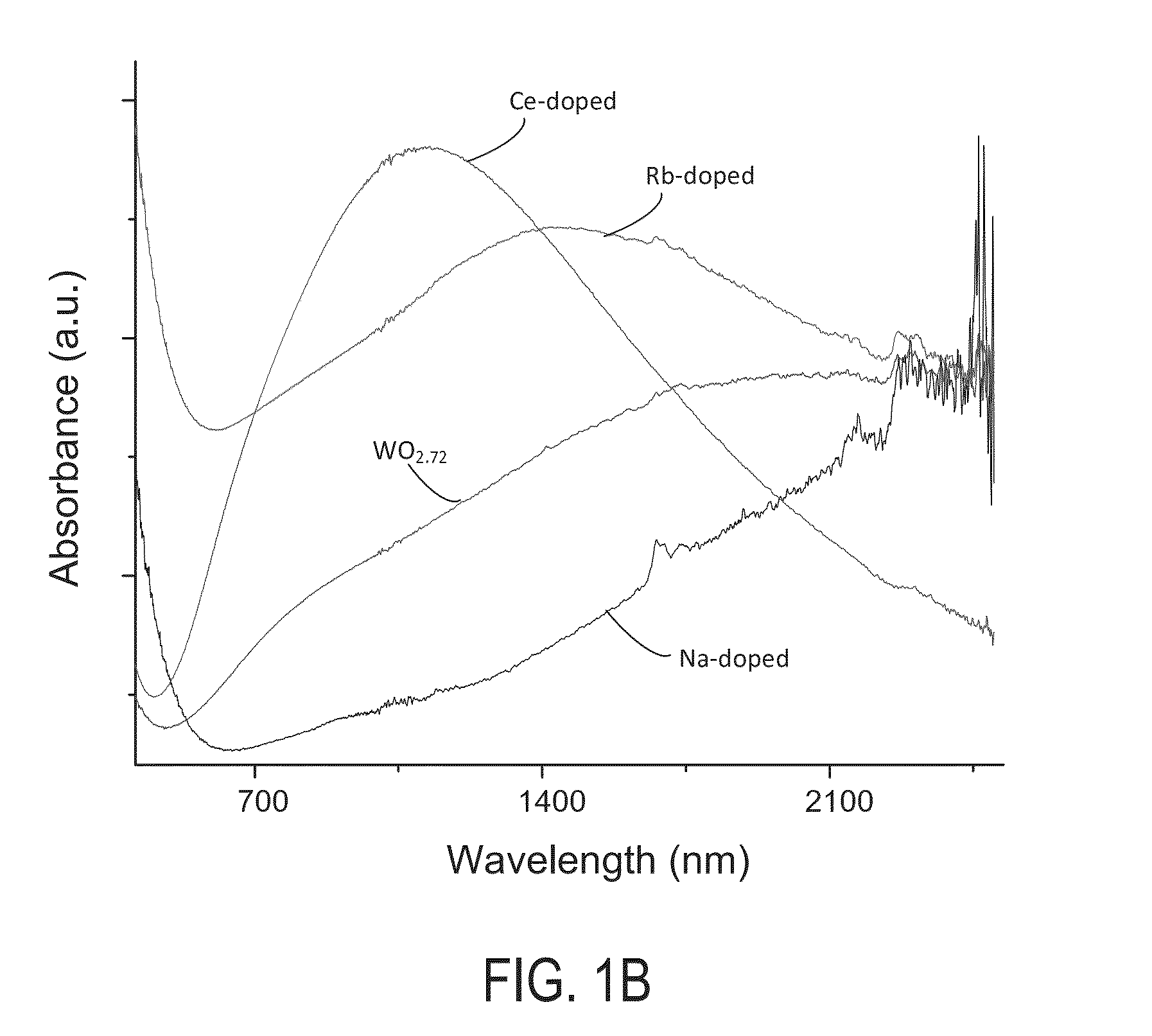

Tungsten bronze with substitutional hetero-atoms at tungsten and oxygen lattice point positions as well as preparation method and application of tungsten bronze

ActiveCN103449526ASimple processLow costMaterial nanotechnologyPolyurea/polyurethane coatingsSodium tungsten bronzeBronze

