Patents

Literature

30results about How to "Improve internal surface quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

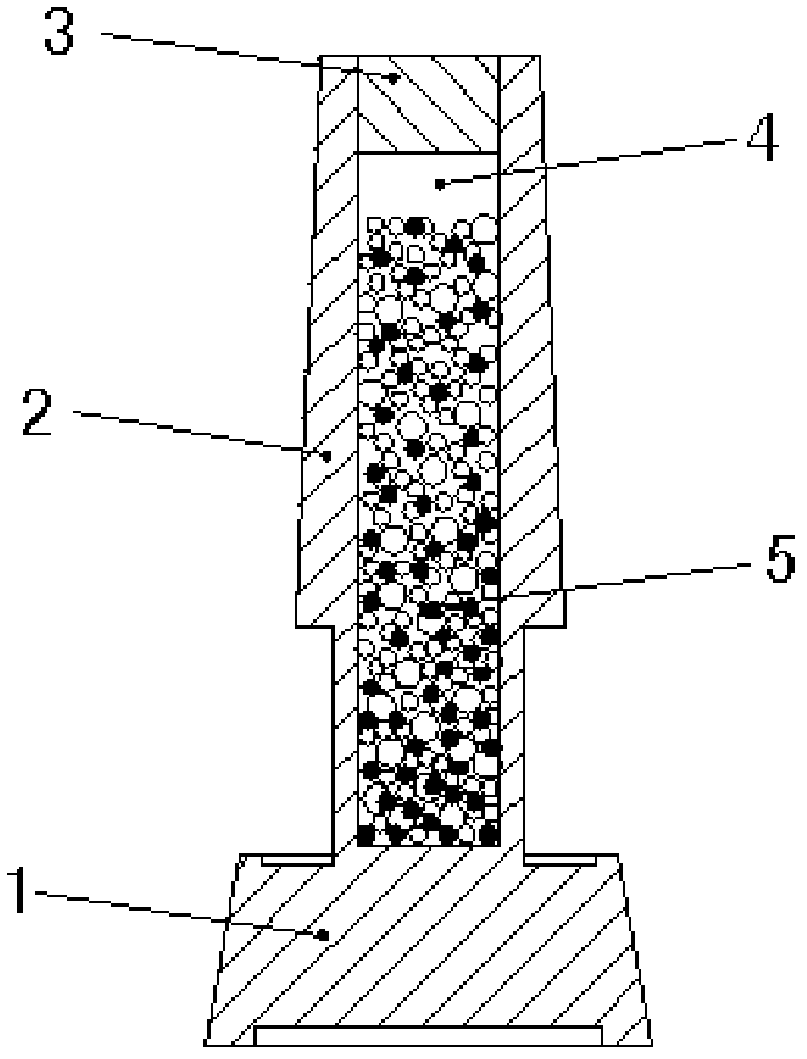

A damping and vibration-reducing tool rod

InactiveCN102275086ALow costLarge aspect ratioMaintainance and safety accessoriesEngineeringMachining process

The invention relates to a damping and vibration reduction cutter rod. The knife rod includes: a knife handle (2) and a cutter head (1) arranged at the lower end of the knife handle (2), and a cylindrical cavity (4) is coaxially arranged in the knife handle (2). Damping particles (5) are sealed and filled in the cylindrical cavity (4). The present invention has the advantages that: 1) the anti-vibration cutter of the particle damping and vibration-reduction system is used in the vibration-damping cutter bar, which can realize a large length-to-diameter ratio at a relatively low cost, making the processing process simpler and more efficient. high. 2) The vibration-damping tool holder of the present invention can improve the machining precision of the tool and prolong the life of the tool. 3) At the same time, in mechanical processing, the use of vibration-damping tools can improve the quality of surface processing and greatly improve work efficiency, especially in boring tools, using this vibration-damping tool bar to bore and cut deep holes, improve the quality of the inner surface and speed up boring Cutting speed will help a lot.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +3

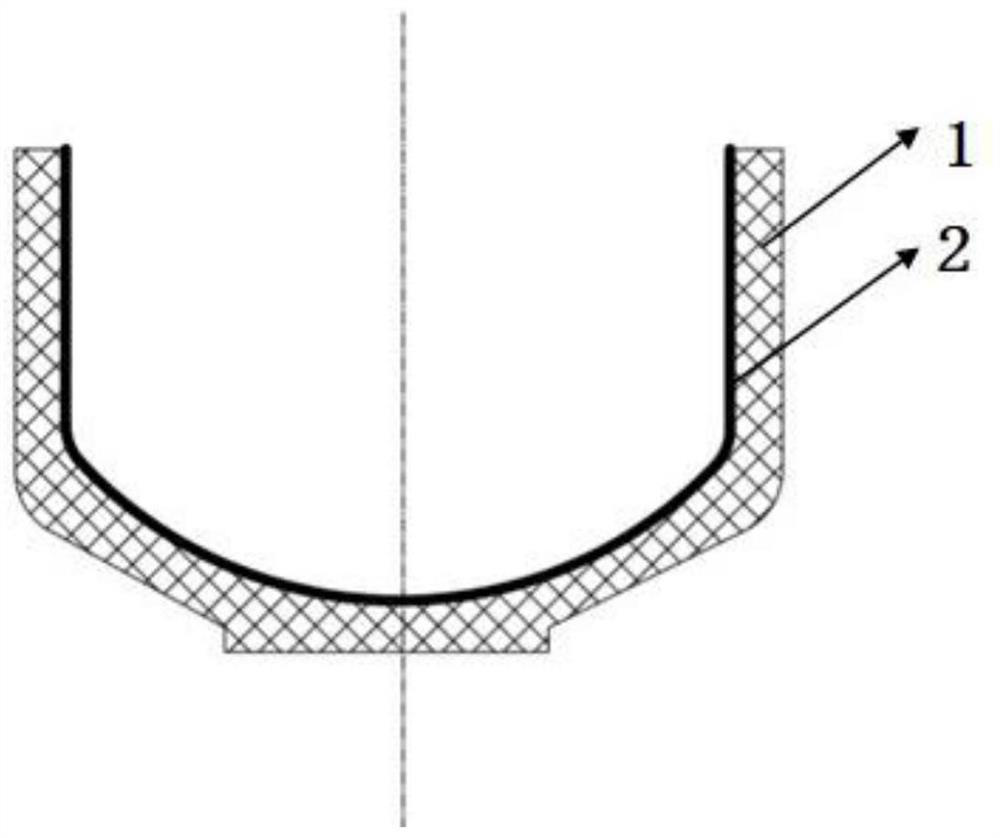

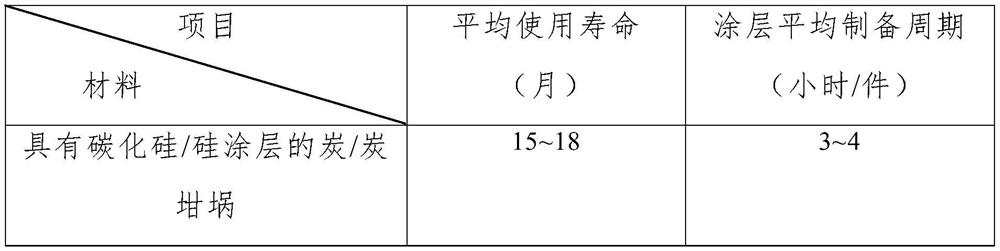

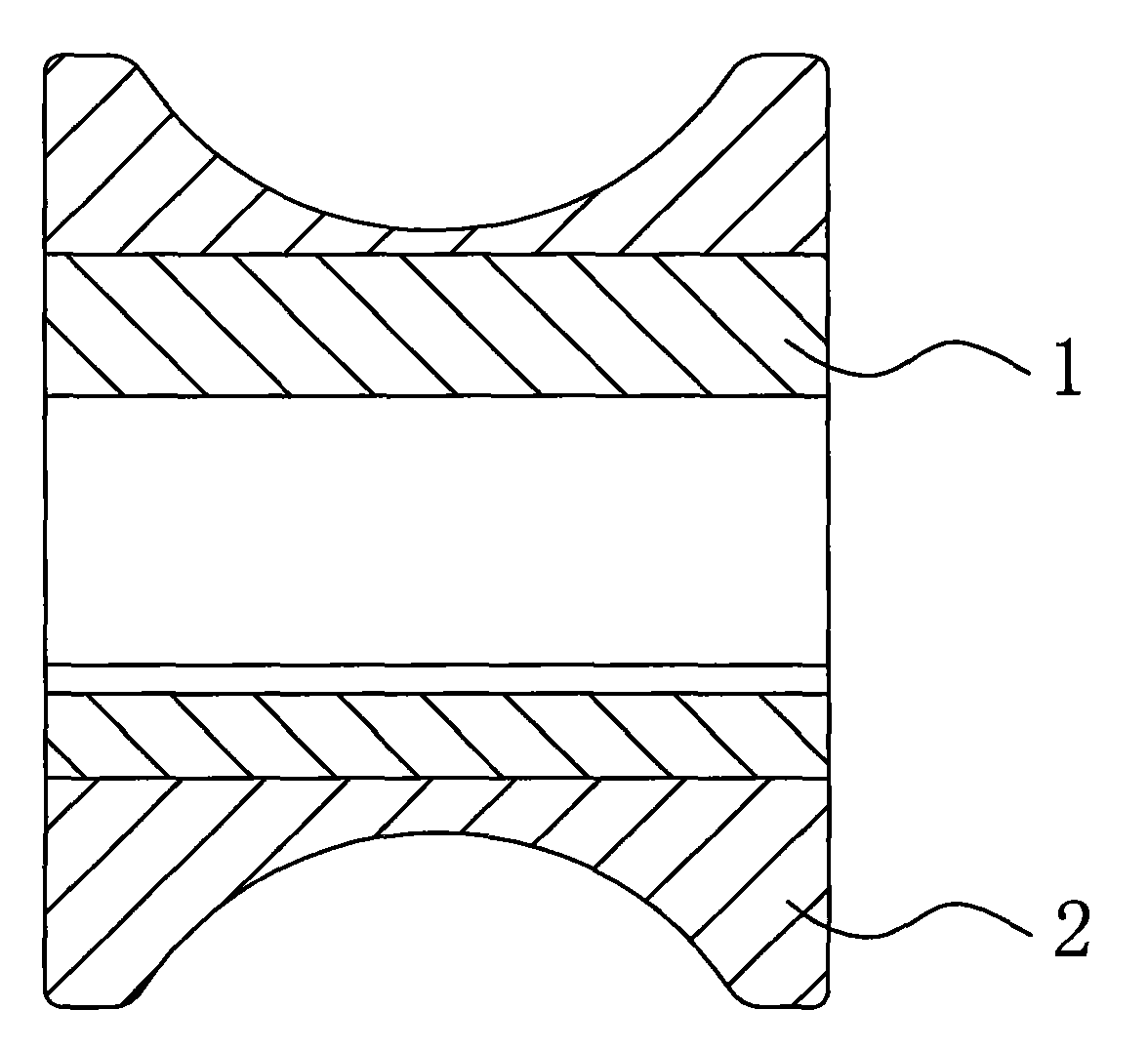

Carbon/carbon crucible with silicon carbide/silicon coating and preparation method thereof

ActiveCN111848201AExtended service lifeAvoid erosionPolycrystalline material growthBy pulling from meltCarbide siliconCarbon composites

The invention discloses a carbon / carbon crucible with a silicon carbide / silicon coating. The carbon / carbon crucible comprises a carbon / carbon composite crucible and the silicon carbide / silicon coatingcovering the inner surface of the carbon / carbon composite body, wherein the silicon carbide / silicon coating consists of a silicon carbide coating and a silicon coating covering the silicon carbide coating. The invention also discloses a preparation method of the carbon / carbon crucible with the silicon carbide / silicon coating. The method comprises the following steps: 1, densifying a carbon fiberpreform; 2, conducting processing to obtain the carbon / carbon composite crucible; and 3, conducting spraying on the inner surface of a carbon / carbon crucible matrix by adopting a plasma spraying method to obtain the carbon / carbon crucible with the silicon carbide / silicon coating. By arranging the silicon carbide / silicon coating, corrosion of silicon-containing steam to the inner surface of the crucible is avoided, and the service life of the crucible is prolonged; and by adopting the plasma spraying method, the bonding strength of the silicon carbide / silicon coating and the carbon / carbon crucible matrix is improved, and the surface quality of the carbon / carbon crucible with the silicon carbide / silicon coating is improved.

Owner:XIAN CHAOMA SCI TECH

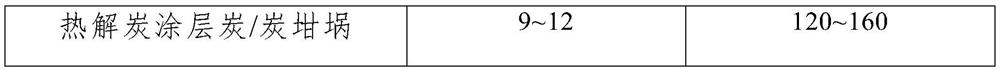

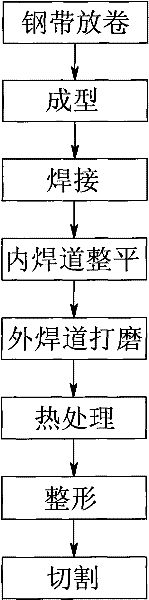

Method for preparing welded stainless steel pipe of boiler

ActiveCN101559446AQuality improvementImprove ergonomicsExtrusion diesWelding/cutting auxillary devicesStrip steelHigh surface

The invention discloses a method for preparing a welded stainless steel pipe of a boiler, belonging to the technical field of manufacturing the welded stainless steel pipe. The technical scheme includes the processes: strip steel unreeling, molding, welding, internal weld pass leveling, external weld pass polishing, heat treatment, shaping and cutting, wherein the processes are sequentially and continuously carried out, and a bright heat treatment boiler is used for the heat treatment. The welded stainless steel pipe processed by the method of the invention has the advantages of stable quality, lower manufacturing cost and high surface quality, and the method is used for manufacturing pipes for boiler heat exchangers and condensers.

Owner:广州永大不锈钢有限公司

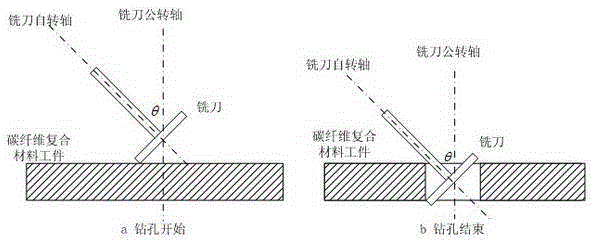

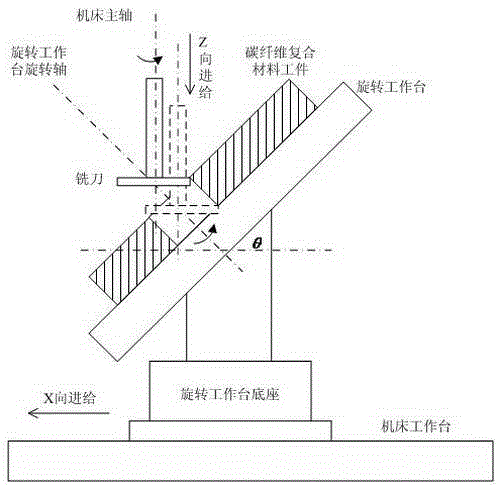

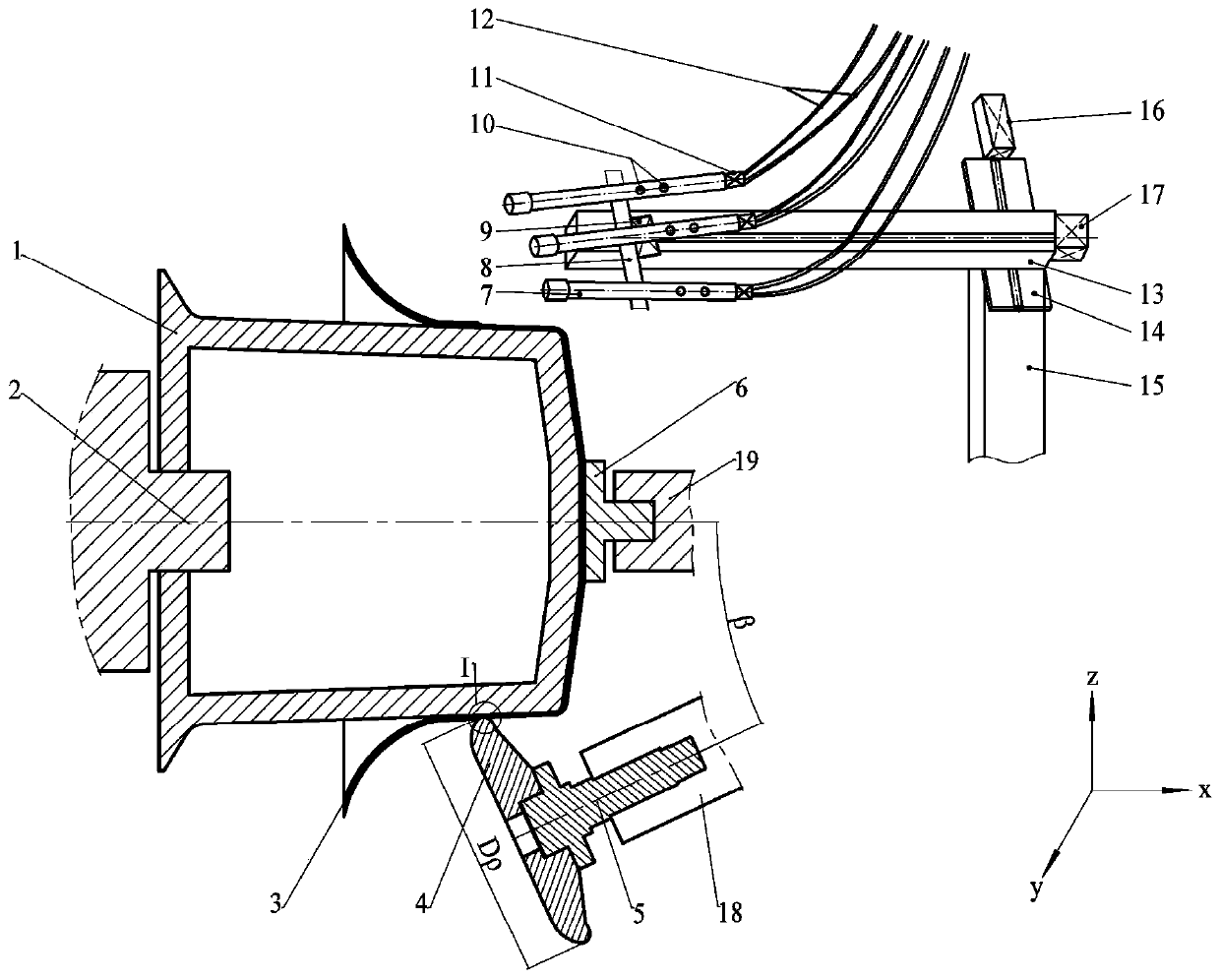

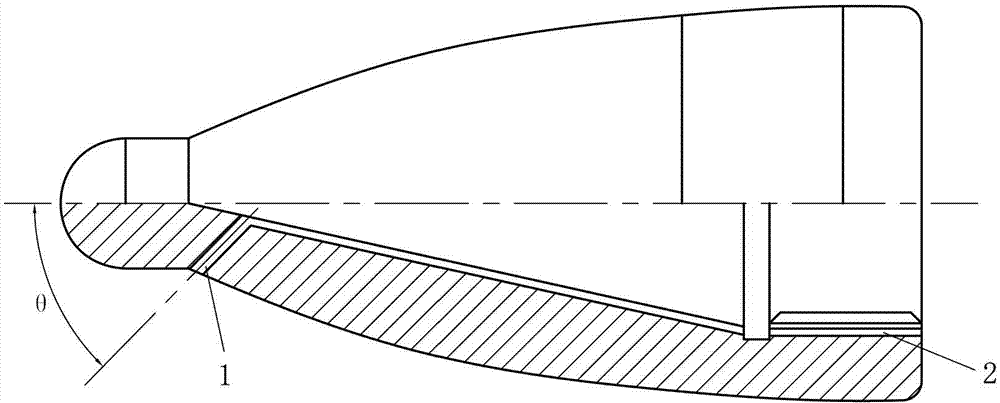

Spinning milling drilling process for carbon fiber composites

InactiveCN105269048AReduce export stratificationImprove internal surface qualityFeeding apparatusMilling equipment detailsCarbon fiber compositeEngineering

The invention relates to a spinning milling drilling process for carbon fiber composites. The invention provides a special mode of motion of a cutter, namely a spinning motion; a milling cutter revolves around a revolution axis while rotating around an own axis. An included angle theta is formed between the rotation axis and the revolution axis; the included angle theta can be adjusted according to a shape of a hole to be machined. The milling cutter is fed toward a surface of a workpiece along the revolution axis at the same time of the spinning motion, and therefore, a hole is machined out in the milling manner. Such a mode of motion has the greatest advantage that a pull to a carbon fiber workpiece at the outlet of the hole can be greatly reduced so that an outlet-layering phenomenon can be reduced.

