Patents

Literature

98 results about "Column design" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

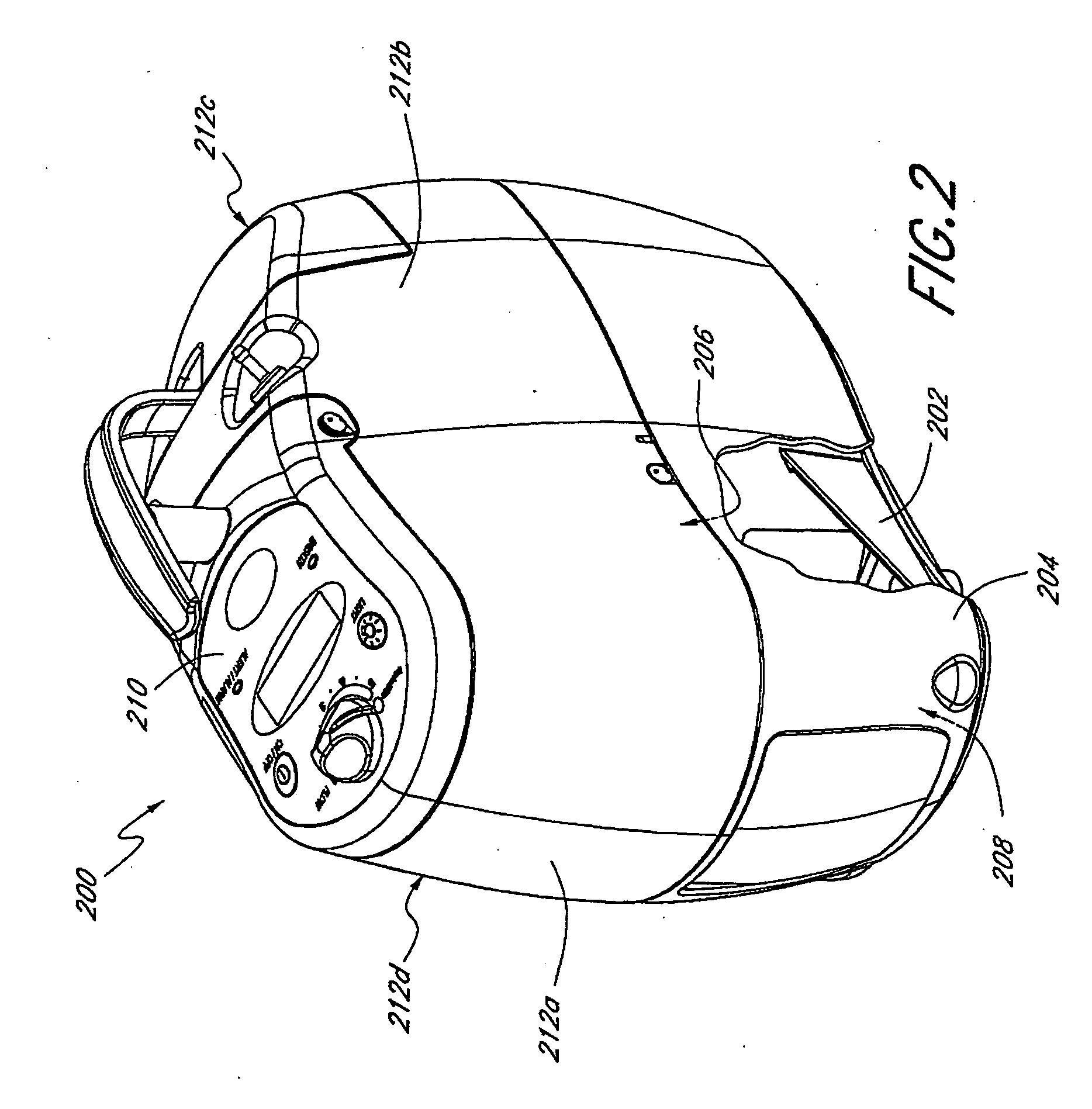

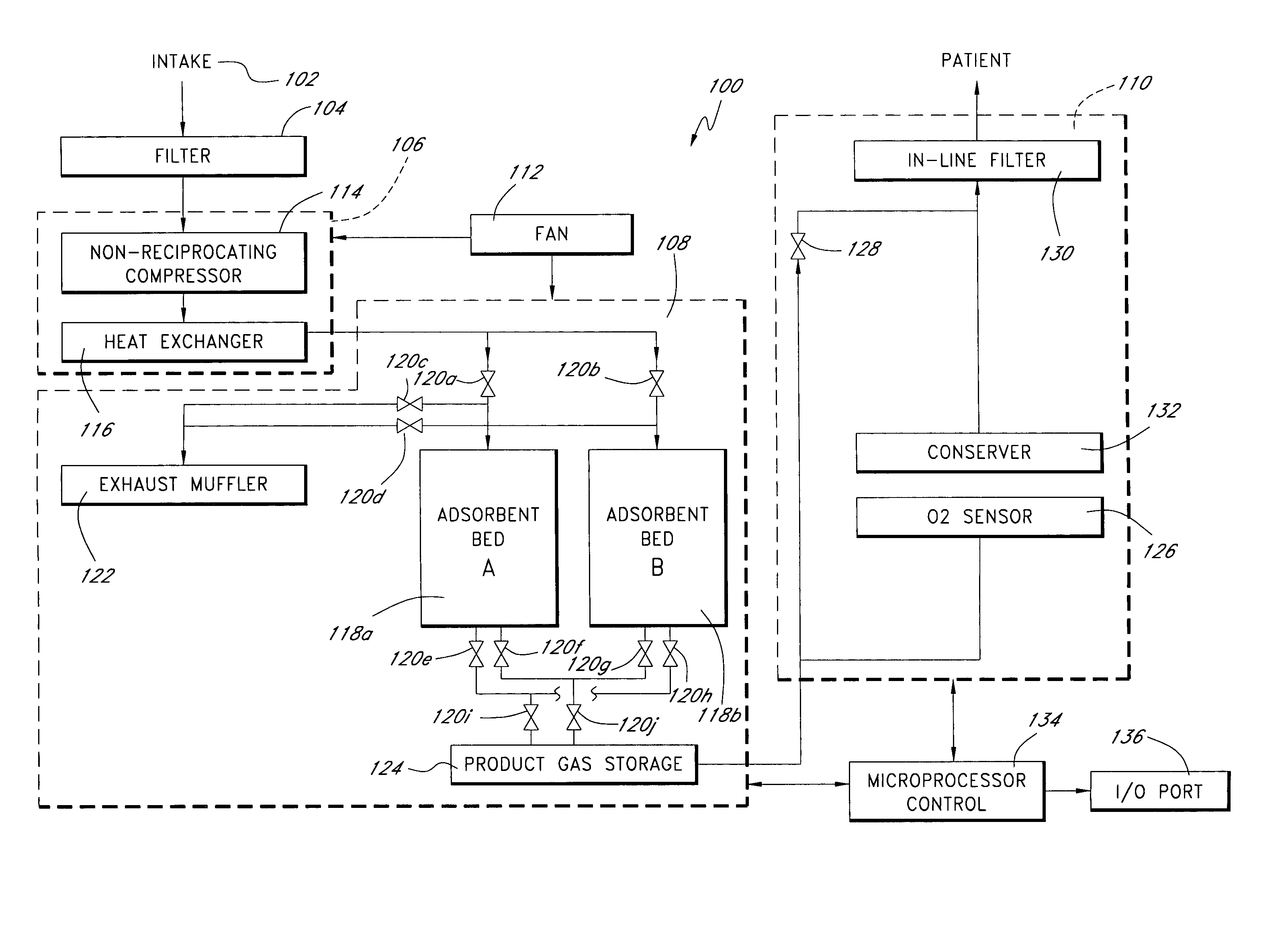

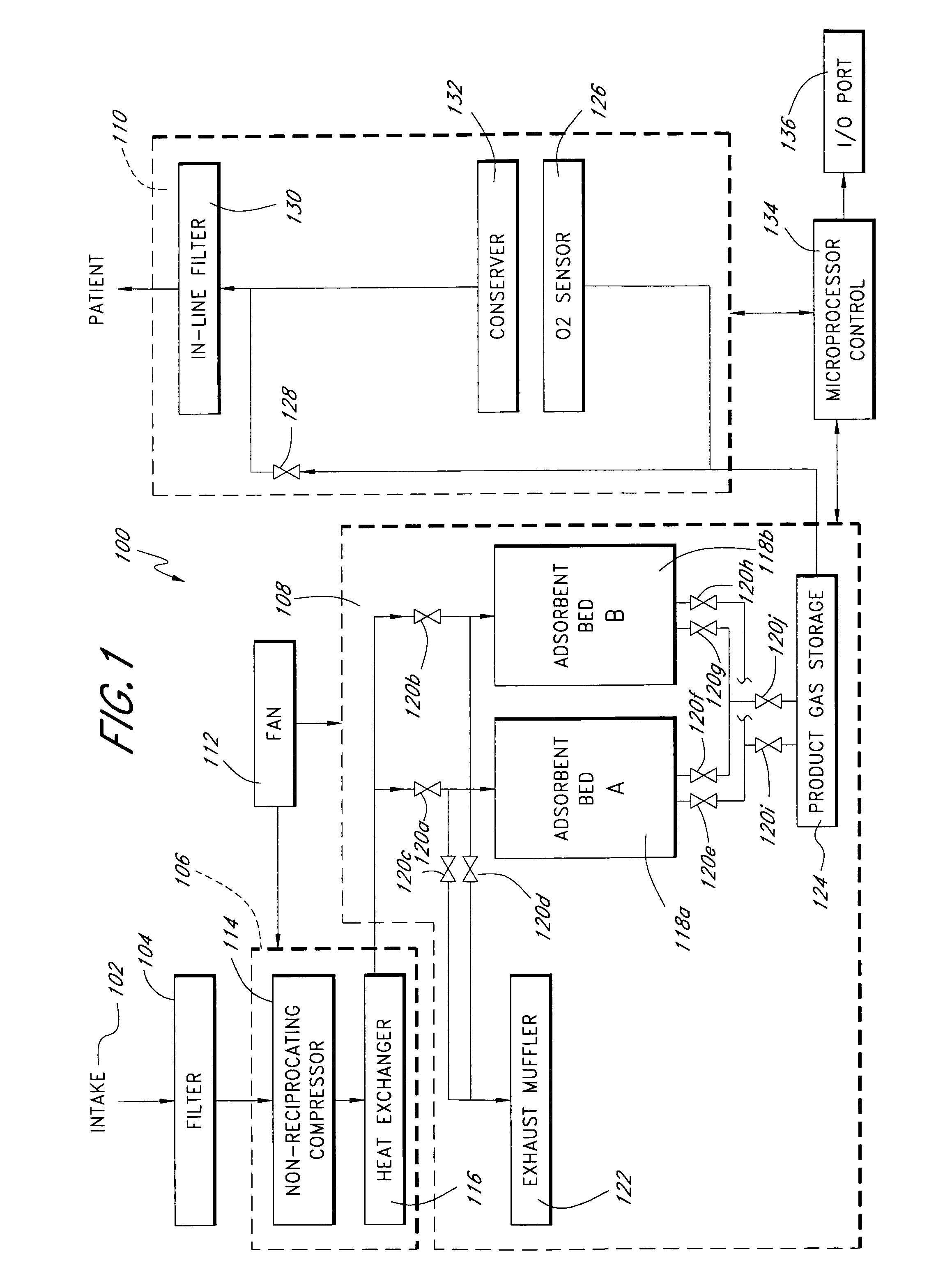

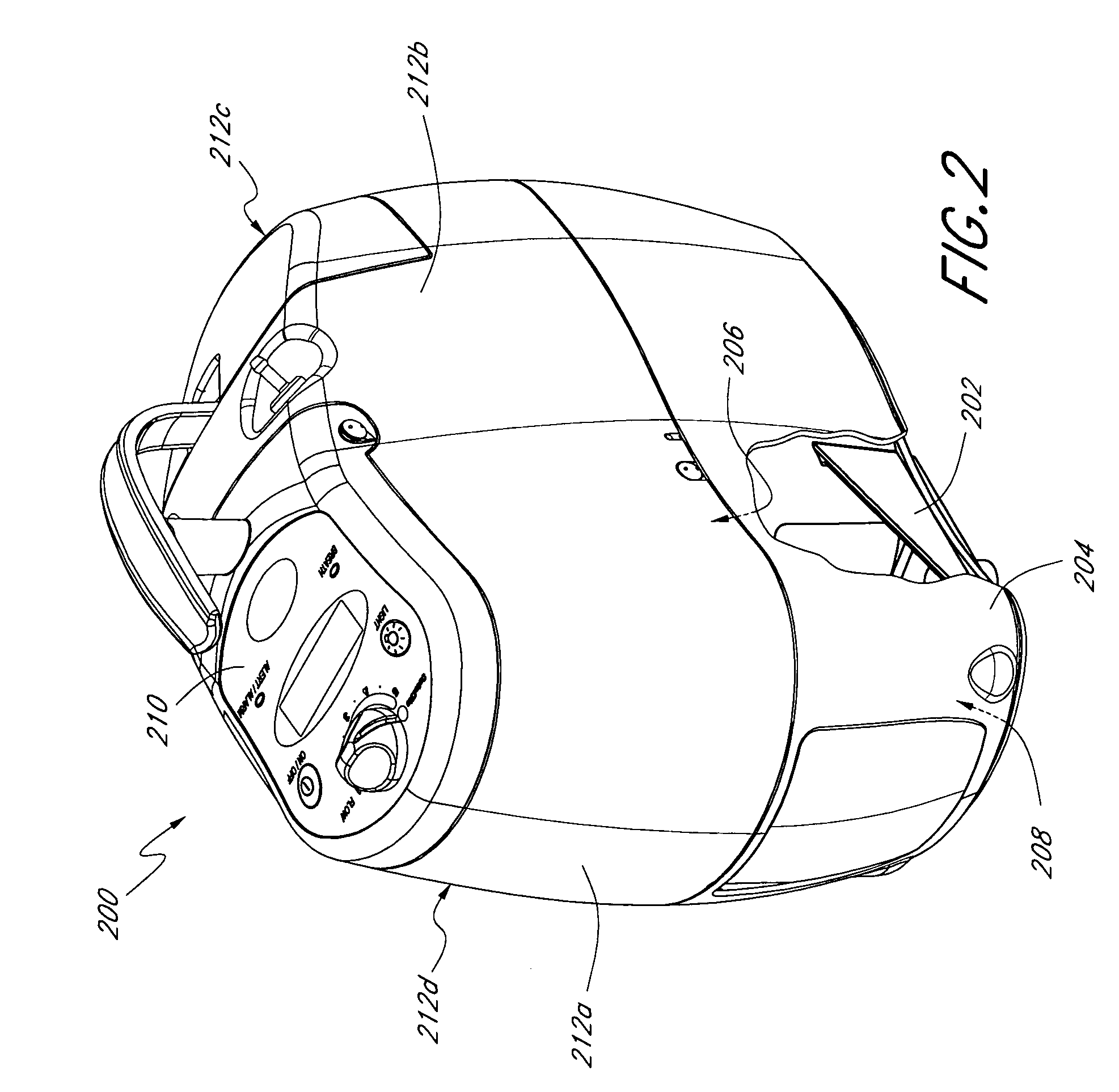

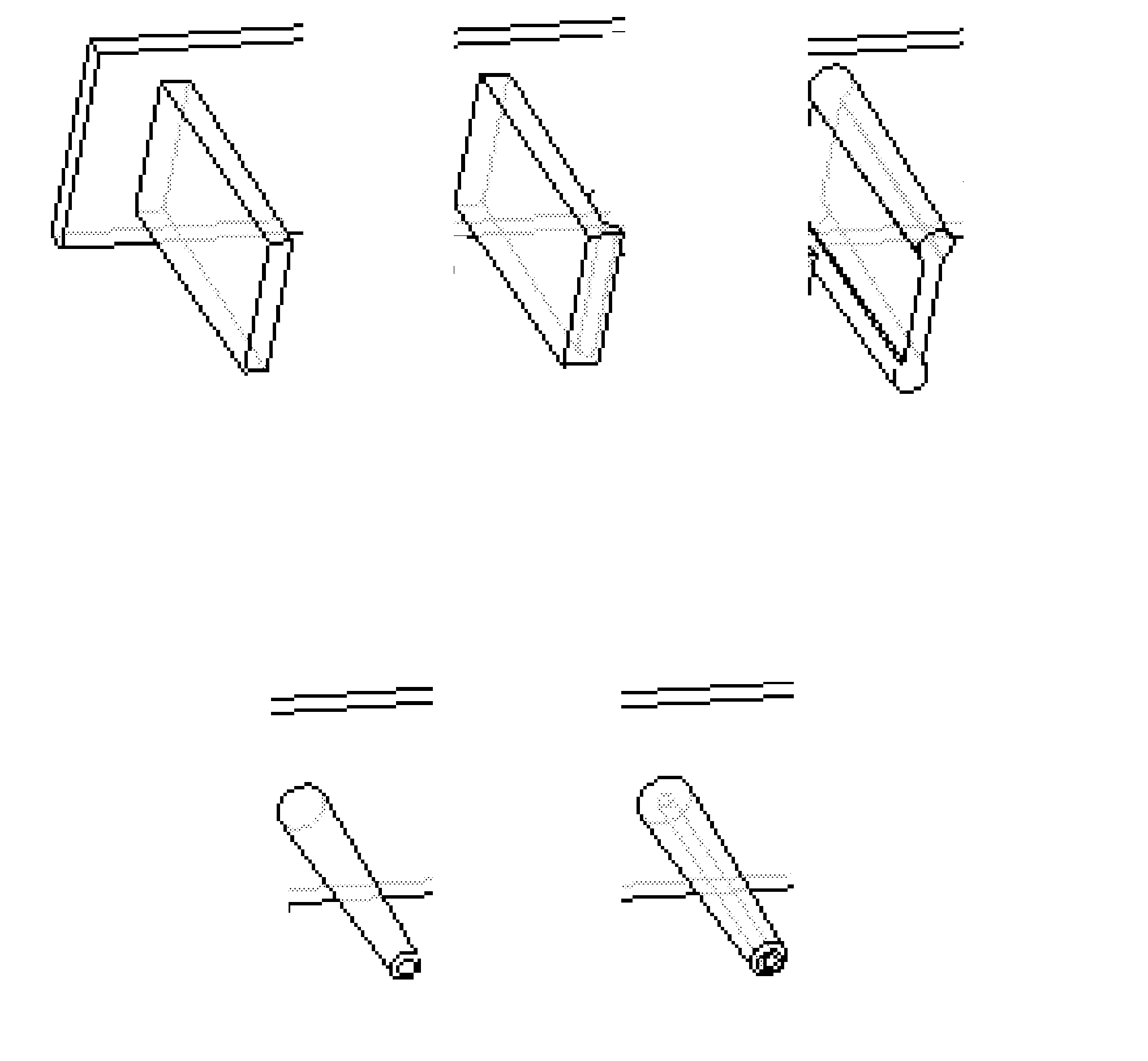

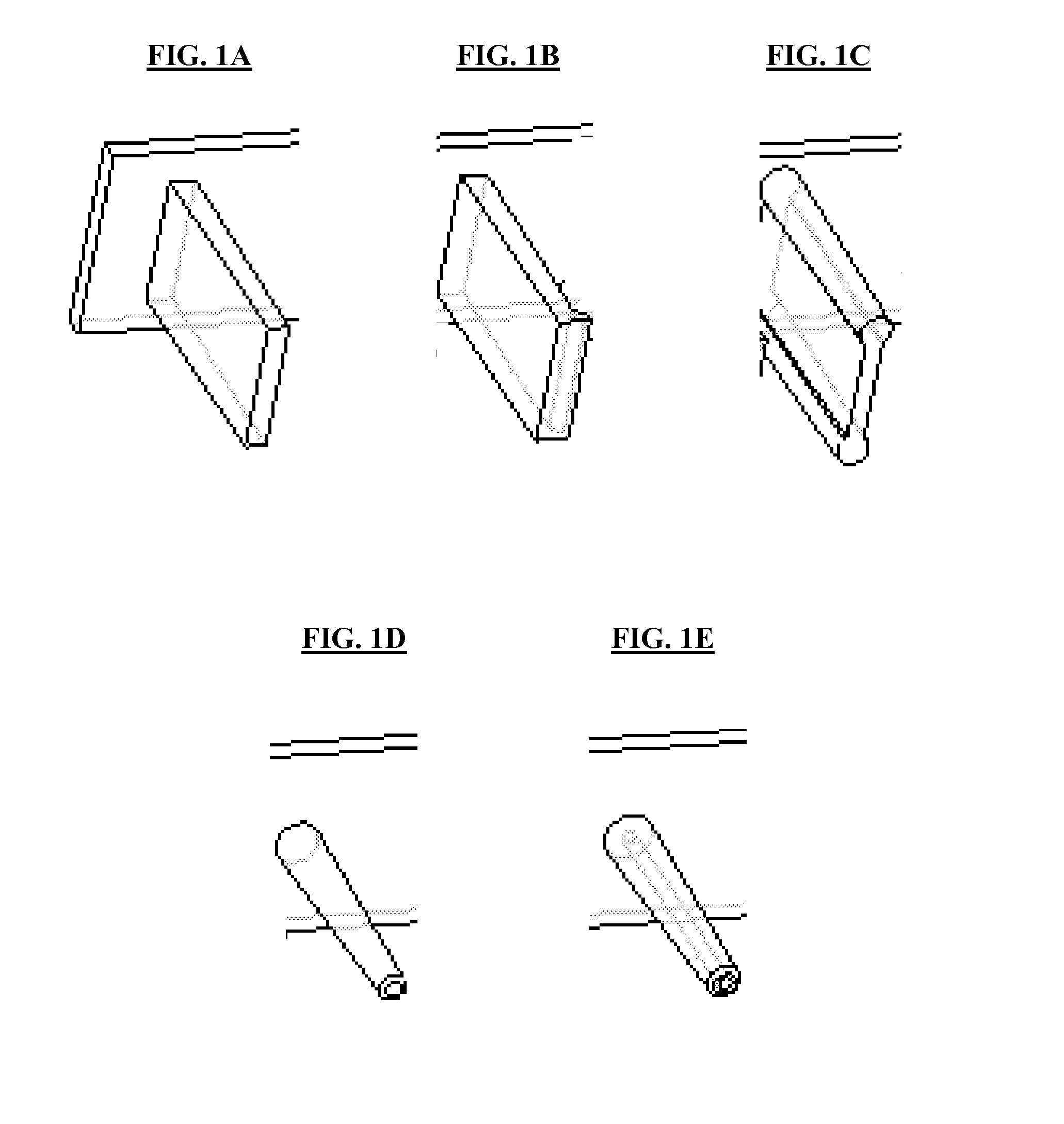

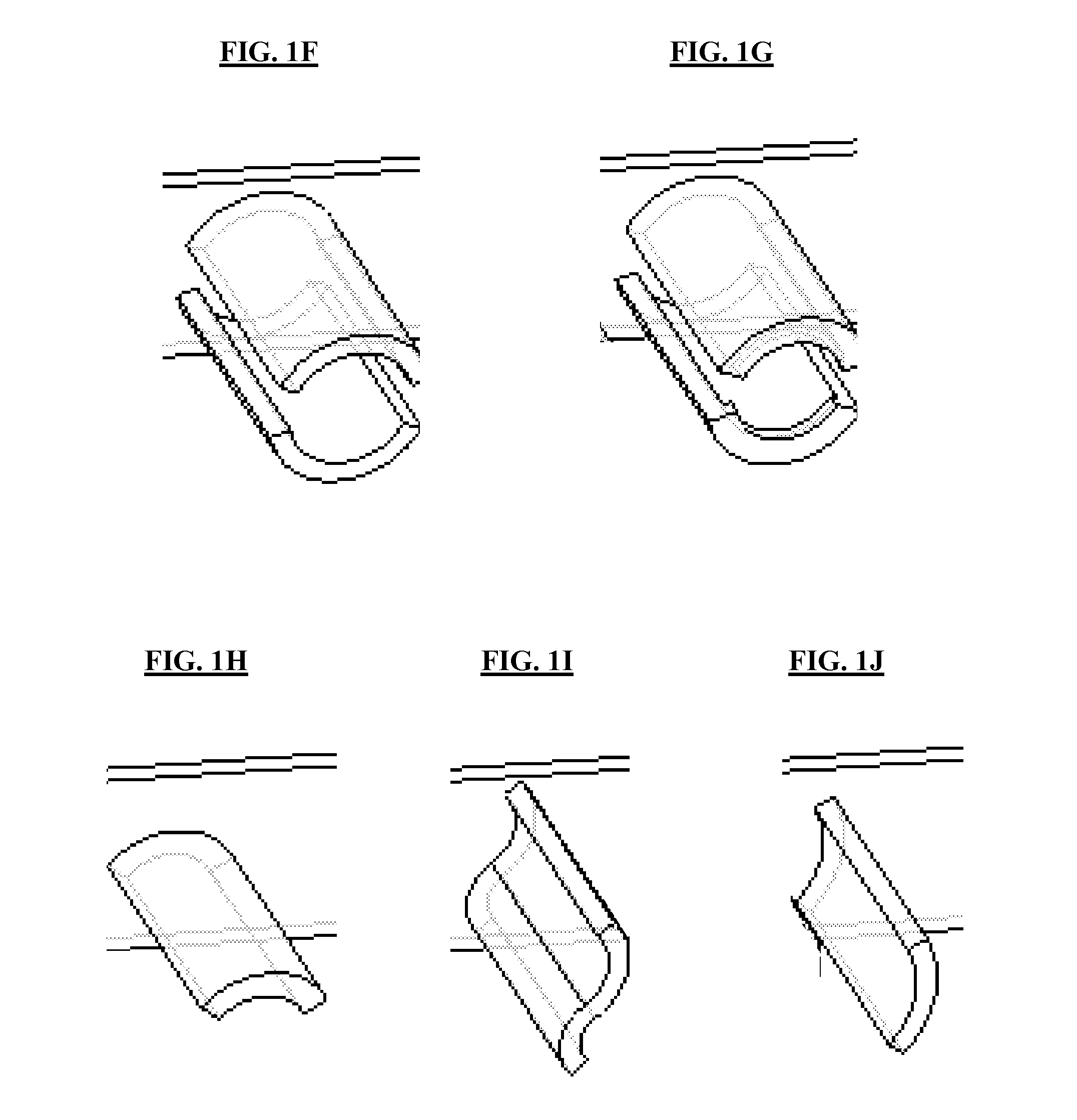

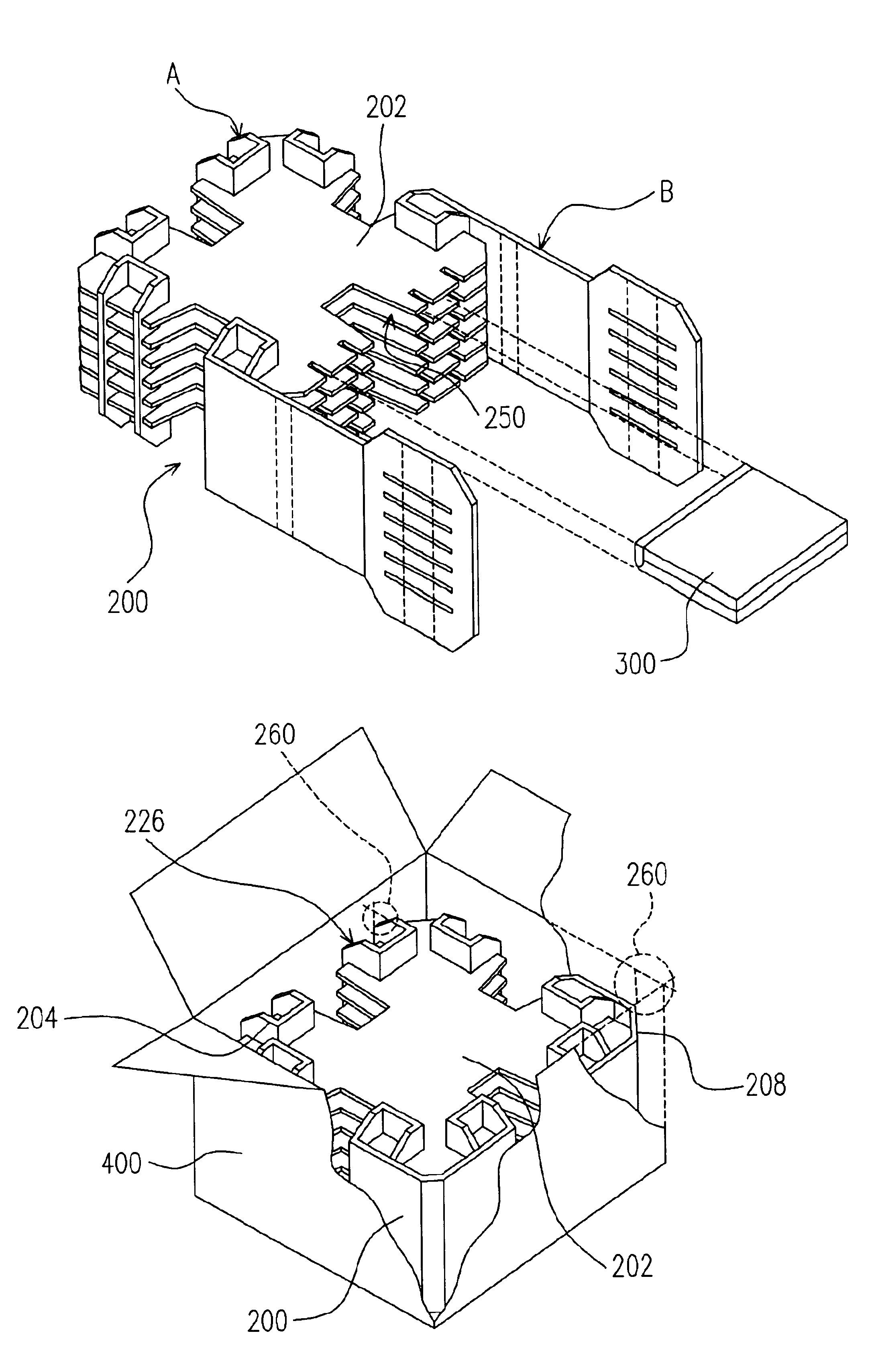

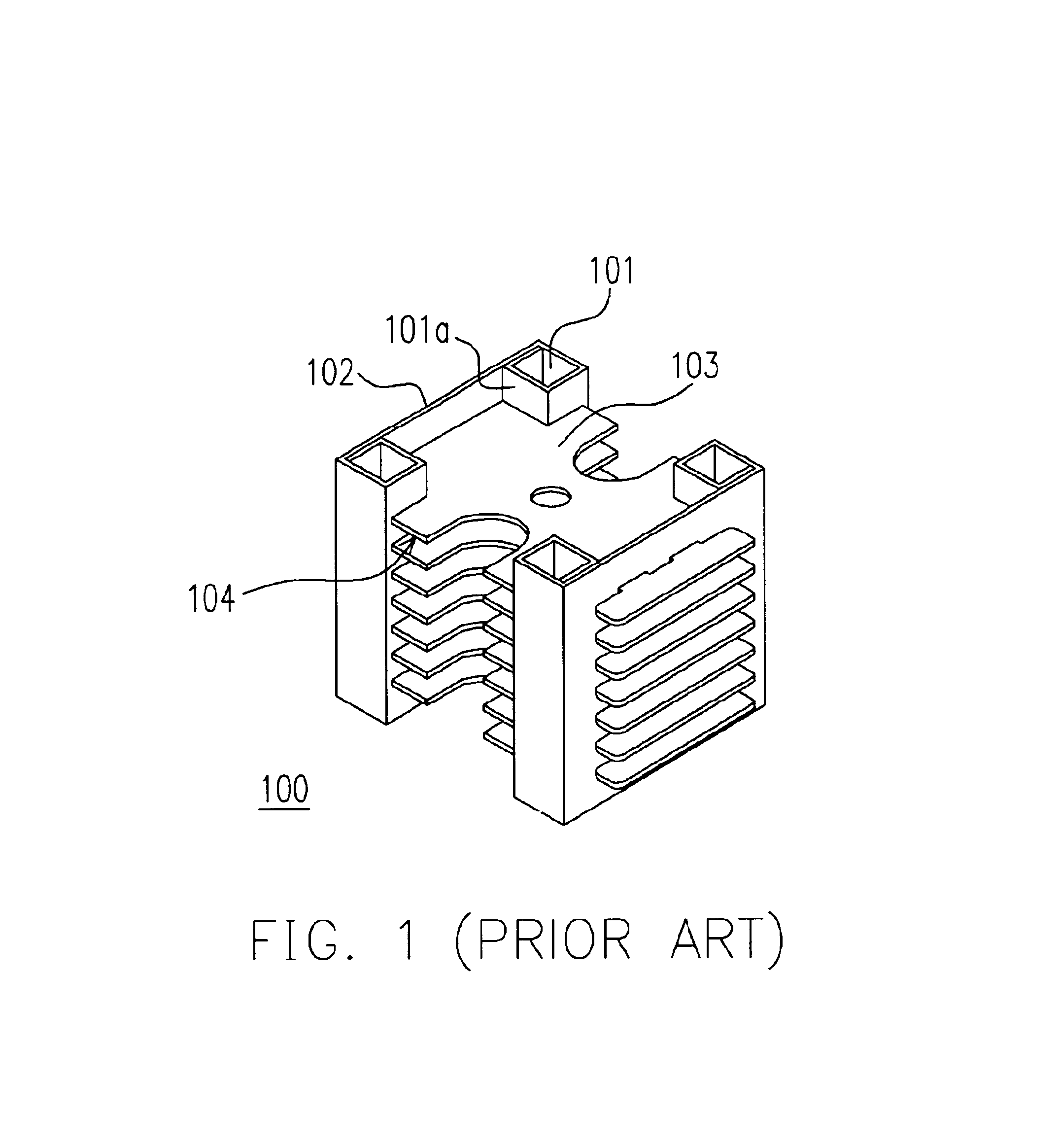

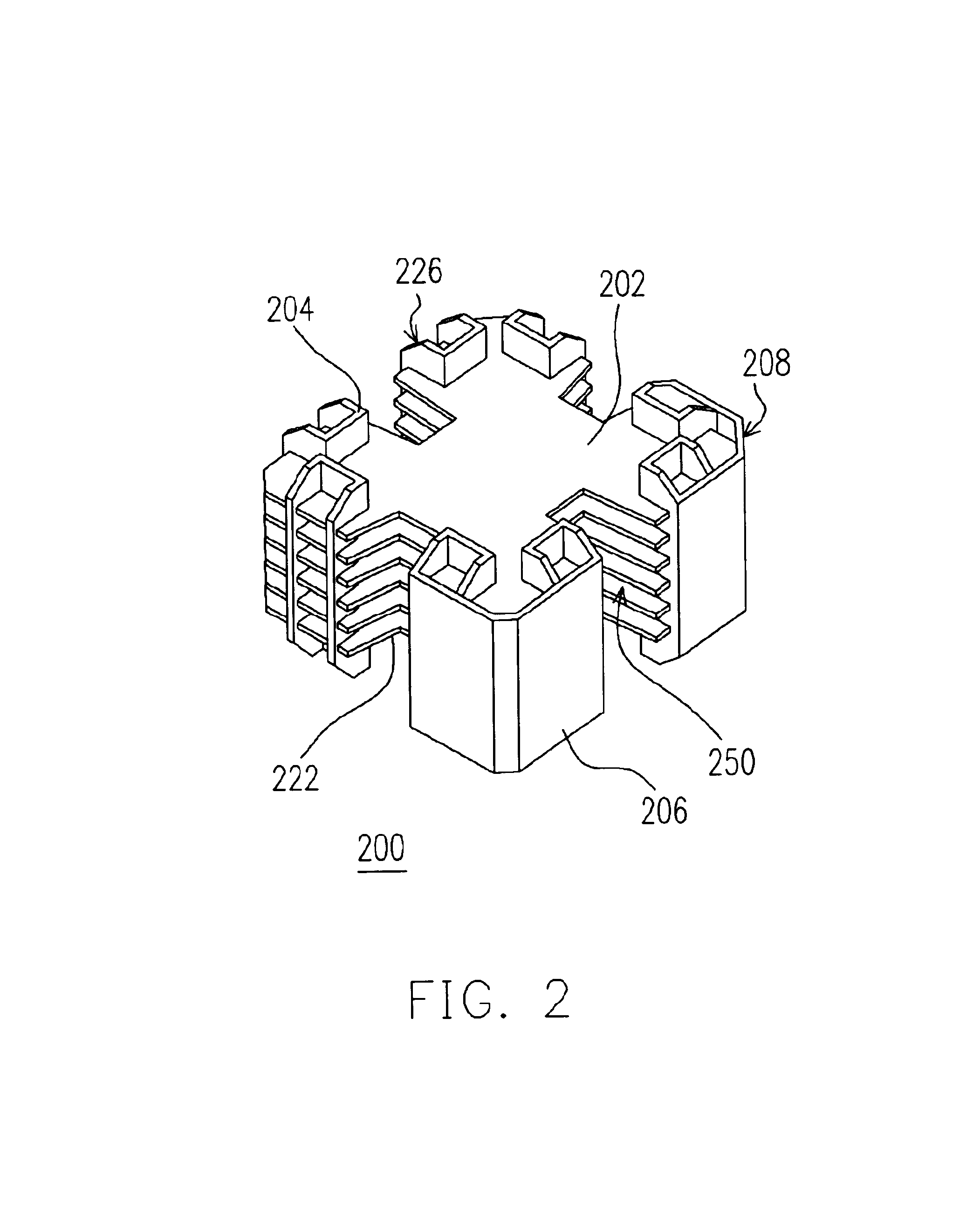

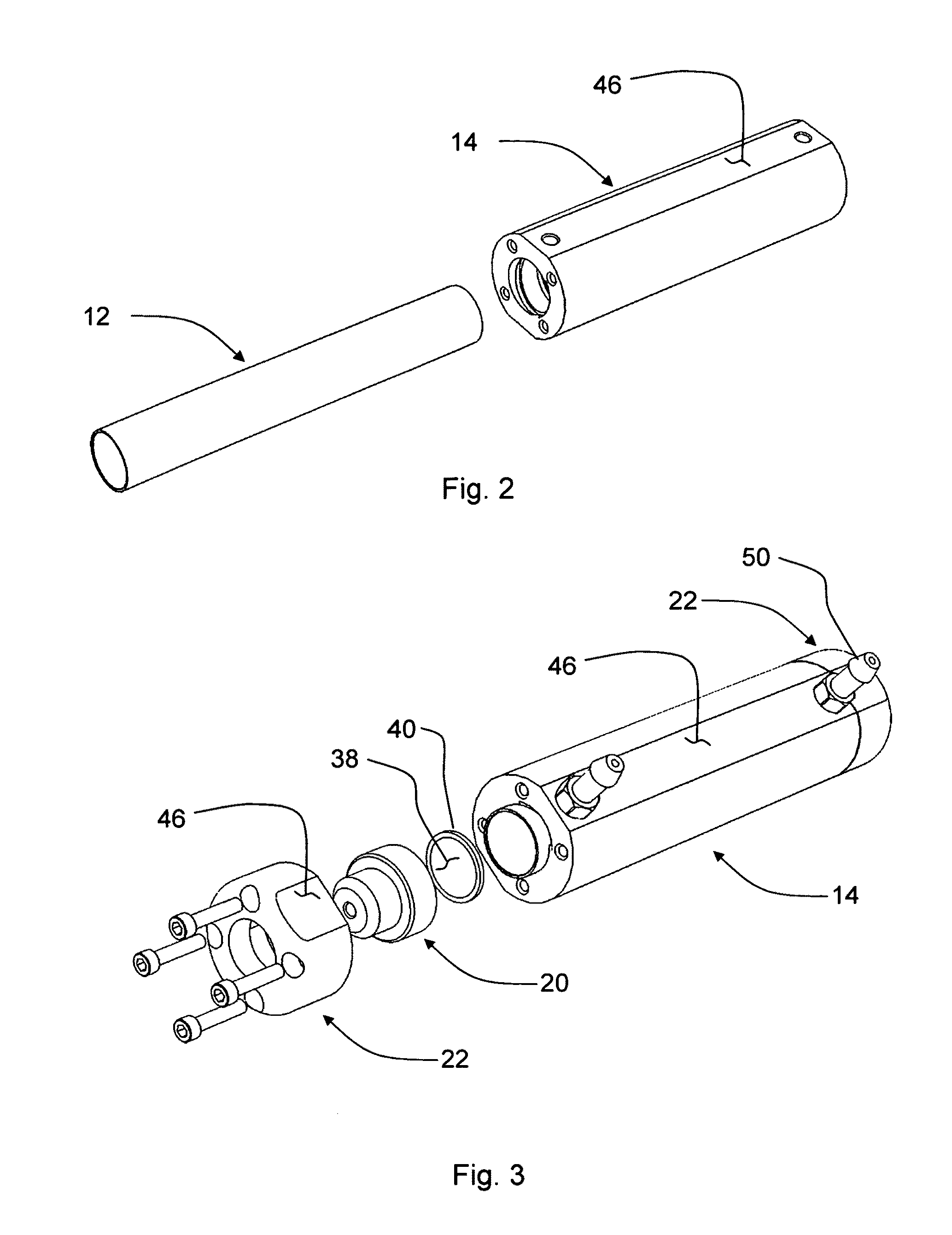

Portable gas fractionalization system

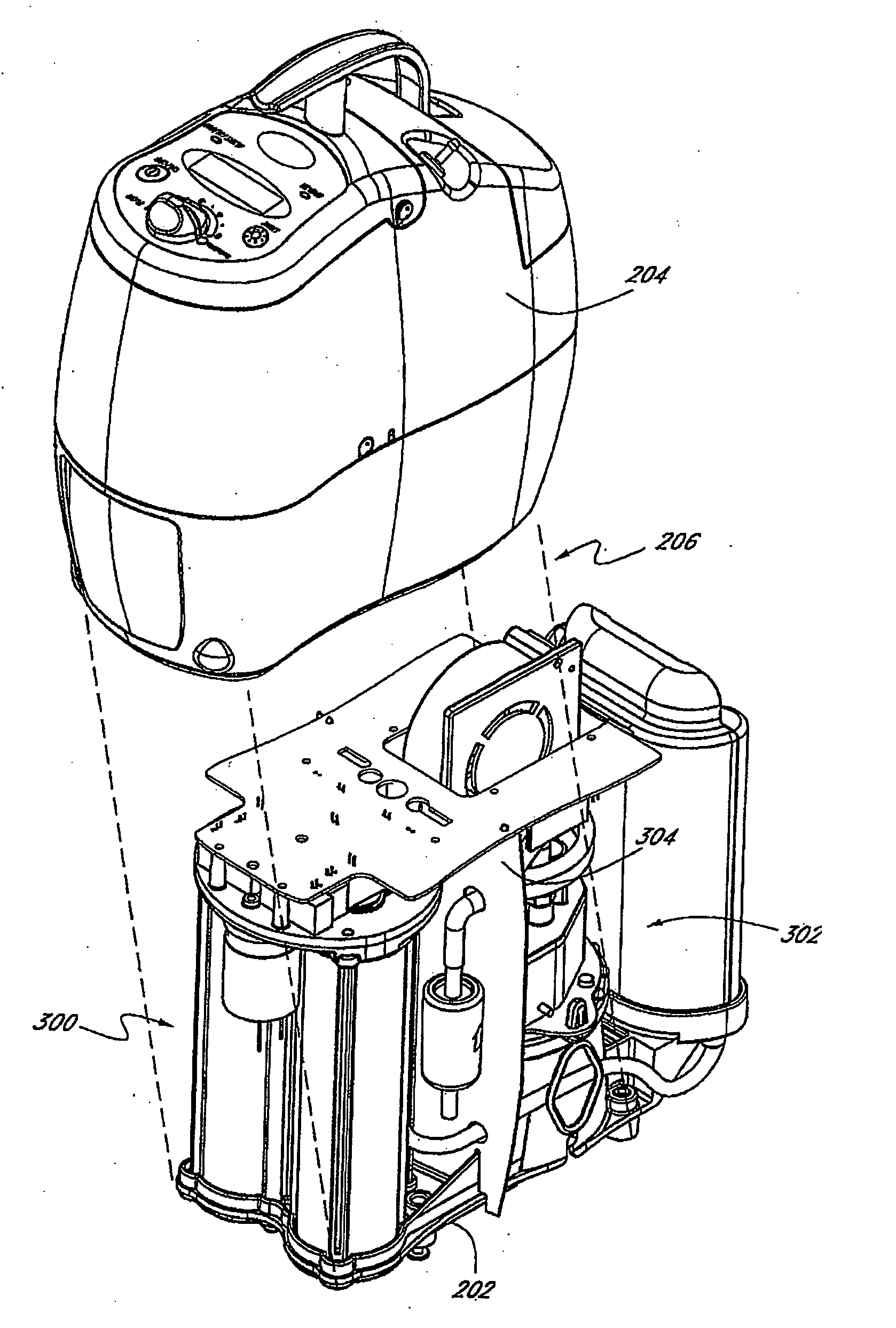

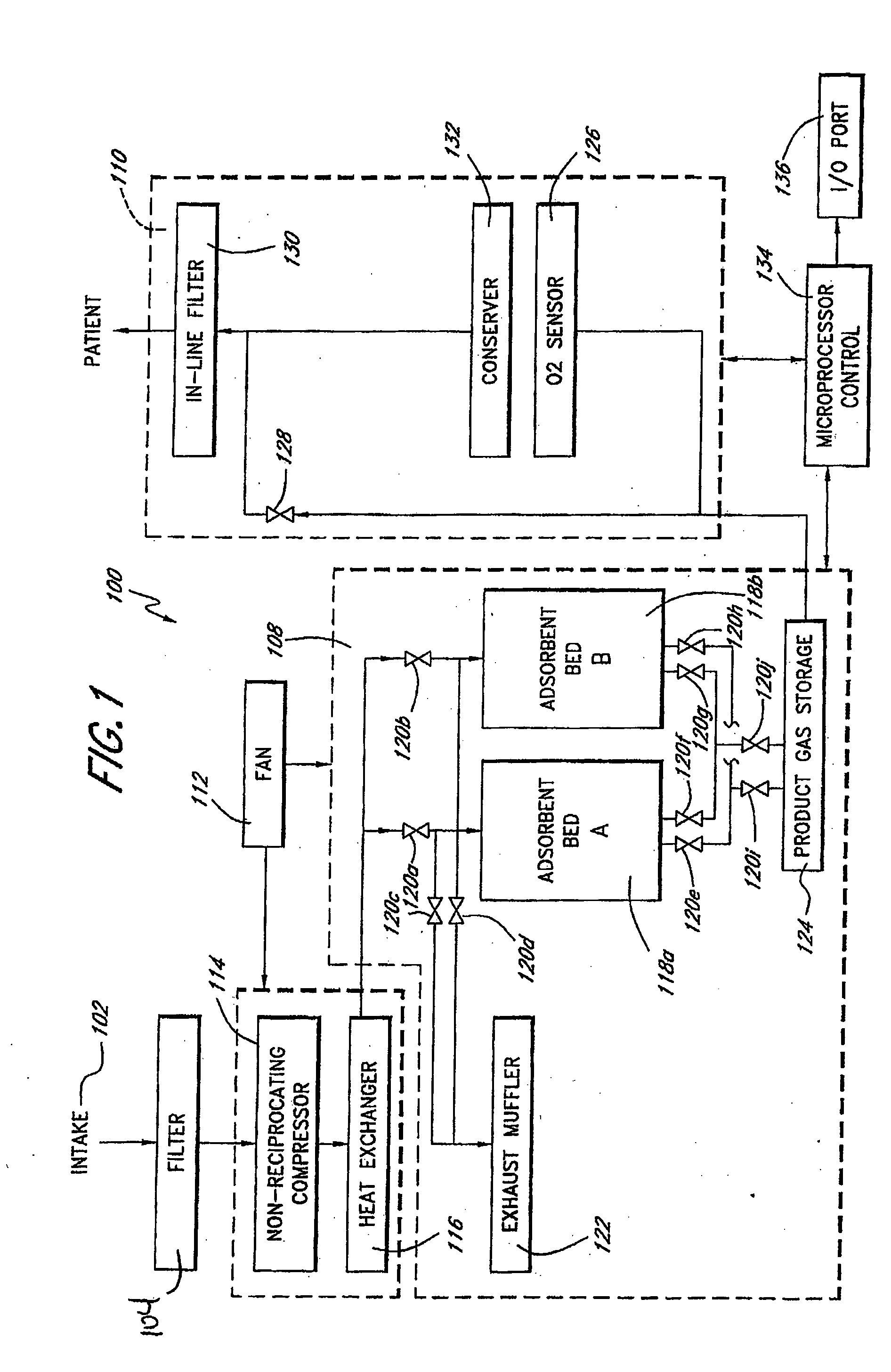

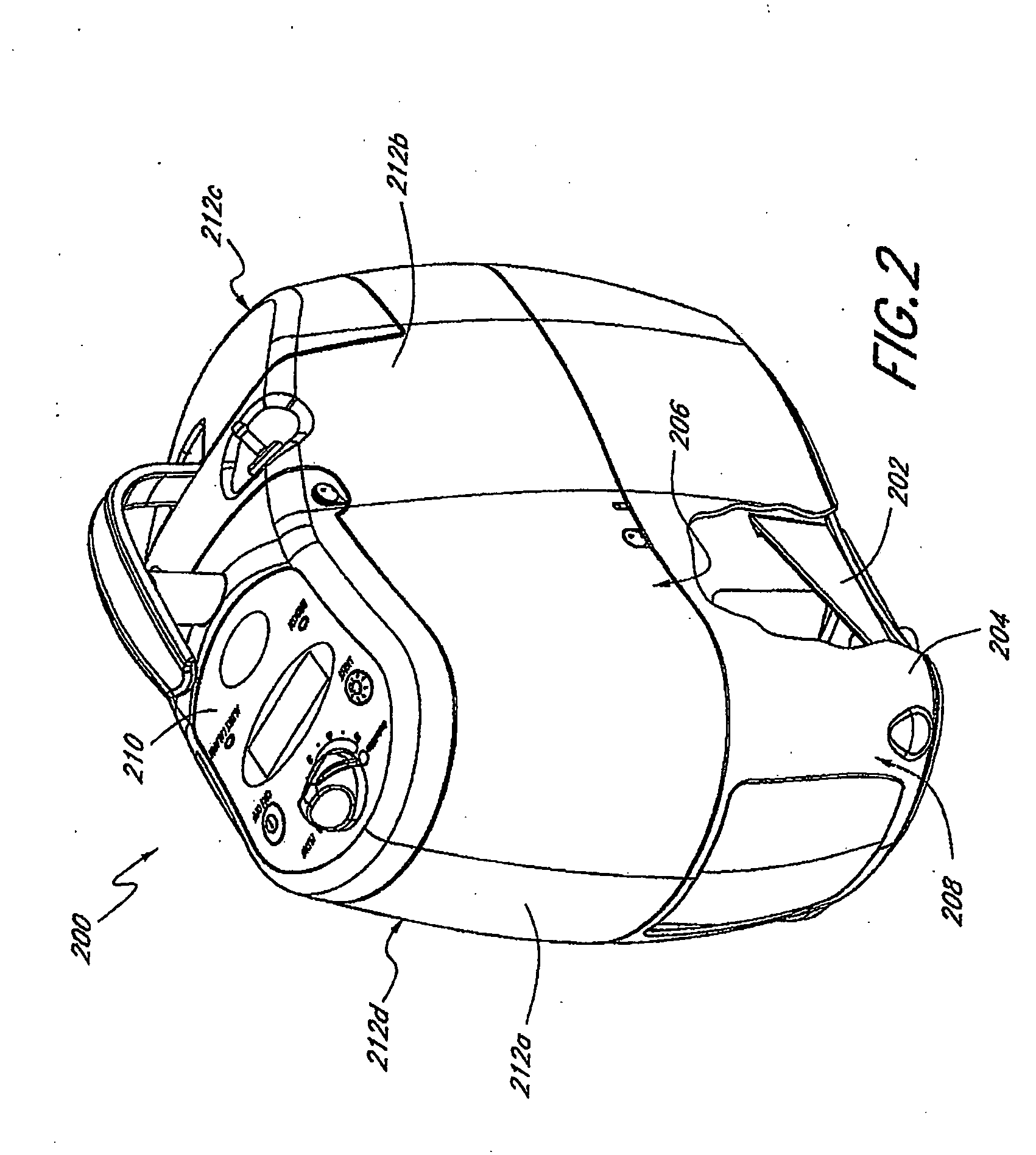

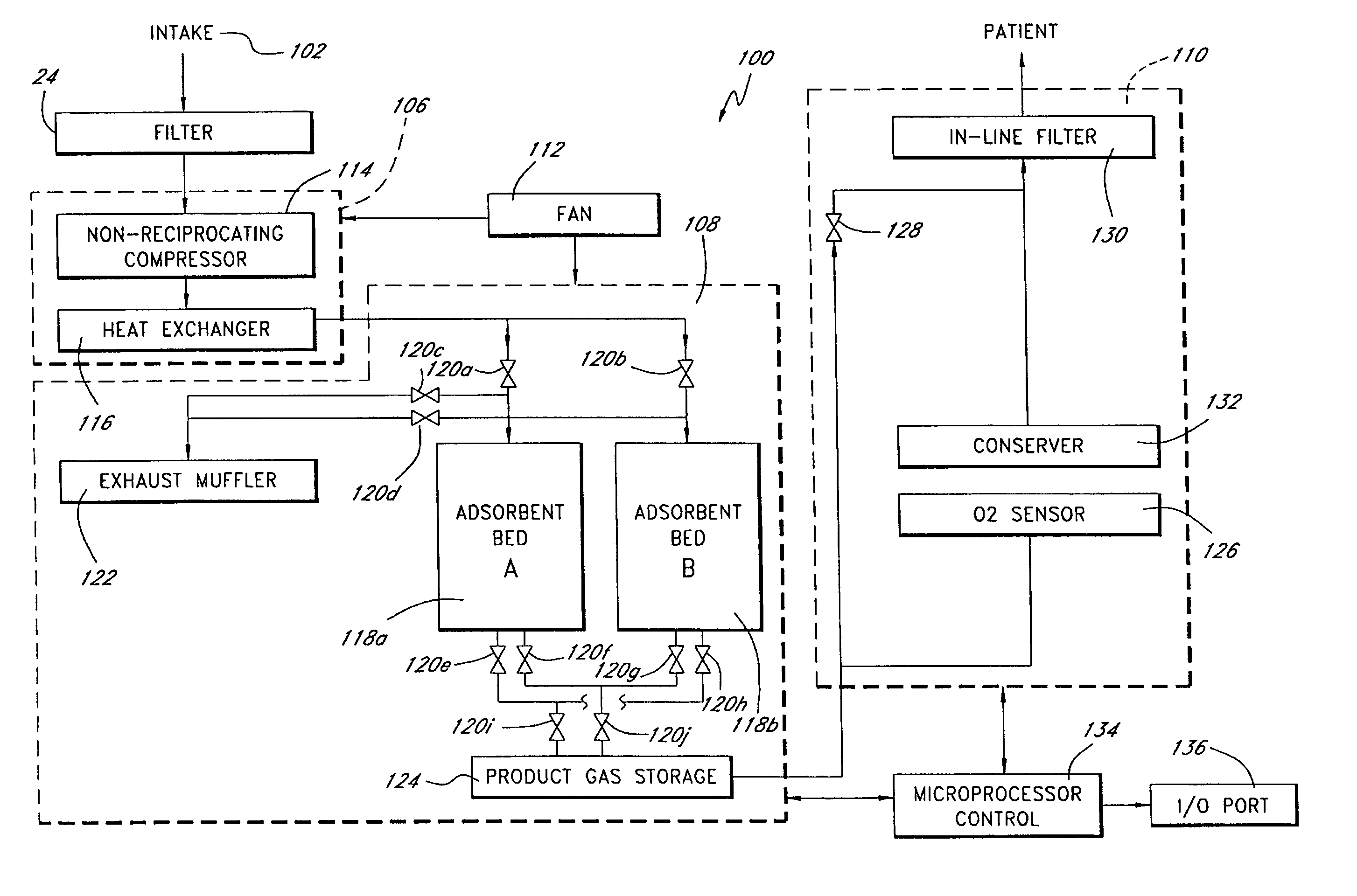

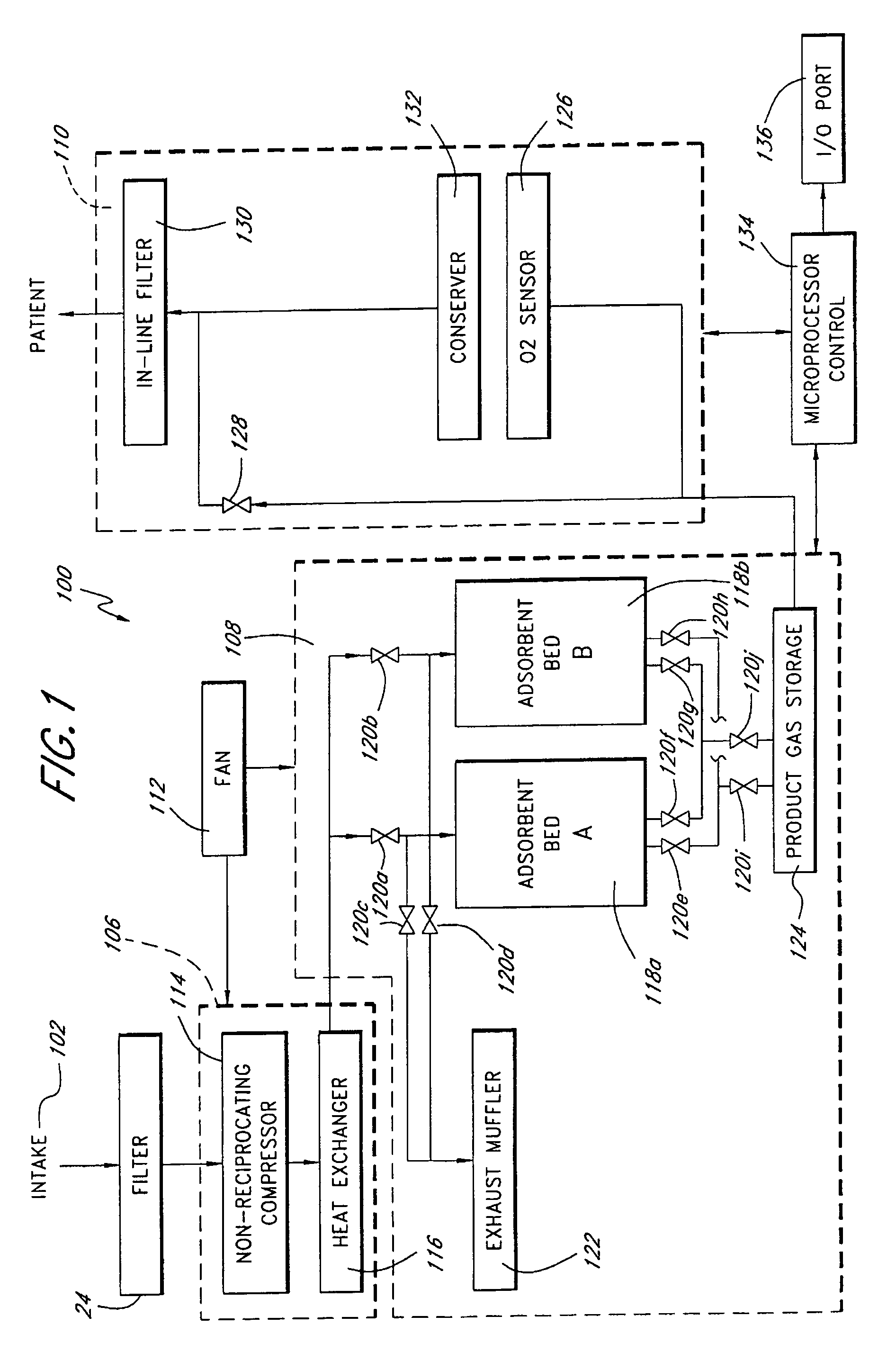

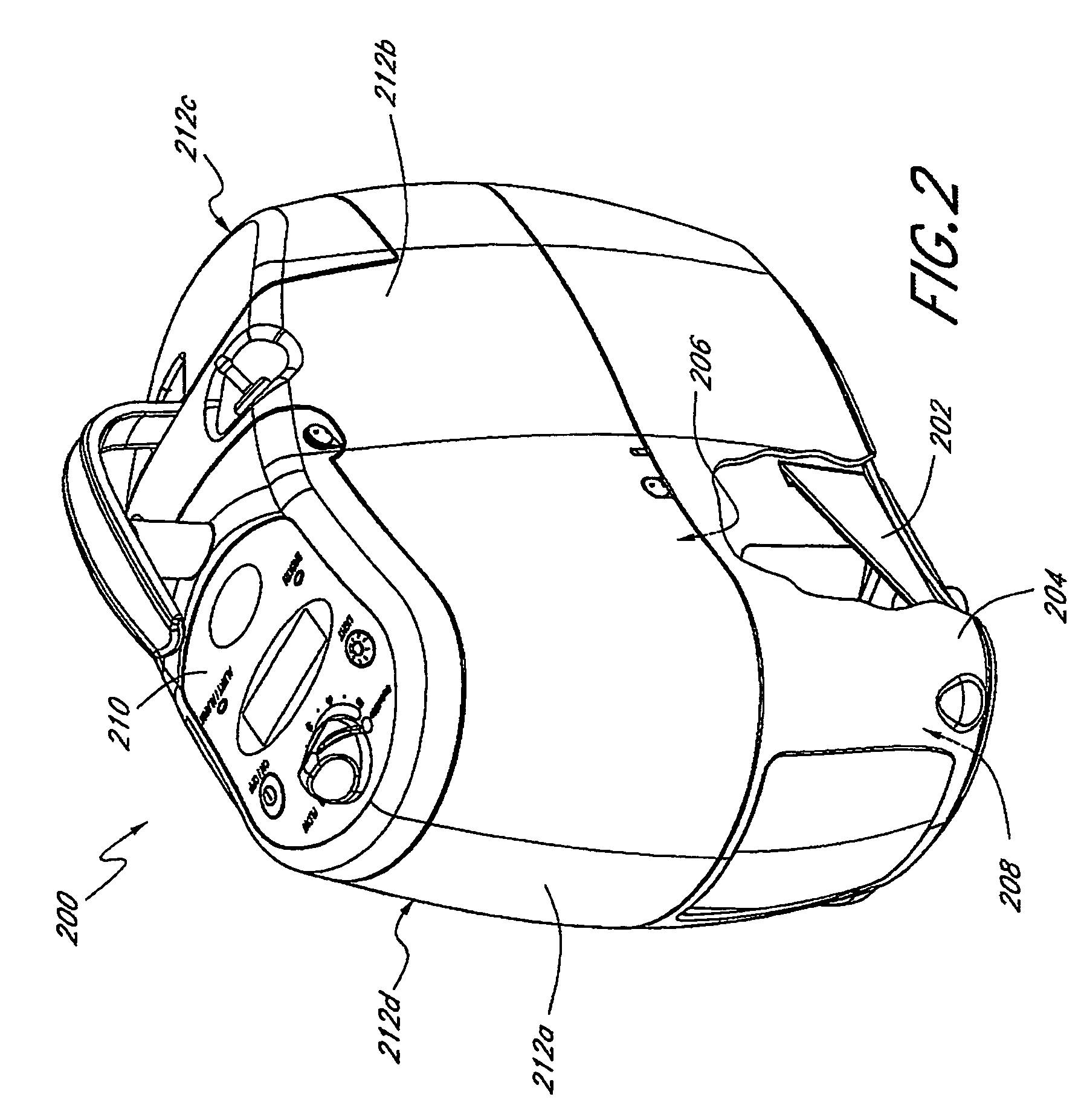

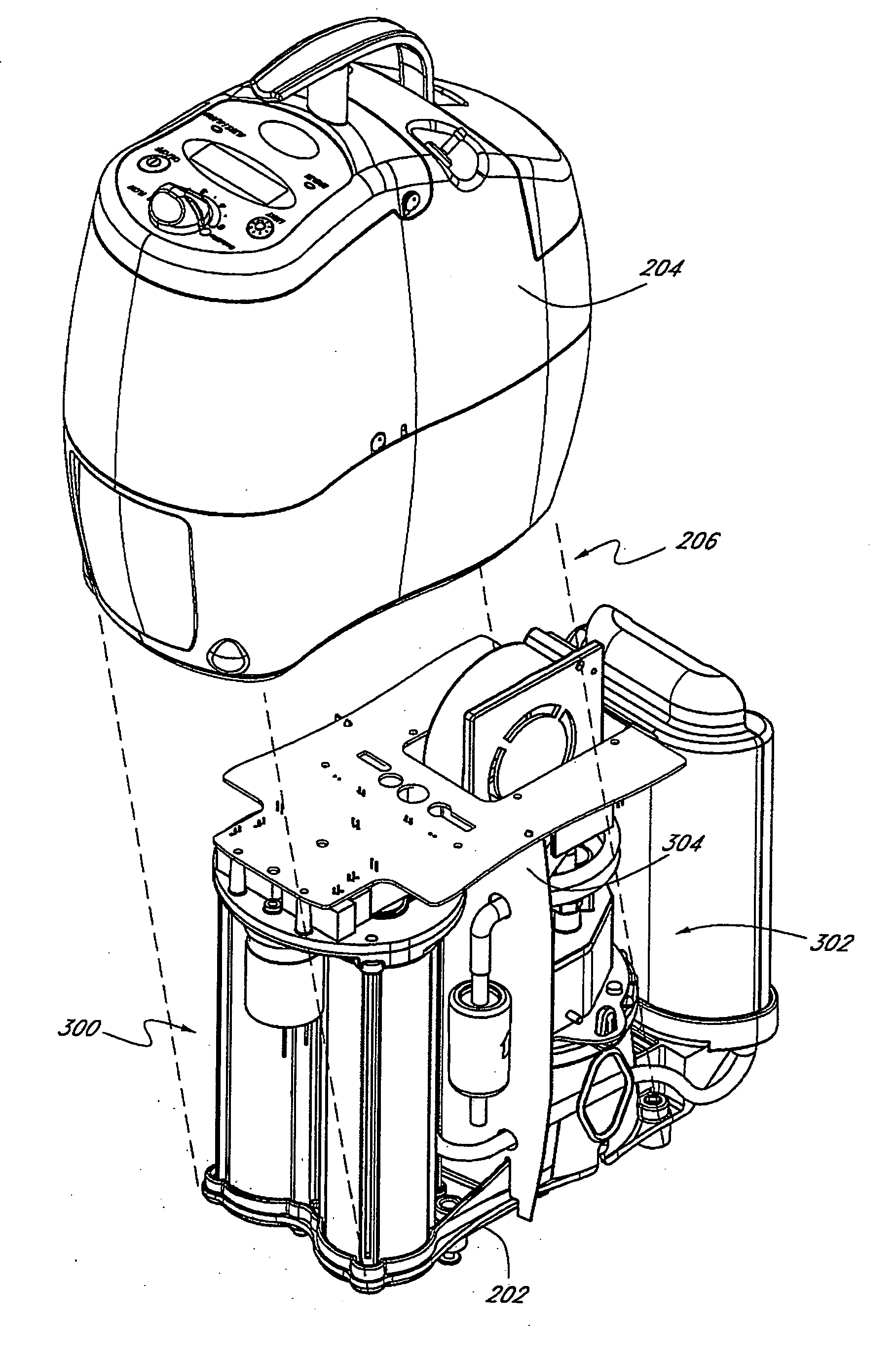

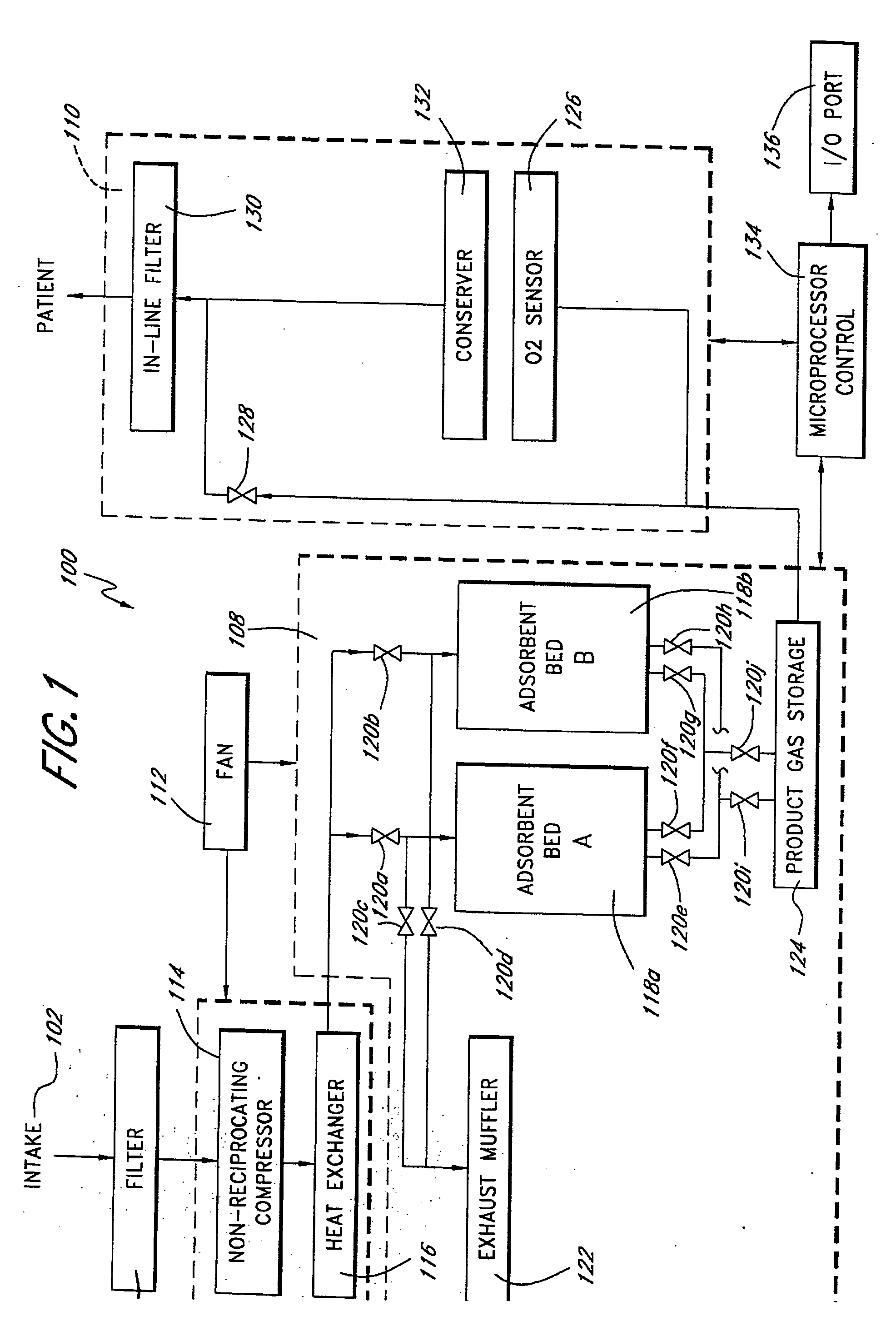

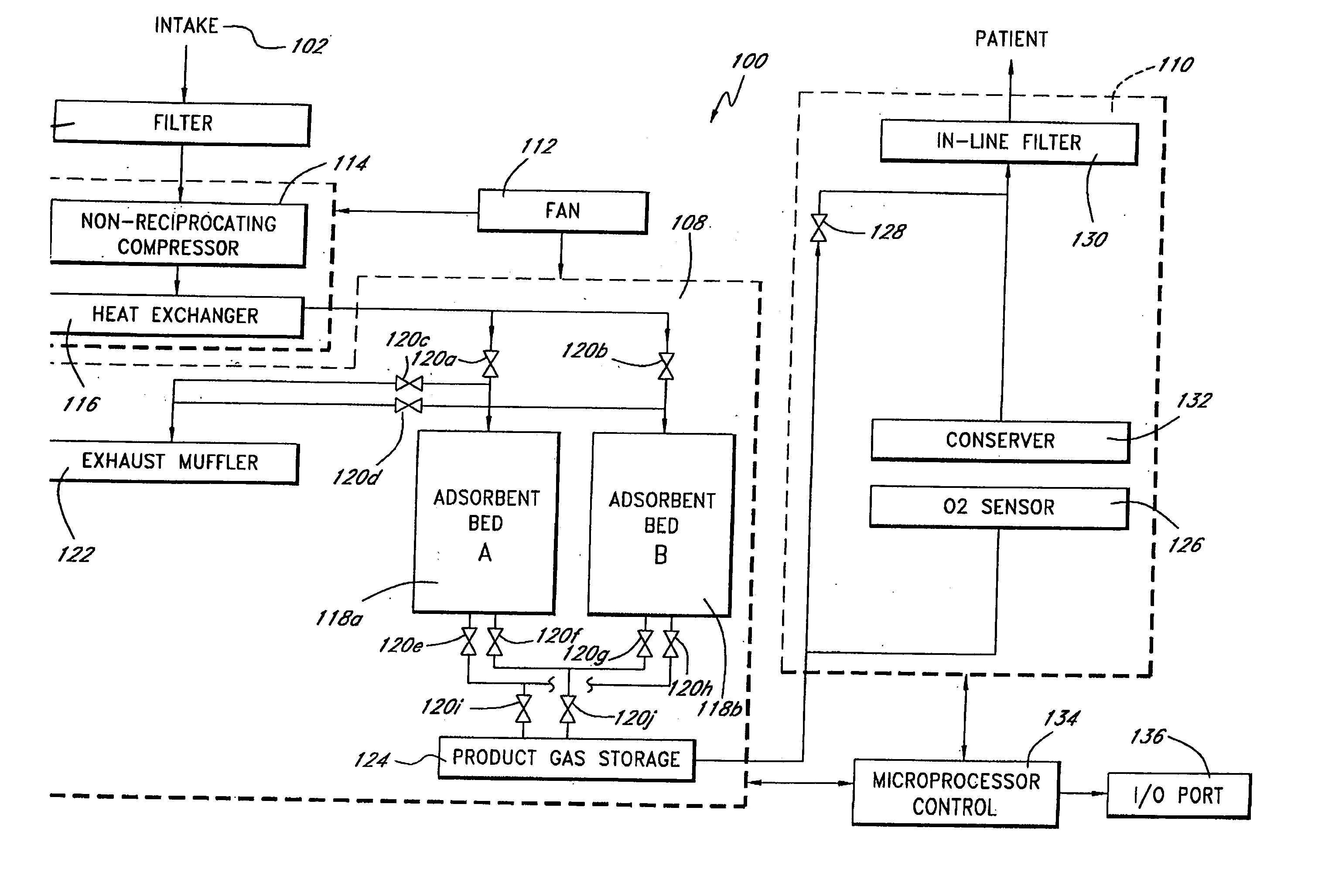

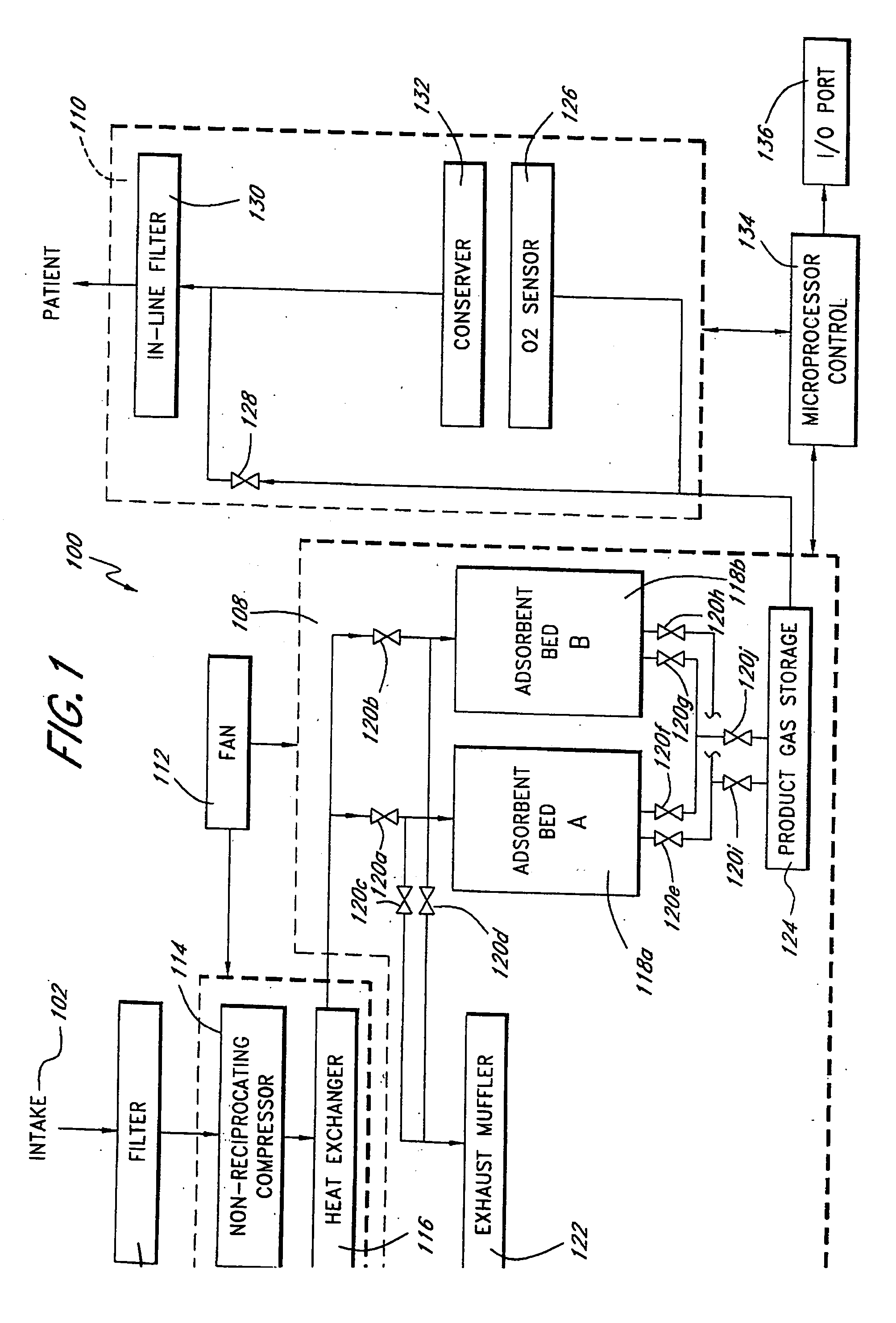

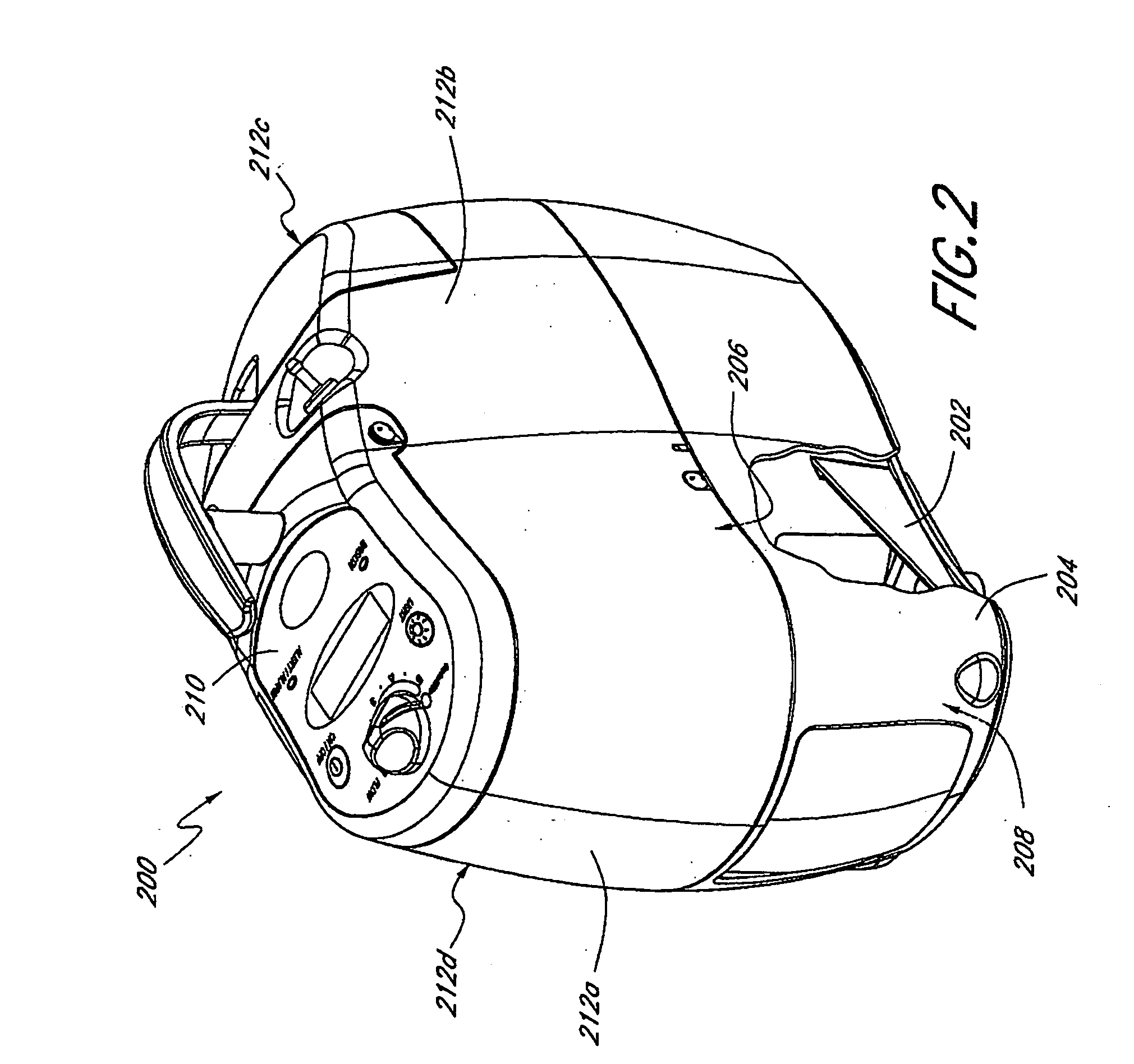

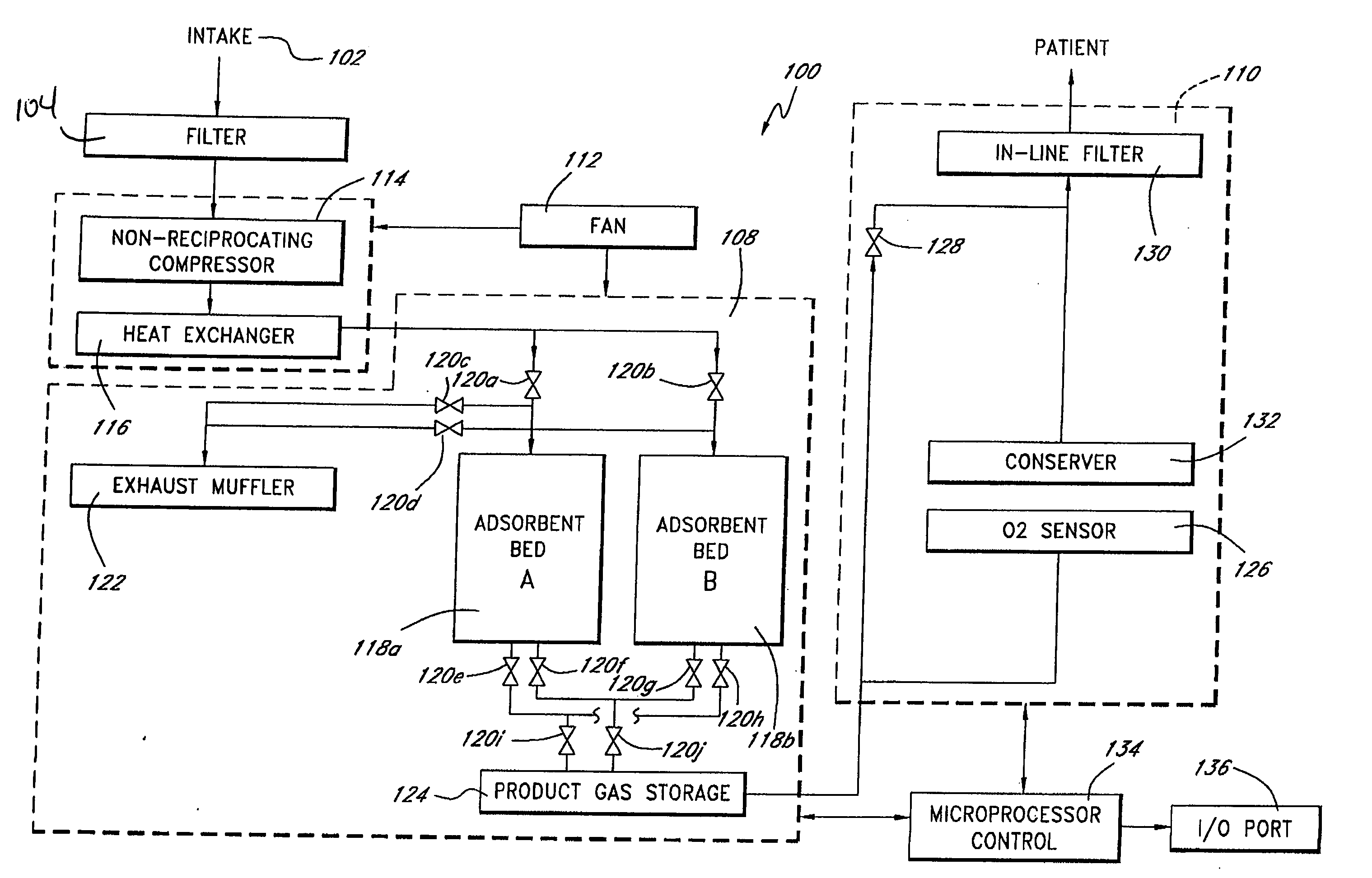

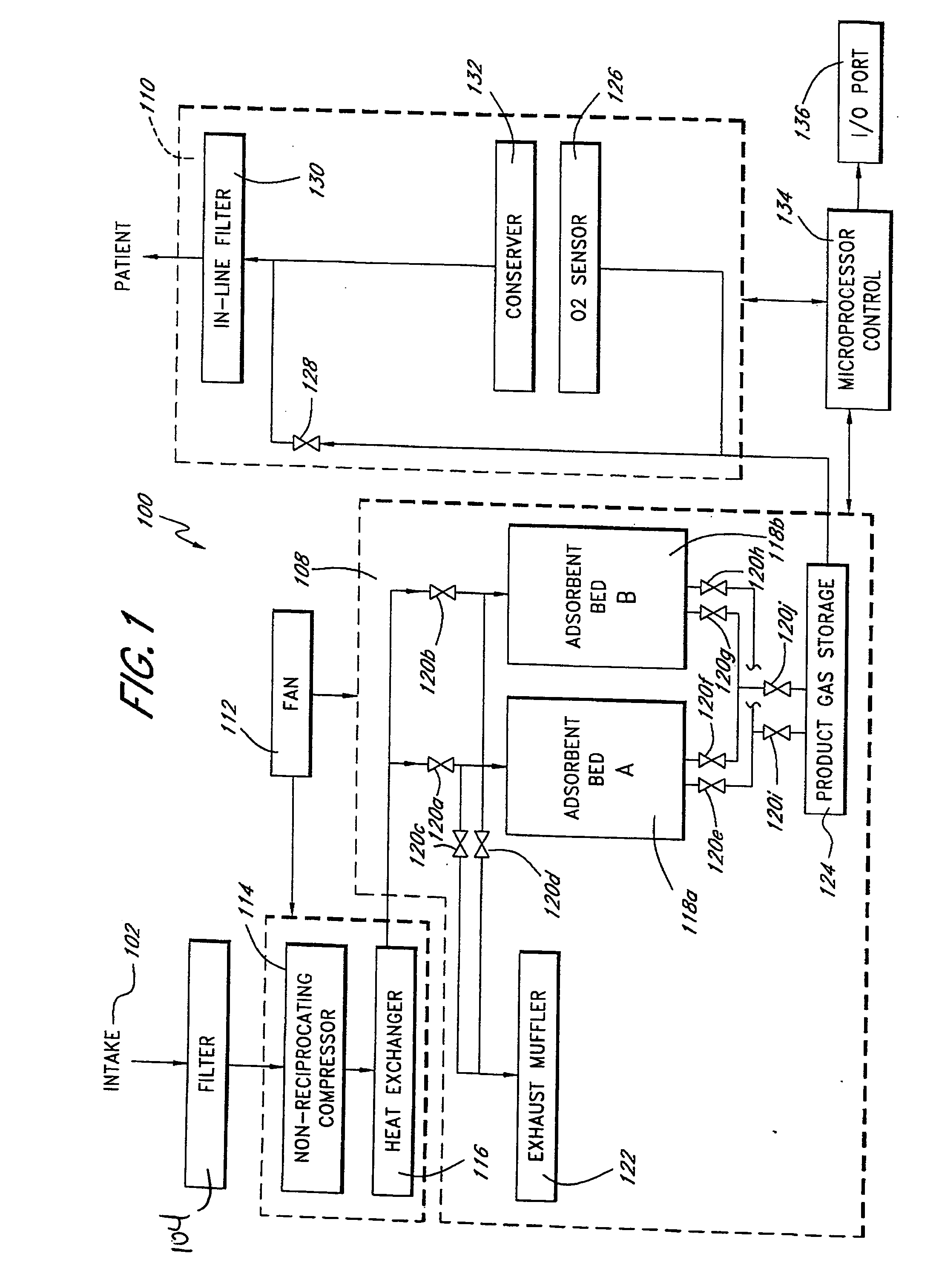

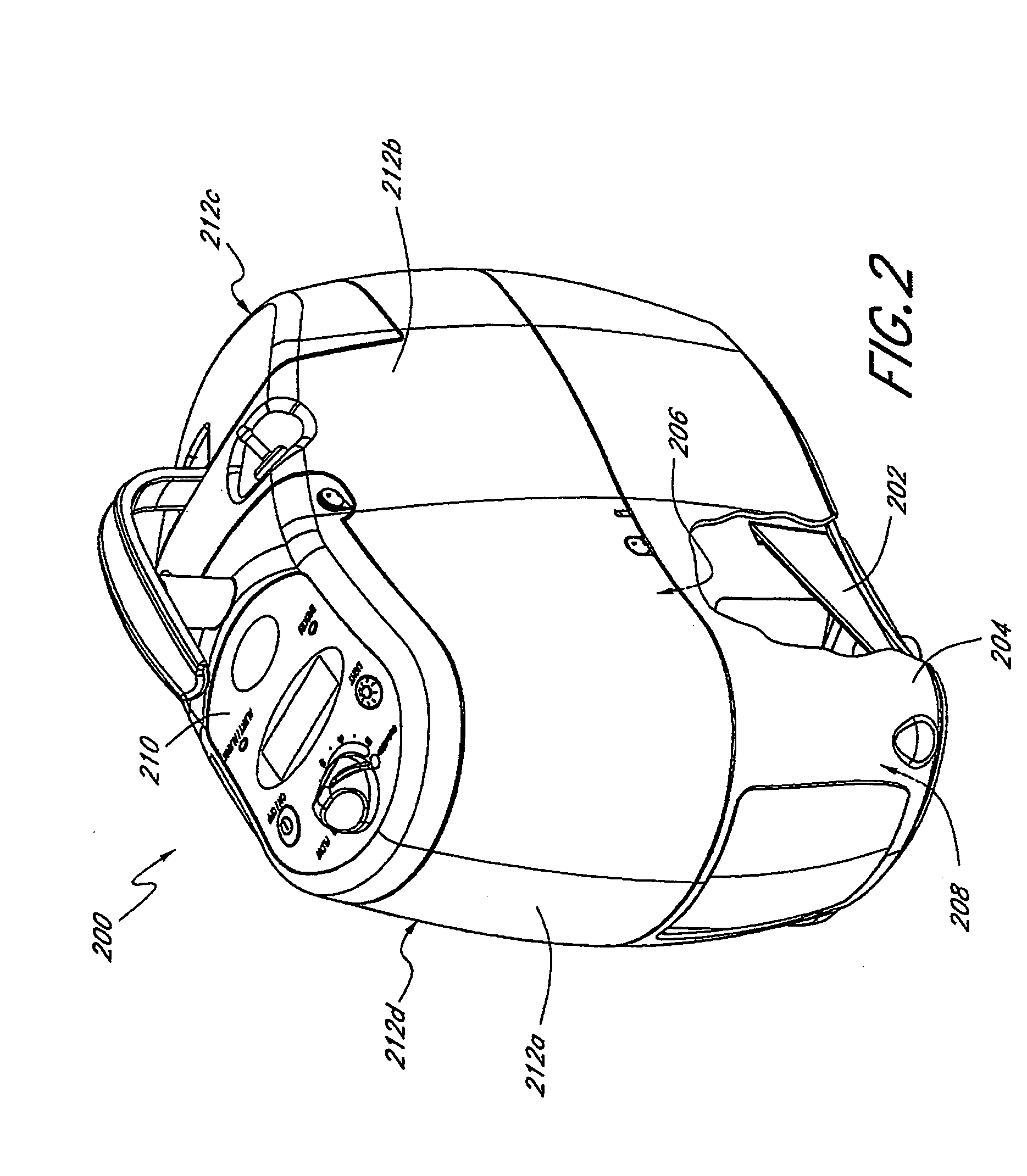

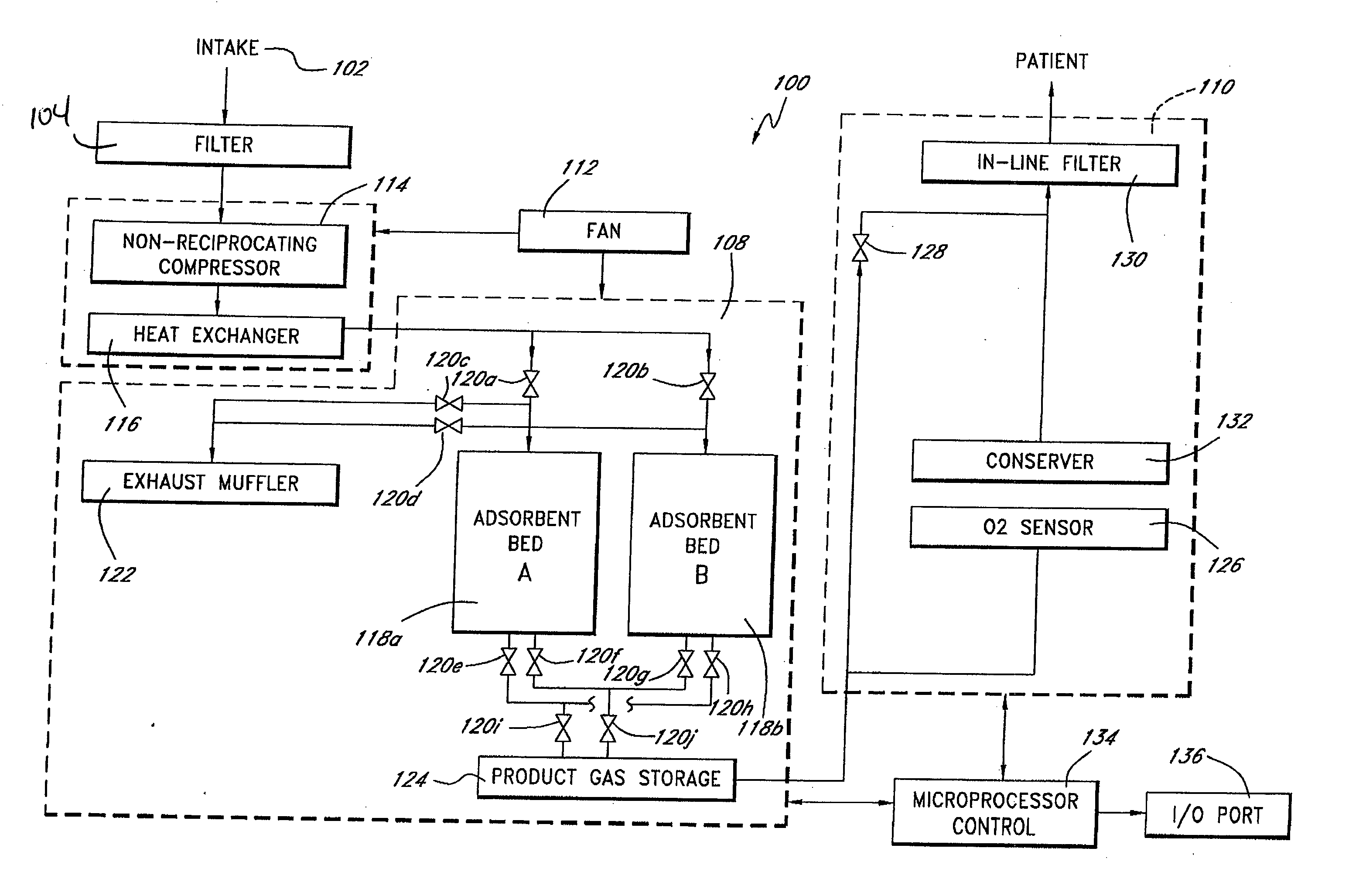

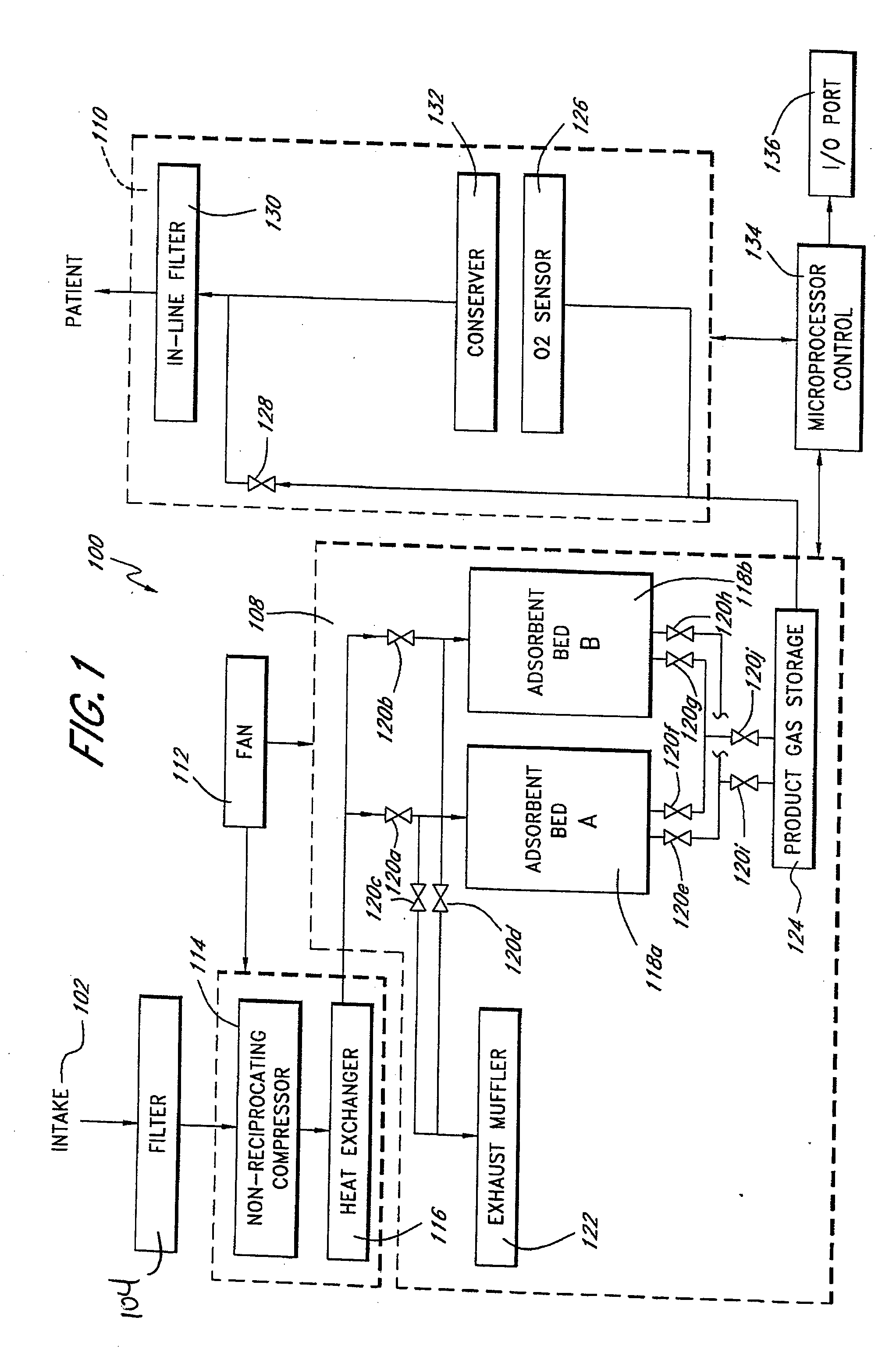

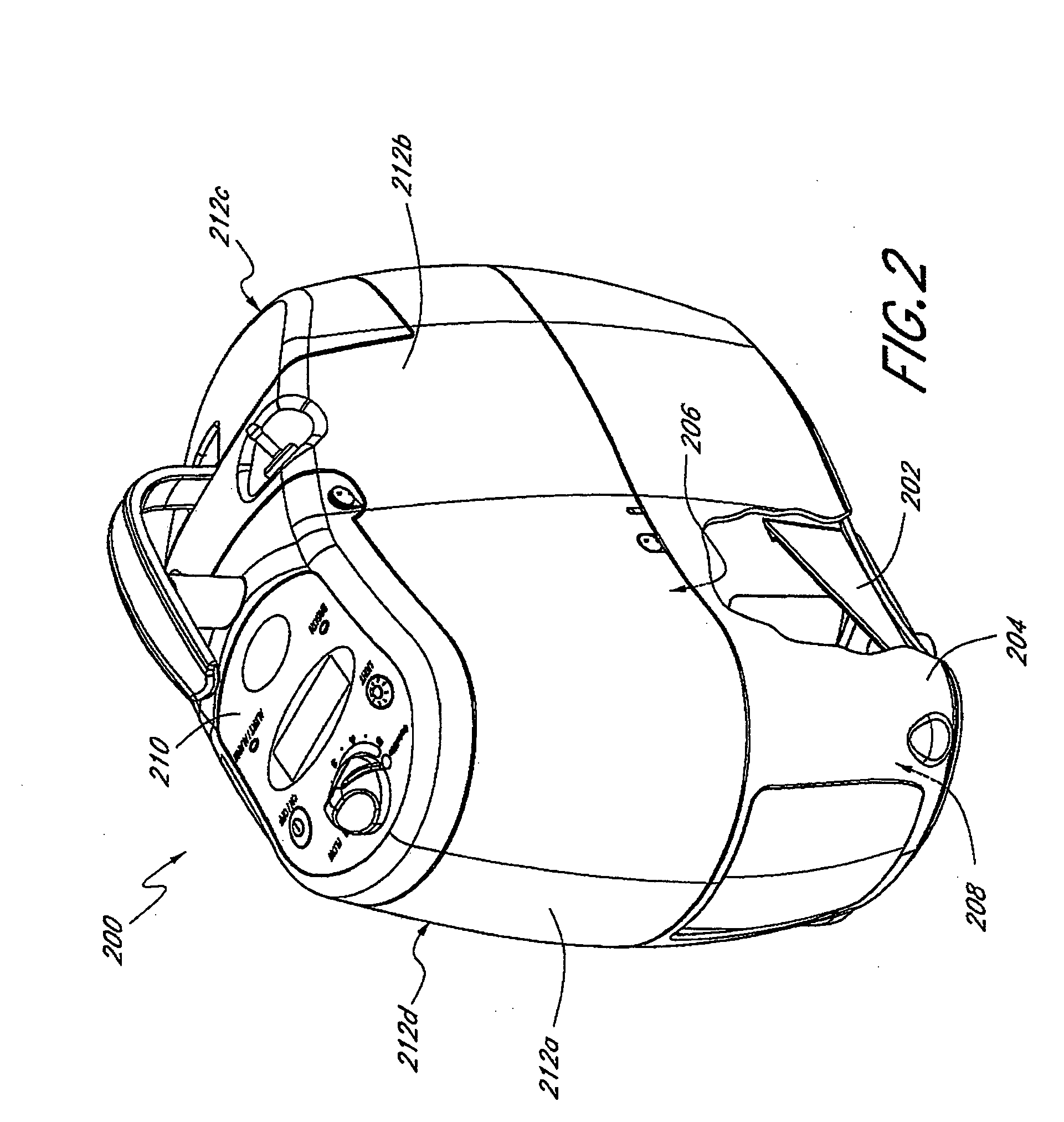

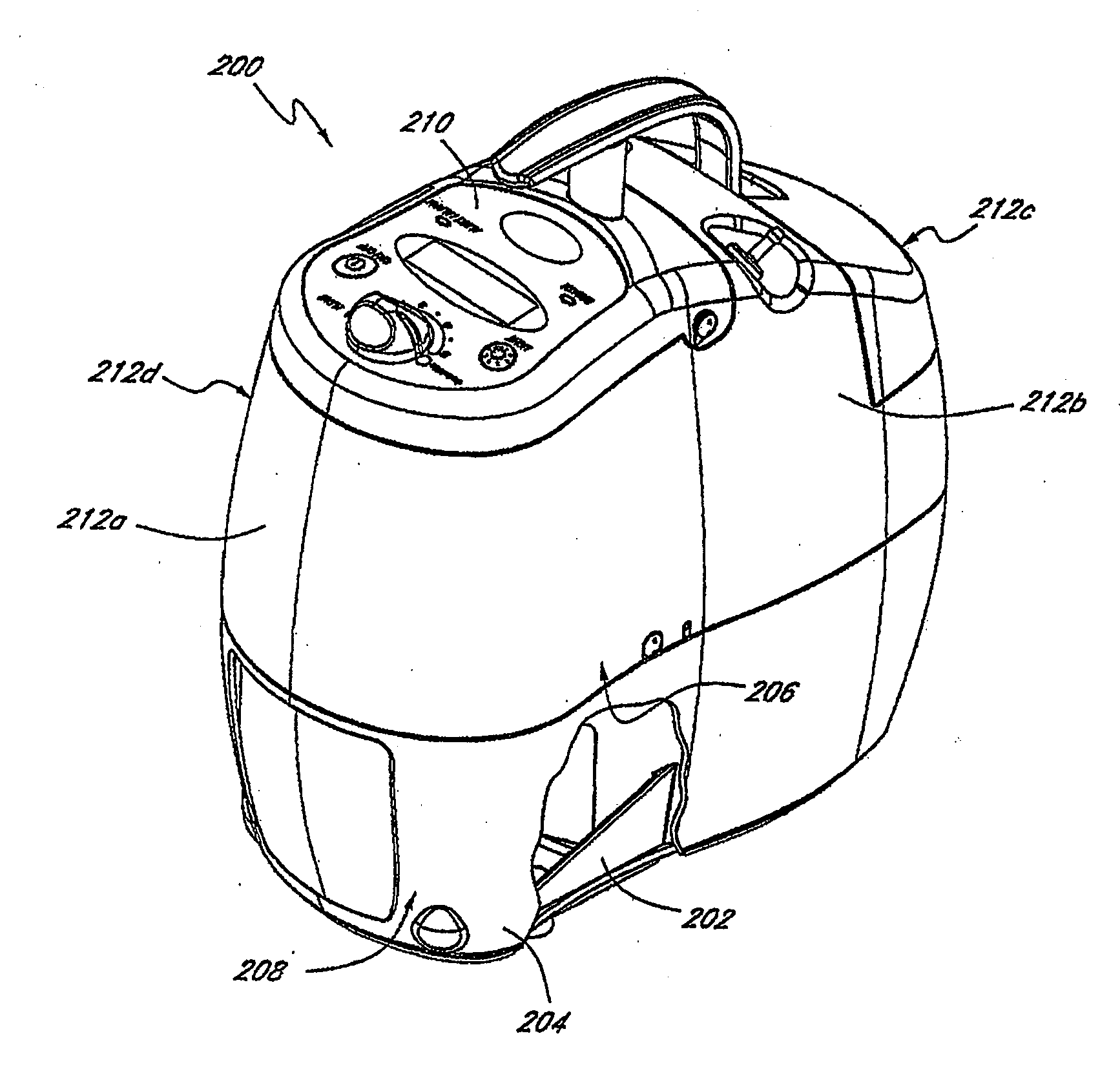

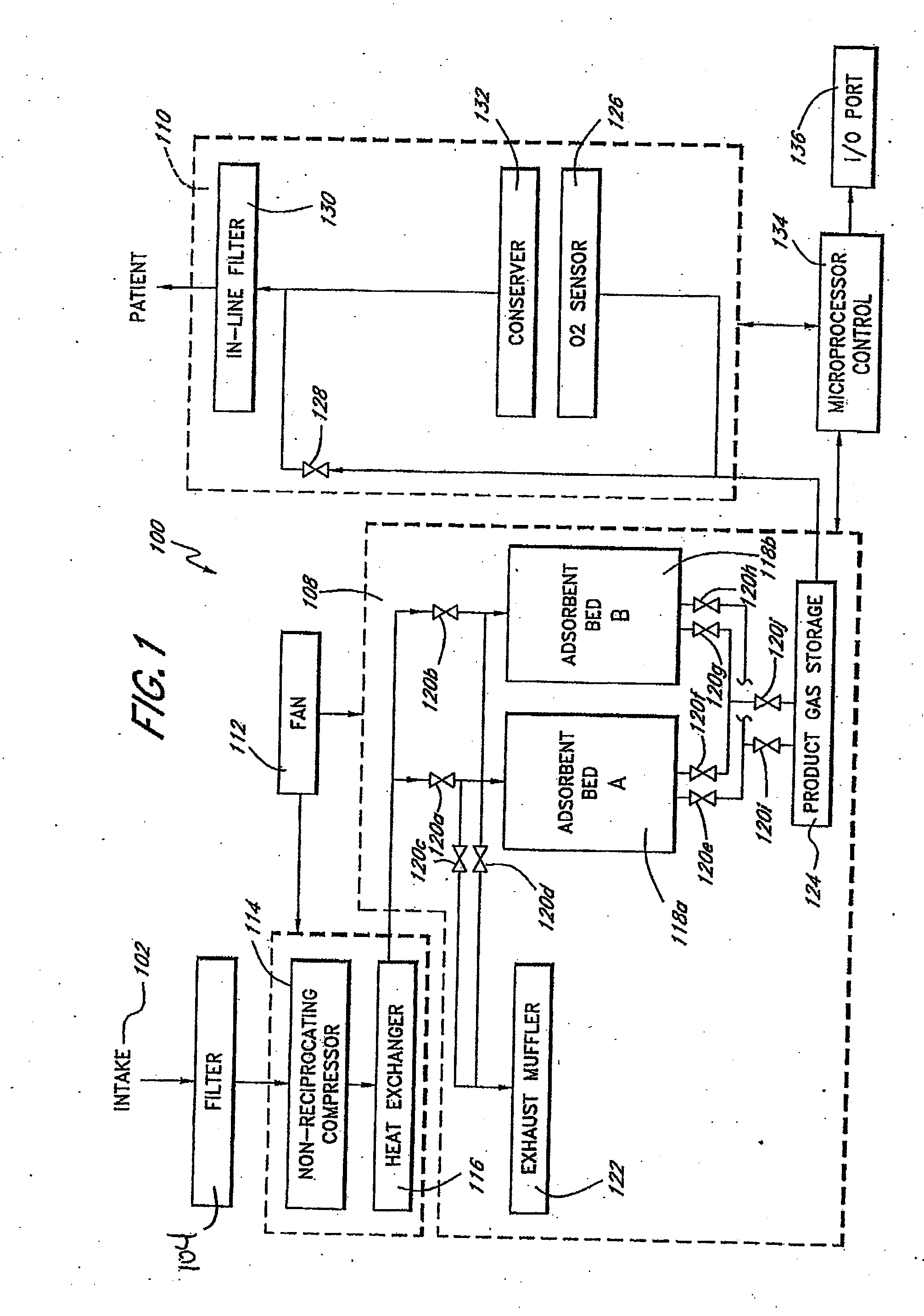

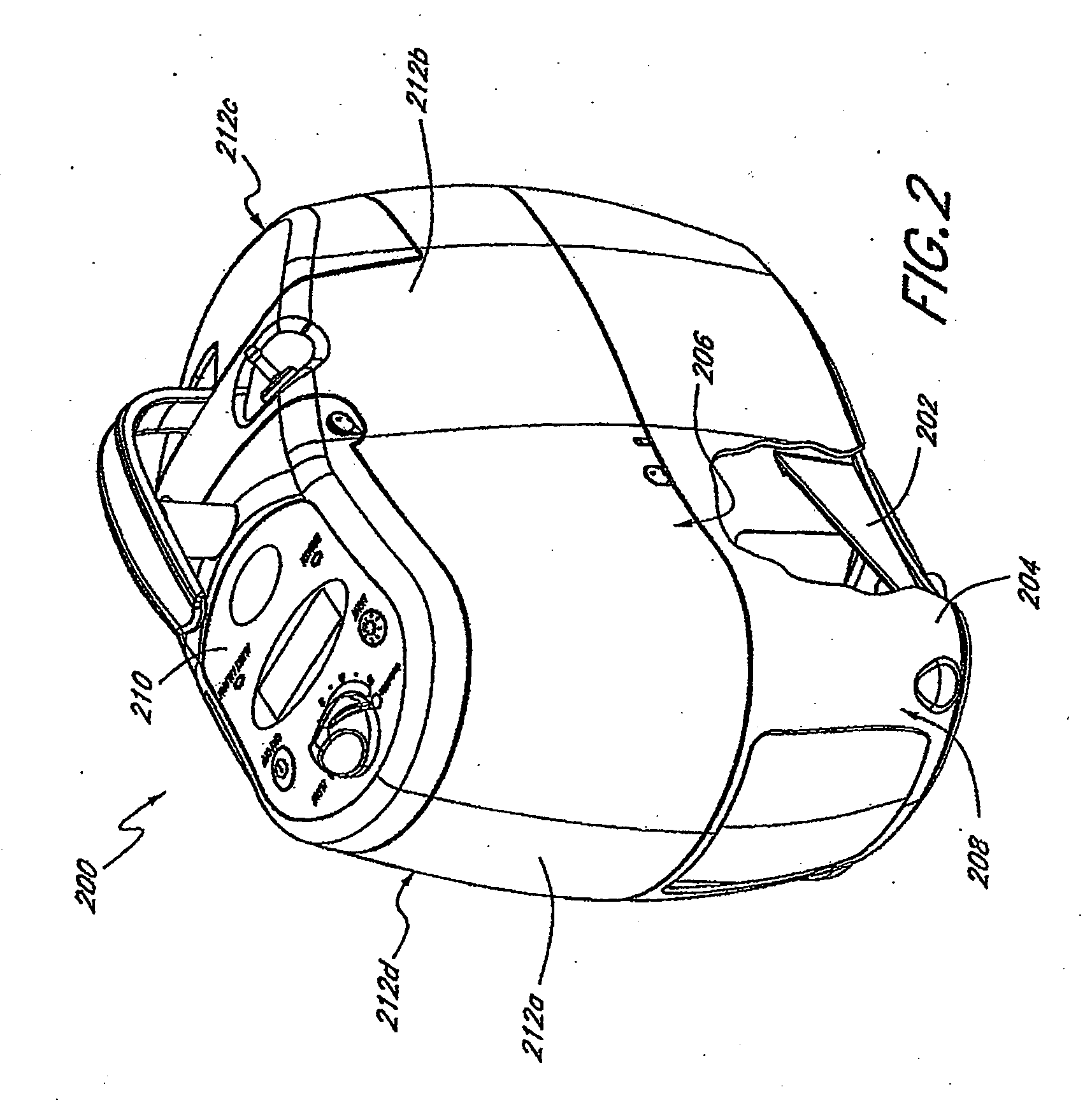

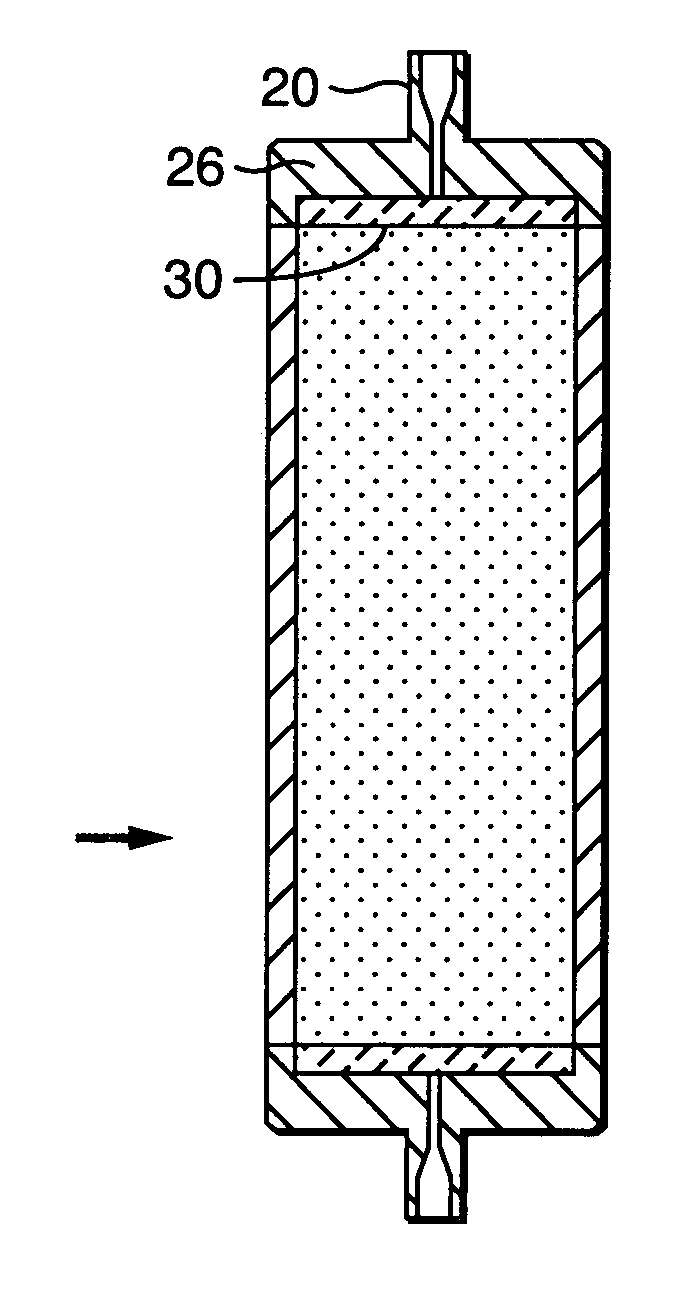

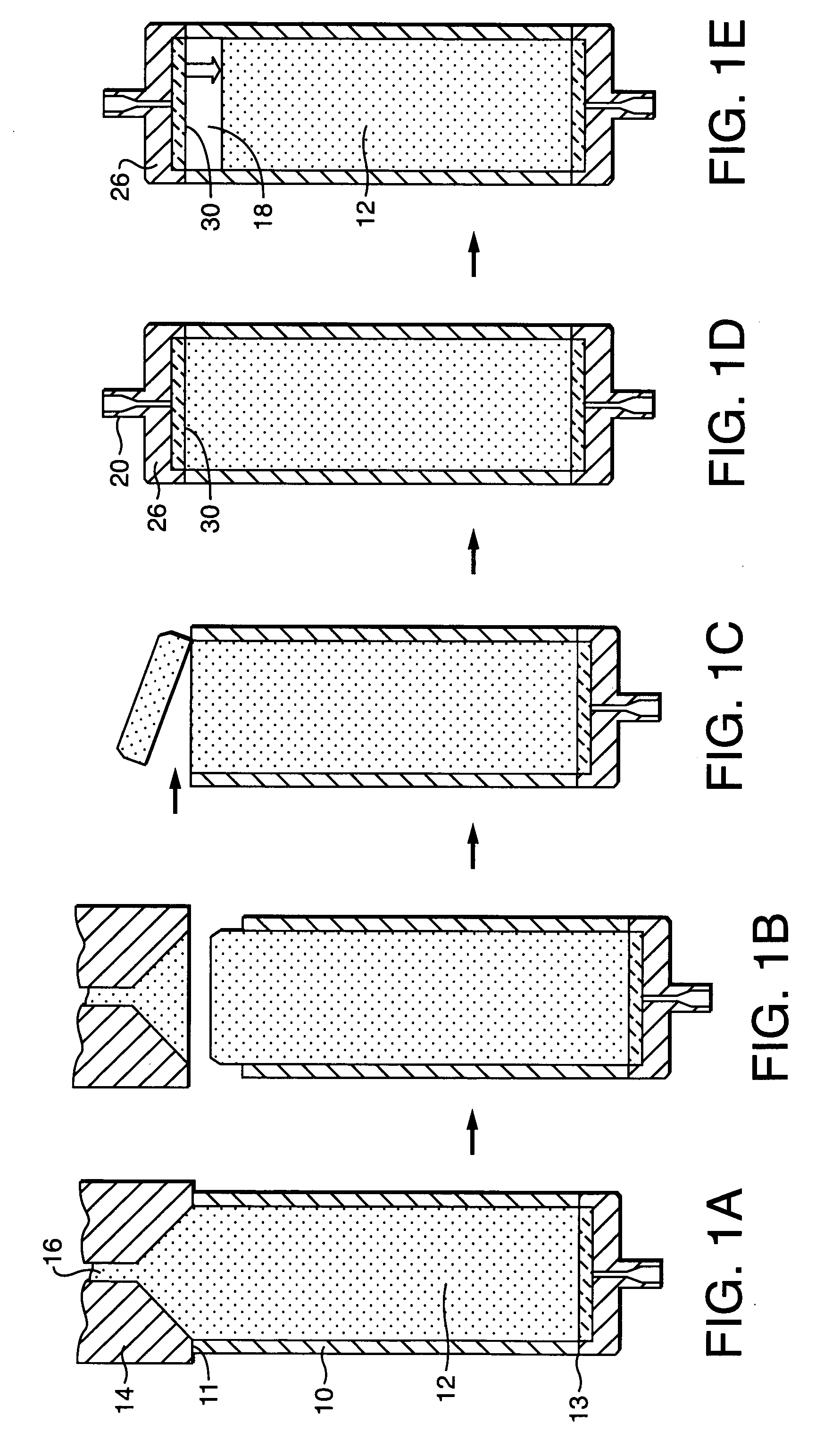

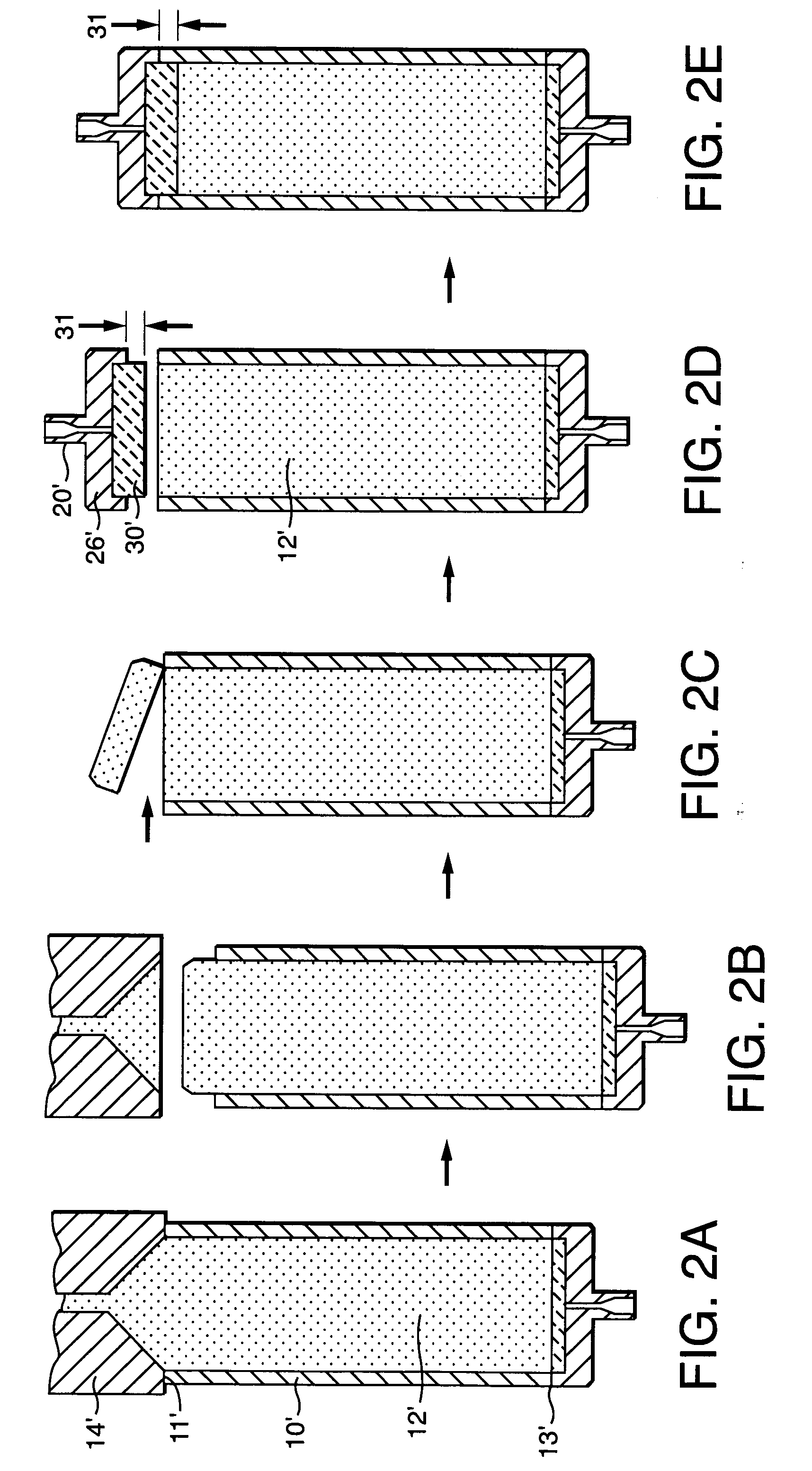

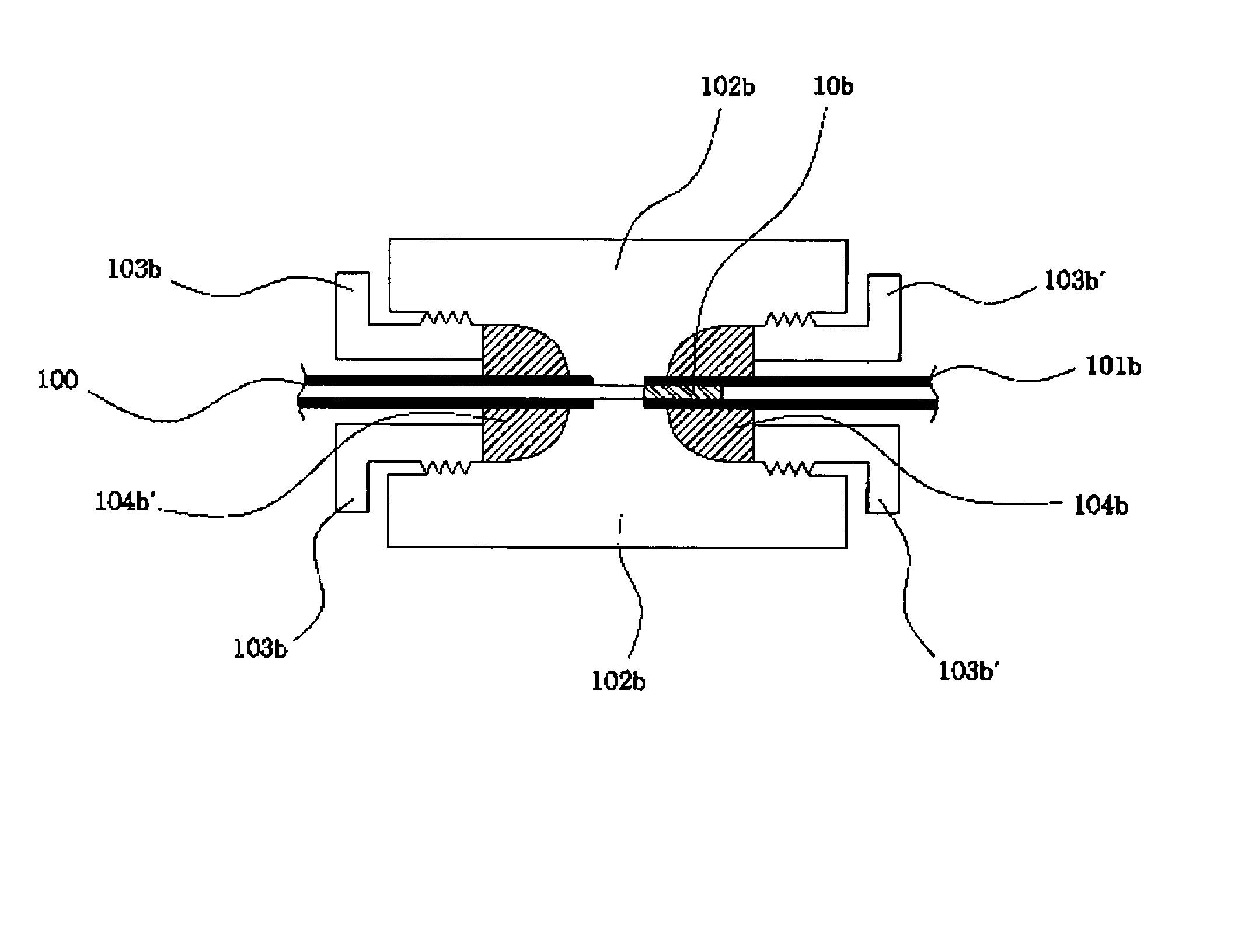

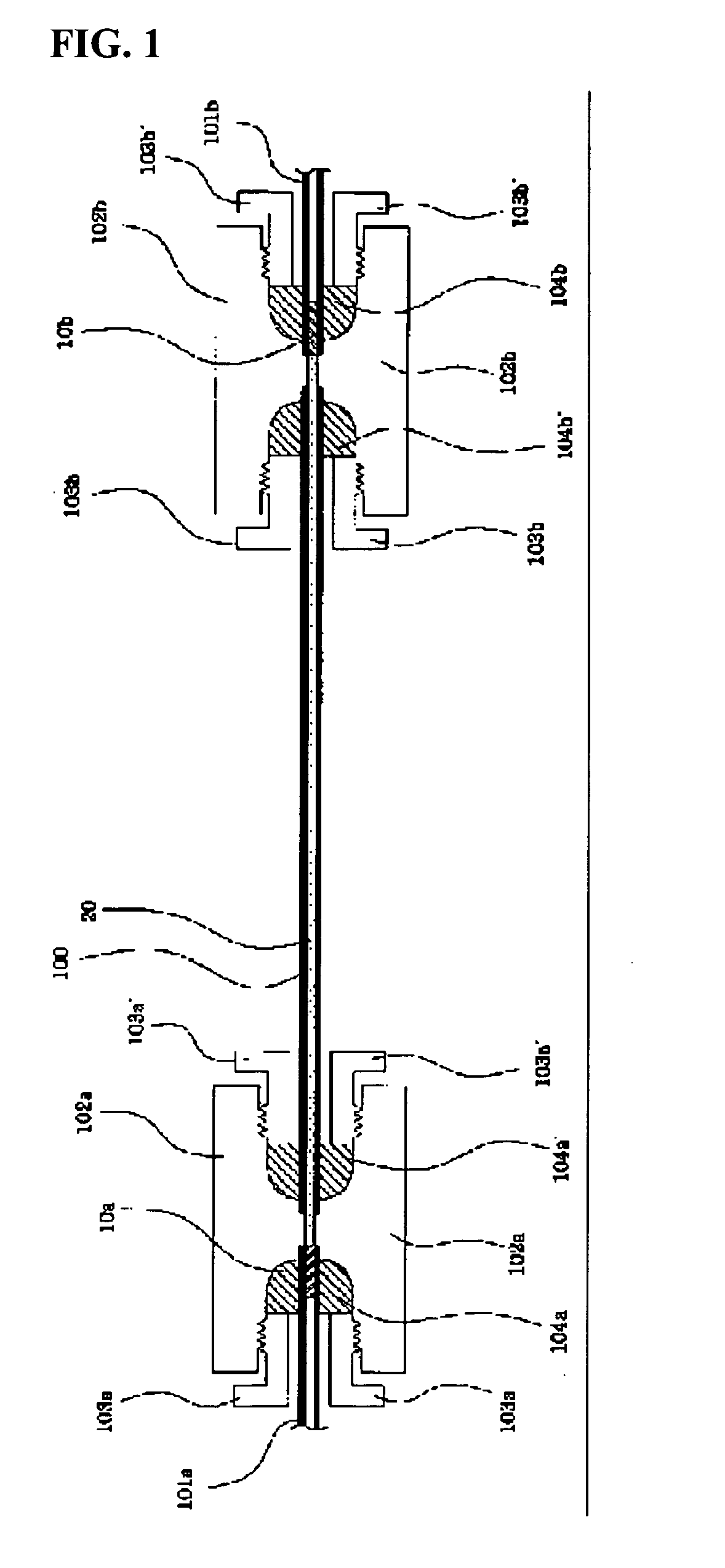

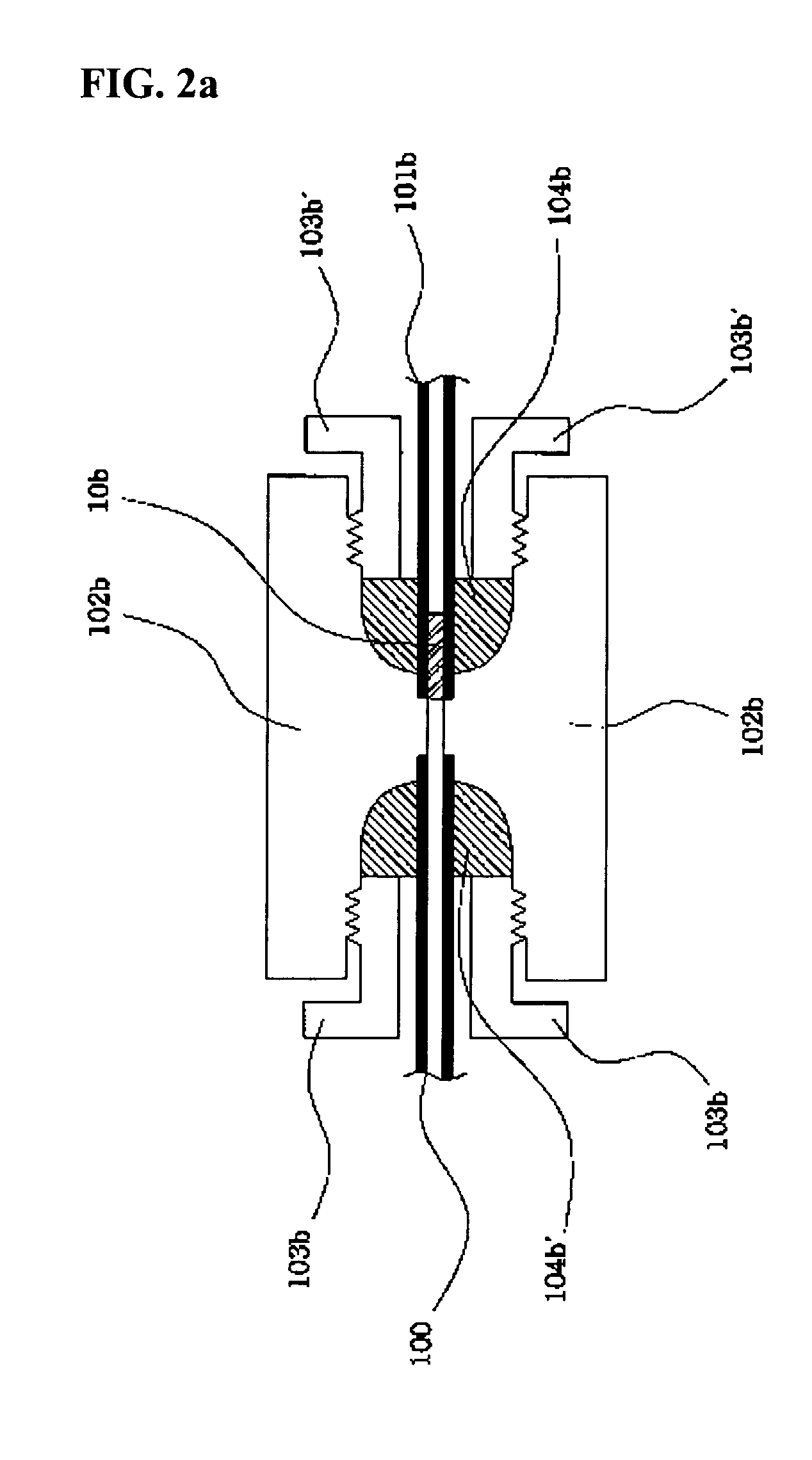

A portable gas fractionalization apparatus that provides oxygen rich air to patients is provided. The apparatus is compact, lightweight, and low-noise. The components are assembled in a housing that is divided into two compartments. One compartment is maintained at a lower temperature than the other compartment. The lower temperature compartment is configured for mounting components that can be damaged by heat. The higher temperature compartment is configured for mounting heat generating components. An air stream is directed to flow from an ambient air inlet to an air outlet constantly so that there is always a fresh source of cooling air. The apparatus utilizes a PSA unit to produce an oxygen enriched product. The PSA unit incorporates a novel single ended column design in which all flow paths and valves can be co-located on a single integrated manifold. The apparatus also can be used in conjunction with a satellite conserver and a mobility cart.

