Patents

Literature

2018results about How to "Reduce heat load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

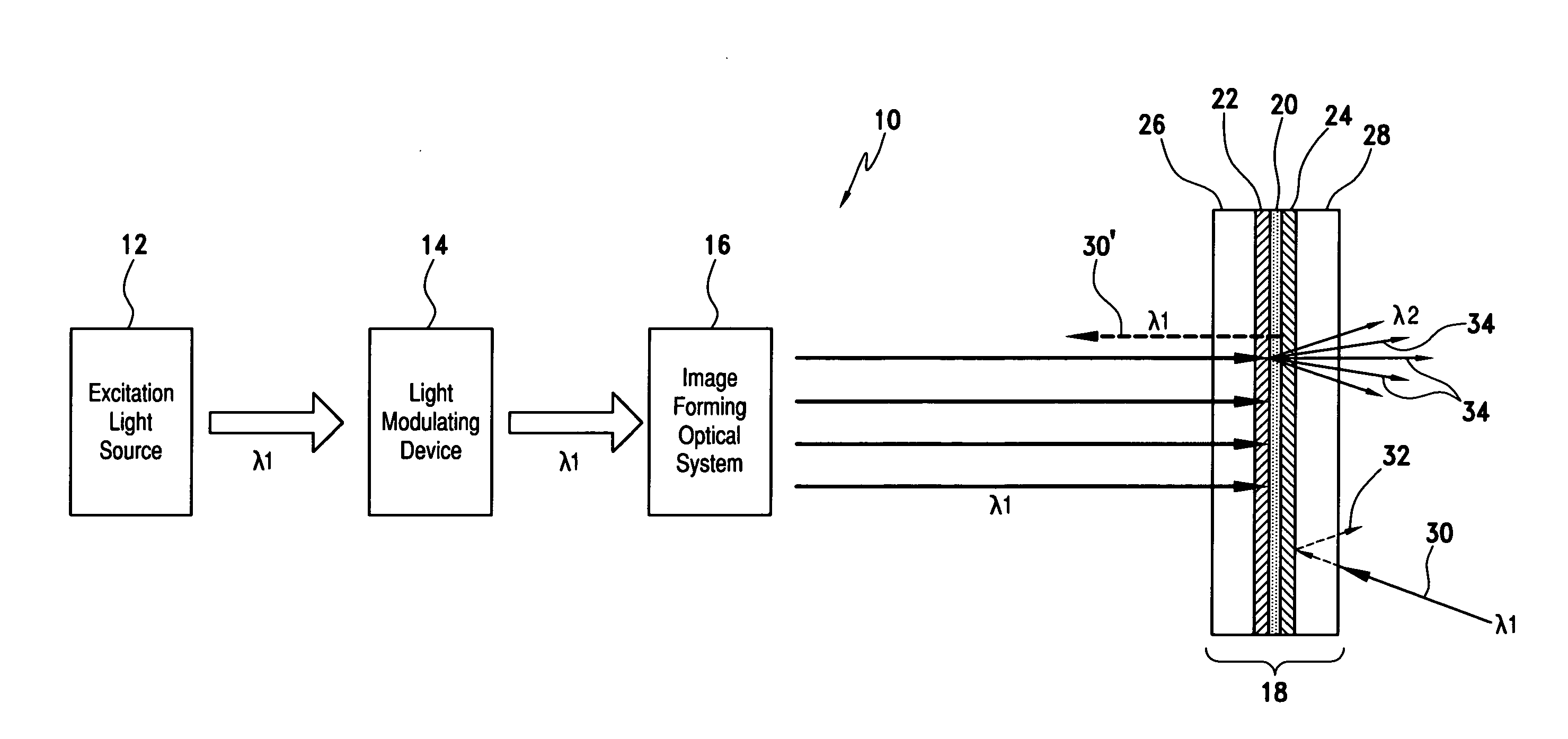

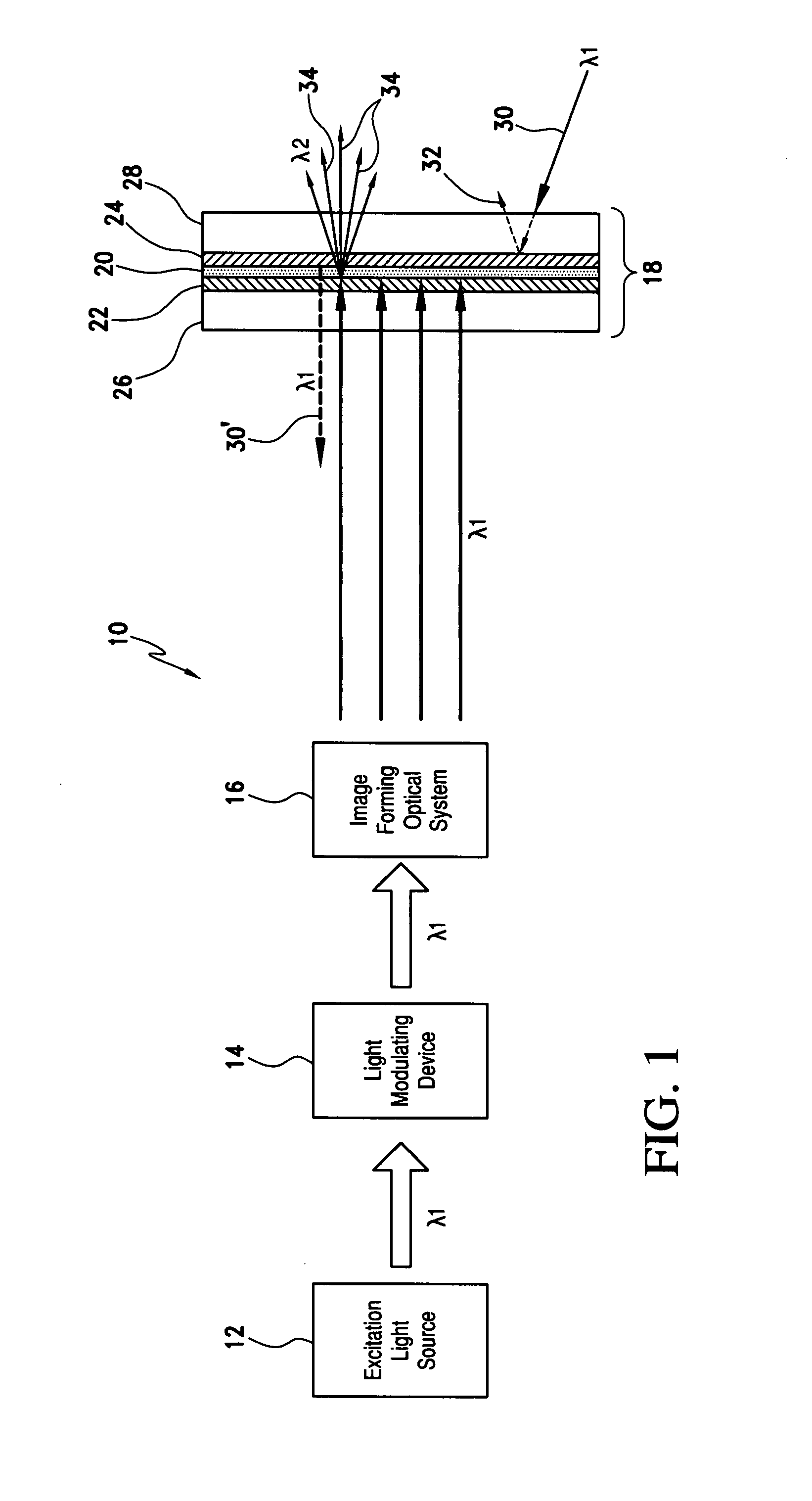

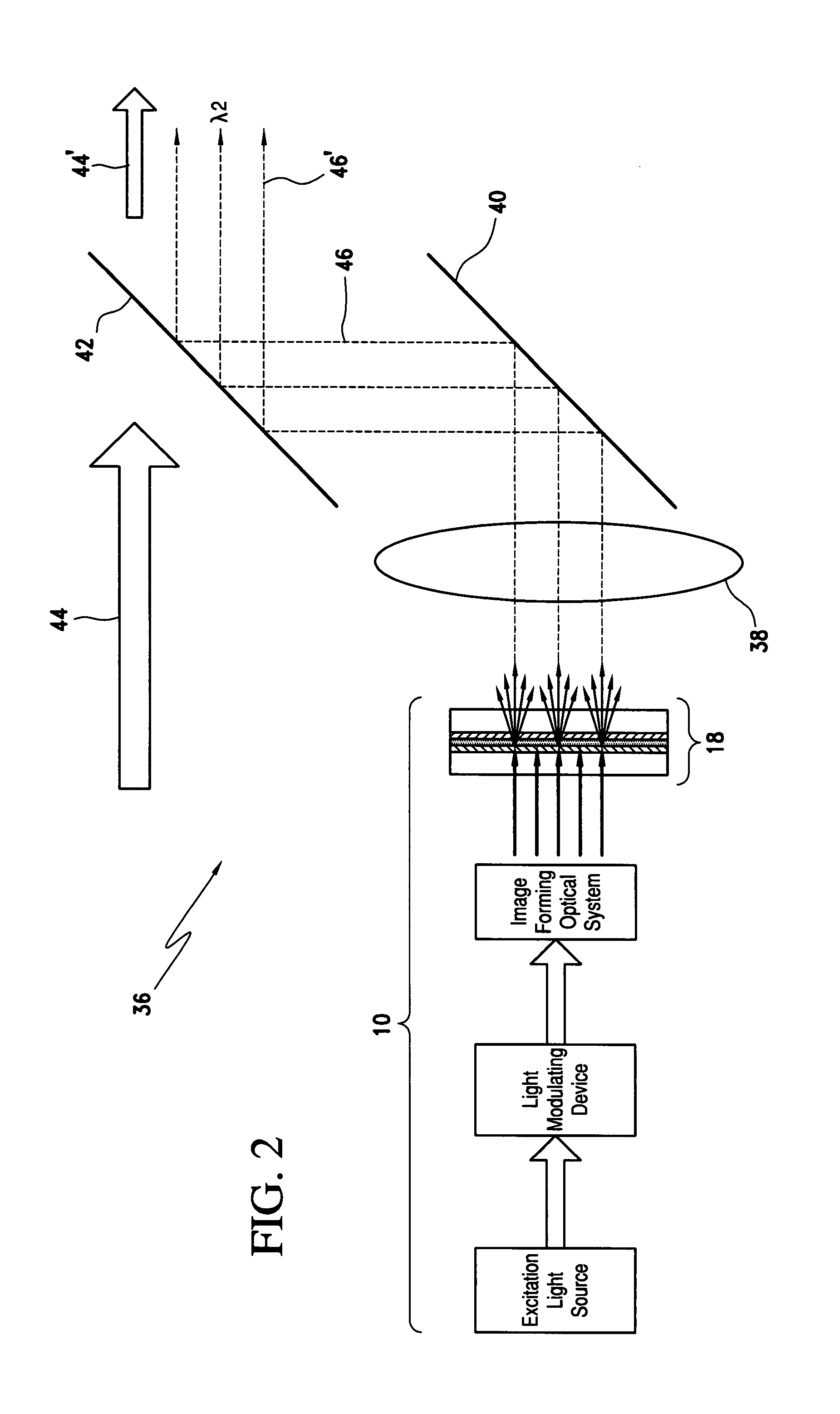

Phosphor screen and displays systems

InactiveUS7733571B1Good optical performanceImprove cooling effectOptical filtersNon-linear opticsPhosphorFluorescence

A phosphor screen for image forming including phosphor material being excitable by light in a wavelength λ1. The phosphor screen receives an optical image from an image forming optical system and produces the optical image at a second wavelength λ2. The phosphor screen includes a phosphor layer comprising the phosphor material. A short-pass reflective coating is positioned on a first side of the phosphor layer. The short-pass reflective coating transmits the wavelength λ1 and reflects the wavelength λ2. A long-pass reflective coating is positioned on a second side of the phosphor layer. The long-pass reflective coating transmits the wavelength λ2 and reflects the wavelength λ1. A first substrate is positioned over the short-pass reflective coating. The first substrate is formed of optically clear and thermal conductive material. A second substrate is positioned over the long-pass reflective coating. The second substrate is formed of long-pass absorptive optical filter material that transmits the wavelength λ2 and absorbs wavelength λ1 from ambient light to prevent the phosphor layer from being excited by the ambient light. The phosphor screen may alternatively be used for a direct-view visual display apparatus. These principles can also be utilized for backlighting and general illumination applications.

Owner:ROCKWELL COLLINS INC

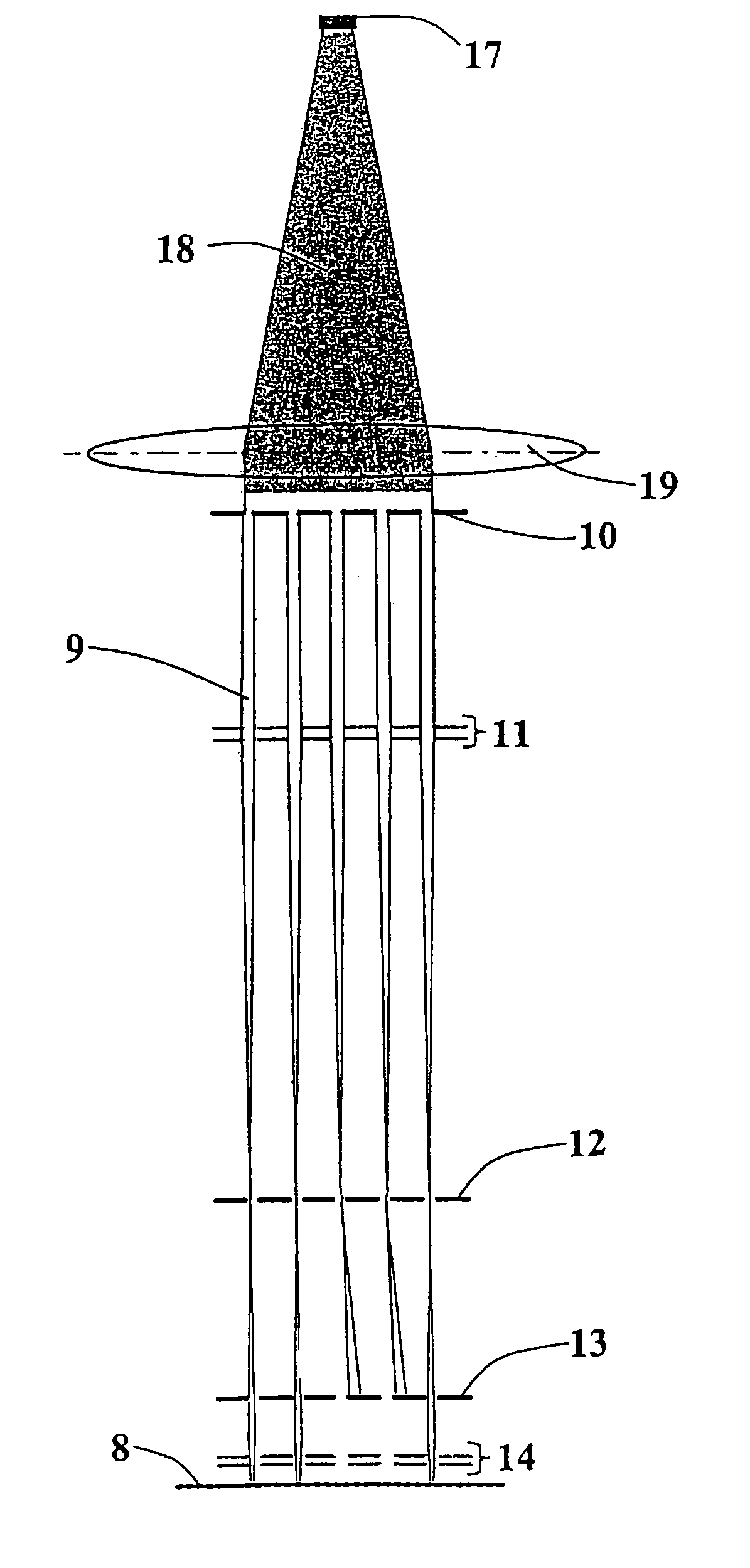

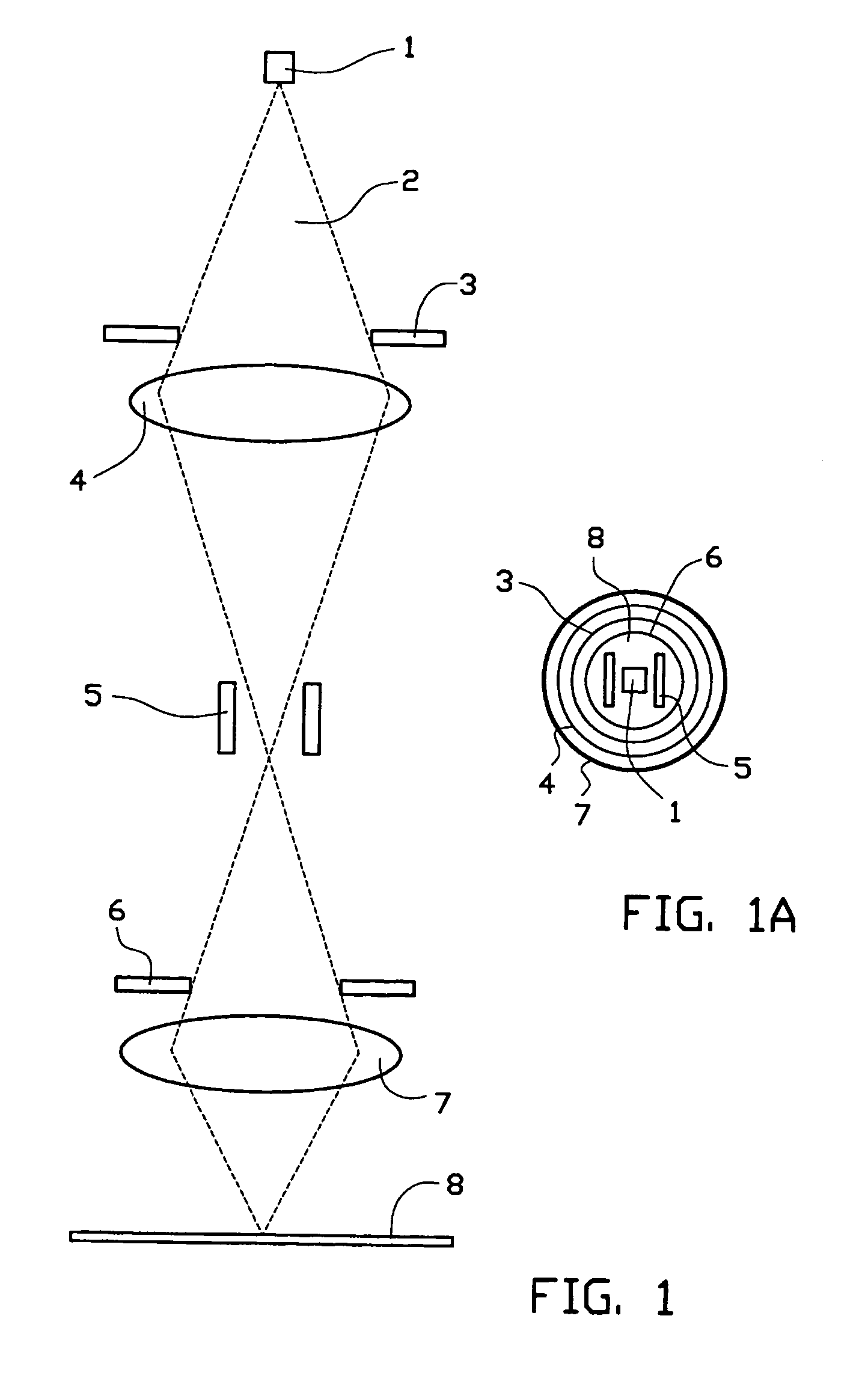

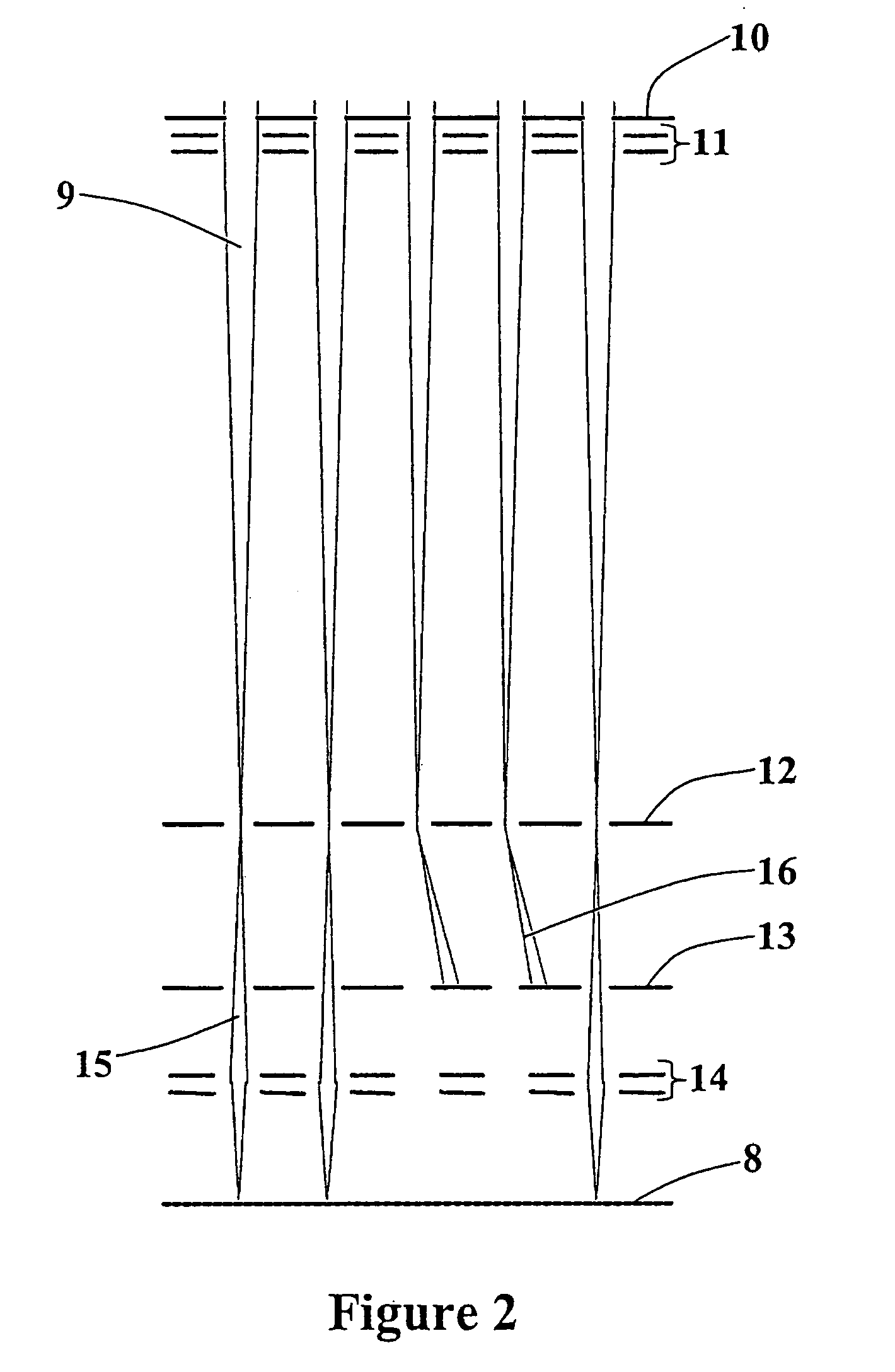

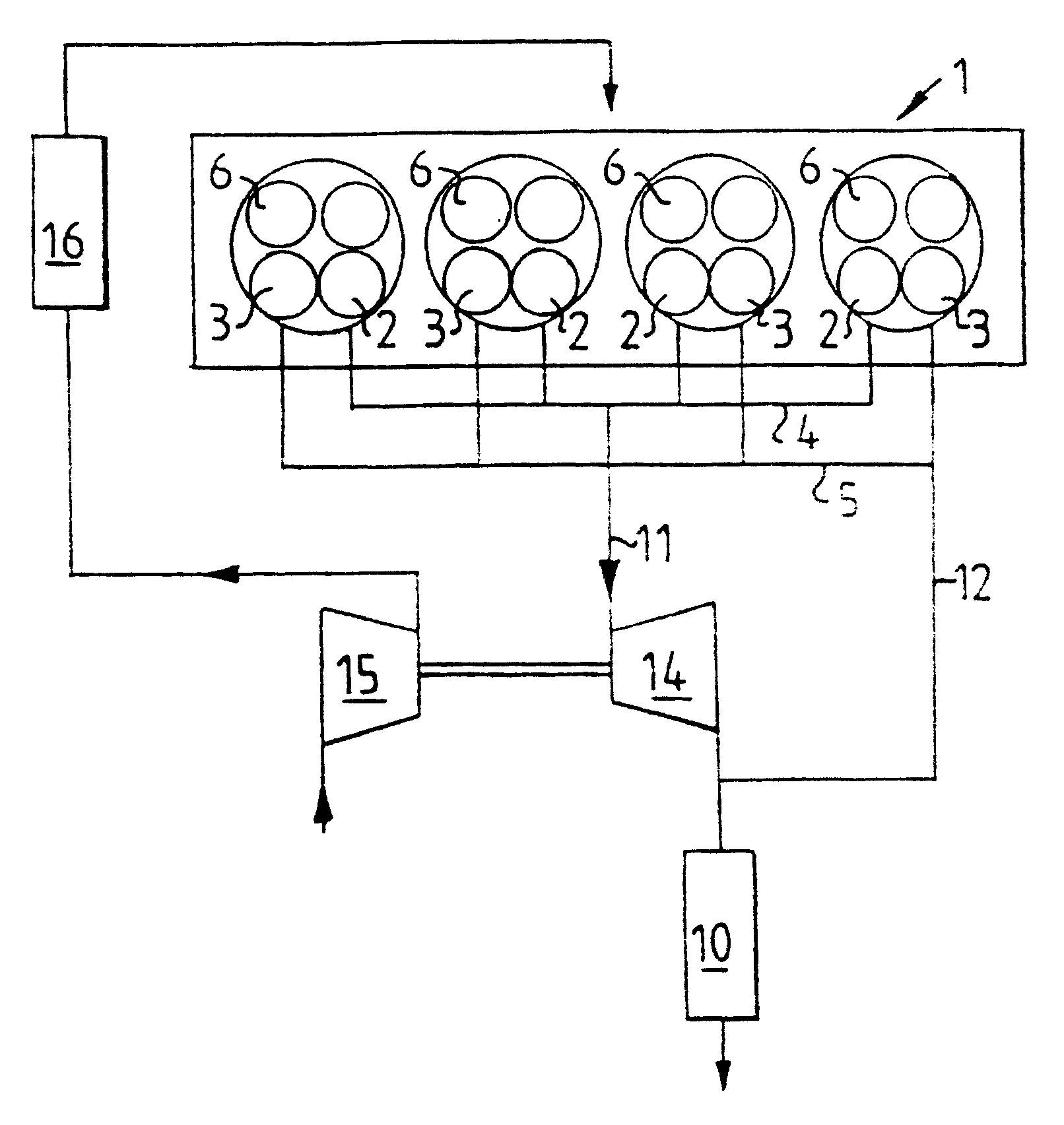

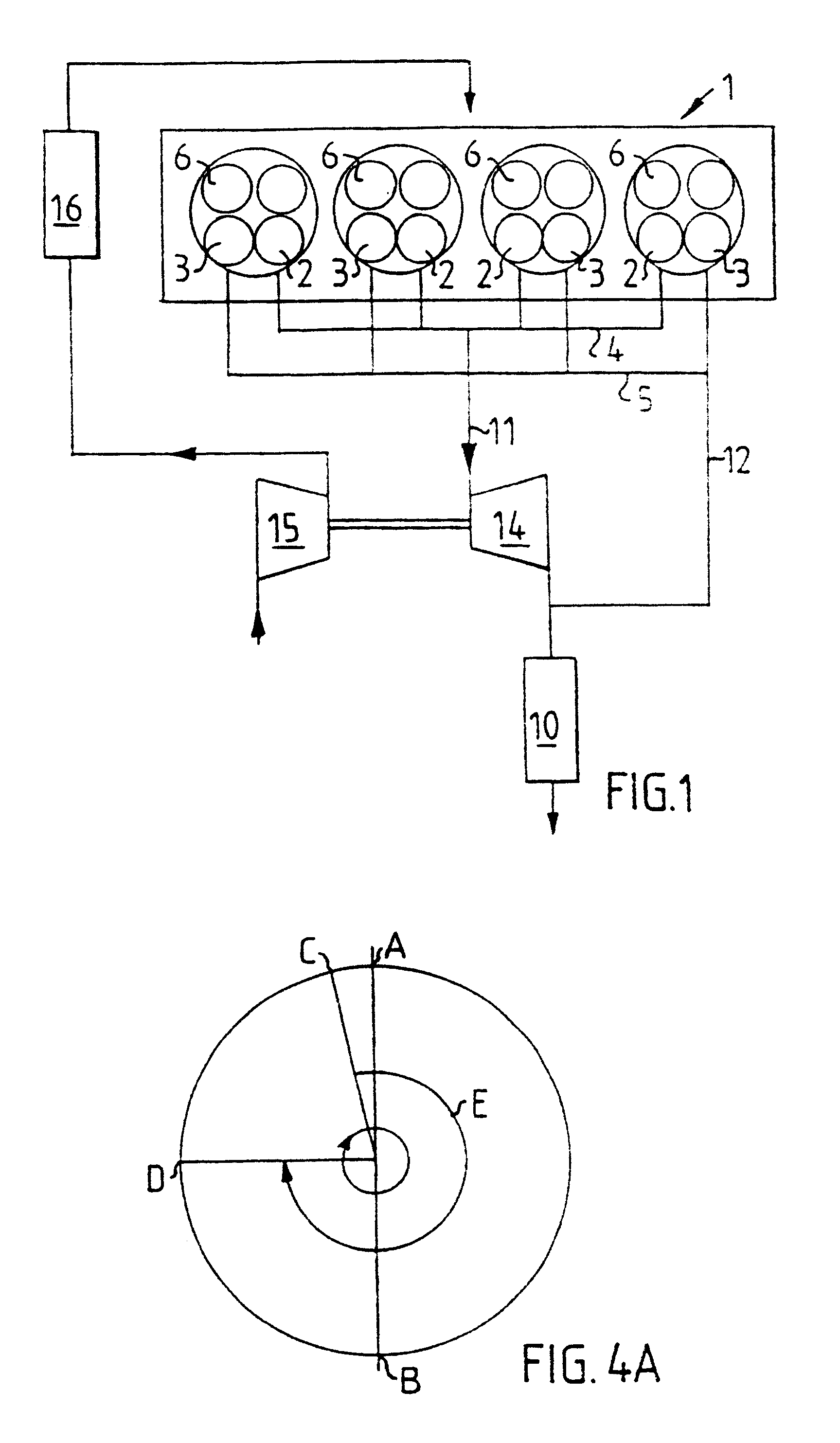

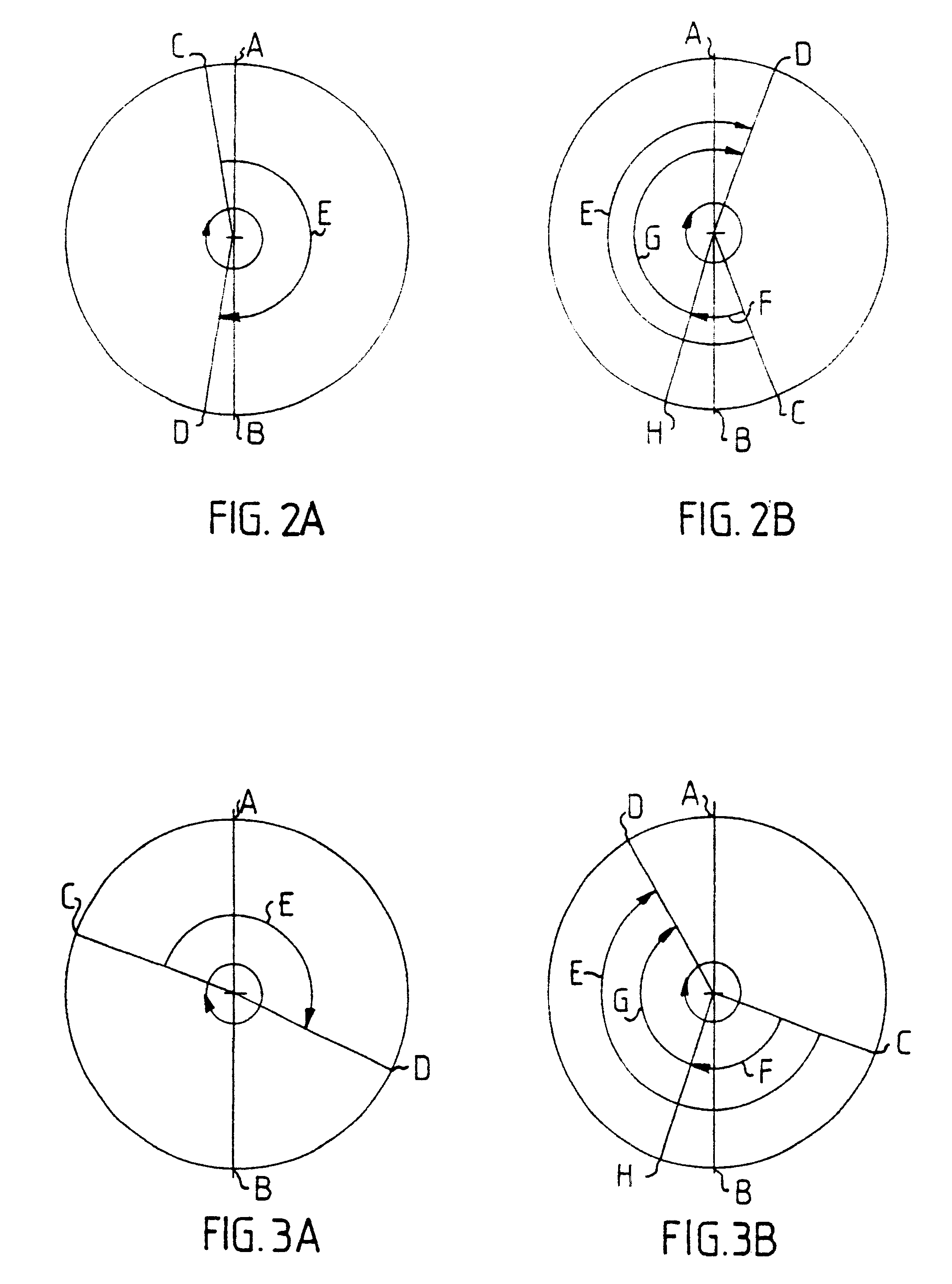

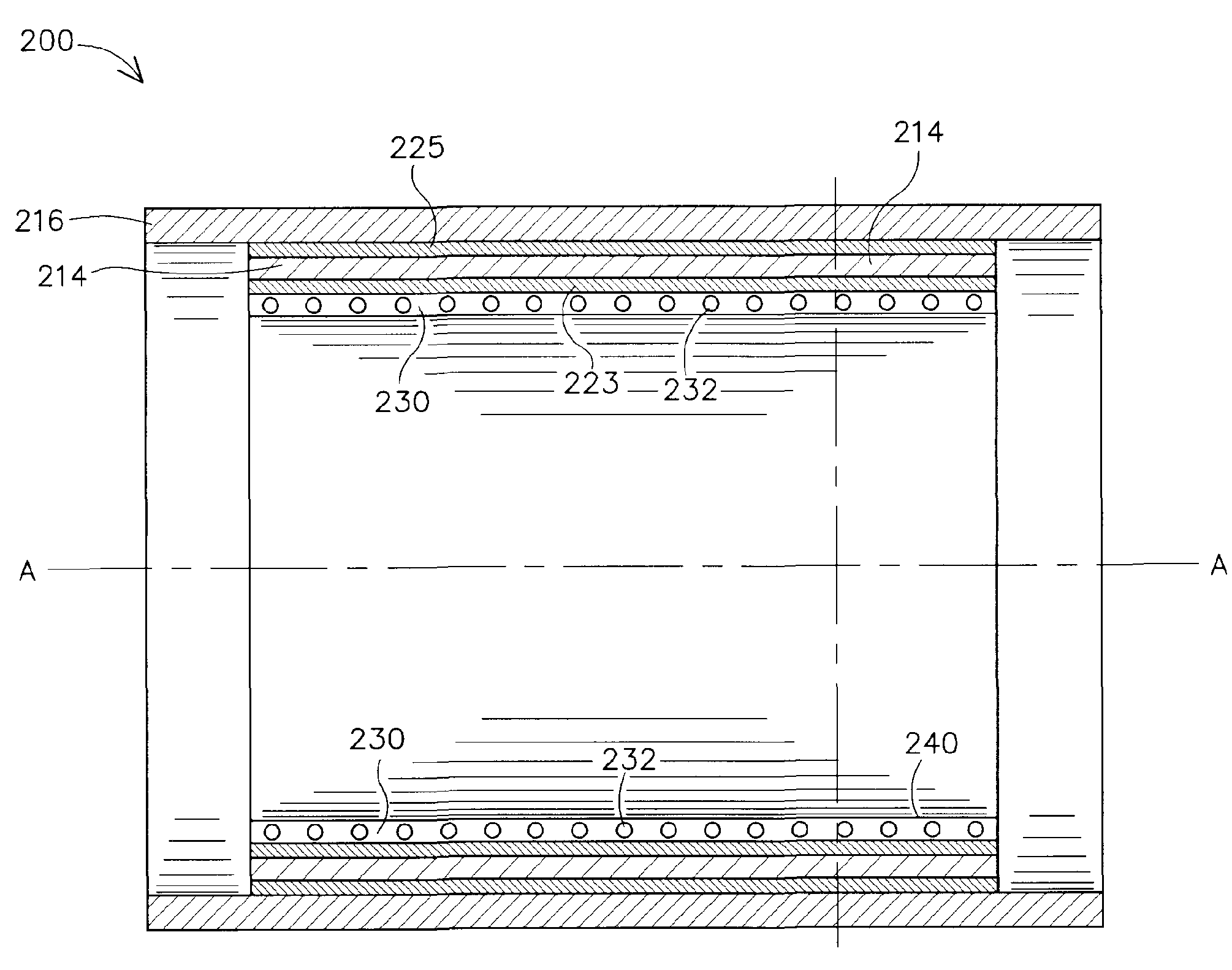

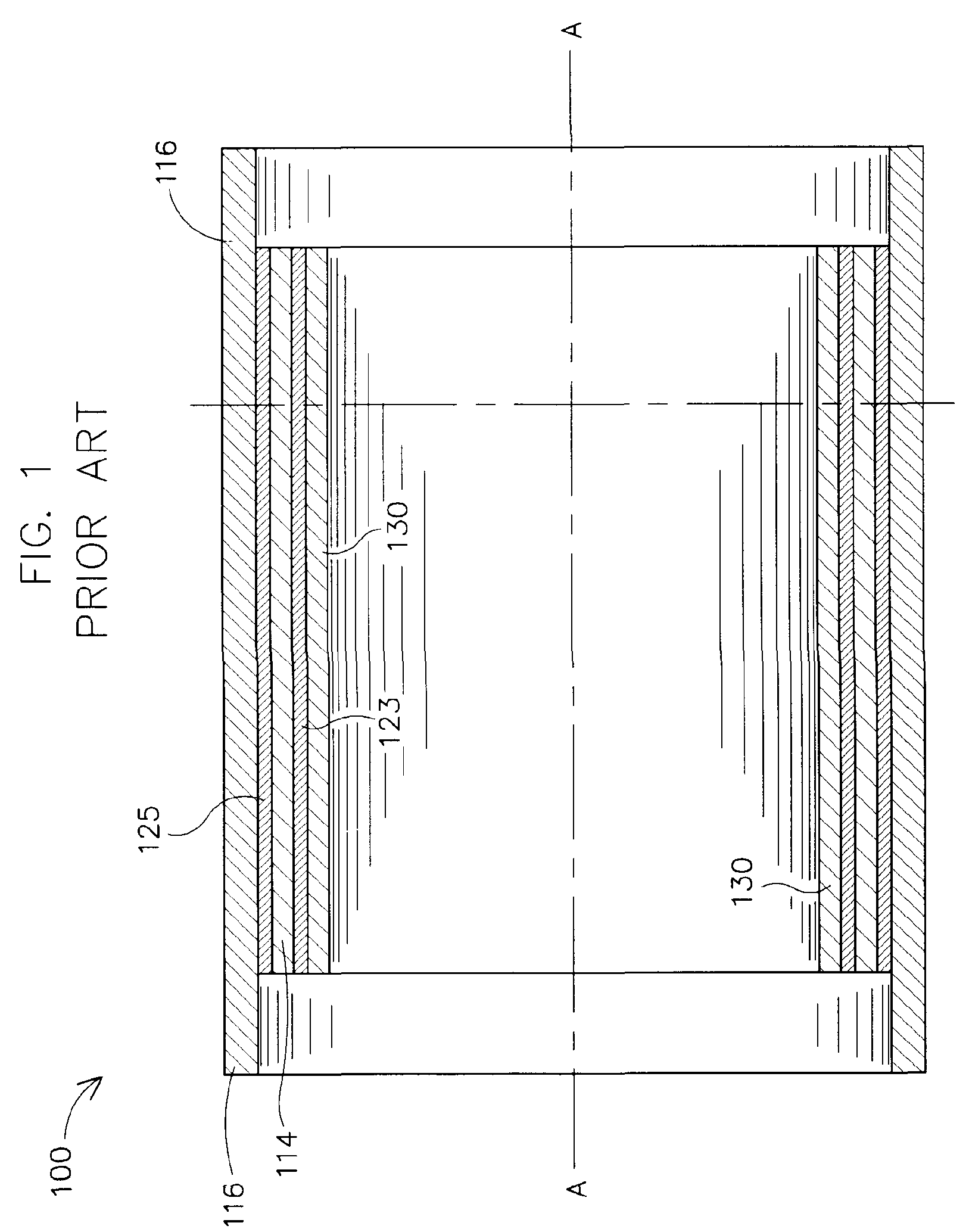

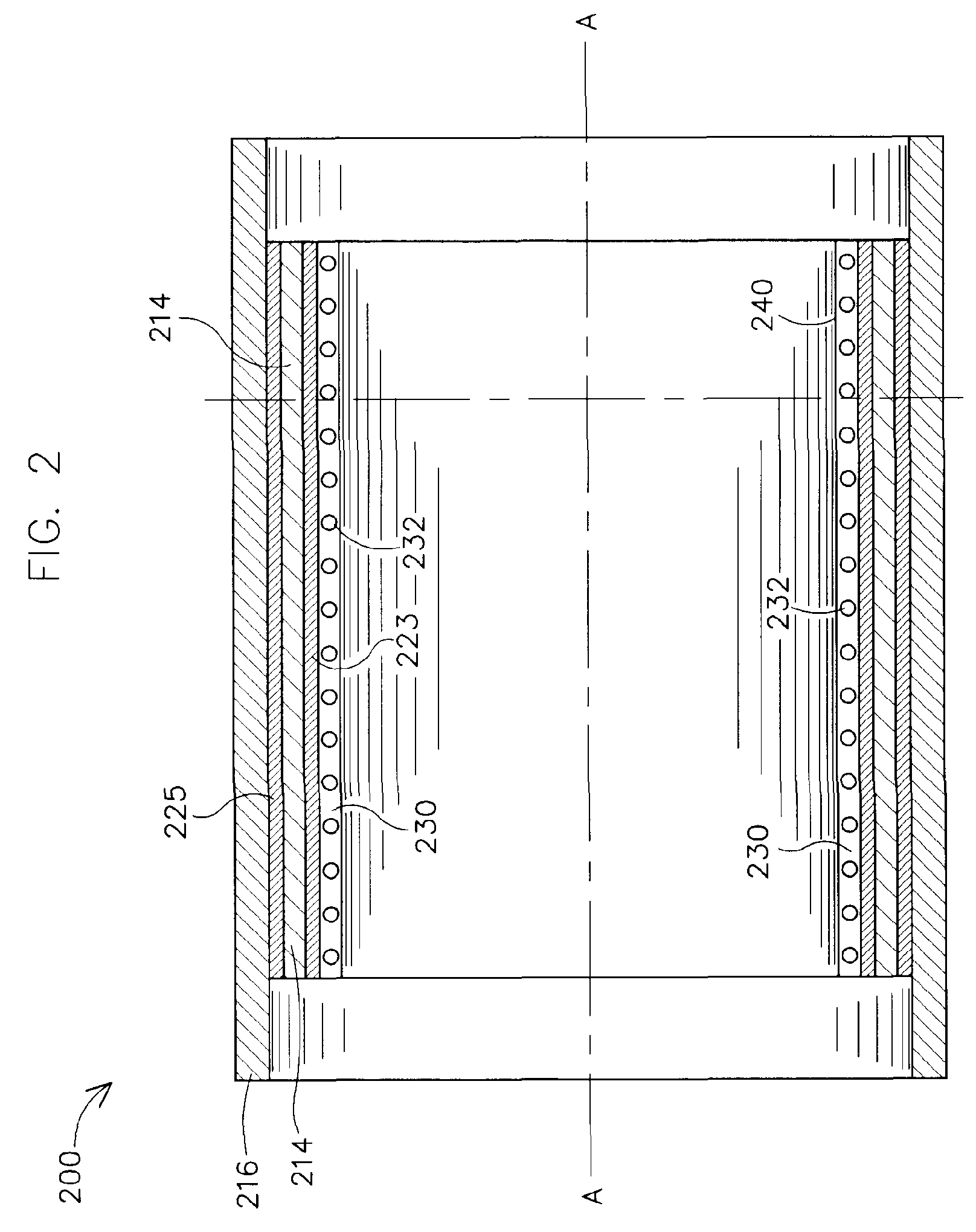

Charged particle beamlet exposure system

InactiveUS7084414B2Improve speed and stabilityOvercome problemsElectric discharge tubesNanoinformaticsControl signalMolecular physics

The invention relates to a charged-particle-optical system for a charged particle beam exposure apparatus, said system comprising:a first aperture means comprising at least a first substantially round aperture for partially shielding an emitted charged particle beam for forming a charged particle beamlet;a lens system comprising at least one lens for focussing a charged particle beamlet from said first aperture within or in the vicinity of an image focal plane of said lens;a deflector means, substantially located in said image focal plane, comprising at least one beamlet deflector for the deflection of a passing charged particle beamlet upon the reception of a control signal, anda second aperture means comprising at least one second substantially round aperture positioned in the conjugate plane of the first aperture, and said second aperture being aligned with said first aperture and said beamlet deflector for blocking said charged particle beamlet upon deflection by said beamlet deflector and to transmit it otherwise.

