Patents

Literature

638 results about "Maintaining equipment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

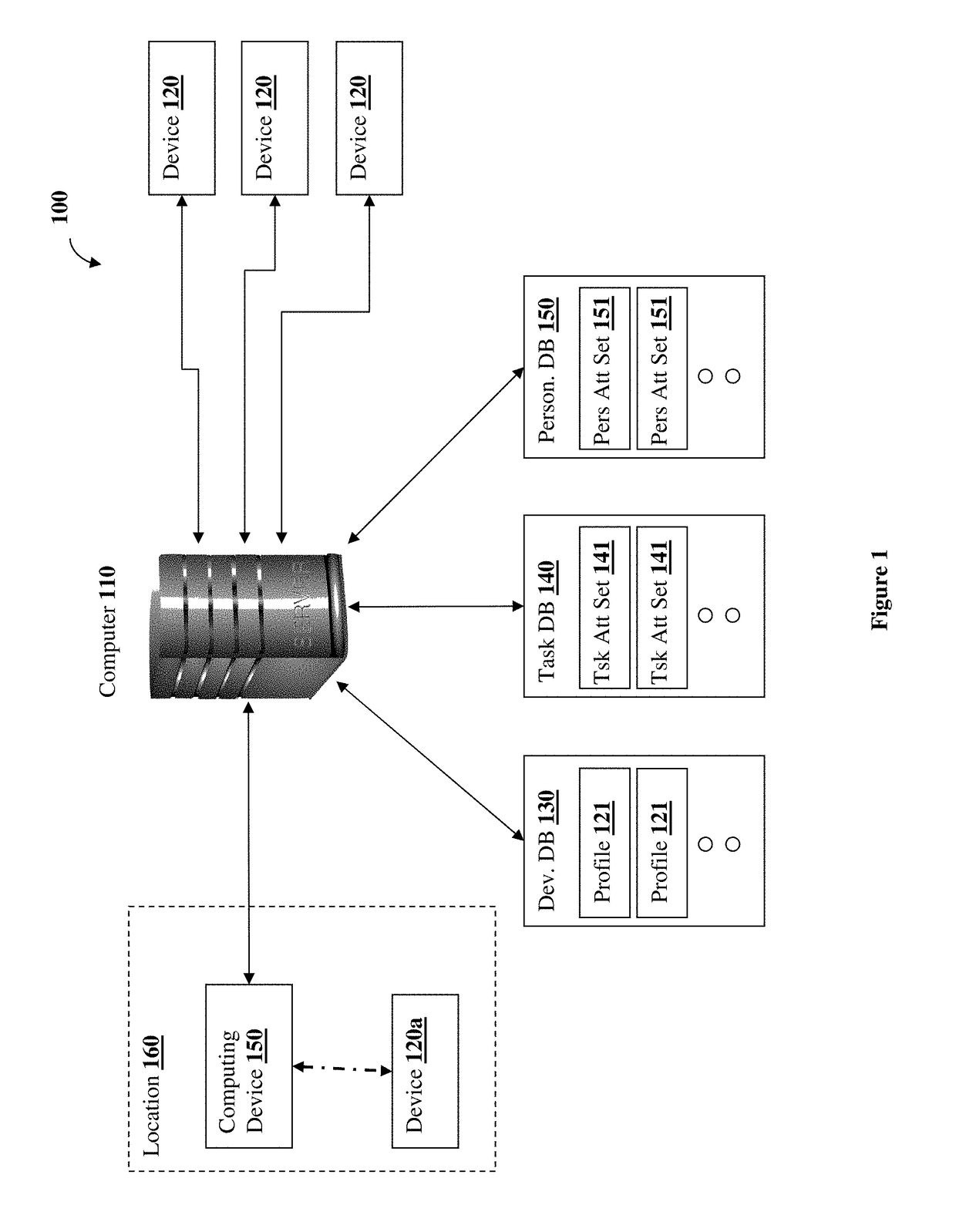

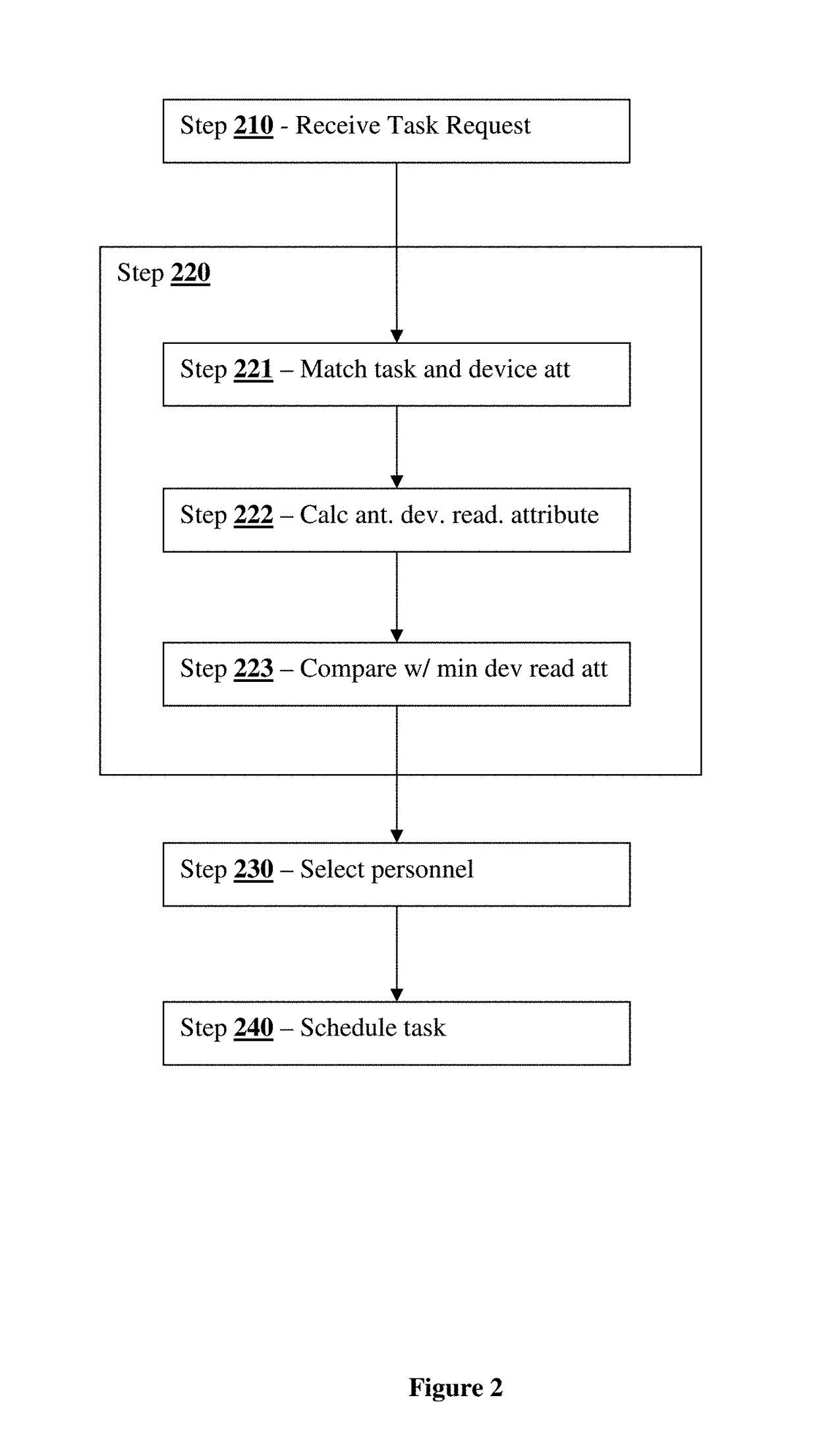

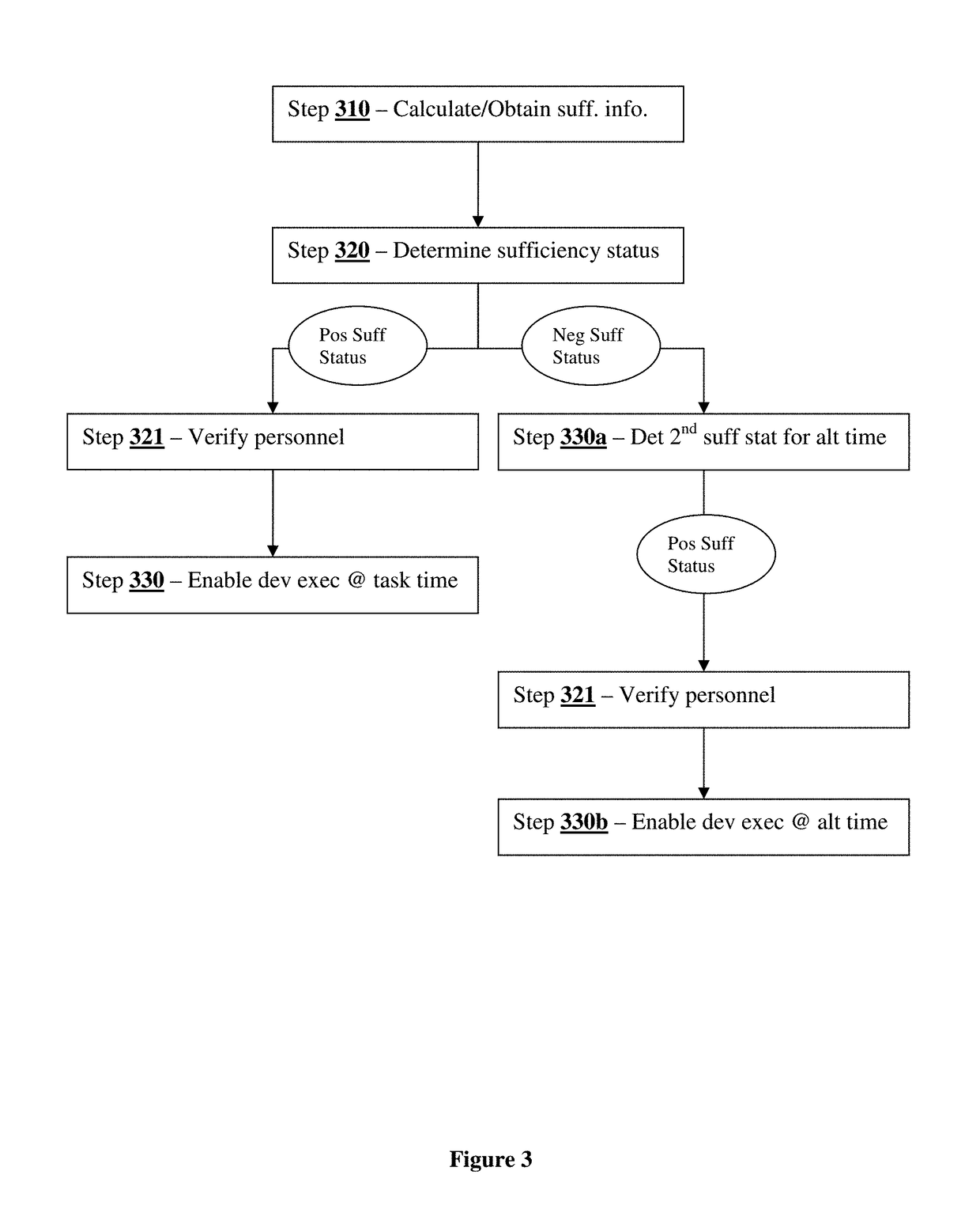

Systems and methods of ensuring and maintaining equipment viability for a task

ActiveUS10163065B1Adjust in timeExtension of timeProgram initiation/switchingOffice automationMonitor equipmentSTAFFING SCHEDULING

A device management system that is capable of scheduling connected devices and personnel for tasks, monitoring the ability of the devices to perform the scheduled task by checking in with the devices based on their uses and locations, and to modify the functioning of the devices according to the tasks scheduled for the devices and their uses. Additionally, the system can incorporate uncommunicated “dumb” devices into the scheduling of tasks and track and manage those devices.

Owner:NMETRIC

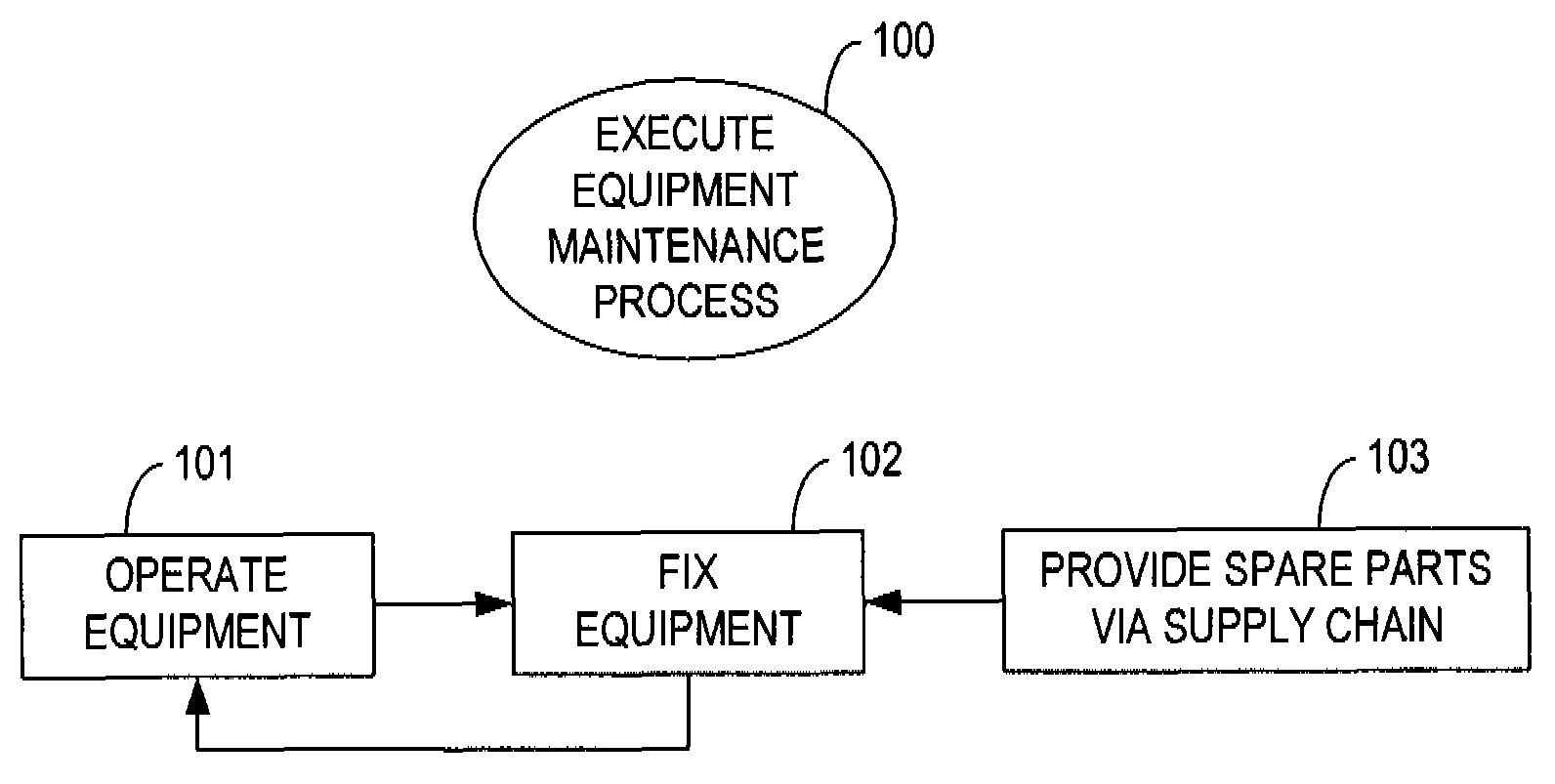

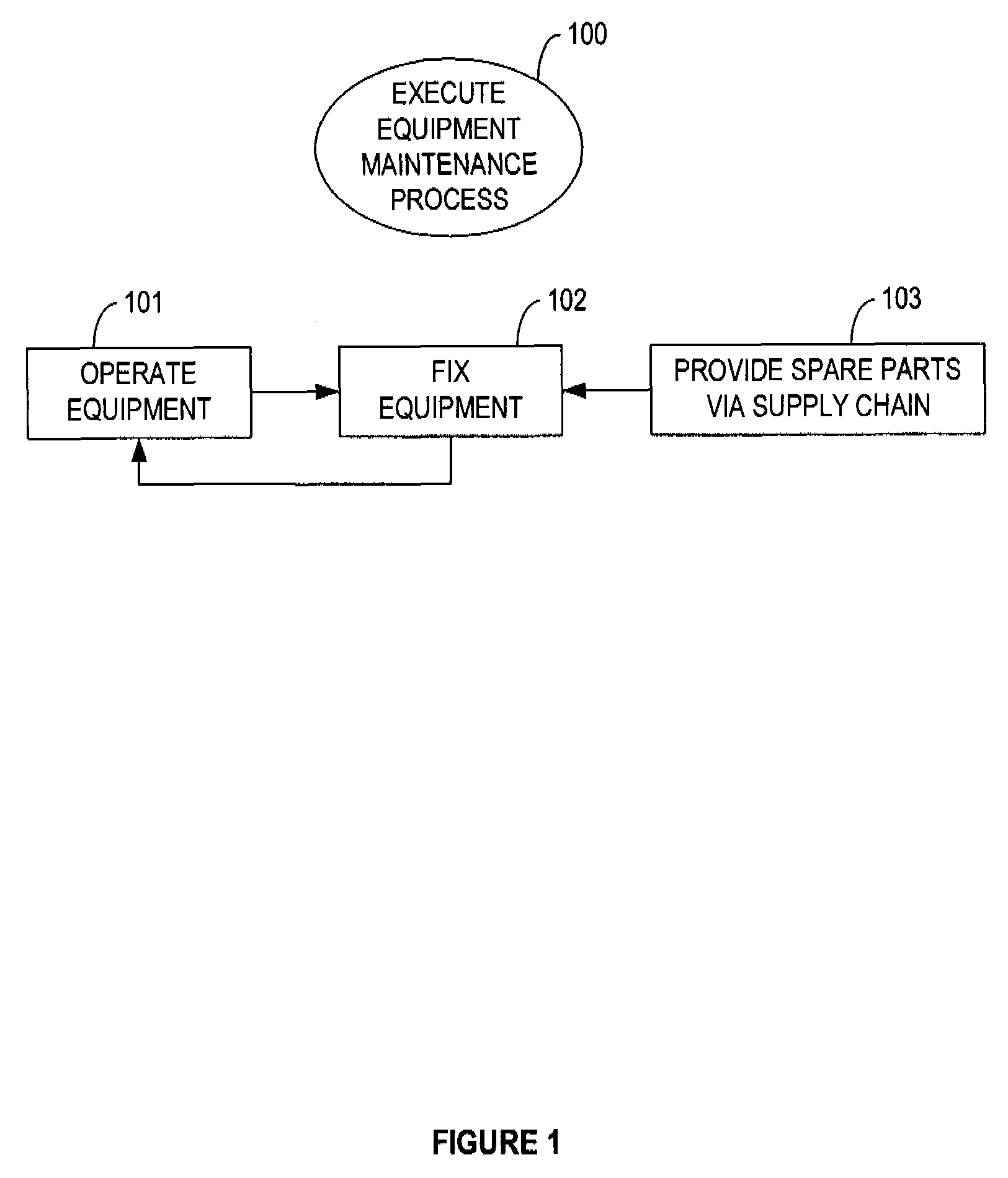

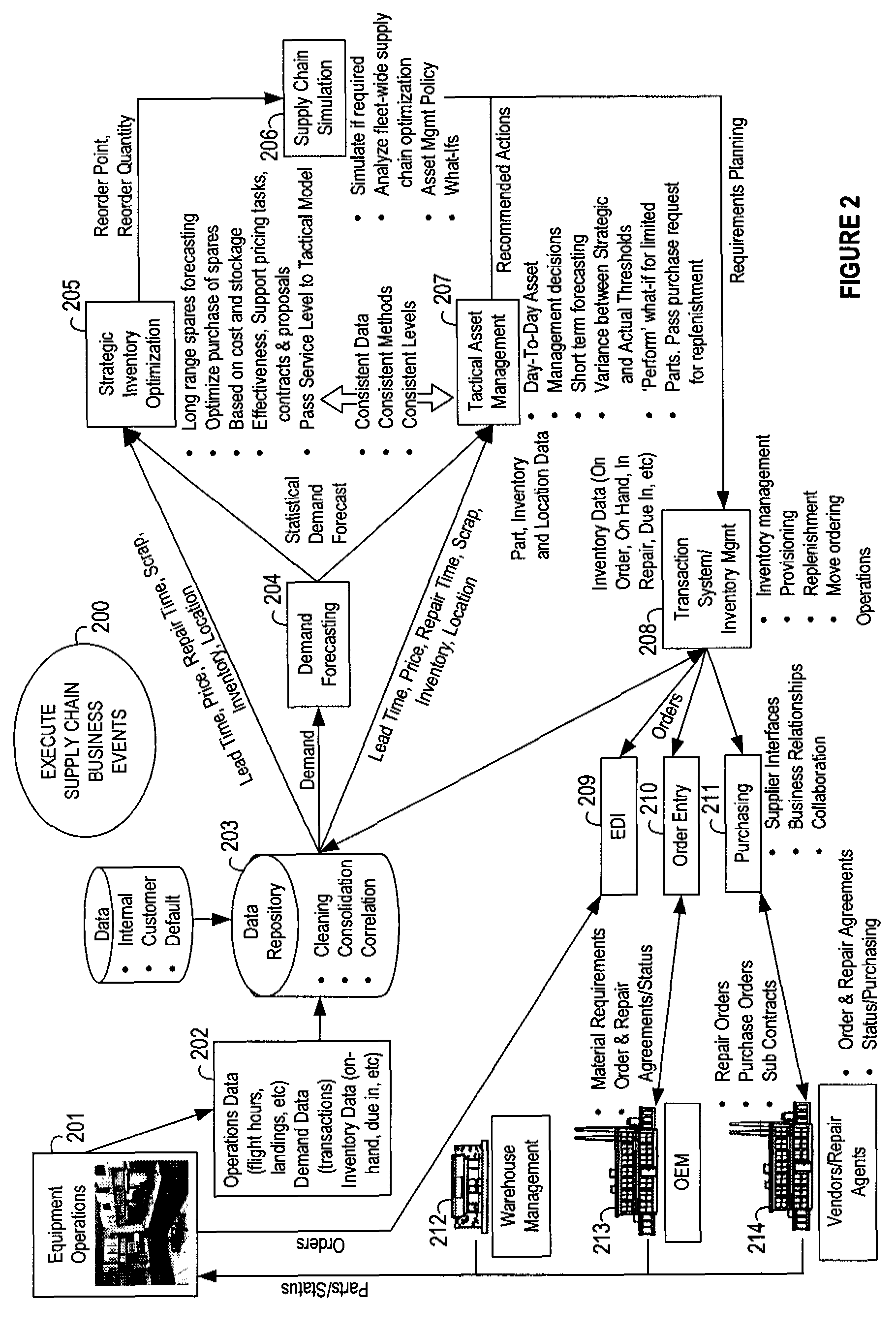

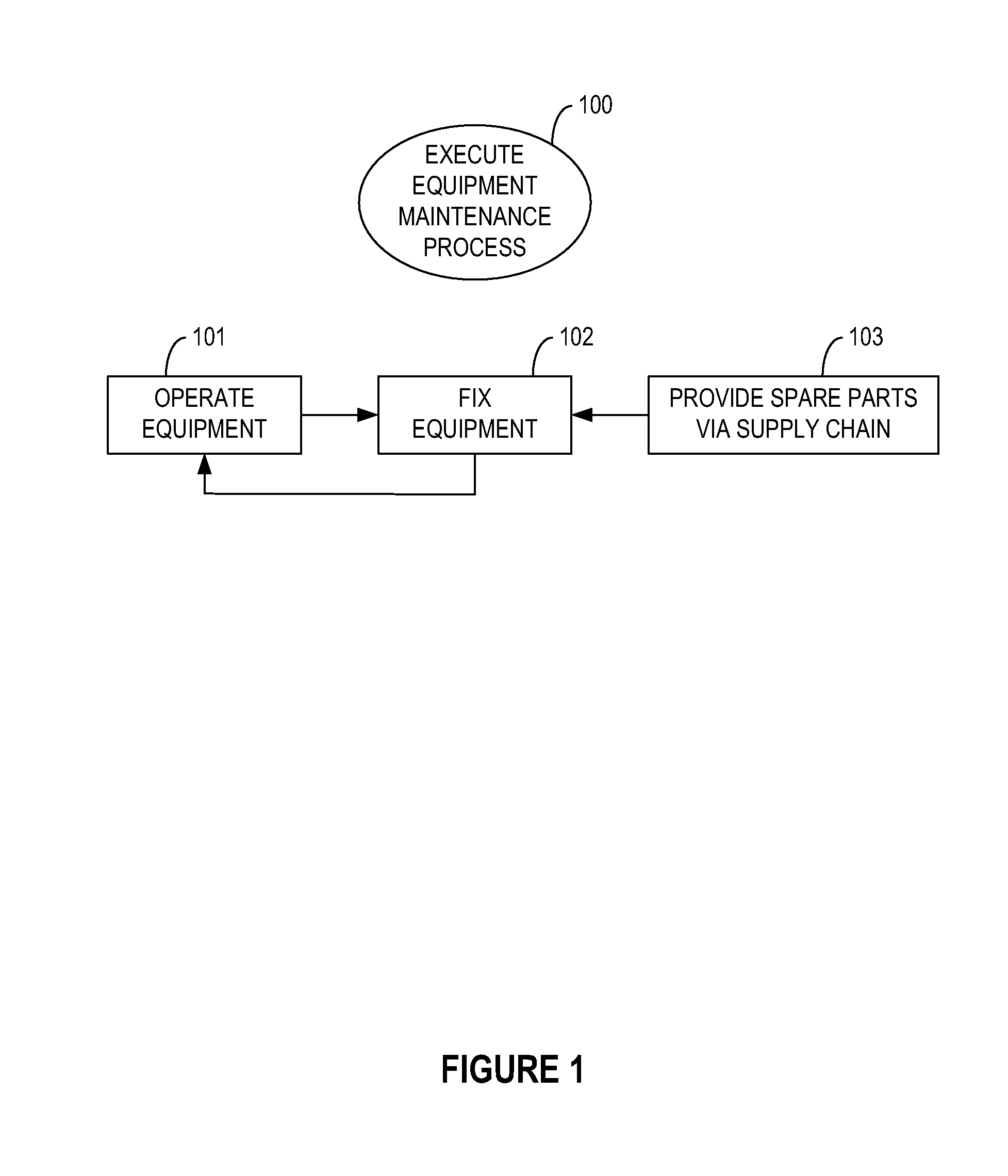

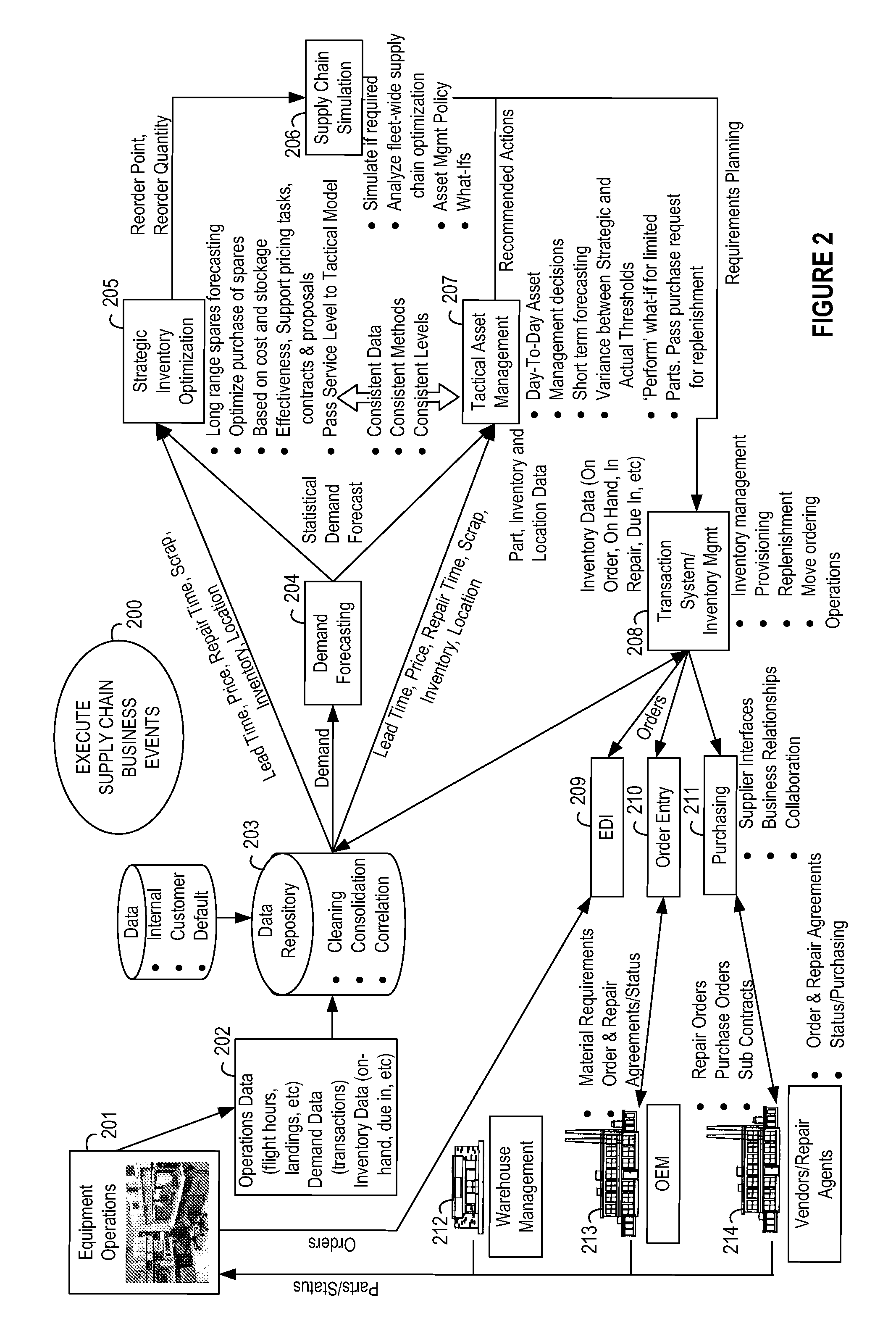

Methods, systems, and computer integrated program products for supply chain management

ActiveUS20070124009A1Additive manufacturing apparatusHand manipulated computer devicesInventory managementComputer integration

A computer program product for managing a supply chain process to maintain equipment is described. The computer program product includes a computer-readable storage medium having computer-readable program code embodied in the medium. The computer-readable program code includes a first executable portion for identifying and capturing data relevant to one or more sets of equipment maintenance requirements, a second executable portion for providing access to the capabilities of a plurality of inventory management, supply chain management, and equipment maintenance applications for preprocessing of the identified and captured data, a third executable portion for receiving the preprocessed data from the plurality of applications, and a fourth executable portion for integrating the preprocessed data into a solution to the one or more sets of equipment maintenance requirements.

