Patents

Literature

1037results about "Venting valves" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

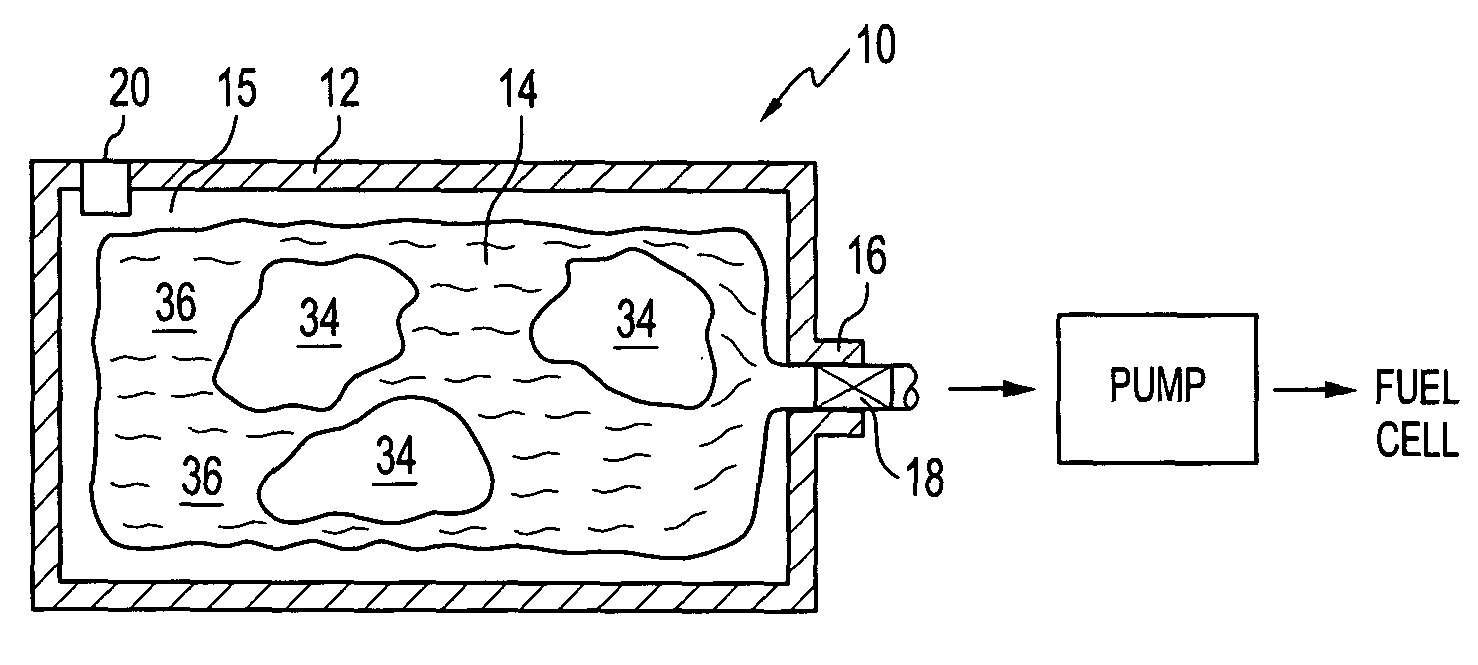

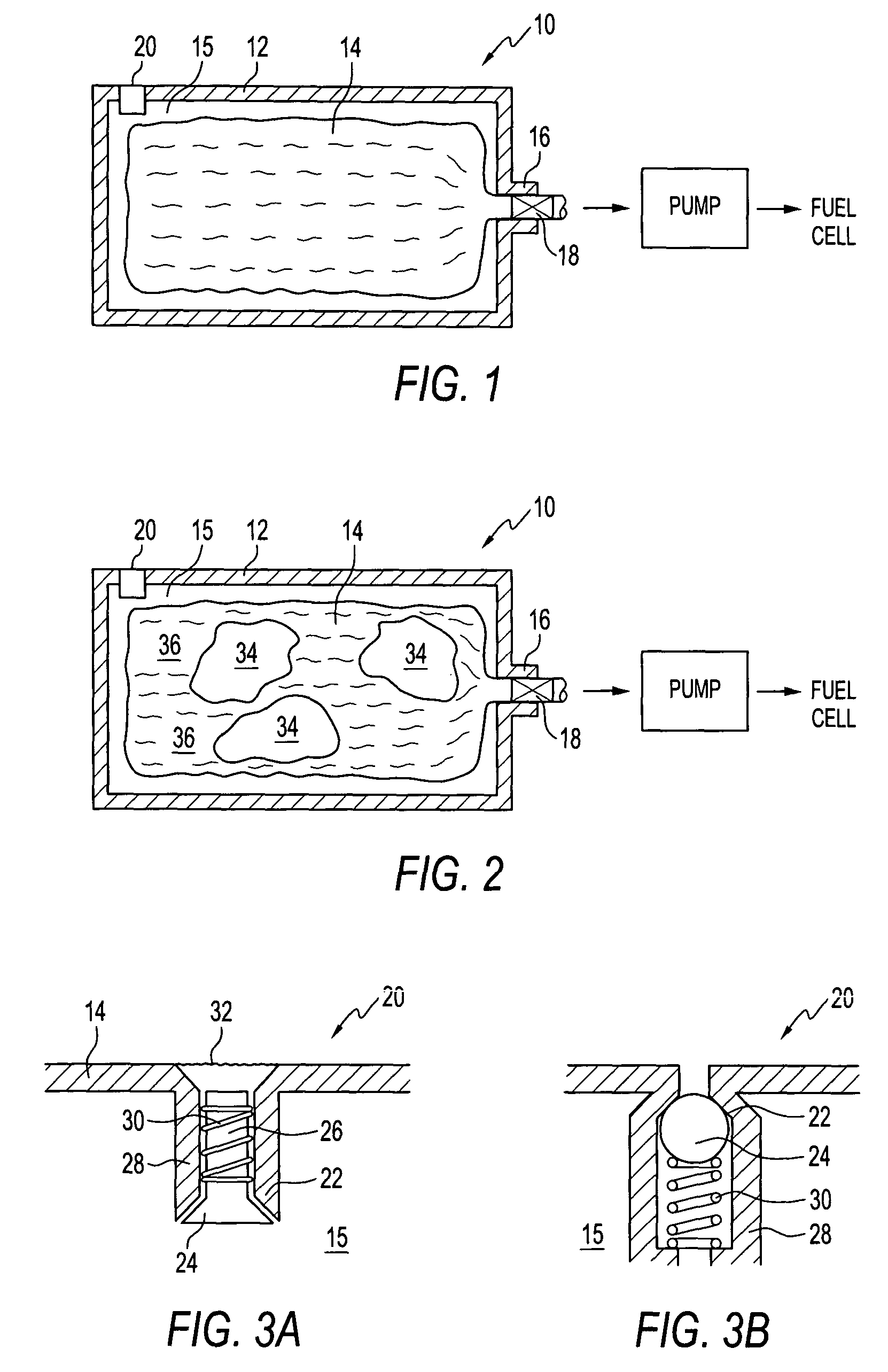

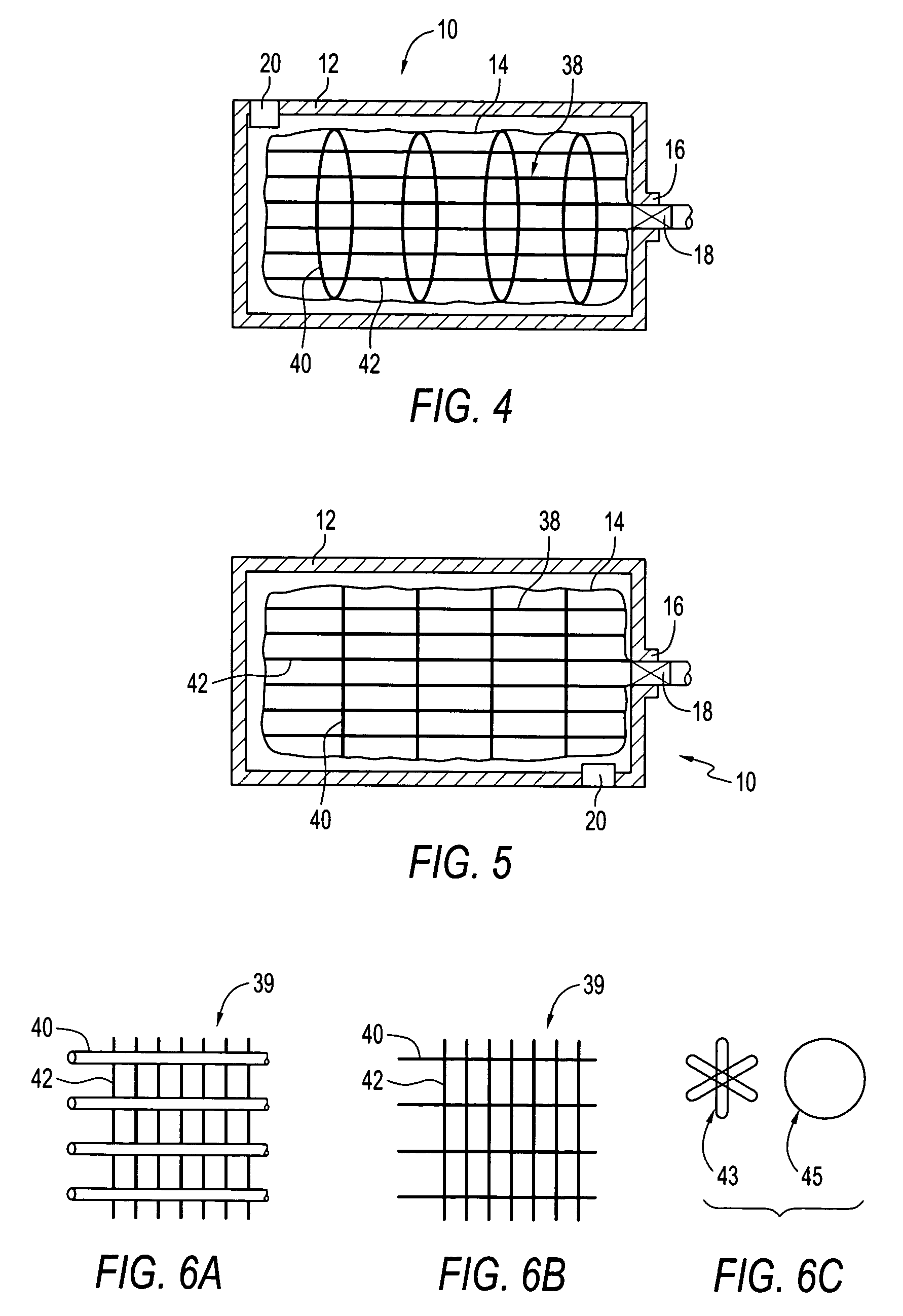

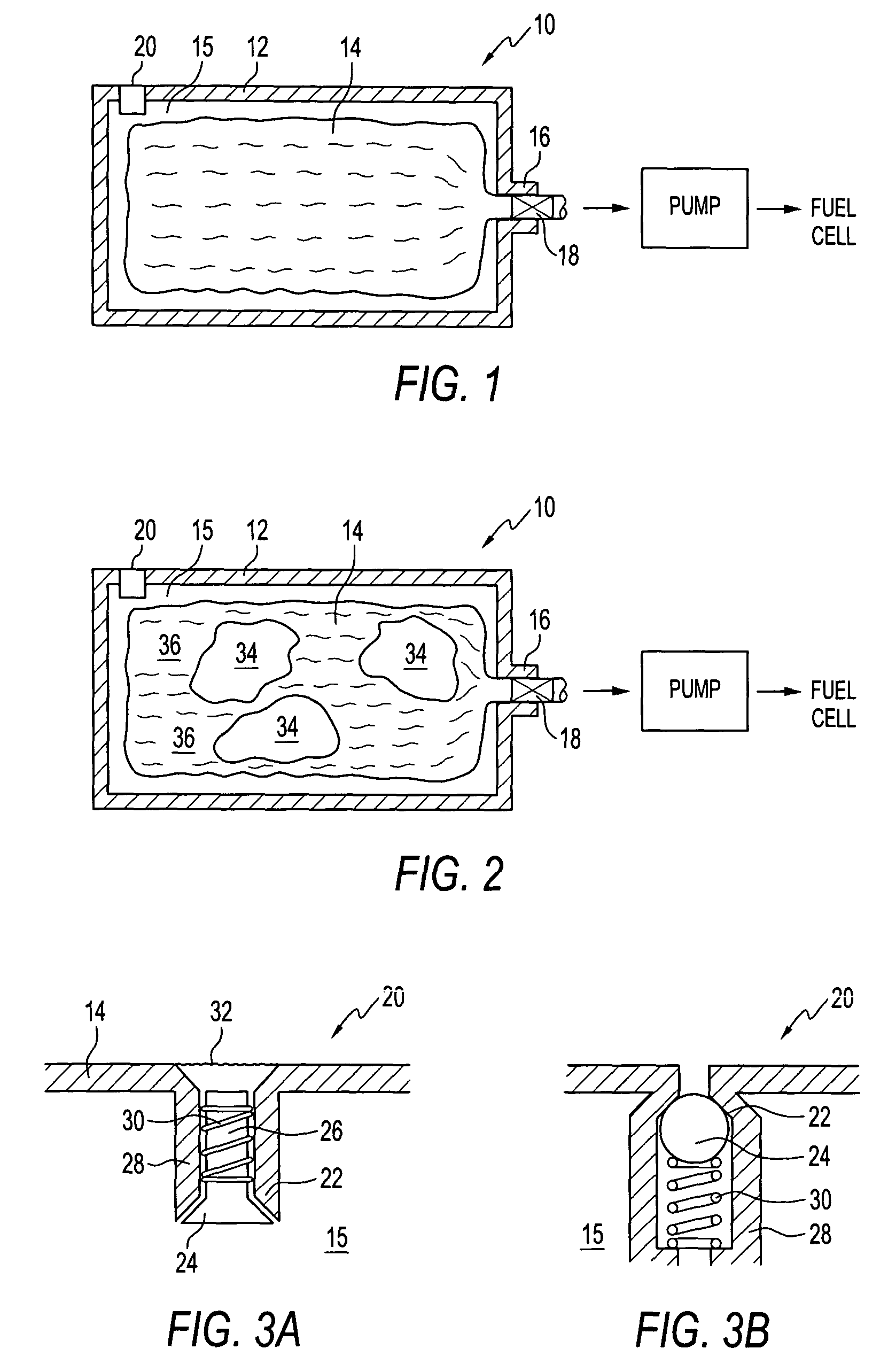

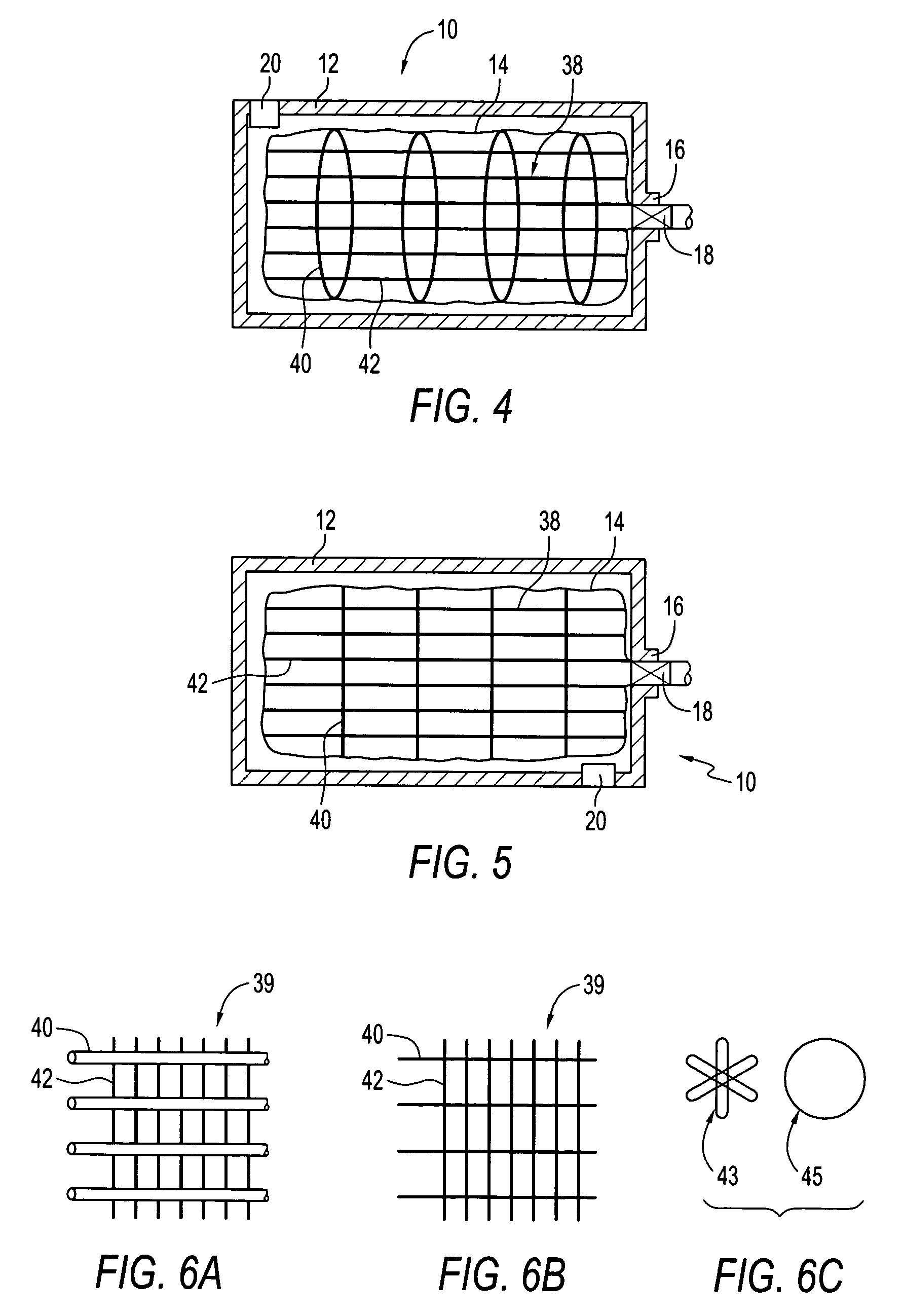

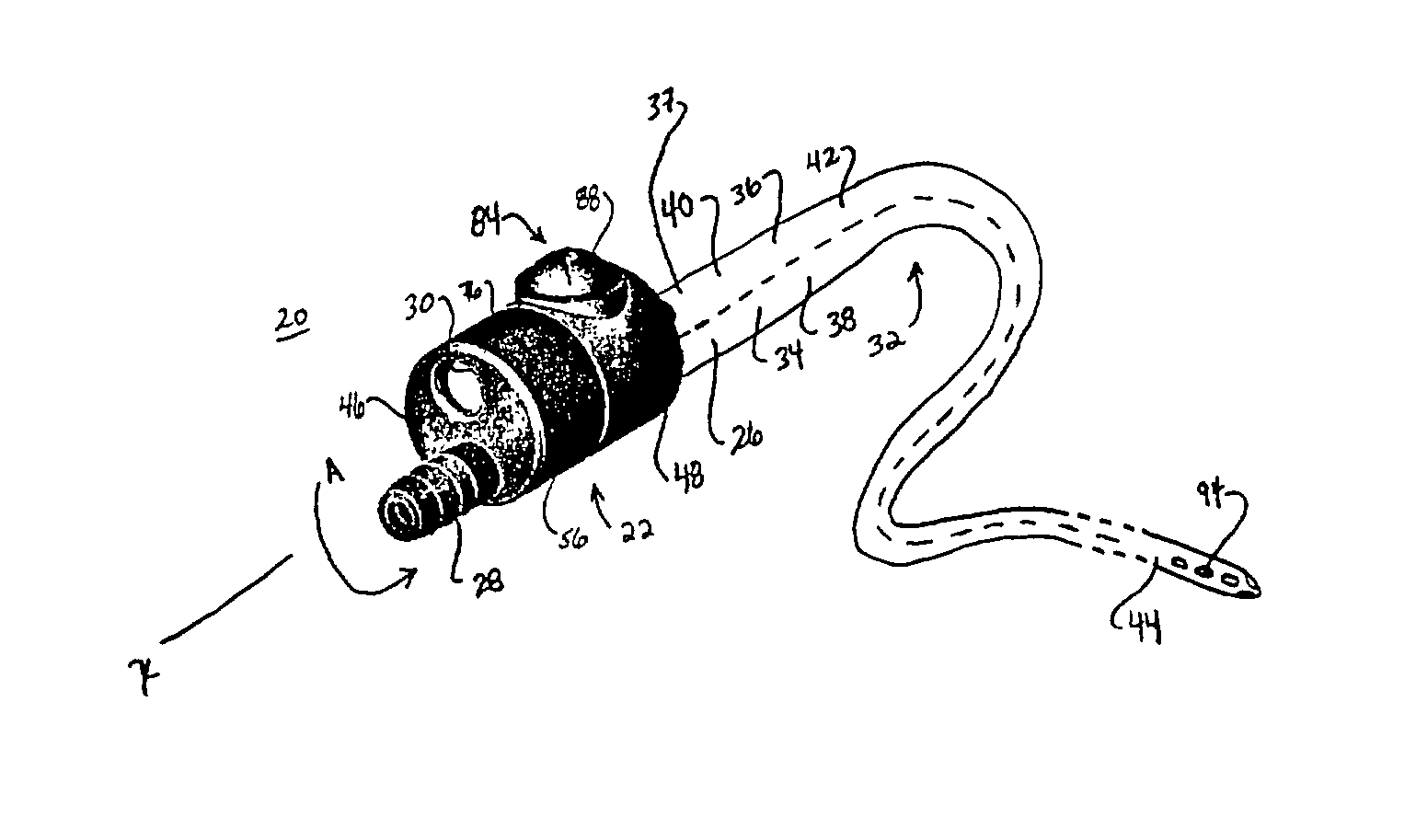

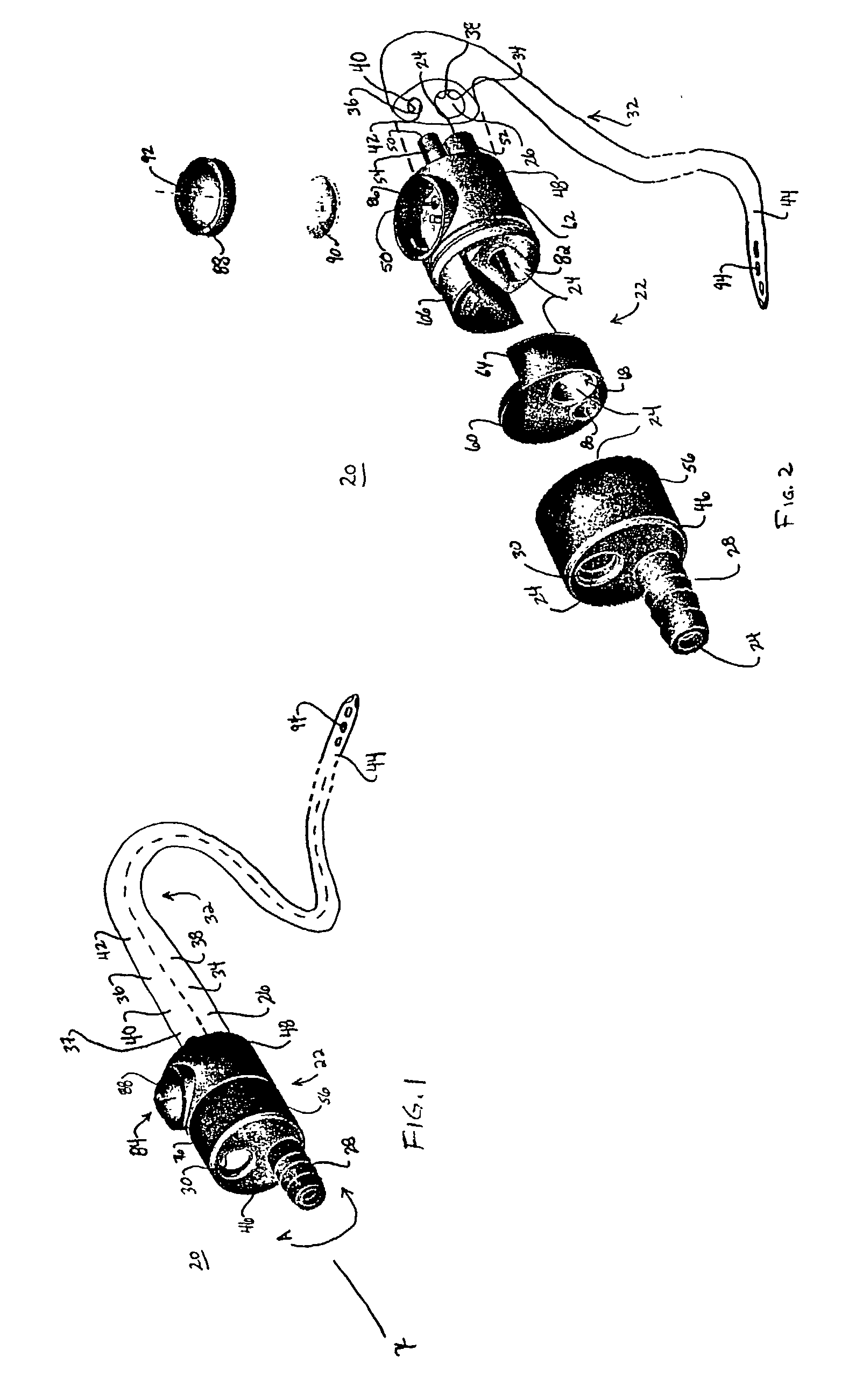

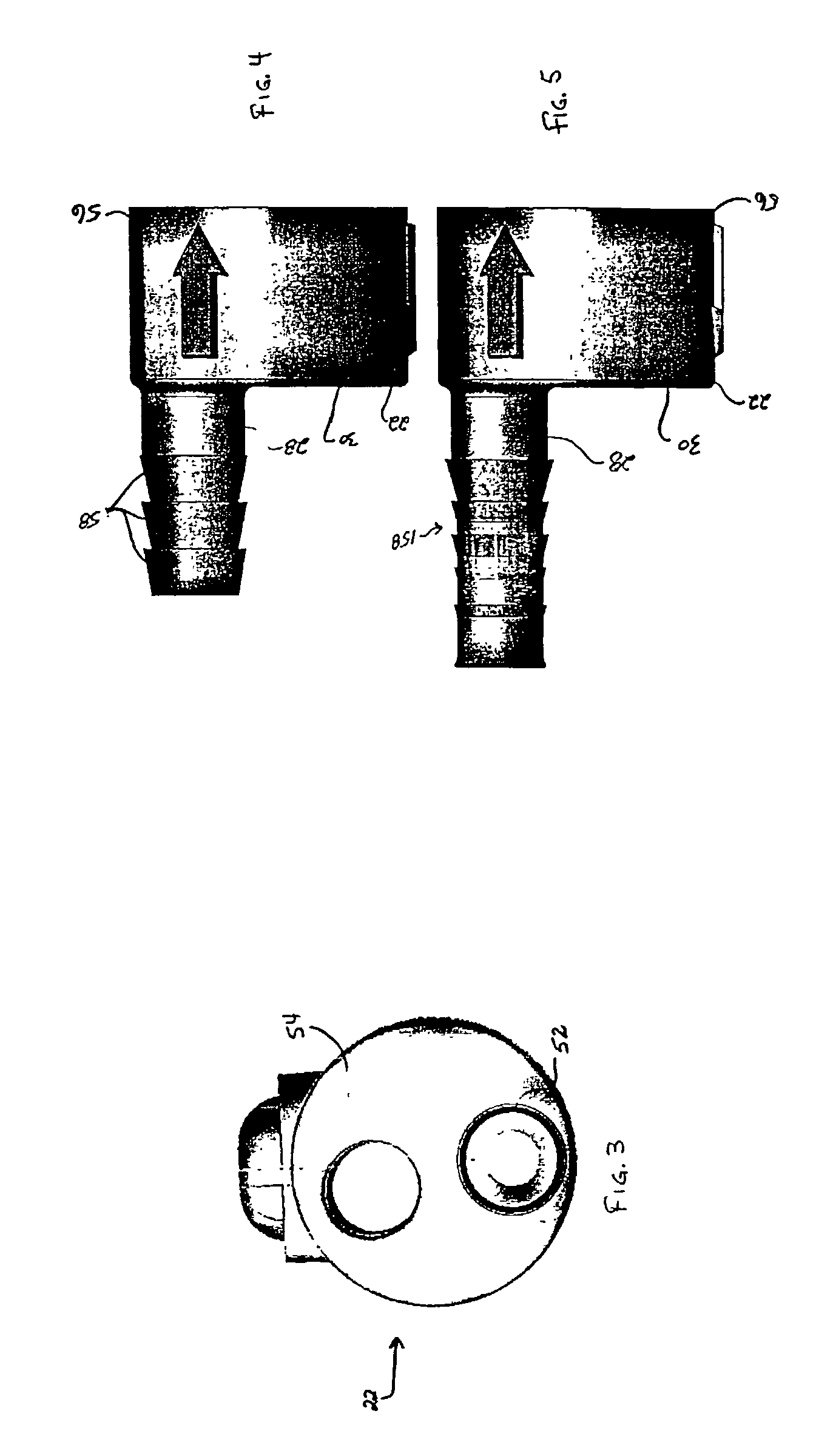

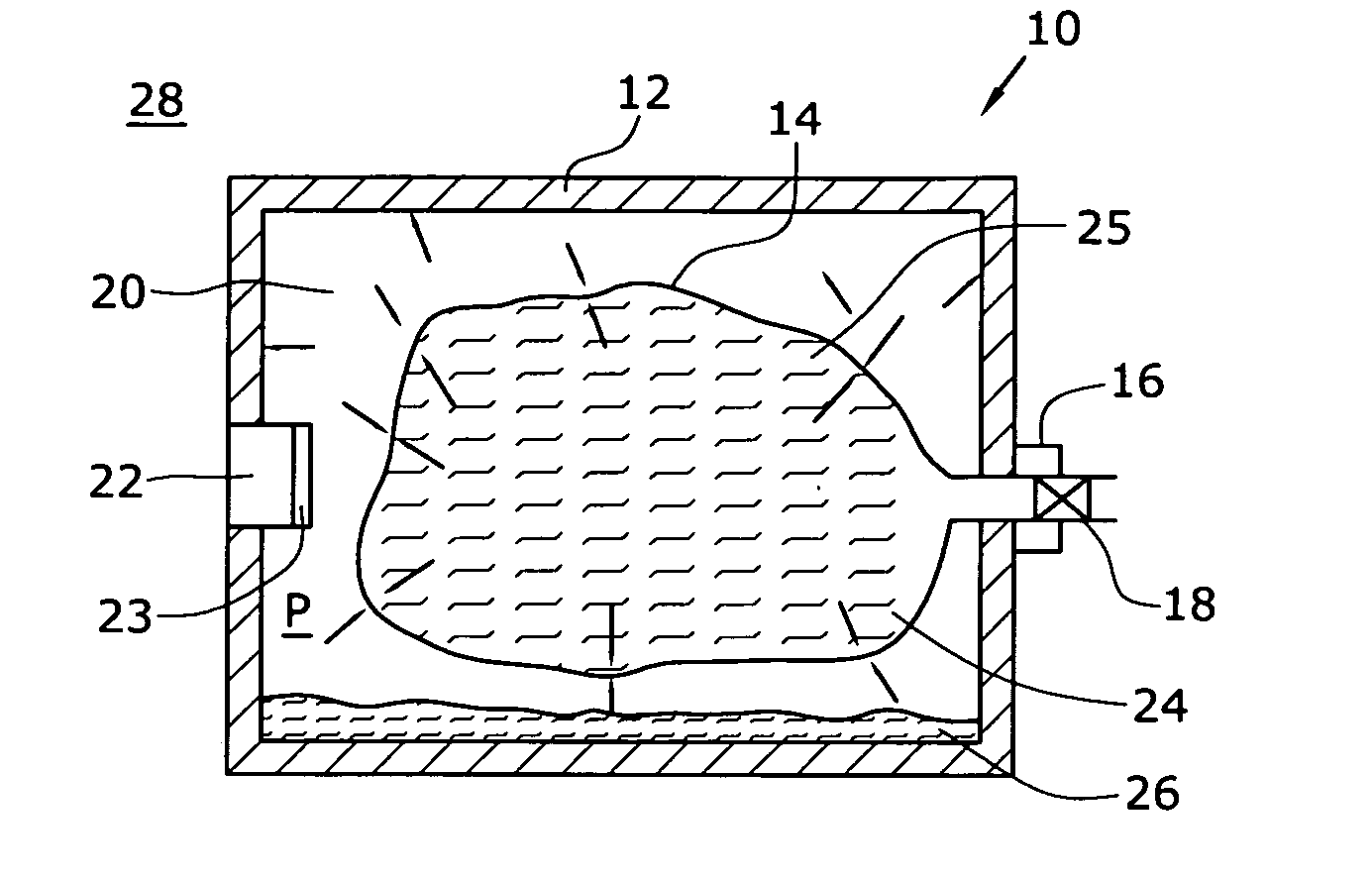

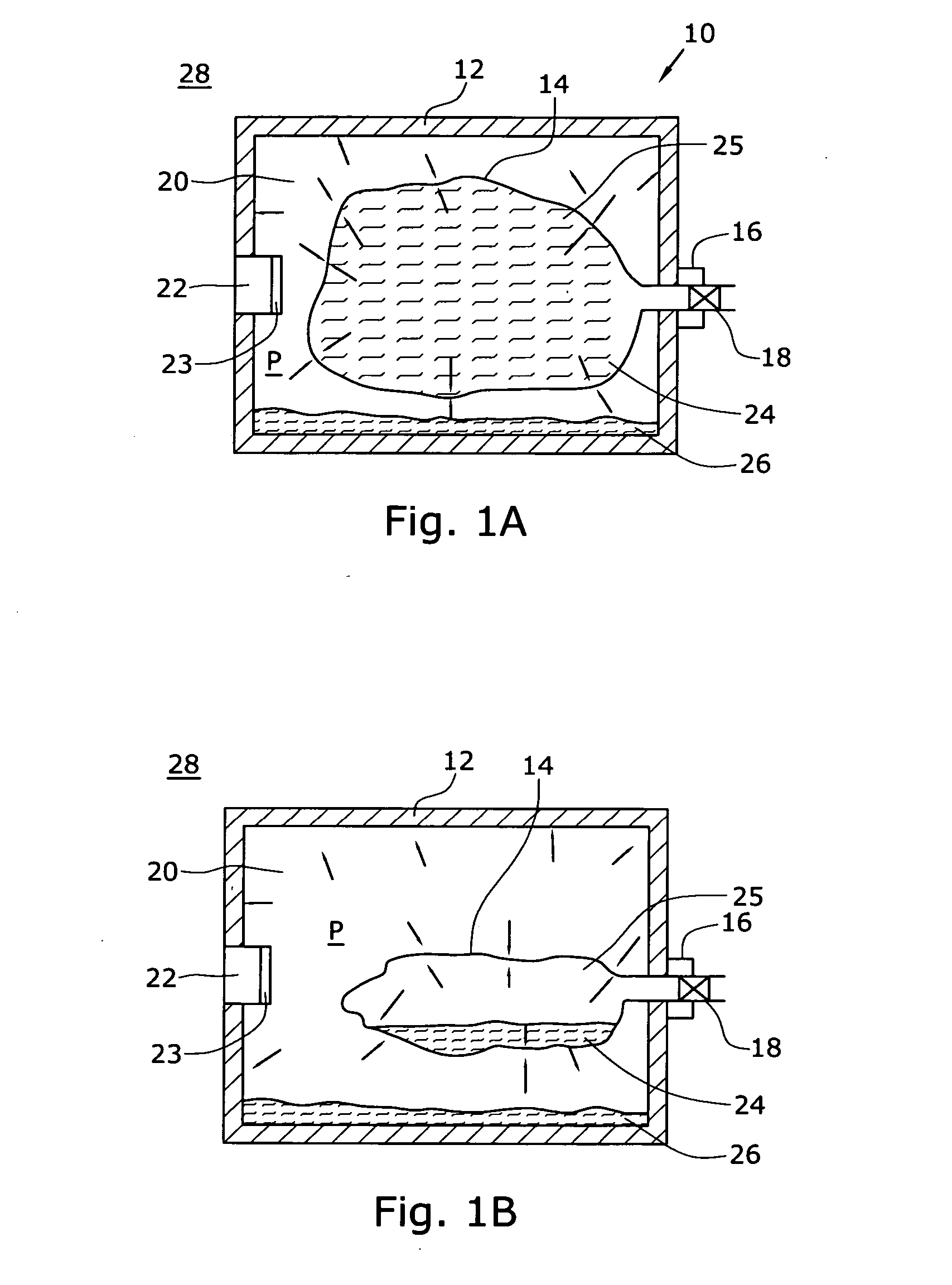

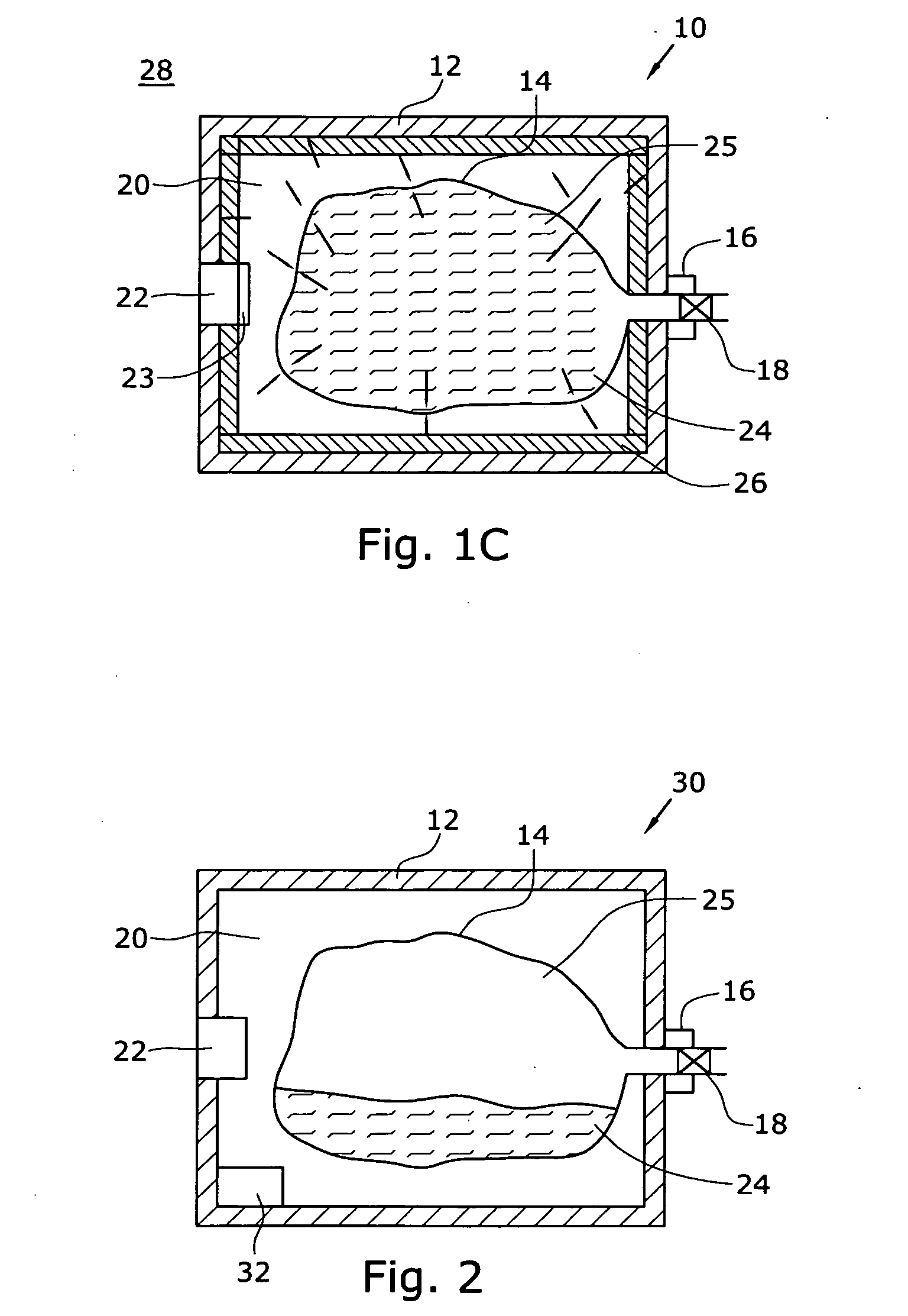

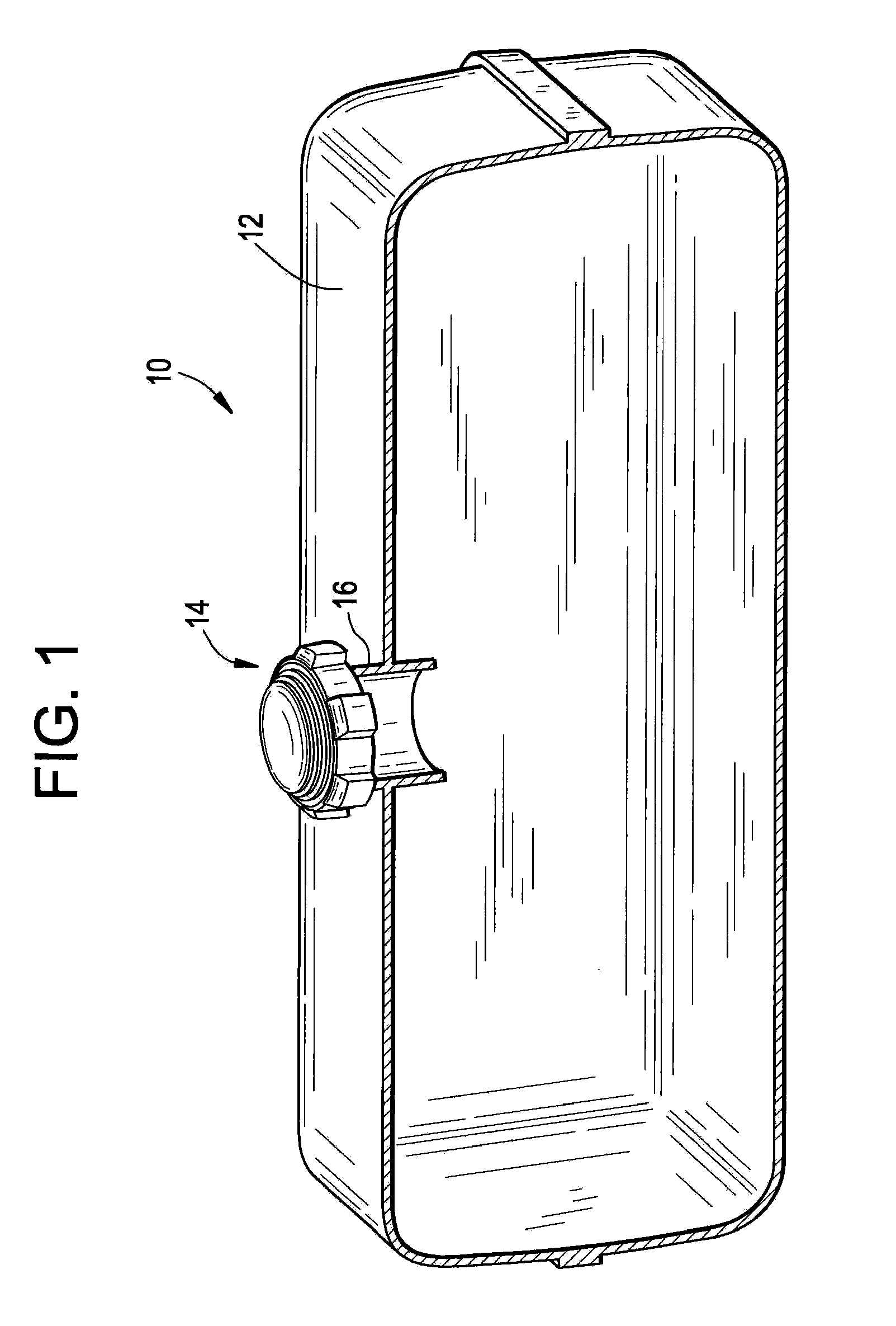

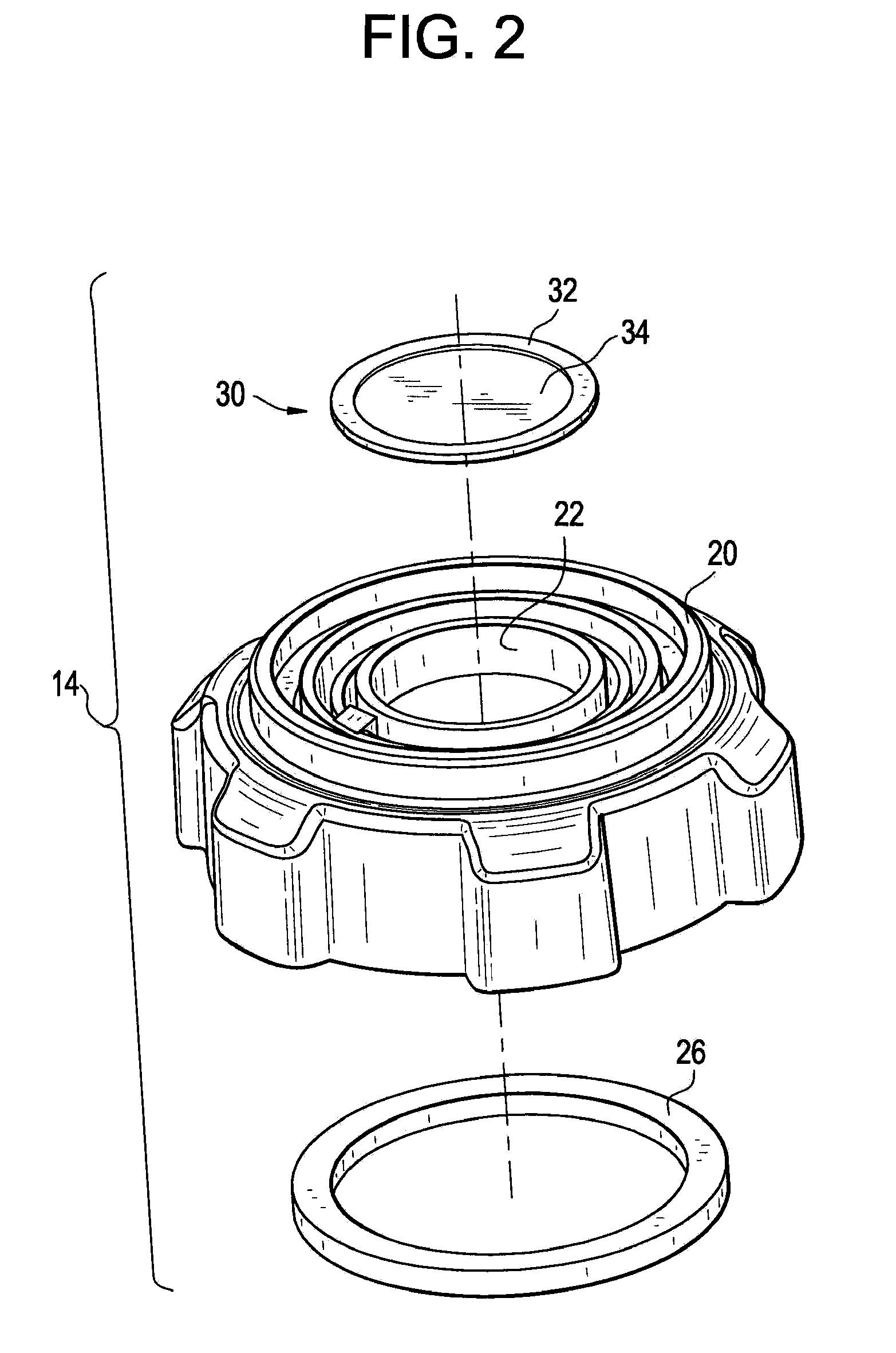

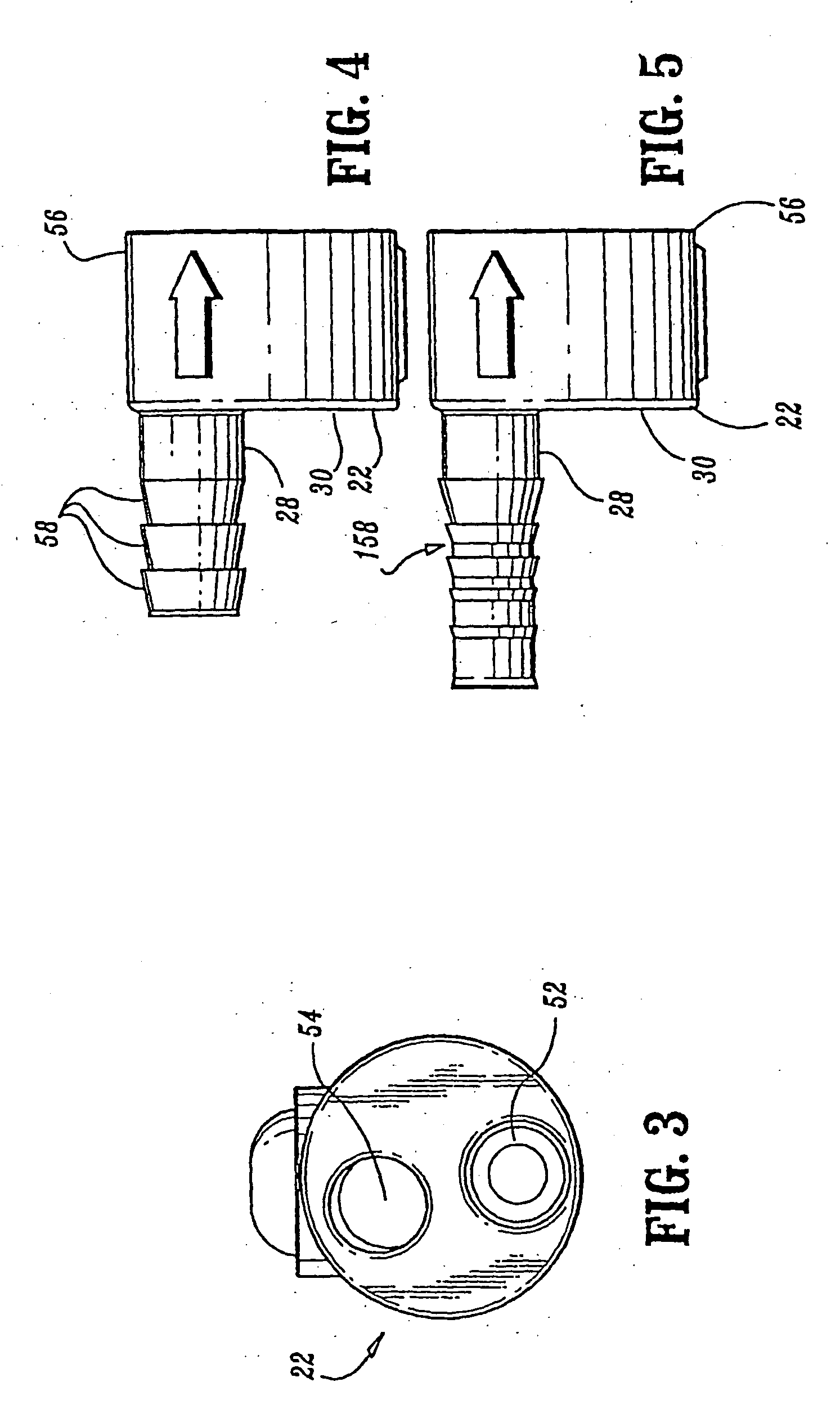

Fuel cartridge with flexible liner

A cartridge connectable to a fuel cell is disclosed. The cartridge comprises an outer casing and an inner flexible liner containing fuel for the fuel cell. The inner flexible liner may have an insert disposed inside the inner liner to facilitate the transport of fuel from the cartridge to the fuel cell. The insert minimizes the fuel that is trapped within the cartridge. The inner flexible liner can be used without the outer casing. The outer casing can be substantially rigid or flexible. The cartridge is also adaptable to receive byproducts from the fuel cell. The cartridge can also be pressurized to push fuel to the fuel cell. Unidirectional relief valves are also disclosed to prevent internal pressure in the cartridge from becoming too high or too low.

Owner:INTELLIGENT ENERGY LTD

Fuel cartridge with flexible liner containing insert

Owner:INTELLIGENT ENERGY LTD

