Patents

Literature

425results about "Evaporators with vertical tubes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

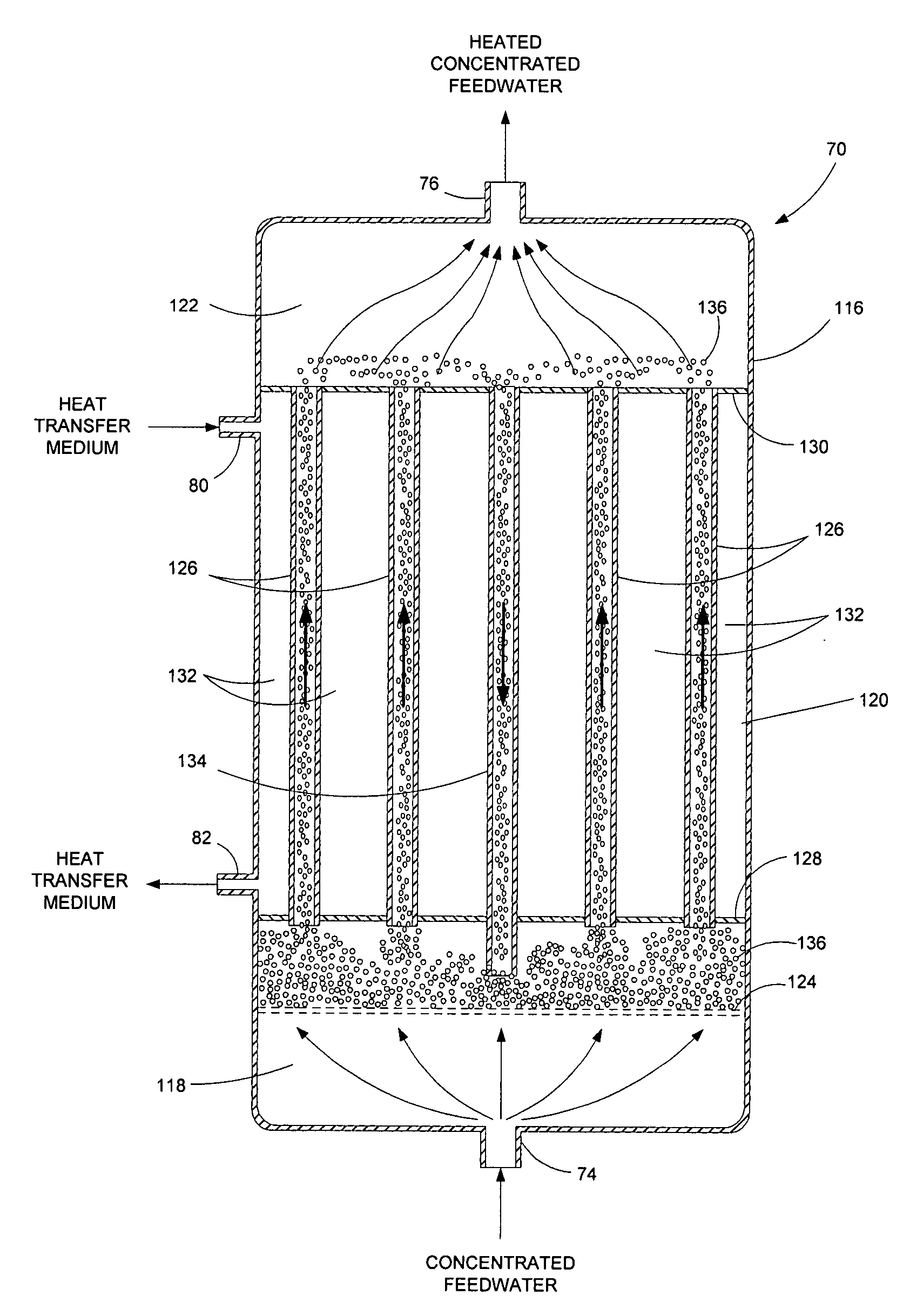

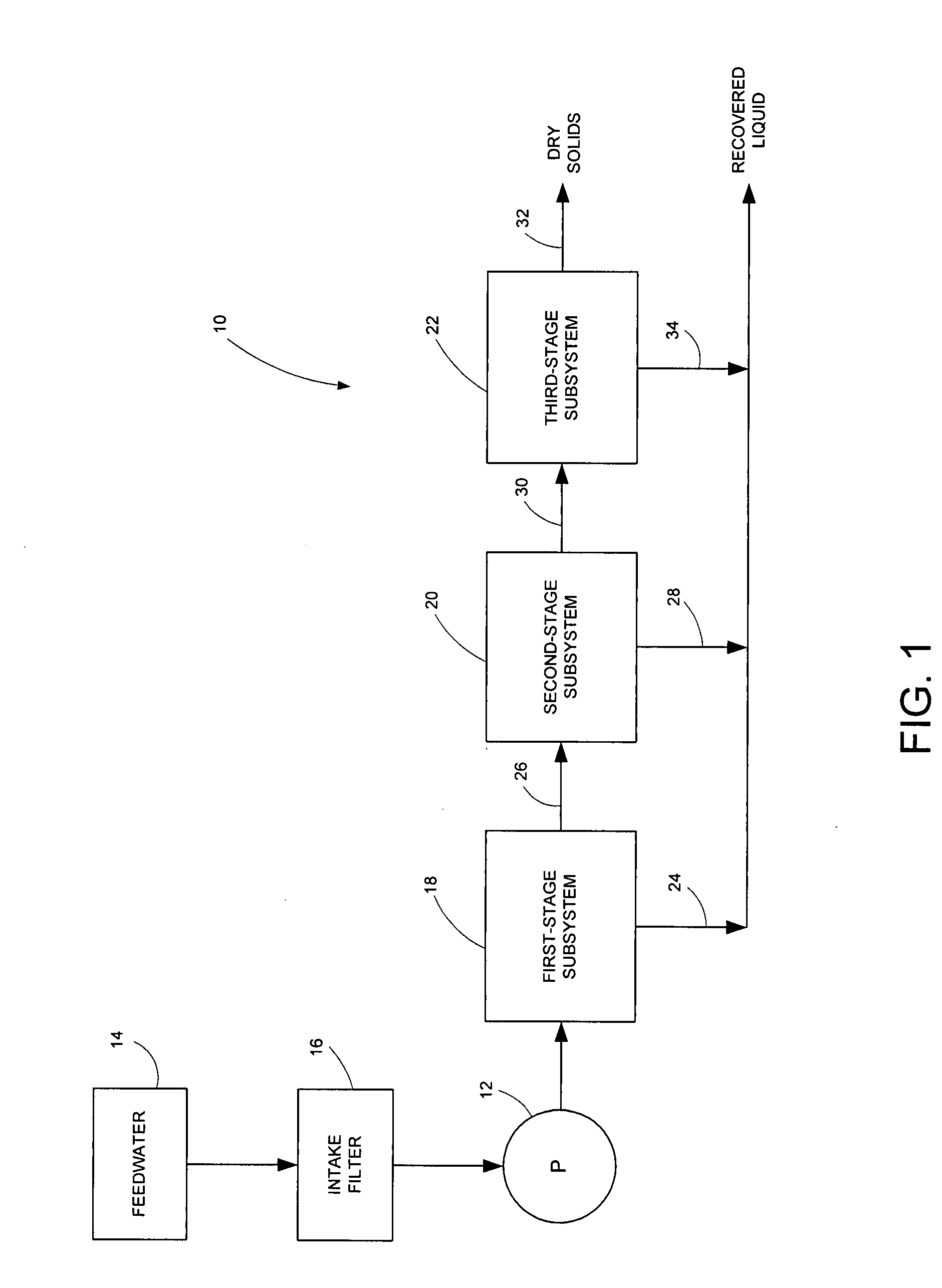

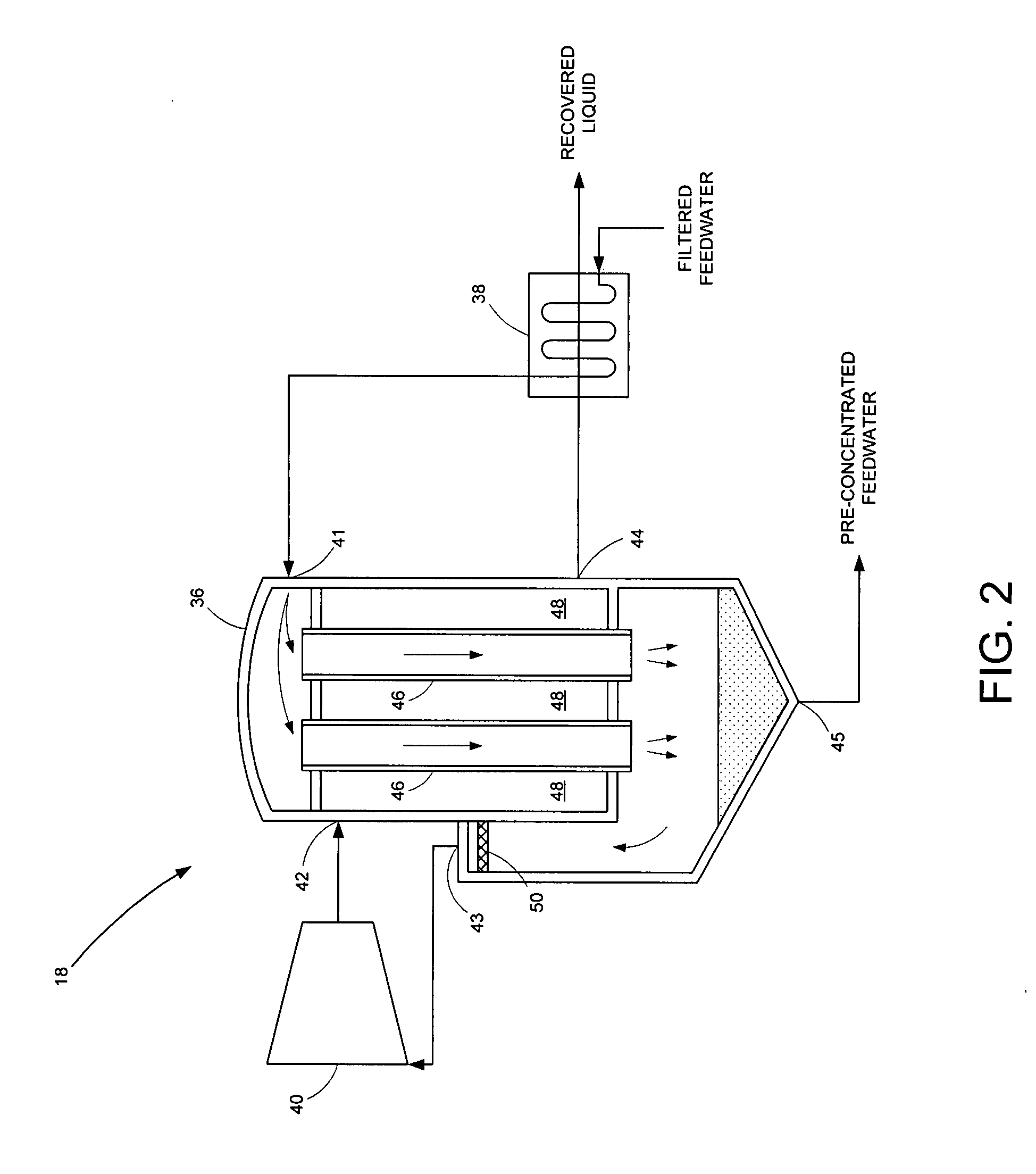

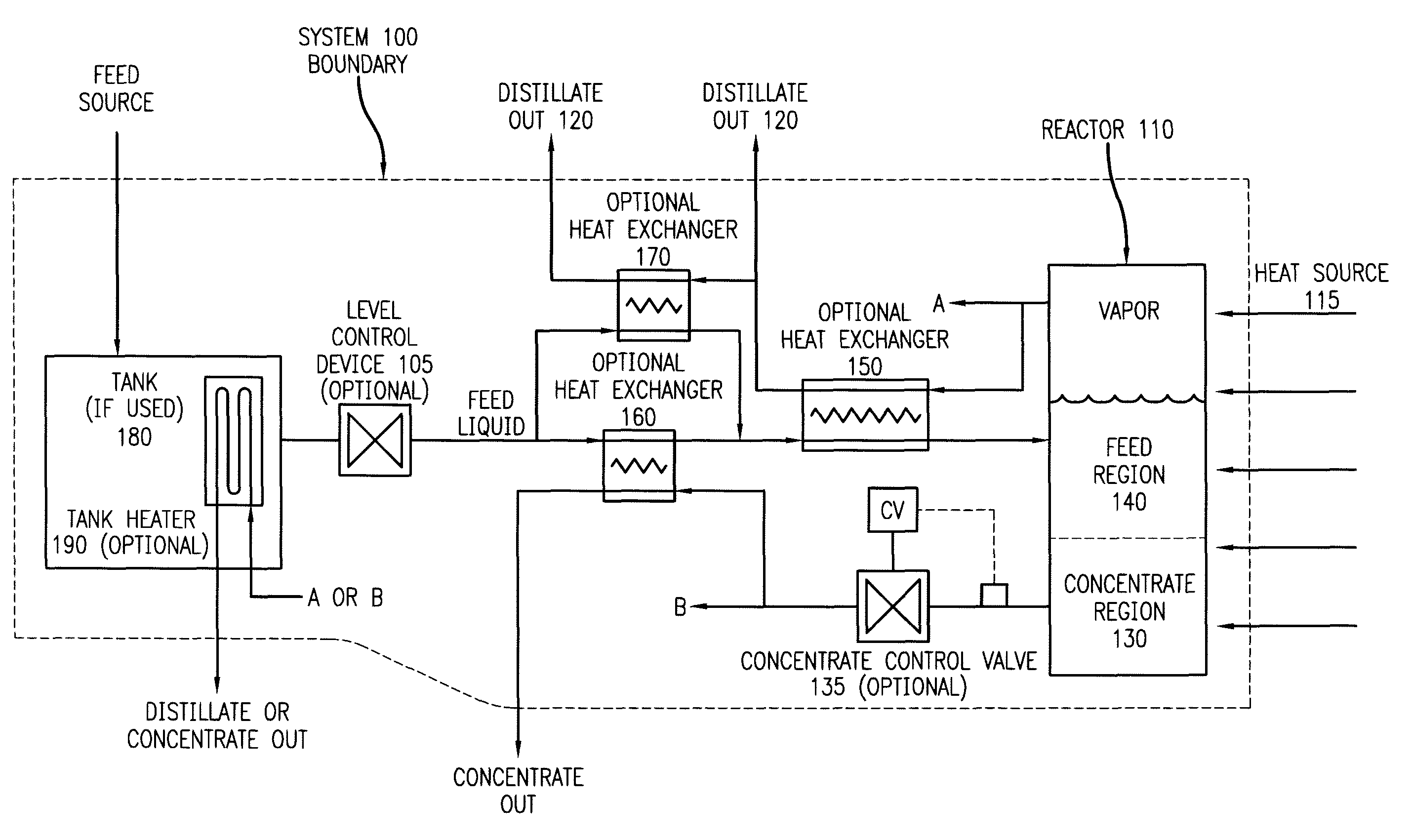

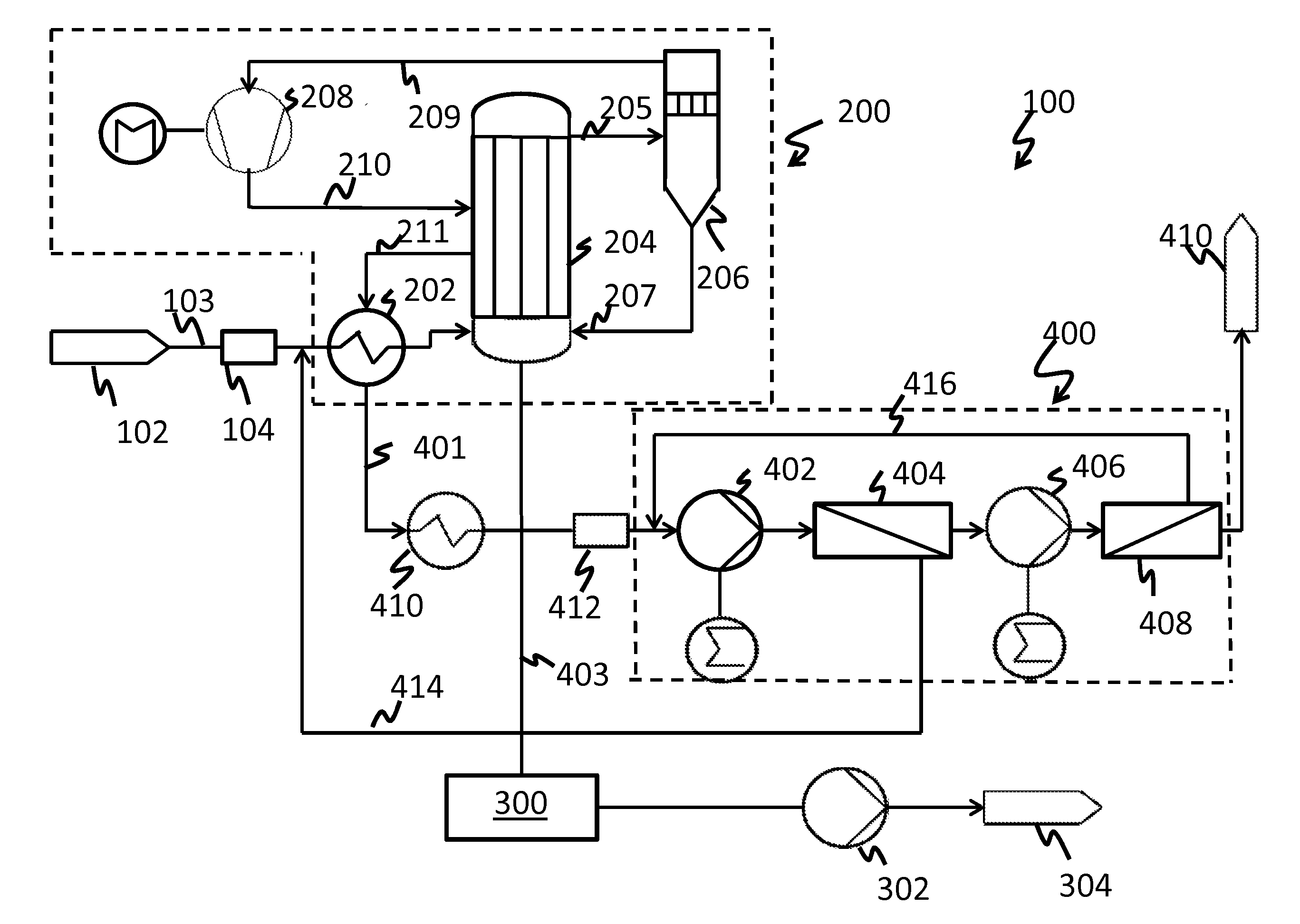

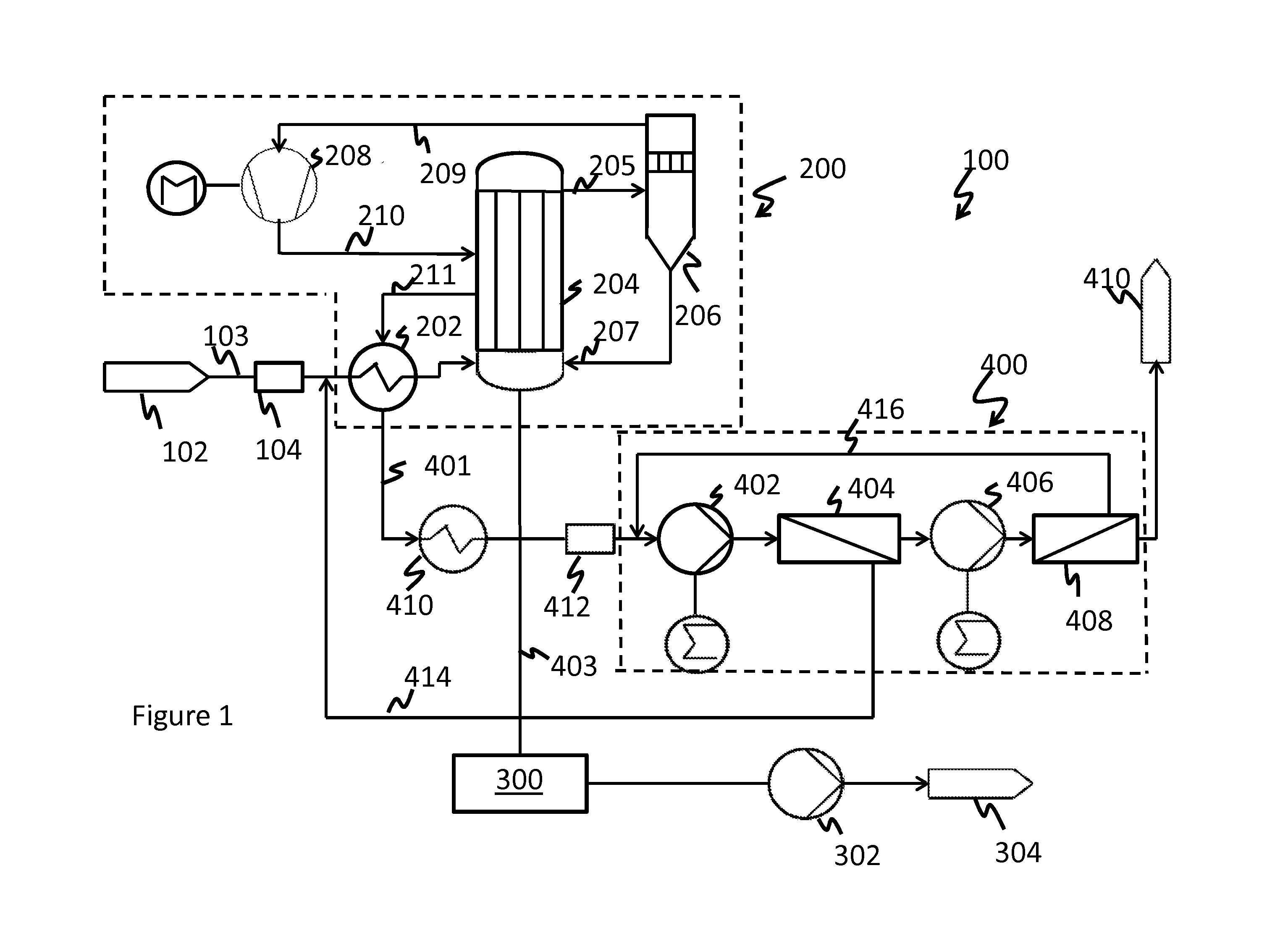

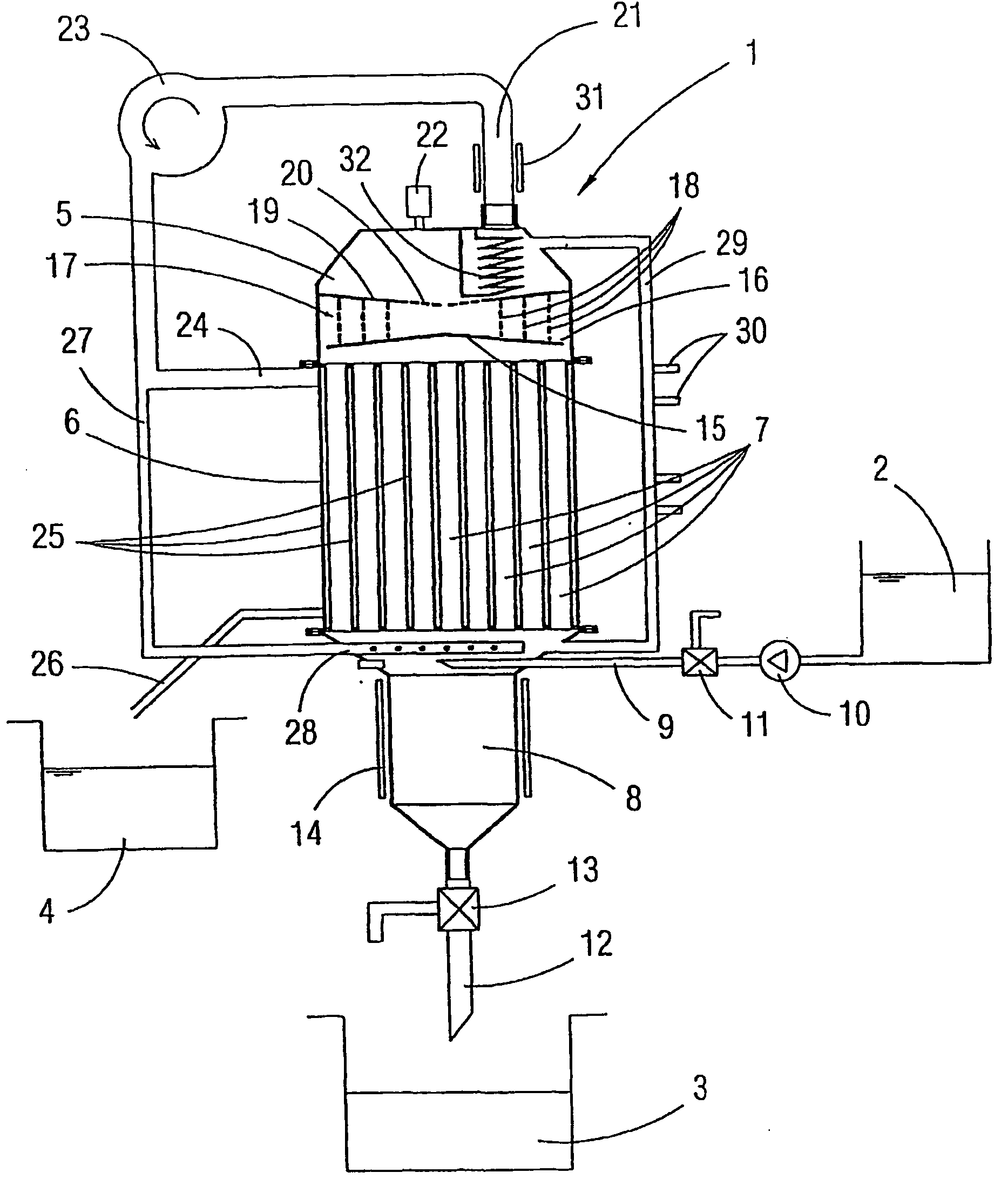

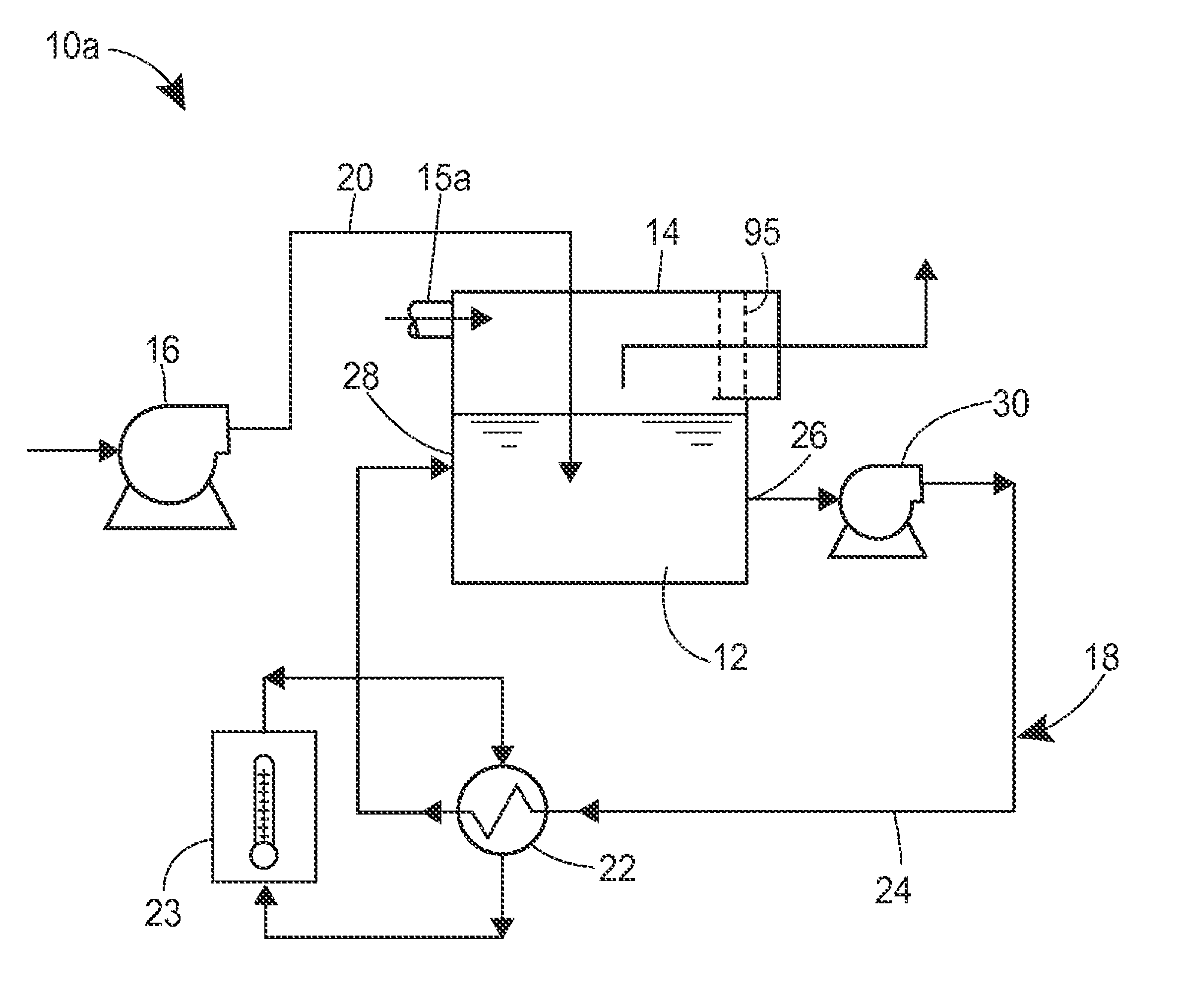

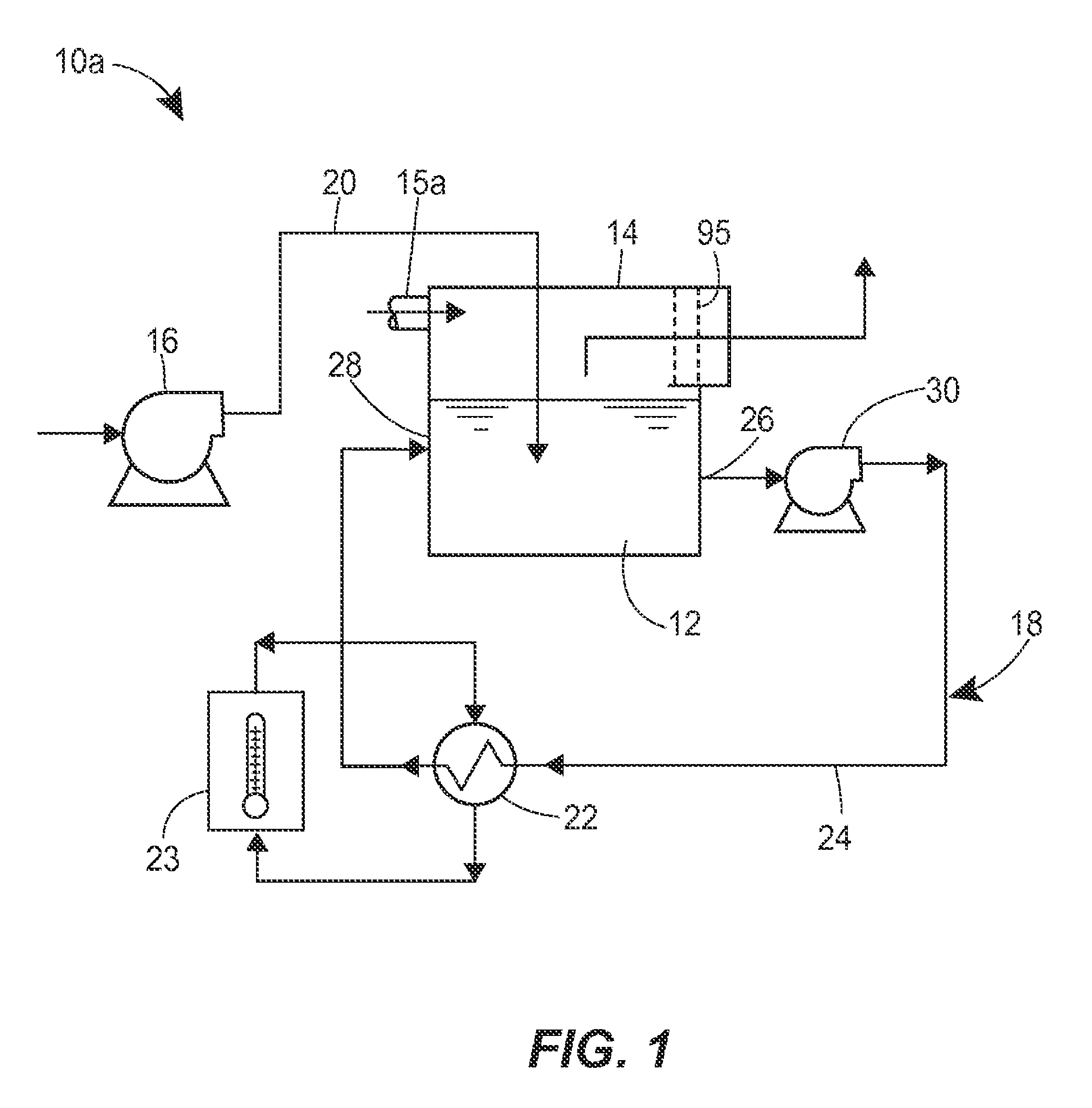

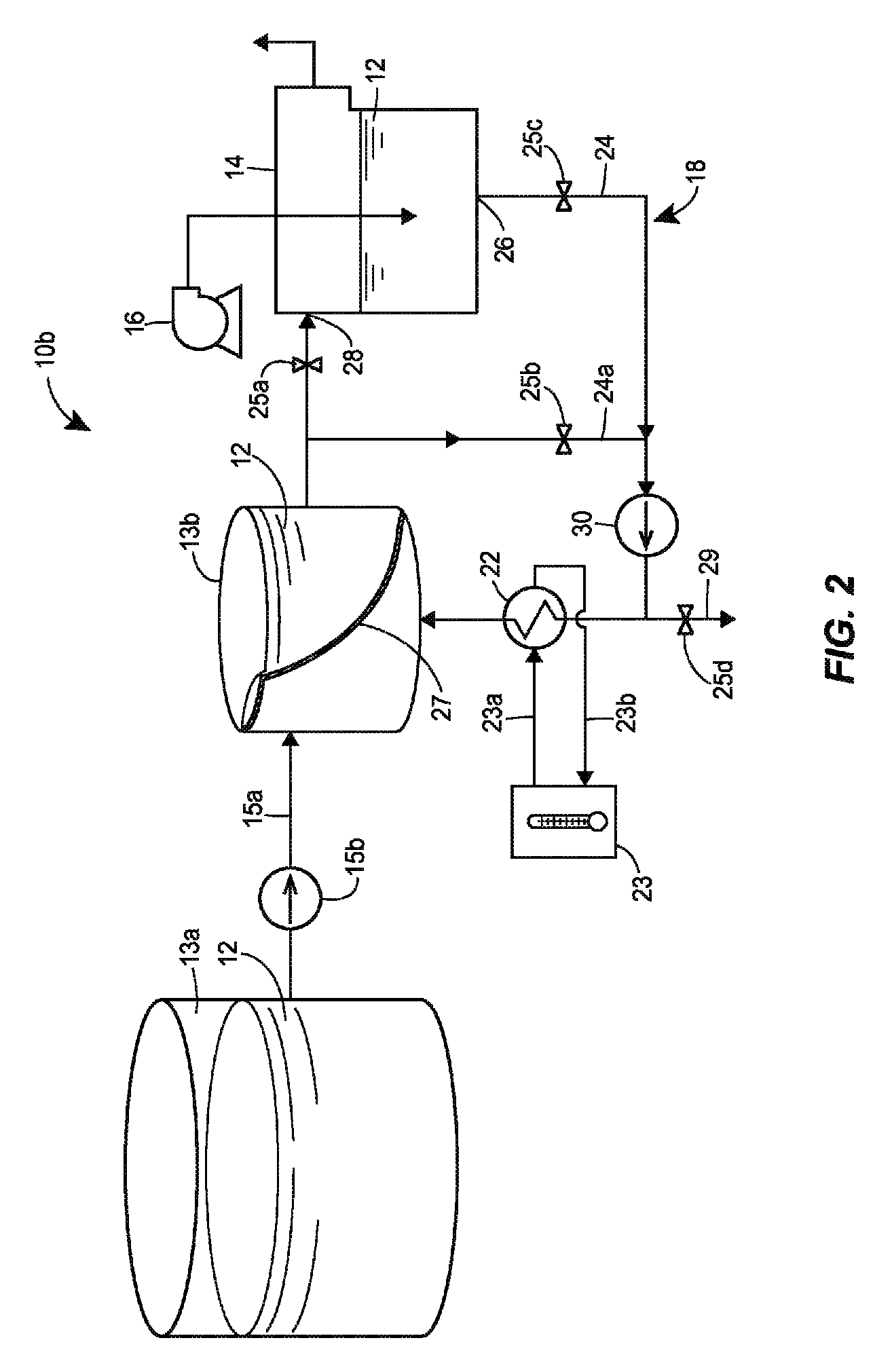

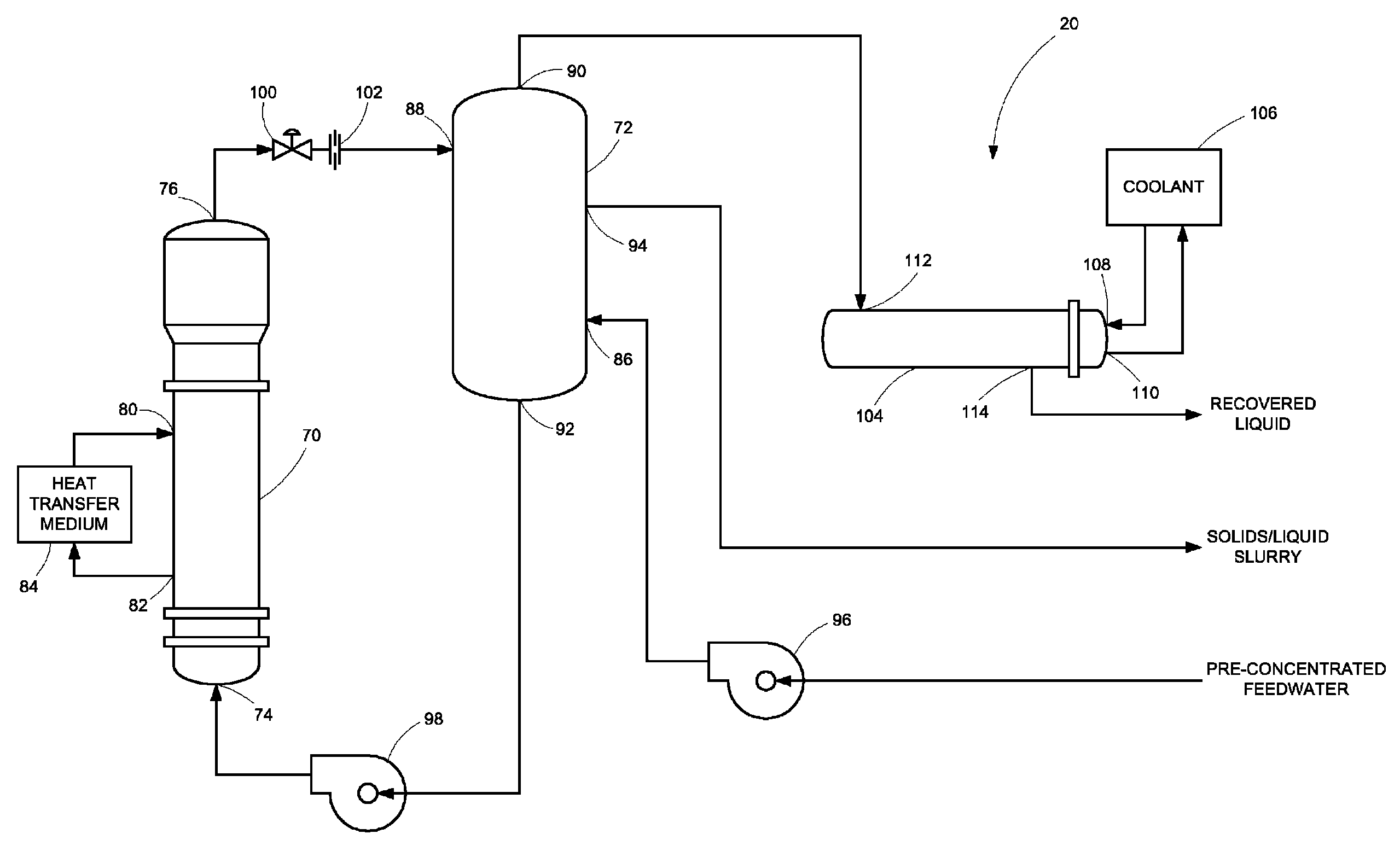

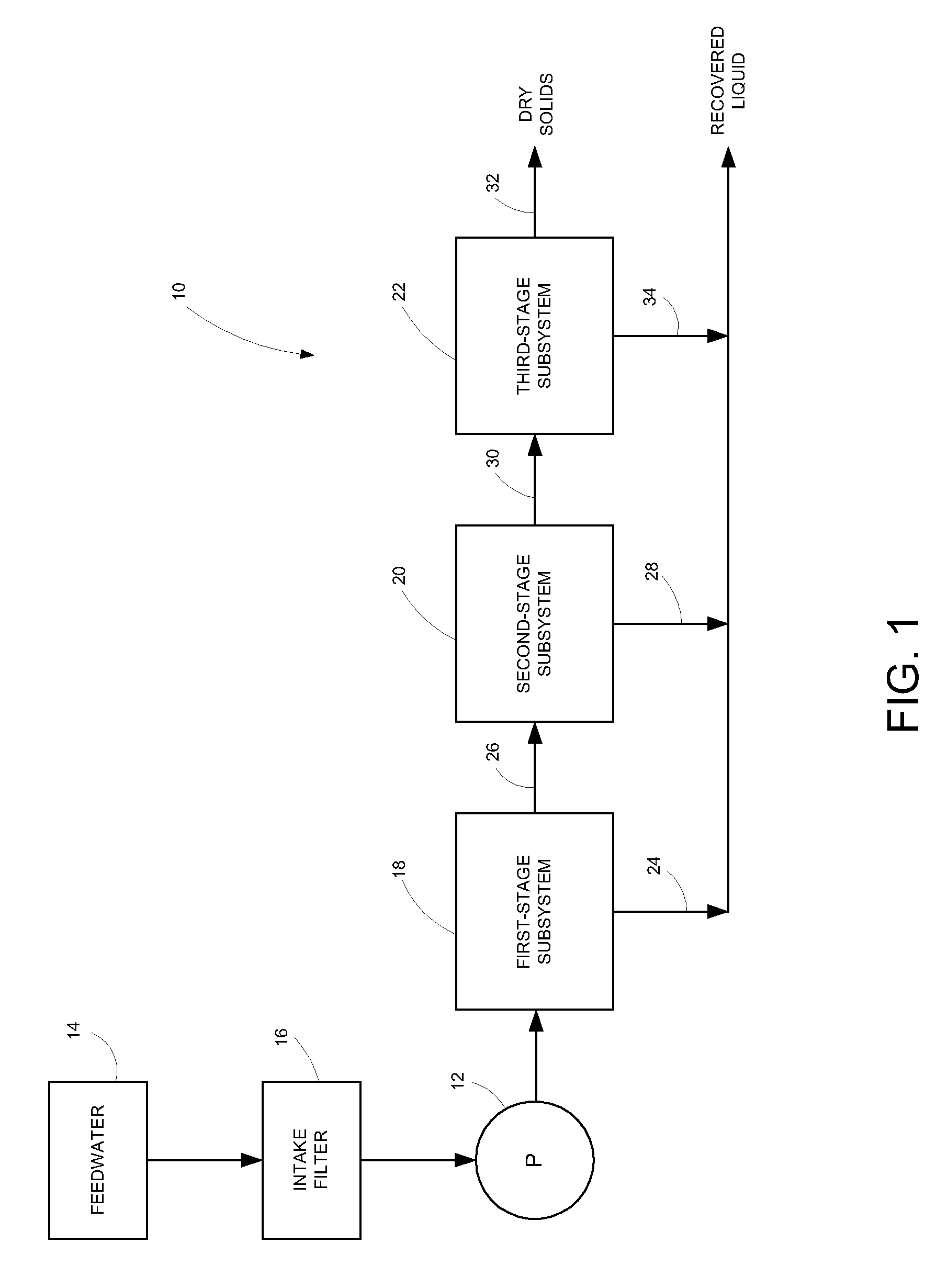

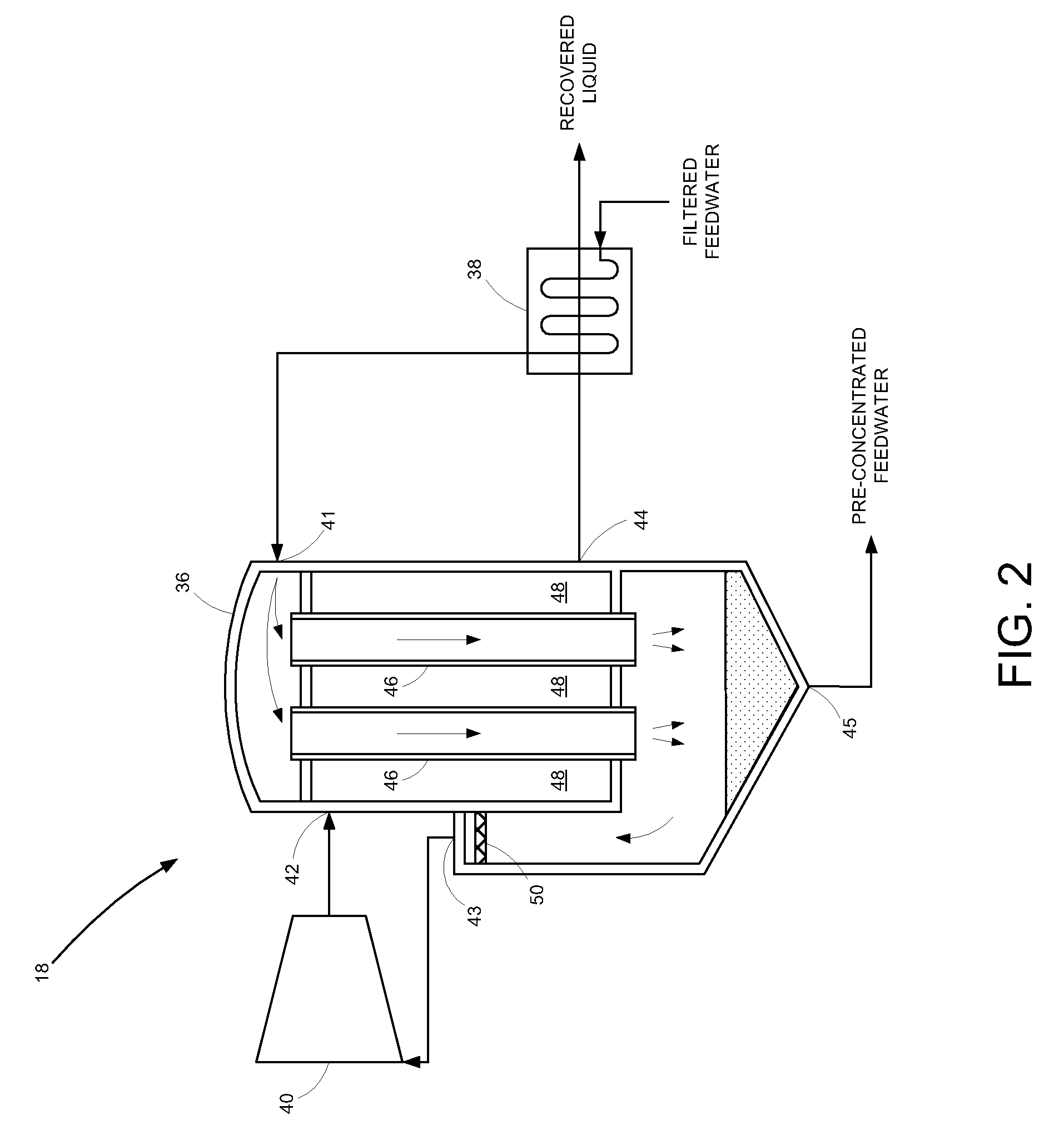

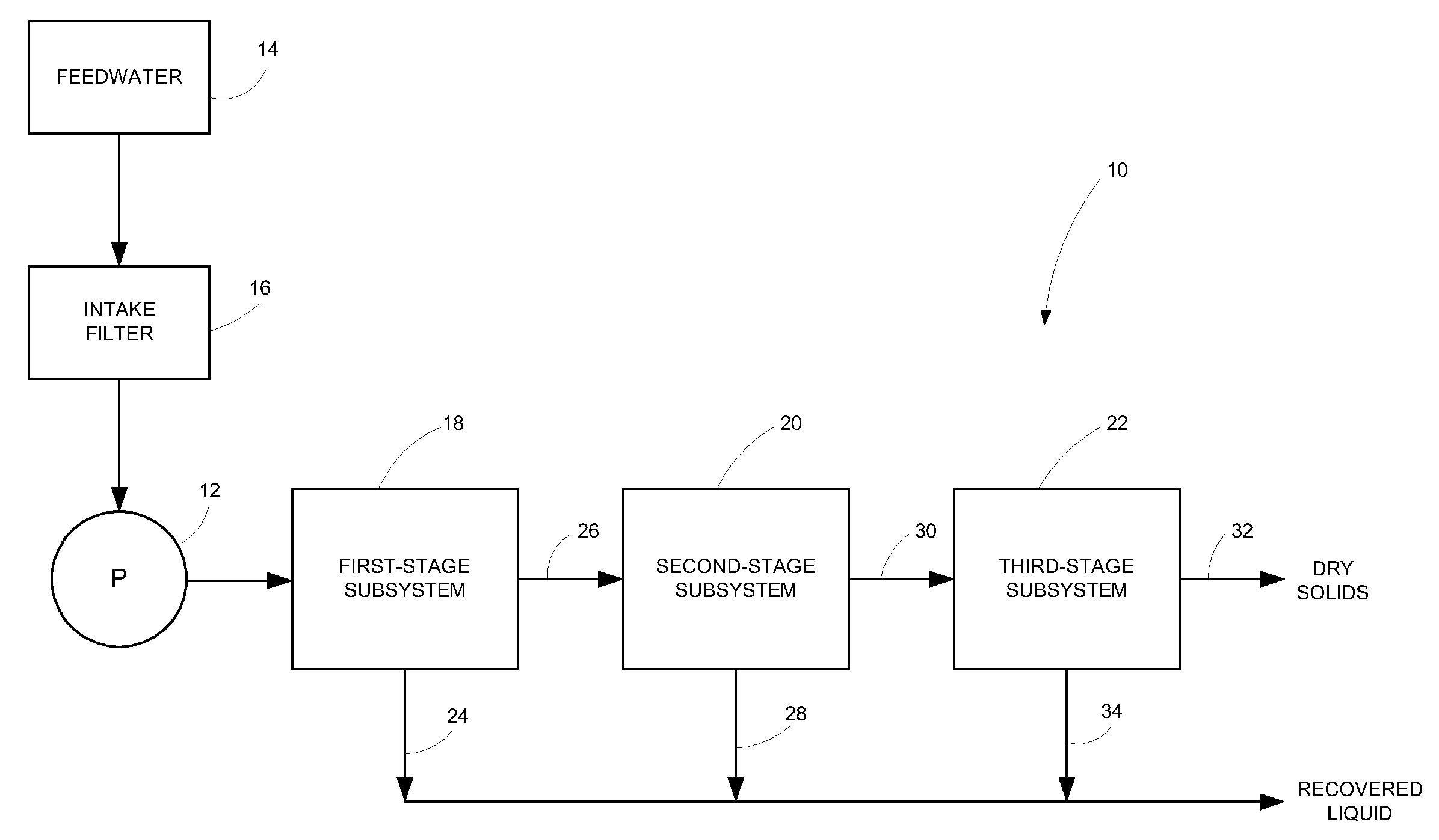

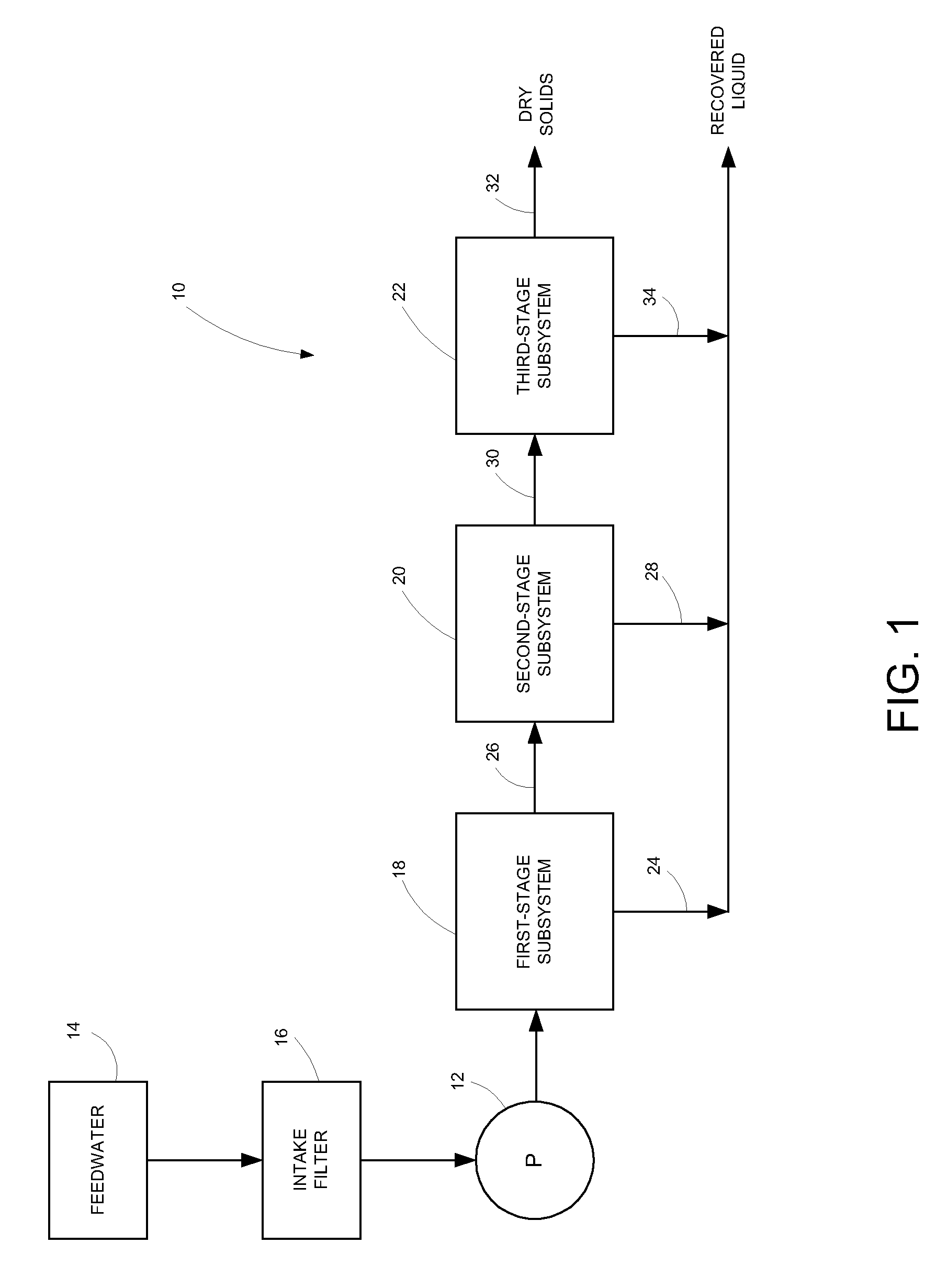

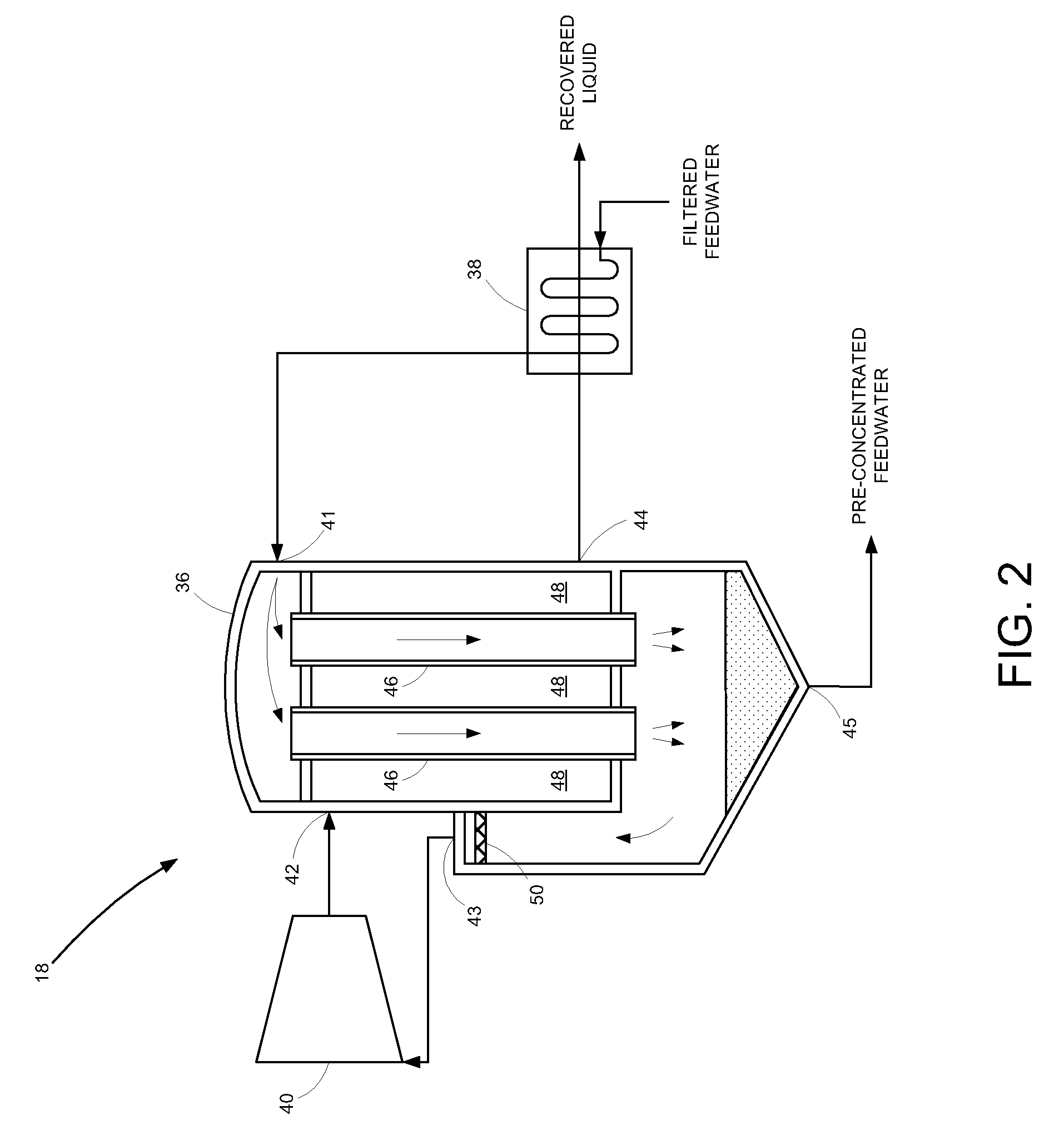

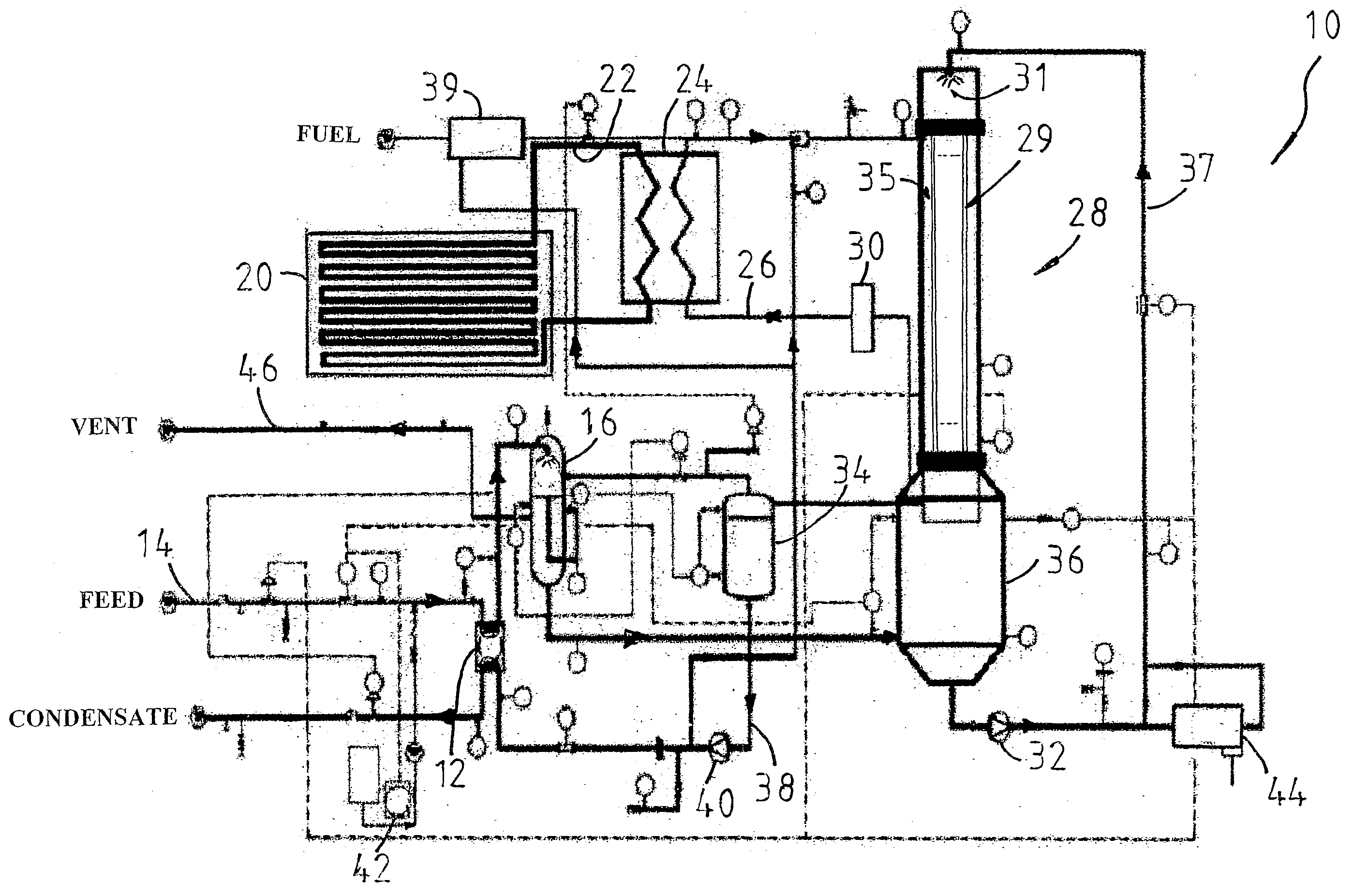