Owner:NANCHANG HANGKONG UNIVERSITY

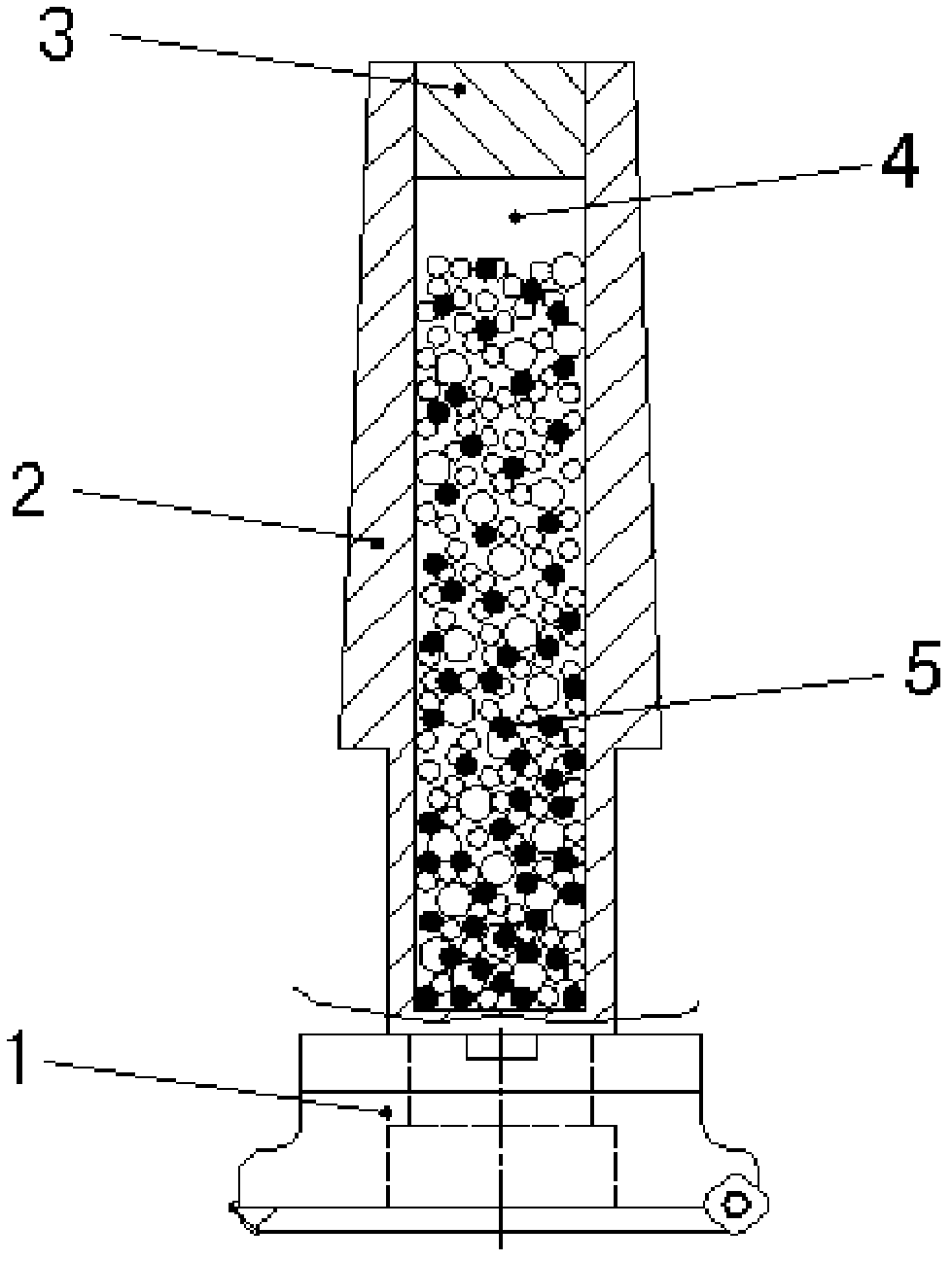

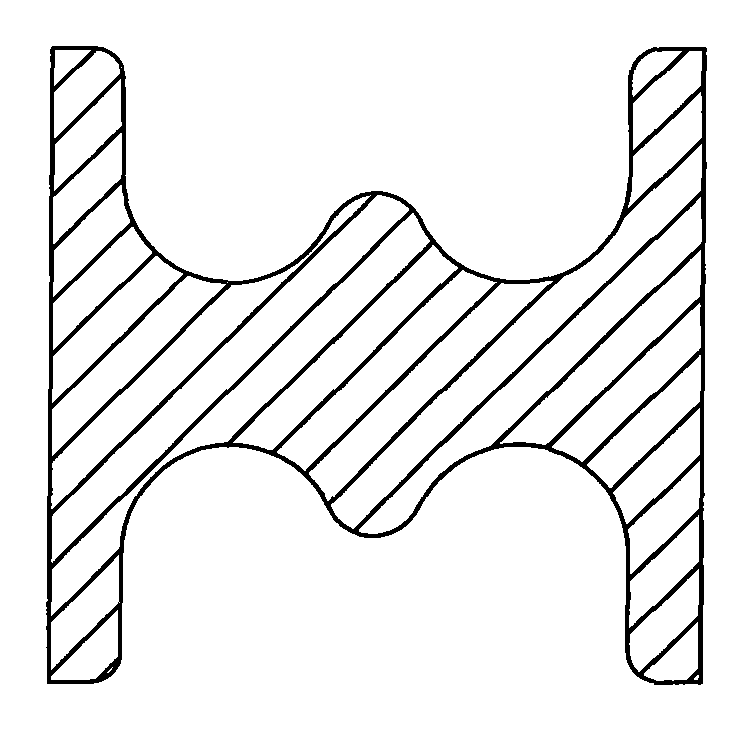

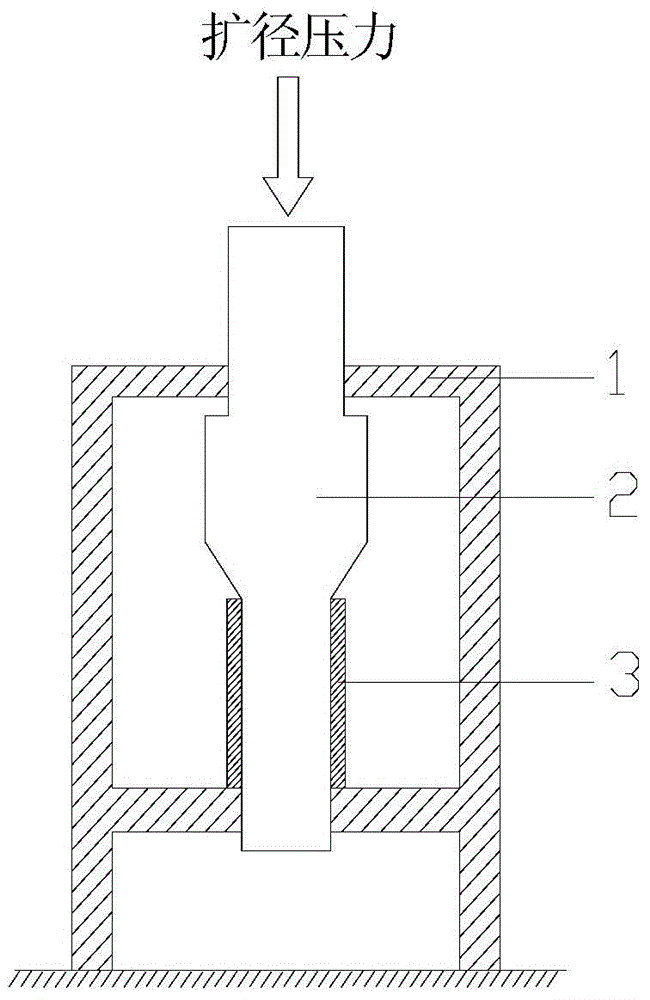

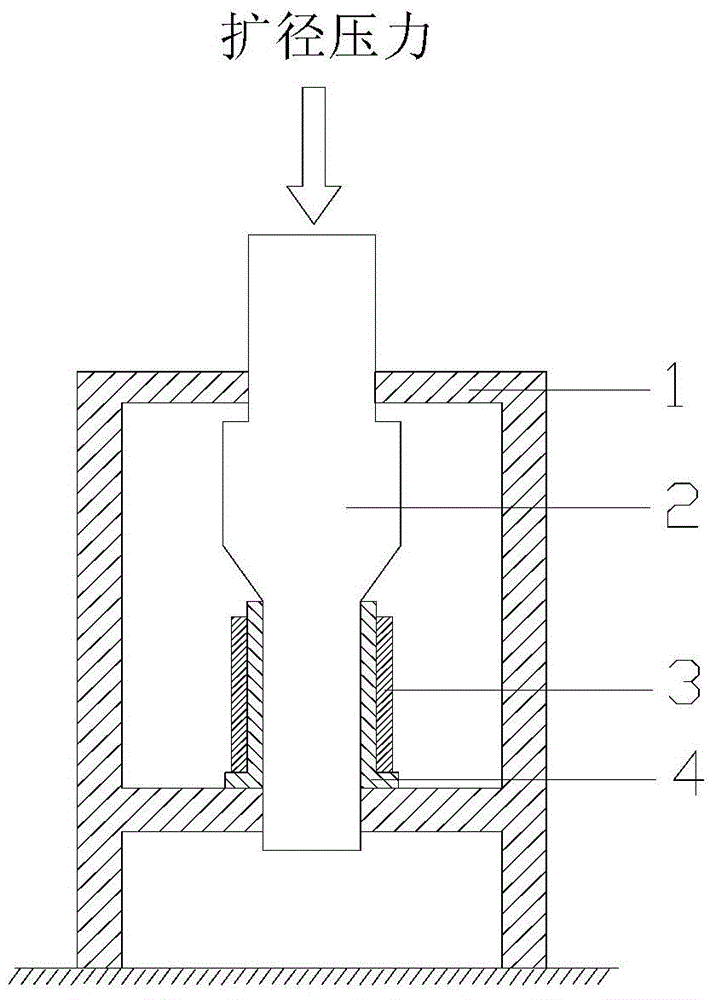

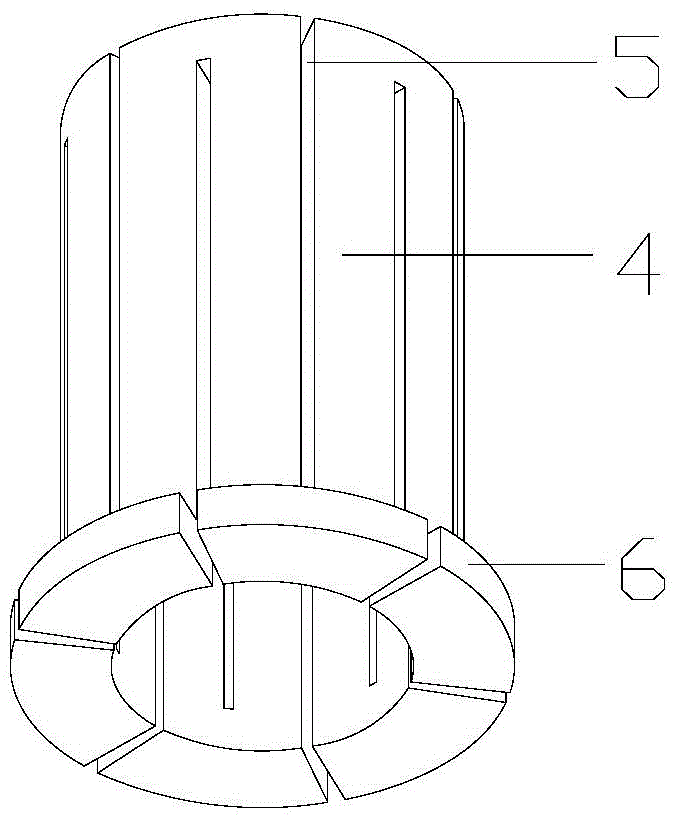

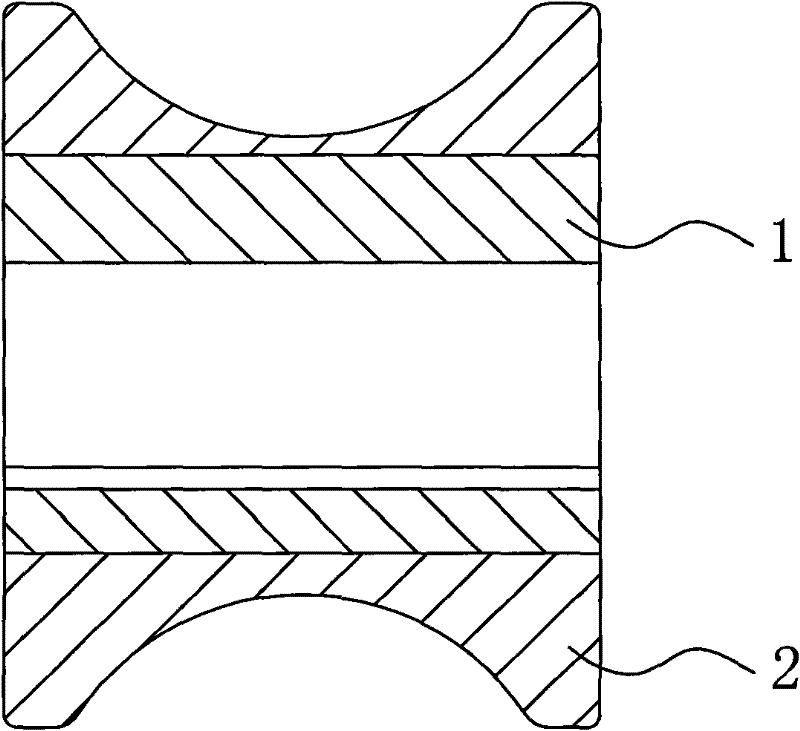

Hole-enlarging deforming device and method for metal pipe fitting

The invention relates to a hole-enlarging deforming device and method for a metal pipe fitting.The device comprises the metal pipe fitting, an expanding support and an expanding die and further comprises an elastic die sleeve placed in the metal pipe fitting. The internal diameter of the elastic die sleeve is in clearance fit with the external diameter of the expanding die. The method comprises following steps: firstly, installing the elastic die sleeve into the metal pipe fitting such that internal diameter of the elastic die sleeve is in clearance fit with the external diameter of the expanding die; secondly, installing the expanding support to a punch press and applying expanding pressure to the expanding die such that a calibrating strap penetrates through the elastic die sleeve and performs expanding operation, and taking down the metal pipe fitting after finishing the above steps. The method helps to avoid direct friction between the metal pipe fitting and the expanding die such that quality of an inner surface of the metal pipe fitting and size precision of the metal pipe fitting after expansion are improved. Therefore, abrasion of the expanding die is effectively reduced and durability of the expanding die is improved. The method can be extensively applied to expanding deforming of the metal pipe fitting, and process-molding of conical pipes for flow instruments in chemical and petroleum fields.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

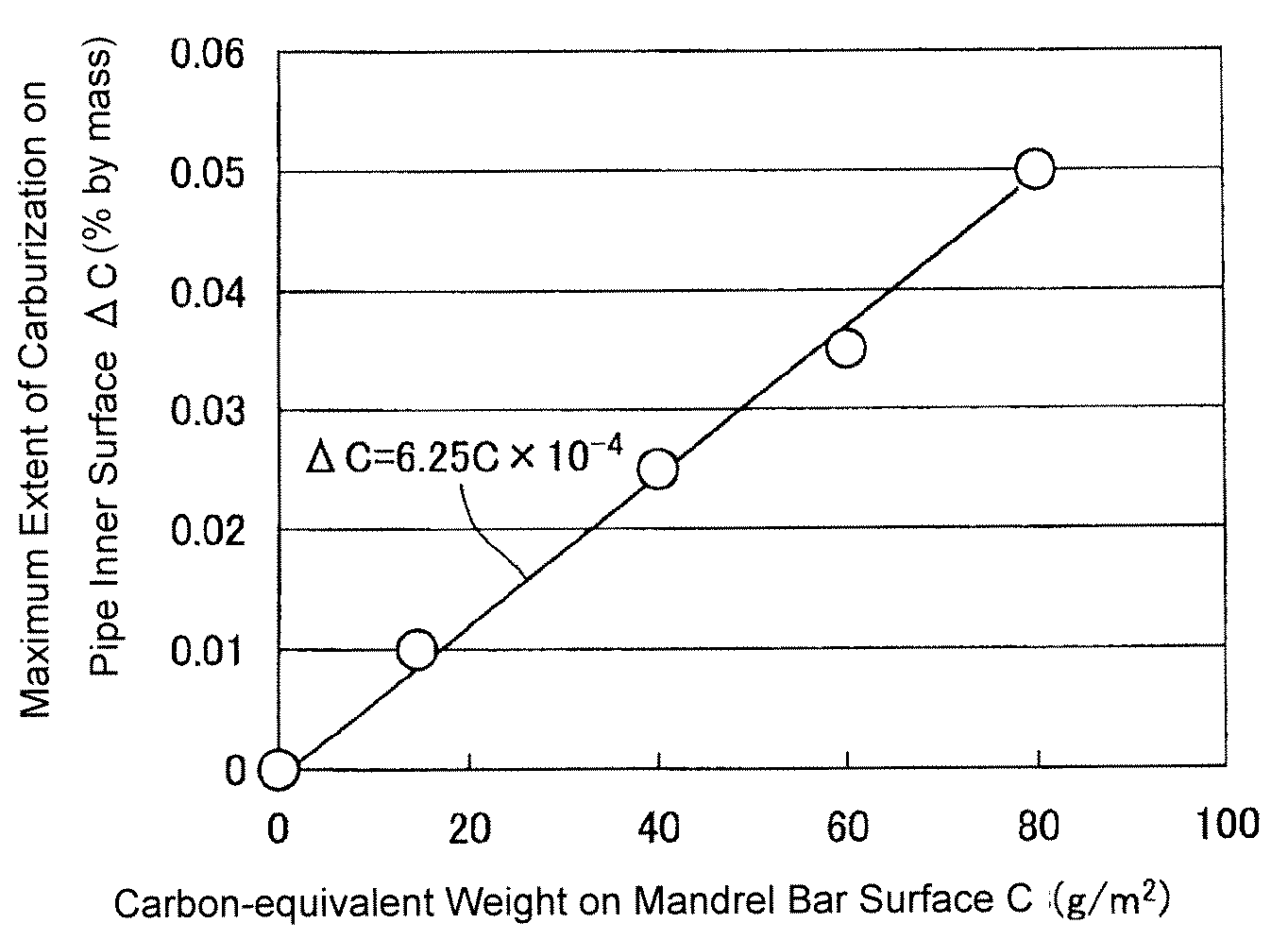

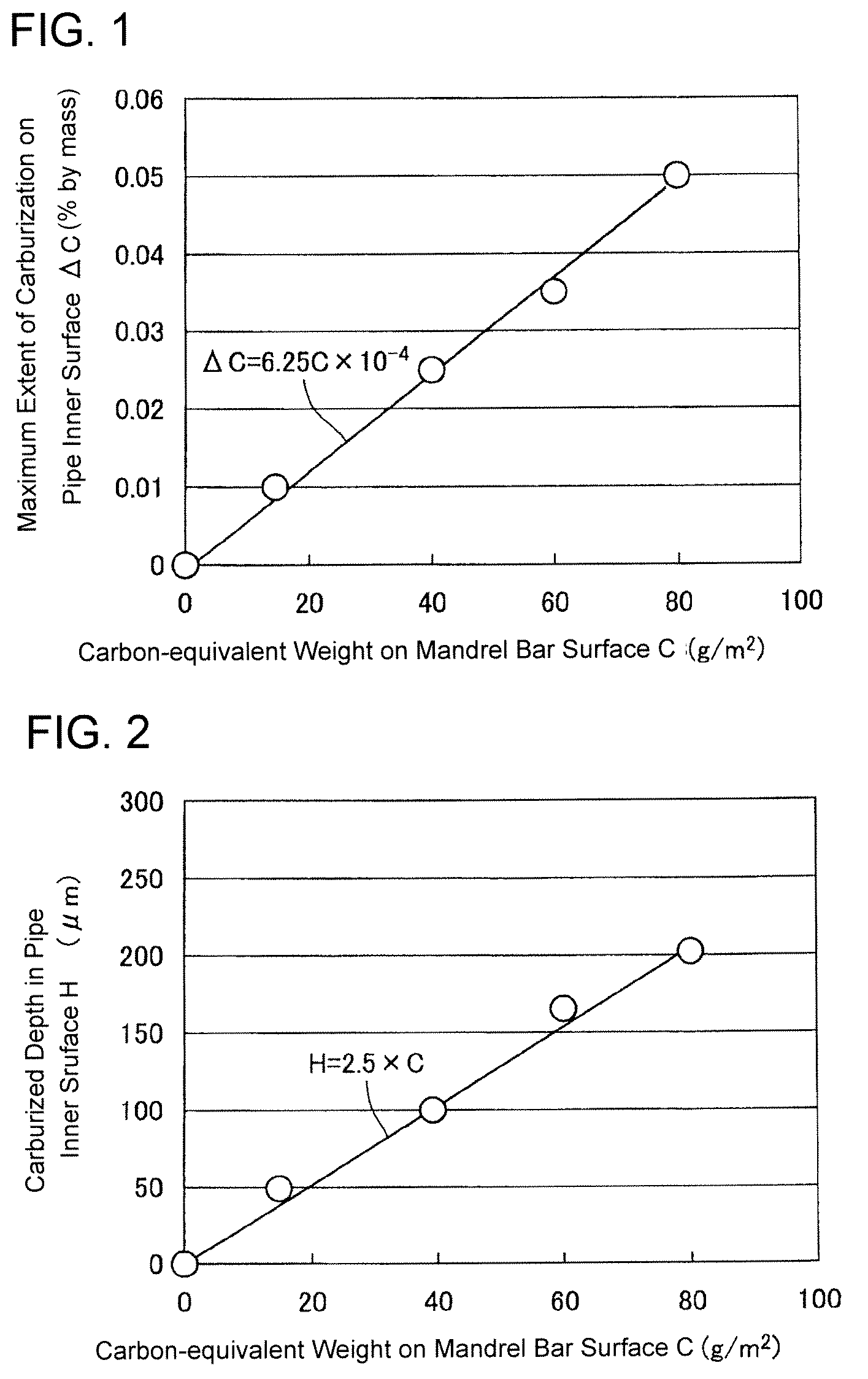

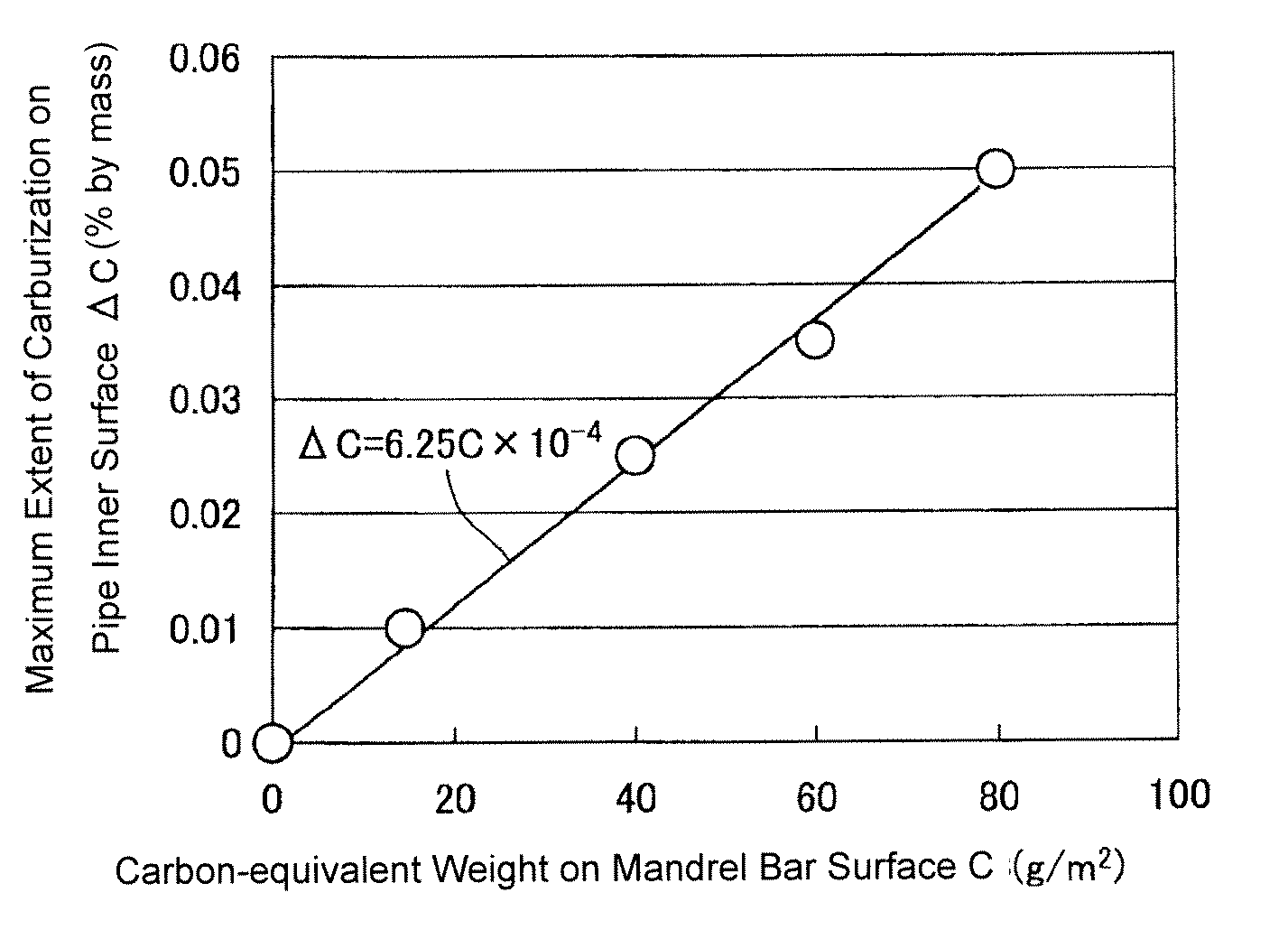

Process for producing seamless stainless steel pipe

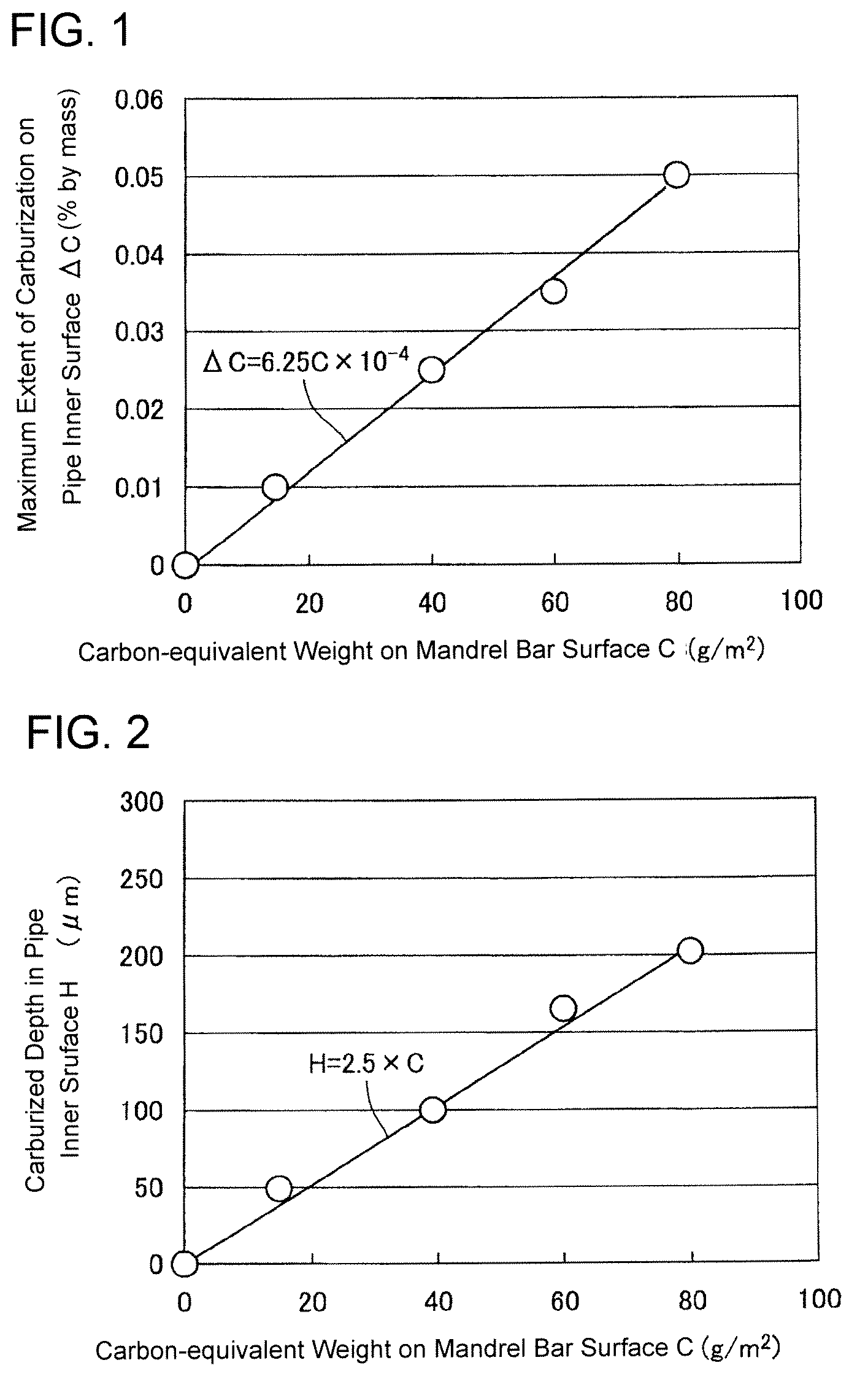

ActiveUS20090084151A1Reduce layeringImprove internal surface qualityMandrelsFurnace typesGraphiteProduct gas