Owner:INOGEN INC

Portable gas fractionalization system

InactiveUS7066985B2Reduce heat loadReduce noiseCombination devicesAuxillary pretreatmentLow noiseProcess engineering

A portable gas fractionalization apparatus that provides oxygen rich air to patients is provided. The apparatus is compact, lightweight, and low-noise. The components are assembled in a housing that is divided into two compartments. One compartment is maintained at a lower temperature than the other compartment. The lower temperature compartment is configured for mounting components that can be damaged by heat. The higher temperature compartment is configured for mounting heat generating components. An air stream is directed to flow from an ambient air inlet to an air outlet constantly so that there is always a fresh source of cooling air. The apparatus utilizes a PSA unit to produce an oxygen enriched product. The PSA unit incorporates a novel single ended column design in which all flow paths and valves can be co-located on a single integrated manifold. The apparatus also can be used in conjunction with a satellite conserver and a mobility cart.

Owner:INOGEN INC

Portable gas fractionalization system

A portable gas fractionalization apparatus that provides oxygen rich air to patients is provided. The apparatus is compact, lightweight, and low-noise. The components are assembled in a housing that is divided into two compartments. One compartment is maintained at a lower temperature than the other compartment. The lower temperature compartment is configured for mounting components that can be damaged by heat. The higher temperature compartment is configured for mounting heat generating components. An air stream is directed to flow from an ambient air inlet to an air outlet constantly so that there is always a fresh source of cooling air. The apparatus utilizes a PSA unit to produce an oxygen enriched product. The PSA unit incorporates a novel single ended column design in which all flow paths and valves can be co-located on a single integrated manifold. The apparatus also can be used in conjunction with a satellite conserver and a mobility cart.

Owner:INOGEN INC

Portable gas fractionalization system

InactiveUS7135059B2Facilitate mounting and removalIncrease the lengthRespiratorsCombination devicesProduct gasProcess engineering