Owner:HEBEI TIANBO CONSTR TECH +1

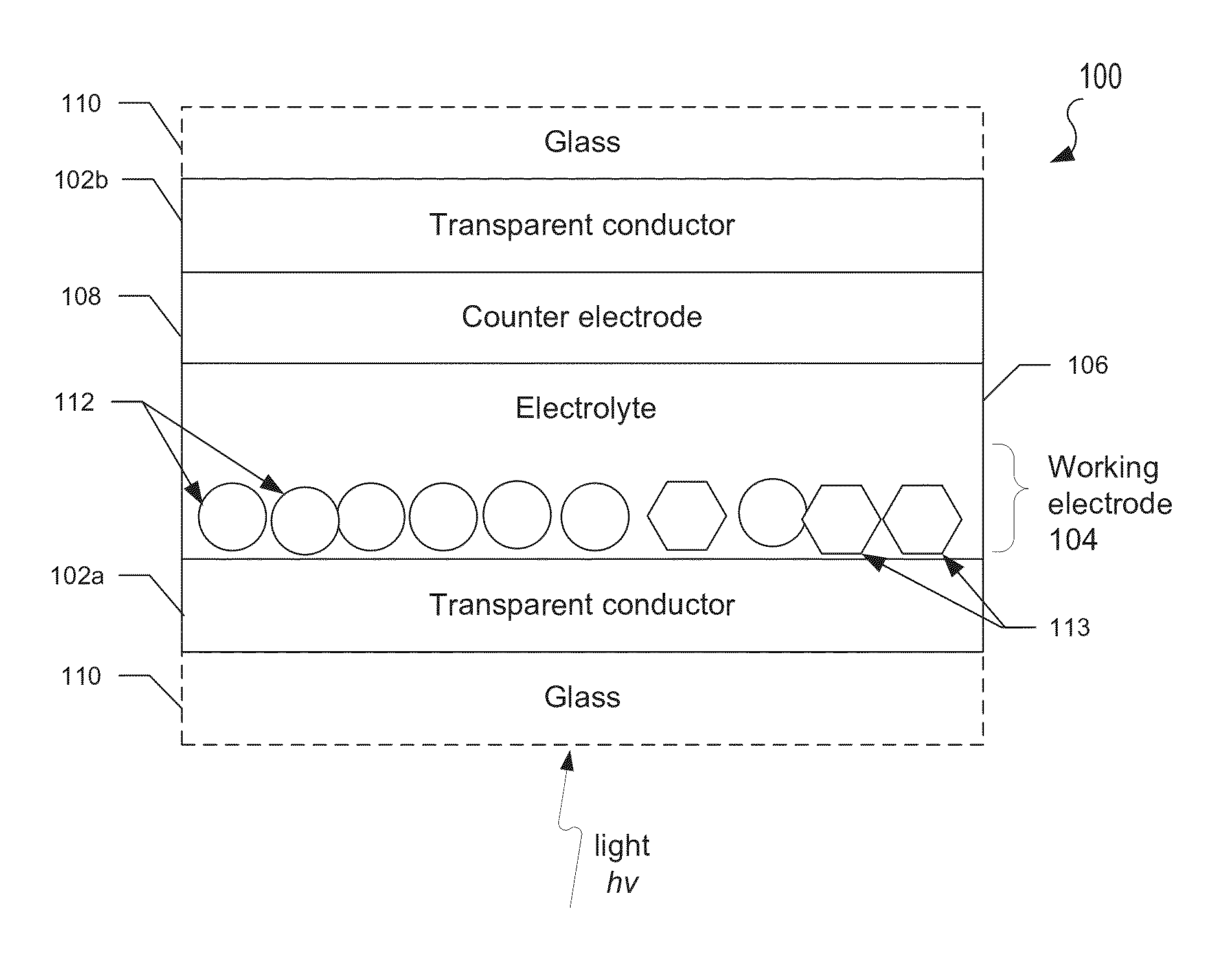

Electrochromic device containing metal oxide nanoparticles and ultraviolet blocking material

An electrochromic device includes a nanostructured transition metal oxide bronze layer that includes one or more transition metal oxide and one or more dopant. The electrochromic device also includes nanoparticles containing one or more transparent conducting oxide (TCO), a solid state electrolyte, a counter electrode, and at least one protective layer to prevent degradation of the one or more nanostructured transition metal oxide bronze. The nanostructured transition metal oxide bronze selectively modulates transmittance of near-infrared (NIR) and visible radiation as a function of an applied voltage to the device.

