Patents

Literature

1835results about "Bottle emptying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

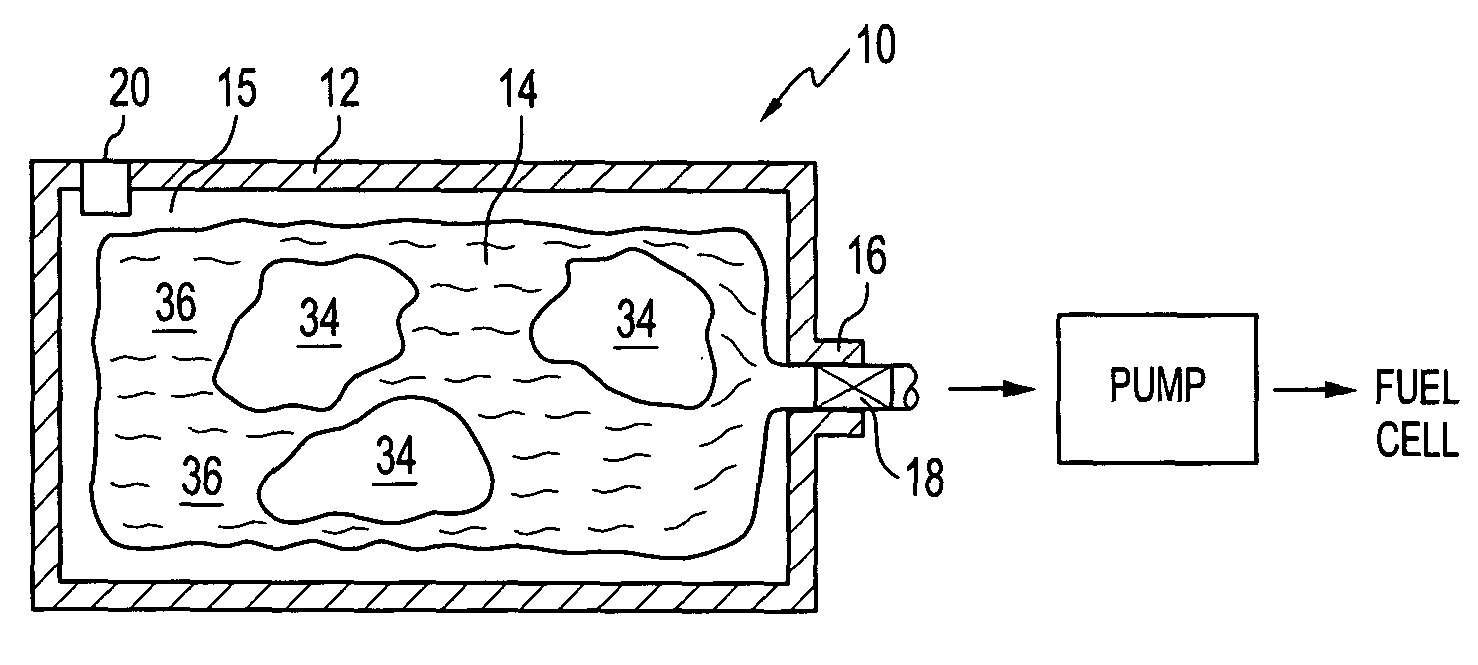

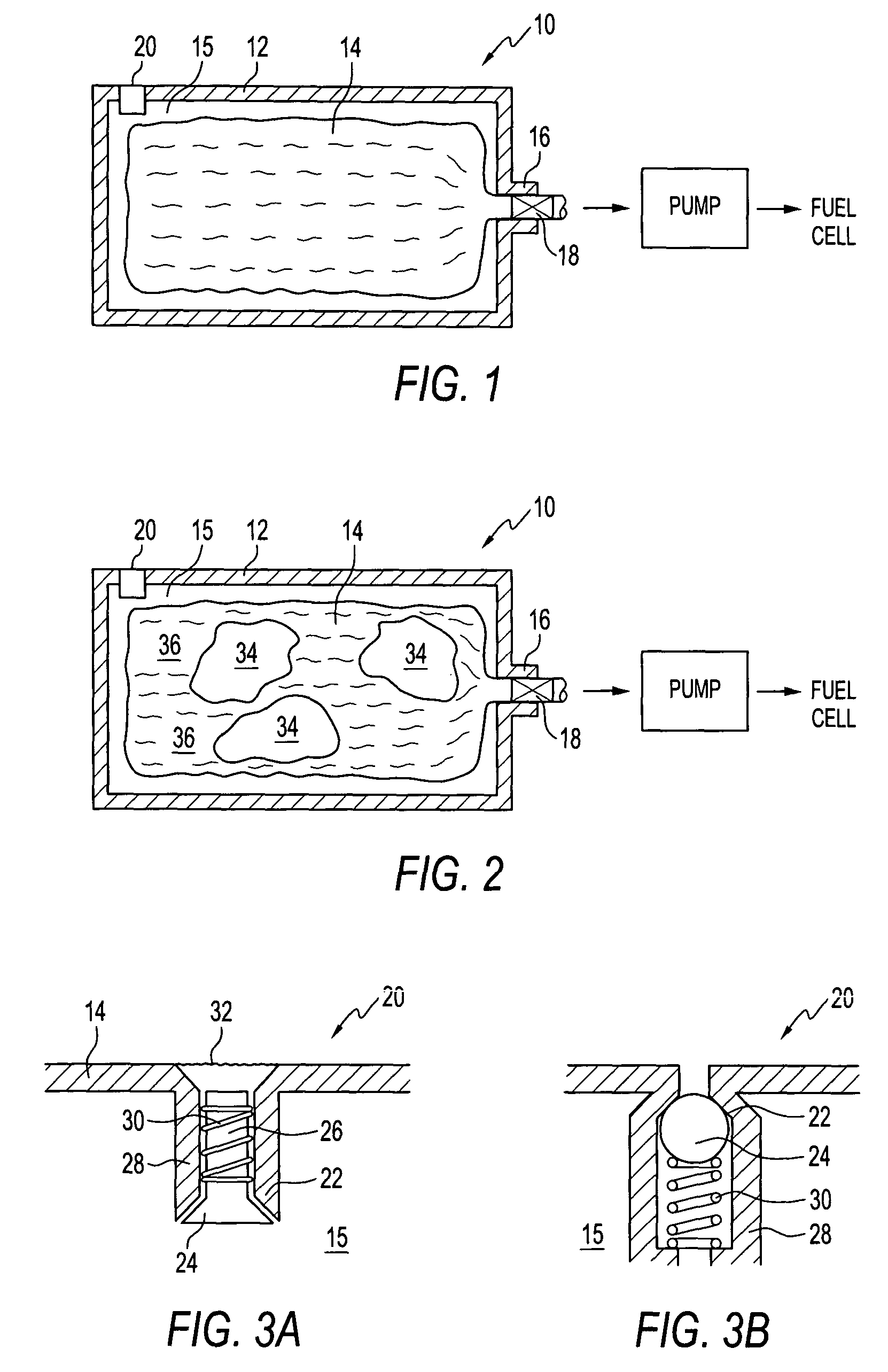

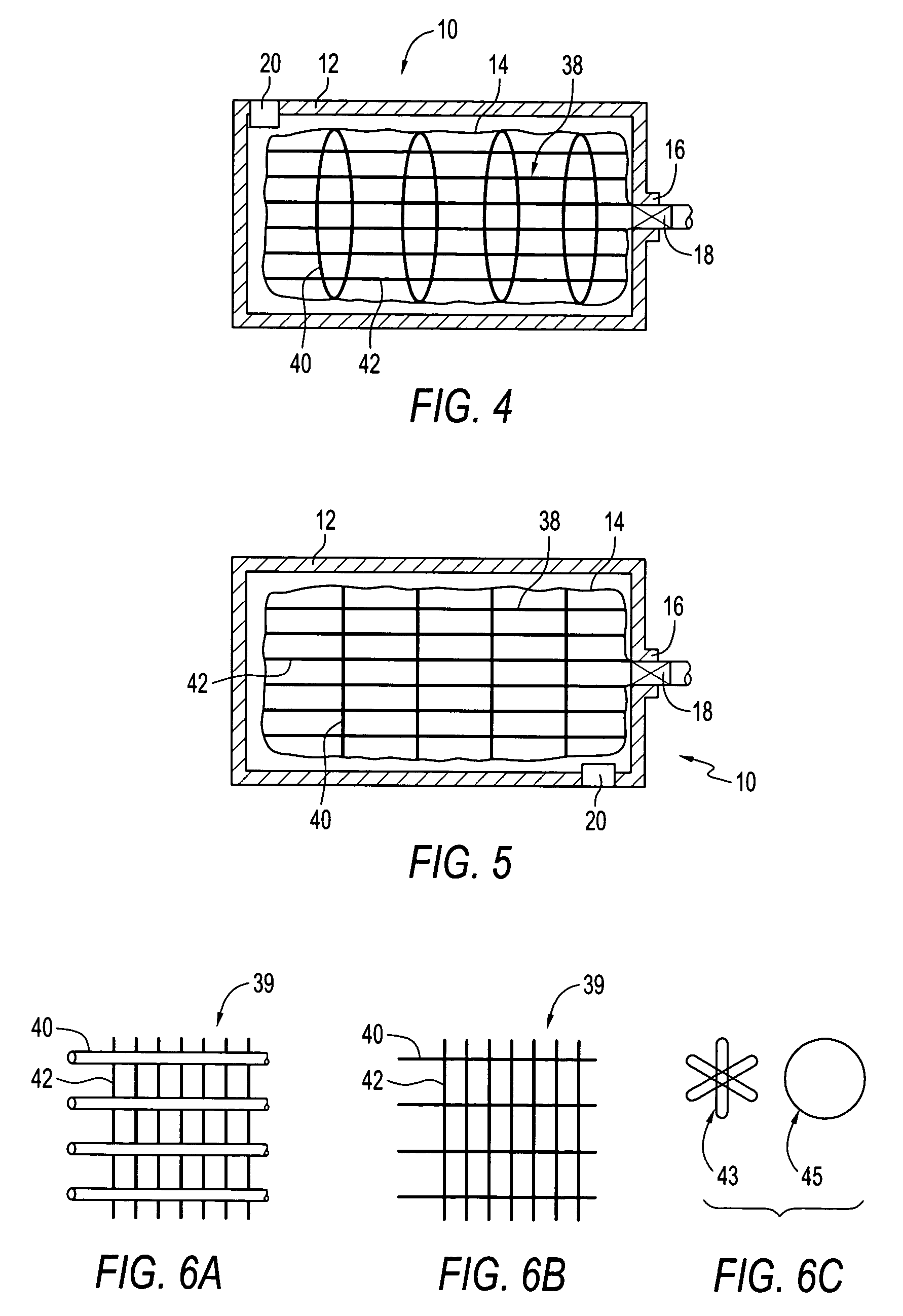

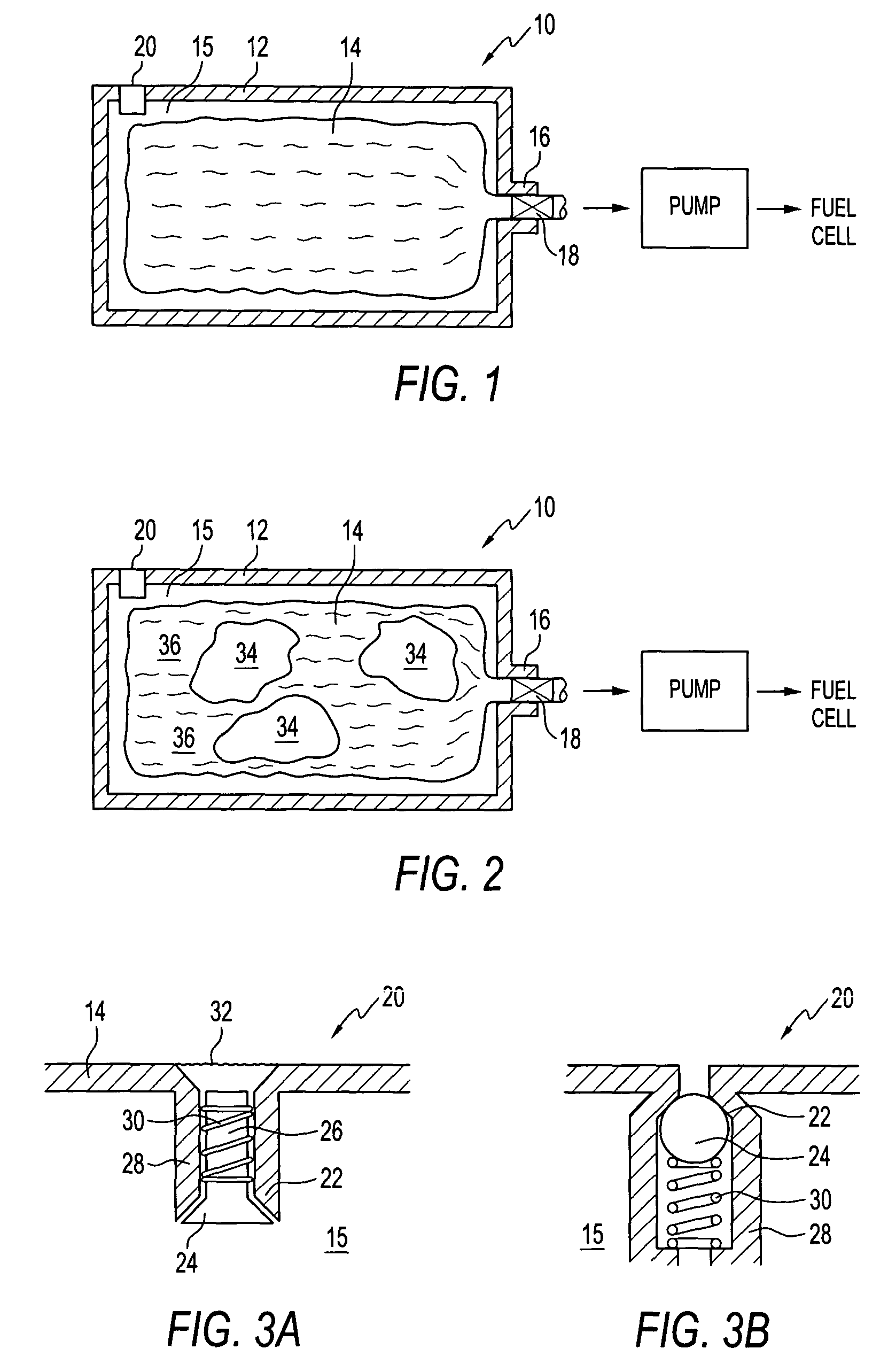

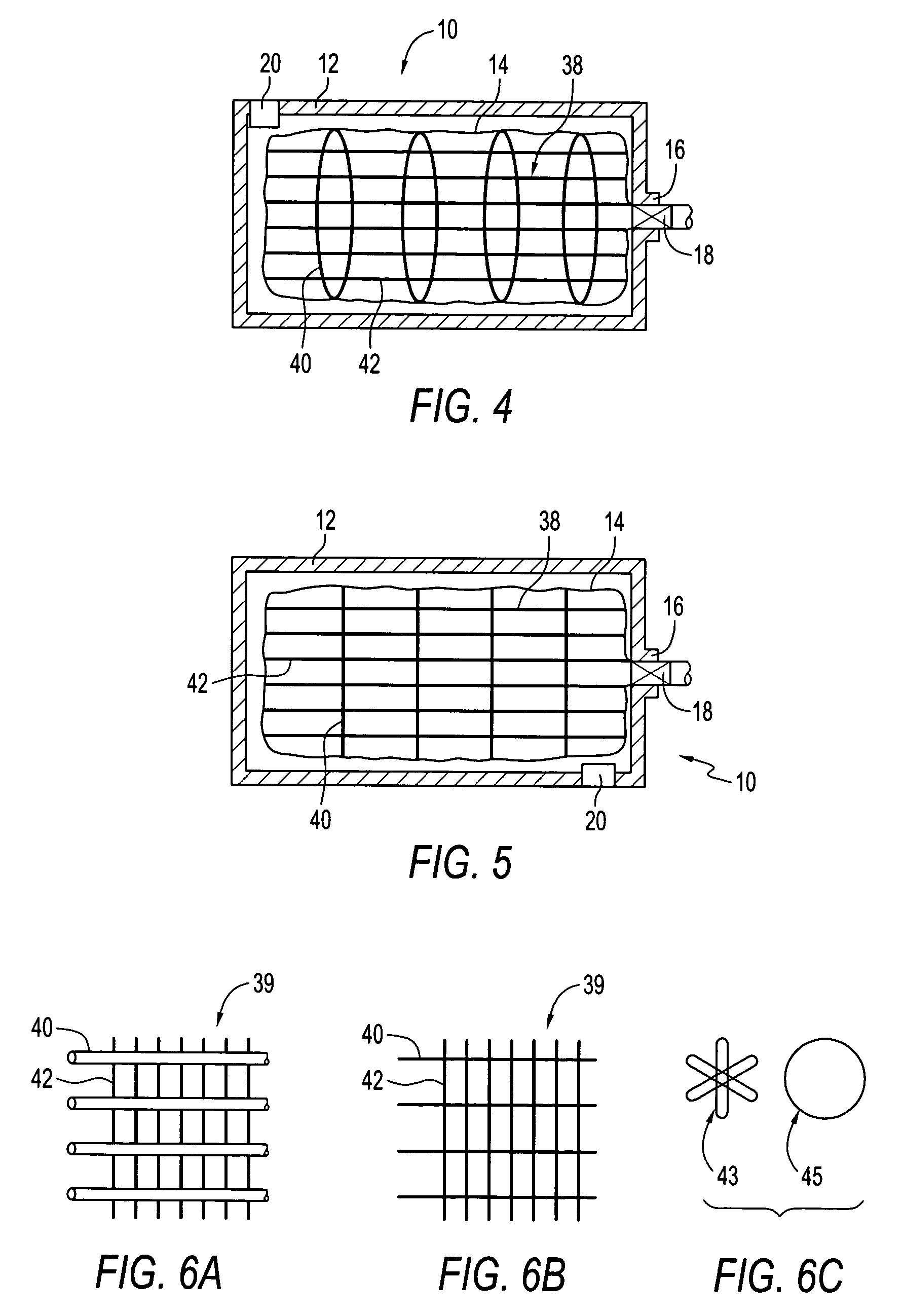

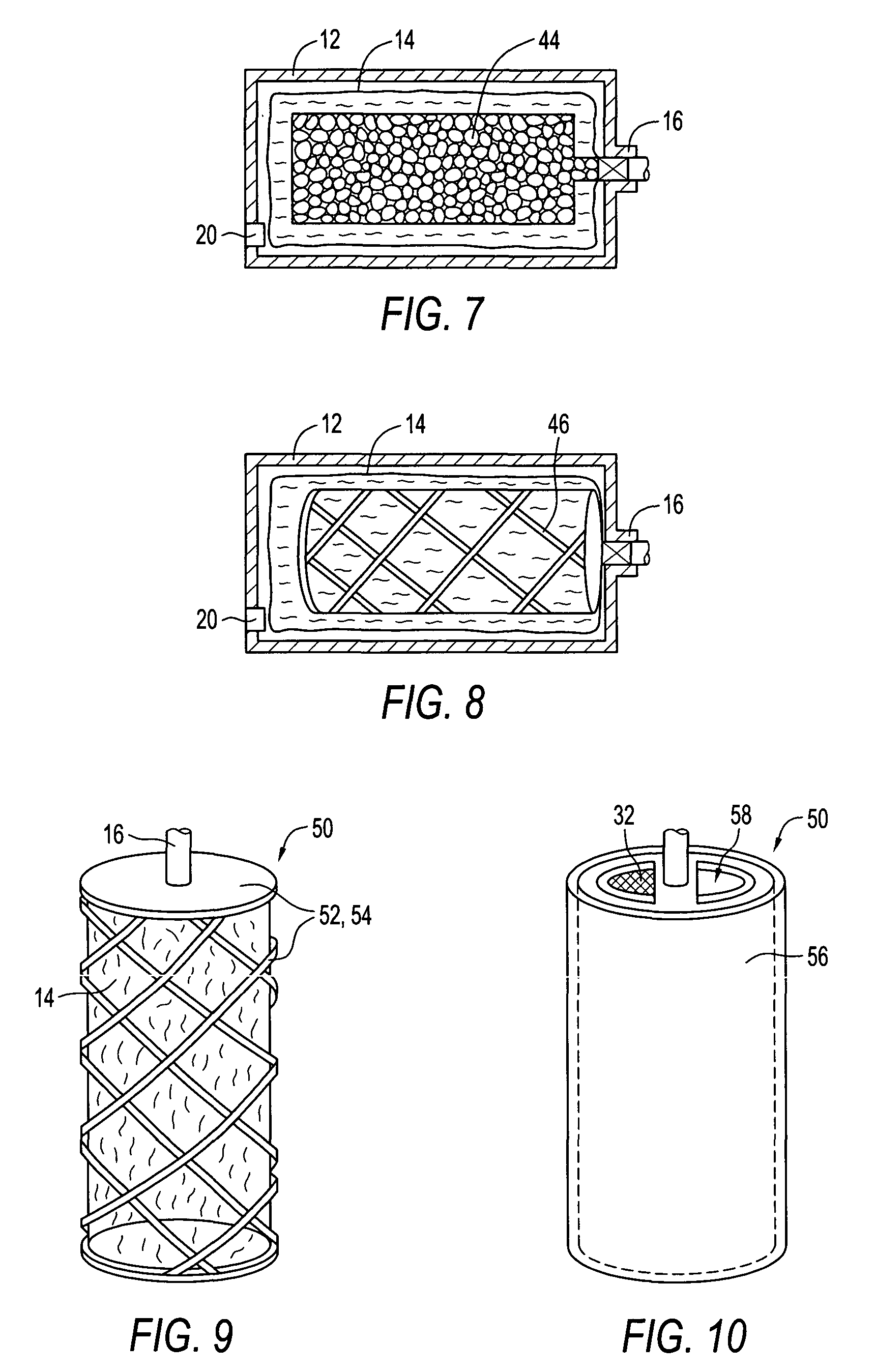

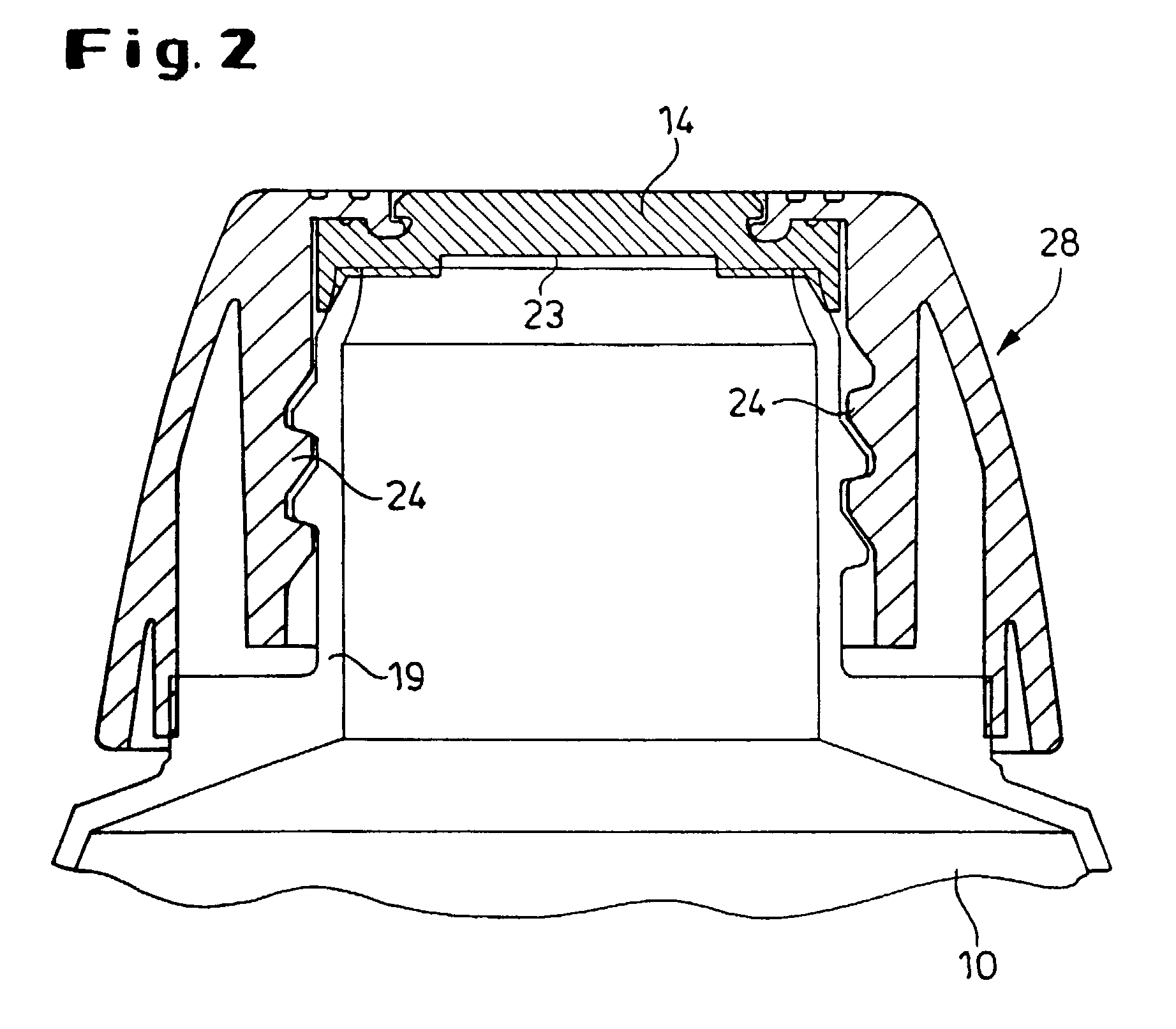

Fuel cartridge with flexible liner

A cartridge connectable to a fuel cell is disclosed. The cartridge comprises an outer casing and an inner flexible liner containing fuel for the fuel cell. The inner flexible liner may have an insert disposed inside the inner liner to facilitate the transport of fuel from the cartridge to the fuel cell. The insert minimizes the fuel that is trapped within the cartridge. The inner flexible liner can be used without the outer casing. The outer casing can be substantially rigid or flexible. The cartridge is also adaptable to receive byproducts from the fuel cell. The cartridge can also be pressurized to push fuel to the fuel cell. Unidirectional relief valves are also disclosed to prevent internal pressure in the cartridge from becoming too high or too low.

