Patents

Literature

40645results about How to "Increase elasticity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

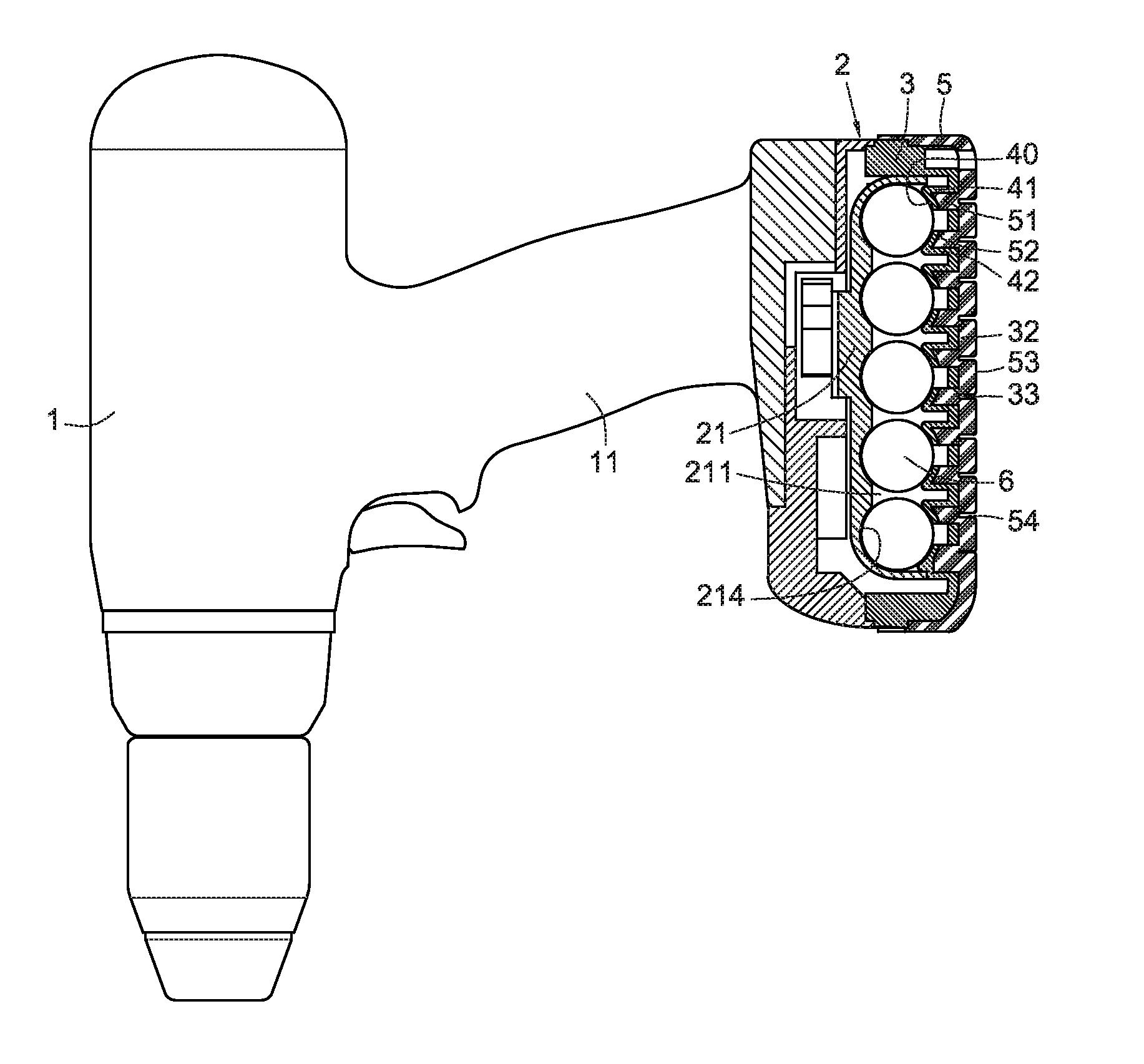

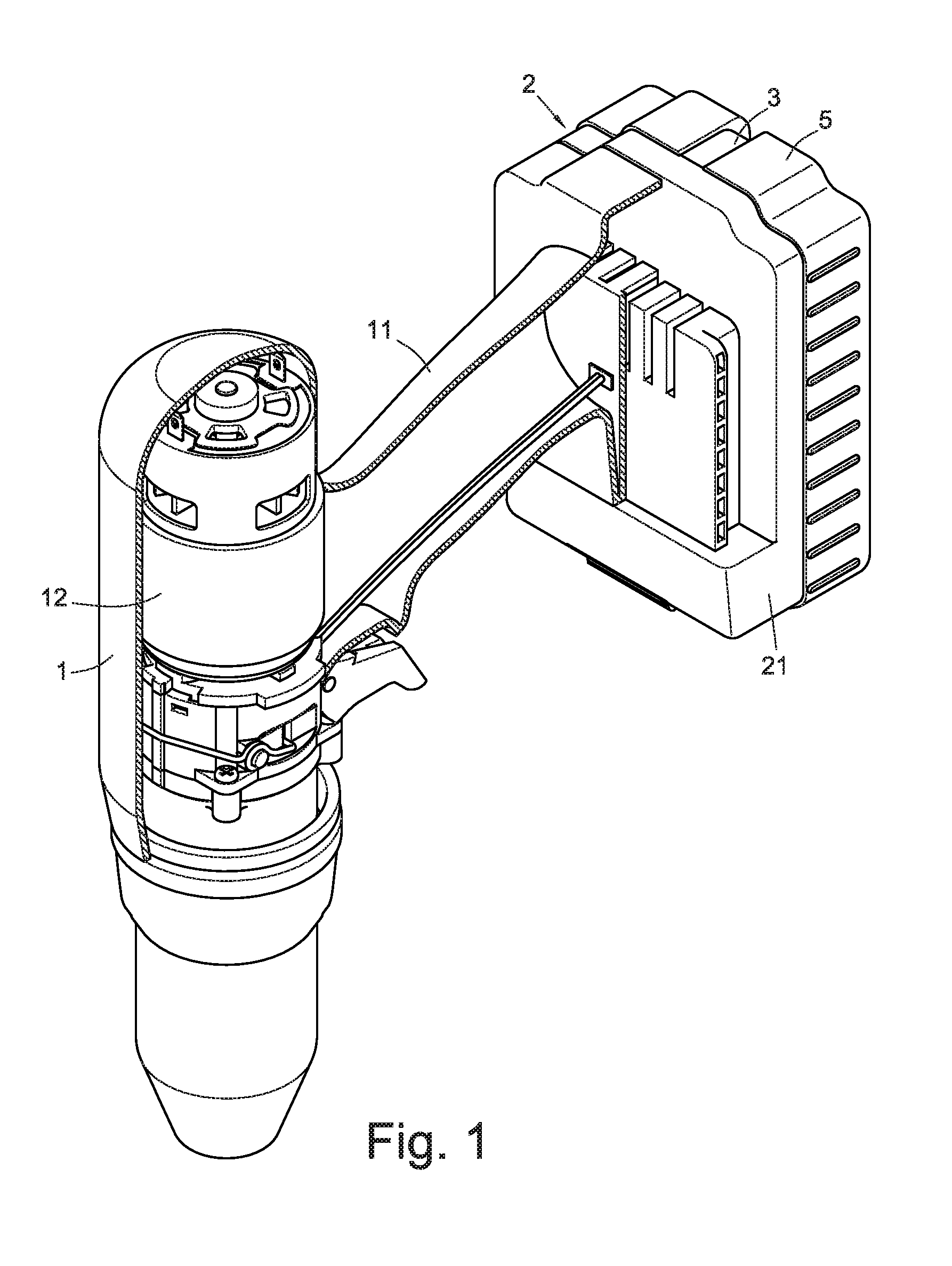

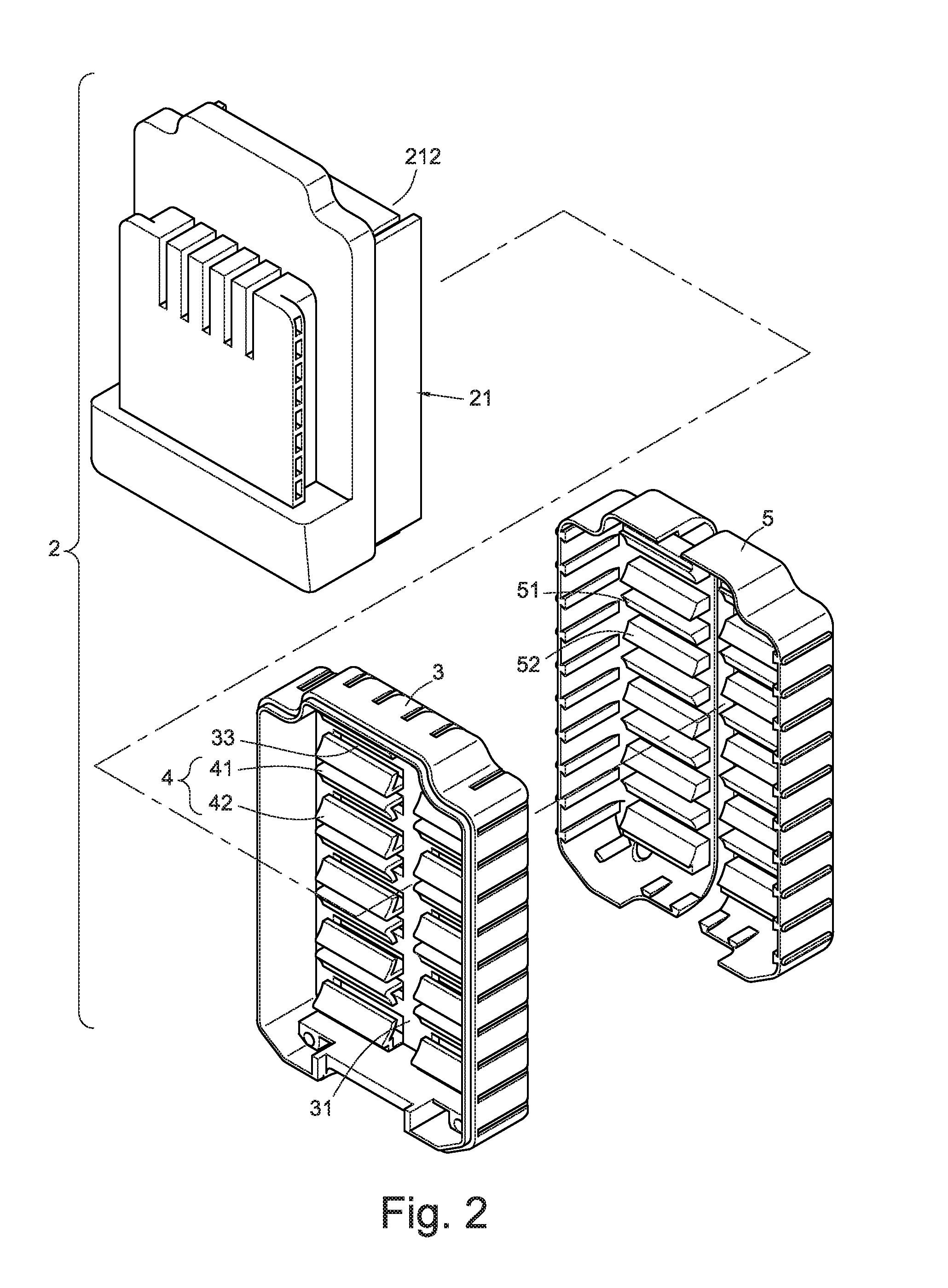

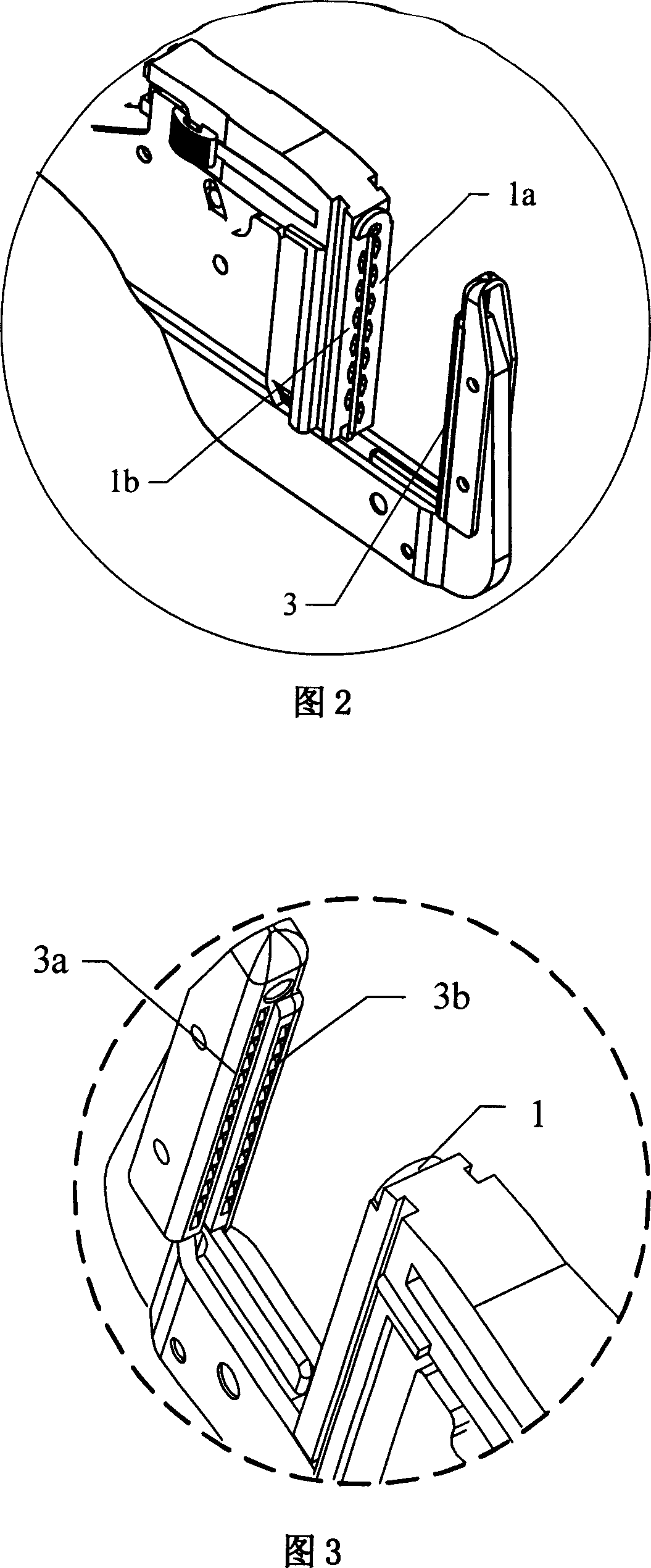

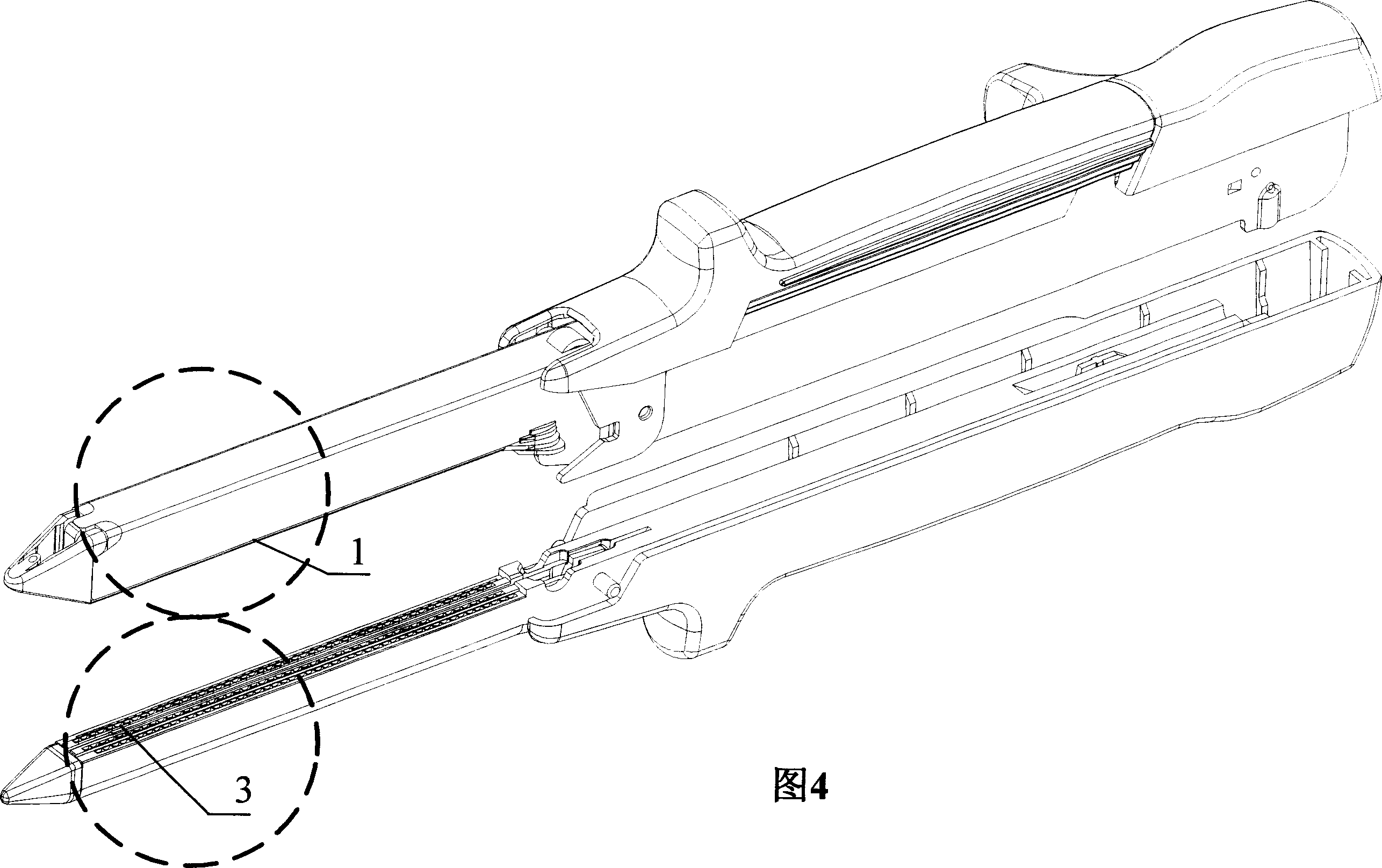

Shock proof structure of battery pack for receiving battery cell

InactiveUS20120251861A1Simple structureUpgrades stabilityBattery isolationPortable power-driven toolsEngineeringAbsorbance

A shock proof structure of a battery pack for receiving a battery cell is formed in an electrical tool. The battery pack includes a base having a space for receiving the battery cell and a lid for opening or closing the space. The space has a plurality of first buckling portions separated by a gap disposed at a bottom side thereof. A plurality of second buckling portions with shock absorbance is formed at an inner sidewall of the lid. The plate sets include two plates separated by a gap are symmetrically positioned. The plates of each plate set have a second buckling portion with a stretching gap formed in between. The second buckling portion is positioned at the opposite end of the first buckling portion to provide the battery cell to be steadily buckled between the first and the second buckling portions.

Owner:DE POAN PNEUMATIC

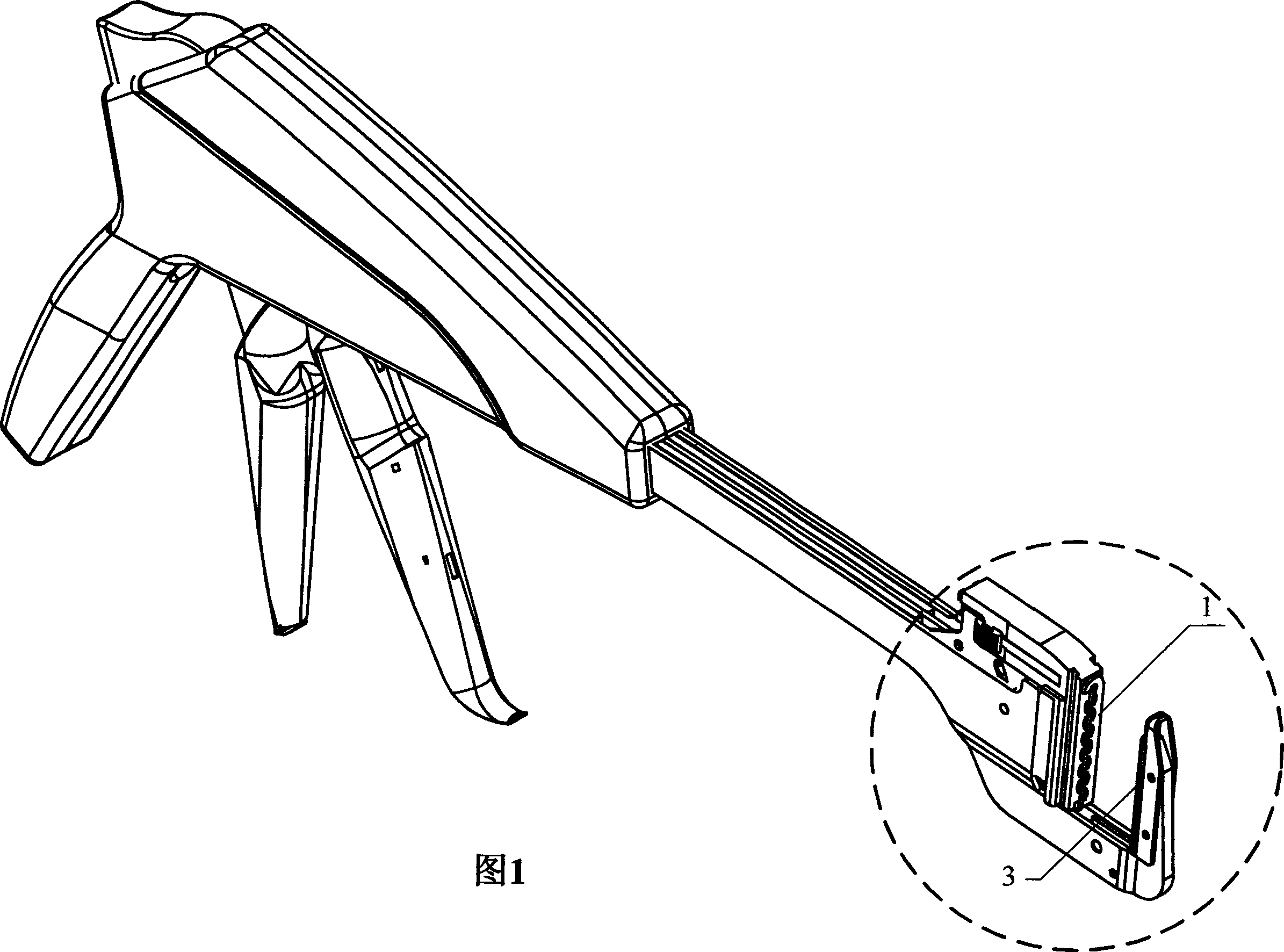

Surgical binding instrument binding mechanism

The invention relates to a binding mechanism of a surgical binding apparatus, which is placed at the head of the surgical binding apparatus and includes a nail pin, a nail pushing plate and a nail block. The nail pushing plate and the nail pin are installed inside the binding apparatus body. The positions of the nail block and the nail pushing plate are opposite. The invention is characterized in that the working faces of nail pin, the nail pushing plate and the nail block are not at the same plane and at least present a step-type fall distributed structure. When the structure is adopted to form an anastomoses opening, the distance between two lines of nails is enlarged; the elasticity of the anastomoses opening which is formed in the operation is increased and is more close to the physiological characteristic of the tissue, which is in favor of the prompt recovery of the tissue. When the nail block is set out from an anastomoses ring or a content object is put through the anastomoses ring after binding, the elasticity of the anastomoses ring becomes larger to allow the nail block or the content object pass through and reduce the probability of damaging the anastomoses ring.

Owner:TOUCHSTONE INTERNATIONAL MEDICAL SCIENCE CO LTD

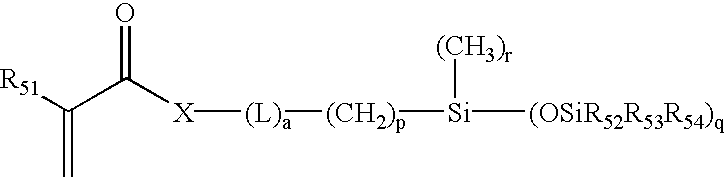

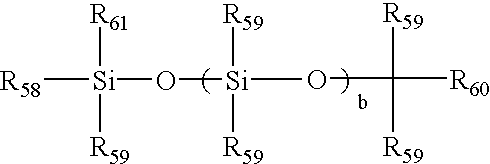

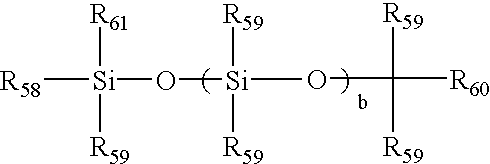

Soft contact lenses

InactiveUS6943203B2Reduces Young 's modulusModulus is reducedOptical partsOptical elementsMonomerSilicone

A soft contact lens containing a silicone-hydrogel made by curing a reaction mixture containing a silicone-containing monomer.

Owner:JOHNSON & JOHNSON VISION CARE INC

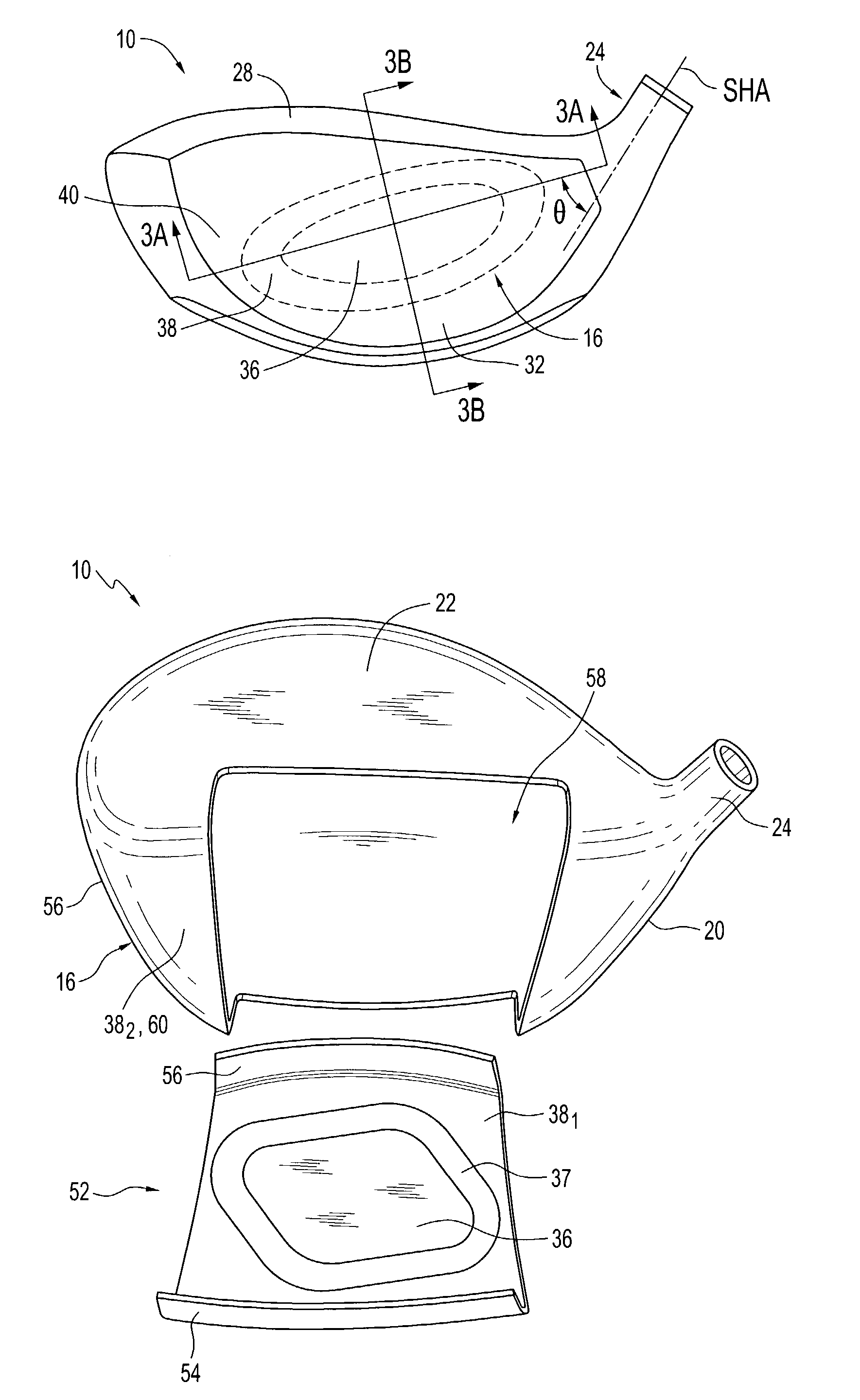

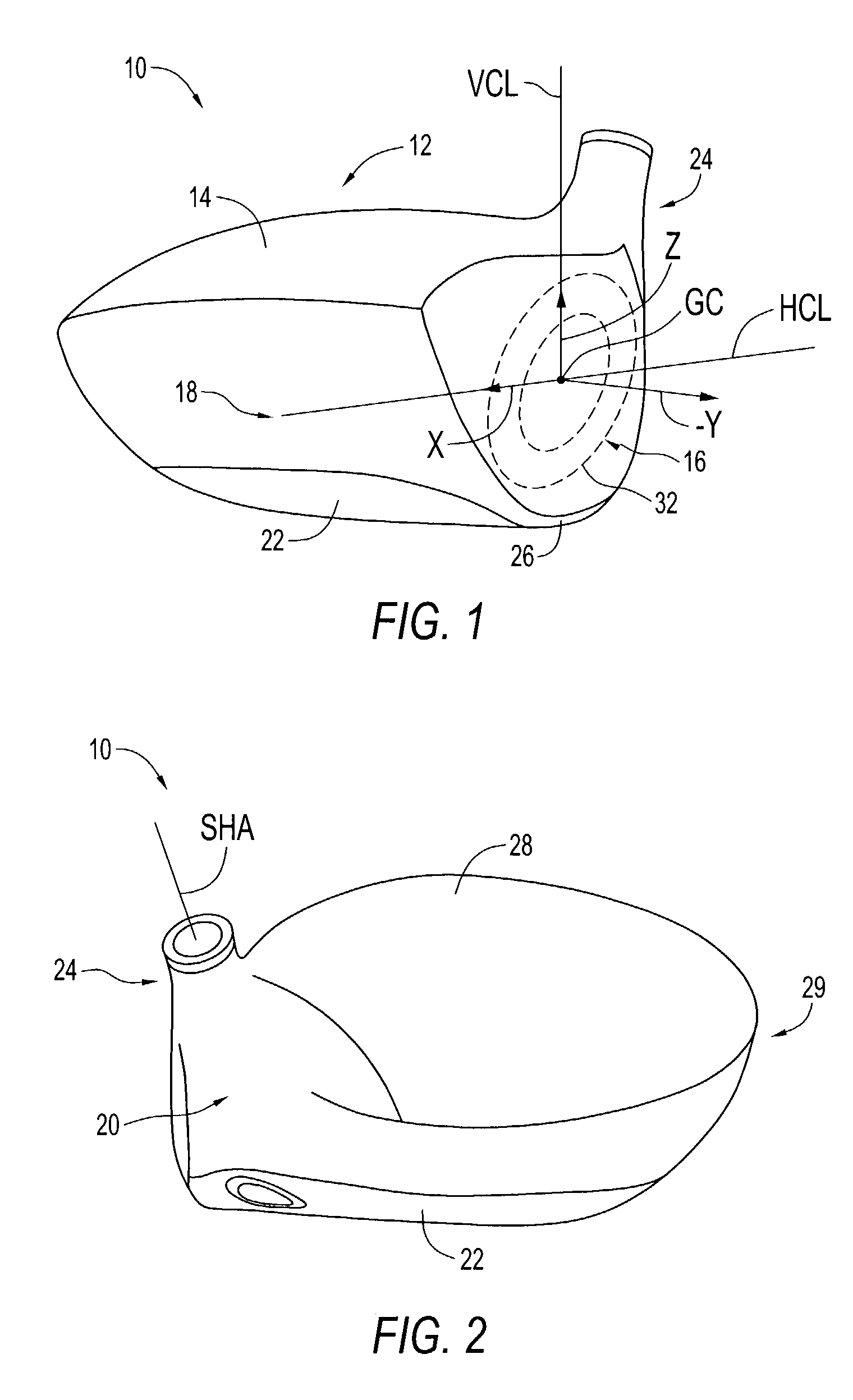

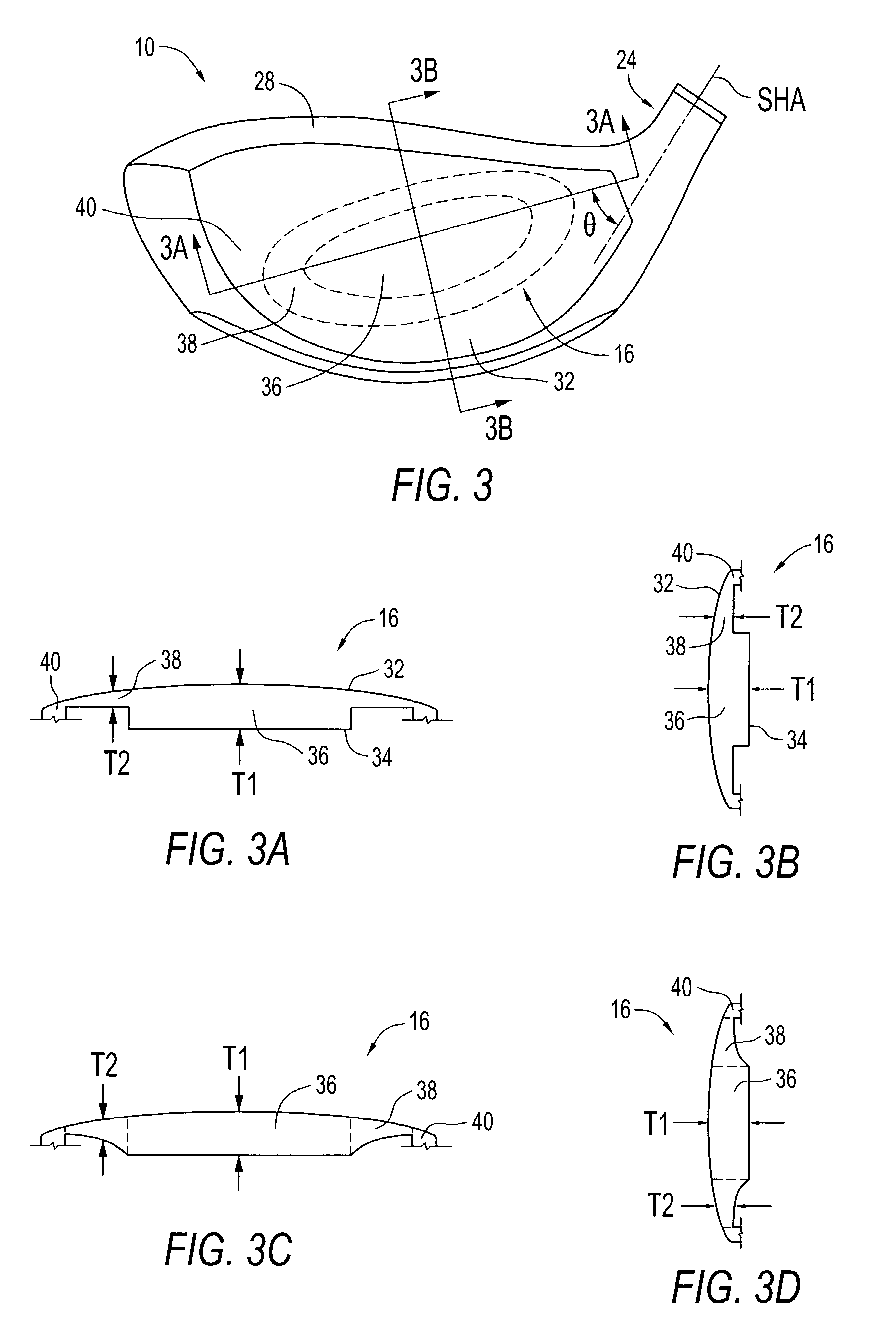

Metal wood club with improved hitting face

InactiveUS7029403B2Increased bending stiffnessIncrease elasticityAnalysing solids using sonic/ultrasonic/infrasonic wavesGolf clubsEllipseBall impact

A golf club head having selectively oriented zones of relatively high flexural stiffness is disclosed. The hitting face is configured and dimensioned so that it includes an inner zone and a concentric intermediate zone. The inner zone has relatively high flexural stiffness and the intermediate zone has relatively lower flexural stiffness. The inner zone may have an elliptical shape or a substantially parallelogram shape. Preferably, the inner zone has a shape that comprises a major axis and a minor axis and the major axis aligns substantially in the direction of high heel to low toe. This arrangement of inner and intermediate zones creates a gradient of flexural stiffness in the direction of high toe to low heel and produces a desirable manipulation COR in that direction. This area of high coefficient of restitution advantageously coincides with the ball impact pattern that golfers typically make on the hitting face. The hitting face also comprises a measurement zone wherein the lowest COR is at least 93% of the highest COR.