Owner:THE BOEING CO

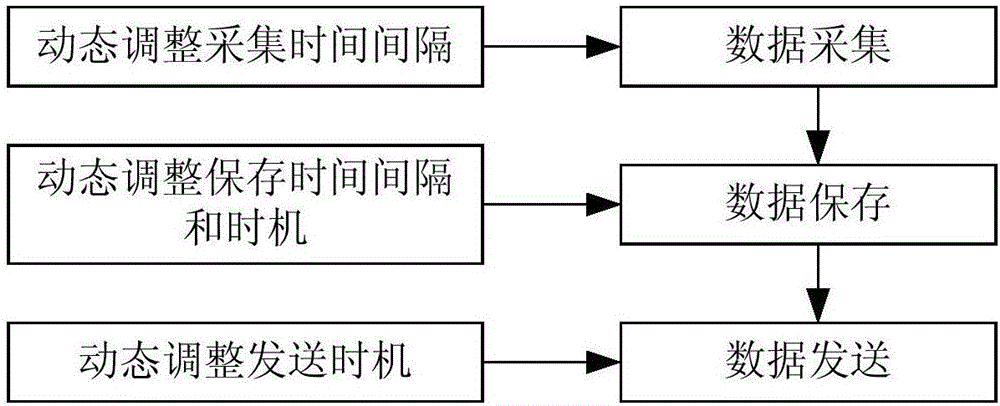

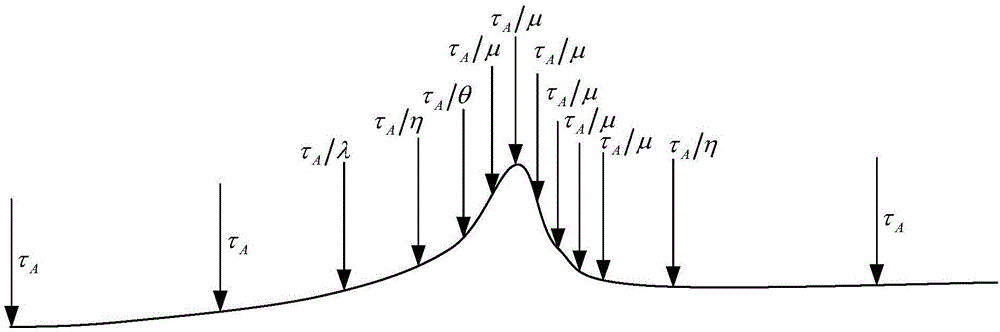

Method for dynamic acquisition and transmission of wireless data

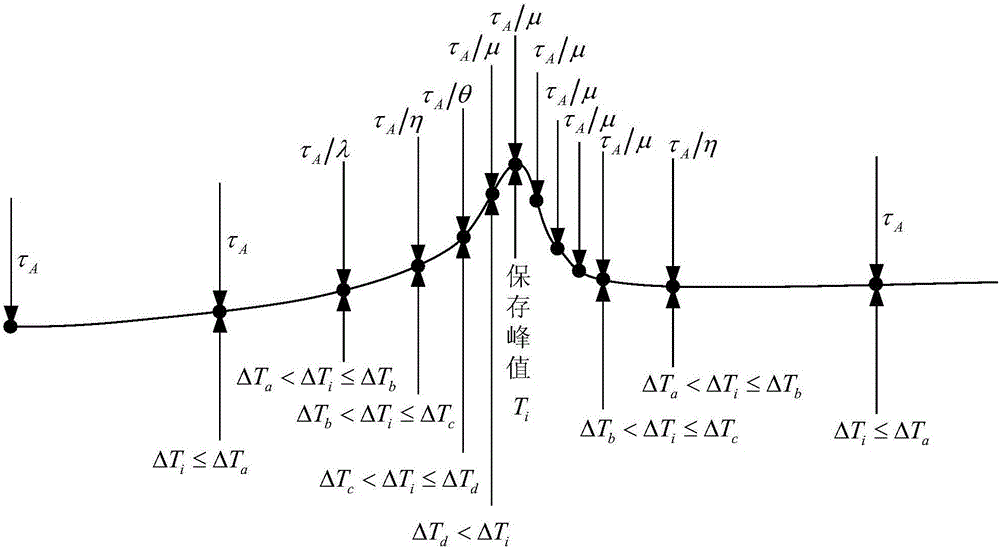

ActiveCN106535253AReduce energy consumptionAchieve acquisitionPower managementNetwork traffic/resource managementData acquisitionWireless data

The invention discloses a method for dynamic acquisition and transmission of wireless data. In a data acquisition process of the method, the time interval for data acquisition is dynamically adjusted, according to the change threshold of data acquisition. In a data storing process, the time interval and opportunity for data storing is dynamically adjusted according to the change threshold of data acquisition. In a data sending process, the opportunity for data sending is dynamically adjusted according to the acquisition value alarming threshold and changing rate alarming threshold of data acquisition. Dynamically increasing or reducing data sampling frequency without increasing power consumption of wireless equipment is realized based on data abnormity degree. Alarm information is timely sent by determination of dynamic data acquisition abnormity, so that managers can maintain equipment as early as possible. Wireless data bulk sent is reduced, and the power consumption of wireless monitoring equipment is reduced. The process state information of entire detected equipment can be monitored without increasing the total transmission data bulk.

Owner:北京必创科技股份有限公司

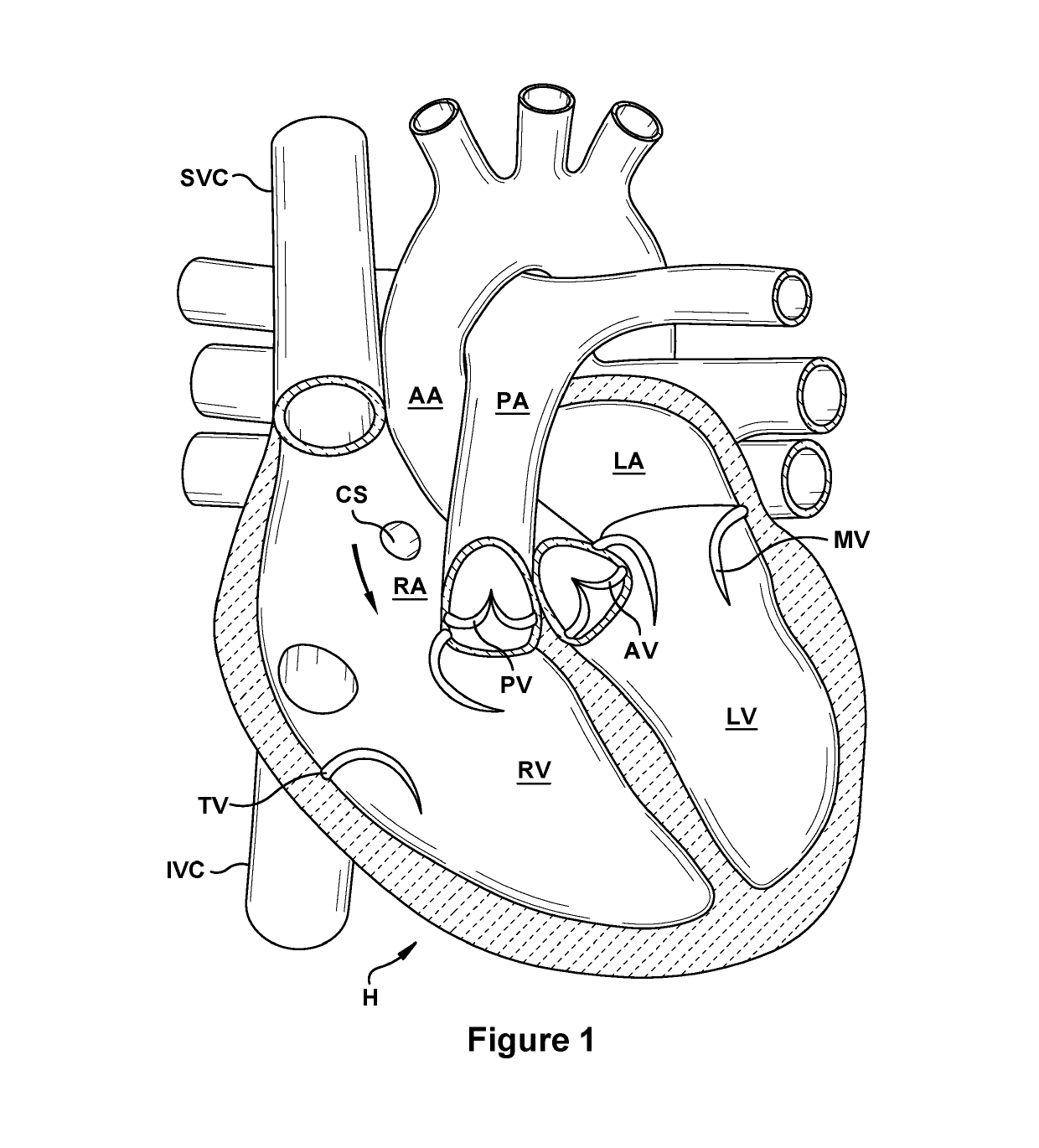

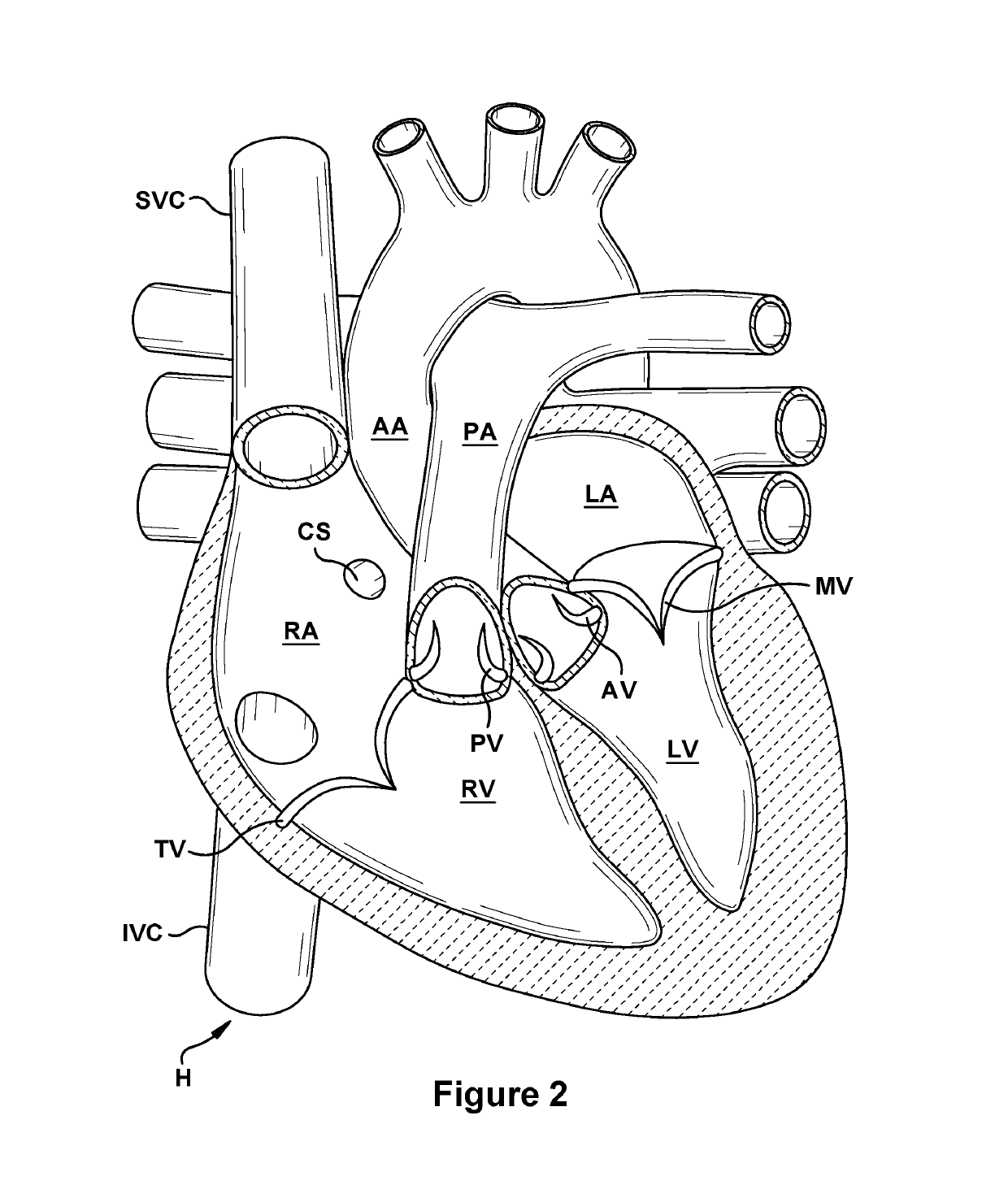

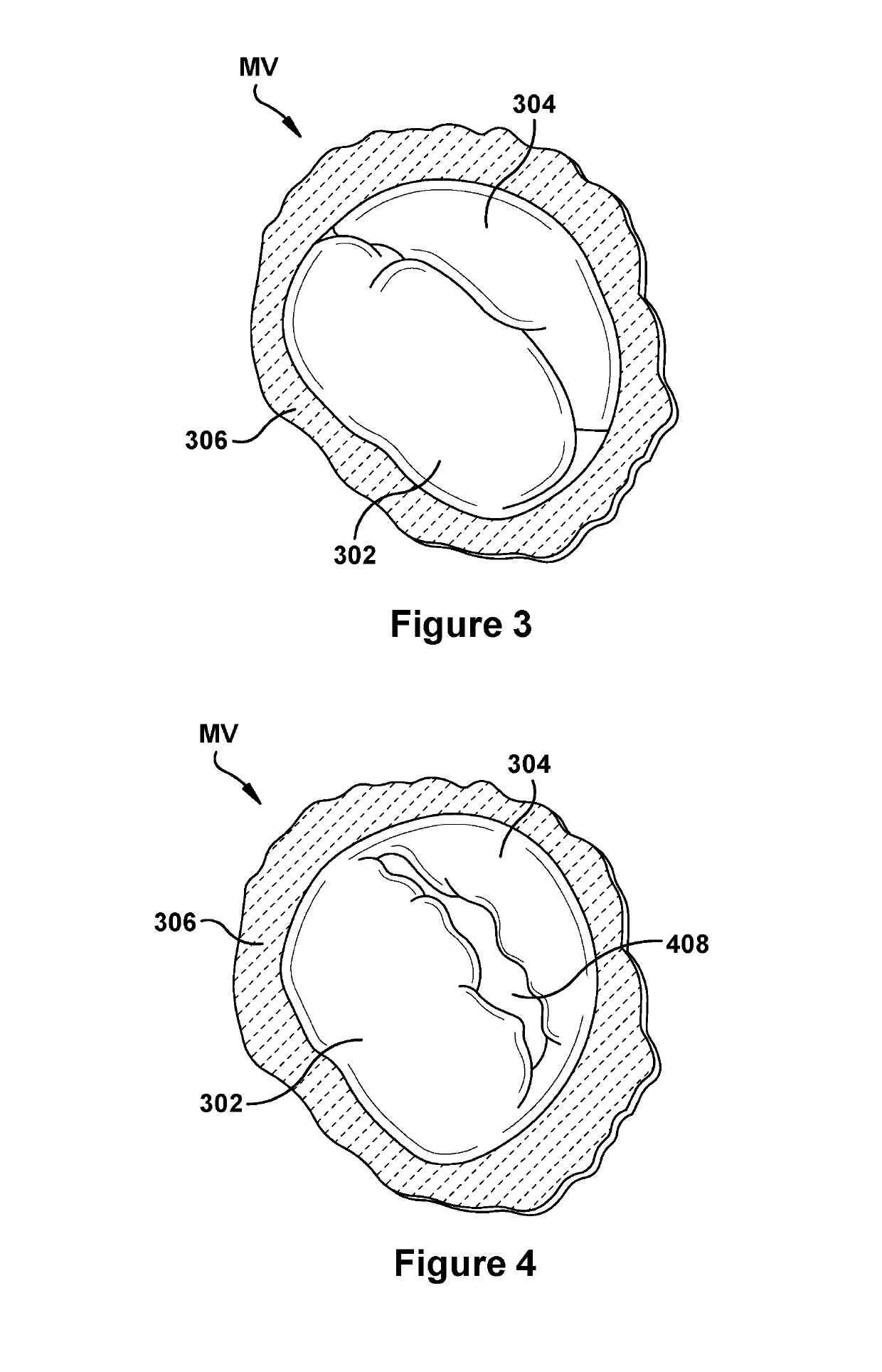

Native valve repair devices and procedures

Owner:EDWARDS LIFESCIENCES CORP

Filter

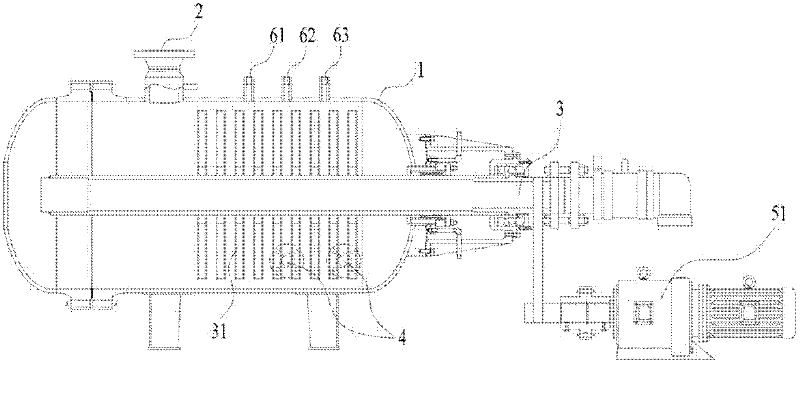

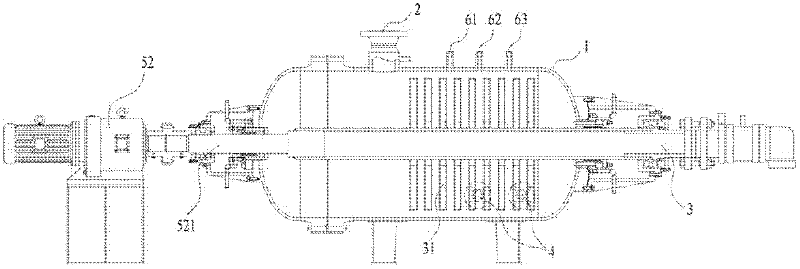

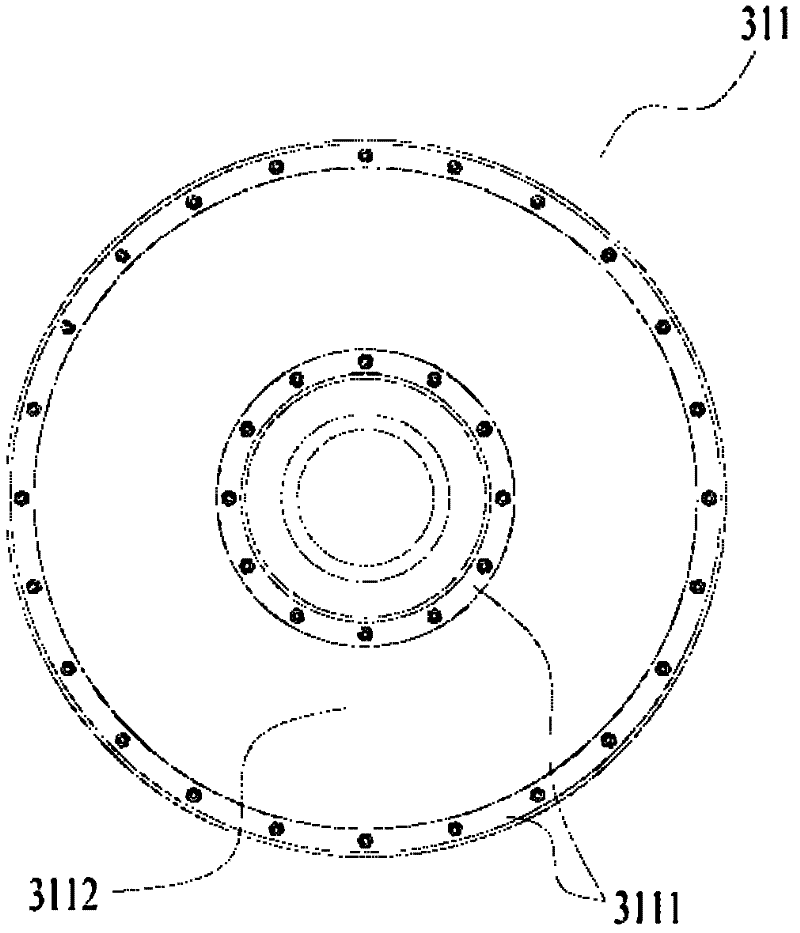

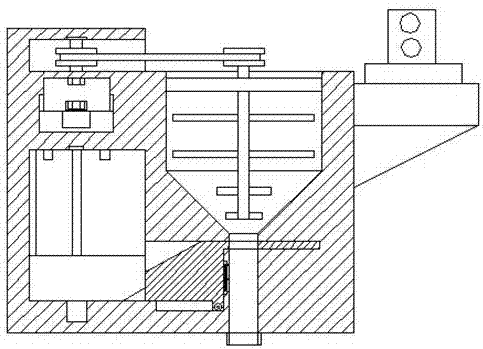

ActiveCN102407045AImprove blockageImprove parts damageStationary filtering element filtersCombustionWater pipe

The invention relates to field of water treatment, in particular to a filter. The filter comprises a tank body, a water inlet pipe, a water outlet pipe, a filtering device and a blow-off pipe, wherein the water inlet pipe is communicated with the inside of the tank body; a part of the water outlet pipe is inserted into the tank body; the filtering device is externally connected to the water outlet pipe inside the tank body, is communicated with the water outlet pipe, and is used for filtering water to be treated and draining the filtered water out of the water outlet pipe; and the blow-off pipe is communicated with the bottom of the tank body, and is used for discharging impurities left after the water to be treated is filtered. In the filter provided by the invention, the water outlet pipe inserted into the tank body is provided with the filtering device, so that the water to be treated is drained through the water outlet pipe after being filtered by the filtering device, and residual impurities left after filtering can be discharged along the blow-off pipe at the bottom of the tank body. Due to the adoption of the filter, the problems of blocking of pipelines and damage to partsin high-temperature combustion furnace equipment caused by directly repeatedly using the water to be treated without filtering are solved, capitals consumed by maintaining equipment are saved, and the utilization ratio and production efficiency of the high-temperature combustion furnace equipment are increased.

Owner:BEIJING WANBANGDA ENVIRONMENTAL PROTECTION TECH

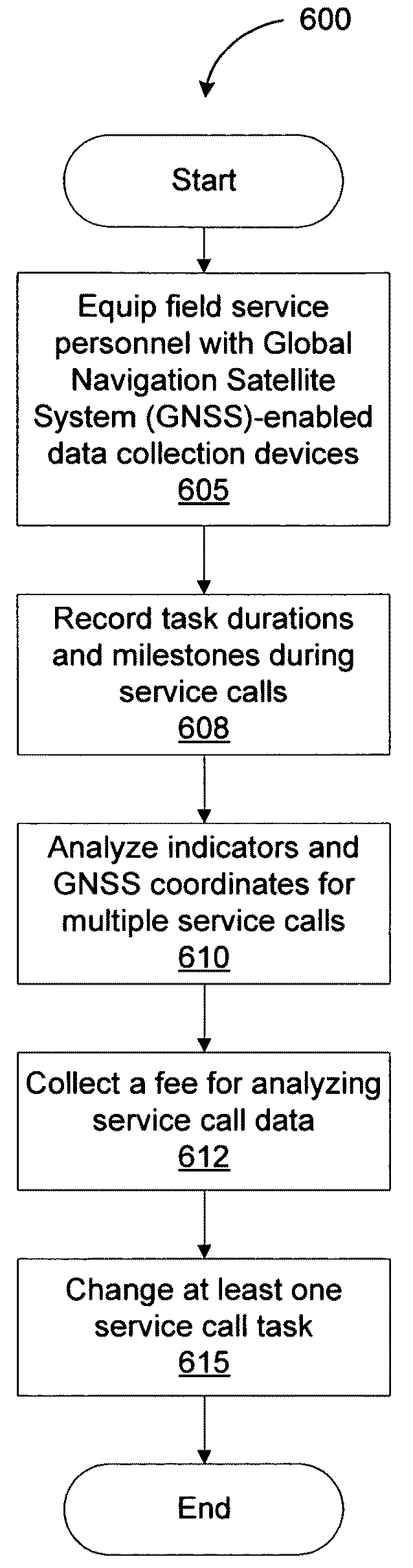

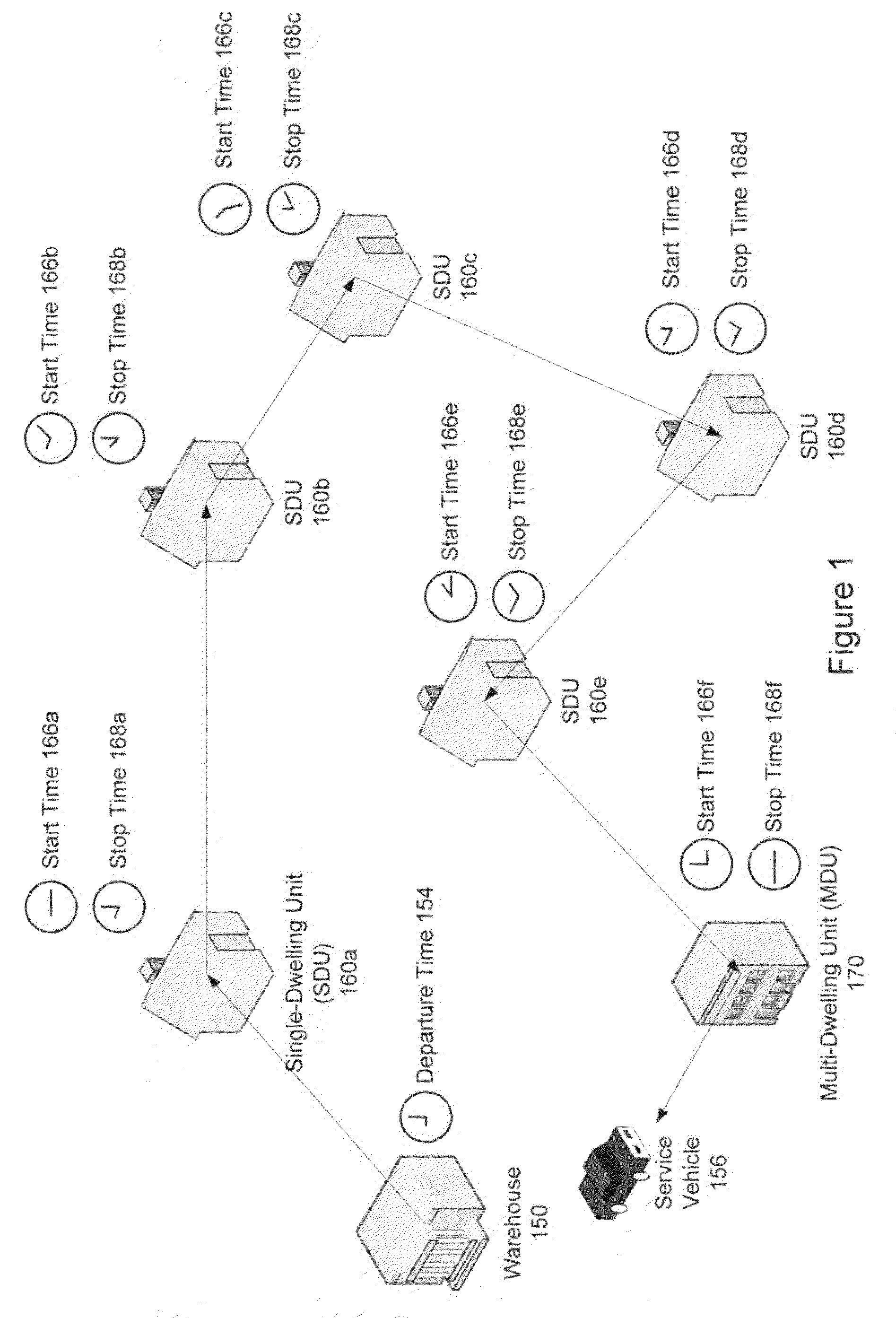

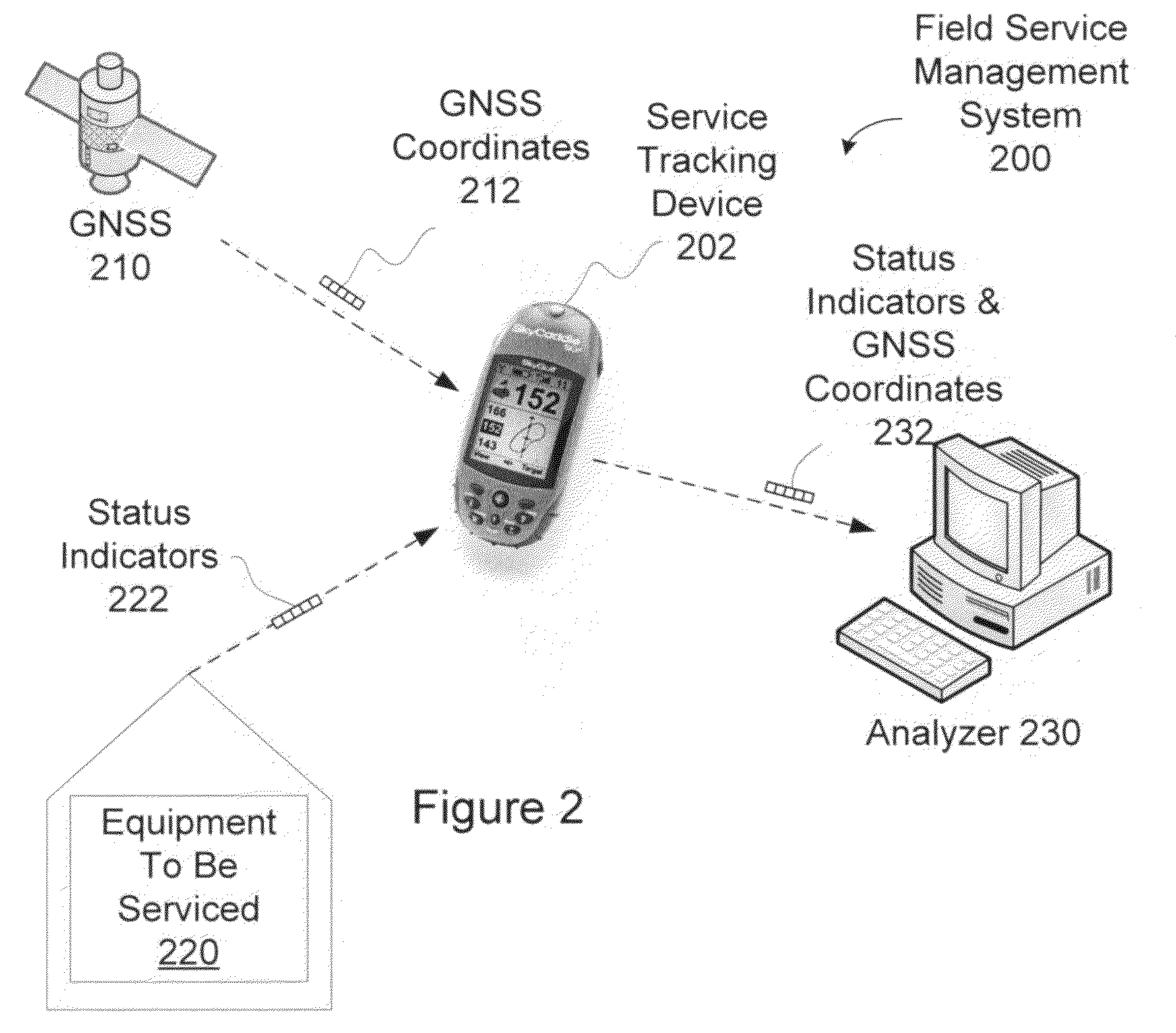

Method and apparatus for field service management

InactiveUS20090319572A1ResourcesSpecial data processing applicationsNetwork terminationService provision

Installing and maintaining equipment, such as optical network terminals (ONTs), at customer sites is time consuming. At present, there is no way to manage field service to improve installation and maintenance procedures. A method or corresponding system in an example embodiment of the present invention provides aids to manage field service to make installation and maintenance procedures more efficient. In one embodiment, field technicians use a data collection device to track installation tasks and corresponding Global Navigation Satellite System (GNSS) coordinates. The collected data and coordinates are analyzed, possibly for a fee, and used to make changes in installation and maintenance procedures. As a result, service provider can save significant cost on future installations and service calls.