A process for producing seamless pipes which comprises conducting a piercing rolling step, a elongating rolling step using a mandrel bar, and a sizing rolling step and subsequently conducting a product heat treatment. In the process, when the carbon-equivalent weight, namely the sum of the weight of graphite in the lubricant and the carbon content in the organic binder, per unit area of the lubricant adhering to the mandrel bar surface in the above-mentioned step of elongating rolling is expressed by C (g / m2) or the maximum extent of carburization in the inner surface of the pipe to be heat-treated but prior to the heat treatment is expressed by ΔC (% by mass), the heating temperature for the pipe to be heat-treated is expressed by T (° C.), and the time during which a decarburizing gas is blown into the inside of the pipe to be heat-treated is expressed by t1 or t2 (seconds), and further, the blowing time calculated taking into account the wall thickness reduction in the step of cold working is expressed by t3 or t4 (seconds), a predetermined relation is satisfied and the actual decarburizing gas blowing time in the heat treatment is longer than the time t1, t2, t3 or t4 (seconds), whereby seamless stainless steel pipes reduced in carburized layer formation can be produced even when the carbon adhesion to the pipe inner surface is caused in, for example, mandrel mill rolling.

Owner:NIPPON STEEL CORP

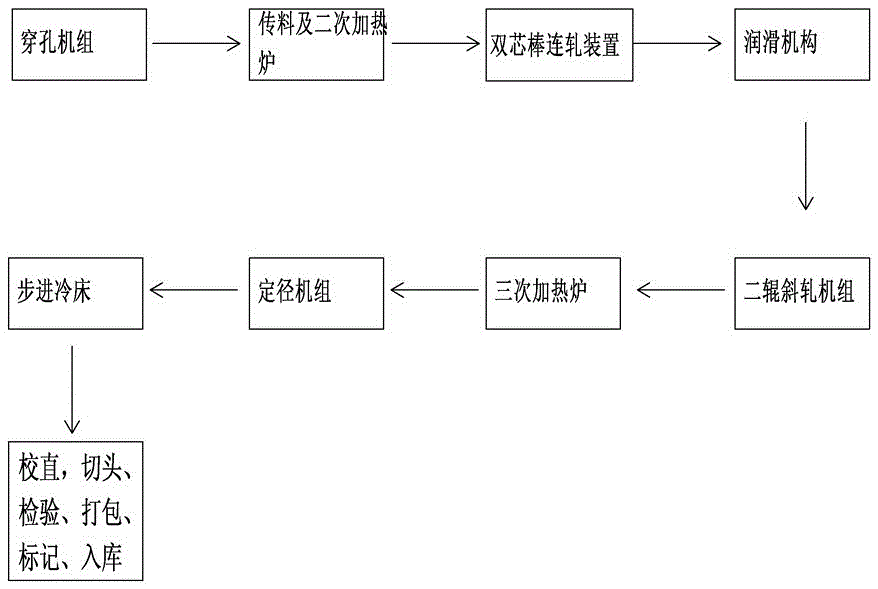

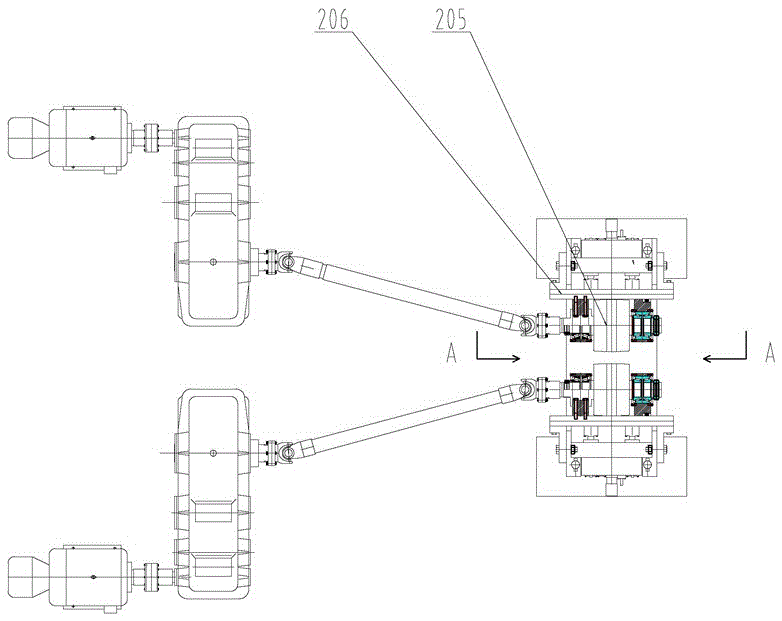

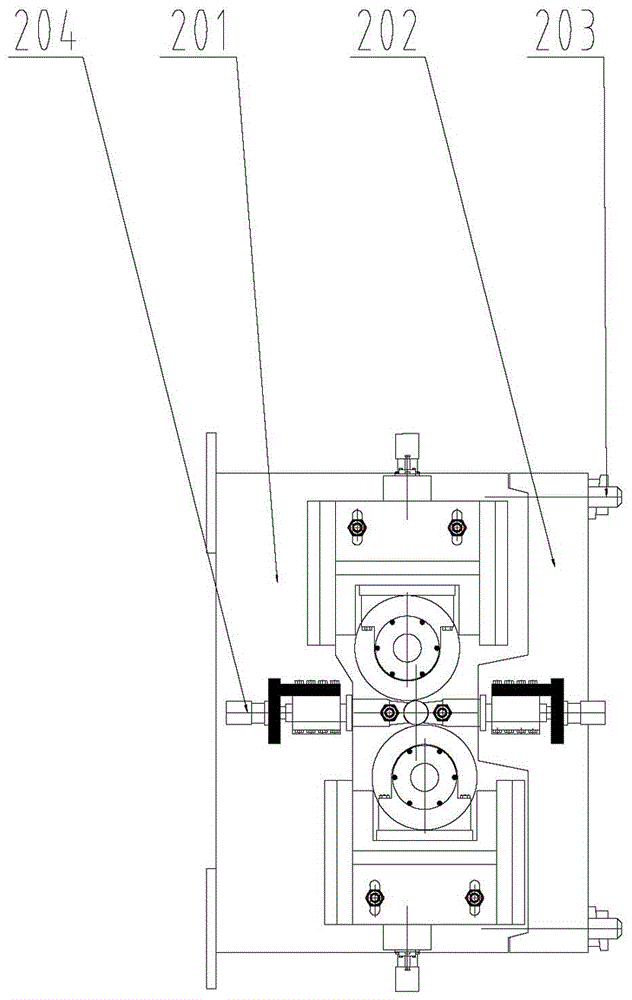

Process for thin-wall hot-rolled seamless steel tube in double mandrel two-roll rotary rolling production

InactiveCN106825106ASolve the problem that the temperature is low and cannot be rolledPlay a lubricating roleMandrelsMetal rolling arrangementsHeating furnaceMaterial Perforation

The invention relates to the technical field of production and processing of seamless steel pipes, and in particular relates to a process for a thin-wall hot-rolled seamless steel tube in double mandrel two-roll rotary rolling production, the thin-wall hot-rolled seamless steel tube is capable of performing two-roll rotary rolling at a high remaining temperature after perforation, the seamless steel tube has the advantages of high production efficiency, high quality and low production cost, a perforated hollow billet is secondarily heated, then a mandril passes through the hollow billet in advance, while the mandril passes through the hollow billet in advance, a lubricant is sprayed, the mandril sprayed with the lubricant passes through the hollow billet, then enters a two-roll rotary rolling set for rolling, a rolled pierced billet enters a three-time heating furnace for three times of heating, after the three times of heating, a hot finished tube is formed by reducing, sizing and shaping, and a finished tube formed by cooling of the hot finished tube is straightened, copped, inspected, packed, labeled, and stored to form a commercial tube, roll burst of the horizontal tissue of the seamless steel tube rolled by the process is not easy to produce, black threads are not easy to produce, the outer diameter sizes of the front end and the back end are improved by 25%, and the accuracy is increased by 20%.

Owner:CHANGGE YIMING MACHINERY

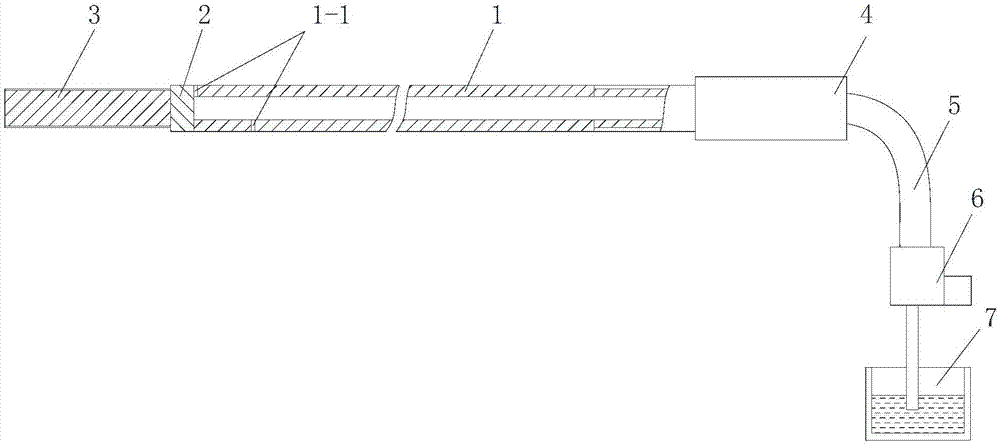

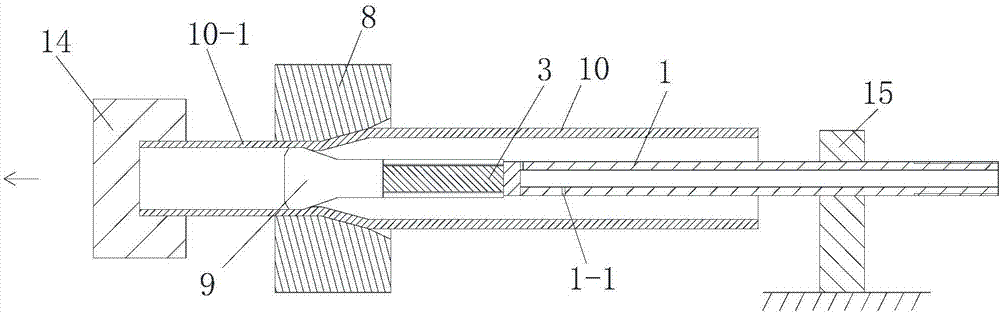

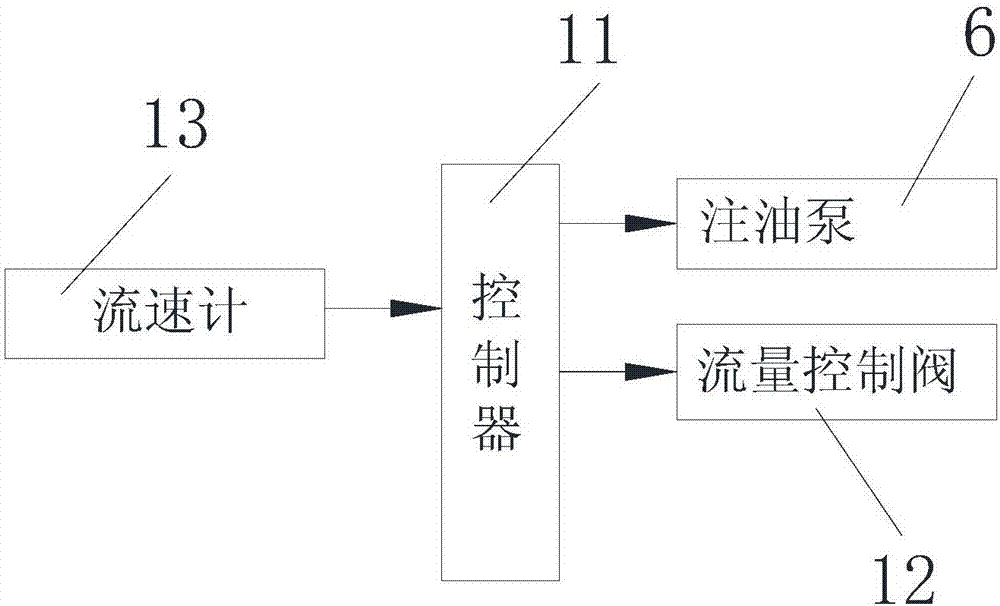

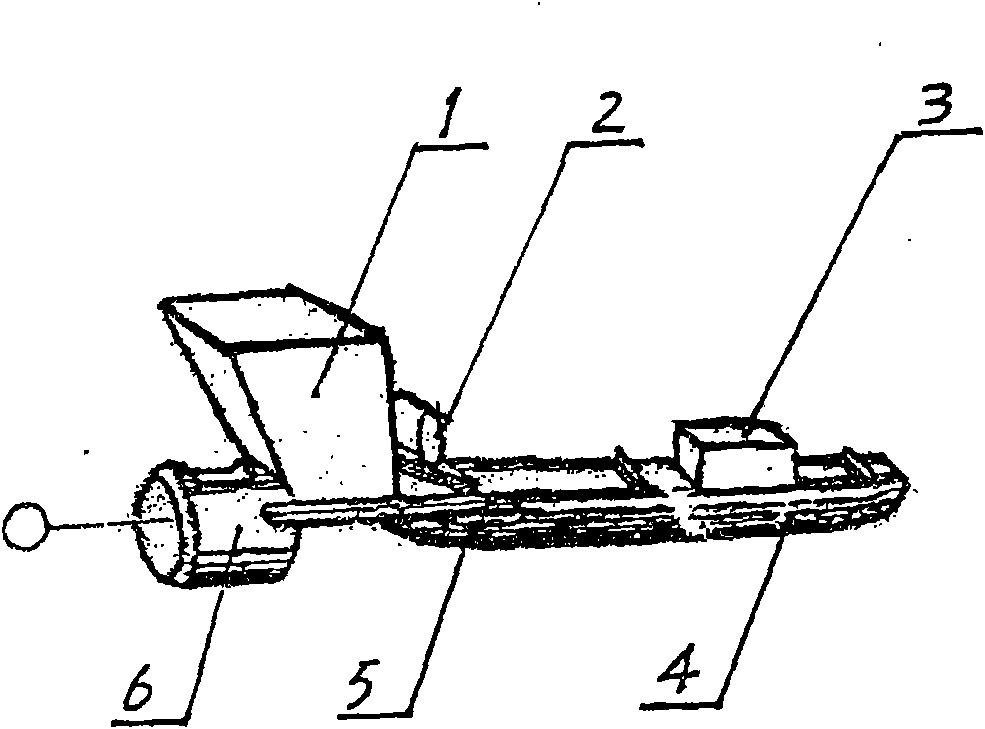

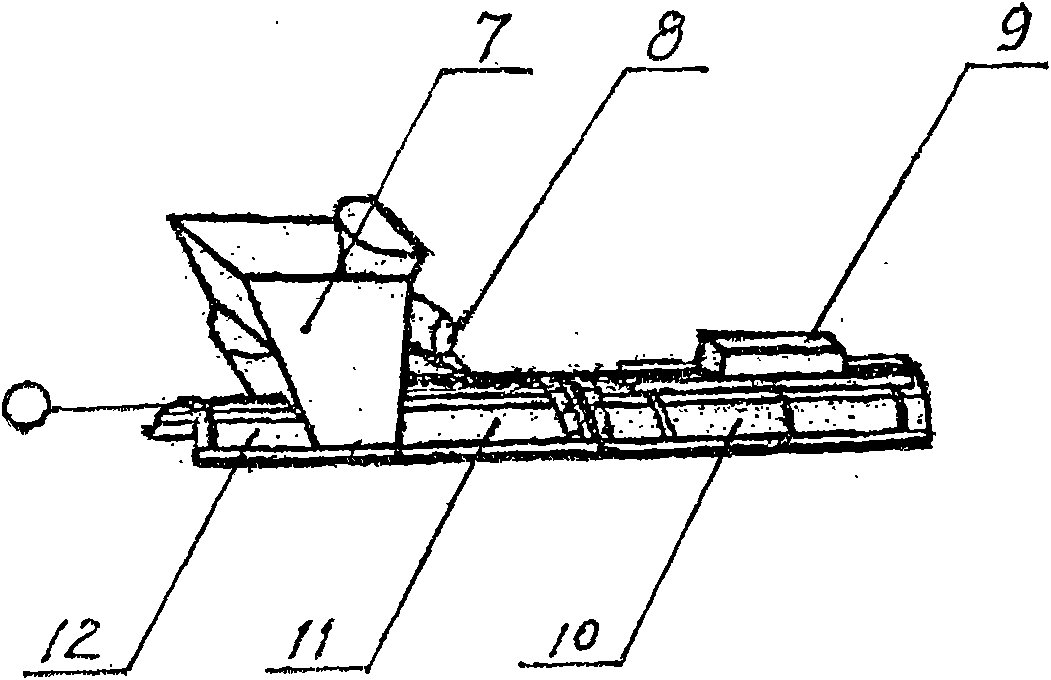

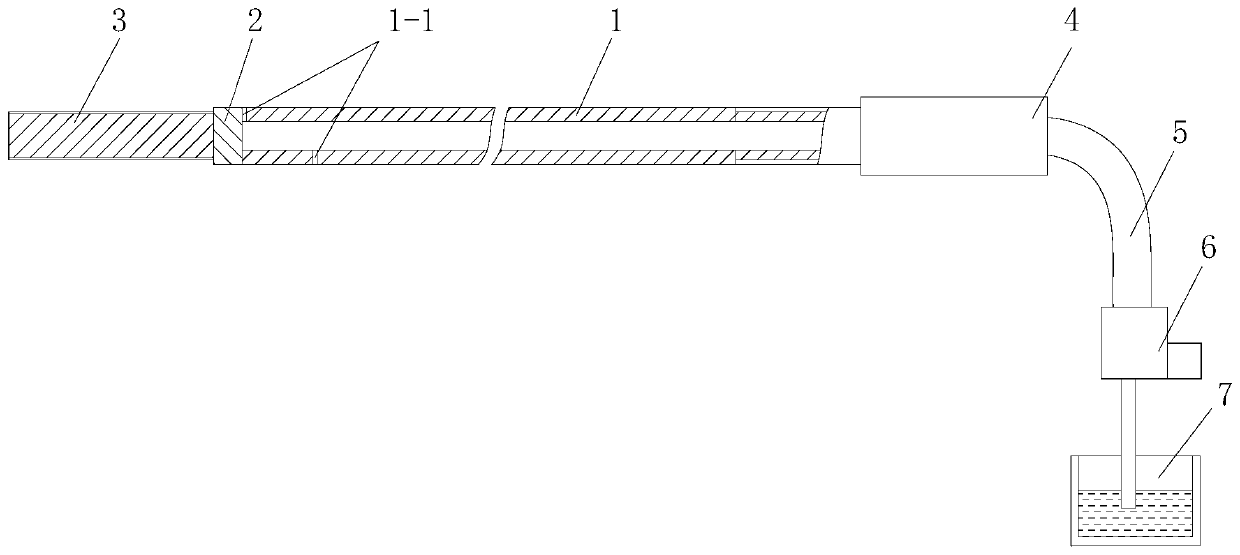

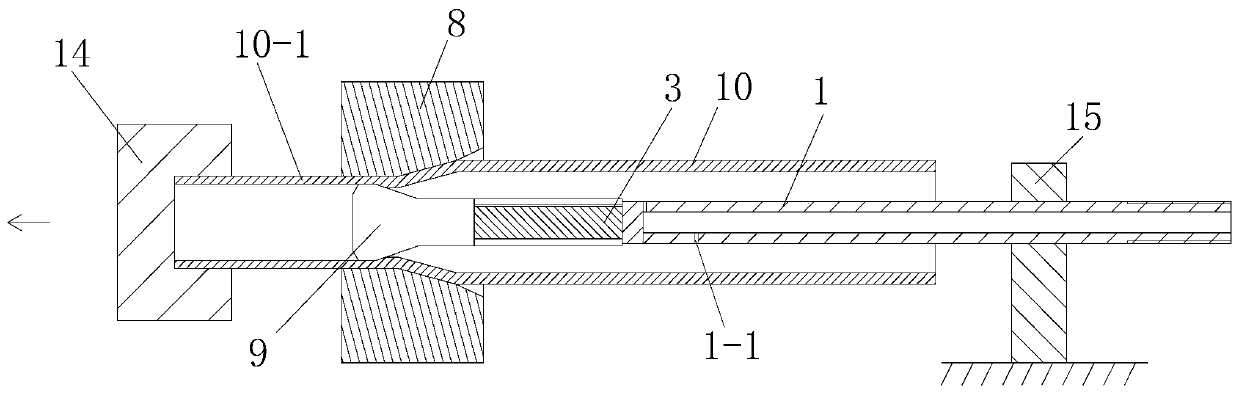

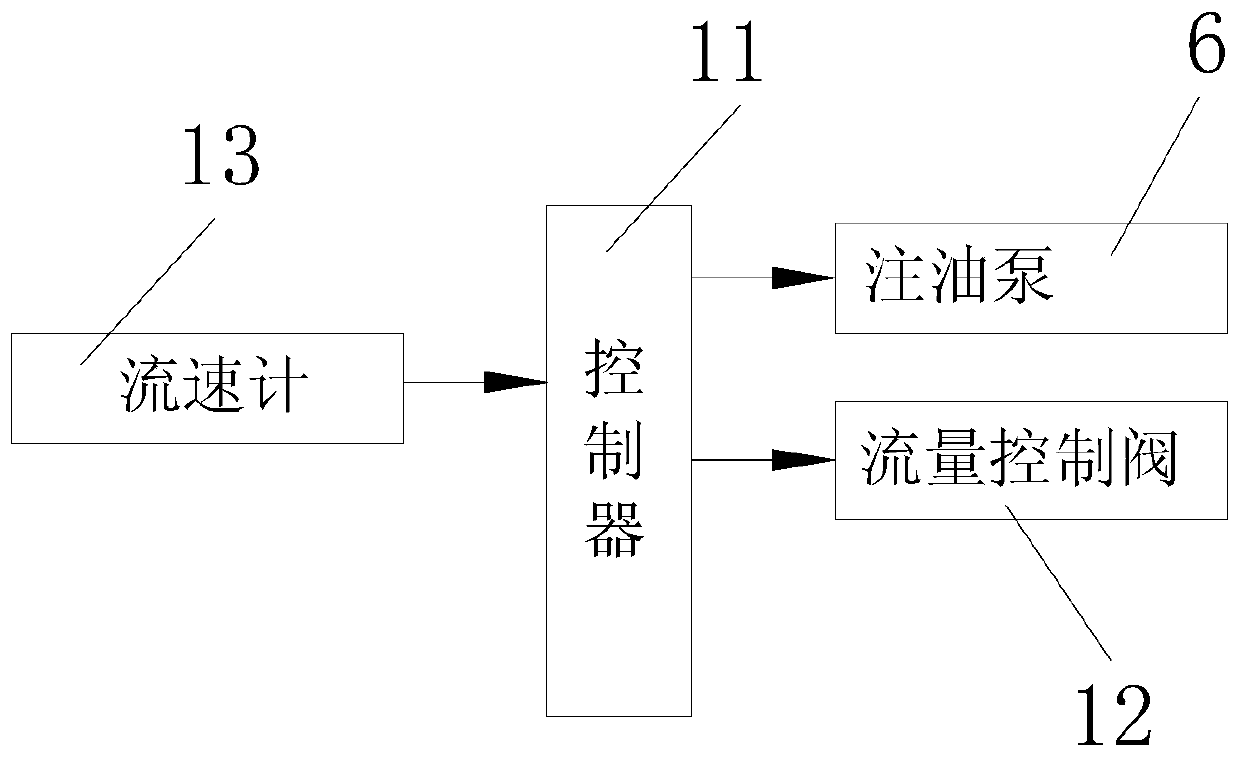

Pipe pulling and drawing lubricating device and pipe pulling and drawing machining method

