Patents

Literature

431results about How to "Solve slippage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

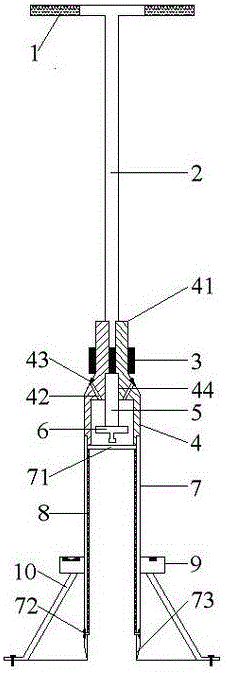

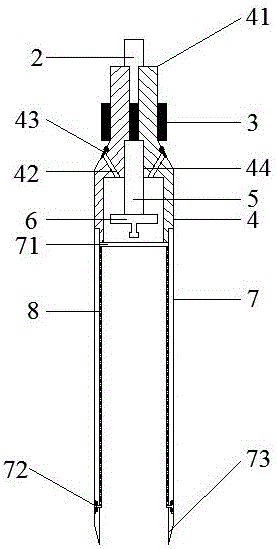

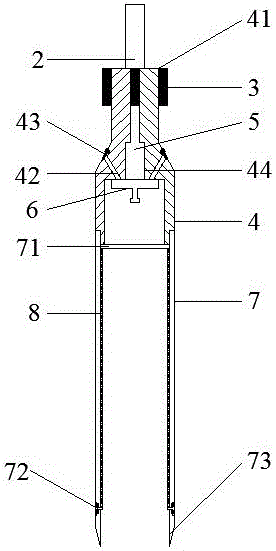

Portable shallow soft soil original state sampling device and sampling method

InactiveCN106769177APrevent slippingQuality assuranceWithdrawing sample devicesSurface layerEngineering

The invention discloses a portable shallow soft soil original state sampling device and a sampling method. A solution is provided for solving the problems that soft soil with a high water content is likely to fall along the inner wall of a sampler, an original state soil column is easily disturbed in repairing, separating and post-treating processes, and the inner cavity of the sampler is difficult to clean and the like. The sampling device comprises the sampler, a positioner and a separator. Smooth sampling is realized through a sampling rod, a steering base, a force transfer base and a sampling barrel; a negative pressure is generated in the inner cavity of the force transfer base by virtue of a piston and a baffle plate, so that a soil sample is prevented from falling. By opening out a liner pipe and the separator, the soil column is repaired, separated and packaged. The method comprises the following steps: removing miscellaneous soil in the surface layer, assembling the sampling device, and pressing the sampler into a specific depth; then lifting up the sampling rod to close the inner cavity of the force transfer seat; and screwing the sampler out, detaching the sampling barrel, pushing the liner pipe out by using the separator and performing packaging with a cover. The device disclosed by the invention is simple in structure, convenient to operate, small in sampling disturbance and high in efficiency.

