Patents

Literature

221results about How to "Reduce stratification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Halogen-free flame-retardant thermoplastic elastomer electrical cable material using polyphenylene ether as base material and preparation method thereof

InactiveCN101358028AGood compatibilityReduce stratificationInsulated cablesInsulated conductorsElastomerPolyphenylene oxide

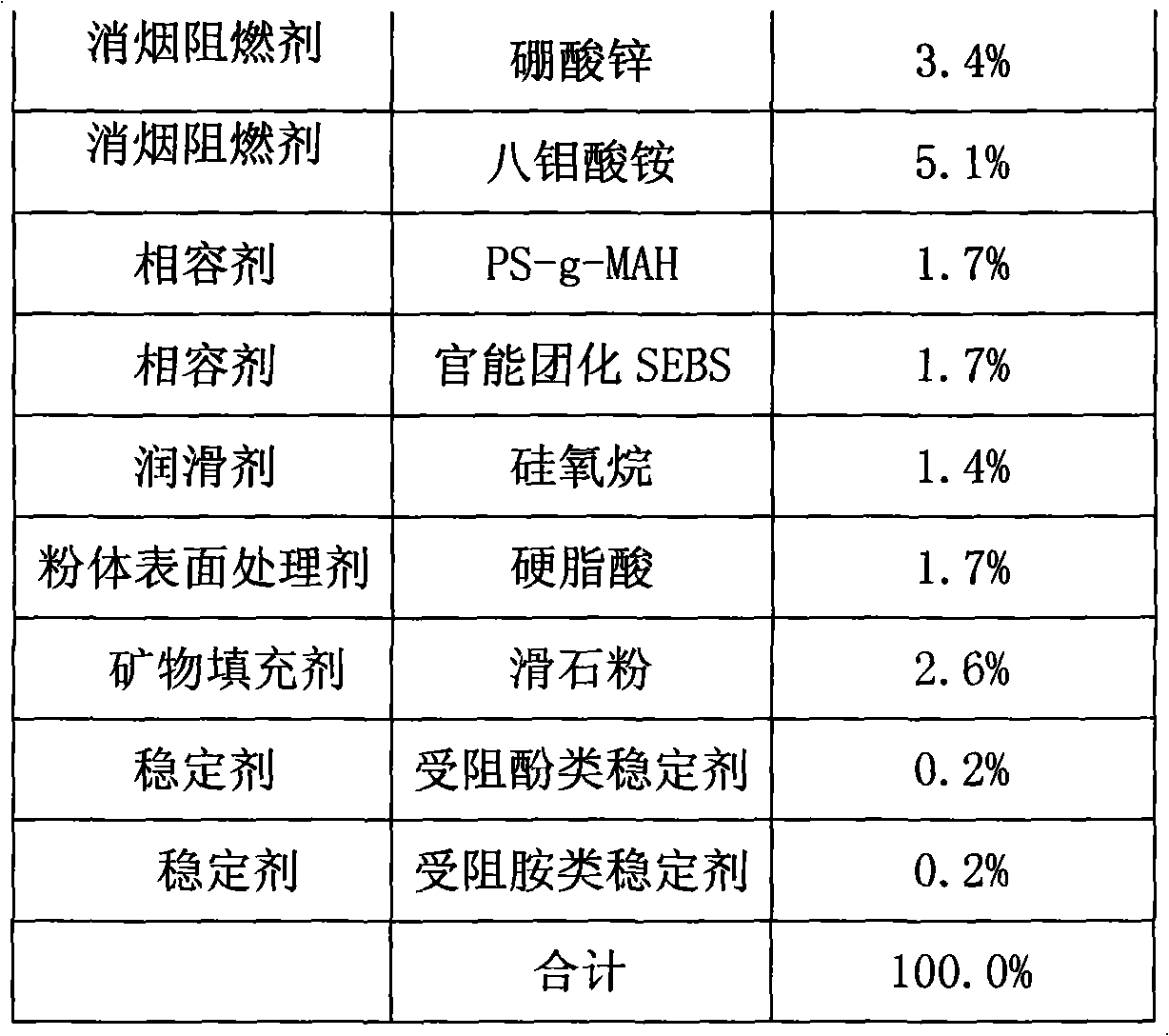

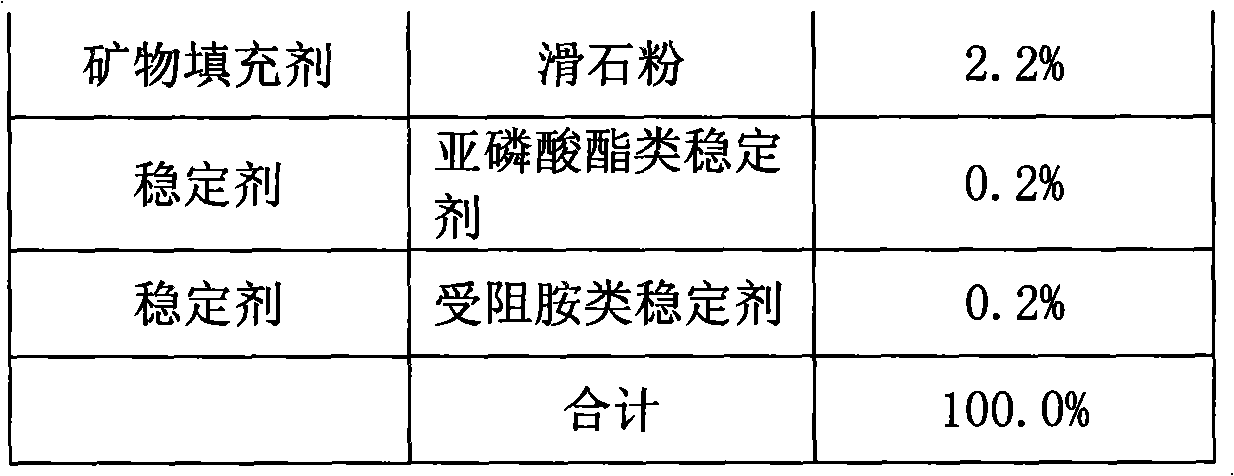

The invention discloses a halogen-free flame-retardant thermoplastic elastomer cable material with polyphenylether as the base materials and a preparation method thereof. The raw material of the cable material contains the components with the following weight percentage: 10 to 35 percent of matrix resin A; 5 to 15 percent of matrix resin B; 10 to 25 percent of elastomer; 5 to 25 percent of softening plasticizer; 8 to 15 percent of flame-retardant plasticizer; 20 to 40 percent of smoke-suppression flame retardant; 3 to 10 percent of compatilizer; 1 to 5 percent of lubricant; 1 to 5 percent of powder surface conditioner; 0 to 10 percent of mineral filler; 0.1 to 1 percent of stabilizing agent. The invention adds matrix resin, polyphenylether of strong polarity and functional group of styrene-ethylene / butylene-styrene segmented copolymer, which effectively improves the compatibility of non-polar elastomer with polyphenylether; the invention also adds plasticizer, which reduces the hardness of the material and increases the flexibility; and through the optimization and interaction of the softening plasticizer and the flame-retardant plasticizer, the invention reduces the hardness and improves the tactility of the material, and the flame retardant performance is excellent.

Owner:NINGBO SHIP PLASTIC CO LTD

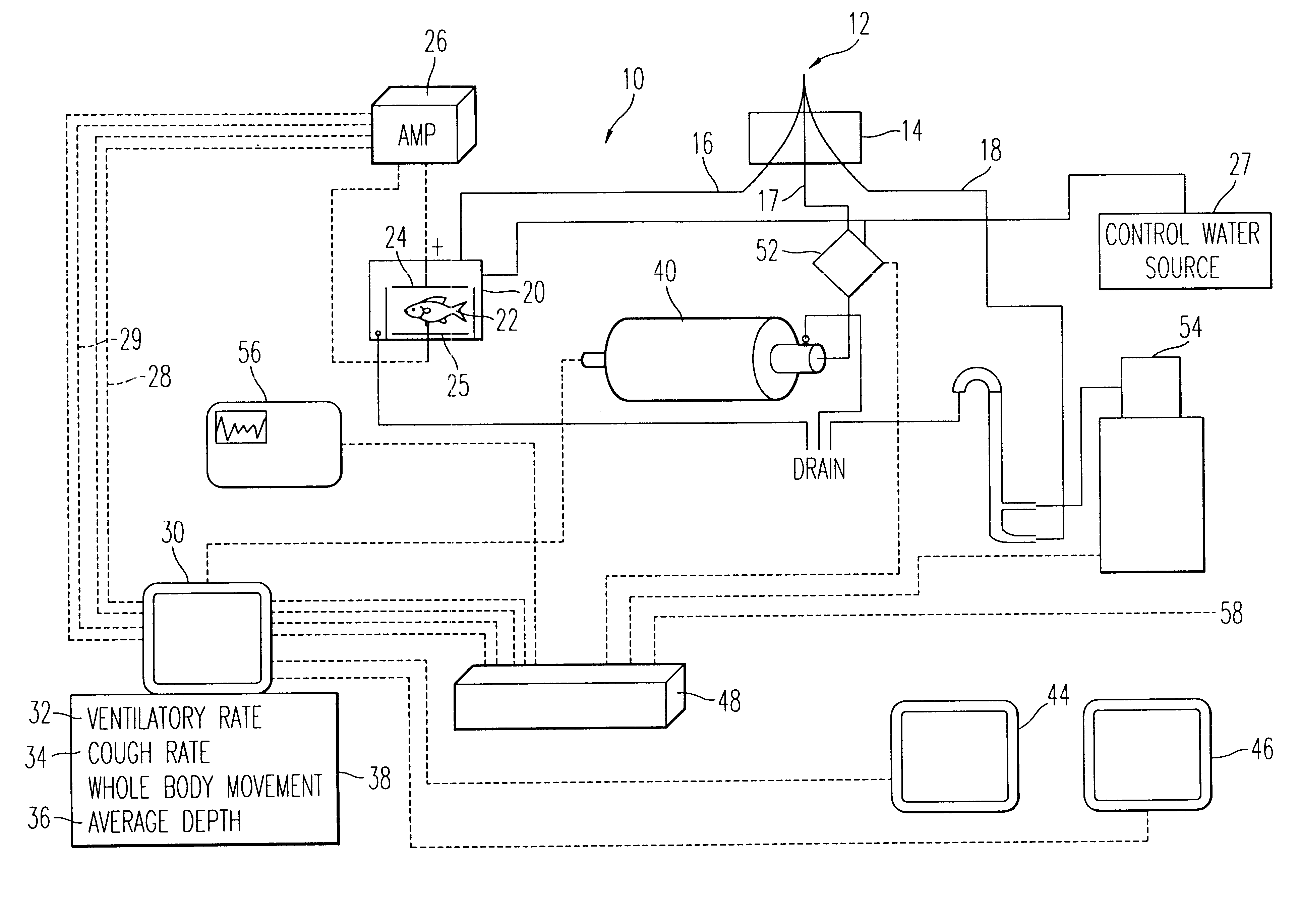

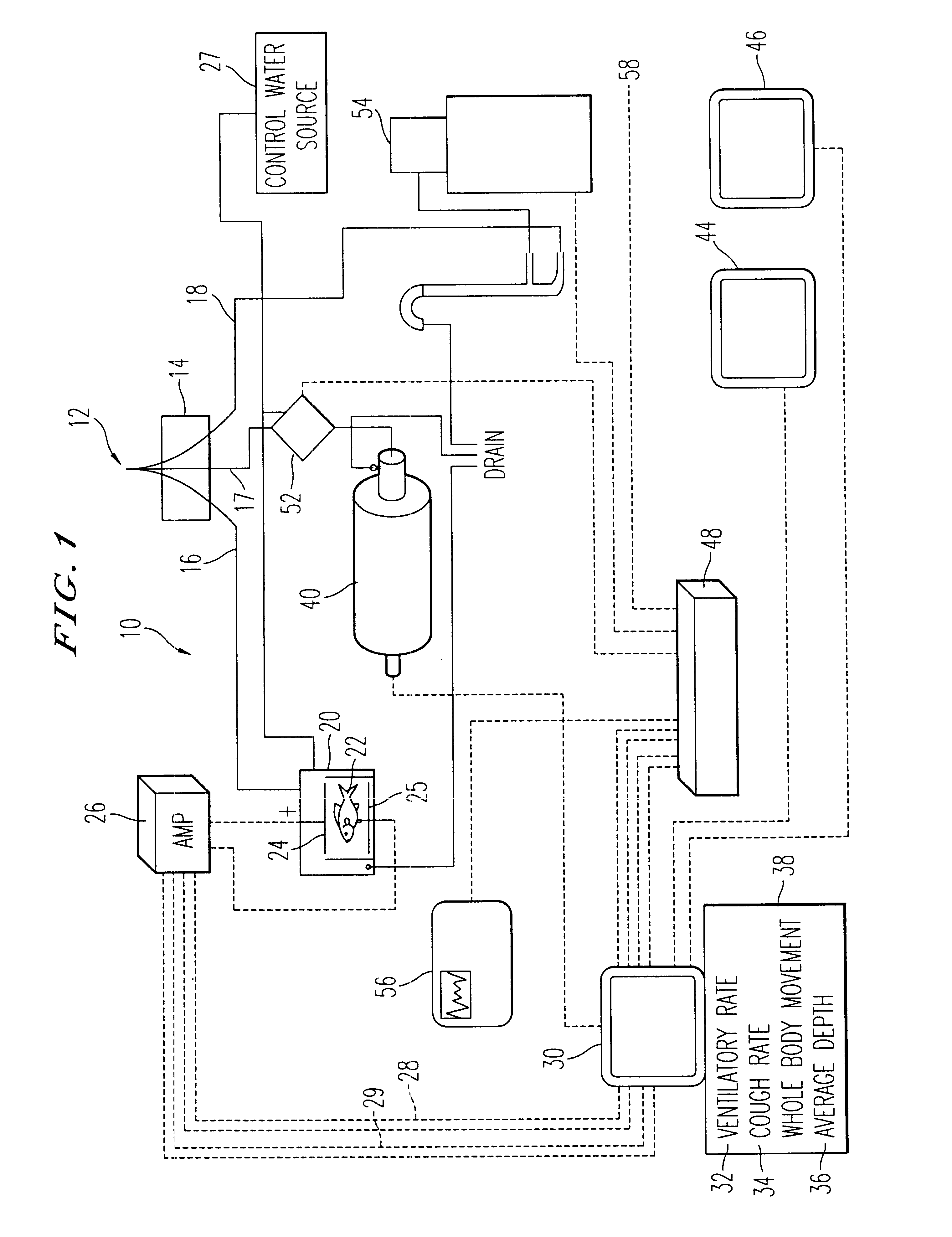

Apparatus and method for automated biomonitoring of water quality

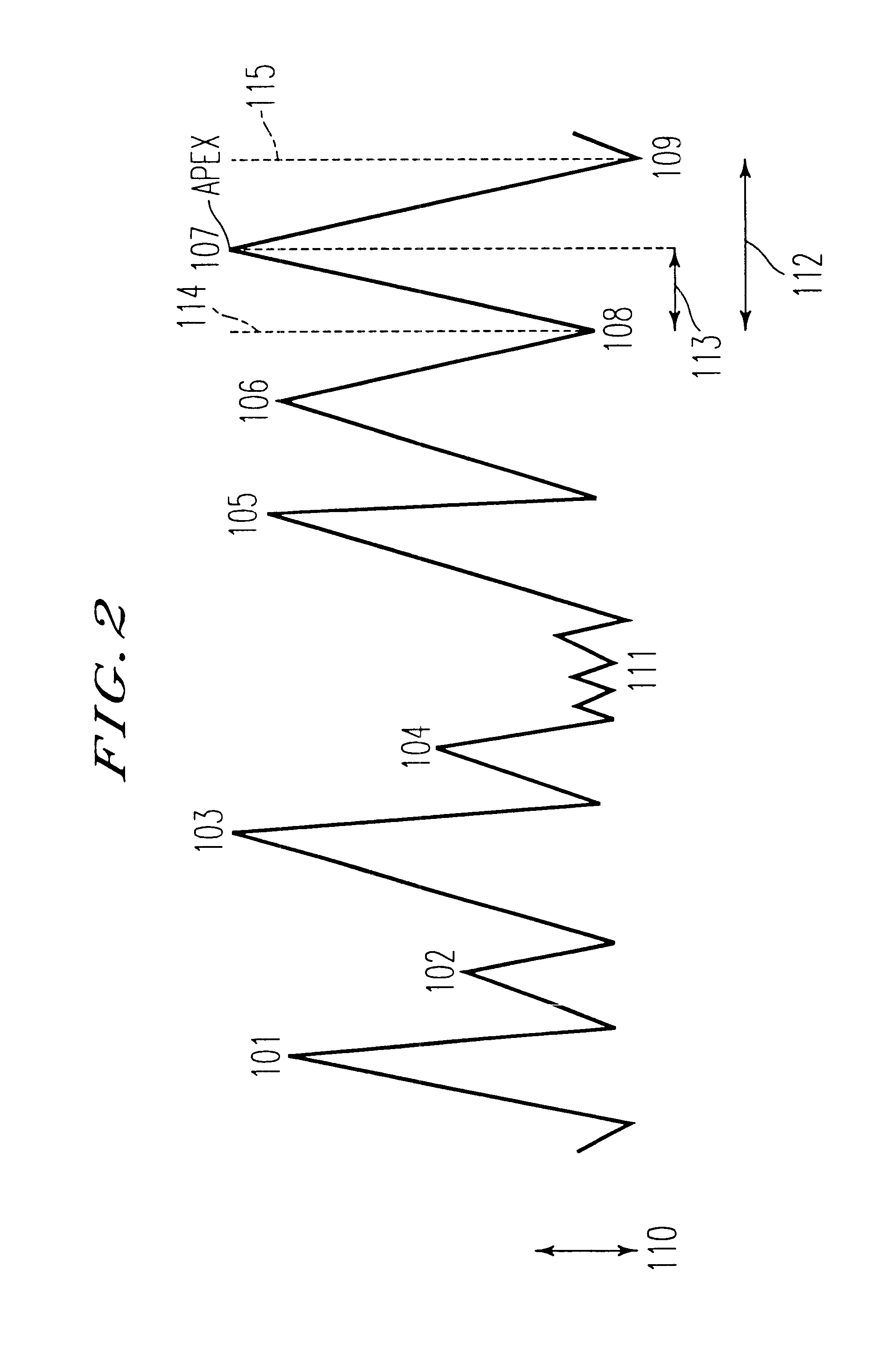

InactiveUS6393899B1Improved waveform processing of data signalLow spuriousPisciculture and aquariaTesting waterWater qualityEngineering

An automated biomonitoring system for monitoring water quality includes an exposure chamber for housing an aquatic organism having ventilatory behavior and body movement sensitive to water quality. Electrodes capture electrical signals produced by the organism during its ventilatory behavior and body movement, and a controller responsive to signals from the electrodes determines one or more ventilatory parameters based on the signals. The ventilatory parameters are compared with corresponding thresholds to determine when the water to which the organism is exposed has caused physiological stress to the organism. The signals captured by the electrodes may be corrected for variations in water conductivity so that the signals processed by the controlled are not influenced by conductivity.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