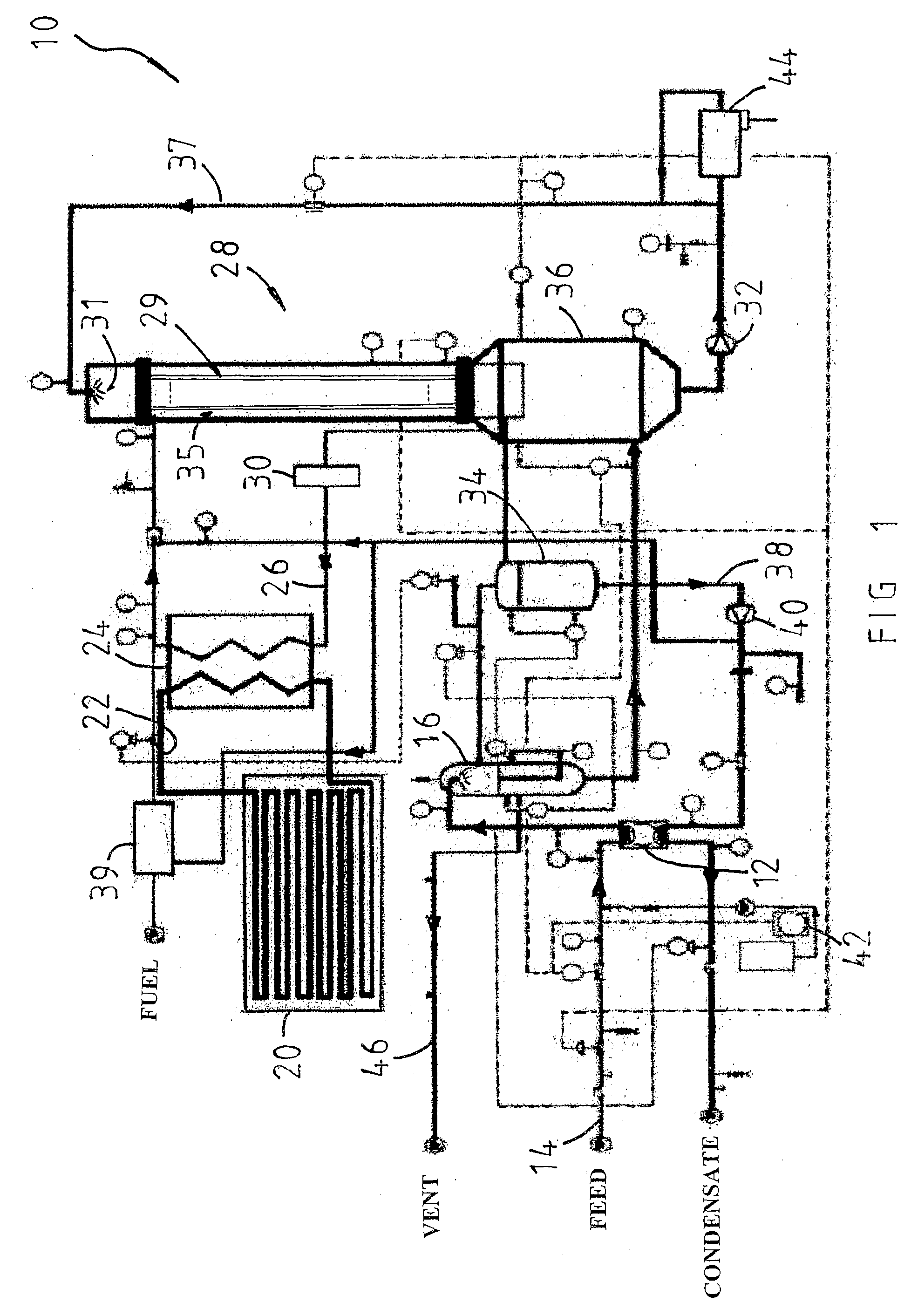

Method and system for treating feedwater

InactiveUS20090020481A1Easy to understandLiquid degasificationSedimentation separationFluidized bedSlurry

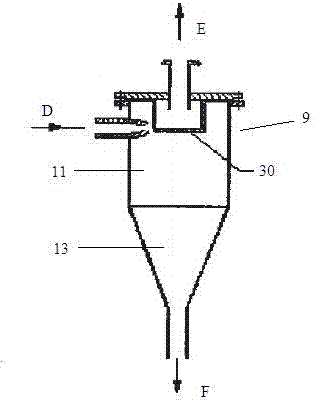

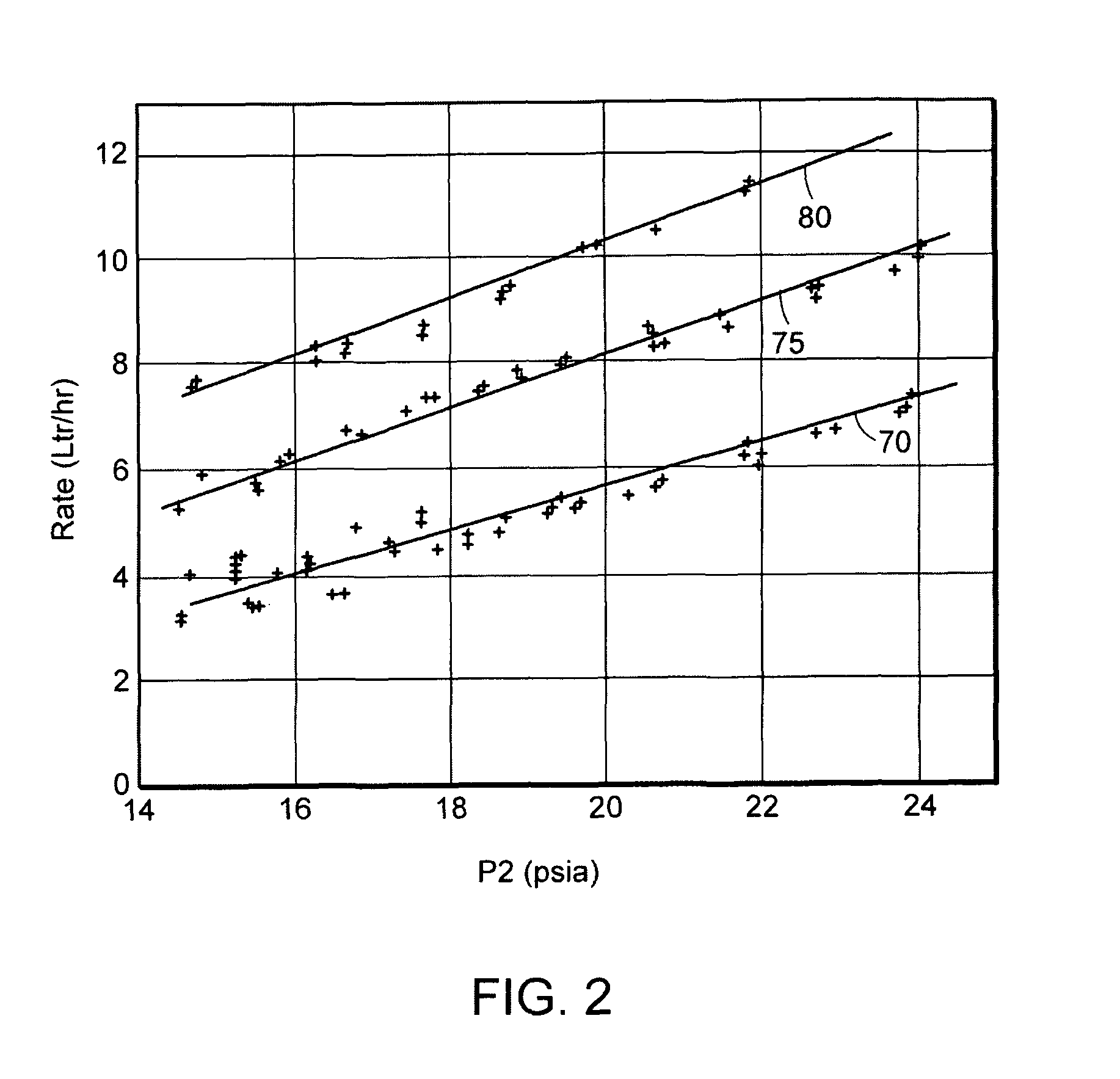

A system for treating feedwater includes a fluidized bed heat exchanger unit connected to receive feedwater and a flash concentrator column connected to receive feedwater discharged from the fluidized bed heat exchanger unit. A spray dryer is provided to receive a solids / liquid slurry discharged from the flash concentrator column. Feedwater can be treated by converting dissolved solids in the feedwater to suspended solids, vaporizing a portion of the feedwater to produce a solids / liquid slurry, and separating solids from the solids / liquid slurry.