ActiveCN107990135AThere will be no missingSo as not to damageProportioning devicesConduits/junctionsFuel tankMachining

The invention discloses a pipe pulling and drawing lubricating device, and further discloses a pipe pulling and drawing machining method. The pipe pulling and drawing lubricating device comprises an oil supplying mechanism arranged on a chain broaching machine and a lubricating pipe connected with the oil supplying mechanism. The oil supplying mechanism comprises an oil box for storing lubricatingoil, an oil injecting pipe connected with the lubricating pipe and an oil injecting pump connected to the position between the oil box and the oil injecting pipe. The lubricating pipe is composed ofa flat and straight steel pipe, a sealing plate arranged at one end of the flat and straight steel pipe and a connecting rod mounted on the end face of the sealing plate and used for being connected with a pulling and drawing core head. The flat and straight steel pipe is composed of an oil injecting section, a clamping section and a connecting section. The pipe pulling and drawing machining method comprises the steps of 1, preparation of a to-be-pulled-drawn pipe blank, 2, mounting of a pulling and drawing external mold and the to-be-pulled-drawn pipe blank, 3, mounting of the lubricating device and the pulling and drawing core head, and 4, lubricating and pulling-drawing of the to-be-pulled-drawn pipe blank. According to the pipe pulling and drawing lubricating device, the purpose that the lubricating oil is continuously injected into the pipe blank can be achieved, the phenomena that adding of the lubricating oil is uneven, and the local lubricating oil of the inner wall of a pipe is absent cannot occur, and the quality of the inner surface of the pipe after being pulled and drawn is improved.

Owner:西安诺博尔稀贵金属材料股份有限公司

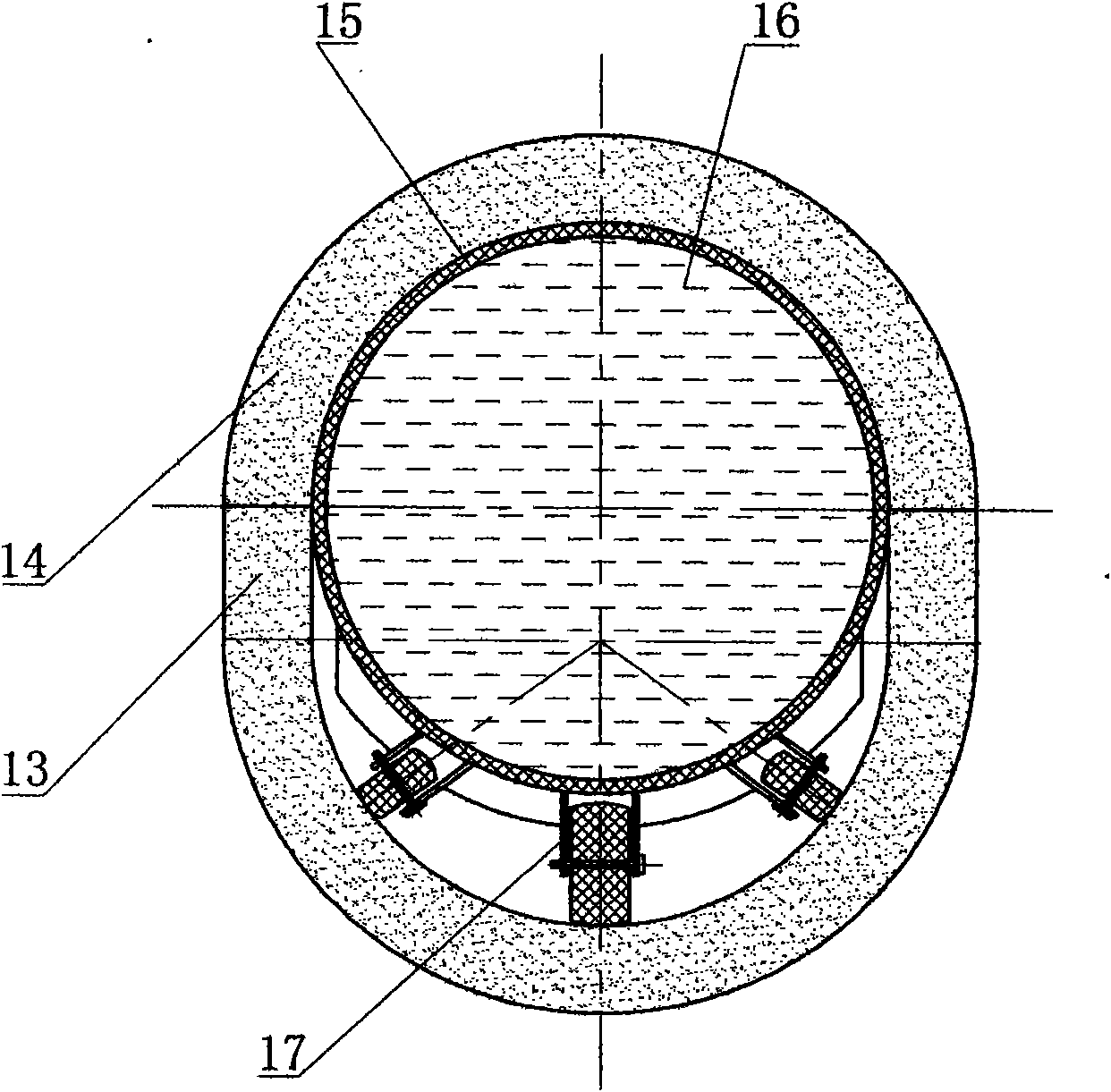

Construction machine for casting underdrain on site by cement

InactiveCN101619570AReduce labor intensityEasily damagedIrrigation ditchesArtificial water canalsUltimate tensile strengthWood plank

The invention relates to a construction machine for casting underdrain on site by cement, mainly comprising an upper half pipe molding slip form, a lower half pipe molding slip form, water sacs, a small trolley, and the like. The construction machine is mainly used for casting the underdrain used for irrigating or draining farmland on site by cement. The construction machine adopts the technical scheme that the water sacs are inlaid on the small trolley, are filled with pressure water and are used as cast-in-situ inner forms so as to replace the wood plate stumpage formwork of the prior art, thereby saving the time of erecting or disassembling the wood former and greatly shortening the construction period. The invention disassemblies the wood formwork without requiring a worker to plunge into the underdrain, thereby eliminating unsafe factors and reducing the labor intensity of workers; and the inner face of the underdrain cast by the construction machine is smooth and continuous without uneveness, thereby improving the quality of the underdrain, saving a great amount of wood and reducing the construction cost.