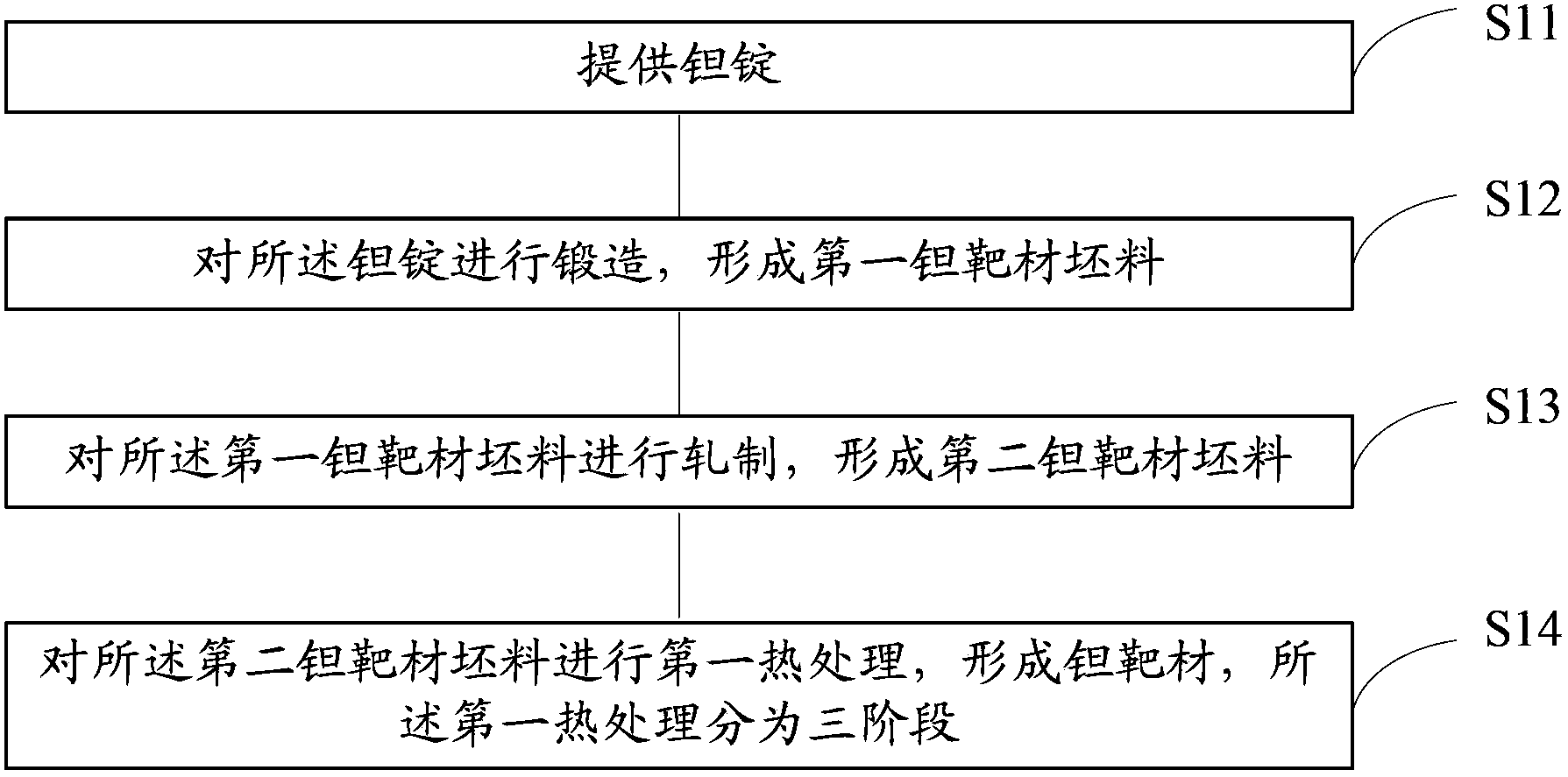

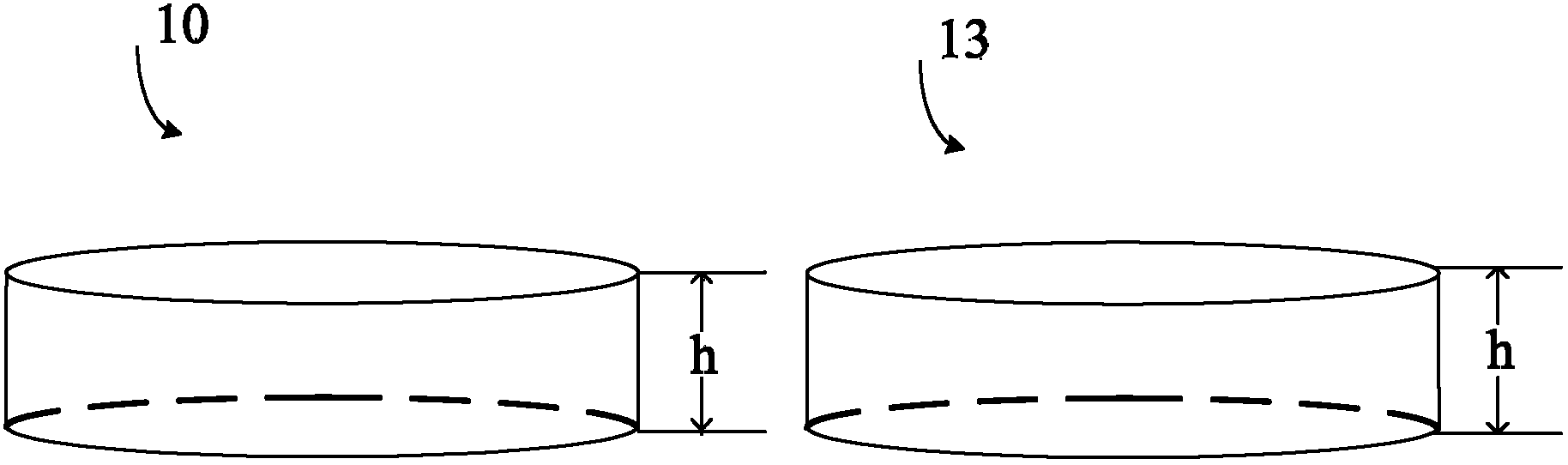

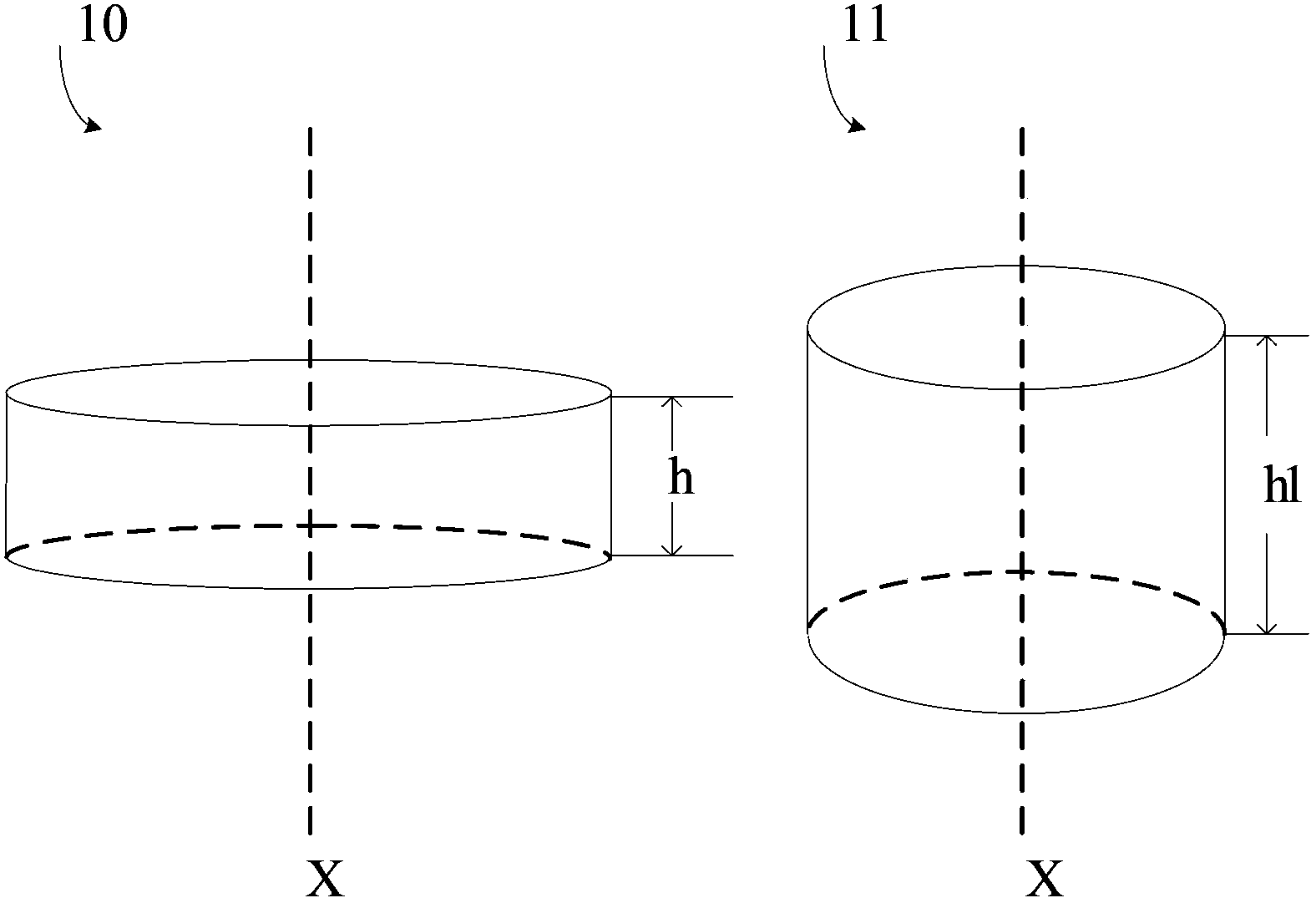

Production method of tantalum target and tantalum target component

ActiveCN103572223AReduce residual stressUniform crystal orientationVacuum evaporation coatingSputtering coatingCrystalliteHolding time

The invention provides a production method of a tantalum target and a tantalum target component. The production method of a tantalum target comprises the following steps of providing a tantalum ingot; forging the tantalum ingot to form a first tantalum target blank; rolling the first tantalum target blank to form a second tantalum target blank; performing first heat treatment on the second tantalum target blank to form the tantalum target, wherein the first heat treatment is divided into three stages: the temperature of the first stage of heat treatment is 550-750 DEG C, and the temperature is maintained for 30-90 minutes; the temperature of the second stage of heat treatment is 750-950 DEG C, and the temperature is maintained for 30-90 minutes; the temperature of the third stage of heat treatment is 950-1,200 DEG C, and the temperature is maintained for 30-90 minutes. By adopting the technical scheme, the main crystal orientation of the obtained tantalum target is (100), and the crystal orientation on the cross section is uniform; moreover, the tantalum target with fine grain and uniform internal organization also can be obtained.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

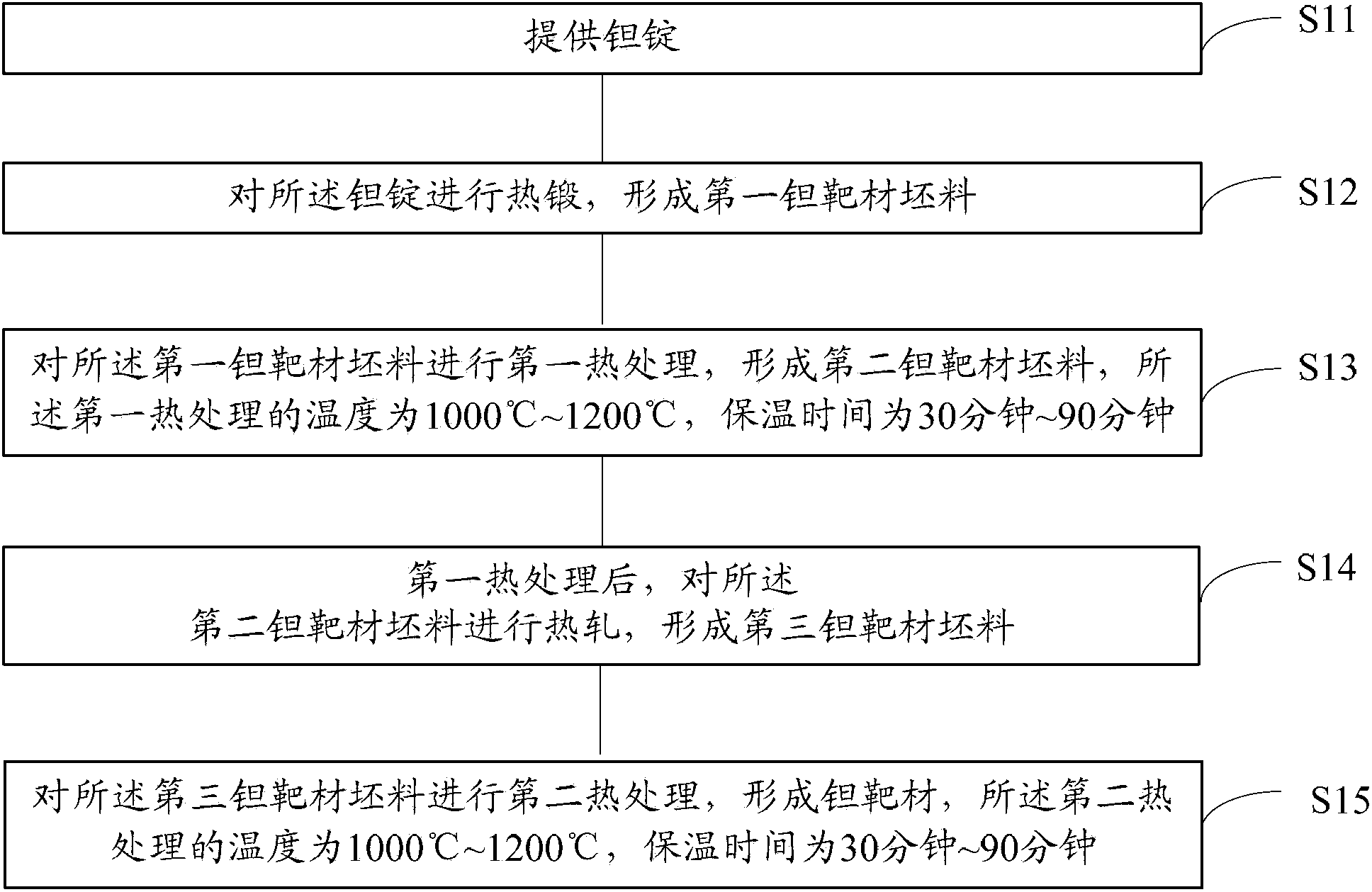

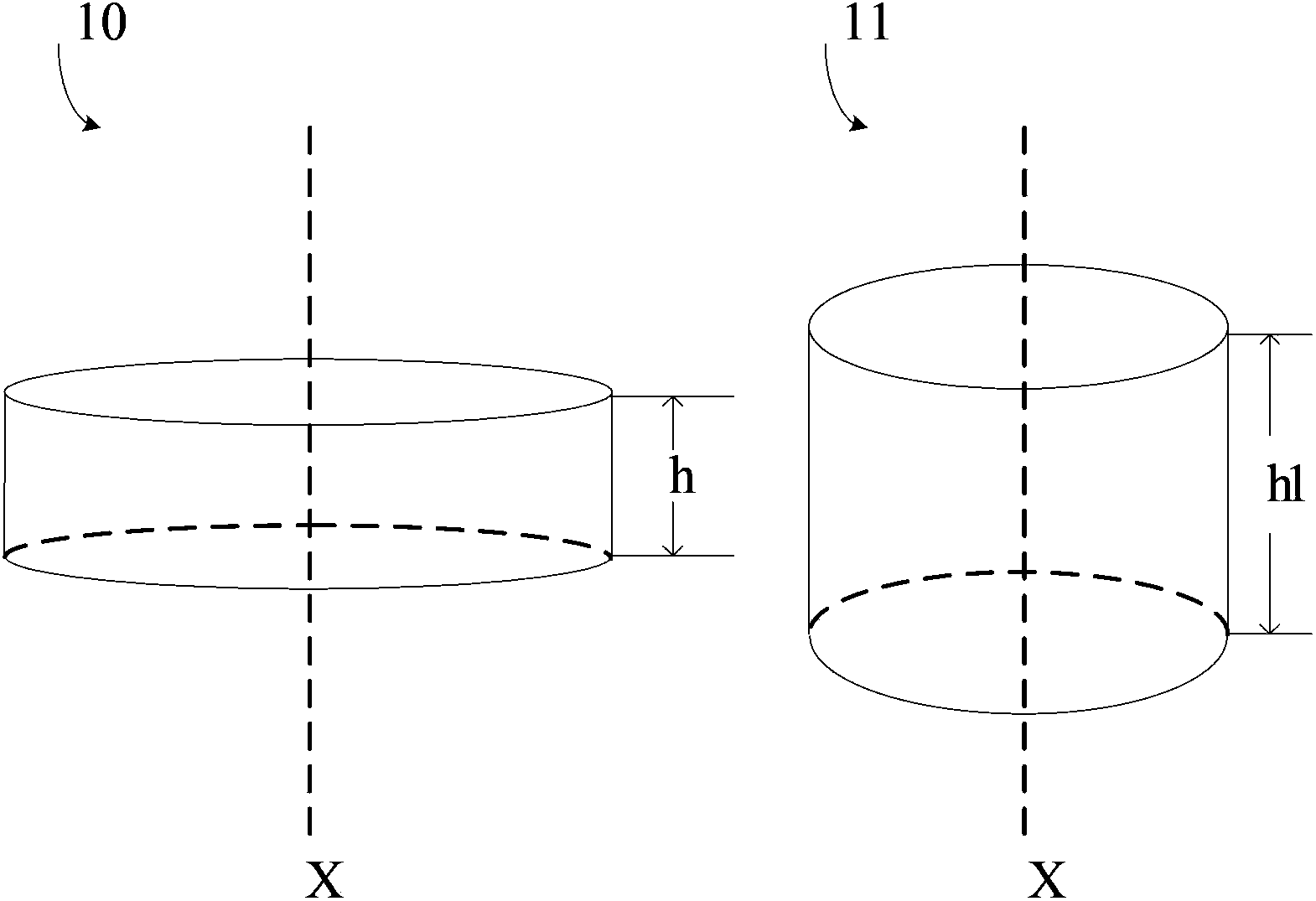

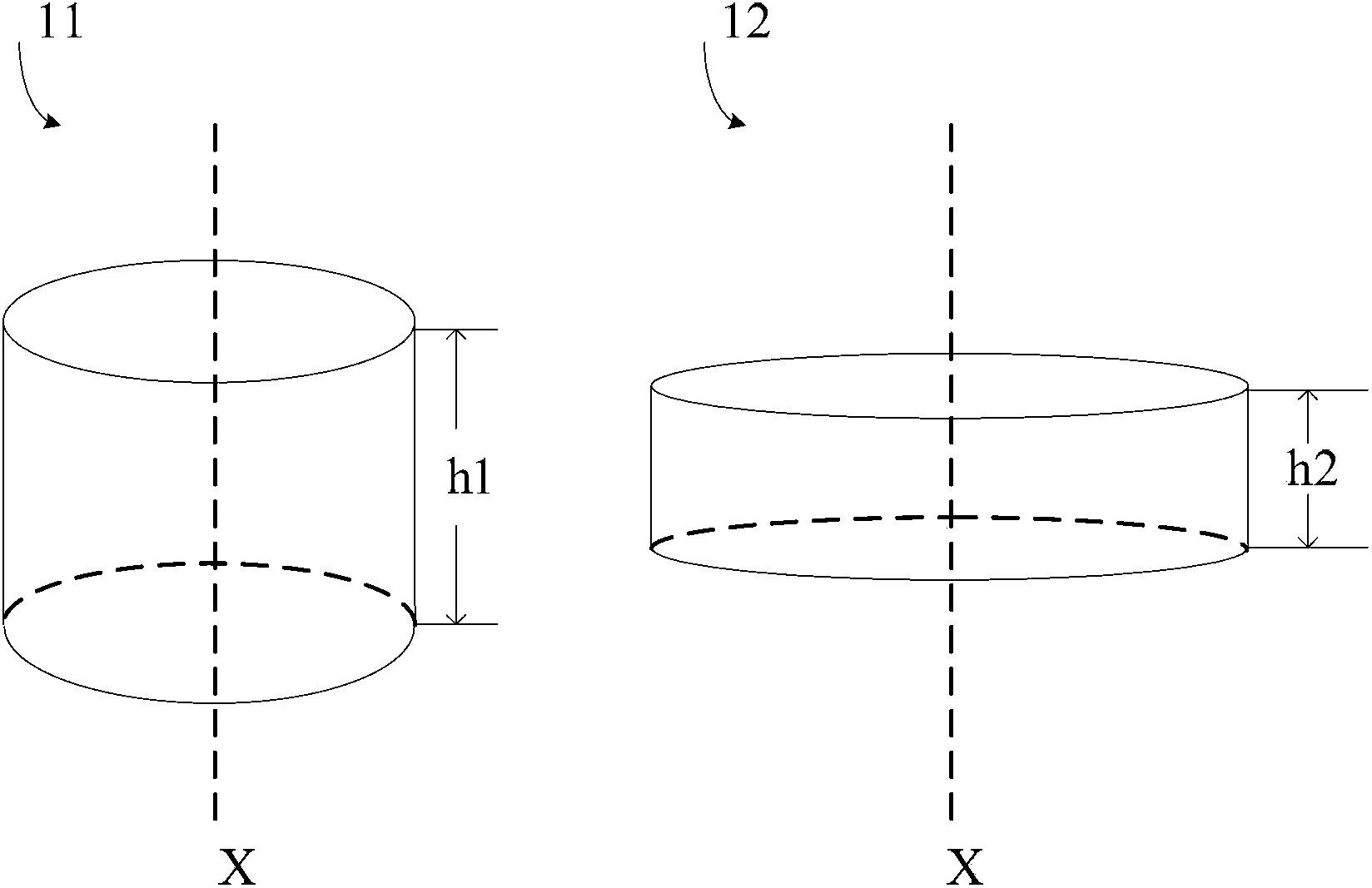

Production method of tantalum target and tantalum target component

ActiveCN103572225ADense tissueReduce unevennessVacuum evaporation coatingSputtering coatingIngotSemiconductor

The invention provides a production method of a tantalum target and a tantalum target component. The production method of a tantalum target comprises the following steps of providing a tantalum ingot; performing hot forging on the tantalum ingot to form a first tantalum target blank; performing first heat treatment on the first tantalum target blank to form a second tantalum target blank, wherein the temperature of the first heat treatment is 1,000-1,200 DEG C, and the temperature is maintained for 30-90 minutes; after the first heat treatment, performing hot rolling on the second tantalum target material to form a third tantalum target blank; performing second heat treatment on the third tantalum target blank to form the tantalum target, wherein the temperature of the second heat treatment is 1,000-1,200 DEG C, and the temperature is maintained for 30-90 minutes. By adopting the technical scheme, the produced tantalum target has relatively uniform internal organization and good magnetic property; moreover, by adopting the tantalum target to produce a tantalum target component for a semiconductor, the formed film has relatively good quality.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

