Reverse Closing Technology of Seamless Gas Cylinders

A gas cylinder and reverse technology, which is applied in the field of closing technology of gas storage cylinders, can solve problems such as hidden safety hazards, inner surface wrinkles, and material over-ablation, so as to improve production efficiency and product quality, and achieve shoulder increase. Thick, to avoid the effect of layer separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

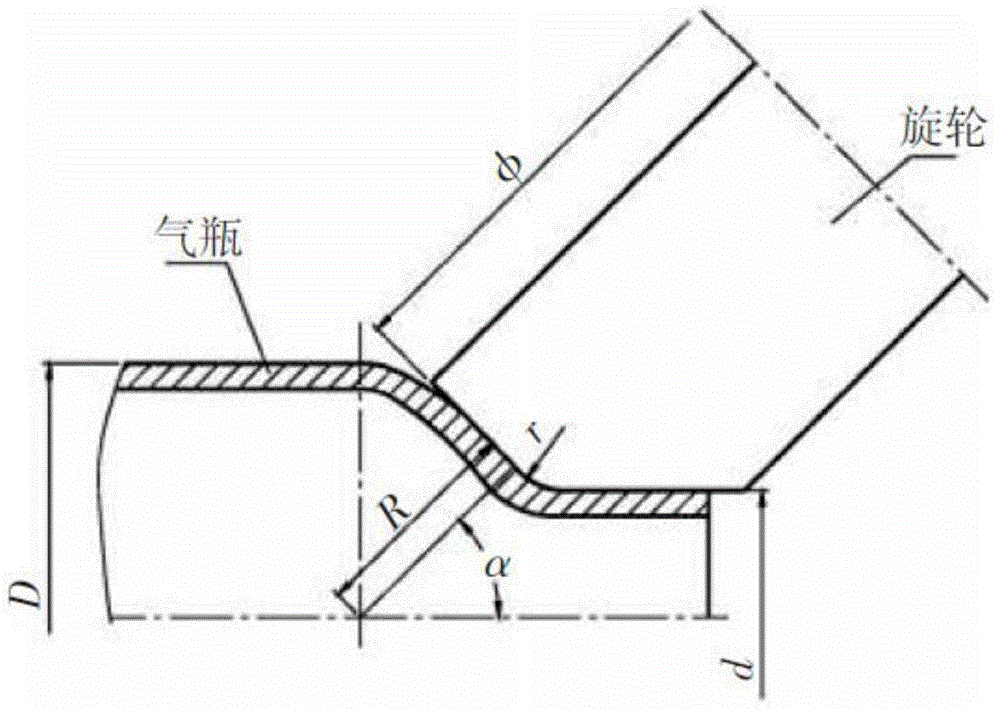

[0022] refer to figure 1 As shown, the present invention discloses a seamless gas cylinder reverse closing process. Generally, the shoulder shape of the seamless gas cylinder has two types: hemisphere and cone. In this embodiment, the shoulder of the gas cylinder to be formed The type is a hemisphere, and the reverse closing process of the seamless gas cylinder is described through the following steps, and the process includes the following steps:

[0023] A. combined figure 1 , when the shoulder shape of the gas cylinder is a hemisphere, that is, when R=D / 2, the forming angle of the rotary wheel is: Among them, R is the external radius of the gas cylinder, D is the external diameter of the gas cylinder, and d is the external diameter of the gas cylinder nozzle; according to the above calculation formula, the following data can be deduced: for example, when D=140, d=42, Then α=17.4°; after that, according to the calculated roller forming angle, select the hot work die stee...

Embodiment 2

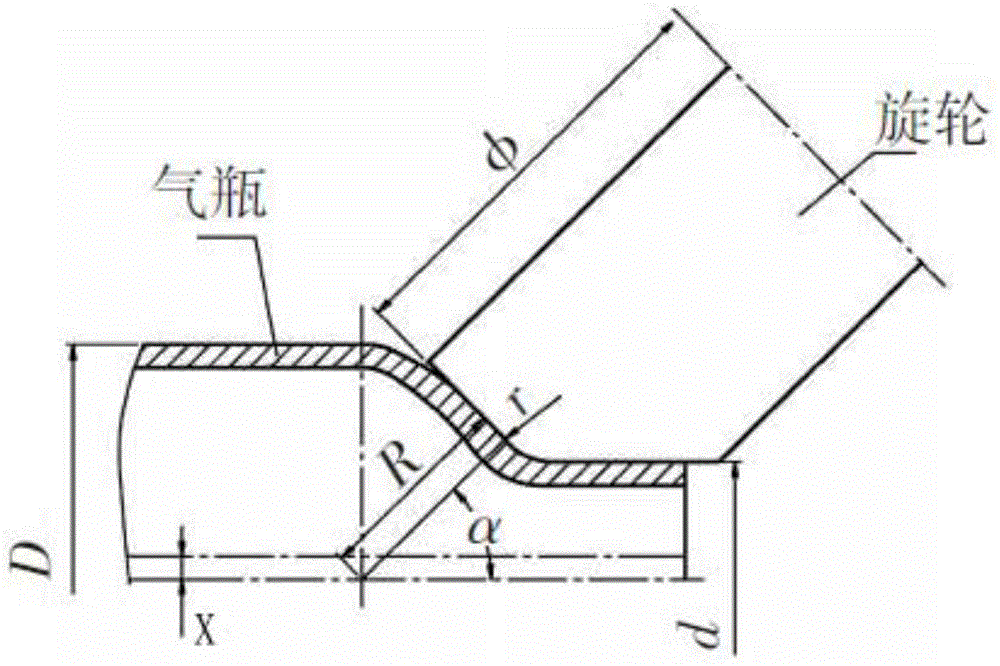

[0032] refer to figure 2 As shown, it is the second specific embodiment of a seamless gas cylinder reverse closing process disclosed by the present invention. In this embodiment, the shoulder shape of the gas cylinder to be formed is a cone. Therefore, the gas cylinder closing process , including the following steps:

[0033] A. combined figure 2 As shown, when the shoulder shape of the gas cylinder is a cone, the forming angle of the rotary wheel is: In the formula: x is the displacement of the swing center of the rotary wheel, when hour, Among them, R is the outer radius of the gas cylinder, D is the outer diameter of the gas cylinder, and d is the outer diameter of the mouth of the gas cylinder; through the above calculation formula, the angle of the rotary wheel is calculated, and the hot work die steel with comprehensive mechanical properties is selected for wheel manufacturing;

[0034] B. The design of the ferrule: design the ferrule card size according to the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com