Owner:JILIN UNIV

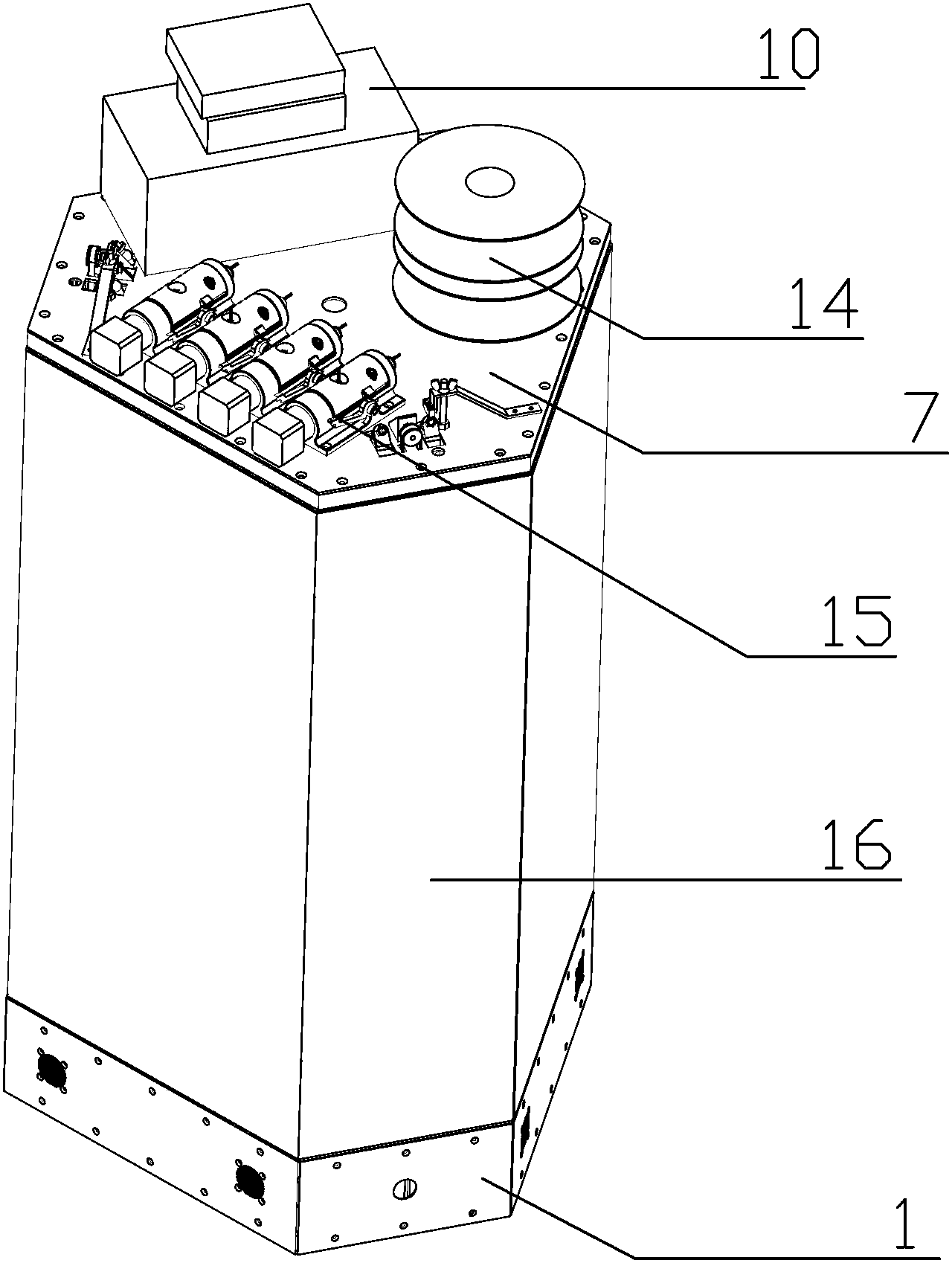

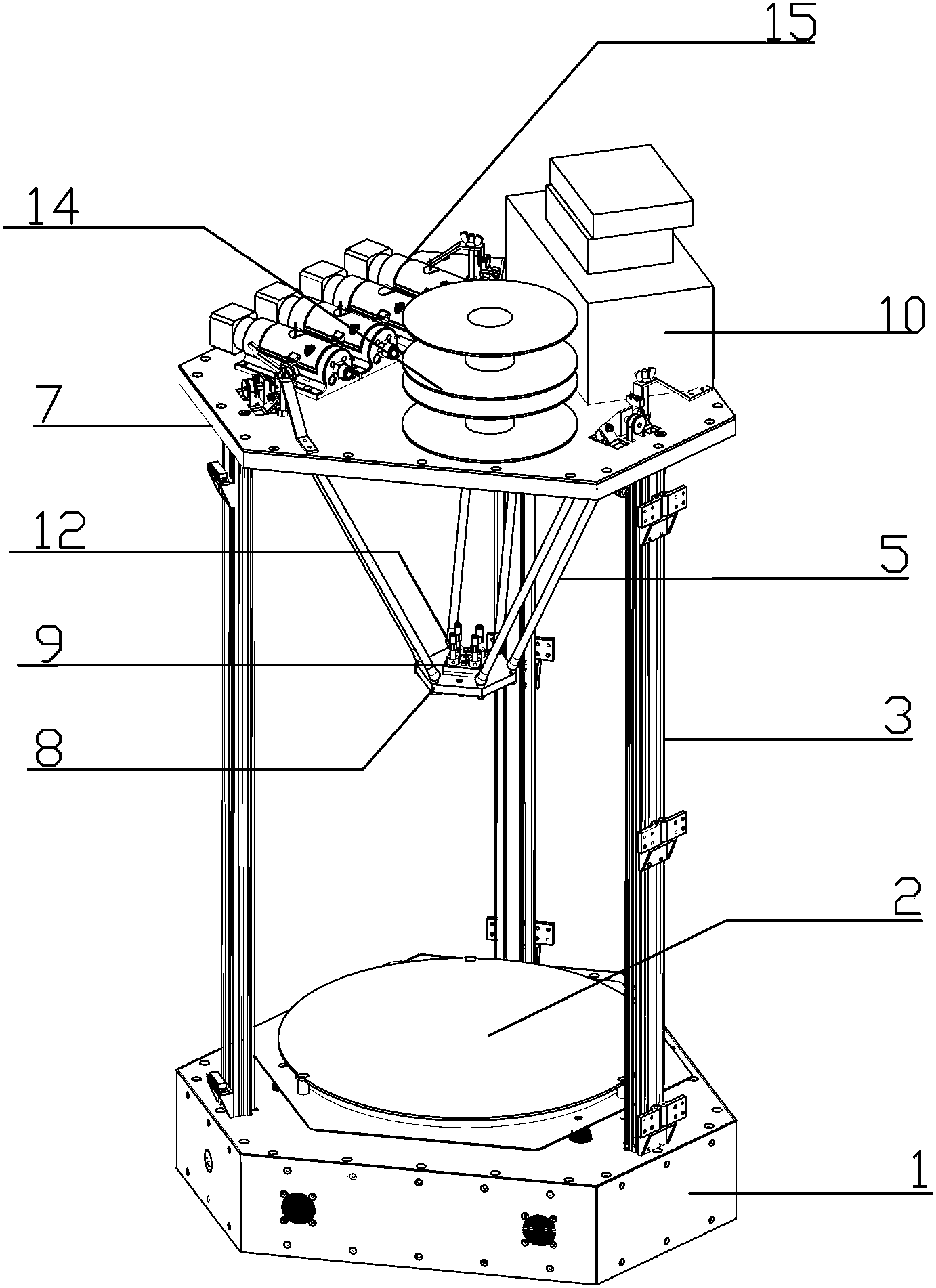

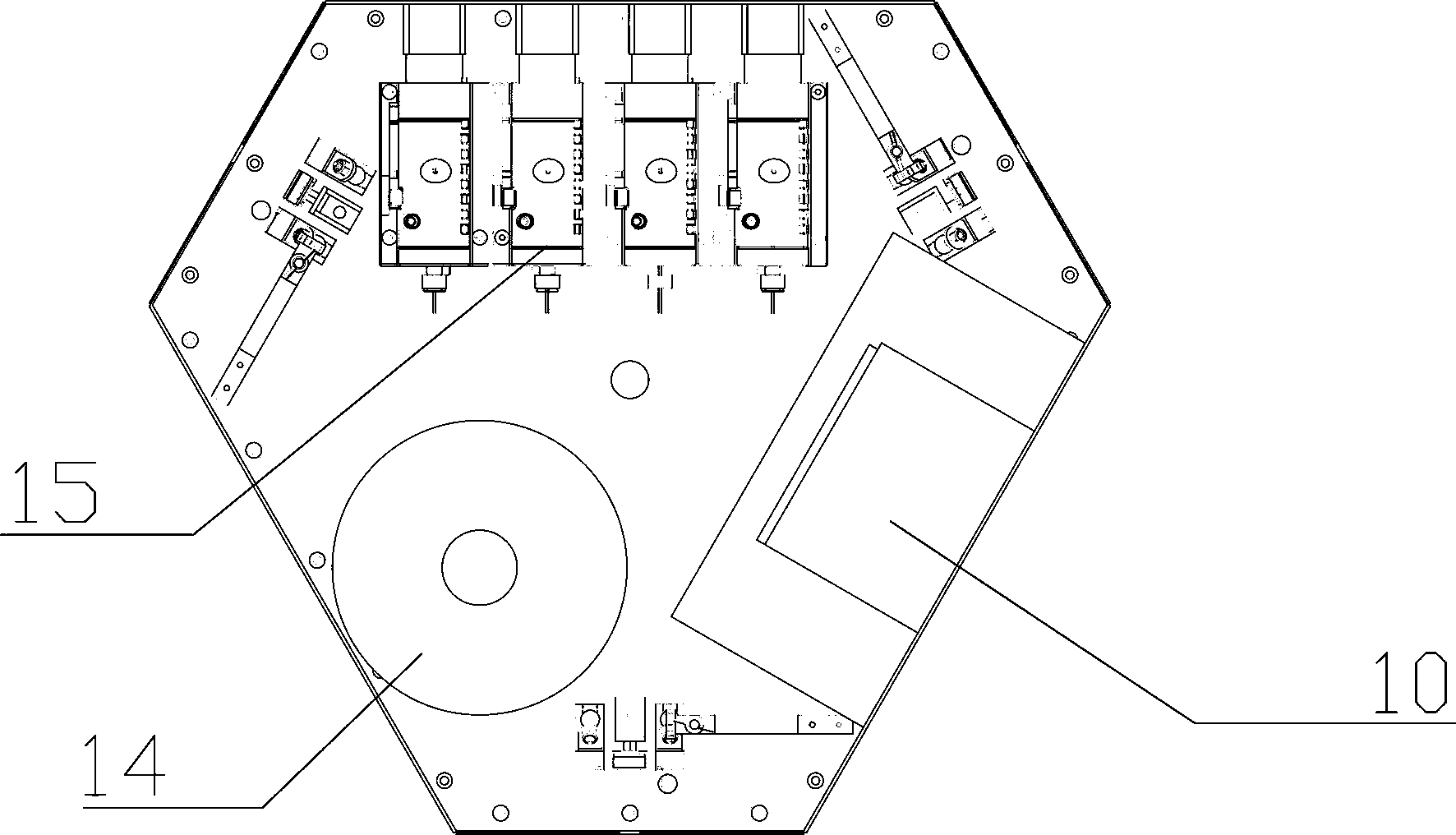

3D printer

The invention relates to a 3D printer based on a fusion accumulation rapid-forming process. The 3D printer is characterized by comprising a transmission mechanism, a worktable, a feeding mechanism and an isolating device. By utilizing a specific driving wheel and driven wheel and line transmission fit manner, the friction coefficient is increased, the problem that a belt wheel slips in a belt transmission process is solved, and transmission motion is accurate and reliable.

