Patents

Literature

2333results about "Transfer printing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

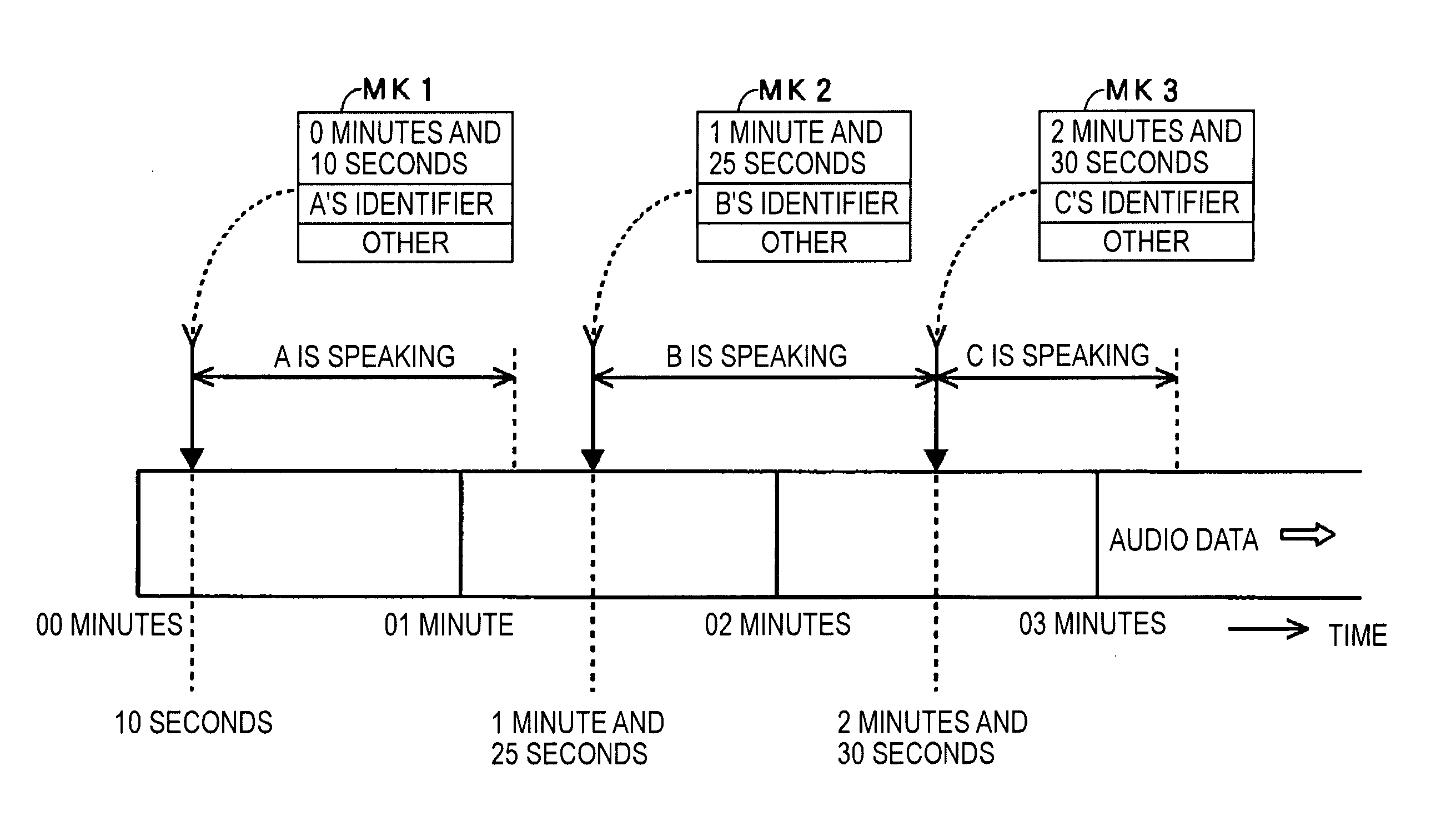

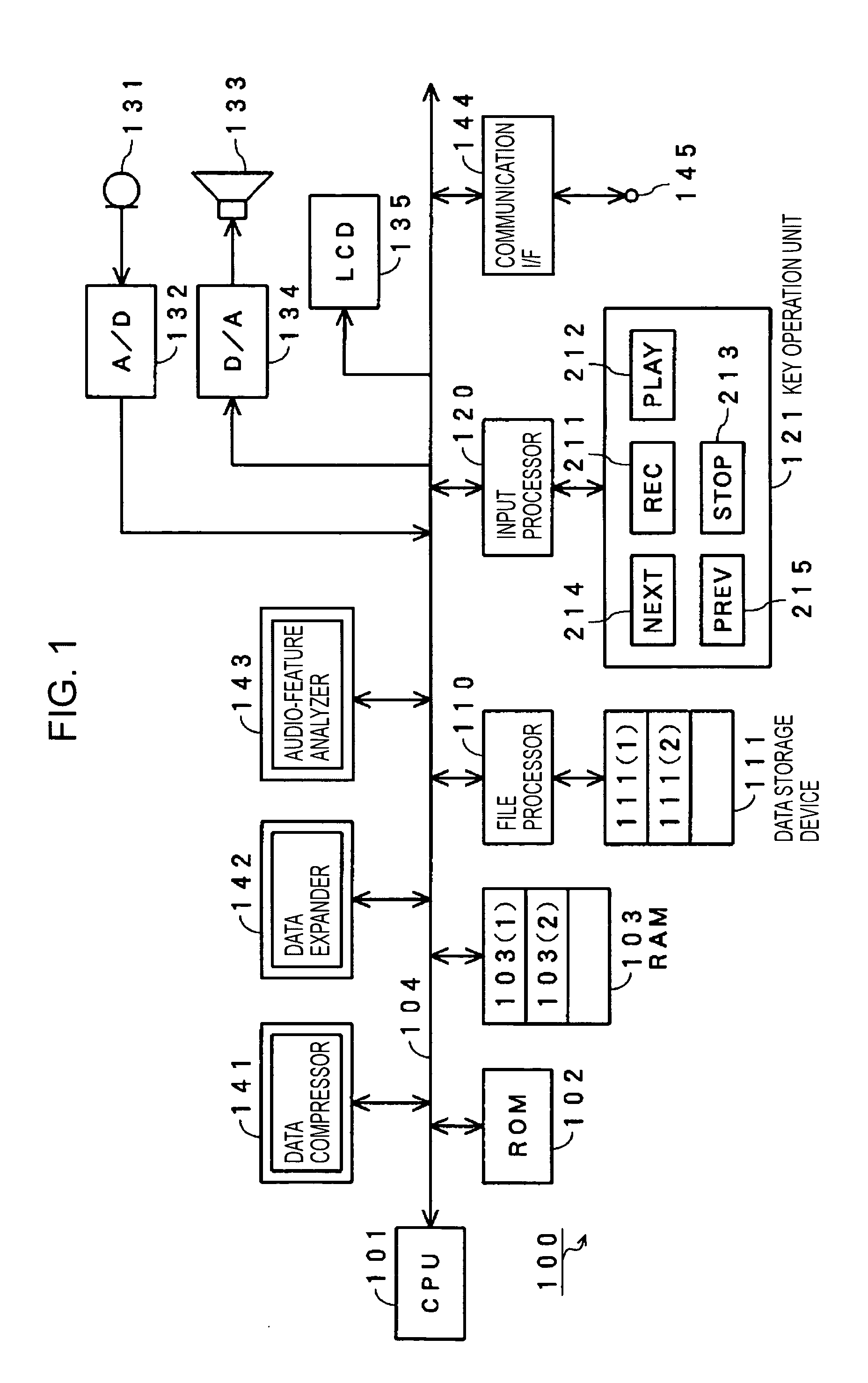

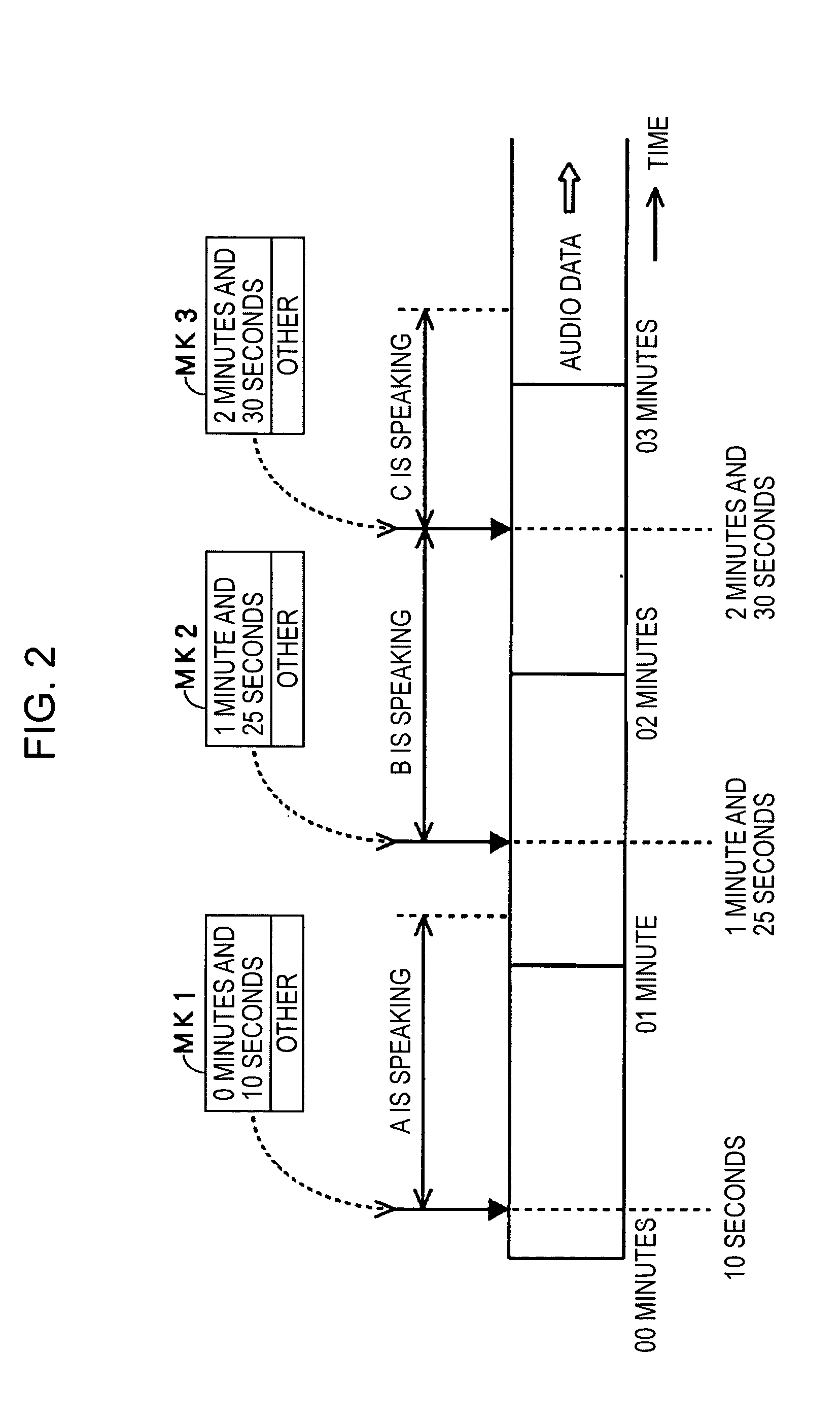

Audio signal processing apparatus and audio signal processing method

InactiveUS20050182627A1Improve usabilityThe process is convenient and fastTransfer printingElectronic editing digitised analogue information signalsKey pressingComputer science

An audio-feature analyzer automatically detects points of change in audio signals to be processed. A central processing unit (CPU) obtains point-of-change information indicating positions of the points of change in the audio signals, and the point-of-change information is recorded on a data storage device. The CPU identifies point-of-change information in accordance with an instruction input by a user via a key operation unit, and audio data corresponding to the point-of-change information identified is located so that processing such as playback of audio data to be processed can be started therefrom.

Owner:SONY CORP

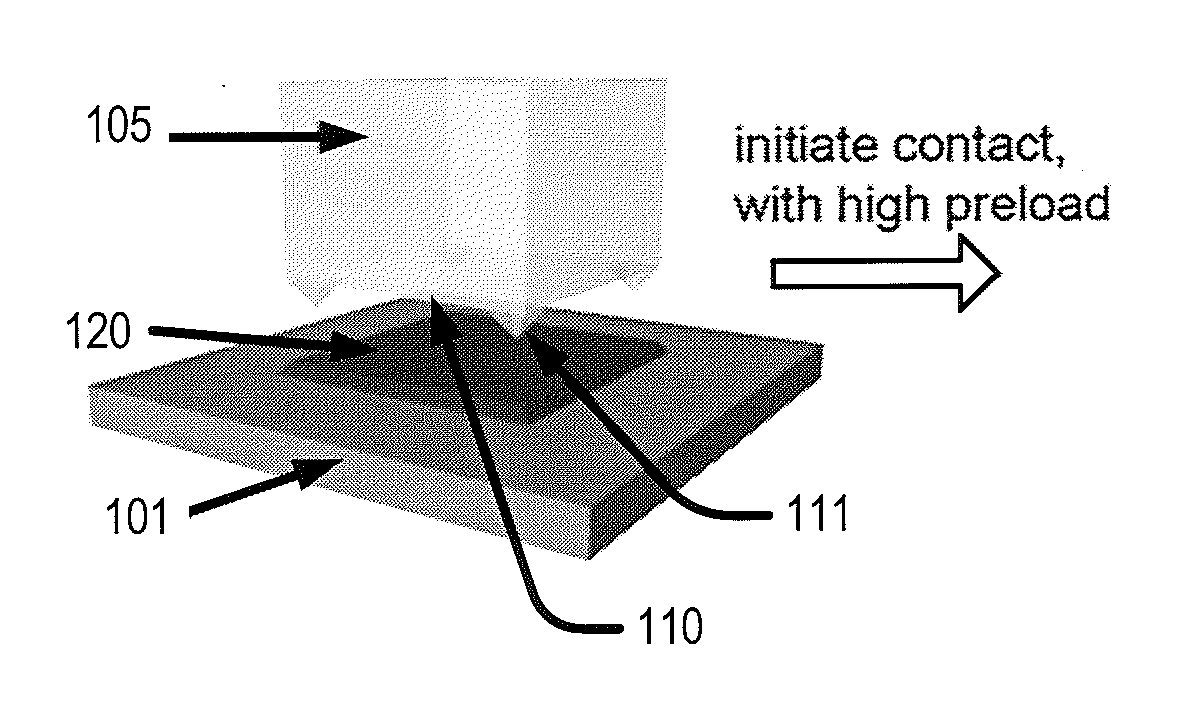

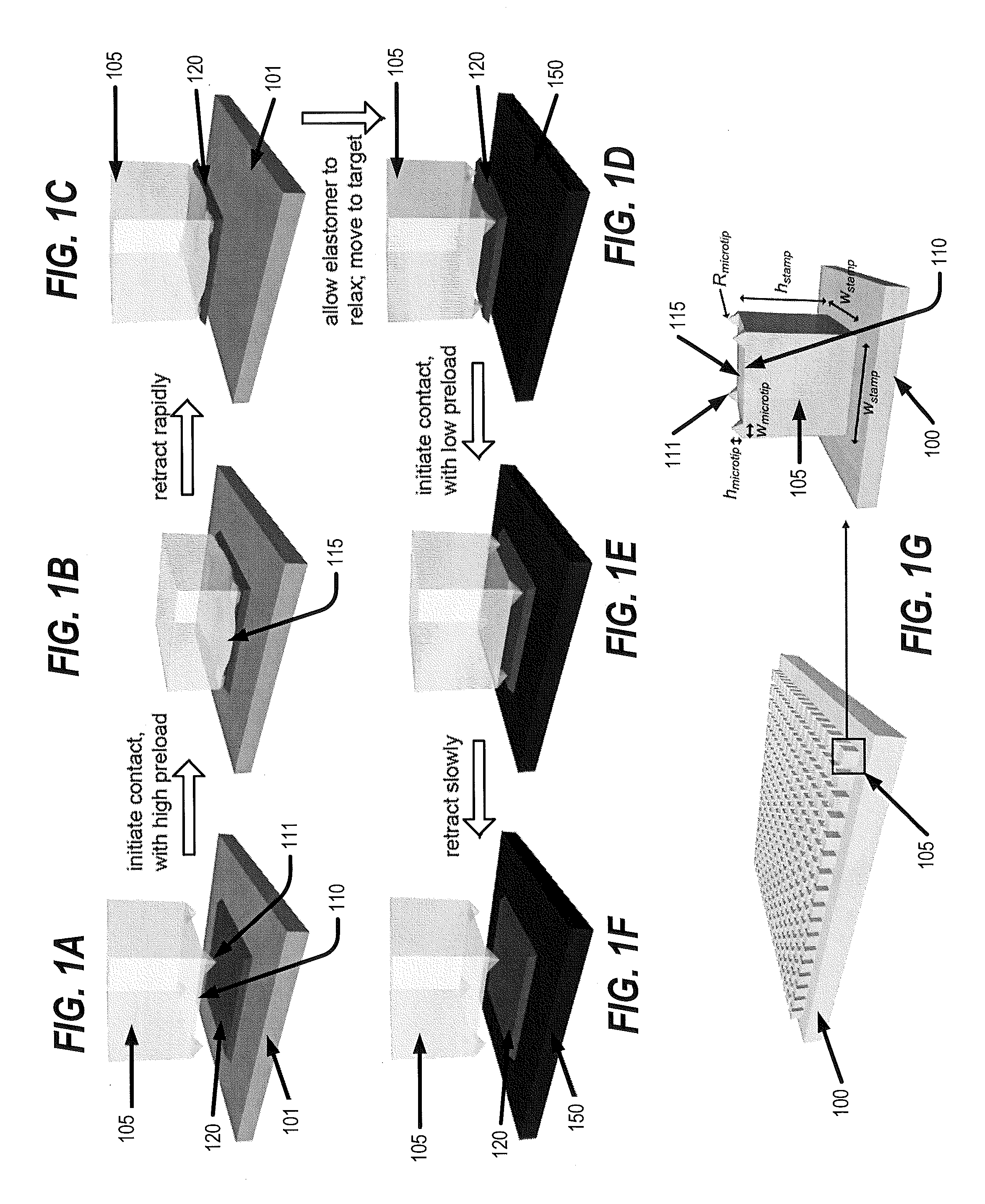

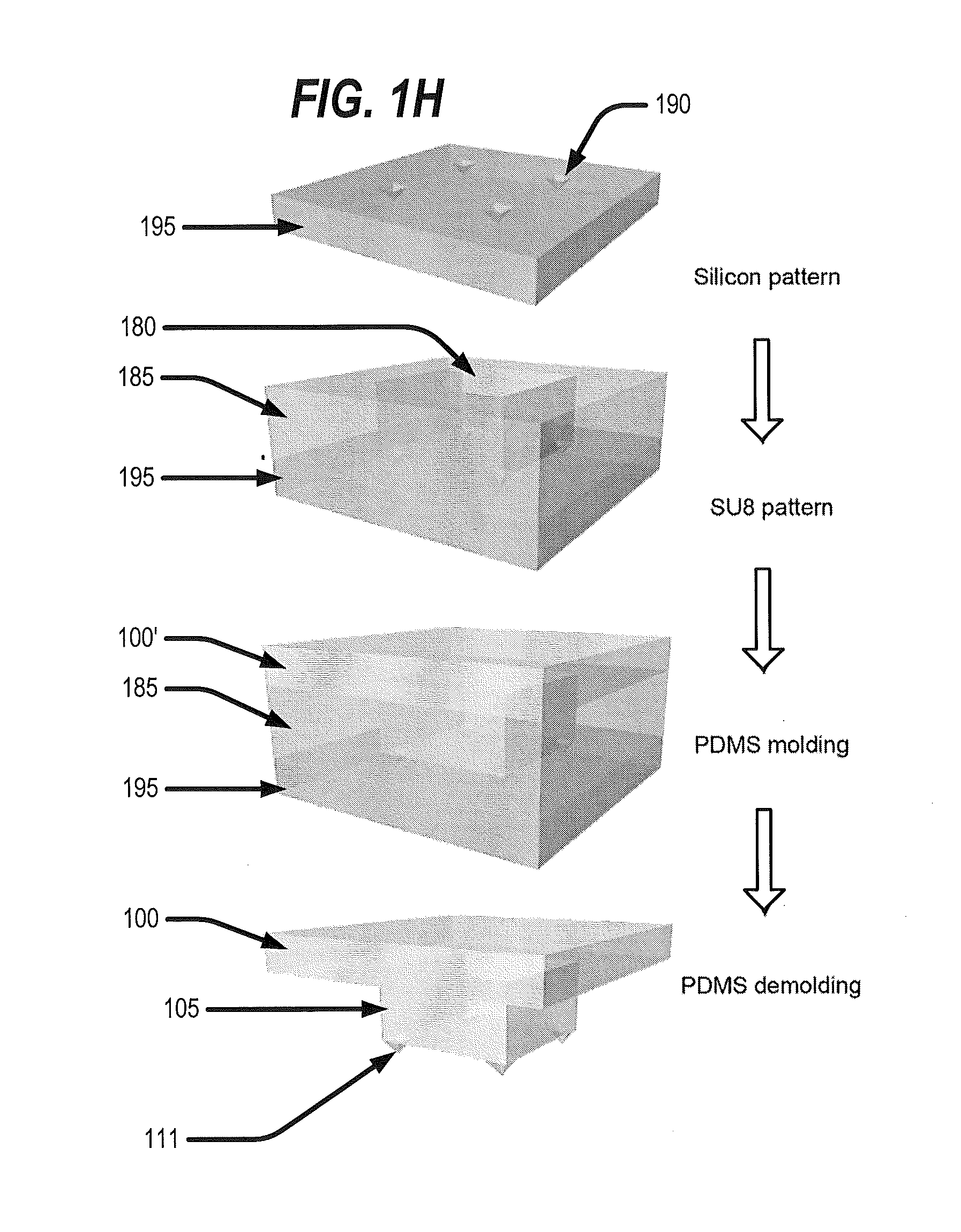

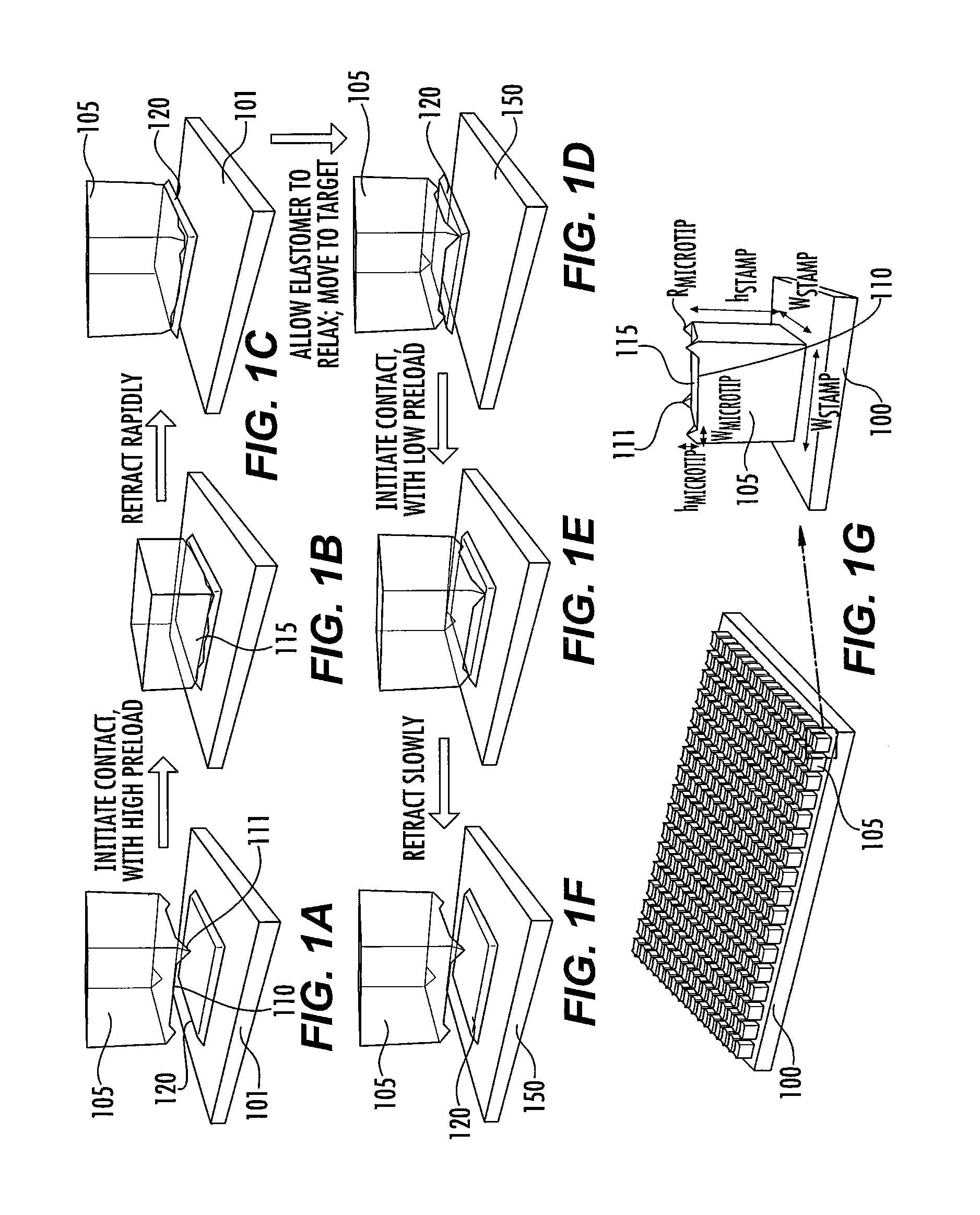

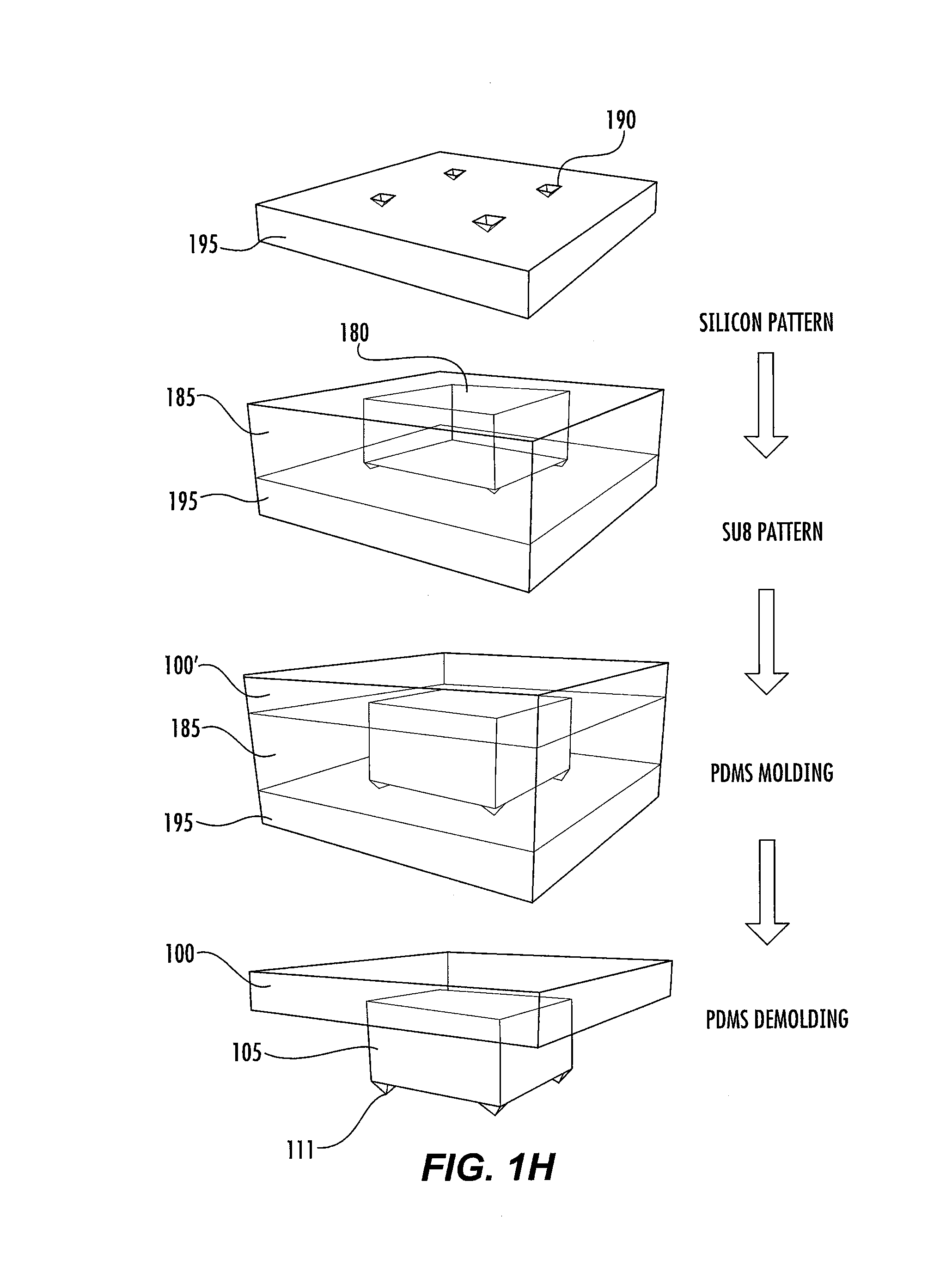

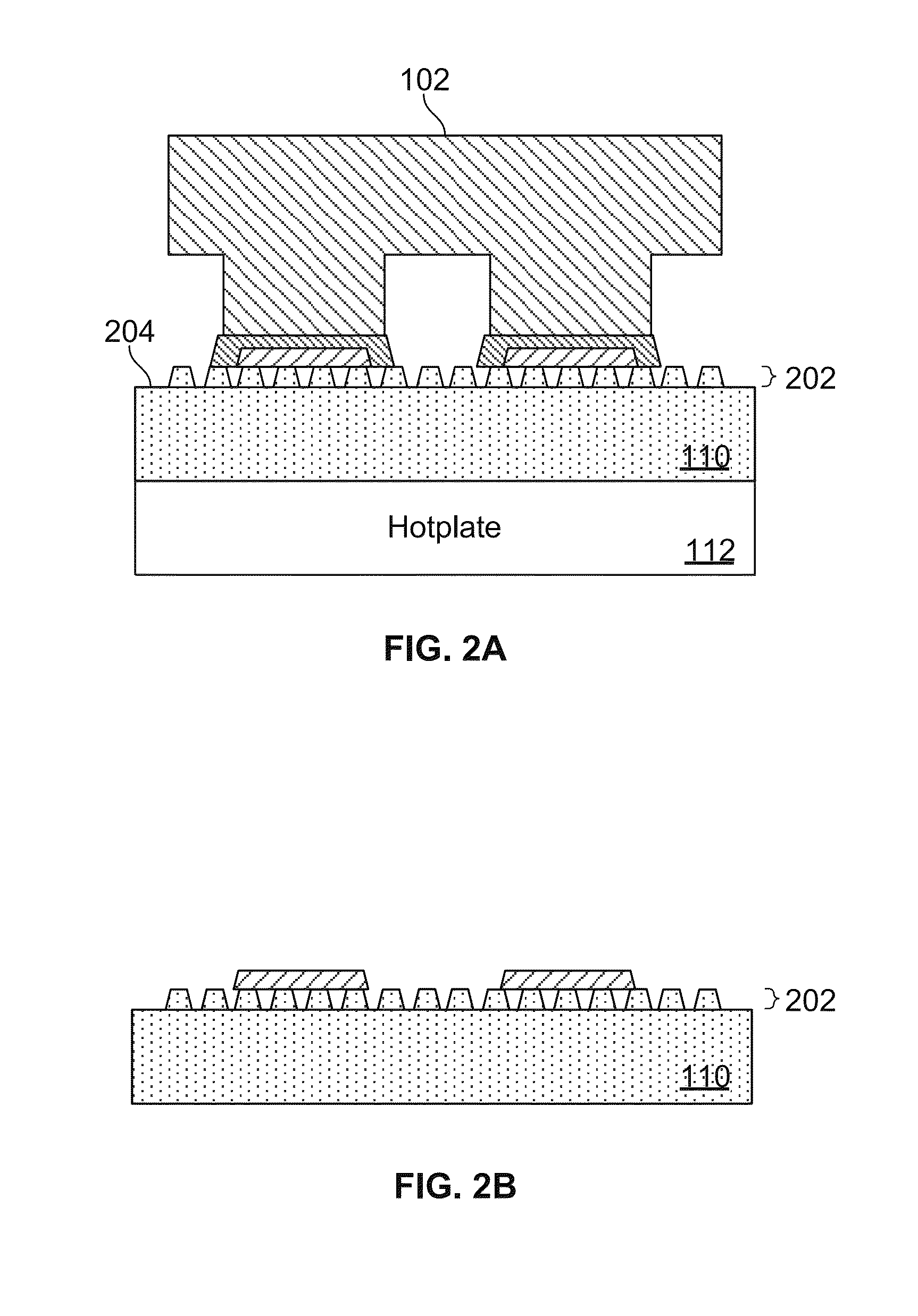

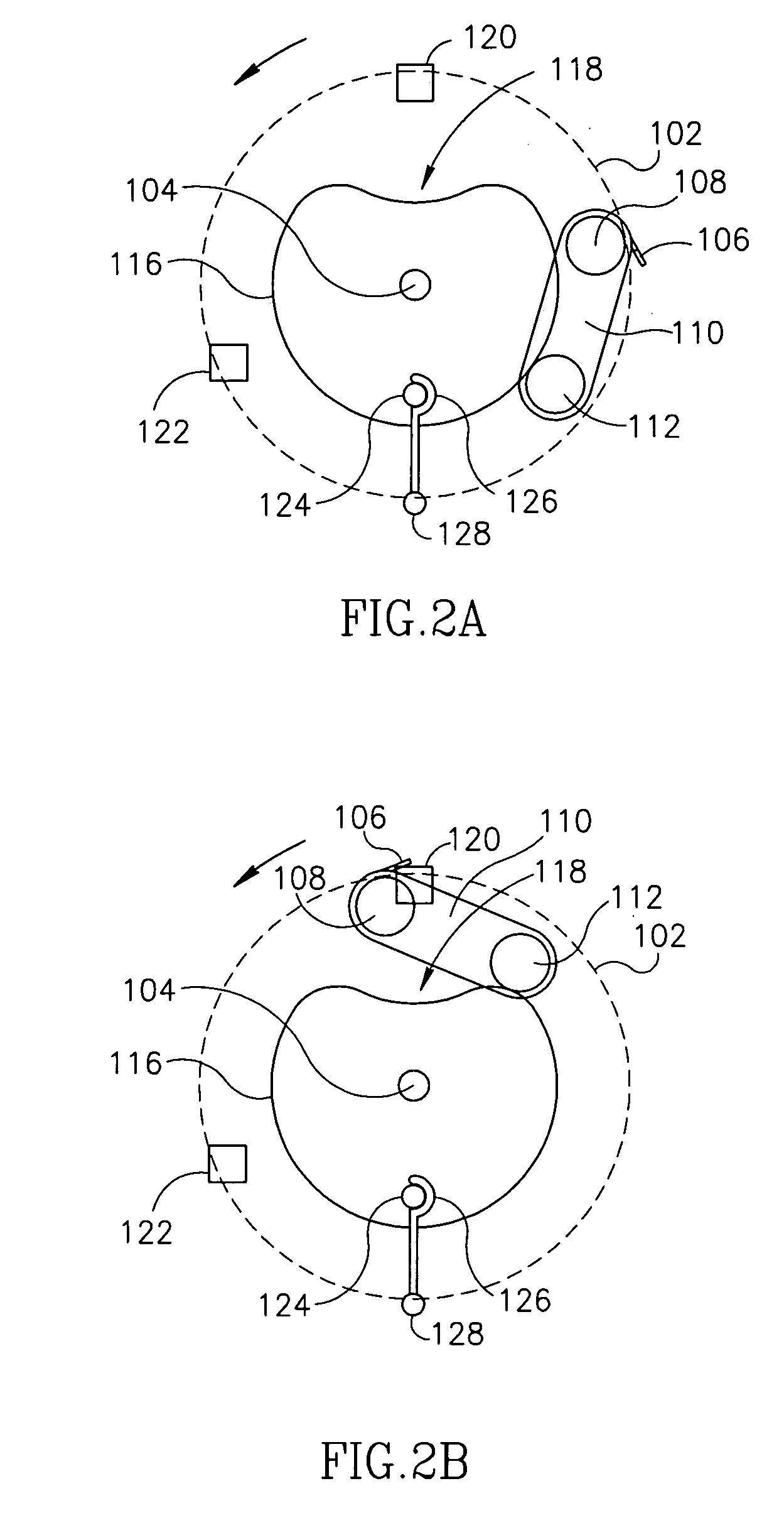

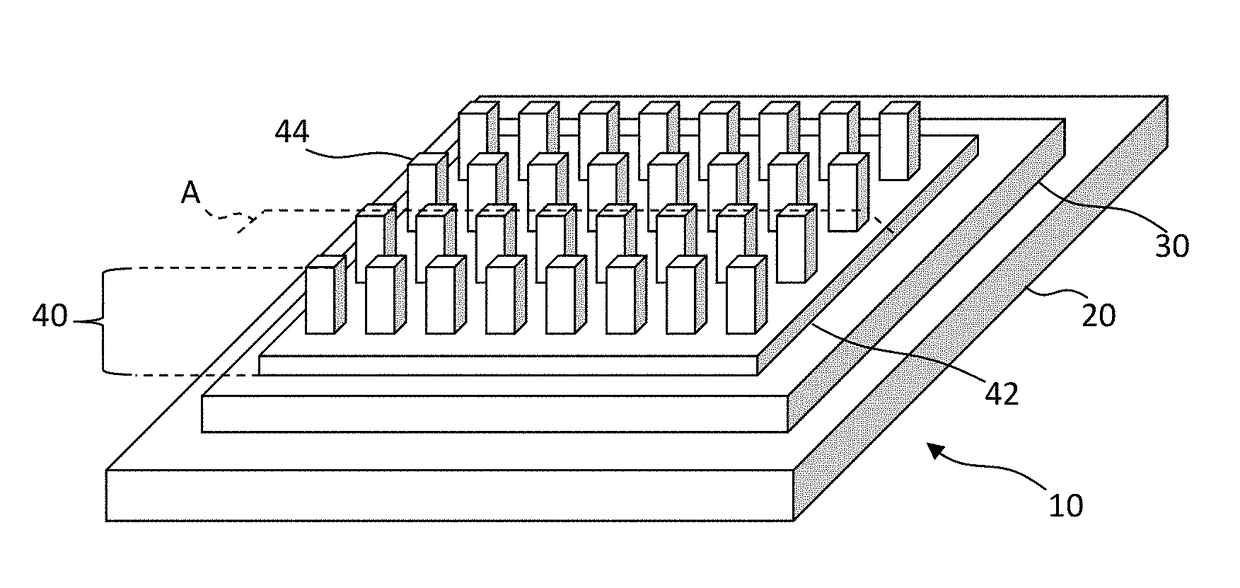

Printing transferable components using microstructured elastomeric surfaces with pressure modulated reversible adhesion

ActiveUS20130069275A1Extra featureSolve the lack of adhesionTransfer printingSemiconductor/solid-state device detailsElastomerReversible adhesion

