Patents

Literature

1842results about How to "Guaranteed pass rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

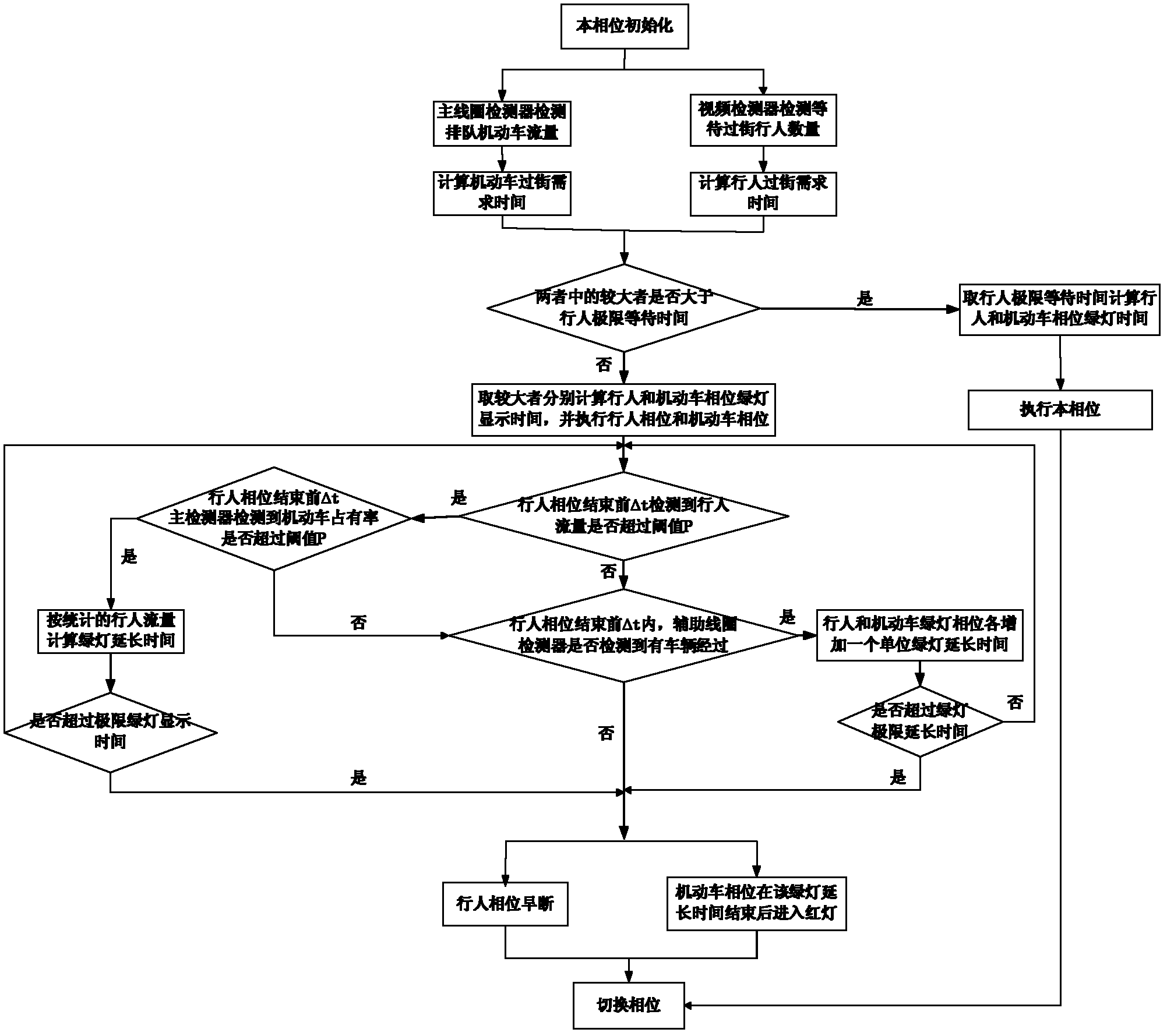

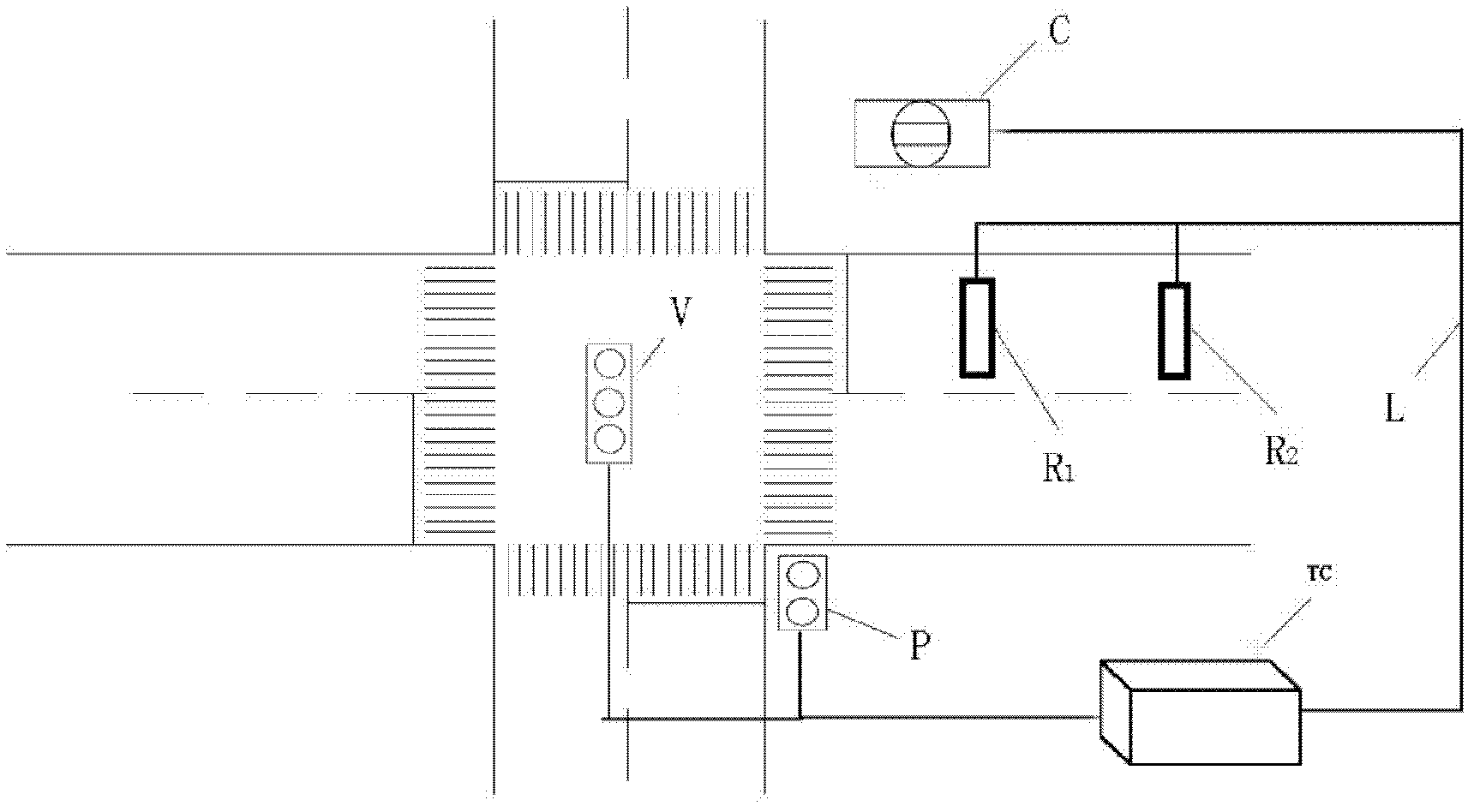

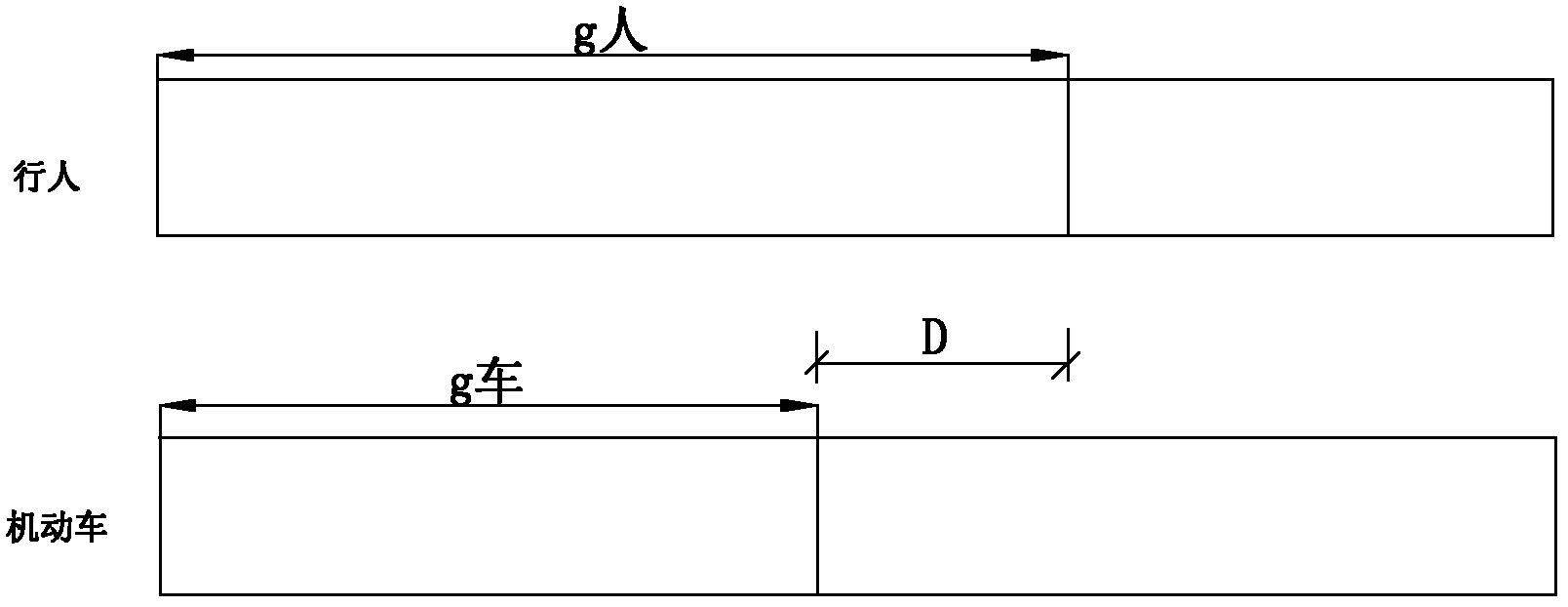

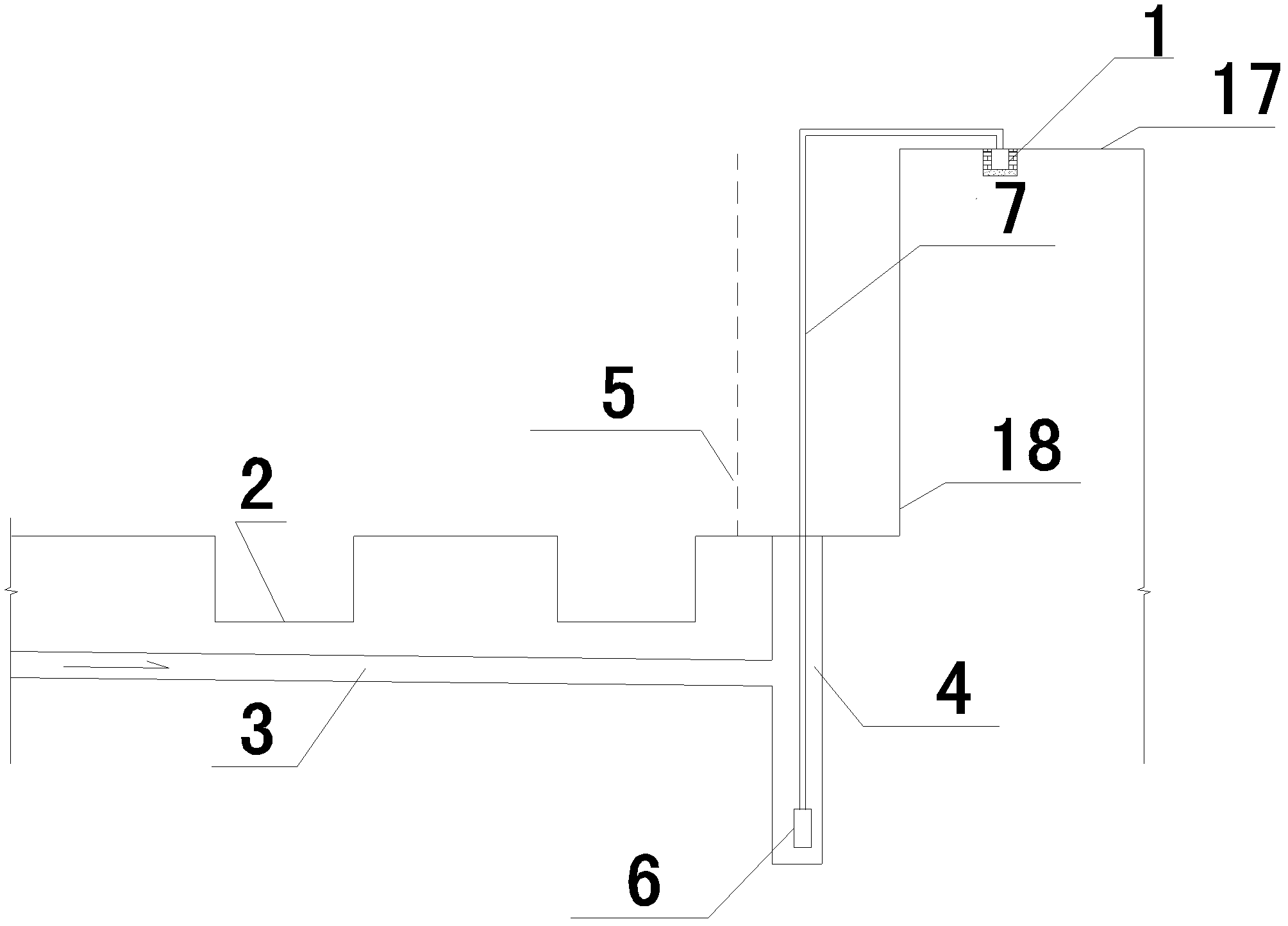

Intelligent traffic signal control system considering safety of cross-street pedestrians

InactiveCN102419907AAchieve securityAchieve efficiencyControlling traffic signalsTraffic signalPass rate

The invention provides an intelligent traffic signal control system considering the safety of cross-street pedestrians; the intelligent traffic signal control system comprises inductance coil detectors, video detectors, a traffic signal controlling machine and signal lamps; a two-phase total-inductive control mode is adopted in a road crossing; the two inductance coil detectors are embedded in each inlet lane, wherein the main inductance coil detector is embedded at a stop line of the inlet lane and is used for detecting traffic flow of a road section; the auxiliary inductance coil detector is embedded at the possible maximum queuing part of an advanced position of the main inductance coil detector and is used for assisting the main inductance coil detector to detect motor vehicles; pedestrian cross-street waiting areas at two ends of each pedestrian crossing are respectively provided with the video detector for detecting flow of crossing pedestrians; the traffic signal controlling machine carries out data exchange with the main inductance coil detector, the auxiliary inductance coil detector and the video detectors by data lines and simultaneously controls the signal lamps positioned at the pedestrian crossing and the road crossing by the data lines. According to the intelligent traffic signal control system, the safety and the passing efficiency of the cross-street pedestrians can be realized, and the passing rate of the motor vehicles is ensured.

