Material high-temperature mechanical performance test device in aerodynamic heat-force coupling environment

A technology of high temperature mechanics and testing equipment, applied in the direction of analyzing materials, measuring devices, scientific instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0022] The invention provides a device for testing high-temperature mechanical properties of materials in an aerodynamic thermal-mechanical coupling environment.

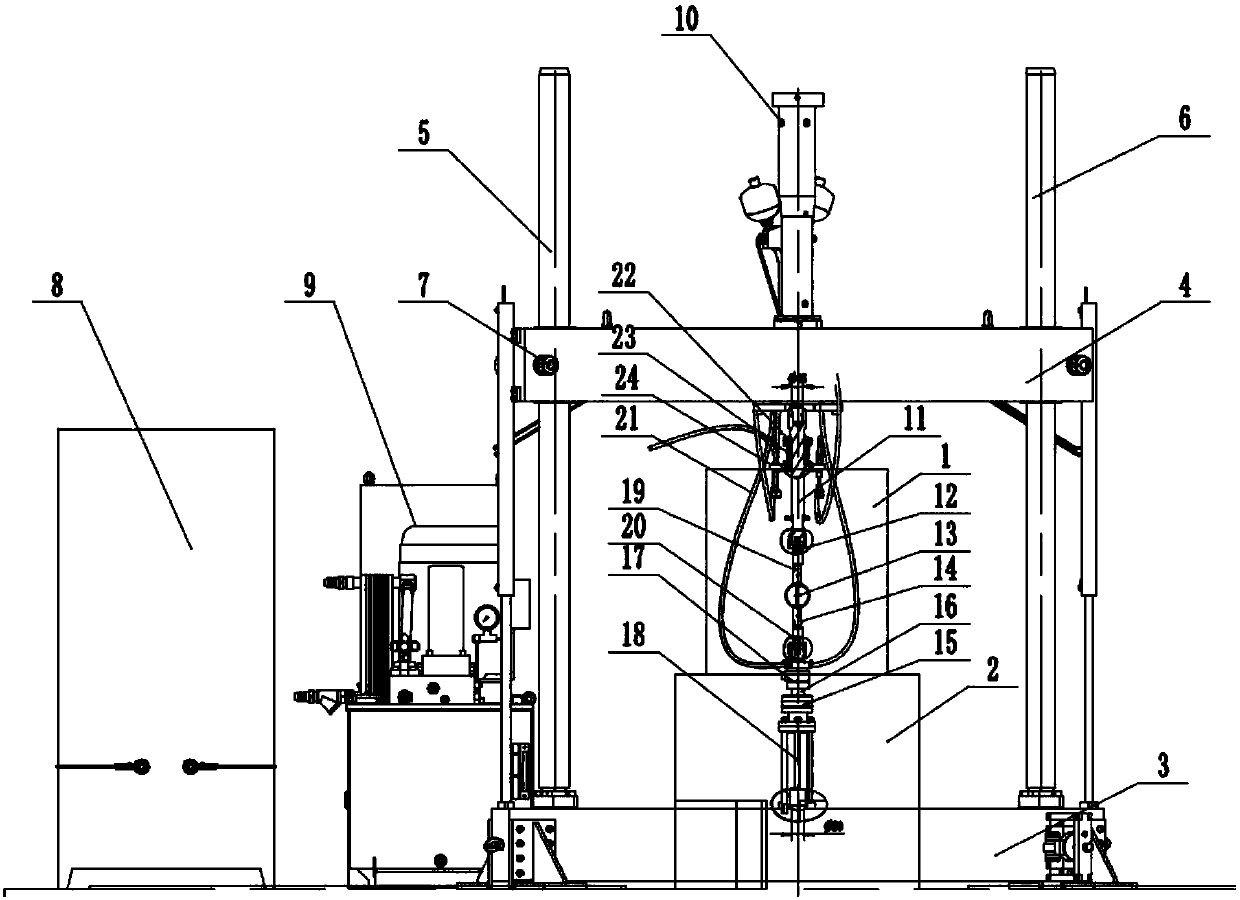

[0023] Such as figure 1 As shown, the lower crossbeam 3 of the equipment passes through the steel pipe embedded in the lower end of the base 2 of the environmental simulation test chamber 1, and passes through the base 2, so that the center of the mechanical loading axis is located at the high temperature center of the environmental simulation test chamber 1; the left column 5 and the right column 6. The lower end is fixed on the lower beam 3 in the form of threads, and the upper ends of the left column 5 and the right column 6 pass through the upper beam 4;

[0024] The oil source 9 supplies...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com