Owner:ACUSHNET CO

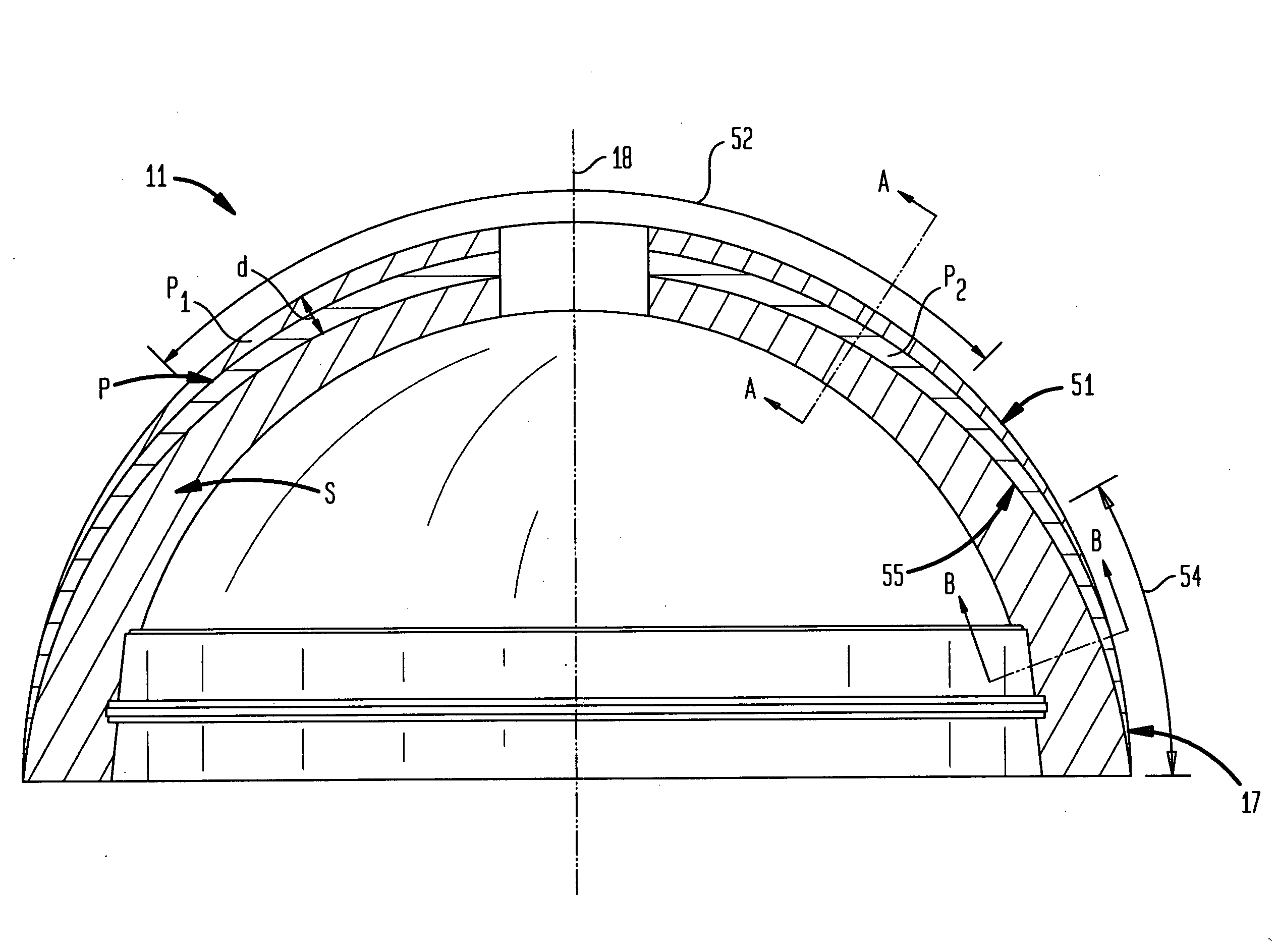

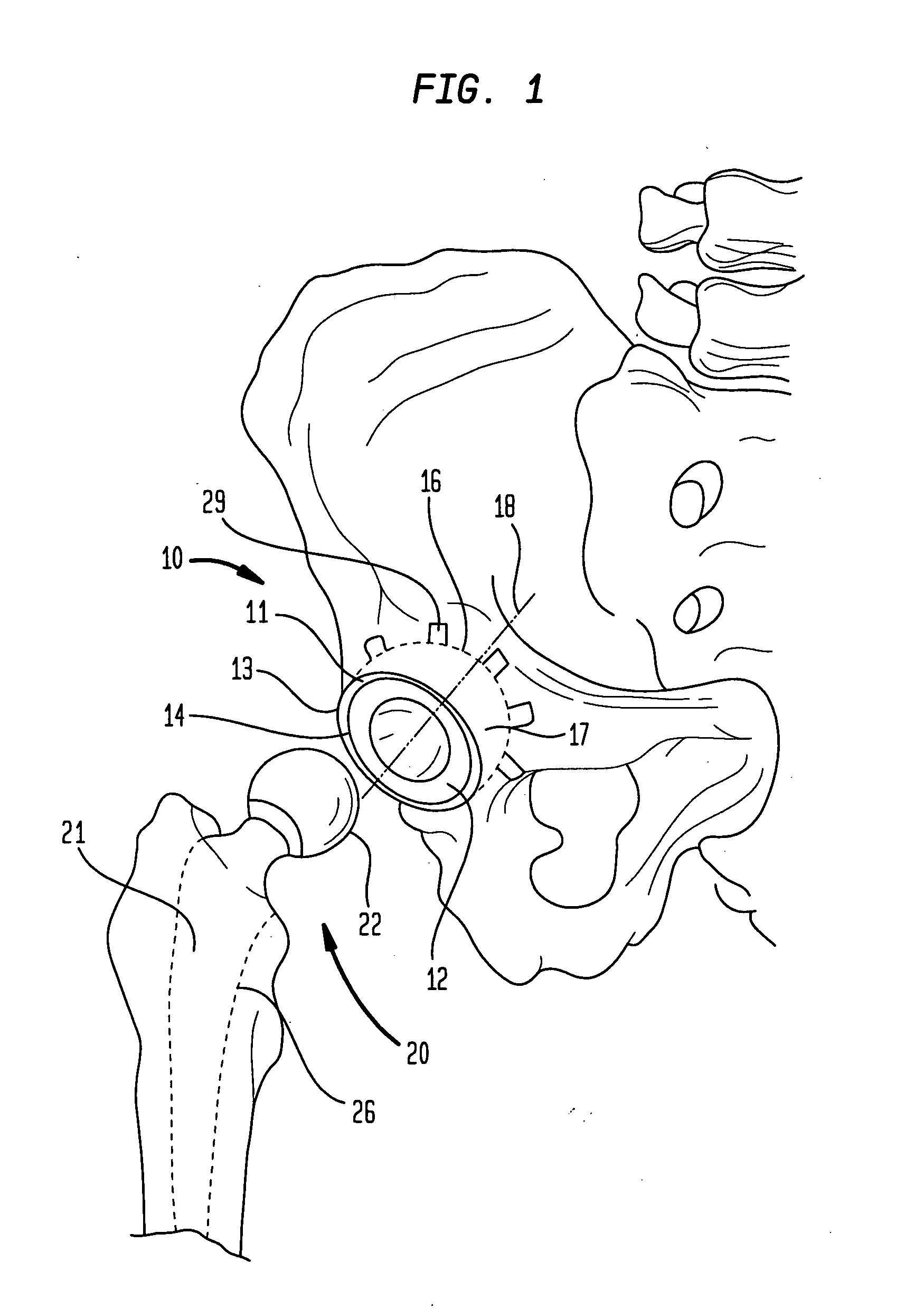

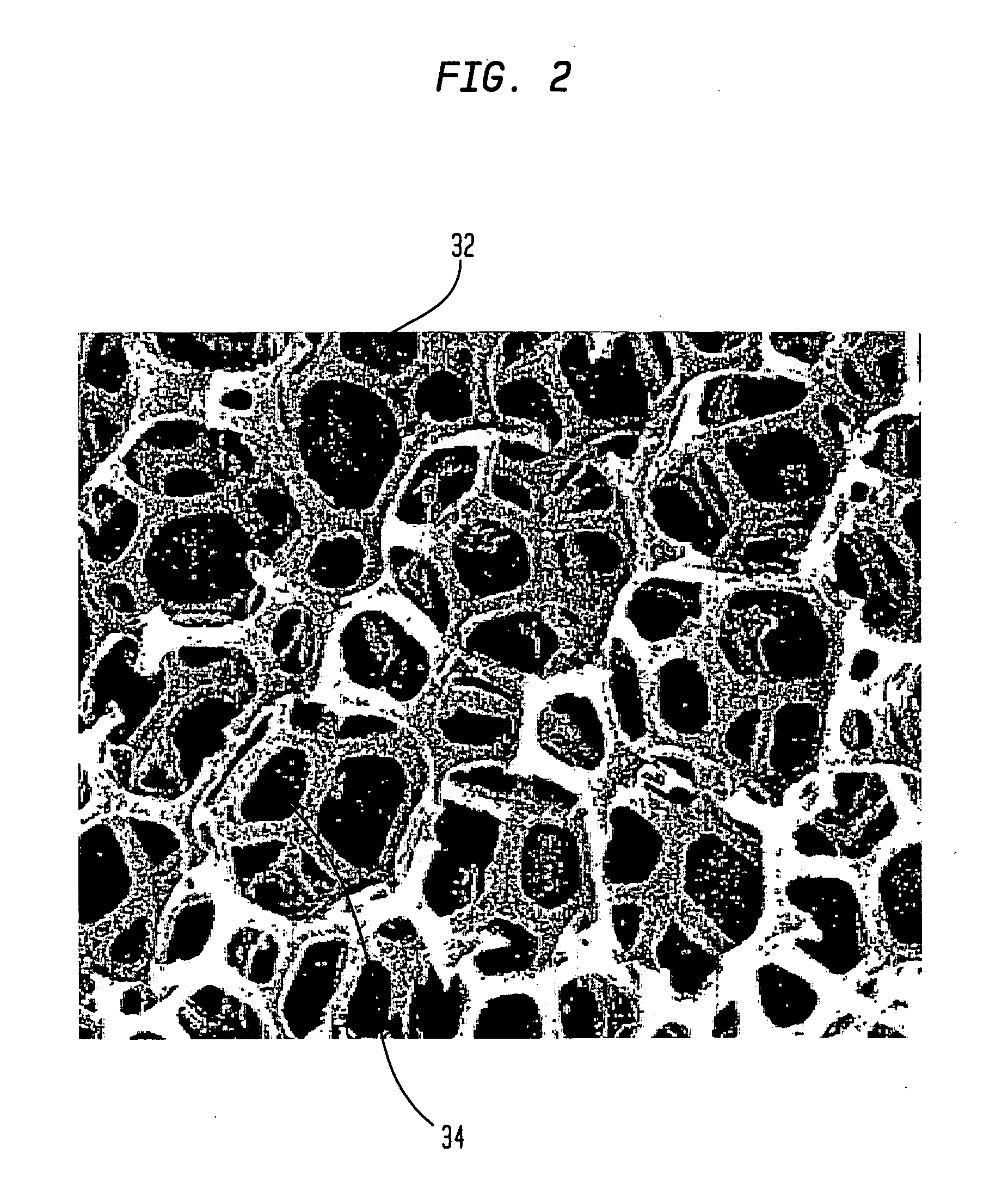

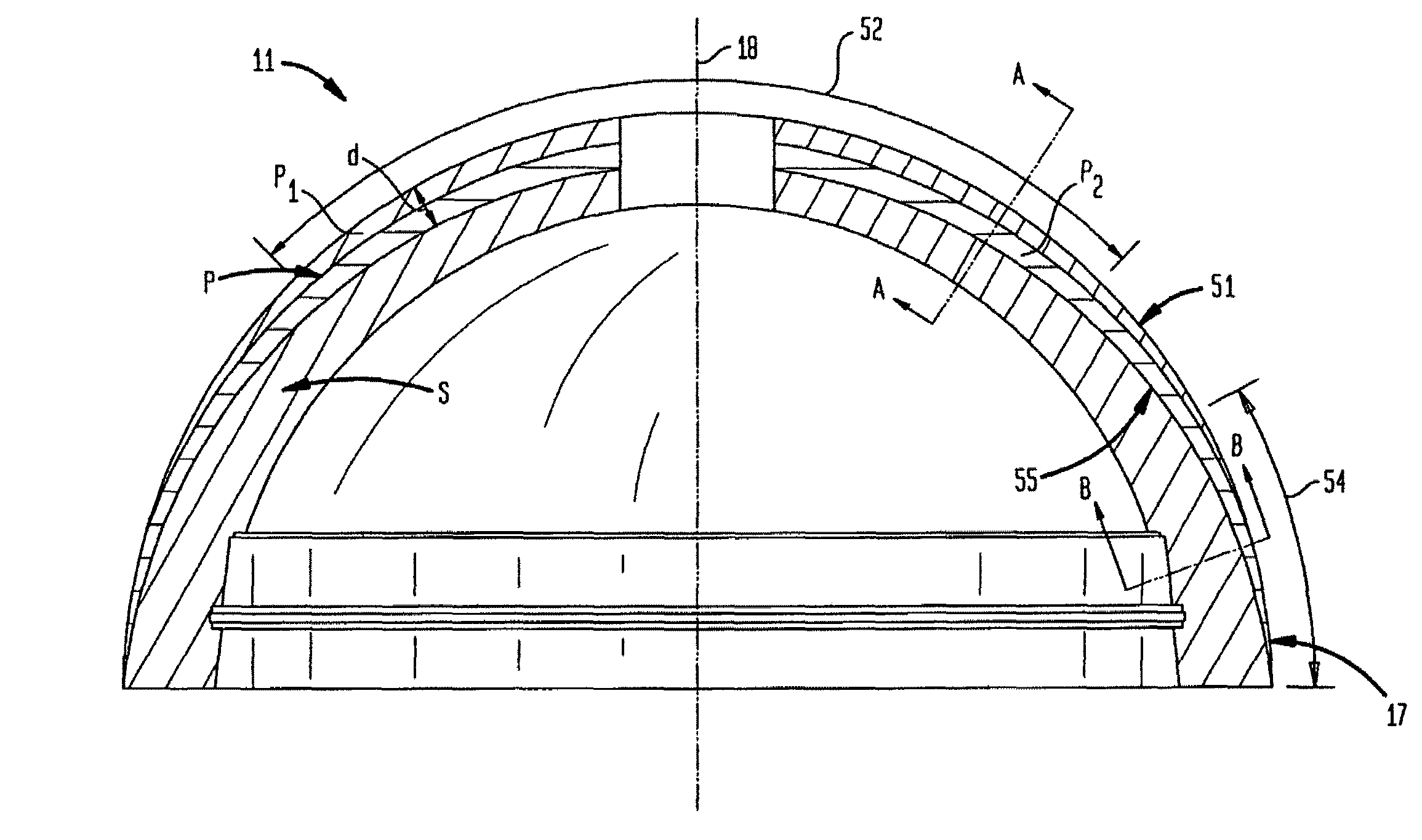

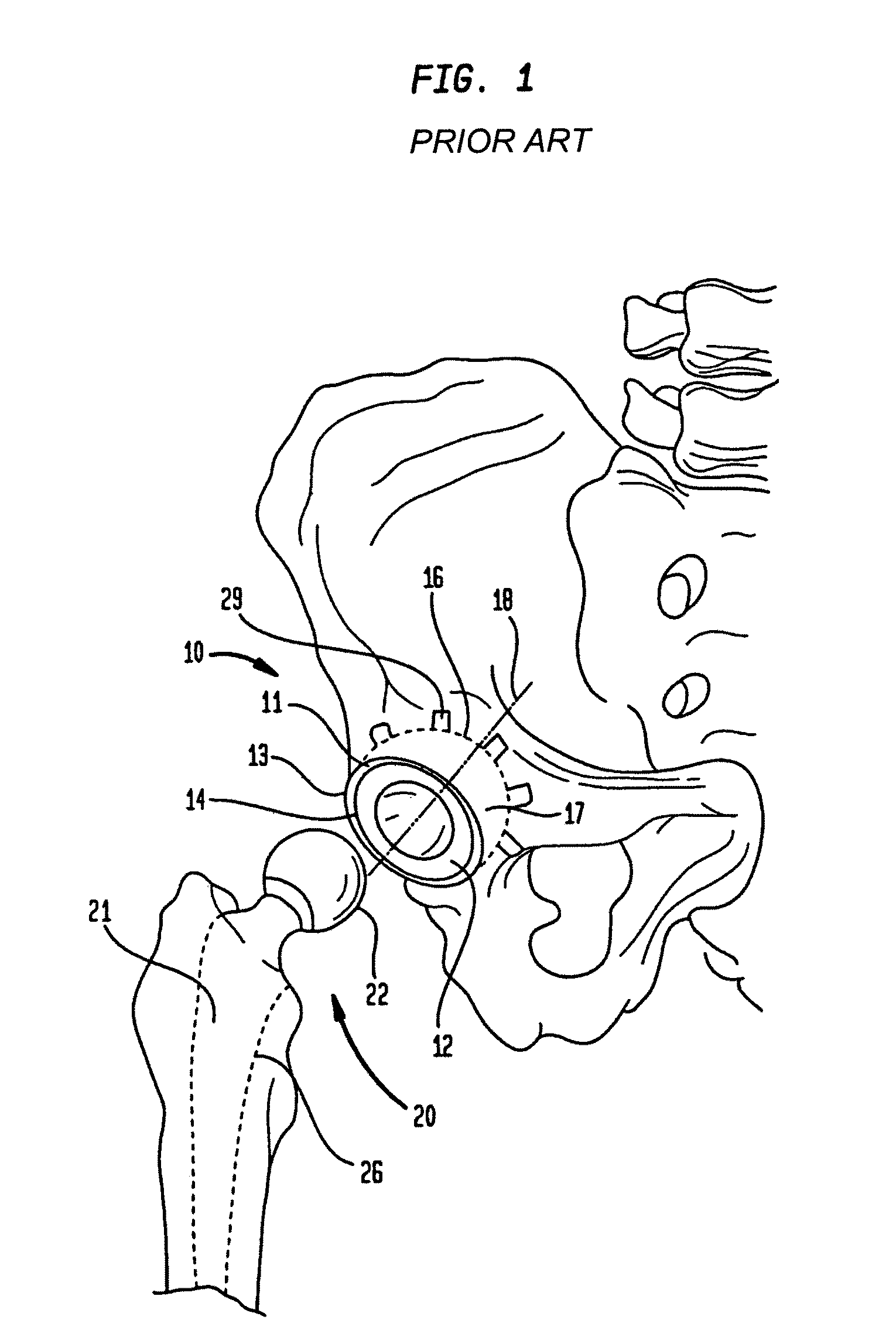

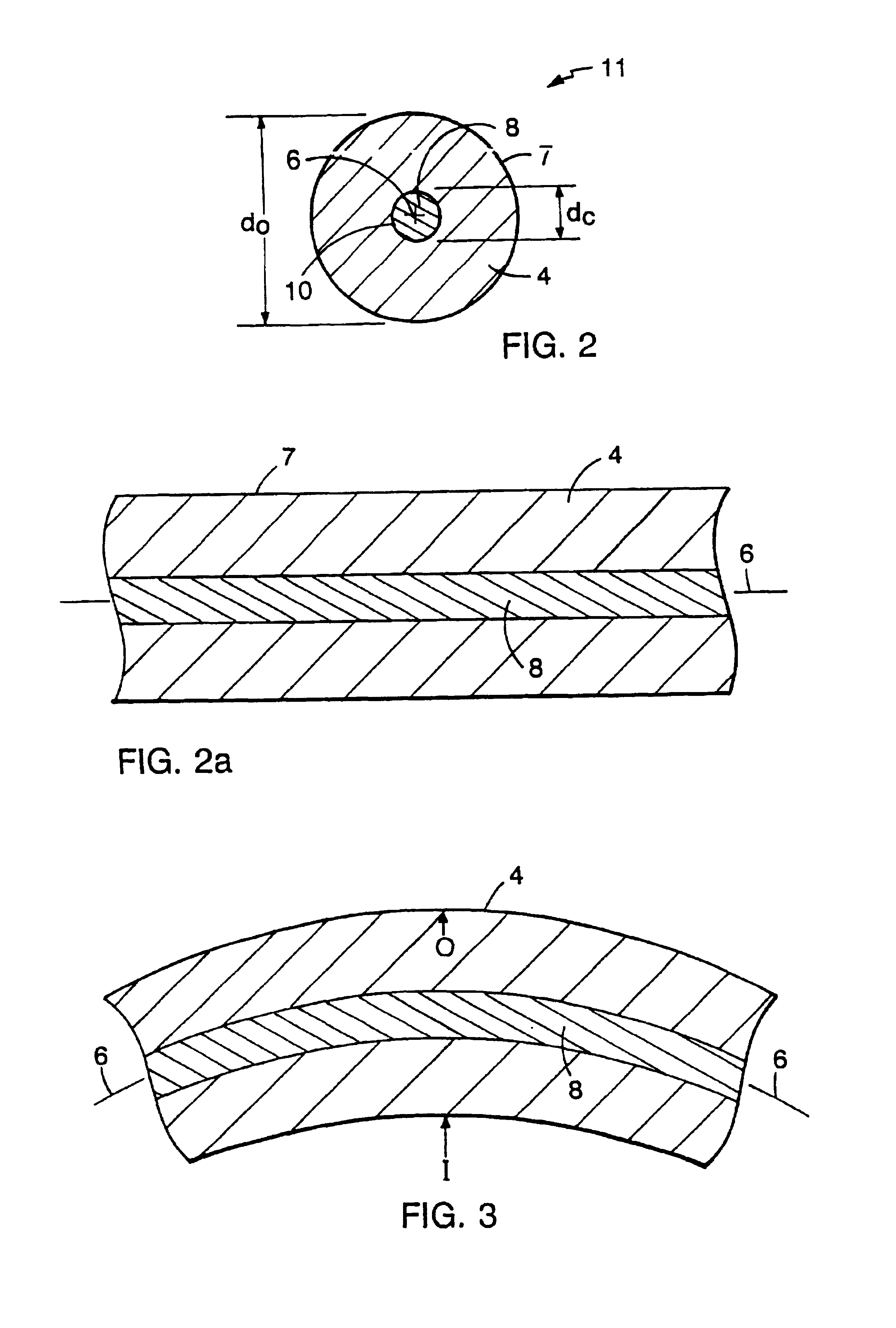

Gradient porous implant

ActiveUS20070150068A1Optimize performanceOptimizes various mechanical and biological requirements of the implants performanceAdditive manufacturing apparatusBone implantPorous metalMedical treatment

An implantable medical device includes a porous metal foam or foam-like structure having pores defined by metal struts or webs wherein the porous structure has directionally controlled pore characteristics. The pore characteristics controlled include one or more of the metal structure porosity, pore size, pore shape, pore size distribution and strut thickness. The pore characteristics may vary in one or more directions throughout the structure. Preferably the pore characteristics are controlled to match the porous metal structure to various mechanical and biological requirements of different regions of the structure in order to optimize aspects of the implants performance and may vary not only over the surface of the porous structure but through the depth of the porous structure. The thickness of the porous metal structure may also be modified to establish a thickness profile that optimizes mechanical and biological requirements of the implants performance. Acetabular cup embodiments of the invention are described. Various methods of manufacturing implants having directionally controlled pore characteristics are described.

Owner:HOWMEDICA OSTEONICS CORP

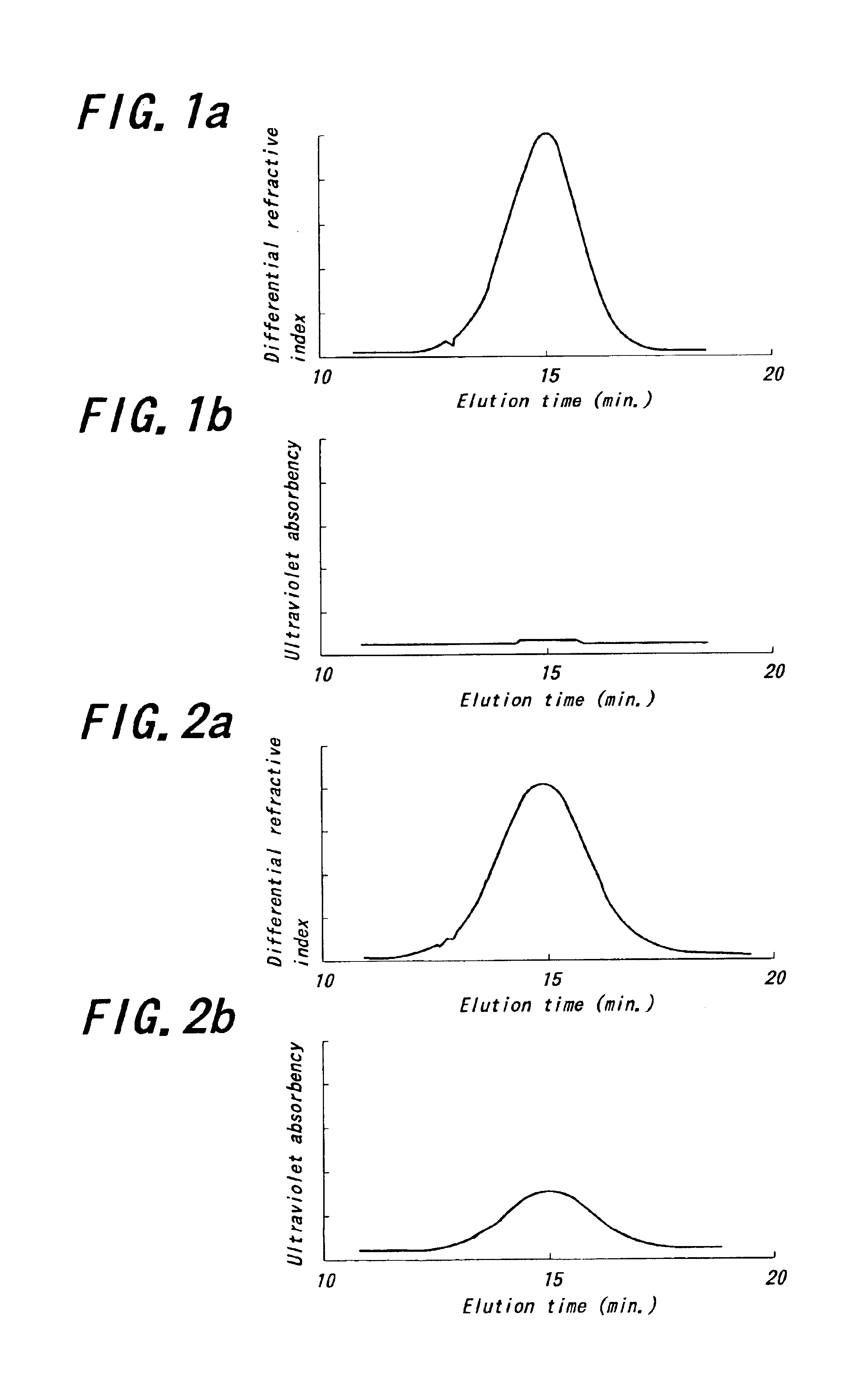

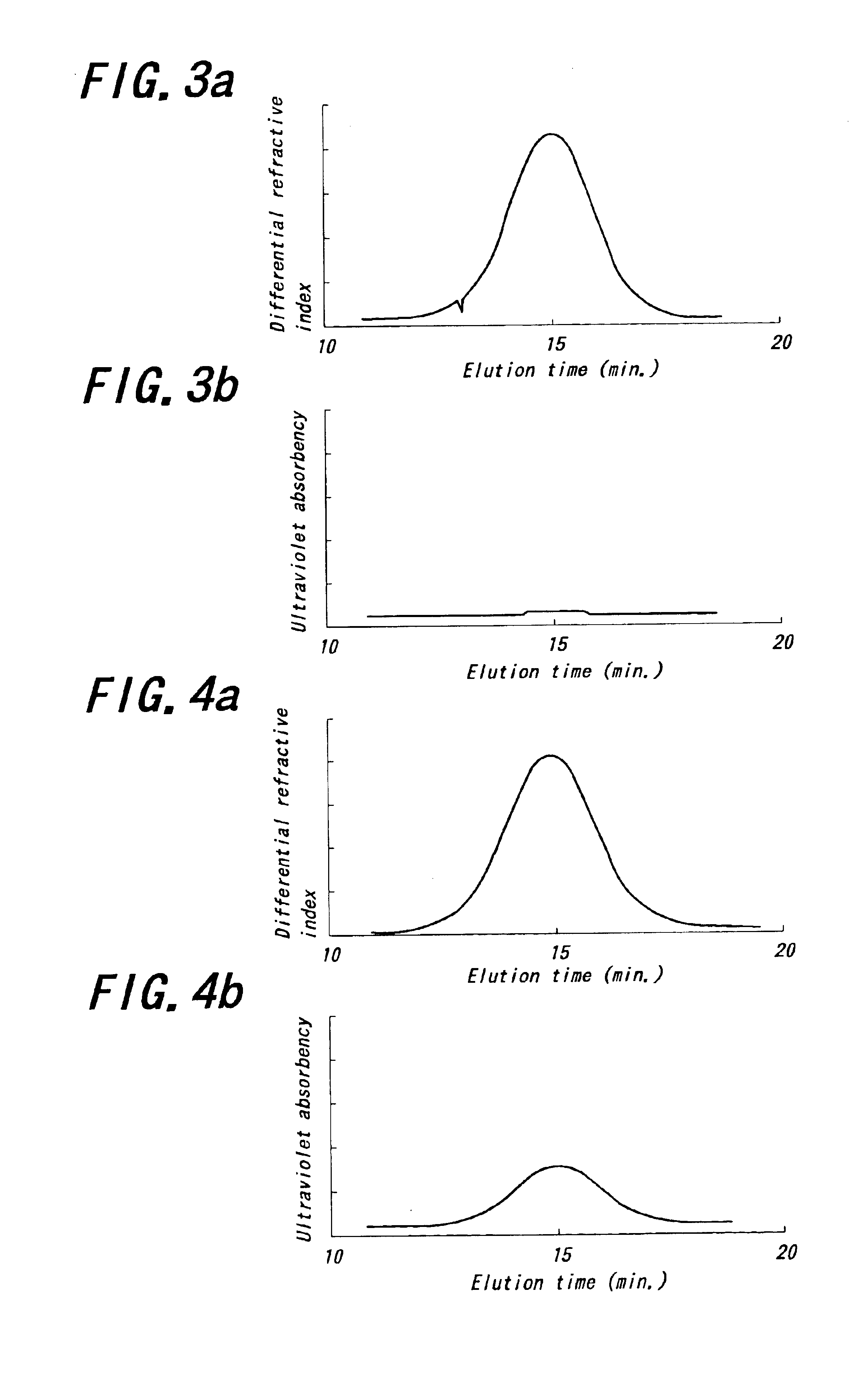

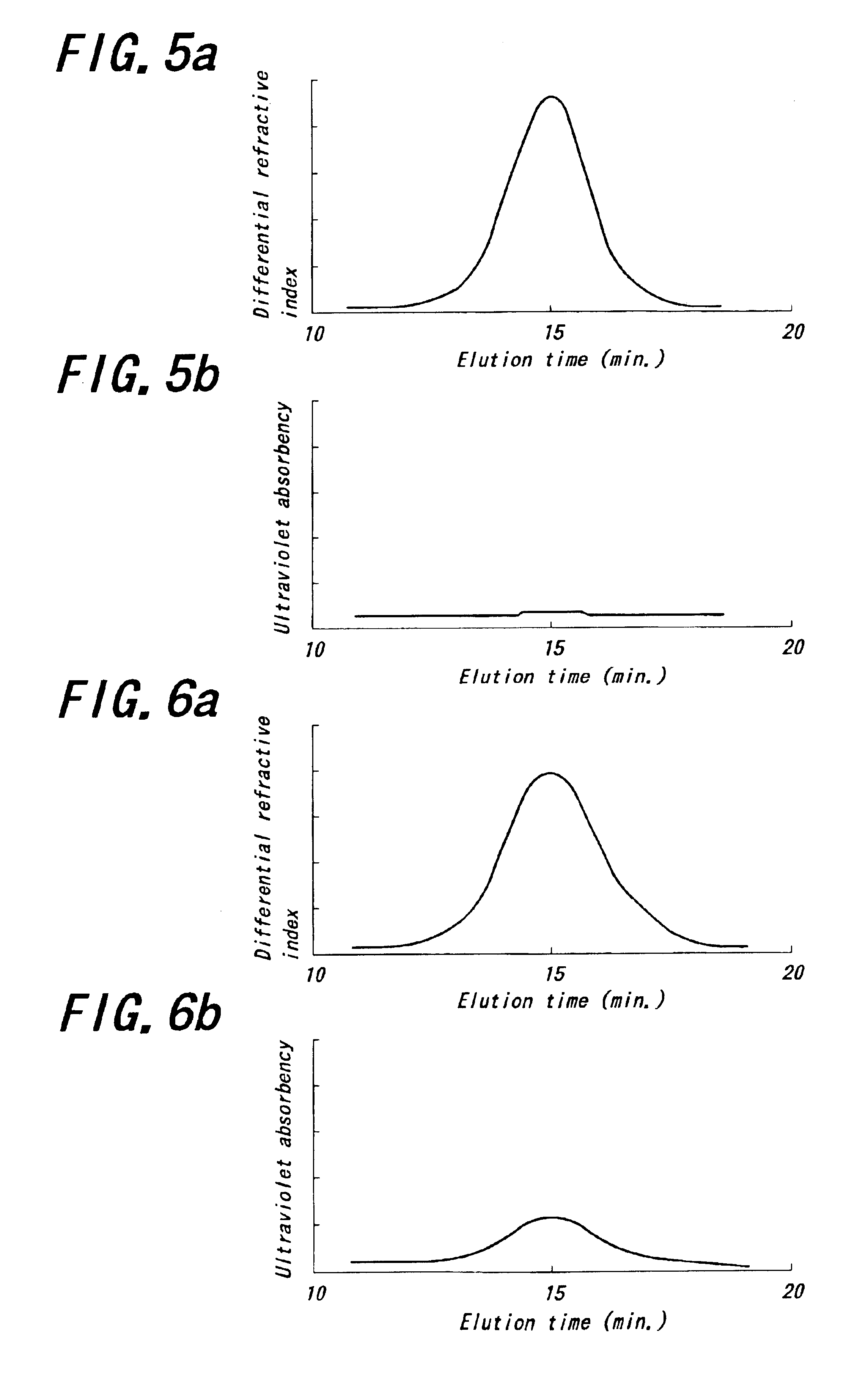

Modified conjugated diene polymer and method of producing the same and rubber composition

A novel modified conjugated diene polymer is obtained by polymerizing a conjugated diene compound with a specified catalyst consisting of components (a)-(c) and then reacting with at least one specified compound selected from the group consisting of components (d)-(l), and has a content of cis-1,4-bond of not less than 85% and a ratio of weight average molecular weight to number average molecular weight of not more than 4. And also, a rubber composition comprises the modified conjugated diene polymer a rubber ingredient.

Owner:JSR CORPORATIOON +1

Gradient porous implant

ActiveUS7578851B2Optimizes various mechanical and biological requirements of the implants performanceIncreasing the thicknessAdditive manufacturing apparatusBone implantPorous implantMedical device

An implantable medical device includes a porous metal foam or foam-like structure having pores defined by metal struts or webs wherein the porous structure has directionally controlled pore characteristics. The pore characteristics controlled include one or more of the metal structure porosity, pore size, pore shape, pore size distribution and strut thickness. The pore characteristics may vary in one or more directions throughout the structure. Preferably the pore characteristics are controlled to match the porous metal structure to various mechanical and biological requirements of different regions of the structure in order to optimize aspects of the implants performance and may vary not only over the surface of the porous structure but through the depth of the porous structure. The thickness of the porous metal structure may also be modified to establish a thickness profile that optimizes mechanical and biological requirements of the implants performance. Acetabular cup embodiments of the invention are described. Various methods of manufacturing implants having directionally controlled pore characteristics are described.

