Formula of copper nickel tin alloy strip and production process

A production process and alloy strip technology, which is applied in the formulation and production process of copper-nickel-tin alloy strips, can solve the problems of endangering the health of production personnel, the existence of toxic pollutants, production and application constraints, and achieve the elimination of hot rolling The process and production process are short and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with the embodiment shown in the accompanying drawings, the present invention is described in detail as follows:

[0033] The formula of the copper-nickel-tin alloy strip of the present invention includes Ni, Sn, Zr and Cu, wherein Ni accounts for 19.0-21.0% (weight), Sn accounts for 4.0-6.0% (weight), and Zr accounts for 0.01-0.05% (weight) ), the rest is Cu.

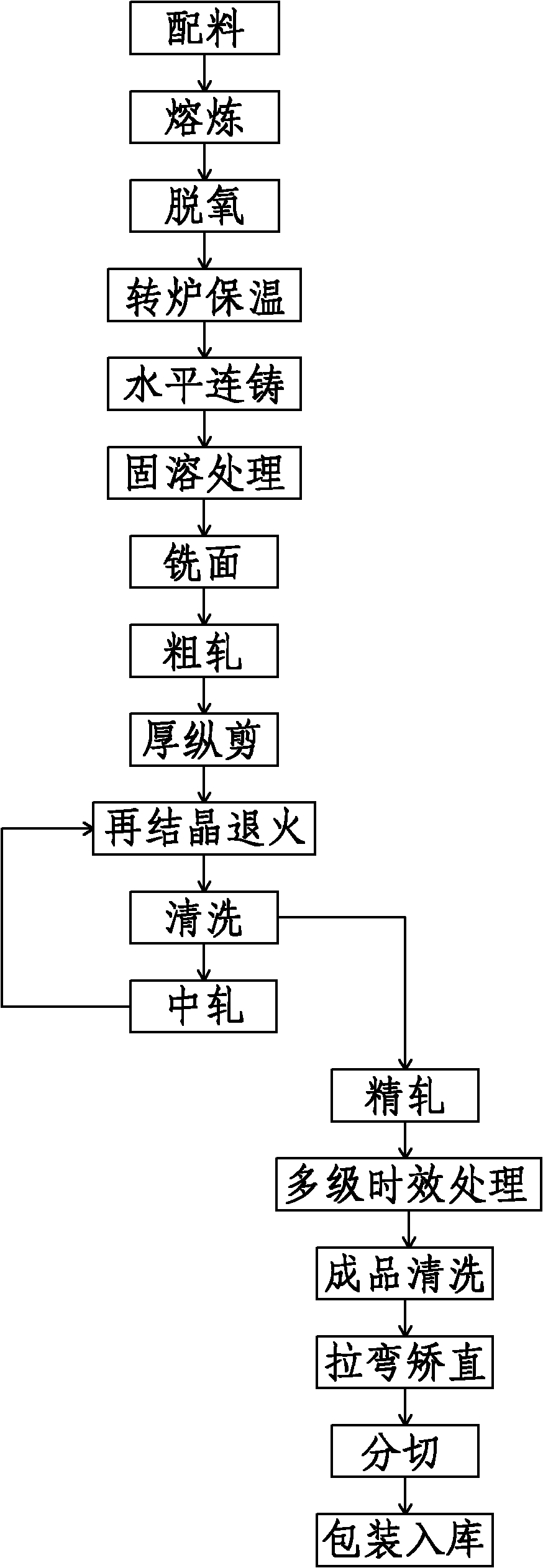

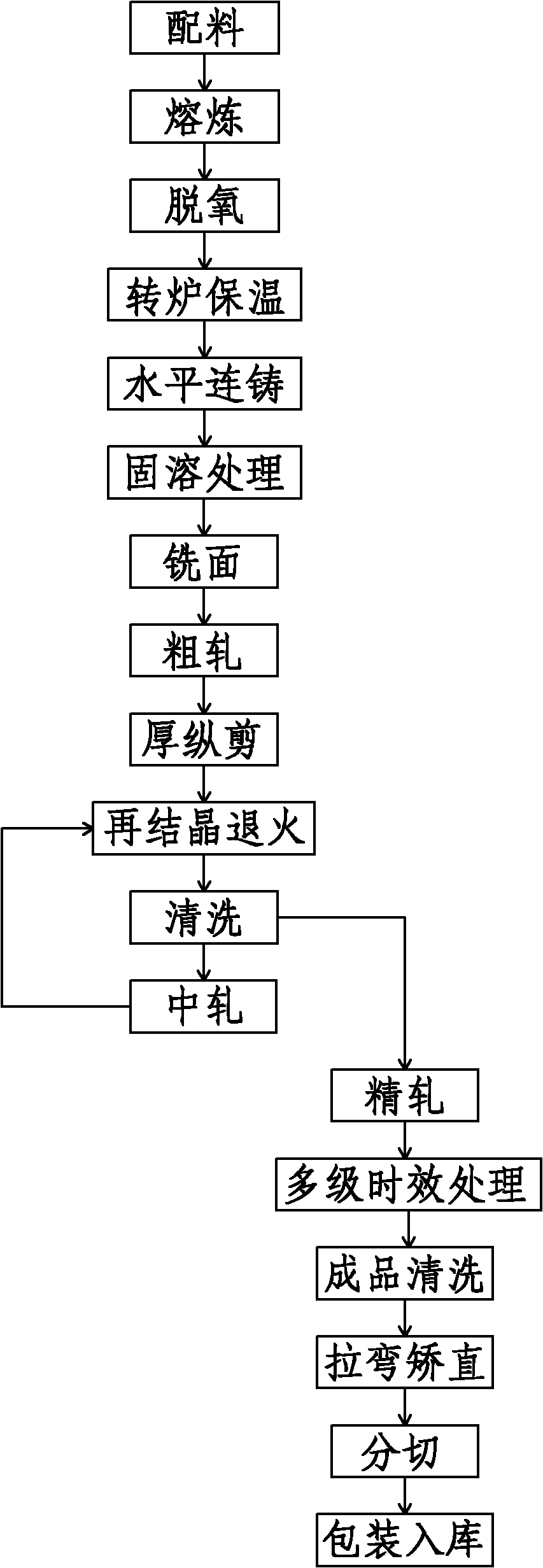

[0034] as attached figure 1 As shown, the production process steps of the above-mentioned copper-nickel-tin alloy strip are as follows:

[0035] (1) Add the above-mentioned proportioned raw materials into the smelting furnace, select high-quality charcoal as the covering agent for oxygen barrier covering, use a double melting channel iron core power frequency induction furnace, and control the melting temperature within the range of 1250±30°C. In the process, use a spectrum analyzer to detect the composition of the copper alloy in the smelting furnace, and adjust the corresponding composit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com