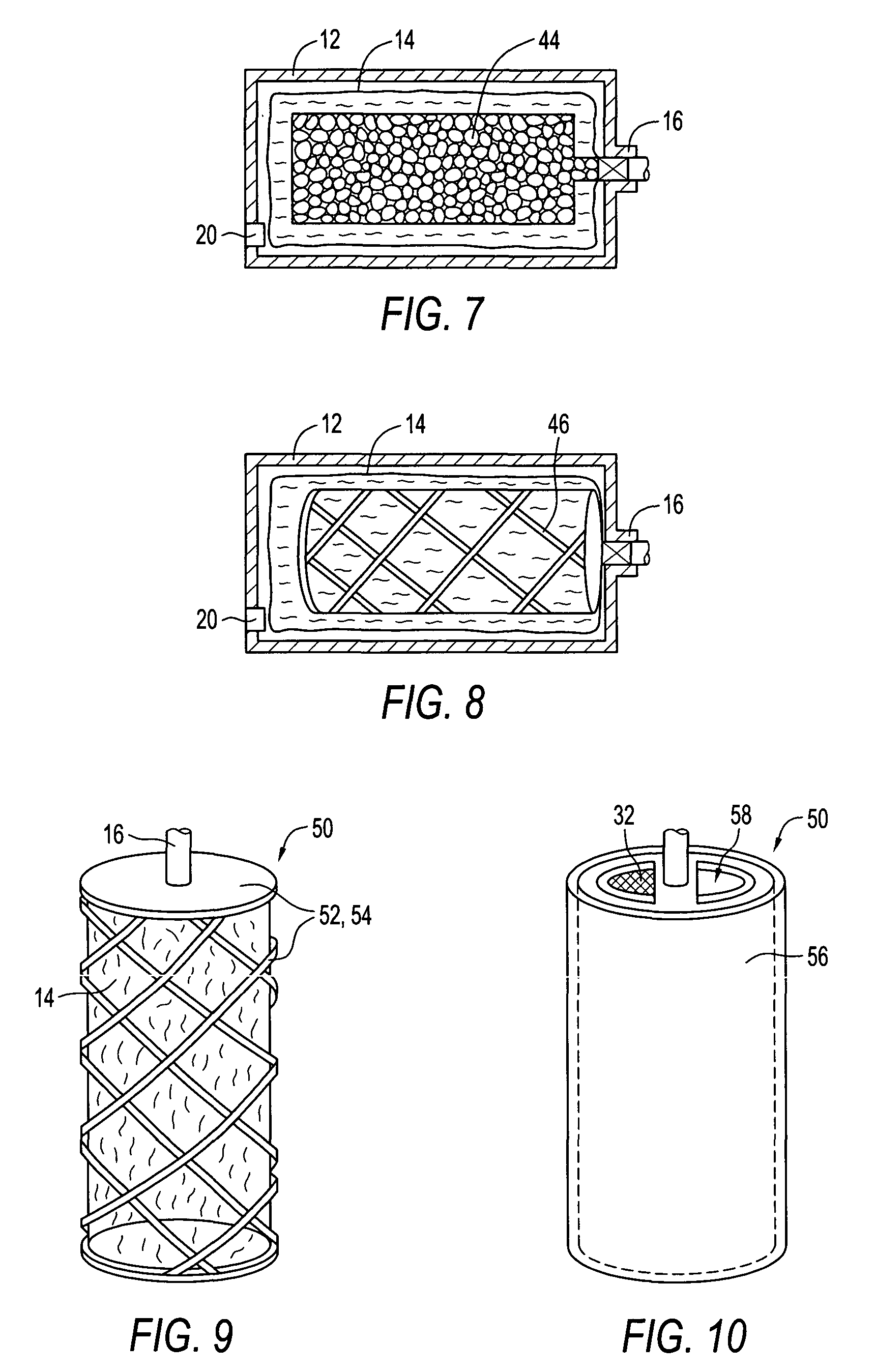

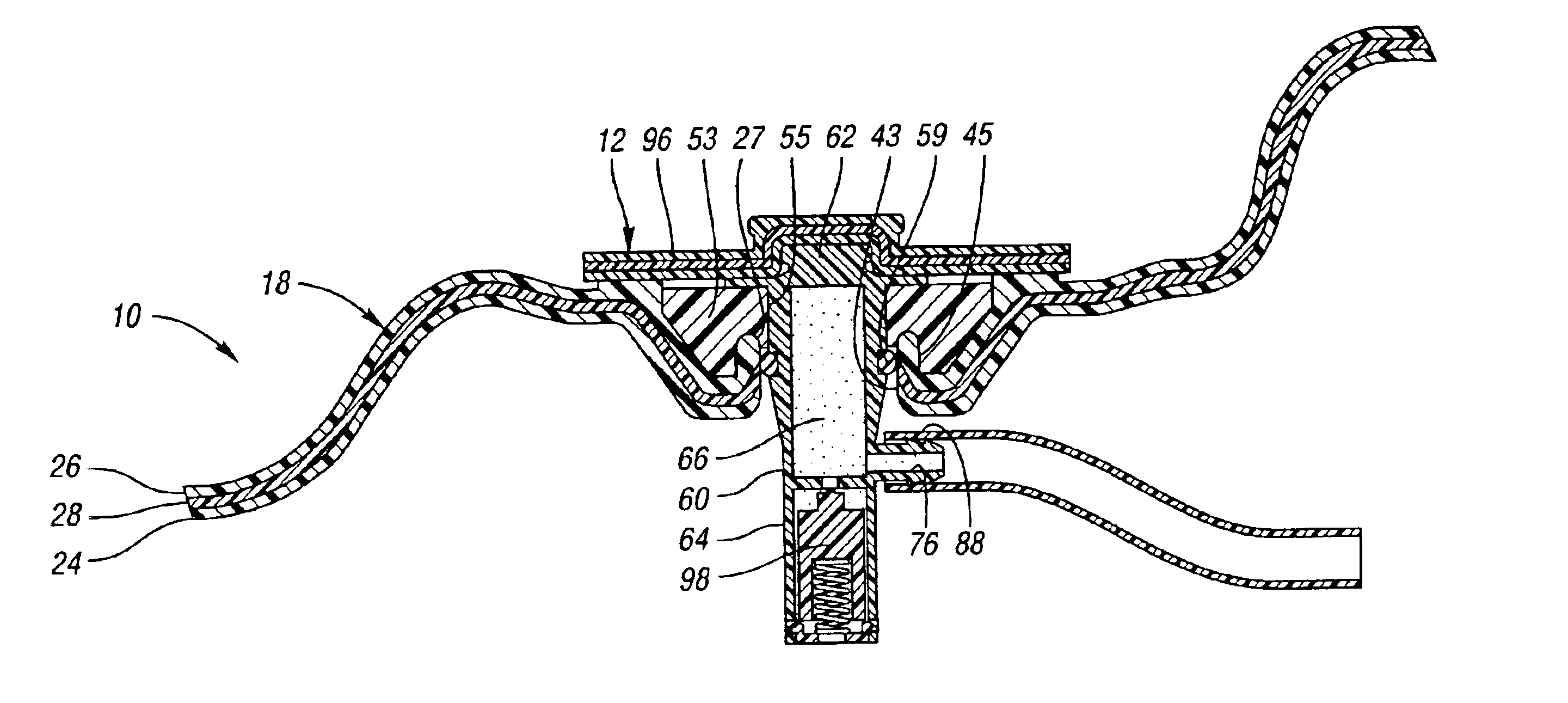

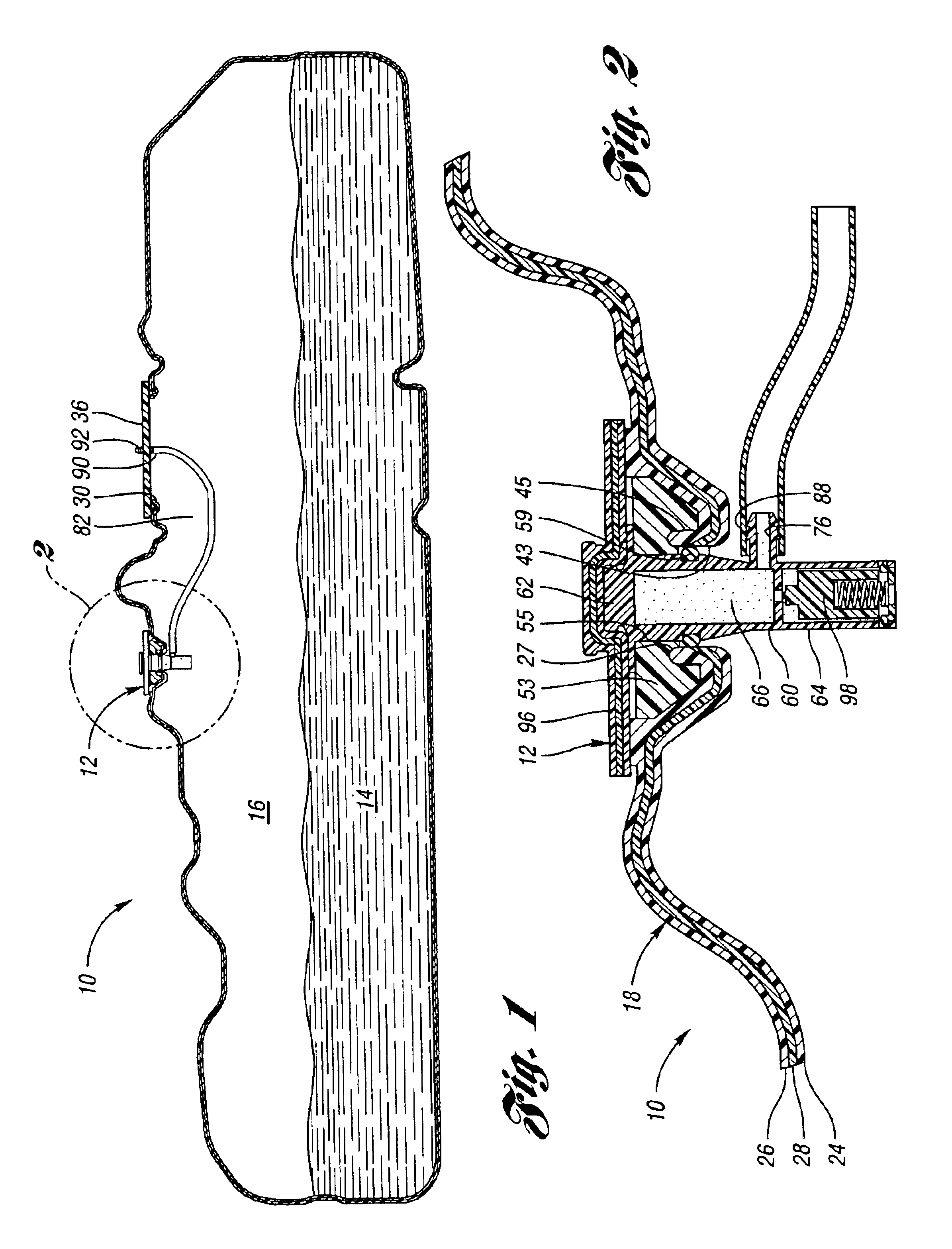

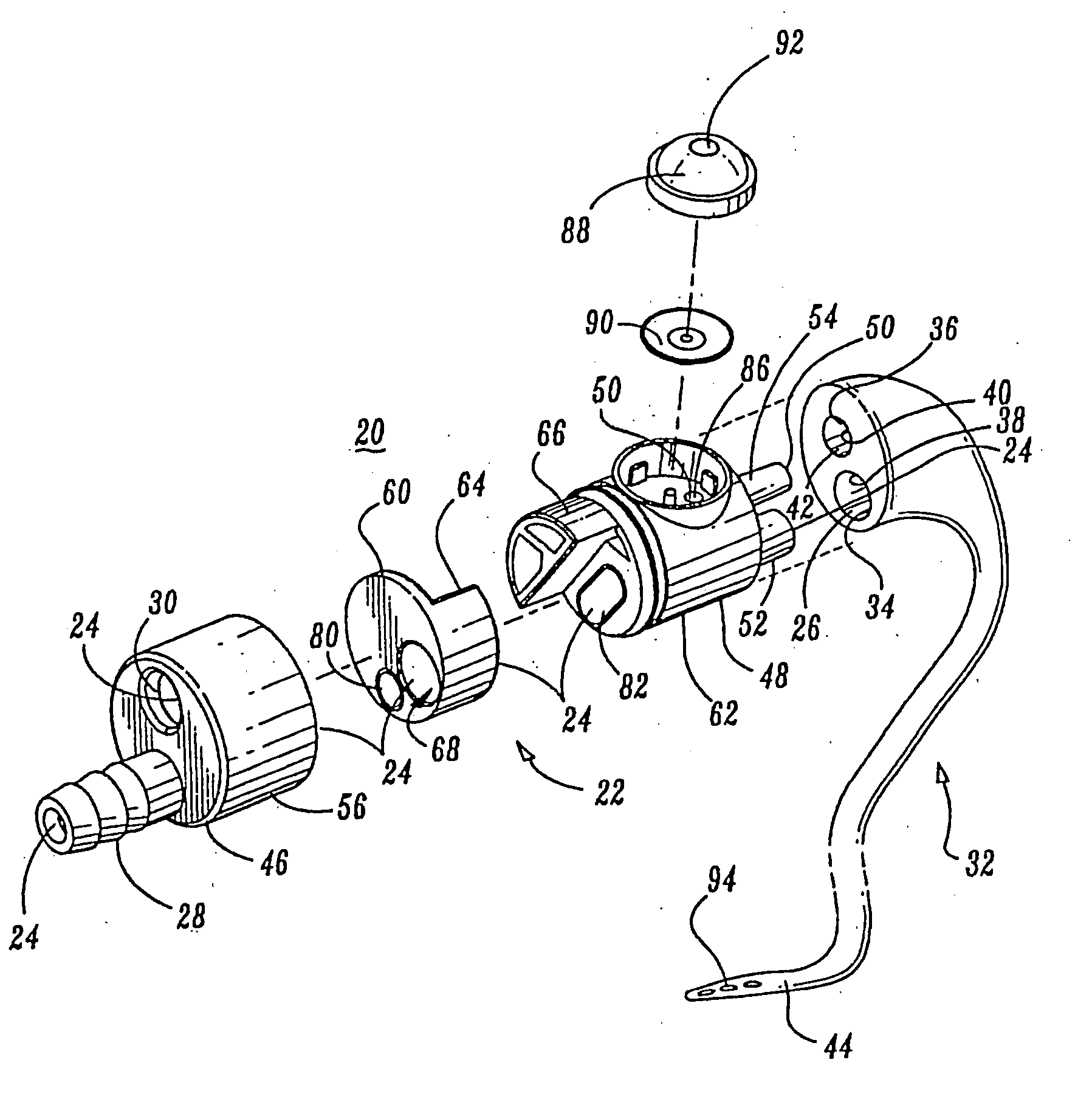

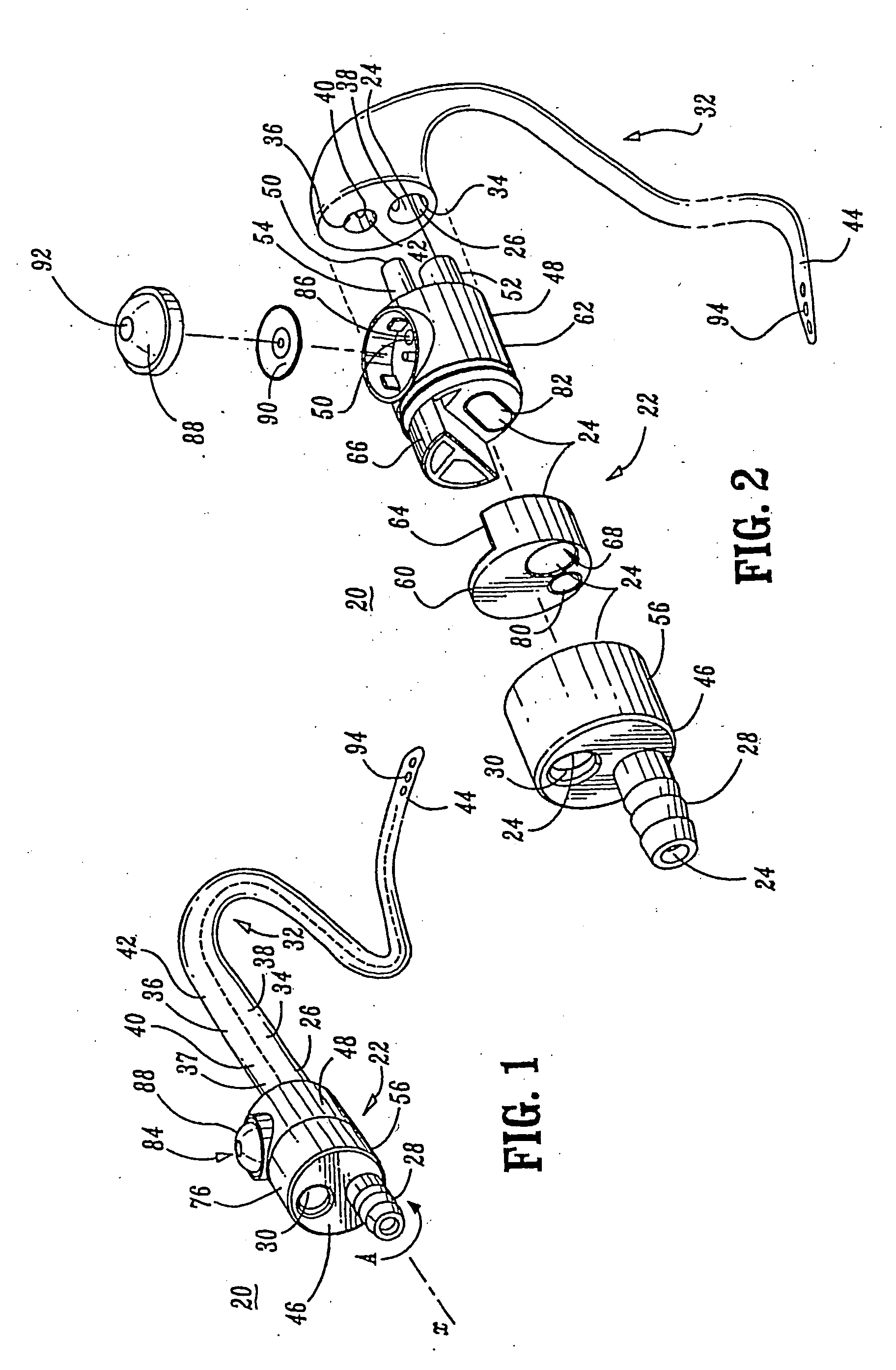

Single lumen adapter for automatic valve

InactiveUS20060129092A1Prevent leakageMinimize disease propagationFluid pressure sealed jointsMedical devicesSurgeryMedical device

A fluid adapter for connection between a valve having a plurality of ports and a tube has a housing with a distal end and a proximal end. The tube has a single lumen. The proximal end has a first opening connecting to a first lumen being disposed through the housing. The proximal end has a second opening being separated by the first opening by a distance. The second opening is connecting to a second lumen being disposed through the housing. The distal end has the first lumen connecting to a single outlet and the second lumen terminates in the housing. The adapter also has the single outlet of the housing connected to the intermediate tube. The intermediate tube is connected to the tube to permit fluid to traverse through the tube and the valve. Additionally, a valve system has a valve connector including a portion of a first passageway with the valve connector further including a suction port and an introduction port that are spaced apart. The suction port and the introduction port establish fluid communication between the portion of the first passageway and the suction port or the introduction port. At least one port of the valve connector has a collar. The collar is adapted to press fit with a medical device.