Owner:WUHAN UNIV OF TECH

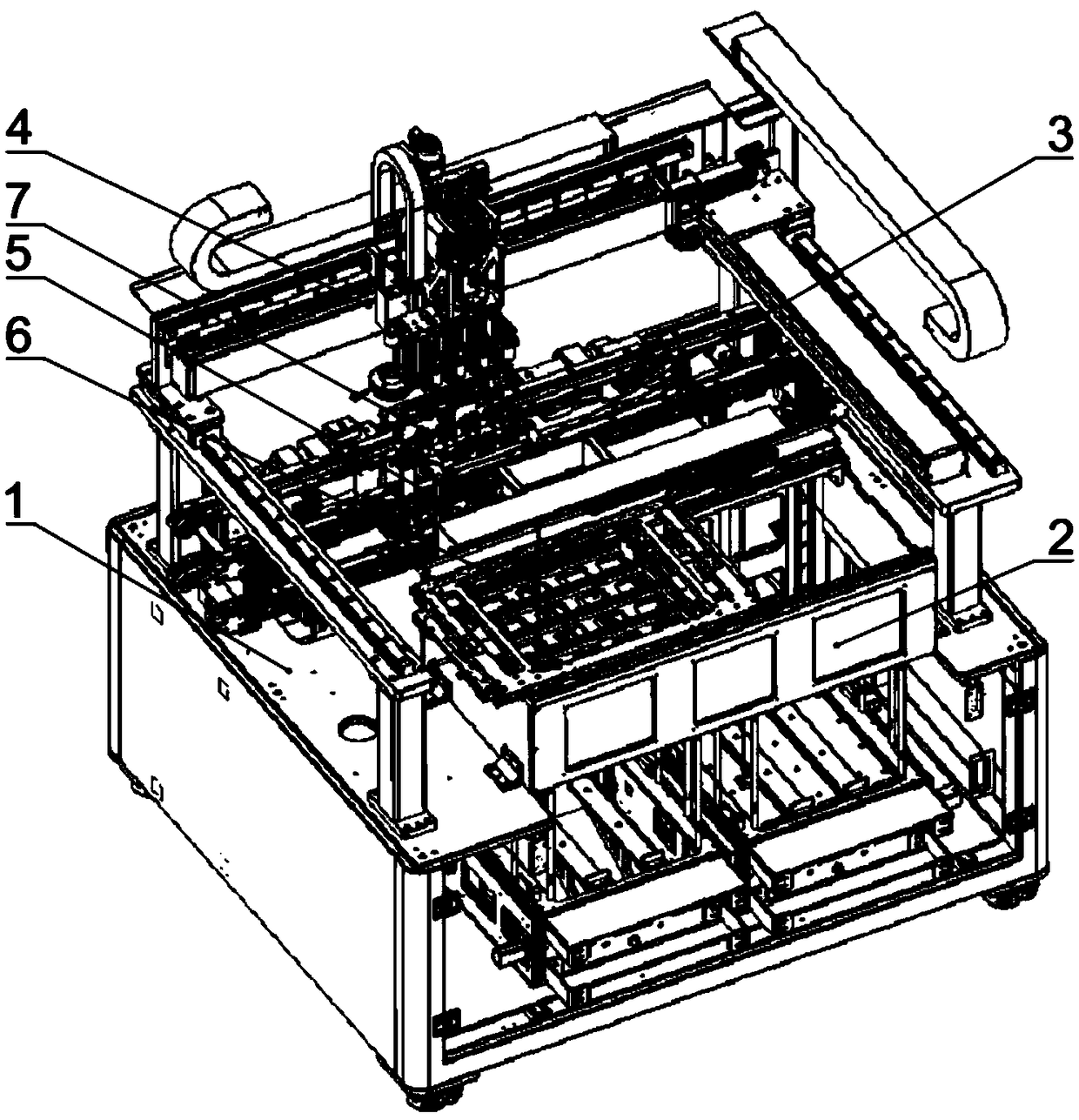

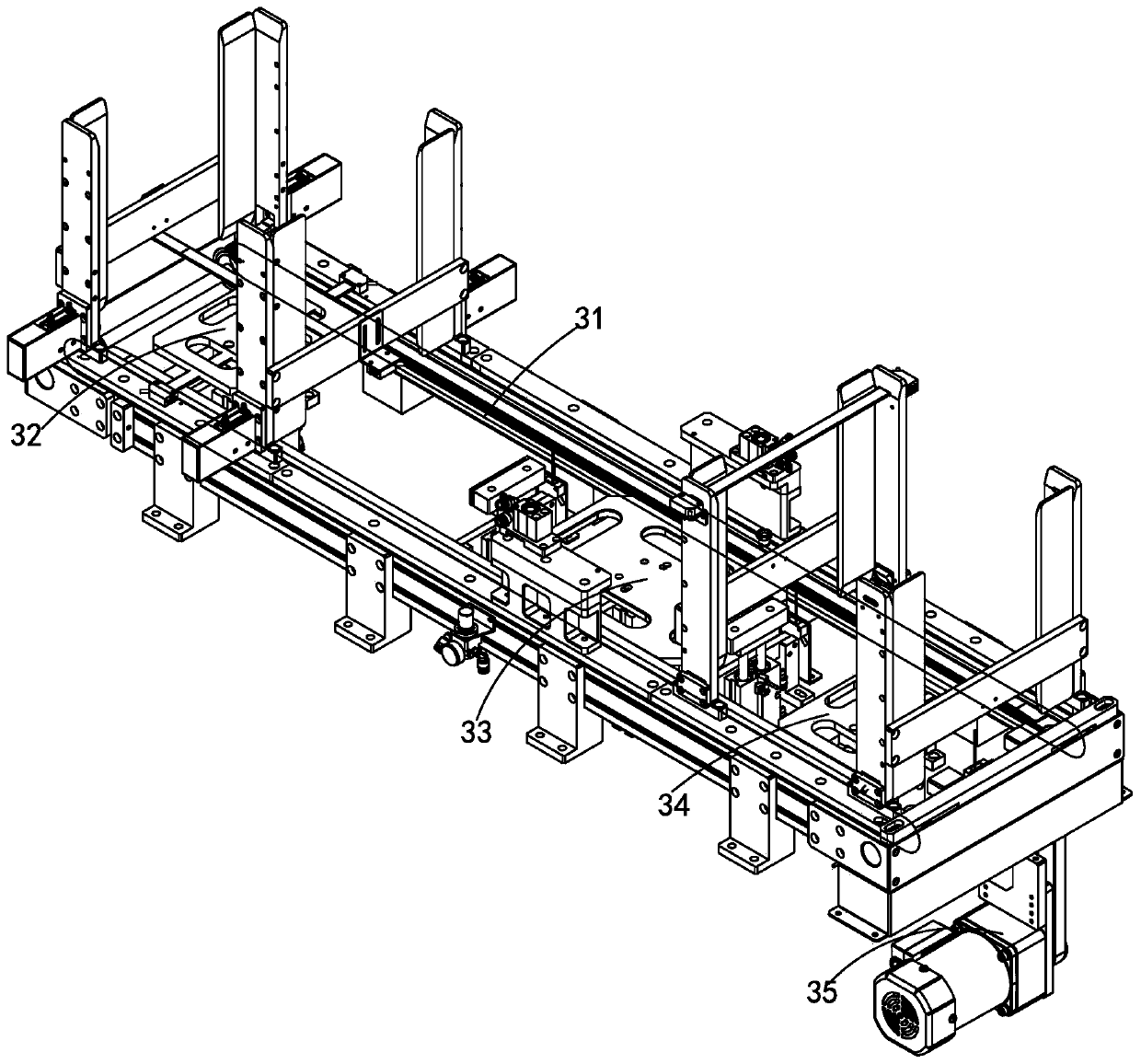

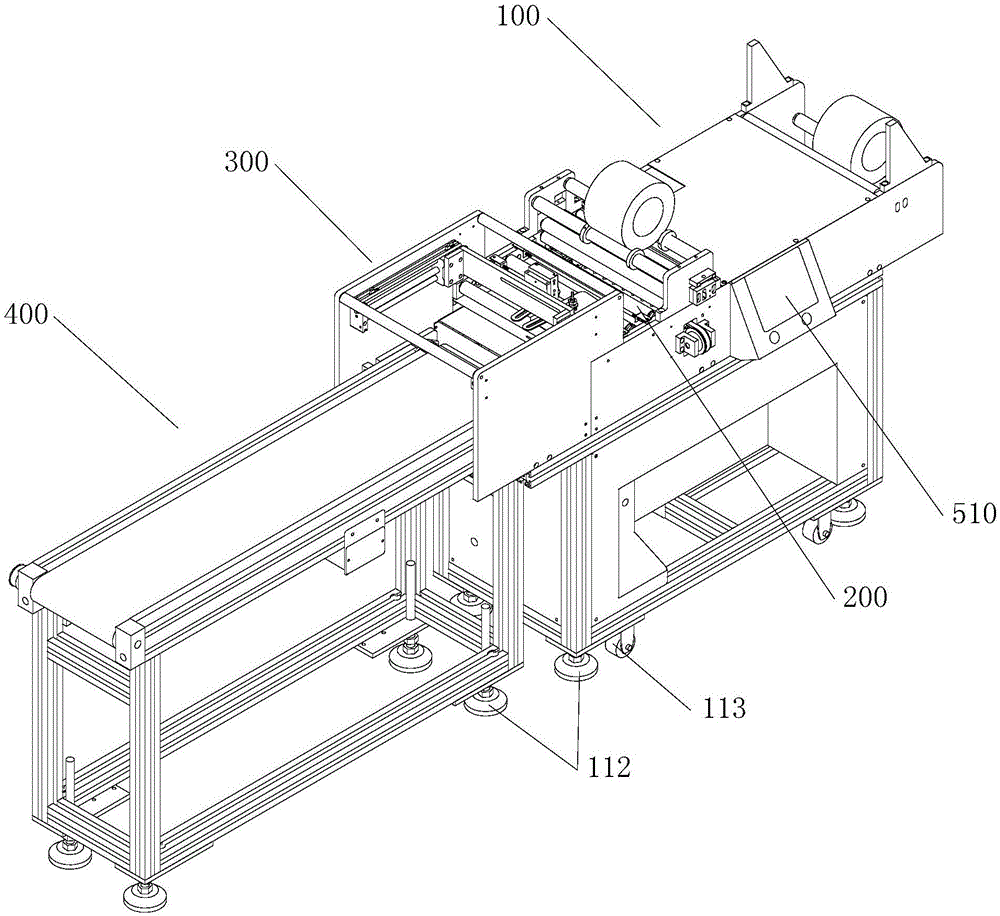

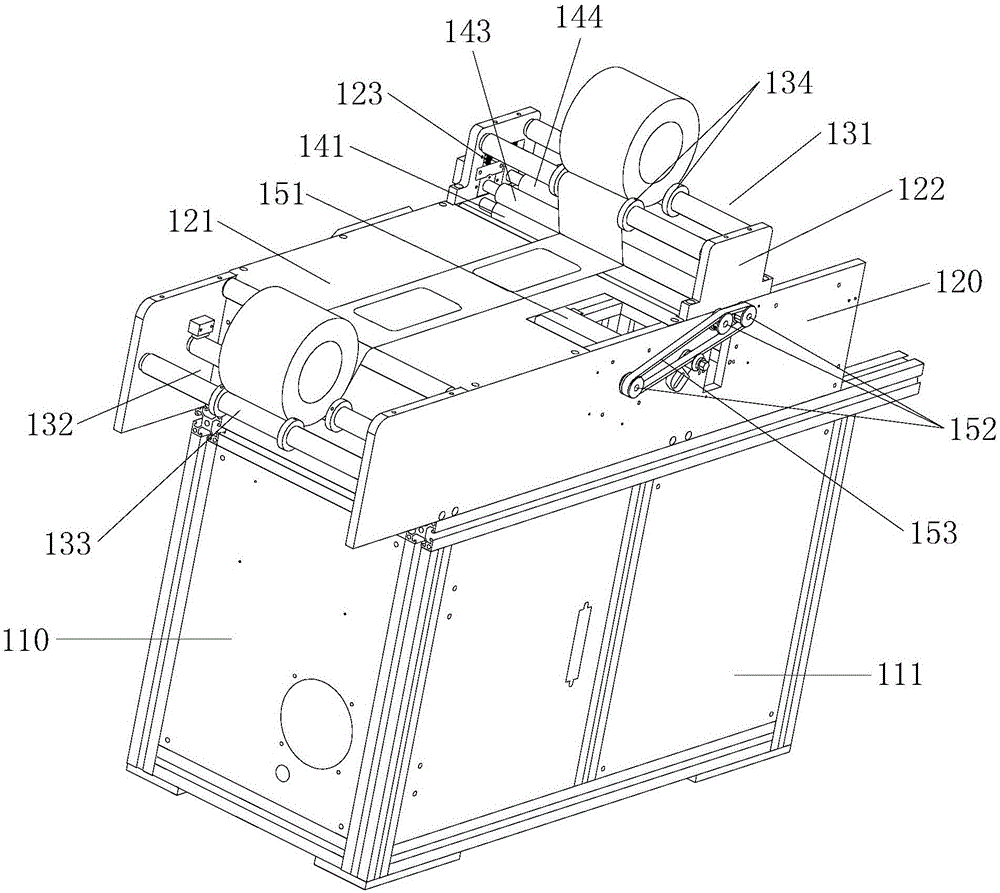

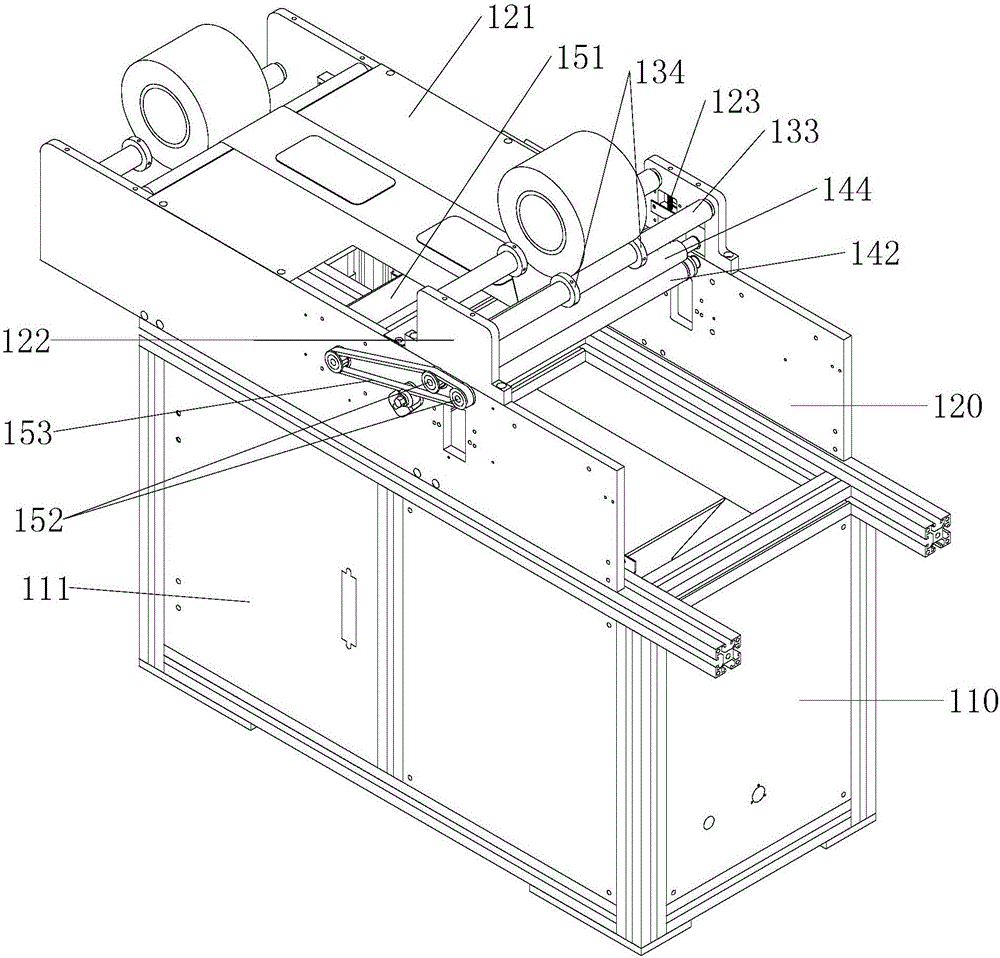

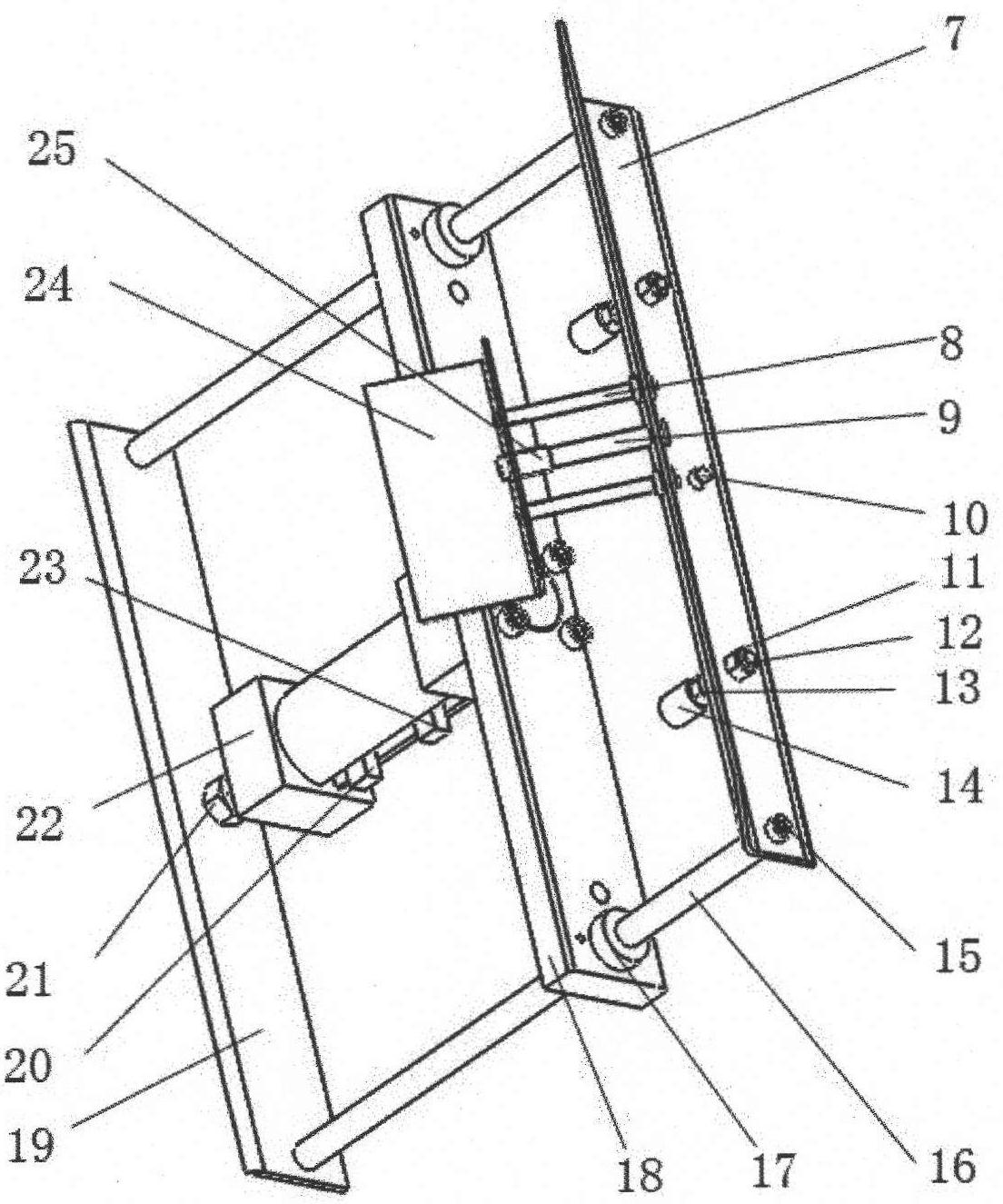

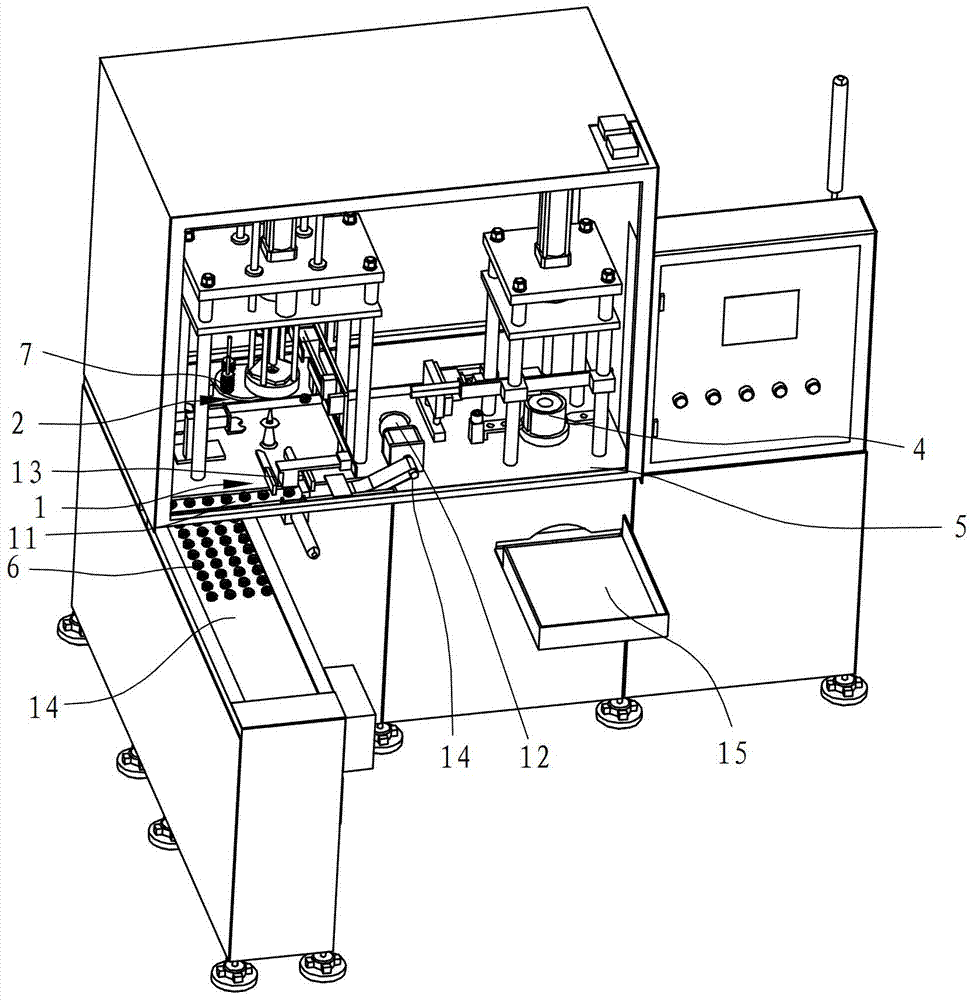

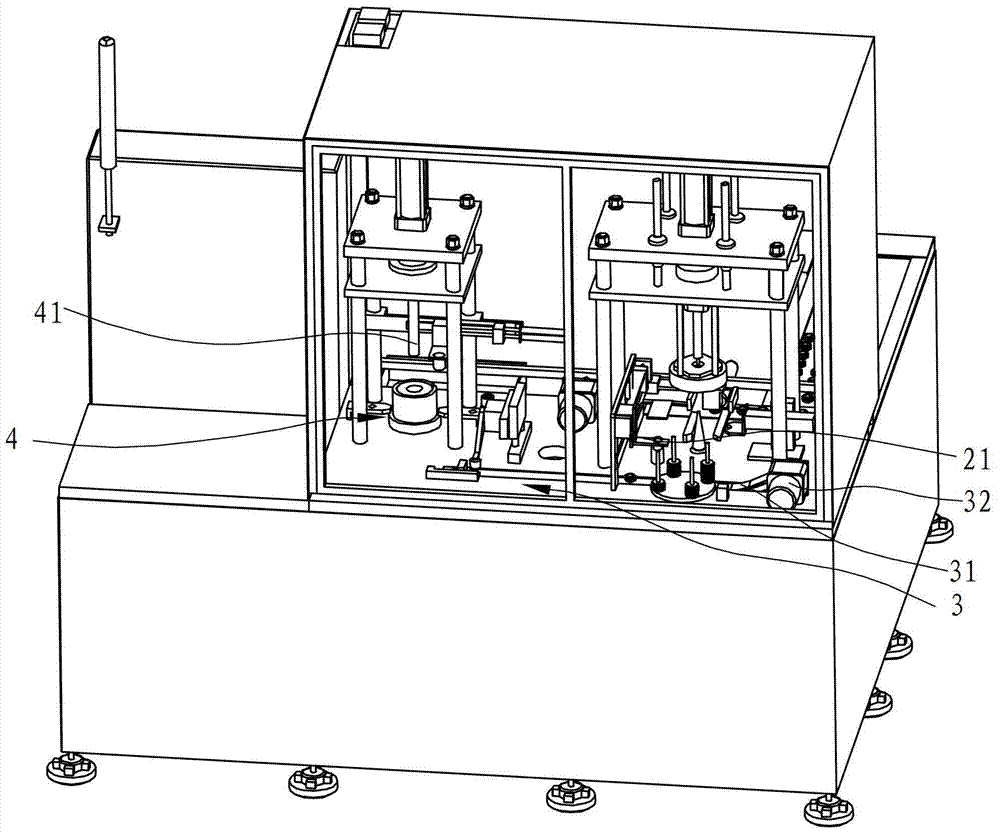

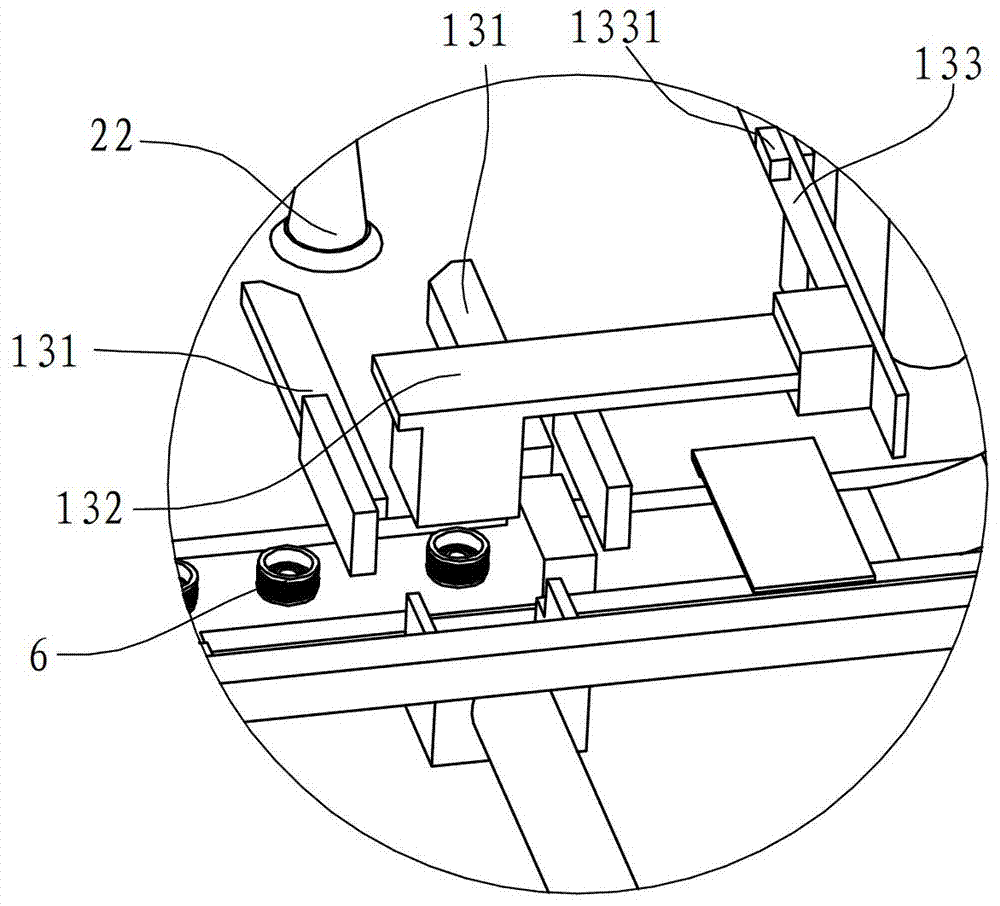

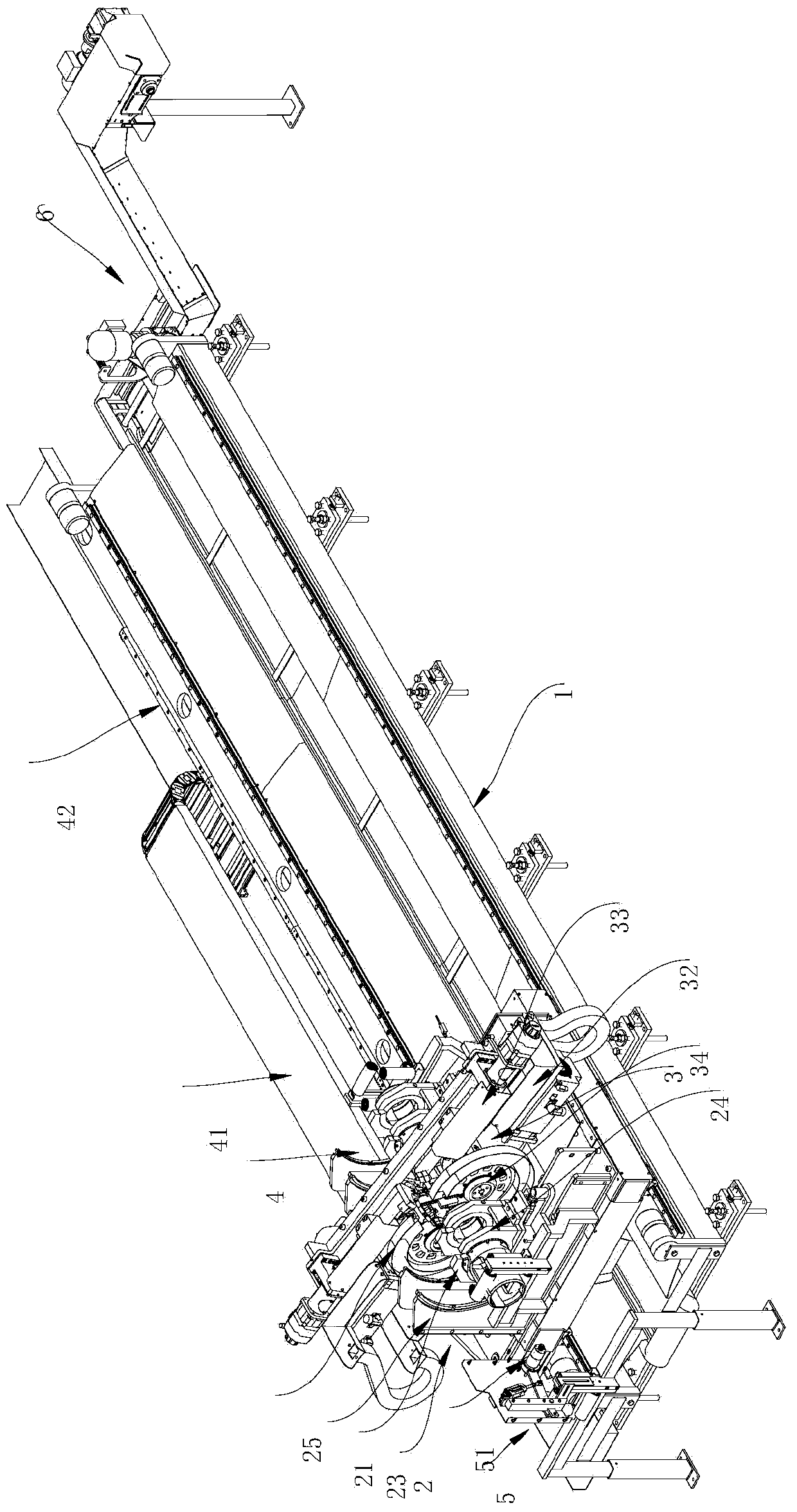

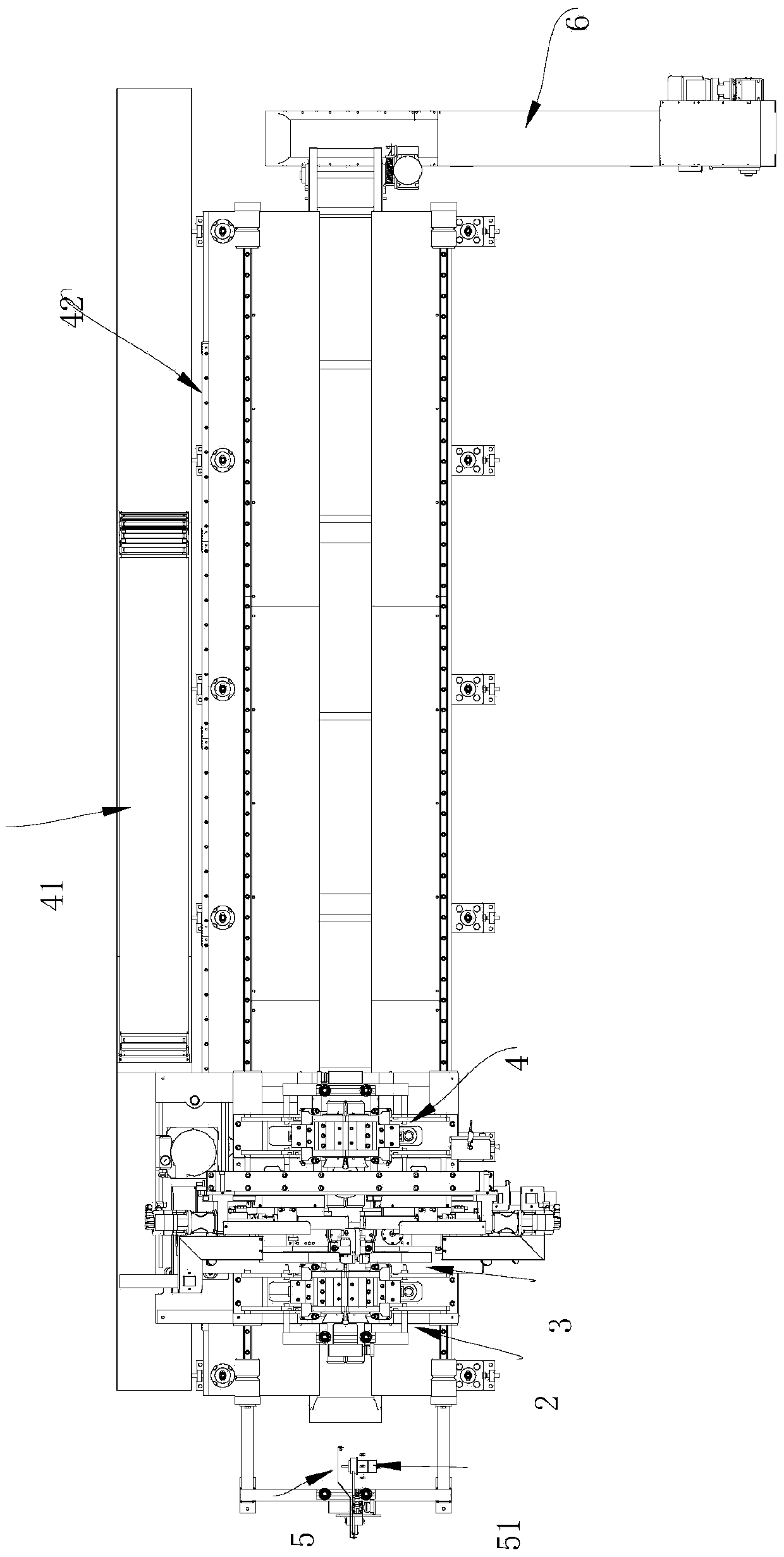

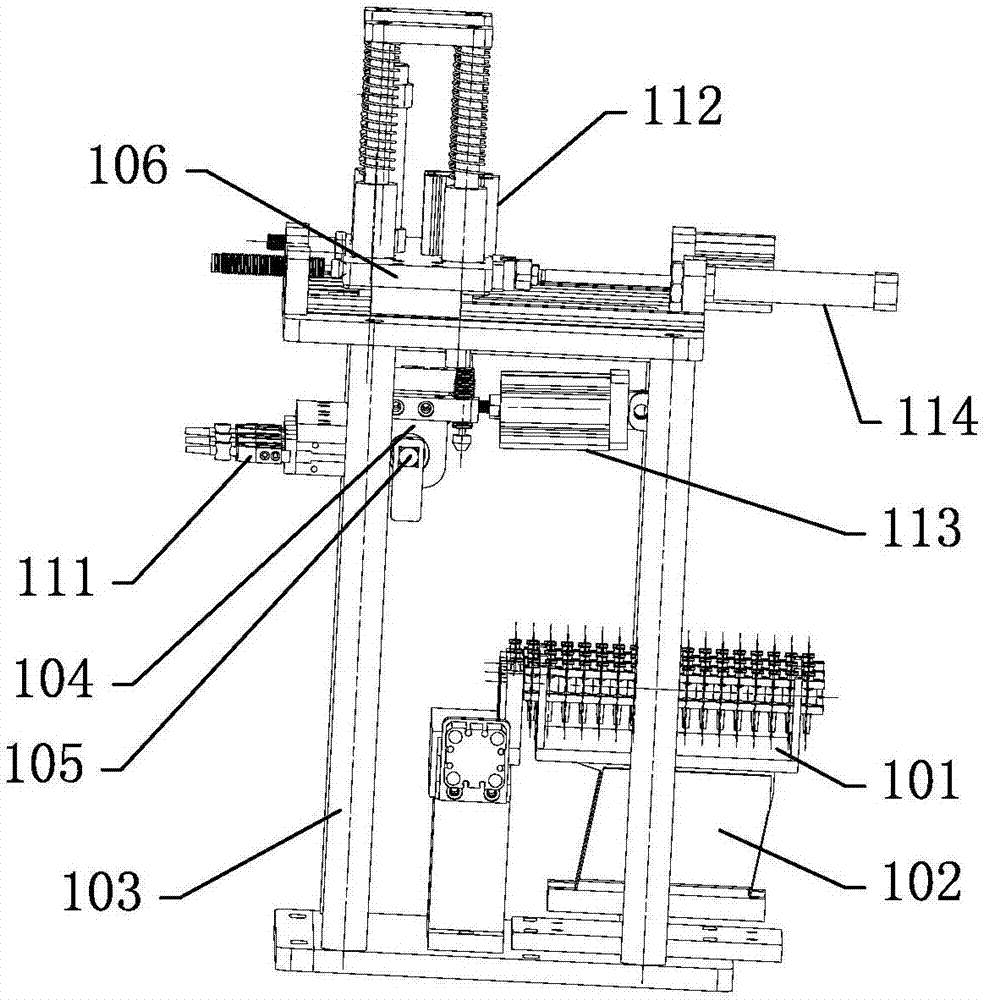

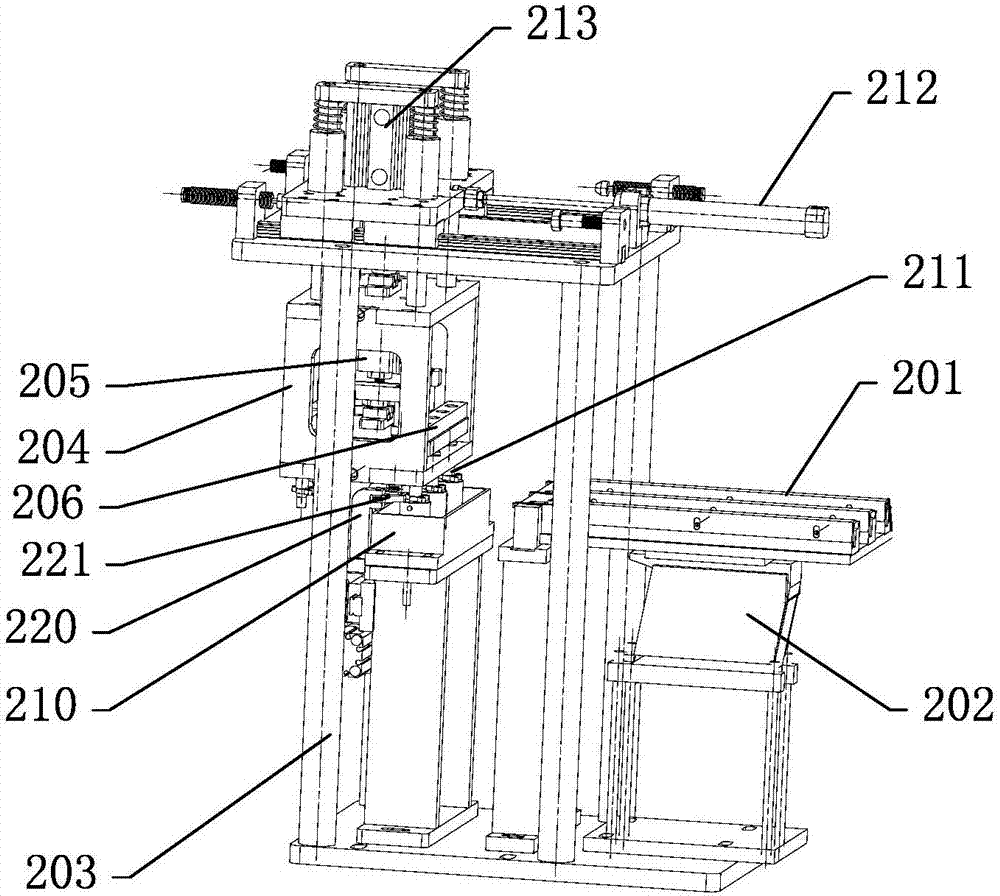

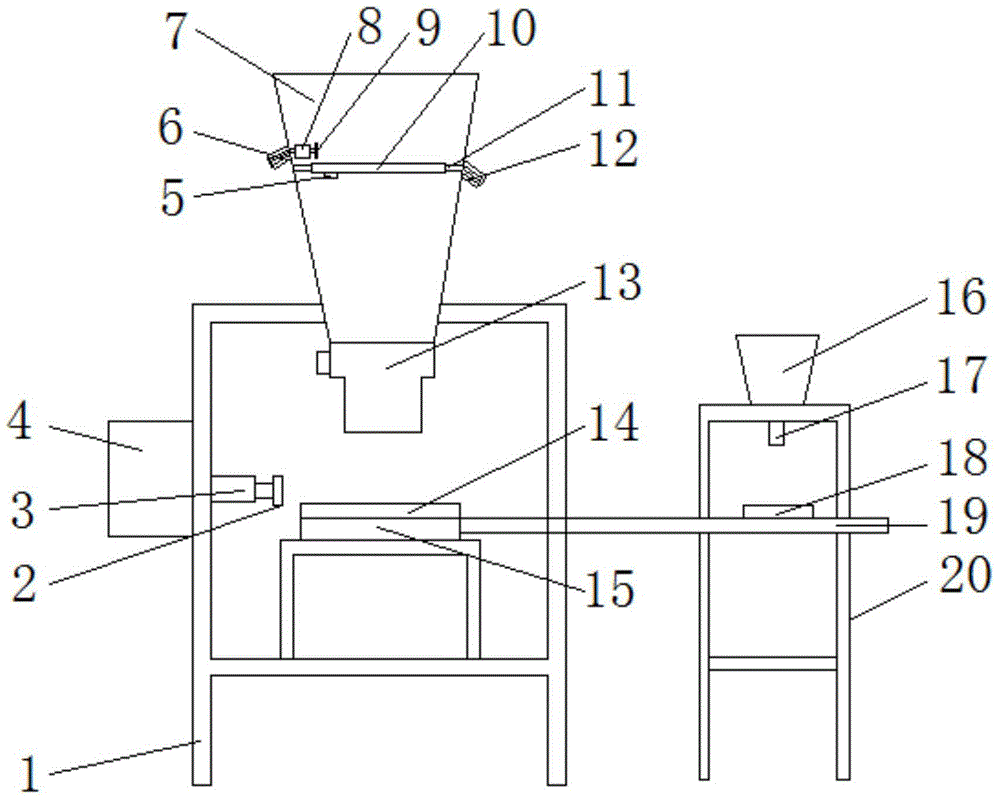

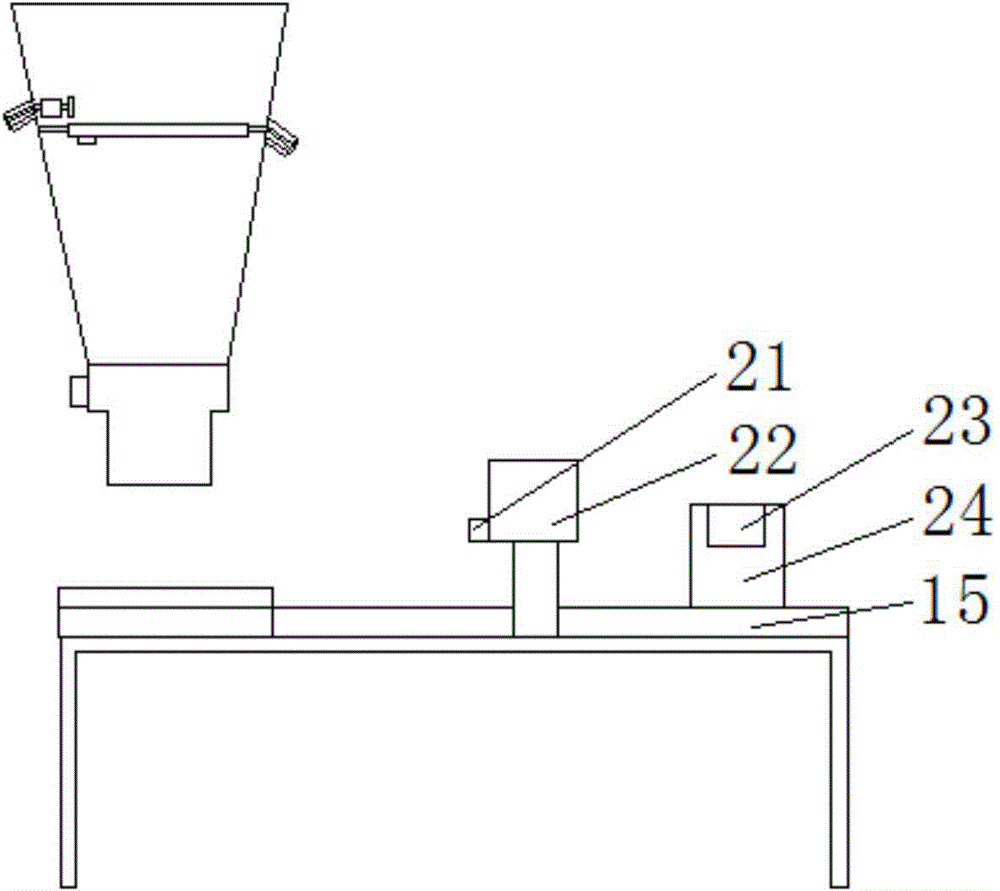

Workpiece feeding device and method

PendingCN109132526AAchieve continuous supplyRealize the loading function of magazine typeConveyorsControl devices for conveyorsEngineeringMechanical engineering

The invention provides a workpiece feeding device. The workpiece feeding device comprises a working platform, a supplying mechanism, a conveying line mechanism, a workpiece carrying mechanism and a screening mechanism, wherein a supplying position is arranged on the supplying mechanism; a mounting position is arranged on the conveying line mechanism. According to the device, the workpiece carryingmechanism is capable of clamping a workpiece from the supplying position; the workpiece subjected to detecting and screening of the screening mechanism moves and then is mounted to a target carrier at the mounting position; the supplying mechanism and the workpiece carrying mechanism realize automatic workpiece supplying and feeding and mounting; the workpiece can be detected through the screening mechanism in the carrying process, so that the qualification rate of the workpiece is ensured; the workpiece is carried through the conveying line mechanism utilizing the carrier, and thus the flow-line type processing work is realized. The invention also provides a workpiece feeding method. With the adoption of the device and the method, the workpiece is automatically fed and detected, and thusthe convenience of production management is ensured.