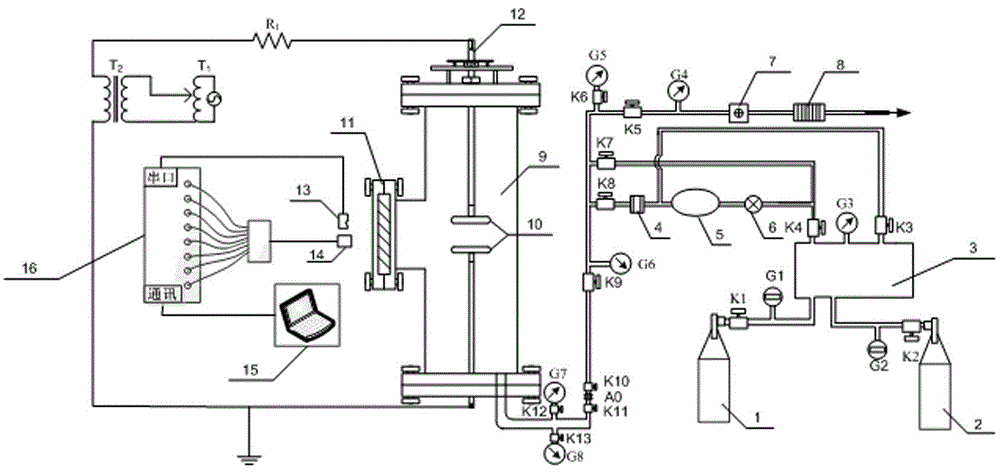

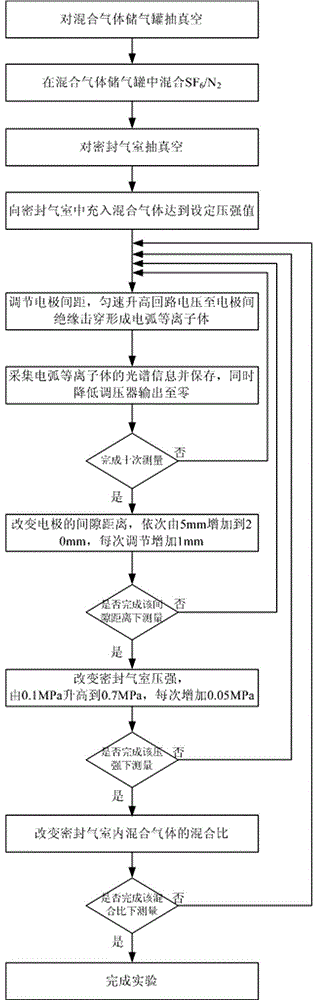

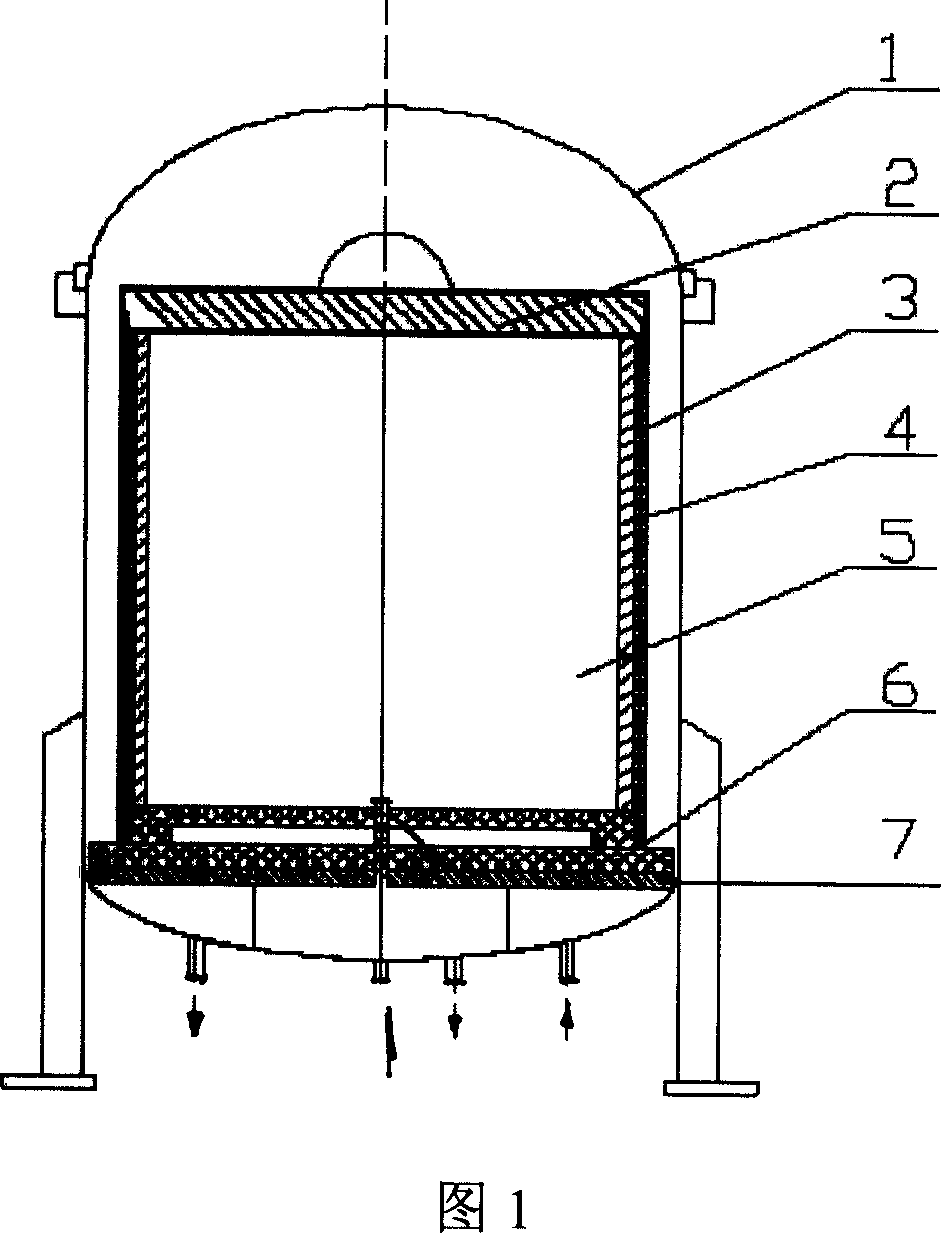

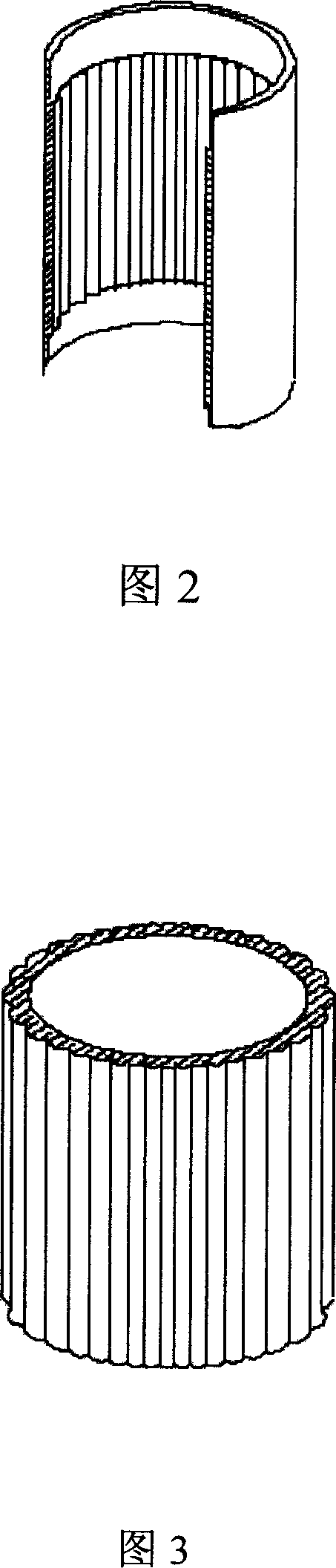

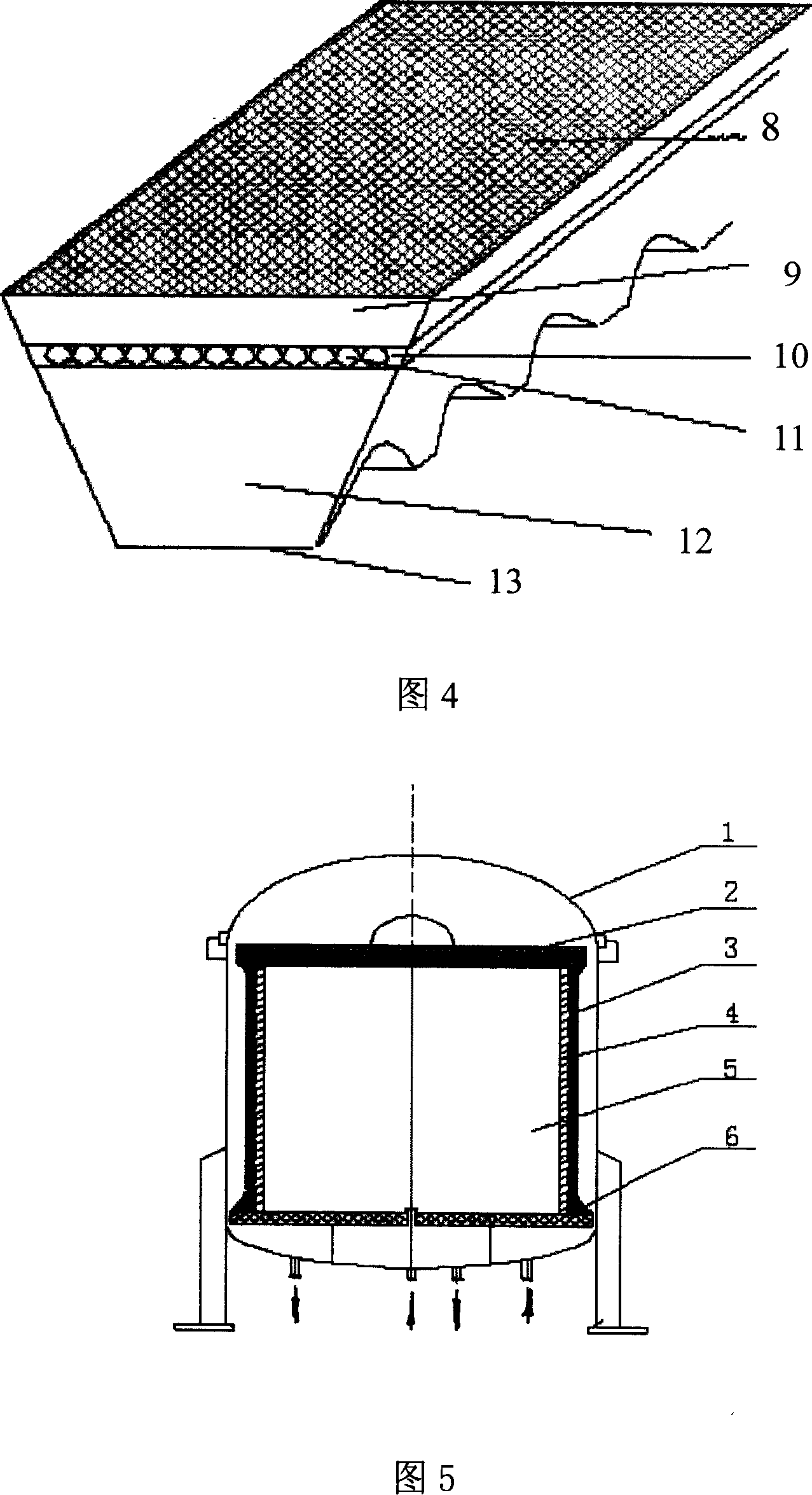

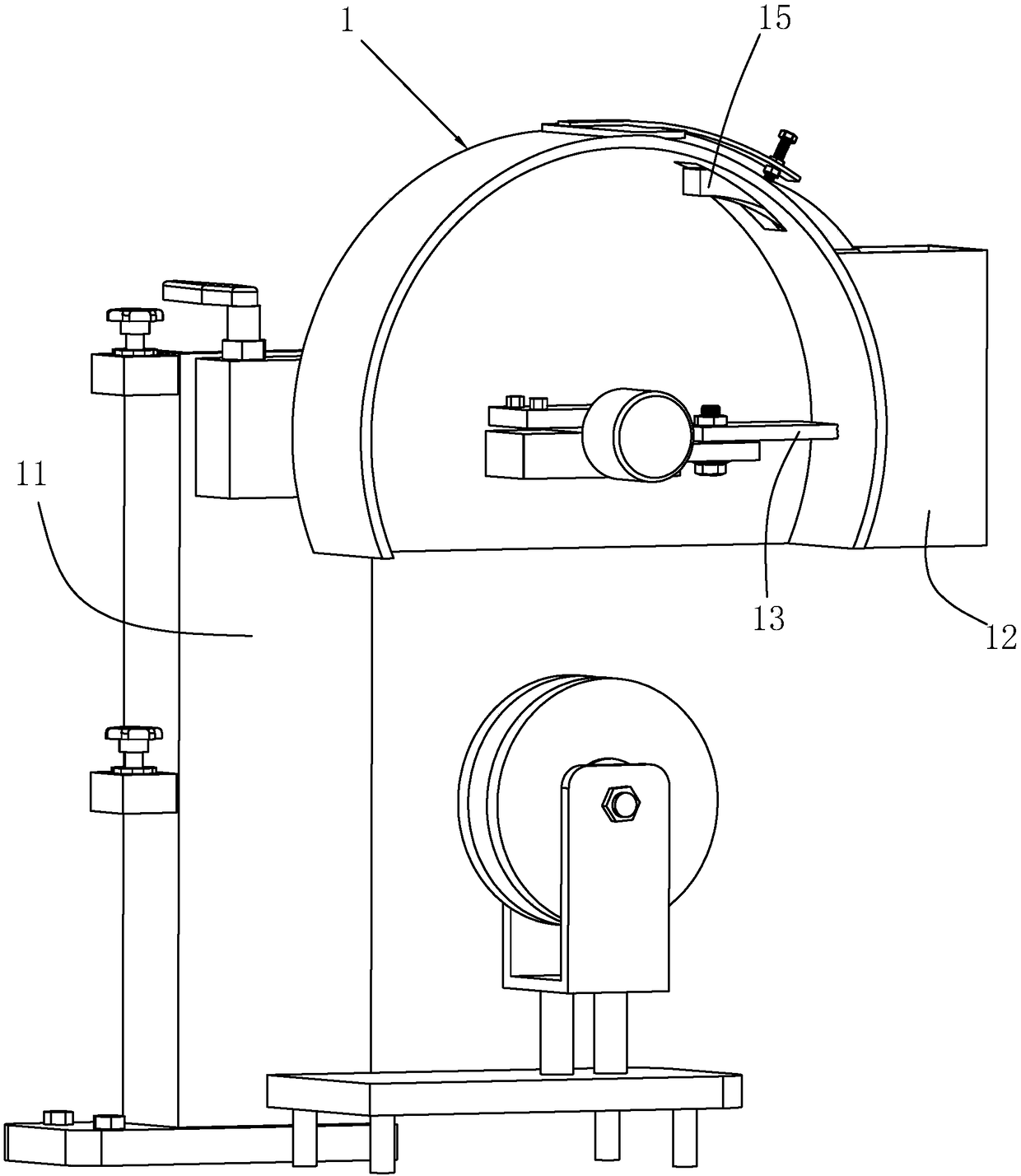

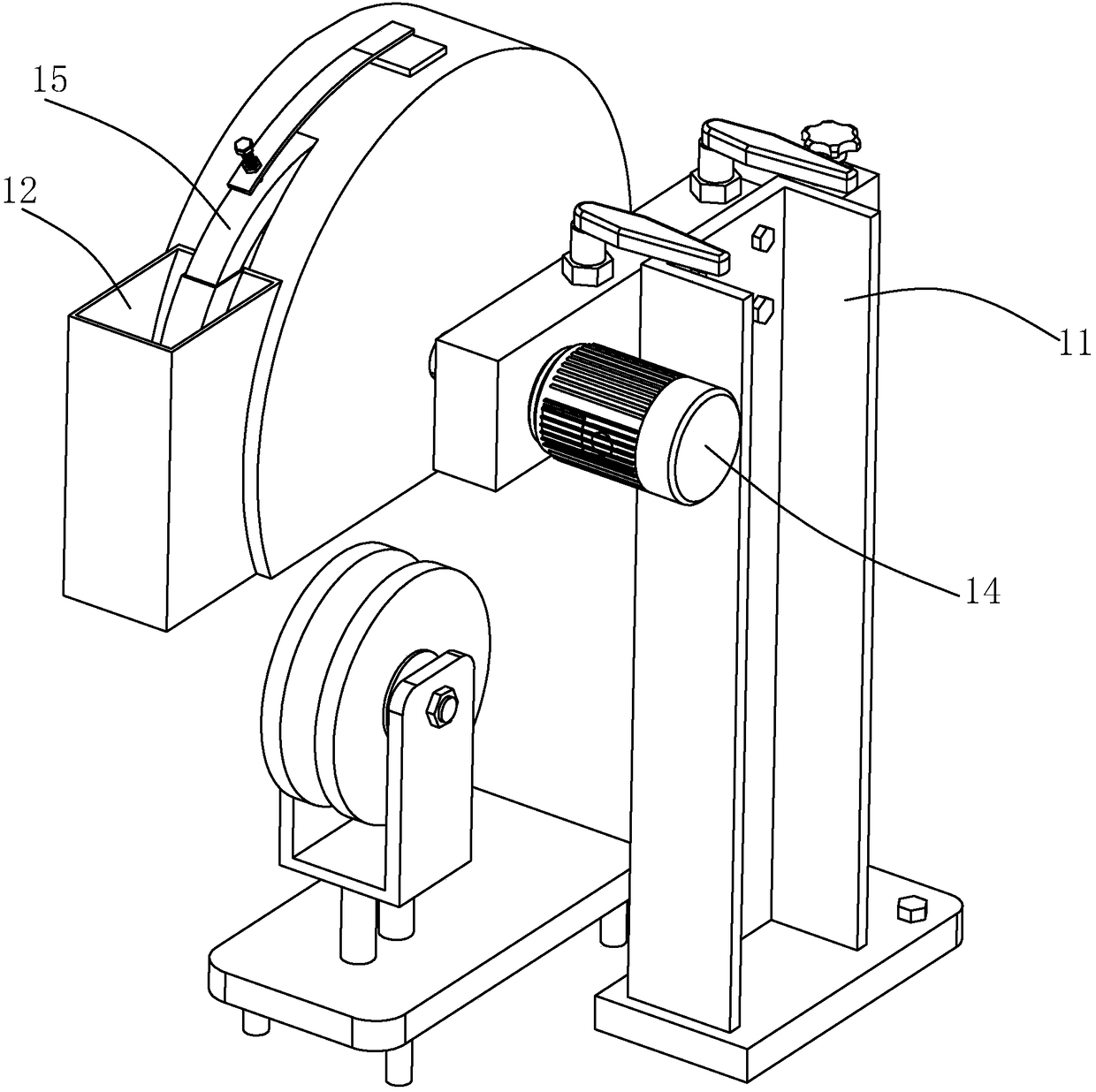

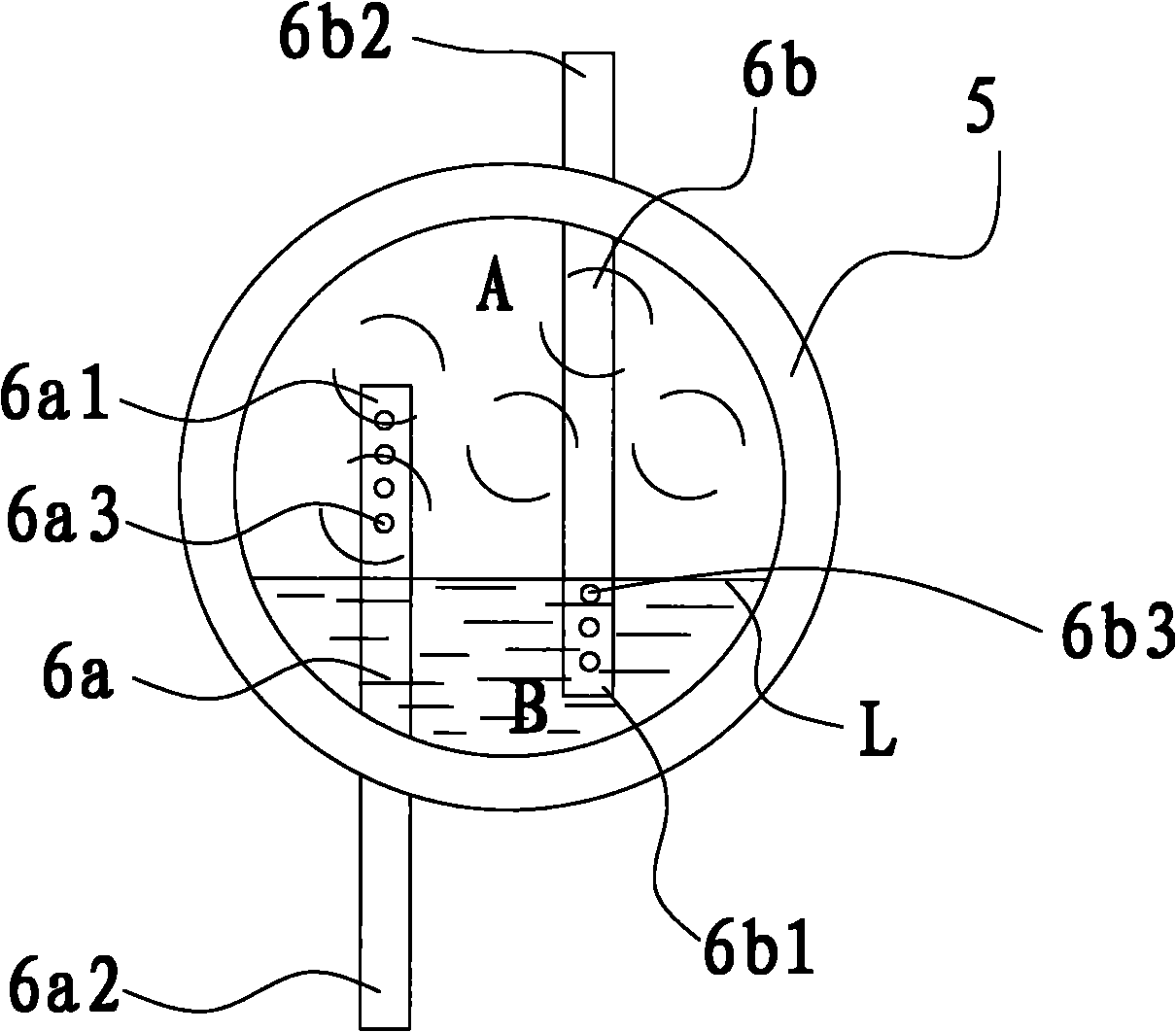

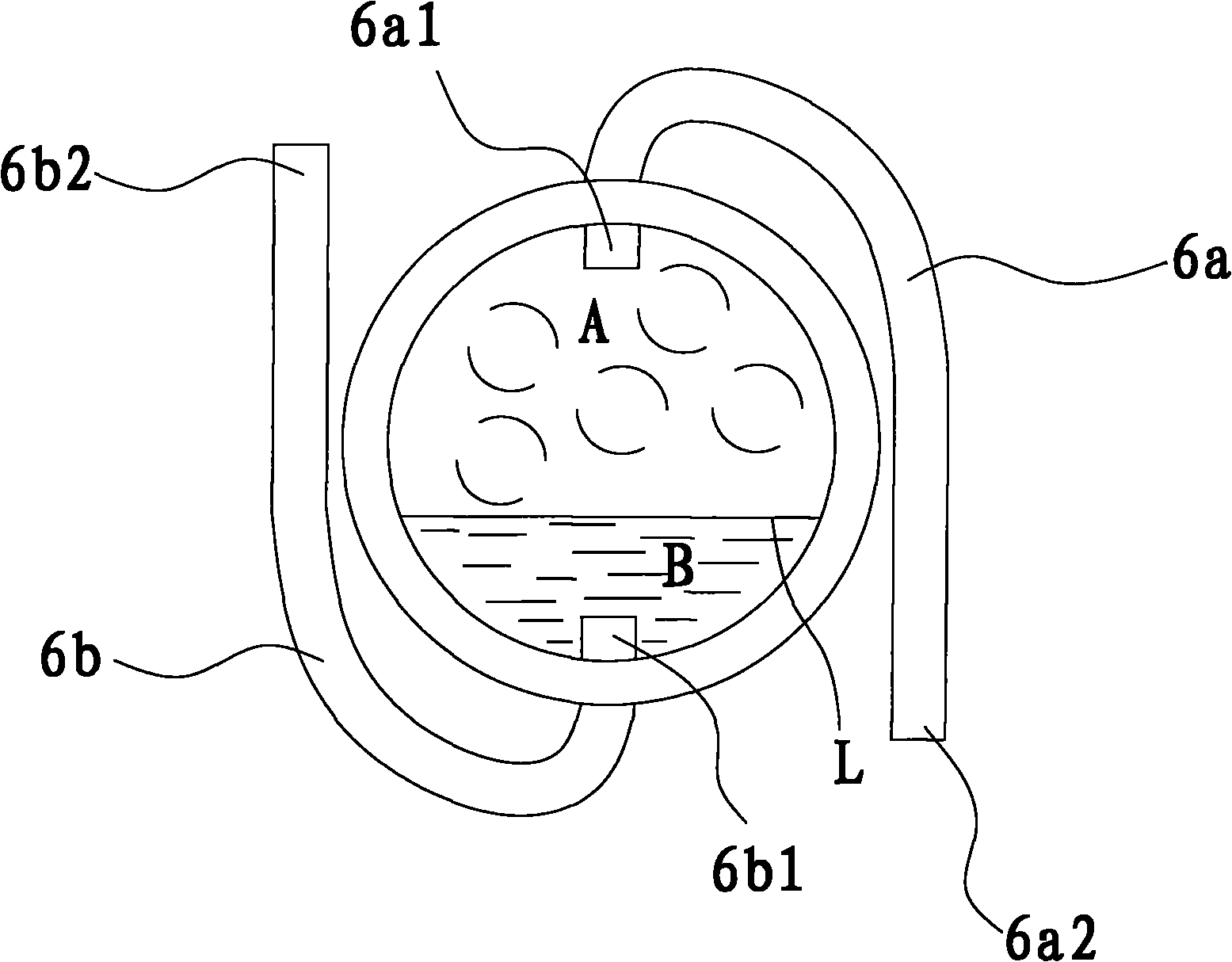

Plasma spectral measurement device and method for SF6 mixed gas

InactiveCN105699366AEfficient Spectral DetectionGuaranteed purityAnalysis by thermal excitationMeasurement deviceFiltration

The invention discloses a plasma spectral measurement device and method for SF6 mixed gas. The device is composed of an SF6 mixed gas charging, discharging and recycling device, an SF6 mixed gas arc plasma generation device and a spectrum detection device. The SF6 mixed gas charging, discharging and recycling device comprises two high-pressure gas cylinders used for storing SF6 gas and another kind of gas respectively, a mixed gas storage tank, a compressor, a filtration and absorption device, a vacuum pump and gas connecting pipelines. The SF6 mixed gas arc plasma generation device comprises two electrodes, a sealed gas chamber, a voltage regulator, a transformer, a water resistor and a connecting line. The method includes the following process steps that firstly, the mixed gas storage tank is vacuumized; secondly, the SF6 gas and the other kind of gas are fully mixed in the mixed gas storage tank; thirdly, the sealed gas chamber is vacuumized, and then the mixed gas is charged into the sealed gas chamber to a preset pressure intensity value; fourthly, loop voltage is regulated, and arc plasma is formed; fifthly, spectral information of the arc plasma is collected.

Owner:STATE GRID LIAONING ELECTRIC POWER RES INST +2

Method for detecting acid stratification in a battery

ActiveUS20070065713A1Reduce stratificationAccurate predictionBatteries circuit arrangementsCurrent/voltage measurementState of chargeRest period

A method for detecting acid stratification in a battery includes the following steps: determining a first state of charge value during a load period of the battery on the basis of an estimated open-circuit voltage, determining a second state of charge value during a rest period of the battery following the load period on the basis of a measured open-circuit voltage, comparing the first state of charge value to the second state of charge value, and detecting acid stratification when a defined deviation of the first state of charge value from the second state of charge value is exceeded.

Owner:ROBERT BOSCH GMBH

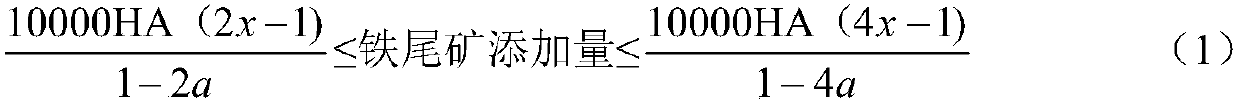

Improvement method of sandy clay loam saline-alkaline soil

InactiveCN107912098ASimple processEasy to implementOther chemical processesCereal cultivationBiogasOrganic acid

The invention aims to solve the problem that there is few study on effective and lasting improvement methods of sandy clay loam saline-alkaline land in the prior art and provides an improvement methodof sandy clay loam saline-alkaline soil. Improver iron tailings are added into the sandy clay loam saline-alkaline soil, and the iron tailings are utilized to change proportion of sand, powder and clay particles in sandy clay loam and reasonably adjust texture composition to modify the sandy clay loam saline-alkaline soil into loam, so that a lot of capillary pores can be retained, a lot of non-capillary pores and macrocracks can be formed, permeability is improved, water draining and salt washing are facilitated, capillary water can be blocked from going up, salt accumulation is reduced, andsoil salinity can be lowered effectively; by adding organic acid, composted sludge or composted biogas residue, compatibility between iron tailings sand and natural soil is improved, differential settlement and stratification in the process of saline-alkaline soil improvement are avoided or reduced to form soil structure uniform in texture, and lasting improvement of the saline-alkaline soil andstability of soil texture are realized.