Owner:HIVISQ TECH SOCIEDAD LTD

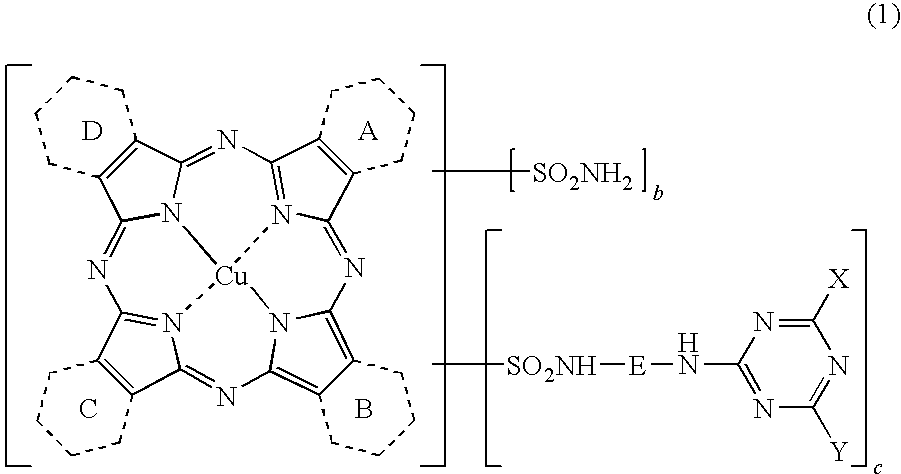

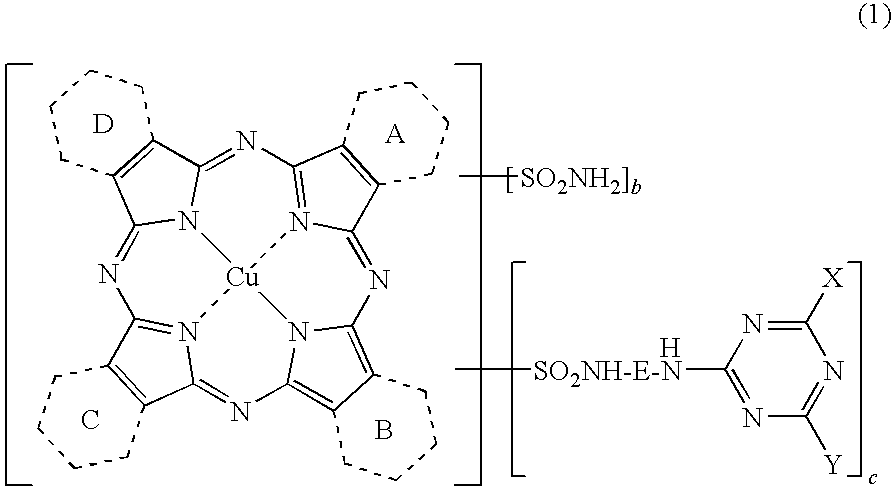

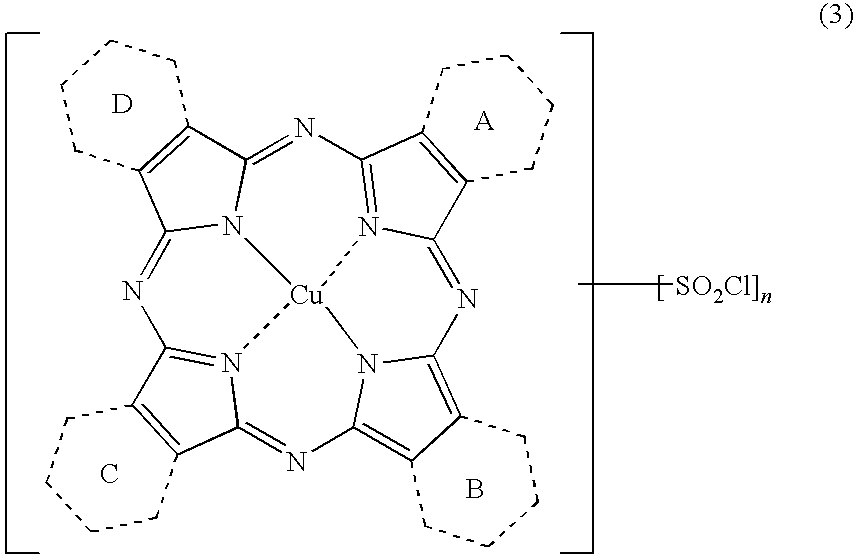

Porphyrazine coloring matter, ink, ink set and colored product

ActiveUS7585361B2Excellent toneGood light fastnessOrganic chemistryMeasurement apparatus componentsPorphyrazineNitrogen

The present invention relates to a porphyrazine coloring matter represented by the following formula (1):(wherein, A, B, C and D independently represents a 6-membered ring having aromaticity, at least one or more is a benzene ring, at least one or more contains a nitrogen-containing heteroaromatic ring; in addition, E represents alkylene and each of X and Y independently represents a substituted or unsubstituted anilino group or a substituted or unsubstituted naphthylamino group; and b is 0 to 2.9, c is 0.1 to 3 and the sum of b and c is 1 to 3) which has a good hue as a cyan ink, is excellent in light fastness, ozone fastness and moisture fastness, and does not cause bronze phenomenon, as well as is thus suitable for inkjet recording.

