Patents

Literature

536 results about "Thermo mechanical" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

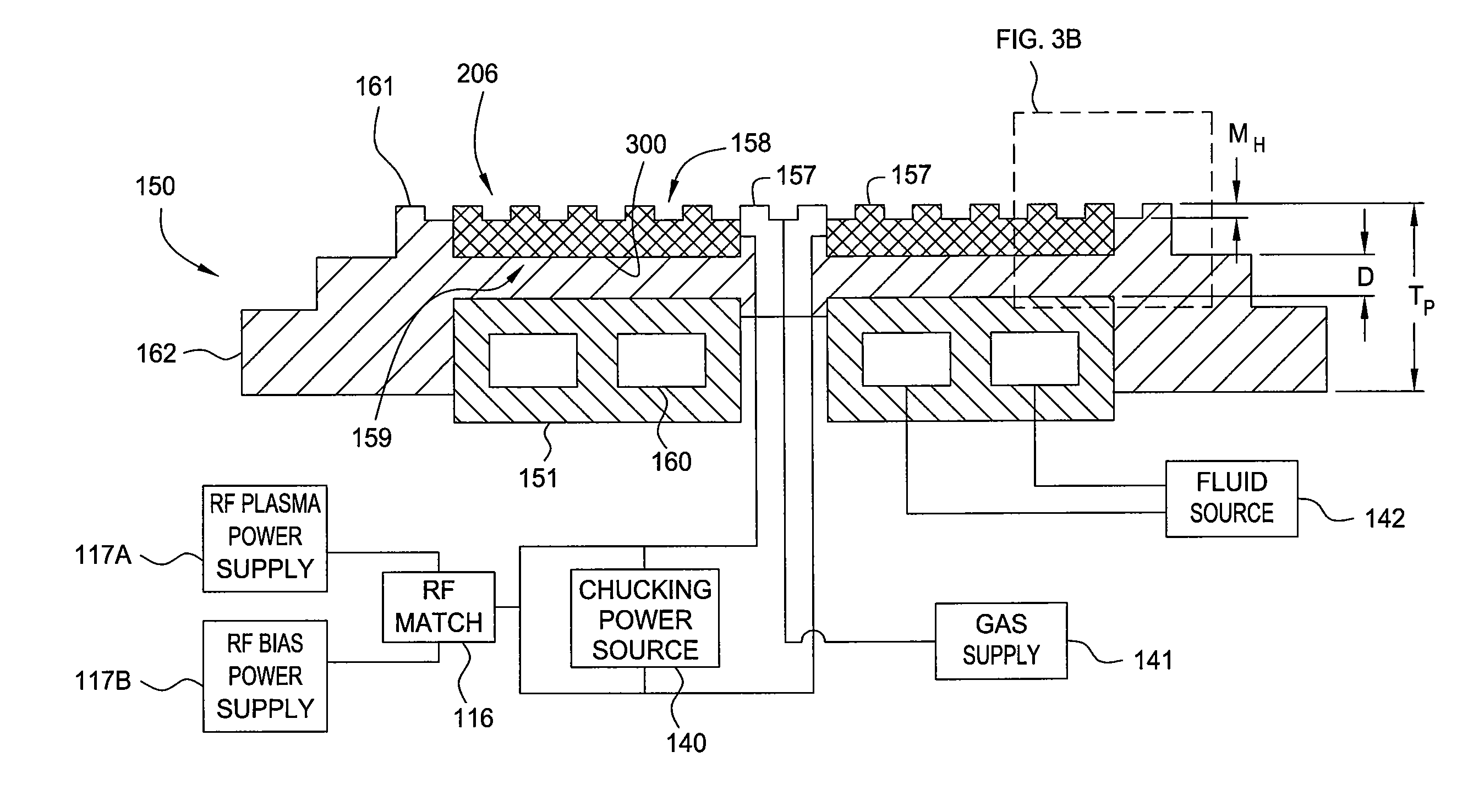

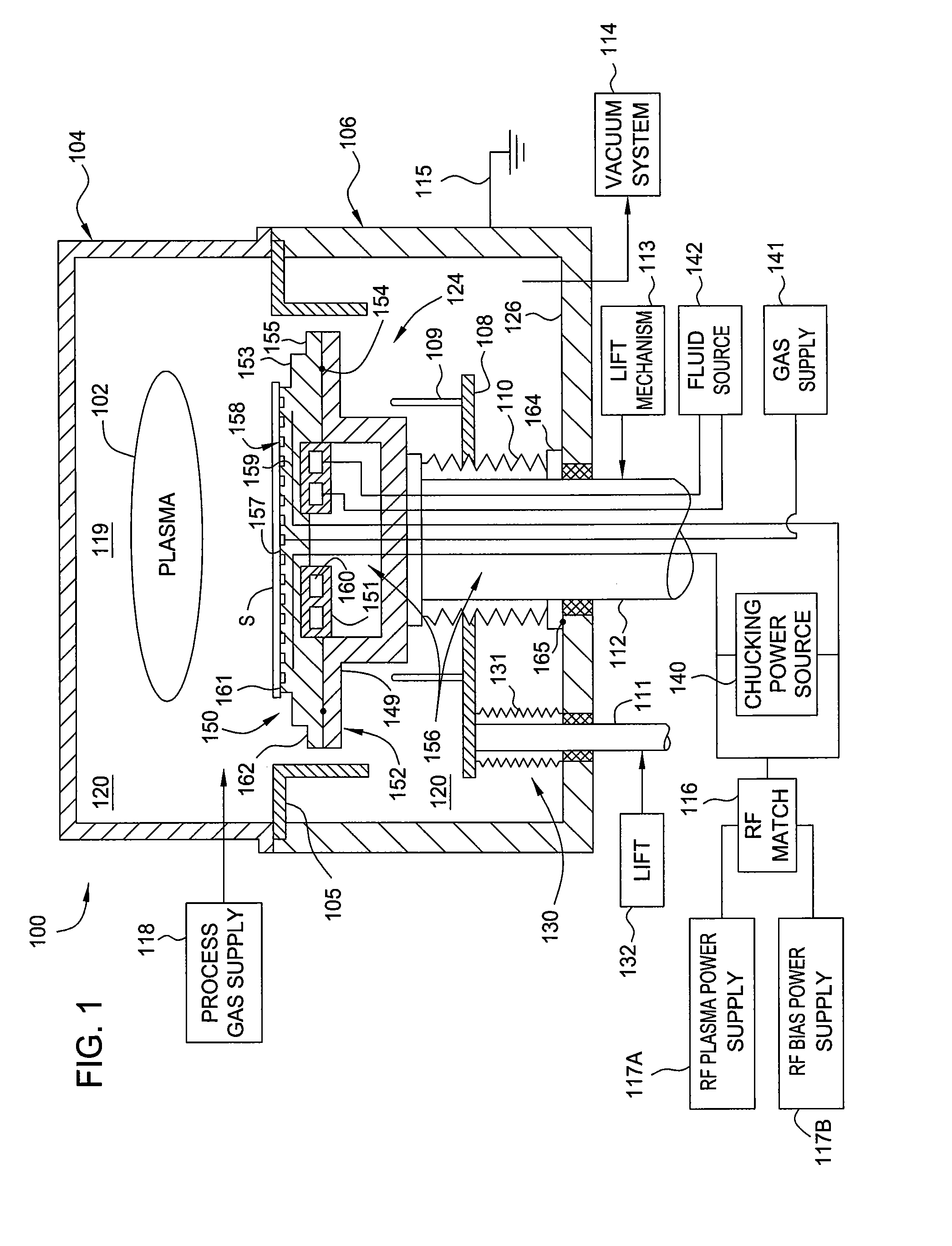

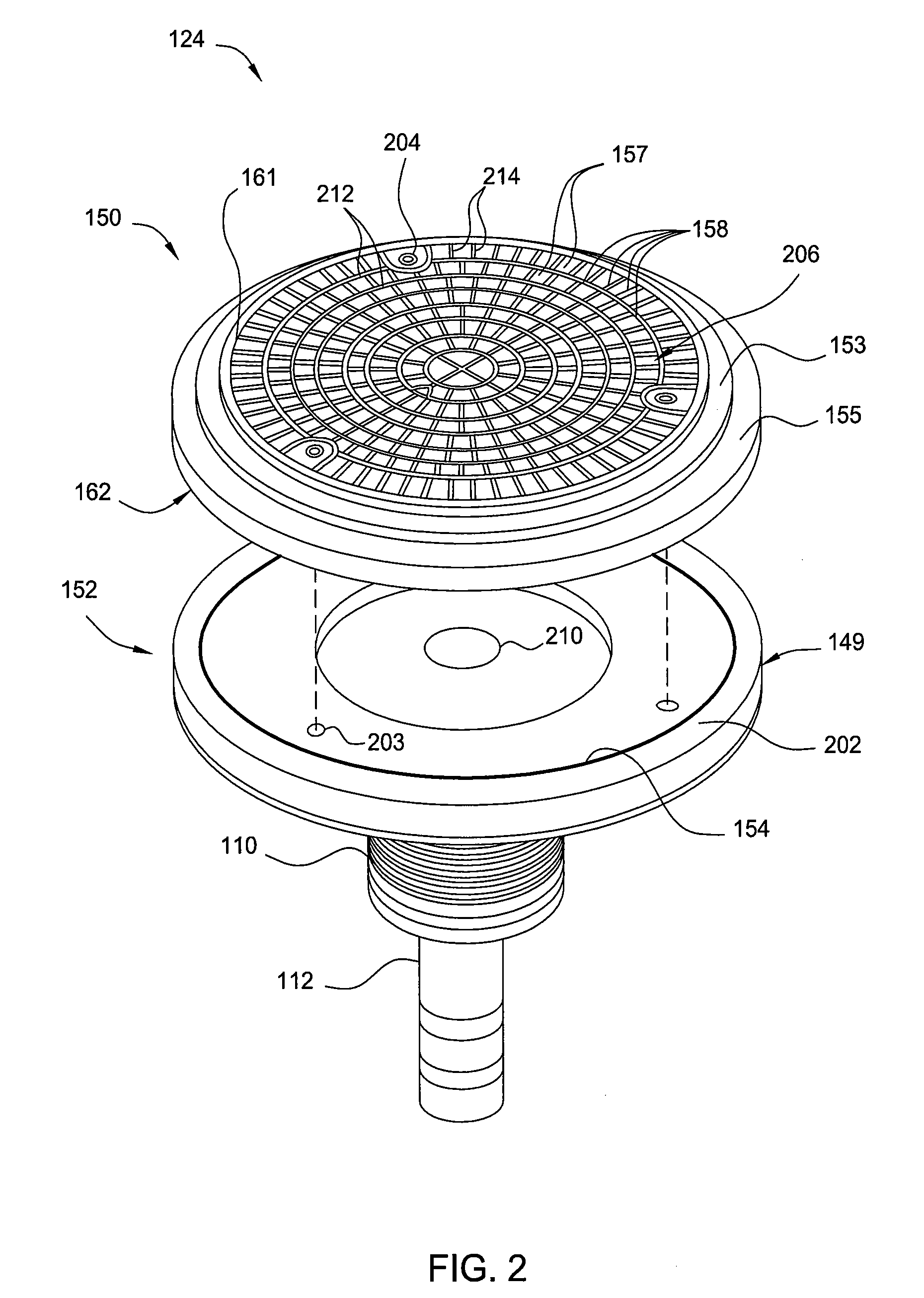

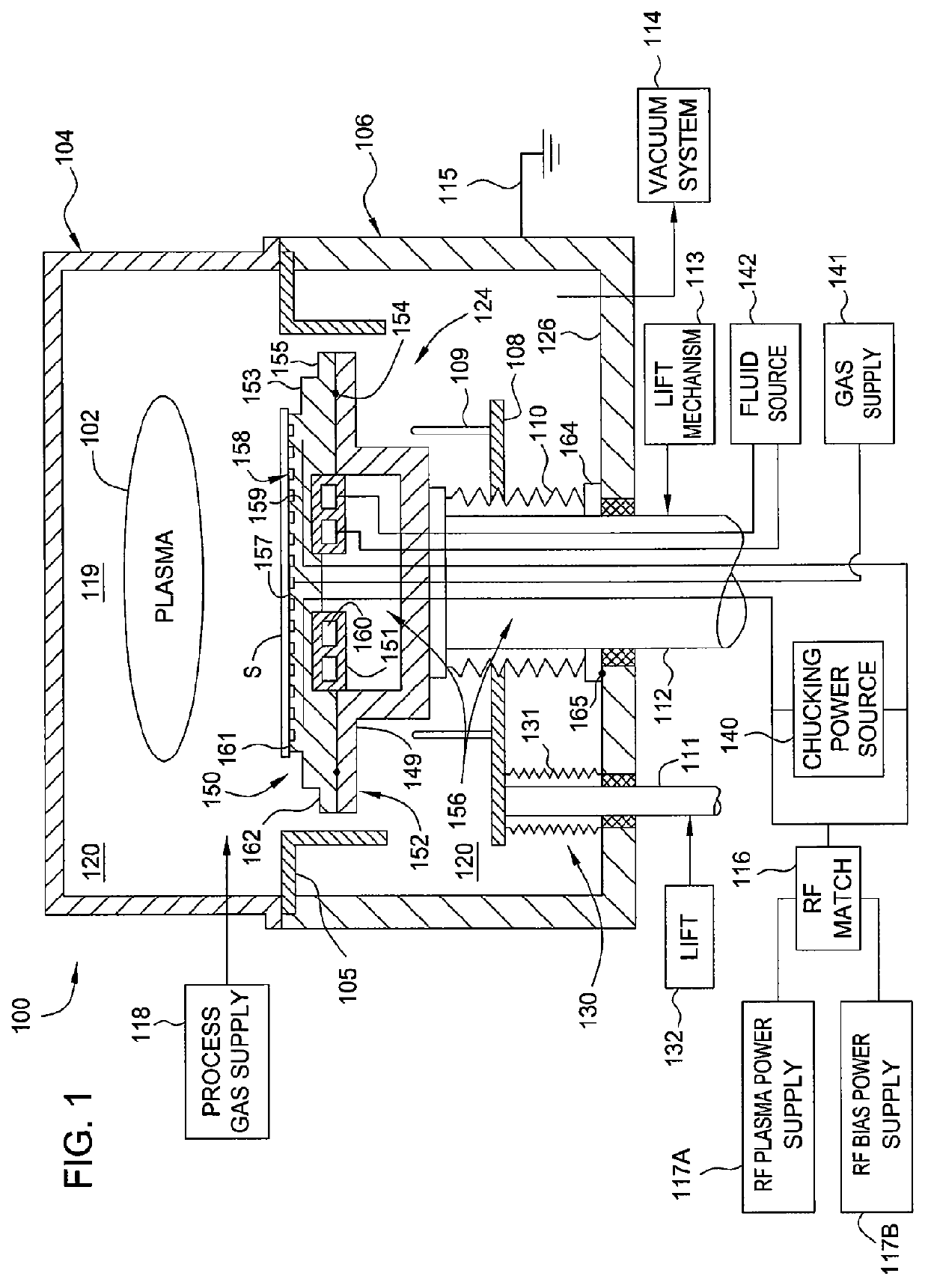

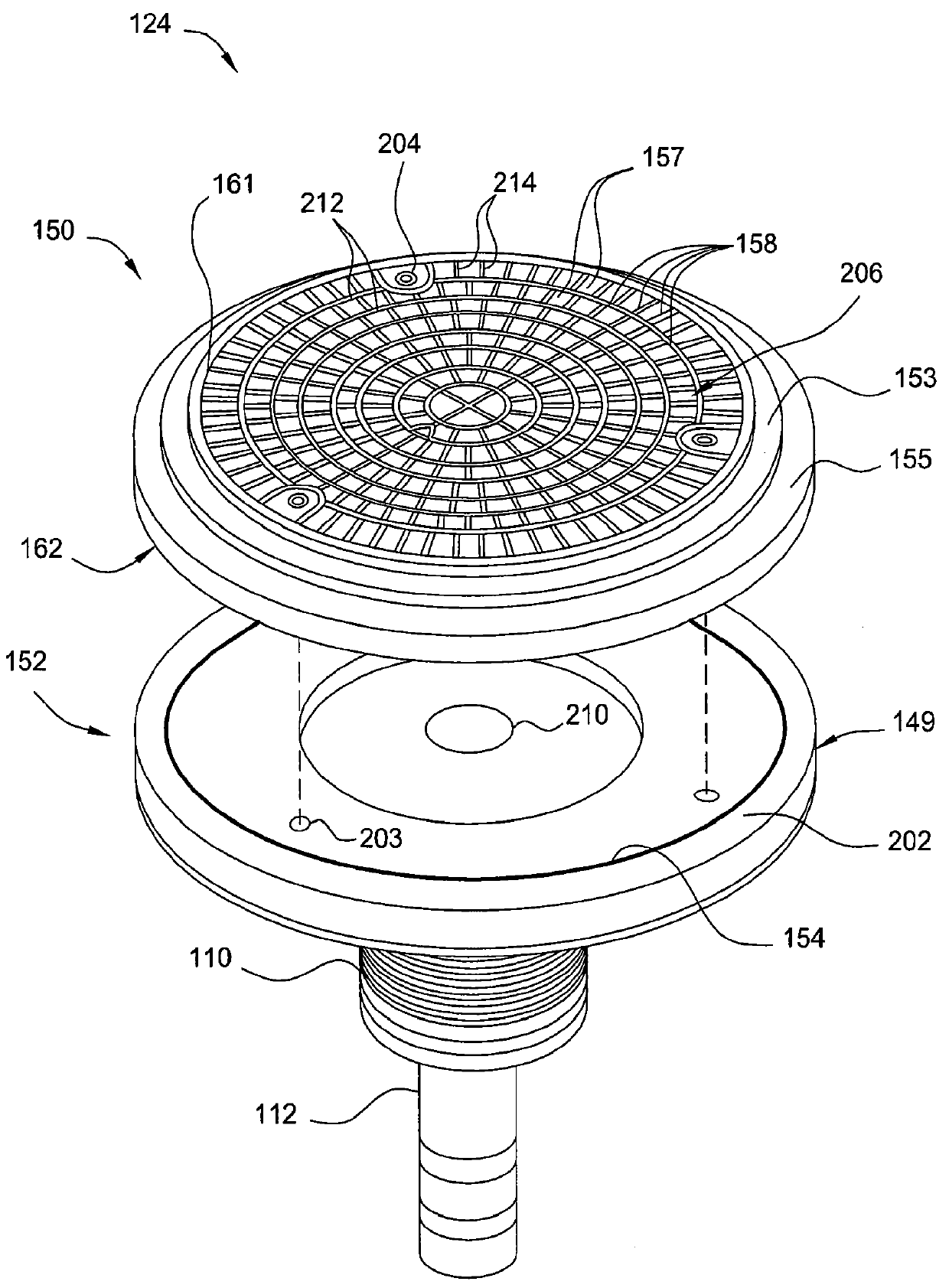

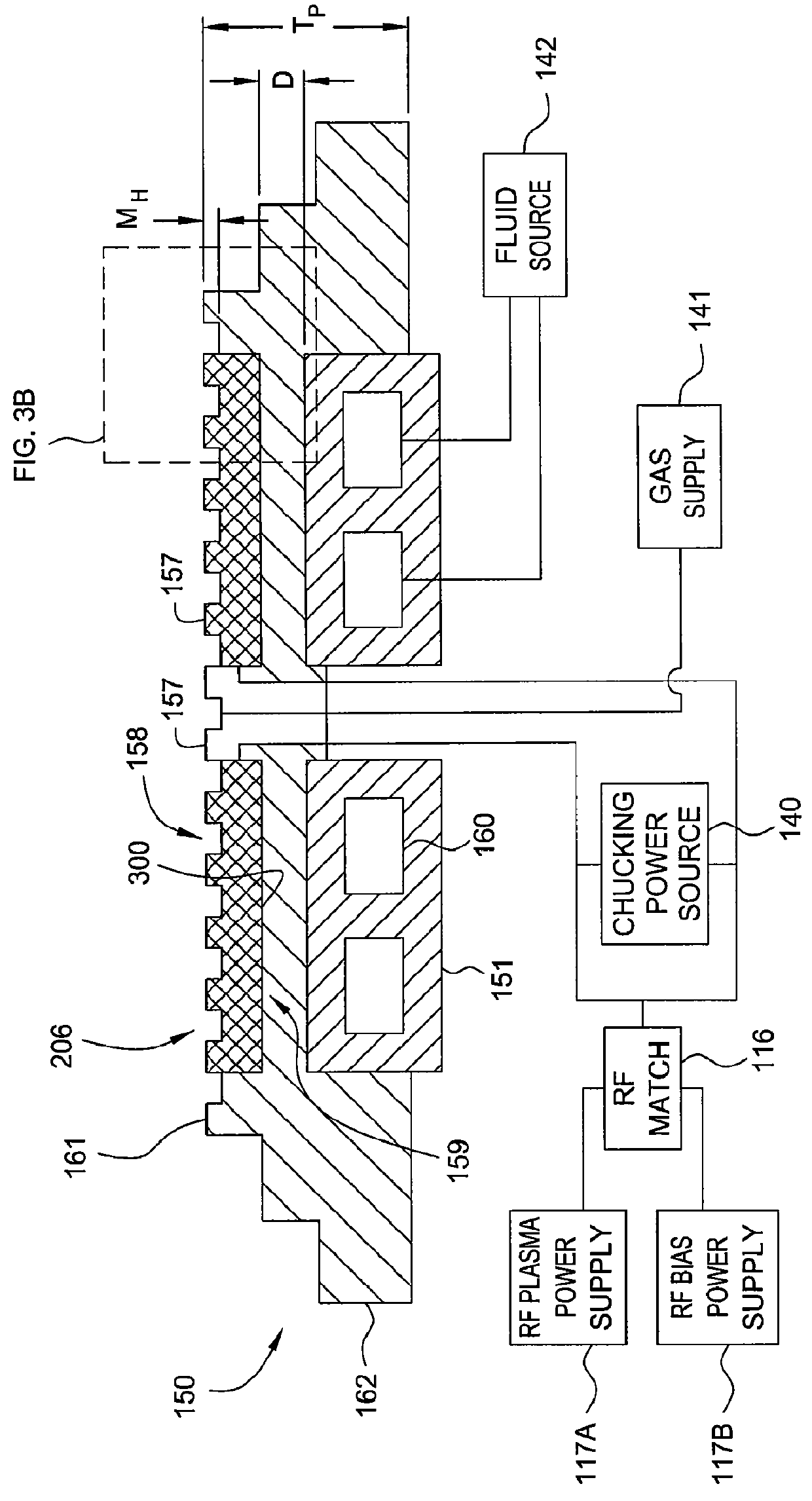

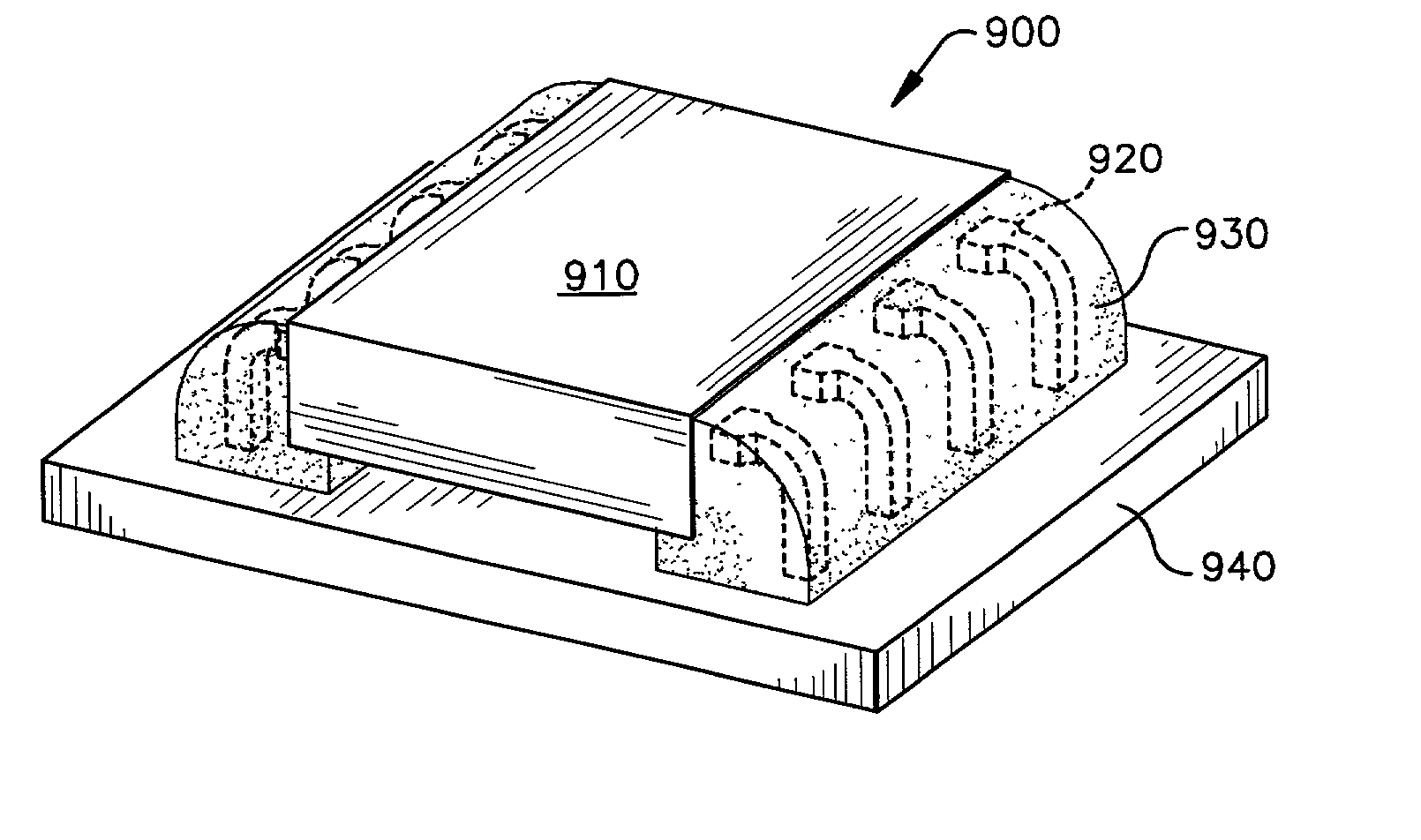

Electrostatic chuck assembly

ActiveUS20100039747A1Efficient couplingCost effectiveElectric discharge tubesSolid-state devicesUltra-high vacuumThermal expansion

Embodiments of the present invention provide a cost effective electrostatic chuck assembly capable of operating over a wide temperature range in an ultra-high vacuum environment while minimizing thermo-mechanical stresses within the electrostatic chuck assembly. In one embodiment, the electrostatic chuck assembly includes a dielectric body having chucking electrodes which comprise a metal matrix composite material with a coefficient of thermal expansion (CTE) that is matched to the CTE of the dielectric body.

Owner:APPLIED MATERIALS INC

Electrostatic chuck assembly

ActiveUS8390980B2Efficient couplingCost effectiveElectric discharge tubesSolid-state devicesUltra-high vacuumThermal expansion

Embodiments of the present invention provide a cost effective electrostatic chuck assembly capable of operating over a wide temperature range in an ultra-high vacuum environment while minimizing thermo-mechanical stresses within the electrostatic chuck assembly. In one embodiment, the electrostatic chuck assembly includes a dielectric body having chucking electrodes which comprise a metal matrix composite material with a coefficient of thermal expansion (CTE) that is matched to the CTE of the dielectric body.

