Unit type mold cutter for reeled paper

A roll paper, unit type technology, which is applied in the field of multi-function automatic hot stamping and die-cutting equipment of flat pressing unit type, can solve the problems of difficulty in popularization and inability to realize other processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

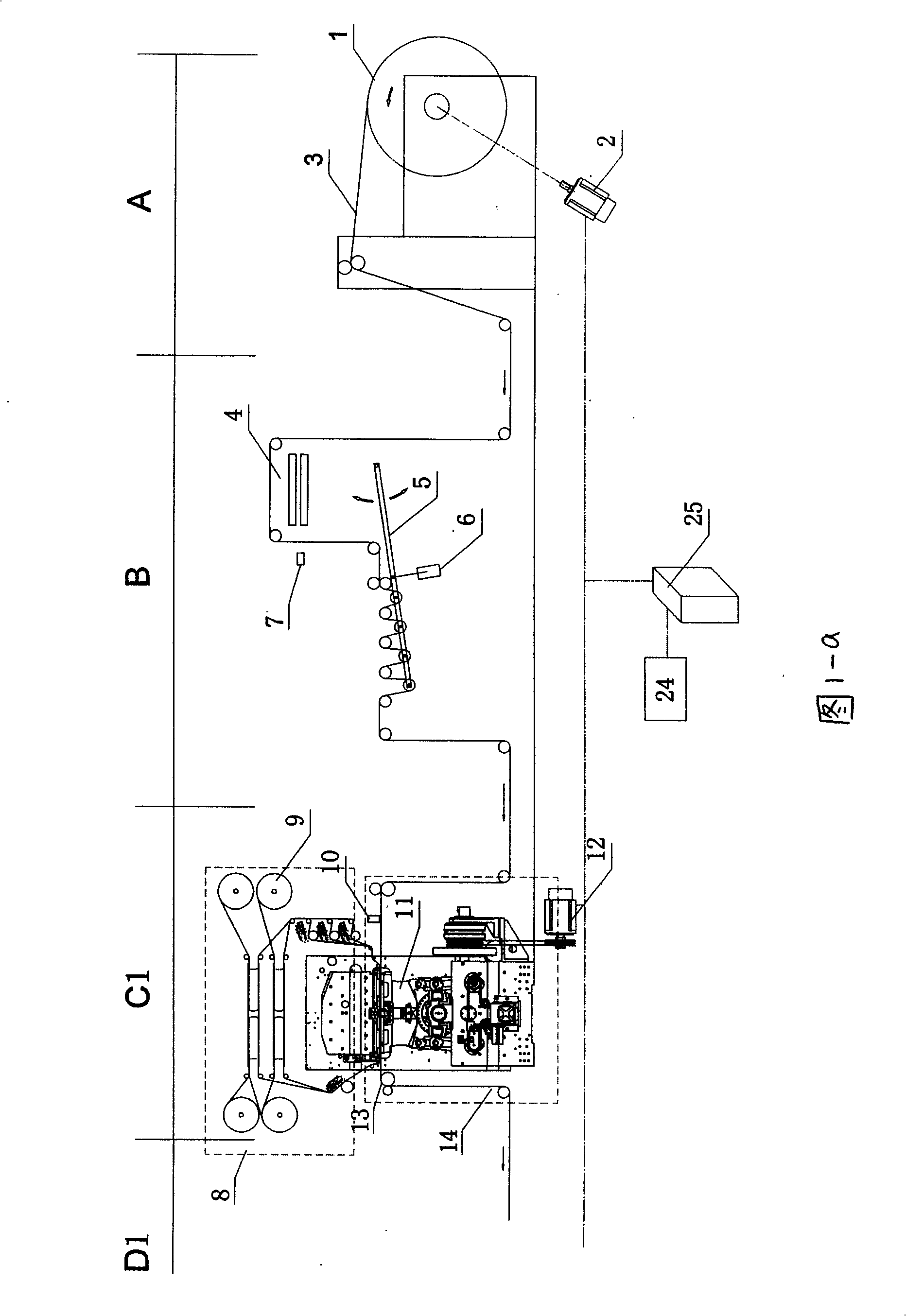

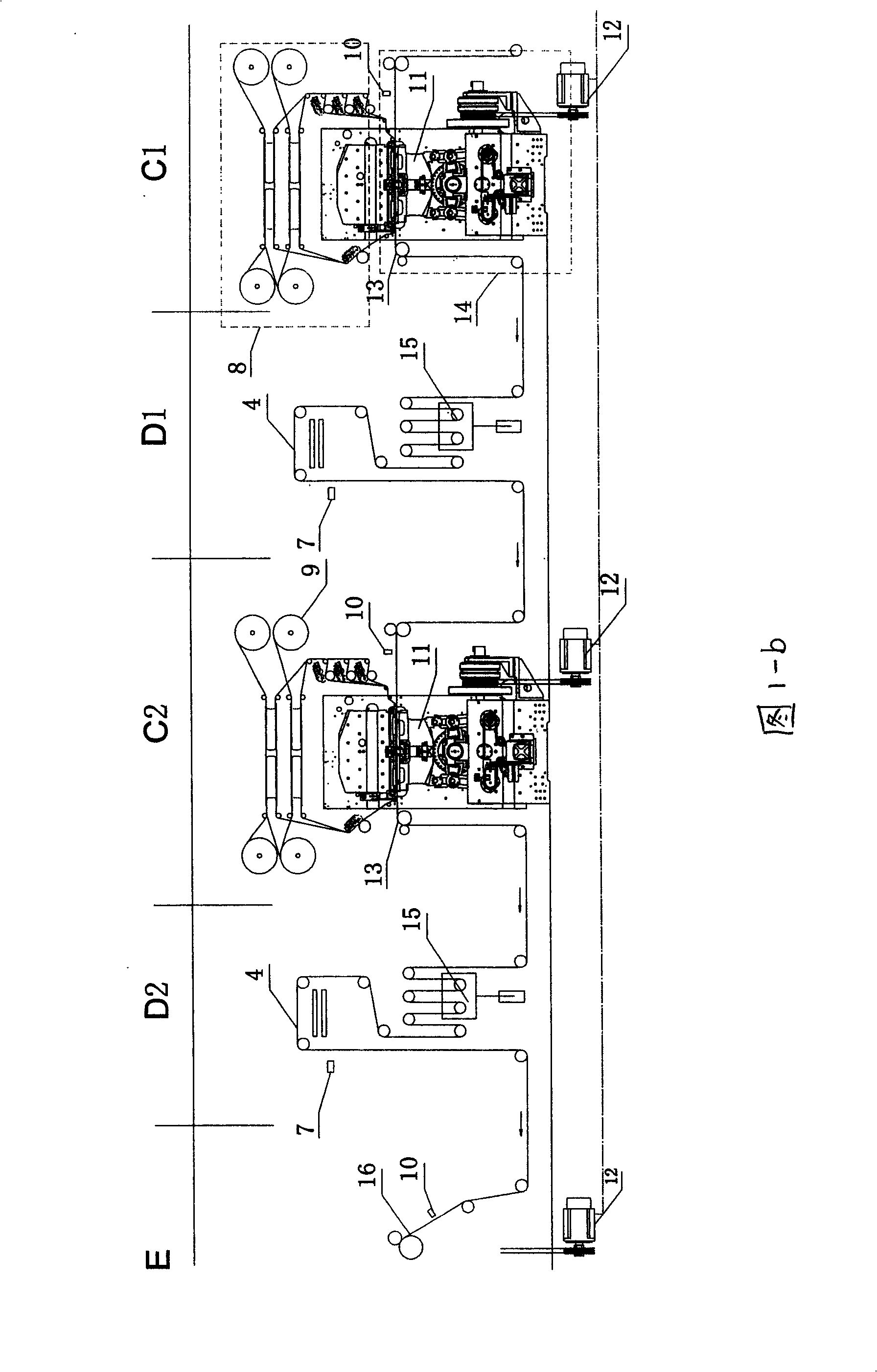

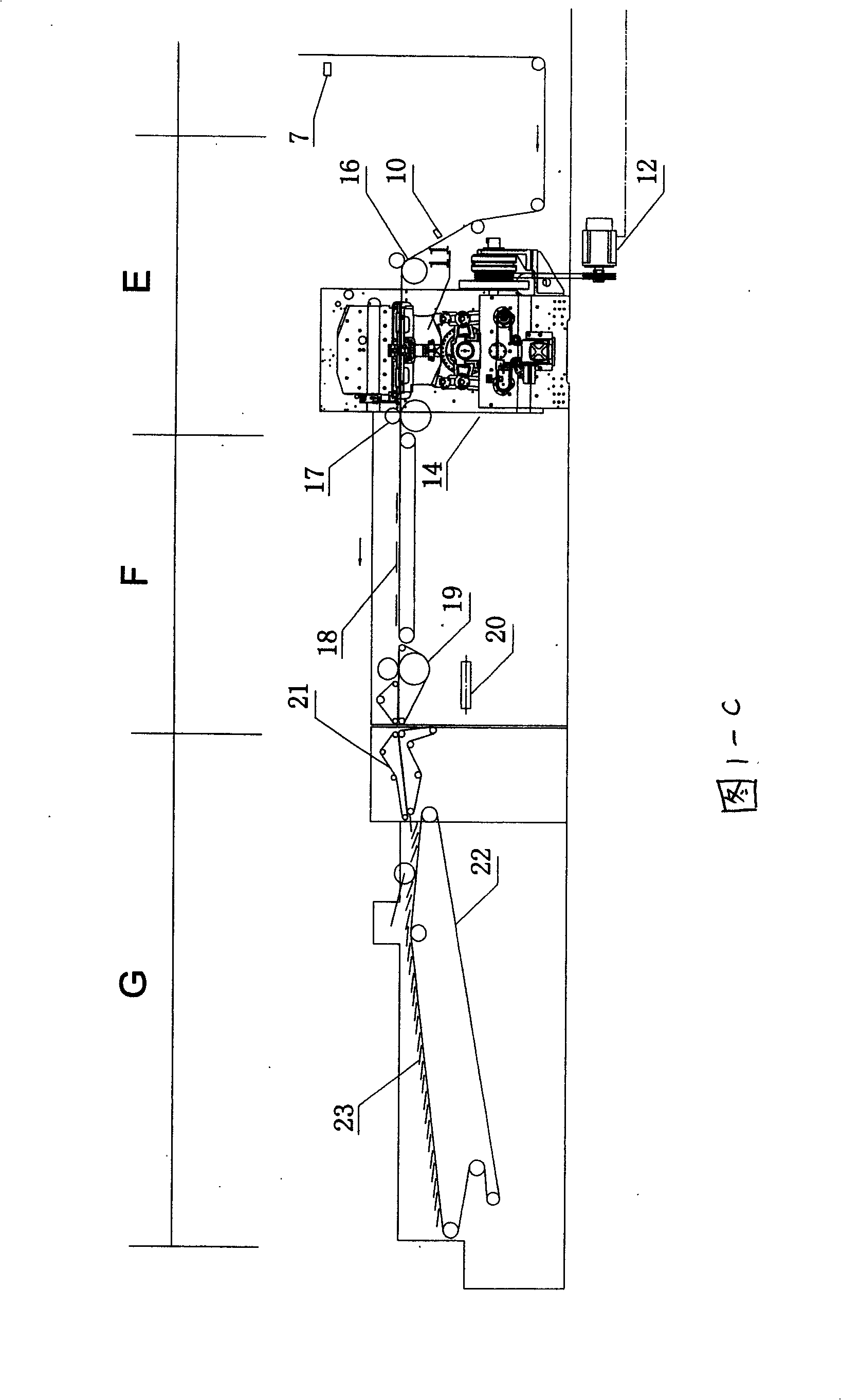

[0018] Embodiment: A roll paper flattening unit-type multi-function automatic hot stamping machine, equipped with multiple sets of hot stamping units, and can realize the functions of in-line die-cutting and waste cleaning, and finally realize the collection of finished products.

[0019] This embodiment first includes a roll paper unwinding device A that realizes the continuous supply of paper to the paper storage device B of the next station, drives the unwinding motor 2 that continuously feeds the roll paper 1, and the opened paper 3 passes through a series of The drum is continuously conveyed downstream, and the speed of the unwinding motor 2 is fed back through the control system to ensure that the paper maintains a relatively constant tension.

[0020] The downstream of the roll paper discharge device A is connected to a paper storage device B that can receive the continuously conveyed paper material 3 and ensure that the tension of the paper on the paper path is relative...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com