Owner:朱兴建

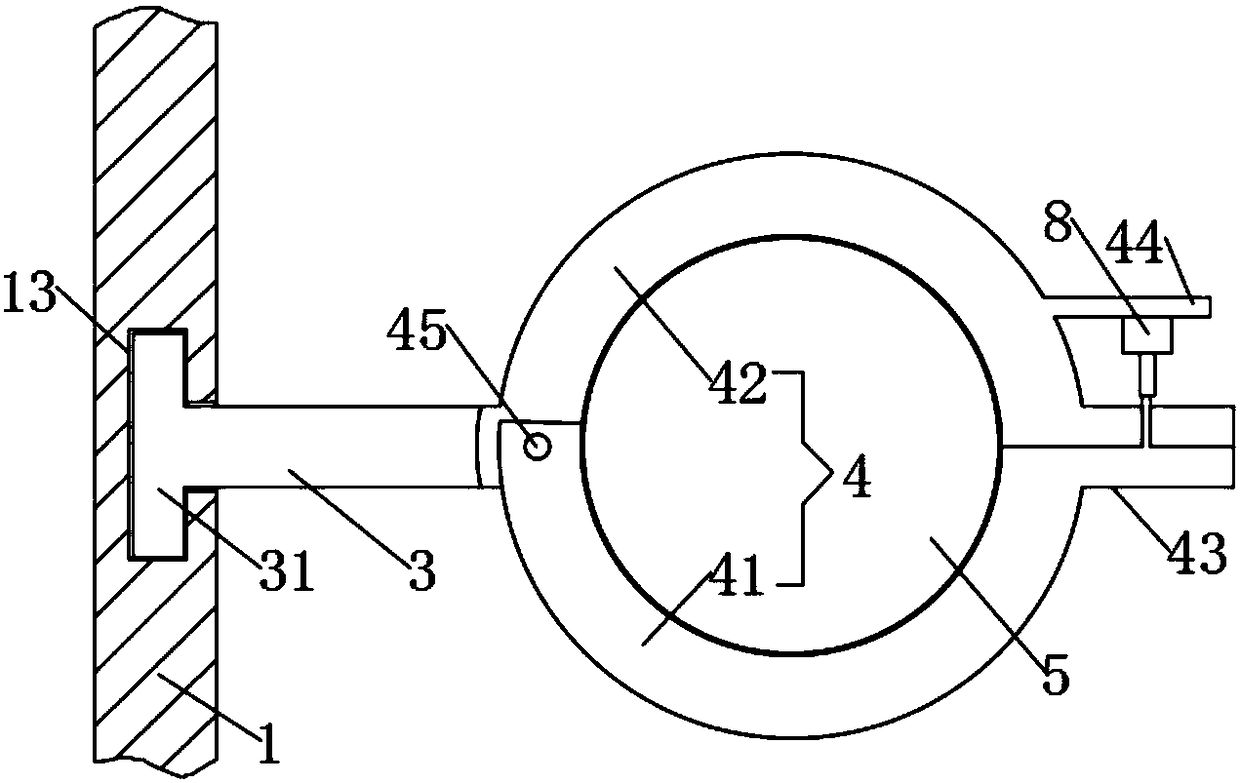

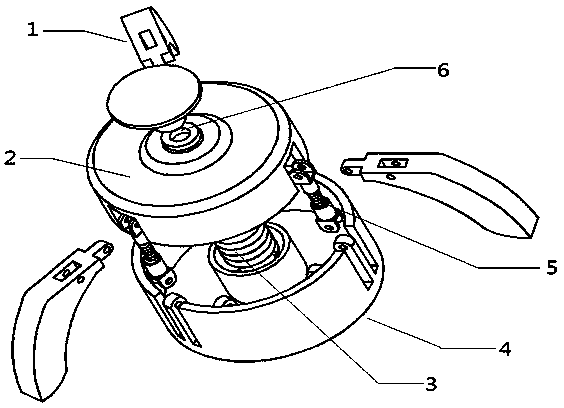

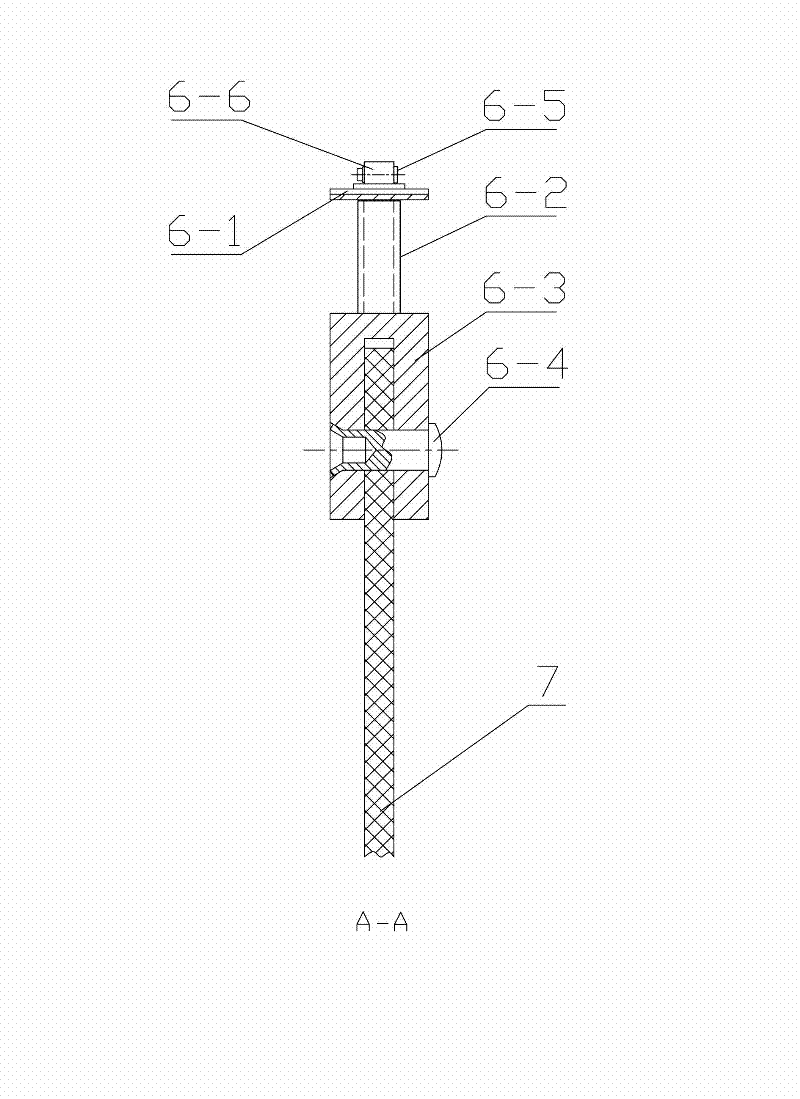

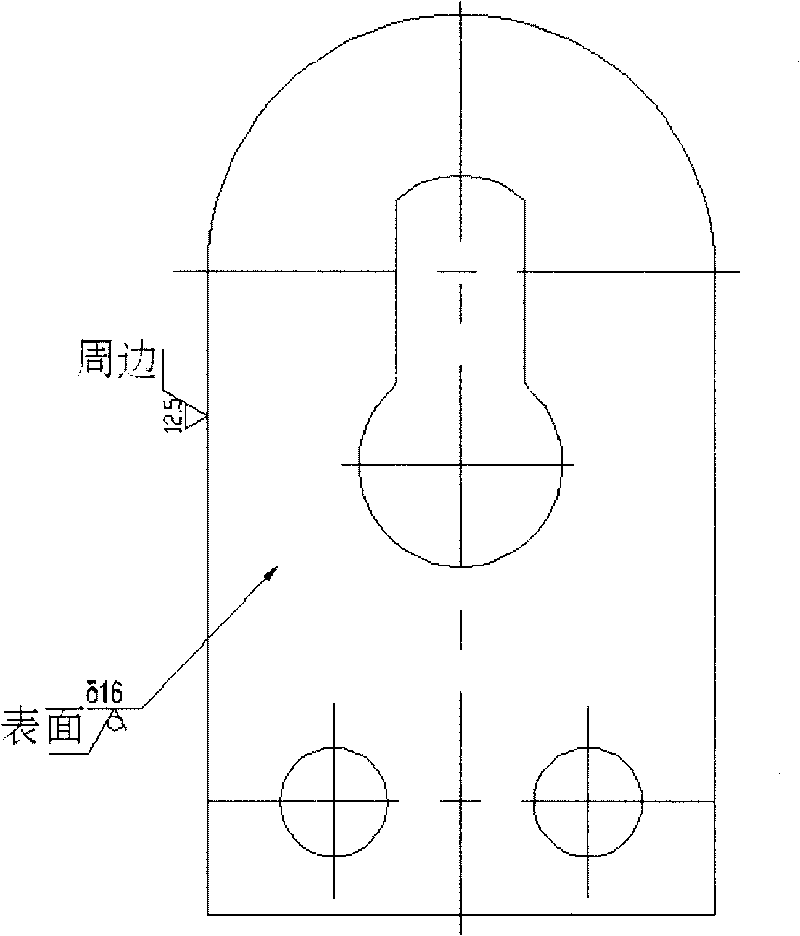

Combined mechanism of ratchet of high-voltage-cable walking robot

ActiveCN102259341AImprove driving abilityEasy to walkProgramme-controlled manipulatorGripping headsMotor drivePositive pressure

The invention relates to a combined mechanism of a ratchet of a high-volatage-cable walking robot. The combined mechanism is characterized by comprising a wheel type walking mechanism and claw-type clamping mechanisms, wherein the wheel type walking mechanism is used for walking on a high-voltage cable, the claw-type clamping mechanisms are used for clamping the high-voltage cable and provides positive pressure, the wheel type walking mechanism and the claw-type clamping mechanisms are arranged on a robot frame, and the claw-type clamping mechanisms are used in pairs. The combined mechanism disclosed by the invention utilizes a principle of an under-actuated mechanism, and two motion manners of rotation and movement are realized through one motor-driven clamping mechanism; through a self locking mechanism, the clamping mechanism is automatically locked after closed, thus the energy consumption is reduced; and the invention has the advantages of small and novel structure, high clampingefficiency and wide application range.