Owner:ASML NETHERLANDS BV

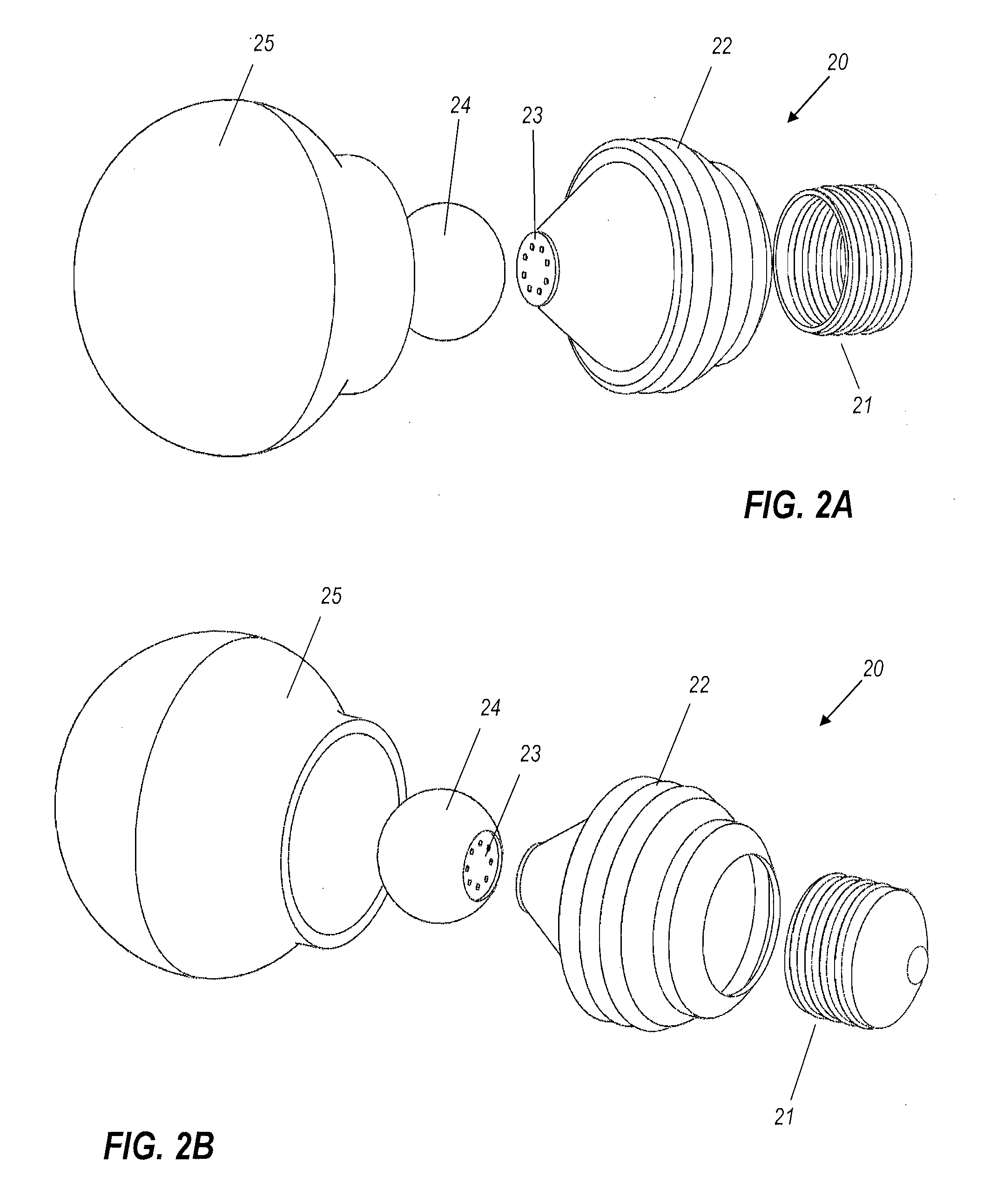

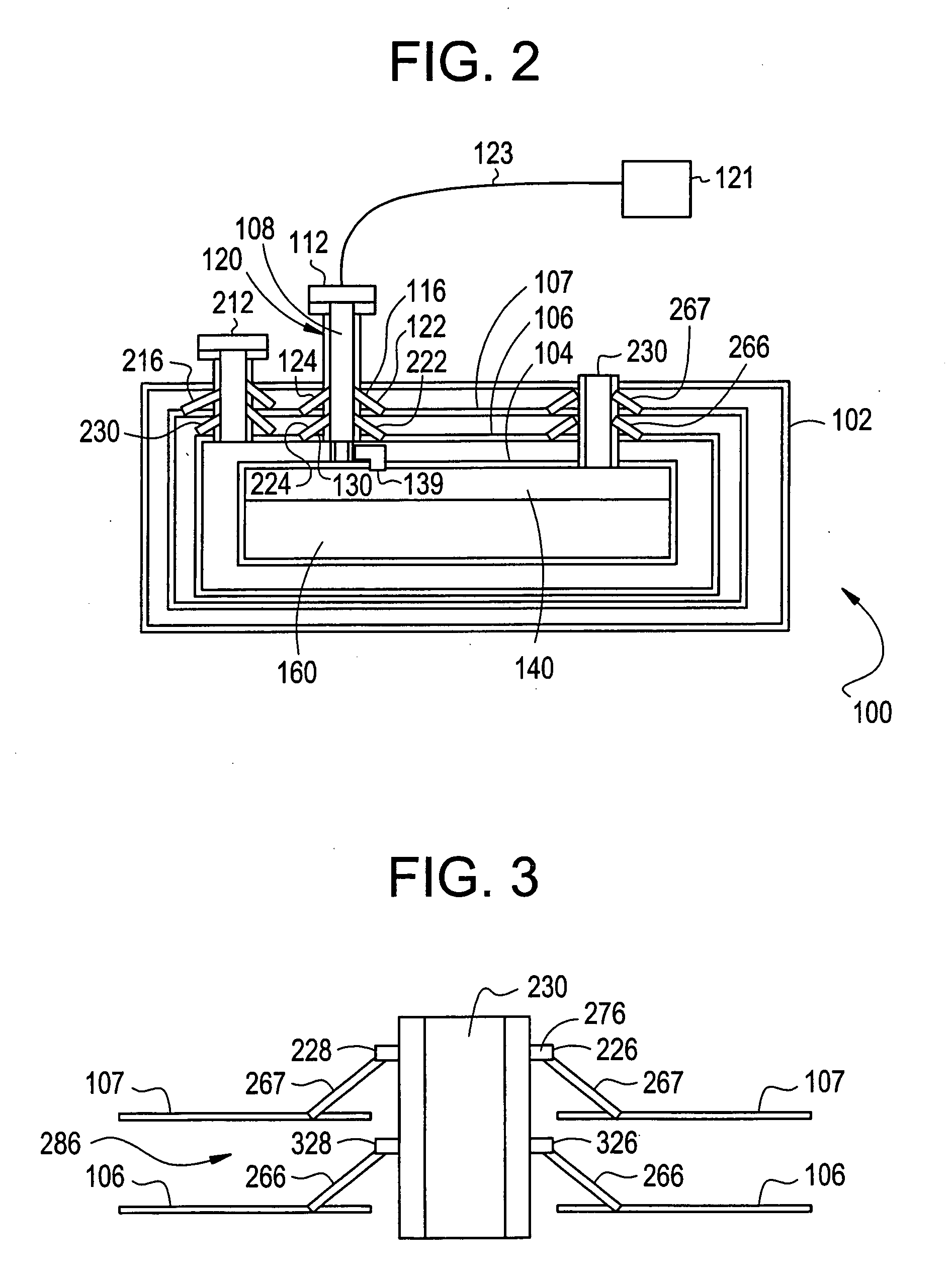

Thin film thermoelectric devices for hot-spot thermal management in microprocessors and other electronics

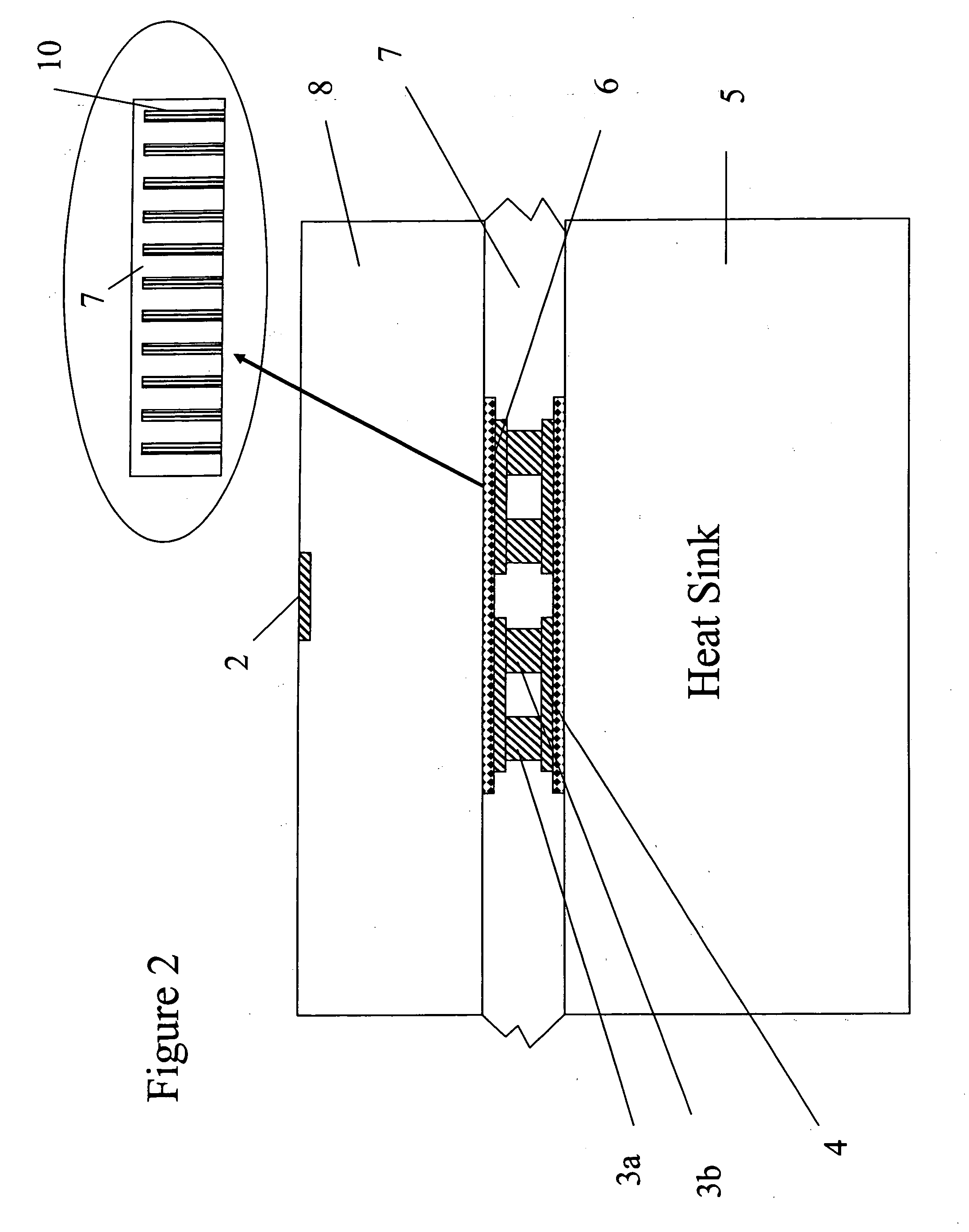

ActiveUS20060086118A1Improve efficiencyReduce heat loadThermoelectric device with peltier/seeback effectDomestic cooling apparatusEngineeringSolid medium

A structure, system and method for controlling a temperature of a heat generating device in a solid medium, wherein heat is extracted from the medium into at least one heat extraction device, the heat extraction device dissipates heat into an environment apart from the medium by a heat sink thermally coupled to the heat extraction device; and heat from the medium is dissipated into the heat sink by a first thermal interface material thermally coupling the heat sink to the medium.

Owner:LAIRD THERMAL SYST INC

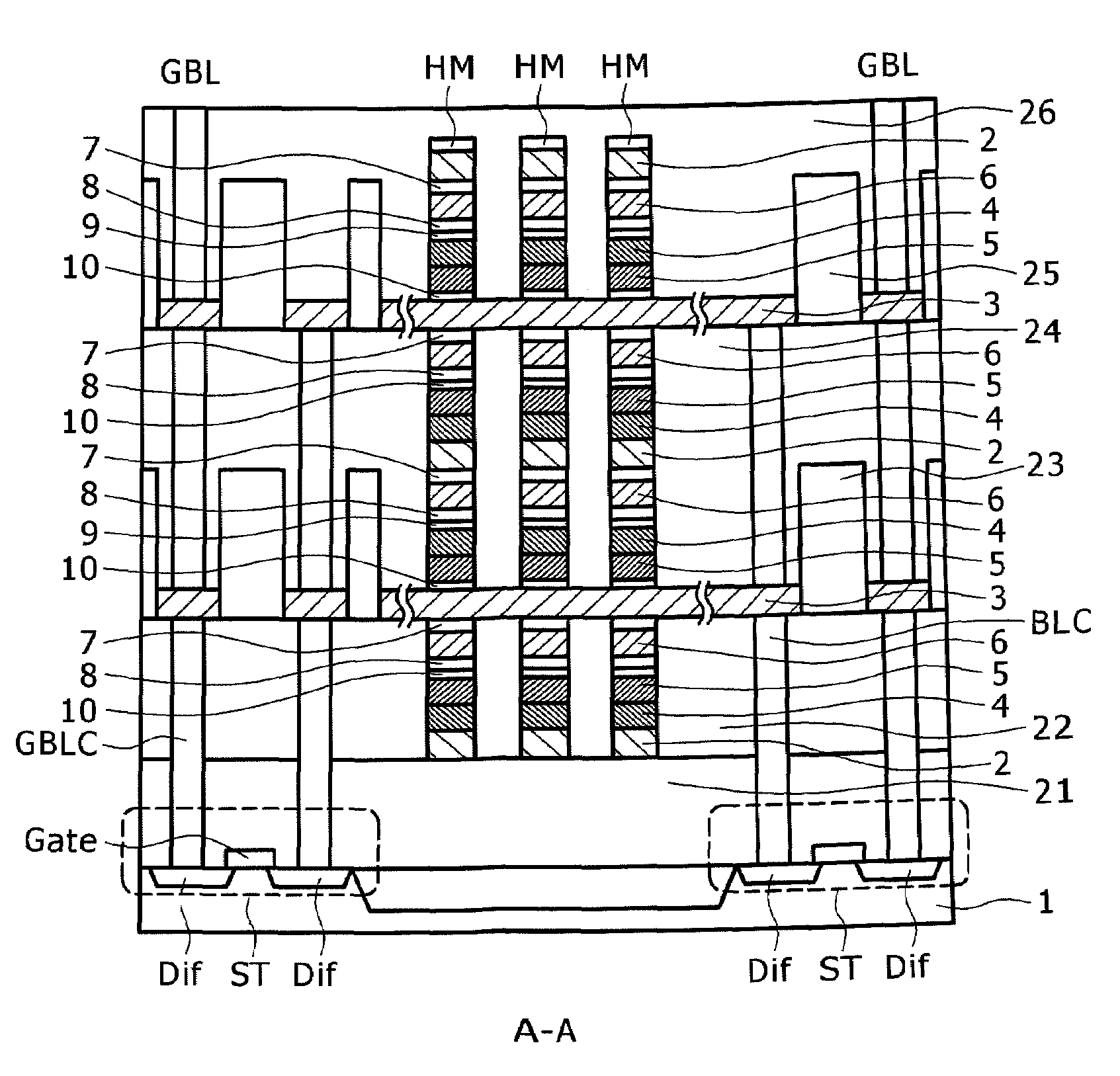

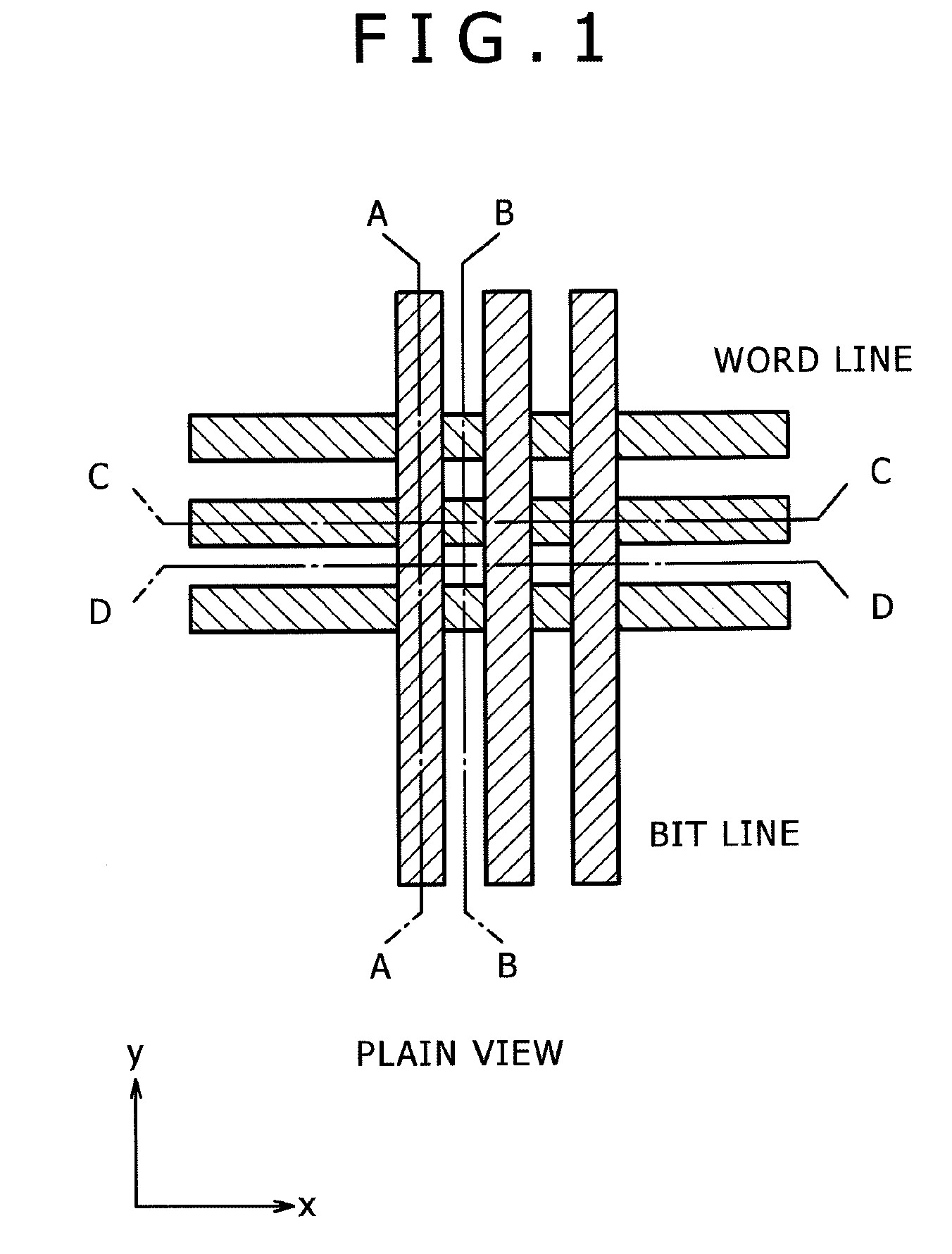

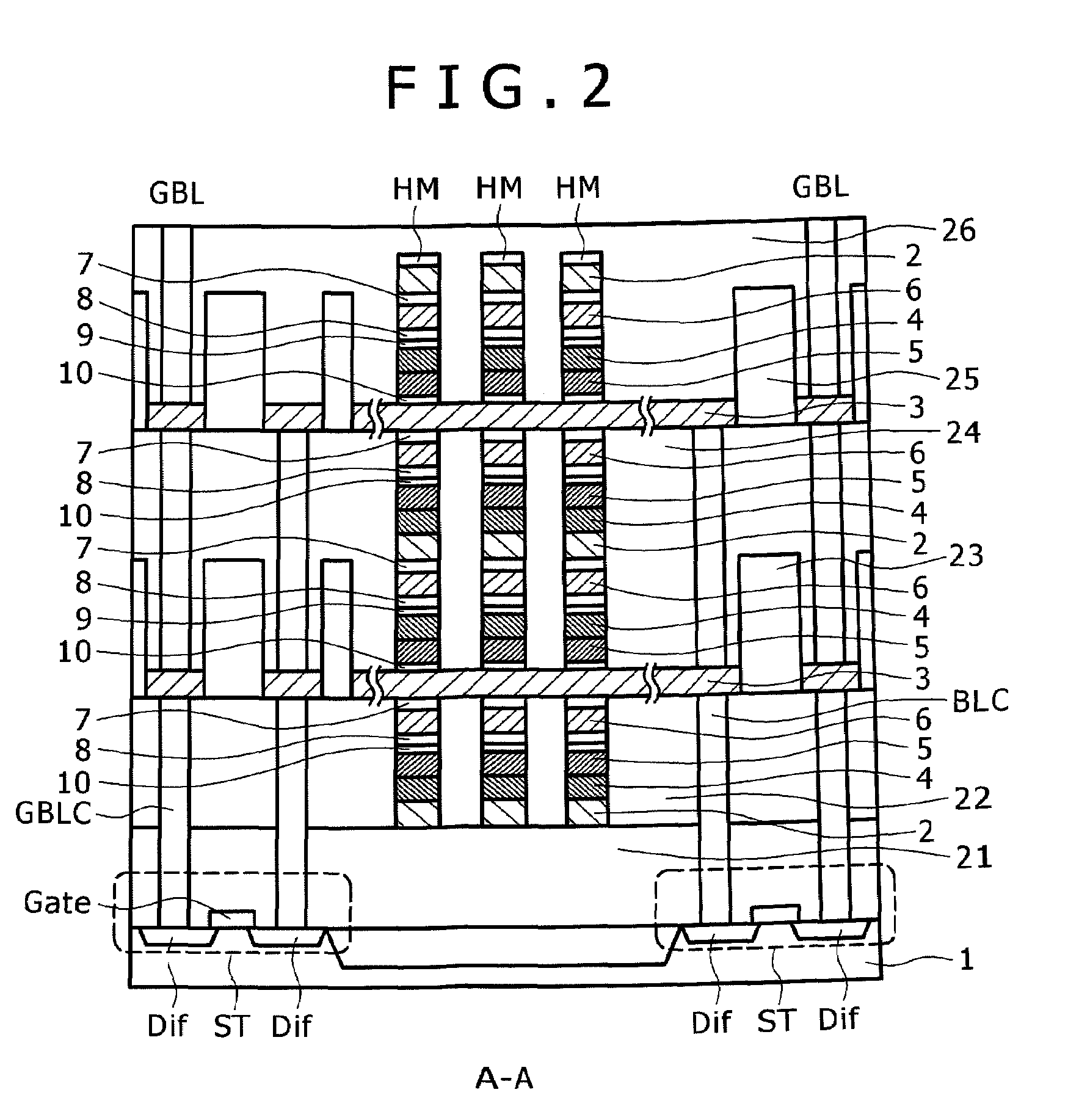

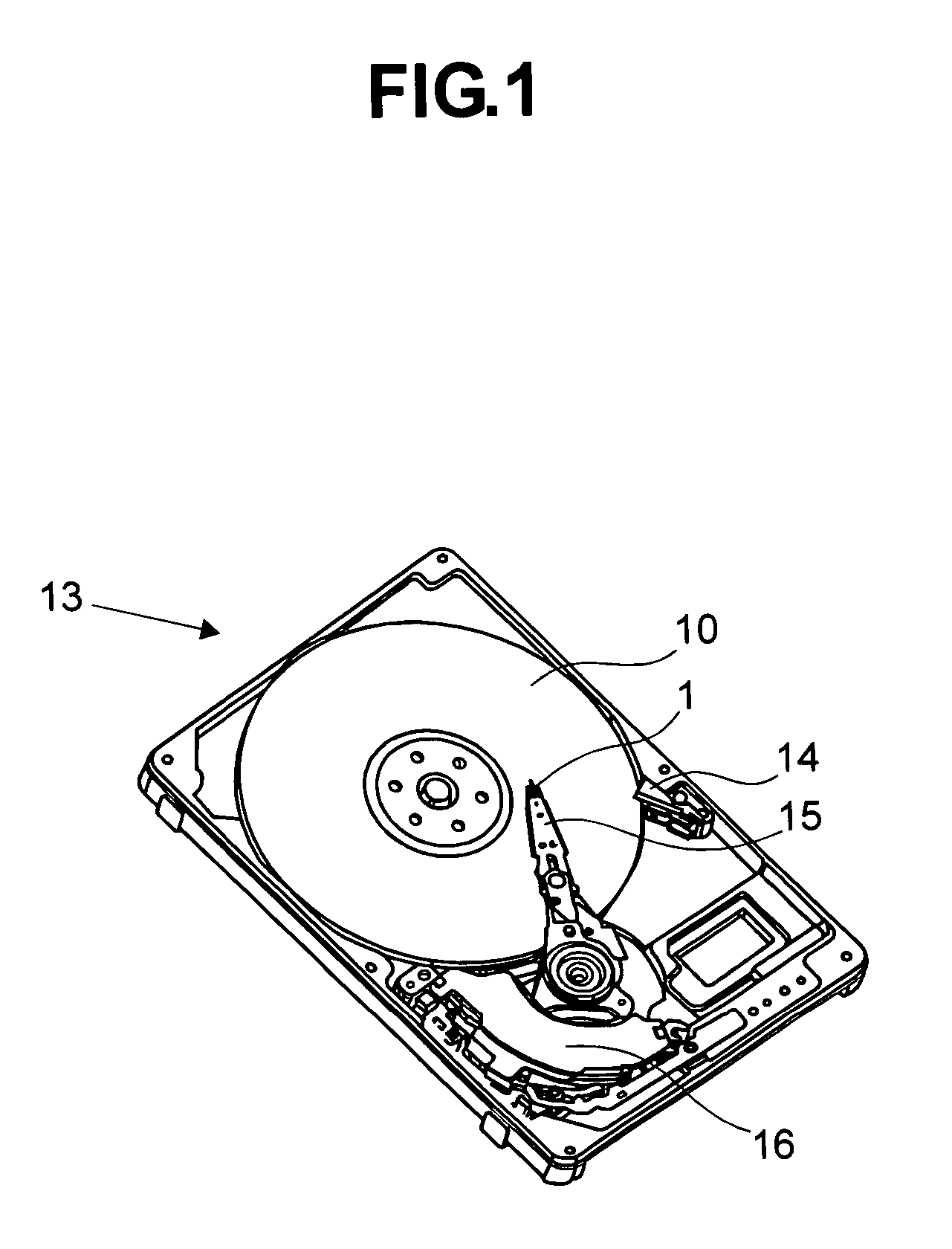

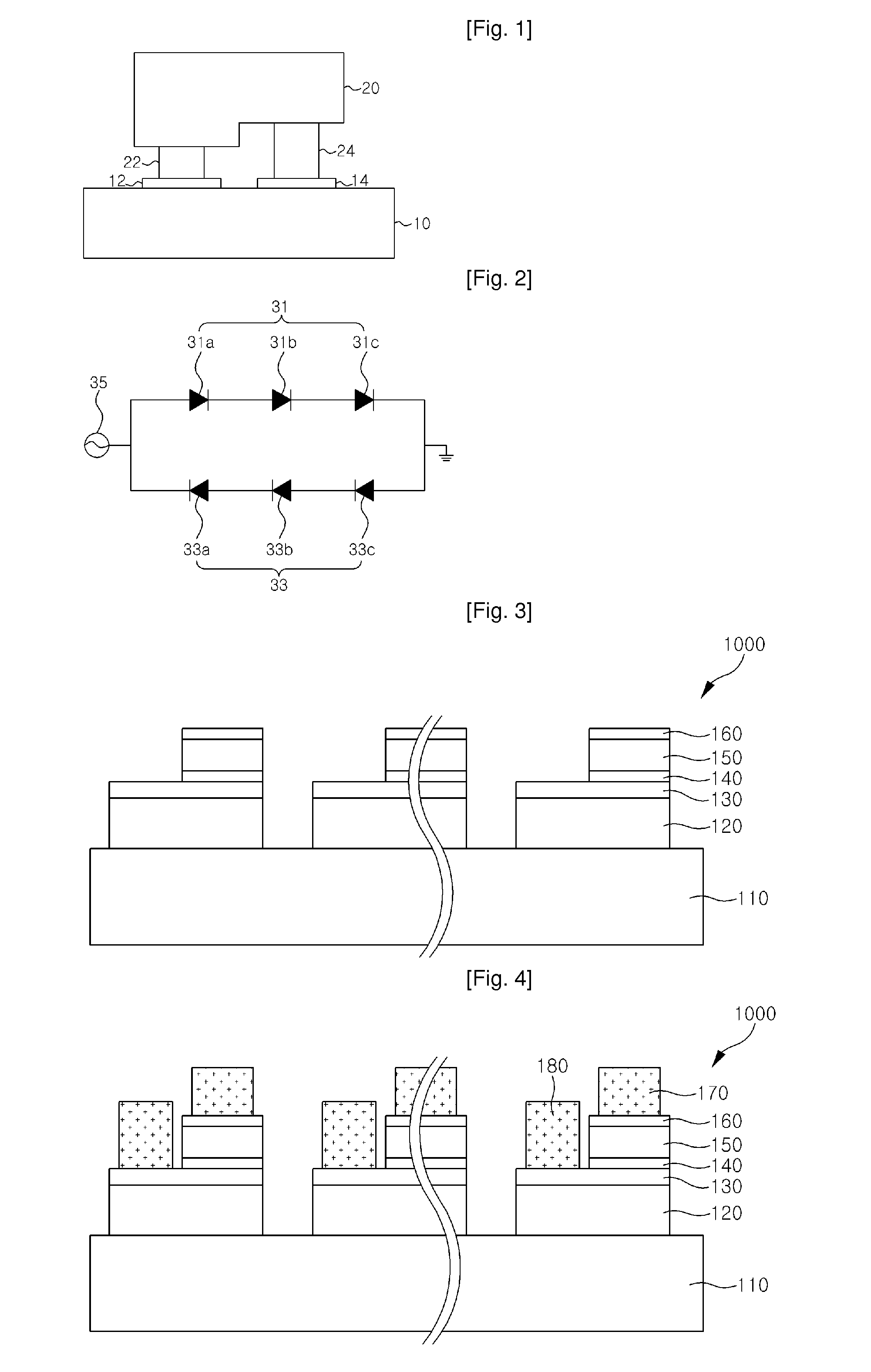

Semiconductor memory device and manufacturing method thereof

InactiveUS20090267047A1Large capacityImprove performanceSolid-state devicesSemiconductor/solid-state device manufacturingPhase-change memoryDevice material

The present invention can promote the large capacity, high performance and high reliability of a semiconductor memory device by realizing high-performance of both the semiconductor device and a memory device when the semiconductor memory device is manufactured by stacking a memory device such as ReRAM or the phase change memory and the semiconductor device. After a polysilicon forming a selection device is deposited in an amorphous state at a low temperature, the crystallization of the polysilicon and the activation of impurities are briefly performed with heat treatment by laser annealing. When laser annealing is performed, the recording material located below the silicon subjected to the crystallization is completely covered with a metal film or with the metal film and an insulating film, thereby making it possible to suppress a temperature increase at the time of performing the annealing and to reduce the thermal load of the recording material.