Owner:COVIDIEN AG

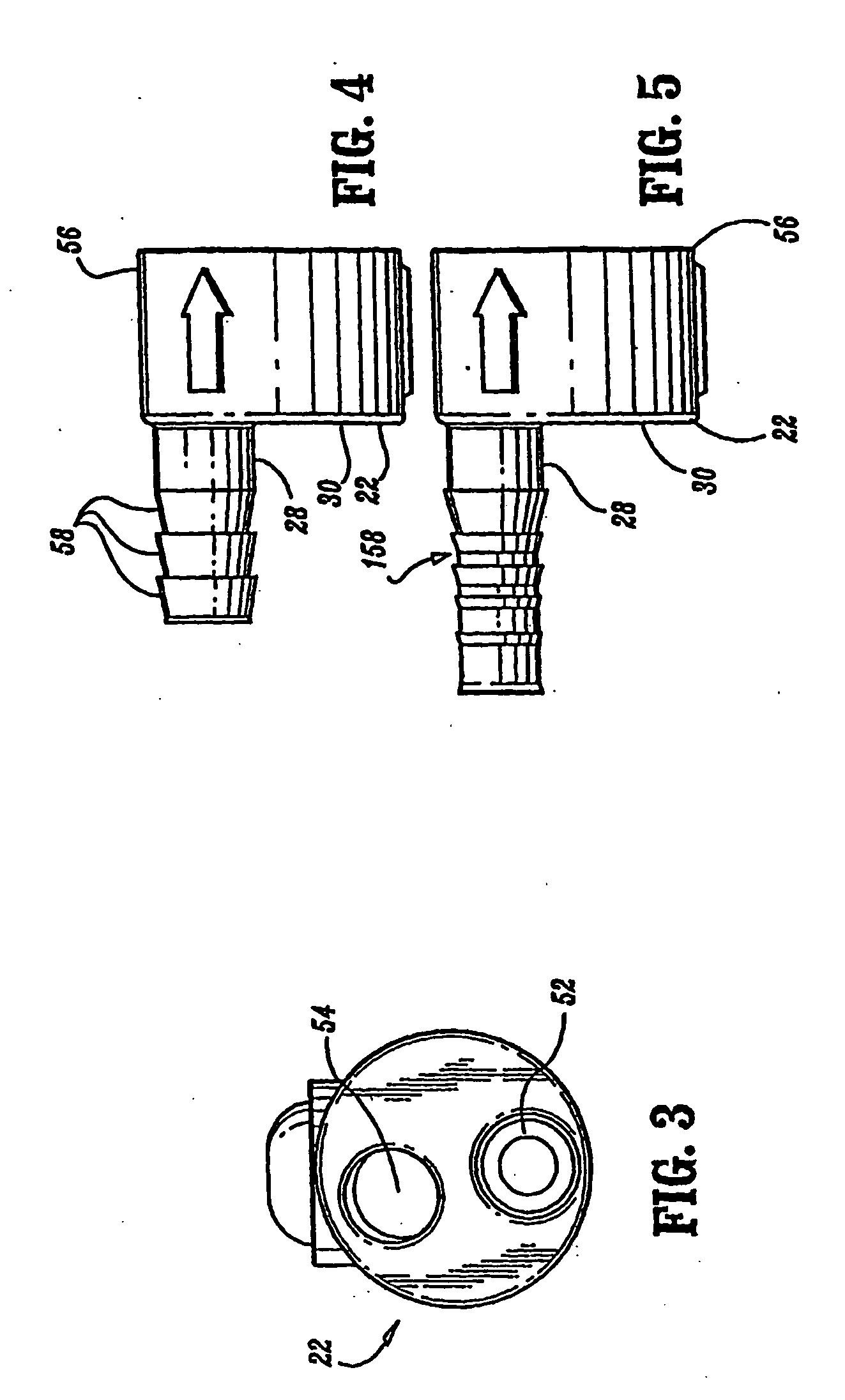

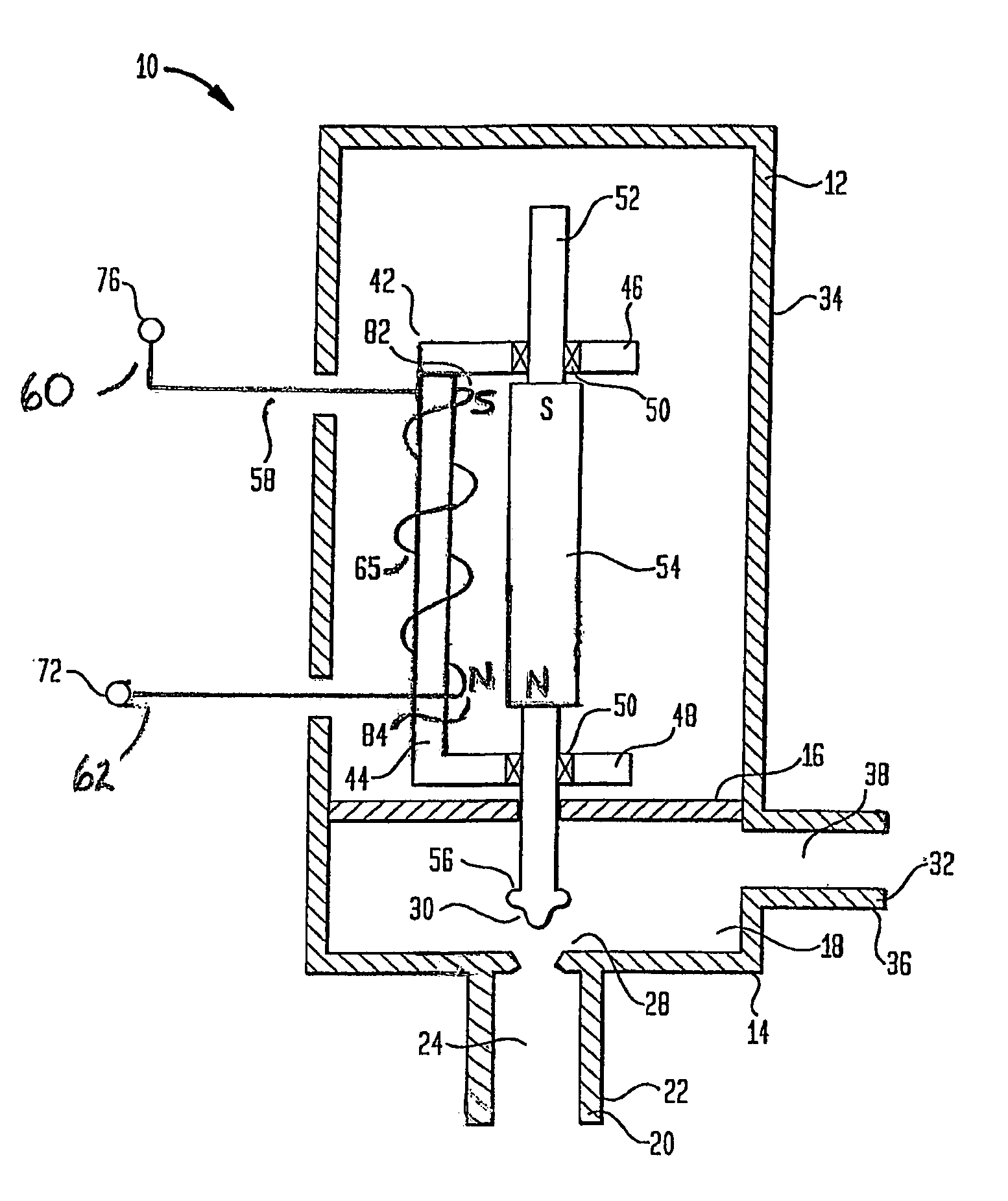

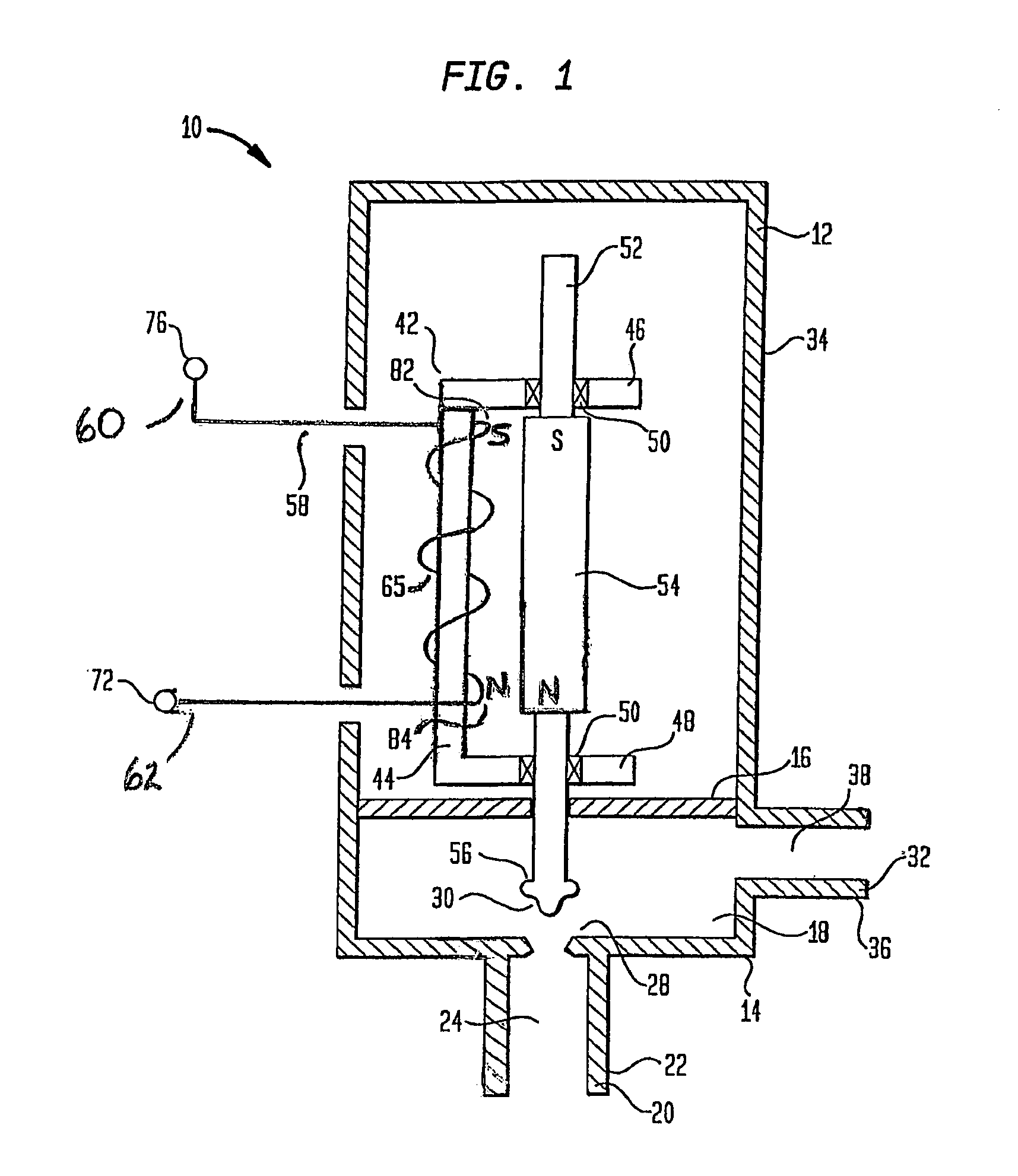

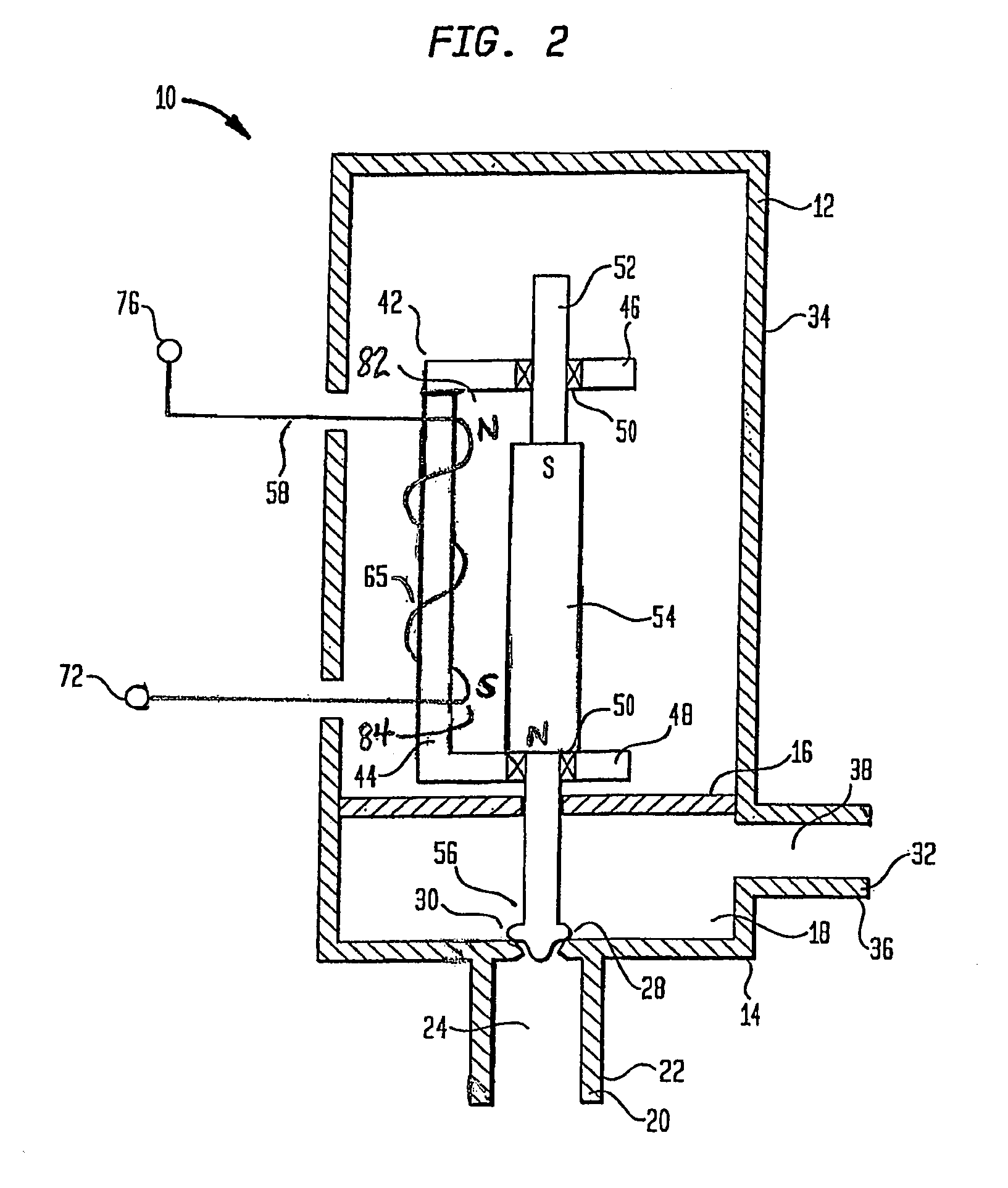

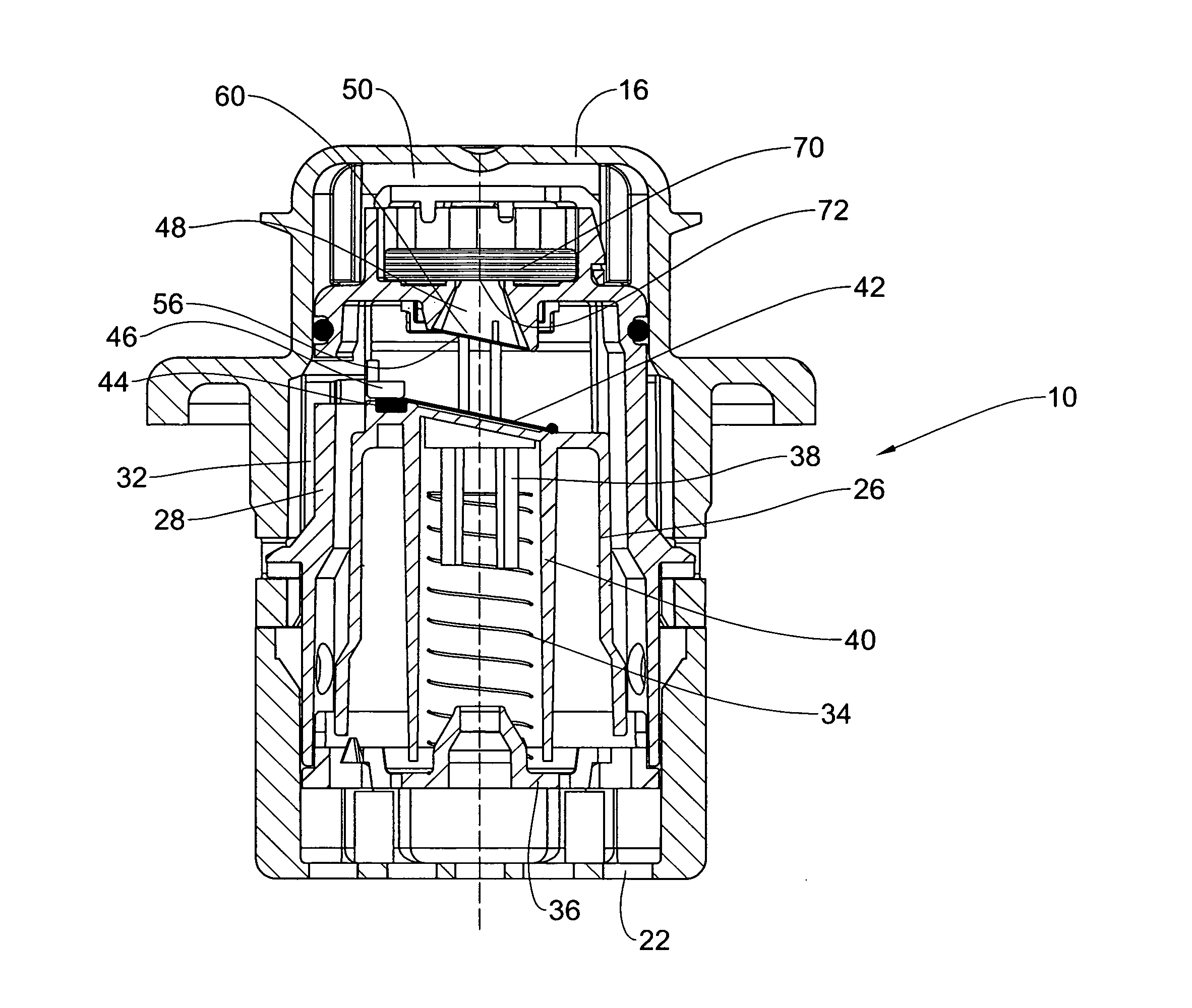

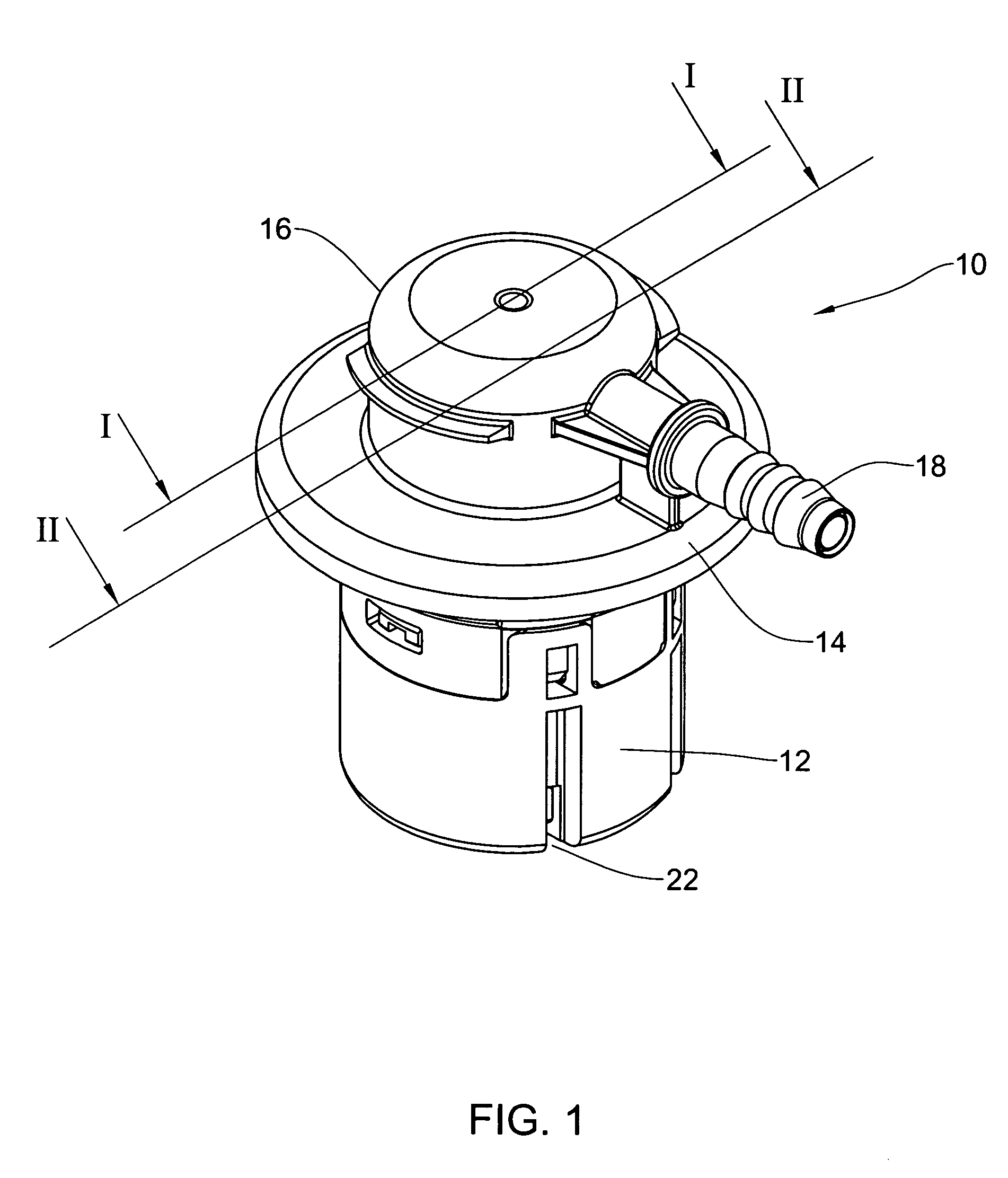

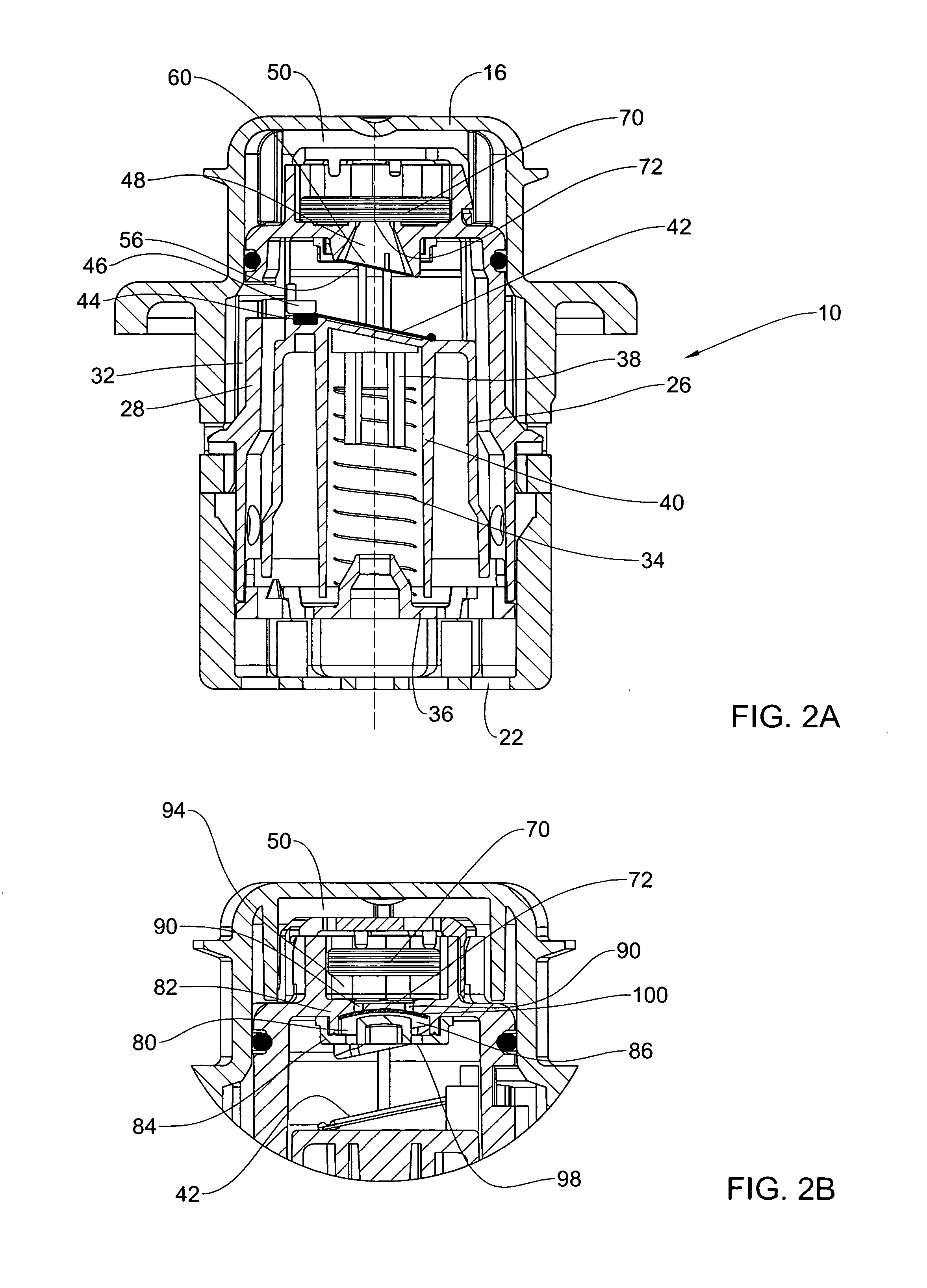

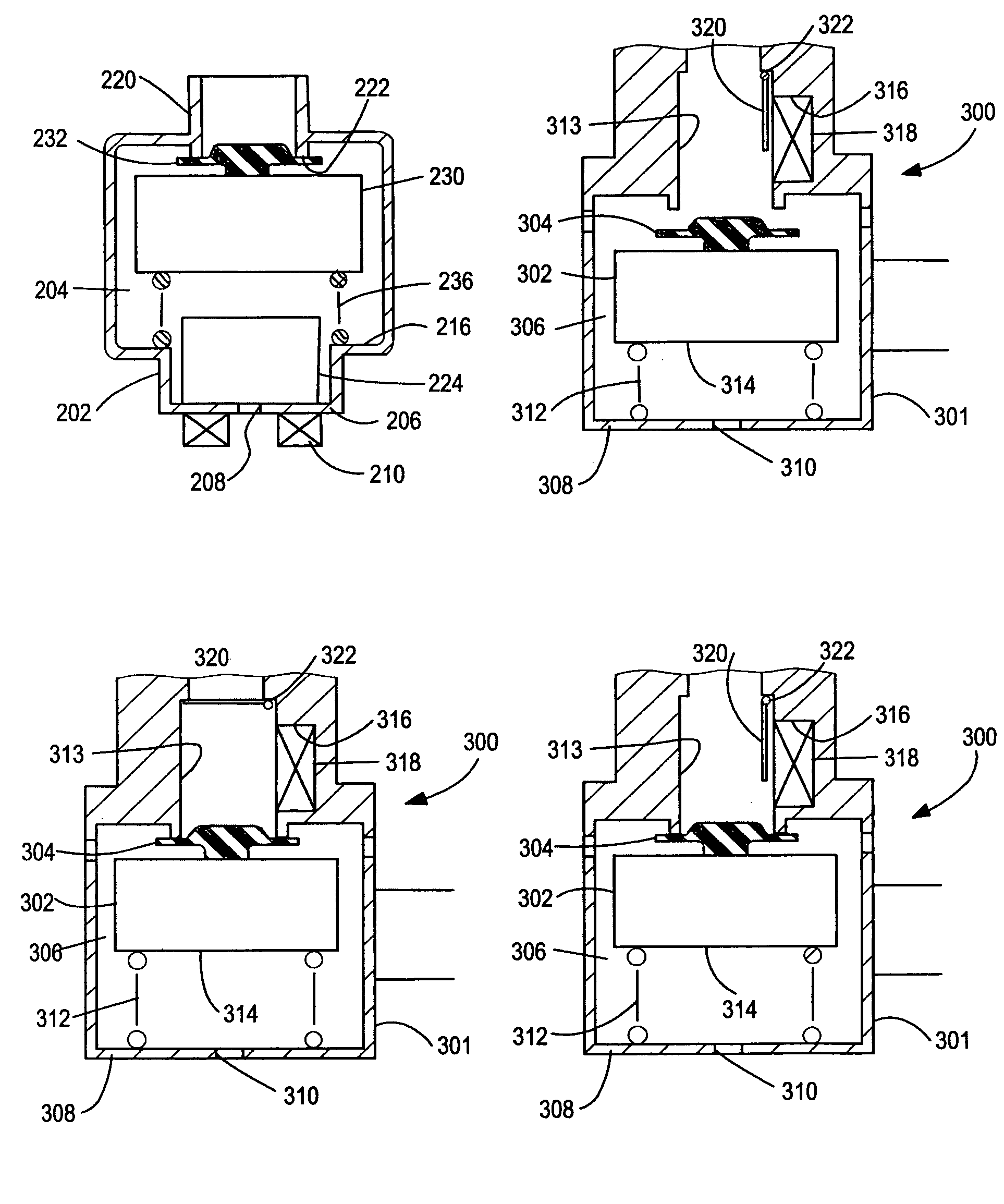

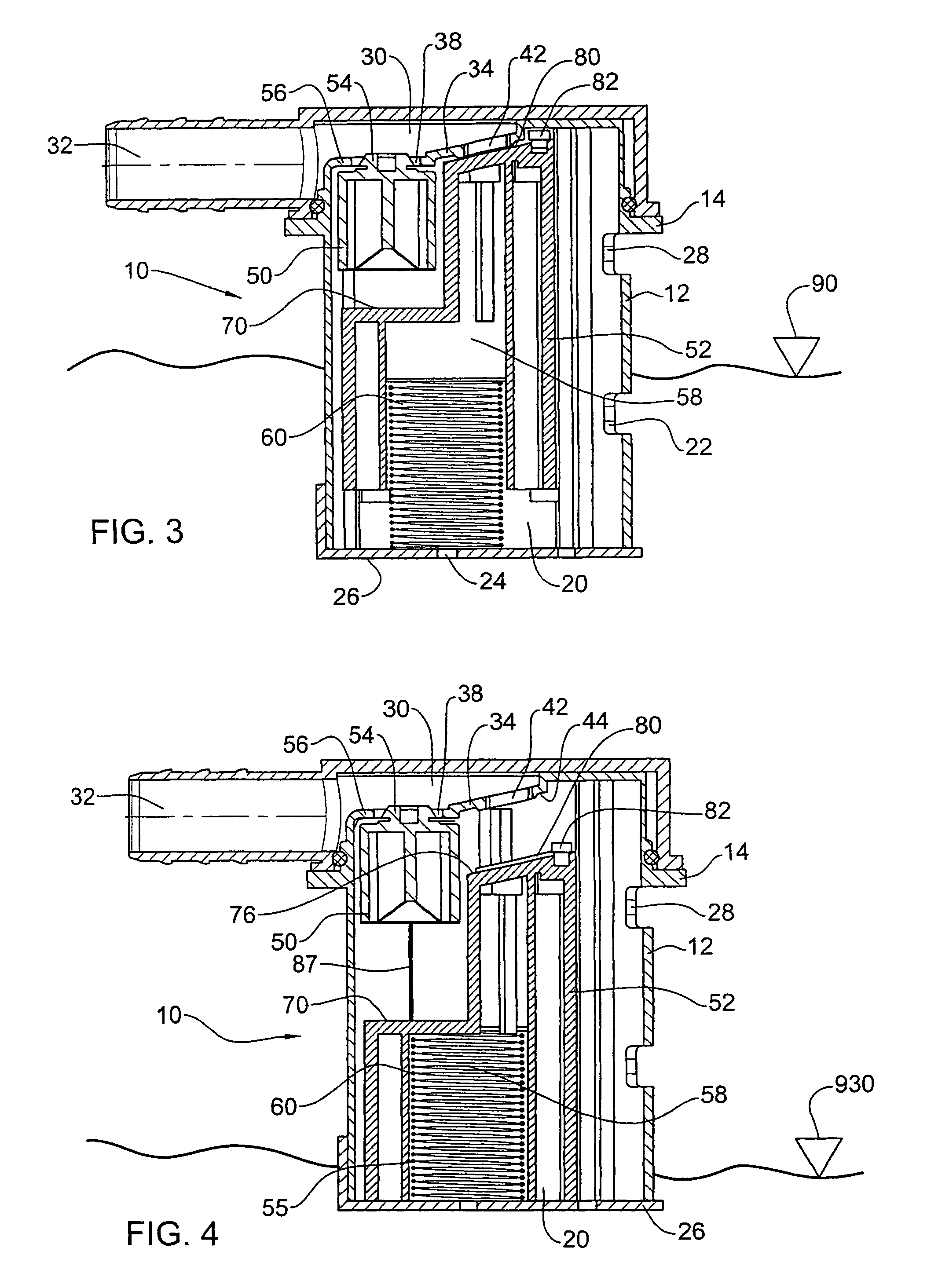

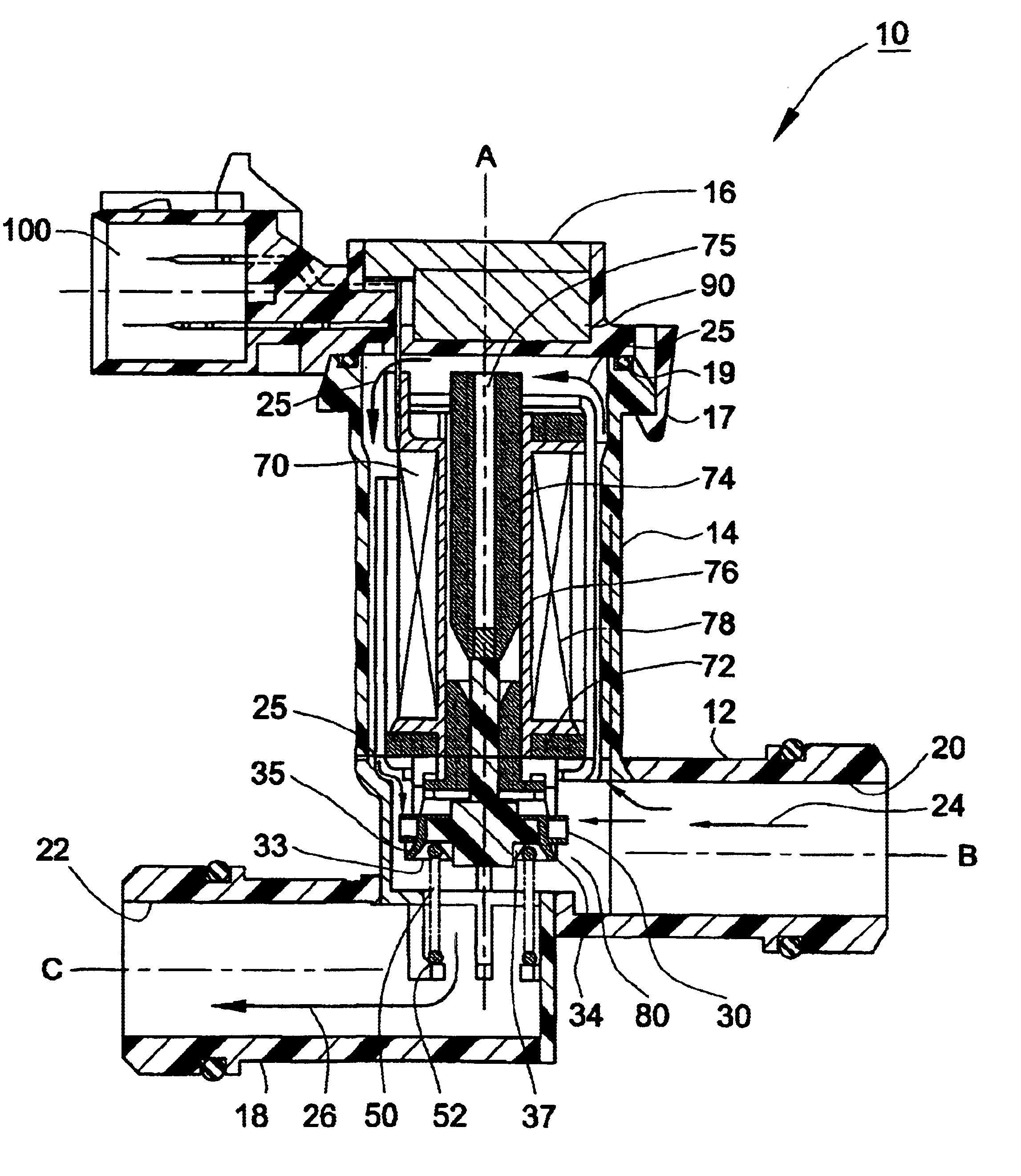

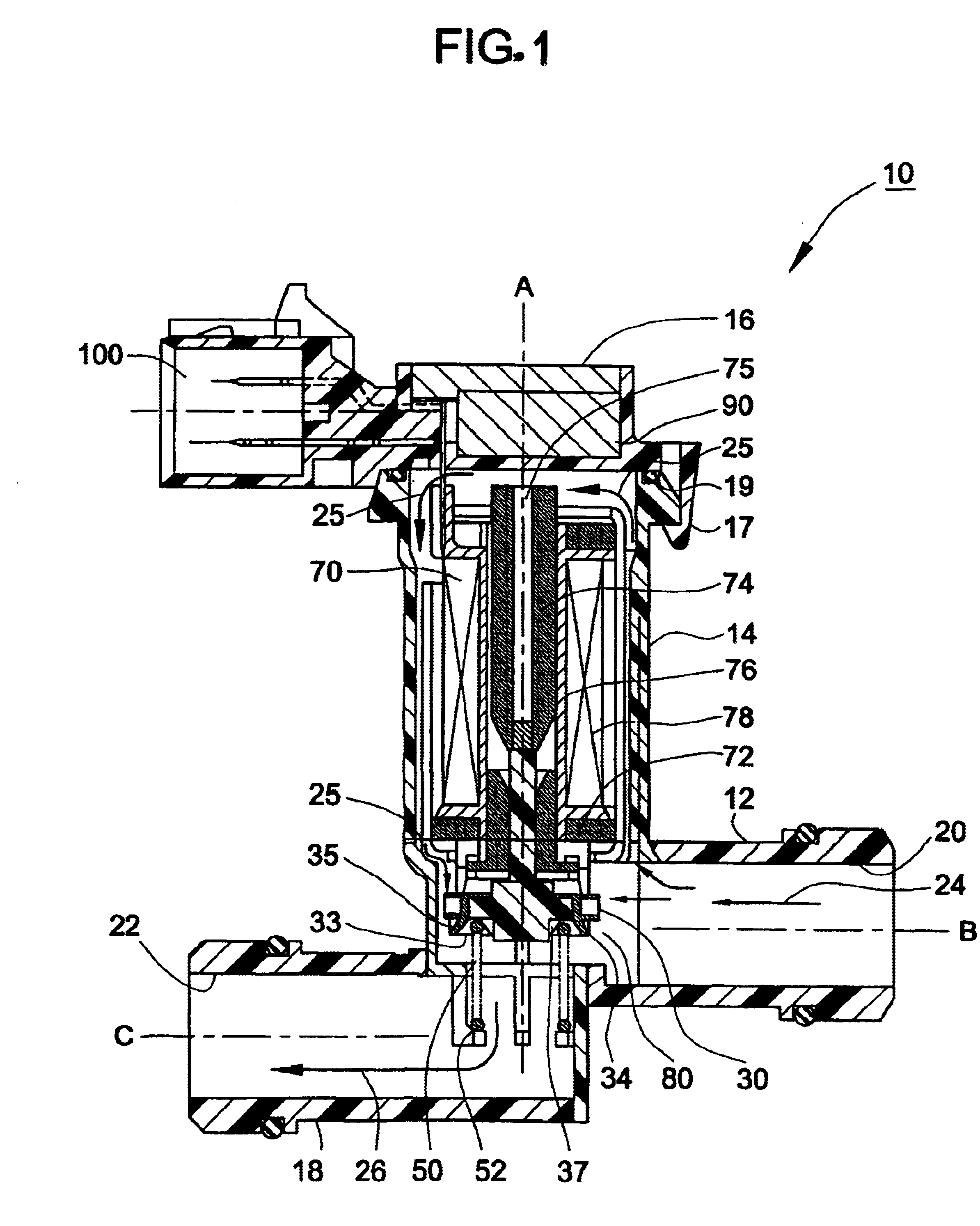

Bipolar valve having permanent magnet

ActiveUS7011076B1Operating means/releasing devices for valvesNon-fuel substance addition to fuelBobbinSolenoid valve

A solenoid for use in valves used in evaporative emission control systems, such as canister purge valves or vent solenoid valves. The solenoid includes a housing having an inlet port and an outlet port. The housing further includes a guide element having a bobbin section. A valve shaft is slidably mounted to the guide element, wherein the valve shaft includes a permanent magnet and a valve element. The valve element is movable between a closed position wherein the inlet port is closed and an open position wherein the inlet port is opened. A coil is formed on the bobbin adjacent the magnet. In use, the coil generates directional magnetic fields oriented to cause the magnet to be repelled to move the valve element to the open position and oriented to cause a magnetic attraction with the magnet to move the valve element to the closed position.

Owner:SIEMENS VDO AUTOMOTIVE CORP

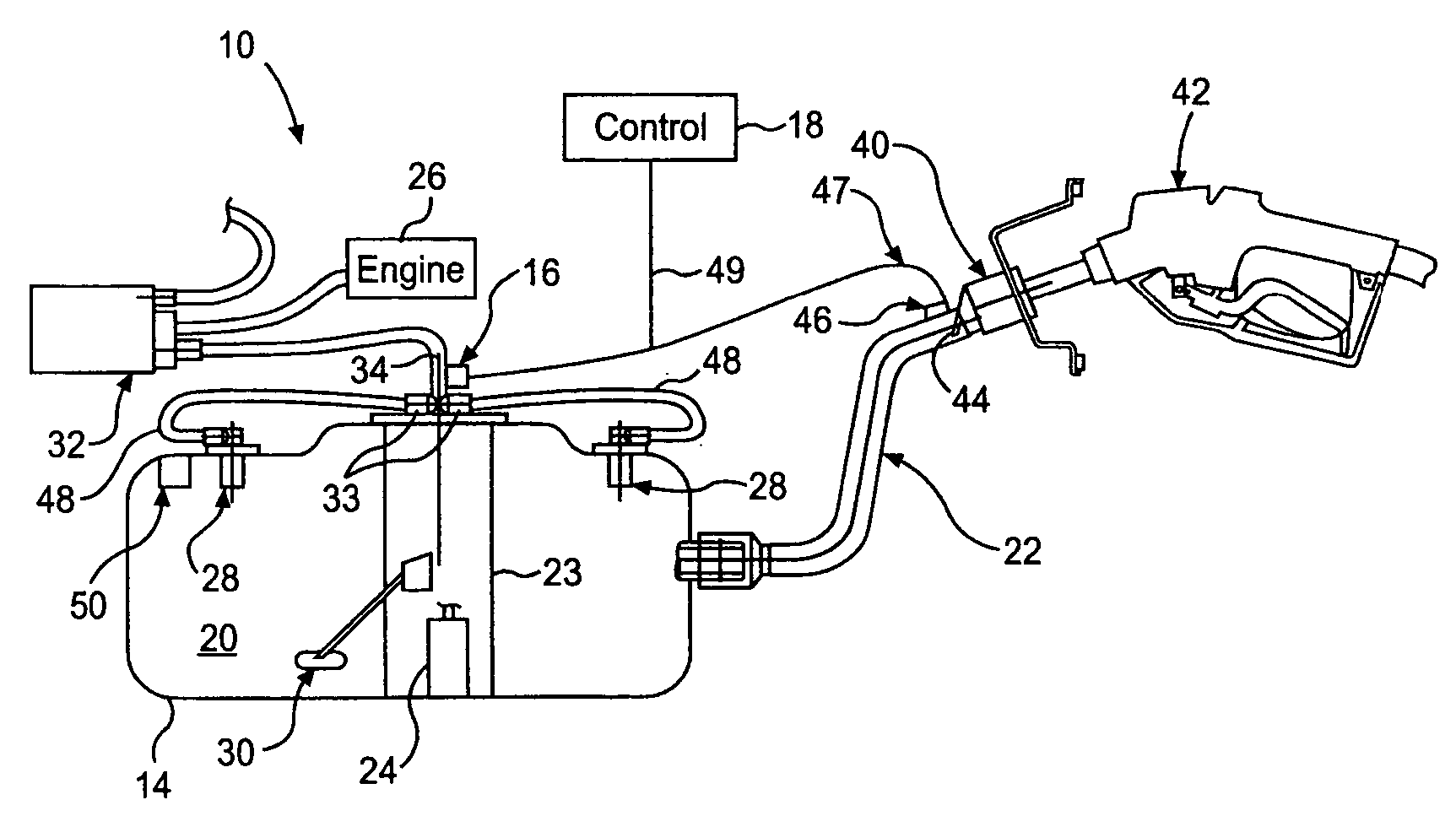

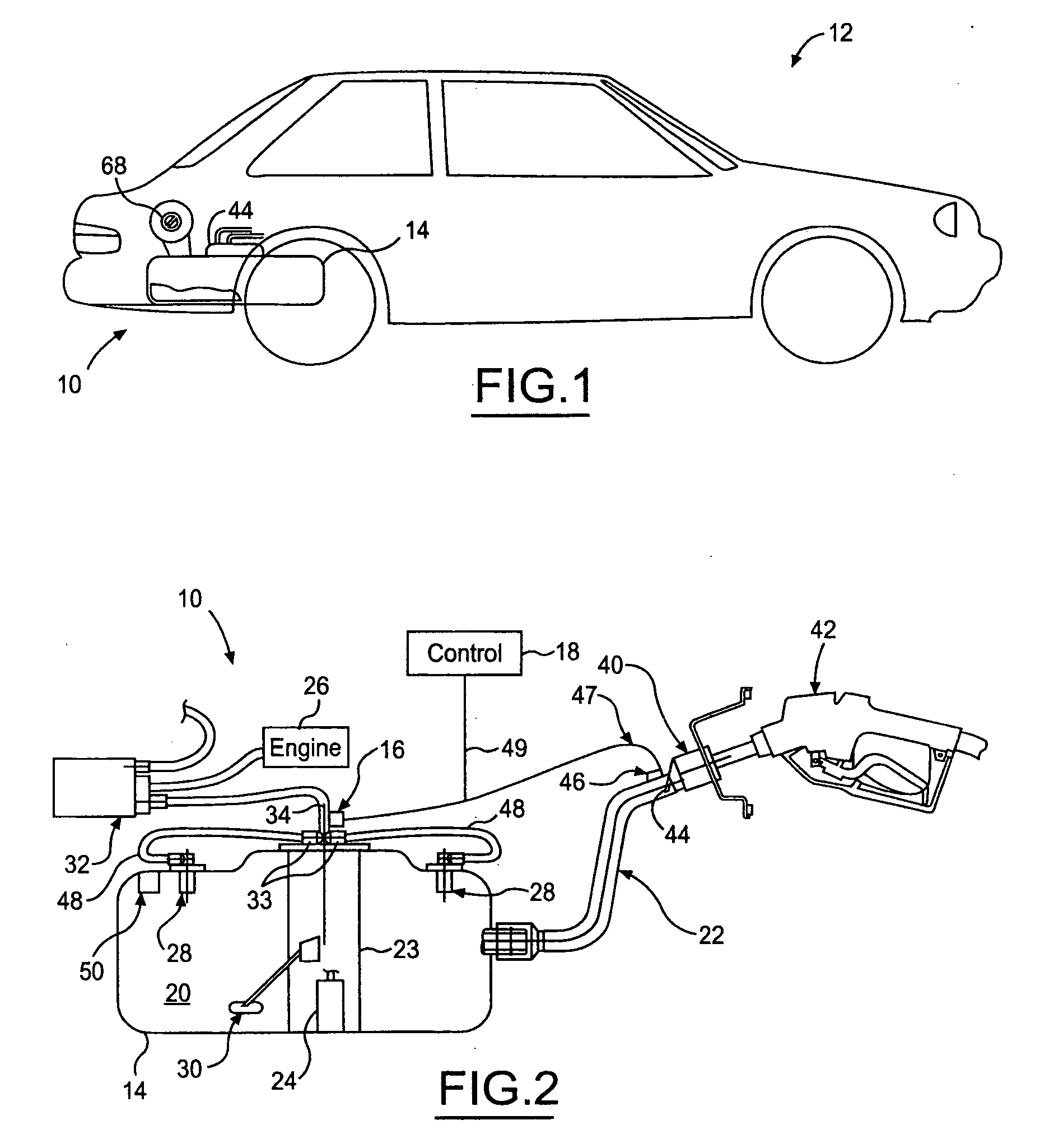

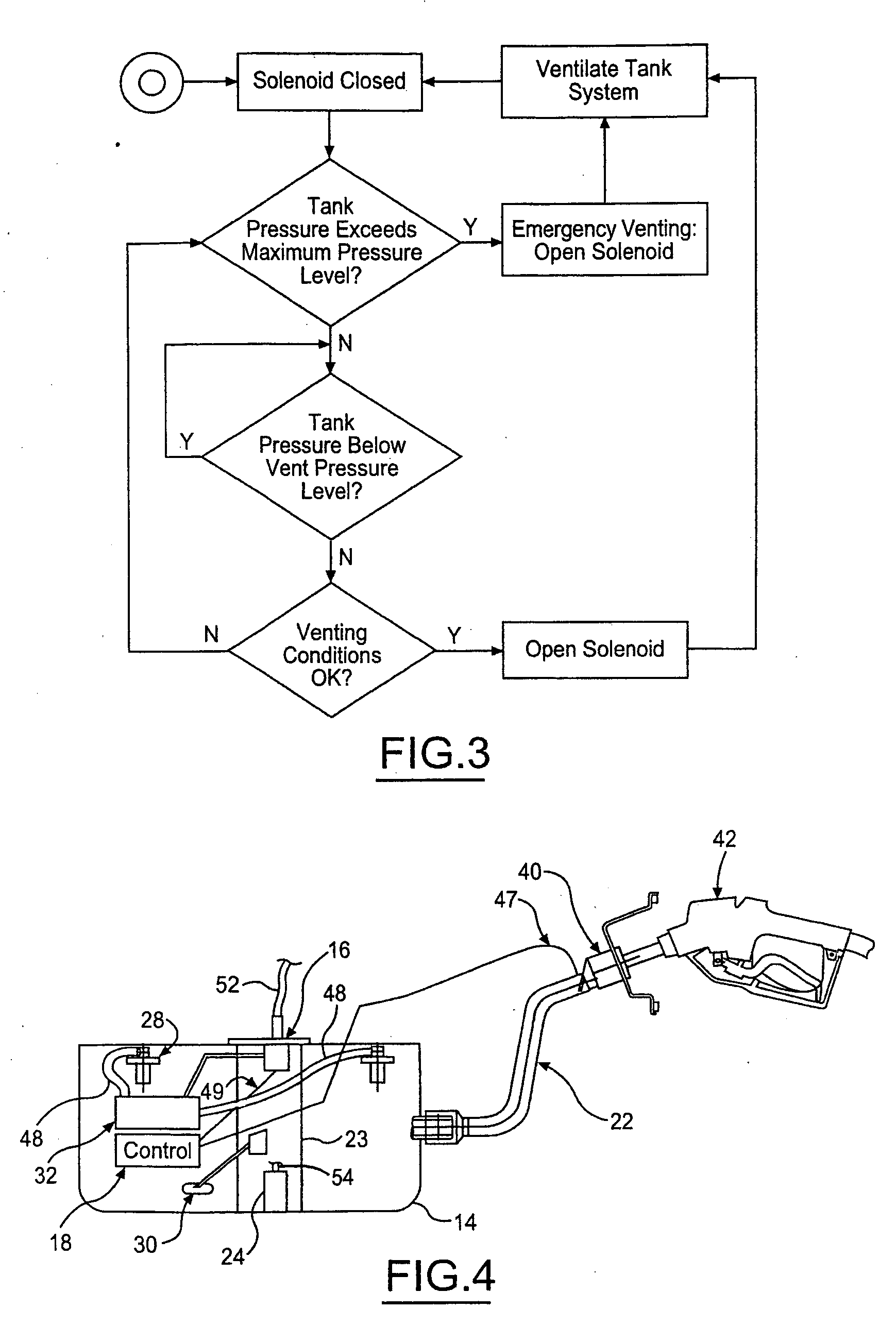

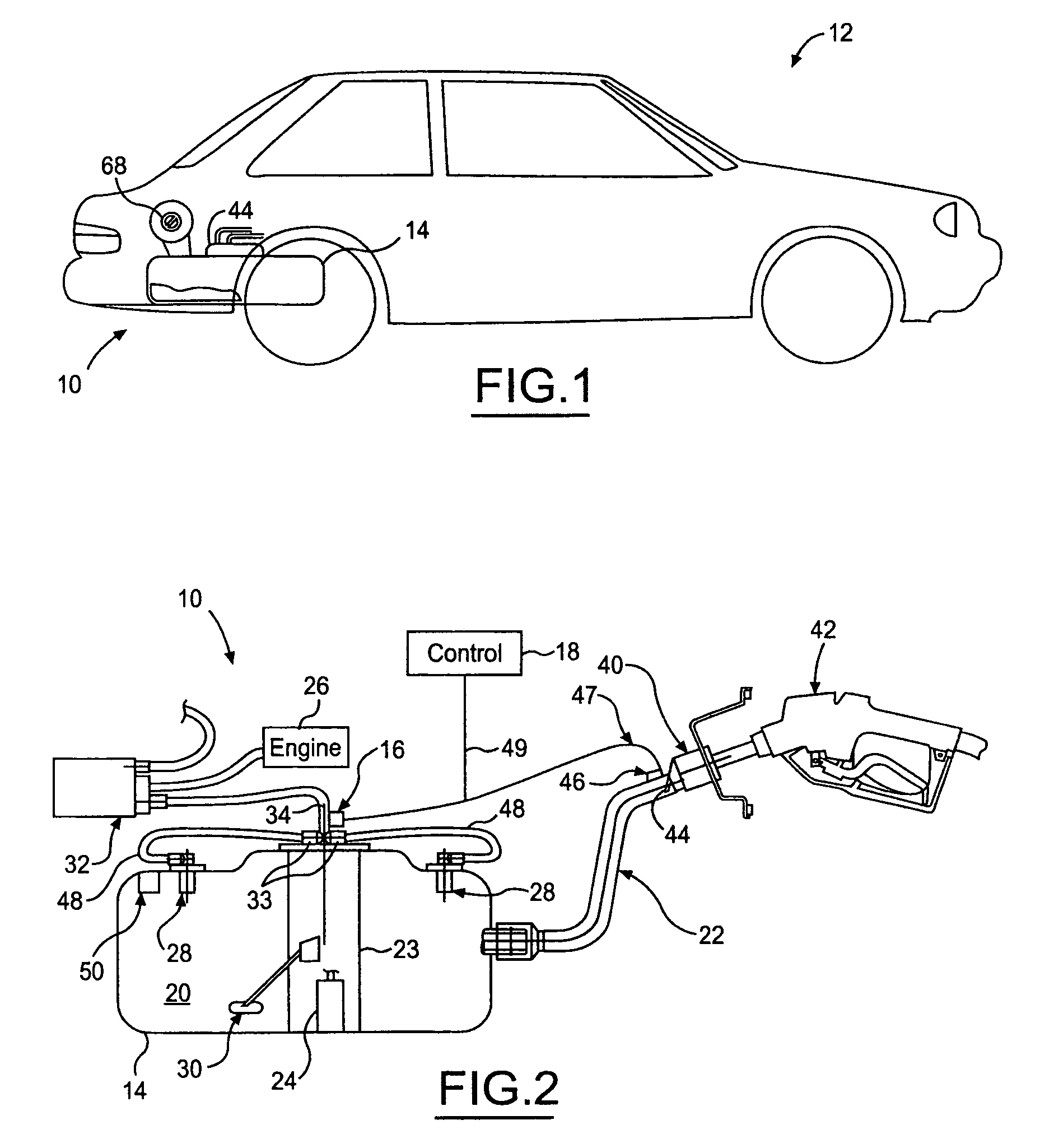

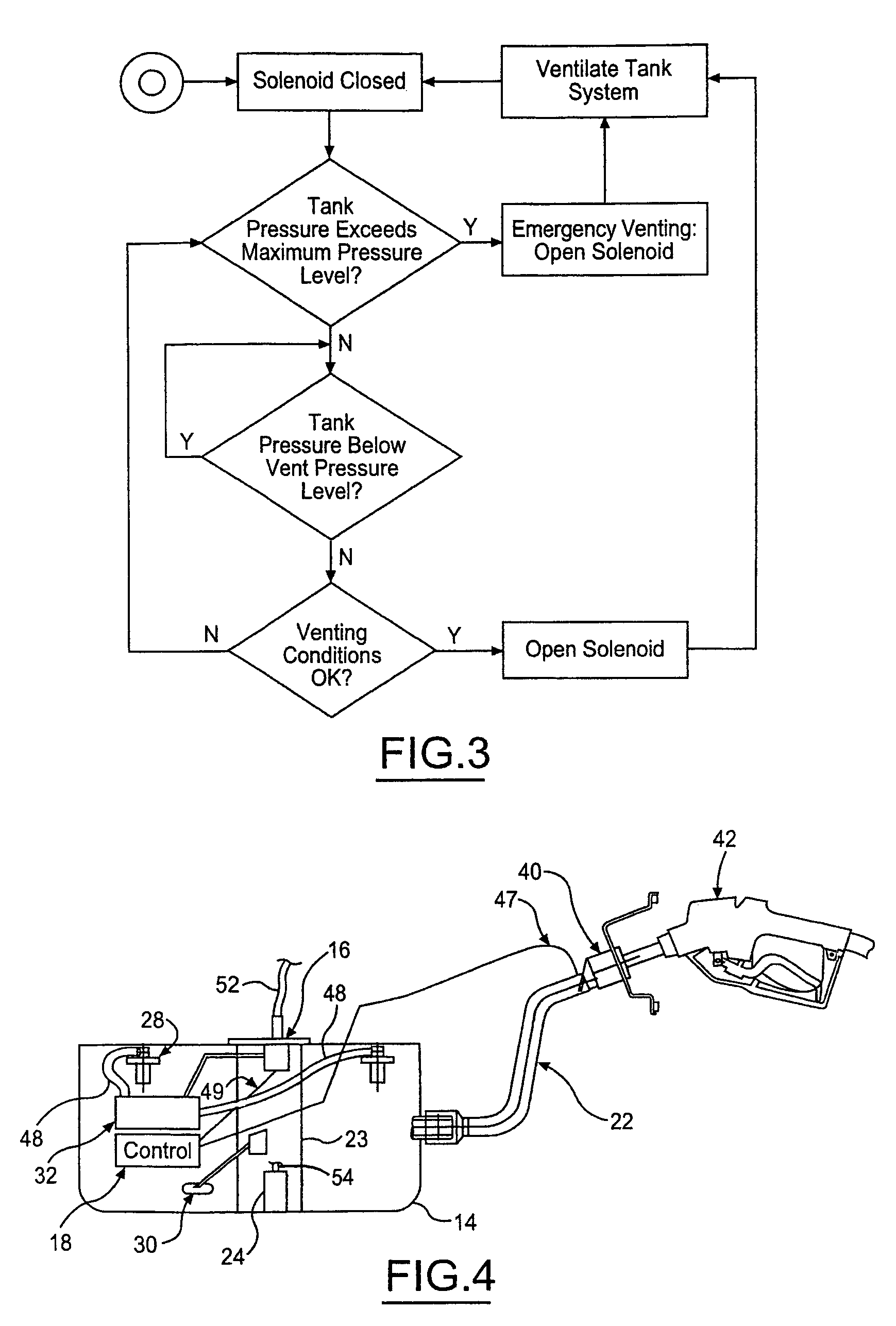

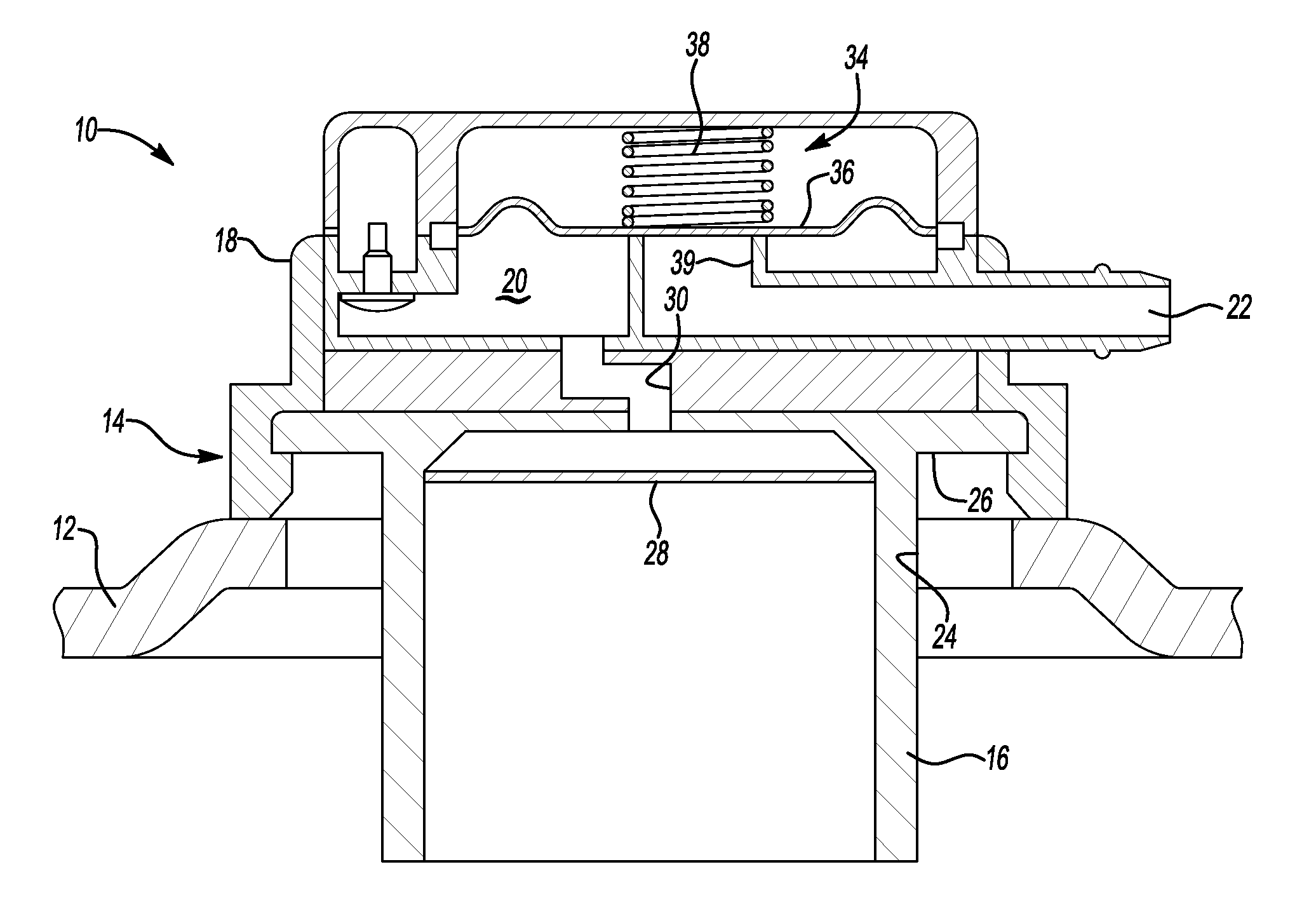

Vehicle fuel system

ActiveUS20050279406A1Increase usable volumeSimple designOperating means/releasing devices for valvesLarge containersEngineeringMovement control

A fuel system with a fuel tank having at least one opening into an interior of the fuel tank, and an electrically operated vent valve having an inlet communicated with the interior of the fuel tank and an outlet for venting fuel vapor from the fuel tank. The vent valve is movable in response to an electric signal between an open position allowing fuel vapor through the outlet and a closed position to restrict fluid flow through the outlet. A controller is operably communicated with the vent valve to control application of an electric signal to the vent valve and thereby control at least in part the movement of the vent valve between its open and closed positions. In one embodiment the controller is responsive to a fill level in the fuel tank to control the position of the vent valve and thereby the fill level attained within the fuel tank.