Owner:WATERVAP +1

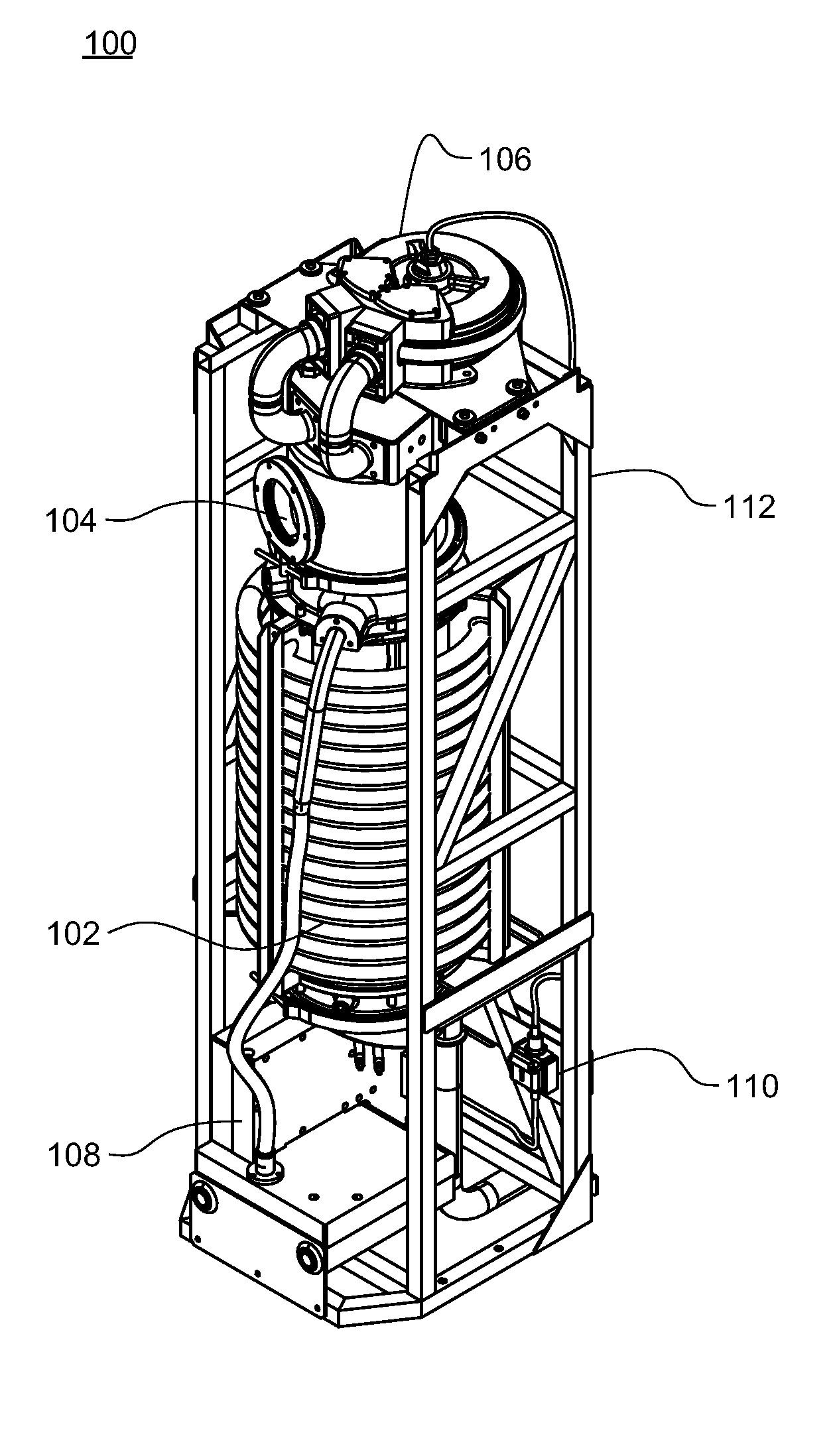

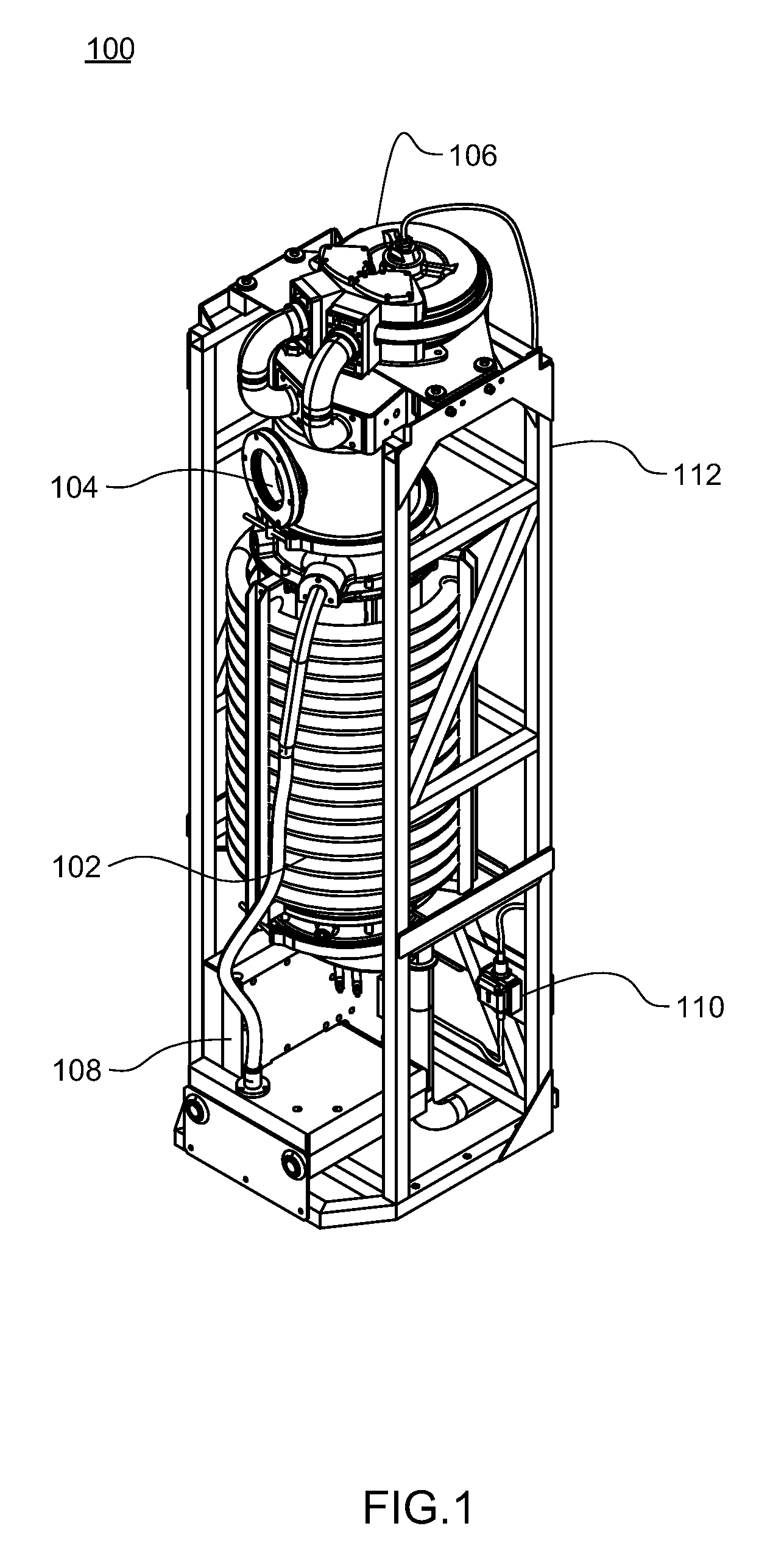

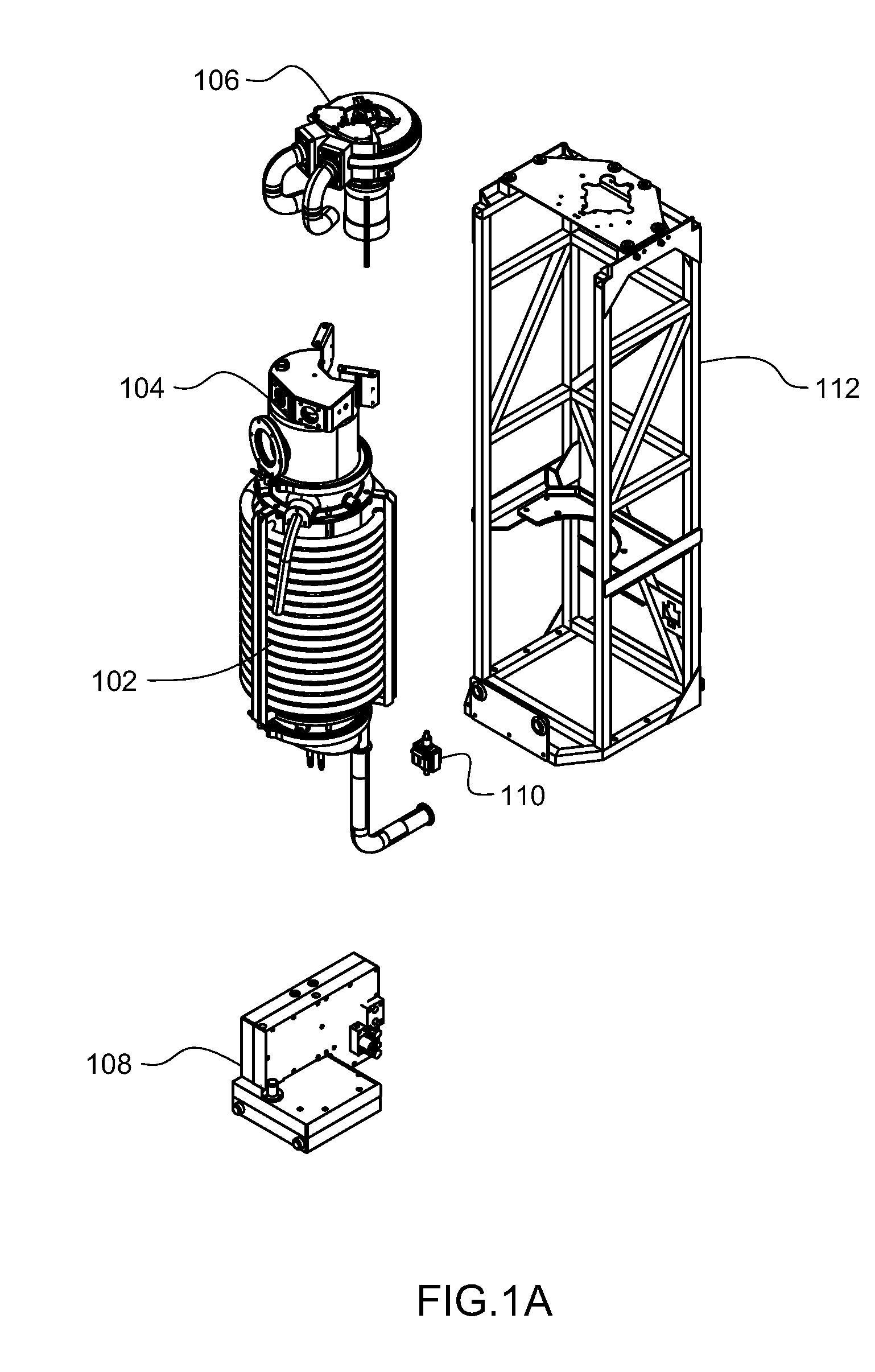

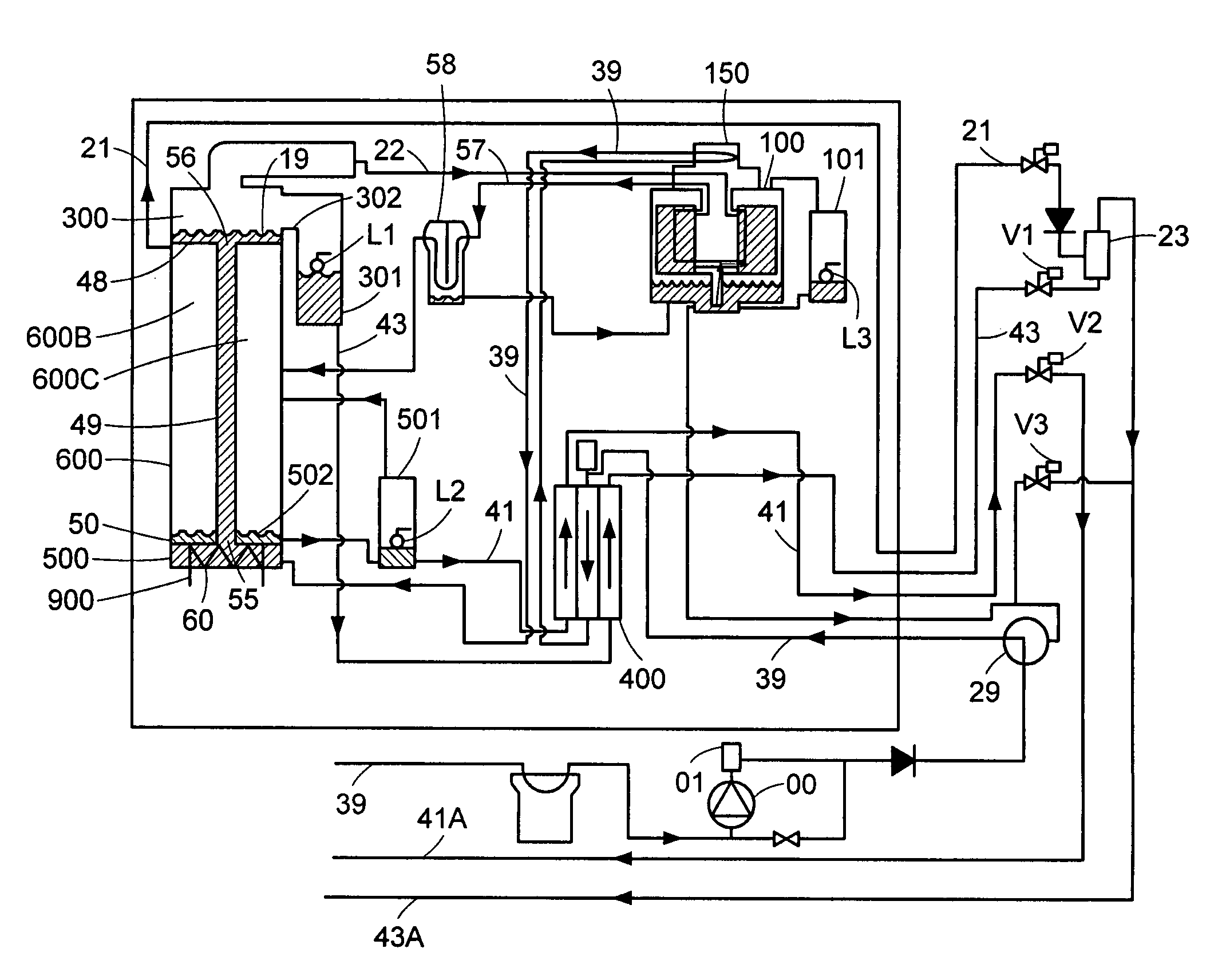

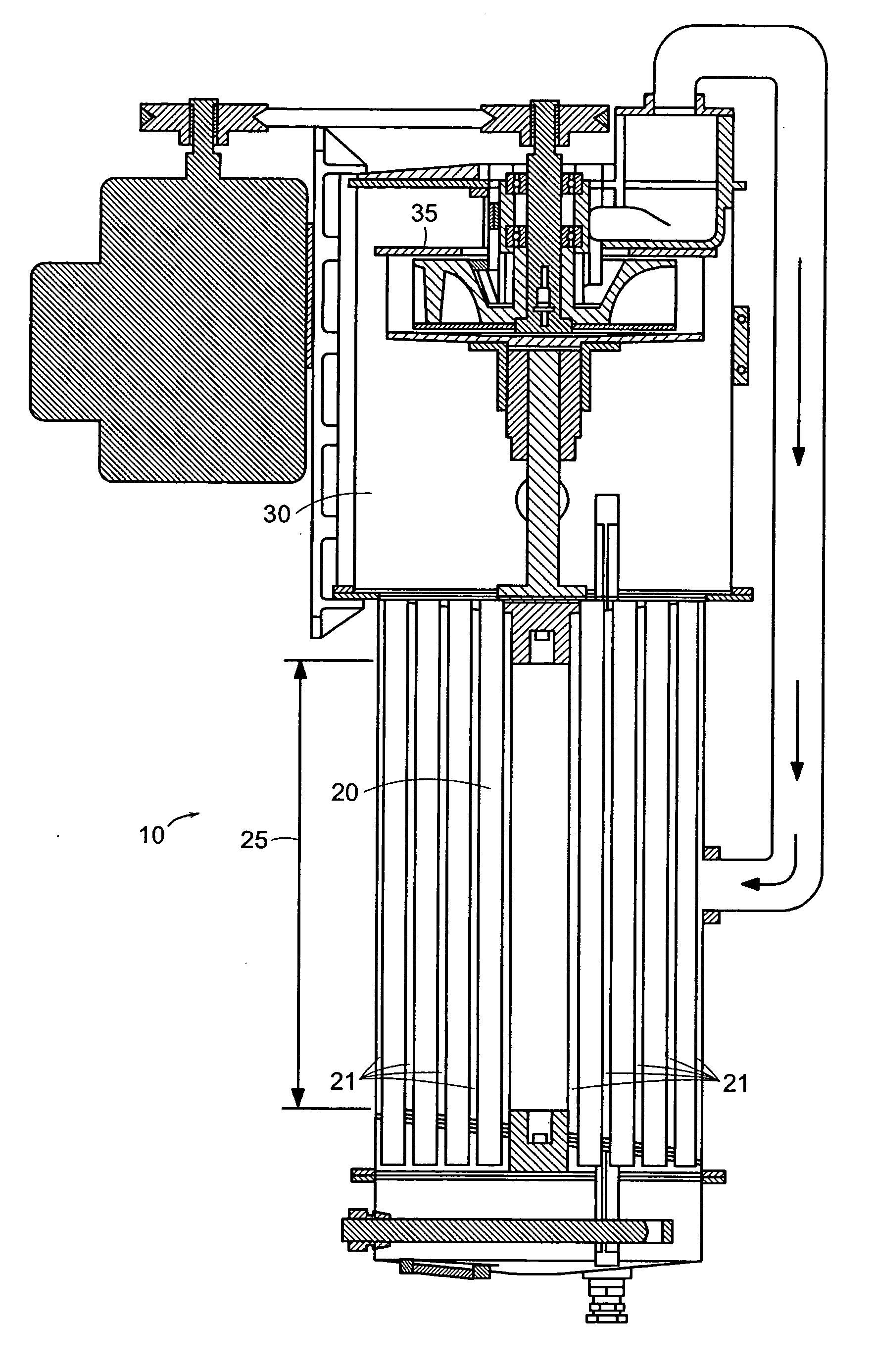

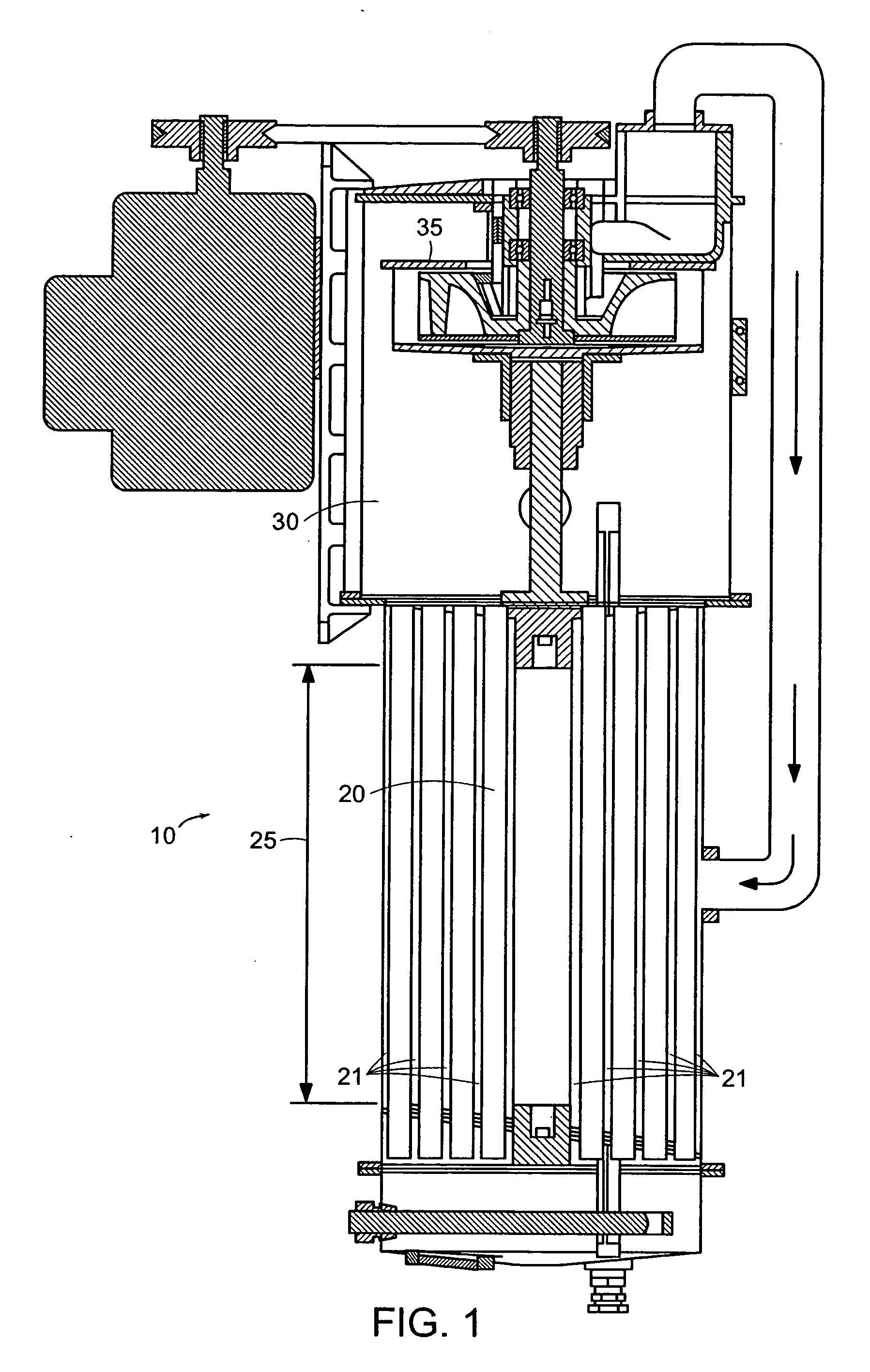

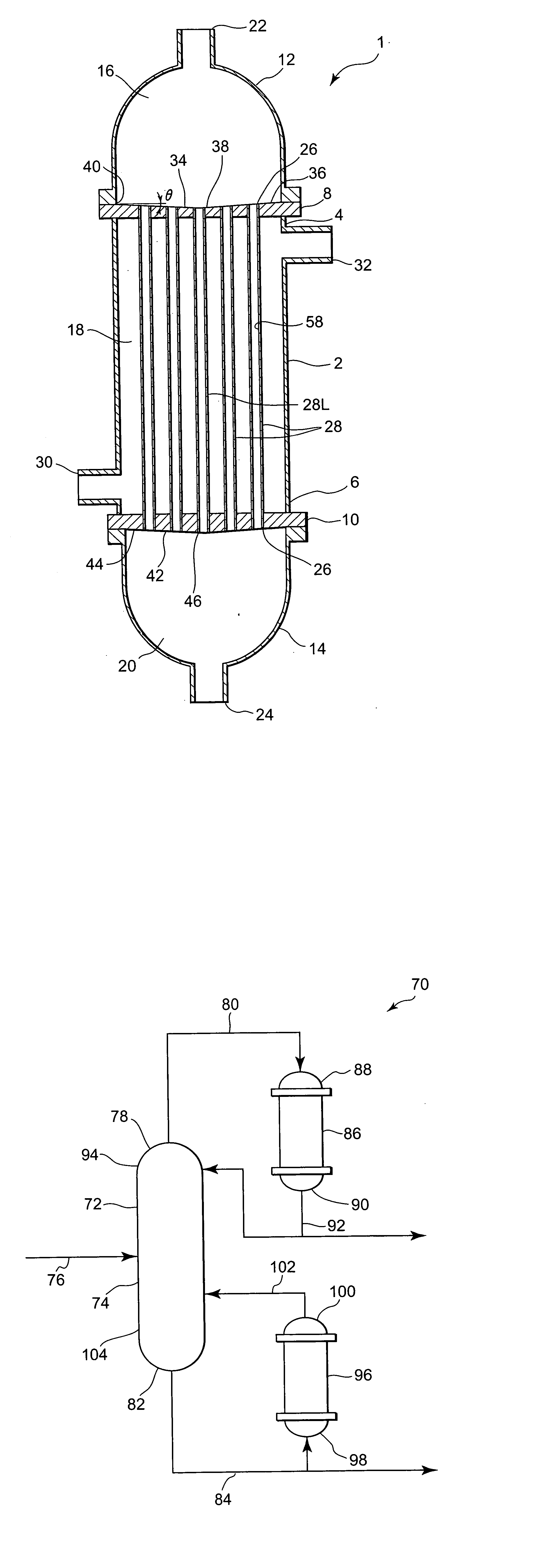

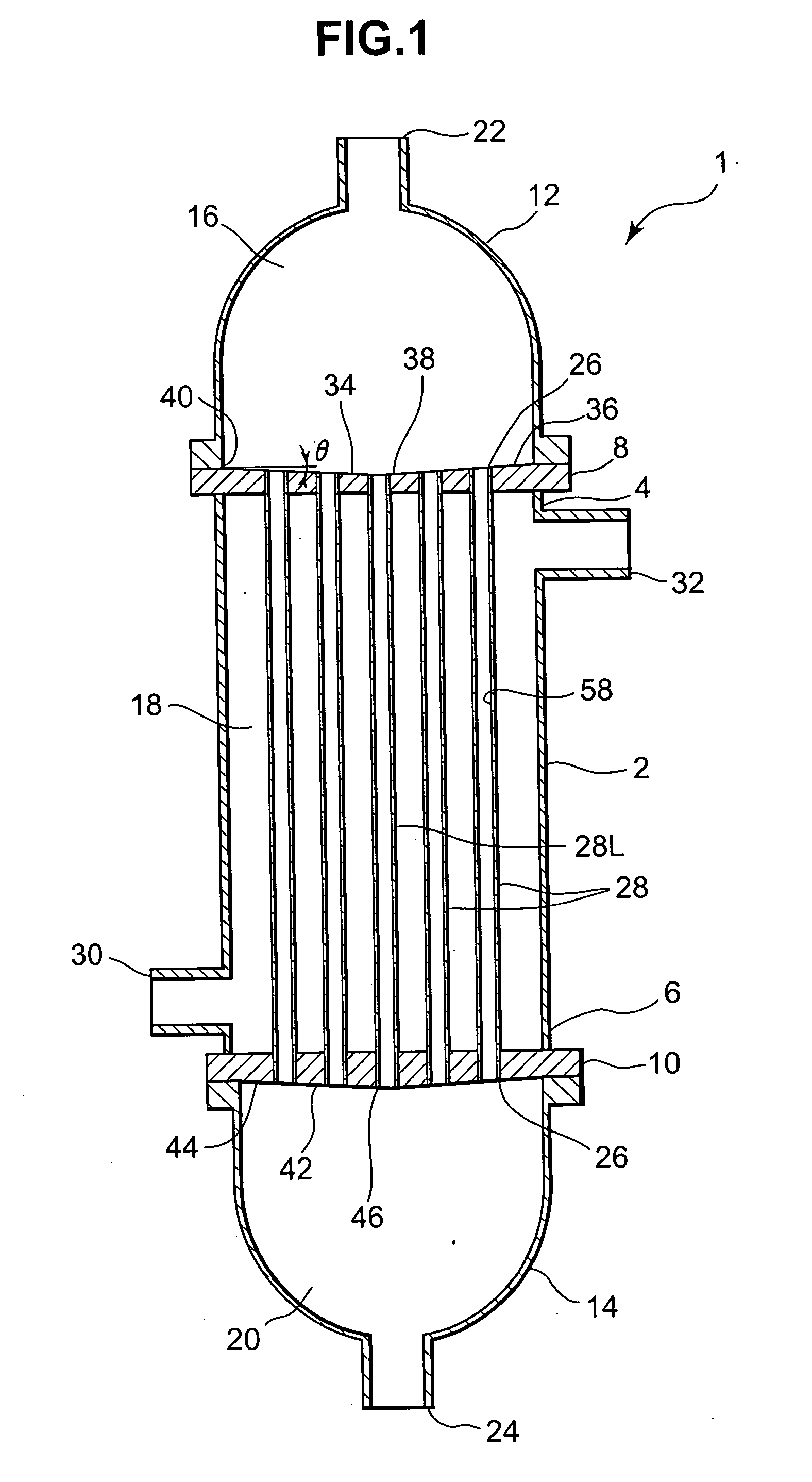

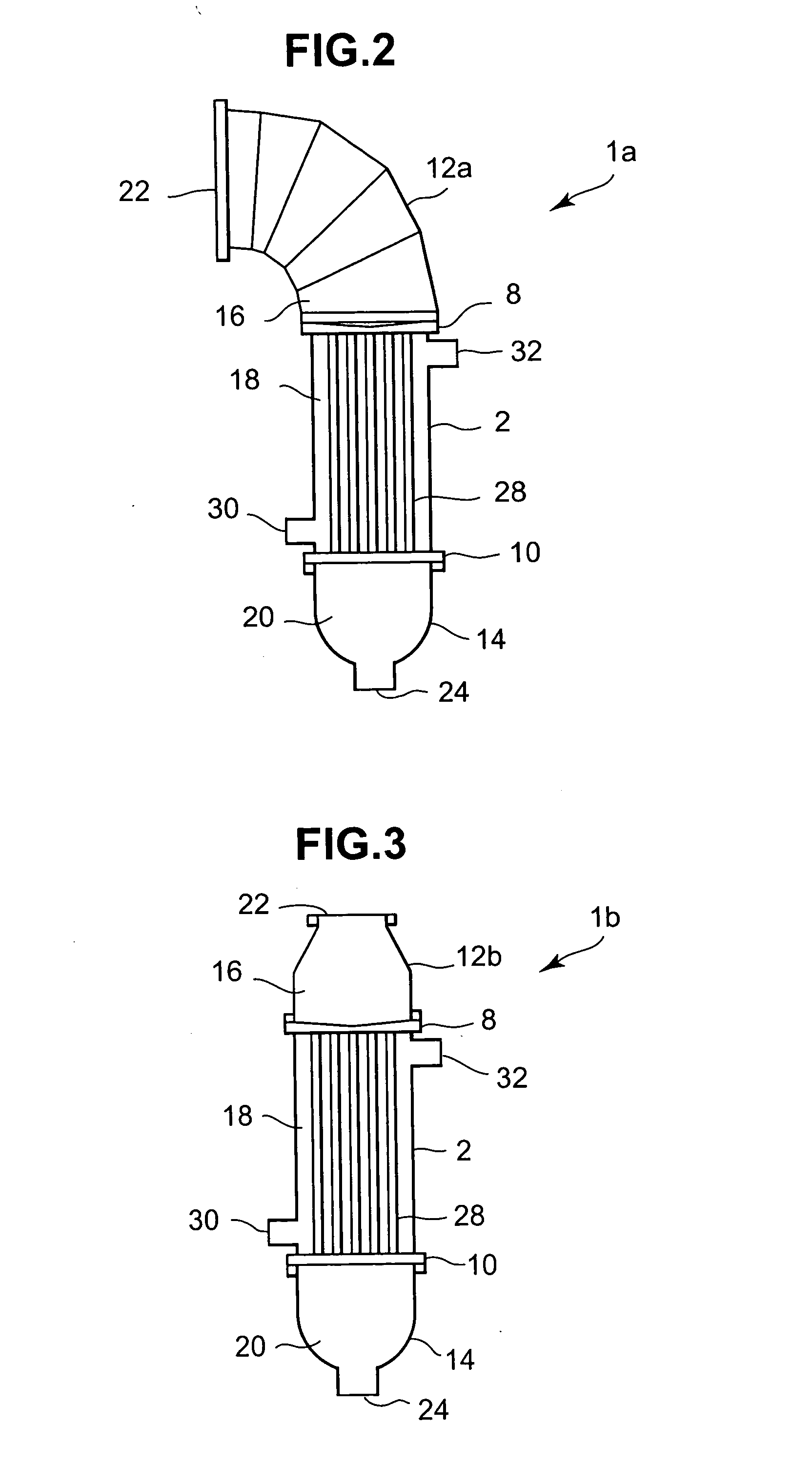

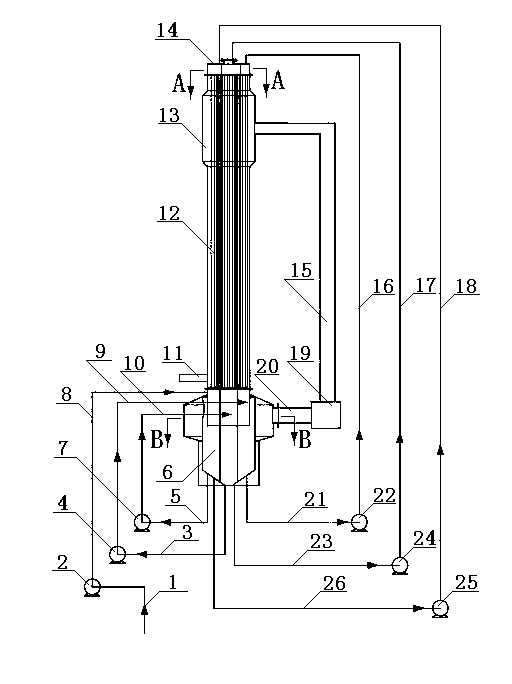

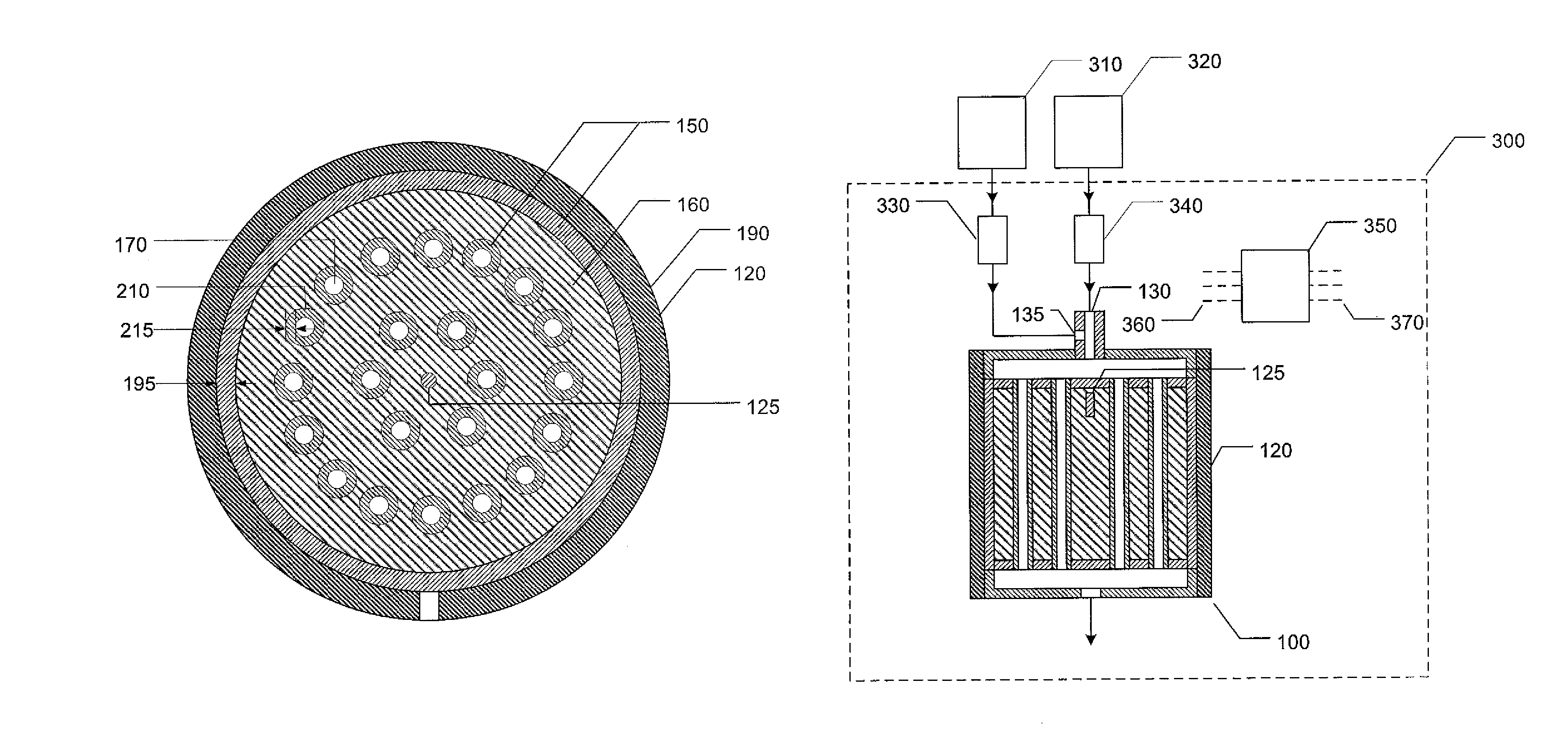

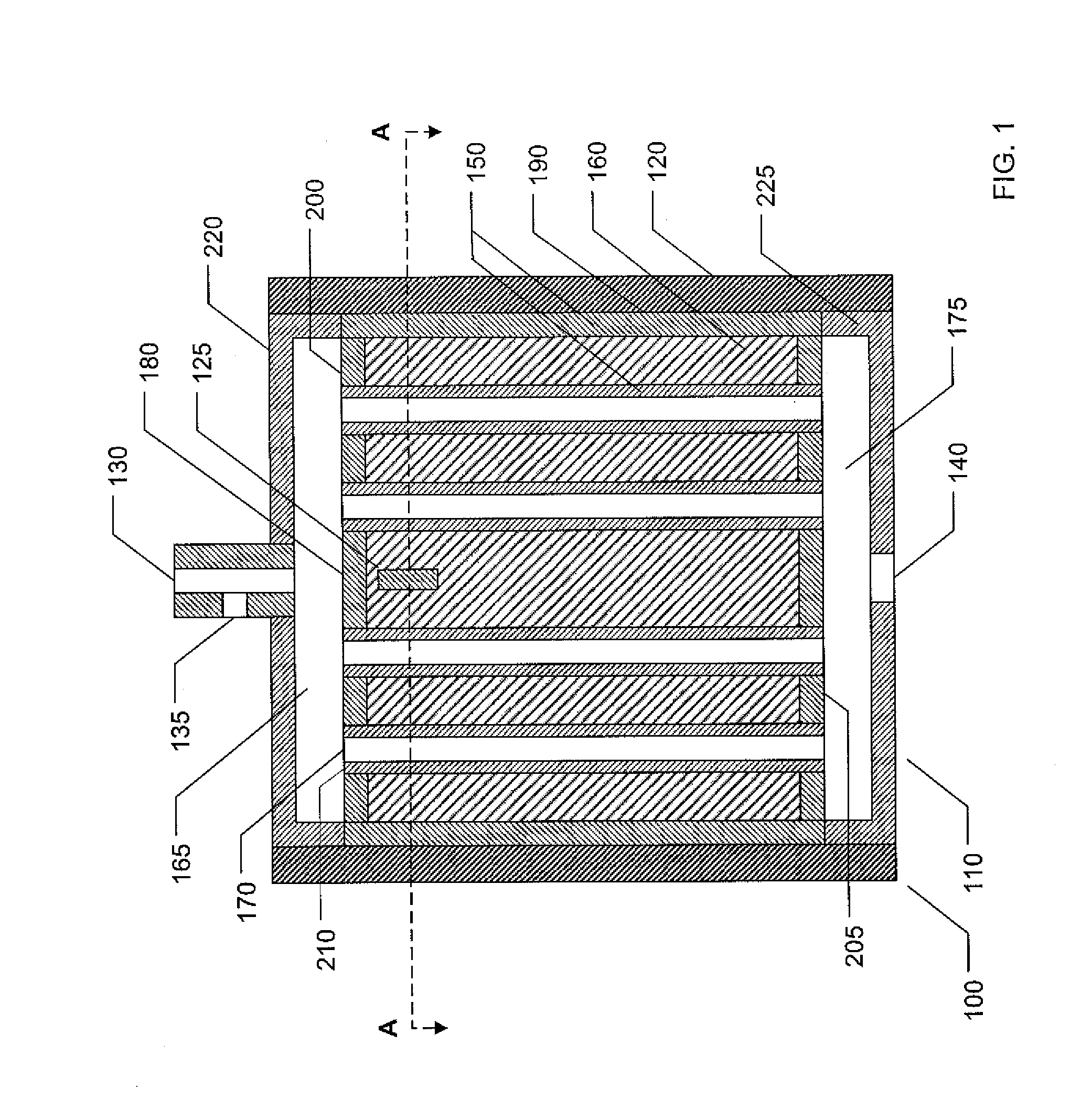

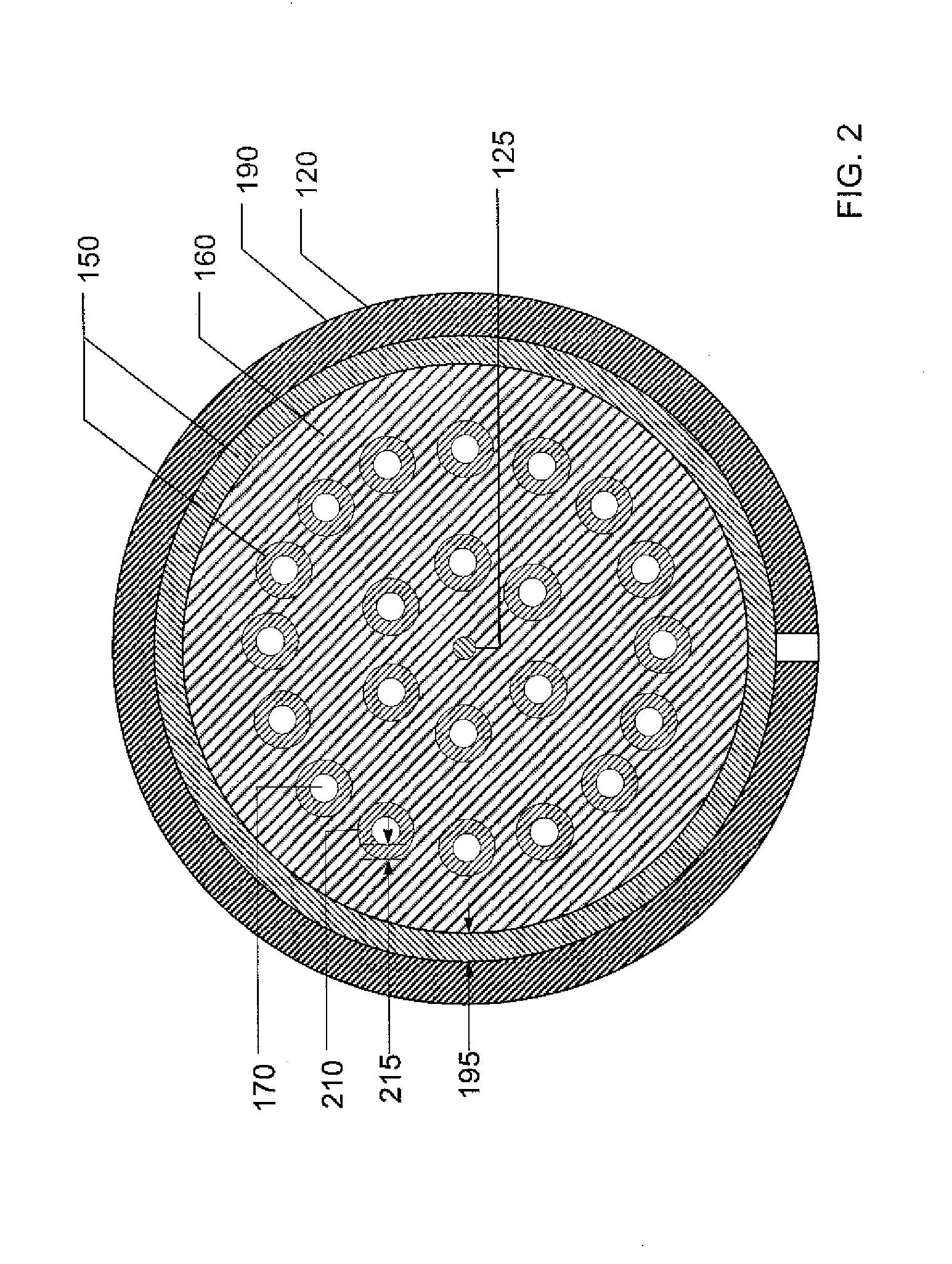

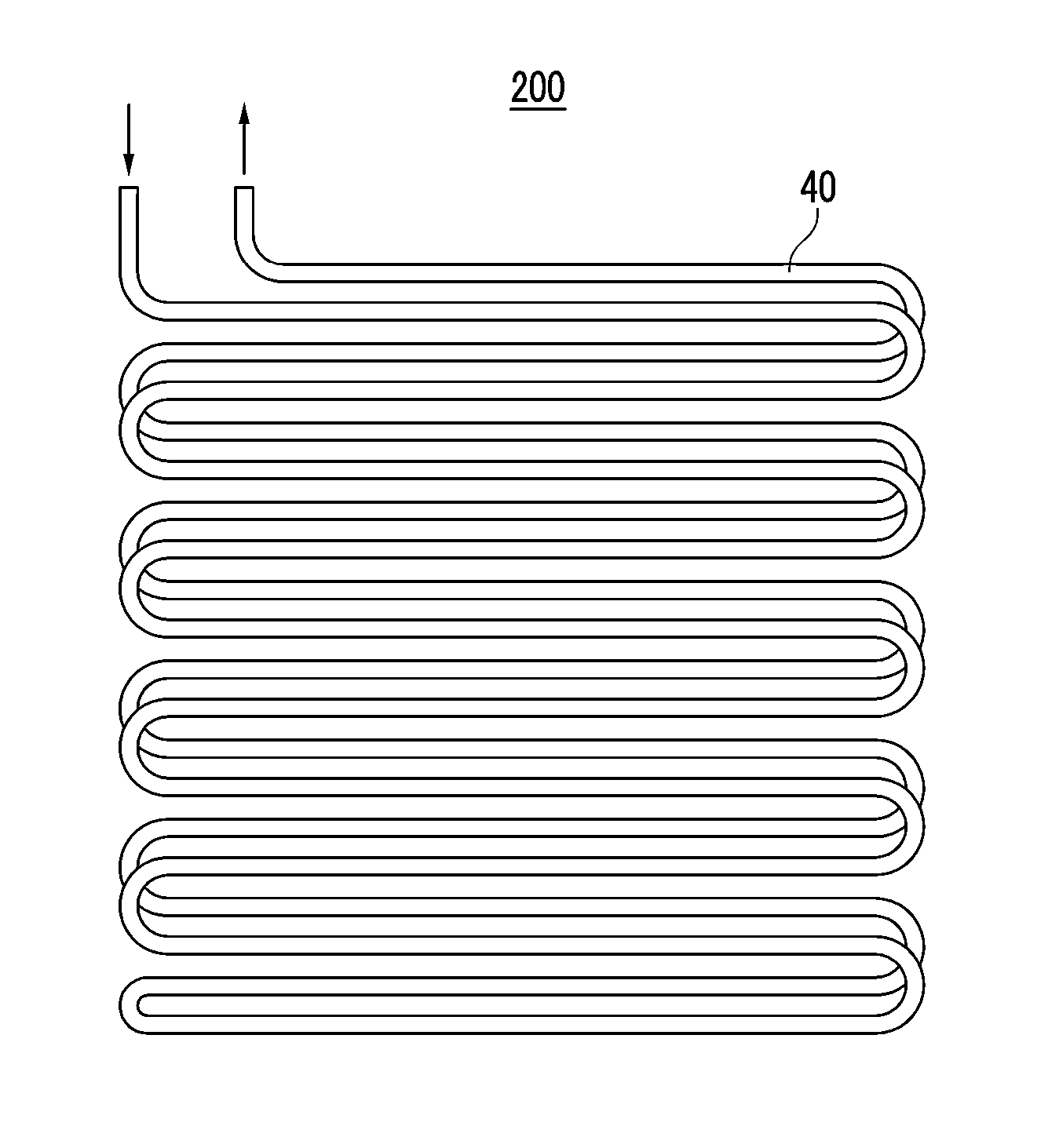

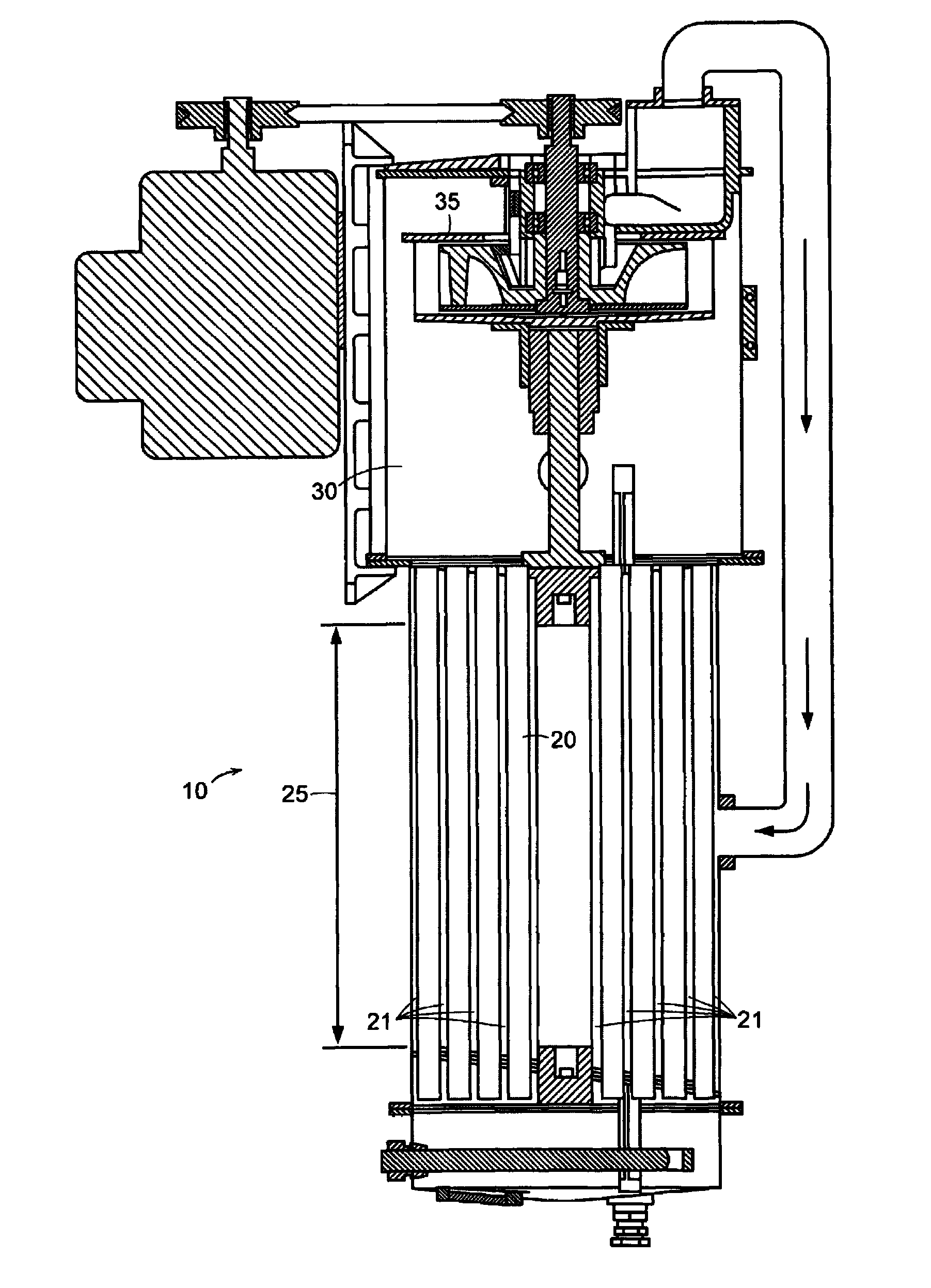

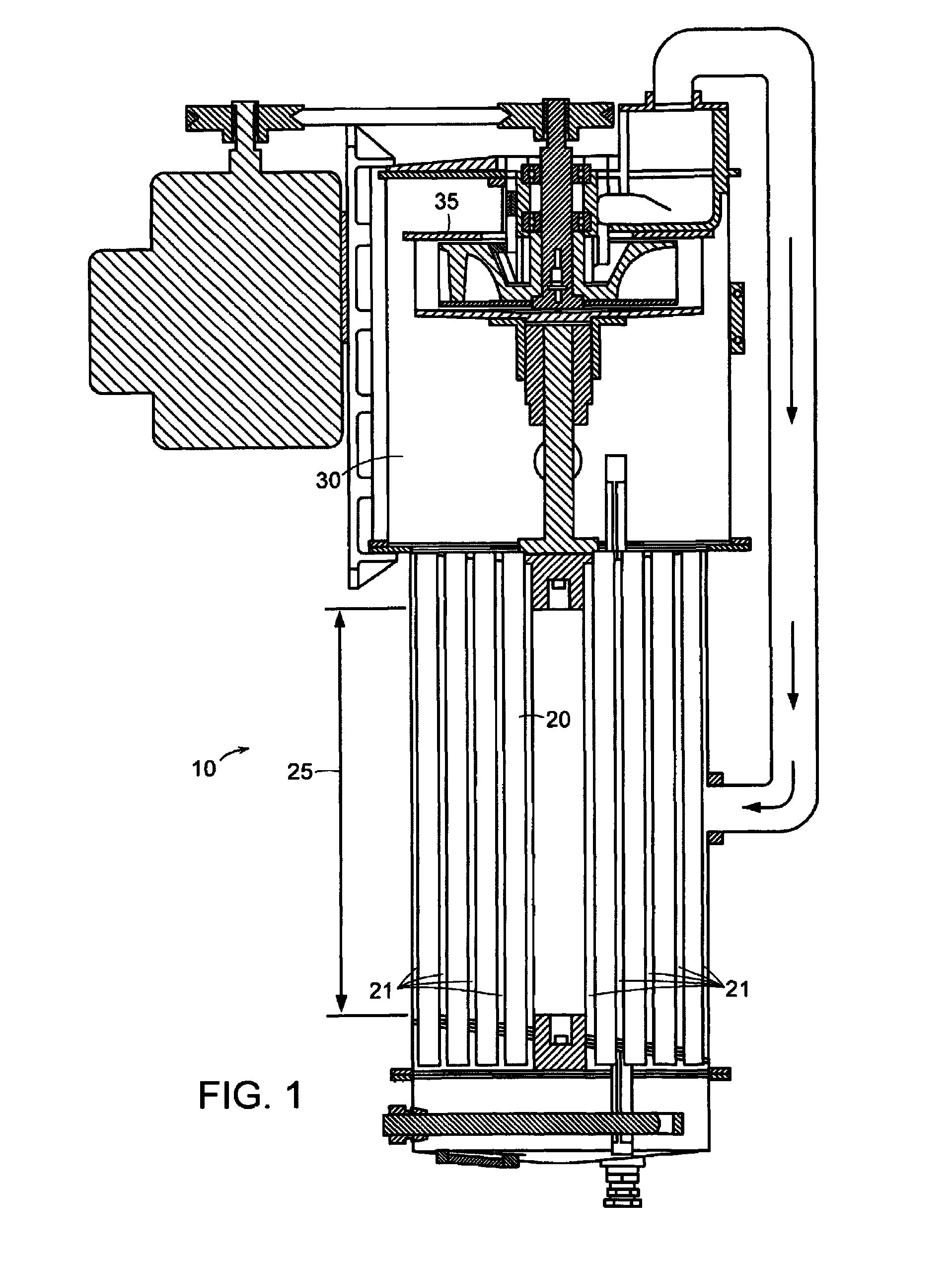

Water Vapor Distillation Apparatus, Method and System

ActiveUS20090025399A1Semiconductor/solid-state device detailsSolid-state devicesWater vaporEngineering

A fluid vapor distillation apparatus. The apparatus includes a source fluid input, and an evaporator condenser apparatus. The evaporator condenser apparatus includes a substantially cylindrical housing and a plurality of tubes in the housing. The source fluid input is fluidly connected to the evaporator condenser and the evaporator condenser transforms source fluid into steam and transforms compressed steam into product fluid. Also included in the fluid vapor distillation apparatus is a heat exchanger fluidly connected to the source fluid input and a product fluid output. The heat exchanger includes an outer tube and at least one inner tube. Also included in the fluid vapor distillation apparatus is a regenerative blower fluidly connected to the evaporator condenser. The regenerative blower compresses steam, and the compressed steam flows to the evaporative condenser where compressed steam is transformed into product fluid.

Owner:DEKA PROD LLP

Liquid ring pumps with hermetically sealed motor rotors

ActiveUS7465375B2Easy maintenanceMaximize energy efficiencyGeneral water supply conservationDistillation regulation/controlDrive shaftDistillation

Owner:DEKA PROD LLP

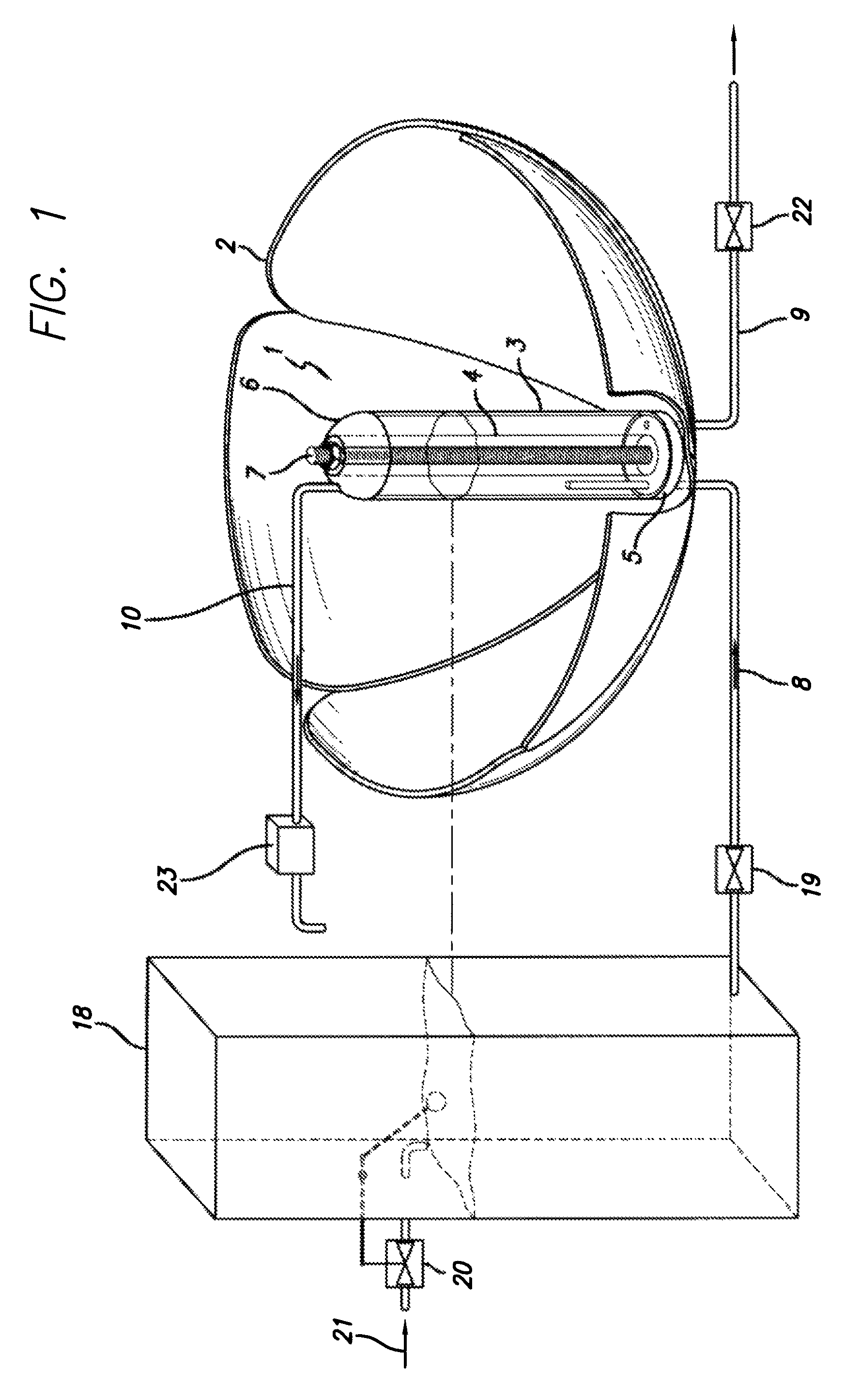

Solar distillation device

A solar distillation apparatus utilizing a substantially vertical reactor assembly is disclosed. The reactor includes a tubular outer shell, a base, a cap, and a central tension member. The annular space between the outer tube and the central tension member forms the reactor chamber. Seawater or other feed liquid enters the reactor chamber through the base plate. Reflected or direct solar energy heats the feed liquid, generating low pressure vapor. The vapor exits the reactor through the cap structure or the base. The concentrate left behind settles by gravity to the bottom region of the reactor's liquid column. Extension tubes on the feed openings allow feed liquid to enter the liquid column above the concentrate layer and avoid excessive mixing of the feed liquid and the concentrate. The concentrate exits the reactor through one or more openings in the base.

Owner:MCCLURE MILES

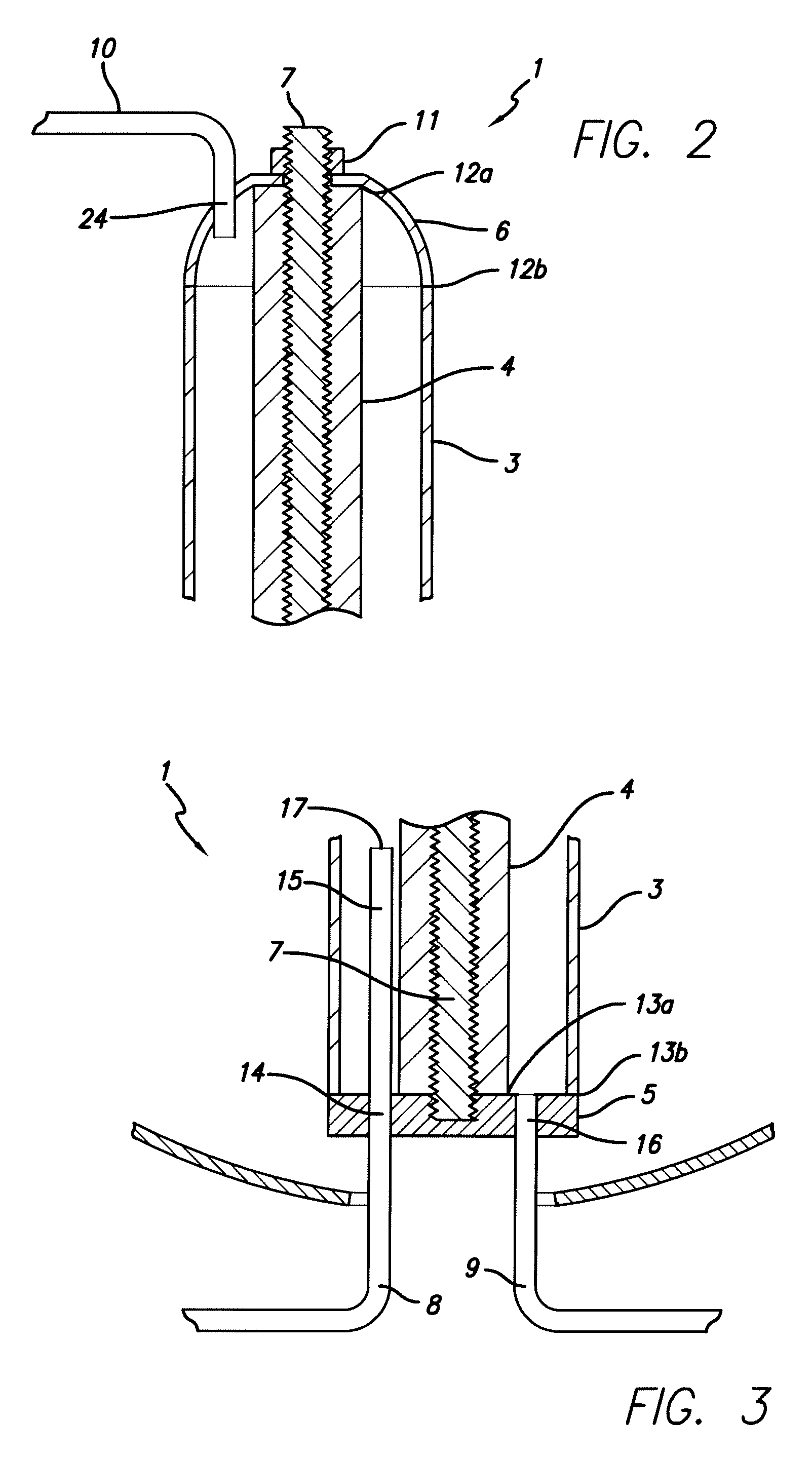

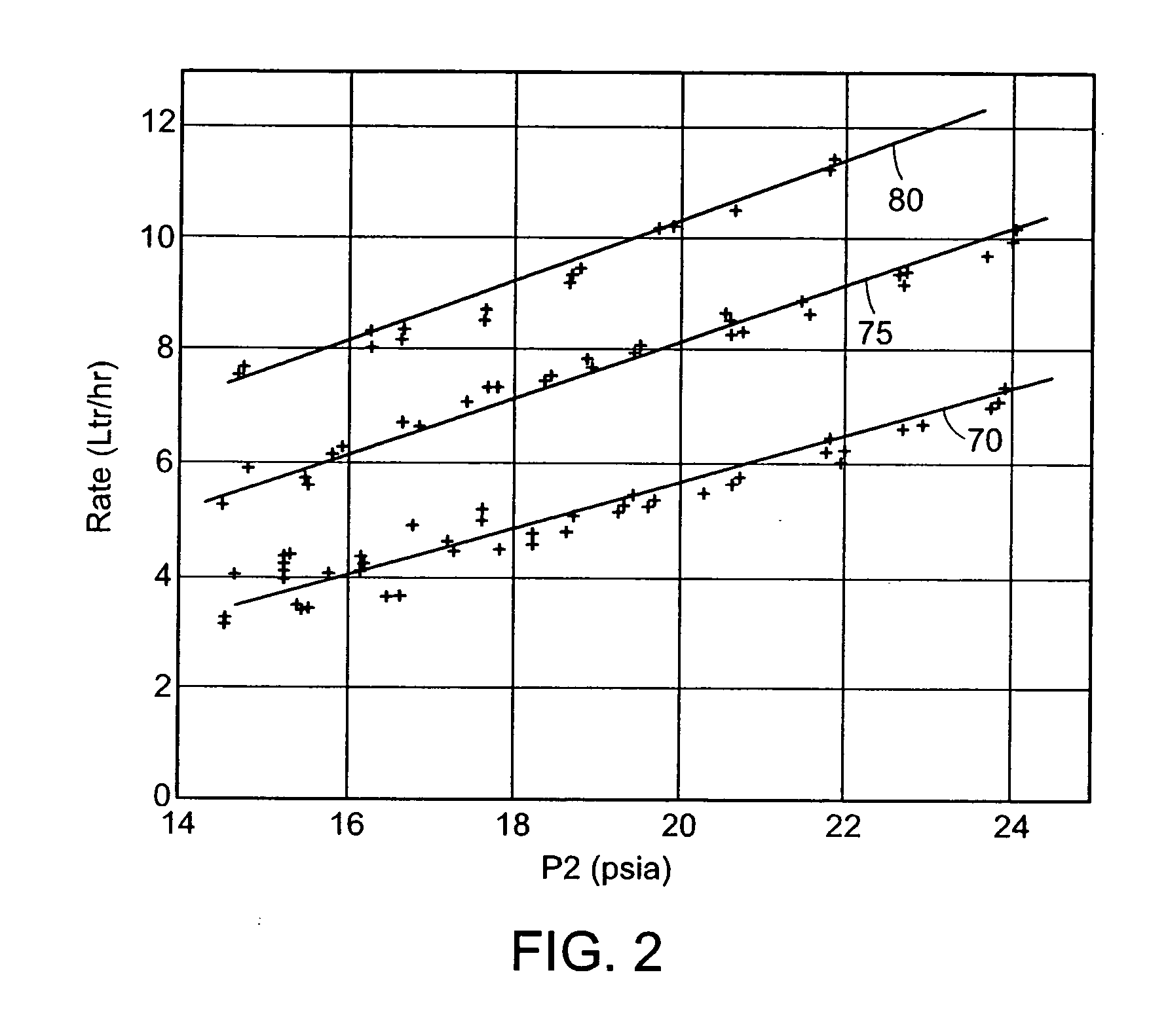