Owner:HITACHI LTD

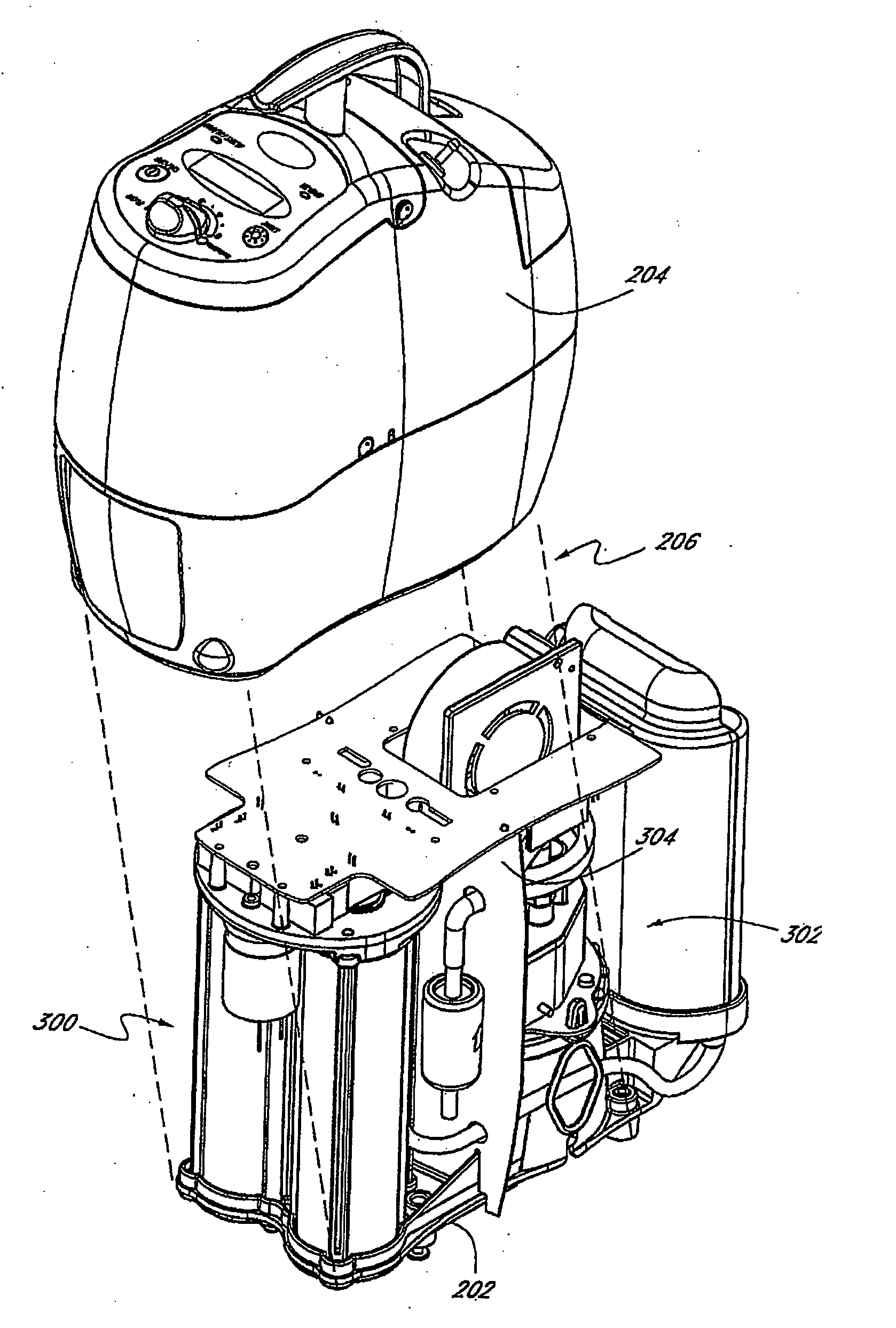

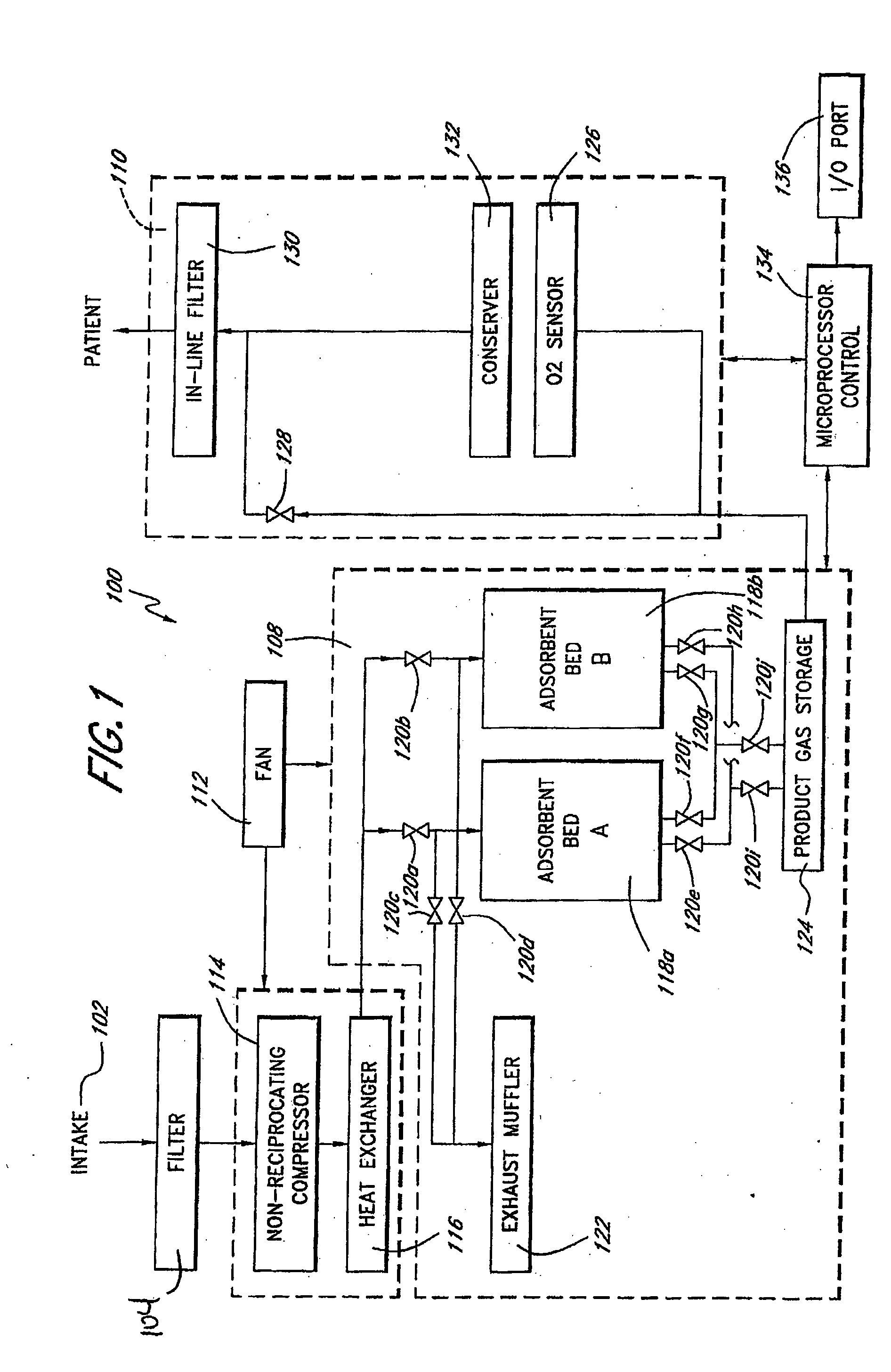

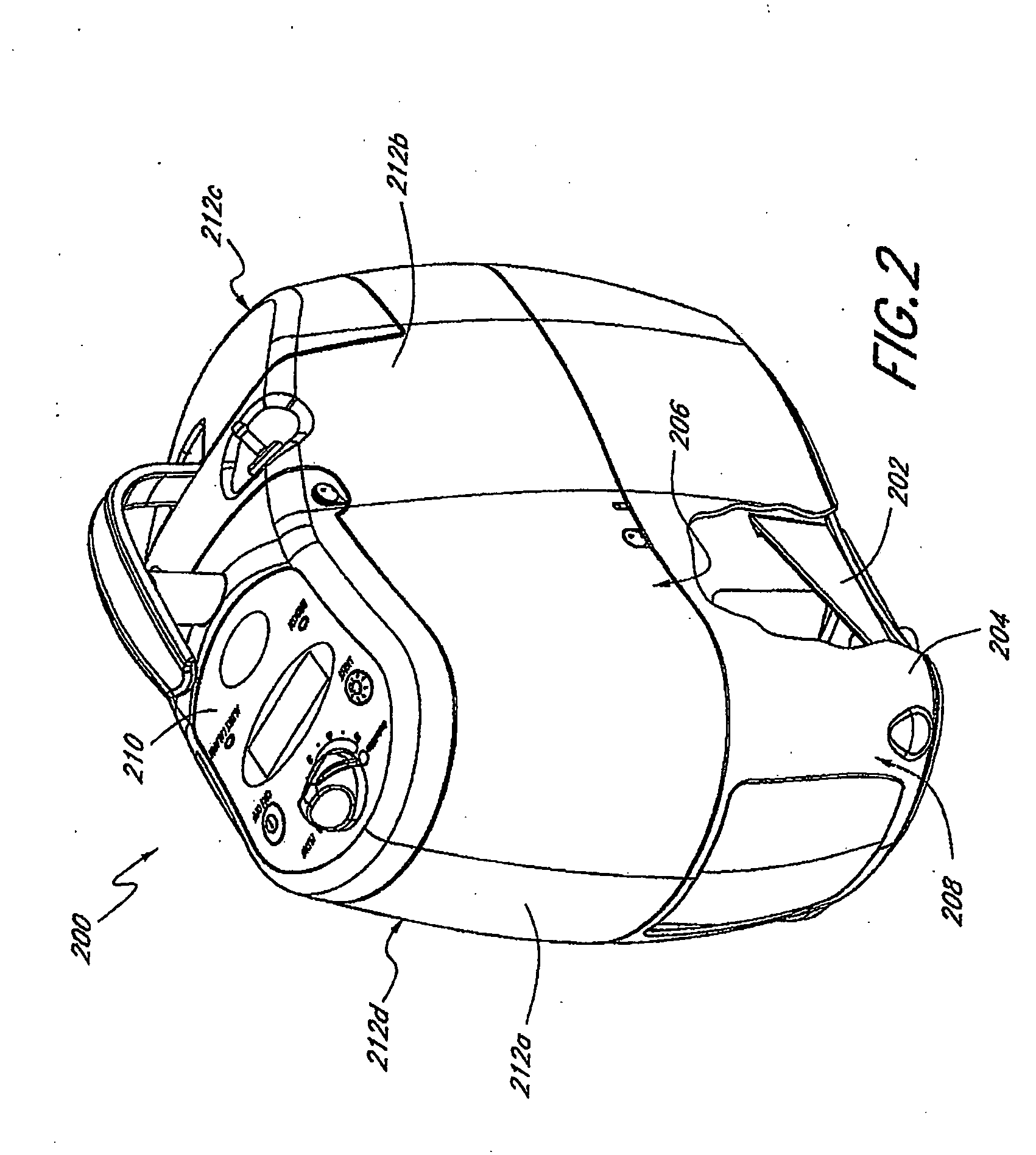

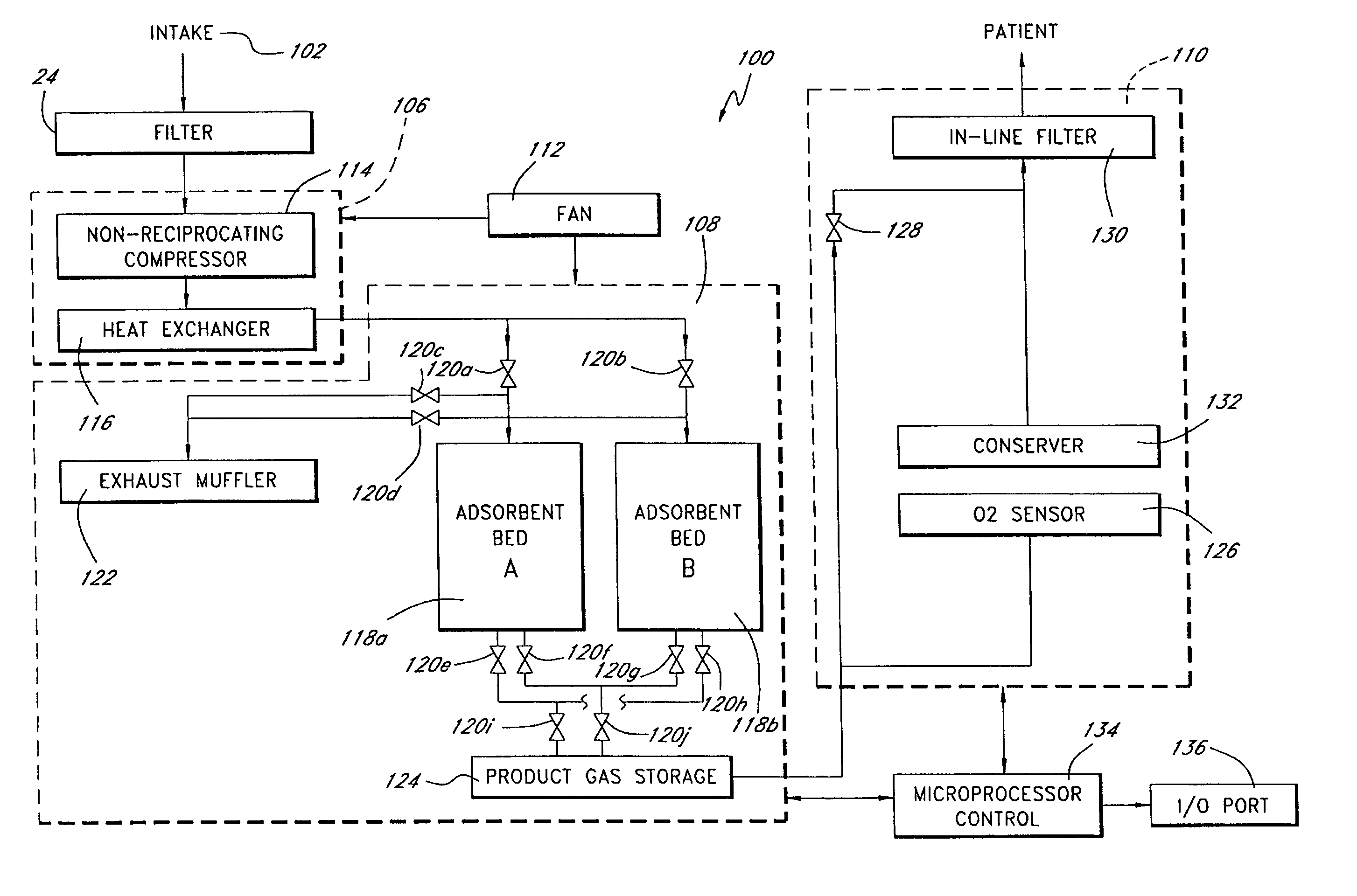

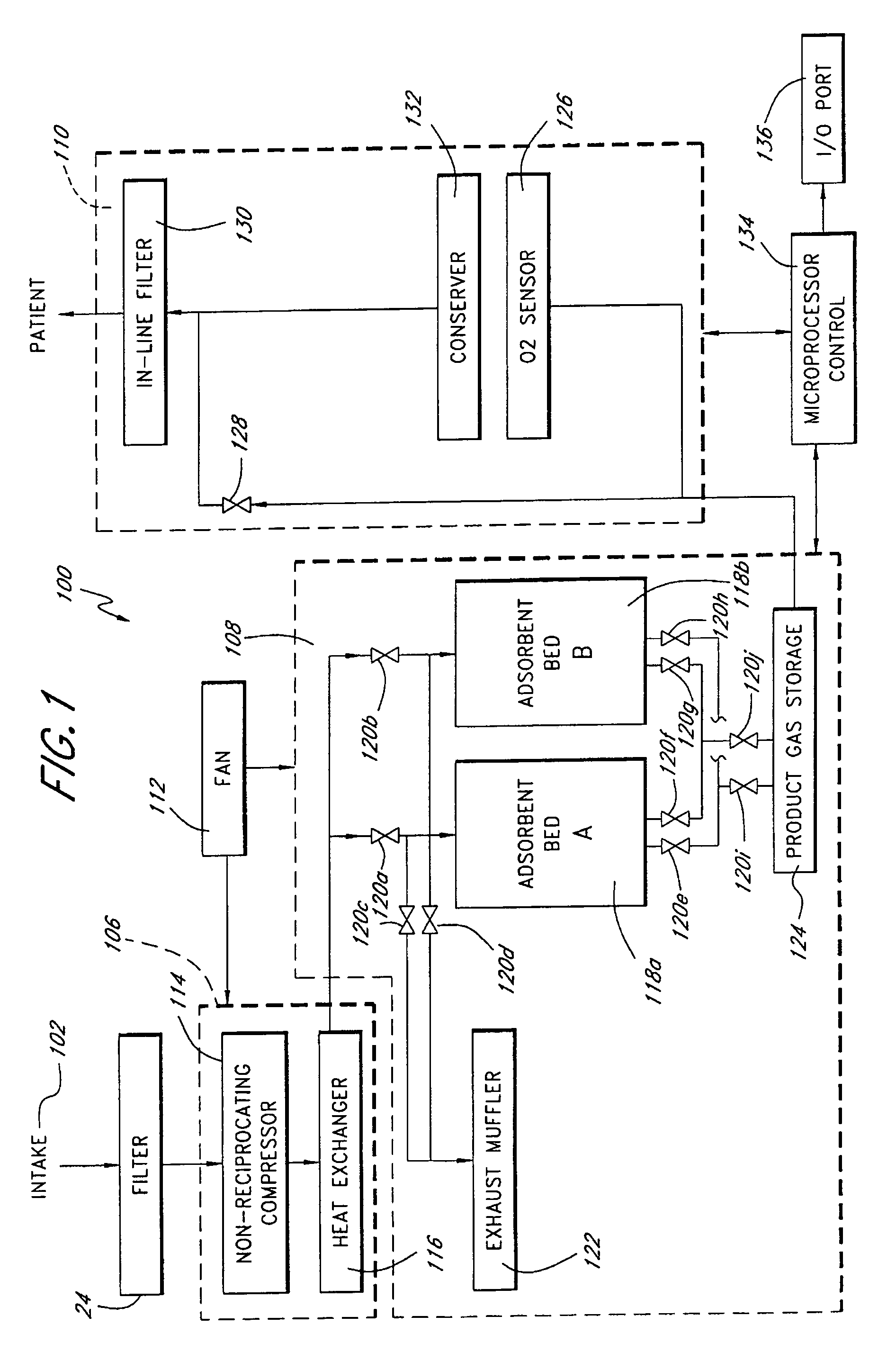

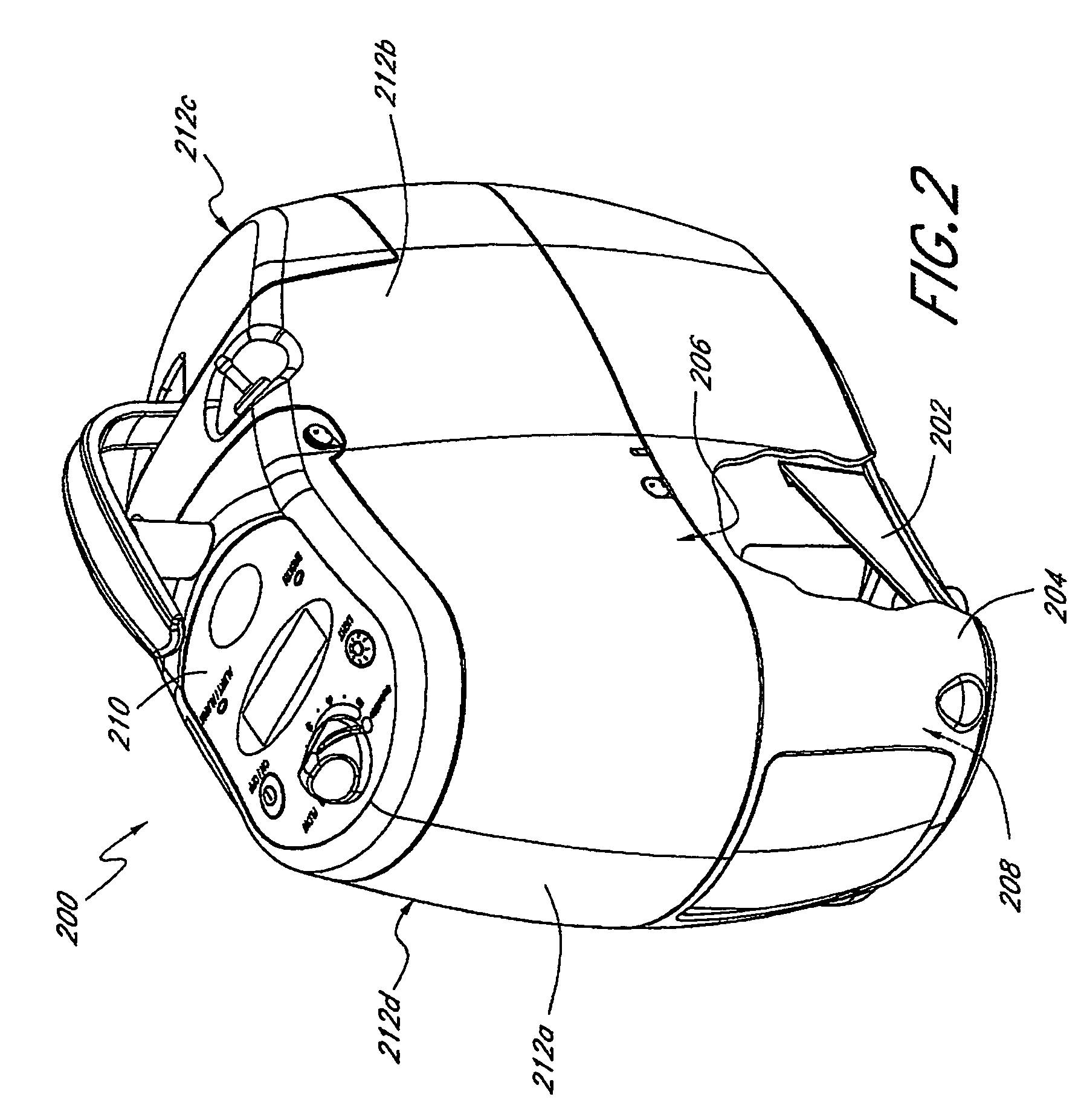

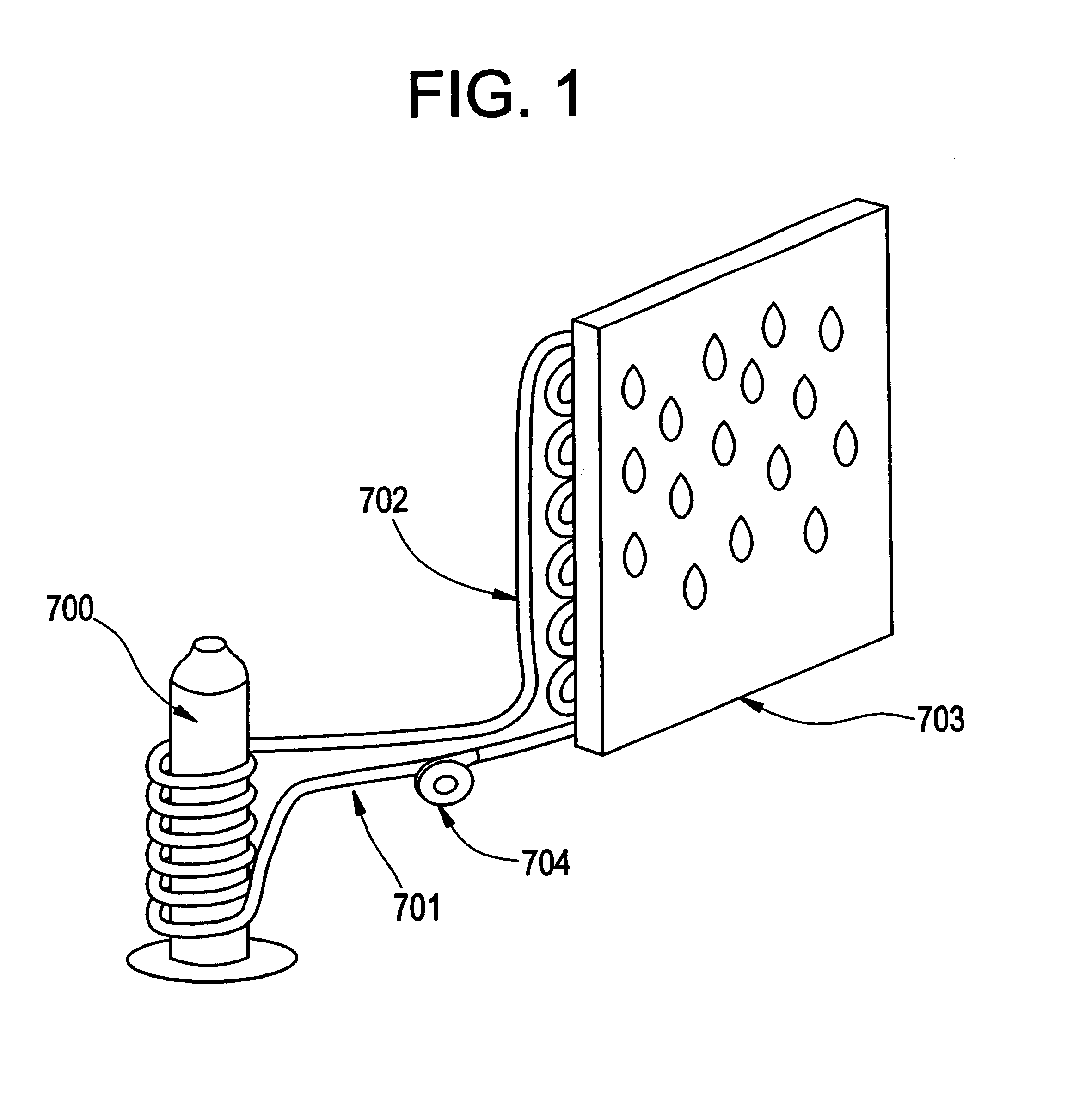

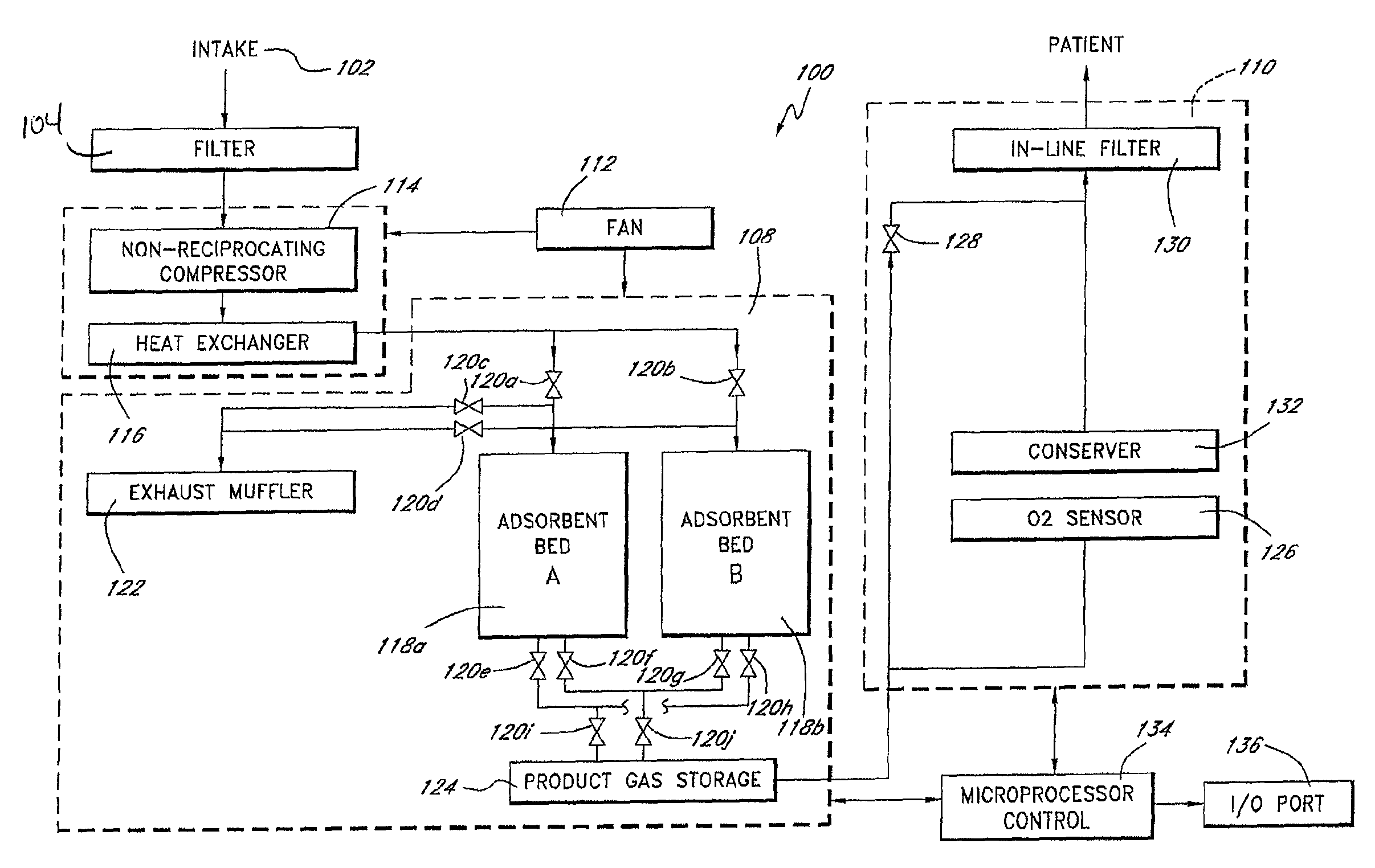

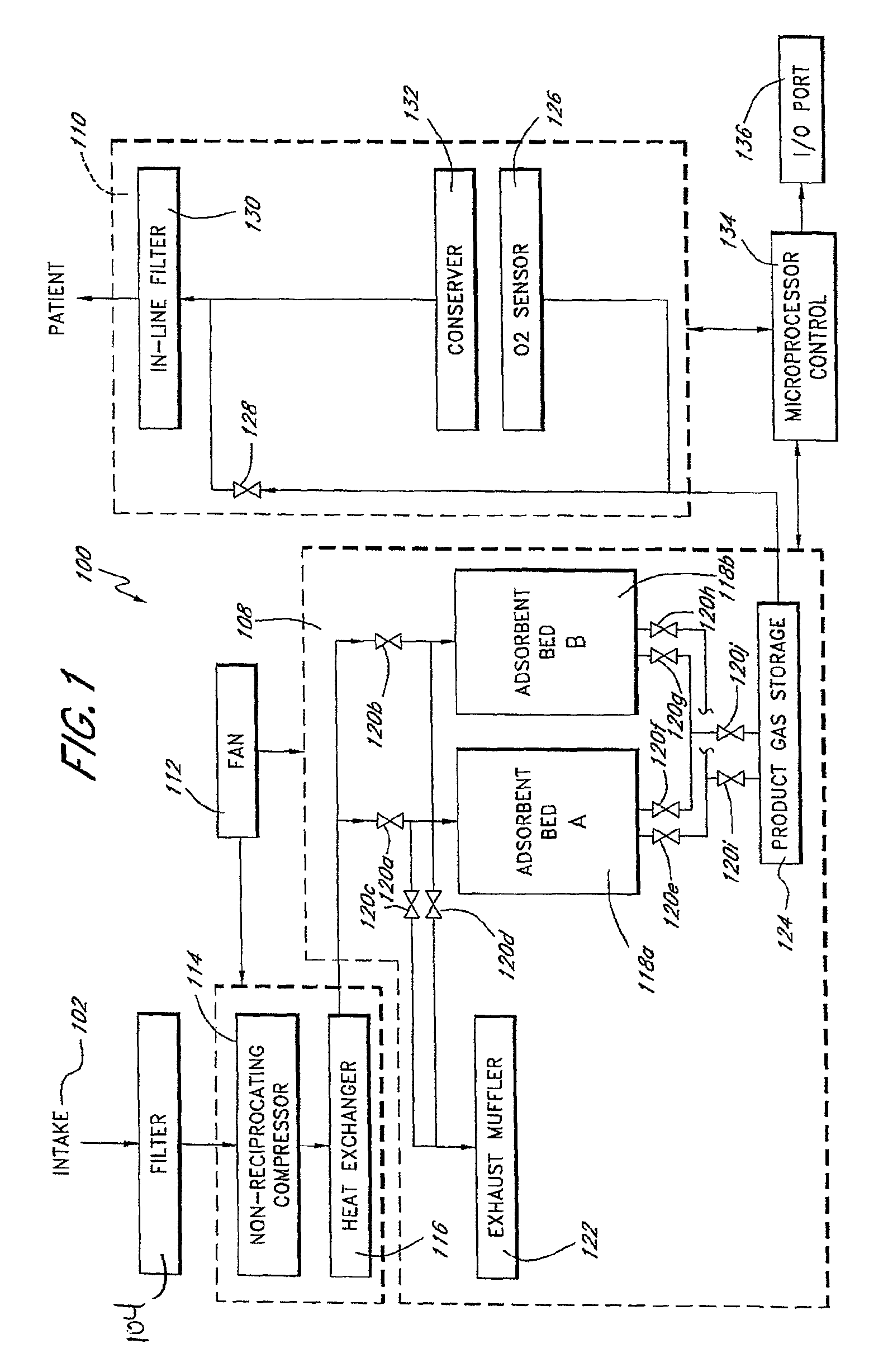

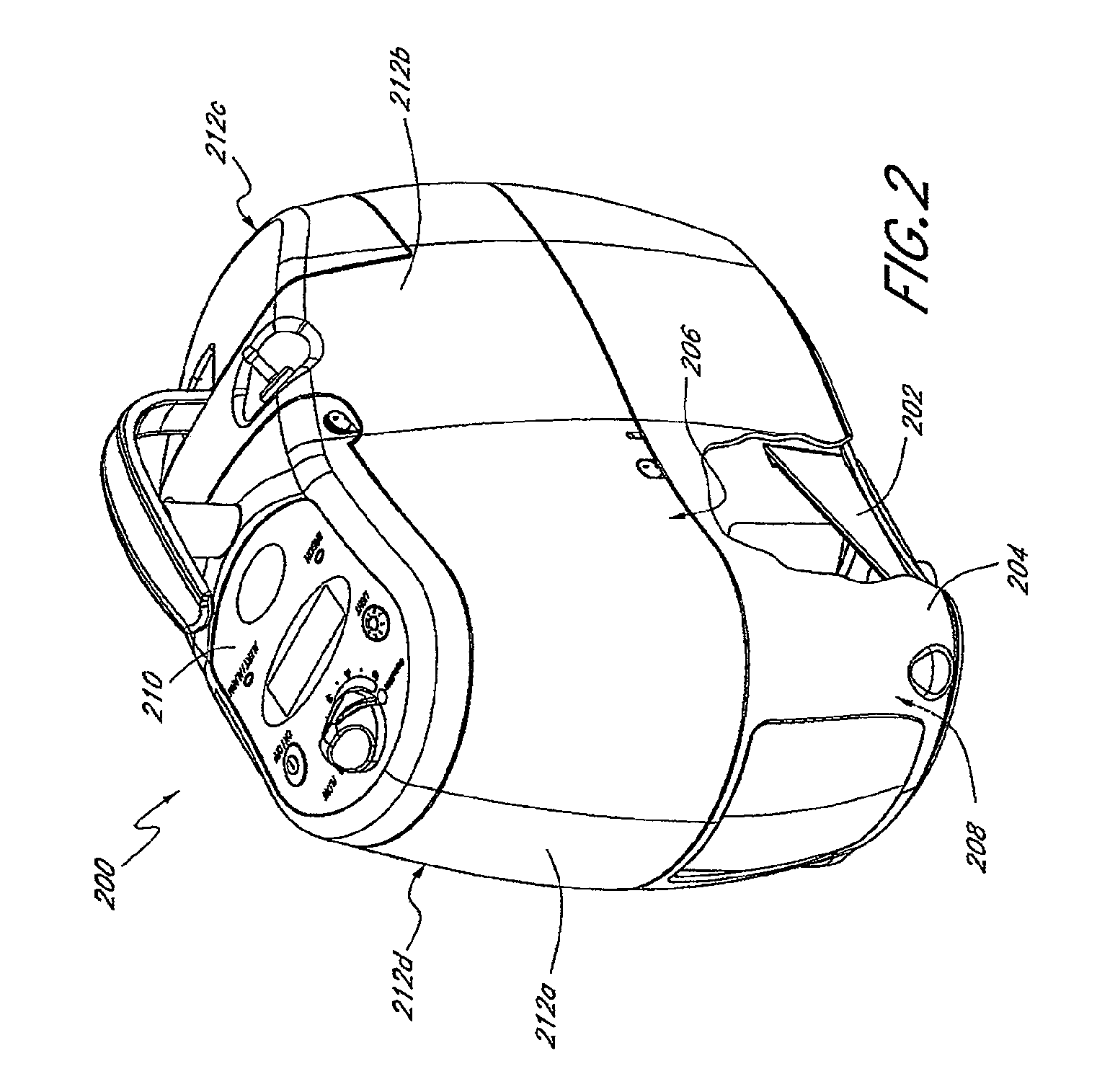

Portable gas fractionalization system

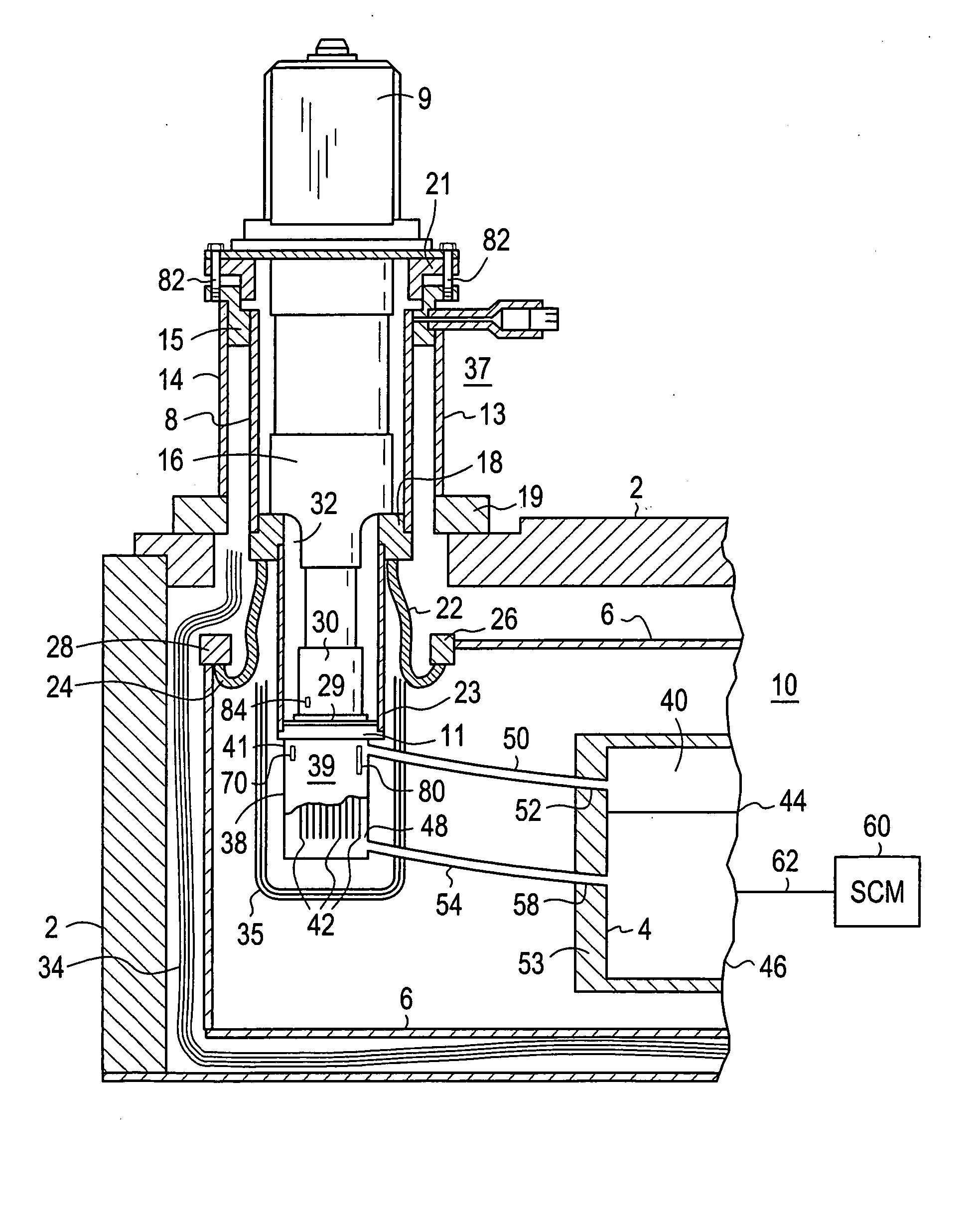

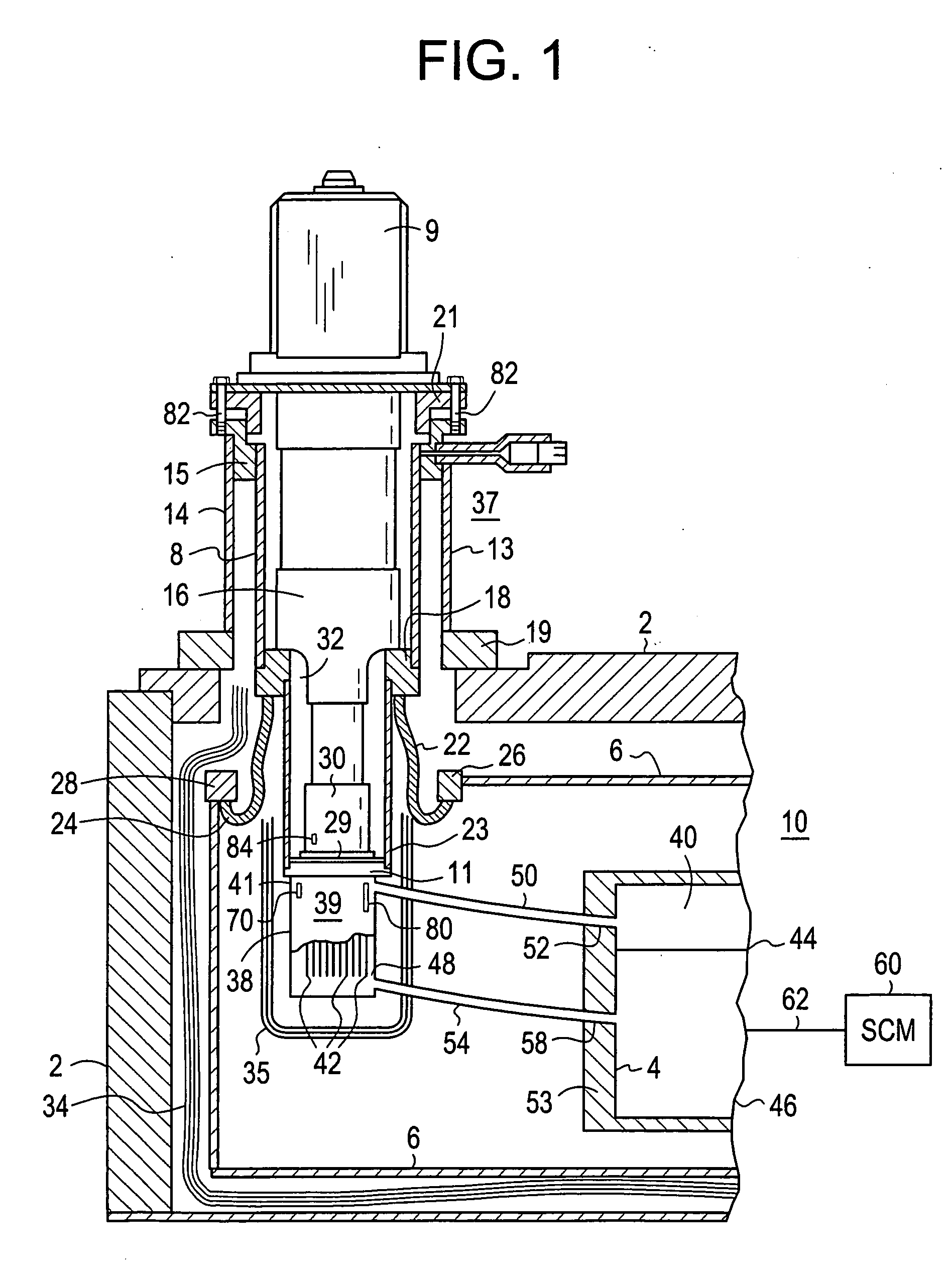

A portable gas fractionalization apparatus that provides oxygen rich air to patients is provided. The apparatus is compact, lightweight, and low-noise. The components are assembled in a housing that is divided into two compartments. One compartment is maintained at a lower temperature than the other compartment. The lower temperature compartment is configured for mounting components that can be damaged by heat. The higher temperature compartment is configured for mounting heat generating components. An air stream is directed to flow from an ambient air inlet to an air outlet constantly so that there is always a fresh source of cooling air. The apparatus utilizes a PSA unit to produce an oxygen enriched product. The PSA unit incorporates a novel single ended column design in which all flow paths and valves can be co-located on a single integrated manifold. The apparatus also can be used in conjunction with a satellite conserver and a mobility cart.

Owner:INOGEN INC

Portable gas fractionalization system

InactiveUS7066985B2Reduce heat loadReduce noiseCombination devicesAuxillary pretreatmentLow noiseProcess engineering

A portable gas fractionalization apparatus that provides oxygen rich air to patients is provided. The apparatus is compact, lightweight, and low-noise. The components are assembled in a housing that is divided into two compartments. One compartment is maintained at a lower temperature than the other compartment. The lower temperature compartment is configured for mounting components that can be damaged by heat. The higher temperature compartment is configured for mounting heat generating components. An air stream is directed to flow from an ambient air inlet to an air outlet constantly so that there is always a fresh source of cooling air. The apparatus utilizes a PSA unit to produce an oxygen enriched product. The PSA unit incorporates a novel single ended column design in which all flow paths and valves can be co-located on a single integrated manifold. The apparatus also can be used in conjunction with a satellite conserver and a mobility cart.