Owner:TI GRP AUTOMOTIVE SYST LLC

Roll over vent valve

ActiveUS8109285B2Severe consequenceSevere safetyNon-fuel substance addition to fuelCheck valvesExhaust valveInlet valve

A roll-over vent valve comprising a housing formed with a fluid inlet and a fluid outlet, a valve seating bounding an outlet aperture of the housing, a float member received within the housing and axially displaceable between a sealed position wherein a sealing member thereof sealingly bears against the valve seating of the outlet aperture to seal the fluid outlet, and an open position wherein the sealing member is disengaged from the valve seating whereby the fluid outlet is in flow communication with the fluid inlet. There is further provided a pressure-retention device extending intermediate the valve seating and the fluid outlet, to thereby shut fluid flow therebetween as long as pressure differential between the fluid inlet and the fluid outlet does not exceed a minimal pressure threshold. The valve further comprises a one-way fluid inlet valve being in flow communication with said fluid outlet to allow fluid flow towards said fluid inlet a substantially high flow rate at the event of under-pressure at the fluid inlet.

Owner:RAVAL - AGRI COOP SOCIETIES

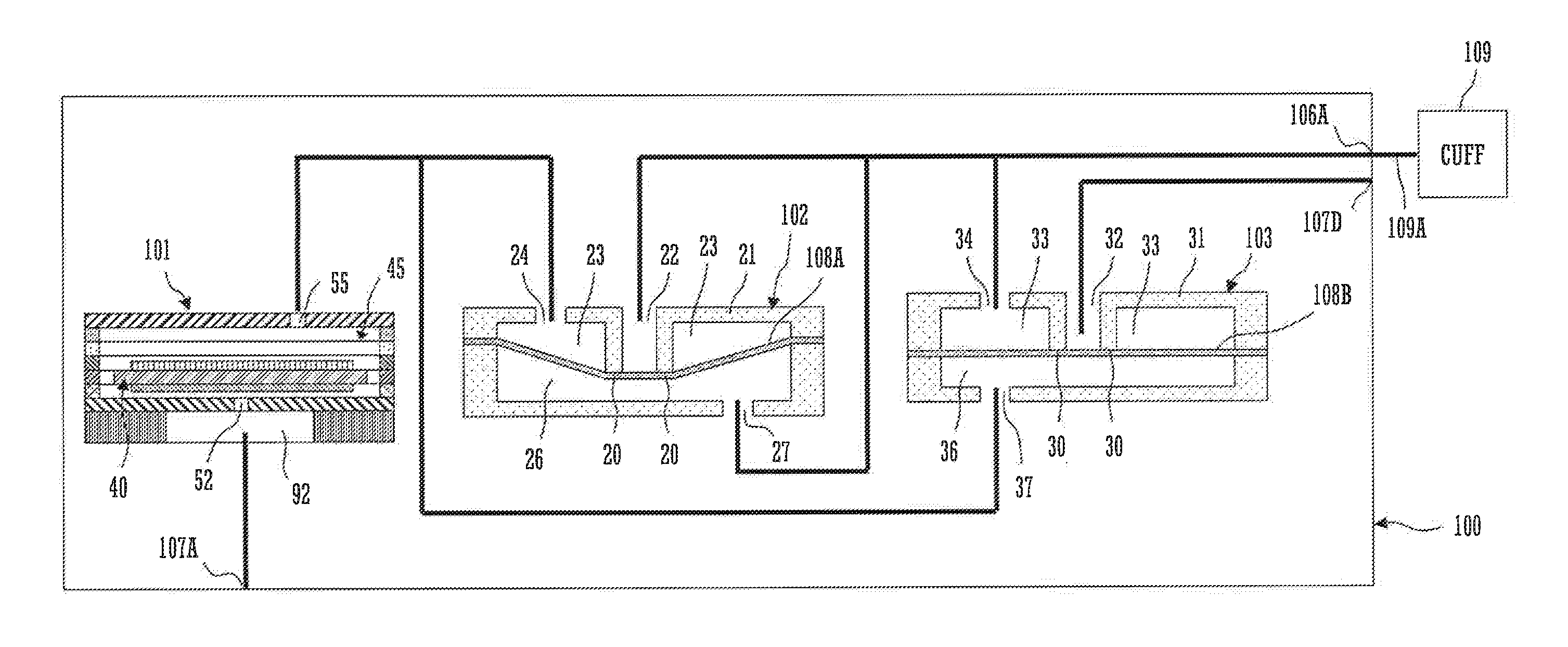

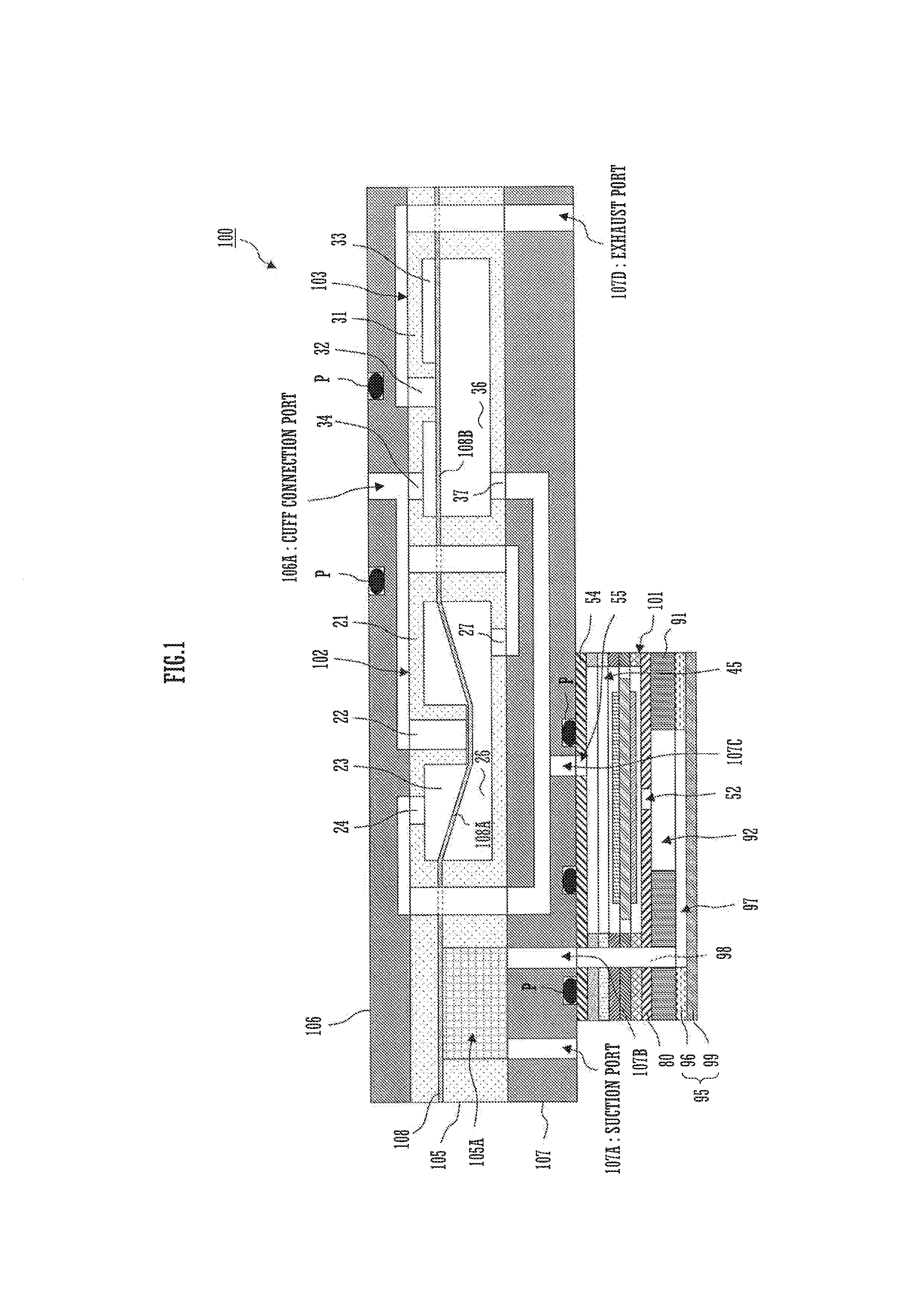

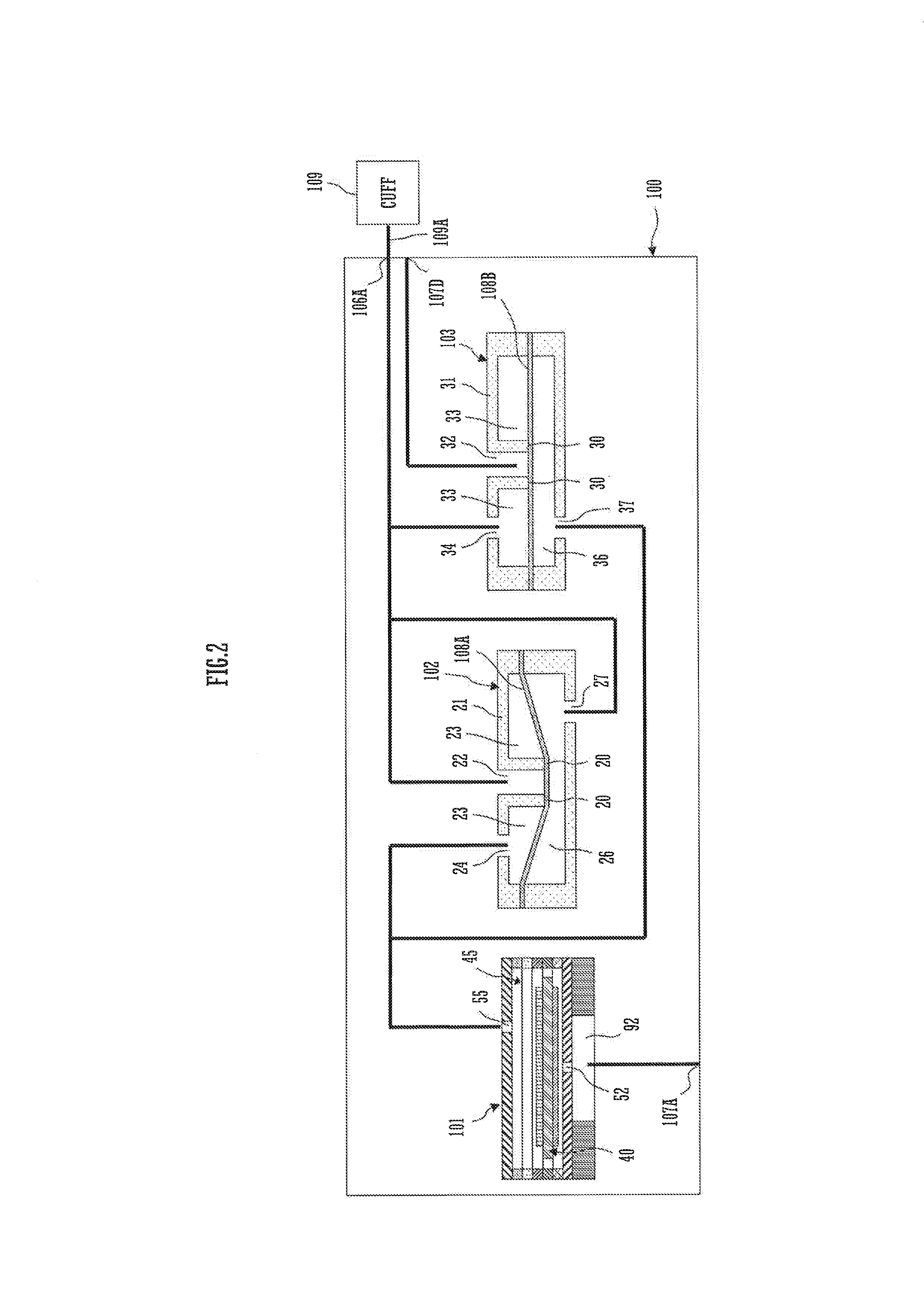

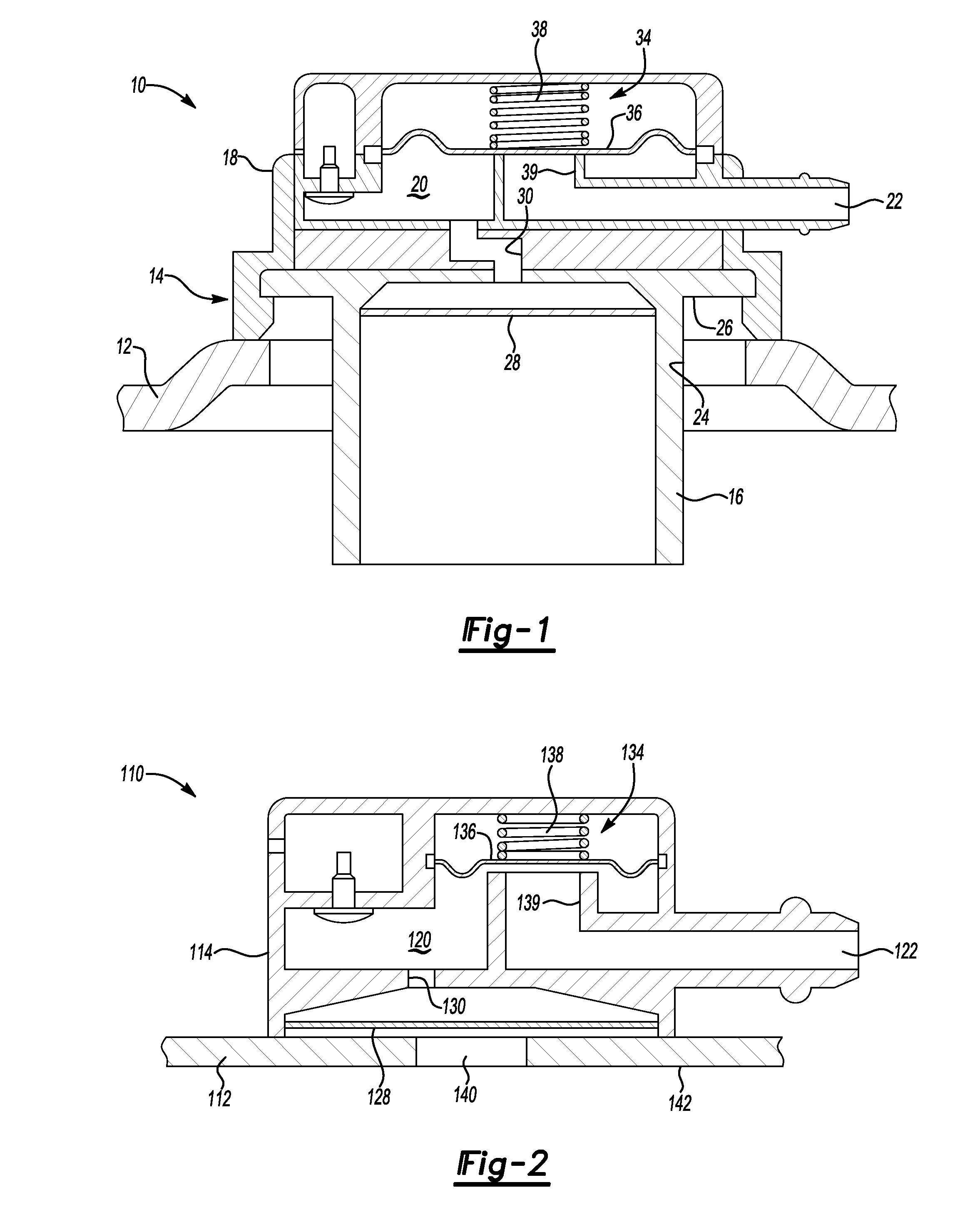

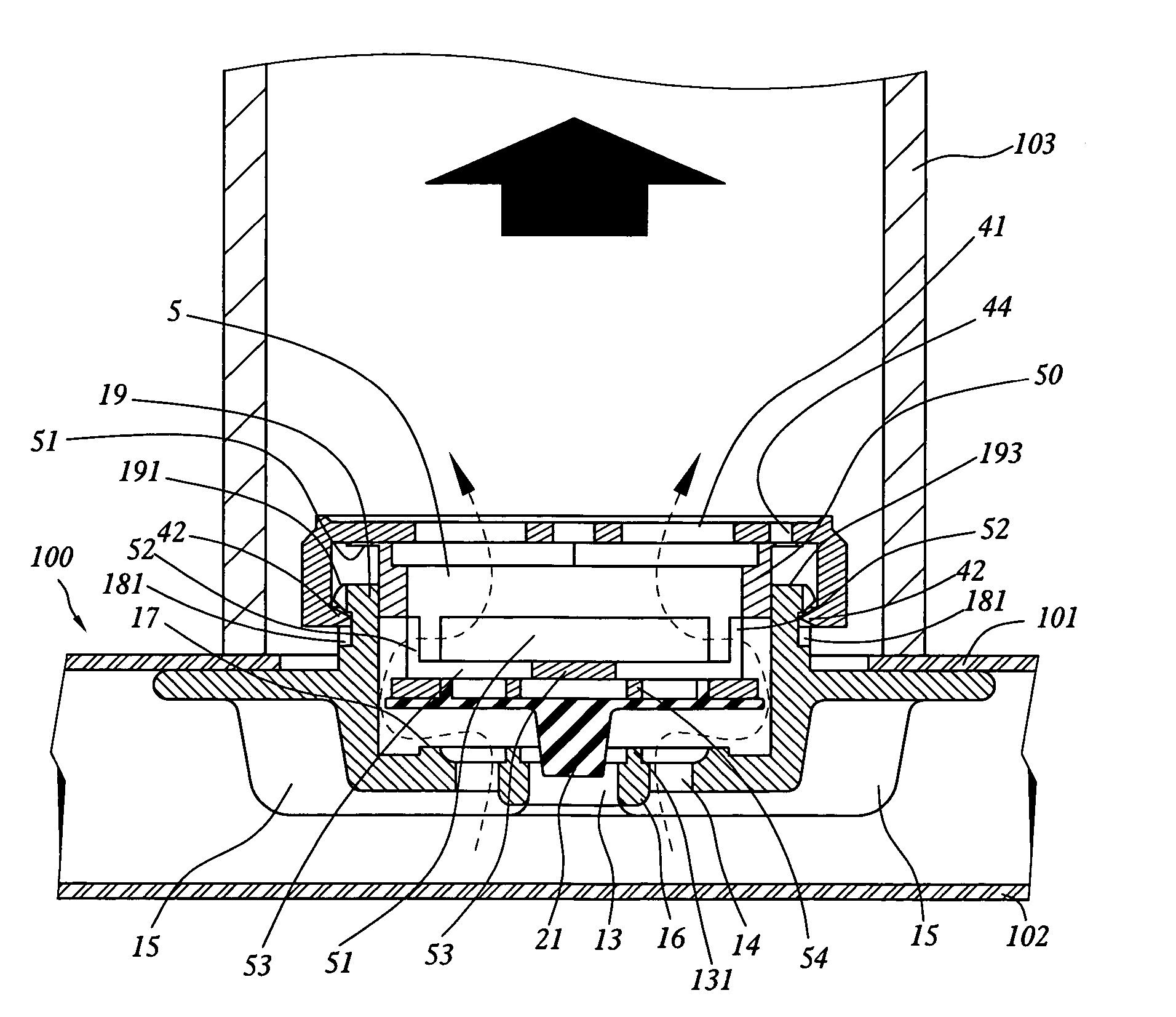

Valve, fluid control device

ActiveUS20130178752A1Small and low profileReduce manufacturing costEngine diaphragmsFlexible member pumpsFluid controlExhaust valve

In a fluid control device, a check valve includes a first valve housing and a first diaphragm. The first diaphragm defines a first valve chamber and a second valve chamber. An exhaust valve includes a second valve housing and a second diaphragm. The second diaphragm defines a third valve chamber and a fourth valve chamber. The check valve is opened and closed by a difference in pressure between the first valve chamber and the second valve chamber. The exhaust valve is opened and closed by a difference in pressure between the third valve chamber and the fourth valve chamber.

Owner:MURATA MFG CO LTD +1

Vehicle fuel system

ActiveUS7347191B2Increase usable volumeOperating means/releasing devices for valvesLarge containersExhaust valveEngineering

A fuel system with a fuel tank having at least one opening into an interior of the fuel tank, and an electrically operated vent valve having an inlet communicated with the interior of the fuel tank and an outlet for venting fuel vapor from the fuel tank. The vent valve is movable in response to an electric signal between an open position allowing fuel vapor through the outlet and a closed position to restrict fluid flow through the outlet. A controller is operably communicated with the vent valve to control application of an electric signal to the vent valve and thereby control at least in part the movement of the vent valve between its open and closed positions. In one embodiment the controller is responsive to a fill level in the fuel tank to control the position of the vent valve and thereby the fill level attained within the fuel tank.