Owner:孙加林

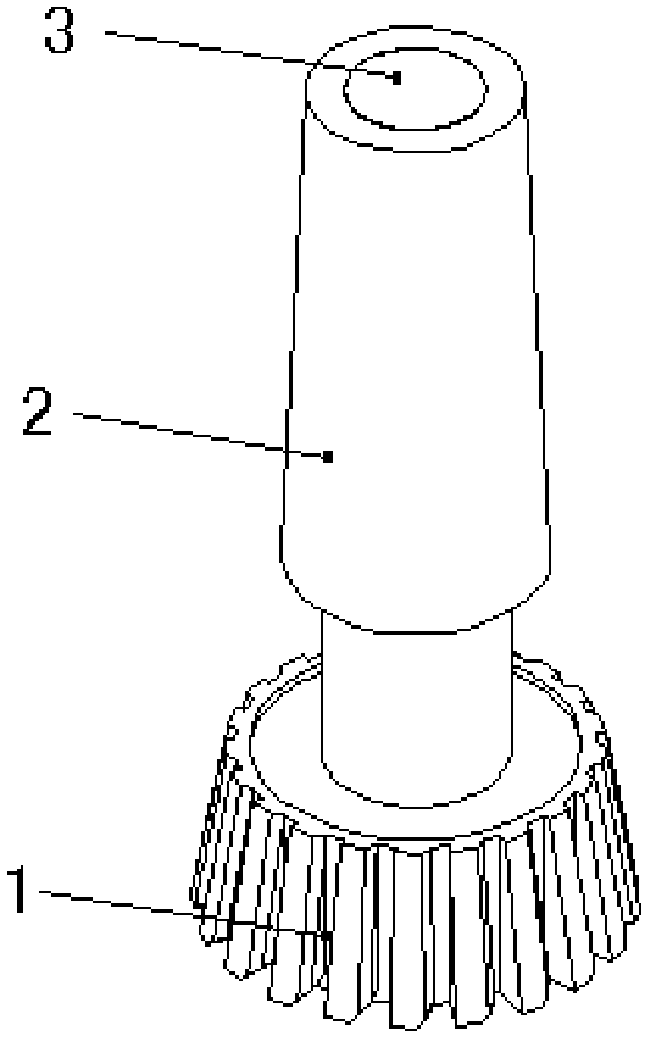

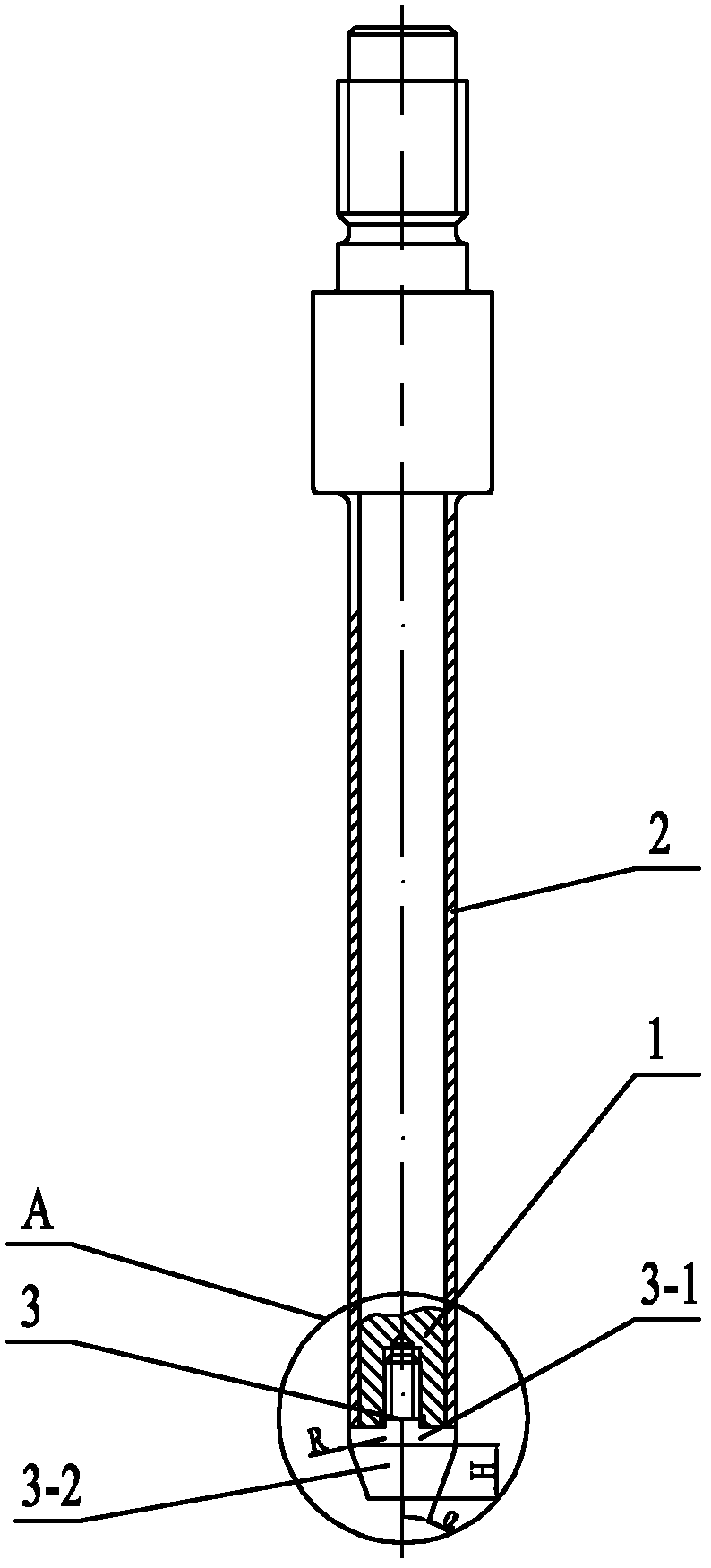

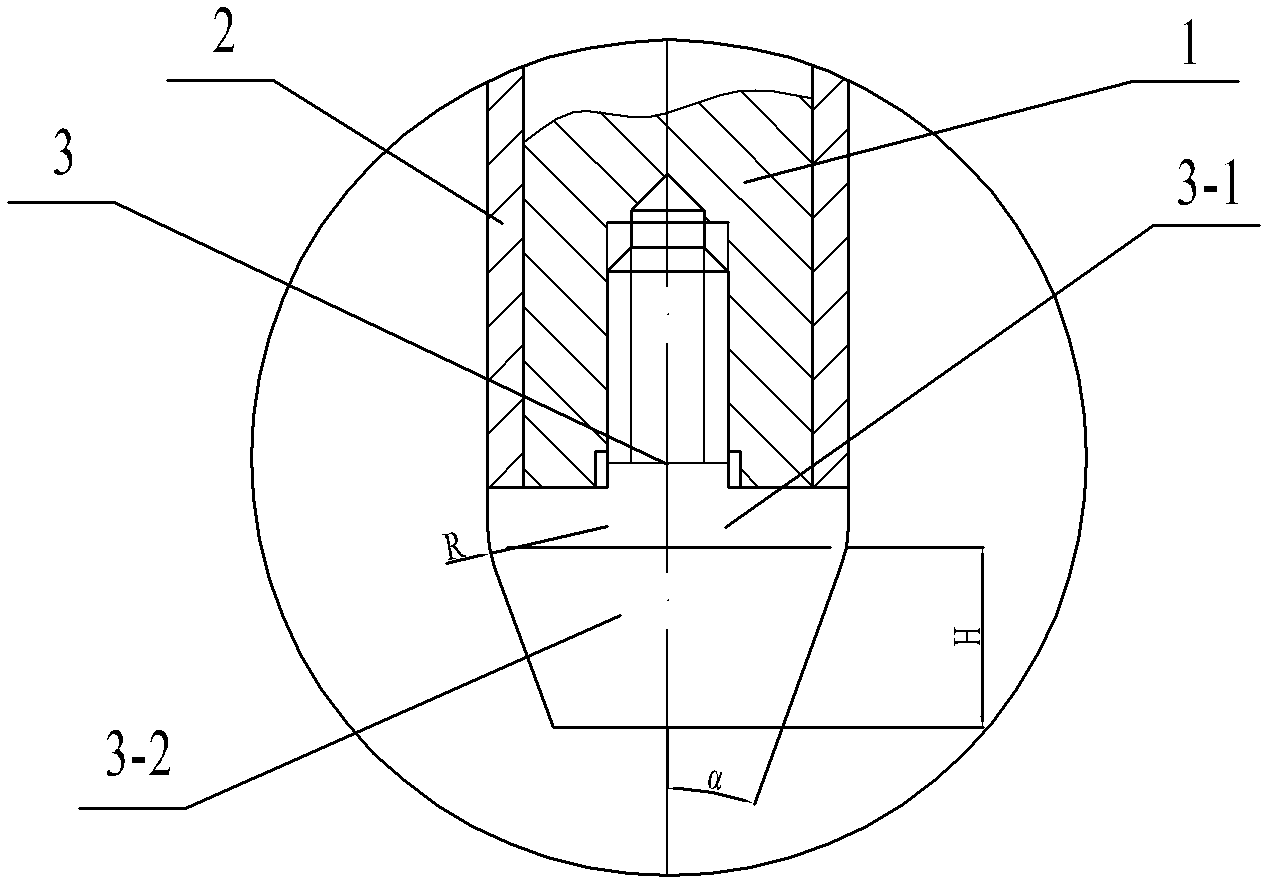

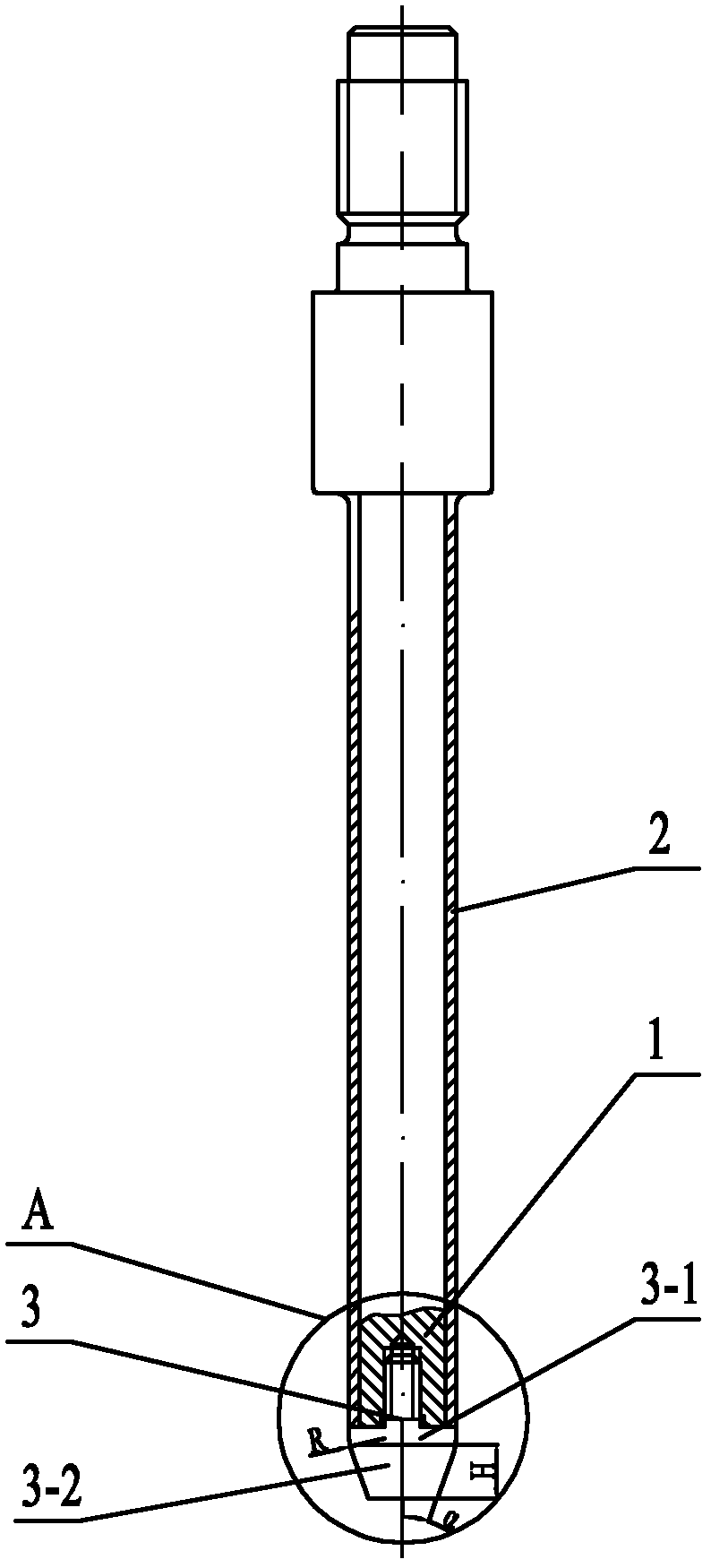

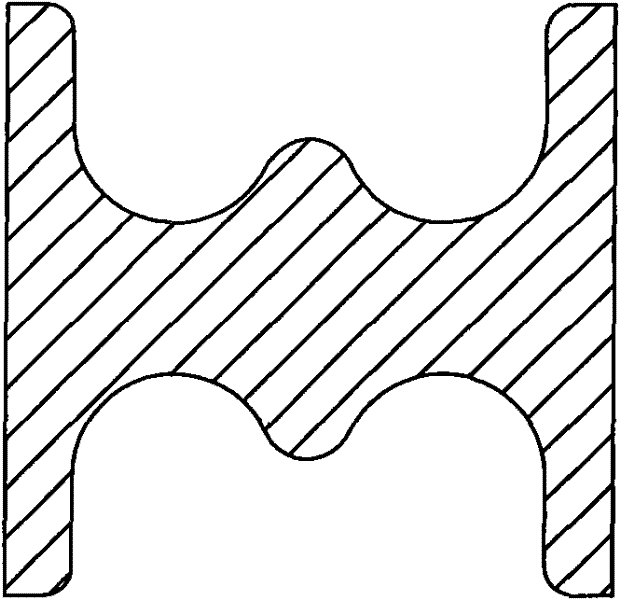

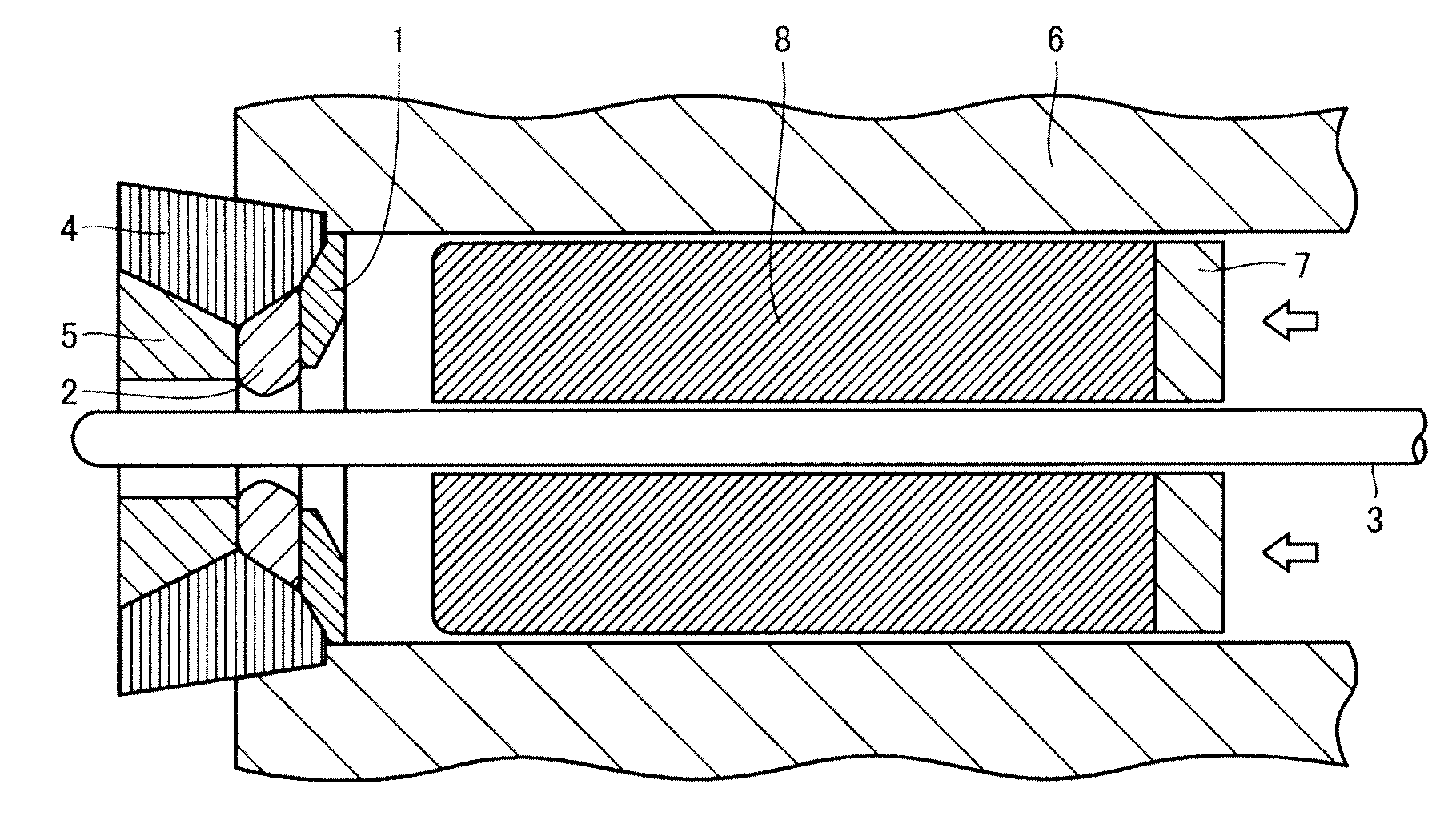

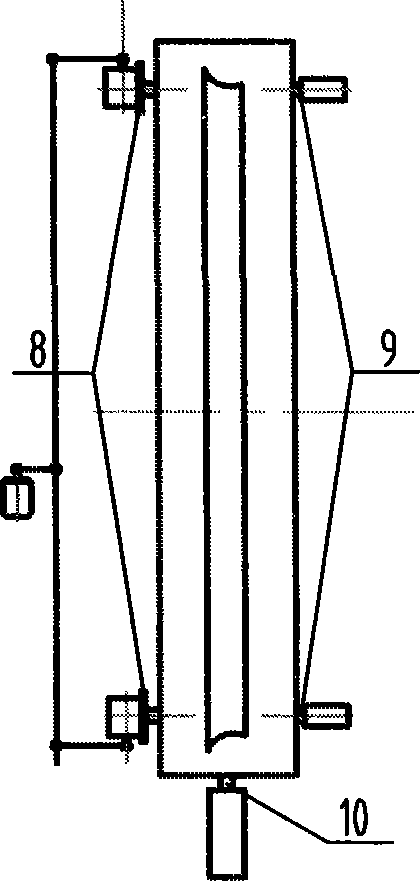

Squeezing needle used for producing lubrication-free heat squeezing seamless pipe material

InactiveCN102489539AImprove internal surface qualityEasy to operateExtrusion mandrelsCemented carbideLubrication

The invention relates to a squeezing needle used for producing a lubrication-free heat squeezing seamless pipe material, and relates to the squeezing needle used for producing the heat squeezing seamless pipe material. According to the invention, the problem that oil mark on the surface of the pipe material caused by uneven coating of lubricating oil when the squeezing needle is used can be solved, and the problem that metal is easy to adhere on the surface of the squeezing needle so that the scratch is generated on the interior surface of the pipe material can be solved. The squeezing needle used for producing the lubrication-free heat squeezing seamless pipe material comprises a needle core (1), a cemented carbide coat (2) and a screw (3), the needle core (1) is arranged in the cemented carbide coat (2), the lower end of the needle core (1) is parallel with the lower end of the cemented carbide coat (2), the needle core (1) is sealed in the cemented carbide coat (2) through the screw (3). The squeezing needle is used for producing the lubrication-free heat squeezing seamless pipe material.

Owner:NORTHEAST LIGHT ALLOY CO LTD

Preparation method of welded stainless steel pipe for boiler

ActiveCN101559446BQuality improvementImprove ergonomicsExtrusion diesWelding/cutting auxillary devicesManufacturing technologyPlate heat exchanger

The invention discloses a method for preparing welded stainless steel pipes for boilers, which belongs to the technical field of welded stainless steel pipe manufacturing. The key points of the technical solution include steel strip unwinding, forming, welding, inner bead leveling, outer bead grinding, and heat treatment , Shaping and cutting, wherein the above-mentioned processes are carried out continuously in sequence, and the heat treatment adopts a brilliant heat treatment furnace. The welded stainless steel pipe processed by the method of the invention has the advantages of stable quality, low manufacturing cost and good surface quality, and is used for manufacturing pipes for boiler heat exchangers and condensers.

Owner:广州永大不锈钢有限公司

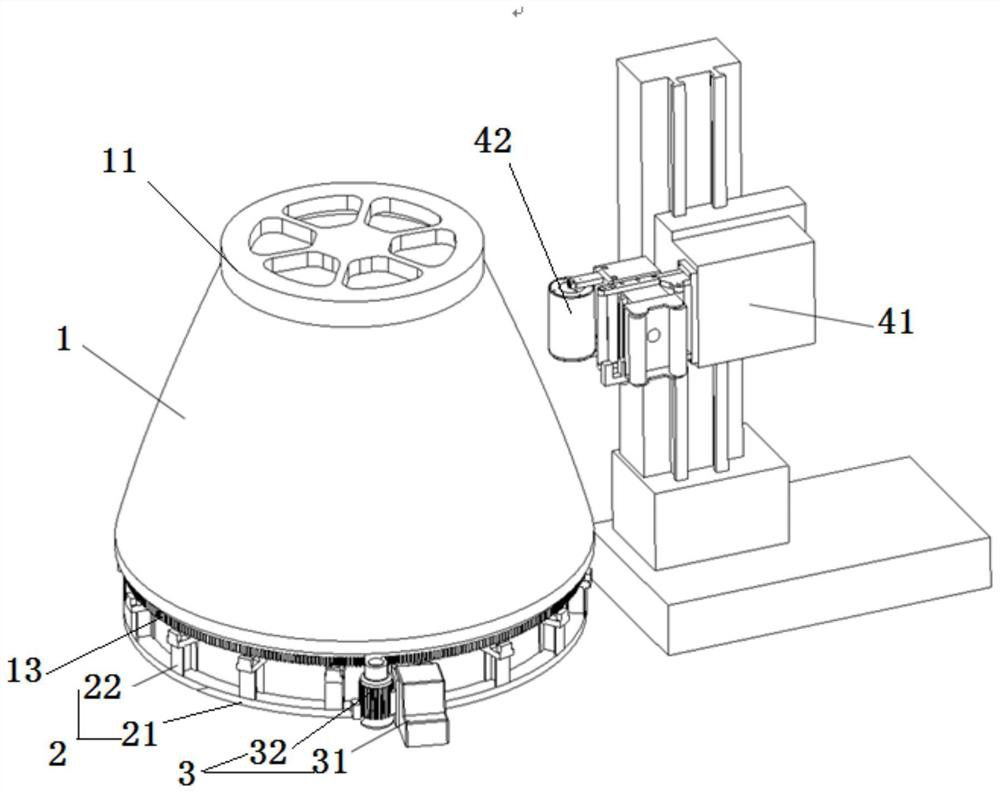

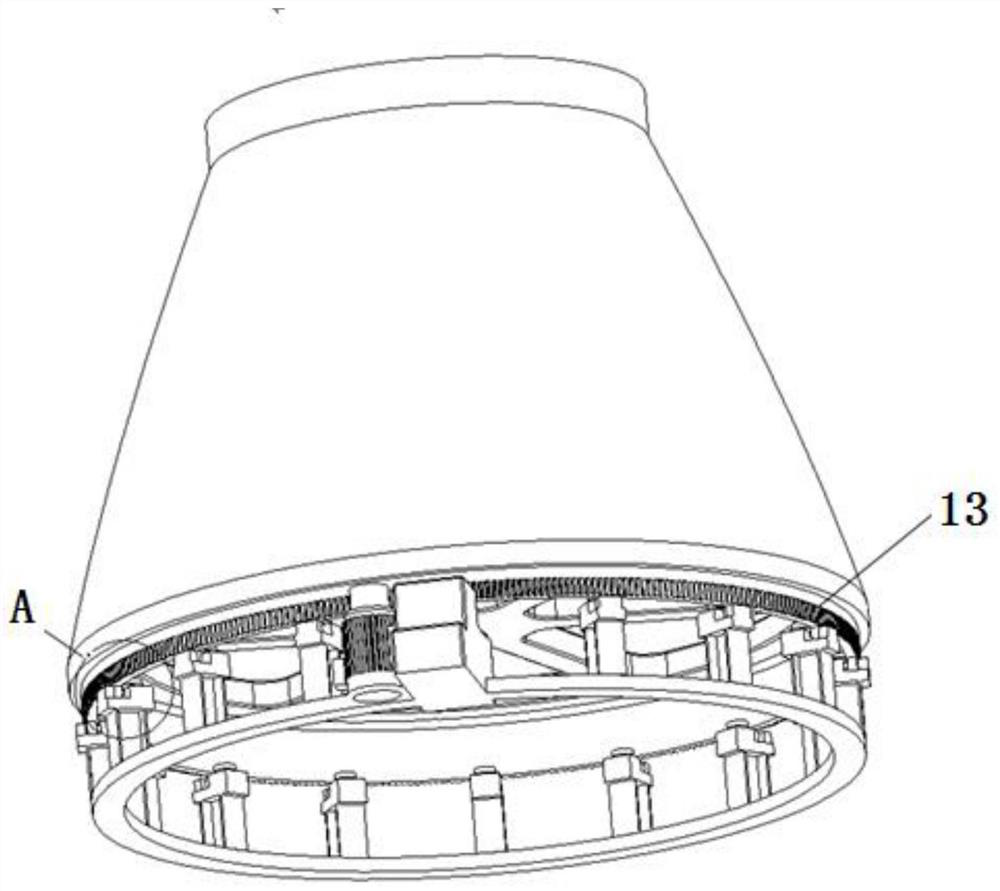

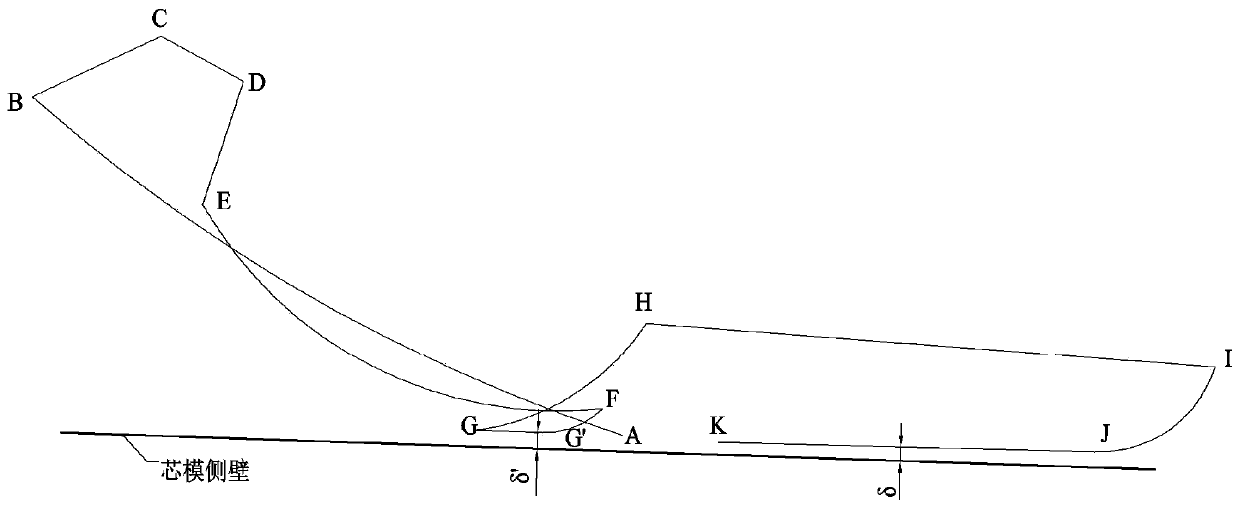

Vertical composite winding process for prepreg tape at expansion section of oversized spray pipe

PendingCN114193749AGuaranteed stabilityGuaranteed validityDomestic articlesCarbon fibersInsulation layer

The invention provides a vertical composite winding process for an oversized spray pipe expansion section prepreg tape, which comprises the following steps of: placing an expansion section core mold on a rotary track, rotating the expansion section core mold under the driving of a rotary driving mechanism, winding an ablation layer and a heat insulation layer by using a vertical tape winding mechanism, and then performing vacuum packaging and curing to obtain the oversized spray pipe expansion section prepreg tape. Laying the carbon fiber structure layer, performing vacuum packaging and curing, and finally demolding to form a product. According to the invention, the vertical winding forming of the prepreg tape at the expansion section of the oversized composite material spray pipe with the outlet diameter of phi 3.5 m-phi 4 m can be realized, and the problem of looseness of the heavier prepreg tape caused by traditional long-period horizontal winding is avoided; the vertical rotary curing of the expansion section of the oversized composite material spray pipe can be realized, the uniform heating of a product is ensured, the reaction rate of each part is consistent, and meanwhile, the problem that a prepreg tape slides towards the small-diameter end of a core mold due to the softening of resin in the curing and heating stage of the product is solved.

Owner:长春长光宇航复合材料有限公司

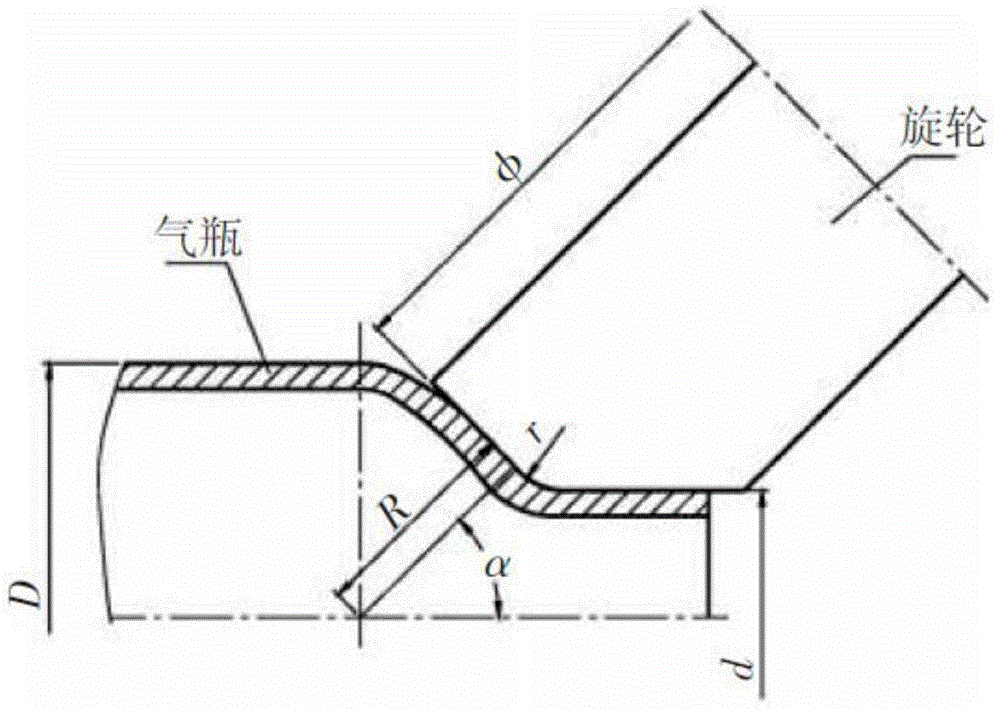

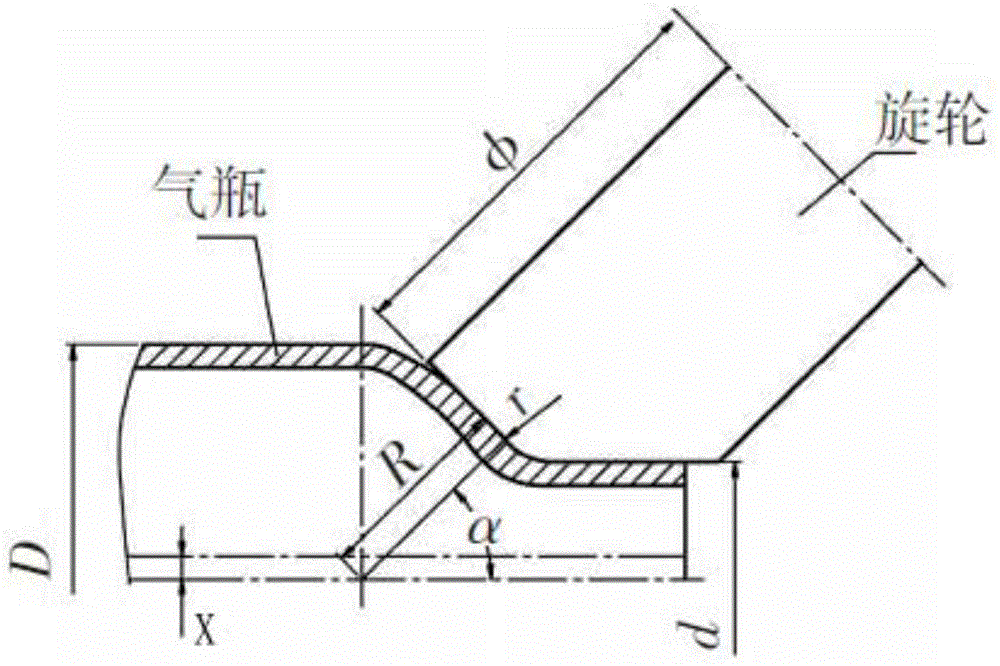

Reverse Closing Technology of Seamless Gas Cylinders

ActiveCN104772404BAvoid the pitfalls of layer separationImprove closing effectHollow articlesGas cylinderBottle

The invention discloses a reverse sealing process of a seamless gas cylinder, and relates to the technical field of gas storage cylinder closing process; the invention comprises the following steps: A, rotary wheel design; B, ferrule design; C, clamping workpiece; D , the adjustment of the workpiece; E, the preheating of the workpiece; F, the closure of the workpiece; The feature of thickening, combined with the advantages of smooth and smooth inner and outer surfaces of the positive closing, greatly improves the production efficiency and product quality, and realizes a technological breakthrough.

Owner:LIAONING METAL TECH

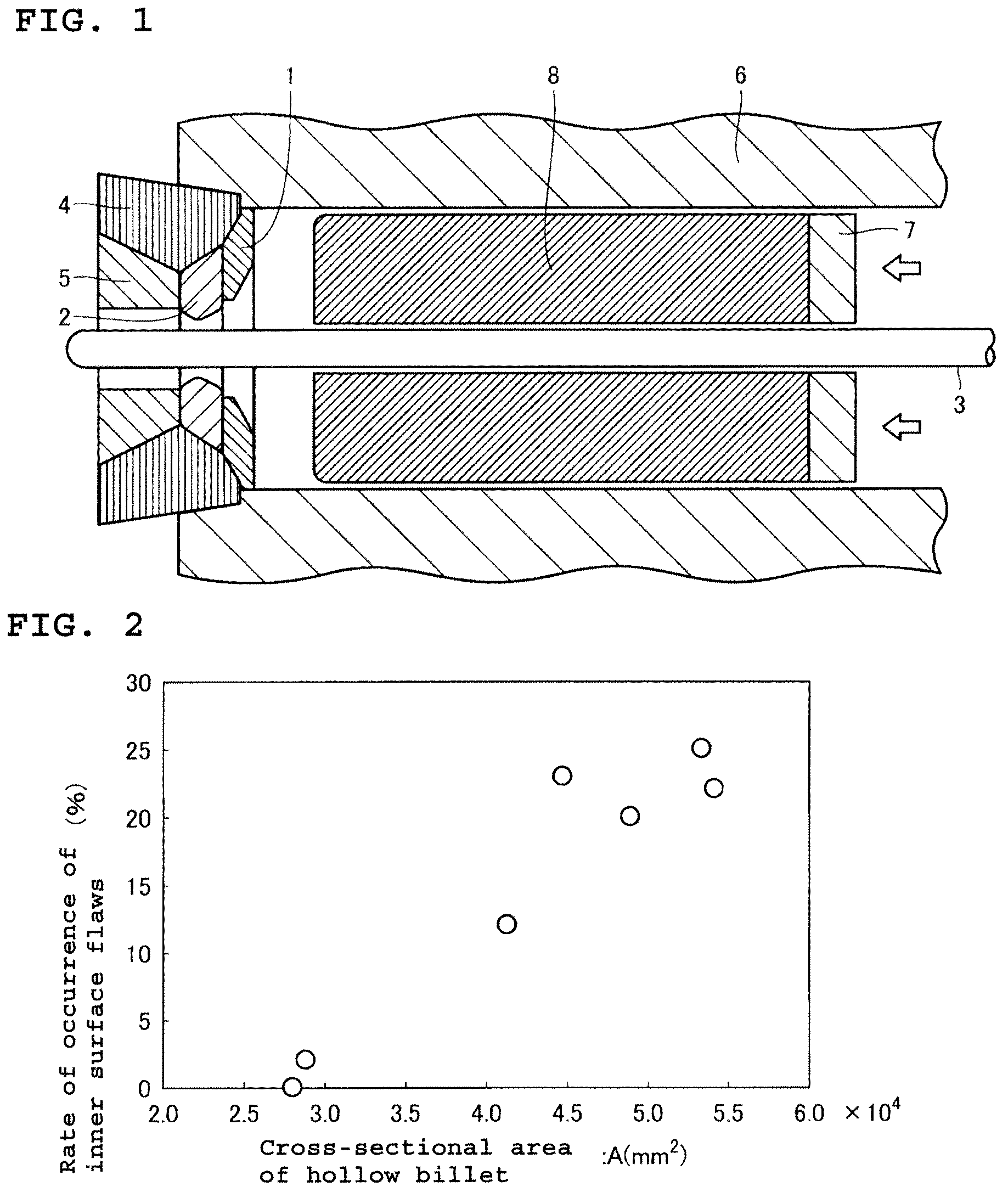

Process for producing high-alloy seamless tube

ActiveUS8245552B2Improve internal surface qualityAvoid it happening againExtrusion diesExtrusion control devicesAlloyHeating temperature

A starting material to be extruded made of a high alloy comprising, in mass %, Cr: 20 to 30% and Ni: more than 22% and 60% or less is heated to a temperature predetermined according to the contents of Mo and W and is subjected to a hot-extrusion process, the heating temperature T (° C.) satisfying a relationship of Formula (1), (2), or (3), which is expressed in terms of the average cross-sectional area A (mm2) of the starting material to be extruded, the extrusion ratio EL (−), and the extrusion speed V (mm / s). As a result, a high-alloy seamless tube can be produced without generating cracking and / or seam flaws.When 0%≦Mo+0.5W<4%: T≦1343−0.001322×A−1.059×EL−0.129×V (1)When 4%≦Mo+0.5W<7%: T≦1316−0.001322×A−1.059×EL−0.129×V (2)When 7%≦Mo+0.5W: T≦1289−0.001322×A−1.059×EL−0.129×V (3)

Owner:NIPPON STEEL CORP

Method for increasing medical embedded stainless steel tube inner surface quality

The process of treating medical implanted stainless steel pipe in high inner surface quality includes soaking medical implanted stainless steel pipe in mixed treating fluid comprising stainless steel pickling solution and nanometer alumina particle inside a treating trough, heating the treating fluid to 50-100 deg.c, pressing the treating fluid into the pipe and circulating with a water pump, treating for 0.5-60 min, and flushing the taken out pipe with flowing water. Compared with available technology, the present invention has the advantages of high polishing effect, excellent anticorrosive performance, wide application range and other features.