Owner:APPLIED MATERIALS INC

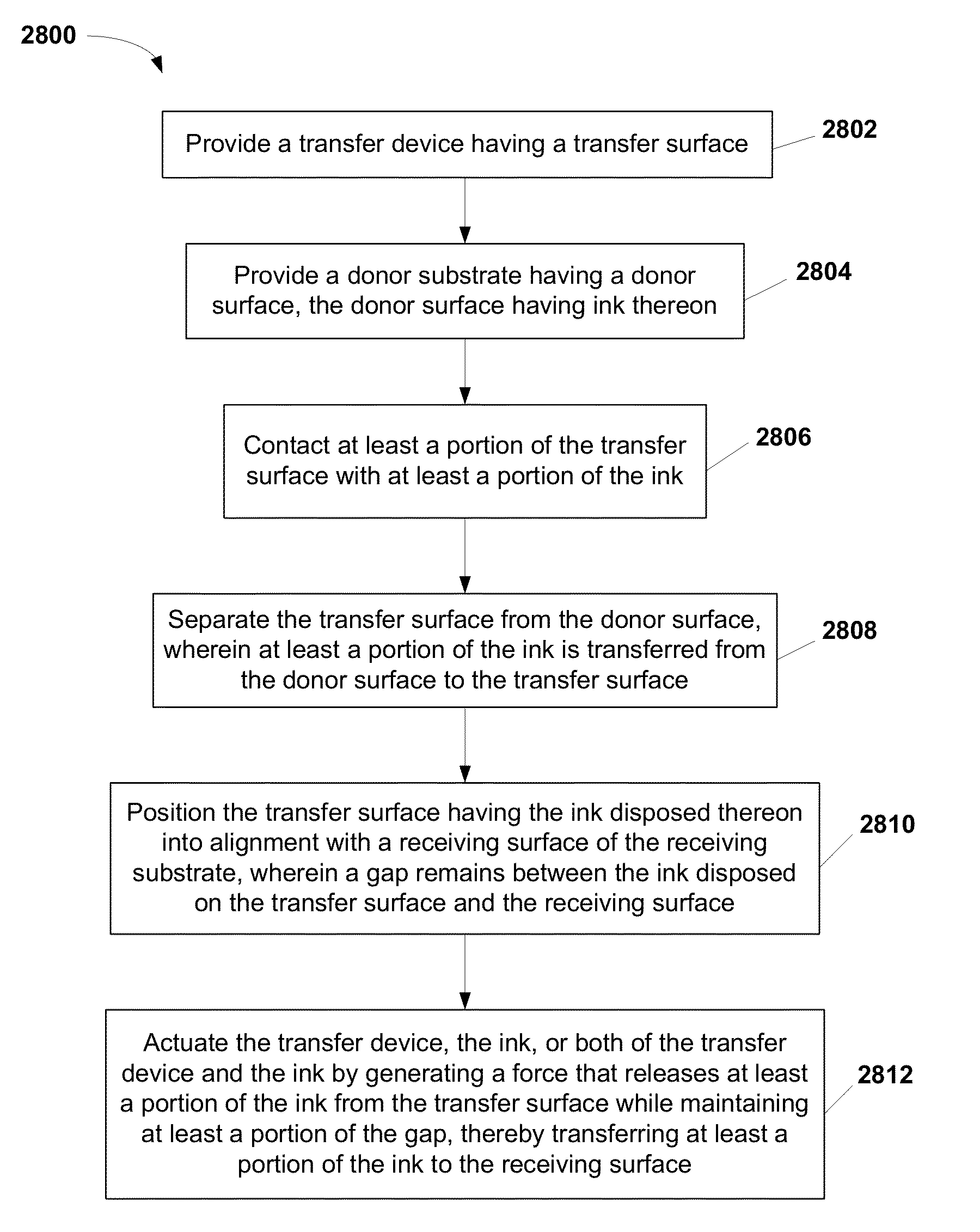

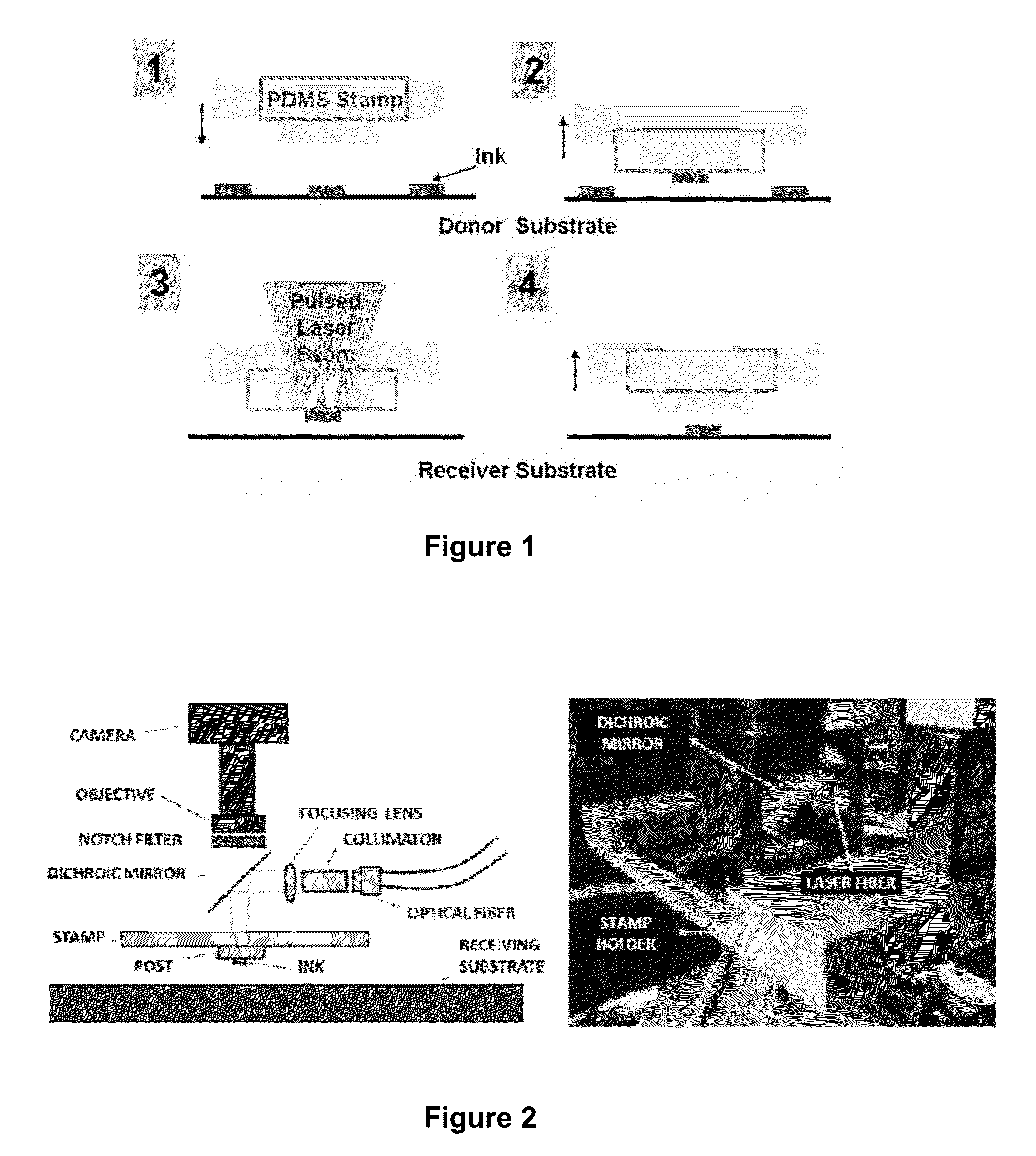

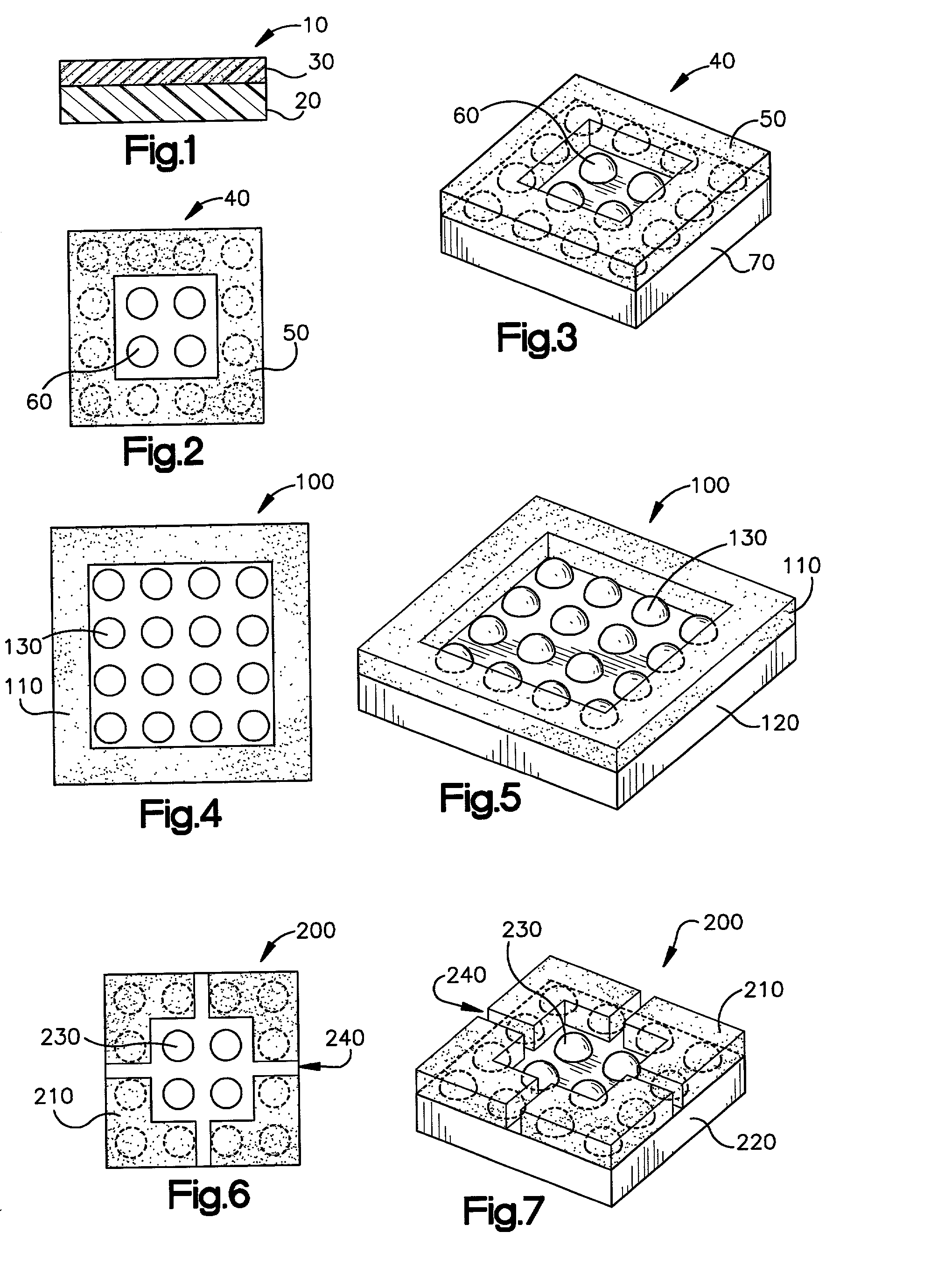

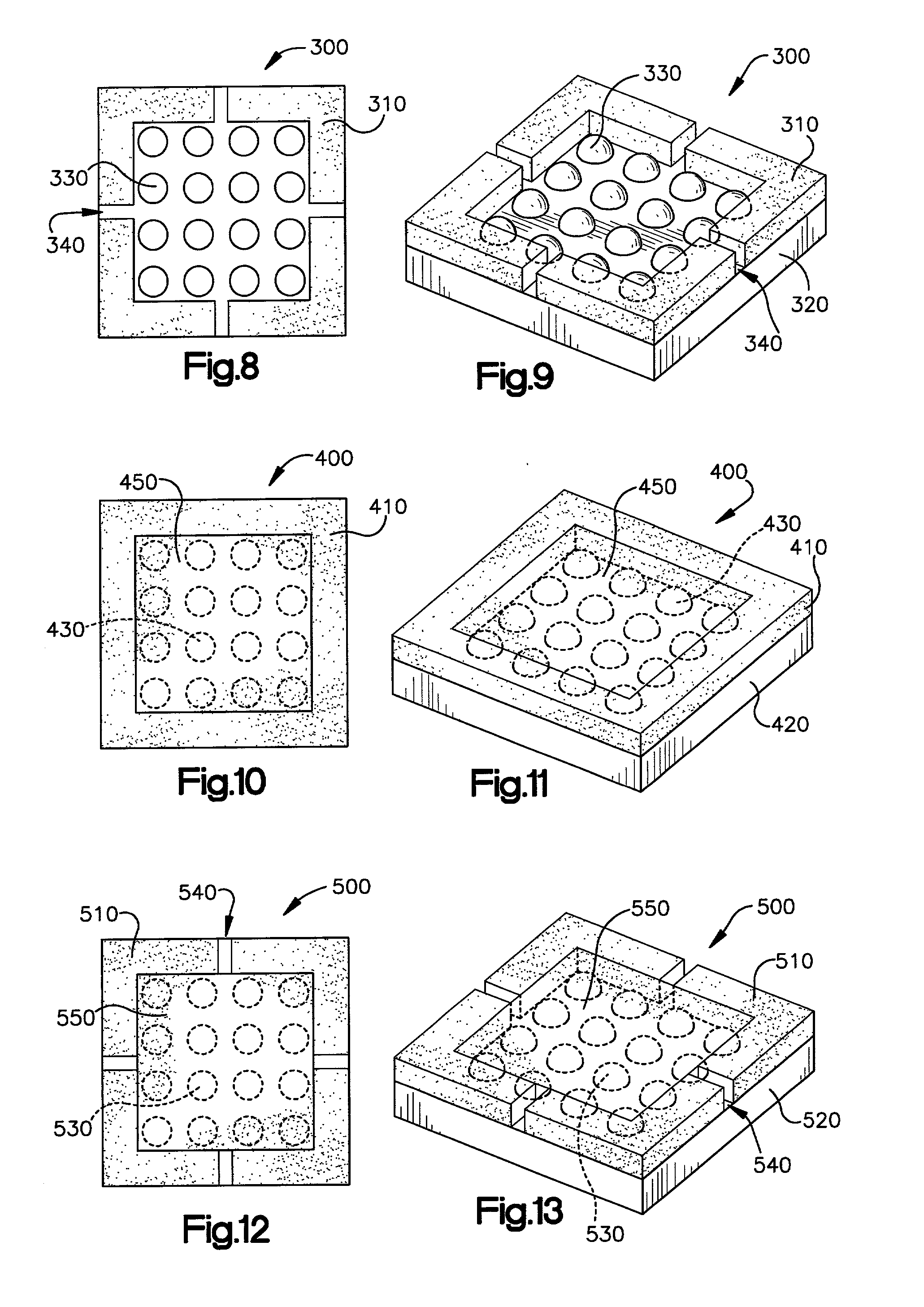

Non-contact transfer printing

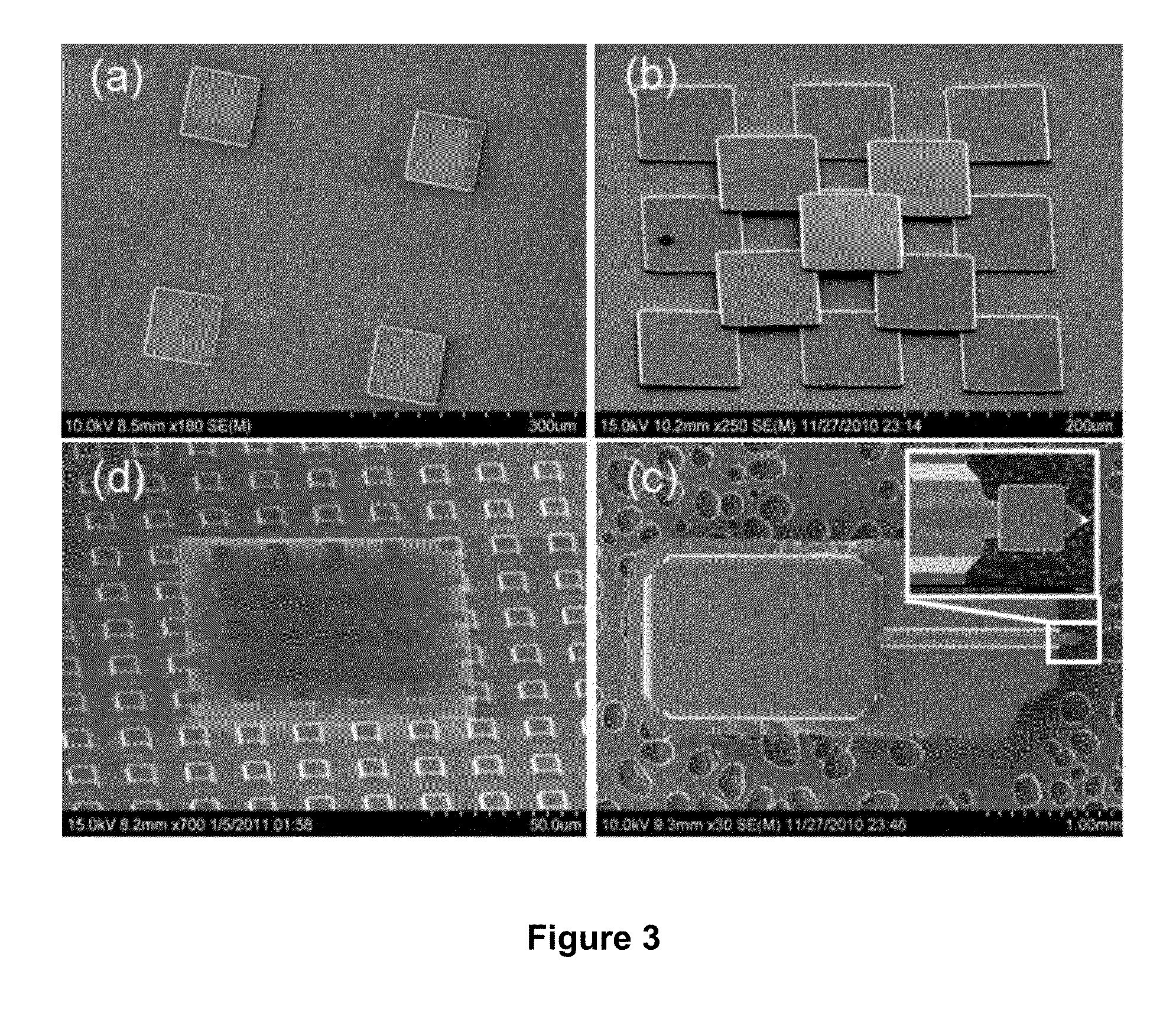

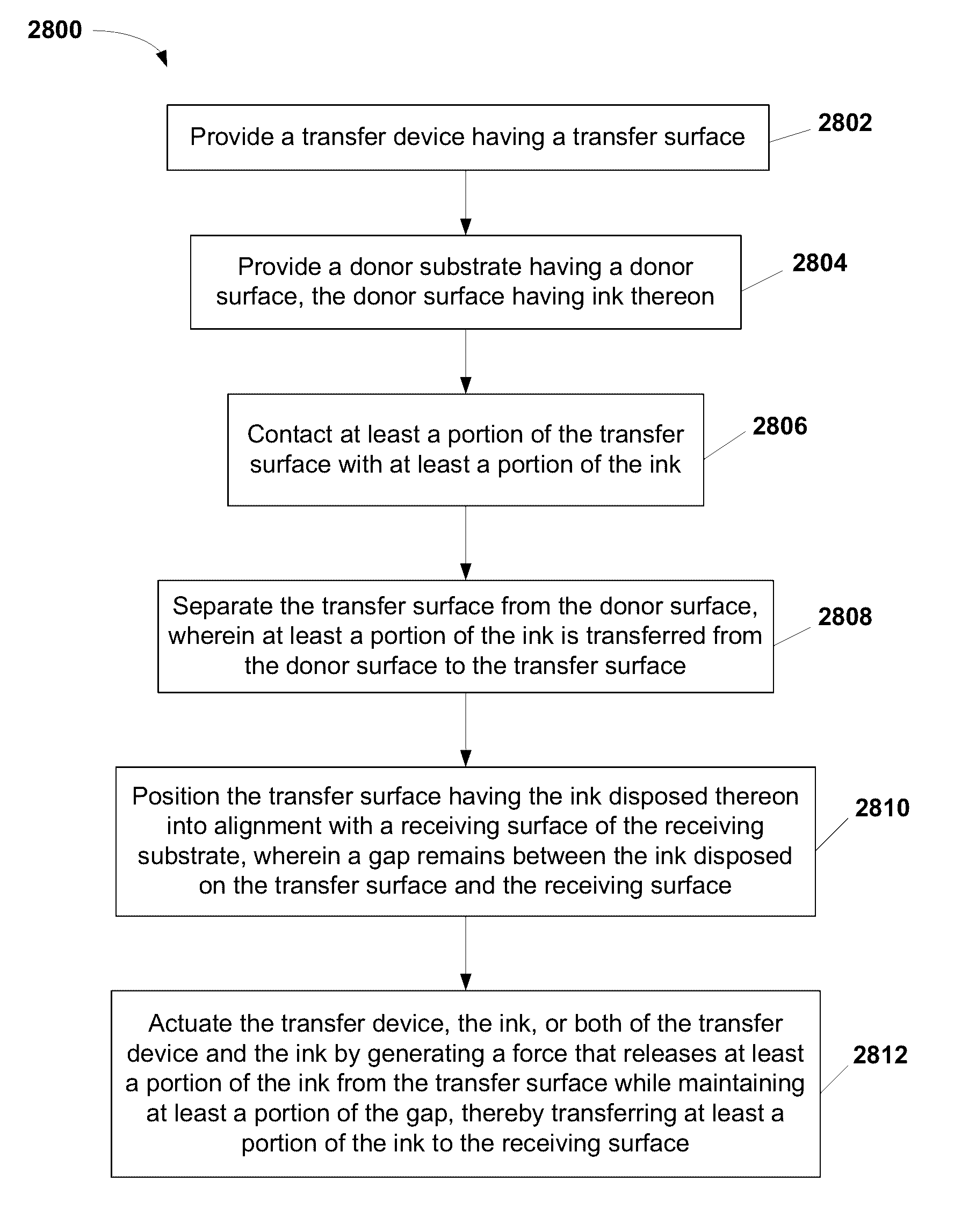

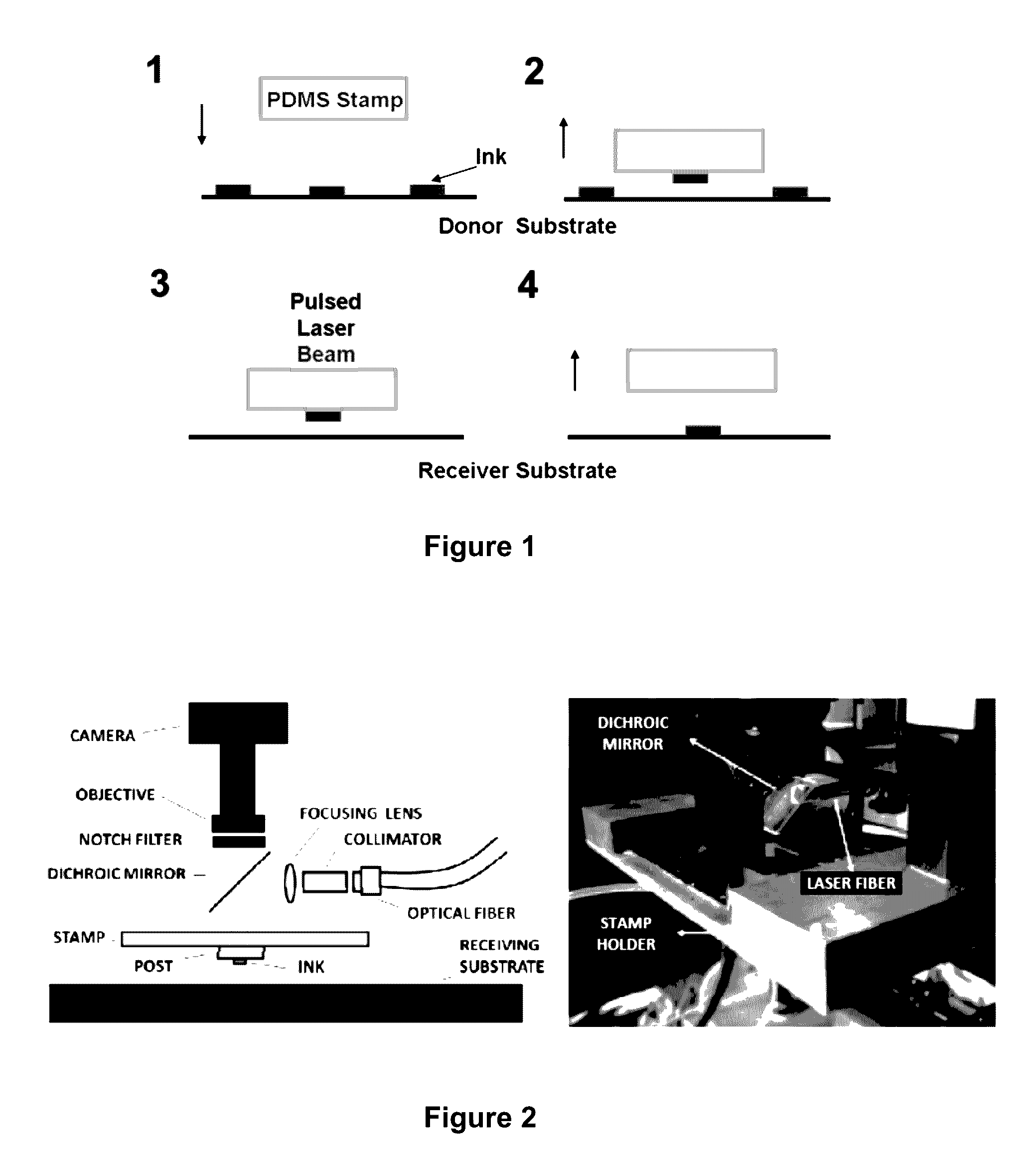

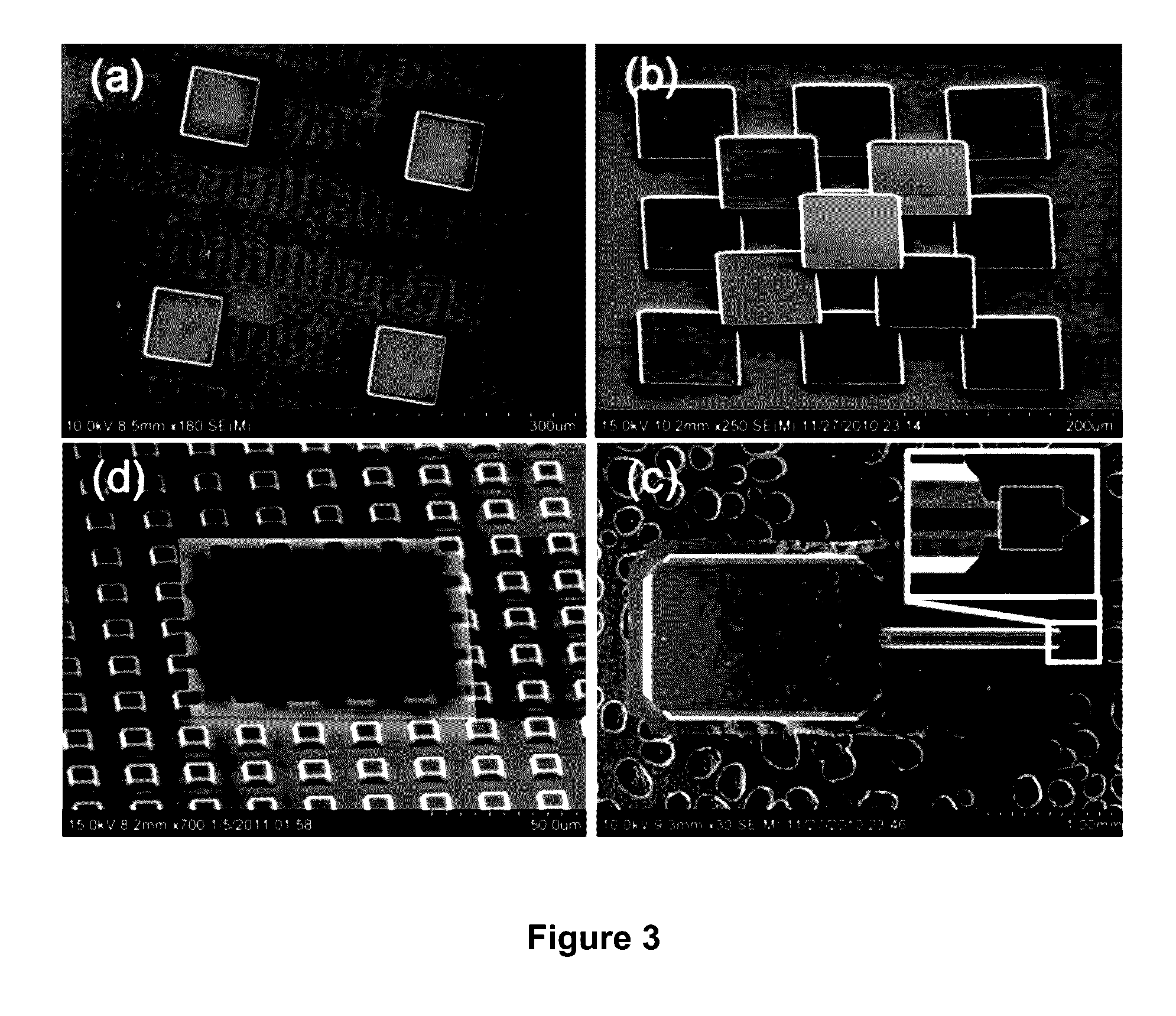

ActiveUS20130036928A1Avoid damageNot to damageTransfer printingDuplicating/marking methodsNano-deviceLight-emitting diode

A transfer printing process that exploits the mismatch in mechanical or thermo-mechanical response at the interface of a printable micro- or nano-device and a transfer stamp to drive the release of the device from the stamp and its non-contact transfer to a receiving substrate are provided. The resulting facile, pick-and-place process is demonstrated with the assembling of 3-D microdevices and the printing of GAN light-emitting diodes onto silicon and glass substrates. High speed photography is used to provide experimental evidence of thermo-mechanically driven release.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

Non-contact transfer printing

ActiveUS9555644B2Avoid damageNot to damageTransfer printingDuplicating/marking methodsNano-deviceLight-emitting diode

A transfer printing process that exploits the mismatch in mechanical or thermo-mechanical response at the interface of a printable micro- or nano-device and a transfer stamp to drive the release of the device from the stamp and its non-contact transfer to a receiving substrate are provided. The resulting facile, pick-and-place process is demonstrated with the assembling of 3-D microdevices and the printing of GAN light-emitting diodes onto silicon and glass substrates. High speed photography is used to provide experimental evidence of thermo-mechanically driven release.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

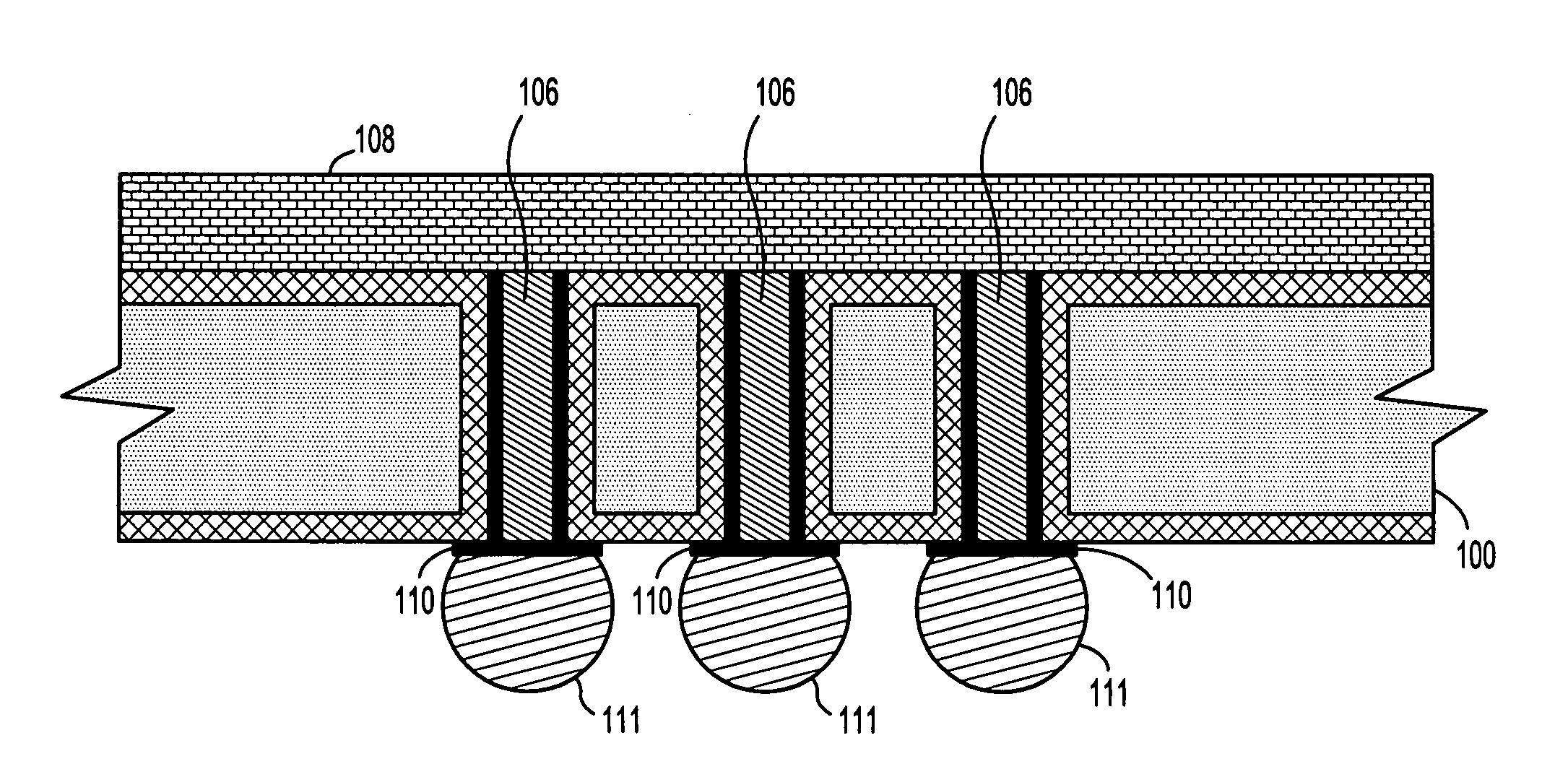

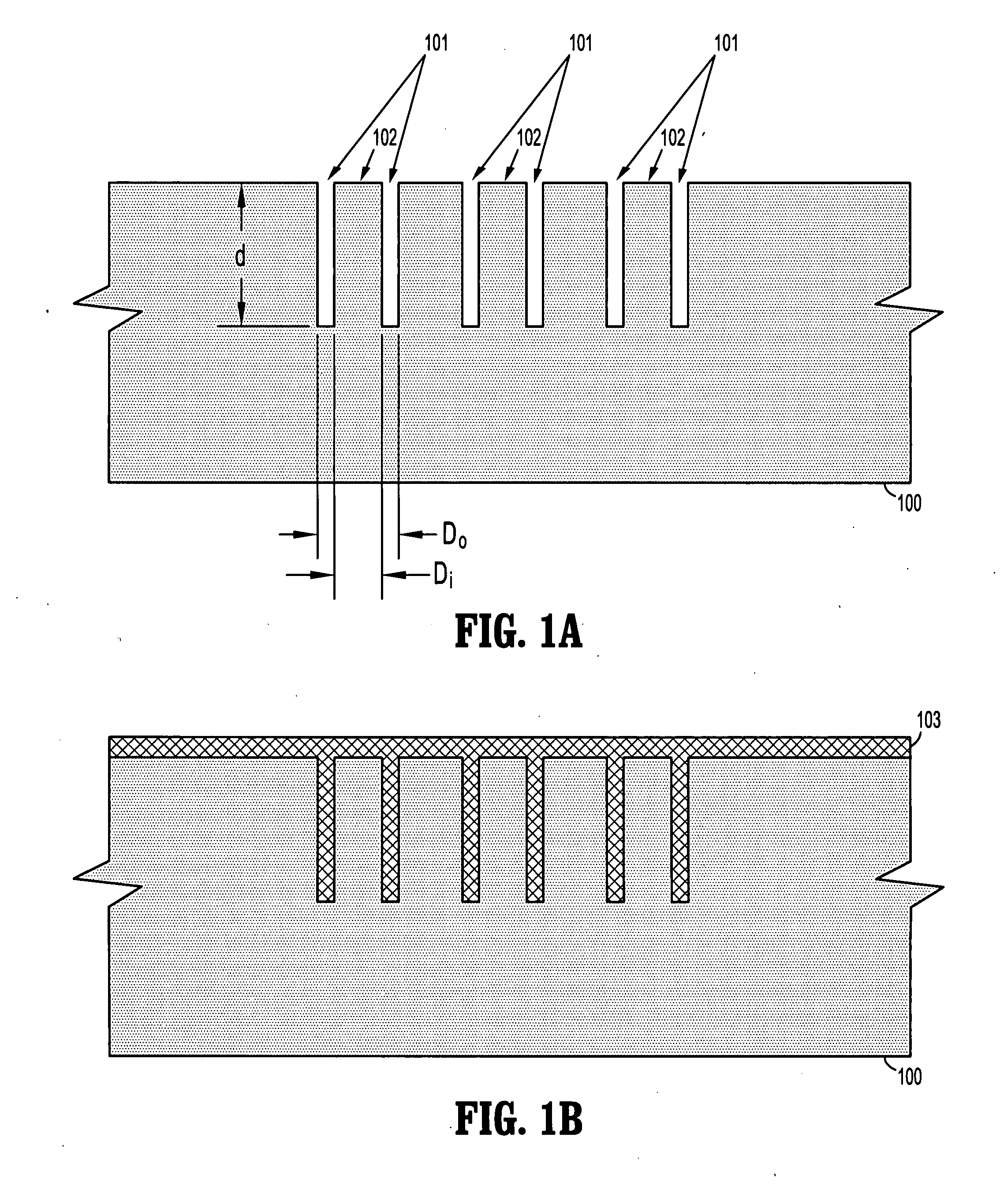

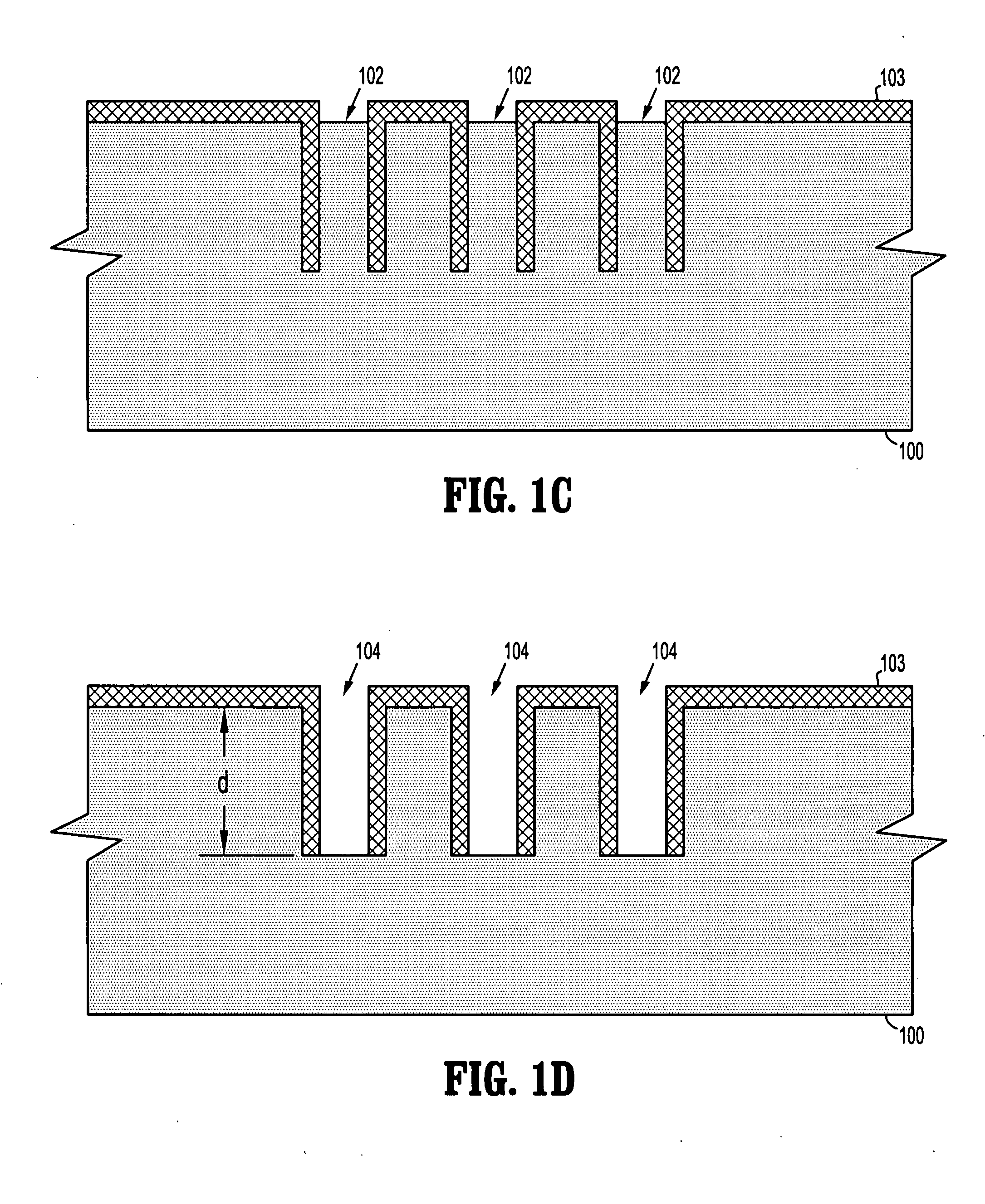

Methods for fabricating silicon carriers with conductive through-vias with low stress and low defect density

InactiveUS20080164573A1High-density packagingReduce stressSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorMicrometer

Methods are provided for fabricating silicon carriers with conductive through-vias that allow high-yield manufacture of silicon carrier with, low defect density. In particular, methods are provided which enable fabrication of silicon, carries with via diameters such as 1 to 10 microns in diameter for a vertical thickness of less than 10 micrometers to greater than 300 micrometers, which are capable robust to thermal-mechanical stresses during production to significantly minimize the thermal mechanical movement at the via sidewall interface between the silicon, insulator, liner and conductor materials.

Owner:GLOBALFOUNDRIES US INC

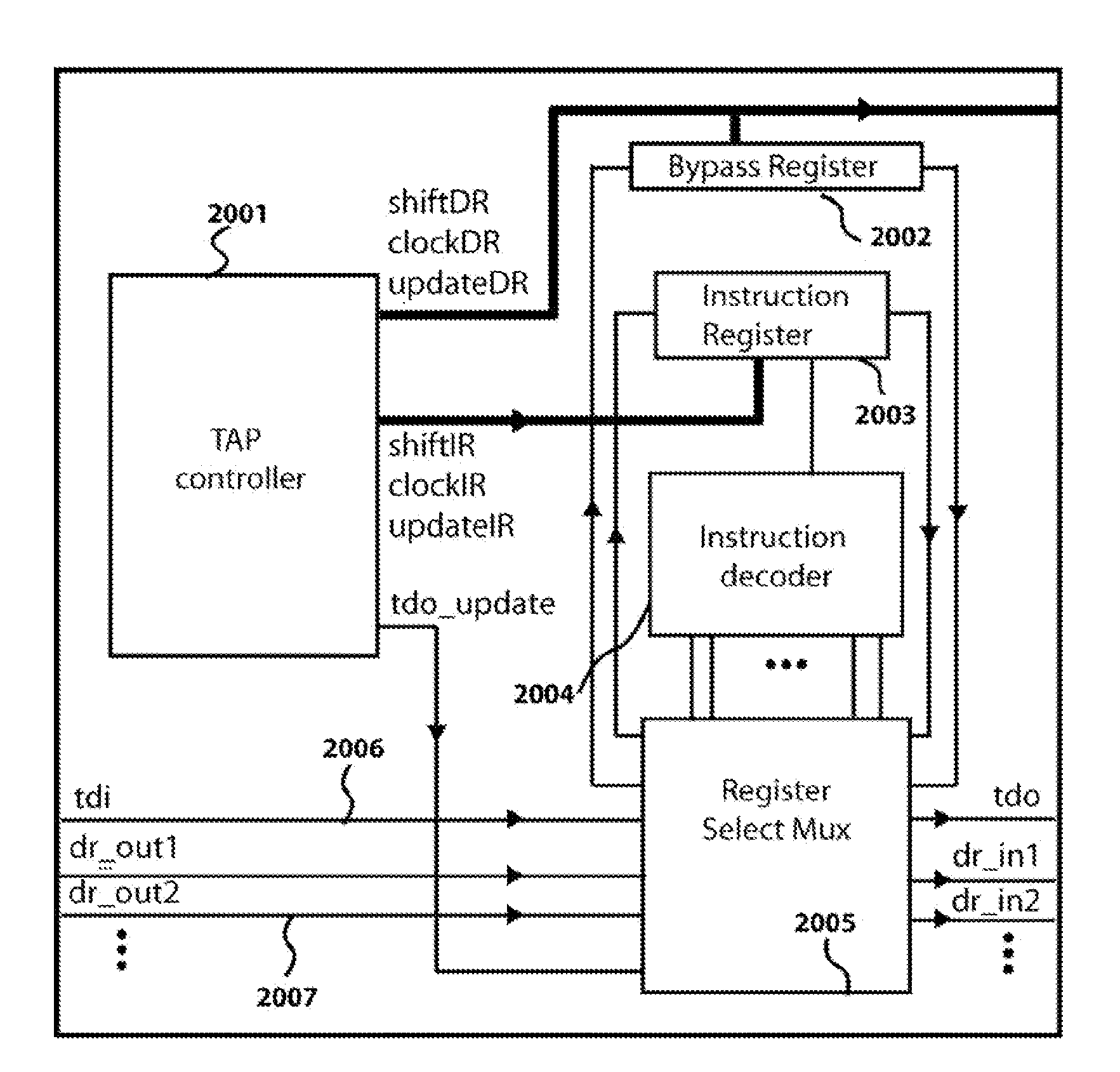

Methods, apparatus and system to support large-scale micro- systems including embedded and distributed power supply, thermal regulation, multi-distributedsensors and electrical signal propagation

InactiveUS20130285739A1Improve production yieldReduce mechanical stressPrinted circuit assemblingSemiconductor/solid-state device detailsStructure of Management InformationEngineering

The present invention relates to technologies for integrated circuits and Large Area Integrated Circuits (LAICs), which are integrated circuits made from photo-repetition of one or several reticle image fields, stitched together on at least one lithographic process layer. It also relates to a specific class of LAIC that can connect to the contacts of other ICs placed on its surface, where specific contact detection algorithms means are disclosed. The innovations include means for defect tolerance of serial communication links, means for efficient diagnosis of short and stuck-at faults in regular reconfigurable network, means for a programmable interposer for rapid prototyping of 3D stacked chips, means to build efficient large area micro-system devices (LAMS), with distributed and configurable hierarchical structures for power supply, thermal regulation and signal propagation, means to reduce mechanical / thermal / thermo-mechanical issues in LAMS devices, means to propagate analog signal on a configurable digital network, means to predict thermo-mechanical stress peaks.

