Full-automation powder quantitatively feeding device

A quantitative feeding device, fully automatic technology, applied in packaging, loading/unloading, transportation and packaging, etc., can solve the problems of unsealed feeding device, complex structure, high-efficiency feeding powder, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

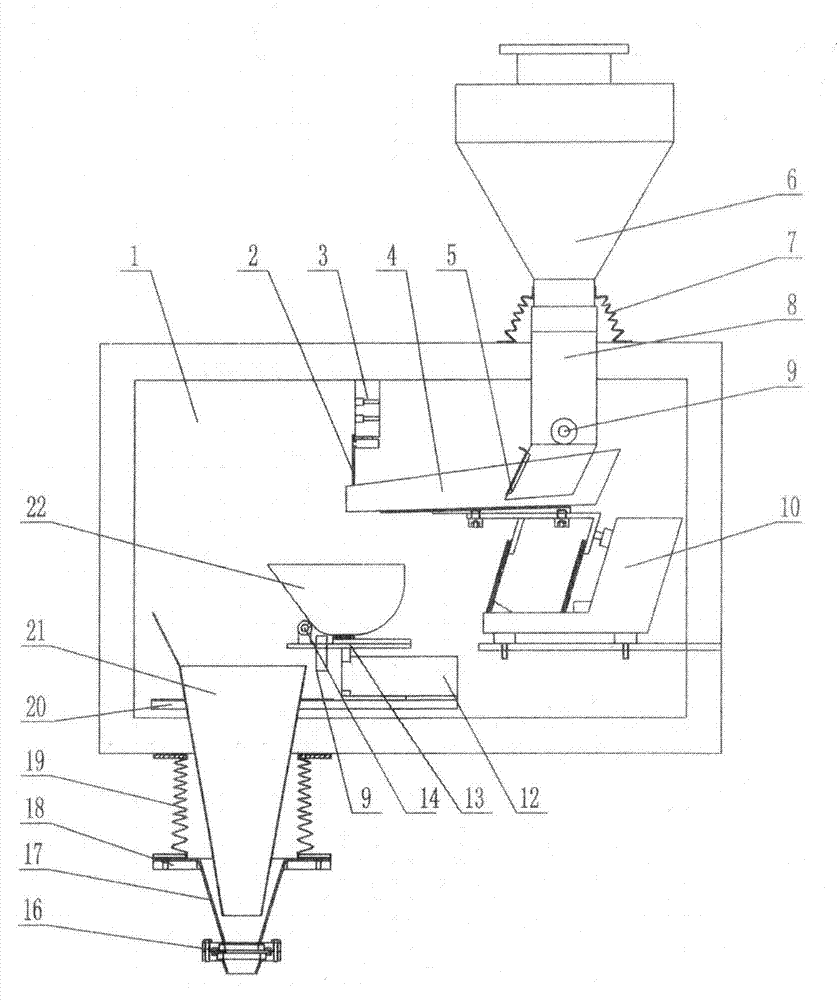

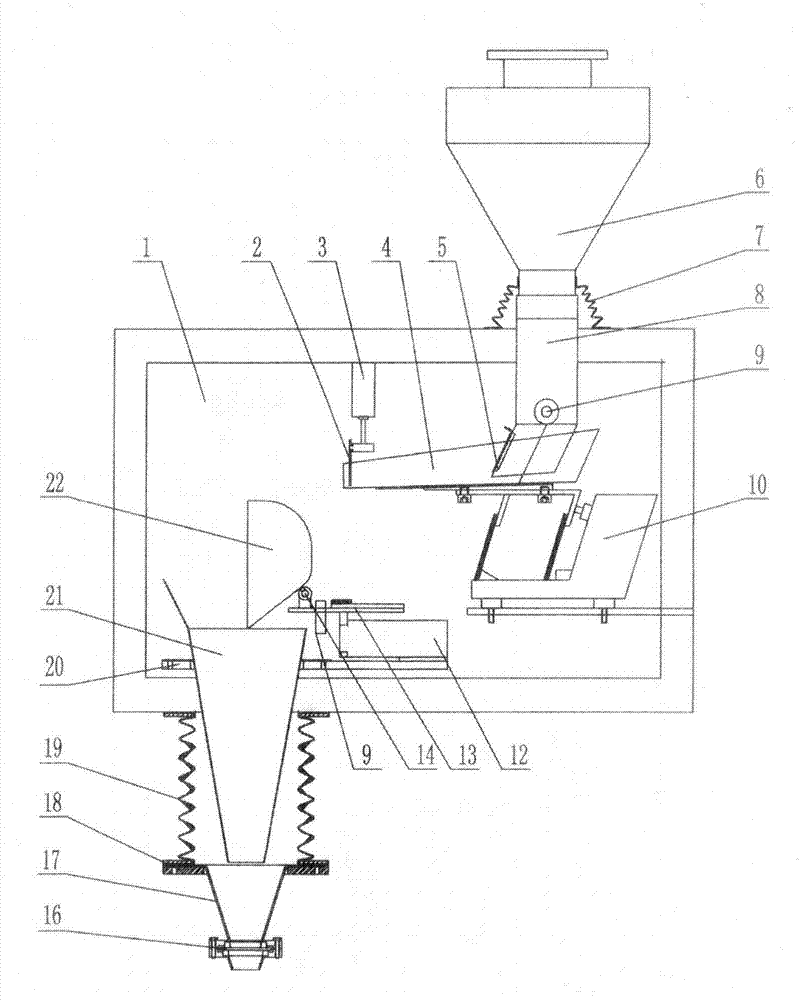

Embodiment 1

[0023] A fully automatic powder quantitative feeding device, suitable for powder materials that do not need to be sealed, including a box body 1, a vibrating feeding device, a weighing device and a feeding device. The vibrating feeding device includes a material barrel 6, a feeding tube 8. Material trough 4, baffle plate 2 and vibrating feeder 10; material barrel 6 is arranged above the box body 1, one end of the feed pipe 8 is connected to the lower outlet end of the material barrel 6, and the other end passes through the opening above the box body 1. The hole enters the inside of the box body 1, a material layer regulator 5 is installed at the port of the feeding pipe 8, and a sensor 9 for detecting whether there is powder in the pipe is installed on the wall of the feeding pipe 8; Installed on the vibrating feeder 10, one end of the outlet of the trough 4 is slightly inclined downward. There is a baffle 2 inside the outlet of the trough 4, the baffle 2 is fixed on the guide...