Owner:INTELLIGENT ENERGY LTD

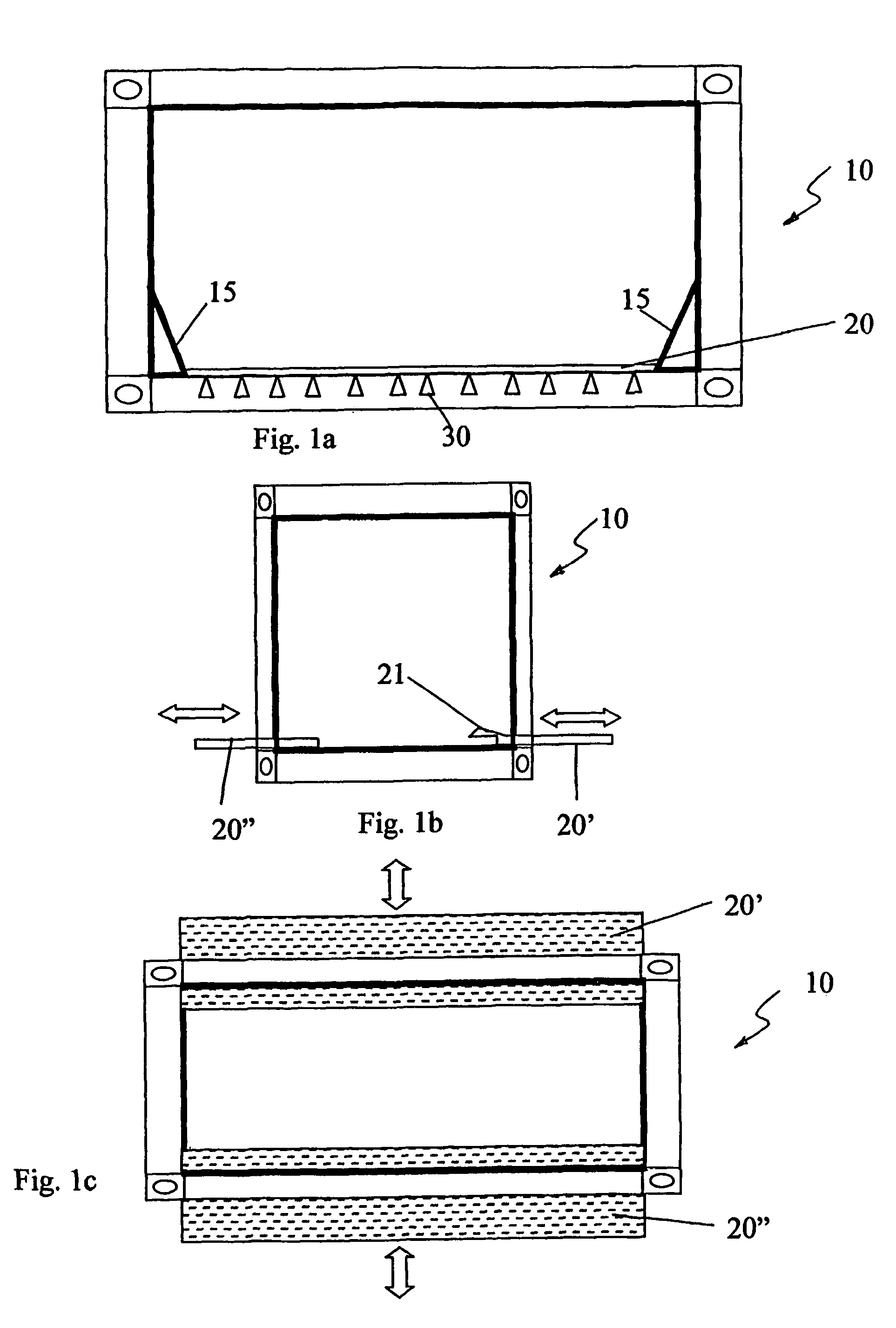

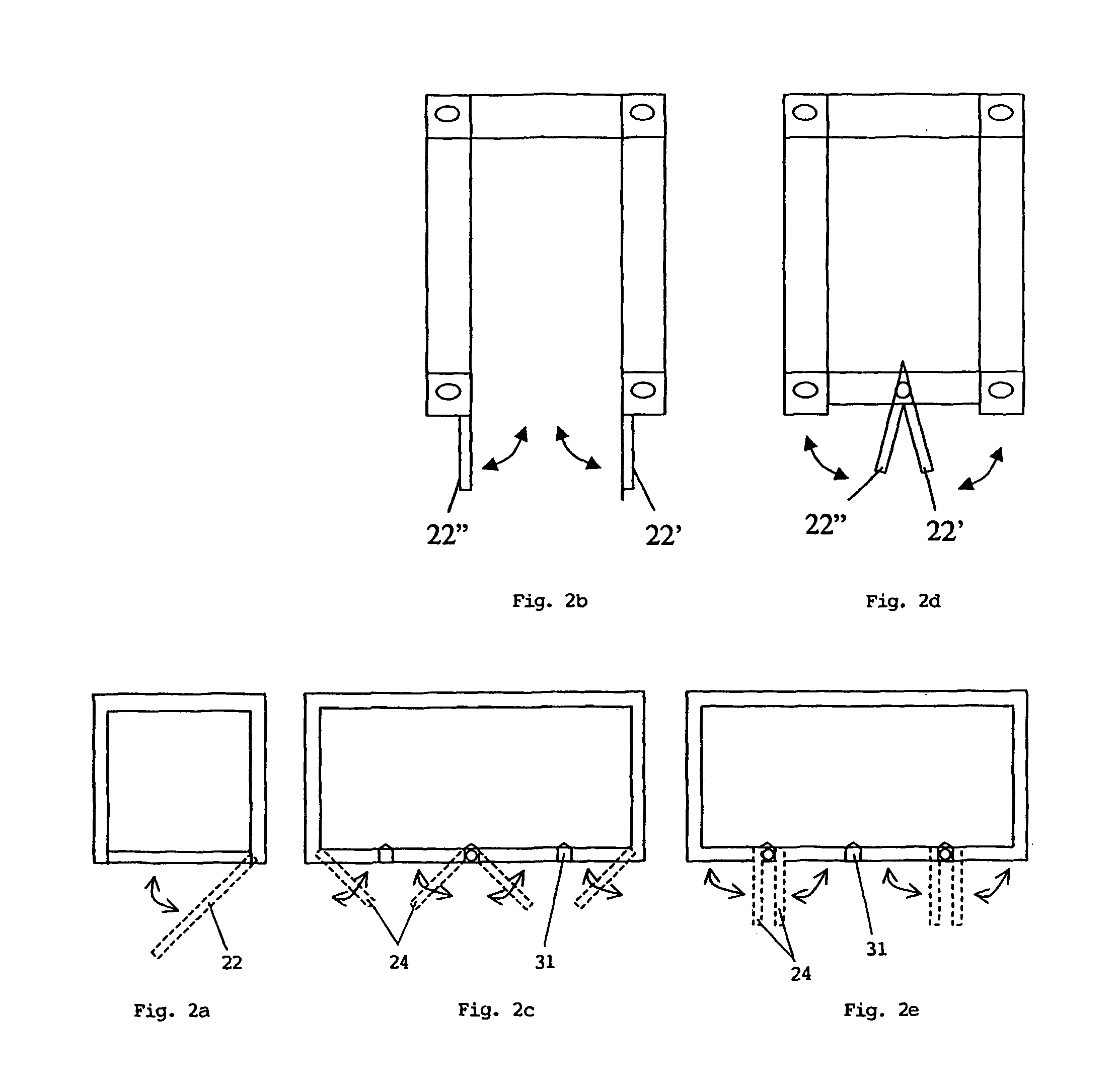

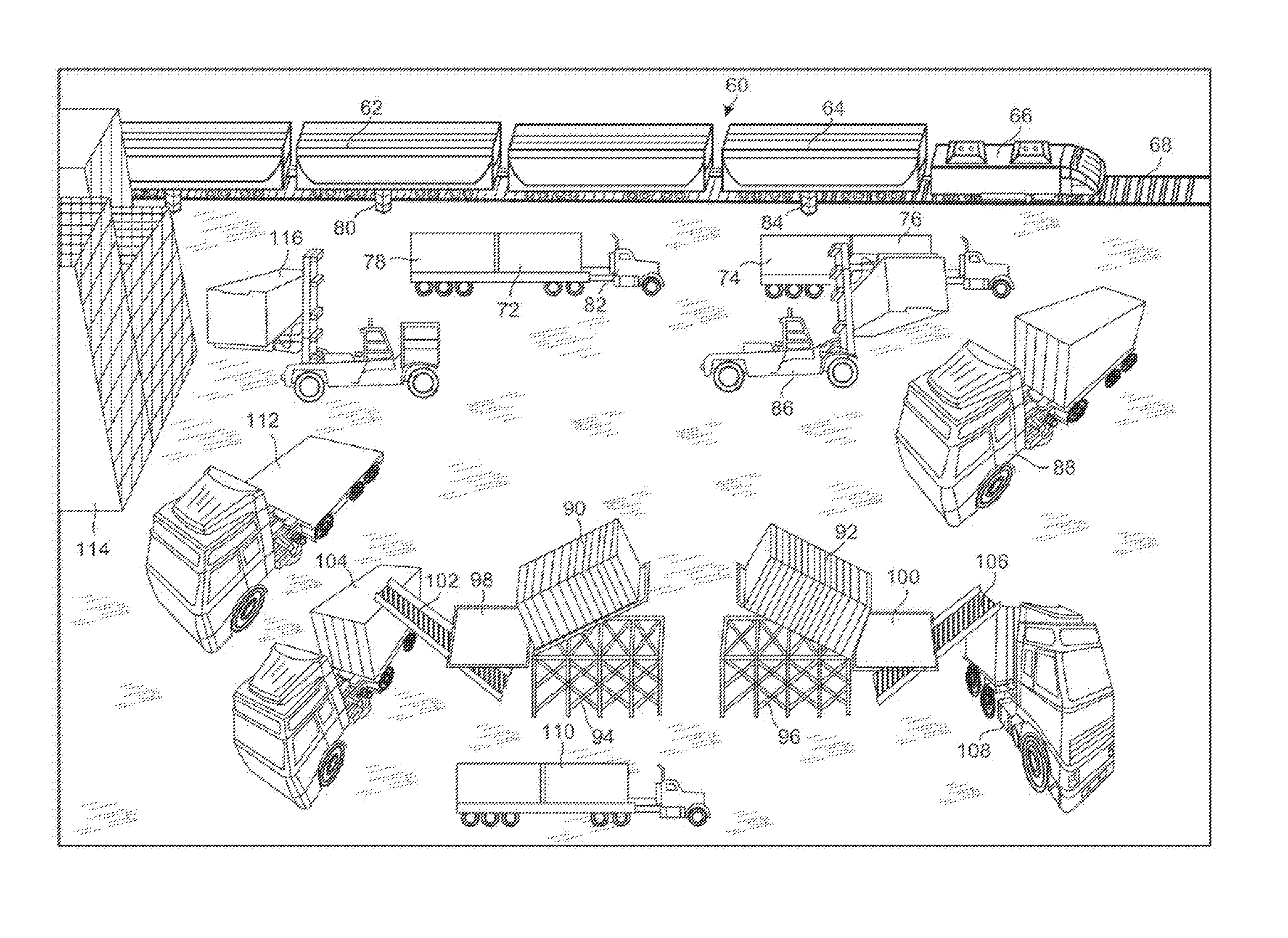

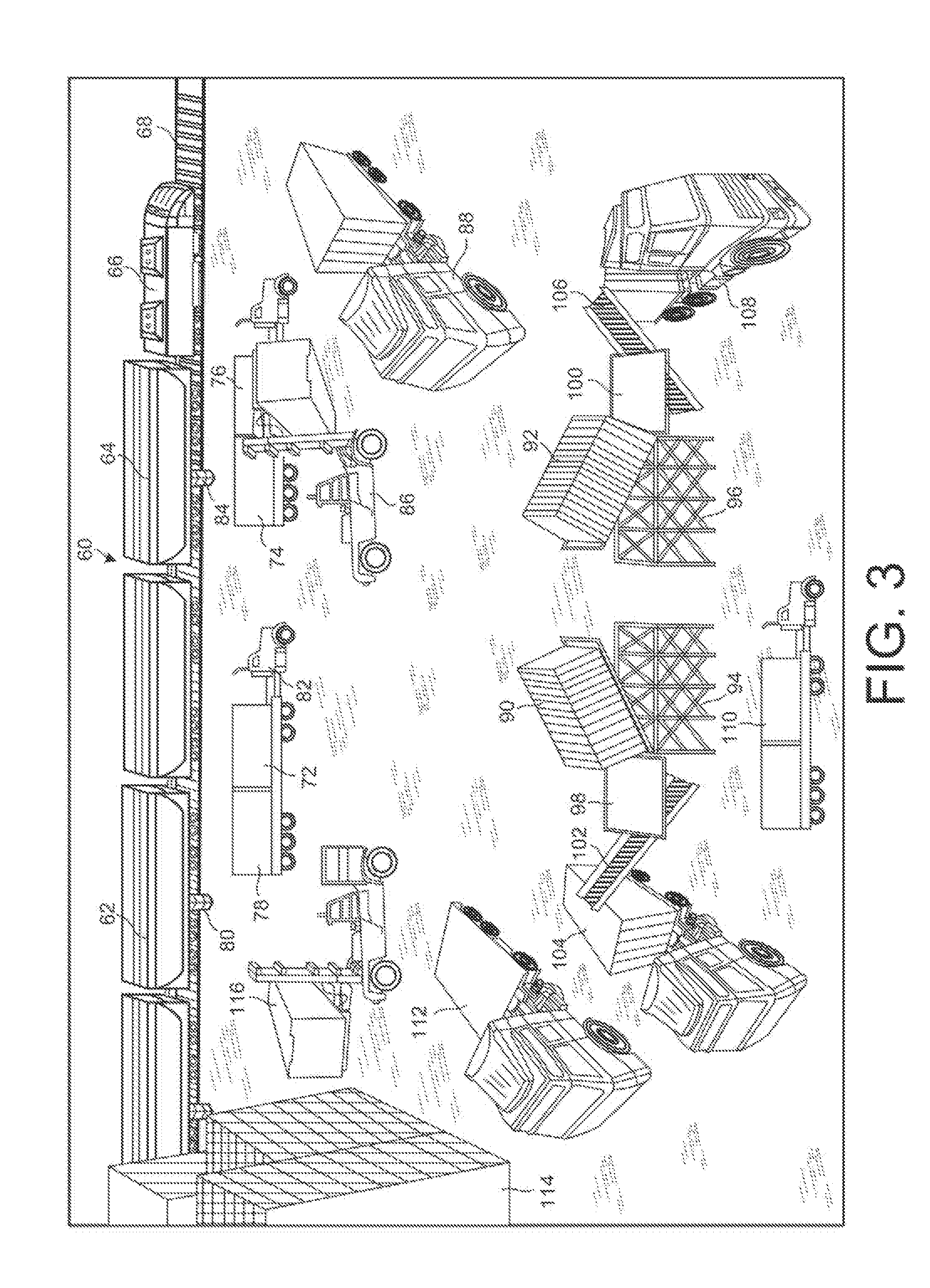

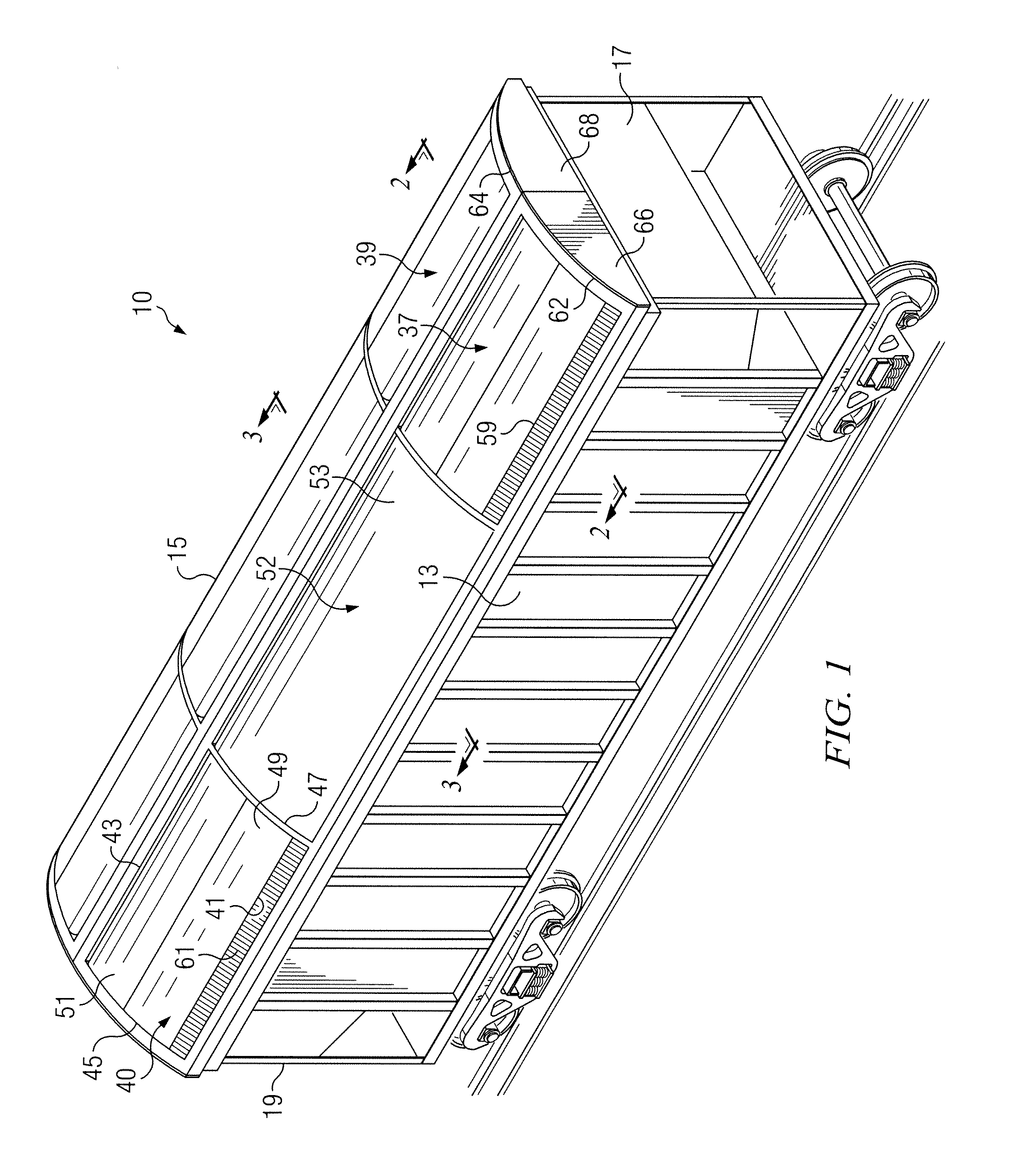

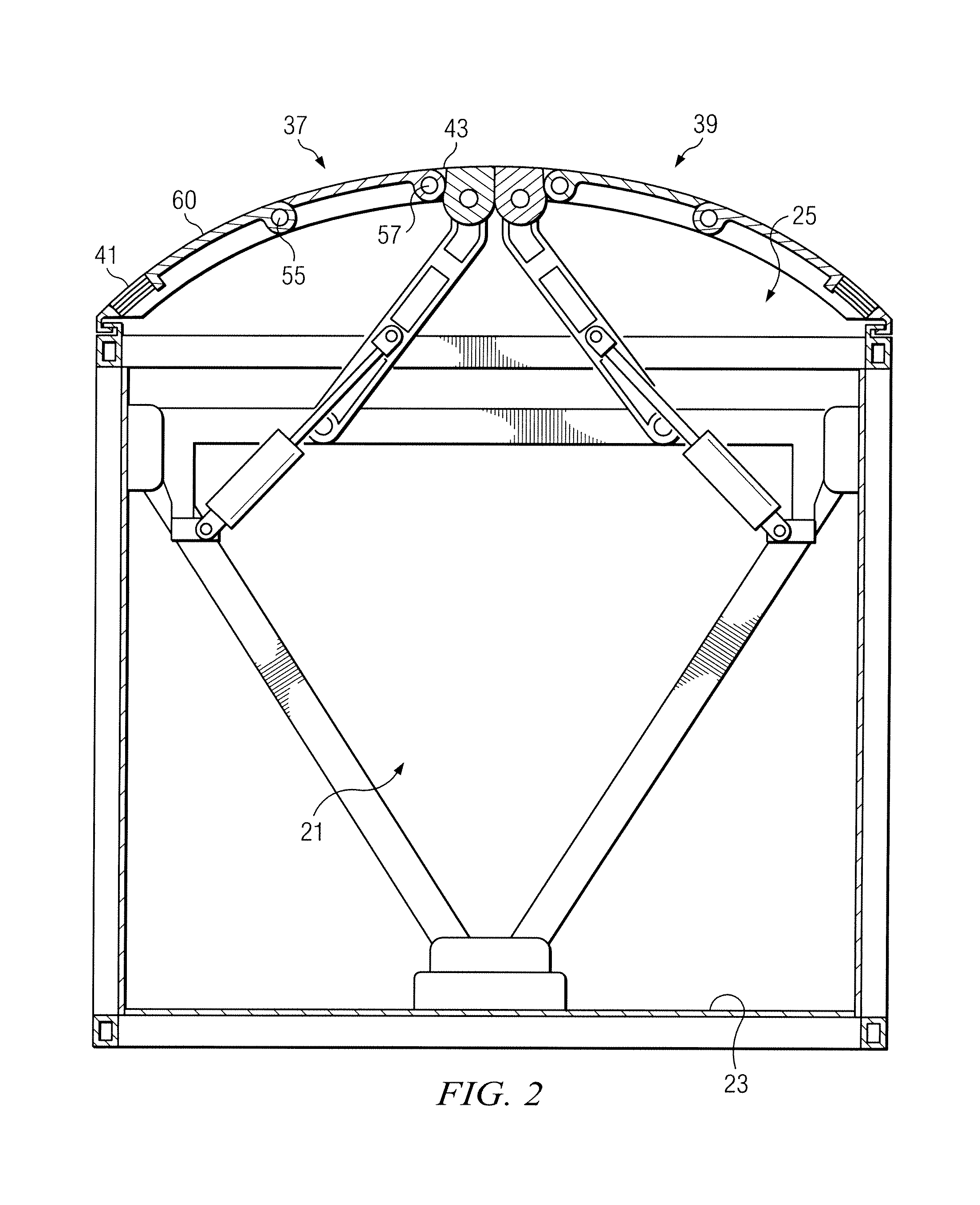

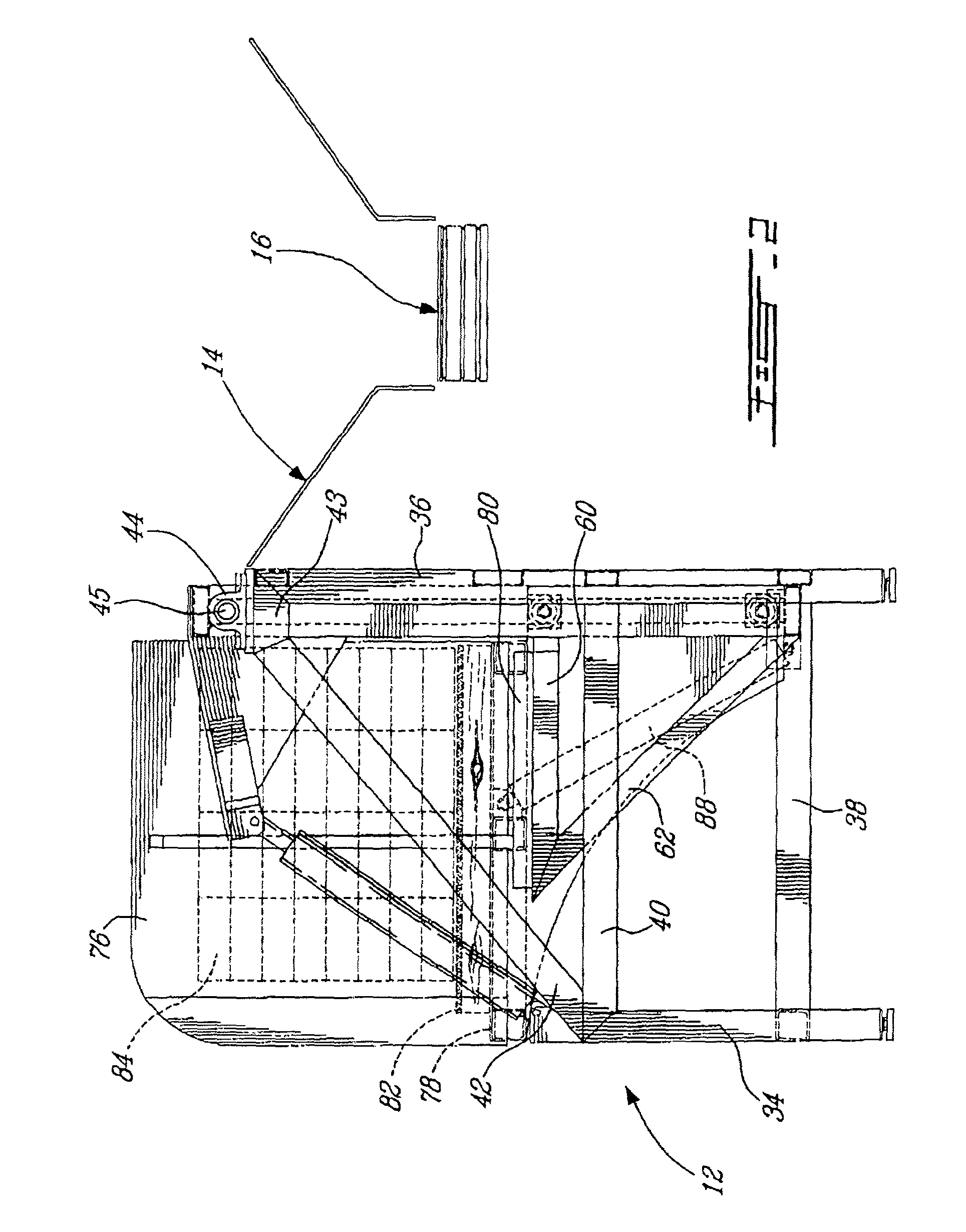

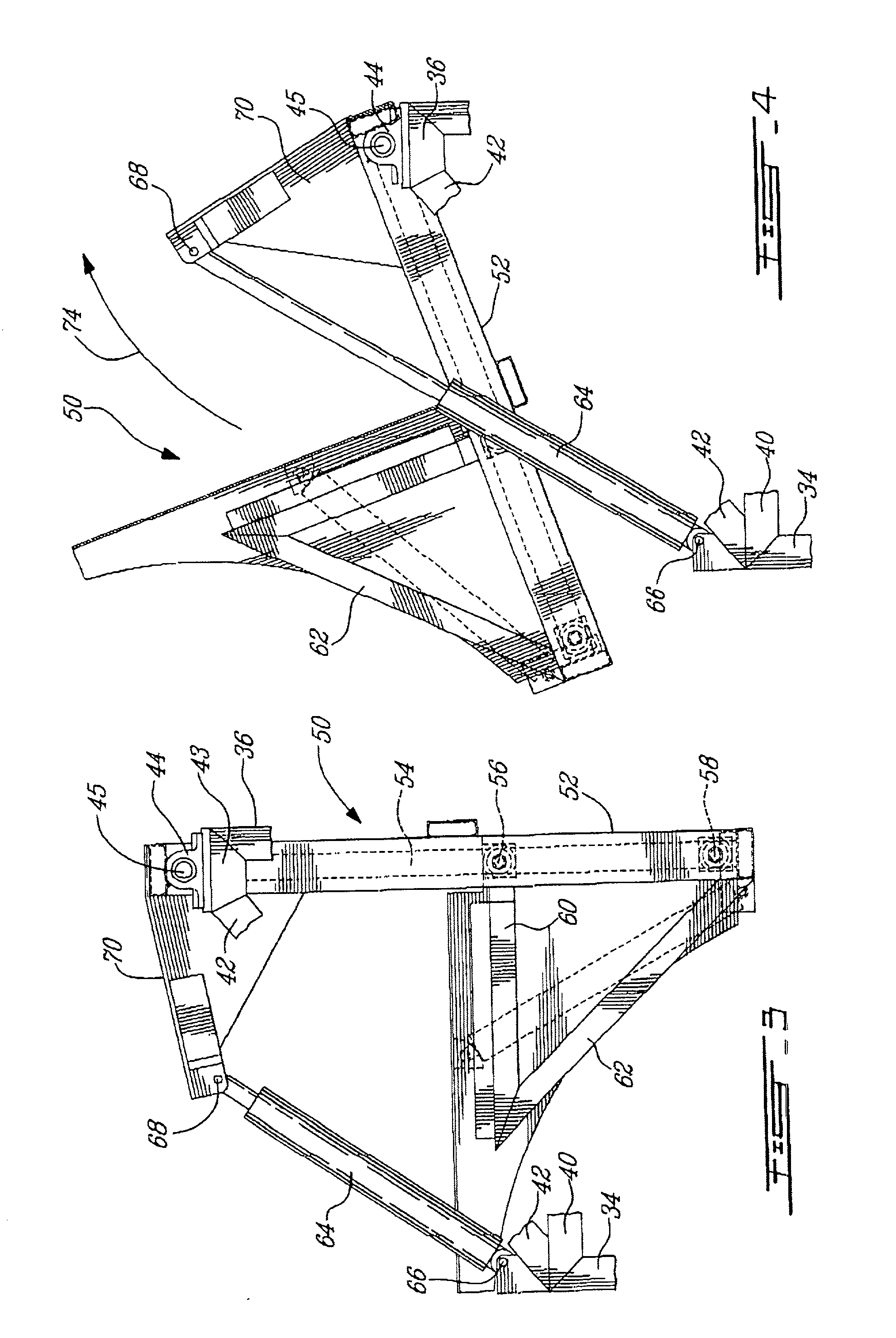

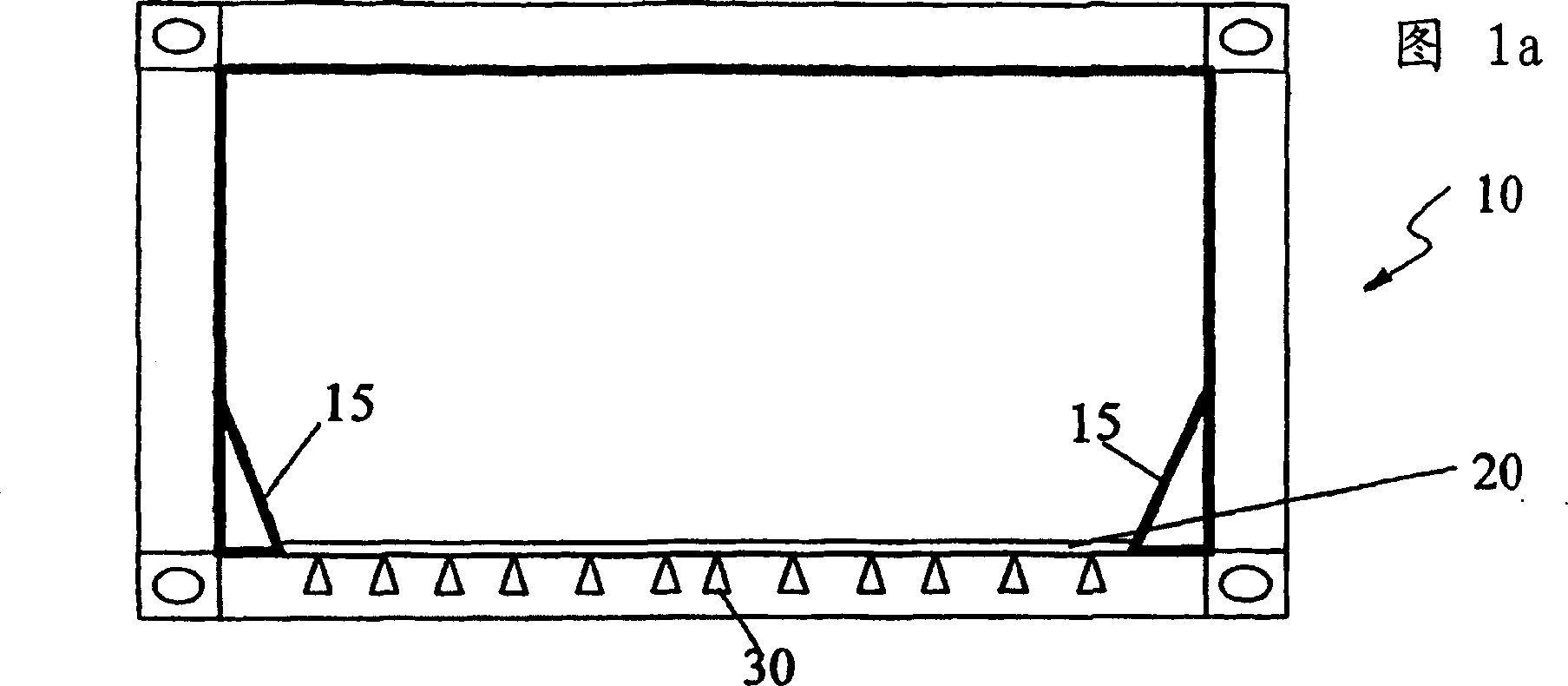

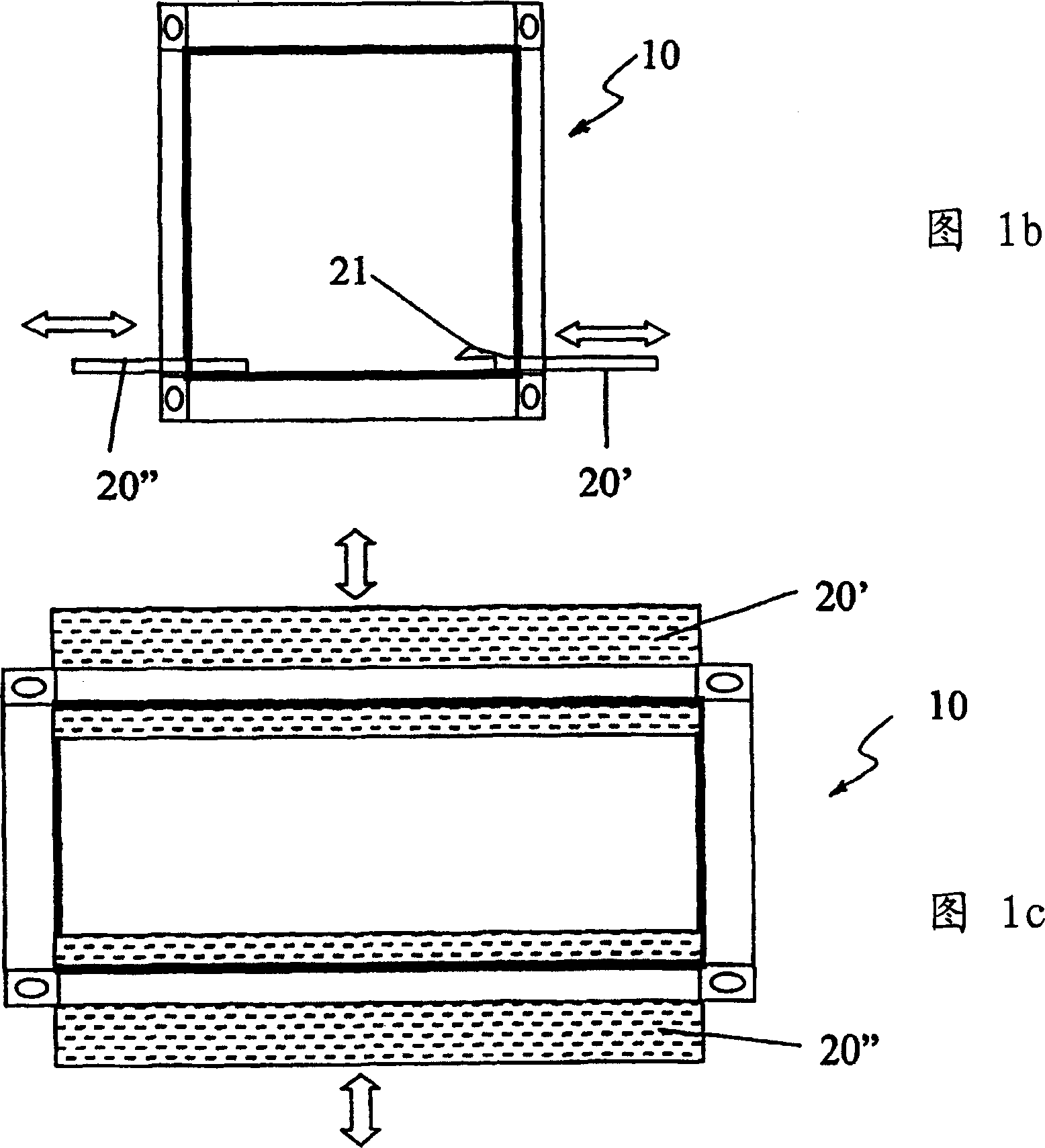

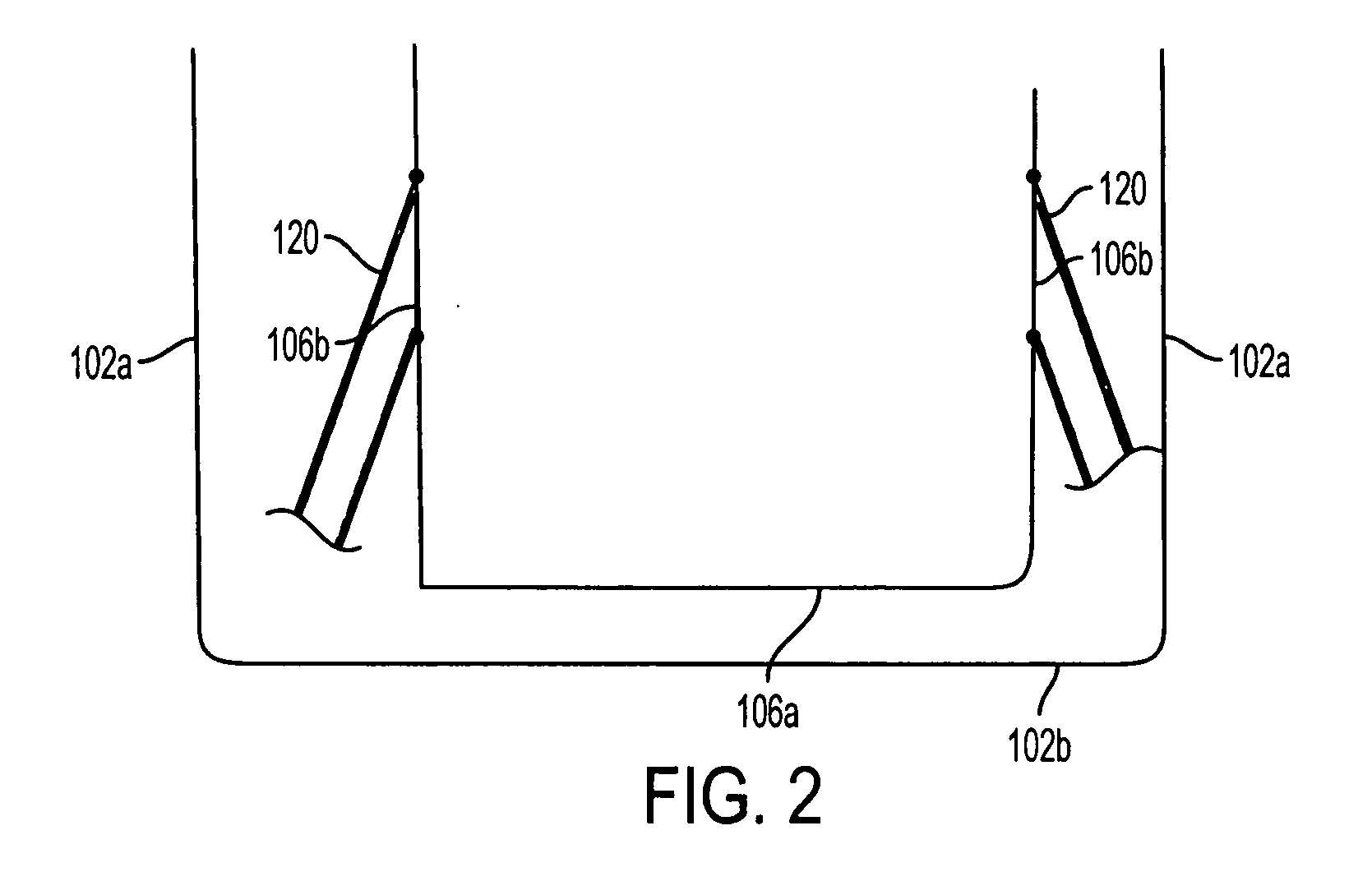

Containerised handling of bulk materials and apparatus therefor

InactiveUS7252309B2Advantageously producedFlow mixersLarge containersParticulate pollutionEngineering

A freight container (10) has a base (20) or a portion thereof that can be opened to discharge its contents. This container (10) has a top which can be opened in similar manner as the base. Another container having at least one compartment, each compartment having a lower section with a reducing cross-sectional area and a pivotably operable closure assembly, with several such closure assemblies being linked together by means of bars. Such a container is used to contain raw building materials for stockpiling of these materials at a container port. It is also used to supply materials to a concrete production plant whee pollution control containers are provided below the supply container and above the scaling and mixing stations to reduce particulate pollution. A pair of slewing apparatuses is also provided to engage both ends of a container and turn the container over about its longitudinal axis, thereby emptying its contents.

Owner:ONG BEE KIM

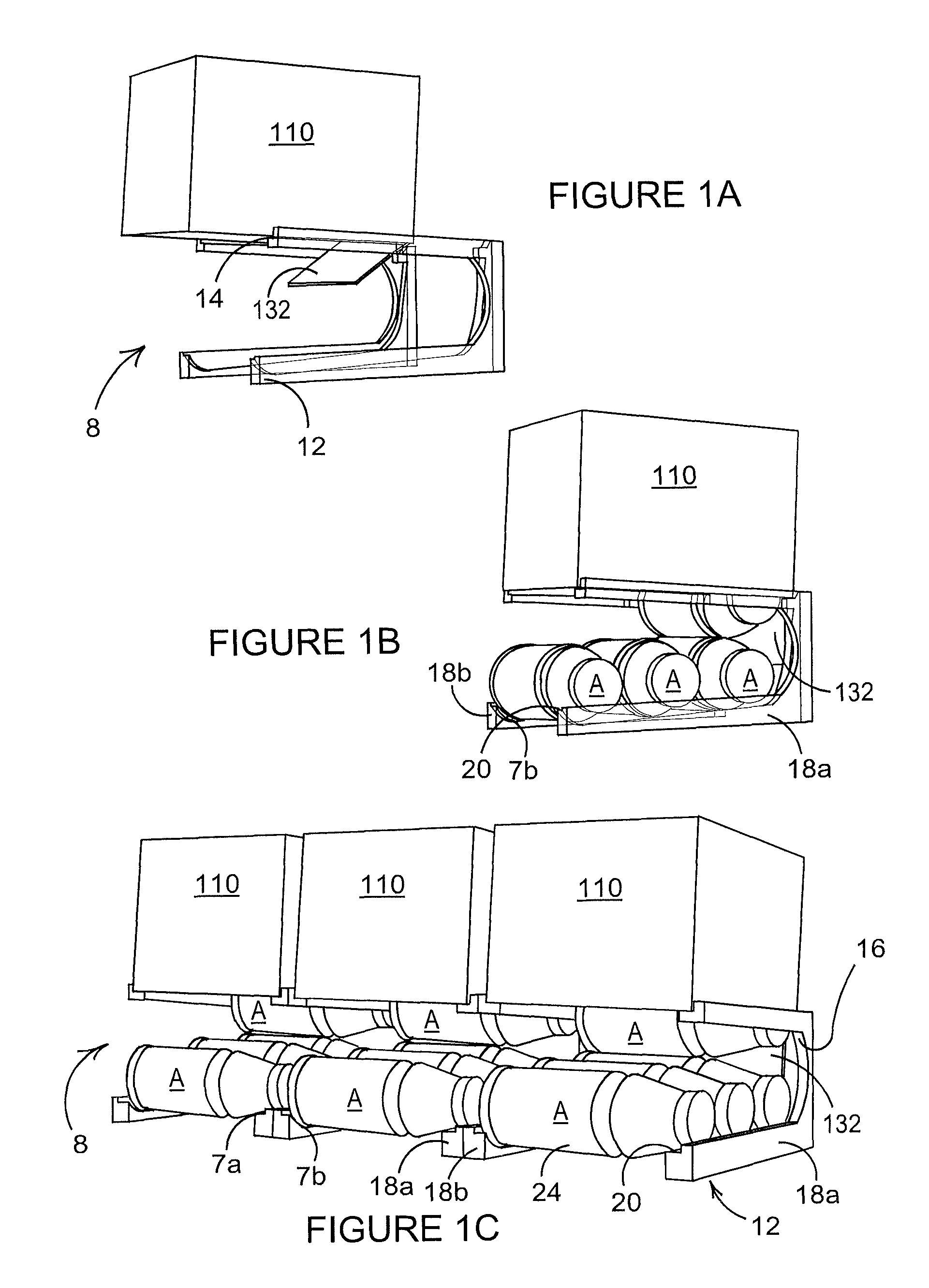

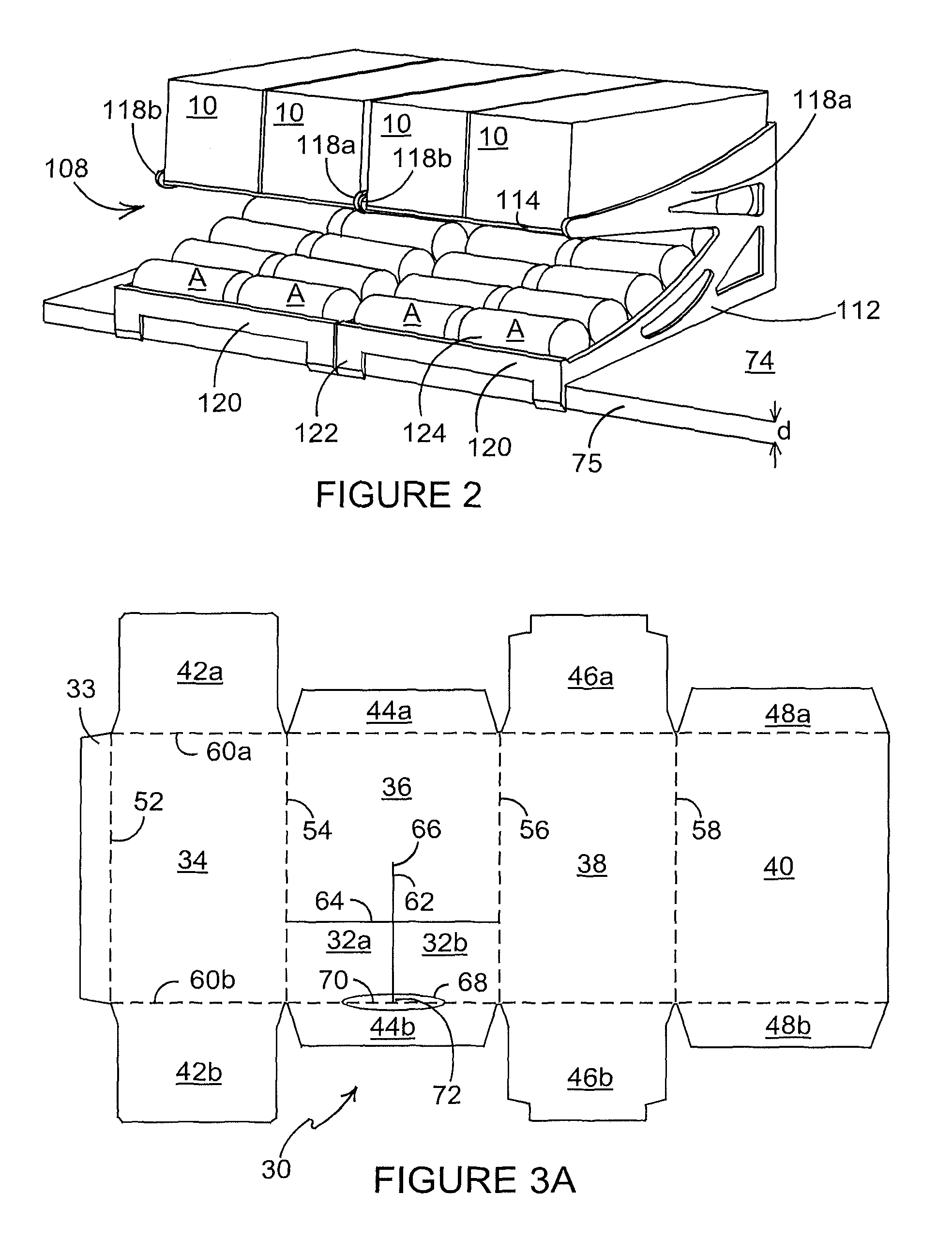

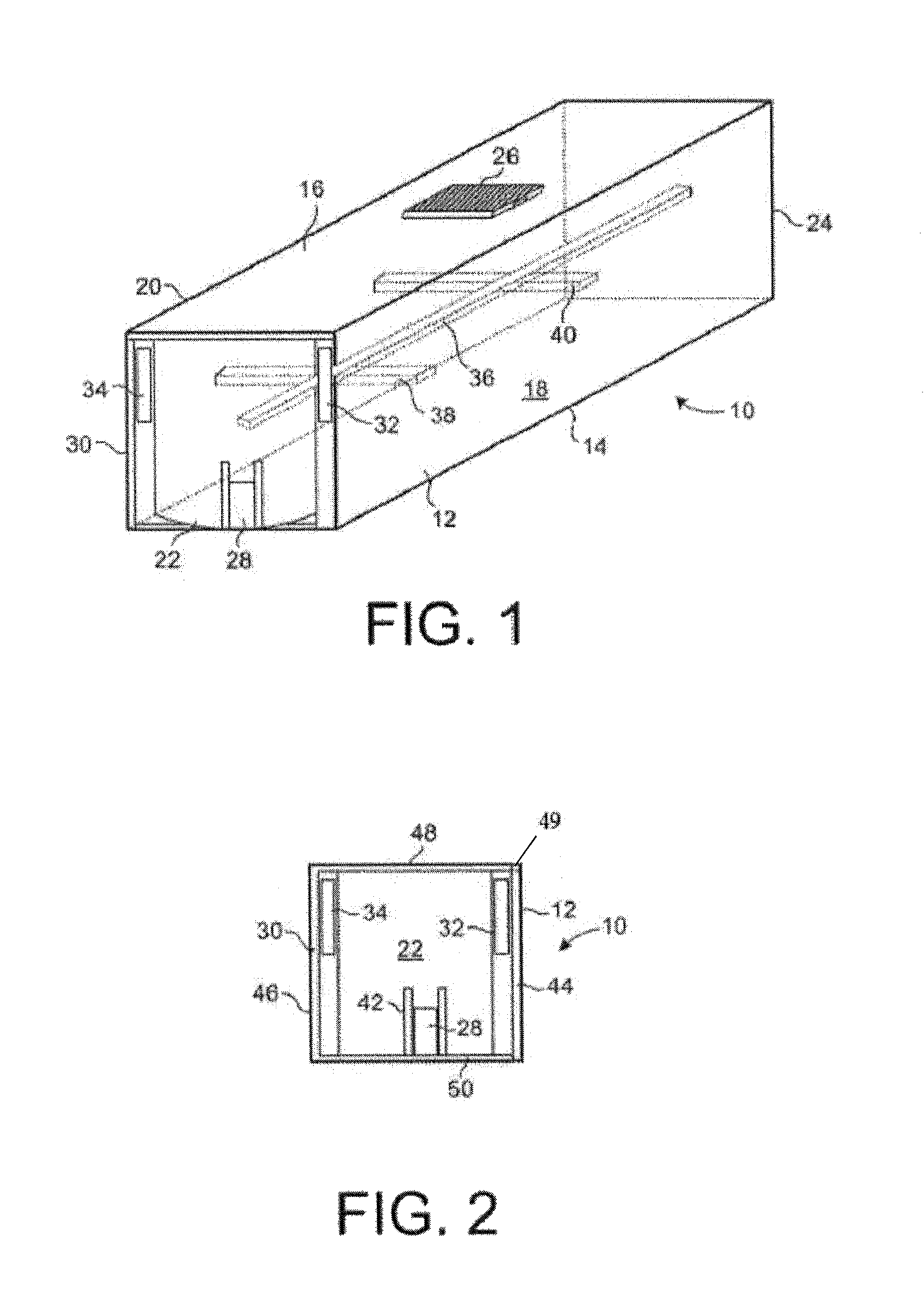

Display system, dispensing device and package for use therein

Disclosed is a system and method for dispensing products provided initially in a package. The system includes a frame and an opening tool. The frame has longitudinally opposed front and rear end sections and includes an upper support deck extending at least partially between the front and rear end sections and below which a product display area is provided. The opening tool is associated with the frame and is arranged to open the package when the package is moved longitudinally on the upper support deck and relative to the opening tool thereby allowing the products to be at least partially dispensed from the package into the product display area.