Owner:ANSTEEL GRP MINING CO LTD

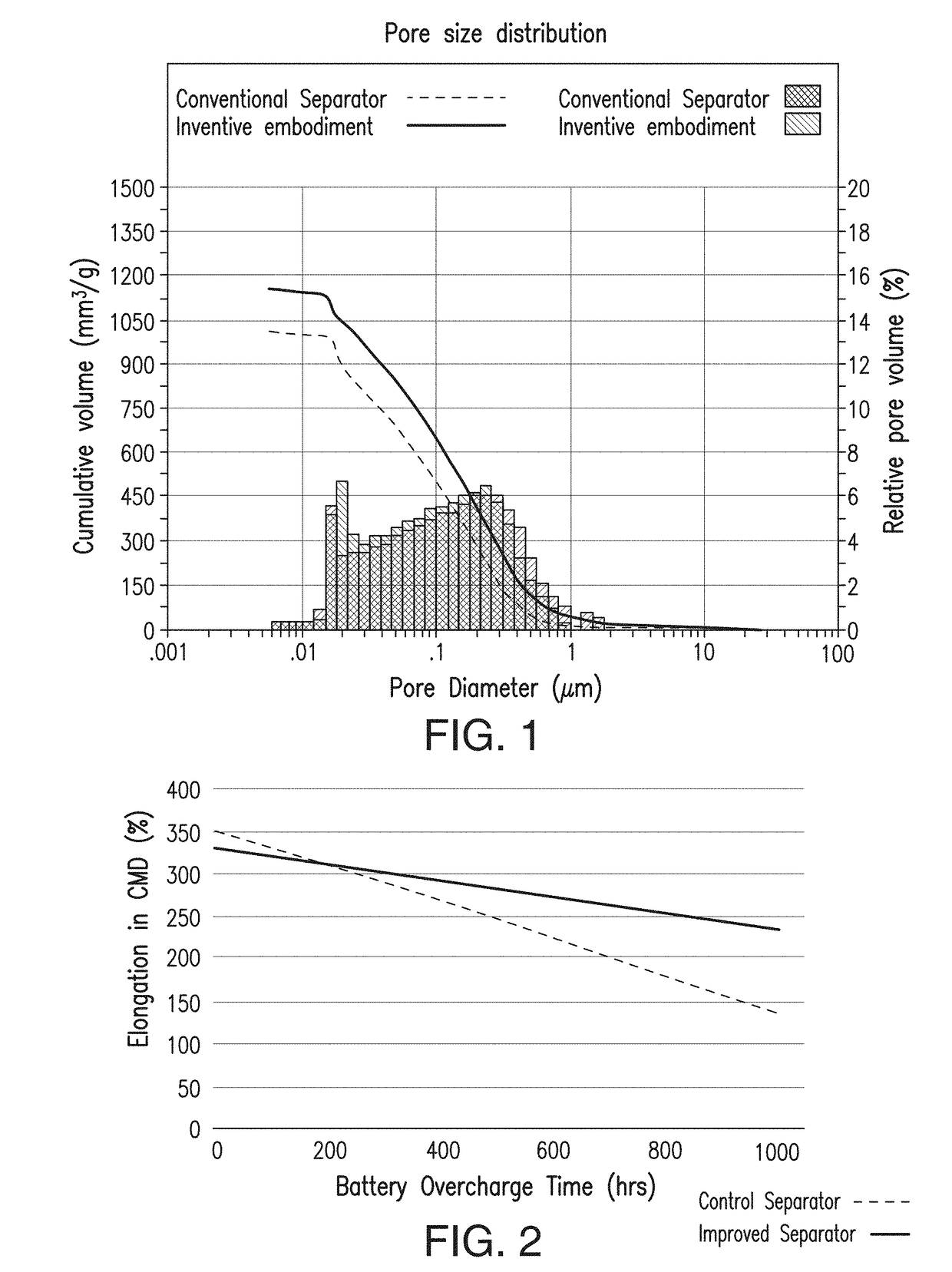

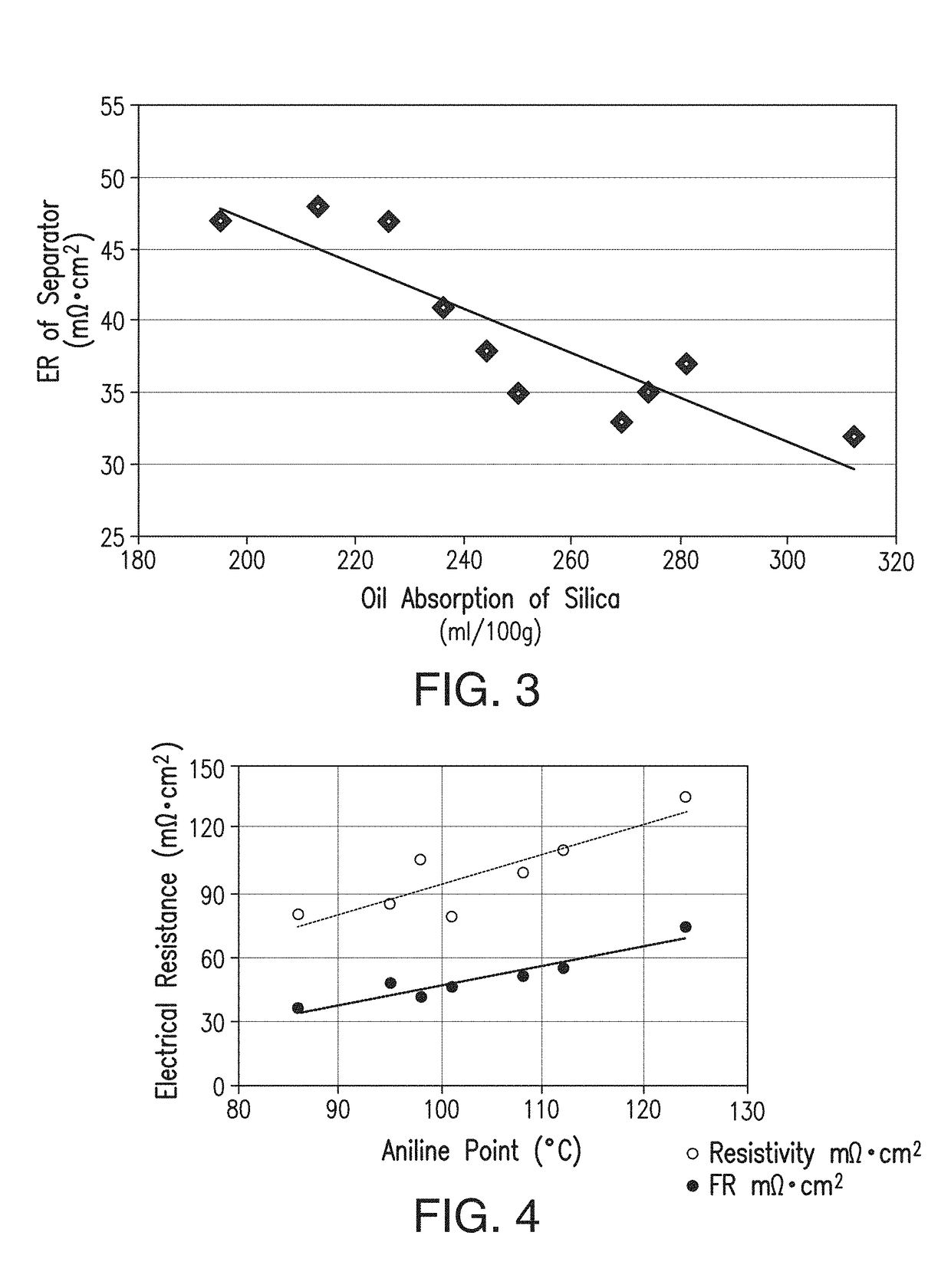

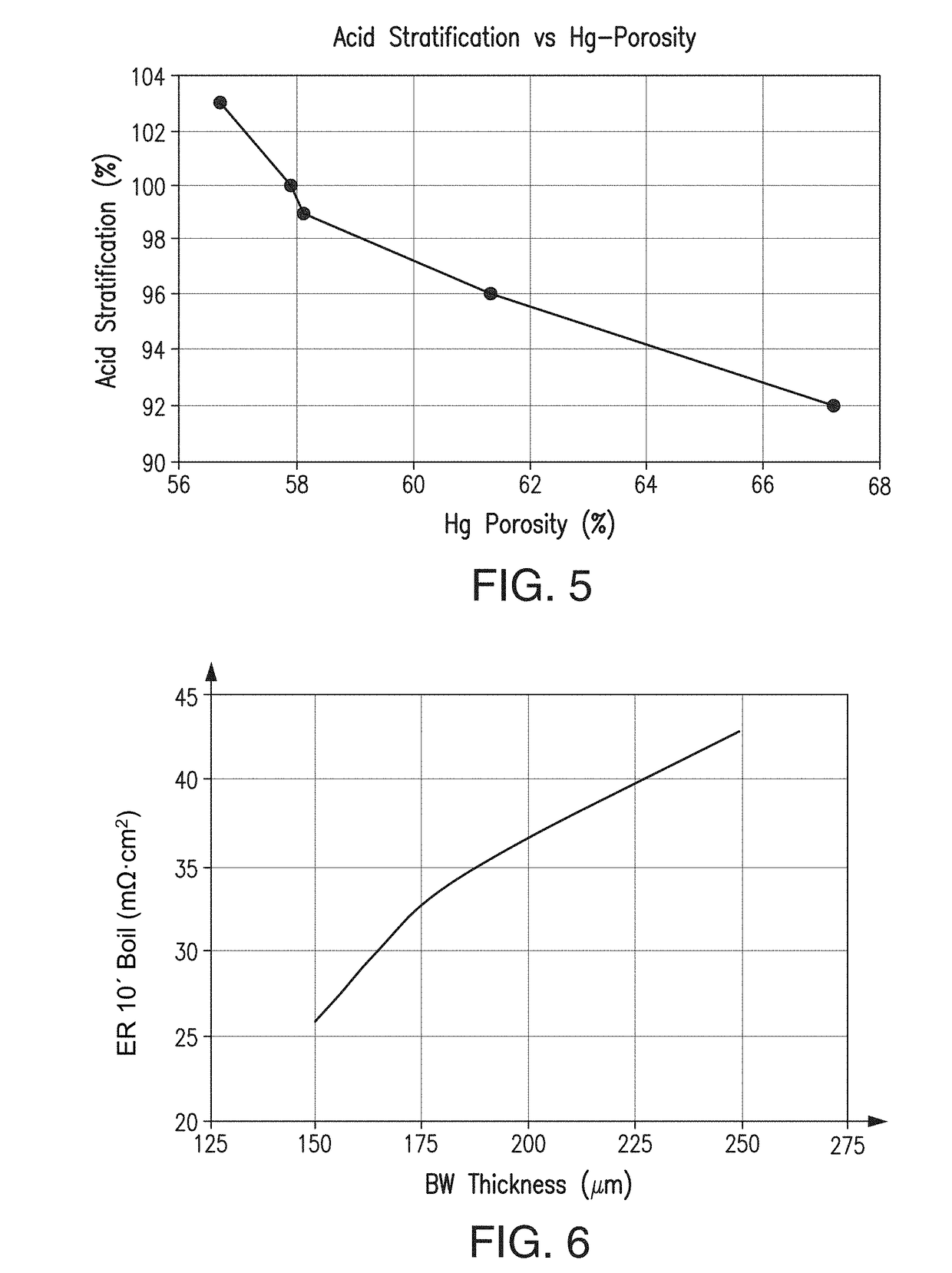

Separators for enhanced flooded batteries, batteries, and related methods

ActiveUS20170294636A1Reduced internal electrical resistanceIncreased cold cranking ampSilicaCell seperators/membranes/diaphragms/spacersFriabilityUltrahigh molecular weight polyethylene

A battery separator has performance enhancing additives or coatings, fillers with increased friability, increased ionic diffusion, decreased tortuosity, increased wettability, reduced oil content, reduced thickness, decreased electrical resistance, and / or increased porosity. The separator in a battery reduces the water loss, lowers acid stratification, lowers the voltage drop, and / or increases the CCA. The separators include or exhibit performance enhancing additives or coatings, increased porosity, increased void volume, amorphous silica, higher oil absorption silica, higher silanol group silica, reduced electrical resistance, a shish-kebab structure or morphology, a polyolefin microporous membrane containing particle-like filler in an amount of 40% or more by weight of the membrane and ultrahigh molecular weight polyethylene having shish-kebab formations and the average repetition periodicity of the kebab formation from 1 nm to 150 nm, decreased sheet thickness, decreased tortuosity, separators especially well-suited for enhanced flooded batteries.

Owner:DARAMIC LLC

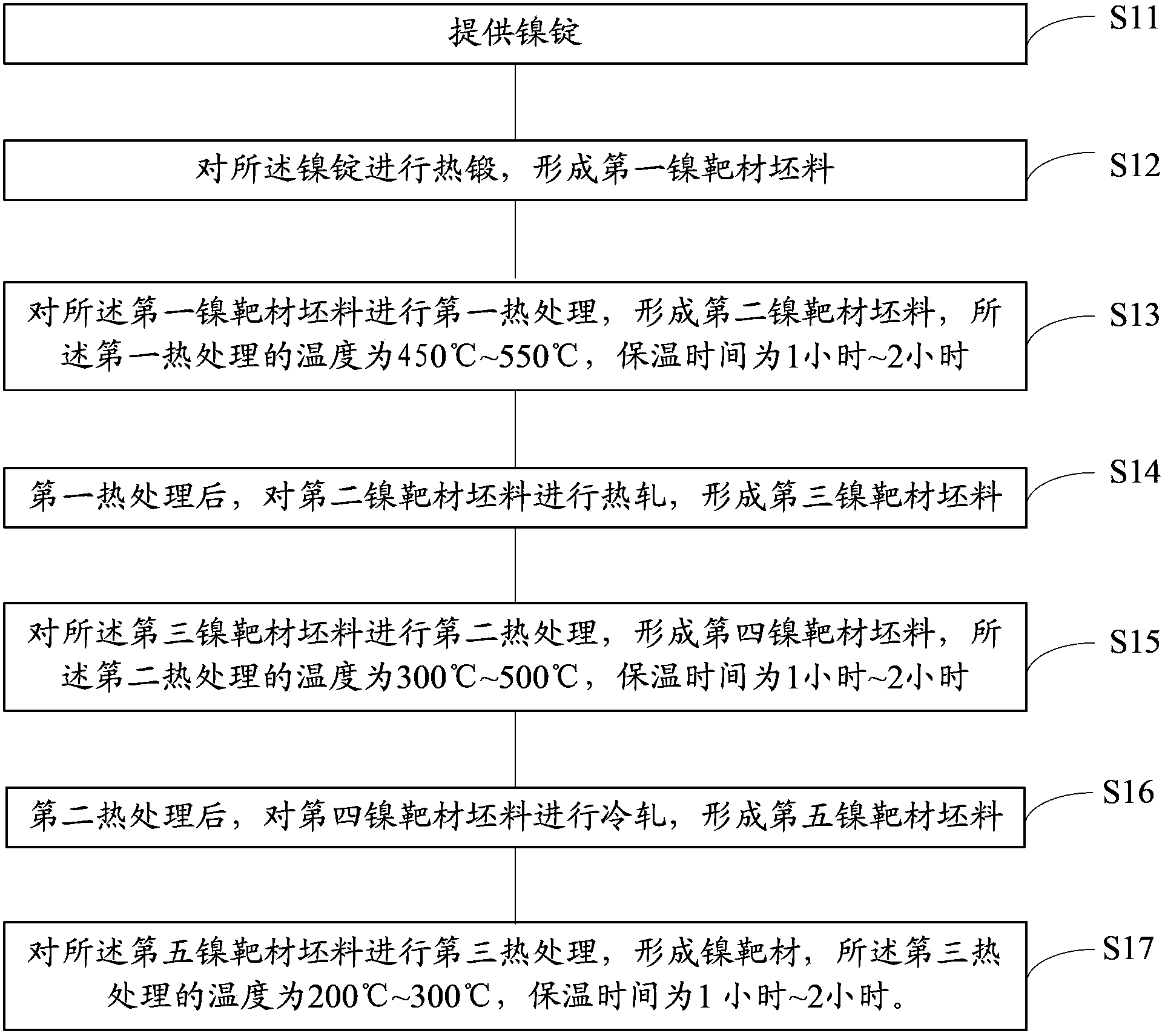

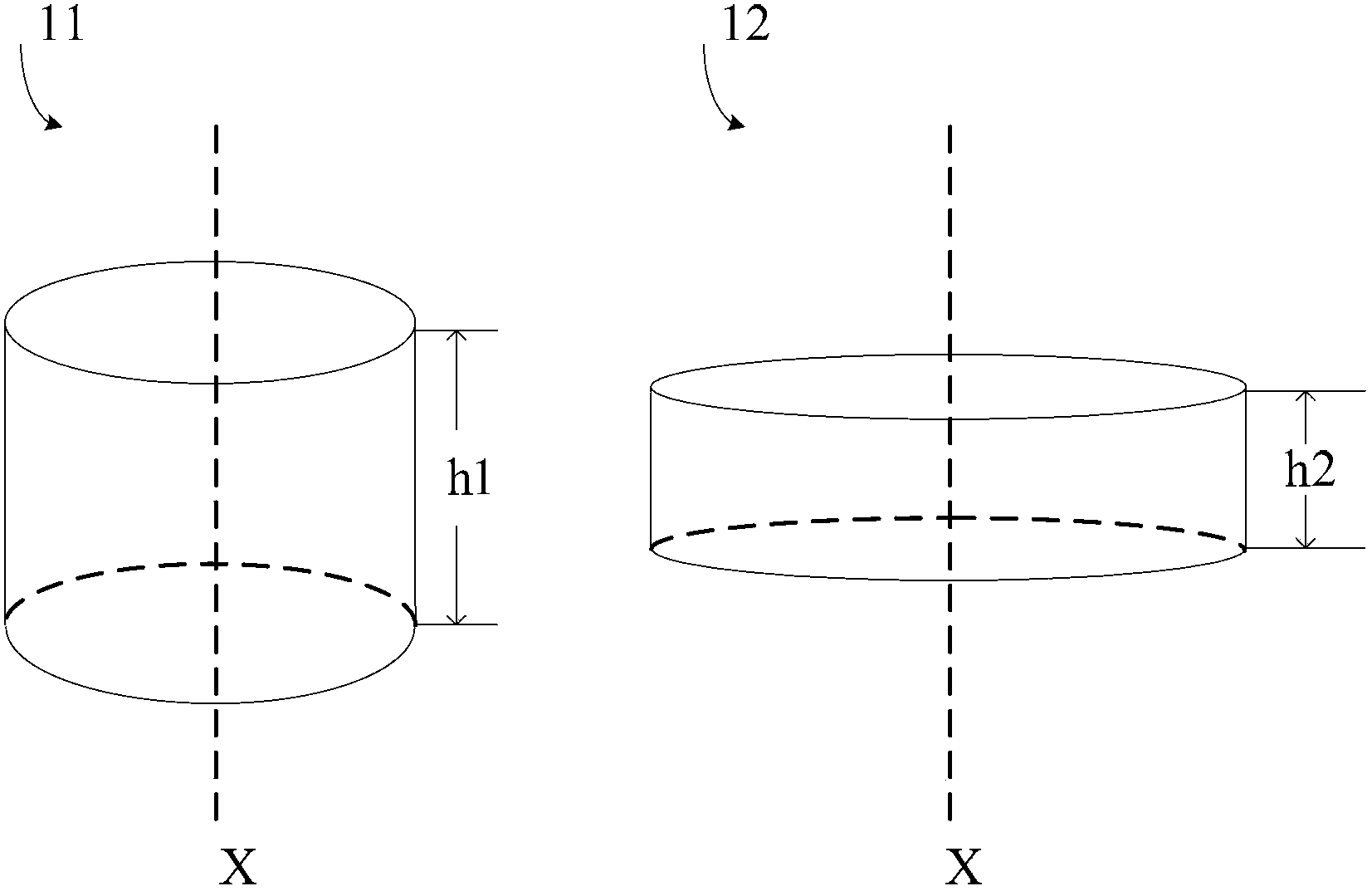

Production method of nickel target and nickel target component

ActiveCN103572224ADense tissueReduce hardnessVacuum evaporation coatingSputtering coatingIngotMaterials science

The invention provides a production method of a nickel target and a nickel target component. The production method of the nickel target comprises the following steps of providing a nickel ingot; performing hot forging on the nickel ingot to form a first nickel target blank; performing first heat treatment on the first nickel target blank to form a second nickel target blank, wherein the temperature of the first heat treatment is 450-550 DEG C, and the temperature is maintained for 1-2 hours; after the first heat treatment, performing hot rolling on the second nickel target blank to form a third nickel target blank; performing second heat treatment on the third nickel target blank to form a fourth nickel target blank, wherein the temperature of the second heat treatment is 300-500 DEG C, and the temperature is maintained for 1-2 hours; after the second heat treatment, performing cold rolling on the fourth nickel target blank to form a fifth nickel target blank; performing third heat treatment on the fifth nickel target blank to form the nickel target, wherein the temperature of the third heat treatment is 200-300 DEG C, and the temperature is maintained for 1-2 hours. By adopting the technical scheme, the produced nickel target has relatively uniform internal organization and good magnetic property.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