Owner:SUZHOU RS TECH

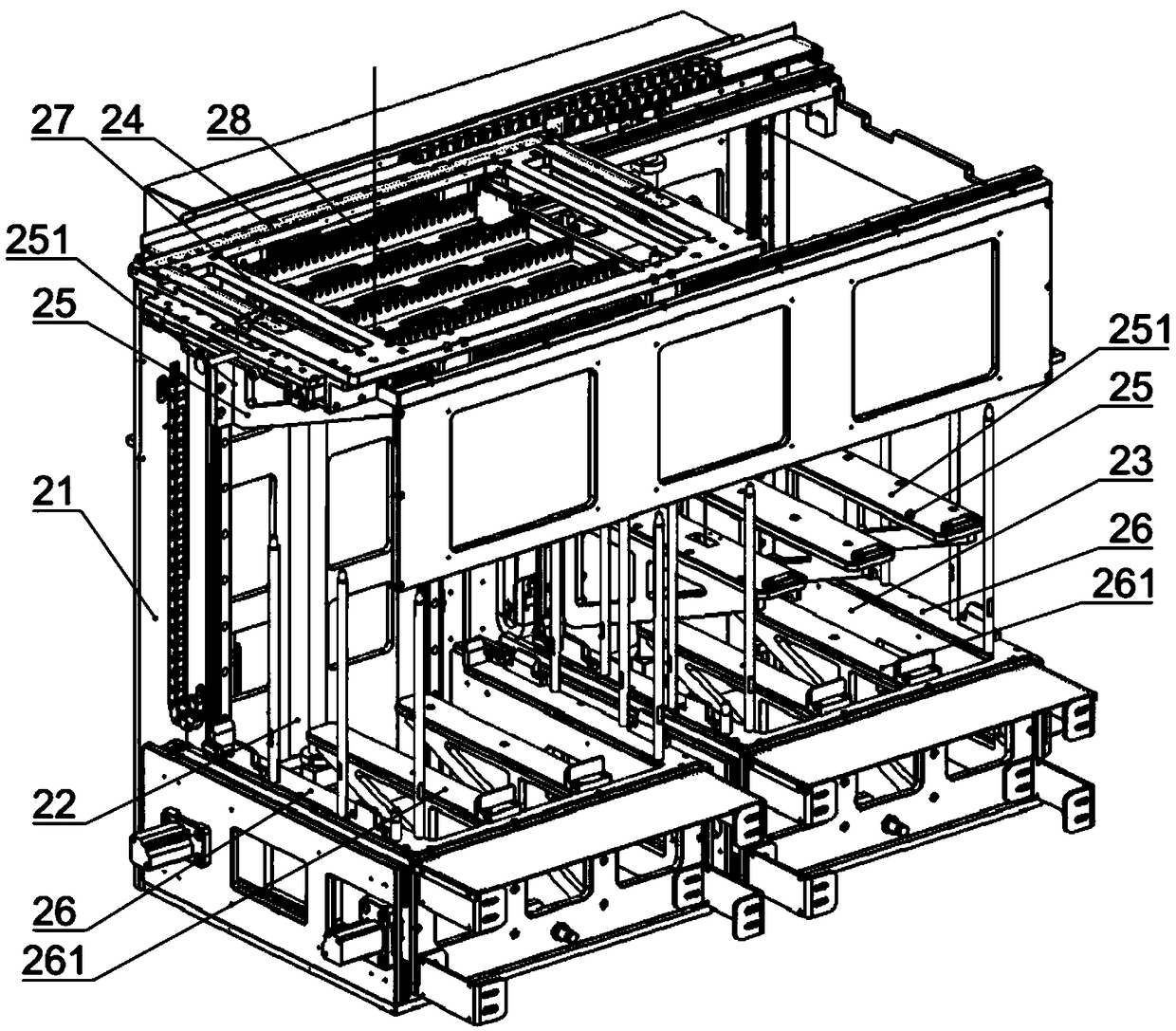

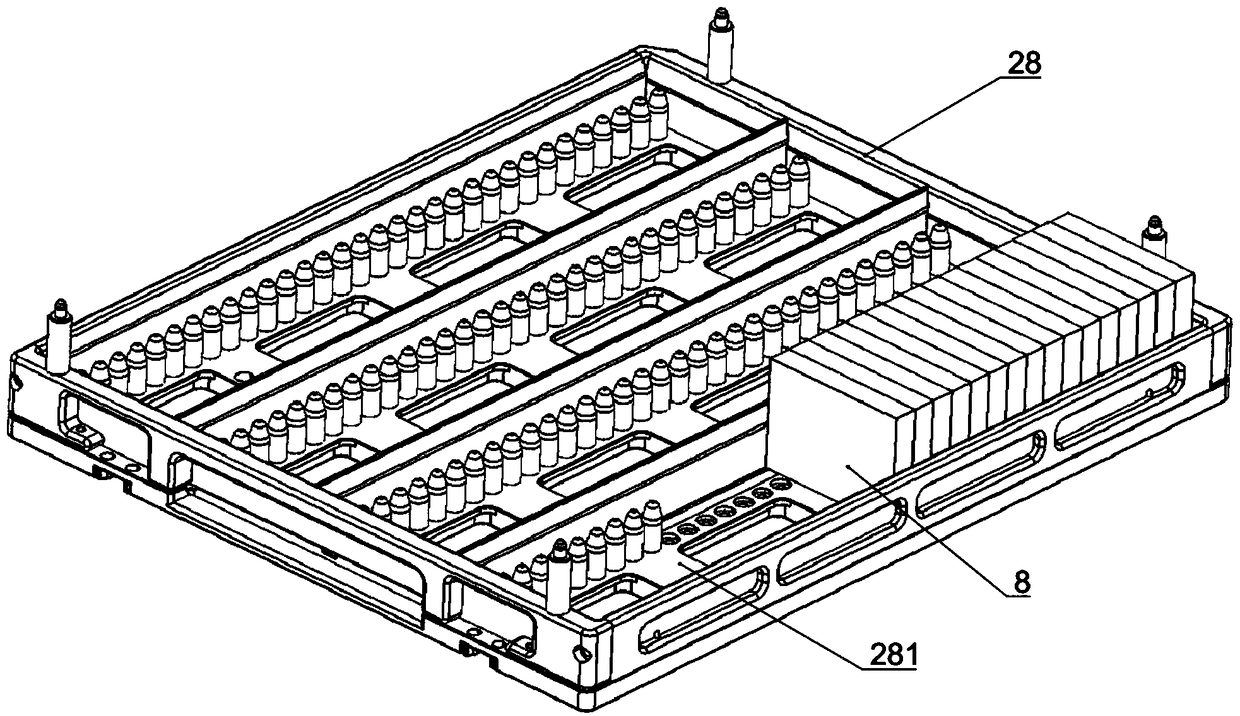

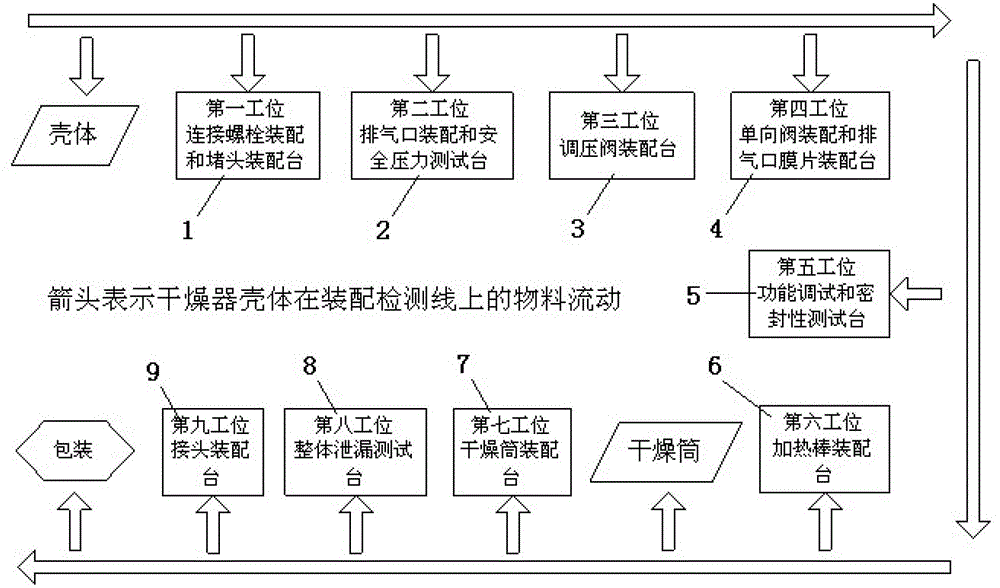

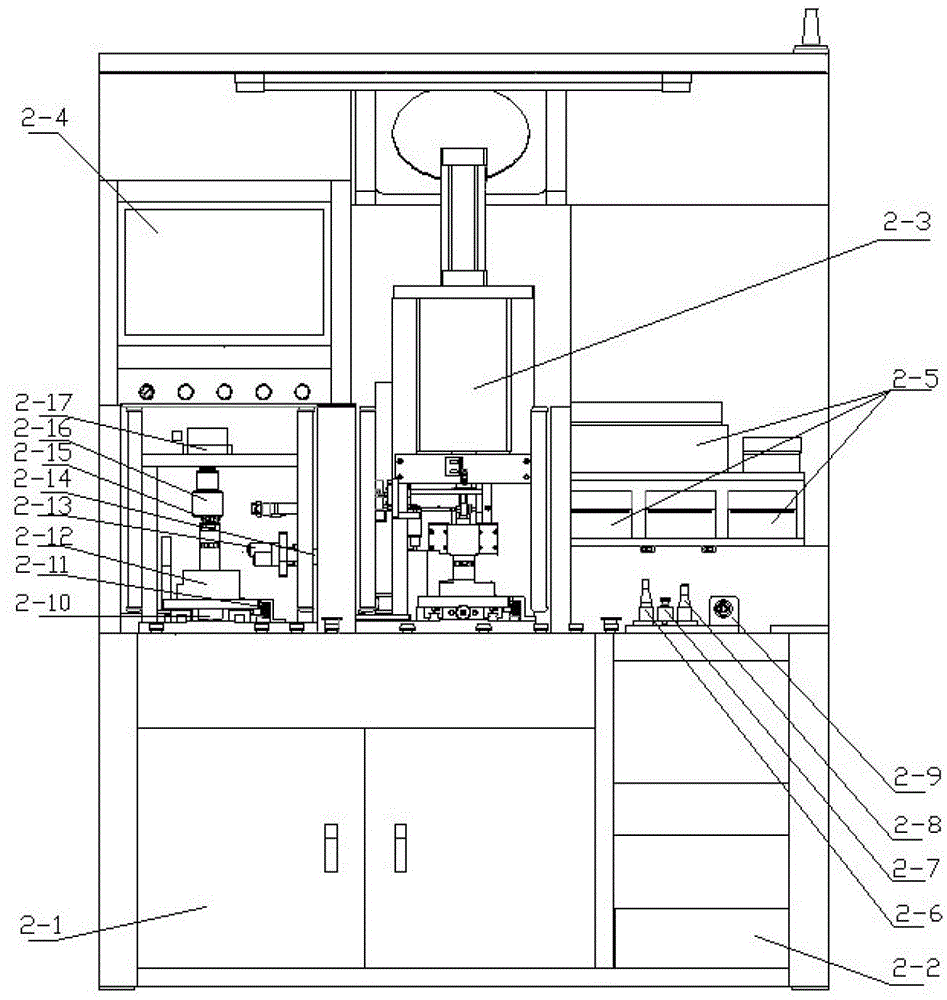

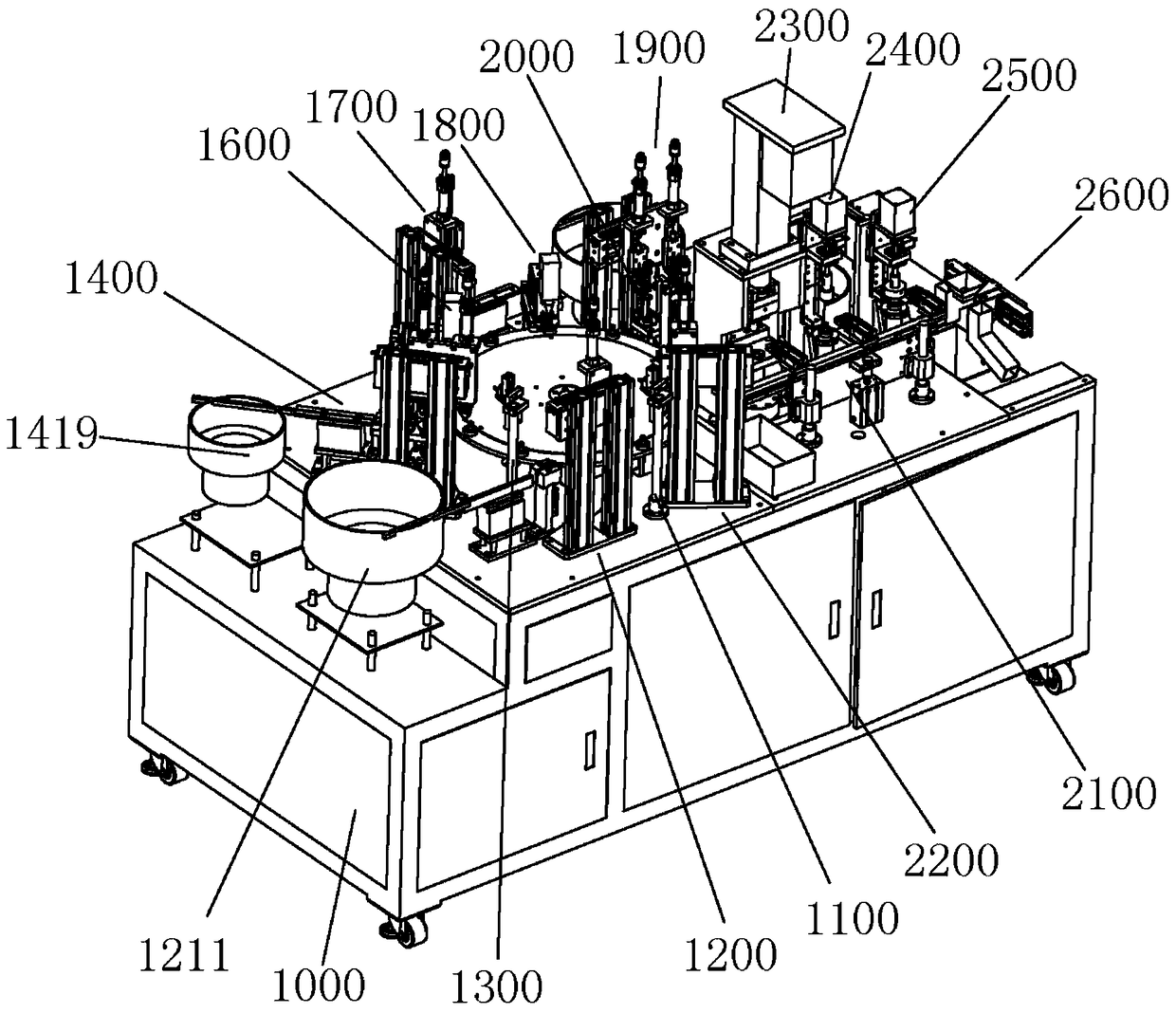

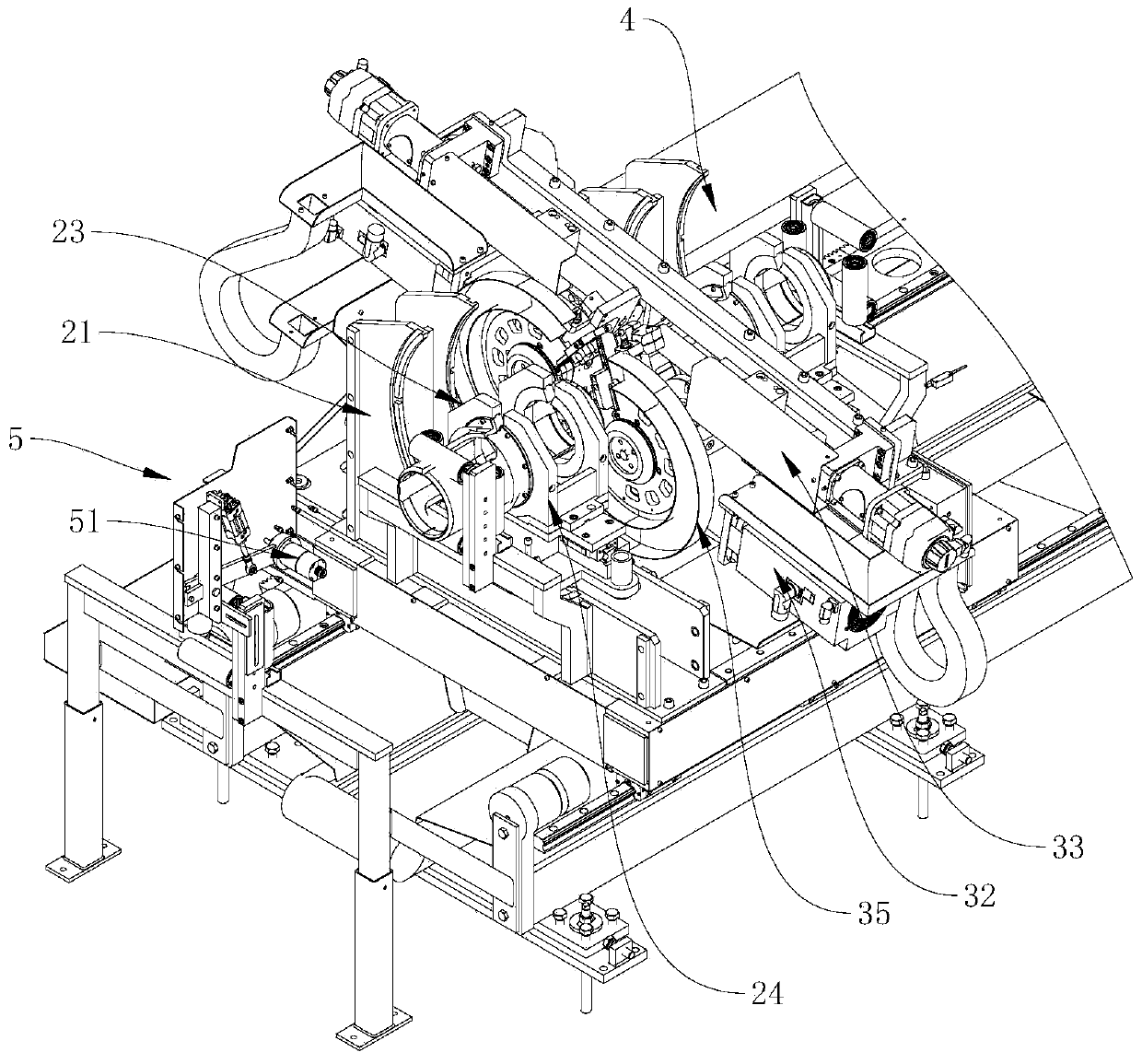

Automobile air dryer assembling and testing production line

ActiveCN103182645AReasonable structural designFlexible layout adjustmentVehicle testingMeasurement of fluid loss/gain rateTest efficiencyProduction line

The invention discloses an automobile air dryer assembling and testing production line. At present, assembly of most of automobile air dryers at home is in a scattered operation state and a testing method is a manual intermittent partial testing method; however, selection and matching of the conventional assembling and testing equipment are not reasonable enough and poor in coordination; and therefore, the assembling process of the automobile air dryer is poor in smoothness and low in assembling and testing efficiency. The automobile air dryer assembling and testing production line comprises a U-shaped workbench line body, wherein the U-shaped workbench line body comprises six assembling workstations, two testing workstations and an assembling and testing workstation, namely a first workstation, a second workstation, a third workstation, a fourth workstation, a fifth workstation, a sixth workstation, a seventh workstation, an eighth workstation and a ninth workstation sequentially; the adjacent workstations are related to each other through a material conveying belt. A shell of the assembled and tested air dryer is transferred among the workstations through the material conveying belts between the workstations, working procedures are continuous, and the workstations are related through the material conveying belts, so that the assembling pace is ensured and the manufacturing cost is reduced.