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS +1

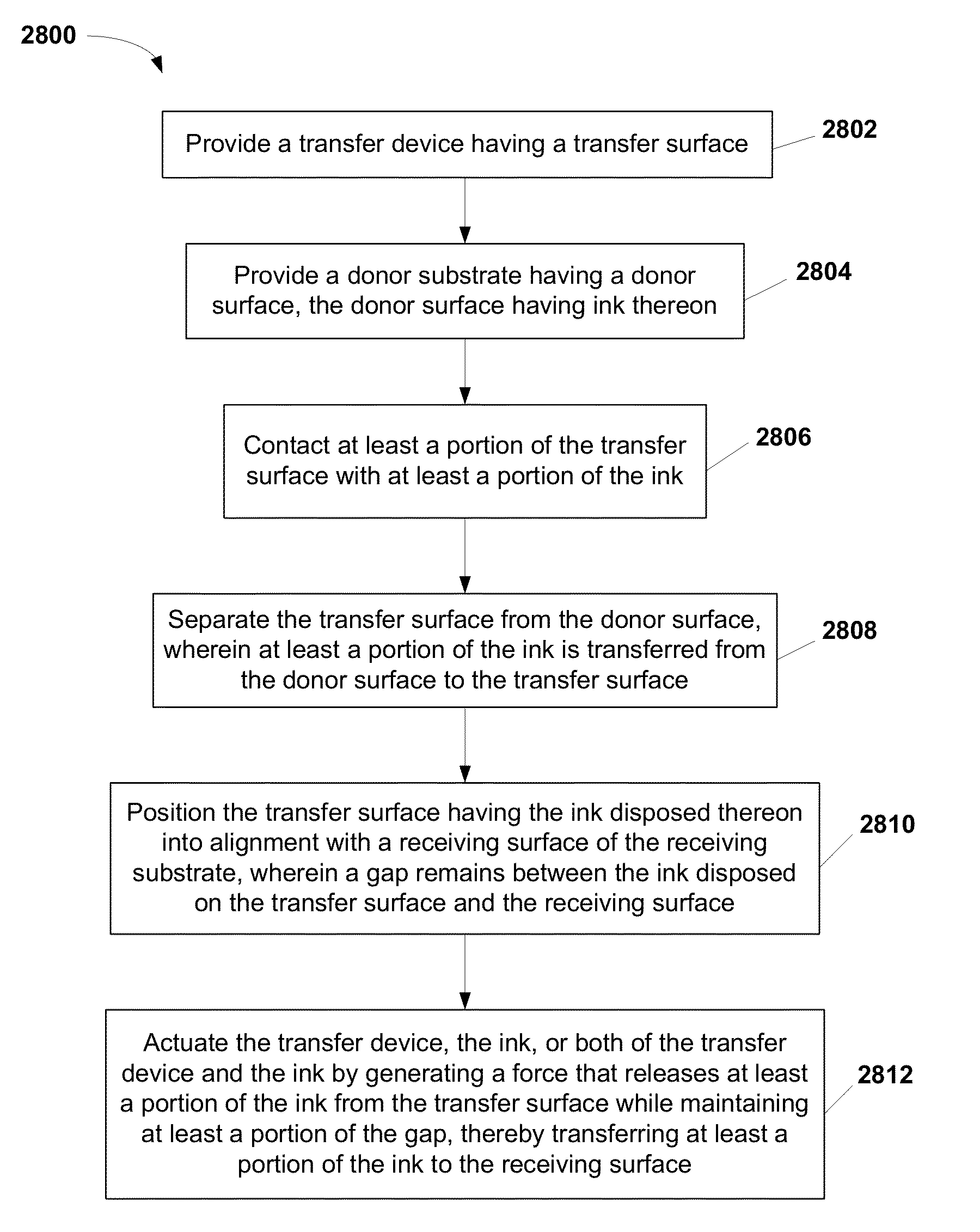

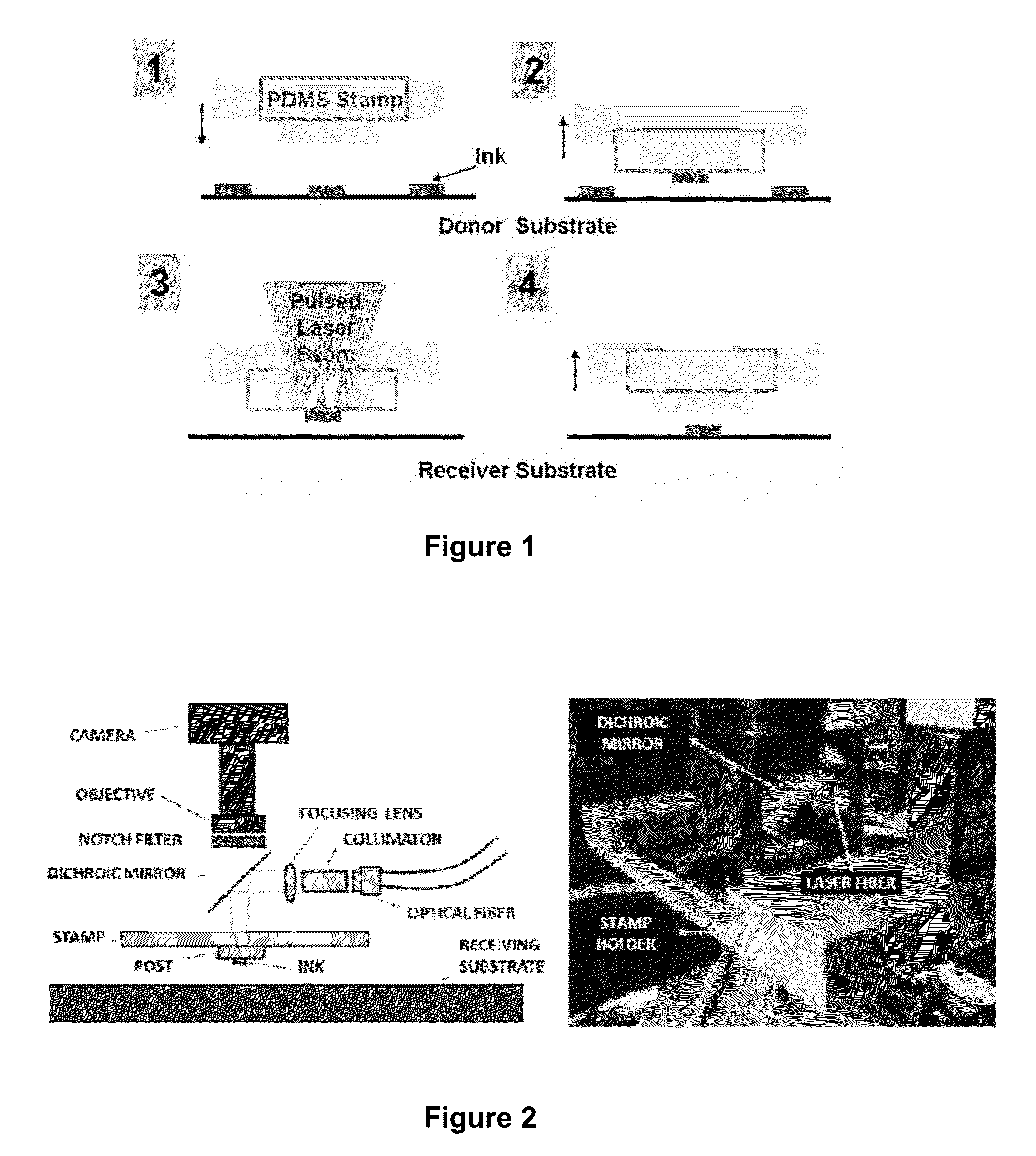

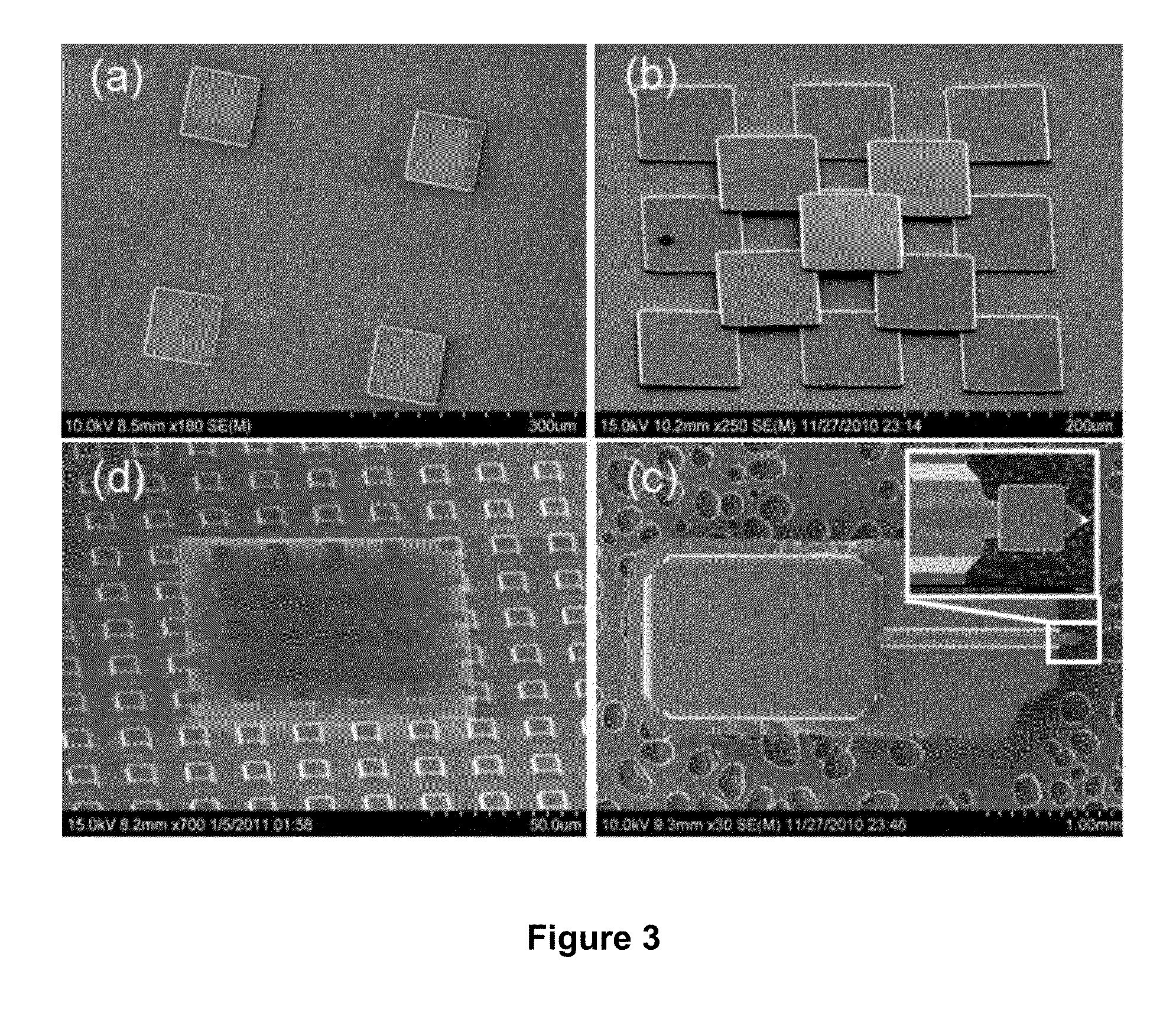

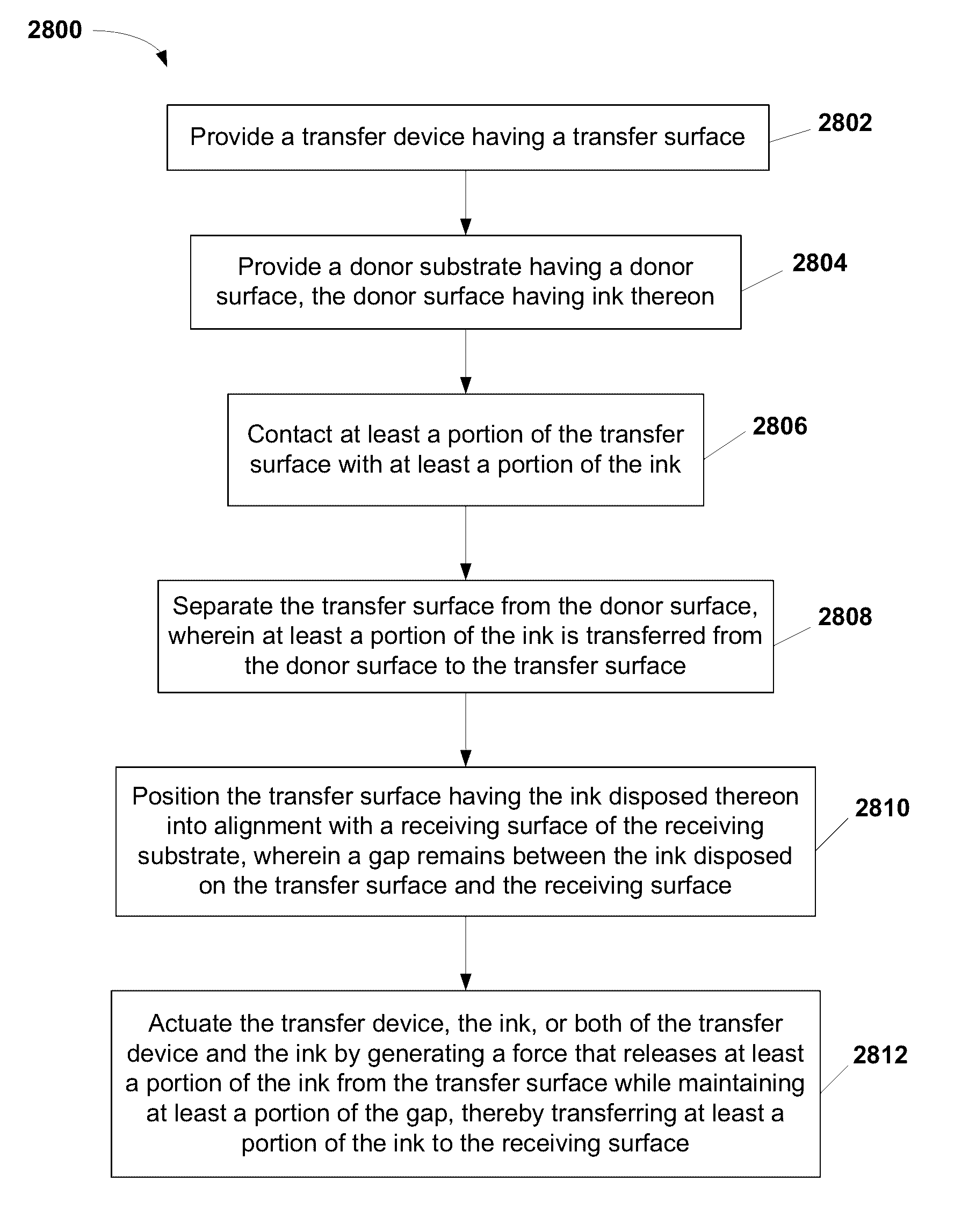

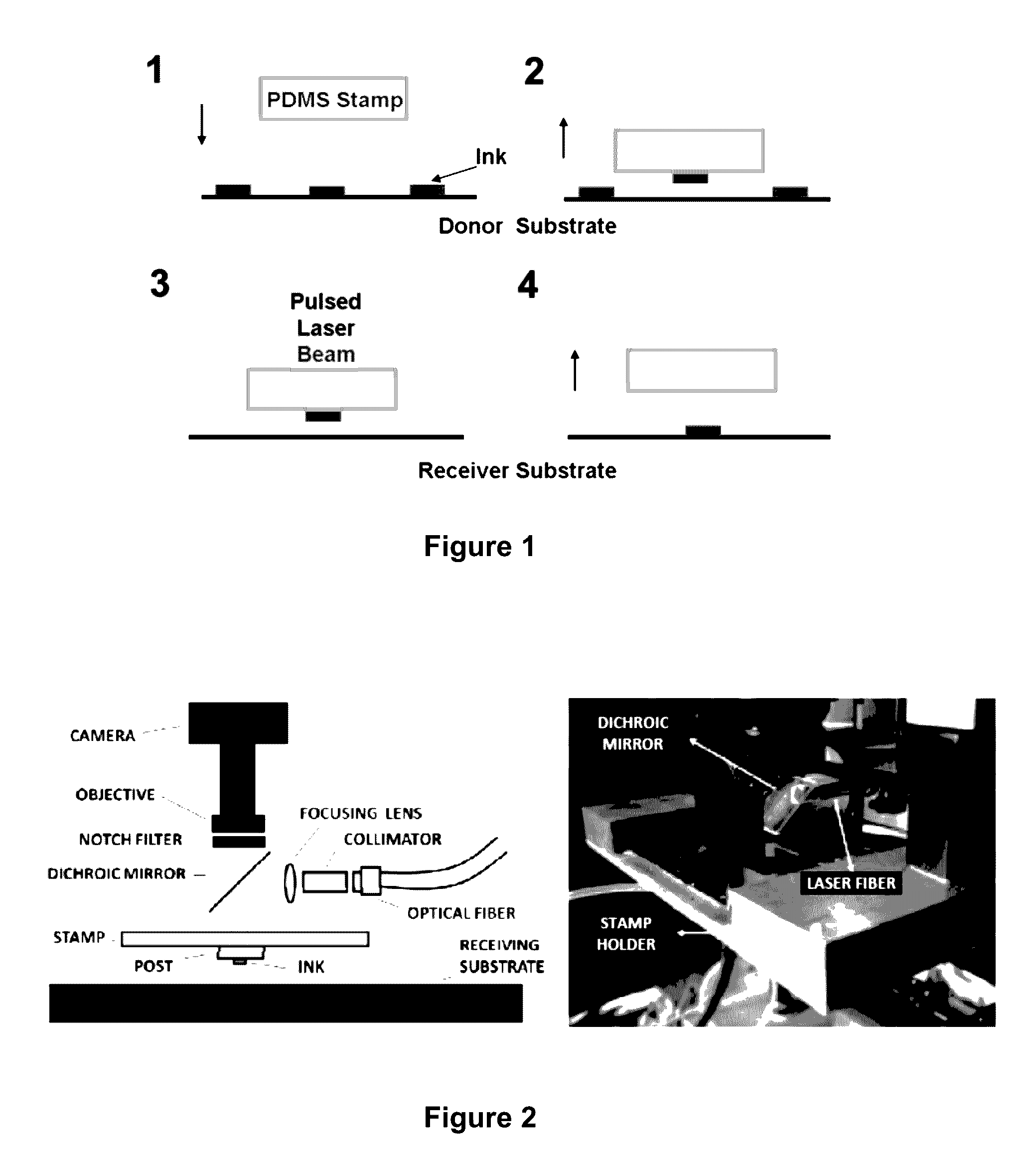

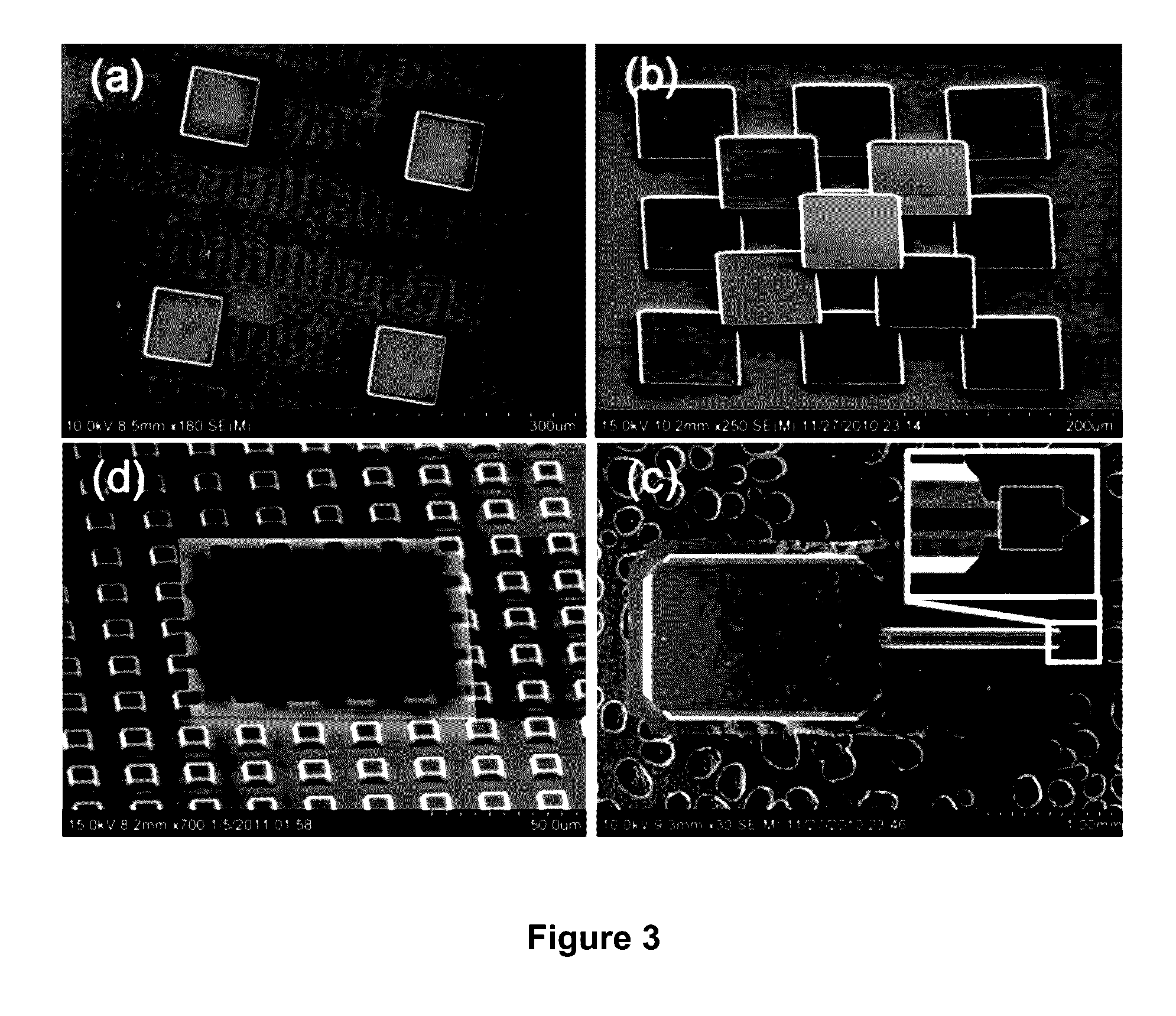

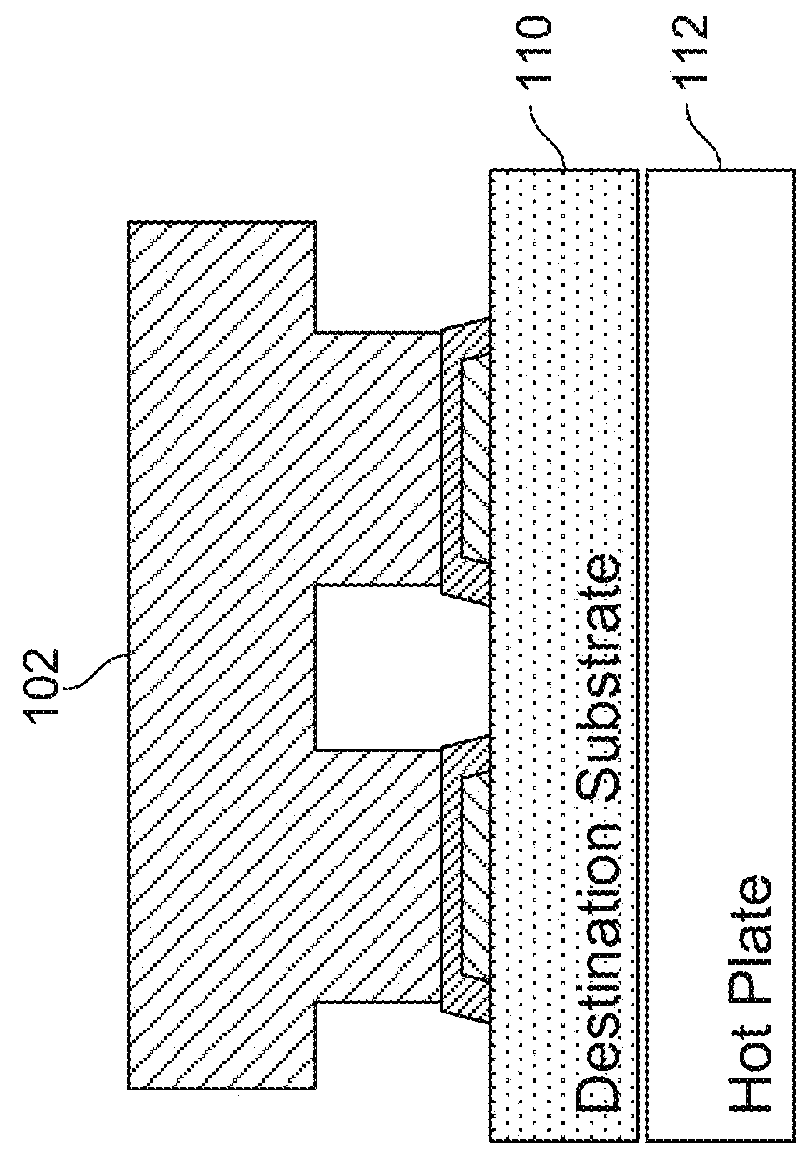

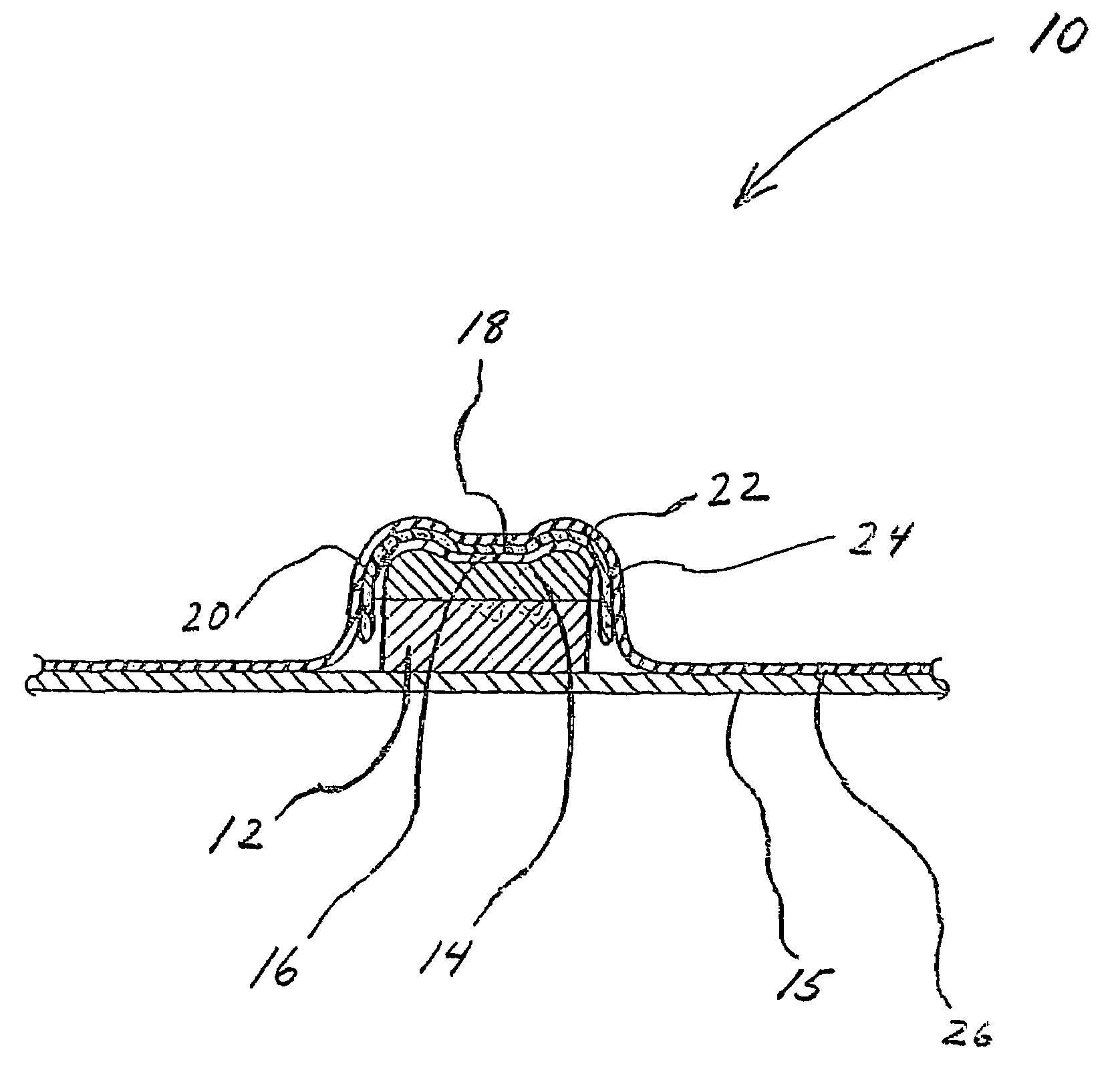

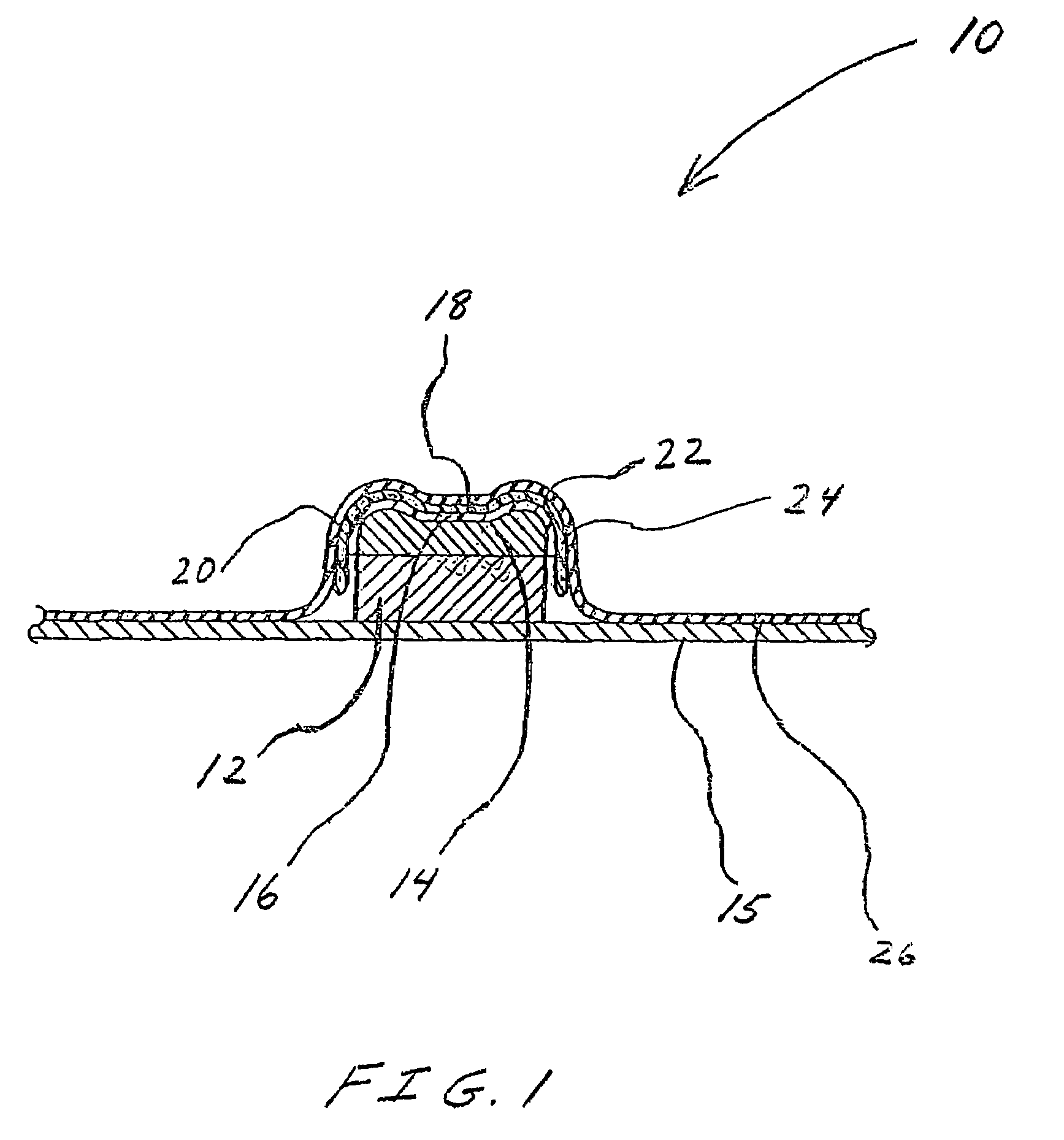

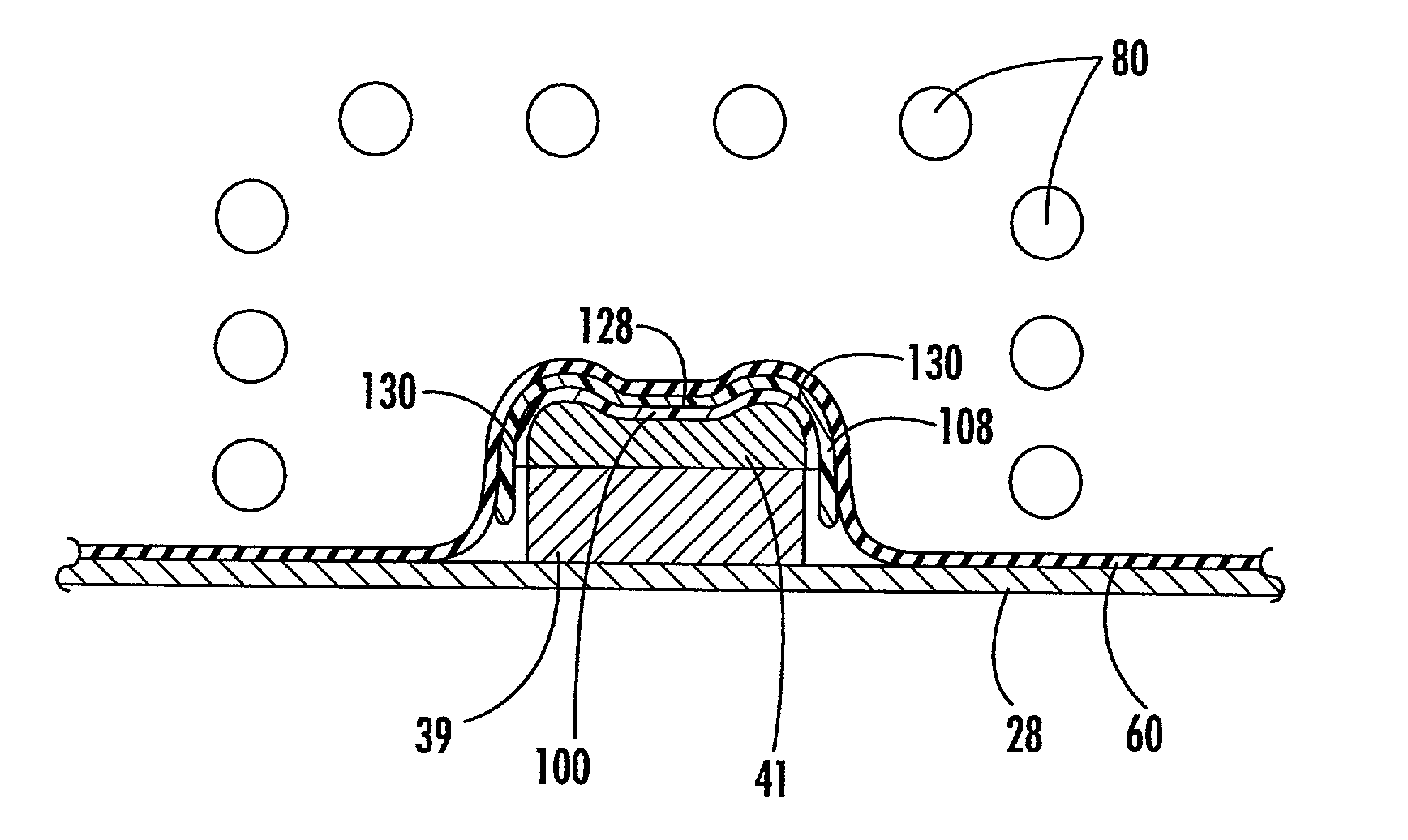

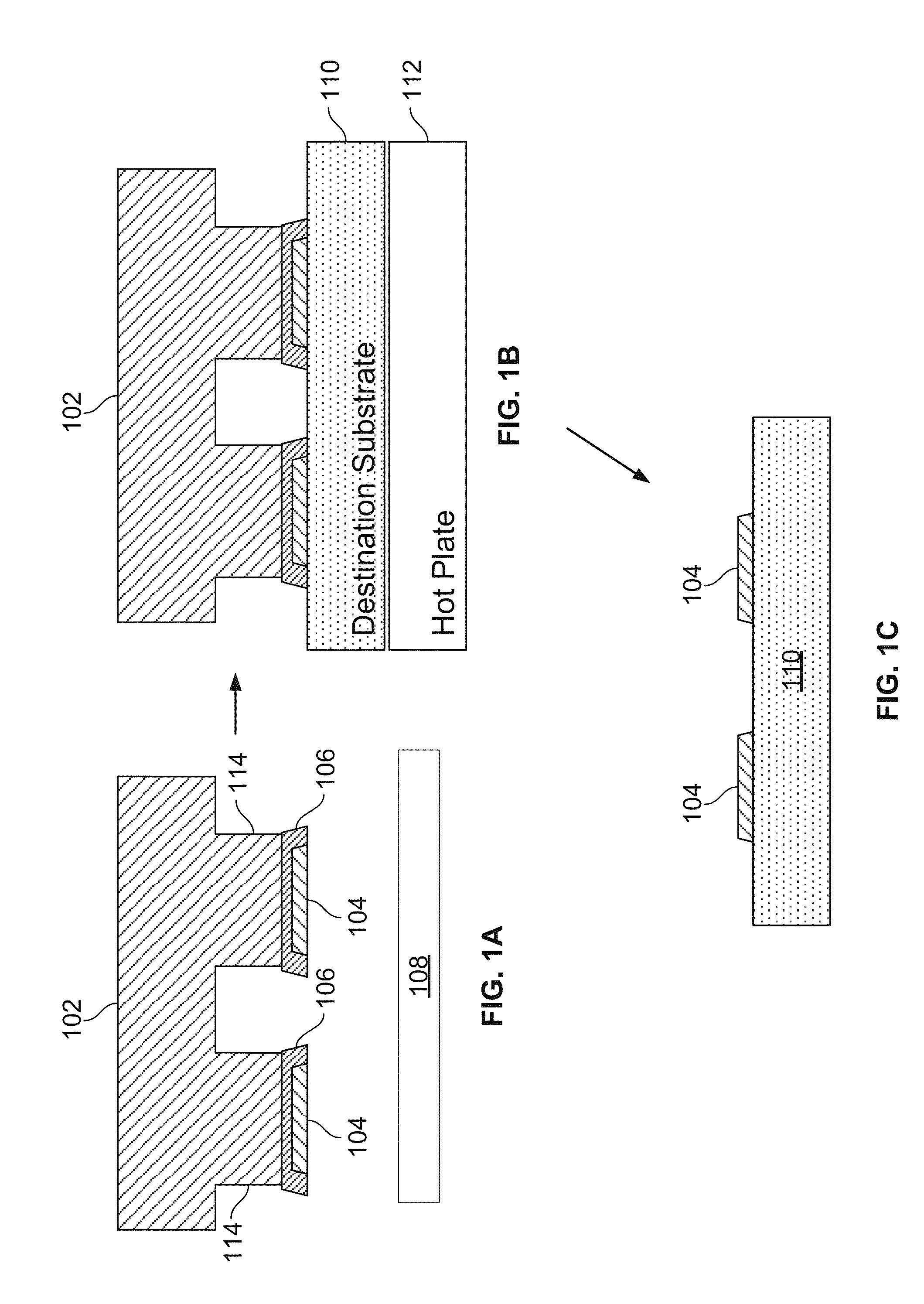

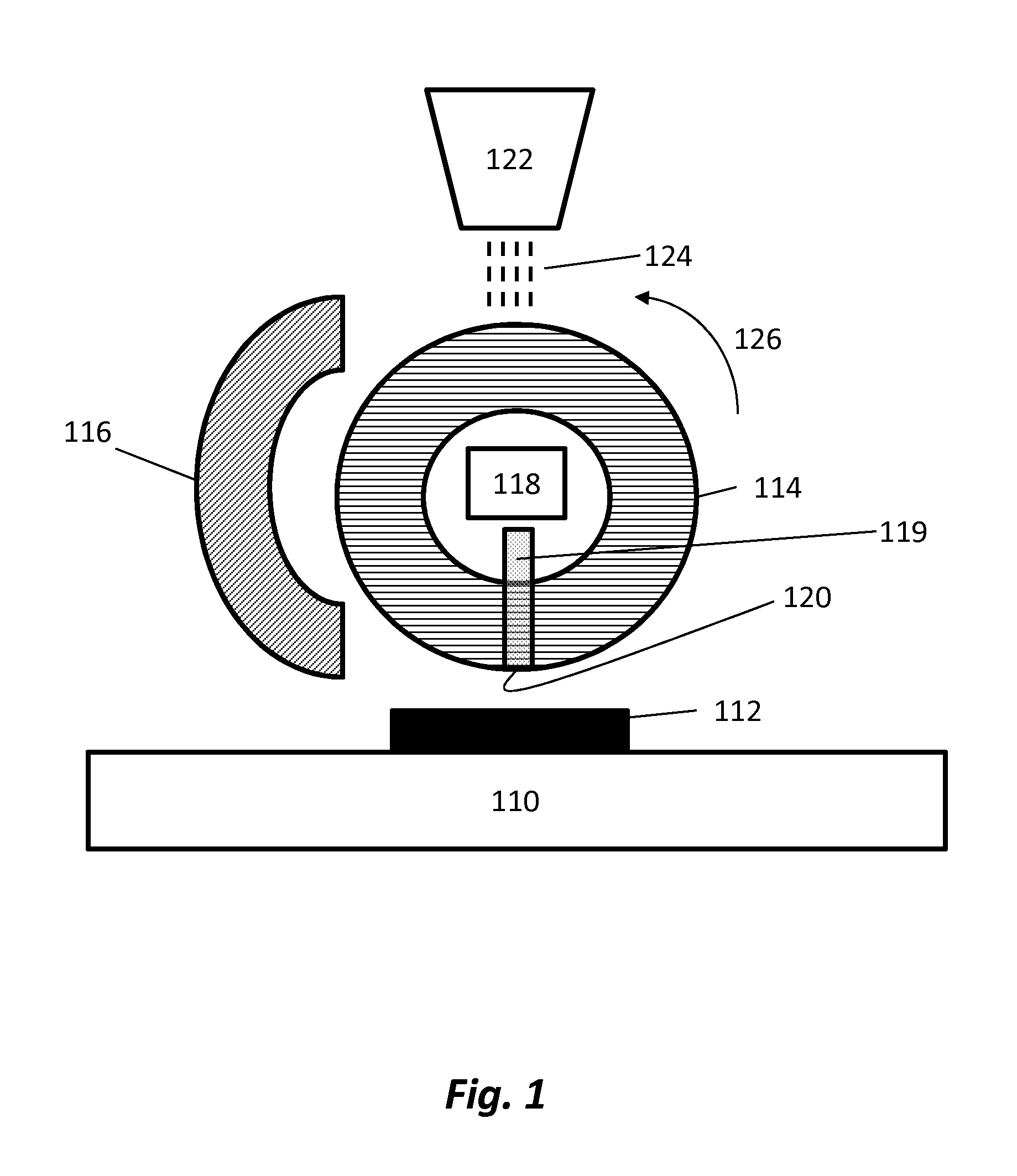

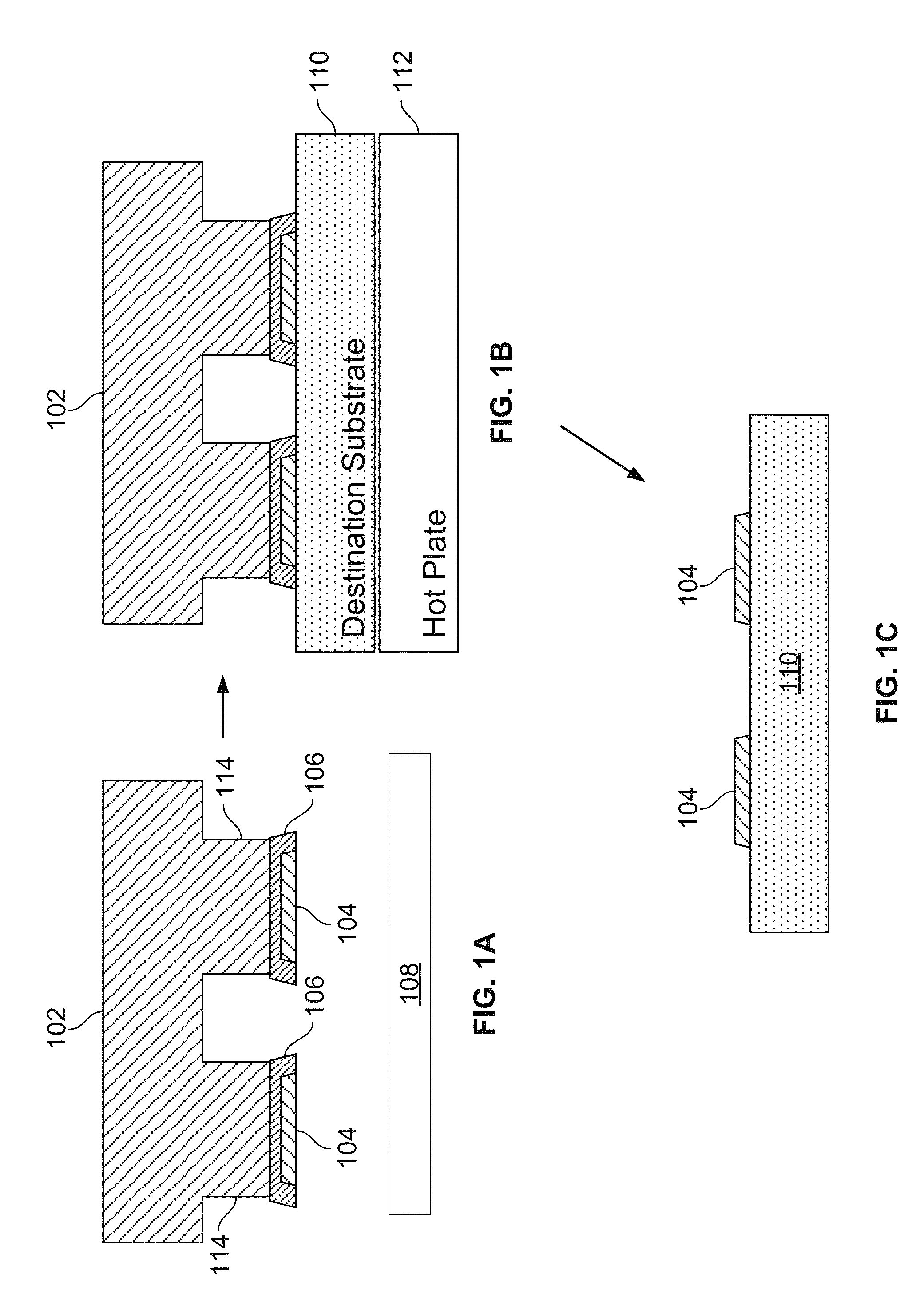

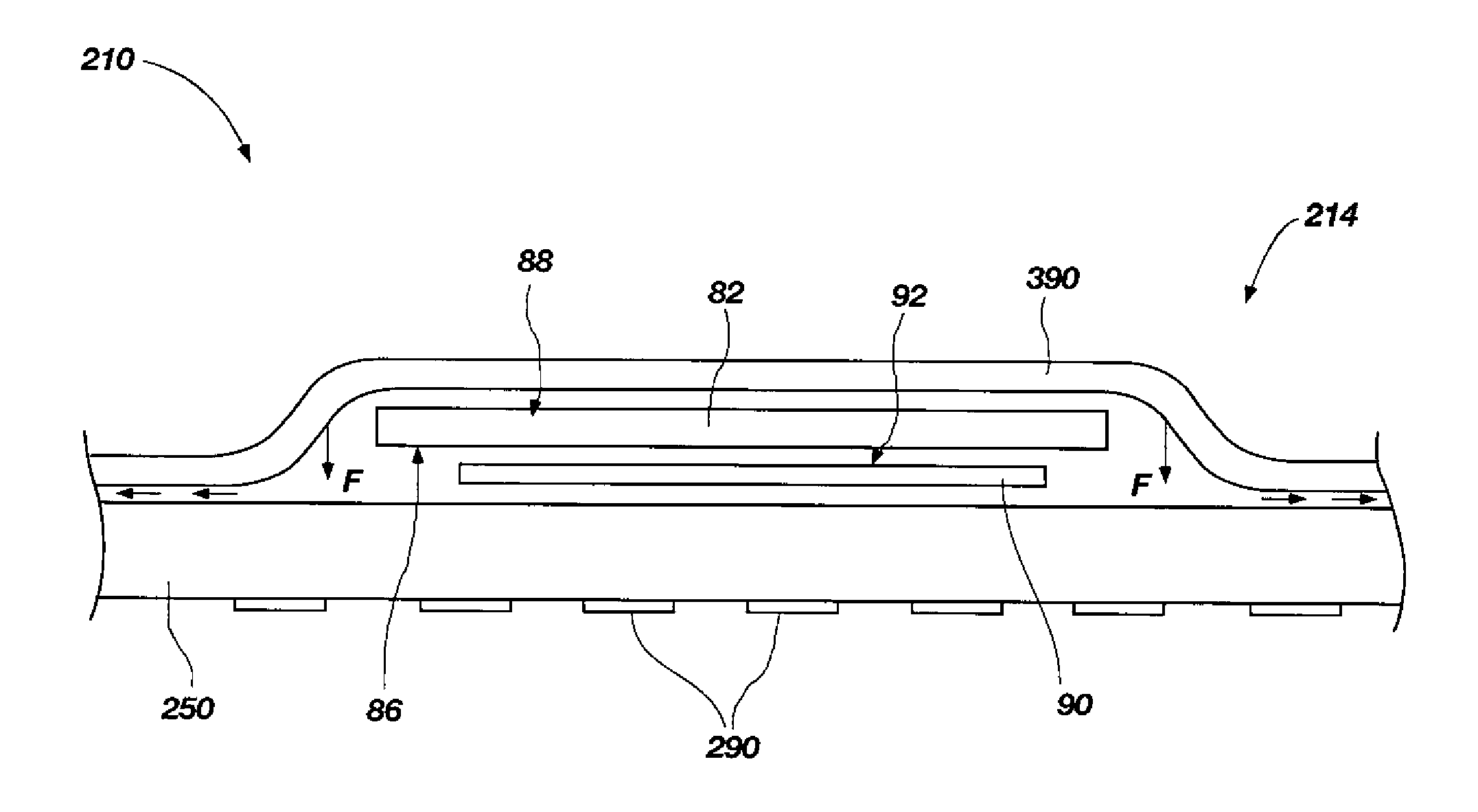

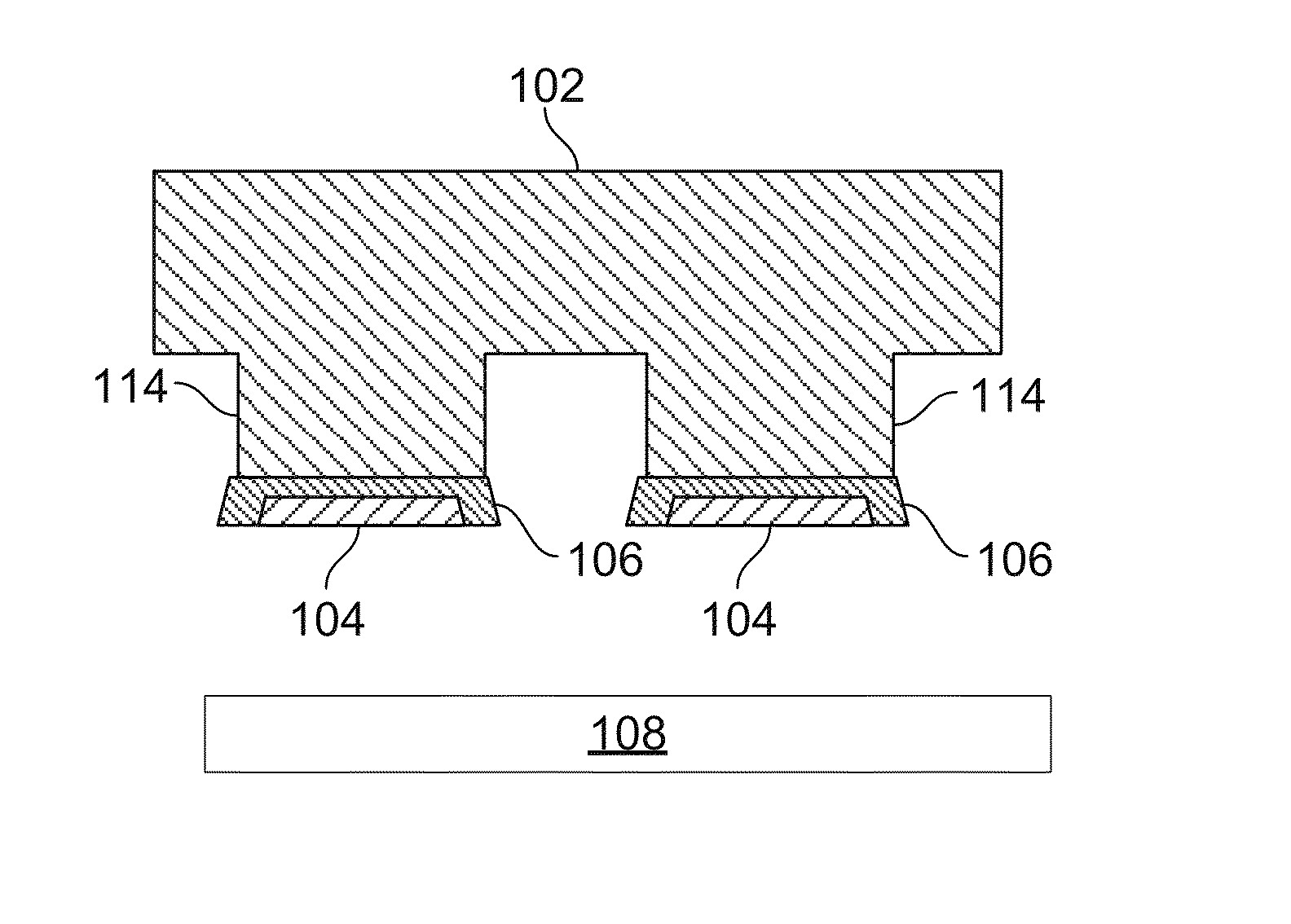

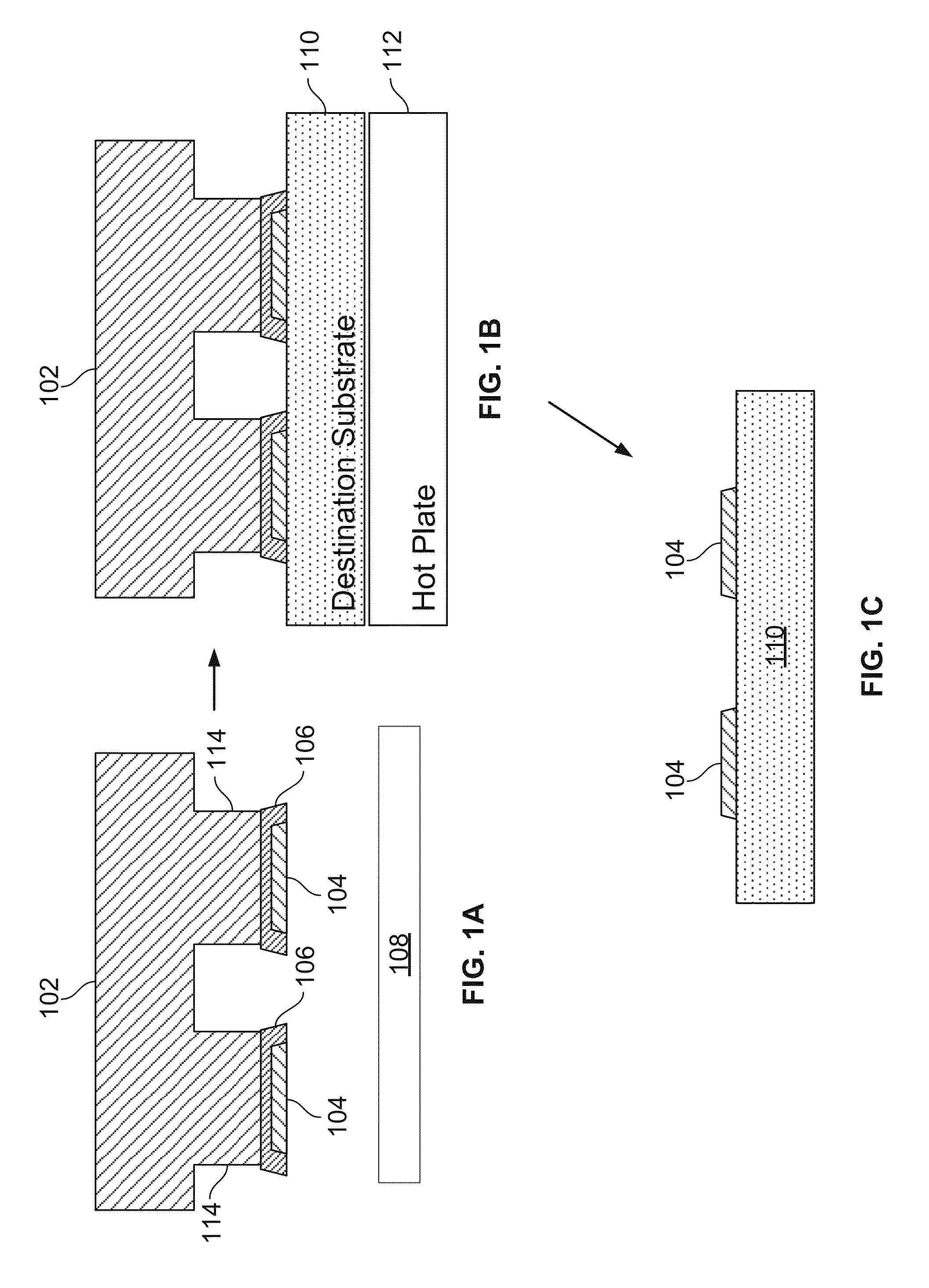

Non-contact transfer printing

ActiveUS20130036928A1Avoid damageNot to damageTransfer printingDuplicating/marking methodsNano-deviceLight-emitting diode

A transfer printing process that exploits the mismatch in mechanical or thermo-mechanical response at the interface of a printable micro- or nano-device and a transfer stamp to drive the release of the device from the stamp and its non-contact transfer to a receiving substrate are provided. The resulting facile, pick-and-place process is demonstrated with the assembling of 3-D microdevices and the printing of GAN light-emitting diodes onto silicon and glass substrates. High speed photography is used to provide experimental evidence of thermo-mechanically driven release.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

Non-contact transfer printing

ActiveUS9555644B2Avoid damageNot to damageTransfer printingDuplicating/marking methodsNano-deviceLight-emitting diode

A transfer printing process that exploits the mismatch in mechanical or thermo-mechanical response at the interface of a printable micro- or nano-device and a transfer stamp to drive the release of the device from the stamp and its non-contact transfer to a receiving substrate are provided. The resulting facile, pick-and-place process is demonstrated with the assembling of 3-D microdevices and the printing of GAN light-emitting diodes onto silicon and glass substrates. High speed photography is used to provide experimental evidence of thermo-mechanically driven release.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