Owner:CHANGSHU MICROTUBE TECH

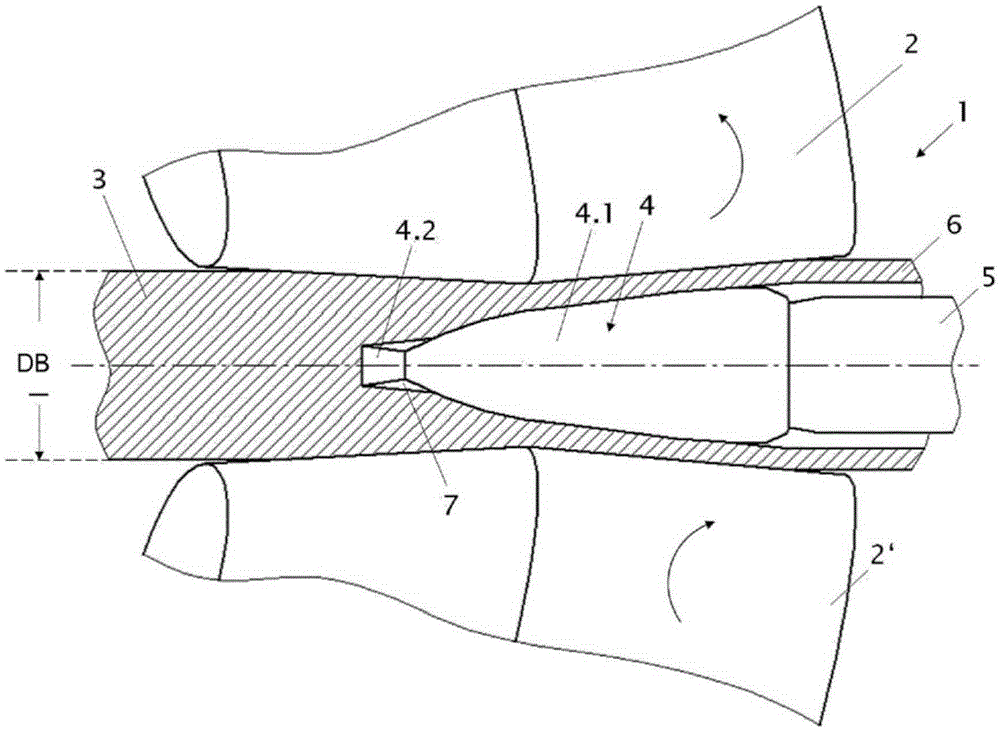

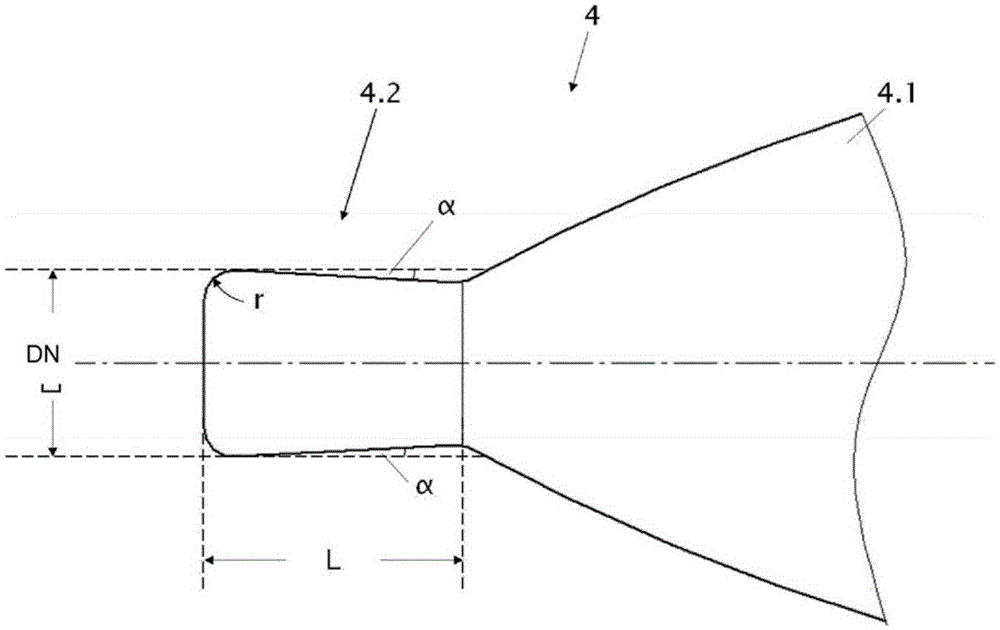

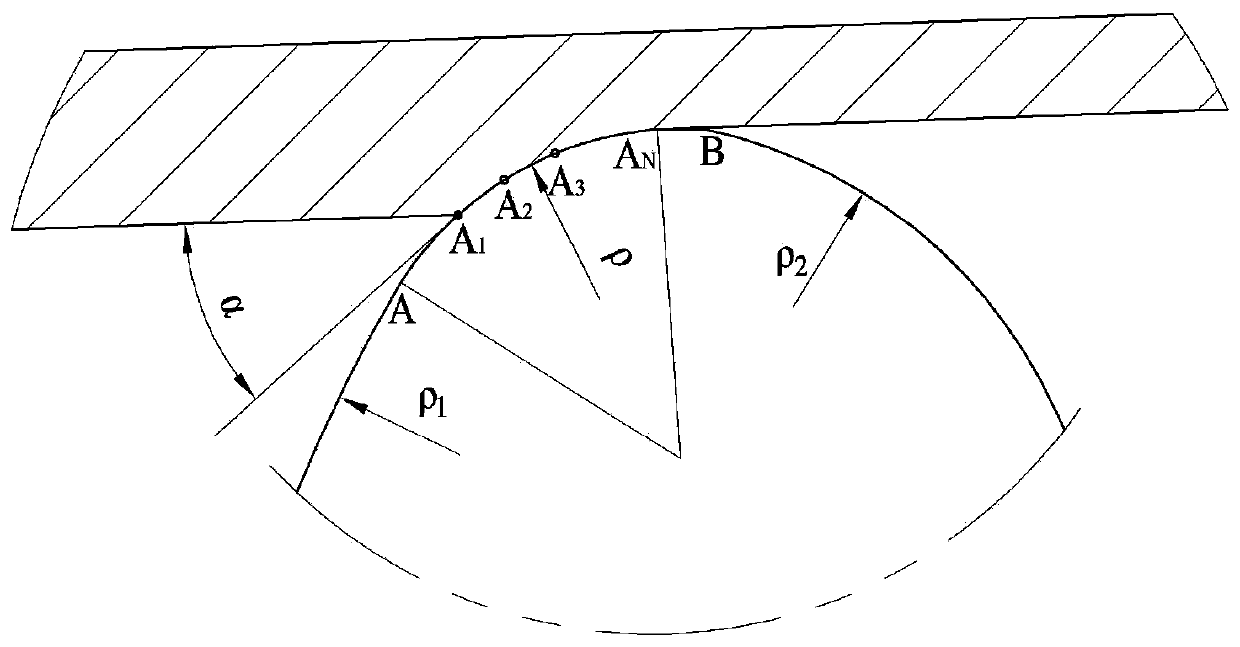

Piercing mandrel having an improved service life for producing seamless tubes

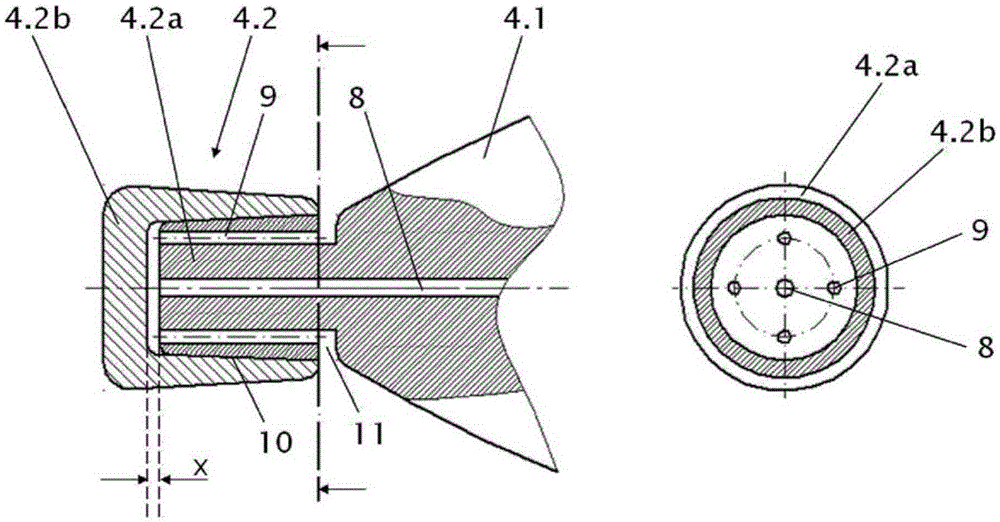

ActiveCN105377459AExtended service lifeImprove internal surface qualityMandrelsMetal rolling arrangementsEngineeringMetal

The invention relates to a piercing mandrel(4)for piercing heated round blooms(3)made of metal,in order to produce seamless tubes (6),the piercing mandrel comprising a piercing mandrel nose(4.2)and a piercing mandrel main body(4.1)that can be connected to a mandrel bar(5).According to the invention, the external diameter of the piercing mandrel nose(4.2)is conically tapered in the longitudinal direction towards the piercing mandrel main body (4.1),in order to increase the service life of the piercing mandrel when cross-roll piercing round blooms made of metal,in particular made of more highly alloyed steel materials that are difficult to form,while taking into consideration a qualitative improvement of the inner surface of the pierced round blooms,and while reducing the cost of tools.

Owner:VALLOUREC DEUT

Self-lubricating shaft sleeve chamfering device

PendingCN114211055AAvoid scratchesPrevent embeddingCleaning using toolsStructural engineeringKnife holder

The self-lubricating shaft sleeve chamfering device comprises a rack and a tool rest movably connected to the rack, and a cleaning part is arranged on the tool rest; the cleaning part comprises a protection cleaning head, the protection cleaning head is in sliding connection with the tool rest through a moving shaft, the sliding direction of the protection cleaning head is the same as the sliding direction of the tool rest on the rack, and a mounting base is arranged at the end, away from the tool rest, of the moving shaft; the protective cleaning head is arranged, when chamfering cutting is carried out, the protective cleaning head can protect the inner surface of a shaft sleeve from being scratched by cutting chips and preventing copper powder from being embedded, the quality of the inner surface of a product is improved, the machining procedure of manual cleaning is reduced, and the labor cost is reduced; the production efficiency is improved.

Owner:合肥波林新材料股份有限公司

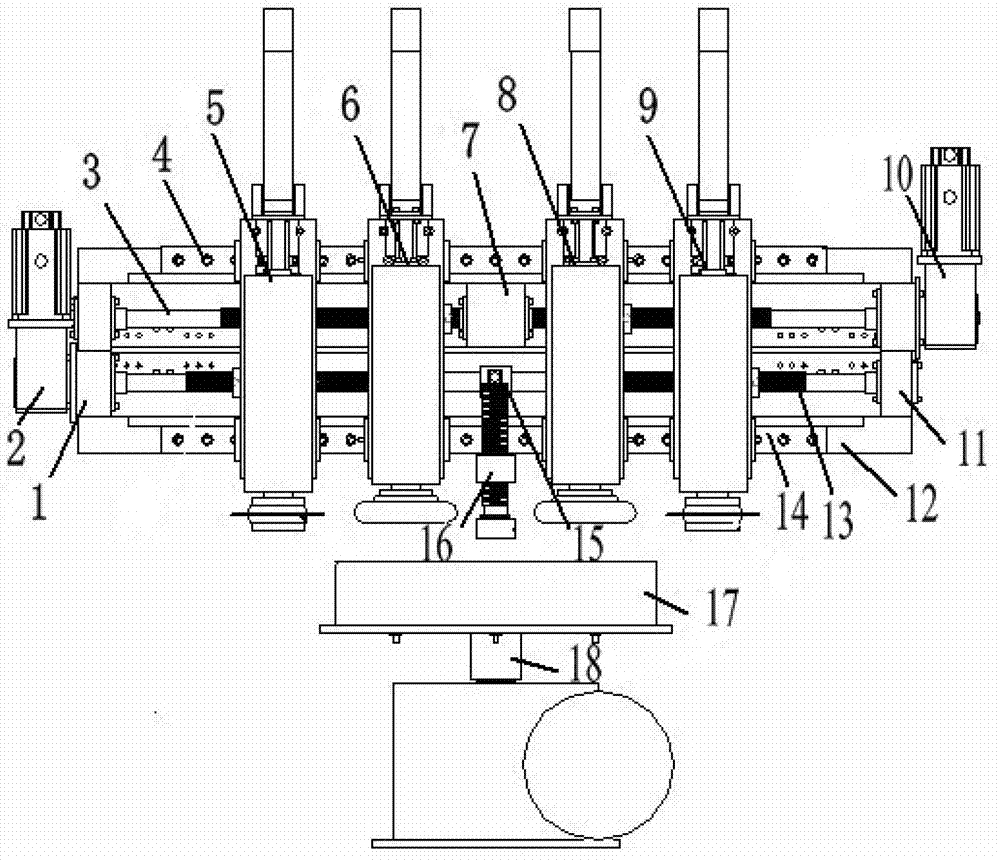

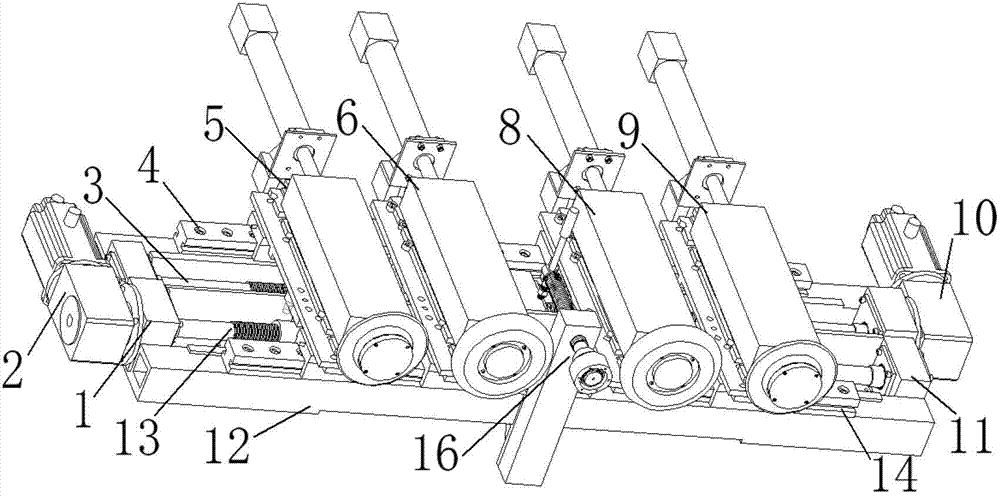

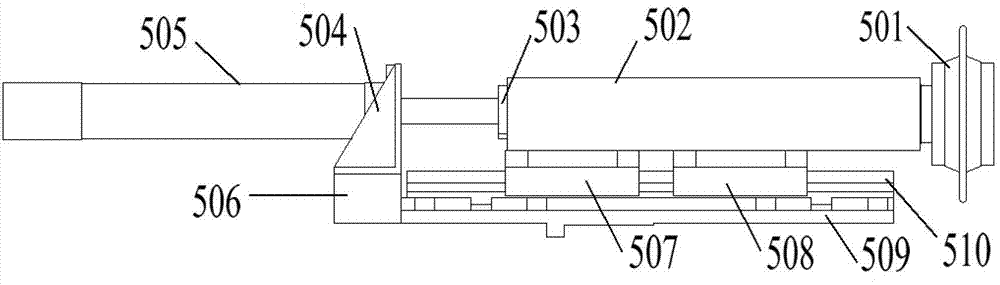

Opposite roller type flexible spinning alternating current servo direct drive structure

ActiveCN103317006BHigh precisionExpand the scope of processingShaping toolsAlternating currentControl theory

Provided is a flexible opposite roller spinning alternating current servo direct drive structure. Horizontal synchronous feed movement of internal spinning rollers and external spinning rollers is achieved respectively by utilizing a servo motor to drive screw rods, the internal spinning rollers and the external spinning rollers perform longitudinal movement by electric cylinder driving, and the whole processing process is finished under the control of a servo system. Horizontal synchronous feed of the internal spinning rollers, horizontal synchronous feed of the external spinning rollers and longitudinal asynchronous feed of the spinning rollers can be achieved in the opposite roller spinning process, complex workpiece processing can be finished, workpiece positions can be controlled in real time in a mode of adopting the servo motor to drive the screw rods and an electric cylinder driving mode, and the flexible opposite roller spinning alternating current servo direct drive structure is convenient to operate and large in applied range and overcomes the shortcoming that opposite roller spinning position adjustment is invariable.

Owner:XI AN JIAOTONG UNIV

Method for increasing medical embedded stainless steel tube inner surface quality

The process of treating medical implanted stainless steel pipe in high inner surface quality includes soaking medical implanted stainless steel pipe in mixed treating fluid comprising stainless steel pickling solution and nanometer alumina particle inside a treating trough, heating the treating fluid to 50-100 deg.c, pressing the treating fluid into the pipe and circulating with a water pump, treating for 0.5-60 min, and flushing the taken out pipe with flowing water. Compared with available technology, the present invention has the advantages of high polishing effect, excellent anticorrosive performance, wide application range and other features.

Owner:CHANGSHU MICROTUBE TECH

A treatment method for pit defects in continuous rolling carbon steel or low alloy steel pipes

ActiveCN104404561BImprove internal surface qualityEliminate inner pit defectsPolishing machinesGrinding wheelContinuous rolling

The invention discloses a method for treating inner pit defects inside a continuous rolling carbon steel tube or a low-alloy steel tube. The method comprises the following steps: pickling by using an acid liquid which is prepared from the following components in parts by volume for the first time: 10-15 parts of 33% technical hydrochloric acid, 1-3 parts of nitric acid and 20 parts of water, subsequently performing grinding wheel polishing on the continuous rolling carbon steel tube with inner pit defects or inner pit areas of the low-alloy steel tube, and further pickling for a second time by using another acid liquid which is prepared from the following components in parts by volume: 10-15 parts of 33% technical hydrochloric acid and 20 parts of water, wherein the concentration of FeCl2 in the acid liquids for pickling is controlled to be 35-75g / L each time. By adopting the method of twice pickling and once grinding wheel polishing, the inner pit defects distributed in the inner surfaces of the continuous rolling carbon steel tube and the low-alloy steel tube are eliminated, the quality of the inner surfaces of cold-drawn steel tubes is improved, and the purpose of completely eliminating oxidized iron skin on inner surfaces of steel tubes is achieved.

Owner:PANGANG GROUP CHENGDU STEEL & VANADIUM

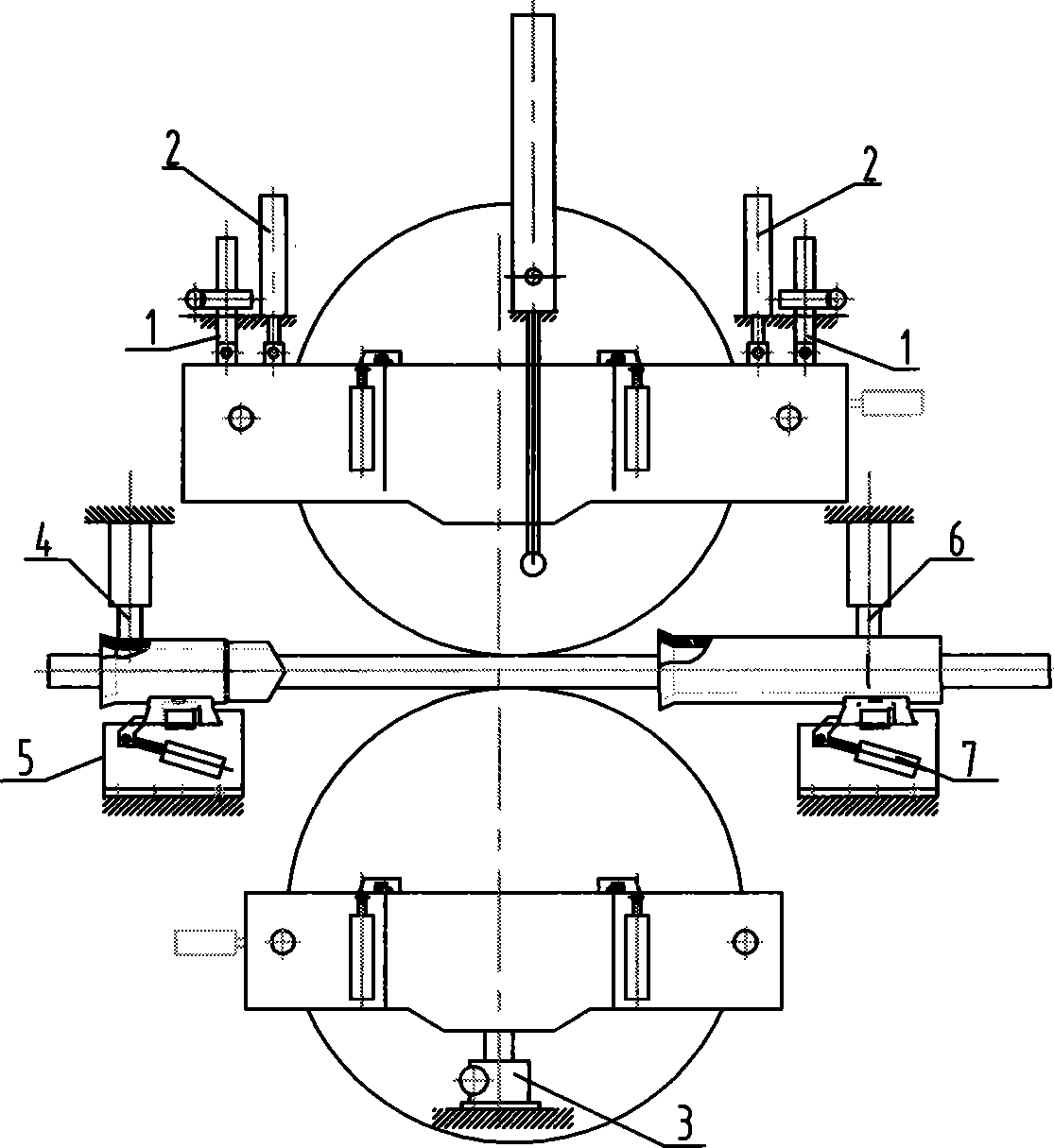

A device and method for molybdenum crucible double-wheel staggered hot-state powerful spinning

ActiveCN109500188BGuaranteed plastic stabilityGood repeatabilityShaping toolsHollow articlesThermal stateCrucible

The invention discloses a molybdenum crucible double-wheel staggered thermal state powerful spinning forming device, which includes a setting system, two sets of spinning forming systems and two sets of automatic online heating systems; the two sets of spinning forming systems are distributed in axial staggered distances On both sides of the shaping system, two sets of automatic online heating systems are respectively distributed on both sides of the shaping system; the shaping system is used for shaping the molybdenum plate, the spinning forming system is used The molybdenum sheet is heated during press forming. The device can use the molybdenum plate as the raw material to produce molybdenum metal rotary products with large length-to-diameter ratio, variable cross-section and curved generatrix at one time without interruption. The molybdenum crucible prepared by the spinning forming method of the device has uniform circumferential wall thickness, uniform wall thickness thinning transition in the height direction, accurate size, no cracks, and no surface defects.