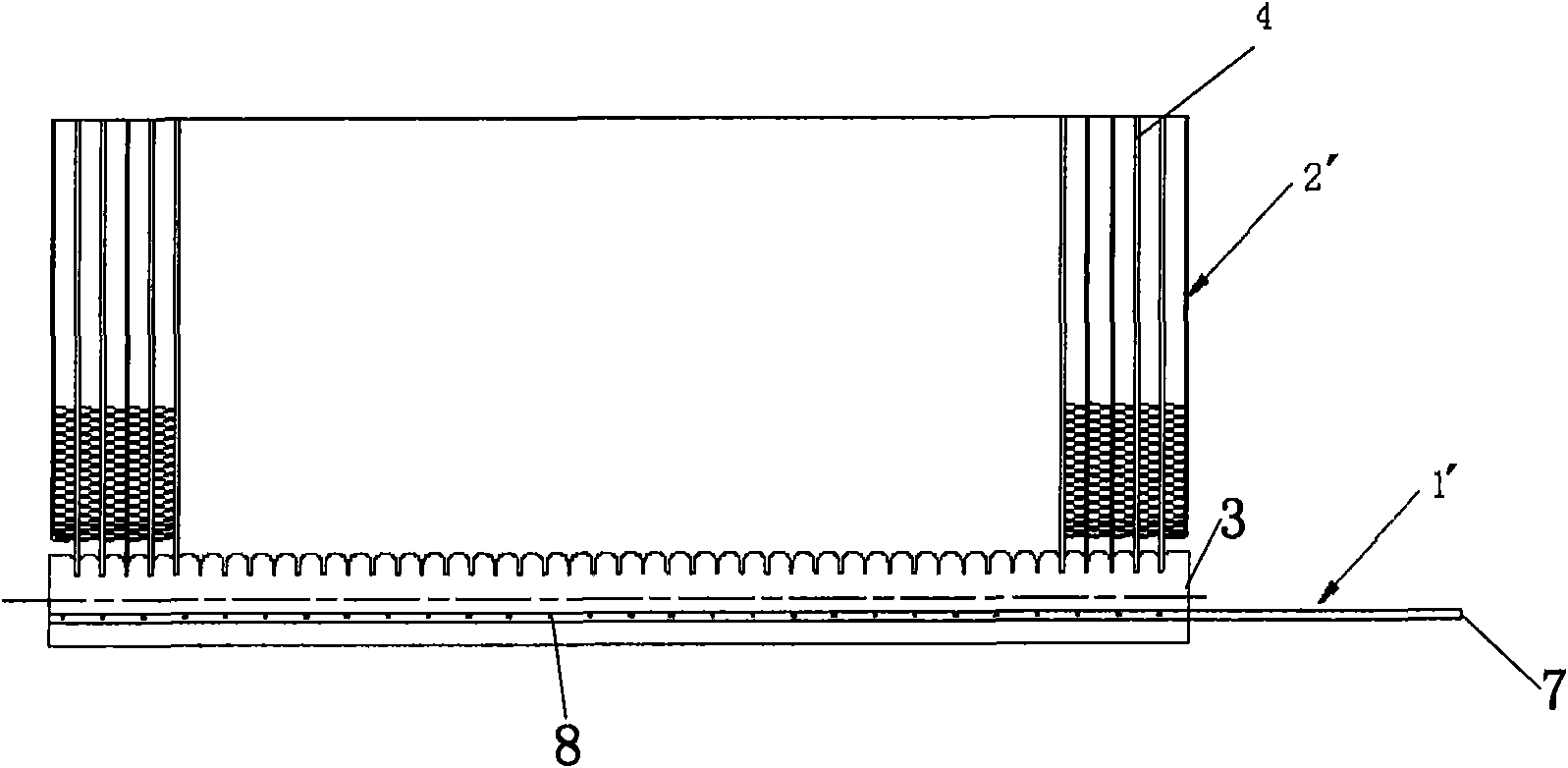

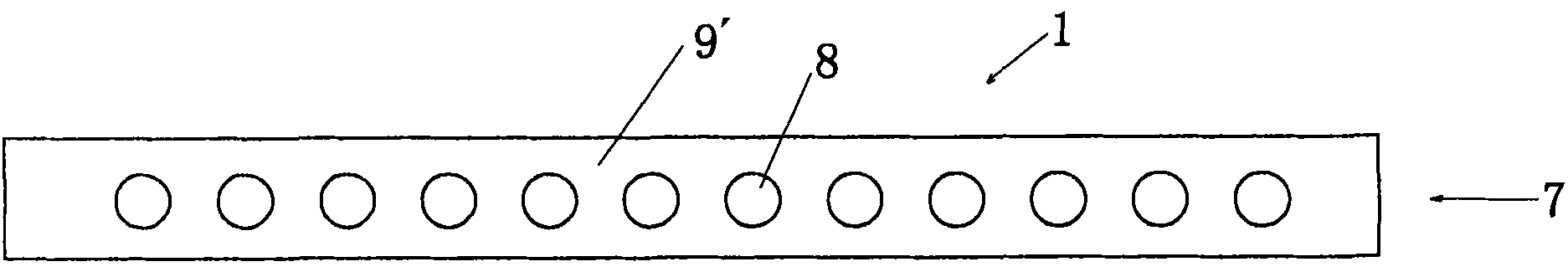

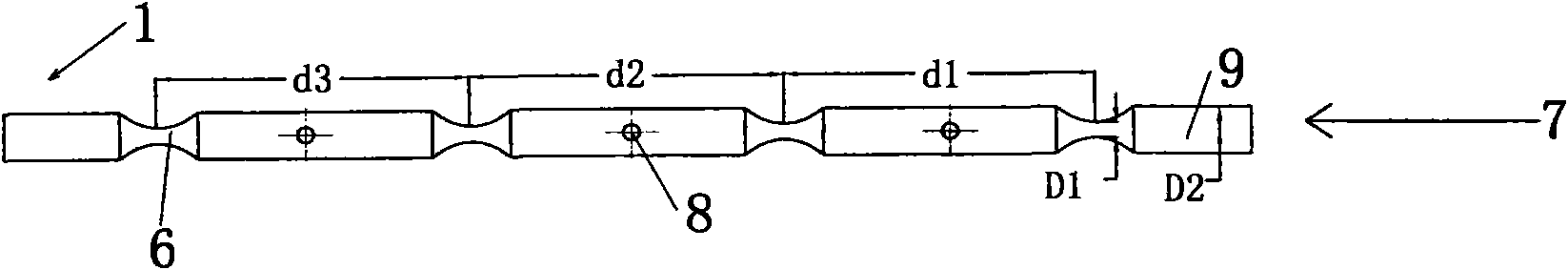

Refrigerant distributor for heat exchanger and heat exchanger

ActiveCN101788243AReduce stratificationWell mixedEvaporators/condensersStationary conduit assembliesRefrigerant distributionPlate heat exchanger

The invention provides a refrigerant distributor for a heat exchanger, which comprises a pipe used for distributing a refrigerant. The pipe is provided with a channel which is arranged in the pipe and is used for the refrigerant to flow. The channel is provided with at least one part, the sectional area of which is reduced. As the refrigerant distributor adopts the above structure, the layering of the refrigerant in the distribution pipe is reduced and the distribution of the refrigerant is uniform.

Owner:SANHUA(HANGZHOU) MICRO CHANNEL HEAT EXCHANGER CO LTD

Reverse-forming sulfuration method for sealed type tooth-shaped edge V tape of rubber lagging

It relates to the glue sleeve seal teeth shape reversed V shape forming sulfuration. It makes belt blank at the inner mold, installs the round cylinder glue sleeve with teeth on the surface inside and smooth surface inside both ends on the glue sleeve base and fastened with shrouding rings, putting them into sulfur can, hanging belt blank into glue sleeve, covering the top cap and the cap of the sulfur can, sequentially opening the outside pressure and inner pressure steam for sulfuration, stripping the belt blank round cylinder with vertical rack outside and the cutting belt blank round cylinder, getting many teeth shape cutting V belt. It solves the sealing issue at both ends of the glue sleeve, eliminating the bubbling stratification defect of the product, increasing effective cutting 2-4 lines, reducing material consumption and cost.

Owner:ZHEJIANG ZIJINGANG RUBBER BELT

Preparation method of dried beancurd stick and dried beancurd stick prepared thereby

InactiveCN101971887AIncrease productionHigh dissolution rateCheese manufactureFood sciencePropionateMildew

The invention relates to a preparation method of dried beancurd stick and dried beancurd stick prepared thereby. The preparation method comprises the following steps: 1) grinding peeled soybean into soybean milk; 2) carrying out homogenization treatment on the soybean milk and preparing the homogenized soybean milk; 3) adding a mildew preventive and a film-forming agent in the homogenized soybean and carrying out heating and milk boiling treatment; and 4) heating, uncovering bamboo and forming. The method adopts a water grinder for grinding and high-pressure homogenization, and improves the dissolution rate of protein, thus improving the yield of the dried beancurd stick; film-forming agent Curdlan is added in the homogenized soybean milk so as to accelerate the film forming speed; and mildew preventive calcium propionate is added to effectively restrain the growth of the mould, and prolong the shelf life of the dried beancurd stick. The invention has the advantages of low cost, simple and easy technique and larger application and promotion values.

Owner:健盛食品股份有限公司

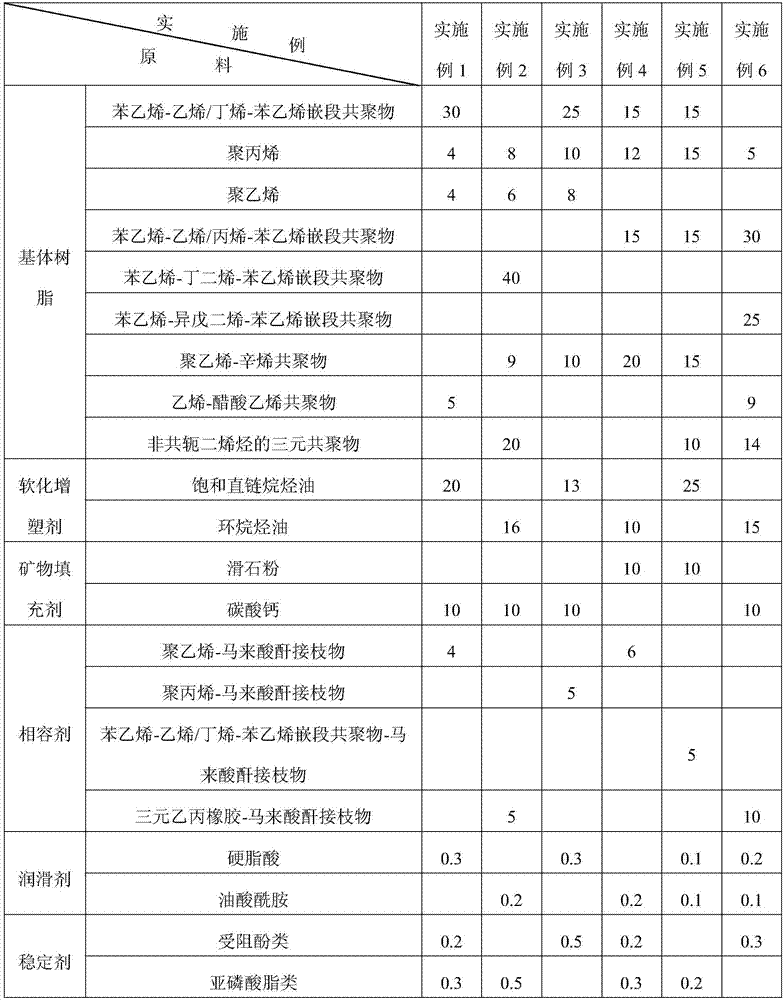

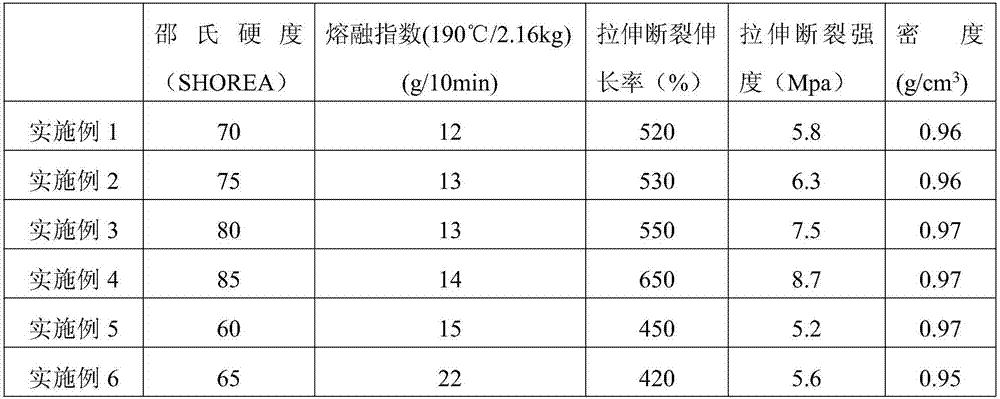

Thermoplastic elastomer, preparation method thereof and wood-plastic floor containing thermoplastic elastomer

The invention discloses a thermoplastic elastomer. The thermoplastic elastomer contains the following components in parts by weight: 40-90 parts of matrix resin, 5-30 parts of a softening plasticizer, 3-15 parts of a mineral filling agent, 3-15 parts of a compatilizer, 0.2-2 parts of a lubricating agent and 0.2-0.5 part of a stabilizer. The invention further discloses a preparation method of the thermoplastic elastomer. The preparation method comprises the following steps: sequentially adding the matrix resin, the softening plasticizer, the mineral filling agent, the compatilizer, the lubricating agent and the stabilizer into a high-speed mixer, and uniformly mixing, so as to obtain a mixture; and putting the mixture into a double-screw extruder, extruding at 170-195 DEG C, and sequentially carrying out bar drawing, water tank cooling and granulation, so as to obtain the thermoplastic elastomer. A wood-plastic floor is prepared from the thermoplastic elastomer disclosed by the invention. The thermoplastic elastomer provided by the invention has the advantages of strong coating cohesive force, soft texture, wear resistance, light specific gravity and the like; and furthermore, the prepared wood-plastic floor coated with the thermoplastic elastomer has the functions of shock absorption, skid prevention and noise reduction.

Owner:东莞市建泓新材料科技有限公司

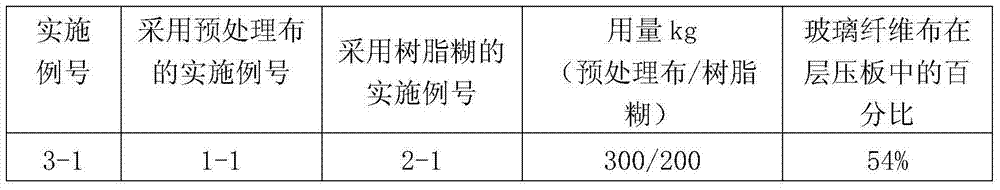

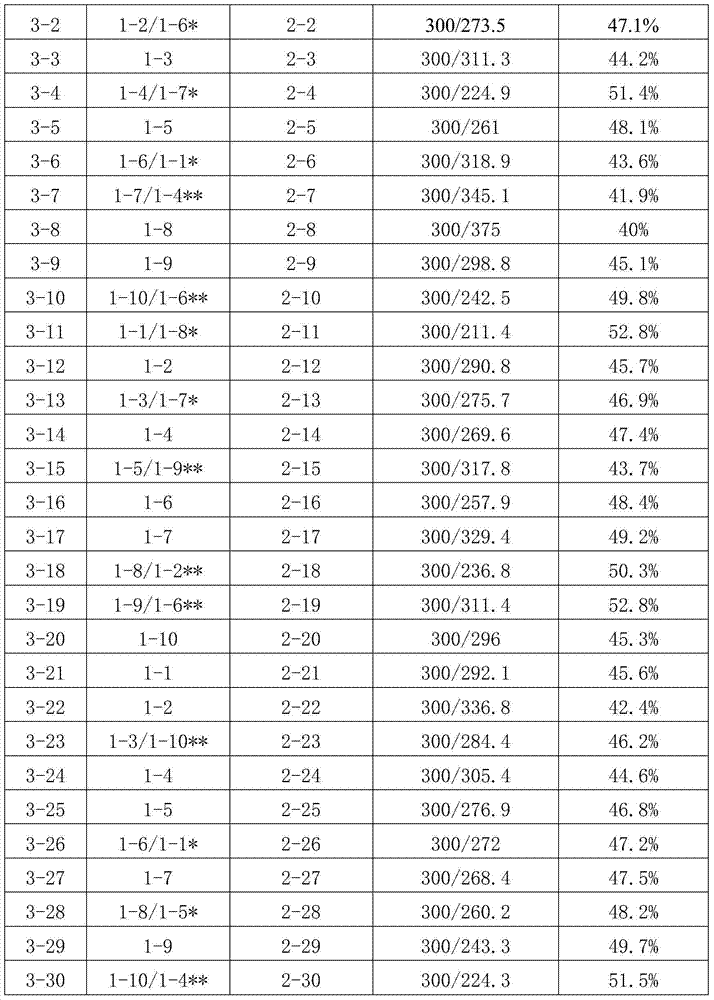

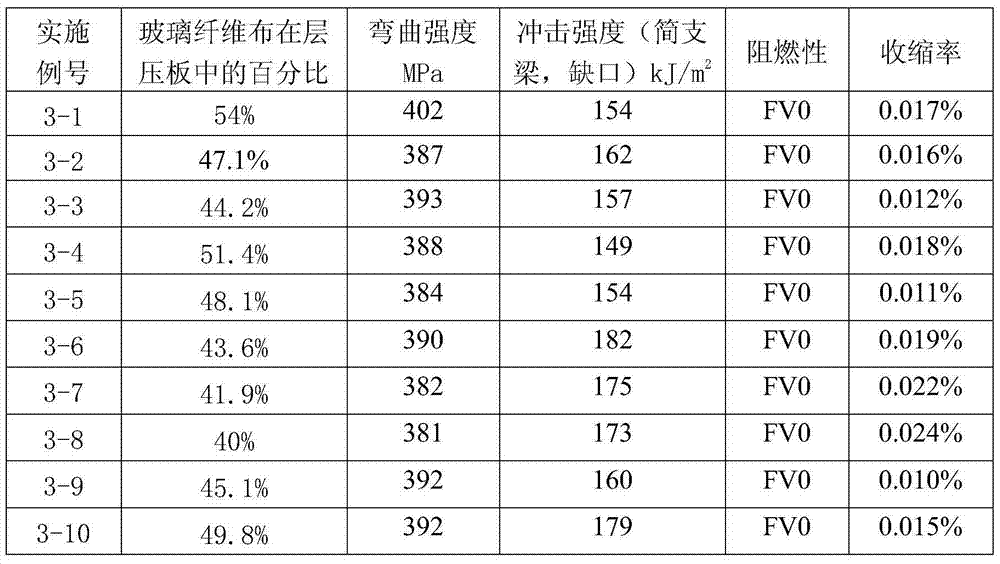

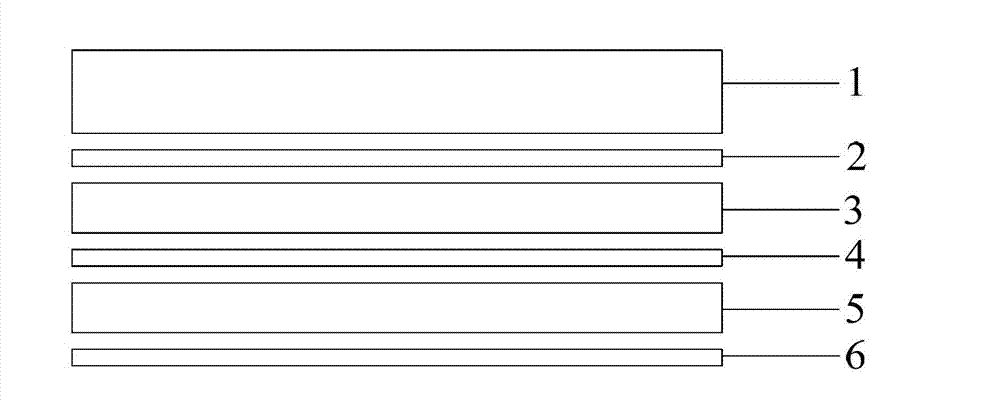

Unsaturated polyester glass fibre cloth laminated board and preparation method thereof

ActiveCN103496236AHigh mechanical strengthIncrease crosslink densitySynthetic resin layered productsLaminationGlass fiberFiber

The invention discloses an unsaturated polyester glass fibre cloth laminated board. The unsaturated polyester glass fibre cloth laminated board is characterized by being formed by more than one layer of overlapped unsaturated polyester glass fibre cloth prepreg through hot pressing, wherein each layer of unsaturated polyester glass fibre cloth prepreg is formed by one layer of glass fibre cloth to be pretreated and resin paste coating two sides of the glass fibre cloth to be pretreated. A preparation method of the unsaturated polyester glass fibre cloth laminated board comprises the following steps: preparing the glass fibre cloth to be pretreated, preparing the resin paste, and preparing the unsaturated polyester glass fibre cloth laminated board through hot pressing. According to the invention, the unsaturated polyester glass fibre cloth laminated board has the characteristics of high mechanical strength, halogen-free flame retardance, low shrinking percentage and the like, and is particularly applicable to components with high-strength insulation structures of motors, electrical appliances, high-tension power transmission and transformation equipment and the like.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