A portable gas fractionalization apparatus that provides oxygen rich air to patients is provided. The apparatus is compact, lightweight, and low-noise. The components are assembled in a housing that is divided into two compartments. One compartment is maintained at a lower temperature than the other compartment. The lower temperature compartment is configured for mounting components that can be damaged by heat. The higher temperature compartment is configured for mounting heat generating components. An air stream is directed to flow from an ambient air inlet to an air outlet constantly so that there is always a fresh source of cooling air. The apparatus utilizes a PSA unit to produce an oxygen enriched product. The PSA unit incorporates a novel single ended column design in which all flow paths and valves can be co-located on a single integrated manifold. The apparatus also can be used in conjunction with a satellite conserver and a mobility cart.

Owner:INOGEN INC

Portable gas fractionalization system

A portable gas fractionalization apparatus that provides oxygen rich air to patients is provided. The apparatus is compact, lightweight, and low-noise. The components are assembled in a housing that is divided into two compartments. One compartment is maintained at a lower temperature than the other compartment. The lower temperature compartment is configured for mounting components that can be damaged by heat. The higher temperature compartment is configured for mounting heat generating components. An air stream is directed to flow from an ambient air inlet to an air outlet constantly so that there is always a fresh source of cooling air. The apparatus utilizes a PSA unit to produce an oxygen enriched product. The PSA unit incorporates a novel single ended column design in which all flow paths and valves can be co-located on a single integrated manifold. The apparatus also can be used in conjunction with a satellite conserver and a mobility cart.

Owner:INOGEN INC

Portable gas fractionalization system

ActiveUS20050072298A1Reduce heat loadReduce noiseCombination devicesAuxillary pretreatmentLow noiseCombined use

A portable gas fractionalization apparatus that provides oxygen rich air to patients is provided. The apparatus is compact, lightweight, and low-noise. The components are assembled in a housing that is divided into two compartments. One compartment is maintained at a lower temperature than the other compartment. The lower temperature compartment is configured for mounting components that can be damaged by heat. The higher temperature compartment is configured for mounting heat generating components. An air stream is directed to flow from an ambient air inlet to an air outlet constantly so that there is always a fresh source of cooling air. The apparatus utilizes a PSA unit to produce an oxygen enriched product. The PSA unit incorporates a novel single ended column design in which all flow paths and valves can be co-located on a single integrated manifold. The apparatus also can be used in conjunction with a satellite conserver and a mobility cart.