Owner:MEADWESTVACO CORP

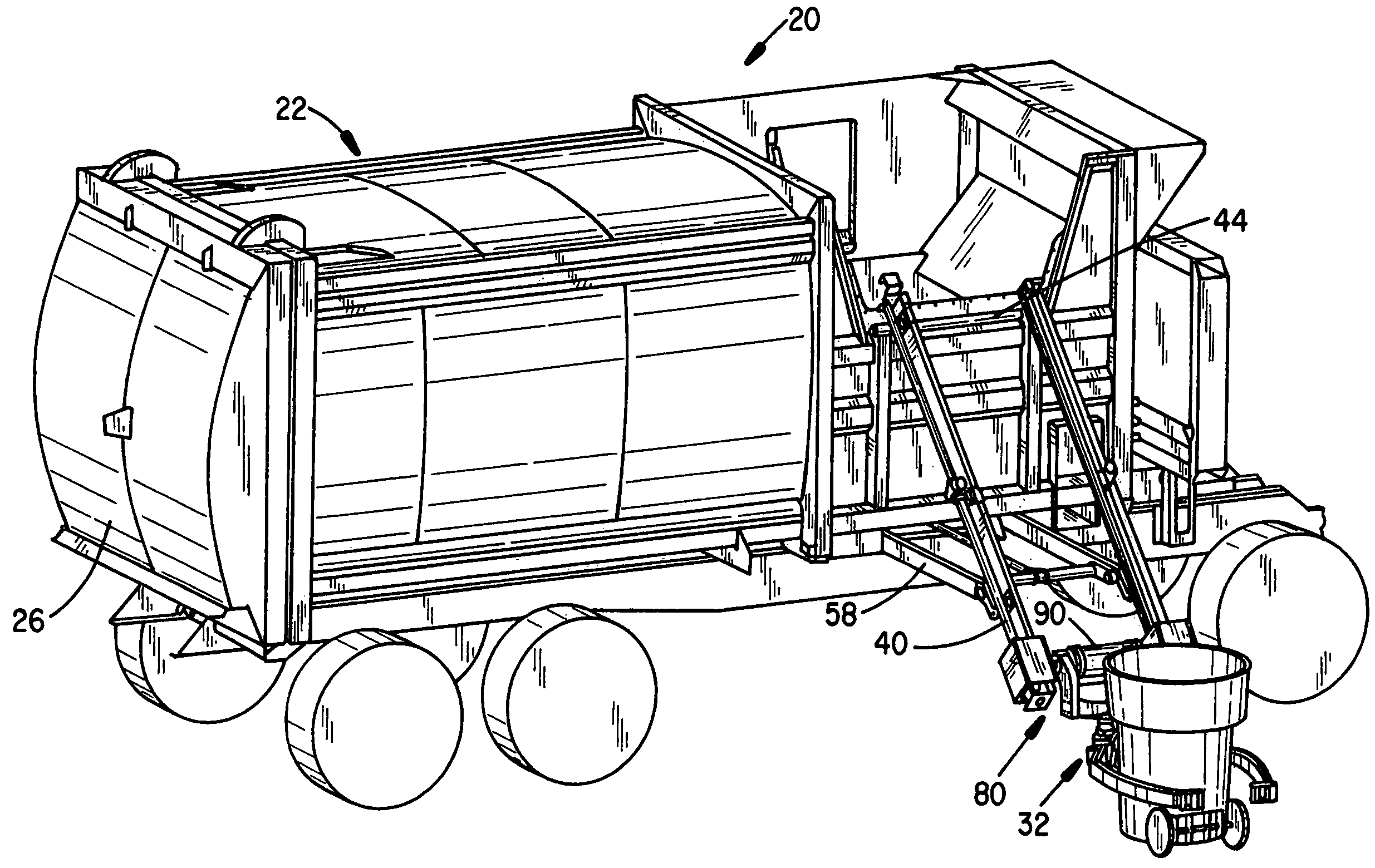

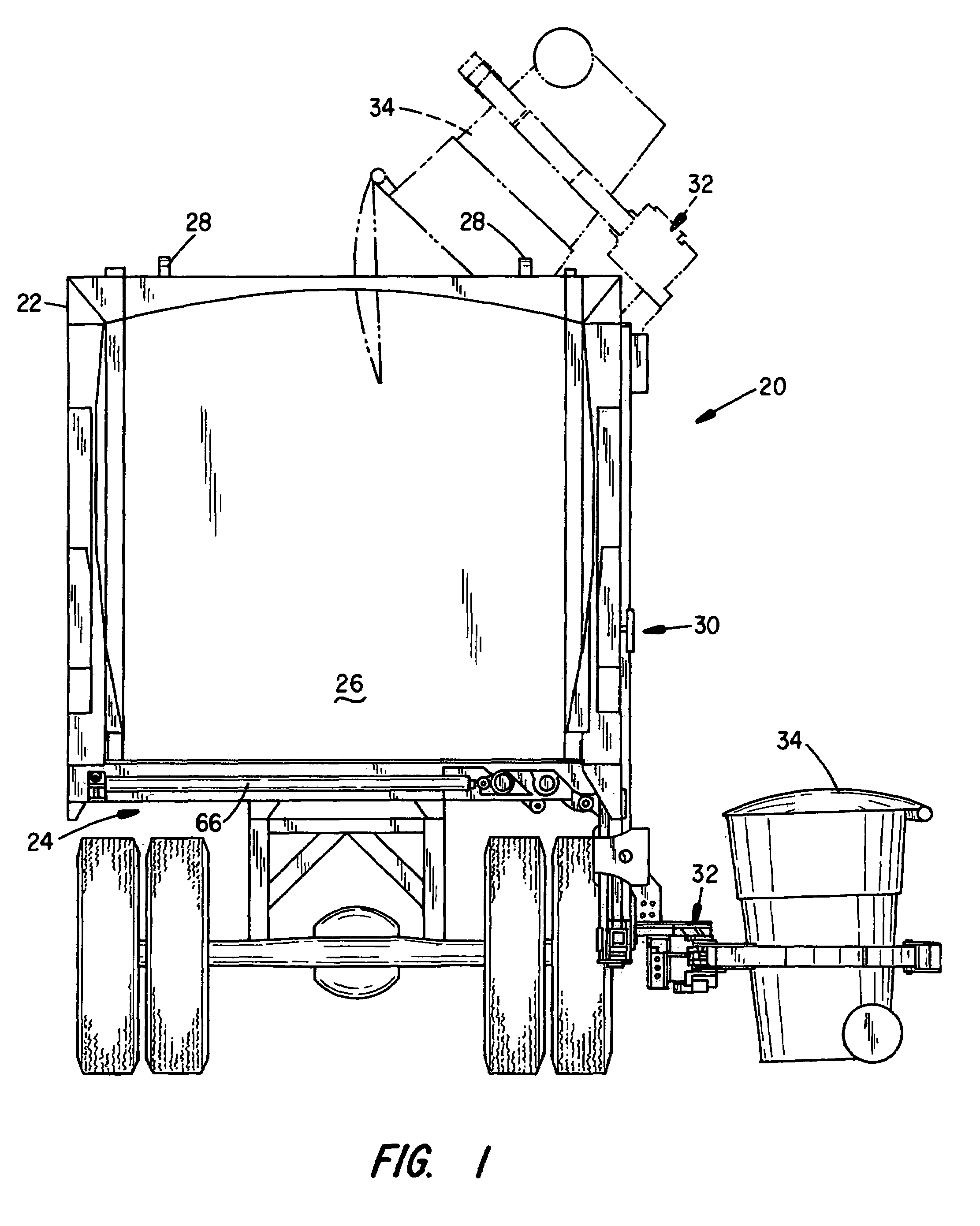

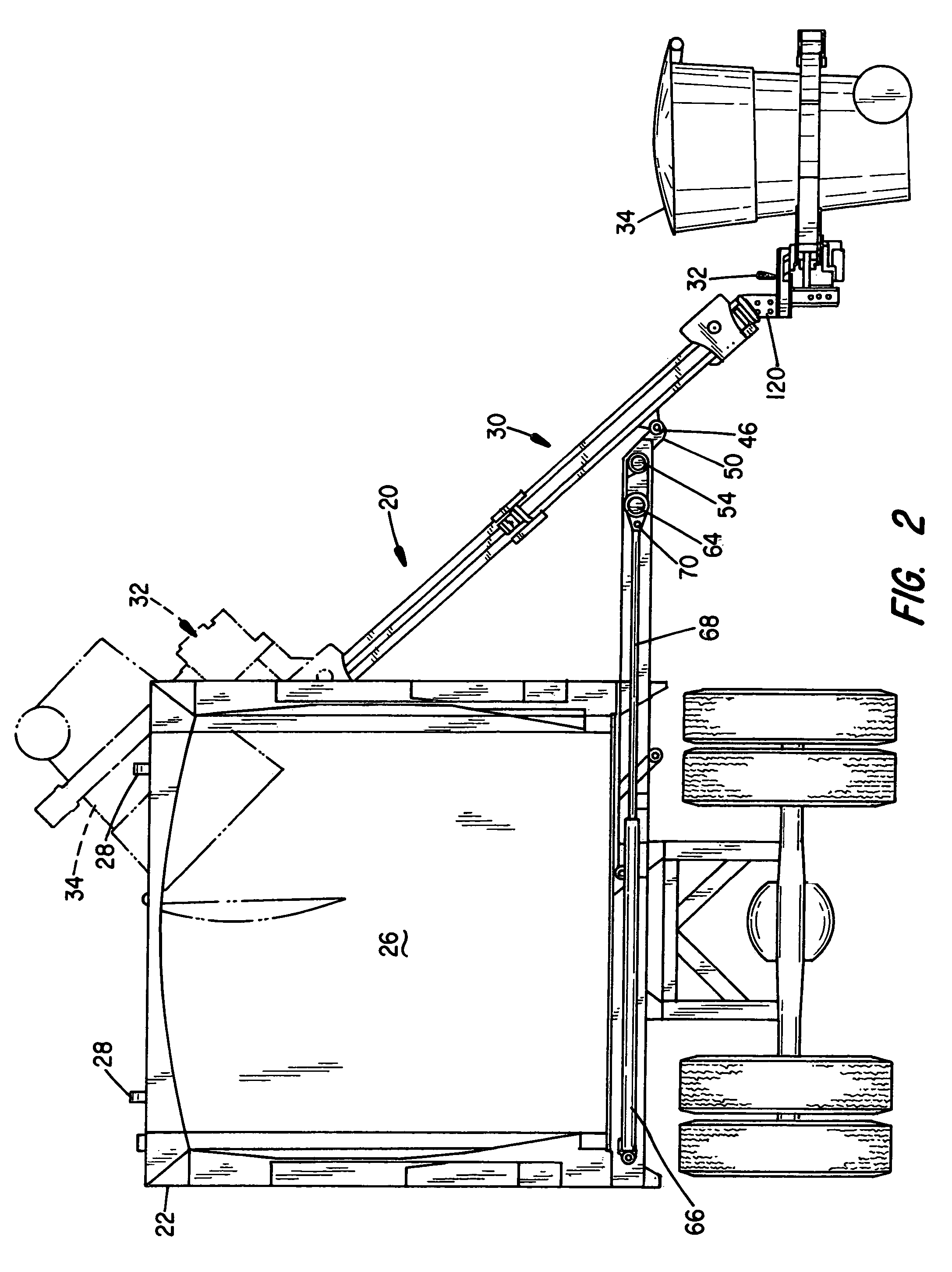

Automated loader

A container handling mechanism suitable for mounting on the side of a refuse vehicle for loading material from refuse containers is disclosed that includes a lift assembly, having a pair of spaced, generally parallel lift support members, attachable to a refuse vehicle, a carriage device reciprocally operable along the lift support members of the lift assembly, a container grabbing system carried by the carriage device and further including a pair of opposed grabber fingers and an actuator system for closing and opening the grabber fingers to engage and release containers of interest, the container grabbing system being vertically pivotable on a short radius for adjusting the position of and tipping a container. A chain and cylinder drive system operates the carriage device along the lift assembly, and a control system controls operation of the container handling mechanism.

Owner:MCNEILUS TRUCK & MFG INC

Fuel cartridge with flexible liner containing insert

Owner:INTELLIGENT ENERGY LTD

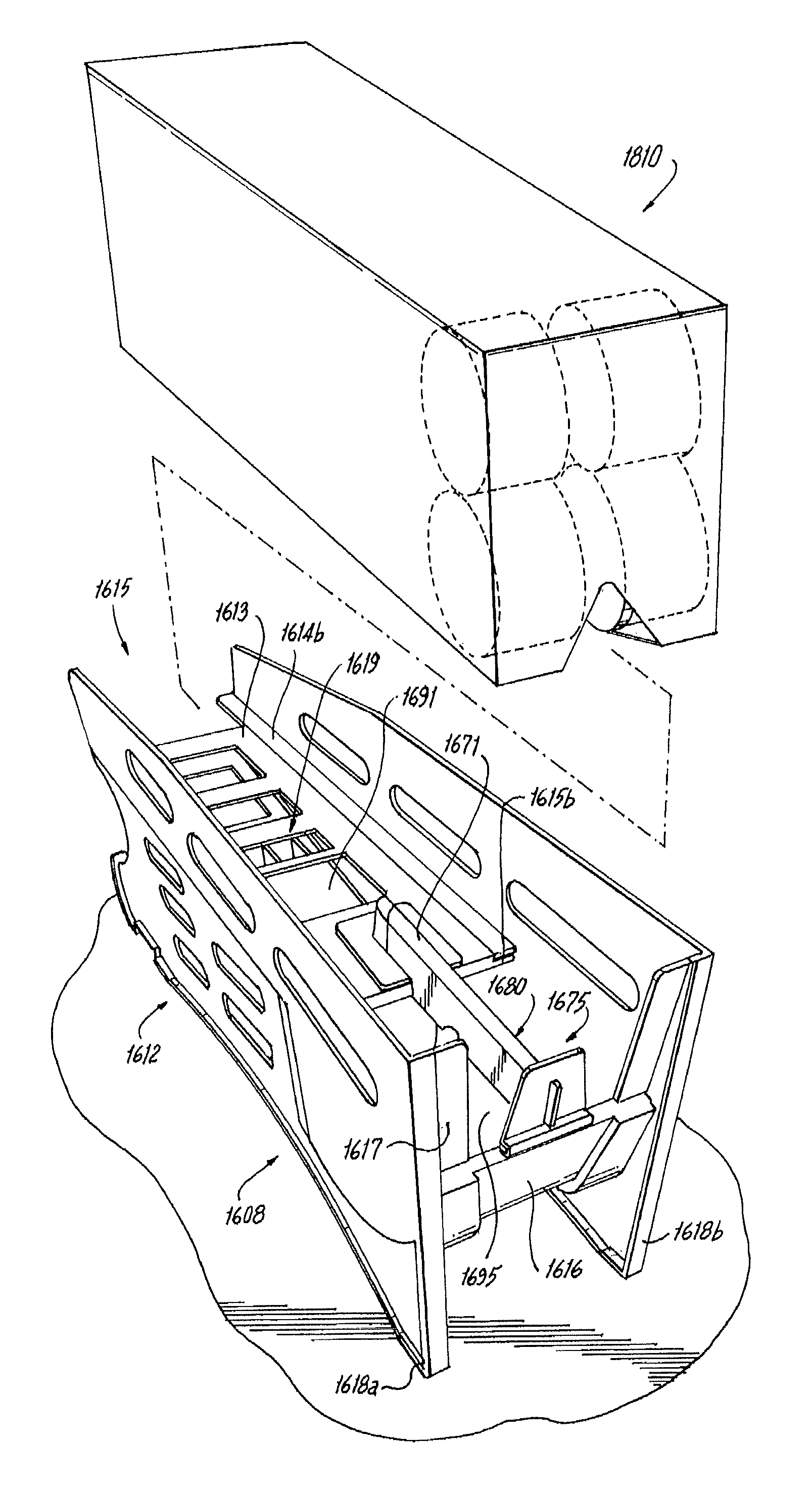

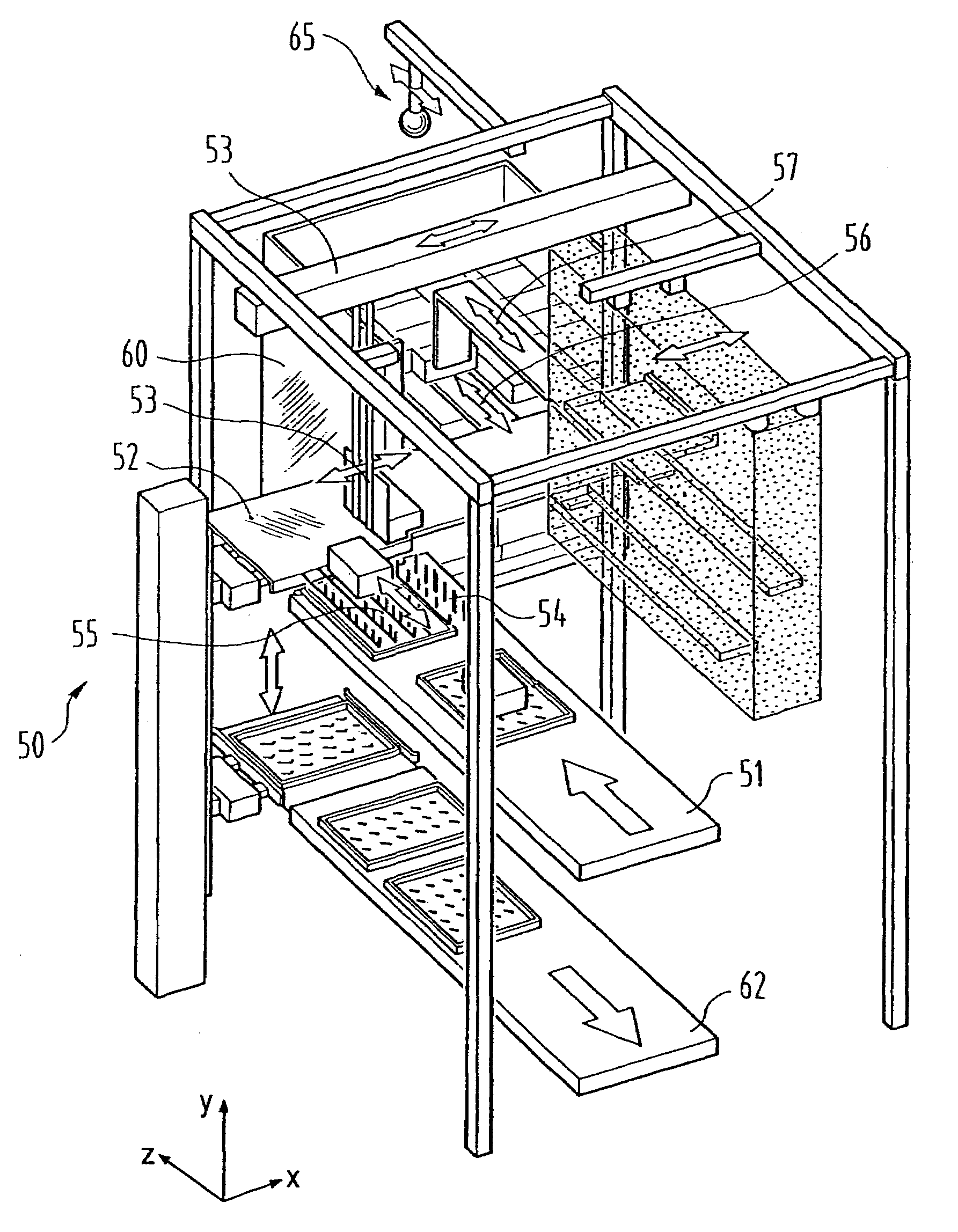

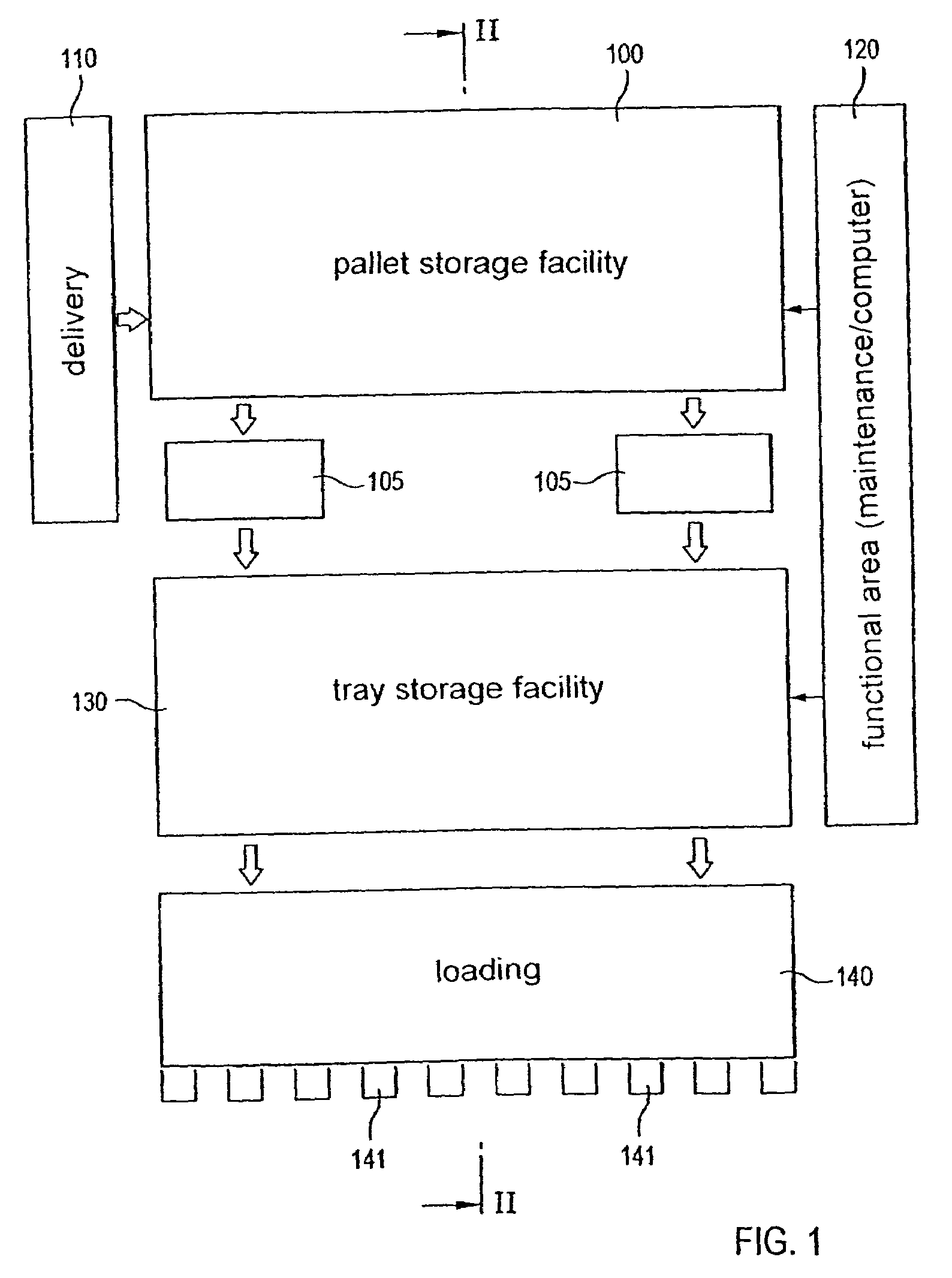

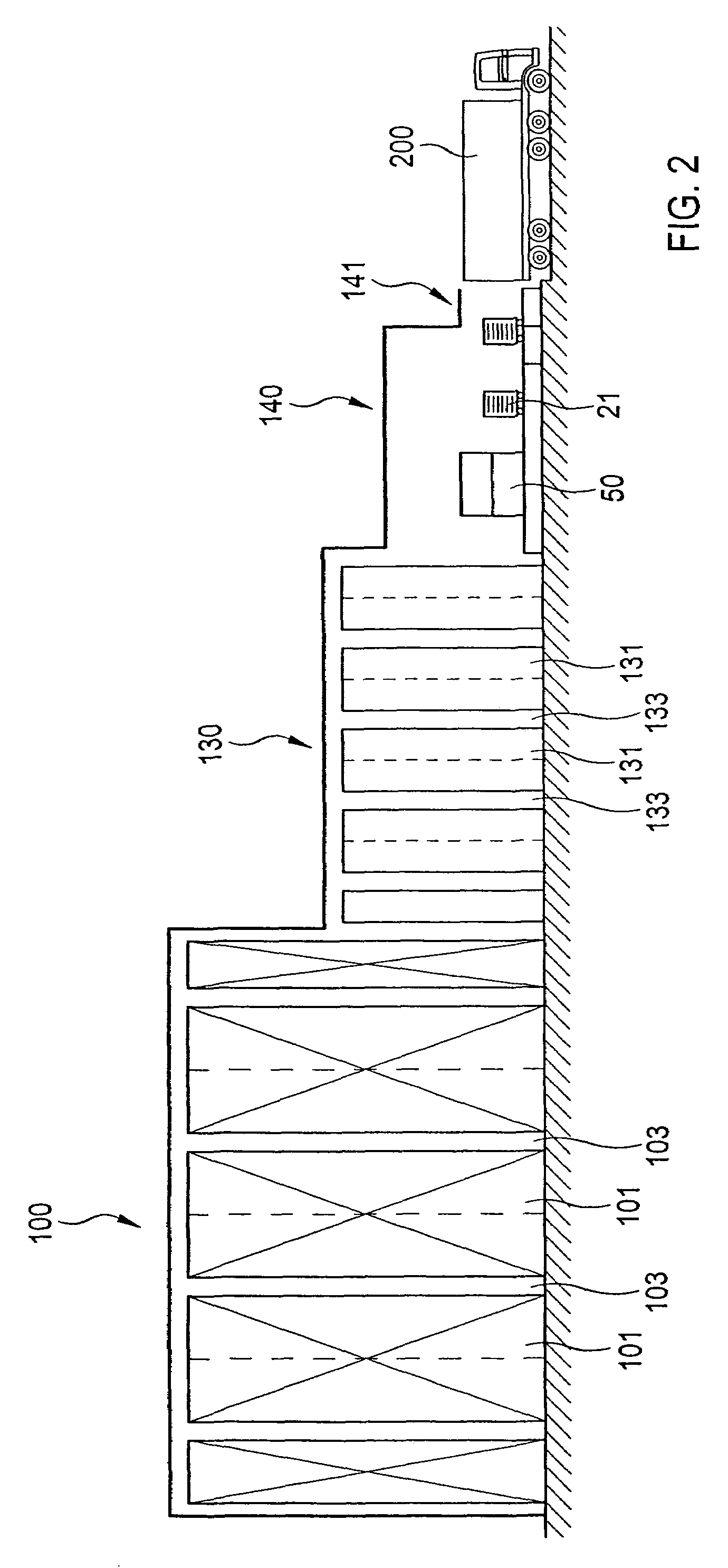

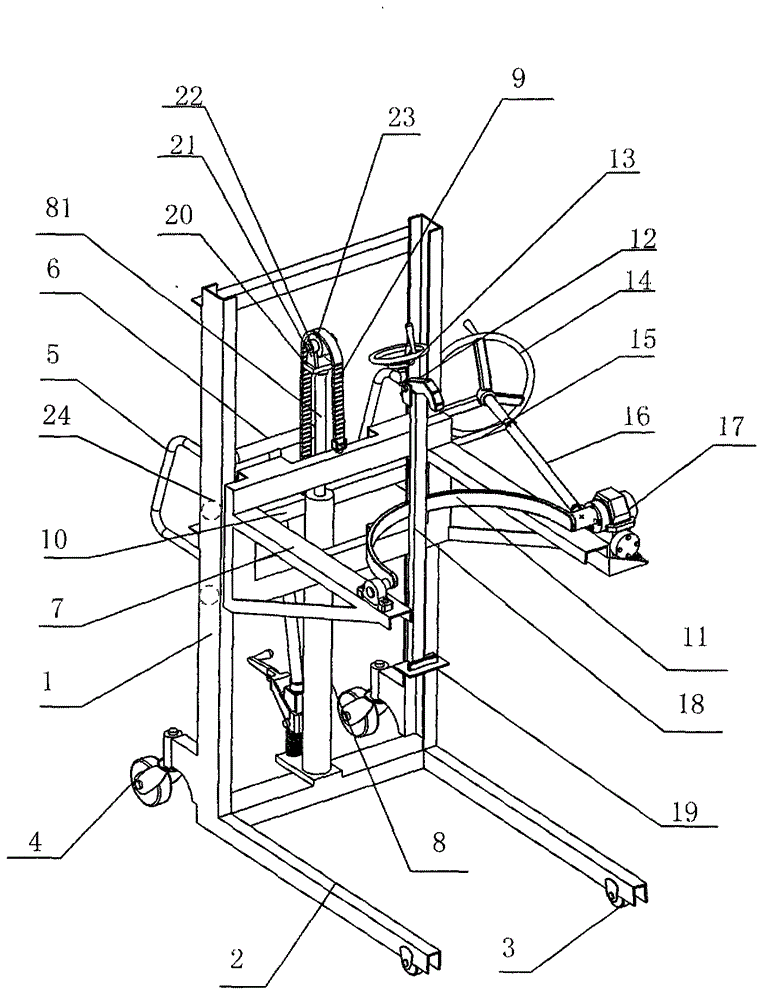

Automated system and method of storing and picking articles

ActiveUS7097045B2Extensive mechanization and automationIncrease profitabilityConveyorsArticle unpackingOrder formEngineering

An automated storage system for storing and picking articles delivered on incoming load carriers such as pallets comprises a device (depalletizer) for separating the article packing units, a tray storage facility (130) for storing the packing units (15) on trays (10), a take-off conveying system (42, 45, 135) for removing and feeding the packing units (15) in sequence for loading onto order load carriers, and a loading station (140) for loading the packing units (15) in a defined loading sequence onto order load carriers (20) for dispatch e.g. by lorry. The invention enables fully mechanized and automated storage and picking of the articles.