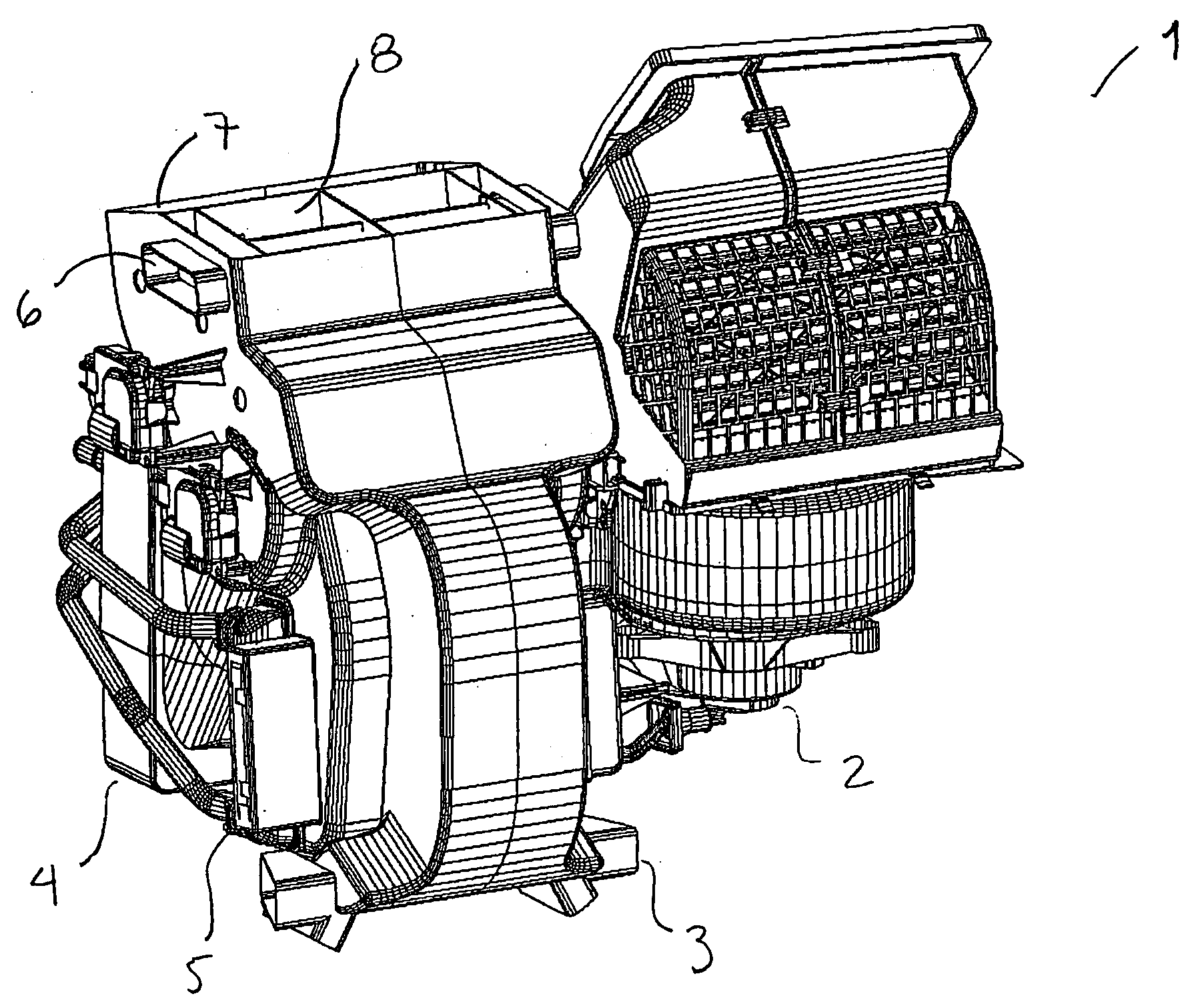

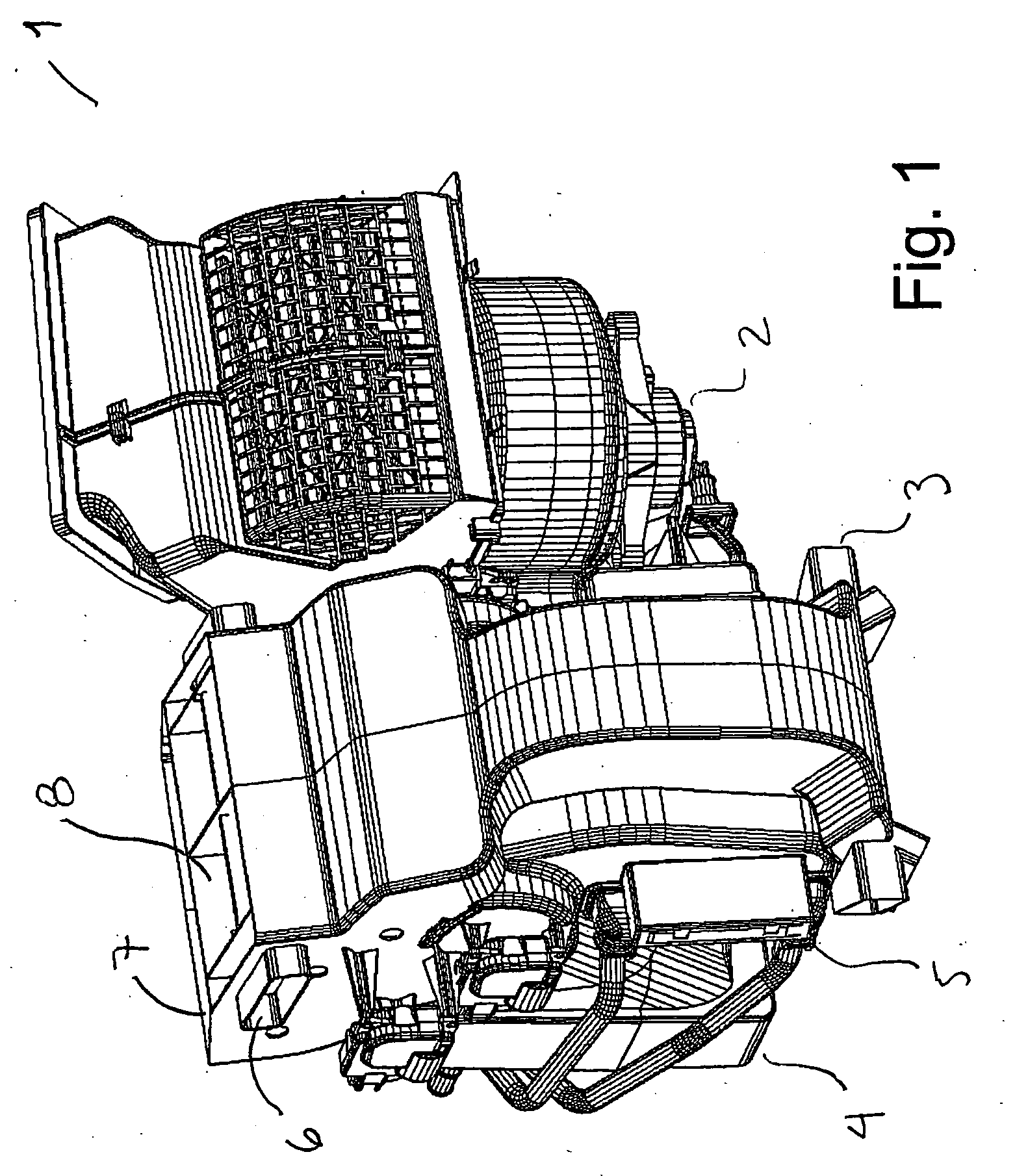

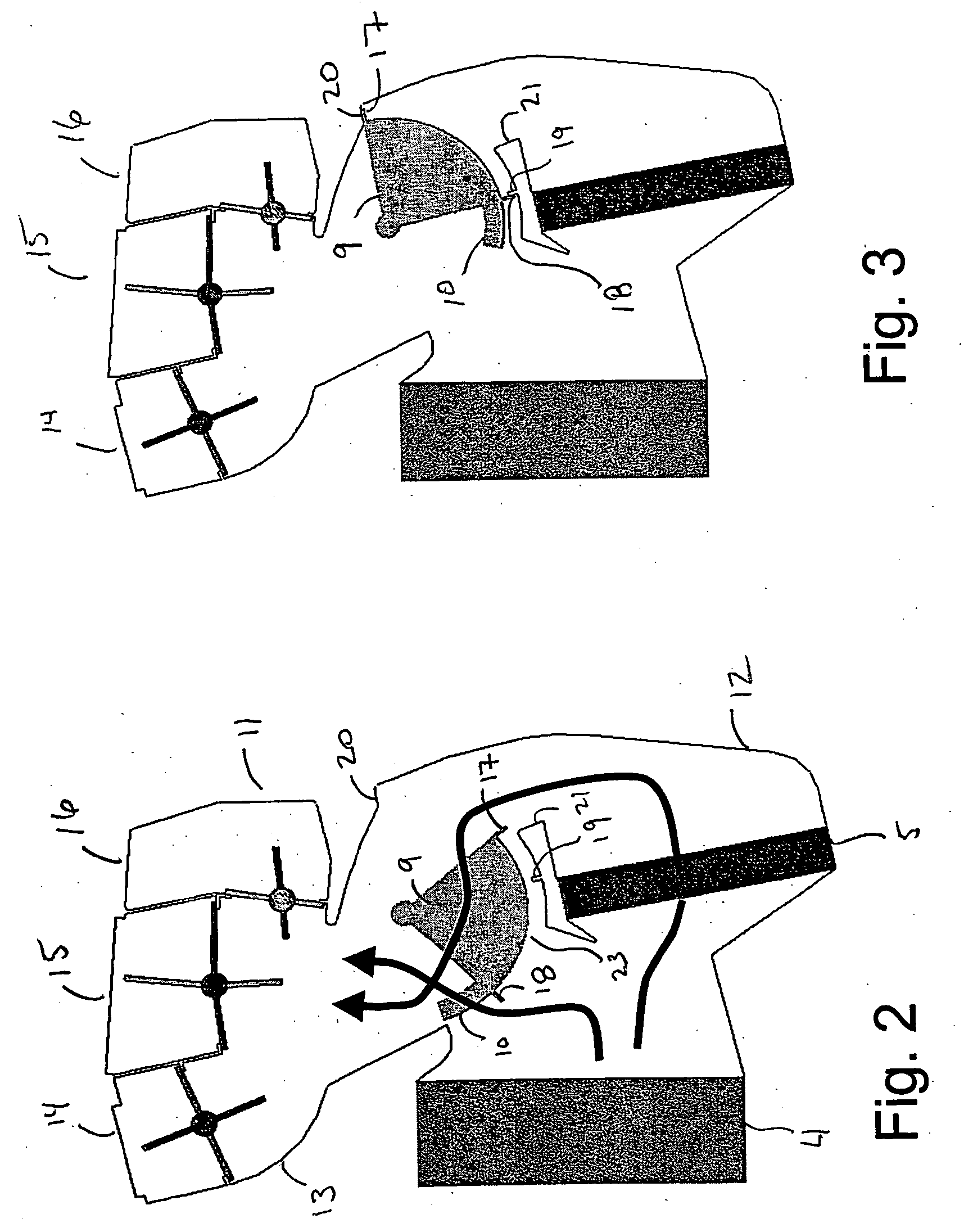

Air control door with integrated stratification feature

InactiveUS20060154592A1Air stratification is decreasedWell mixedVehicle heating/cooling devicesVehicle cleaningCold airControl theory

An air control door with stratification feature is provided. The door includes a mixing section comprised of air guides that define spaced apart air passages. In a mixed mode application, where mixing of both hot and cold air streams is desired, the air control door directs the two air streams into each other, thereby promoting mixing of such air streams and reducing air stratification. By integrating a mixing section with the air control door, the present invention reduces the size, number and complexity of components required to reduce air stratification to an acceptable level.

Owner:BEHR GMBH & CO KG

Blocky carpet and preparation method thereof

ActiveCN102920295AImprove waterproof performanceReduce warpageFibre treatmentSynthetic resin layered productsAdhesiveCarvacryl acetate

The invention provides a blocky carpet and a preparation method thereof. The carpet comprises multiple layers of structures which are sequentially a blank carpet layer, an ethylene-vinyl acetate copolymer (EVA) adhesive layer, a first polyurethane (PU) adhesive layer, a glass wool cloth layer, a second PU adhesive layer and a non-woven fabric protection layer, wherein the EVA adhesive layer is prepared from 30 to 50 weight parts of ethylene-vinyl acetate copolymer, 10 to 50 weight parts of calcium carbonate, 1 to 2 weight parts of auxiliary materials, 8 to 40 weight parts of insoluble silicate substances, and 10 to 20 weight parts of water. Compared with a blocky carpet in which an asphalt layer is connected with an EVA adhesive layer in the prior art, the blocky carpet which is prepared from an EVA adhesive containing silicate substances and is provided with the double PU adhesive layers has the advantage that the insoluble silicate substances are added into the EVA adhesive, a good waterproof effect is achieved, the infiltration of the moisture is reduced, and the required baked strength is reduced, so that the warpage of the blocky carpet is reduced; and by the double PU adhesive layers, a layering phenomenon caused by the difference of materials of the asphalt layer and the PU adhesive layer is also reduced.

Owner:威海海马地毯集团有限公司

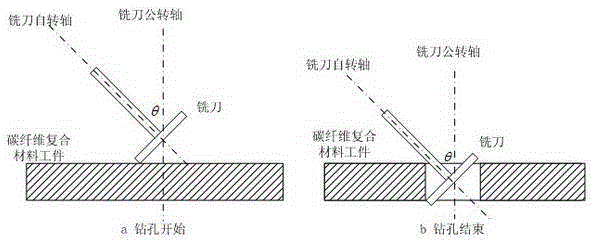

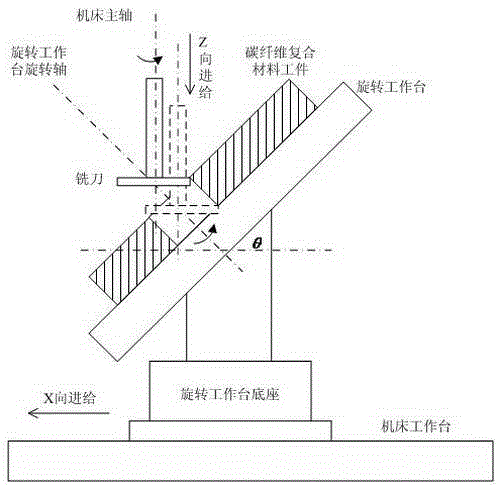

Spinning milling drilling process for carbon fiber composites

InactiveCN105269048AReduce export stratificationImprove internal surface qualityFeeding apparatusMilling equipment detailsCarbon fiber compositeEngineering

The invention relates to a spinning milling drilling process for carbon fiber composites. The invention provides a special mode of motion of a cutter, namely a spinning motion; a milling cutter revolves around a revolution axis while rotating around an own axis. An included angle theta is formed between the rotation axis and the revolution axis; the included angle theta can be adjusted according to a shape of a hole to be machined. The milling cutter is fed toward a surface of a workpiece along the revolution axis at the same time of the spinning motion, and therefore, a hole is machined out in the milling manner. Such a mode of motion has the greatest advantage that a pull to a carbon fiber workpiece at the outlet of the hole can be greatly reduced so that an outlet-layering phenomenon can be reduced.

Owner:NANCHANG HANGKONG UNIVERSITY

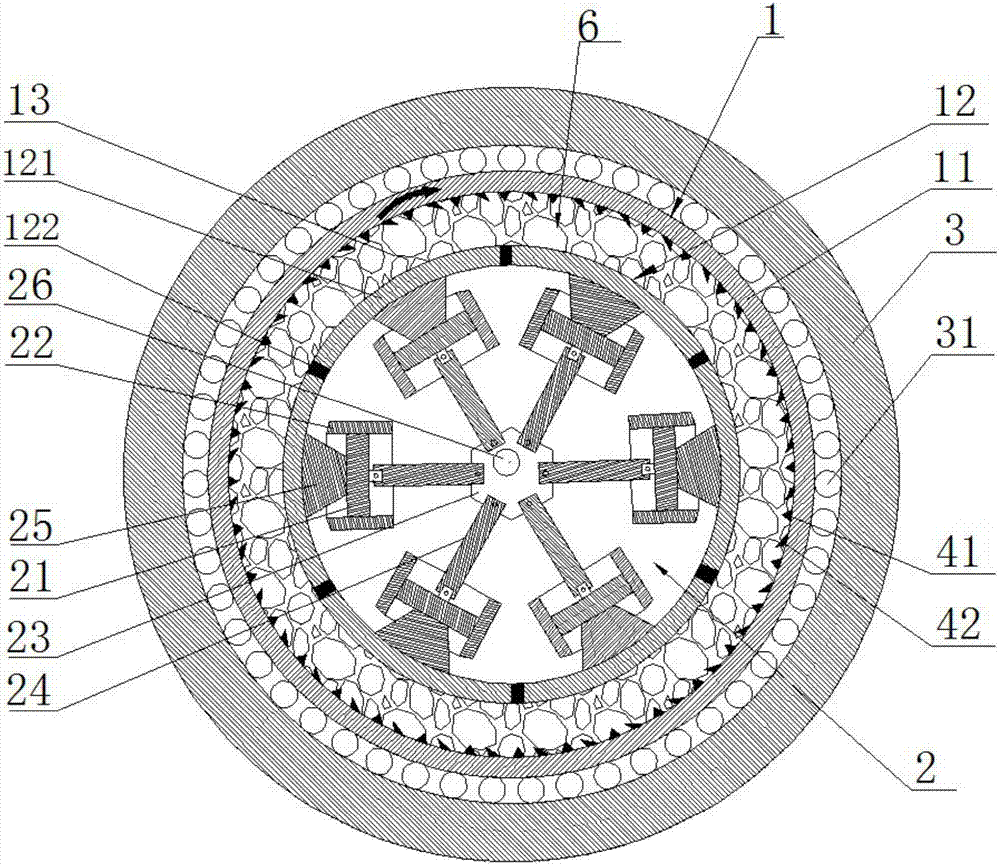

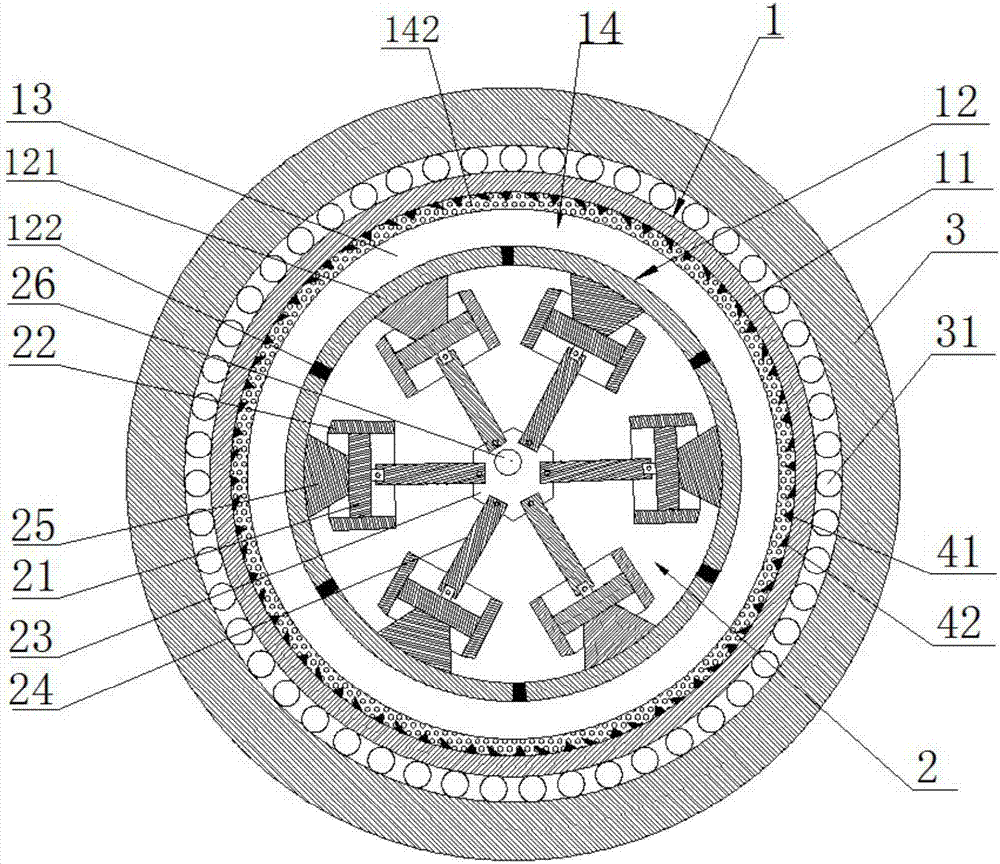

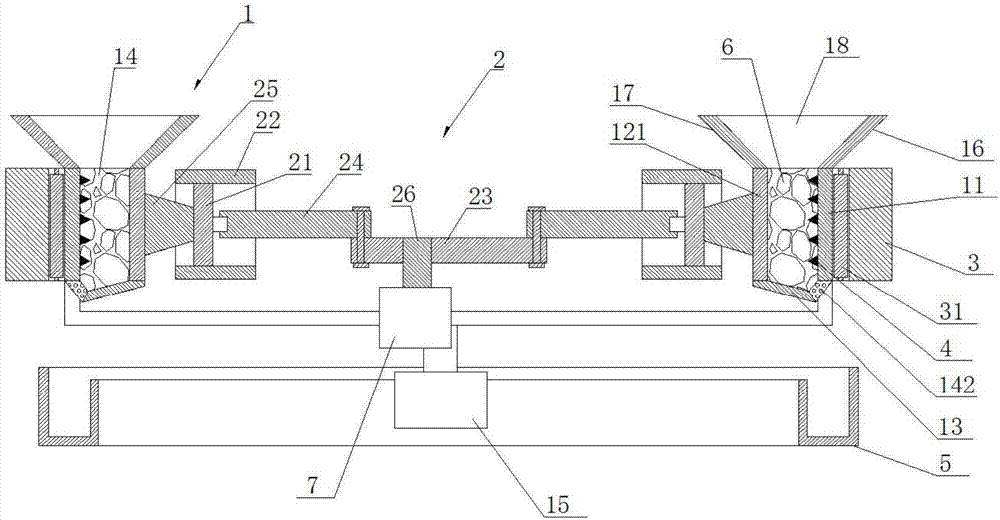

Crusher

InactiveCN107029821AEvenly brokenImprove energy utilizationGrain treatmentsElectric machineryEngineering

The invention relates to a crusher, comprising a crushing device and a driving device; the crushing device comprises an outer plate, an inner plate and a bottom plate; the outer plate, the inner plate and the bottom plate are enclosed into a horizontal annular crushing chute; the outer plate is composed of a The first motor drives and rotates; the inner plate is formed by connecting a plurality of pressing plates in sequence through elastic connecting bodies; the inner side of the outer plate in the annular breaking trough is provided with crushing tines; A turntable, a plurality of pistons facing the pressure plate respectively and sleeves slidingly matched with the pistons; one end of a first connecting rod is hinged on the piston, and the other end is hinged on the turntable; one end of a second connecting rod is connected to the piston, The other end is connected to the pressing plate; the turntable is driven to rotate by a rotating shaft eccentrically arranged on the turntable; the crusher can significantly improve the energy utilization rate, with small vibration, low noise, and even crushing.

Owner:郑小华

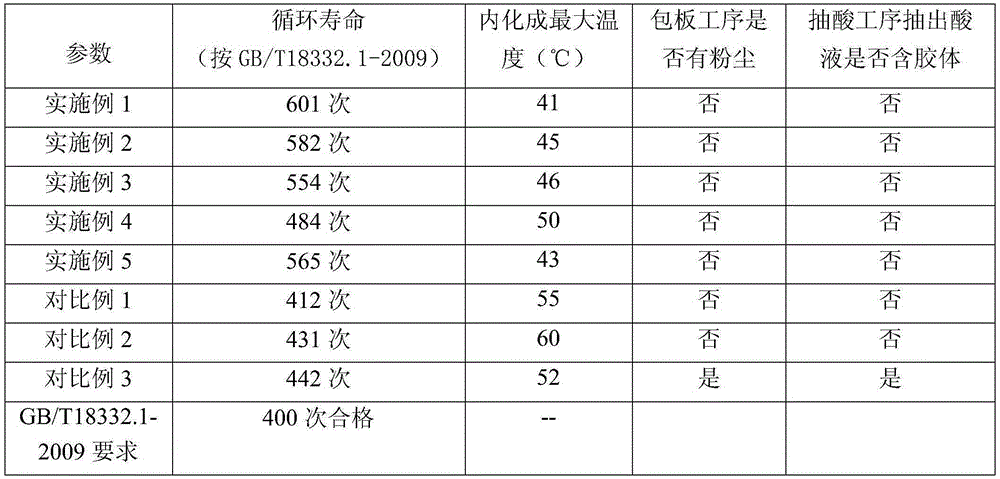

Silicon dioxide colloid pole plate and preparation method and application thereof

The invention discloses a silicon dioxide colloid pole plate and a preparation method and application thereof. The preparation method comprises the following steps of spraying and applying a silicon dioxide colloid aqueous solution on the front side and the back side of a fresh pole plate, and allowing the fresh pole plate to stand to obtain a wet pole plate, wherein the concentration of a silicon dioxide colloid in the silicon dioxide colloid aqueous solution is 0.2-0.5 wt%; and carrying out temperature-control drying on the wet pole plate to obtain the silicon dioxide colloid pole plate. By the method, the consistency of the silicon dioxide colloid on the surface of the pole plate is improved, a phenomenon of acid liquid layering is reduced, the oxygen combination efficiency of the pole plate is reduced, the water loss of a battery is reduced, and the service lifetime of the battery is improved.