Owner:INOGEN INC

Solid state light fixture with cooling system with heat rejection management

ActiveUS8651704B1Increase operating powerReduce in quantityPlanar light sourcesMechanical apparatusSemiconductor materialsElectrical battery

Systems and methods for solid-state light source heat management are provided. A solid-state light source, e.g. having one or more LEDs, can be mounted within an enclosure. In some embodiments, a heat sink associated with semiconductor material and / or power electronics can be placed on a separate side of the enclosure that is thermally insulated or separated from the state-light source. The enclosure can include a first side or portion that allows light from the solid-state-light source (e.g., LEDs) to pass through to a target area. A fluid transfer conduit may be connected to the second side or portion of the enclosure for passing a fluid (e.g., air, water, coolant, etc.) across the heat sink to transport heat generated by the power electronics and / or semiconductor material away. The heated fluid can then be routed to, as examples, an HVAC system, a vent, water heating systems, heat exchanger systems, and / or storage systems (e.g., batteries).

Owner:MUSCO

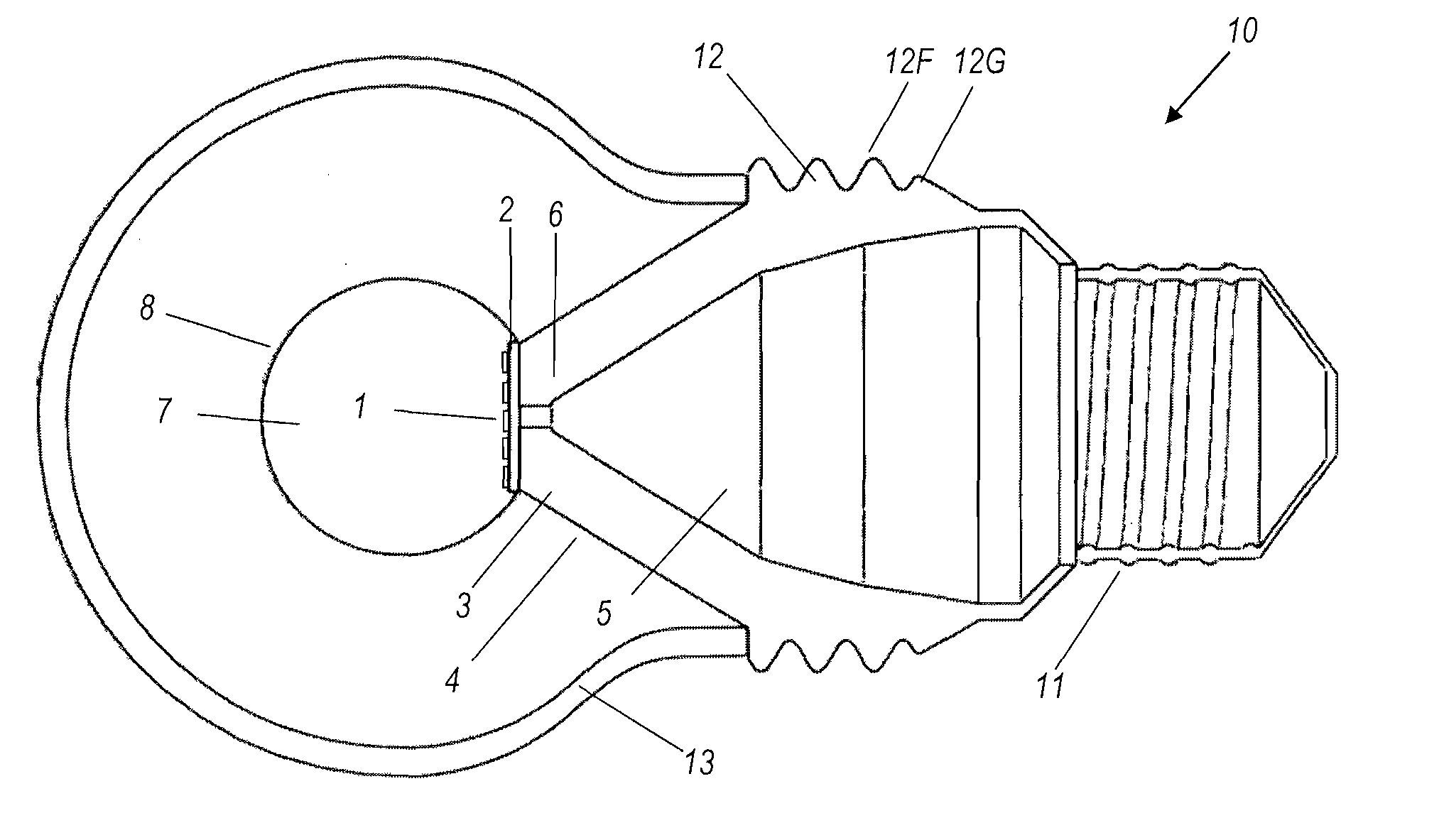

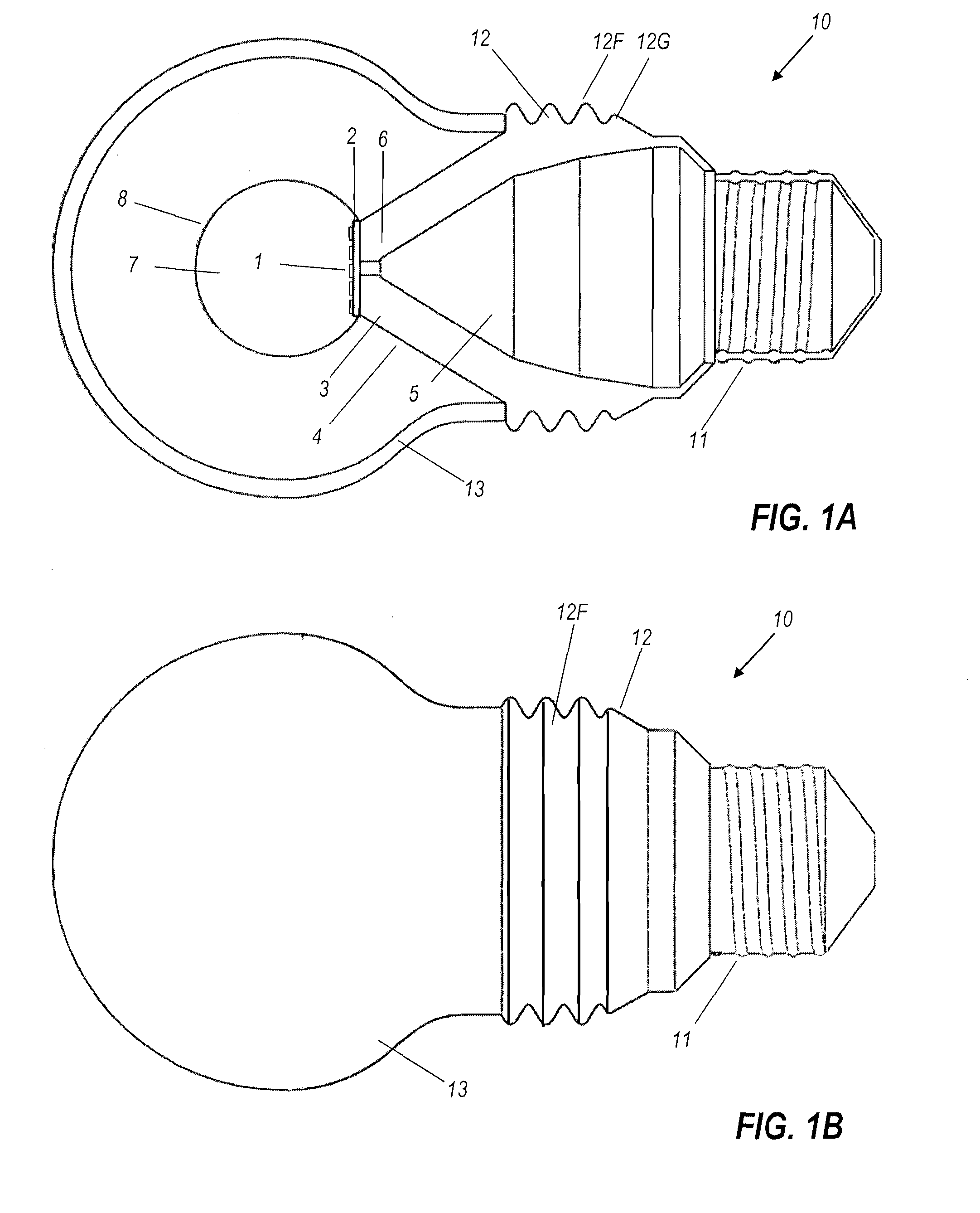

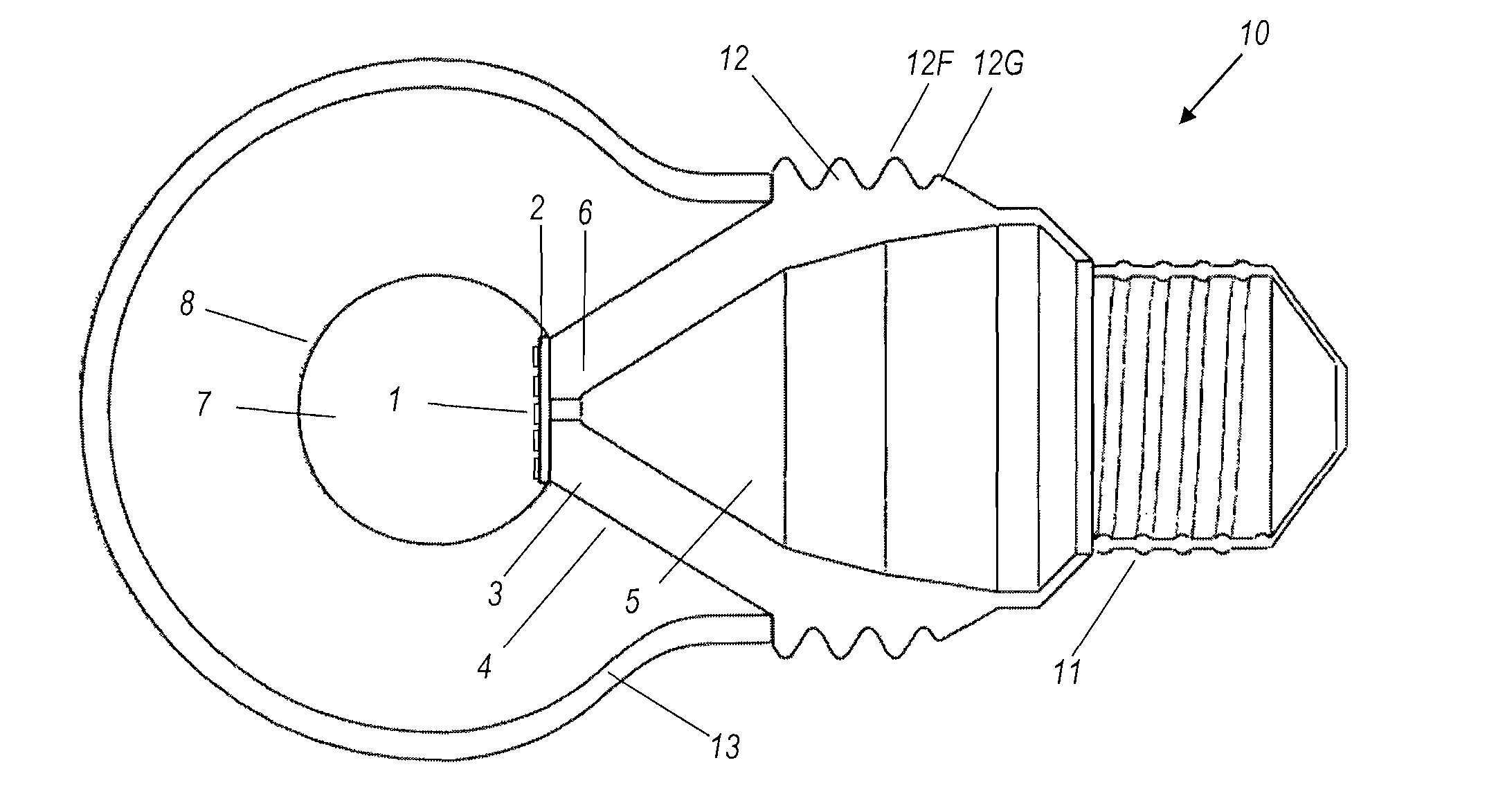

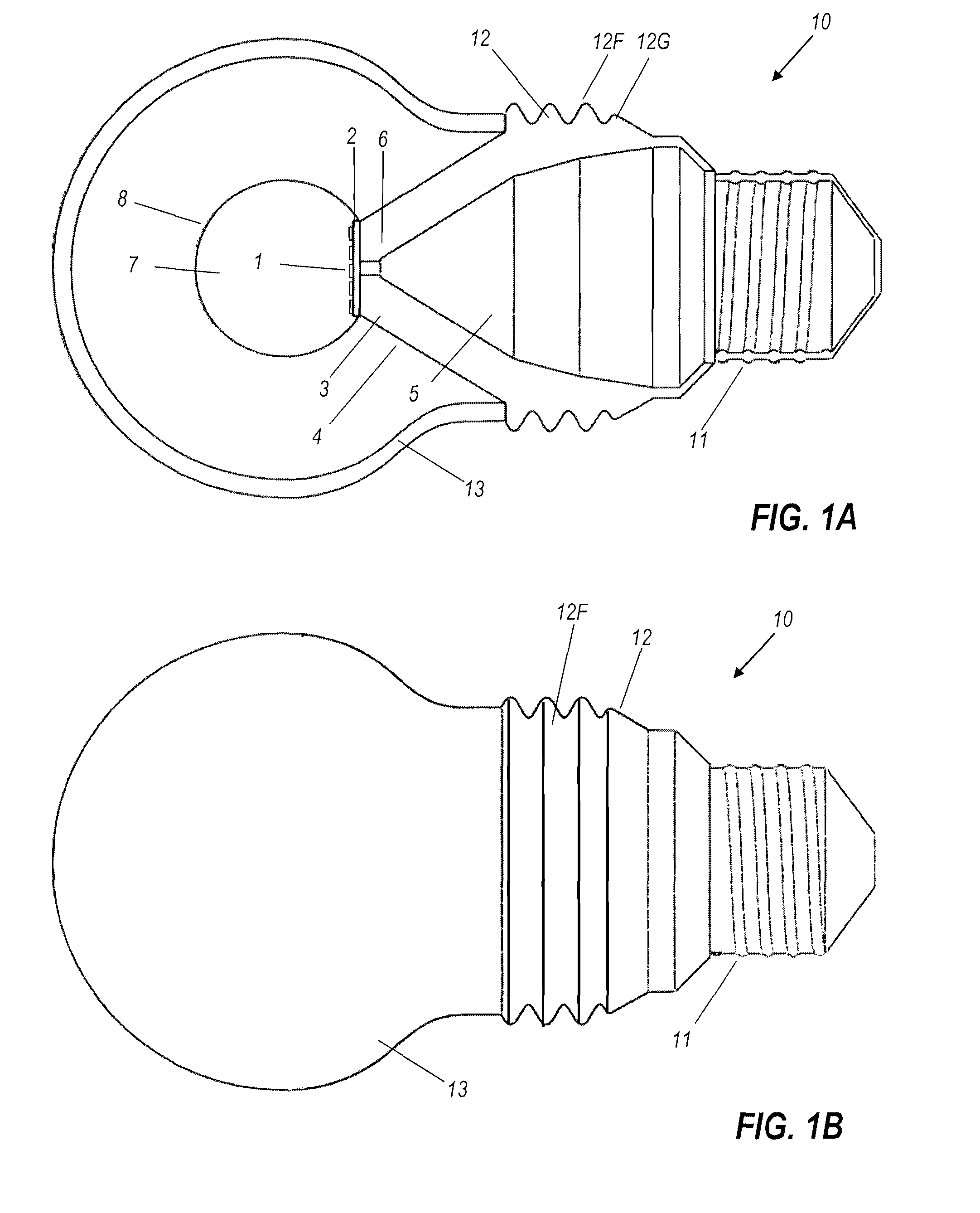

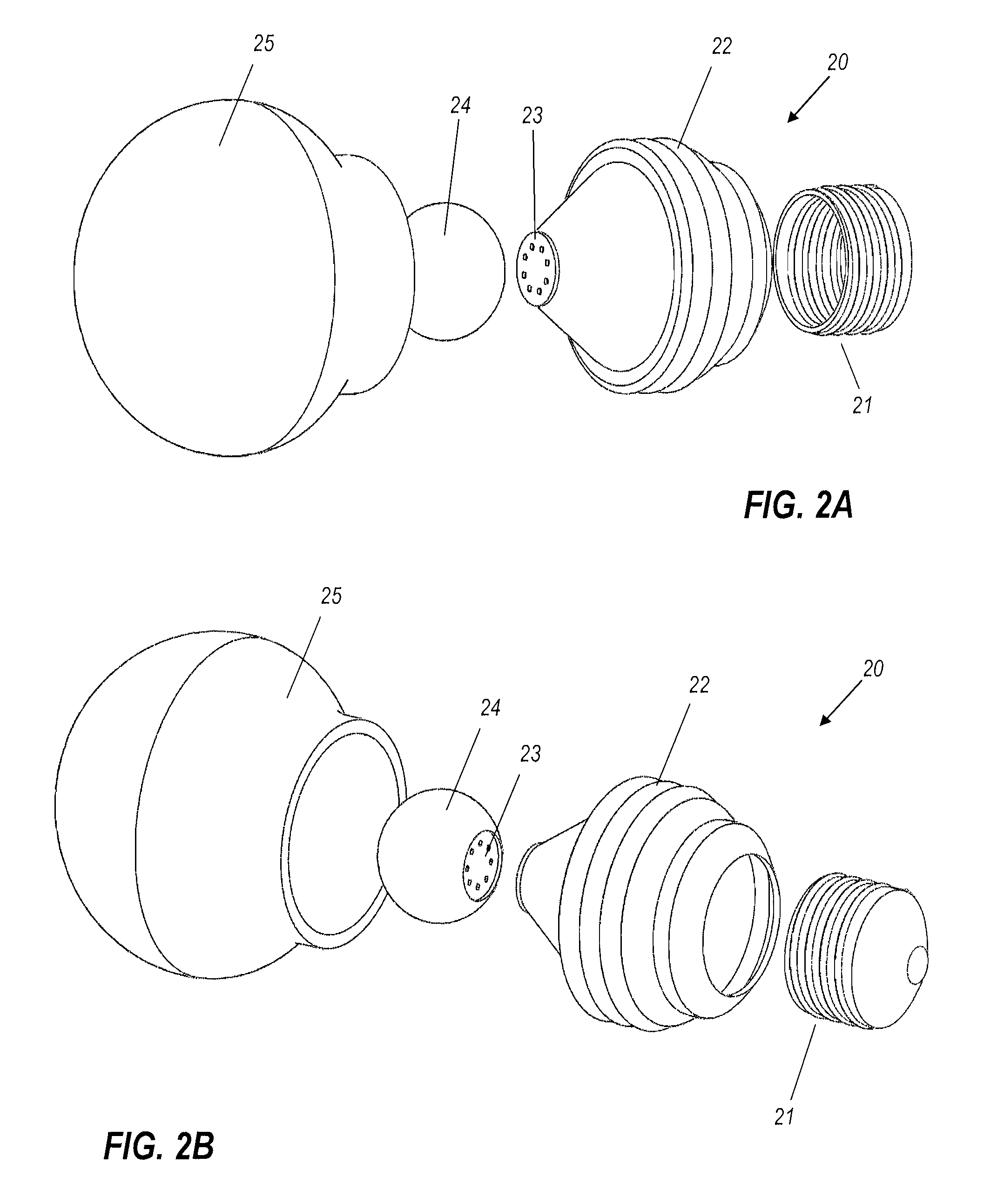

Solid-state light bulb

InactiveUS20110095686A1Reduce decreaseAvoid problemsLight source combinationsLighting support devicesHeat conductingLed array

An example of this light bulb has a light emitting element (which may be an LED array) mounted on a circuit board. The circuit board is mounted on one end of a heat-conducting frame. An Edison screw or other suitable connector, for attaching the light bulb electrically and mechanically to a receptacle, is mounted on the other end of the frame. A transparent phosphor-coated ball has a flat chord face optically bonded to said array. A light-permeable globular enclosure is mounted on the frame, surrounding the ball and both homogenizing the white light output of the bulb but also concealing the yellowing unlit appearance of the remote phosphor ball centrally located within it.