Method and apparatus for phase change enhancement

ActiveUS20050183832A1Distillation regulation/controlVacuum distillation separationEngineeringPhase change

A method of operating an evaporator is described. In evaporator feed water, a Taylor bubble is developed which has an outer surface including a thin film in contact with an inner surface of an outer wall of an evaporator tube. The Taylor bubble is heated as it rises within the evaporator tube so that liquid in the thin film transitions into vapor within the bubble.

Owner:DEKA PROD LLP

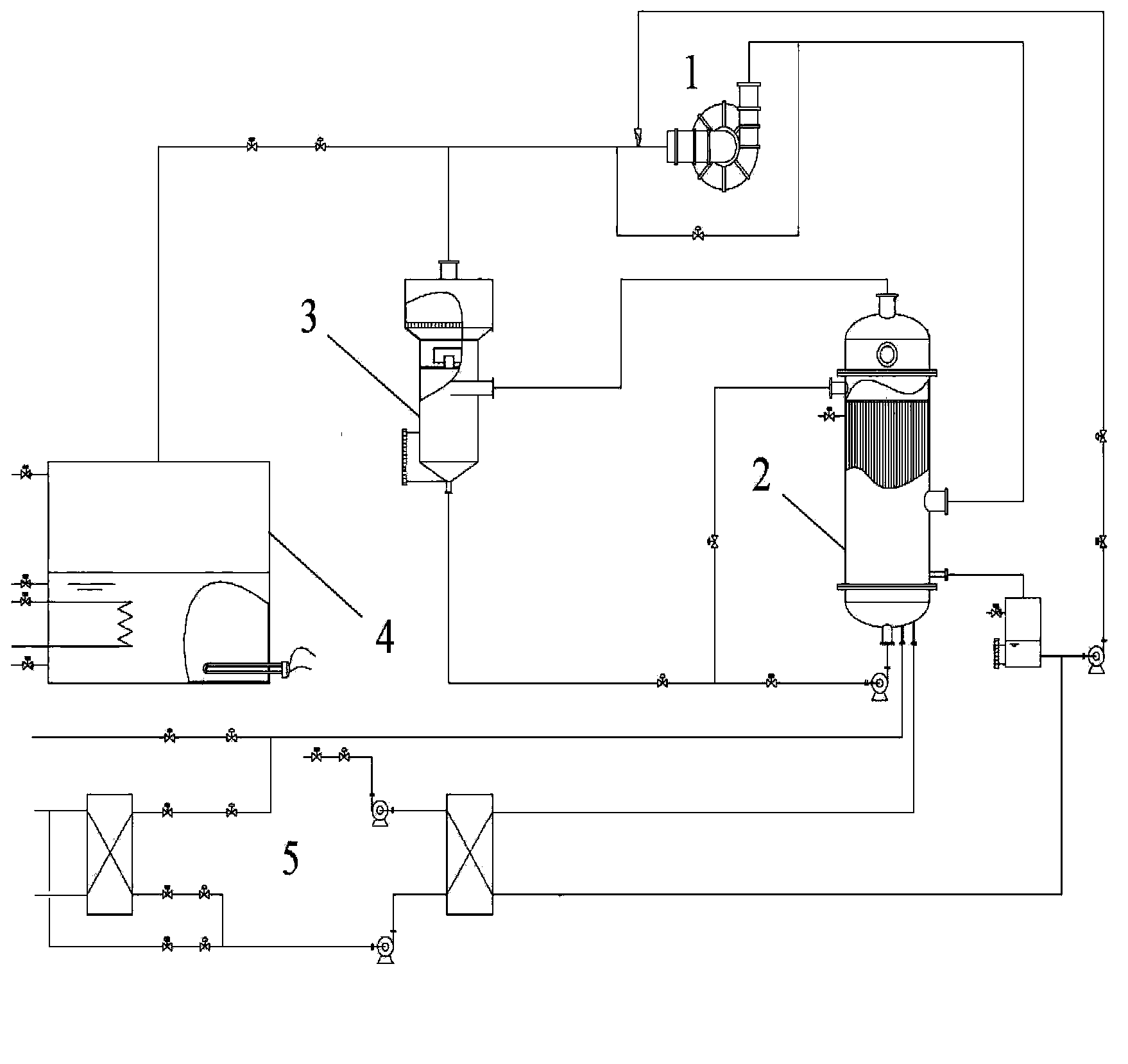

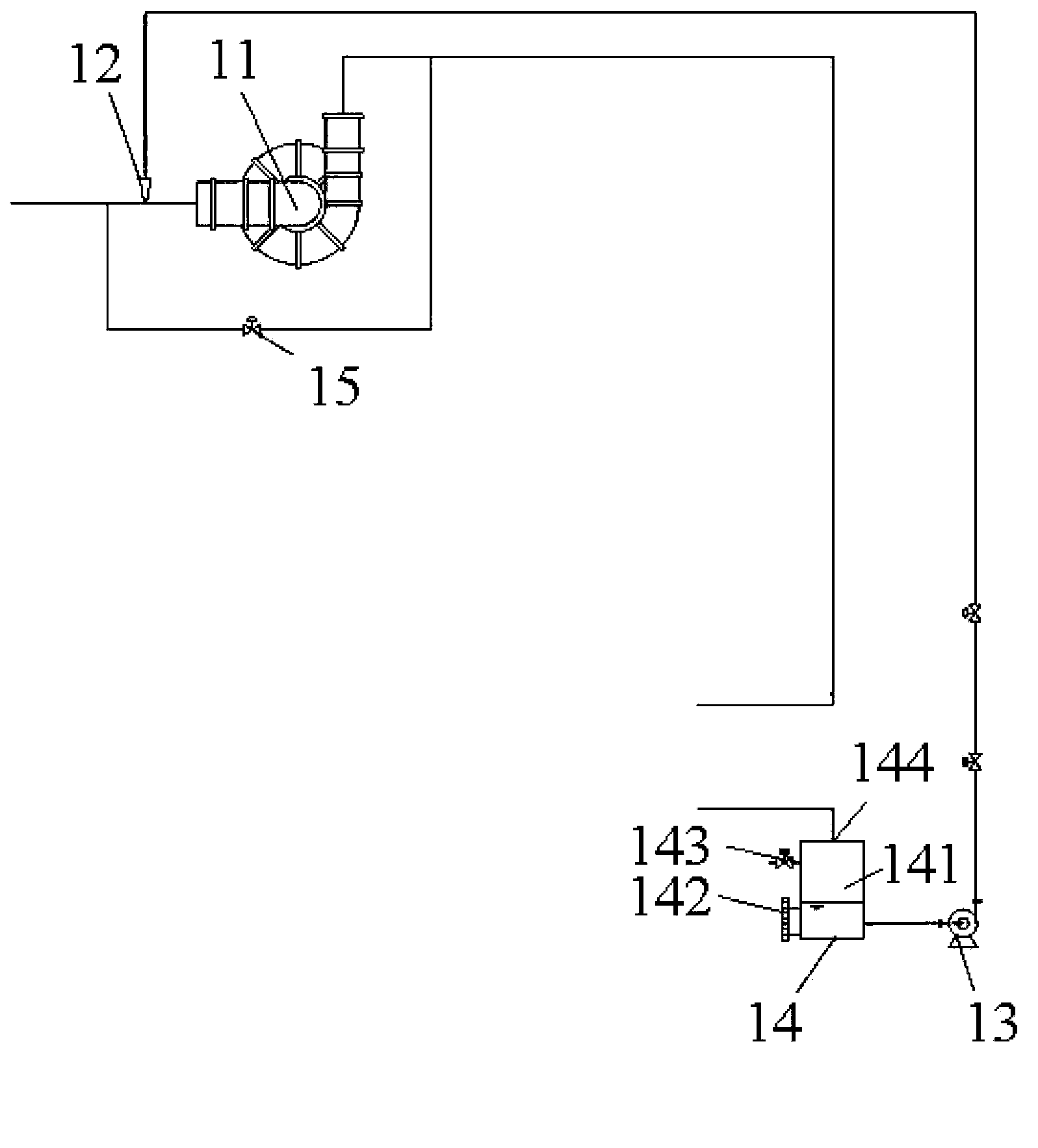

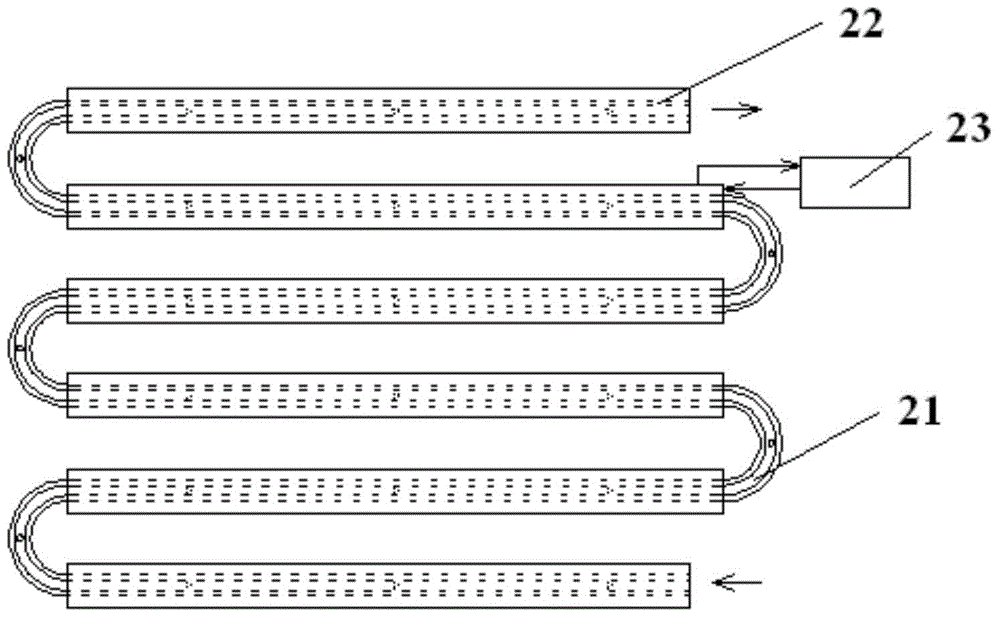

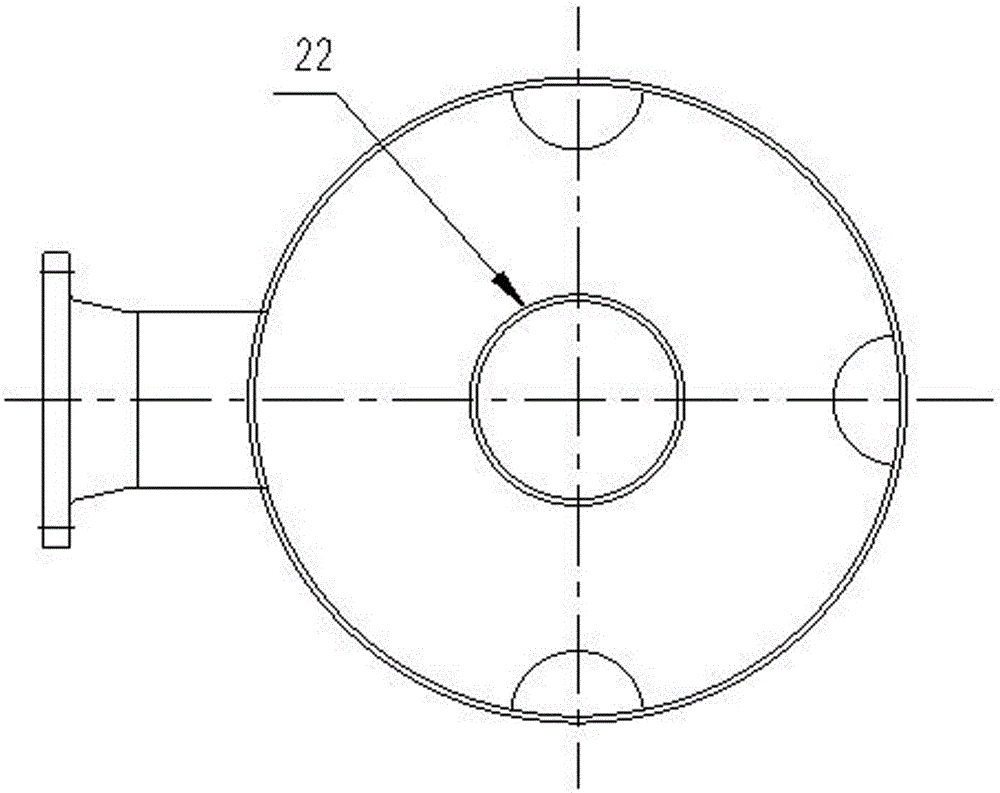

MVR heat pump evaporation system

ActiveCN103908788AReduce consumptionFast startupEvaporator accessoriesEvaporators with vertical tubesWater vaporEvaporation

The invention discloses an MVR heat pump evaporation system, which comprises a water vapor compression system, an evaporator, a separator, an energy storage water tank and a waste heat recovery system. The vapor outlet of the energy storage water tank and the vapor outlet of the separator are both in connection with the vapor inlet of the water vapor compression system, the vapor outlet of which is connected to the vapor inlet of the evaporator. The vapor outlet of the evaporator is connected to the vapor inlet of the separator, and the stock solution inlet and the concentrated solution outlet of the evaporator are both in connection with the waste heat recovery system. The MVR heat pump evaporation system provided by the invention recovers low grade waste heat, i.e. makes use of the energy storage water tank to convert hot water sensible heat into low-pressure vapor latent heat for recycling during starting, thus enhancing the start-up speed of the system, avoiding the influence of non-condensable gas air circulation in the system on compressor performance, recovering all the latent heat of secondary vapor generated in a solution evaporation process, saving primary energy, greatly reducing the energy consumption during solution evaporation, and avoiding pollution.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Method of treatment of amine waste water and a system for accomplishing the same

Disclosed herein is a system comprising an evaporation unit comprising a first heat exchanger in fluid communication with a second heat exchanger; where the first heat exchanger is operative to heat an effluent stream comprising an amine solvent and / or amine byproducts and water and to discharge the effluent stream to the second heat exchanger; where the second heat exchanger is operative to convert the effluent stream into a distillate stream and a concentrate stream; and a reverse osmosis unit in fluid communication with the evaporation unit; where the reverse osmosis unit comprises a first reverse osmosis unit that is operative to receive the distillate stream and to separate water from byproducts of the amine solvent such that the water has a purity of greater than 95%, based on the weight of the distillate stream.