Owner:TELLABS VIENNA

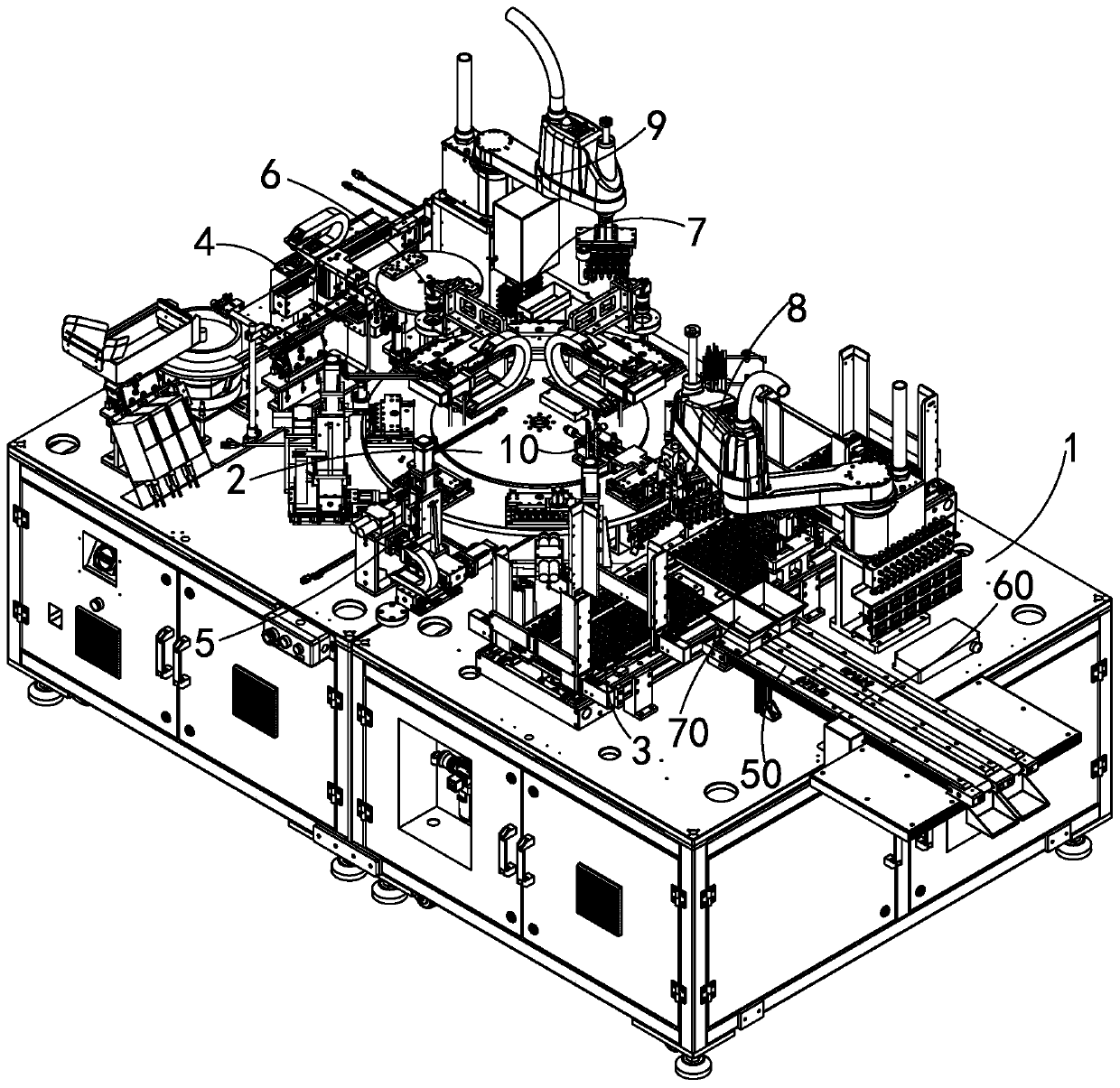

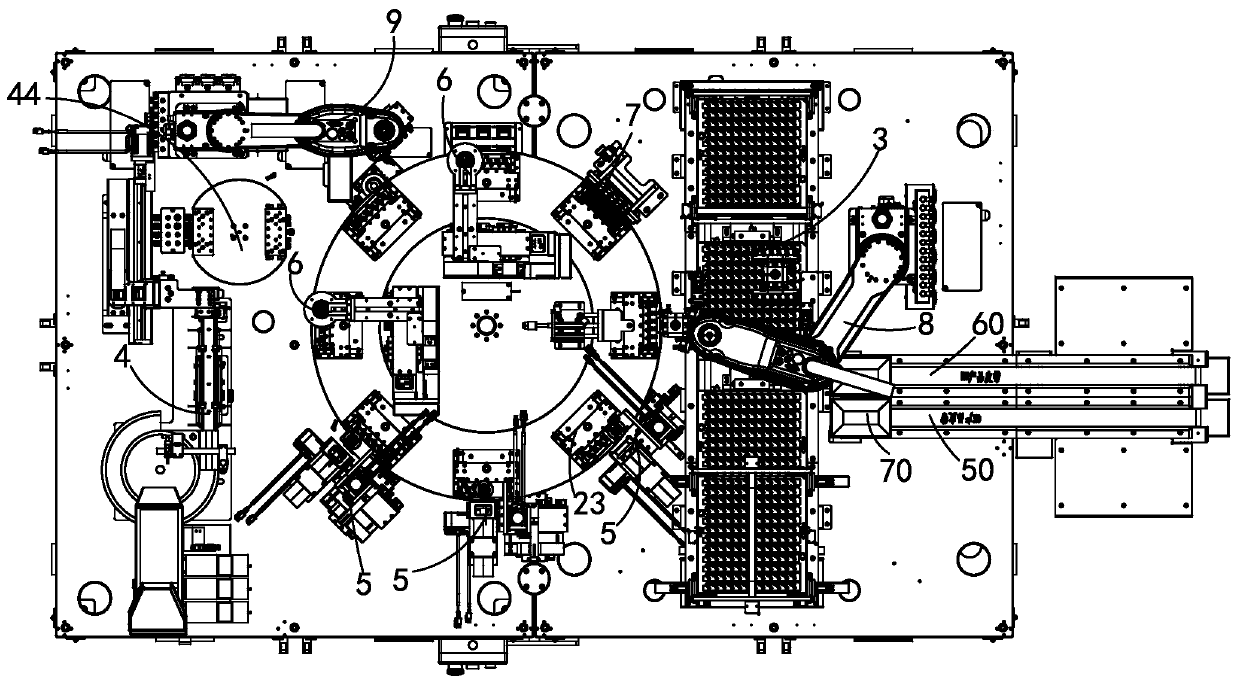

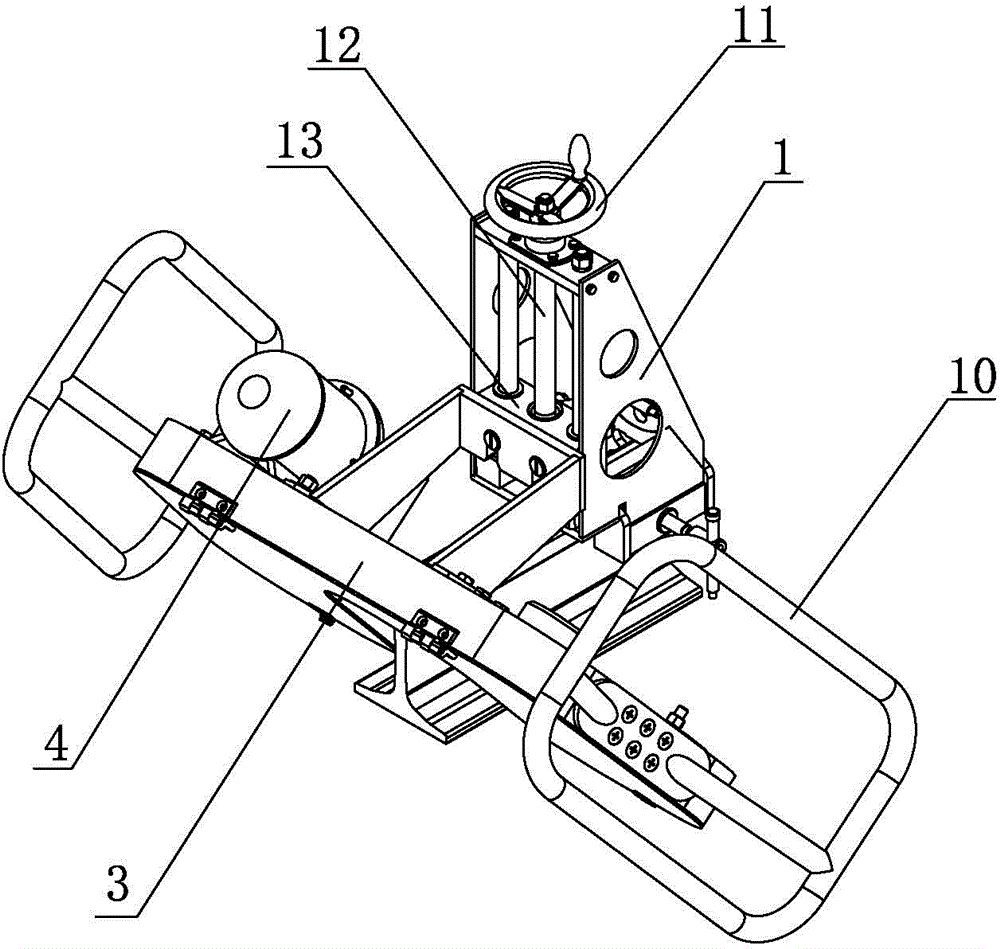

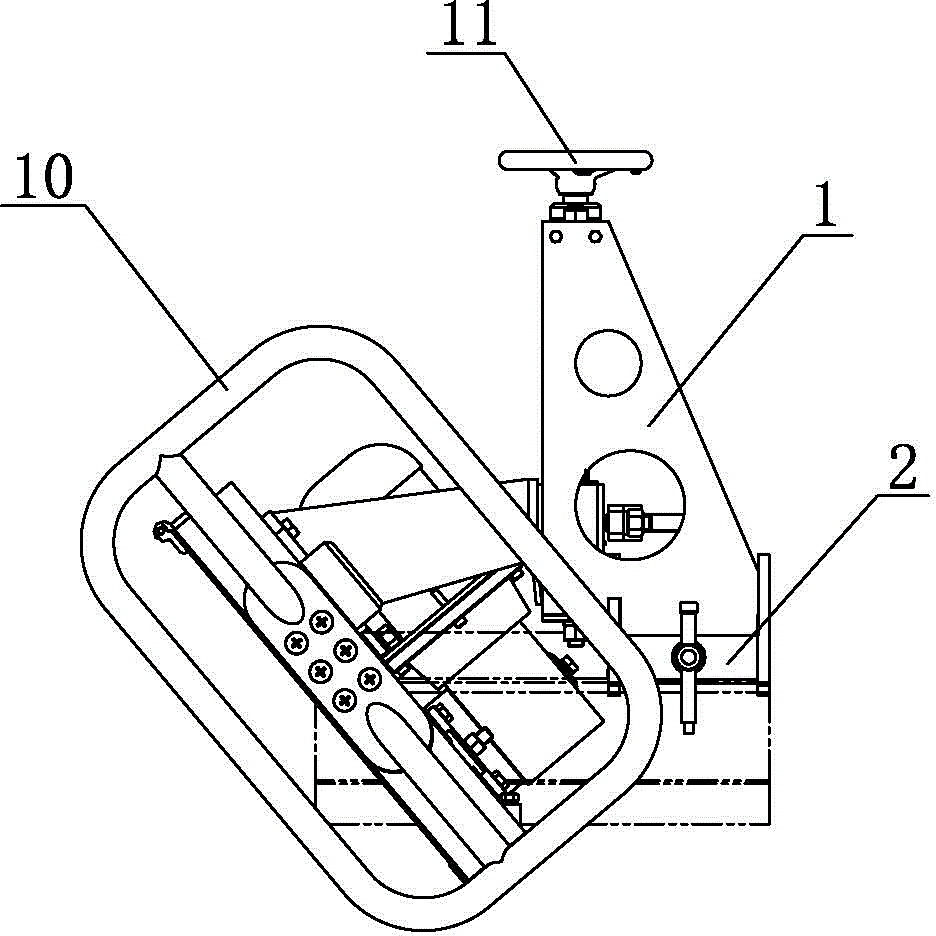

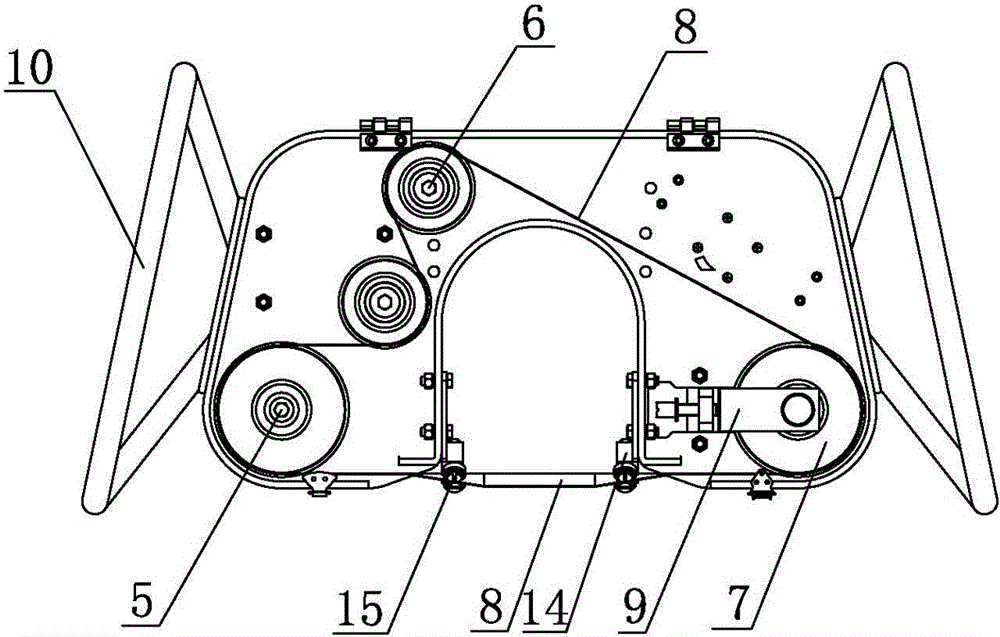

Automatic adhesive-dispensing pressure-maintaining equipment

PendingCN110586416AAccurate pressing forceAssemble firmlyLiquid surface applicatorsMaterial gluingAdhesiveMaintaining equipment

The invention discloses automatic adhesive-dispensing pressure-maintaining equipment. The automatic adhesive-dispensing pressure-maintaining equipment comprises an equipment machine table, a rotary workbench, as well as a first loading mechanism, a second loading mechanism, an adhesive-dispensing mechanism, a CCD detection mechanism, a pressure-maintaining mechanism, a first carrying robot and a second carrying robot which are sequentially and circumferentially arranged at the periphery of the rotary workbench, wherein the rotary workbench comprises a small rotary disc installed on the equipment machine table and a large rotary disc arranged at the periphery of the small rotary disc in a sleeved manner; a plurality of rotary disc jigs are arranged on the large rotary disc along the same circumference in a manner of uniform distribution; the adhesive-dispensing mechanism is configured to comprise a three-axis displacement device, a base, a needle barrel and an adhesive-dispensing needlehead; the adhesive-dispensing needle head is arranged on the three-axis displacement device through the base; the three-axis displacement device is used for driving the adhesive-dispensing needle head to move in X-axis direction, Y-axis direction and Z-axis direction; the needle barrel is arranged on the three-axis displacement device through the base; and the needle head of the adhesive-dispensing needle head is enabled to carry out adhesive-dispensing operation on a first material part to be treated. The automatic adhesive-dispensing pressure-maintaining equipment is high in adhesive-dispensing speed and efficiency, and stable in quality.

Owner:苏州德机自动化科技有限公司

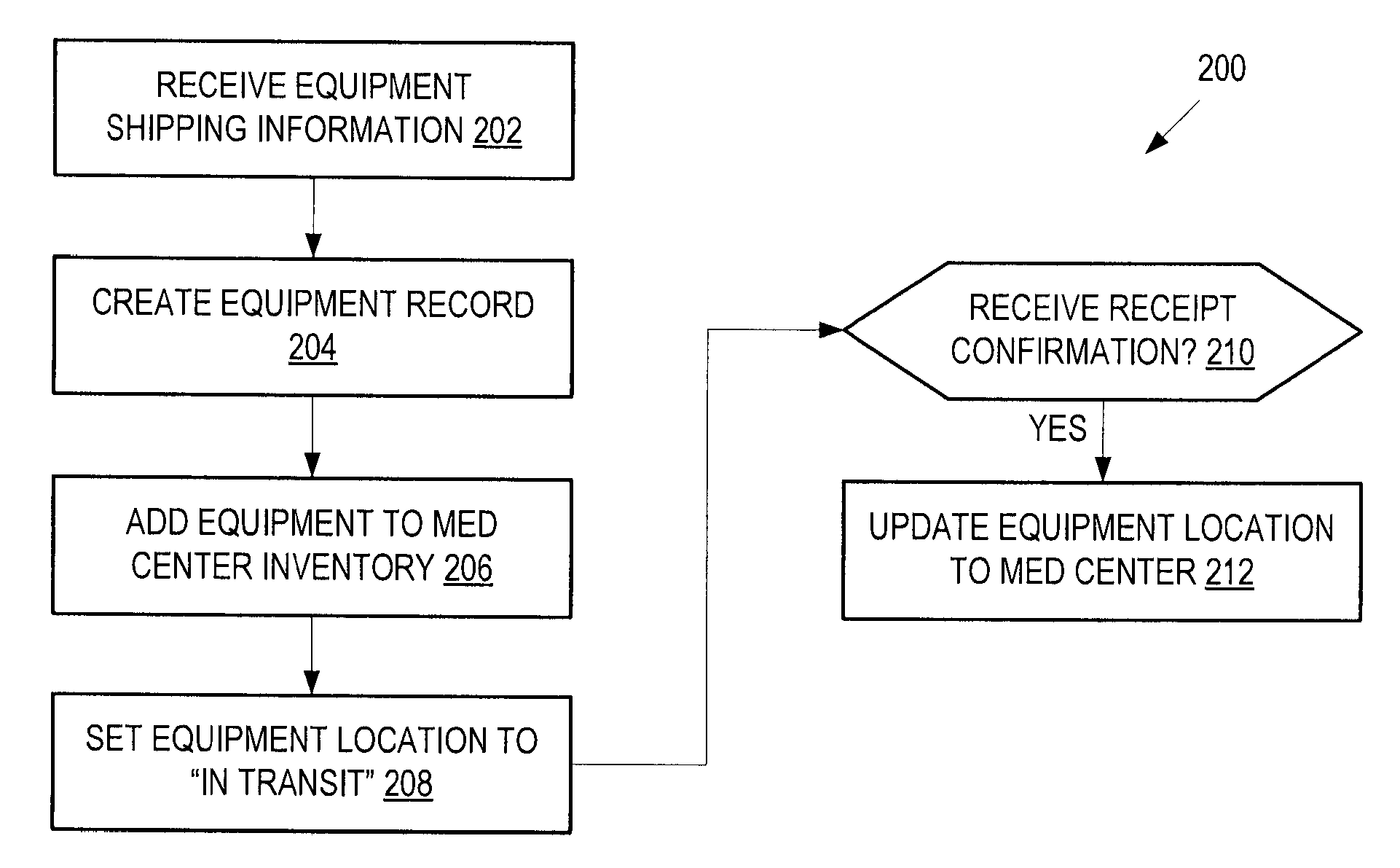

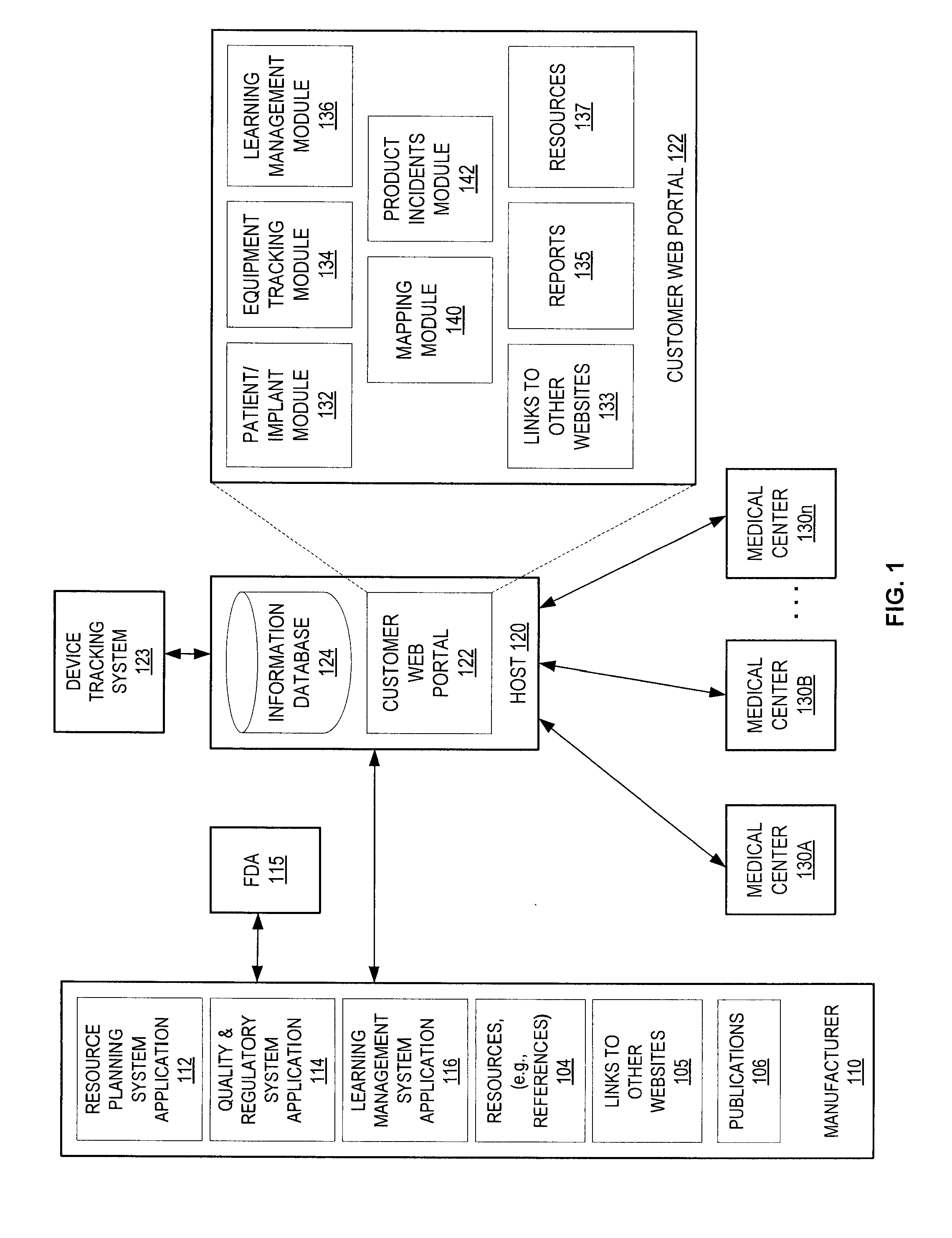

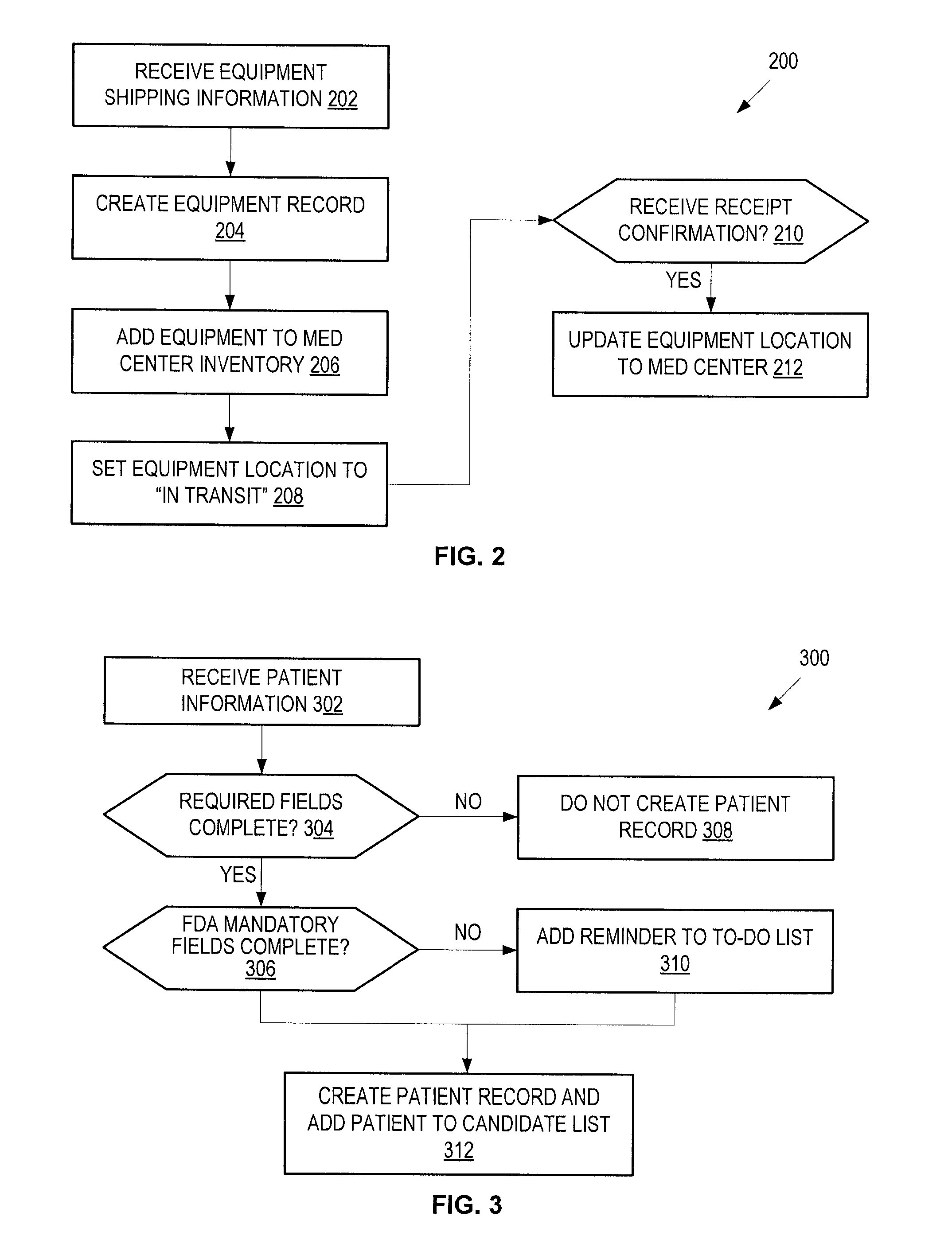

Medical equipment customer web portal

ActiveUS20130253952A1Easy to returnData processing applicationsTelemedicineMedical equipmentMedical treatment

A system for managing medical equipment is described. The system includes an equipment tracking module to maintain equipment records corresponding to medical equipment that are shipped from a medical equipment manufacturer to a medical center. The system also includes a patient information tracking module to maintain patient records corresponding to patients of the medical center and to associate the patient records with the equipment records when the patients are equipped with the medical equipment. In addition, the system includes a mapping module to provide locations of medical facilities capable of providing support for the medical equipment for patients that have been discharged from the medical center. Other embodiments are also described.