Owner:HOWMEDICA OSTEONICS CORP

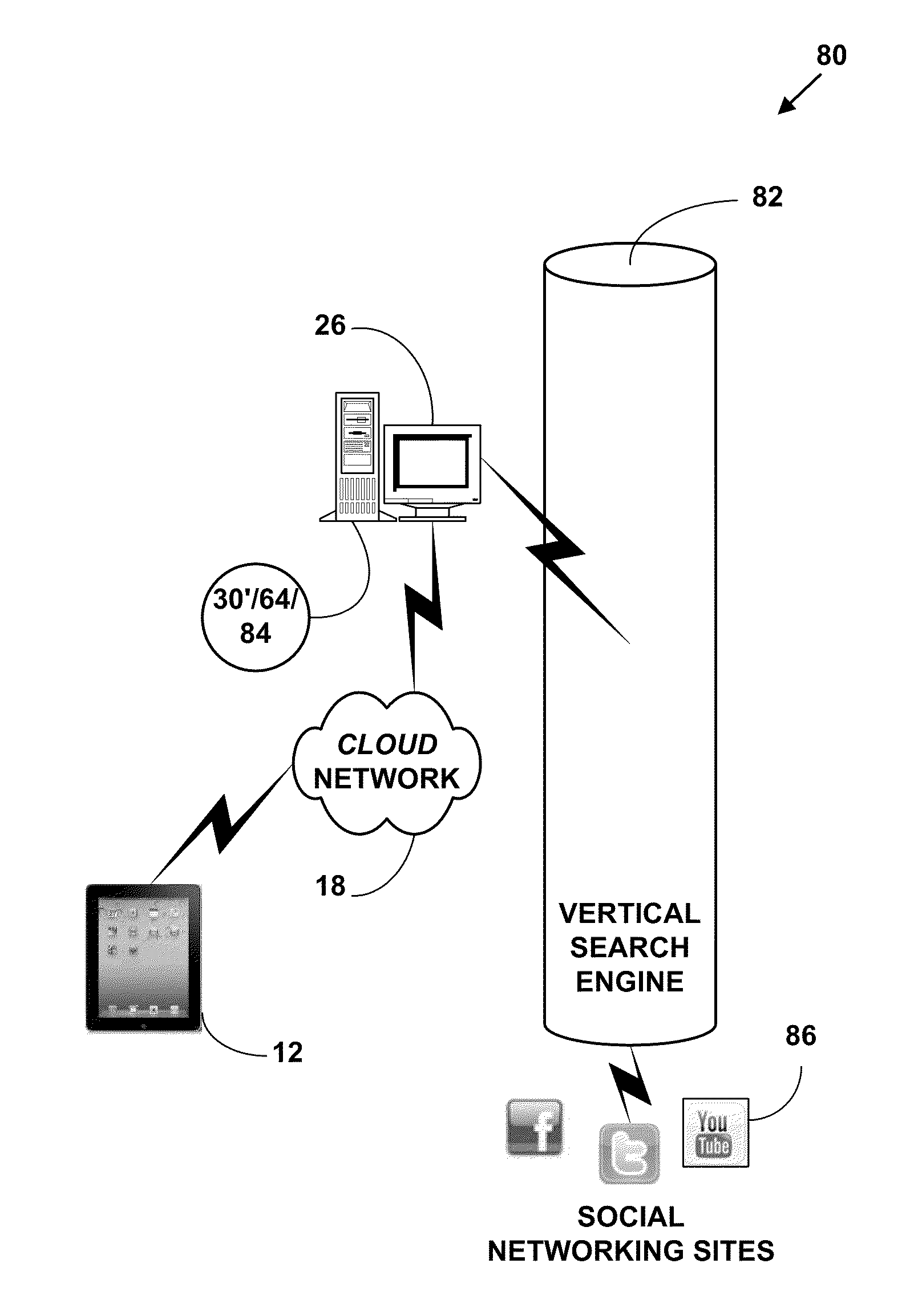

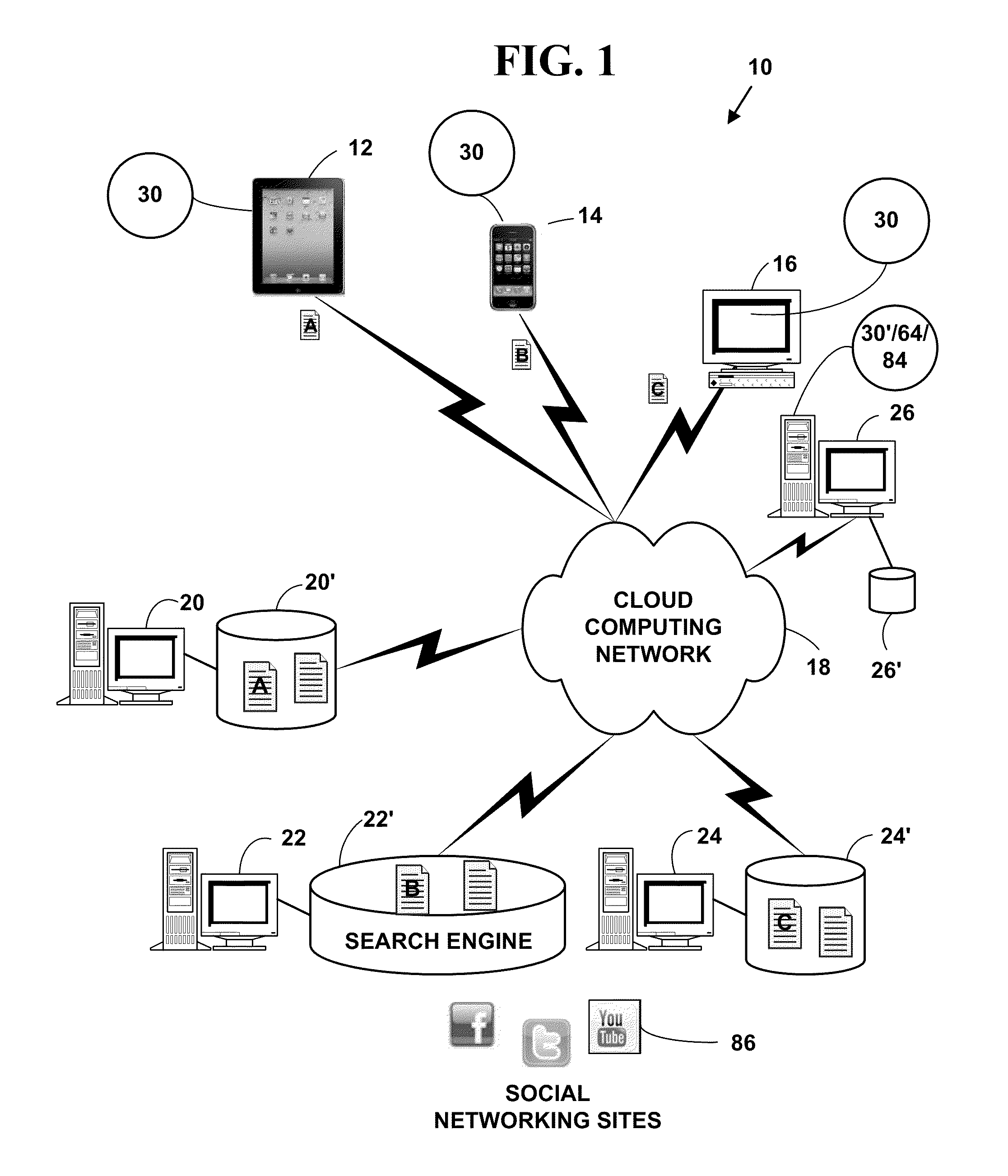

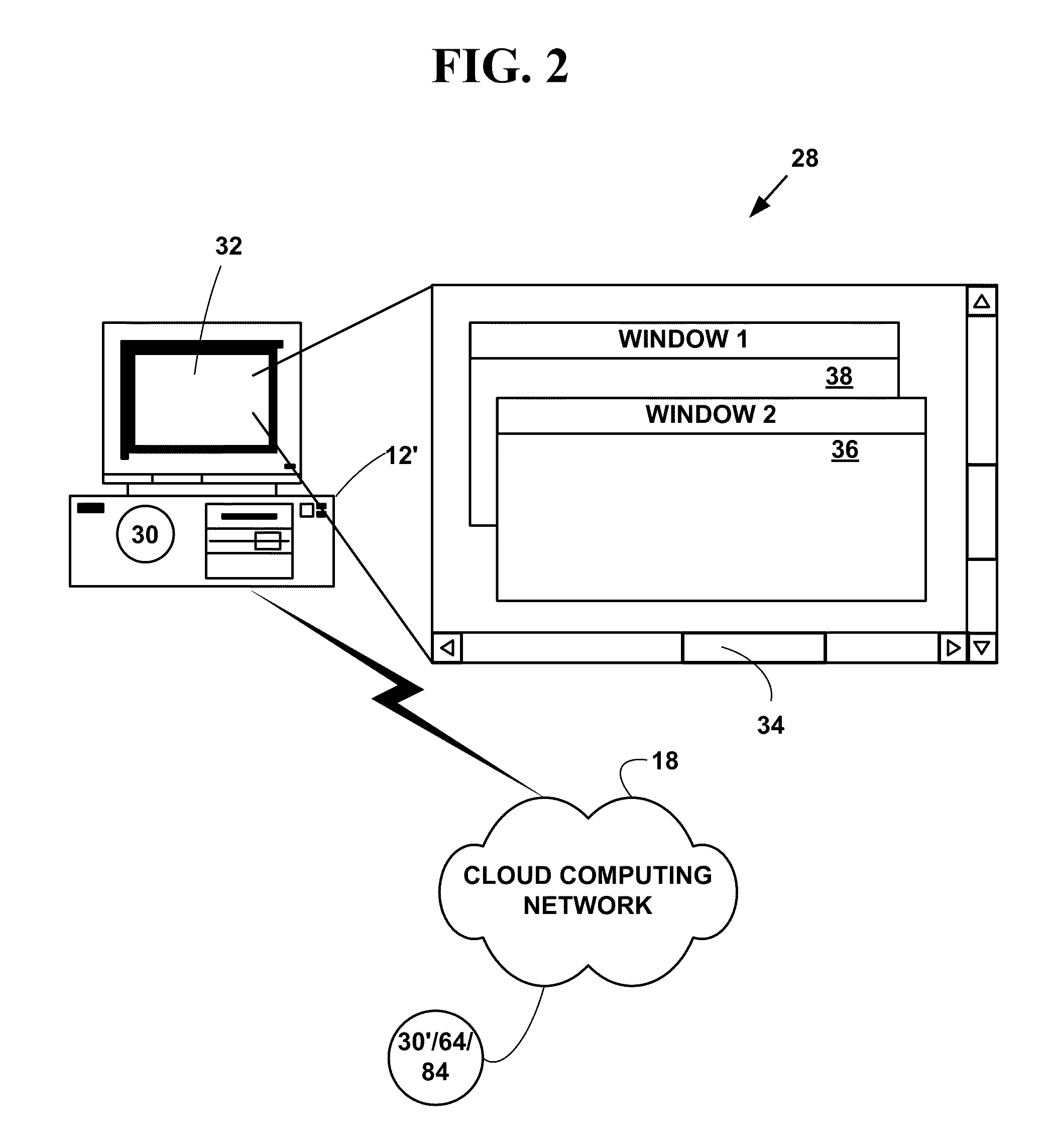

Method and system for creating vertical search engines with cloud computing networks

InactiveUS20110208710A1ImproveLess bandwidthWeb data indexingDigital data processing detailsBroadband networksElectronic information

A method and system for creating vertical search engines with cloud computing networks. The cloud computing networks include a cloud communications network using public networks, private networks, community networks and hybrid networks. The cloud communications network provides on-demand vertical search services, broadband network access, resource pooling, rapid elasticity and measured electronic services for vertical search engines. The method and system dramatically improve a vertical search engine infrastructure used by searchers by providing vertical electronic information using less bandwidth and less processing cycles via the cloud communications network than via a non-cloud communications network. Custom vertical search engines can be created by a user with QR bar codes and other types of bar codes and other types of custom information.

Owner:LESAVICH ZACHARY C

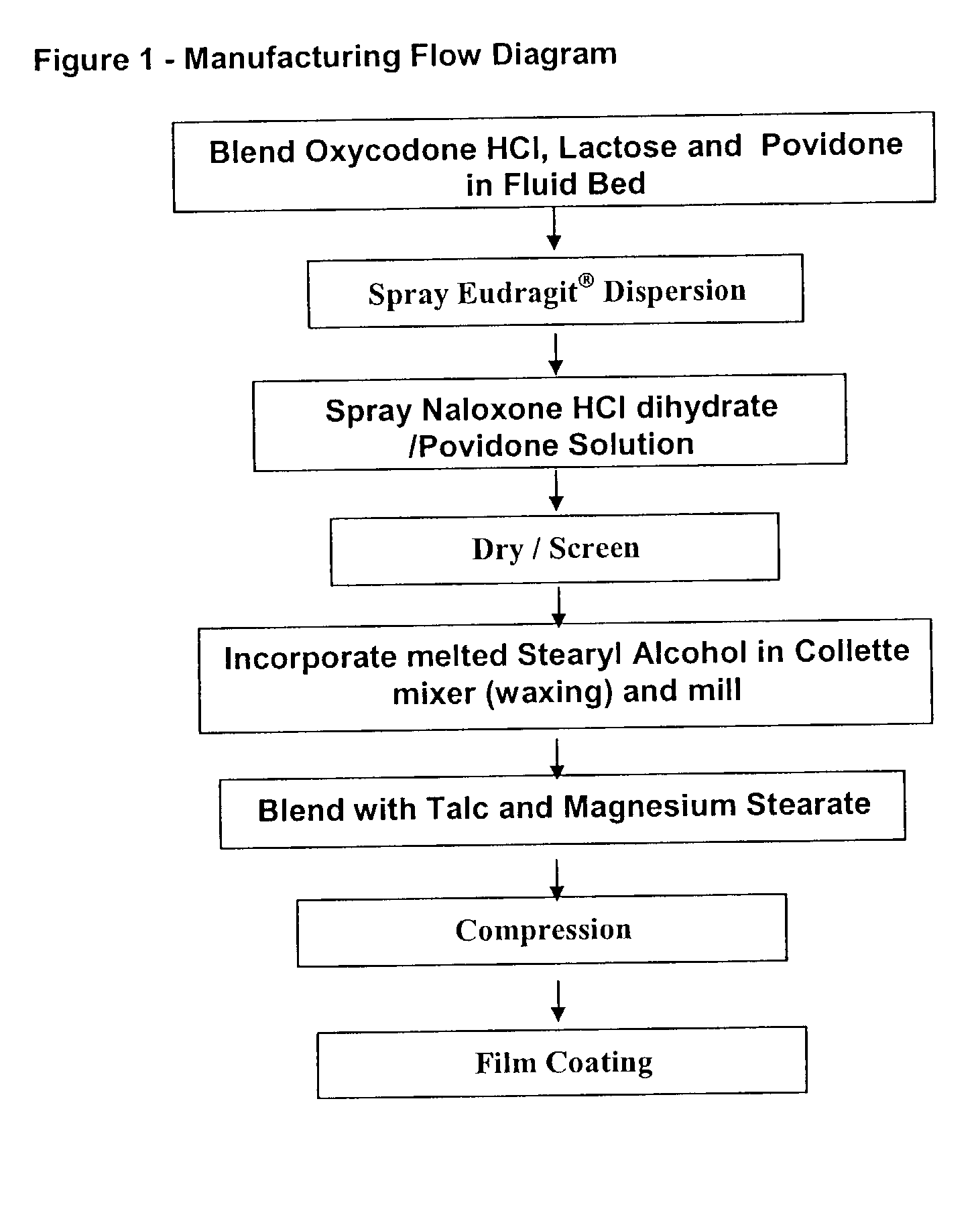

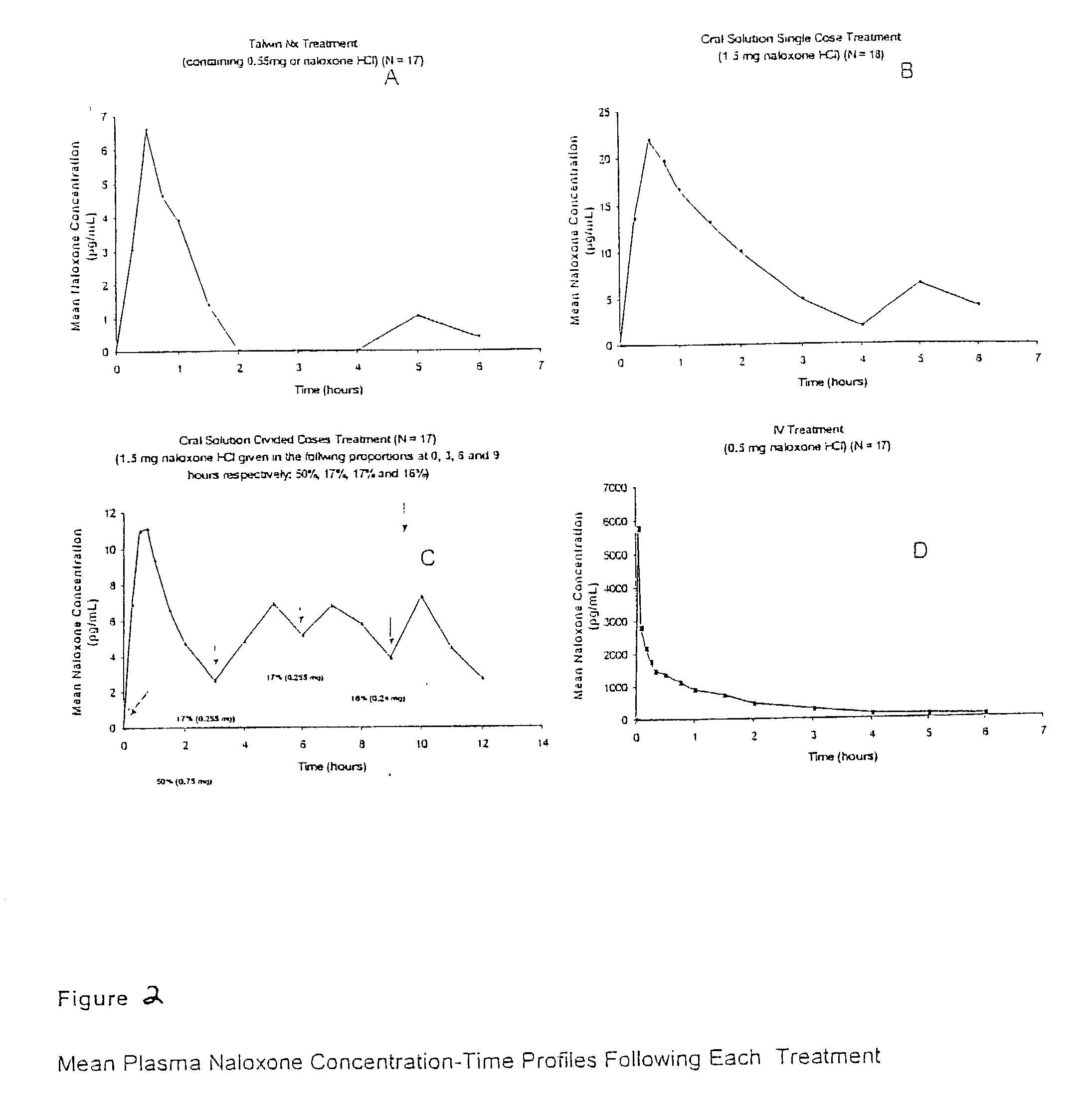

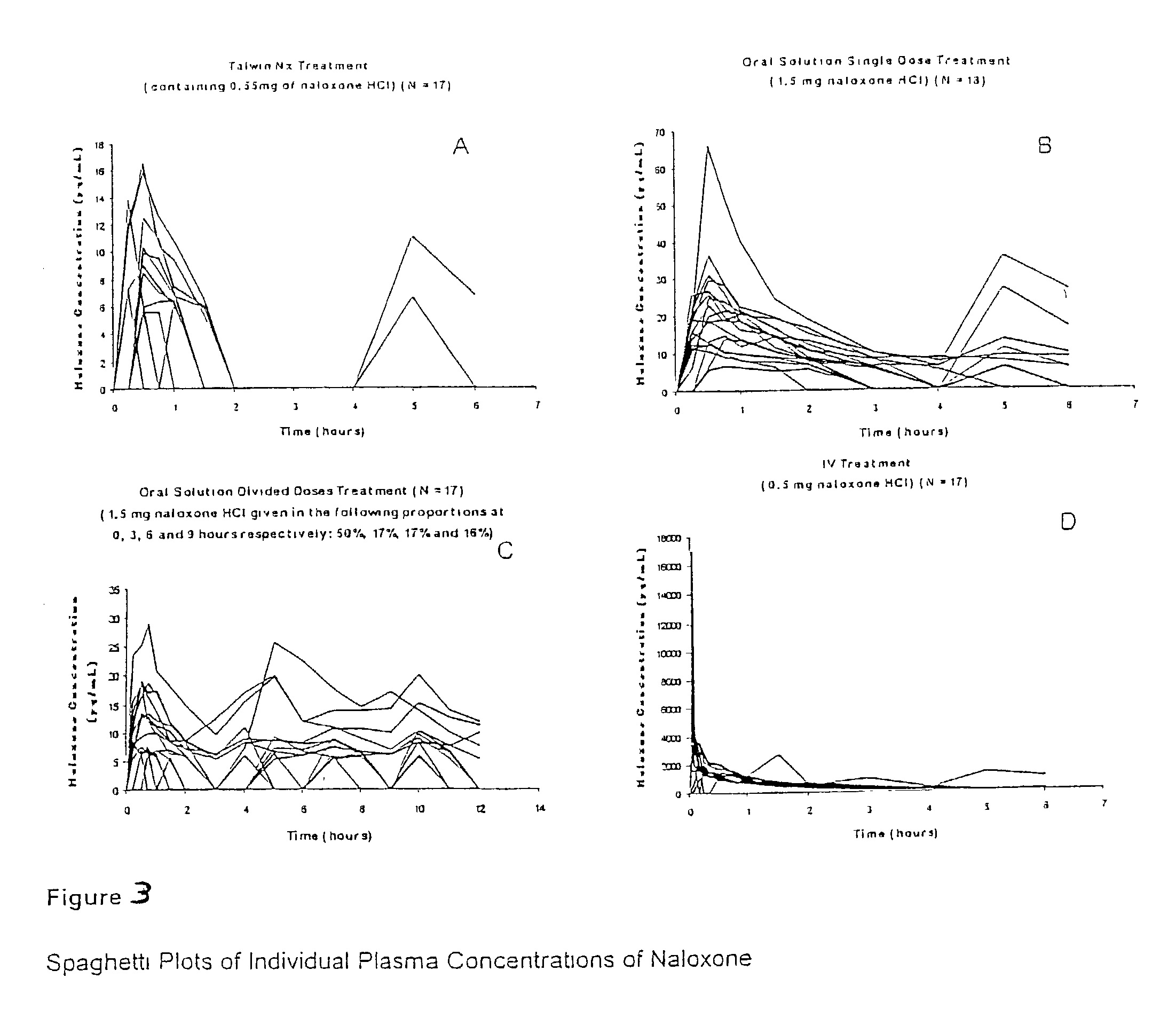

Pharmaceutical combinations of oxycodone and naloxone

InactiveUS20030069263A1Increase elasticityReduced tendencyPowder deliveryBiocideOxycodonePharmacology

Disclosed in certain embodiments is a pharmaceutical composition comprising from 10 to 40 mg of oxycodone or a pharmaceutically acceptable salt thereof and 0.65 to 0.90 mg naloxone or a pharmaceutically acceptable salt thereof.

Owner:PURDUE PHARMA LP

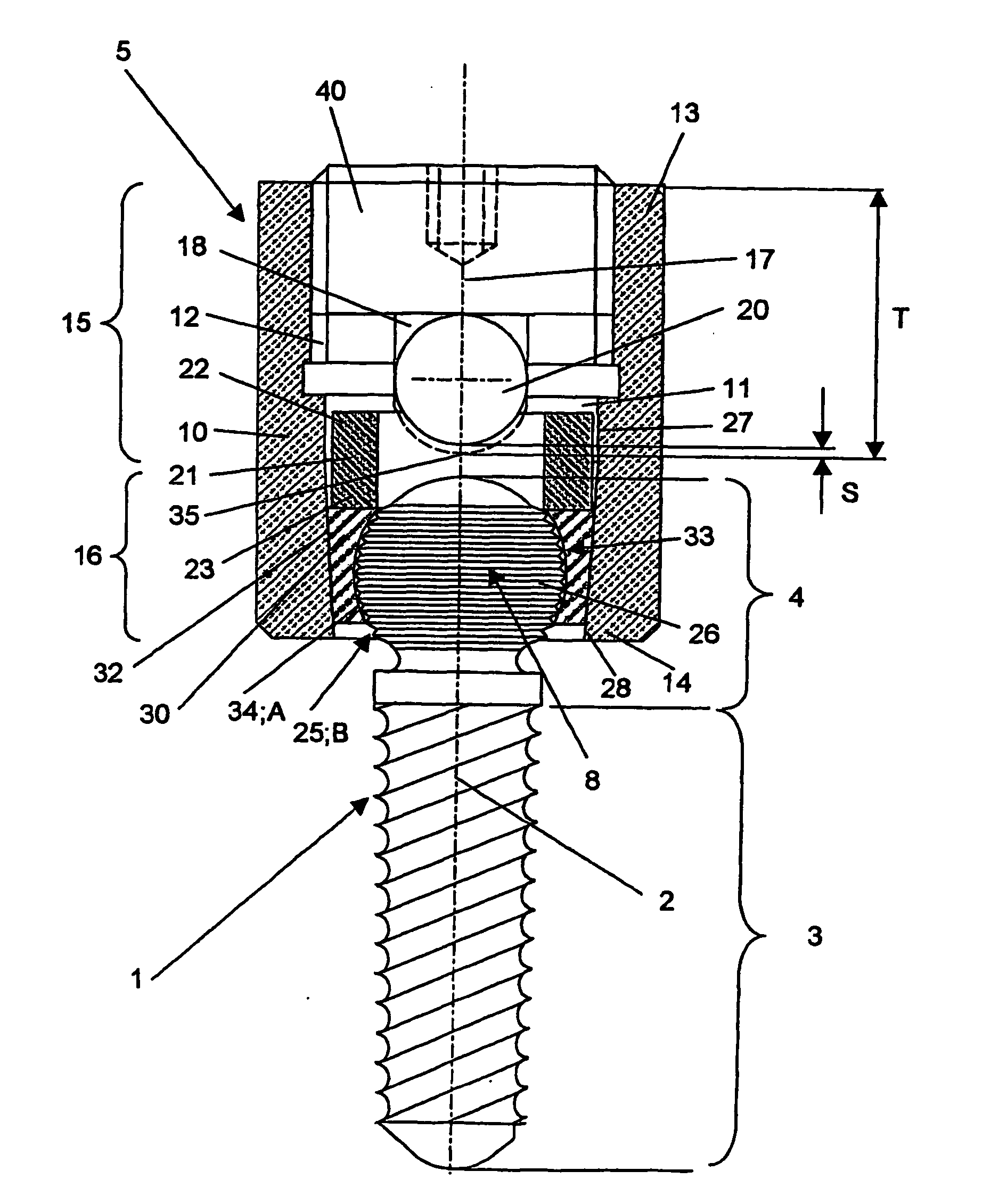

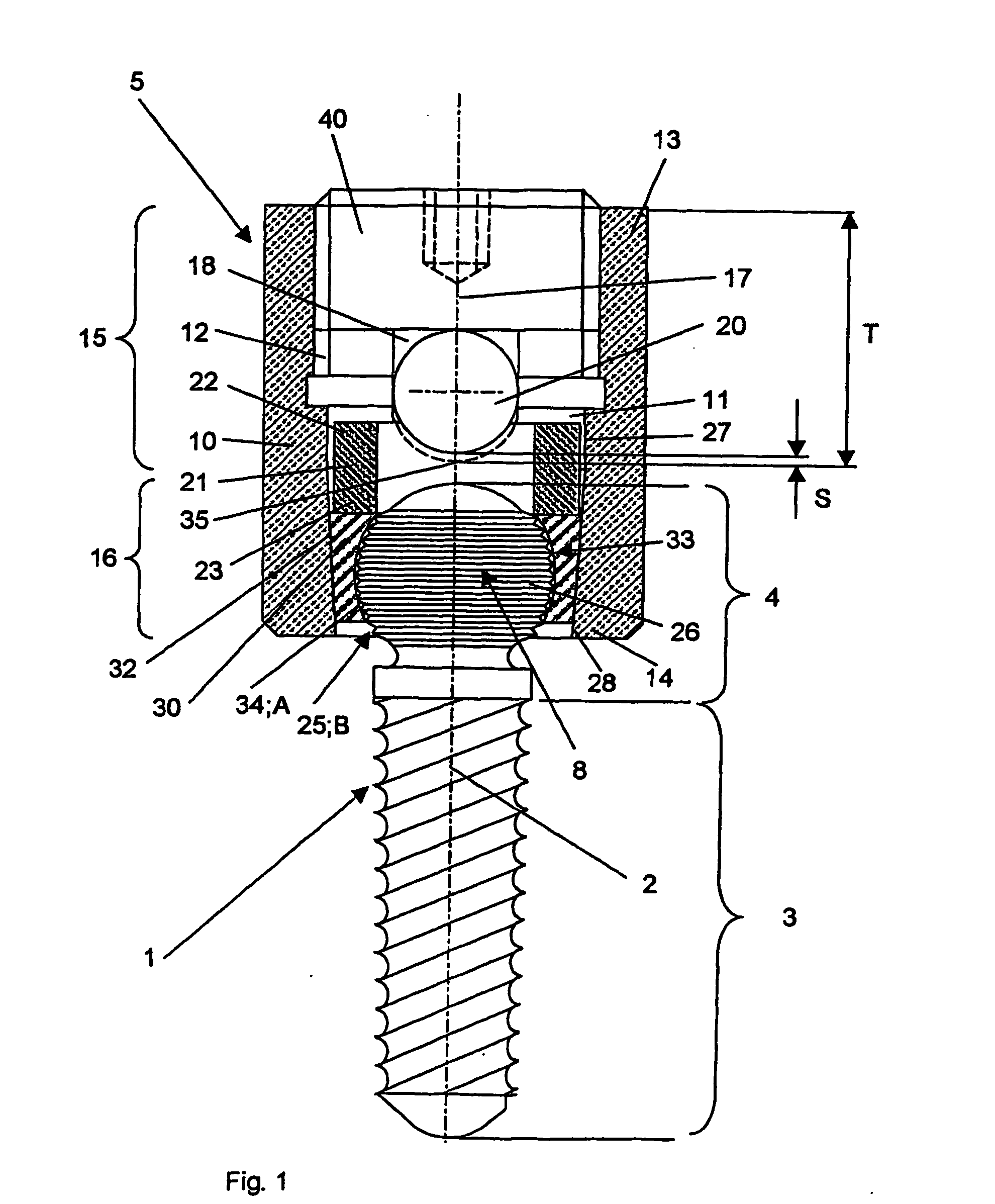

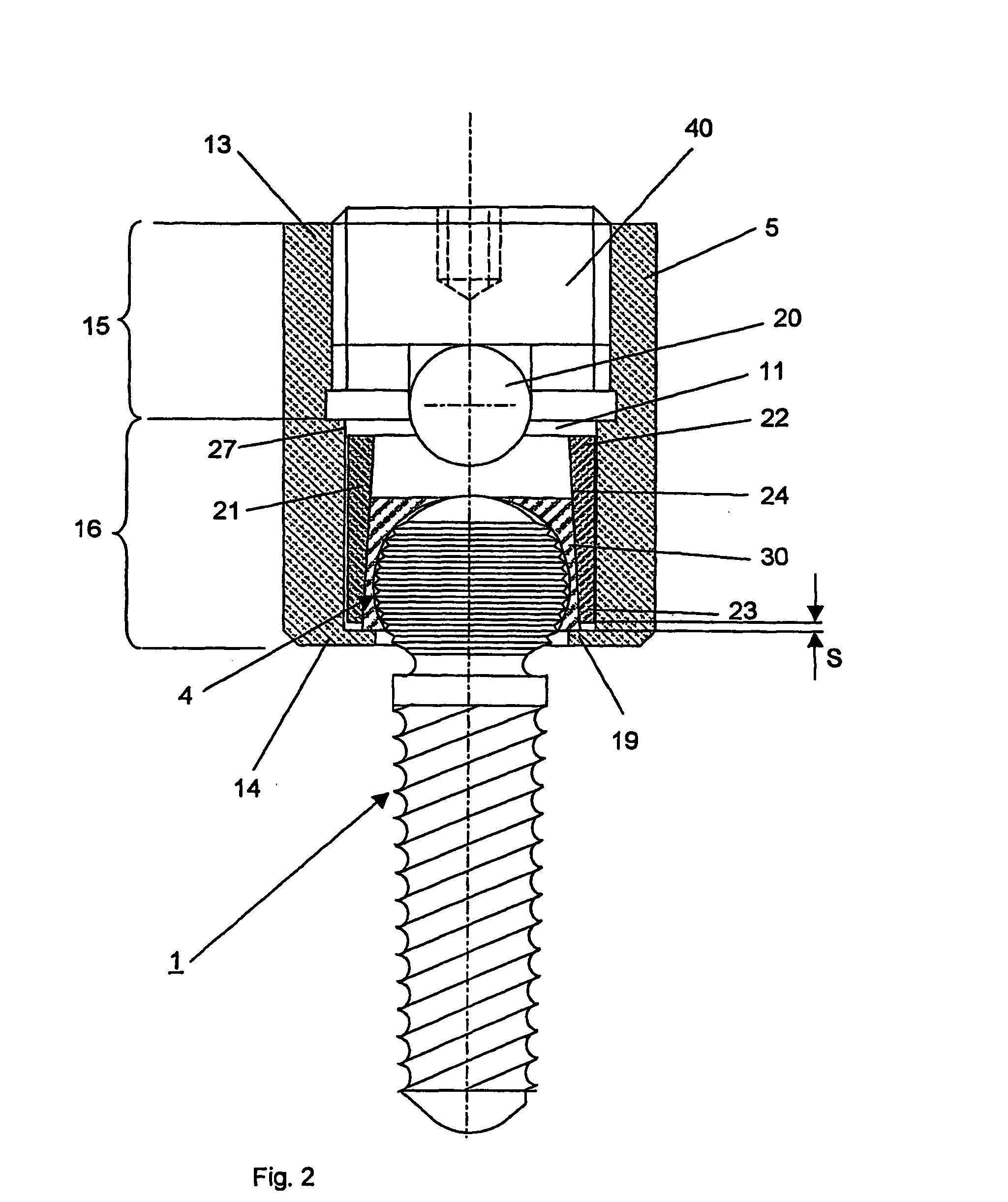

Device for the dynamic fixation of bones

InactiveUS20070233087A1Relieve pressureIncrease elasticitySuture equipmentsInternal osteosythesisDynamic fixationCoaxial cavity

An intermediate element for a detachable, lockable, ball joint-like connection in a device for the dynamic fixation of bones has a longitudinal axis, an outer wall concentric with the longitudinal axis, and an inner wall forming a coaxial cavity. Either the outer wall or the inner wall comprises one of two contact zones that form the ball joint-like connection. The intermediate element is at least partly made of a super-elastic or visco-elastic material.

Owner:SYNTHES USA

Biodegradable injectable implants containing glycolic acid

InactiveUS7314636B2Non-migratoryEasy to moveSolution deliveryPharmaceutical non-active ingredientsEmulsionGlycolic acid