Owner:NIPPON KAYAKU CO LTD

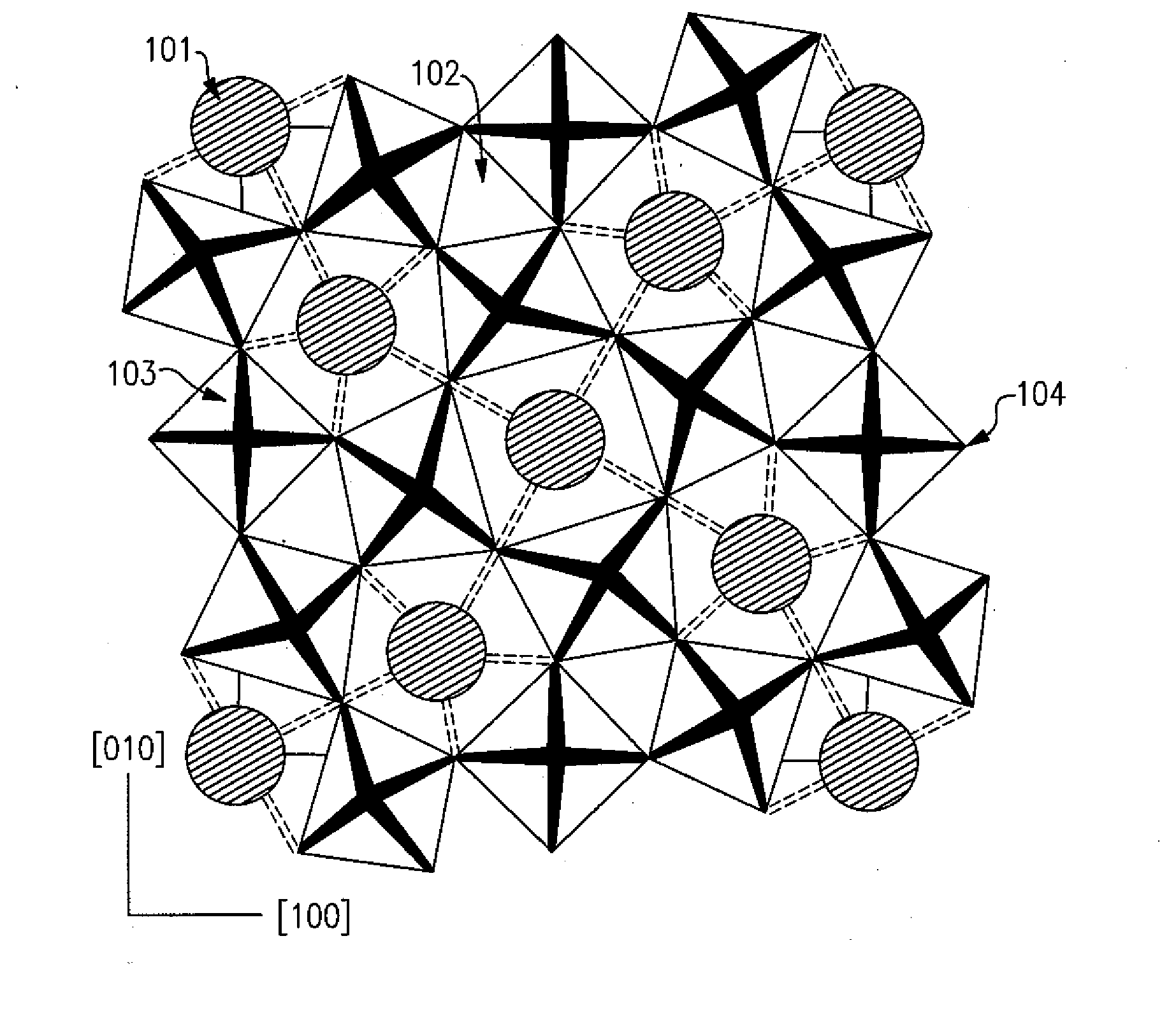

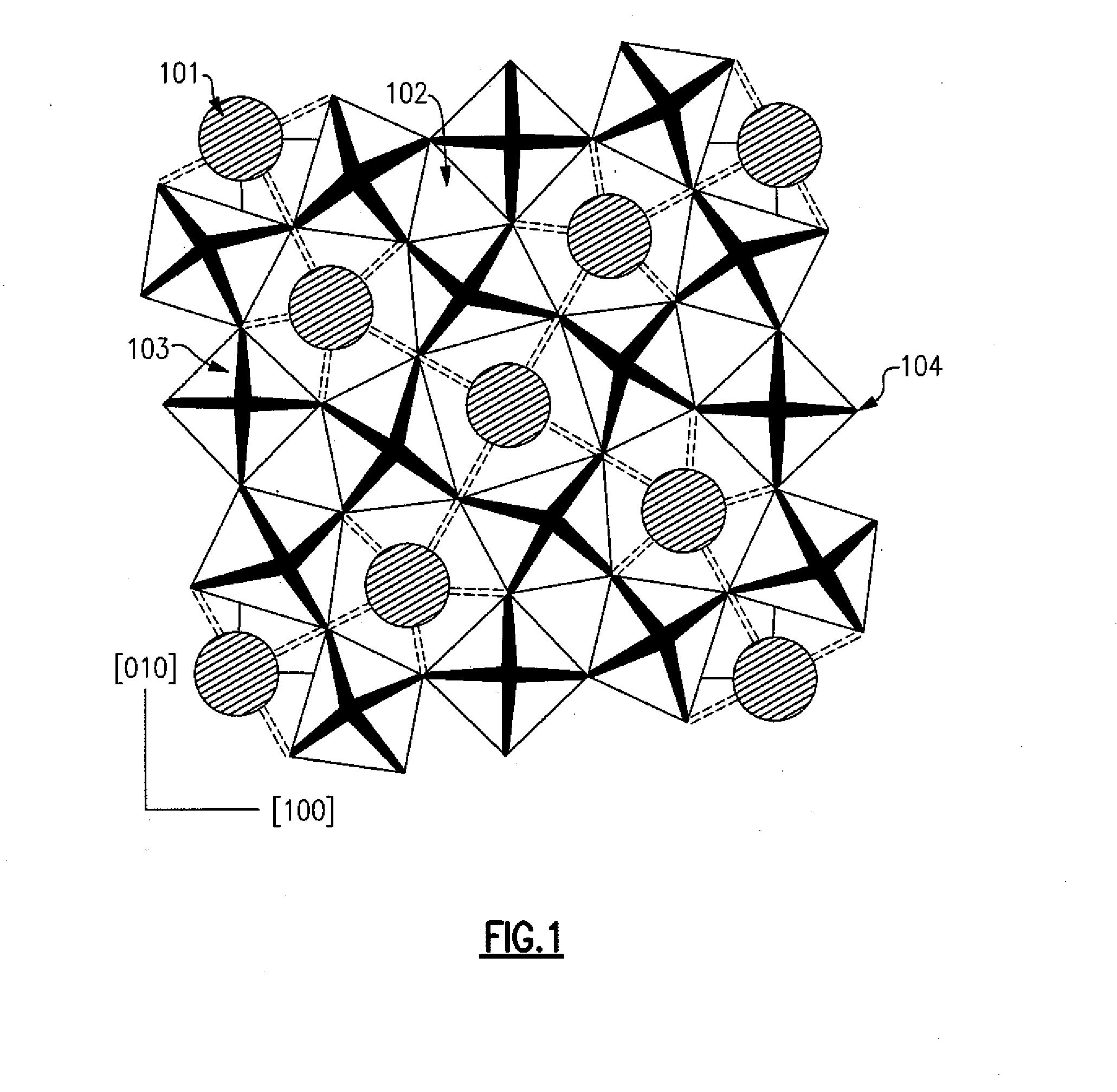

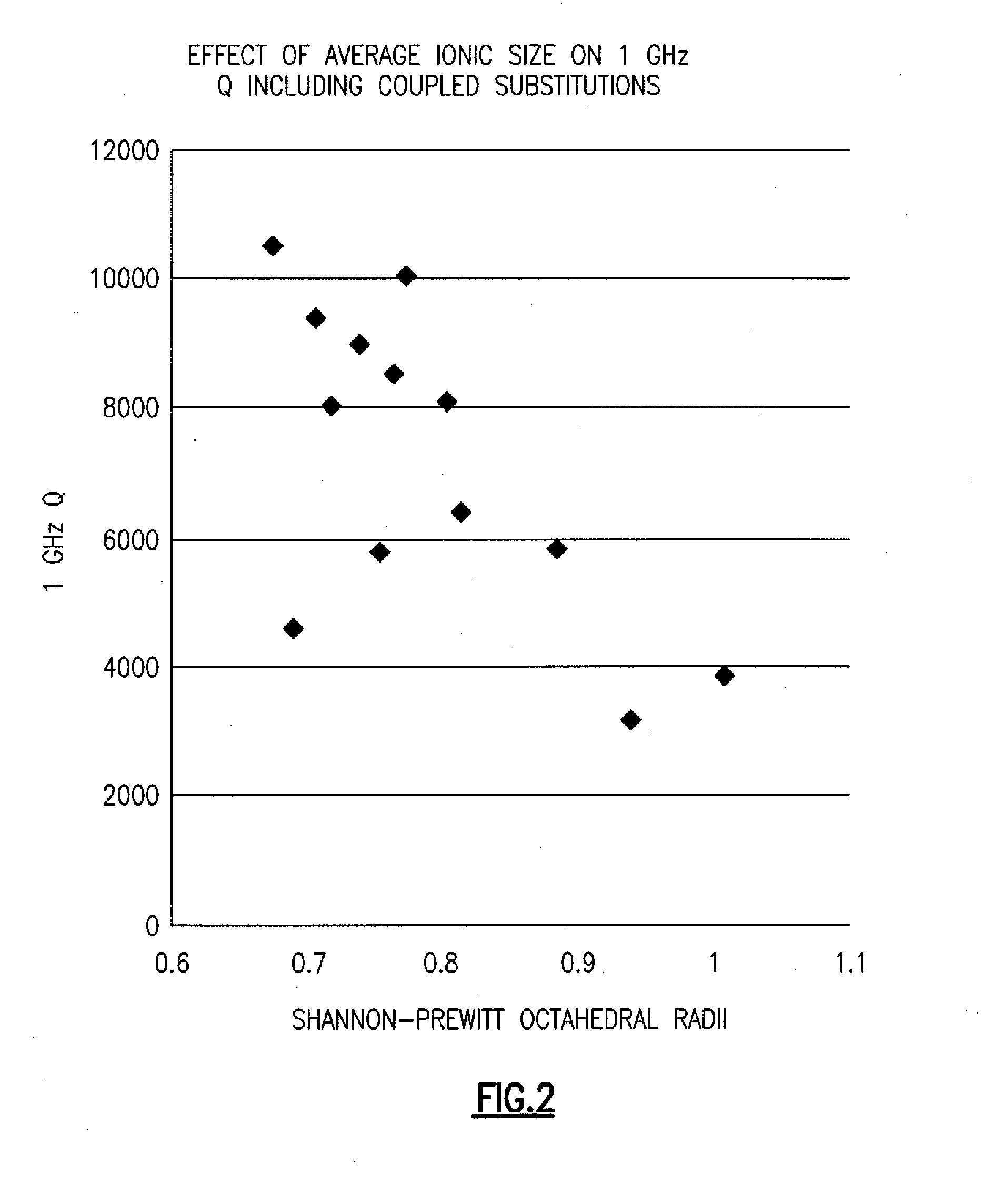

Novel enhanced high q material compositions and methods of preparing same

A framework for developing high quality factor (Q) material for electronic applications in the radio frequency range is provided. In one implementation, ceramic materials having a tungsten bronze crystal structure is modified by substituting one or more elements at one or more lattice sites on the crystal structure. The substitute elements are selected based on the ionic radius and other factors. In other implementations, the modified ceramic material