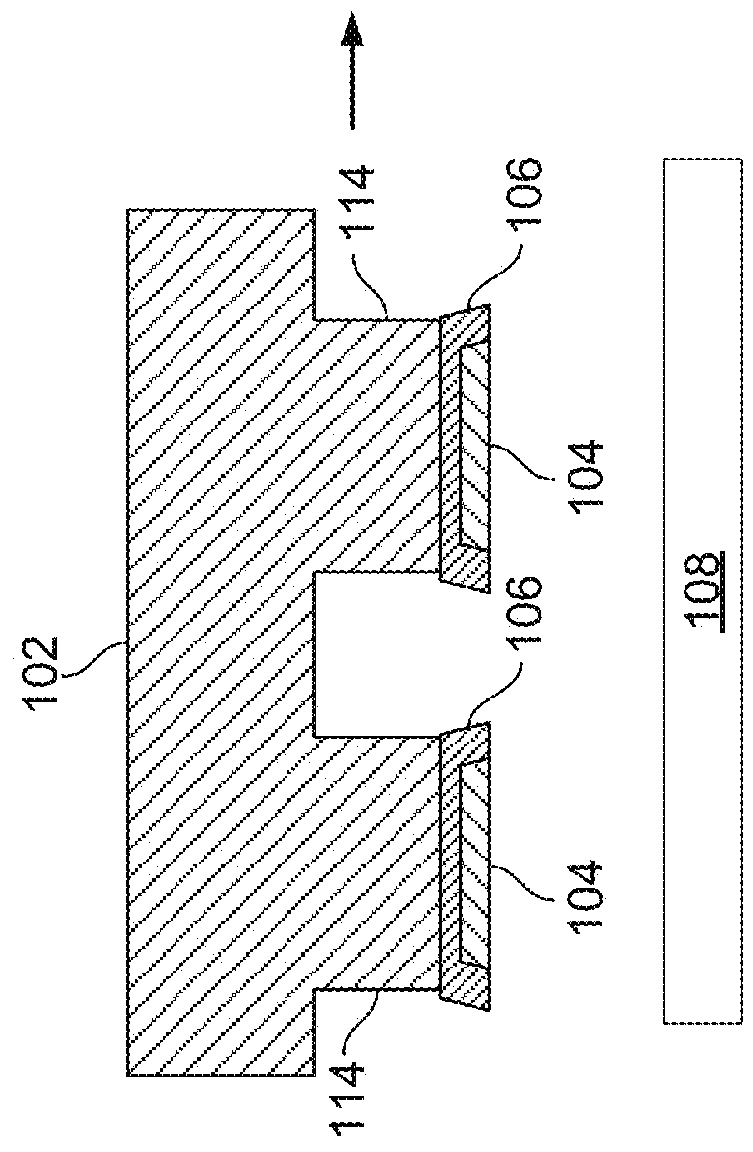

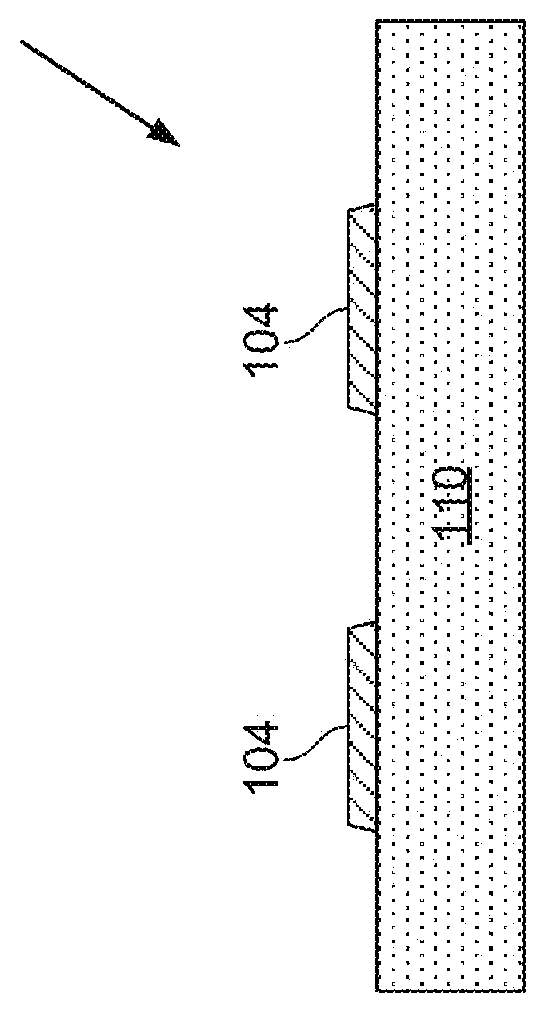

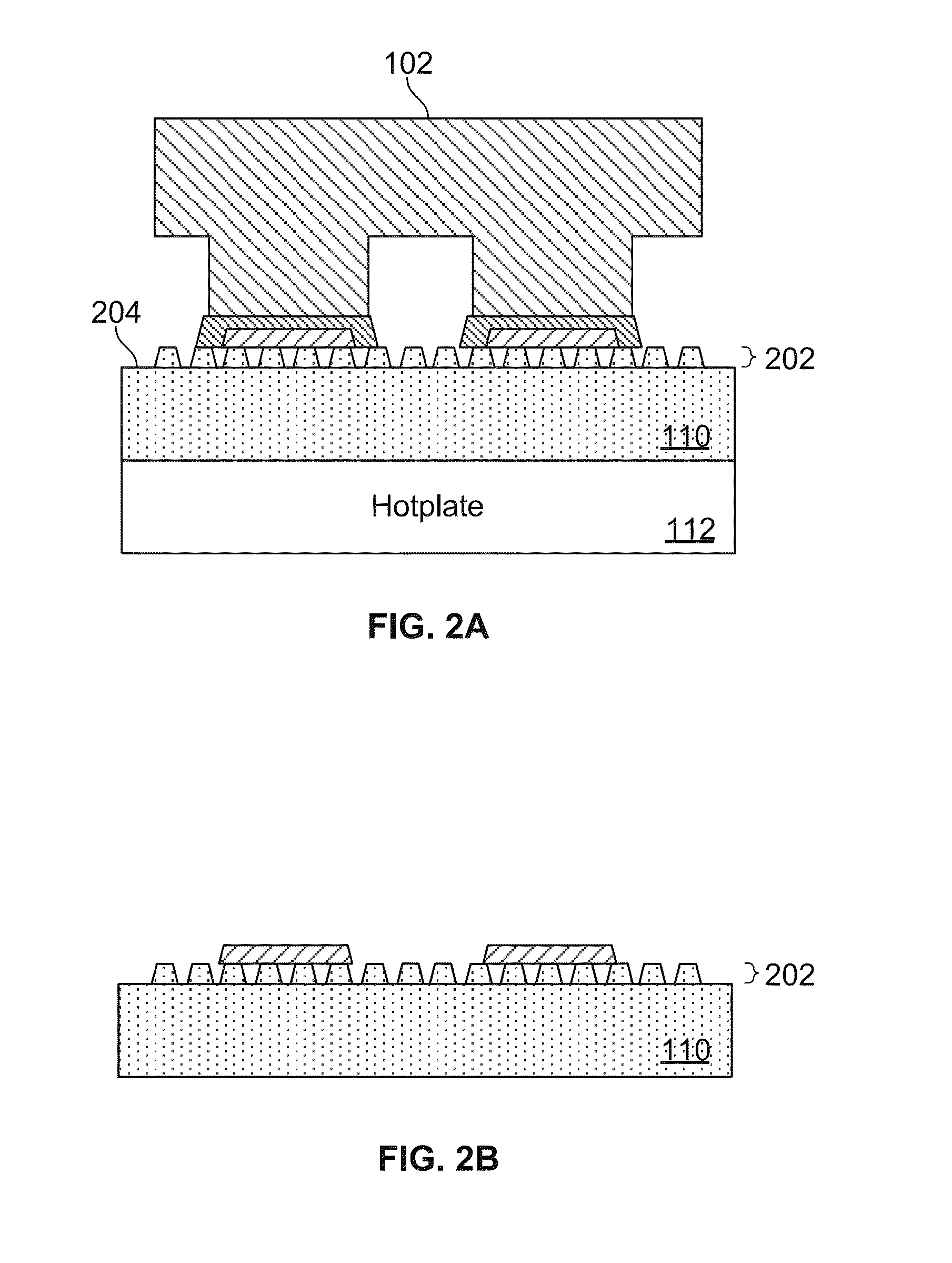

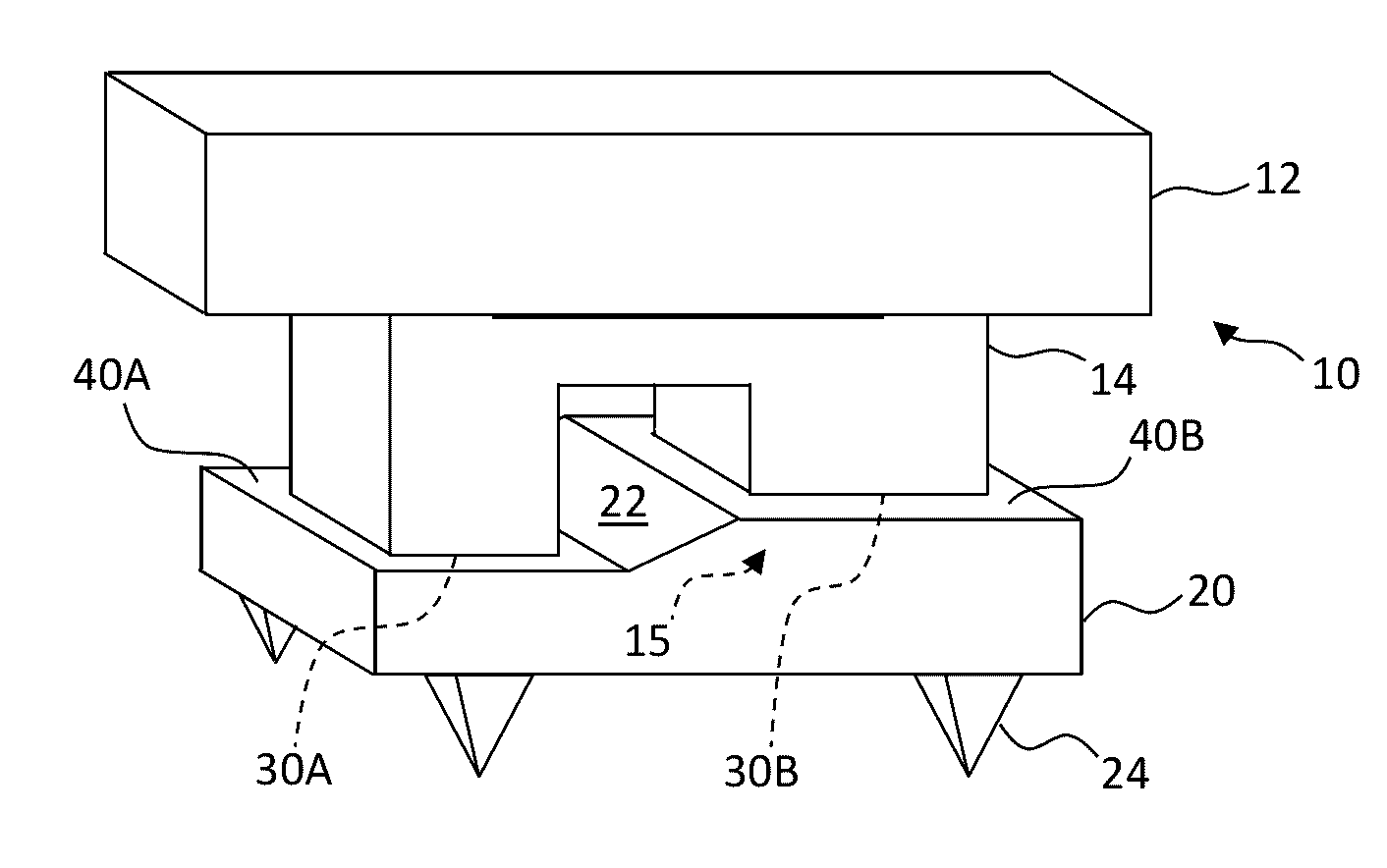

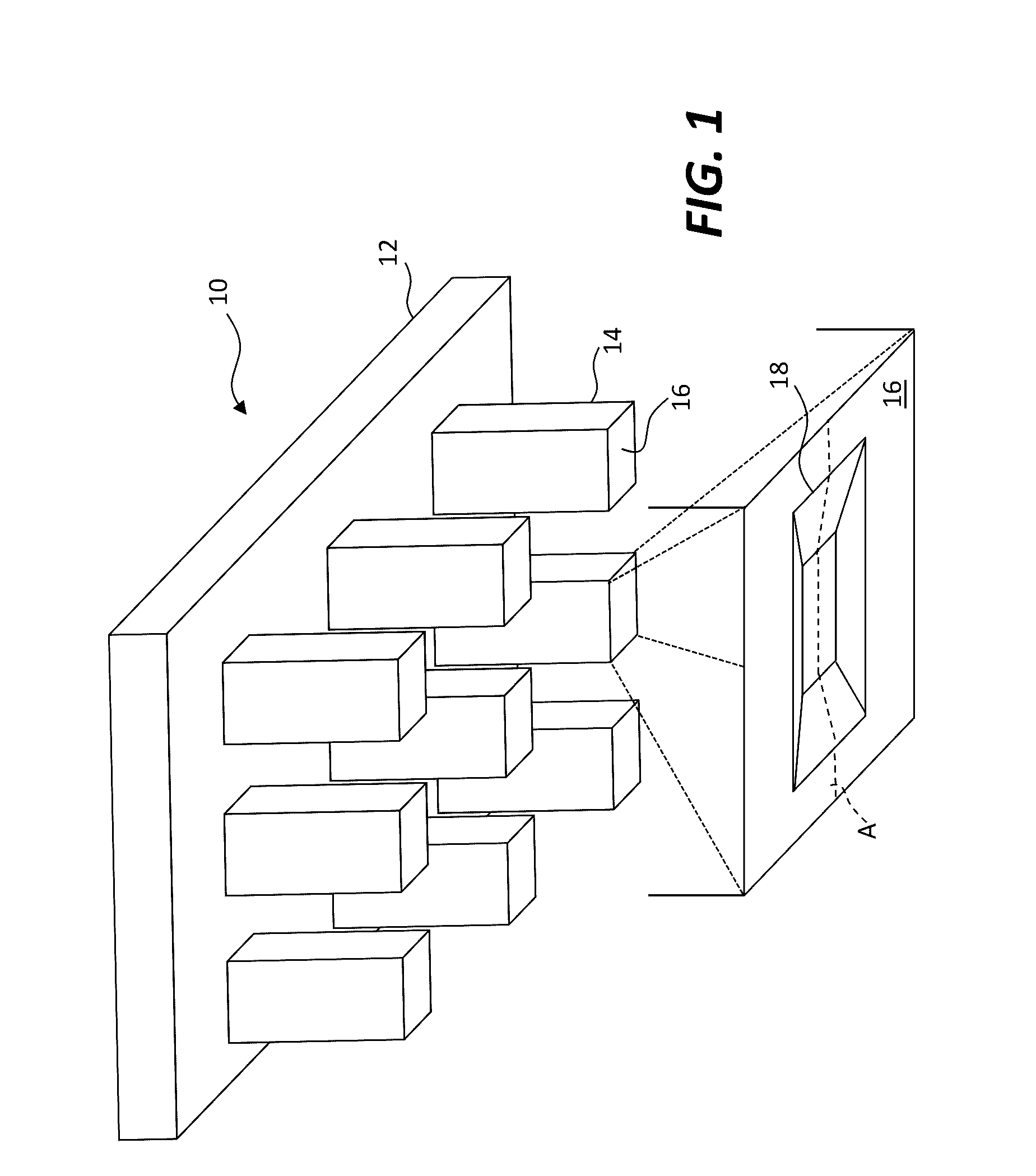

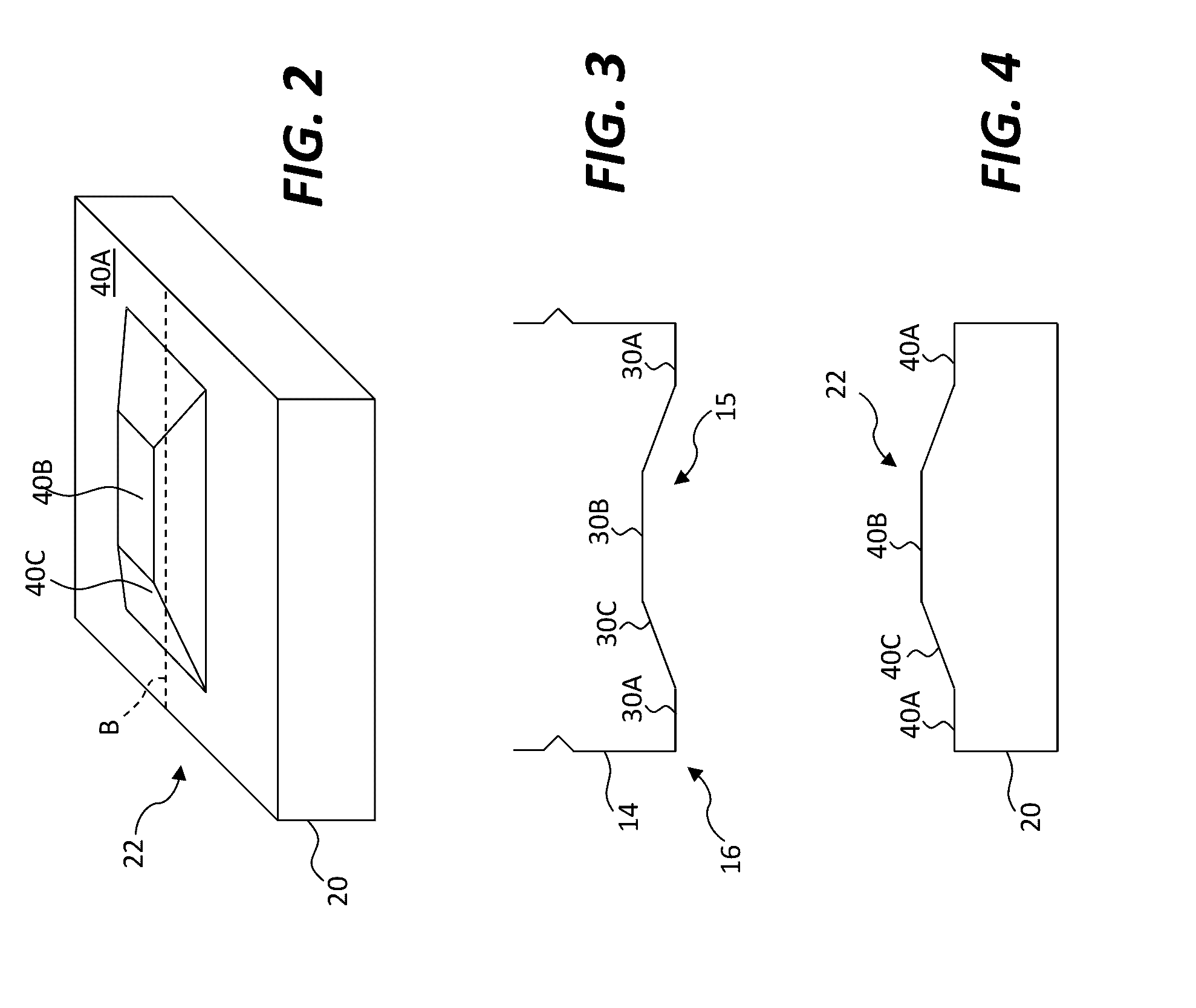

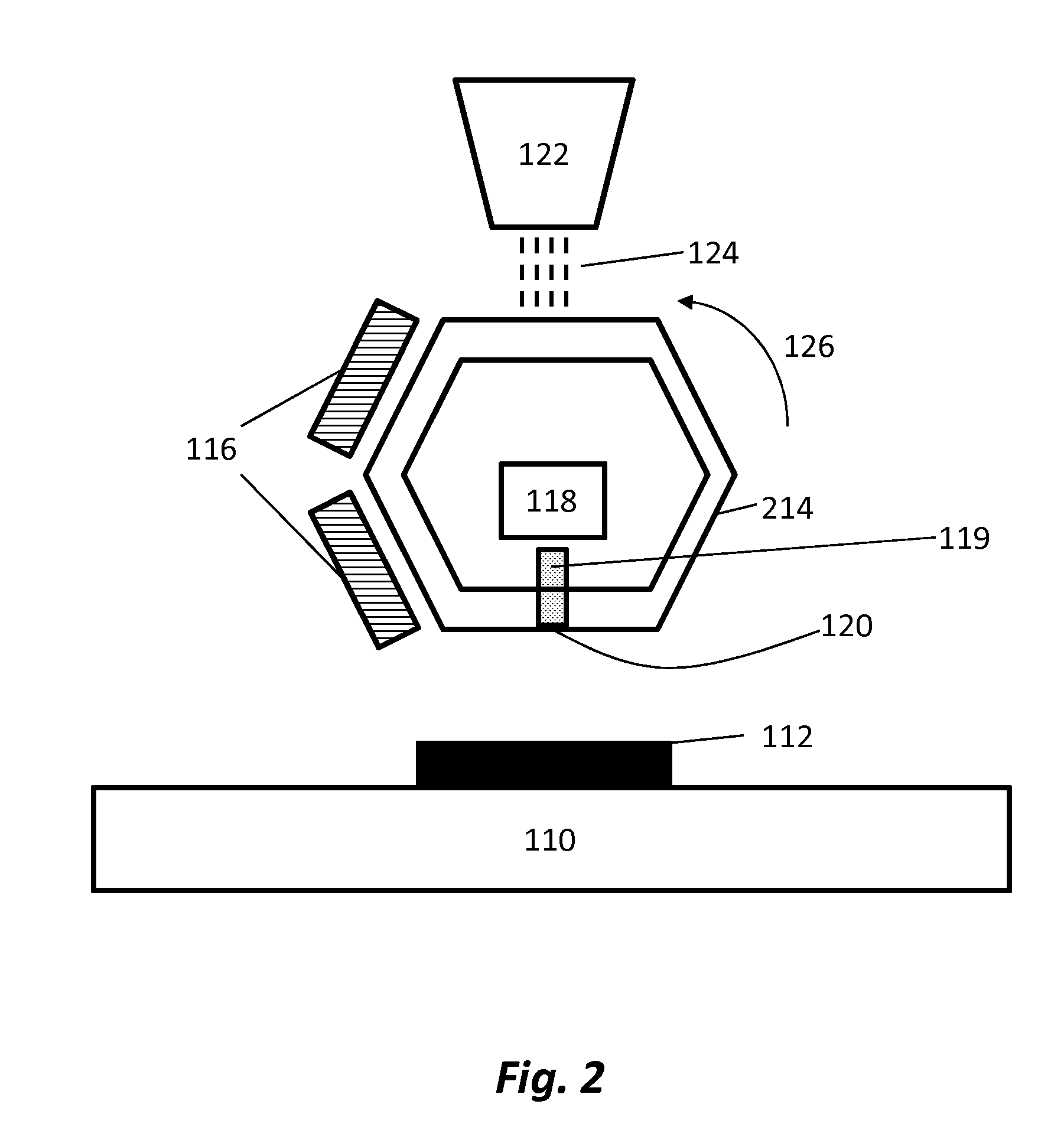

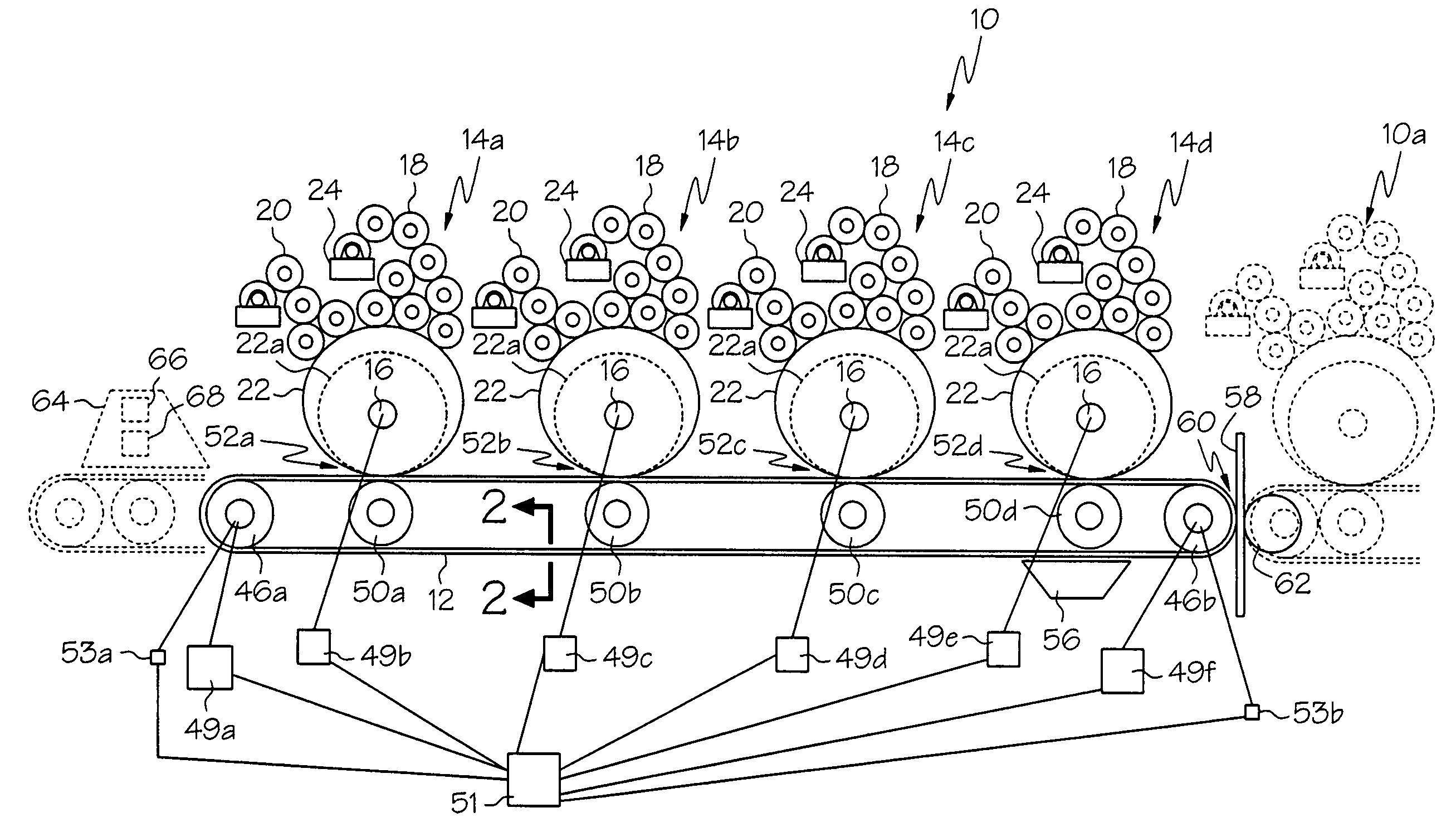

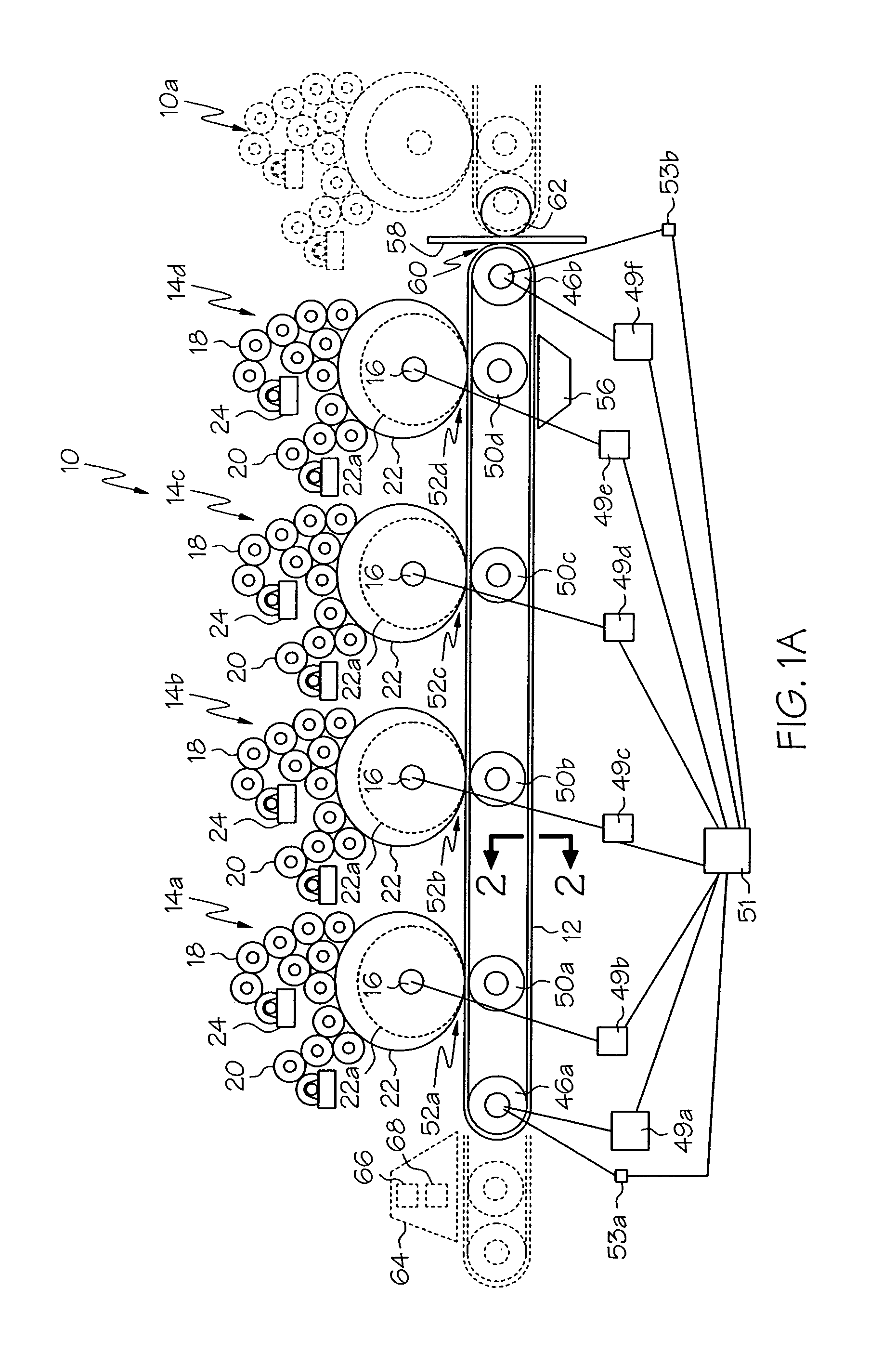

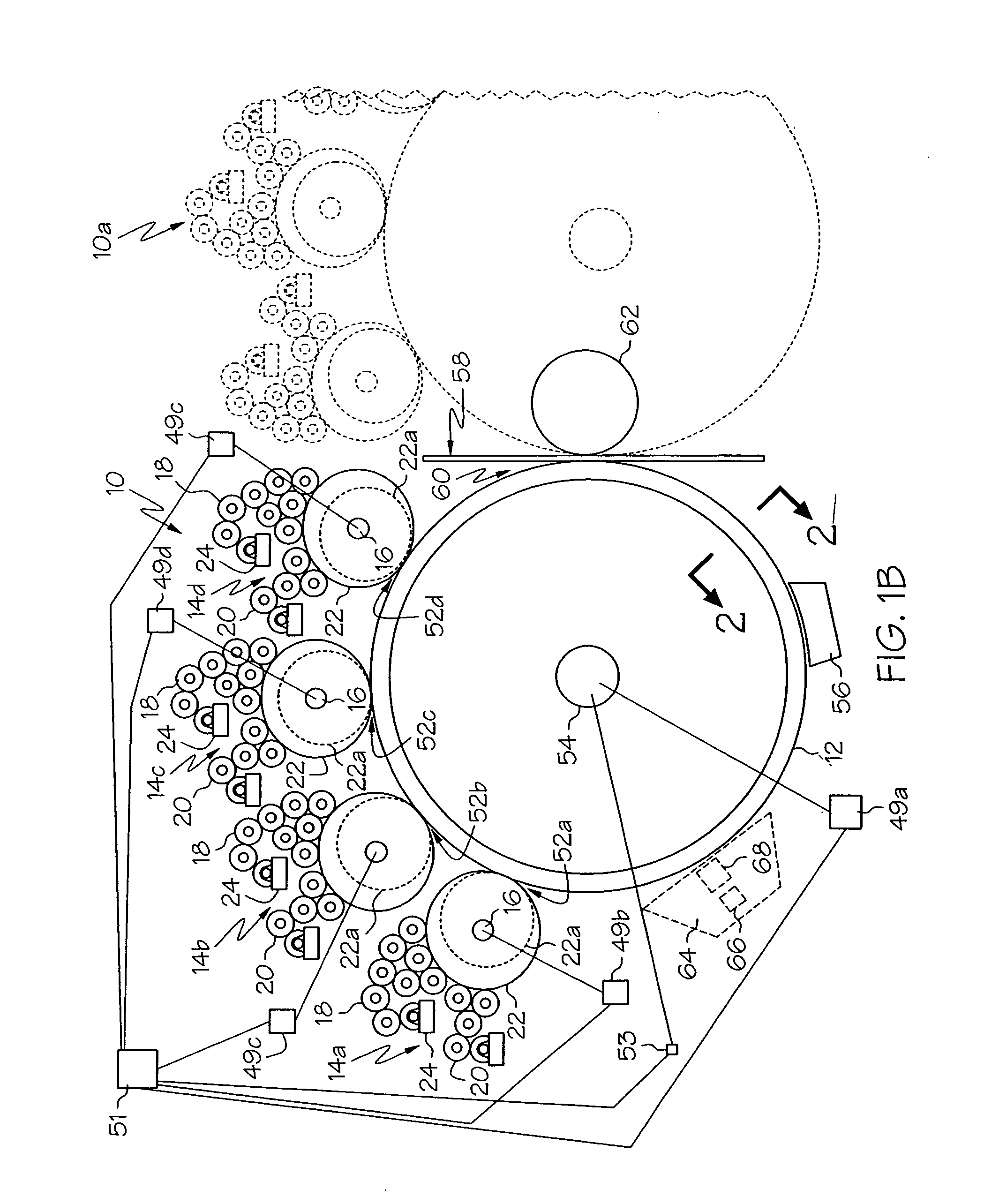

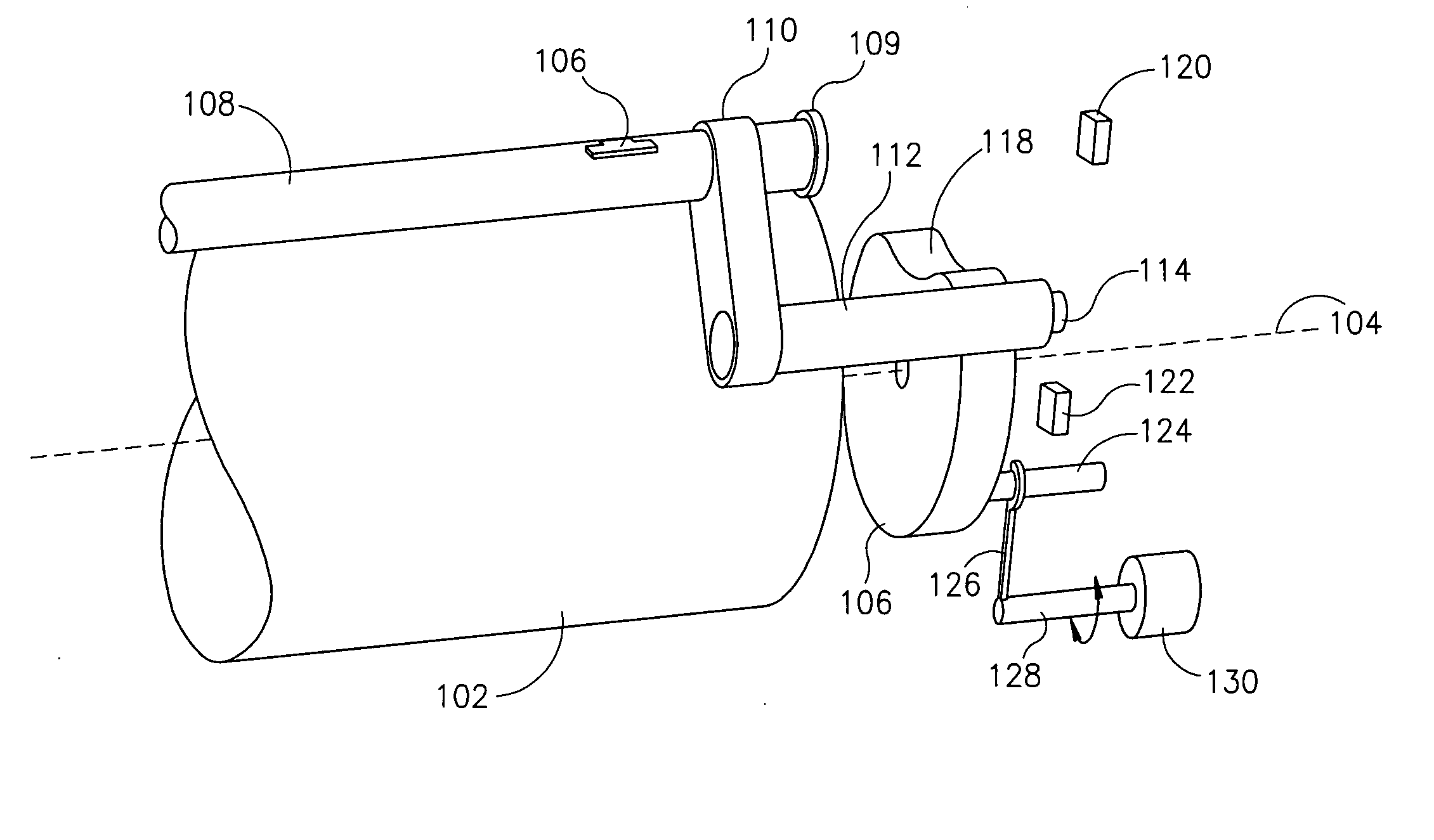

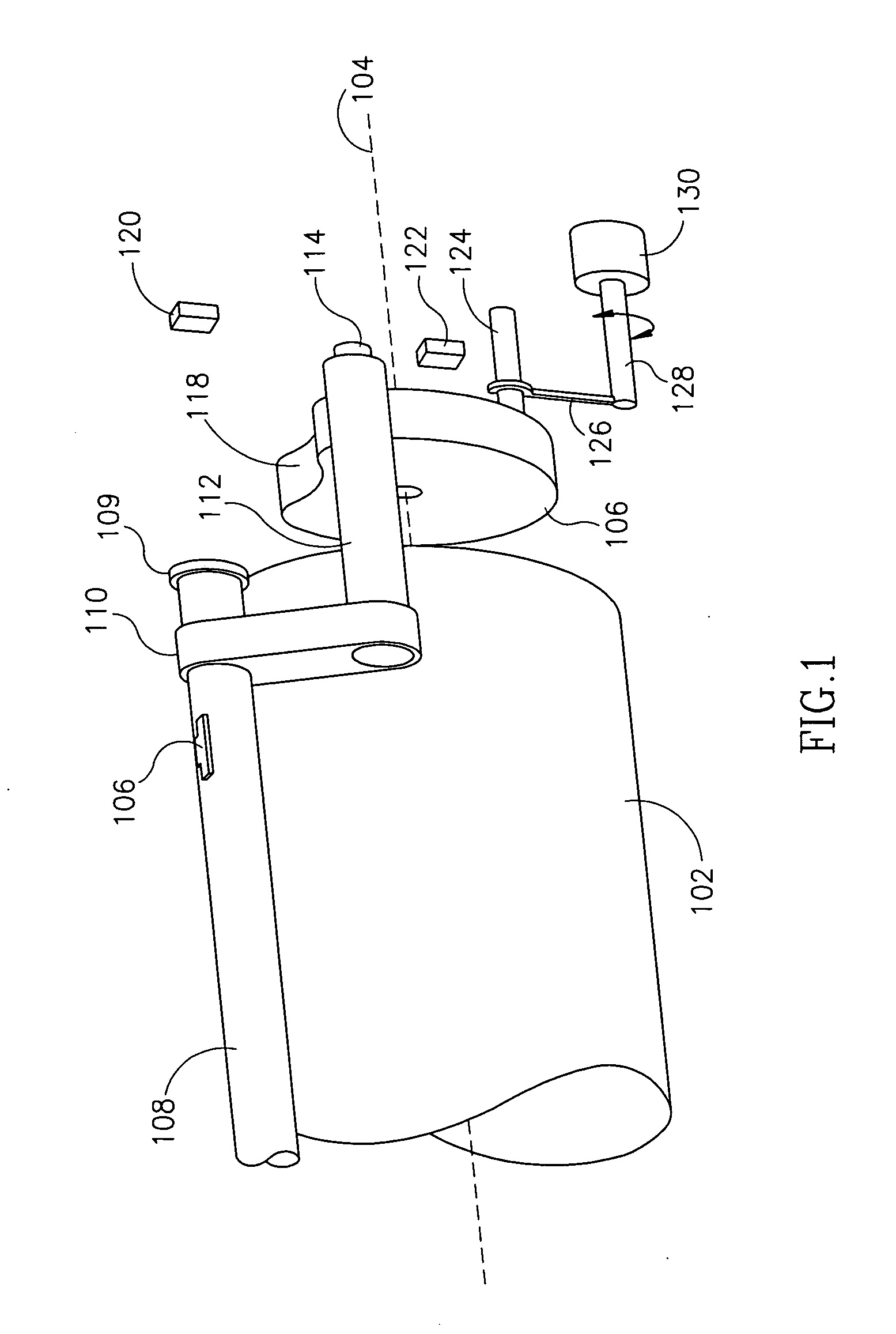

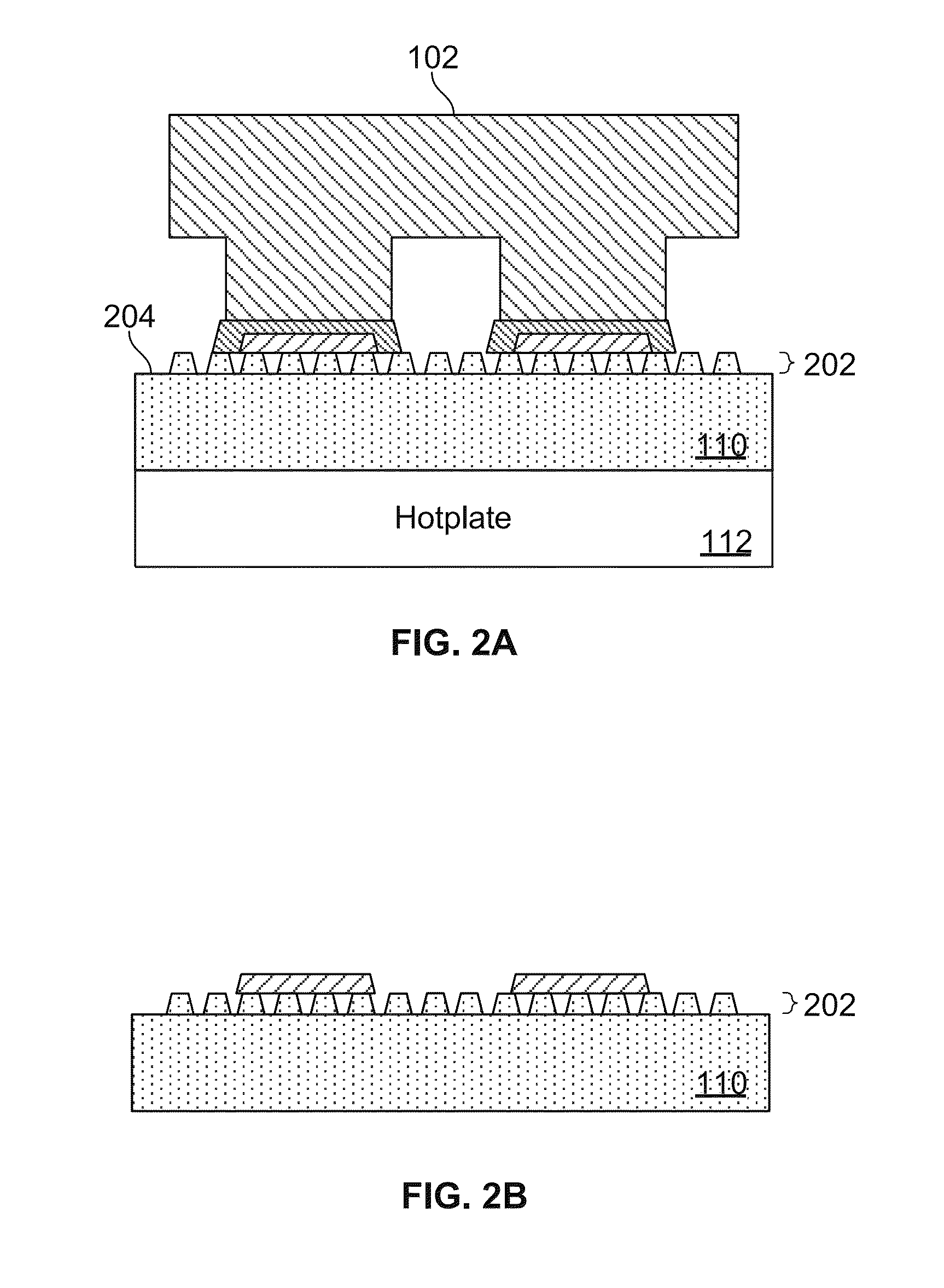

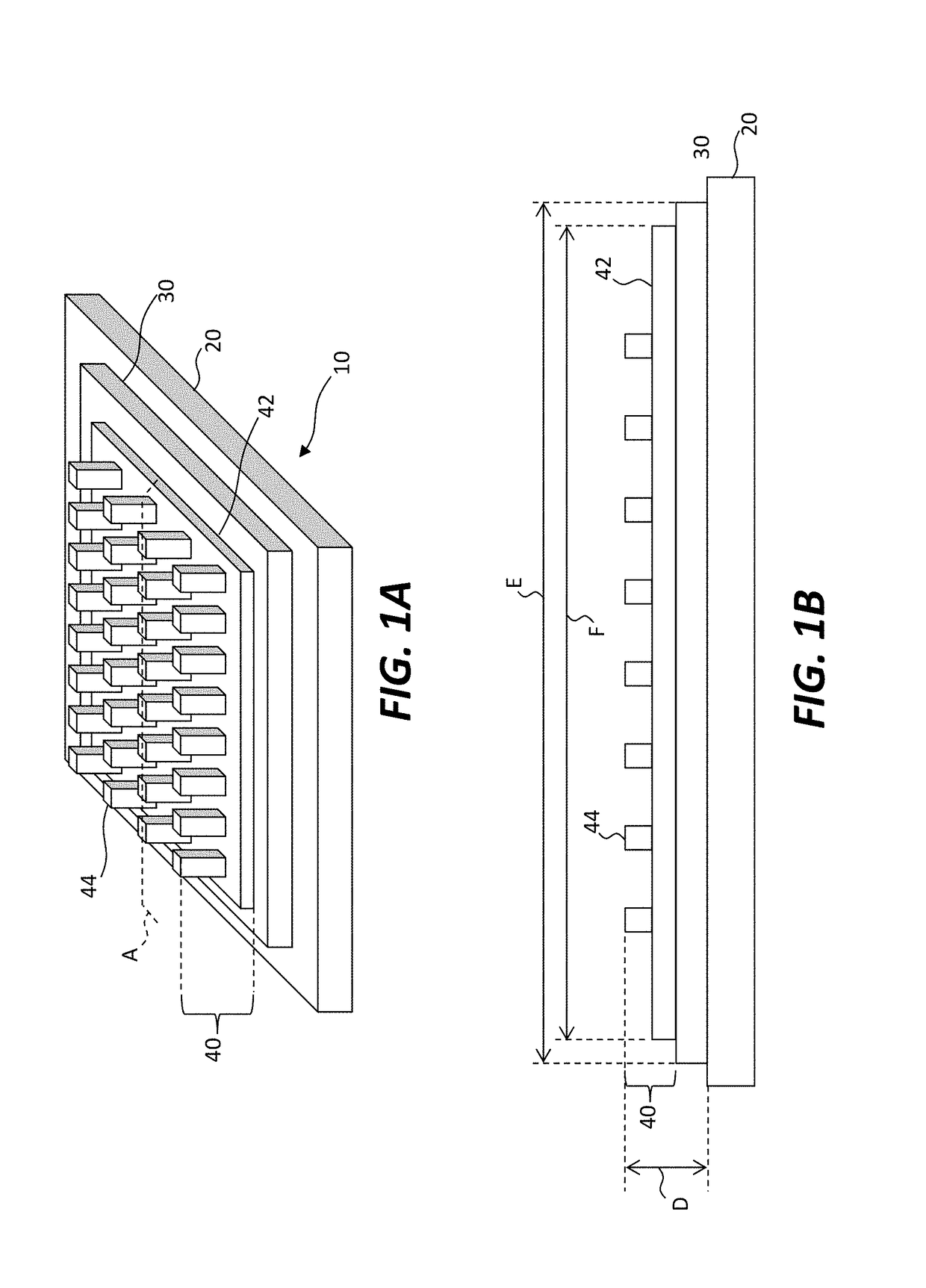

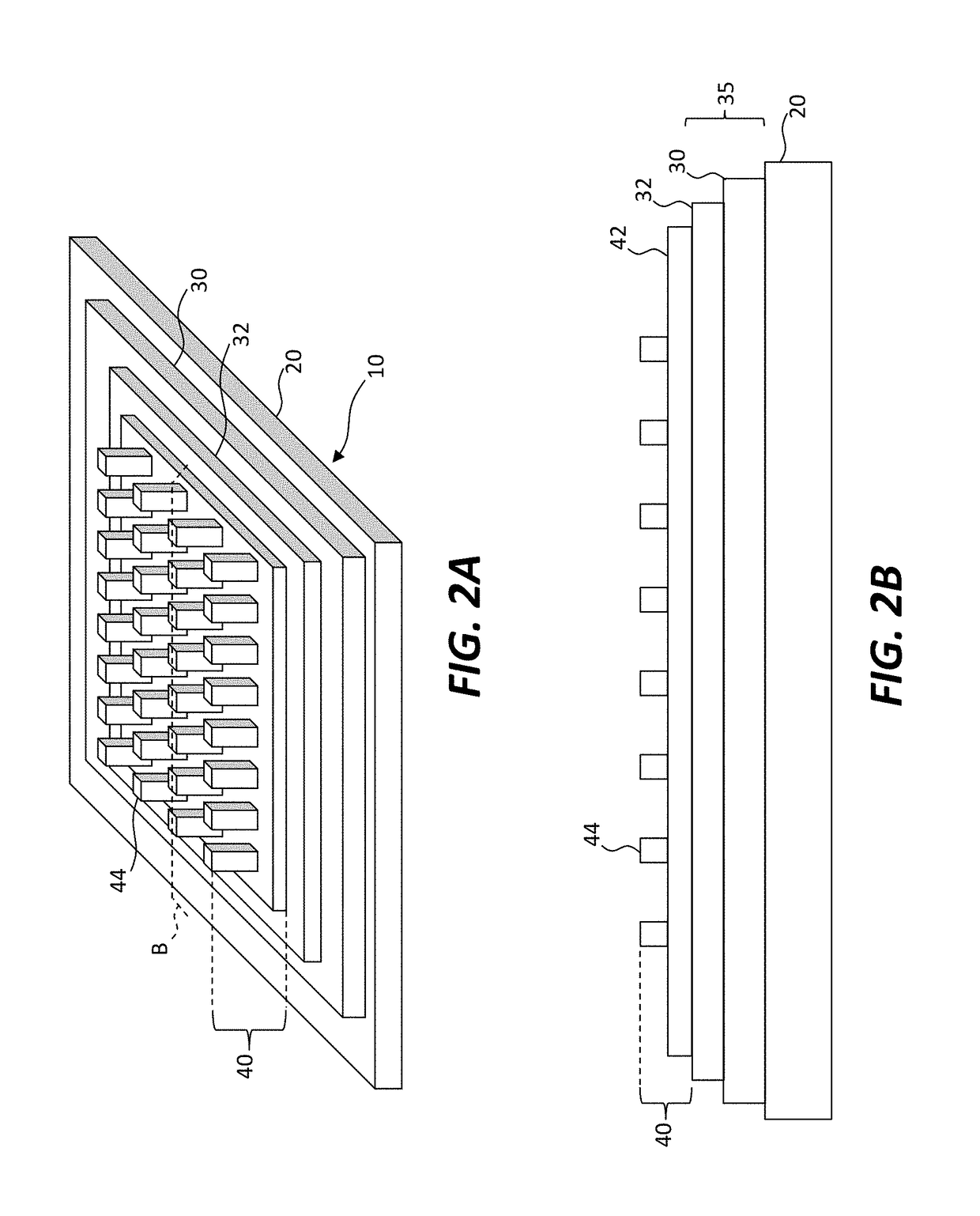

Apparatus and methods for micro-transfer-printing

ActiveUS9358775B2Increase heightImprove adhesionTransfer printingSemiconductor/solid-state device detailsSemiconductorSeparation system