Owner:LOGISTIK INFORMATIK

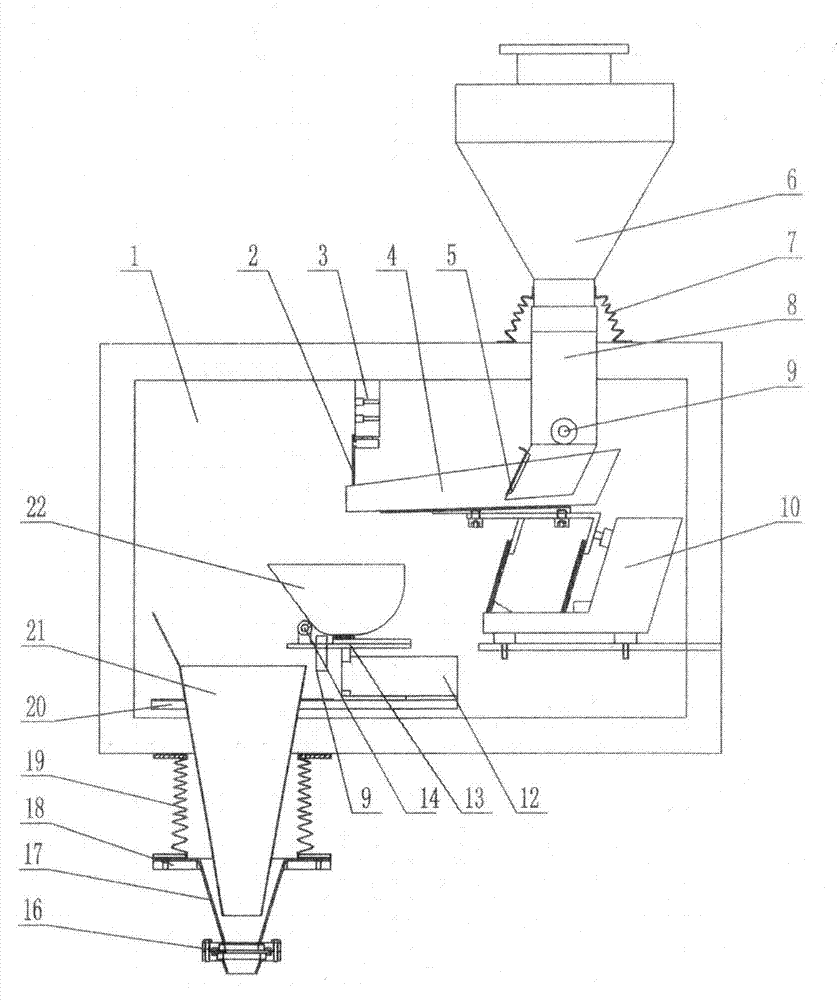

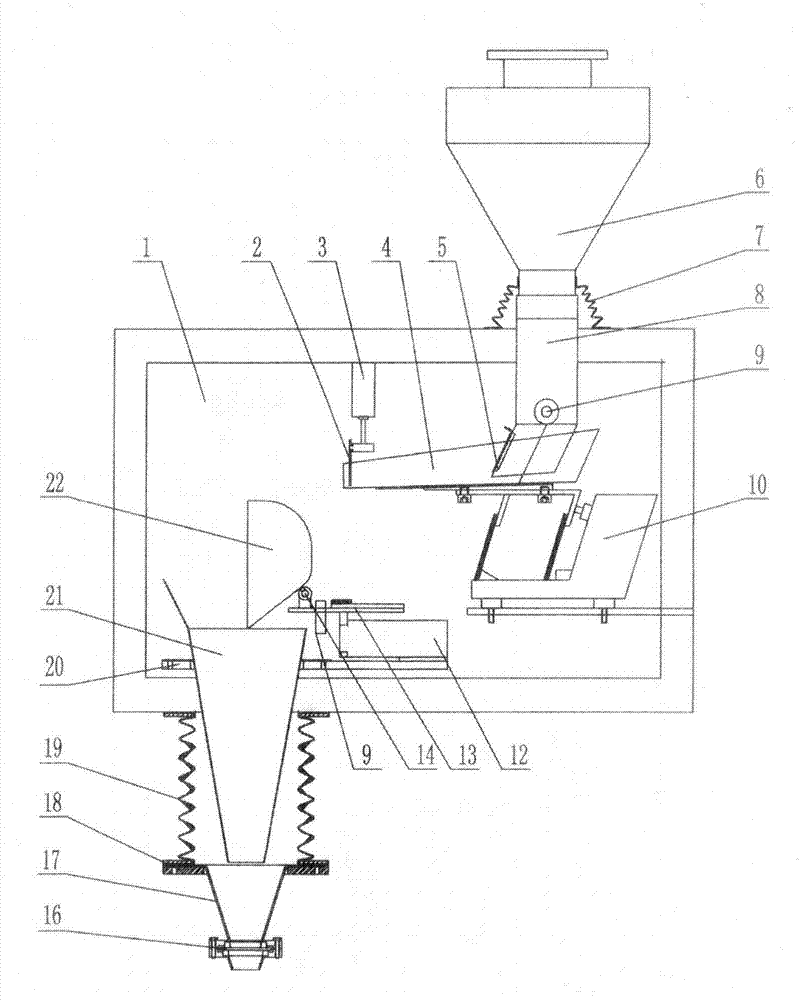

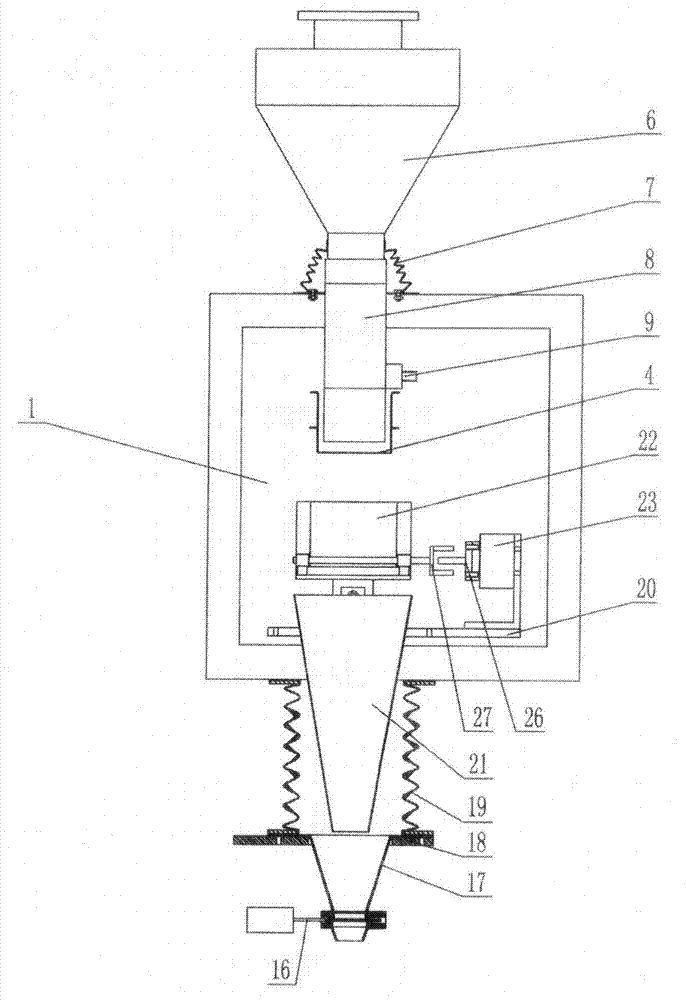

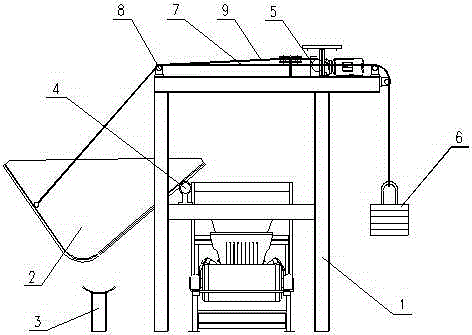

Full-automation powder quantitatively feeding device

ActiveCN103662860AUniform flowHigh speed and controllable flowLarge containersBottle emptyingEngineeringAutomation

The invention relates to a full-automation powder quantitatively feeding device which comprises a box body, a vibration feeding device, a weighing device and a feeding device body. The full-automation powder quantitatively feeding device is characterized in that the vibration feeding device comprises a material barrel, a feeding pipe, a material groove and a vibration feeder. The material barrel is arranged above the box body, one end of the feeding pipe is connected with a lower outlet end of the material barrel and the other end of the feeding pipe penetrates into the box body through an opened hole above the box body. A sensor is arranged on the wall of the feeding pipe and controlled by a PLC. The material groove is formed below the feeding pipe and installed in the vibration feeder. The weighing device is located below an outlet of the material groove. The feeding device body is located below the weighing device. The full-automation powder quantitatively feeding device is high in feeding speed and accurate in weighing.

Owner:QIANDONG RARE EARTH GRP

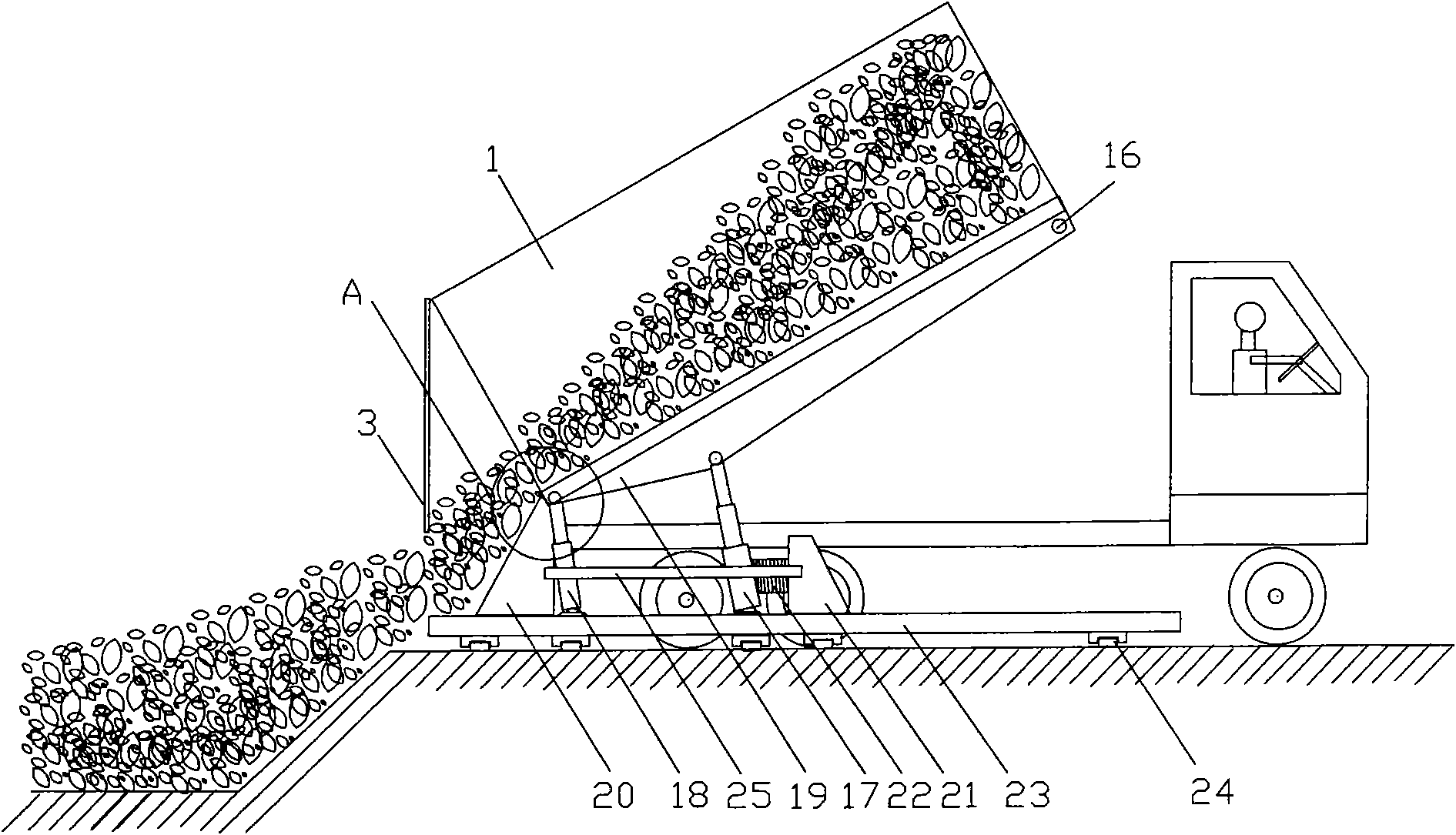

Containerized transport method of a large quantity of solid bulk cargos as well as solid bulk cargo container and decrater thereof

InactiveCN101823630AImproving the quality of bulk cargo transportationReduce shipping costsLarge containersBottle emptyingCoalService quality

The invention relates to a bulk cargo containerized and closed transport method of a large quantity of solid bulk cargos from a mine opening solid bulk cargo stock dump to a user solid bulk cargo stock dump as well as a solid bulk cargo transport container and a decrater thereof. The large quantity of solid bulk cargos represented by coal are difficult to avoid the phenomena, i.e. serious solid bulk transport environmental pollution, faulty goods doping, sundries doping, variety complexity, and the like, and losses, i.e. running, leakage, spillage, and the like; and in an adopted containerized mode, the cargos can fast and safely reach a destination on time following a container regular ship as general cargos are cased, thereby avoiding the phenomena, i.e. poor cargo quality, cargo damage and cargo loss, reducing the environmental pollution and enhancing the transport service quality of coal mines, ports and automobiles.

Owner:游勇

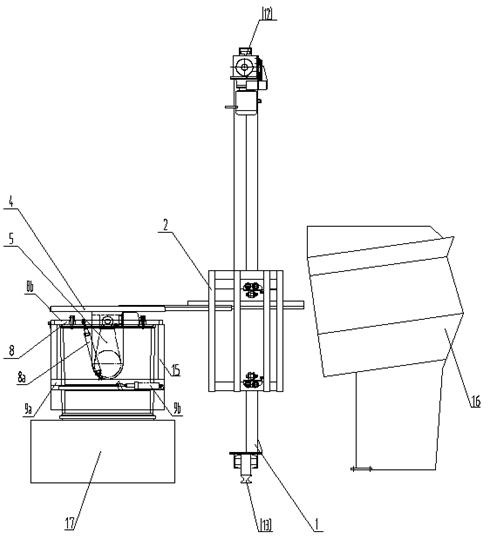

Ton bag feeding device and feeding method

ActiveCN103407797AAchieve accurate meteringRealize deliveryConveyorsBottle emptyingVacuum pumpingEngineering

The invention discloses a ton bag feeding device and a feeding method. The device comprises a support device, a ton bag clamping turnover mechanism, a turnover motive power mechanism, a material collection hopper, a belt weigher and a vacuum absorption device. The method comprises the following steps: putting ton bag packed material into a turnover cage, hanging lifting lugs of the ton bag on ton bag hooks, compressing a vacuum sucker to be clung to the bottom of the ton bag, starting a vacuum pumping device, and absorbing the ton bag by the vacuum sucker; starting a motor, overturning the turnover cage, flowing the material in the ton bag into the material collection hopper, enabling the ton bag to be absorbed due to the absorbing force of the vacuum sucker, and dropping the material gradually until all material in the ton bag is poured out; rotating the turnover cage in an opposite direction, closing the vacuum pumping device, and taking the ton bag down. The device and the method can realize mechanized operation to clean up once; no manual assistance is needed; accurate measuring and delivering of the material are realized; the vacuum sucker adopts an elastic structure; the service life is long; the equipment is simple, and 360 degrees overturning of the ton bag can be realized; the method is suitable for the discharging and the delivering of various ton bag packed material, especially particles and powdery material.

Owner:度测(上海)科技服务中心

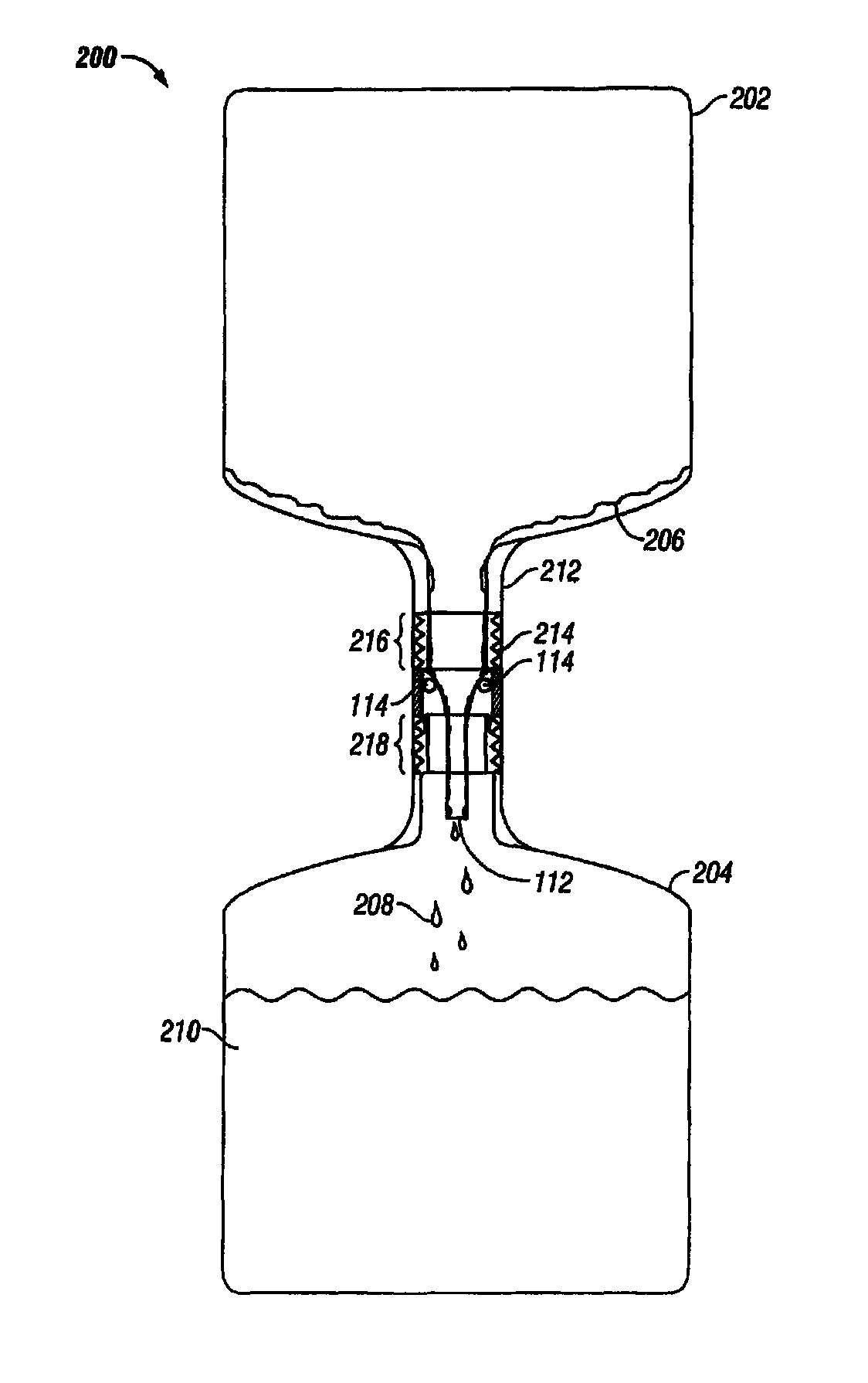

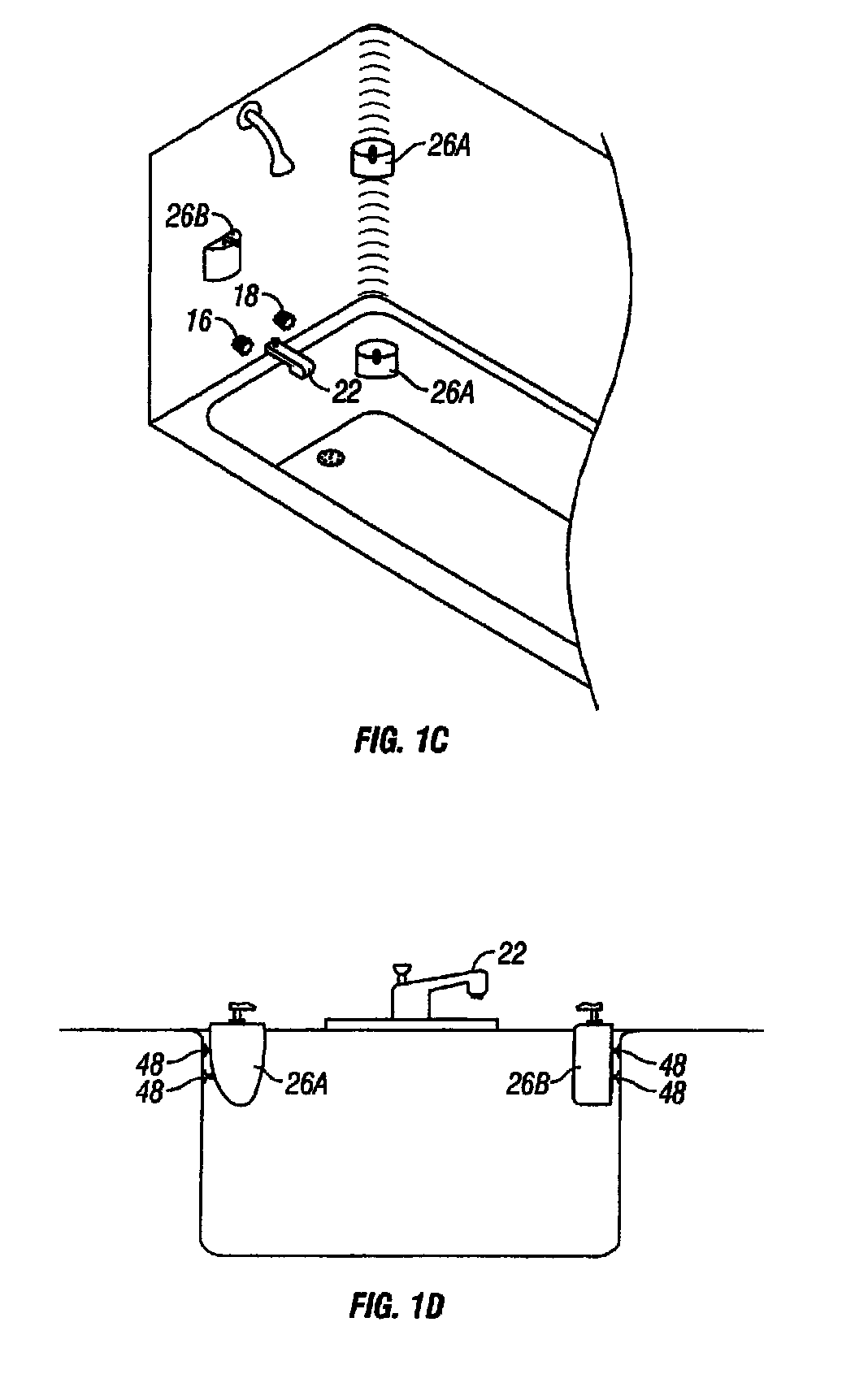

Reclosable fitment for connecting a reservoir to a dispensing appliance

The present invention is directed to a device for the delivery of products, preferably cleaning products which comprise an active ingredient and more preferably cleaning products which comprise a surfactant. The device includes at least one liquid reservoir for containing at least one product and a dispensing appliance for delivering the product. The dispensing appliance comprises at least one piercing means or at least one pierceable means, and the reservoir respectively comprises at least one corresponding pierceable means or at least one piercing means, such that the pierceable means recloses when the reservoir is removed from the dispensing appliance. Preferably, the piercing means is achieved by at least one needle.

Owner:THE PROCTER & GAMBLE COMPANY

Methods of storing and moving proppant at location adjacent rail line

Owner:SANDBOX ENTERPRISES LLC

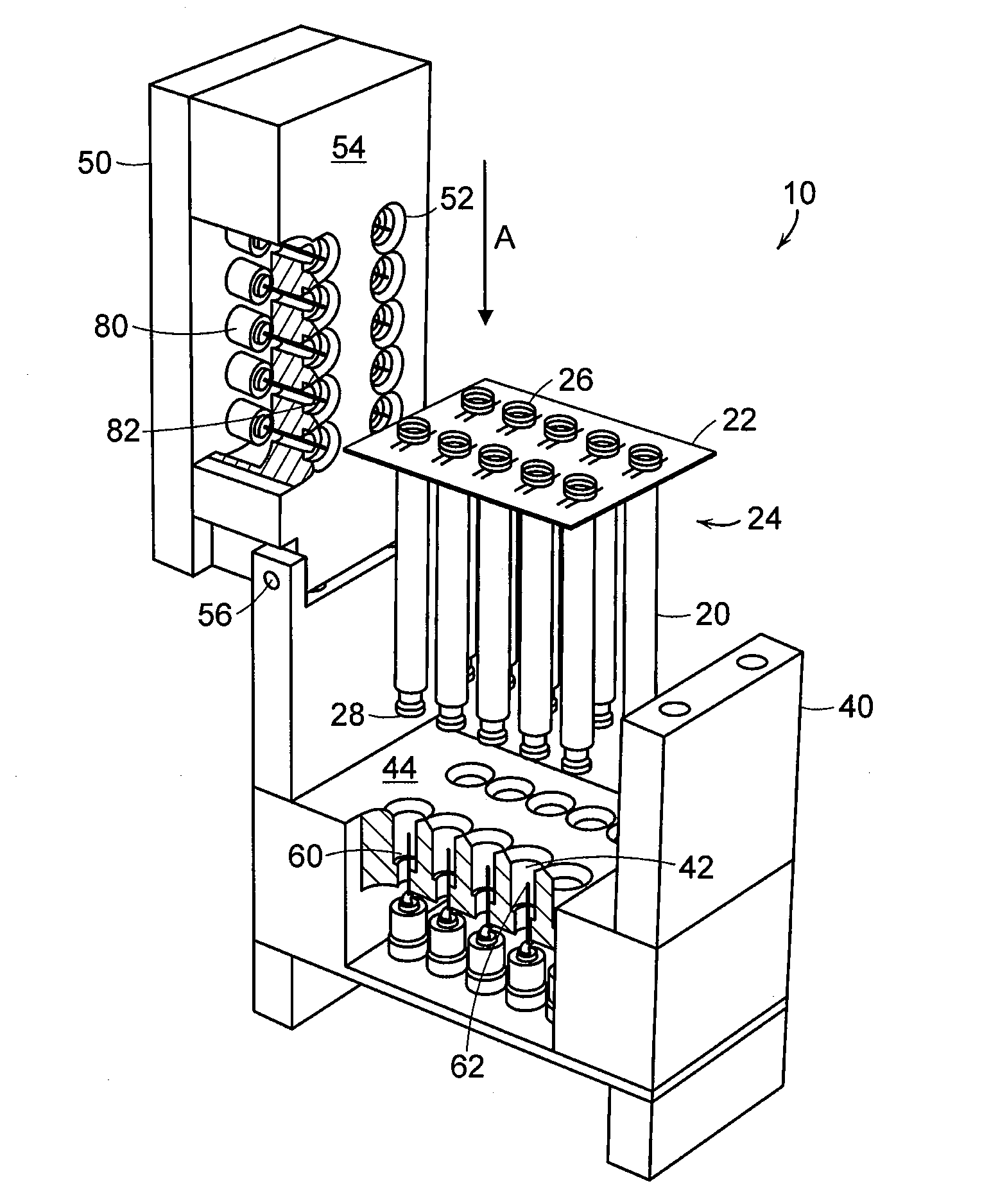

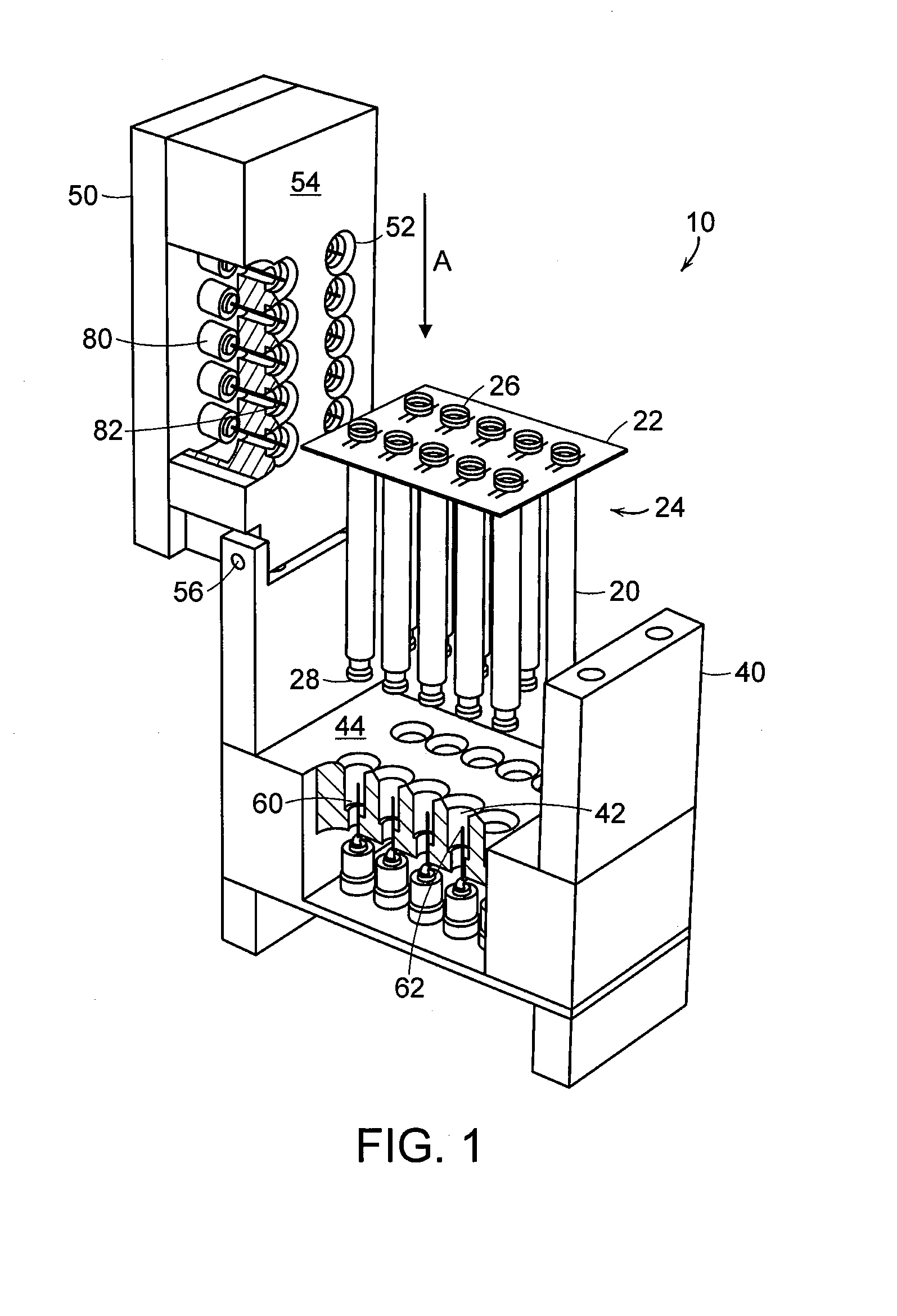

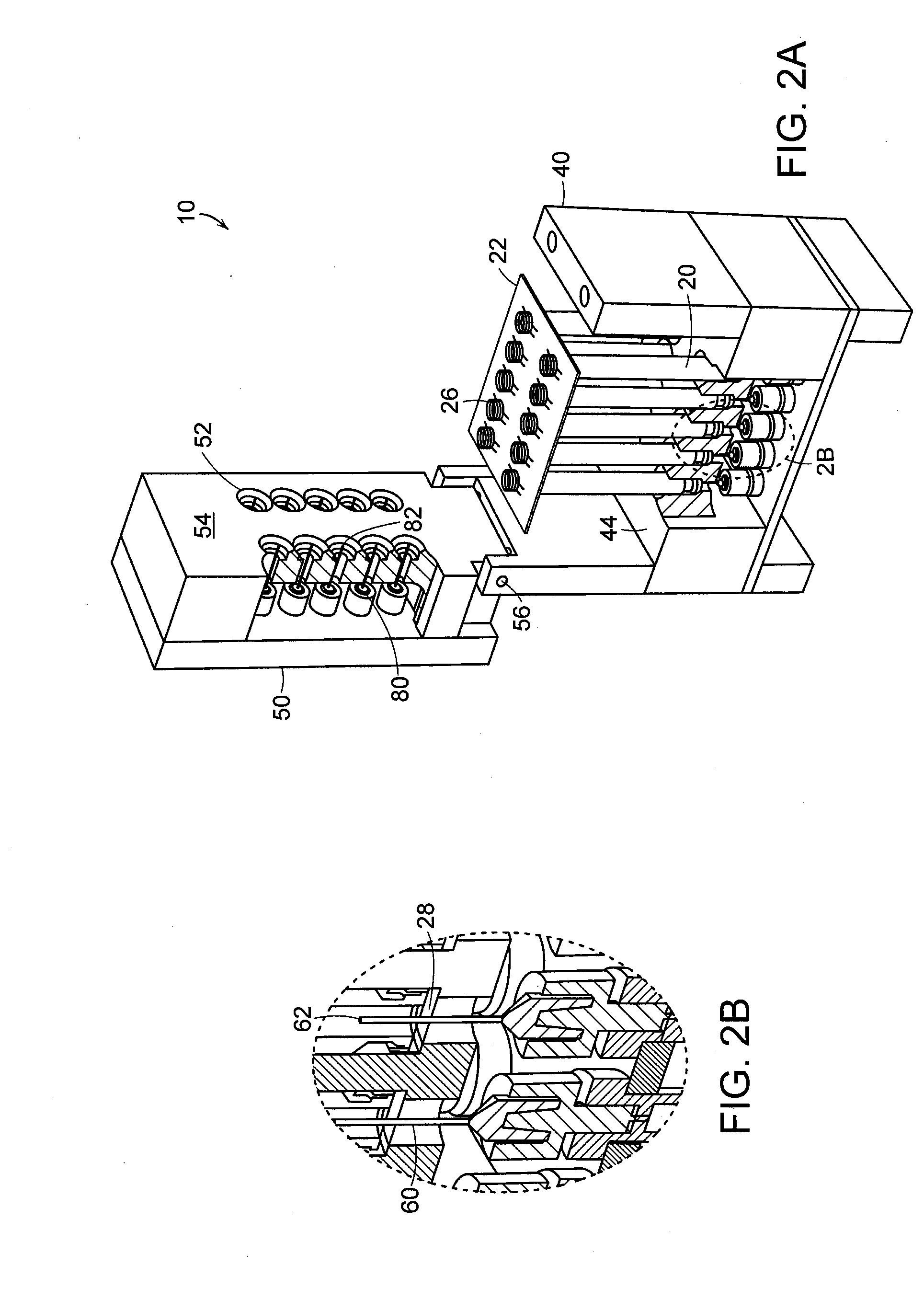

Liquid Handling System and Methods for Mixing and Delivering Liquid Reagents

InactiveUS20090246085A1Safe and easy wayReduce the possibilityAnalysis using chemical indicatorsClosuresEngineeringHandling system

A liquid storage apparatus provides a safe and easy to use device for efficiently managing liquid reagents used in a variety of laboratory equipment. The liquid storage apparatus helps reduce the likelihood of accidents, allows for flexibility of experimental design, and helps maximize the use of chemical regents to prevent waste. The apparatus includes a plurality of containers with a pierceable septum interface at each end. The apparatus also includes a lower array of needles with each of the lower needles in the lower array of needles arranged to penetrate the bottom pierceable septum of a different one of the containers. The apparatus further includes a piercing device arranged to penetrate the top pierceable septum of a different one of the containers. Each of the piercing devices include a passageway so gas can flow into the pierced container.

Owner:FLUIDIGM CORP

Facility for automatically collecting waste liquid in volumetric flasks

InactiveCN102745636AEasy to operateSimple structureTight-fitting lid removalThreaded caps removalLiquid wasteMaterial resources

The invention discloses facility for automatically collecting waste liquid in volumetric flasks. The technical scheme of the facility includes that the facility for automatically collecting waste liquid comprises a fixing device, a power transmission device, a single-shaft robot, a transportation device and a rotary fixture. A container containing waste liquid is arranged on the fixing device, the fixing device on a conveyor is driven by a motor to be conveyed to an operation table, a cover of the container is unscrewed and placed in a cover collecting disc by a manipulator, the fixing device is transported to the rotary fixture above a waste liquid collecting barrel by a sucker, is fixed in a fixed sleeve, is turned and shaken by a rotating cylinder so that the waste liquid can be poured out, and finally is transported to the conveyor to be moved out of the operation table. The facility for automatically collecting waste liquid is simple in structure, convenient to operate, labor-saving, material-resource-saving, time-saving, safe, quick, high-efficient and automatic. Frequent working procedures are avoided.