Owner:TI GRP AUTOMOTIVE SYST LLC

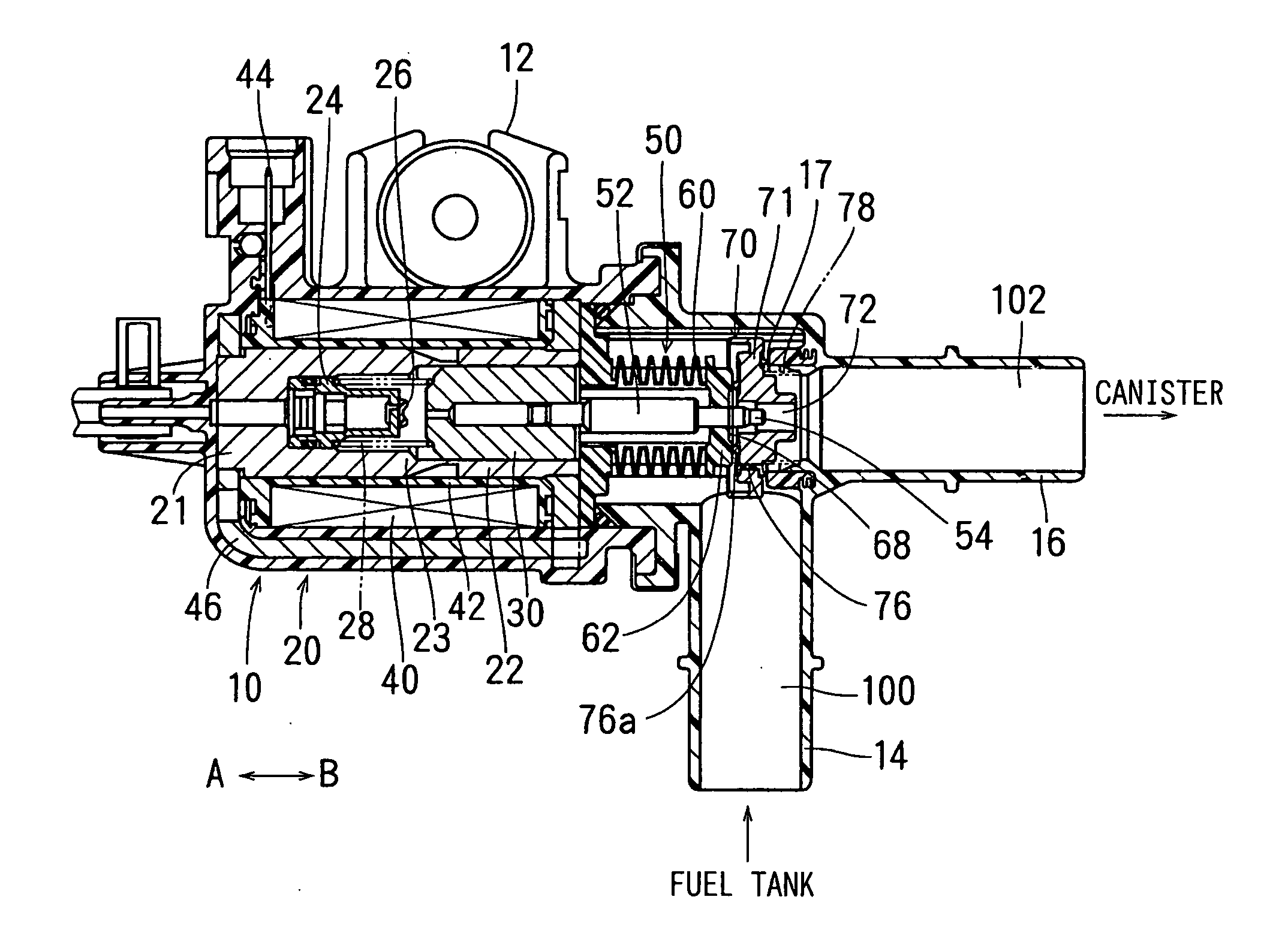

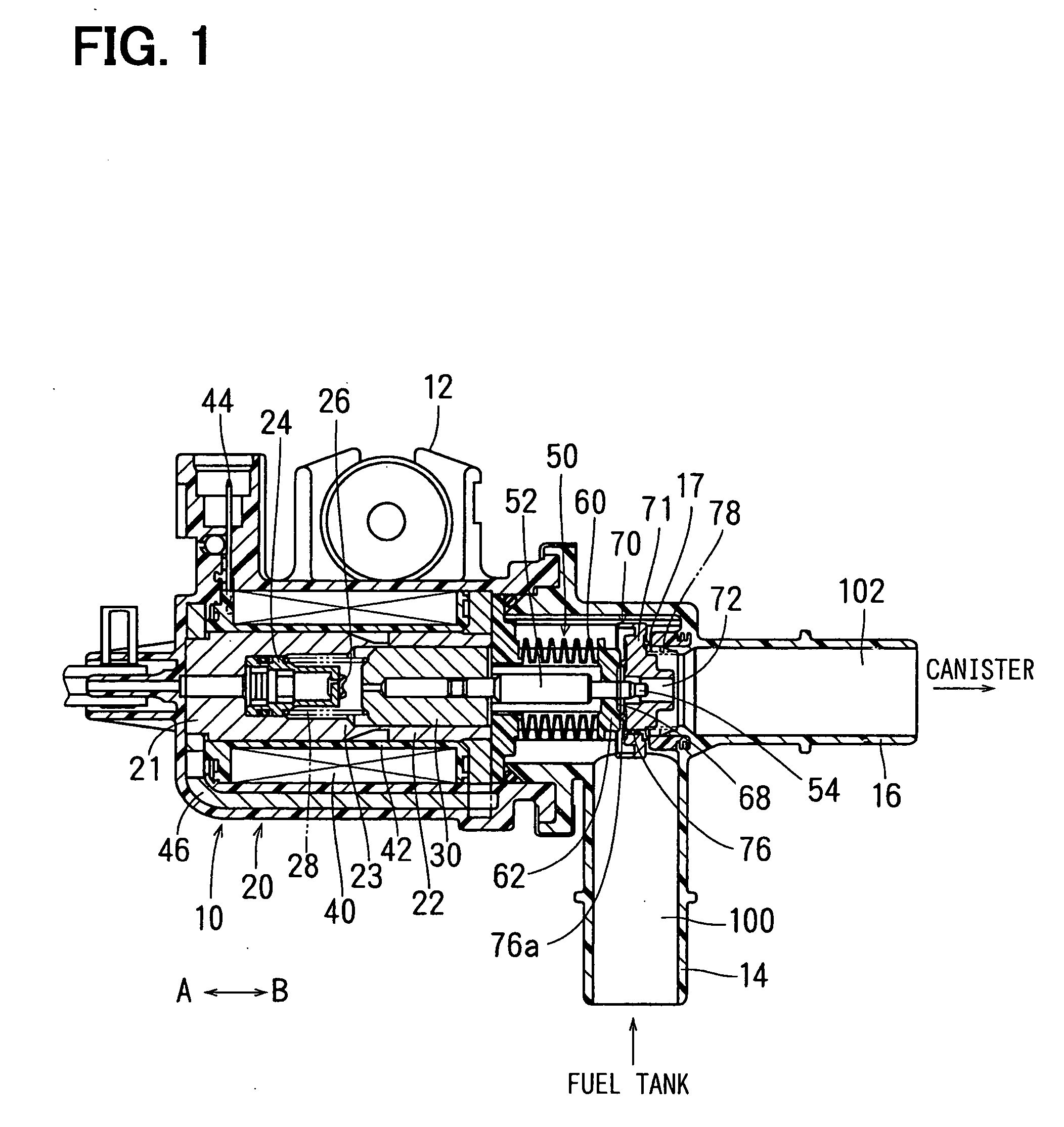

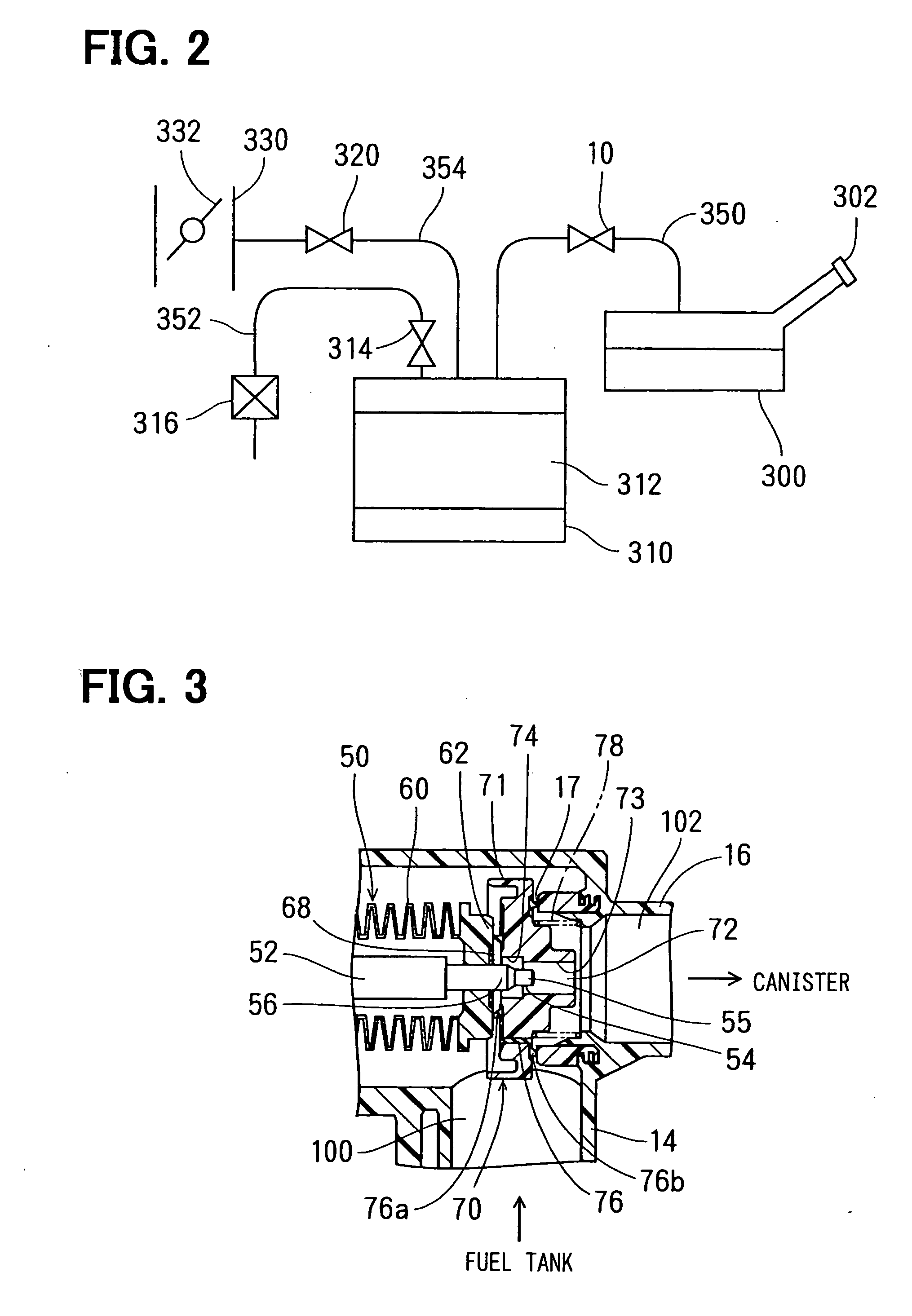

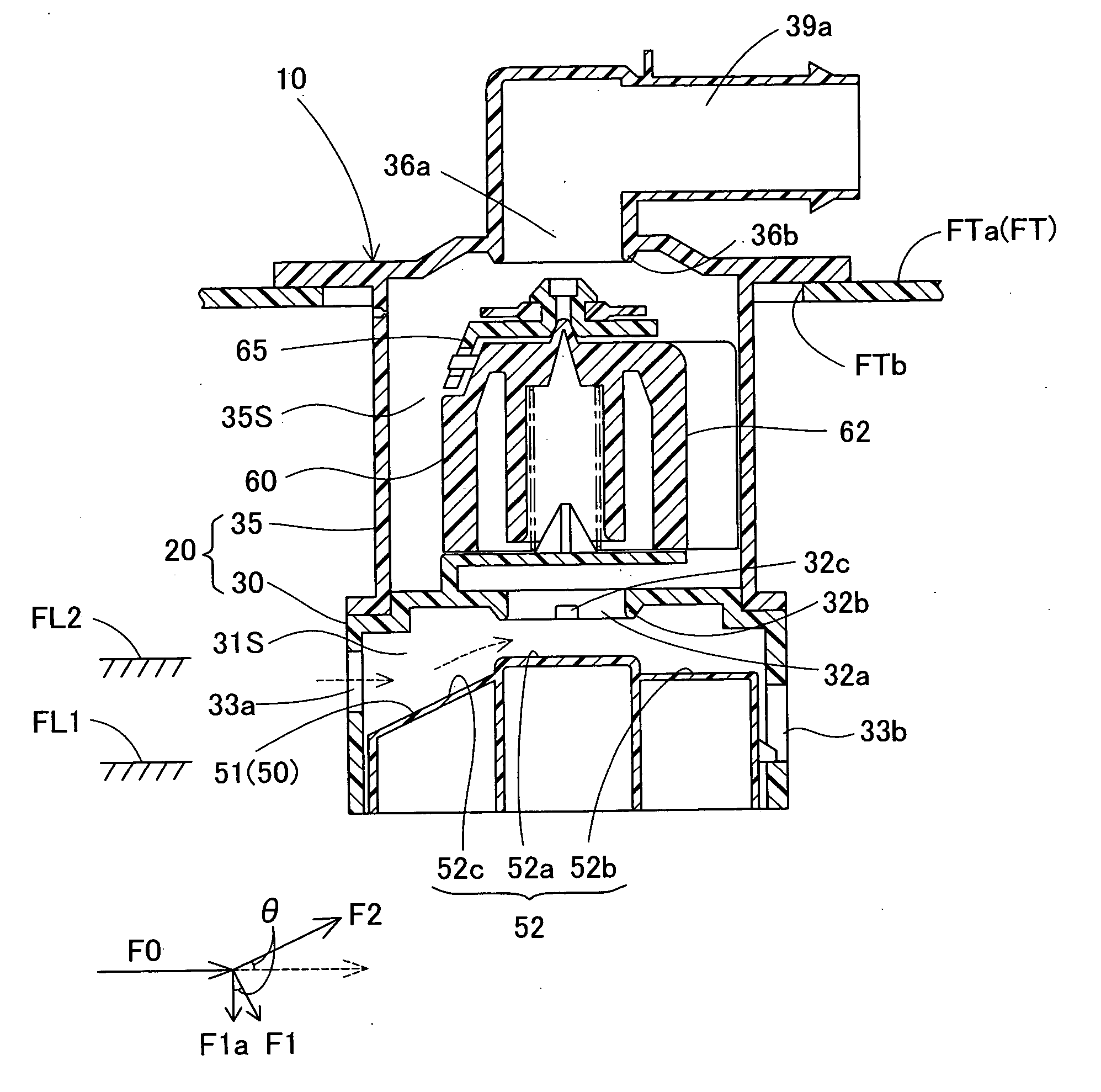

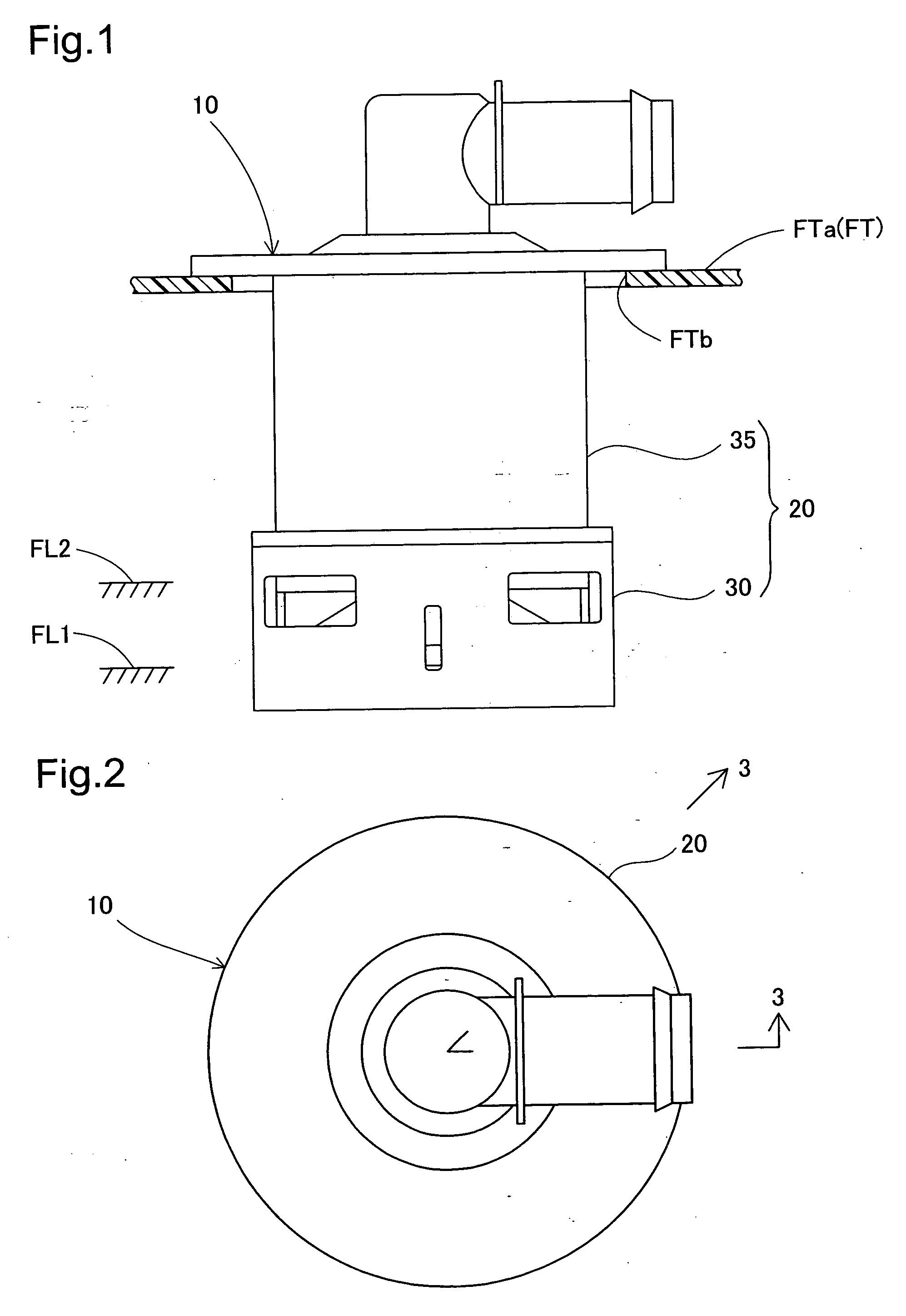

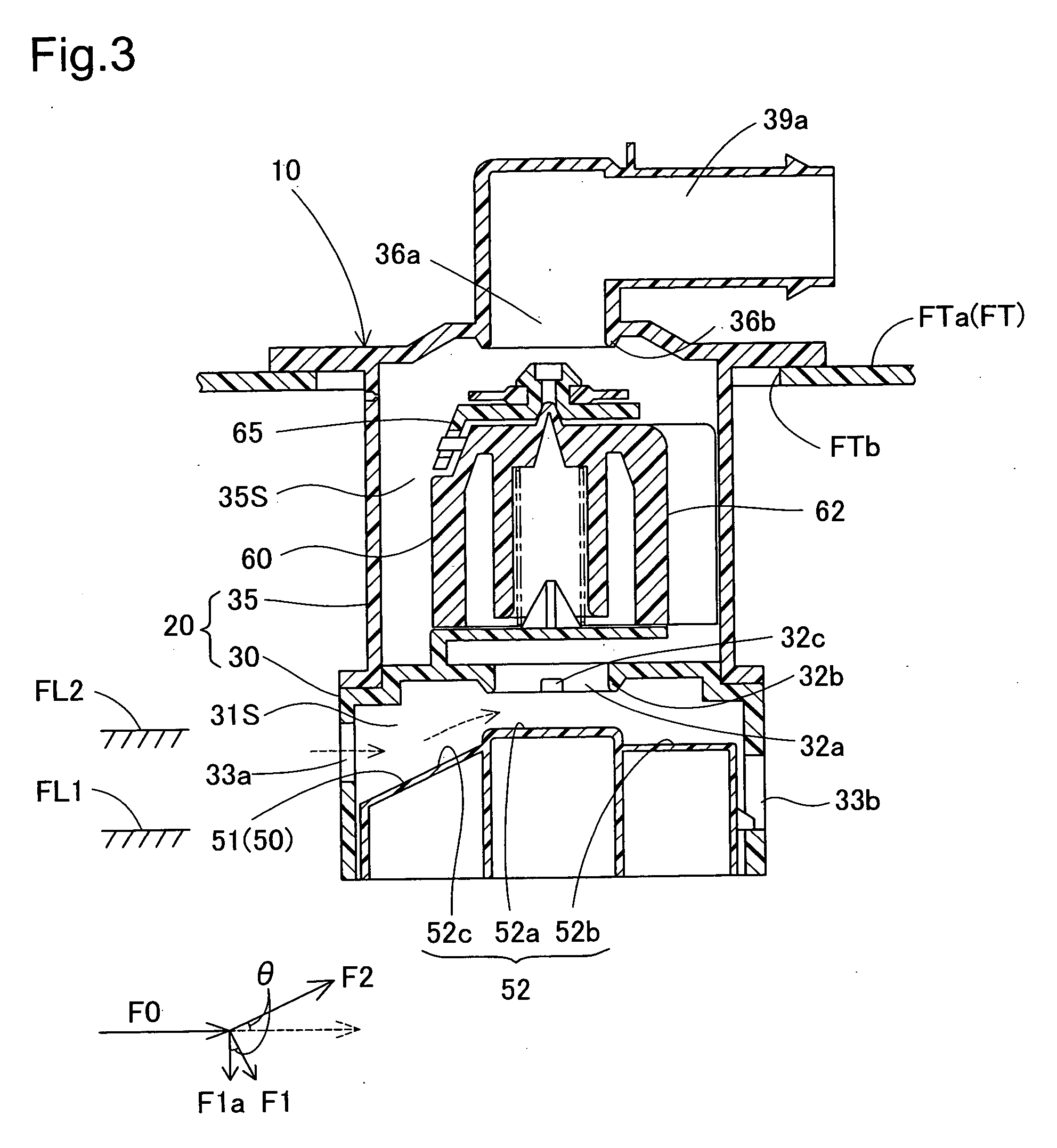

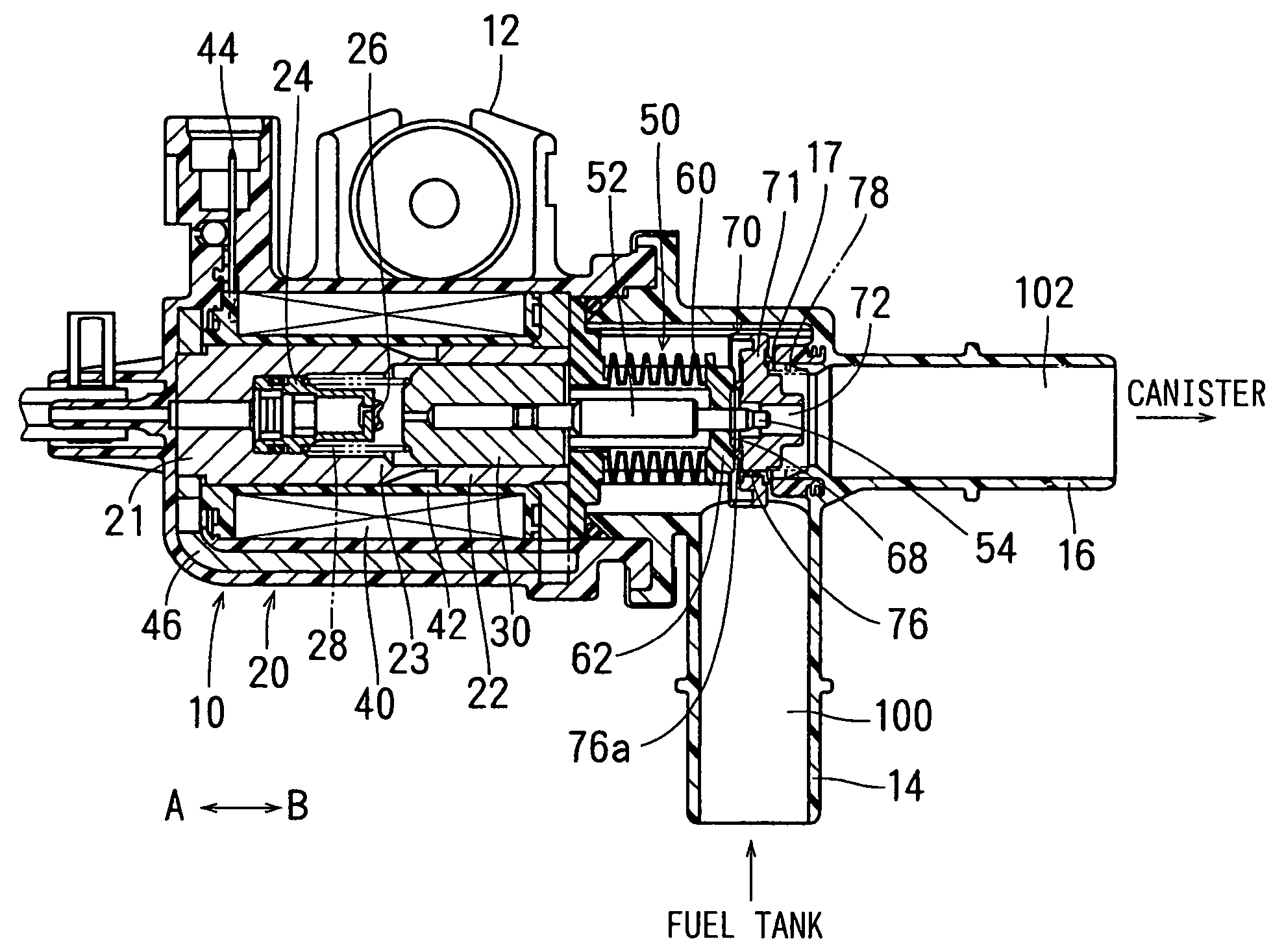

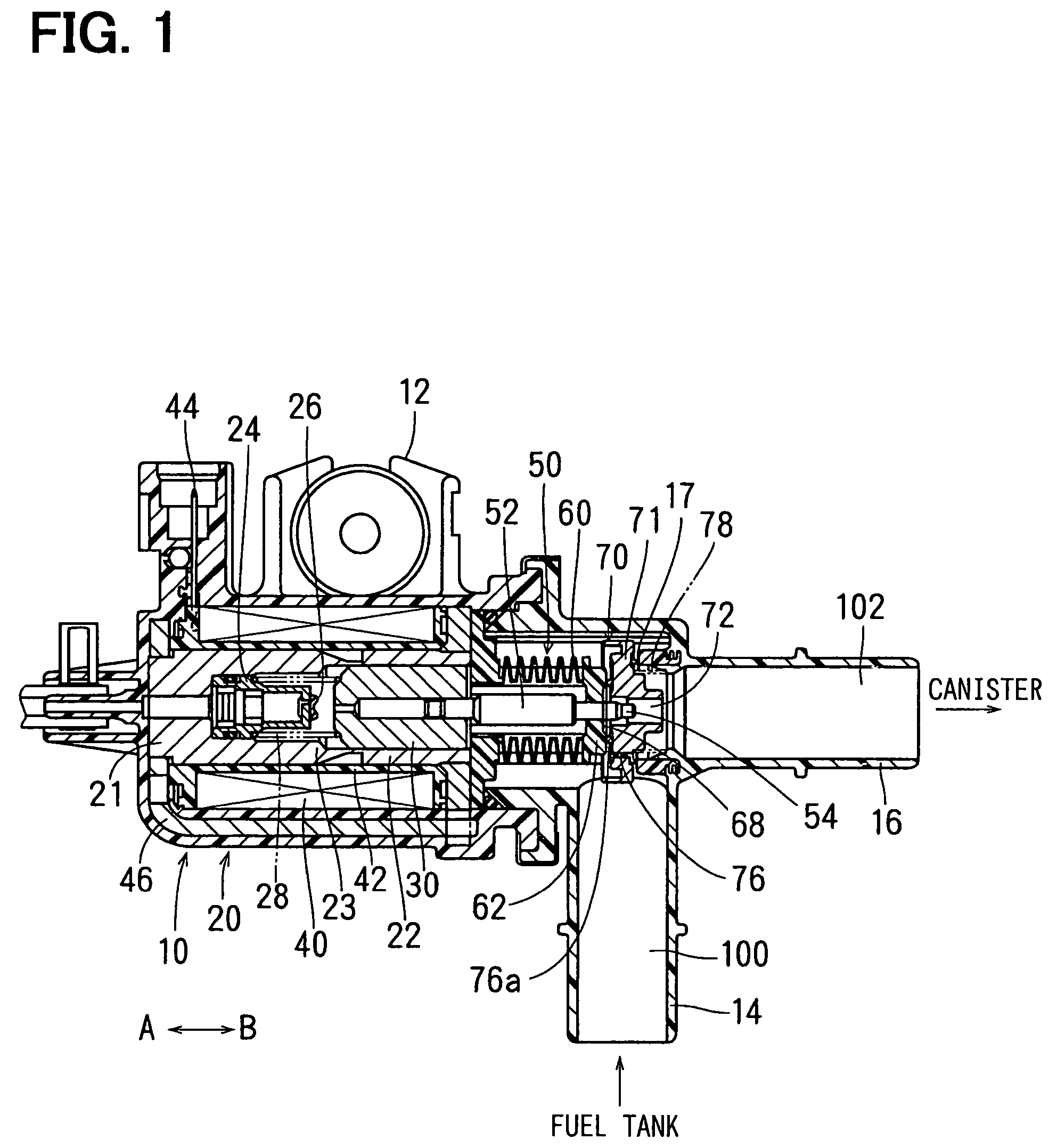

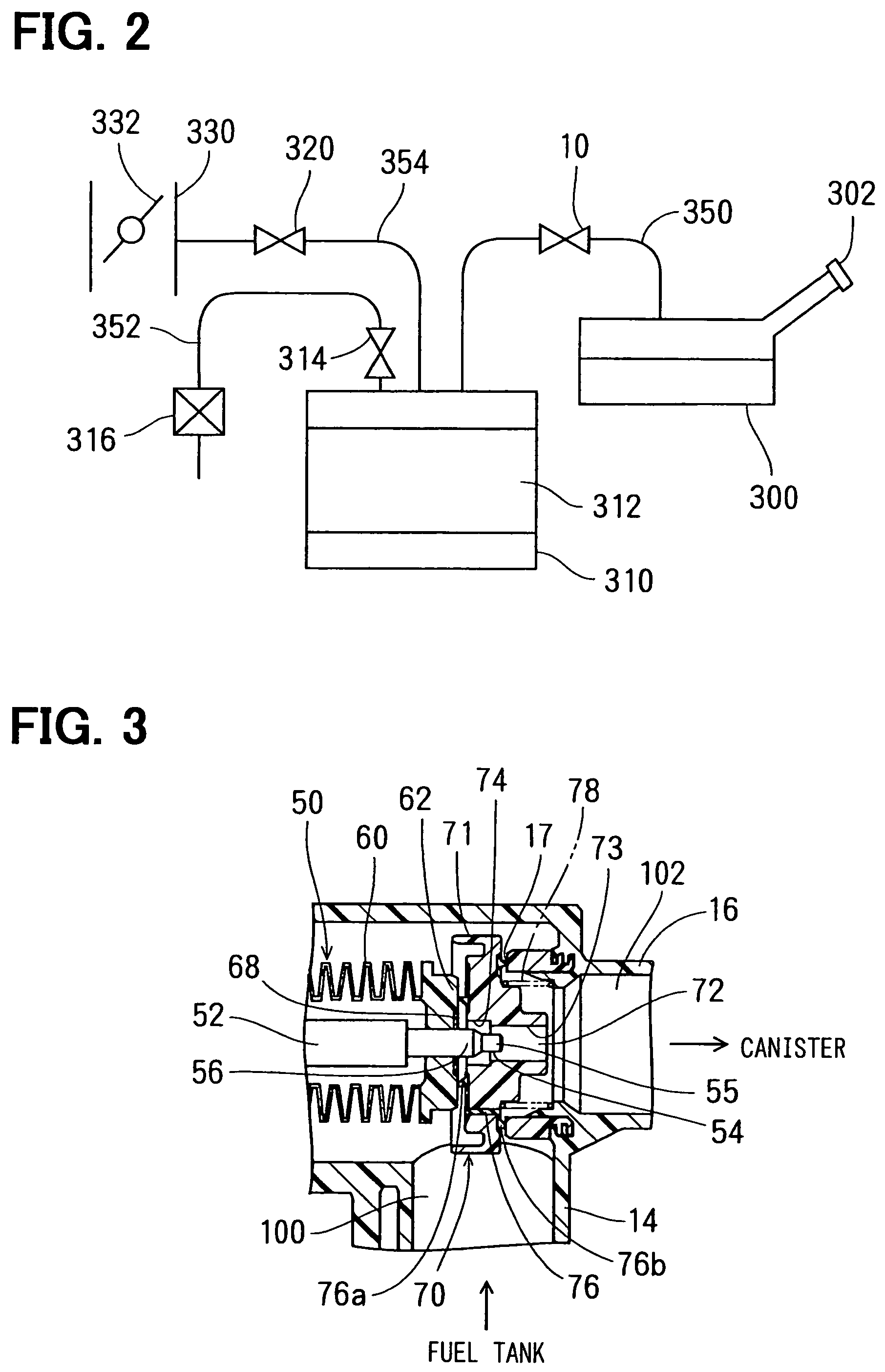

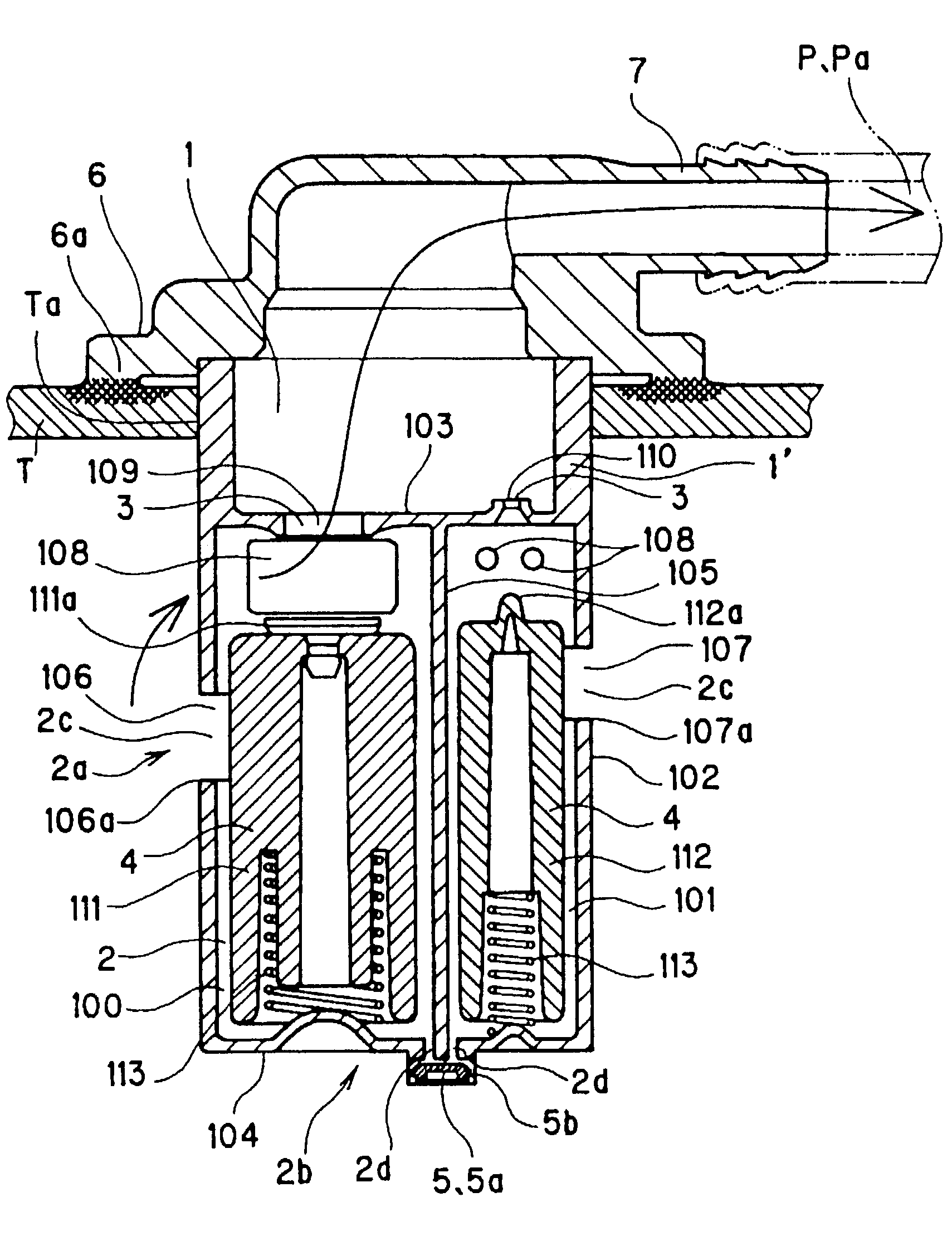

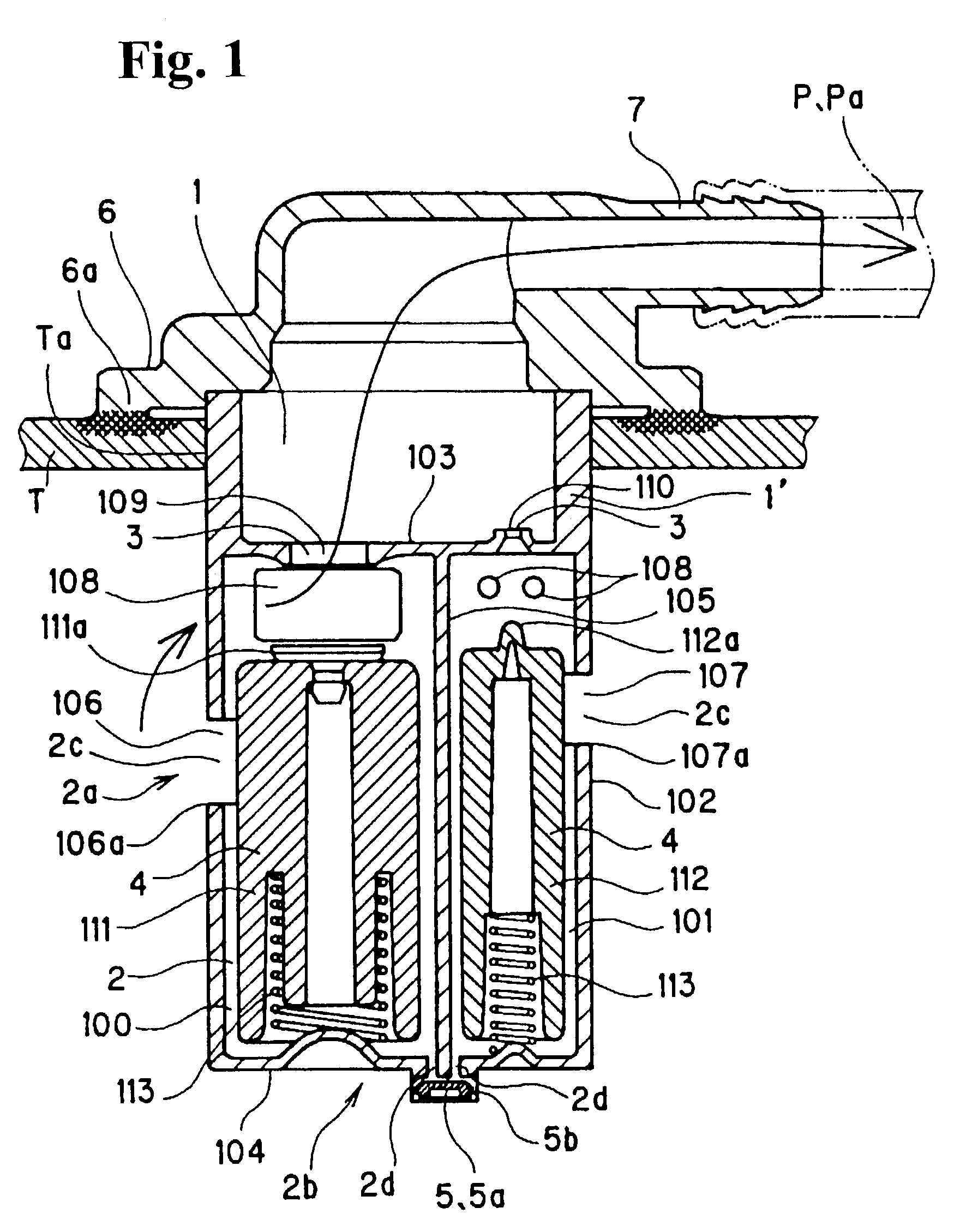

Electromagnetic valve and vapor fuel treating system applying the same

ActiveUS20050217734A1Increase the opening areaPreventing flow communicationDiaphragm valvesOperating means/releasing devices for valvesSolenoid valveFuel treatment

A first connecting pipe of an electromagnetic valve connects with the fuel tank, and a second connecting pipe connects with a canister. A spring urges a moving core and a first valve body in a closing direction of a electromagnetic valve. A shaft of the first valve body includes a fluid-amount controlling portion on the top. The fluid-amount controlling portion is inserted to the communicating passage while a contact member of bellows seats on a convex of a rubber member, and is tapered in an inserted direction. When a coil is energized, the first valve body is lifted in the direction in which the fluid-amount controlling portion retracts from the communicating passage.

Owner:DENSO CORP

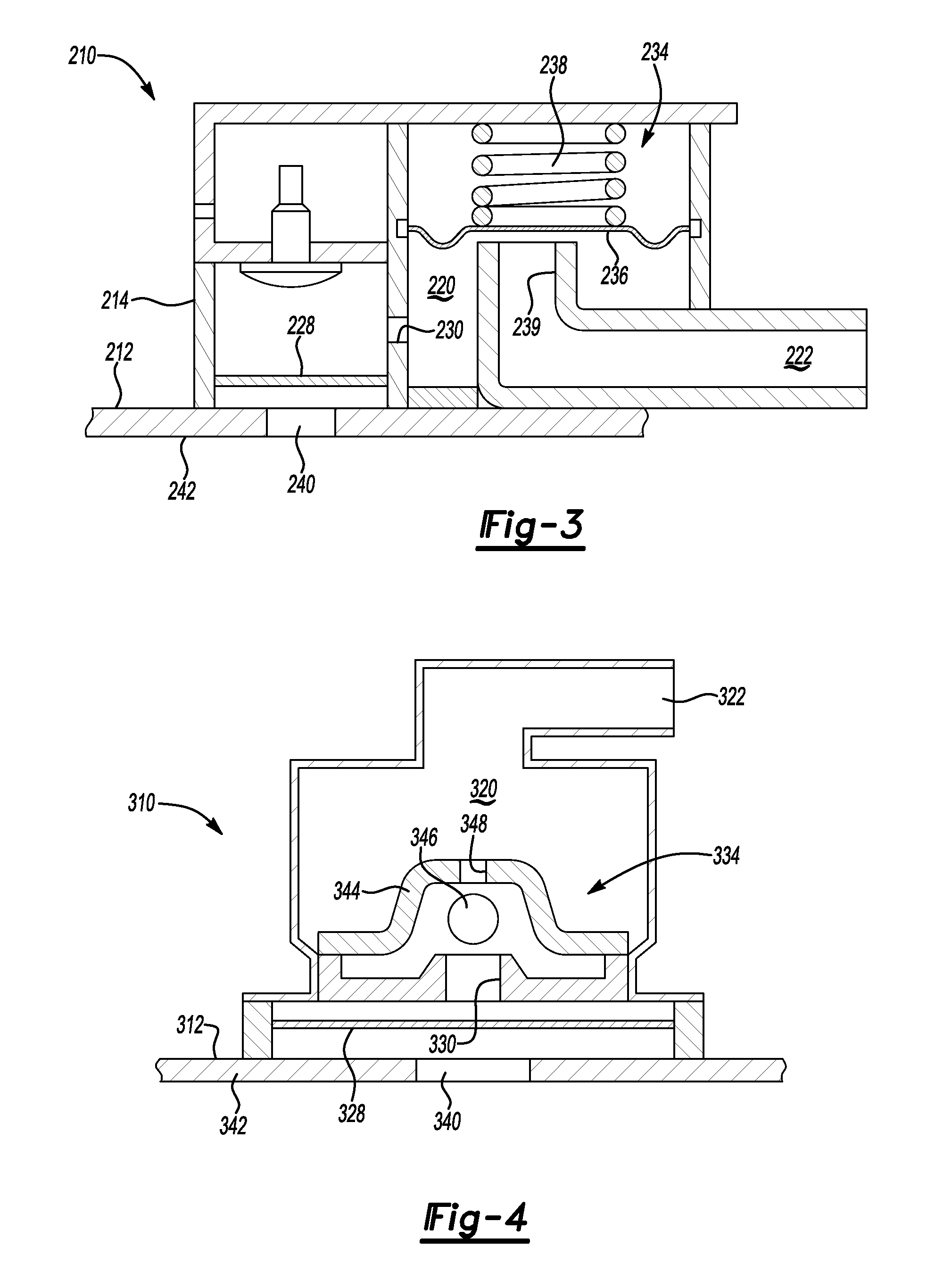

Small engine emissions control valve

ActiveUS20100319789A1Obstruct passageNon-fuel substance addition to fuelLighting and heating apparatusControl flowFuel tank

A valve assembly for a fuel tank for a small engine includes a housing. A membrane is supported by the housing such that the membrane covers a housing opening. The membrane allows the passage of vapor through the membrane and into the housing cavity and prevents the passage of liquid through the membrane. A pressure relief valve is supported by the housing to control flow of a vapor through the housing cavity.

Owner:EATON INTELLIGENT POWER LTD

Dual function valve for fuel tank

ActiveUS7207347B2Improve sealingPrevent splashLarge containersEqualizing valvesFuel tankDual function

Owner:RAVAL - AGRI COOP SOCIETIES

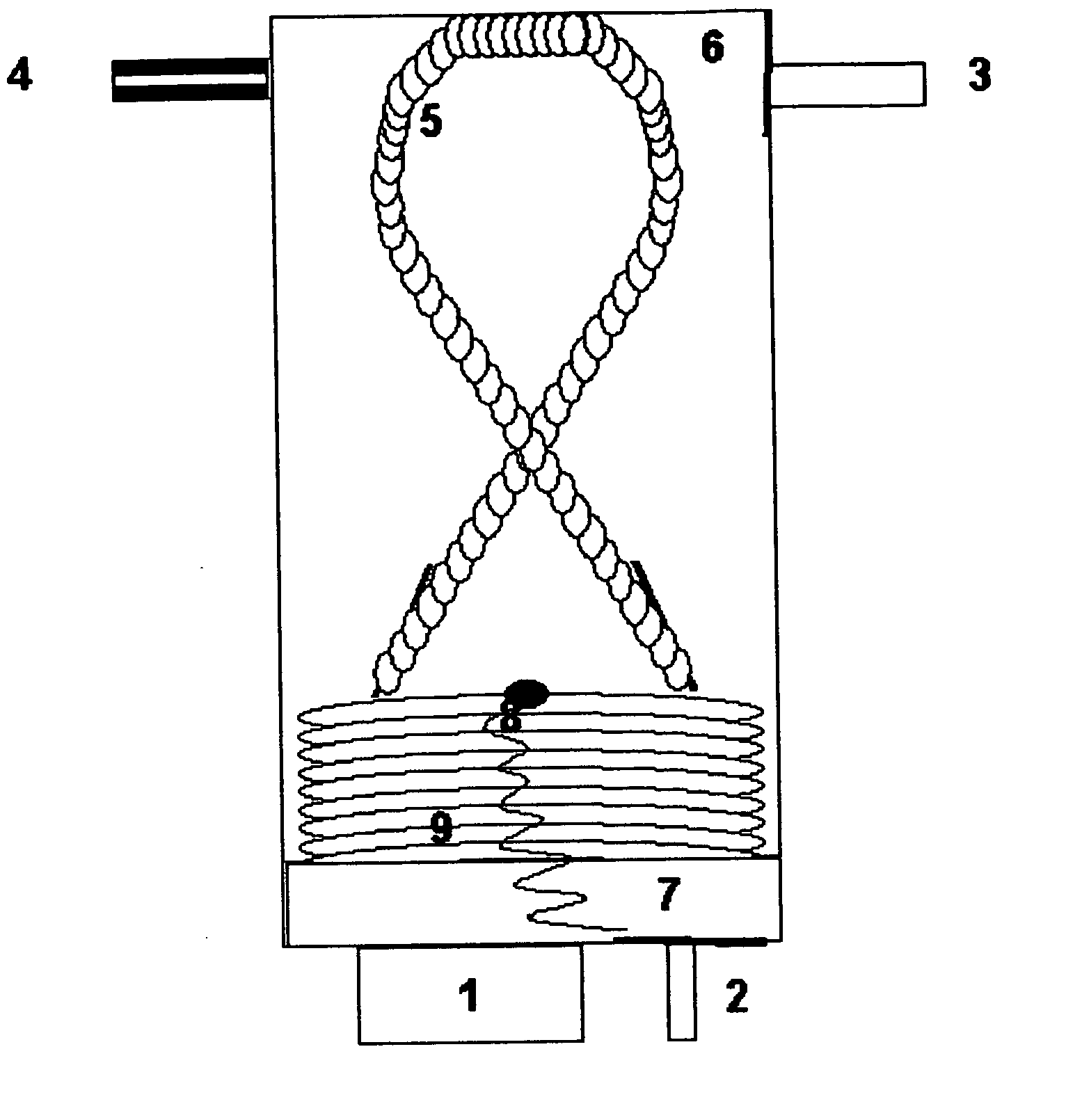

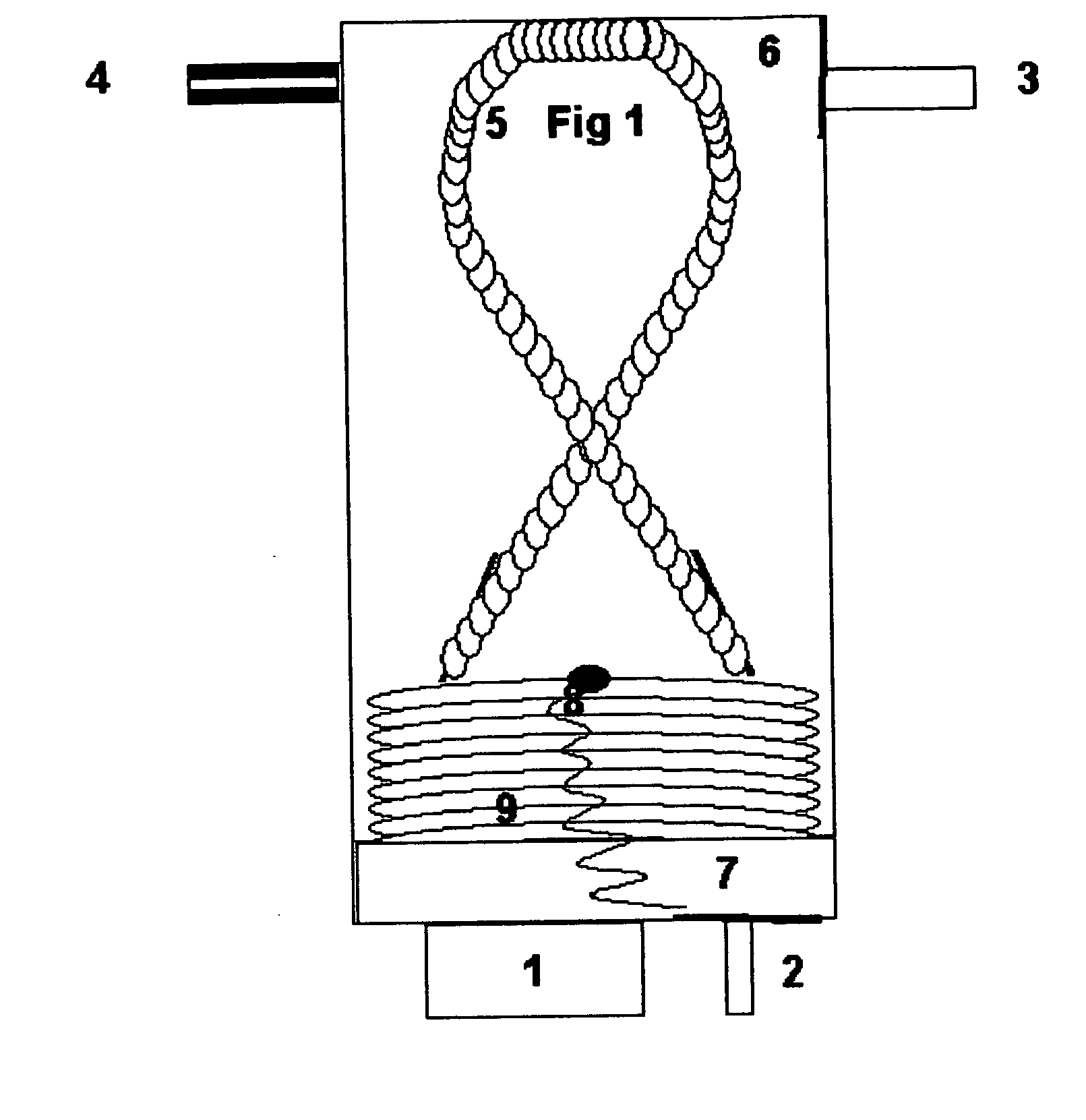

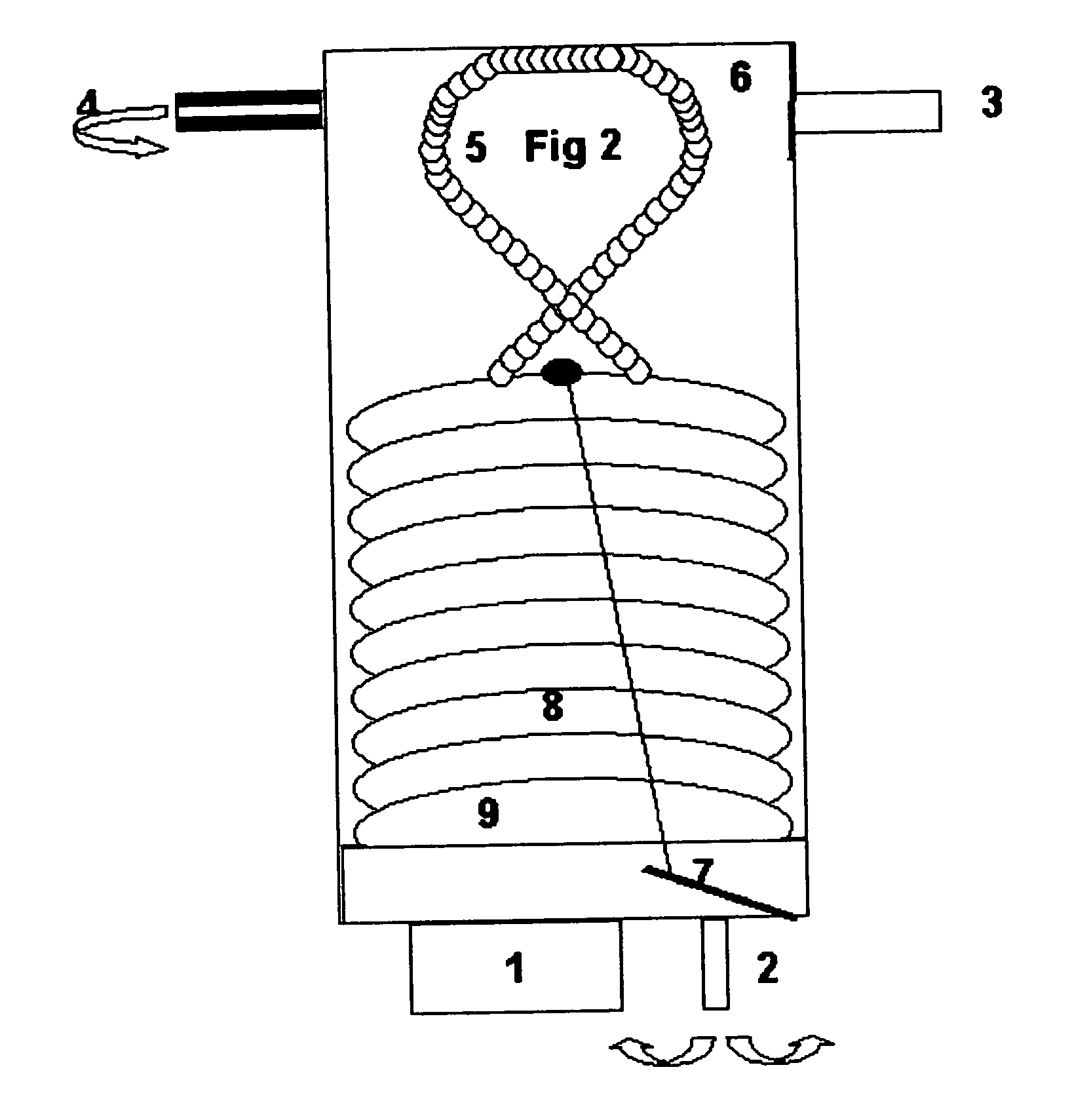

Ventilator safety valve

InactiveUS20070181125A1Simple methodPrevents volutrauma and barotraumaRespiratorsOperating means/releasing devices for valvesTime delaysManual ventilation

The system and method for preventing volutrauma and barotrauma in patients connected to a ventilator or a manual ventilation system detects elevated airway pressures above a safety pressure and during a time longer than the normally used inspiratory time periods, opens a safety valve to reduce airway pressure below the dangerous values, generates an alarm and closes again the airway system allowing further ventilation. This ventilator safety valve can work repetitively thereby protecting continuously the airway, but at the same time generating a simple method of escape ventilation. Two prototypes of this invention system are build, an electric system driven by computer software written in lab view and a mechanical pneumatic system with a concertina, a spring and an air reservoir under the concertina emptying through a micro opening allowing a time delay before a valve is opened.

Owner:MULIER JAN PAUL

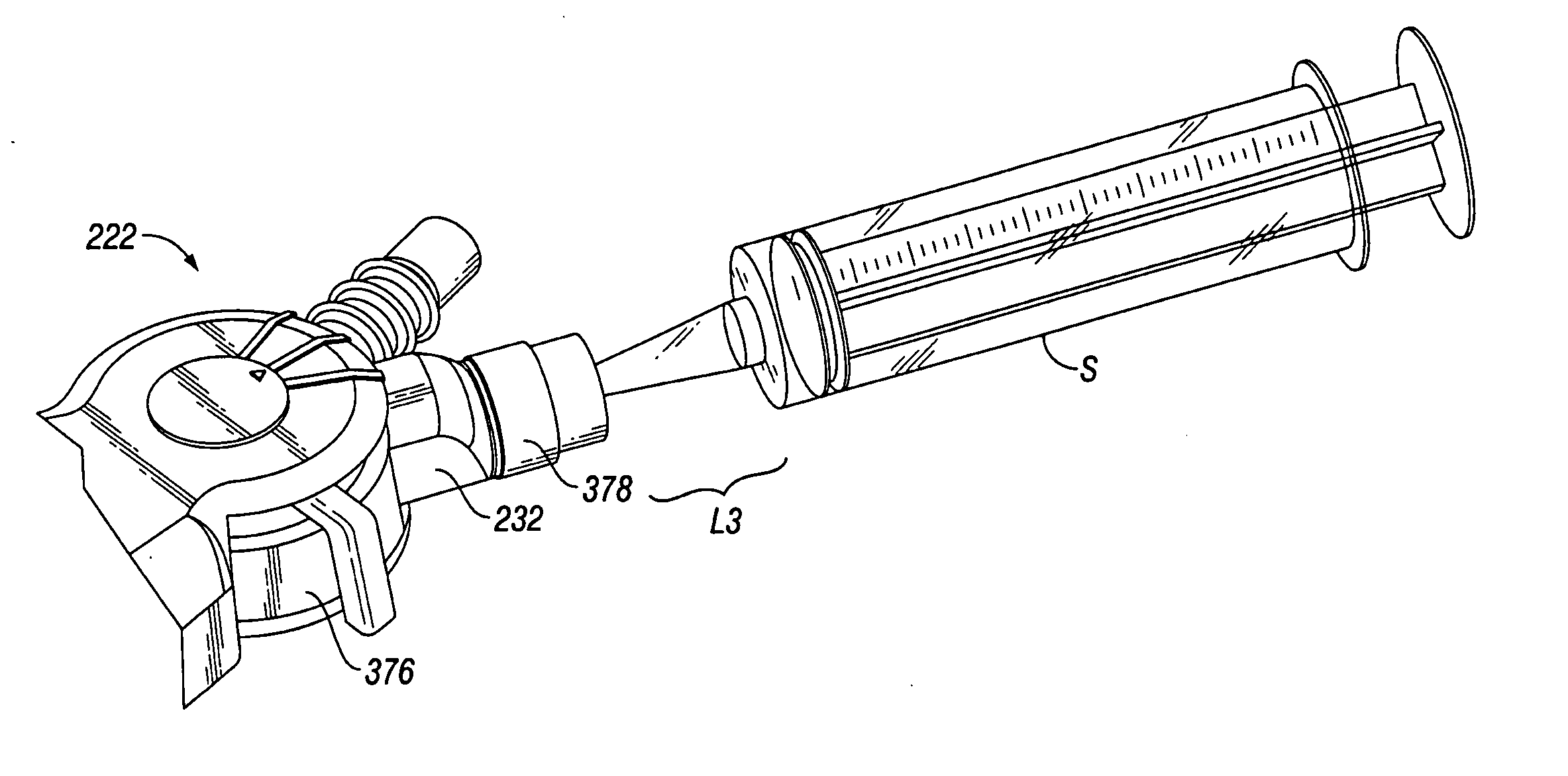

Automatic valve

InactiveUS20040082909A1Prevent leakageIncrease contactMedical devicesMultiple way valvesEngineeringVALVE PORT

A valve system is provided that includes a valve connector that has a portion of a first passageway. The valve connector includes a suction port and an introduction port that are spaced apart and in substantially parallel alignment. The suction port and the introduction port are manipulable to establish fluid communication between the portion of the first passageway and the suction port or the introduction port. The valve connector may have a rotatable outer cap that includes the suction port and the introduction port. The cap being configured to facilitate manipulation of the suction port and the introduction port for establishing fluid communication with the portion of the first passageway. The introduction port may include a normally closed valve. The valve connector may be attached to a dual lumen nasogastric tube. In an alternate embodiment, the valve connector further includes a portion of a second passageway that includes a relief port. The relief port can include a one-way valve.