Owner:TRANSFERT PLUS S E C +2

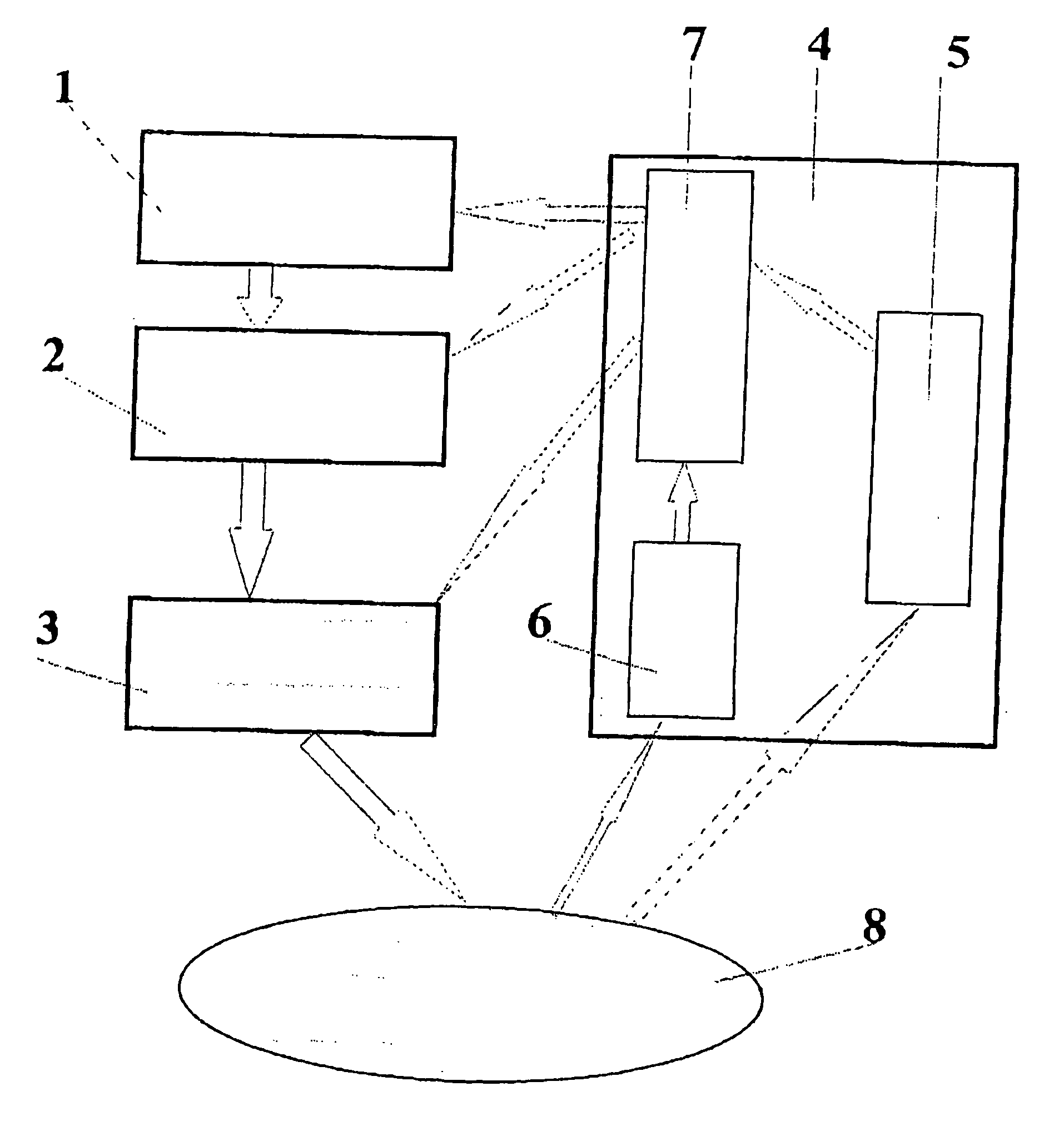

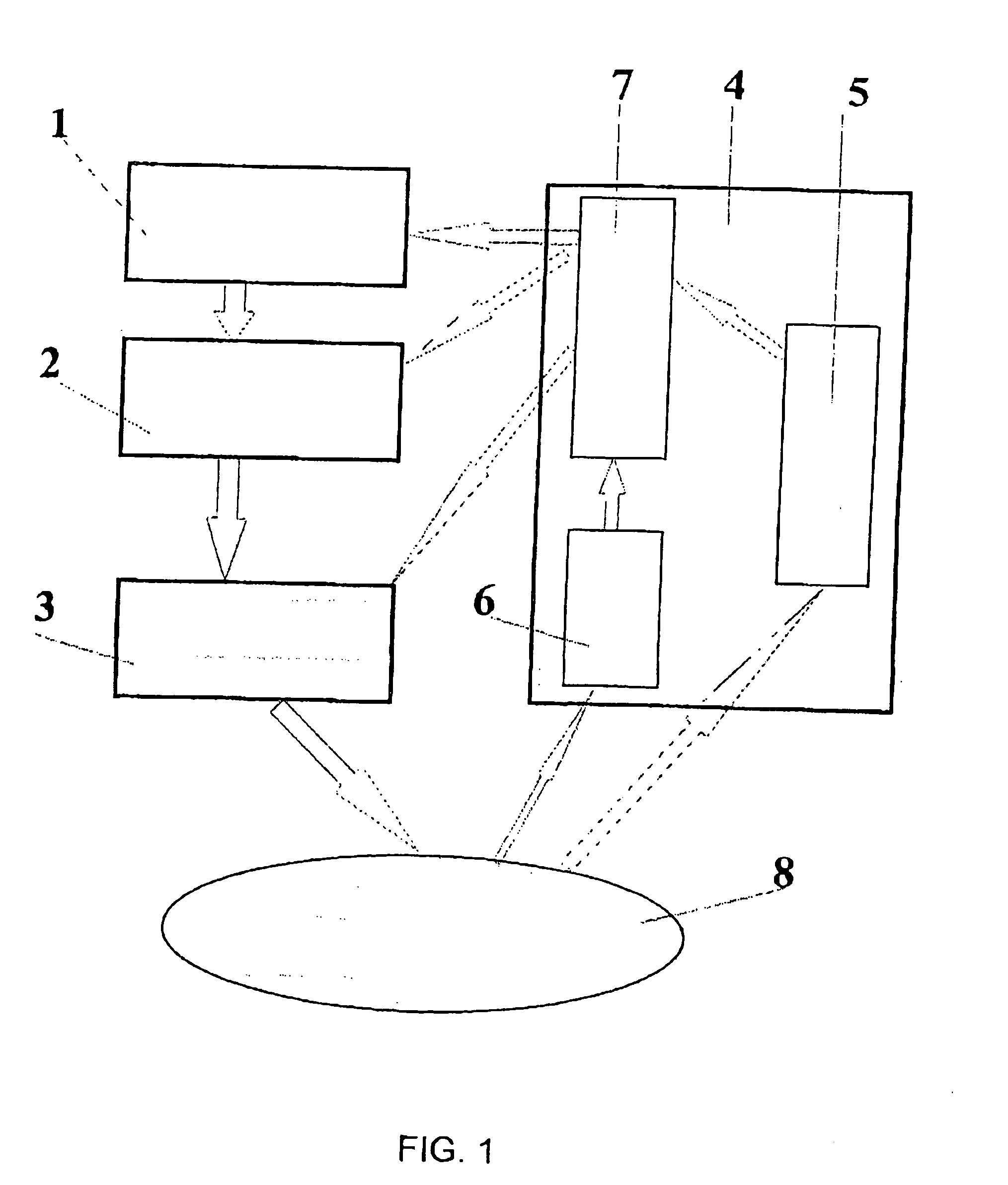

Method and apparatus for opto-thermo-mechanical treatment of biological tissue

InactiveUS20050119643A1Increase and decrease abilityEfficiency of influenceElectrotherapyControlling energy of instrumentOptical radiationControl signal

The invention relates to a method and apparatus for opto-thermo-mechanical treatment of biological tissue. A biological tissue area 8 is irradiated with a radiation in the optical wavelength range with predetermined parameters, the radiation being modulated and spatially formed under a predetermined law; the irradiation is accompanied by simultaneous thermal and mechanical treatment of the area 8; concurrently with the irradiation of the biological tissue area, spatial distribution of physico-chemical and geometrical characteristics is measured both in the zone of direct optical treatment and in close vicinity, using a control diagnostic system 4; a data processing unit 7 coordinates parameters of optical radiation spatial formation and modulation with each other and with the biological tissue characteristics and provides a control signal to an optical radiation power and time modulation control unit 2 and a device 3 for delivering optical radiation and forming spatial distribution of optical radiation power on the surface and in the bulk of the biological tissue 8. Optical radiation parameters are adjusted responsive to control signals of the control-diagnostic system 4 during irradiation as a function of continuously changing characteristics of spatial distribution of physico-chemical and geometrical characteristics both in and beyond the directly treated biological tissue area.

Owner:ARCUO MEDICAL

Thermoplastic elastomer composition

The present invention relates to a soft thermoplastic elastomer composition that is free of thermoplastic resin that can be utilized in manufacturing shoe sole inserts, seals, gaskets, wheels, and that can be overmolded on a hard substrate, such as a metal or a thermoplastic resin, for grips or handles on various household items. The present invention more specifically discloses a thermoplastic elastomer composition that is made by a process comprising: (1) mixing (A) a block copolymer comprising a first polymeric block that is comprised of repeat units that are derived from a vinyl aromatic monomer and a second block that is comprised of repeat units that are derived from a conjugated diolefin monomer, wherein the repeat units in the second block are hydrogenated, and wherein the repeat units in the second block are elastomeric in nature, (B) a crosslinkable elastomer, and (C) an oil, to produce an un-crosslinked three component blend; and (2) dynamically crosslinking the crosslinkable elastomer in the un-crosslinked three component blend during a thermo-mechanical mixing step; wherein the thermoplastic elastomer composition is void of thermoplastic resins.

Owner:THE GOODYEAR TIRE & RUBBER CO +1

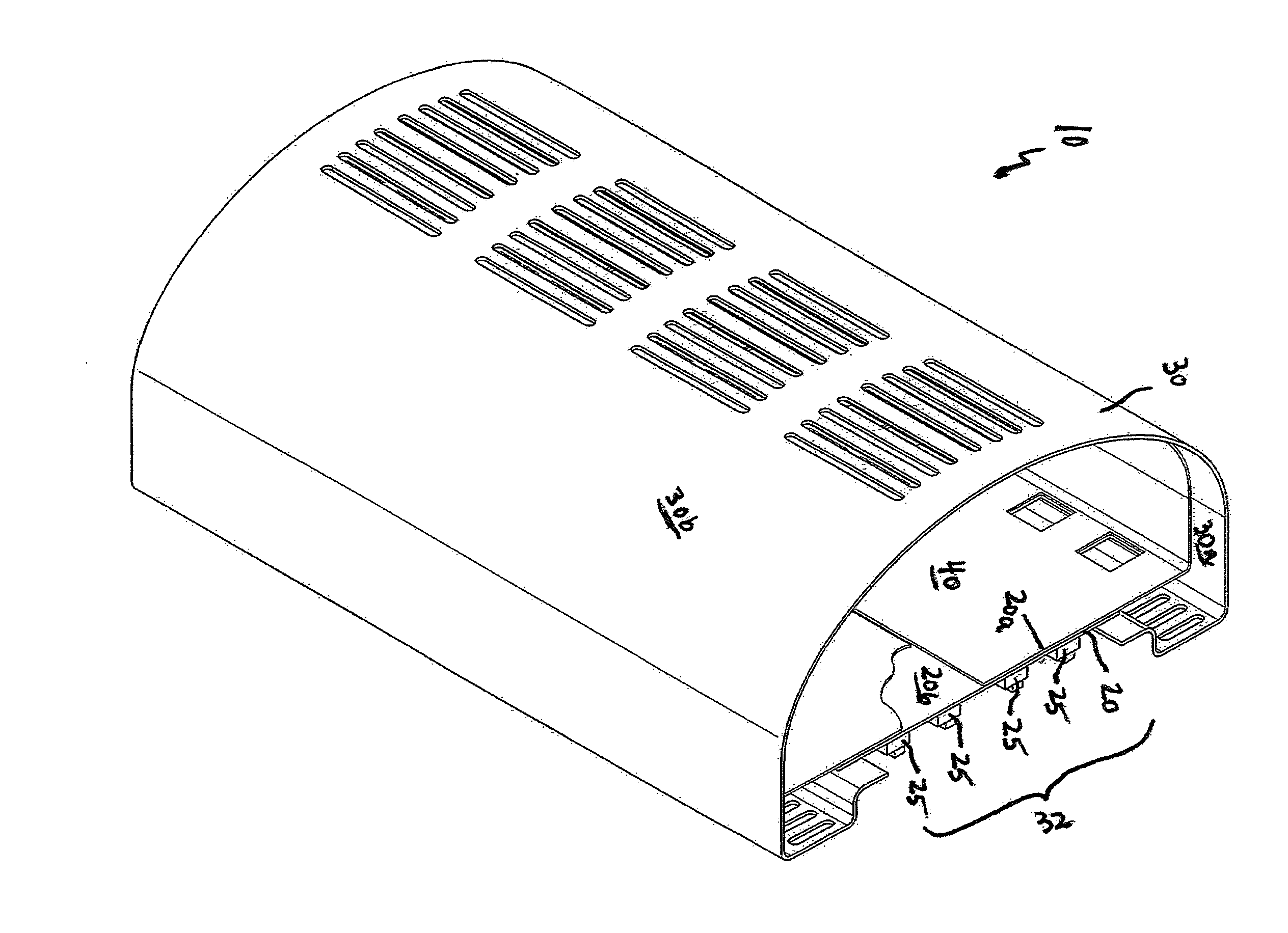

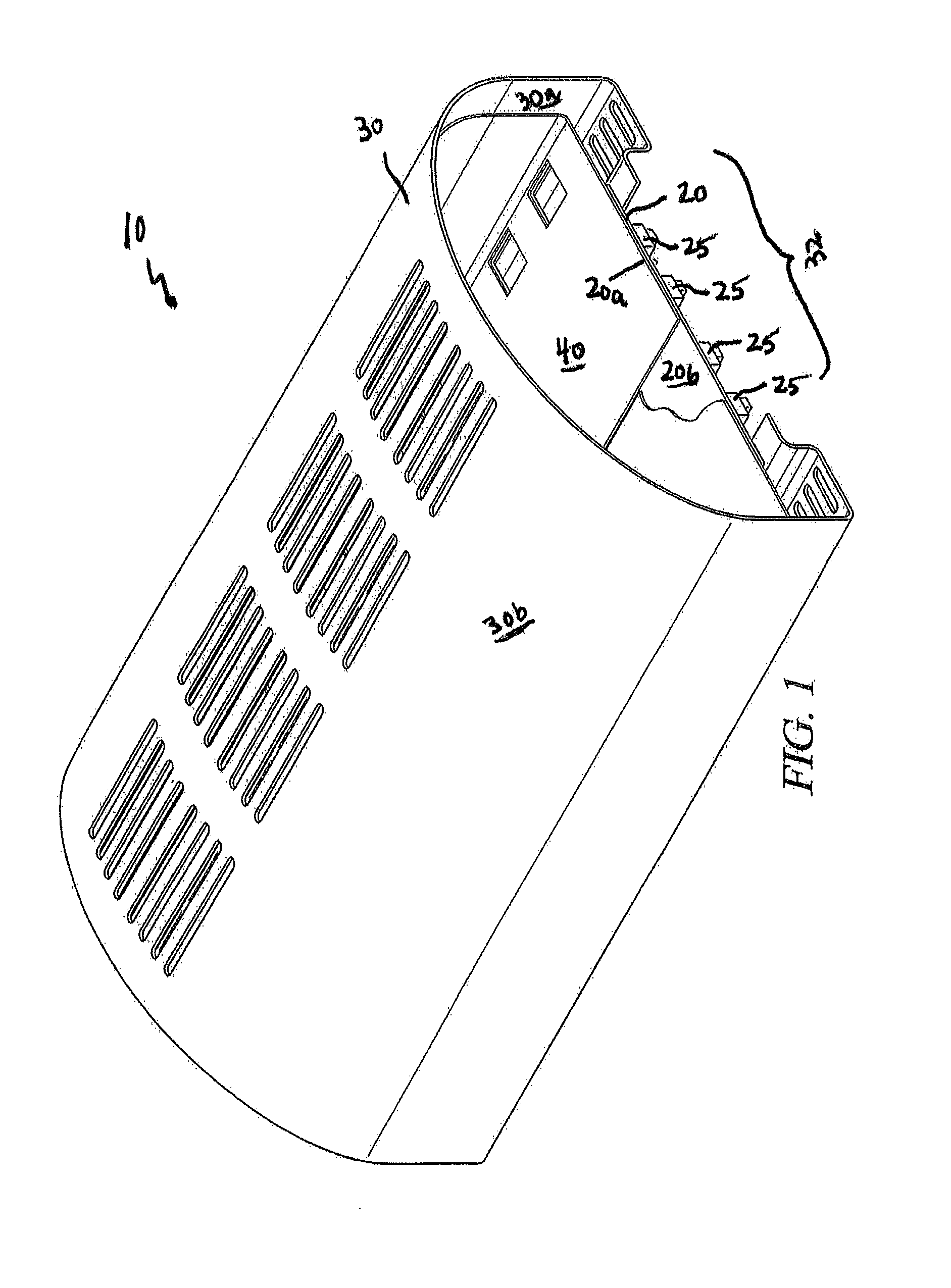

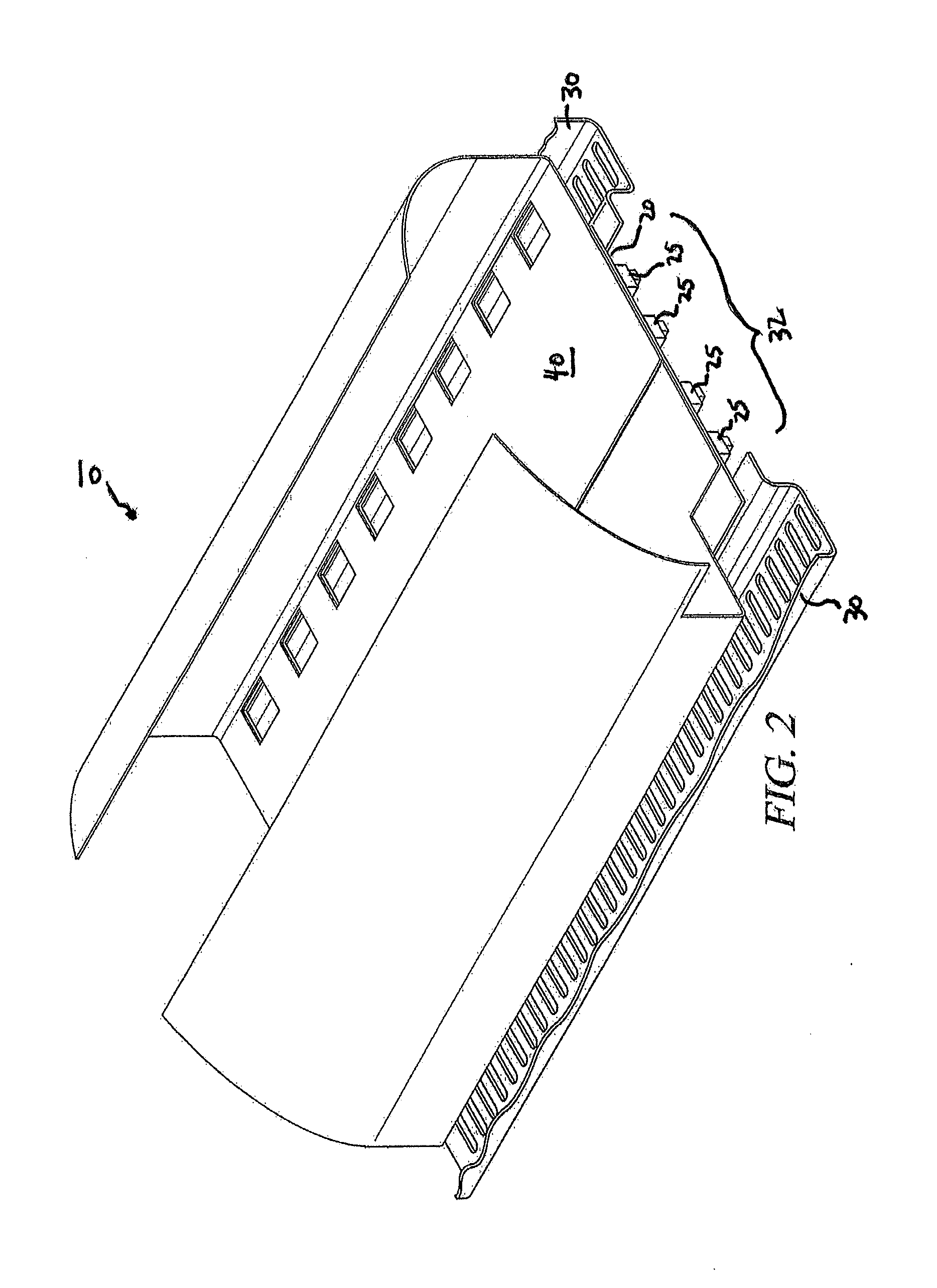

LED Light Fixture With Improved Thermal Management

A light fixture (10), having a circuit board (20) having first and second major surfaces (20a and 20b); at least one light emitting diode (25) mounted on the first major surface (20a) of the circuit board (20); an enclosure (30) formed of a material having two major surfaces (30a and 30b) and a thermo-mechanical design constant of at least 20 mm-W / m*K and shaped so as to define an opening (32) and a cavity (33), one of the major surfaces (30a) of the material defining the surface of the cavity (33) and the enclosure (30) positioned so as to enclose the second major surface (20b) of the circuit board (20); a heat spreader (40) having a surface area at least twice that of the circuit board and a thermo-mechanical design constant of at least 10 mm-W / m*K, the heat spreader (40) positioned in thermal contact with both the circuit board (20) and the enclosure (30).

Owner:GRAFTECH INT HLDG INC

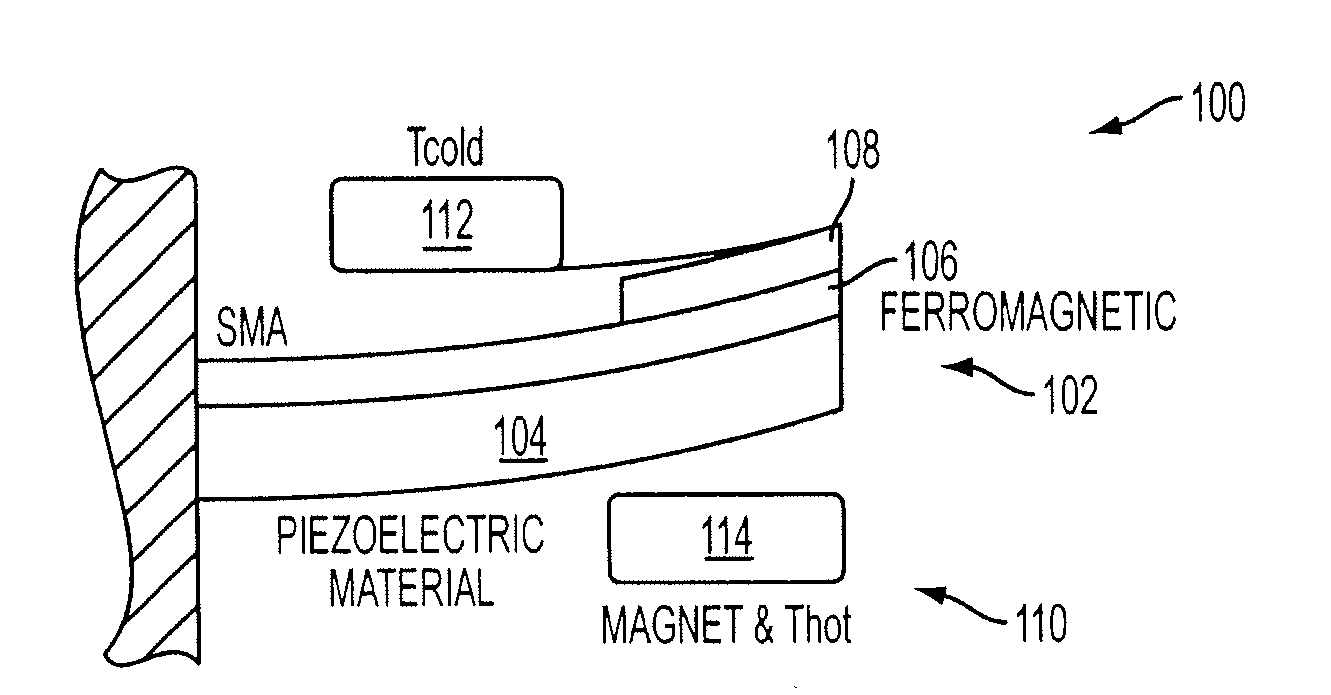

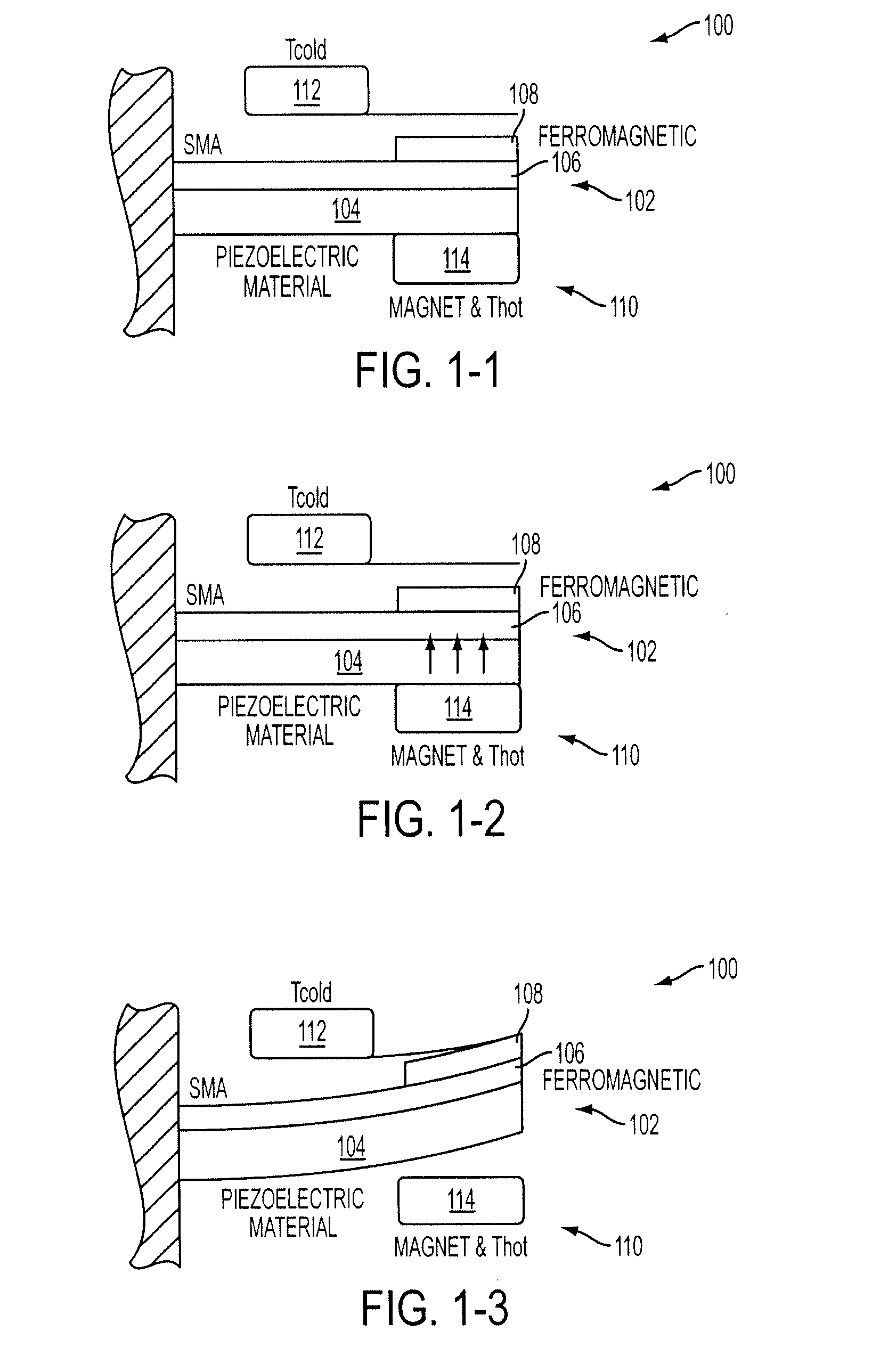

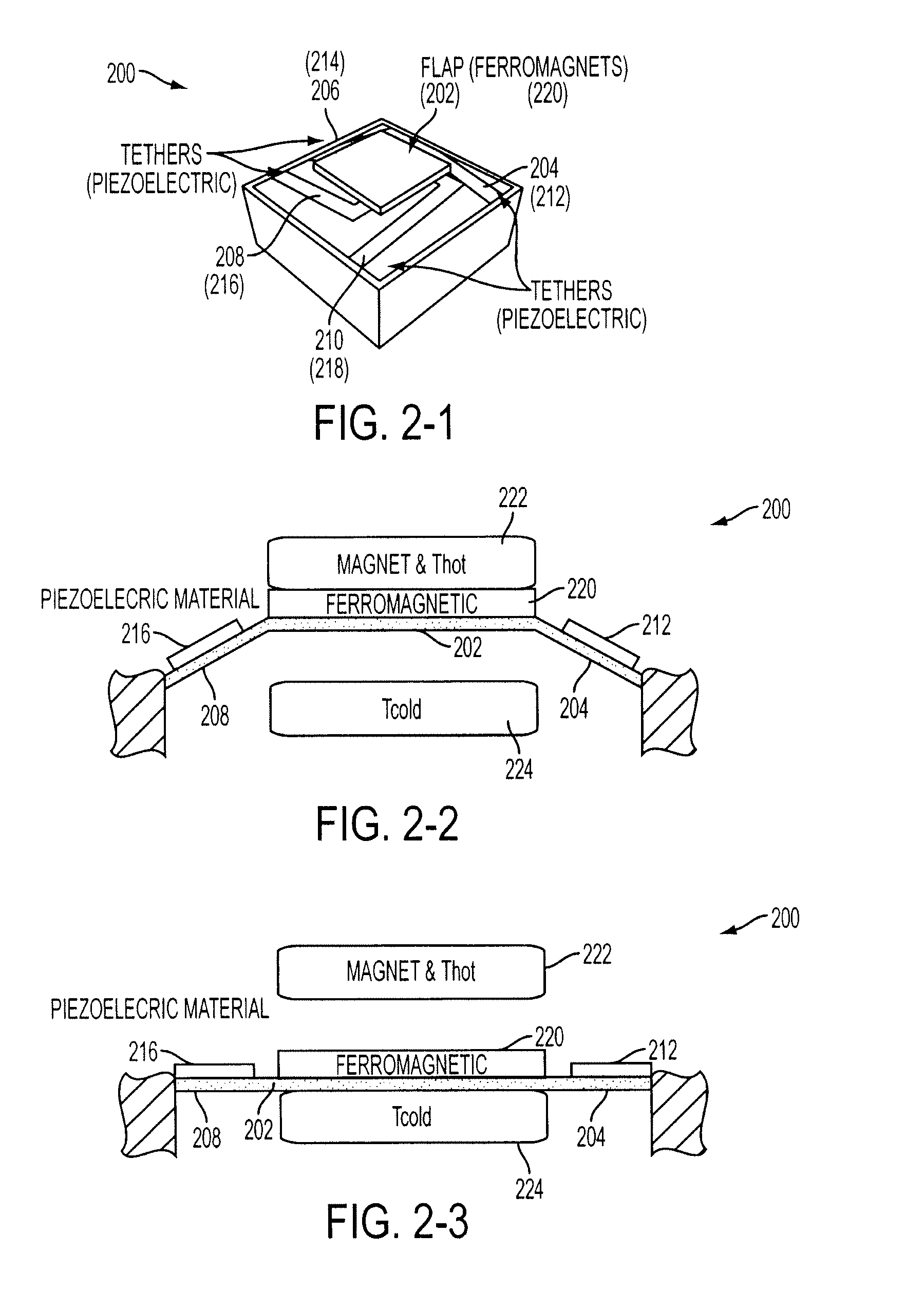

Energy harvesting by means of thermo-mechanical device utilizing bistable ferromagnets

InactiveUS20090315335A1Available energySimple designPiezoelectric/electrostriction/magnetostriction machinesMachines/enginesThermal energyElectricity

An inventive energy harvesting apparatus may include a ferromagnetic material and / or a shape memory alloys to convert thermal energy to mechanical energy to electrical energy. The apparatus is subjected to a thermal gradient to cause beams to bend thus creating stress / strain in a piezoelectric material, or creating magnetic flux in a magnetic path. The charges created in this process can be transferred to electrical batteries.