Owner:GENERAL ELECTRIC TECH GMBH

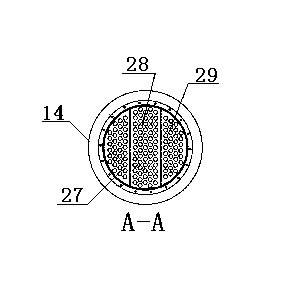

Vertical multitubular heat exchanger and distillation column system including the same

ActiveUS20050040023A1Continuous operationCharging-discharging device combinationsEvaporation with vapour compressionDistillationEngineering

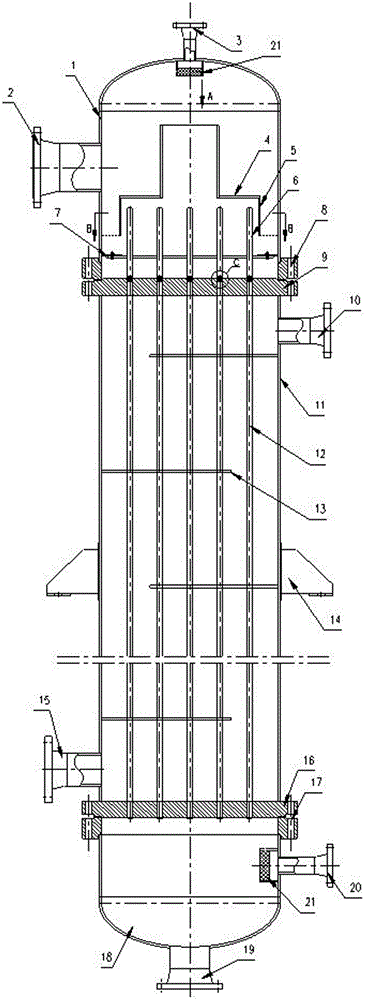

A vertical multitubular heat exchanger that can prevent clogging of a polymerized material and is continuously operable for an extended period of time is provided. The vertical multitubular heat exchanger (1) of the present invention introduces a process fluid containing an easily-polymerizable substance into heat exchanger tubes (28) to perform heat exchange. The vertical multitubular heat exchanger (1) includes a shell (2) extending in a vertical direction, an upper tube sheet (8) and a lower tube sheet (10) respectively disposed at the upper portion (4) and the lower portion (6) of the shell (2), and a plurality of heat exchanger tubes (28) whose outer circumferences (26) of both ends are respectively fixed to the upper tube sheet (8) and the lower tube sheet (10). An upper surface (34) of the upper tube sheet (8) is formed to be sloped and at least one of the heat exchanger tubes (28) is disposed in the vicinity of the lowest position of the upper surface (34) of the upper tube sheet (8).

Owner:MITSUBISHI CHEM CORP

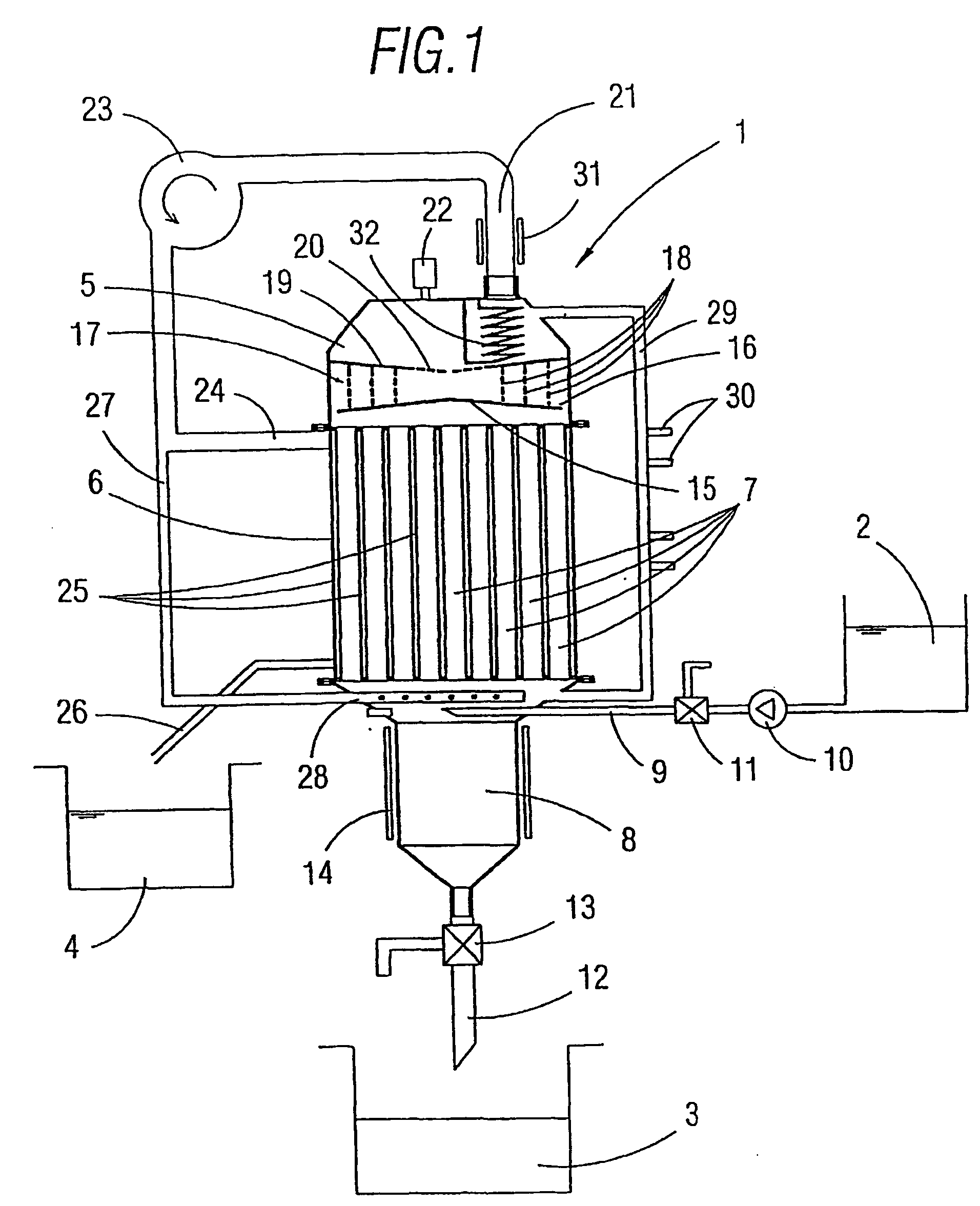

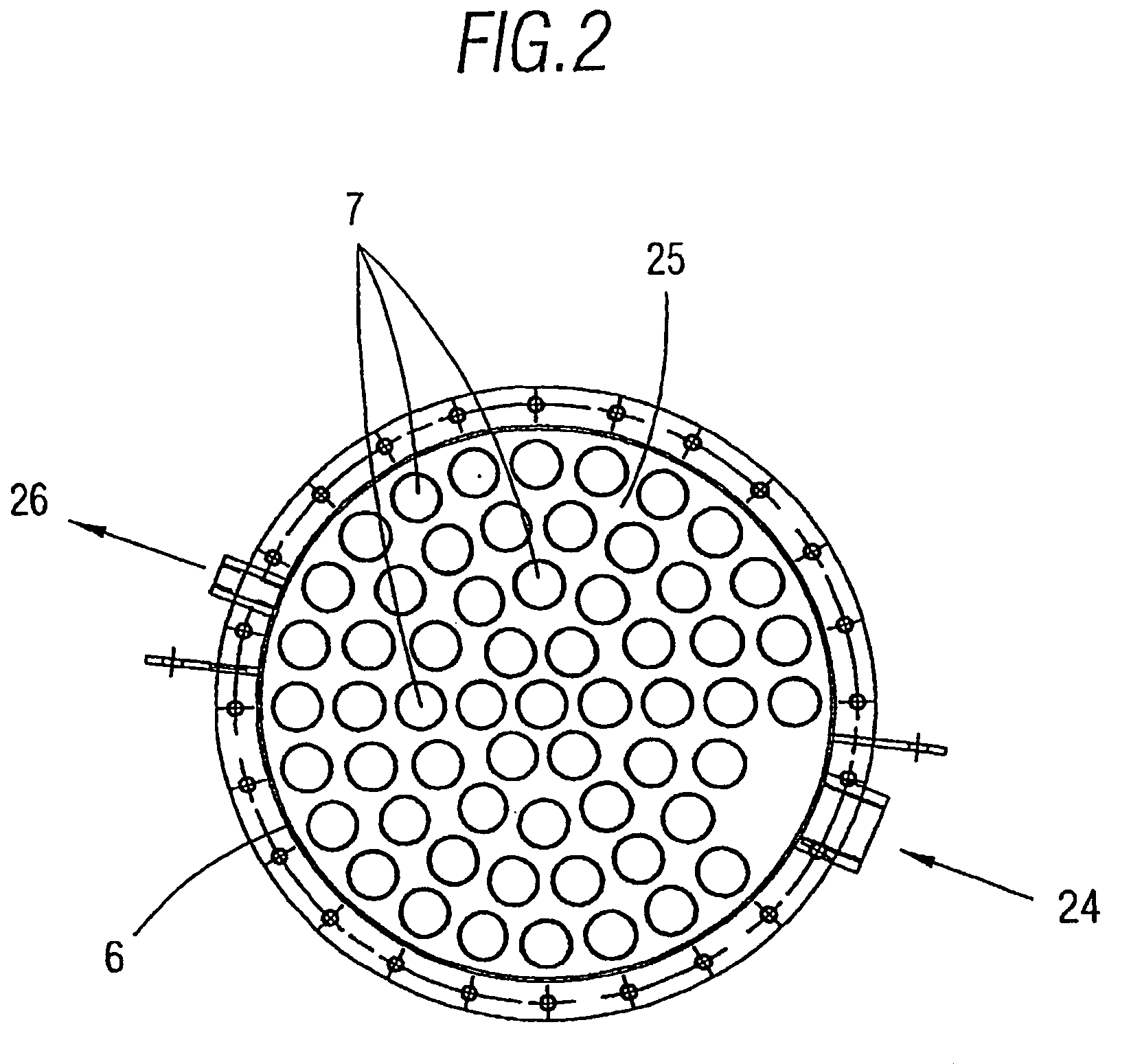

Distiller for liquids, liquids distillation method and equipment for treating sewage, which equipment includes said distiller

InactiveUS20050051418A1Problems of largeIncrease in sizeEvaporation with vapour compressionVapor condensationEvaporationEngineering

The distiller includes an exchanger (6) of tubes (7) which fill with the liquid to be treated, means (14) of heating, means (23) for compressing the steam from evaporation of the liquid, means (24) for feeding the compressed steam around the tubes (7) and means (27, 28) for inducing turbulence into the liquid, preferably by making the compressed steam bubble inside it. The method includes heating the liquid and supplying it to the tubes of the exchanger, compressing the resulting steam and bringing it into contact with the exterior of the tubes. The equipment uses a distiller such as that described. The invention permits treatment of sewage and other liquids by distillation, with minimum energy consumption and in a small space.

Owner:TECNICAS MODULARES E IND

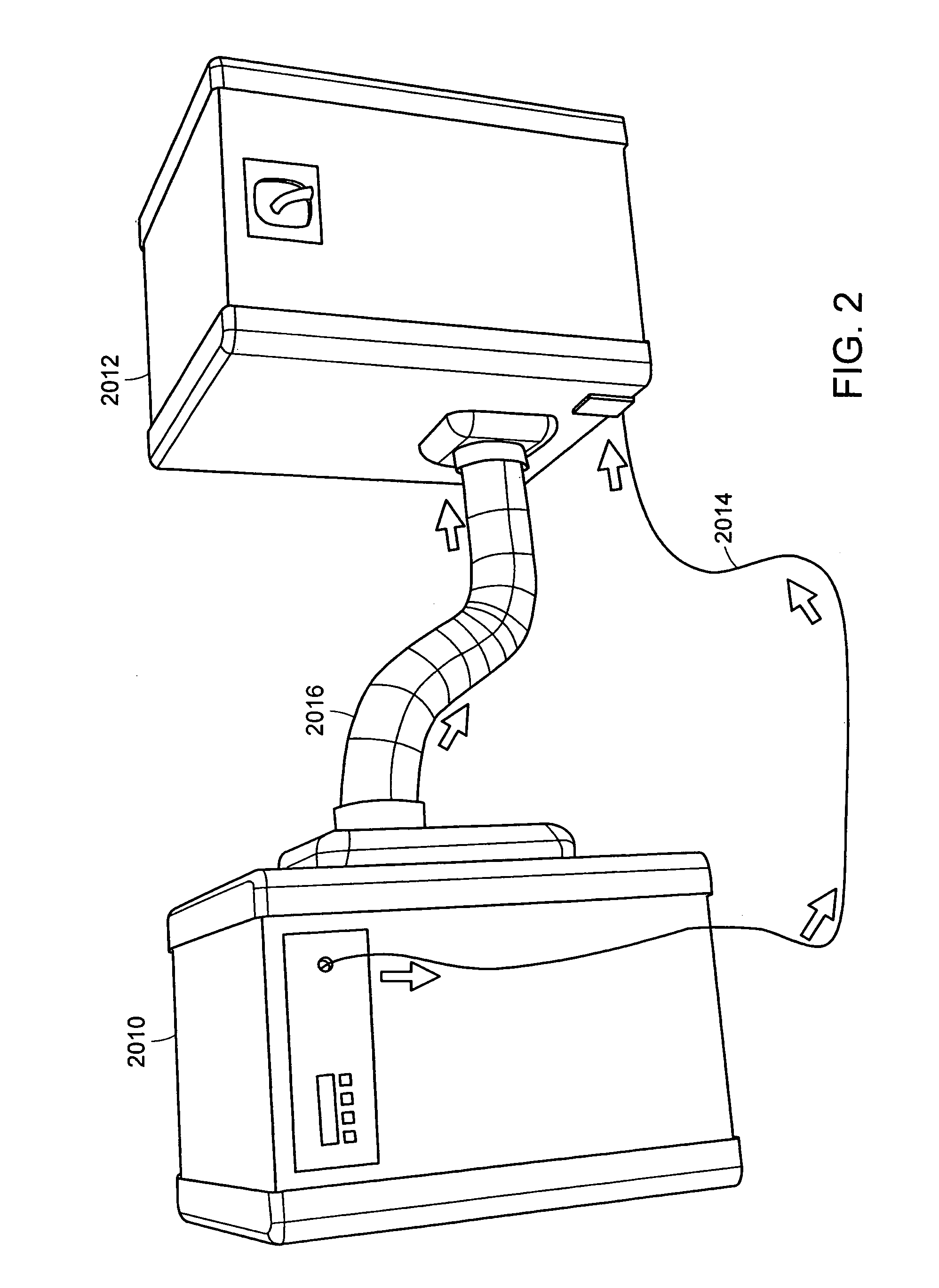

Liquid evaporation system with heated liquid

InactiveUS8623174B1Liquid separation auxillary apparatusDrying using combination processesWater vaporWastewater

A liquid evaporation system for evaporating clean water from a reservoir of wastewater includes a liquid evaporator to evaporate and separate water vapor from the wastewater in a confined space, an air blower to supply air to the liquid evaporator, and a wastewater heating system arranged to collect heat to heat the wastewater in the reservoir.

Owner:HEARTLAND TECH PARTNERS

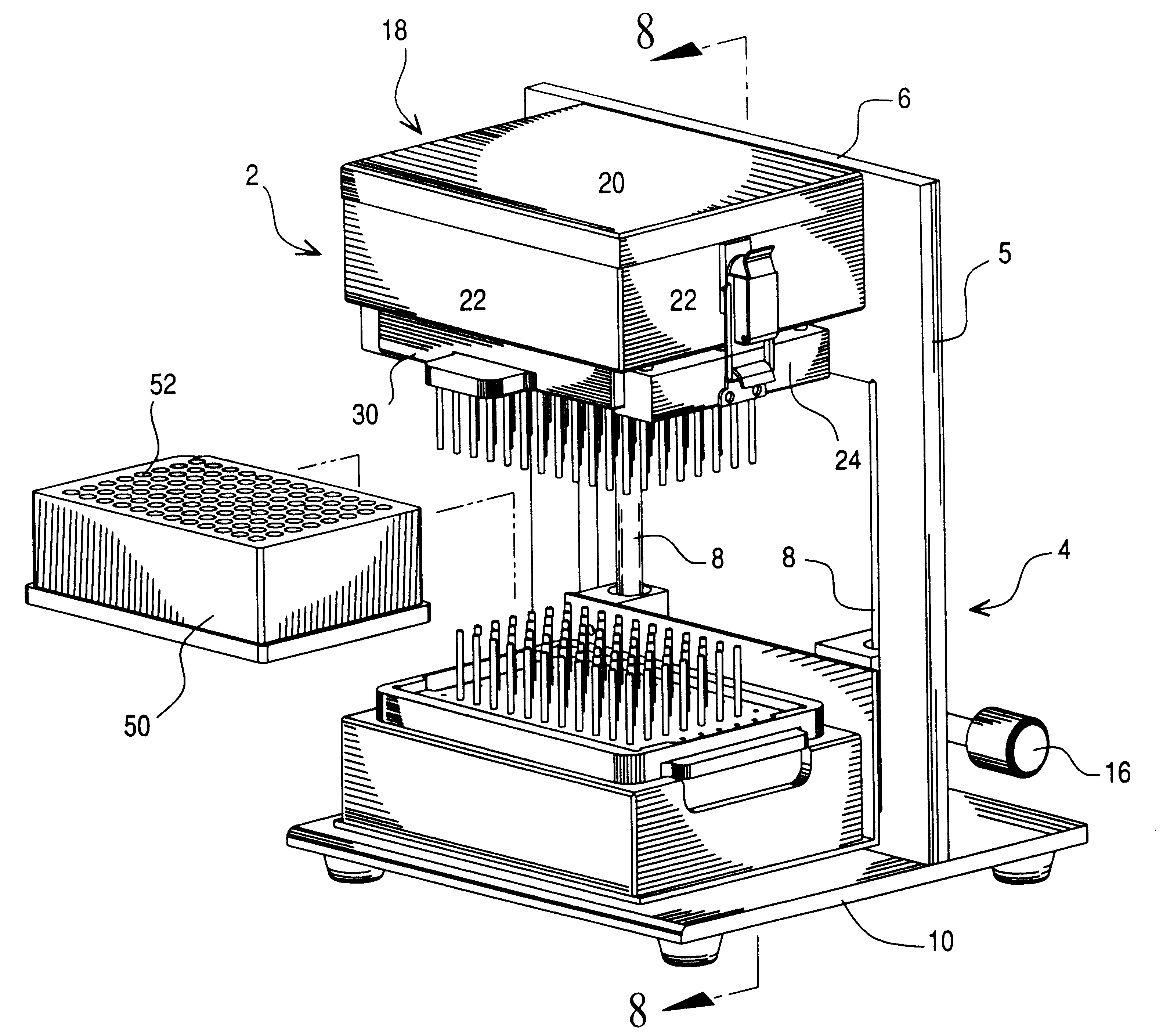

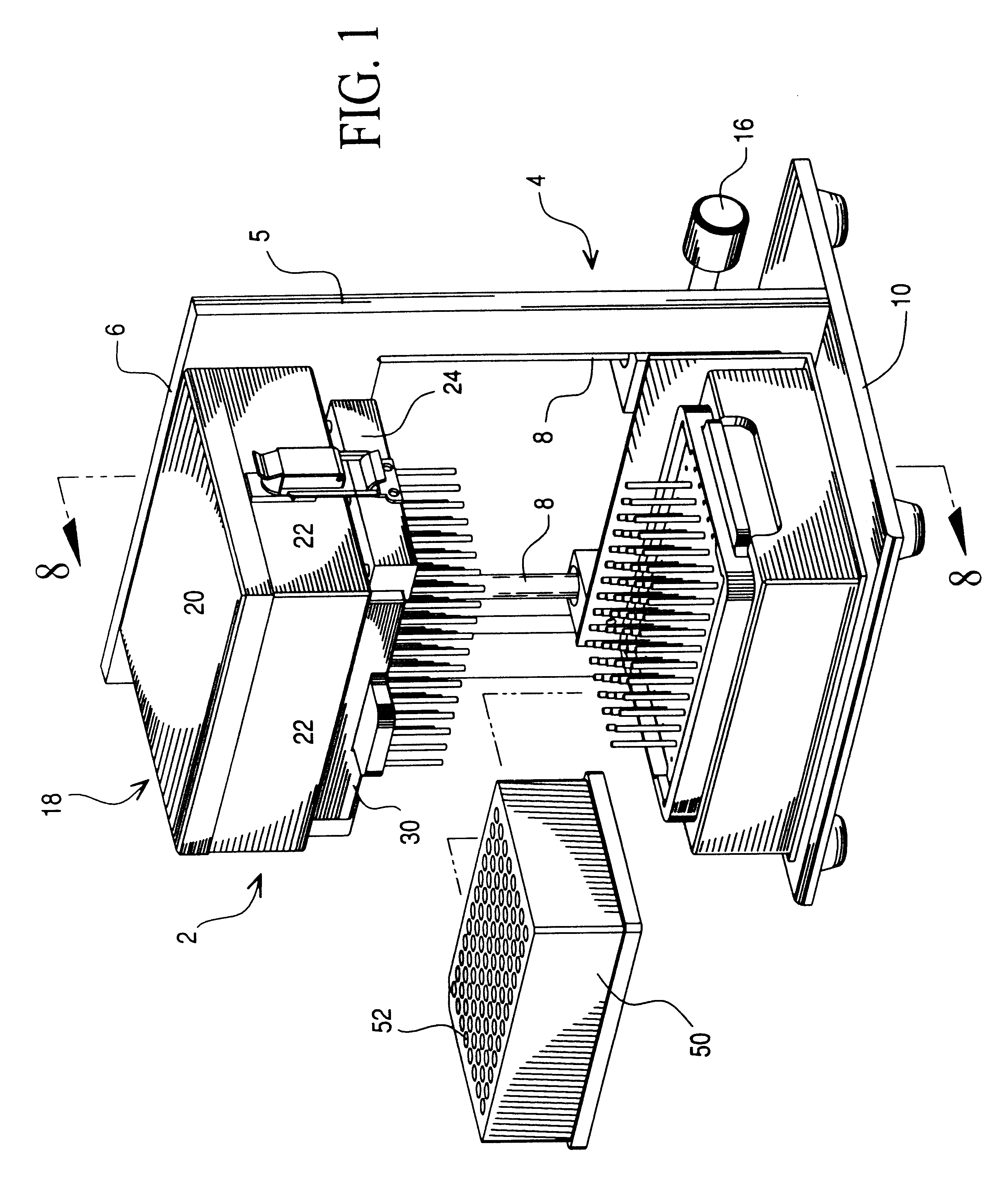

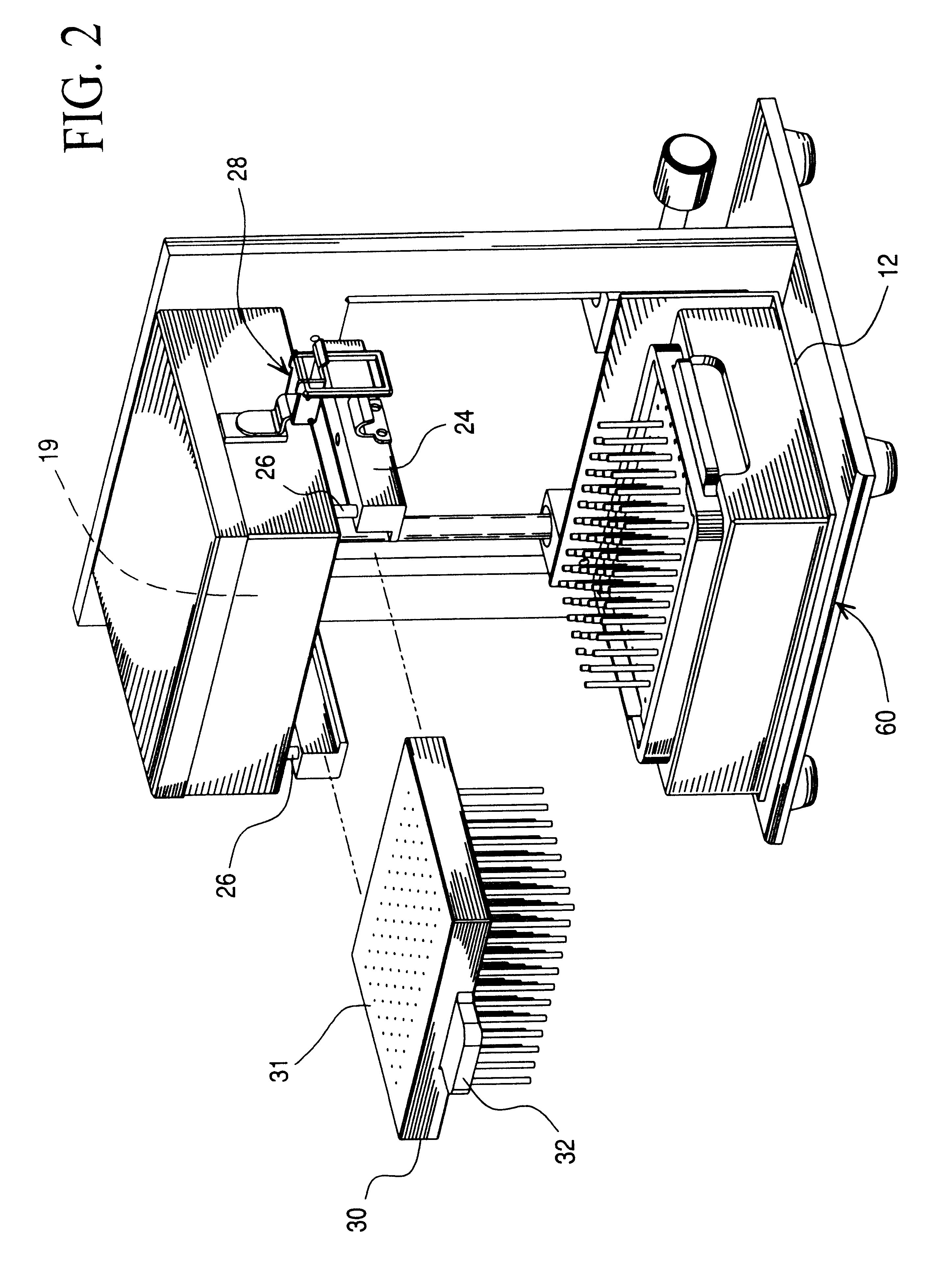

Solid phase evaporator device

InactiveUS6464943B1Easy to useReduce processWithdrawing sample devicesPreparing sample for investigationLaboratory deviceModularity

A laboratory evaporator device is disclosed which is modular in form so that the modular member supporting depending, upraised hollow needles or tubes through which evaporating fluid is conducted, may be individually sterilized and cleansed to thereby forestall cross-contamination. The laboratory device is simple in use, of relatively low cost and is of rugged construction.

Owner:YIU FELIX H

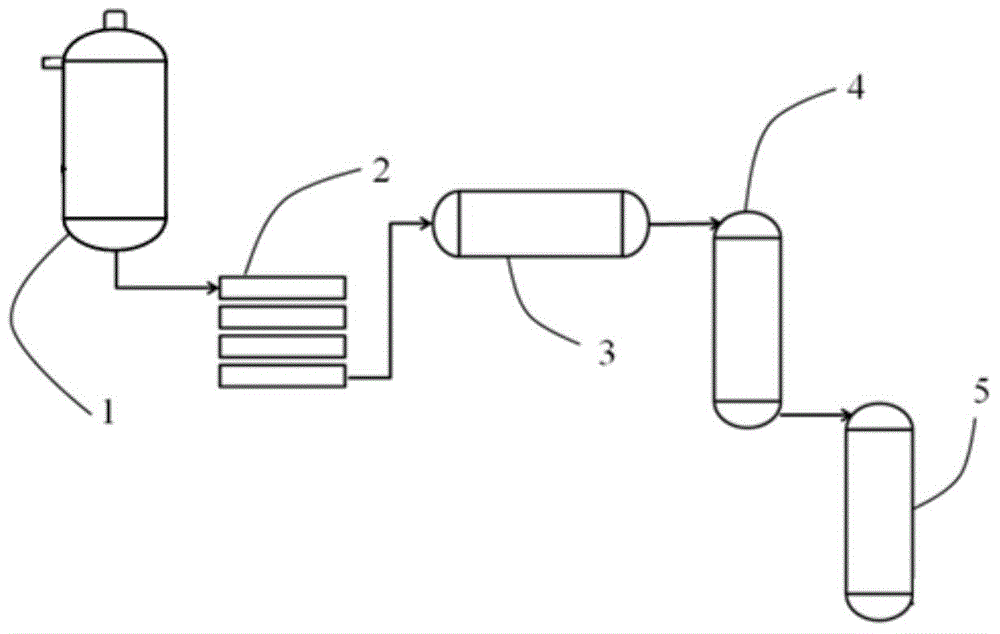

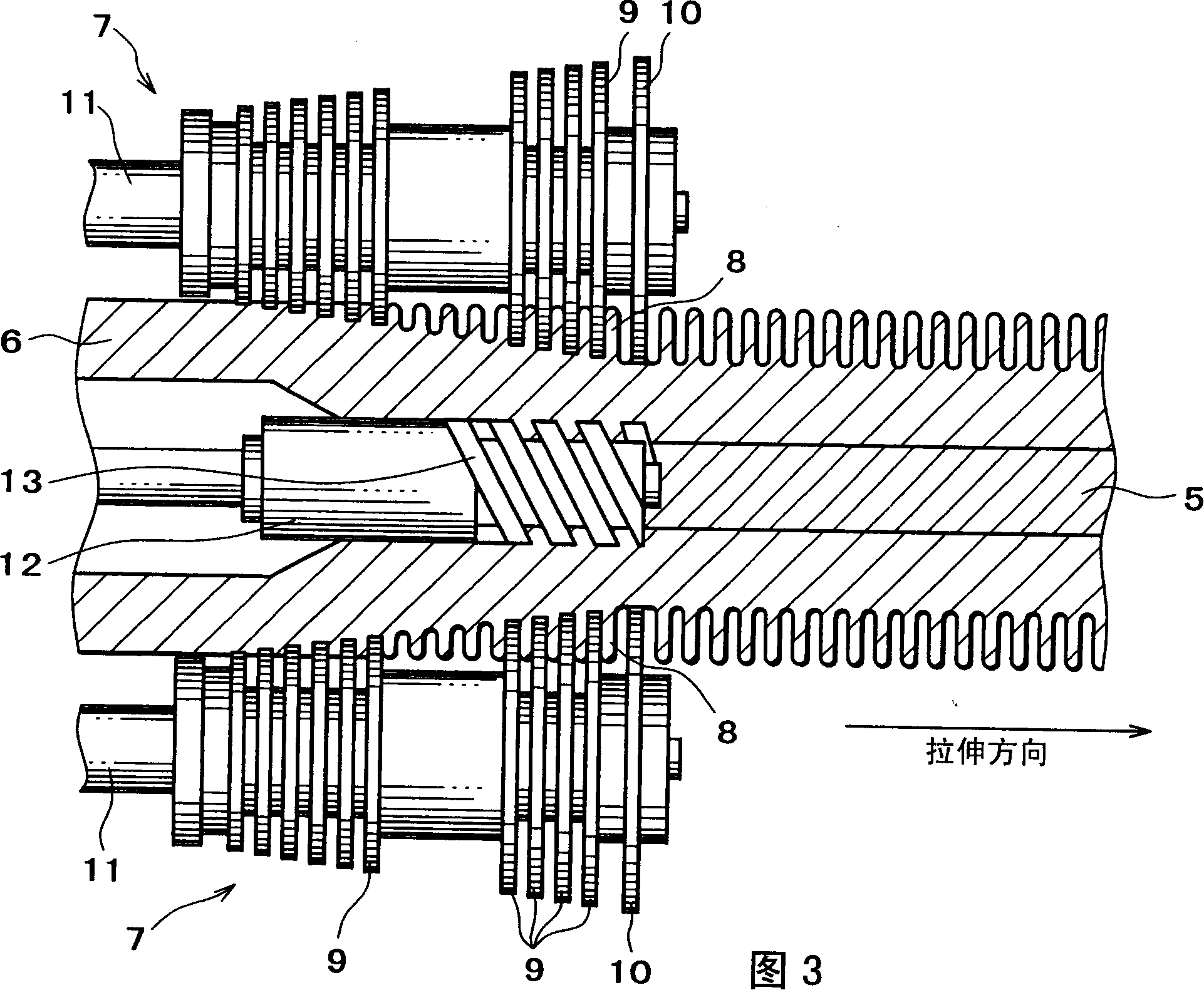

Production equipment and method of polyamide 5X

ActiveCN105885037ASuitable for continuous polymerization processGuaranteed uptimeEvaporator accessoriesChemical/physical/physico-chemical stationary reactorsPolyamideProcess engineering

The invention provides production equipment and method of polyamide 5X. The production equipment comprises a concentration device, a prepolymerization device, a pressure reducing device, a separating device and a final polymerization device which are connected in sequence. The concentration device, the prepolymerization device, the pressure reducing device, the separating device and the final polymerization device are adopted in the production equipment of polyamide 5X, operation of all production links is guaranteed, and the production equipment and method are especially suitable for producing polyamide 5X.

Owner:CATHAY R&D CENT CO LTD +2

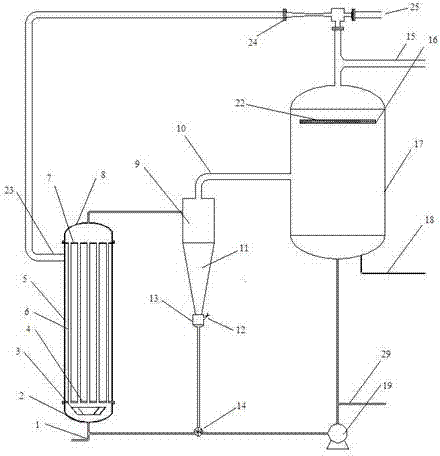

Full-automatic descaling multi-effect evaporator

ActiveCN102921179AFast flowAvoid formingEvaporator accessoriesMultiple-effect evaporationMultiple-effect evaporatorEngineering

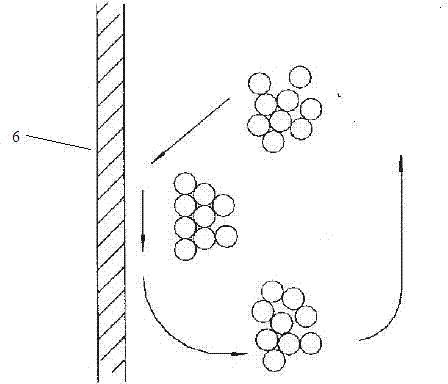

The invention discloses a full-automatic descaling multi-effect evaporator, which comprises a heater and an evaporation chamber, wherein a granule distributor which can make fluid be distributed to tube nests of the heater uniformly is arranged at the bottom of the heater; and a granule separator is also arranged between the heater and the evaporation chamber. Due to the adoption of the technical scheme, the full-automatic descaling multi-effect evaporator has the advantages that a descaling process can be simplified, heat transfer is enhanced, and a heat transfer coefficient is increased, so that the evaporator can clean and remove scales online to realize continuous production. According to the optimized technical scheme, an intensifier ring is arranged in the granule separator, and a granule separation chamber and a granule storage chamber are also formed in the granule separator, so that liquid forms a vortex which rotates at high speed when passing through the cylindrical granule separation chamber under the action of centrifugal force formed by the intensifier ring to do circular rotary motion, so that granular solids are separated from the liquid quickly.