Owner:昆山市工业技术研究院有限责任公司

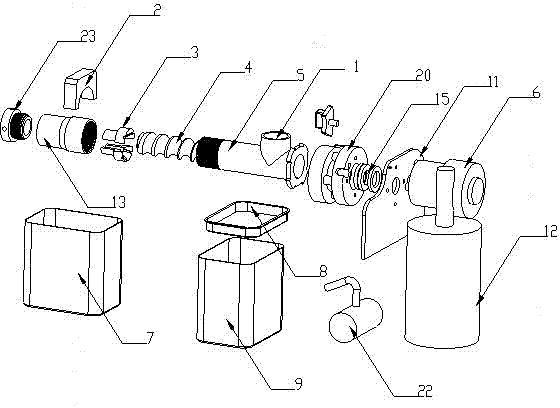

Household two-level pressing low temperature oil press

InactiveCN102774029AAchieving secondary pressingImprove oil yieldPressesReduction driveElectric machine

The invention relates to a household two-level pressing low temperature oil press. The oil press comprises an oil press base, a pressing mechanism and a driving mechanism, the pressing mechanism is installed on the oil press base, the driving mechanism is used for providing motive power for the pressing mechanism, the pressing mechanism includes a barrel, a pressing head, a pressing shaft and a pressing head casing, the barrel is provided with a feed port and an oil outlet, one end of the barrel is connected with the oil press base, the pressing head casing is connected with the other end of the barrel, one end of the pressing shaft is provided with screw threads and sleeved in a chamber formed by the barrel and the pressing head casing, the other end of the pressing shaft extends out of the barrel to serve as a rotating bar to be connected with the driving mechanism, the pressing head is installed in the pressing head casing, pressing space is formed by one side of the pressing head and one corresponding end of the pressing shaft, one or a plurality of material passing holes is / are arranged on the pressing head, one side surface of the pressing head where the pressing head is in a cut grafting with the pressing shaft is provided with a groove, one or a plurality of oil guide grooves which is / are communicated with the material passing holes is / are mounted on the wall surface of the groove, a heater is arranged on the pressing head casing or the barrel, and the driving mechanism and the heater are connected with a power supply. The driving mechanism includes a motor and a speed reducer which are disposed on the oil press base, and the speed reducer is in a transmission connection with a rotating shaft of the motor and the rotating bar of the pressing shaft. By means of the household two-level pressing low temperature oil press, the low temperature cold pressing can be achieved, the oil yield is high, the produced oil quality is good, and the oil press is easy to clean.