In an aspect, a system and method for assembling a semiconductor device on a receiving surface of a destination substrate is disclosed. In another aspect, a system and method for assembling a semiconductor device on a destination substrate with topographic features is disclosed. In another aspect, a gravity-assisted separation system and method for printing semiconductor device is disclosed. In another aspect, various features of a transfer device for printing semiconductor devices are disclosed.

Owner:X DISPLAY CO TECH LTD

Printing transferable components using microstructured elastomeric surfaces with pressure modulated reversible adhesion

ActiveUS9412727B2Solve the lack of adhesionTransfer printingSemiconductor/solid-state device detailsElastomerReversible adhesion

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS +1

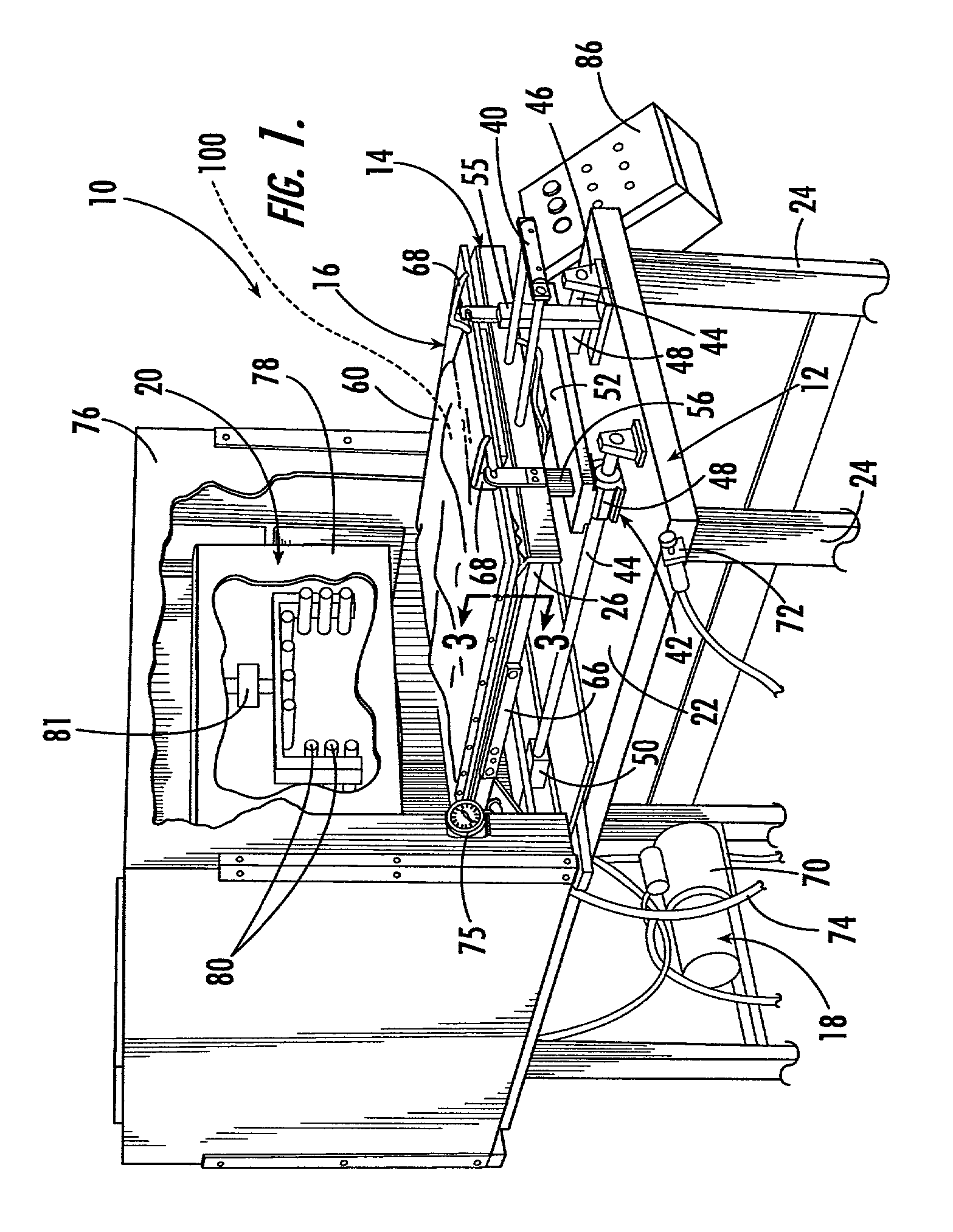

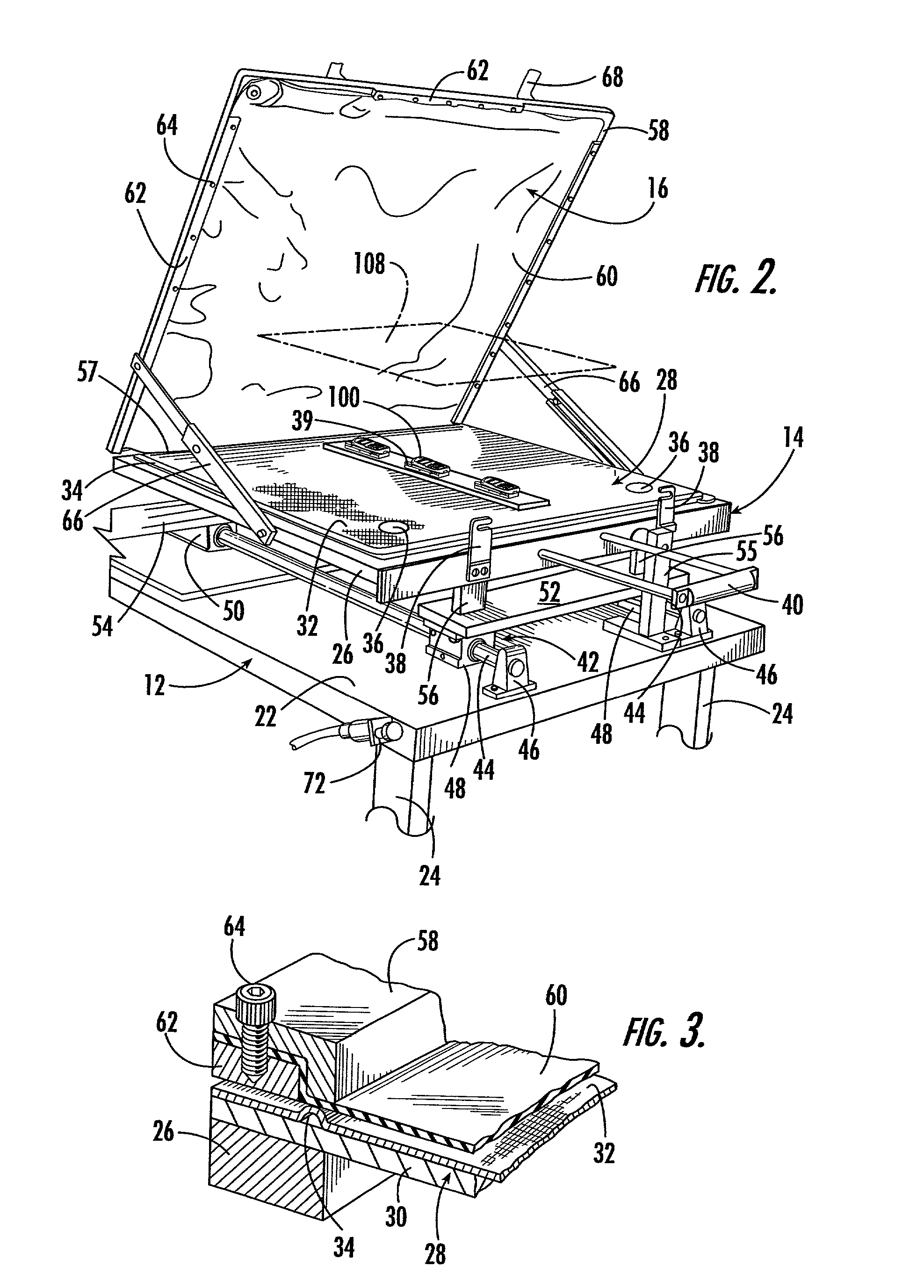

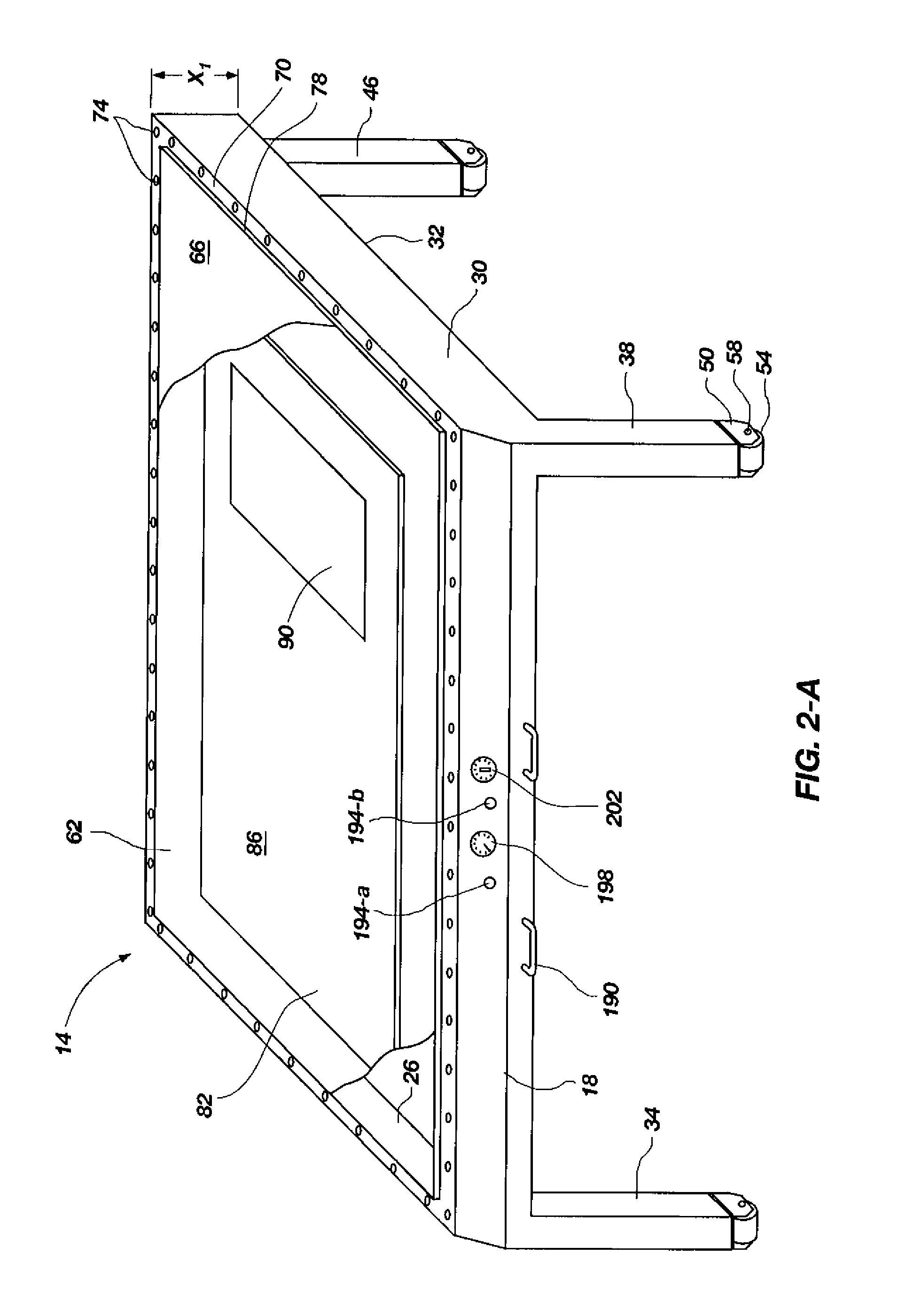

Method for thermally printing a dye image onto a three dimensional object using flexible heating elements