Owner:JINDUICHENG MOLYBDENUM CO LTD

Hydraulic pressure anti-rust agent for boiler auxiliary machine container products, and preparation method thereof

The invention relates to a hydraulic pressure anti-rust agent for boiler auxiliary machine container products, and a preparation method thereof. In the prior art, the problem of the inner surface rust after hydraulic pressure tests of boiler auxiliary machine container products (such as oxygen removing devices, hydrophobic expansion devices, and the like) has not been effectively solved, seriously affects the quality of the product inner surface, and further can cause the potential threat to the safe operation of the boiler auxiliary machine container. The hydraulic pressure anti-rust agent comprises the following raw materials by weight: 10-15 parts of a methacrylic acid polymer, 0.5-1 part of dibutyl phthalate, 0.5-1 part of dicresyl phosphate, 25-28 parts of butyl acetate, 3-5 parts of butanol, 8-12 parts of acetone, and 40-50 parts of toluene. The hydraulic pressure anti-rust agent of the present invention is used as the boiler auxiliary machine container anti-rust material.

Owner:HARBIN BOILER

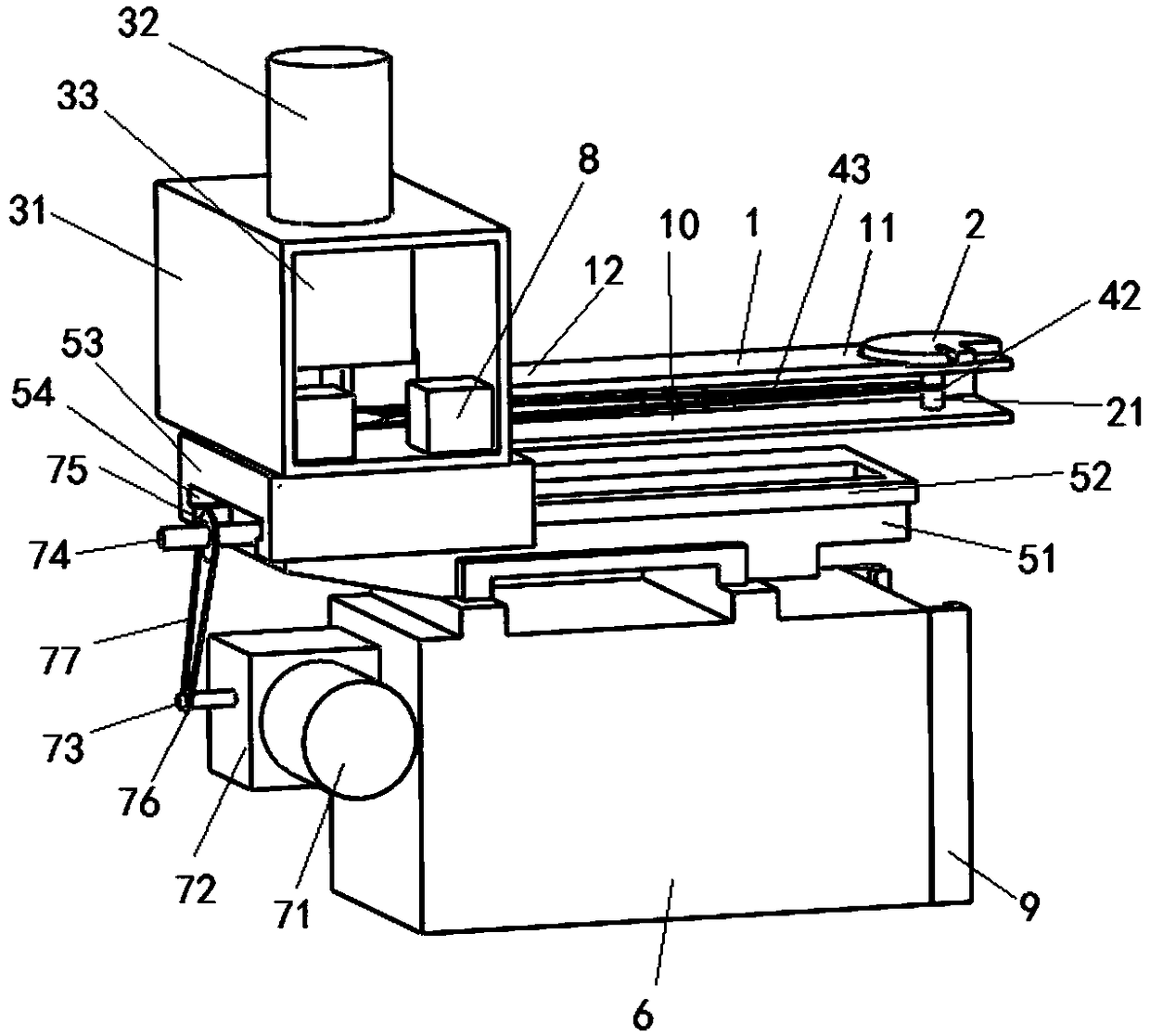

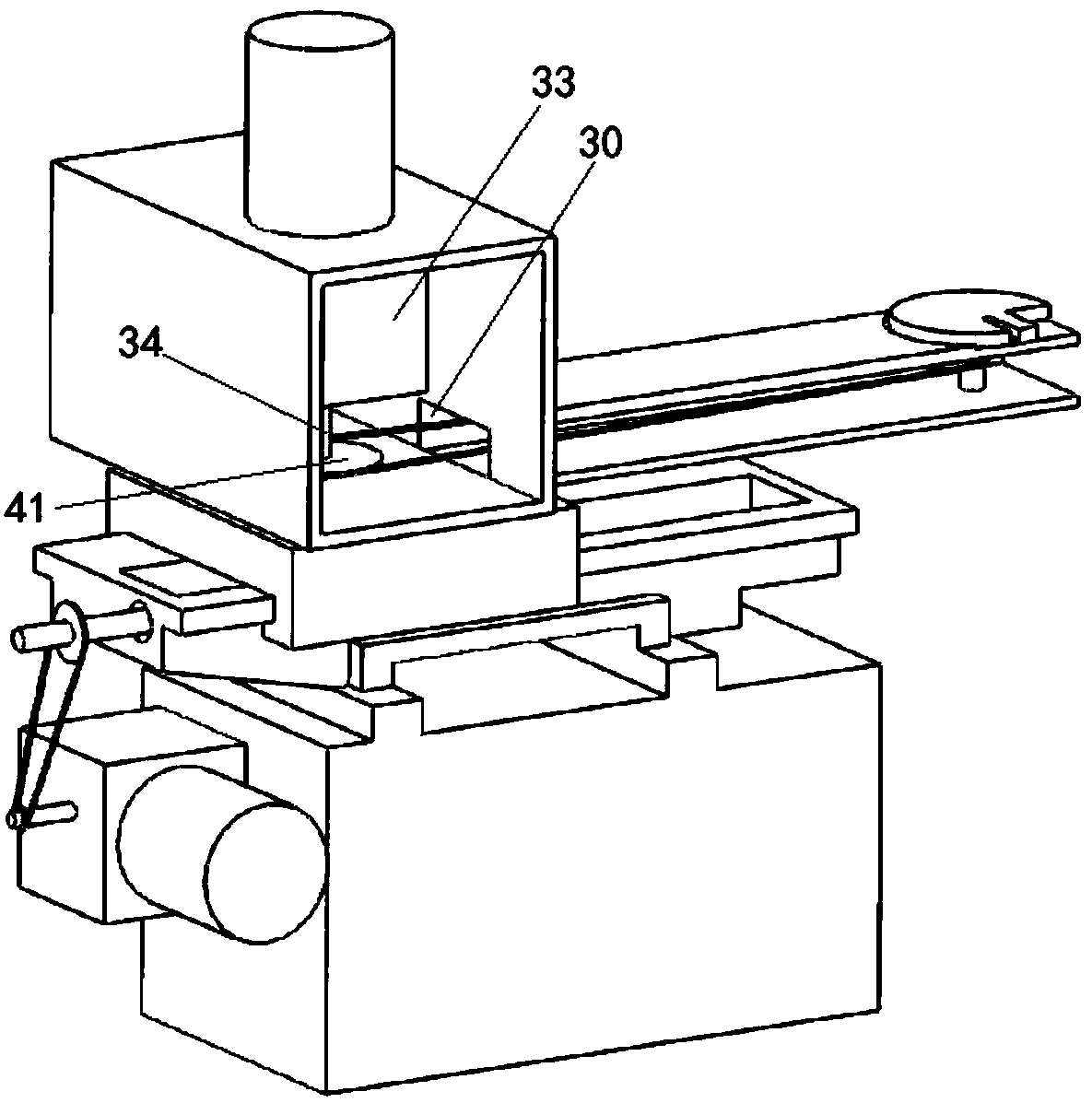

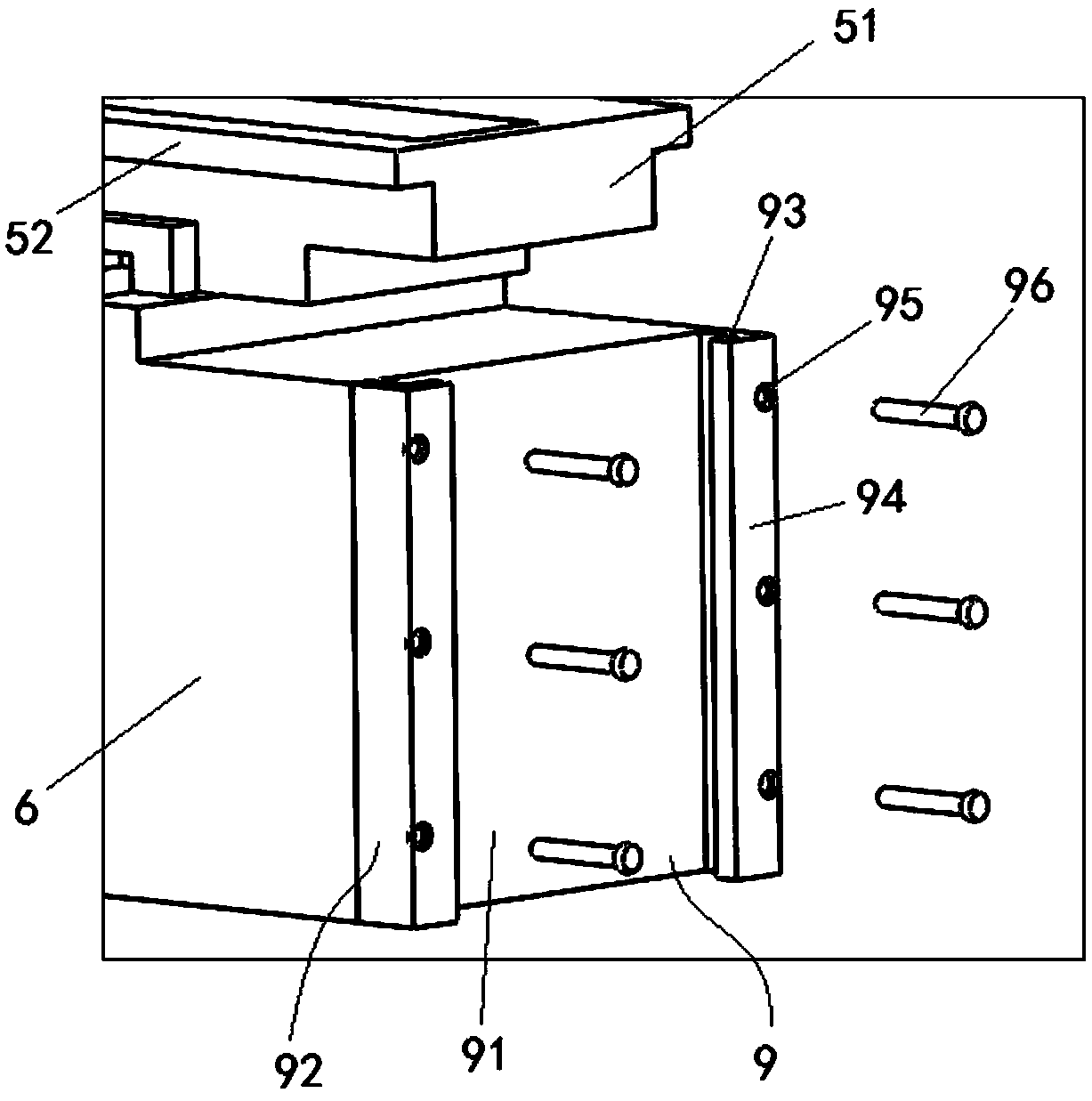

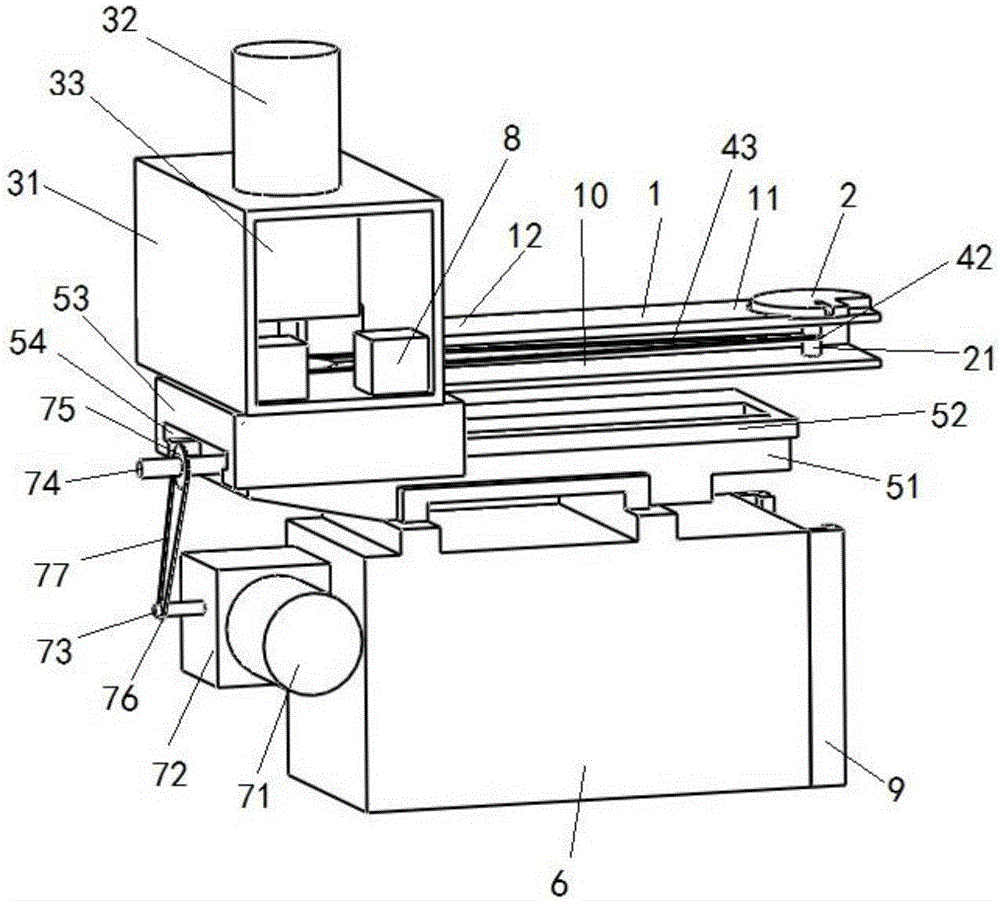

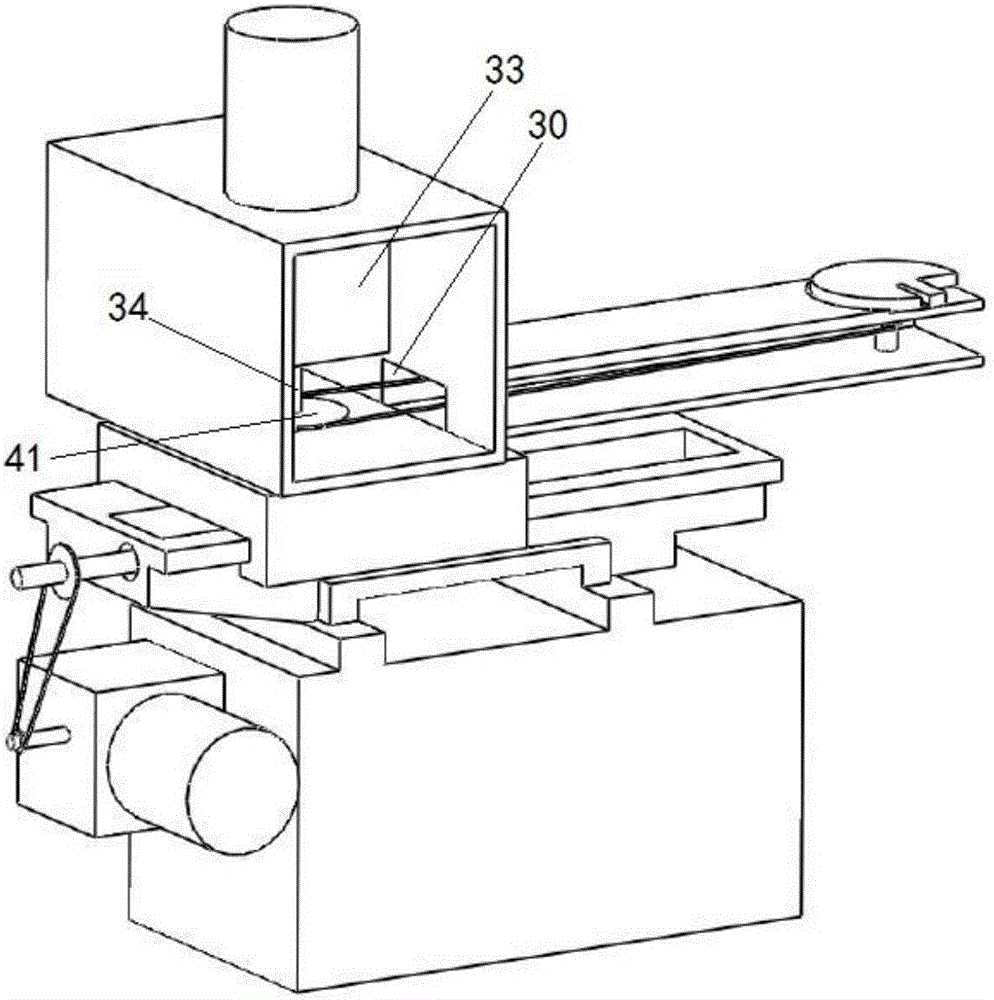

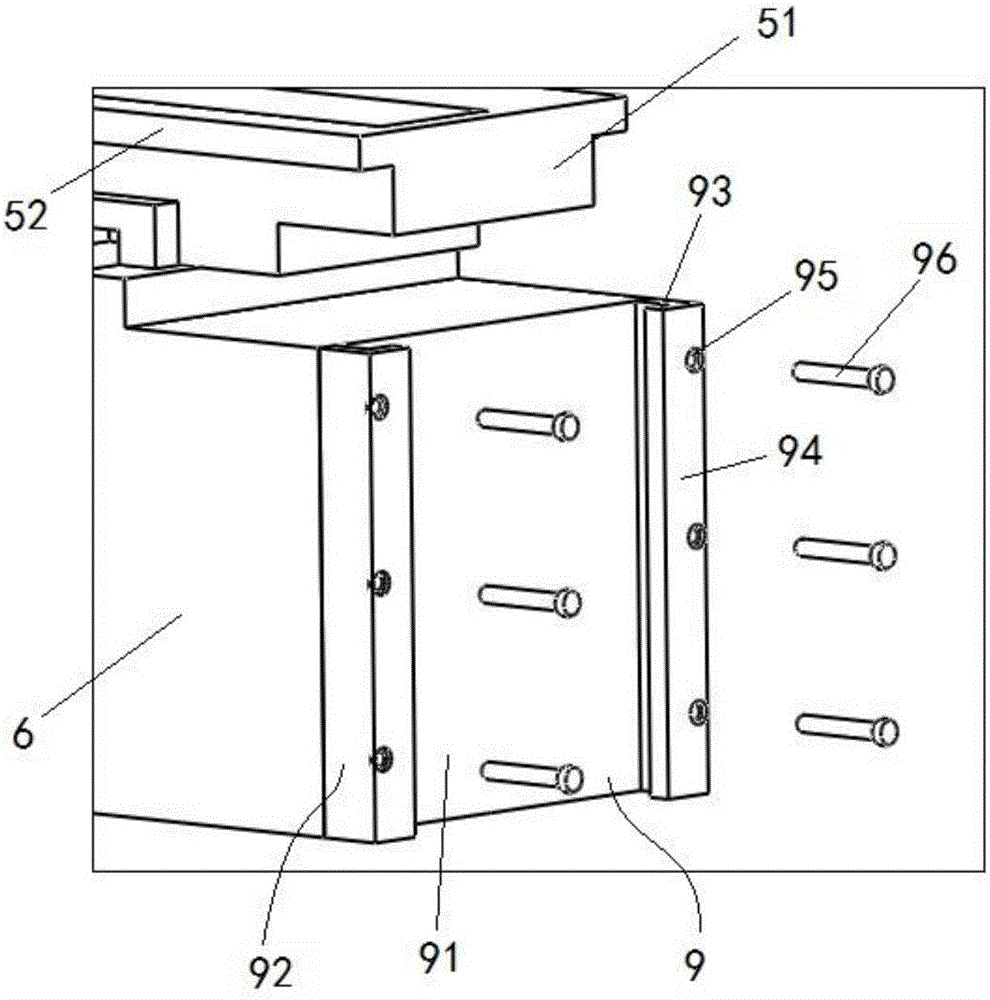

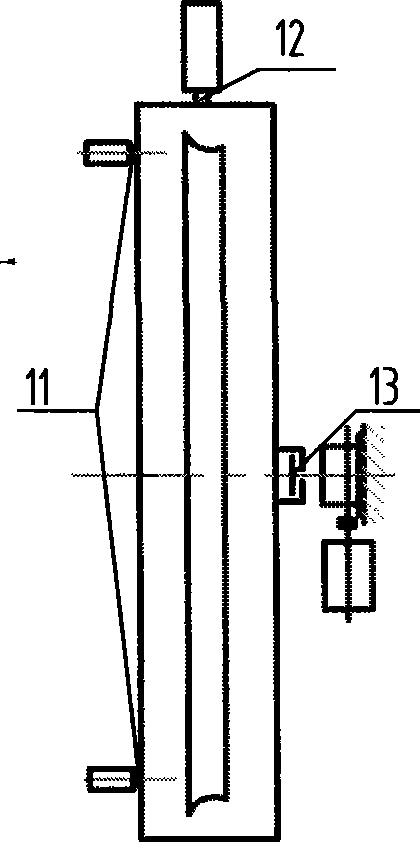

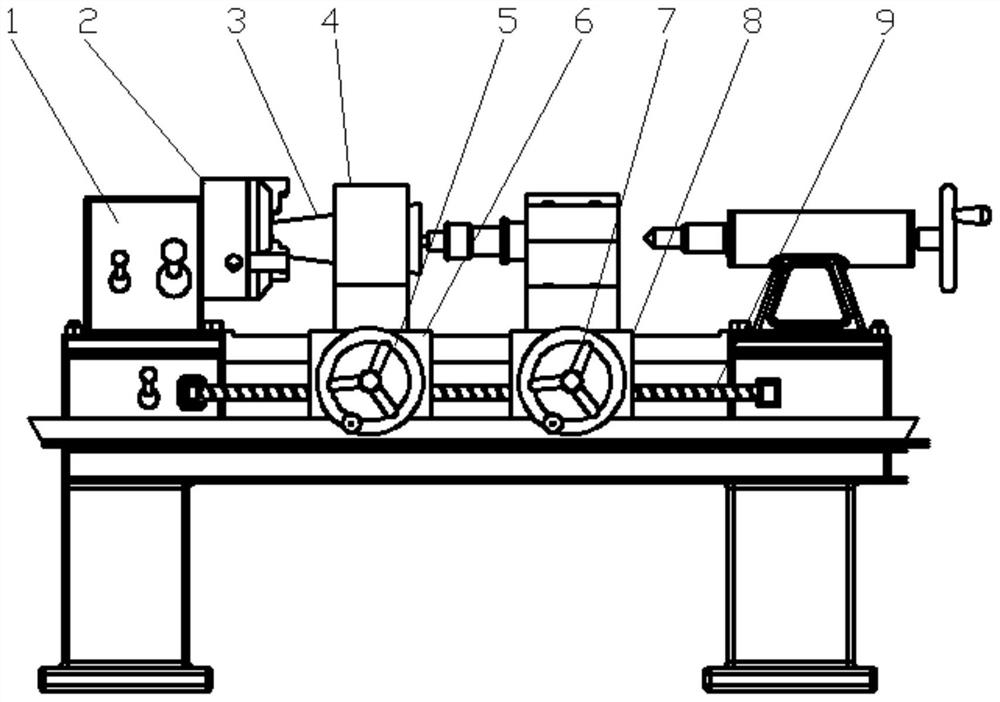

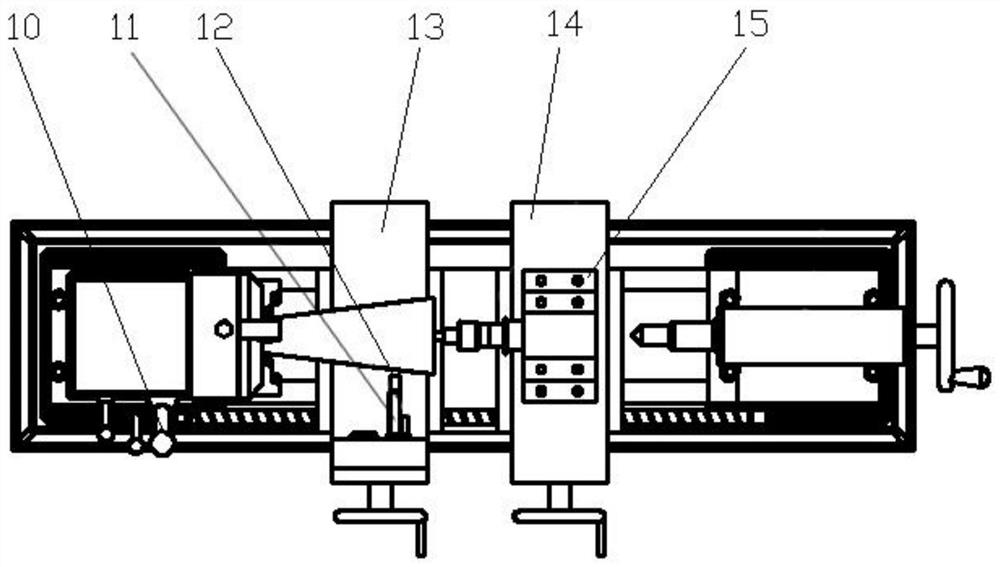

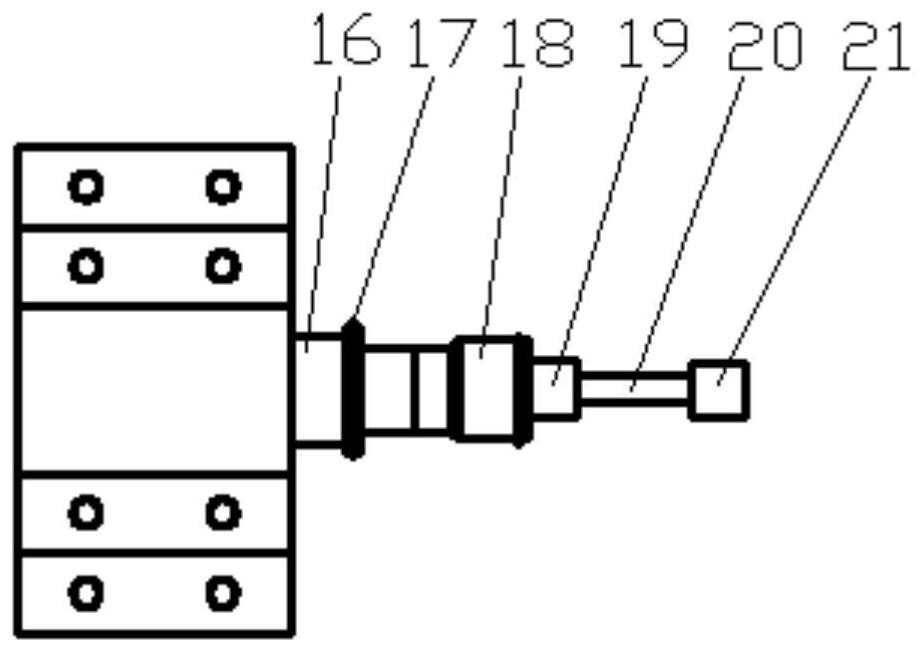

A surface processing equipment

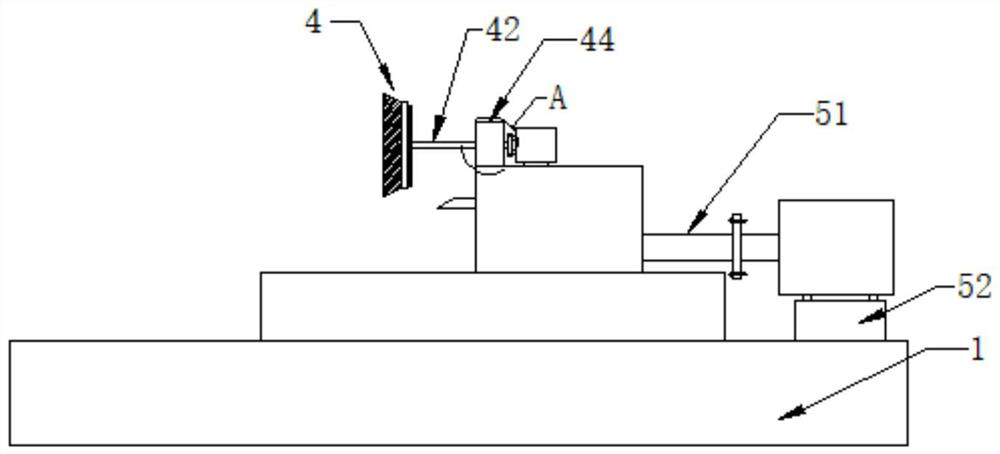

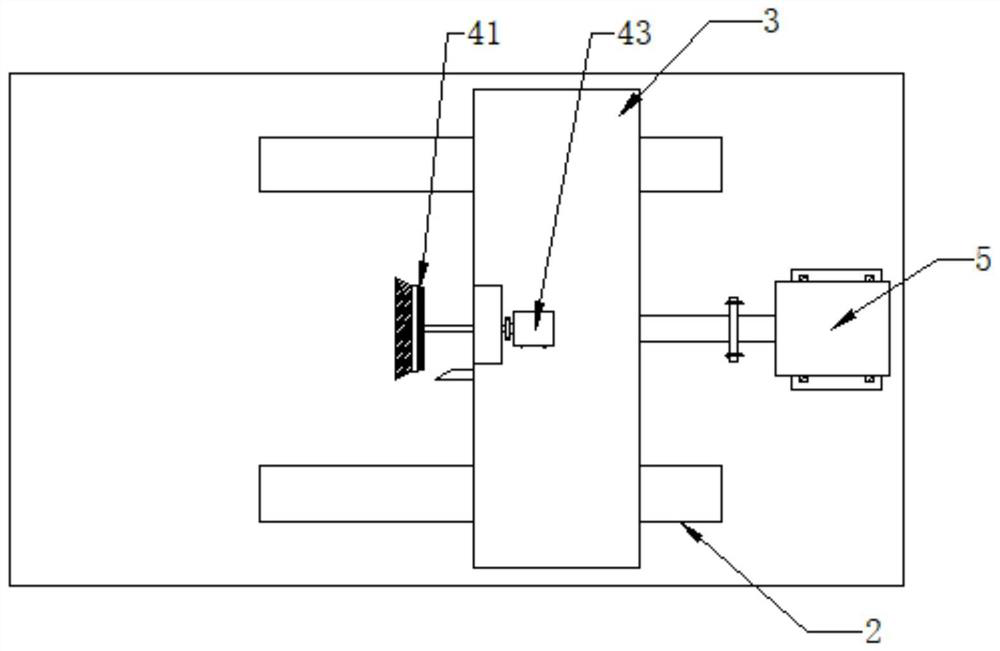

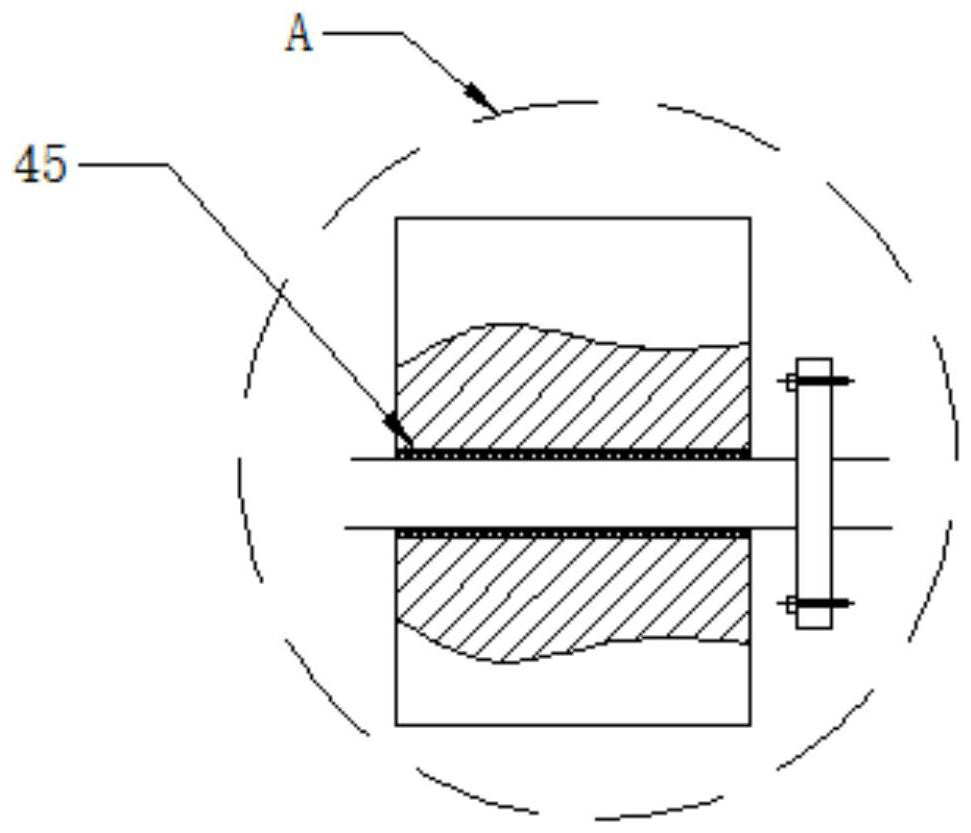

InactiveCN106346057BImprove stabilityNot easy to shakeMilling cuttersFeeding apparatusState of artEngineering

Owner:BEIJING GUODIAN FUTONG SCI & TECH DEV

Surface processing equipment

InactiveCN106346057AImprove stabilityNot easy to shakeMilling cuttersFeeding apparatusState of artEngineering

The invention provides surface processing equipment. The surface processing equipment comprises a cantilever, a tool rest and a drive mechanism, wherein the cantilever is of a cuboid shape with a hollow inner cavity and is provided with a first end capable of extending into a deep cavity and a second end opposite to the first end; the tool rest is rotatably mounted at the first end through a mounting shaft and used for mounting a tool; the drive mechanism is fixedly connected with the second end to support the cantilever and is used for driving the tool rest to rotate. Compared with the prior art, the surface processing equipment has the advantages that the cantilever which can extend into a deep cavity is arranged between the drive mechanism and the tool rest, so that the processing equipment can directly process the inner surface of the deep cavity; a work piece to be processed need not be segmented, a connecting process is avoided, simple processing process is achieved, and the processed inner surface is high in quality; the cantilever is of the cuboid shape with the hollow inner cavity, so that the stability of the cantilever is enhanced, the cantilever is less prone to shaking during the inner surface processing of the deep cavity, and the inner surface processing quality can be further improved.

Owner:BEIJING GUODIAN FUTONG SCI & TECH DEV

Pipe drawing lubrication device and pipe drawing processing method

ActiveCN107990135BThere will be no missingSo as not to damageDrawing diesProportioning devicesTube drawingEngineering

The invention discloses a pipe pulling and drawing lubricating device, and further discloses a pipe pulling and drawing machining method. The pipe pulling and drawing lubricating device comprises an oil supplying mechanism arranged on a chain broaching machine and a lubricating pipe connected with the oil supplying mechanism. The oil supplying mechanism comprises an oil box for storing lubricatingoil, an oil injecting pipe connected with the lubricating pipe and an oil injecting pump connected to the position between the oil box and the oil injecting pipe. The lubricating pipe is composed ofa flat and straight steel pipe, a sealing plate arranged at one end of the flat and straight steel pipe and a connecting rod mounted on the end face of the sealing plate and used for being connected with a pulling and drawing core head. The flat and straight steel pipe is composed of an oil injecting section, a clamping section and a connecting section. The pipe pulling and drawing machining method comprises the steps of 1, preparation of a to-be-pulled-drawn pipe blank, 2, mounting of a pulling and drawing external mold and the to-be-pulled-drawn pipe blank, 3, mounting of the lubricating device and the pulling and drawing core head, and 4, lubricating and pulling-drawing of the to-be-pulled-drawn pipe blank. According to the pipe pulling and drawing lubricating device, the purpose that the lubricating oil is continuously injected into the pipe blank can be achieved, the phenomena that adding of the lubricating oil is uneven, and the local lubricating oil of the inner wall of a pipe is absent cannot occur, and the quality of the inner surface of the pipe after being pulled and drawn is improved.

Owner:西安诺博尔稀贵金属材料股份有限公司

Process for producing seamless stainless steel pipe

ActiveUS8307688B2Improve internal surface qualityReduce layeringMandrelsFurnace typesGraphiteEquivalent weight

A process for producing seamless pipes which comprises conducting a piercing rolling step, a elongating rolling step using a mandrel bar, and a sizing rolling step and subsequently conducting a product heat treatment. In the process, when the carbon-equivalent weight, namely the sum of the weight of graphite in the lubricant and the carbon content in the organic binder, per unit area of the lubricant adhering to the mandrel bar surface in the above-mentioned step of elongating rolling is expressed by C (g / m2) or the maximum extent of carburization in the inner surface of the pipe to be heat-treated but prior to the heat treatment is expressed by ΔC (% by mass), the heating temperature for the pipe to be heat-treated is expressed by T (° C.), and the time during which a decarburizing gas is blown into the inside of the pipe to be heat-treated is expressed by t1 or t2 (seconds), and further, the blowing time calculated taking into account the wall thickness reduction in the step of cold working is expressed by t3 or t4 (seconds), a predetermined relation is satisfied and the actual decarburizing gas blowing time in the heat treatment is longer than the time t1, t2, t3 or t4 (seconds), whereby seamless stainless steel pipes reduced in carburized layer formation can be produced even when the carbon adhesion to the pipe inner surface is caused in, for example, mandrel mill rolling.