Owner:唐华

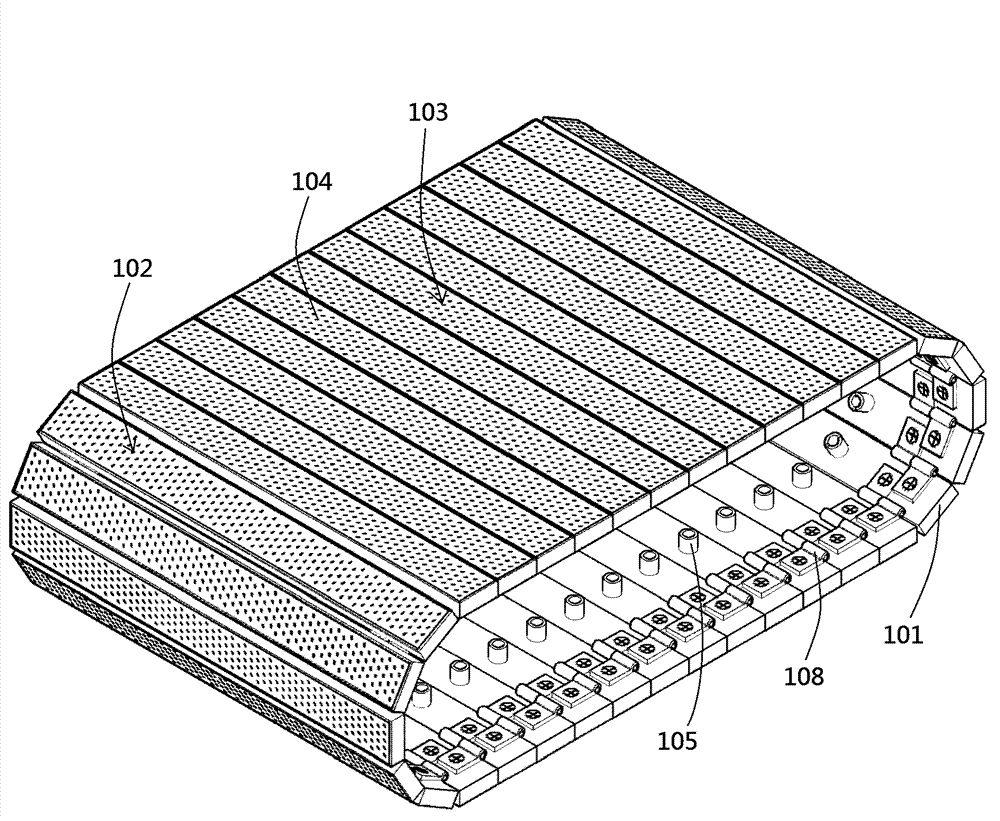

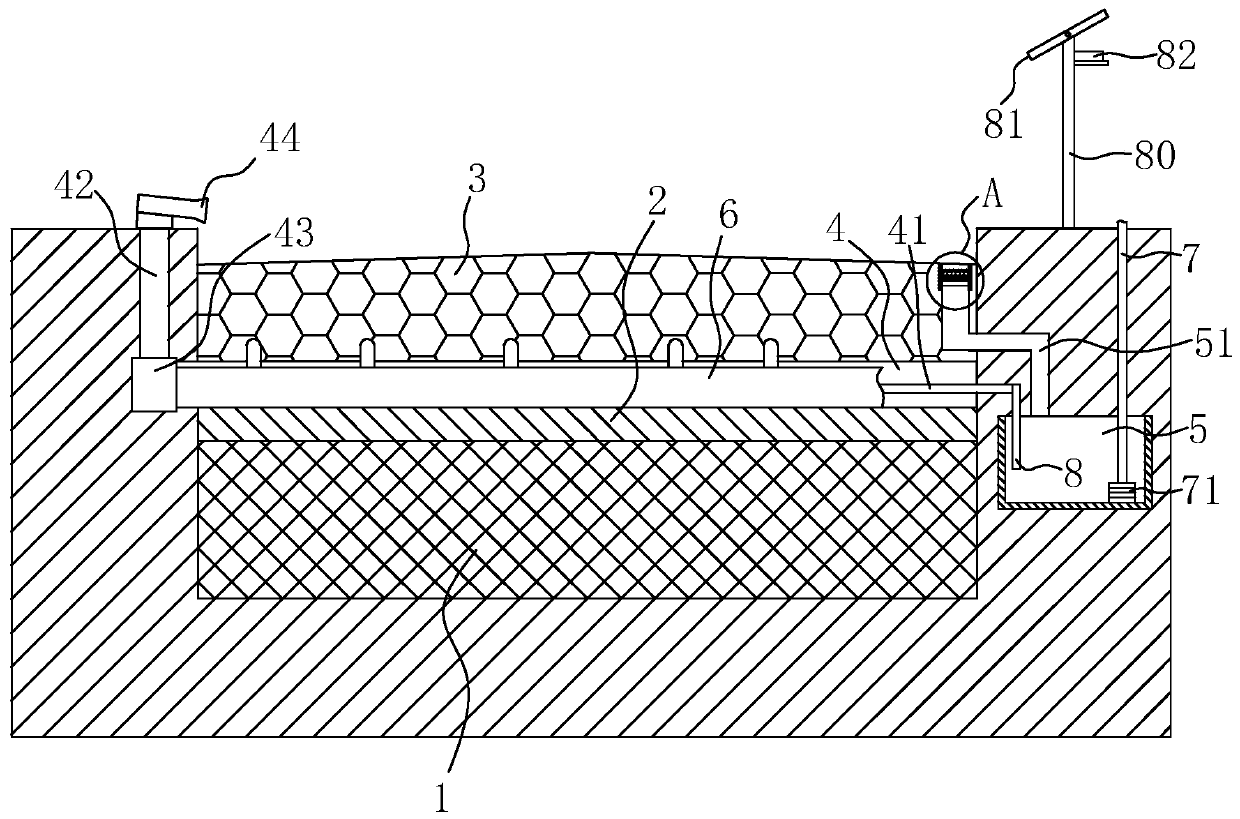

Vacuum absorption conveying belt

InactiveCN103523453AImprove transmission efficiencySolve slippage and deformationConveyorsEngineeringElectrical and Electronics engineering

The invention discloses a vacuum absorption conveying belt. An existing conveying belt does not have a vacuum absorption function. An existing absorption platform cannot achieve continuous conveying. According to the technical scheme, a plurality of vacuum absorption units are movably connected to form the conveying belt, the absorption planes of the vacuum absorption units are combined to form a vacuum absorption conveying object-carrying face, so that the vacuum absorption units have a continuous conveying function; or a penetrating air absorption hole is formed in the conveying belt, then a plurality of vacuum back shells are arranged on the back face of the hole, and the conveying belt has a vacuum absorption function. A limiting device, a transmission auxiliary device and a vacuum system are arranged, and accordingly vacuum absorption and continuous conveying are achieved at the same time.

Owner:晏石英

Preparation method of polyolefin microporous membrane

The invention provides a preparation method of polyolefin microporous membrane, comprising the following steps of: (1) mixing polyolefin resin and diluent according to the weight percent ratio of 10-60%:40-90%; (2) extruding and molding the mixture in an extrusion-blow molding manner to form bubble and cooling; (3) sizing the superposed and drawn membrane; (4) extracting diluent and drying; (5) performing transverse stretching and sizing treatment; and (6) rolling. By adopting the method of forming the bubble in a blow molding way, the invention avoids uneven structure caused by different cooling on the both surfaces in the casting process of general bidirectional stretching technique as well as uneven structure caused by slippage during longitudinal stretching, solves the problem of slippage of rollers during longitudinal stretching and ensures balanced longitudinal and transverse properties to finally obtain the polyolefin microporous membrane with even structure. Besides, the invention has the advantages of little investment, small occupation area, no slitter edge, easily-controlled production field, and the like.

Owner:SHENZHEN SENIOR TECH MATERIAL

Ceramic tile adhesive

The invention discloses ceramic tile adhesive, comprising the following components according to parts by weight: 300-400 parts of ordinary Portland cement, 50-100 parts of heavy calcium, 200-250 parts of 40-mesh to 70-mesh quartz sand, 350-400 parts of 70-mesh to 100-mesh quartz sand, 10-20 parts of redispersible emulsion powder, 4-8 parts of organosilicon water repellent, 2-3.5 parts of cellulose, 1-1.5 parts of lignocellulose and 1-2 parts of polyvinyl alcohol. The ceramic tile adhesive has high adhesive powder and low plasticity, is good in constructability and is resistant to aging.