Owner:CENT TESTING INT GRP CO LTD

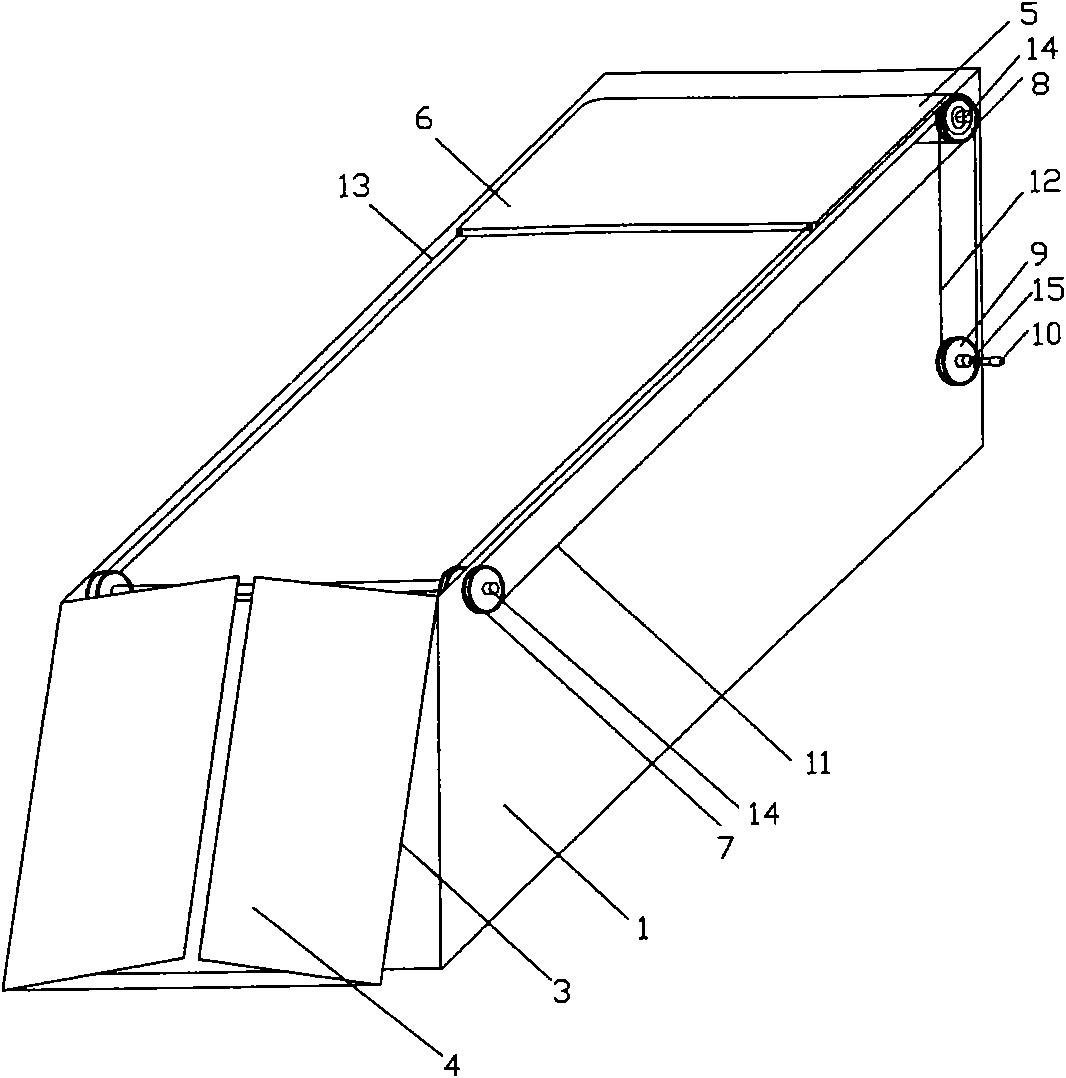

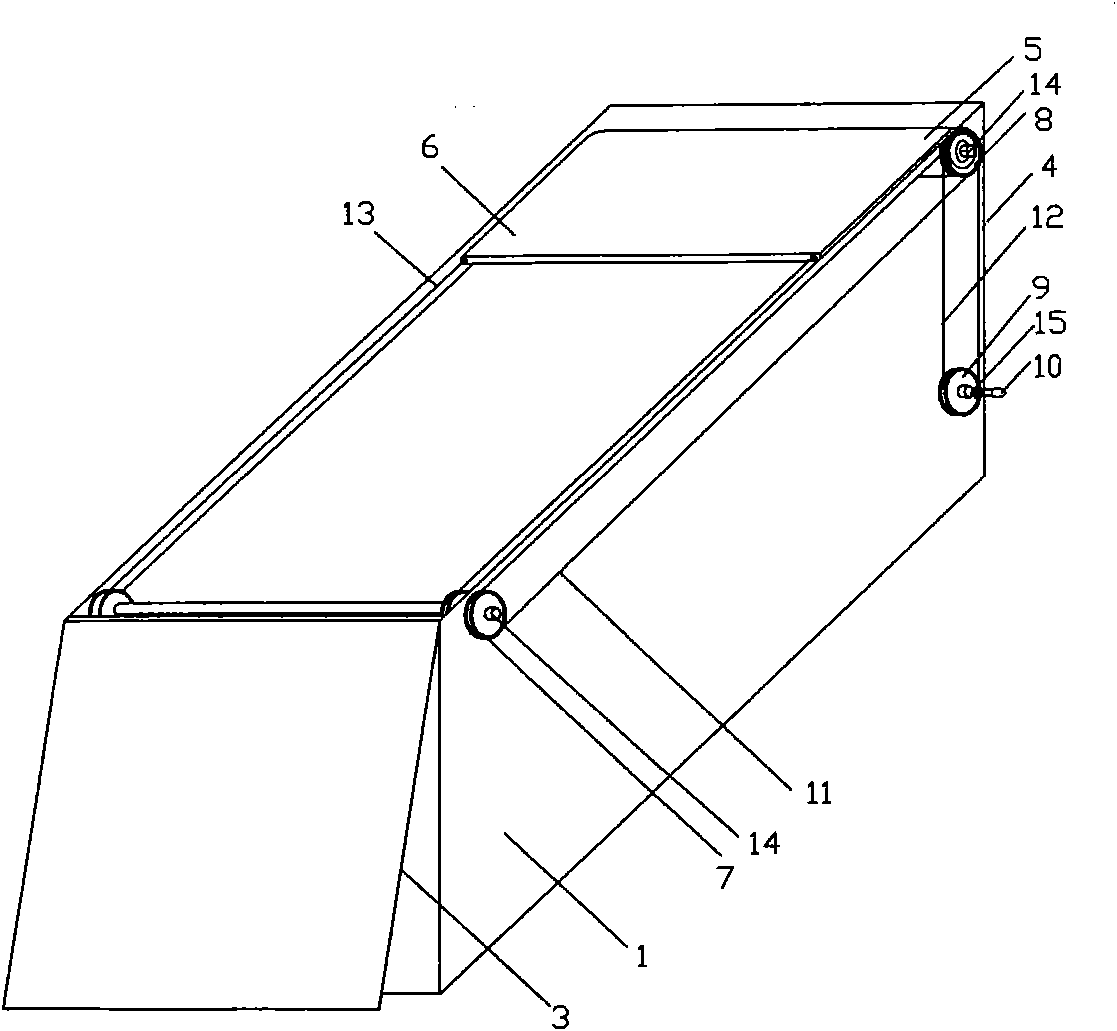

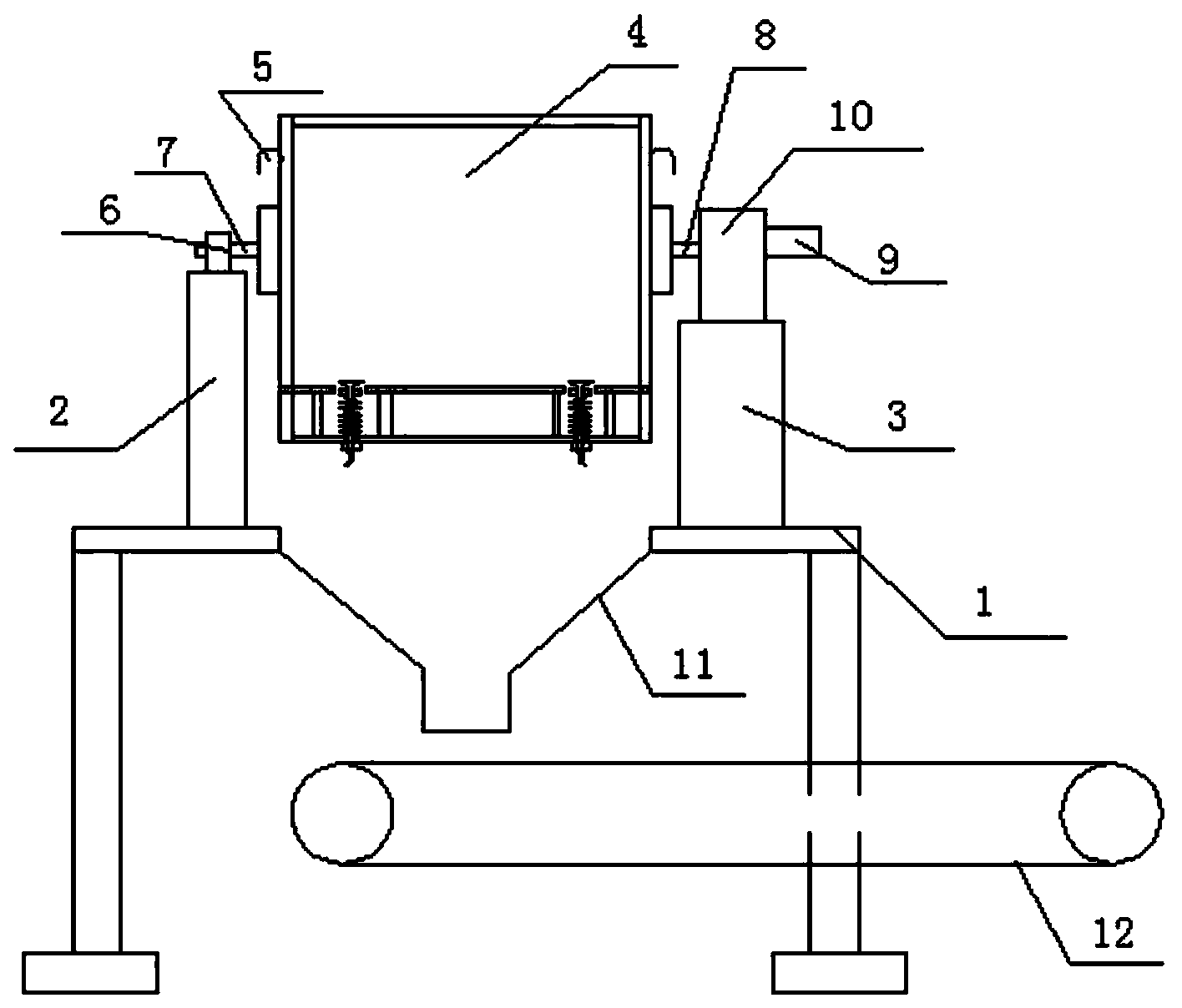

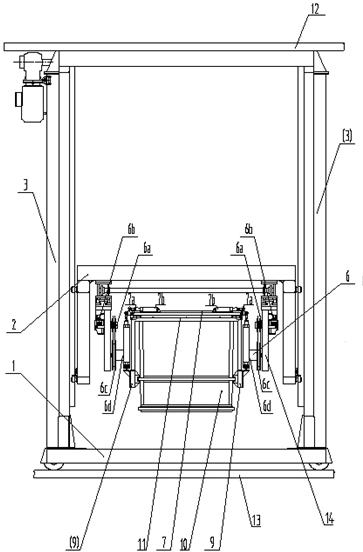

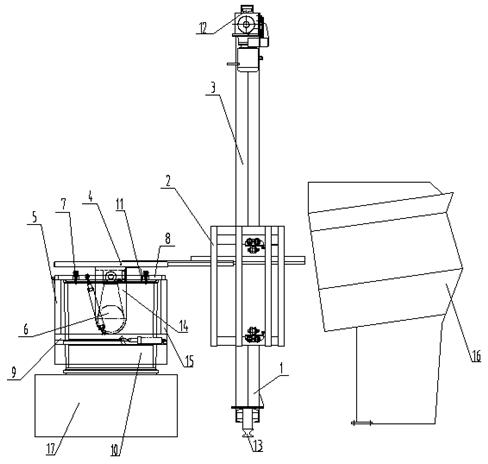

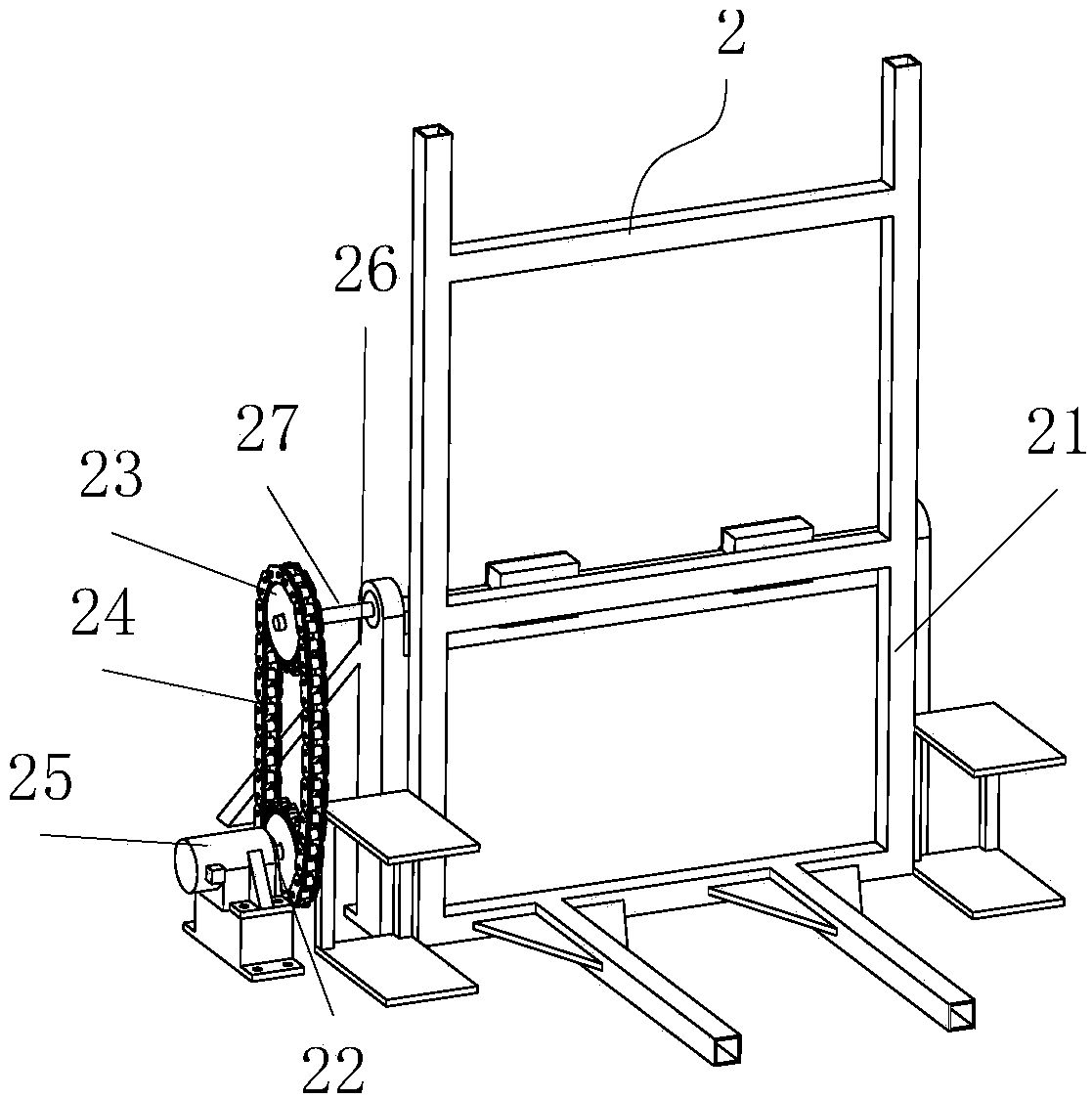

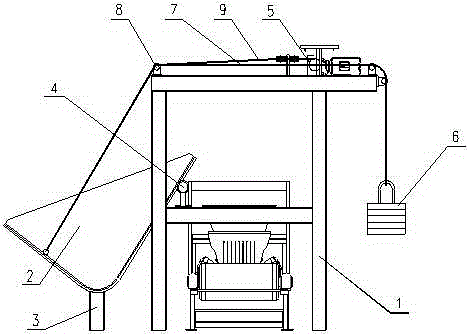

Translation type movable box overturning and material dumping device

InactiveCN102530573ASolve the spill problemOvercome the disadvantages of single functionBottle emptyingEngineeringMechanical engineering

The invention relates to a translation type movable box overturning and material dumping device. The translation type box overturning and material dumping device comprises a trolley (1) which travels between a skyrail (12) and a ground rail (13) and can reciprocate along the rails, a lifting table (2) which is arranged between two uprights (3) at two sides of the trolley and can move up and down along the uprights (3), a fork device (4) which is arranged on the lifting table (2) and can horizontally extend and retract in perpendicular to the traveling direction of the trolley, and a box overturning and material dumping device (5) which is arranged at the bottom of the fork device (4) and can be overturned. According to the translation type movable box overturning and material dumping device provided by the invention, the box overturning radius is small, the working process is stable and reliable, multiple functions can be realized, the equipment investment cost is saved, the materials are prevented from being scattered to the outside of the boxcar in moving and overturning processes at the same time, and the production cost can be reduced.

Owner:YUNNAN KUNMING SHIPBUILDING DESIGN & RESEARCH INSTITUTE

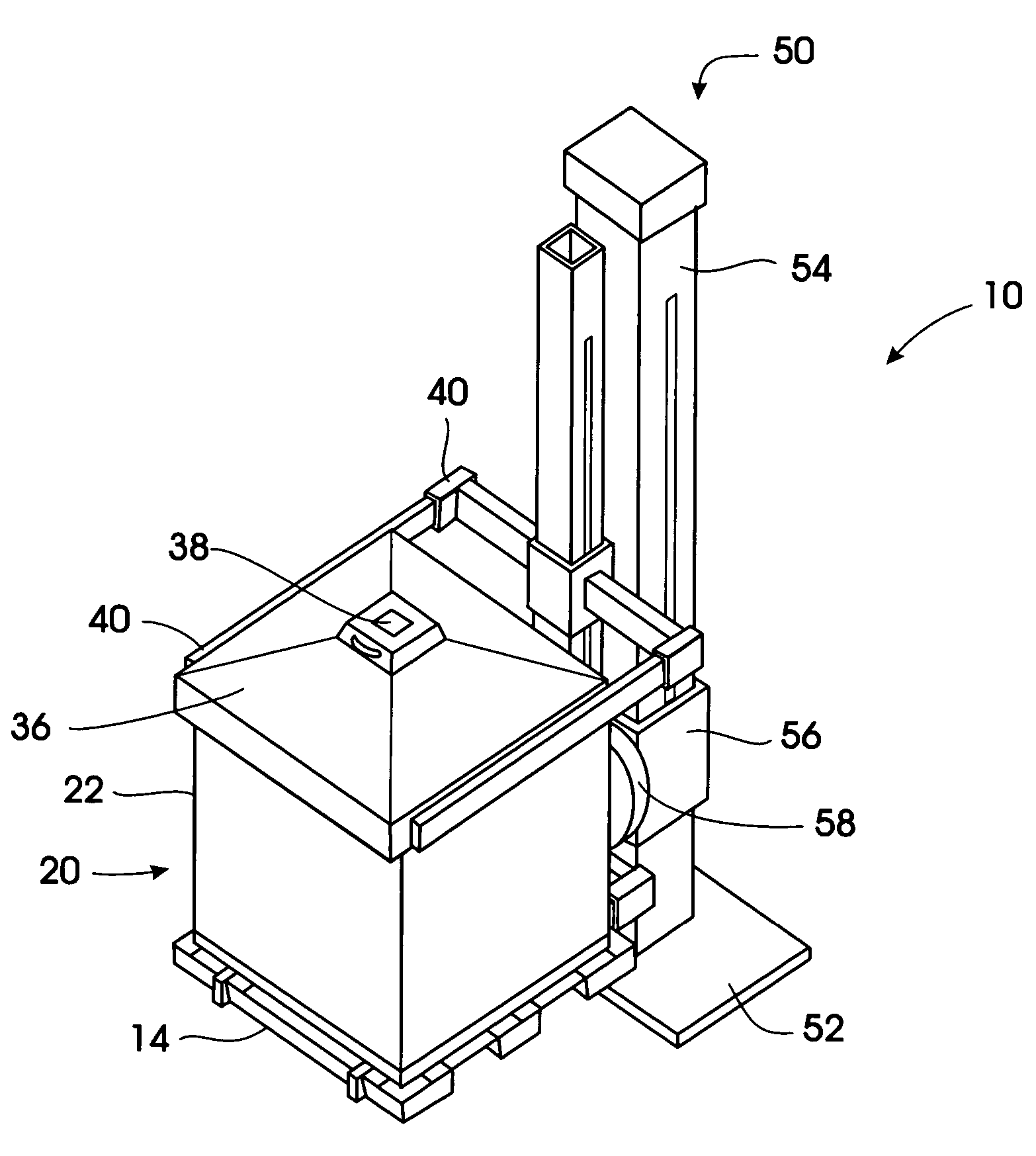

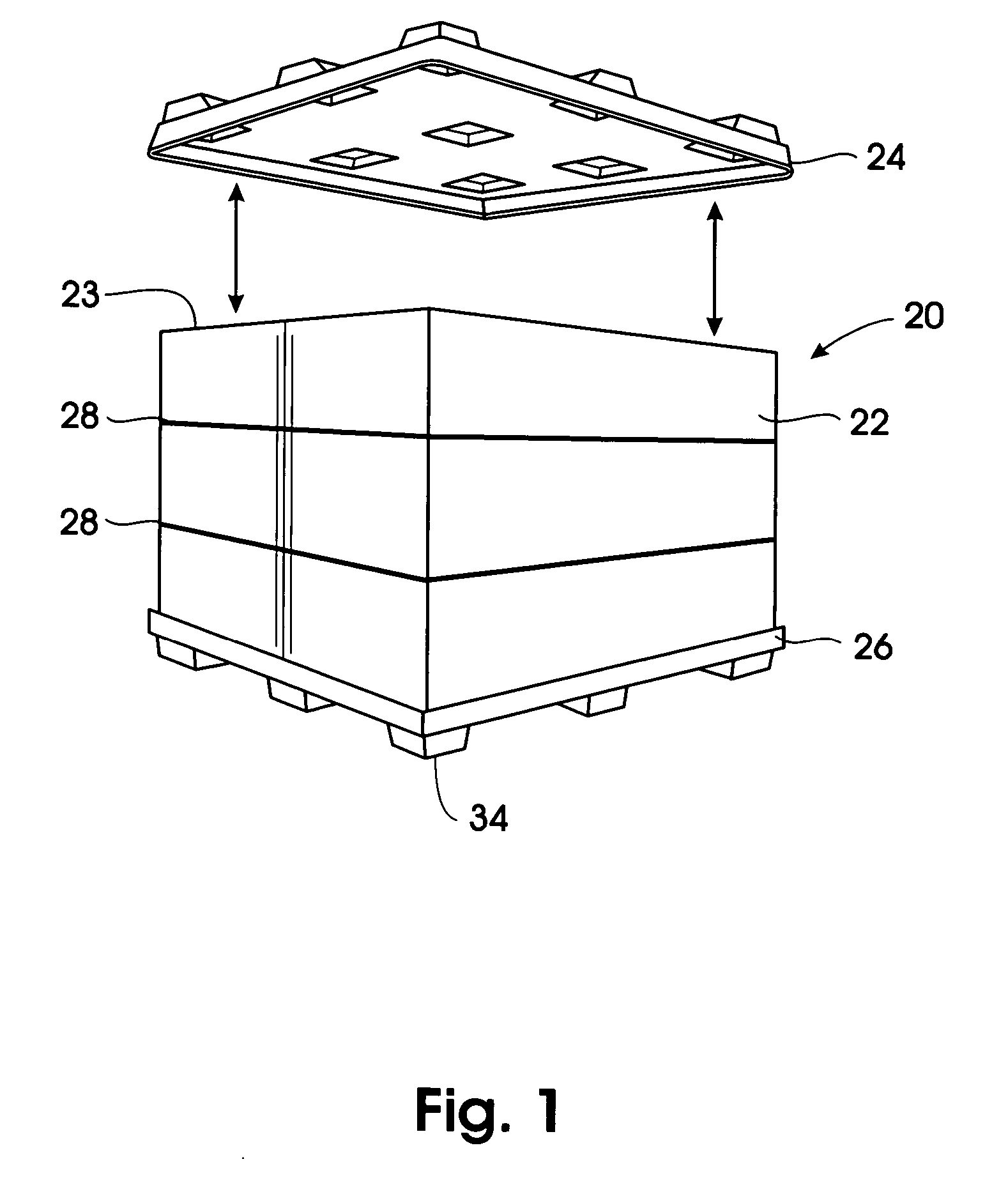

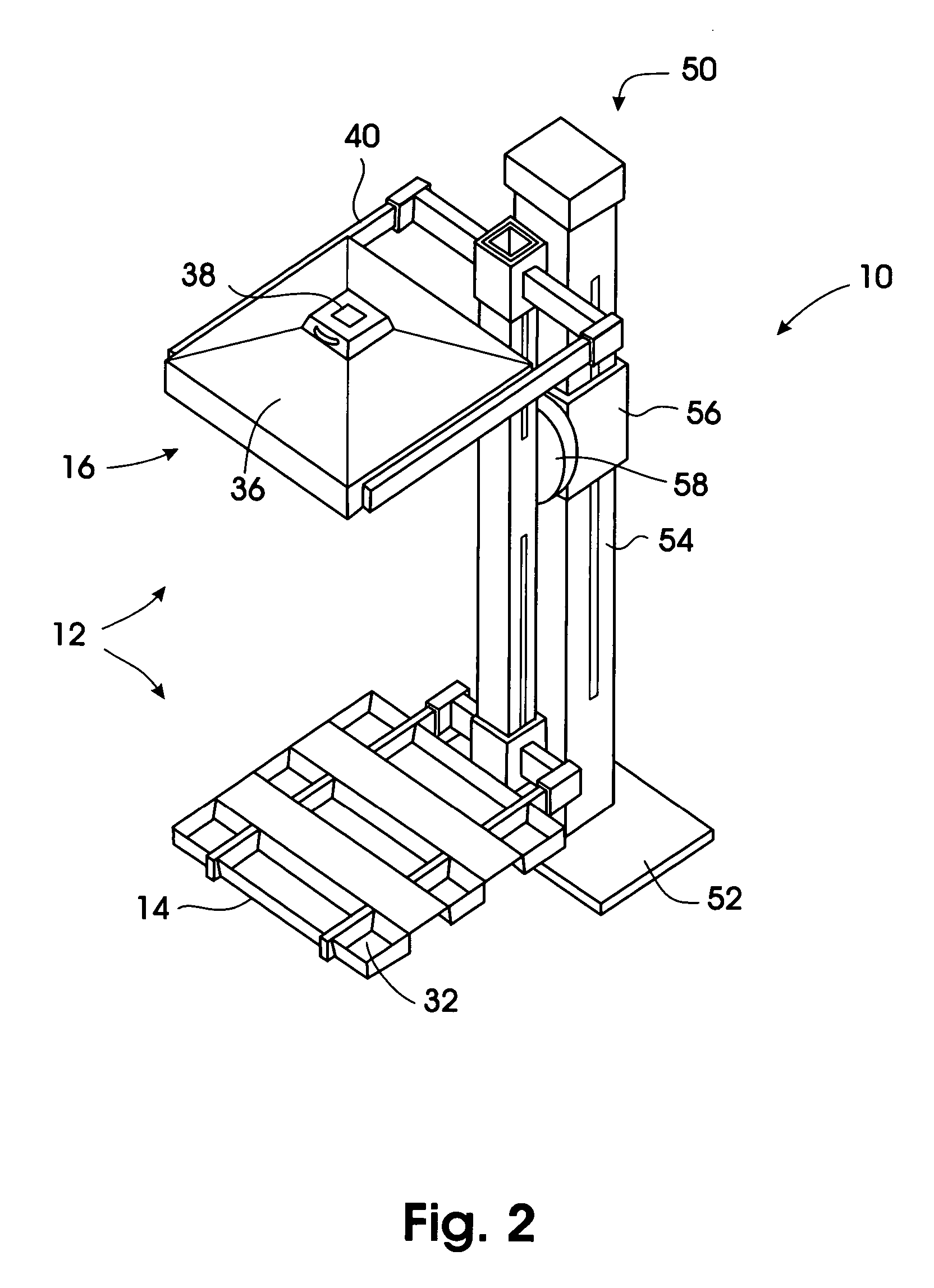

Dispensing system for returnable bulk containers

InactiveUS20050115982A1Low costEffective volumePower operated devicesArticle unpackingEngineeringVALVE PORT

A dispensing system for returnable bulk shipping containers and more particularly to a apparatus and method for selectively emptying the contents of bulk containers which, when emptied, can be returned to the supplier for refilling. The apparatus comprises a hoist having vertical lift capability. A rotator provided on the hoist provides horizontal rotation capability to a container press. A funnel cap is provided with the container press which is configured to replace the cover of the container, thereby retaining any structural integrity afforded by the cover. The funnel cap includes a selectively operable valve. The funnel cap operates in conjunction with a platen which is used to initially support the container in its upright position. The funnel cap and platen are movable away from one another to enable containers to be inserted or removed therefrom. The funnel cap and platen are movable toward one another to enable a container to be engaged and retained therein. The funnel cap and platen exert sufficient force on the container such that during lift and rotation of the container, it will not fall out. Once inverted, the contents of the container will have been gravitationally fed into the funnel. The valve in the funnel may then be selectively operated to dispense discreet quantities of flowable material.

Owner:SERTAPAK PACKAGING

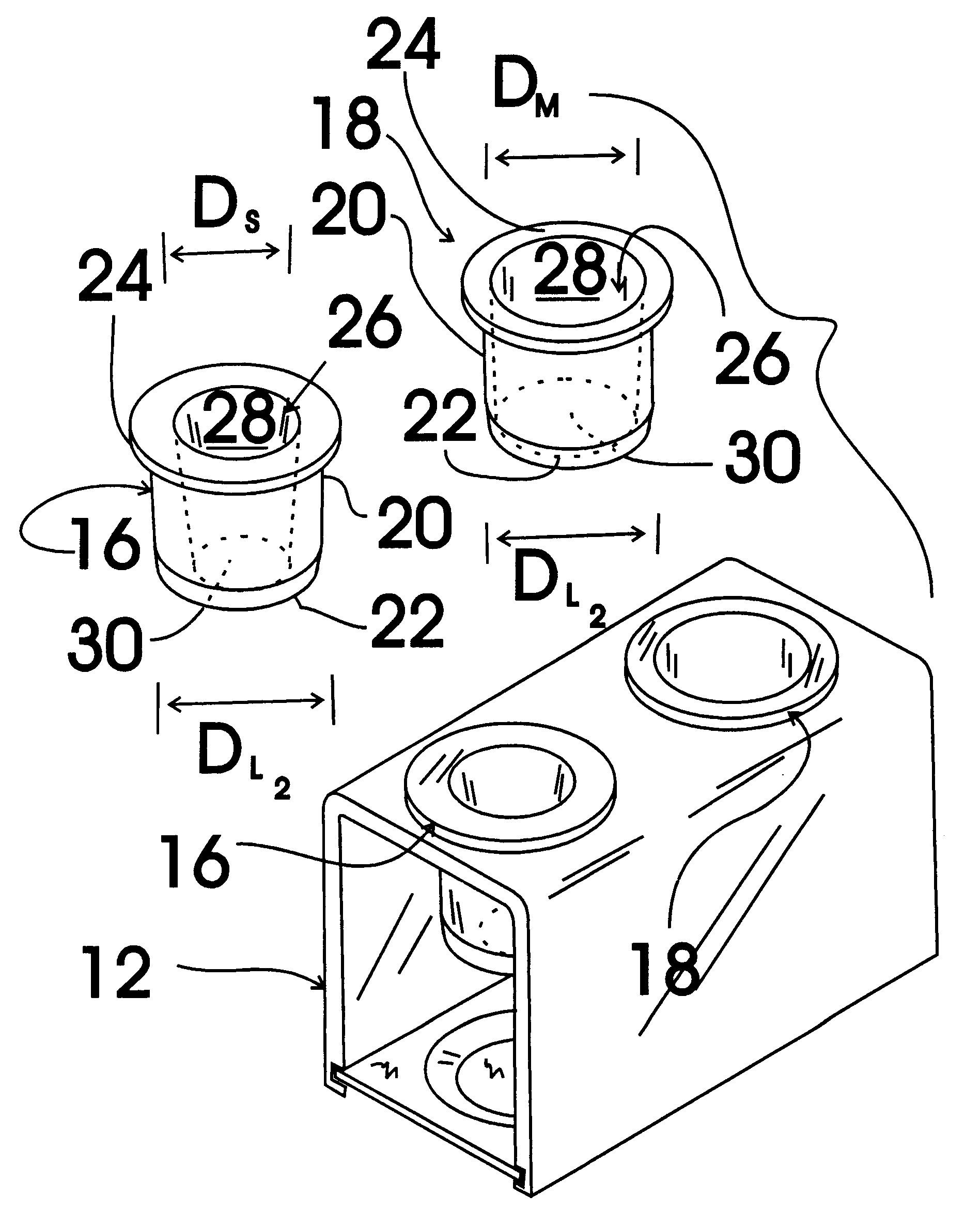

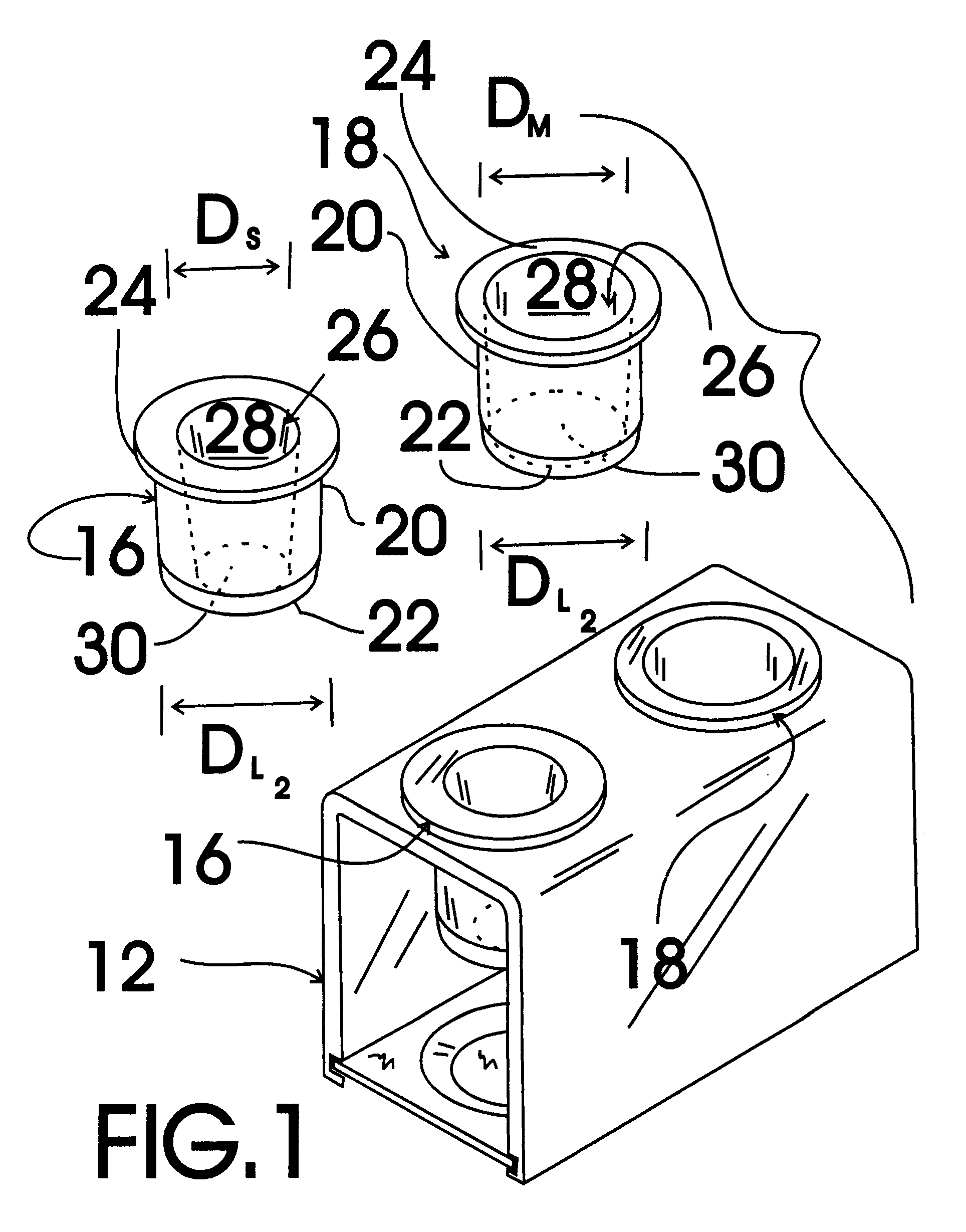

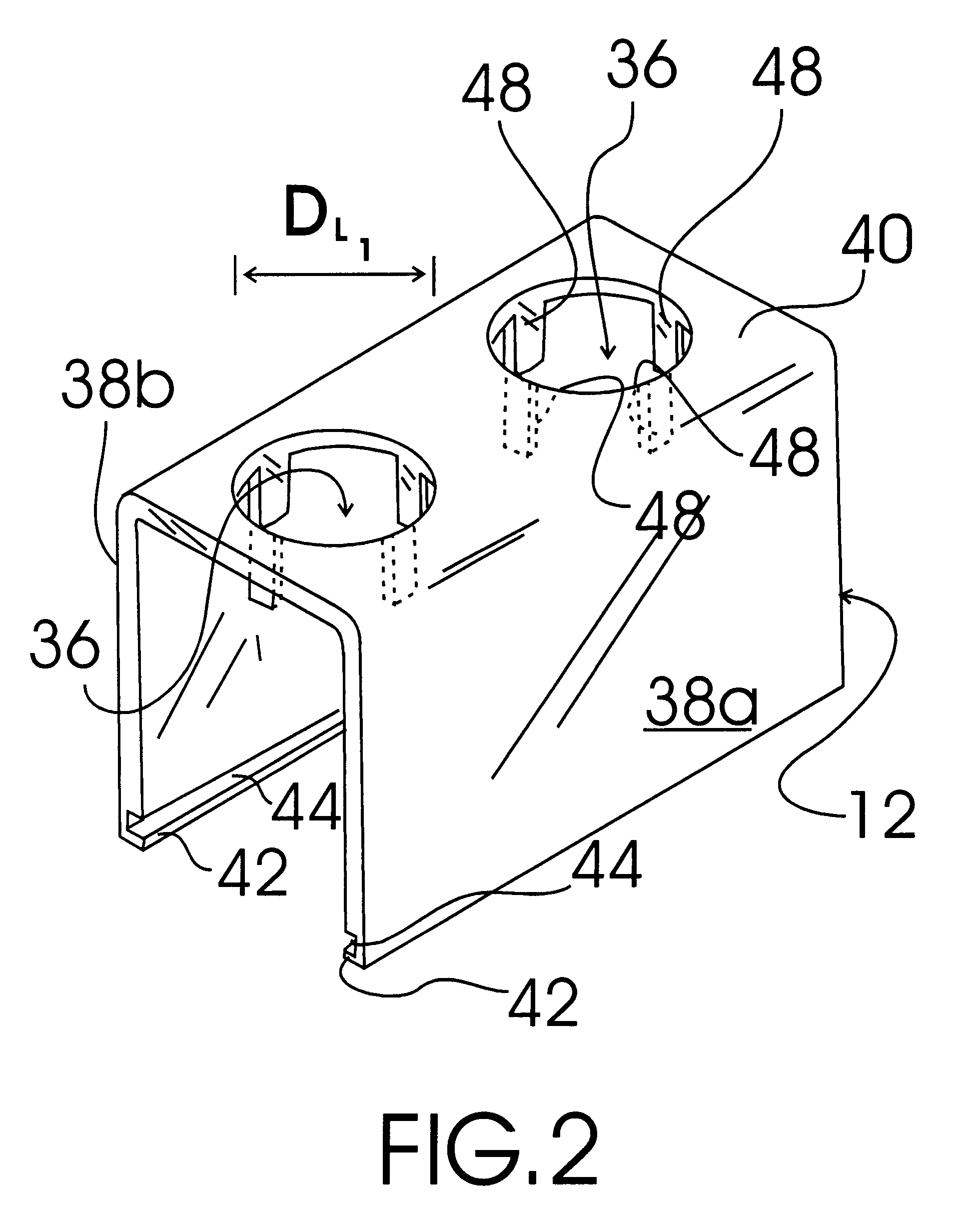

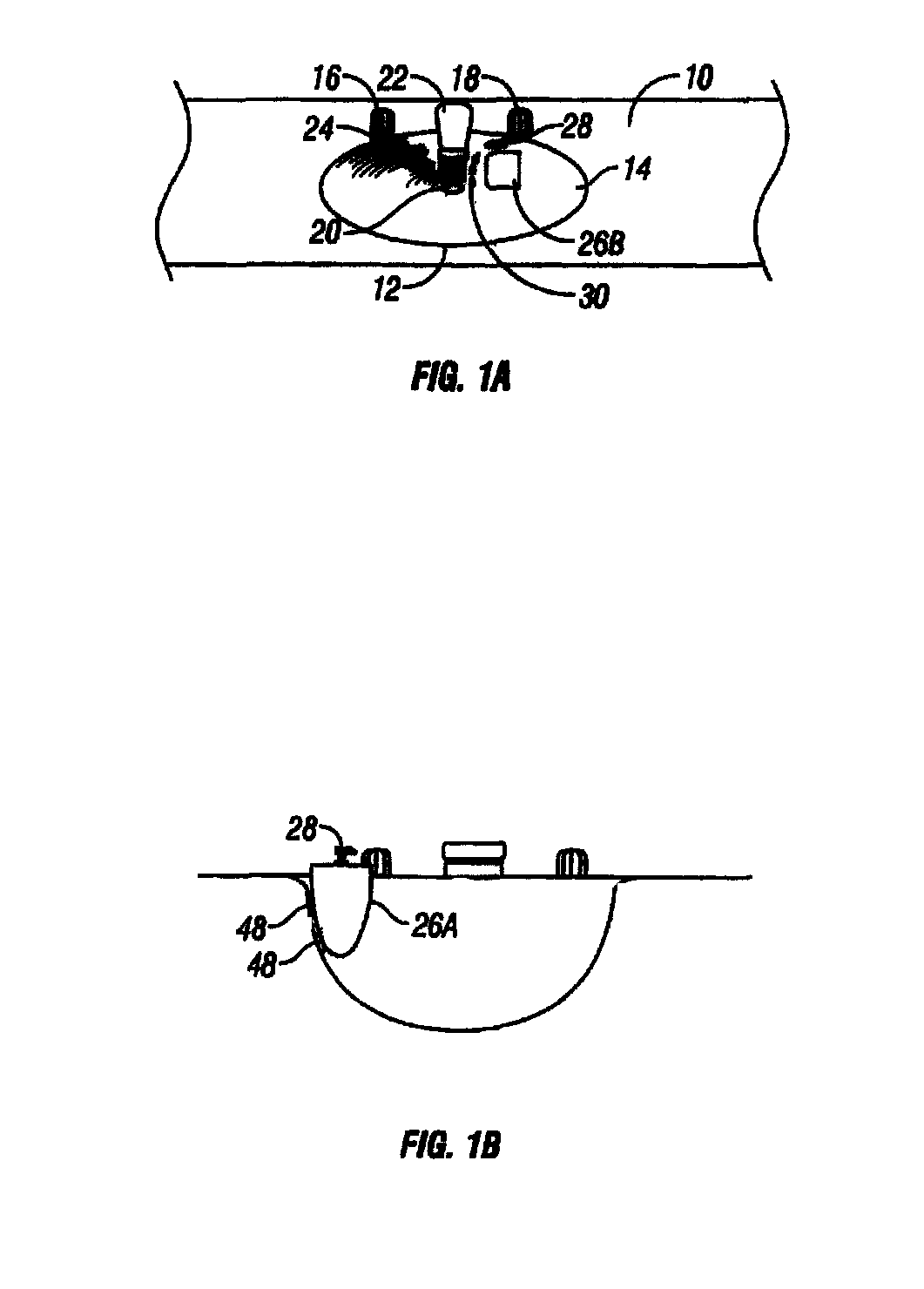

Bottle rack system

A bottle rack system for storing direct dispense bottles, such as used to store and dispense ketchup, salad dressing, steak sauce, etc., in an inverted position with the bottle cap positioned below the bottle bottom so that the contents of the bottle accumulate adjacent to the dispensing opening of the direct dispense bottle so as to be readily available for dispensing. The bottle rack system includes a bottle support member, a slide-in drip tray, two small diameter neck inserts, and two medium diameter neck inserts.