Owner:ZHEJIANG TIANNENG POWER ENERGY

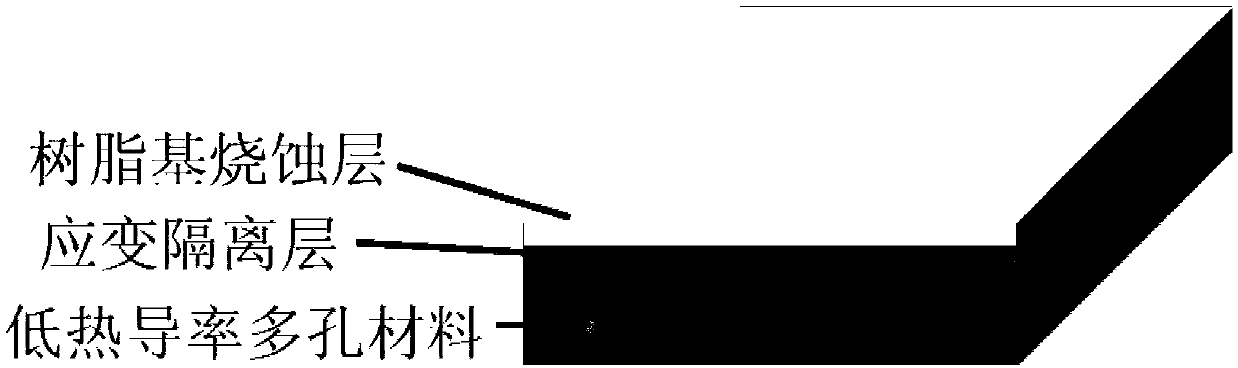

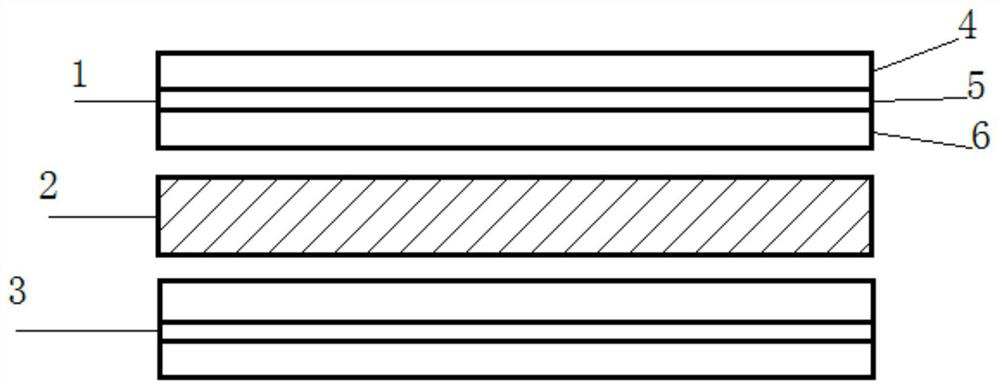

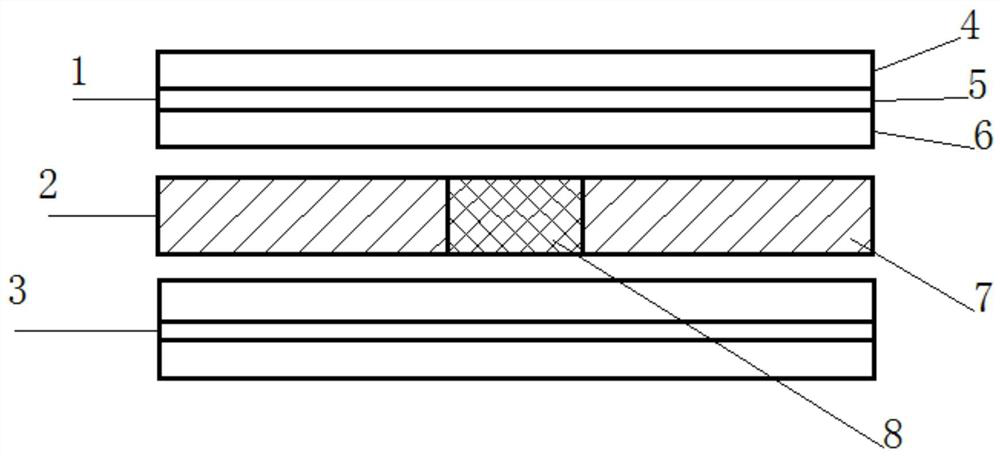

Multilayer stage heat protection material and preparing method thereof

ActiveCN111331875ACushion the shockAvoid collapse failureWeight reductionFuselage insulationVulcanizationAdhesive

The invention provides a multilayer stage heat protection material and a preparing method thereof. The material comprises an outer layer, a strain isolation layer and an inner layer which are connected in sequence, the outer layer is a fiber reinforced resin-based composite, the strain isolation layer is a high-temperature-resisting rubber layer, the inner layer is a fiber reinforced resin-based porous composite, the high-temperature-resisting rubber layer is vulcanized to be connected with the inner layer, prepreg of the outer layer is cured and then connected to the strain isolation layer, and the method comprises the steps of forming the inner layer, wherein short cut fiber net blanks of the set layer number are laid in a mold, and needling is carried out to obtain a fiber reinforced body; injecting a solution of resin of the inner layer into the fiber reinforced body to be cured; forming the strain isolation layer, wherein the surface of the inner layer is coated with a certain thickness of rubber adhesive capable of being vulcanized at the room temperature, and vulcanizing and shaping are carried out; and forming the outer layer, wherein prepreg of the outer layer is mounted on the strain isolation layer to be cured. The technical problems that according to an existing heat protection material, inner and outer layers are prone to cracking and layering, and the heat protection material fails directly can be solved.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

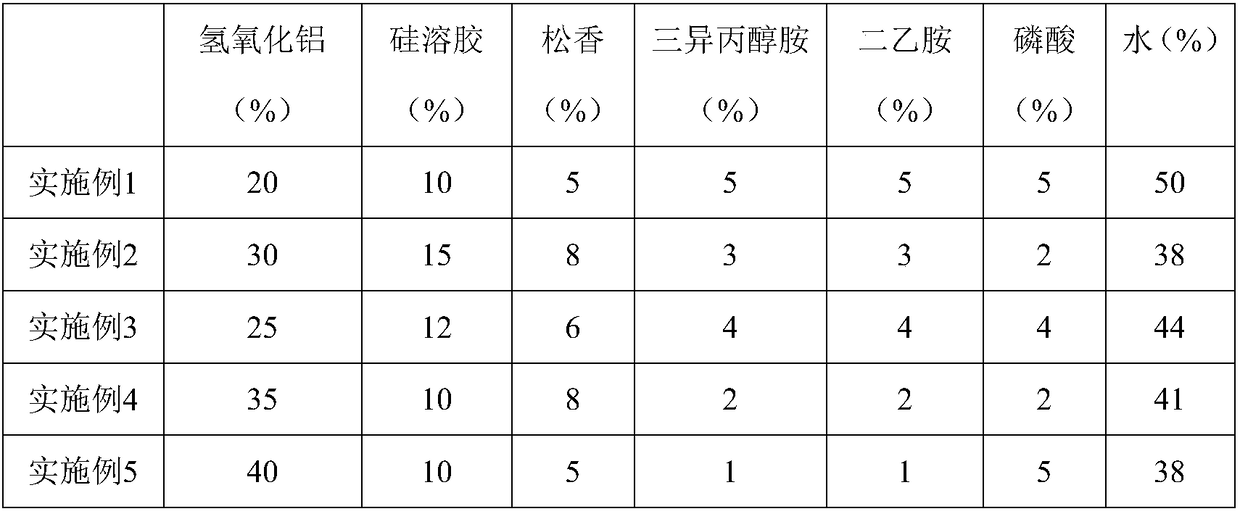

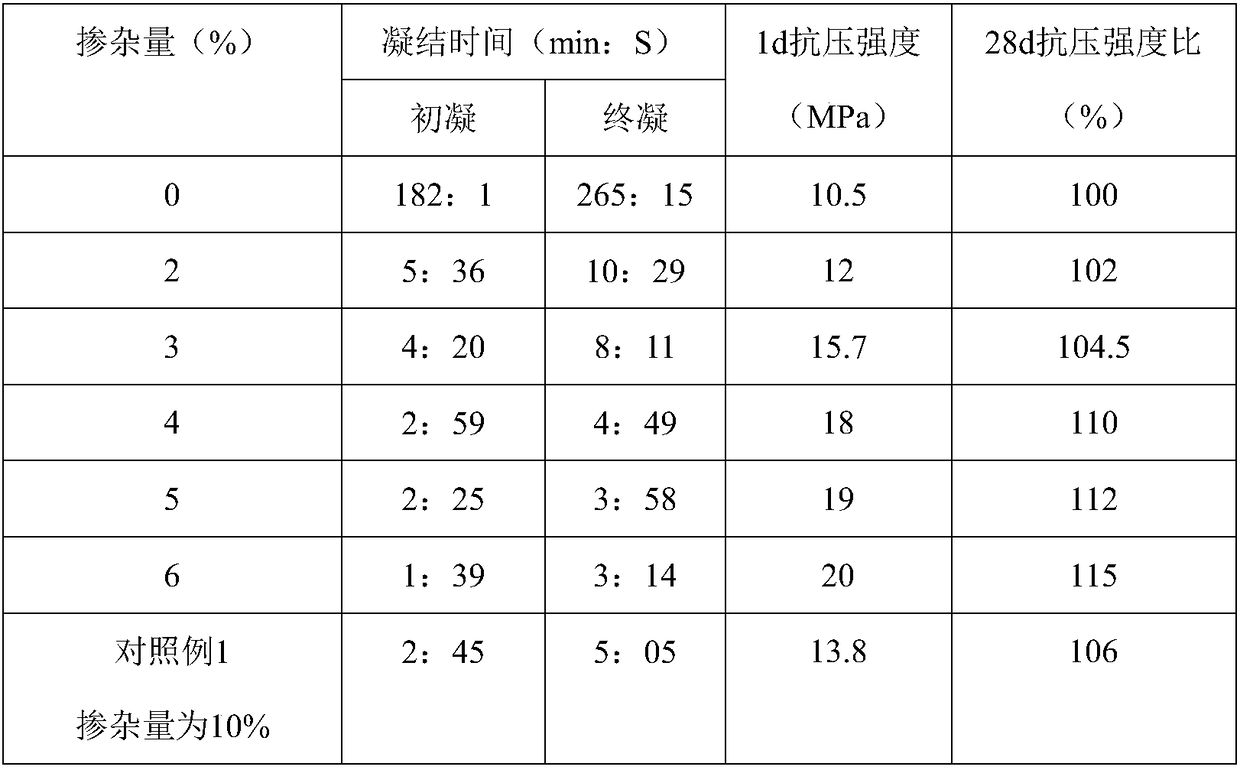

Novel foundation pit waterproof curtain additive material alkali-free liquid accelerator and preparation method thereof

The invention relates to a novel foundation pit waterproof curtain additive material alkali-free liquid accelerator and a preparation method thereof. The novel foundation pit waterproof curtain additive material alkali-free liquid accelerator comprises the following components in percentage by mass: 20-40% of aluminium hydroxide, 10-15% of silica sol, 3-10% of rosin, 1-5% of triisopropanolamine, 1-5% of diethylamine, 1-5% of phosphoric acid and 35-55% of water. The silica sol is silica sol modified by a silane coupling agent; the silane coupling agent is an alkyl alkoxy silane coupling agent and has a structural formula of YRnSiX3. The novel foundation pit waterproof curtain additive material alkali-free liquid accelerator has a stable solution system, does not contain any sulfate ion, alkali metal ion, chloride ion or any other corrosive substance and is stable in quality, excellent in adaptability, low in doping amount, high in condensation rate and high in strength; even if stored at a normal temperature for six months, the accelerator does not have a layering phenomenon.

Owner:江苏地基工程有限公司

Borosilicate glass medicinal tube and production method thereof

InactiveCN108516682AReduce alkalinityReduce stratificationGlass severing apparatusChemical reactionLepidolite

The invention relates to a borosilicate glass medicinal tube and a production method thereof, and relates to the technical field of medicinal tube production. The problem is solved that glass residuesare generated during sheet stripping of existing medicinal glass tubes. The borosilicate glass medicinal tube specifically comprises following components including borax, quartz sand, spodumene, lepidolite, cullet, vanadium oxide, cerium oxide, sodium chloride, sodium carbonate and sodium sulfate. Sodium sulfate added in the components has a chemical reaction with alkaline substances on the surface of the glass in sulfur dioxide generated at high temperature to generate sulfate easily washed by water, the alkali amount of the surface of the glass is reduced accordingly, the occurrence of a stratification phenomenon is further reduced, and therefore the occurrence of a sheet stripping phenomenon is reduced.

Owner:成都市金鼓药用包装有限公司

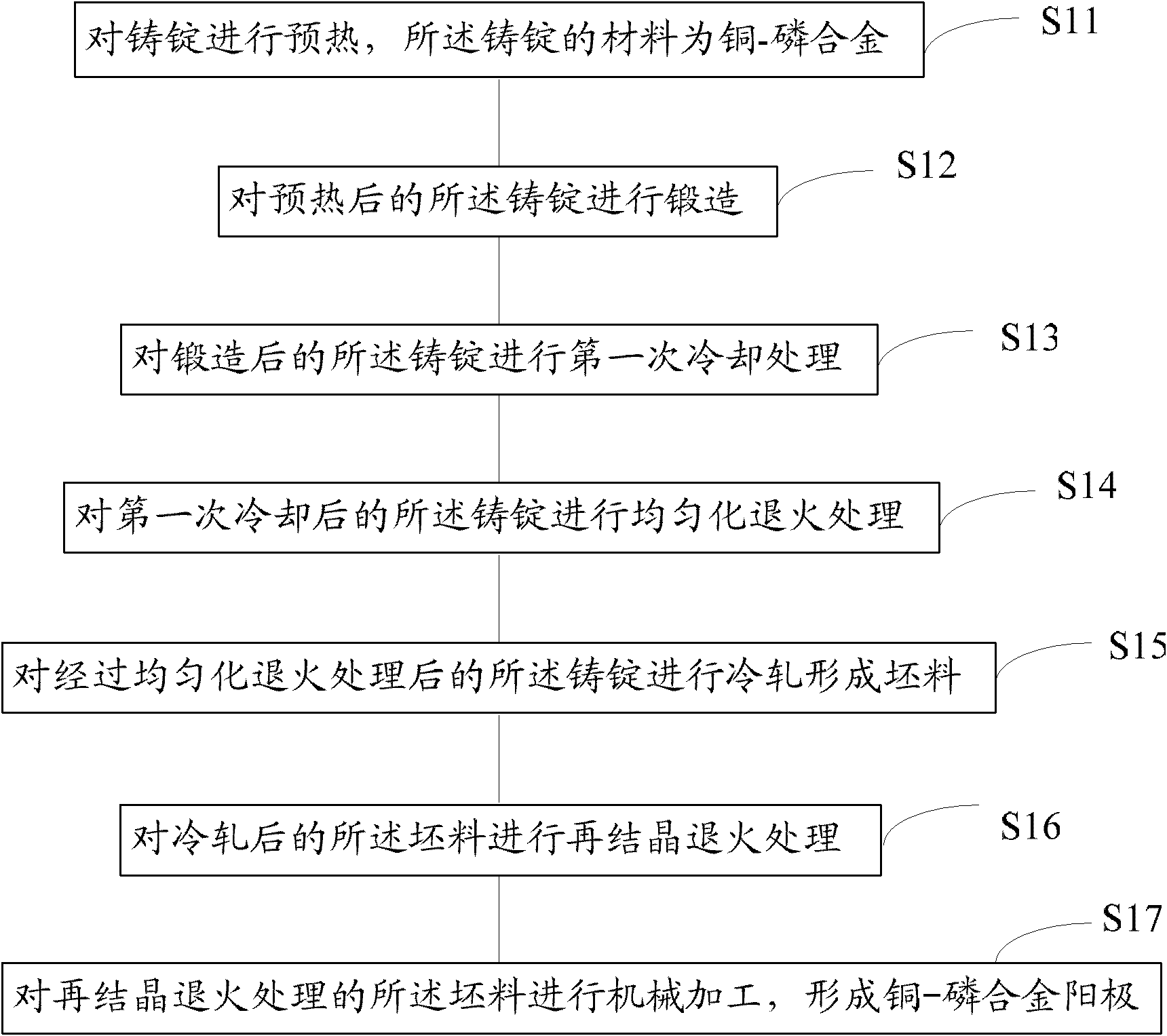

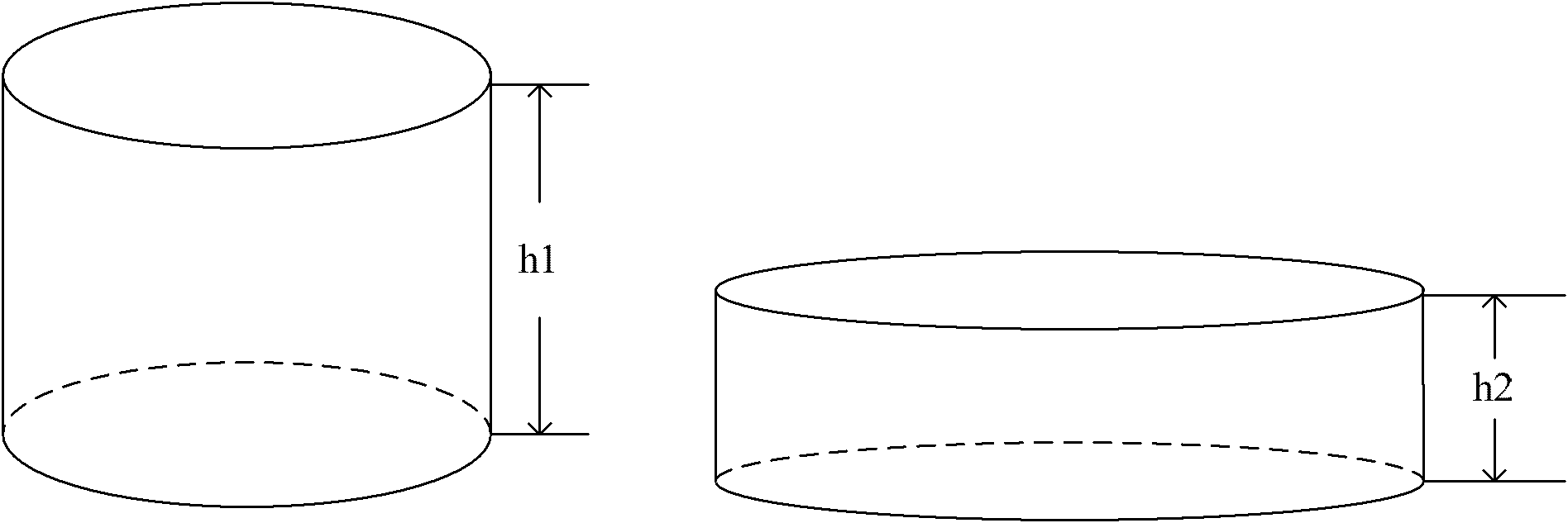

Method for preparing anode made of copper-phosphorus alloy

A method for preparing an anode made of a copper-phosphorus alloy comprises the following steps in sequence: preheating an ingot made of the copper-phosphorus alloy; forging the ingot; conducting homogenized annealing treatment on the ingot; conducting cold rolling on the ingot to form a blank; conducting recrystallization annealing treatment on the blank; and machining the blank, so as to form the anode made of the copper-phosphorus alloy. According to the method, the combination of repeated plastic deformation with a specific deformation rate and annealing treatment under specific temperature is mainly adopted, and the deformation rate of the plastic deformation, the temperature during the annealing treatment, and the time of the annealing treatment are controlled, so as to produce the anode meeting the requirements on compact and uniform internal structure and no lamination for electroplating.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

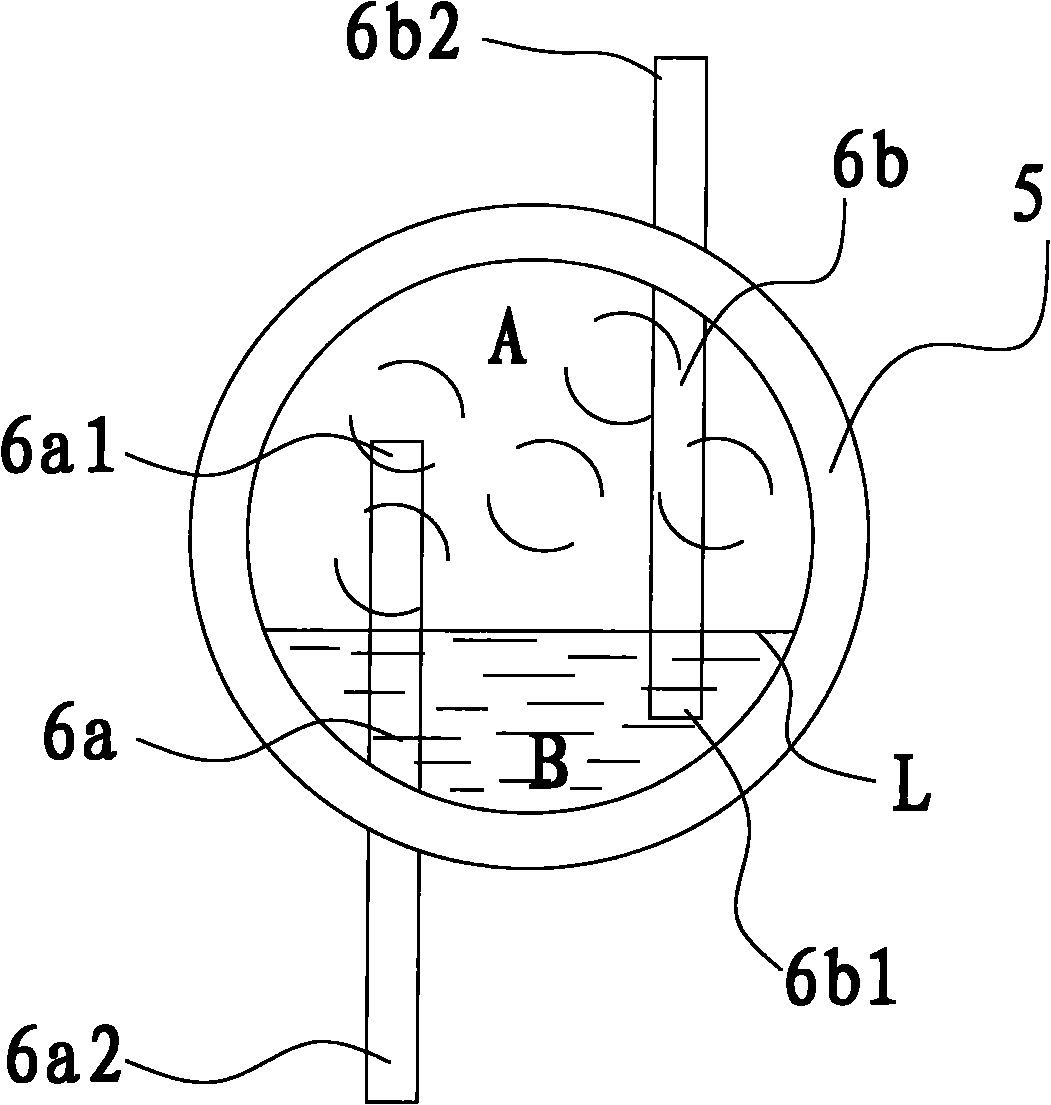

Refrigerant distributing device and heat exchanger with same

InactiveCN102072684AWell mixedReduce stratificationEvaporators/condensersHeat exchanger casingsInternal cavityEngineering

The invention provides a refrigerant distributing device and a heat exchanger with the same. The refrigerant distributing device comprises a conduit, a first distributing pipe and a second distributing pipe, wherein the inner cavity of the conduit is divided into an upper cavity and a lower cavity; the first distributing pipe is provided with a gas phase refrigerant inlet and a gas phase refrigerant outlet and limits a first end inserted into the conduit and a second end extending out of the conduit; the gas phase refrigerant inlet is arranged in the upper cavity; the gas phase refrigerant outlet is arranged outside the conduit, with the opening downward; the second distributing pipe is provided with a liquid phase refrigerant inlet and a liquid phase refrigerant outlet and limits a first end inserted into the conduit and a second end extending out of the conduit; the liquid phase refrigerant inlet is arranged in the lower cavity; and the liquid phase refrigerant outlet is arranged outside the conduit, with the opening upward. The refrigerant distributing device has the following advantage: the gas phase and liquid phase refrigerants are mixed uniformly, thus the heat exchange efficiency is high.

Owner:SANHUA HANGZHOU MICRO CHANNEL HEAT EXCHANGER

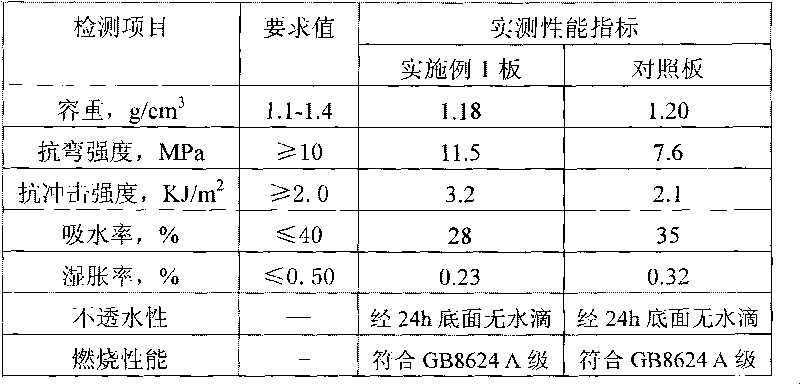

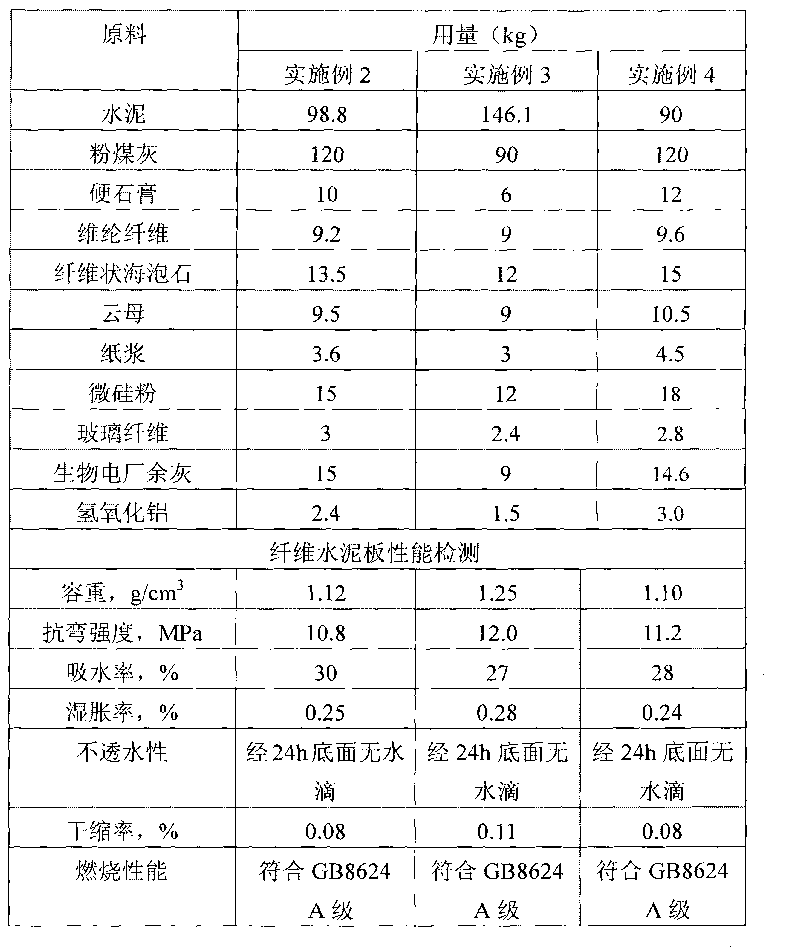

Fibre cement plate with high doping quantity of fly ash

InactiveCN101736853AReduce dosageIncrease dosageConstruction materialSolid waste managementEmberAluminium hydroxide

The invention discloses an economic type fibre cement plate with high doping quantity of fly ash and a preparation method thereof. The light fibre cement plate comprises cement, fly ash, anhydrite, polyvinylformal fibre, fibrous meerschaum, mica, pulp, micro silicon powder, glass fibre, biological power plant ember and aluminium hydroxide. A right amount of micro silicon powder and a right amount of anhydrite are added, the bending strength of a plate material can be greatly enhanced, the industrial wastes of the fly ash, the biological power plant ember and the like are doped, and the material cost can be lowered. The wet process of an asbestos-free cement flat plate is adopted, a wetted plate blank does not need to be pressurized, and the fibre cement plate has the advantages of economy, applicability, flame retardant, light weight, small contraction, environmental protection, moisture prevention and good durability after being cured by steam.