Owner:MEDGRAFT MICROTECH

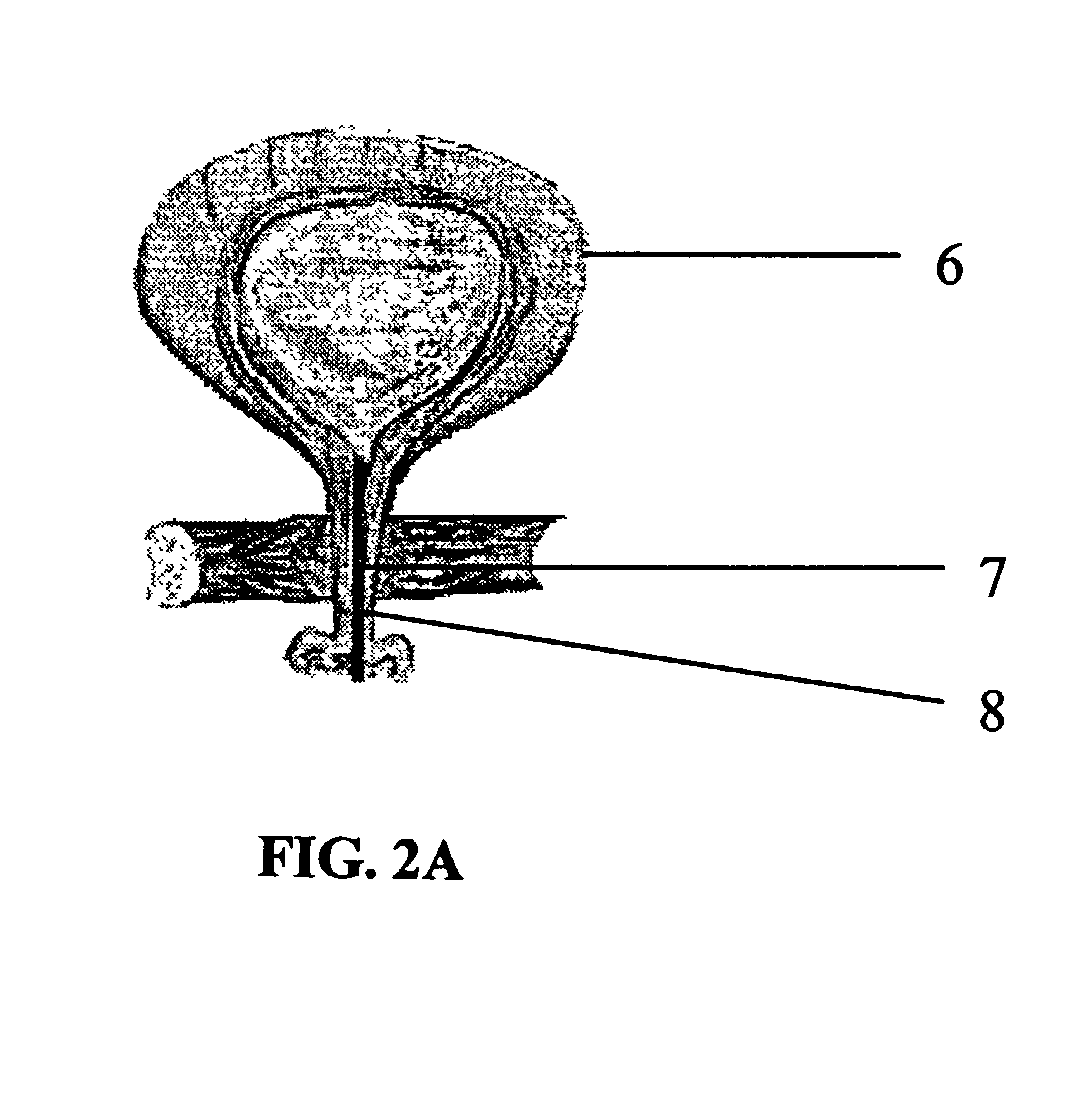

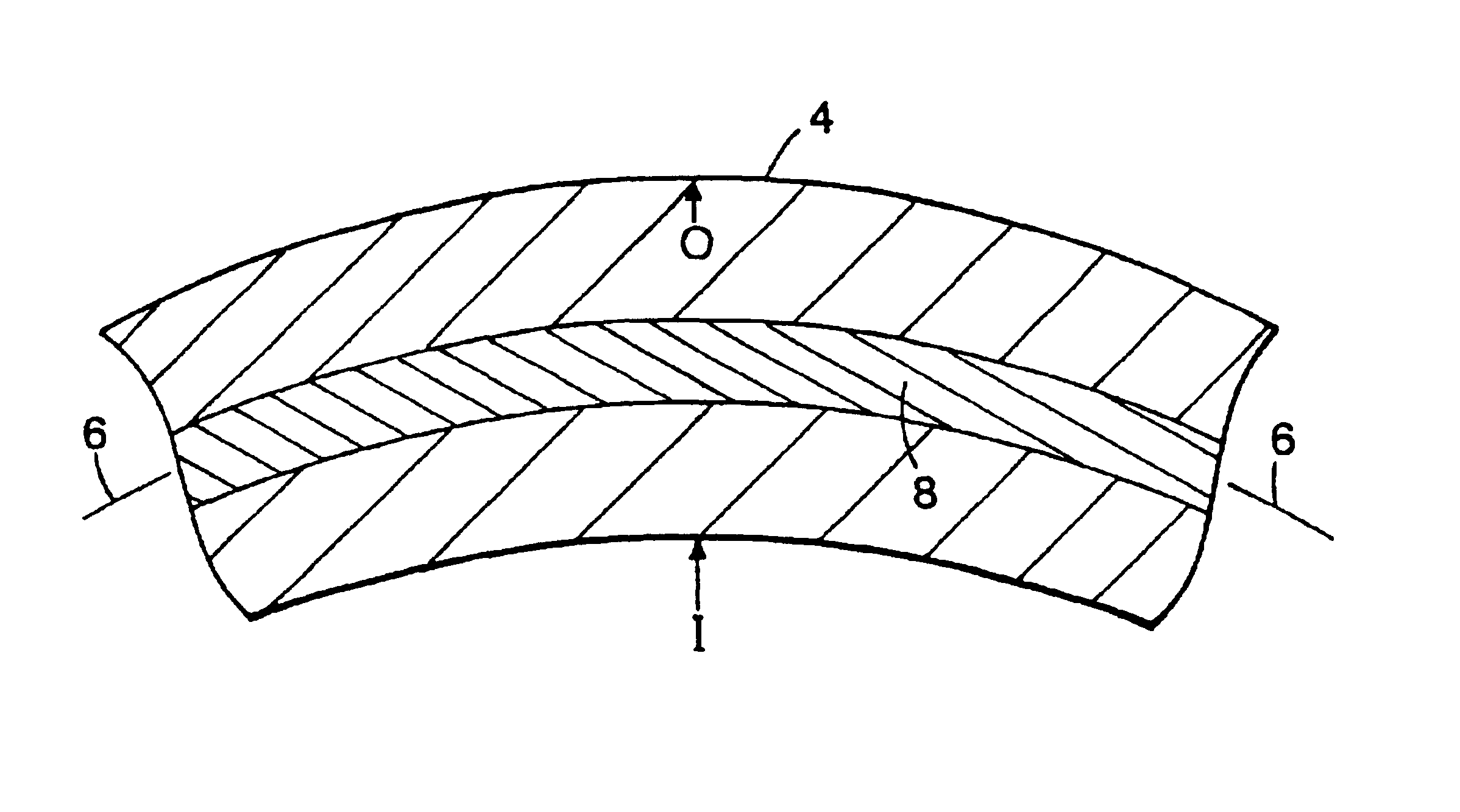

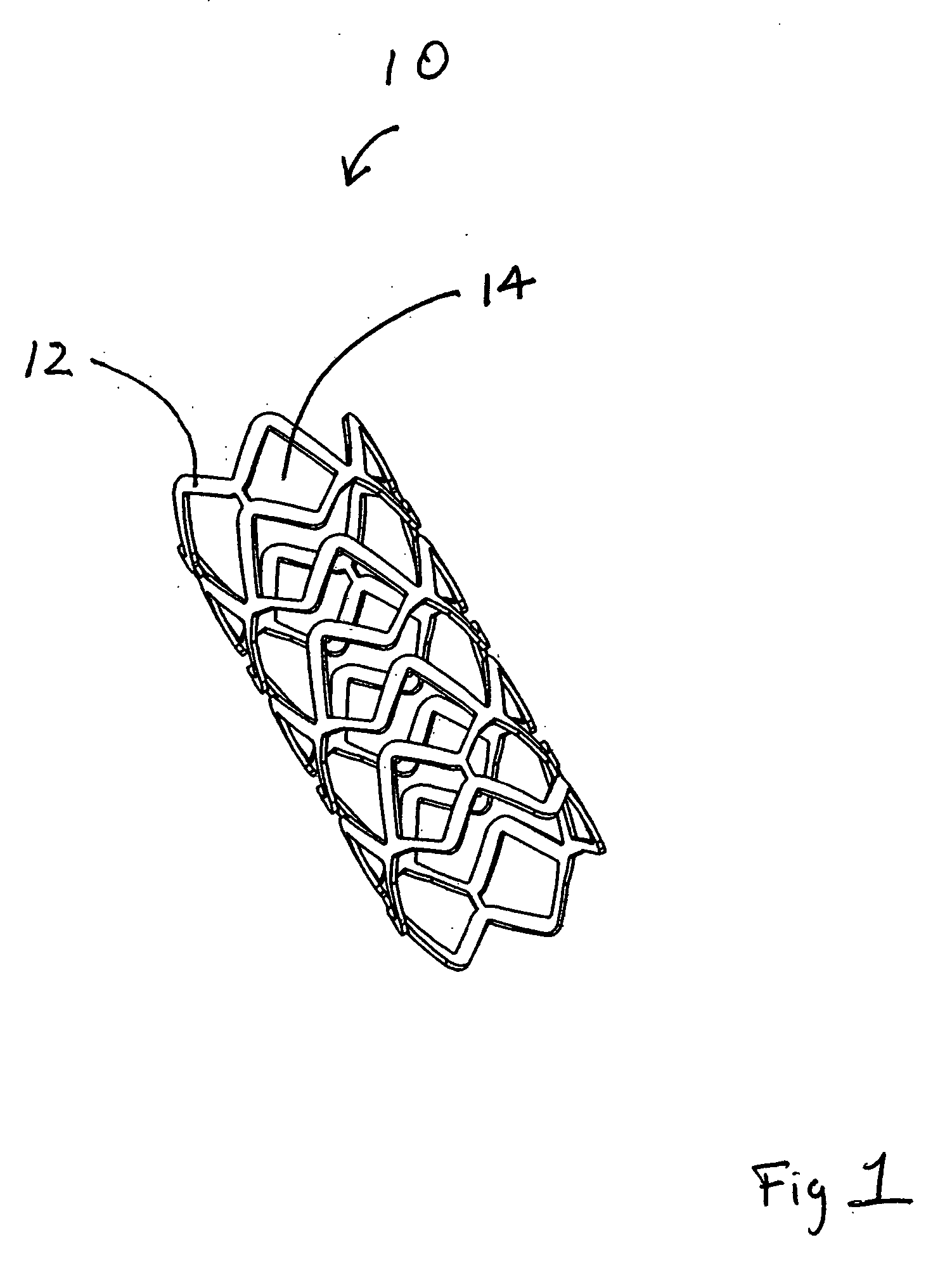

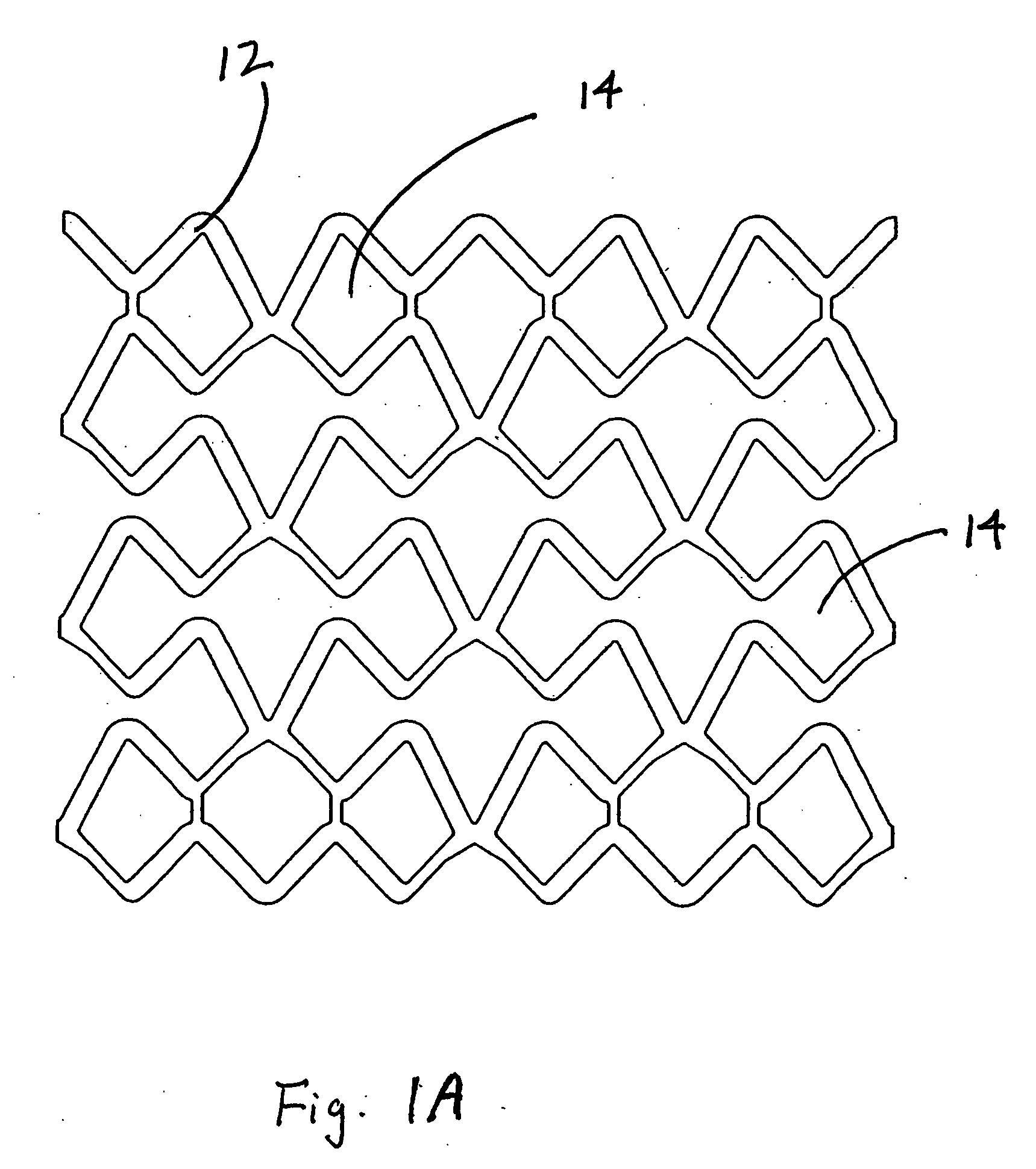

Tubular medical endoprostheses

InactiveUS7101392B2More elasticityImprove radiopacityStentsWeft knittingMetal filamentInsertion stent

A tubular prosthesis device for use within the body. The device includes, a metal filament material formed of metal outer member having an exposed outer surface and a core within the extended outer member formed of a different metal than the outer member. The core is secured within and substantially enclosed by the outer member. The device can be reduced to a small size for introduction into the body lumen and expandable to a sufficiently large size to engage the wall of the body lumen. Stents formed of composite wires are shown.

Owner:BOSTON SCI SCIMED INC

Thiol-modified hyaluronan

InactiveUS6884788B2High activityControl moreBiocideOrganic active ingredientsUrea derivativesCross-link

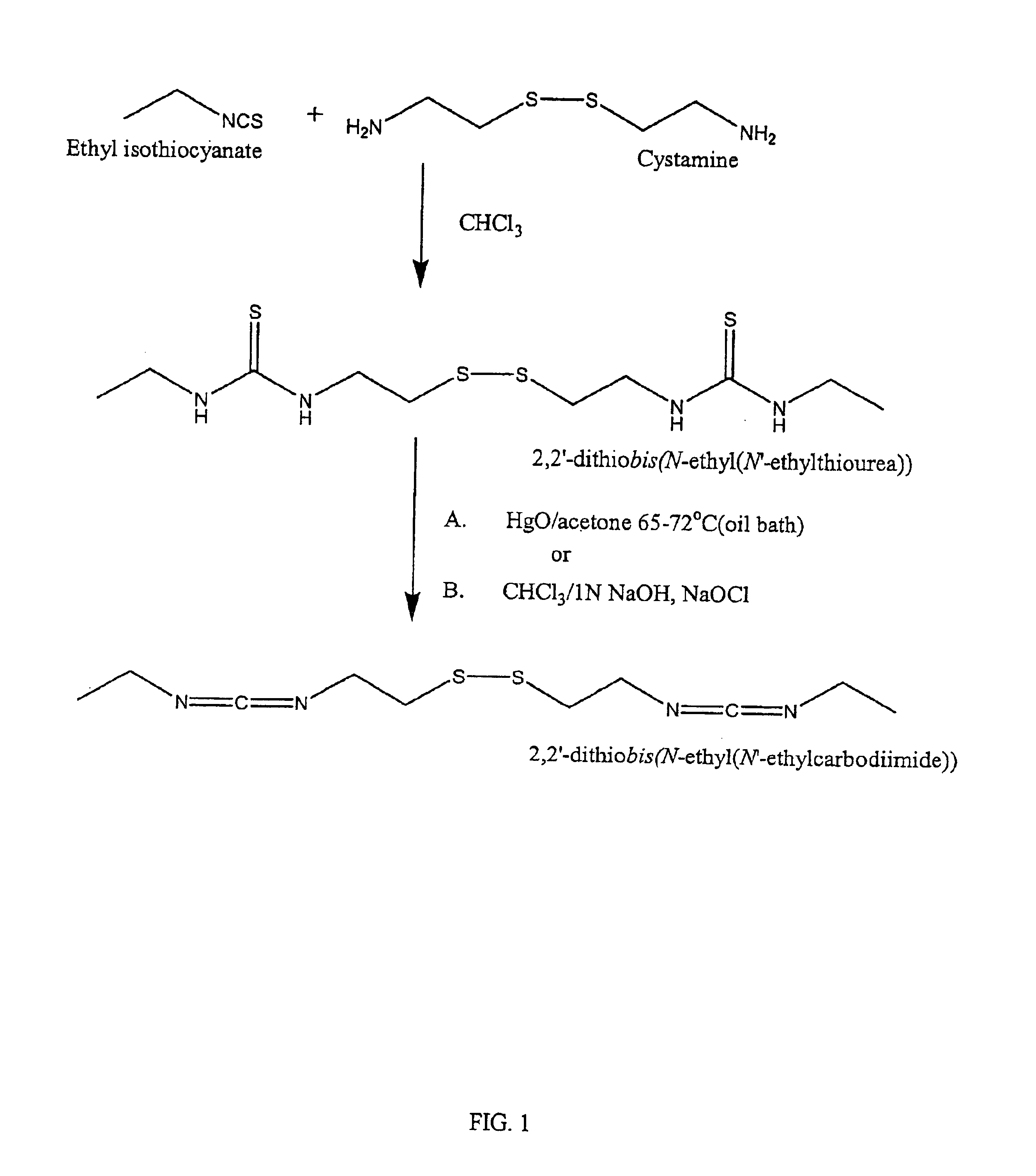

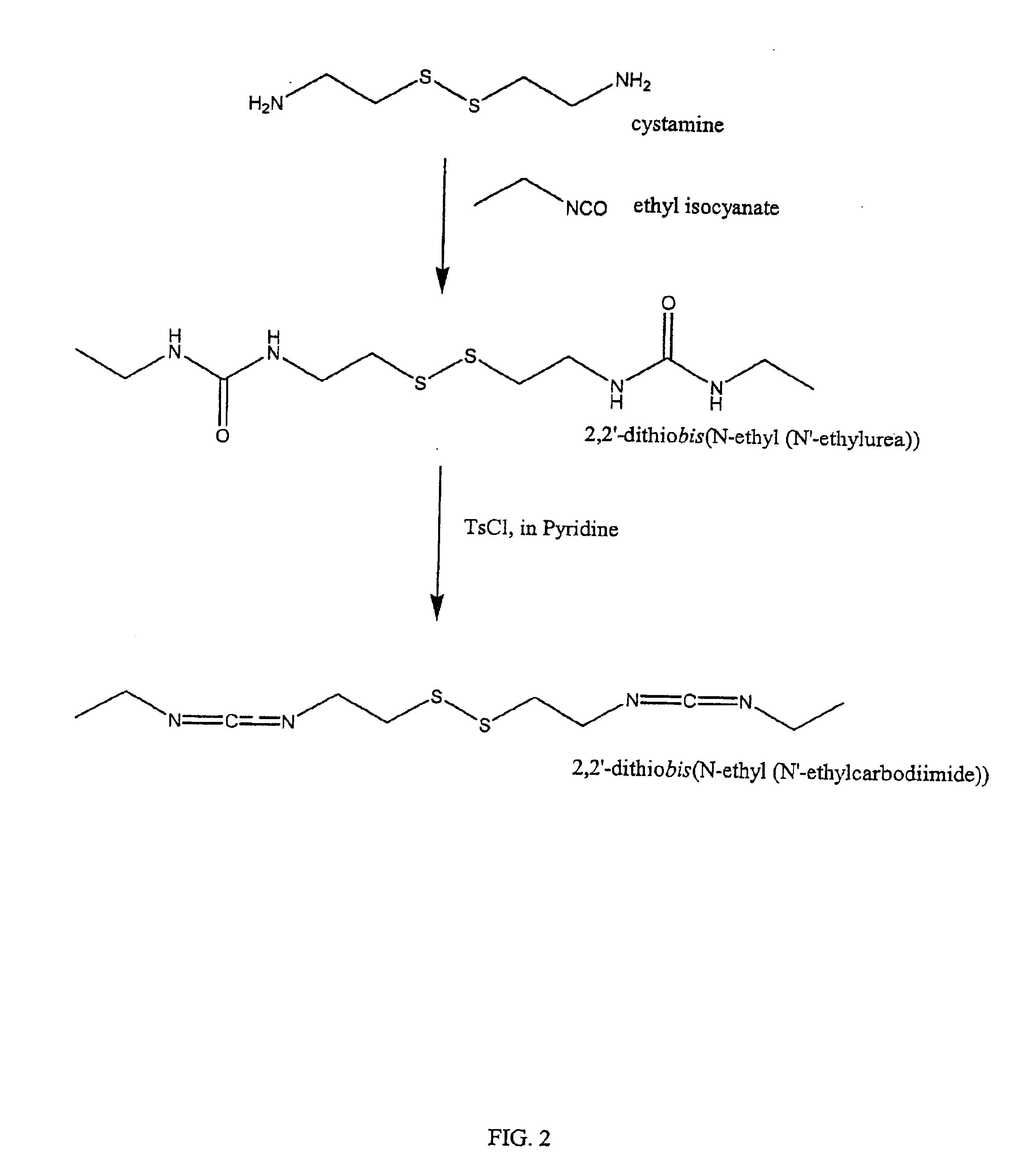

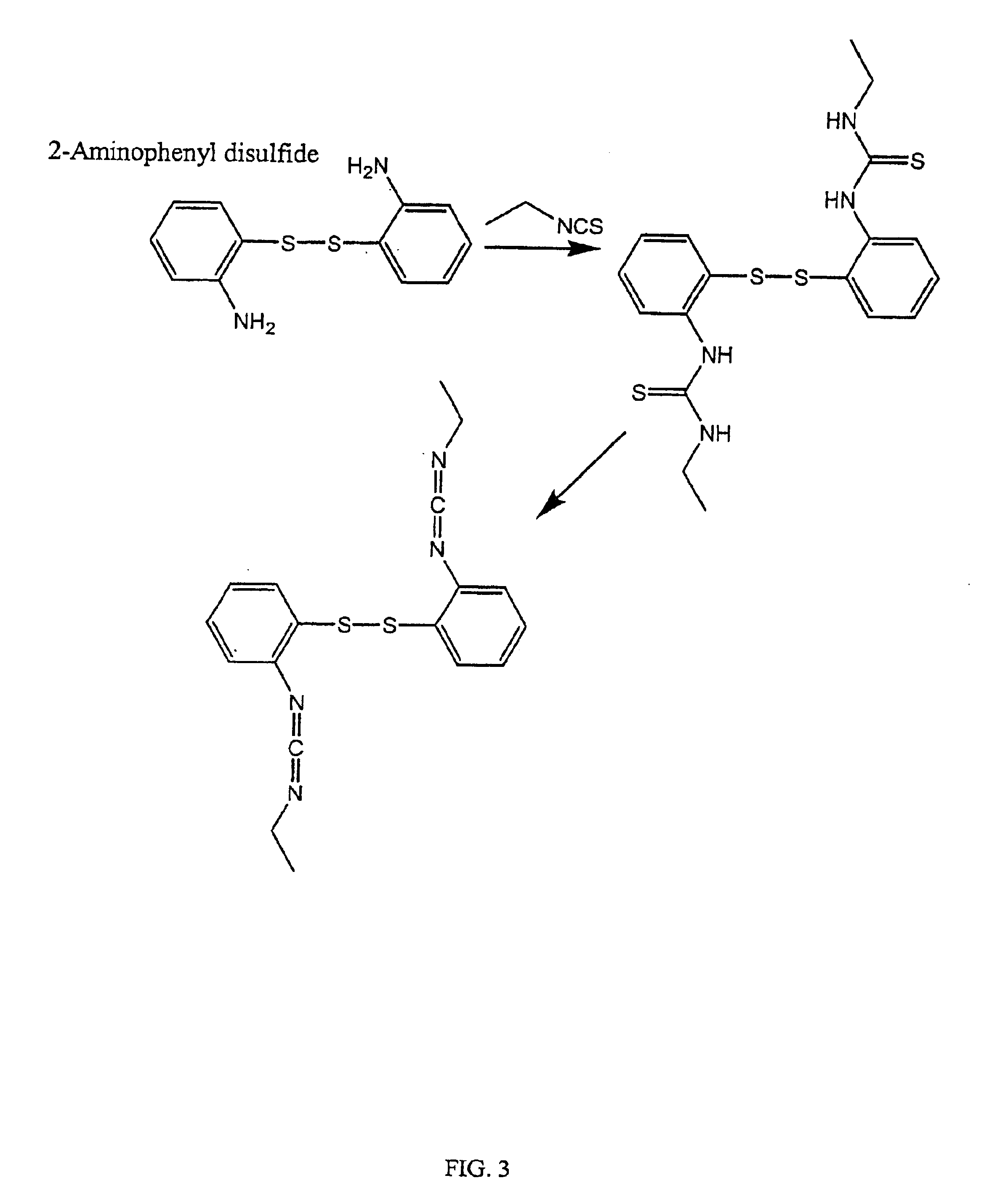

The present invention relates to biscarbodiimides, thiourea derivatives, urea derivatives, and cross-linked hyaluronan derivatives having at least one intramolecular disulfide bond, and methods of preparation thereof. The invention also includes thiolated hyaluronan derivatives and salts thereof having at least one pendant thiol group or a modified pendant thiol group, and methods of preparation thereof. An example of a modified pendant thiol group is a sulfhydryl group linked to a small molecule such as a bioactive agent, for example a drug or pharmaceutically active moiety. A hyaluronan derivative having a sulfhydryl group linked to a pharmaceutically active moiety is useful as a sustained or controlled release drug delivery vehicle. Compositions containing the hyaluronan derivatives of the invention can reversibly viscosify in vivo or in vitro, in response to mild changes in condition, and are thus useful in ophthalmic surgery and in tissue engineering.

Owner:ANIKA THERAPEUTICS INC

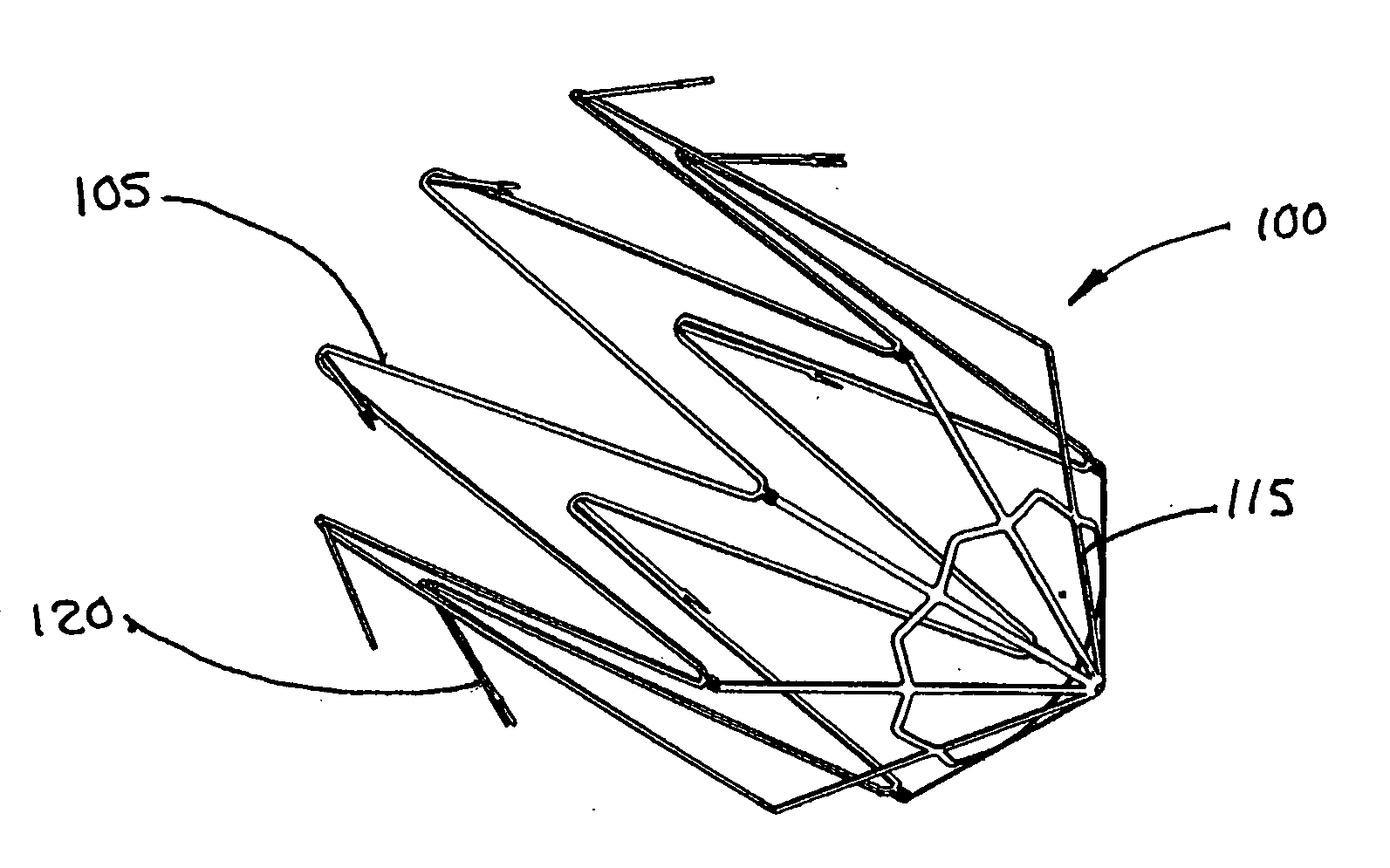

Bioabsorbable self-expanding endolumenal devices

InactiveUS20060025852A1Enhance tissue complianceReliable deploymentStentsOcculdersThermal transitionMedical device

The present invention is directed to bioabsorbable self-expanding medical devices for use inside or outside body conduits that self-expand at, or below, normal human body temperature without requisite for a polymeric thermal transition

Owner:WL GORE & ASSOC INC

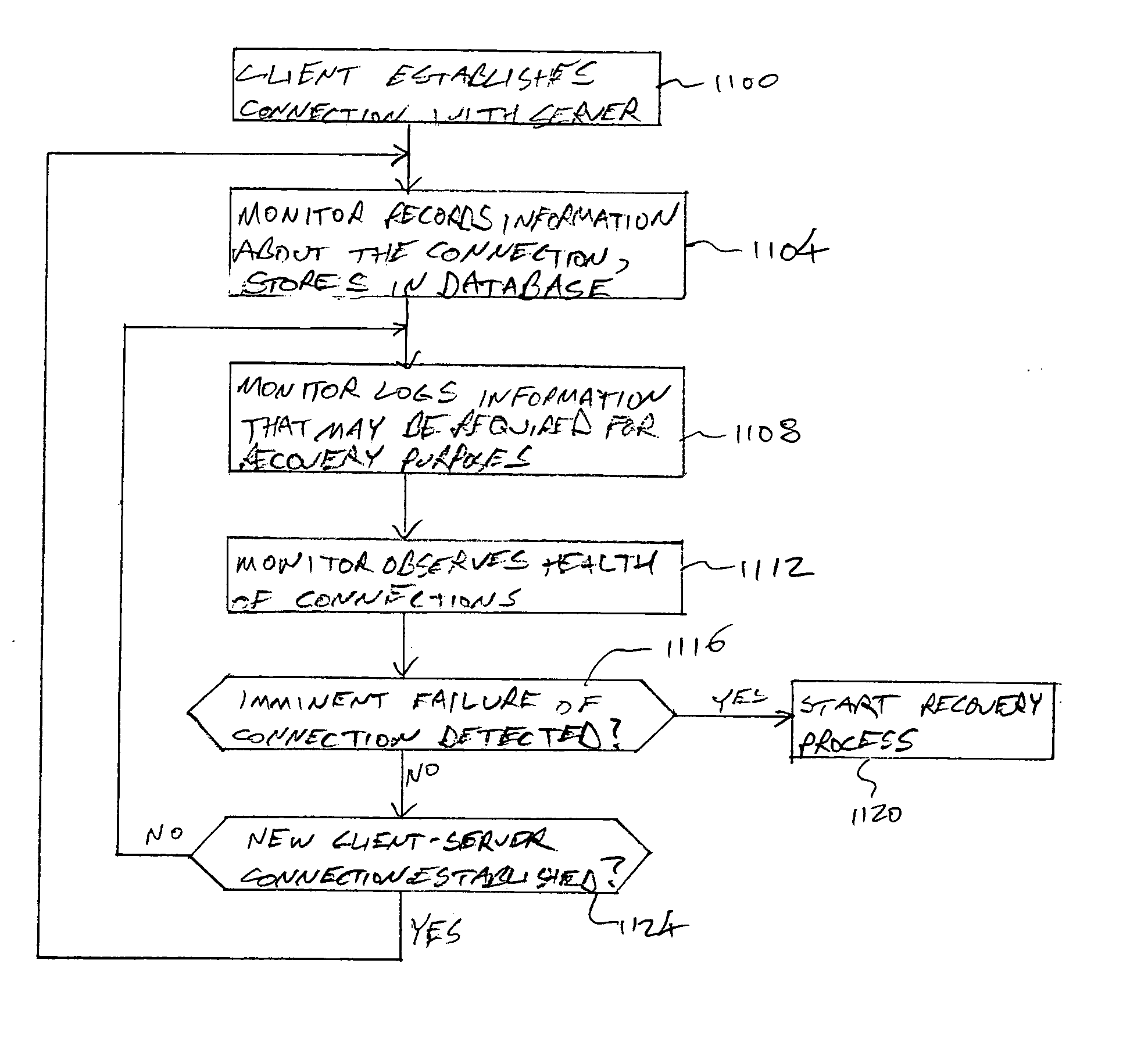

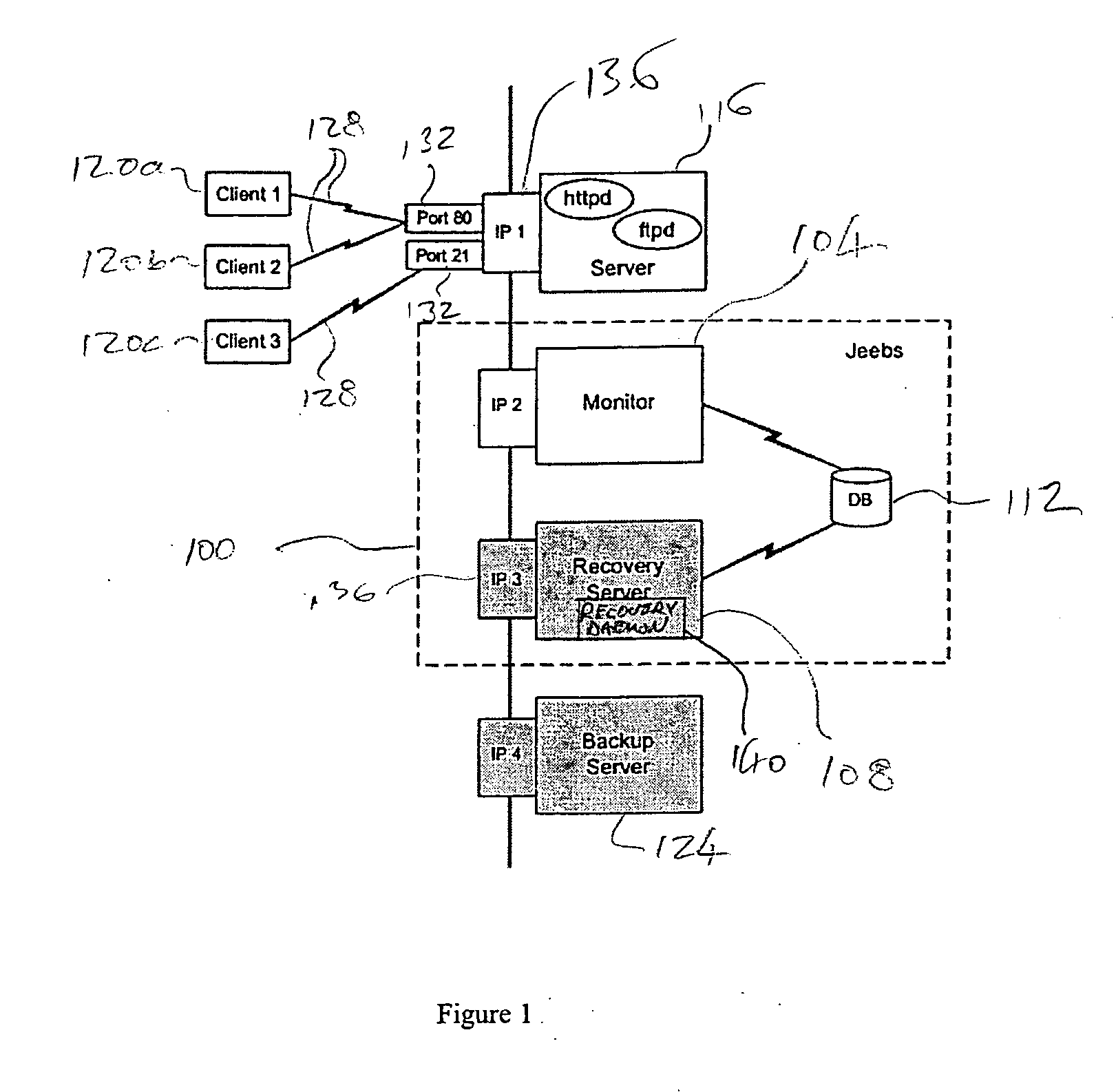

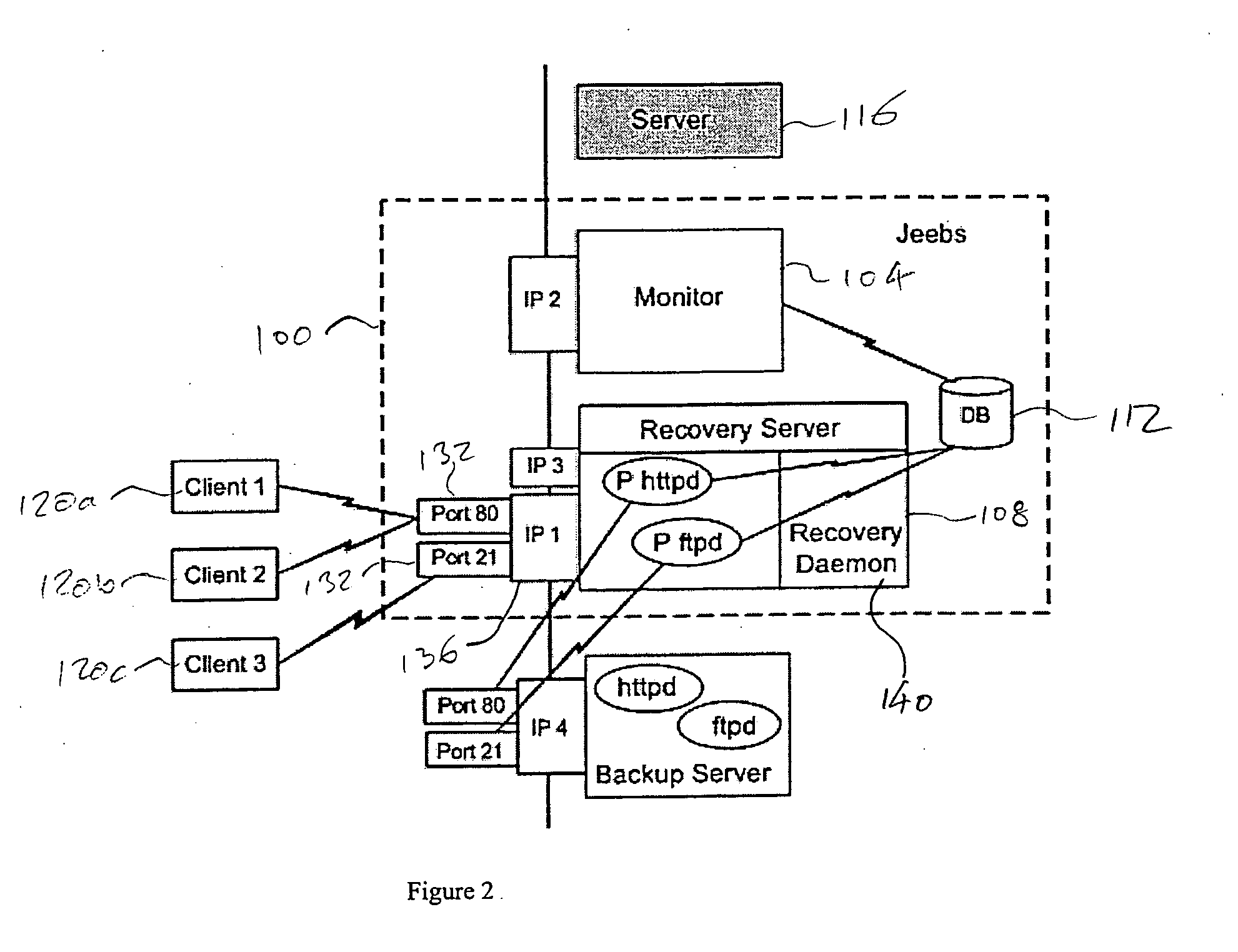

Techniques for client-transparent TCP migration

InactiveUS20050086342A1Improve reliabilityOvercome deficienciesDigital computer detailsData switching networksFailoverClient-side

Embodiments of the present invention provide increase resiliency to server failures by migrating TCP-based connections to backup servers, thus mitigating damage from servers disabled by attacks or accidental failures. The failover mechanism described is completely transparent to the client. Using these techniques, simple, practical systems can be built that can be retrofitted into the existing infrastructure, i.e. without requiring changes either to the TCP / IP protocol, or to the client system.