Owner:LIGHT PRESCRIPTIONS INNOVATORS

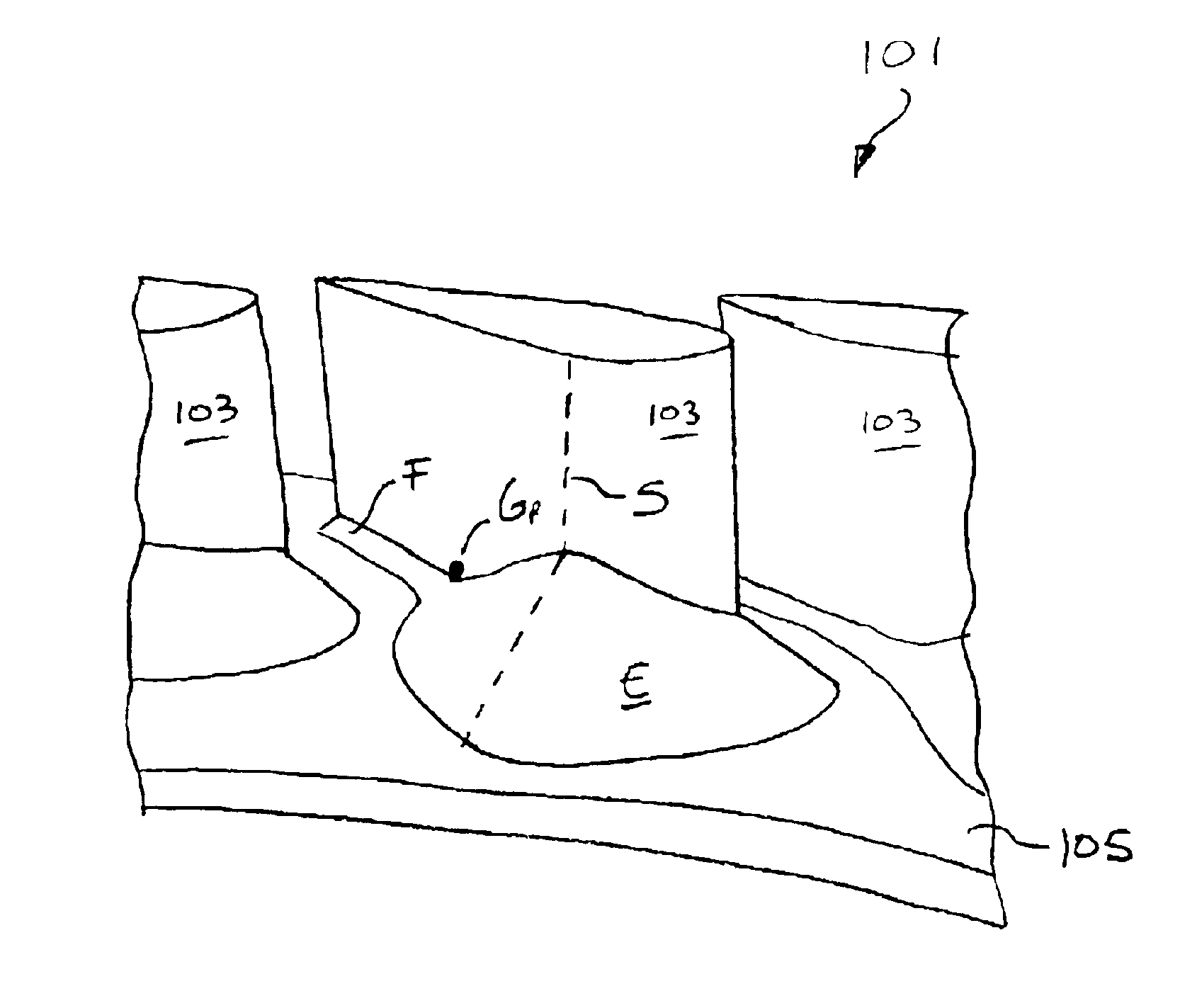

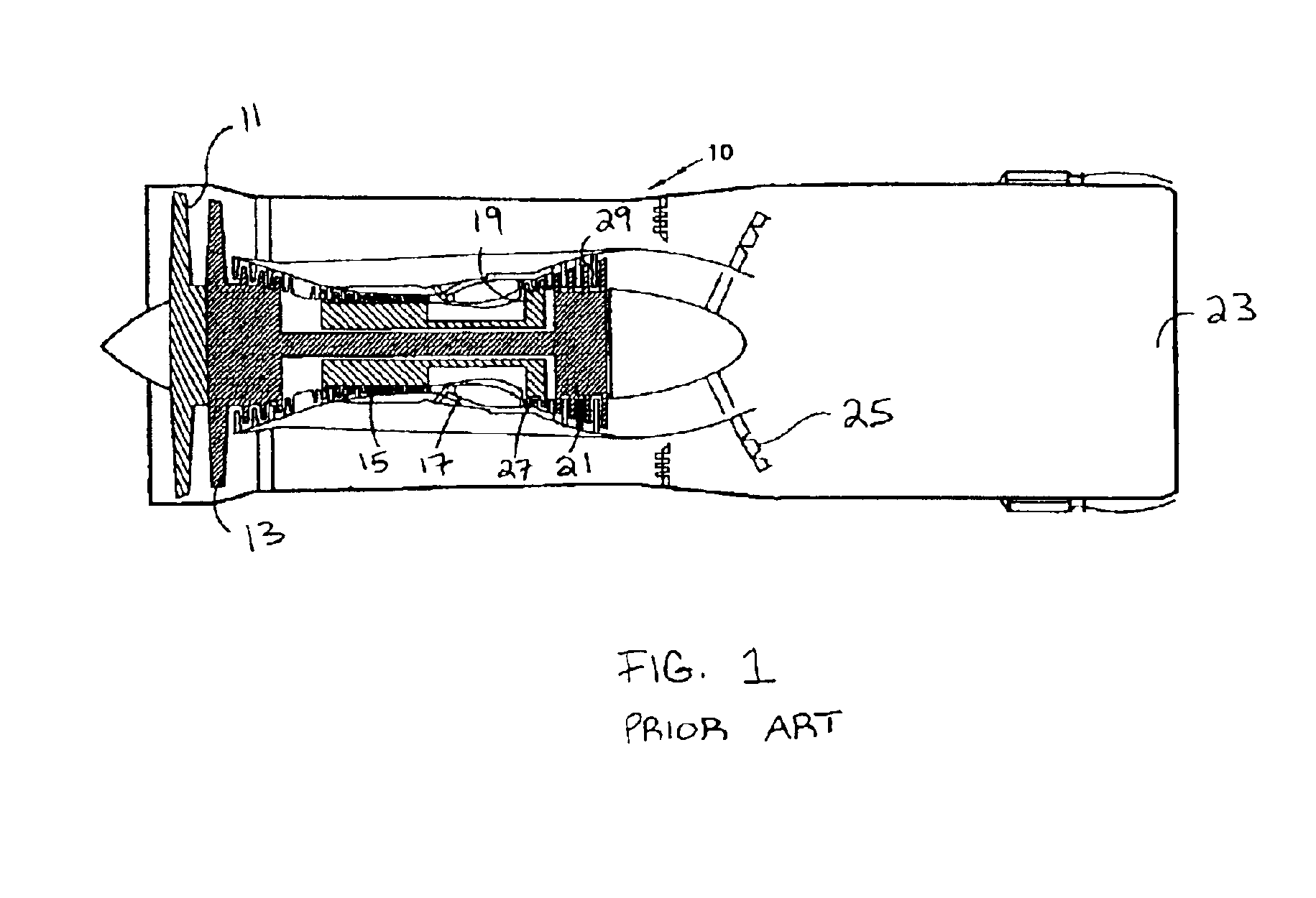

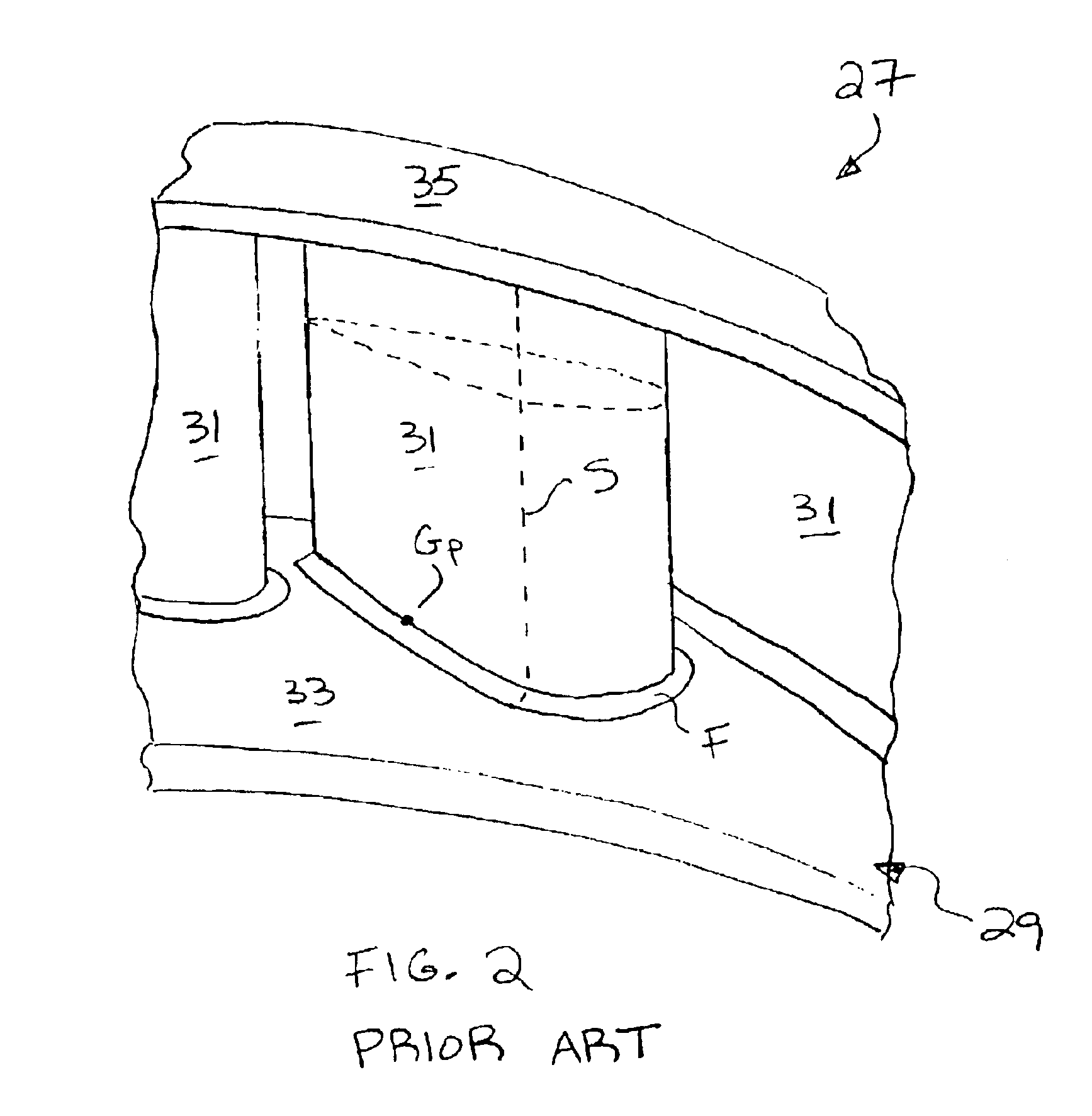

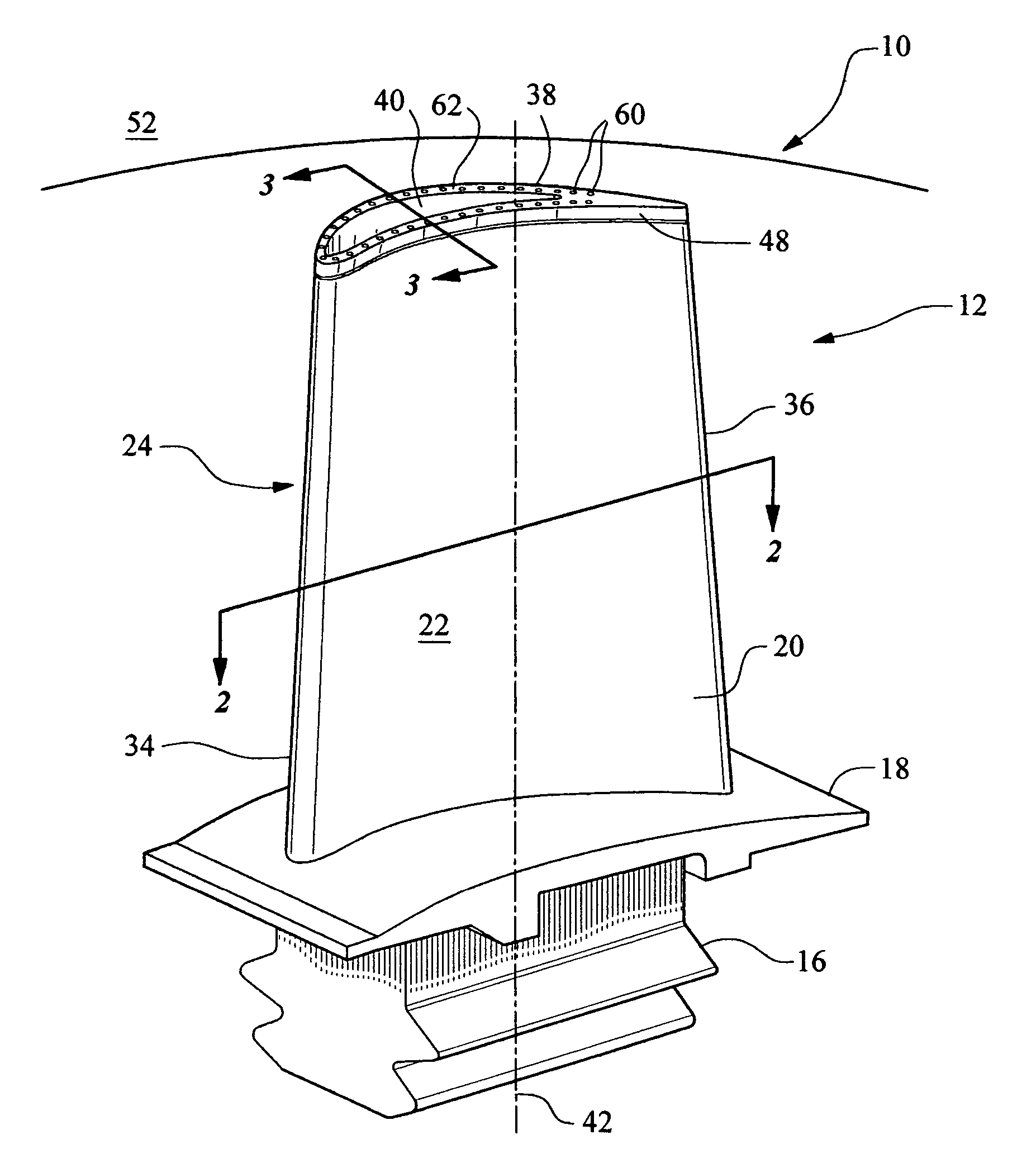

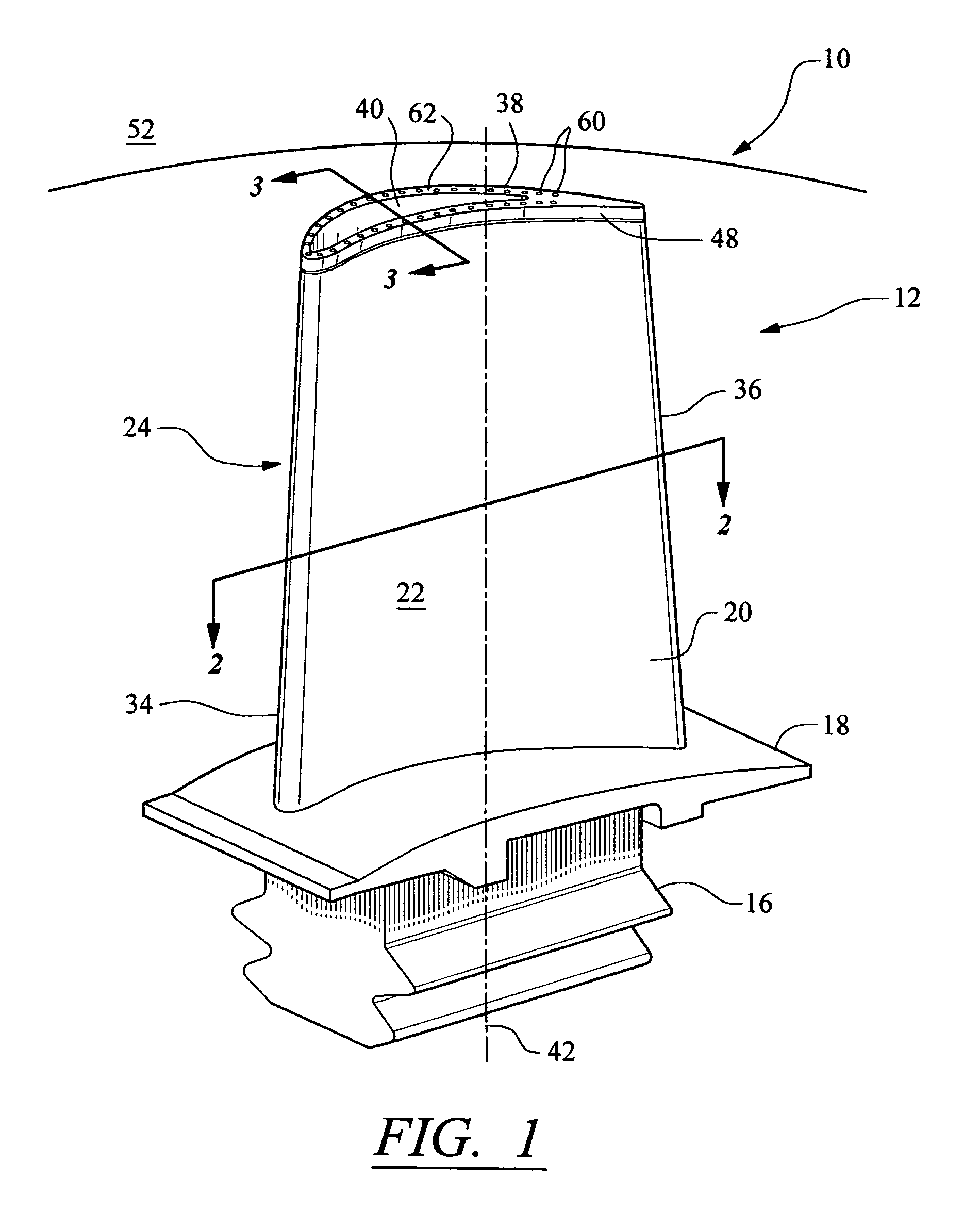

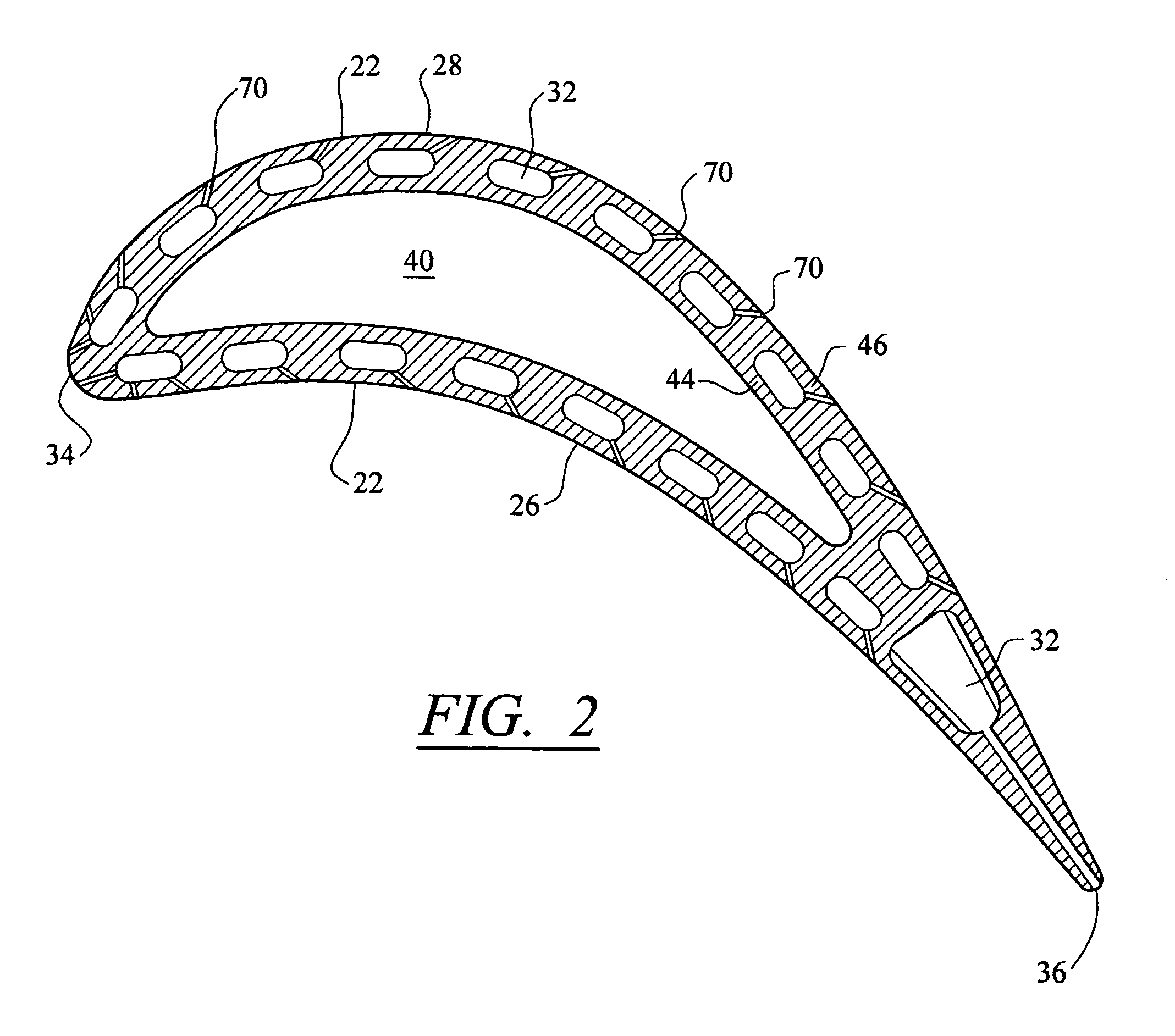

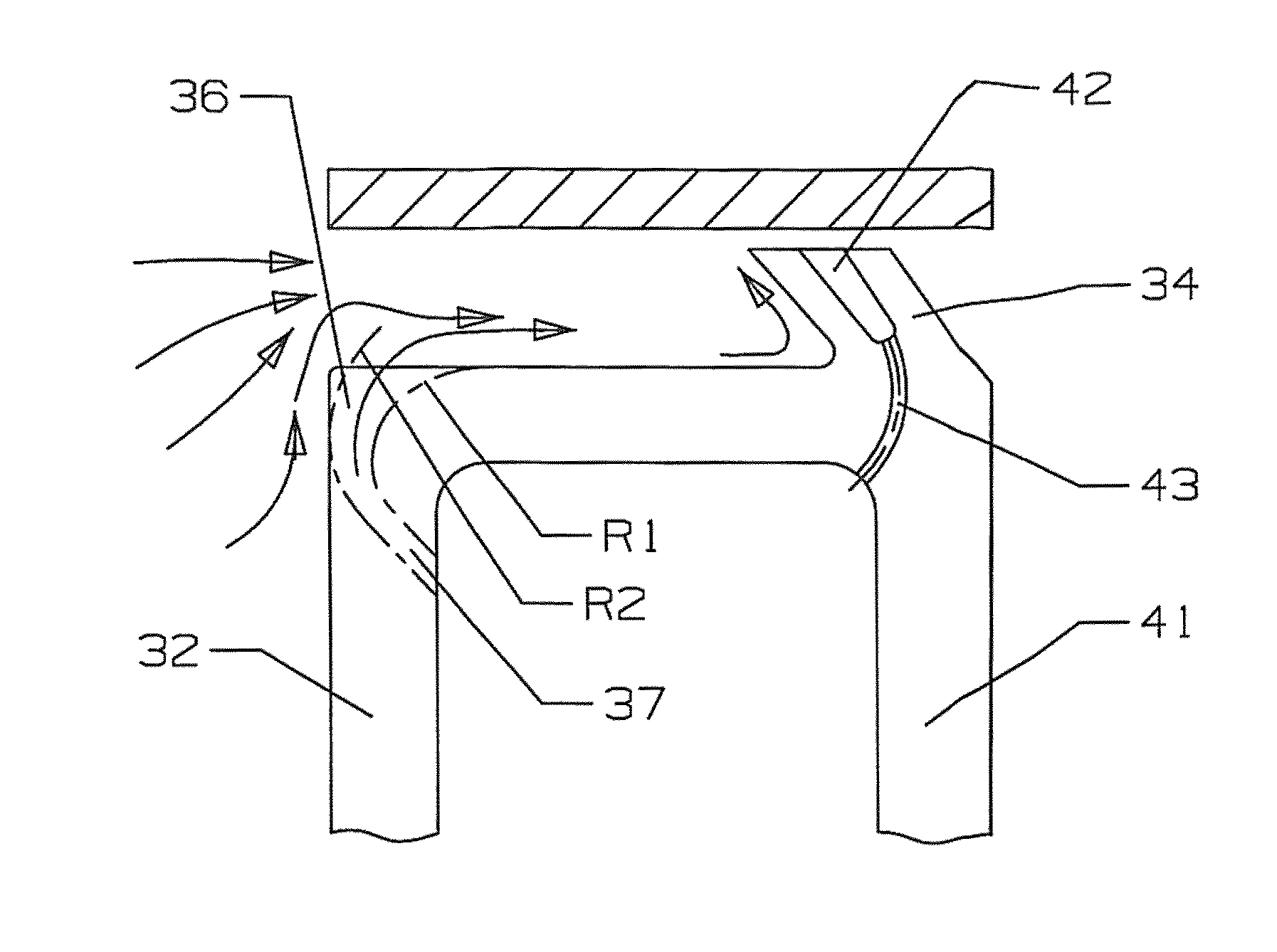

Flow directing device

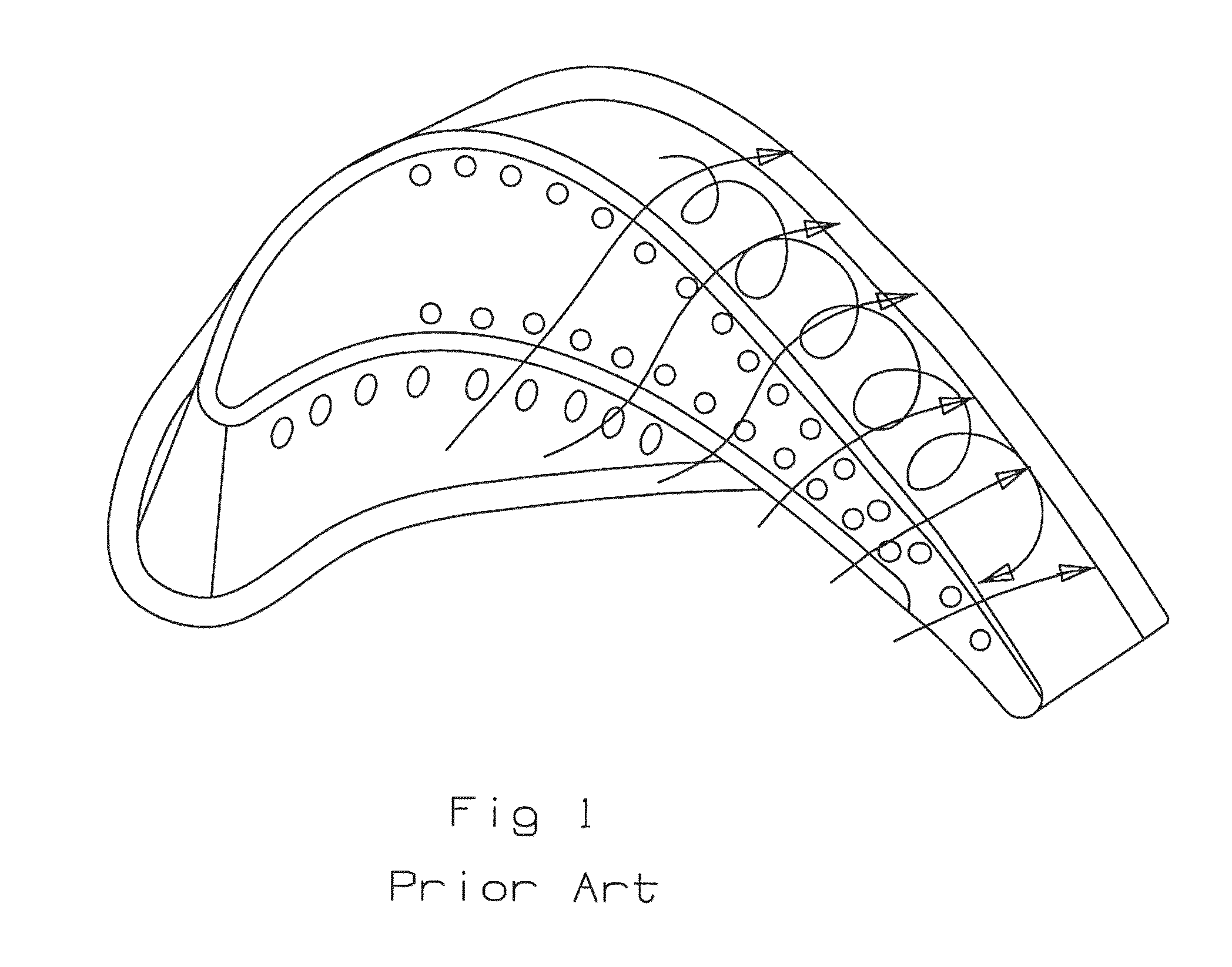

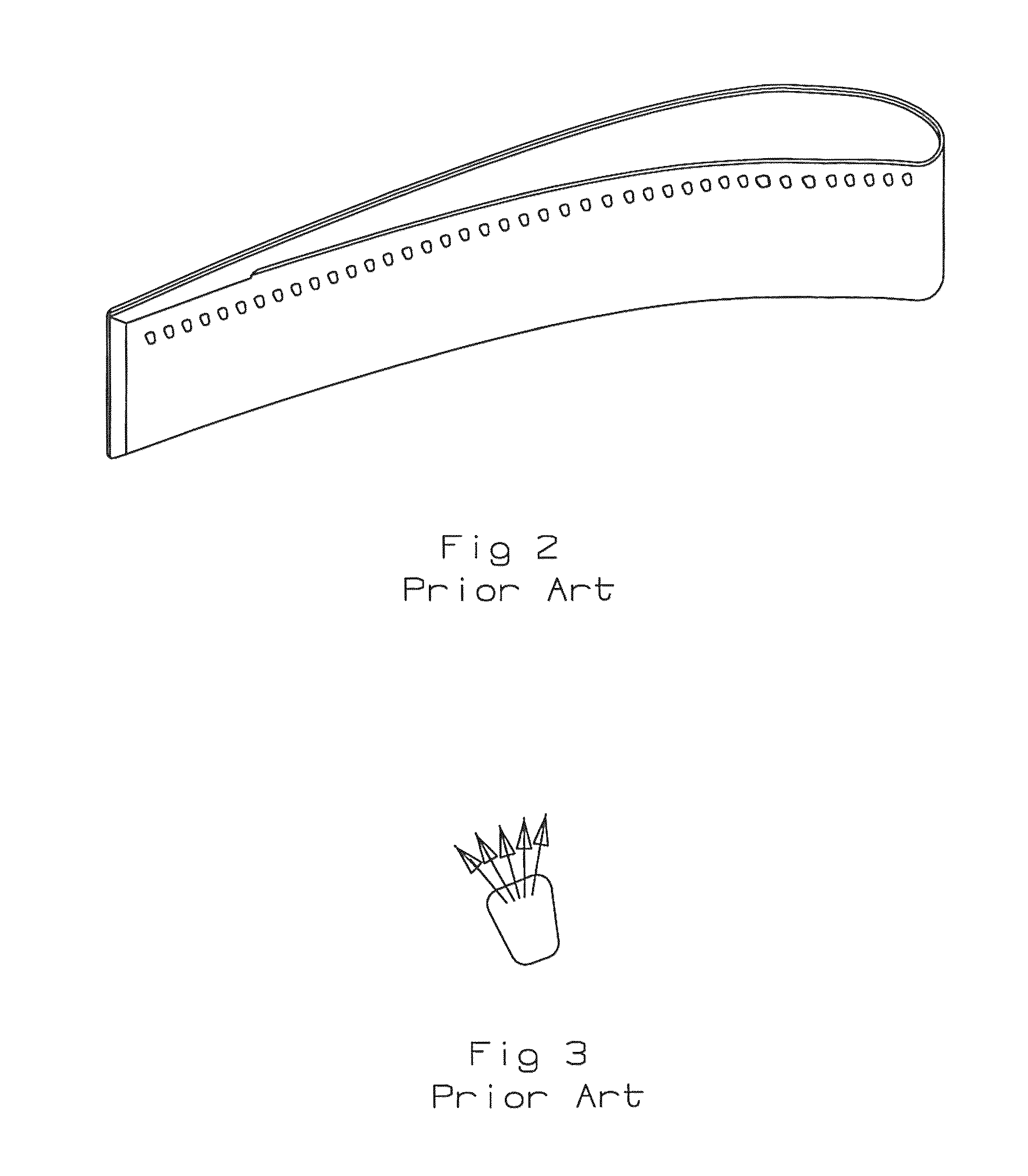

InactiveUS6969232B2Reduce heat loadHigh temperaturePropellersGas turbine plantsTrailing edgeLeading-edge slats

A flow directing device of a gas turbine engine, comprising: an airfoil having a leading edge, trailing edge, suction side and pressure side; a wall abutting the airfoil; and a fillet between the airfoil and wall. The fillet has an enlarged section at the leading edge, along the suction and pressure sides, and towards the trailing edge. The device could be part of a vane segment. In addition to eliminating a horseshoe vortex, the device also reduces heat load on the airfoil by directing the cooler gas from the proximal end of the airfoil to the hotter gas at the medial section of the airfoil.

Owner:RAYTHEON TECH CORP

Solid-state light bulb

InactiveUS8322896B2Reduce heat loadAccelerated dissipationLight source combinationsLighting support devicesPhosphorLed array

An example of this light bulb has a light emitting element (which may be an LED array) mounted on a circuit board. The circuit board is mounted on one end of a heat-conducting frame. An Edison screw or other suitable connector, for attaching the light bulb electrically and mechanically to a receptacle, is mounted on the other end of the frame. A transparent phosphor-coated ball has a flat chord face optically bonded to said array. A light-permeable globular enclosure is mounted on the frame, surrounding the ball and both homogenizing the white light output of the bulb but also concealing the yellowing unlit appearance of the remote phosphor ball centrally located within it.

Owner:LIGHT PRESCRIPTIONS INNOVATORS

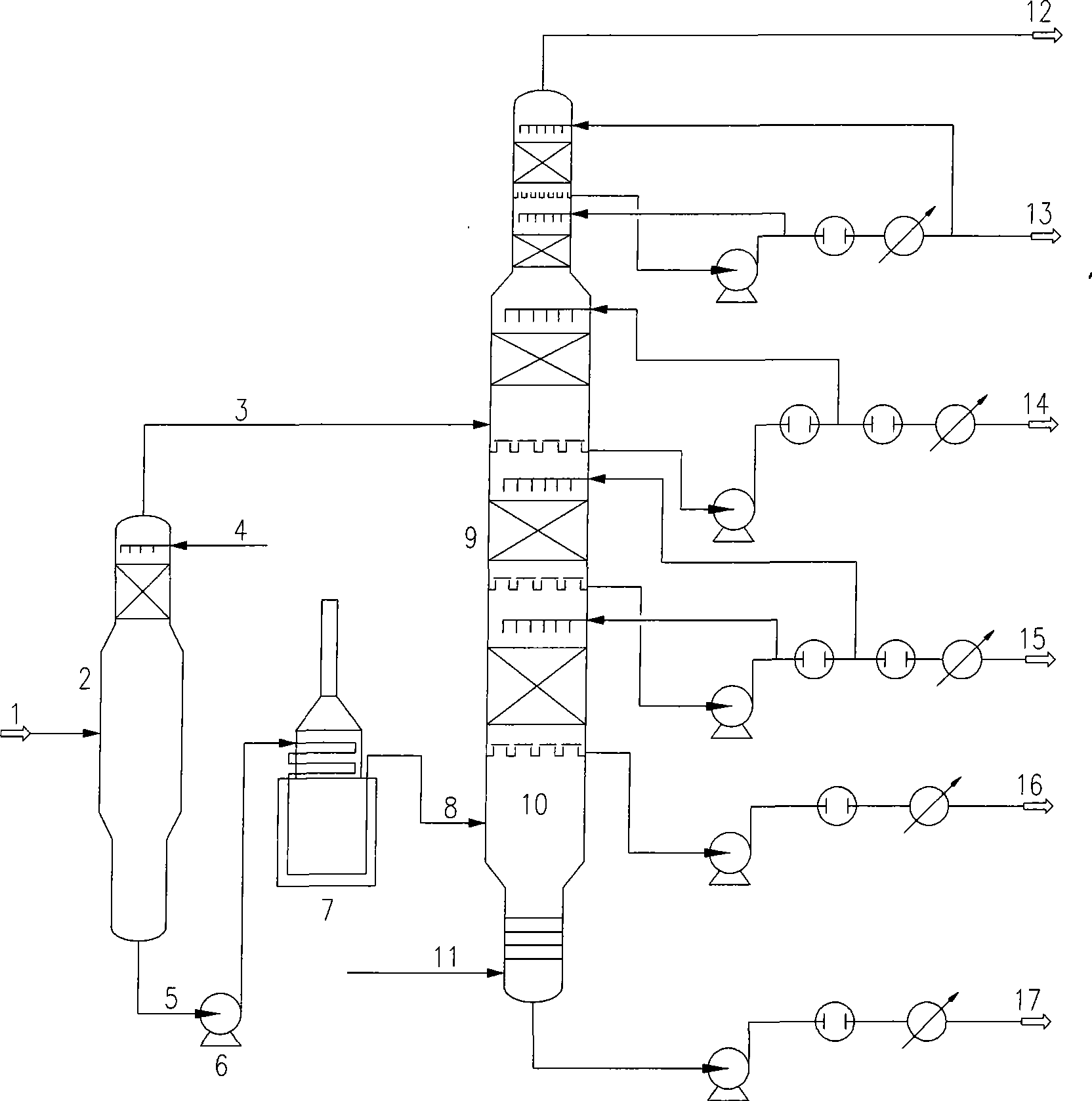

Atmospheric vacuum distillation method and apparatus with vacuum flash vaporizer

InactiveCN101376068AReduce the amount of feedEasy to handleVacuum distillation separationVacuum distillationVaporizationPulp and paper industry

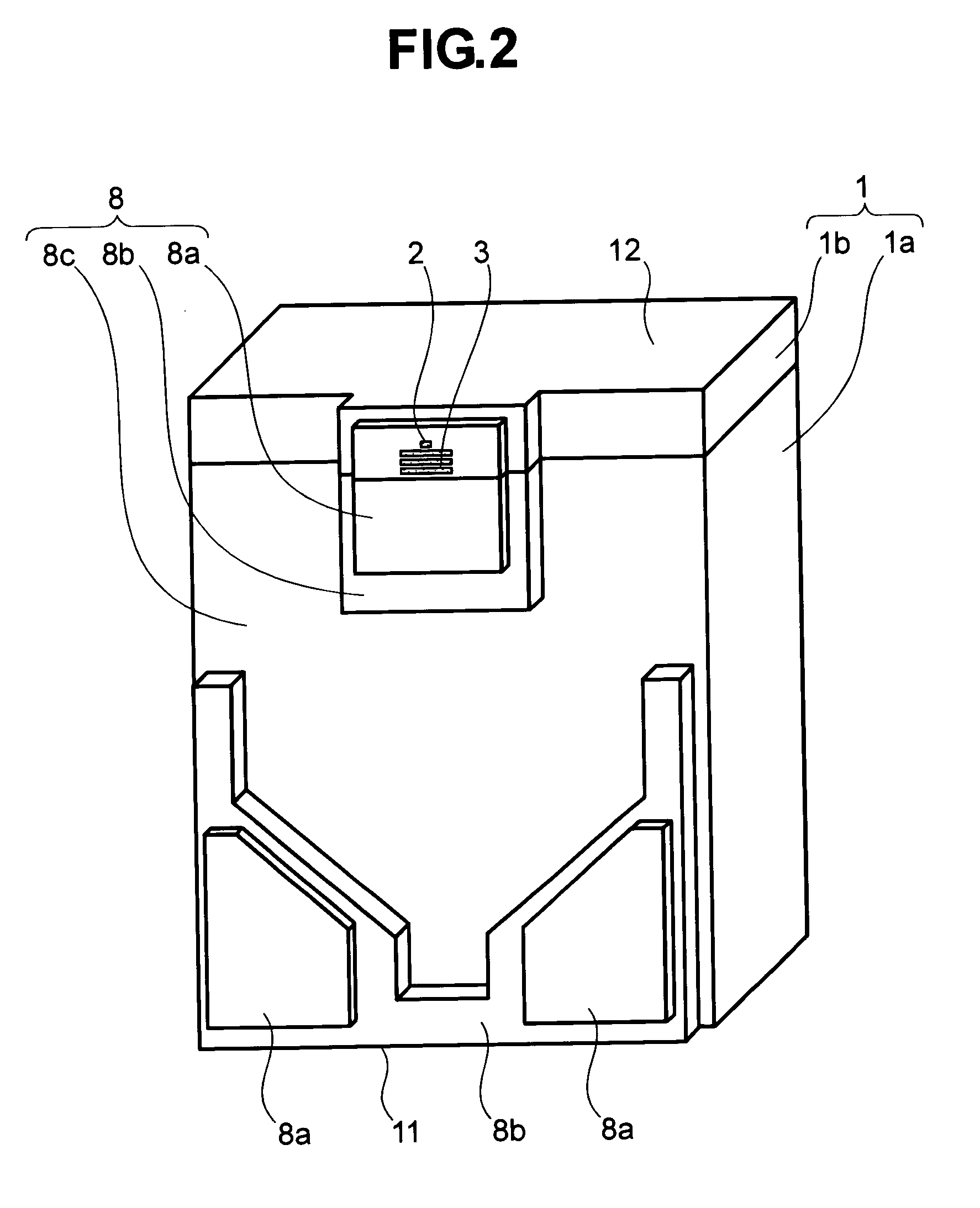

The invention relates to an atmospheric and vacuum distillation device with a vacuum flash tower and a method thereof. The atmospheric and vacuum distillation device with a vacuum flash tower is characterized in that the vacuum flash tower arranged in front of a vacuum furnace is connected with the vacuum furnace and a vacuum tower through a pump and a pipeline. Constant bottom oil (1) is introduced into the vacuum flash tower (2)at first, and the operation pressure at the top part of the vacuum flash tower is higher than the operation pressure at the top part of the vacuum tower (9) by10 to 200mmHg; Flash cap gas (3) is introduced into the upper part or the lower part of an outlet for a side product which is similar to Flash cap gas fraction; flash bottom oil (5) is introduced into the vacuum furnace (7) through a flash bottom oil pump (6); when the flash bottom oil is heated to 350 to 430 degrees, air-liquid mixing vacuum tower feed material is obtained through partial vaporization and is introduced into a flash evaporation segment (10) of the vacuum tower through a transfer line (8); and products with different fractions are drawn from the side of the vacuum tower and vacuum residue is drawn from the bottom of the vacuum tower. Through adding the vacuum flash tower to improve the working process of the atmospheric and vacuum distillation device, the invention achieves the advantages of increasing treatment capacity, increasing vacuum distillation yield, and reducing energy consumption.

Owner:TIANJIN UNIV +2

Production of potable water and freshwater needs for human, animal and plants from hot and humid air

InactiveUS6868690B2Reduces cargo spaceMinimize any benefitGeneral water supply conservationSeawater treatmentParticulatesFresh water organism

Systems and methods are disclosed for extracting freshwater from atmospheric humidity in extremely hot and humid climates and supplying freshwater to a small group of people, a building, a farm, or forestation area. The freshwater is treated to provide drinking water by disinfecting to eliminate microorganisms and filtration to remove suspended particulates from air, erosion or corrosion products, and disinfected waste. Compact units provide drinking water for individuals, passengers in cars, vans, trucks, or recreational boats, or crewmembers on a seagoing cargo ship whether from atmospheric humidity or from moisture-laden gases. Furthermore, systems are disclosed for the ample supply of freshwater with minimal treatment for small- to large-sized buildings in a manner that alleviates the heat load on buildings. Collection of freshwater from hot humid ambient air is also provided for other uses, such as irrigation and farm animal drinking. Various methods are used for condensation of water vapor suspended in the air as alternative to conventional refrigeration cycles using CFC refrigerants. Devices are disclosed using naturally occurring brackish cold water, circulation of cooling water cooled by thermoelectric cooling or thermoacoustic refrigeration as well as evaporative cooling and transpiration cooling. Water produced by the systems may flow under gravitational forces entirely or with the assistance of boasting pumps.

Owner:FAKIEH RES & DEV CENT

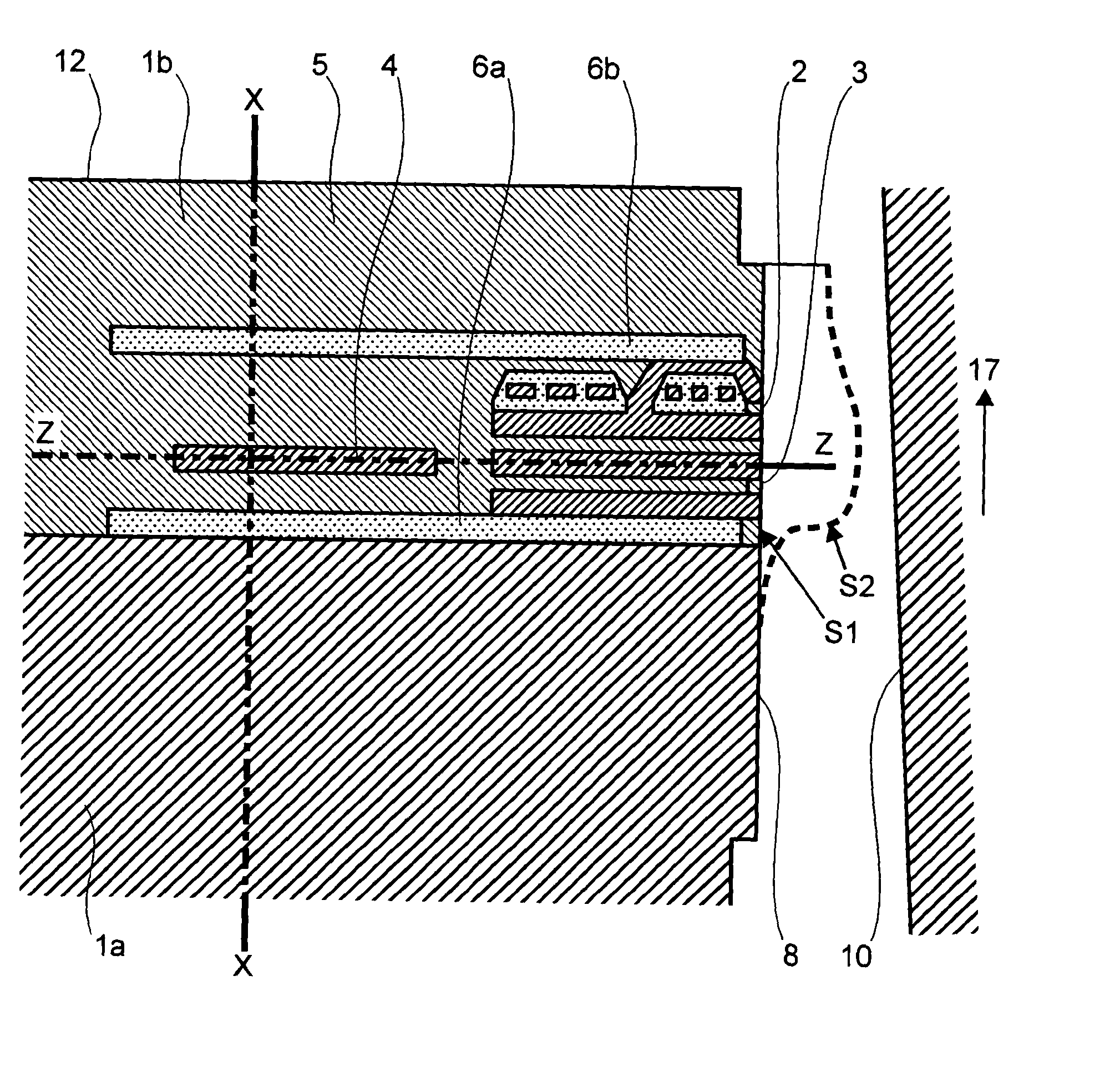

Magnetic head slider and magnet disk apparatus

ActiveUS20050024775A1Improve efficiencySmall loadHeads using thin filmsFluid-dynamic spacing of headsElectric forceThermal expansion

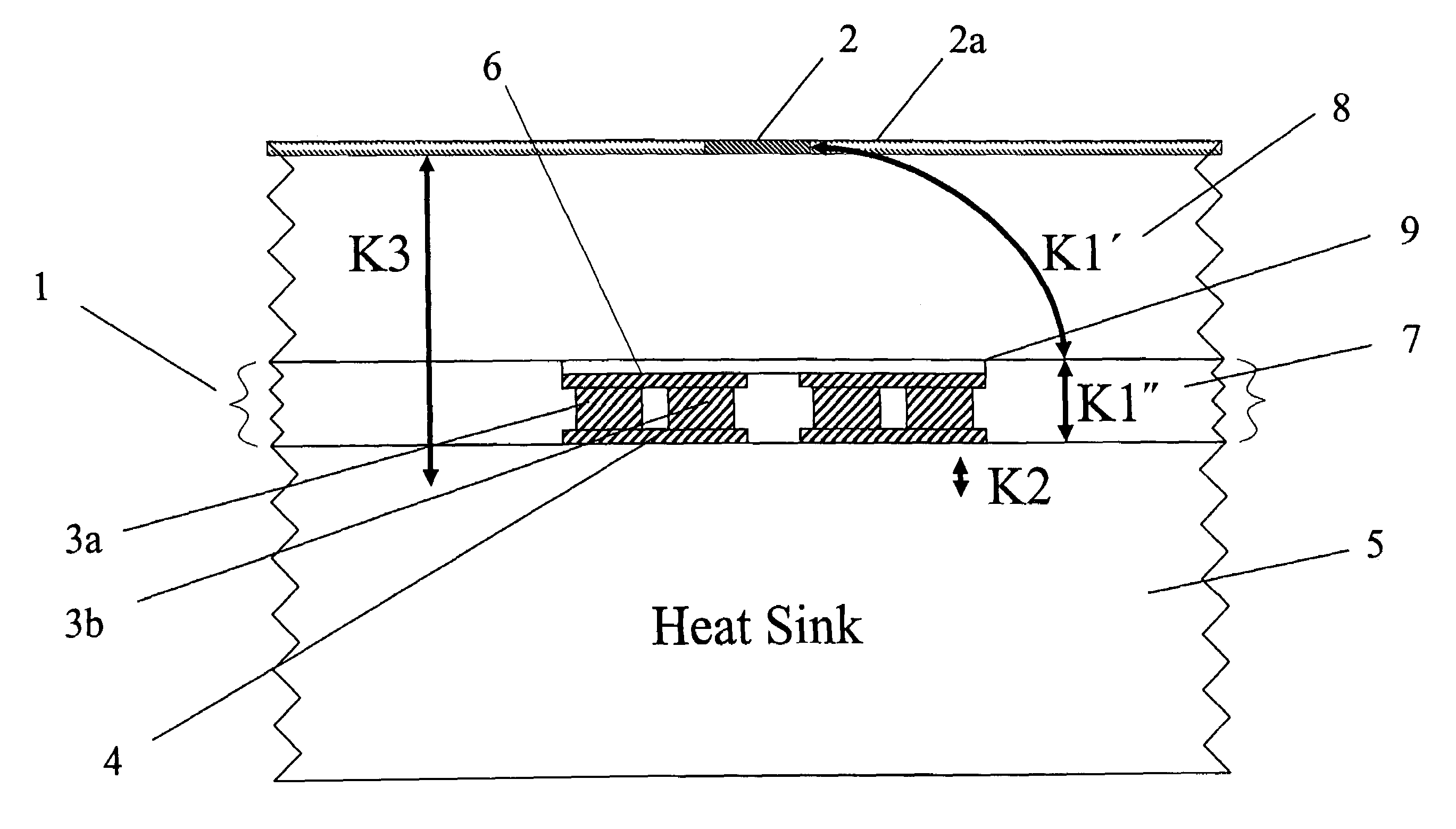

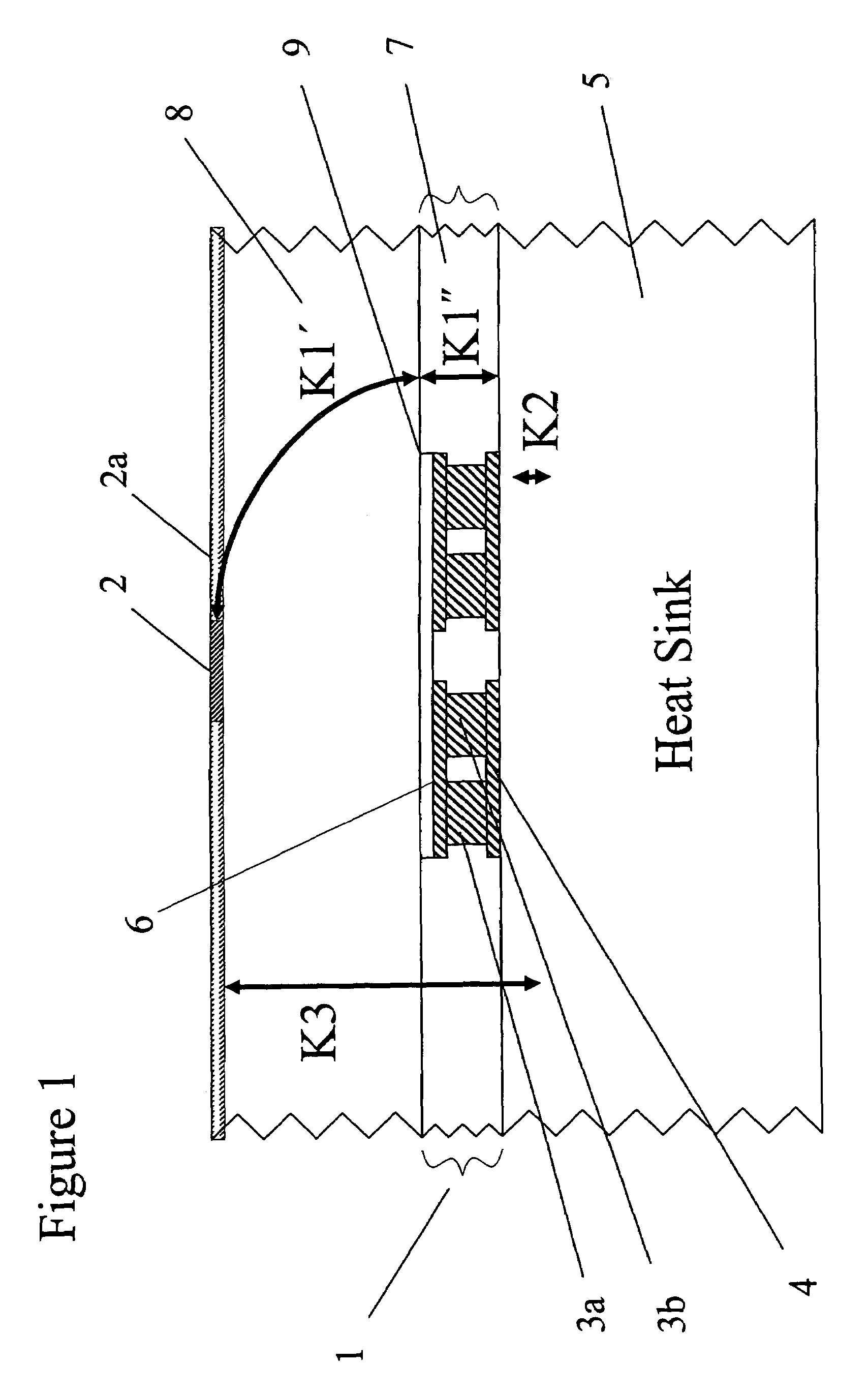

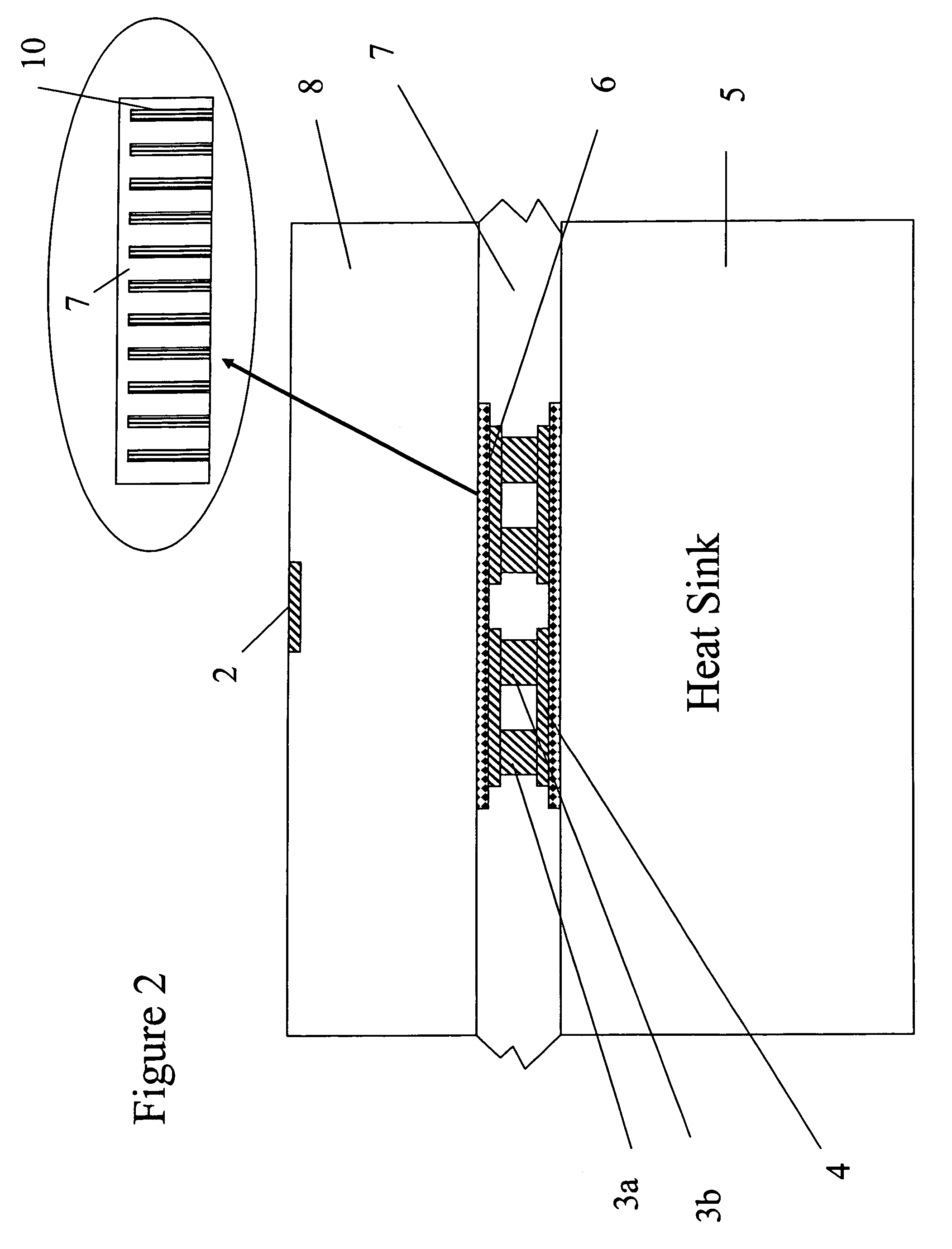

In a slider using thermal expansion type, being adjustable on a flying height thereof, having problems to be solved, i.e., to reduce the electric power consumption, and to lesson the heat load upon a reproducing element thereof, wherein a heating device 4 is located separating from tip portions of the recording and reproducing elements 2 and 3. Also, for deforming only the vicinity of the heating device 4 and the recording and reproducing elements 2 and 3, so as to protrude from, the heating device 4 and the recording and reproducing elements 2 and 3 are surrounded by a resin film 6 of small rigidity, thereby increasing an amount of protrusion of the recording and reproducing elements 2 and 3 per a unit of electric power, but without increasing temperature of the reproducing element 3, with an aim of the structure of cutting off the force from materials of circumferences against the deformation.

Owner:HITACHI GLOBAL STORAGE TECH JAPAN LTD +1

Thin film thermoelectric devices for hot-spot thermal management in microprocessors and other electronics

ActiveUS7523617B2Improve efficiencyReduce heat loadThermoelectric device with peltier/seeback effectDomestic cooling apparatusEngineeringSolid medium

A structure, system and method for controlling a temperature of a heat generating device in a solid medium, wherein heat is extracted from the medium into at least one heat extraction device, the heat extraction device dissipates heat into an environment apart from the medium by a heat sink thermally coupled to the heat extraction device; and heat from the medium is dissipated into the heat sink by a first thermal interface material thermally coupling the heat sink to the medium.