Owner:RGT UNIV OF CALIFORNIA

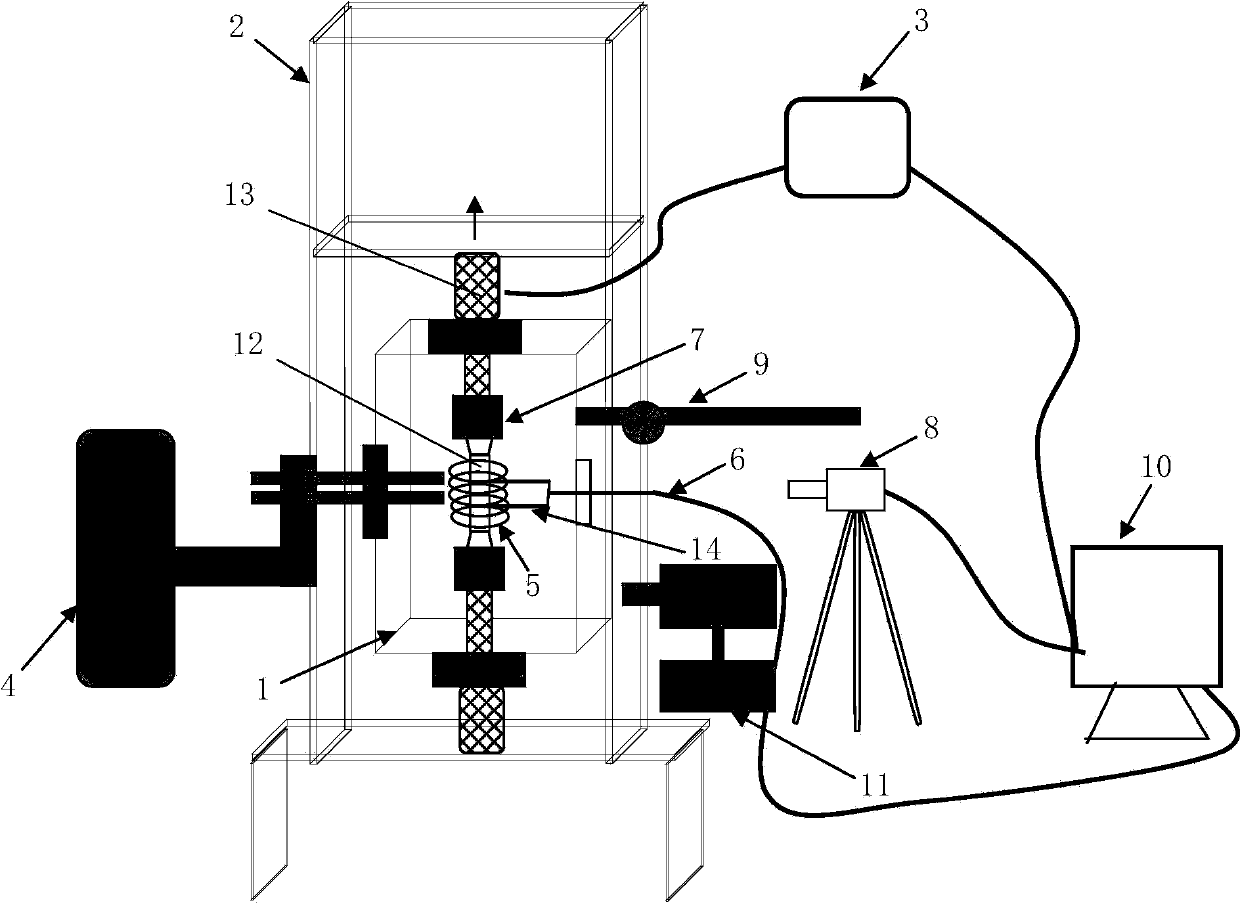

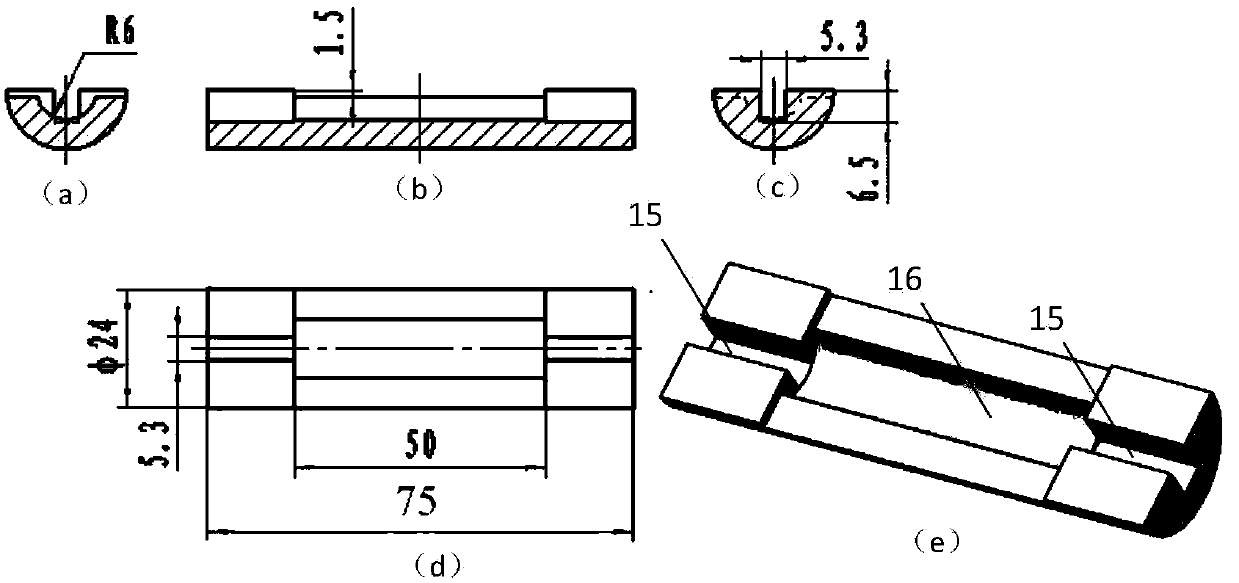

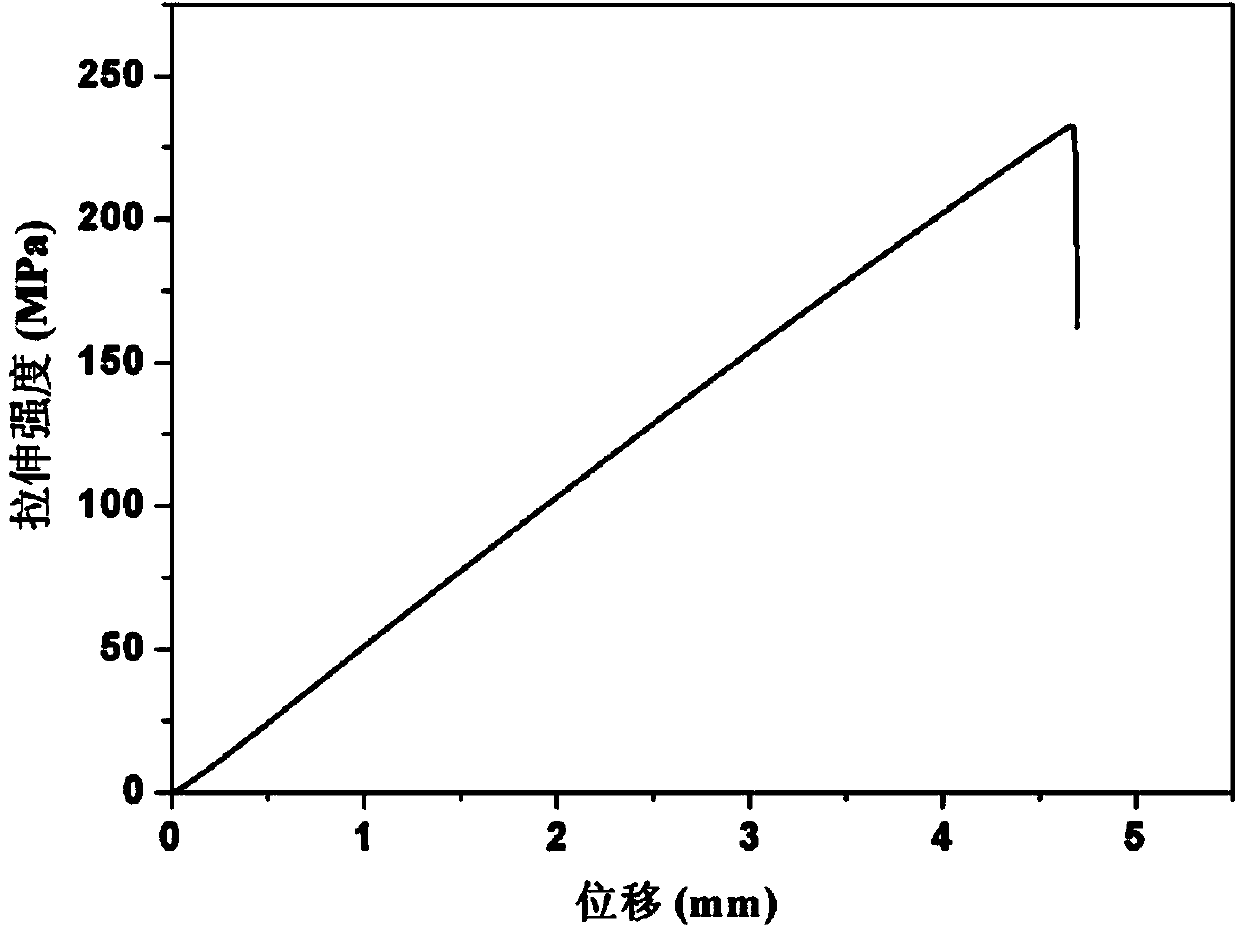

Thermo-mechanical-environmental coupling effect testing device and application from room temperature to ultrahigh temperature

ActiveCN104215521APrecise temperature controlTestable tensile strengthWeighing by removing componentMaterial strength using tensile/compressive forcesPower control systemTest fixture

The invention relates to the field of test of mechanical properties of materials and in particular relates to a thermo-mechanical-environmental coupling effect testing device and application from room temperature to ultrahigh temperature. The device comprises an electronic universal testing machine, a loading control system, a power supply control system, an induction heater, a strain measurement system, a sample clamp, a temperature measuring system, a pressure control system, a display and analysis system and a vacuum system, wherein a vacuum cavity in the electronic universal testing machine is in a fully water-cooled design, and various functional windows, such as a sensor connector of the clamp and the electronic universal testing machine, an infrared or thermocouple temperature measuring opening of the temperature measuring system, a pressure control opening of the pressure control system, an induction power supply introduction opening of the power supply control system, an extensometer introduction opening of the strain measurement system and a connector of the vacuum system and the vacuum cavity, are reserved in different parts of the vacuum cavity. The device disclosed by the invention can quantitatively research the thermo-mechanical-environmental coupling effect and has the advantages of diversified tested mechanical property parameters, high sample heating and cooling speed and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

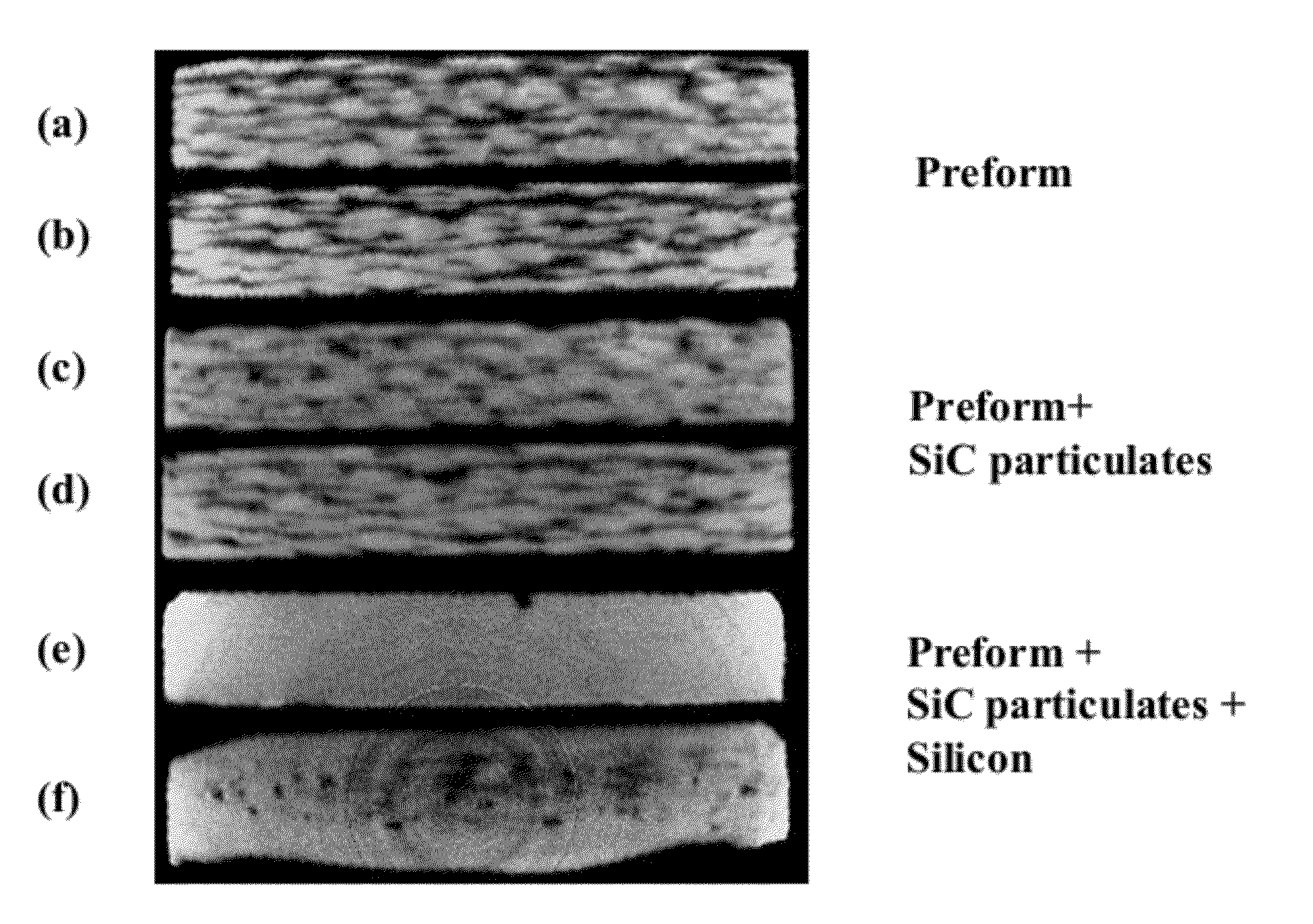

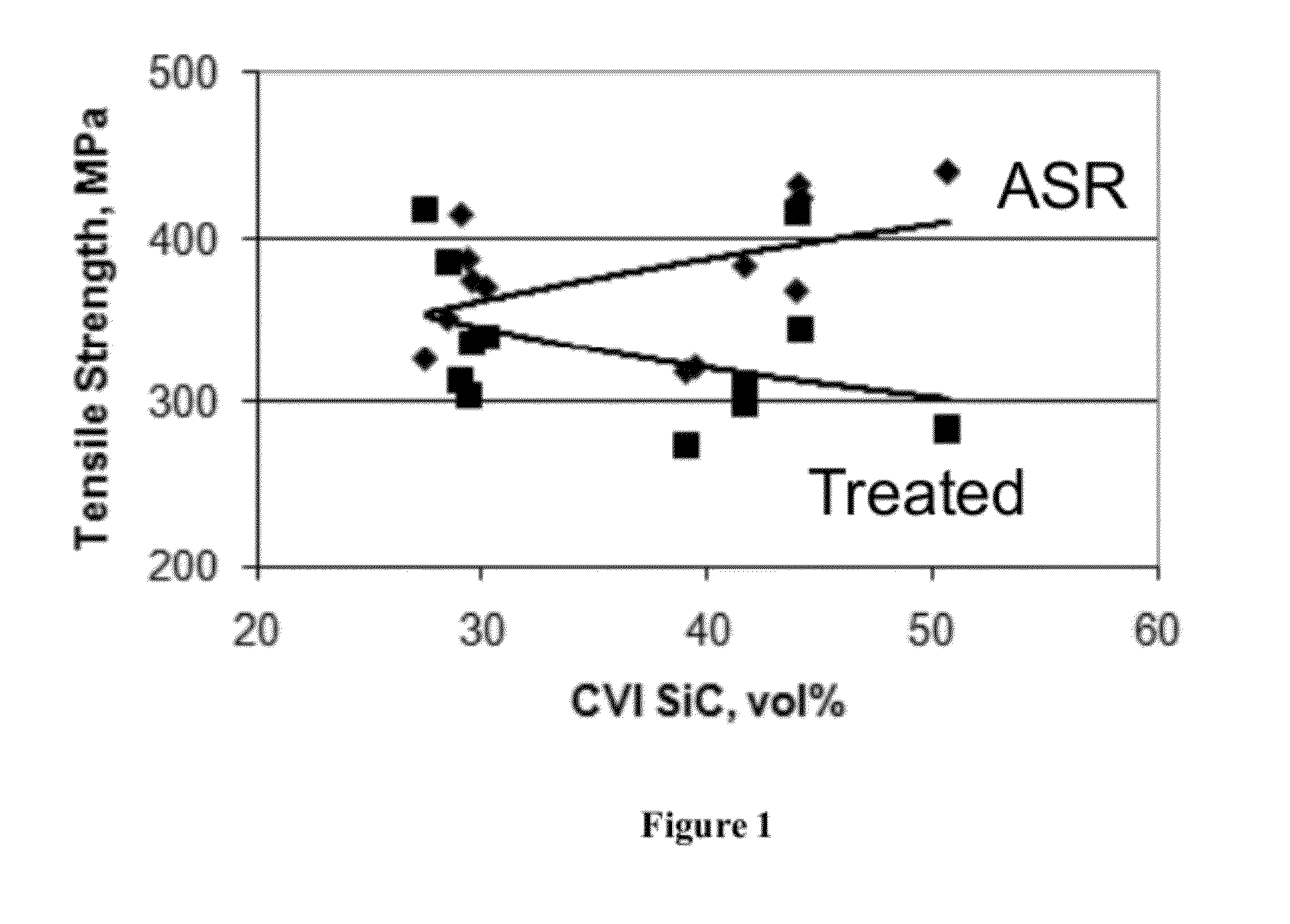

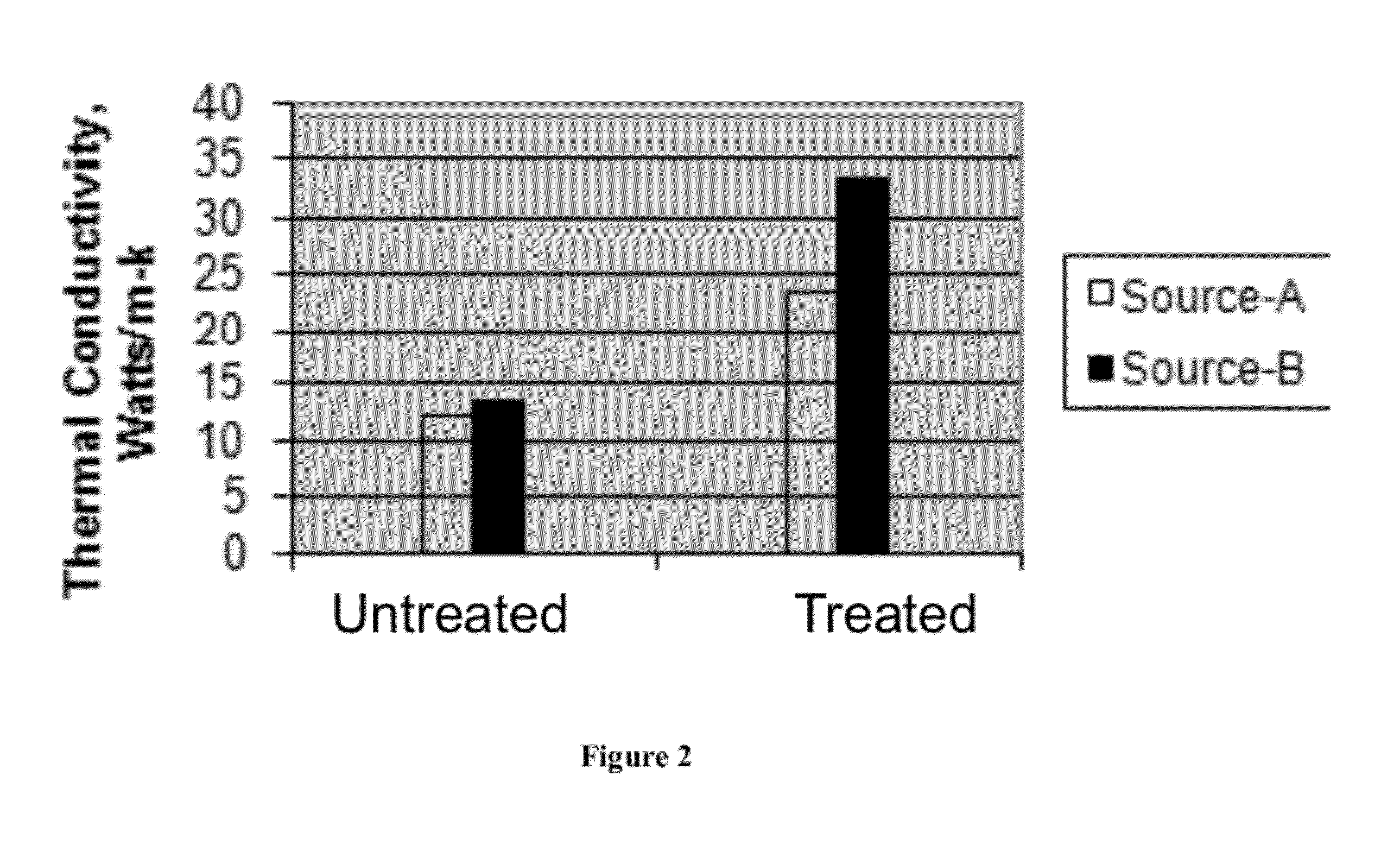

Method of improving the thermo-mechanical properties of fiber-reinforced silicon carbide matrix composites

InactiveUS20120076927A1Improve featuresImprove propertiesCeramic shaping apparatusCoatingsParticulatesGas phase

A thermal treatment process for improving thermo-mechanical properties of ceramic matrix composite materials such as silicon carbide (SiC) matrix composites is described. The treatment process removes excess silicon and / or other process-related defects from the SiC-based matrix as well as the fiber interfacial coating. This invention can be practiced with minimal strength loss for as-fabricated composites formed from high-strength continuous-length ceramic and carbon-based fibers that are functionally stable to 1600° C. and above. The invention provides a method for significantly improving composite thermal conductivity and creep resistance, and for reducing composite porosity. It has been demonstrated using state-of-the-art 2D woven SiC / SiC composites containing Sylramic-iBN SiC fibers, boron-nitride-based interfacial coatings, and hybrid matrices that are based on SIC formed by chemical vapor infiltration (CVI) and by a combination of CNI, SiC particulate infiltration, polymer infiltration and pyrolysis, and melt infiltration of silicon, silicon-based alloys, and silicides.

Owner:US SEC THE ARMY THE

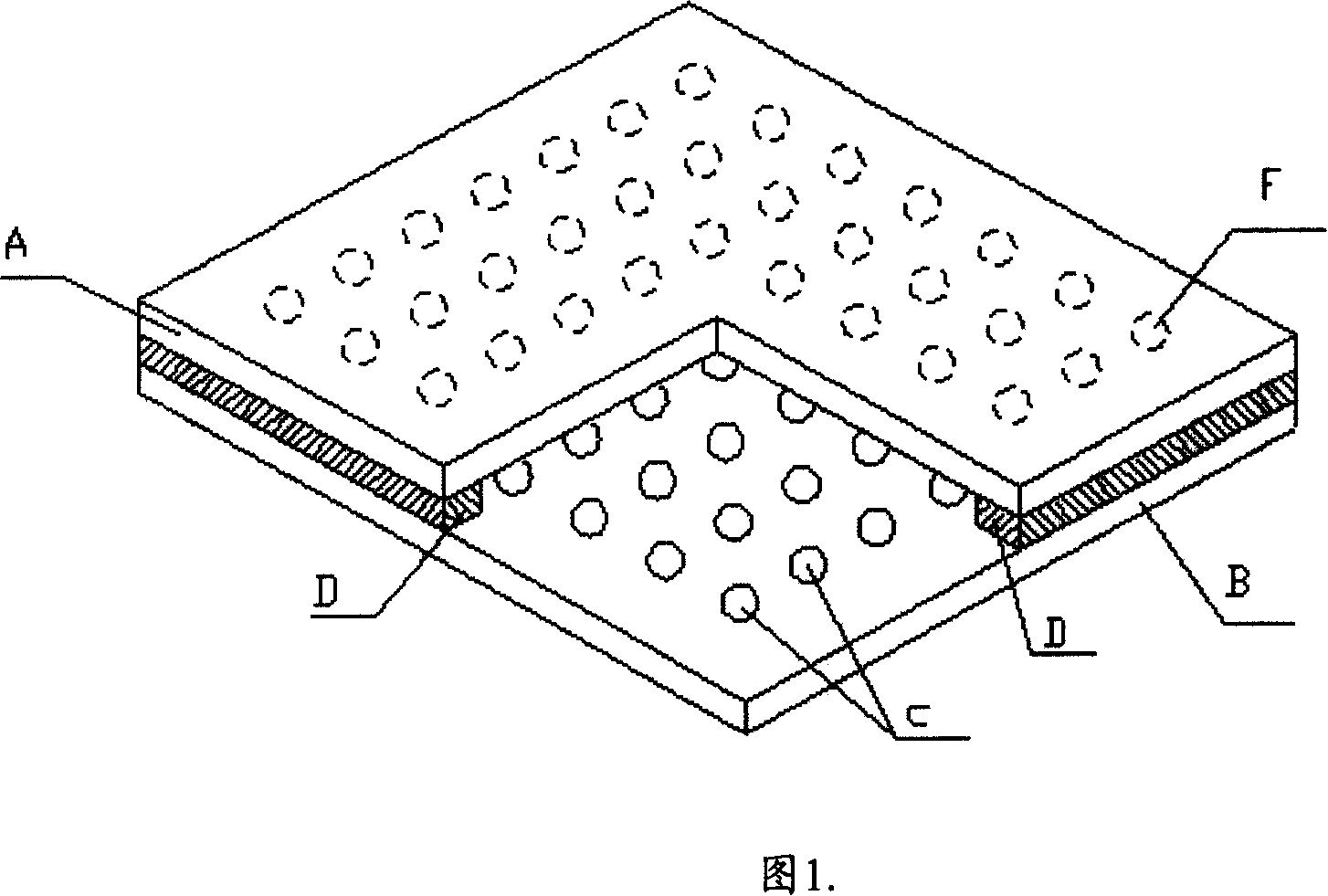

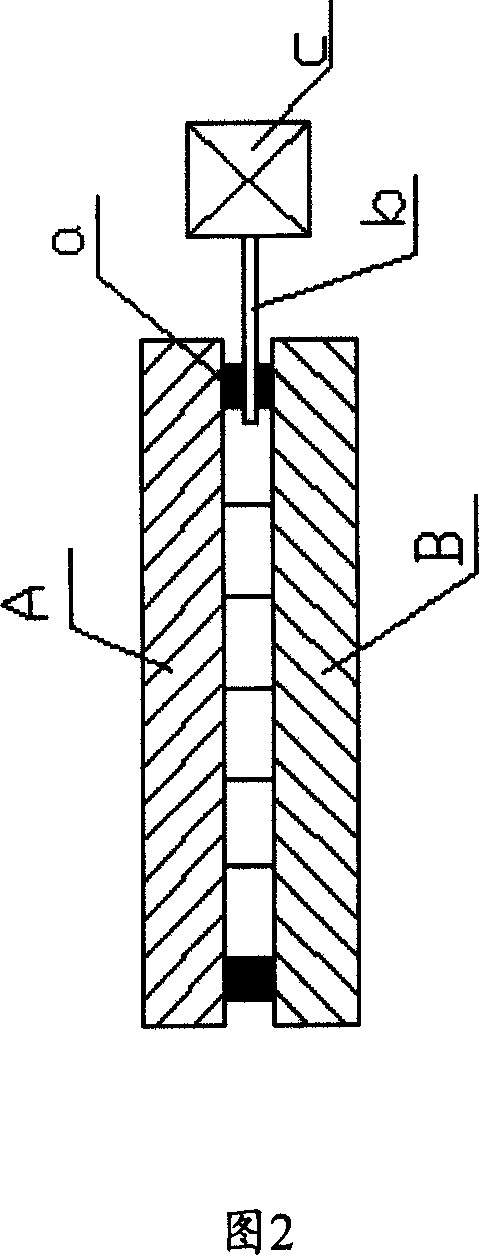

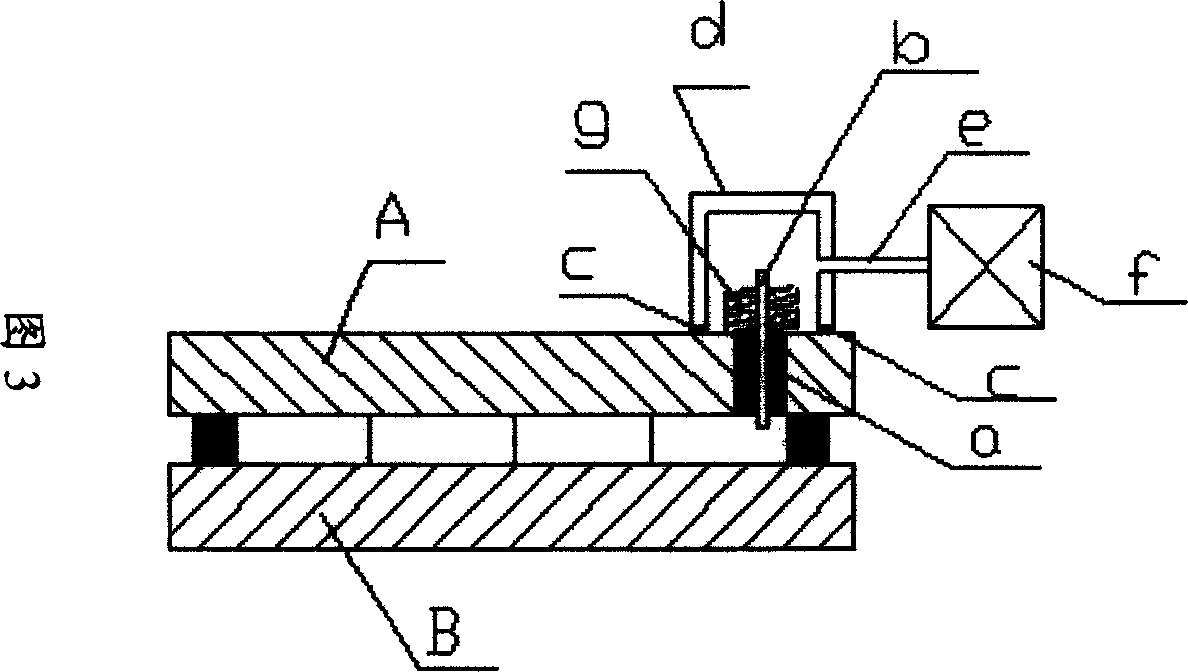

New method and equipment for preparing vacuum glass faceplate

InactiveCN101050056AImprove production efficiencyImprove yield and mechanical strengthGlass reforming apparatusElectric heatingEngineering

This invention discloses novel method and apparatus for producing vacuum glass. The method comprises: producing isolated supporting points between glass panels and airtight sealing layers at the edges of glass panels by screen printing process, sealing the edges, exhausting, sealing the exhaust mouth, baking, examining, and framing. The softening temperature and thermal and mechanical properties of the low-melting-point glass used for isolated supporting points and airtight sealing layers, and the thickness of isolated supporting points should precisely match the thickness of airtight sealing layers. The exhaust and sealing apparatus comprises: a sealed vacuum chamber for fixing the surface of the vacuum glass panel with exhaust holes downward onto the sealing table, and a movable ejection pin with an electric heating device below the exhaust holes; or a bell jar with a sealing ring, and movable ejection pin with an electric heating device below the exhaust holes. After exhausting, the ejection pin heats the metal plate sintered with low-melting-point glass to the sealing temperature of the low-melting-point glass, and seals by tip layering onto the exhaust holes.

Owner:罗建超

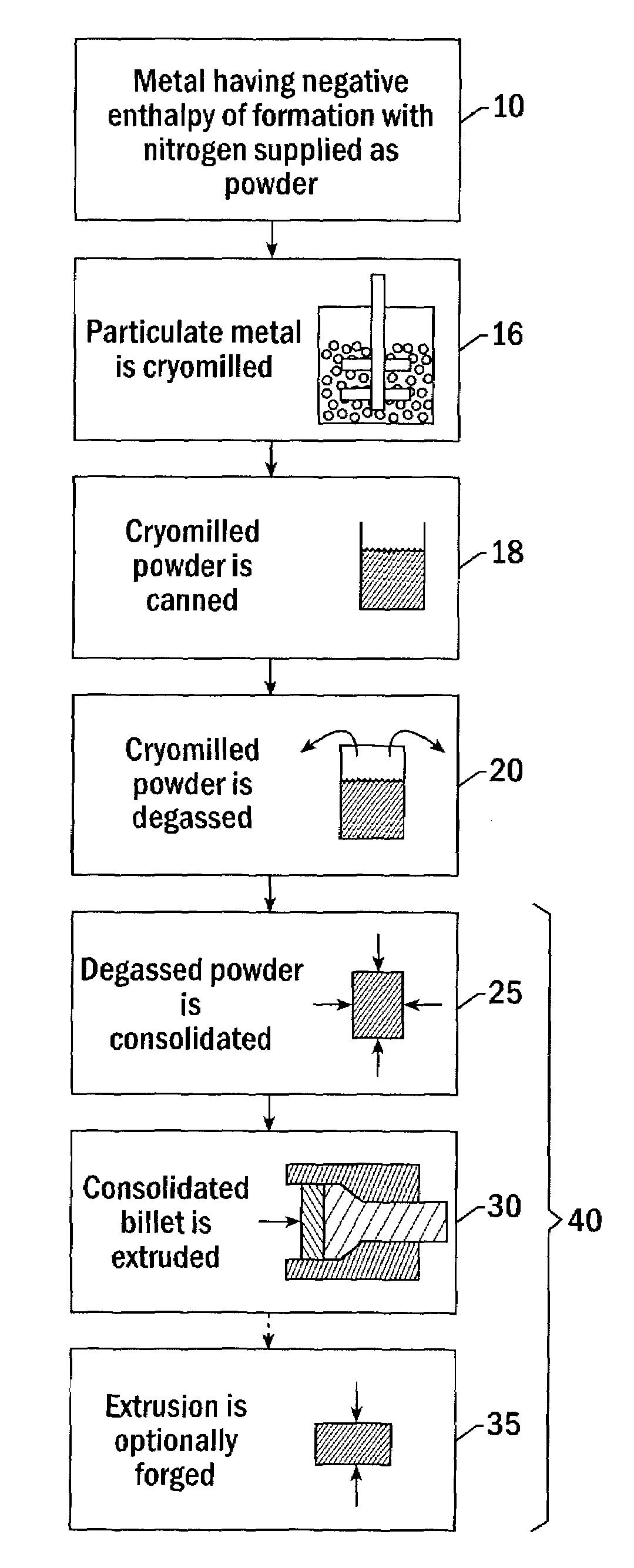

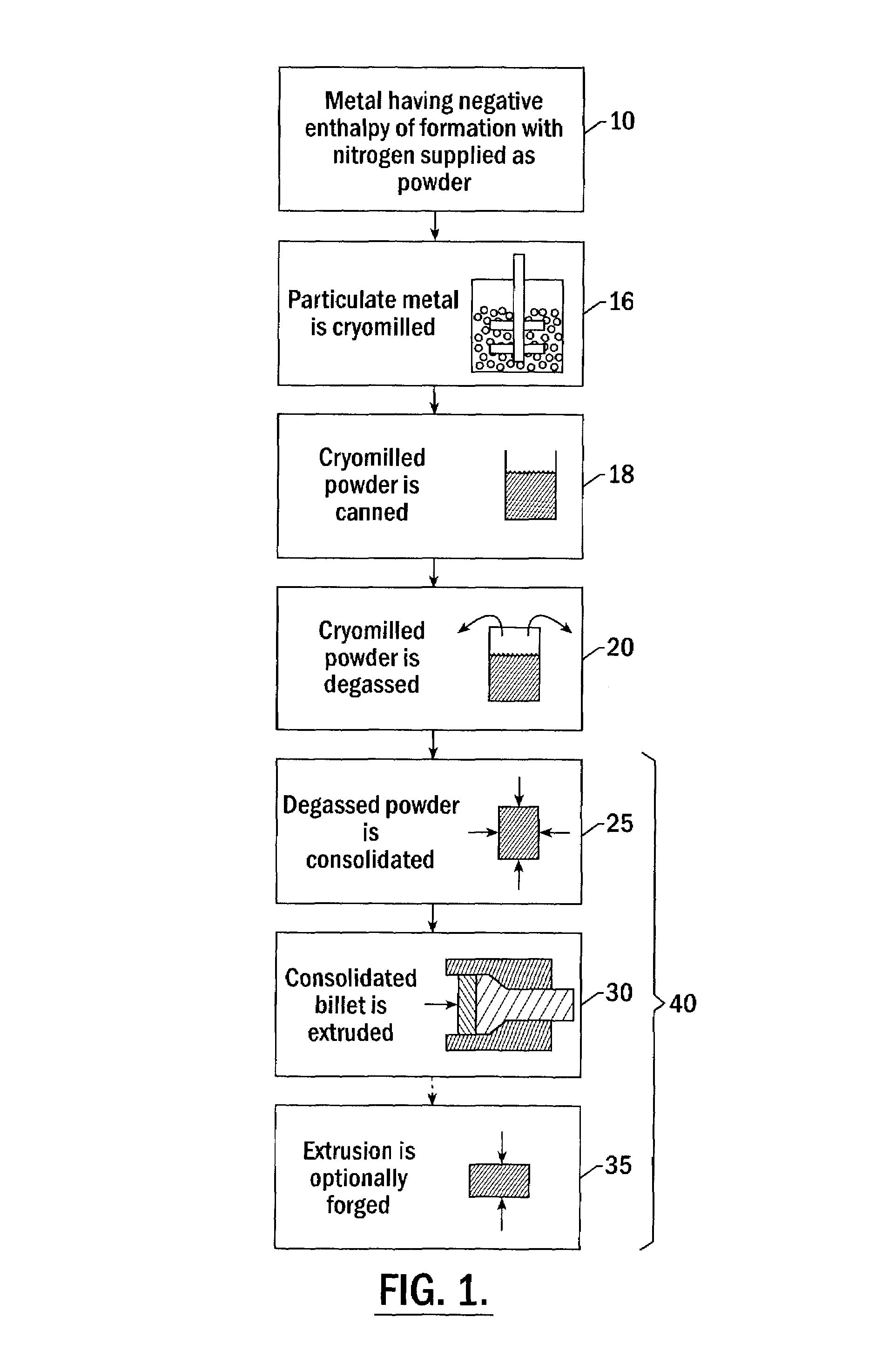

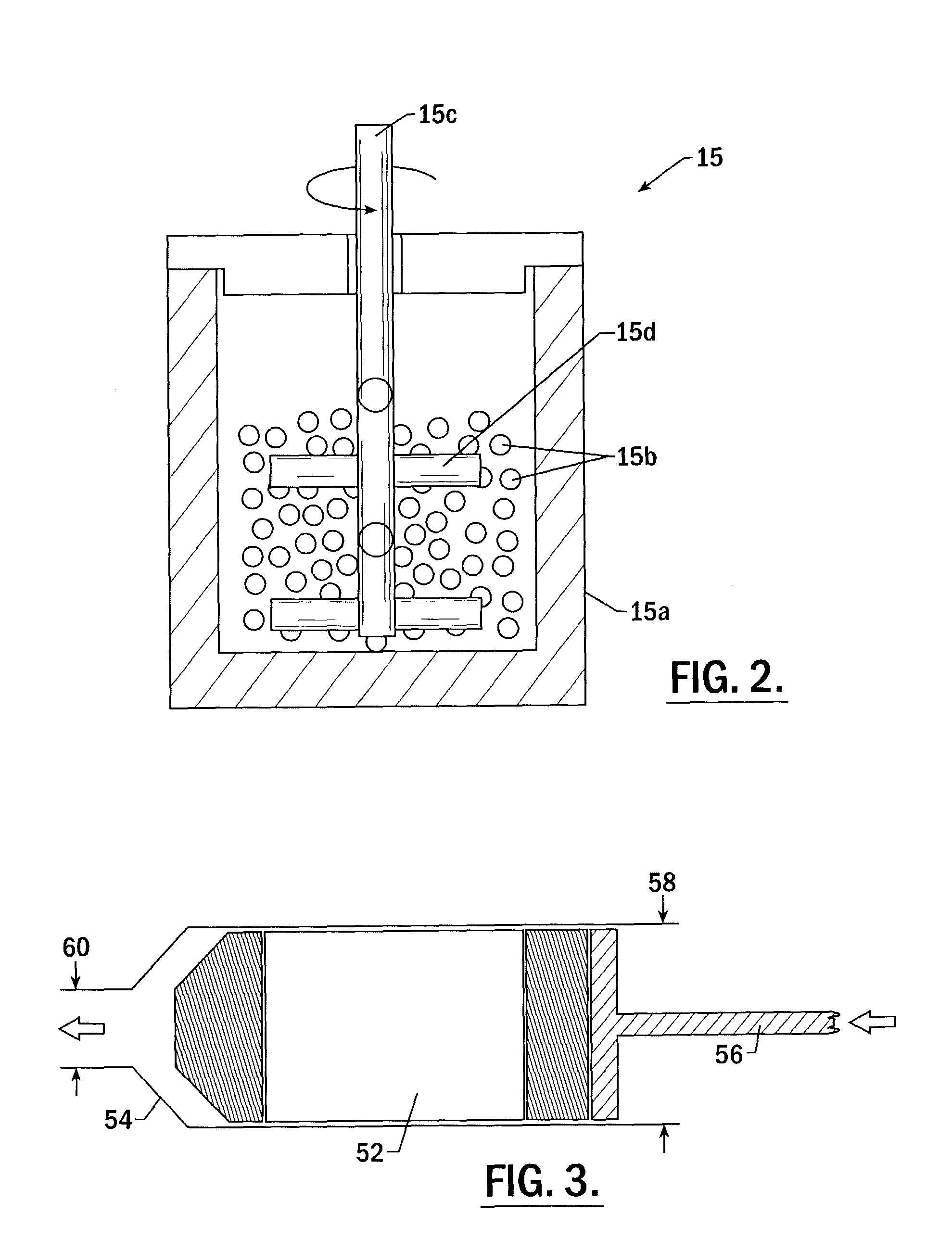

Method for preparing nanostructured metal alloys having increased nitride content

InactiveUS7344675B2Reduce grain growthHigh strengthTransportation and packagingMetal-working apparatusMetal alloyHigh intensity

A method of producing high strength nanophase metal alloy powder by cryomilling metal powder under conditions which cause the formation of intrinsic nitrides, and of producing high strength metal articles by subjecting the nitrided cryomilled powder to thermo-mechanical processing. The intrinsic nitrides present within the alloy significantly reduce grain growth during thermo-mechanical processing, resulting in formed metal products of high strength and improved ductility.