Owner:江苏蓝圈新材料股份有限公司

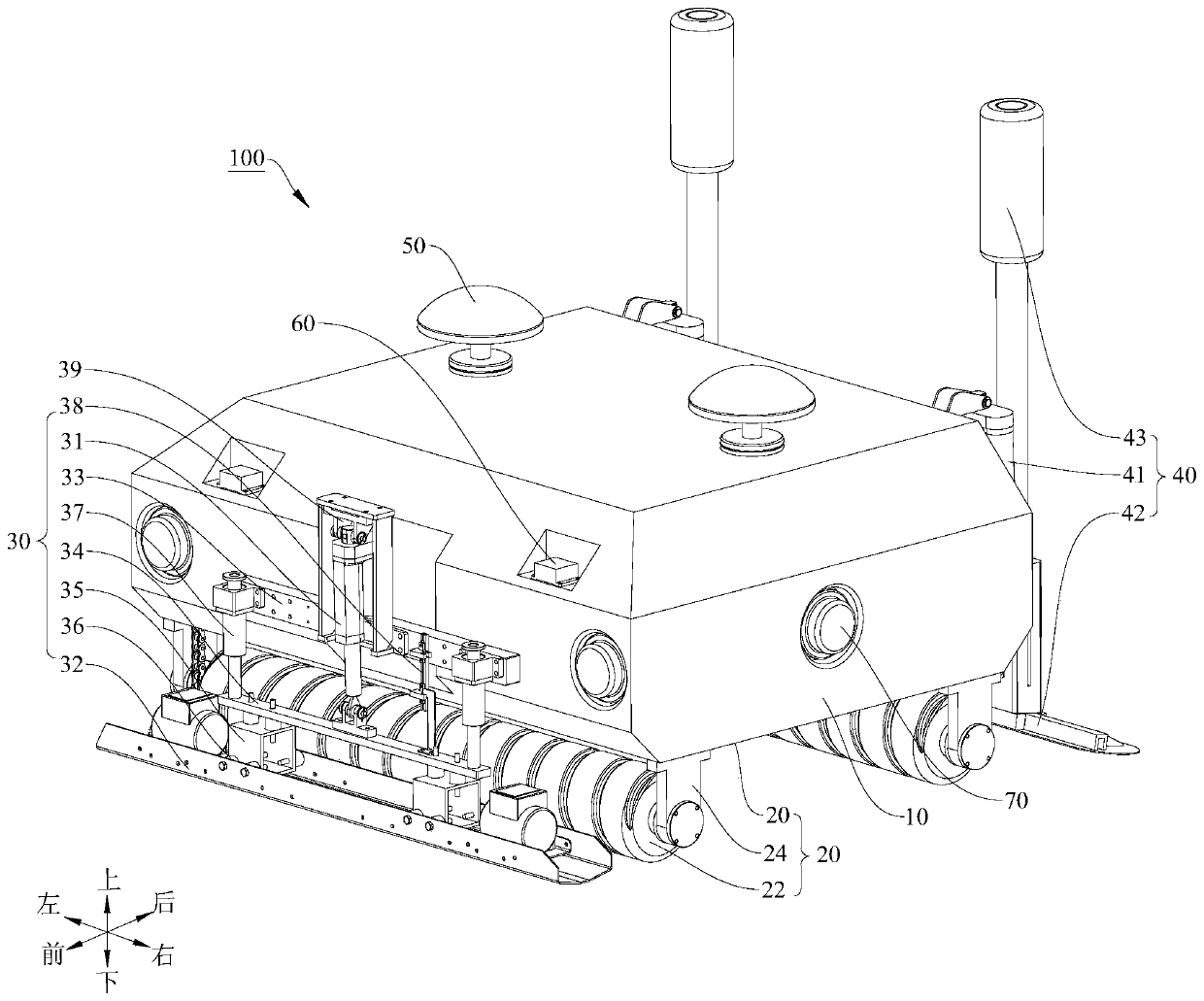

Leveling robot

ActiveCN110924686ARealize unmanned operationReduce manual operationsBuilding material handlingPath planManual handling

The invention discloses a leveling robot. The leveling robot comprises a chassis, a walking mechanism, a pulp lifting mechanism, a leveling mechanism and a navigation control module, wherein the walking mechanism is arranged on the chassis; the walking mechanism comprises a chassis and a roller; the roller is arranged on the chassis in a pivoted mode; a spiral groove in threaded extension around the axis of the roller is arranged on the surface of the roller; the pulp lifting mechanism comprises a first lifting piece and a vibration plate; the first lifting piece is connected with the vibration plate; the leveling mechanism comprises a second lifting piece, a scraper and a pavement detecting piece; the second lifting piece is connected with the scraper; the pavement detecting piece is electrically connected with the second lifting piece; and the navigation control module is arranged on the chassis for realizing the path planning and controlling the leveling robot to operate. The invention provides a new realization method for leveling treatment of concrete casting construction surfaces in the building industry, and facilitates realization of unmanned operation in the construction environment. The whole robot can save a lot of manual operations, and is low in labor intensity, low in cost and high in efficiency.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