Owner:BURT ANDREW +2

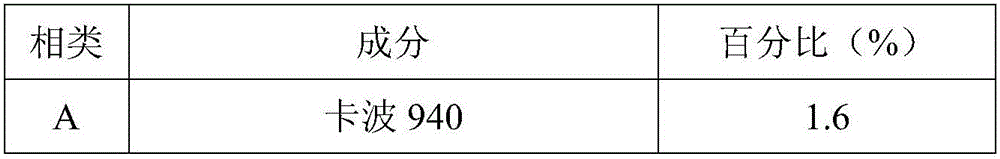

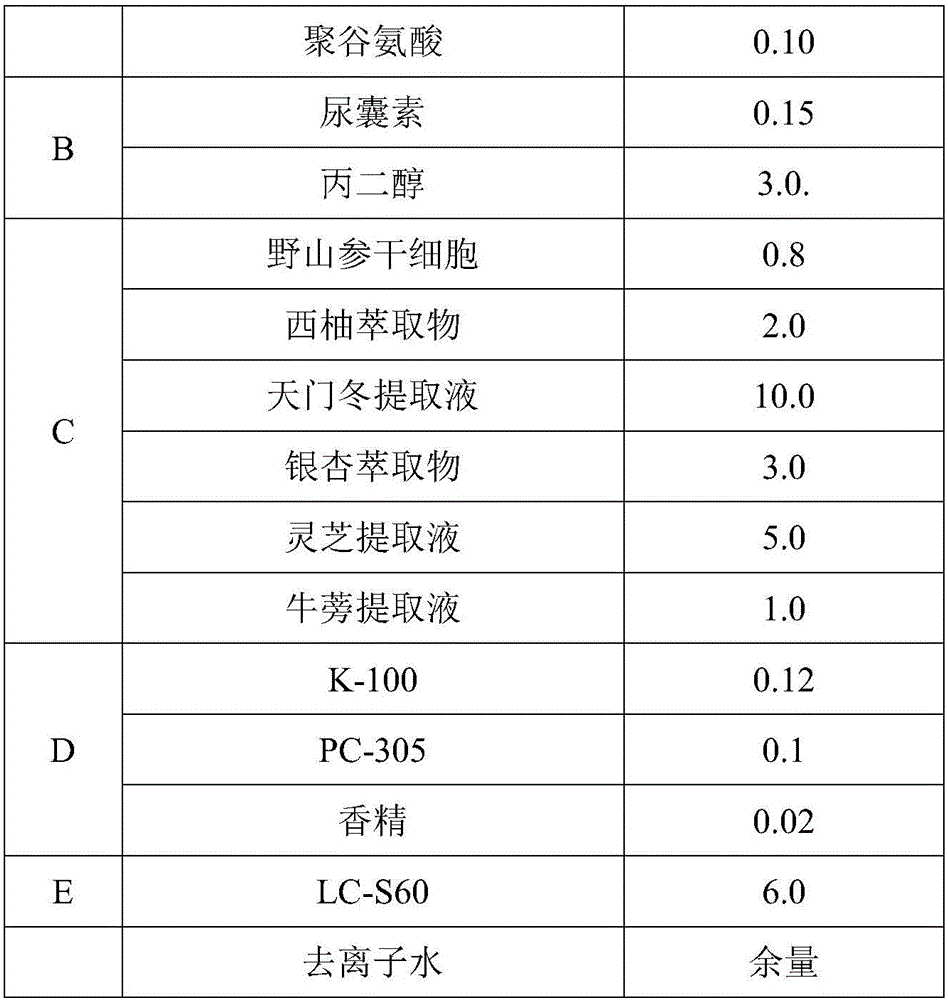

Natural plant extract composition and application thereof in cosmetics

ActiveCN105748343ASpeed up the repair processIncrease elasticityCosmetic preparationsToilet preparationsBiologyInflammation

The invention relates to the technical field of cosmetics, in particular to a natural plant extract composition and application thereof in the cosmetics. The natural plant extract composition is prepared from the following raw materials in parts by weight: 0.1 to 10 parts of plant stem cells, 2 to 10 parts of grapefruit extracts, 1 to 10 parts of radix asparagi extracting solution, 1 to 10 parts of gingko extracts, 5 to 10 parts of lucid ganoderma extracting solution, and 1 to 5 parts of burdock extracting solution. The natural plant extract composition provided by the invention not only has remarkable moisturizing and anti-aging effect, but also has the effects in removing acnes, adjusting grease secretion, resisting inflammation and relieving, and can be used for preparing moisturizing, anti-aging or acne-removing cosmetics.

Owner:GUANGDONG COOWAY BIOTECH CO LTD

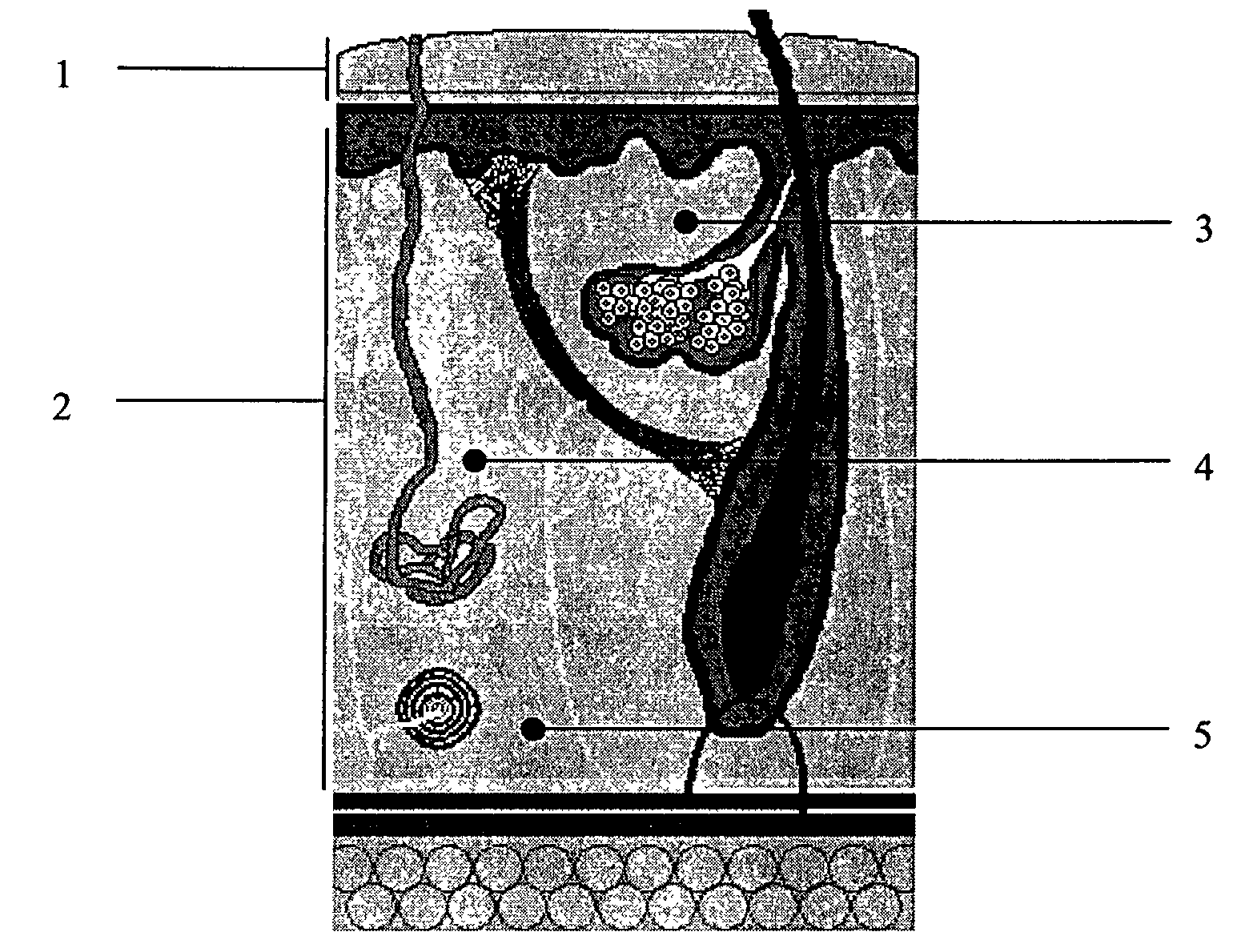

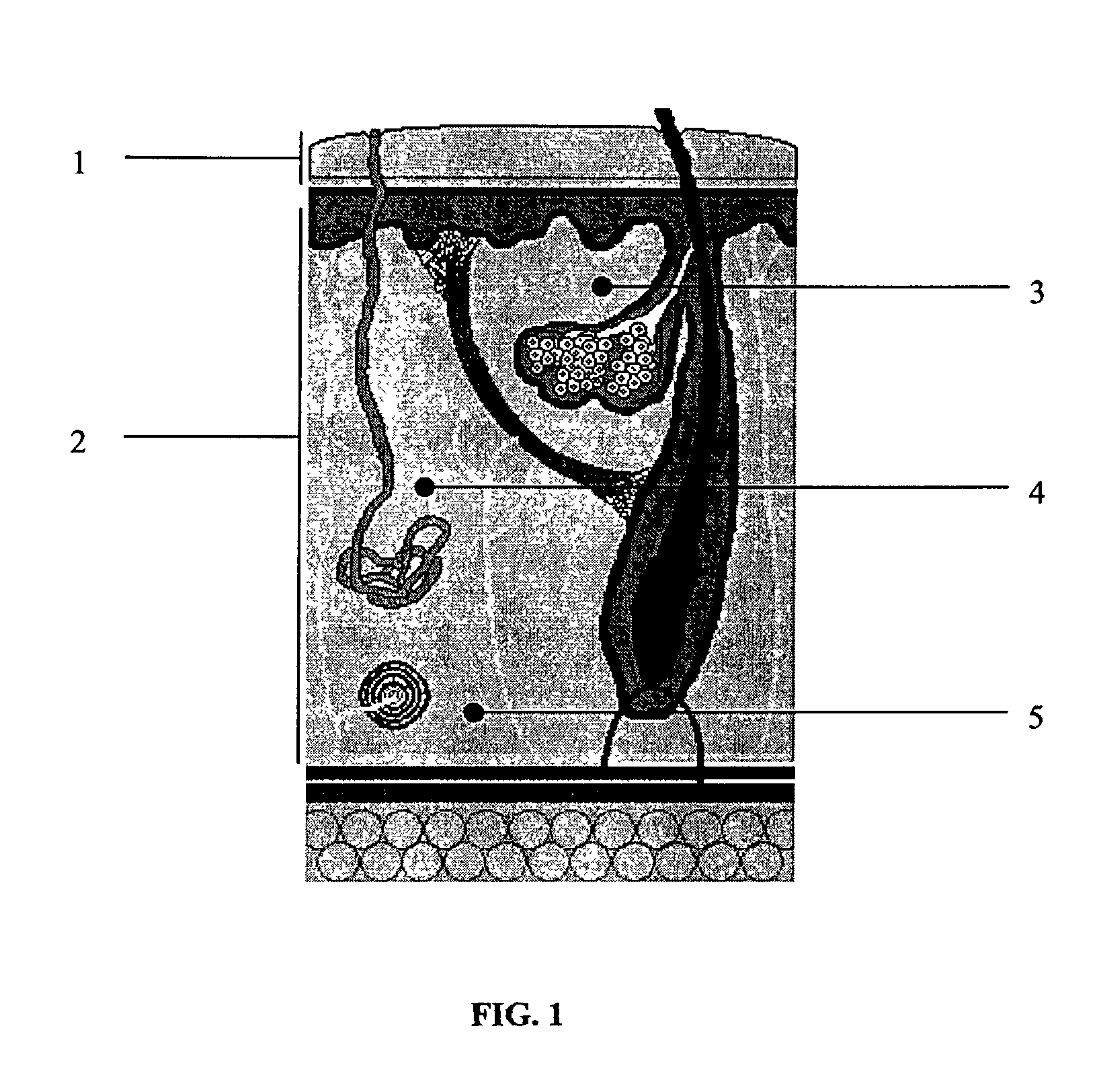

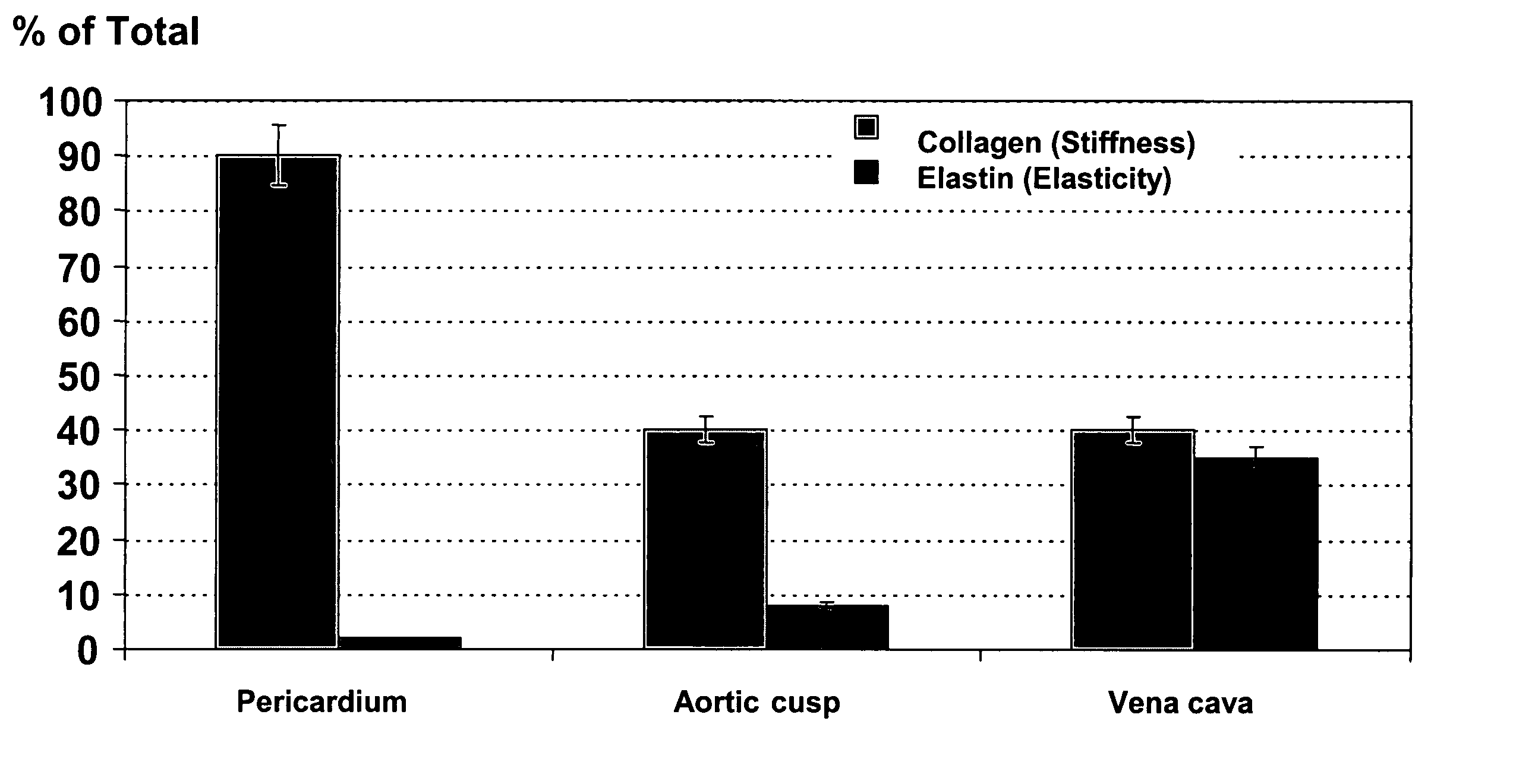

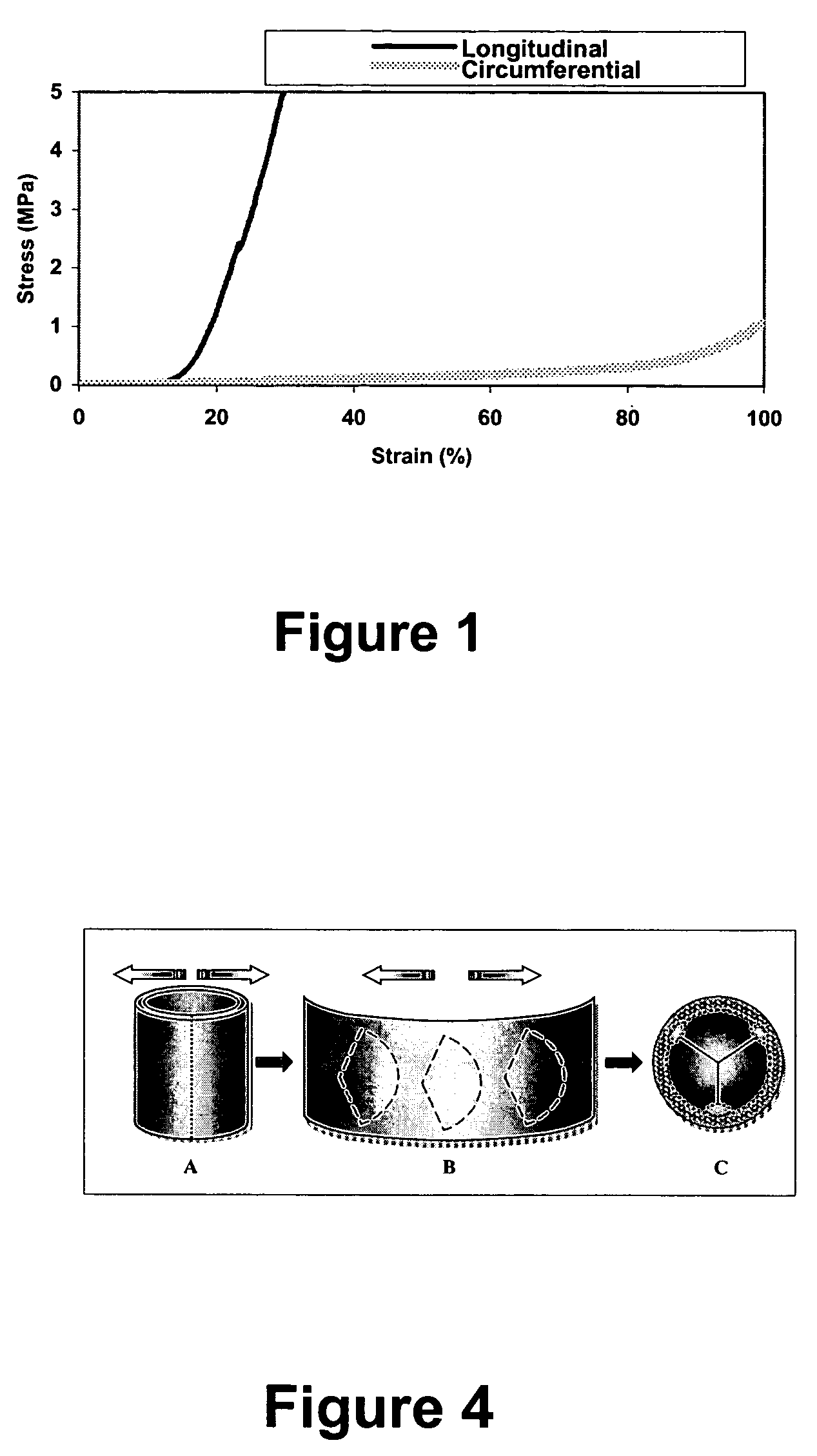

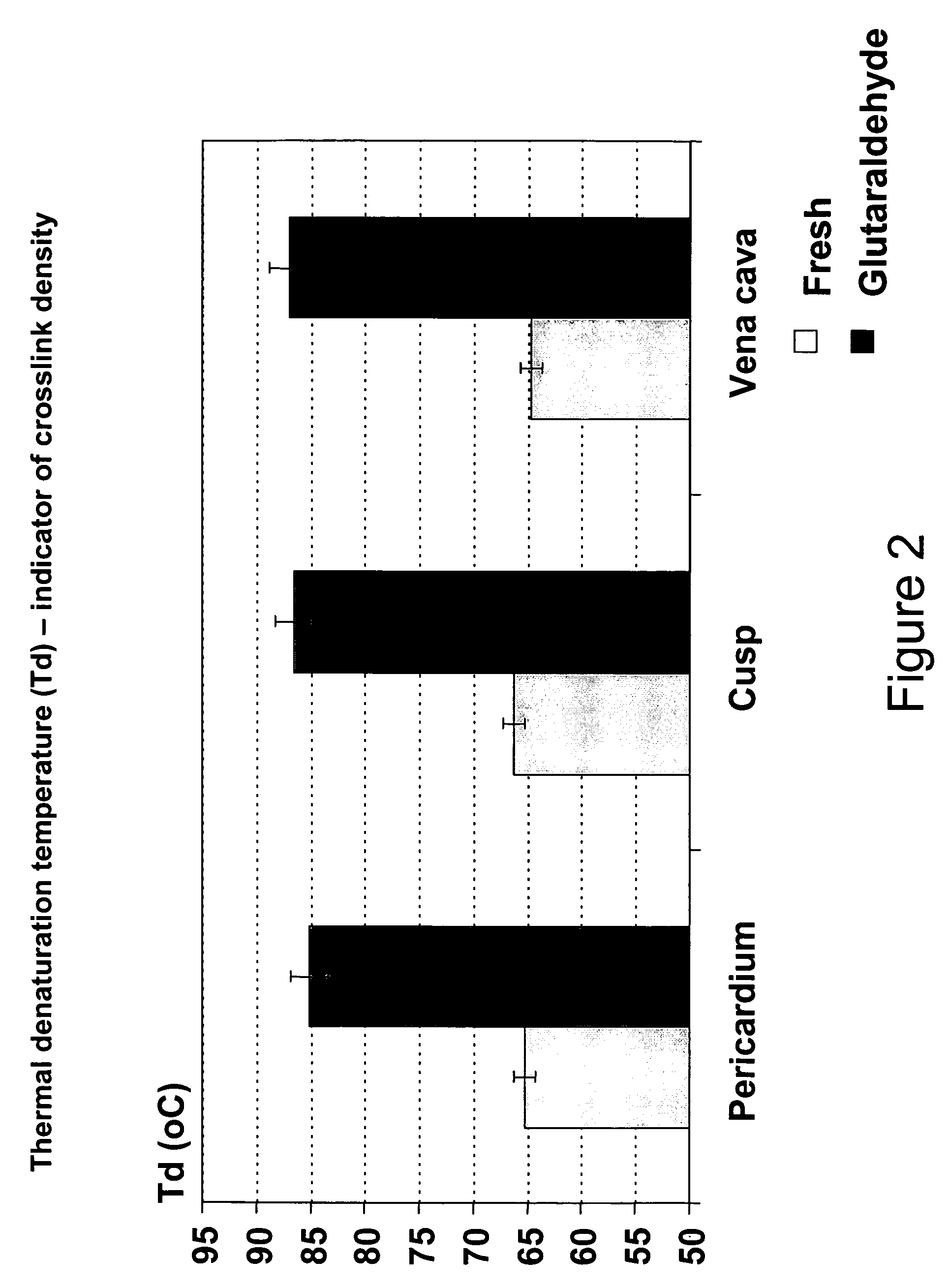

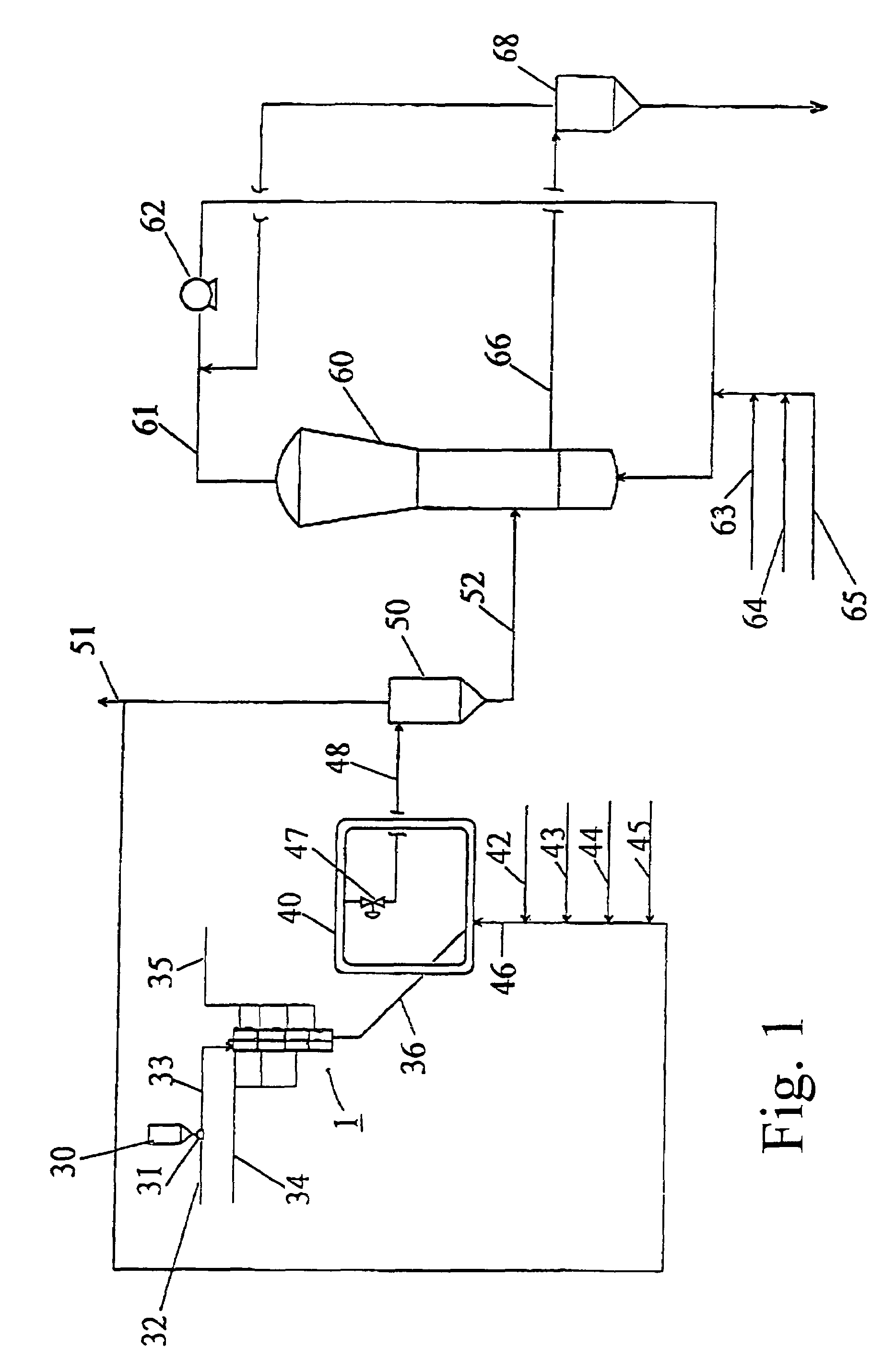

Tissue material and process for bioprosthesis

A biomaterial useful for bioprostheses such as bioprosthetic heart valves is provided in which the fixed tissue has improved elastic properties. The high elastin-containing biomaterial is further characterized by having anisotropic properties wherein the biological material has a greater stiffness in one direction and a greater elasticity in a cross direction. For instance, the biological material has an elastin content of about 30% by weight. In one embodiment, the biological material is vena cava tissue.

Owner:CLEMSON UNIV RES FOUND

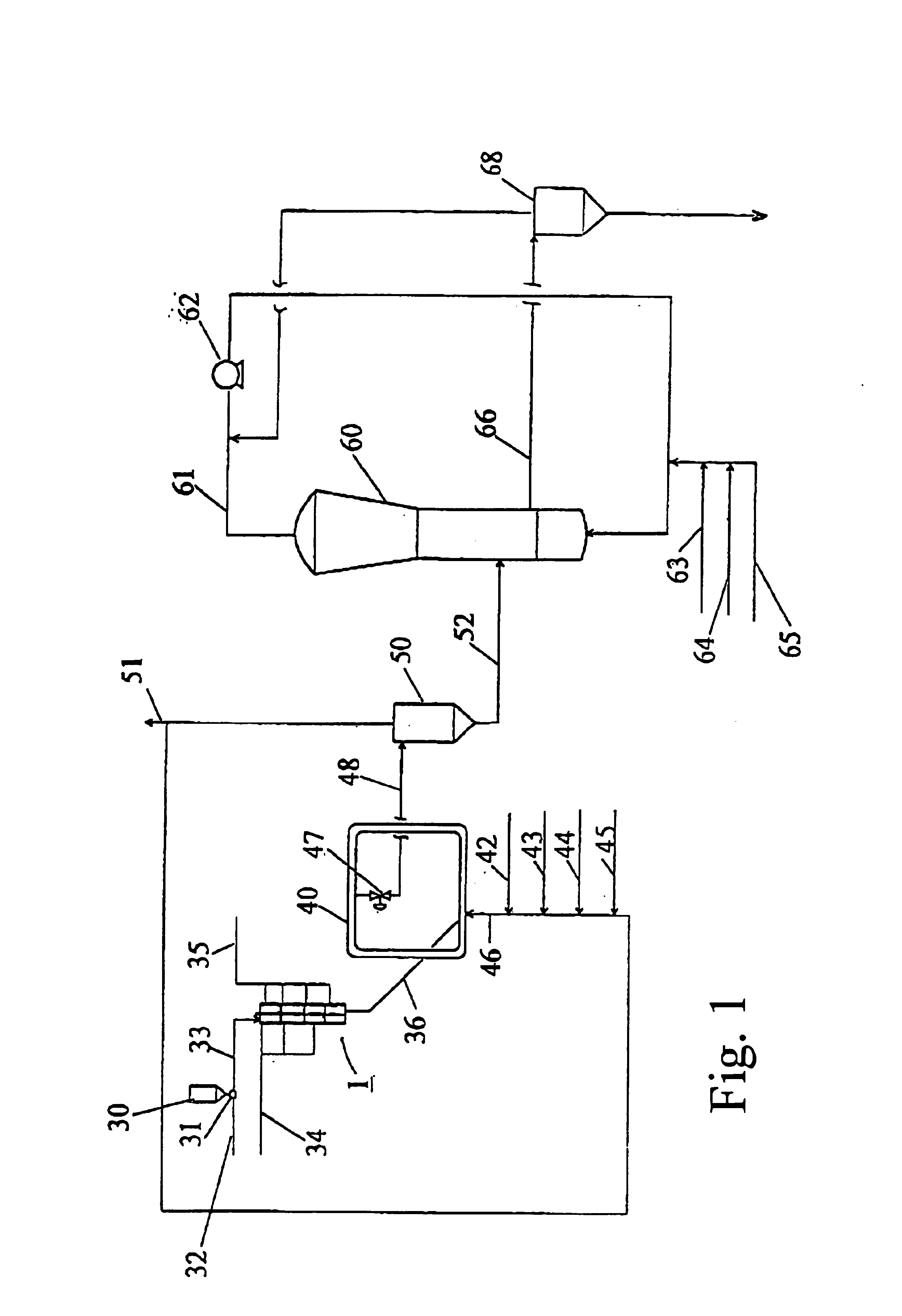

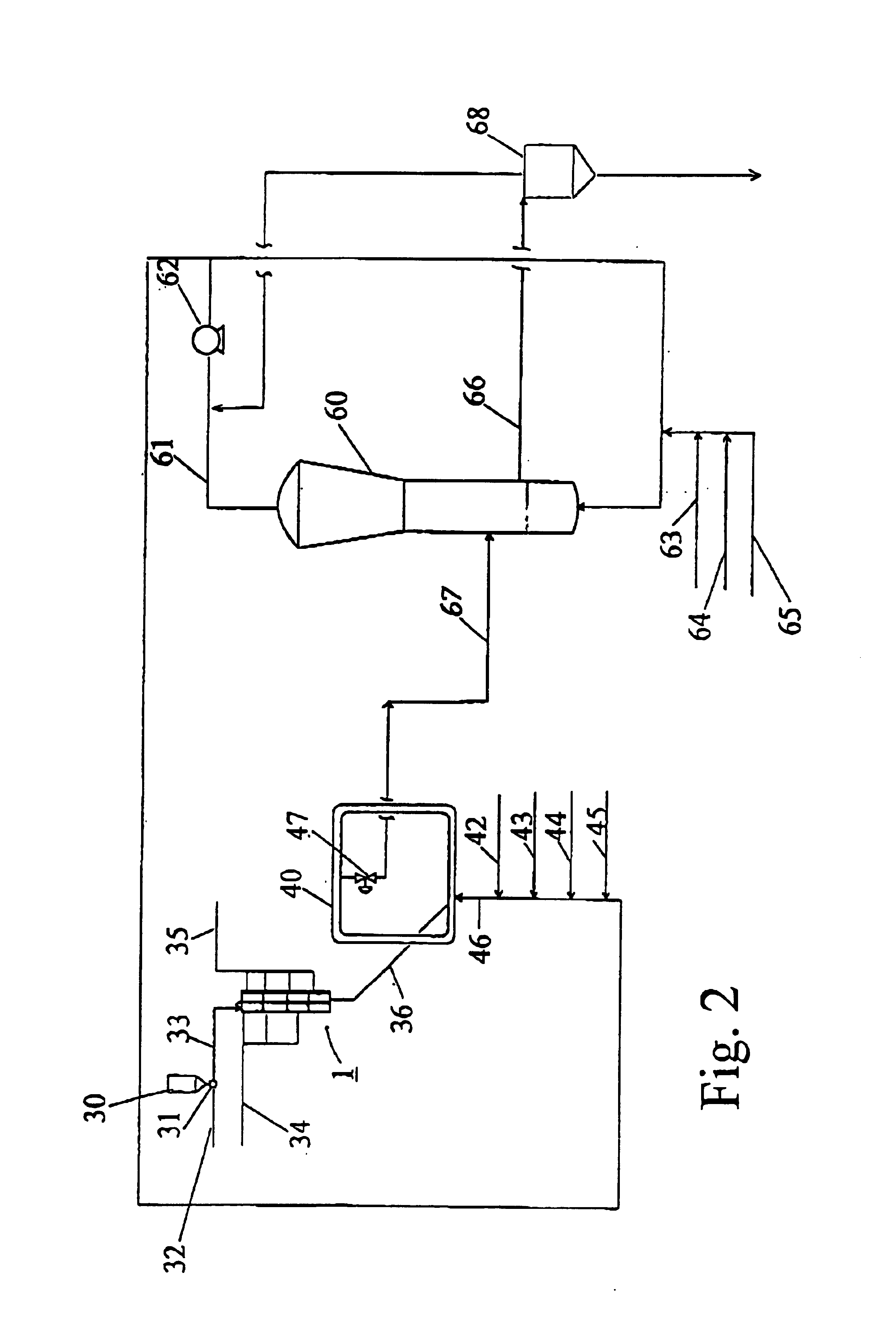

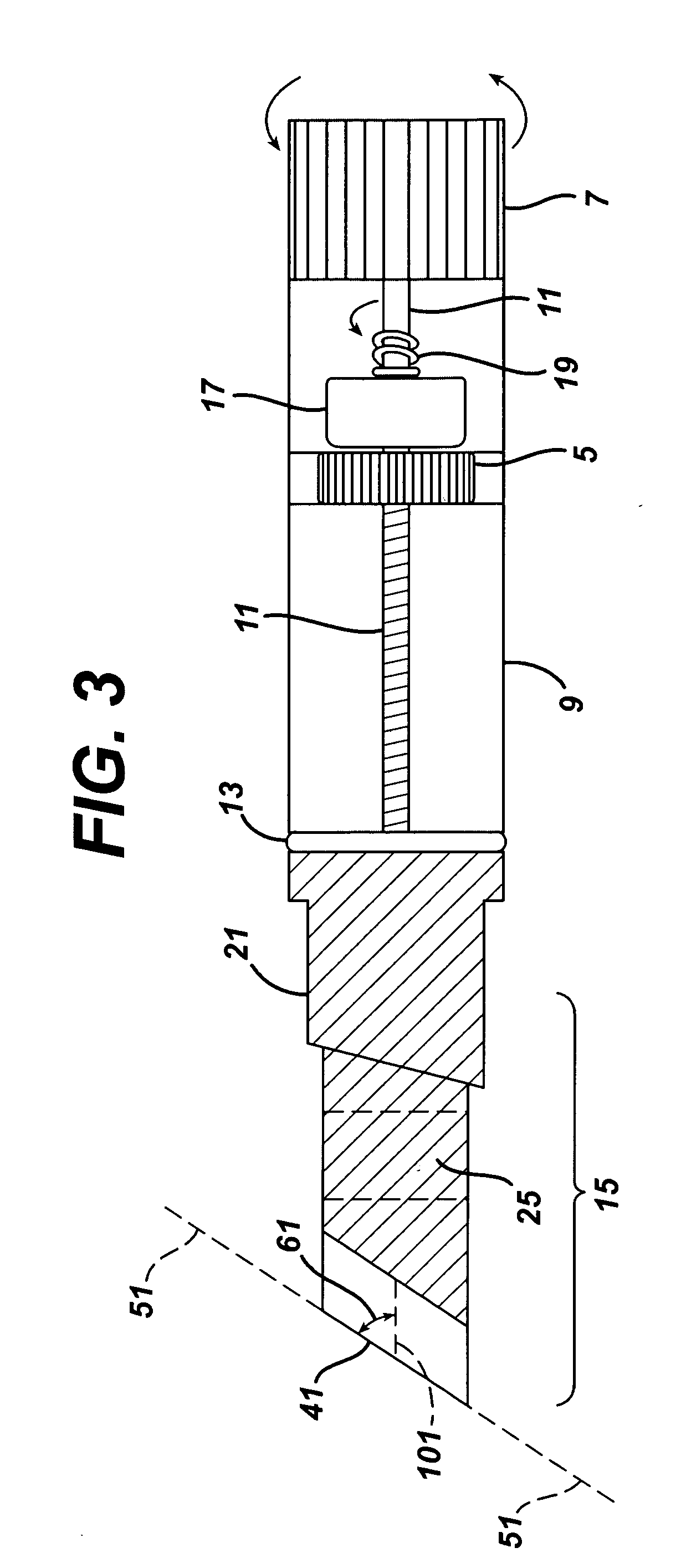

High melt strength polypropylene

InactiveUS7365136B2Improve melt strengthHigh viscosityChemical/physical/physico-chemical stationary reactorsPolymer sciencePtru catalyst

The present invention concerns a high melt strength propylene polymer or copolymer suitable for manufacturing foams and thermoformed product exhibiting a melt strength of at least 3 g and comprising a high molar mass portion and a low or medium molar mass portion. The polymers are produced by subjecting propylene and optionally other olefins to polymerization in a plurality of polymerization reactors connected in series, employing different amounts of hydrogen as a molar mass modifier in at least two of the reactors, and carrying out the polymerization reaction in the presence of a catalyst system capable of catalyzing the formation of a high molar mass polymerization product having a MFR2 of less than 0.1 g / 10 min and a low or medium molar mass polymerization product having a MFR2 of more than 0.5 g / 10 min.