Owner:CARDINAL HEALTH IRELAND UNLTD

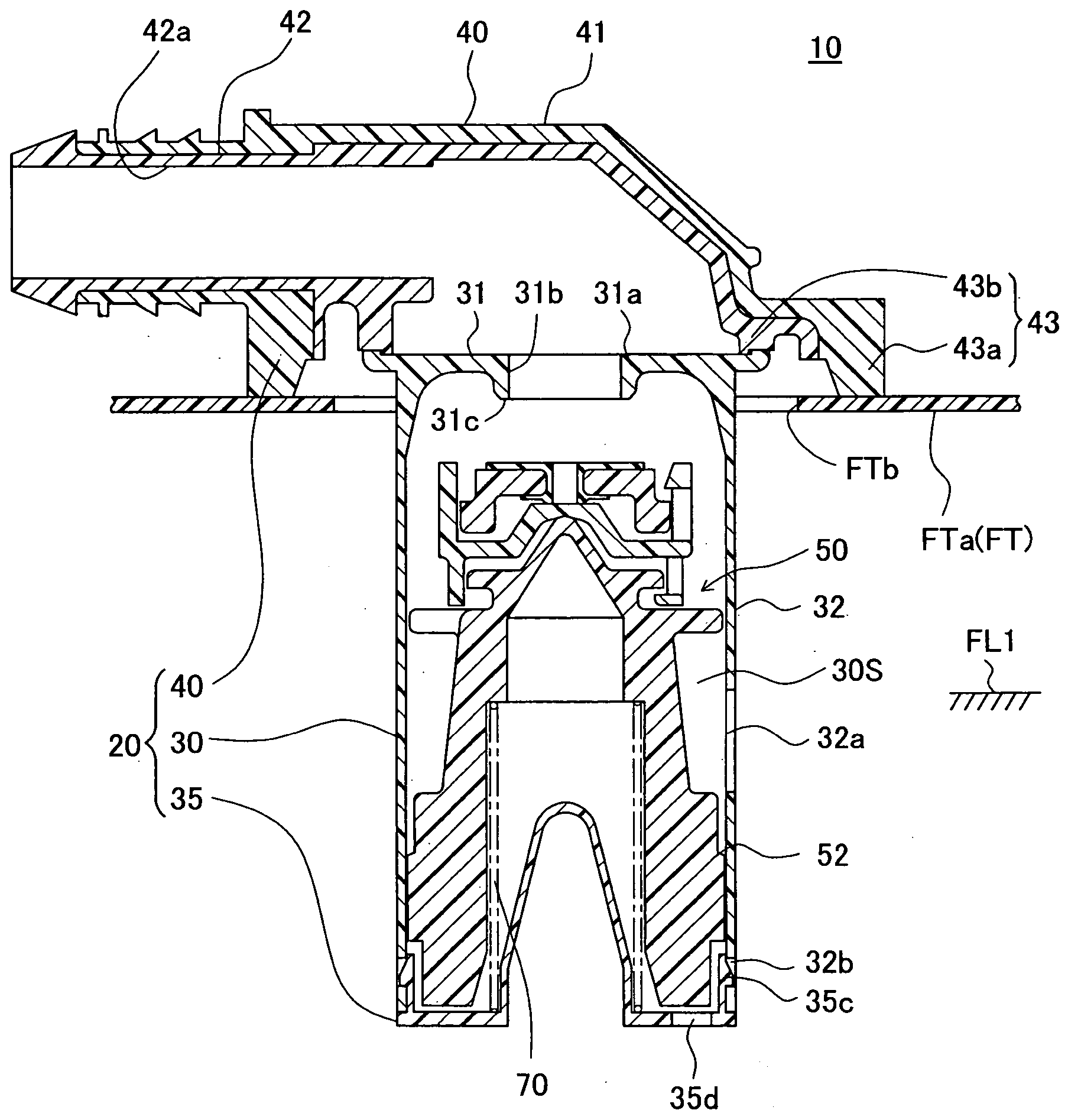

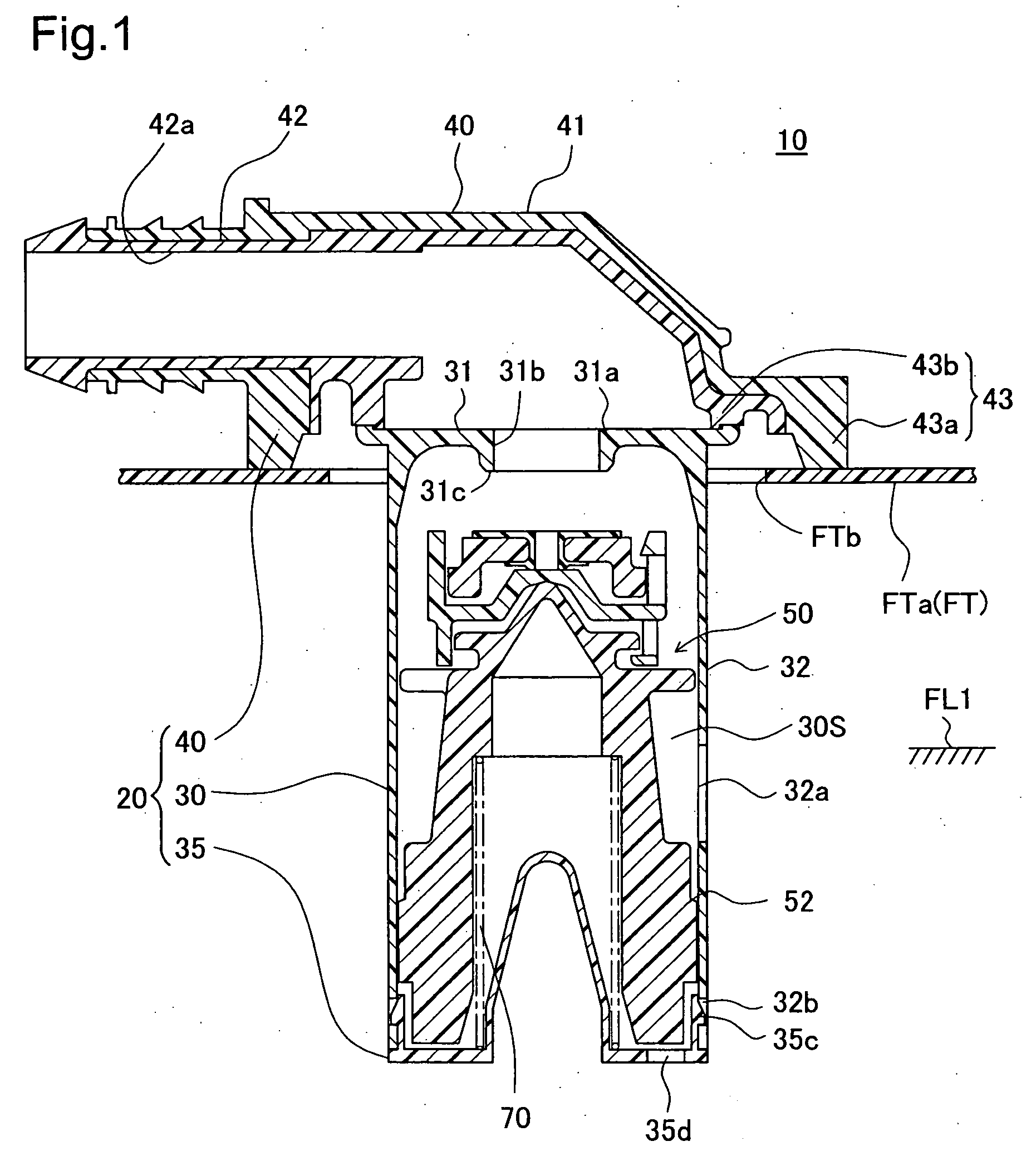

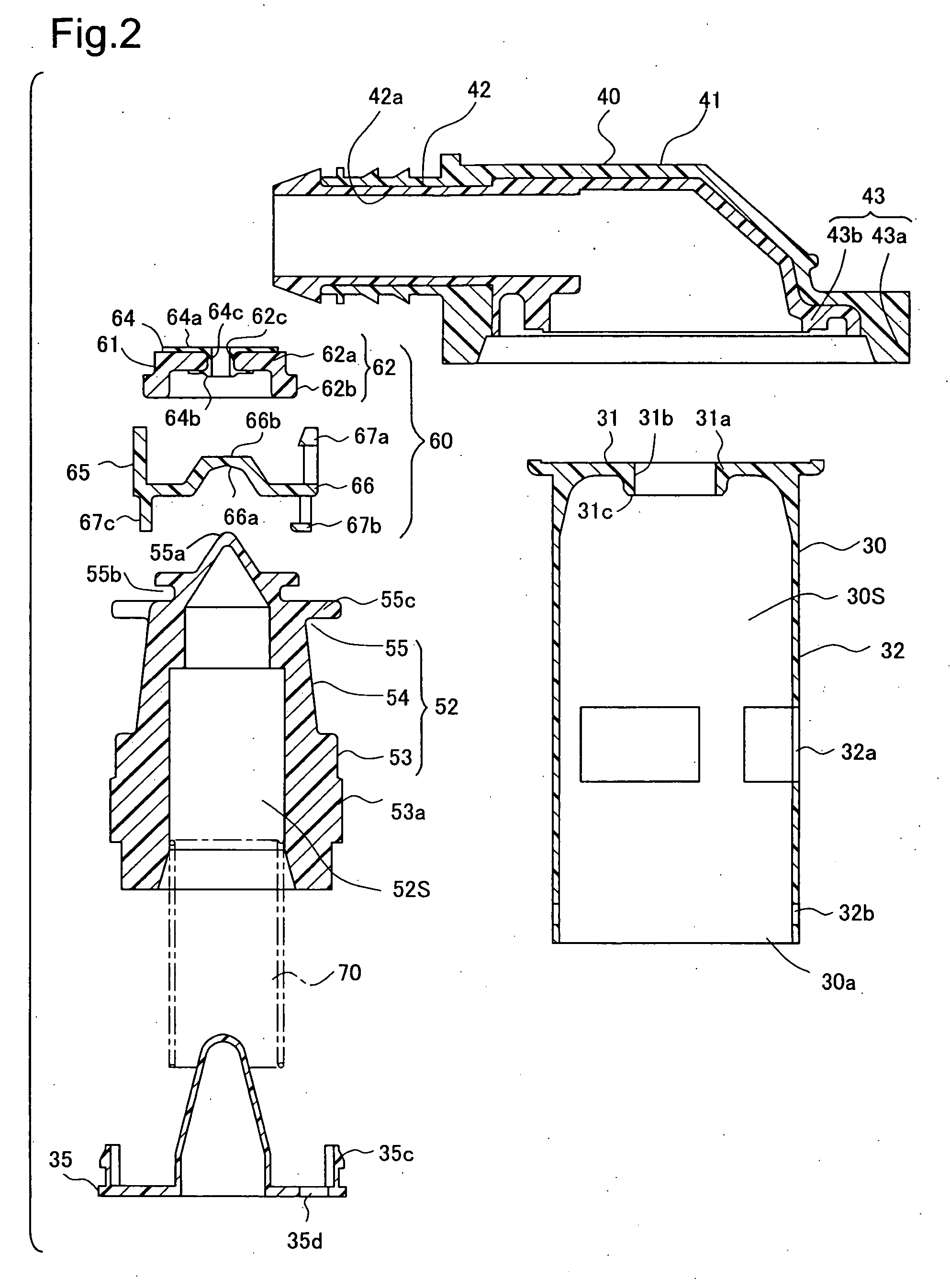

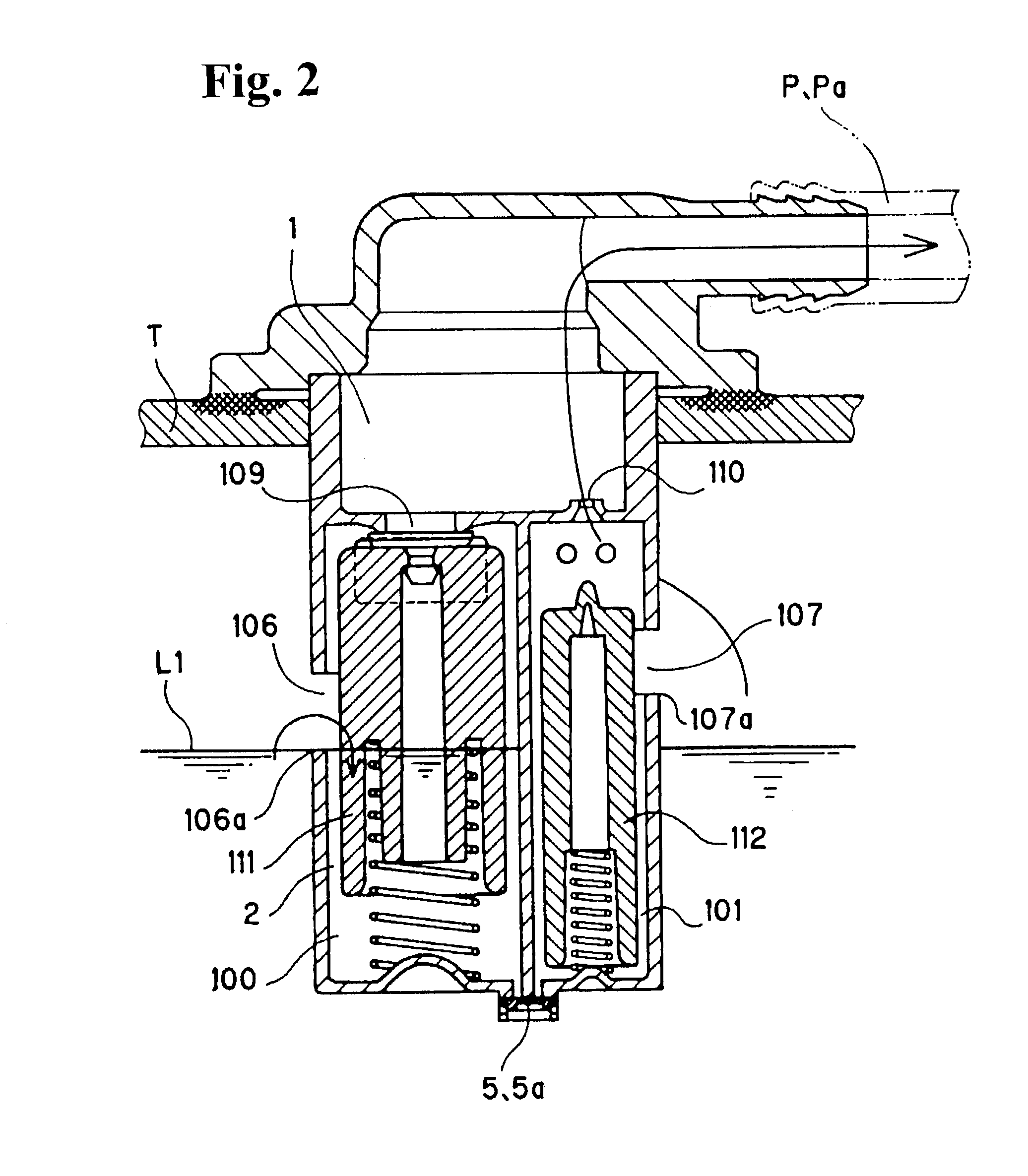

Fuel cut off valve

The fuel cut off valve comprises a casing, a float that rises and falls with increases and decreases in the buoyant force depending on the fuel liquid level within a valve chamber, and a valve mechanism that opens and closes a connecting passage through the rising or falling of the float, equipped on the upper part of the float. The valve mechanism comprises a supported part, and when the supported part is supported by a support part of the float, the center of gravity is provided below the support portion, so that the supported part is balanced on a single support portion. The fuel cut off valve can provide excellent seal performance when a vehicle is at an angle, and that can be miniaturized.

Owner:TOYODA GOSEI CO LTD

Fuel cartridge of a fuel cell with fuel stored outside fuel liner

ActiveUS20070077463A1Minimize permeation of fuelReactant parameters controlLiquid transferring devicesFuel cellsFuel supply

A fuel supply connectable to a fuel cell is disclosed. The fuel supply comprises an outer casing and a fuel liner and an effective amount of fuel in the space between the outer casing and the fuel liner to control the pressure inside the fuel liner. In one example, the fuel inside the fuel liner is methanol, and the fuel between the outer casing and the fuel liner is methanol or methanol gel.

Owner:INTELLIGENT ENERGY LTD

Fuel cut off valve

A fuel valve comprises a first valve chamber and a second valve chamber within a casing, where a first valve mechanism and a second valve mechanism are housed in the respective valve chambers. A first float of the first valve mechanism rises when the fuel level reaches a first liquid level, to close a first connection conduit. The second valve mechanism rises to close a second connection conduit when a second liquid level, which is higher than the first liquid level is reached. A valve conduit, which acts as a restriction path, is provided between the first valve chamber and the second valve chamber. The valve conduit is formed with a conduit area that is less than that of the first connection conduit, so as to increase the pressure within the fuel tank when the first connection conduit is closed.