Owner:TC1 LLC

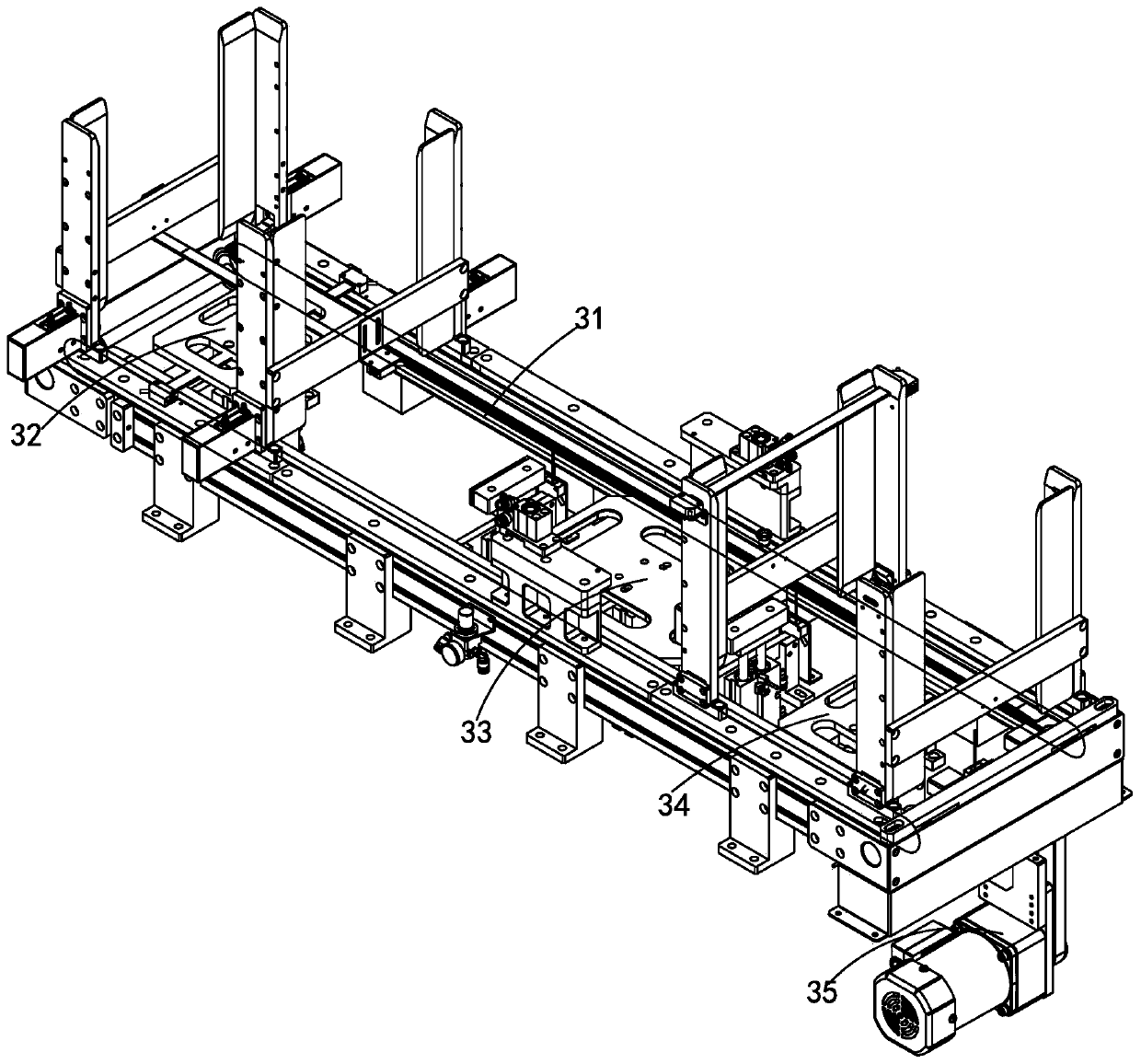

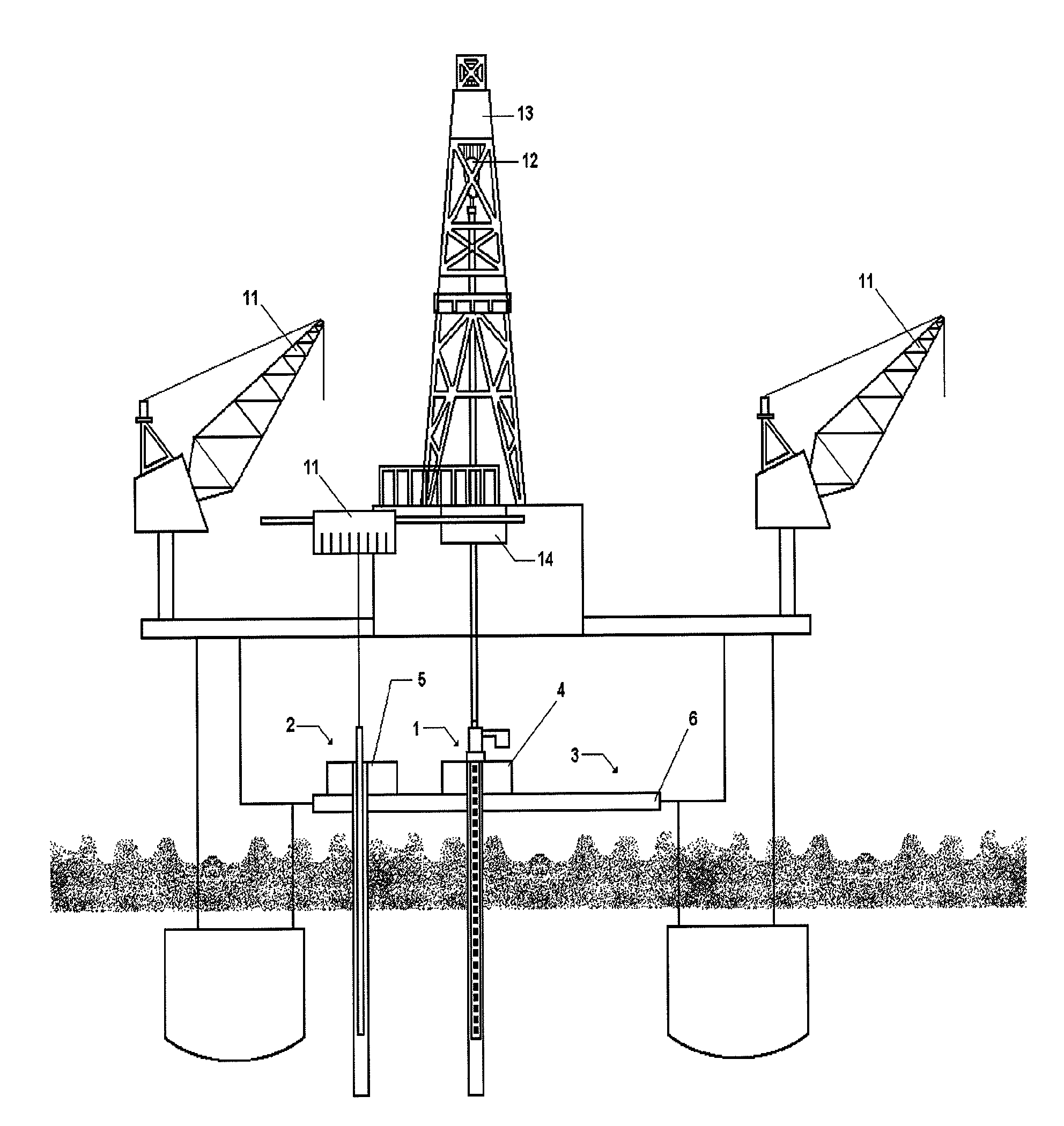

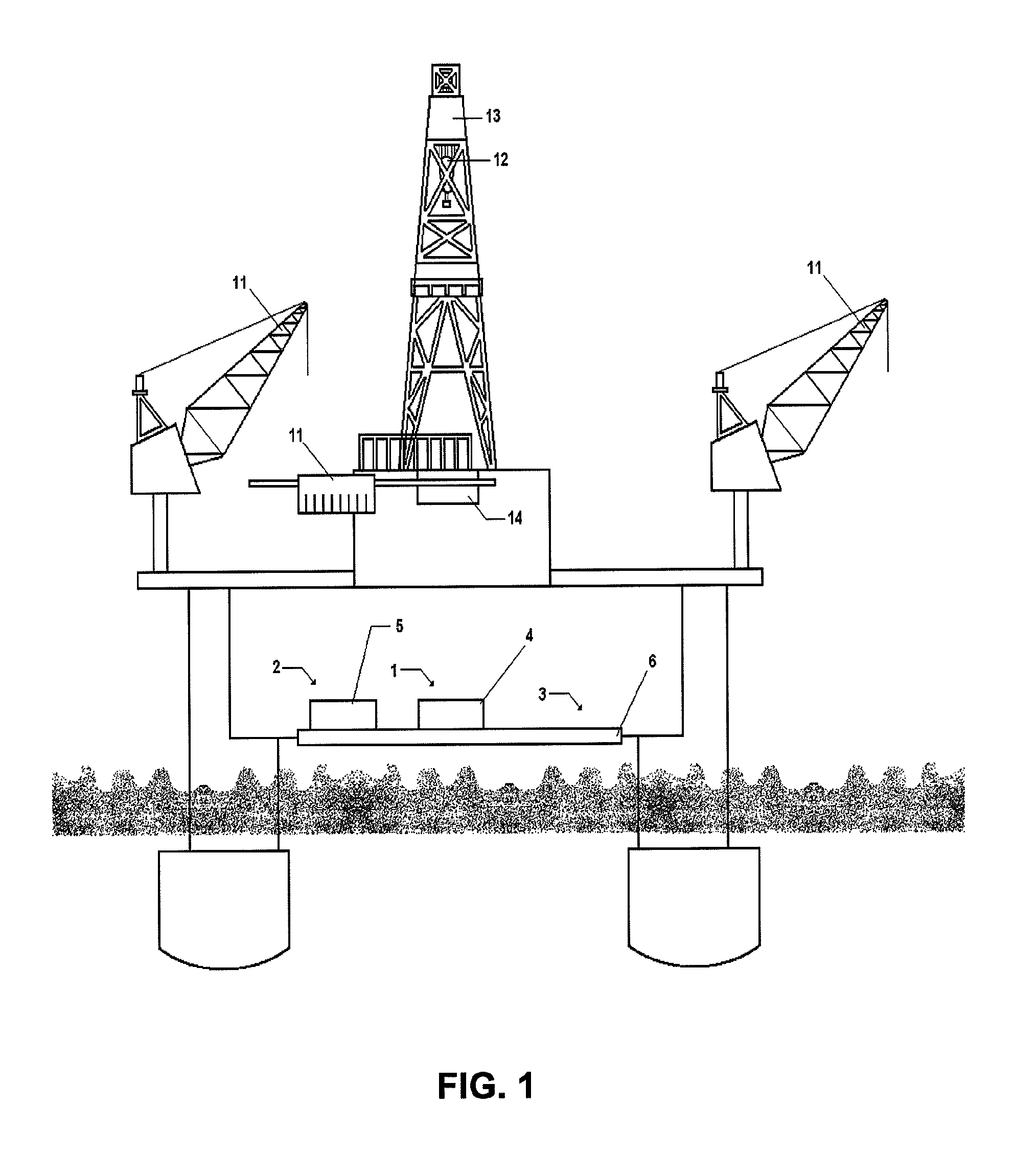

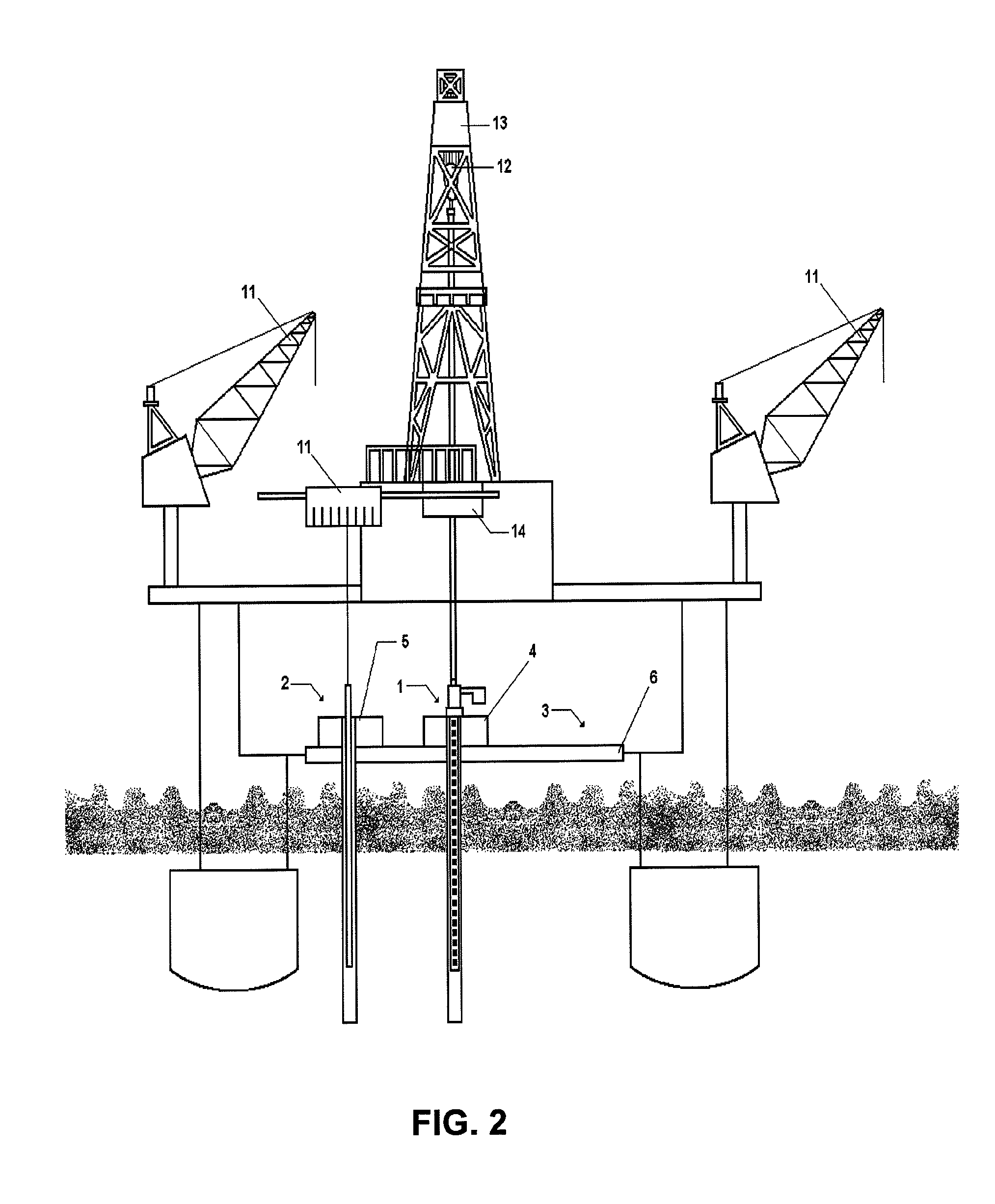

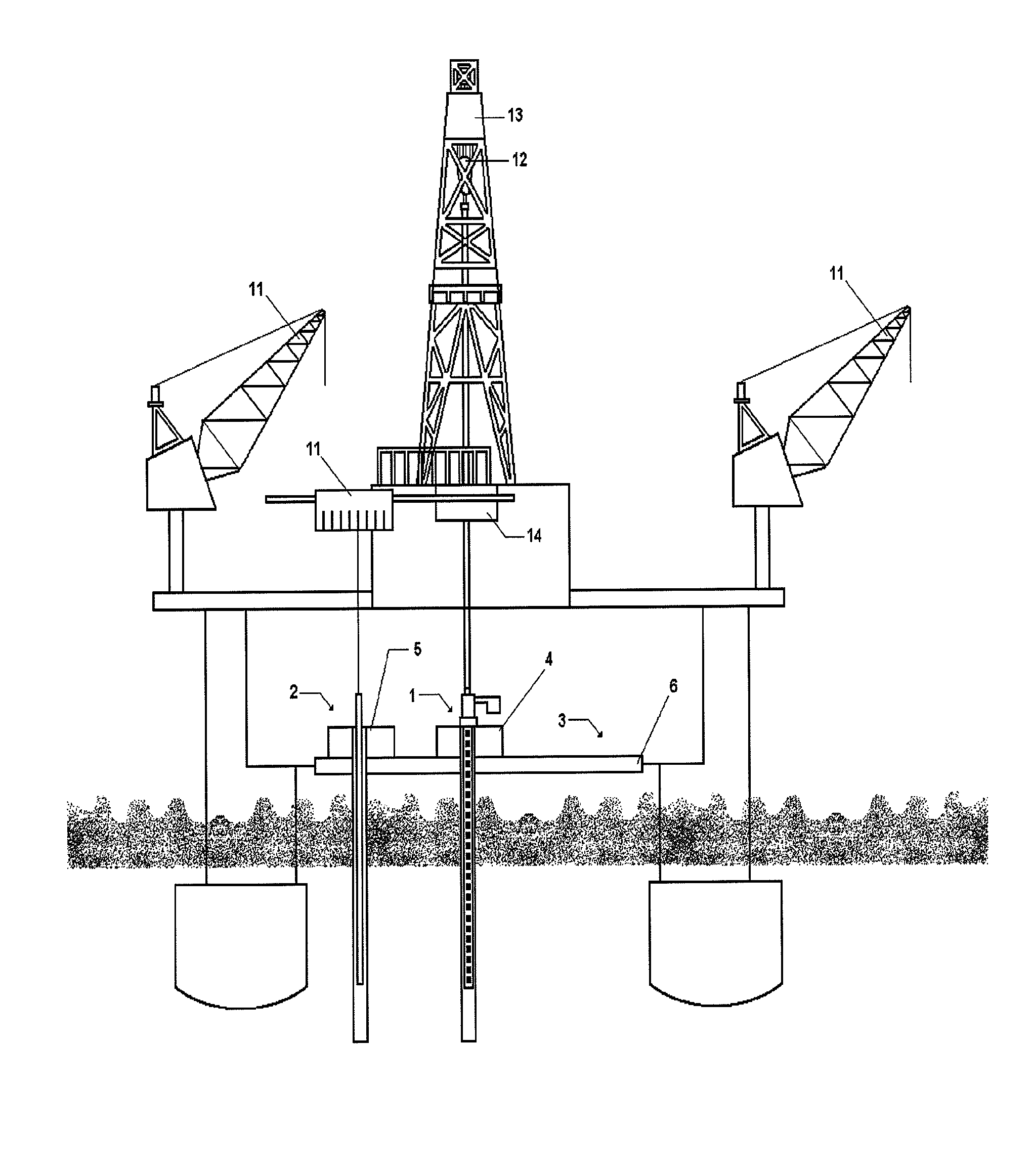

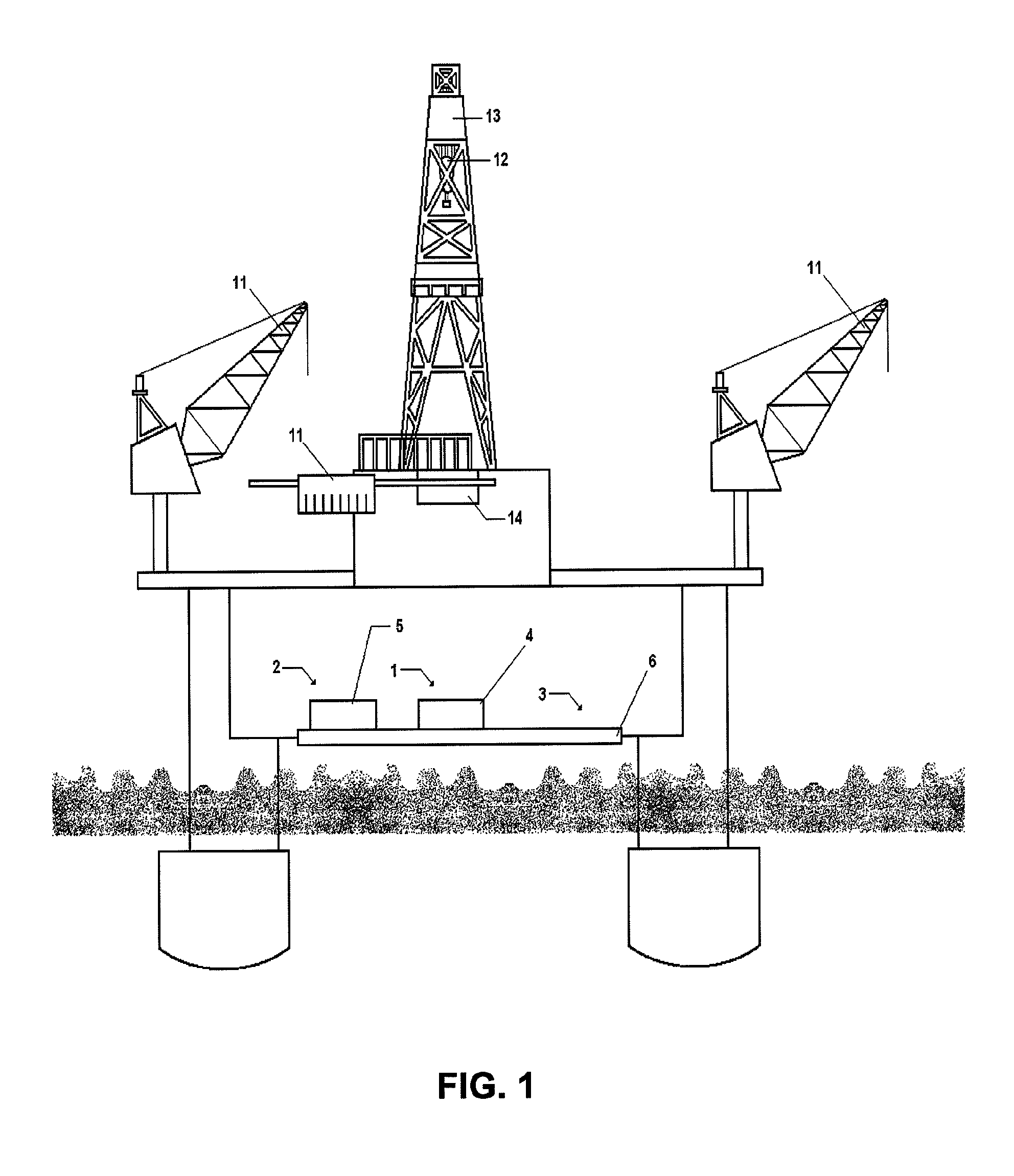

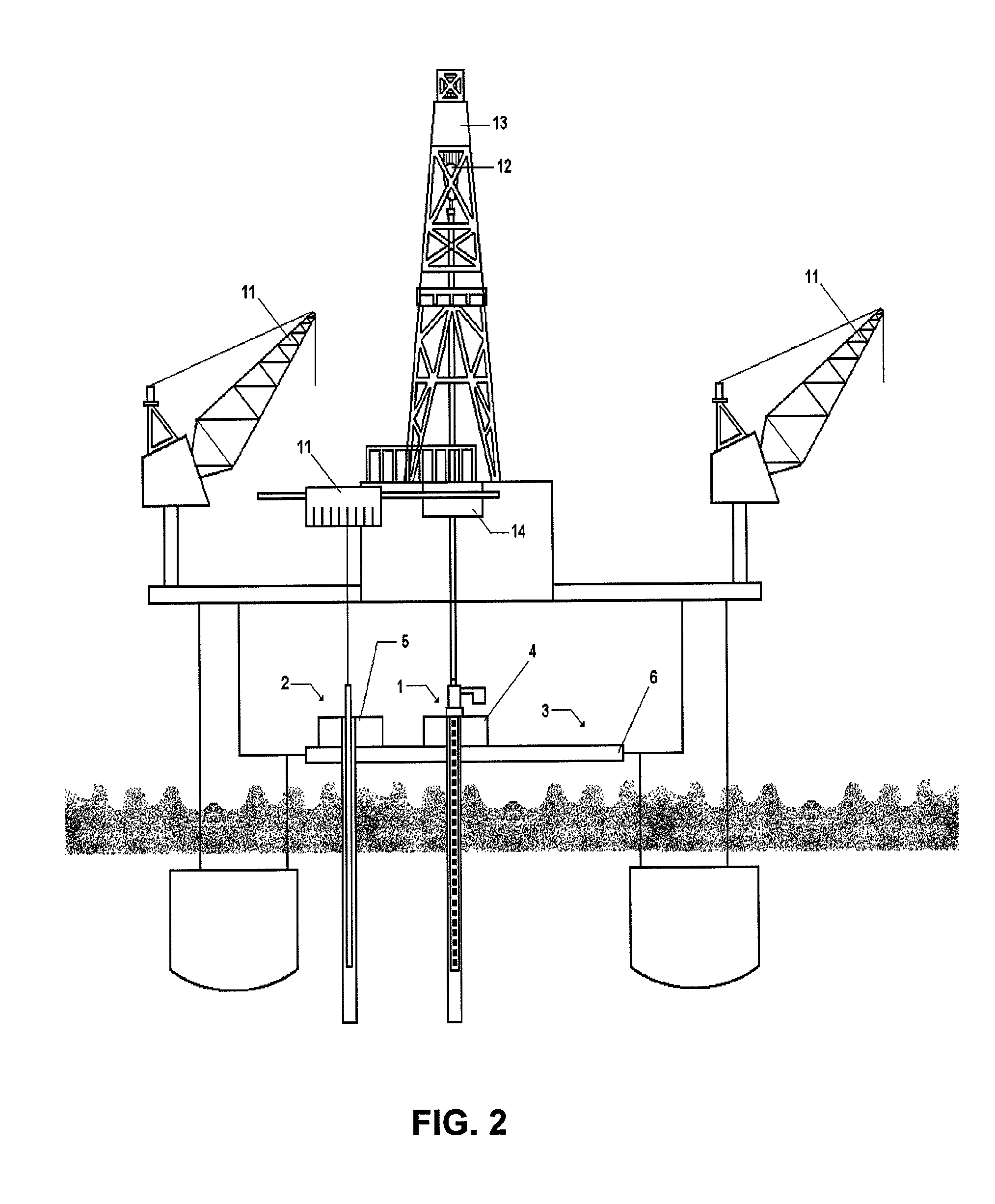

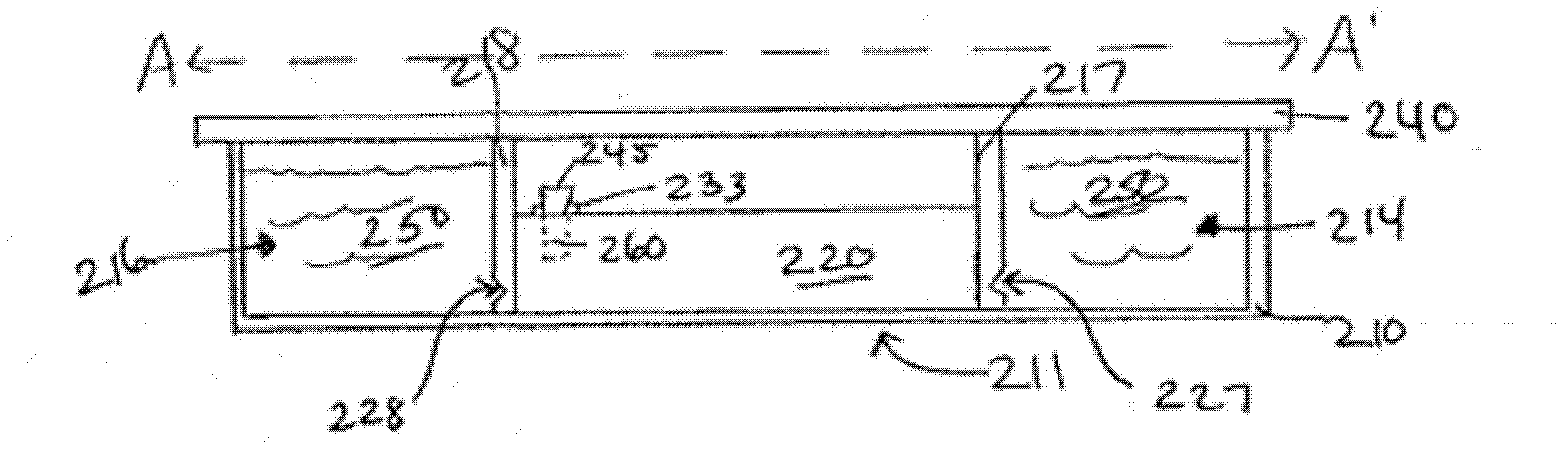

System and method for simultaneous sea drilling operations

ActiveUS20100071906A1Amount of timeLow costArtificial islandsWaterborne vesselsWell drillingEngineering

A system and method for carrying out simultaneous operations of assembling, dismantling, and maintaining equipment installed by an oil rig, using the tools, systems, and the areas available on the rig itself. The system includes two parallel and separated sustaining beams and two mobile bases supported on the beams to carry out the simultaneous operations. This system allows a method for simultaneously assembling two items of subsea equipment which are to be installed to be performed. Also, this system allows a method for simultaneously replacing and assembling subsea equipment to be performed. Additionally, the equipment can be lowered or recovered using either a derrick and pipe string or a winch and steel cable.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

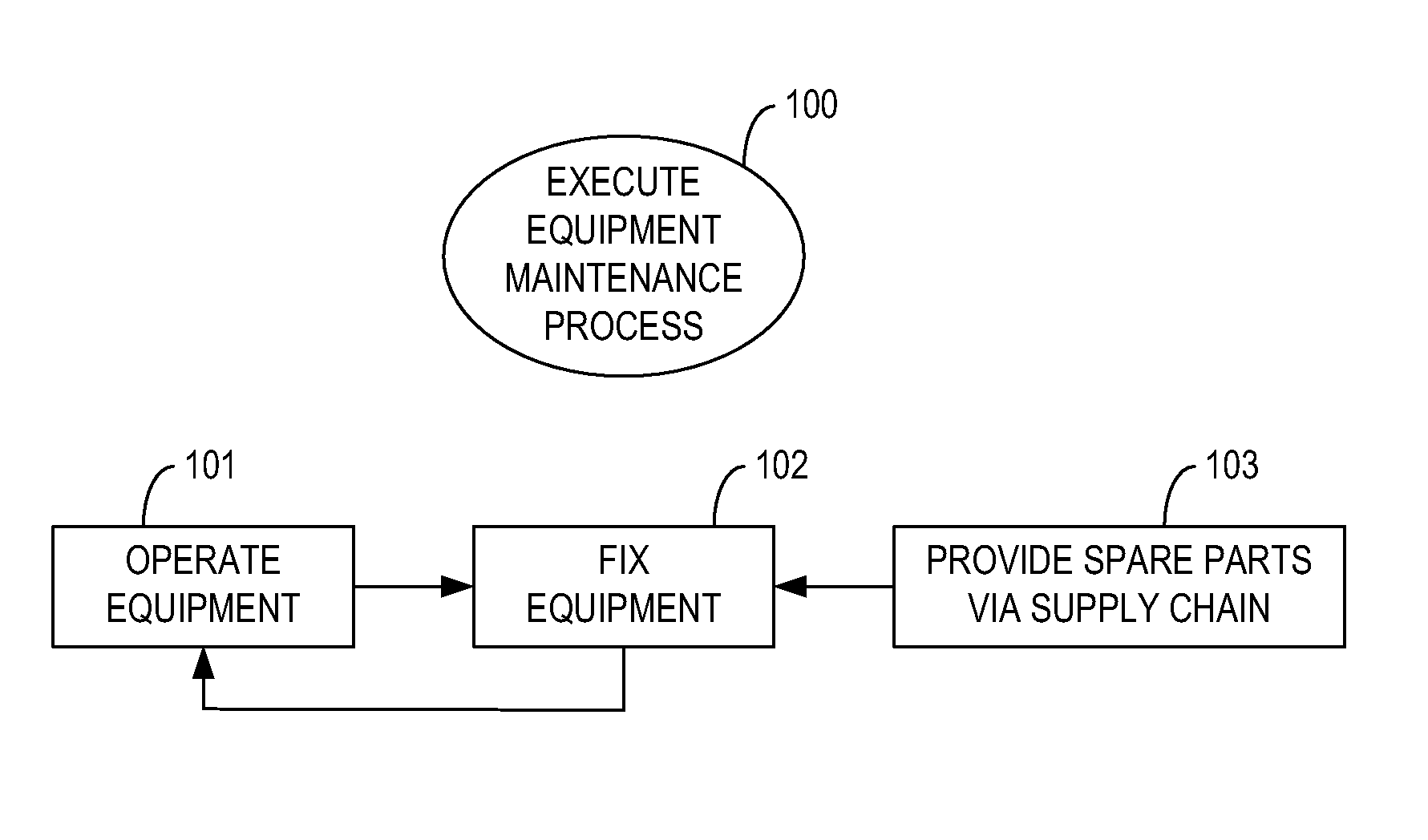

Methods, systems, and computer integrated program products for supply chain management

ActiveUS8229791B2Additive manufacturing apparatusHand manipulated computer devicesInventory managementComputer integration

A computer program product for managing a supply chain process to maintain equipment is described. The computer program product includes a computer-readable storage medium having computer-readable program code embodied in the medium. The computer-readable program code includes a first executable portion for identifying and capturing data relevant to one or more sets of equipment maintenance requirements, a second executable portion for providing access to the capabilities of a plurality of inventory management, supply chain management, and equipment maintenance applications for preprocessing of the identified and captured data, a third executable portion for receiving the preprocessed data from the plurality of applications, and a fourth executable portion for integrating the preprocessed data into a solution to the one or more sets of equipment maintenance requirements.