InactiveUS7563341B2Increase flexibilityTransfer printingLamination ancillary operationsMetal foilComputer science

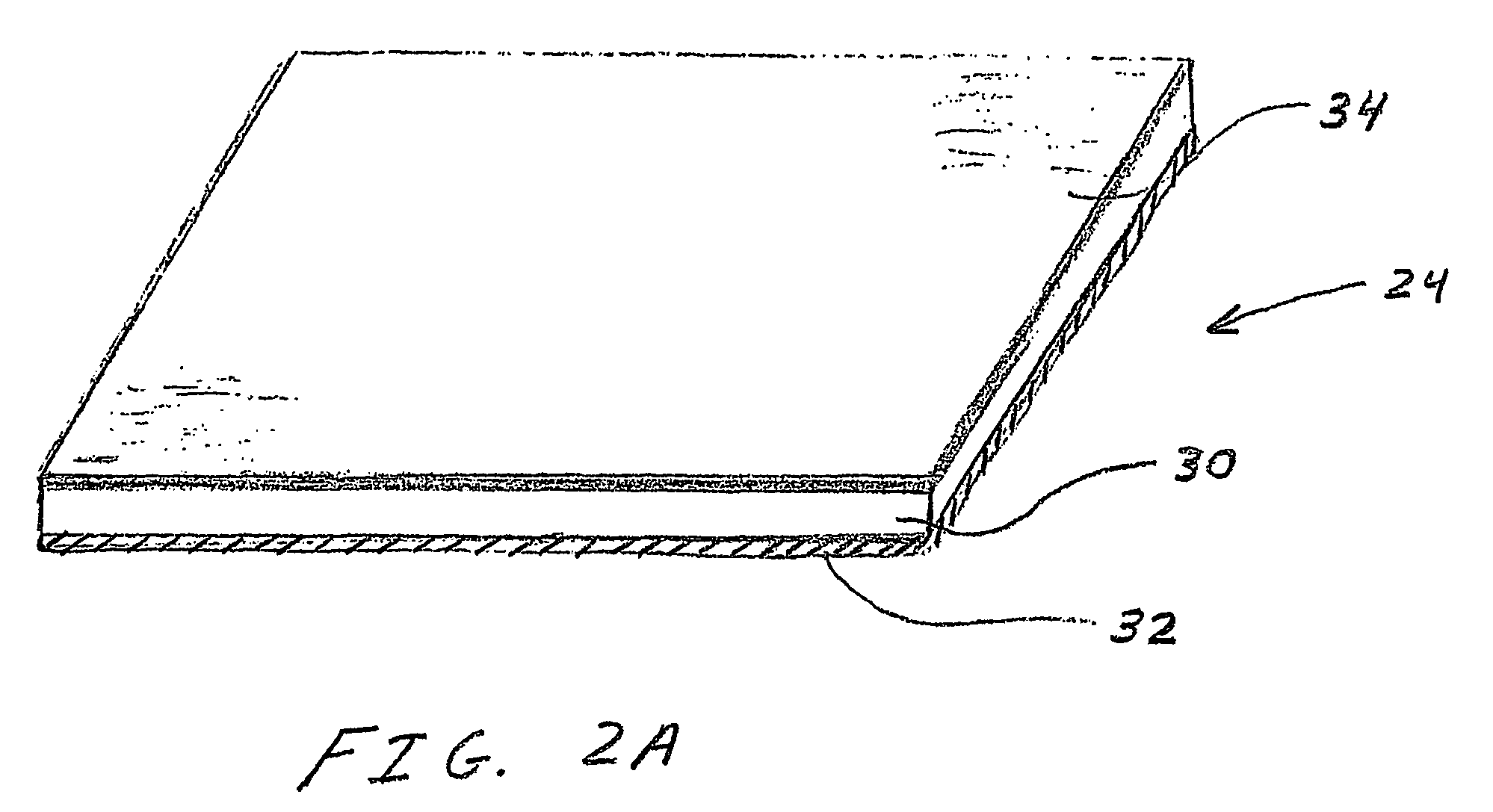

The present invention relates to a method for thermally printing a pre-selected dye image (45) onto a three dimensional object (16). The method involves placing an image carrier sheet (24) containing a pre-selected dye image (45) over the object (16). A flexible membrane (26) is lowered over the object (16) and the image carrier sheet (24). A vacuum is established under the membrane (26) causing the image carrier sheet (24) to conform to the shape of the object (16). The membrane (26) or image carrier sheet (24) carry flexible heating elements (36), which are heated, to thermally transfer the dye image (45) onto the object (16). The flexible heating elements (36) can be made by etching an electrical circuit in a metal foil (34) which is bonded to a film substrate (30).

Owner:KII TEKU INC

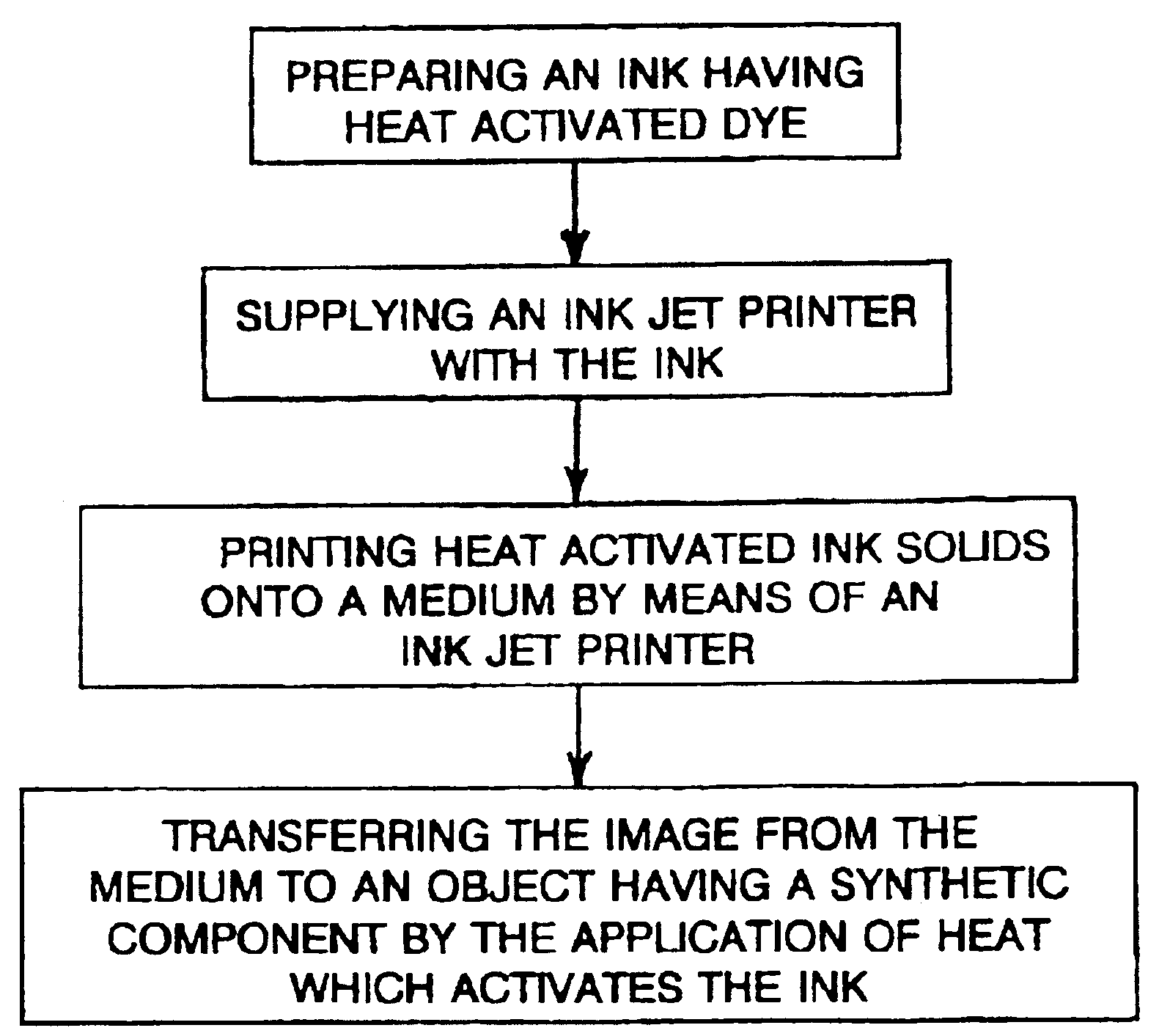

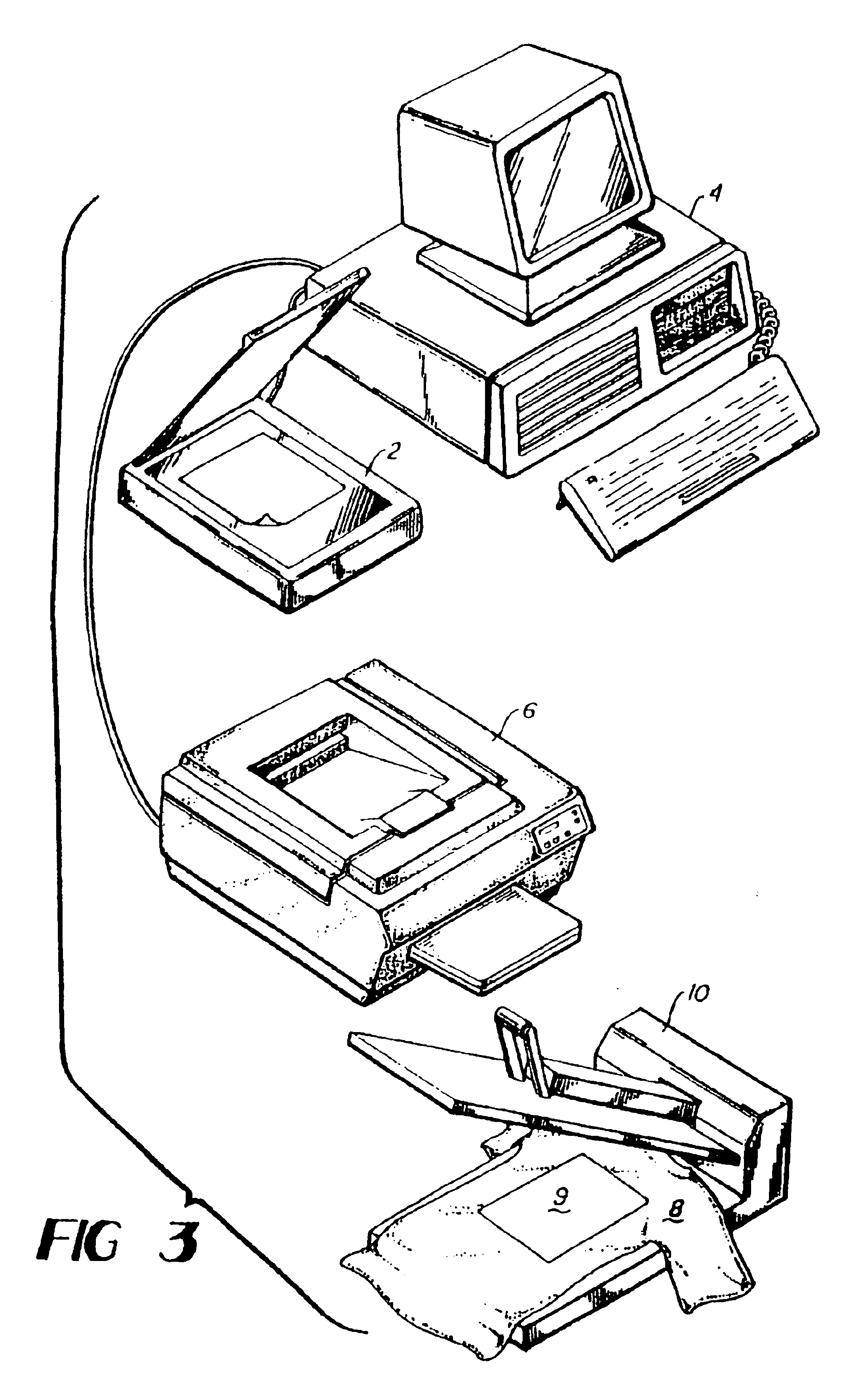

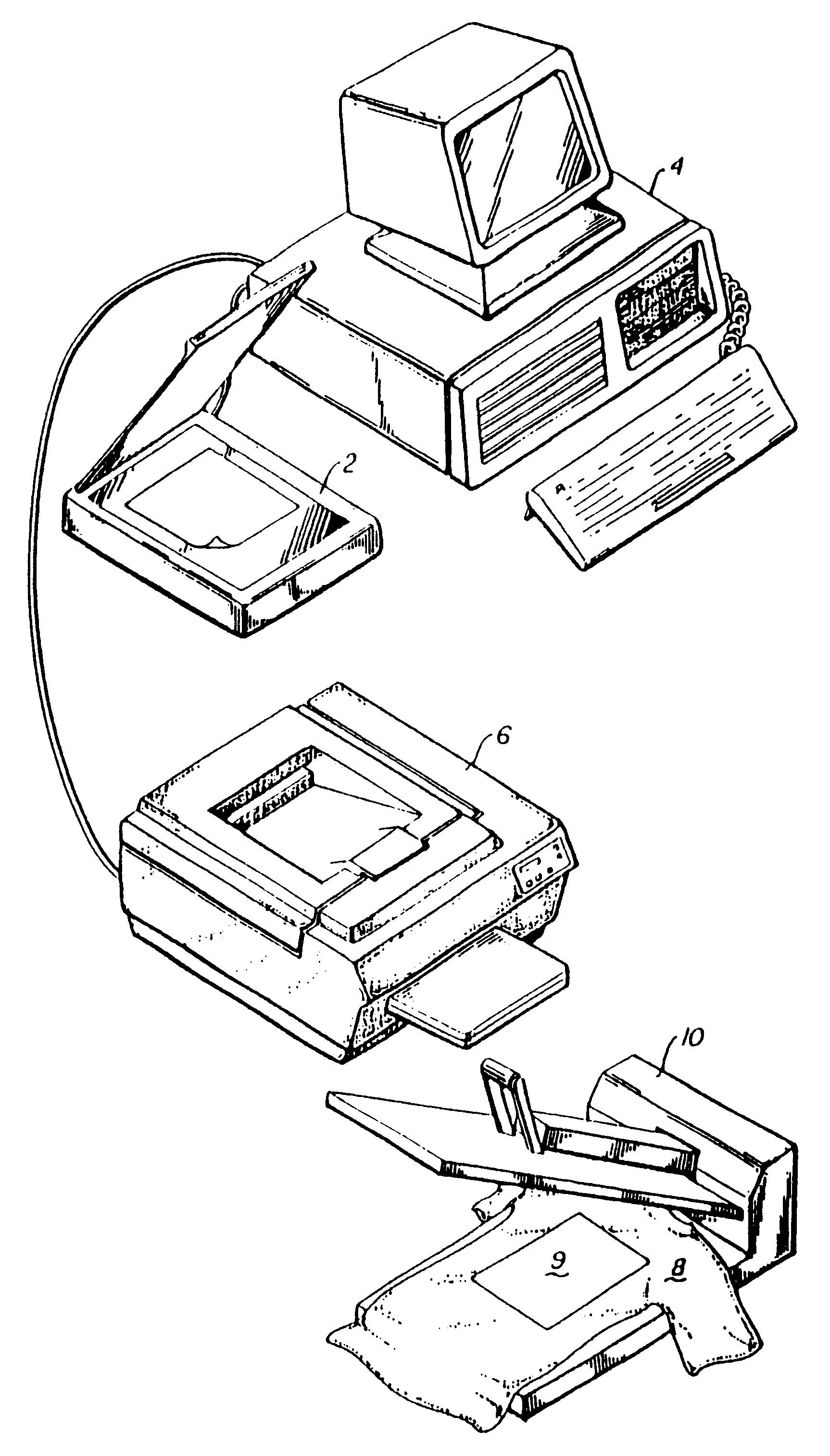

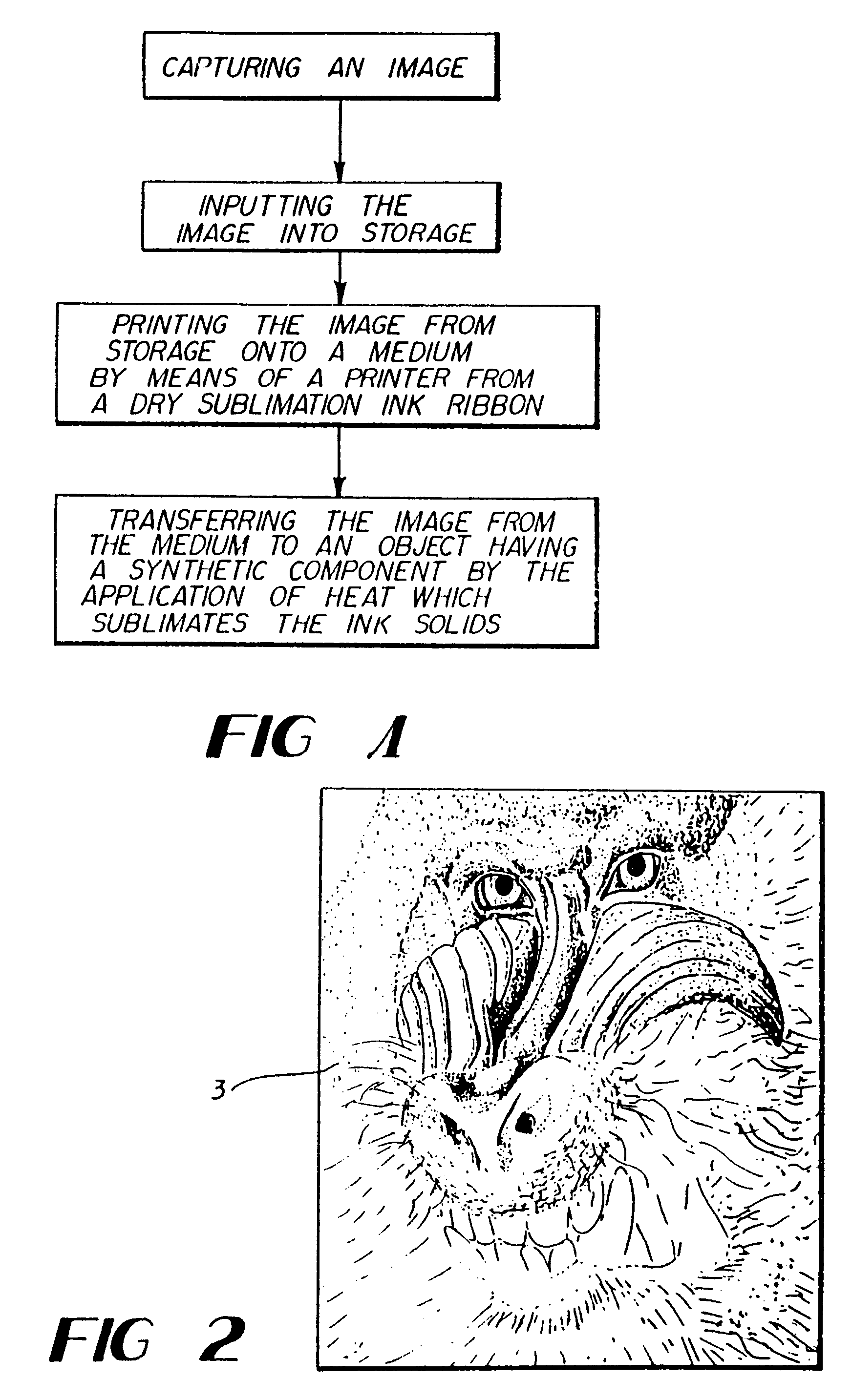

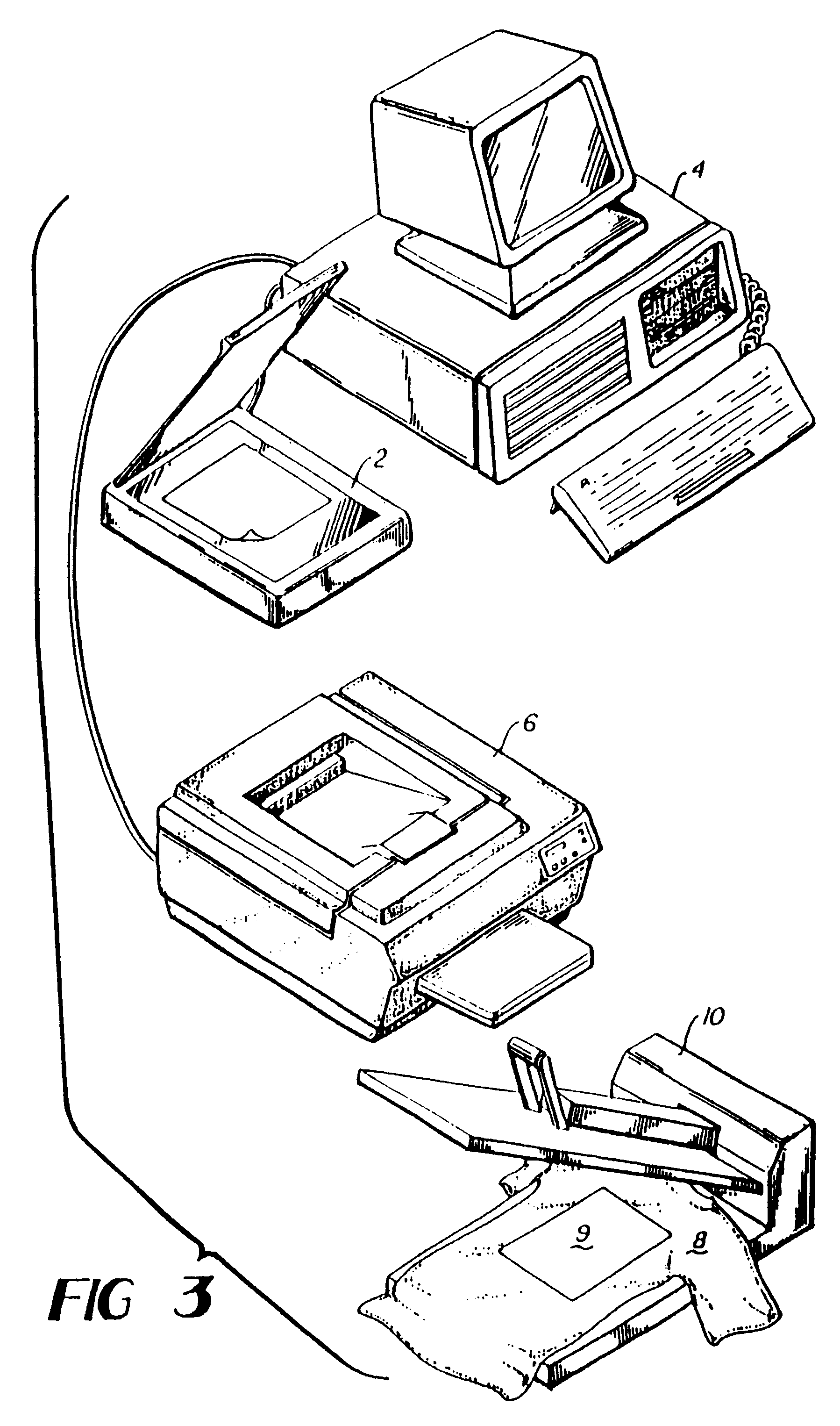

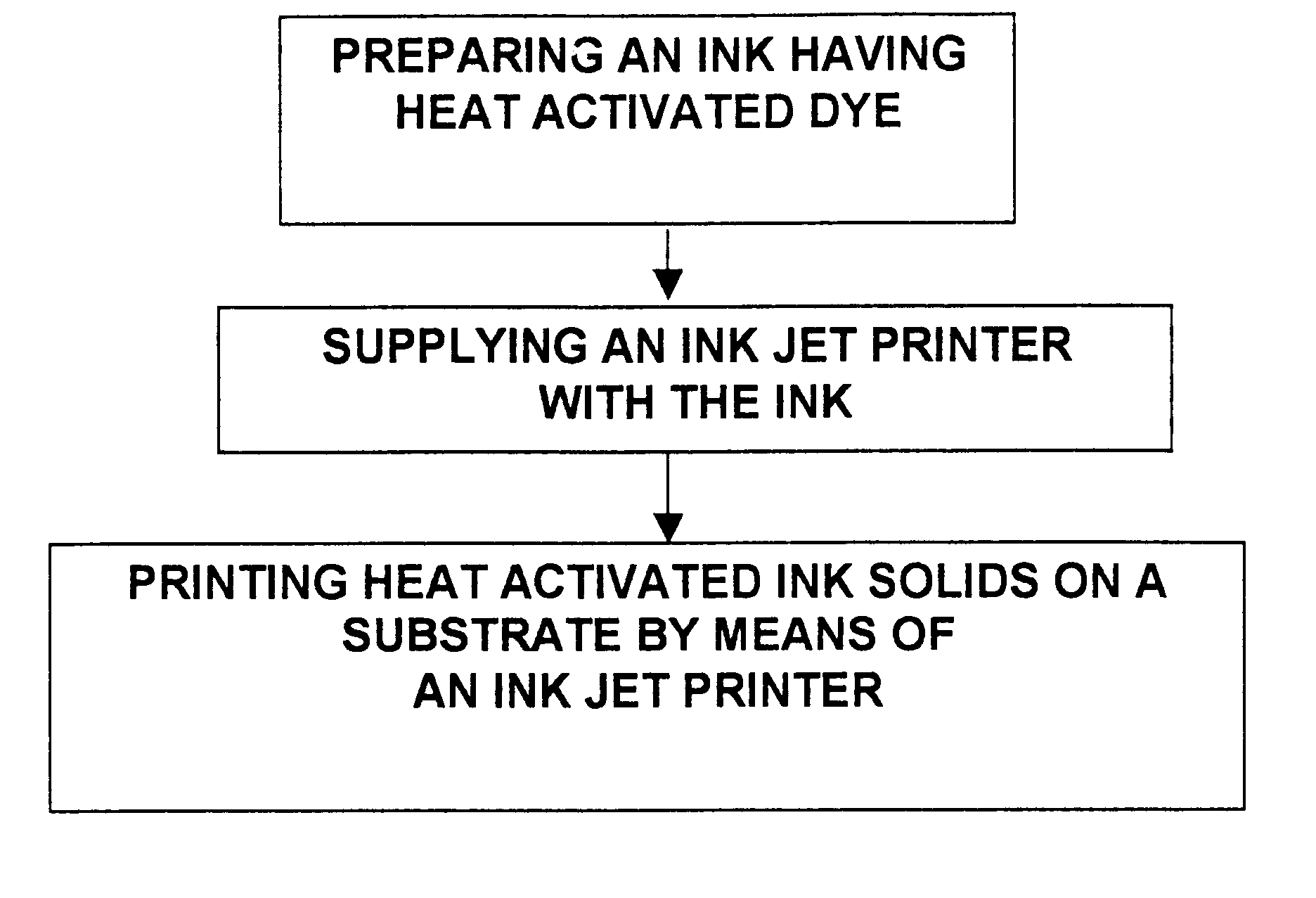

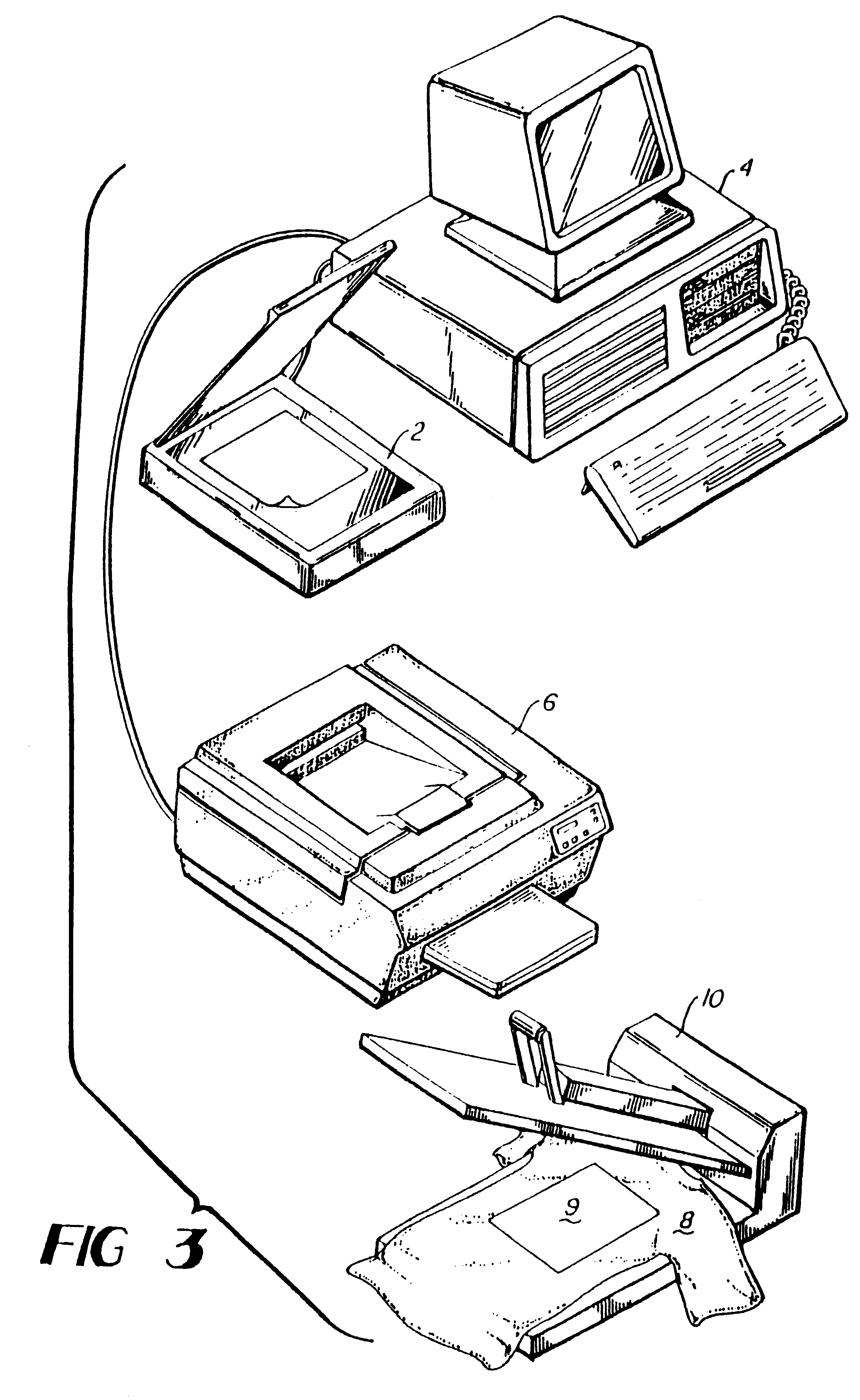

Permanent heat activated ink jet printing process

InactiveUS6450098B1Improve bindingFacilitate and withstand temperatureTransfer printingMeasurement apparatus componentsEngineeringComputer drive

Owner:SAWGRASS SYST INC

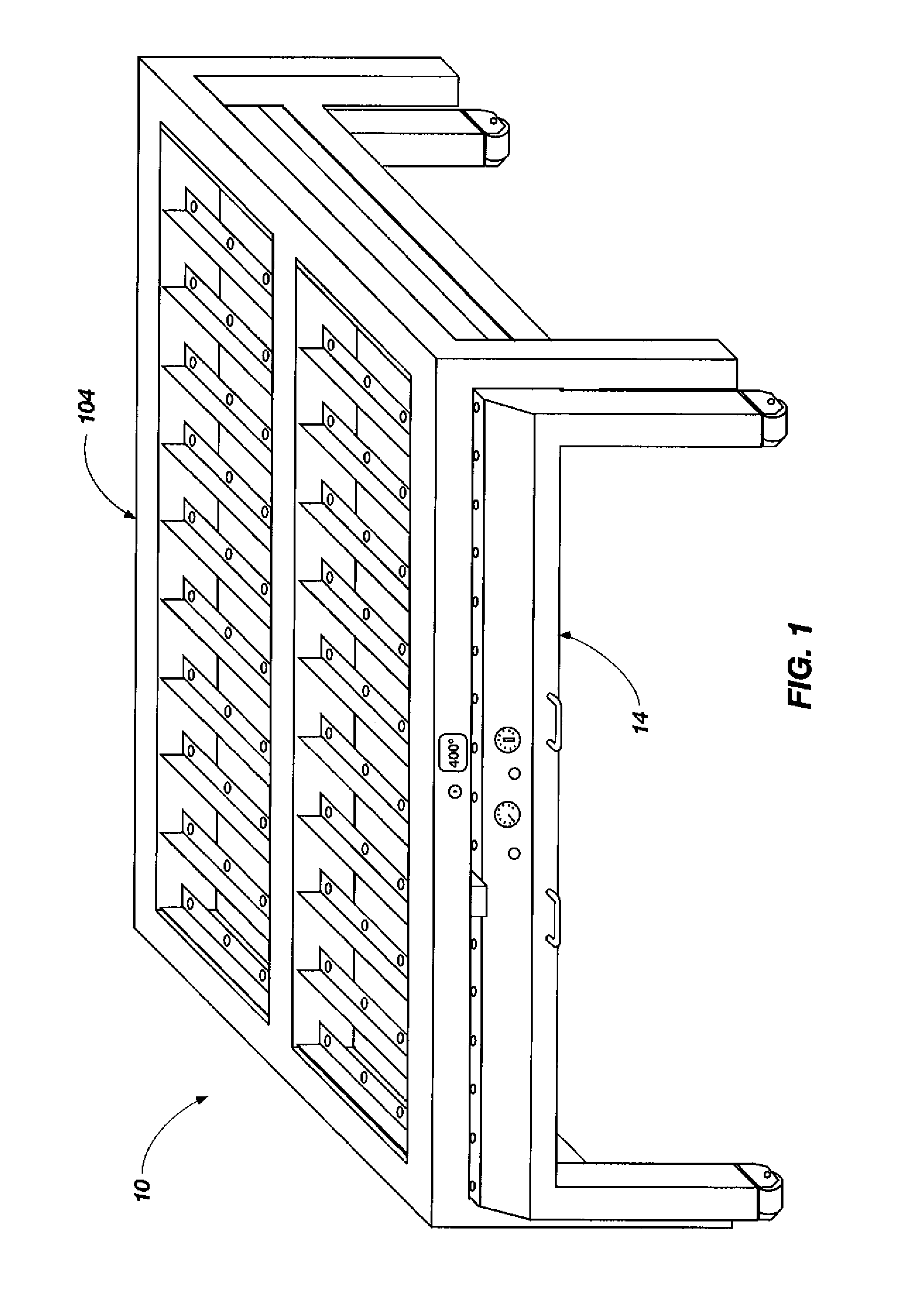

Apparatus with multi-directional radiation emitters for printing a dye image onto a three dimensional object

InactiveUS7137426B2Improve heating efficiencyEfficient transferTransfer printingDigitally marking record carriersEngineeringMirror image

The present invention provides an apparatus and method for applying preselected dye images to three dimensional objects, having plastic outer surfaces, utilizing flexible carrier sheets bearing dyes in the mirror images of the preselected images, where the sheets are overlaid in registration with the objects and maintained in pressurized engagement therewith while the sheets and the objects are heated. The present invention includes a bed for receiving at least one three-dimensional object member thereon with a flexible dye bearing carrier sheet placed in registration on the object and a resiliently flexible membrane, which is positionable over the sheet on the member. A vacuum assembly of the apparatus is operable to evacuate the area between the membrane and the bed in order to draw the membrane into pressurized engagement with the flexible sheet on the member thereby drawing the flexible sheet around the various surfaces of the three dimensional object. Radiant heating elements are operable both to preheat the carrier sheet, improving its flexibility and to heat the membrane after the vacuum assembly has been actuated, whereby the dye on the sheet is applied to the surfaces of the object to produce the preselected image thereon.