Owner:LAIRD THERMAL SYST INC

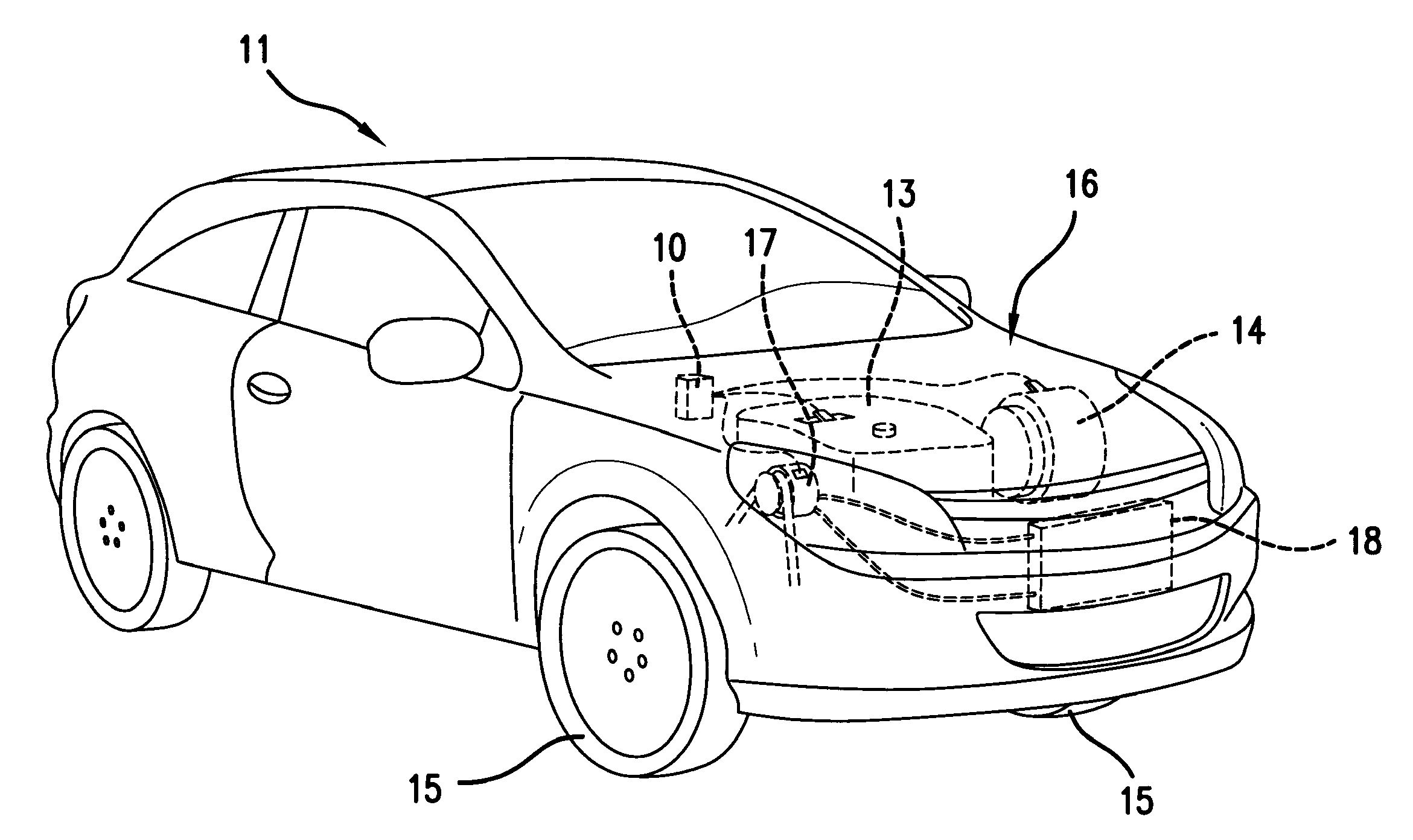

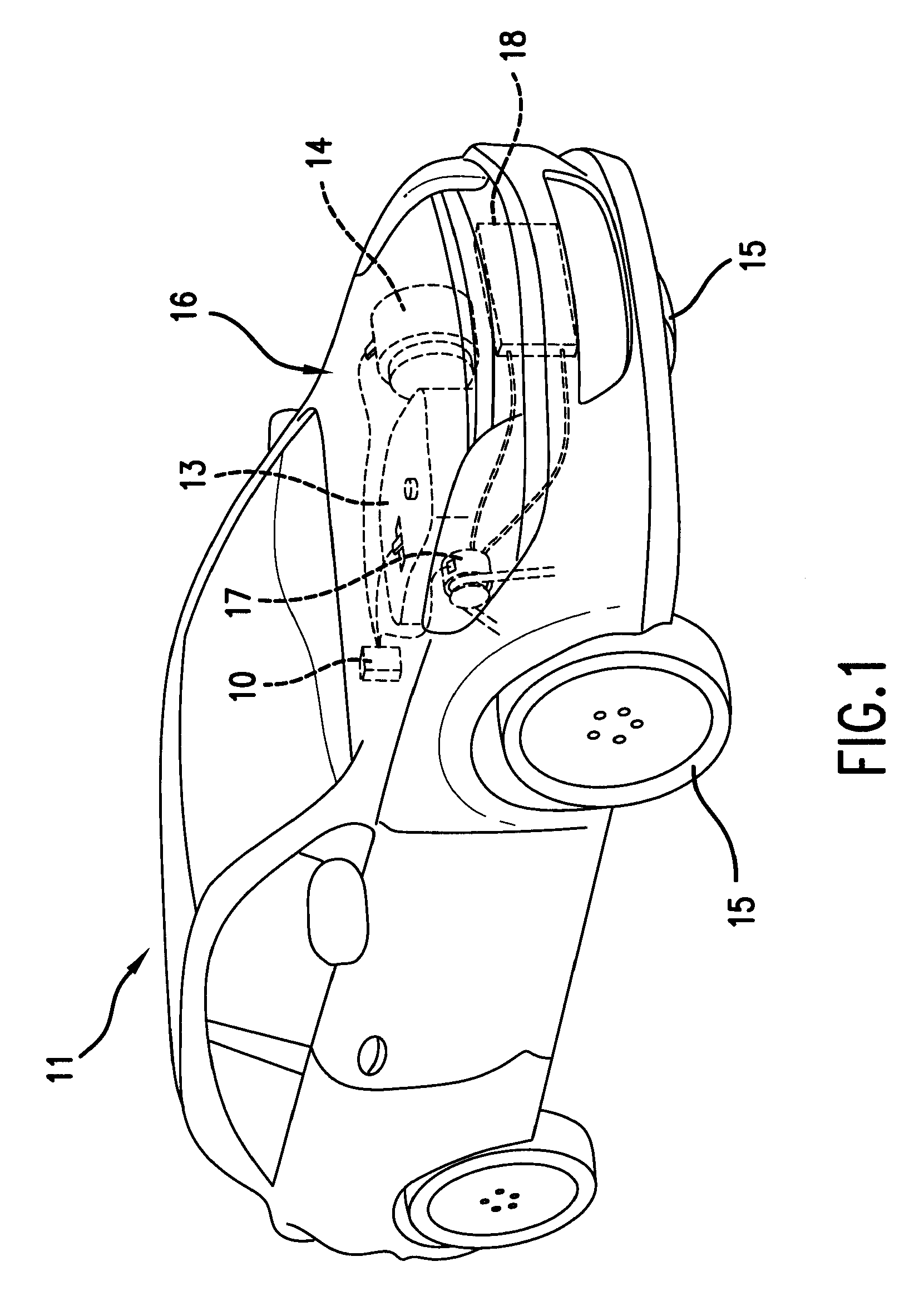

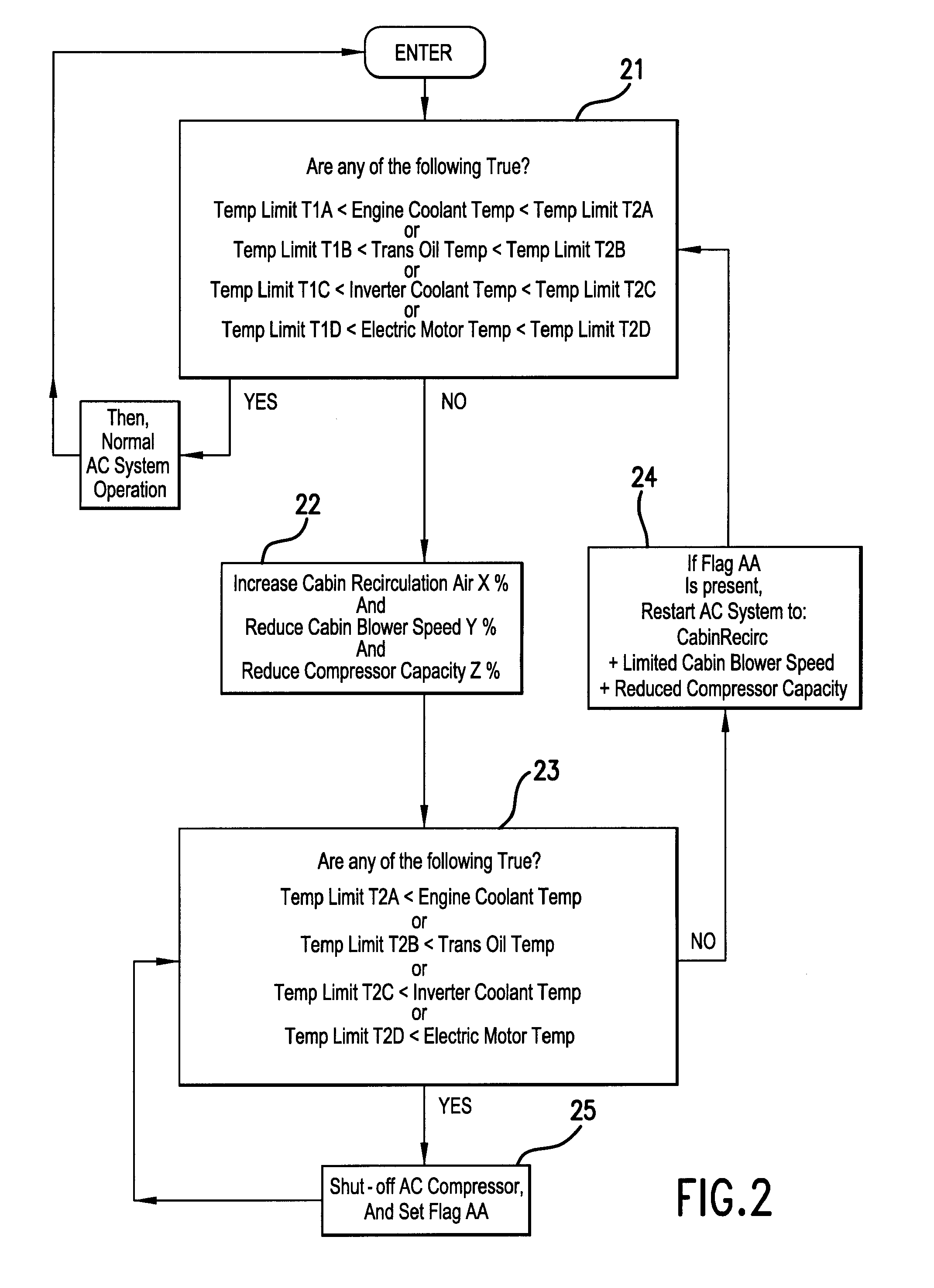

Methods of Optimizing Vehicular Air Conditioning Control Systems

InactiveUS20080034767A1Reduction in propulsion cooling system sizeReduce heat loadCompression machines with non-reversible cycleVehicle heating/cooling devicesElectric driveOperating temperature

Air conditioning system controls are optimized for an air conditioning system having a compressor in IC engine vehicles and in hybrid or fuel cell vehicles having electric drive motors by first determining the operating temperature of at least one of the following vehicle components: engine coolant and transmission oil for all types of vehicles, and for hybrid or fuel cell vehicles also determining the operating temperature of inverter coolant and the electric drive motors. At least one operating temperature is then compared to lower and upper temperature limits. If the operating temperature is outside of the temperature limits air conditioner heat load is reduced by at least one of the following steps: increasing cabin air recirculation, reducing cabin blower speed and reducing air conditioner compressor capacity. Subsequent to reducing air conditioner heat load, selected operating temperature or temperatures are monitored to determine if the operating temperature exceeds the upper temperature limit or limits. If the operating temperature or temperatures exceed the upper limit or limits the compressor is shut off.

Owner:GM GLOBAL TECH OPERATIONS LLC

Combustion engine

InactiveUS6460337B1Improve performanceReduce the temperatureValve arrangementsInternal combustion piston enginesExhaust valveCombustion

A turbo-fed internal combustion engine has a first and a second exhaust-gas valve per cylinder, these exhaust-gas valves each being connected to their respective exhaust manifold. One exhaust manifold conducts exhaust gases to an exhaust-gas turbine and the other exhaust manifold conducts subsequent exhaust gases past this exhaust-gas turbine which drives a compressor for charge air. The intake valve of the cylinder is arranged so as, as the engine speed increases, to close either earlier, before the piston reaches its bottom dead center, or later, after the piston has passed its bottom dead center. In this way, the temperature increase resulting from compression in the cylinder is reduced. Cooled air from the compressor can be taken in so as to obtain an adequate degree of filling in the cylinder, with a lower final temperature.

Owner:SAAB AUTOMOBILE AB

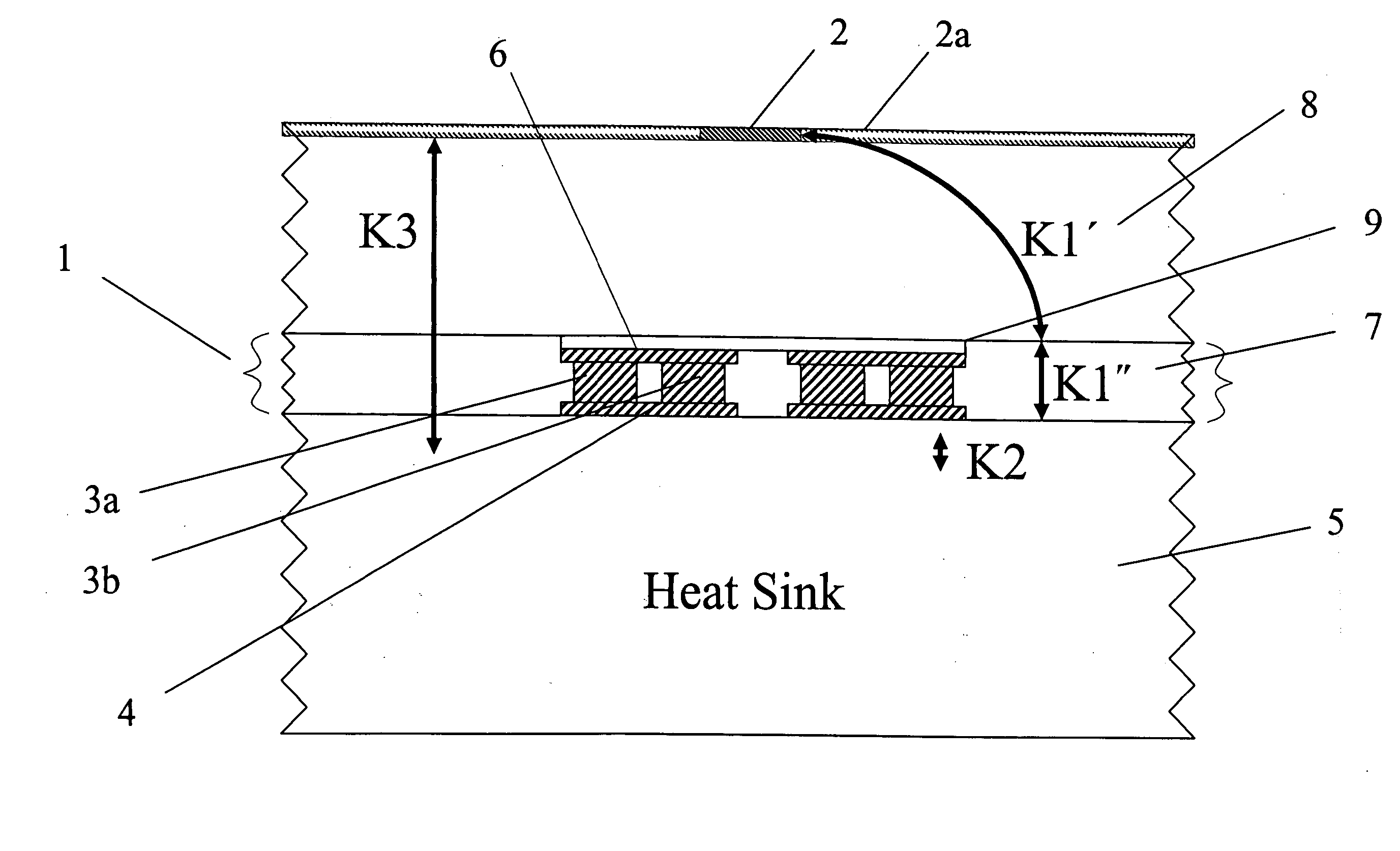

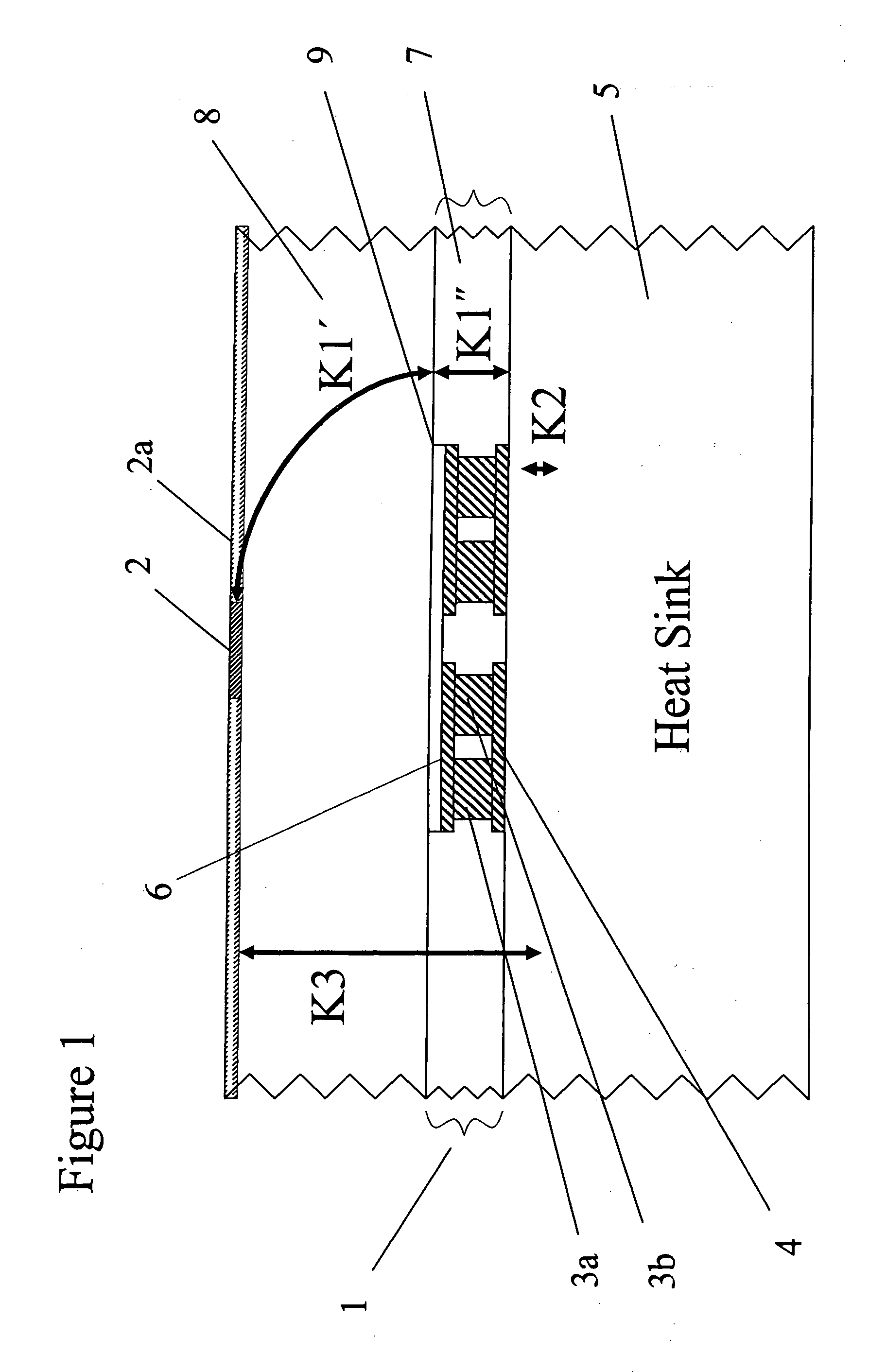

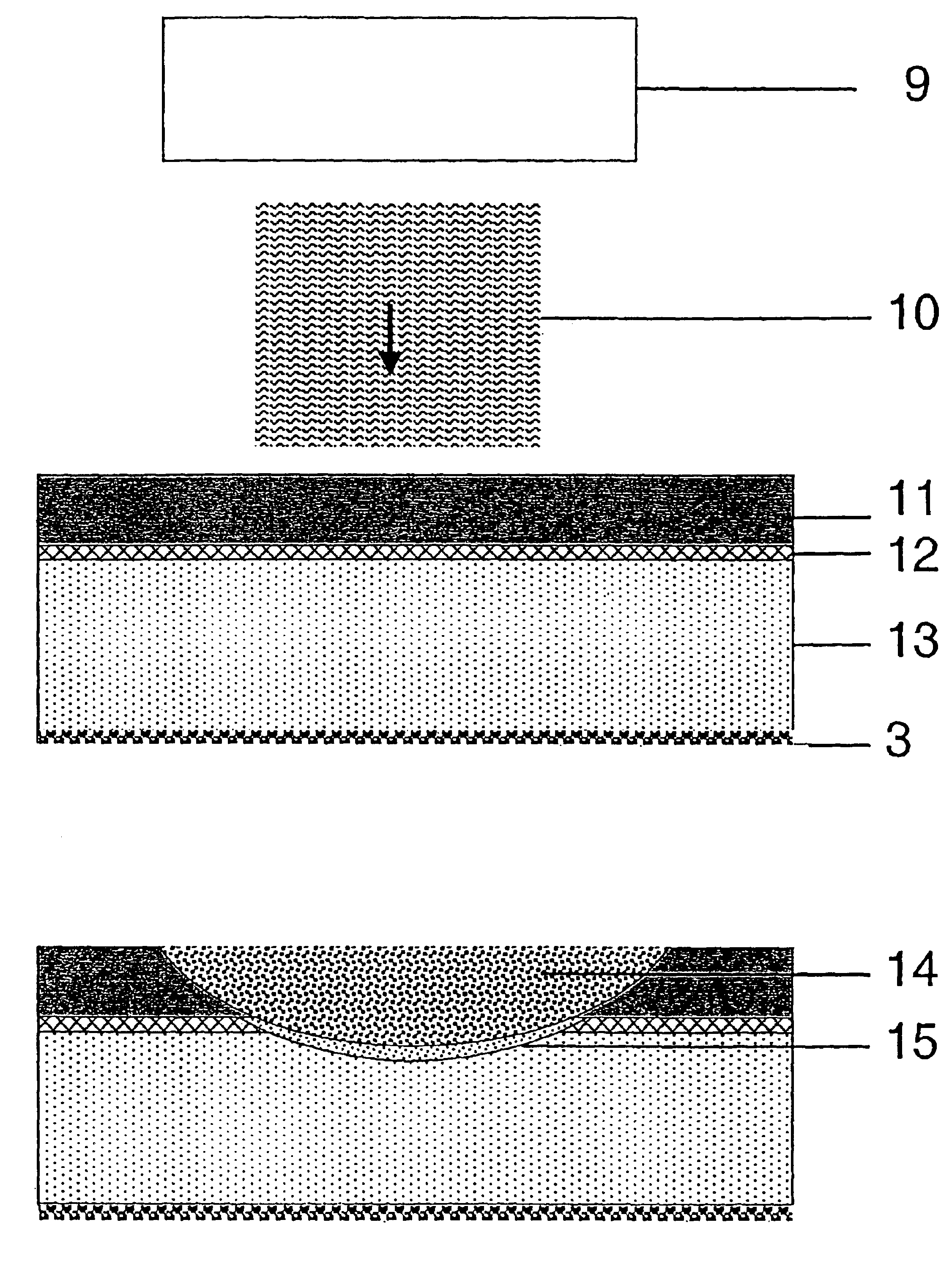

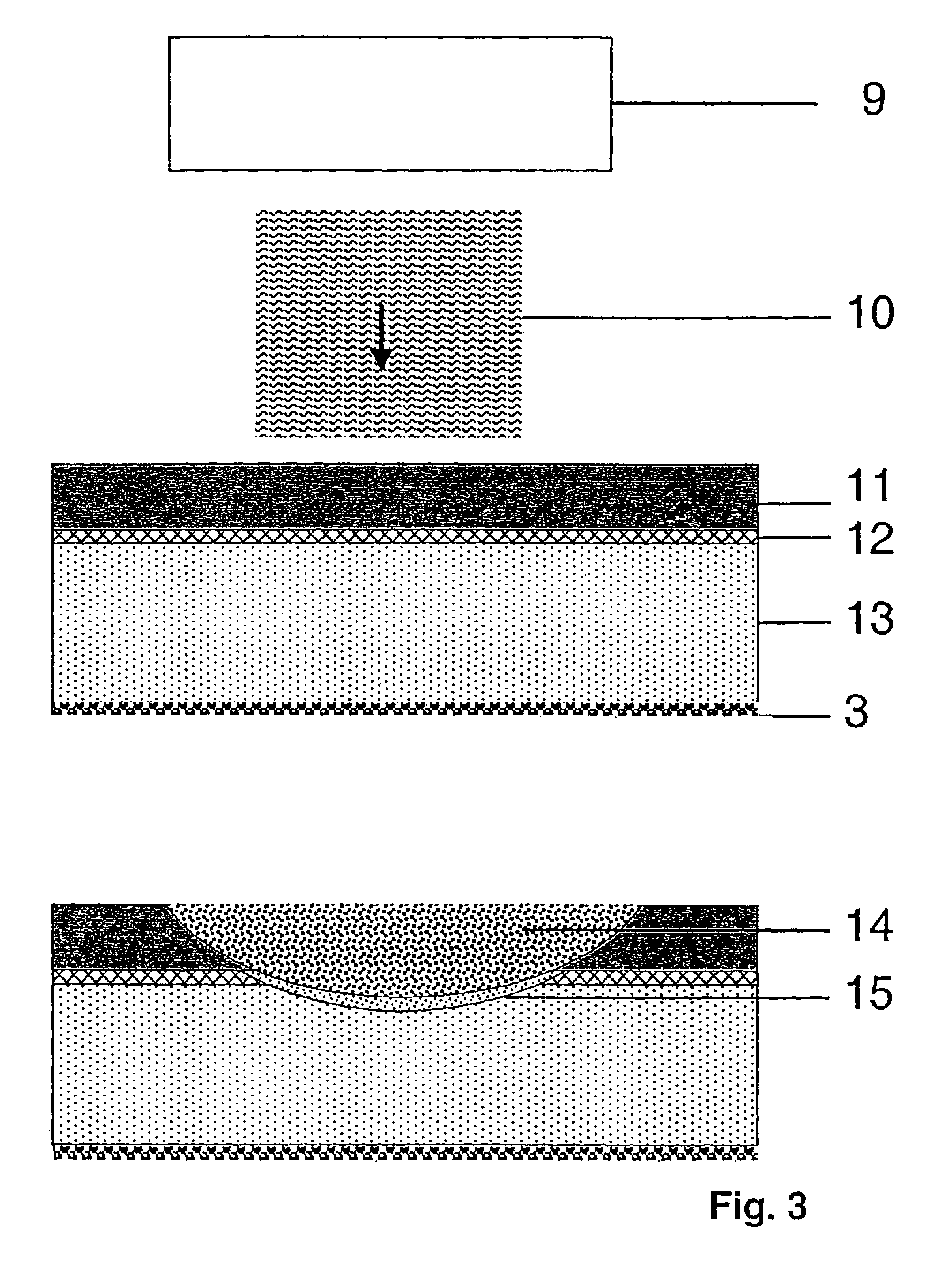

Method of producing a semiconductor-metal contact through a dielectric layer

InactiveUS6982218B2Reduce recombination rateSuitable energy densitySemiconductor/solid-state device manufacturingPhotovoltaic energy generationControl mannerDielectric layer

A method of electrically contacting a semiconductor layer (13) coated with at least one dielectic layer (12) which is coated with a metal layer the metal layer (11) is applied on the dielectric layer (12) and the metal layer (11) is temporarily locally heated in a line, linear or dotted pattern by means of a source of radiation (9) in a controlled manner in such a way that a local molten mixture, is formed consisting exclusively of the metal layer (11), the dielectric layer (12) and the semiconductor layer (13) are located directly underneath the metal layer (11) and upon solidification, leads to an electrical contact between the semiconductor layer (13) and the metal layer (11).