Owner:INOGEN INC

Portable gas fractionalization system

ActiveUS20050072306A1Prevent movementFacilitate mounting and removalRespiratorsCombination devicesLow noiseCombined use

A portable gas fractionalization apparatus that provides oxygen rich air to patients is provided. The apparatus is compact, lightweight, and low-noise. The components are assembled in a housing that is divided into two compartments. One compartment is maintained at a lower temperature than the other compartment. The lower temperature compartment is configured for mounting components that can be damaged by heat. The higher temperature compartment is configured for mounting heat generating components. An air stream is directed to flow from an ambient air inlet to an air outlet constantly so that there is always a fresh source of cooling air. The apparatus utilizes a PSA unit to produce an oxygen enriched product. The PSA unit incorporates a novel single ended column design in which all flow paths and valves can be co-located on a single integrated manifold. The apparatus also can be used in conjunction with a satellite conserver and a mobility cart.

Owner:INOGEN INC

Portable gas fractionalization system

InactiveUS20080087170A1Reduce heat loadReduce noiseRespiratorsCombination devicesLow noiseCombined use

Owner:DEANE GEOFFREY FRANK +7

Chromatographic column and methods for controlling sorbent density

ActiveUS20050224414A1Easy to fixEasy transferCation exchanger materialsComponent separationSorbentVolumetric Mass Density

Disclosed herein are apparatus and methods for mitigating column bed compression over time. This invention provides for an improved column design and method of controlling bed density in a chromatographic column using a protruding portion of a filter assembly. The invention results in a higher sorbent bed density than can normally be achieved using a fixed length column of conventional design. The invention may be implemented as a unique filter assembly or as a column tailored for the application and a matching filter assembly.

Owner:WATERS INVESTMENTS

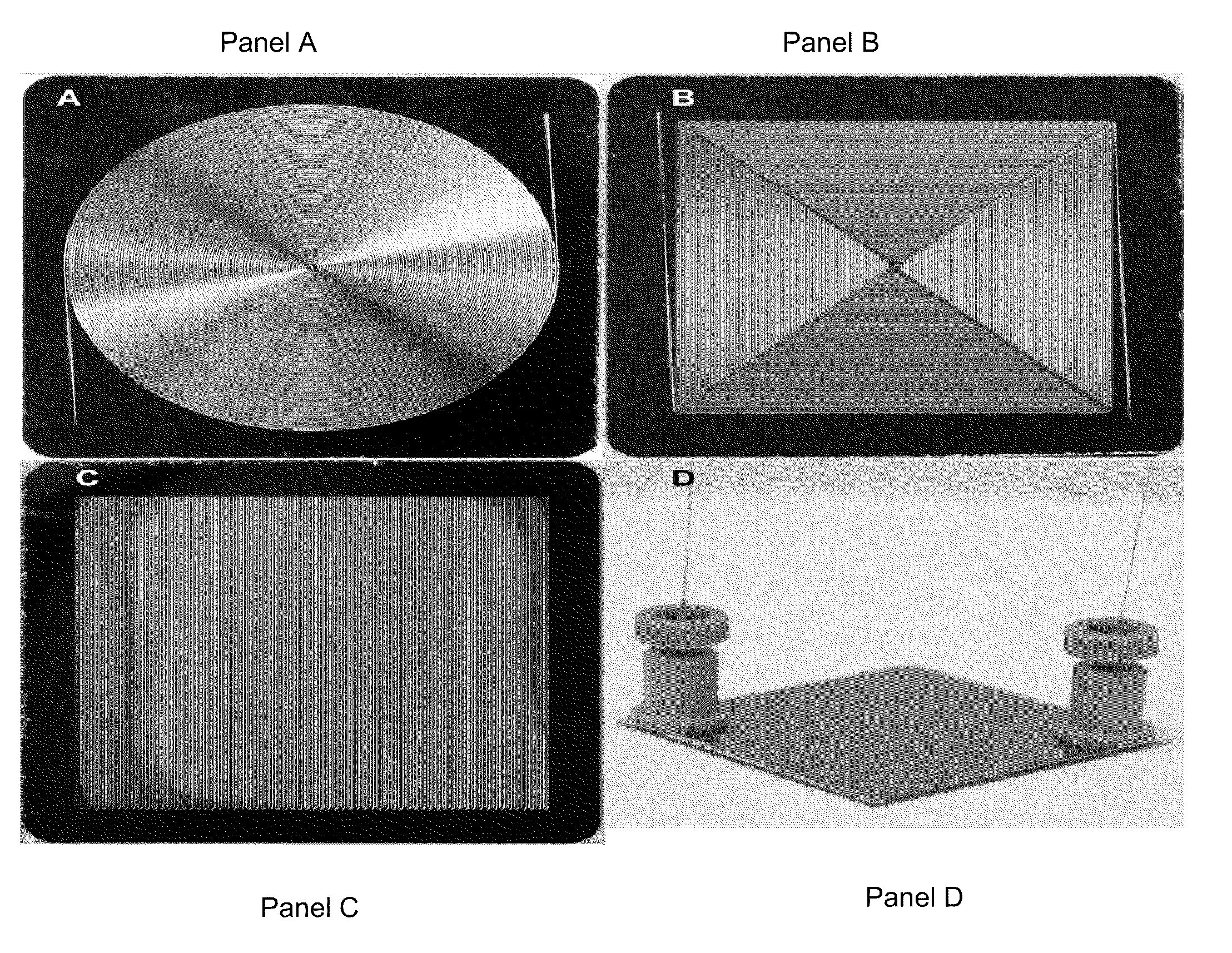

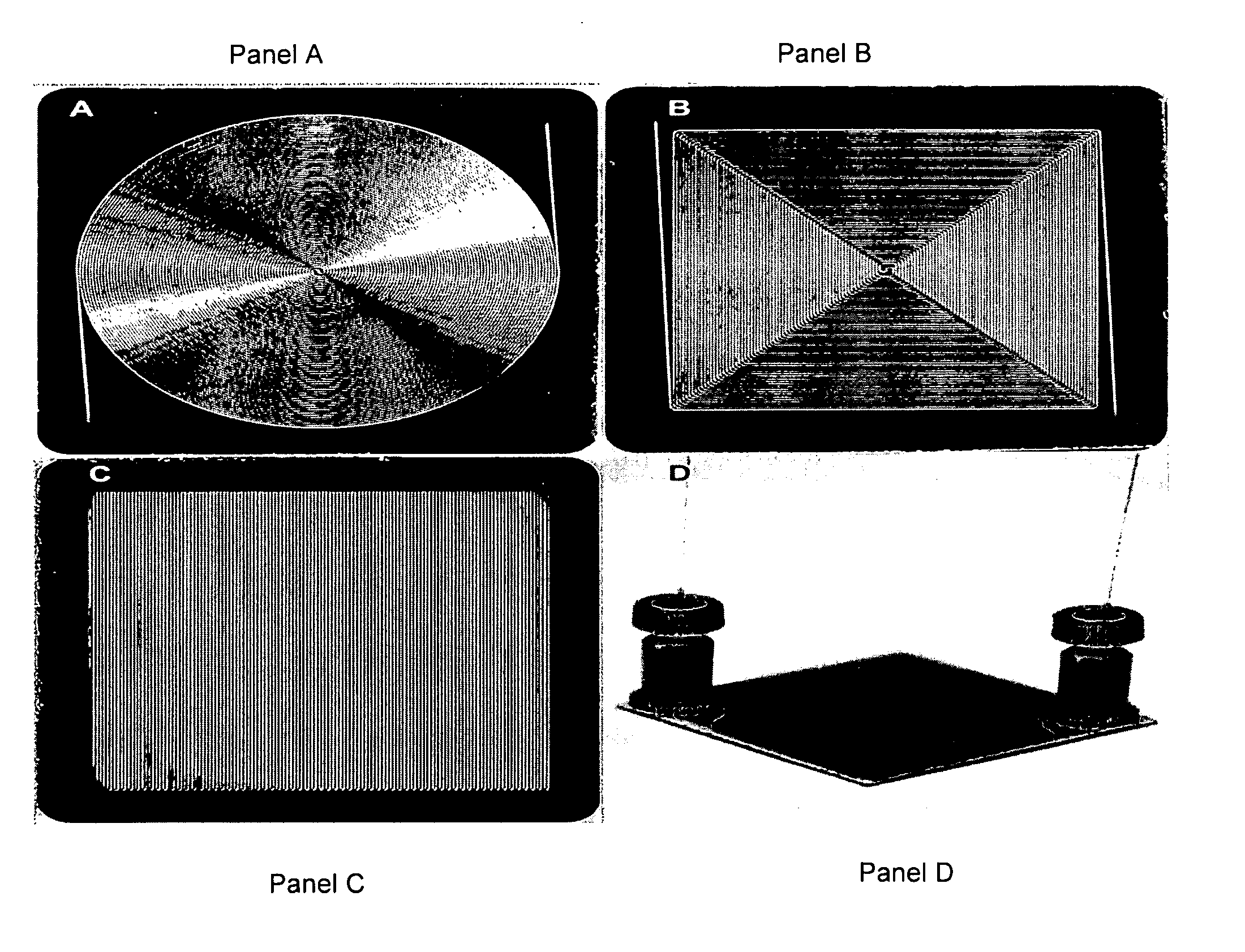

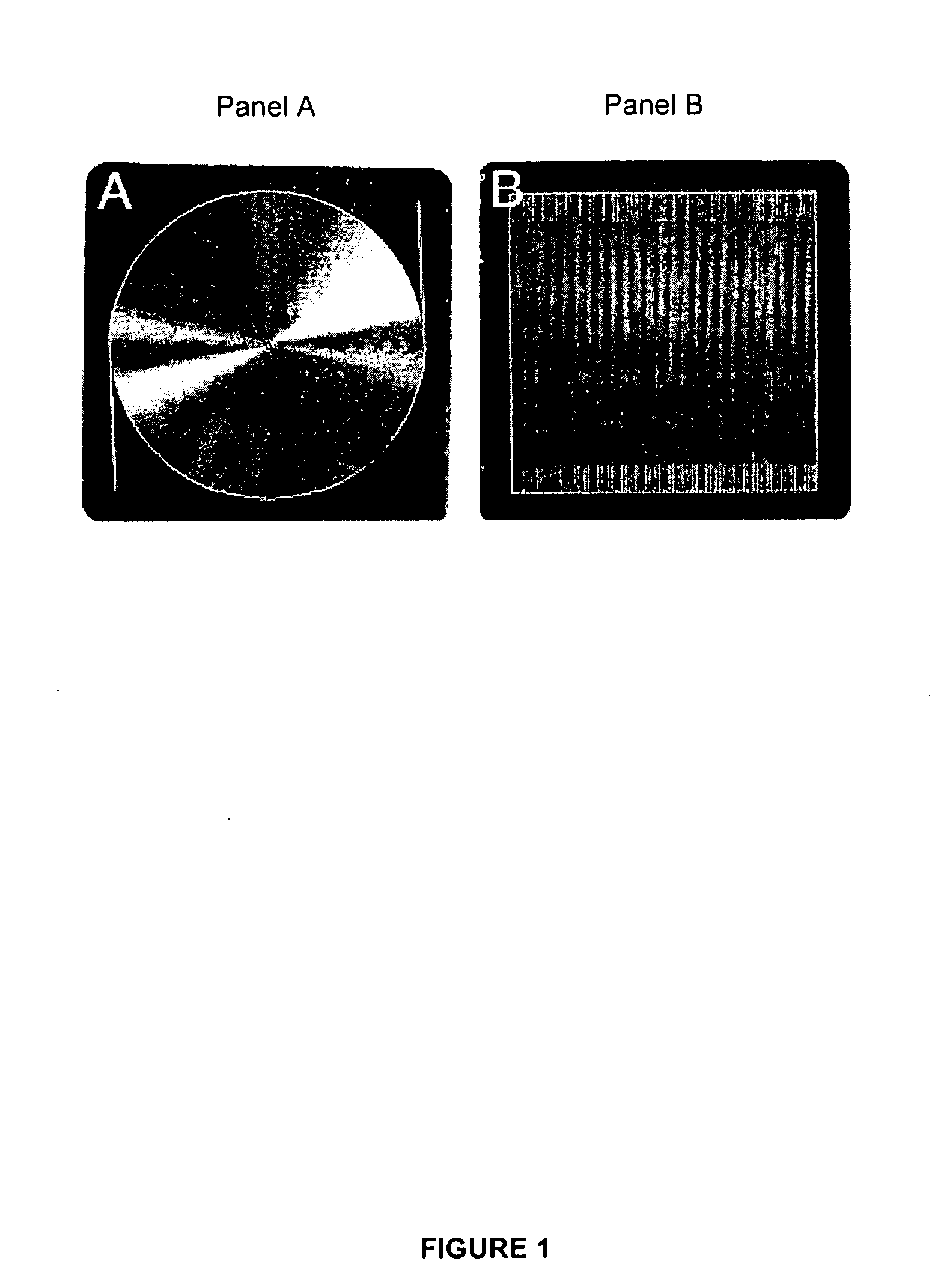

Column design for micro gas chromatograph

ActiveUS8123841B2High resolutionComponent separationDispersed particle separationTarget analysisStationary phase