Owner:FALOR BRIAN K

Tableware cleaning line

PendingCN106725183APrevent overturningAvoid wastingTableware washing/rinsing machine detailsCleaning equipmentSlagEngineering

The invention discloses a tableware cleaning line which comprises a top box elevator, an automatic turnover machine, a coarse washing machine, a box body conveyor, a tableware sorting device, tableware conveyor belts, a can turnover device, a cleaning tunnel, a packaging and conveying belt and a tableware assembly device, wherein the discharge end of the top box elevator is close to the feeding end of the automatic turnover machine; an inclined slag remover and a coarse washing machine elevator are arranged in a pond of the coarse washing machine separately; the discharge end of the coarse washing machine elevator is connected with the feeding end of an anti-patterning machine; the out-box end of the automatic turnover machine is provided with the box body conveyor which passes through a box body cleaning room of the cleaning tunnel; the discharge end of the anti-patterning machine is connected with the feeding end of the tableware sorting device; each tableware outlet of the tableware sorting device is correspondingly provided with one tableware conveyor belt separately; and spoons and chopsticks are directly conveyed through the tableware conveyor belts and enter the feeding end of a spoon and chopstick conveyor mesh belt. According to the tableware cleaning line, classifying and cleaning of the tableware are achieved, cleaning is more thorough, and the cleaning efficiency of a table set is greatly improved.

Owner:SHANDONG DINGTAISHENG FOOD IND EQUIP

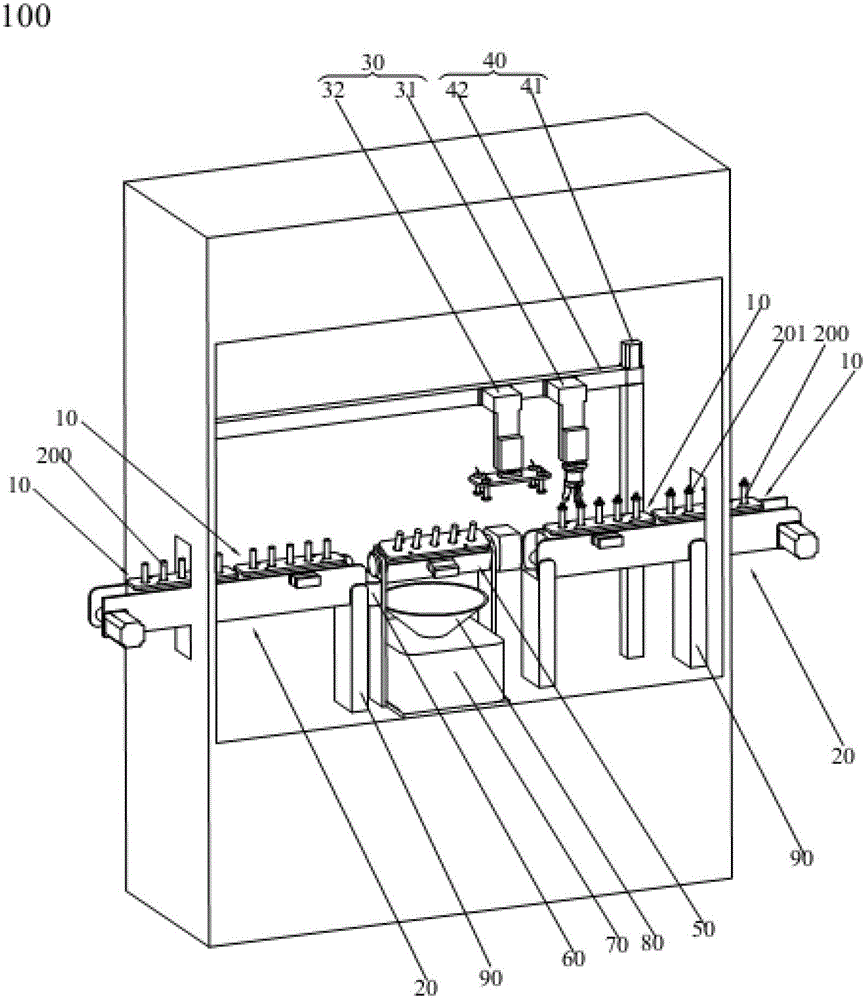

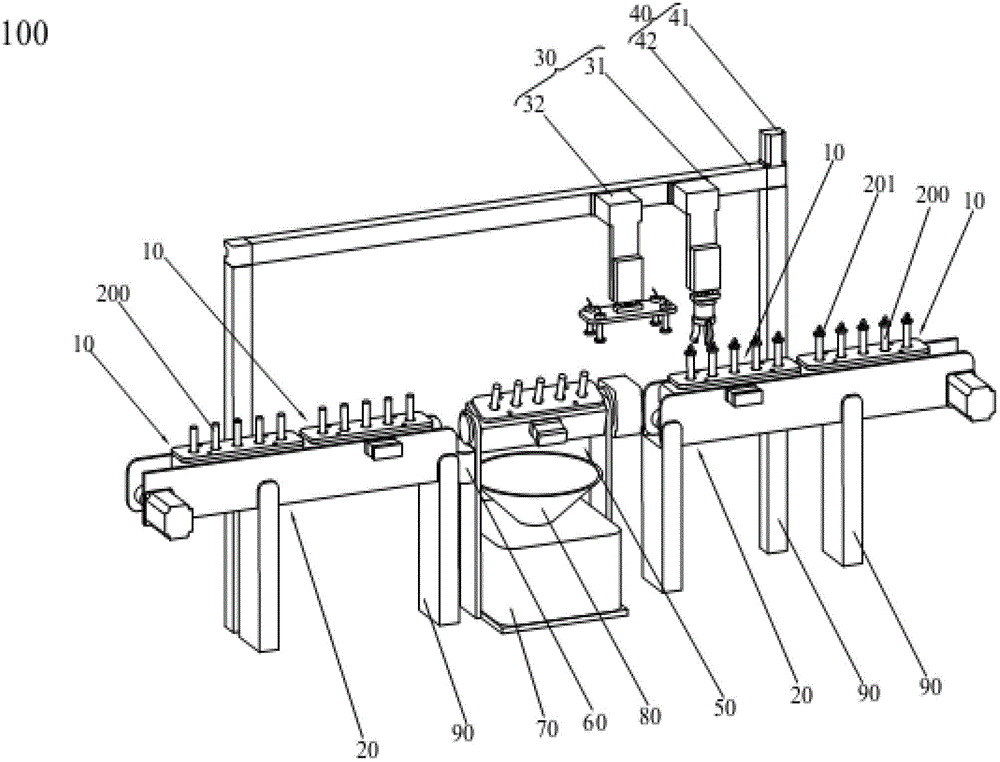

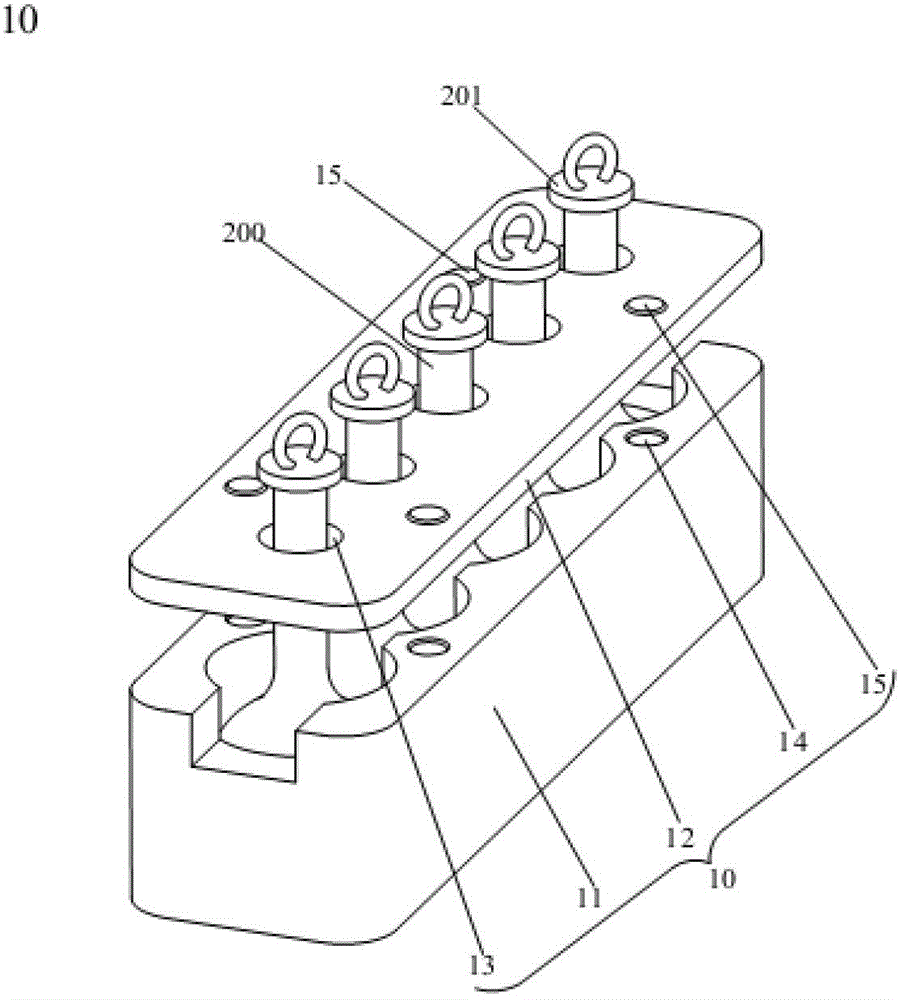

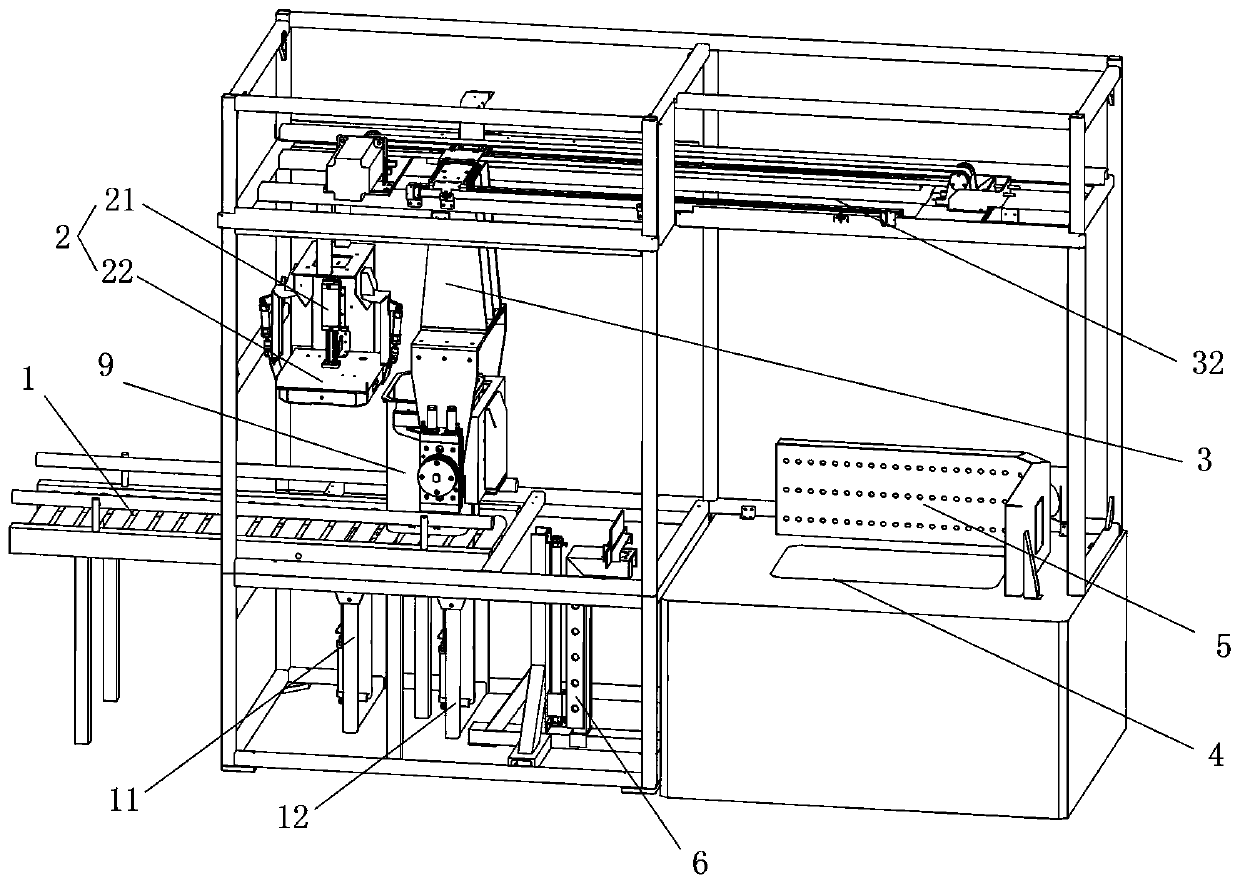

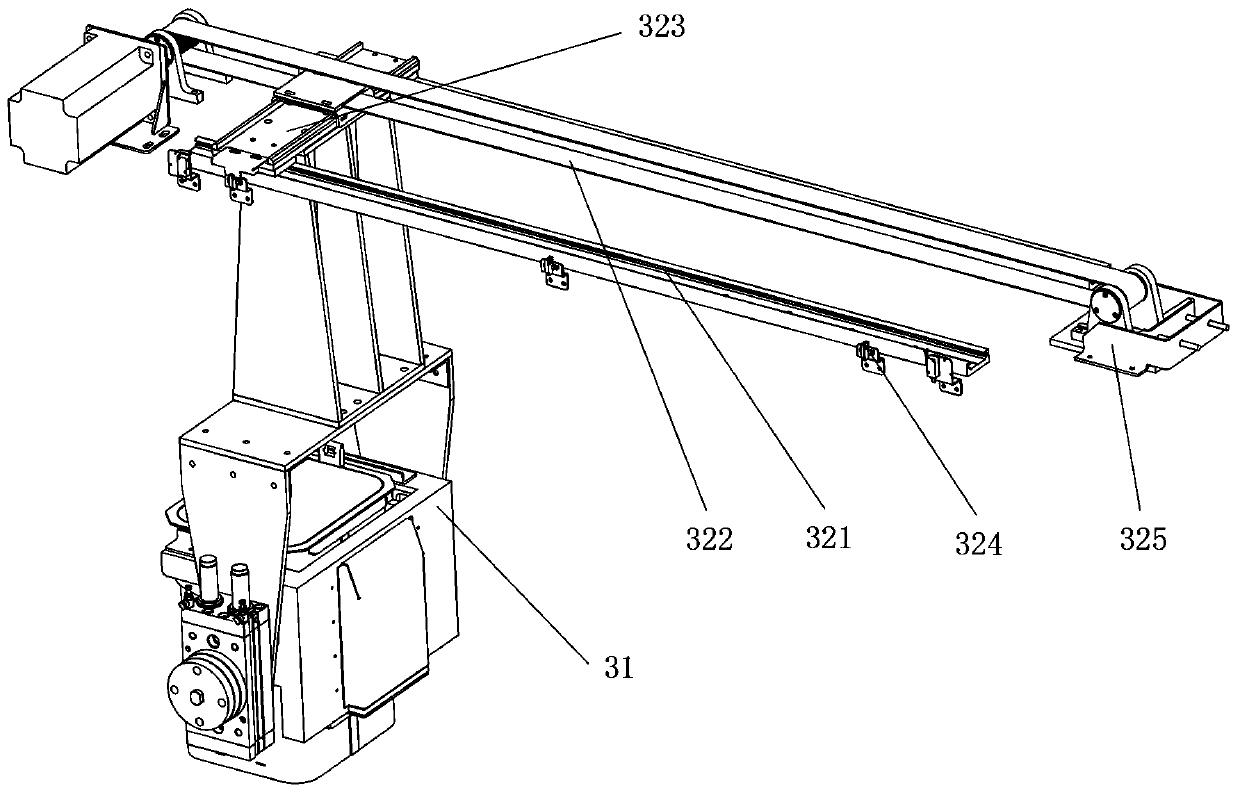

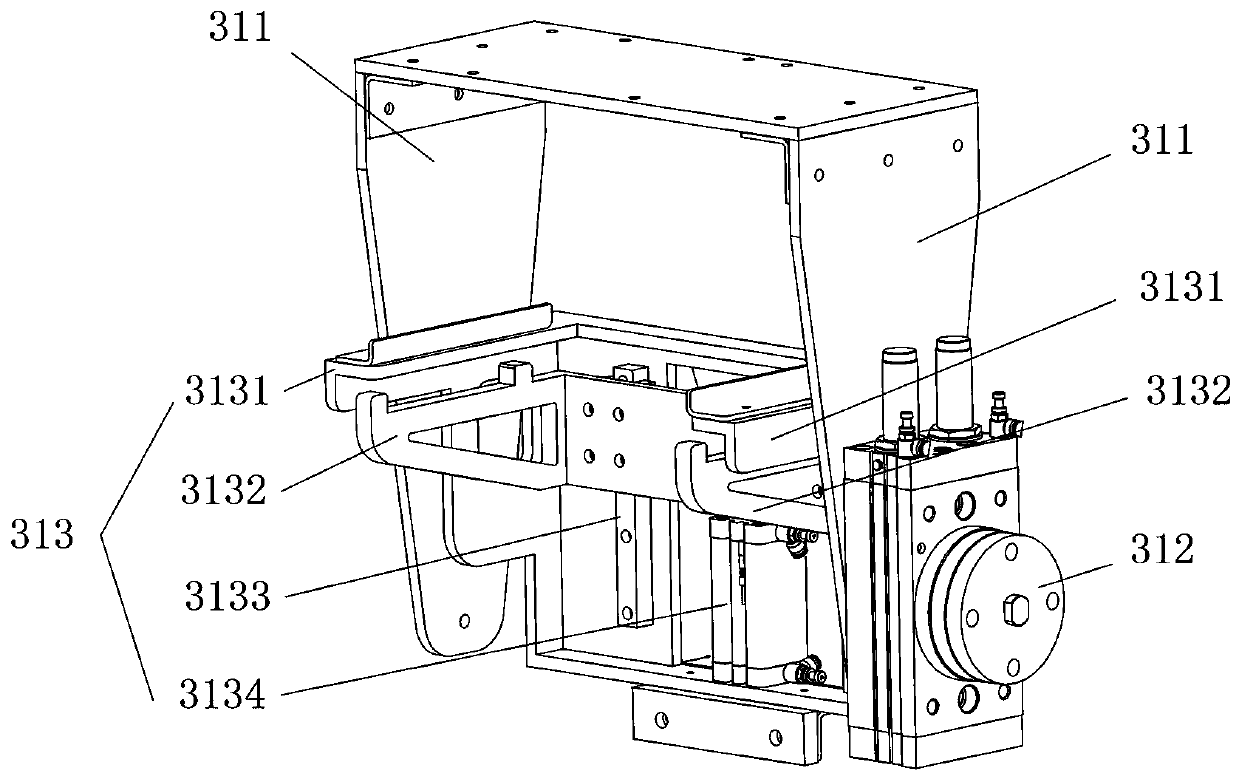

Automatic feeding equipment for samples

ActiveCN108045976AHigh degree of automationMeet unattended operation requirementsConveyorsBottle emptyingAutomatic test equipmentEngineering

The invention discloses automatic feeding equipment for samples. The automatic feeding equipment comprises a conveyor line device for conveying the sample barrels. An uncovering unlocking device and apouring manipulator device are sequentially arranged above the conveyor line device, and the pouring manipulator device comprises a clamping overturning manipulator and a pouring conveyor line. The sample barrels are conveyed to the position below the uncovering unlocking device in the forward direction, unlocked and uncovered and then continuously conveyed to the position below the pouring manipulator device in the forward direction. The clamping overturning manipulator is used for clamping the sample barrels and driving the sample barrels to be conveyed to a feeding station in the forward direction under driving of the pouring conveyor line to enable the sample barrels to be overturned at the feeding station to complete pouring unloading. After pouring unloading is completed, the samplebarrels are driven by the clamping overturning manipulator to be conveyed to the conveyor line device in the reverse direction, covered through the uncovering unlocking device, and then conveyed through the conveyor line device in the reverse direction. The automatic feeding equipment has the advantages that the automatic and intelligent degrees are high, safety is high, the manual labor intensity can be relieved, and work continuity is kept.

Owner:HUNAN SUNDY SCI & TECH DEV

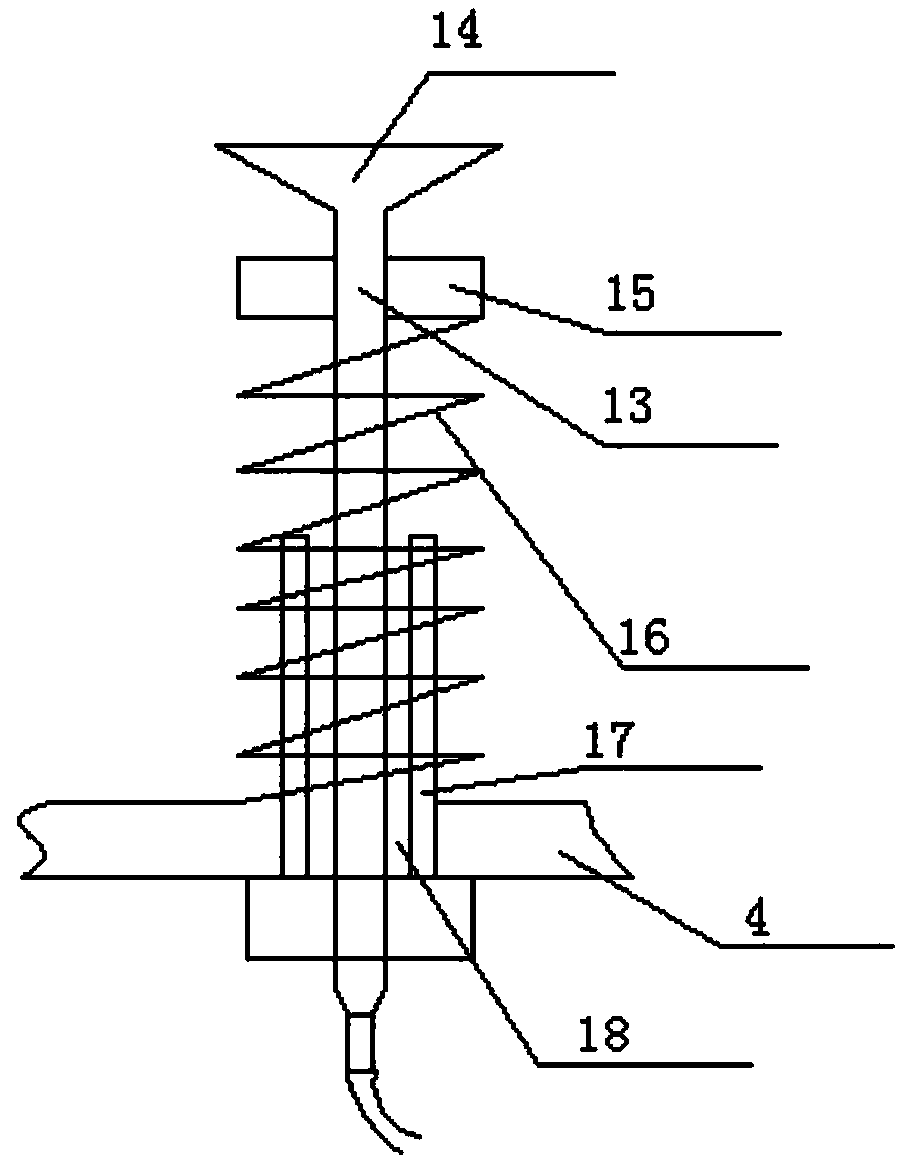

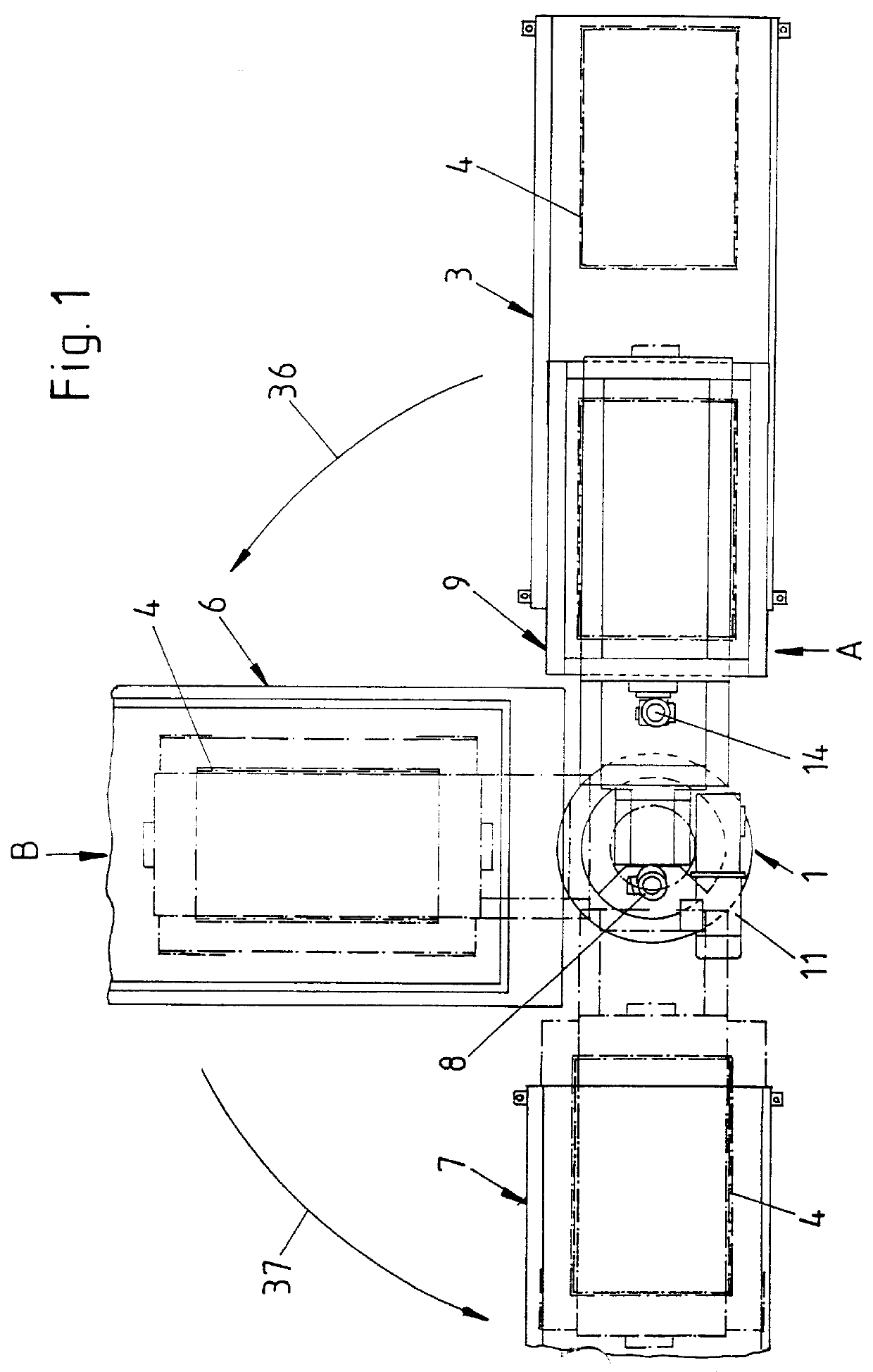

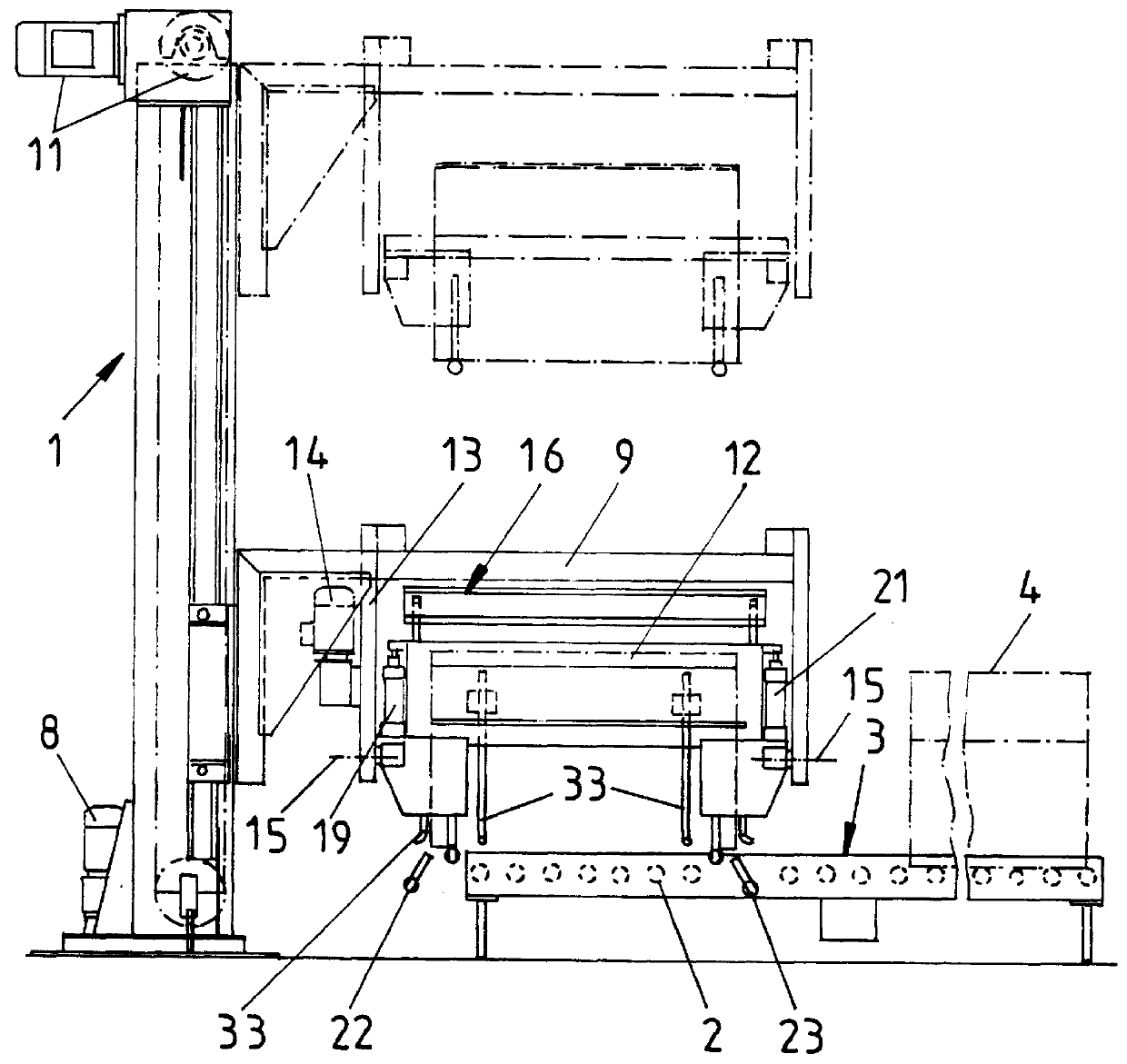

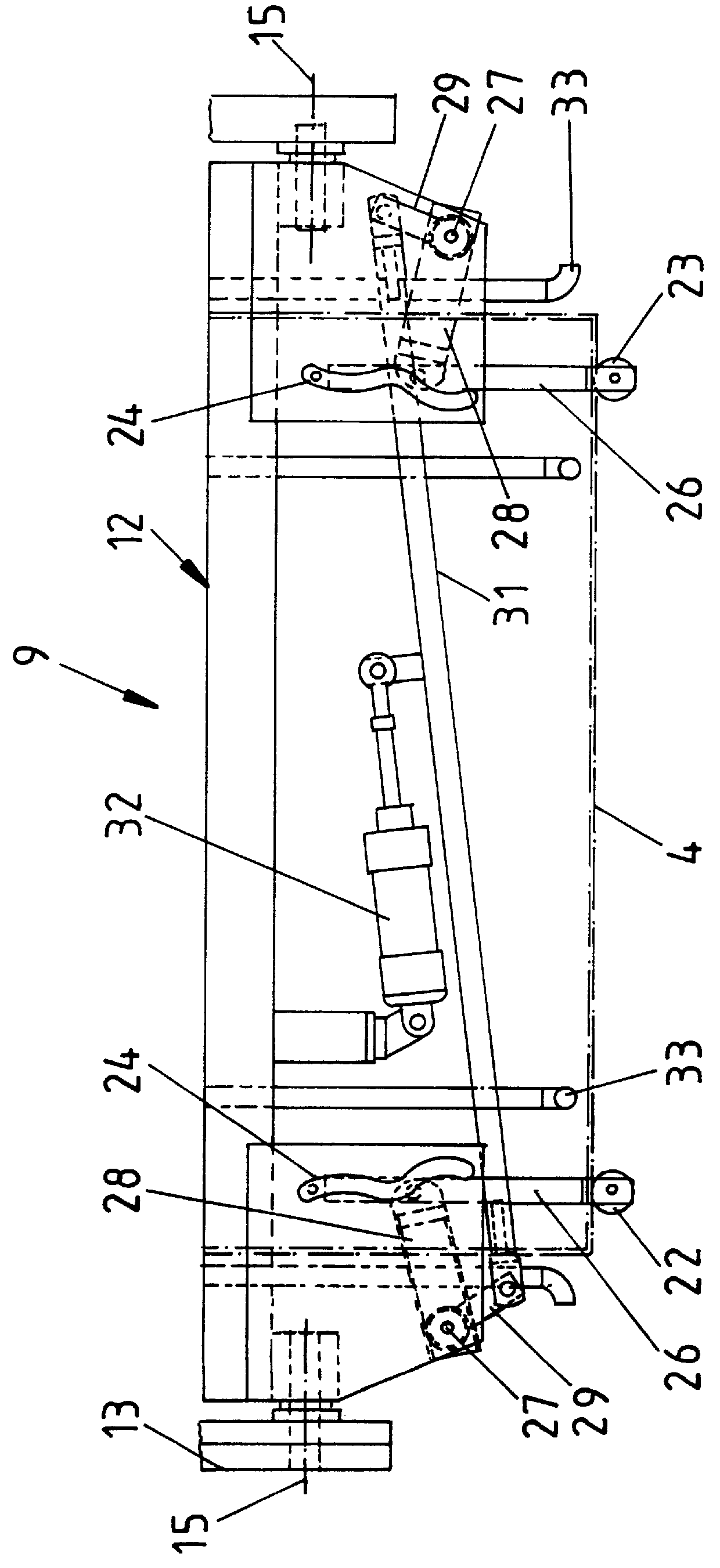

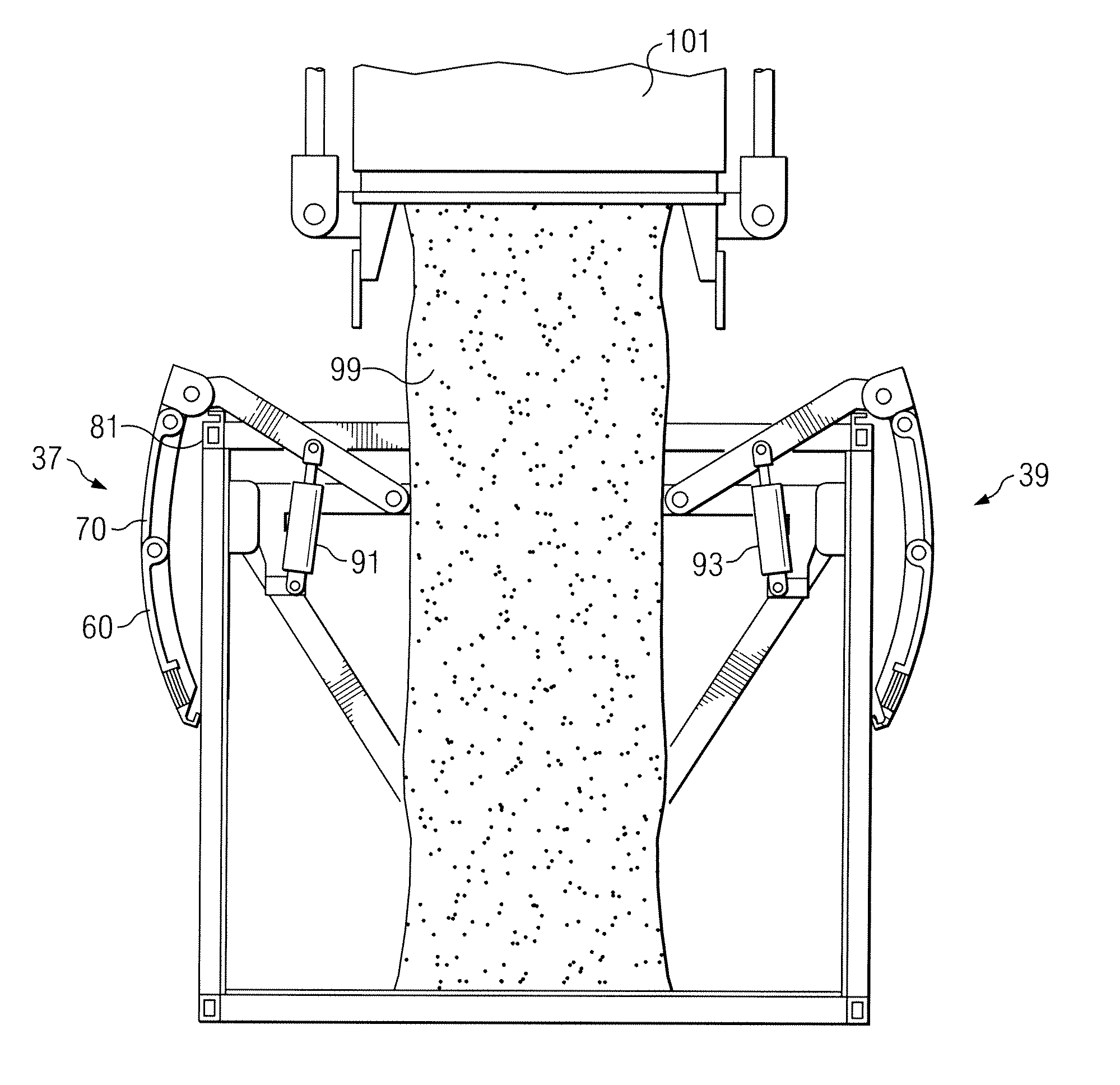

Method of and apparatus for emptying containers for flowable materials such as comminuted tobacco leaves

The contents of successive containers for comminuted tobacco leaves are transferred onto or into a receiver (such as a belt conveyor) at a transfer station where an indexible upright manipulator carries a lifter and an evacuating device including a tilting unit. Successive containers, delivered to the transfer station by a roller conveyor or the like, are lifted by the lifter off the conveyor and the manipulator is thereupon indexed to deliver the lifted container to a location above the receiver. The tilting unit is thereupon caused to tilt the container to thus transfer, by gravity flow, the contents of the container onto an openable intercepting device at a level between the tilter and the receiver. The intercepting device is thereupon opened to permit the intercepted material to descend onto or into the receiver. The manipulator is thereupon indexed to move the emptied container to a position above a further conveyor serving to transport empty containers away from the transfer station. The multi-stage transfer of particulate material from a container above the receiver onto or into the receiver reduces the generation of dust and the likelihood of undesirable comminution of such material.