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

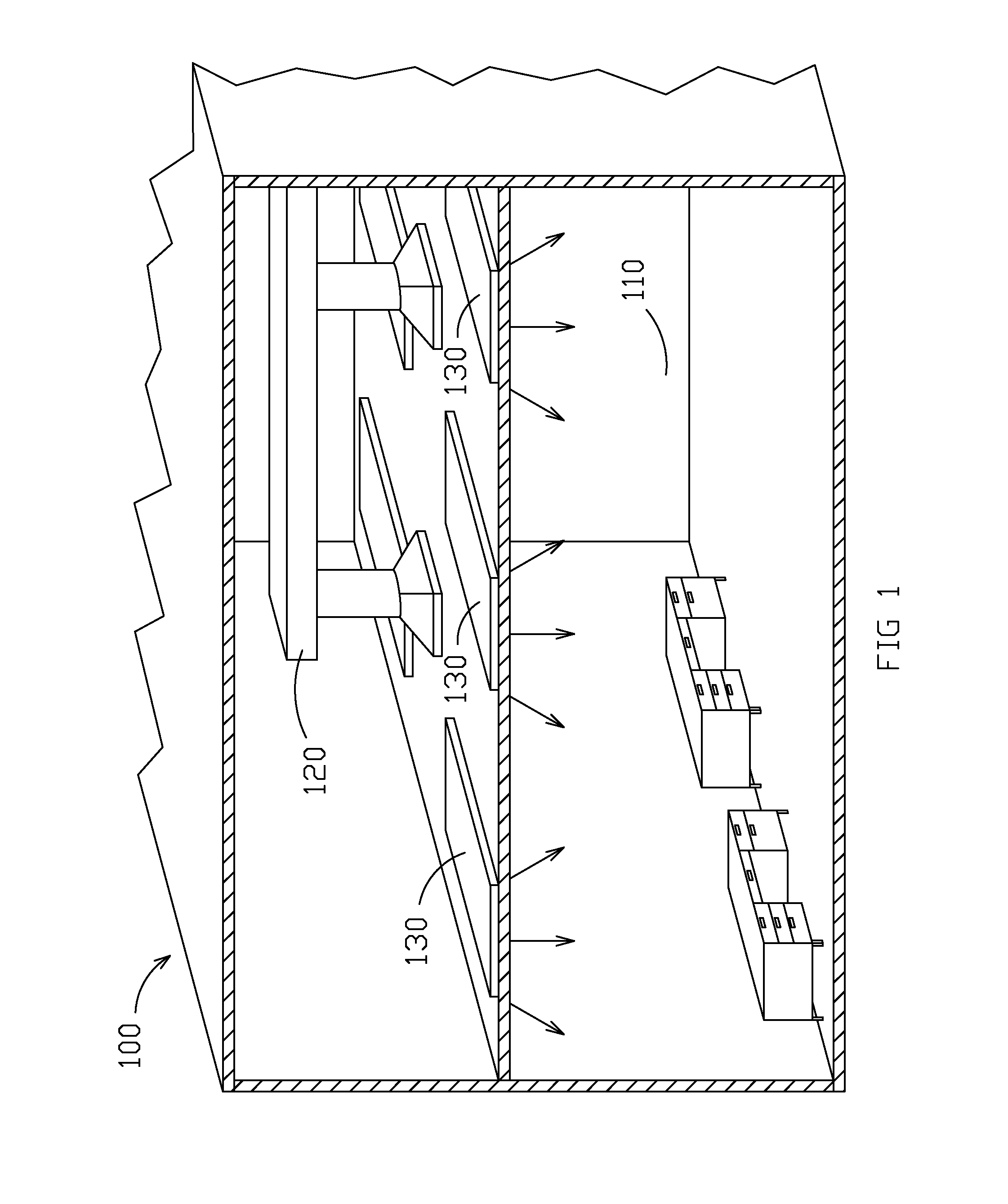

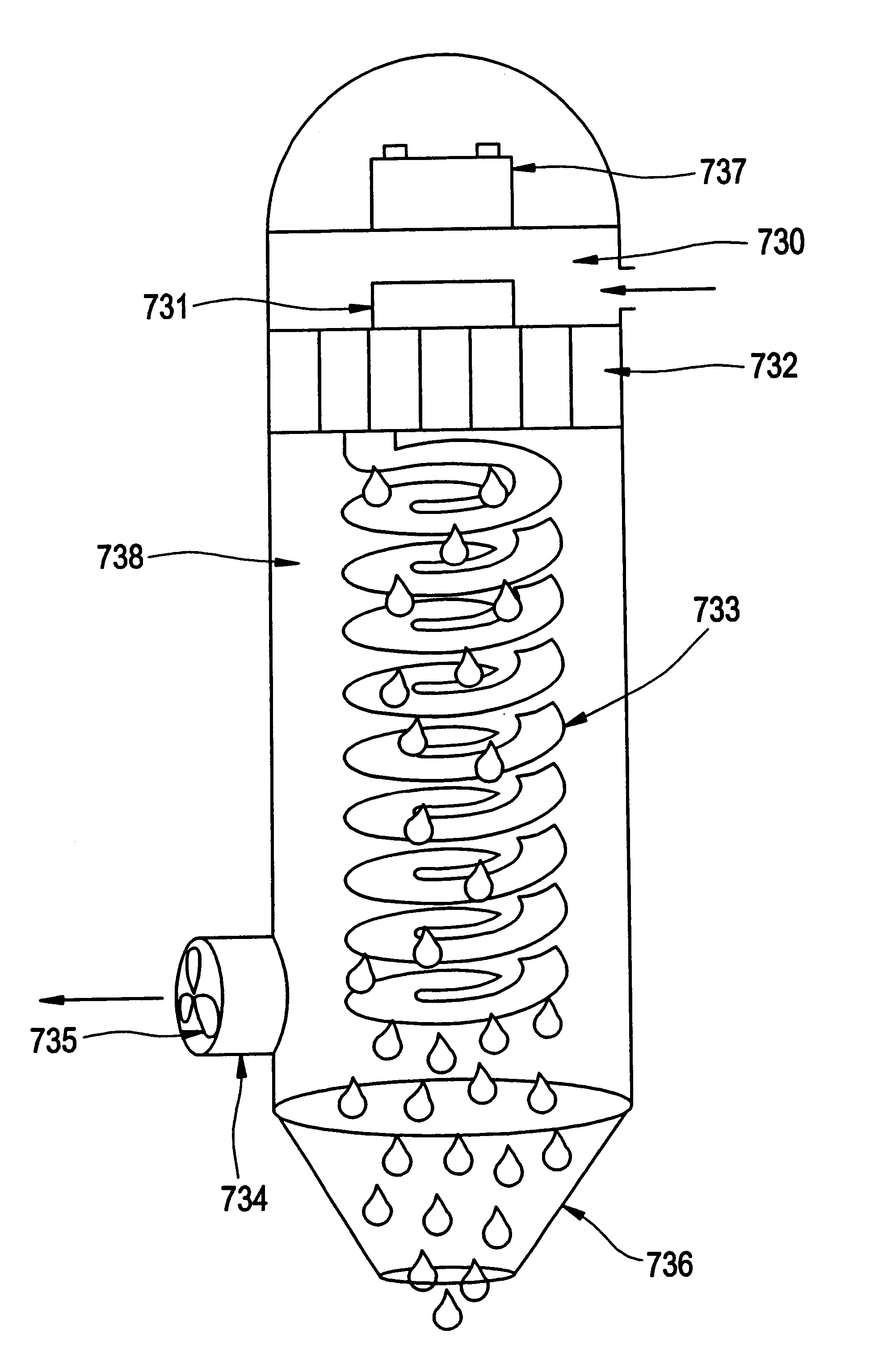

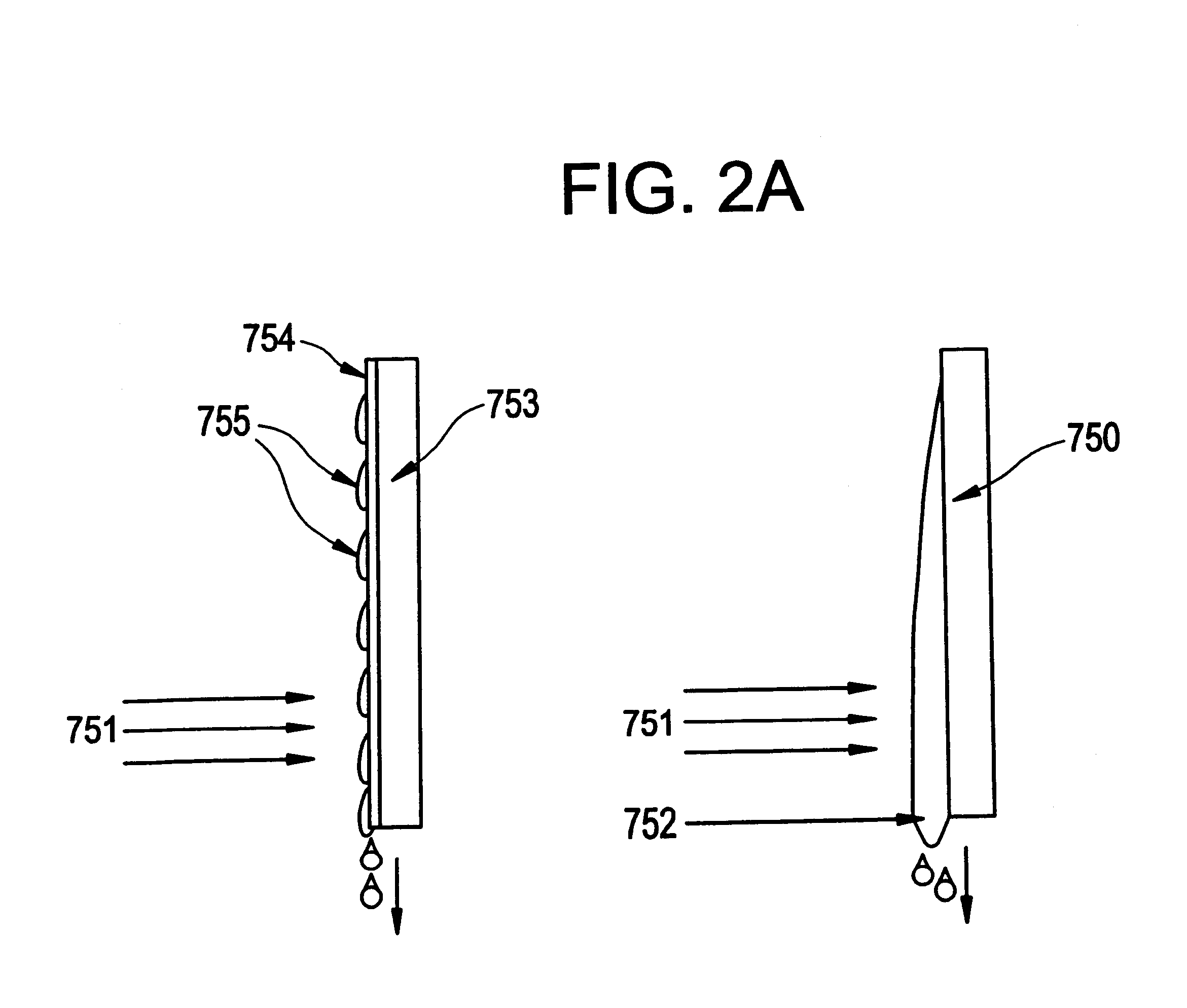

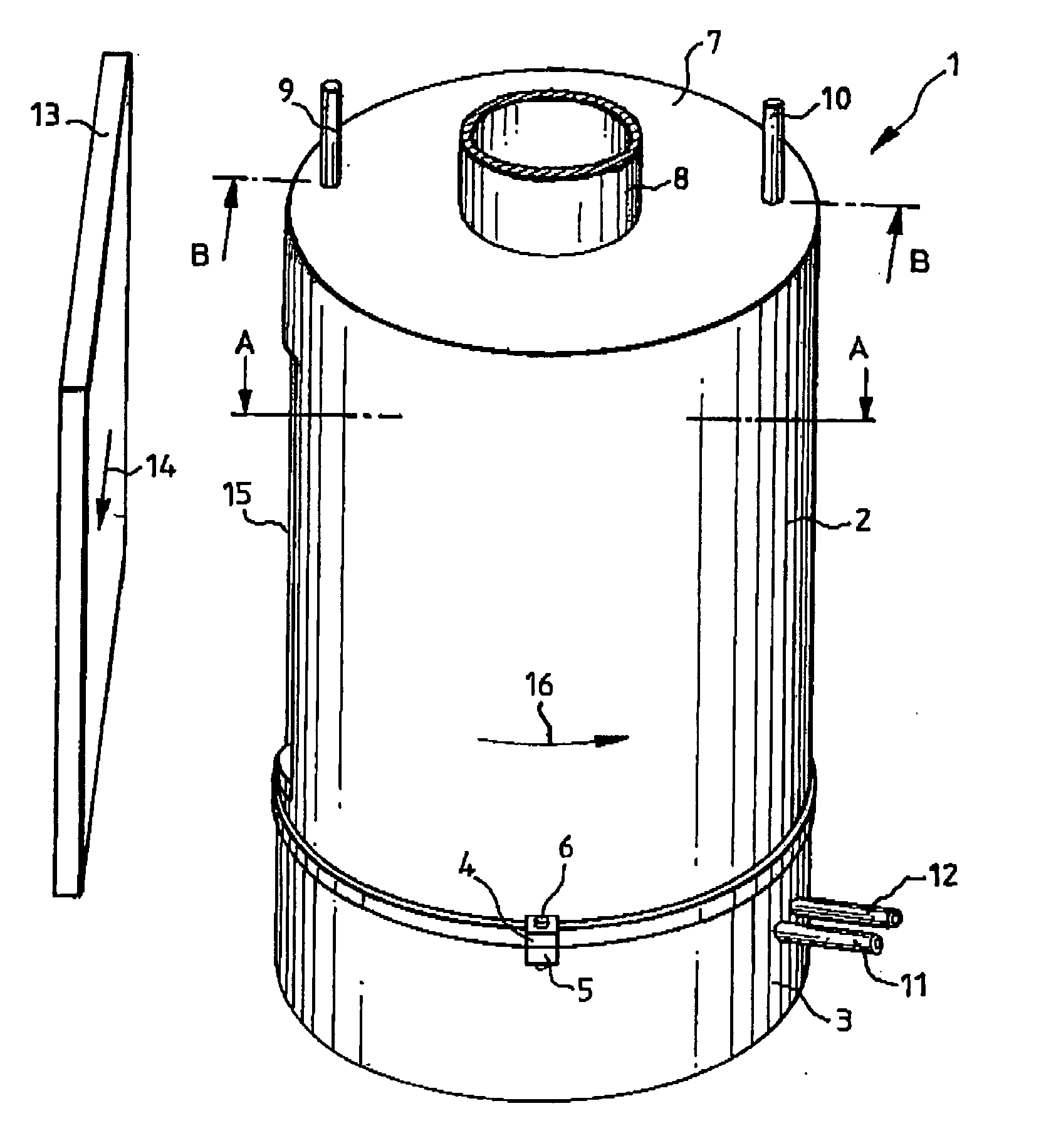

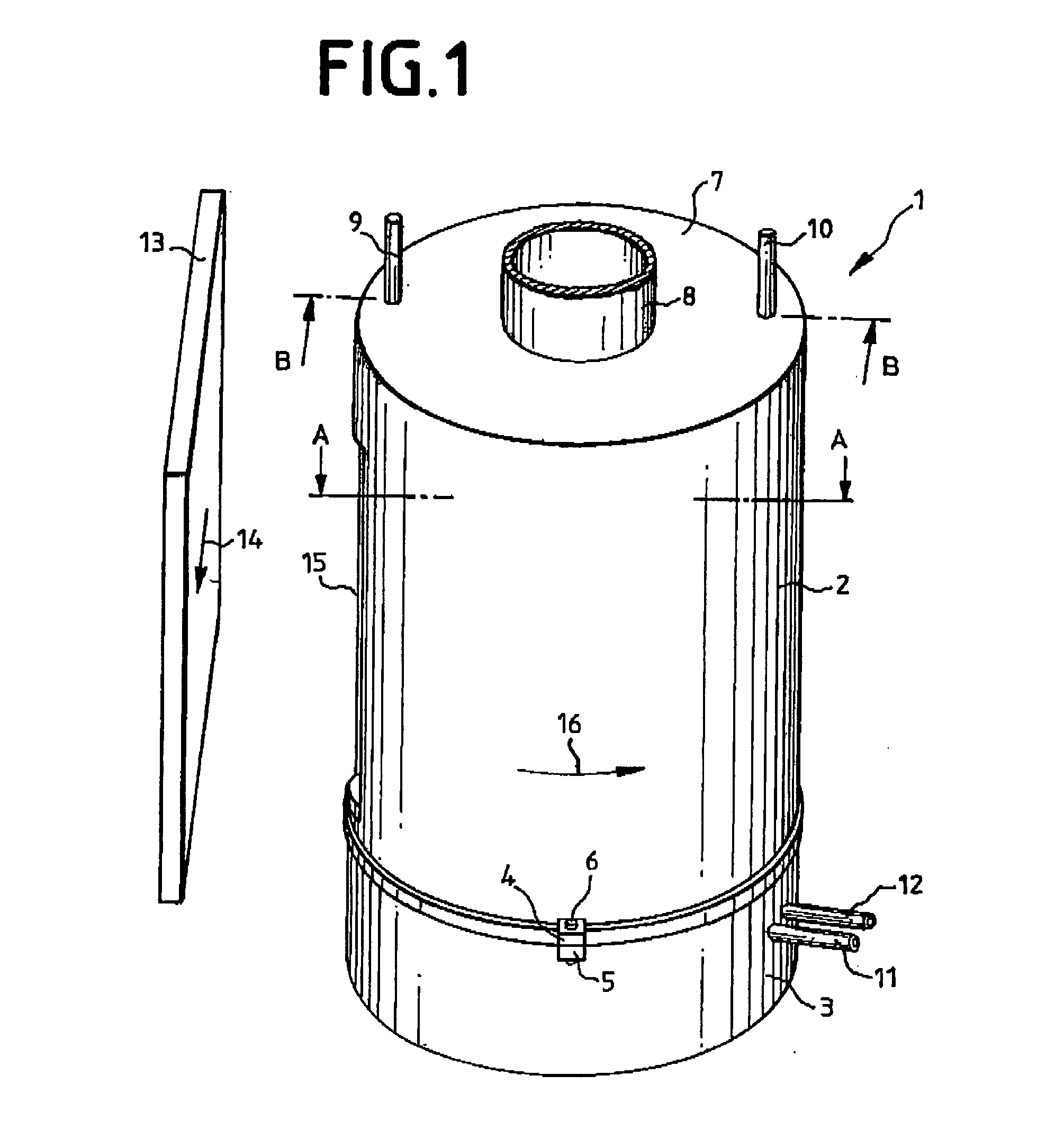

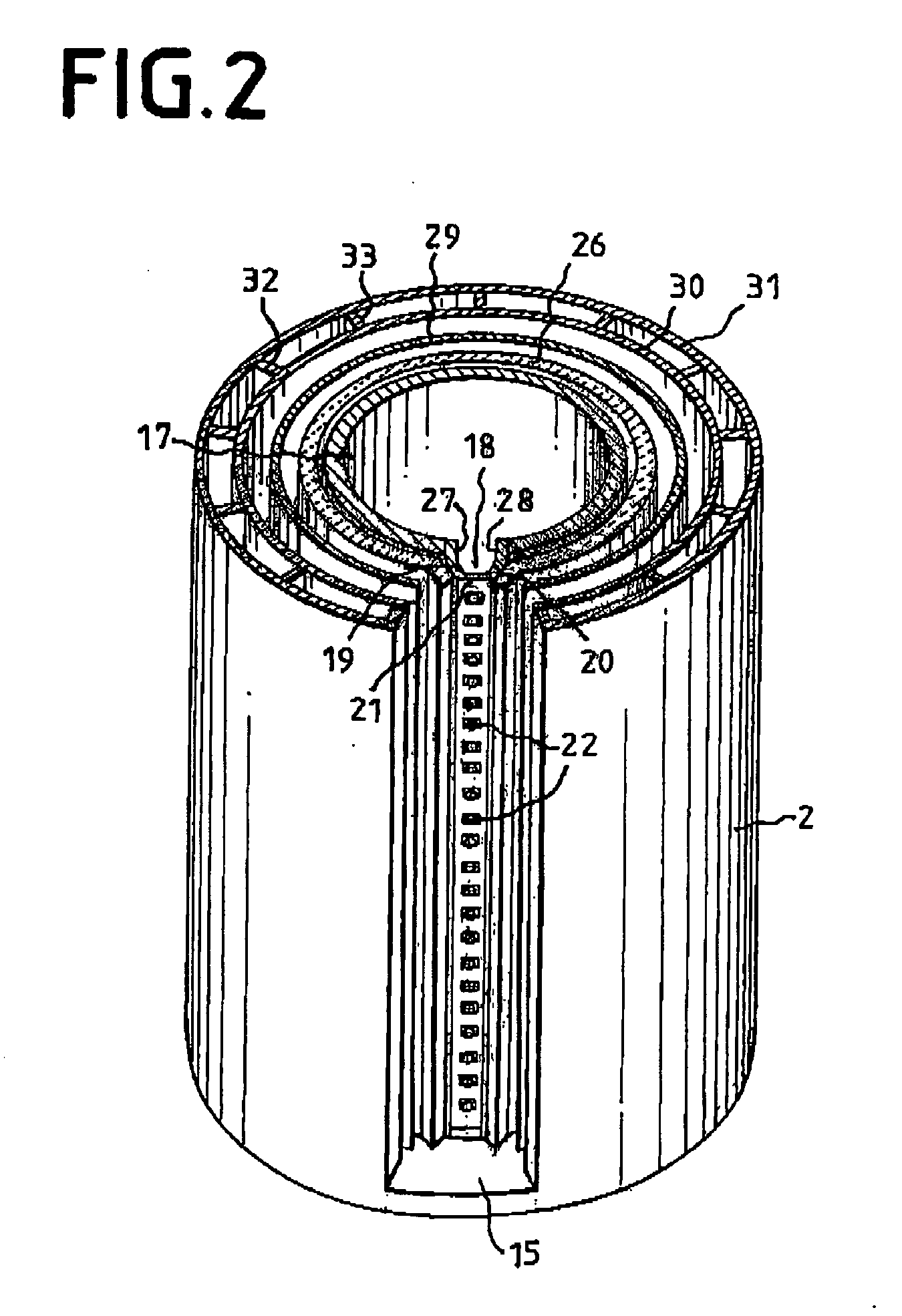

Apparatus for active cooling of an MRI patient bore in cylindrical MRI systems

InactiveUS7015692B2Increases patient comfortReduce heat loadElectromagnets without armaturesTransformers/inductances coolingActive coolingEngineering

The present invention provides for a cooling system for circulating a coolant to cool the patient bore. In one embodiment, that patient bore consists of two concentric cylinders separated by spacers running either longitudinally or helically. In another embodiment of the present invention, fluid may be passed either helically or longitudinally through tubes bonded to the outer diameter of the patient bore such that the parts of the bore that are exposed to the patient are directly cooled. In a third embodiment, the RF coil could form part of the patient bore, with the helical or longitudinal fluid channels surrounding the patient bore.

Owner:GE MEDICAL SYST GLOBAL TECH CO LLC

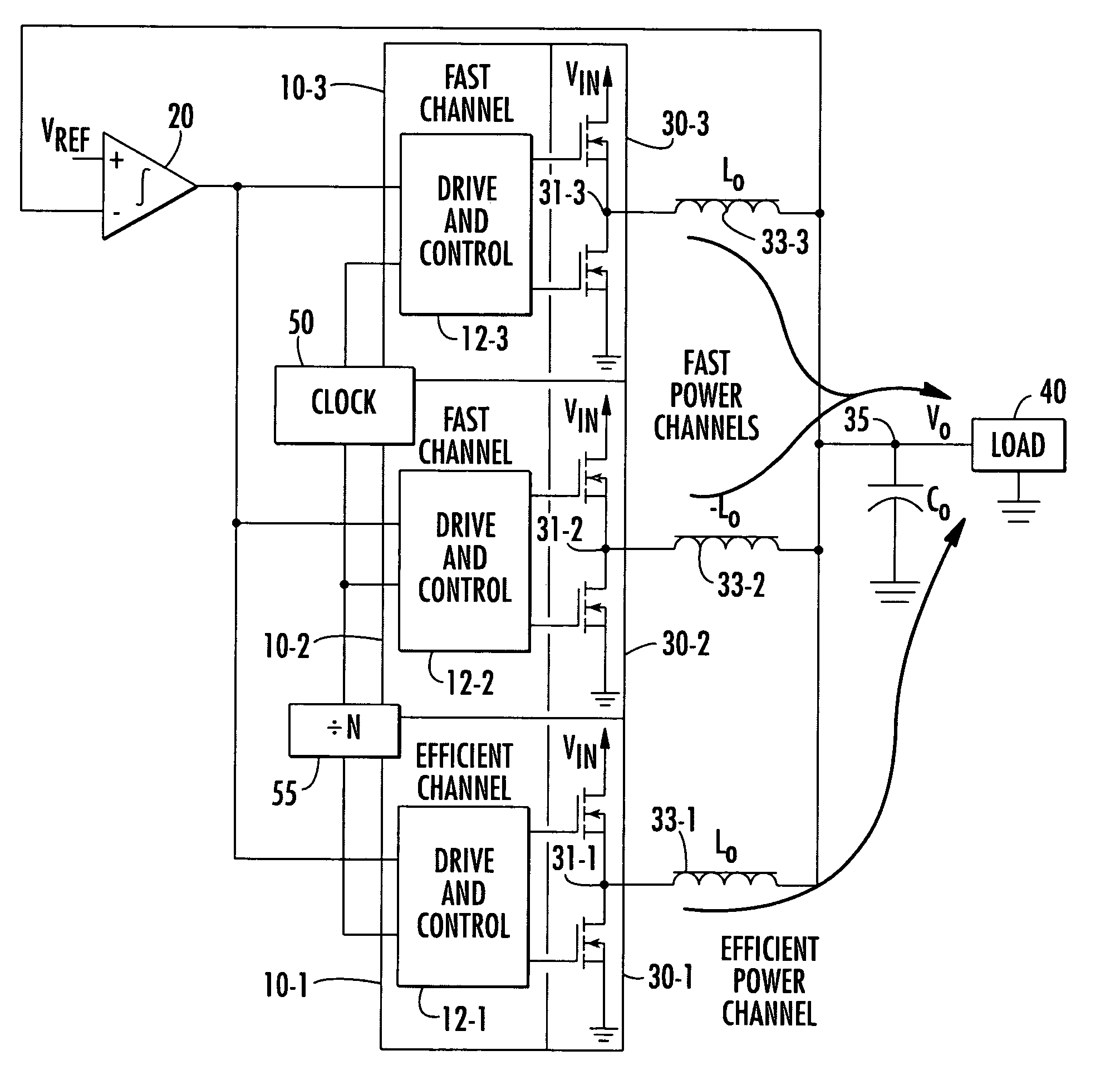

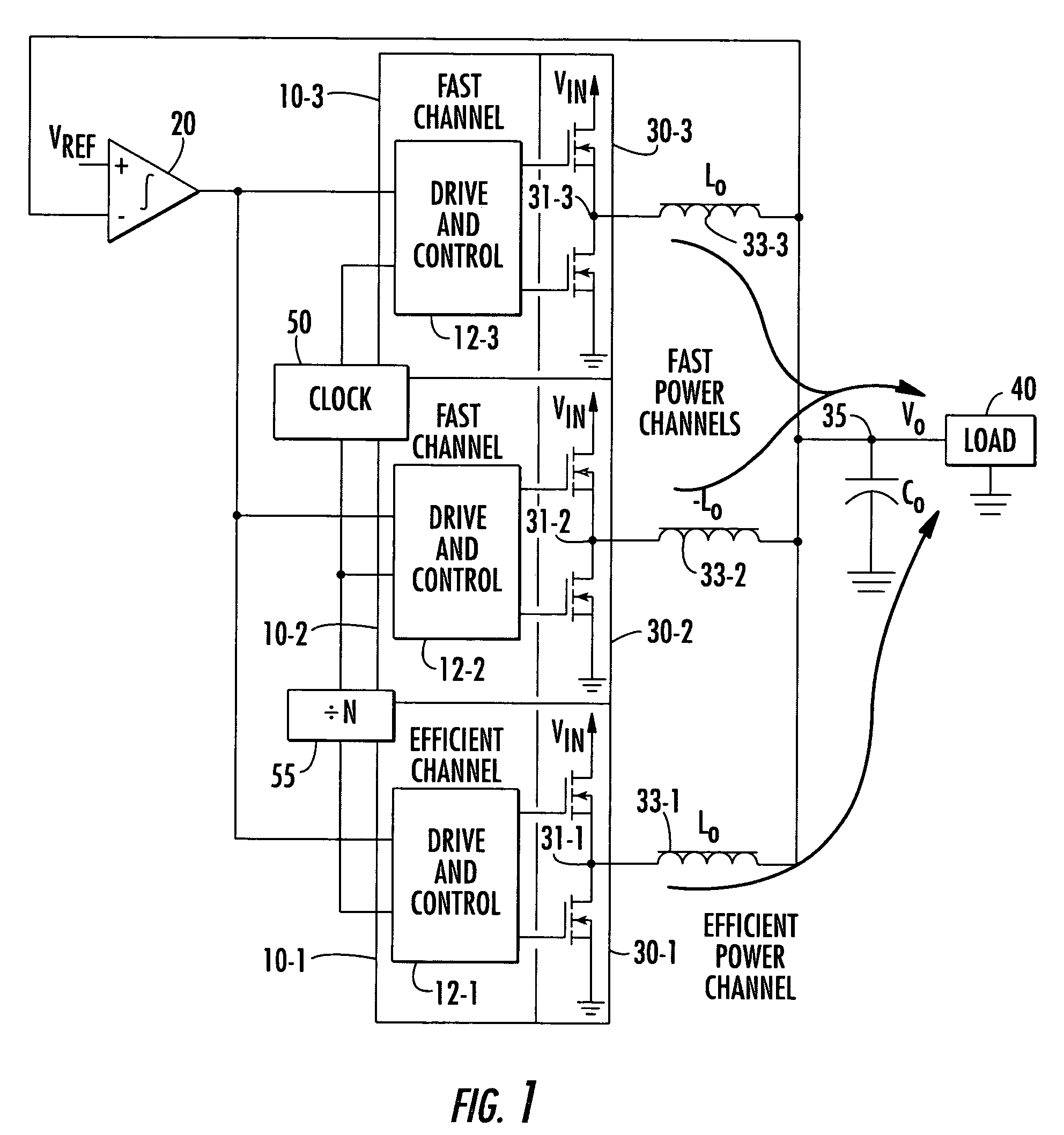

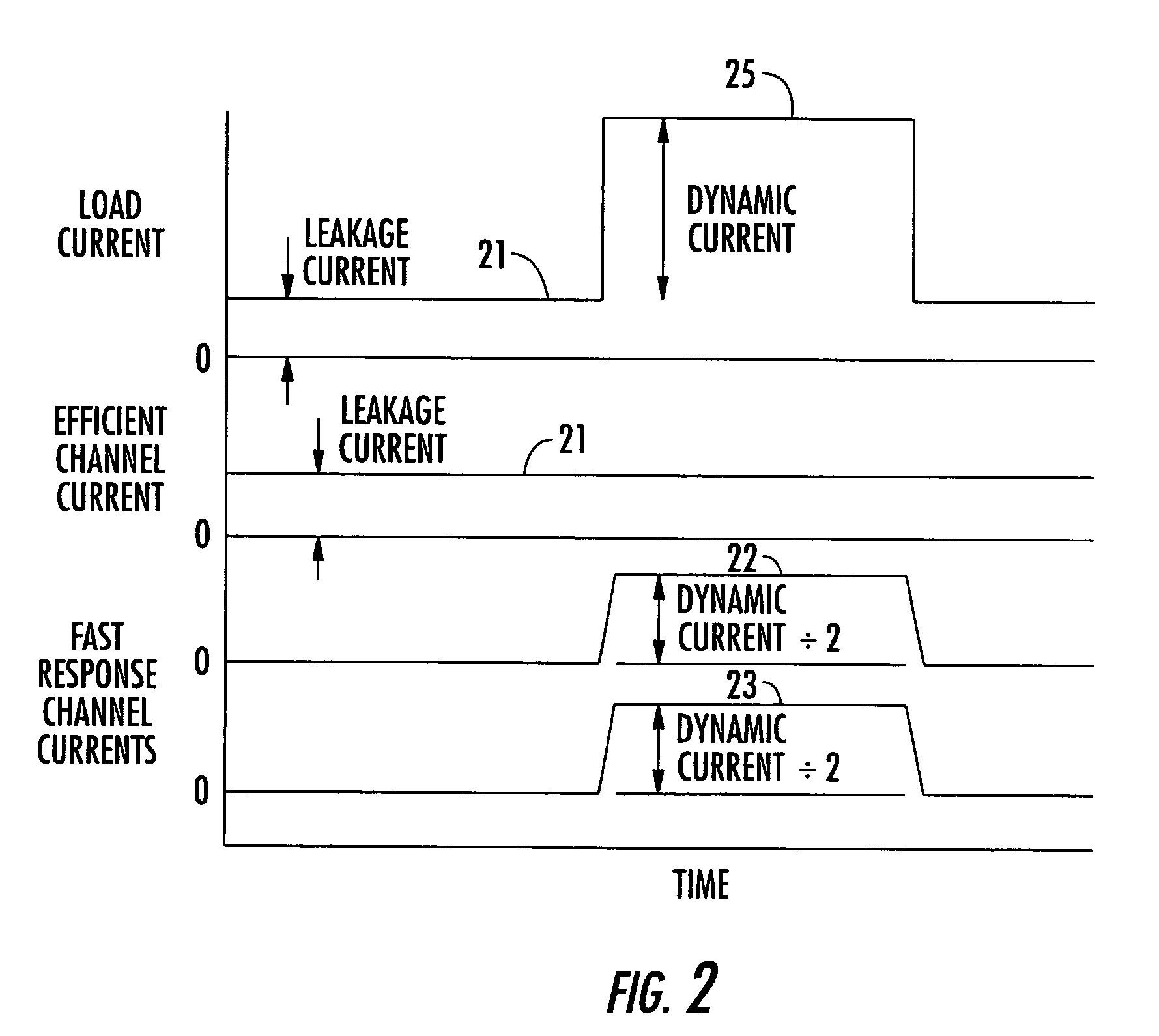

Asymmetrical multiphase DC-to-DC power converter

ActiveUS6995548B2Improve efficiencyLeakage currentEfficient power electronics conversionApparatus without intermediate ac conversionDc dc converterTransverter

A multiphase DC-DC converter architecture, in which respectively different channels have different operational performance parameters. These different parameters are selected so as to enable the converter to achieve an extended range of high efficiency. The converter contains a combination of one or more fast response time-based converter channels, and one or more highly efficient converter channels in respectively different phases thereof and combines the outputs of all the channels. The efficiency of the asymmetric multiphase converter is higher at light loads (up to approximately 12 amps), enabling it to offer longer battery life in applications that spend most of their operating time in the leakage mode, as noted above.

Owner:INTERSIL INC

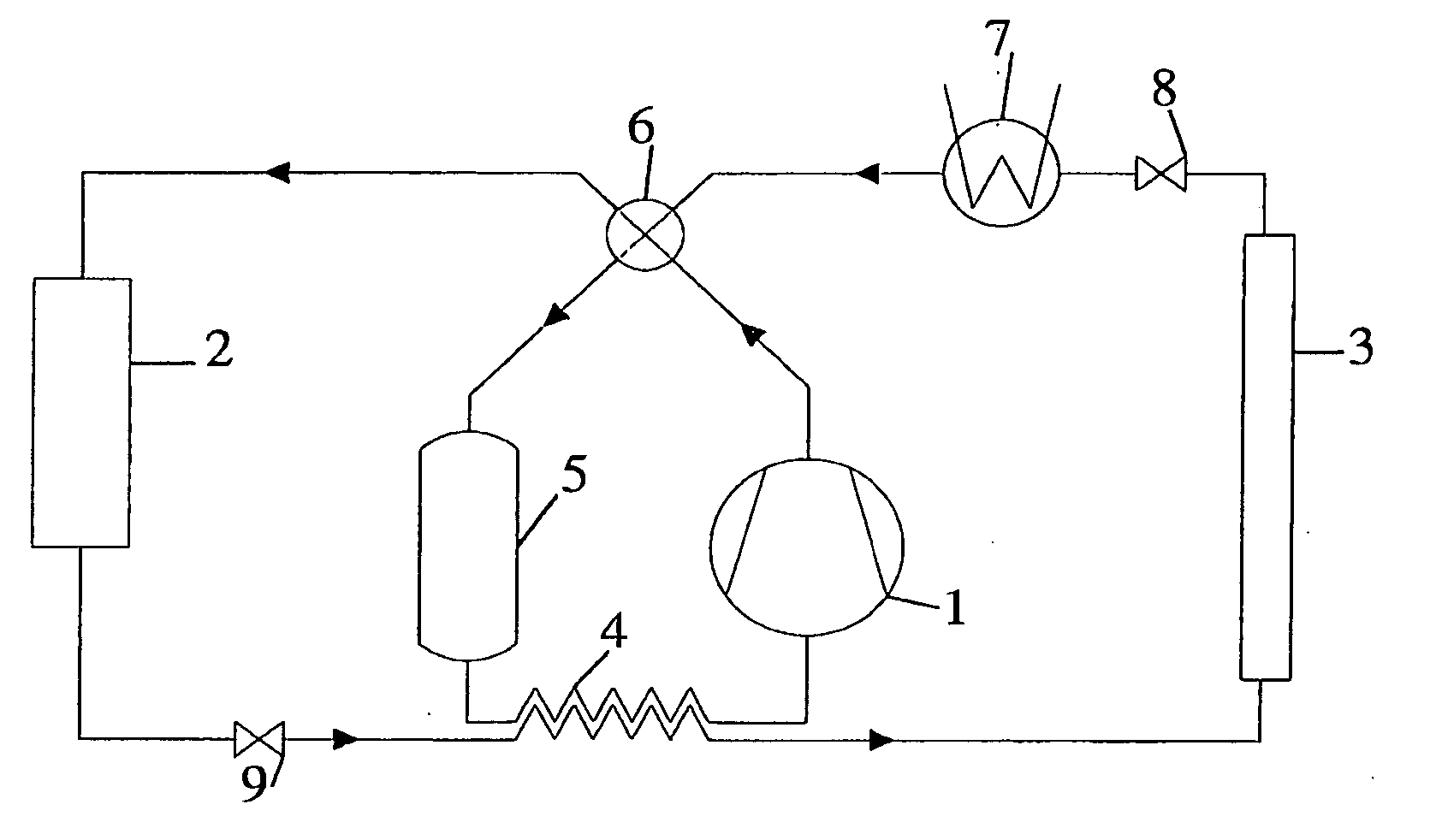

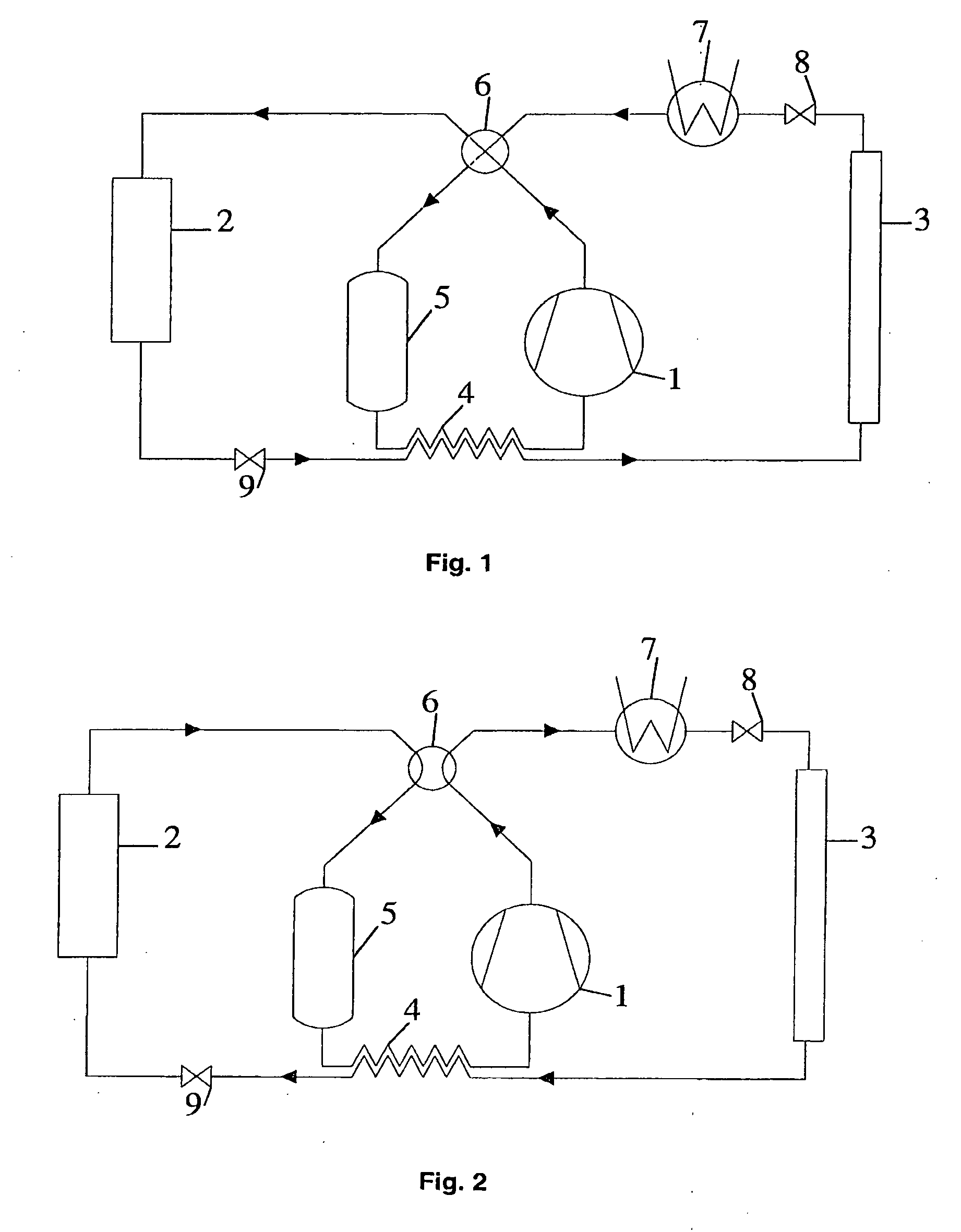

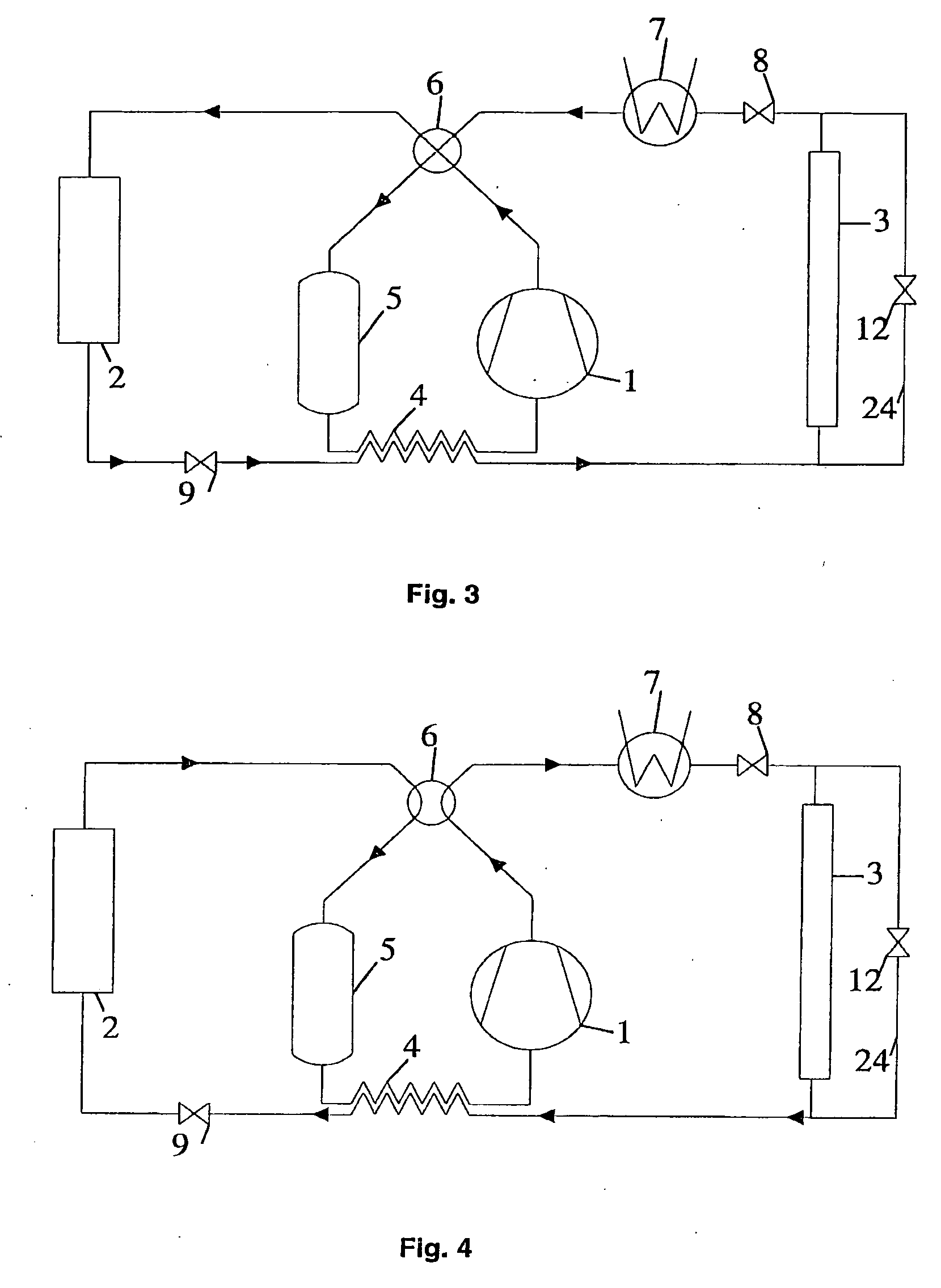

Vapor compression system for heating and cooling of vehicles

InactiveUS20050103487A1Heating fastReduce heat loadAir-treating devicesRailway heating/coolingEngineeringHeat pump

Reversible vapor compression system including a compressor (1), an interior heat exchanger (2), an expansion device (6) and an exterior heat exchanger (3) connected by means of conduits in an operable relationship to form an integral main circuit. A first means is provided in the main circuit between the compressor and the interior heat exchanger, and a second means is provided on the opposite side of the main circuit between the interior and exterior heat exchangers to enable reversing of the system from cooling mode to heat pump mode and vice versa.

Owner:SINVENT AS

Vapor deposition device

InactiveUS20070022955A1Improve efficiencyReduce weightVacuum evaporation coatingSputtering coatingGas phaseEngineering

A vapor deposition device for the vapor deposition of a substrate, and specifically particular of a substrate comprising heat-sensitive substances, for example OLEDs. To keep heat away from these substances, the vapor deposition device includes an evaporator tube with a special nozzle bar. This nozzle bar, which comprises several linearly arranged openings, projects with respect to the evaporator tube in the direction toward the substrate to be coated.