is prepared in combination with compositions such as rutile or a perovskite to form a orthorhombic hybrid of perovskite and tetragonal tungsten bronze.

Owner:ALLUMAX TTI LLC

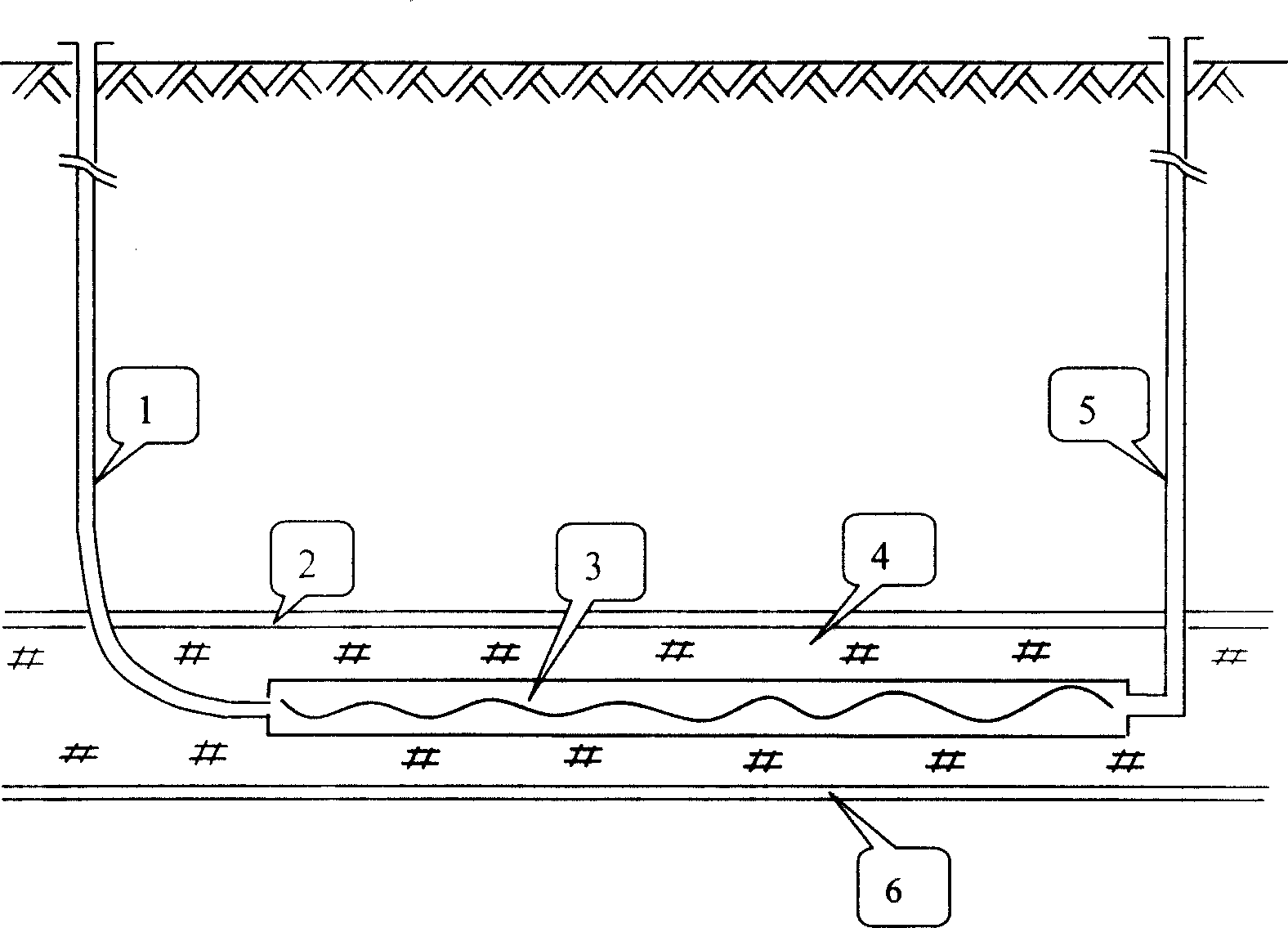

Rock salt deposit horizontal chamber type oil-gas depot and its building method

InactiveCN1676880APrevent leakageGuaranteed long-term stabilityMining devicesDirectional drillingSalt depositBronze

The invention discloses a bronze-type horizontal salt rock oil gas reservoir and its building method. This invention get rid of the present problem of bronze-type vertical reservoir and provides a kind of product method that can build a bronze-type horizontal salt rock oil gas reservoir in a salt-rock samdwich and salt-hill-type mine bed. The oil gas reservoir presents bronze-type room, the section of which is almost round and which spreads along the layers. The spreading direction, the length and the radius of the horizontal bronze room are decided by the characteristics and the thickness. The invention takes the advantage of the technology of directional drilling and connecting well and the technology of controlling solution. No only the building speed is fast, but also the invention avoids the waste and pollution to raw oil by the oil cushion. It is building method which has a great capability, runs stably and safety, and is economy.