Owner:HAUNI MASCHINENBAU AG

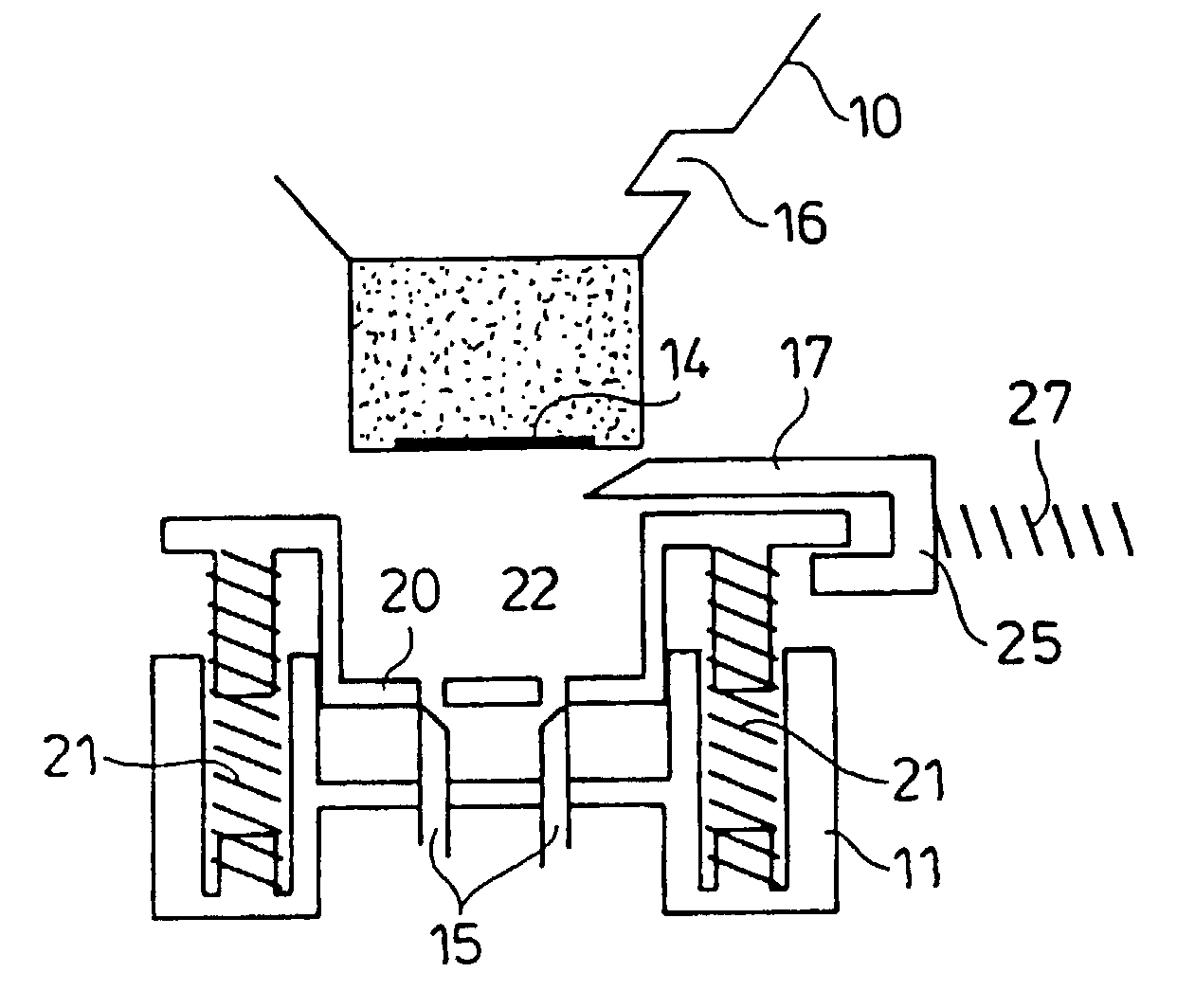

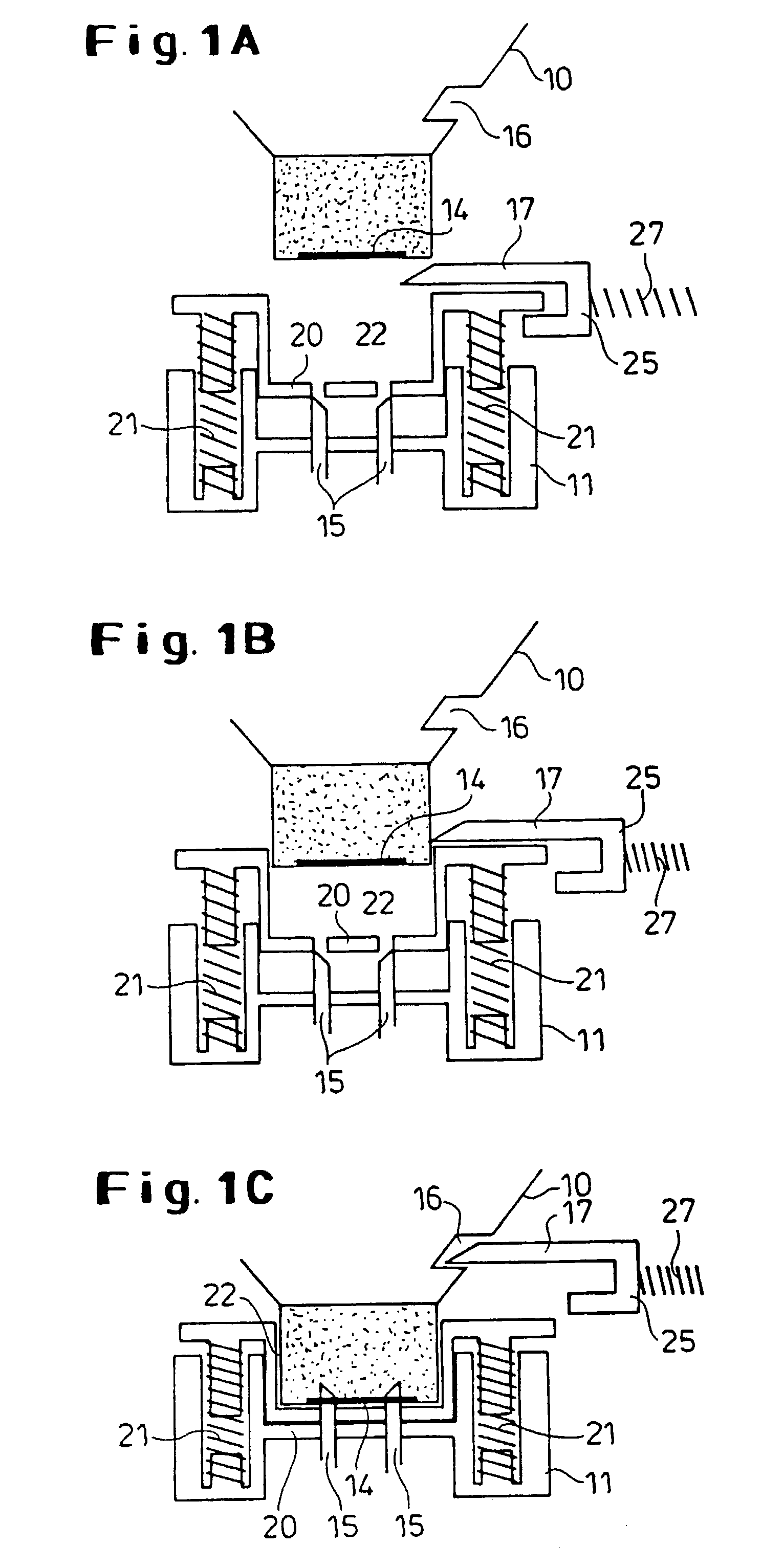

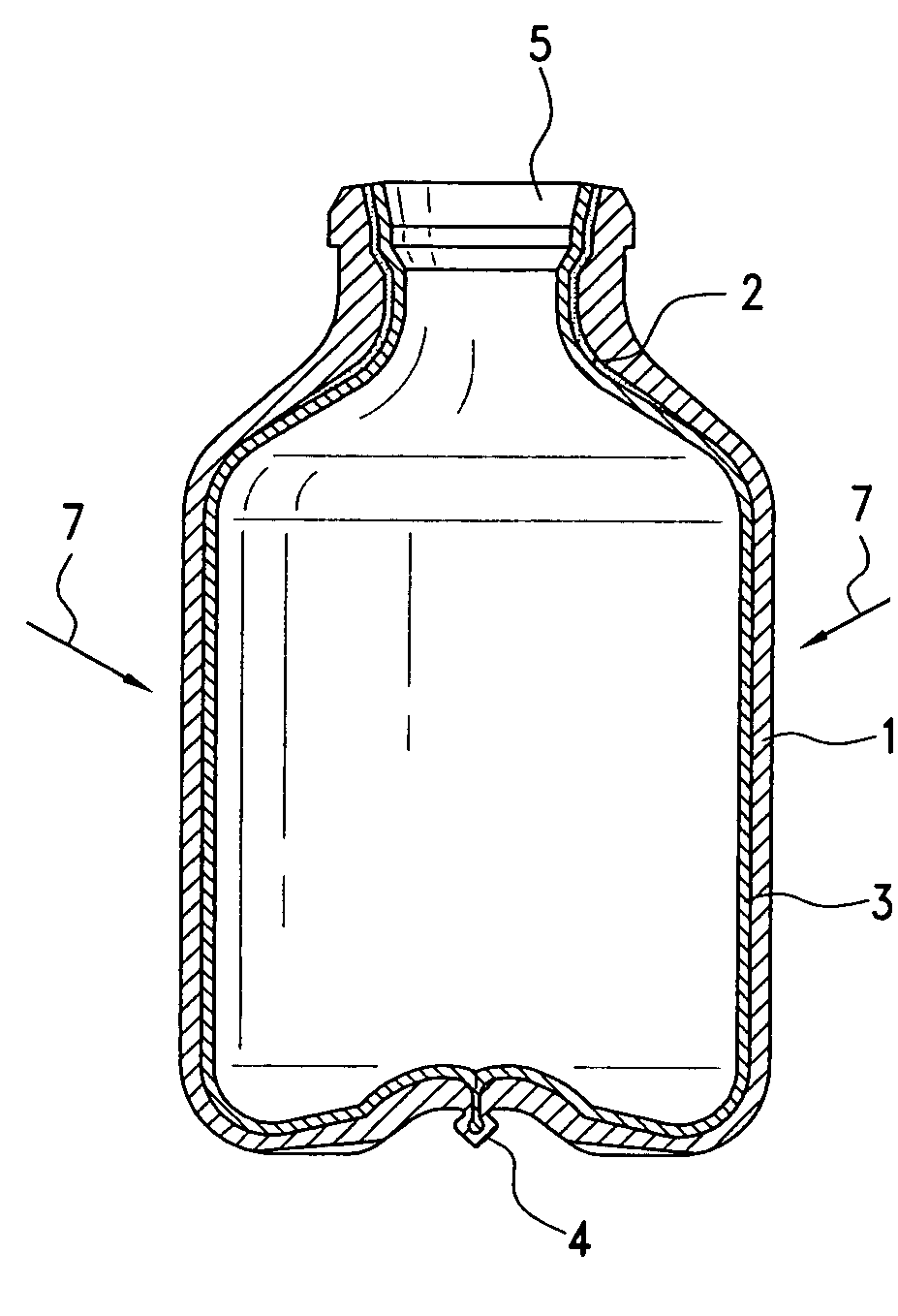

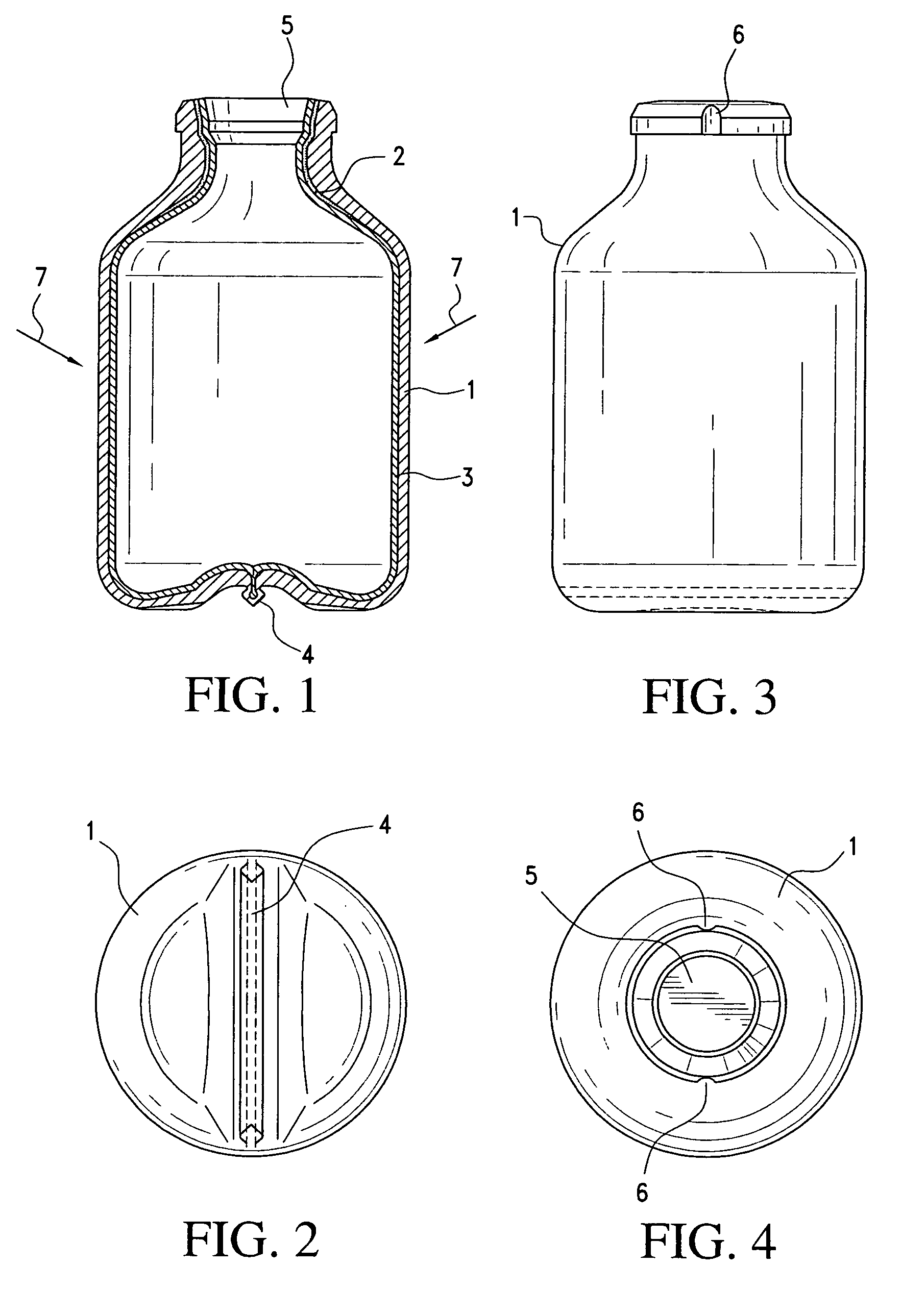

Container comprising an inner pouch

InactiveUS7017761B1Advantageous pressure compensationFirmly connectedBottlesLarge containersSodium bicarbonateEngineering

A container comprises a substantially dimensionally stable outer wall and an easily deformable inner pouch which gradually contracts upon discharge of the contents of the container. As a result, pressure compensation is provided in the increasing space between the outer wall and the inner pouch. The outer wall and the inner pouch have, therebetween, a layer of a pressure compensating material that expands when acted upon by an agent. The expanding layer comprises, in an exemplary embodiment, citric acid and sodium bicarbonate foam acting against the inner pouch. The foamed pressure-compensating layer supports the inner pouch so that no vacuum is generated in the pouch.

Owner:CAPLAST GMBH

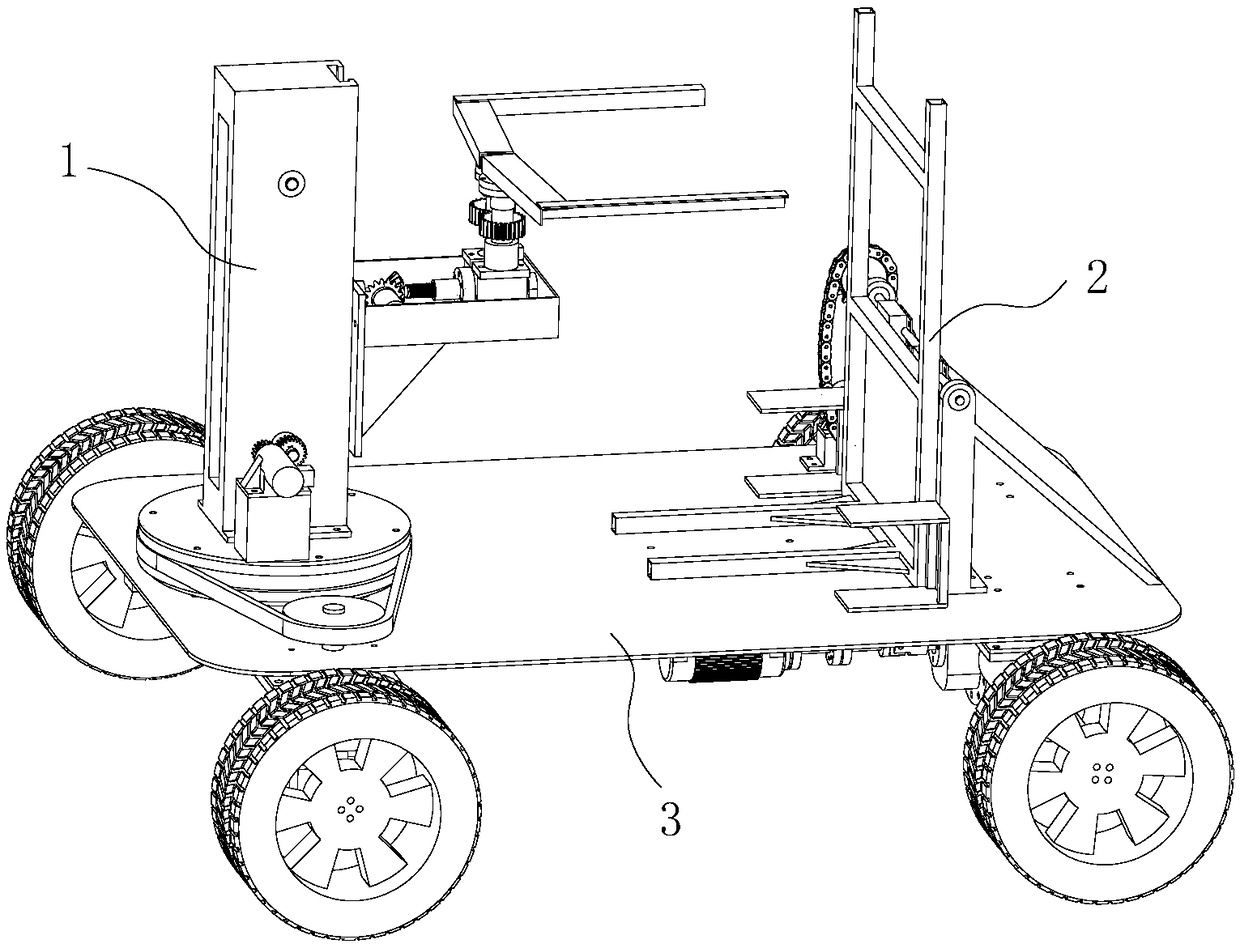

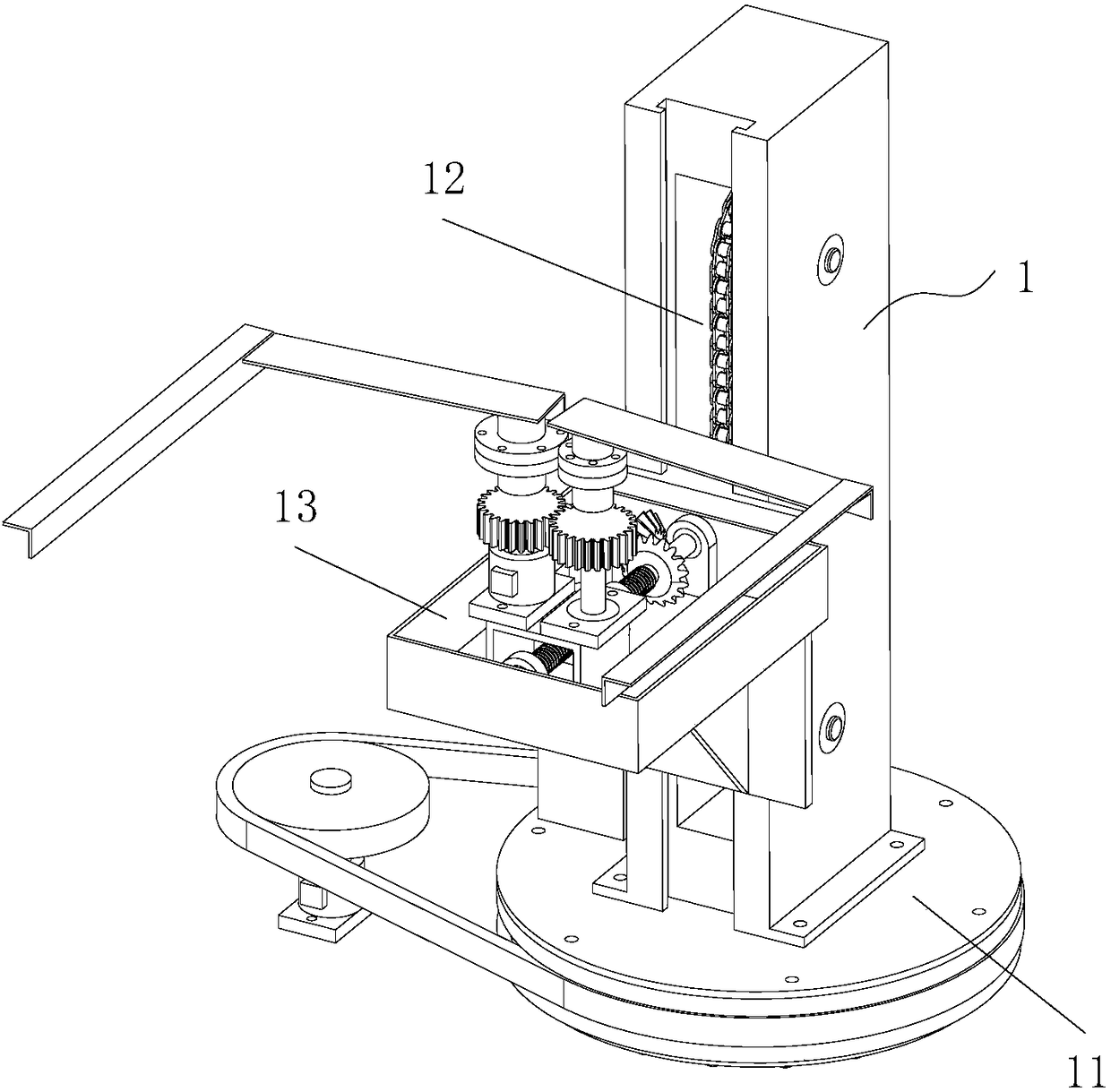

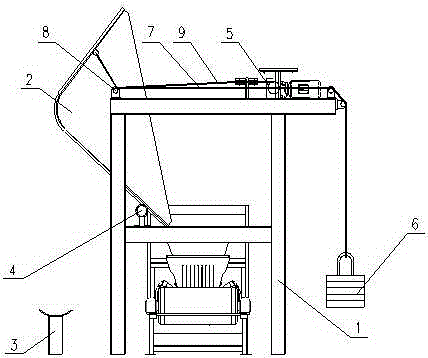

Sanitation robot used for garbage can carrying and unloading and control method thereof

PendingCN108341257ARealize intelligent handlingSolve cleanupConveyorsBottle emptyingJunk boxEngineering

The invention discloses a sanitation robot used for garbage can carrying and unloading and a control method thereof. The sanitation robot is constituted by a rotatable grabbing mechanism, a dumping mechanism and a chassis. The rotatable grabbing mechanism rotates in the horizontal direction under driving of a rotating mechanism and linearly slides in the vertical direction under driving of a lifting mechanism, and grabbing and moving in an opposite-pull mode are achieved. According to the dumping mechanism, under driving of a rotating frame driving mechanism, a rotating frame is driven by a rotary shaft to overturn in the front-back direction along a bevel supporting frame to achieve dumping of garbage cans. The control method comprises the steps of loading, transporting and placing of theempty garbage cans, and grabbing and unloading of the filled garbage cans. Integration of a carrying mechanism and the dumping mechanism is achieved, garbage can replacing and garbage dumping can beconveniently and rapidly completed in sequence, the problem that garbage is not cleared timely is solved, the environment is beautified, and labor force is also liberated.

Owner:JILIN UNIV

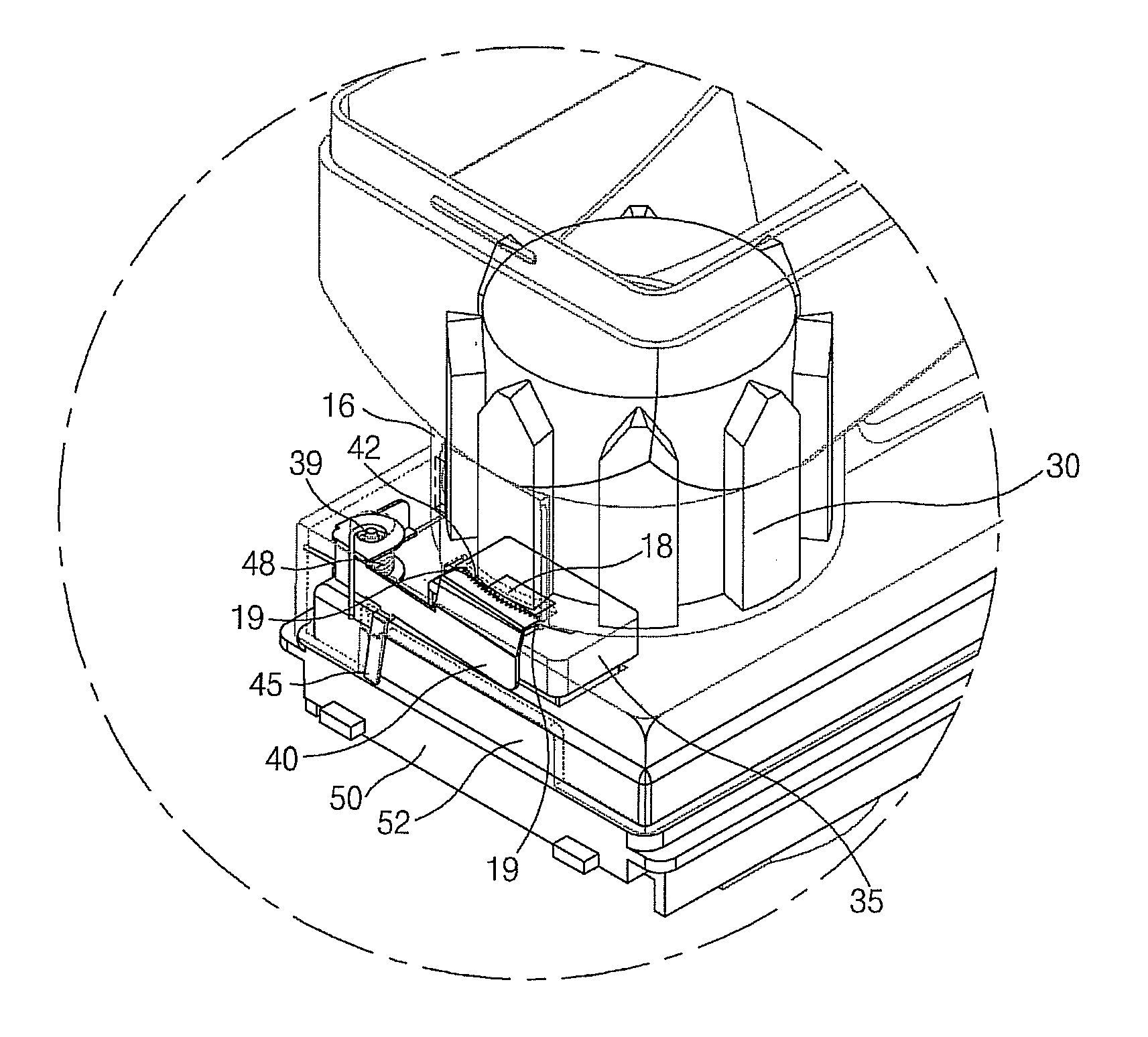

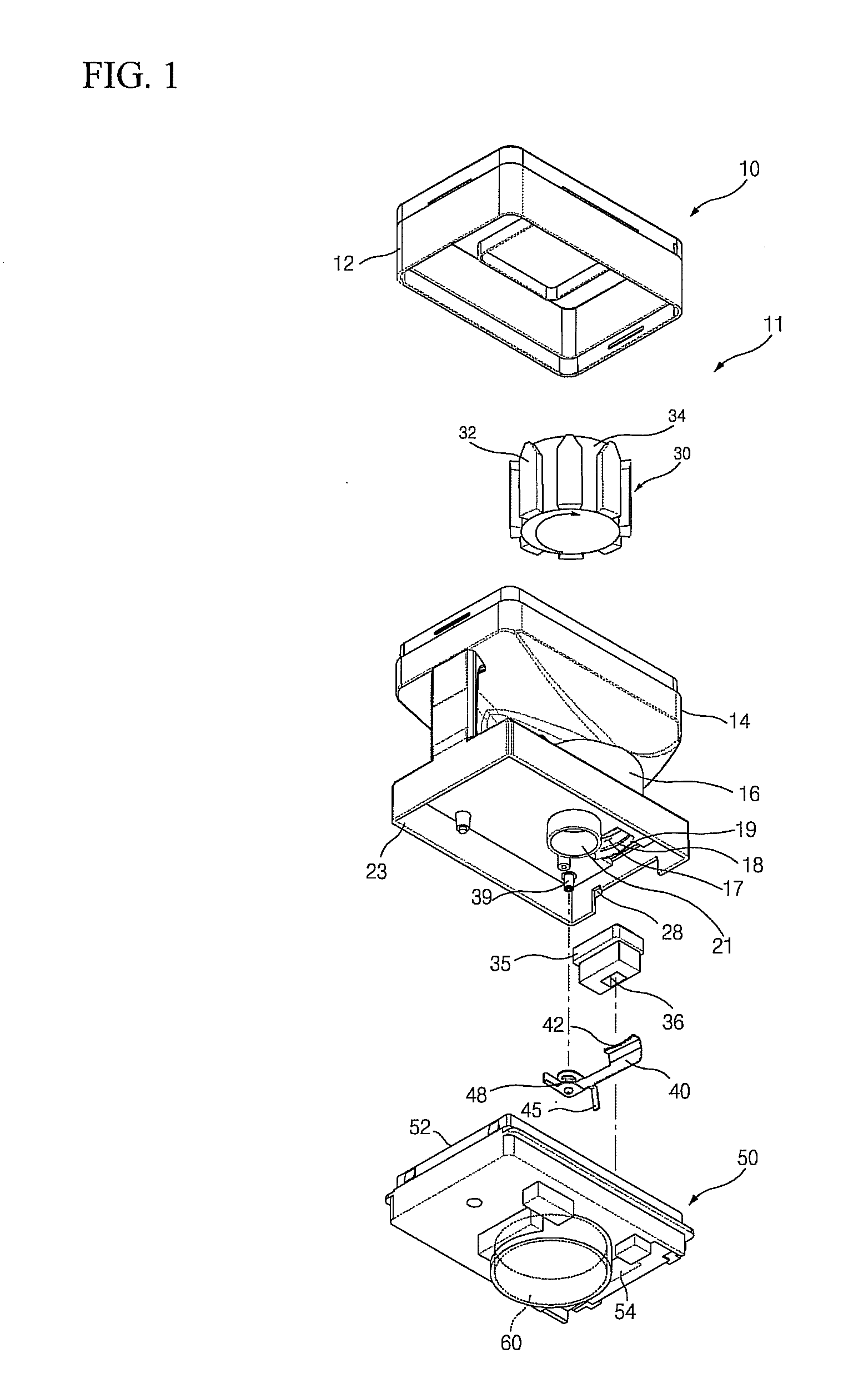

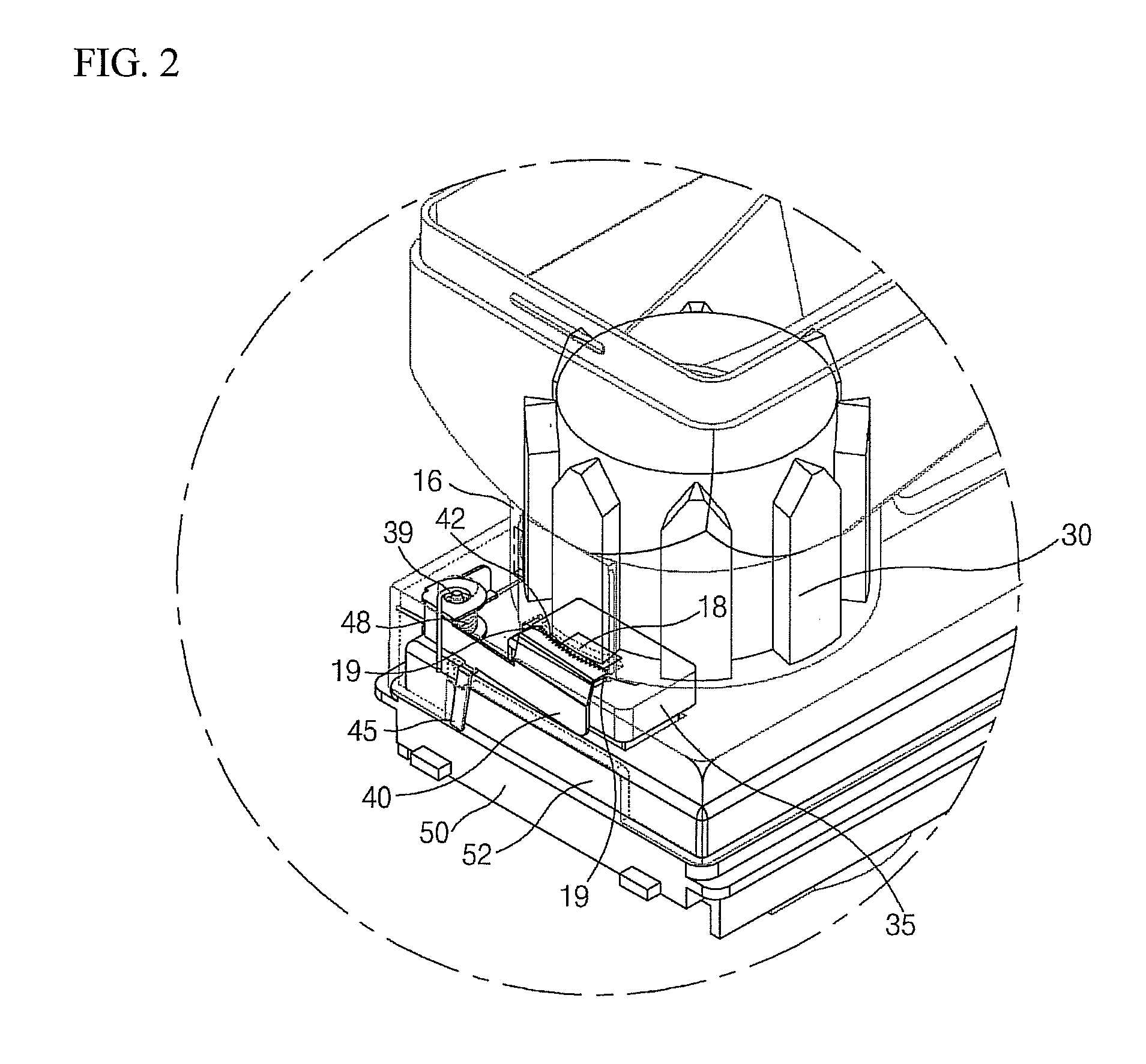

Tablet cassettes of tablet medicine packing apparatus

InactiveUS20130233894A1Avoid wastingMovable measuring chambersCoin-freed apparatus detailsMagnetic tapeEngineering

A tablet cassette of tablet medicine packing apparatus is disclosed. The tablet cassette includes a tablet outlet opened such that tablets contained inside thereof to be discharged, a drum opening and closing the tablet outlet selectively, a lever controlling movement of the drum when the cartridge is separated from the cartridge installation unit, wherein the lever includes a drum contacting unit to be pressed elastically in the direction of contacting with the drum, while the drum contacting unit is separated from the drum when the cartridge is mounted on the cartridge installation unit.