Owner:THE BOEING CO

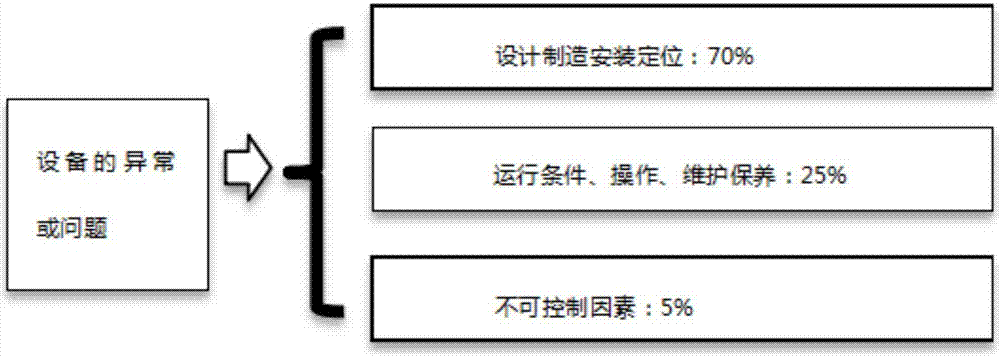

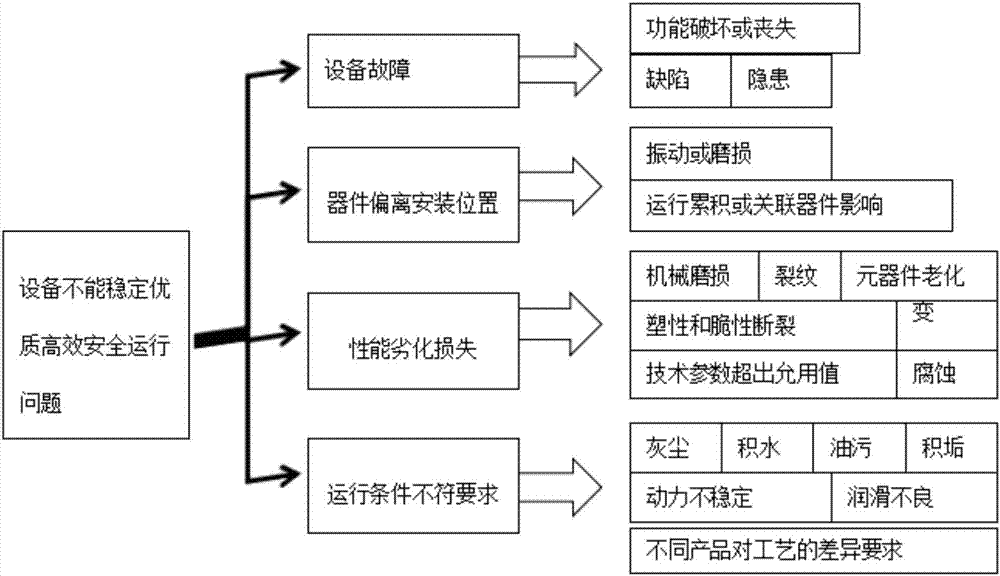

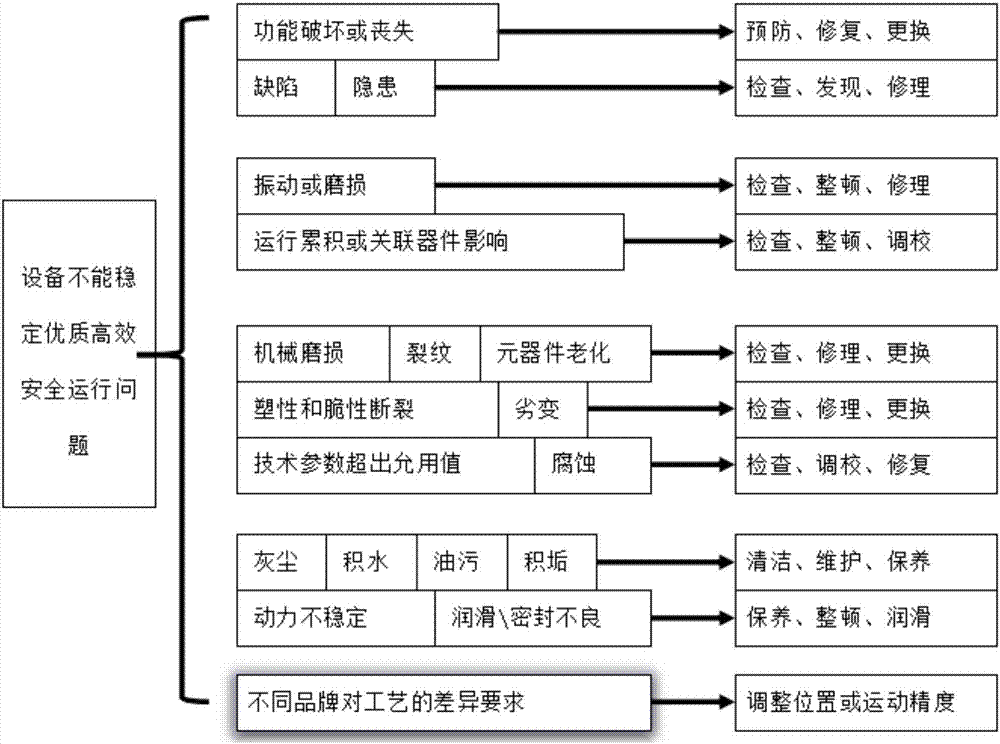

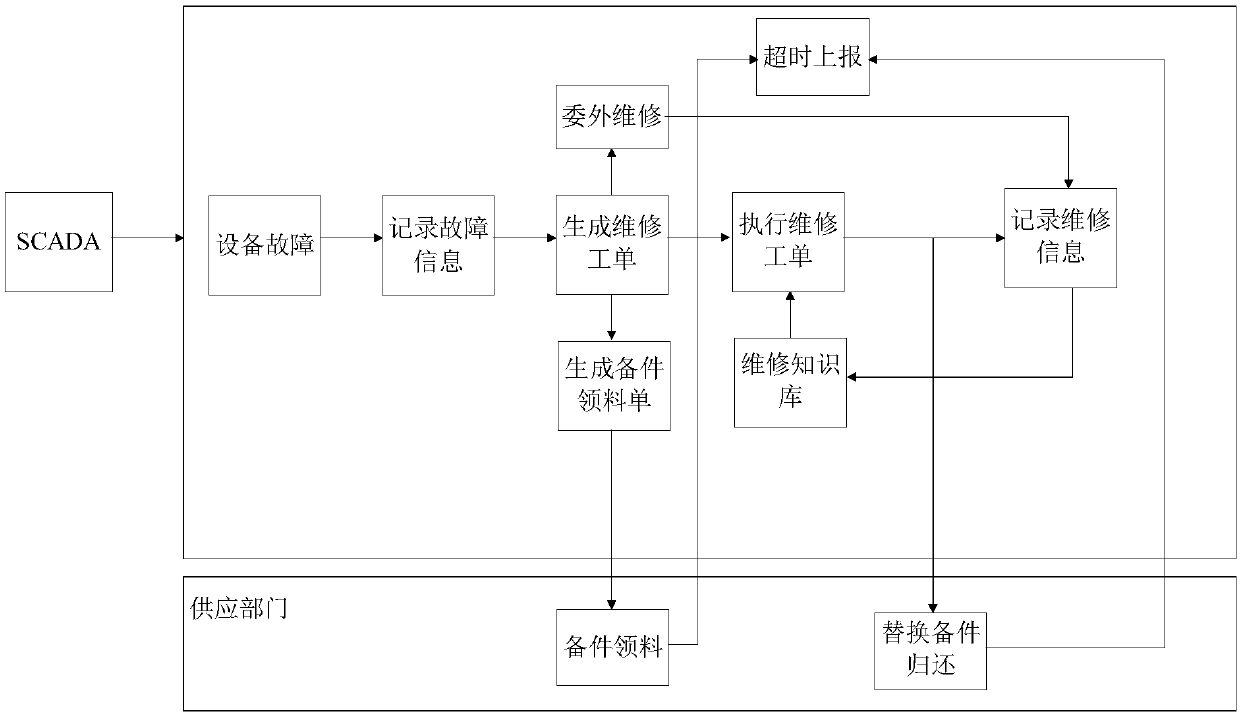

Method and system for inspecting and maintaining equipment

The present invention provides a method and a system for inspecting and maintaining equipment. According to the method, an equipment functional part is adopted as an object. After that, an inspection and maintenance strategy, spare part materials, an inspection and maintenance standard, and an inspection and maintenance service process, which are adaptive to the technical characteristics of the equipment functional part, are established. The method specifically comprises the steps of S1, identifying the critical functional part of the equipment; S2, establishing a standing book for the critical functional part; S3, conducting the factor and precautions analysis on the critical functional part of the equipment; S4, according to the factor analysis result, establishing an inspection and maintenance structure; S5, according to the inspection and maintenance structure, establishing the inspection and maintenance operation standard for the equipment; S6, setting the inspection and maintenance service flow; S7, according to the inspection and maintenance service flow, conducting the routine inspection and maintenance on the equipment. According to the technical scheme of the invention, the service management process and the service operation behavior of the equipment are in the controlled state. Therefore, the efficient and stable operation of equipment is guaranteed. The quality requirements of products are met and the safety production is ensured.

Owner:GUANGZHOU KINGTANG DATA

Method and apparatus for reducing supply orders in inventory management

ActiveUS8024236B2Minimizing number of orderReduce in quantityDigital data processing detailsLogisticsInventory managementEngineering

Owner:EASTMAN KODAK CO

Scheduled overhaul management module for EAM system of power plant

InactiveCN101763582AImprove work efficiencyAvoid unexpected breakdownsResourcesProduction ratePower station

The invention relates to a scheduled overhaul management module for an EAM system of a power plant, which comprises an overhaul item projecting submodule for generating overhaul items and setting process control conditions of each overhaul item; and an overhaul process management submodule for searching the items to be overhauled in the system according to the process control conditions, generating an overhaul task list and controlling the items of the overhaul items in the task list. Preventive equipment maintenance is to maintain equipment periodically according to a period and a conventional time interval and is a normal measure for equipment maintenance and management. A plurality of equipment can be prevented from sudden failures and avoided from halt out of the schedule through reasonable preventive maintenance. Equipment scheduled overhaul management is to track and manage the whole process of the preventive maintenance of the equipment, and can greatly improve the working efficiency of equipment manager, reduce labor intensity, greatly ensure the normal running of the equipment and further improve the production rate of the equipment.

Owner:国能浙江北仑第三发电有限公司

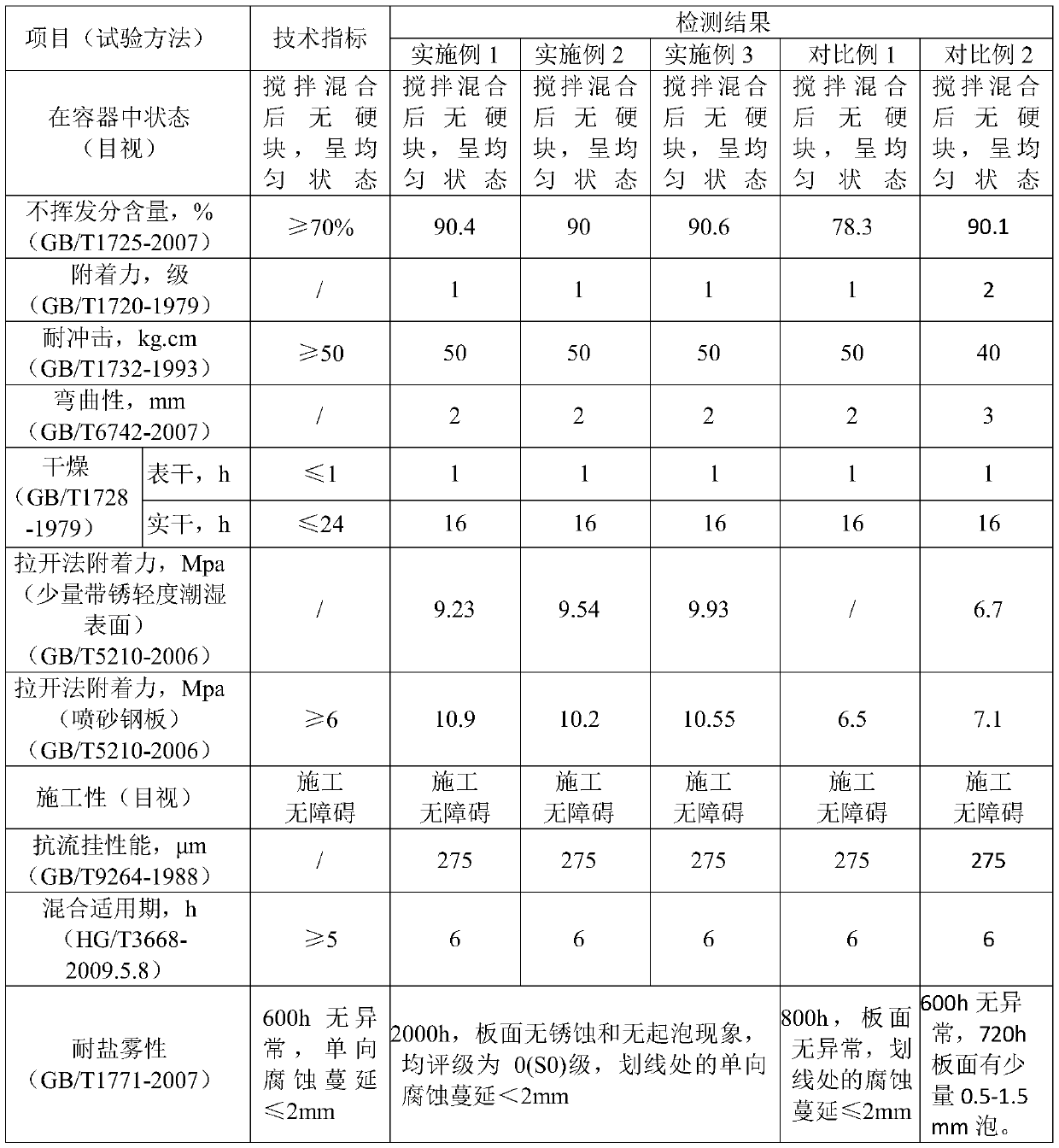

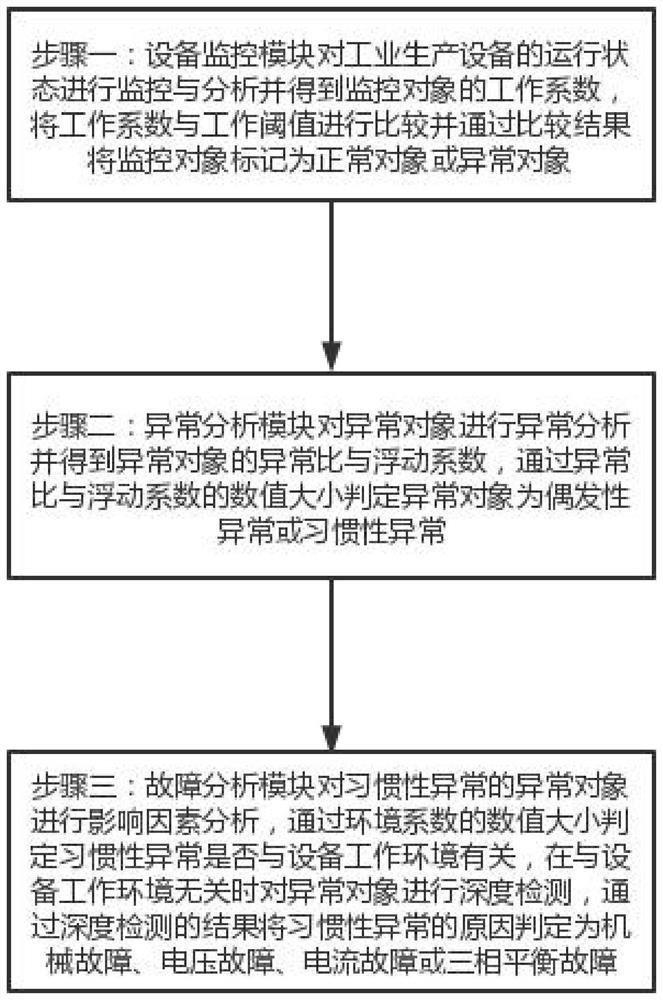

High-solid surface-tolerant epoxy zinc-rich primer and preparation method and application thereof

ActiveCN110144160AIncrease crosslink densityImprove penetration resistanceAnti-corrosive paintsEpoxy resin coatingsChemical industryEpoxy

The invention relates to a high-solid surface-tolerant epoxy zinc-rich primer. The primer is prepared from a component A and a component B according to a weight ratio of (16-20):1; the component A comprises the following components in parts by weight: 5-9 parts of liquid phenolic epoxy resin, 6-15 parts of E20 solid epoxy resin, 0.5-1.5 parts of an active diluent, 0.1-0.3 part of a dispersing agent, 70-80 parts of main rust-proof pigment, 2-6 parts of chemical anti-rust pigment, 1.5-2.5 parts of an anti-settling agent and 3-4 parts of an organic mixed solvent; and the component B comprises thefollowing components in parts by weight: 1.5-2.5 parts of a polyamide curing agent, 2-3 parts of a Mannich base curing agent, 0.3-0.6 part of a silane coupling agent and 0.2-0.6 part of an organic mixed solvent. The invention also relates to a preparation method of the primer and a coating film. The primer is high in solid content and low in VOC content, is resistant to corrosion, has a long effect, has good adhesive force and salt fog resistance, and is particularly suitable for repairing and maintaining equipment in industries such as chemical industry, thermoelectricity, machinery and thelike.

Owner:江阴市大阪涂料有限公司

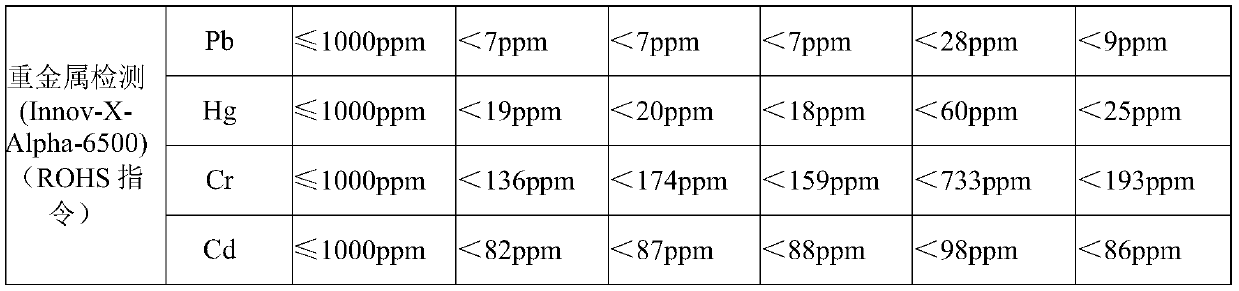

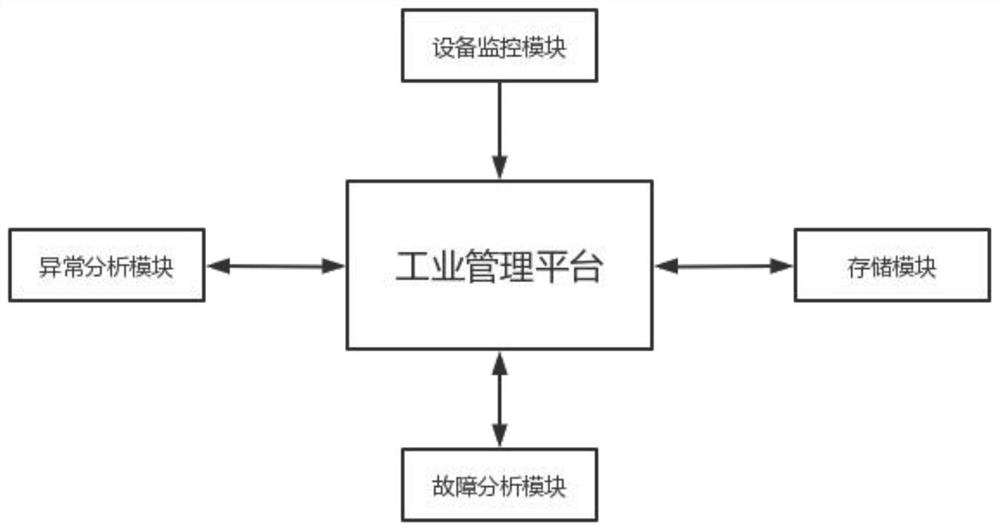

Intelligent industrial data management system based on Internet of Things controller

PendingCN114859845AAffect normalImprove inspection and maintenance efficiencyTotal factory controlProgramme total factory controlData managementFault analysis

The invention belongs to the field of industrial management, relates to a data processing technology, is used for solving the problems of resource waste and equipment loss caused by the fact that an existing industrial data management system mainly maintains equipment in a periodic maintenance mode, and particularly relates to an intelligent industrial data management system based on an internet of things controller, which comprises an industrial management platform, the industrial management platform is in communication connection with an equipment monitoring module, an abnormity analysis module, a fault analysis module and a storage module; the equipment monitoring module is used for monitoring and analyzing the operation state of the industrial production equipment, acquiring vibration data, noise data and temperature data of a monitored object, performing numerical calculation to obtain a working coefficient of the monitored object, and marking the monitored object as a normal object or an abnormal object according to the numerical value of the working coefficient; the running state of the monitored object is monitored according to the numerical value of the working coefficient, and feedback is performed in time when the monitored object runs abnormally.

Owner:CHINA APPLIED TECH CO LTD

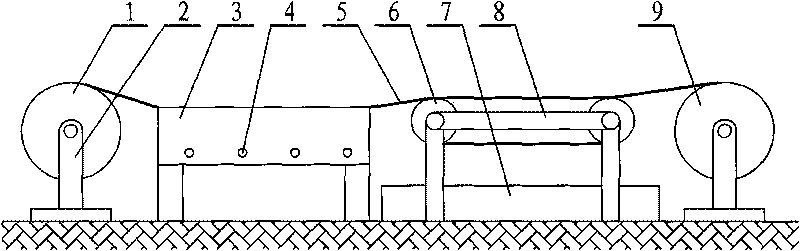

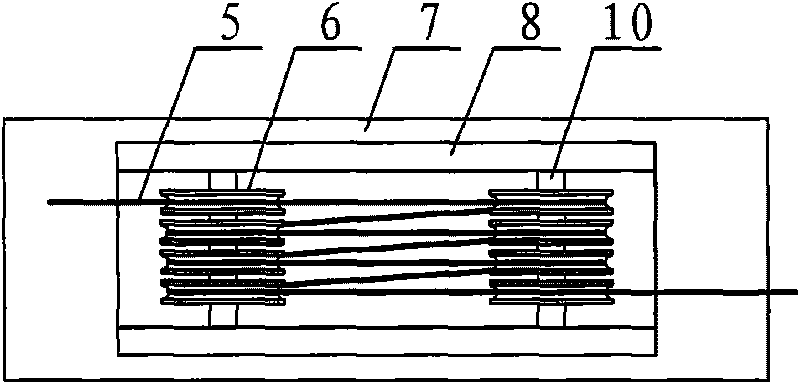

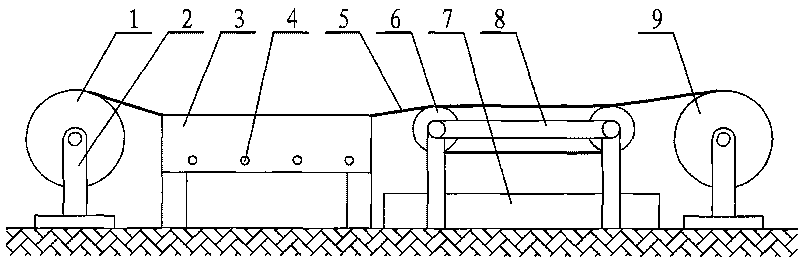

Device for soaking oil on steel rope surface

InactiveCN101701427AAvoid pollutionExtended cooldownRope making machinesReduction driveBlock and tackle

The invention relates to steel rope maintaining equipment, in particular to a device for soaking oil on the steel rope surface. The device comprises a grease heating groove, an electrical heating device, a steel rope release frame and a steel rope traction device, wherein the electrical heating device and the steel rope release frame are installed in the grease heating groove. The device for soaking oil on the steel rope surface is characterized in that a pulley block is installed behind the grease heating groove, and an oil receiving disk is arranged under the pulley block; and the steel rope traction device is driven to rotate by a motor and a speed reducer. Because the pulley block is additionally arranged behind the grease heating groove, and the oil receiving disk is arranged under the pulley block, thereby enabling the cooling time of a steel rope soaked with the oil to be prolonged by the pulley block; meanwhile, the dropping grease of the steel rope in the cooling process falls into the oil receiving disk, on one hand, a plurality of grease are recovered, on the other hand, the problem of pollution of the grease to the environment is solved.