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

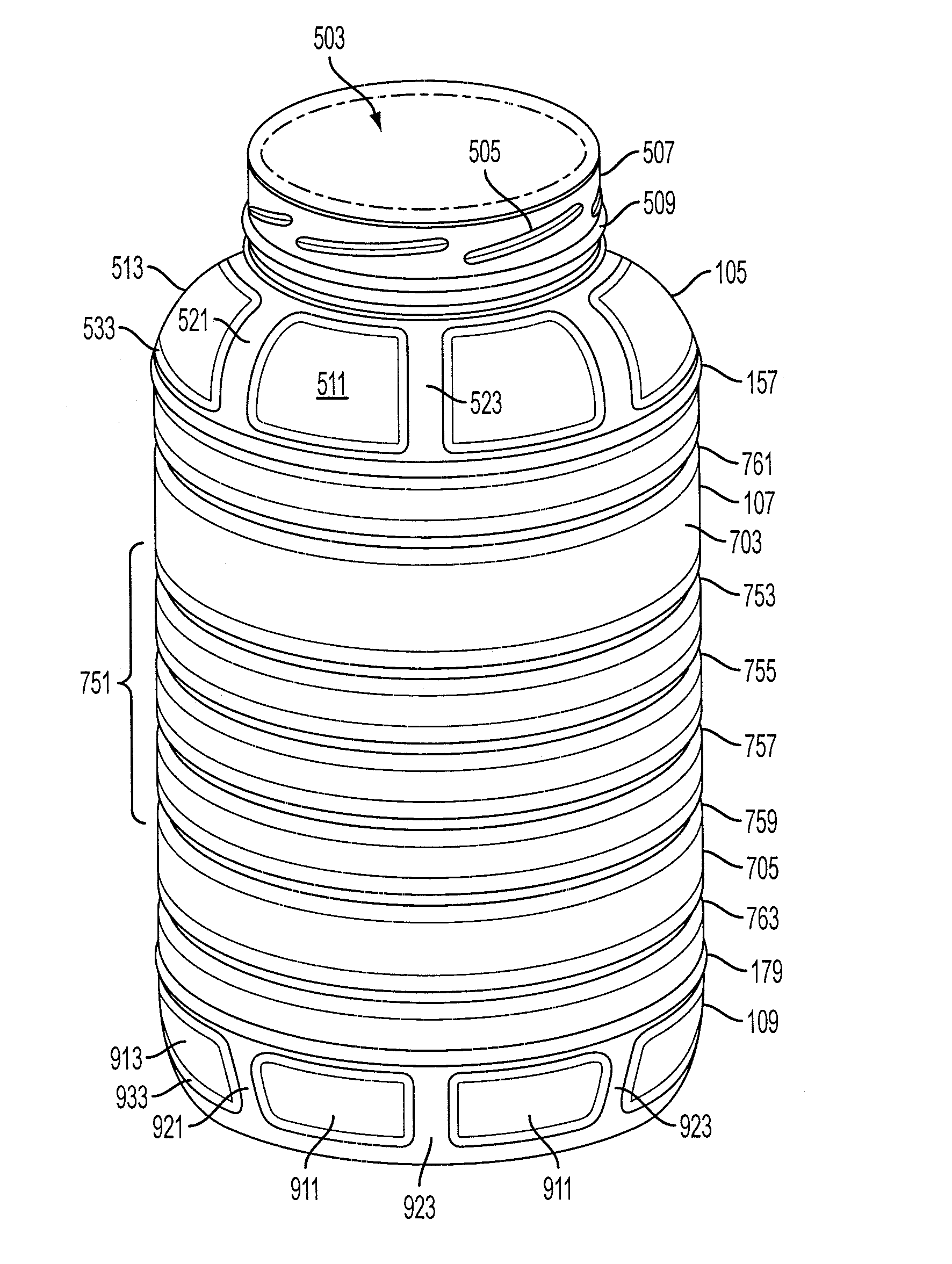

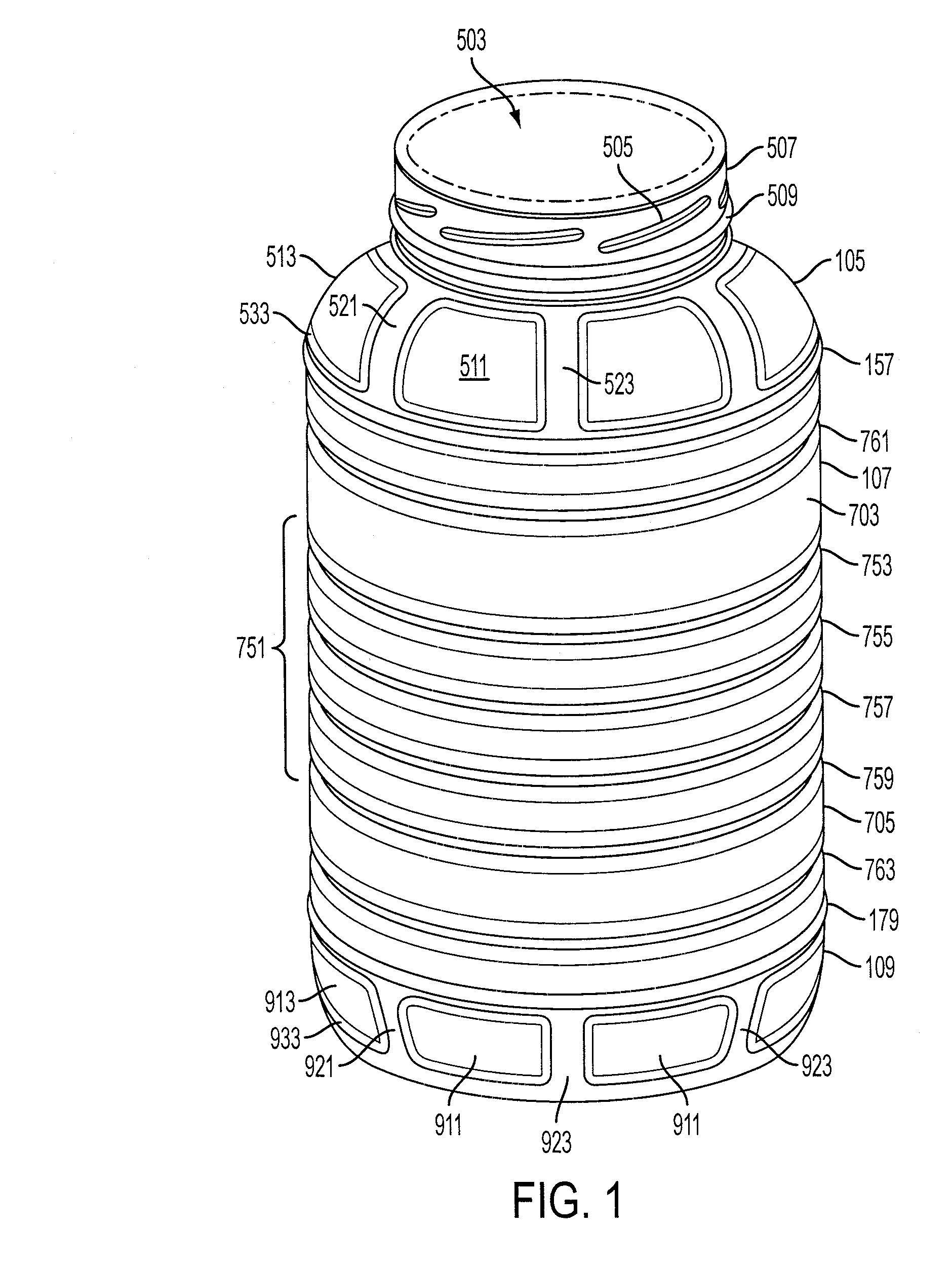

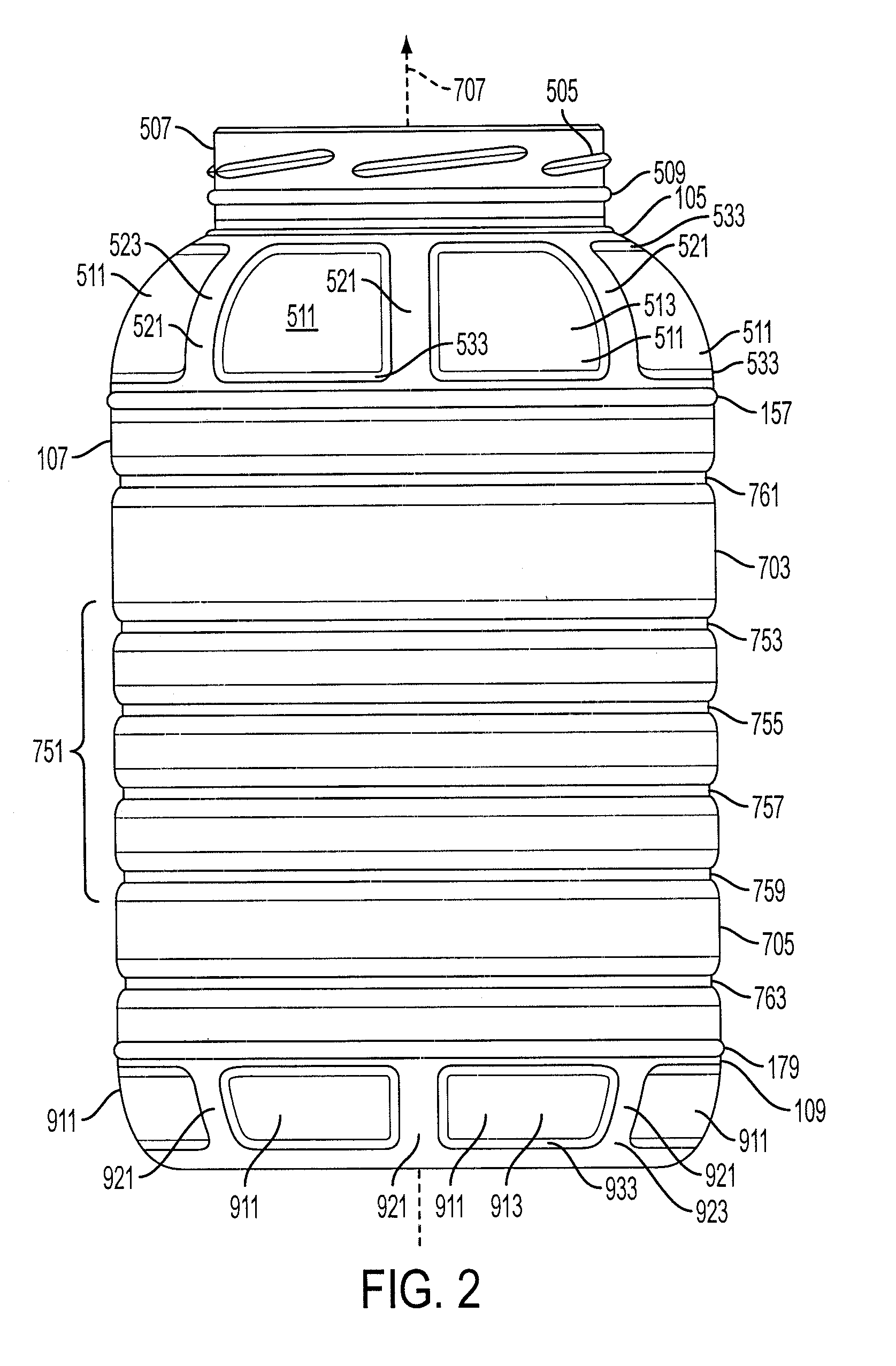

Container with Improved Crush Resistance

InactiveUS20070012650A1Improve stress resistanceImprove abilitiesLarge containersRigid containersUltimate tensile strengthMechanical engineering

A plastic container having improved crush resistance through the inclusion of a window and column design which is principally intended to increase its load bearing ability and / or a series of circumferential ribs intended to improve the container's circumferential strength to inhibit deformation during vacuum filling. The plastic container can be used in place of glass containers of similar volume.