Owner:HANGZHOU WOLEI INTELLIGENT TECH

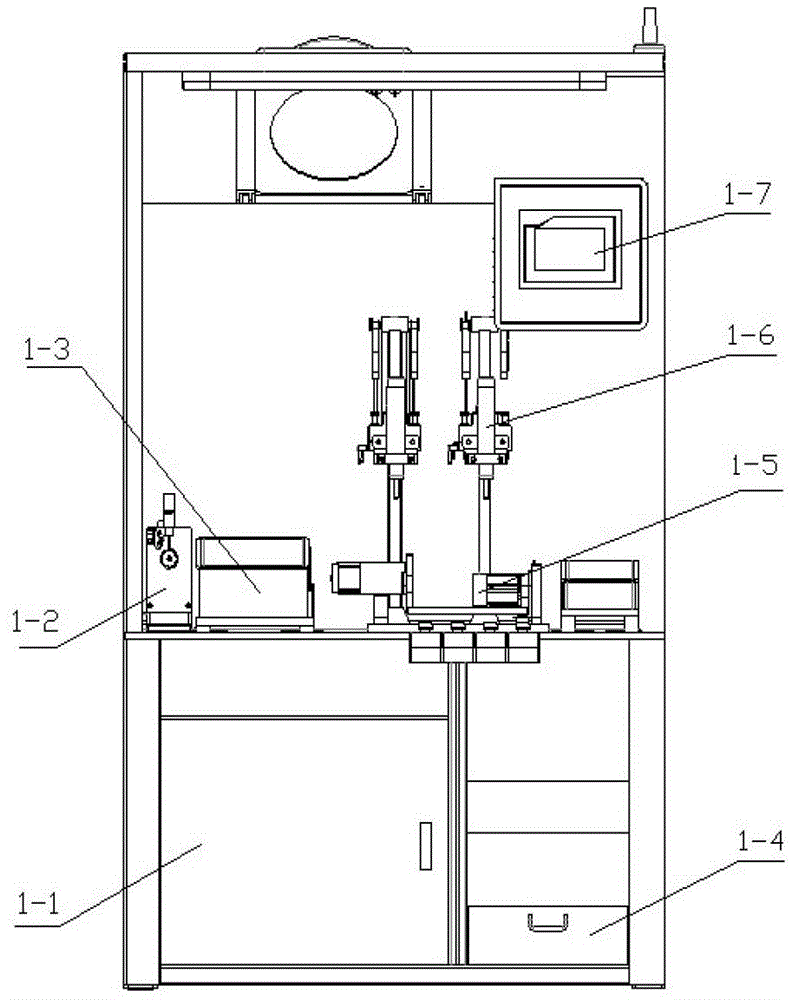

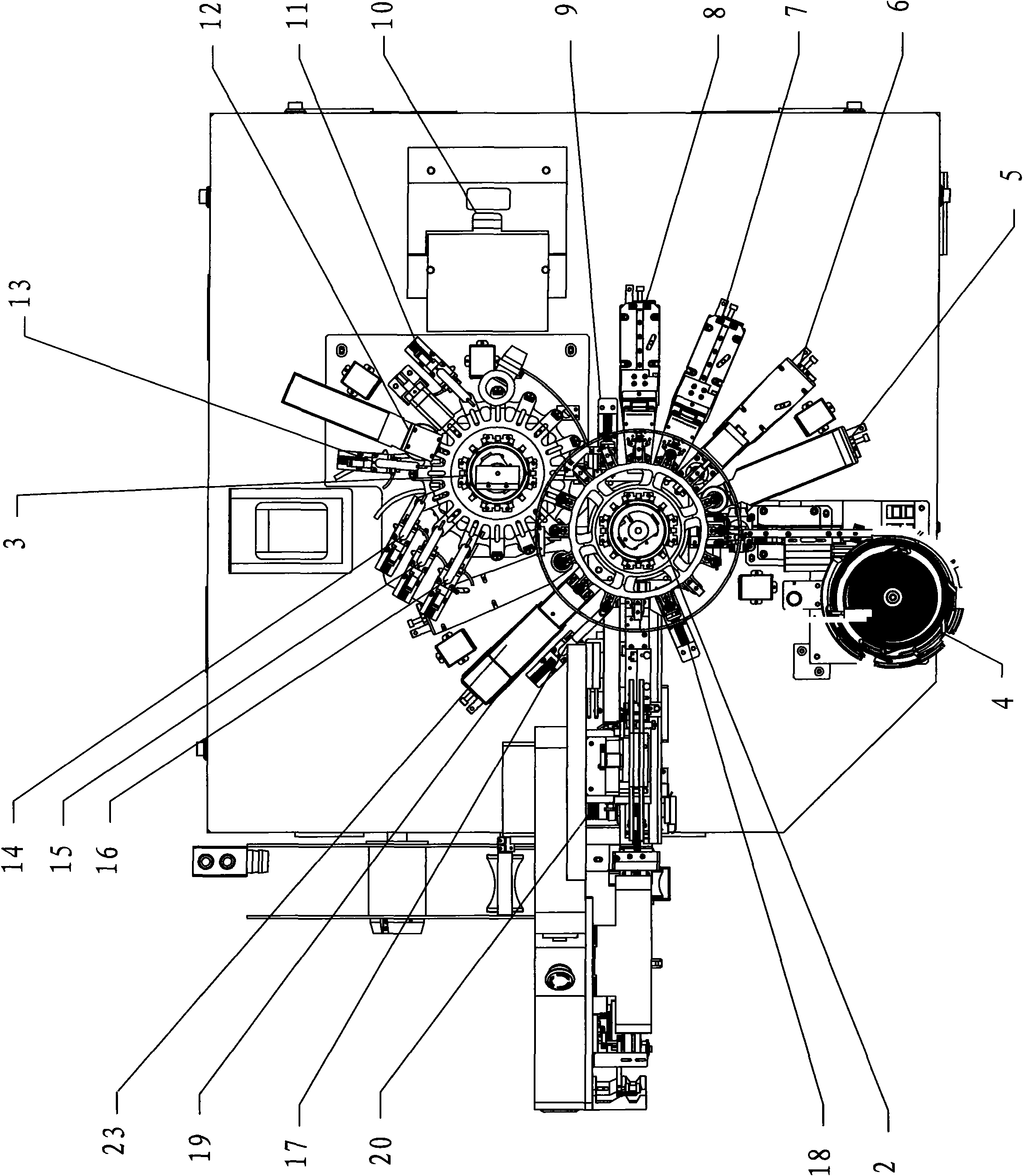

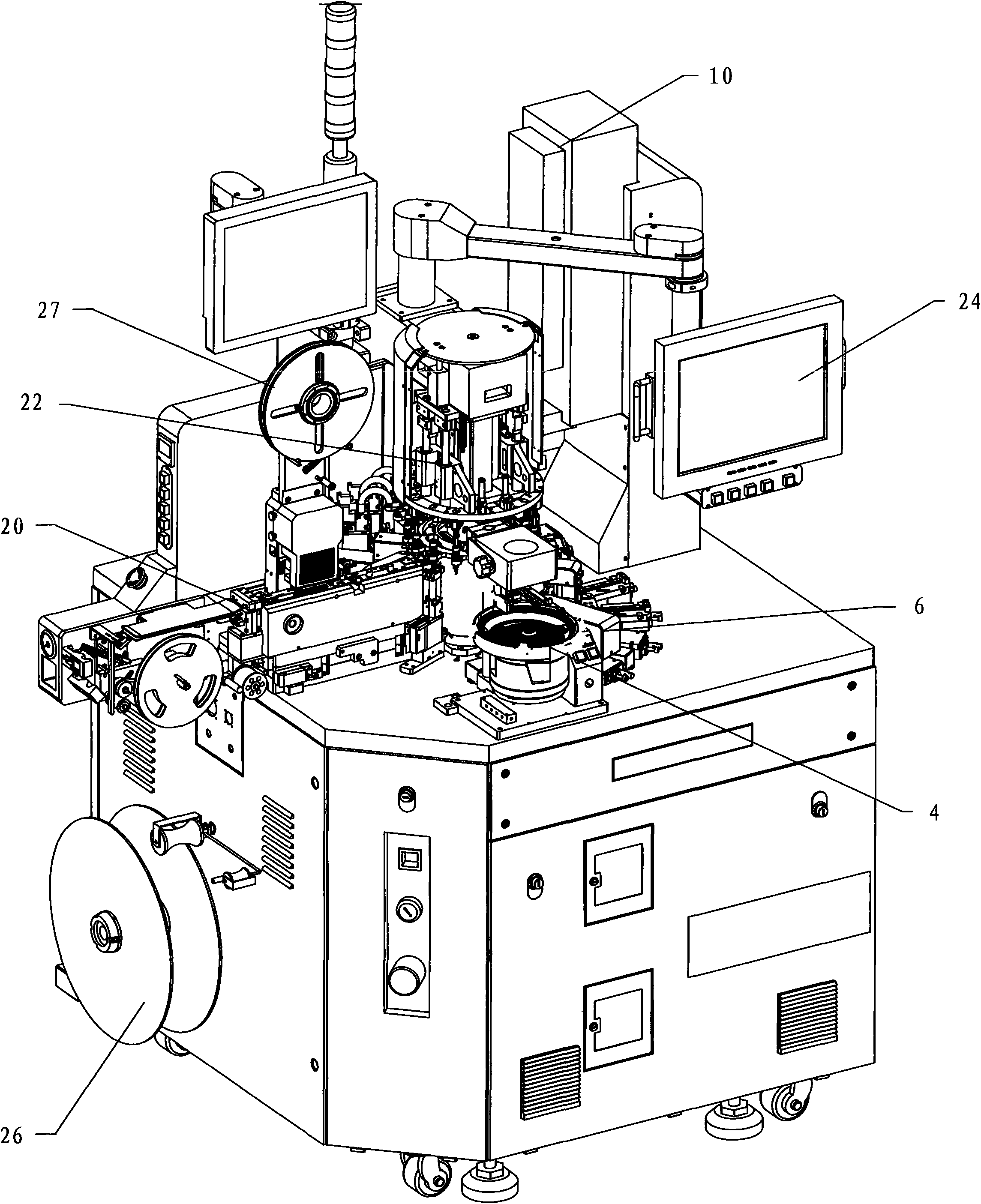

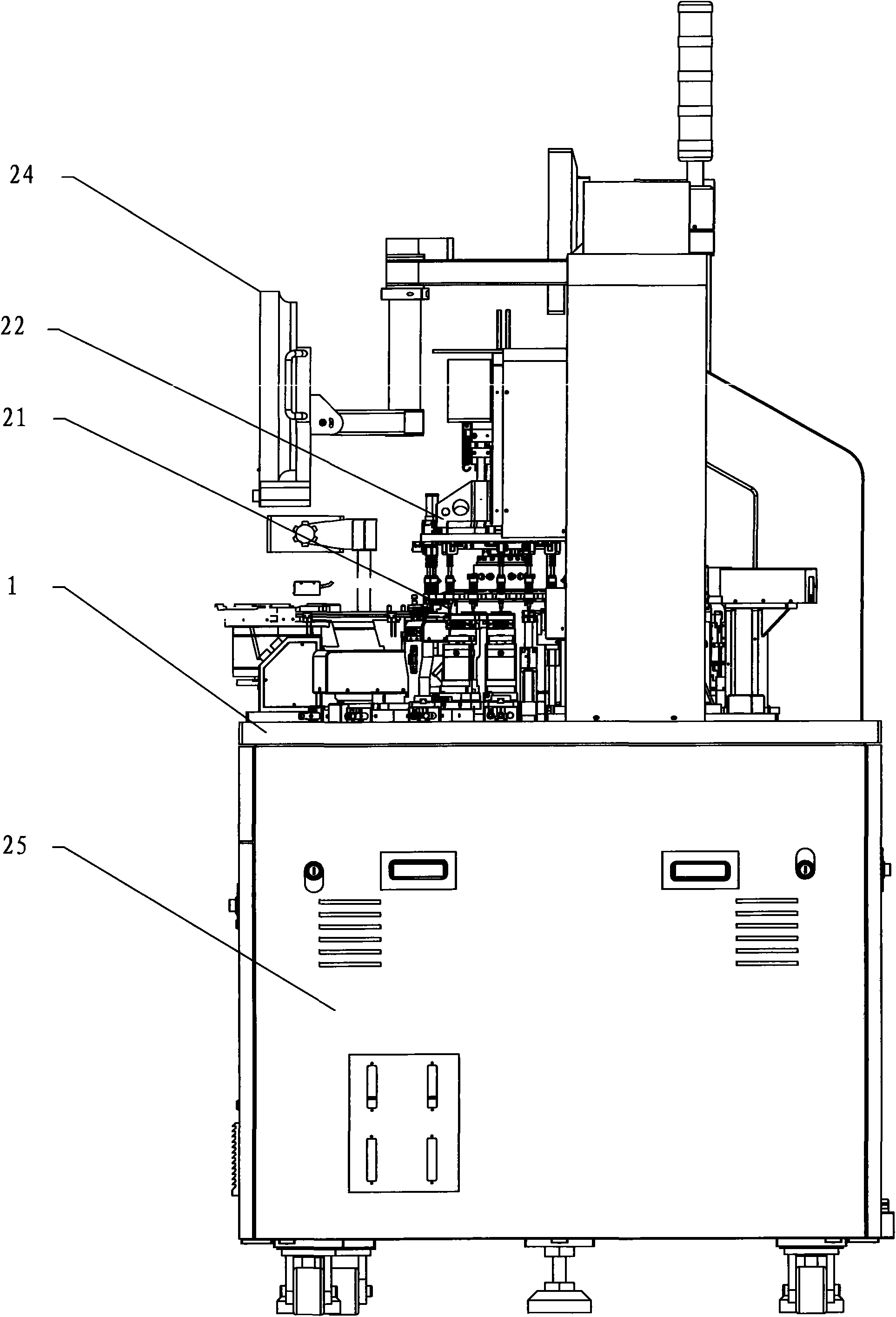

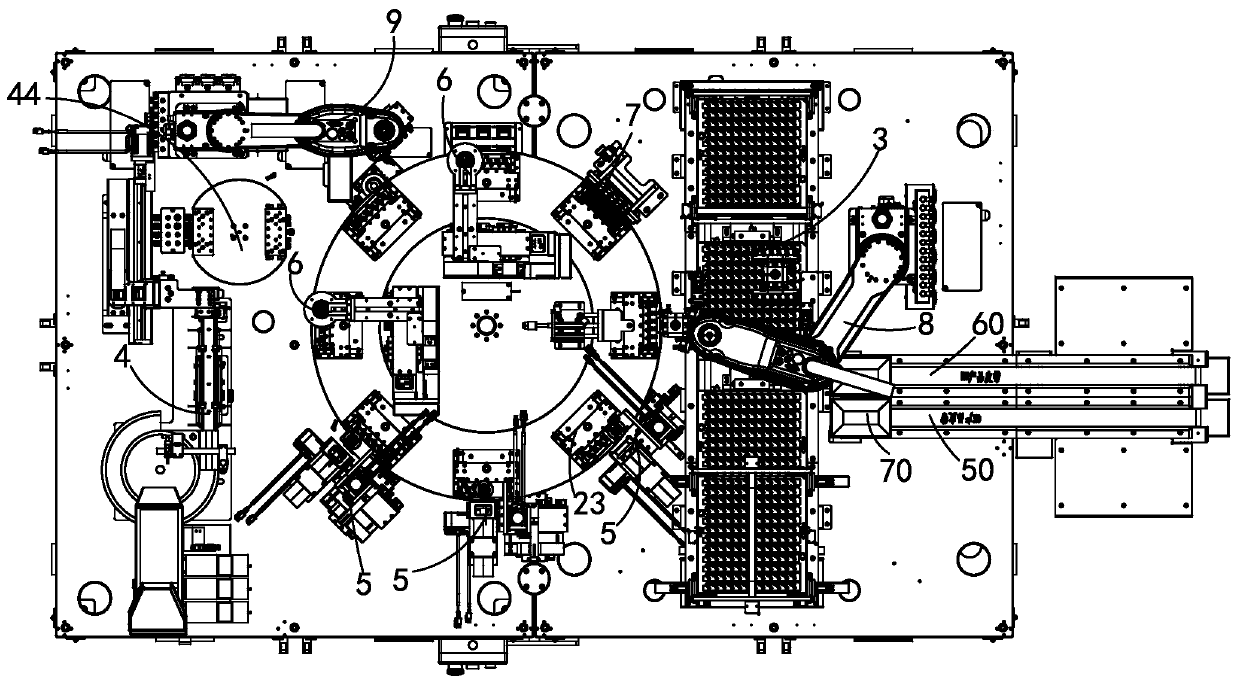

All-in-one machine of semiconductor device for testing, sorting, marking and braiding and one-stop processing method

ActiveCN101989535AImprove work efficiencyGuaranteed pass rateSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingEmbedded systemSemiconductor

The invention discloses an all-in-one machine of a semiconductor device for testing, sorting, marking and braiding and a one-stop processing method. A scheme in the invention is as follows: the semiconductor device is transported to a device processing system arranged on each station to be processed by the all-in-one machine. The all-in-one machine comprises a machine body and each device processing system, wherein the machine body is provided with a main turret system and a laser marking turret system respectively with 16 working positions; each station of the main turret system is provided with a suction nozzle mechanism for picking, placing and transporting the device; the main turret system is also provided with a suction nozzle pressing mechanism; each station of the laser marking turret system is provided with a device transmission mechanism; and the suction nozzle mechanism and the device transmission mechanism successively transmit the semiconductor device to each device processing system to finish one-stop continuous processing. By the implementation of the invention, various functions such as testing, sorting, marking, braiding, outputting and the like which originally need to be finished by various equipment are finished on one equipment, thus saving cost and improving working efficiency.

Owner:深圳市复德科技有限公司

Corrugated board production quality regulation and control method based on machine vision

ActiveCN113934190APrecisely control the amount of glueImprove product qualityProgramme total factory controlTarget surfaceMachine vision

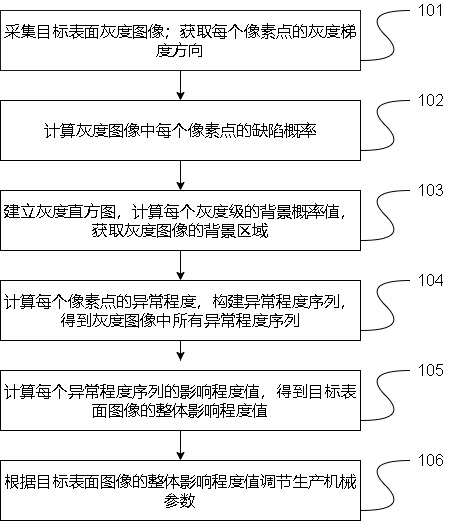

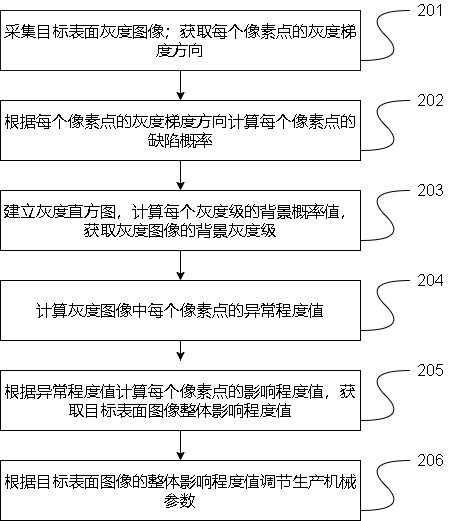

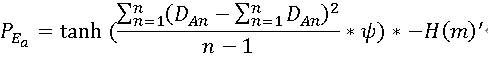

The invention discloses a corrugated board production quality regulation and control method based on machine vision, relates to the field of artificial intelligence, and is mainly used for mechanical parameter control of corrugated board production. The method comprises the steps of obtaining a target surface grayscale image; obtaining the gray gradient direction of each pixel point; calculating the defect probability of each pixel point; establishing a gray level histogram, calculating a background probability value of each gray level, and obtaining a background region of the gray level image; calculating the abnormal degree of each pixel point in the grayscale image, and constructing a sequence of all abnormal degrees in the grayscale image; calculating an influence degree value of each abnormal degree sequence to obtain an overall influence degree value of the target surface image; and adjusting production machinery parameters according to the overall influence degree value of the target image. According to the technical means provided by the invention, the influence degree of the defect is calculated through the target surface grayscale image, so that the mechanical parameters are adjusted, and the product quality and the production efficiency are improved.

Owner:武汉春田纸品包装有限公司

Automatic adhesive-dispensing pressure-maintaining equipment

PendingCN110586416AAccurate pressing forceAssemble firmlyLiquid surface applicatorsMaterial gluingAdhesiveMaintaining equipment

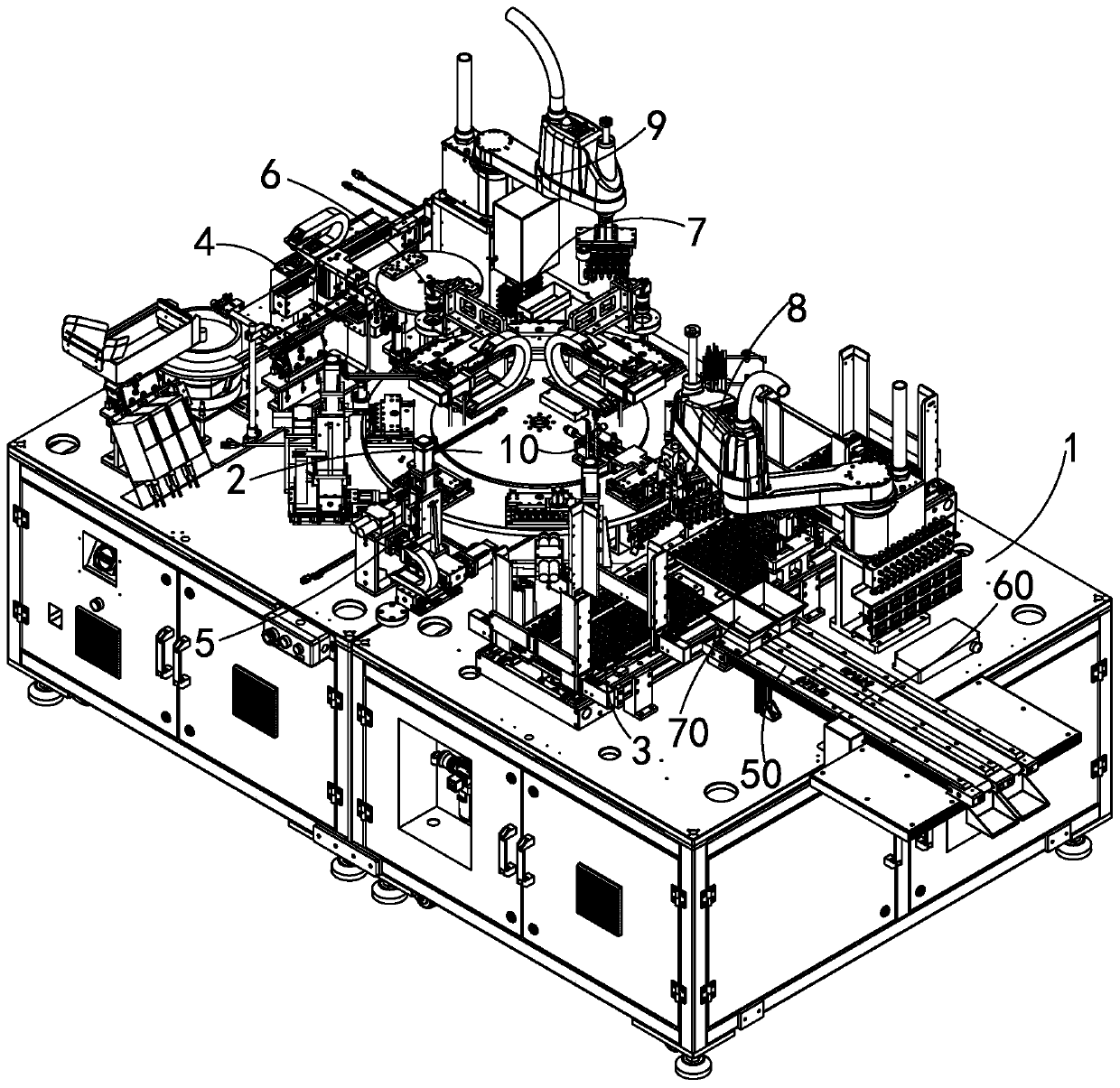

The invention discloses automatic adhesive-dispensing pressure-maintaining equipment. The automatic adhesive-dispensing pressure-maintaining equipment comprises an equipment machine table, a rotary workbench, as well as a first loading mechanism, a second loading mechanism, an adhesive-dispensing mechanism, a CCD detection mechanism, a pressure-maintaining mechanism, a first carrying robot and a second carrying robot which are sequentially and circumferentially arranged at the periphery of the rotary workbench, wherein the rotary workbench comprises a small rotary disc installed on the equipment machine table and a large rotary disc arranged at the periphery of the small rotary disc in a sleeved manner; a plurality of rotary disc jigs are arranged on the large rotary disc along the same circumference in a manner of uniform distribution; the adhesive-dispensing mechanism is configured to comprise a three-axis displacement device, a base, a needle barrel and an adhesive-dispensing needlehead; the adhesive-dispensing needle head is arranged on the three-axis displacement device through the base; the three-axis displacement device is used for driving the adhesive-dispensing needle head to move in X-axis direction, Y-axis direction and Z-axis direction; the needle barrel is arranged on the three-axis displacement device through the base; and the needle head of the adhesive-dispensing needle head is enabled to carry out adhesive-dispensing operation on a first material part to be treated. The automatic adhesive-dispensing pressure-maintaining equipment is high in adhesive-dispensing speed and efficiency, and stable in quality.

Owner:苏州德机自动化科技有限公司

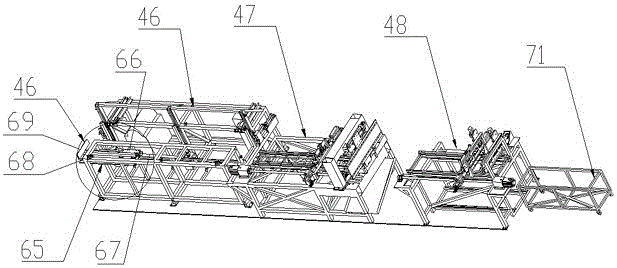

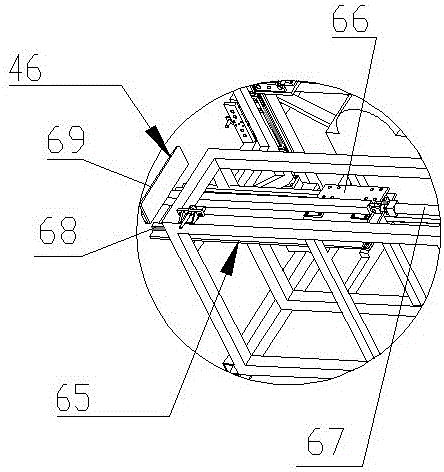

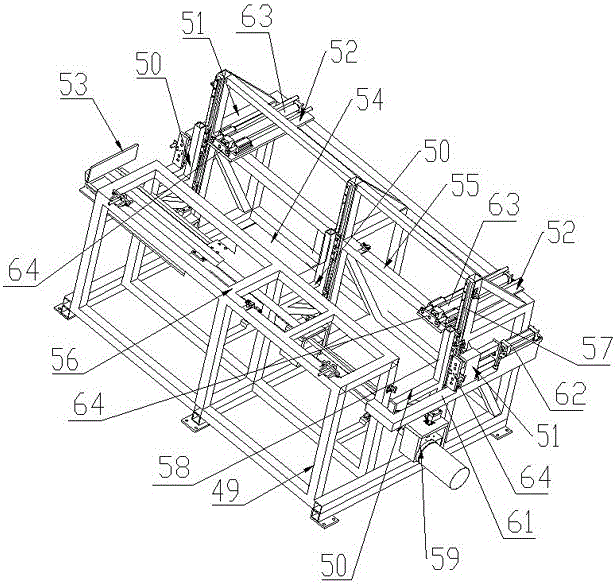

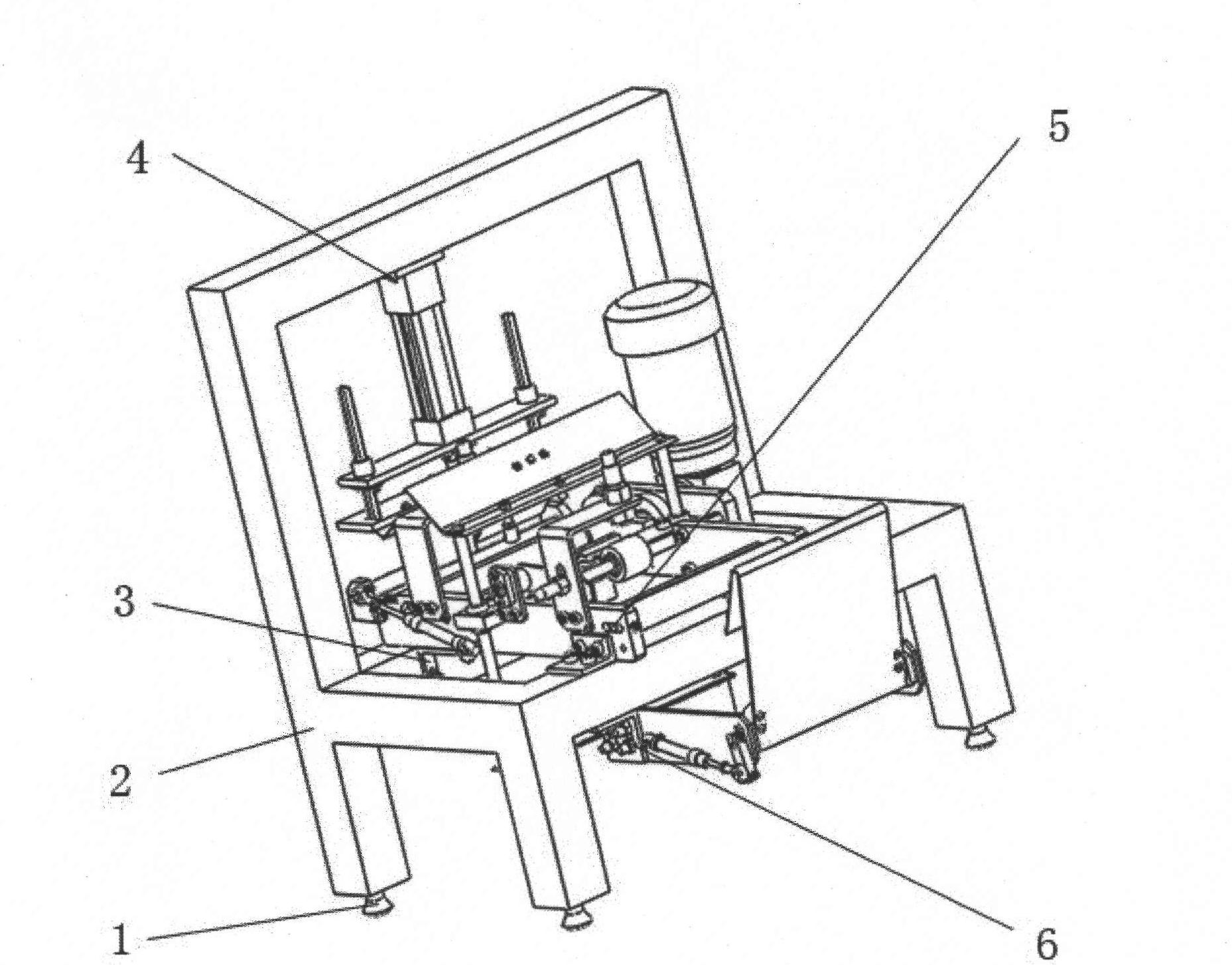

Automatic assembly line for feeding, cutting and punching pipe automatically

ActiveCN106271629AHigh degree of automationImprove cutting efficiencyMetal sawing devicesOther manufacturing equipments/toolsPunchingAssembly line

The invention discloses an automatic assembly line for feeding, cutting and punching a pipe automatically. The automatic assembly line comprises a front feeding mechanism, a middle feeding and cutting mechanism and an automatic punching and unloading mechanism which are arranged in sequence from left to right; the front feeding mechanism comprises a first supporting frame, a lifting mechanism, a pipe clamping mechanism, a transverse pushing mechanism and a longitudinal pushing mechanism; the middle feeding and cutting mechanism comprises a second supporting frame, a first clamping conveying mechanism, an automatic cutting mechanism and an automatic clamping mechanism; the automatic punching and unloading mechanism comprises a third supporting frame, a second clamping conveying mechanism, a drilling clamping mechanism and two sliding drilling mechanisms which are positioned on the right side of the second clamping conveying mechanism and are arranged at an interval. The automatic assembly line can realize automatic feeding, and is low in labour intensity and high in work efficiency; the pipe can be cut automatically; the cutting quality is good; high-efficiency cutting operation of one or more pipes can be realized synchronously; the punching operation can be performed on the two ends of the pipe simultaneously; the function of clamping a plurality of pipes at one time and punching the pipes in sequence can be realized.