Owner:JIANGSU HUATAI HEAVY IND EQUIP

Heat transferring tube for downward flow fluid membrane distiller

InactiveCN1391080AImprove moisture spreadingImprove heat transfer performanceTubular elementsEvaporators with vertical tubesEngineeringRefrigerant

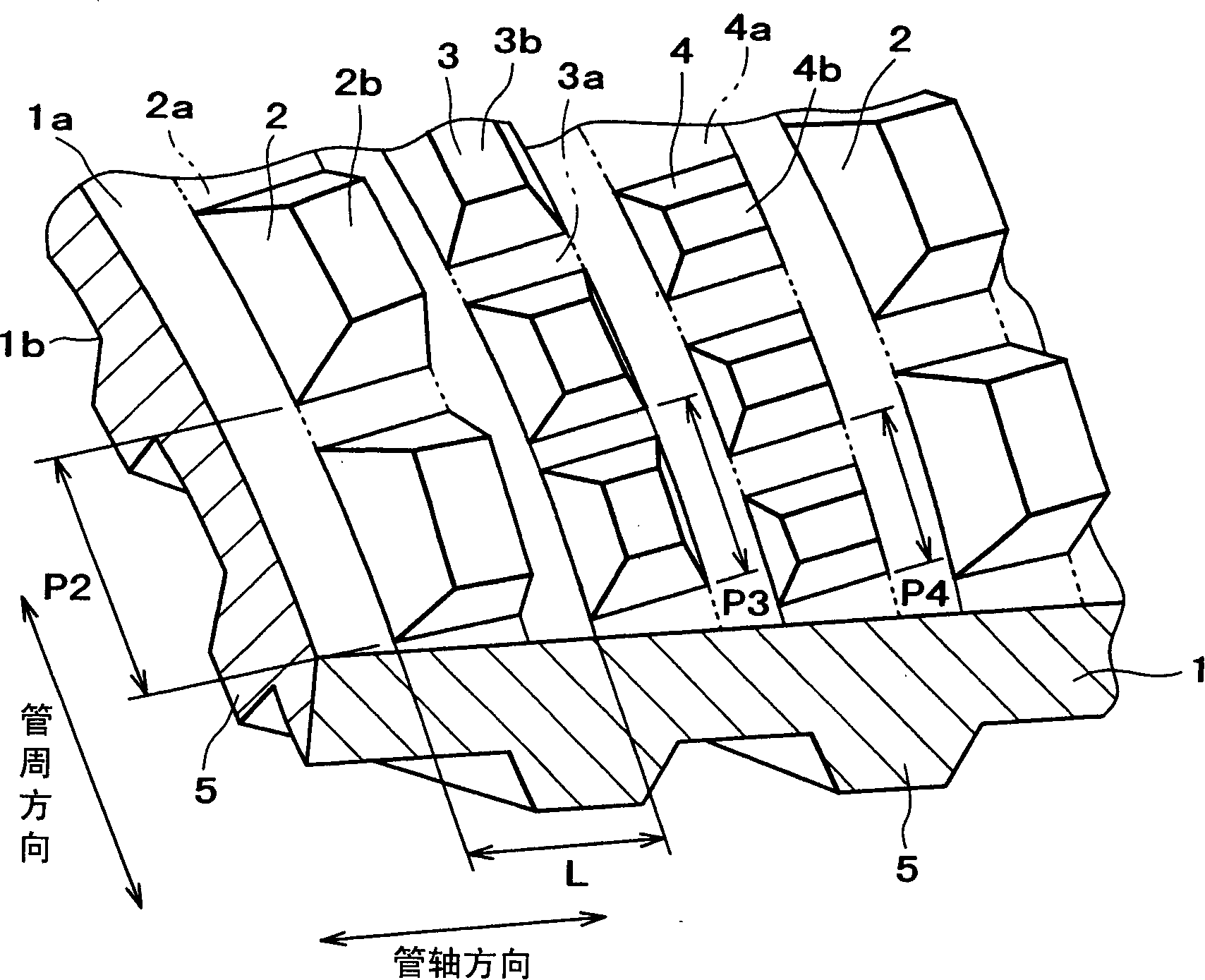

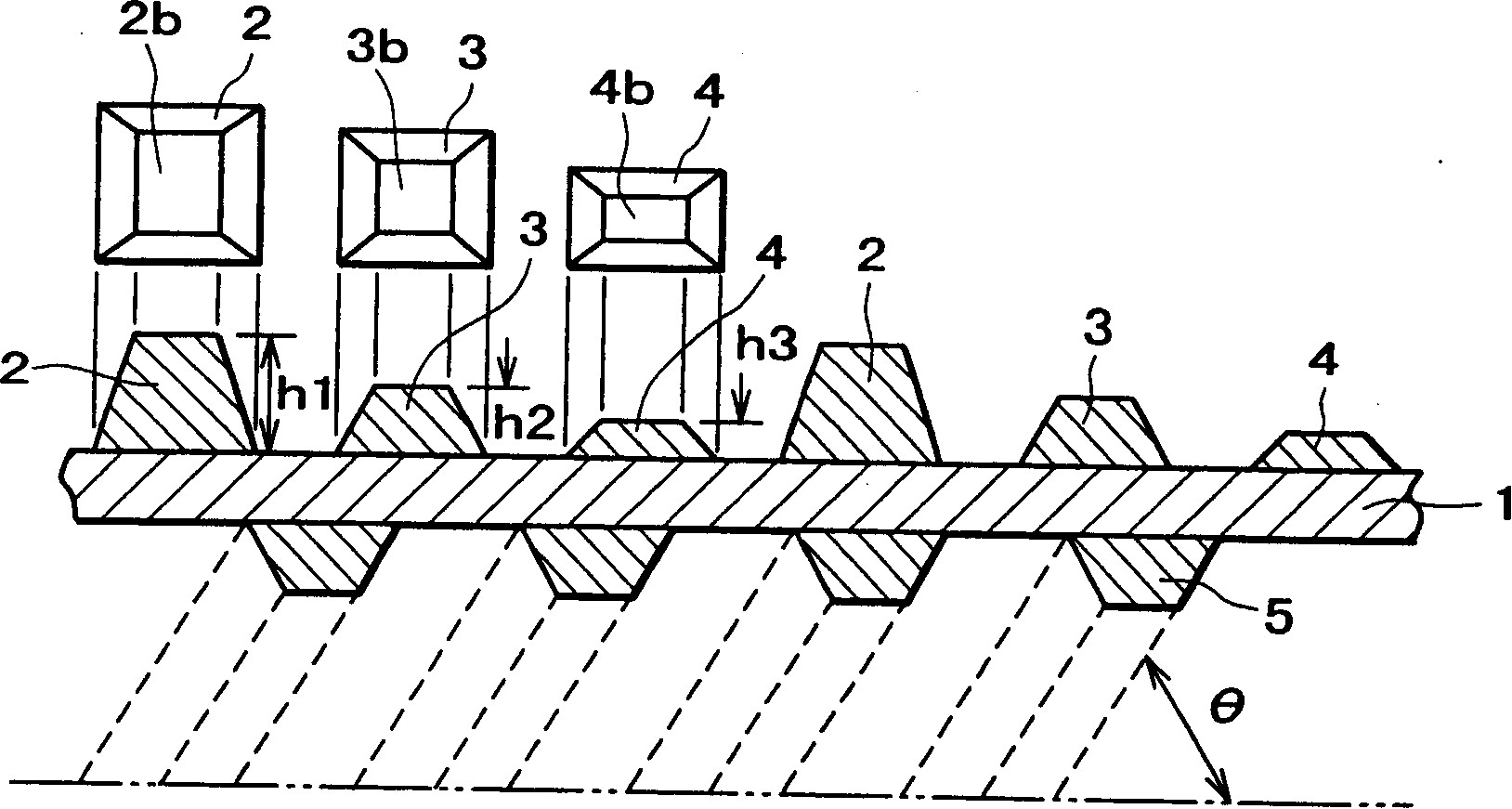

The present invention provides a heat transfer tube for a falling film type evaporator, in which water spreading characteristics, particularly the water spreading characteristics in the tube axis direction, enhancing the heat transfer ability. Three types of projections 2, 3, and 4 are formed on an external surface 1a of a heat transfer tube body 1. A respective plurality of projections 2 to 4 are arranged spirally in parallel to one another, forming projection groups 2a to 4a. The number of each projection group 2 to 4 is one. Pitches P2 to P4 for the projections 2 to 4 are in the range of 0.35 mm<=P4 F28F 1 / 42 9 17 0 2002 / 6 / 12 1391080 2003 / 1 / 15 1228603 2005 / 11 / 23 2005 / 11 / 23 2005 / 11 / 23 Kobe Steel Ltd. Japan Ota Yoshio Saiki Chikara Takahashi Hiroyuki wang huimin 11021 The Patent Agency of the Chinese Academy of Sciences Inside the Chinese Academy of Sciences, No.52 Sanlihe Road, Fuwai, Beijing 100864 Japan 2001 / 6 / 12 2001-177516

Owner:KOBE STEEL LTD

Method and system for treating feedwater

Owner:AHT SOLUTIONS +1

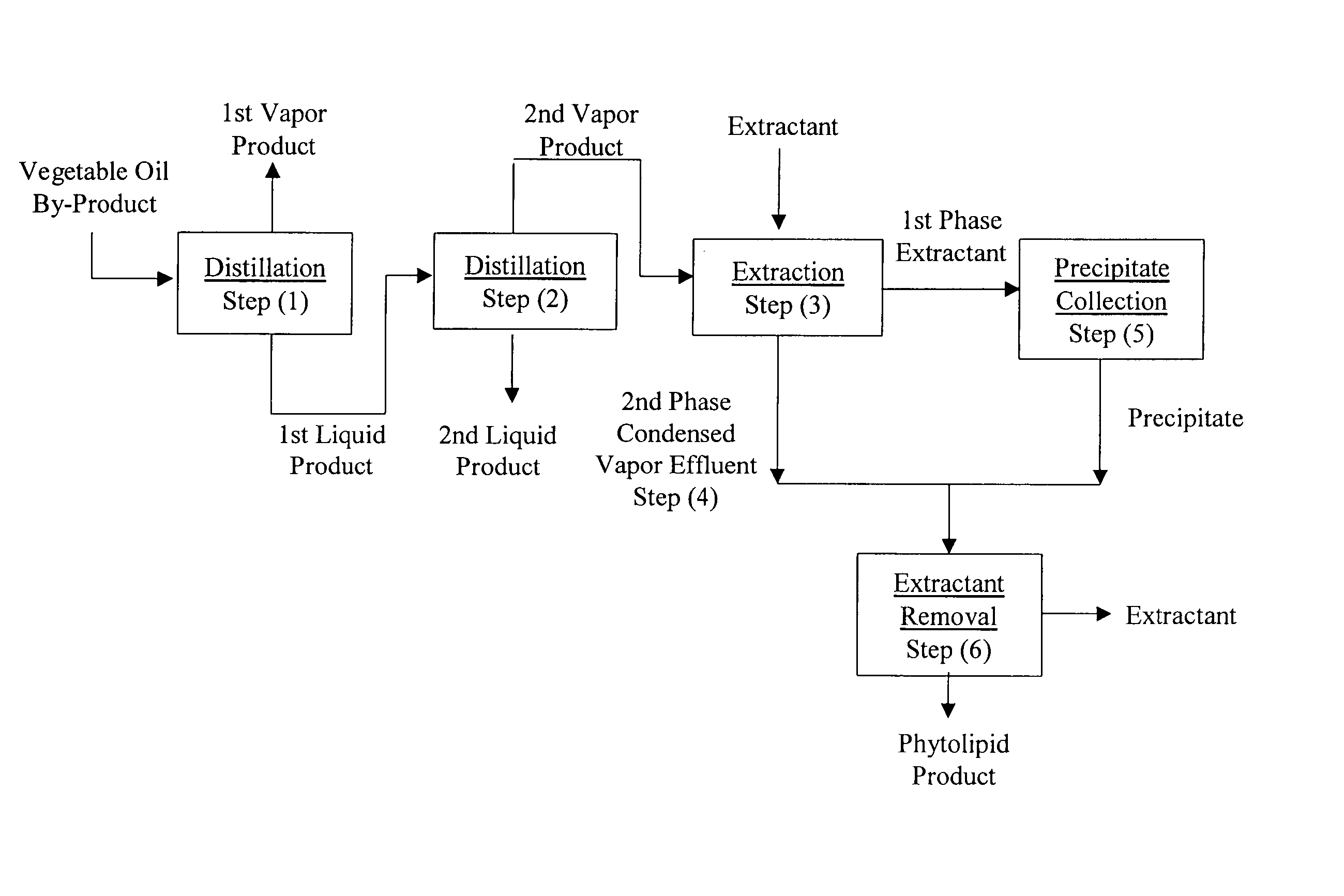

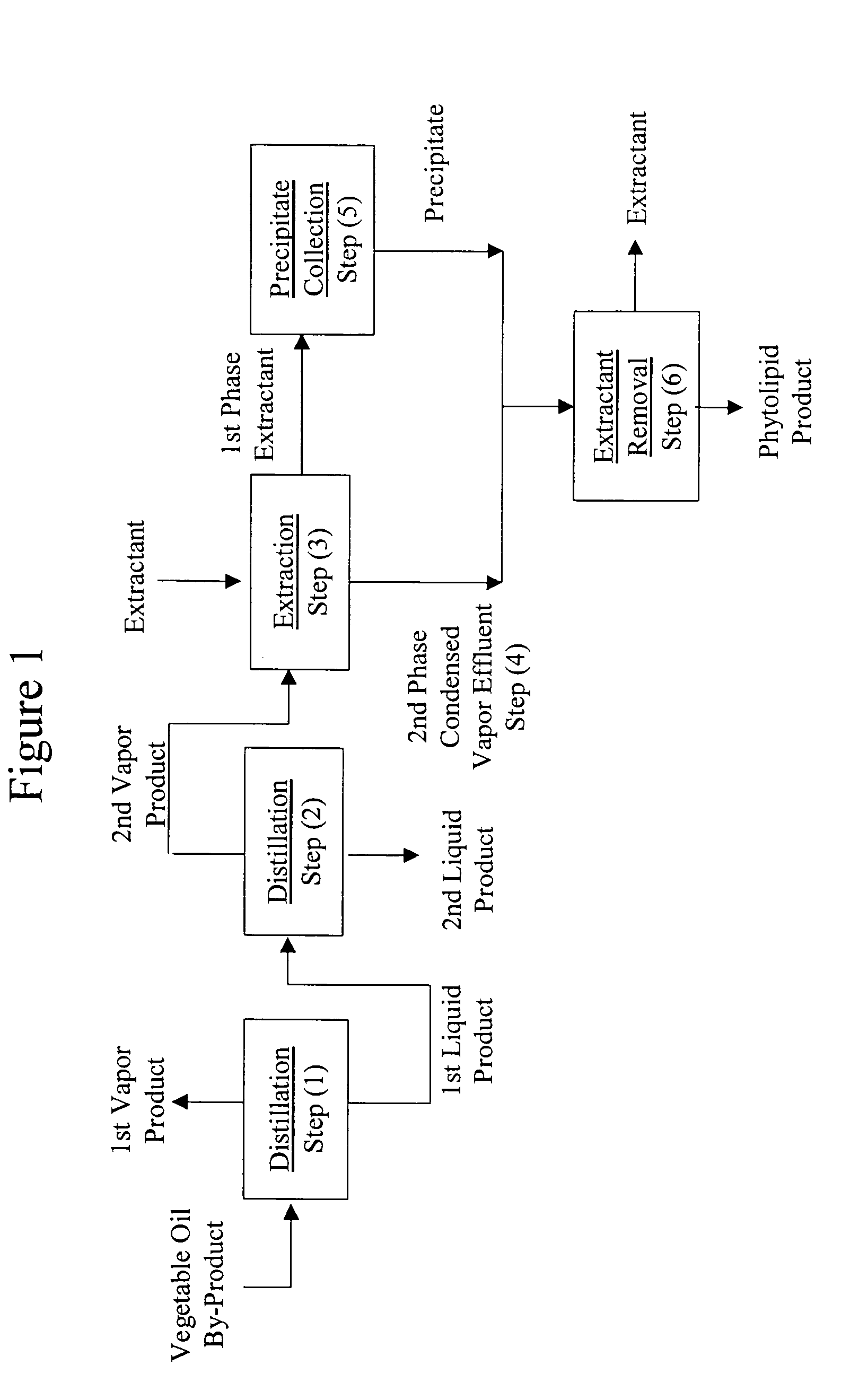

Process for the recovery of a phytolipid composition

InactiveUS20050051419A1Easy to prepareLow viscosityFatty oils/acids recovery from wasteEdible oils/fats ingredientsVegetable oilMedicine

Disclosed is a process for the recovery of a phytolipid composition from a vegetable oil by-product. The phytolipid composition produced comprises squalene, phytosterols, mixed tocopherols and tocotrieneols, and vegetable wax and is useful as an emollient. The phytochemical composition may be applied directly to the skin to provide emolliency. Alternatively, the phytolipid composition may be formulated in various aqueous or anhydrous cosmetic compositions such as creams, lotions, gels, ointments, lip balms, sticks, or pencils for treatment of the skin and lips. The phytolipid composition also may be incorporated into foods, beverages, and nutraceuticals to provide health benefits.

Owner:EASTMAN CHEM CO

Method and system for treating feedwater

A system for treating feedwater includes a fluidized bed heat exchanger unit connected to receive feedwater and a flash concentrator column connected to receive feedwater discharged from the fluidized bed heat exchanger unit. A spray dryer is provided to receive a solids / liquid slurry discharged from the flash concentrator column. Feedwater can be treated by converting dissolved solids in the feedwater to suspended solids, vaporizing a portion of the feedwater to produce a solids / liquid slurry, and separating solids from the solids / liquid slurry.

Owner:AHT SOLUTIONS +1

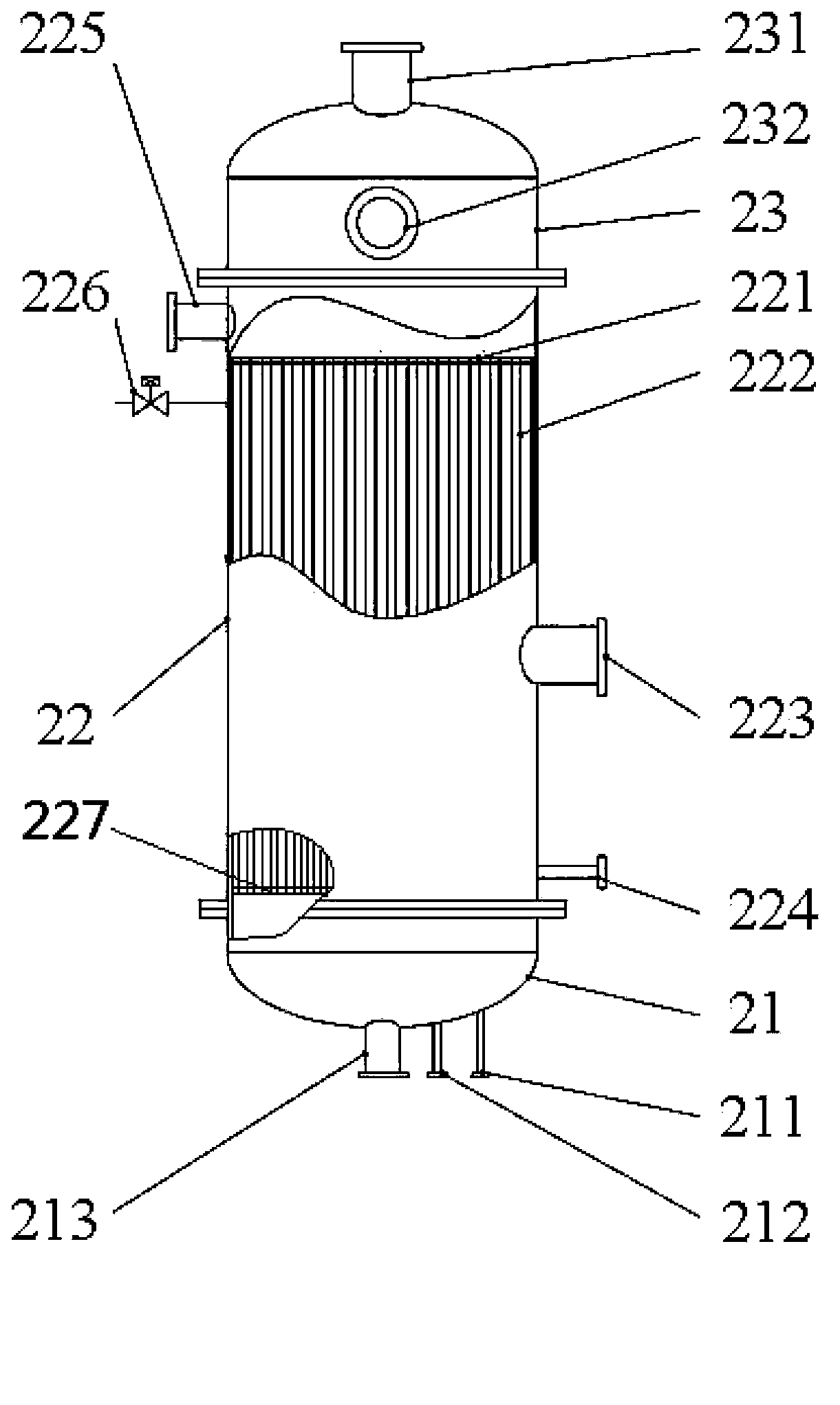

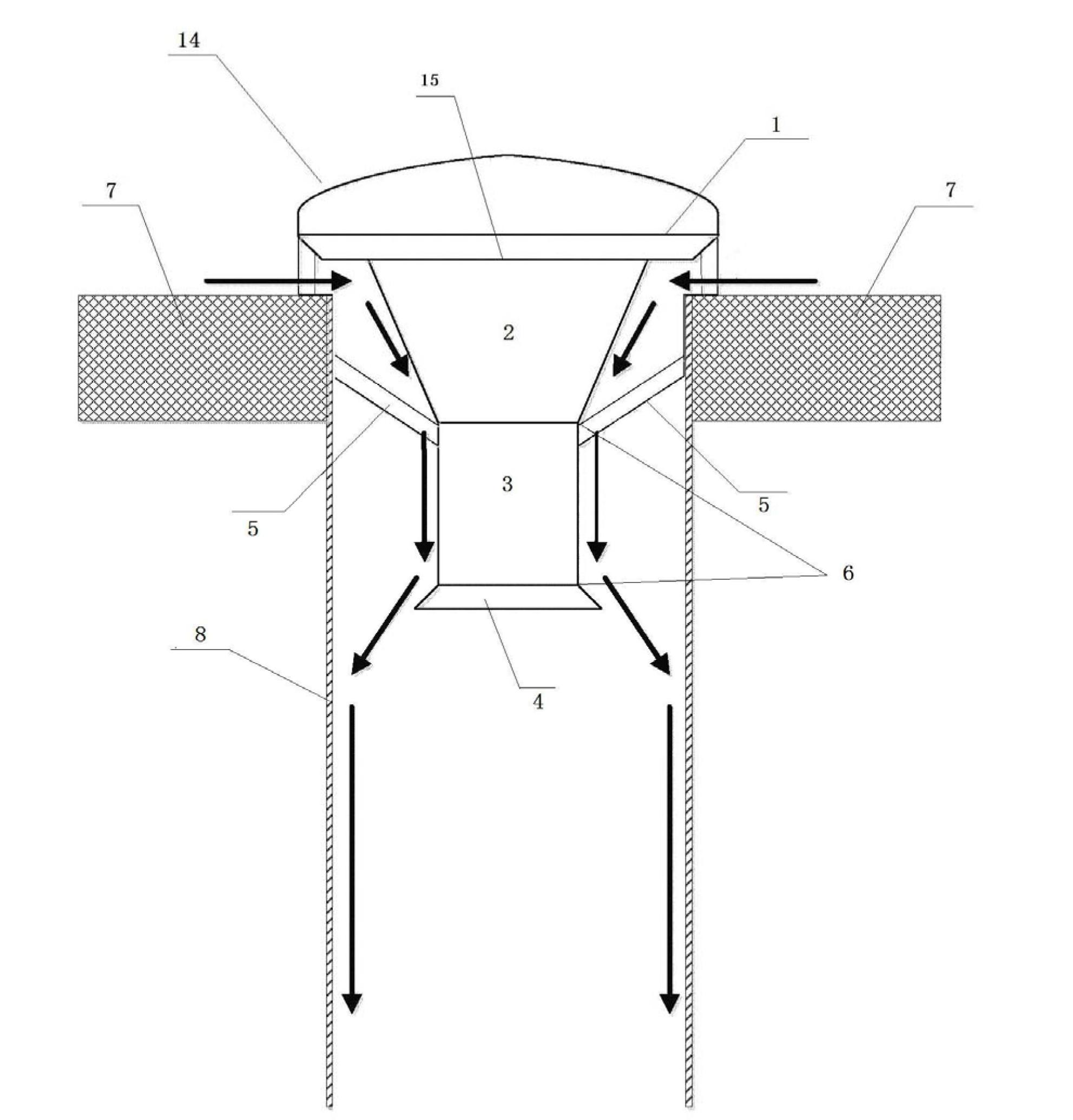

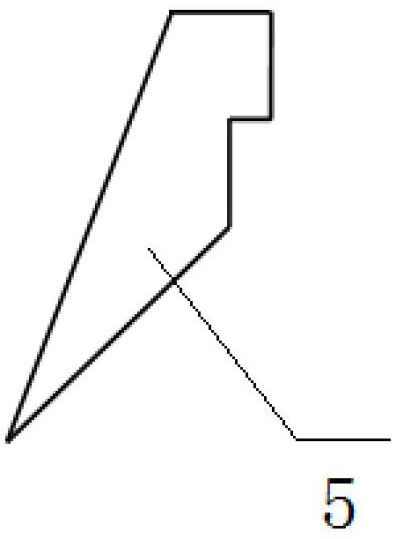

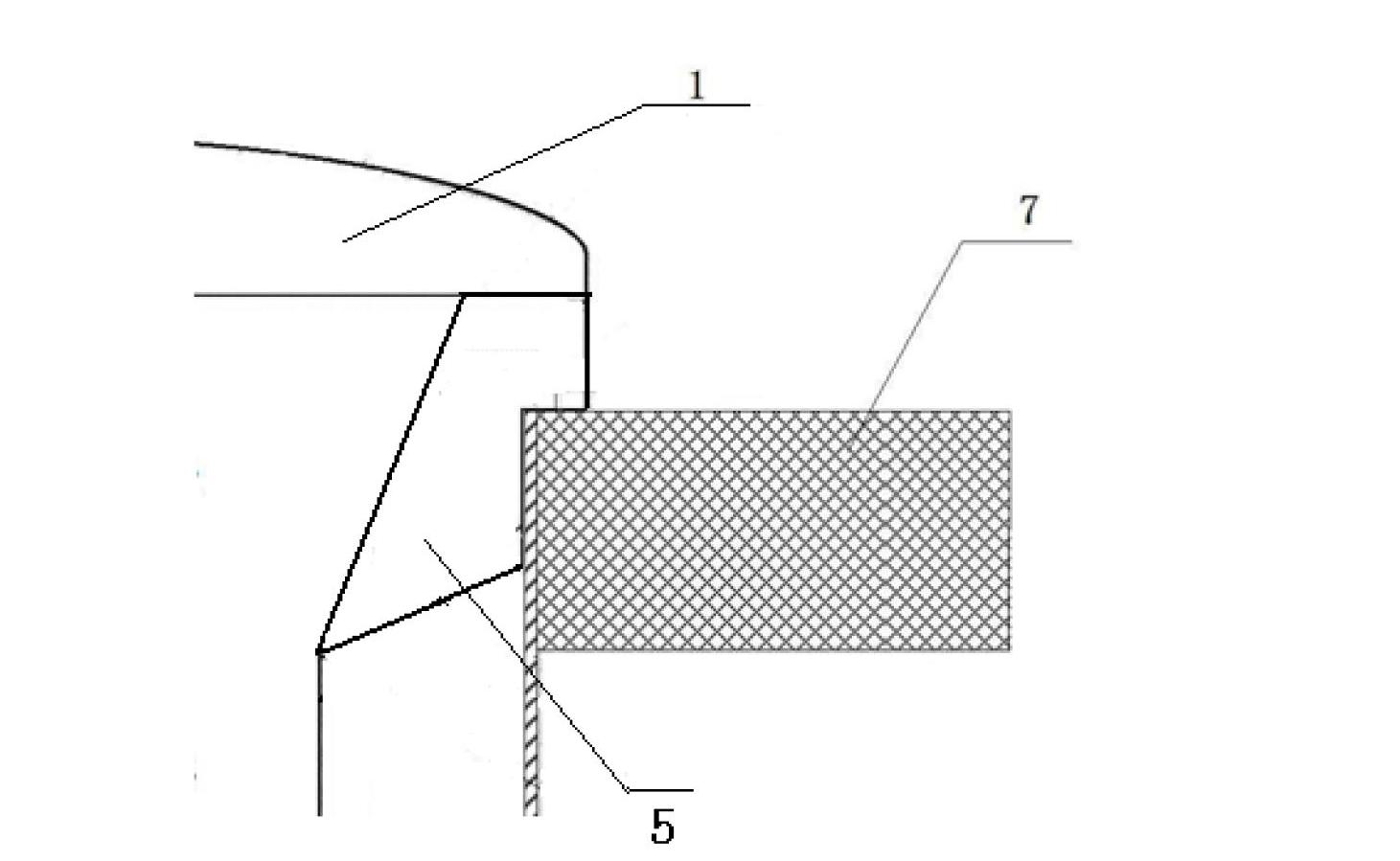

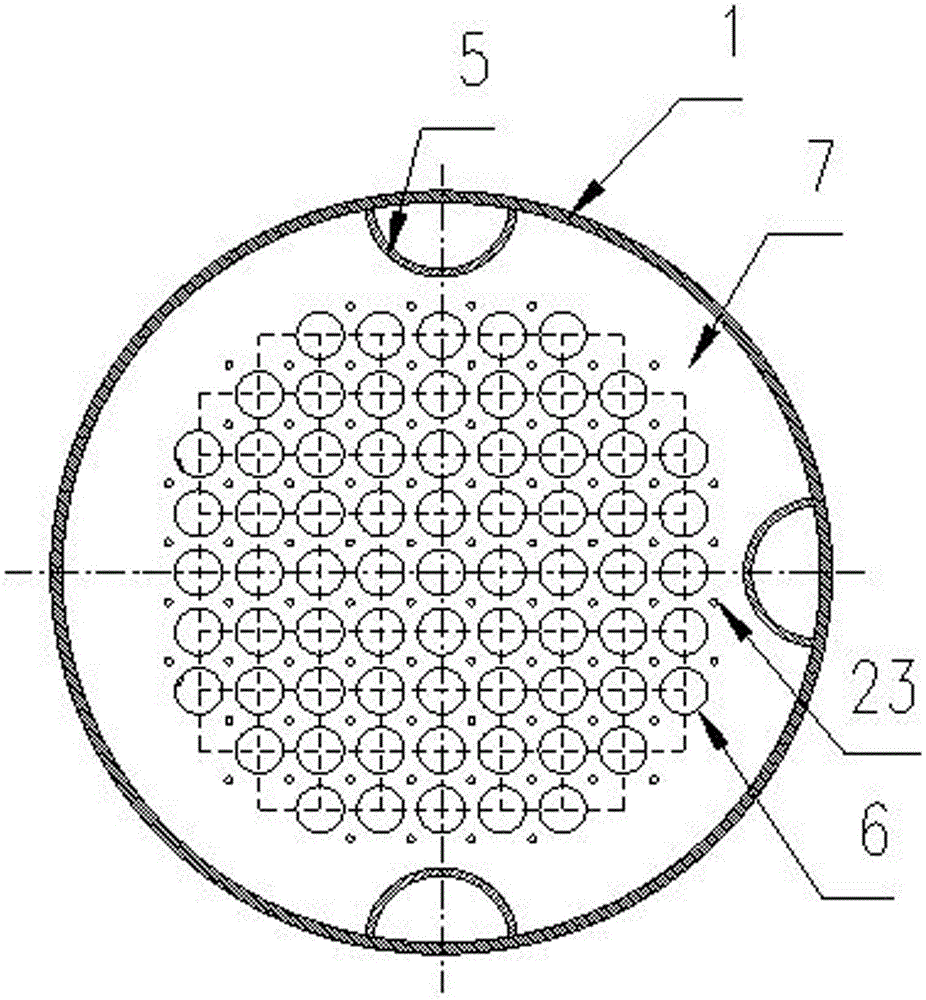

Liquid distributor and vertical tube falling film evaporator comprising same

ActiveCN102657948AReduce areaReduce depositionEvaporator accessoriesEvaporators with vertical tubesVertical tubeEngineering

The invention discloses a liquid distributor and a vertical tube falling film evaporator comprising the same. The liquid distributor mainly comprises a flow-guiding body and a support component, wherein the surrounding of a main body of the flow-guiding body is a concave surface, and the basal area of a top cover of the flow-guiding body is larger than the area of a tube mouth of a heat exchange tube of the vertical tube falling film evaporator; and the flow-guiding body is movably or fixedly supported in a corresponding position of the upper part in the heat exchange tube of the vertical tube falling film evaporator through the support component, so that a certain gap exists between the undersurface edge of the top cover of the flow-guiding body and the upper surface of a tube plate of the vertical tube falling film evaporator to form an intake channel. The vertical tube falling film evaporator comprises the liquid distributor. According to the structure of the flow-guiding body of the liquid distributor, on one hand, the area of a low-speed liquid area is reduced, therefore the deposition of suspended solids can be reduced; and on the other hand, the inner wall of the heat exchange tube forms smooth liquid flow with few bubbles and a uniform liquid film is easier to form.