Owner:NIPPON STEEL CORP

Piercing plug device of piercer, piercer and production method of seamless steel tubes

InactiveCN103240274AImprove internal surface qualitySolve internal surface defectsMandrelsMetal rolling arrangementsNitrogenEngineering

The invention provides a piercing plug device of a piercer, the piercer and a production method of seamless steel tubes. The piercing plug device of the piercer comprises a piercing plug and a piercing plug bar, a gas transmission pipeline is formed inside the piercing plug and the piercing plug bar, and one or a plurality of gas outlet holes which are communicated with the gas transmission pipeline is formed on the nose portion of the piercing plug. The piercer comprises the piercing plug device of the piercer. The production method of the seamless steel tubes comprises a step of tube blank piercing, and during the step of tube blank piercing, the piercer is used for piercing, and nitrogen or inert gas is lead into the gas transmission pipeline so as to enable the nitrogen or the inert gas to fill between the piercing plug and the a tube blank during piercing. By utilizing the technology of the piercing plug device of the piercer, the piercer and the production method of the seamless steel tubes, the influence of a central tearing cavity on inner surface of a hollow billet is reduced, and the inner surface quality of the hollow billet which is subjected to cross rolling piercing is improved.

Owner:PANGANG GROUP CHENGDU STEEL & VANADIUM

Heating method of hollow ingot

The invention discloses a heating method of a hollow ingot. The heating method comprises the following steps that (1) a graphite rod is placed in the hollow ingot, wherein the length of the graphite rod is the same as that of the hollow ingot, and the diameter of the graphite rod is 2mm-8mm smaller than the inner diameter of the hollow ingot; (2) the hollow ingot with the graphite rod is placed ina copper ingot heating furnace to be heated; and (3) after the hollow ingot with the graphite rod reaches the process temperature, the hollow ingot is pushed out of the copper ingot heating furnace and conveyed to an extruder, and the hollow ingot is extruded after the graphite rod in the hollow ingot is taken out. The heating method of the hollow ingot effectively solves the problem of oxidationof the inner surface of the hollow ingot in the heating process, so that the pipe yield is greatly increased; the method is simple, convenient to operate, good in using effect and capable of reducingmetal loss; and according to the heating method of the hollow ingot, the one-time yield of pipes is greatly improved, and obvious economic benefits can be obtained.

Owner:JINCHUAN GROUP LIMITED

All direction multifunctional adjustment disc extending machine

InactiveCN101104179BIncrease the elongation factorImproved Wall Thickness AccuracyMetal rolling stand detailsGuiding/positioning/aligning arrangementsHydraulic cylinderCircular disc

The invention relates to an omnidirectional multi-functional disk type elongating mill, the diameters of an upper and a lower guide disk are increased; the lifting of the upper guide disk adopts a turbine, a worm and a leading screw device; the lifting of the lower guide disk adopts a standard spiral elevator; and the axial direction adjustment is realized by the standard spiral elevator; the positive direction location, lateral direction location and upper and lower direction location are realized by a hydraulic cylinder. The axial direction adjustment of the roller is realized by the standard spiral elevator; the radial direction is adjusted by the combination of a non-standard spiral elevator and the hydraulic cylinder; the locking device adopts the hydraulic cylinder and an adjusting wedge mechanism. Guide bushes of an outlet and an inlet port adopt the upper-pressing and lower-locking of the hydraulic cylinder. The reliability is increased by adopting the hydraulic system; the enlarged diameters of guide disks can improve the locking condition of the roller, the elongation coefficient is increased, screw threads in the steel tube are reduced after rolling, and the variety of products is enlarged; gaps of the axial direction and radial direction of the guide disks and the roller are reduced, and the stability of the rolling is strengthened; the structure of the side pressure oil cylinder of the roller is simple, and the running is reliable; the guide bushes of the outlet and inlet port adopt the upper-pressing and lower-locking device to realize the double-assurance.

Owner:ANGANG STEEL CO LTD

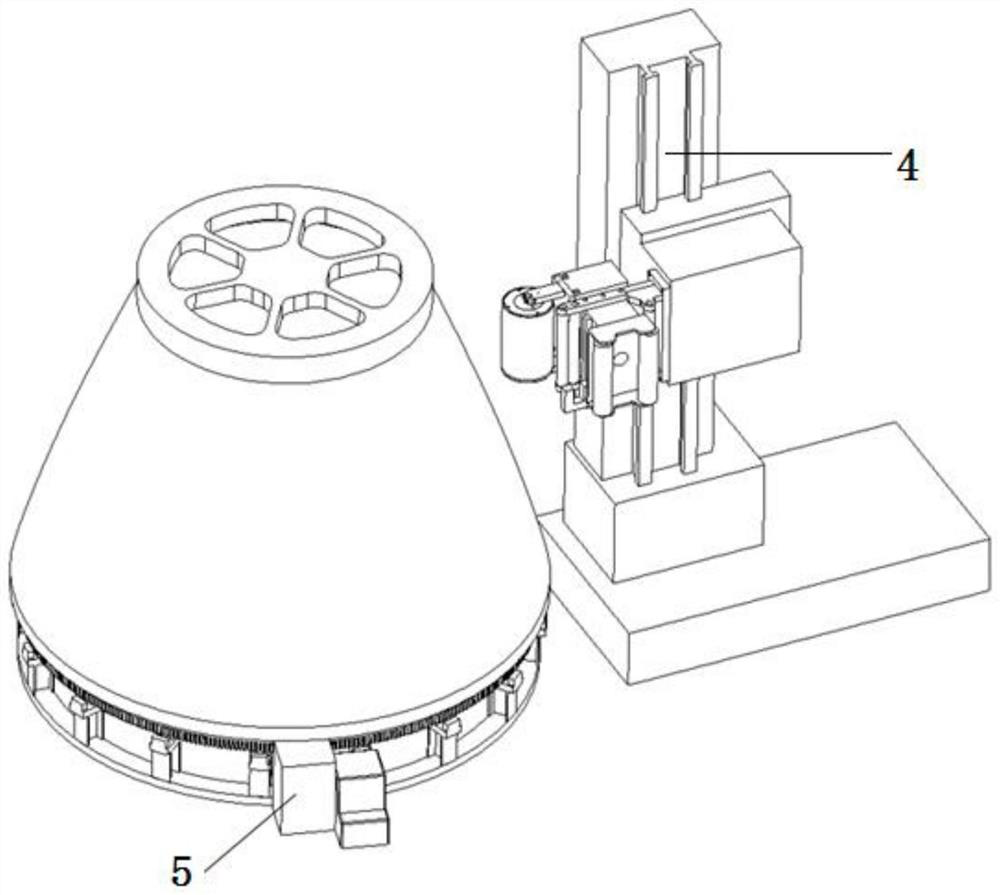

Magnetic particle grinding device and process for machining inner wall of conical part

PendingCN112123032AGuaranteed distanceGood grinding effectGrinding drivesGrinding feed controlMagnetic polesEngineering

The invention aims at providing a magnetic particle grinding device and process for machining the inner wall of a conical part. The device comprises a machine tool, an external magnetic pole device and an internal ultrasonic vibration magnetic pole device; the external magnetic pole device is arranged outside a workpiece and is capable of being driven by a first sliding table on the machine tool to move in the axial direction of the workpiece; and the internal ultrasonic vibration magnetic pole device is coaxial with the workpiece and is capable of being driven by a second sliding table on themachine tool to feed an auxiliary magnetic pole into the workpiece. According to the magnetic particle grinding device and process, finishing machining of conical inner walls can be achieved, the surface quality and the service life of the workpiece can be improved, and the grinding speed and quality are effectively improved.

Owner:UNIV OF SCI & TECH LIAONING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com