Owner:JIANGSU JINPENG VEHICLE CO LTD

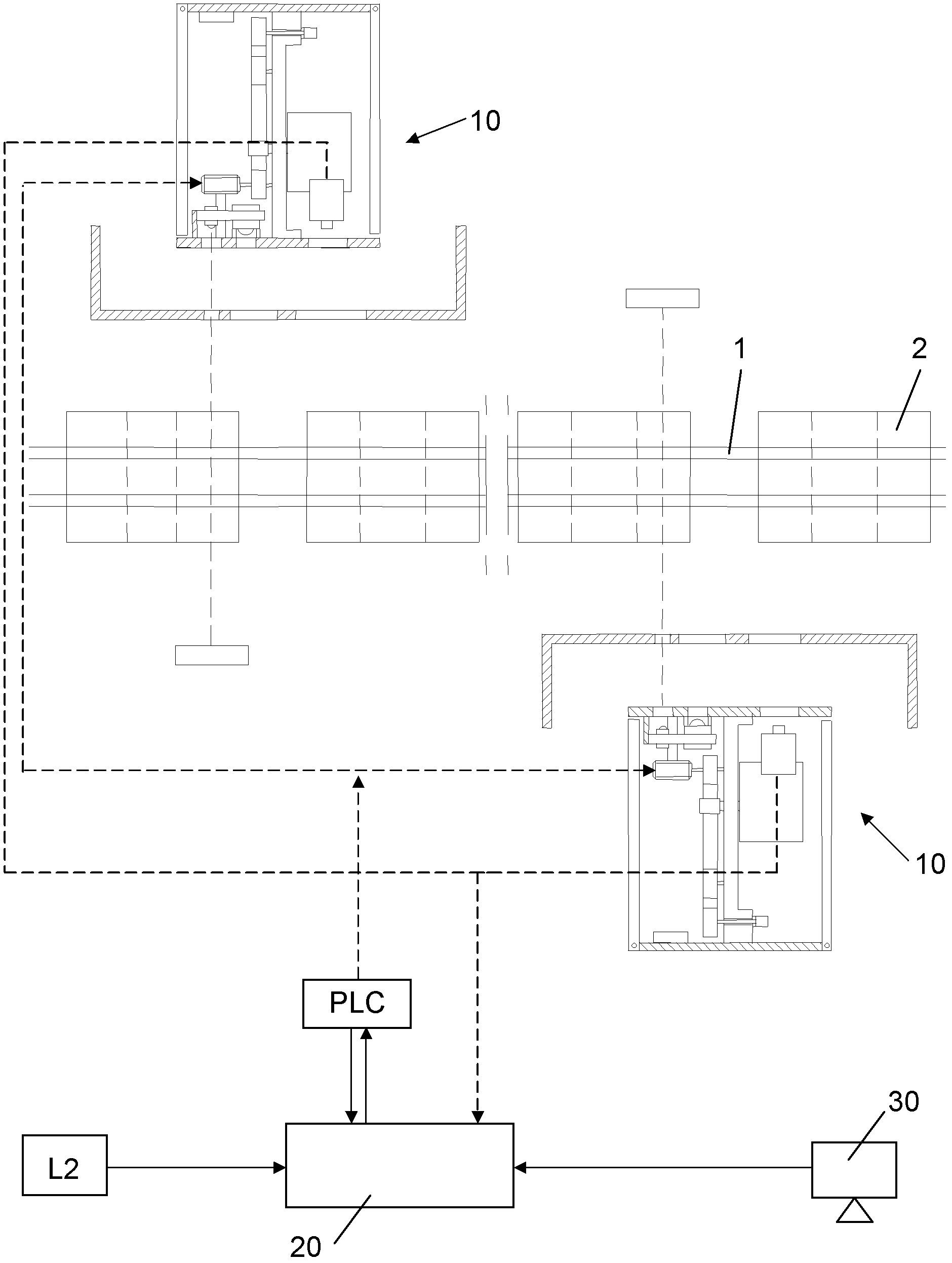

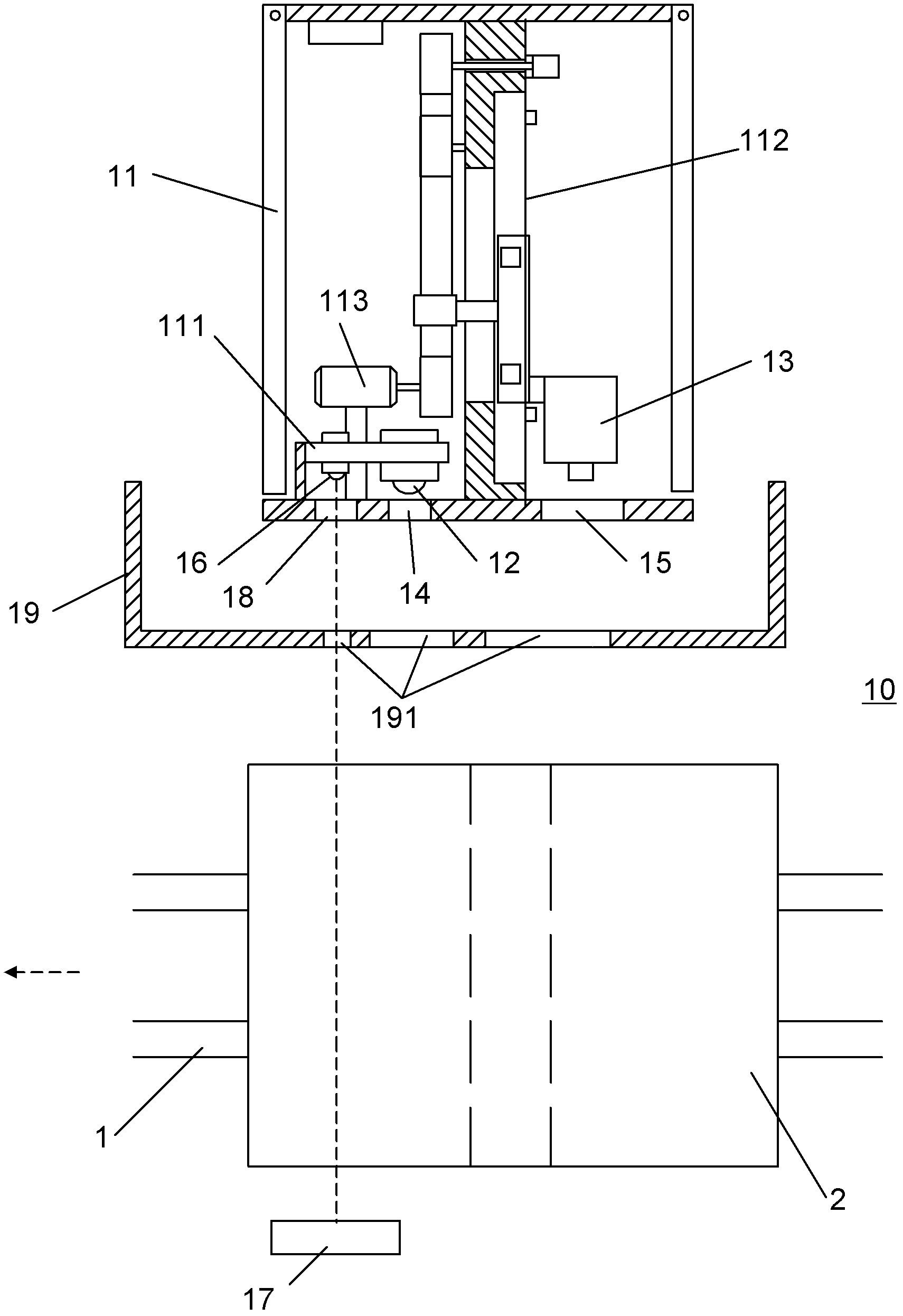

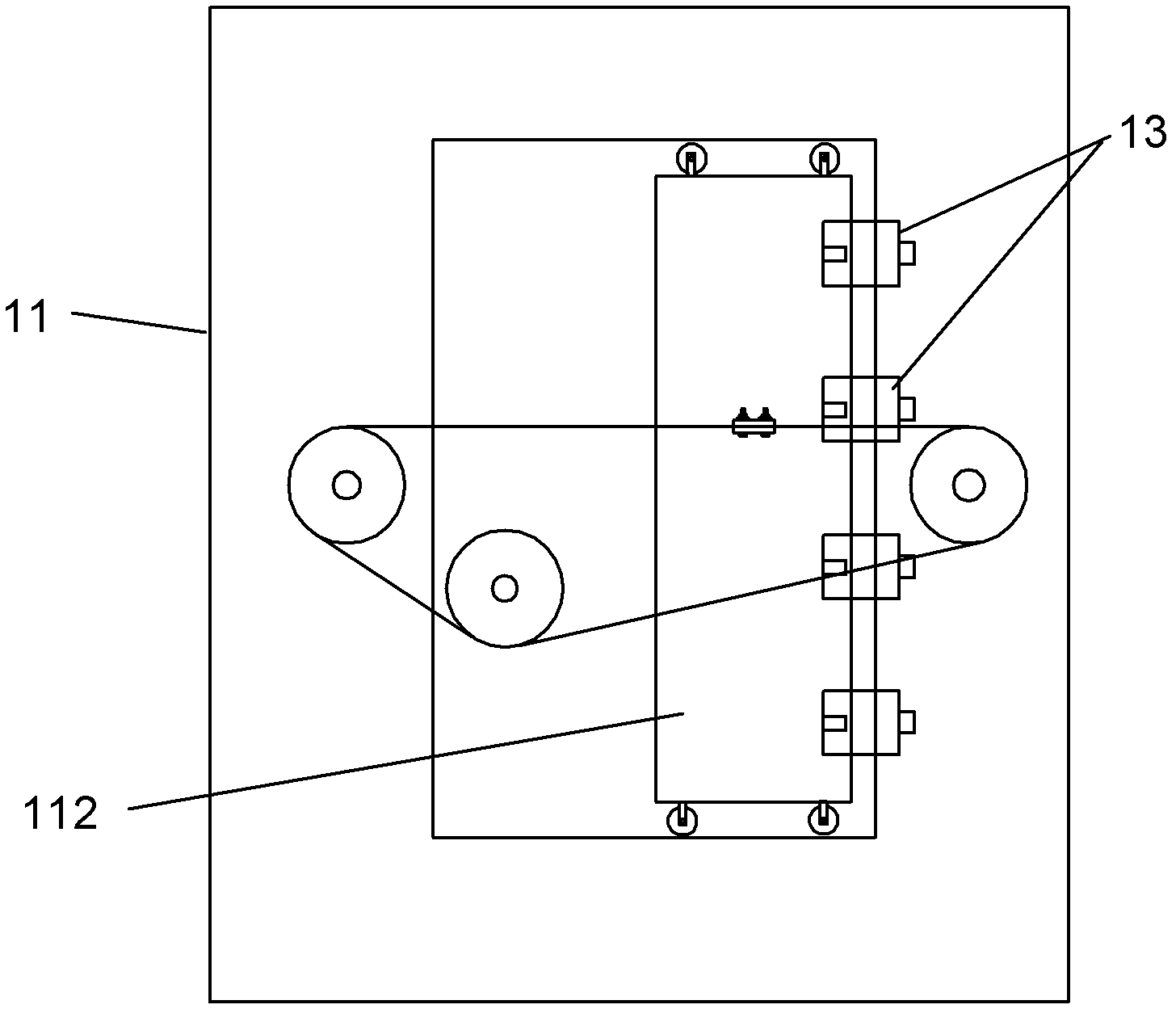

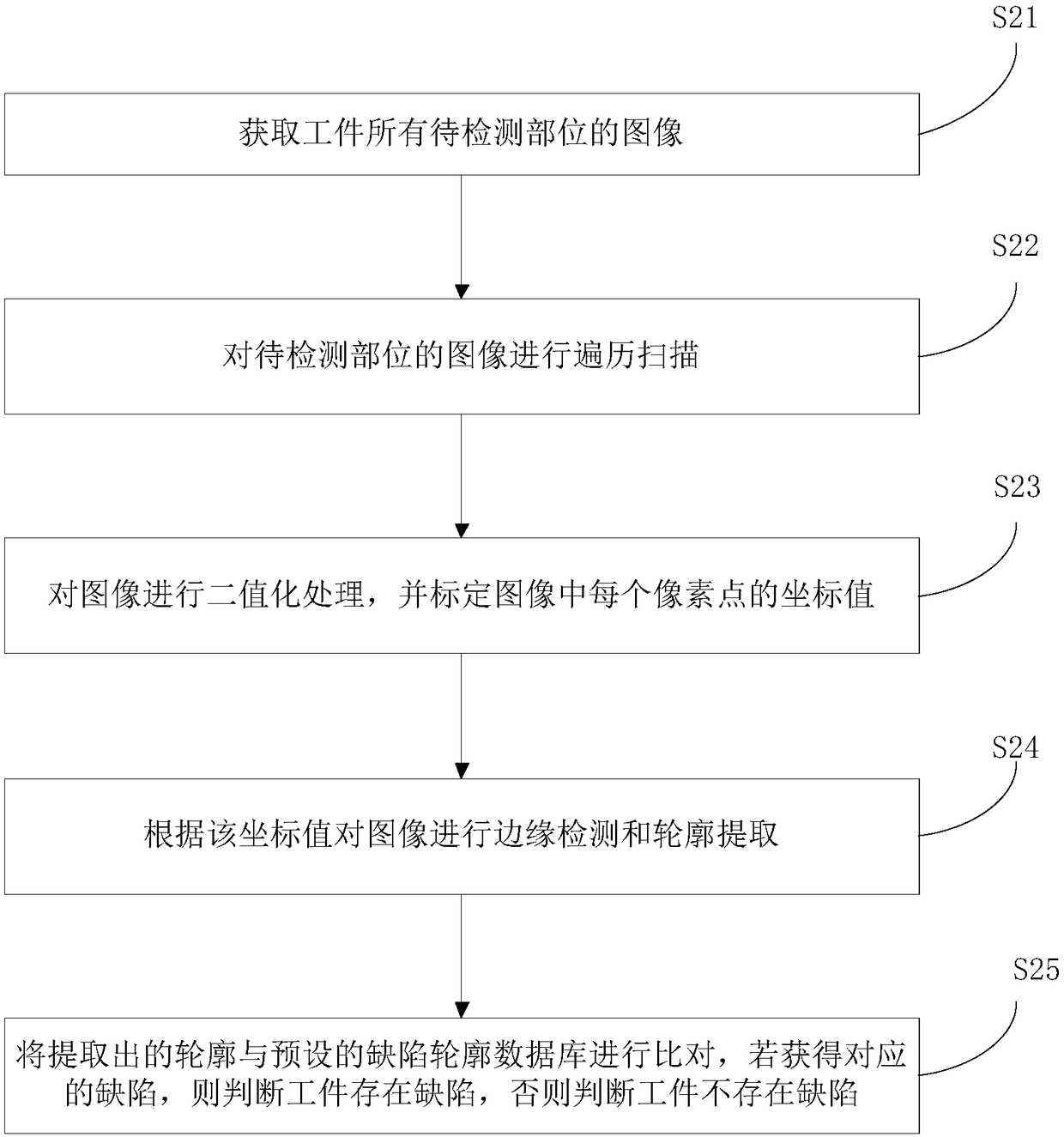

Steel coil end portion quality detection system and method thereof

InactiveCN103207185AGuaranteed pass rateReduce labor intensityOptically investigating flaws/contaminationImaging processingVisual inspection

The invention discloses a steel coil end portion quality detection method. The detection method comprises the following steps: arranging an imaging device at each of two sides of a steel coil convey chain, respectively shooting the end portions at two sides of the pass-through steel coil through controlling the imaging devices by PLC to obtain images, and processing and comparing the images through an image processing server to realize defect determination; and querying historic image information and the defect detection result in real time through an image operation terminal. The invention also discloses a steel coil end portion quality detection system. The detection system and the detection method can mitigate the labor intensity and damages of high temperature radiation to human bodies, and effectively avoid the subjectivity and false negatives caused by visual inspection, so various defects existing in the end portions of the steel coil are effectively and objectively detected and assessed, and the qualified rate of finished steel coil is guaranteed.

Owner:BAOSHAN IRON & STEEL CO LTD

Button battery for improving utilization rate of radial space

PendingCN110459705AIncrease profitMeet the needs of fully automated productionFinal product manufactureSmall-sized cells cases/jacketsElectricityButton battery

The invention discloses a button battery for improving the utilization rate of radial space, which comprises a metal housing and an electric core arranged in the metal housing, wherein the electric core comprises a positive plate and a negative plate. The button battery further comprises a cover plate arranged on the metal housing, wherein the cover plate and the metal housing have the same polarity, and the cover plate and the metal housing are welded into a whole by laser, so that the sealing property of the battery housing is more reliable. The outer side of the cover plate is provided witha convex cap, the cover plate and the cap are provided with an insulating piece therebetween which prevents a short circuit between the cover plate and the cap, one of the positive plate and the negative plate is electrically connected with the metal housing or the cover plate, the other of the positive plate and the negative plate is electrically connected with the cap, and the electric core andthe outside are only separated by the single-layer metal housing, so that the utilization rate of the radial space of the battery is improved. Meanwhile, the process of the button battery is simpler,the requirement of full-automatic production of the battery is met, the production efficiency of the battery is improved, and the qualification rate is also well guaranteed.

Owner:CHONGQING VDL ELECTRONICS

Automatic coating and cutting machine

ActiveCN106079810ALow costReduce labor costsLamination ancillary operationsLaminationGlass coverControl system

The invention relates to an automatic coating and cutting machine. The automatic coating and cutting machine mainly comprises a coating mechanism and a cutting mechanism successively used for processing materials, a collecting mechanism for collecting the coated and cut material, a transport mechanism for transporting the material and an electric control system, wherein the material such as a glass cover plate is fed from one side of the coating mechanism and is collected after being coated with a film and cut, and finally the material is output from one side of the transport mechanism. The automatic coating cutting machine can substitute a great amount of labor, so that the labor cost is saved; the efficiency is improved, and the automation degree is high; the equipment stability is high, the coating effect is tidy and has no bubble, the cutting is standard and orderly, the material can be effectively and orderly collected and transported, and the qualification rate of products can be guaranteed.

Owner:深圳市银浩自动化设备有限公司

Method for preparing tobacco stalk particles

ActiveCN101601502AGuaranteed pass rateReduce processing linksTobacco treatmentProcess engineeringMachining process

The invention relates to a method for preparing tobacco stalk particles. Tobacco stalks are subjected to pretreatment, pelletization, sieving, decompression, soaking, expansion, drying and shaping to prepare the tobacco stalk particles. The method can effectively control the shape and the particle diameter of the tobacco stalk particles, can reach the quality requirement of a product process with only once expansion and shaping treatment, has good expansion effect and can effectively reduce a machining process link, thereby reducing the broken particles and ensuring the qualification rate of a product.

Owner:云南瑞升香料技术有限公司

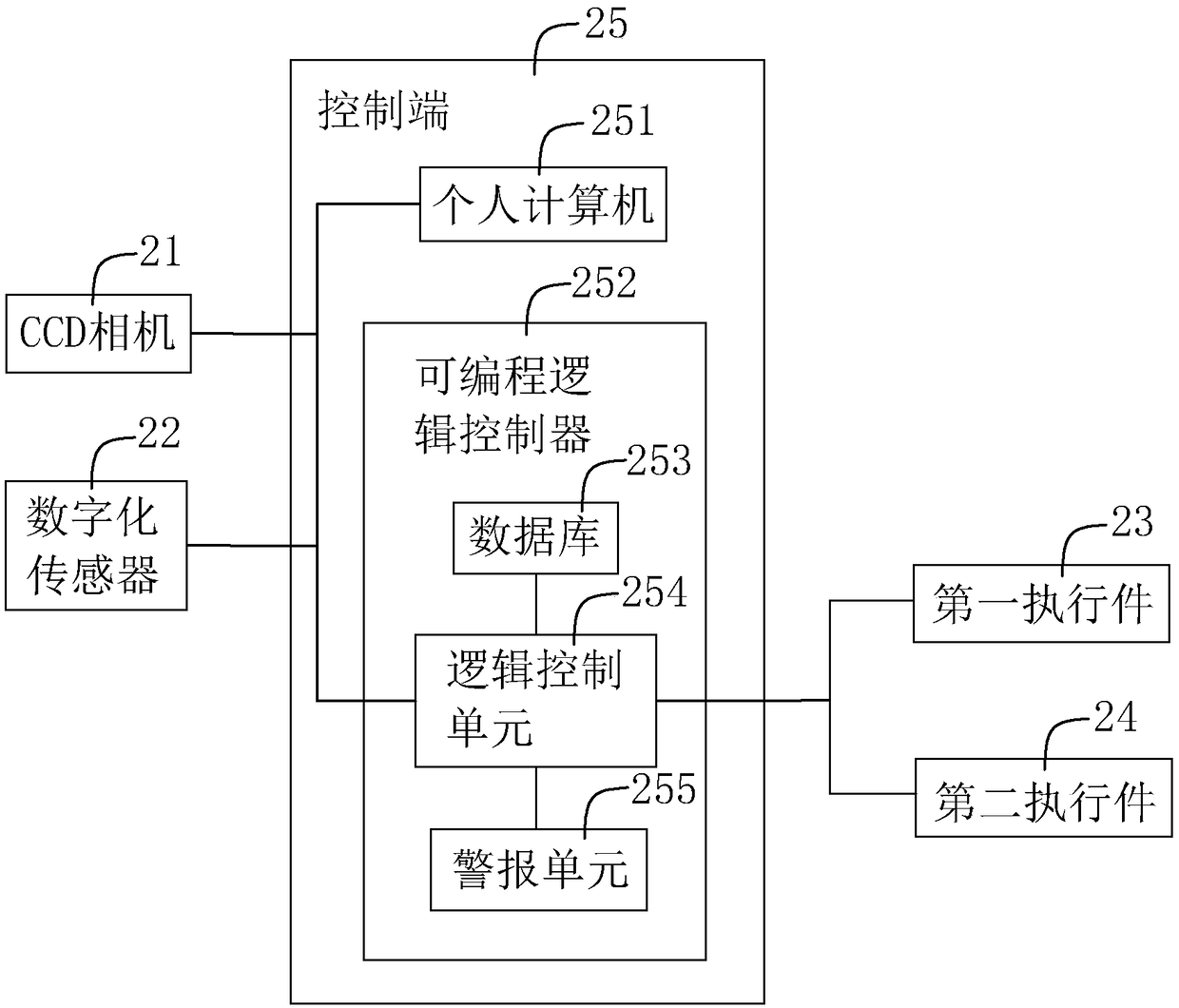

Digital detection system based on diamond roller dressing grinding machine

PendingCN108161742AHigh degree of automationReduced scrap and tooling costsGrinding feed controlAbrasive surface conditioning devicesCcd cameraMachining process

The invention discloses a digital detection system based on a diamond roller dressing grinding machine, and relates to the field of computer numerical control (CNC) grinding machines. The invention aims to solve the problem that the dressing time of a grinding wheel is hard to control and the automatic dressing can not be achieved. The digital detection system is technically characterized in thatthe overall surface roughness of the grinding wheel is observed through a CCD camera, and the surface residual stress, degree of passivation and degree of thermal damage of the grinding wheel and a diamond roller are monitored by a digital sensor, transmitted to a control terminal, and compared with the preset target grinding data stored in a database; a first executive component and a second executive component are controlled to act by judgment of the results, so that the ratio of the relative grinding speed to the tangential feed rate is decided, till the real-time grinding data and the target grinding data are matched finally; and thus, the degree of automation in the grinding process of the grinding machine and the working efficiency are improved, and the qualification rate of productsis ensured.

Owner:SUZHOU WENTE DIAMOND WHEEL

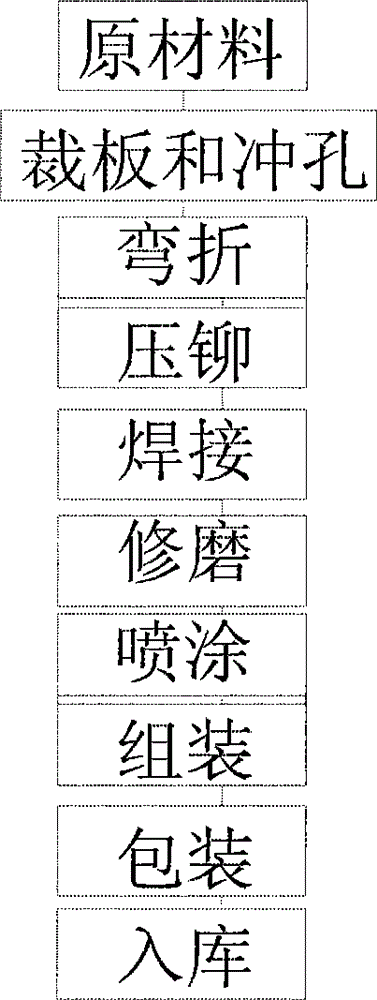

Production method for optical fiber cable distribution box

The invention discloses a production method for an optical fiber cable distribution box. The production method comprises the following steps: punching, bending, press riveting, welding, polishing, plastic spraying, assembling and warehousing, wherein the bending process is performed from inside to outside, from small to big and from special to general; whether studs are pressed tightly or pressed out to exceed the surface of a workpiece is checked before press riveting; characteristics of whether the studs are pressed tightly or pressed out to exceed the surface of the workpiece and the like are checked before press riveting. The production method has the benefits that the production method can ensure that the accuracy of processes of punching, bending, press riveting, welding, polishing, plastic spraying and the like is greatly improved during production of the optical fiber cable distribution box, the processing efficiency is improved, product protection is improved, and finally the product qualification rate is ensured.

Owner:YOSHIHIRO COMM EQUIP GRP CO LTD

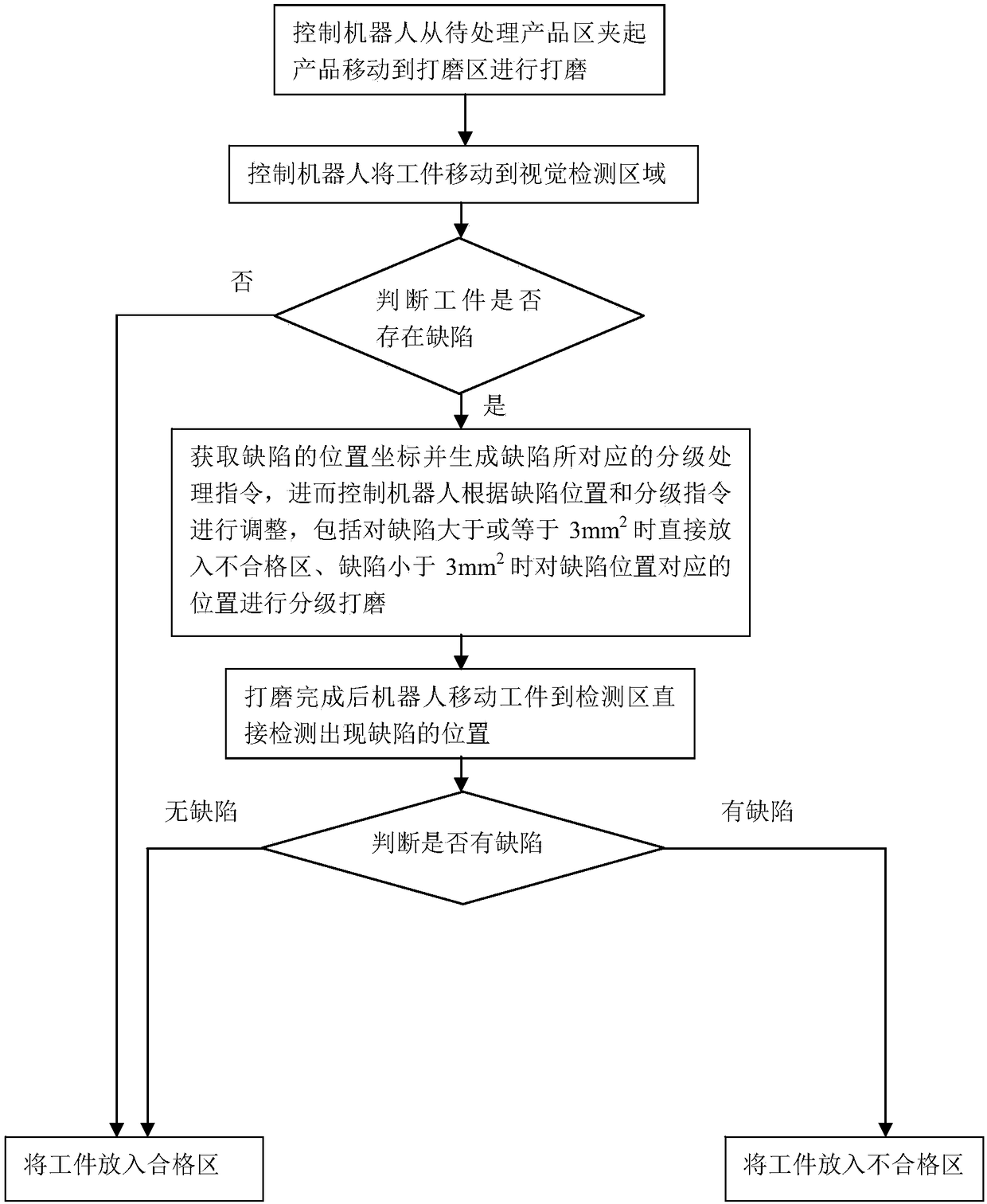

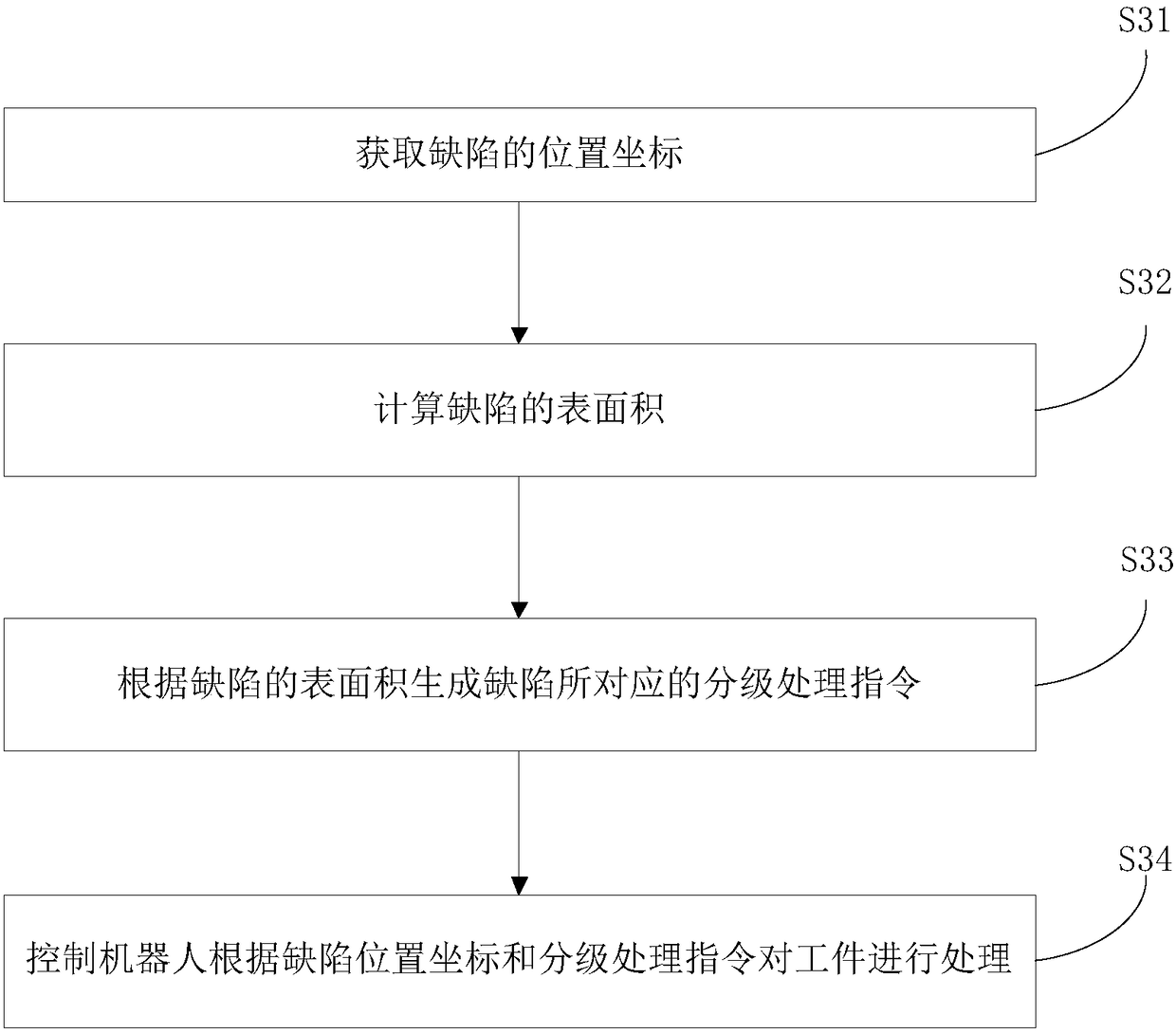

Robot polishing method and system based on visual inspection

ActiveCN108226164AIncrease productivityGuaranteed accuracyBelt grinding machinesGrinding feed controlSanderSimulation

The invention discloses a robot polishing method and system based on visual inspection. The system comprises a robot, a shielding case, a polishing belt sander, a computer, an end fixture for clampinga workpiece, and a camera for acquiring images. The camera is arranged in the shielding case; the robot is connected with the end fixture; the computer is connected with the robot, the camera and thepolishing belt sander; the computer comprises a workpiece moving module, a defect detecting module and a defect processing module. According to the robot polishing method and the system based on visual inspection provided by the invention, through integrating workpiece defect detection and workpiece polishing, the production efficiency is greatly improved. The robot polishing method and the system based on visual inspection provided by the invention is excellent in performance and can be widely applied to the technical field of workpiece processing.

Owner:深圳市智能机器人研究院

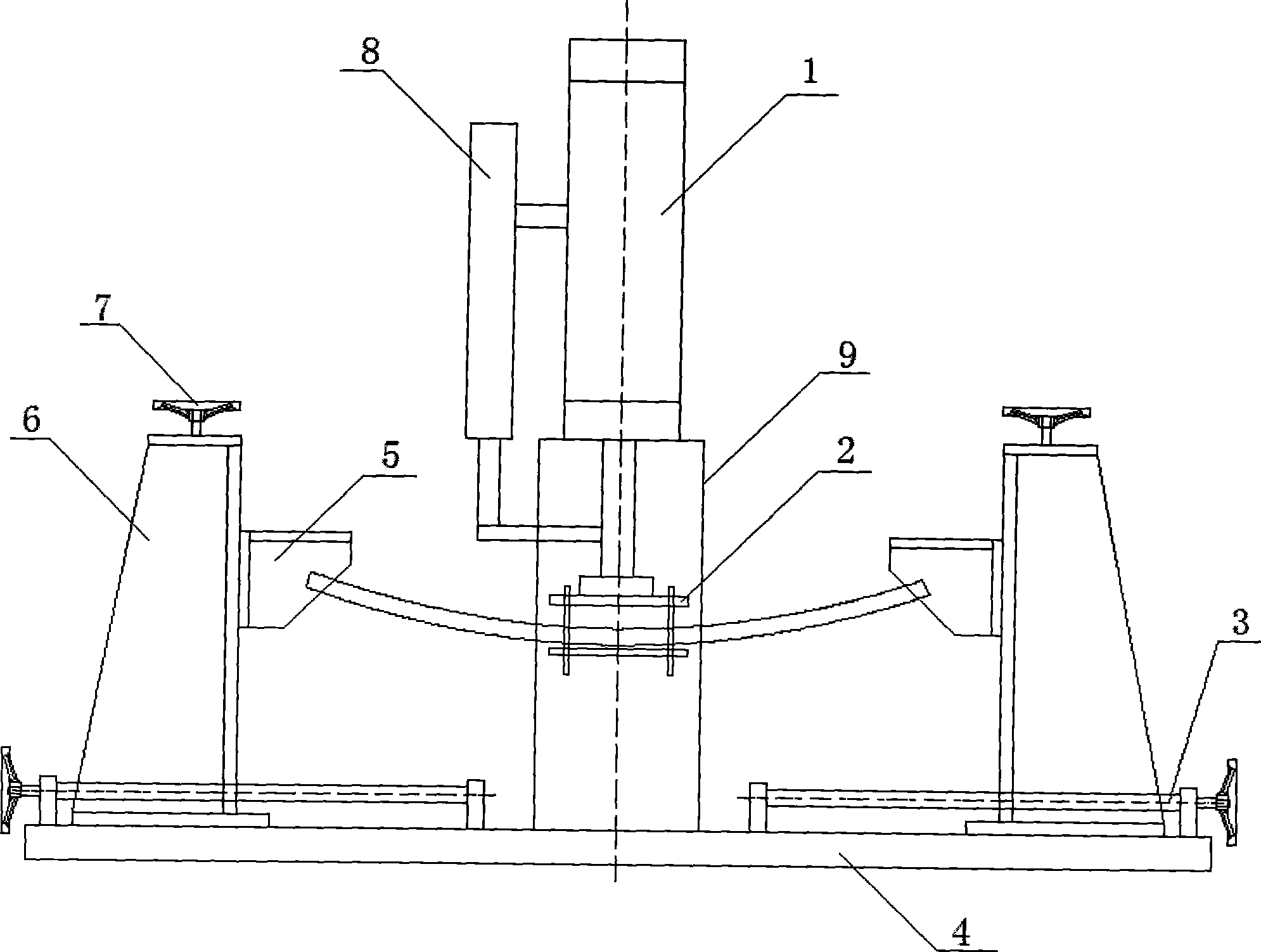

Steel plate spring assembly fatigue tester

InactiveCN101413858ASimple structureEasy to operateMaterial strength using repeated/pulsating forcesSteel platesStructural engineering

The invention relates to a steel plate spring assembly fatigue machine, which comprises a servo hydraulic cylinder and the like. A bracket is arranged in the middle of a base and is fixed with the servo hydraulic cylinder; a cylinder rod of the servo hydraulic cylinder is downward, and the head of the cylinder rod is provided with a jig; the outside of the servo hydraulic cylinder is fixedly provided with a displacement pickup; a head bulk head of the displacement pickup is connected with the cylinder rod; the two ends of the base are respectively provided with a support; the lower part of the support is processed with a screwed hole which a screw passes through; the two ends of the screw are supported and arranged on the base by a bearing; one end of the screw is provided with a handwheel; the inner sides of the two supports are respectively provided with a support jig; the end of the support jig is also processed with a screwed hole which is matched with the screw; the head of the screw is extended to the upper part of the supports and is provided with the handwheel. The fatigue machine has simple structure, convenient operation, space saving and low cost; the precise fatigue test can be carried out on the steel plate spring by the fatigue machine, thus guaranteeing the quality of products complying with standard code before installation and the product percent of pass.