Owner:THE BOEING CO

Flip chip ball grid array package

InactiveUS7224048B1EffectiveRelieve pressureSemiconductor/solid-state device detailsSolid-state devicesBall grid arraySemiconductor

A flip-chip ball grid array integrated circuit package with improved thermo-mechanical properties is provided. The package includes a substrate having first and second surfaces and a plurality of conductive traces therebetween. A semiconductor die is flip-chip mounted to the first surface of the substrate and electrically connected to ones of the conductive traces. An intermetallic heat spreader is fixed to a back side of the semiconductor die and a plurality of contact balls are disposed on the second surface of the substrate. The contact balls are in the form of a ball grid array and ones of the contact balls of the ball grid array are electrically connected to ones of the conductive traces.

Owner:UTAC HEADQUARTERS PTE LTD

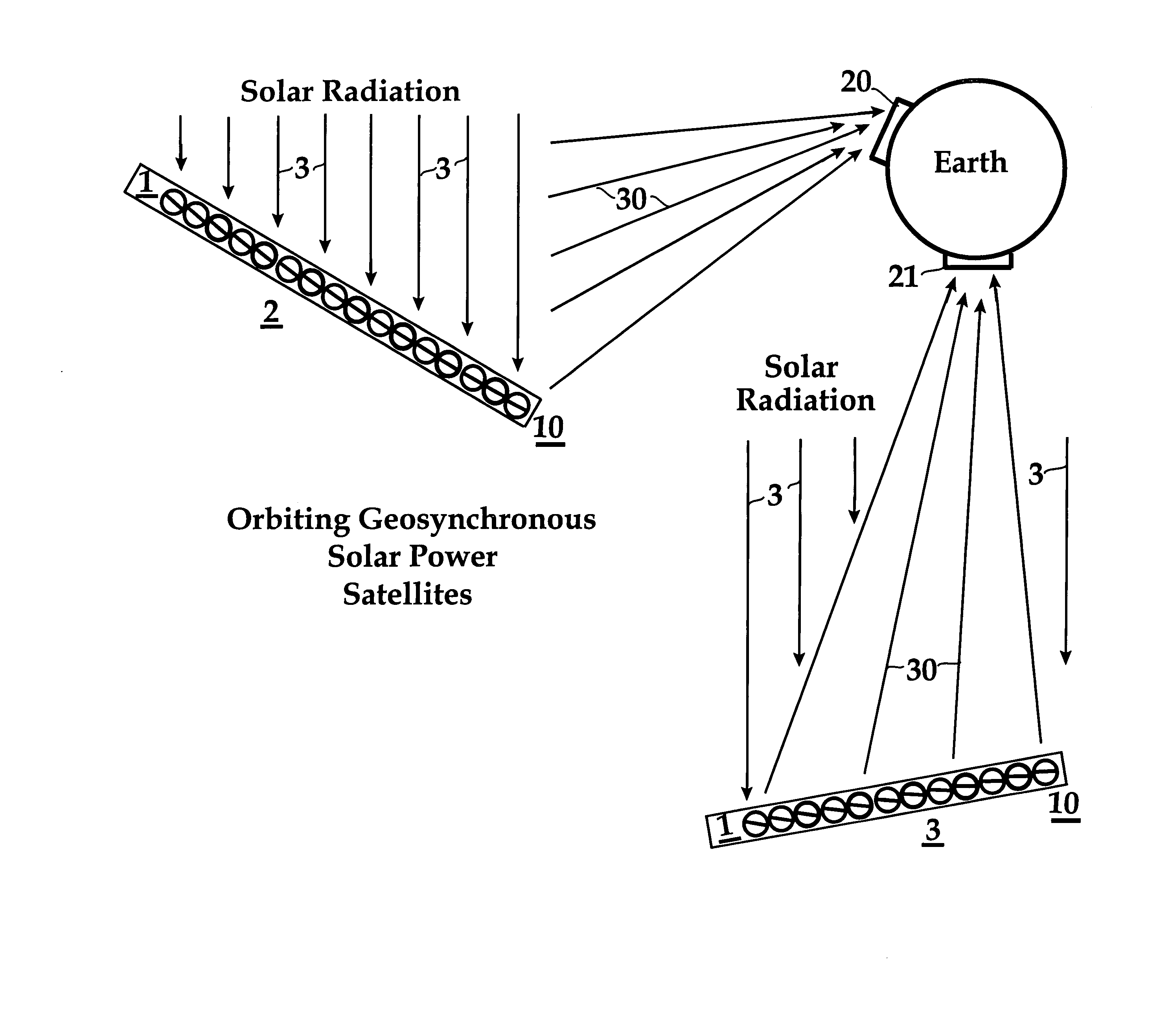

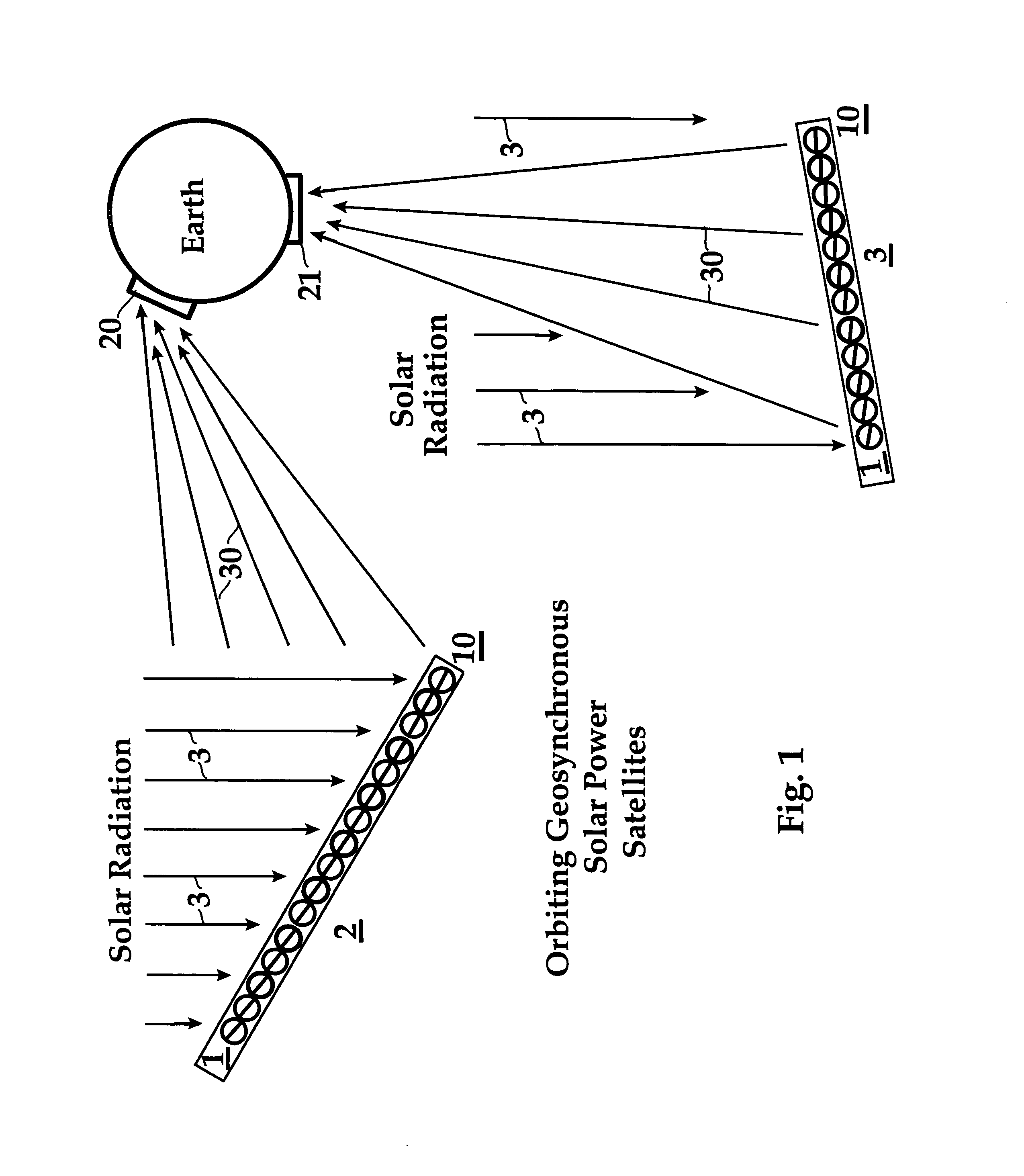

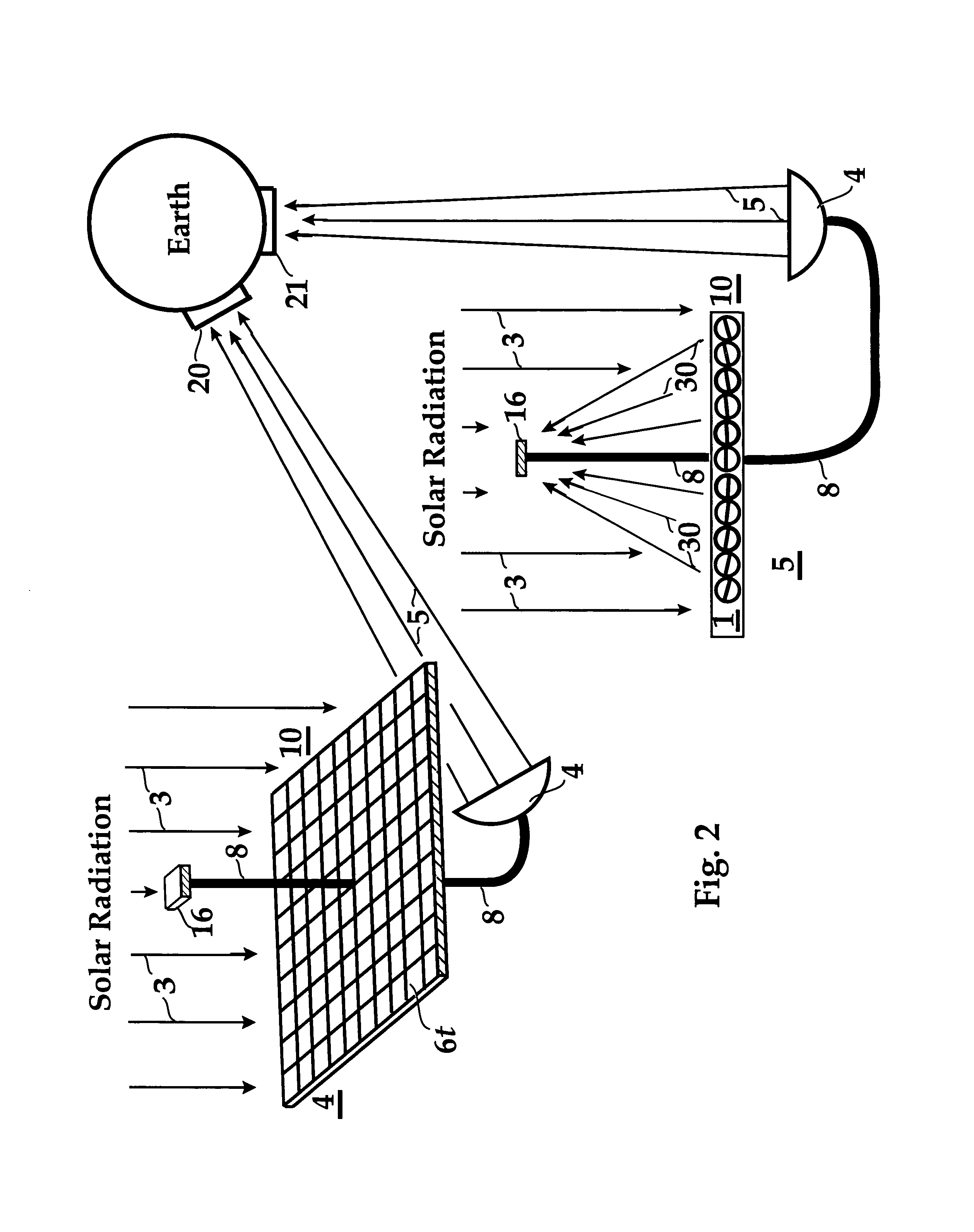

Micro-optics concentrator for solar power satellites

InactiveUS7077361B1Low costAffordable solar energySolar heating energyCosmonautic vehiclesSolar powerSolar power satellites

There is an increasingly intense need to harness solar energy due to an ever growing shortage of conventional energy sources, The instant invention is concerned with method and apparatus for solar concentrator micro-mirrors on solar power satellites and the moon to focus and reflect large quantities of solar energy. Method and apparatus are taught for directly reflecting solar energy to the Earth; reflecting solar energy to a microwave converter in space which transmits microwave energy to the Earth; and reflecting solar energy to a laser radiation converter which beams laser radiation to the Earth. The concentrated energy received at the Earth may be converted directly to electricity or indirectly by thermo-mechanical means. The advantages and disadvantages of the different means of sending such concentrated energy to the Earth are discussed. A particularly important objective of this invention is the focussing of sunlight for solar power conversion and production. The instant invention can contribute to the goal of achieving environmentally clean solar energy on a large enough scale to be competitive with conventional energy sources.

Owner:RABINOWITZ MARIO

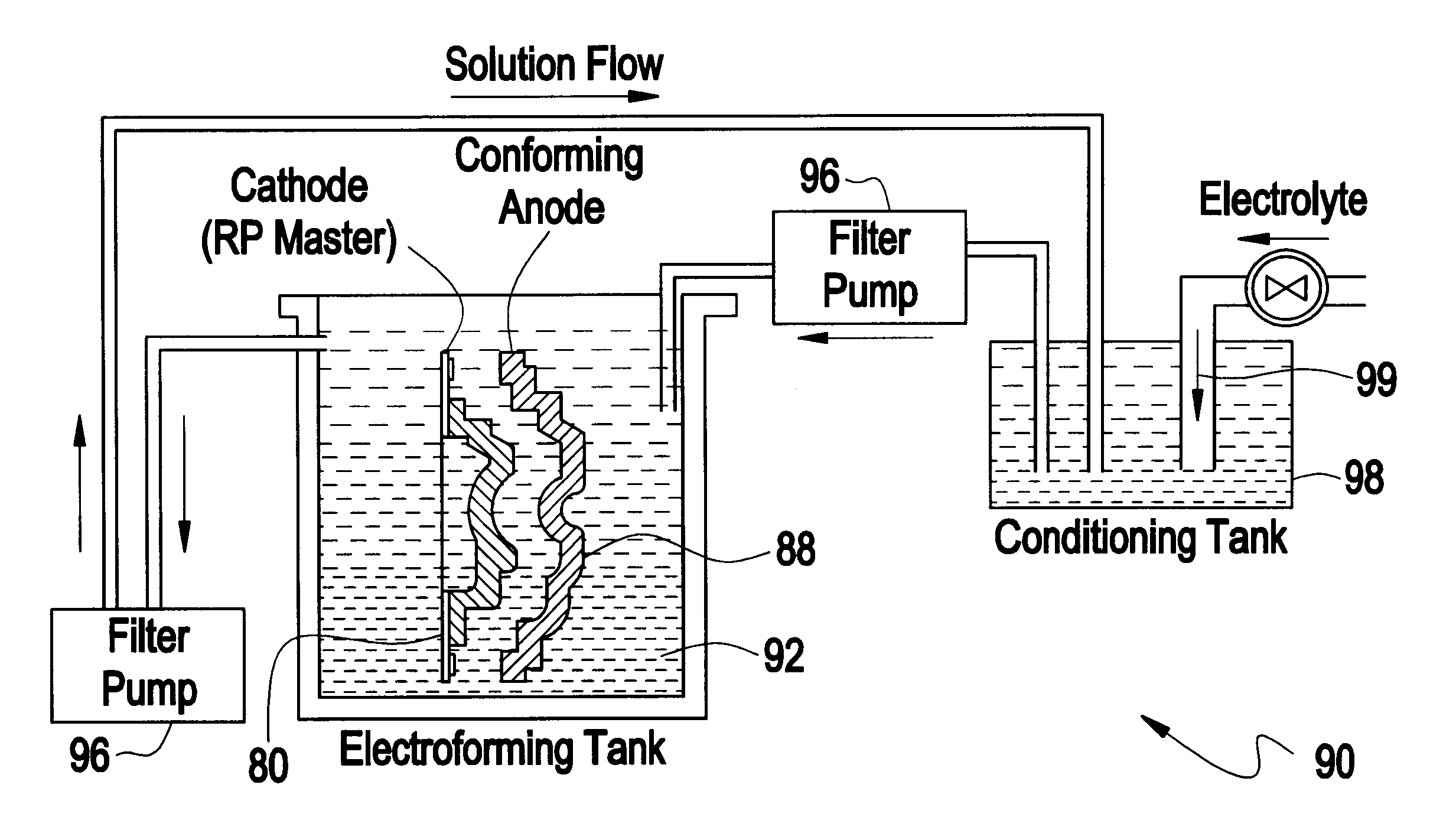

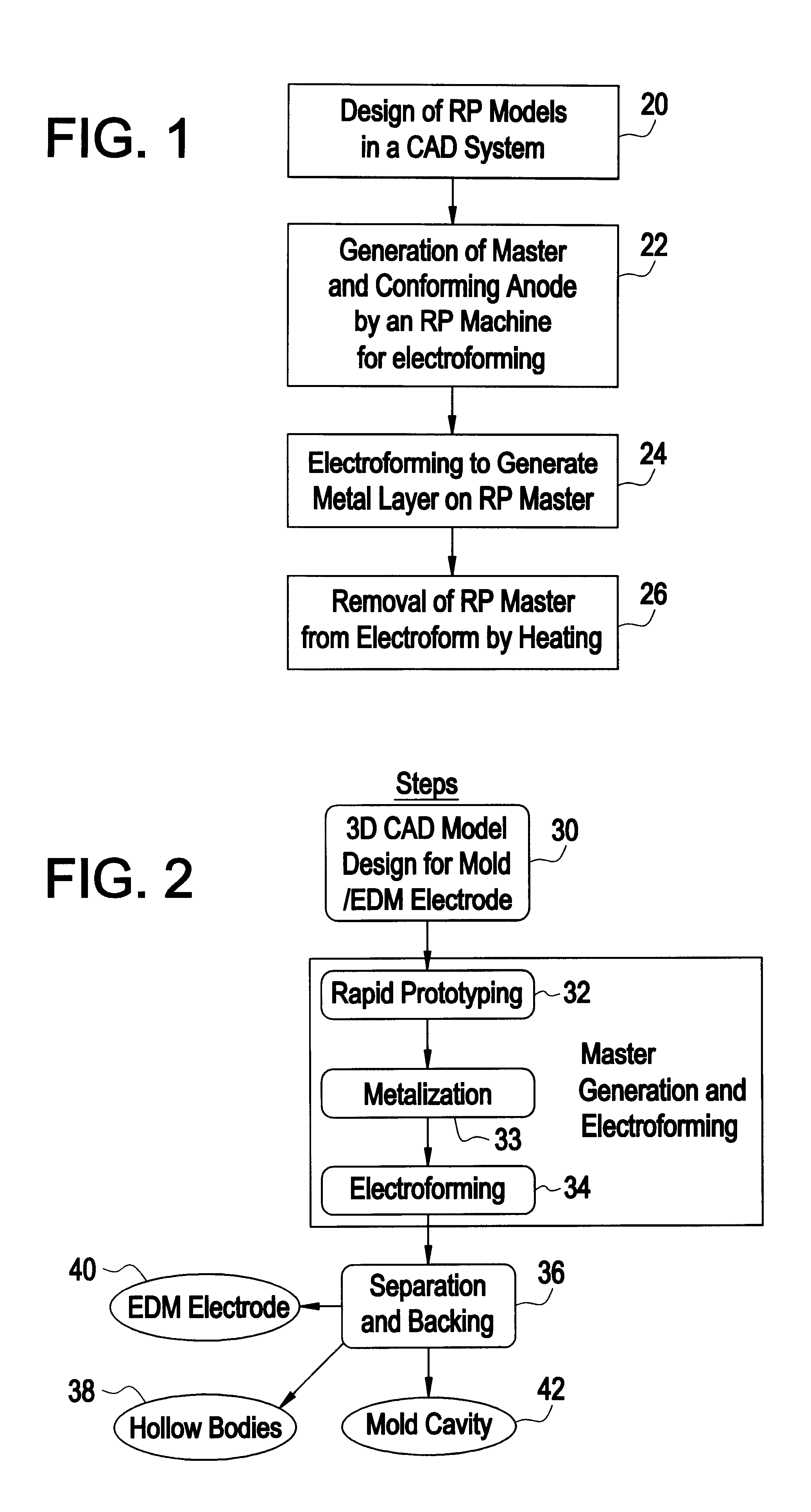

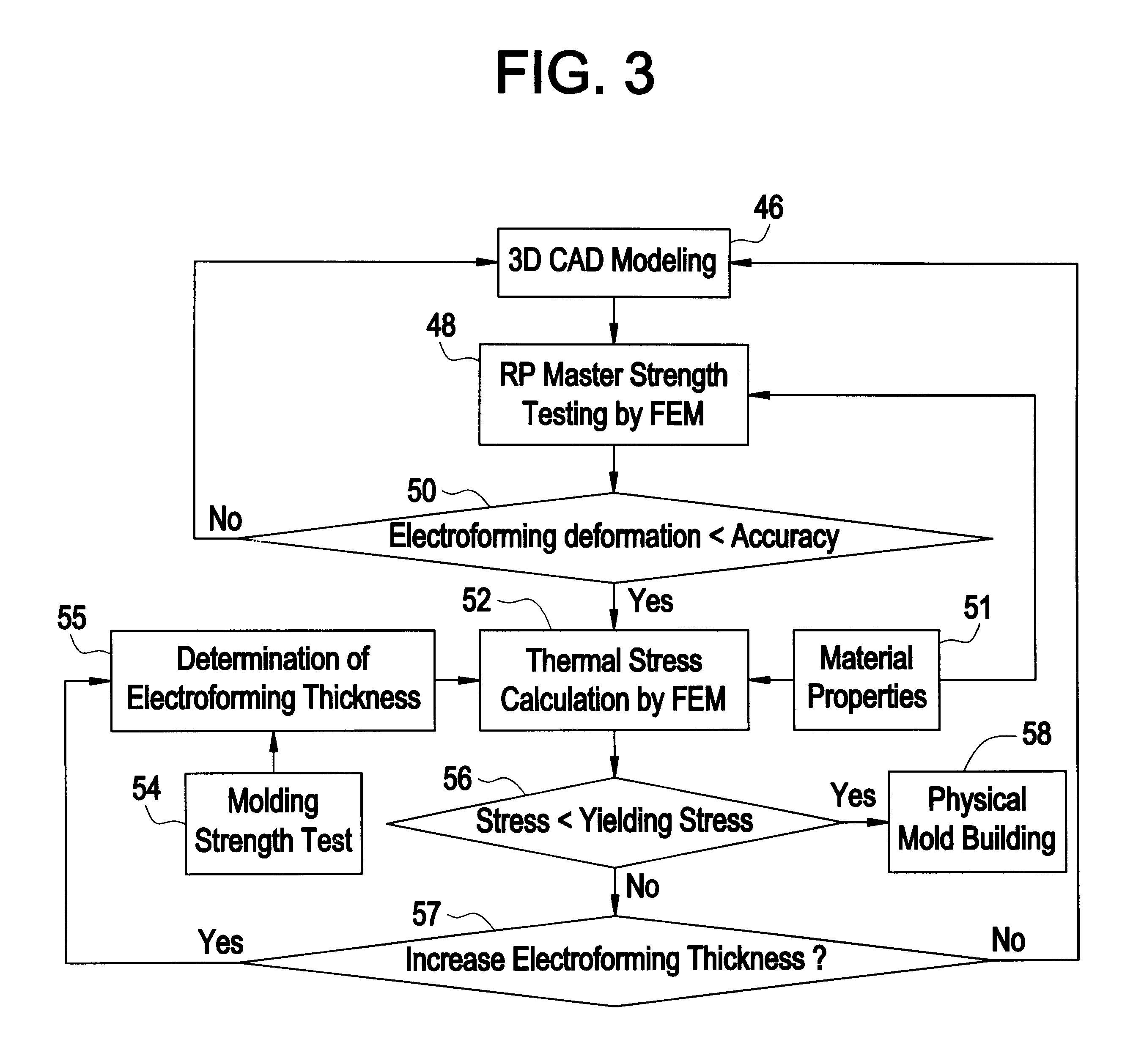

Rapid production of engineering tools and hollow bodies by integration of electroforming and solid freeform fabrication

InactiveUS6409902B1Stay in shapeAvoid insufficient thicknessAdditive manufacturing apparatusFoundry mouldsElectrolysisElement analysis

This invention describes a rapid tooling process that integrates solid freeform fabrication (SFF) with electroforming to produce metal tools including molds, dies, and electrical discharge machining (EDM) electrodes. An SFF part is metalized by electroless plating and then placed in an electroplating solution, where metal is deposited upon the part by electrolysis. When the desired thickness of metal has been reached, the SFF part is removed from the metal shell. The shell is then optionally backed with other materials to form a mold cavity, and EDM electrode, or other desired parts for tooling. Thermomechanical modeling and numerical simulation with finite element analysis (FEA) is used to determine the geometry of the SFF part and the electroform thickness for minimizing the manufacturing time and cost while satisfy the tooling requirement.

Owner:NEW JERSEY INSTITUTE OF TECHNOLOGY

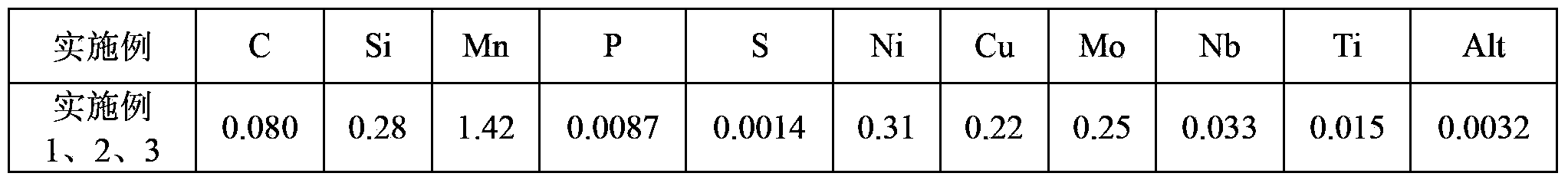

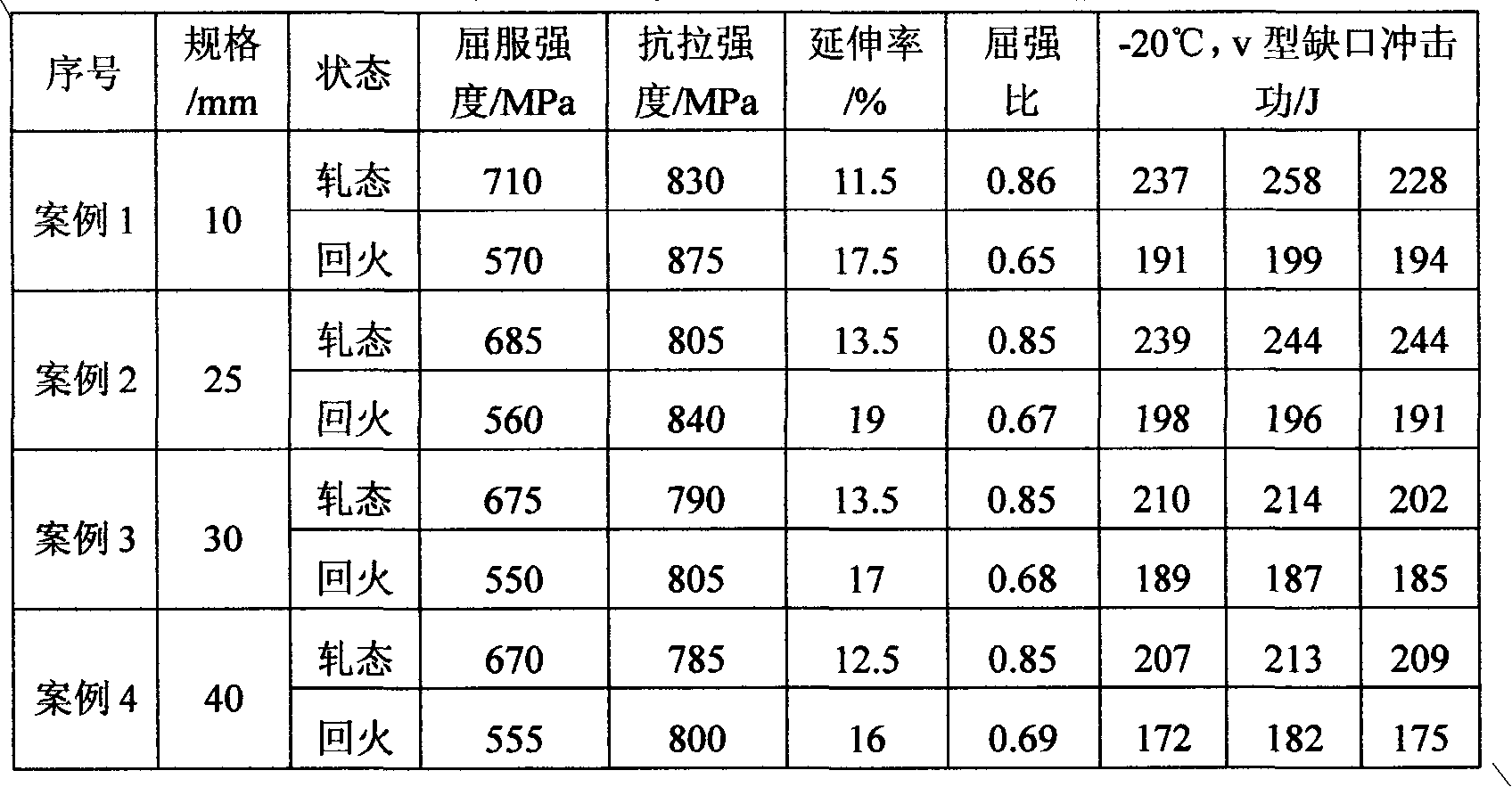

Low-yield ratio and high-strength steel for bridges and manufacturing method thereof

The invention discloses low-yield ratio and high-strength steel for bridges and a manufacturing method thereof. The steel comprises the following chemical components by weight percent : 0.06-0.10 percent of C, 0.20-0.45 percent of Si, 1.20-1.50 percent of Mn, no more than 0.010 percent of P, no more than 0.0020 percent of S, 0.30-.060 percent of Ni, 0.20-0.50 percent of Cu, 0.15-0.50 percent of Mo, 0.025-0.060 percent of Nb, no more than 0.035 percent of Ti, 0.020-0.040 percent of Alt, and Fe and unavoidable impurities in balancing amount. According to the invention, through smelting, refining, performing a reasonable thermo-mechanical control process (TMCP) and optimizing tempering heat treatment production, the tensile strength of the steel is 700-780 MPa, the yield strength is 530-600MPa, the extensibility is greater than or equal to 18 percent, the yield ratio is less than or equal to 0.80, and 40 below zero DEG C low-temperature longitudinal impact is greater than or equal to 100 J, so that the steel is good in obdurability matching and low in the yield ratio, is provided with excellent performance of shock prevention, and is stable in production process and strong in operability.