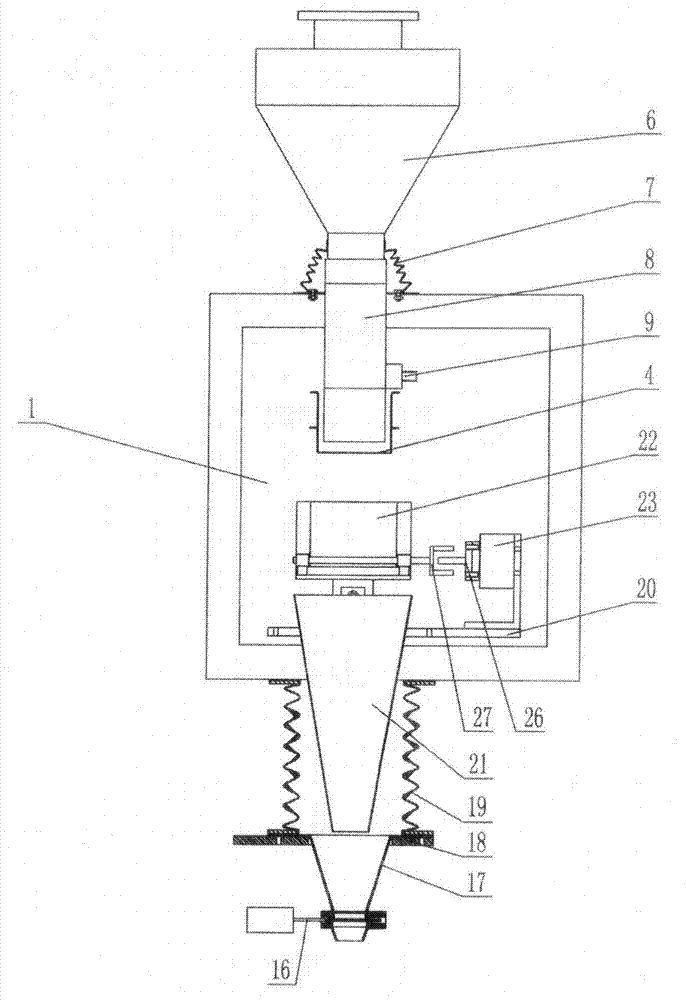

Embodiment 2

[0027] The quantitative feeding device used in the automatic magnetic powder powder forming press includes a box body 1, a vibrating feeding device, a weighing device and a feeding device, the box body 1 is a sealed box body, and the vibrating feeding device includes a barrel 6 , feed pipe 8, trough 4, baffle plate 2 and vibrating feeder 10; material bucket 6 is arranged on the top of the box body 1, and the connection between the material bucket 6 and the box body 1 is sealed by an elastic bellows 7, and the two The sealing box 1 is a cuboid made of profiles, the upper and lower sides are sealed with steel plates, and the surroundings are sealed with transparent materials to observe the powder weighing situation; one end of the feeding pipe 8 is connected to the lower outlet end of the material barrel 6, and the other end is passed through The opening above the box body 1 enters the inside of the box body 1, a material layer regulator 5 is installed at the port of the feeding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com