Owner:KUNSHAN INNOVATION TESTING INSTR CO LTD

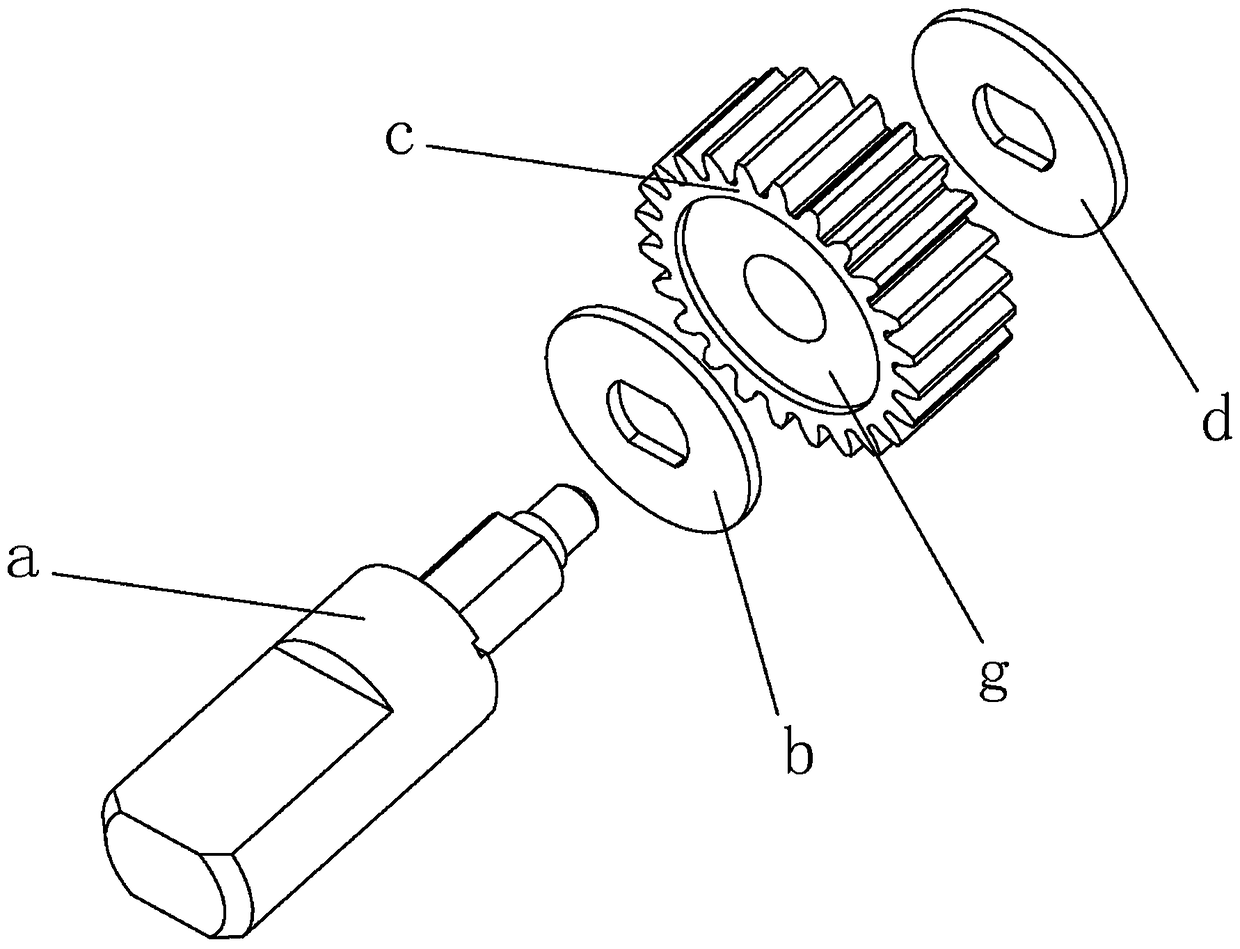

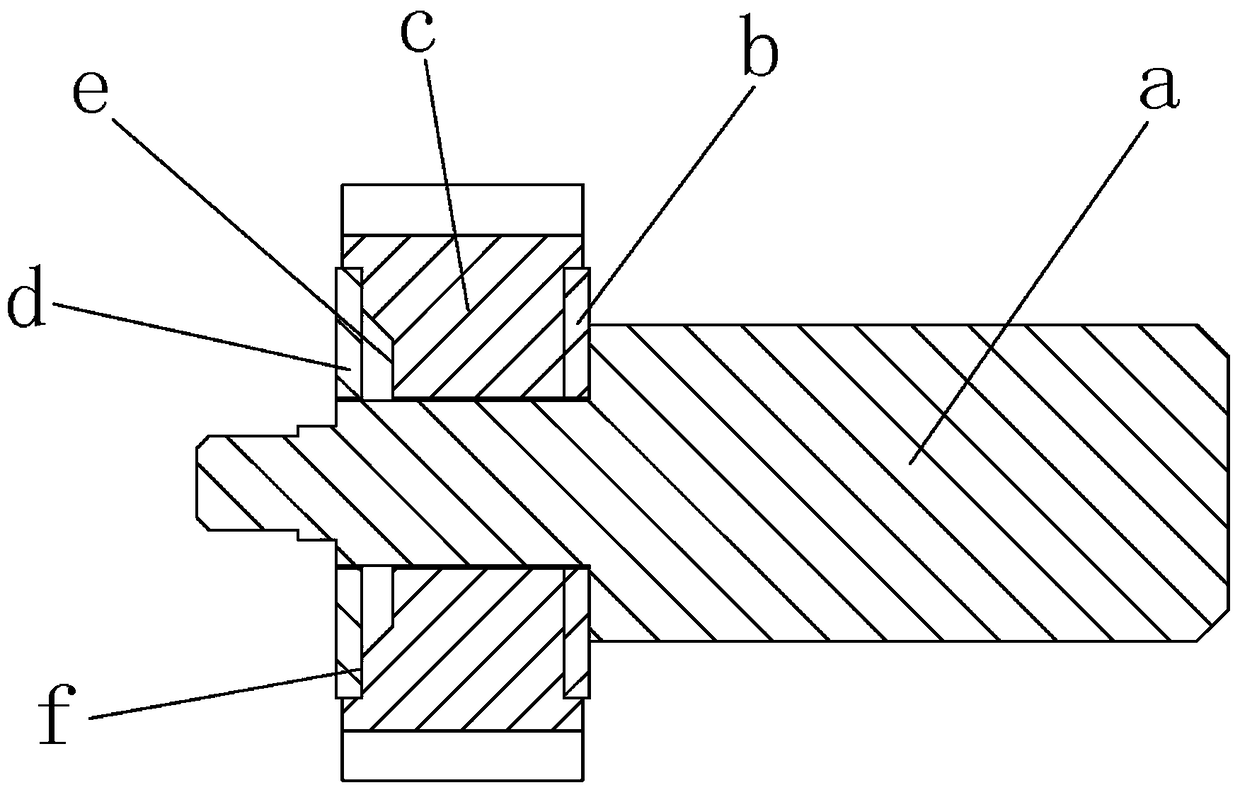

Motor rotation shaft assembly method and assembly machine implementing same

PendingCN108768110AEasy to analyzeHigh degree of automationAssembly machinesManufacturing dynamo-electric machinesGear wheelControl system

The invention discloses a motor rotation shaft assembly method comprising the steps as follows: a rotary disc is arranged on a machine stand, and an axis rod fixed seat detection device, an axis rod transportation and installation device, an axis rod detection device, a lower pressing ring transportation and installation device, a lower pressing ring detection device, a first oil injection device,a gear transportation and installation device, a second oil injection device, an upper pressing ring transportation and installation device, an upper pressing ring detection device, a finished product moving device and a defective product recycling device are arranged around the rotary disc; a riveting device, a running-in device, a friction force detection device and a sorting device are installed on one side of the rotary disc; and a PLC control system for controlling the device is also installed on the machine stand. Five processes such as automatic assembling, riveting, detecting slippingfriction force and sorting are combined together. The invention also discloses equipment for implementing the method. According to the equipment and the method, the product friction force is controlled in a closed loop, the degree of automation is high, the production cycle of products is effectively shortened, the production cost is reduced; during a production process, detection can be performed according to user demands and product characteristics, the production status can be conveniently better analyzed, an alarm can be given for the abnormal condition during the production process; theproduction abnormity can be eliminated in time, and the product qualification ratio is ensured.

Owner:广东英达思迅智能制造有限公司

Forging method of valve

InactiveCN105397416AGuaranteed pass rateHigh precisionValve arrangementsProcessing costMachining time

The invention relates to a forging method of a valve. The method specifically comprises the following steps: (1) preparing a sample; (2) testing; (3) blanking; (4) heating a blank; (5) preparing a blank; (6) pre-forging; (7) refining; (8) thermally cutting edges; (9) inspecting for the first time; (10) thermally treating; (11) performing shot blasting; (12) inspecting for the last time. With the adoption of the forging method, an A105 steel forging of the valve can be uniformly forged, the processing costs a little time, and the forging accuracy is high.

Owner:WENZHOU YANZHI VALVE FACTORY

Automatic edge sealing and finished product sorting device for panty-hose packaging bag

InactiveCN102689714ASimple structureEasy to disassembleWrapper twisting/gatheringPackaging automatic controlMechanical engineeringTransmission system

The invention provides an automatic edge sealing and finished product sorting device for a panty-hose packaging bag, which is characterized by comprising a transmission system for transmitting a panty-hose packaging bag, wherein an edge turning device and a sorting device are respectively arranged at the inlet and the outlet of the transmission system, a heat-sealing device is arranged above the edge turning device, a compressing device is arranged in the middle of the transmission system, a detection mechanism is further arranged on the transmission system, when the panty-hose packaging bag on the transmission system is transmitted to a proper position, the panty-hose package bag is compressed by the compressing device, later, edge turning to the bag mouth of the panty-hose packaging bag is performed by the edge turning device, heat-sealing to the edge turned panty-hose packaging bag is performed through the heat-seal device, after heat sealing, the length and the thickness of the panty-hose packing bag are detected by a detection mechanism,and finally, accepted products and degraded products are sorted through the sorting device. The invention has the advantages that the structure is simple, the demounting is easy, the processing cost is greatly saved, and the popularization and applicability of the automatic edge sealing and finished product sorting device are enhanced.

Owner:DONGHUA UNIV +1

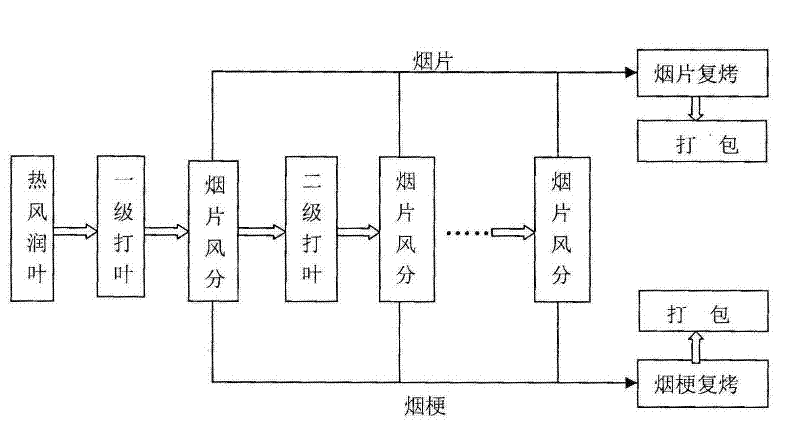

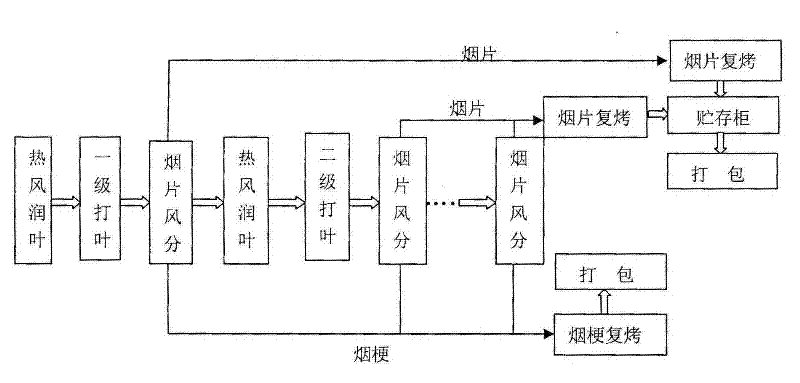

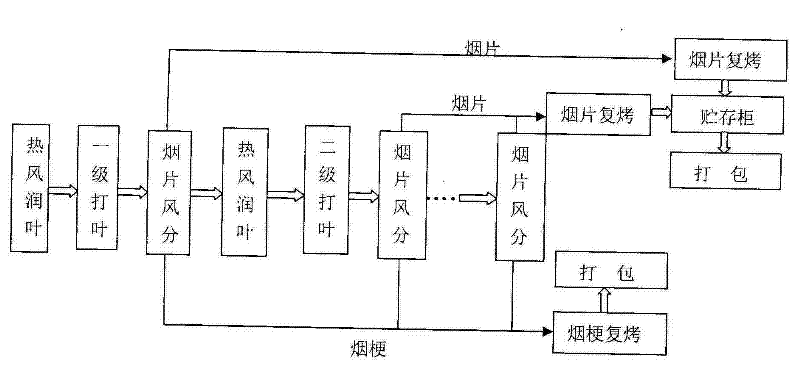

Novel threshing and redrying process based on tobacco mechanics characteristic differences

ActiveCN102488306AImprove lubricityGuaranteed pass rateTobacco preparationTobacco treatmentAgricultural scienceAgricultural engineering

A threshing and redrying process based on tobacco mechanics characteristic differences comprise links of primary threshing, secondary threshing, tobacco air separating, tobacco redrying and packaging. The threshing and redrying process is characterized in that according to measured tobacco mechanics characteristic indexes, tobaccos are divided into a type I of tobaccos and a type II of tobaccos, a hot air humidifying link is added between the primary threshing link and the secondary threshing link for the type I of tobaccos, tobaccos produced from the primary threshing link, the secondary threshing link and follow-up various process links are respectively redried, moisture content of the type I of tobaccos is reduced before the type I of tobaccos enter the primary threshing link, and tobaccos produced from the primary threshing link are in low-strength redrying; and the type II of tobaccos are in threshing and redrying according to existing threshing and redrying process flow. The novel threshing and redrying process is based on the tobacco mechanics characteristic differences, is complete and feasible threshing and redrying process flow and control technology for resolving the problem of tar extrusion and caking of tobacco during processing, and by the aid of the threshing and redrying process flow and control technology, threshing and redrying processing technical level and comprehensive tobacco quality further can be improved.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

Full-automatic encapsulated piston production equipment

The invention discloses full-automatic encapsulated piston production equipment. The equipment comprises a feeding mechanism, a pre-encapsulation mechanism and an encapsulation mechanism which are sequentially arranged on a stander, and is characterized by also comprising a turning conveying mechanism between the pre-encapsulation mechanism and the encapsulation mechanism, and a control module for controlling the four mechanisms, wherein the feeding mechanism comprises a conveying belt I and a feeding clamp for pushing pistons to be encapsulated on the conveying belt I to the pre-encapsulation mechanism; the pre-encapsulation mechanism comprises a turntable for holding a film, a conical die, a film taking manipulator for conveying the film to the conical die, a lower pressing head above the conical die, and a clamping manipulator for lifting the conical die; and the turning conveying mechanism comprises a conveying belt II for conveying the pre-encapsulated pistons automatically pushed by the pre-encapsulation mechanism, a turning manipulator which is positioned at the tail end of the conveying belt II and is used for turning the pre-encapsulated pistons, and a shaping arm which is used for shaping the pre-encapsulated pistons and conveying the shaped pistons to the encapsulation mechanism.

Owner:NINGBO XIAYI ELECTROMECHANICAL TECH CO LTD

Saw cutting machine for special pipes

ActiveCN103801762ANot easy to shakeAvoid damageMetal sawing devicesEngineeringMechanical engineering

The invention discloses a saw cutting machine for special pipes. The saw cutting machine comprises a machine base, a feeding clamp assembly, a saw cutting device and a discharging clamp assembly. The saw cutting device is installed on the machine base. The feeding clamp assembly is fixed to the upstream side of the saw cutting device and comprises an arc-shaped chute base, a rotating base, a first clamp half body, a second clamp half body, a clamping power device and a locking device, wherein the arc-shaped chute base is fixed to the machine base, the rotating base is installed on the arc-shaped chute base and locked by the locking device, at least one of the first clamp half body and the second clamp half body is installed on the rotating base in a sliding mode, and the clamping power device is fixed to the rotating base to drive the first clamp half body or / and the second clamp half body to get close to each other or get away from each other in a sliding mode. The discharging clamp assembly is installed on the downstream side of the saw cutting device and driven by a discharging power device to slide. The saw cutting machine can clamp the pipes optionally in different directions, make cross sections of cut pipes neat, improve cutting quality and prevent damage to the surfaces of the pipes.

Owner:SUZHOU KINKALTECK MACHINERY TECH

Method for preparing energy-saving metal-based ceramic inert anode material for nonferrous metal electrowinning

ActiveCN101538724ALarge specific surface areaExtended service lifeElectrodesAlloy substrateManganese

The invention relates to a method for preparing an energy-saving metal-based ceramic inert anode material for nonferrous metal electrowinning, and the method is characterized in that: a serrated pattern is compressed on the surface of a polar plate with a lead-based multinary alloy substrate, and a PbO2 and MnO2 conductive ceramics is prepared on the surface of the serrated pattern. The method adopts the physical and the electro-chemical methods for preparing the metal-based ceramic inert anode material which takes lead-based multinary alloy as the substrate. When the metal-based ceramic inert anode material is used in electrowinning, as the surface of an anode is the conductive ceramic material, the surface of the anode is in the insoluble state, thereby being capable of reducing the pollution of lead dissolution of the anode to a cathode product, improving the quality of the cathode product and ensuring the qualified rate of a cathode zinc No. 0 product to achieve 99 percent. The use of the compound electrode can significantly reduce the bath voltage during the electrowinning process and further reduce the power consumption. When in electrowinning of zinc, copper, nickel, cobalt, manganese and the like, the bath voltage can be reduced by 0.3-0.5V, and the current efficiency can be improved by 2-3 percent.