Owner:NANJING IRON & STEEL CO LTD

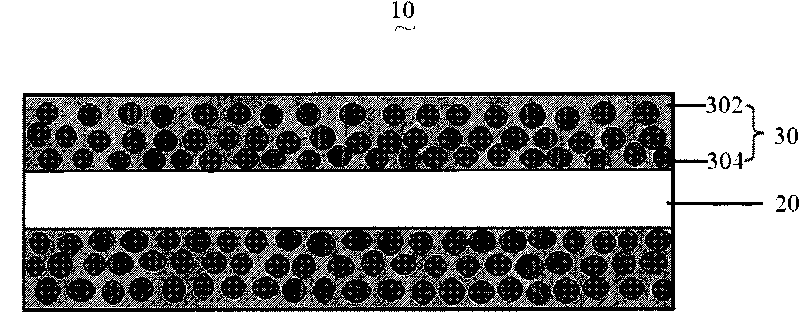

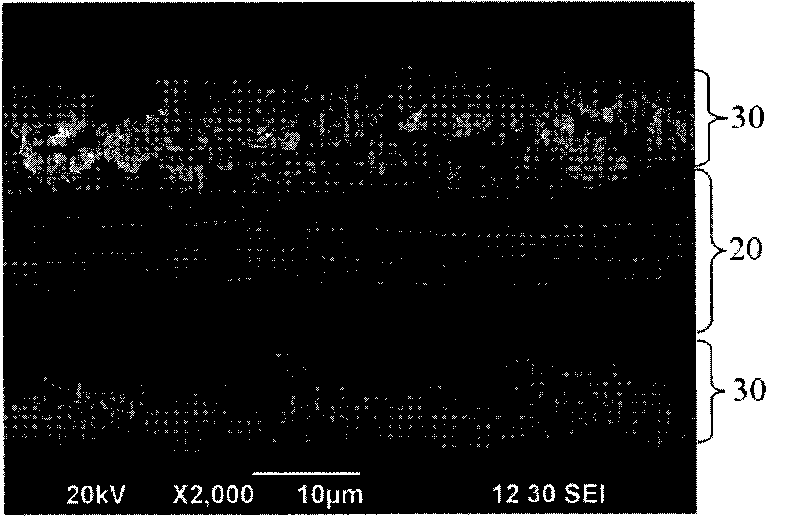

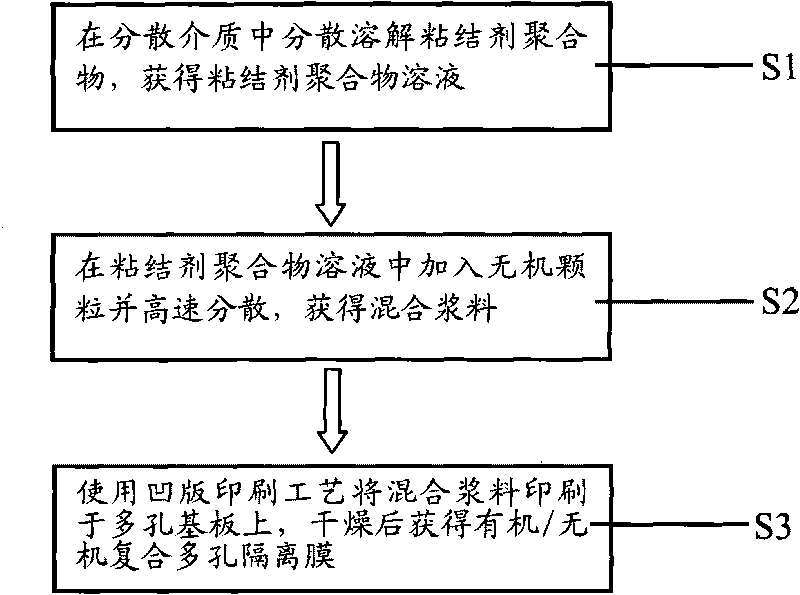

Organic/inorganic composite porous isolating membrane

InactiveCN101707242AHigh thermomechanical stabilityImprove heat stabilitySynthetic resin layered productsSecondary cellsPorous substrateInorganic particle

The invention discloses an organic / inorganic composite porous isolating membrane, which comprises a porous substrate with holes, and an organic / inorganic composite layer arranged on at least one surface or a partial surface area of the porous substrate, wherein the organic / inorganic composite layer is a layer of a mixture of inorganic particles and adhesive polymer; the inorganic particles are interconnected and are fixed through the adhesive polymer; and gaps among the inorganic particles form holes. In the organic / inorganic composite layer of the organic / inorganic composite porous isolating membrane, a weight ratio of the inorganic particles with good thermol stability to the adhesive polymer is between 80 percent: 20 percent and 99.5 percent: 0.5 percent; and the organic / inorganic composite layer has good supporting function. Therefore, the organic / inorganic composite porous isolating membrane has high thermo-mechanical stability.

Owner:DONGGUAN AMPEREX TECH

Mixture containing fluororesin and prepreg prepared from same, and copper clad laminate

ActiveCN106854330AEasy to operateMild preparation conditionsSynthetic resin layered productsGlass/slag layered productsPolymer scienceResin matrix

The invention specifically relates to a mixture containing fluororesin and a preparation method thereof, belonging to the field of communication materials. A prepreg prepared by impregnating a glass fabric in dispersion liquid of the mixture containing fluororesin and then carrying out drying and the like has uniform glue content, good impregnation quality, strong resin adhesion, smooth surface and appropriate toughness and viscosity. The invention also relates to a high-frequency copper clad laminate prepared from the prepreg, or a film or copper foil made of the mixture containing fluororesin. The prepared copper clad laminate has good thermal-mechanical properties, excellent dielectric properties and high copper foil strength, and can meet requirements on the comprehensive properties of substrate materials in the field of high-frequency communication. According to the invention, the processing properties of traditional fluororesin are greatly improved by using fluorine-containing resin with a low melting point; and a coupling agent is cooperatively used, so interaction between an inorganic filling material and glass fabric and a resin matrix is improved, dispersibility of the inorganic filling material, processing aids and the like in the fluororesin is enhanced, and the overall performance of the copper clad laminate is made more stable.

Owner:CHANGZHOU ZHONGYING SCI & TECH CO LTD

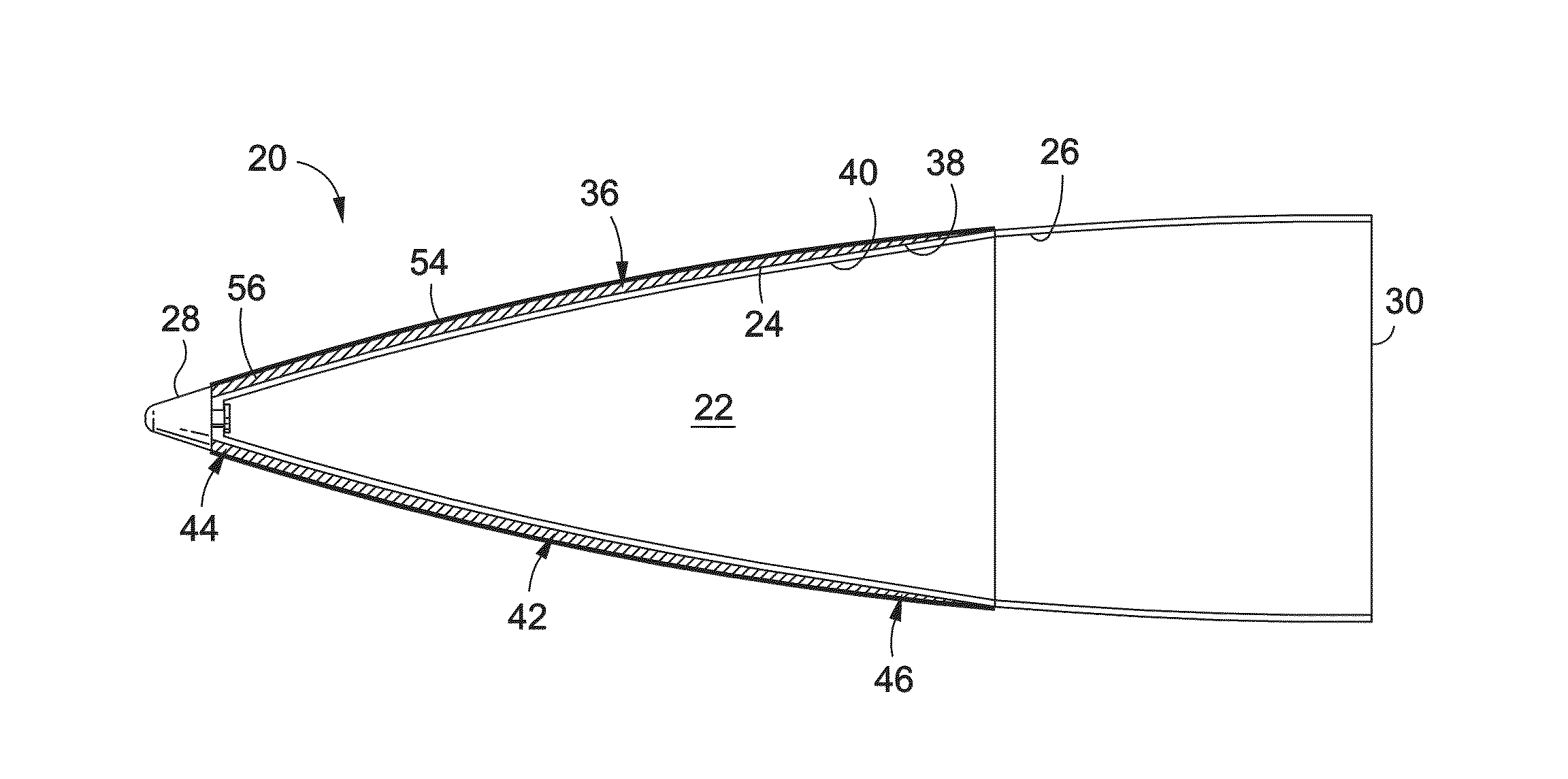

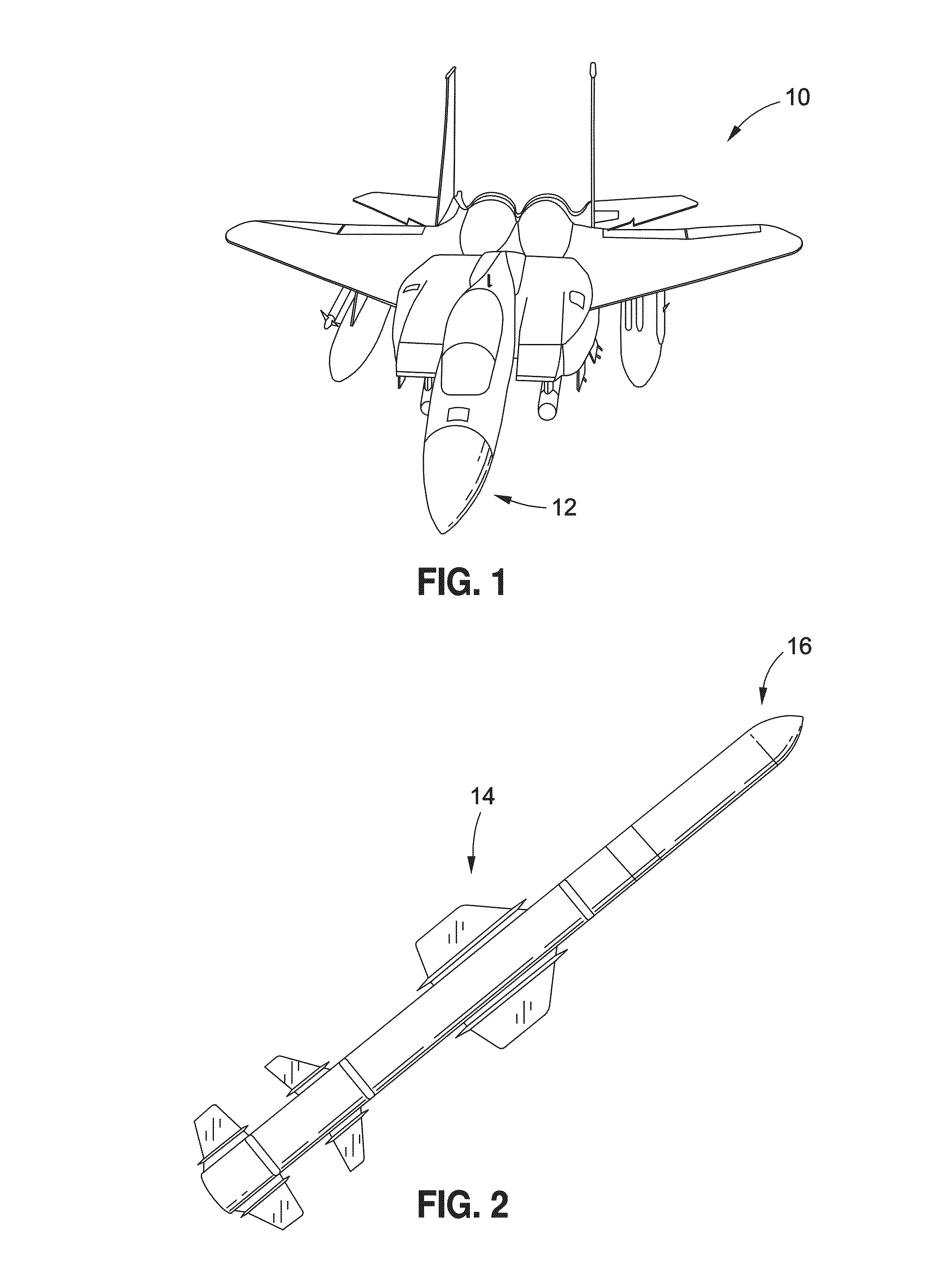

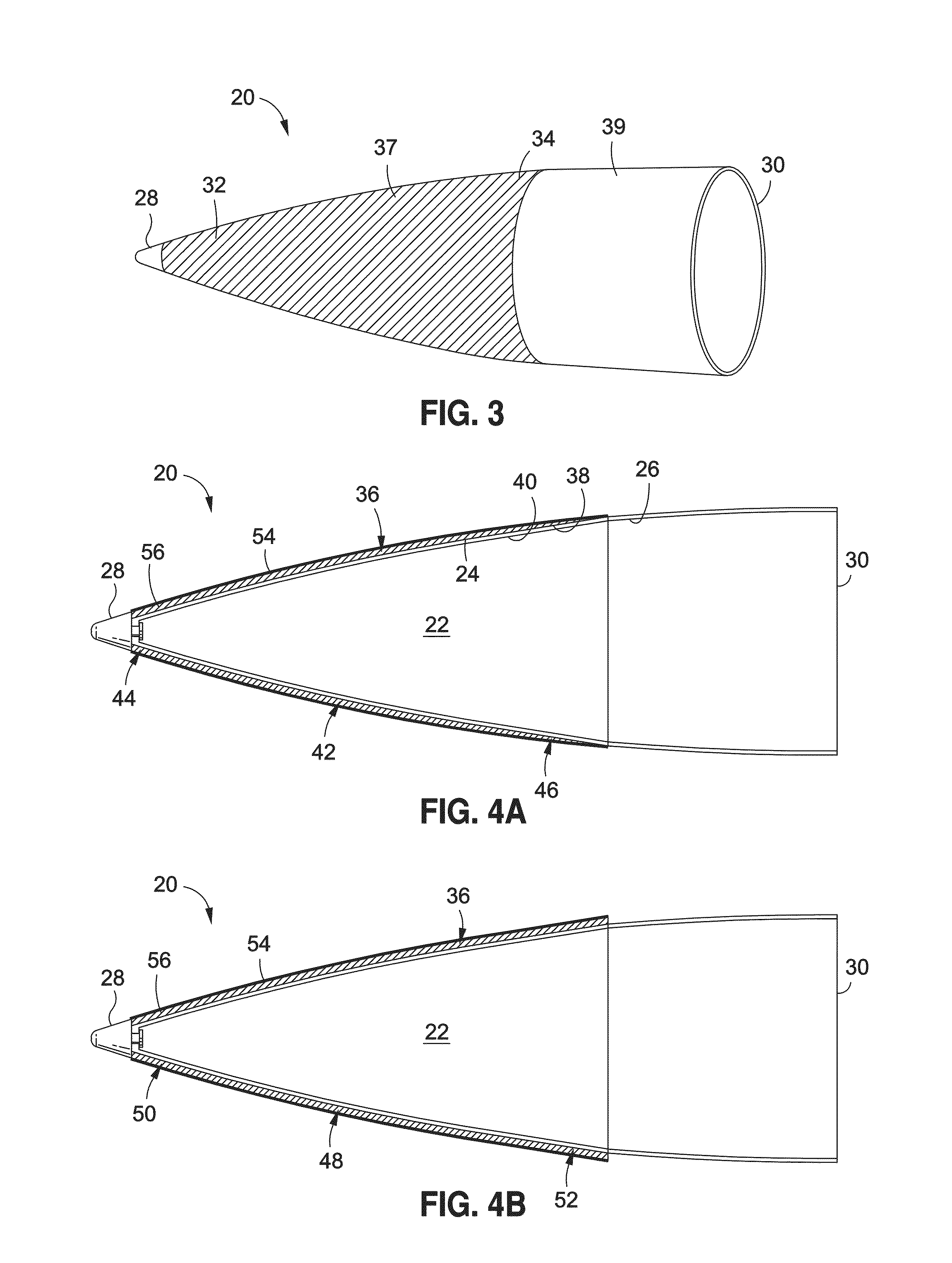

Thermal barrier coated RF radomes and method

ActiveUS8765230B1Improve performanceLow costLiquid surface applicatorsAntenna adaptation in movable bodiesRadio frequencyThermal barrier coating

Thermal barrier coated RF radomes and a method for making the same are provided. In an embodiment of the disclosure, there is provided a method for making a thermal barrier coated radio frequency (RF) radome. The method comprises providing a radio frequency (RF) radome. The method further comprises applying a thermal barrier coating having a dielectric constant less than about 2.0 onto a surface of the radome to form a thermal barrier coated RF radome. The thermal barrier coating reduces a structure temperature of the radome by greater than 300 degrees Fahrenheit to enhance thermo-mechanical properties and performance of the RF radome.

Owner:THE BOEING CO

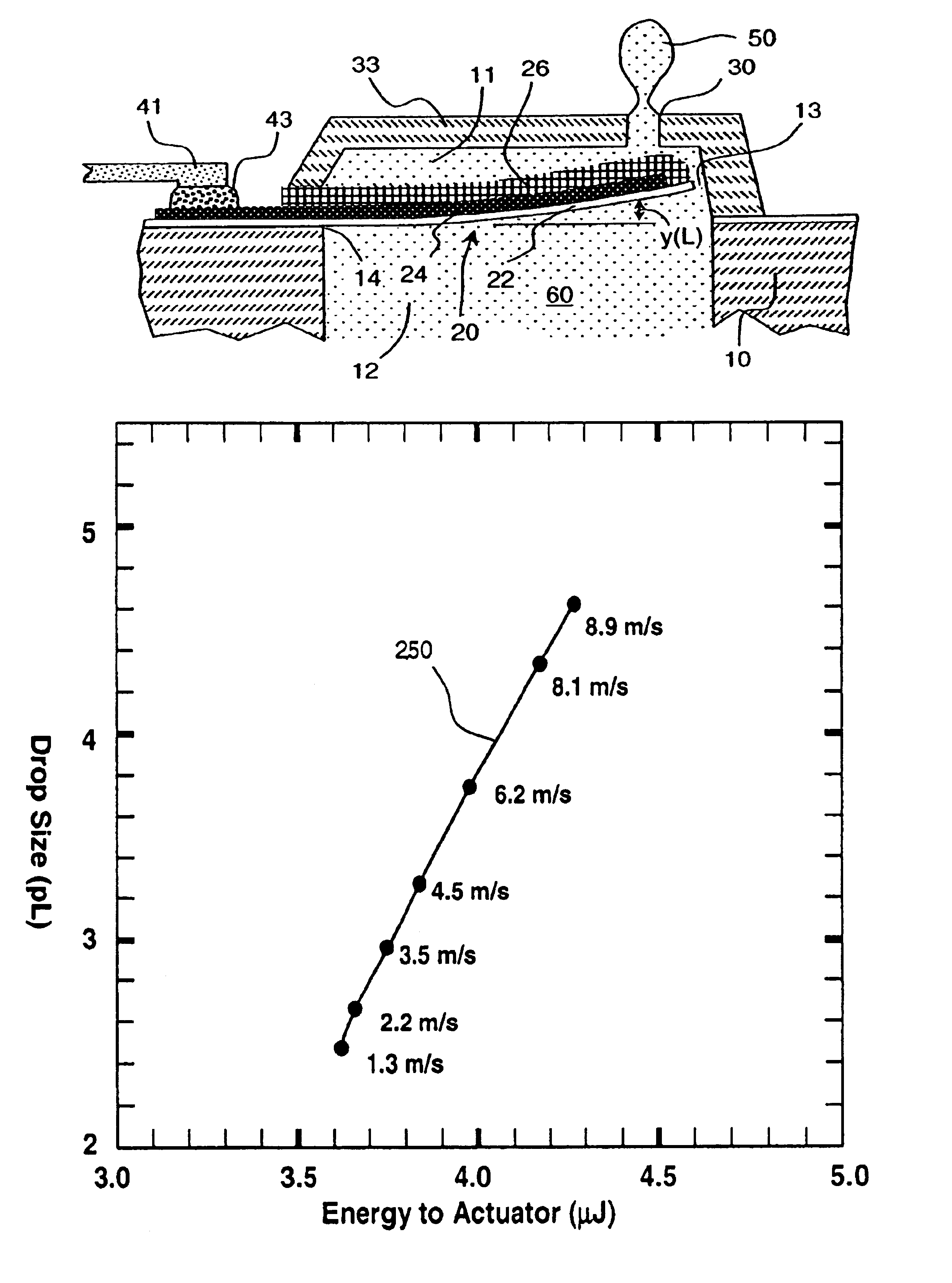

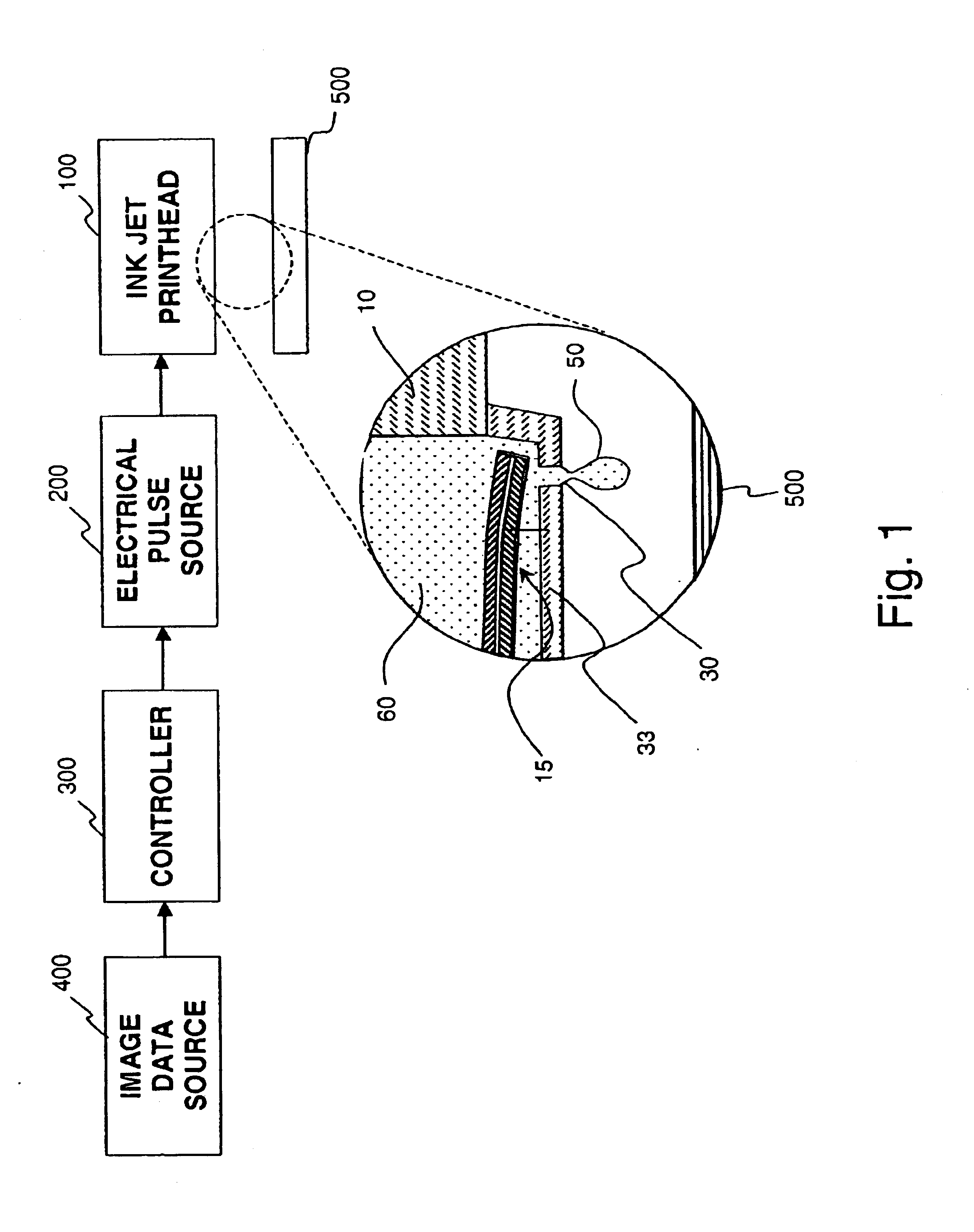

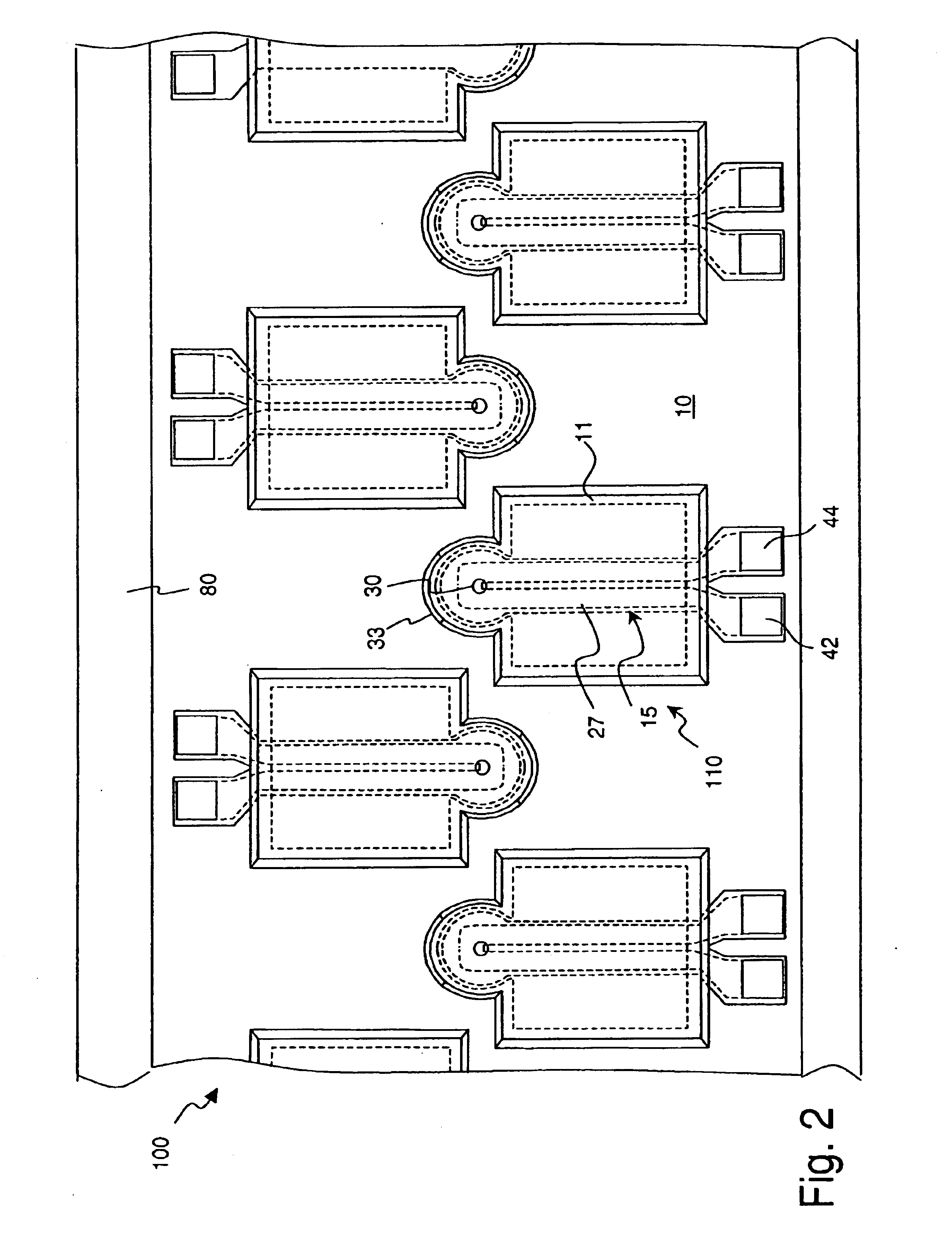

Thermo-mechanical actuator drop-on-demand apparatus and method with multiple drop volumes

InactiveUS6896346B2Data switching by path configurationOther printing apparatusEngineeringArrival time

An apparatus and method of operating a liquid drop emitter, such as an ink jet device, for emitting liquid drops of different volumes. The liquid drop emitter comprises a chamber, filled with a liquid, having a nozzle for emitting drops of the liquid, a thermo-mechanical actuator having a moveable portion within the chamber for applying pressure to the liquid at the nozzle, and apparatus adapted to apply heat pulses to the thermo-mechanical actuator. The method for operating comprises applying a first heat pulse having a first power P1, first pulse duration τp1, and first energy E1=P1×τp1, displacing the movable portion of the actuator so that a drop is emitted having a first drop volume Vd1, and traveling substantially at the target velocity v0; and applying a second heat pulse having a second power P2, second pulse duration τp2, and second energy E2=P2×τp2, displacing the movable portion of the actuator so that a drop is emitted having a second drop volume Vd2 and traveling substantially at the target velocity v0, wherein Vd2>Vd1, E2>E1, τp2>τp1, and P2<P1. An alternate method for operating causes the emission of drops having different volumes traveling at different velocities wherein all velocities are within a pre-determined drop velocity range, vd min to vd max. Further methods for operating an ink jet printhead cause the emission of drops having different volumes and velocities wherein the triggering of the drop emission is delayed so as to result in synchronized arrival times at a print plane.

Owner:EASTMAN KODAK CO

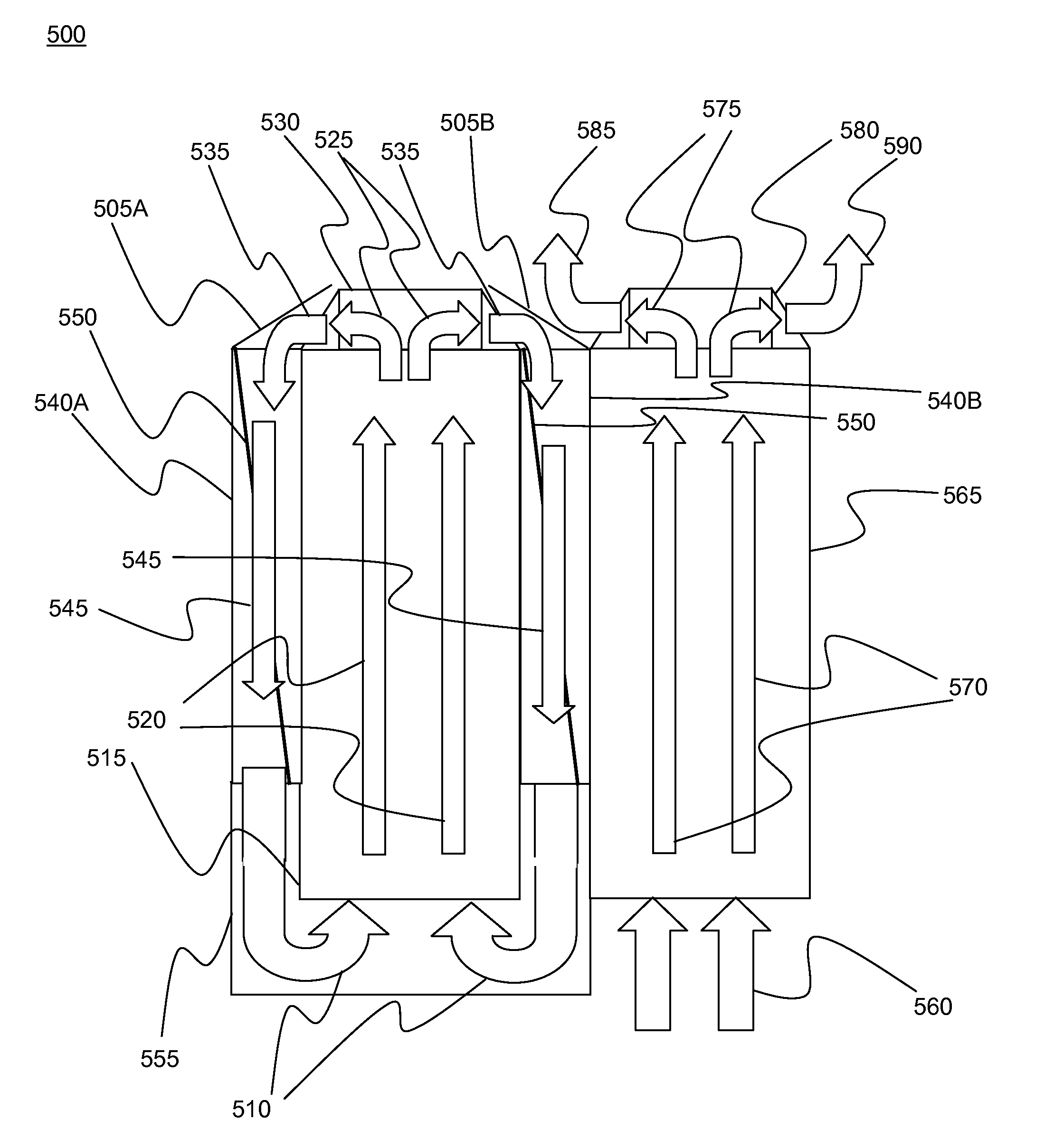

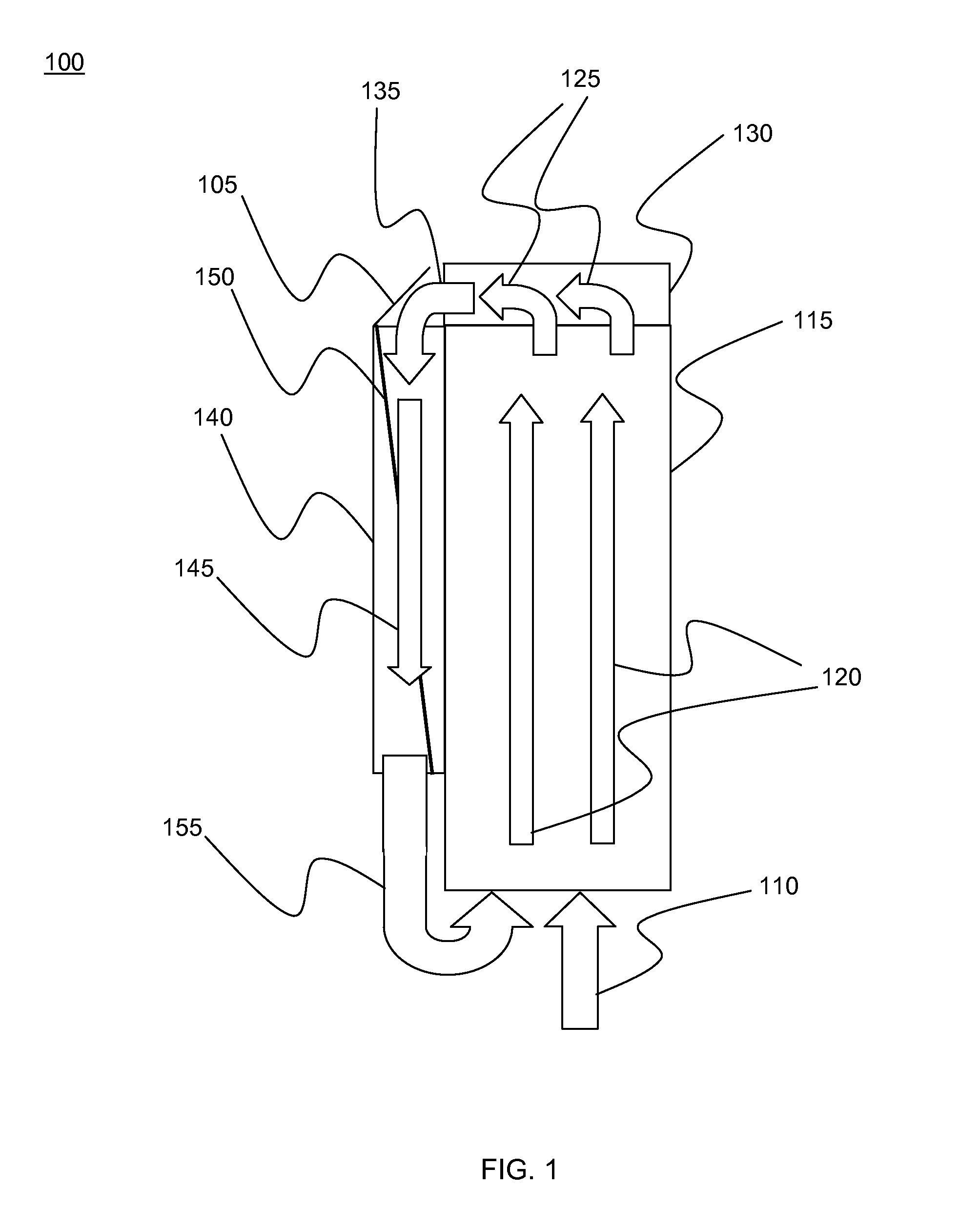

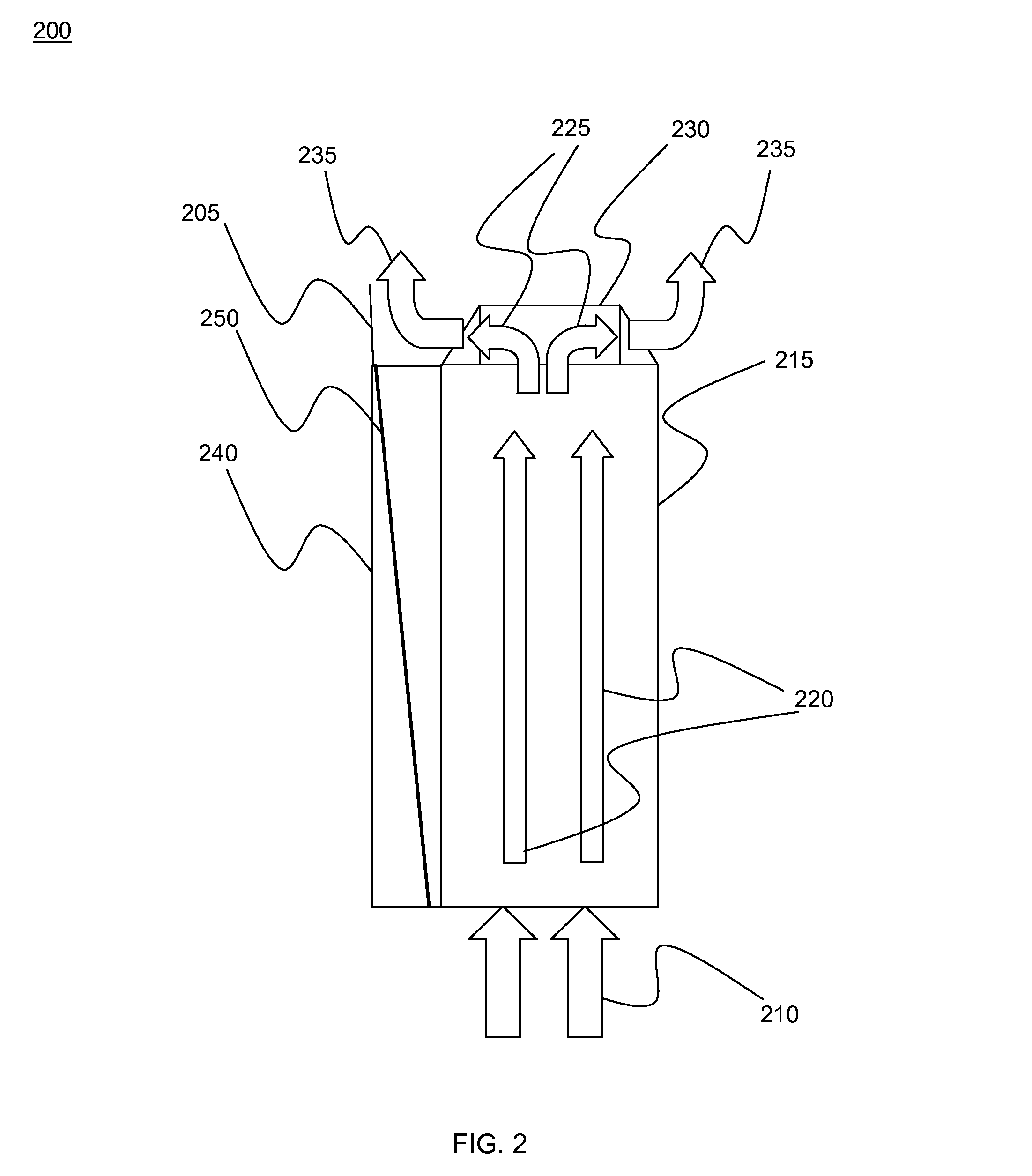

Sidecar in-row cooling apparatus and method for equipment within an enclosure

ActiveUS20100126696A1Firmly connectedThermal expansion is very limitedCasings/cabinets/drawers detailsIndirect heat exchangersEngineeringThermo mechanical

A system and method for integrating sidecar liquid cooling components in-row with associated computer equipment enclosures is disclosed. It includes a fail-safe baffle to exhaust air, a transition frame and containment plenum. It uses standard hose configurations and includes a thermo-mechanical switch, not requiring power to open the component door.