Owner:KII TEKU INC

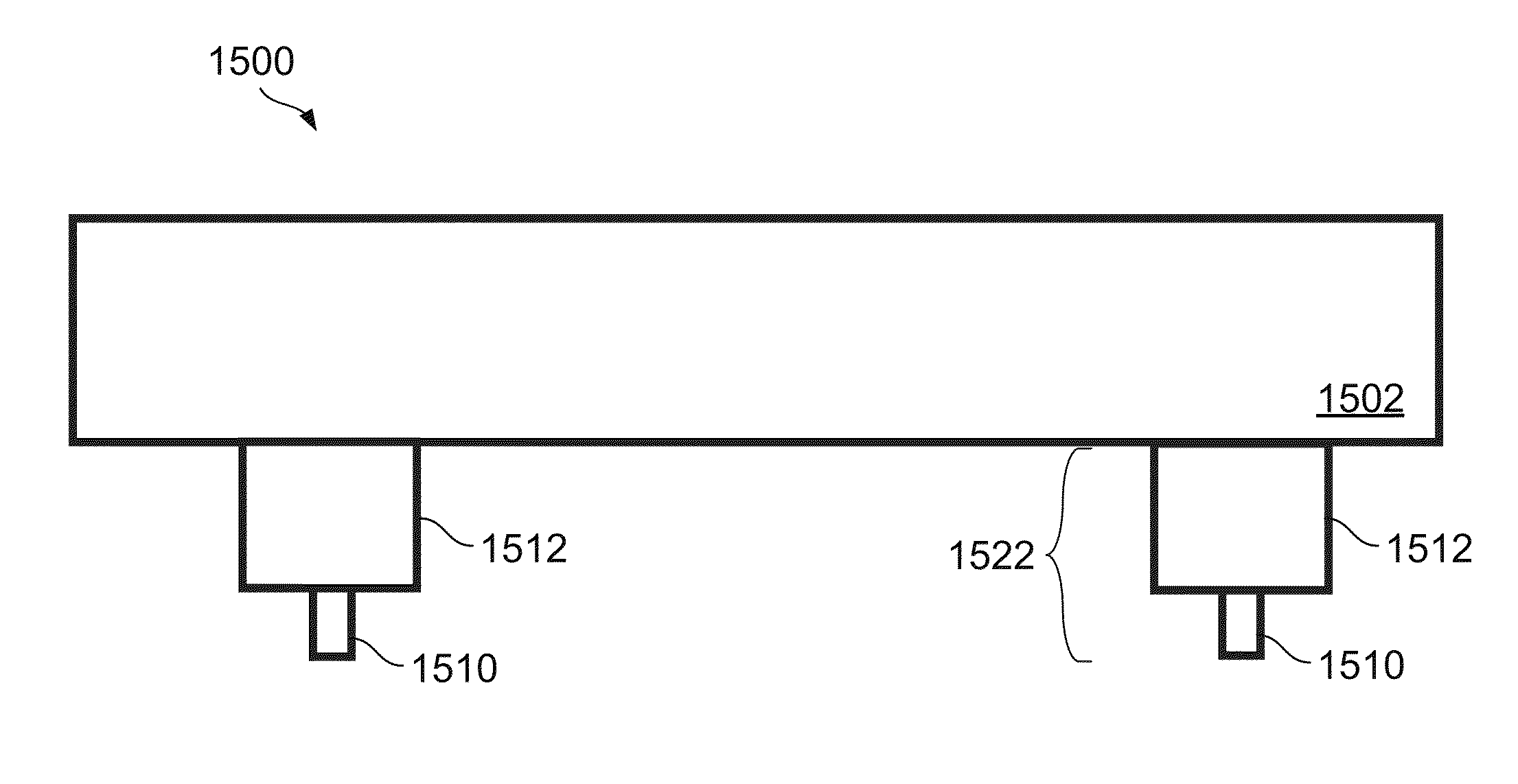

Apparatus and methods for micro-transfer-printing

InactiveUS20160020131A1Increase heightIncrease initial accelerationTransfer printingGripping headsSemiconductorSeparation system

In an aspect, a system and method for assembling a semiconductor device on a receiving surface of a destination substrate is disclosed. In another aspect, a system and method for assembling a semiconductor device on a destination substrate with topographic features is disclosed. In another aspect, a gravity-assisted separation system and method for printing semiconductor device is disclosed. In another aspect, various features of a transfer device for printing semiconductor devices are disclosed.

Owner:X DISPLAY CO TECH LTD

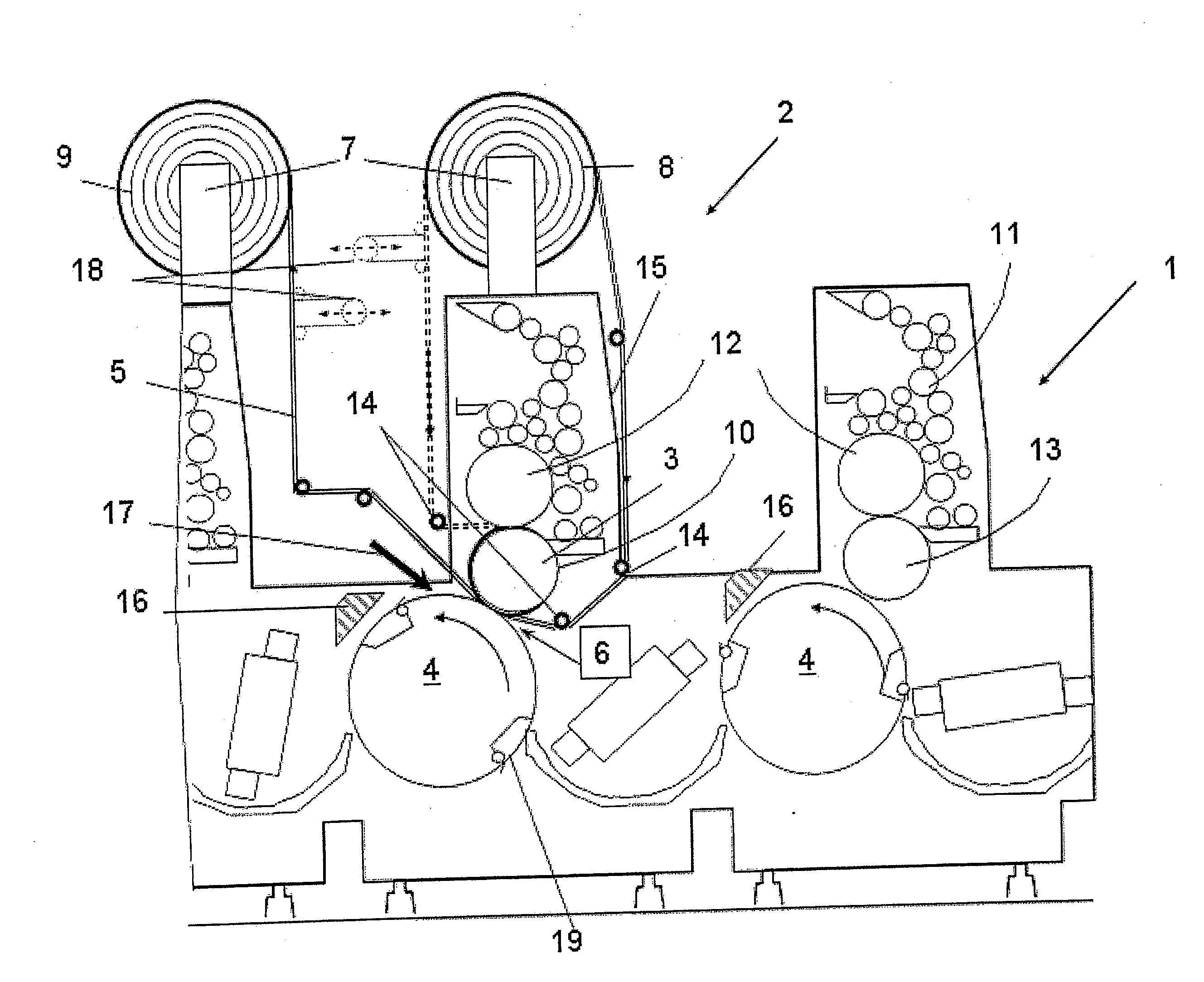

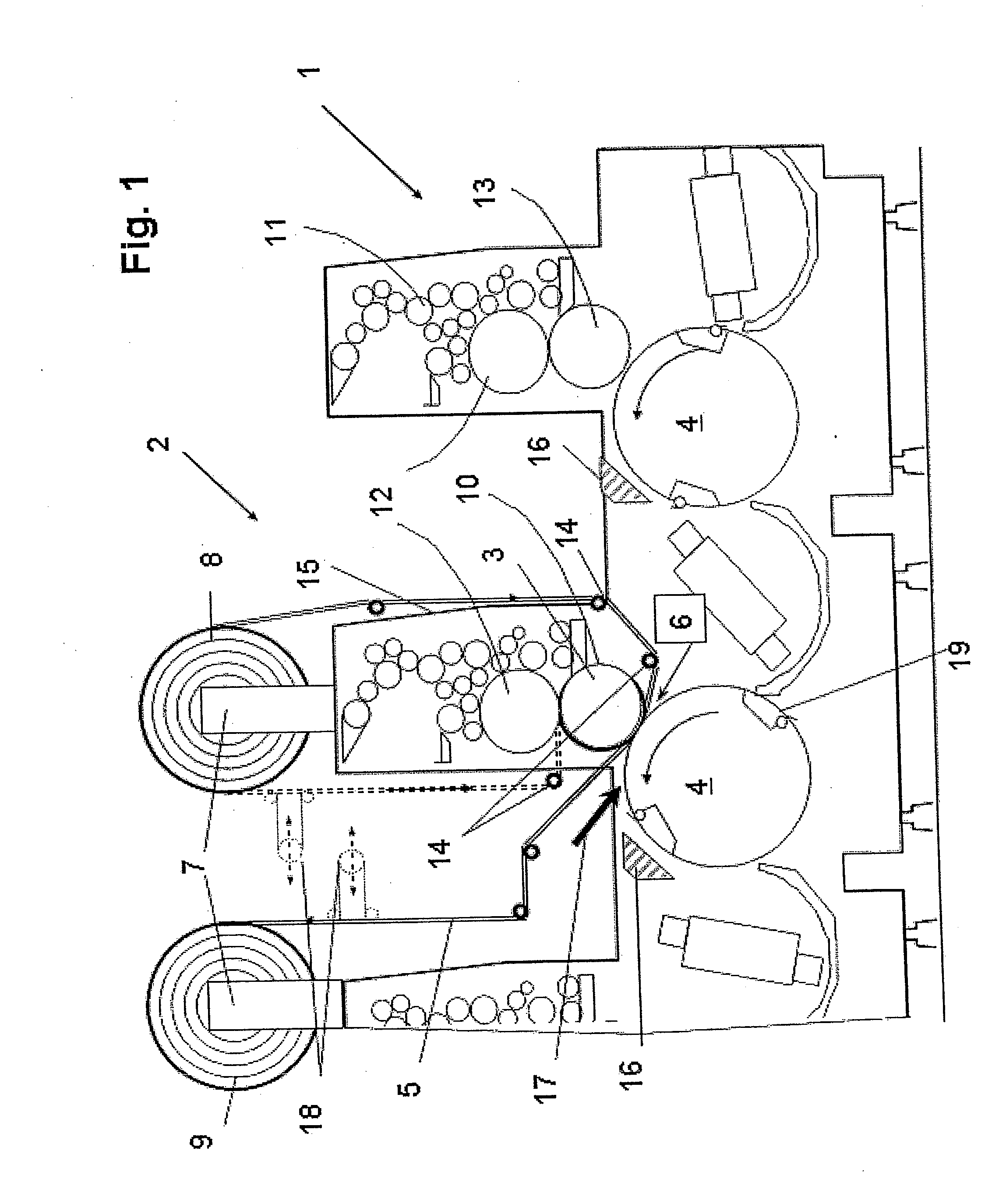

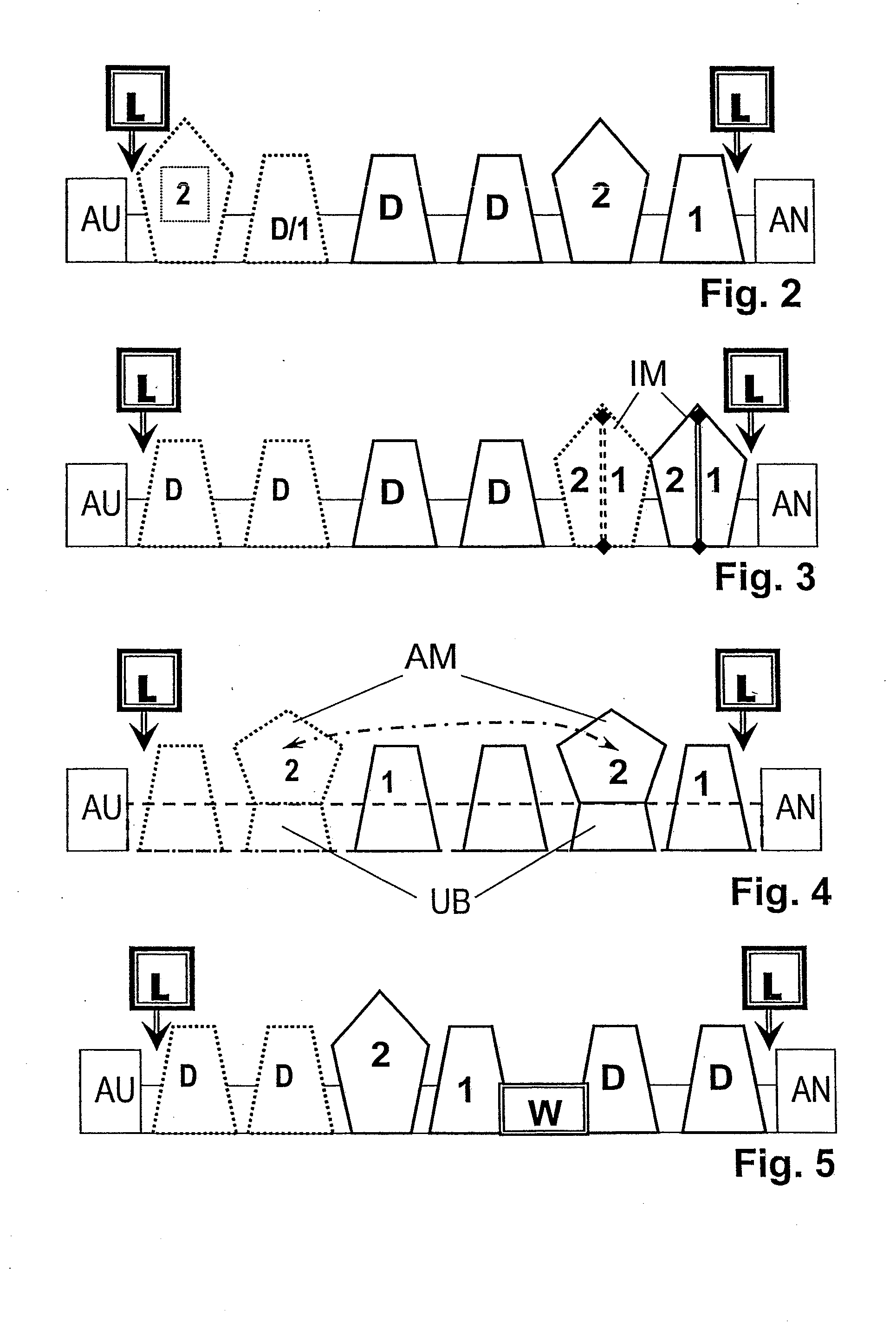

Manufacturing method for packaging and advertising means

InactiveUS20090301649A1Reliably, economically, and preciselyGood effectTransfer printingDecorative surface effectsPrinting pressMechanical engineering

The purpose is to improve the usability of the film coating in a coating module for the transfer of image-forming layers from a transfer film to a printing material. A film transfer module is, for that purpose, arranged in a printing machine for the single-color or multicolor printing of printed sheets. Moreover, one or more coating installations, in the form of varnishing modules, are arranged before and / or after the printing machine. By the application of layers, a subject consisting of a film image and a printed image is coated over part of the surface or over the entire surface. The additional coats serve the function of providing protection, drying, or generating optical effects.

Owner:M A N ROLAND DRUCKMASCHINEN AG

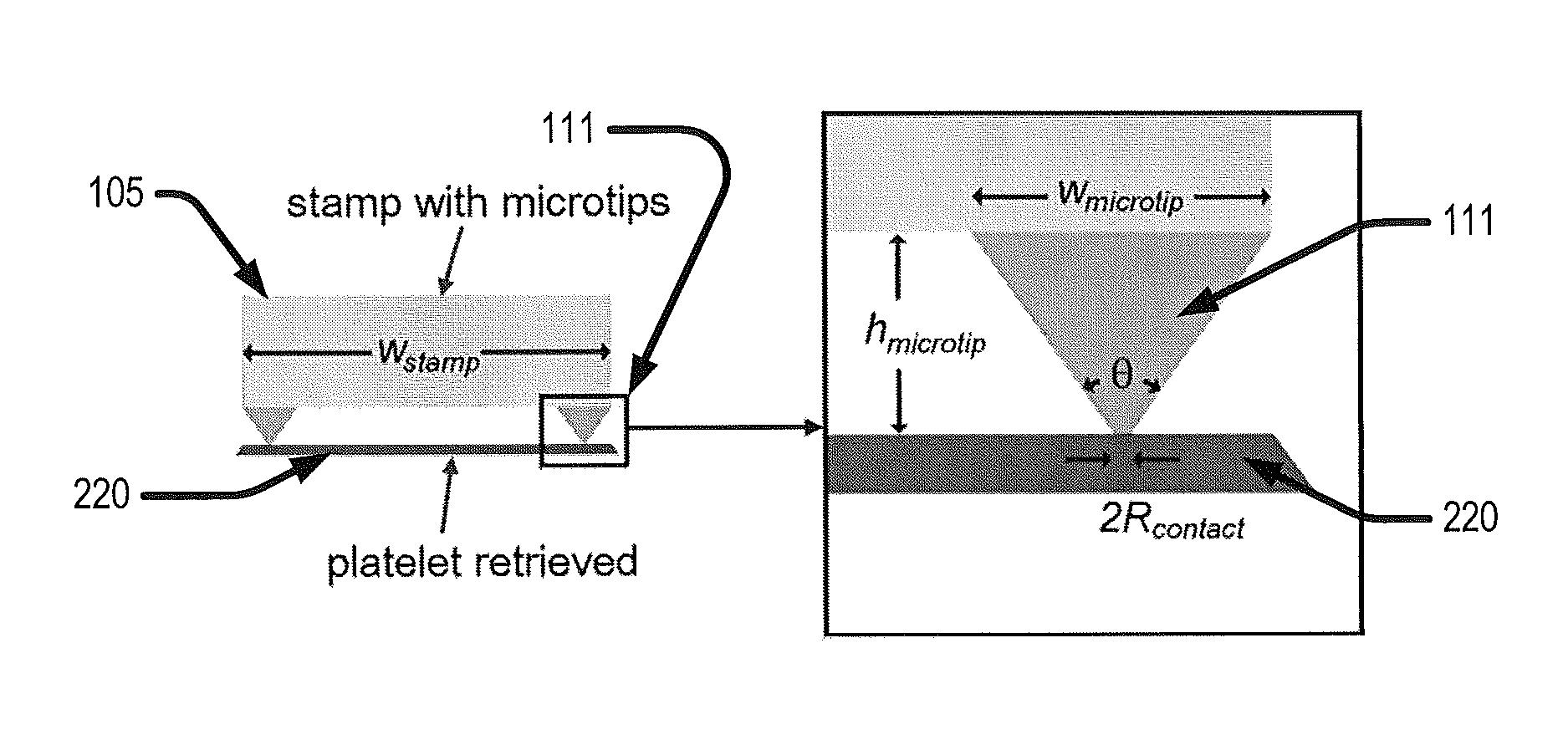

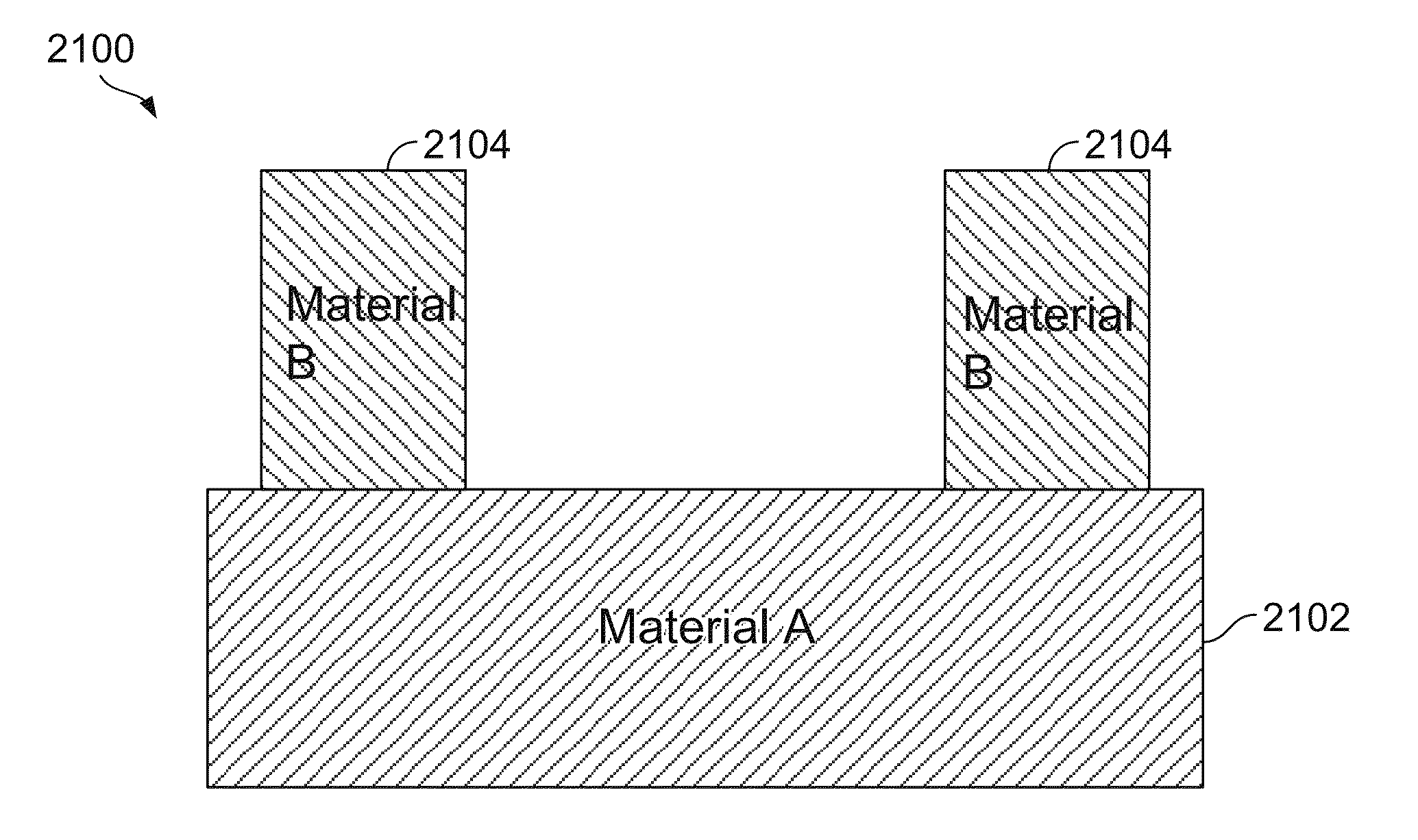

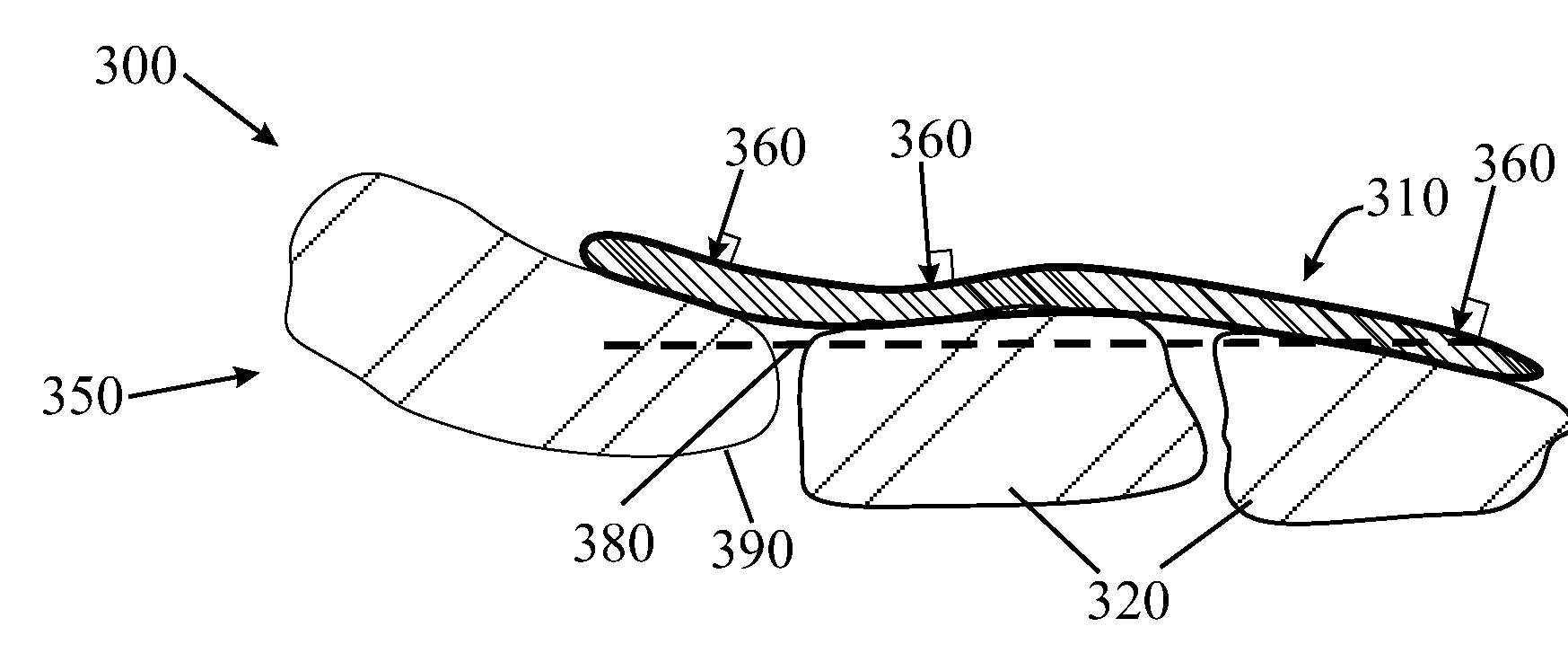

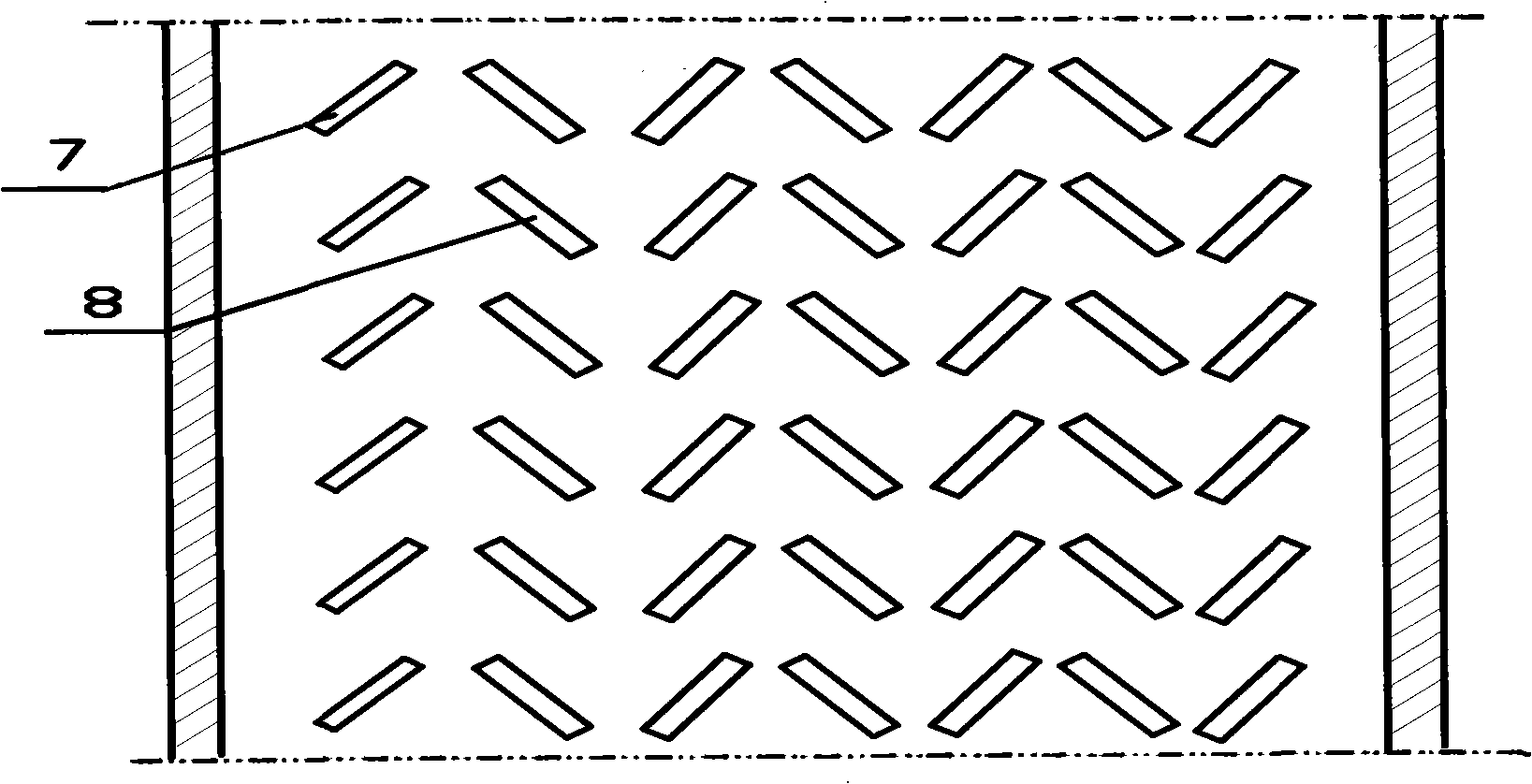

Stamp with structured posts

ActiveUS20170047306A1Great contact surface height variationLittle strengthTransfer printingSemiconductor/solid-state device detailsEngineeringSurface contour

A stamp for micro-transfer printing includes a body and one or more posts extending from the body. At least one of the posts has a non-planar surface contour on the distal end of the post having a size, shape, or size and shape that accommodates a non-planar contact surface of a micro-transfer printable device.

Owner:X DISPLAY CO TECH LTD

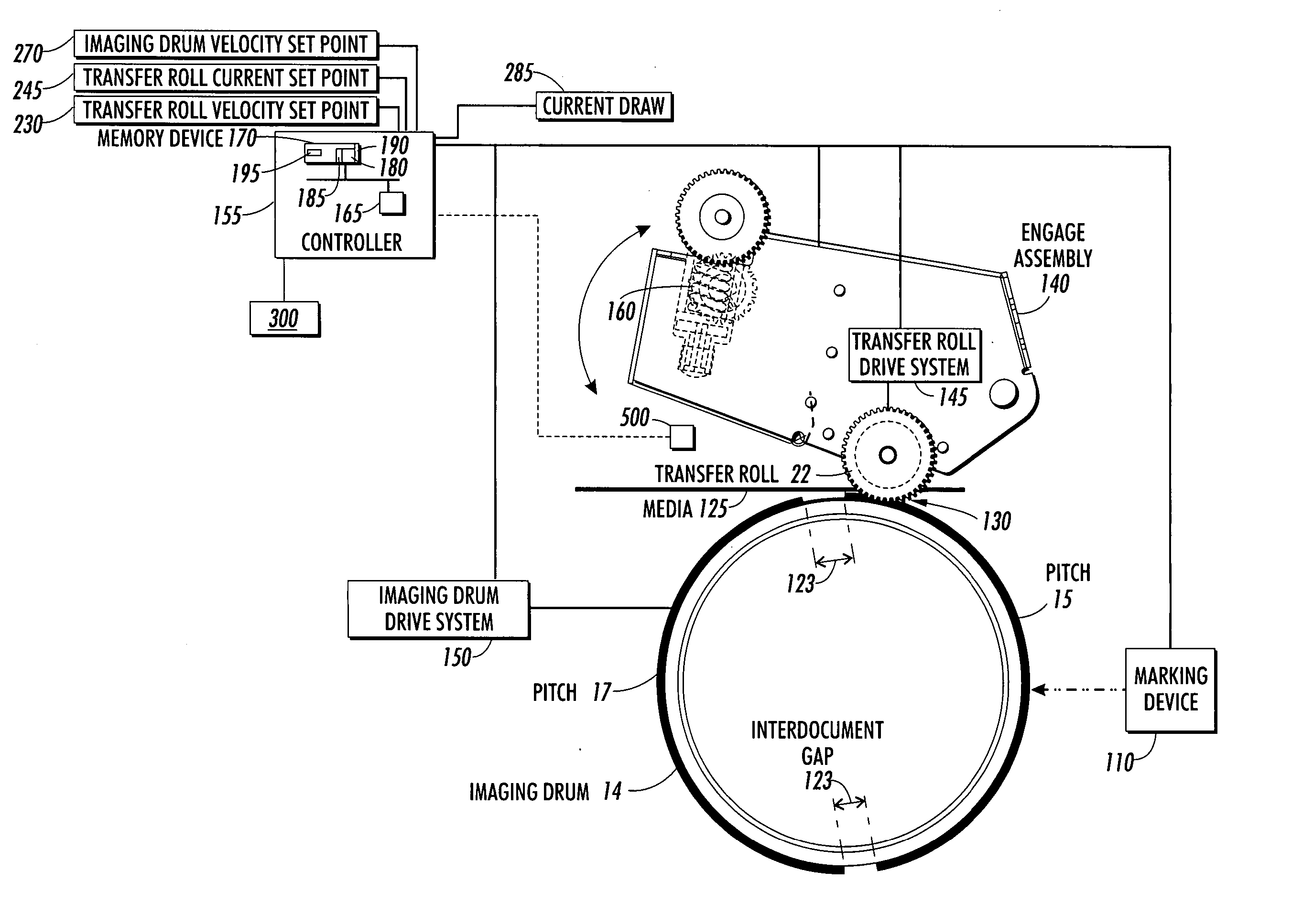

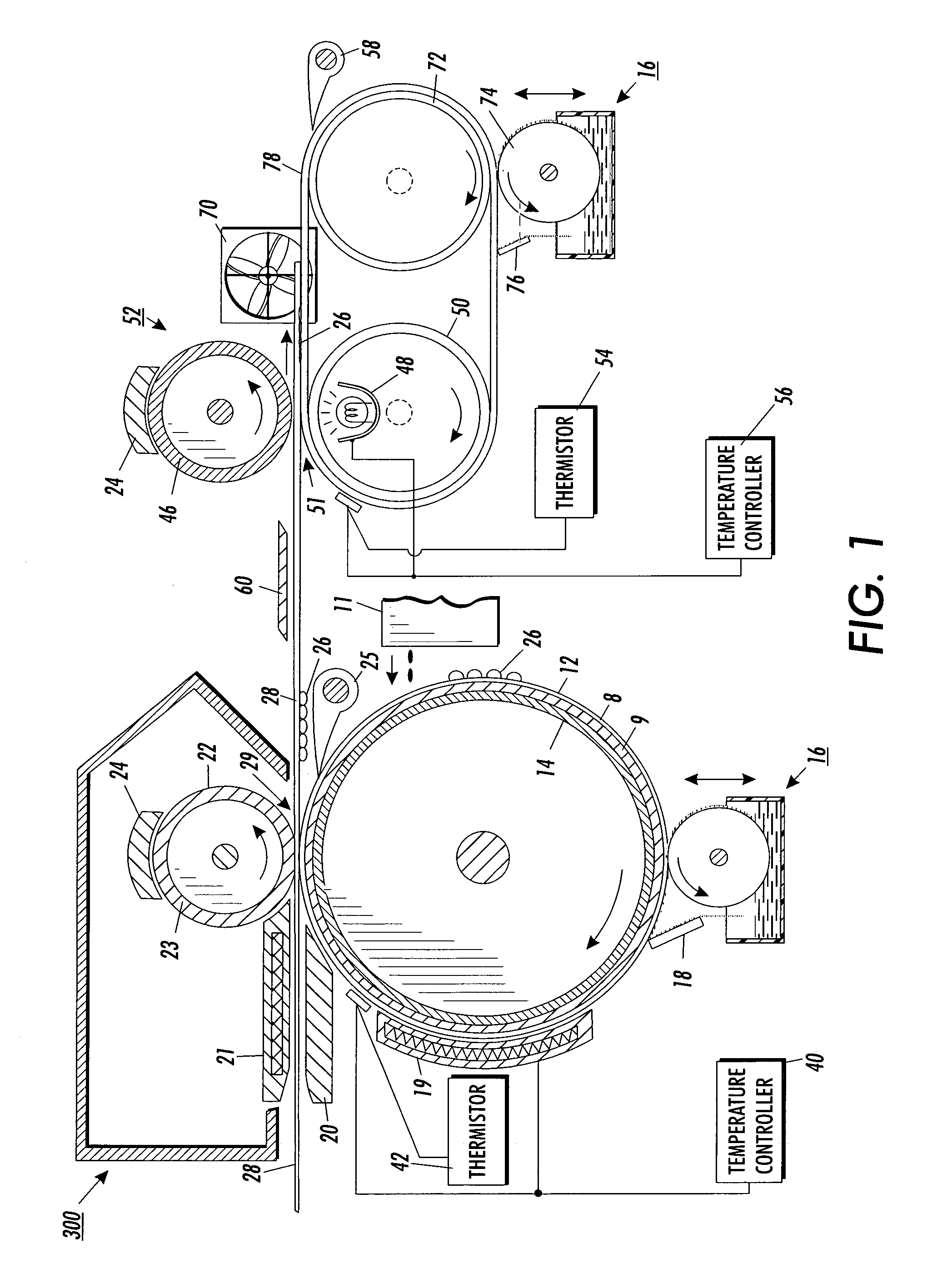

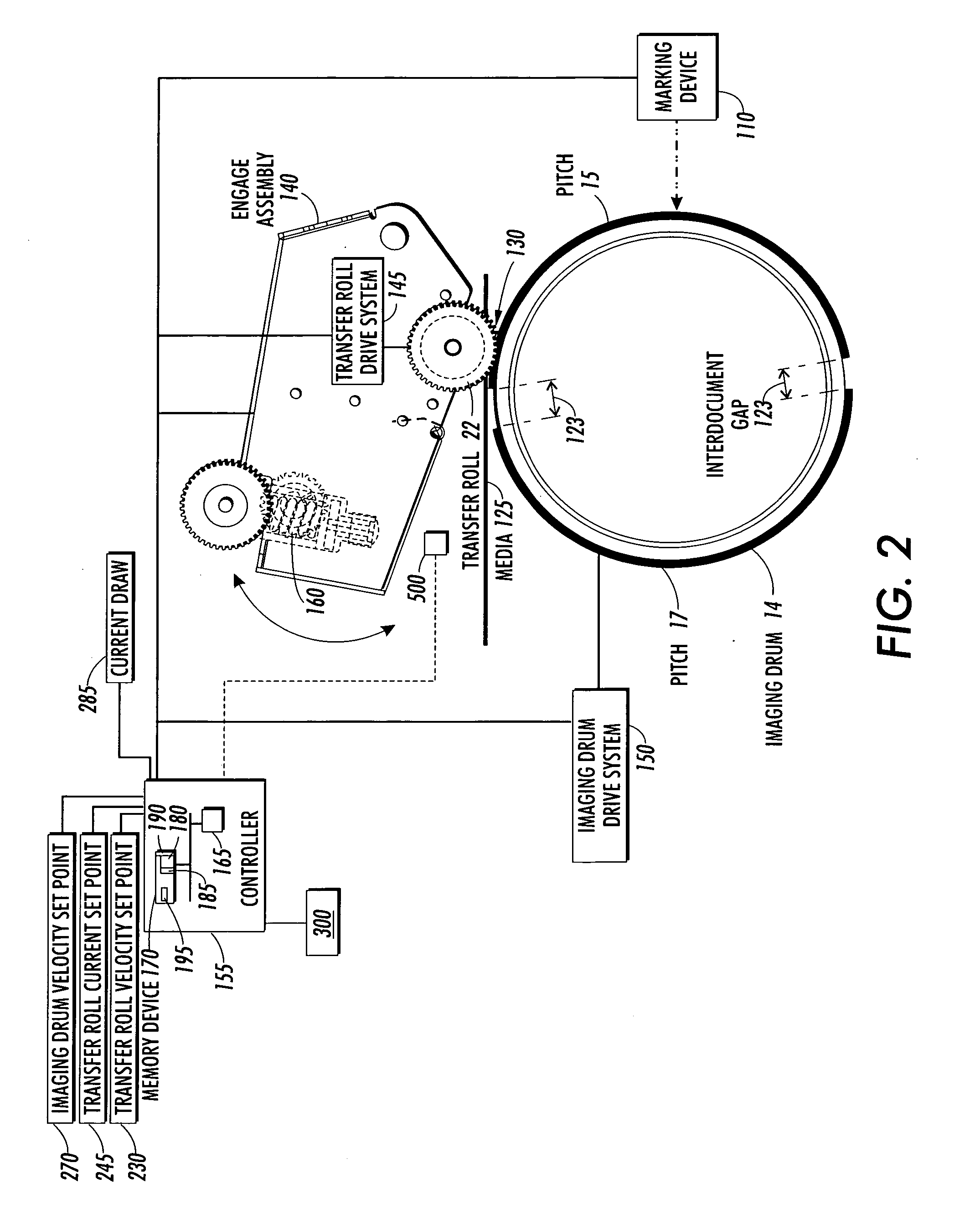

Transfer roll engagement method for minimizing media induced motion quality disturbances