Owner:BOREALIS TECH OY

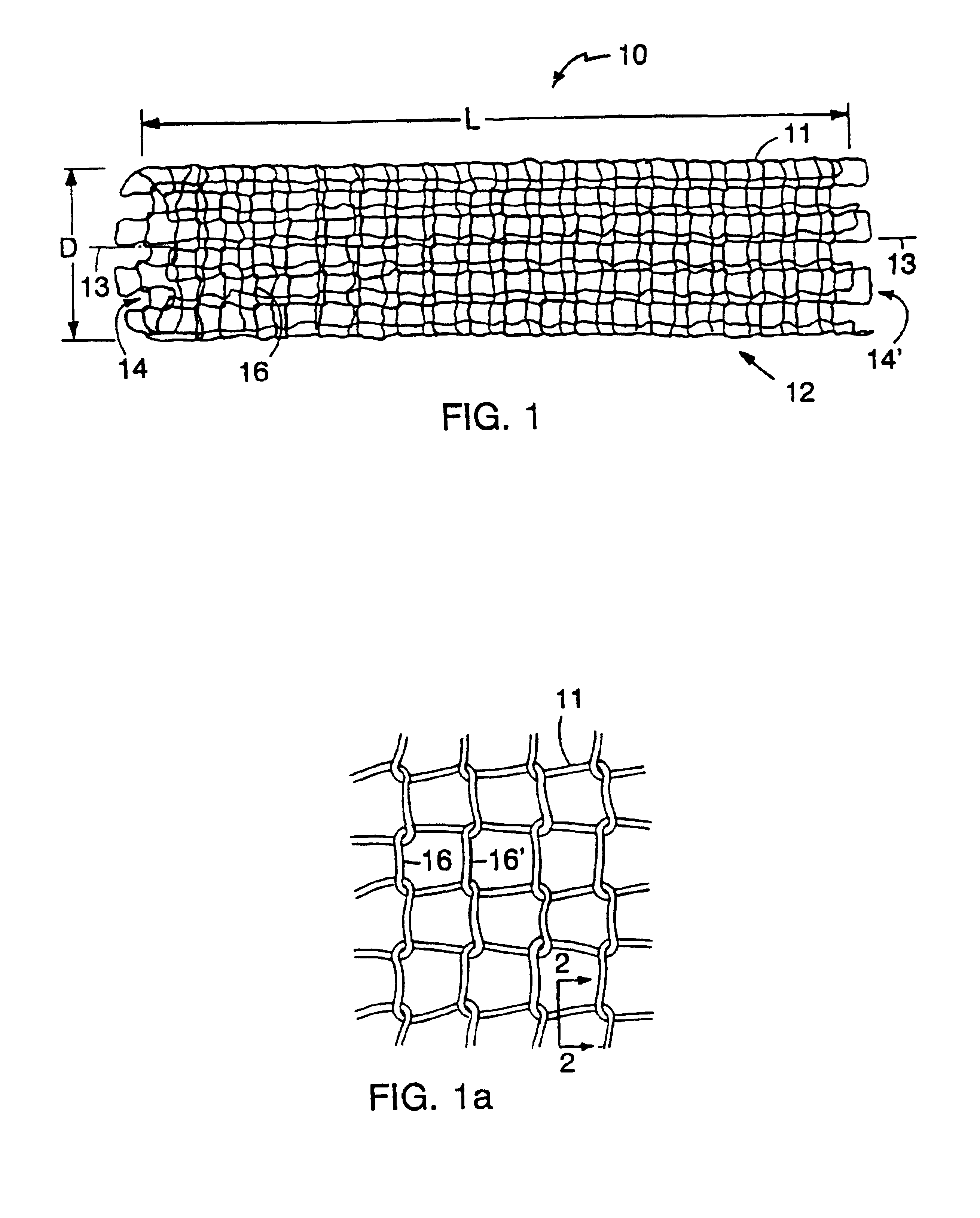

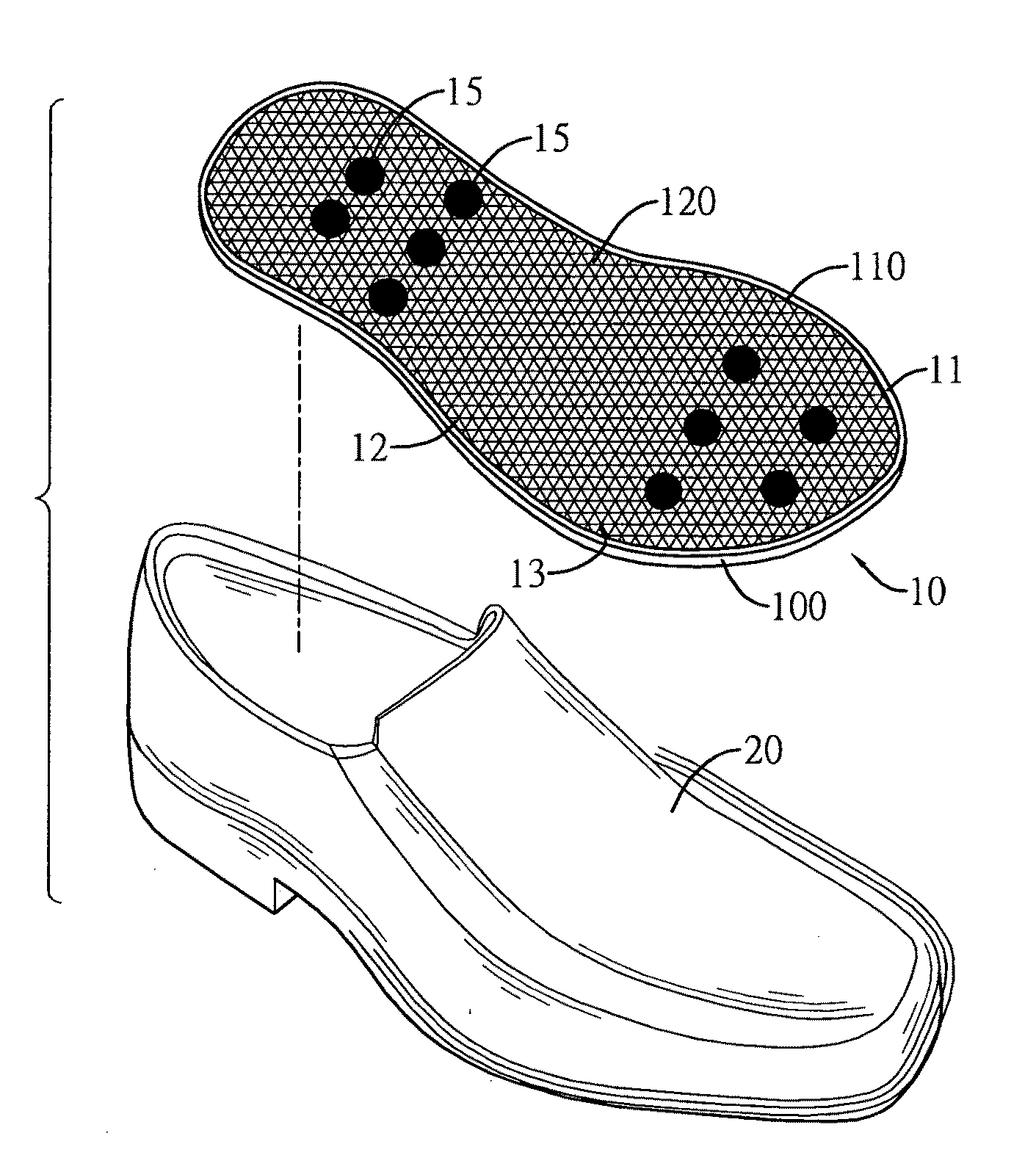

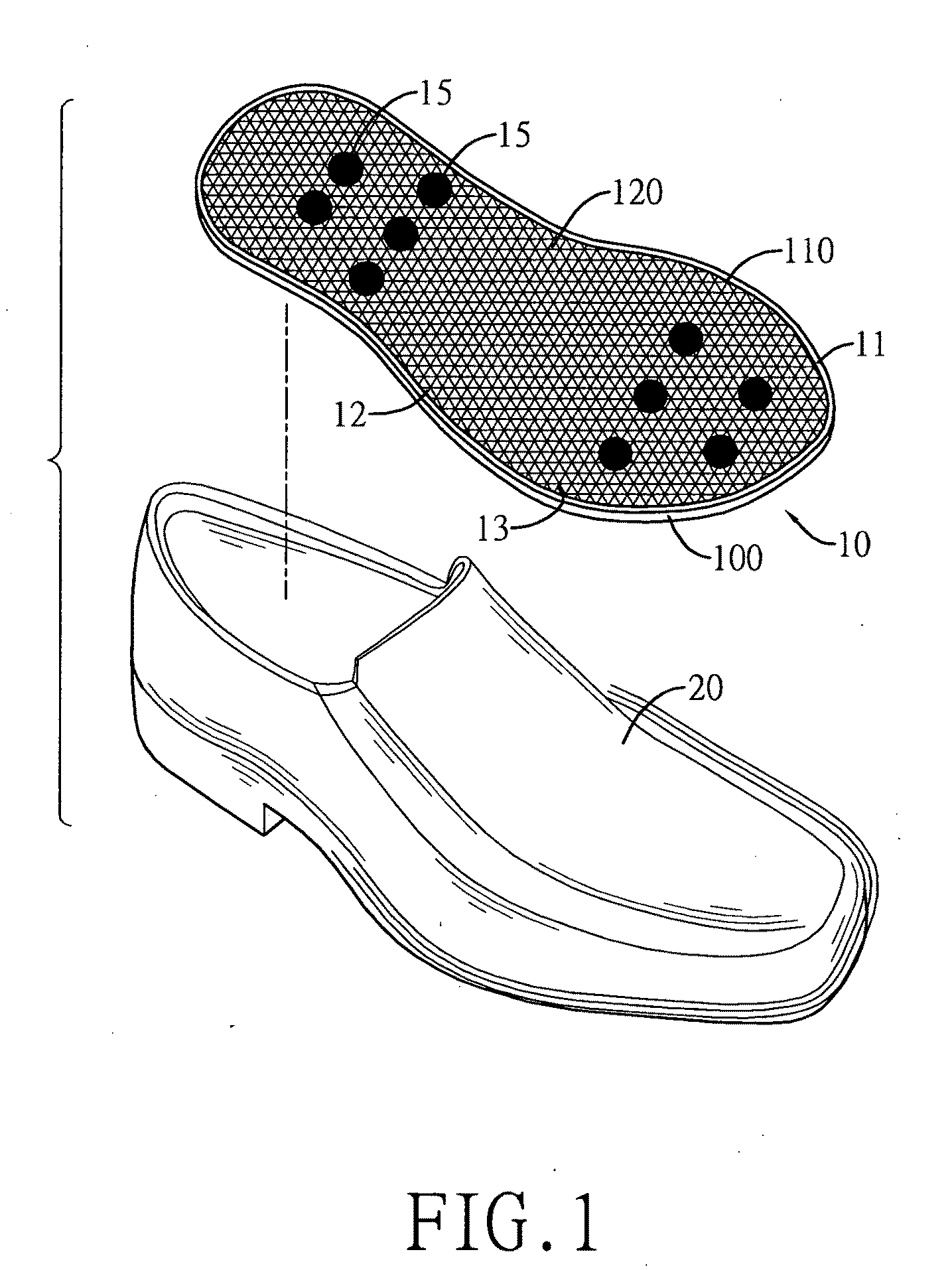

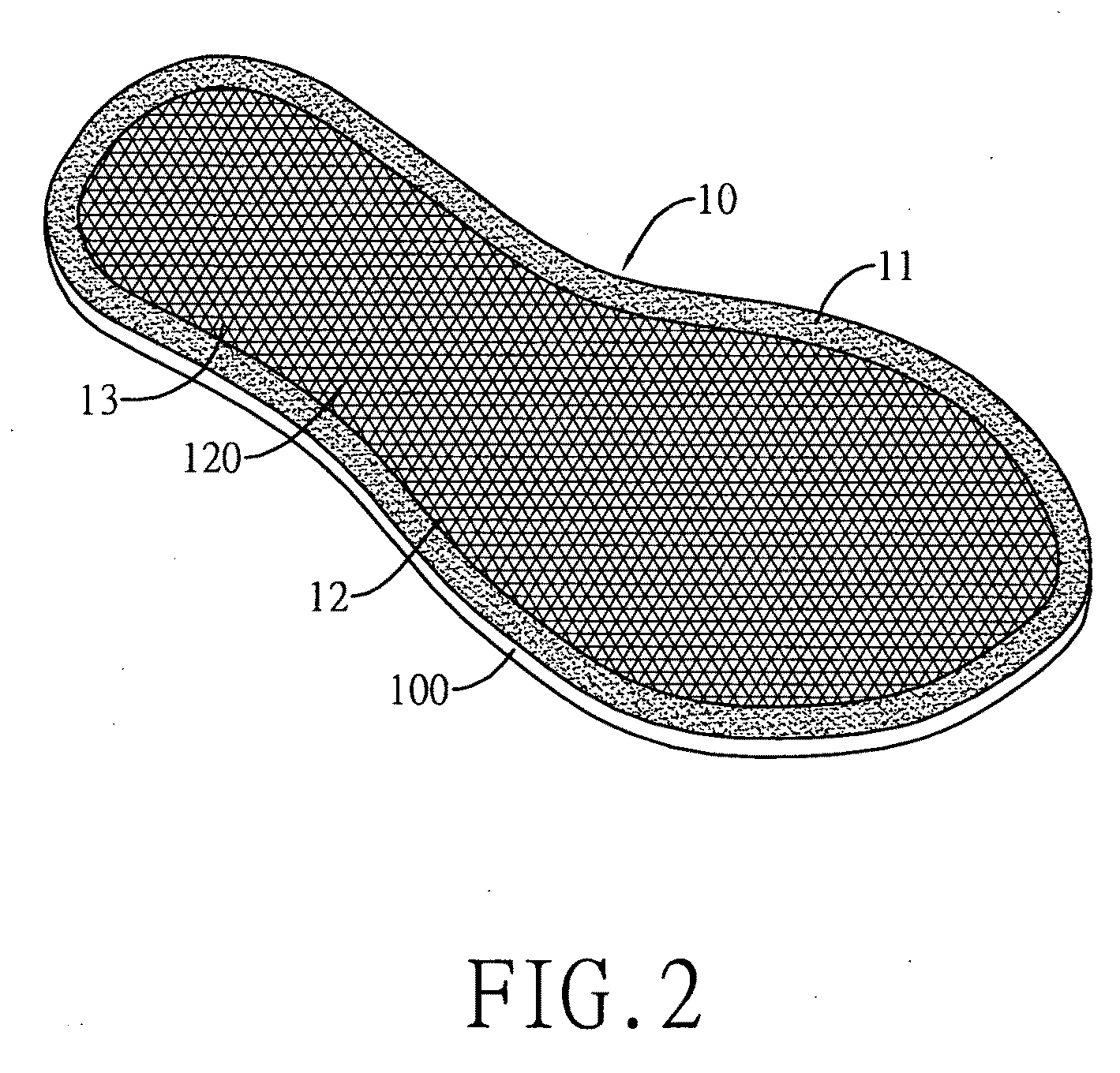

Multi-function health care self-cleaning shoe material

InactiveUS20100050469A1Enhance elasticity and comfortabilityPreserving human healthSolesInsolesPeripheralEngineering

A kind of multi-function health care self-cleaning shoe material comprises a shoe material main body (10). The shoe material main body (10) has a peripheral contour area (11), an inner area (12) and at least a sheet-form web body (120), which is located in the inner area (12) of the main body (10). The web body (120) is fixed on the peripheral contour area (11). The web body (120) is a web-form braid having plural fibers in warp direction (12) and plural fibers in weft direction (13). Many functional particles (130) are contained in the fibers.

Owner:NOVEKO TRADING 2008

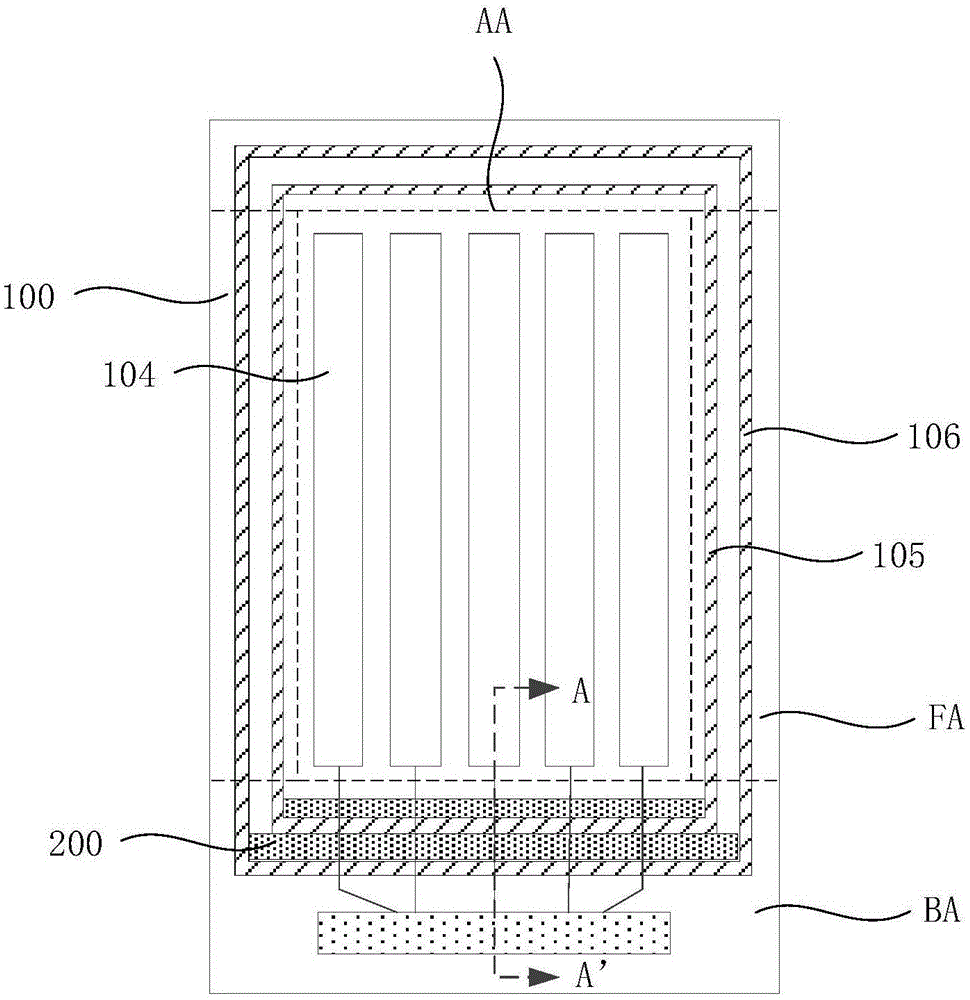

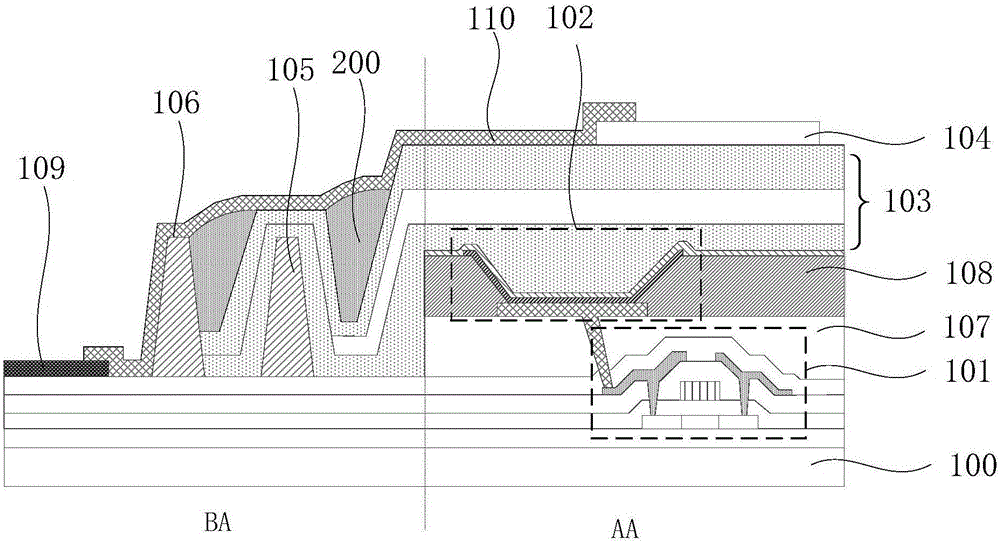

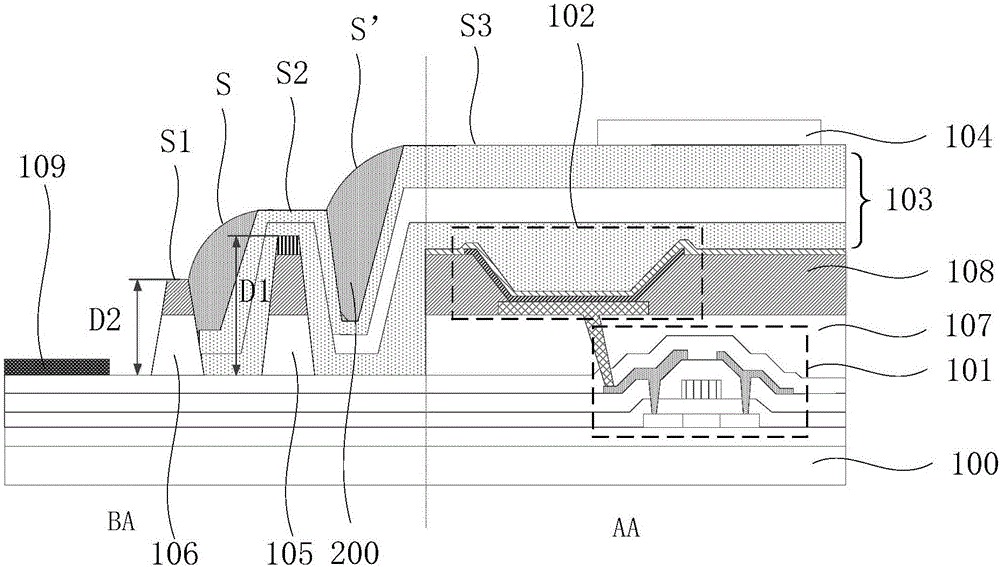

Touch control display panel and touch control display device

ActiveCN106775173AIncrease elasticityAvoid disconnectionInput/output processes for data processingTouch SensesDisplay device

The invention provides a touch control display panel. The touch control display panel comprises a substrate, a thin film transistor array, an organic light emitting unit, a thin film packaging layer and a touch sensing electrode, wherein the thin film transistor array, the organic light emitting unit and the thin film packaging layer are sequentially stacked on the substrate, and the touch sensing electrode is arranged on the side, away from the organic light emitting unit, of the thin film packaging layer. The touch control display panel comprises a display area and a non-display area surrounding the display area. The non-display area is provided with a first dam surrounding the display area, and a second dam surrounding the first dam. The non-display area comprises a binding area and frame areas located on the two sides of the binding area, and at least the binding area, the portion between the first dam and the second dam and the side, close to the display area, of the first dam are filled with organic materials. Touch control electrode lead breakage caused when the touch control electrode leads pass through uneven dam areas is avoided. Besides, the organic materials have good elasticity, can relieve and protect stress accumulation of the touch control electrode leads when the display panel is bent. The provided touch control display panel is more applicable to flexible display.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

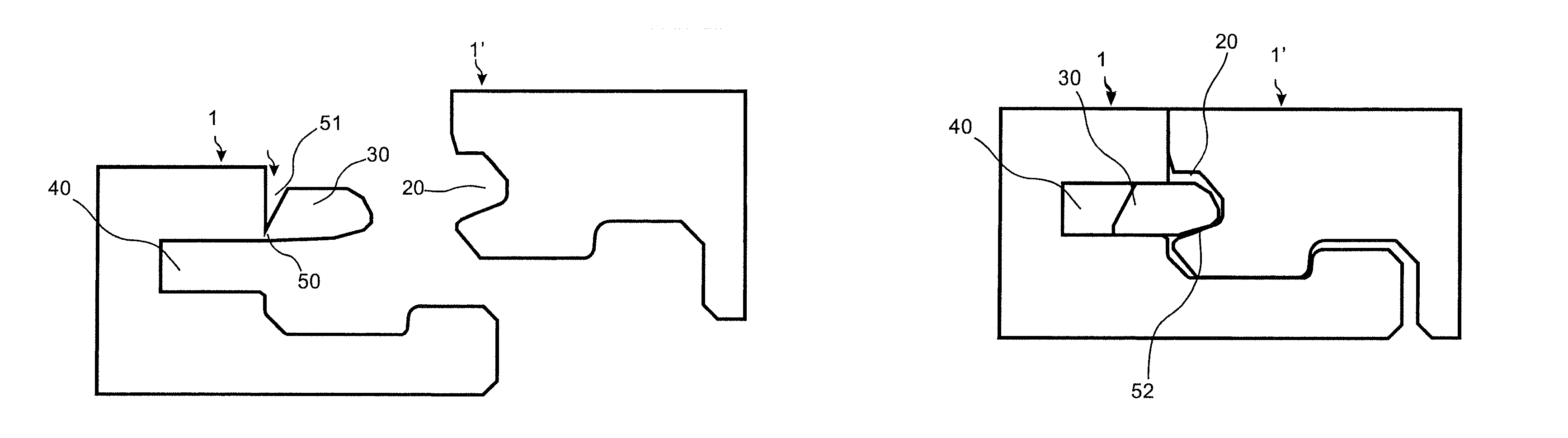

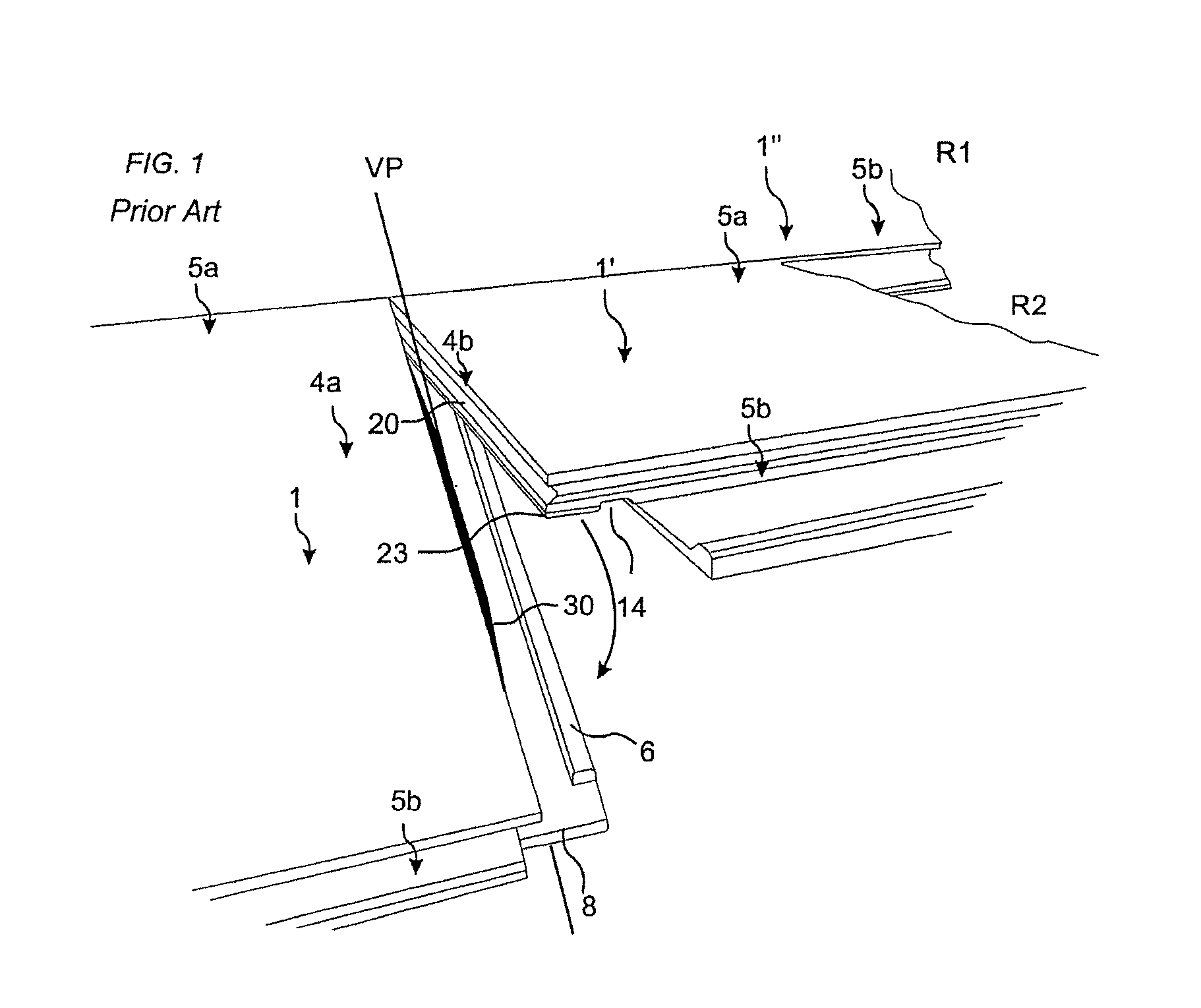

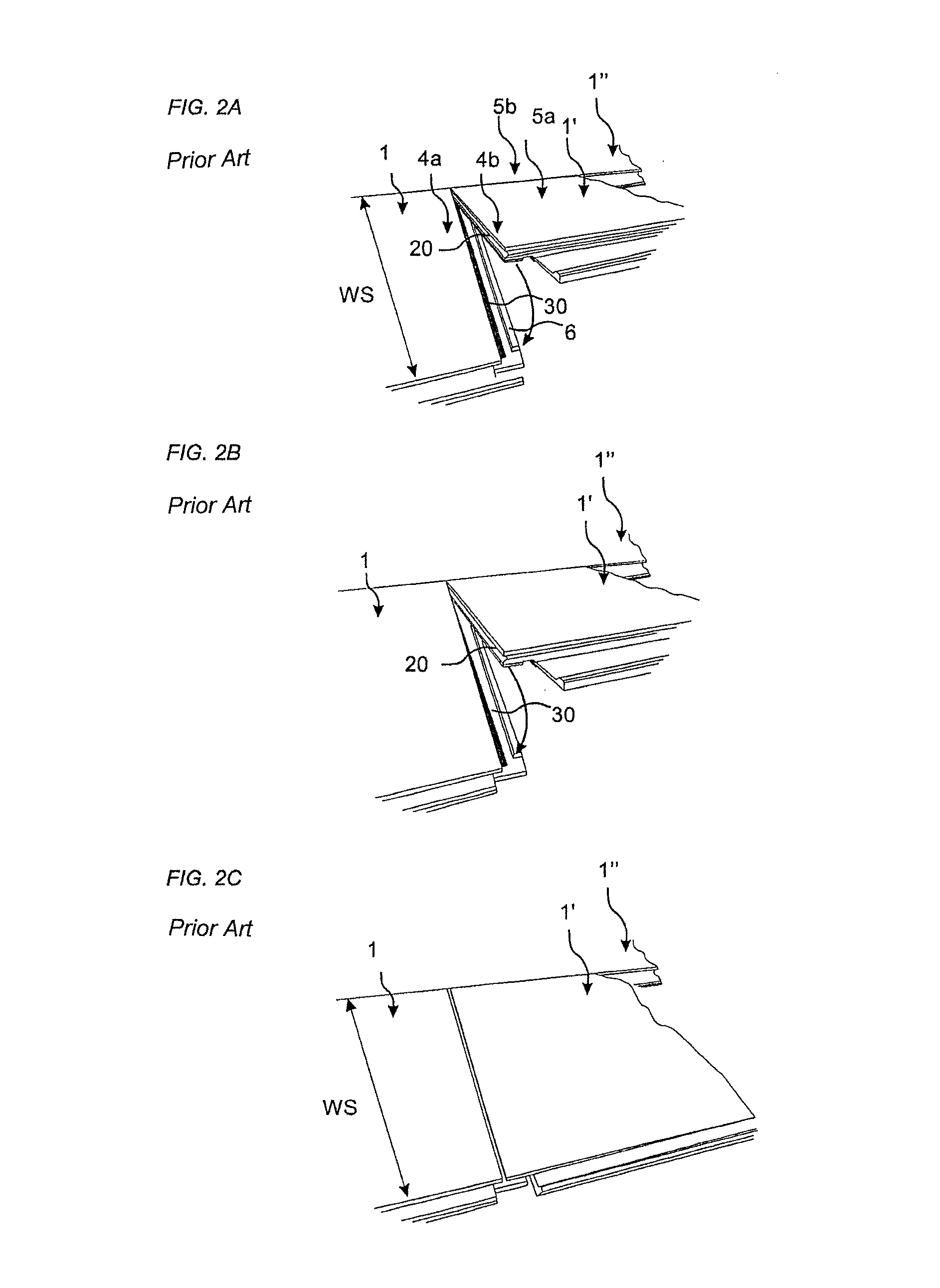

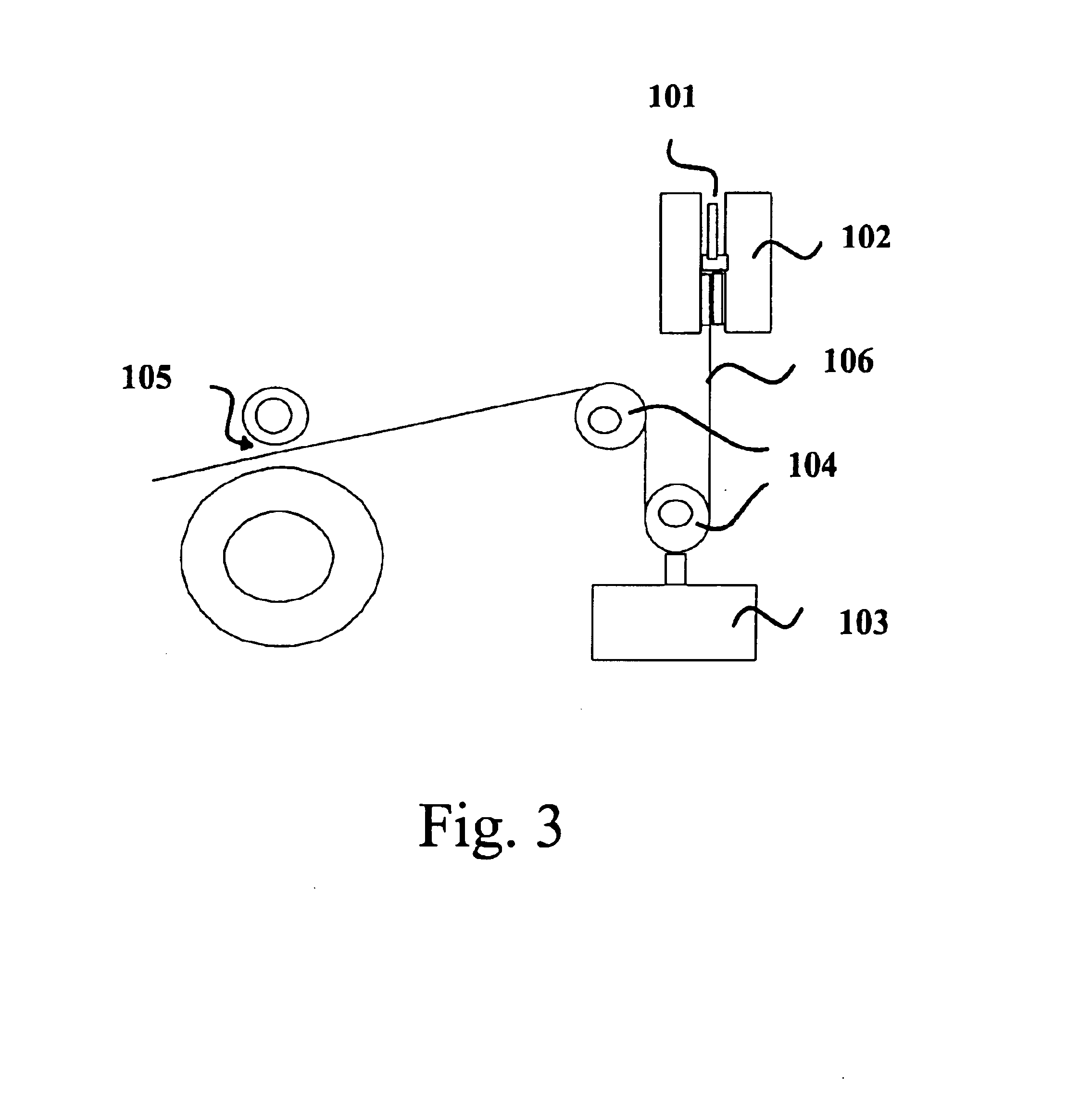

Method for producing a mechanical locking system for building panels

ActiveUS9216541B2Easy to manufactureIncrease elasticityConstruction materialCovering/liningsCivil engineering

Building panels 1, 1′ provided with a mechanical locking system including a tongue 30, at first edge 4a of a first building panel 1, cooperating with a tongue groove 20, at a second edge 4a of an adjacent second building panel 1′, for vertical locking of the building panels and a method for producing such building panels 1, 1′. The method includes the step of forming the tongue of material of the first edge. The insertion groove (40) may have a sidewall (60) at a third edge (5a), which is adjacent the first edge (4a), and may be open at a fourth edge (5b), which is opposite the third edge.