Owner:CHINA BUILDING MATERIALS ACAD

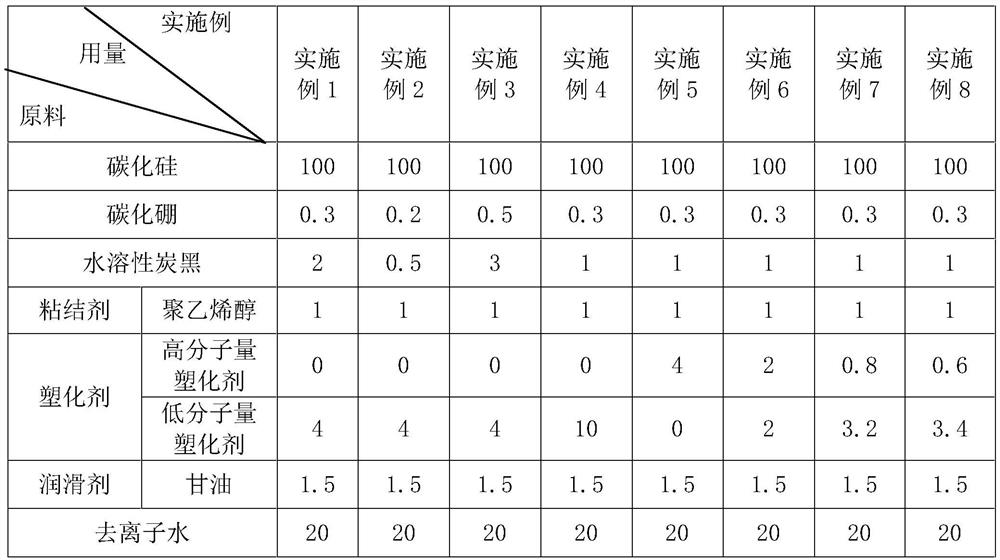

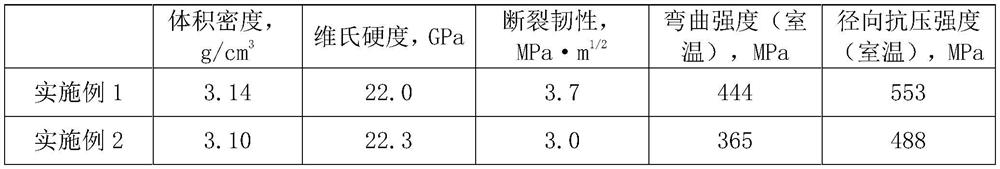

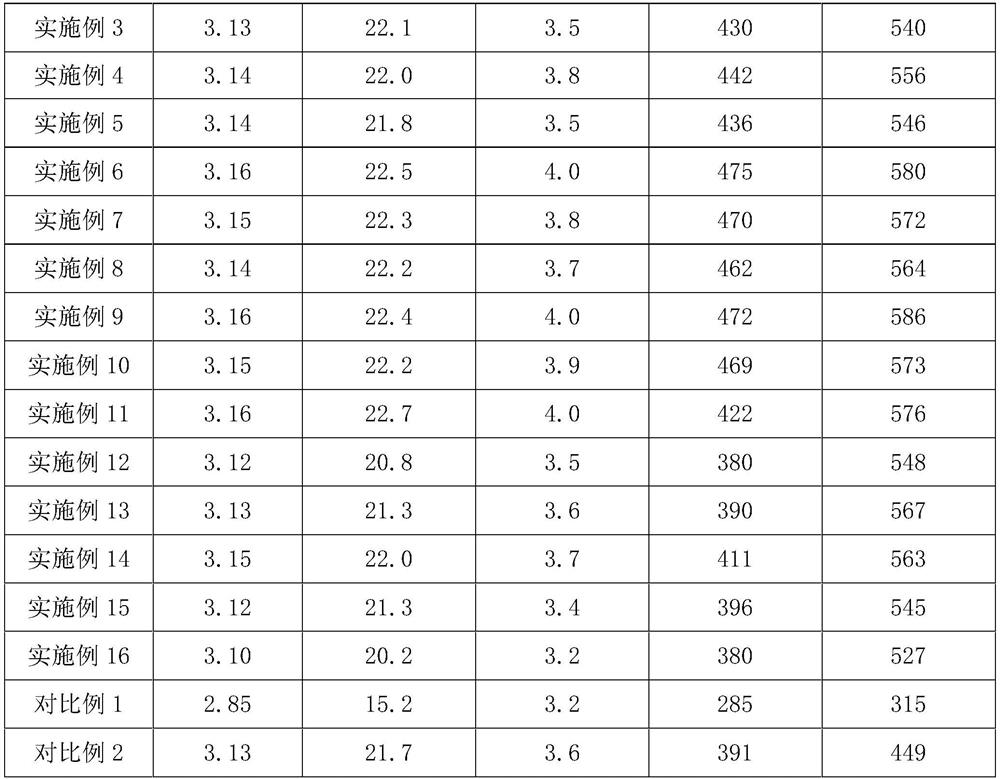

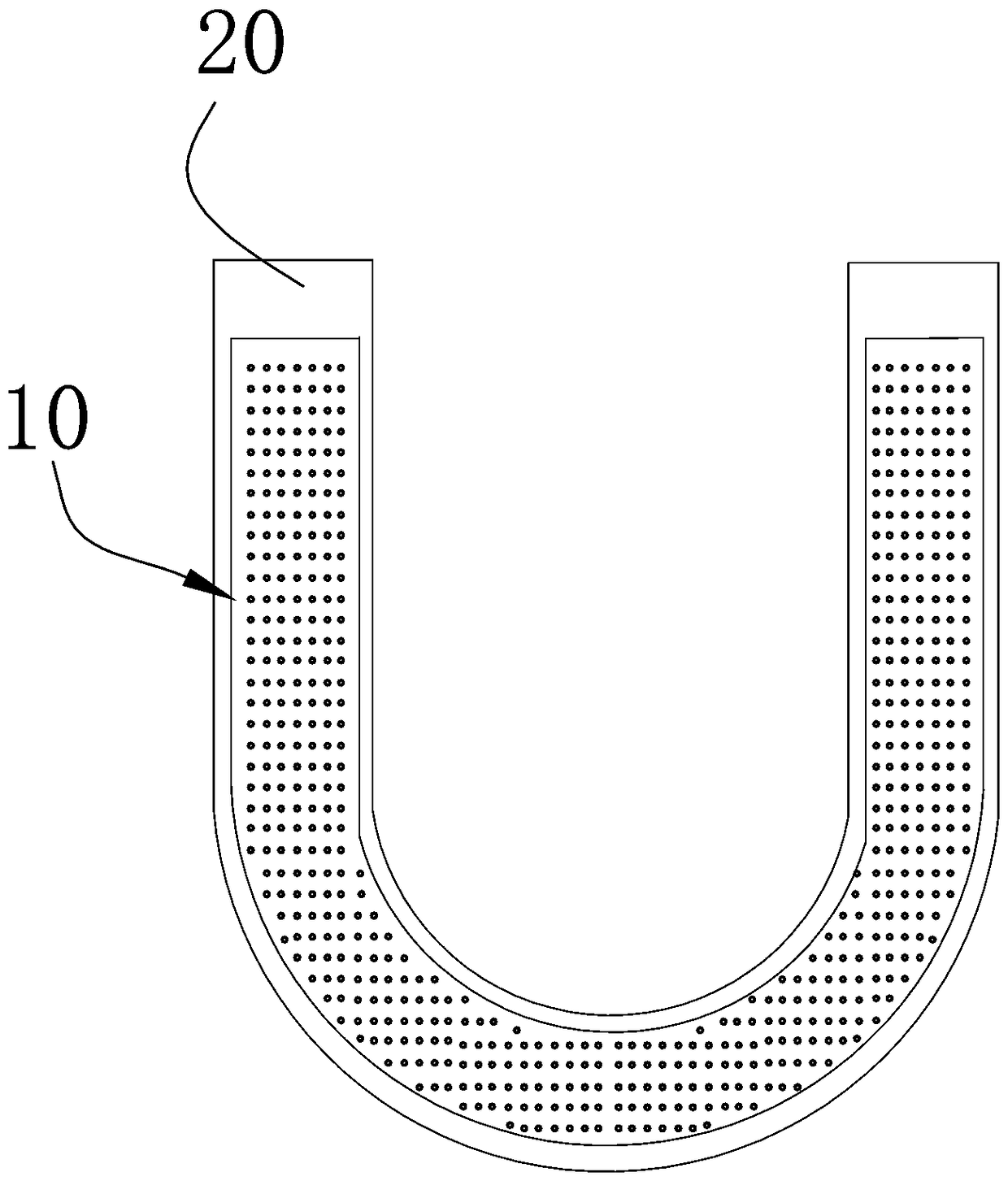

Solid-phase sintered silicon carbide product and preparation method thereof

The invention relates to the field of engineering ceramic materials, and particularly discloses a solid-phase sintered silicon carbide product and a preparation method thereof. The preparation method of the solid-phase sintered silicon carbide product comprises the following steps: grinding raw materials: mixing micron-sized silicon carbide powder with a boron-containing sintering aid, and performing wet grinding to obtain slurry; performing spray granulation: adding water-soluble carbon black and a binder into the slurry, uniformly stirring, and carrying out spray granulation to obtain silicon carbide granulation powder; mixing the materials; aging: aging the wet powder obtained by mixing to obtain an aged material; and performing post-treatment: performing pugging, extrusion, drying and heat treatment on the aged material. The silicon carbide product prepared by the preparation method can be used as a heat exchange tube, a roller rod, a square beam, a micro reaction tube and the like, and has the advantages of high sintering density, high compressive strength and high toughness; in addition, the preparation method has the advantages of low production cost and high production efficiency.

Owner:NANTONG SANZER PRECISION CERAMICS CO LTD

Toilet seat and preparation method

InactiveCN108354502AImprove sealingImprove thermal conductivityBathroom coversHeat conductingCasting mold

The invention discloses a toilet seat and a preparation method. The toilet seat includes a heating unit and a wrapping body; the wrapping body wraps the heating unit through a casting molding process.The toilet seat has the advantages that by means of the toilet seat, the heating unit of the toilet seat is sealed in a toilet seat body to form the integrated toilet seat, not only is the sealing effect great, the safety is high, but also the process is simple, the heat conducting performance is better, and more energy is saved. The invention also provides the preparation method for preparing the toilet seat.

Owner:JOMOO KITCHEN & BATHROOM

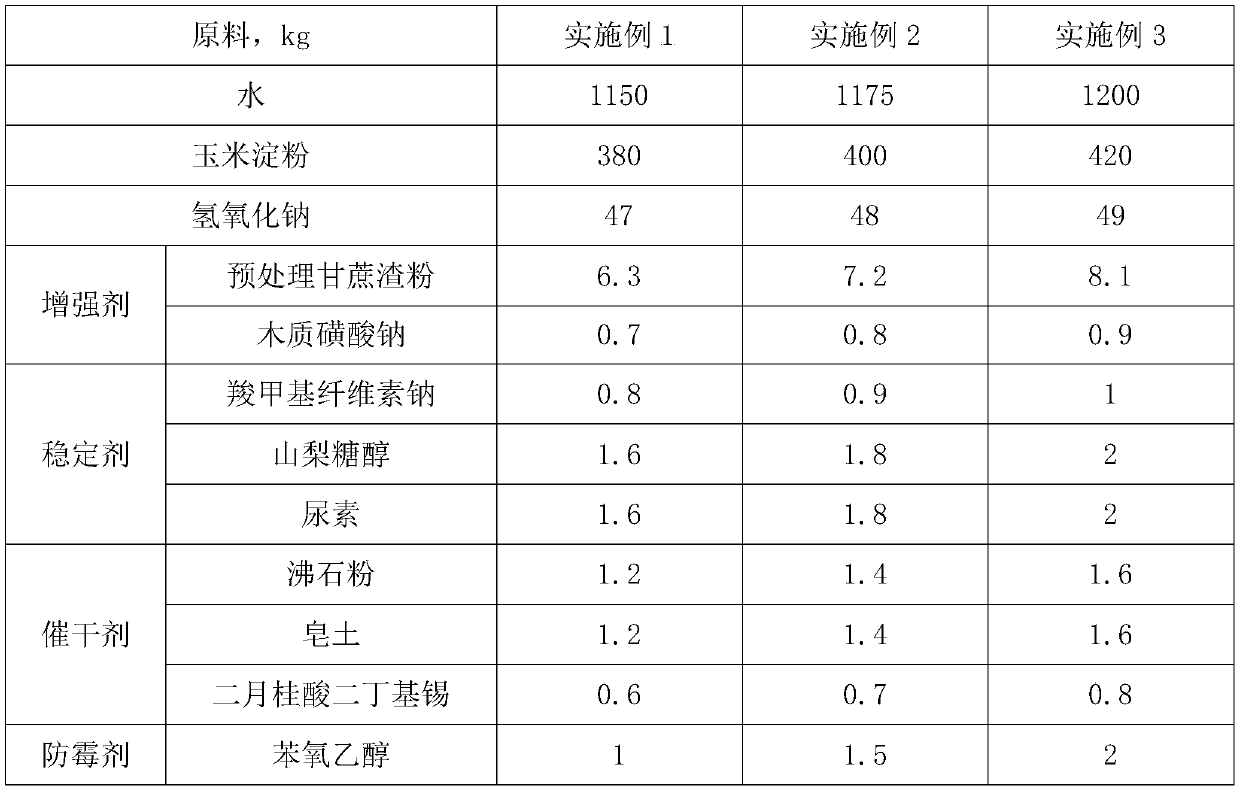

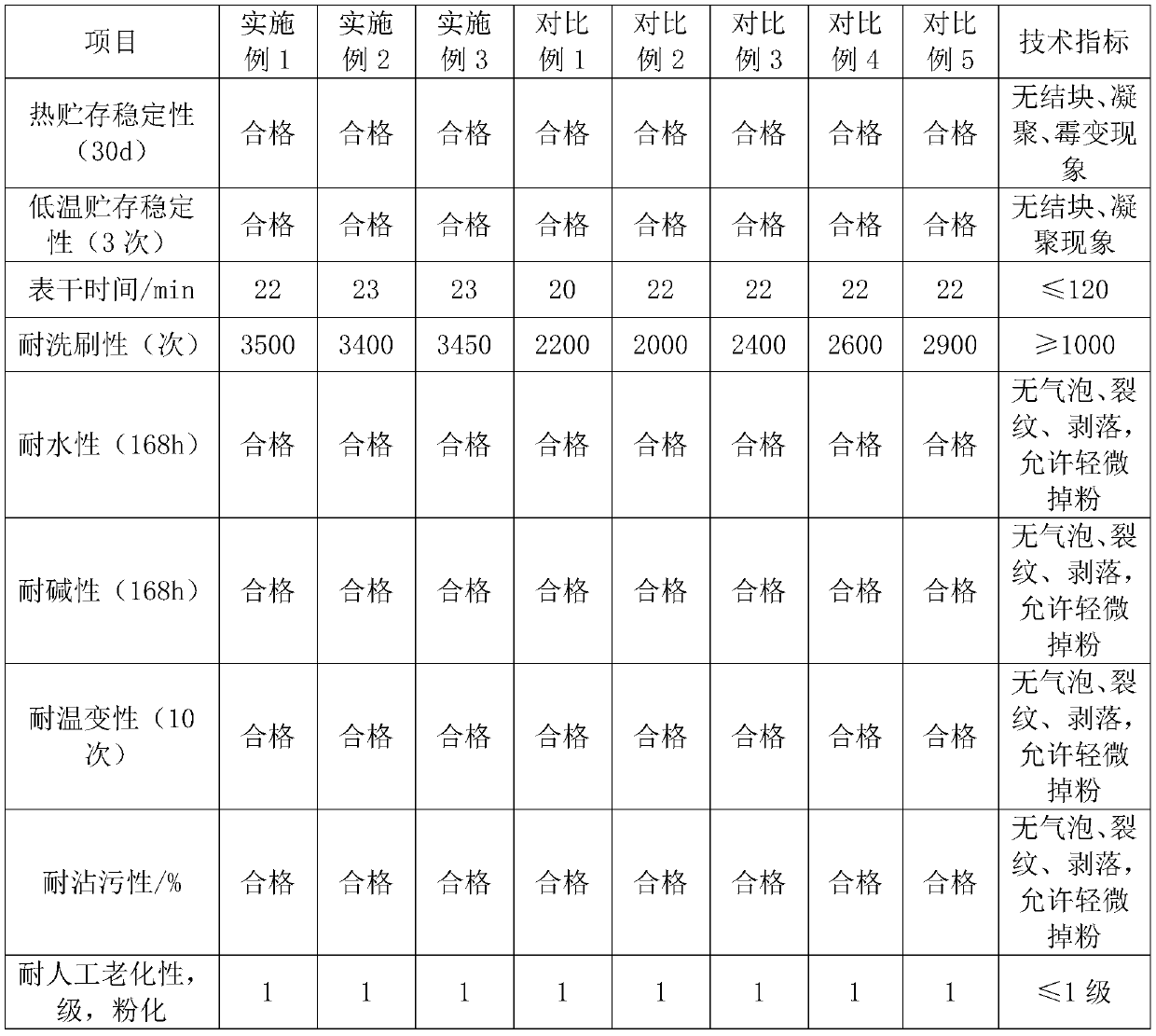

Adhesive for corrugated board and preparation method of adhesive

ActiveCN110305604AAccelerate evaporationIncrease the degree of cross-linkingNon-macromolecular adhesive additivesStarch adhesivesAdhesiveEvaporation

The invention discloses an adhesive for a corrugated board and a preparation method of the adhesive and belongs to the technical field of adhesives. According to key points of the technical scheme, the adhesive for the corrugated board comprises the following components in parts by weight: 380-420 parts of corn starch, 47-49 parts of sodium hydroxide, 7-9 parts of an enhancer, 4-5 parts of a stabilizer, 4.5-5.5 parts of borax, 3-4 parts of a drier and 1-2 parts of a mildew preventive. The drier in the invention can achieve effects of obviously promoting evaporation of water and shortening curing time; and by matching the enhancer and the stabilizer, the crosslinking degree among starch molecules can be improved, tenacity and adhesive strength of the adhesive are improved, an adhesion cracking problem caused by excessive drying is avoided, so that the drying process is simple, and operations are facilitated.

Owner:广东新力德包装科技有限公司

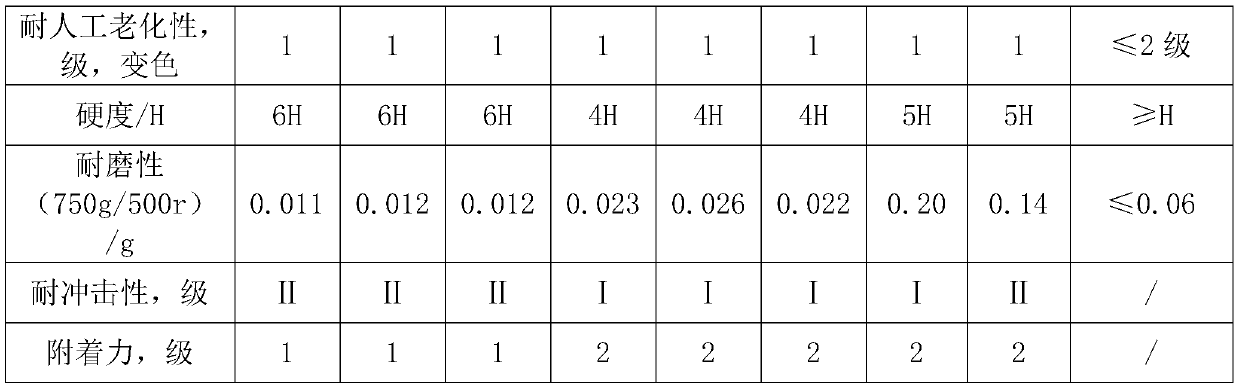

Water-based inorganic floor coating and preparation method thereof

The invention relates to the field of coatings, specifically to a water-based inorganic floor coating and a preparation method thereof. The water-based inorganic floor coating comprises the followingcomponents in parts by weight: 240-260 parts of an inorganic nanometer reinforcing agent, 1.5-2.5 parts of a defoaming agent, 90-110 parts of titanium dioxide, 380-420 parts of a filler, 3-4 parts ofcellulose, 170-175 parts of water, 1-2 parts of a bactericide, 50-70 parts of a film-forming emulsion and 1-3 parts of a film-forming aid, wherein the inorganic nanometer reinforcing agent is preparedfrom nanometer silicon dioxide, a silane coupling agent and organic sepiolite. The water-based inorganic floor coating provided by the invention is high in bonding strength on a cement base surface,does not fall off or peel off, can improve the hardness, wear resistance and impact resistance of the cement base surface, and has very good water resistance and scrubbing resistance.

Owner:杭州蓝田涂料有限公司

Reinforced aramid honeycomb sandwich plate

InactiveCN111873558AImprove adhesionNot easy to layerSynthetic resin layered productsLaminationAdhesiveHoneycomb

The invention relates to a reinforced aramid honeycomb sandwich plate which is composed of an upper skin layer, a middle aramid honeycomb core layer and a lower skin layer, wherein every two adjacentlayers are bonded through an adhesive. The upper skin and the lower skin are each of a three-layer composite structure, and the middle layers are made of aramid pulp. Concave-convex leftover materialsare reserved on the upper edge and the lower edge of the aramid honeycomb core. The wall thicknesses of the hole grids in the middle aramid fiber honeycomb core are the same; or in a certain direction, the wall thickness of the middle hole grid is large, and the wall thicknesses of the hole grids on the two sides are small. The honeycombs of the aramid fiber honeycomb core are hollow, or hollow columns made of aramid fibers are placed in the honeycombs of the aramid fiber honeycomb core. The concave-convex leftover materials are reserved on the upper edge and the lower edge of the aramid honeycomb core, so that the contact area between the aramid honeycomb core and the upper skin and between the aramid honeycomb core and the lower skin is increased, the bonding strength, the bonding strength and the tearing strength are improved, and the aramid honeycomb sandwich plate is not prone to layering. Meanwhile, the middle layer of the upper skin and the middle layer of the lower skin are controlled to be aramid pulp, so that the impact resistance of the aramid honeycomb sandwich plate is improved.

Owner:DONGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com