Owner:VETTE TECH

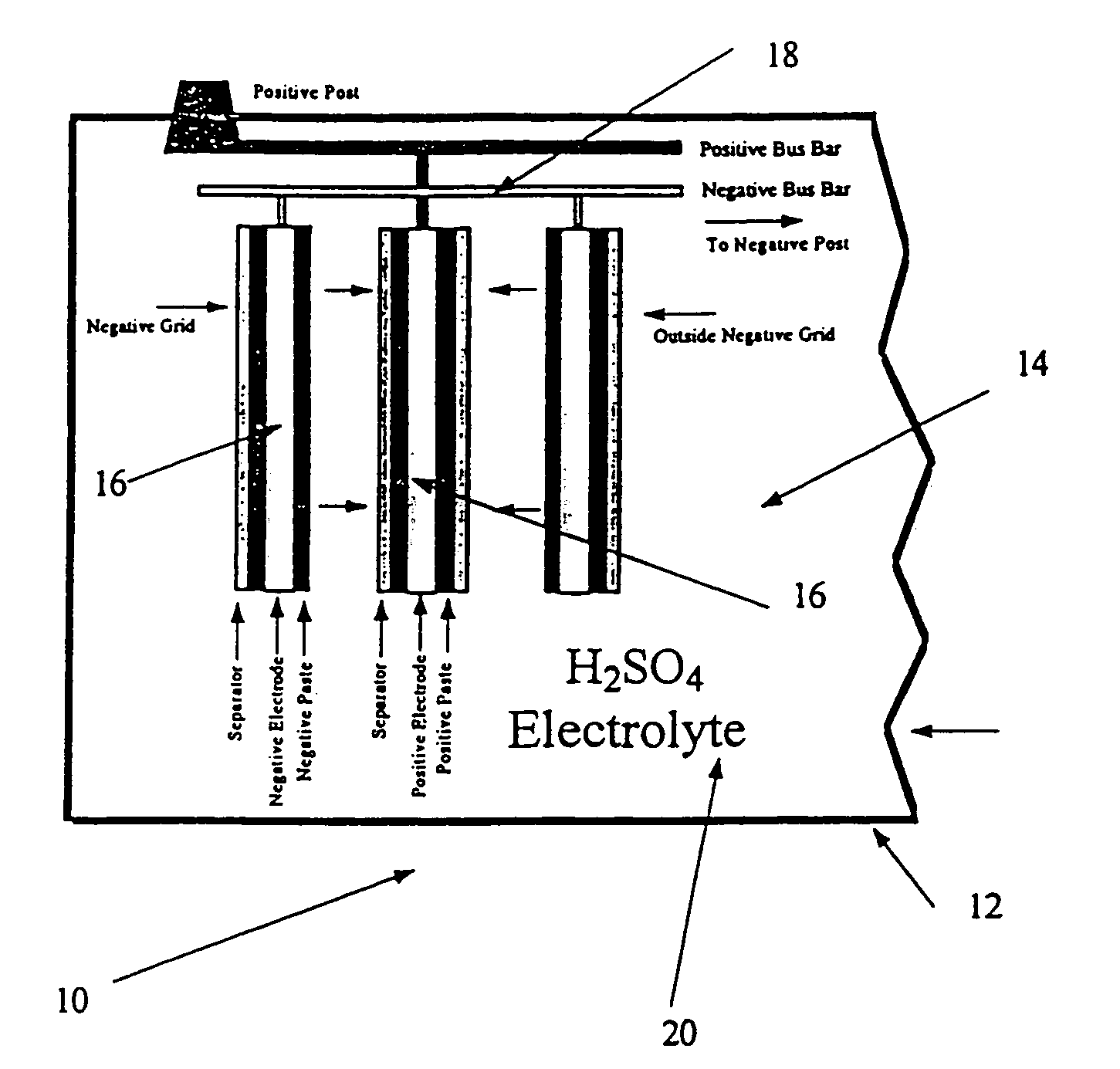

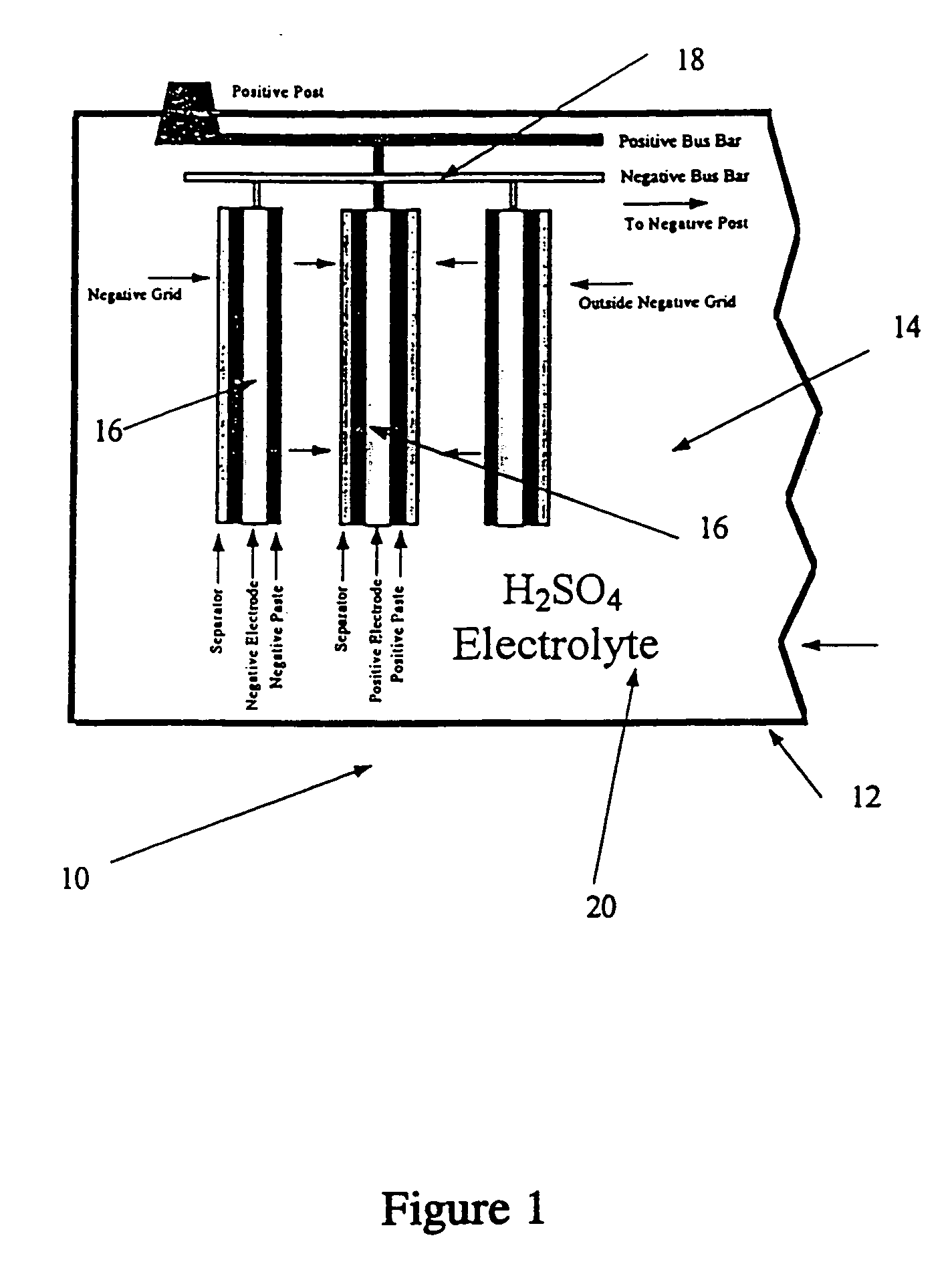

Thermo-mechanical treated lead and lead alloys especially for current collectors and connectors in lead-acid batteries

InactiveUS20040112486A1Improvement in lead-acid battery performanceSmall sizeElectrode carriers/collectorsElectrolysisMetallurgy

Recrystallized lead and lead alloy positive current collectors and connectors such as straps and lugs for use e.g. in lead acid batteries and electrowinning anodes, having an increased percentage of special grain boundaries in at least part of the microstructure, which have been provided by a process comprising of (i) cold or hot rolling or cold or hot extrusion or (ii) steps of deforming the lead or lead alloy, and subsequently annealing the lead or lead alloy. Either a single cycle of working and annealing can be provided, or a plurality of such cycles can be provided. The amount of deformation, the recrystallization time and temperature, and the number of repetitions of such steps are selected to ensure that a substantial increase in the population of special grain boundaries is provided in the microstructure, to improve resistance to creep, intergranular corrosion and intergranular cracking of the current collectors and connectors during battery service, and result in extended battery life and the opportunity to reduce the size and weight of the battery.

Owner:AUST KARL T +5

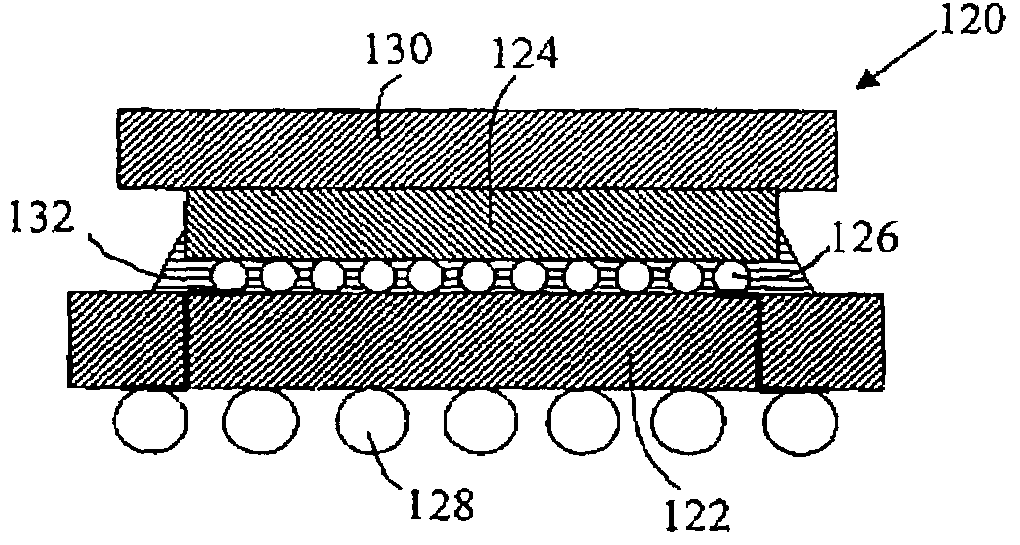

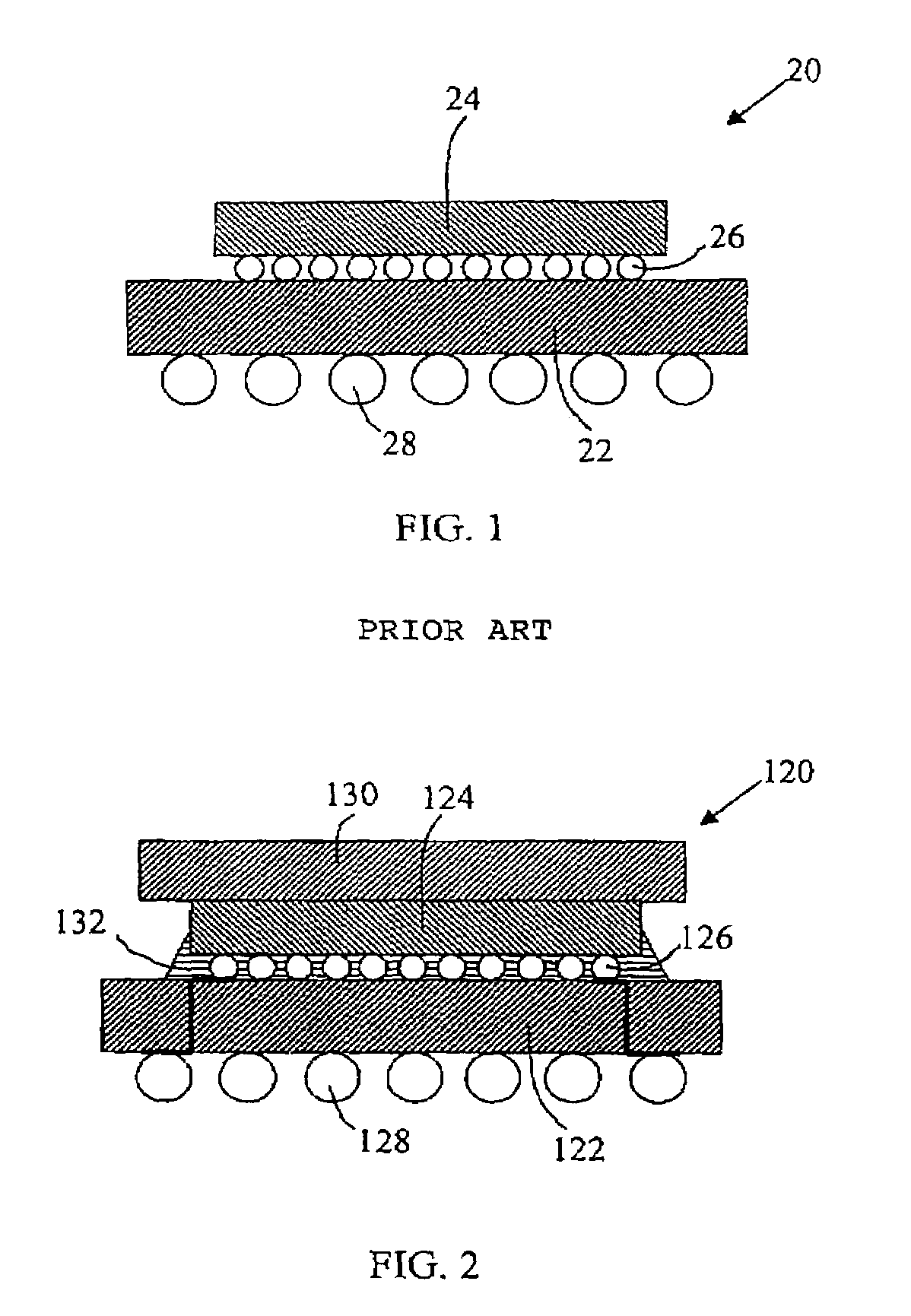

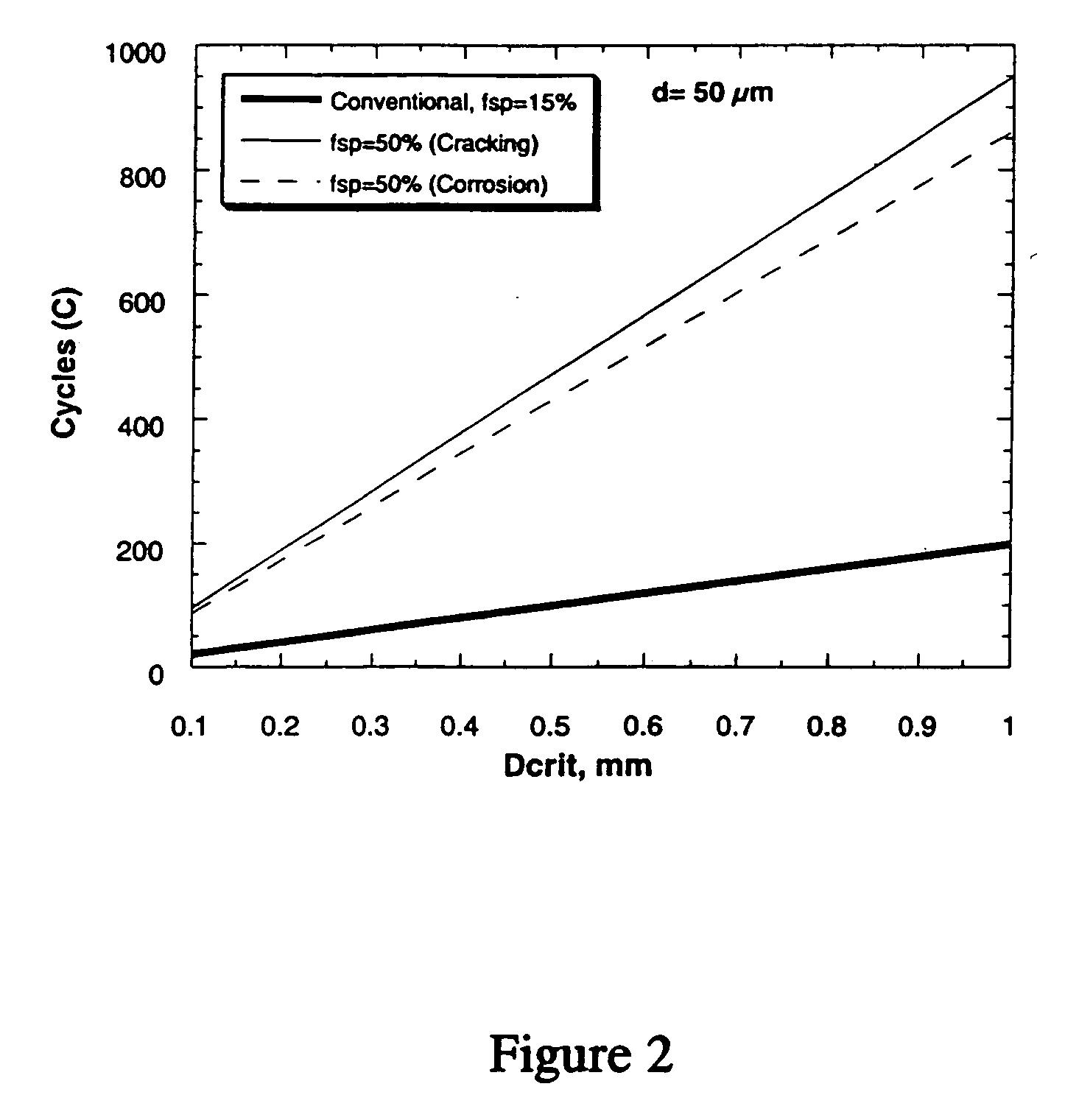

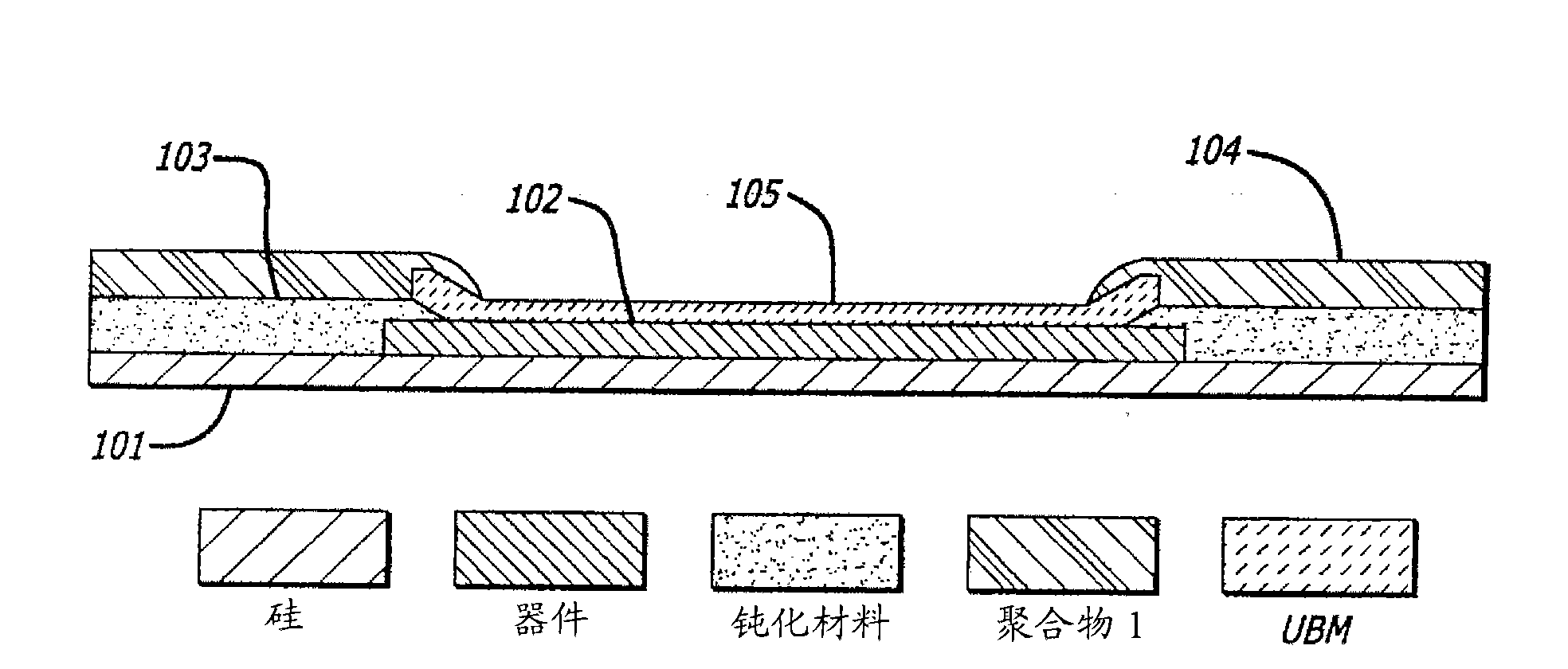

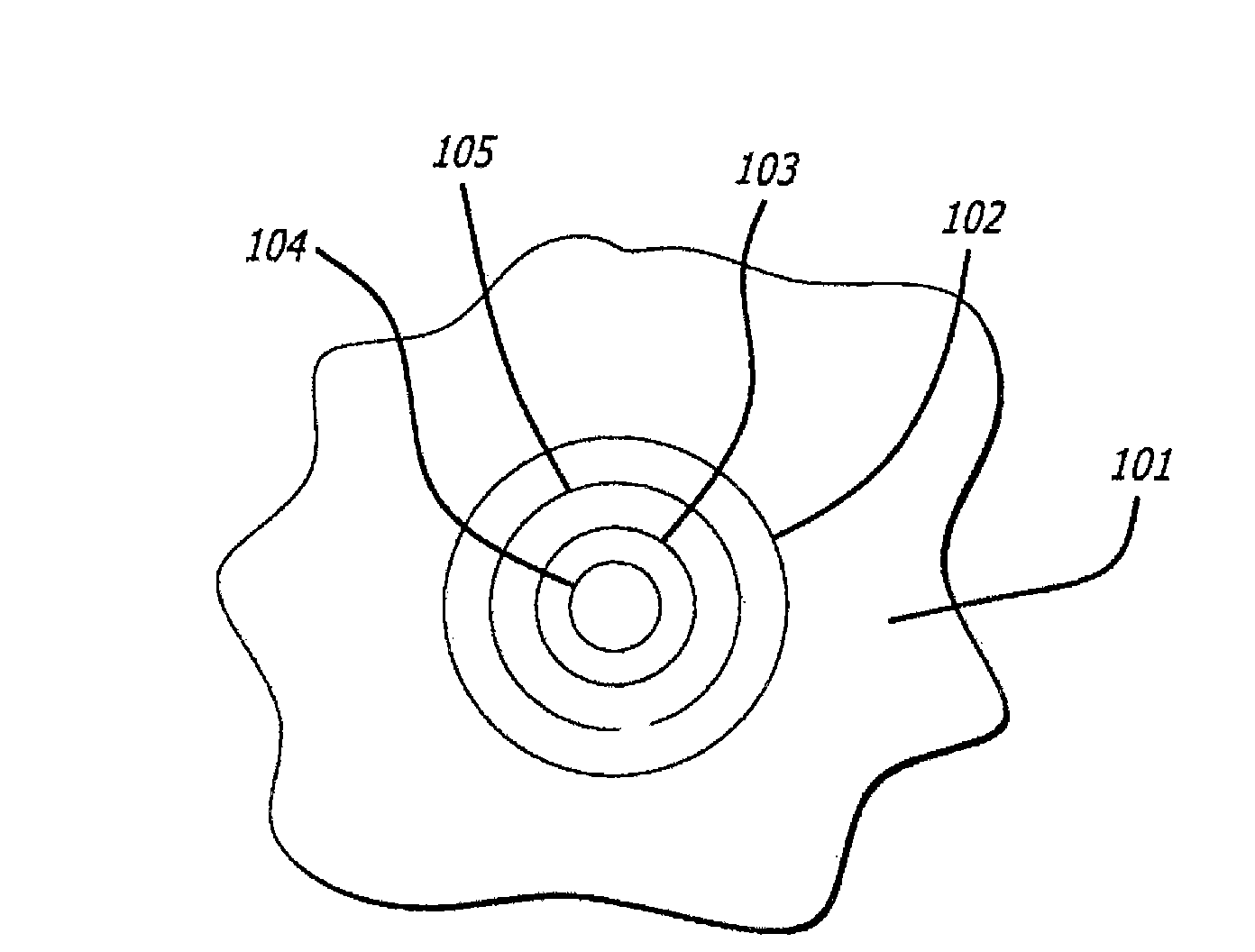

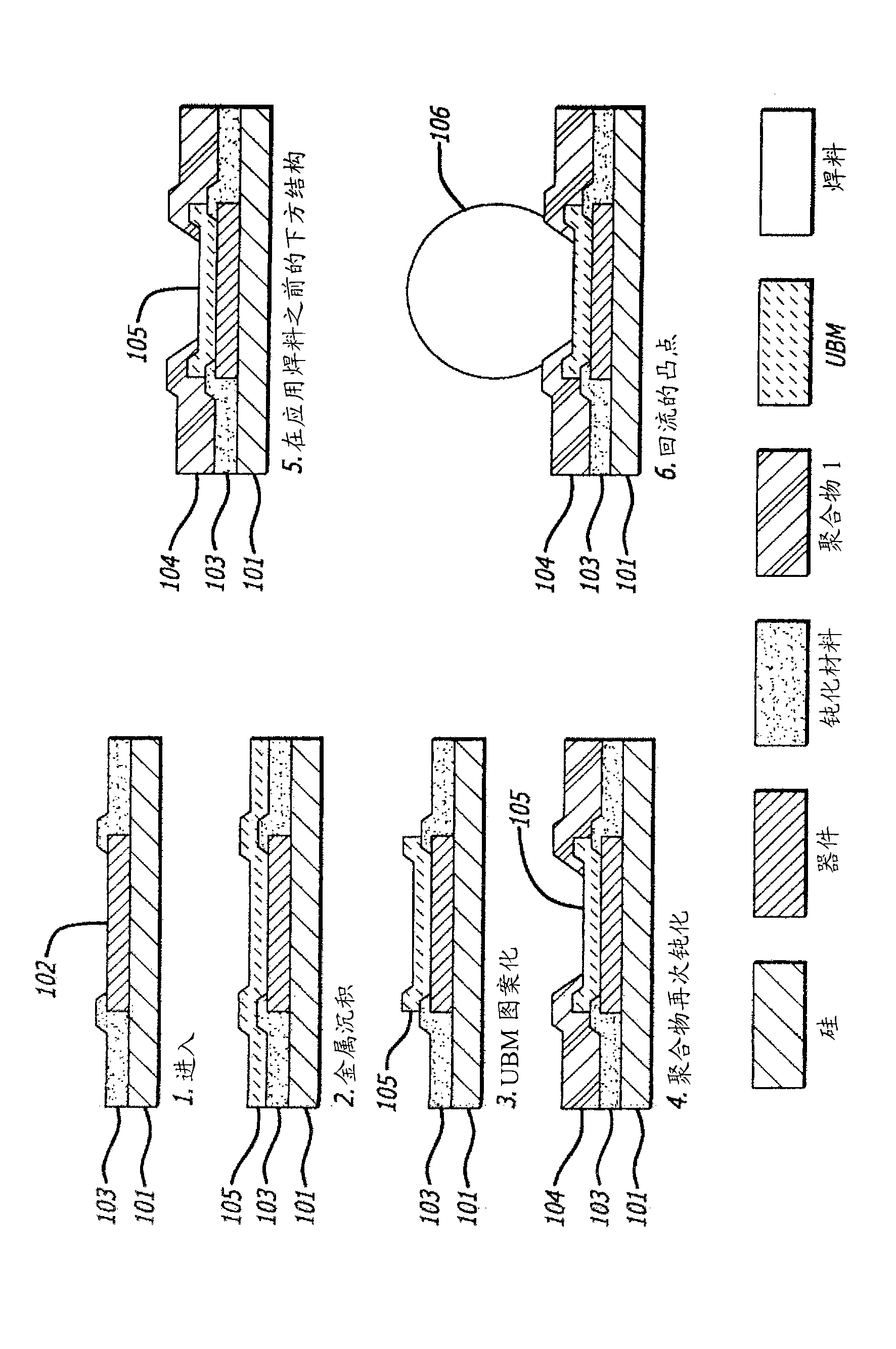

Solder bump interconnect for improved mechanical and thermo mechanical performance

ActiveCN101636831AHigh strengthSemiconductor/solid-state device detailsSolid-state devicesShortest distanceSemiconductor package

An apparatus and method for a semiconductor package including a bump on input-output (IO) structure are disclosed involving a device pad, an under bump metai pad (UBM), a polymer, and a passivation layer. The shortest distance from the center of the device pad to its outer edge, and the shortest distance from the center of the UBM to its outer edge are in a ratio from 0.5:1 to 0.95:1. Also, the shortest distance from the center of the polymer to its outer edge, and the shortest distance from the center of the UBM to its outer edge are in a ratio from 0.35:1 to 0.85:1. Additionally, the shortest distance from the center of the passivation layer to its outer edge, and the shortest distance from the center of the UBM to its outer edge are in a ratio from 0.35:1 to 0.80:1.

Owner:HUATIAN TECH KUNSHAN ELECTRONICS

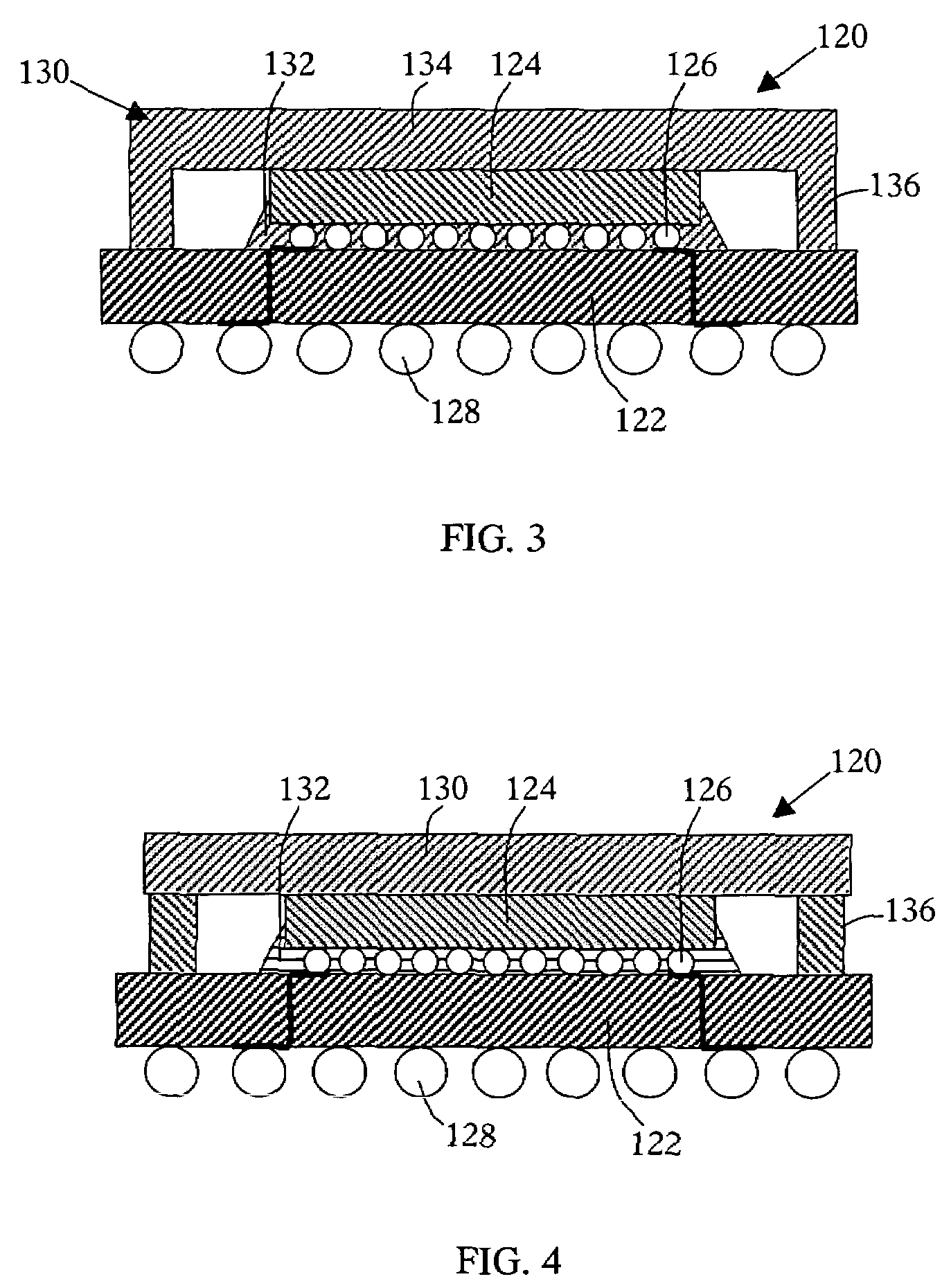

Package level pre-applied underfills for thermo-mechanical reliability enhancements of electronic assemblies

InactiveUS20020162679A1Improved thermomechanical reliabilityImprove reliabilityPrinted circuit assemblingFinal product manufactureSurface mountingMechanical reliability

Surface mount packages having pre-applied underfill thereon and methods of fabricating and using such packages are provided. Supplying customers with packages having pre-applied underfill enhances the thermal and mechanical reliability of surface mount packages and also, mitigates the customers' needs for additional cost, tooling, man-power, and process operations relating to the application and curing of underfill material.