Owner:VÄLINGE INNOVATION AB

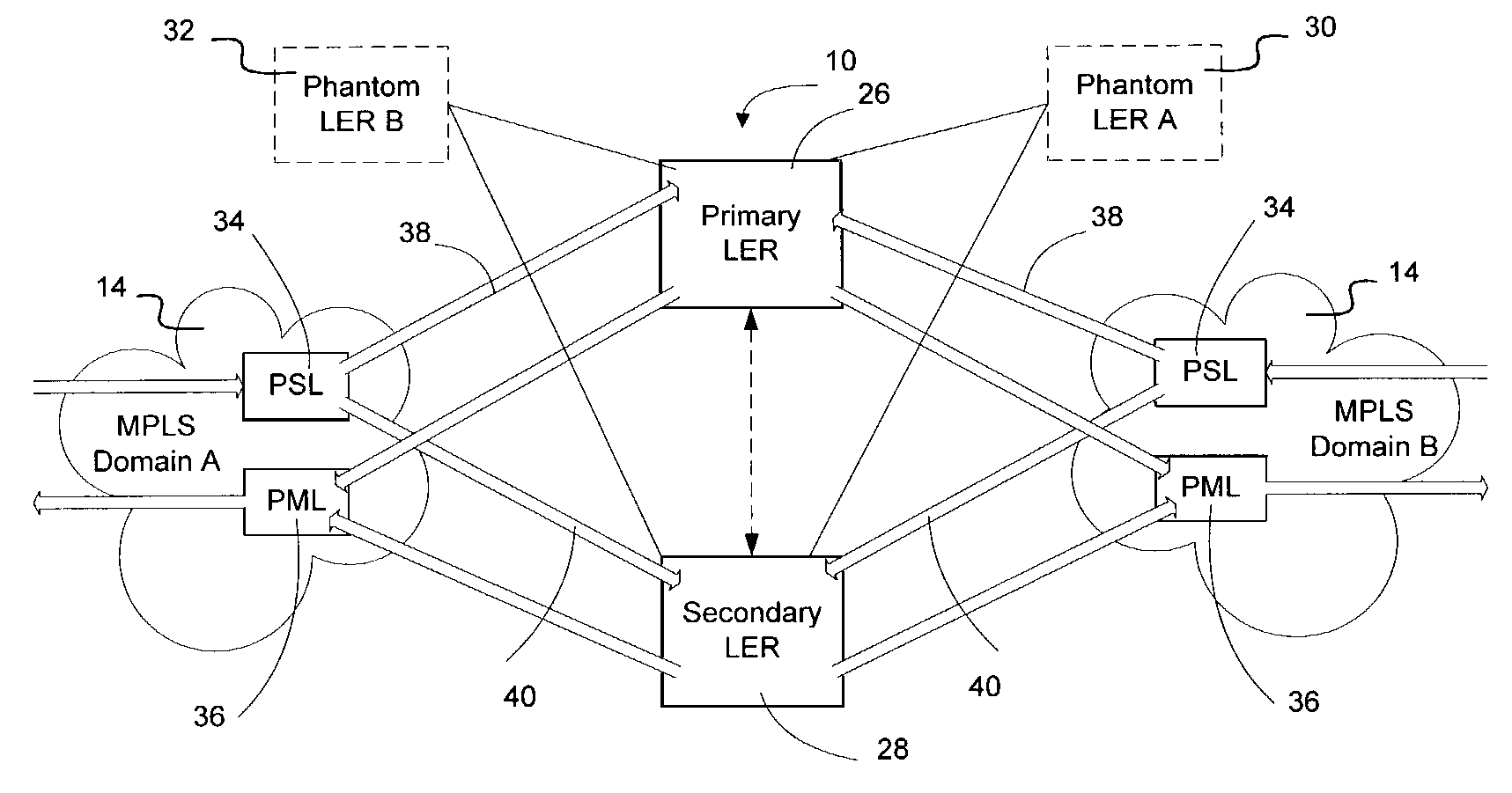

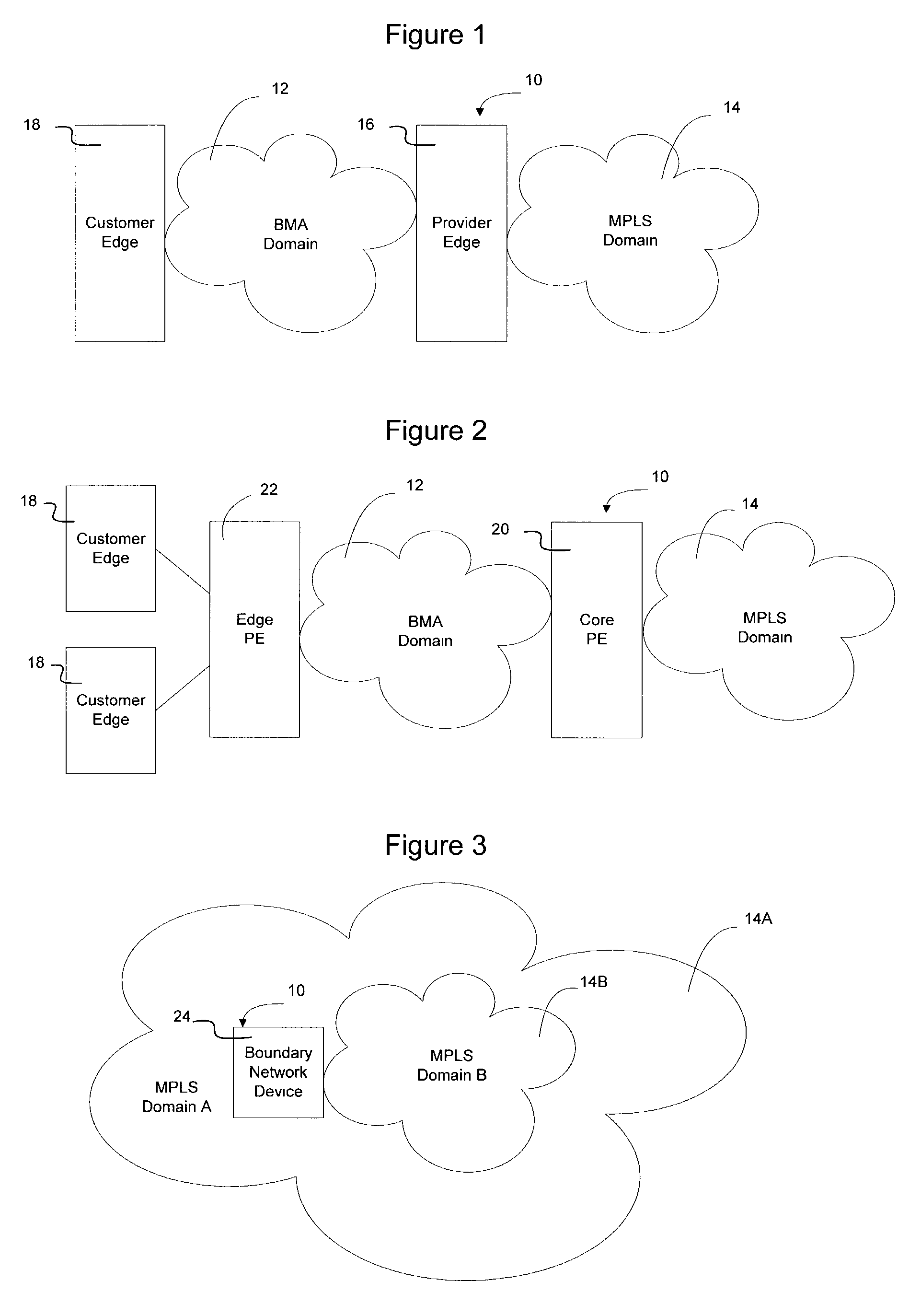

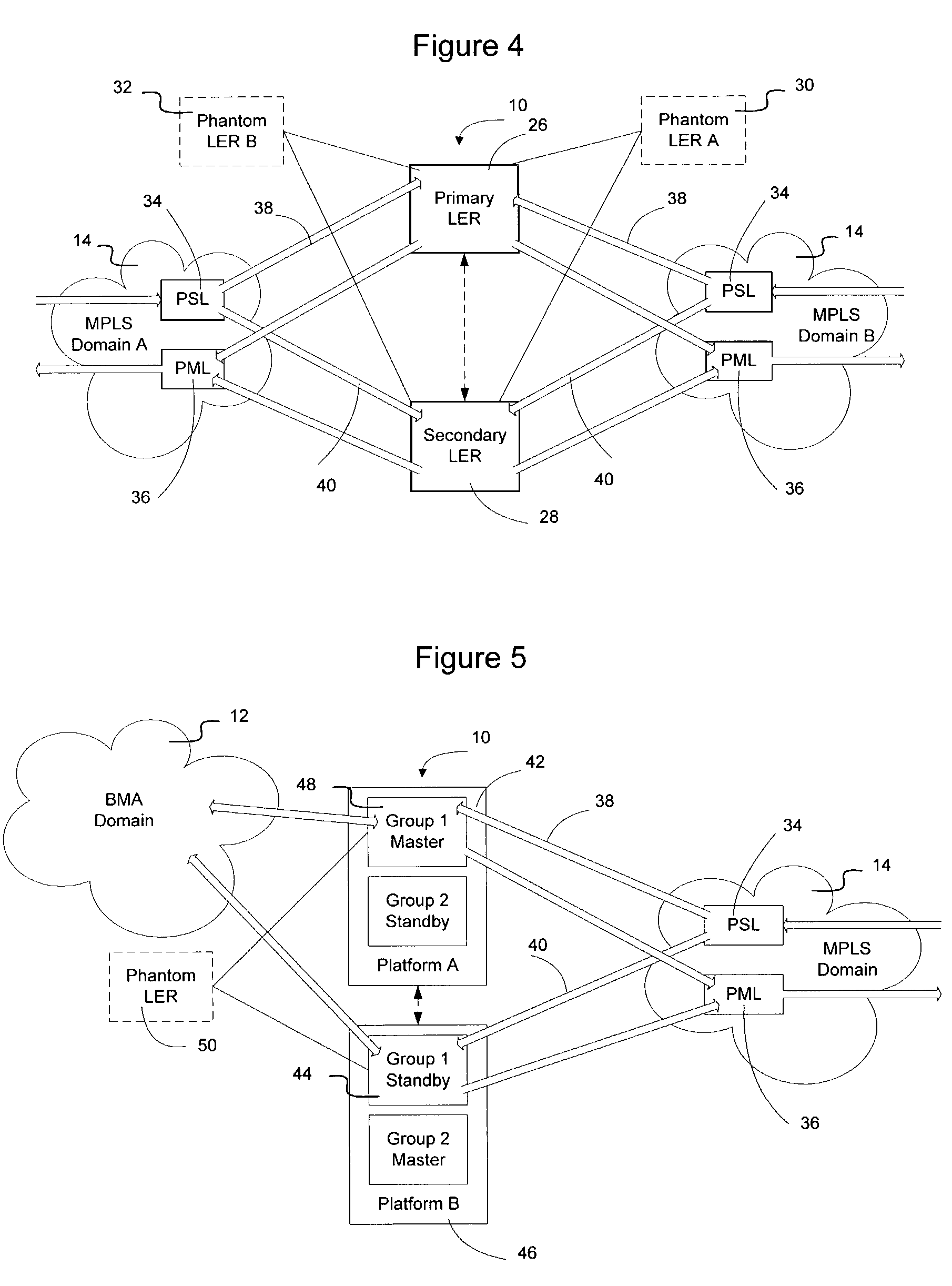

Method and apparatus for achieving transparent redundancy at a hierarchical boundary

InactiveUS7269132B1Achieve redundancyIncrease elasticityError preventionFrequency-division multiplex detailsTraffic volumeMajor and minor

Transparent redundancy may be achieved at a MPLS-MPLS hierarchical boundary or a BMA-MPLS hierarchical boundary by utilizing local repair mechanisms extant in each domain to select automatically the same boundary network devices as the primary and secondary boundary network devices. In the MPLS domain, two LERs advertise the ability to forward traffic to a phantom LER and map all traffic originated into that domain as having been on a path originating at the phantom LER. This will cause the LERs to appear as being one hop away from the phantom LER, causing MPLS to assume the real LERs are part of a LSP terminating at the phantom LER. MPLS local repair will thus establish one of the LERs as the primary LER and the other LER as the secondary LER. In an Ethernet domain, each boundary network device is treated analogously to a router in the VRRP scheme for routers.

Owner:RPX CLEARINGHOUSE

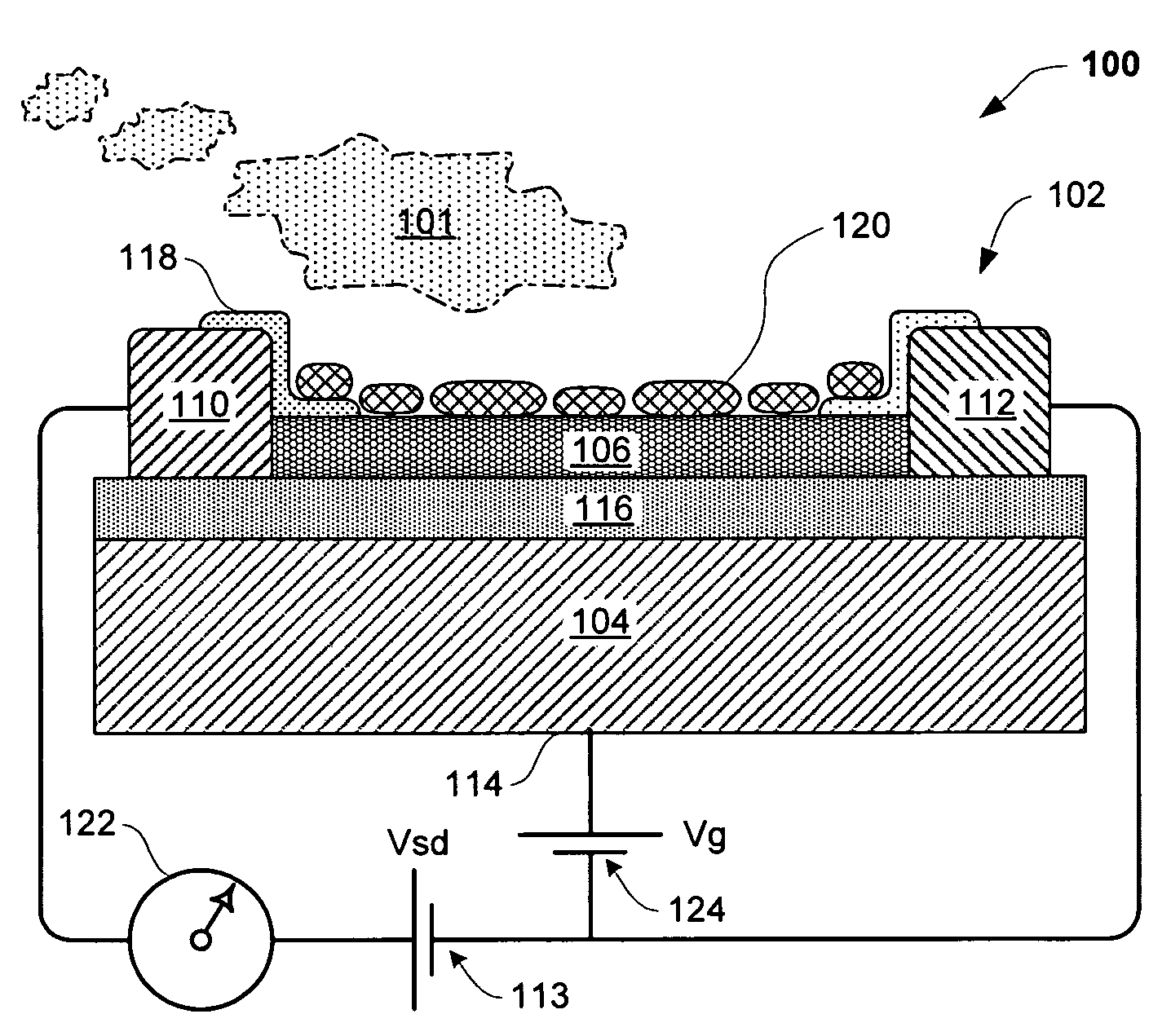

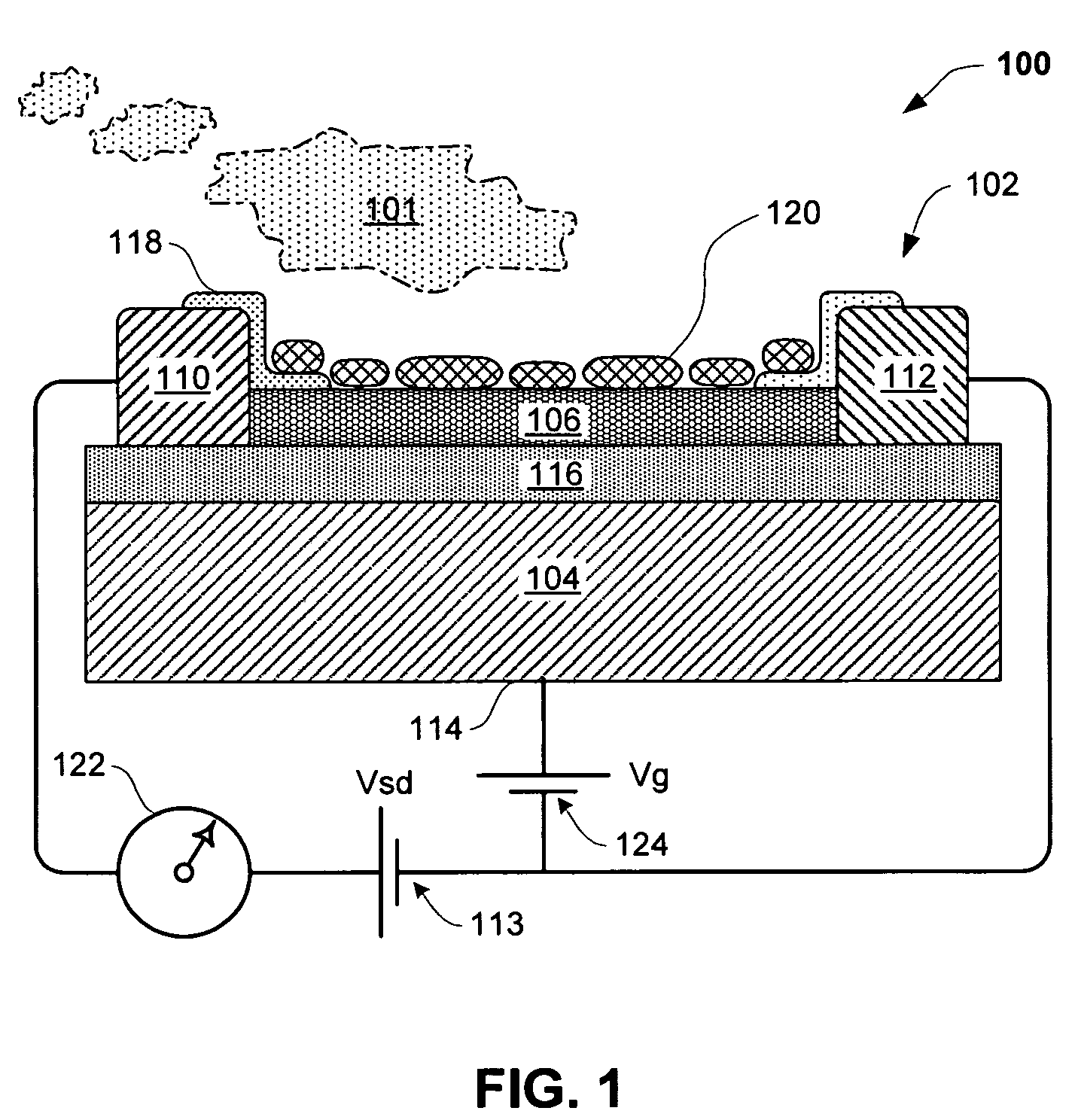

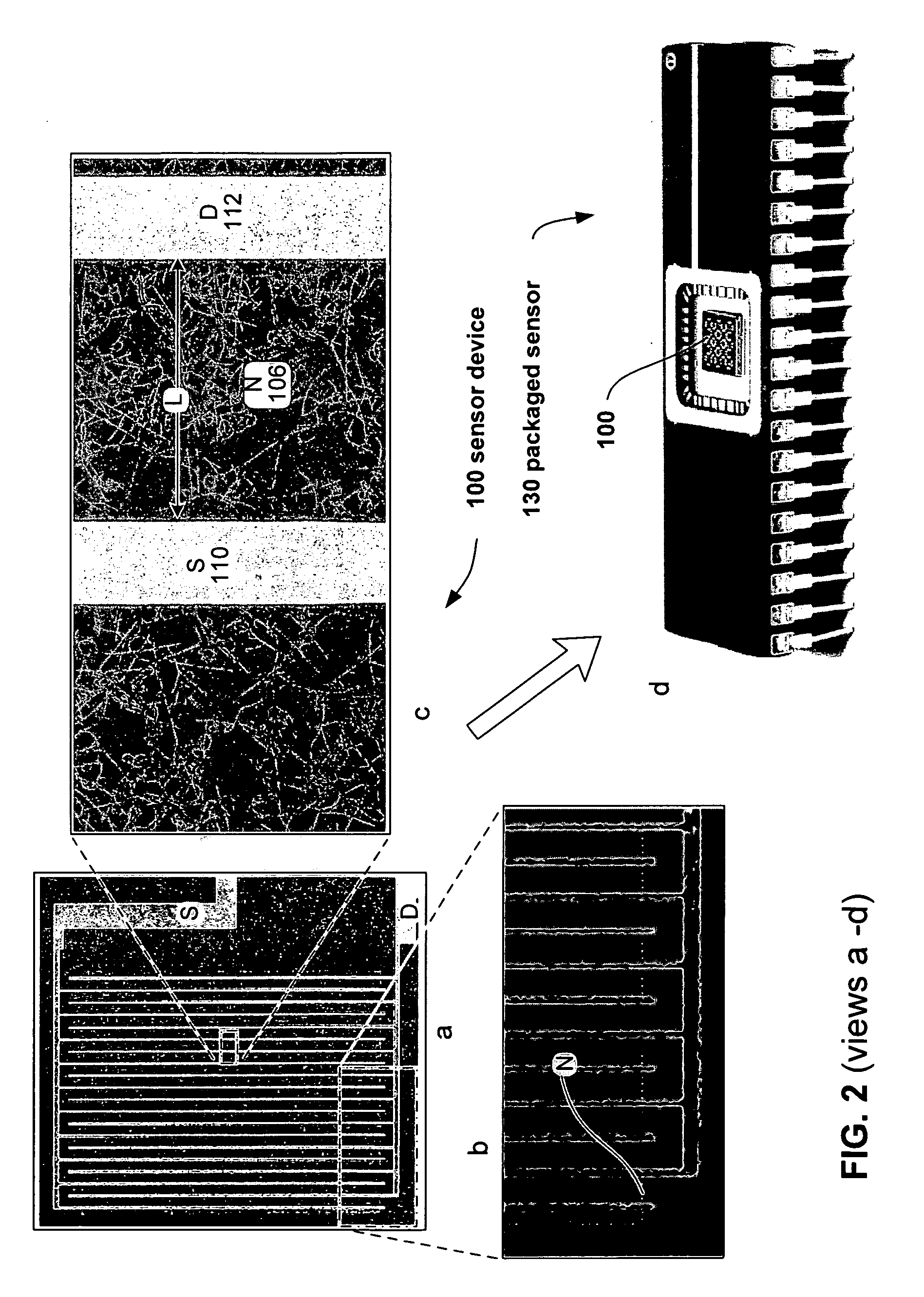

Sensor having a thin-film inhibition layer, nitric oxide converter and monitor

ActiveUS20080221806A1High sensitivityLarge dynamic rangeMaterial nanotechnologyTemperatue controlDiseaseVolatiles

Sensors and detection systems suitable for measuring analytes, such as biomolecule, organic and inorganic species, including environmentally and medically relevant volatiles and gases, such as NO, NO2, CO2, NH3, H2, CO and the like, are provided. Certain embodiments of nanostructured sensor systems are configured for measurement of medically important gases in breath. Applications include the measurement of endogenous nitric oxide (NO) in breath, such as for the monitoring or diagnosis of asthma and other pulmonary conditions.

Owner:NANOMIX

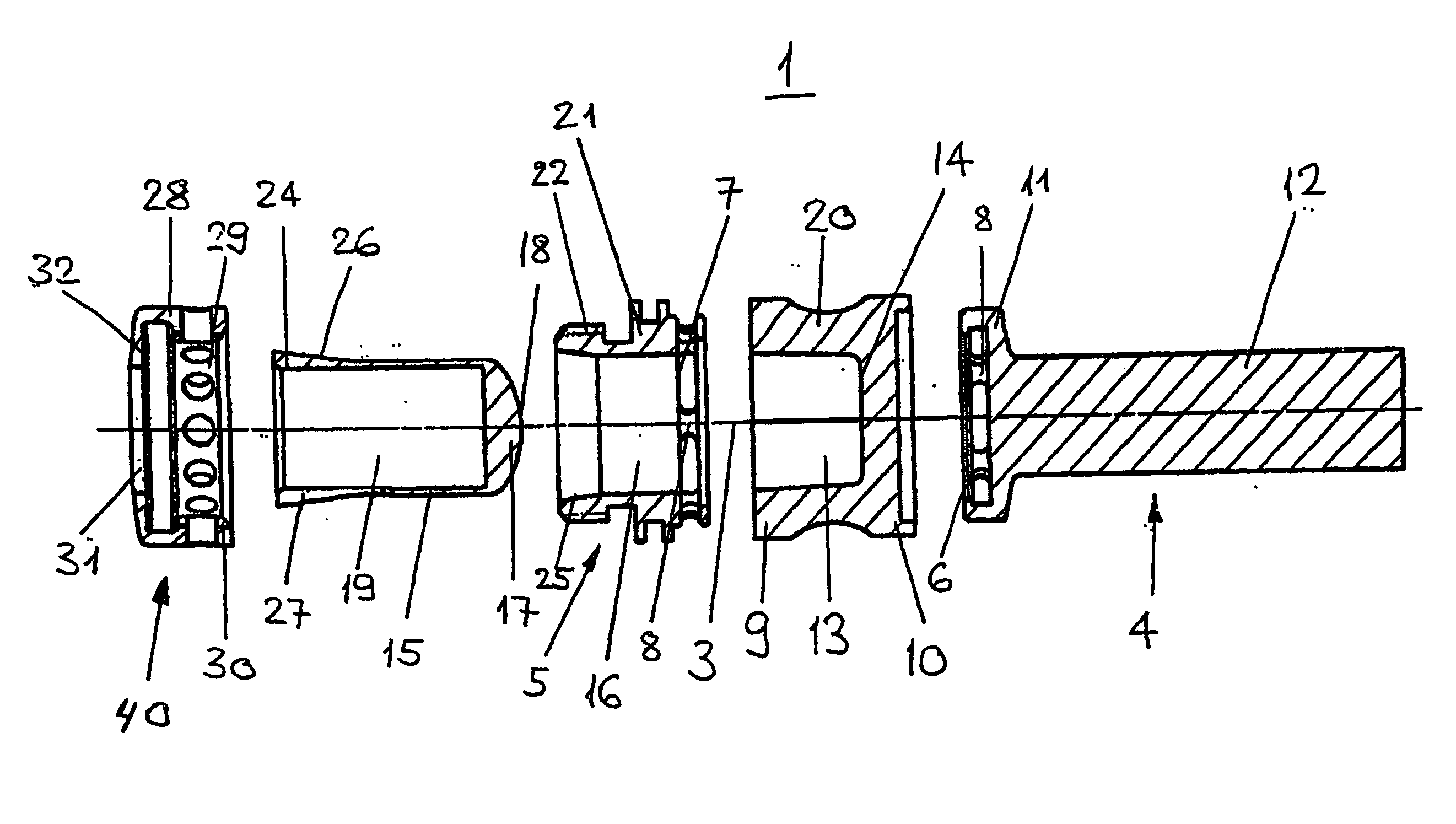

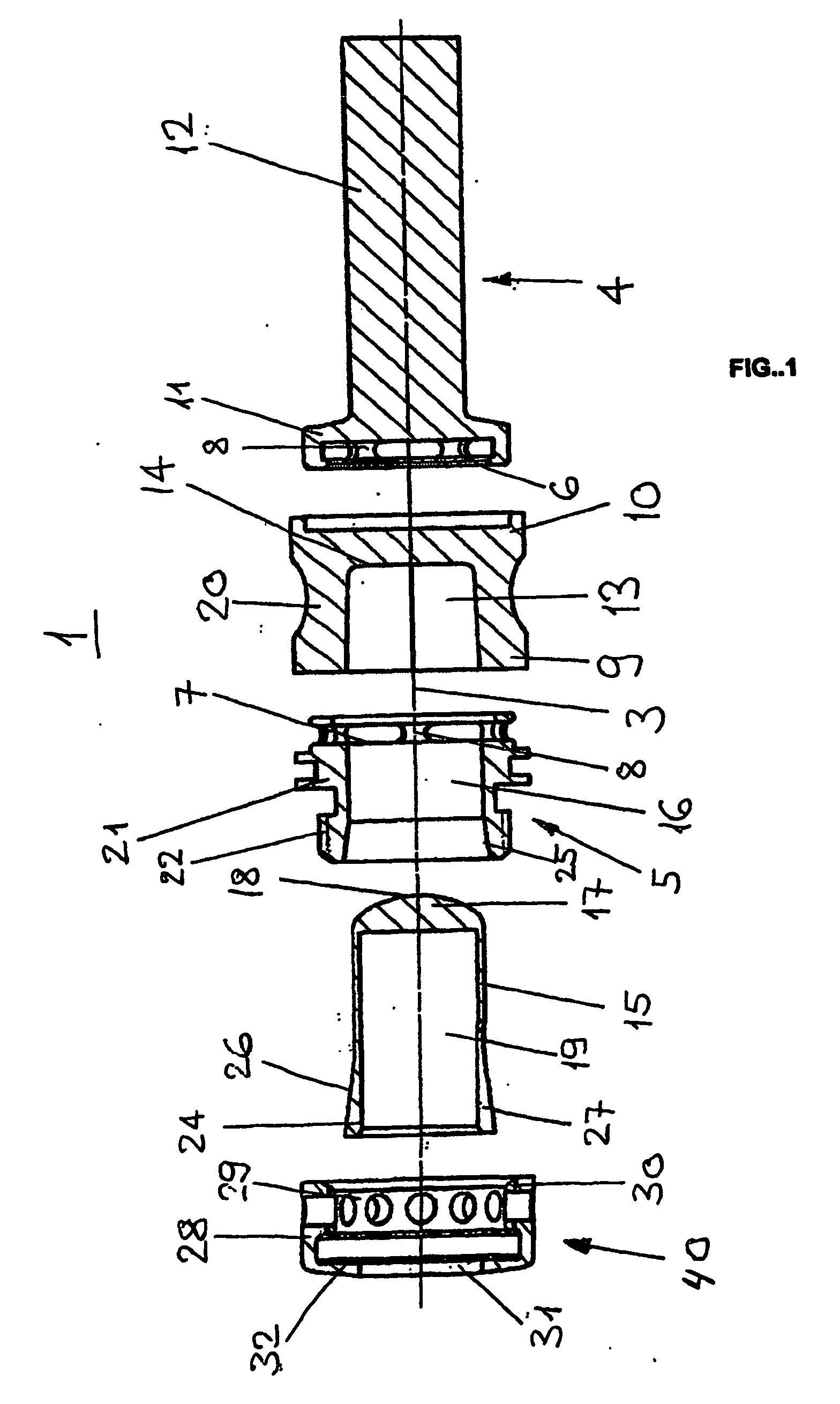

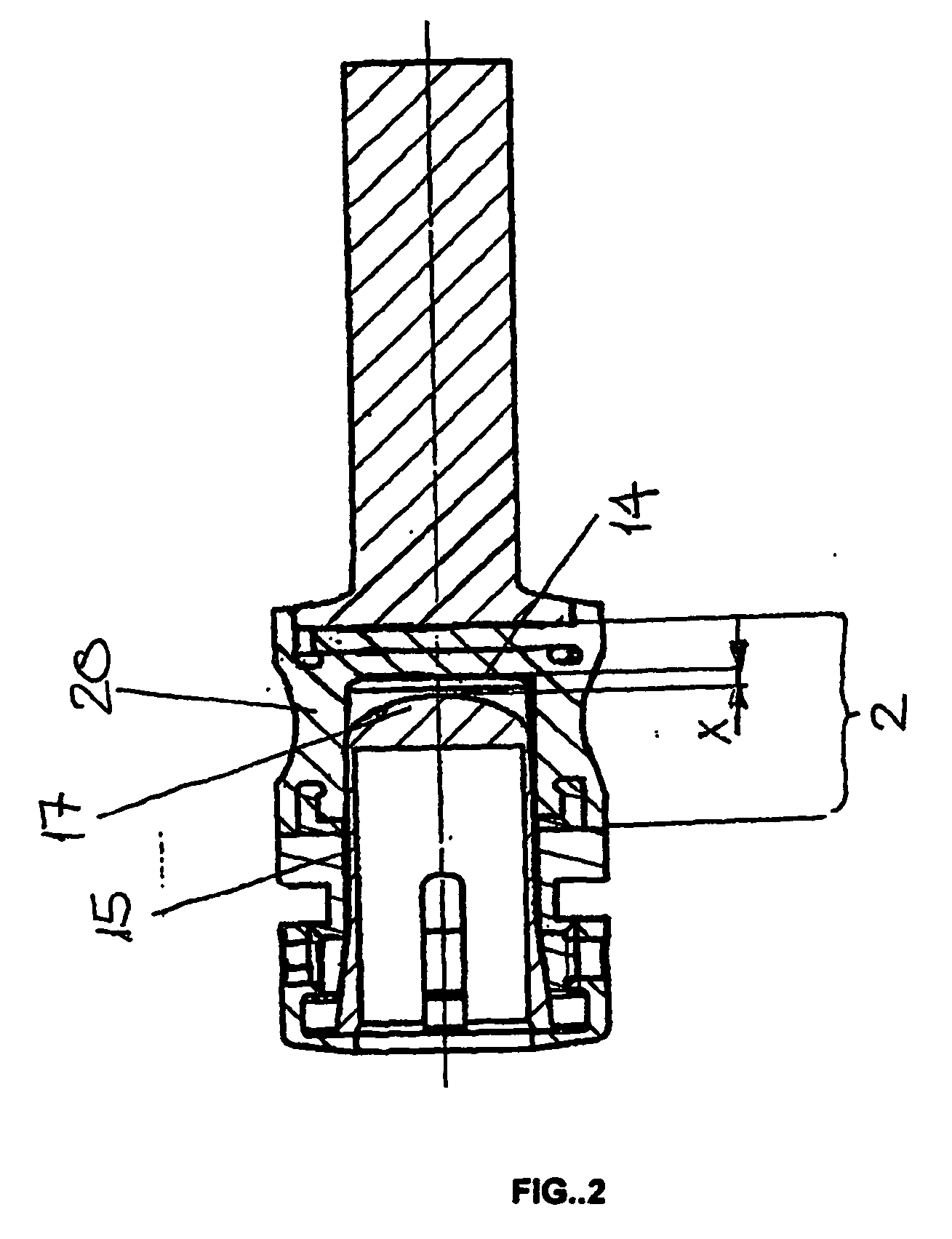

Dynamic damping element for two bones

ActiveUS20060264940A1Increase elasticitySufficient freedom of movementSuture equipmentsPortable framesEngineeringMechanical engineering

A damping element for the dynamic stabilization of two bones, particularly of two adjacent bodies of the vertebra, includes a flexible spring element having a hollow space. The hollow space is open on a first end and closed on a second end by a wall extending transversely to the longitudinal axis of the damping element. A clamping sleeve is inserted at least partially into the hollow space. The sleeve has a front end directed towards the wall of the flexible spring element. The distance between the front end and the wall affects the damping characteristics of the damping element. A coaxial connecting element is attached to each end of the flexible spring element. Each connecting element is configured to be connected within an osteosynthetic stabilizing device.