Owner:TAIYUAN UNIV OF TECH

Elastic brass alloy and preparation method thereof

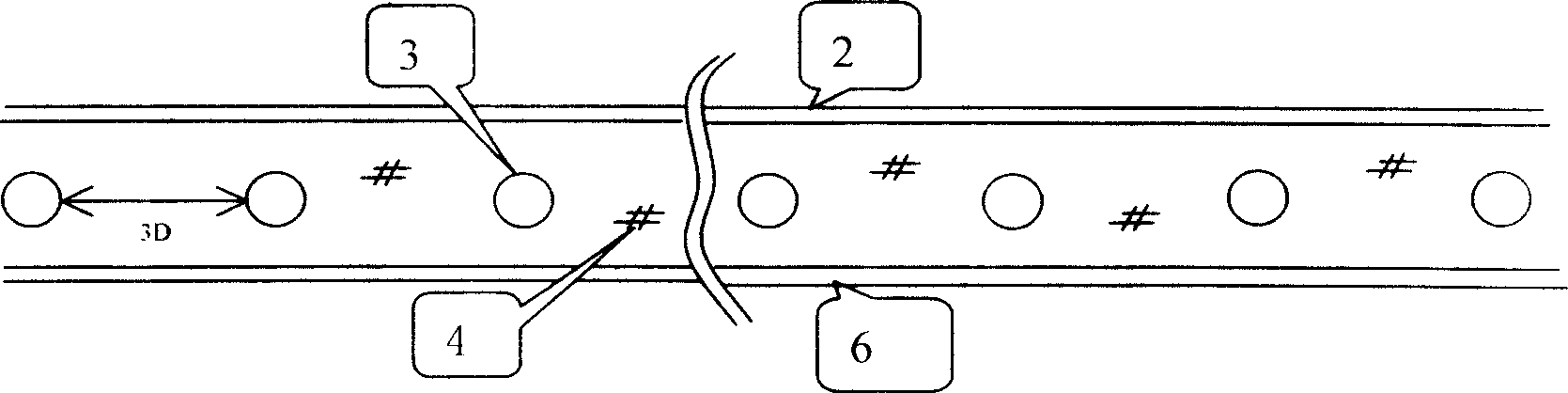

The invention relates to an elastic brass alloy material. The material comprises the following components in percentage by weight: 70 to 71 percent of copper, 24 to 25 percent of zinc, 2 to 3 percent of aluminum, 1 to 3 percent of nickel and 0.5 to 1 percent of chromium. A preparation method comprises the following steps of: smelting; performing hot rolling; performing solid solution treatment; annealing, and performing cold rolling; and performing ageing treatment. The chromium element of which the solid solubility is reduced with the reduction of temperature is added into a metal matrix, a supersaturated solid solution is formed through high temperature sold solution quenching treatment, and is decomposed through ageing treatment to form a large number of fine dispersed Cr particles, and the particles are dispersedly distributed in the matrix to form a precipitated phase, so that the strength, electrical conductivity and elasticity of an alloy are improved. An elastic brass alloy strip prepared by the method meets the technical requirements on temperature rise, electrical performance and the like after being made into a fuse clip, can replace scarce tin phosphorus bronze and is applied to related fields.

Owner:JINTIAN COPPER GROUP CORP NINGBO

Apparatus and method for detecting surface defects on a workpiece such as a rolled/drawn metal bar

InactiveUS20060002605A1Efficiently employedEfficient detectionCharacter and pattern recognitionColor television detailsMetal stripsAlloy

The present invention is directed to solving the problems associated with the detection of surface defects on metal bars as well as the problems associated with applying metal flat inspection systems to metal bars for non-destructive surface defects detection. A specially designed imaging system, which is comprised of a computing unit, line lights and high data rate line scan cameras, is developed for the aforementioned purpose. The target application is the metal bars (1) that have a circumference / cross-section-area ratio equal to or smaller than 4.25 when the cross section area is unity for the given shape, (2) whose cross-sections are round, oval, or in the shape of a polygon, and (3) are manufactured by mechanically cross-section reduction processes. The said metal can be steel, stainless steel, aluminum, copper, bronze, titanium, nickel, and so forth, and / or their alloys. The said metal bars can be at the temperature when they are being manufactured.