Owner:晋宁理工恒达科技有限公司

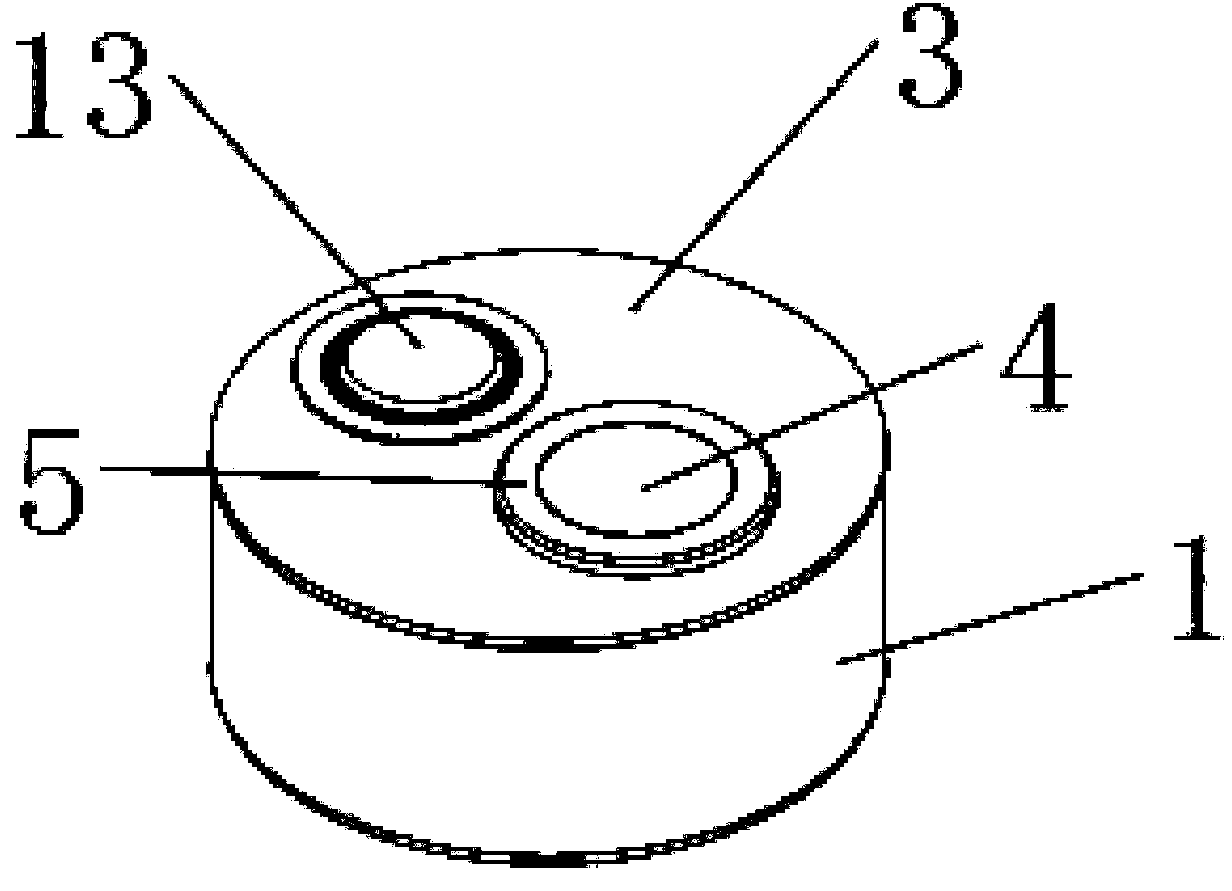

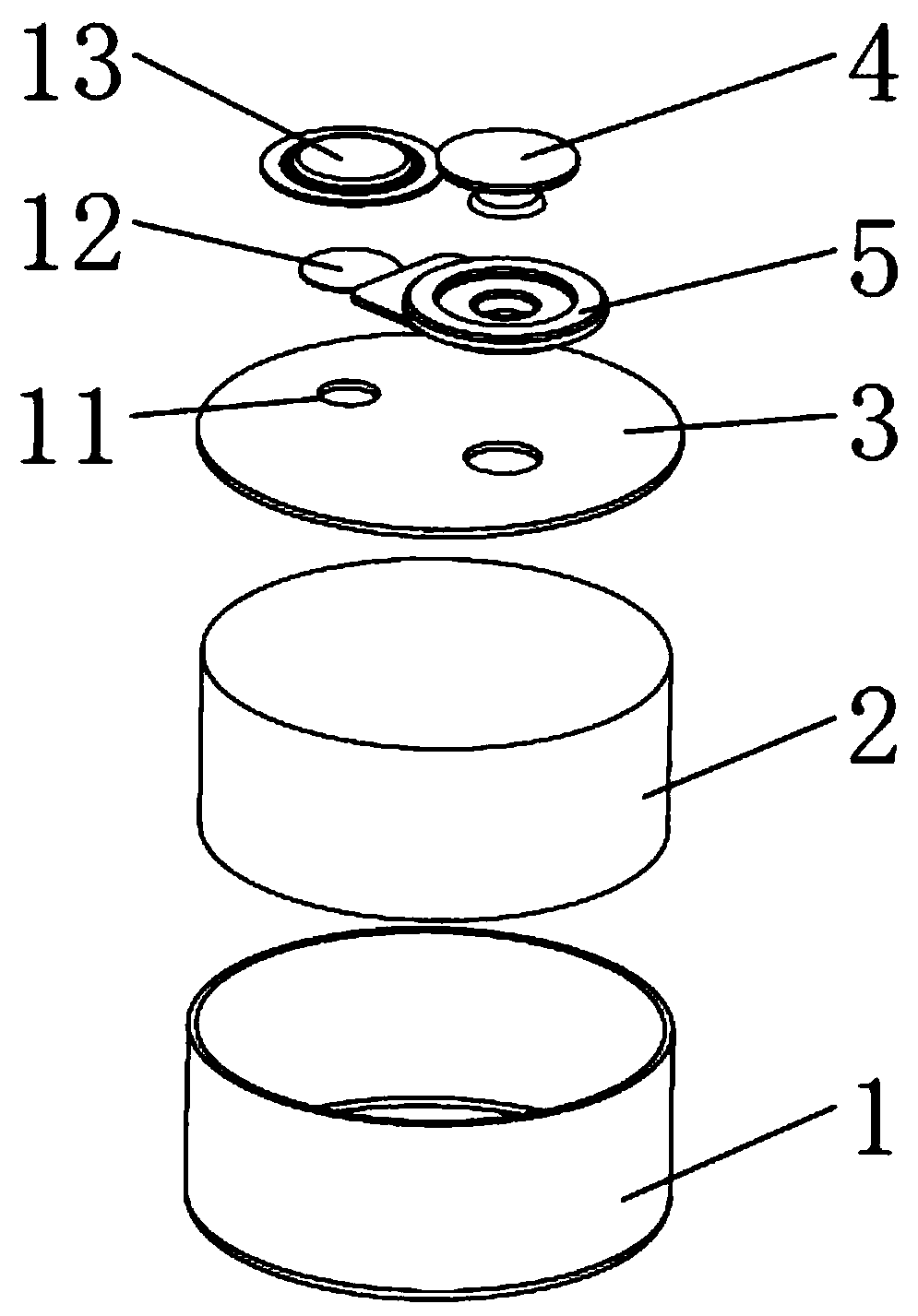

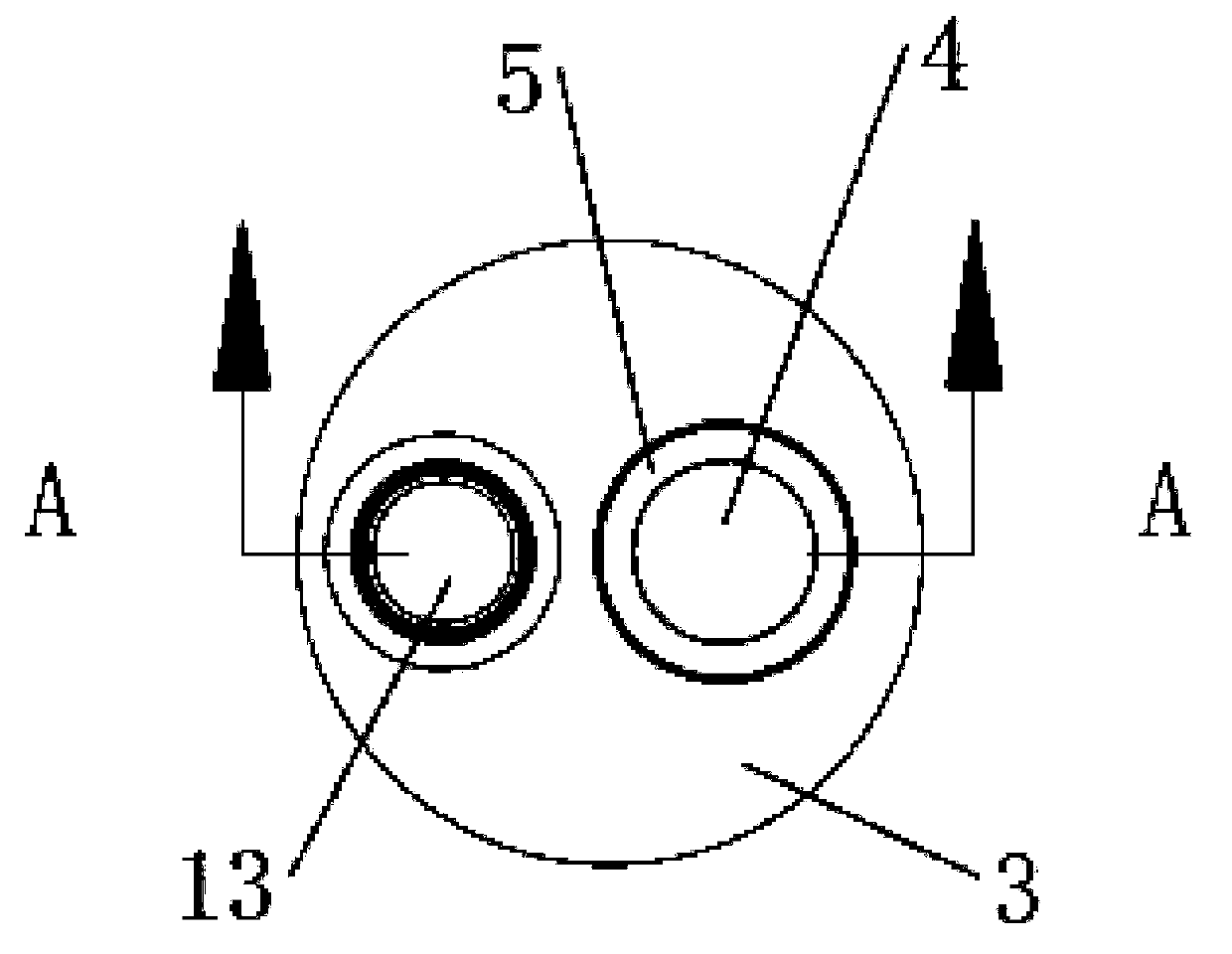

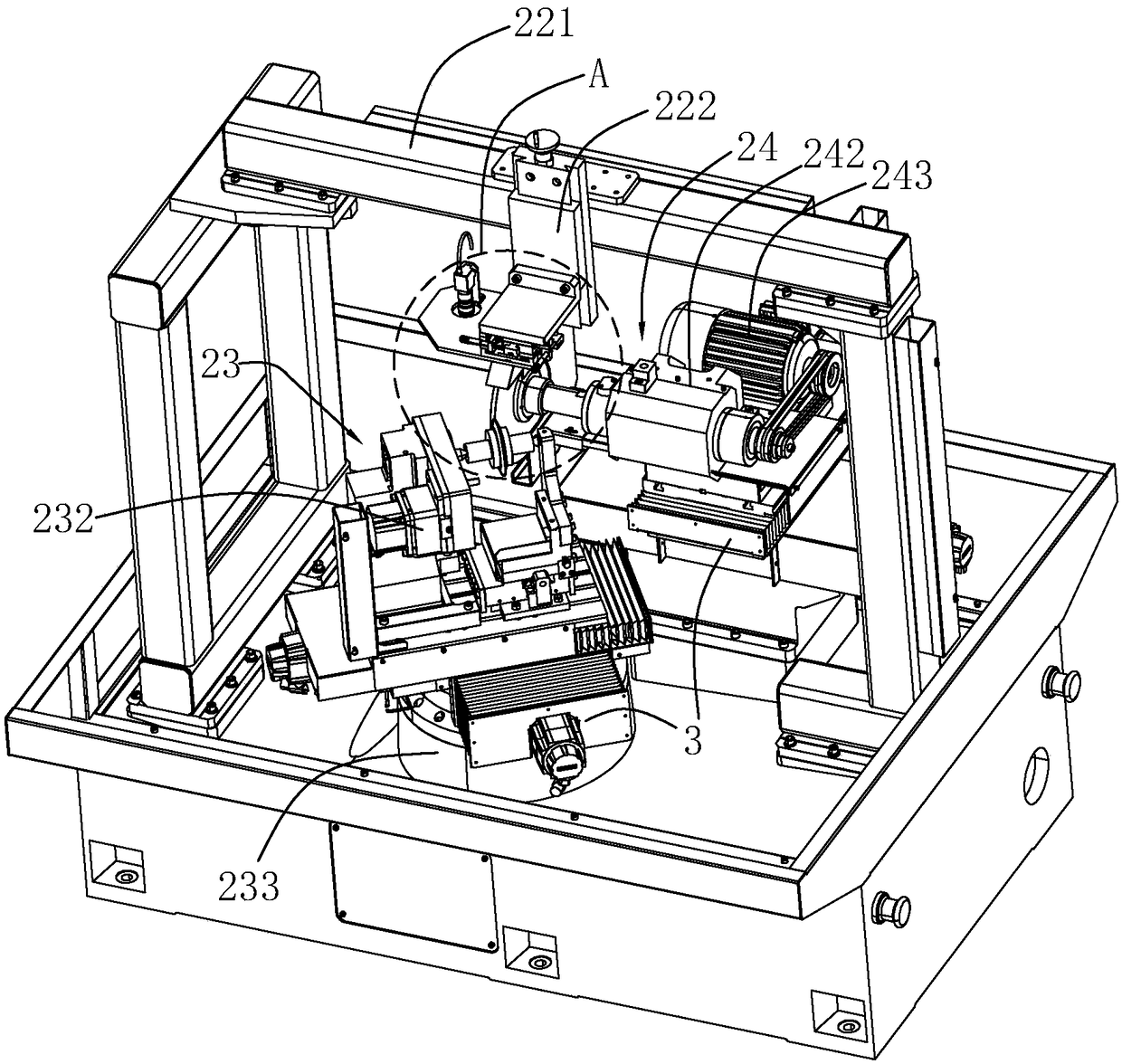

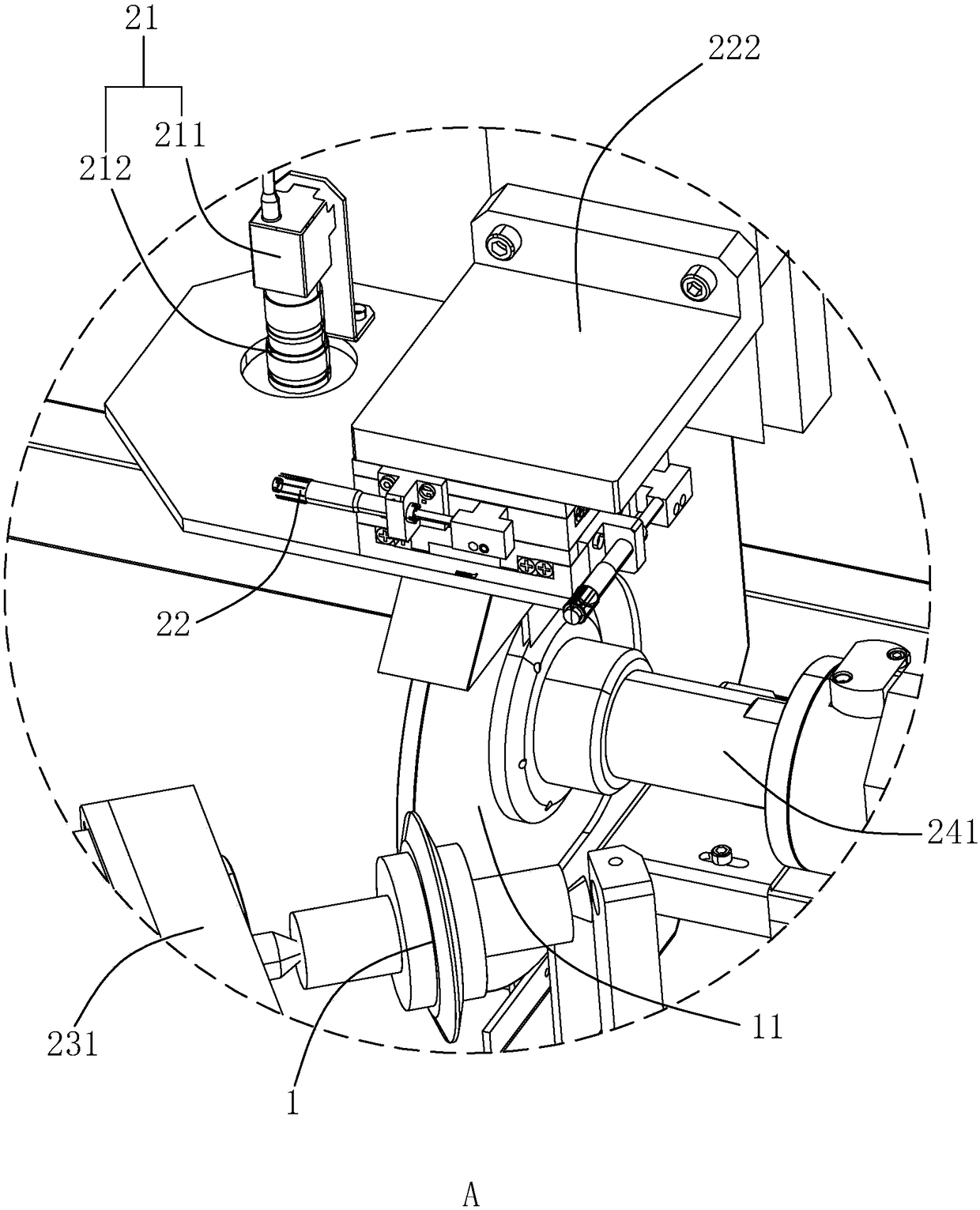

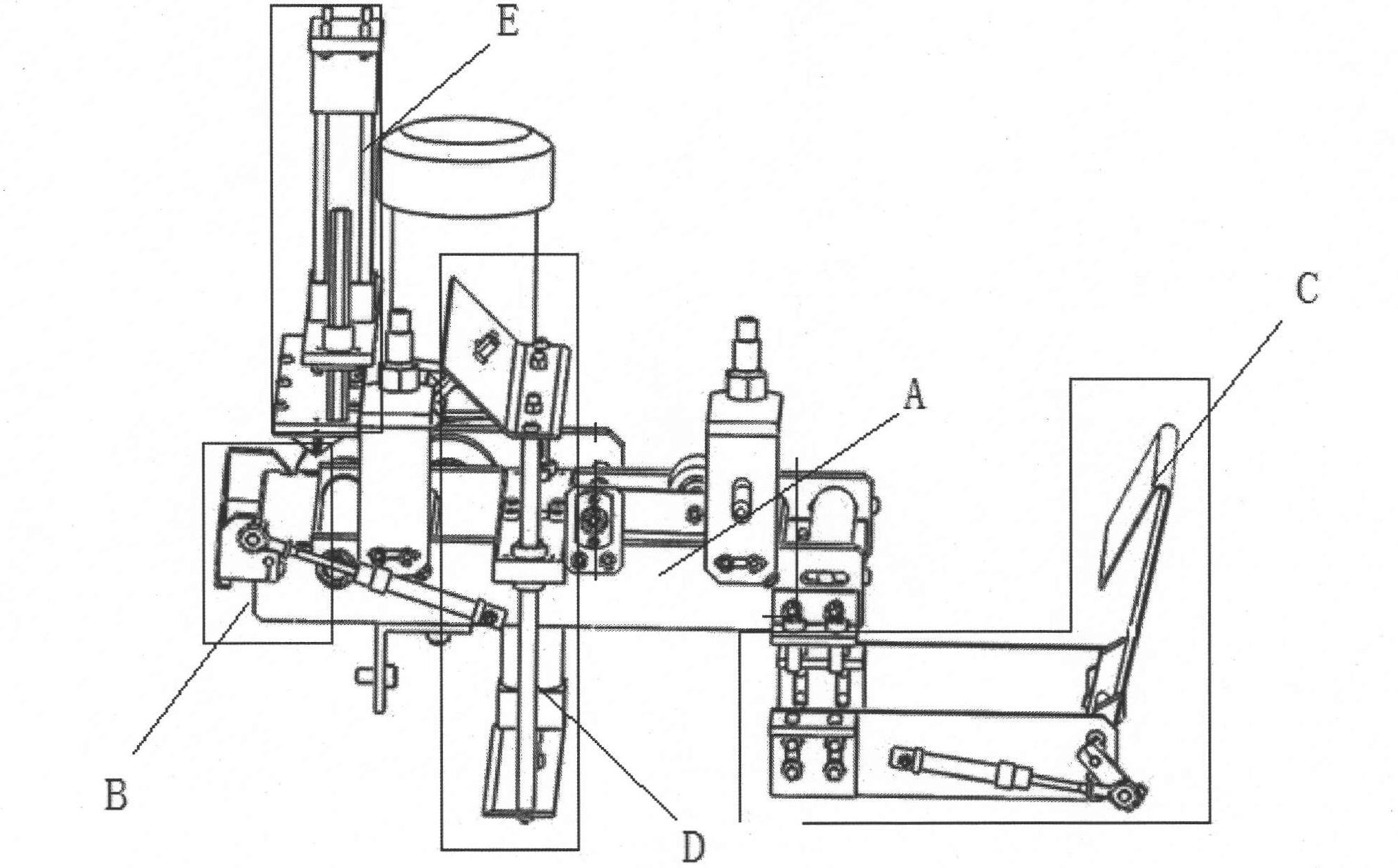

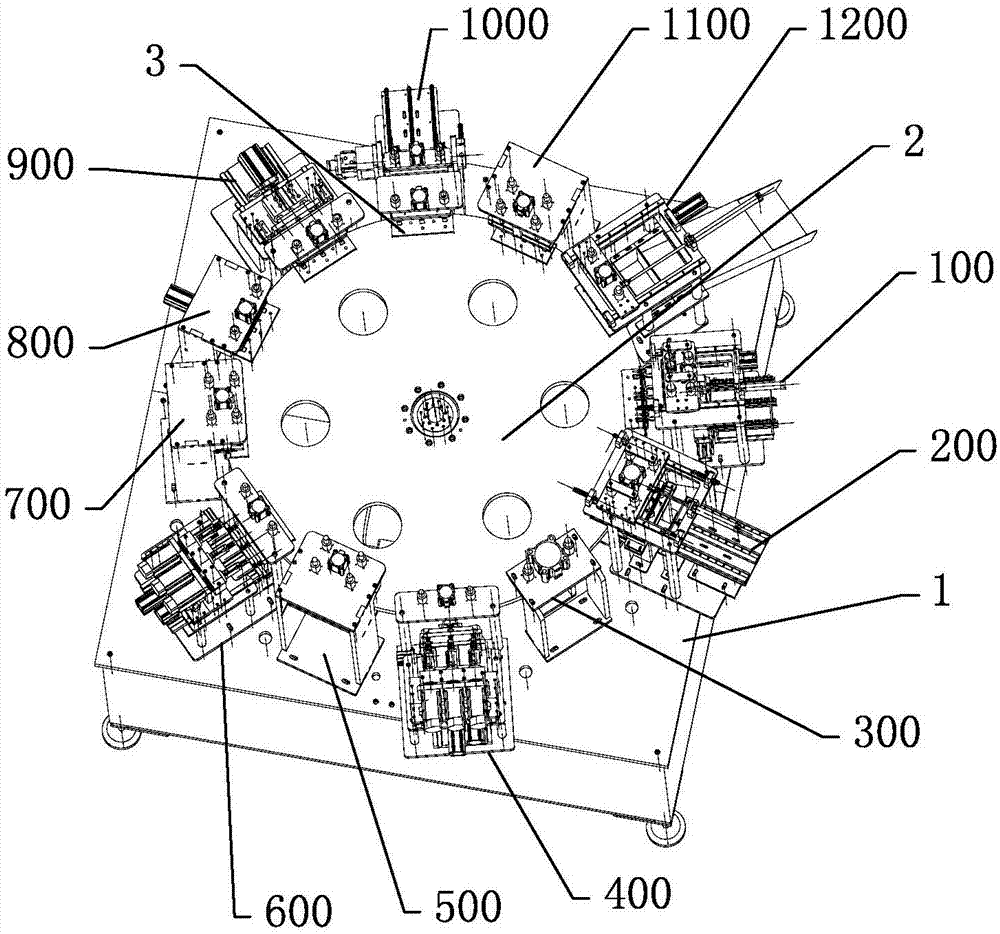

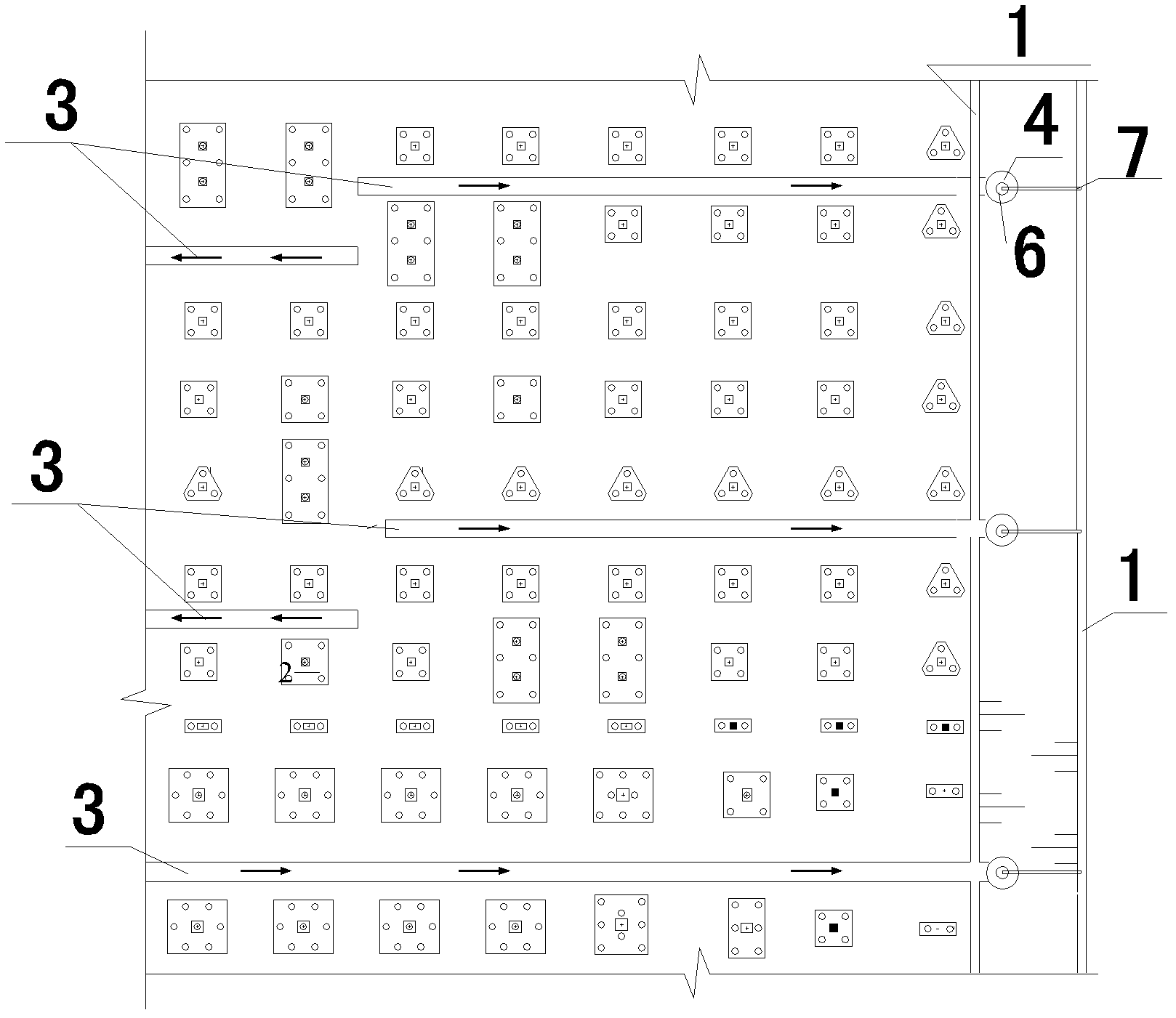

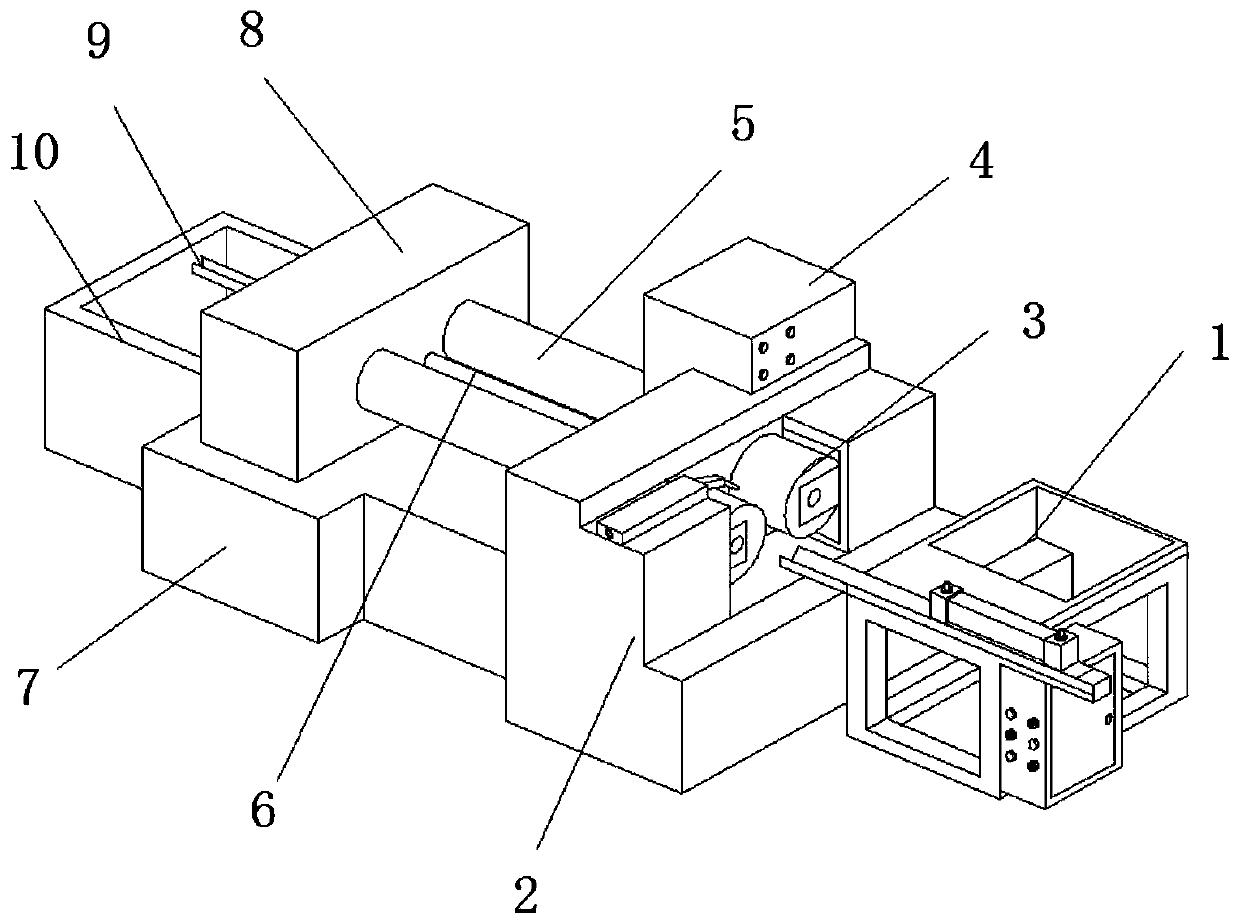

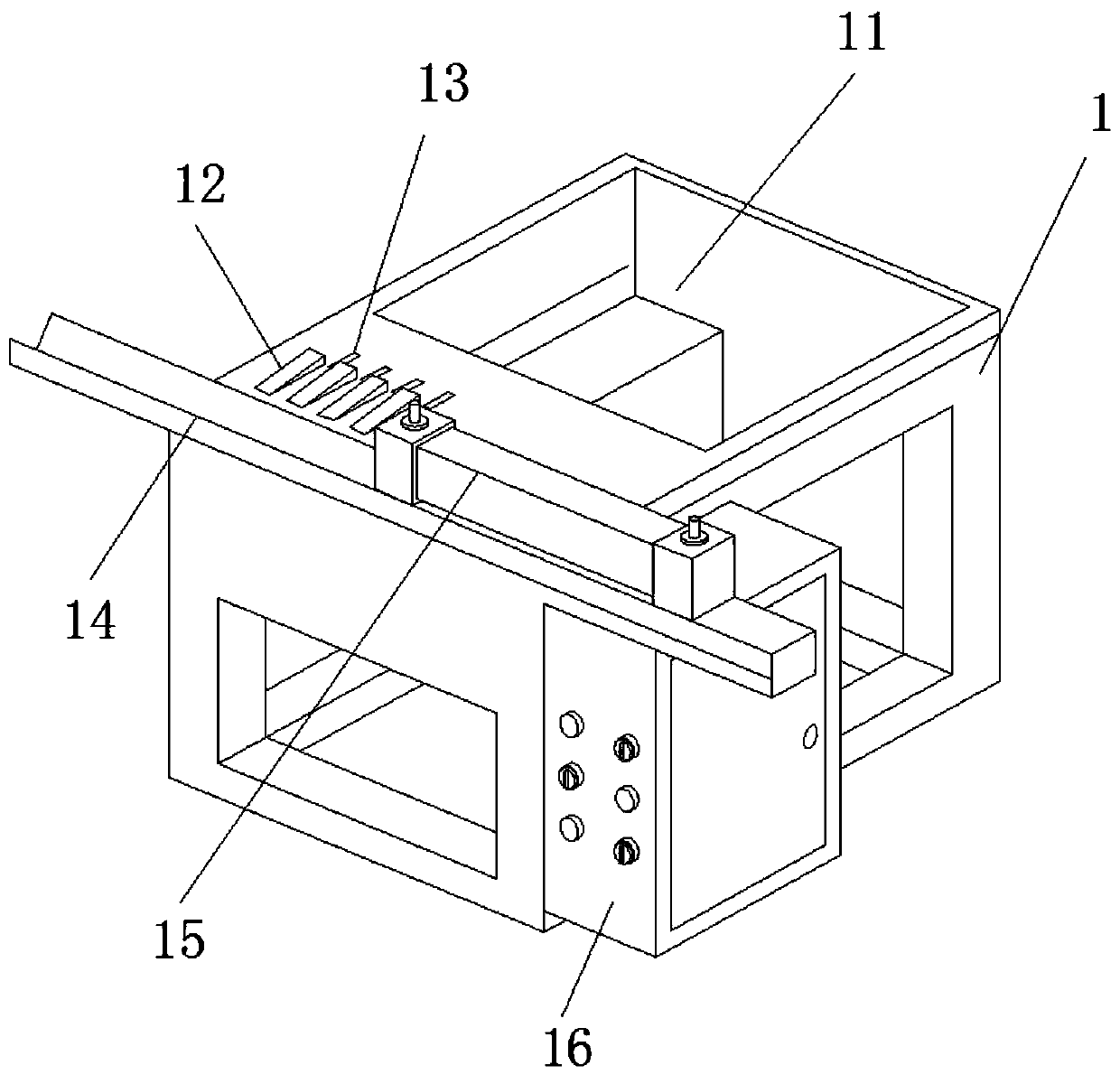

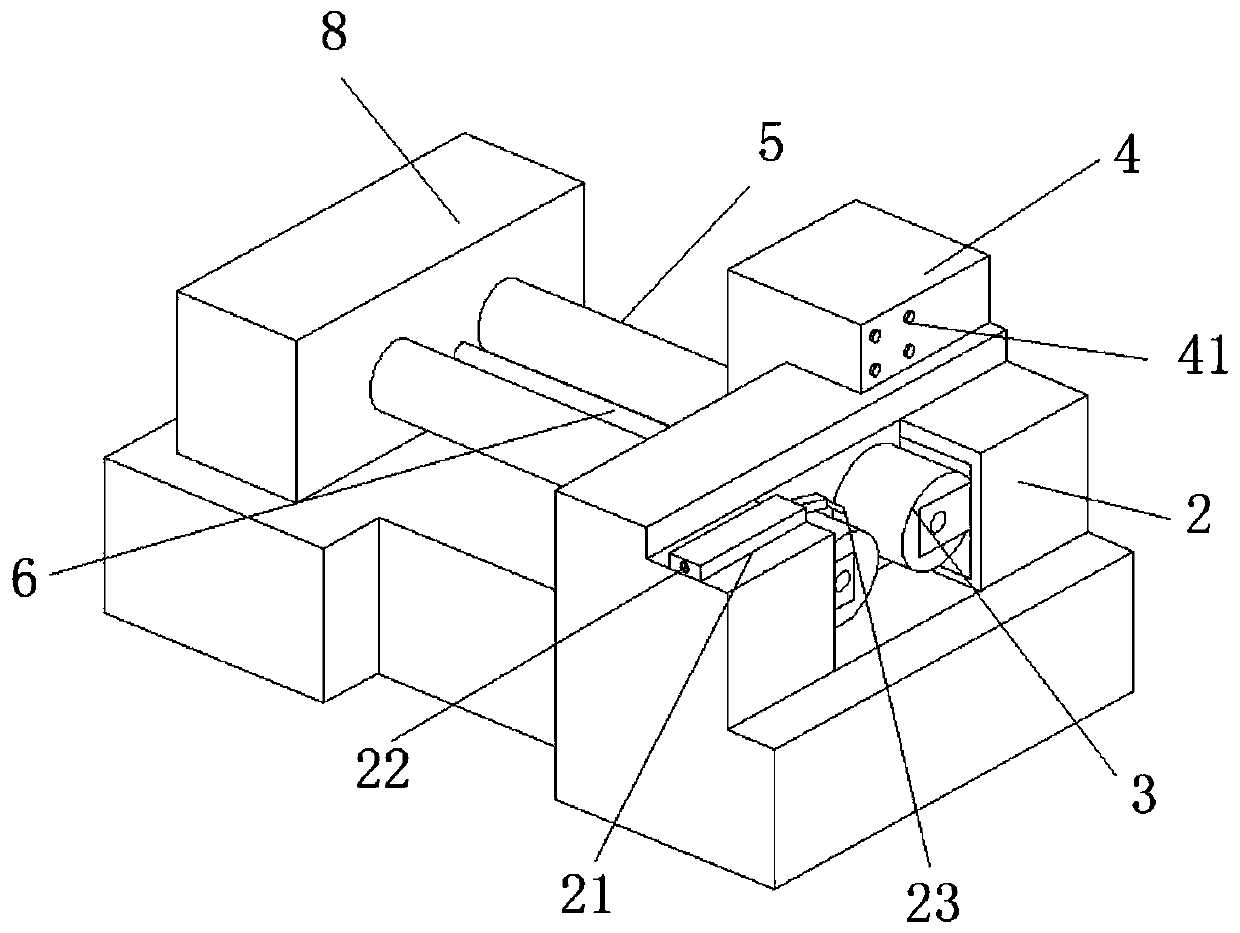

Three-way valve assembly machine and assembly method thereof

PendingCN107263092AEliminate Hygiene ProblemsRealize fully automatic assemblyAssembly machinesPhysicsEngineering

The invention discloses a three-way valve assembly machine and an assembly method thereof, and aims to provide the high-efficiency and high high-precision three-way valve assembly machine and the assembly method thereof. According to the technical scheme, the three-way valve assembly machine comprises a machine frame (1); a multi-station rotary workbench (2) is arranged on the machine frame (1); a plurality of clamps (3) are arranged on the machine frame (1); and aiming at the clamps and movable paths of all the clamps, a valve body feeding station (100), a valve element mounting station (200), a valve element compressing station (300), a first screw top mounting station (400), a first valve body rotating station (500), a second screw top mounting station (600), a second valve body rotating station (700), a gas tightness detection station (800), a spiral head mounting station (900), a sheath mounting station (1000), a valve element rotating station (1100) and a discharging station (1200) are sequentially arranged on the machine frame (1). The three-way valve assembly machine and the assembly method thereof are applicable to the field of assembly.