Owner:SYNTHES USA

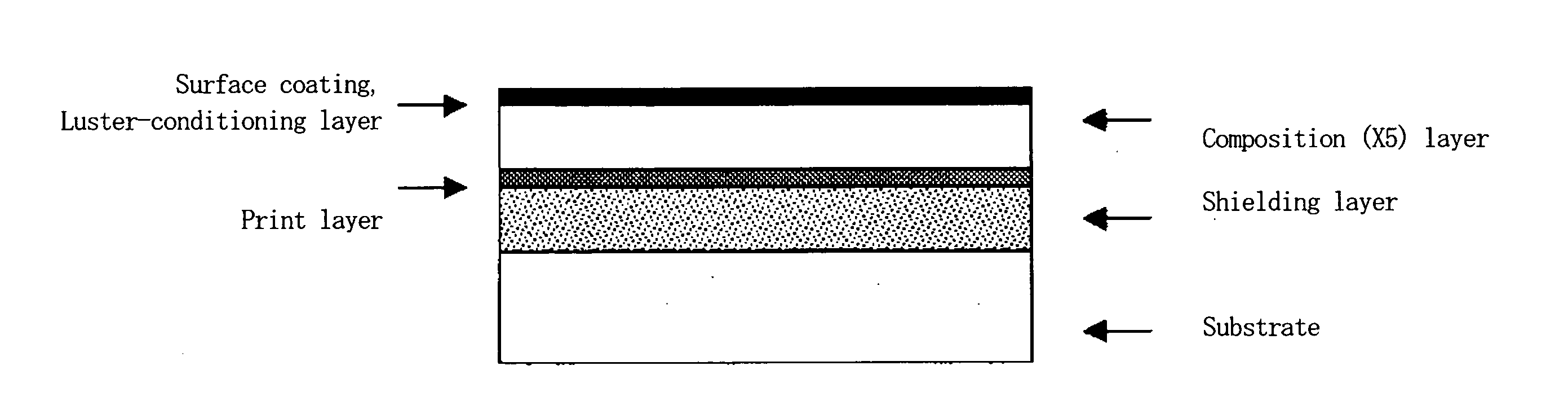

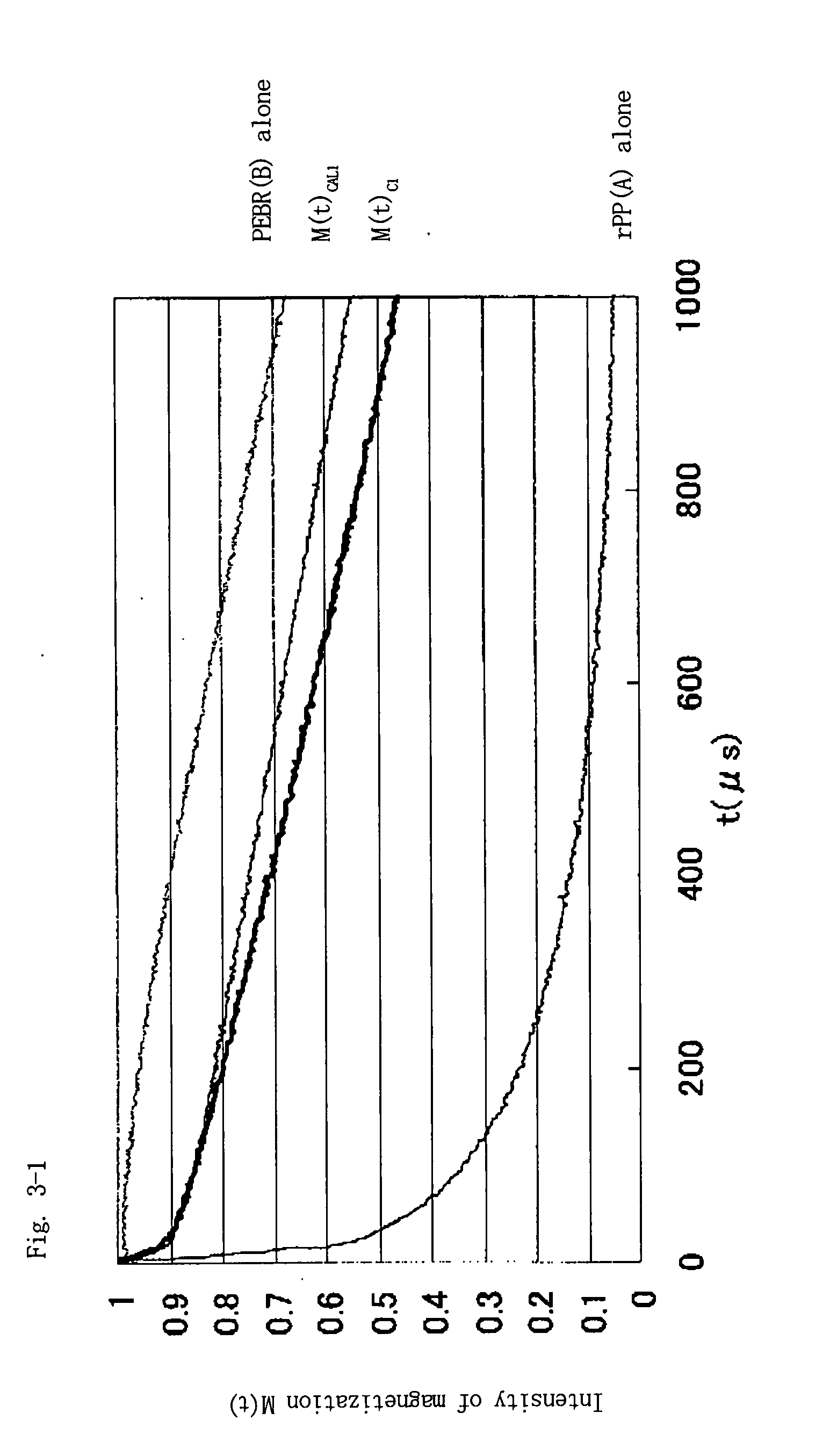

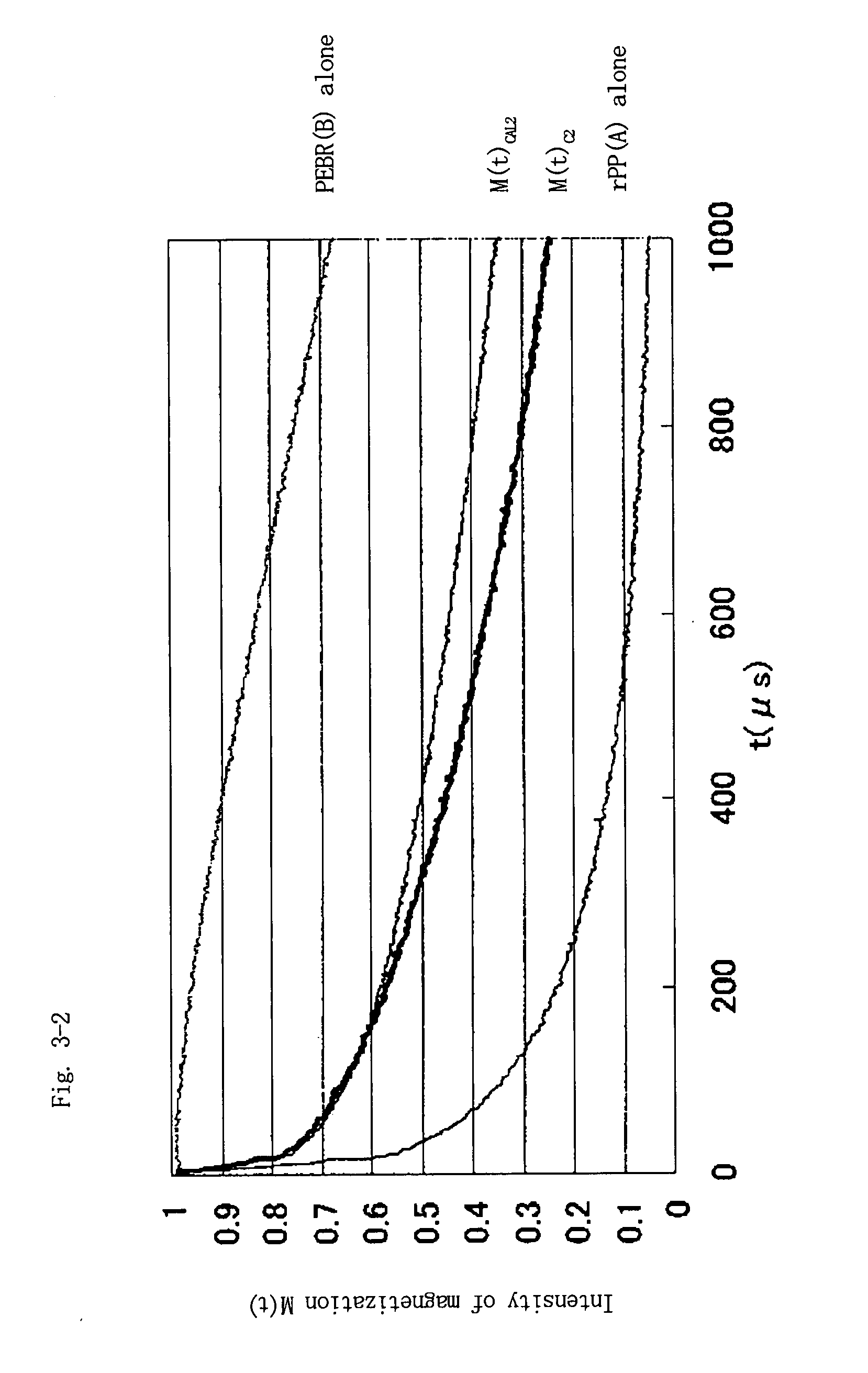

Propylene resin composition and use thereof

ActiveUS20070251572A1Improve mechanical propertiesGood rubber elasticitySolesPlastic/resin/waxes insulatorsElastomerAlpha-olefin

The thermoplastic resin composition (Xi) of the present invention comprises (A1), (B1), (C1), and optionally (D1) below: 1 to 90 wt % of an isotactic polypropylene (A1); 9 to 98 wt % of a propylene / ethylene / α-olefin copolymer (B1) containing 45 to 89 mol% of propylene-derived structural units, 10 to 25 molt of ethylene-derived structural units, and optionally, 0 to 30 mol% of C4-C20 α-olefin-derived structural units (a1); 1 to 80 wt % of a styrene-based elastomer (C1); and 0 to 70 wt % of an ethylene / α-olefin copolymer (D1) whose density is in the range of 0.850 to 0.910 g / cm3, wherein (A1)+(B1)+(C1)+(D1)=100 wt %.

Owner:MITSUI CHEM INC

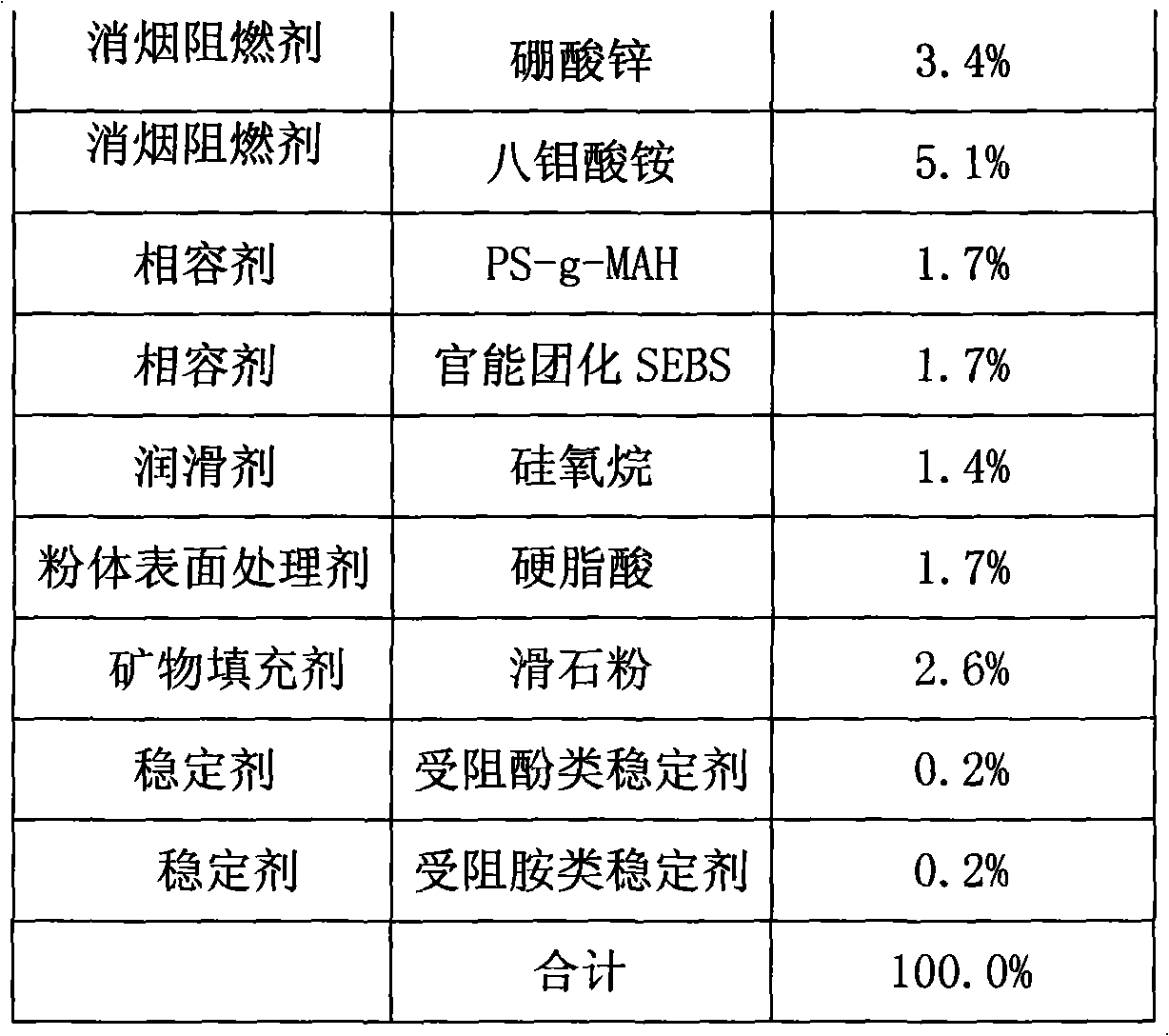

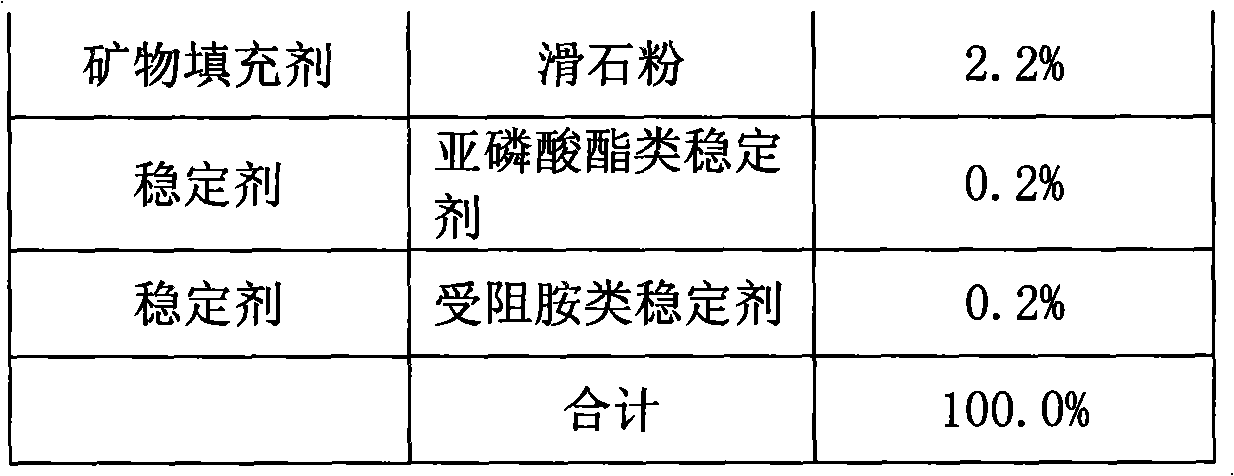

Halogen-free flame-retardant thermoplastic elastomer electrical cable material using polyphenylene ether as base material and preparation method thereof

InactiveCN101358028AGood compatibilityReduce stratificationInsulated cablesInsulated conductorsElastomerPolyphenylene oxide

The invention discloses a halogen-free flame-retardant thermoplastic elastomer cable material with polyphenylether as the base materials and a preparation method thereof. The raw material of the cable material contains the components with the following weight percentage: 10 to 35 percent of matrix resin A; 5 to 15 percent of matrix resin B; 10 to 25 percent of elastomer; 5 to 25 percent of softening plasticizer; 8 to 15 percent of flame-retardant plasticizer; 20 to 40 percent of smoke-suppression flame retardant; 3 to 10 percent of compatilizer; 1 to 5 percent of lubricant; 1 to 5 percent of powder surface conditioner; 0 to 10 percent of mineral filler; 0.1 to 1 percent of stabilizing agent. The invention adds matrix resin, polyphenylether of strong polarity and functional group of styrene-ethylene / butylene-styrene segmented copolymer, which effectively improves the compatibility of non-polar elastomer with polyphenylether; the invention also adds plasticizer, which reduces the hardness of the material and increases the flexibility; and through the optimization and interaction of the softening plasticizer and the flame-retardant plasticizer, the invention reduces the hardness and improves the tactility of the material, and the flame retardant performance is excellent.

Owner:NINGBO SHIP PLASTIC CO LTD

High melt strength polypropylene

The present invention concerns a high melt strength propylene polymer or copolymer suitable for manufacturing foams and thermoformed product exhibiting a melt strength of at least 3 g and comprising a high molar mass portion and a low or medium molar mass portion. The polymers are produced by subjecting propylene and optionally other olefins to polymerization in a plurality of polymerization reactors connected in series, employing different amounts of hydrogen as a molar mass modifier in at least two of the reactors, and carrying out the polymerization reaction in the presence of a catalyst system capable of catalyzing the formation of a high molar mass polymerization product having a MFR2 of less than 0.1 g / l0 min and a low or medium molar mass polymerization product having a MFR2 of more than 0.5 g / 10 min.

Owner:BOREALIS TECH OY

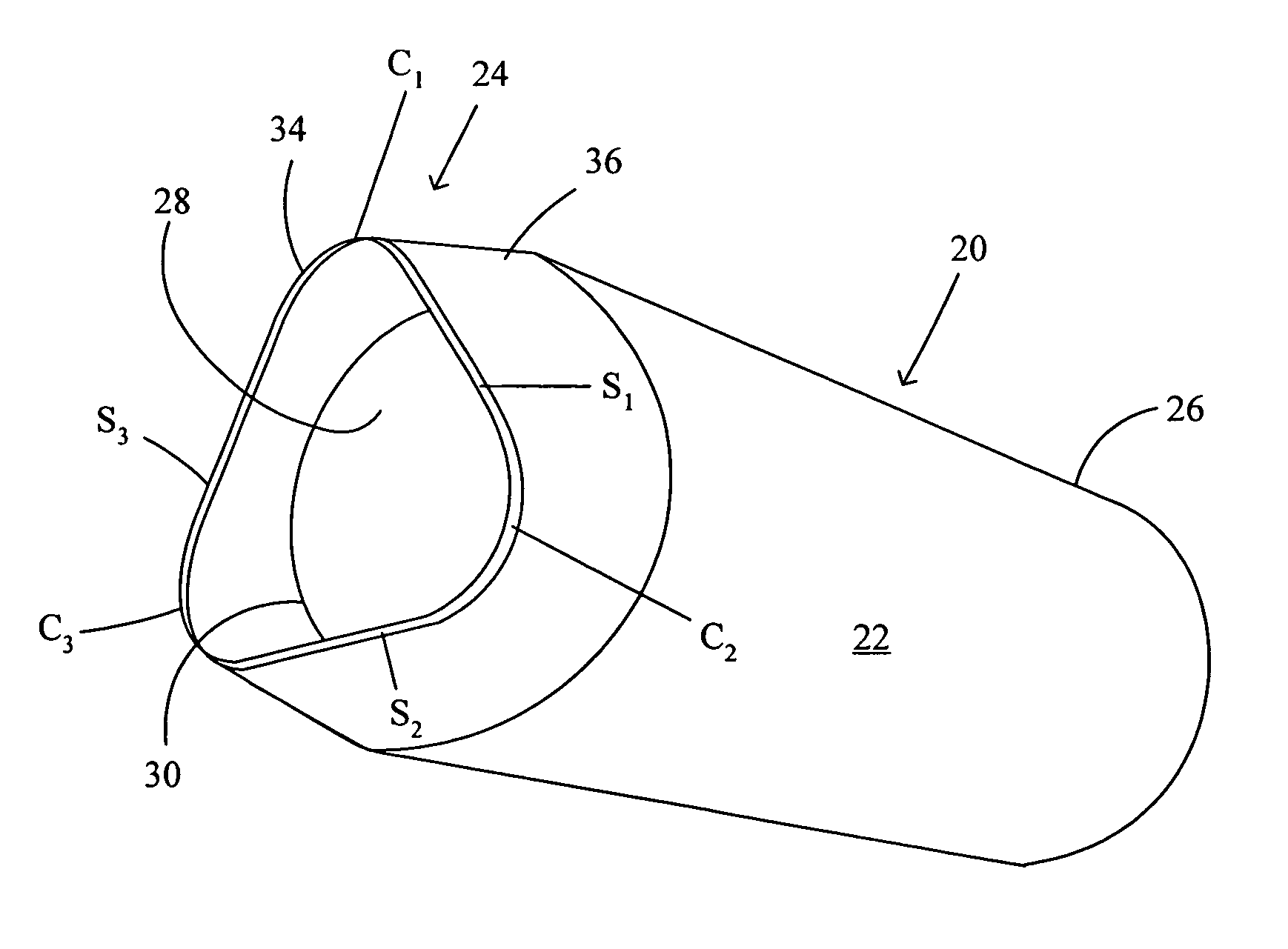

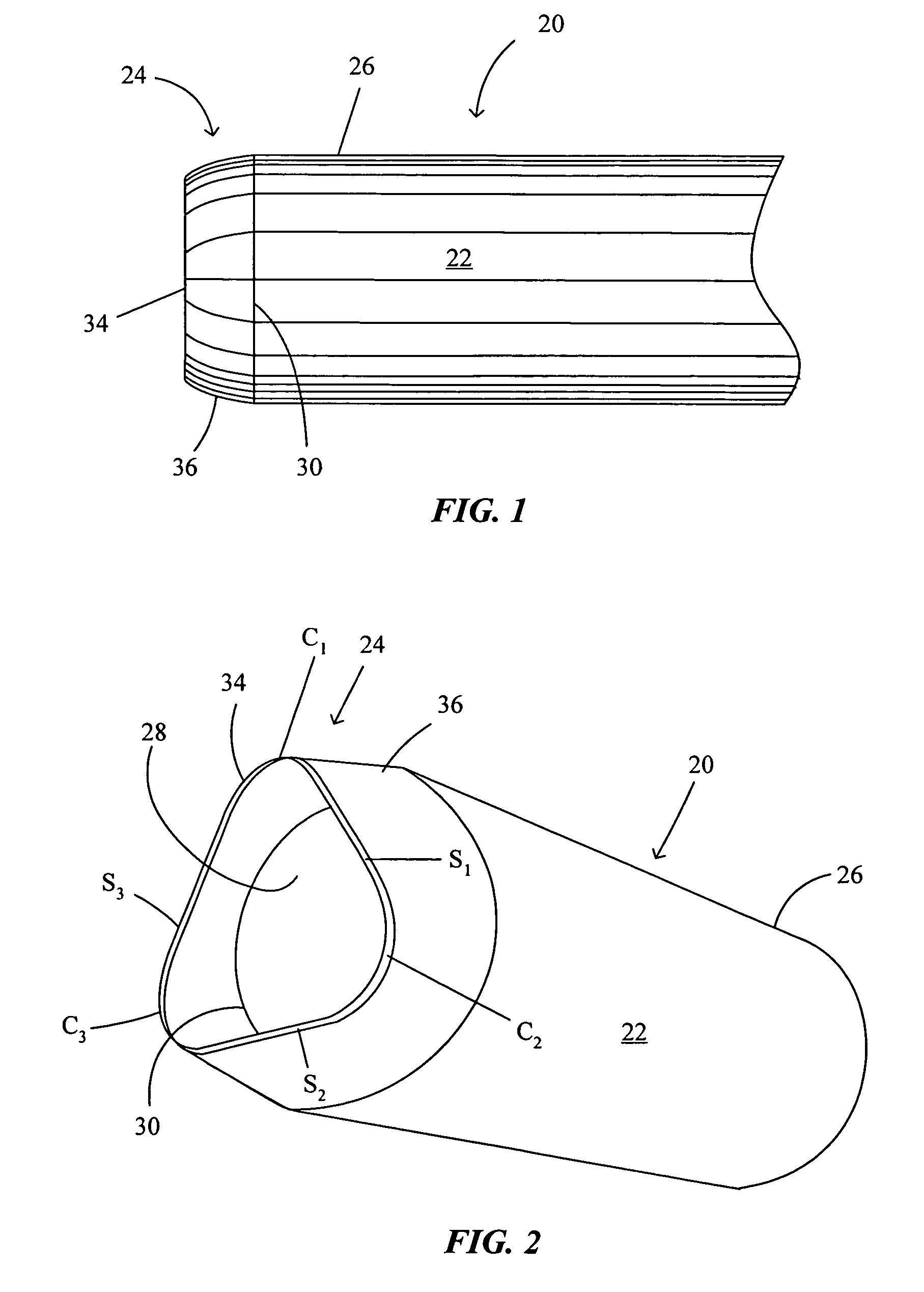

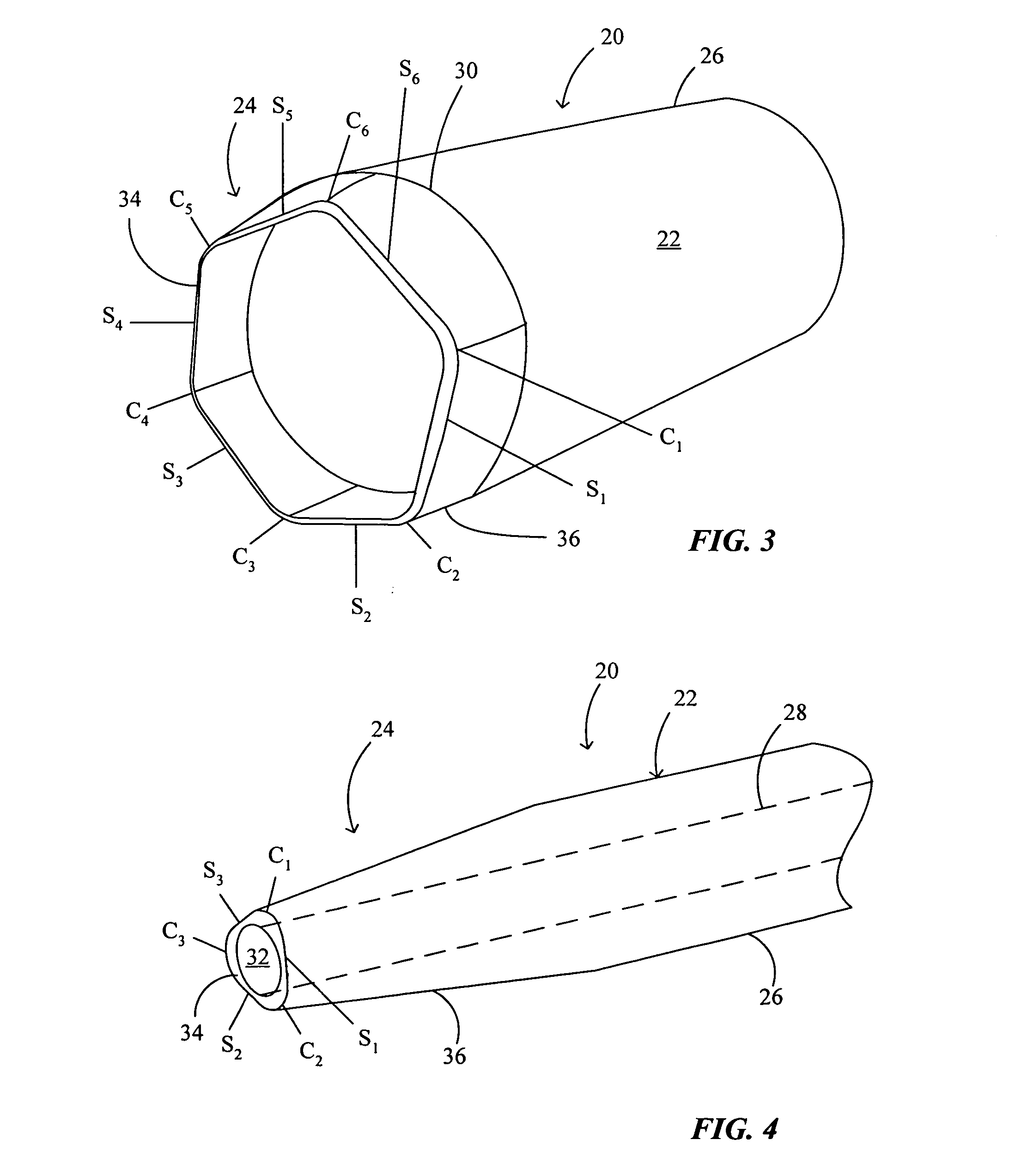

Improved Catheters

Catheters having a tapered, atraumatic distal tip are provided. In one embodiment, the outer surface of the distal portion of the catheter has a generally non-cylindrical and substantially triangular cross-sectional configuration. The inner surface cross-sectional configuration of the distal portion of the catheter may match the outer surface, or it may have a cylindrical or oval configuration. The terminal orthogonal surface of the distal catheter tip is chamfered or rounded or contoured. In another embodiment, inner and / or outer catheter surfaces have a three dimensional surface conformation and may be dimpled or grooved. The grooves may be generally liner or curved or helical or in a spiral configuration. Dimpled and / or grooved surface discontinuities may be provided in connection with and in addition to lubricious coatings, surfaces, and the like.

Owner:PULSAR VASCULAR

Method of using skin compositions including tensioning polymers

InactiveUS20060210513A1Improving skin functionReduce appearance problemsCosmetic preparationsToilet preparationsWrinkle skinThird generation

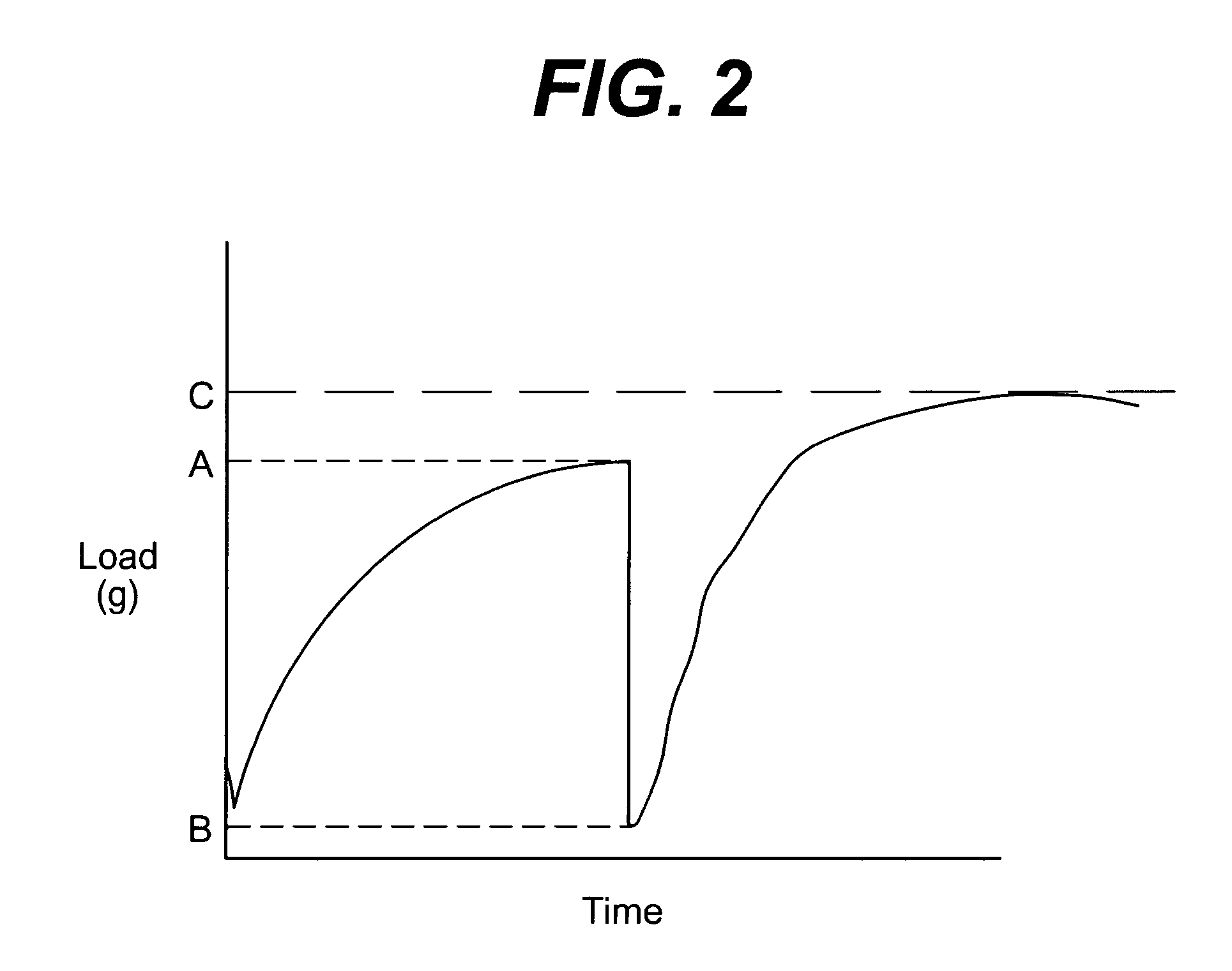

The invention features a method of treating at least one sign of aging on the skin selected from the group consisting of (i) thickening the skin, (ii) enhancing the barrier function of skin, and / or (iii) treating at least one sign of aging on the skin selected from the group consisting of enhancing the elasticity of said skin, enhancing the firmness of said skin, smoothing the surface of the skin, and reducing the appearance of wrinkles on the skin, wherein the method includes applying to skin in need of such treatment a skin care composition including a tensioning polymer, wherein the tensioning polymer has a contractile force greater than about 3 g / mg and a water resistance index from about 0.9 to about 1.9.

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

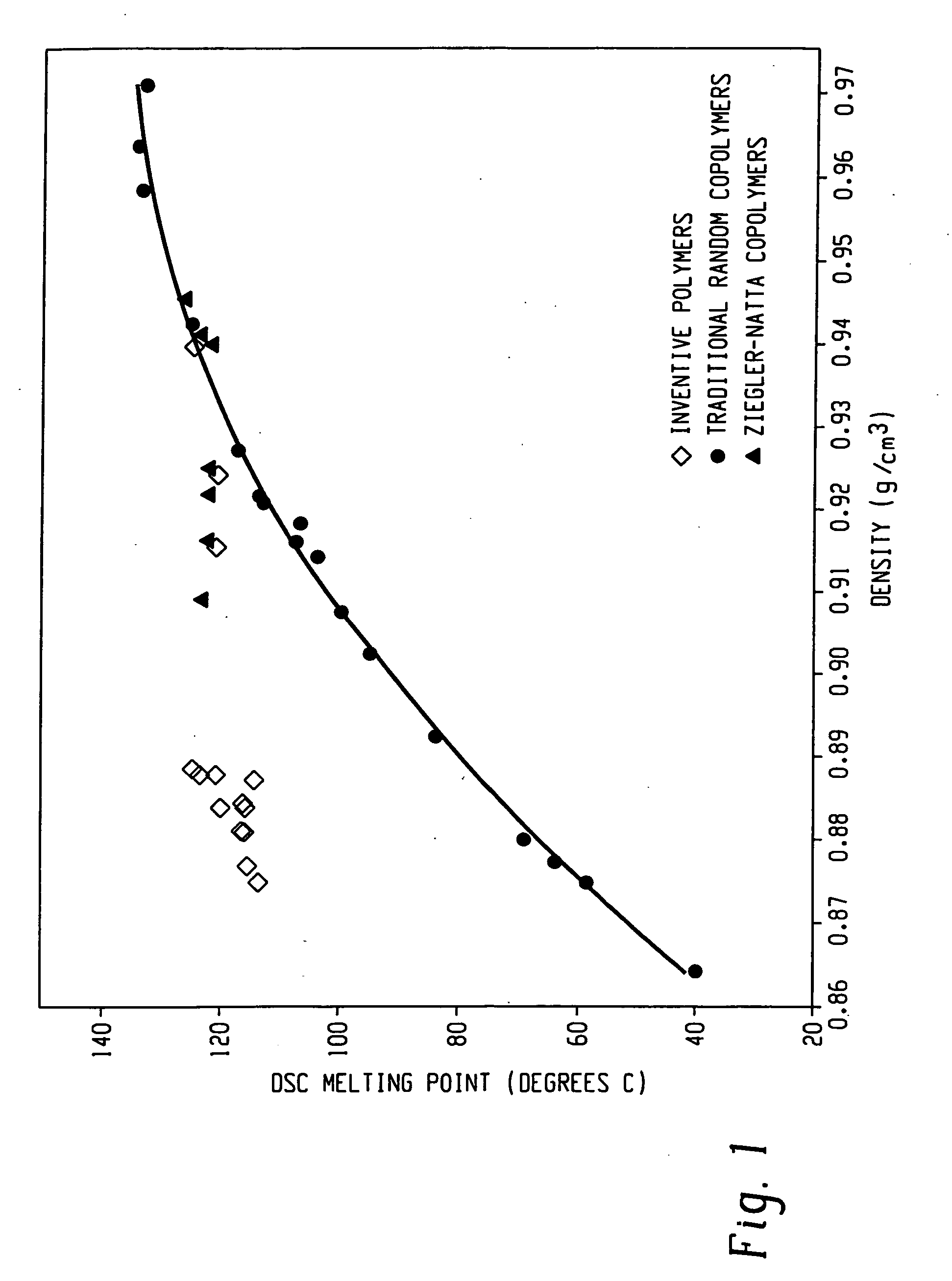

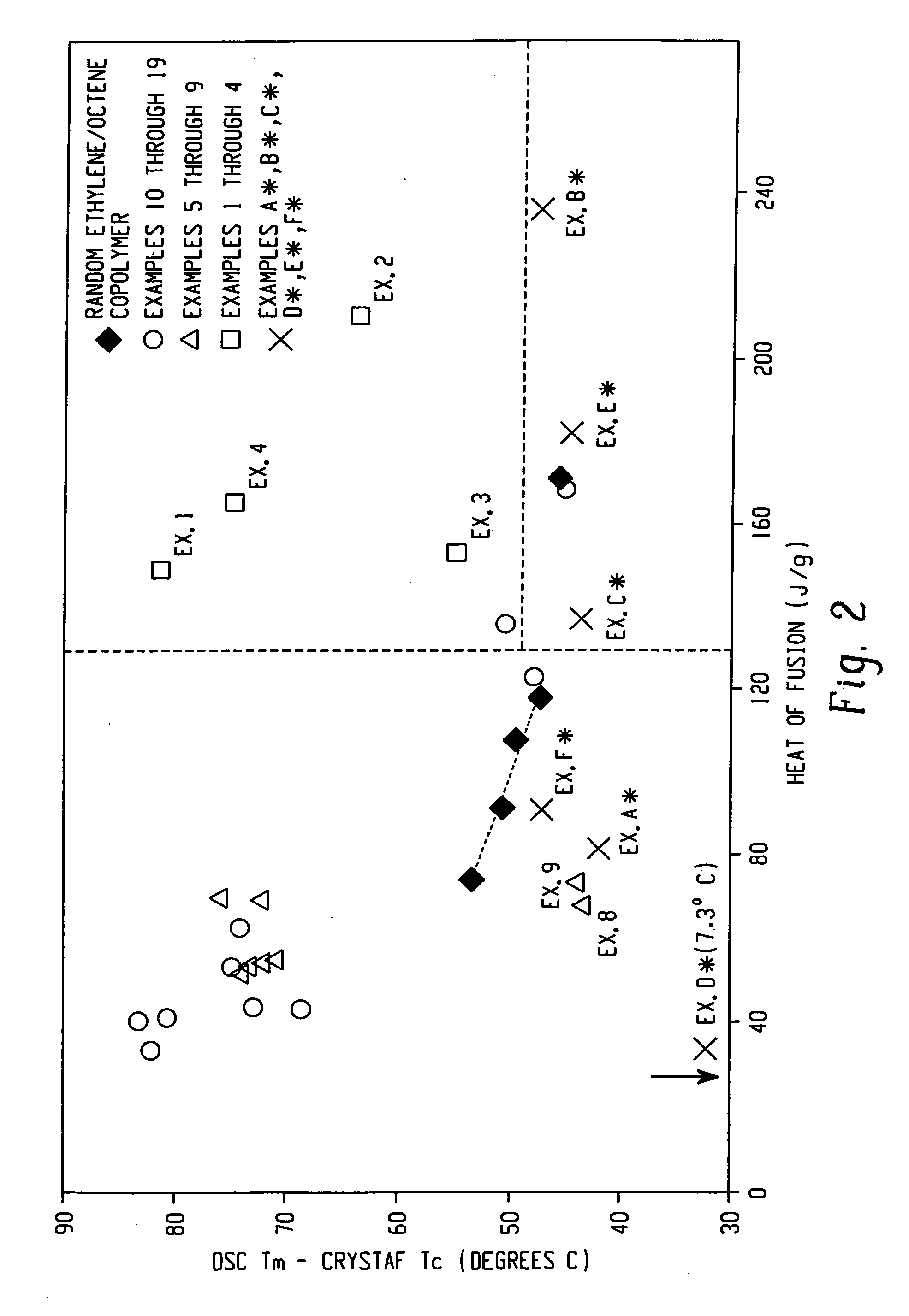

Compositions of ethylene/alpha-olefin multi-block interpolymer for elastic films and laminates

ActiveUS20070078222A1Easy to processHigh tensile strengthPersonal careSynthetic resin layered productsPolyolefinHigh pressure

This invention relates to polyolefin compositions. In particular, the invention pertains to elastic polymer compositions that can be more easily processed on cast film lines, extrusion lamination or coating lines. The compositions of the present invention preferably comprise an elastomeric polyolefin resin and a high pressure low density type resin.

Owner:DOW GLOBAL TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com