Owner:TOYODA GOSEI CO LTD

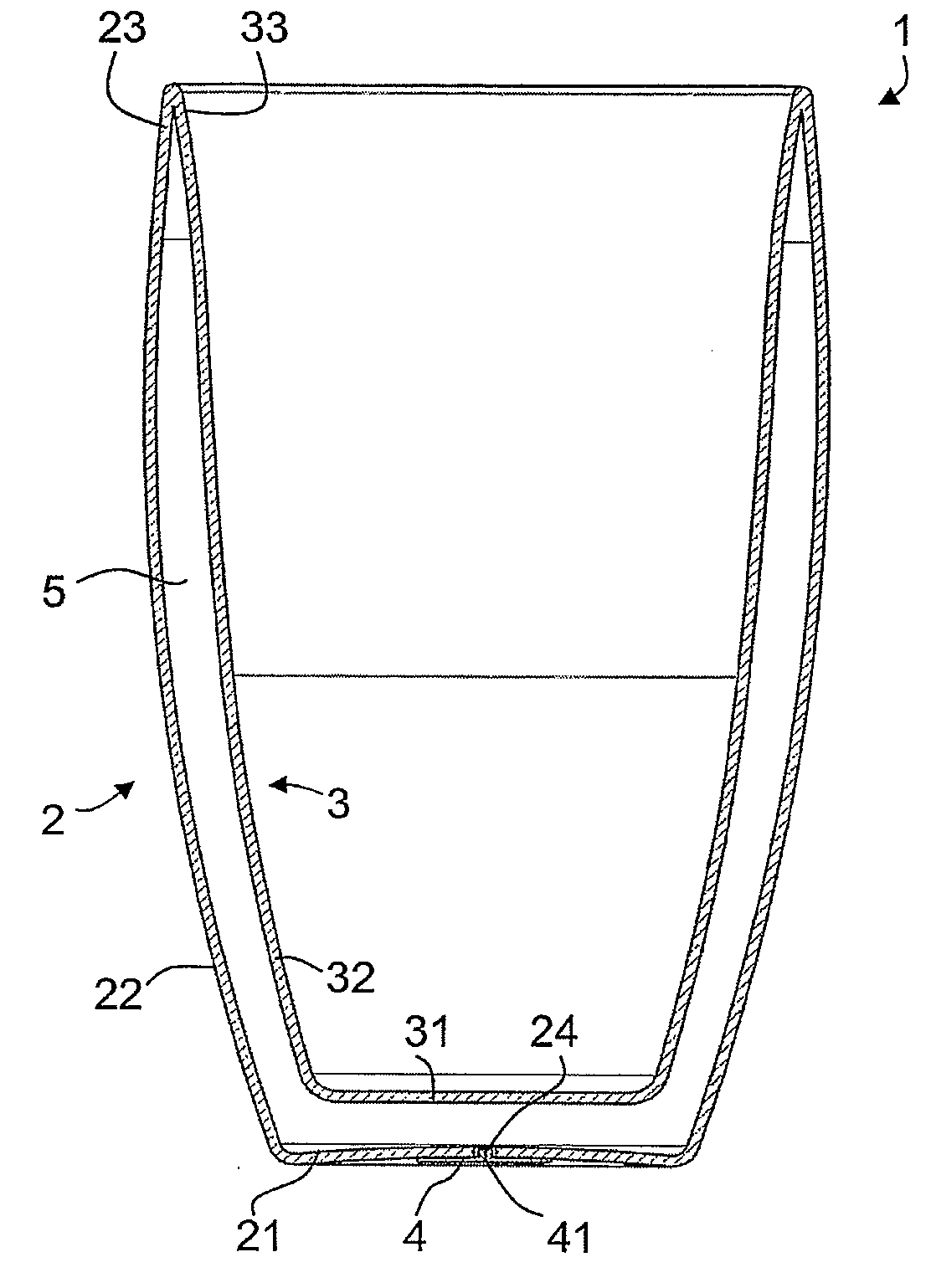

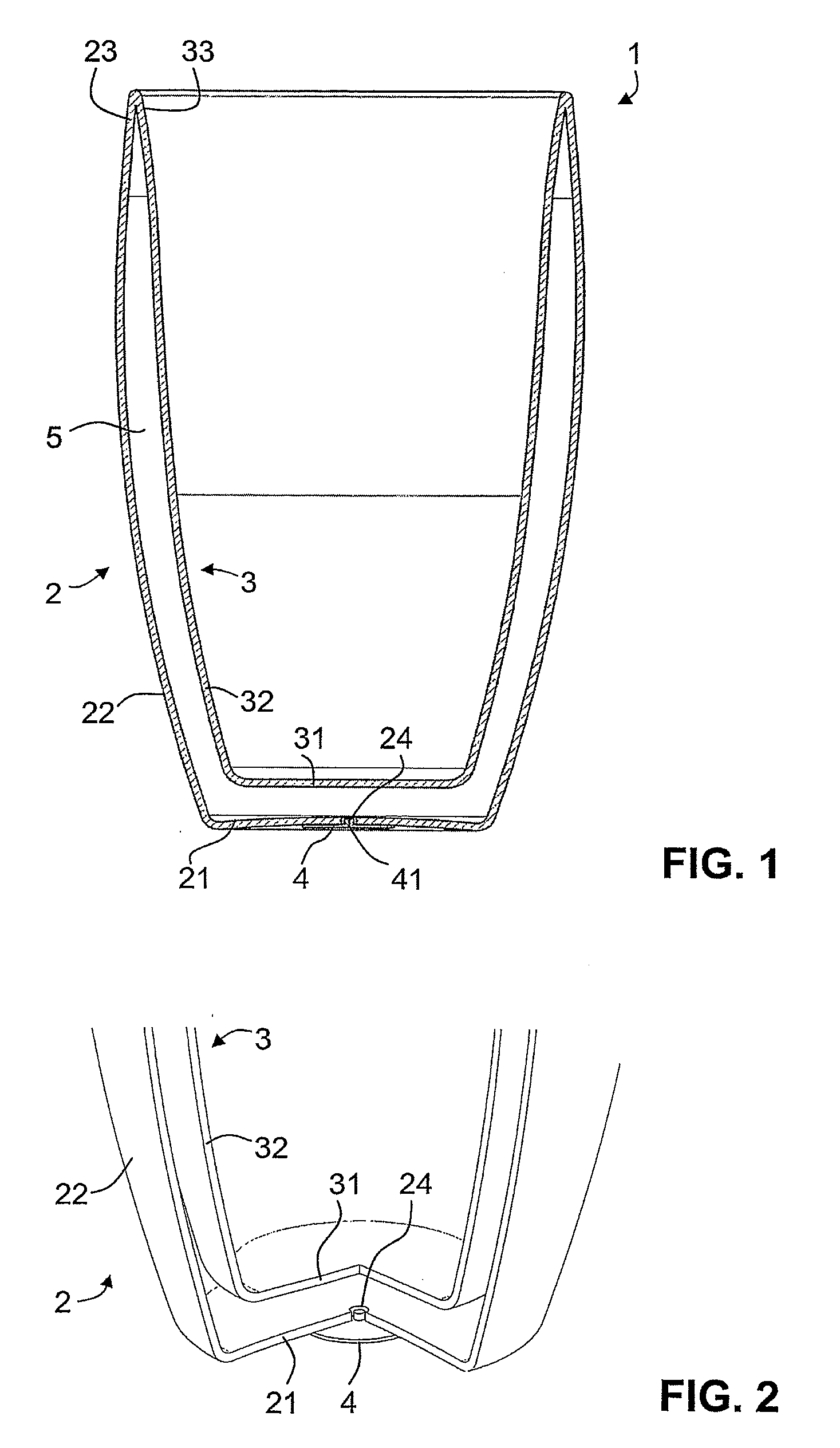

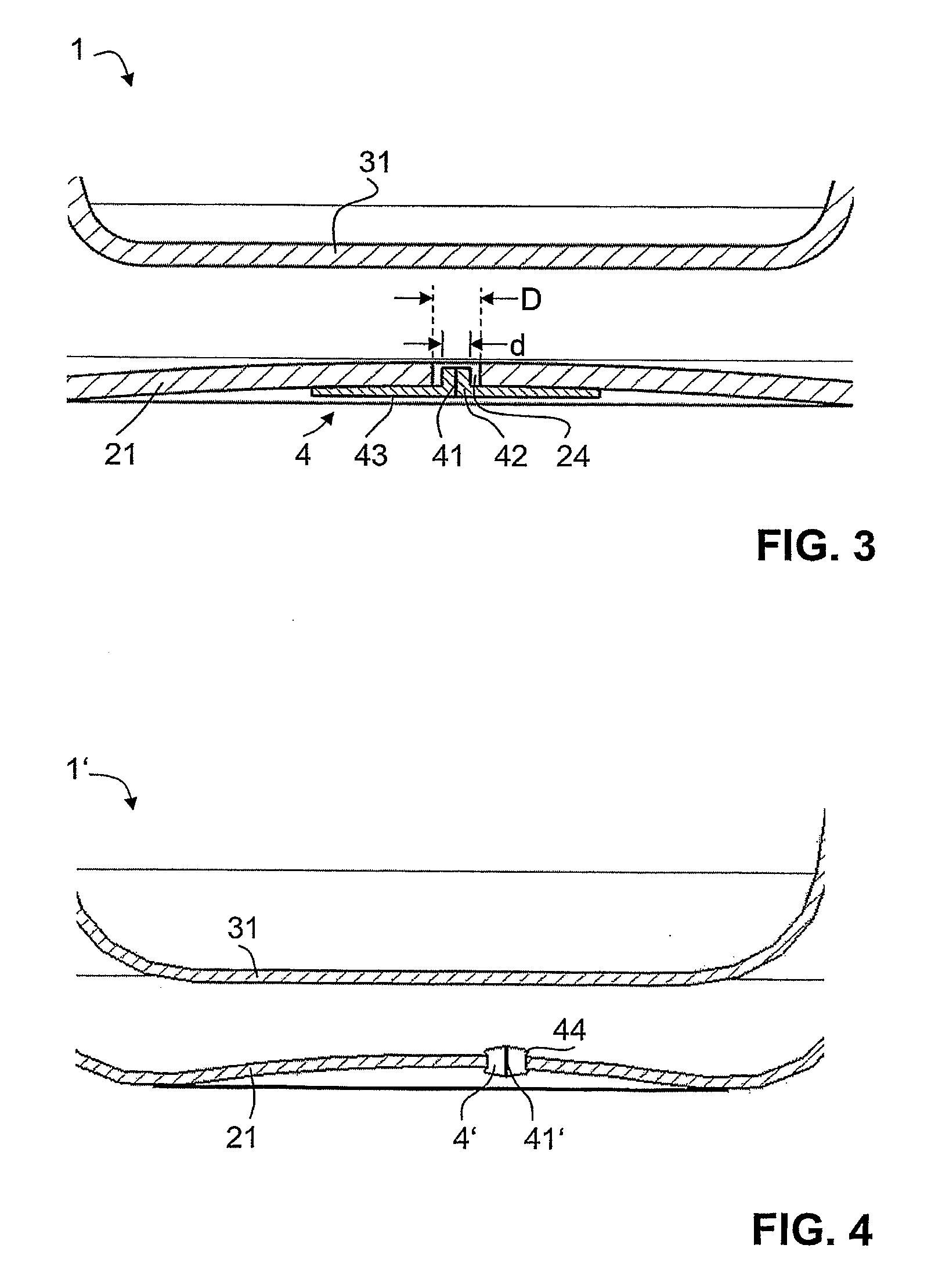

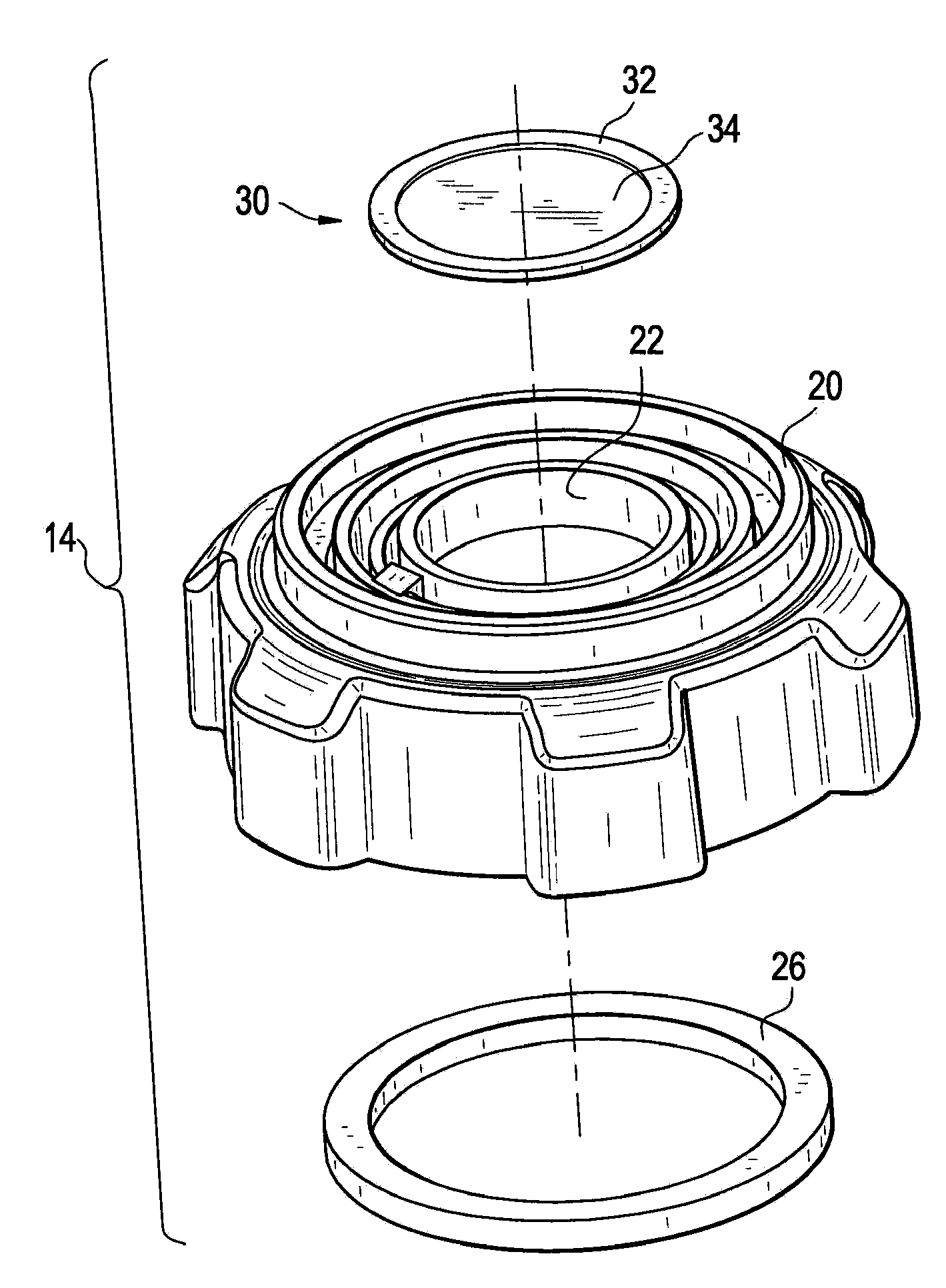

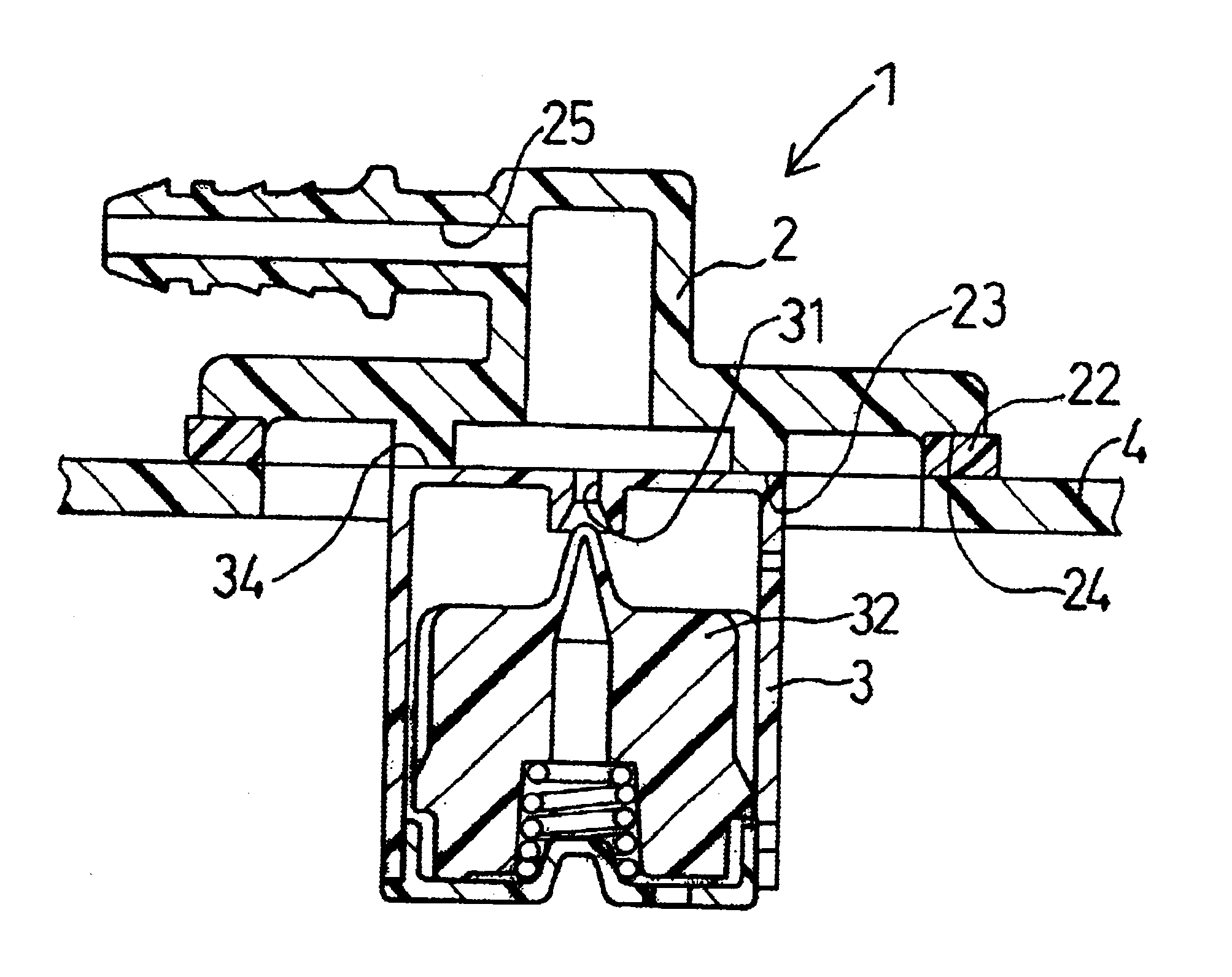

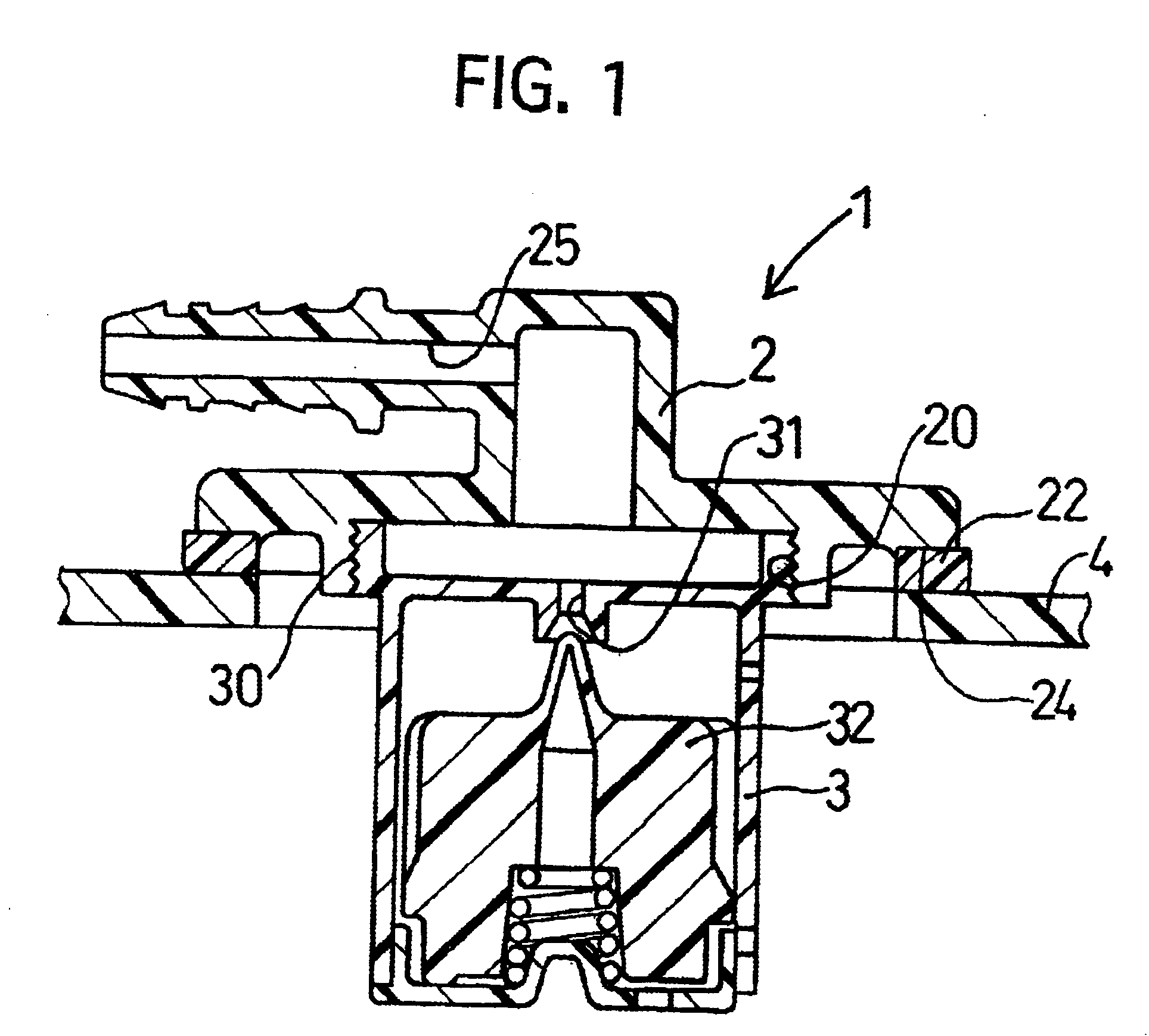

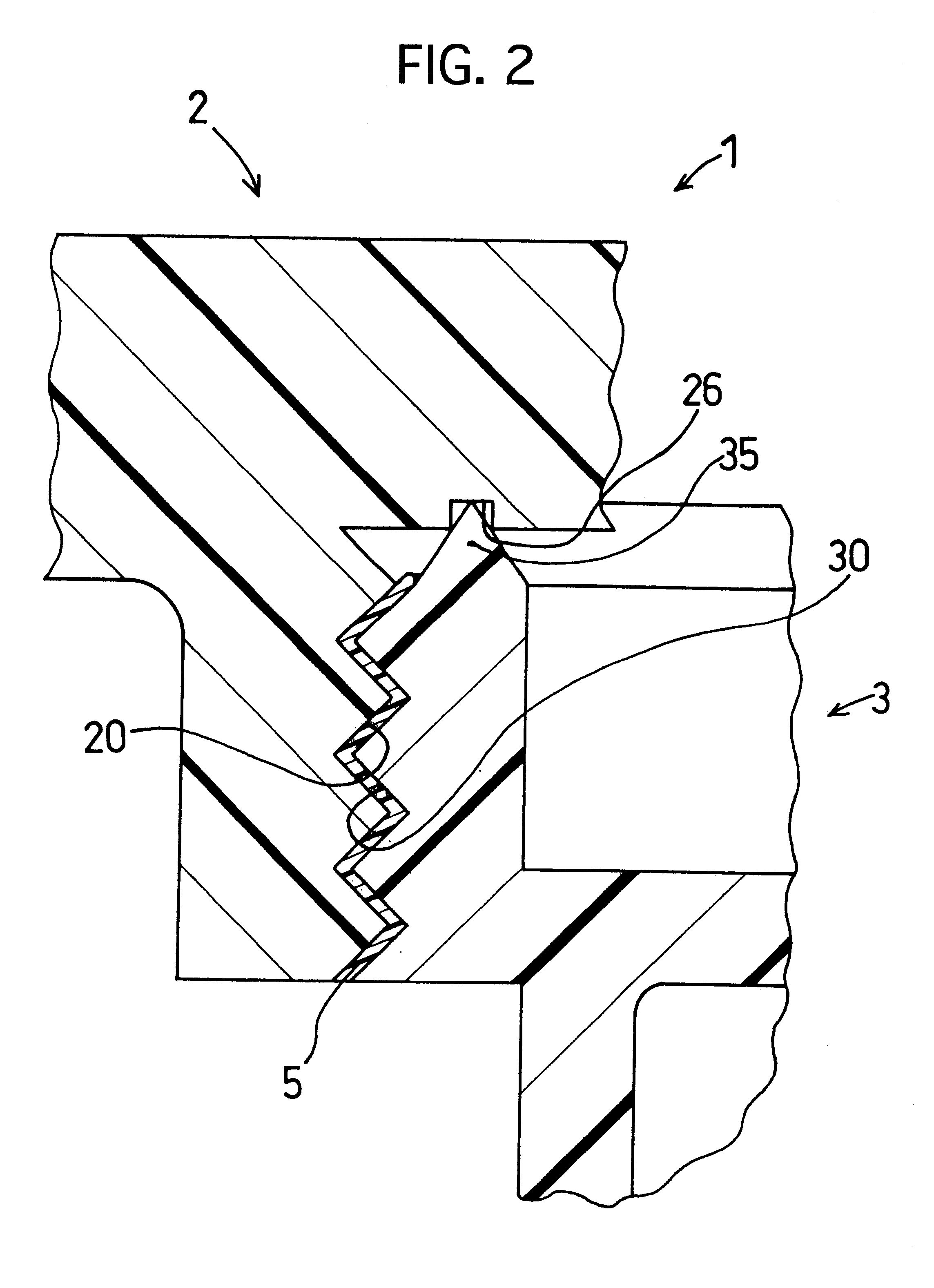

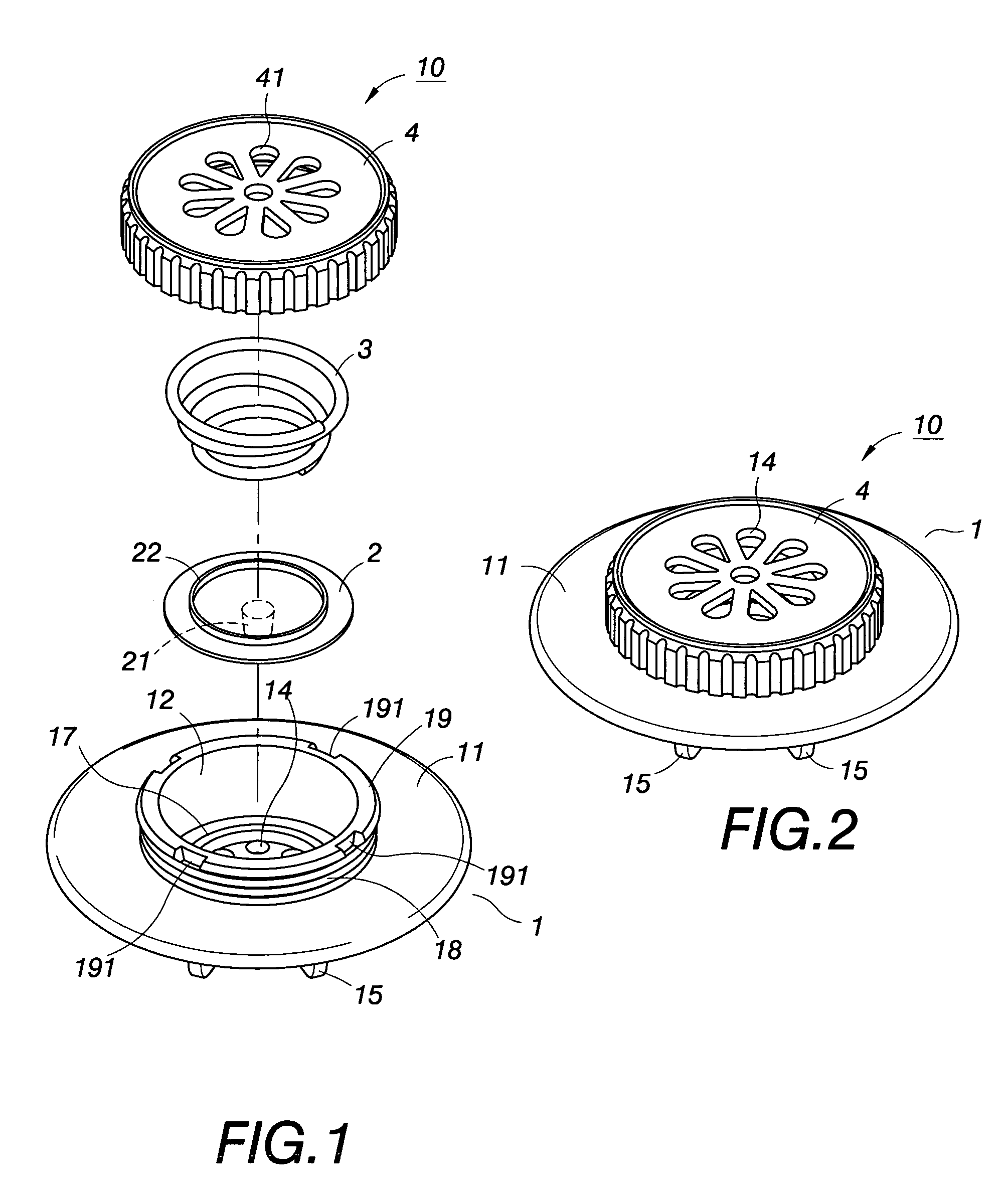

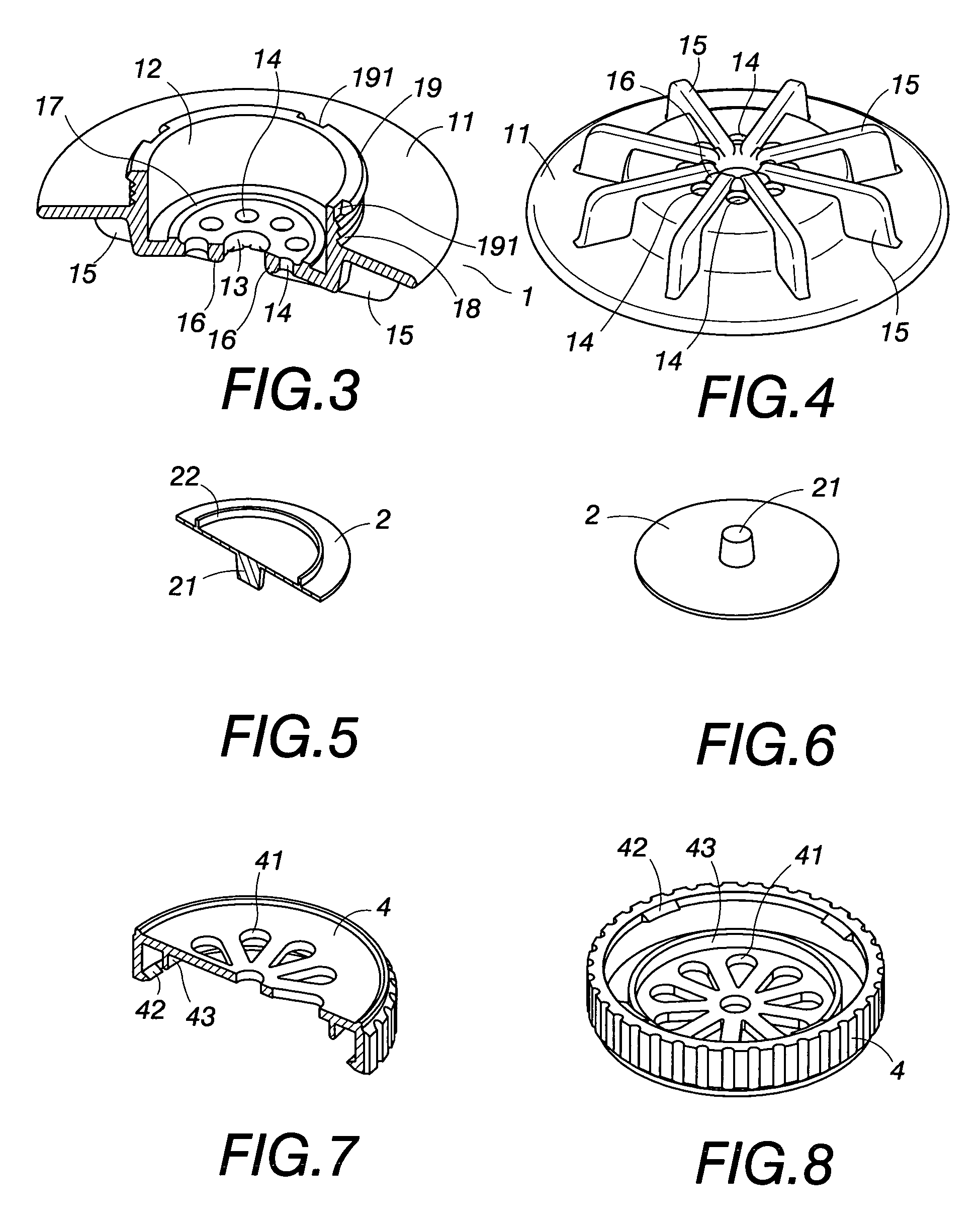

Double-walled vessel having pressure equalization opening

ActiveUS20100288776A1Prevents excessive pressure fluctuationRelieve stressDomestic cooling apparatusLighting and heating apparatusAdhesiveDouble wall

A double-walled vessel (1) is disclosed, which has a pressure equalization opening (24). Said opening is closed by a stopper (4), which has at least one gas passage channel (41). Said channel is configured such that it allows air to pass, while it prevents the penetration of water into the intermediate space. The stopper is preferably made from a silicone-based plastic and fastened to the vessel by means of an adhesive based on acetoxy silicone. For fastening purposes, it may comprise a disk-like fastening flange (43).

Owner:PI-DESIGN AG

Fuel tank vent including a membrane separator

A fuel tank vent includes a nanoporous membrane separator positioned in an opening in a fuel tank to allow vapor from a fuel to flow across a membrane, wherein the membrane comprises a network in which surfaces of the network define a plurality of interconnecting pores extending through the membrane, wherein the plurality of interconnecting pores have a mean pore size of about 0.1 nanometers to about 50 nanometers, and are permeable to a selected one or both of the fuel vapor and air, and impermeable to a liquid fuel; and an oleophobic enhancement coating disposed on surfaces of the plurality of interconnecting pores and configured to provide oleophobicity to the membrane.

Owner:GENERAL ELECTRIC CO

Electromagnetic valve and vapor fuel treating system applying the same

ActiveUS7270310B2Increase the areaAvoid flowDiaphragm valvesOperating means/releasing devices for valvesSolenoid valveFuel treatment

A first connecting pipe of an electromagnetic valve connects with the fuel tank, and a second connecting pipe connects with a canister. A spring urges a moving core and a first valve body in a closing direction of a electromagnetic valve. A shaft of the first valve body includes a fluid-amount controlling portion on the top. The fluid-amount controlling portion is inserted to the communicating passage while a contact member of bellows seats on a convex of a rubber member, and is tapered in an inserted direction. When a coil is energized, the first valve body is lifted in the direction in which the fluid-amount controlling portion retracts from the communicating passage.

Owner:DENSO CORP

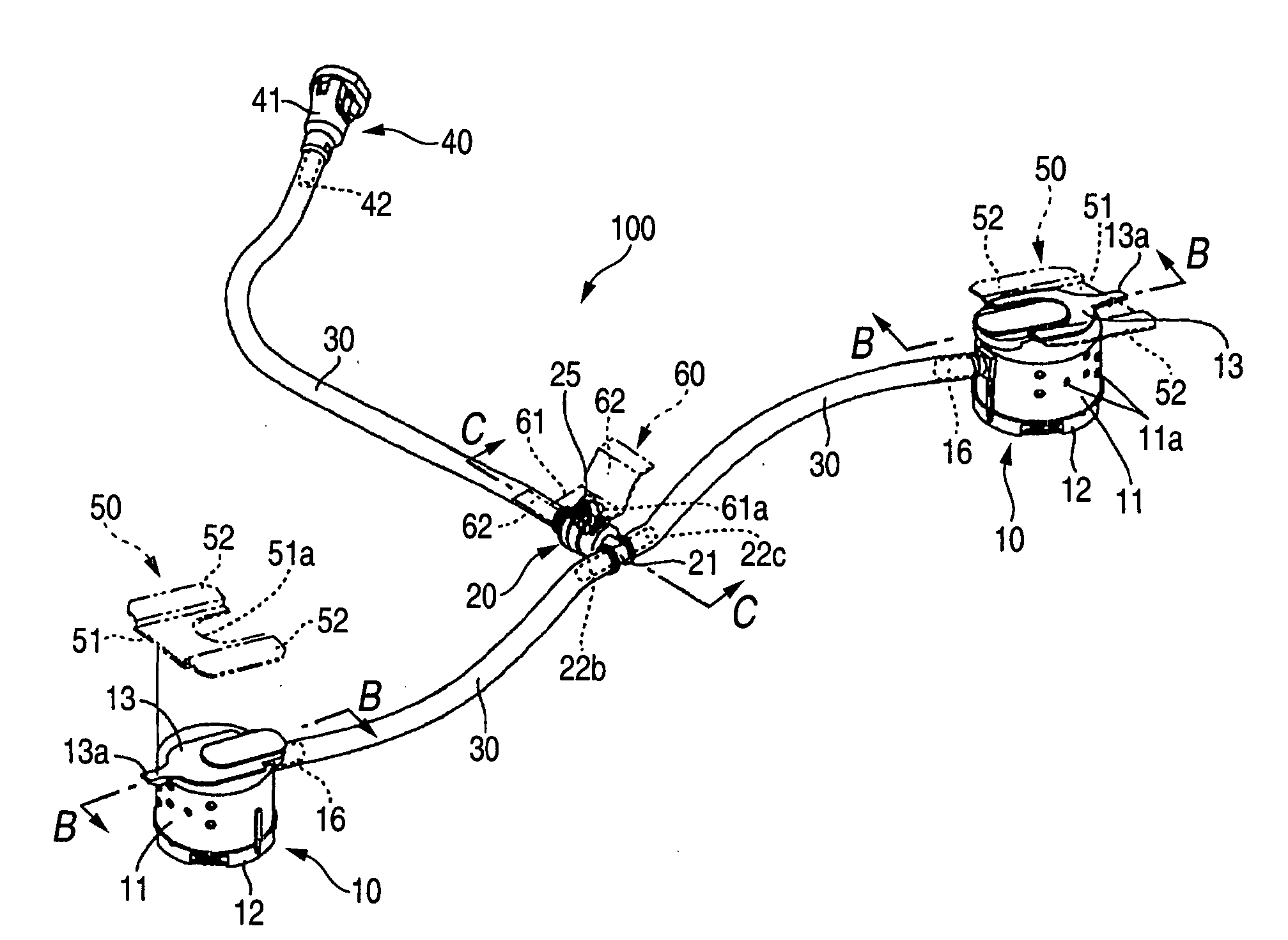

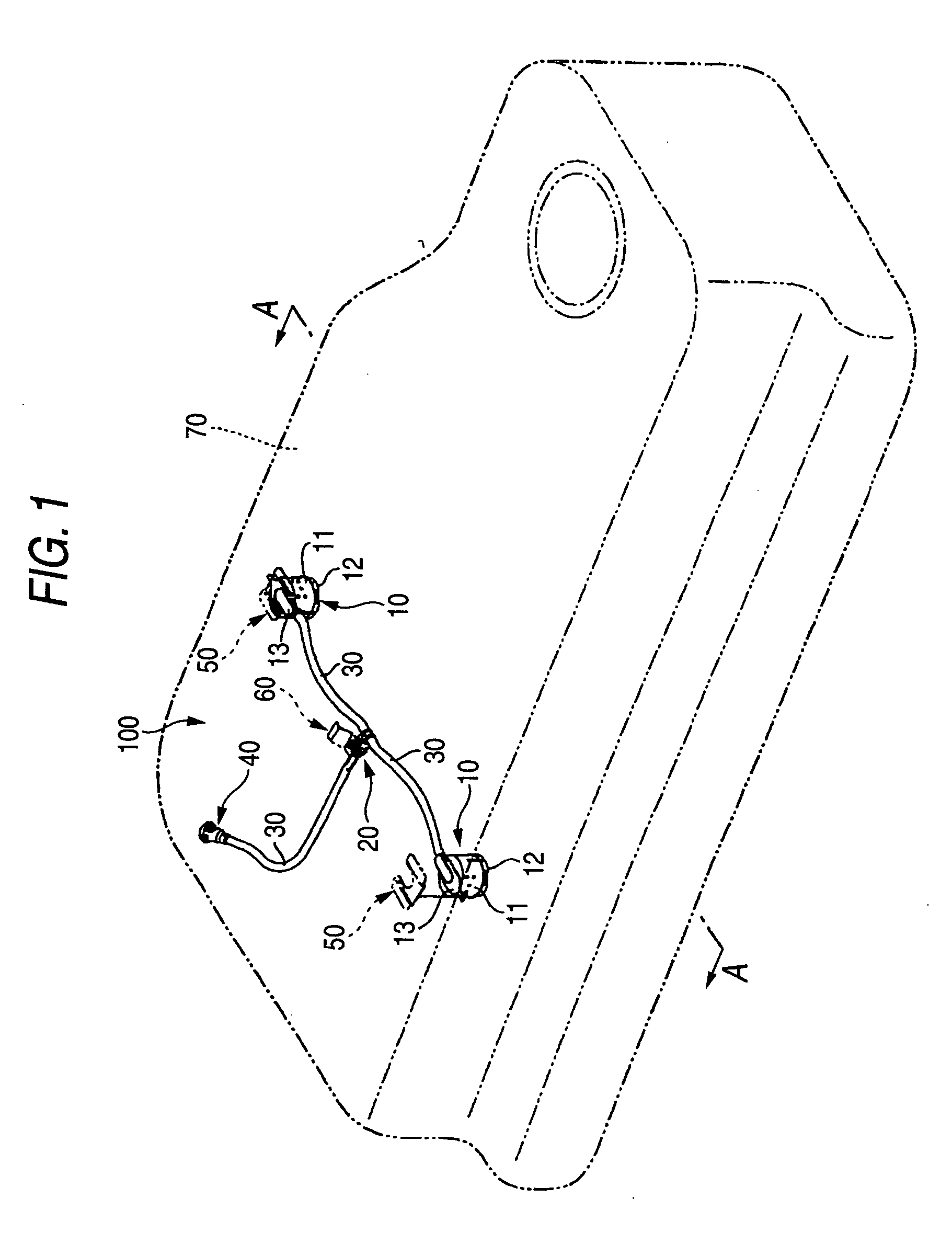

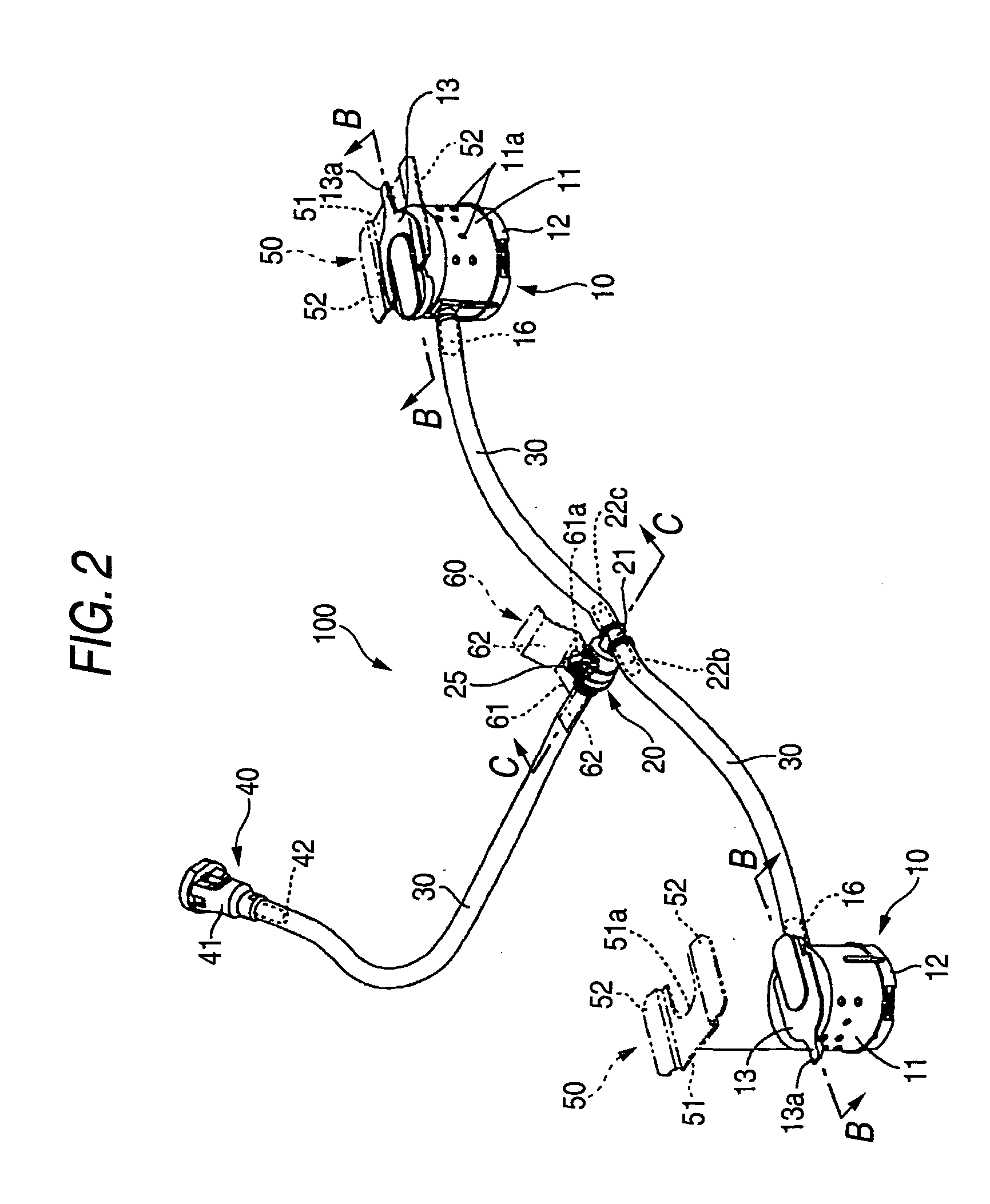

Fuel vapor pipe structure of fuel tank

InactiveUS20050172999A1Relieve pressureNon-fuel substance addition to fuelLarge containersEngineeringFuel vapor

In a fuel vapor pipe structure including a plurality of cut valves for passing or cutting a fuel vapor at inside of a fuel tank, a pipe joint connected to the cut valves for communicating the fuel vapor to a canister, and a resin tube for connecting the cut valve and the pipe joint, the resin tube is bent to pipe by making a length of the resin tube longer than a length of connecting connection tube portions of the cut valve and connection tube portions of the pipe joint and arranging the connection tube portion of the cut valve to shift from a straight line of connecting a center of the cut valve and a center of the pipe joint by a predetermined angle in a horizontal direction.

Owner:PIOLAX CO LTD

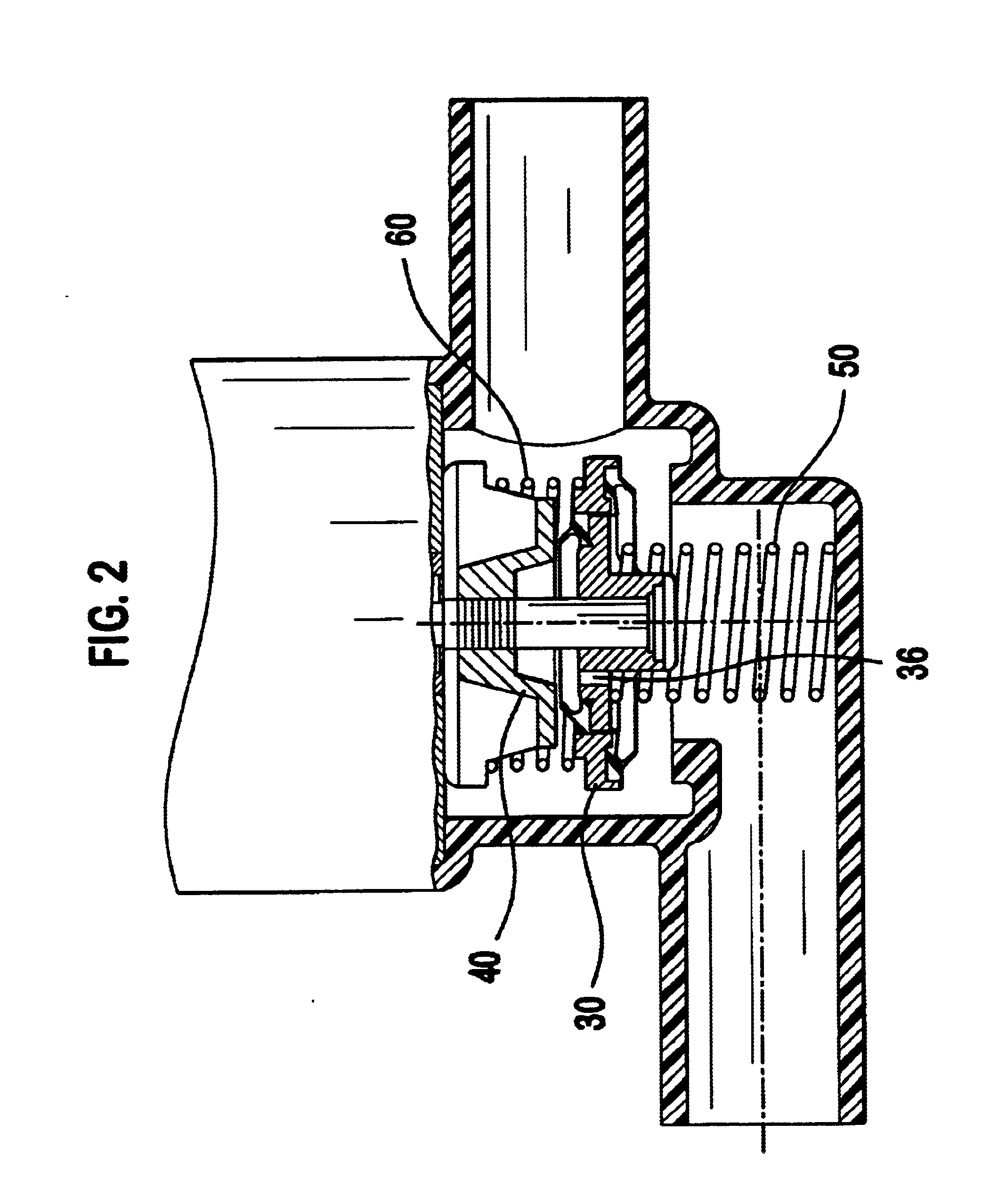

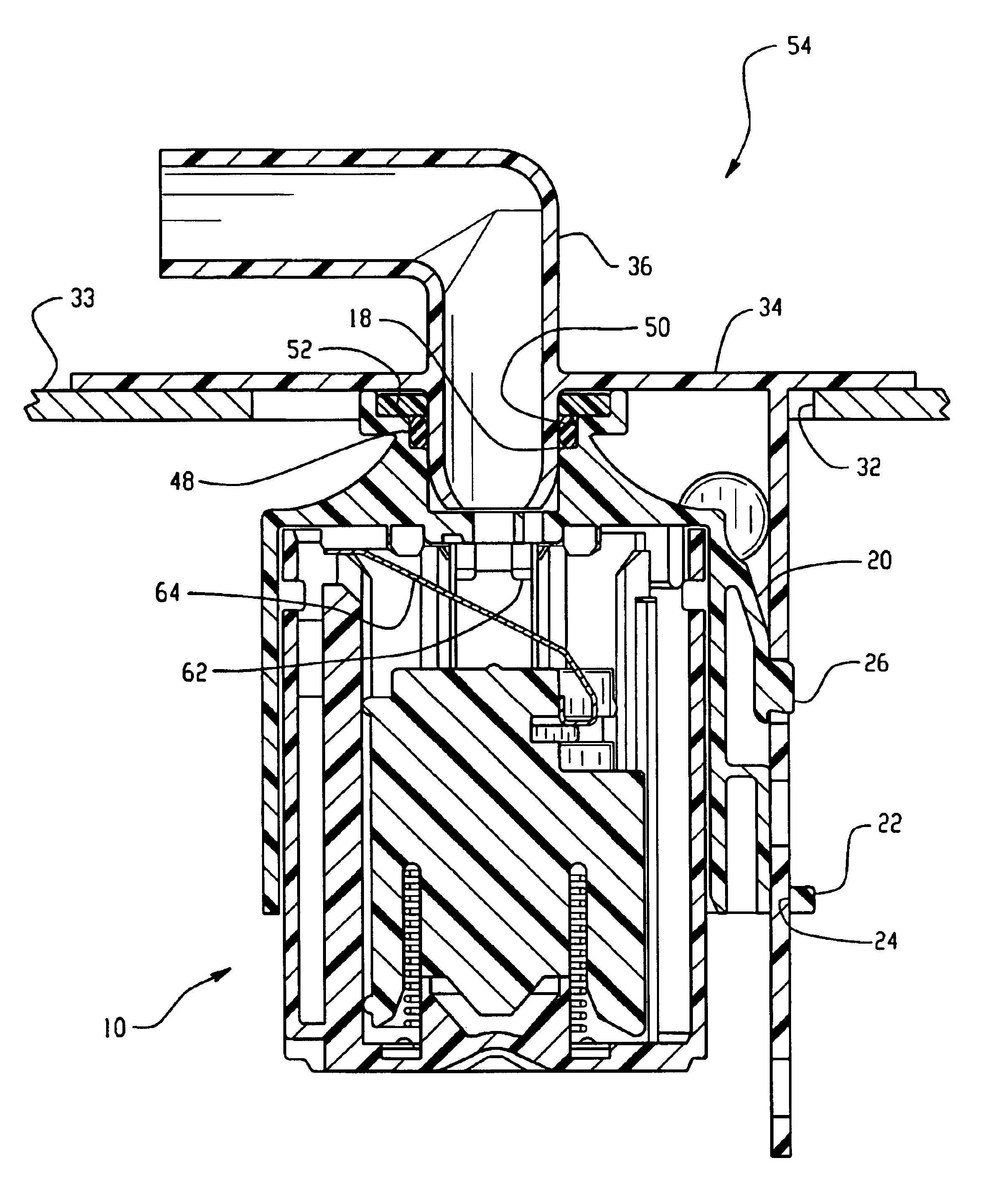

Fuel tank pressure control valve including an integrated sensor

A device for controlling fluid flow between an evaporative emission space of a fuel tank and a fuel vapor collection canister that includes a housing, a valve, a seal, an electric actuator, an electric transducer, and an electrical connector. The housing includes a first port, a second port, and a fluid flow path that extends between the first and second ports. The first port is adapted for receiving fluid flow from the evaporative emission space and is at a first pressure level. The second port is adapted for supplying fluid flow to the fuel vapor collection canister and is at a second pressure level. The valve is movable along an axis with respect to the housing between a first configuration, a second configuration, and an intermediate configuration between the first and second configurations. The first configuration permits substantially unrestricted fluid flow between the first and second ports. The second configuration prevents fluid flow between the first and second ports. The seal is located at an interface between the housing and the valve and includes an annular lip, which projects obliquely with respect to the axis in the first configuration of the valve. The electric actuator is disposed within the housing and is operatively coupled to the valve element. The electric transducer is disposed within the housing and is in fluid communication with the fluid flow path. The electric transducer senses the first pressure level. The electrical connector is disposed on the housing. The electrical connector includes a first set of terminals, which are in electrical communication with the electric actuator and a second set of terminals, which are in electrical communication with the electric transducer.