Owner:中电建宁夏工程有限公司

System and method for simultaneous sea drilling operations

A system and method for carrying out simultaneous operations of assembling, dismantling, and maintaining equipment installed by an oil rig, using the tools, systems, and the areas available on the rig itself. The system includes two parallel and separated sustaining beams and two mobile bases supported on the beams to carry out the simultaneous operations. This system allows a method for simultaneously assembling two items of subsea equipment which are to be installed to be performed. Also, this system allows a method for simultaneously replacing and assembling subsea equipment to be performed. Additionally, the equipment can be lowered or recovered using either a derrick and pipe string or a winch and steel cable.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

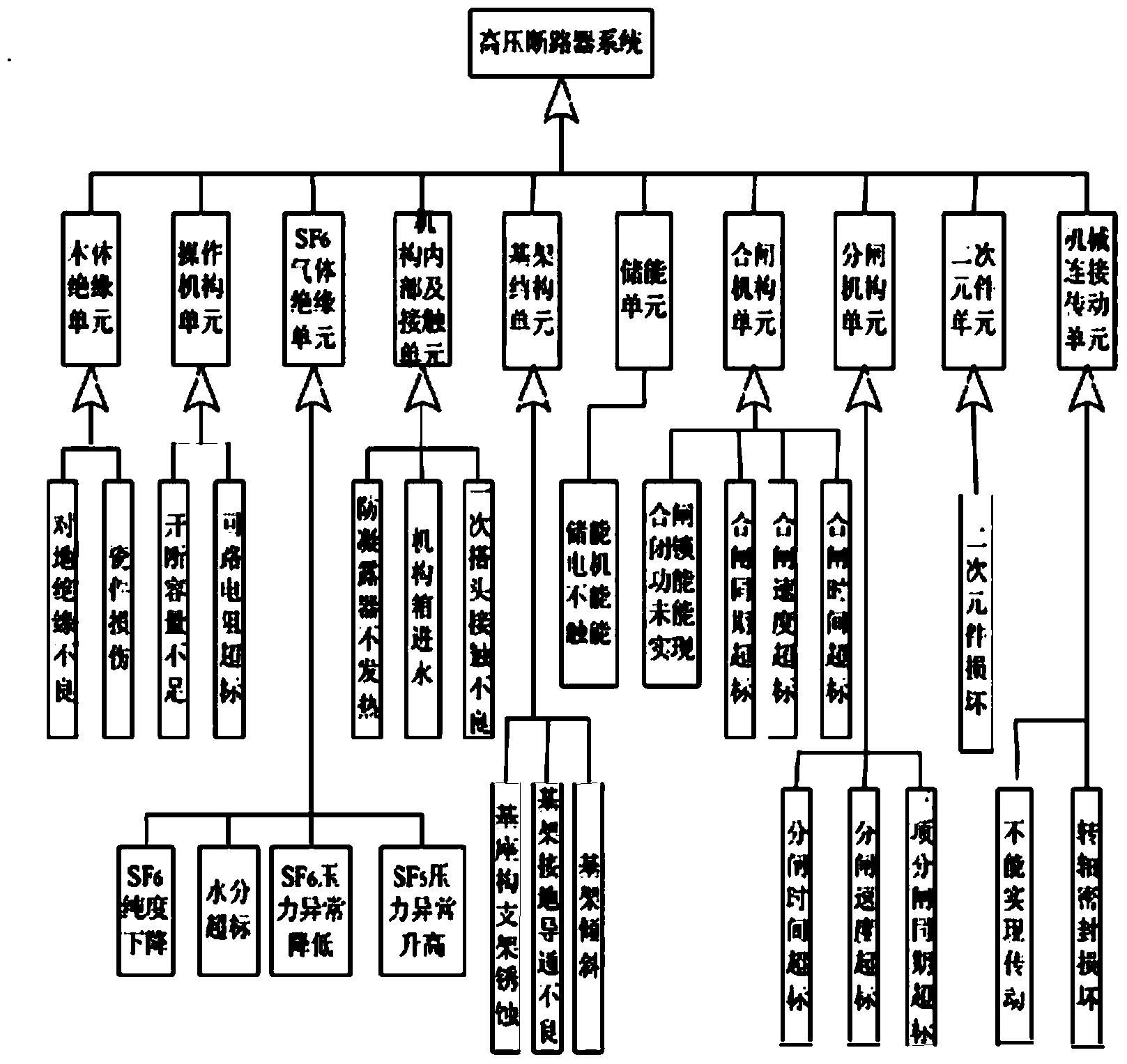

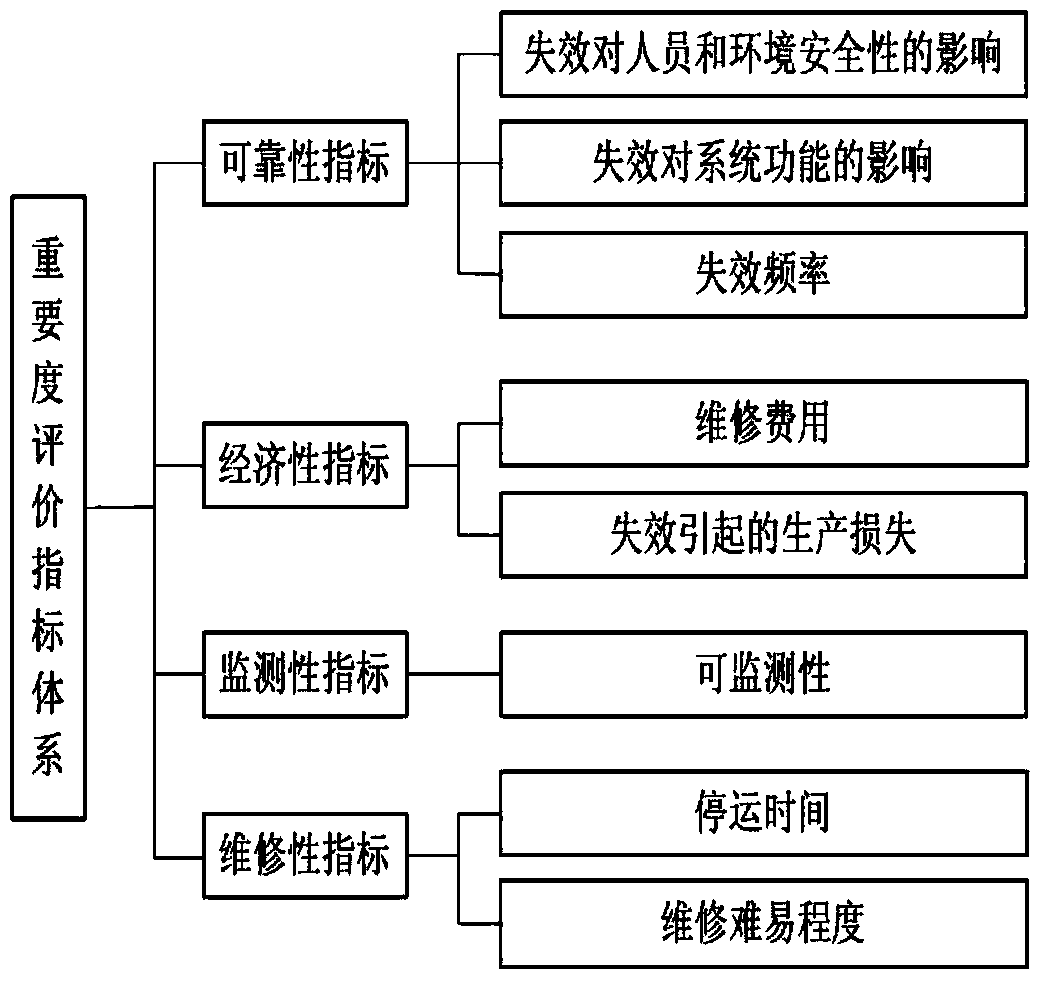

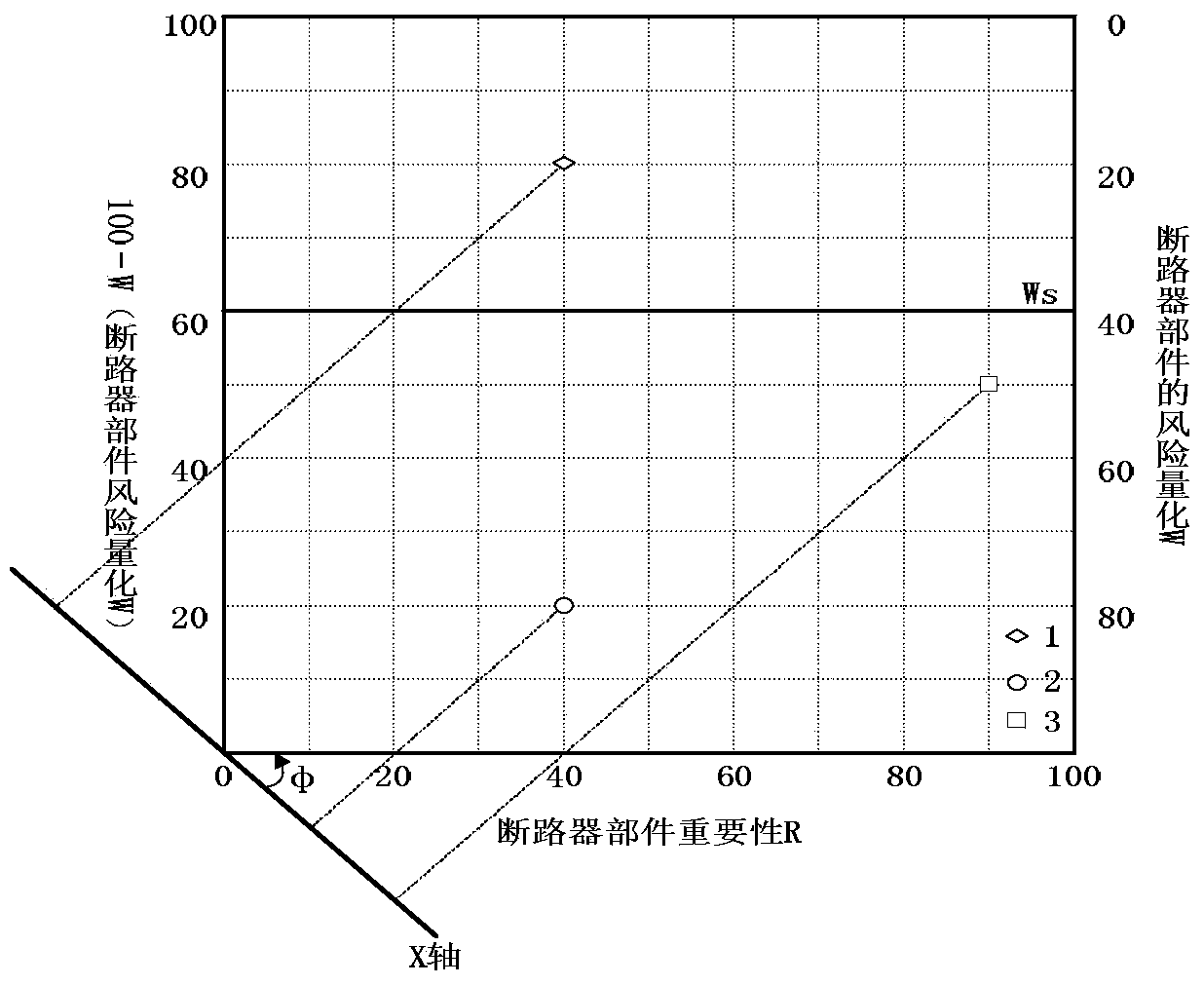

High-voltage circuit breaker component maintaining method

The invention discloses a high-voltage circuit breaker component maintaining method. The method comprises the following steps: performing module division on a circuit breaker by adopting an FMEA (failure mode and effect analysis) in combination with functions and components of the circuit breaker, establishing a risk assessment index system for a high-voltage circuit breaker component on the basis of risk assessment, and performing weight determining on risk assessment indexes by using an analytic hierarchy process; then establishing an importance level assessment index system for the circuit breaker component by applying risk quantification values of failure modes of a weighted grey relationship analysis model to obtain an importance level index of the circuit breaker component; establishing a two-dimensional relationship model between the failure risk degree and the importance of the component according to importance level indexes and the risk quantification values of the circuit breaker component, and taking the degree of urgency of needing maintaining equipment as an intermediate quantity to finally obtain a standard maintaining sequence value.

Owner:ELECTRIC POWER RES INST OF GUANGXI POWER GRID CO LTD

Power maintenance climbing box

ActiveCN108462112ASolve slippageFix security issuesApparatus for overhead lines/cablesEngineeringElectric power

The invention discloses a power maintenance climbing box. The power maintenance climbing box comprises a climbing box body, a tool kit, fixing rods and fixing rings; a fixing plate is arranged at thelower end of the climbing box body; an air cylinder II for driving the tool kit to ascend and descend is arranged on the fixing plate; the upper end of the air cylinder II is connected to the tool kit; the fixing rings at least comprise an upper fixing ring and a lower fixing ring which sleeve a telegraph pole and are connected to the climbing box body through the fixing rods; the at least two fixing rods comprise an upper fixing rod and an lower fixing rod, wherein the upper fixing rod is fixedly arranged at the upper end of the side surface of the climbing box body, and the lower fixing rodis arranged at the lower end of the climbing box body in a sliding mode along the side surface of the climbing box body; and an air cylinder I connected to the upper fixing rod is arranged on the lower fixing rod. The power maintenance climbing box has the advantages that the potential safety hazard that people slide off and are insecure when climbing the telegraph pole through a foot-operated auxiliary device can be eliminated, the problems that the cost is high, and the space is limited due to the fact that maintenance personnel are lifted to a high place to maintain equipment by using a crane can be solved, and the safety performance is higher.

Owner:NINGBO LONGER LIGHTING

Novel bridge maintaining equipment

ActiveCN107044087ARealize automatic reset workRestricted taxi positionBridge erection/assemblyRoads maintainenceAutomatic controlArchitectural engineering

The invention discloses novel bridge maintaining equipment. The novel bridge maintaining equipment comprises a material box, a first sliding cavity is formed in the left side of the material box, a first guide groove is formed in the inner wall of the left side of the first sliding cavity, and a second sliding cavity communicating with the first sliding cavity is formed in the portion, located at the right side of the first sliding cavity, of the material box; an arrangement groove arranged in a vertical-extending mode is formed in the portion, located at the right side of the second sliding cavity, of the material box, a closed groove penetrating through the arrangement groove and extending rightwards is formed in the top of the second sliding cavity, a cone-shaped cavity is formed in the top of the arrangement groove, and a feeding cavity is formed in the top of the cone-shaped cavity; and a third sliding cavity is formed in the portion, located above the first sliding cavity, of the material box, third guide grooves are symmetrically formed in the inner walls of the left and right sides of the third sliding cavity, a screw rod is arranged in the first sliding cavity, a first driver is connected with the bottom of the screw rod, and a lifting block is connected to the screw rod in a threaded fit mode. According to the novel bridge maintaining equipment, the structure is simple, the design is reasonable, operation is simple, stirring and discharging work can be automatically controlled, the labor capacity of workers are reduced, the construction and maintenance speed is enhanced, meanwhile the lighting function is achieved, the use cost is low, and current requirements are met.

Owner:NANTONG YIXUAN IND DESIGN CO LTD

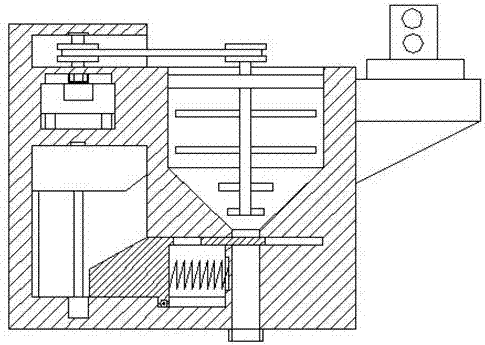

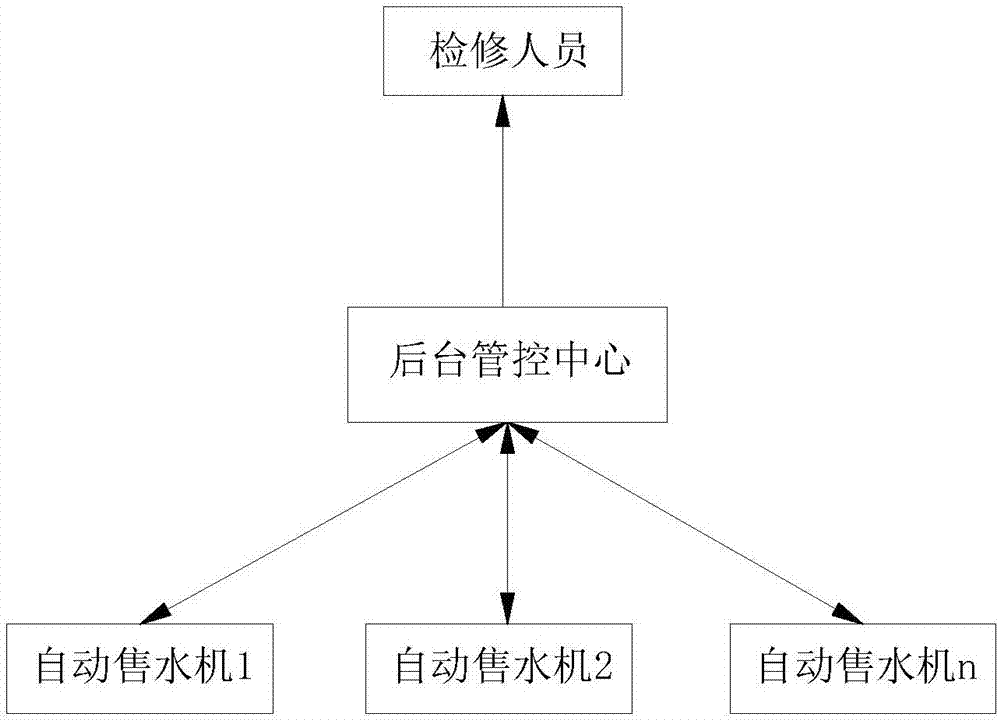

Self-service water vending machine and remote intelligent management and control system thereof

InactiveCN106875569AReal-time monitoring of working statusFlexible purchase methodApparatus for dispensing fluids/granular materialsWater storageElectromagnetic lock

The invention discloses a self-service water vending machine and a remote intelligent management and control system thereof. The water vending machine comprises a box body provided with a purified water storage bucket and a purification treatment device therein, a water vending window, a display screen, a coin mouth, keys, a card sweeping sensing position and a liquid crystal screen are arranged on a box door on the front face of the box body, a water outlet is formed in the water vending window, a window door is arranged on the water vending window, the window door is connected to the box door through an electromagnetic lock, an illumination lamp is arranged above the display screen, and advertisement display areas are arranged on both sides of the box body. The remote intelligent management and control system comprises a background management and control center in wireless communication with each self-service water vending machine and a sub control system arranged in each self-service water vending machine, the background management and control center monitors the working state of each self-service water vending machine in real time, after the self-service water vending machine is faulty, the sub control system sends an overhaul request to the background management and control center, and the background management and control center notifies a maintainer of the ID of the faulty self-service water vending machine, the corresponding fault and the maintenance equipment and materials necessary for onsite maintenance.