Owner:JIANGSU SUNPOWER TECH

Process and apparatus for removing volatile substances from highly viscous media

InactiveUS20050092444A1Reduce heat loadNarrow residence time distributionDrying using combination processesEvaporation with vapour compressionProcess engineeringViscous medium

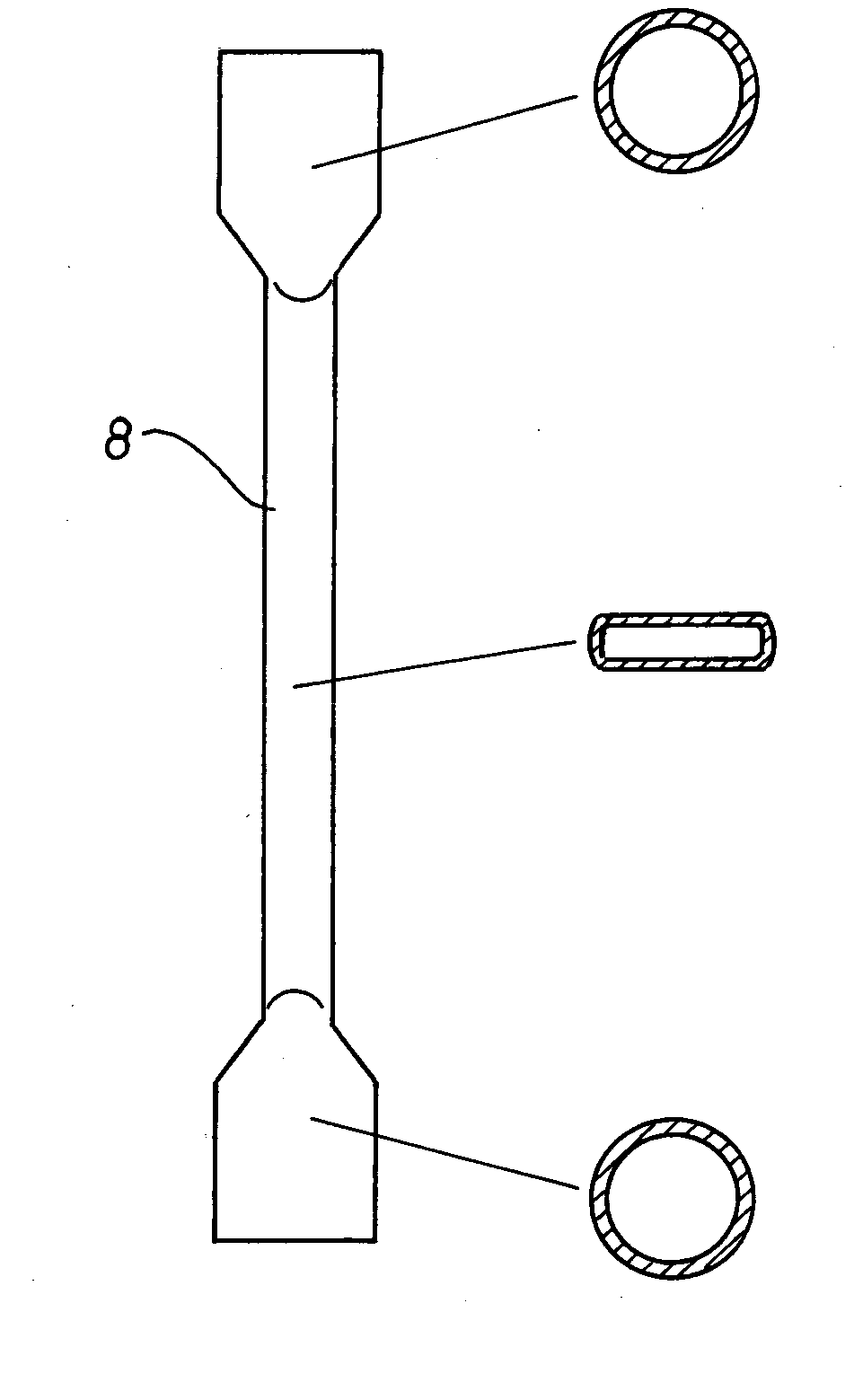

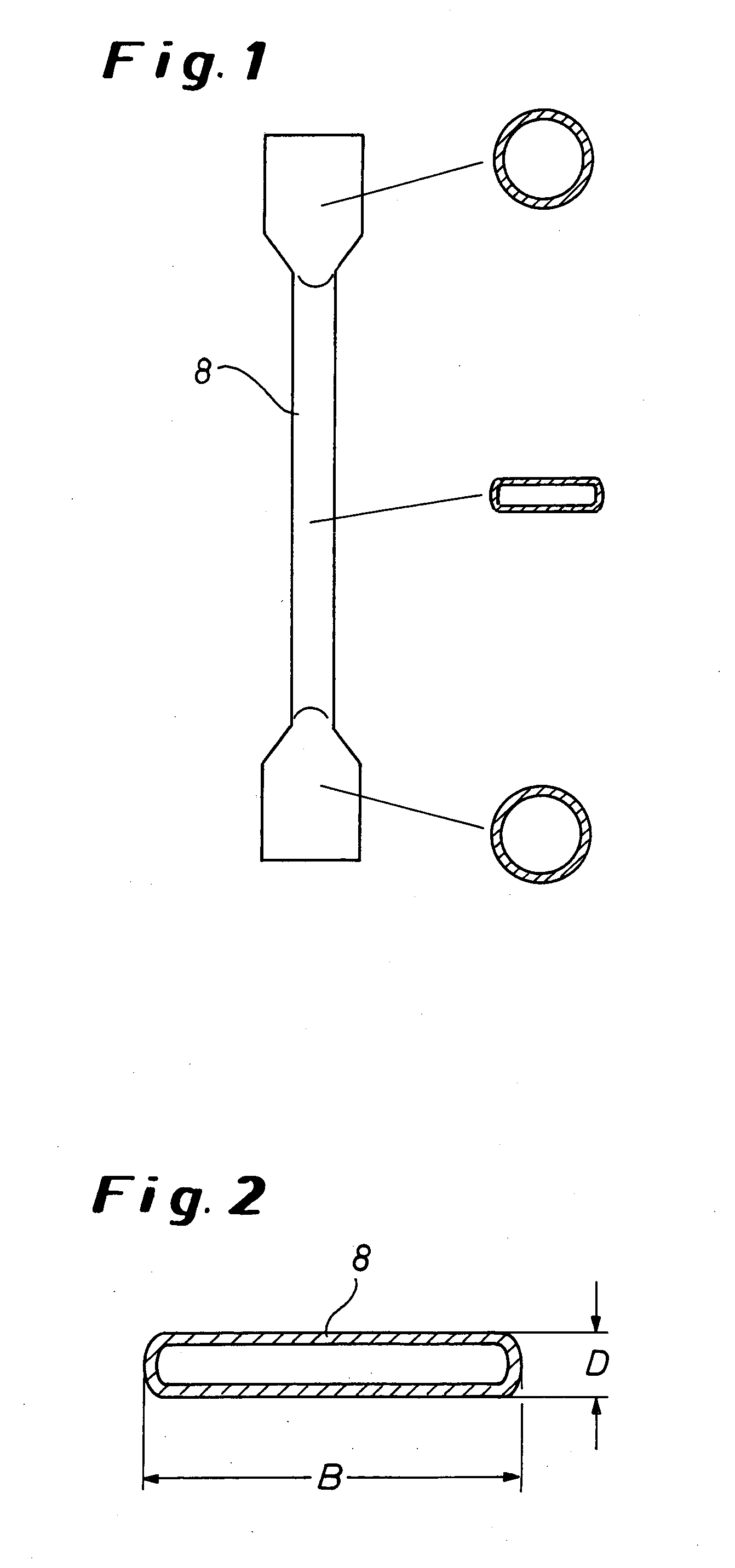

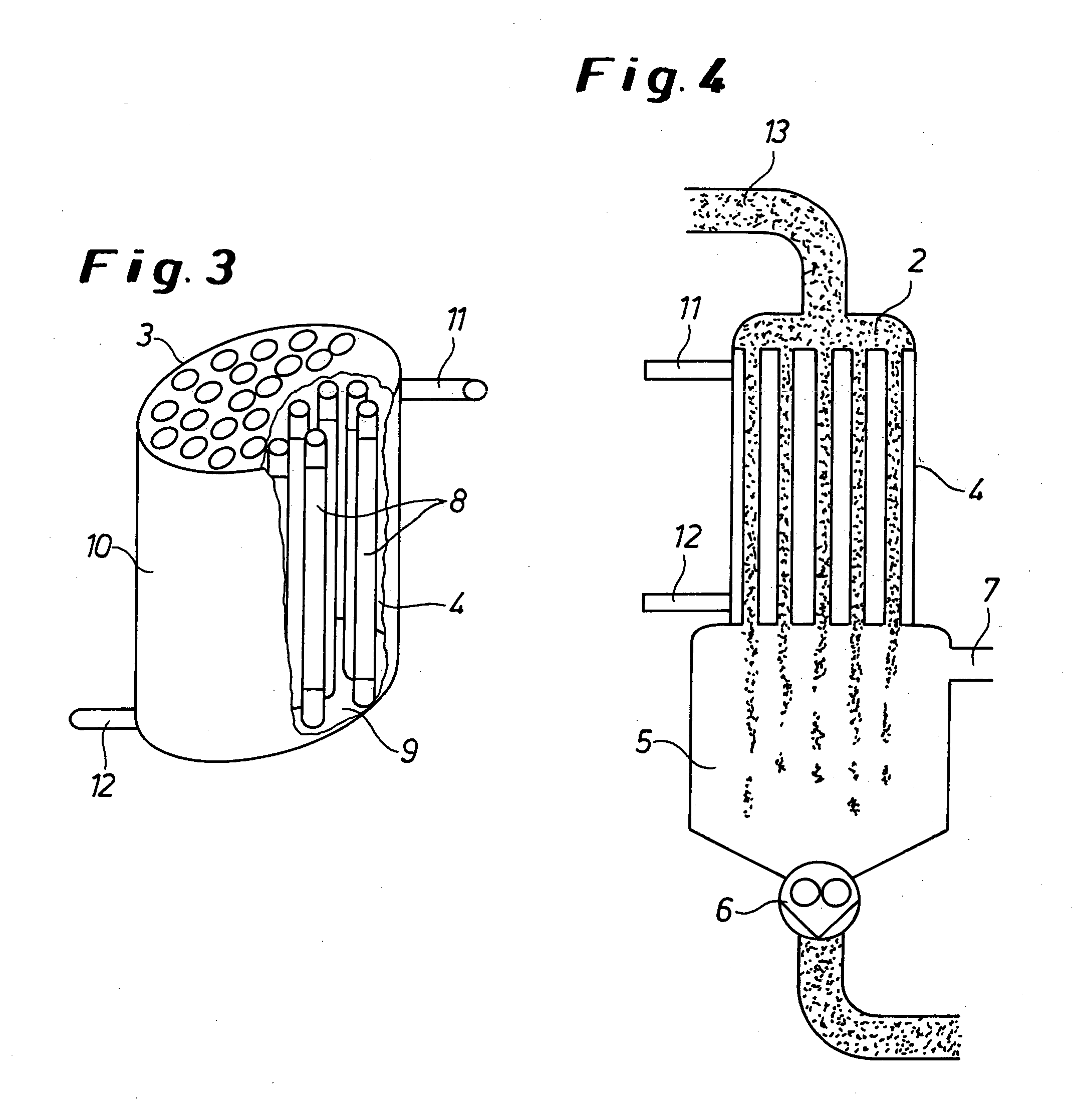

Evaporator apparatus (1) for the treatment of viscous media comprised of at least a feed chamber (2) having a perforated tray (3), a tube-bundle heat exchanger (4) connected thereto having perpendicularly arranged tubes (8) and a devolatilization chamber (5) connected thereto, a discharge unit (6) for the product and a vapor take-off (7) for removing volatile components, the tubes (8) of the heat exchanger (4) having a rectangular cross section over the greater part of their length.

Owner:BAYER TECH SERVICES GMBH

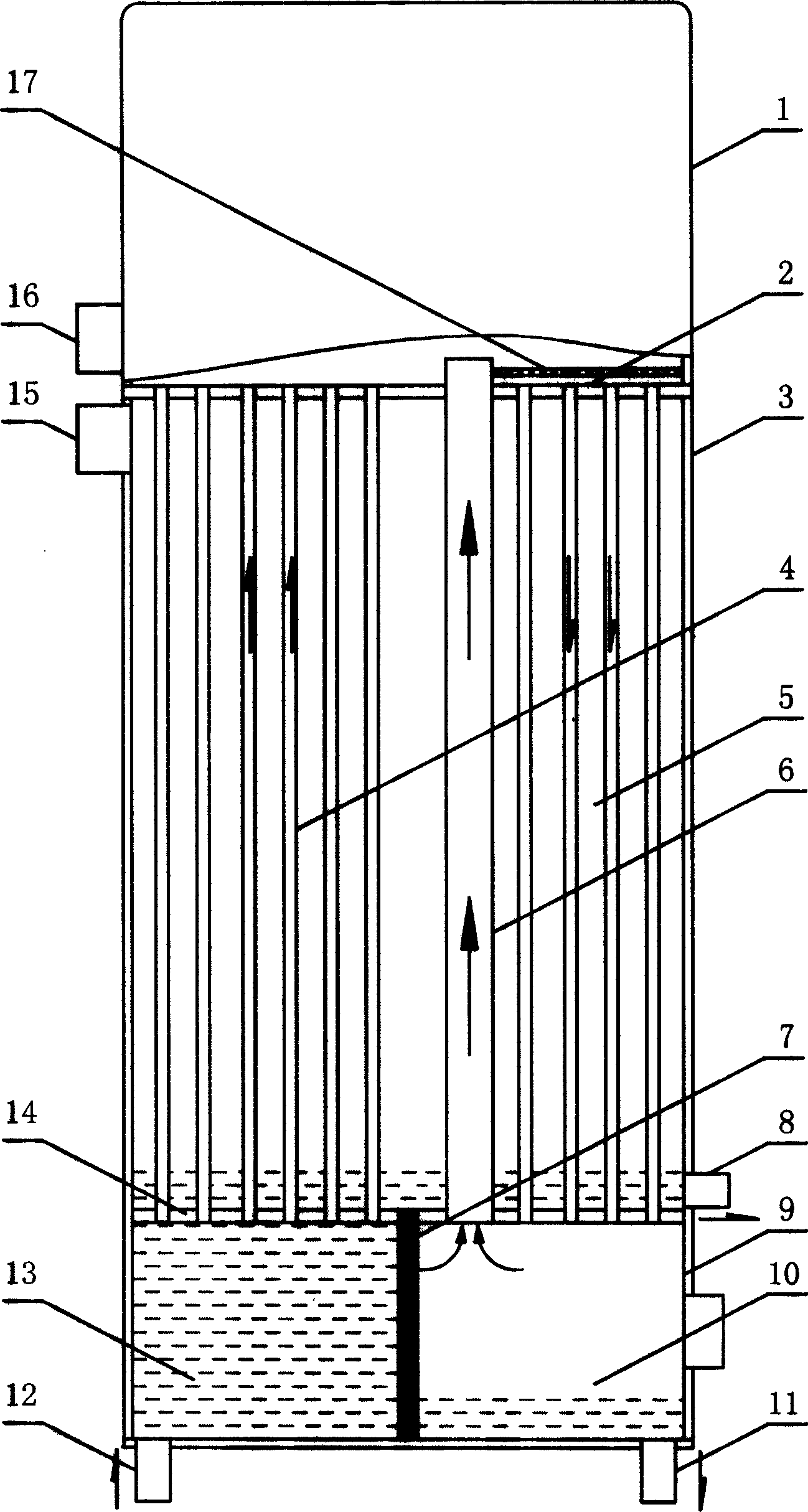

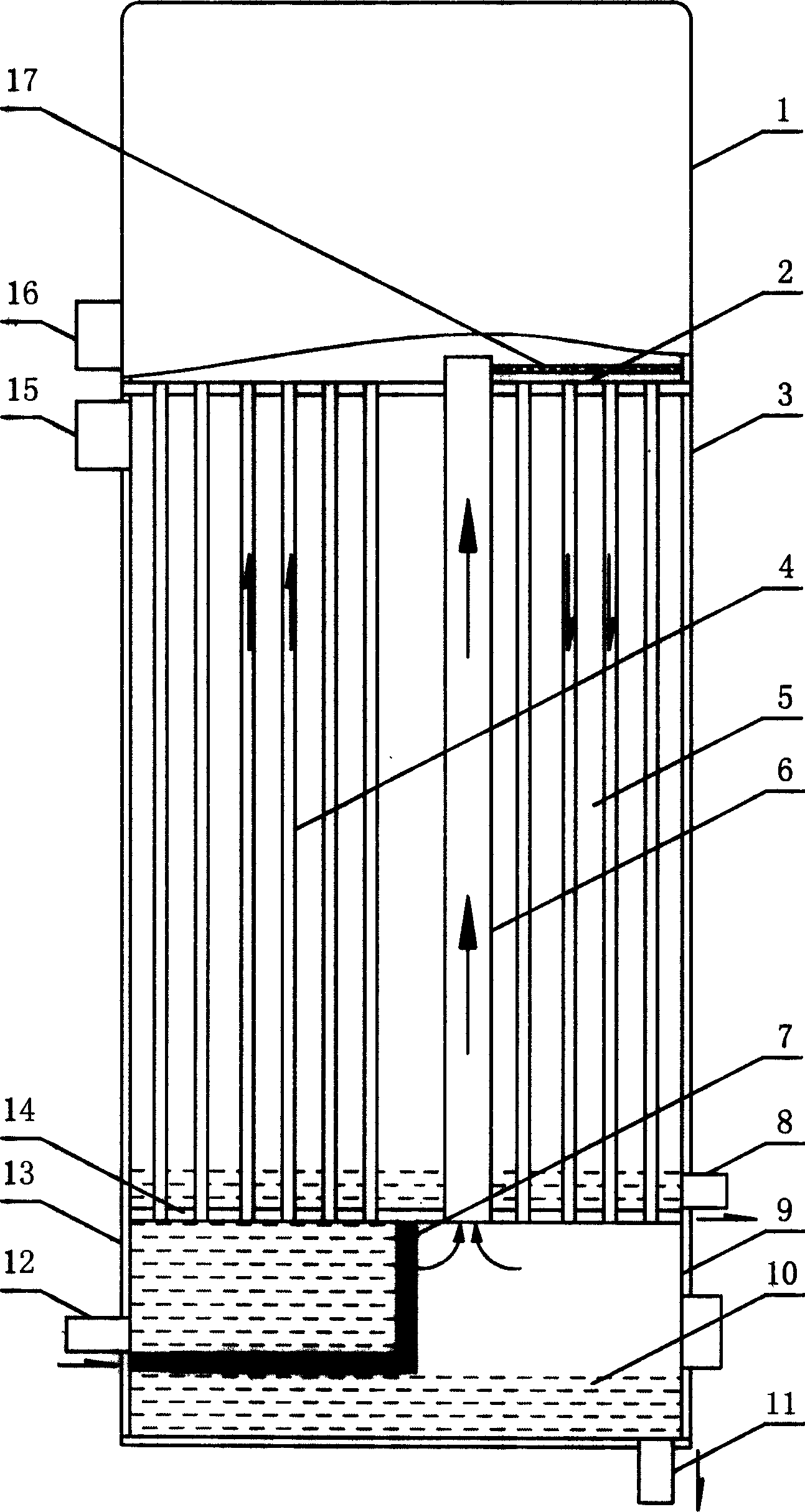

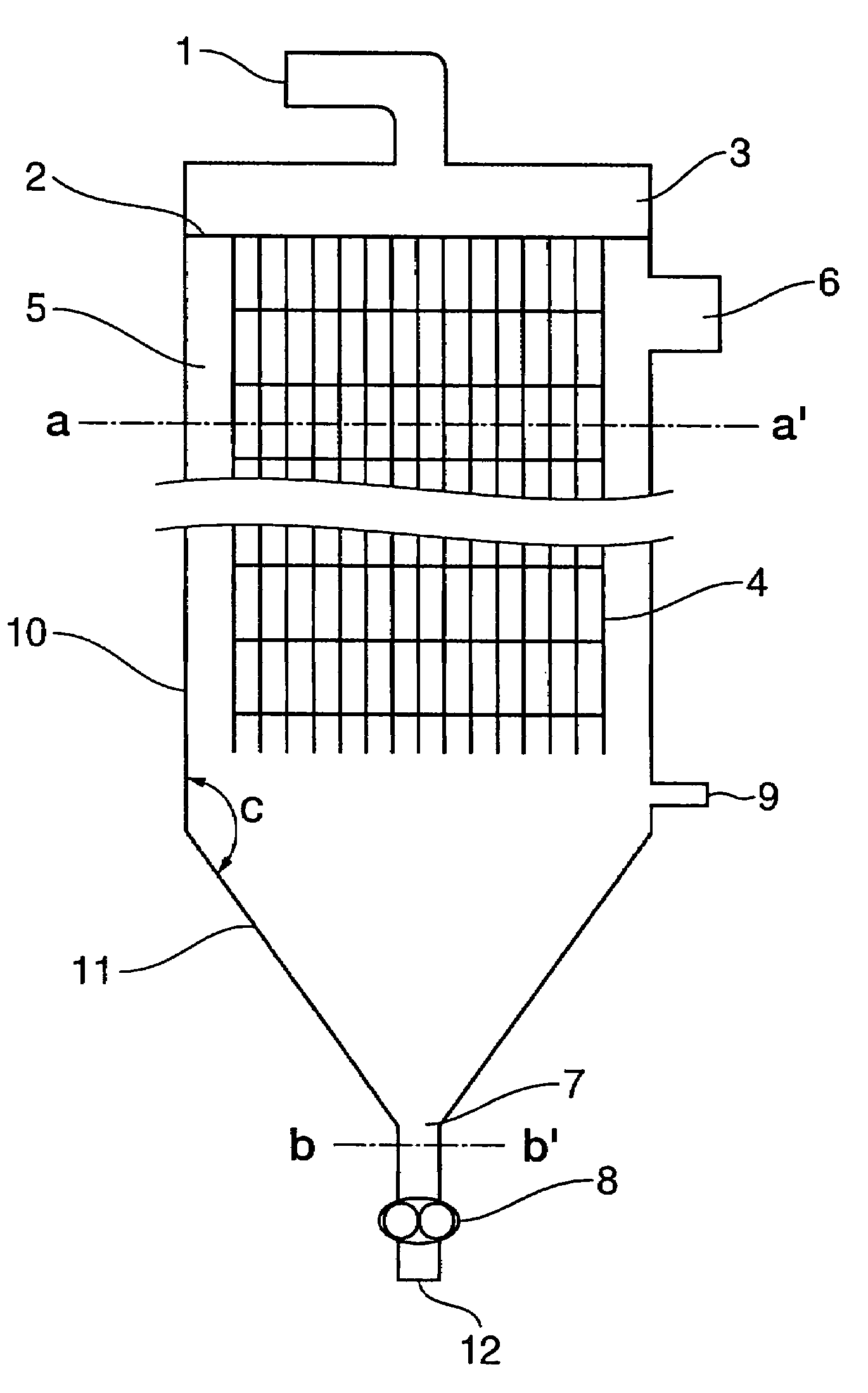

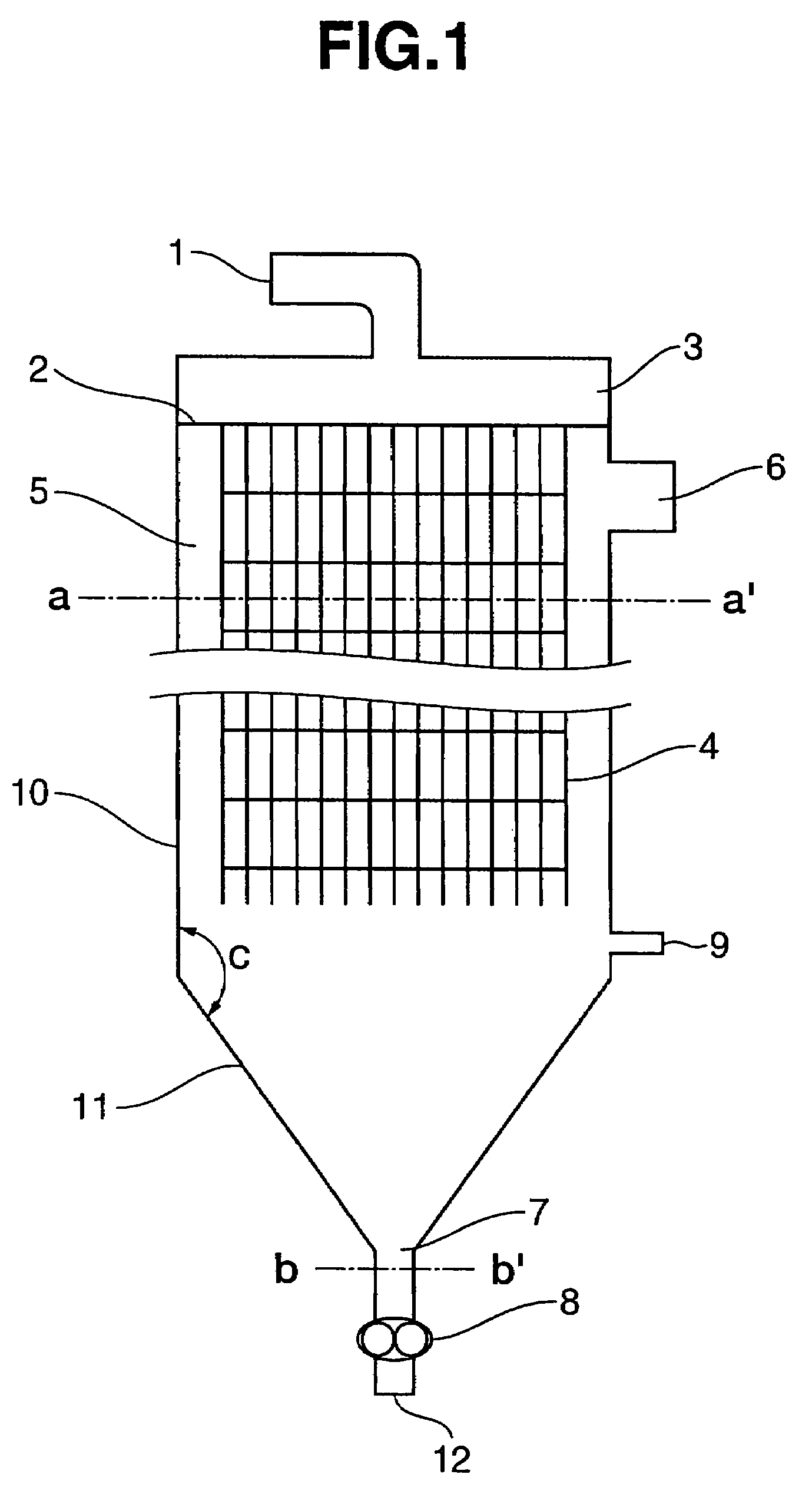

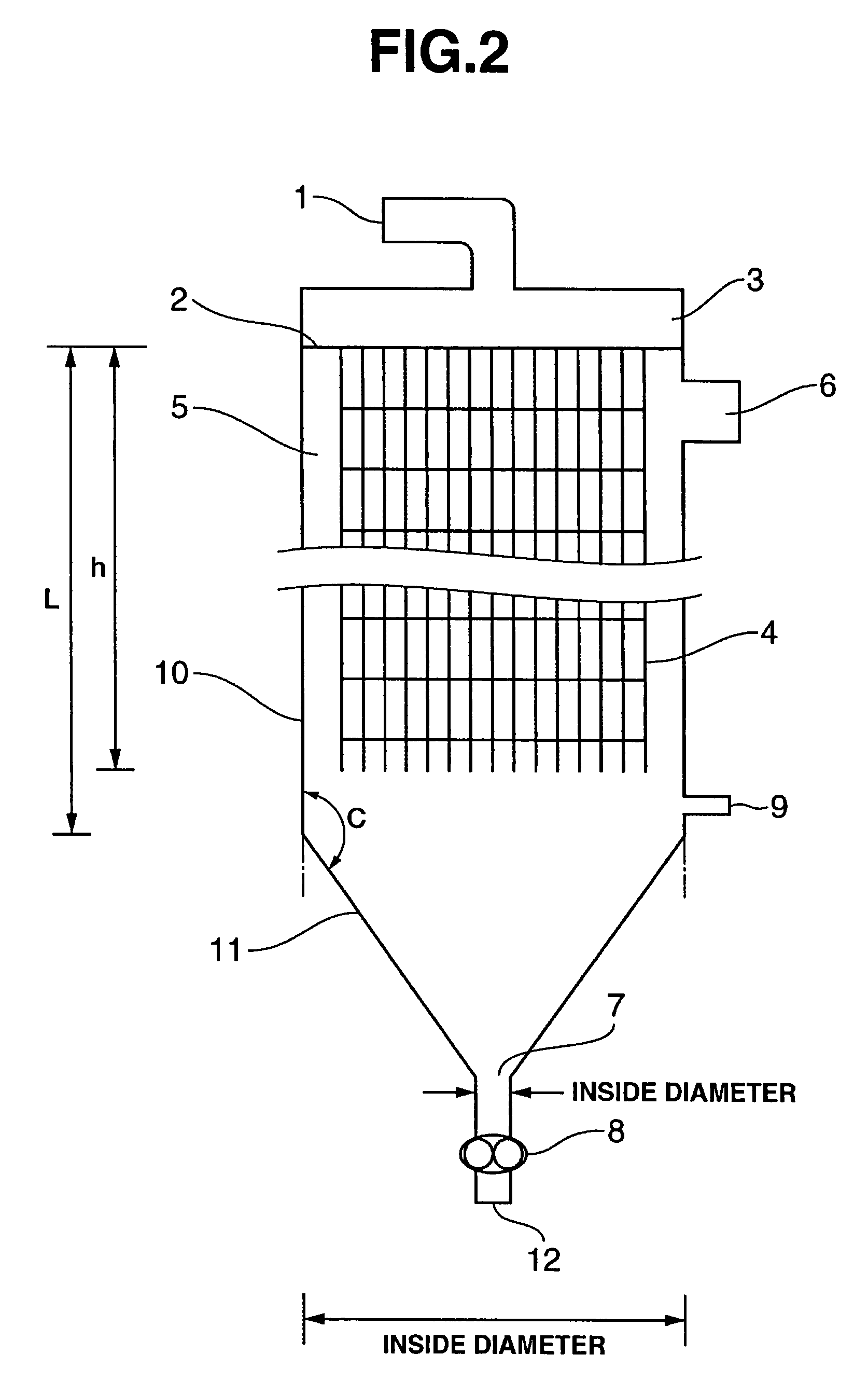

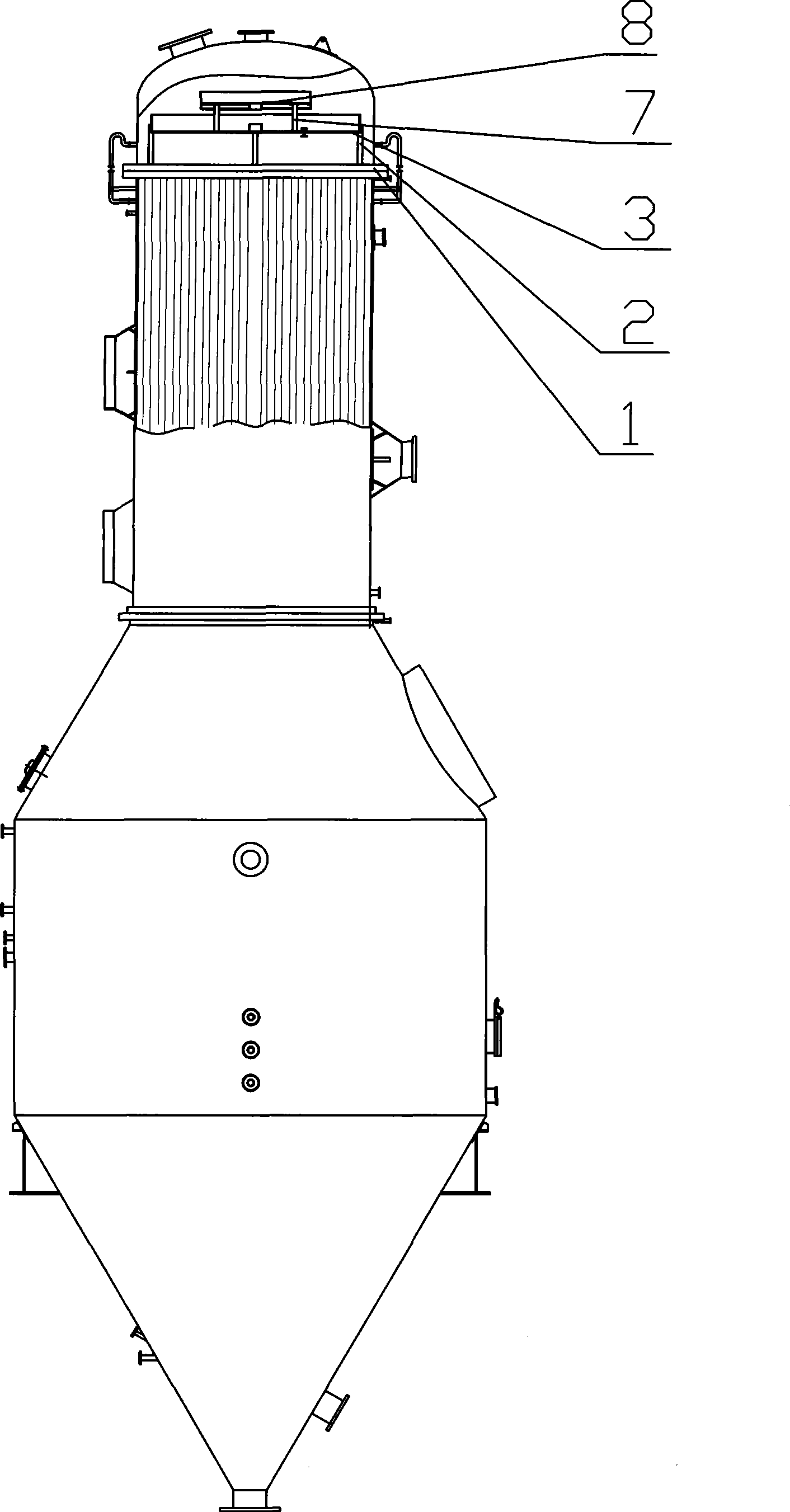

Vertical tube type falling-film evaporator

ActiveCN106178557AGuaranteed centralityHigh recovery rateGeneral water supply conservationEvaporators with vertical tubesVertical tubeEngineering

The invention relates to a vertical tube type falling-film evaporator. The vertical tube type falling-film evaporator comprises an upper tube box, a lower tube box, a casing, multiple heat exchange tubes, an upper tube plate and a lower tube plate, wherein a solution inlet and a secondary steam outlet I are arranged at the upper tube box, a concentrated liquid outlet and a secondary steam outlet II are arranged at the lower tube box, a steam inlet is arranged at the upper part of the casing, and a condensed water outlet is arranged at the lower part of the casing; a film distributing device used for distributing a solution on the inner walls of the heat exchange tubes is arranged in the upper tube box; the film distributing device comprises a liquid bearing plate, a liquid feeding plate, a liquid distributing plate and liquid guiding tubes. By means of a steam stripping effect generated by secondary steam and liquid films, the heat transferring push force and the evaporation efficiency are increased. The liquid films can be uniformly distributed by the film distributing device, the film forming is stable, the wall drying phenomenon is avoided, the recovery rate of secondary steam produced in an evaporator is high, the recovery is convenient, and the heat transferring efficiency is improved.

Owner:LUOYANG SUNRUI SPECIAL EQUIP

Raising membrane distributing water type evaporator

InactiveCN1569299AIncrease profitQuick resultsDistillation in pipe stillsWater/sewage treatment by heatingAgricultural engineeringEvaporation

The invention is a climbing film water evaporator, relating to water evaporating device field. It includes evaporator and matchable pipes. The character lies in: the evaporator body is made up of two segments, the upper one is steam and water separation segment, the lower is evaporating segment. The invention makes the water distribution in climbing film pipes even, and it uses double-evaporation structure, the use factor of heat is upgraded greatly, the evaporator works stably, it can upgrade the efficiency of evaporated water, and reduces the cost.

Owner:淄博华周制药设备有限公司

Water Distillation System

InactiveUS20080277261A1Inexpensive to installBuildAuxillariesDistillation regulation/controlWater sourceBrackish water

A system for distilling sea or brackish water includes a feed water arrangement for supplying feed water from a feed water source to one or more flashing stages. Each flashing stage has a water flash evaporator for vaporizing at least part of the water therein, and a condenser for receiving the vapour and converting at least a part of the vapour into distilled water. A heat storage arrangement provided with a heat generating source for storing heat energy is used to heat a fluid medium flowing through it. A heat exchange arrangement receives the hot fluid medium and transfers heat to a stream of vapour flowing under pressure from each flashing stage. The vapour leaving the heat exchange arrangement being at a raised temperature is arranged to be condensed into water at the condenser and to transfer some of its latent heat to the evaporator.

Owner:GREGORY MARK PAXTON +1

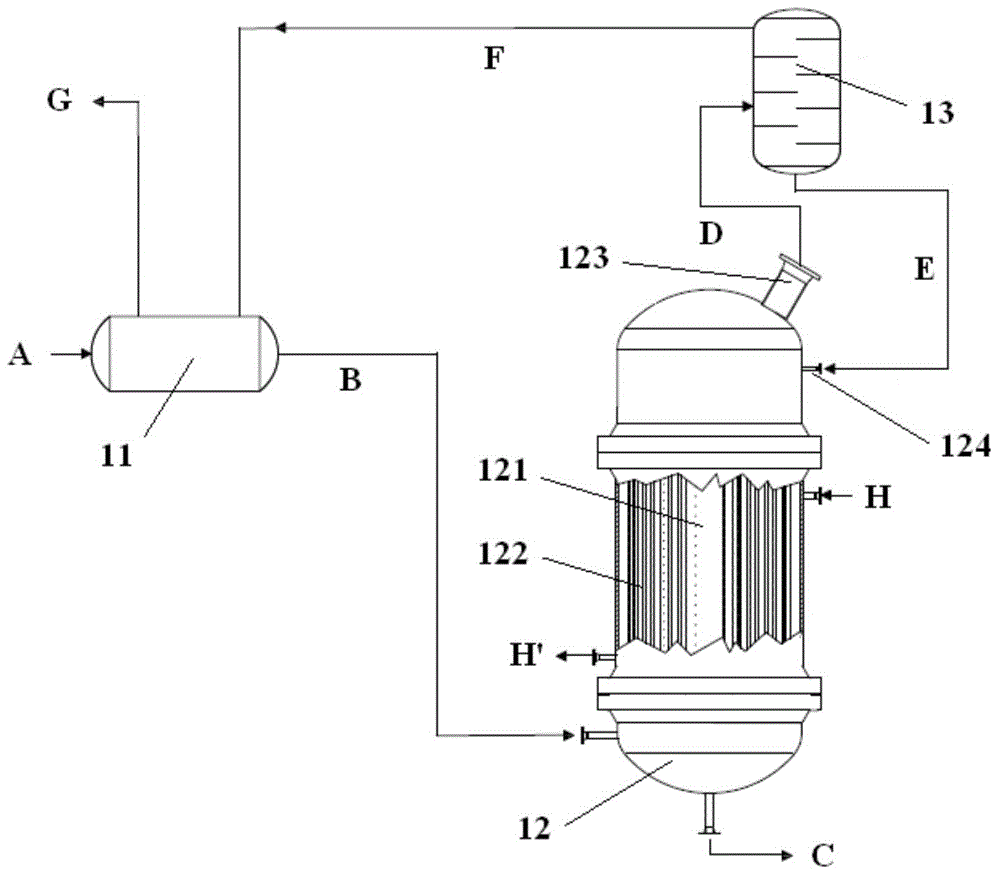

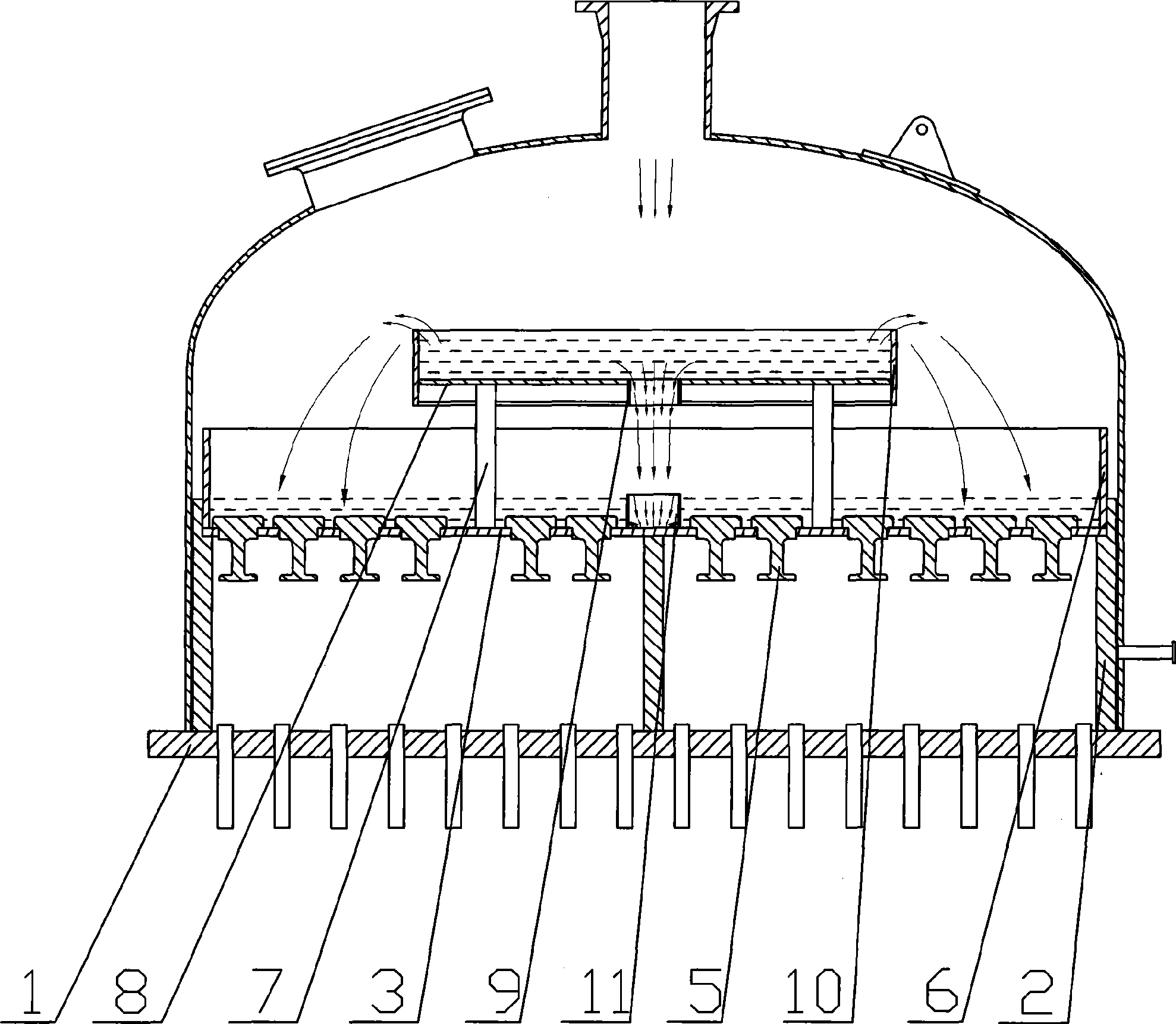

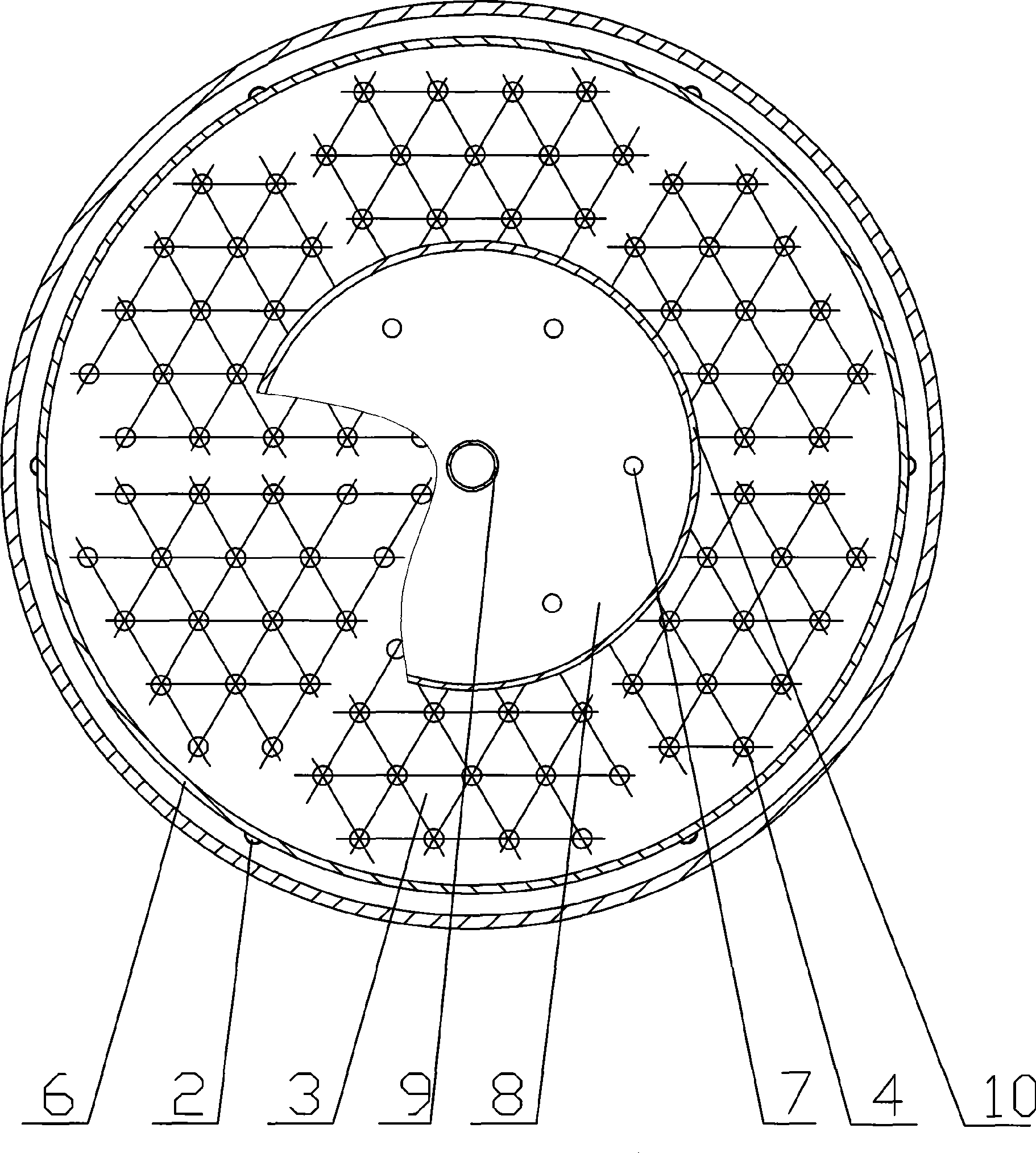

Compound type monomer multi-effect steam mechanical recompression evaporator

ActiveCN102989181ASave energyImprove efficiencyMultiple-effect evaporationEvaporators with vertical tubesCompression PumpEvaporation

The invention discloses a compound type monomer multi-effect steam mechanical recompression evaporator. The compound type monomer multi-effect steam mechanical recompression evaporator comprises a material distributing device, a heater, a steam-water separation chamber and a steam mechanical compression pump, and is characterized in that the material distributing device, the heater and the steam-water separation chamber are sequentially communicated from top to bottom and fixedly connected into a whole; the steam mechanical compression pump can communicate and connect the steam-water separation chamber with the heater through a pipeline; and a material input end of the steam-water separation chamber is connected with a feed pump through the pipeline, and a material output end is communicated and connected with the material distributing device through the pipeline and a circulating pump. The evaporator has the advantages of simple structure and small occupied space, and can achieve the effects of single-effect efficiency, multi-effect evaporation and energy conservation. Secondary steam produced by evaporation of material is recompressed by the steam mechanical pump and then used for heating the material, so that the circulating use is realized and the energy is saved. After the evaporator is opened and runs normally, the fresh steam does not need to be supplemented. The evaporator is suitable for evaporation and concentration of various liquid-containing materials.