Owner:XEROX CORP

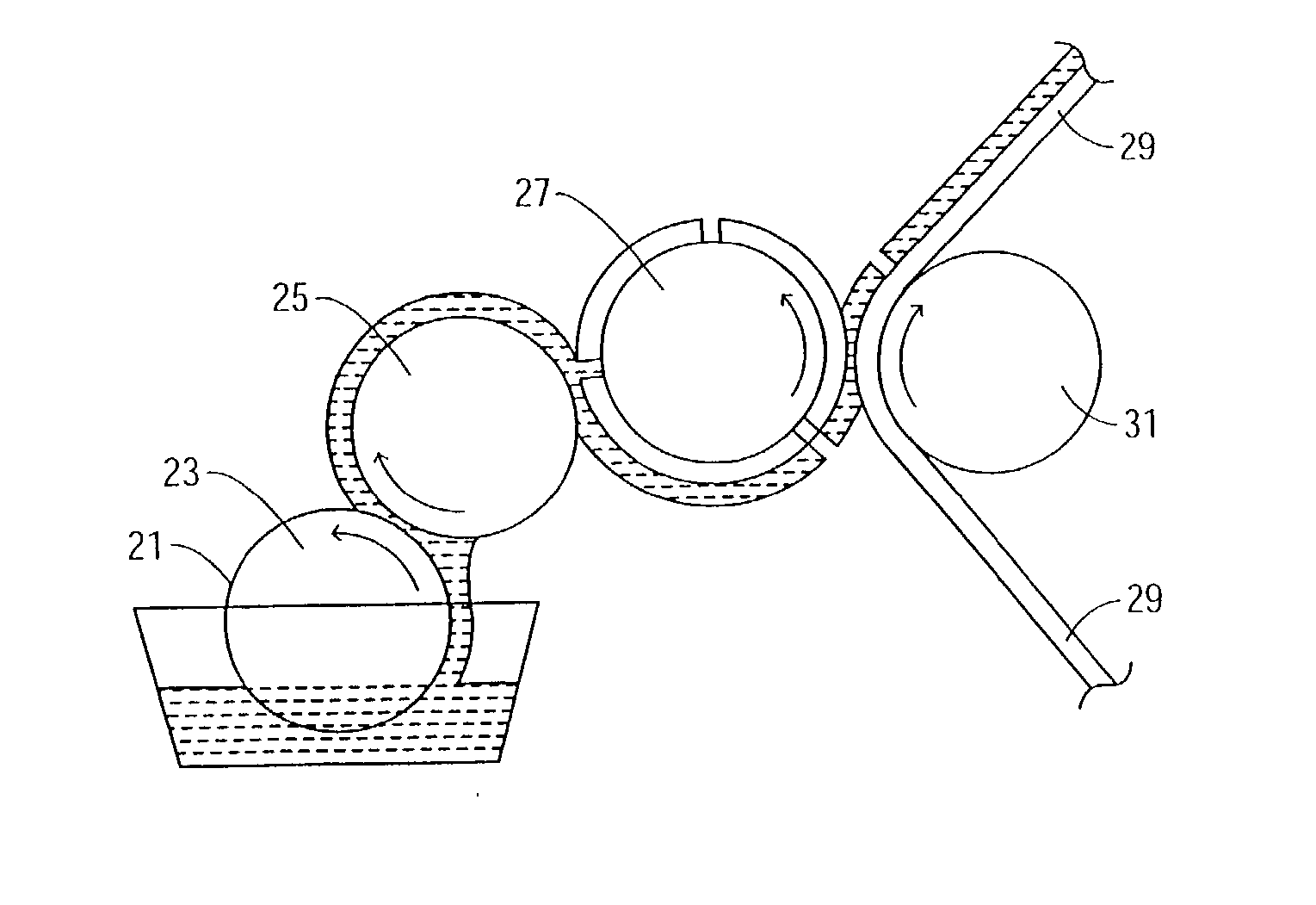

Method and Apparatus for Depositing A Film Using A Rotating Source

The disclosure generally relates to a method and apparatus for depositing a substantially solid film onto a substrate. The solid film can be an Organic Light-Emitting Diode (“OLED”). In one embodiment, the disclosure relates to using a material supply, a rotating or moving mechanism having at least one transfer surface which is supplied with film material in one orientation and delivers film material to the substrate at a second orientation such that film material delivered to the substrate deposits in substantially solid form. The delivery to the substrate can be performed without the transfer surface materially contacting the substrate. The film material can be deposited on the transfer surface in either solid form or in liquid form (e.g., as a mixture of carrier liquid and dissolved or suspended film material).

Owner:KATEEVA

Method of producing a high gloss coating on a printed surface

InactiveUS20030113466A1High coatingLow production costCylinder pressesTransfer printingPresent methodPaper sheet

The present invention is directed to a method for producing a high gloss coating on a printed surface. In the present method, an aqueous coating composition is deposited onto a surface to be printed using a blanket roller coating face which is a low energy, non-stick, smooth surface profile. In the present method, simultaneous with the deposition of aqueous coating onto a substrate, or shortly thereafter, pressure either alone or in combination with heat may be applied to the coating in order to create a substantially tack-free surface conforming to the surface of the coating face. By using a highly polished coating face, high gloss coatings may be readily obtained using this methodology in a number of traditional printing techniques including wet trap inline sheet-fed printing, heat-set offset printing, dry trap inline flexographic printing, offset web-fed printing and gravure printing. Coatings which are produced utilizing the present invention have high gloss values heretofore unobtainable using aqueous coating compositions.

Owner:FRAZZITTA JOSEPH +1

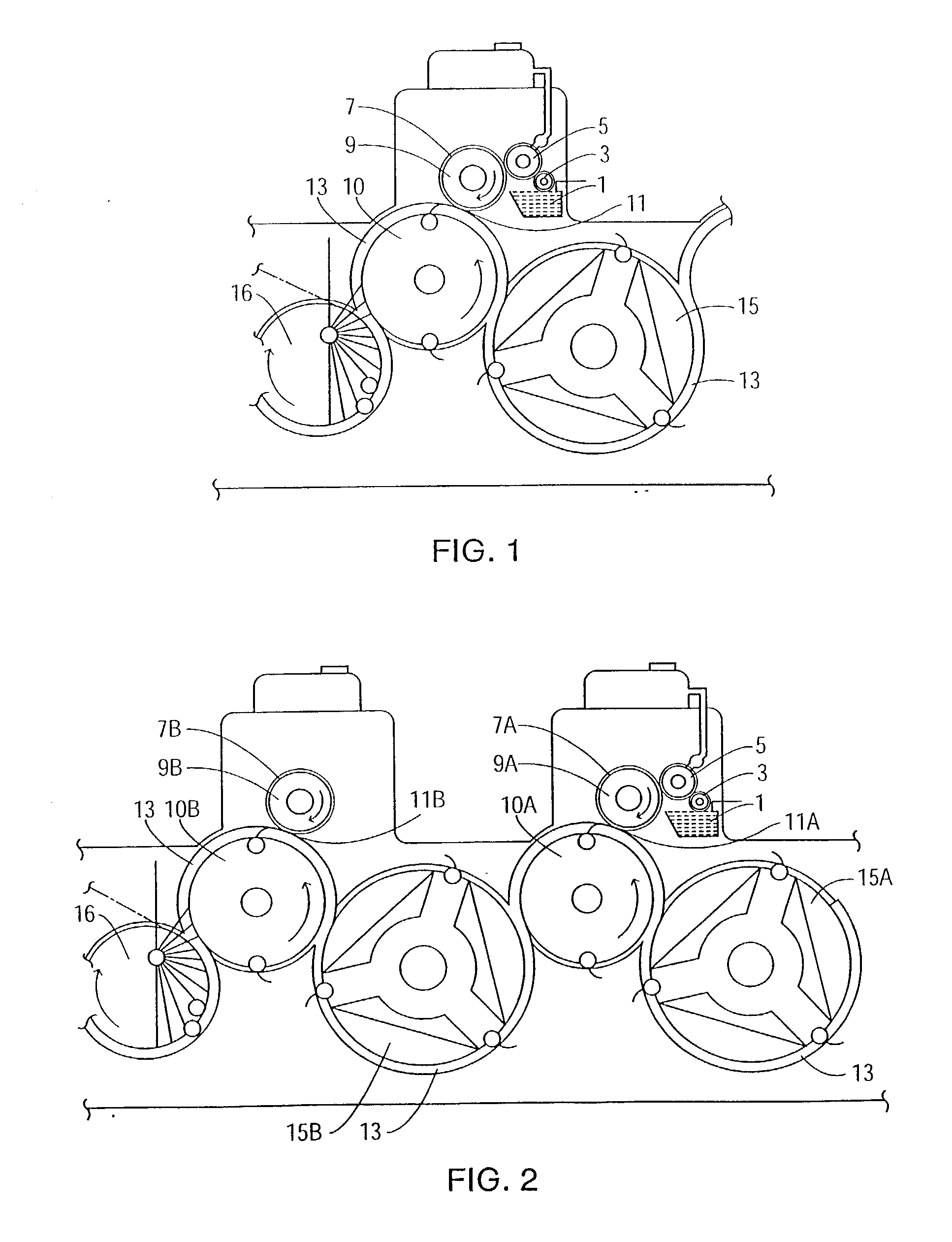

Variable cut-off offset press system and method of operation

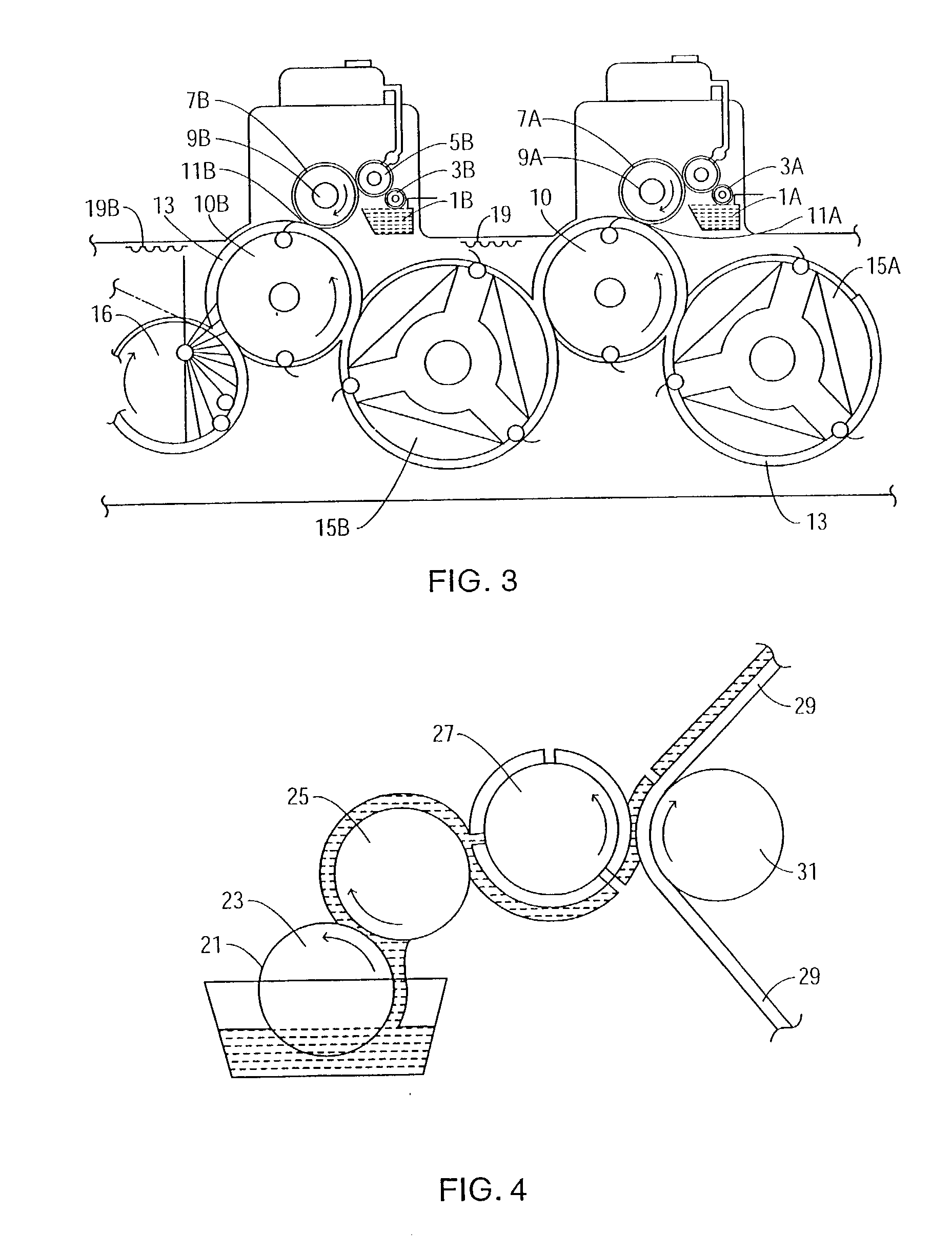

InactiveUS7066088B2Aid in smooth operation of systemIncrease frictionCylinder pressesTransfer printingImage transferCleaning station

A variable cut-off offset press system and method of operation which utilizes a continuous image transfer belt is provided. The offset printing system comprises at least two plate cylinders adapted to have thereon respective printing sleeves. Each of the printing sleeves is adapted to receive colored ink from a respective ink source. An optional coating source may be provided to fully or partially coat the image transfer belt before inking. The system further comprises at least a impression cylinder, wherein the image transfer belt is positioned to contact each of the printing sleeves at respective nips formed between respective ones of the plate cylinders and the at least one impression cylinder. An image belt cleaning station adapted to remove residual ink or coating from the surface of the image transfer belt after image transfer of a multicolored image from the image transfer belt to a substrate is also provided.

Owner:DAY INT

Permanent heat activated ink jet printing process

InactiveUS6966643B2Prevent undesired activationAvoid cakingTransfer printingMeasurement apparatus componentsComputer printingEngineering

Owner:HALE NATHAN +1

Anti-counterfeiting transfer printing technology

InactiveCN101618630APromote degradationNo pollutionTransfer printingVacuum evaporation coatingVacuum pumpingCompanion animal

The invention relates to an anti-counterfeiting transfer printing technology which comprises the following steps: preparing a laser plate; coating a layer of mold release agent or imaging paint on a PET base film; carrying out vacuum pumping on the PET base film and an aluminum material device in a vacuum plating evaporator; then heating the aluminum material and depositing gaseous aluminum particles on the surface of the moving PET base film and / or the surface of the mold release agent or the imaging paint; stamping an embossing pattern on the laser plate on a mold release agent layer or an imaging paint layer and / or an aluminum layer so as to make a holographic transfer film for transfer; bonding the holographic transfer film and backing paper together; separating the PET base film from the paper, wherein the stripped PET base film can be repeatedly used for a coated base film; and coating a layer of aqueous varnish on the surface of the transferred paint layer and / or the aluminum layer. The technology can combine an anti-counterfeiting printing technology with a transfer printing technology, and an aluminum plating layer transferred on the paper can be made to be thin, thereby saving the aluminum material; in addition, the base film used in transfer printing can be repeatedly utilized and does not pollute the environment.

Owner:江苏中印印务集团有限公司

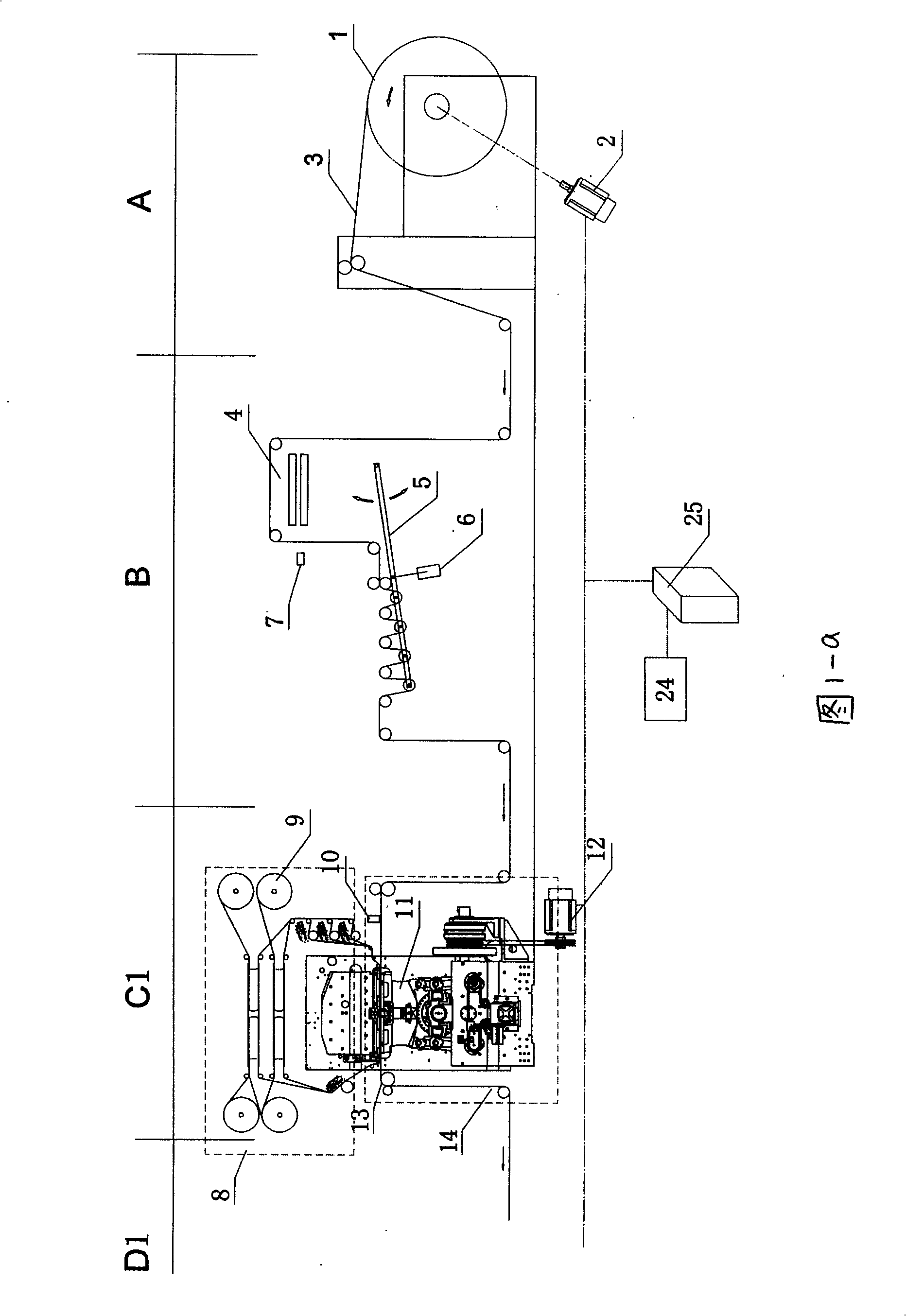

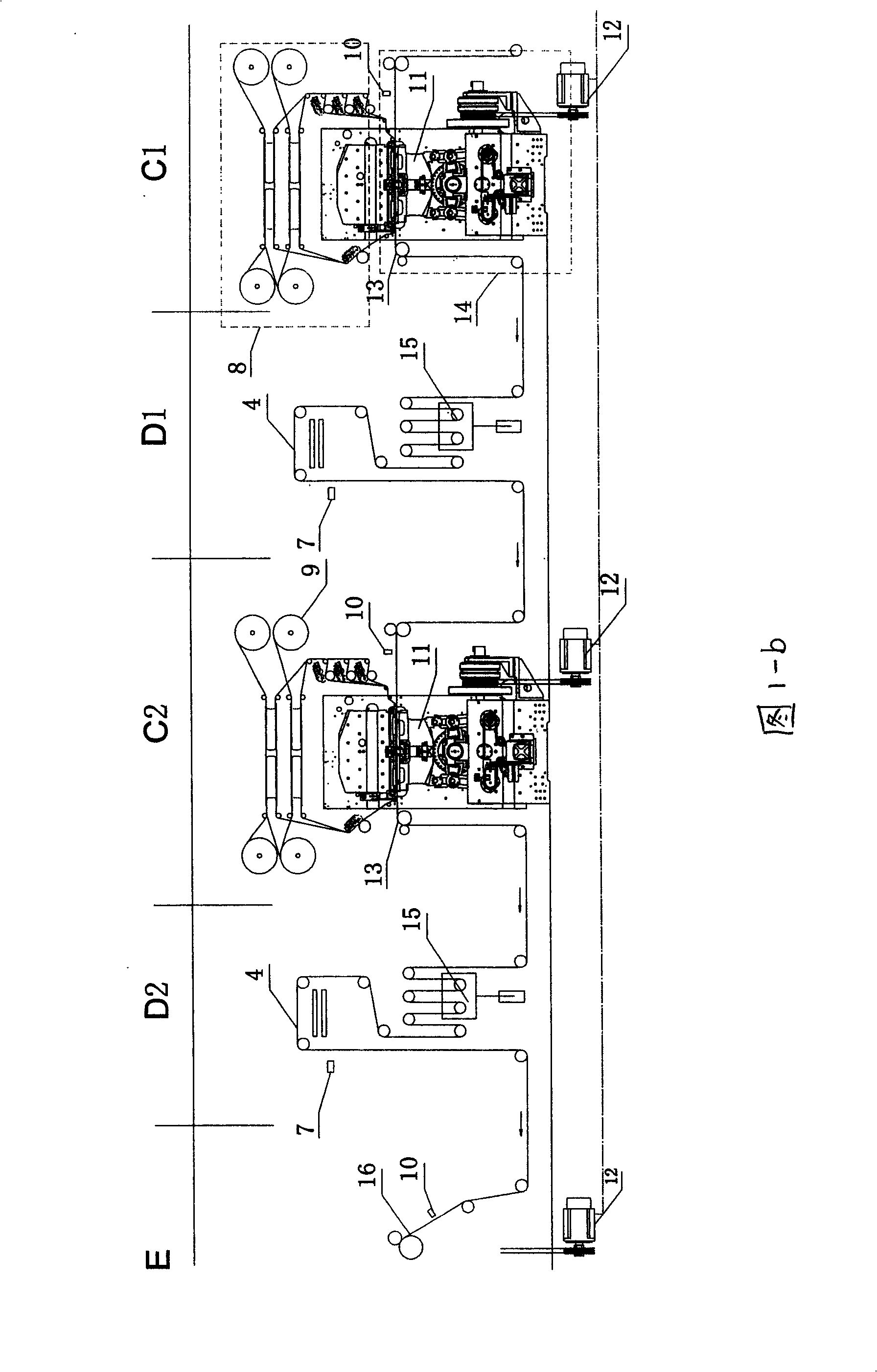

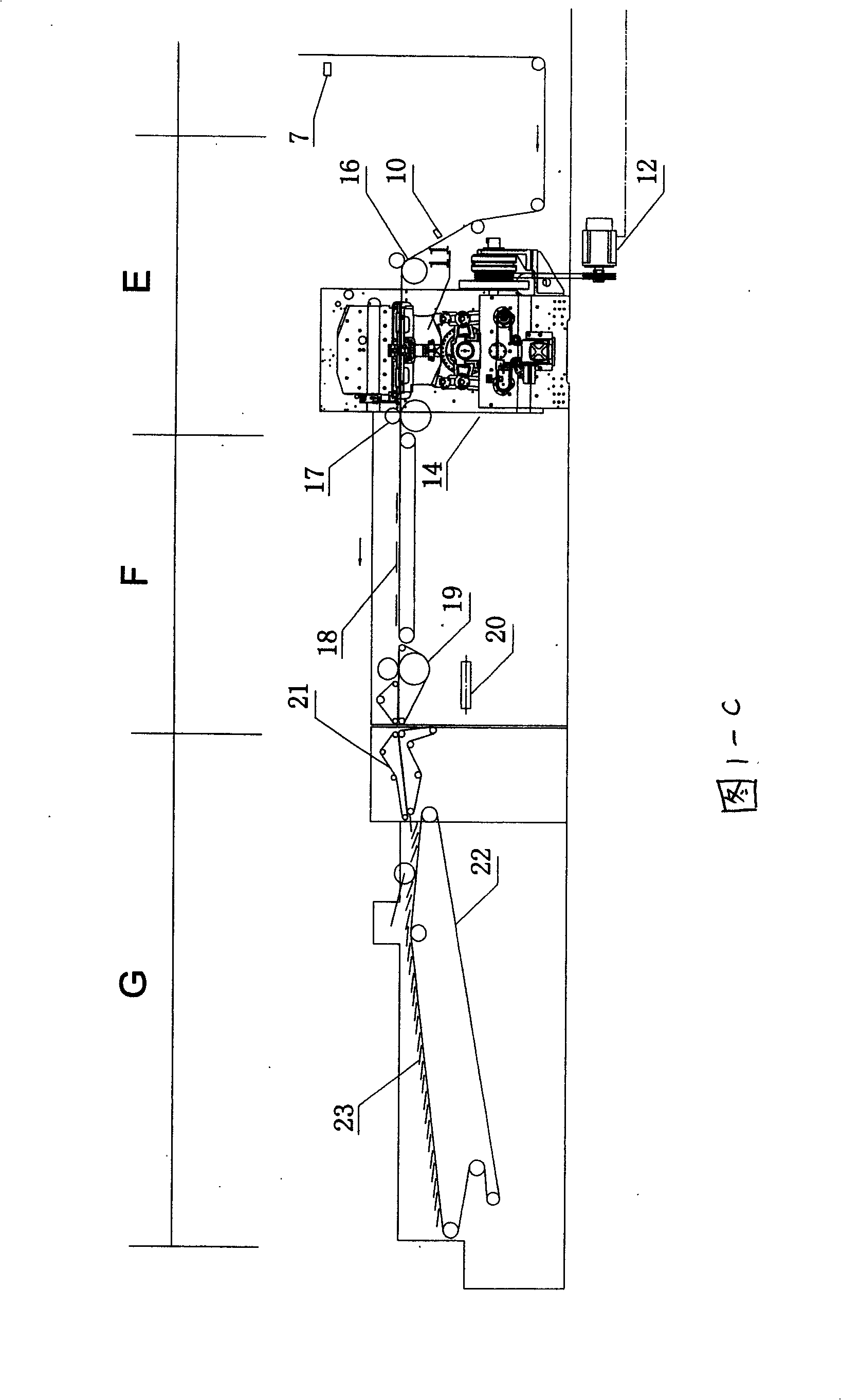

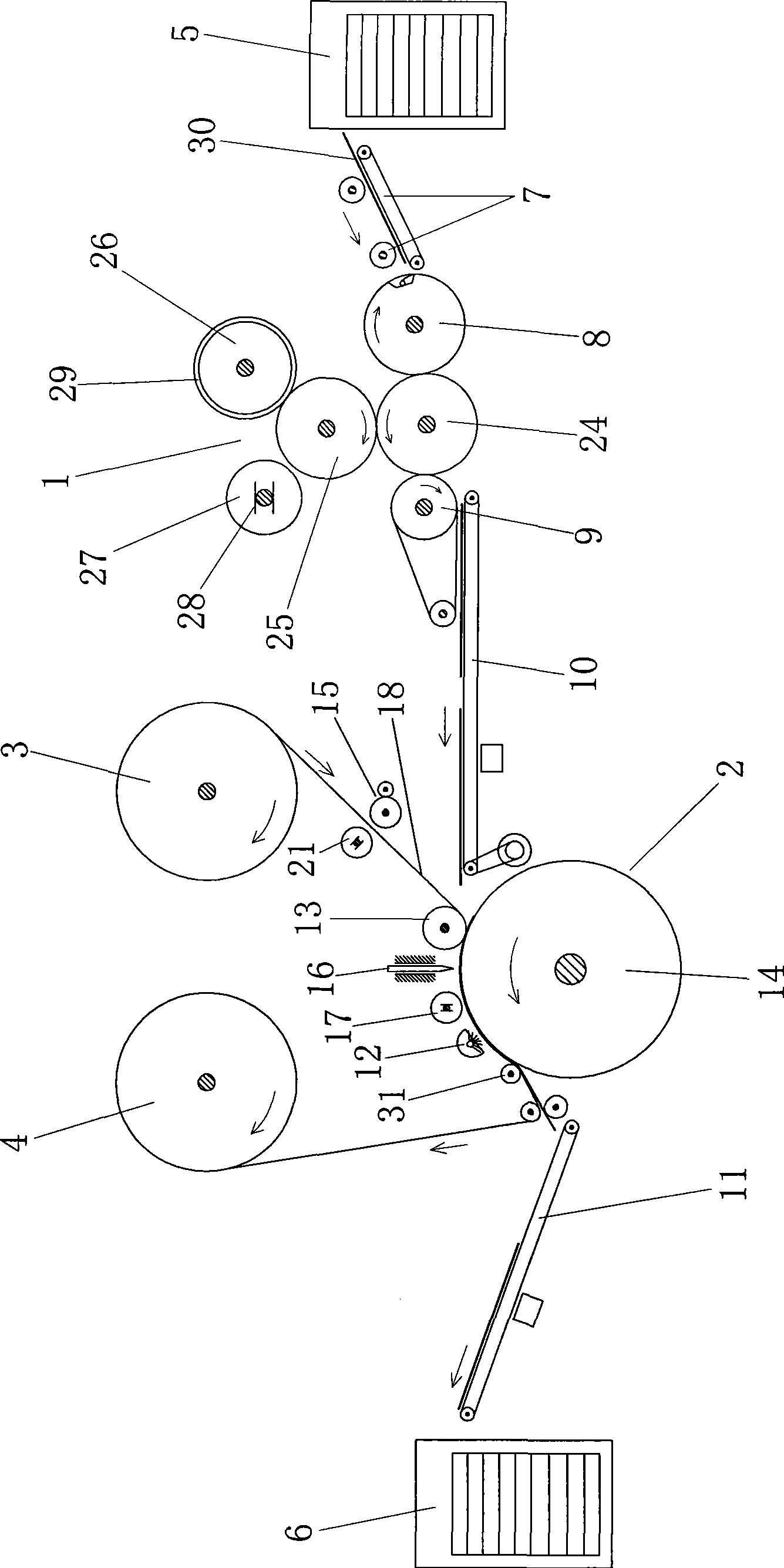

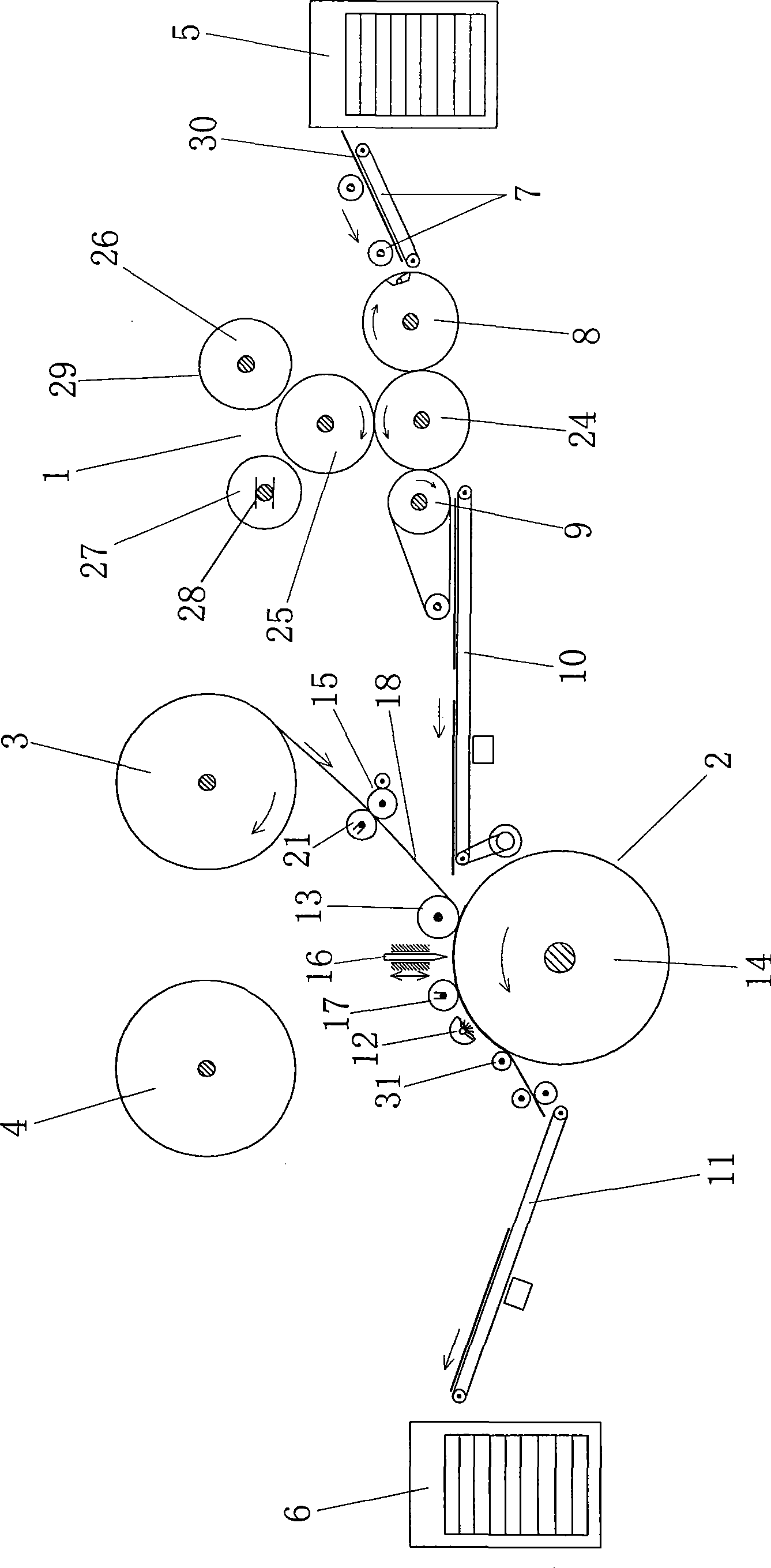

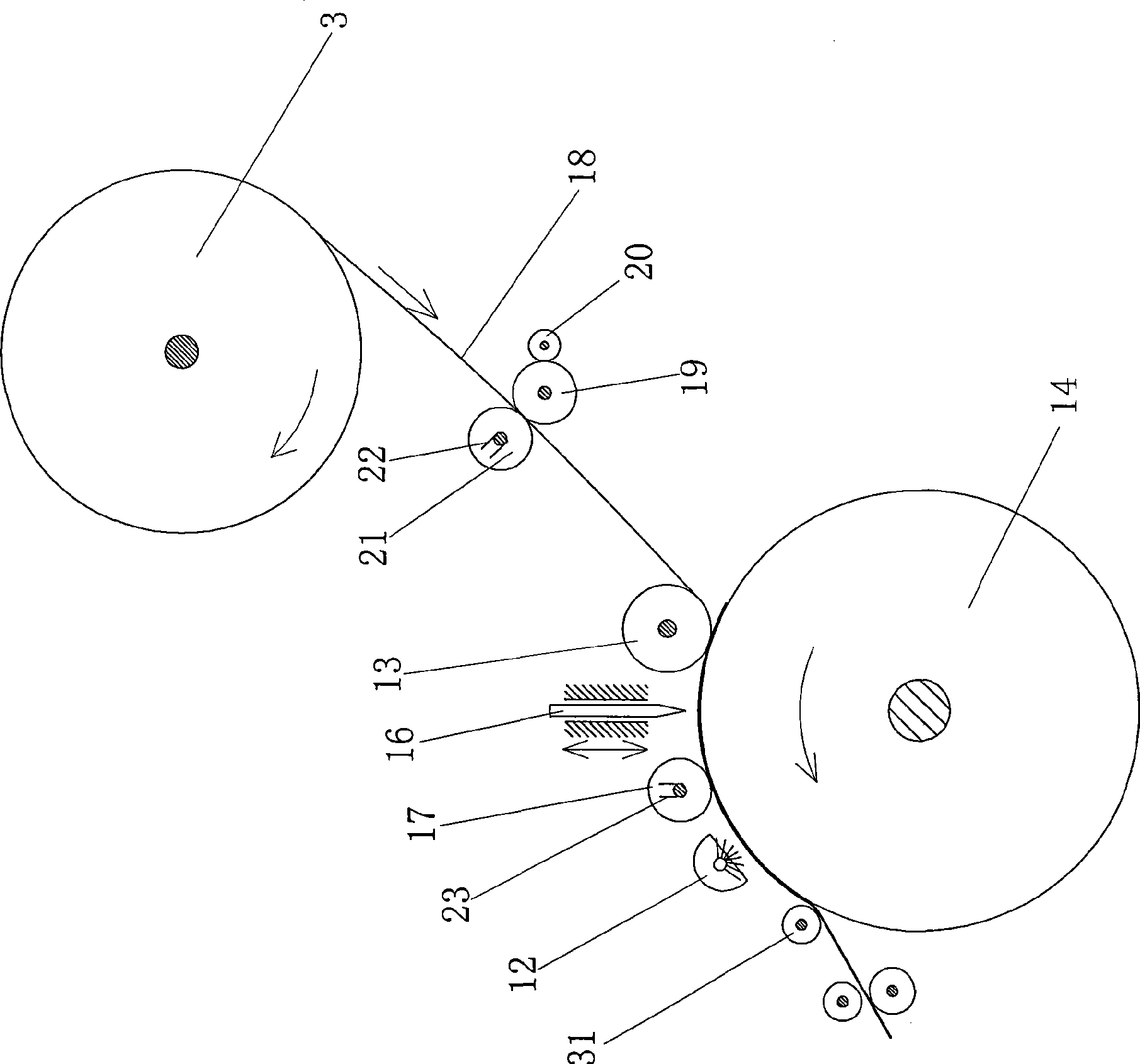

Unit type mold cutter for reeled paper

ActiveCN101407127AProduction effectively adapts toProduction adaptationTransfer printingPlaten pressesHot stampingRolling paper

The invention relates to a roll paper unit-type die cutting machine. The machine consists of a roll paper releasing and winding device, a paper storage device, a hot stamping unit, a tensile force control device, a die cutting unit and a waste cleaning device, wherein the roll paper releasing and winding device consists of roll paper, a motor and paper, the paper storage device consists of a deviation rectifying device, a swinging rod, a constant-force device and a detection sensor of the deviation rectifying device, the hot stamping unit consists of an aluminum foil conveying device, aluminum foil, a sensor, a moving platform, a motor, a paper drawing device and a press mould device, the tensile force control device consists of a deviation rectifying device, a detection sensor of the deviation rectifying device and a constant-force device, the die cutting device consists of a sensor, a motor, a press mould device, a paper drawing device and a paper receiving device, the waste cleaning device consists of paper, waste cleaning device and a slitter edge conveying device, and a sheet material collecting device consists of a paper separating and conveying device, a conveyor belt and paper.