Owner:赵波 +1

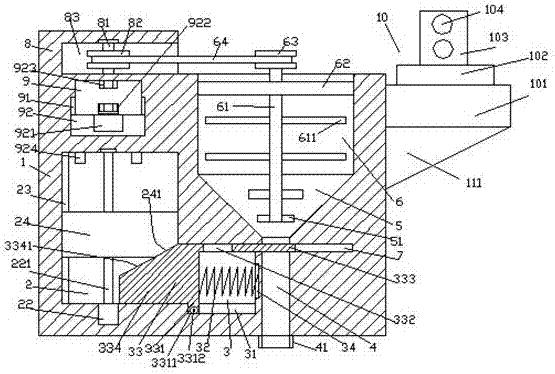

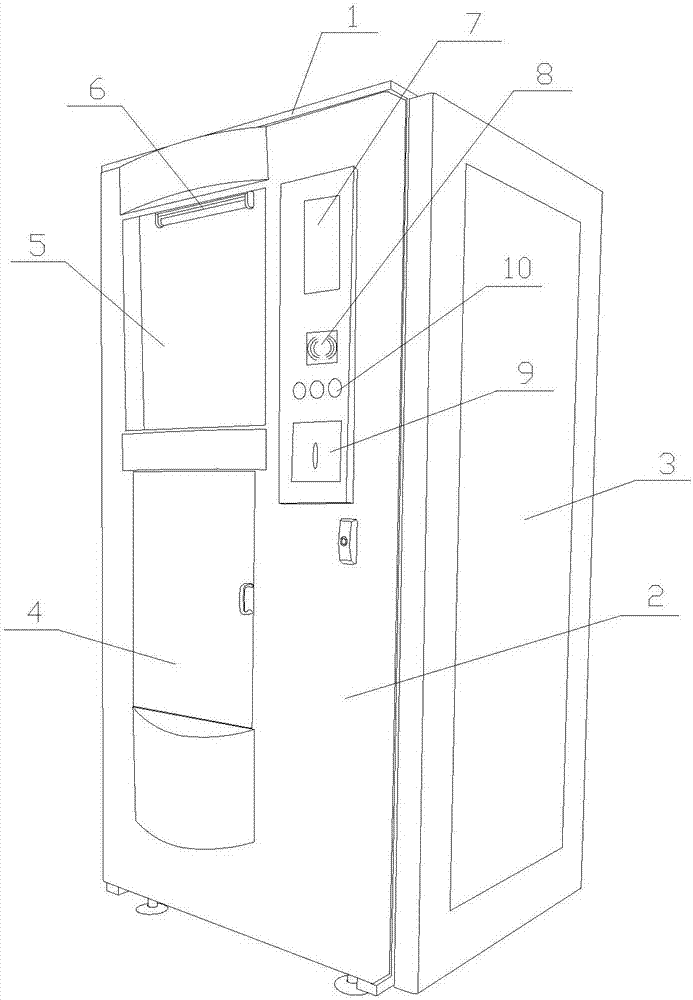

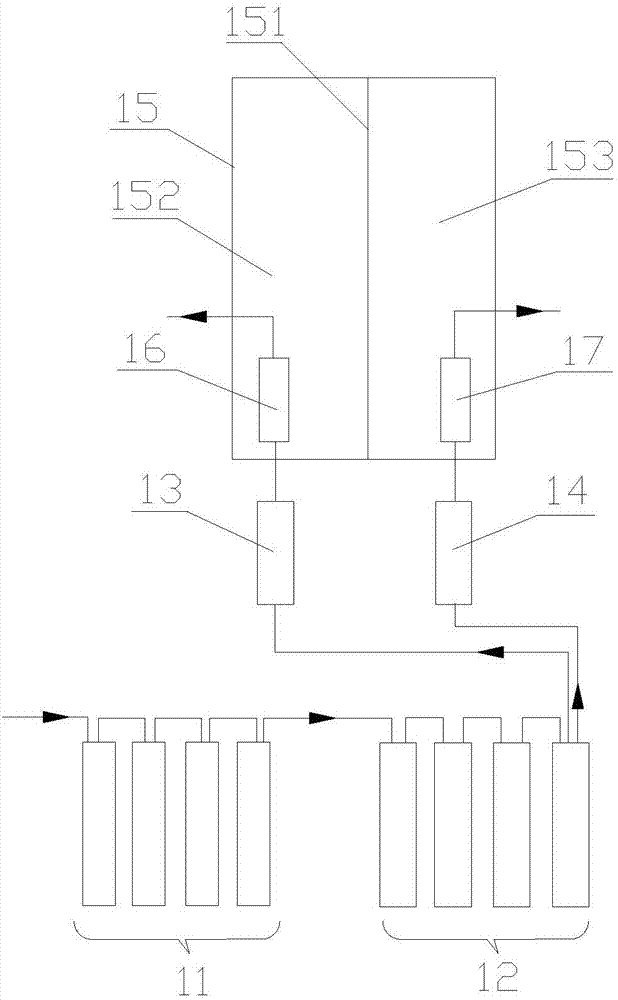

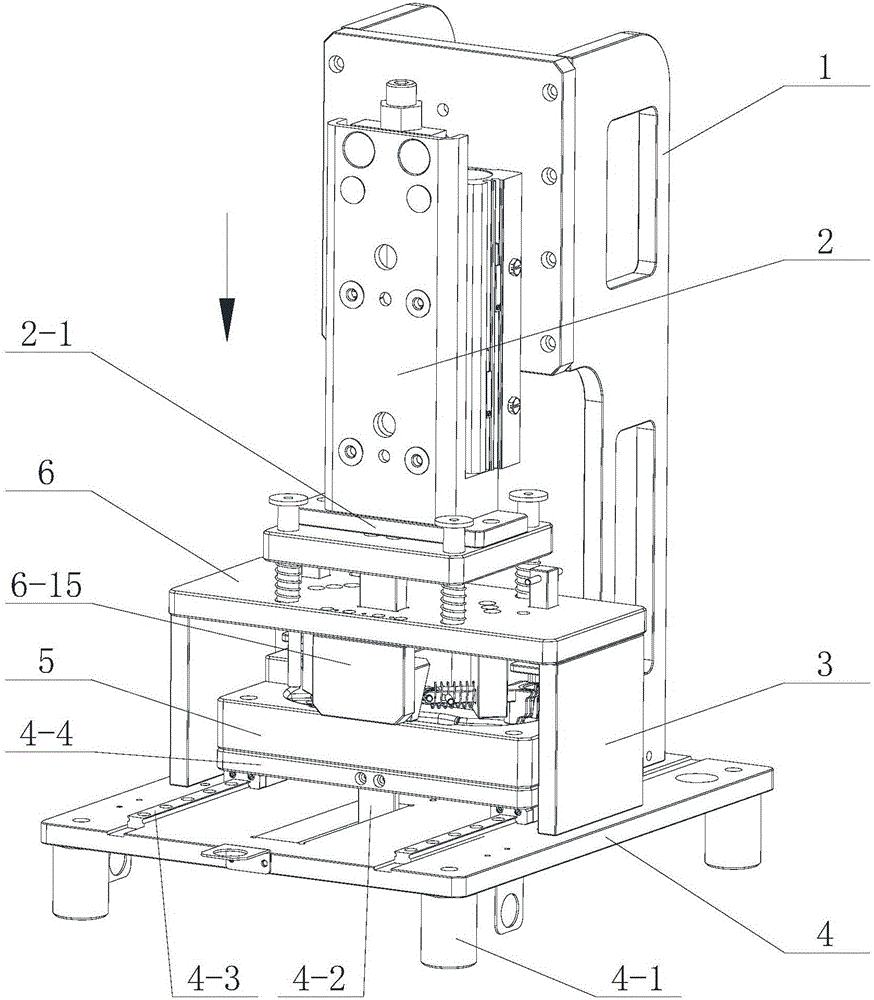

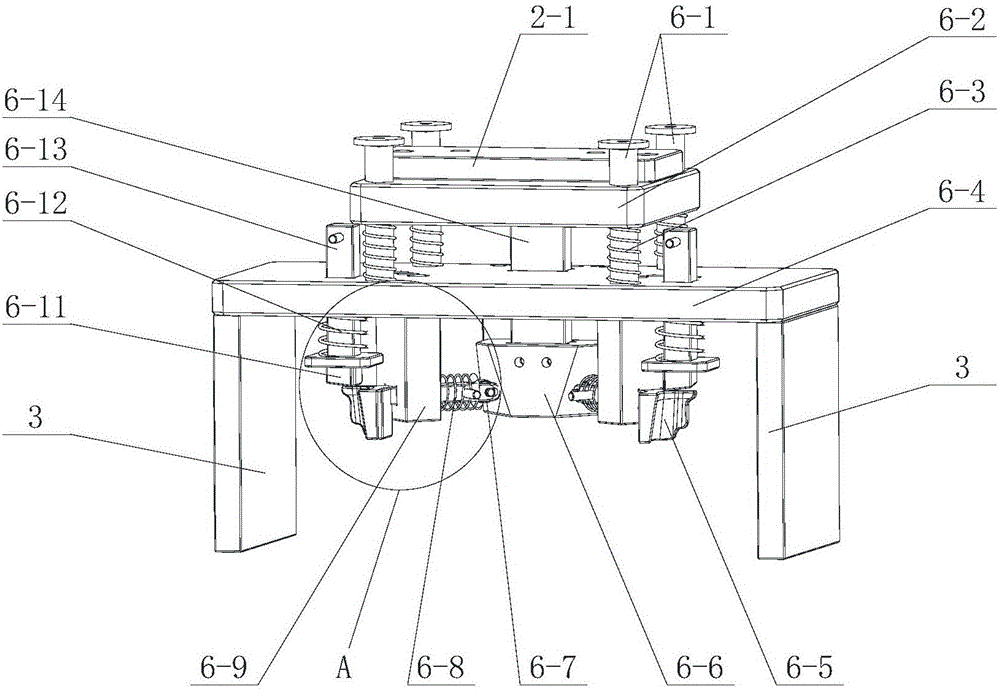

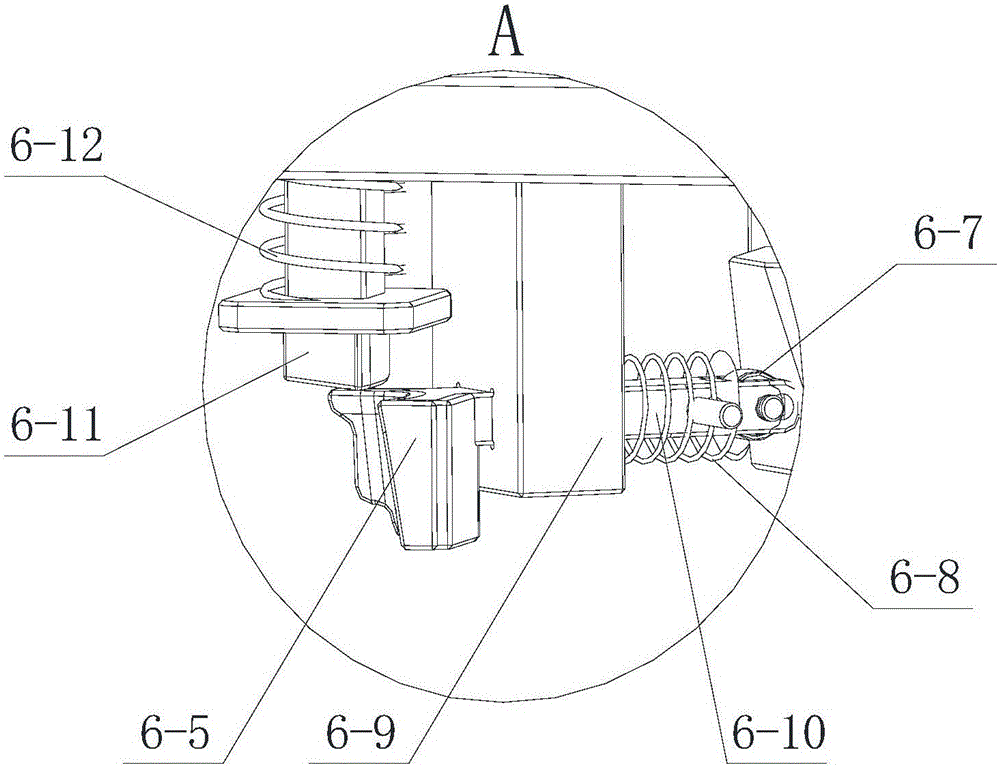

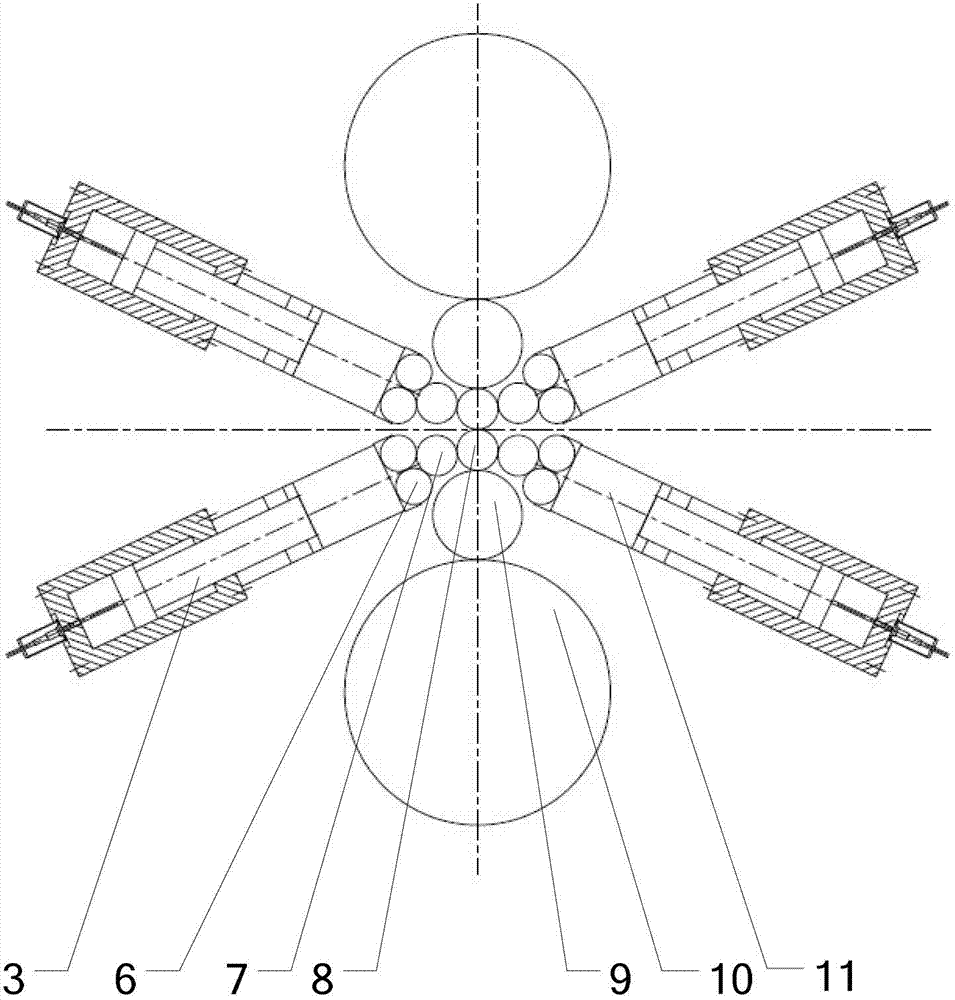

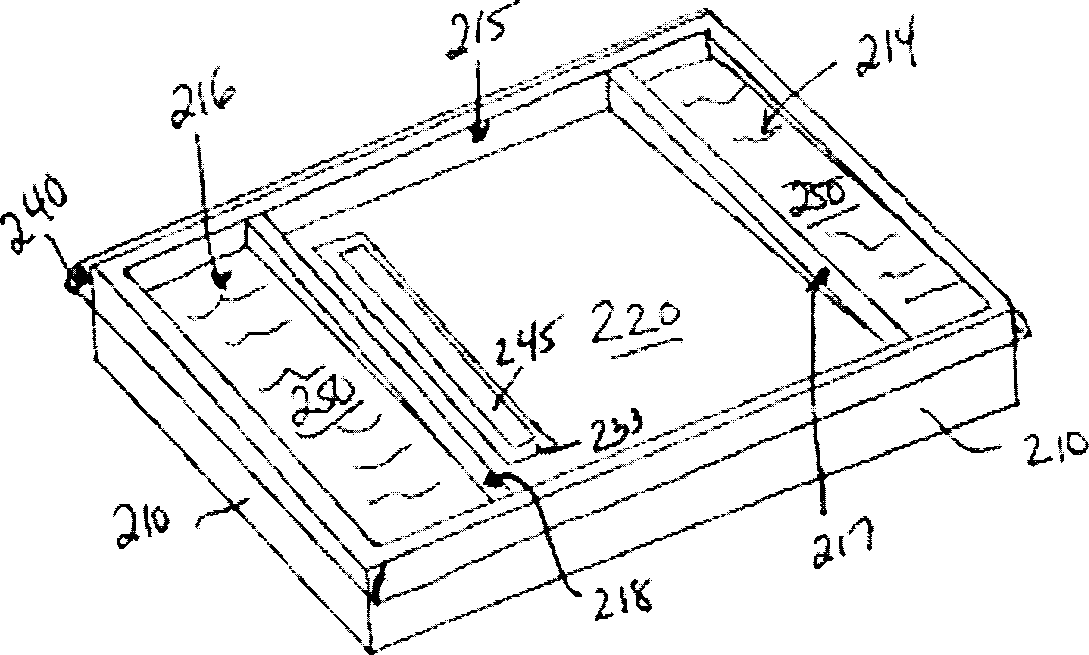

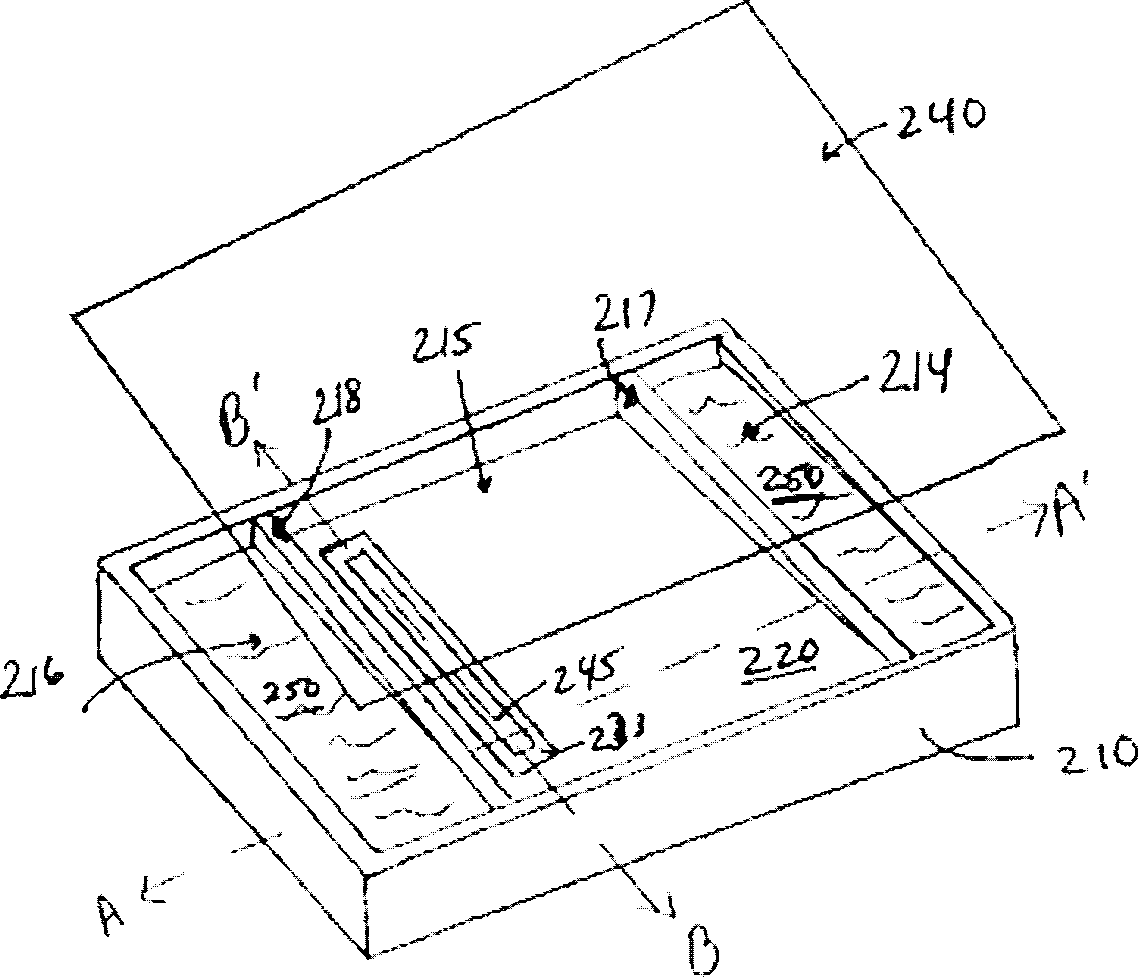

Three-dimensional-direction pressure maintaining equipment

The invention discloses three-dimensional-direction pressure maintaining equipment and solves the technical problems that three-dimensional-direction pressure equipment in the prior art is complex in structure and relatively large in size. The equipment is provided with a rack; a downward-pressing driving mechanism is arranged on the rack; the rack is mounted on a base; a product accommodating plate is arranged on the base and is used for accommodating a product to be subjected to pressure maintaining; the lower side of the downward-pressing driving mechanism is connected with a partial pressure mechanism; the downward-pressing driving mechanism drives the partial pressure mechanism to rise and fall; multiple vertical pressure heads and multiple lateral pressure heads are arranged in the partial pressure mechanism; a partial pressure block matched with the lateral pressure heads is arranged; slopes are arranged on the partial pressure block; the lateral pressure heads can be driven through the slopes to extend out; and in the falling process of the partial pressure mechanism, the vertical pressure heads make contact with the product for pressing firstly, in the process that the partial pressure mechanism continues to fall, the partial pressure block begins to move downwards relative to the lateral pressure heads, the slopes of the partial pressure block drive the lateral pressure heads to extend out to make contact with the product for pressing, and thus three-dimensional-direction pressure maintaining is performed on the product.

Owner:GEER TECH CO LTD

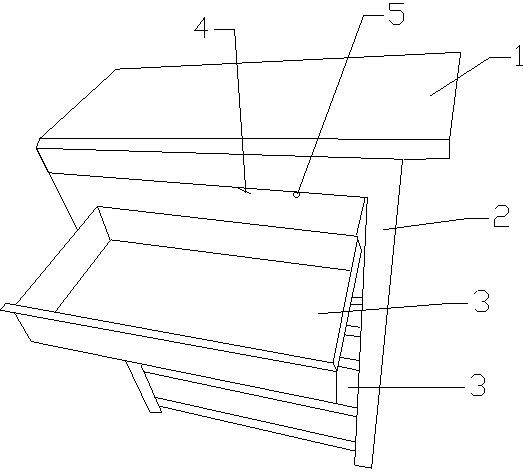

Push-pull type lighting-tool cabinet

InactiveCN103465242AAvoid Dust ProblemsEasy to open and close to save powerPoint-like light sourceLighting elementsStructural engineeringLED lamp

The invention belongs to the field of vehicle maintenance equipment tool cabinets and particularly relates to a push-pull type lighting-tool cabinet. The push-pull type lighting-tool cabinet comprises an upper cover and a cabinet body which are integrally connected. The push-pull type lighting-tool cabinet is characterized in that the cabinet body is of a hollow structure, a plurality of push-pull type drawers arranged in an upper-lower manner are inserted into the cabinet body, and a travel switch and an LED lamp controlled to be turned on and off by the travel switch are correspondingly arranged on an inner wall of the cabinet body and correspond to the push-pull type drawers. When drawers are closed, an elastic pressure piece of the drawer disconnects an electric circuit, and the LED lamp is turned off; when the drawers are pulled open, the elastic pressure piece springs back to enable the electric circuit to be closed, and the LED lamp is turned on; by the arrangement, night lighting is provided, the LED lamp is convenient to turn on and off, and electricity is saved. Each gap between the drawers is 2.5mm-5mm, so that dust is prevented from falling in between the drawers.

Owner:昆山凯恒五金配件有限公司

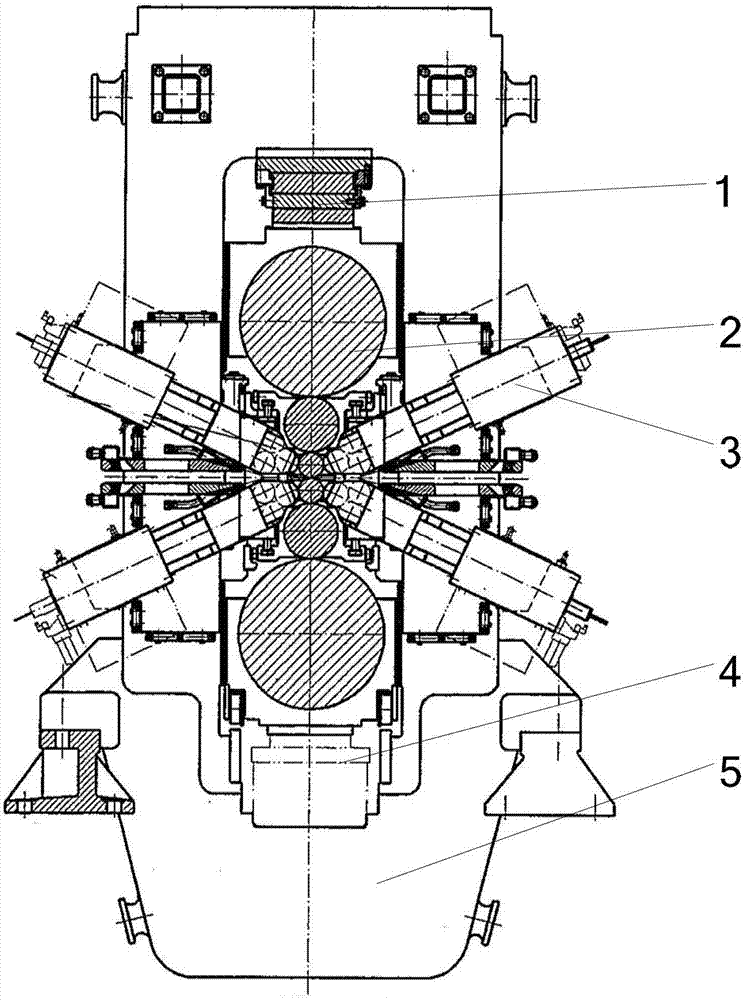

Eighteen-roller rolling mill structure

InactiveCN102886382AStrap for easy observationGuaranteed stiffness requirementsMetal rolling stand detailsCounter-pressure devicesEngineeringLubrication

The invention provides an eighteen-roller rolling mill structure. Side supporting devices of working rollers are respectively arranged in the front and at the back of as well as on and below a rolling mill machine frame assembly; each side supporting device comprises a side supporting bearing pedestal, a side roller and a side supporting roller; the side supporting device comprises a side driving cylinder which is provided with a displacement sensor and a servo valve for controlling the advancing and retreating positions of the side supporting device; when in a rolling work, the side supporting positions are set according to various technical parameters, so that the side deformation caused by the working rollers in a rolling process is counteracted and the rigidities of the working rollers are improved; with the adoption of the small-diameter working rollers and a side driving roller system mode, the demand of roller rigidity in the rolling process is ensured, and meanwhile, the rolling demand of an ultra-thin belt material is satisfied; and the rolling mill structure has the following advantages of high rolling mill opening degree, favorable lubrication for the roller and belt material, high speed, convenience to maintain equipment and low manufacturing cost of the equipment.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