Owner:SIEMENS VDO AUTOMOTIVE CORP

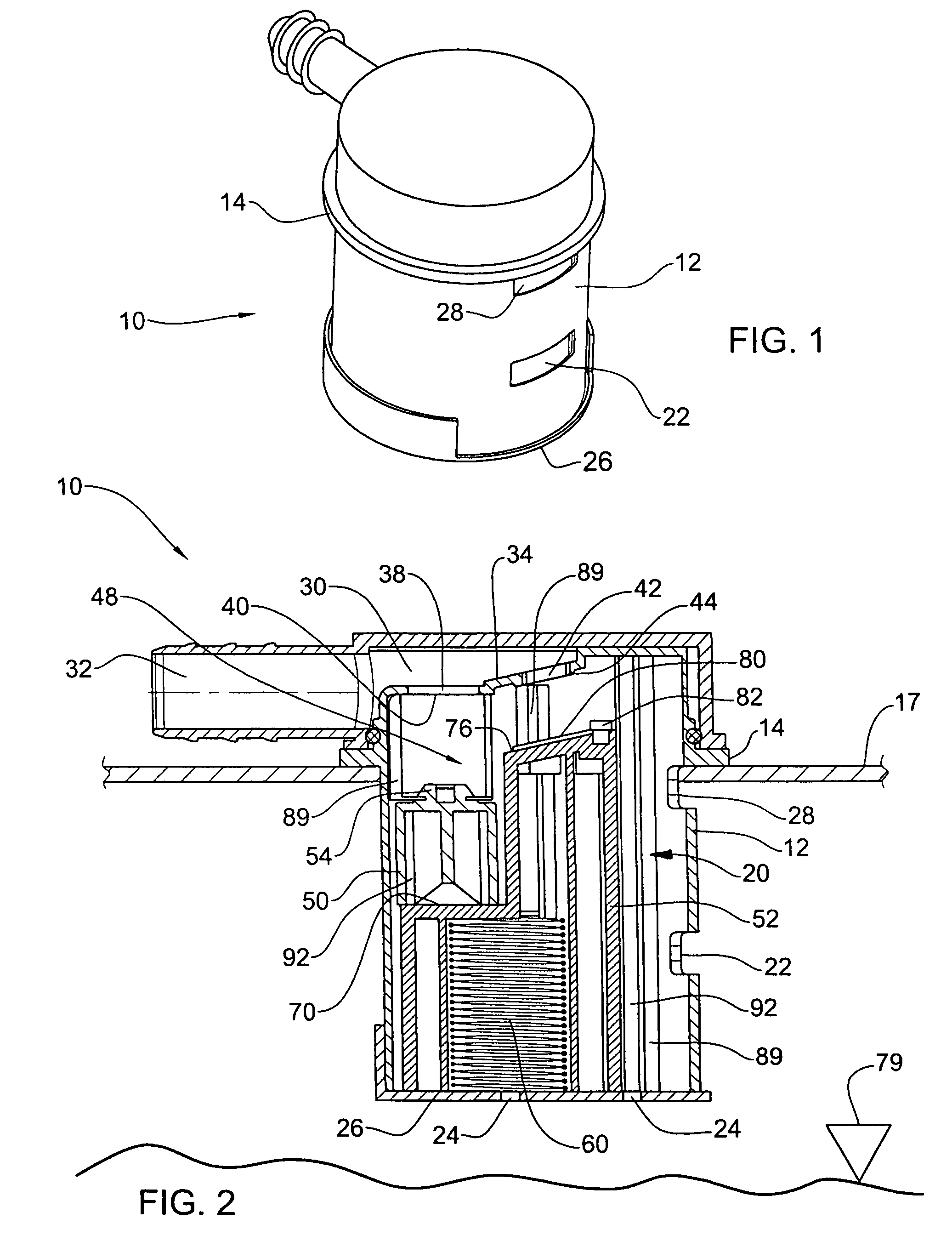

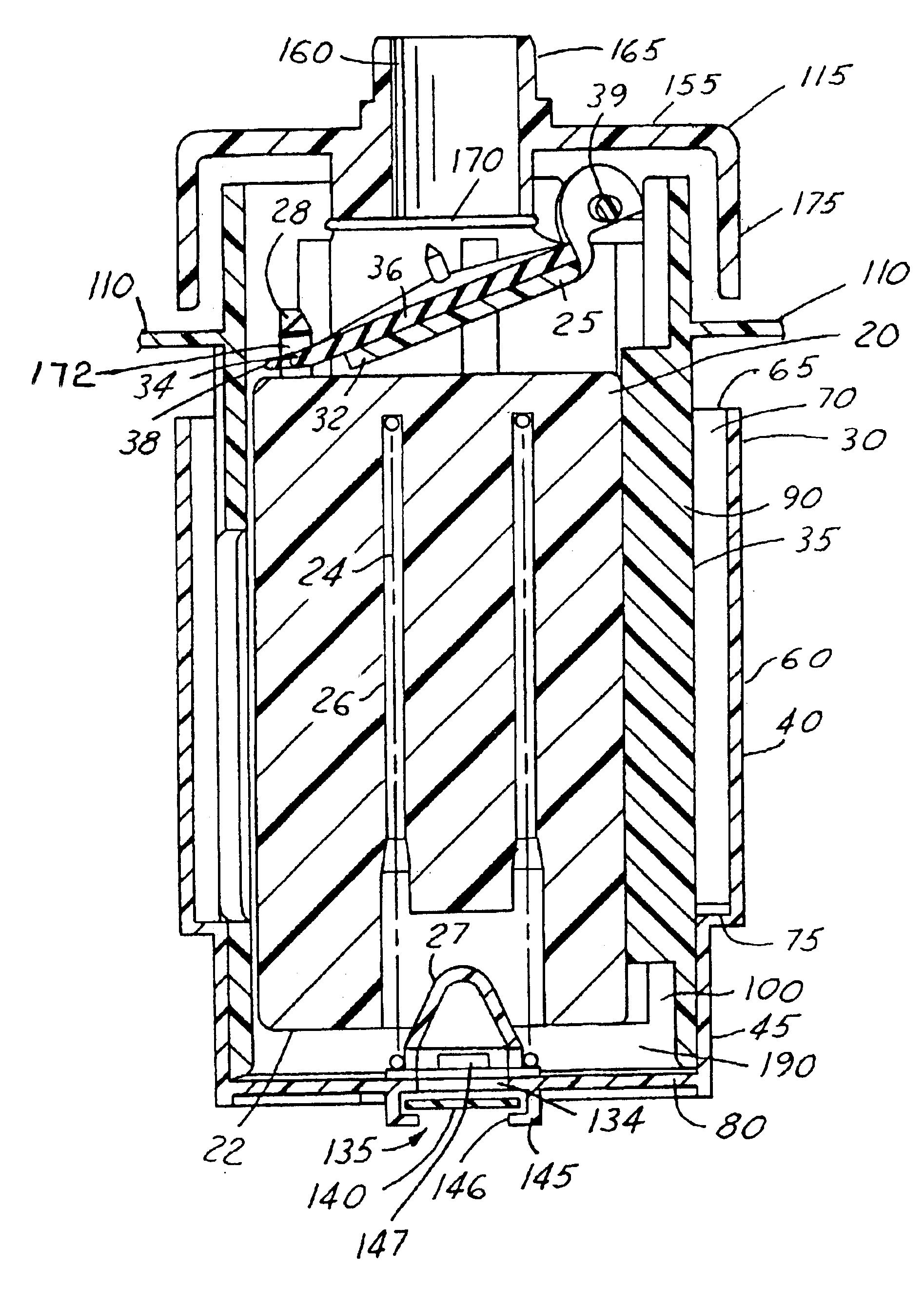

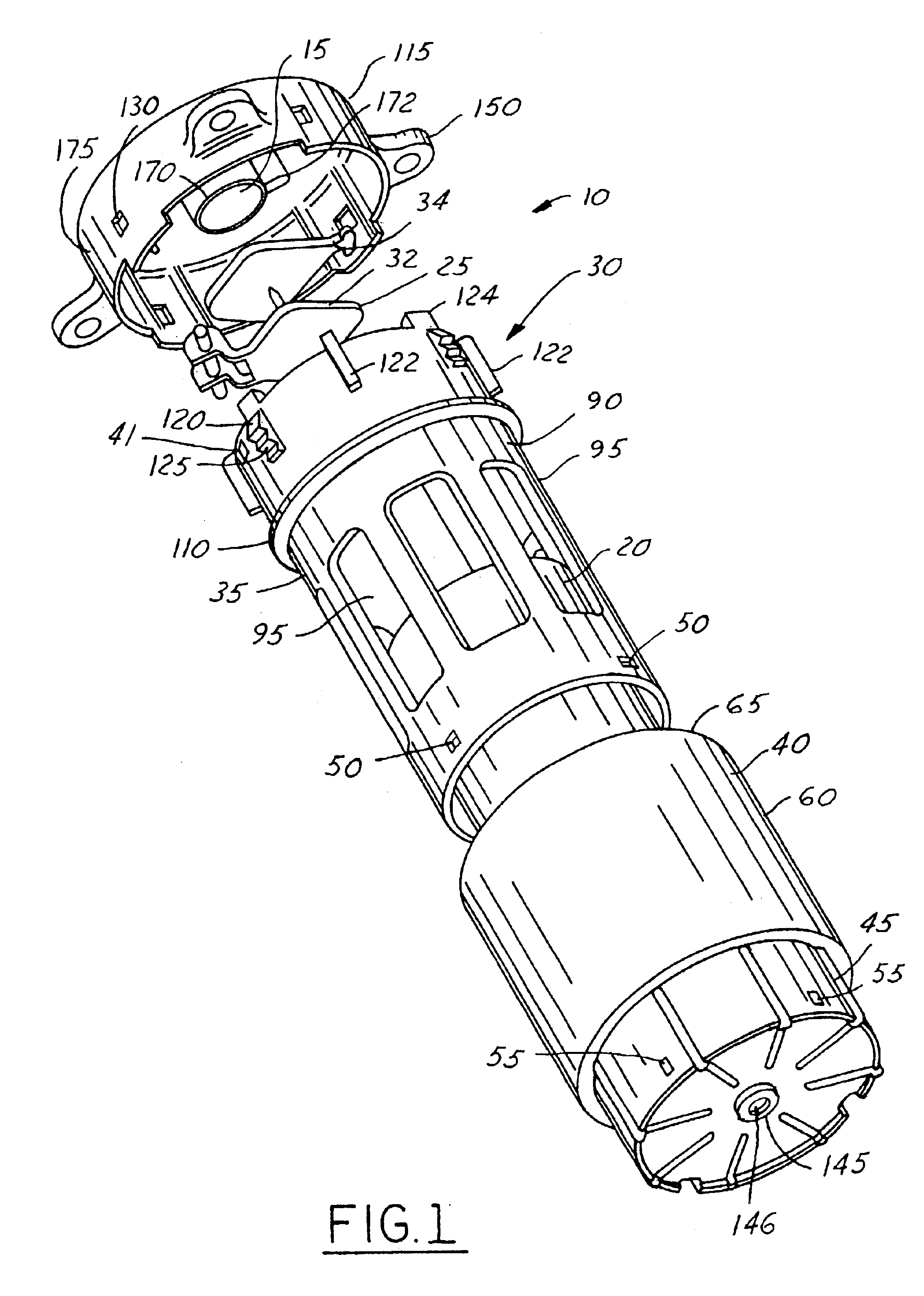

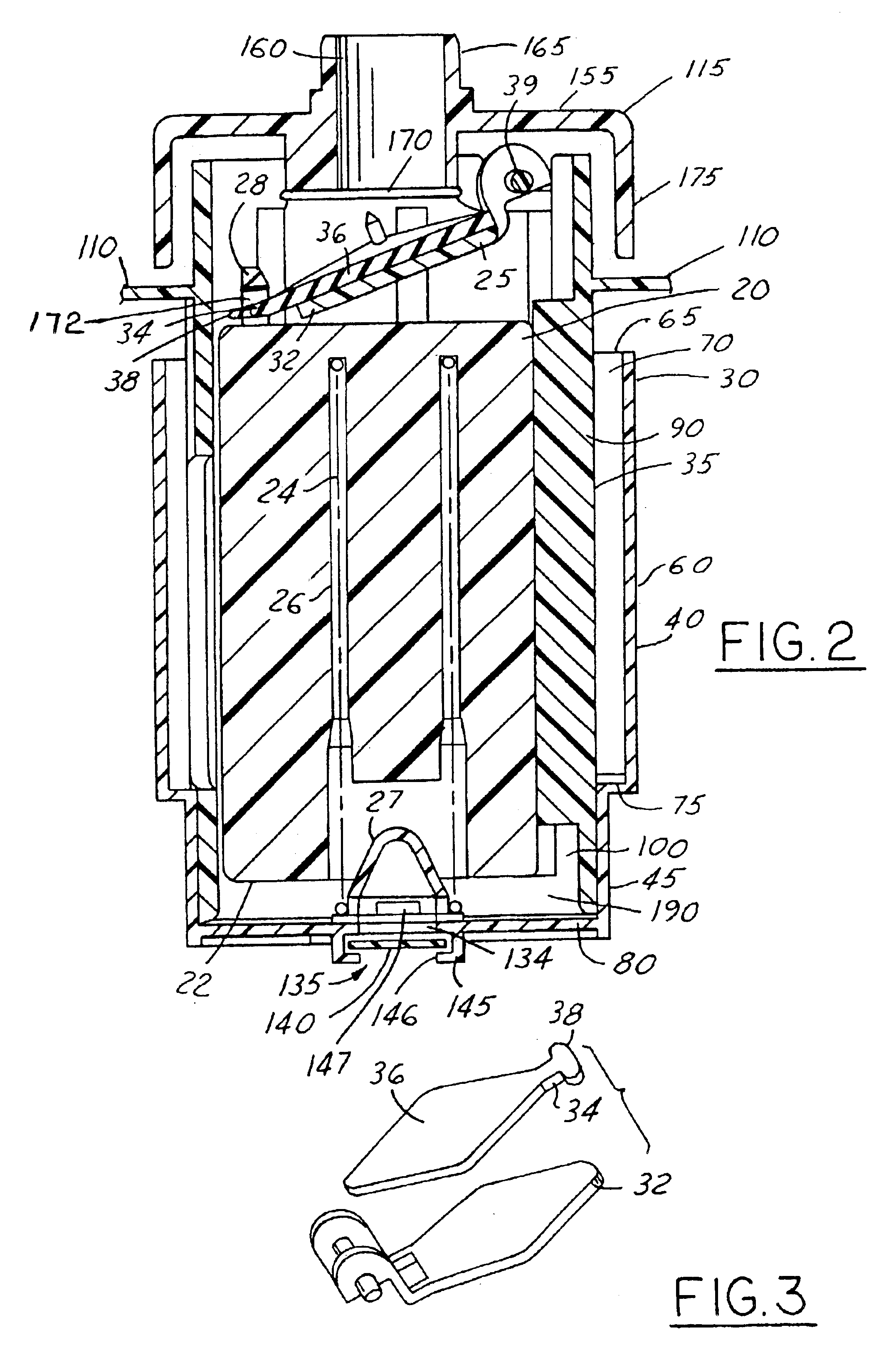

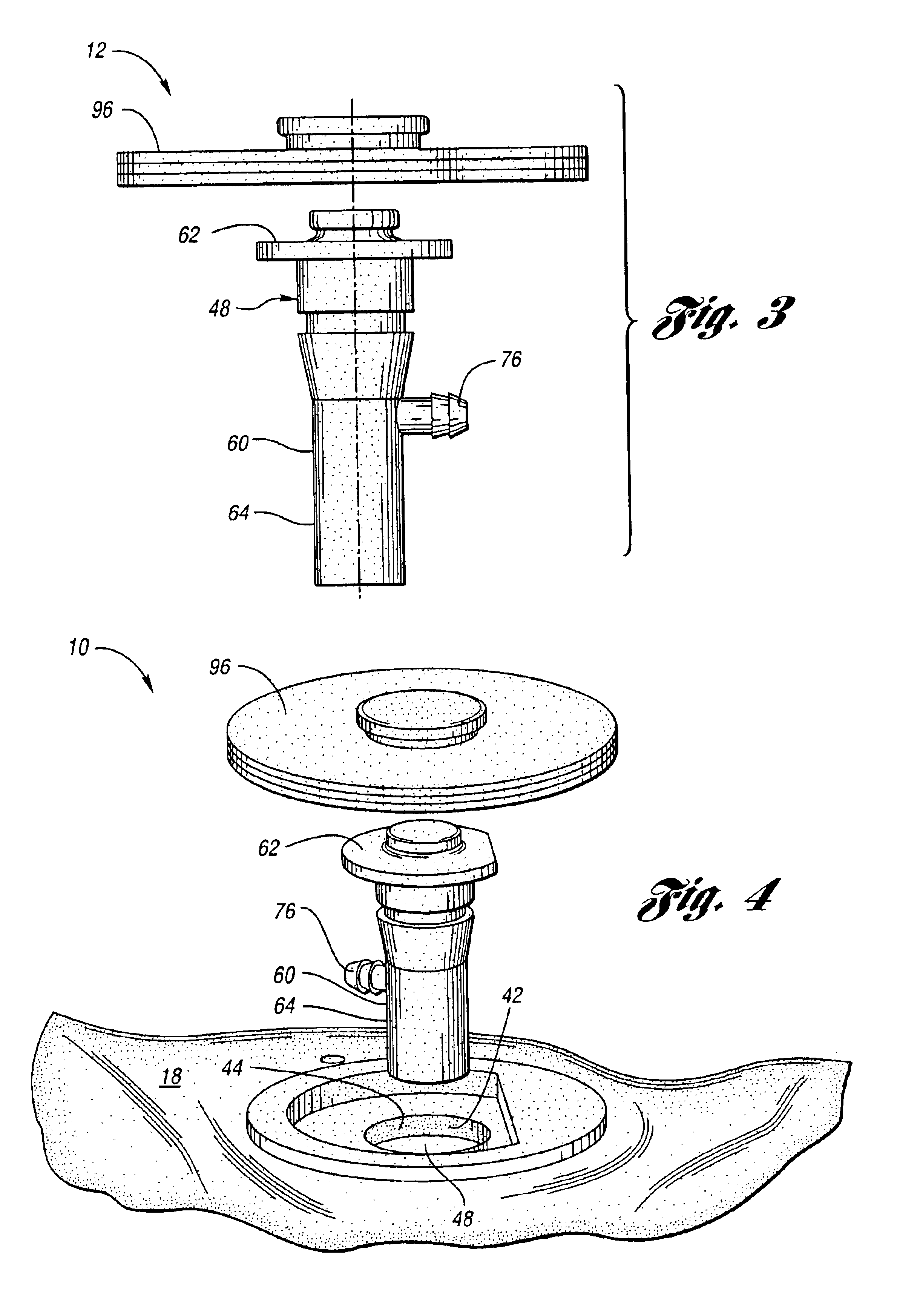

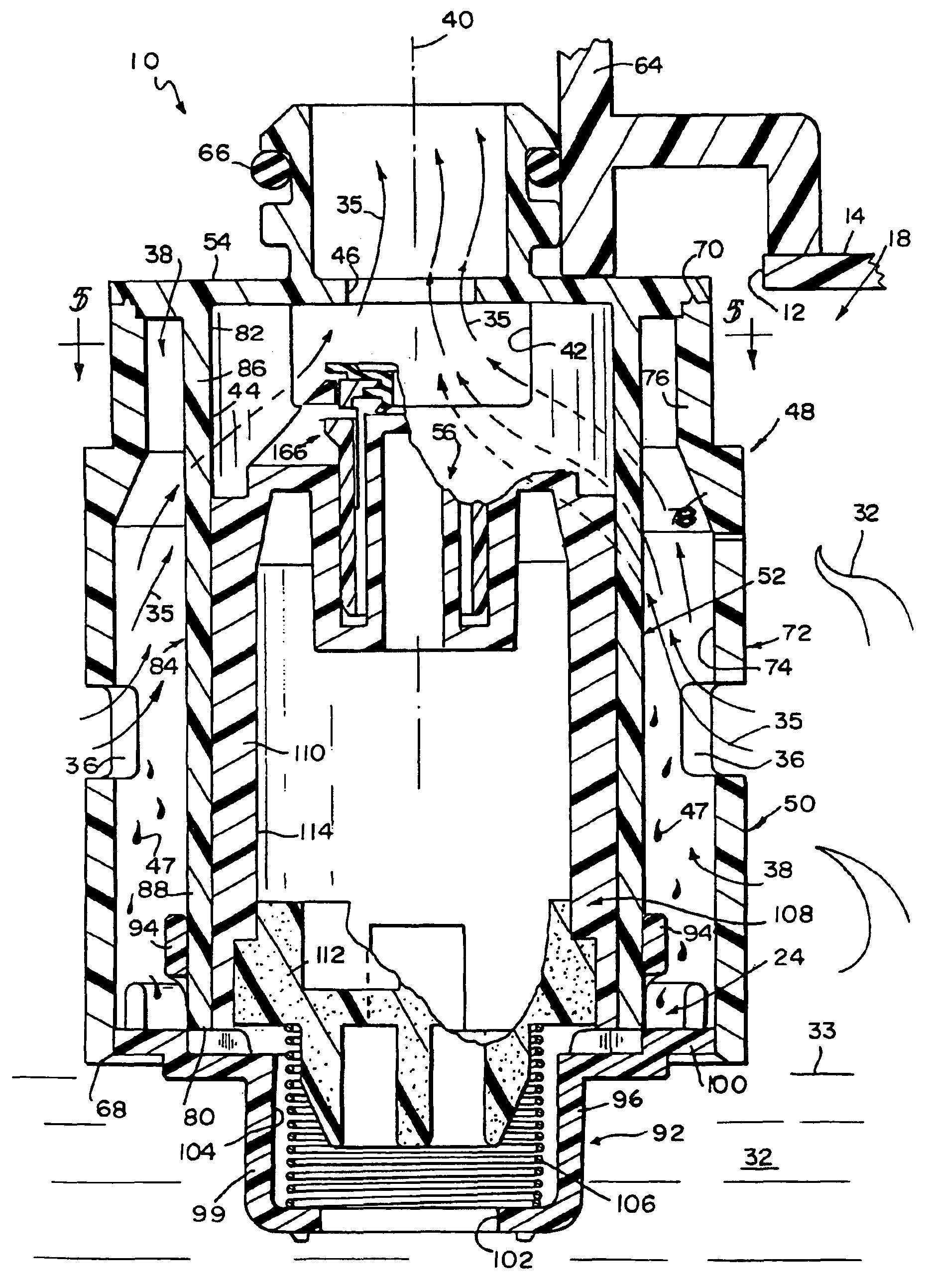

Mounting a fuel vapor management valve internally to a gas tank

InactiveUS6863082B1Simple and effective and yet relatively low-costLarge containersUnderstructuresFuel vaporTransmitter

A plastic bodied fuel vapor management valve has mounting lugs thereon which are adjustably snap-locked onto a bracket provided on a cover for the tank access opening to selectively locate the valve vertically on the bracket. As the valve is engaged with the bracket, a vapor vent fitting provided on the cover is received in the valve outlet and sealed by a seal ring. The cover preferably comprises a mounting flange for a fuel level signal sender.

Owner:EATON CORP

Valve attached to fuel tank

Disclosed is a valve being attached to a fuel tank, the valve permitting a vaporized fuel to flow out and inhibiting a liquid fuel from flowing out. The valve includes a cover and a case. For example, the cover is bonded to an upper portion of a fuel tank, is independent of the fuel tank, and includes a connecting surface to be connected to the fuel tank and a flow-out passage in which a vaporized fuel flows out. The connecting surface has a connector portion formed of a resin exhibiting a good bondability to the fuel tank. The case is screwed to the cover, and includes an evaporator opening and a floating valve. The evaporator opening communicates with the flow-out passage. The floating valve opens or closes the evaporator opening.

Owner:TOYODA GOSEI CO LTD

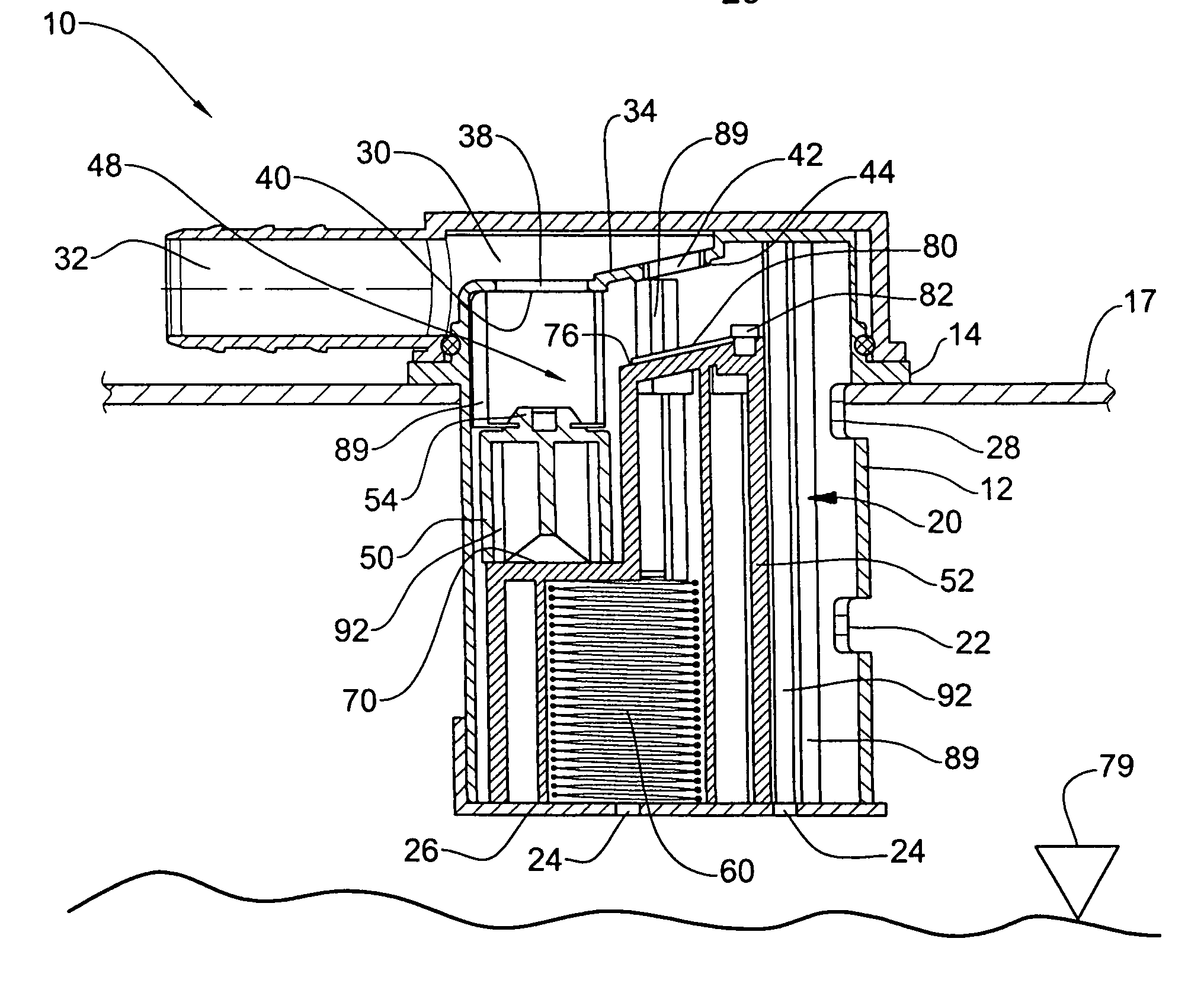

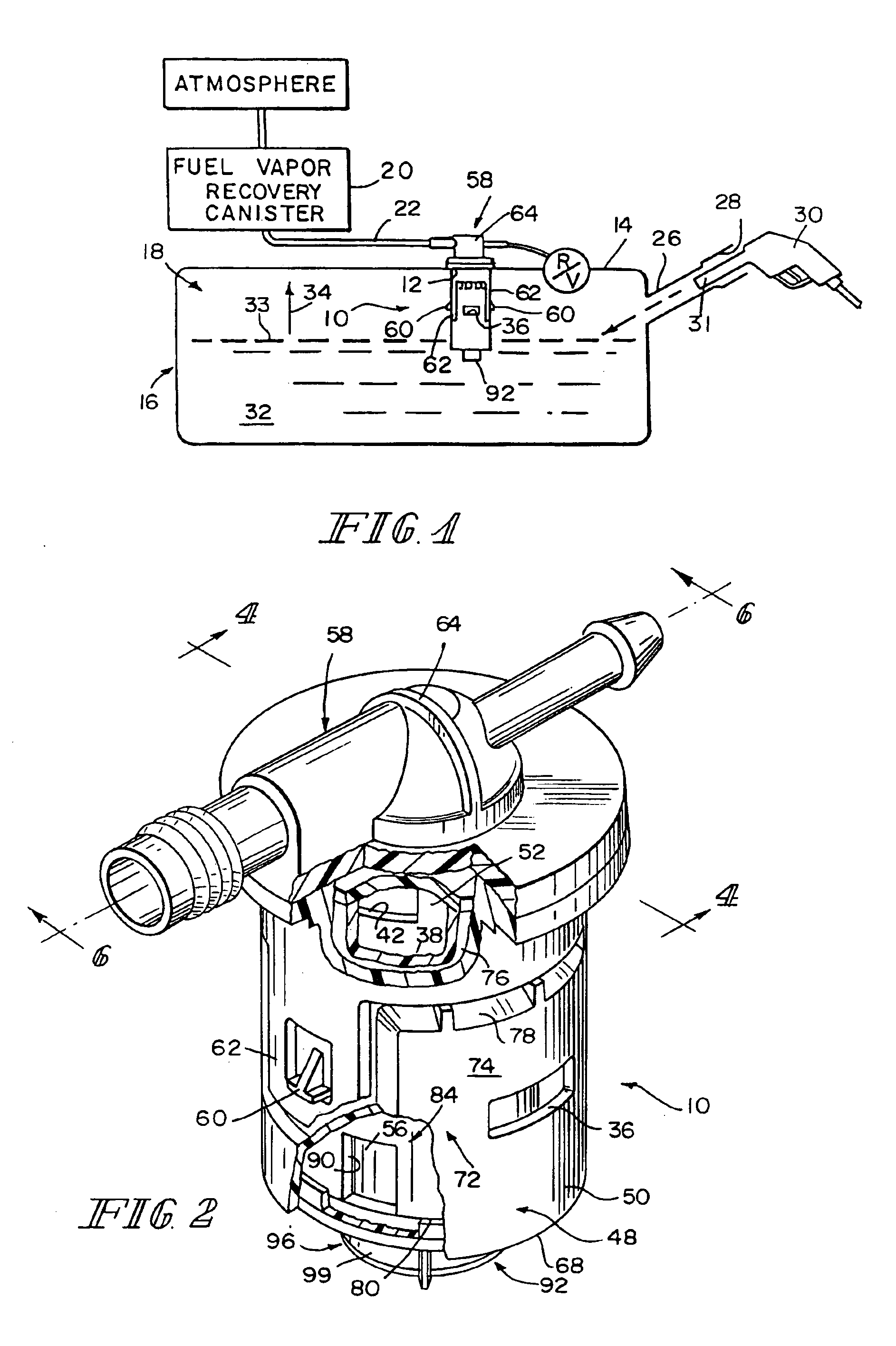

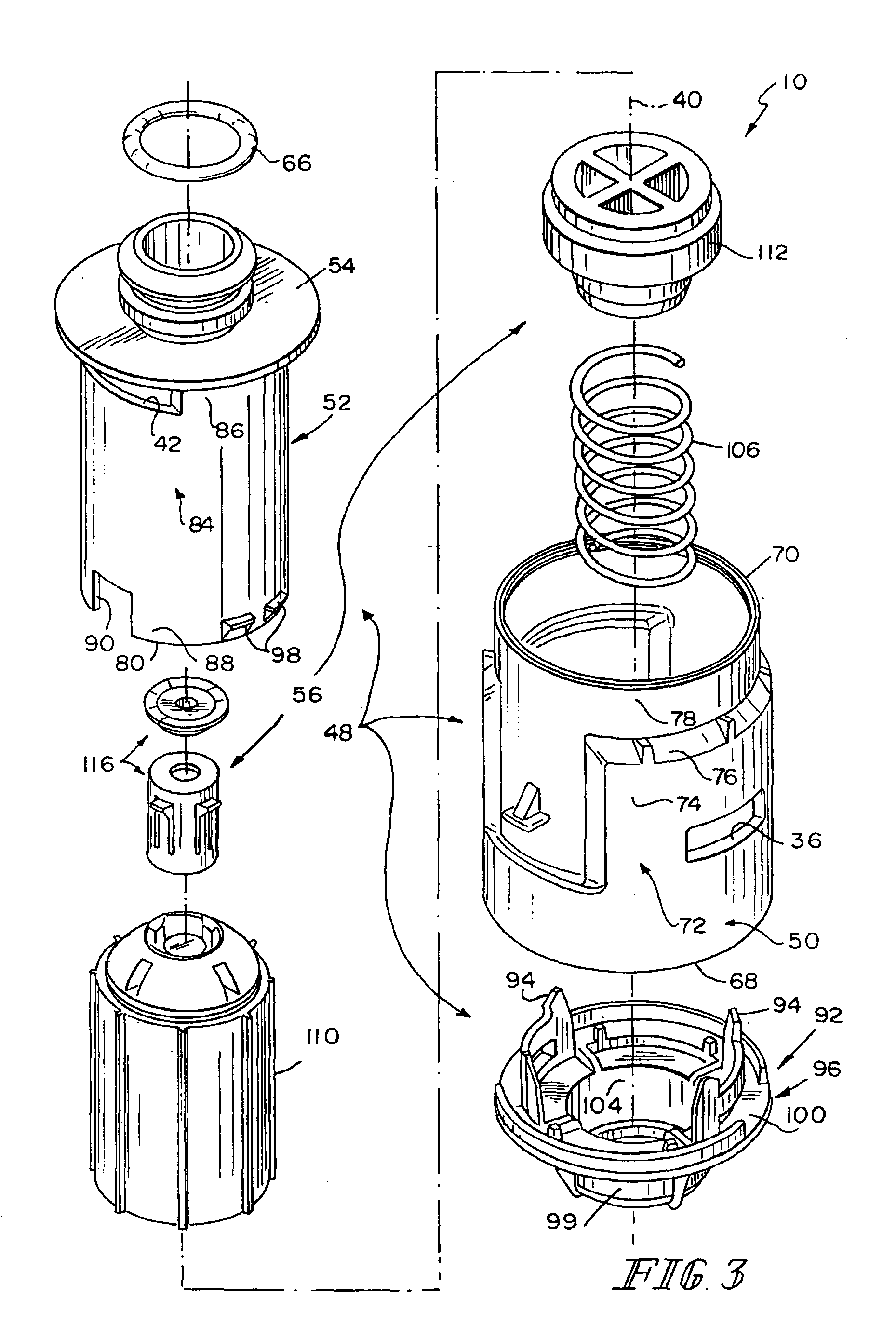

Vapor vent valve

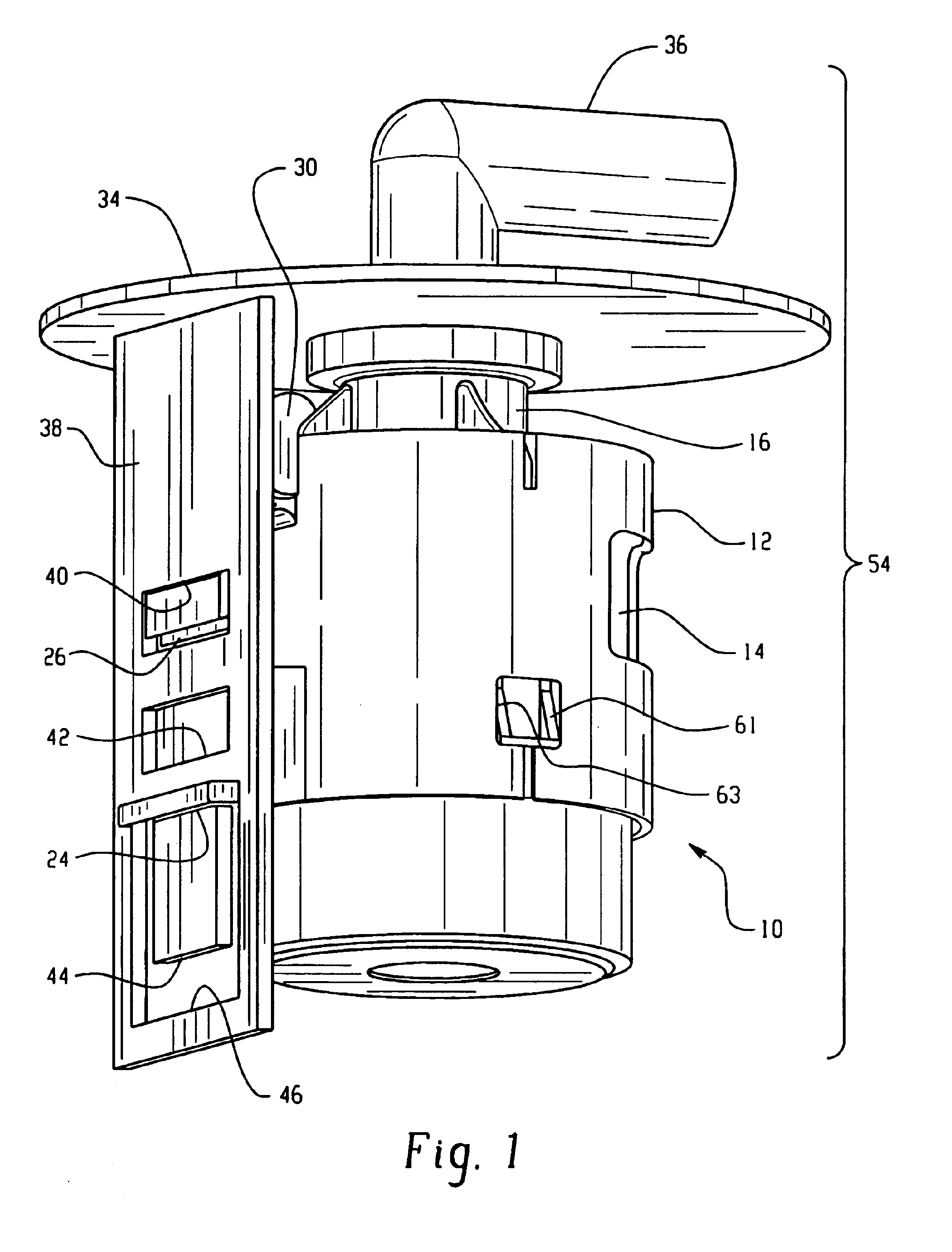

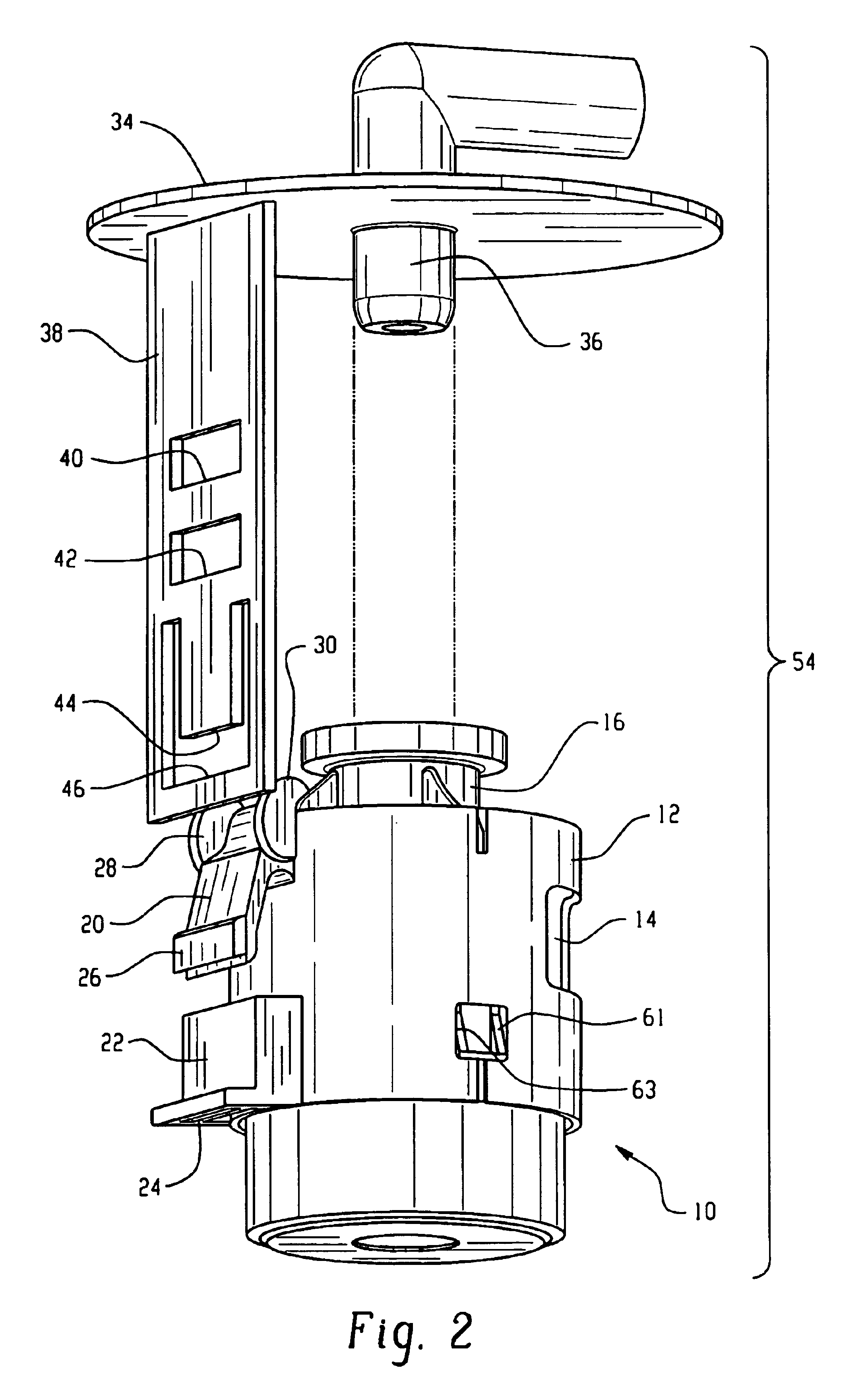

InactiveUS6848463B2High vapor flow rateIncrease capacityLarge containersVenting valvesInterior spaceExhaust valve

A vapor vent valve for a fuel tank that includes a vapor outlet that connects an interior of the fuel tank with an exterior of the fuel tank. The vent valve also includes a fill cup that has an opening at one end and a sidewall that extends from the open end. A shell defines an interior space and is disposed partially in the fill cup. The shell includes a sidewall that has an opening and an upper edge. A flow passage is defined between the fill cup's sidewall and the shell sidewall to allow fluid which flows into the opening of the fill cup to enter the interior space through the opening in the sidewall of the shell. A float is received in the interior space and is responsive to the level of liquid fuel in the interior space. A closure pivotally carried by the shell is movable to a closed position to prevent fluid flow through the vapor outlet. The closure is also movable to an open position which allows fuel vapor to exit the fuel tank. The closure includes a carrier plate that has an elastomeric layer attached to the carrier plate. The elastomeric layer includes a portion that is attached to the float for actuating the closure to the open and closed positions.

Owner:TI GRP AUTOMOTIVE SYST LLC

Over-fueling prevention valve

InactiveUS6959720B2Increase internal pressureImprove the level ofNon-fuel substance addition to fuelLarge containersInternal pressureFuel tank

A fuel valve includes an upper chamber communicating with a ventilation passage of a canister; a lower chamber to be disposed inside a fuel tank; a communicating port between the upper chamber and the lower chamber; and a float member disposed in the lower chamber for blocking the communicating port when fuel flows into the lower chamber. The lower chamber includes a one-way valve formed at a bottom thereof for allowing the fuel to flow out only through the one-way valve, and a fuel inlet formed in a side wall of the lower chamber. When a fuel level inside the fuel tank reaches the main fuel inlet, the fuel flows into the lower chamber to raise the float member. As a result, an internal pressure of the fuel tank increases, so that a sensor at a fueling nozzle side can detect that the fuel tank is filled-up.

Owner:NIFCO INC

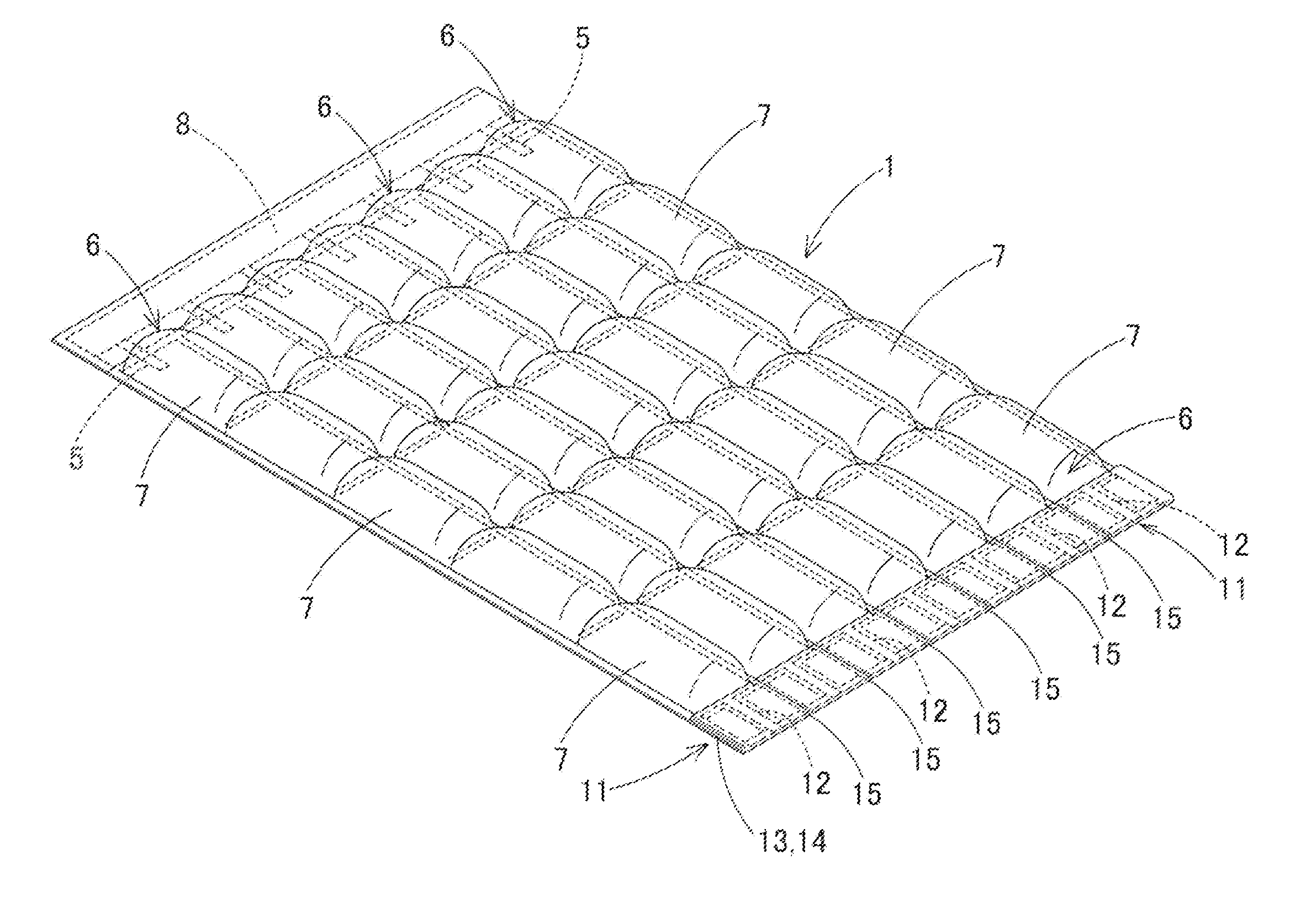

Exhaust valve apparatus and gas filled cushion

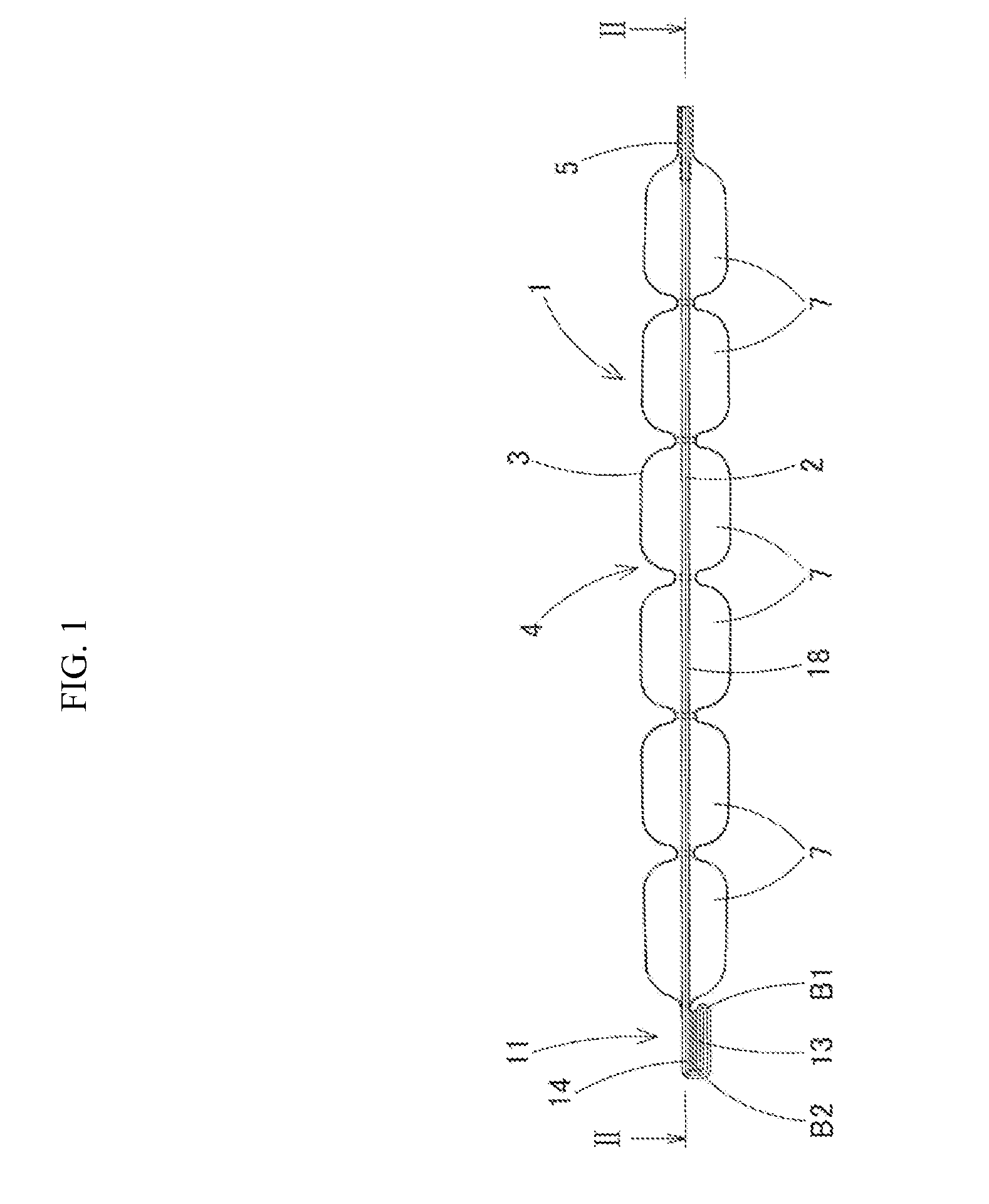

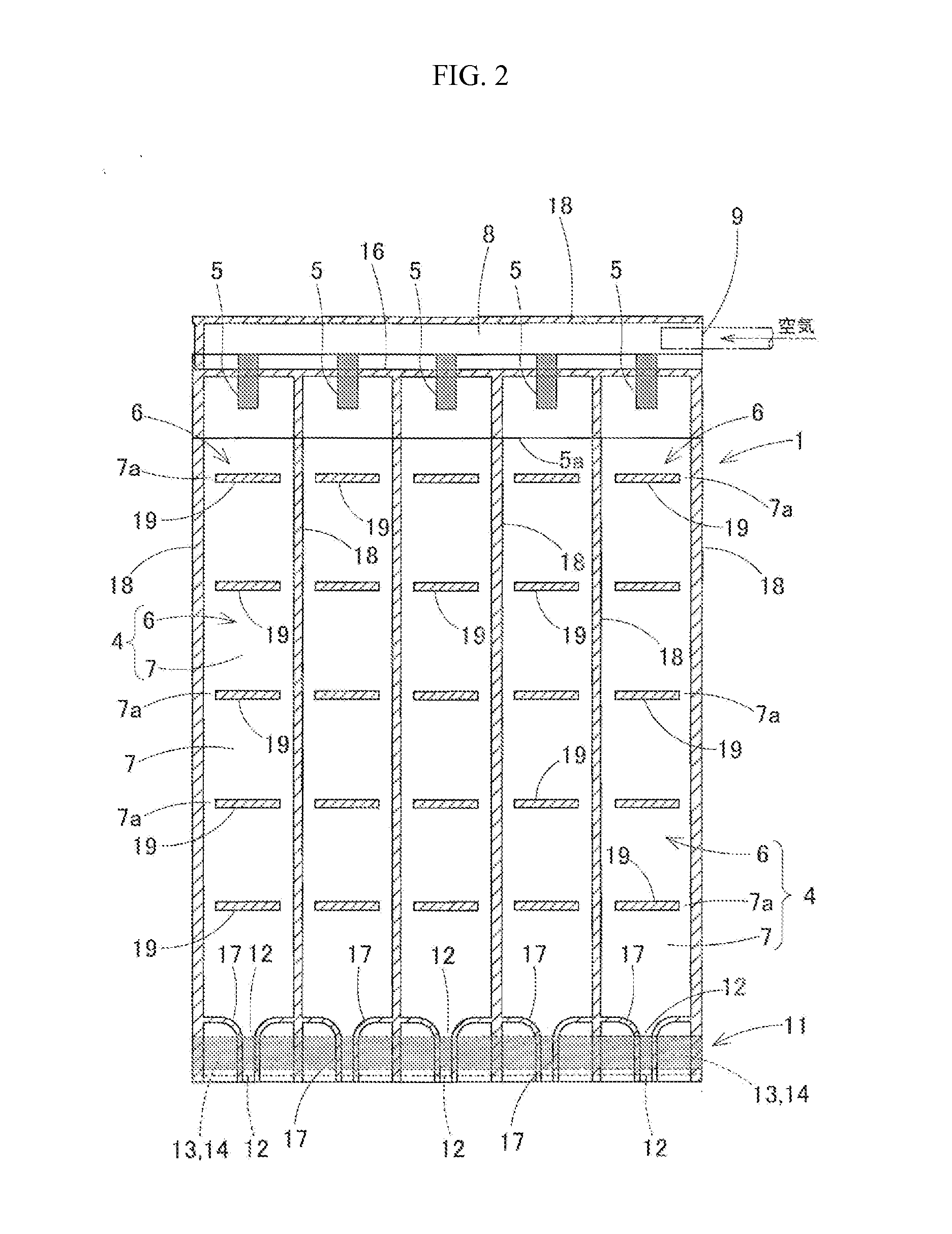

InactiveUS20160058218A1Easy dischargeEasy to usePaper/cardboard articlesDomestic upholsteryCushioningExhaust valve

A gas cushioning material preserved by easily discharging a gas from a bag part and used by filling the bag part with the gas when used again is provided. Gas cells are disposed in parallel in a gas cell row by forming heat-fusion parts in the transverse direction. A discharge valve part for discharging gas is formed at an end portion of each gas cell row. A narrowed discharge passage is formed in the discharge valve part. When the bag part is filled with a gas, the discharge valve part is bent to close the discharge passage, and in the state in which the discharge valve part is bent, a first surface fastener and a second surface fastener formed on a front surface and a rear surface of the discharge valve part are coupled to each other to maintain a closed state of the discharge passage.

Owner:YOSHIFUSA KATSUTOSHI +3

Fuel tank venting system for reduced fuel permeation

The present invention involves a venting system for venting a gaseous fluid from a tank having an aperture and a fuel delivery module cover. The tank is made of a predetermined material. The venting system comprises a venting valve for venting gaseous hydrocarbon fluid at a predetermined pressure from the tank. The valve is disposed through the aperture to define a circumferential space between the inner side of the outer lip and the venting valve. The system further includes a cover comprising the predetermined material and attached to the outer layer to seal the valve between the cover and the outer layer. The system further includes a retention member disposed about the venting valve and attached to the outer layer about the outer side of the outer lip defining an expansion boundary so that the outer lip only expands toward the venting valve to seal the circumferential space when the tank absorbs hydrocarbons.

Owner:PLASTIC OMNIUM ADVANCED INNOVATION & RES SA

Automatic valve

ActiveUS20060122559A1Increase contactEasy and efficient to manufactureMedical devicesOral administration deviceVALVE PORTGreat Relative

Owner:CARDINAL HEALTH IRELAND UNLTD

Fuel tank vent system with liquid fuel filter

A fuel tank vent apparatus comprises a housing. The housing comprises inner and outer sleeves providing a fuel vapor transfer passageway therebetween so that liquid fuel entrained in fuel vapor is shed therefrom as fuel vapor flows from a fuel vapor transfer port formed in the outer sleeve through the fuel vapor transfer passageway to a fuel vapor inlet port formed in the inner sleeve to produce a flow of demoisturized fuel vapor for discharge from the housing.

Owner:STANT USA CORP

One way valve

InactiveUS7513481B2Easy to produceLarge elastic forceOperating means/releasing devices for valvesBagsEngineeringStops device

The present invention is to provide one-way valve of a sealed bag to expel the dead air out from the bag with a preferred air-tight effect. The one-way valve comprises a valve seat, a diaphragm mounted inside the valve seat, the diaphragm is also in linear contact with a projected annular ring, a stop device pressed on the diaphragm, a valve cap screwed to the valve seat and pressed the stop device. Said valve cap has hooks adapted to apertures of the seat, thus keep the cap on the seat not to be separated from thereof. Moving upward or downward the valve cap, the stop device can be controlled to press onto the diaphragm tightly or become loose. An airtight effect is achieved with a pressure exerted between the stop device and the annular ring. Or one-way valve can expel the dead air through the air pores under diaphragm.

Owner:SU FU LONG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com