Owner:PRETIUM PACKAGING

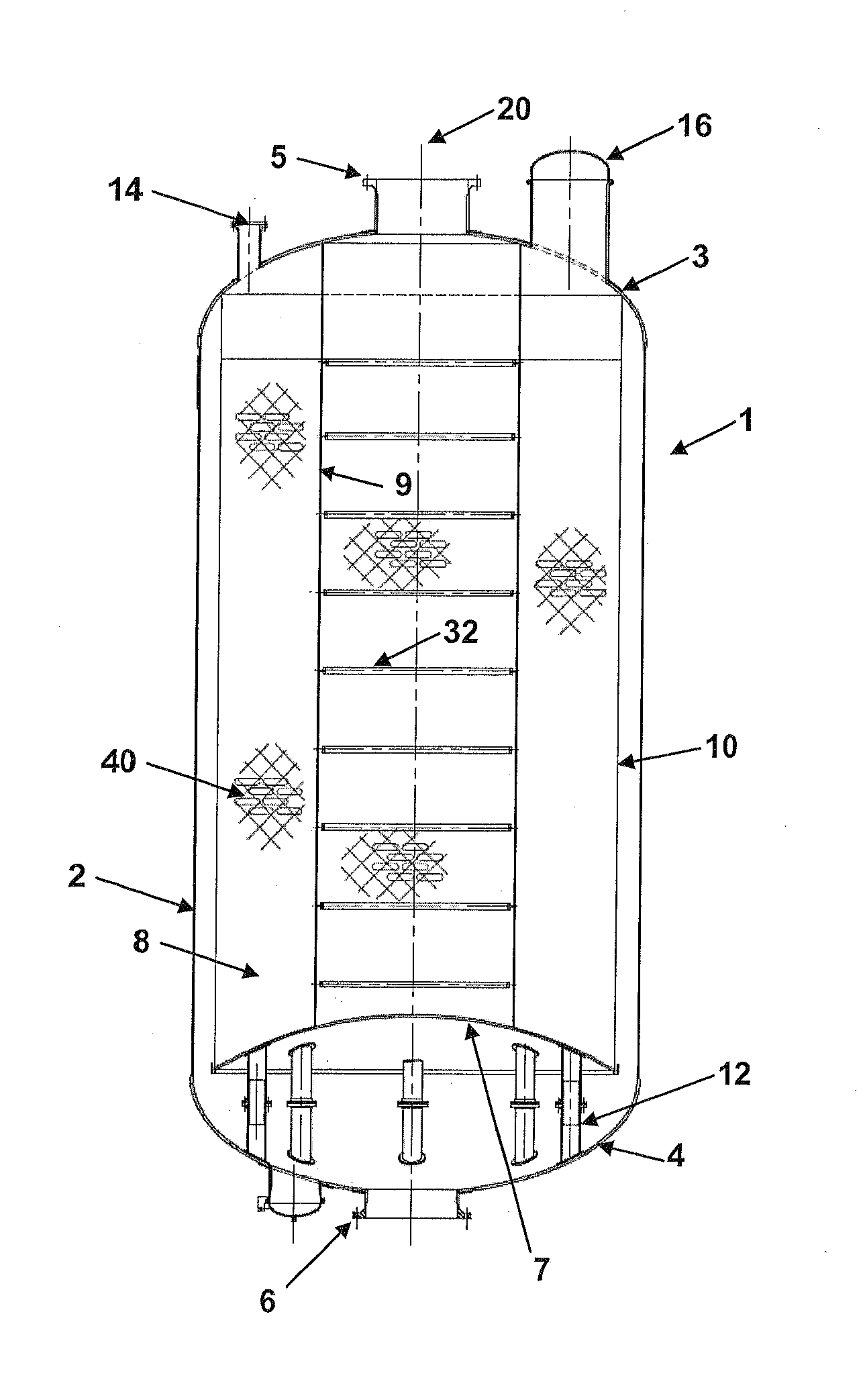

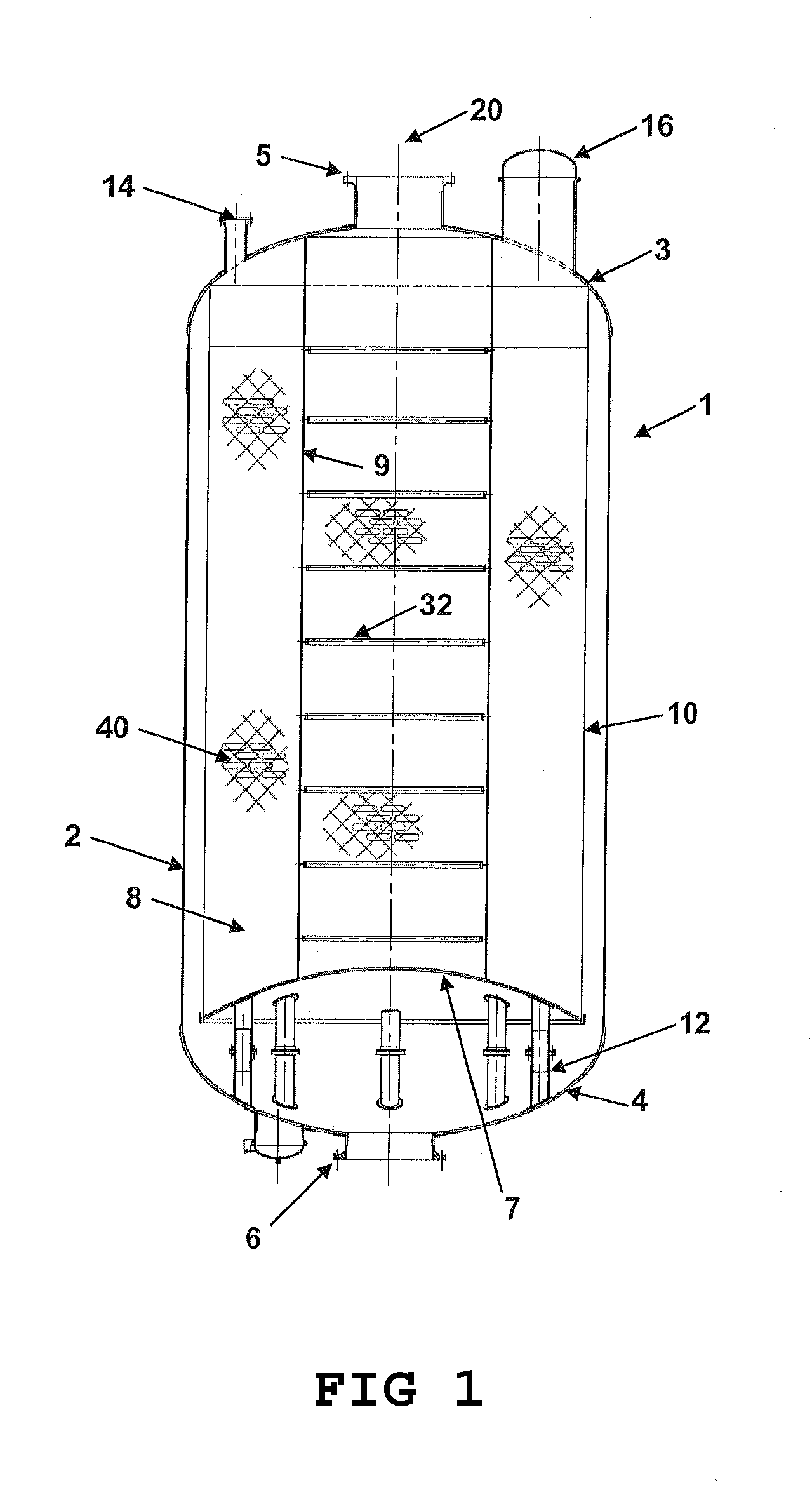

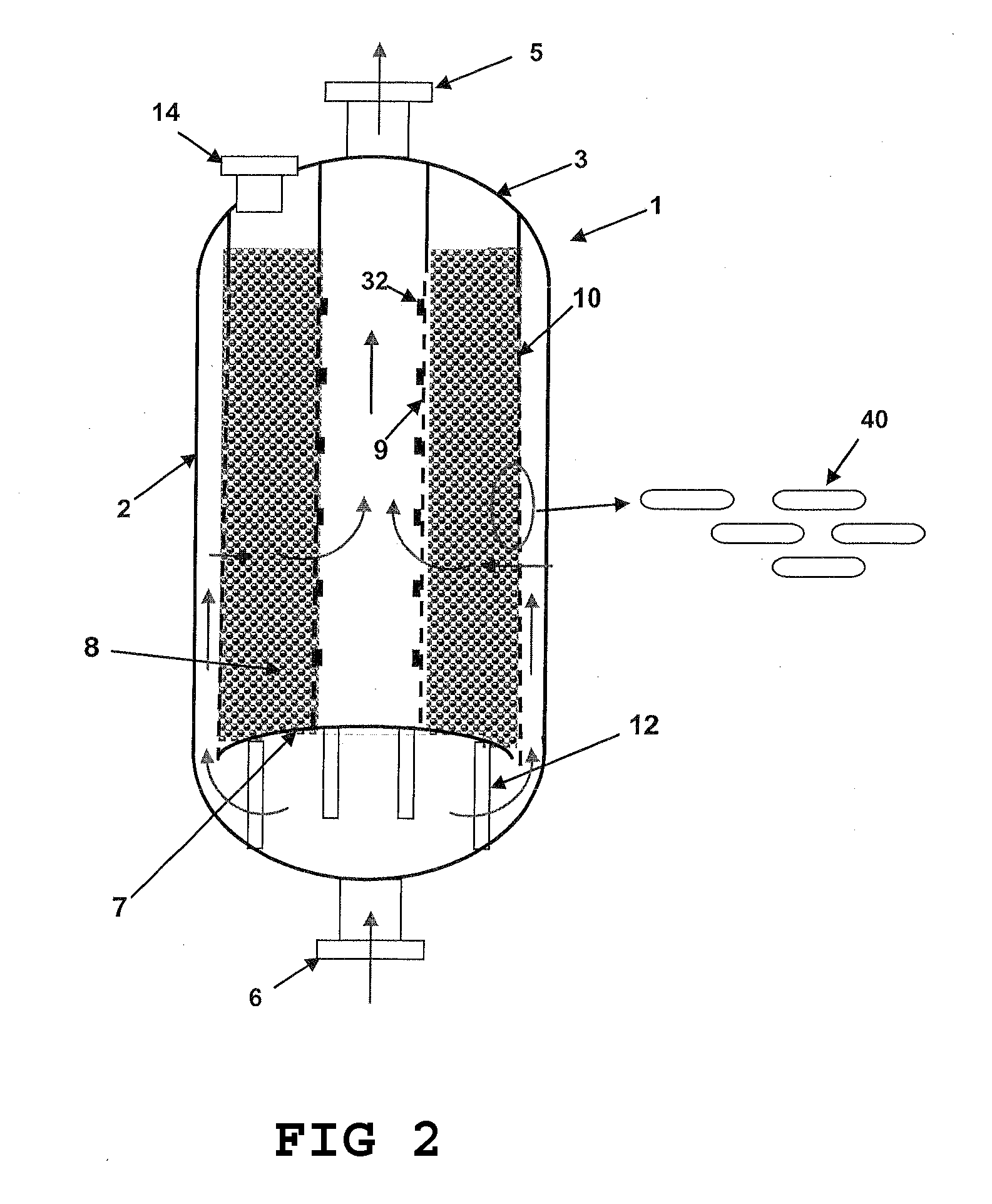

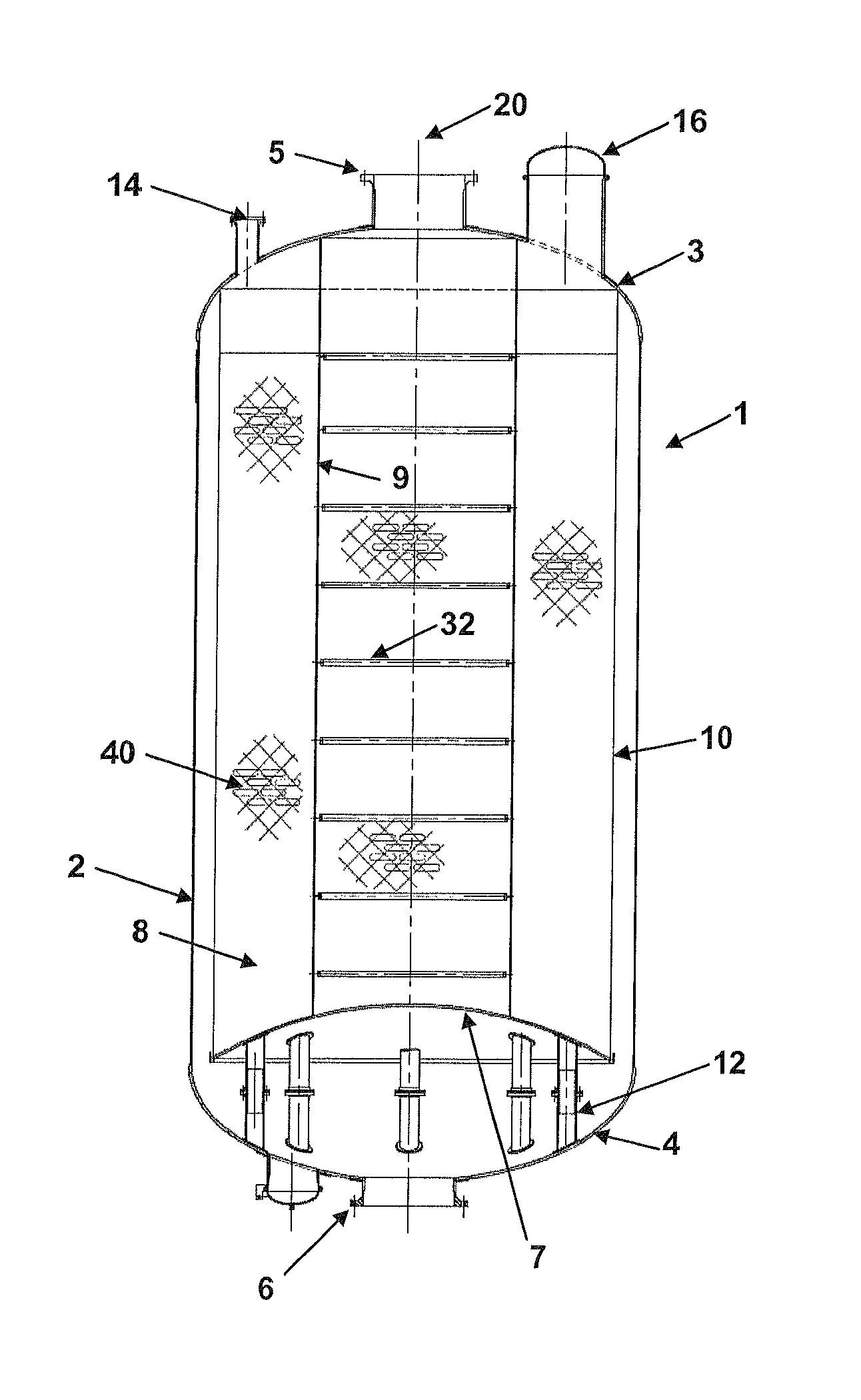

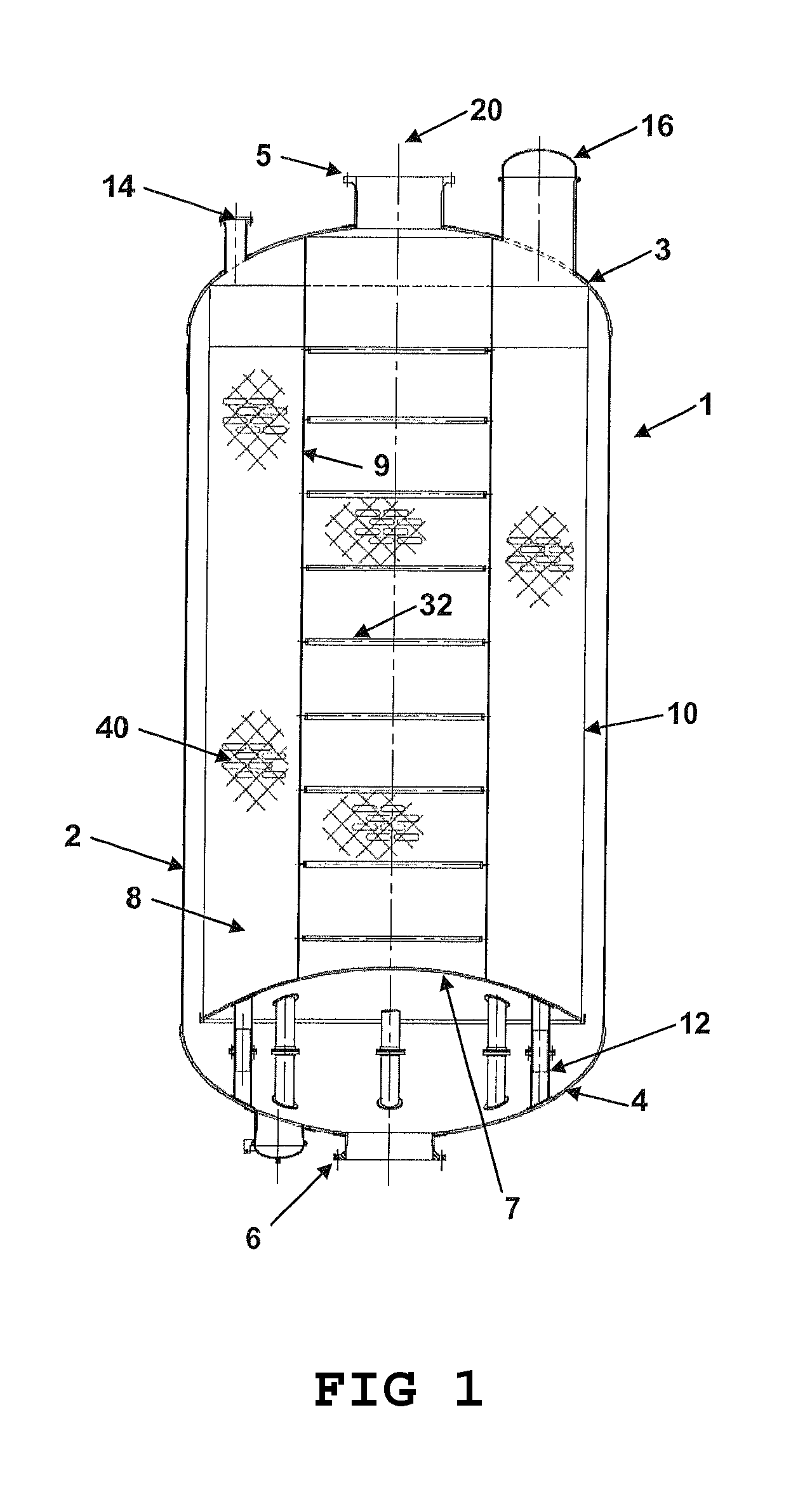

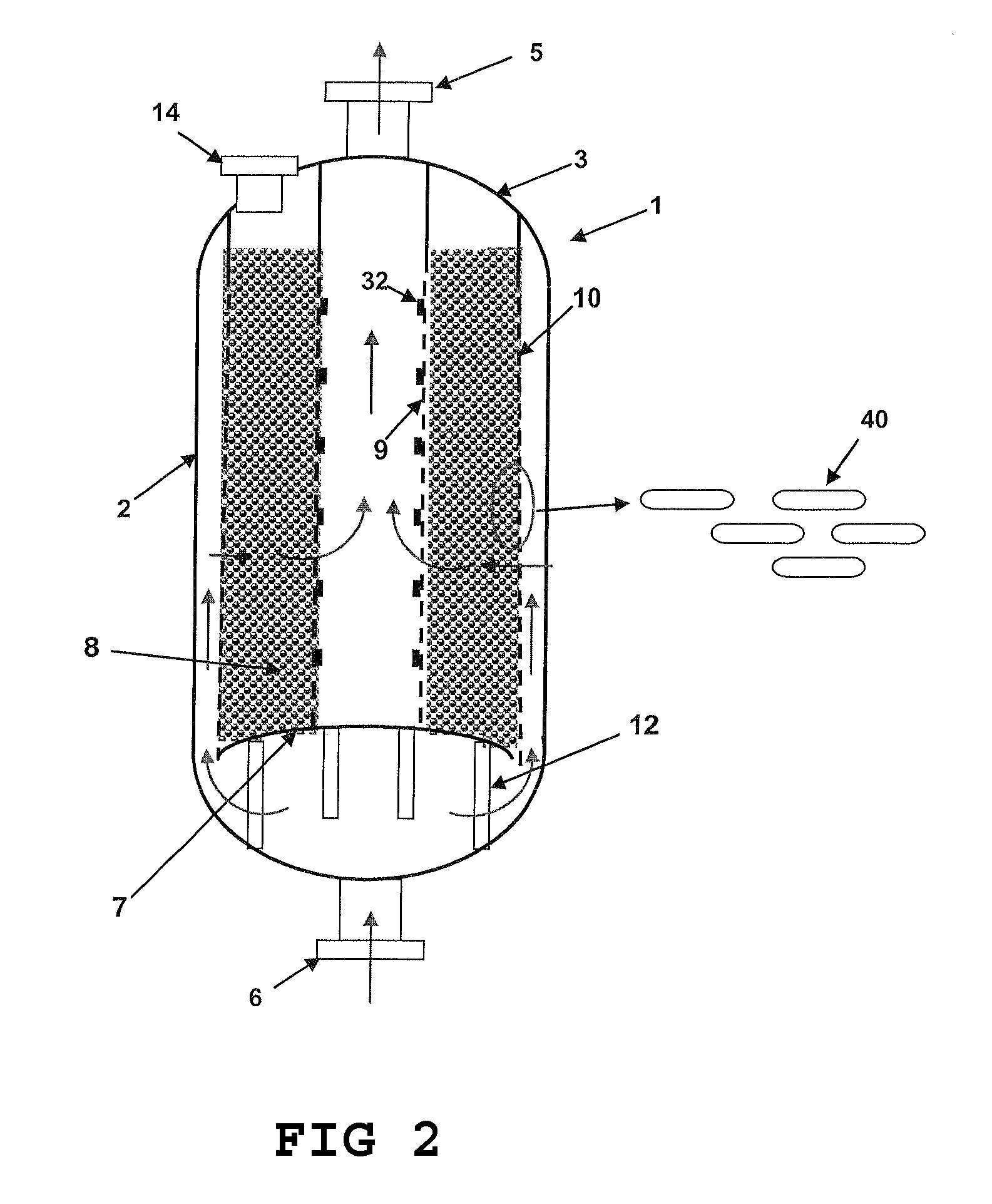

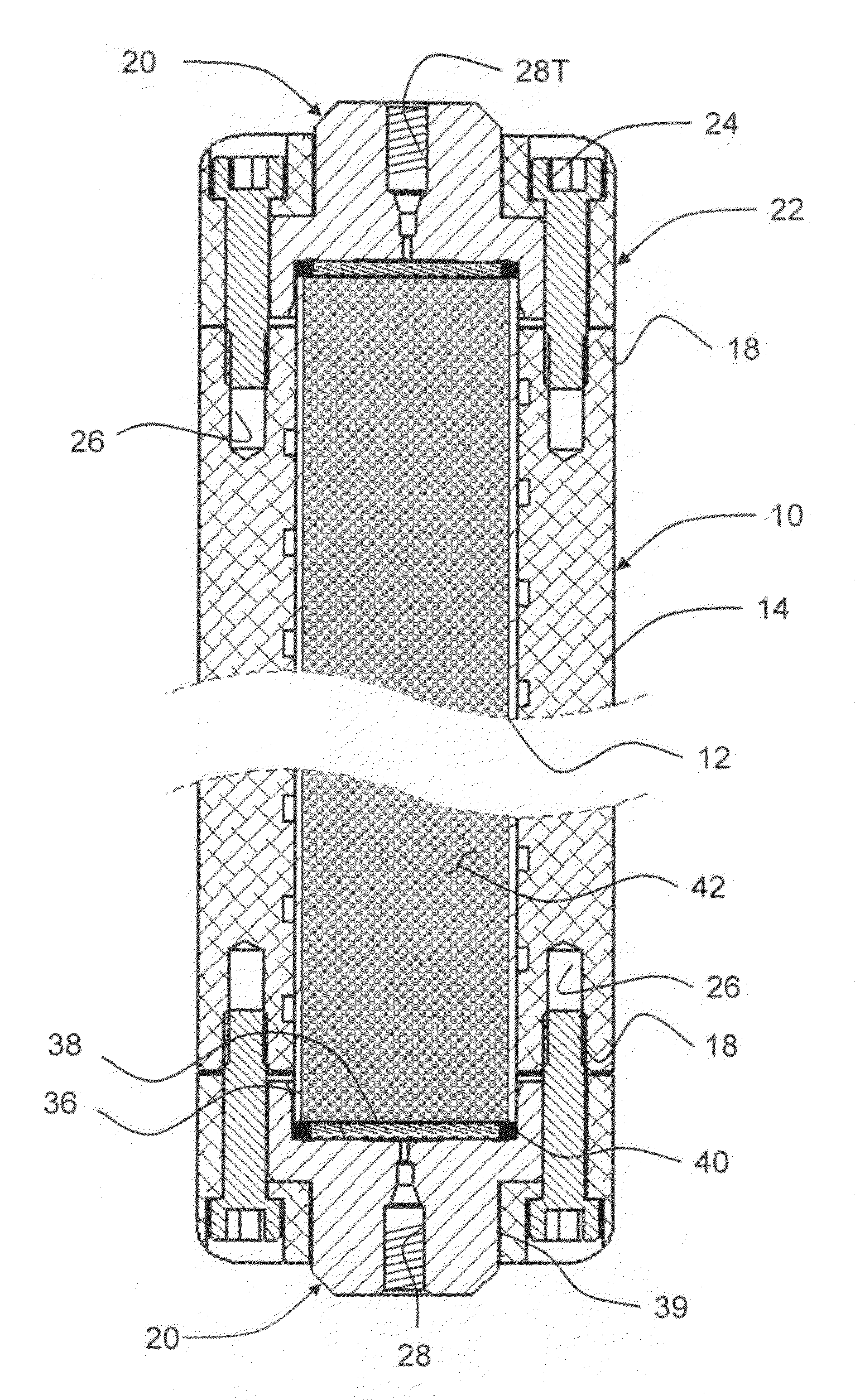

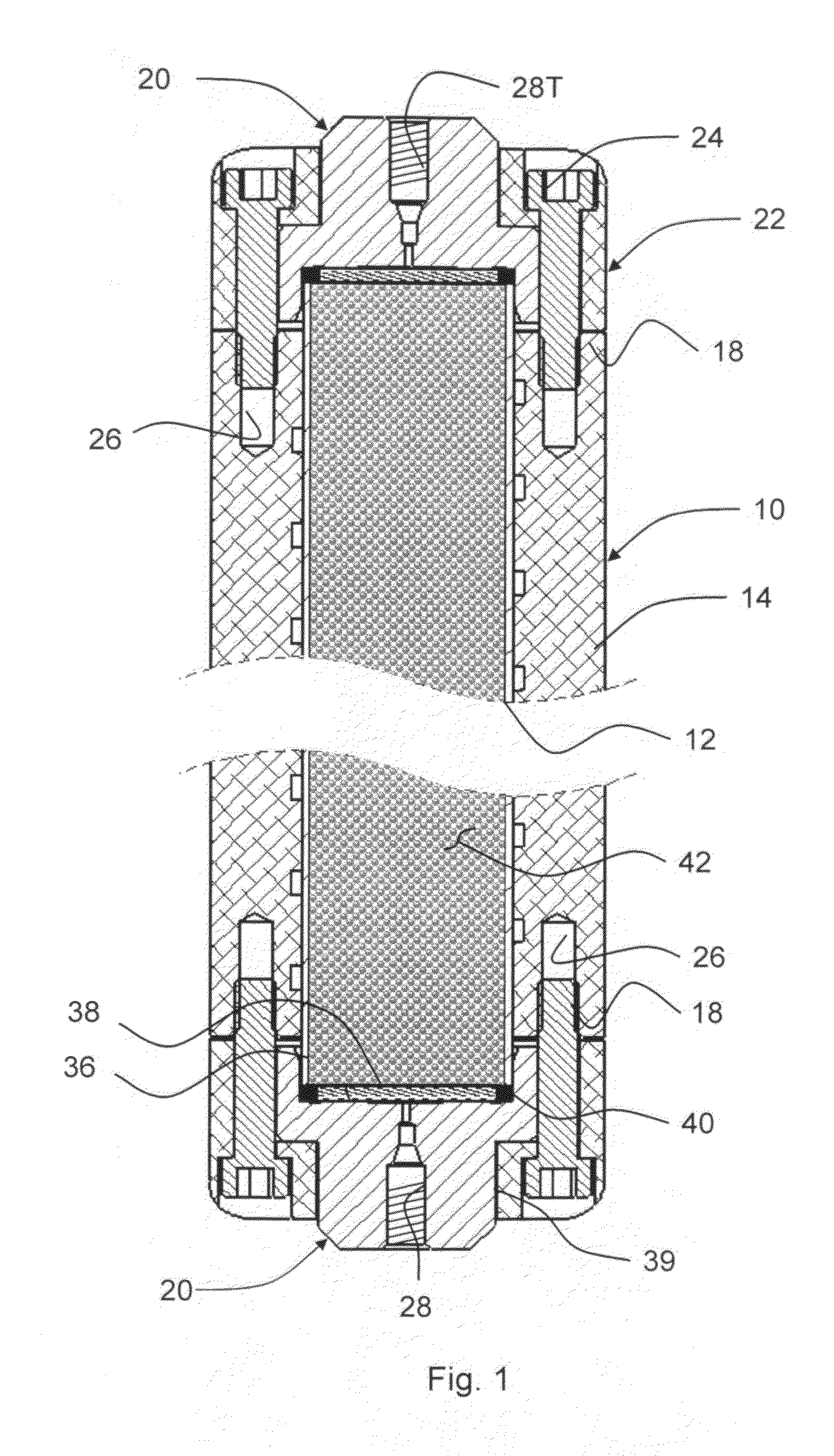

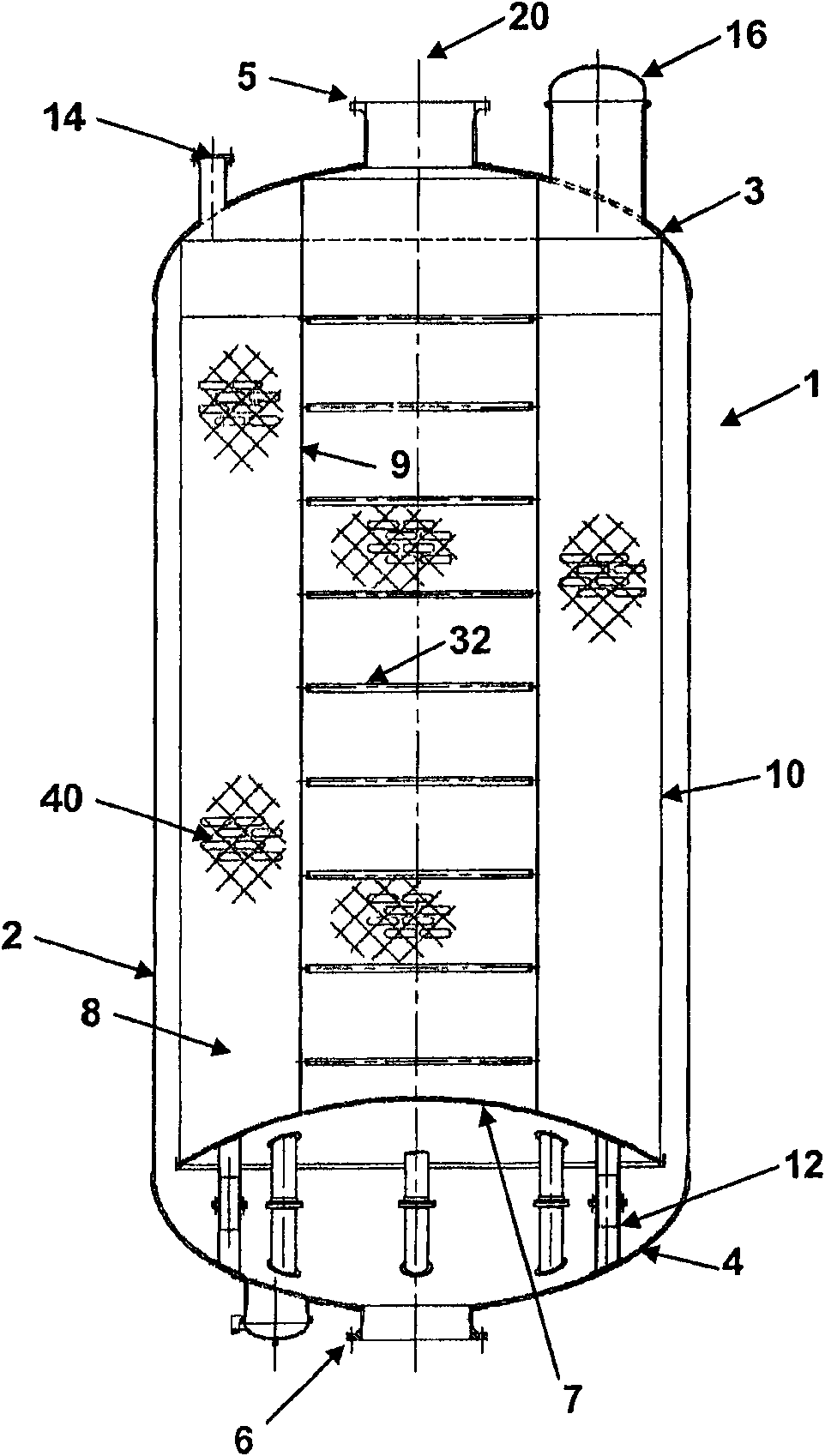

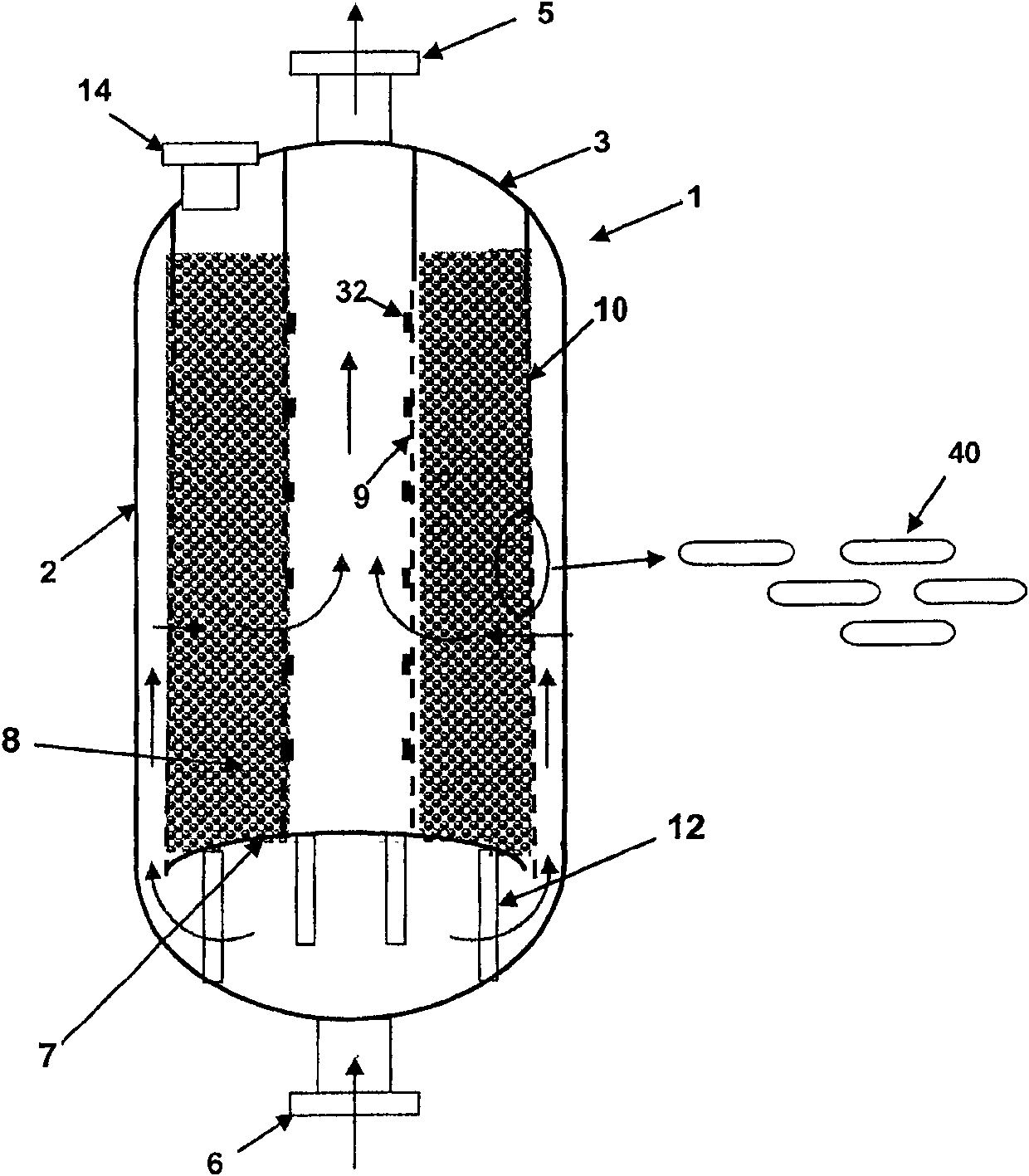

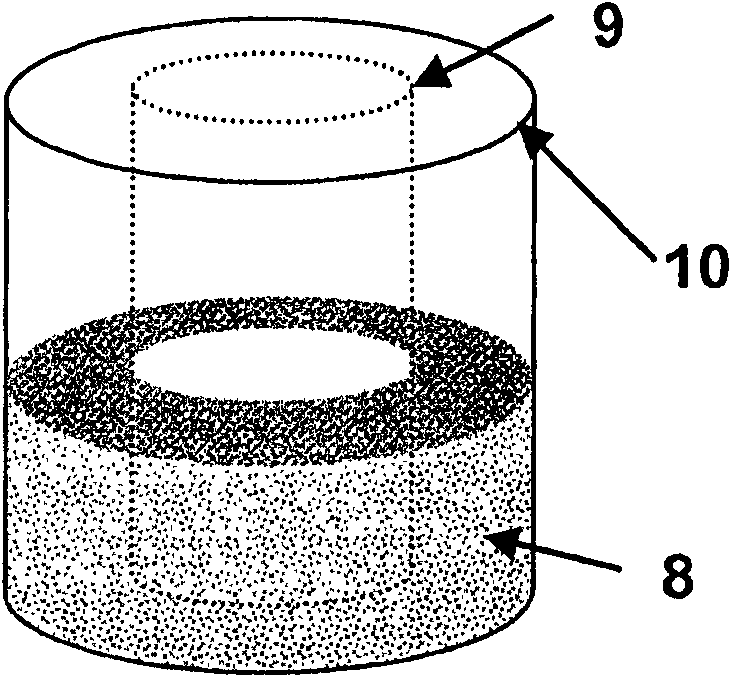

Radial flow reactor with movable supports

InactiveUS20110206581A1Minimize thermally induced stressLoad minimizationGas treatmentPhysical/chemical process catalystsPre stressingEngineering

A radial flow reactor vessel is disclosed for use in gas purification, separation or reaction processes and most suitably used in prepurification processes. The reactor has internal baskets for confining a bed of active material. The baskets are rigidly supported at both the top and bottom ends of the reactor and have walls that are axially flexible and radially rigid. The vessel has multiple movable support columns designed to facilitate pre-stressing of the baskets to offset axial compressive loads induced from thermal cycling.

Owner:PRAXAIR TECH INC

Column Design for Micro Gas Chromatograph

ActiveUS20090178563A1High resolutionImproved channel structureComponent separationDecorative surface effectsTarget analysisStationary phase

Improved micro-columns and methods for producing micro-columns particularly suitable for use in gas chromatographs are disclosed. In particular, following deposition of the stationary phase coating, the micro-columns are subjected to a postcoating treatment with a molecule that binds to the active sites in the stationary phase micro-column thereby eliminating or reducing loss of gas chromatograph performance associated with those active sites. The postcoating treatment molecule binds to the same active sites as the analytes of interest.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

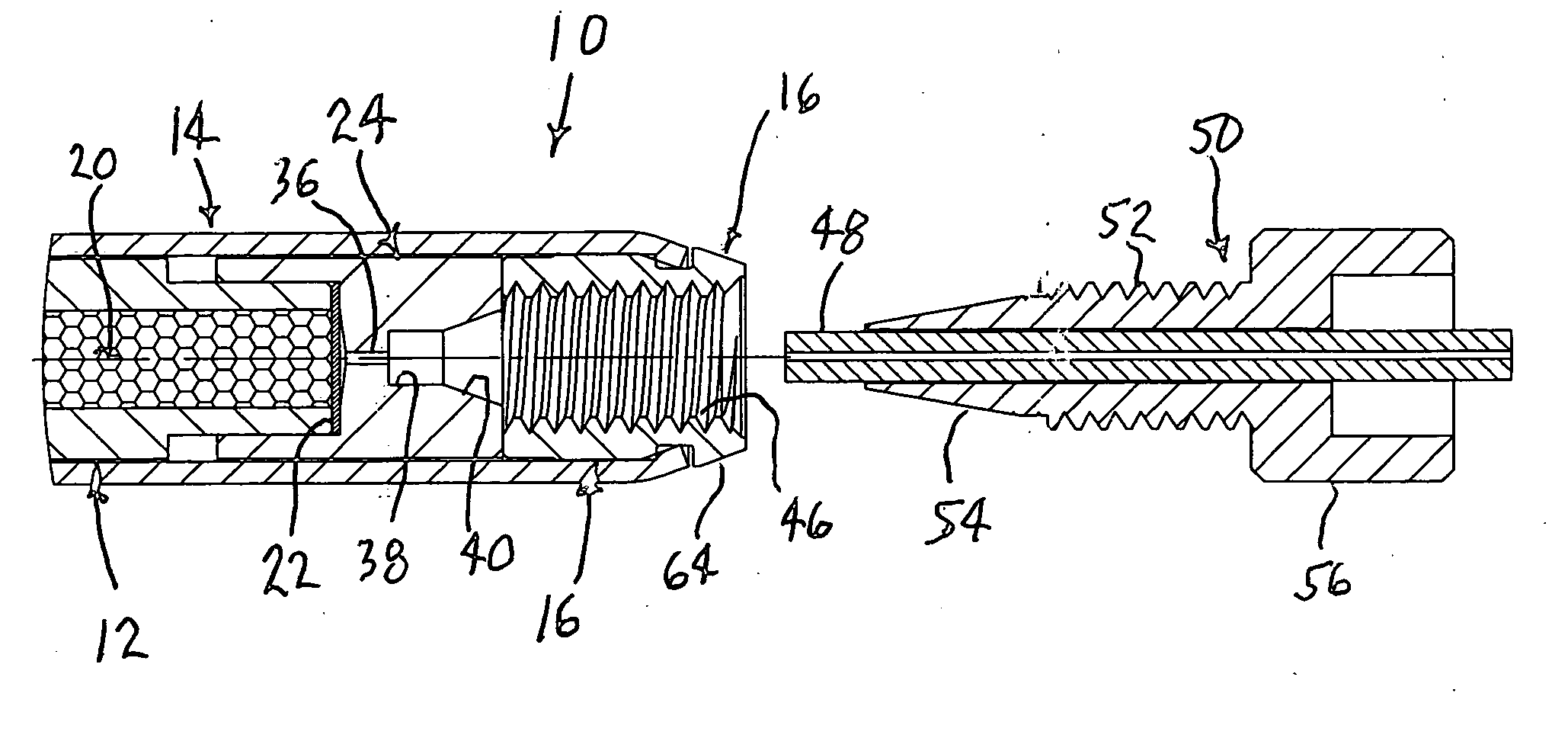

HPLC column design and method of making same

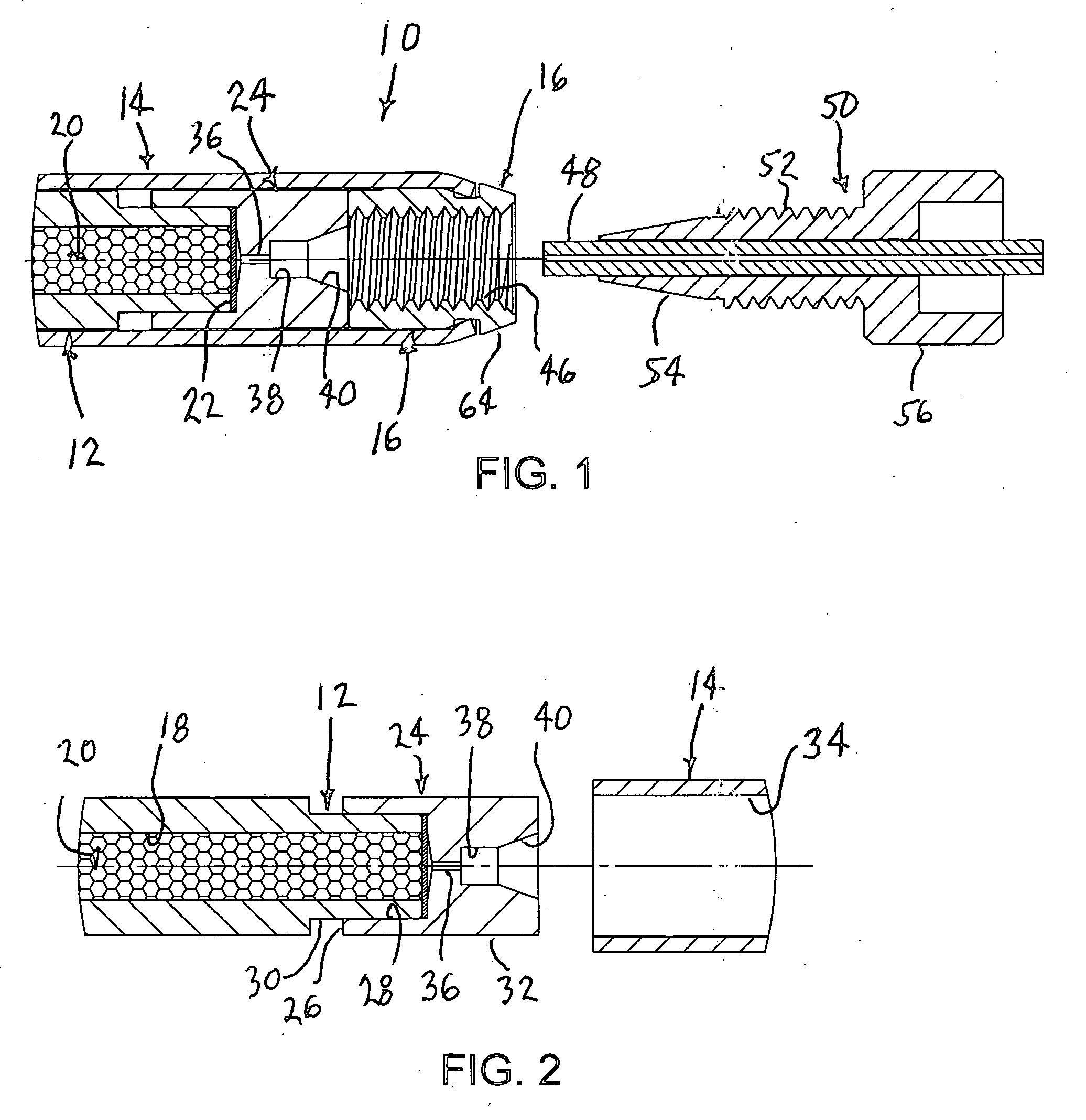

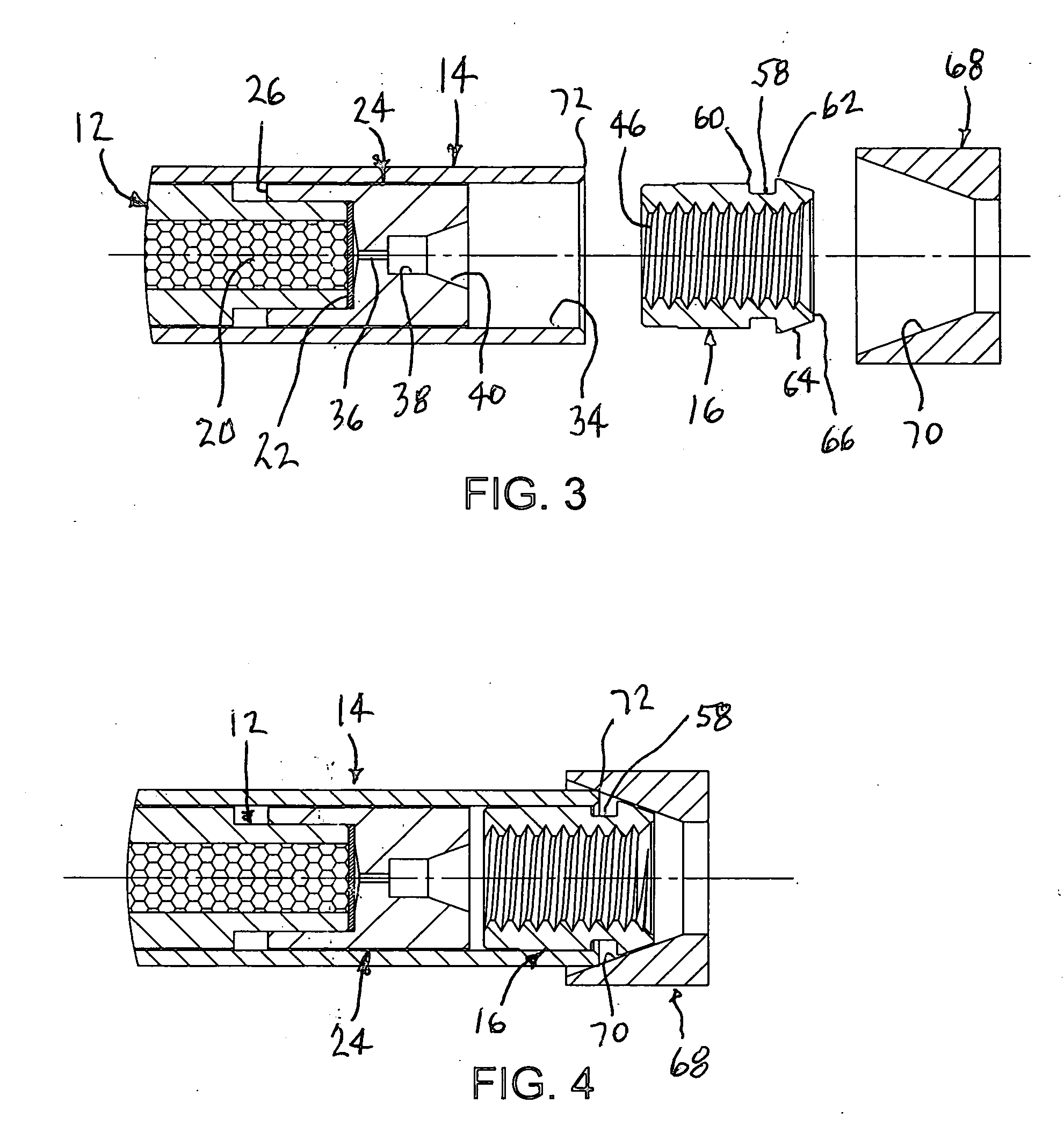

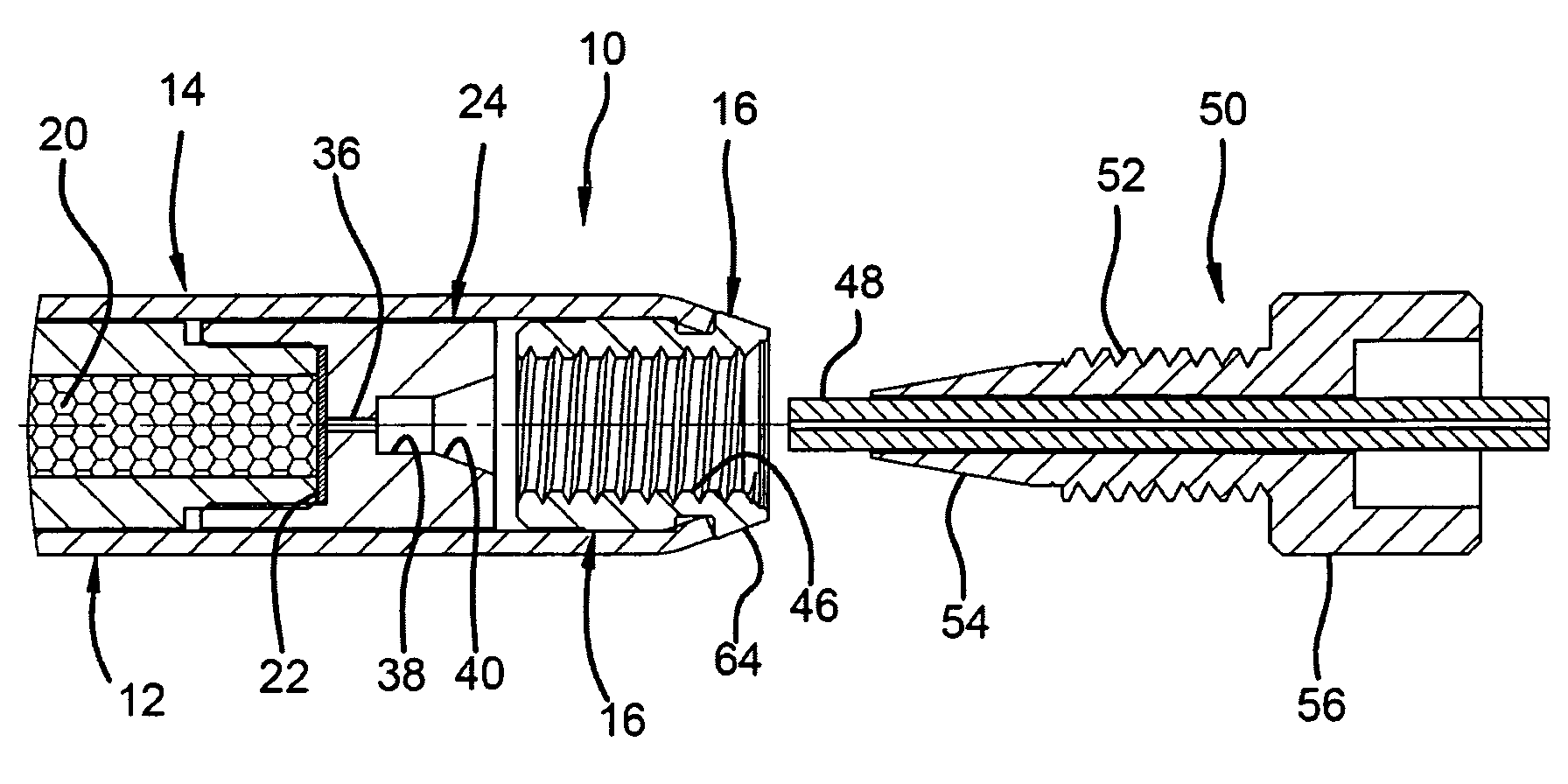

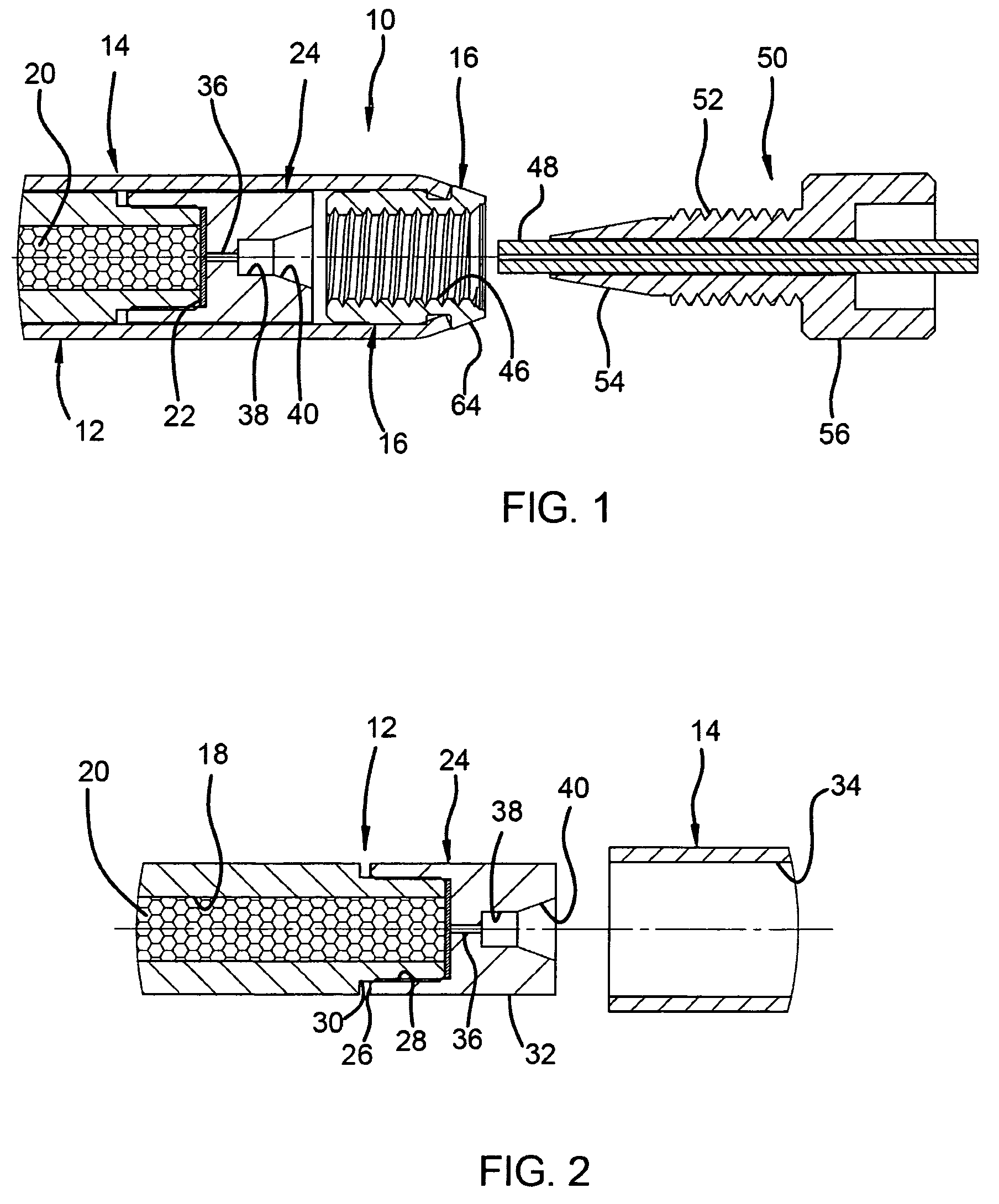

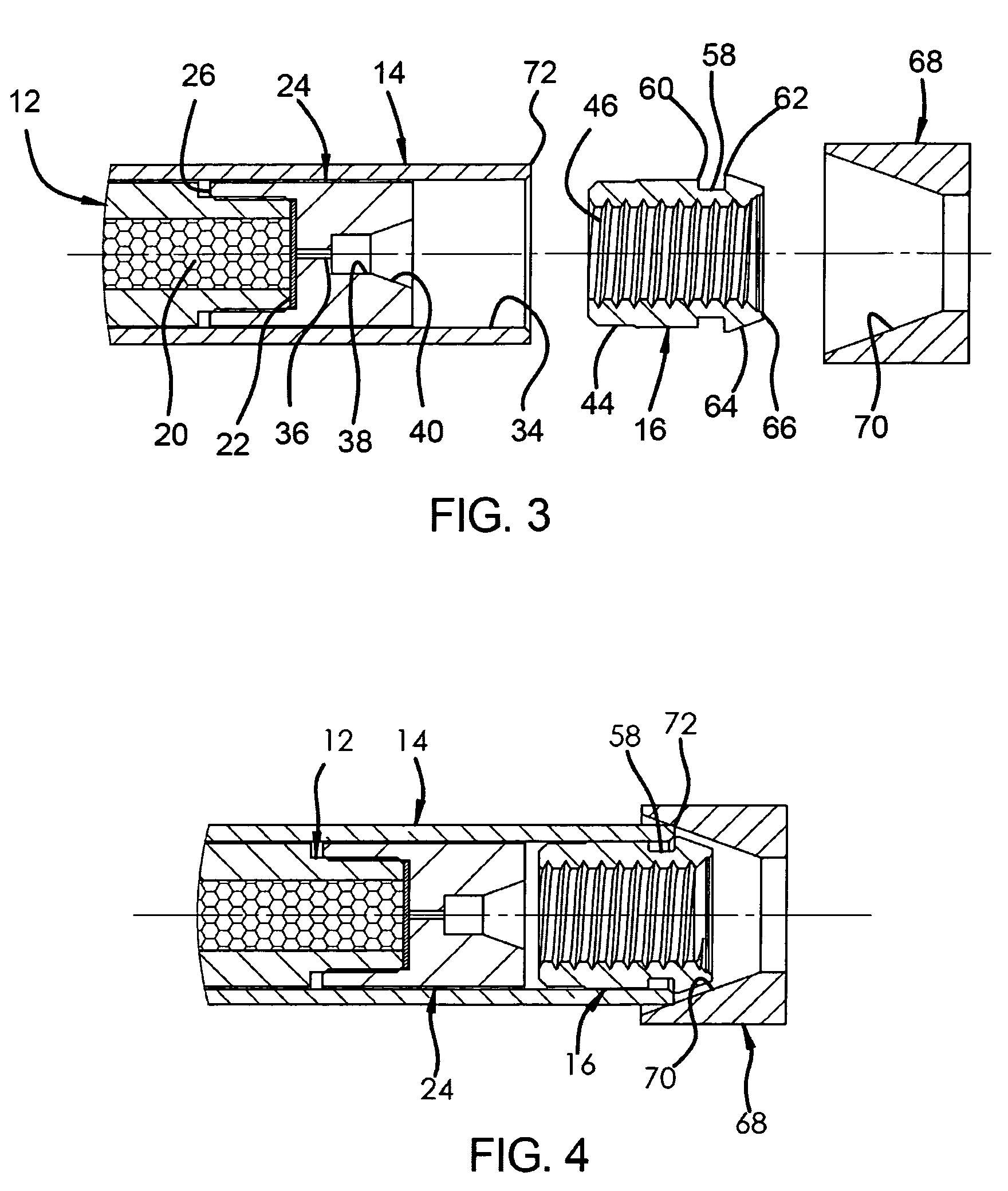

ActiveUS20050199540A1Economical and easy fabricationEasy and economical to fabricateIon-exchange process apparatusComponent separationCouplingCapillary Tubing

The disclosed HPLC column is formed with overlying concentric inner and outer tubes. The flow path is established via the inner tube bore that holds packed absorbent, end filters and capping sealing members, and end coupling members cooperate with the inner tube at its ends. The sealing and end coupling members have conventional configurations for establishing a sealed connection with capillary lines and their fittings, for the series flow testing use through the column. The inventive method and manner of assembly provides that the outer tube overlies all of the inner tube and both sealing members, but only part of each end coupling member. The ends of the outer tube are then deformed radially inward to become mechanically interlocked with the end coupling members, as the column, holding also the filters and sealing members within the inner tube.

Owner:S T E I C TECH

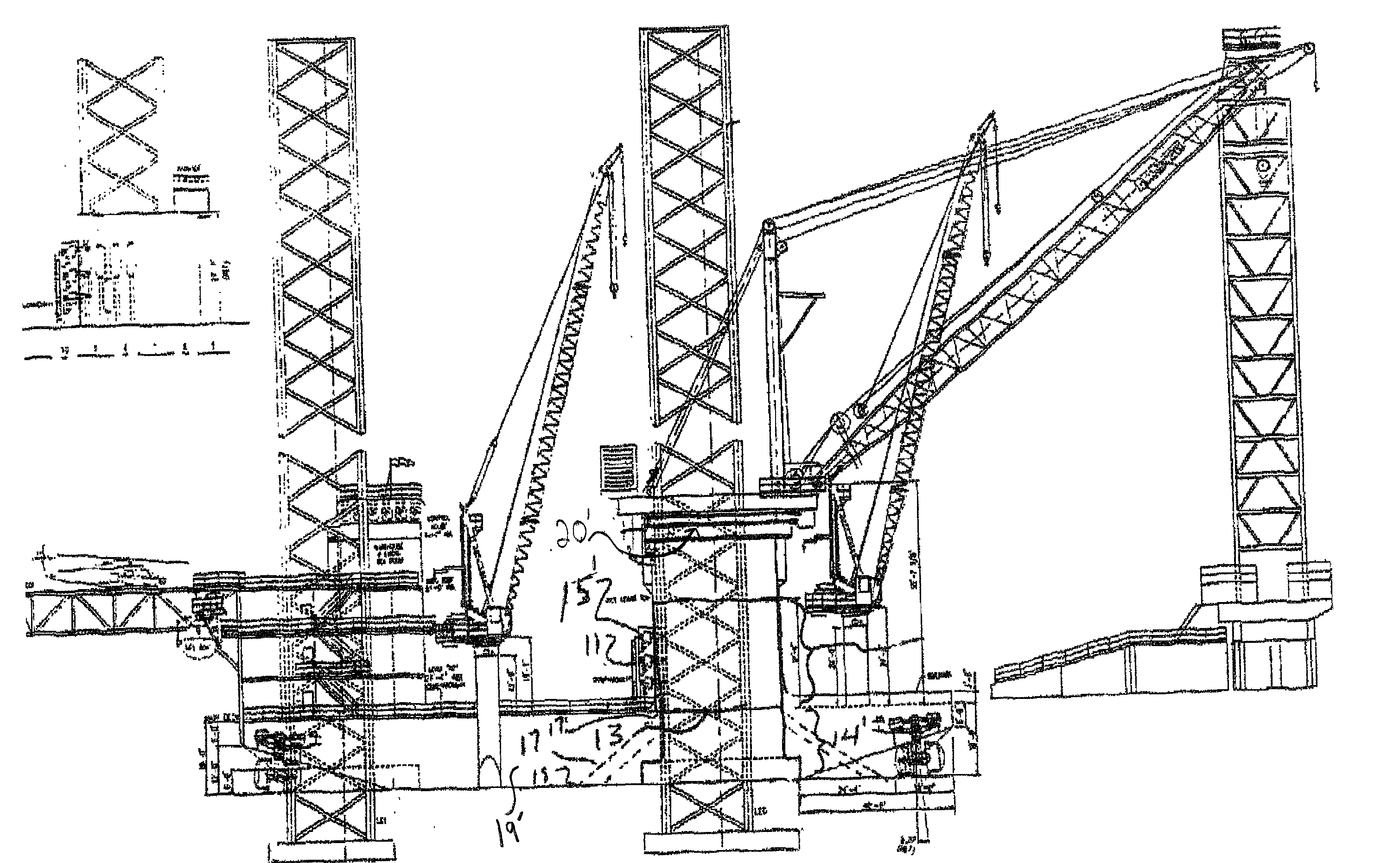

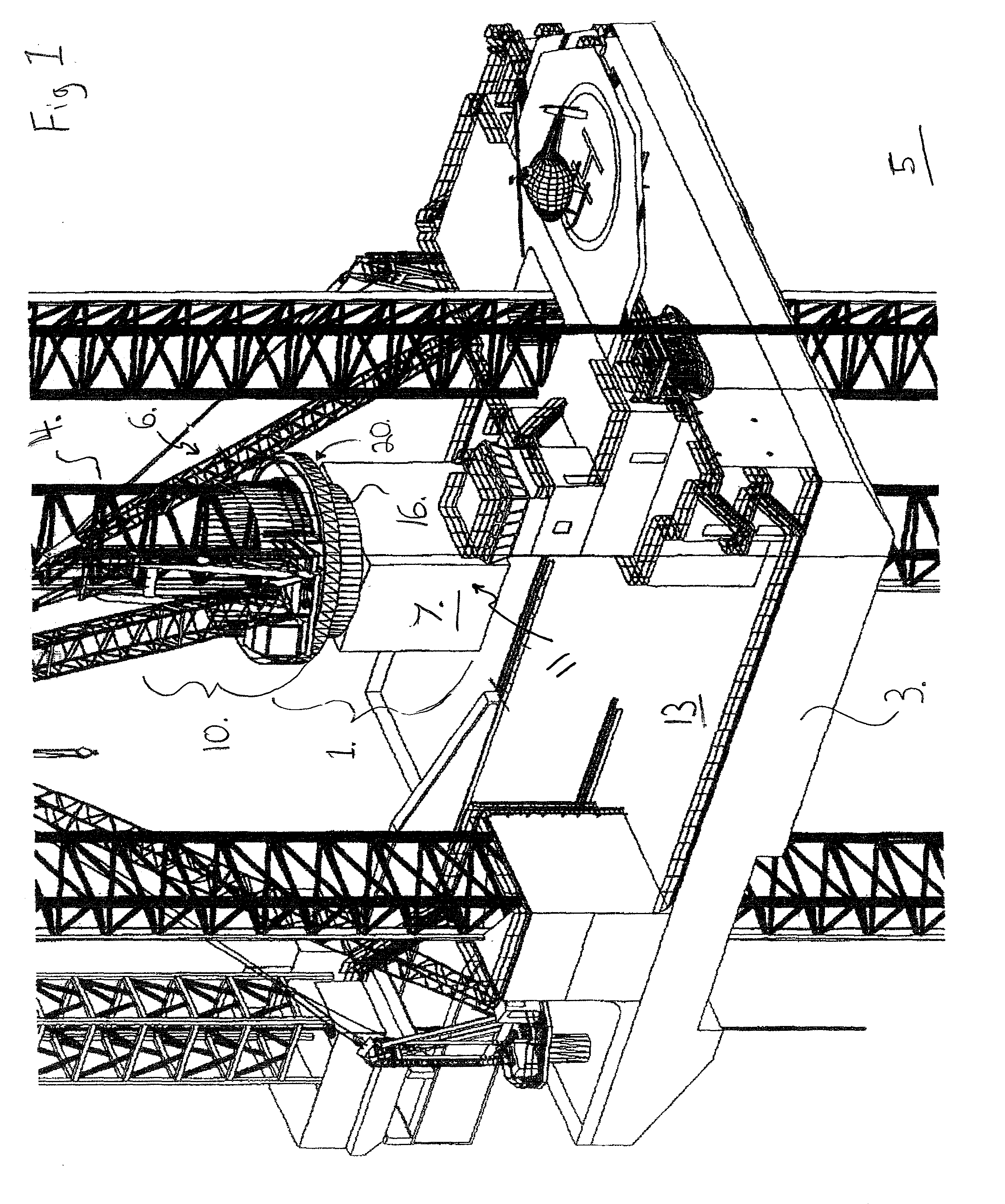

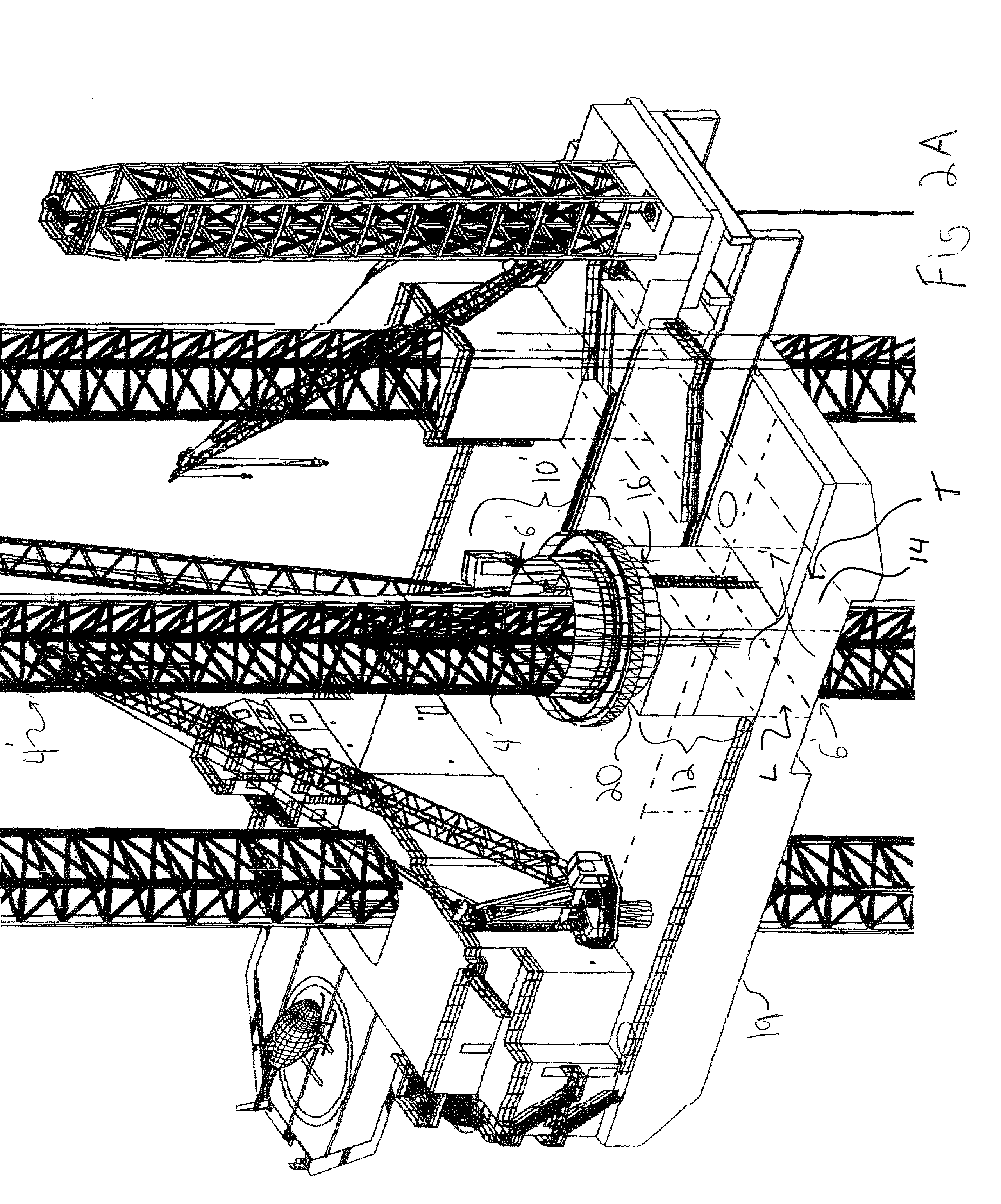

Elevated crane support system and method for elevating a lifting apparatus

InactiveUS20020079278A1Increase capacitySave spaceArtificial islandsDrilling rodsSupporting systemJackscrew

A support structure for supporting a lift crane, and in particular to a lift crane jack-up structures, including rigs, platforms, barges, boats or the like, wherein the lift crane is positioned about a leg of the jack-up structure atop the jack-house. The preferred embodiment of the present invention contemplates a system for elevating a lift crane above the deck and about the leg of the jack-up structure, without relying upon the leg for structural support. A structurally reinforced jack-house having jacking units interfacing with the leg is provided at the deck of the vessel the jack-house configured to engage and support a crane tube column upon the roof of the jack house, which crane tube column in turn has situated thereupon the lift crane. The combined jack-house / crane tube column design allows one to support a crane above the deck in a stable manner independent of the leg situated therethrough, so as to provide a superior structural support for the lift crane, while providing ample space within the jack-house for the jacking units. The combined jack-house / crane support structure thereby affords significant space savings upon deck of the platform, while providing enhanced support of the lift crane. The substructure of the vessel comprises longitudinal and transverse bulkheads intersecting to form a support cell having a perimeter, the portion of the bulkheads forming the cell extend vertically through the deck to form the walls of the jack house and support for the platform. In an alternative embodiment, a truss-type bracing assembly engages the perimeter of the support cell below deck to form a raised platform without walls.