Owner:NOKIA CORP

800 MPa-grade low-yield-ratio structural steel plate and production method thereof

ActiveCN102011068AGood welding performanceGood low temperature impact propertiesYield ratioHeat treated

The method relates to an 800 MPa-grade low-yield-ratio structural steel plate and a production method thereof. The steel comprises the chemical components in percentage by weight: 0.045 to 0.075 percent of C, 0.30 to 0.55 percent of Si, 1.55 to 1.95 percent of Mn, less than or equal to 0.01 percent of P, less than or equal to 0.0025 percent of S, 0.012 to 0.035 percent of Al, 0.15 to 0.25 percent of Cr, 0.15 to 0.3 percent of Mo, 0.2 to 0.4 percent of Cu, 0.2 to 0.4 percent of Ni, 0.008 to 0.04 percent of Nb, 0.008 to 0.04 percent of V, 0.008 to 0.03 percent of Ti, 0.0008 to 0.0015 percent of B, and the balance of Fe and inevitable impurities. The steel is subjected to RH vacuum treatment, ladle furnace (LF) external refining, full protection casting, a thermo mechanical control process (TMCP), and tempering heat treatment to form the steel plate with low yield ratio, high strength and high work hardening rate. The steel plate has the thickness specification of between 10 and 40 mm, the yield strength of more than or equal to 550MPa, the tensile strength of more than or equal to 800 MPa and the yield ratio of less than 0.70, and has excellent low temperature compact performance, cold forming performance and welding performance.

Owner:SHOUGANG CORPORATION

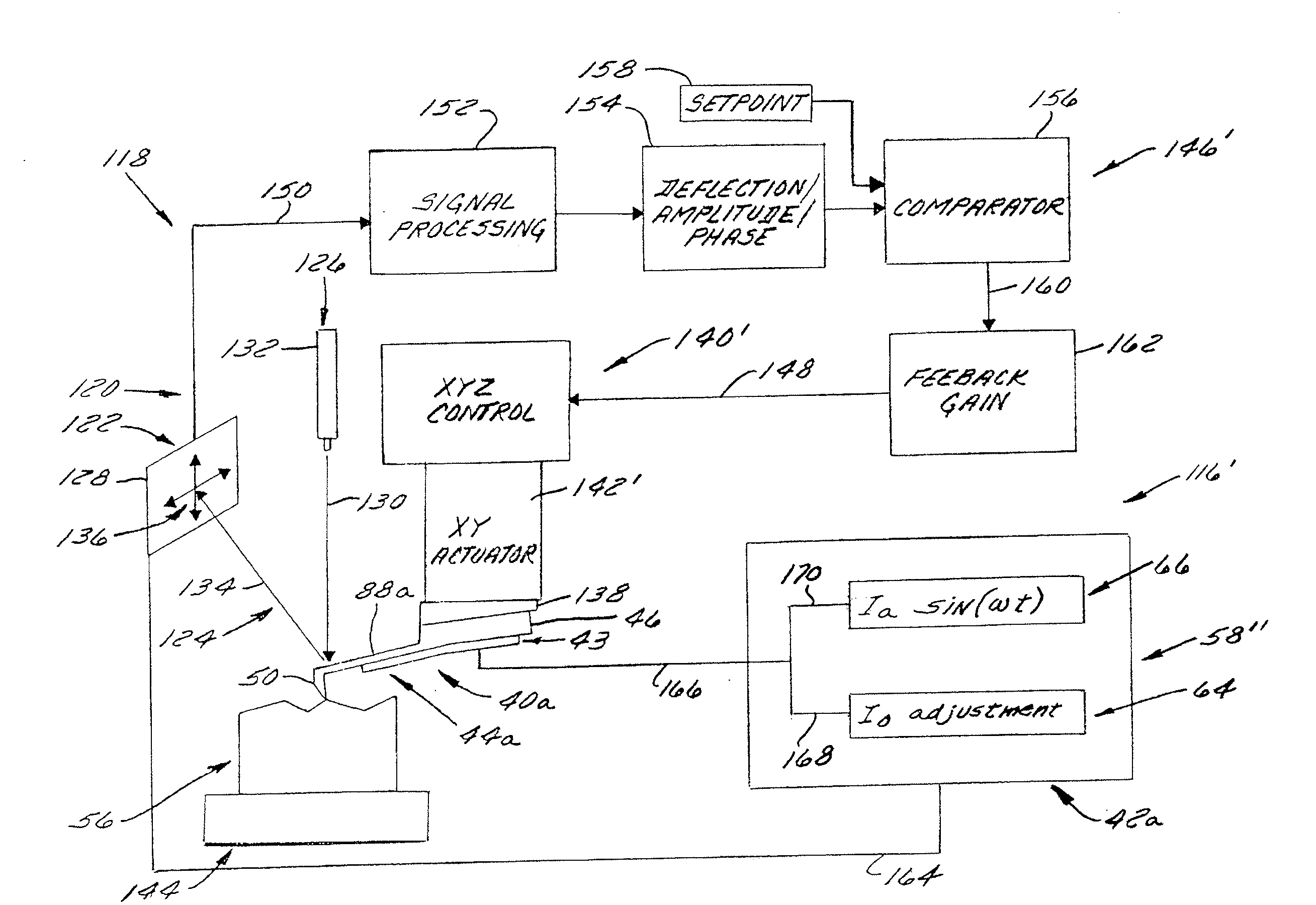

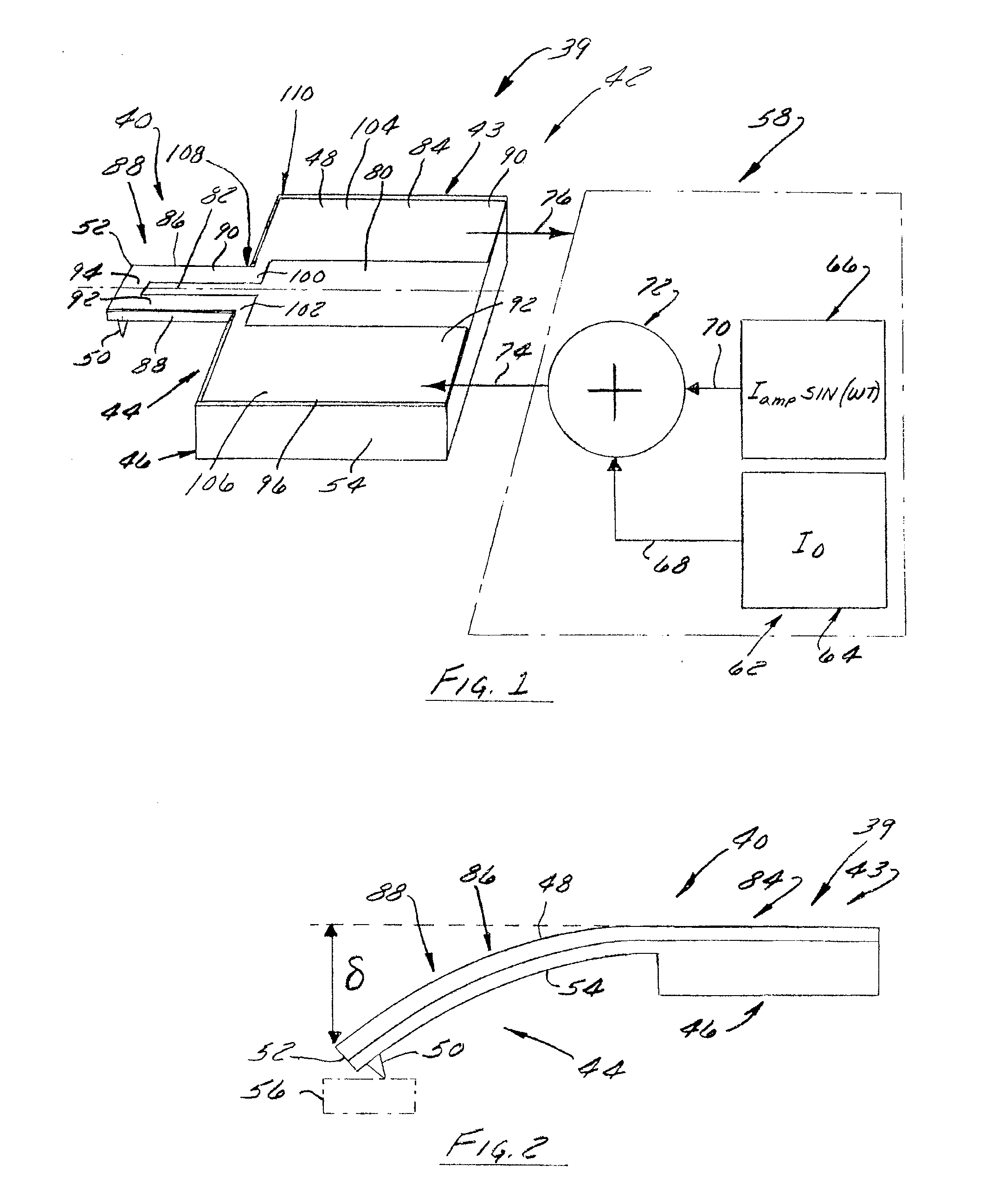

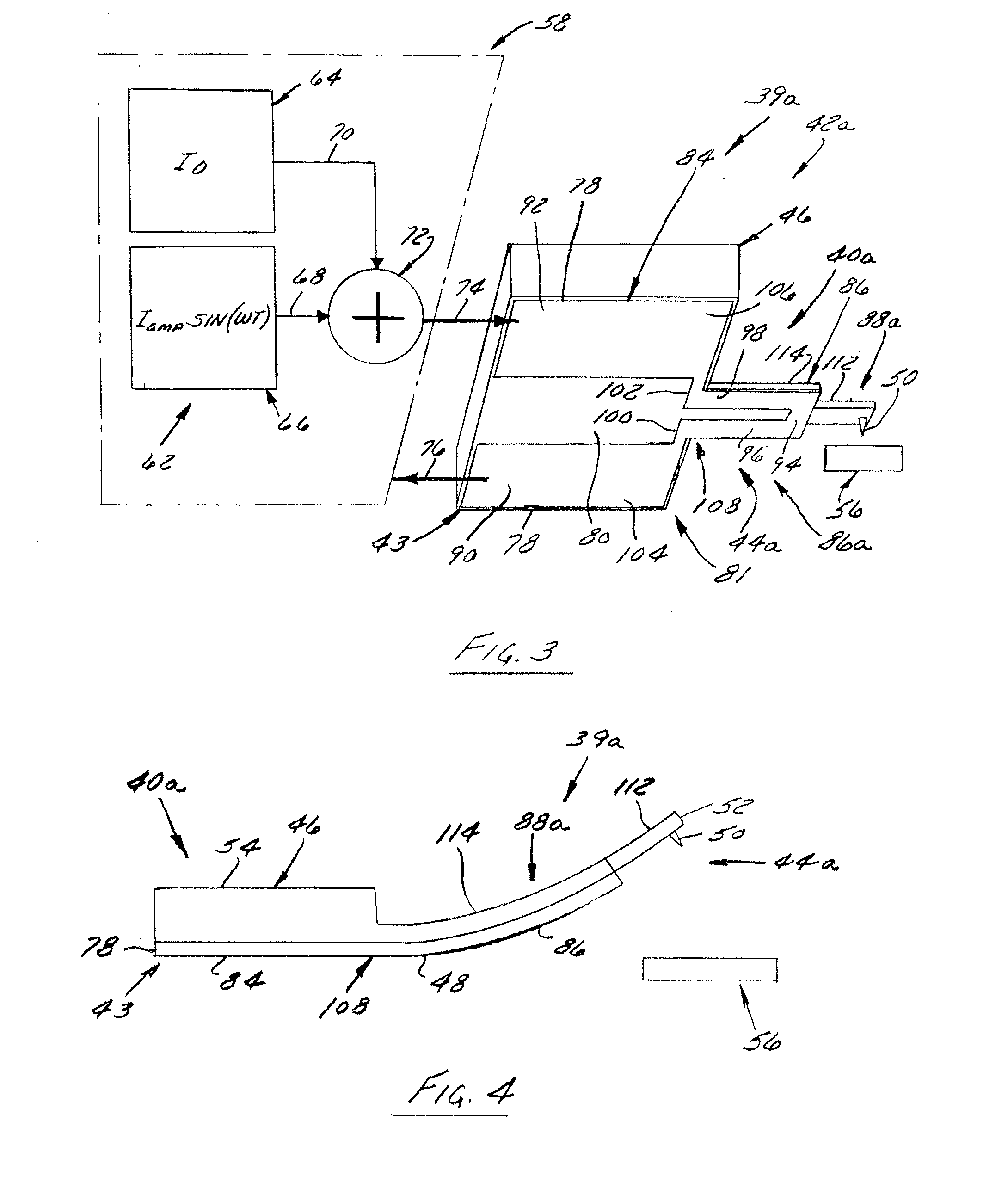

Thermal mechanical drive actuator, thermal probe and method of thermally driving a probe

ActiveUS20080011065A1Improve cooling effectIncrease convective coolingNanotechnologyMechanical roughness/irregularity measurementsThermal dilatationMeasuring instrument

A drive actuator for a measurement instrument having a probe, the drive actuator including a heating element in a thermally conductive relationship with the probe such that application of electric current to the heating element modifies a characteristic of the probe. The probe device includes a probe including a cantilever having a lever made of a material having a selected thermal expansivity and a drive actuator in operable cooperation with the cantilever lever made of a material having a thermal expansivity different than the thermal expansivity of the material of which the cantilever lever is made.

Owner:BRUKER NANO INC

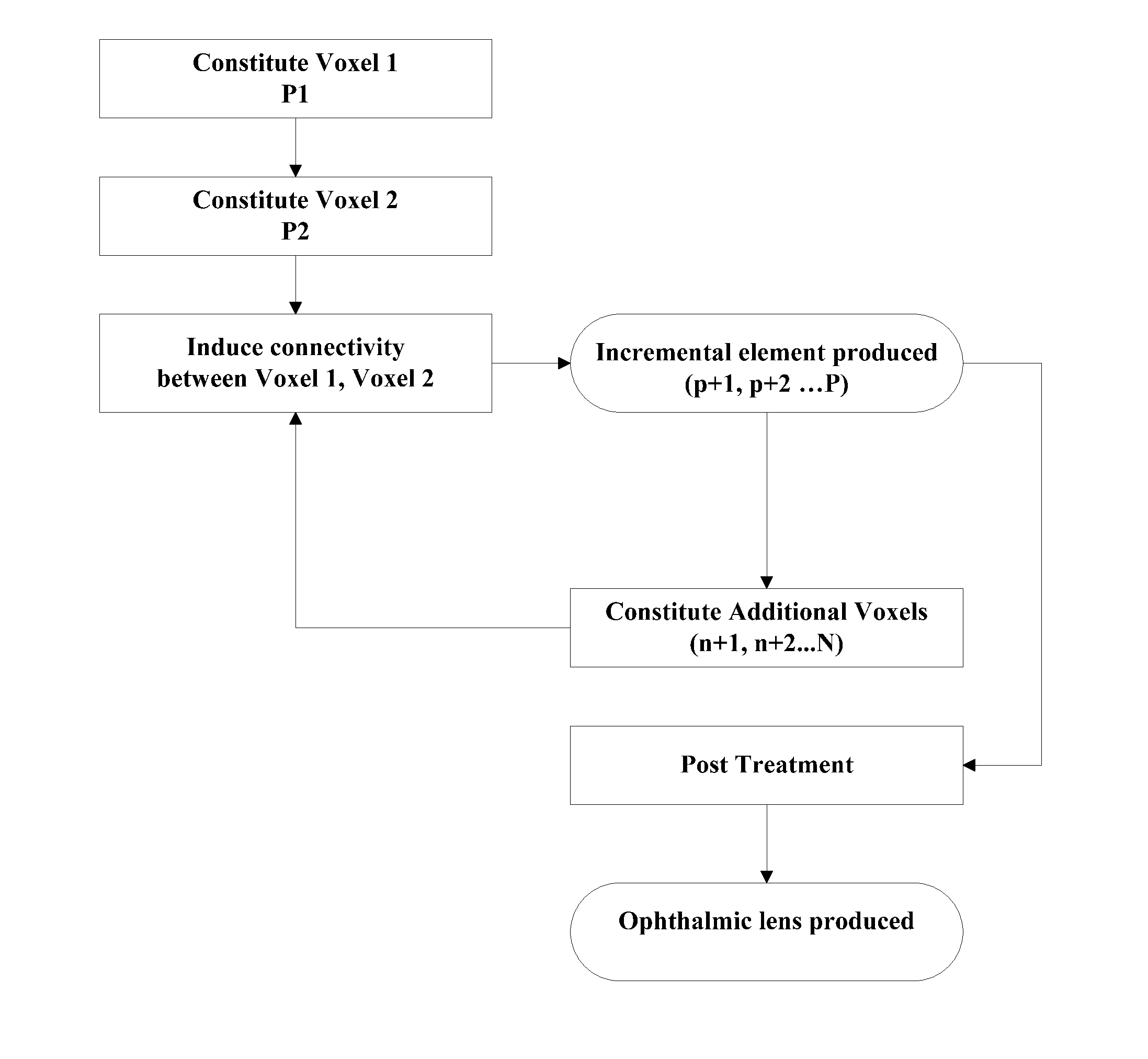

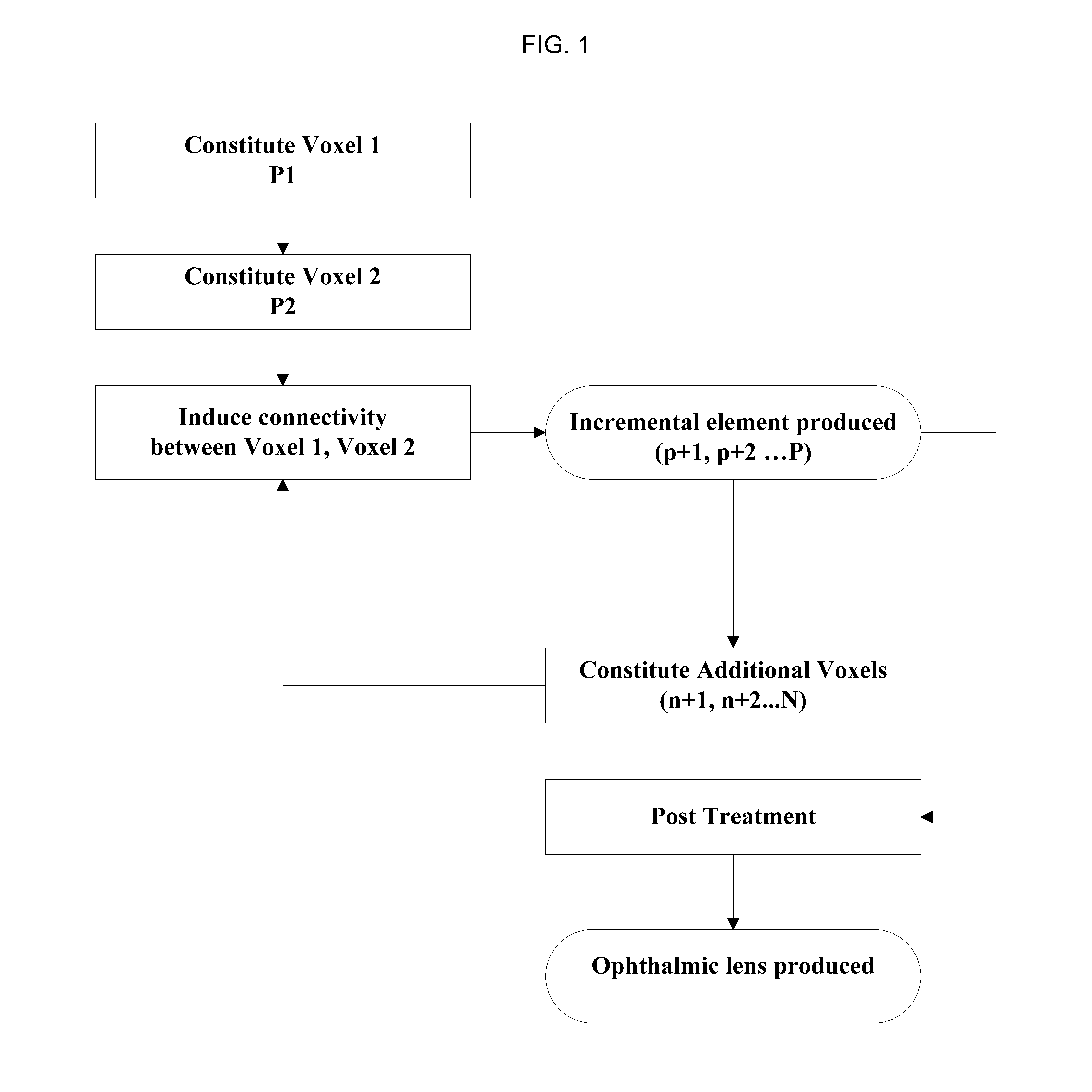

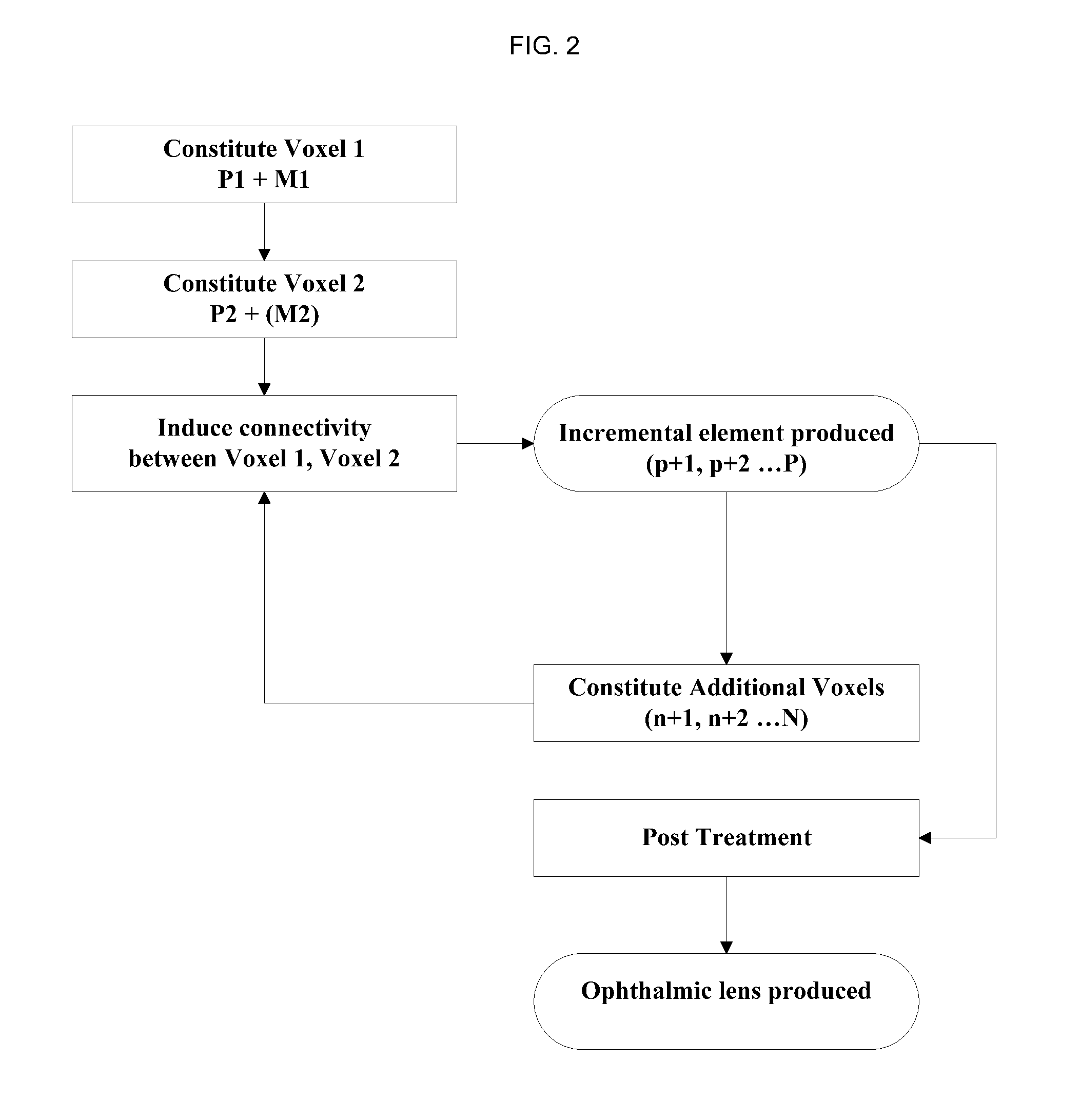

Additive manufacturing for transparent ophthalmic lens

InactiveUS20160167299A1Reduced and no dimensional changeImprove propertiesAdditive manufacturing apparatusOptical articlesOptical transparencyVoxel

Presented herein is a method of manufacturing a three-dimensional ophthalmic lens using additive manufacturing. The method includes constituting voxels of one or more compositions, wherein at least one of the compositions includes one or more pre-polymers or polymers, and inducing connectivity between the voxels, thereby creating one or more incremental elements, repeating the constitution steps, and performing a final post-treatment. Also presented herein is an ophthalmic lens obtained by this method. The lens has good homogeneity and optical clarity, reduced shrinkage, and improved geometric accuracy and thermo-mechanical properties.

Owner:ESSILOR INT CIE GEN DOPTIQUE

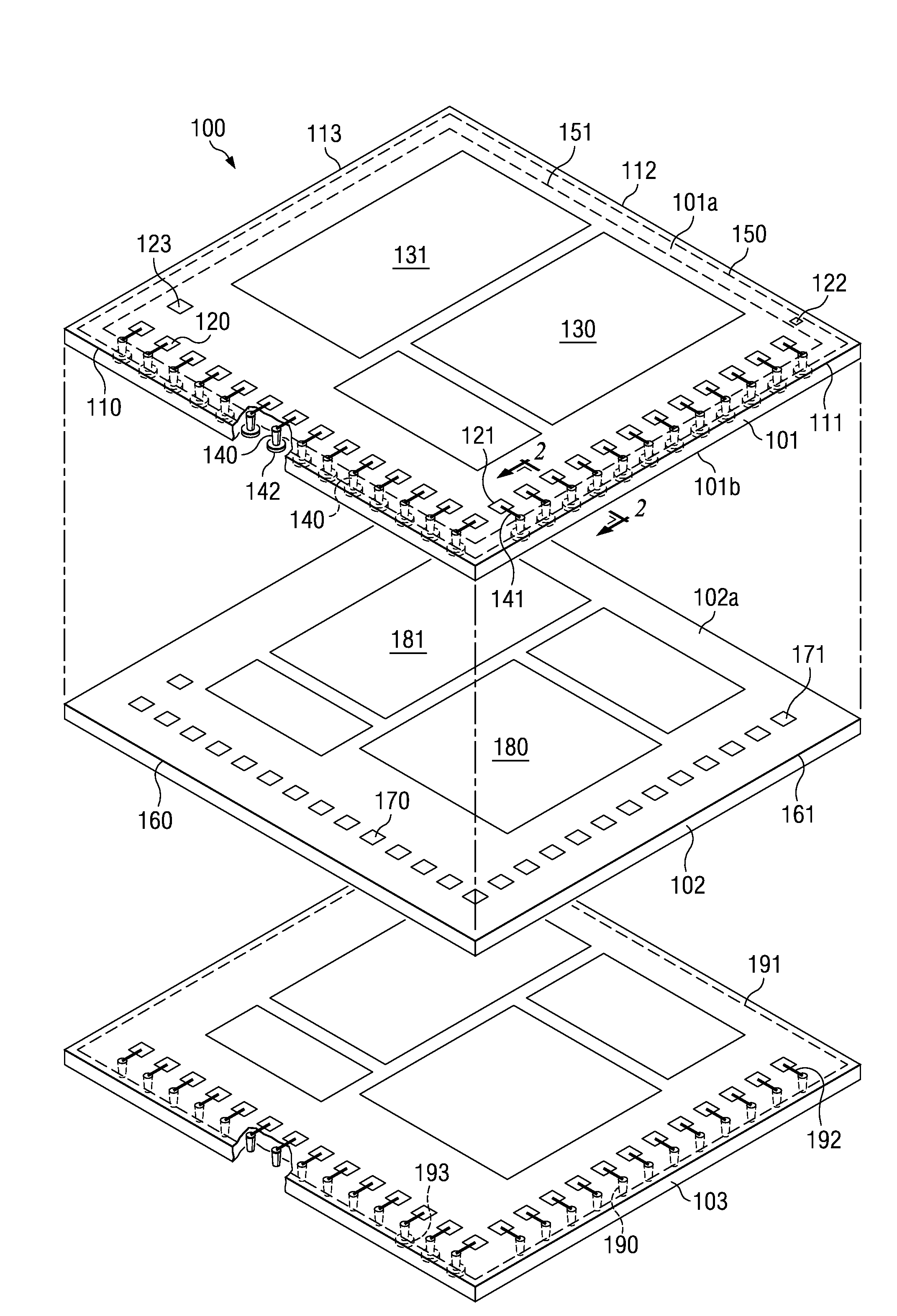

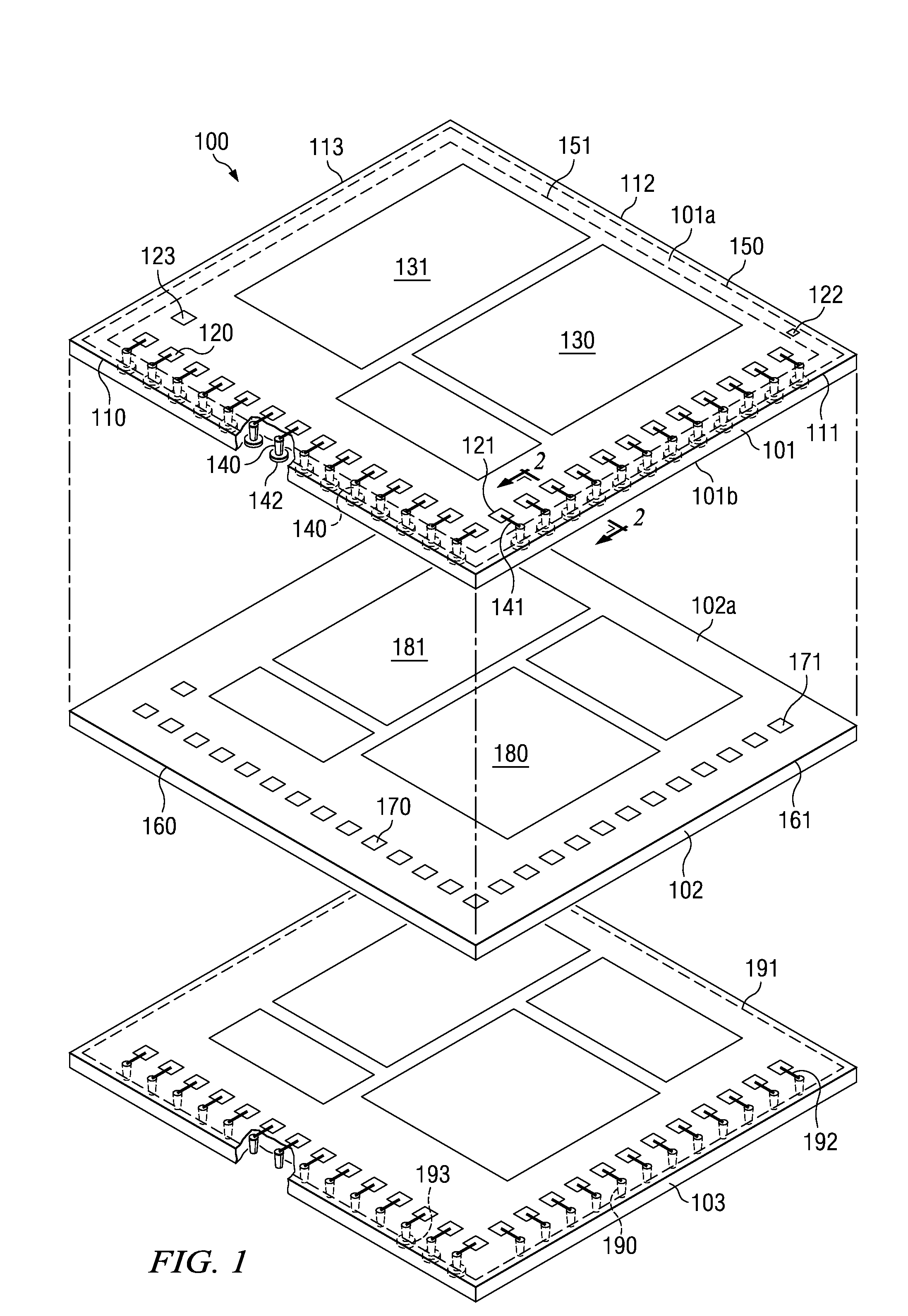

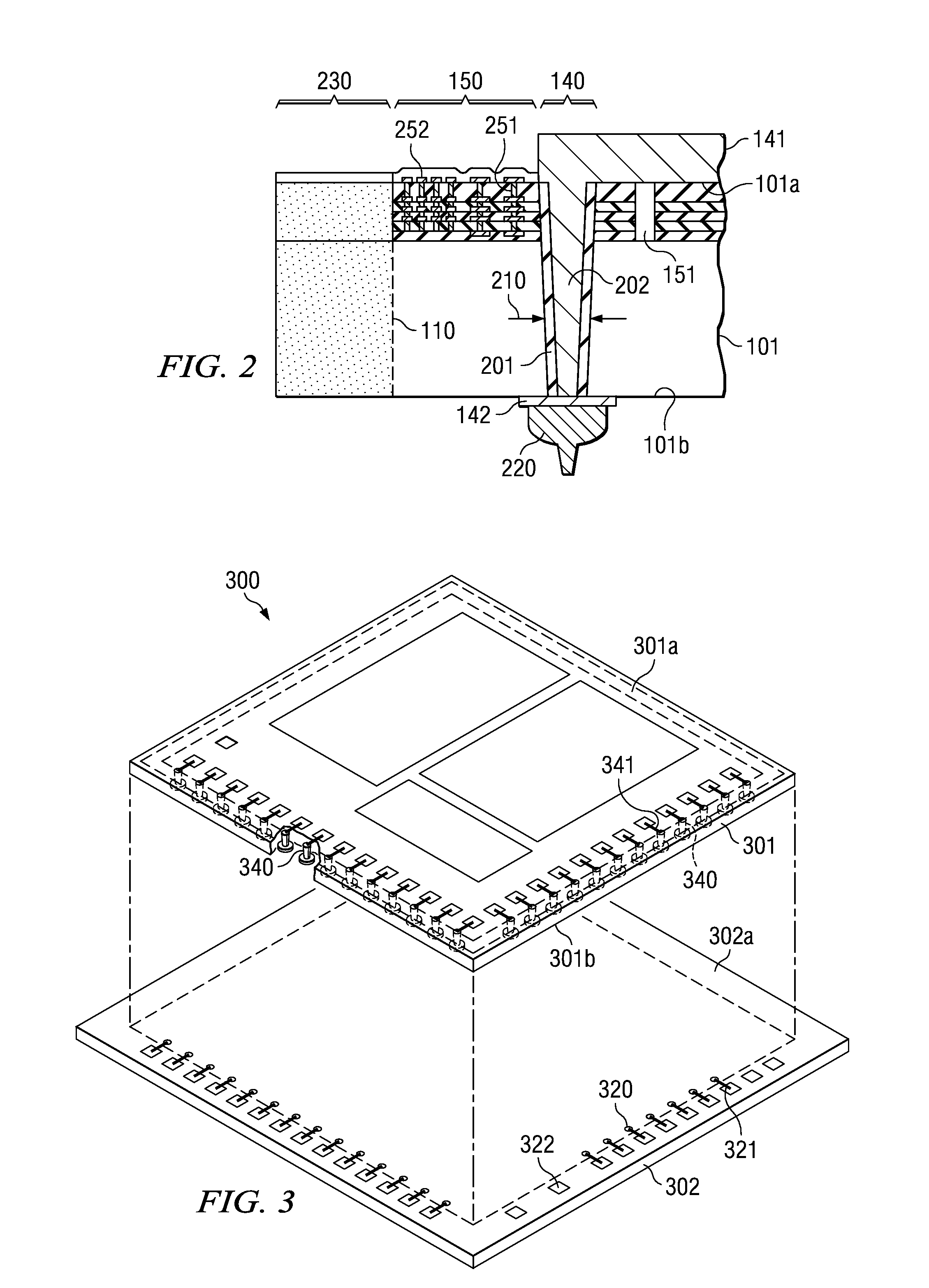

Method for Stacking Semiconductor Chips

ActiveUS20090079067A1Semiconductor/solid-state device detailsSolid-state devicesContact padSemiconductor chip

In a semiconductor system (100) including a chip (101) and a workpiece (102), the chip has metal-filled vias (140) positioned between contact pads (120) and the respective edges (110). In addition, seals against microcracks (150) and thermo-mechanical stress (151) are located between the vias and the active components, and sometimes also between the vias and the respective nearest edge. Workpiece (102) may be another semiconductor chip or a substrate; it has contact pads (170) matching the locations of the vias (140). The chip is vertically stacked on the workpiece so that each contact pad (170) is aligned and in electrical contact with the corresponding via (140).

Owner:TEXAS INSTR INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com