Owner:CRETEM +2

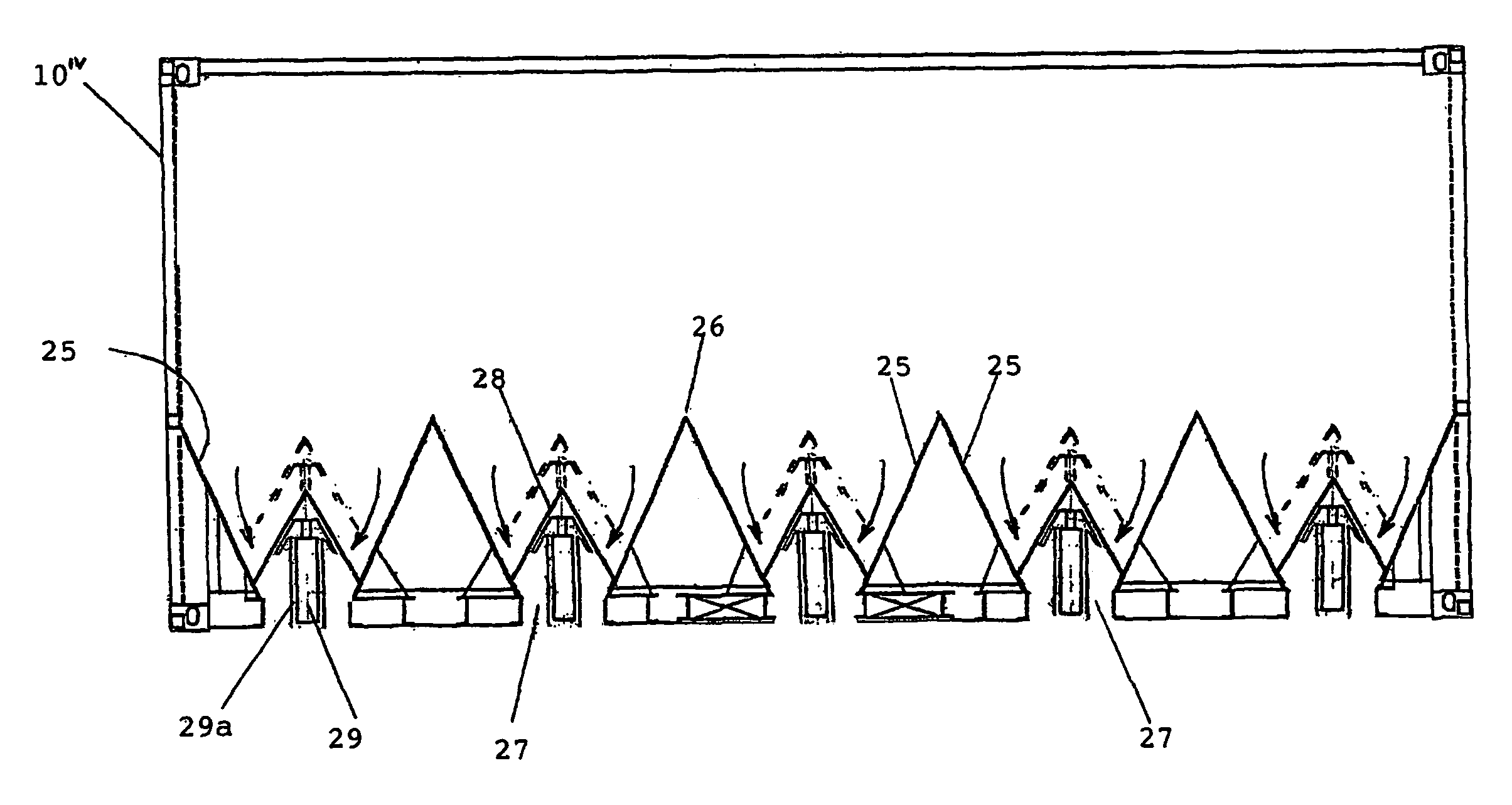

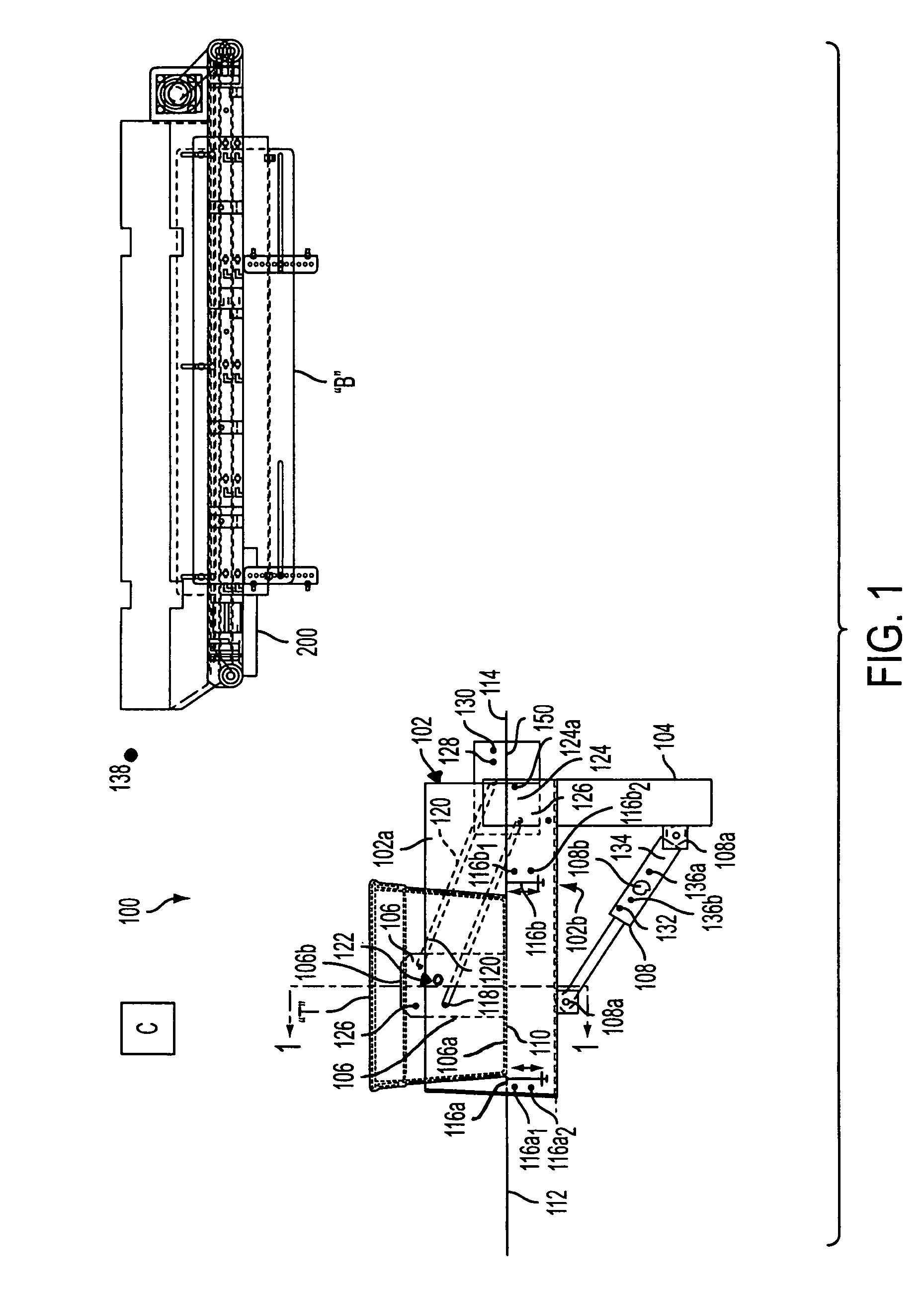

Cover System for Open Top Rail Cars

ActiveUS20120048140A1Reduce air resistanceImprove fuel economyRefuse transferringTiltable roofsCovering systemAir door

An improved rail car is pulled by an engine for transporting coal or other porous dust bearing materials. The car has opposing long sidewalls and opposing shorter end walls, which together define an initially open interior, a bottom and an open top. The open top of the car is covered by at least one pair of main doors in the form of opposing hinged A-frame sections which are pivotable between a closed, transport position and an open loading position which exposes the rail car interior for loading. The A-frame sections also have longitudinally spaced edges which are spaced apart to form a discharge door opening. A discharge door is located in each of the discharge door opening and is pivotally hinged within the respective door opening so that it opens under the influence of gravity in a rotary dumping operation. The discharge doors, together with the A-frame sections, form a door-within-a-door operating configuration.

Owner:COALCAP

Guiding device capable of directly receiving materials on ground in bulk cargo conveying process

InactiveCN105197619AIncrease reservesConvenient and accurate receiving and unloading methodBottle emptyingLoading/unloadingEngineeringYard

A guiding device capable of directly receiving materials on the ground in a bulk cargo conveying process comprises a bracket, a hopper, a hopper support, a hinge shaft, an electrical barrel, a balancing weight, a twisted rope, fixed pulleys and a balance weight rope, wherein the bracket crosses over the receiving section of a ground adhesive tape machine in a storage yard and is used for fixing the rotating hinge shaft of the hopper and the electrical barrel, a lifting pull ring of the hopper and the balancing weight are pulled through the twisted rope winding around the fixed pulleys and the balance weight rope, the hopper is arranged on one side of the ground adhesive tape machine, the pull ring is arranged at the lifting end of the hopper, the electrical barrel is fixed on the bracket and connected with the hopper through the twisted rope, the fixed pulleys are fixed on the bracket and are guide pulleys for connection ropes between the hopper and the balancing weight and between the hopper and the electric barrel, and the balance weight rope is connected between the hopper and the balancing weight and winds around one fixed pulley. The technological procedure is simplified, the equipment cost is reduced, the equipment failure rate is reduced, the working efficiency is improved, and the guiding device is applied to multiple industrial fields such as mines, metallurgy, coal, ports, electric power, building materials and the like.

Owner:NORTHERN HEAVY IND GRP CO LTD

Manual mechanical oil-pouring device

InactiveCN102718077AImprove work efficiencyReduce labor intensityBottle emptyingSteering wheelEngineering

The invention relates to a manual mechanical oil-pouring device which comprises a portal frame, a pedestal, front wheels, steering wheels and armrests, wherein the bottom end of the portal frame is connected with the pedestal; the front wheels and the steering wheels are respectively installed at the bottom of the front end and the rear end of the pedestal; and the armrests are installed at the upper part of the portal frame. The manual mechanical oil-pouring device is characterized in that a lifting frame corresponding to the pedestal is installed on the portal frame and is driven by a lifting mechanism to move up and down on the portal frame; the manual mechanical oil-pouring device further comprises a semicircle hoop; one end of the semicircle hoop is rotationally installed on the lifting frame; the other end of the semicircle hoop is connected with a turnover mechanism; and a clamping mechanism is installed on the semicircle hoop. The manual mechanical oil-pouring device has the advantages that through the organic coordination of the clamping mechanism, the lifting mechanism and the turnover mechanism, oil in an oil drum is directly poured out after the oil drum is leaned, so as to replace an oil-pumping mode in the prior art. Therefore, the manual mechanical oil-pouring device improves work efficiency and reduces labor intensity.

Owner:王晓彬

Dumping device for concrete blocks, bricks, paving stones or the like

There is described a dumping device for use in a system for tumbling products, such as concrete blocks, bricks, paving stones or the like loaded in successive layers on a pallet. The dumping device comprise a pallet receiving structure pivotally mounted on a fixed frame, the structure including a tilting and a movable floor that receives the pallet with the layers of products thereon. The structure is first tilted to a predetermined angle corresponding to a product unloading position; thereafter, the floor is pushed intermittently so that the layers are unloaded in succession layer by layer onto a product conveying station and, thereafter, to a tumbler. Sensors are provided to indicate the presence or absence of the products at the conveying station and to give a signal to intermittently actuate the floor.

Owner:VEZINA SYLVAIN

Filling adapter

A filling adapter for conveying liquid from a first liquid container to a second liquid container is provided. The filling adapter includes an adapter body having a top end and an opposite button end, the top end adapted for fitting an opening in the first liquid container, the bottom end adapted for fitting an opening in the second liquid container, and an open path in the adapter body from the top end to the bottom end for communicating liquid from the opening in the first liquid container to the opening in the second liquid container.

Owner:MBHD ENTERPRISES

Containerised handling of bulk materials and appts therefor

A freight container (10) has a base (20) or a portion thereof that can be opened to discharge its contents. This container (10) has a top which can be opened in similar manner as the base. Another container having at least one compartment, each compartment having a lower section with a reducing cross-sectional area and a pivotably operable closure assembly, with several such closure assemblies being linked together by means of bars. Such a container is used to contain raw building materials for stockpiling of these materials at a container port. It is also used to supply materials to a concrete production plant whee pollution control containers are provided below the supply container and above the scaling and mixing stations to reduce particulate pollution. A pair of slewing apparatuses is also provided to engage both ends of a container and turn the container over about its longitudinal axis, thereby emptying its contents.

Owner:王美金

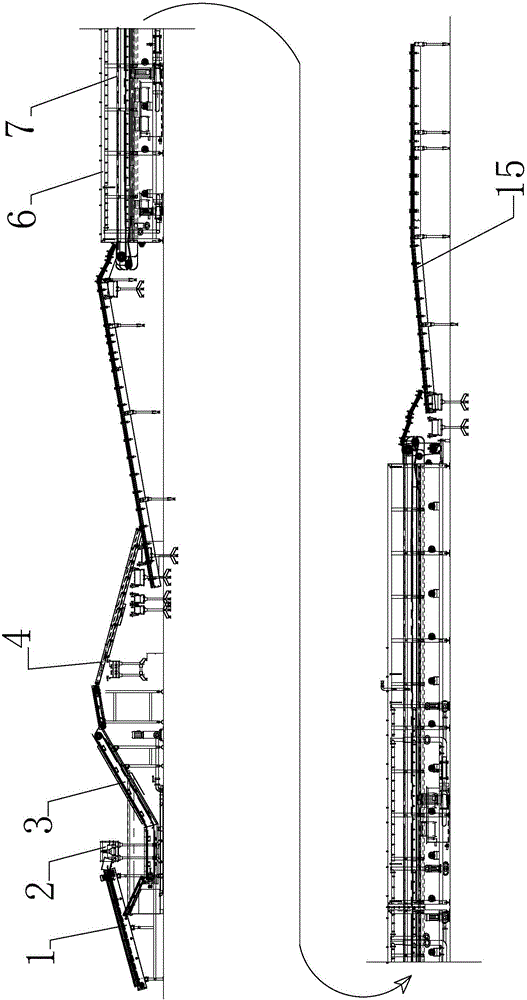

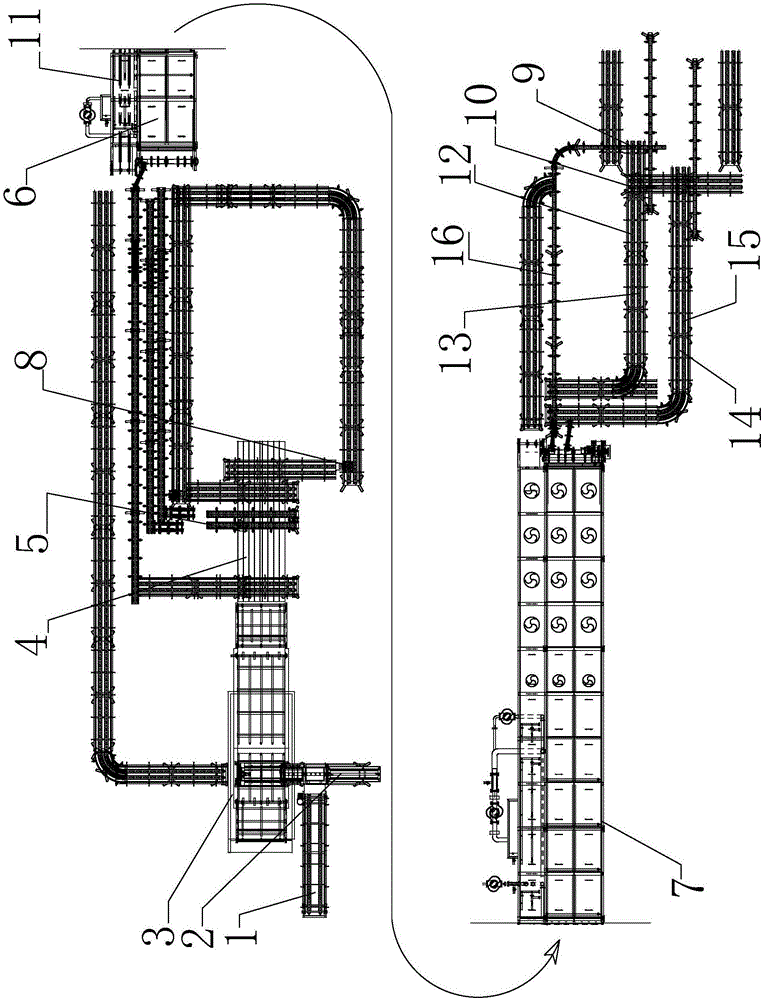

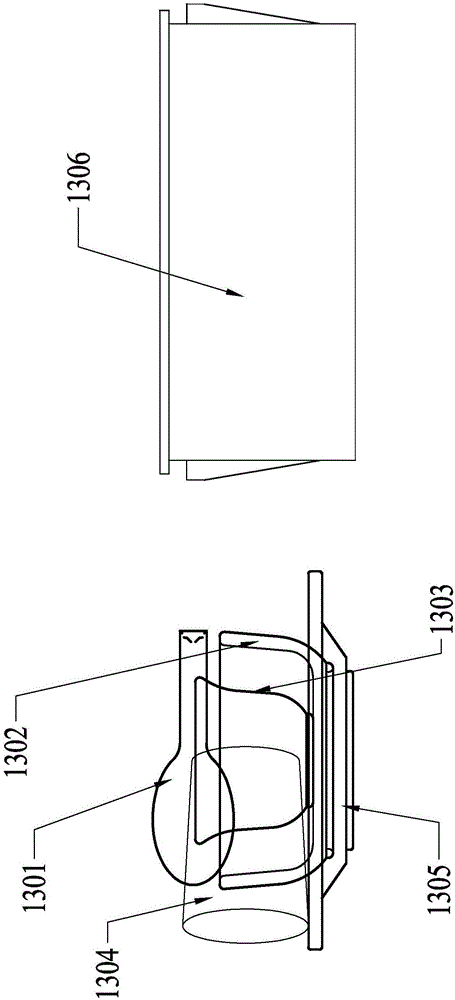

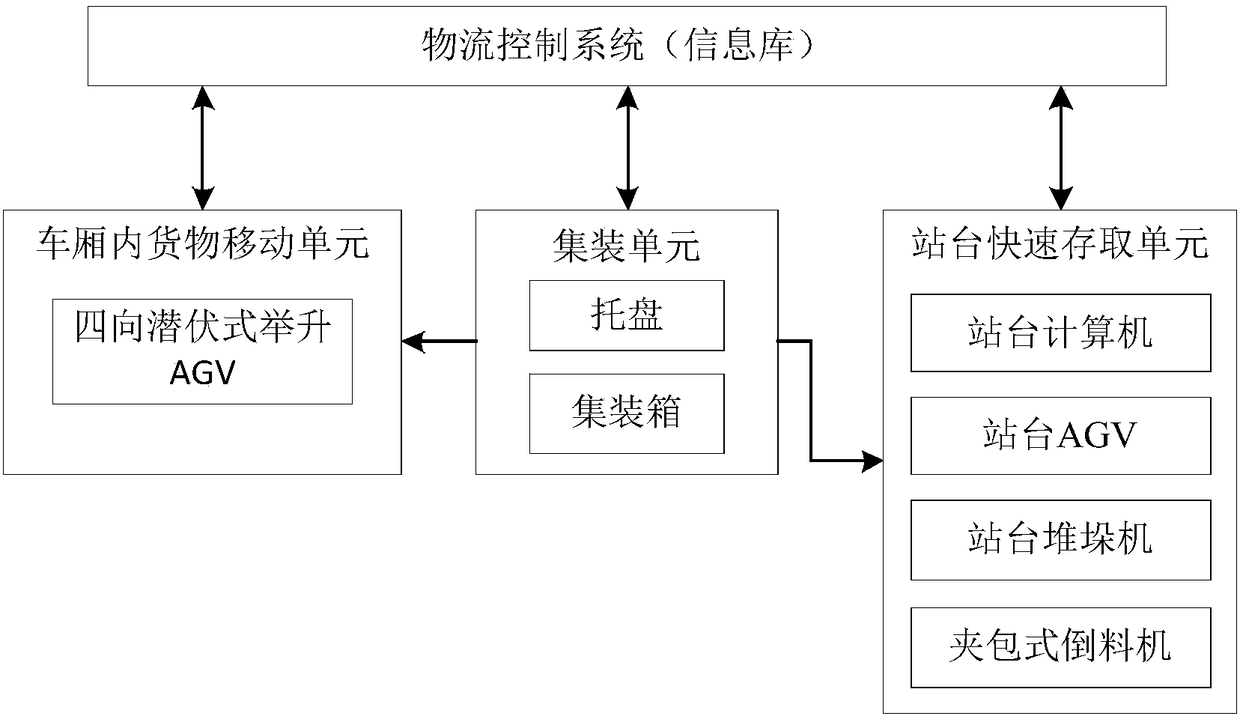

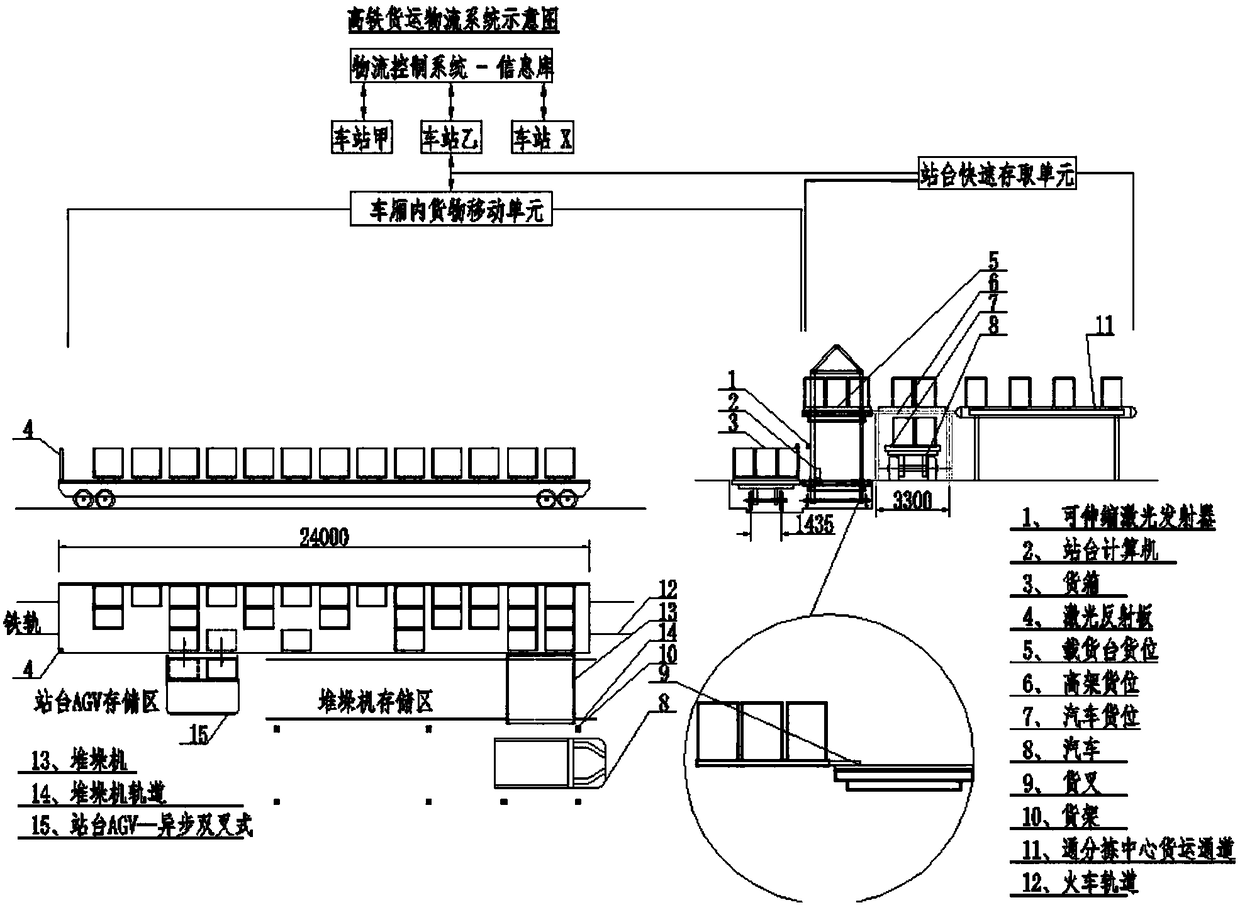

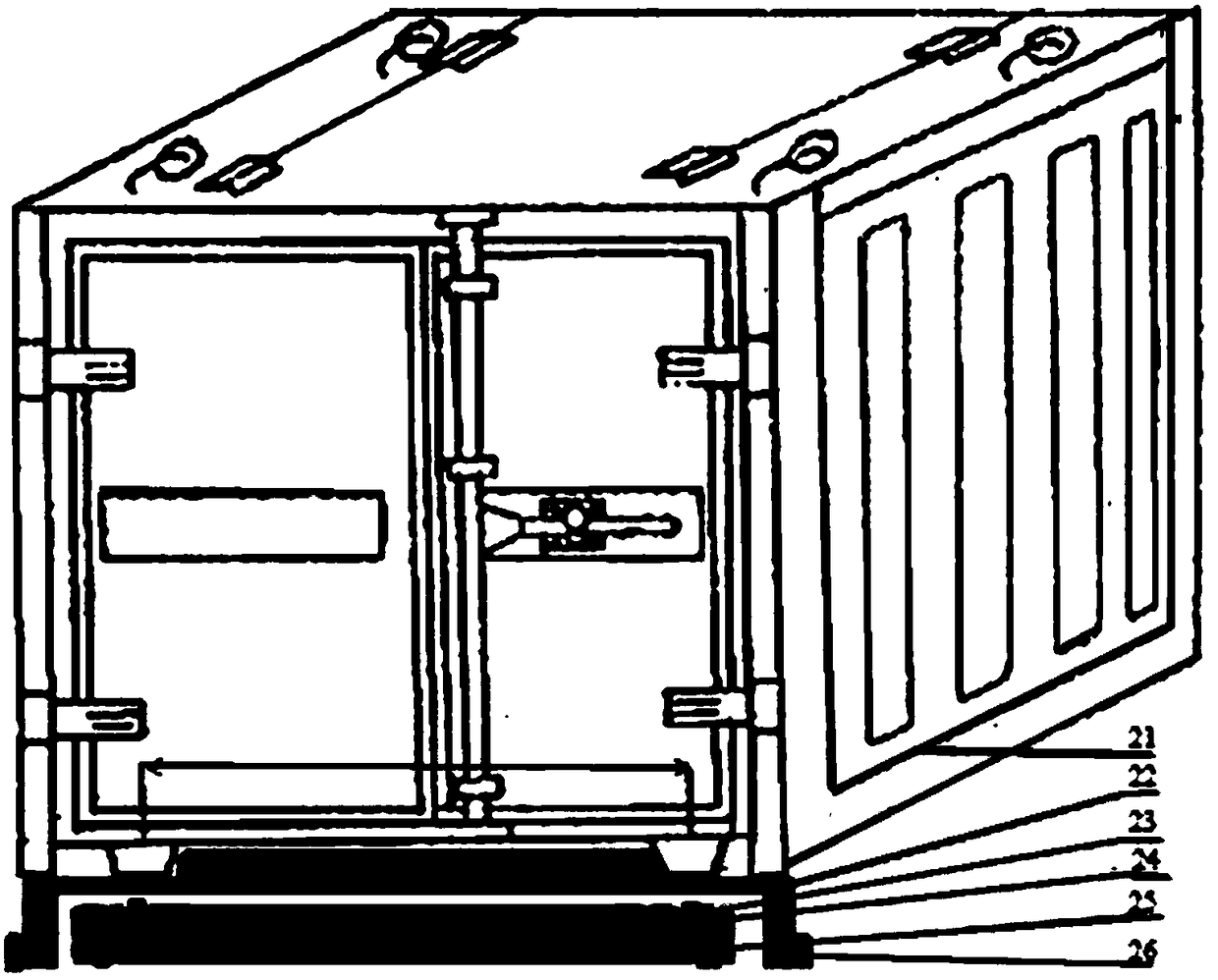

High-speed train express mail logistics system

ActiveCN108090710APrecise positioningRealize flexible rotary unloadingLogisticsBottle emptyingAviationLogistics management

The invention discloses a high-speed train express mail logistics system, and belongs to the railway transport field; the high-speed train express mail logistics system comprises a logistics control system, a cargo moving unit in a compartment, a packaging unit and a platform fast access unit; the logistics control system processes related information of the to-be-moved packaging unit, and sends the information to the cargo moving unit in the compartment and the platform fast access unit; the cargo moving unit in the compartment receives the related information from the logistics control system, and moves the packaging unit to an easy-to-load / unload position; the platform fast access unit roughly positions a target compartment, accurately locates the packaging unit, and carries loading / unloading motions after location. The high-speed train express mail logistics system can fast load / unload, can realize high-speed train passenger and freight shared utilization, and allows the high-speedtrain to replace partial aviation and road transports with a high automation level, thus saving space and loading and unloading time, improving the logistics efficiency and benefits, and facilitatingenvironmental protection.

Owner:北京达特集成技术有限责任公司

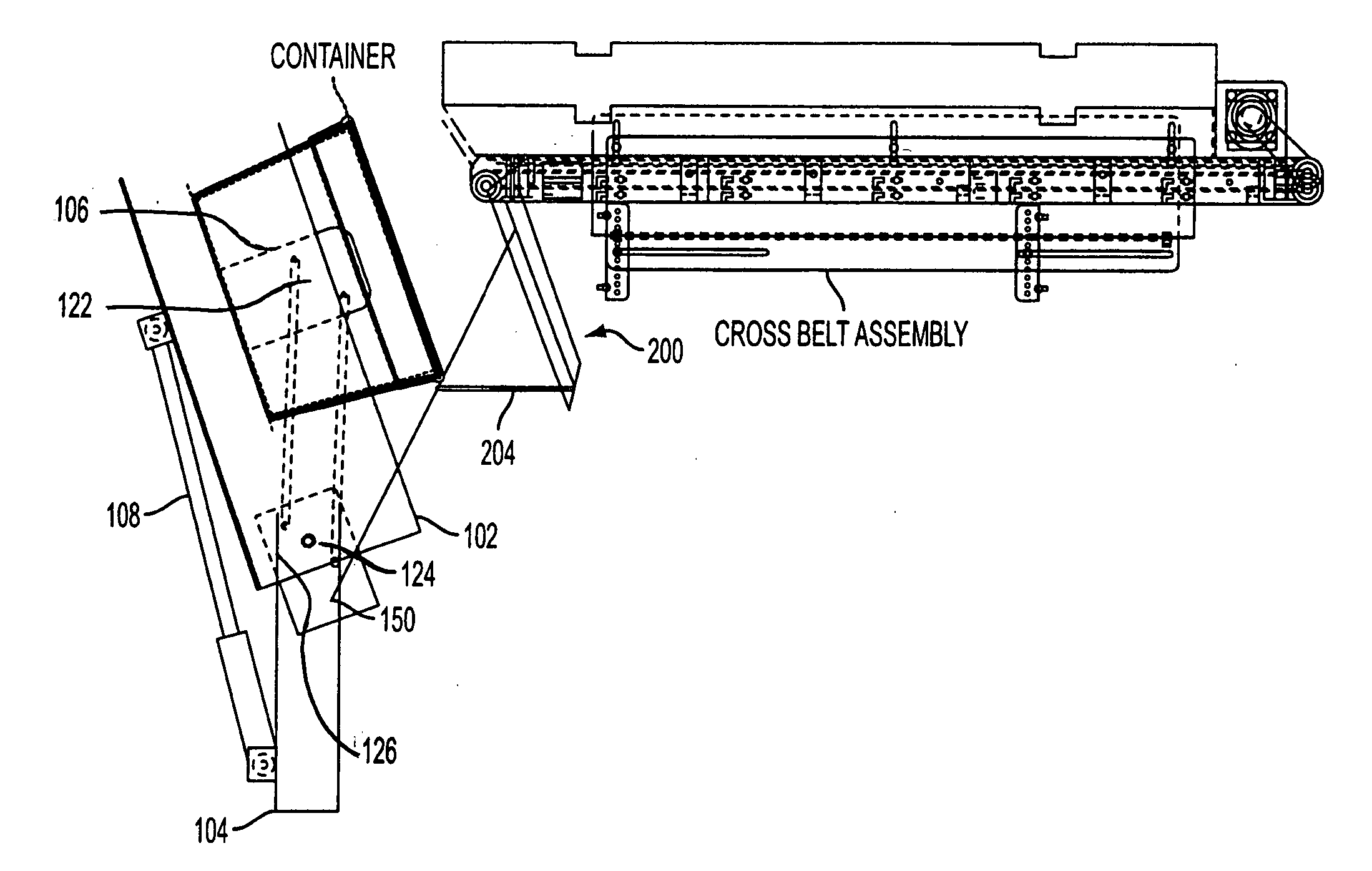

Dual mode stacking system and method of use

An apparatus and method for orienting a container. The apparatus includes a frame moveable between a lowered position and a raised, substantially vertical position. A container cradle is pivotably connected to the frame and selectively positionable to a substantially vertical stacking position or a substantially horizontal stacking position when the frame is in the raised, substantially vertical position. The method includes, amongst other features, orienting the container into a horizontal stacking position or maintaining the container in a same orientation as the frame when in the raised vertical position. In the latter orientation, product or other objects can be stacked in a vertical orientation.

Owner:LOCKHEED MARTIN CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com