Owner:THE LEVINGSTON

Method of efficient production of test tube potato and culture box thereof

InactiveCN1488244ALight textureIncrease light receiving areaHorticulture methodsPlant tissue cultureSucroseSaccharum

The invention is a fast tube potato breeding method and the equipment. Use detoxicated potato non-virus tube seedling by tissue culture as material, adopt MS culture medium, without any grower to obtain the test-tube potato seedling with no any growth material and its cane sugar concentration 6%-10%, then place in culture box for liquid culture, light intensity 2000-3000lux, and illuminate for about 8 hours every day, and according to sensitivity of different potato varieties to short sunlight, make illumination adjustment. It designs a special culture box for tube potato, composed of under tube body and box cover, ventilate column designed on the cover. It can produce for 5-6 times each year. Unit area of culture room can produce 100,000-200,000 tube potatoes.

Owner:HUBEI BIO GREAT AGRI TECH

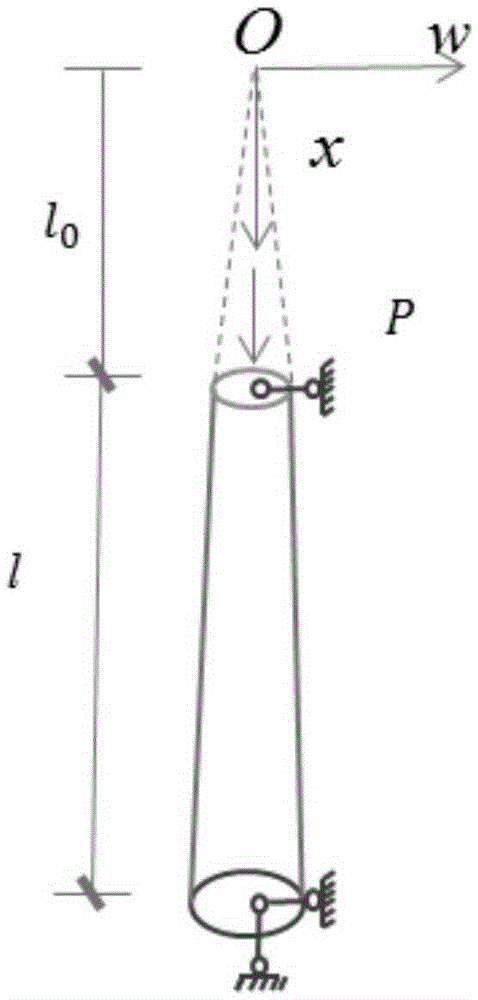

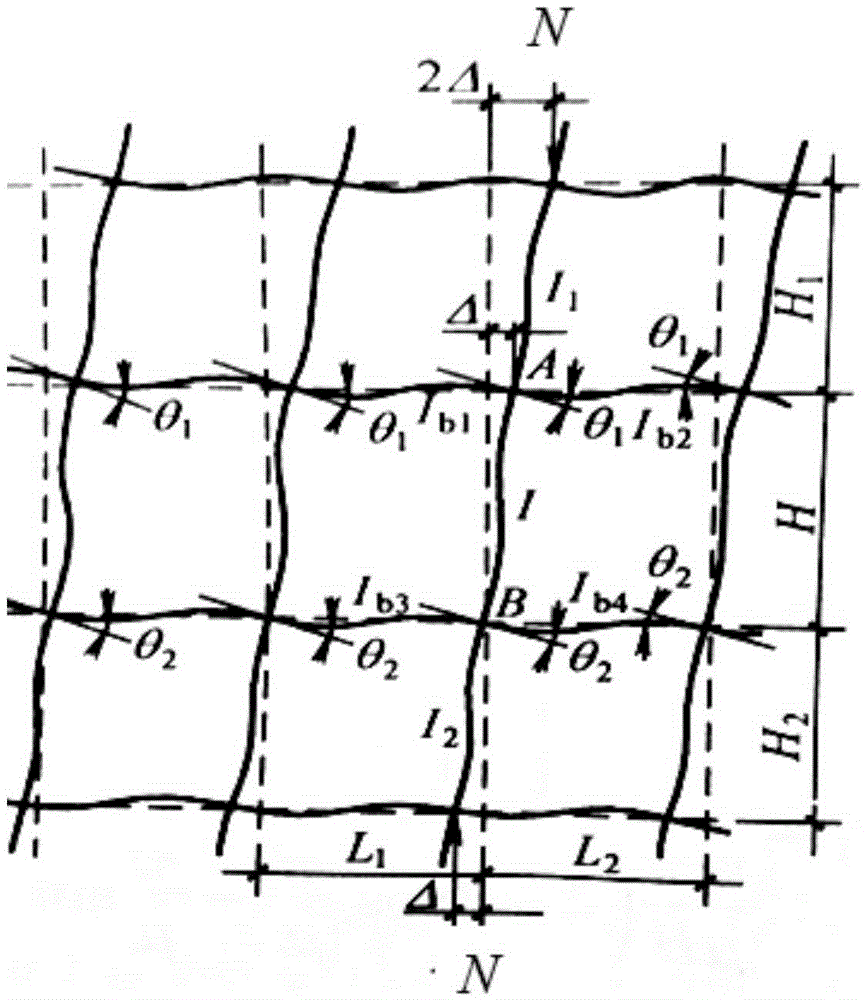

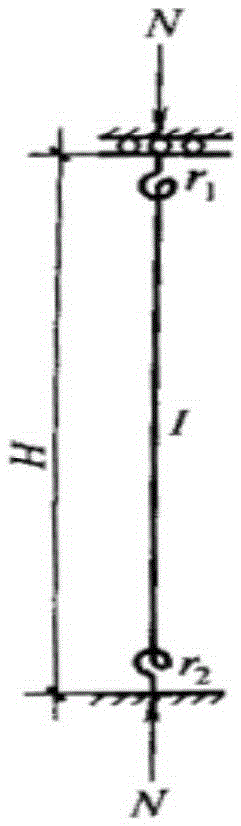

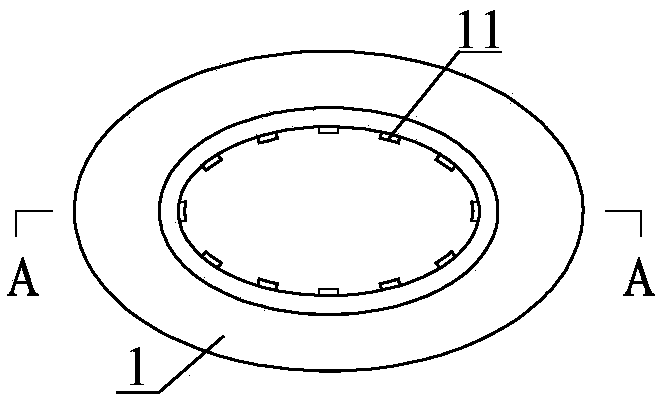

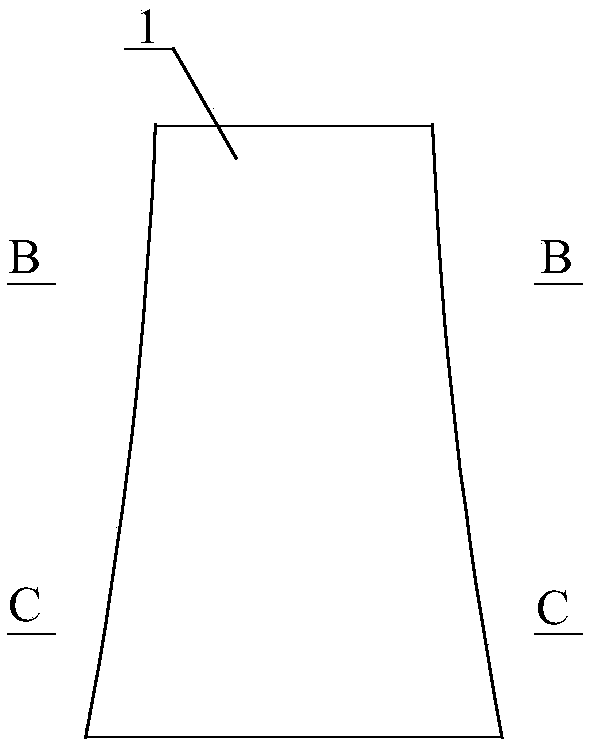

Method for calculating equivalent calculation length and stability of steel tube concrete tapered column in view of integral space action

ActiveCN105279325AReliable methodSpecial data processing applicationsFinite element softwareComputer science

The invention discloses a method for calculating equivalent calculation length and stability of a steel tube concrete tapered column in view of an integral space action, and belongs to the field of steel tube concrete tapered column design. The method comprises the steps of: calculating an eigenvalue load of the steel tube concrete tapered column in view of the integral space action through finite element software, performing eigenvalue buckling analysis on a column with two hinged ends without the space action, and analyzing a buckling eigenvalue of a column with two hinged ends, a small head and a uniform section without the space action; calculating a calculation length coefficient of a supporting column in view of an integral space restriction action; obtaining an equivalent calculation length coefficient of the steel tube concrete tapered column with two hinged ends under an equivalent uniform-section column; and obtaining an equivalent calculation length coefficient of the tapered column in view of the integral space action. The invention provides a judgment method for the equivalent calculation length and stability of the steel tube concrete tapered column in view of the integral space action, so that a practical, efficient and accurate engineering application calculation method is obtained.

Owner:成都建筑材料工业设计研究院有限公司

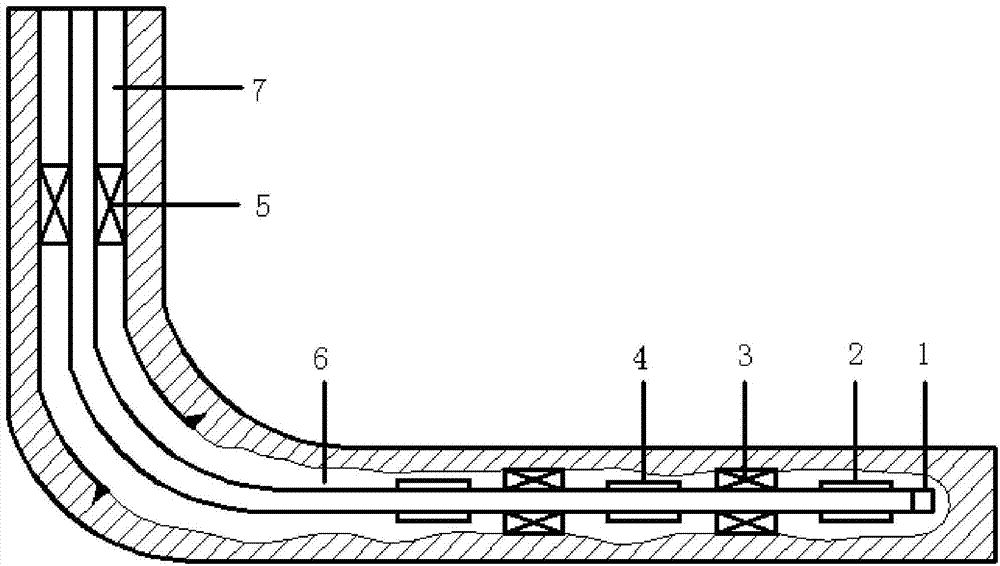

Segment transforming process for well-completion acid fracturing of open-hole horizontal well of oil gas well

The invention belongs to the field of a capacity increasing revamp technology of an oil gas well, in particular to a segment transforming process for the well-completion acid fracturing of an open-hole horizontal well of an oil gas well. The process comprises the following steps: firstly, tubular column design; secondly, tubular column tripping in; thirdly, delivering and feeding a ball into a seat; fourthly, setting an open hole packer and a suspending packer, and packing a floor stratum and suspending a tool on a designed position; fifthly, releasing grip, and correcting the depth and determining the actual position of a suspended packer (5); sixthly, adjusting the length of the returned tubular column according to a depth correction result and an oil pipe stretching distance in the above steps, and returning the oil pipe and reloading a wellhead; changing a wellhead packer group into an oiling (gas) tree, connecting a ground pipeline and realizing the standard pressure test; seventhly, pressing and cutting a sliding sleeve pin of a delivery sieve tube (2), and extruding the volume of an oil tube to hold clear water; and eighthly, carrying out reservoir reform and fracturing truck construction to finally complete the segment transformation of the acid fracturing. According to the segment transforming process provided by the invention, the problems that a reservoir of the horizontal well is bad in connectivity and low in oil well yield can be solved, and the well yield can be significantly improved by the well completion increase yield.

Owner:XINJIANG GANGTUO ENERGY TECH

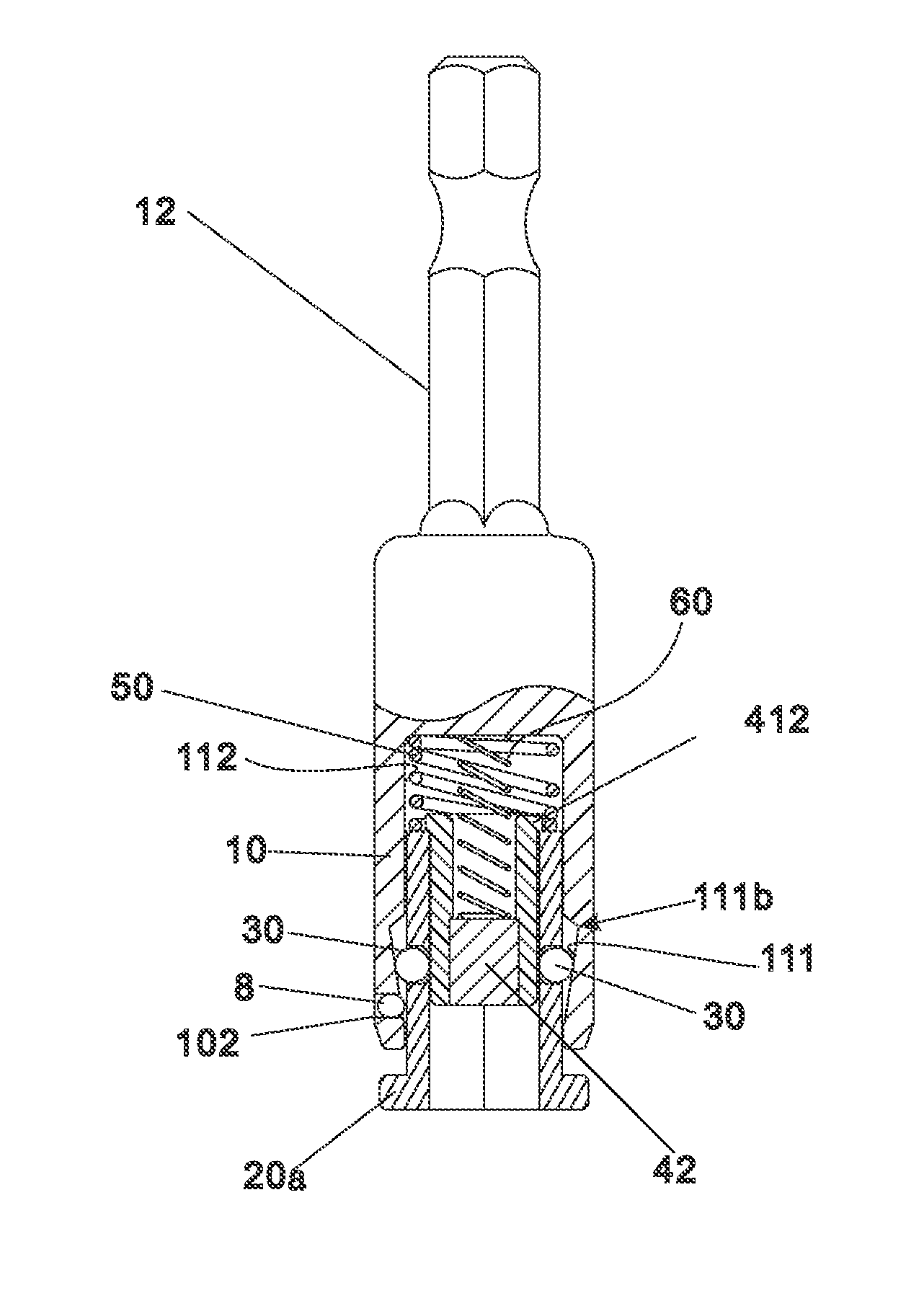

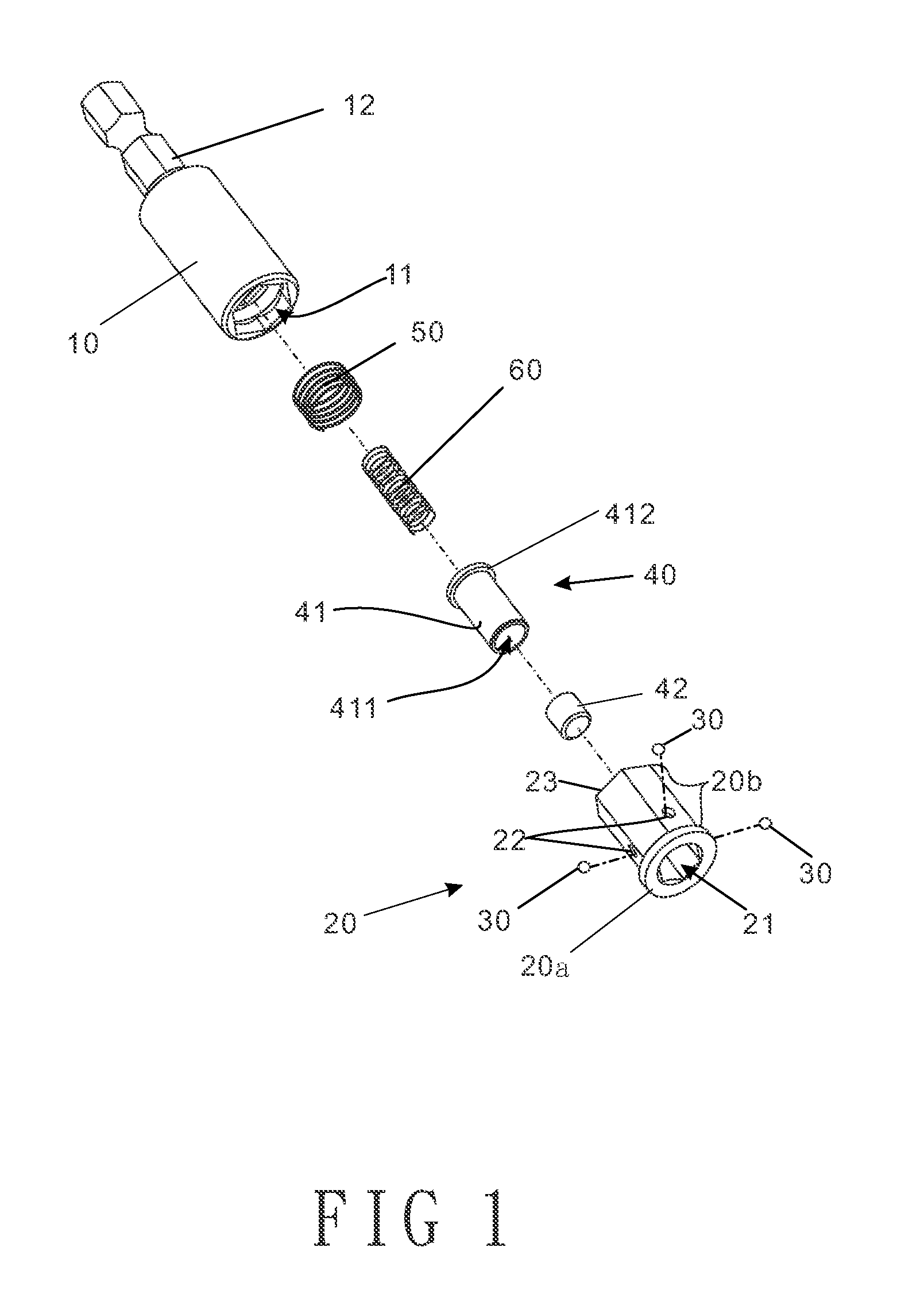

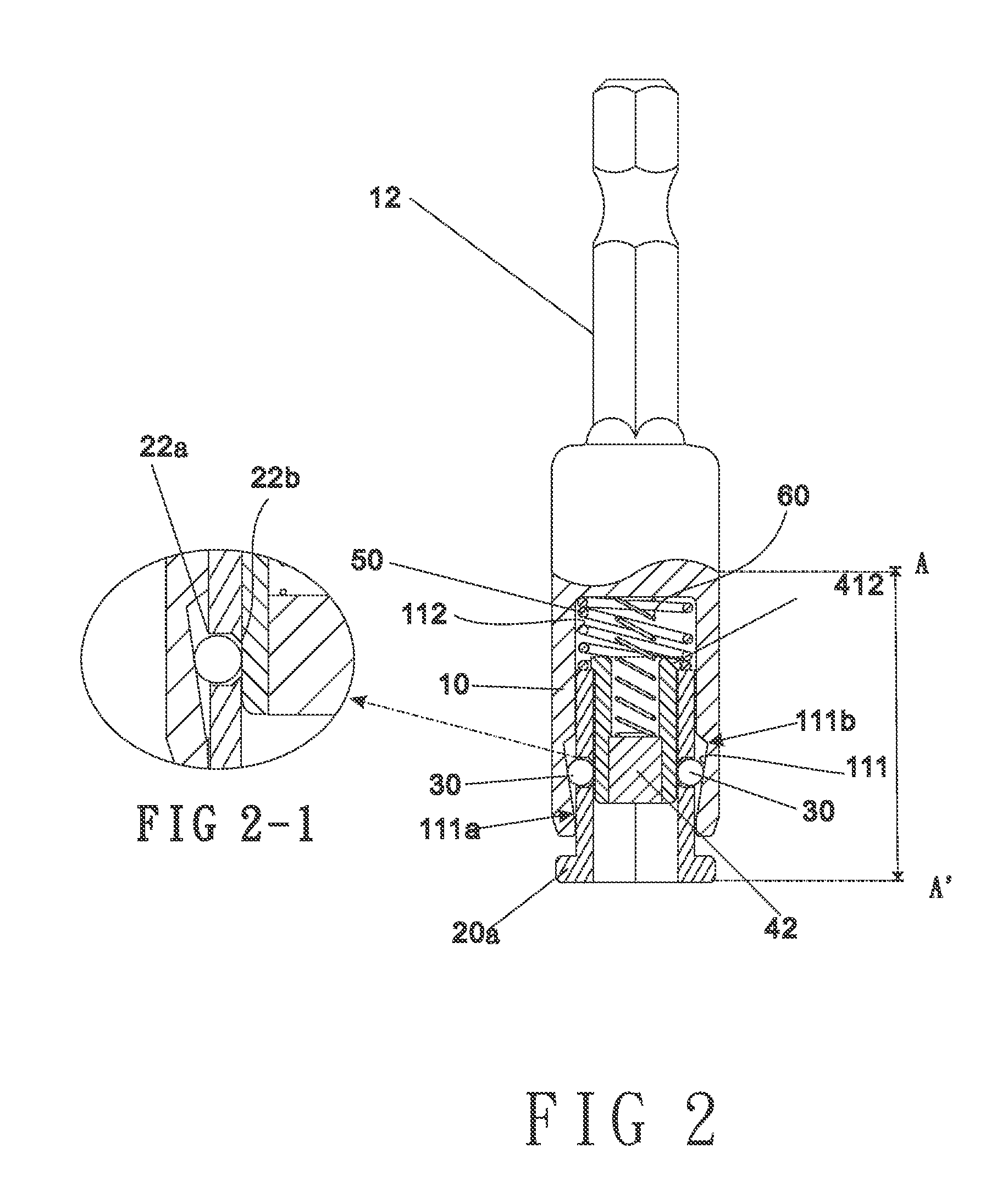

Tool joint

InactiveUS20150102567A1Avoid assemblyEasy to installSleeve/socket jointsSpannersEngineeringSacroiliac joint

A tool joint is revealed. The tool joint includes a first main body, a second main body, locking members and a sleeve set. The first main body consists of a mounting part, a stopping part and a rear part. The second main body is disposed in the mounting part and having a polygonal assembly slot penetrating the second main body. Insertion holes are disposed close to an opening end of the assembly slot. The second main body is a polygonal column whose shape matches that of the polygonal assembly slot. The locking member is against the stopping part. The sleeve set is mounted in the assembly slot. The tool joint features on that the second main body is unable to rotate radially in the mounting part by the polygonal column design of the second main body locked with walls of a polygonal slot of the mounting part.

Owner:CHAN FU YI

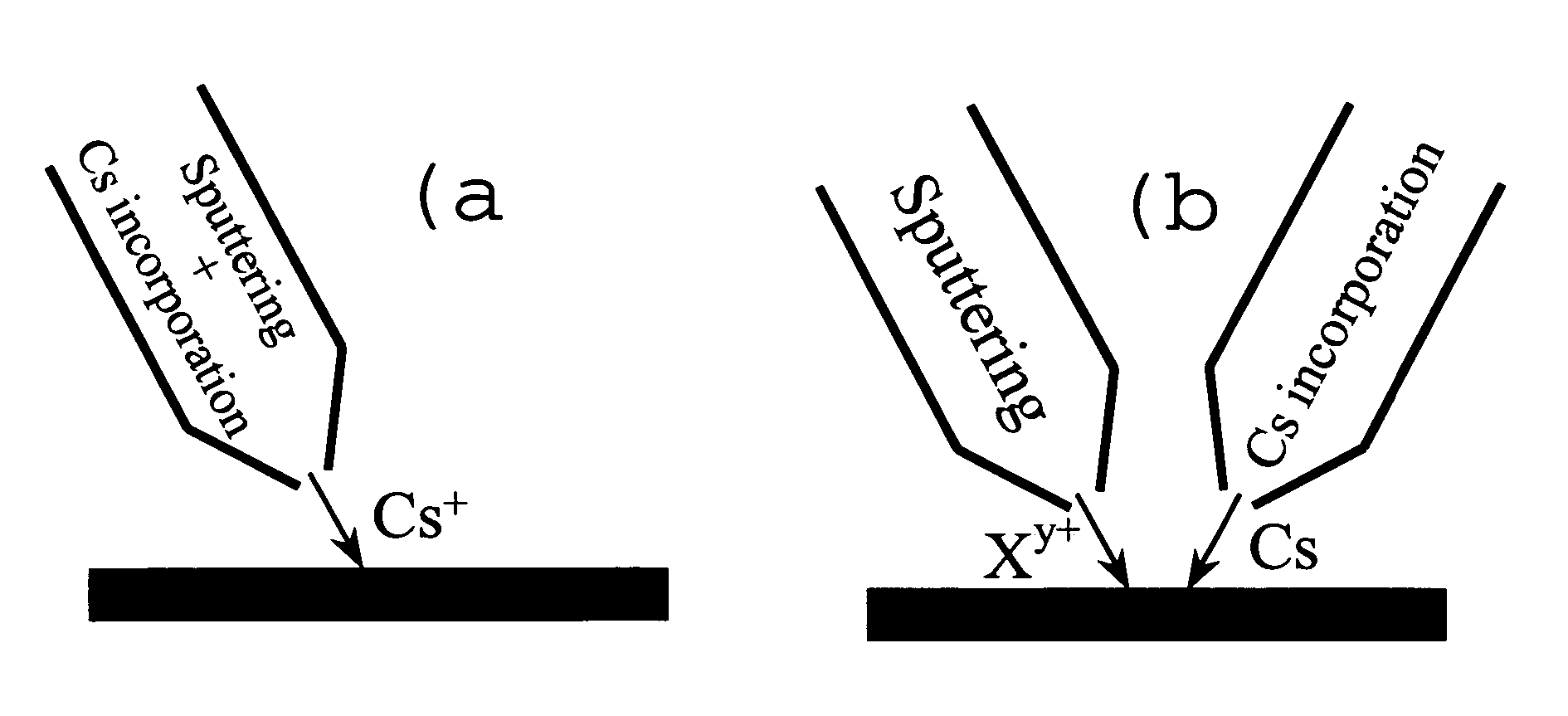

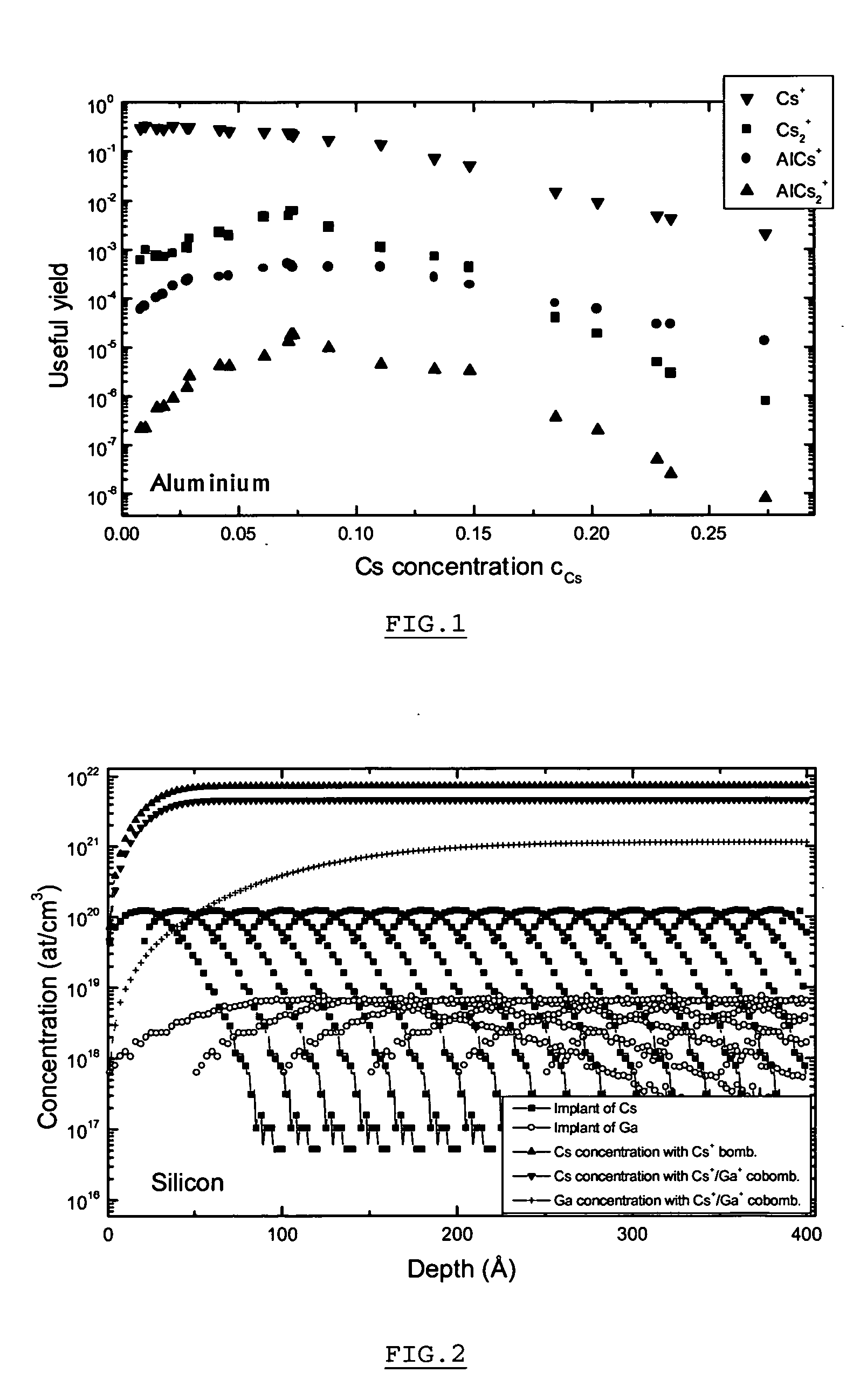

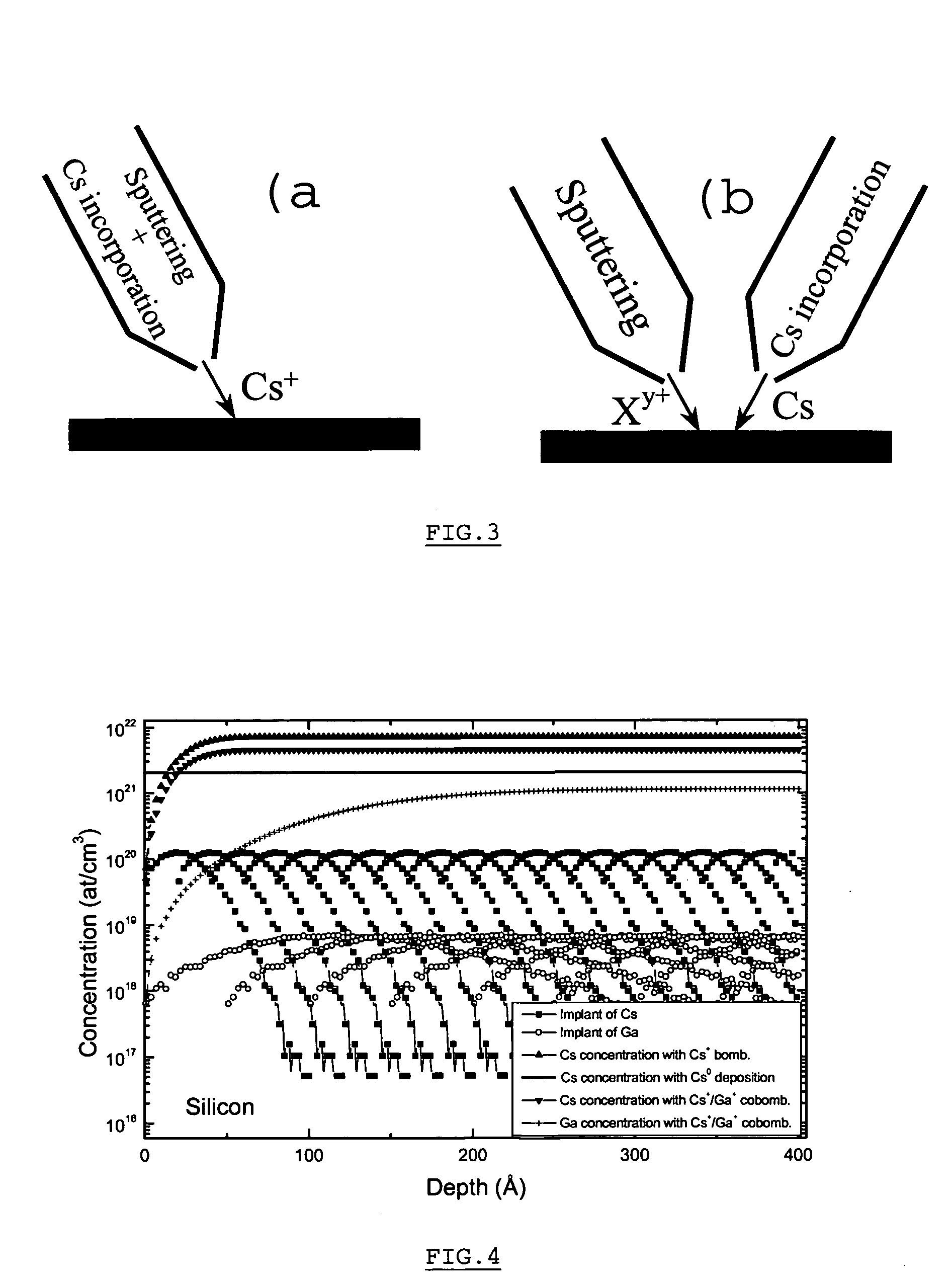

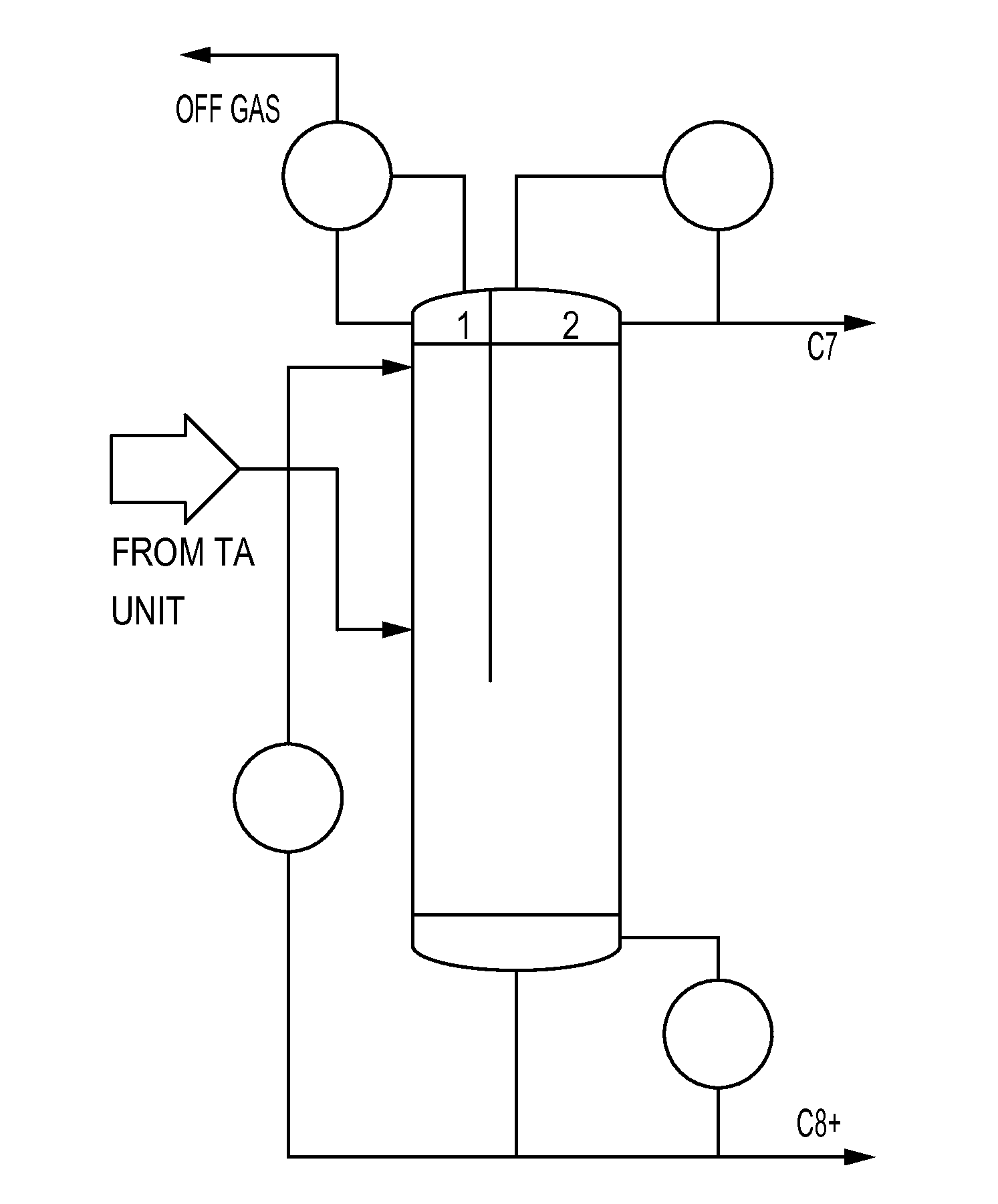

Method and apparatus for in situ depositing of neutral cs under ultra-high vacuum to analytical ends

ActiveUS20060011865A1Laser detailsMaterial analysis using wave/particle radiationUltra-high vacuumElectron spectroscopy

The present invention relates to a method for modifying the electronic properties of a surface to analytical ends, such as SIMS or electron spectroscopy, characterised in that it comprises in situ deposition of pure neutral cesium (Cs0), under ultra-high vacuum, said neutral cesium being enabled in the form of a collimated adjustable stream. The invention relates also to the special column designed for implementing the method and to the corresponding energy and / or mass analyser instrument.