Owner:贵港市飞创节能设备有限公司

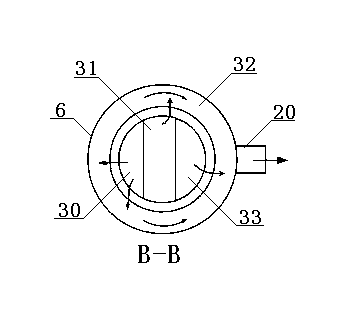

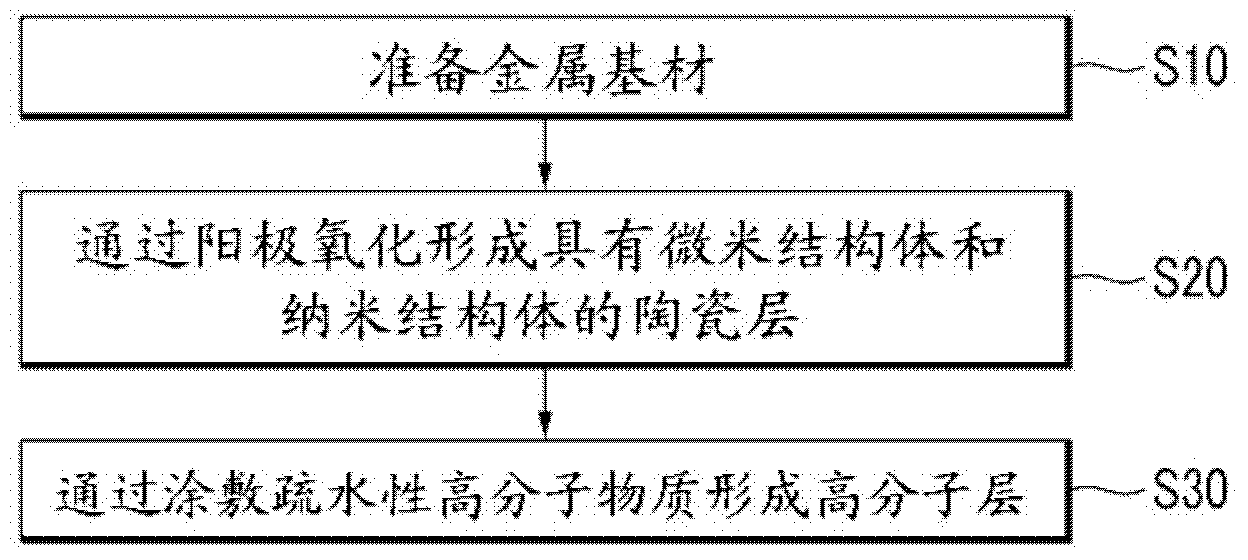

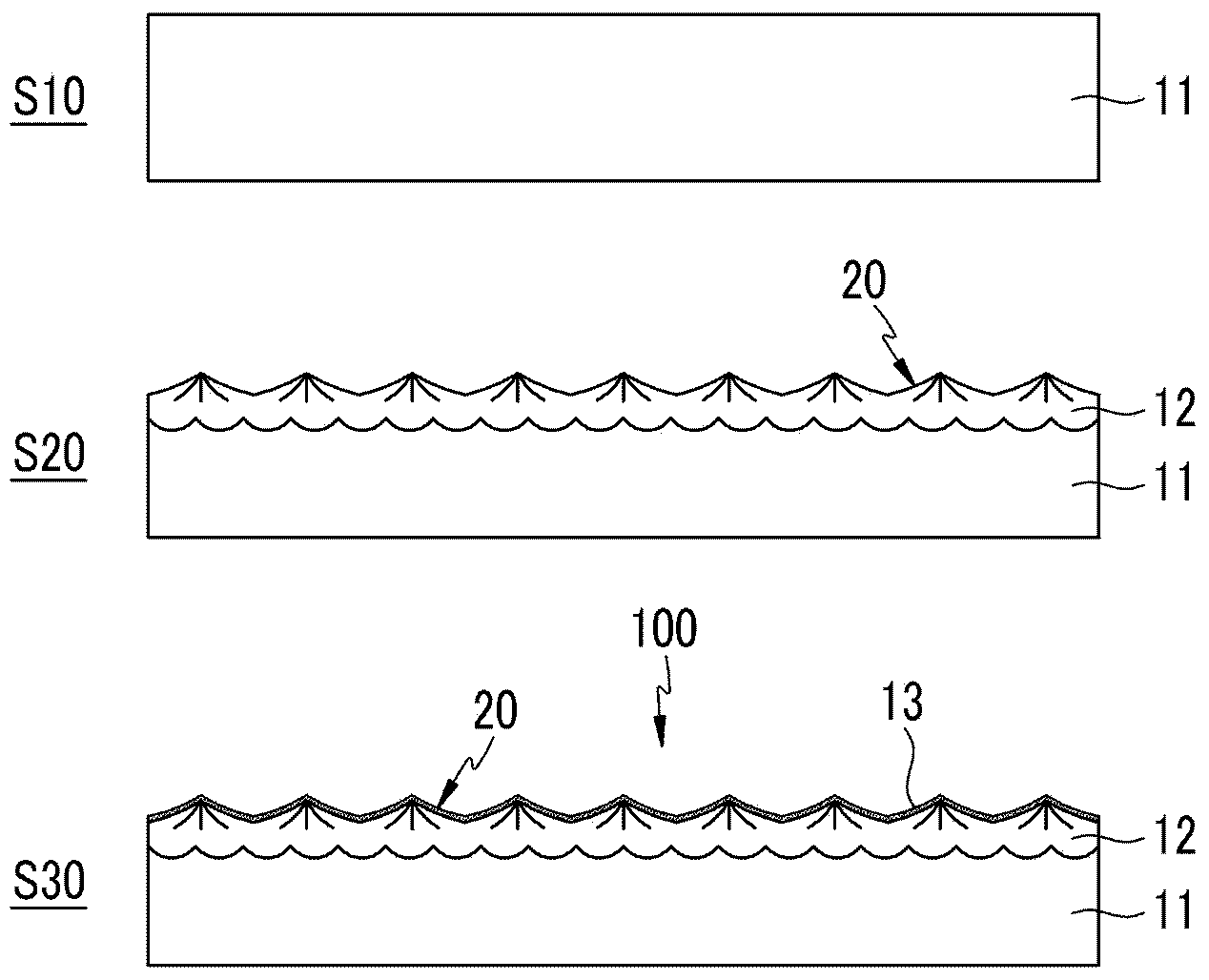

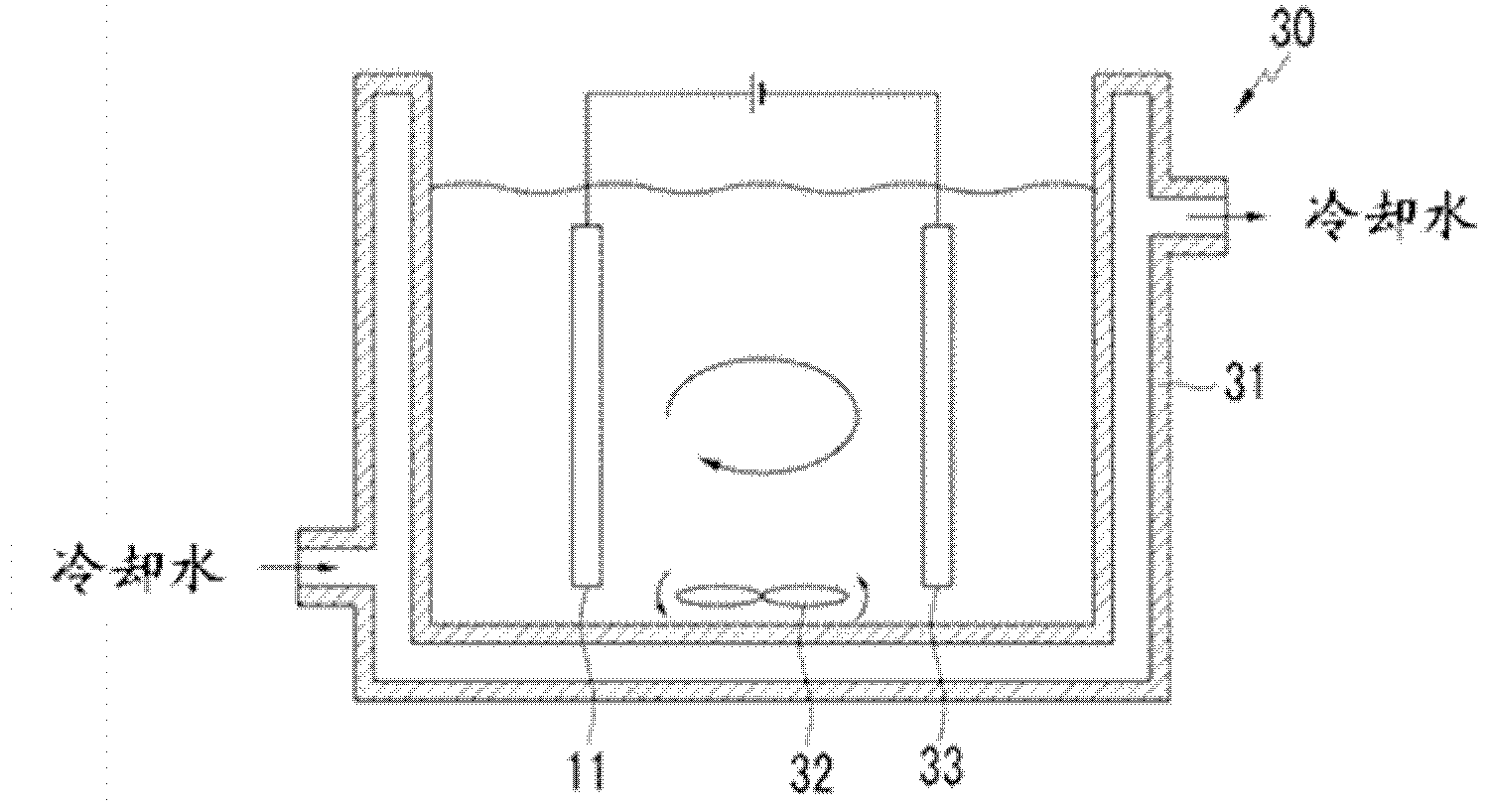

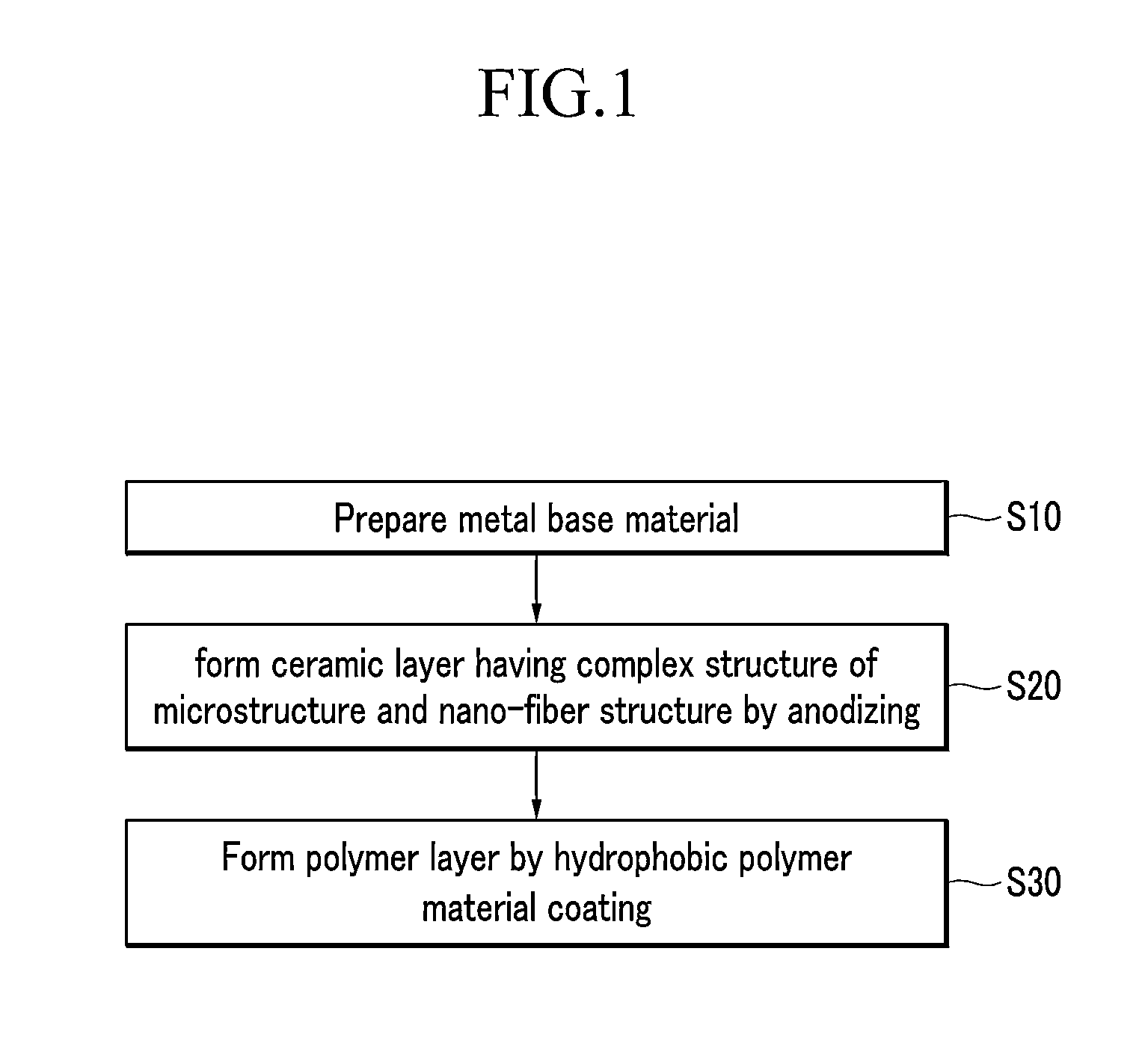

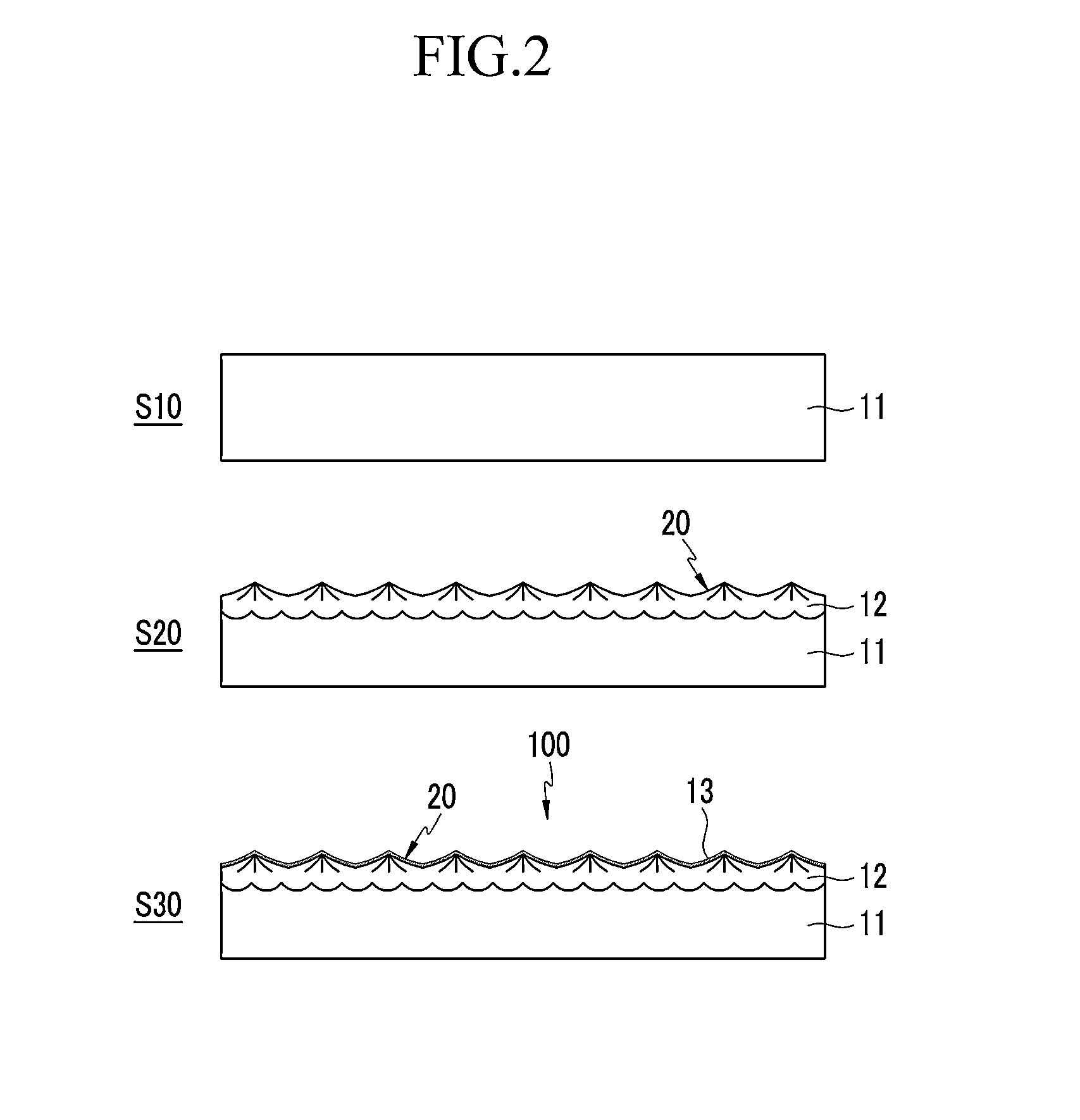

Method for processing super-hydrophobic surface, and evaporator having super-hydrophobic surface

ActiveCN103702928AIncreased durabilityShorten the timeMaterial nanotechnologyFixed microstructural devicesMicro structureHydrophobic polymer

Owner:POSTECH ACAD IND FOUND

Method and apparatus for generating vapor at high rates

The present disclosure relates to an apparatus and a method for vaporizing a liquid to form vapor preferably in a gas stream. The apparatus includes a composite metal structure, the structure comprising a plurality of passageways for providing heat to vaporize the liquid in the gas stream to form a gas / vapor mixture. A non-corrosive interface lies between the metal structure and the gas / vapor mixture, the interface being chemically inert to the gas / vapor mixture and the structure permitting heat to be conducted rapidly therethrough to vaporize the liquid. The apparatus further includes an inlet for the gas and an inlet for the liquid to be vaporized to flow into the plurality of passageways and an exit through which the gas / vapor mixture exits the apparatus.

Owner:MSP

Method for processing a super-hydrophobic surface, and evaporator having the super-hydrophobic surface

ActiveUS20140182790A1Increased durabilityTime for processing is reducedMaterial nanotechnologyAnodisationHydrophobic polymerNanofiber

A method for fabricating a super-hydrophobic surface having excellent surface strength and an evaporator having the super-hydrophobic surface fabricated by the method are provided. The method includes preparing a metal base material, anodizing the metal base material to form a ceramic layer having a complex structure of a microstructure and nano-fiber structures on a surface of the metal base material, and applying a hydrophobic polymer material on the complex structure to form a polymer layer having the same surface shape as the complex structure.

Owner:POSTECH ACAD IND FOUND

Method and apparatus for phase change enhancement

ActiveUS7785448B2Distillation regulation/controlVacuum distillation separationEngineeringPhase change

A method of operating an evaporator is described. In evaporator feed water, a Taylor bubble is developed which has an outer surface including a thin film in contact with an inner surface of an outer wall of an evaporator tube. The Taylor bubble is heated as it rises within the evaporator tube so that liquid in the thin film transitions into vapor within the bubble.

Owner:DEKA PROD LLP

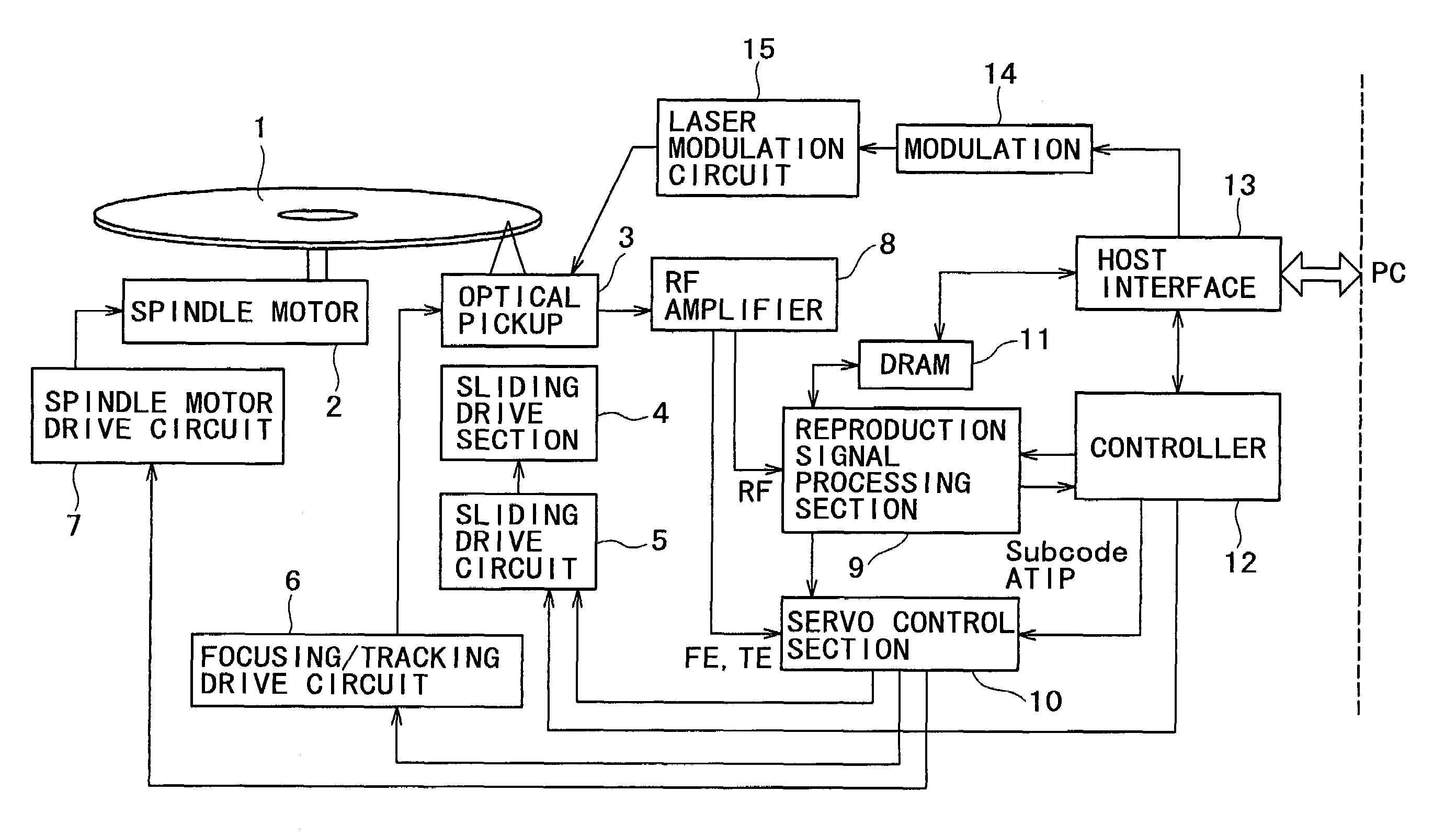

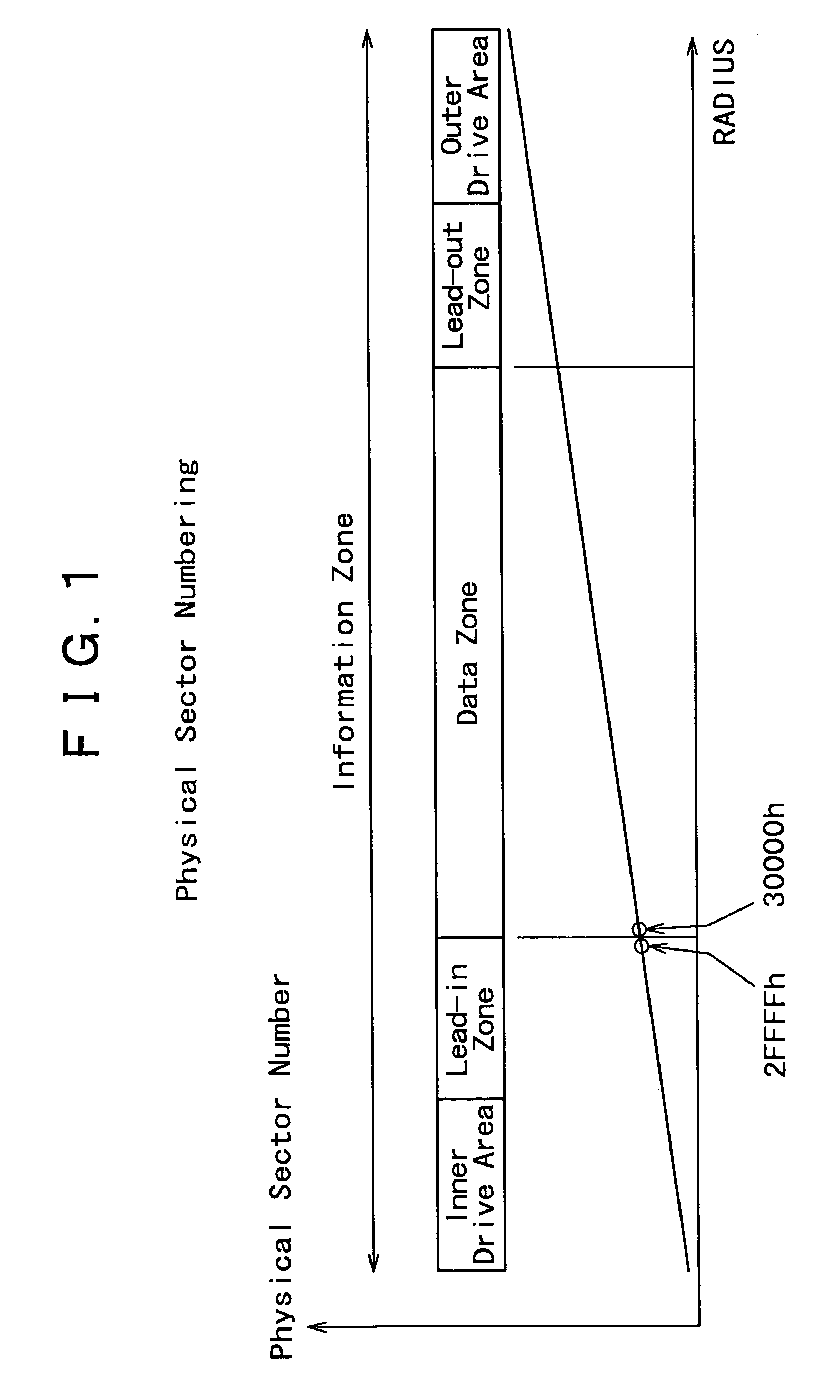

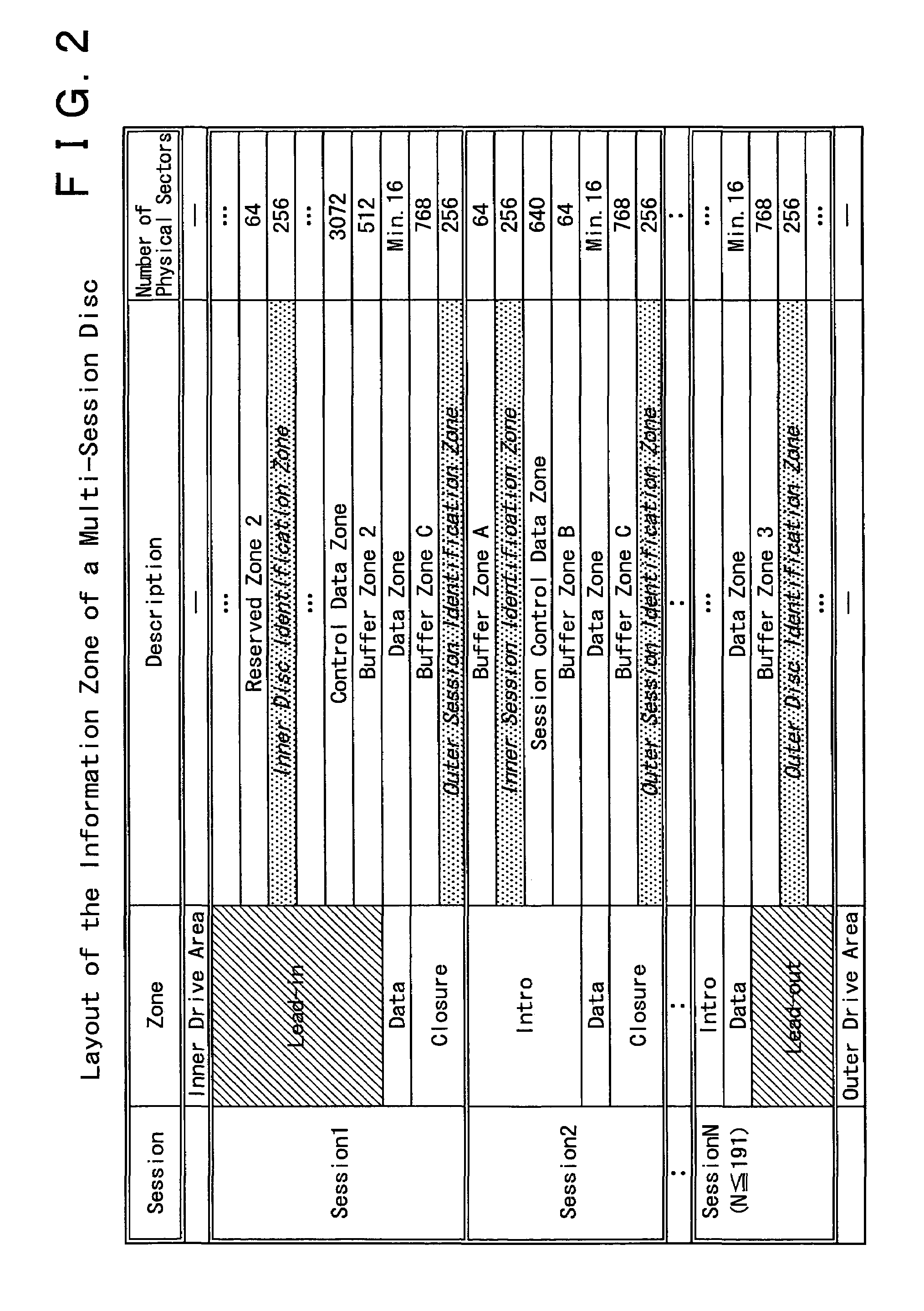

Recording medium, recording apparatus and recording method

InactiveUS7423952B2Precise managementAssure compatibilityRecord information storageOptical record carriersRecording layerData recording

A recording medium of the recordable type in the form of a multi-layer disc or the like which is improved in compatibility and feasibility in use and a recording apparatus and a recording method ready for the recording medium are disclosed. A region for recording interlayer folding back position information is set on the recording medium (for example, “End sector number in Layer 0” or a session item type 3). In response to a fact that recording on a certain recording layer reaches a maximum recording range or that data recording advances from a certain recording layer to a next recording layer, interlayer folding back position information is recorded on the recording medium. This signifies that such recording is performed when advancement of the data recording to another recording layer is performed at a stage prior to disc closing or session closing or when it is predicted that such advancement of the data recording occurs soon. Also where the disc is of the type for which multi-session recording is performed, interlayer folding back position information is recorded with regard to a session in which folding back is performed.

Owner:SONY CORP

Industrial evaporation apparatus

ActiveUS7658817B2Efficient ConcentrationLittle changeEvaporator accessoriesEvaporators/condensersEvaporationEngineering

An industrial evaporation apparatus having a specified structure in which there are guides that do not themselves have a heat source, a flow path controlling member having a function of making the liquid fed onto a perforated plate from a liquid receiving port flow mainly from a peripheral portion toward a central portion of the perforated plate is provided in a liquid feeding zone, and formula (1) to (5), or formula (1) to (10), or formula (1) to (12), are satisfied.

Owner:ASAHI KASEI KK

Film-distributing device of tube-type down-flow evaporator

InactiveCN101376066AExtended service lifeSimple structureEvaporators with vertical tubesEngineeringTubes types

The invention discloses a cloth membrane device of a long-tube falling film evaporator, which comprises an upper tube sheet arranged in the housing of the evaporator, a plurality of lower support rods arranged on the upper tube sheet, and a distribution tray arranged at the upper end part of the lower support rod, wherein a plurality of distribution holes which are evenly distributed and communicated from top to bottom are formed on the distribution tray, and cloth membrane apparatus is arranged in the distribution holes; a lap of check rings are arranged on the distribution tray, and a plurality of support rods are formed on the distribution tray; an overfall tray is arranged on the support rods and a connecting pipe is arranged at the middle of the overfall tray; and a lap of overflow dam is arranged at the periphery of the overfall tray, and a corresponding overflow pipe is arranged at the middle part of the distribution tray which corresponds to the connecting pipe. The cloth membrane device has the advantages of simple structure and evenly distributed cloth membrane; besides, no dry film and split film are generated in a heating pipe, so that the service life of the long-tube falling film evaporator can be prolonged.

Owner:苏州市中衡压力容器制造有限公司

Popular searches

Energy based wastewater treatment Water/sewage treatment by degassing Filtration separation Water/sewage treatment by flocculation/precipitation Cascade evaporators Evaporation by spraying Rotary non-positive displacement pumps Water conservation Closed-cycle gas positive displacement engine plant Semiconductor devices

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com