Owner:OG TECH INC

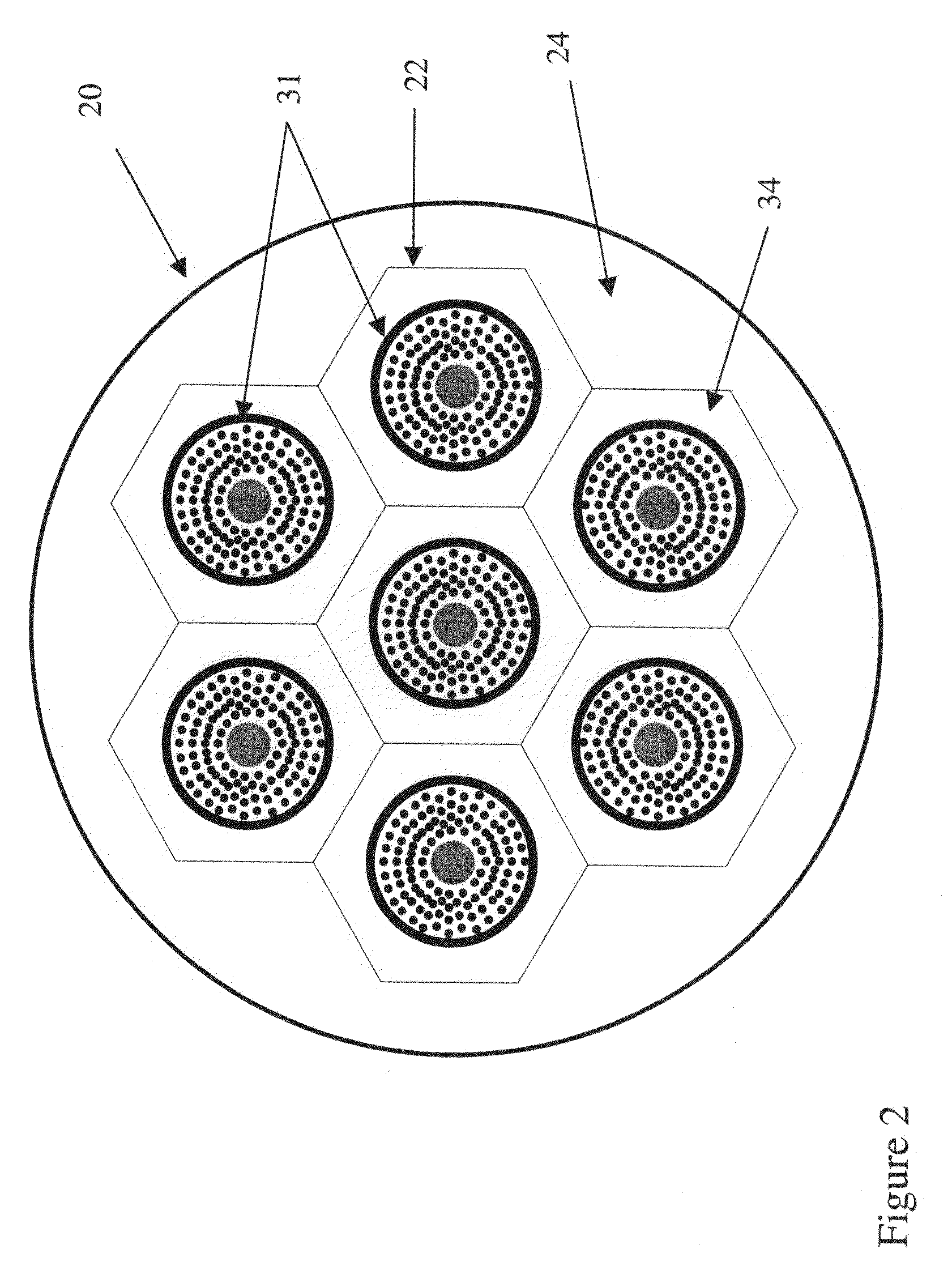

Critical current density in Nb3Sn superconducting wire

Owner:BRUKER OST LLC

Copper base alloy, and cast ingot and parts to be contacted with liquid

By exactly comprehending the true properties of the rare elements (such as Bi and Se) which are alternative components for Pb, the alloy is enabled to secure machinability equal to the bronze alloy (CAC406) generally used hitherto and acquire mechanical properties at least equal to the CAC406 as well in spite of a decrease in the content of the rare elements (such as Bi and Se) in the alloy. Further, it is possible to suppress the occurrence of casting defects by elucidating the unresolved influence of the decrease of the alternative components (such as Bi and Se) for Pb on the wholesomeness of a casting. Moreover, it is possible, by decreasing the rare elements, to produce a copper-based alloy containing rare elements at a low cost and to provide a cast ingot and a liquid-contacting part each using the alloy. The copper-based alloy, and the cast ingot and liquid-contacting part each using the alloy individually contain at least 2.8 to 5.0 wt % of Sn, 0.4 to 3.0 wt % of Bi and satisfying 0<Se≦0.35 wt % to enable securing prescribed machinability and wholesomeness of a casting and exalt mechanical properties thereof.

Owner:KITZ CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com