Owner:CENT RECH PUBLIC GABRIEL LIPPMANN

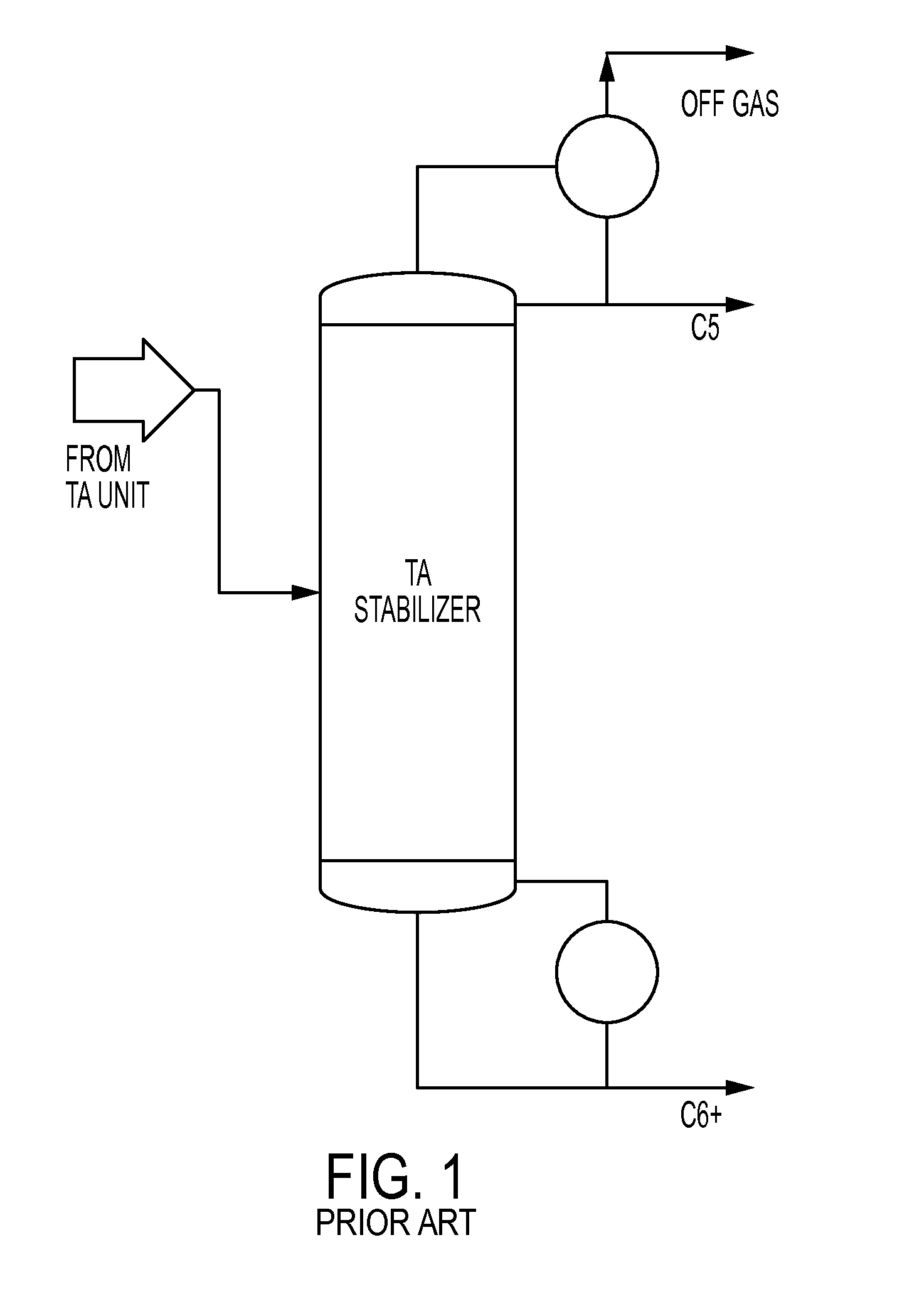

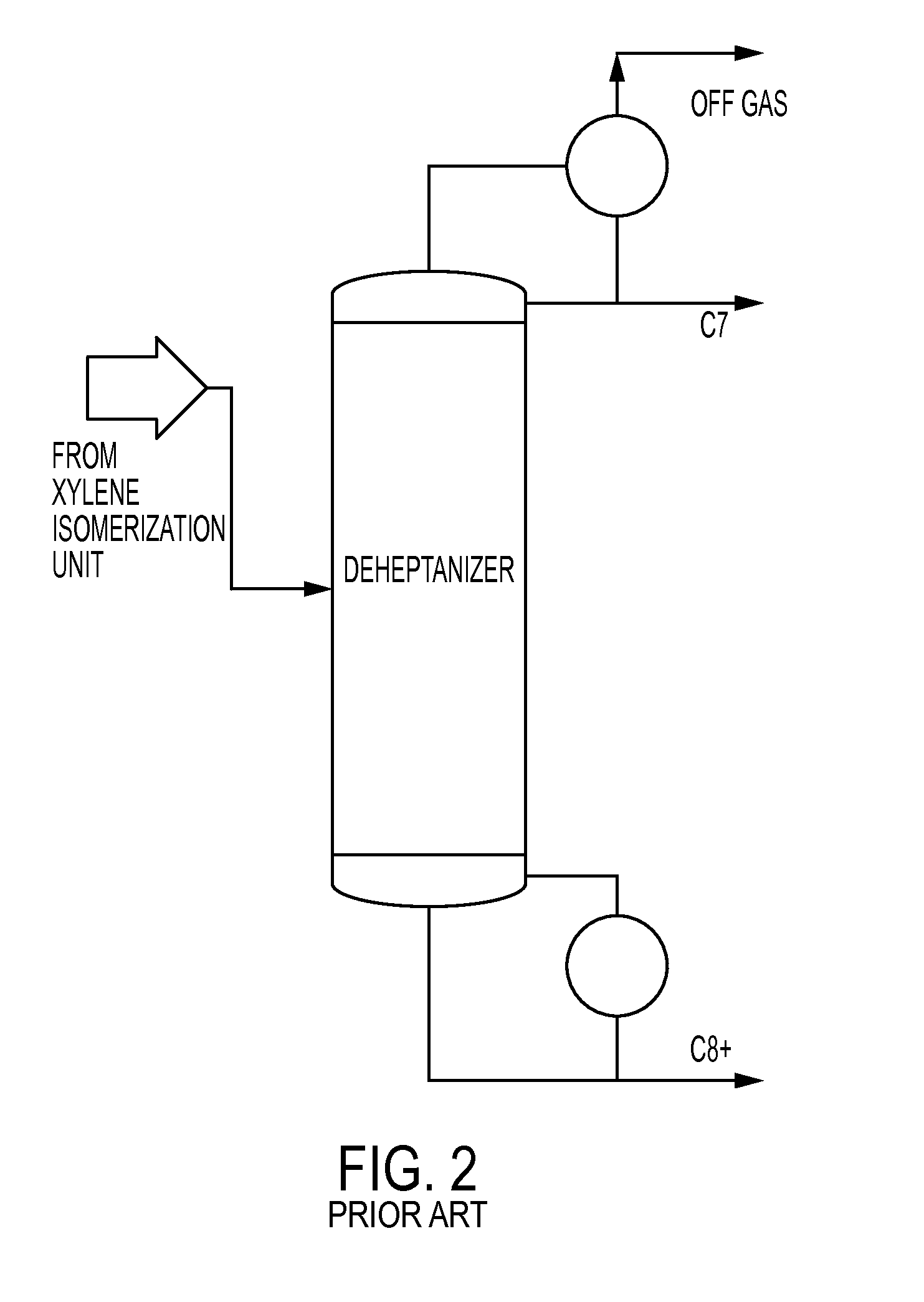

Method of carrying out absorption/distillation in a single column design

Embodiments of the invention are directed to a process wherein two different unit operations (absorption and distillation) take place on either side of a top dividing wall column. One side of the dividing wall column uses absorption to separate non-condensable components from the feed; the other side of the dividing wall uses distillation to separate heavier liquid components.

Owner:SULZER MANAGEMENT AG

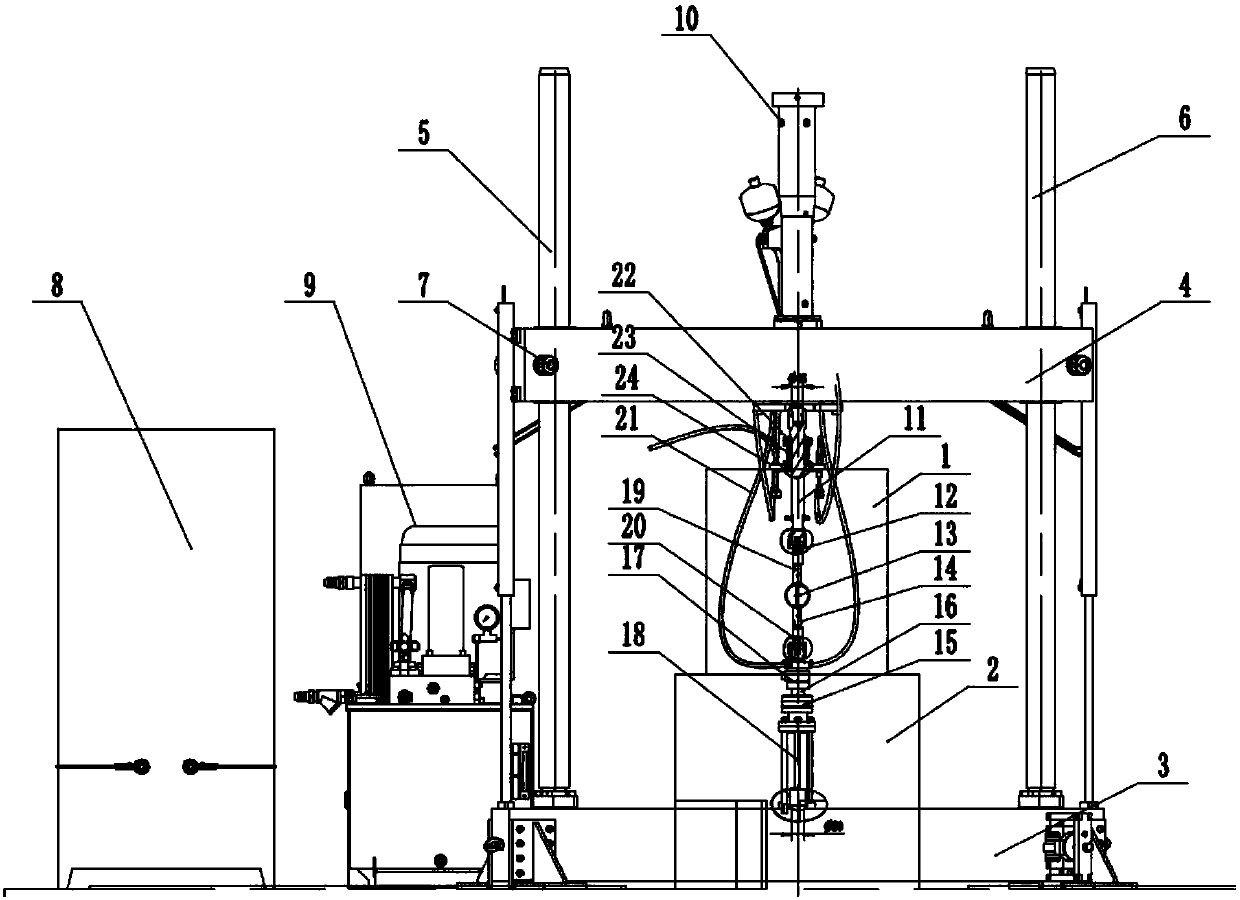

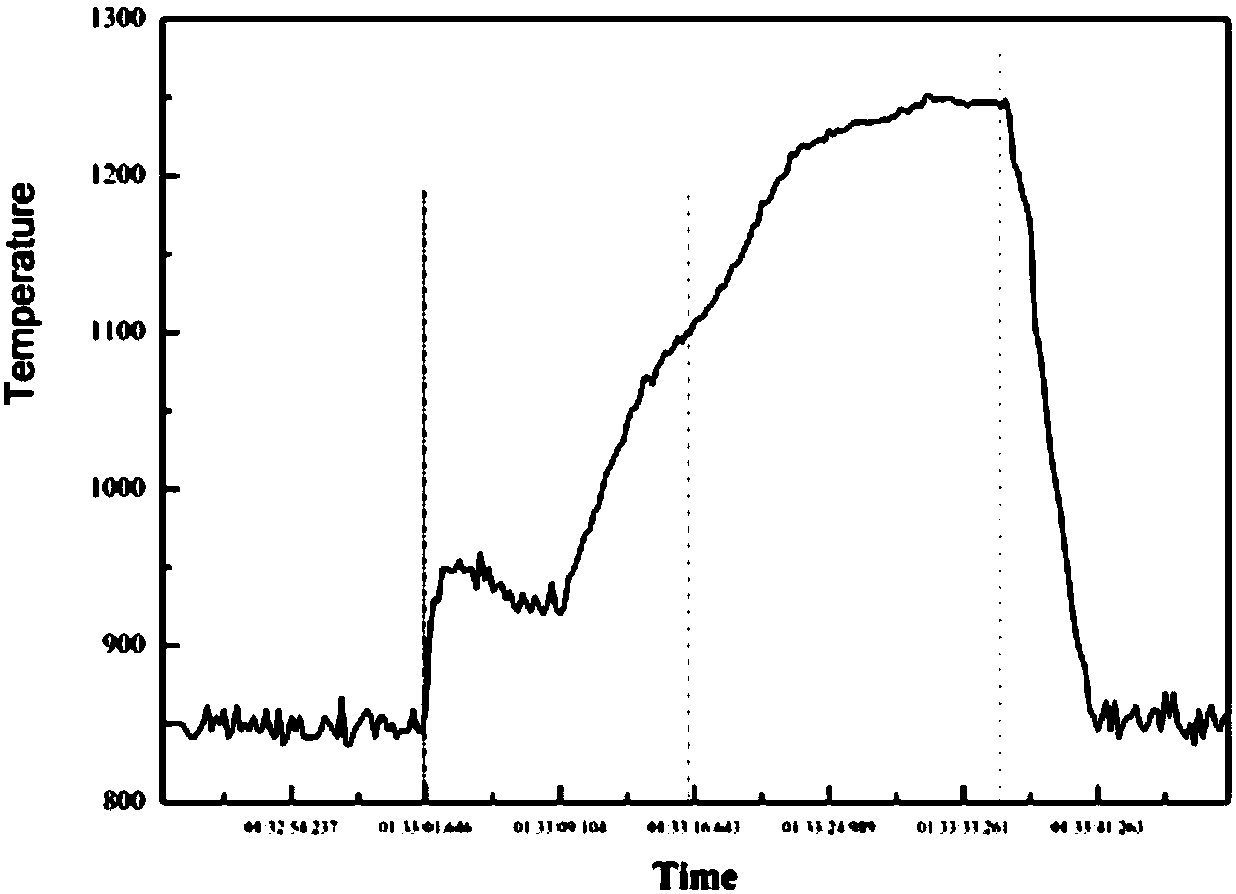

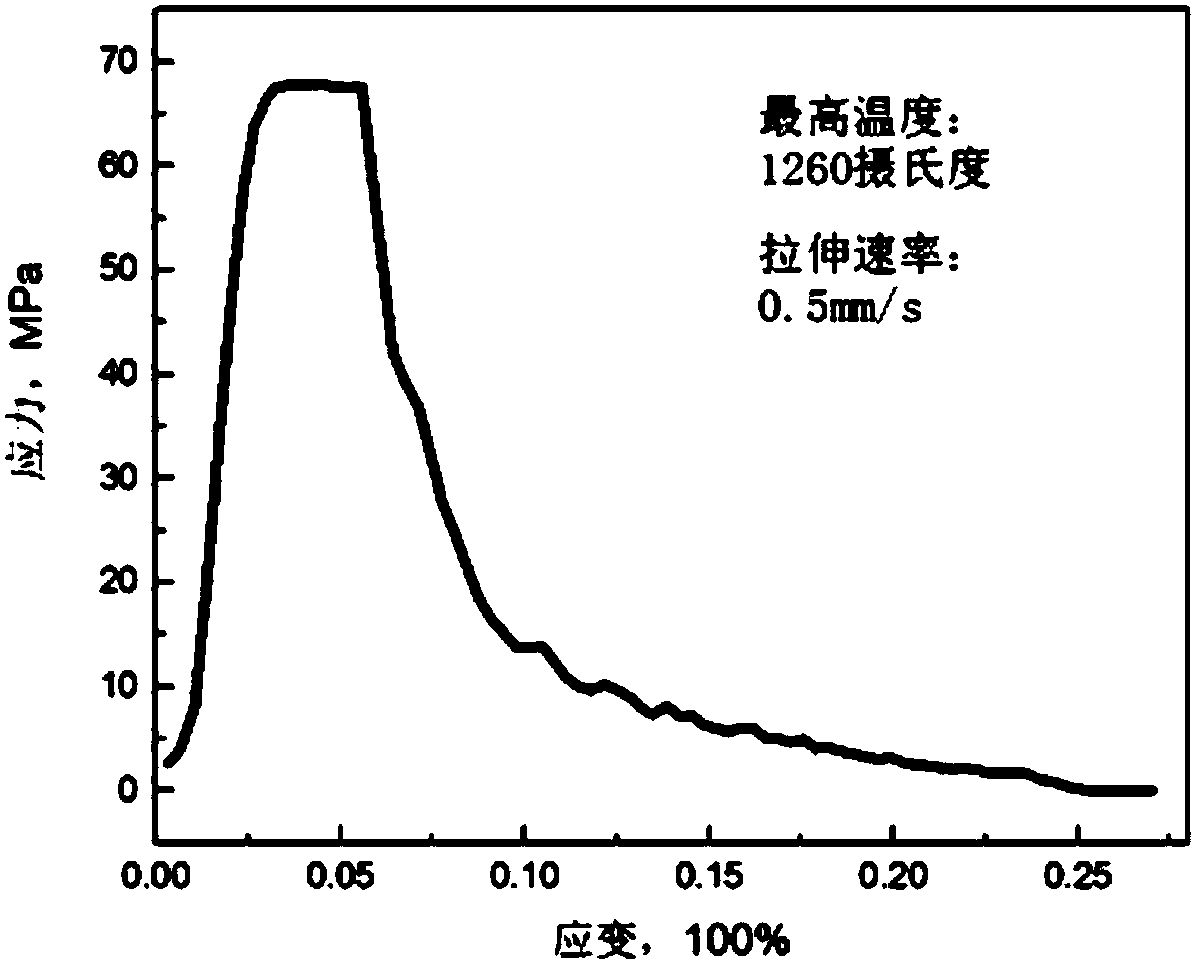

Material high-temperature mechanical performance test device in aerodynamic heat-force coupling environment

PendingCN107727487AAdjustable lengthAdjustment diameterStrength propertiesElectro hydraulicEngineering

The invention provides a material high-temperature mechanical performance test device in an aerodynamic heat-force coupling environment, which belongs to the technical field of the test of material high-temperature mechanical performance. The material high-temperature mechanical performance test device comprises a main machine framework, a mechanical loading system and a clamp water cooling system, wherein the main machine framework adopts a double-stand-column design, the lower end of an oil cylinder mechanism of the mechanical loading system penetrates through an upper crossbeam of the mainmachine framework and is fixed with the upper crossbeam in a thread manner, an upper drawing bar, an upper clamp and the like of the mechanical loading system are connected to the lower end of the oilcylinder mechanism, and other parts of the mechanical loading system are successively connected with a lower crossbeam. The clamp water cooling system is used for cooling a sample clamping mechanismin the mechanical loading system. The material high-temperature mechanical performance test device designs the main machine which can be matched with a coherent jet aerodynamic-heat coupling environment simulation test cabin, has a unique structure design, integrates multiple advanced test technologies, and can well implement the ultrahigh-temperature mechanical performance test of a ceramic material in the coherent jet aerodynamic-heat coupling environment.

Owner:UNIV OF SCI & TECH BEIJING

Stainless steel tubing/frit with sintered inorganic particle, the chromatography comprising it, and their manufacturing method

InactiveUS20040238447A1Simple design convenienceLow costIon-exchange process apparatusOxide/hydroxide preparationSilicon dioxideInorganic oxide

This invention is about metal tubing / frit applicable in liquid chromatography and a chromatography column manufactured by using the same. In detail, this invention is about manufacturing the metal tubing / frit by treating a powdered inorganic oxide such as silica, alumina, zirconia, and titania with a strong base, drying it with some humidity included, scrubbing it into powders, putting it in the tip of a chromatographic metal tubing at a proper depth, and by sintering the powders to form a durable sintered frit on the inner wall. This invention is also about a liquid chromatographic column manufactured by installing the metal tubing / frit's with a sintered end frit at the column inlet and outlet unions and by placing the cylinder-like column main body tubing packed with a stationary phase between the unions. The metal tubing / frit manufactured according to the description above is not placed inside the column as in the conventional column design, thus it is easily replaced and fixed without disassembling the column, and the column of this design can displace the conventional microcolumn of complicated production process and high cost.

Owner:CHEONG WON JO +1

Radial flow reactor with movable supports

InactiveUS8216343B2Reduce adverse effectsLoad minimizationGas treatmentPhysical/chemical process catalystsPre stressingEngineering

A radial flow reactor vessel is disclosed for use in gas purification, separation or reaction processes and most suitably used in prepurification processes. The reactor has internal baskets for confining a bed of active material. The baskets are rigidly supported at both the top and bottom ends of the reactor and have walls that are axially flexible and radially rigid. The vessel has multiple movable support columns designed to facilitate pre-stressing of the baskets to offset axial compressive loads induced from thermal cycling.

Owner:PRAXAIR TECH INC

Flooring apparatus and systems for improved reduction of impact forces during a fall

InactiveUS20110072748A1Stiffness can be optimizedIncrease stiffnessBuilding roofsConstruction materialBrickEngineering

This invention provides a flooring apparatus comprising: (a) a flooring plate; (b) a plurality of columns extending from an underside of the flooring plate, wherein at least some of the columns deform when the flooring plate is subjected to a pressure equal to or greater than a critical buckling pressure; and (c) a matrix material in at least partial contact with the columns. The present disclosure includes many variations of such apparatus, such as various column designs, material selection criteria, and end-use considerations. This invention also provides a flooring system for mitigating injuries associated with falls, the system comprising a plurality of flooring apparatus each provided in accordance the present disclosure. The flooring system can include one or more types of modular tiles, or any other configuration (such as mats).

Owner:SORBASHOCK

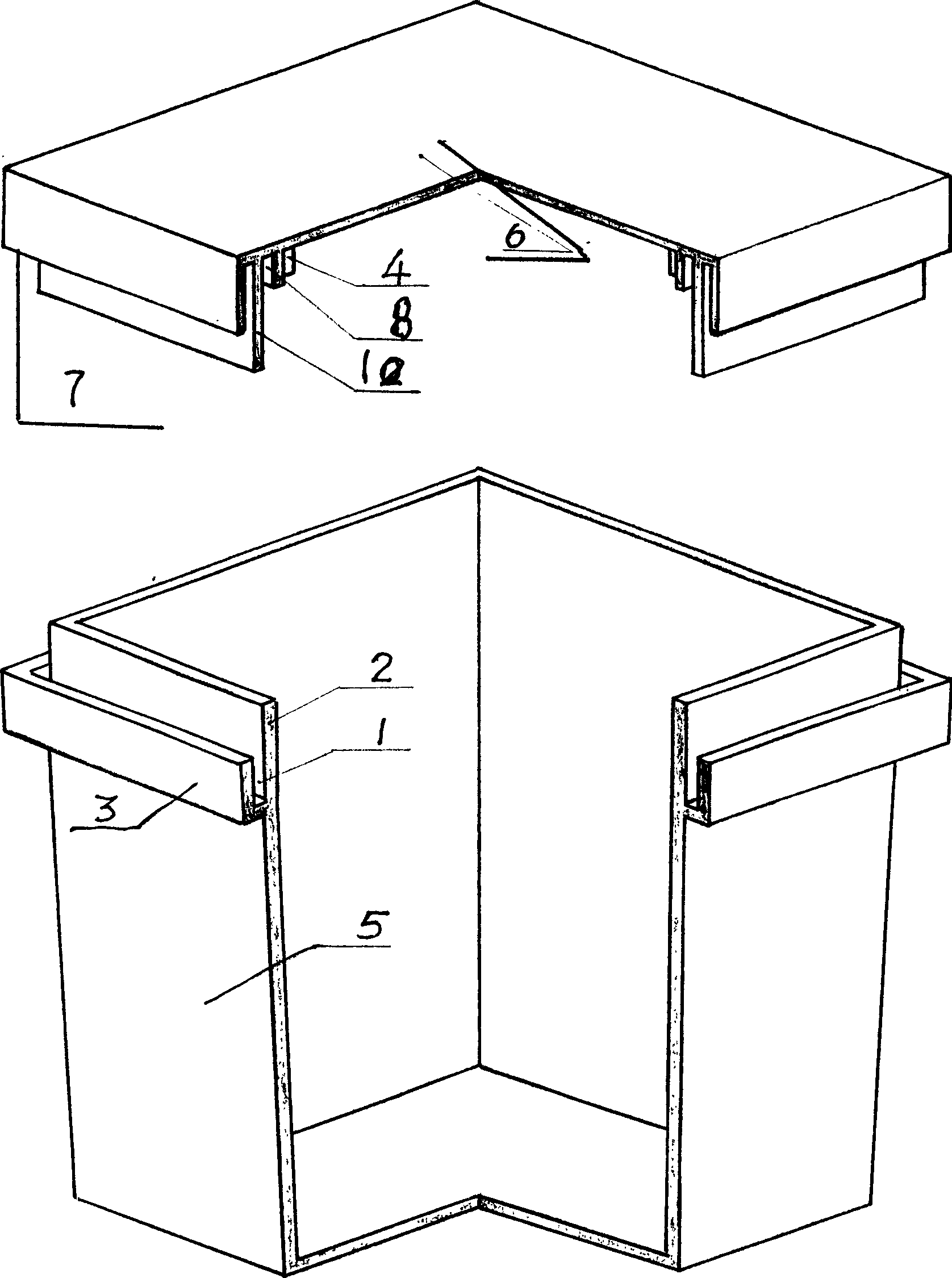

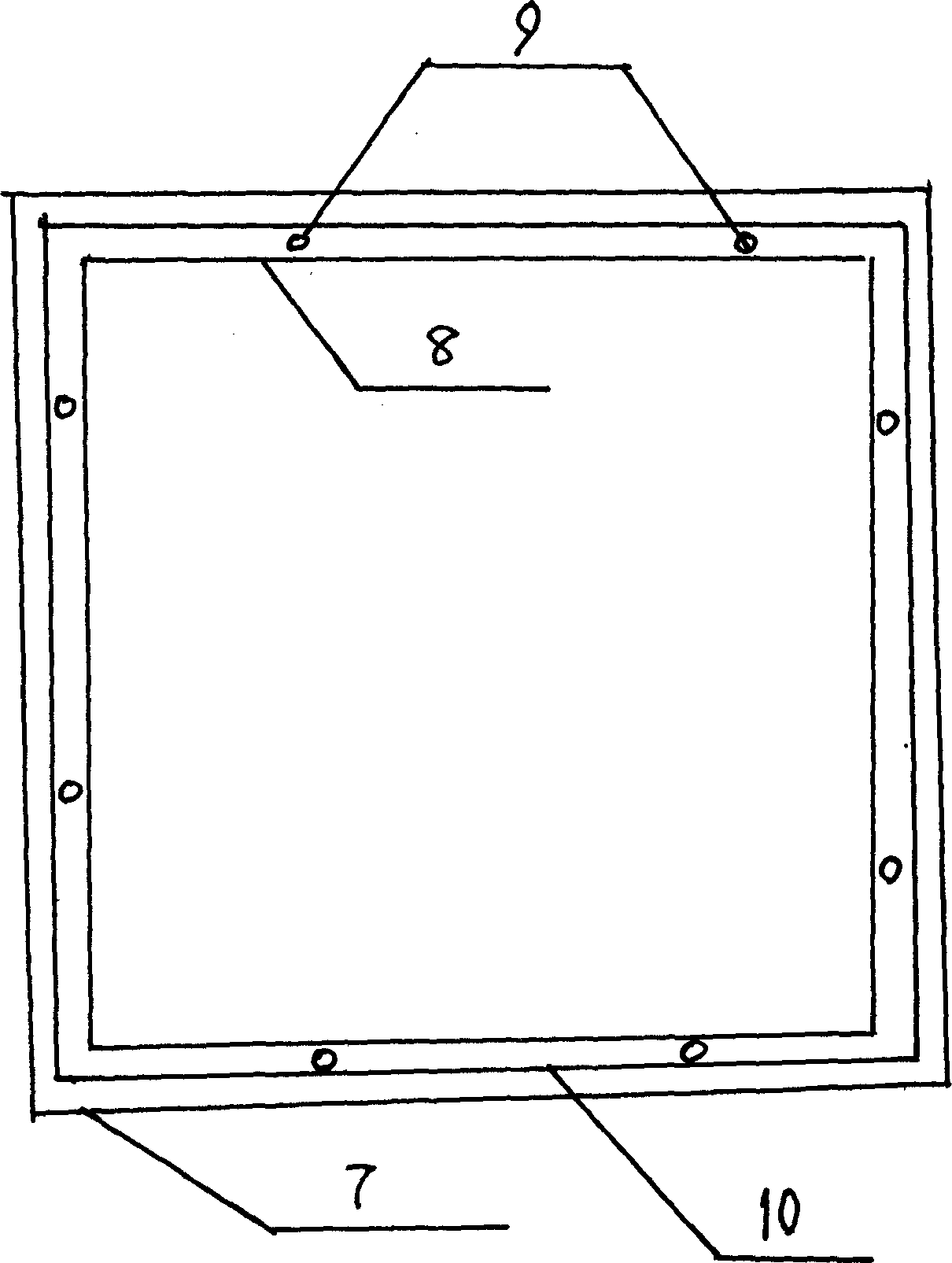

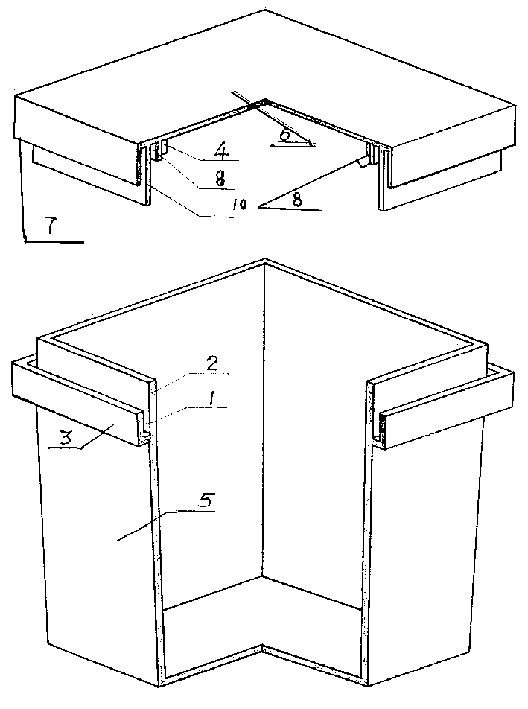

Buffer packing apparatus

InactiveUS6837421B1Protection from damageEasy to identifyContainers to prevent mechanical damageRigid containersComputer scienceColumn design

A buffer packing apparatus for packing a plurality of objects is provided. The buffer packing apparatus comprises a plurality of rectangular partition boards and a plurality of buffer columns. The rectangular partition boards form a plurality of compartments for buffering and accommodating the objects. Through the selection of different buffer column designs, orientation of the objects inside the buffer packing apparatus can be easily identified. With chamfers on every corner of the buffer packing apparatus, the shock produced by an external impact can be readily absorbed thereby increasing the buffering capacity of the packing.

Owner:ARIMA COMP

HPLC column design and method of making same

ActiveUS7125489B2Easy and economical to fabricateCheap to makeIon-exchange process apparatusComponent separationCouplingEngineering

The disclosed HPLC column is formed with overlying concentric inner and outer tubes. The flow path is established via the inner tube bore that holds packed absorbent, end filters and capping sealing members, and end coupling members cooperate with the inner tube at its ends. The sealing and end coupling members have conventional configurations for establishing a sealed connection with capillary lines and their fittings, for the series flow testing use through the column. The inventive method and manner of assembly provides that the outer tube overlies all of the inner tube and both sealing members, but only part of each end coupling member. The ends of the outer tube are then deformed radially inward to become mechanically interlocked with the end coupling members, as the column, holding also the filters and sealing members within the inner tube.

Owner:S T E I C TECH

Glass fiber mesh reinforced concrete permanent column formwork and preparation method thereof

InactiveCN108797892ASolve molding problemsReduce difficultyAdditive manufacturing apparatusStrutsGlass fiberFiberglass mesh

Owner:SOUTHEAST UNIV

HPLC preparative column design

InactiveUS20100089811A1Low column costLow costIon-exchange process apparatusComponent separationCoolant flowEngineering

The preparative column has an inner thin wall HPLC compatible material tube, packed with absorbent particles, with filters and end fittings of HPLC compatible material at the tube ends. An aluminum outer sleeve tightly overlies and reinforces the inner tube, aluminum end caps overlie the end fittings and are secured to the outer sleeve. End connections in the end fittings allow solvent and sample flow through the packed absorbent. Exterior axial flats on the aluminum sleeve and end caps provide broad contact against flat thermal surfaces of conventional temperature controllers, thereby yielding effective thermal transfer there between. The flats further minimize column rolling on flat level surfaces and provide favorable locations for connection taps for conveying coolant flow through passages formed in the sleeve.

Owner:ZELECHONOK YURY +1

Radial flow reactor with movable supports

InactiveCN102166500AReduce mechanical stressReduced responseGas treatmentDispersed particle separationPre stressingEngineering

The invention relates to a radial flow reactor with movable supports, especially discloses a radial flow reactor vessel for use in gas purification, separation or reaction processes and most suitably used in prepurification processes. The reactor has internal baskets for confining a bed of active material. The baskets are rigidly supported at both the top and bottom ends of the reactor and have walls that are axially flexible and radially rigid. The vessel has multiple movable support columns designed to facilitate pre-stressing of the baskets to offset axial compressive loads induced from thermal cycling.

Owner:PRAXAIR TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com