Owner:APPLIED MATERIALS GMBH & CO KG

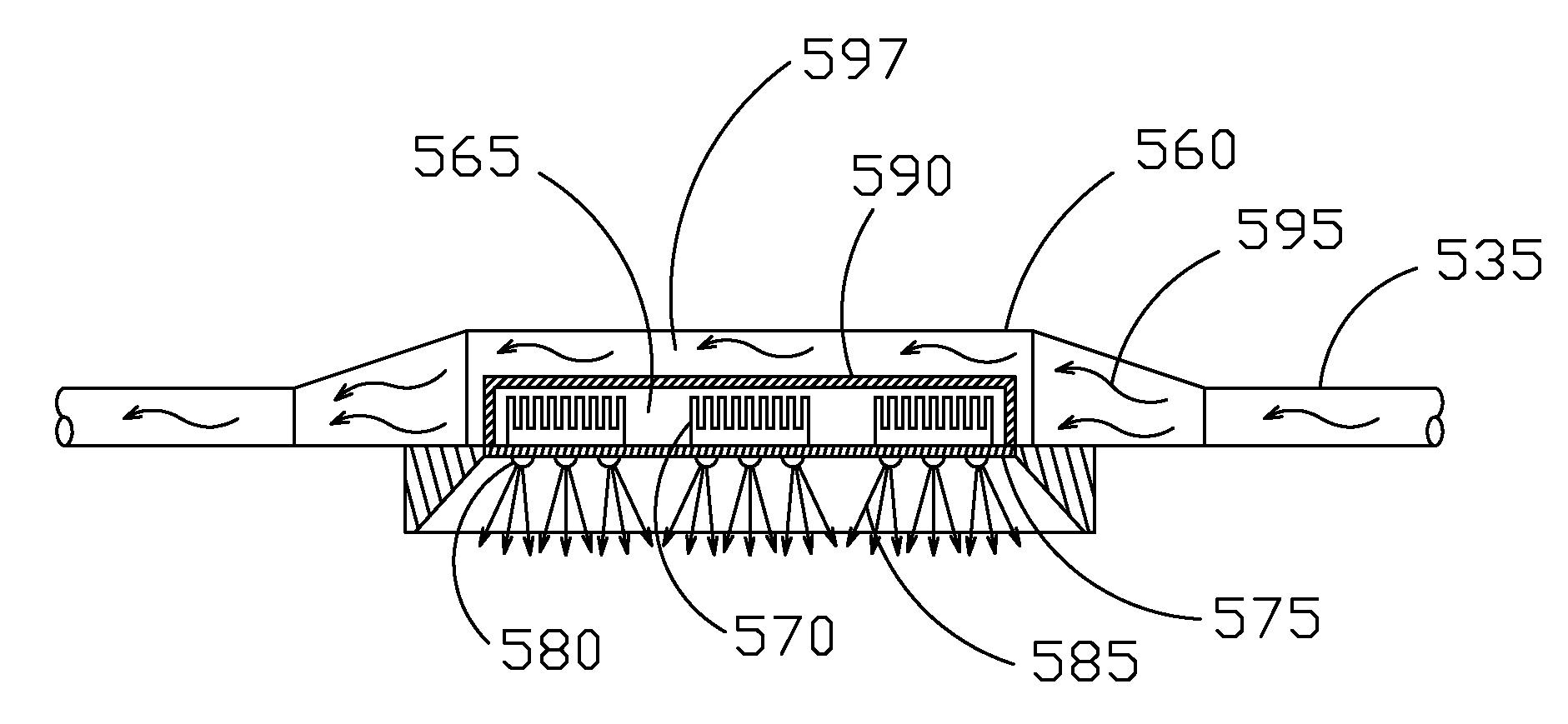

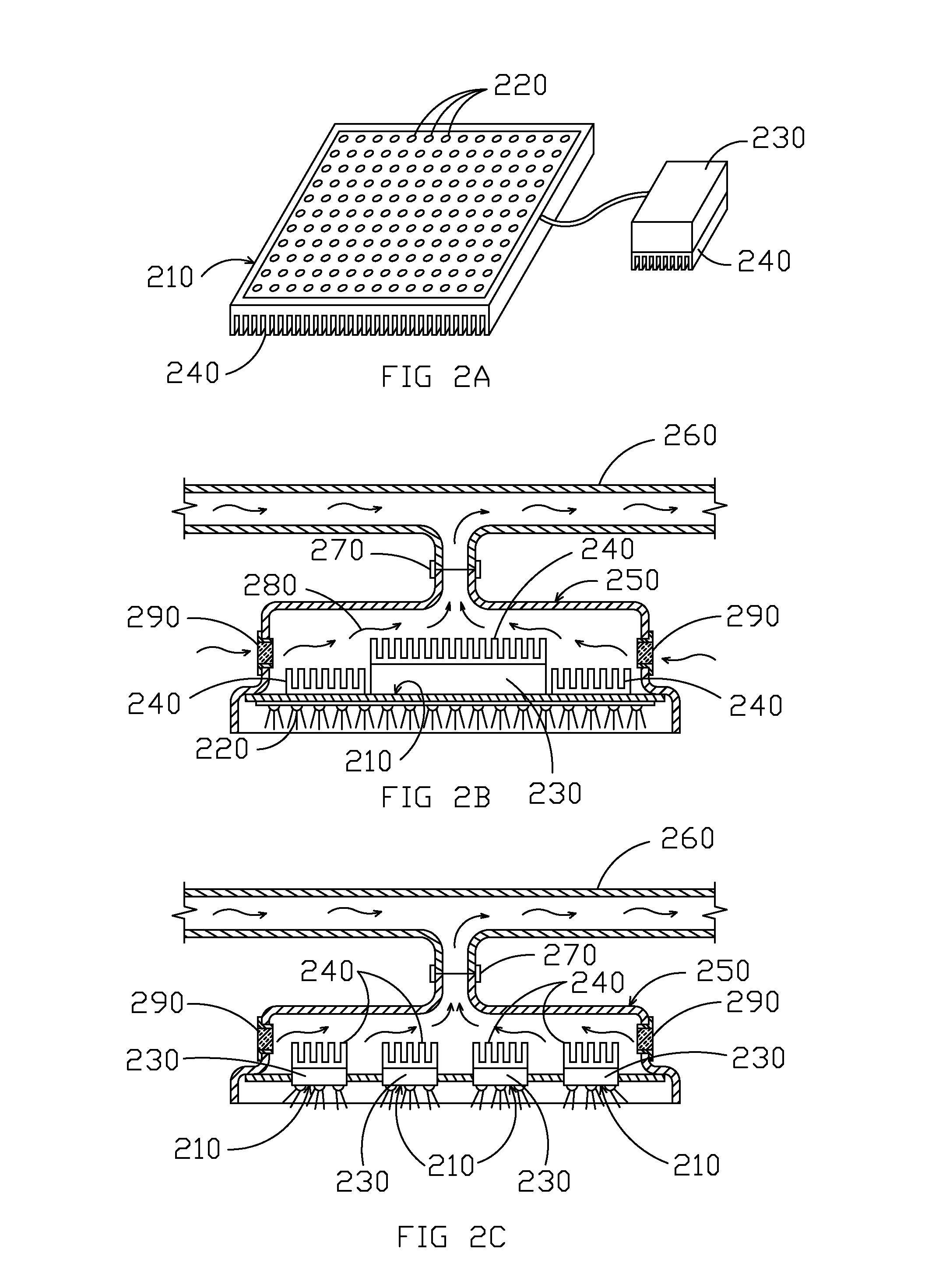

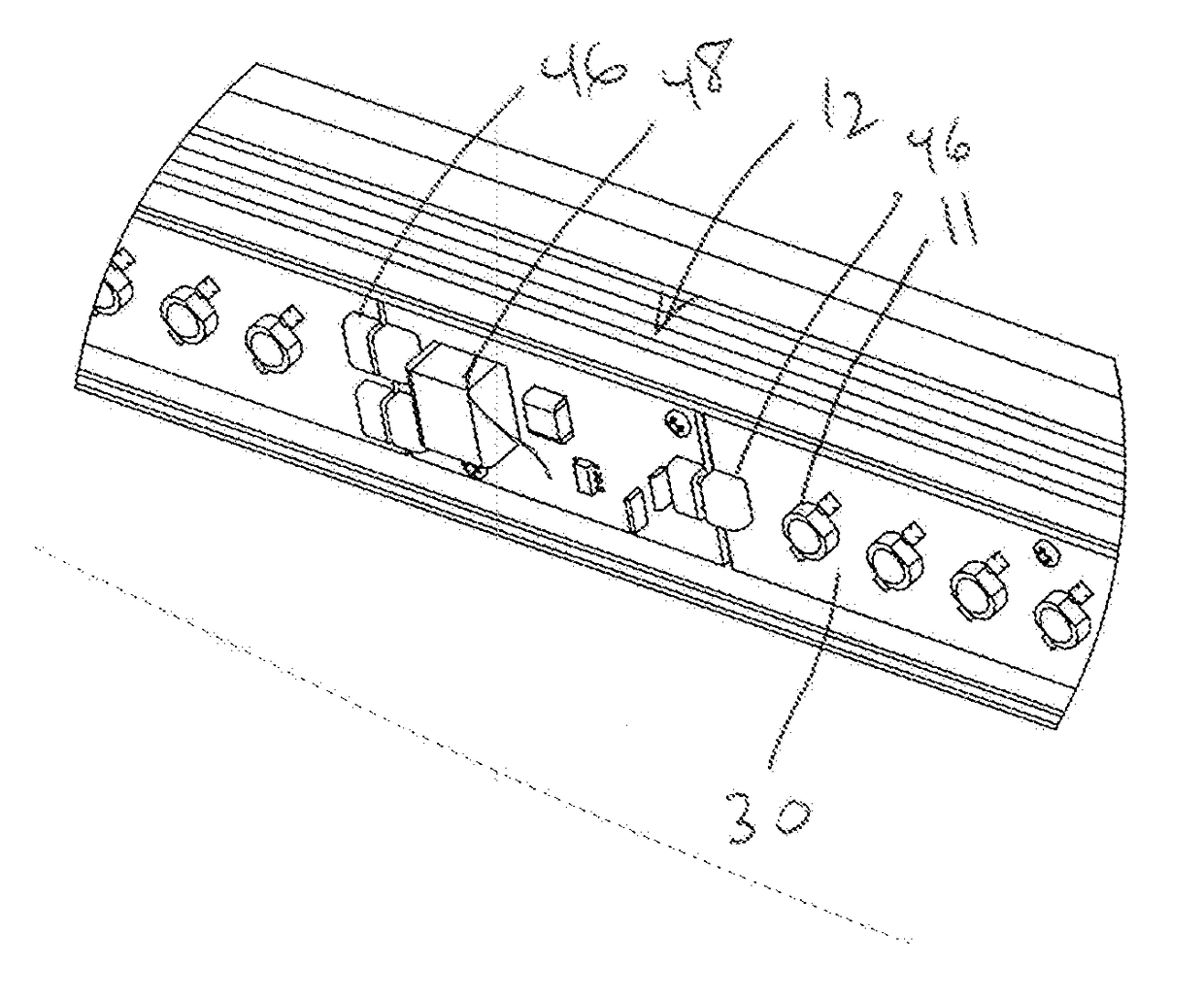

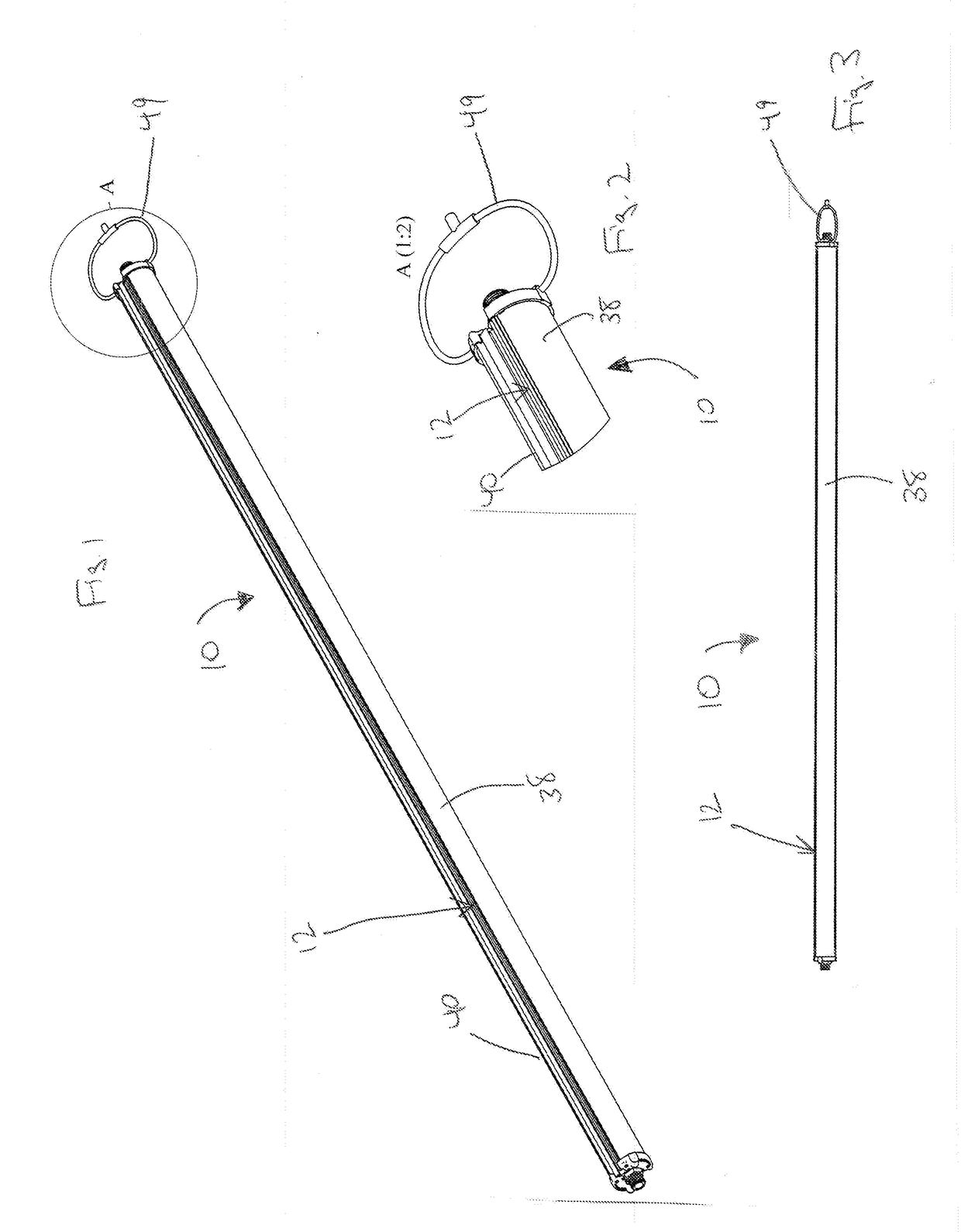

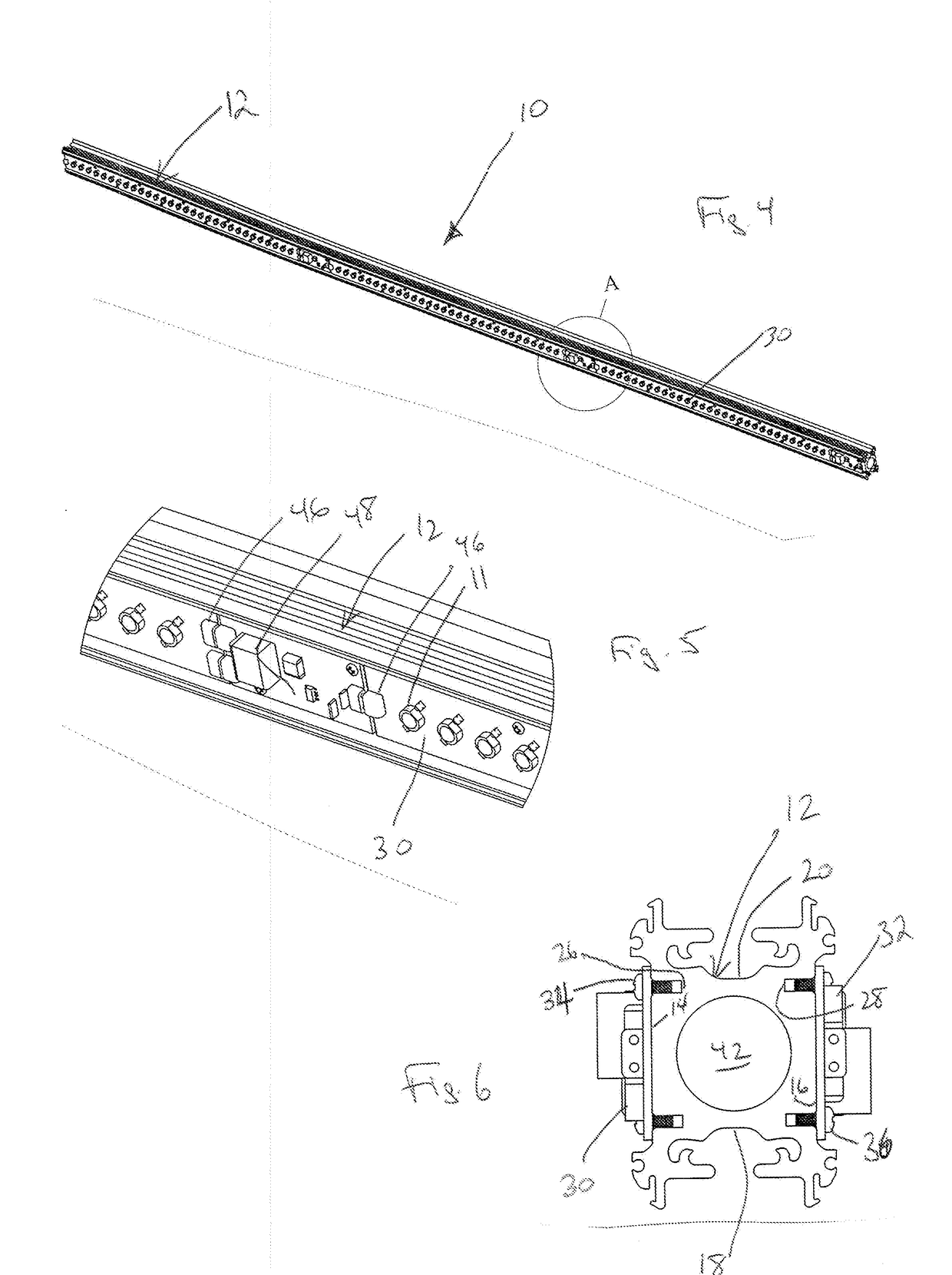

Water-Cooled LED Lighting System for Indoor Farming

ActiveUS20170146226A1High intensity lightReducing and eliminating heat loadElongate light sourcesClimate change adaptationActive coolingEffect light

A lighting system for indoor farming for delivering high intensity light while reducing or eliminating heat loads in a growing environment is provided. The lighting system comprises a lighting housing having a first end, a second end, a first side, a second side opposite the first side, a third side between the first side and the second side, and a fourth side opposite the third side. A first LED board is mounted to the first side and a second LED board is mounted to the second side. A first shroud covers the first LED board and a second shroud covers the second LED board. A coolant passage is formed completely through the lighting housing. A coolant liquid is receivable through the coolant passage. The coolant liquid provides active cooling, of the lighting housing from heat created by the first and second LED boards.

Owner:MJNN LLC

Superconductive magnet including a cryocooler coldhead

ActiveUS20060022779A1Reduce evaporation rateReduce heat loadMagnetic measurementsCompression machinesCryocoolerMechanics

A zero boiloff cryogen cooled recondensing superconducting magnet assembly including superconducting magnet coils suitable for magnetic resonance imaging including a cryogen pressure vessel to contain a liquid cryogen reservoir to provide cryogenic temperatures to the magnet coils for superconducting operation; a vacuum vessel surrounding the pressure vessel and spaced therefrom; a first thermal shield surrounding and spaced from the pressure vessel; a second thermal shield surrounding and spaced from the first thermal shield and intermediate the vacuum vessel and the first shield; a cryocooler thermally connected by a first and a second thermal interface to the first and second thermal shields, respectively; a recondenser positioned in the space between the pressure vessel and the first thermal shield and thermally connected by a thermal interface to the cryocooler to recondense, back to liquid, cryogen gas provided from the pressure vessel; and means for returning the recondensed liquid cryogen the pressure vessel; wherein the second thermal shield surrounding the first thermal shield reduces a radiation heat load from the first thermal shield to the pressure vessel lowering boiloff of cryogen gas under conditions of failure or power off of the cryocooler.

Owner:GENERAL ELECTRIC CO

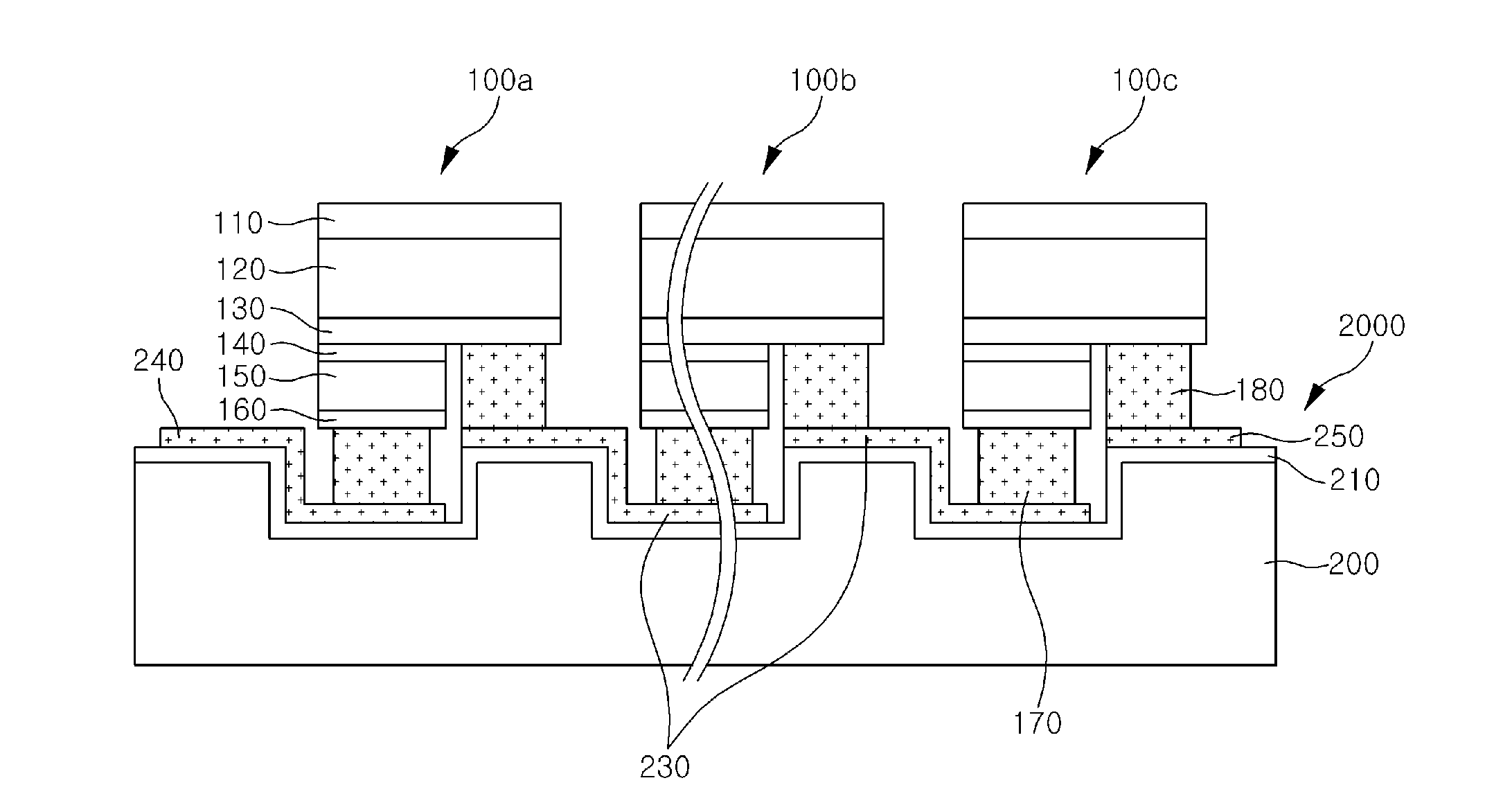

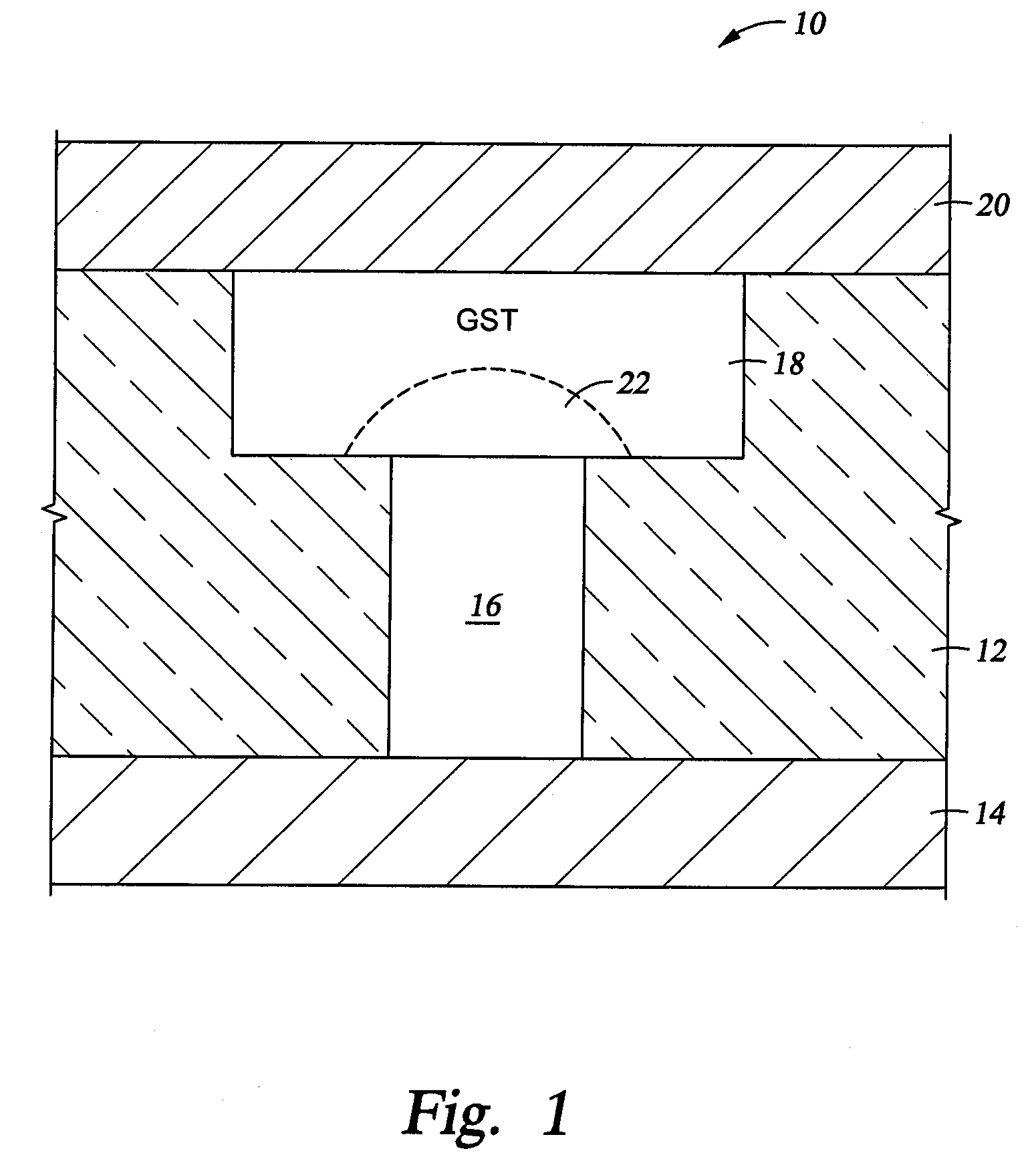

Light emitting device having a plurality of light emitting cells and package mounting the same

ActiveUS7723736B2Convenient lightingReduce heat loadSemiconductor/solid-state device detailsSolid-state devicesAC powerLight emitting device

Disclosed is a light emitting device having a plurality of light emitting cells and a package having the same mounted thereon. The light emitting device includes a plurality of light emitting cells which are formed on a substrate and each of which has an N-type semiconductor layer and a P-type semiconductor layer located on a portion of the N-type semiconductor layer. The plurality of light emitting cells are bonded to a submount substrate. Accordingly, heat generated from the light emitting cells can be easily dissipated, so that a thermal load on the light emitting device can be reduced. Meanwhile, since the plurality of light emitting cells are electrically connected using connection electrodes or electrode layers formed on the submount substrate, it is possible to provide light emitting cell arrays connected to each other in series. Further, it is possible to provide a light emitting device capable of being directly driven by an AC power source by connecting the serially connected light emitting cell arrays in reverse parallel to each other.

Owner:SEOUL VIOSYS CO LTD

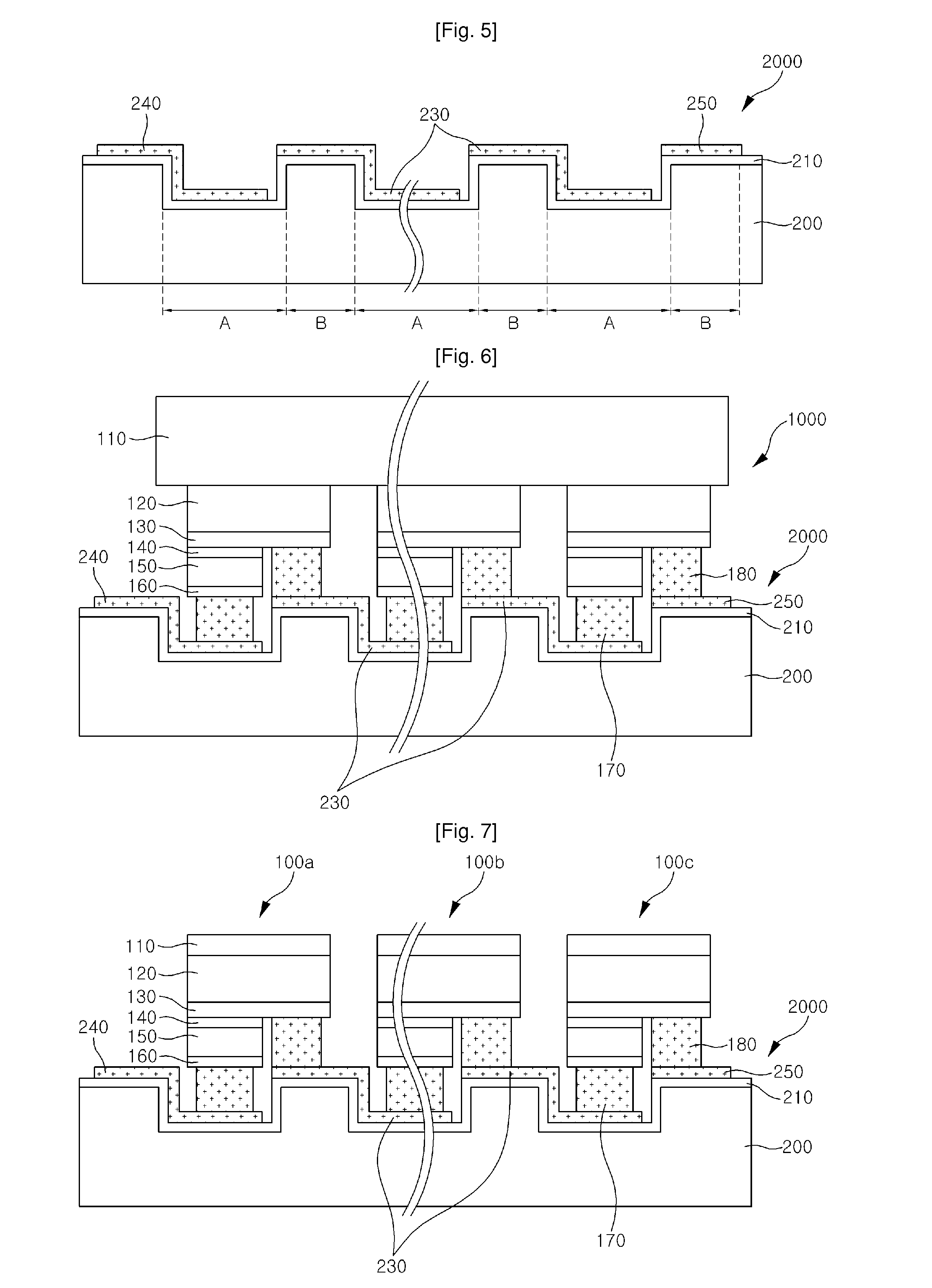

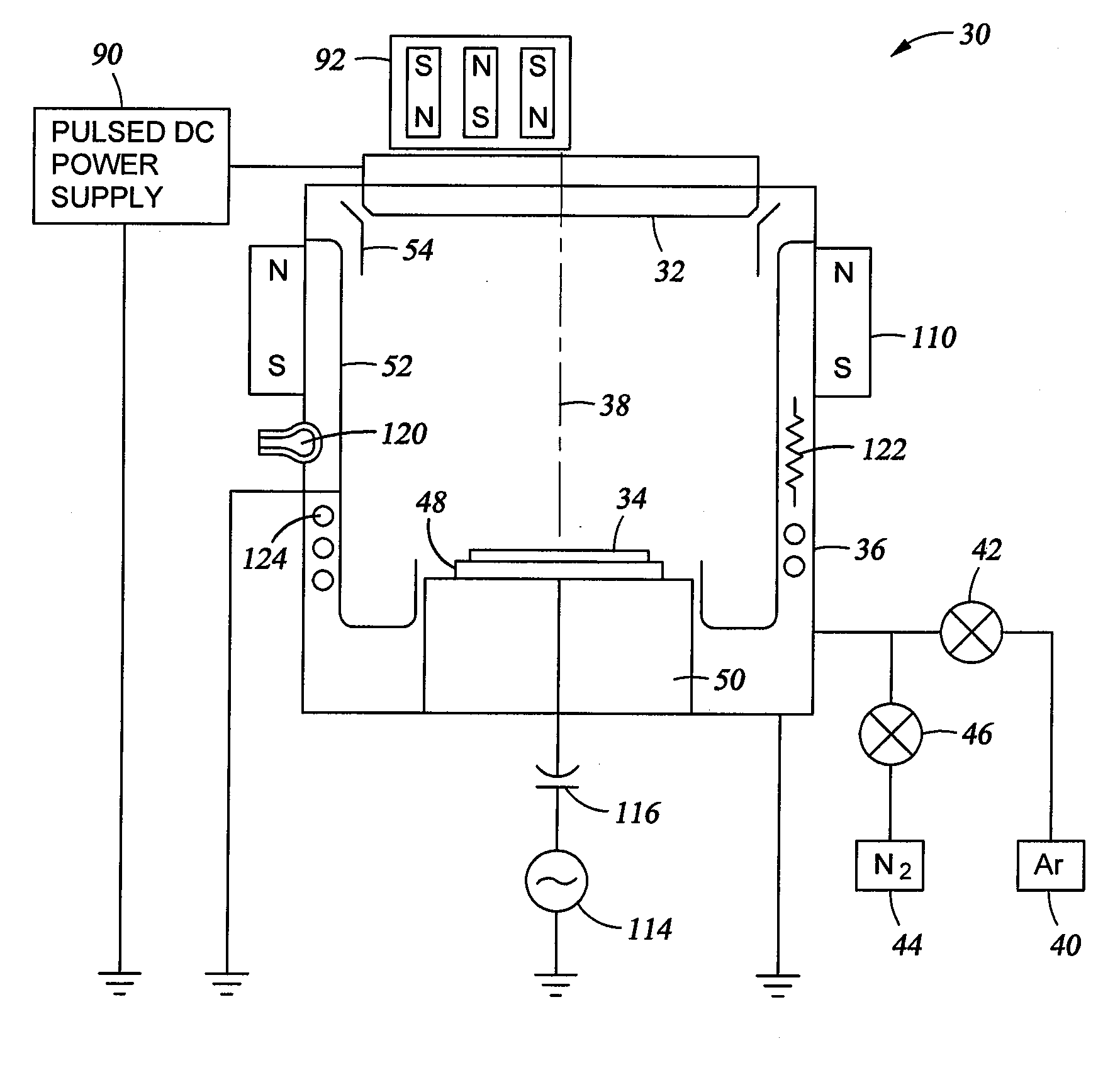

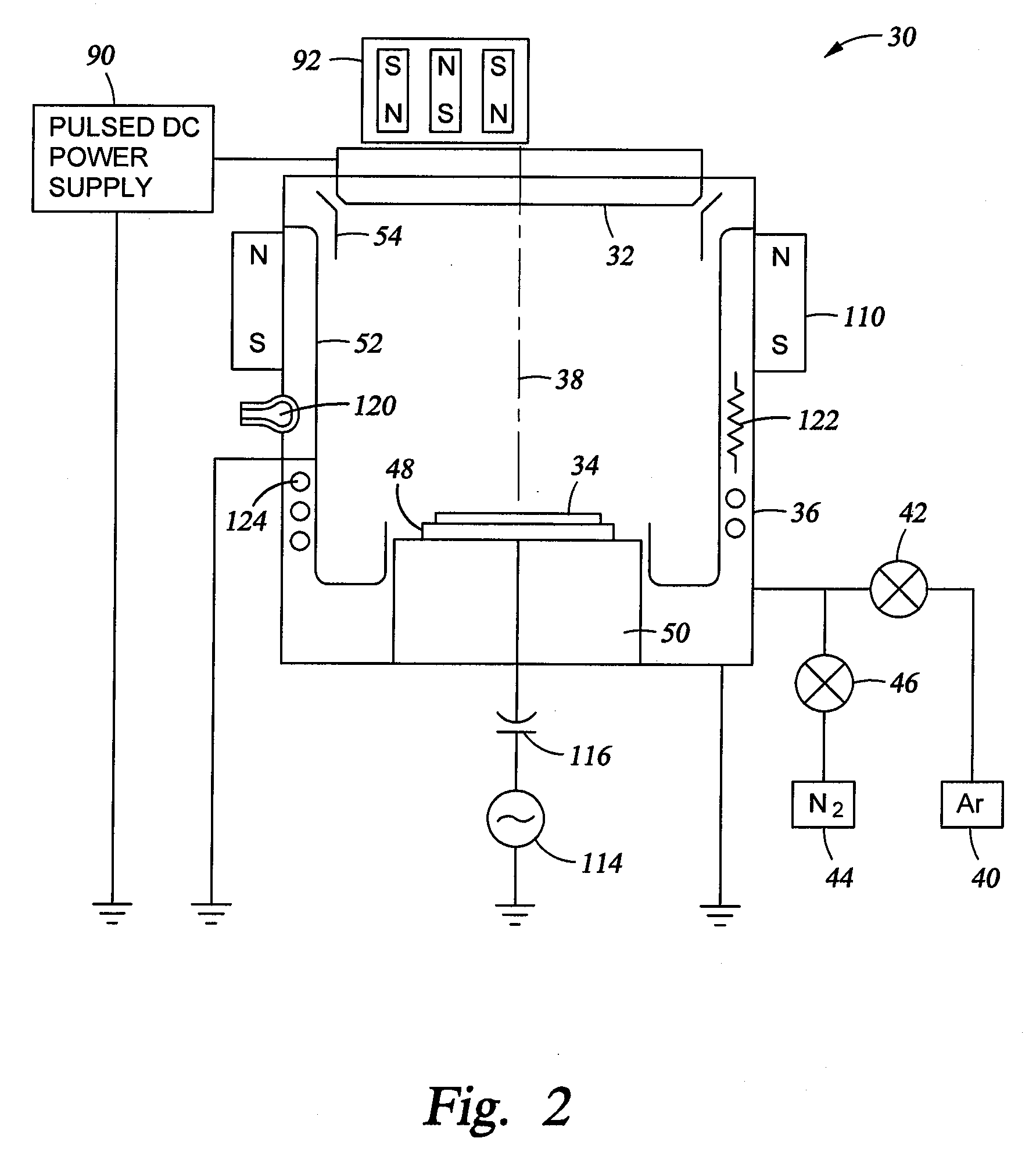

Sputtering of thermally resistive materials including metal chalcogenides

ActiveUS20080099326A1Reduce heat loadLow thermal conductivityVacuum evaporation coatingSputtering coatingPhase-change memoryMetal chalcogenides

A plasma sputtering method for metal chalcogenides, such as germanium antimony telluride (GST), useful in forming phase-change memories. The substrate is held at a selected temperature at which the material deposits in either an amorphous or crystalline form. GST has a low-temperature amorphous range and a high-temperature crystalline range separated by a transition band of 105-120° C. Bipolar pulsed sputtering with less than 50% positive pulses of less than 10:s pulse width cleans the target while maintain the sputtering plasma. The temperature of chamber shields is maintained at a temperature favoring crystalline deposition or they may be coated with arc-spray aluminum or with crystallographically aligned copper or aluminum.

Owner:APPLIED MATERIALS INC

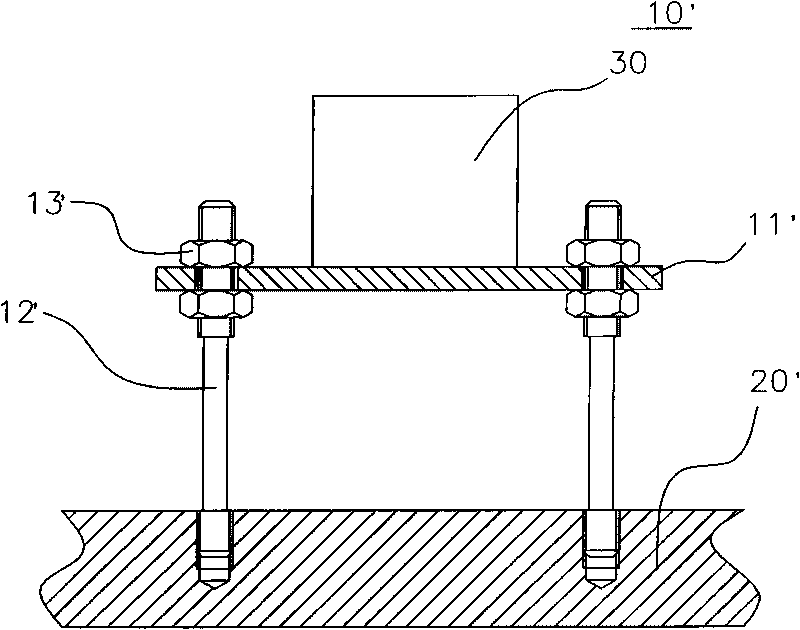

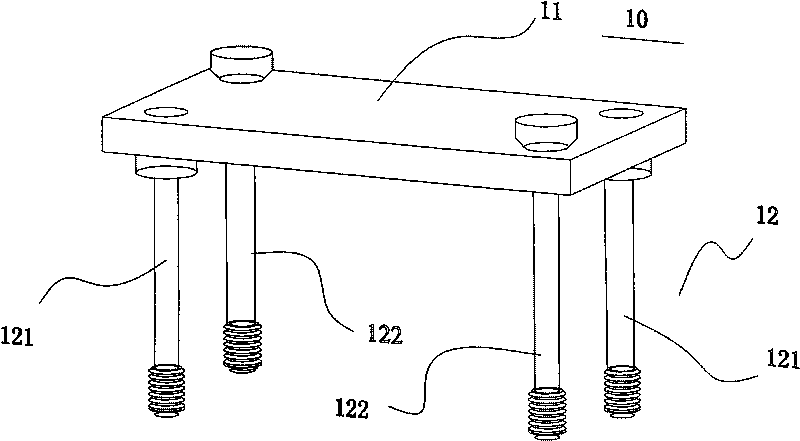

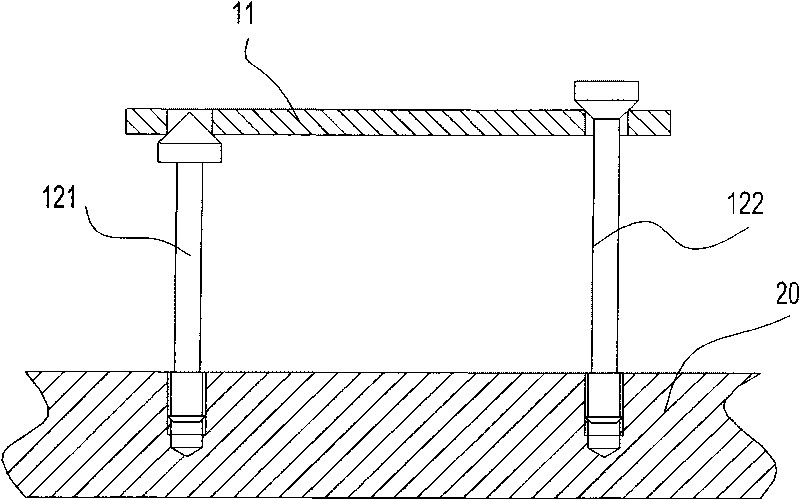

Adiabatic supporting device

ActiveCN101738127AGuaranteed stabilityReduce thermal contact areaHeat exchanger casingsEngineeringVacuum chamber

An adiabatic supporting device is used for supporting low temperature devices in a low temperature vacuum system. The supporting device comprises a cold platform with a plurality of mounting holes and support bars used for supporting the cold platform. The bottoms of the support bars are fixedly connected with a vacuum chamber. The support bars comprise upward ejecting support bars and downward pressing support bars. The upper parts of the upward ejecting support bars are matched with the mounting holes by way of point contact or line contact and the upward ejecting support bars provide upward ejecting force to the cold platform. After the downward pressing support bars pass through the mounting holes, the tops of the downward pressing support bars are matched with the mounting holes by way of point contact or line contact and the downward pressing support bars provide downward pressing force to the cold platform. The upward ejecting force reaches equilibrium with the downward pressing force. The supporting device furthest reduces the heat contact area under the premise of ensuring the stability of the mechanical structure and changes from the original nut surface contact to the current line contact or point contact, thus reducing heat leakage from the vacuum chamber to the cold platform and greatly reducing heat load.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Preformulation for tabletting natural mixtures of conjugated estrogens

InactiveUS20050009800A1Easy to processLow hormone concentrationOrganic active ingredientsBiocideConjugated Equine EstrogensConjugated oestrogens

A pharmaceutical preformulation in the form of a solid, free-flowing dry extract of a natural mixture of conjugated equine estrogens, which is particularly suitable use in for solid galenic forms, e.g. tabletting. The conjugated estrogens are available for further galenic processing in a form which assures the chemical stability of the hormones and permits advantageous processing into solid galenic forms, for example a tablet. The invention furthermore relates to a method for producing these preformulations in the form of a dry extract.

Owner:ABBVIE PHARMA GMBH

Cooling system for a tip of a turbine blade

InactiveUS7029235B2Reduce effective sizeGenerally concave shapePropellersRotary propellersTurbine blade

A turbine blade for a turbine engine having at least one secondary flow deflector proximate to a blade tip for reducing the effective flow path between the blade tip and an adjacent outer seal. The turbine blade may be a superblade having a central opening forming a hollow turbine blade. The turbine blade may include a secondary flow deflector on upstream sides of the pressure side wall and the suction side wall. The downstream sides of the pressure and suction side walls may include chamfered corners. The secondary flow deflector reduces the effective flow path between the blade tip and an outer seal in numerous ways.

Owner:SIEMENS ENERGY INC

Turbine blade with tip section cooling

InactiveUS8066485B1Improve cooling effectImprove efficiencyPropellersRotary propellersTurbine bladeEngineering

A turbine rotor blade with a single tip rail on the suction side of the blade tip, and in which the pressure side tip edge includes a row of trench film slots that each having side walls that are open on the pressure side wall and extend onto the tip floor and have side walls with a curvature toward the trailing edge of the blade tip. The trench film slots also have a curved inboard surface and a curved outboard surface in which the inboard surface curvature is less than the outboard surface curvature. The tip rail includes a slot opening onto the top surface and extending the length of the tip rail with a row of metering and cooling holes opening into the slot. The metering and cooling holes have a curvature toward the pressure side edge of the tip floor to increase a heat transfer rate form the metal.

Owner:FLORIDA TURBINE TECH

Portable gas fractionalization system

InactiveUS7922789B1Reduce heat loadReduce noiseCombination devicesAuxillary pretreatmentLow noiseLinear compressor

A portable gas fractionalization apparatus that provides oxygen rich air to patients is provided. The apparatus is compact, lightweight, and low-noise. The components are assembled in a housing that is divided into two compartments. One compartment is maintained at a lower temperature than the other compartment. The lower temperature compartment is configured for mounting components that can be damaged by heat. The higher temperature compartment is configured for mounting heat generating components. An air stream is directed to flow from an ambient air inlet to an air outlet constantly so that there is always a fresh source of cooling air. The apparatus utilizes a PSA unit to produce an oxygen enriched product. The PSA unit incorporates a novel compressor system which includes the use of free piston linear compressors so as to reduce power consumption, noise and vibration reduction.

Owner:INOGEN INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com