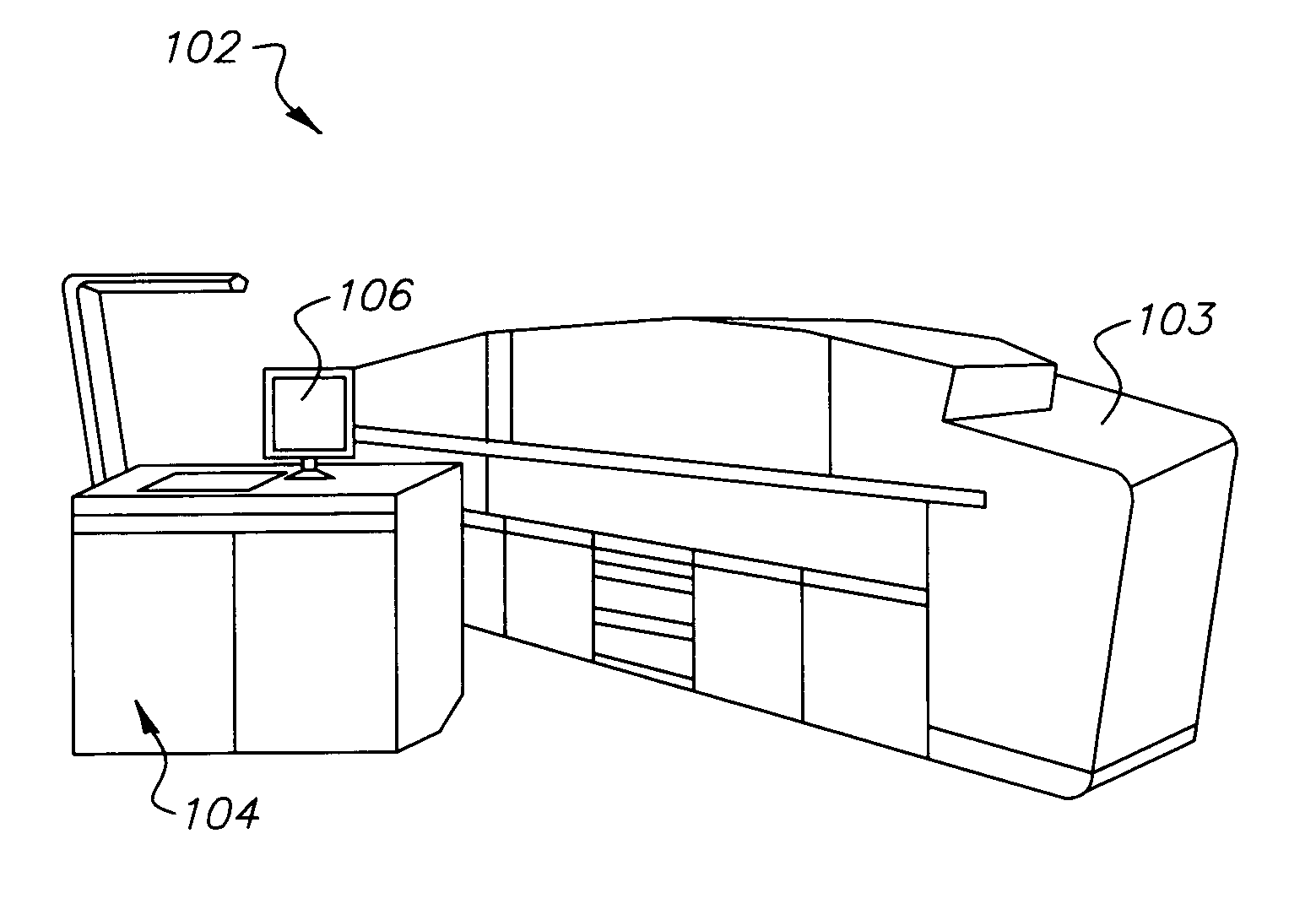

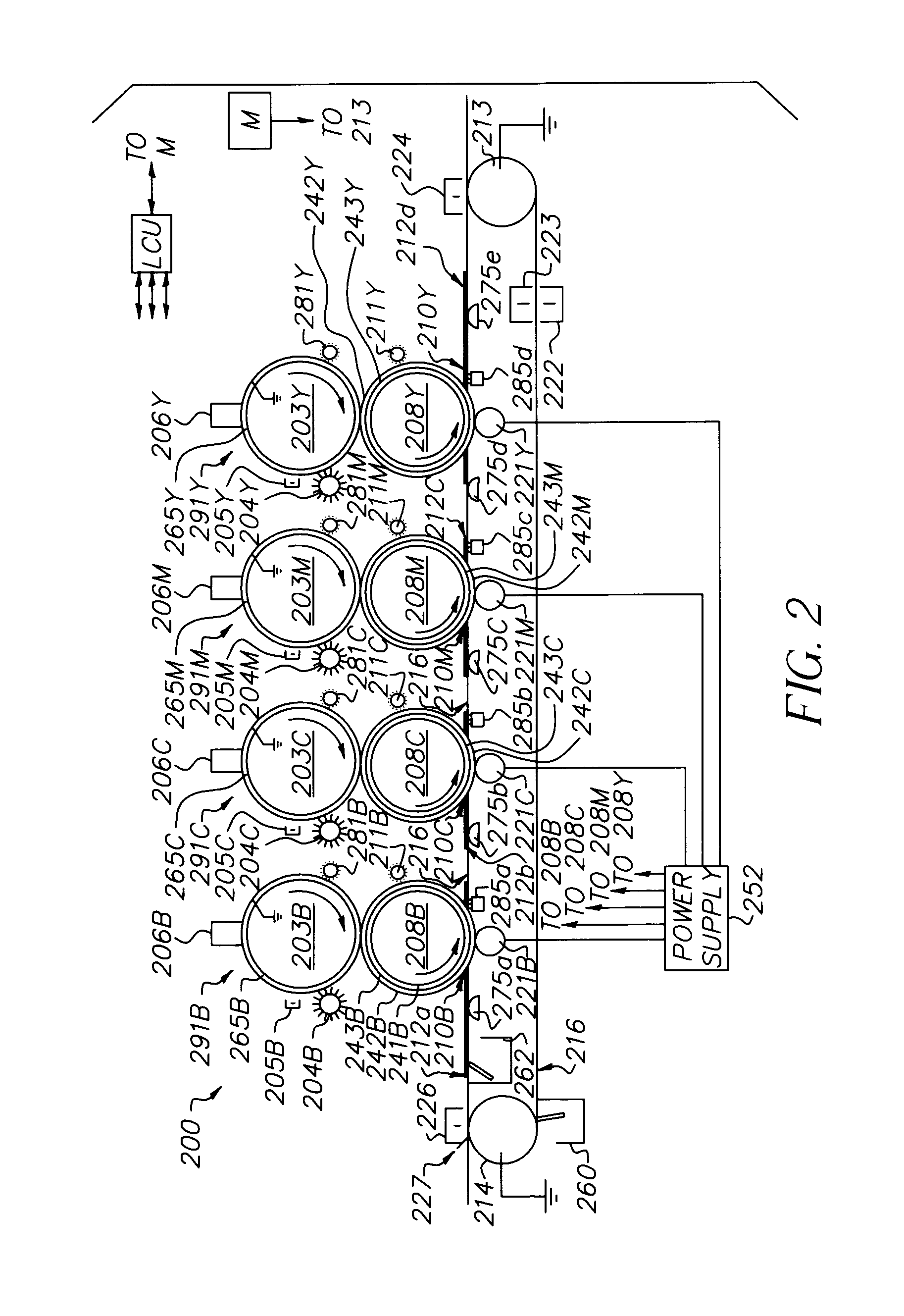

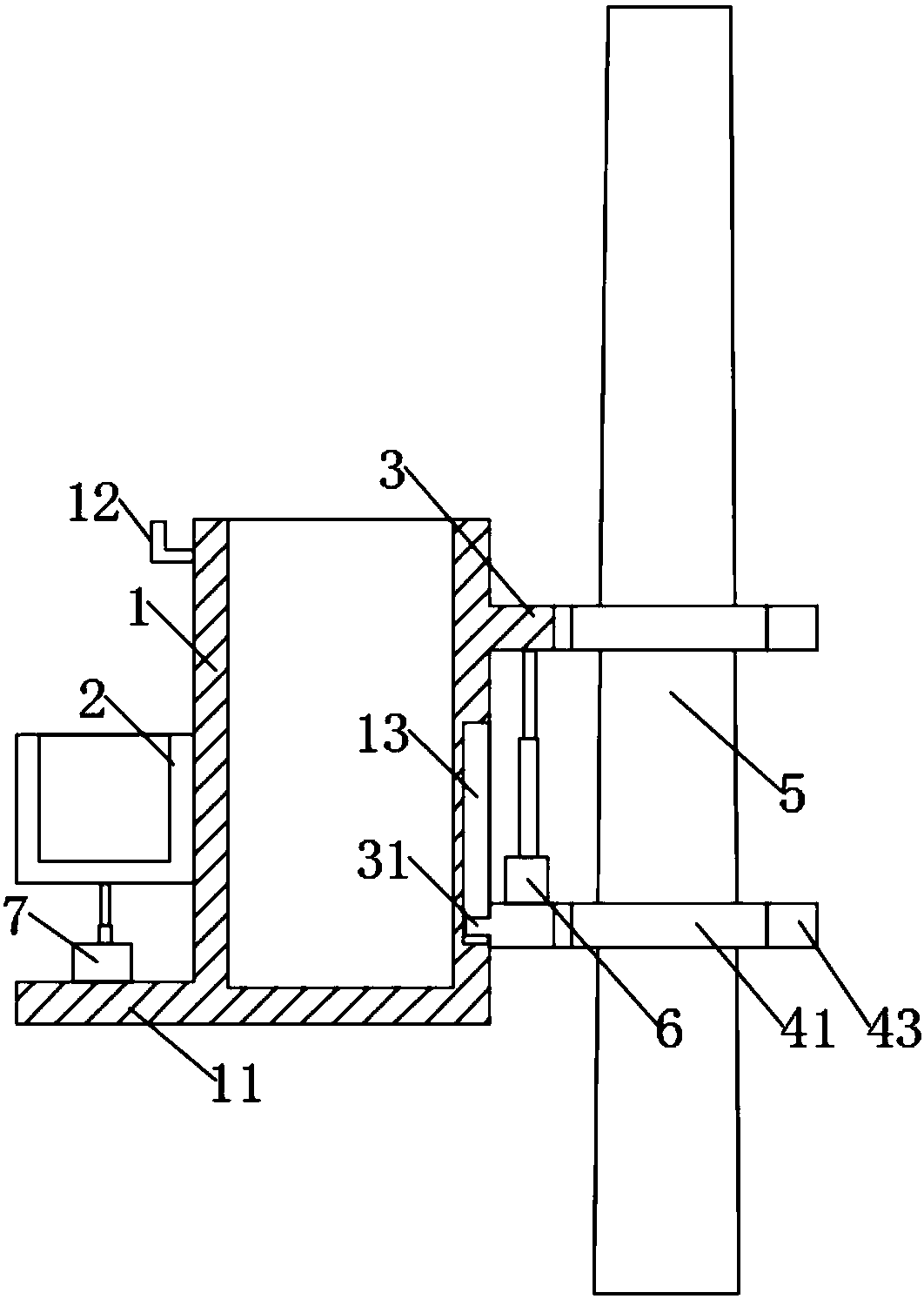

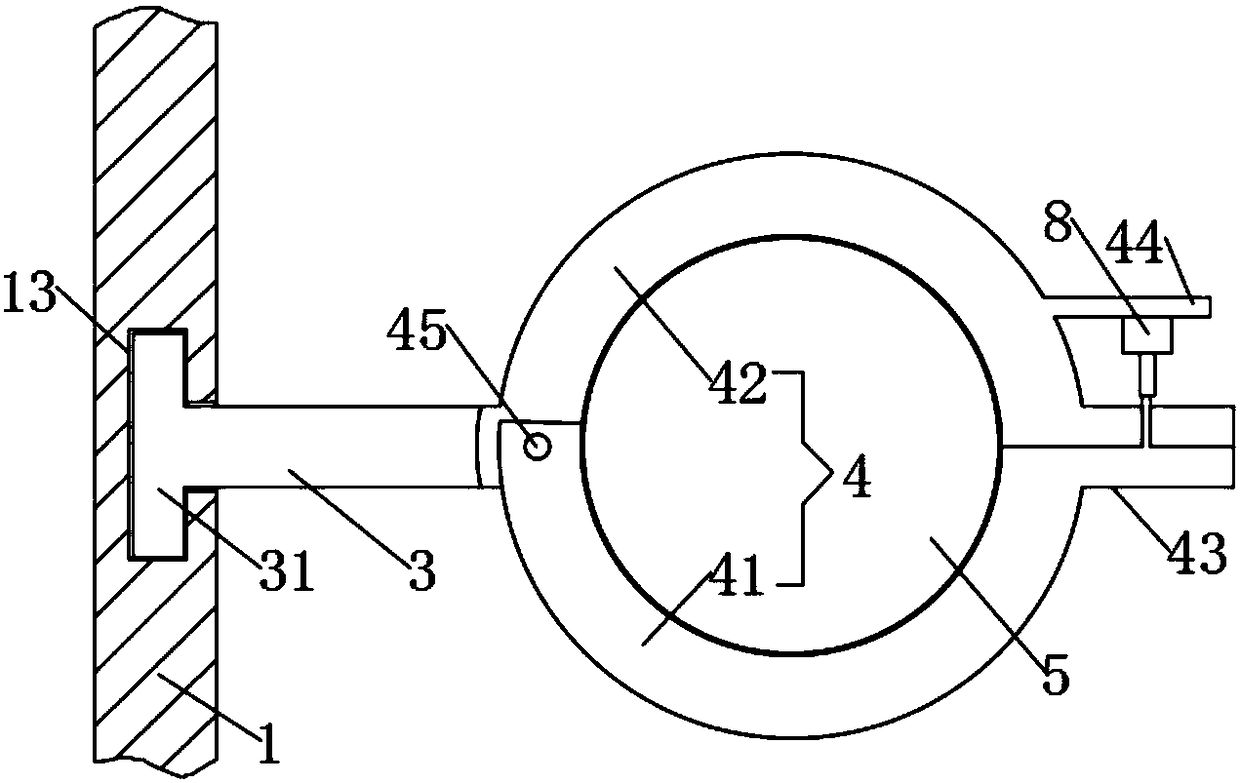

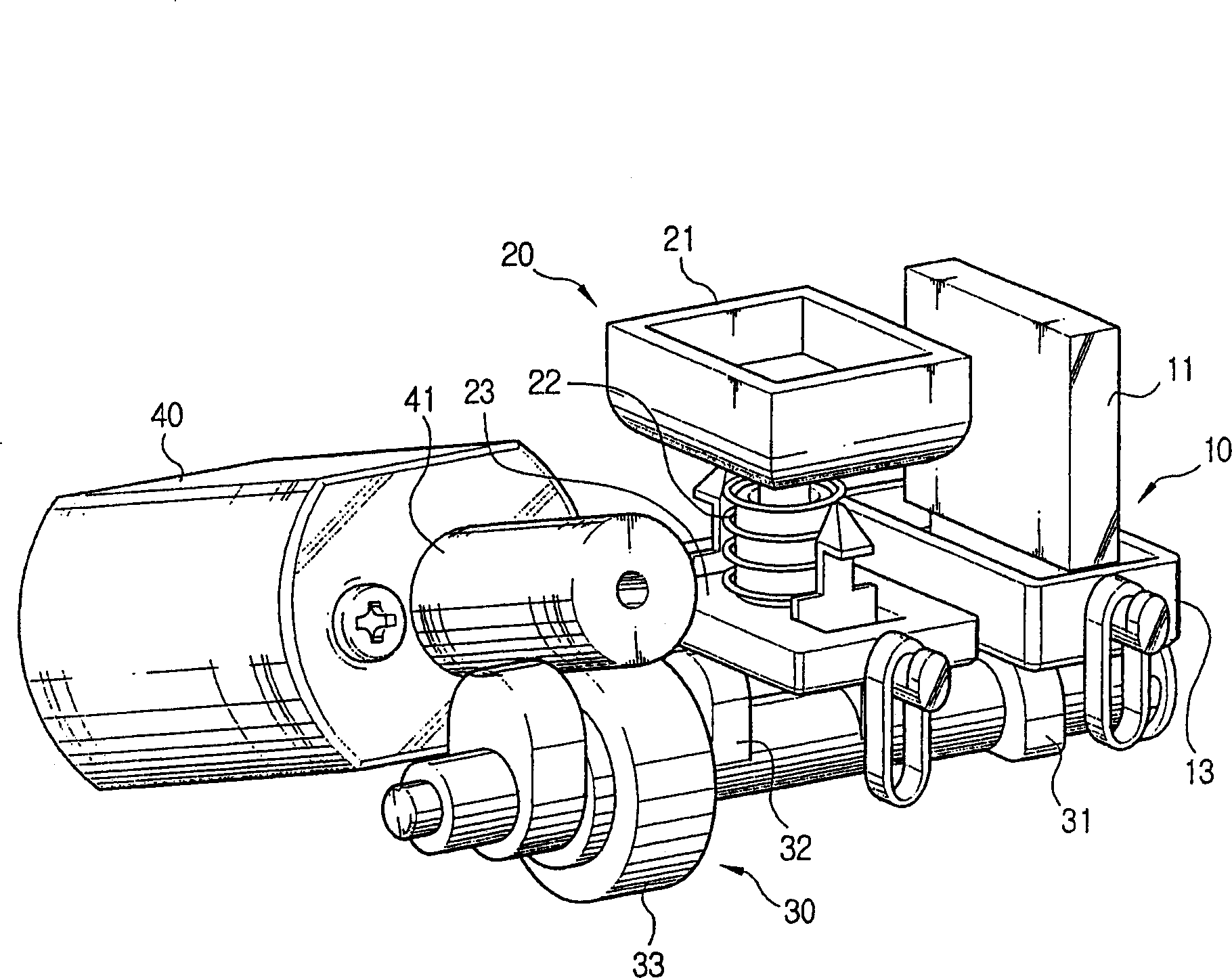

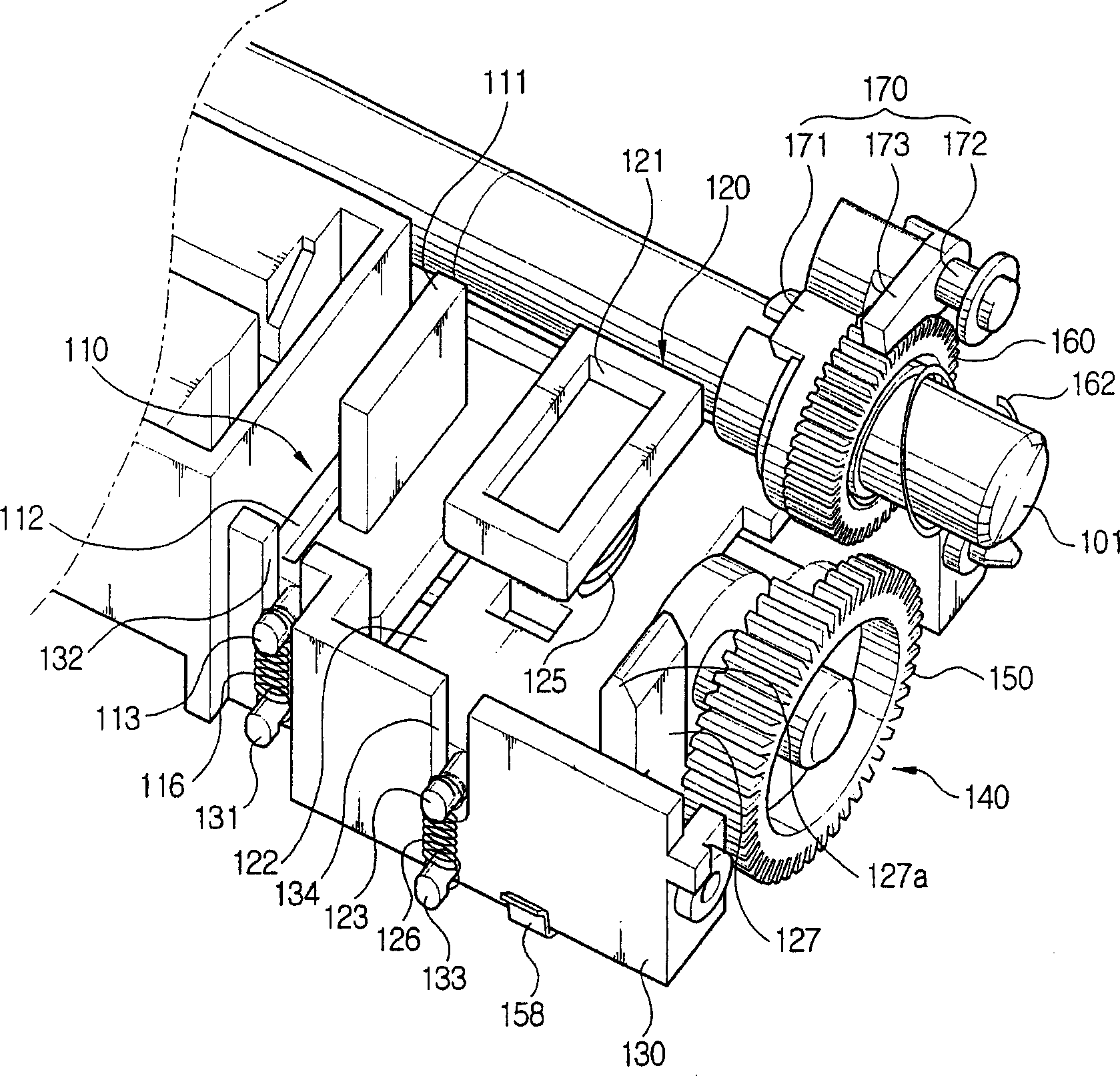

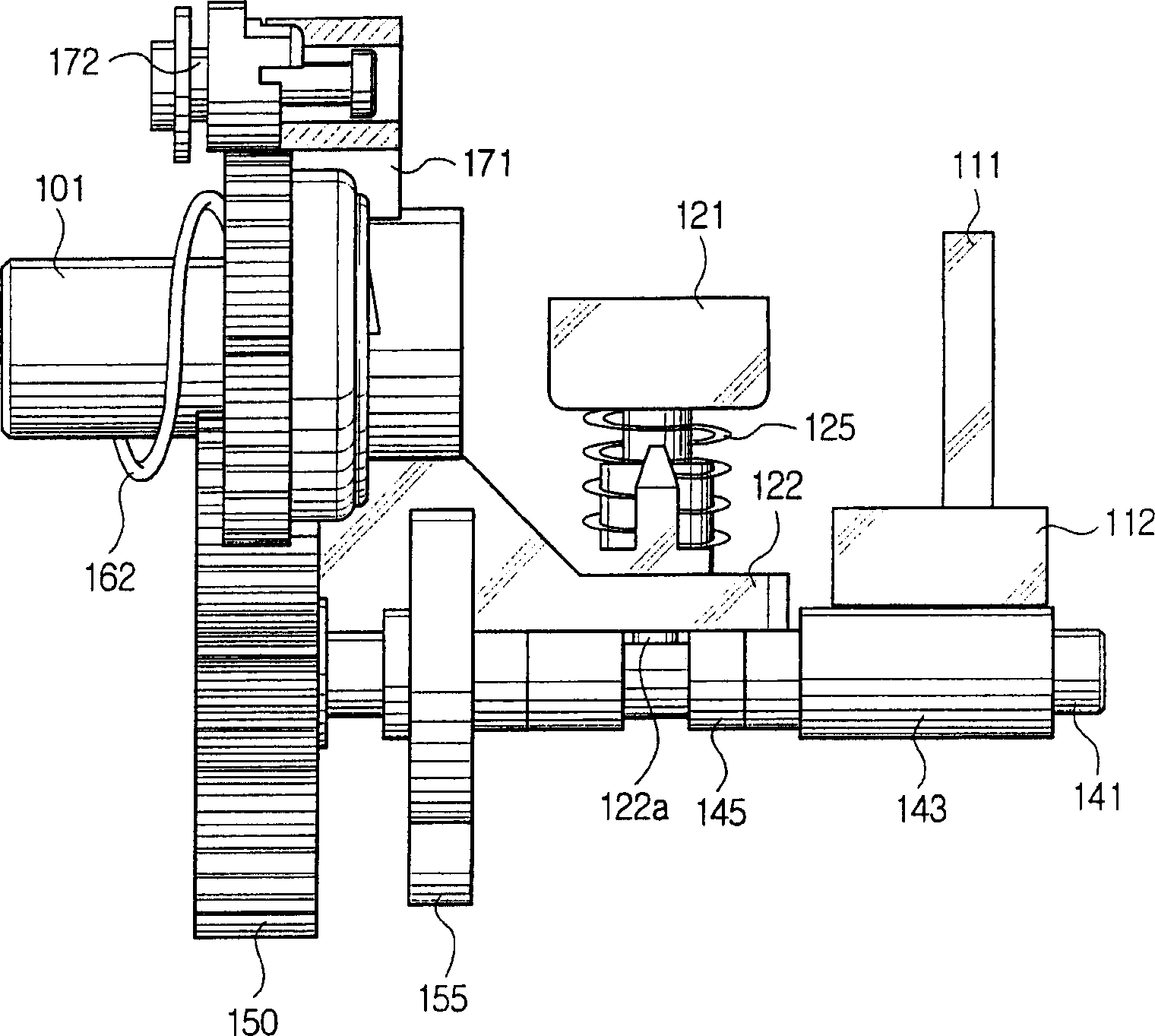

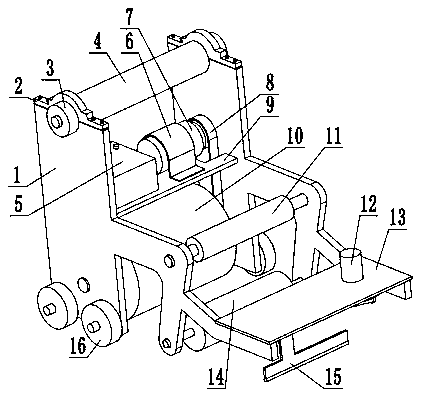

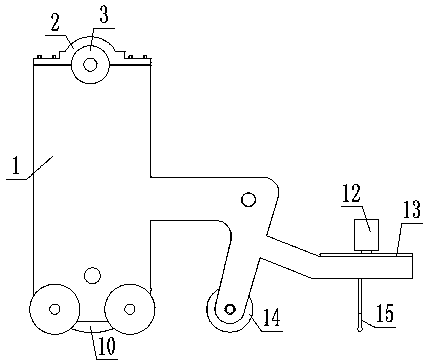

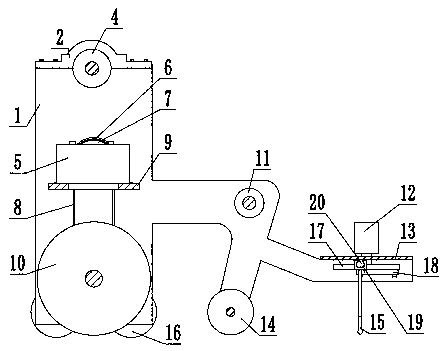

Maintaining equipment for ink-jet printer

An inkjet printer driving a maintenance apparatus using a power to a feed roller. In the inkjet printer, the maintenance of the maintenance apparatus is started by a carriage. The maintenance apparatus includes a maintenance member which cleans and covers the nozzle of a print head, a maintenance cam which controls the maintenance member through a rotating motion, a maintenance gear which is disposed at one end of the maintenance cam and has a cut off portion in which a part of gear teeth is partially cut off in a face width direction, and a connection gear disposed on a shaft of the feed roller to be able to move in a shaft direction by the carriage and transmit the power of the feed roller. During the printing operation of the carriage, the connection gear is placed on the cut off portion, and then engaged with the teeth of the maintenance gear disposed adjacent to the cut off portion by the pushing of the carriage. The connection gear is supported in the shaft direction of the feed roller by a return spring, and the return spring returns the connection gear to place the connection gear on the cut off portion of the maintenance gear when the connection gear is not forced by the carriage.

Owner:SAMSUNG ELECTRONICS CO LTD

Integrated horizontal gel electrophoresis device

InactiveCN102423633ASimple processing capacityEasy to operateDispersed particle separationElectrophoresisFuel tank

The invention discloses an integrated horizontal gel electrophoresis device. The device is mainly formed in the way that: an injection-molded horizontal electrophoresis device is provided with a gel tank between an anode tank and a cathode tank; the anode tank is separated from the gel tank by a first inner tank wall of the device; the inner tank wall is provided with a breakable weak part; the cathode tank is separated from the gel tank by another inner tank wall of the device; the inner tank wall is also provided with a breakable weak part; electrophoresis buffer solution is stored in the anode tank and the cathode tank; prefabricated gel is positioned in the gel tank, the bottom edge of the prefabricated gel is directly contacted with the inner bottom of an electrophoresis tank mould; and the gel tank, the anode tank and the cathode tank are combined together to constitute the ready-to-use integrated electrophoresis device. The invention provides the simple and easy-to-use improved electrophoresis device; the device has simple treatment process and operation steps, and structure and performance stability, and is time-saving and low in cost; and parts of components are disposable consumables, so that the time consumed for cleaning and maintaining equipment is saved.

Owner:杭州吉来生物技术有限公司

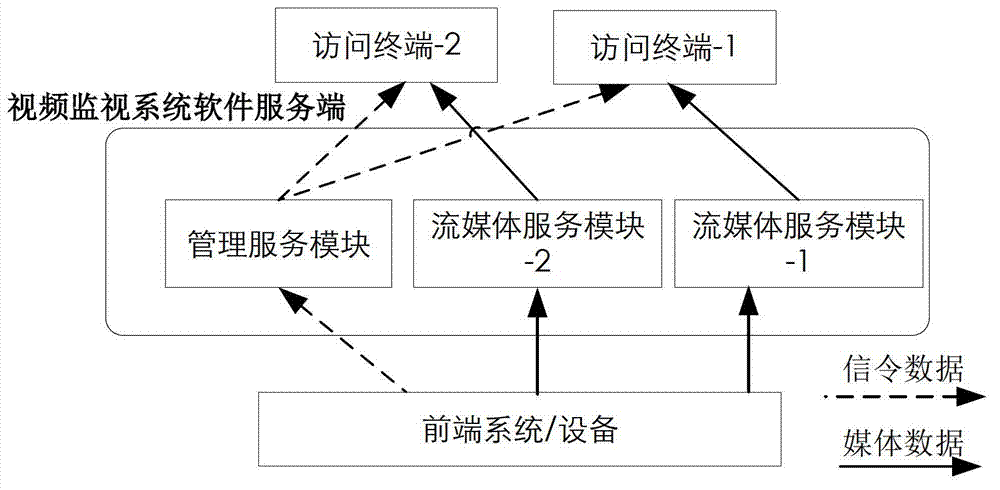

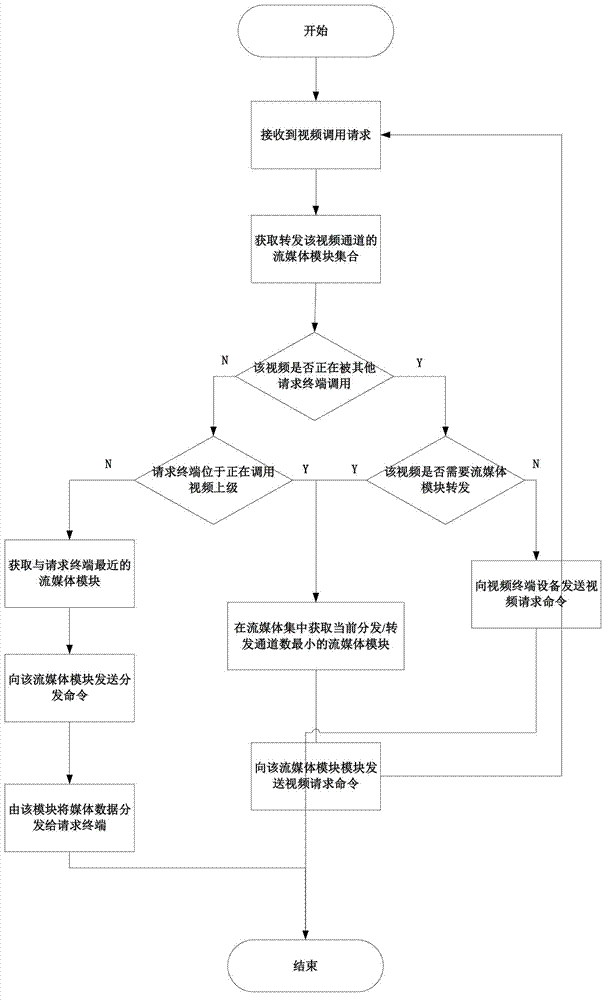

Media data access and scheduling system architecture design method based on multi-node cooperation

ActiveCN102857439ARealize call requirementsRealize load balancing functionSelective content distributionData switching networksThird partyData access

The invention discloses a media data access and scheduling system architecture design method based on multi-node cooperation. The multi-point cooperation and the unit type deployment of streaming media modules are realized through a management service module for processing signaling data and uniformly maintaining equipment of a system, and a plurality of streaming media service modules for distributing and forwarding media data, i.e. the plurality of streaming media service modules can be deployed at one same stage or an upper and lower stages so as to work cooperatively; the load balance of hardware equipment and network resources is solved effectively, the network resources are utilized maximally, the redundancy occupation of the network resources is avoided, the load balance of the system can be realized without adding third-party software or hardware, the cost on constructing the software and the hardware is reduced, and thus the method has a good application prospect.

Owner:STATE GRID ELECTRIC POWER RES INST +2

Electric rail sawing machine

InactiveCN105798381AIncrease the lengthReduce cutting densityMetal sawing devicesDrive wheelEngineering

The invention relates to railway laying and maintaining equipment, in particular to an electric rail sawing machine fast in cutting and long in service life. The electric rail sawing machine is characterized by comprising a rail clamping mechanism and a cutting mechanism; the cutting mechanism is installed on the rail clamping mechanism; the rail clamping mechanism comprises a rack, a steel rail clamp and a lifting device; the steel rail clamp is fixed to the bottom of the rack; the lifting device is connected with the top of the rack; and the cutting mechanism and the lifting device are connected and installed. By means of the electric rail sawing machine, the rail clamping mechanism is used for making the electric rail sawing machine fast move on a steel rail and clamping the steel rail during work, and the cutting quality is improved; and in addition, the manner of combining drive wheel, a driven wheel set and tensioning wheels is adopted, unidirectional movement of a cutting saw blade is matched, the cutting density of the cutting saw blade in unit length is effectively reduced, fast cooling of the cutting saw blade in unit length is facilitated when cutting is not conducted, and the purpose of prolonging the service life is achieved.

Owner:昆明奥通达铁路机械有限公司

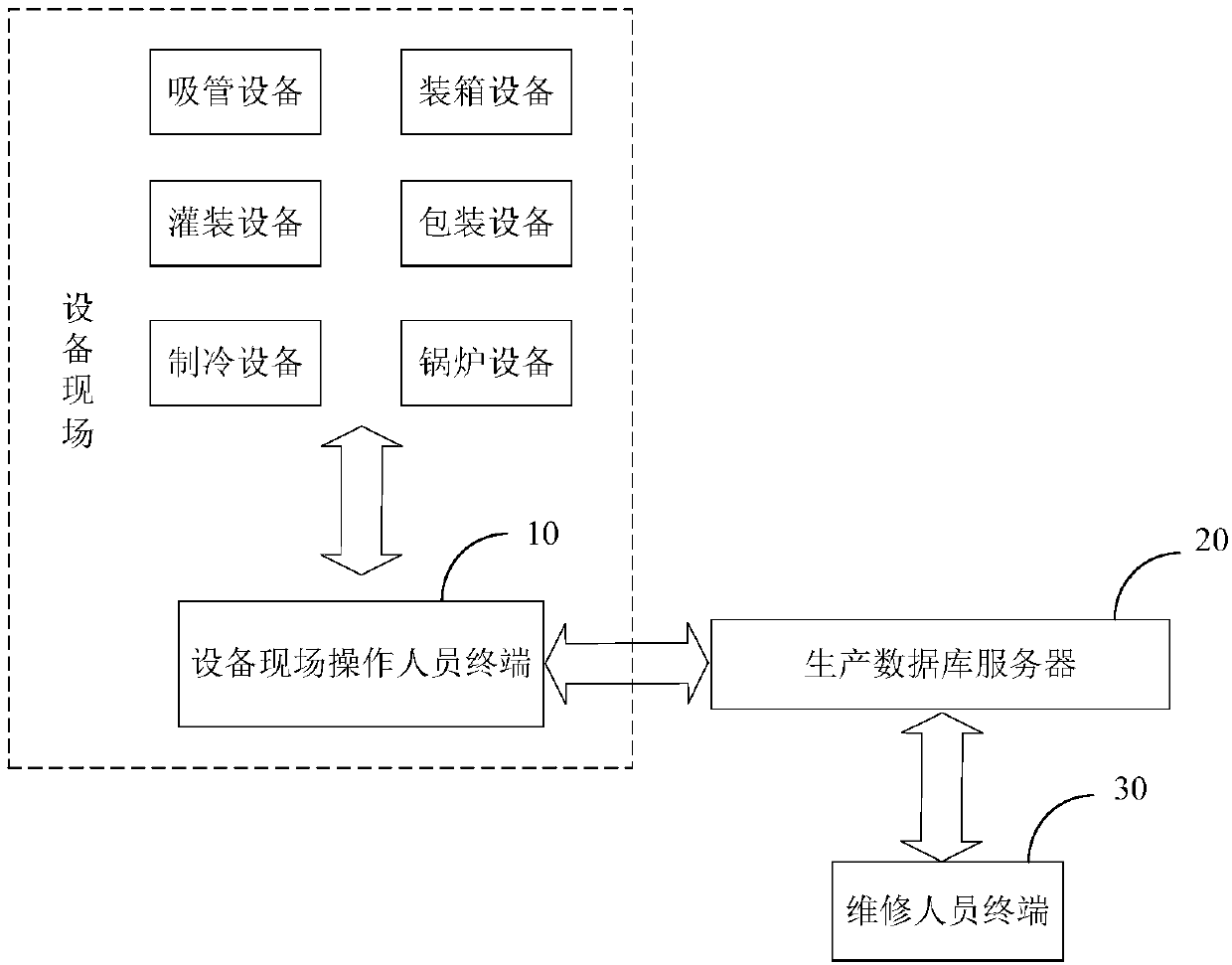

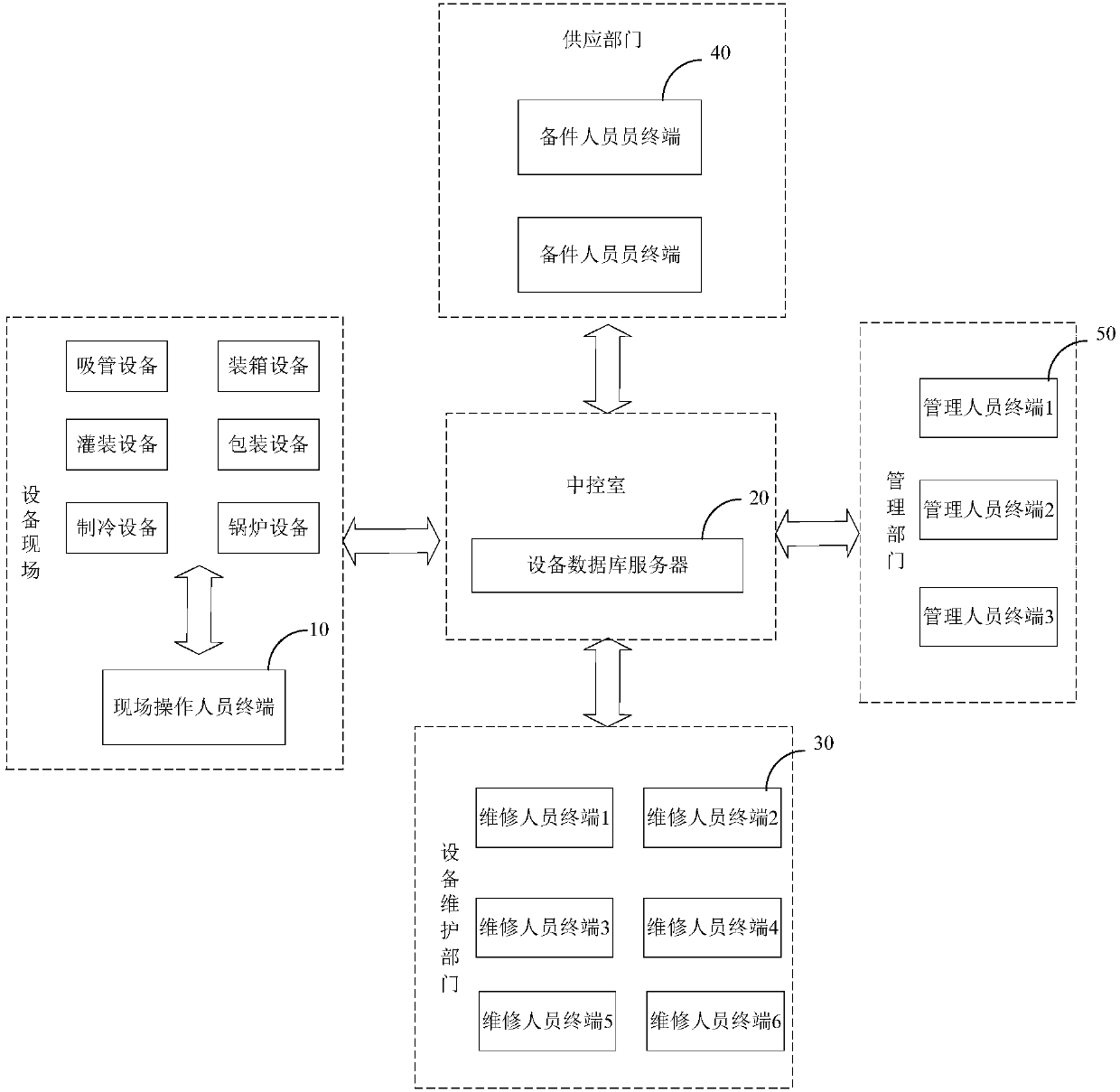

Factory equipment processing system, equipment database server and method

InactiveCN109862048AImprove maintenance efficiencyIncrease productivityTransmissionInstrumentsDatabase serverComputer terminal

The invention provides a factory equipment processing system, equipment database server and a method, The system comprises: an equipment field operator terminal, which is used for receiving a to-be-maintained equipment fault signal and to-be-maintained equipment information when the equipment has a fault, and sending the to-be-maintained equipment fault signal and the to-be-maintained equipment information to an equipment database server after receiving a repair request instruction input by the equipment field operator; equipment database server which is used for generating a maintenance workorder according to the to-be-maintained equipment fault signal and the to-be-maintained equipment information; Generating a fault solution of the to-be-maintained equipment according to the to-be-maintained equipment fault signal and the relation between the equipment fault signal and the fault solution, and sending the maintenance work order and the fault solution of the to-be-maintained equipment to a maintenance personnel terminal; And a maintenance personnel terminal which is used for displaying the maintenance work order and the fault solution of the to-be-maintained equipment. Accordingto the technical scheme, the maintenance efficiency is improved, and the labor cost is reduced.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

Waterproof coiled material laying tool

ActiveCN110924608AEasy waterproof maintenanceImprove waterproof repair speedBuilding repairsRoof toolsElectrical batteryElectric machine

The invention relates to the field of building maintenance equipment and tools, in particular to a waterproof coiled material laying tool. The number of supporting plates is two and the two supportingplates are placed in parallel; a storage roller, a battery, an electrode fixing shell, a floor sweeping motor, a synchronous belt, a motor fixing base, a cleaning wheel, an adjusting wheel and a compacting wheel are located between the two supporting plates; the battery, the electrode fixing shell and the floor sweeping motor are placed at the upper end of the motor fixing base, and the floor sweeping motor is connected with the cleaning wheel through the synchronous belt in a transmission mode; a fastening motor is located at the upper end of a connecting plate, the connecting plate is fixedto the supporting plates, a sliding rod is fixed to the lower end of the connecting plate, and a sliding block is matched with the sliding rod; and a rotary wheel is connected with a motor shaft of the fastening motor, a convenient tool for waterproof repair of a building roof can be provided, the current problem of manually laying waterproof cloth can be solved, and the roof waterproof repair speed is improved.

Owner:YIWU INDAL & COMMERICAL COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com