Owner:WENLING DEGUANG AUTOMATION EQUIP

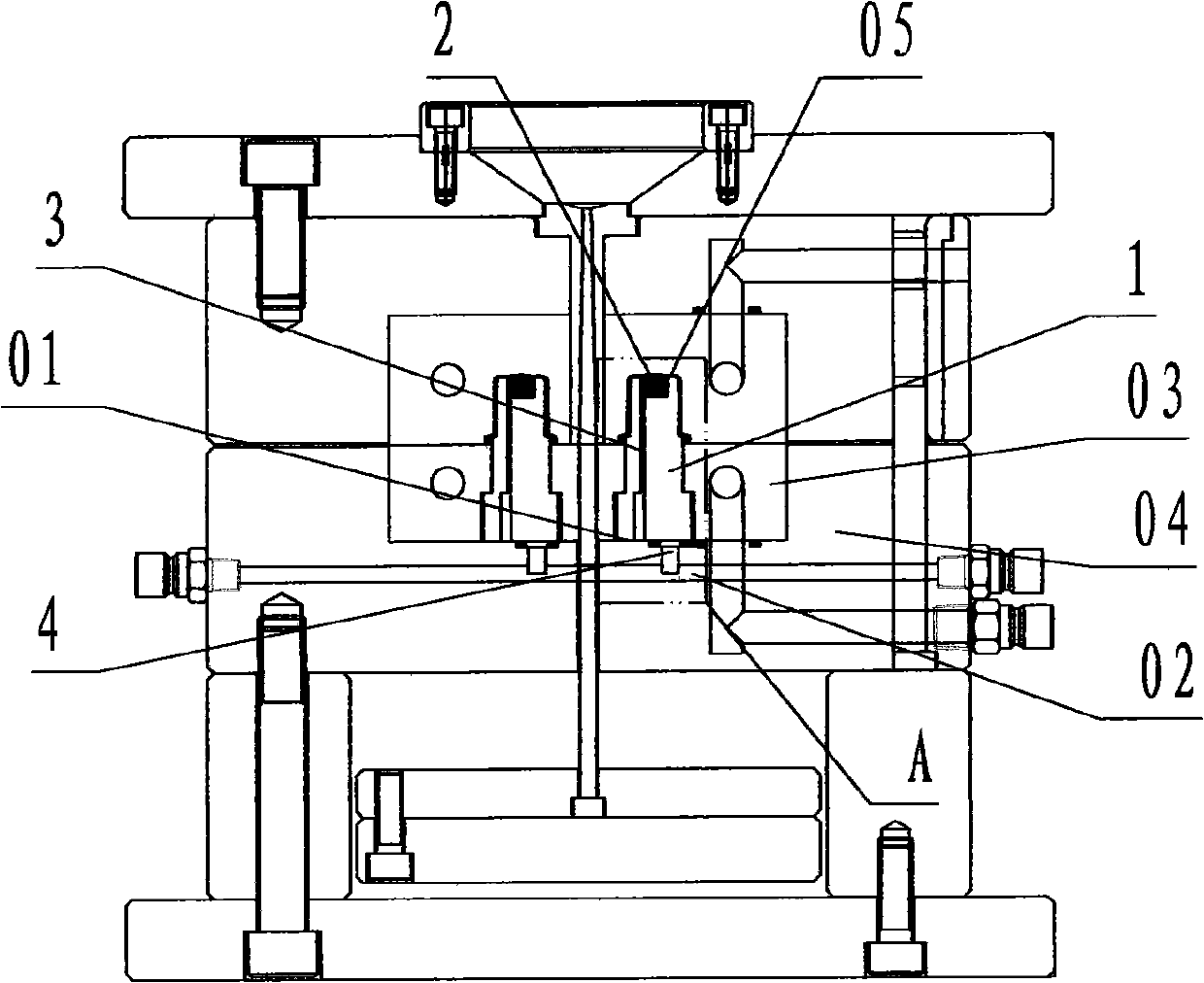

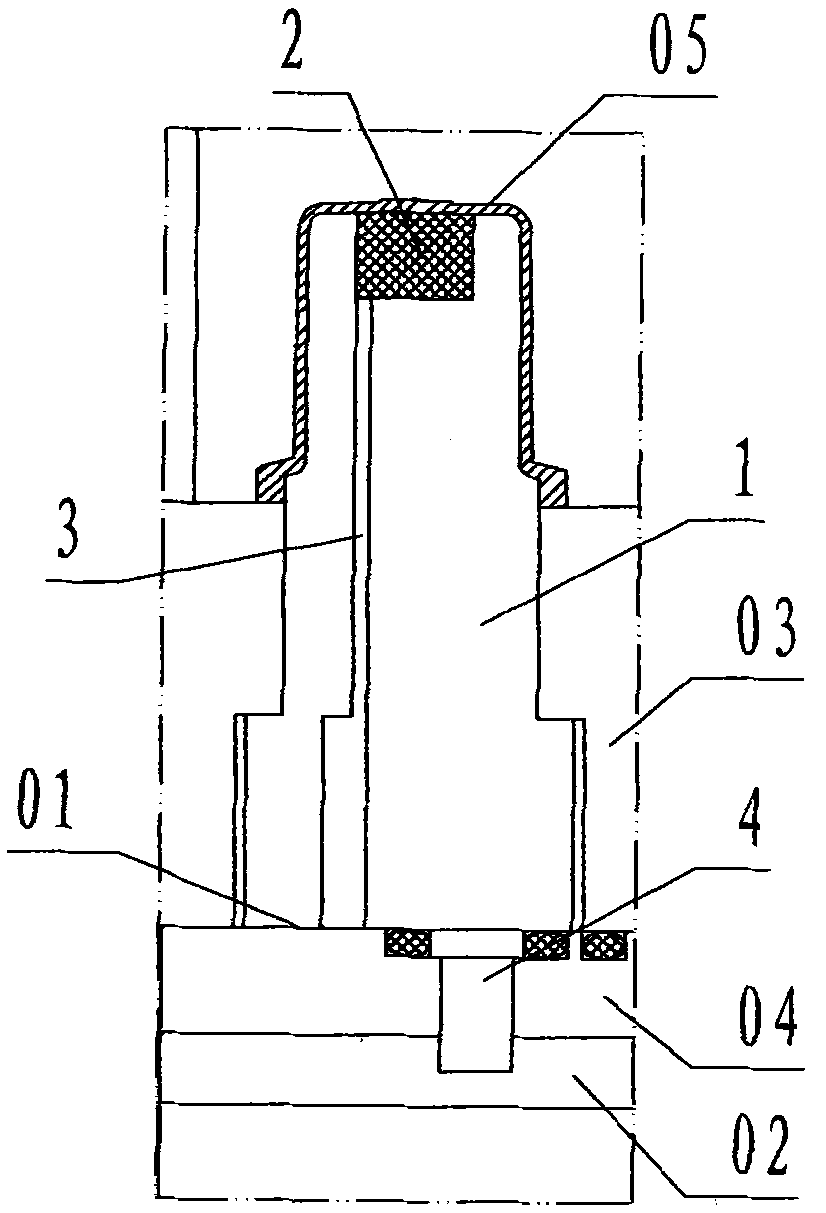

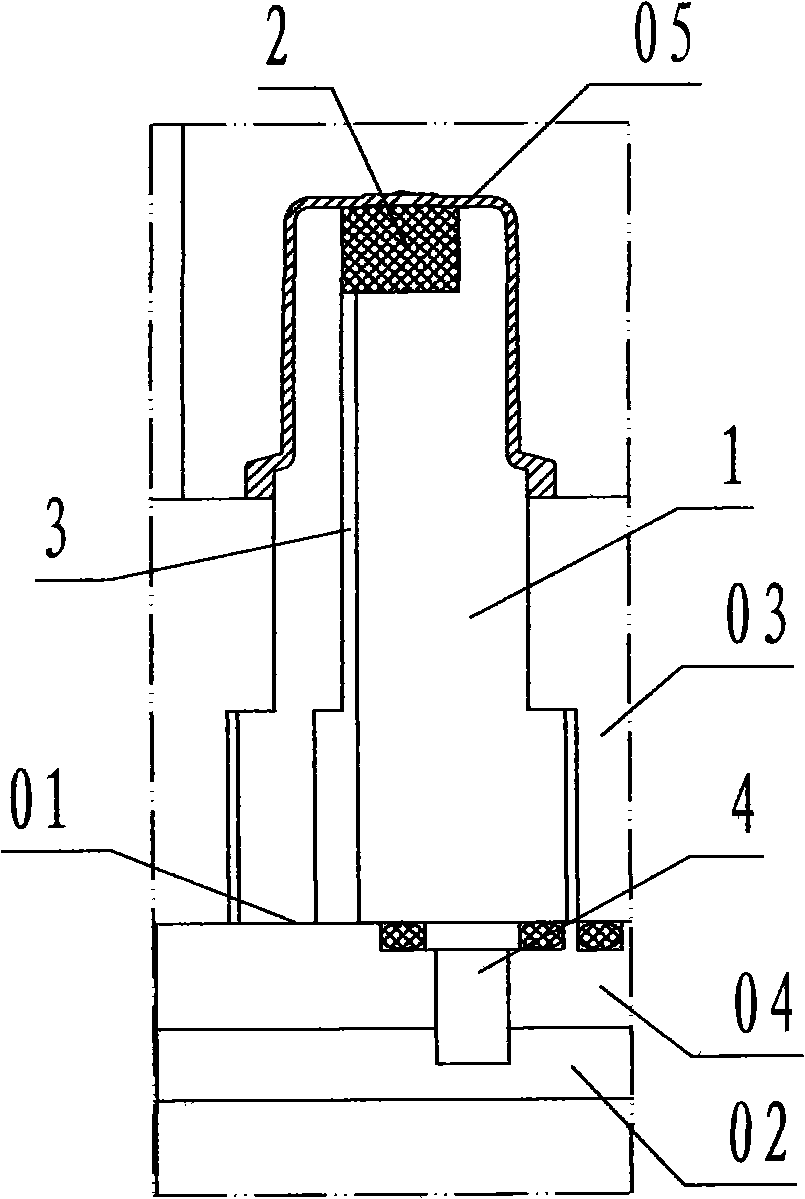

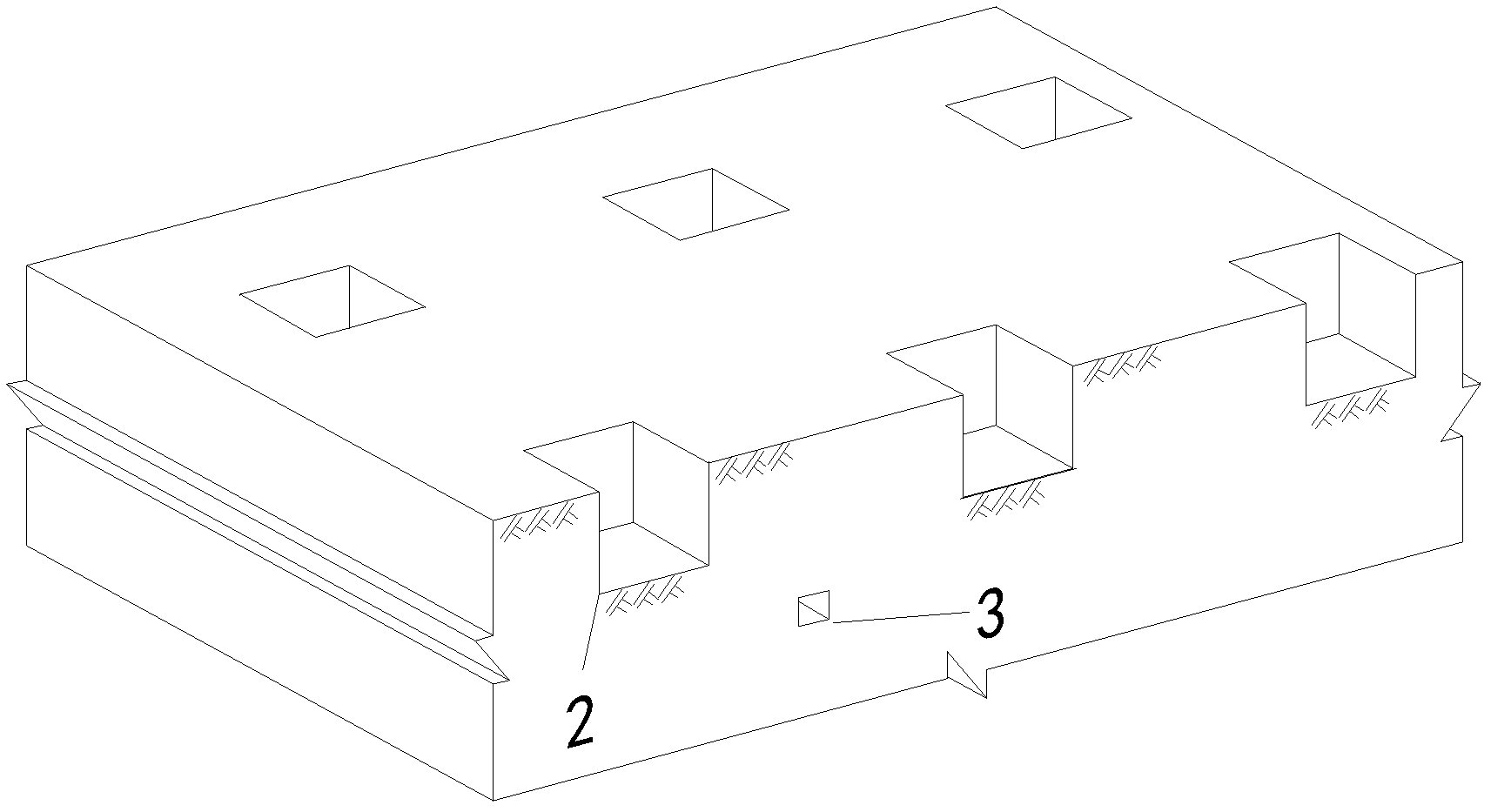

Injection mold core with air suction, discharge and rapid cooling functional structure

The invention provides an injection mold core with an air suction, discharge and rapid cooling functional structure. The injection mold core consists of a core body (1), a ventilated surface (2), an air suction and discharge channel (3) and a heat-conductive pin (4). In the injection mold core, the technical scheme that: the core body is made from a beryllium copper material with high heat conductivity; the ventilated surface which is made of porous ventilated steel is fixedly inlaid at the top of the core body; the air suction and discharge channel which is connected with a mold is reserved in the core body; and the heat-conductive pin which is directly inserted into a mold cooling water pipe is arranged at the bottom of the core body is adopted, so that the problems of low qualification rate, high cost and poor quality consistency of products in the molding of small-diameter deep-cavity injection products in the prior art are solved. The injection mold core with the air suction, discharge and rapid cooling functional structure provided by the invention fulfills the aims of improving the qualification rate, reducing the cost and ensuring the quality consistency of the products of the molding of the small-diameter deep-cavity injection products by increasing cooling rate and improving air suction and discharging conditions of the core body structurally.

Owner:NINGBO RUIYUAN MOLD & PLASTICS

Waterproof construction method and system for bottom plate of high-water-level basement

ActiveCN102535488AAvoid situations where you cannot enter a processShorten the construction periodFoundation engineeringBasementStructure of the Earth

The invention discloses a waterproof construction method for a bottom plate of a high-water-level basement. The method comprises the following steps of: (1) partitioning water on a soil layer in a depth range of a foundation pit from the periphery of the foundation pit by using a waterproof curtain of a foundation pit support, and forming drainage ditches on the ground surface of the foundation pit support and at the bottom periphery of the foundation pit; (2) forming more than one dredging ditch below partitioning positions among pile bearing platforms, wherein the distance between the bottom of each pile bearing platform and the top of the dredging ditch is 500 to 1,000mm; and (3) forming a corresponding dewatering well at the periphery of the foundation pit according to a water outlet end of the dredging ditch, and arranging a submerged pump in the dewatering well, wherein the submerged pump is communicated with the drainage ditches through water suction pipes. The invention also discloses a waterproof system for the bottom plate of the high-water-level basement. By the method and the system, the problems of low dryness of flexible waterproof layer construction surfaces, over-high cost of jet grouting piles, high water seepage degree, high labor consumption, high material consumption and the like in the prior art are solved; and the system has the characteristics of effectively dewatering the basement, shortening construction periods, saving the cost and conveniently controlling construction quality, along with a simple structure, low manufacturing cost and the like.

Owner:广东中城建设集团有限公司 +1

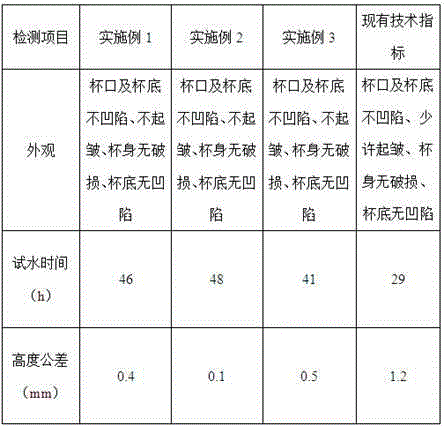

Preparation technology of disposable paper cup

InactiveCN105342292AImprove qualityGuaranteed bonding qualityDrinking vesselsMolding machinePaperboard

The invention discloses a preparation technology of a disposable paper cup. Before printing, rectangular paper is subjected to corona treatment, the surface tension of the treated rectangular paper is 40-50 nM / m, the surface tension of the rectangular paper can meet requirements of printing during printing, printing quality is guaranteed, adhesion temperature and adhesion temperature of a paper board forming machine can be controlled, adhesion quality of the paper cup can be guaranteed, so that yield of the paper cup is guaranteed, after a finished product is formed, the disposable finished paper cup is placed in a disinfection cabinet and is disinfected for 6-8 hours and at the temperature of 100-120 DEG C, and the quality of the disposable paper cup can be improved. A cup body produced by the method is regular in appearance, market potential is huge, and the prospect is wide.

Owner:ANQING SHENGHUA PAPER PACKAGING

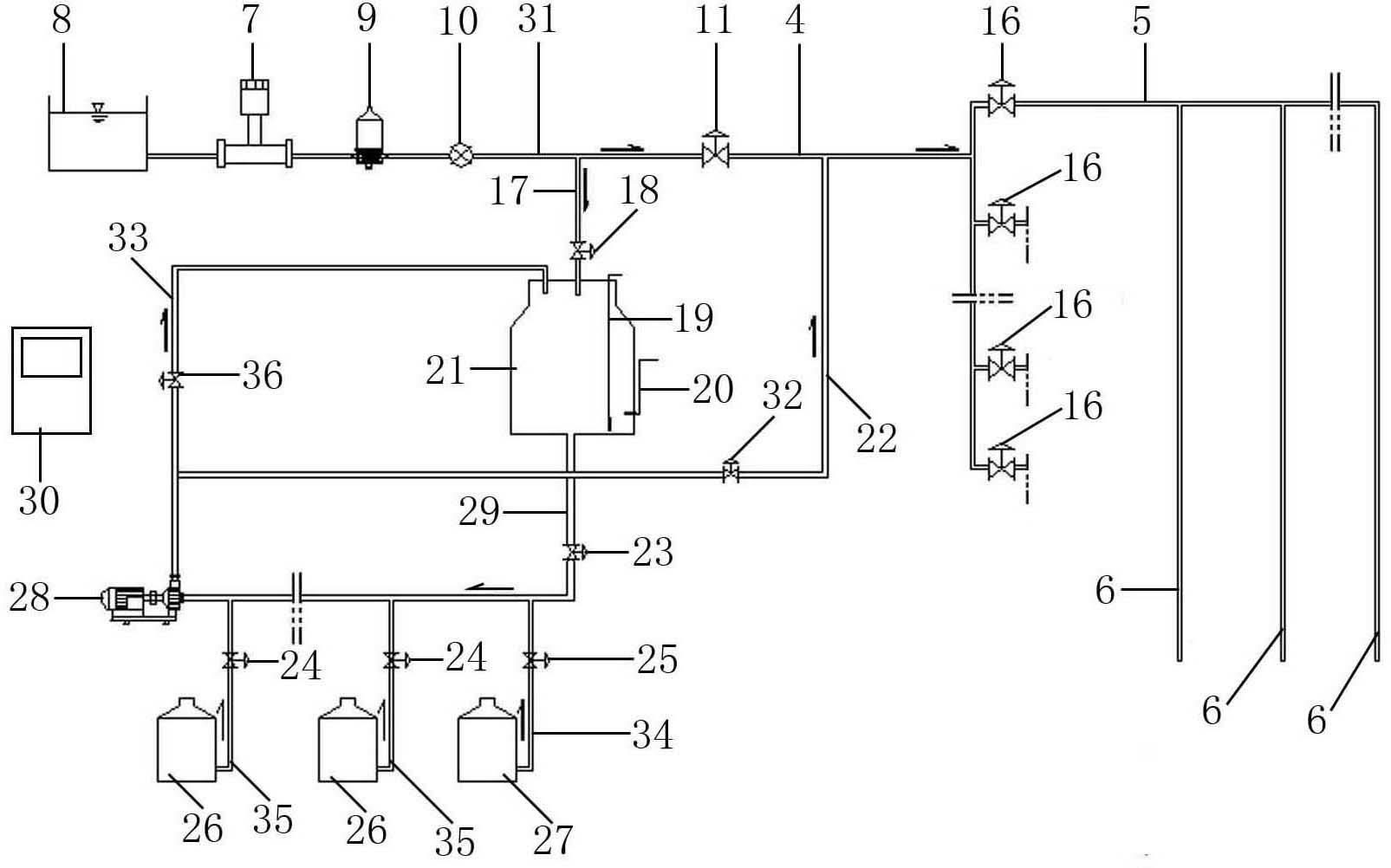

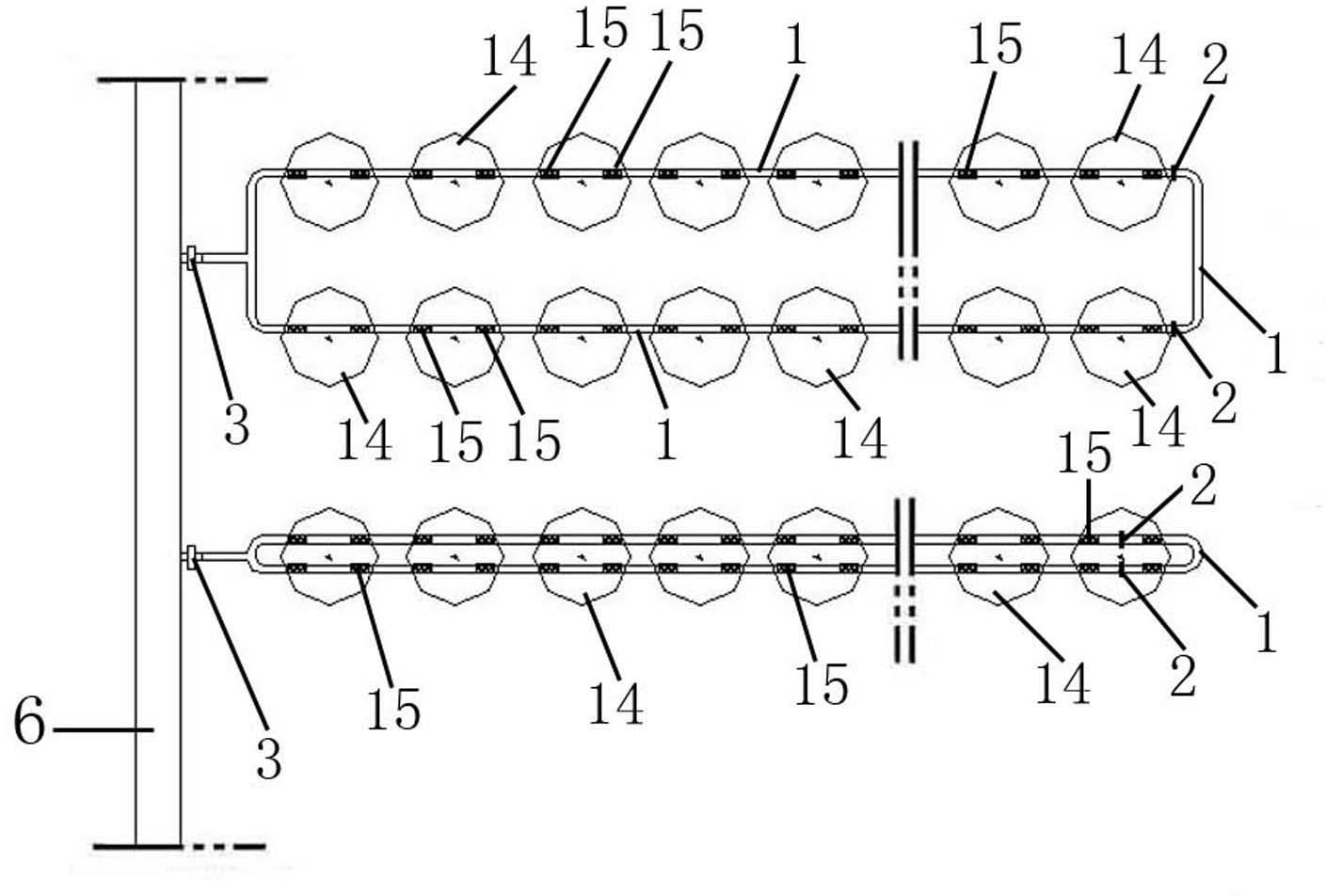

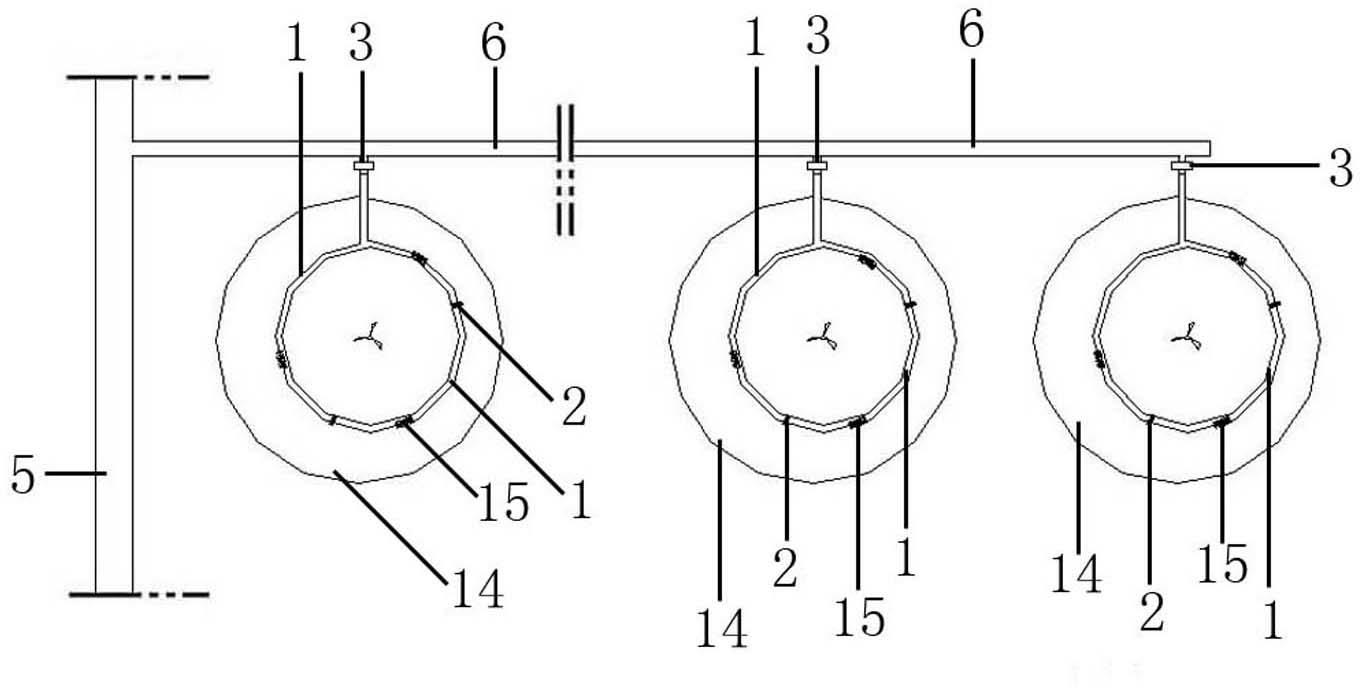

Closed-loop group flow drop irrigation, preparation and fertilization system as well as irrigation method, nutrient liquid preparation method and fertilization method

InactiveCN102318467AStrong flowUniform and stable flowFertilising methodsPressurised distribution of liquid fertiliserWater sourceLiquid storage tank

The invention relates to an irrigation method of a closed-loop group flow drop irrigation, preparation and fertilization system, a nutrient liquid preparation method and a fertilization method. The system is divided into an irrigation subsystem, a nutrition liquid preparation subsystem and a control subsystem and is composed of an impounding reservoir, a water division pump, a water source transportation pipeline, a water injection pipeline, a stored nutrient liquid output pipeline, a nutrient liquid storage tank, a nutrient liquid transportation pipeline, a nutrient liquid mother solution storage tank, an acid / base solution storage tank, a self-priming pump, a main controller, a main transportation pipeline, a branch pipe pipeline, a capillary pipeline, a supporting and positioning fixture, a flow stabilizer, a closed-loop group flow drop irrigation pipeline and water droppers, wherein the water source transportation pipeline is connected with the water injection pipeline and the main transportation pipeline; the main transportation pipeline is provided with the branch pipe pipeline; the branch pipe pipeline is provided with the capillary pipeline; the capillary pipeline is provided with the closed-loop group flow drop irrigation pipeline; and the closed-loop group flow drop irrigation pipeline is provided with the water droppers, and one water dropper is arranged on each drop irrigation point. The system disclosed by the invention is scientific in design, reasonable in structure and easy and simple to operate, and has the characteristics of remarkable property, strong function, low price and obvious benefits.

Owner:TIANJIN WATER RESOURCES RES INST

Biomass fuel and production method thereof

The invention relates to the technical field of biomass fuels, in particular to biomass fuel and a production method thereof. According to the production method, the materials, such as biogas residue, crop stalks, marshal sludge and sawdust, are mixed prior to being treated via a fermentation process; thus, organics are biologically react microscopically, the materials act with one another, the structure of biomass is enhanced, crushing and compressing treatment of the materials is easier, the difficulty and energy consumption of the biomass fuel is lowered, and the cost of biomass fuel production is lowered. In addition, pulverized coal is subjected to crushing treatment and added with illegal cooking oil and gasoline; thus, the waste, the illegal cooking oil and the gasoline are made full use, the ignition point of the biomass fuel is lowered, and the ignition cost of the biomass fuel in applications is lowered.

Owner:玉林市新滔环保科技有限公司

Automatic packer

ActiveCN104691796AAchieve cullingRealize feedingPackaging automatic controlSolid materialPlastic packagingAutomation

The invention discloses an automatic packer. The automatic packer comprises a frame I, a hopper I fixed on the frame I, a qualified product conveying belt, a rejecting device, an unqualified product conveying belt, a frame II and a hopper II fixed on the frame II, wherein an overturning plate is arranged in the hopper I; a weight sensor is arranged on the overturning plate; the lower part of the hopper I is connected with a bagging machine; the rejecting device comprises a cylinder I and a pushing plate connected to a pushing rod; an automatic plastic packaging machine, a labeling machine and a label making machine are arranged on the qualified product conveying belt; an infrared sensor is arranged on the automatic plastic packaging machine; the unqualified product conveying belt penetrates through the frame II. According to the automatic packer, the overturning plate with the weight sensor and the pushing plate are arranged in the hopper I; the materials are fed stably; the uneven stirring and the secondary pollution caused by artistic stirring are avoided; the rejecting device is capable of rejecting unqualified materials and supplementing; the qualified rate of products is ensured; the production efficiency and the automation degree of the equipment are improved.

Owner:天津雍和包装股份有限公司

Screw thread rolling machine

InactiveCN110586818APersonal safetyReduce scatterMetal-working feeding devicesScrew-threads articlesKey pressingEngineering

The invention discloses a screw thread rolling machine. The machine comprises a feeding mechanism, wherein one end of the feeding mechanism is fixedly provided with a storage box, and falling stop blocks are fixedly arranged at the upper end of the feeding mechanism; discharging through grooves are formed in the ends, close to the storage box, of the falling stop blocks, a feeding channel is fixedly arranged at the end, away from the discharging through grooves, of the falling stop blocks, a feeding air cylinder is fixedly arranged on the feeding channel, and a discharging push block is fixedly arranged on the feeding air cylinder; and an electric control box is fixedly arranged on the outer side of the feeding mechanism, a maintenance door is movably arranged on the electric control box,a function key is fixedly arranged at the end, adjacent to the maintenance door, of the electric control box, and an adjusting knob is fixedly arranged on the outer side of the function key. According to the screw thread rolling machine, the feeding mechanism capable of automatic feeding is added, so that an operator can be liberated, only raw materials in the storage device are required to placeon the feeding mechanism, therefore the direct contact between the operator and the equipment is reduced, and the operator is better protected.

Owner:浙江君悦标准件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com