Owner:MASTERWORK GROUP CO LTD

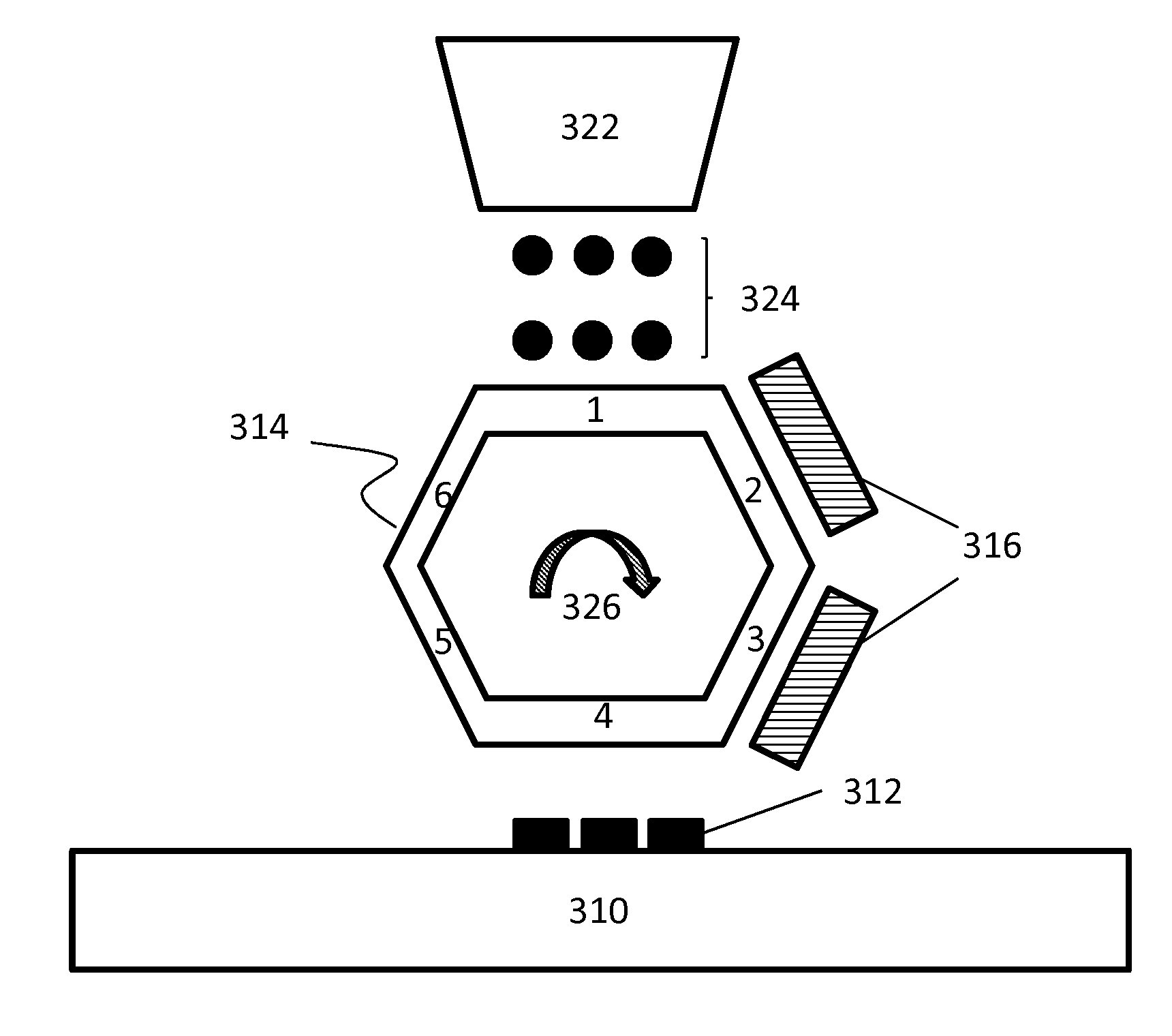

Apparatus and methods for micro-transfer-printing

ActiveUS20160016399A1Increase heightIncrease initial accelerationTransfer printingPlaten pressesSeparation systemSemiconductor

In an aspect, a system and method for assembling a semiconductor device on a receiving surface of a destination substrate is disclosed. In another aspect, a system and method for assembling a semiconductor device on a destination substrate with topographic features is disclosed. In another aspect, a gravity-assisted separation system and method for printing semiconductor device is disclosed. In another aspect, various features of a transfer device for printing semiconductor devices are disclosed.

Owner:X DISPLAY CO TECH LTD

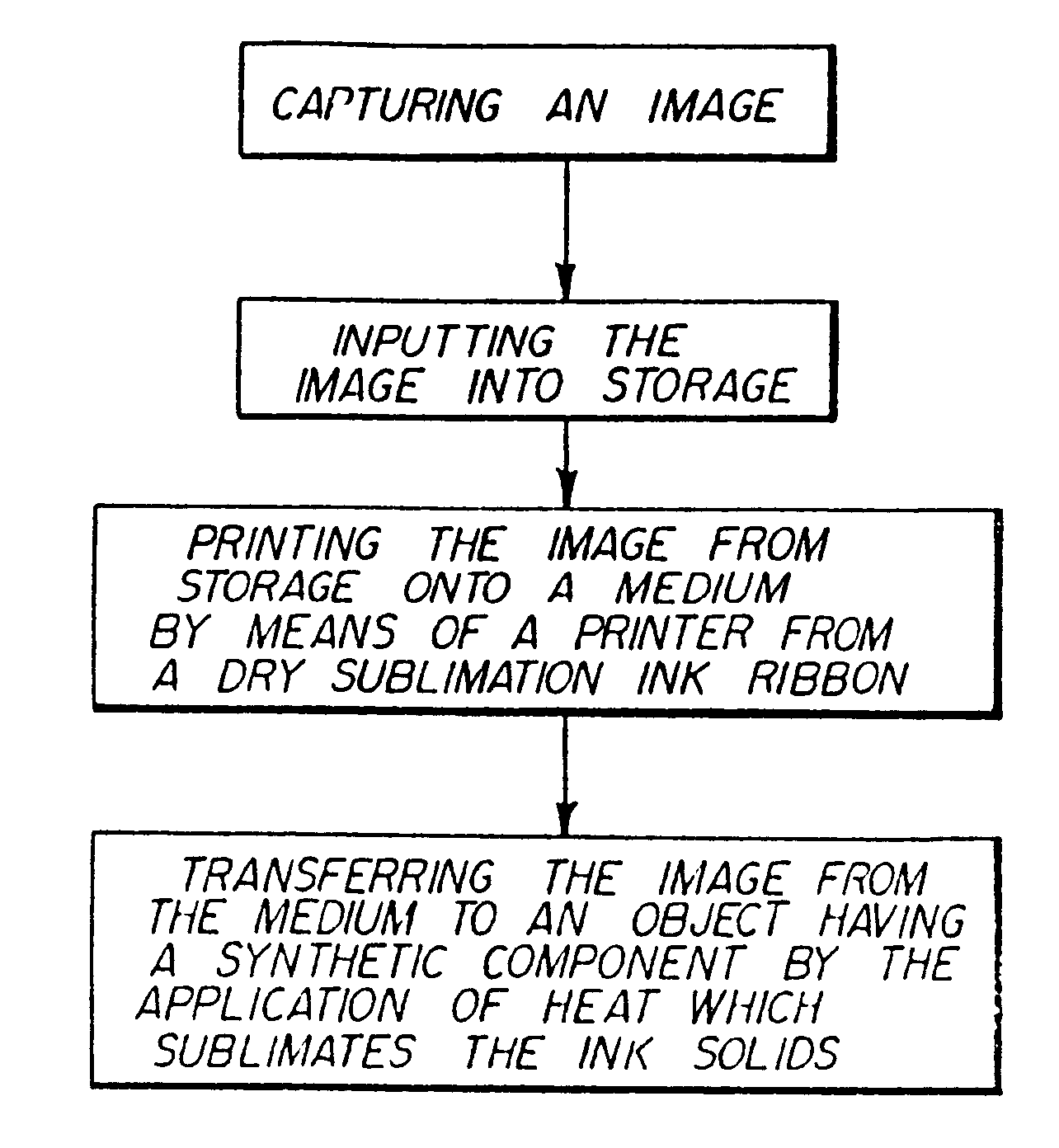

Permanent heat activated printing process

InactiveUS6425331B1Improve bindingFacilitate and withstand temperatureTransfer printingMeasurement apparatus componentsComputer printingEngineering

Owner:SAWGRASS SYST INC

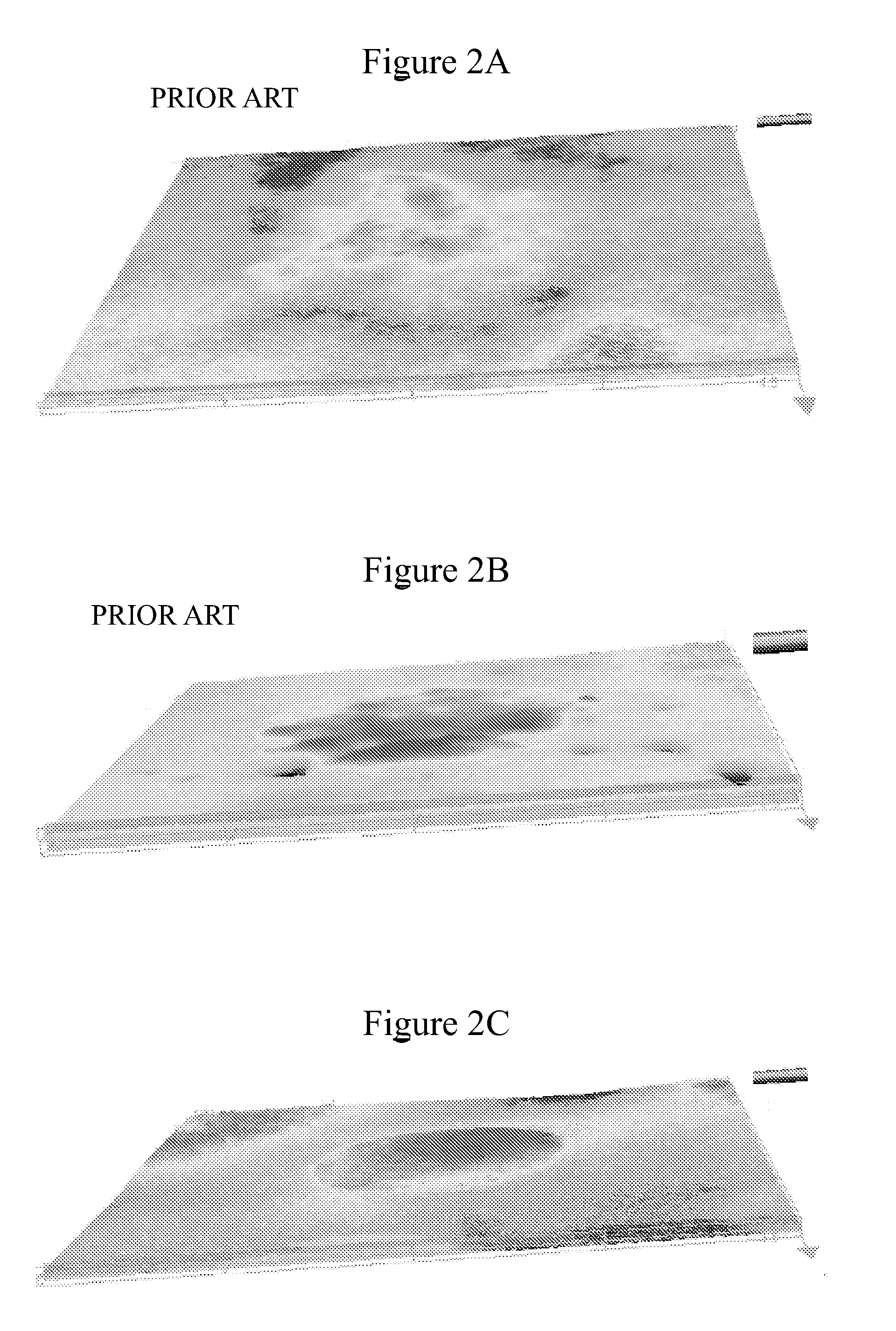

Method and system for printing onto a deformable cast polymer article

A printing system configured to print an image onto a deformable cast polymer article comprising: (a) means for supporting a deformable cast polymer article in preparation for printing thereon, the means for supporting comprising a pressure platen, the deformable cast polymer comprising a finished surface to be printed on and a secondary surface; (b) an image transfer medium located contiguous with the finished surface, the image transfer medium configured to produce the image on the finished surface upon transfer of an ink image, comprising one or more inks, supported by the image transfer medium; (c) means for applying pressure to the deformable cast polymer article in the form of a deformable pressure applicator, such as a flexible membrane, the means for applying being flexible and configured to deform and conform to a surface of the deformable cast polymer article, and to cause an opposing surface of the deformable cast polymer article, under heat, to inelastically deform and conform to the pressure platen, the means for applying also being configured to cause the image transfer medium to conform to the finished surface such that substantially all of the ink image is caused to be in contact with the finished surface; and (d) means for heating at least a portion of the cast polymer to a pre-determined temperature for a pre-determined time sufficient to achieve the inelastic deformation of at least a portion of the cast polymer article, and to effectuate the transfer of the ink image to the finished surface.

Owner:TRUSTONE PROD

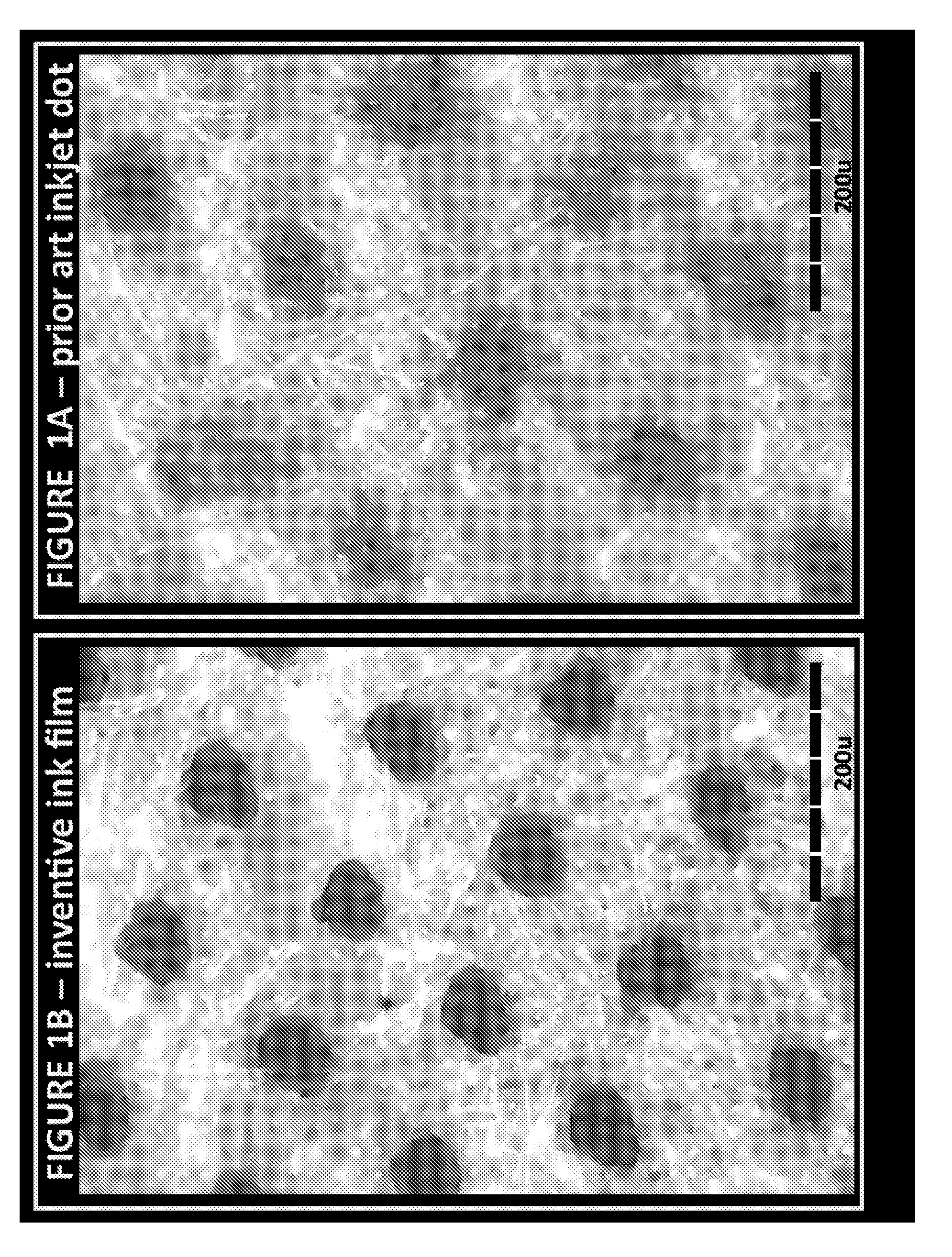

Ink film constructions

An ink film construction comprising: (a) a printing substrate; and (b) at least one ink film, fixedly adhered to a top surface of the printing substrate, the ink film having an upper film surface distal to the top surface of the substrate, wherein a surface concentration of nitrogen at the upper film surface exceeds a bulk concentration of nitrogen within the film, the bulk concentration measured at a depth of at least 30 nanometers below the upper film surface, and wherein a ratio of the surface concentration to the bulk concentration is at least 1.1 to 1.

Owner:LANDA

Grippers malfunction monitoring

A system for printing an image on a printing media, comprising: a) an impression roller; b) a gripper which receives the printing media when said gripper is open, closes to hold the printing media to the impression roller while the image is printed, and opens to release the printing media from the impression roller; and c) at least one sensor which senses whether the gripper is open or closed.

Owner:HEWLETT PACKARD DEV CO LP

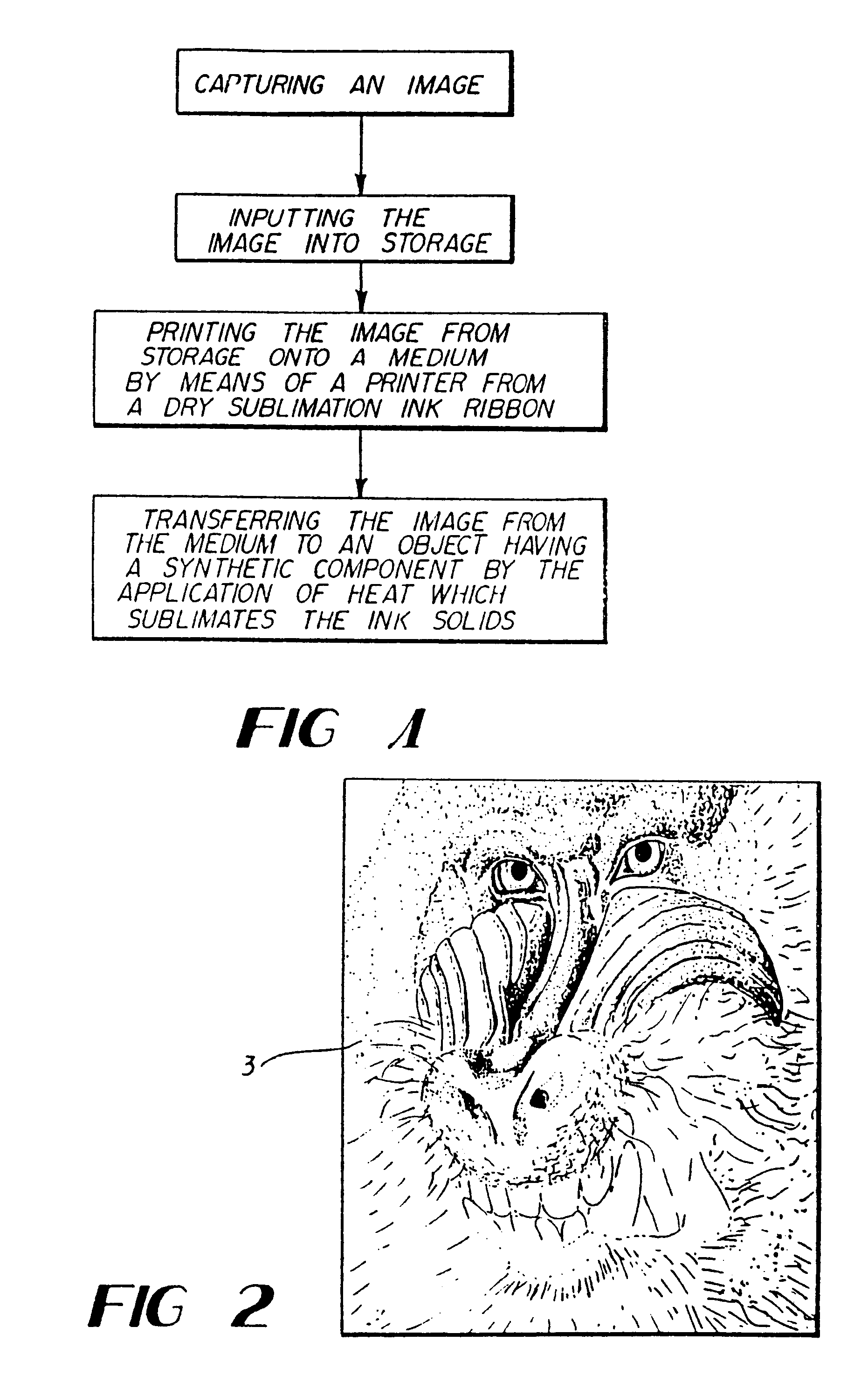

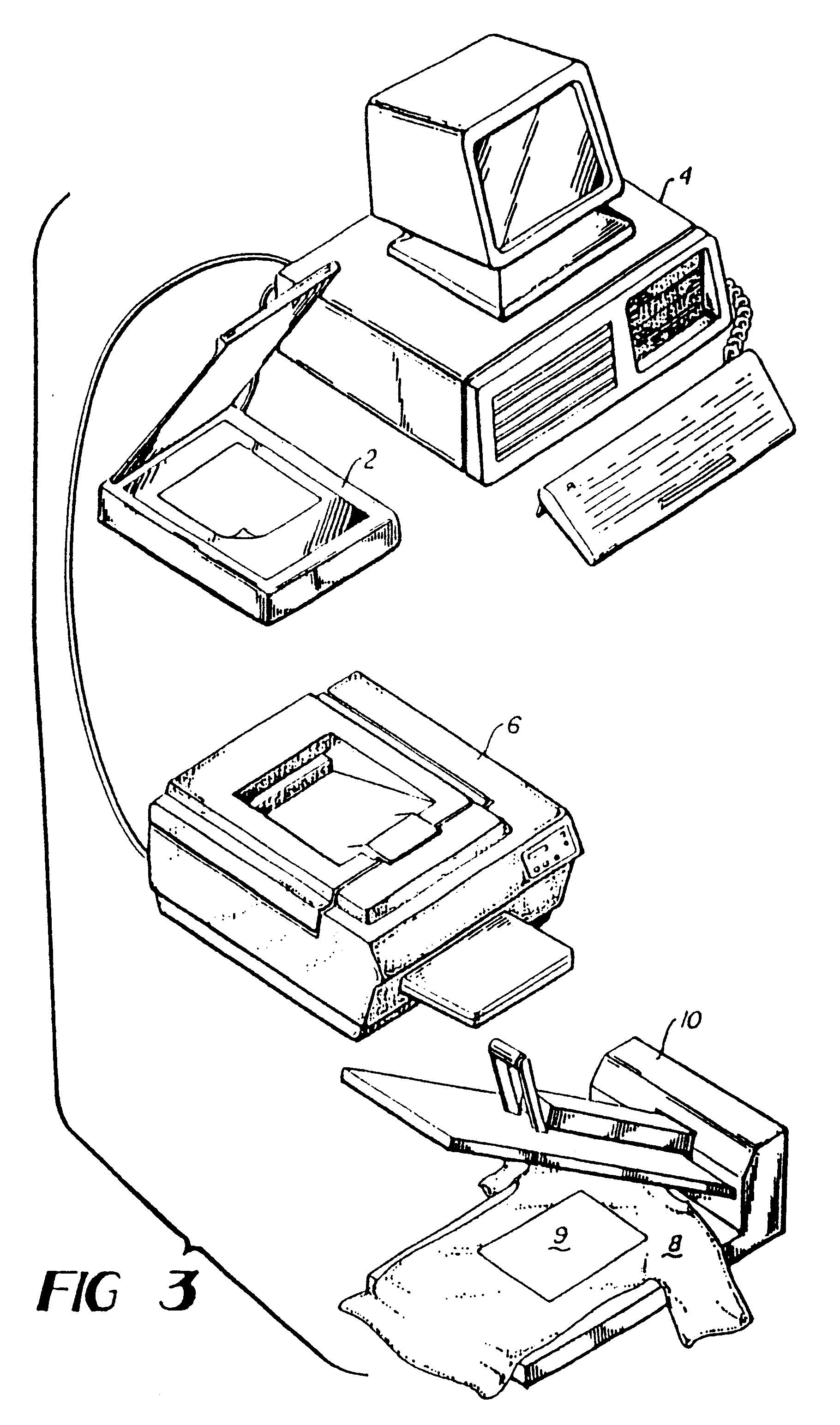

Printed media produced by permanent heat activated printing process

InactiveUS6439710B1Prevent undesired activationAvoid cakingTransfer printingMeasurement apparatus componentsEmulsionEngineering

The present invention is a method of producing a printed a by printing heat activated ink solids in a non activated form onto a medium in a desired image by means of an ink jet printer. The invention is printed using ink or dye compositions comprising heat activated ink or dye solids. The ink compositions used to print the medium are solid at ambient temperature when used with phase change ink jet printers, and are emulsions when used with liquid ink jet printers such as free flow and bubble jet printers. The dye solids are printed in the desired design by means of a printer onto a substrate, which becomes the printed medium. The substrate may be paper, or it may be other material.

Owner:SAWGRASS SYST INC

Apparatus and methods for micro-transfer-printing

ActiveUS20160020127A1Increase heightIncrease initial accelerationTransfer printingSemiconductor/solid-state device detailsEngineeringSemiconductor

In an aspect, a system and method for assembling a semiconductor device on a receiving surface of a destination substrate is disclosed. In another aspect, a system and method for assembling a semiconductor device on a destination substrate with topographic features is disclosed. In another aspect, a gravity-assisted separation system and method for printing semiconductor device is disclosed. In another aspect, various features of a transfer device for printing semiconductor devices are disclosed.

Owner:X DISPLAY CO TECH LTD

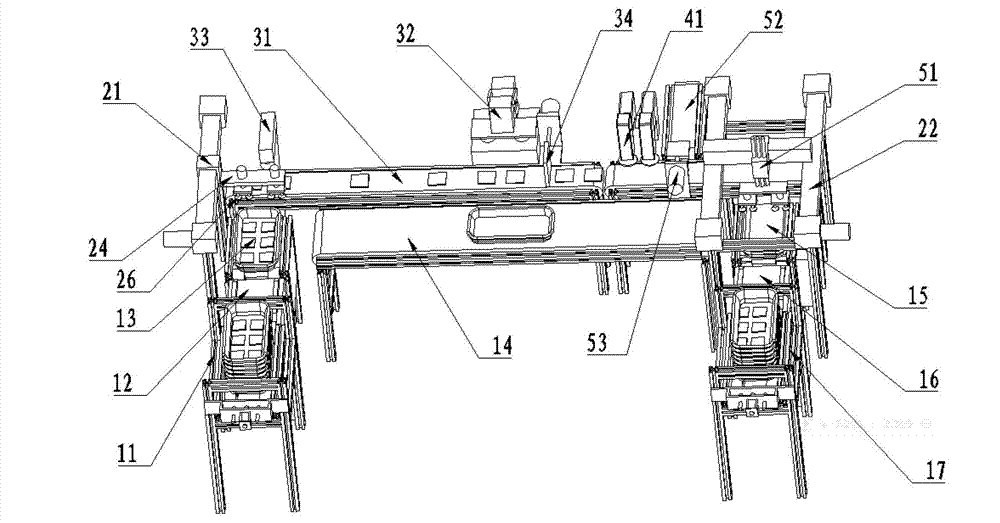

Multipurpose plant for surface treatment of printing material

InactiveCN101486270AIncrease the function of laminating operationLower investment priceTransfer printingLaminationUltravioletEngineering

The invention relates to a multipurpose device for processing the surface of a printing material. The invention aims to solve the problems that the prior film laminating machine and other devices for decorating and processing the surface of the printing material are independent production devices which cost higher when bought together, occupy larger working space and have low device utilization rate. The technical proposal has the following key points: the device comprises a machine frame and a printing mechanism arranged thereon, a laminating mechanism, a laminating film unreeling mechanism, a laminating film winding mechanism, a printing material discharge mechanism, a printing product receiving mechanism, a plurality of transmitting and transmission fixing mechanisms, and an ultraviolet irradiator, wherein the laminating mechanism consists of an upper laminating roller and a lower laminating roller which are matched with each other; and the ultraviolet irradiator is arranged behind the laminating machine. The multipurpose device is characterized in that the machine frame is also provided with a hot-melt adhesive applicator, a film cutting mechanism, and a carrying roller which is arranged behind the upper laminating roller and is matched with the lower laminating roller; and a coating machine is arranged on a laminating film output path of the laminating film unreeling mechanism, and the film cutting mechanism is arranged between the upper laminating roller and the carrying roller or behind the carrying roller, and is matched with the lower laminating roller.

Owner:GUANGDONG MAGNOLIA PACKING MACHINERY

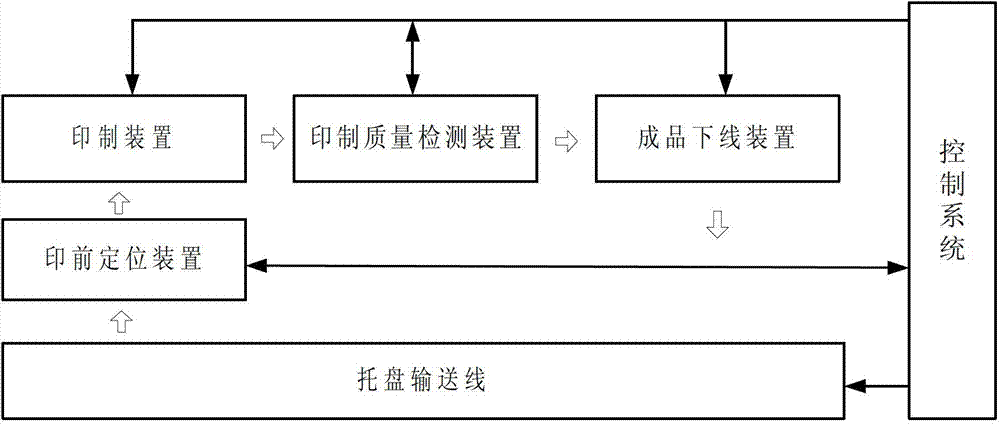

Automatic printing production line of panel trademarks

InactiveCN102922870AReduce labor costsIncrease productivityTransfer printingPrinting press partsPad printingProduction line

The invention provides an automatic printing production line of panel trademarks. The automatic printing production line comprises a tray conveying line, a pre-print positioning device, a printing device, a printing quality detection device, a finished product discharging device and a control system, wherein the tray conveying line, the pre-print positioning device, the printing device, the printing quality detection device and the finished product discharging device are electrically connected with the control system. According to the automatic printing production line of panel trademarks, the product to be printed is grabbed from a tray on the tray conveying line by a first mechanical arm and is placed onto a printing conveyor line after adjusting the direction, the printing quality is detected after a pad printing machine finishes printing, and a first air cylinder directly pushes unqualified products onto an unqualified product conveying line and grabs qualified products into the tray of a blanking turning machine. The above process is automatically finished by the control system, so that the labor cost is greatly saved, the production efficiency is increased, and the printing quality can be ensured simultaneously.

Owner:衡宝(上海)电气有限公司

Heating roller heating method and heating roller

InactiveCN101254638AImprove uniformityUniform temperatureTransfer printingBox making operationsLiquid mediumHeat conducting

The invention discloses a heating roller heating method and a heating roller. The heating roller is heated in an oil, steam, electric or electromagnetic heating manner, and is characterized in that the heating roller has an interlayer structure, a thermally-conductive liquid medium is filled in the interlayer of the heating roller for homogenizing the temperature of the heating roller; and the outer surface of the heating roller is heated in a heat conduction manner through the thermally-conductive liquid medium in the interlayer of the heating roller. The heating roller structure comprises a heating roller with the interface structure, and the thermally-conductive liquid medium in the interface of the heating roller for homogenizing the temperature of the heating roller. The thermally-conductive liquid medium can be heat conducting oil, molten metal such as potassium and sodium, pure water, ethanol-like substance, etc.

Owner:株洲科力通用设备有限公司

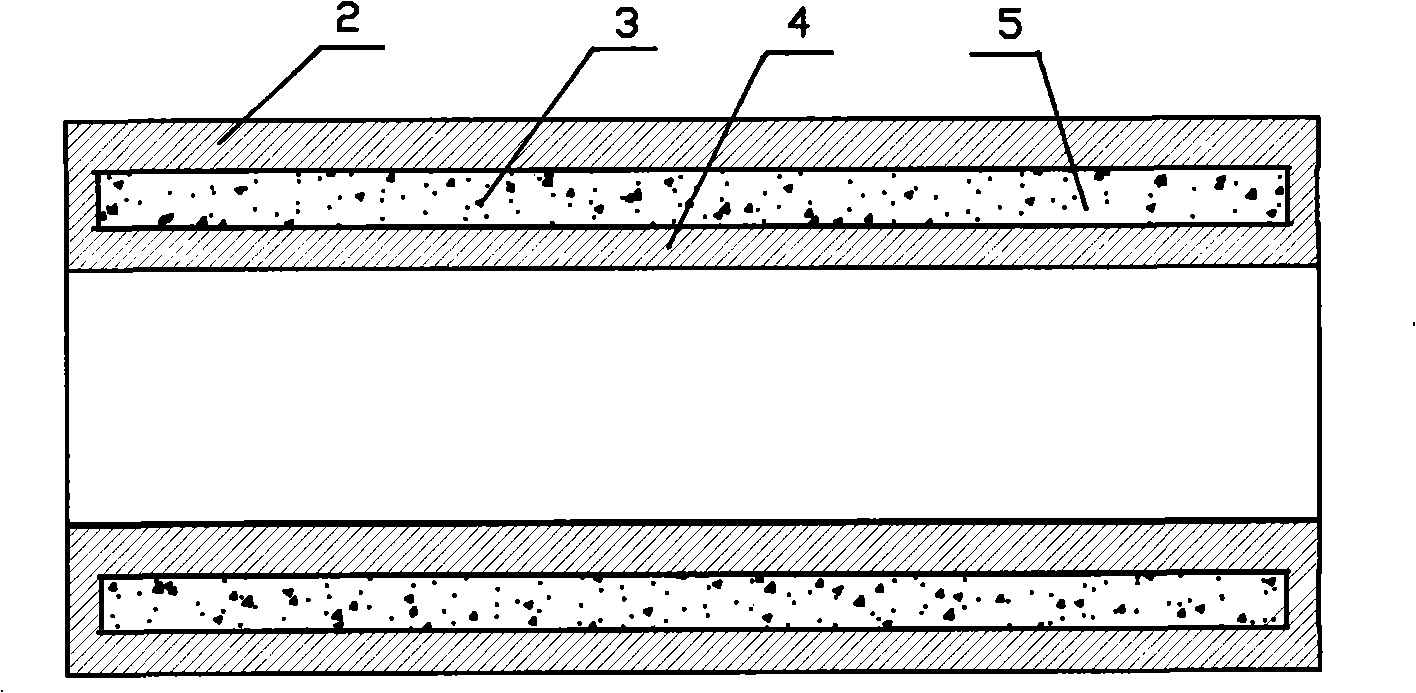

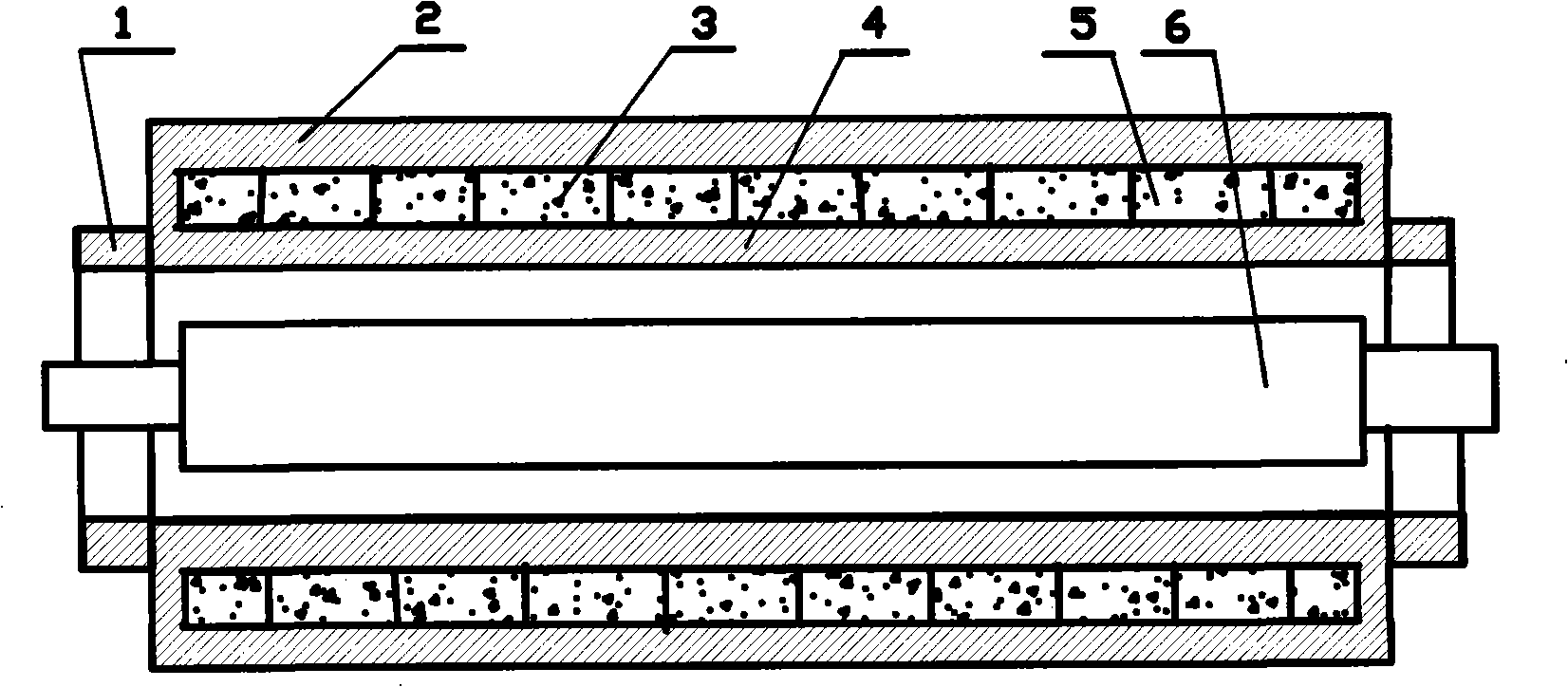

Multi-layer stamp

ActiveUS20170173852A1High precisionImprove flatnessTransfer printingSolid-state devicesThermal expansionTransfer printing

A stamp for micro-transfer printing includes a support having a support stiffness and a support coefficient of thermal expansion (CTE). A pedestal layer is formed on the support, the pedestal layer having a pedestal layer stiffness that is less than the support stiffness and a pedestal layer coefficient of thermal expansion (CTE) that is different from the support coefficient of thermal expansion (CTE). A stamp layer is formed on the pedestal layer, the stamp layer having a body and one or more protrusions extending from the body in a direction away from the pedestal layer. The stamp layer has a stamp layer stiffness that is less than the support stiffness and a stamp layer coefficient of thermal expansion that is different from the support coefficient of thermal expansion.

Owner:X DISPLAY CO TECH LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com