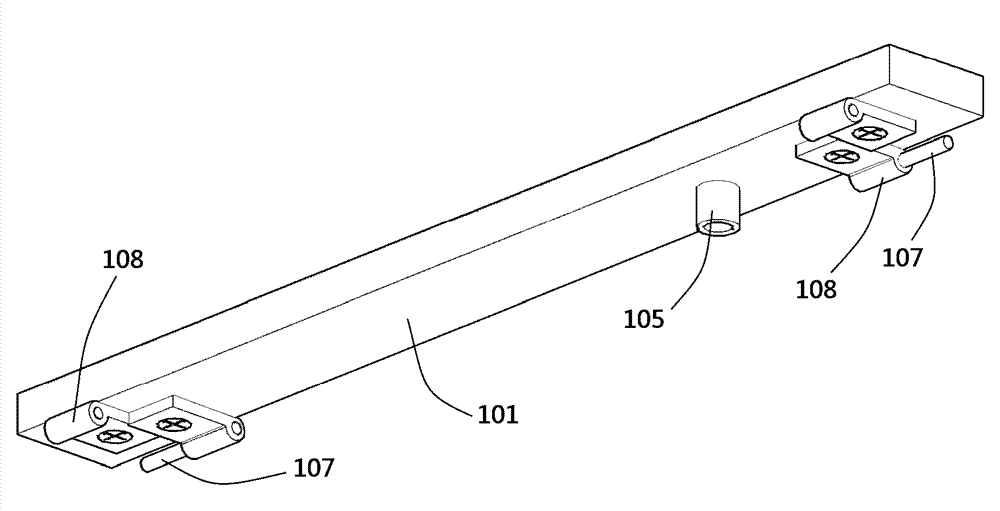

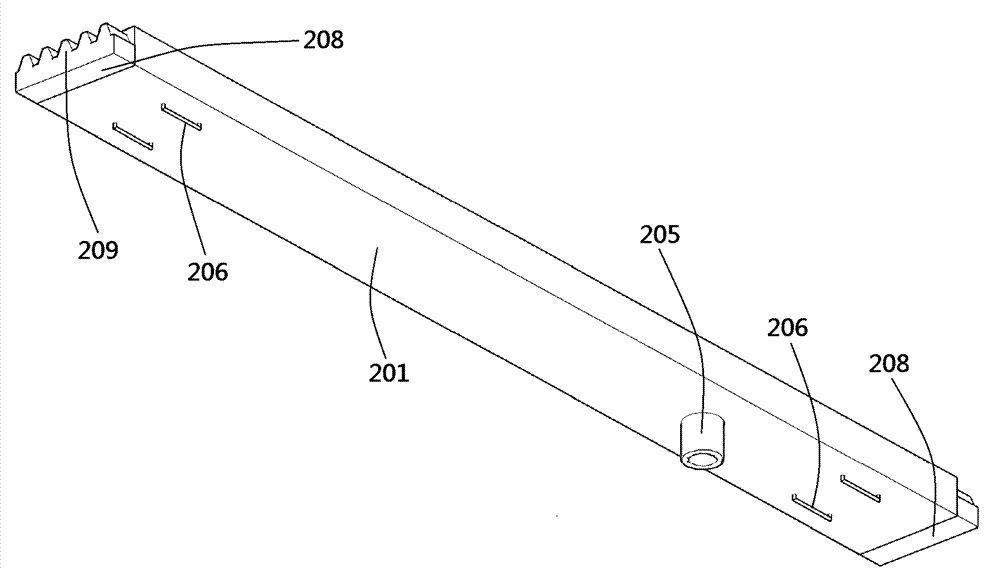

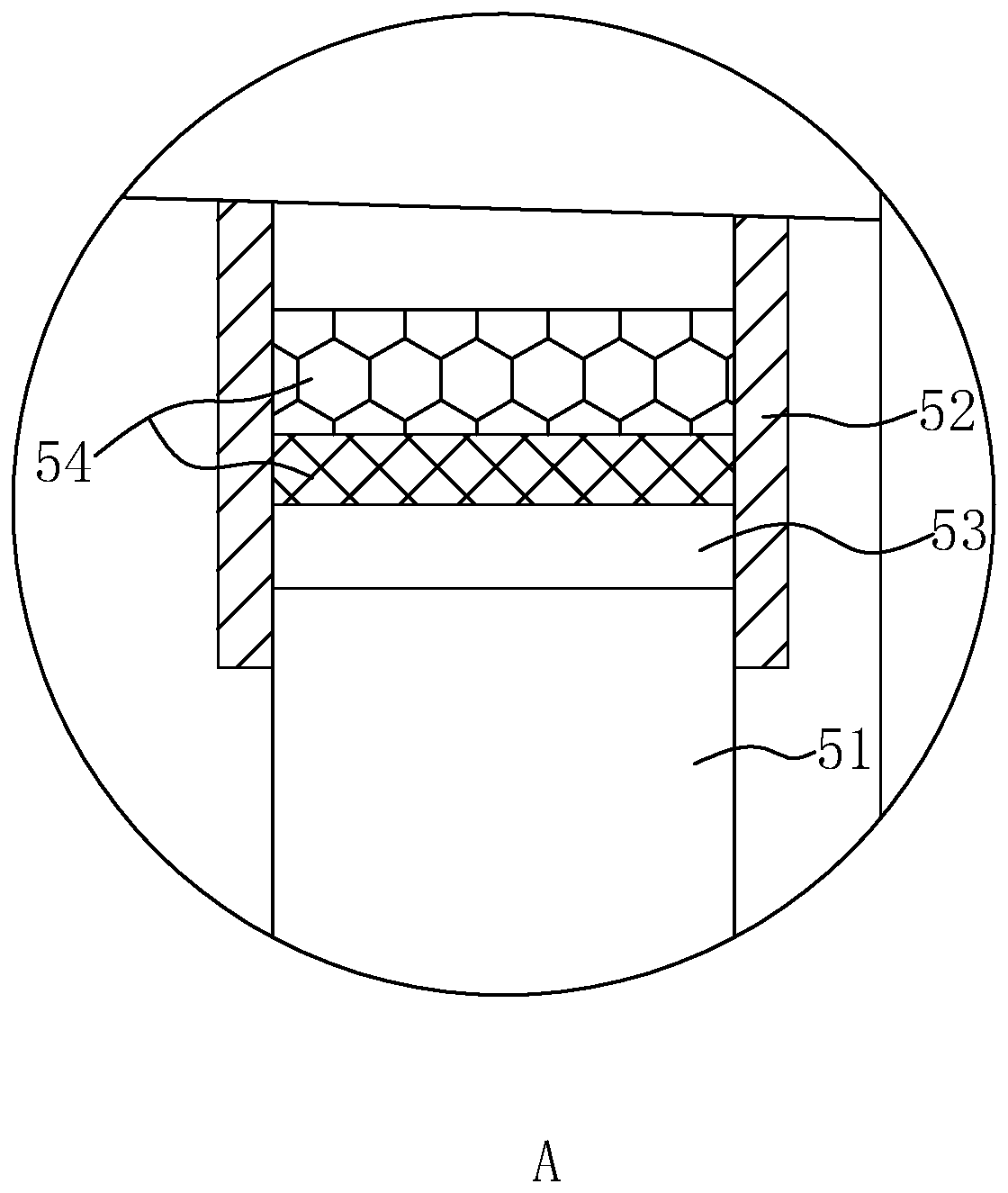

Belt conveyor slippage and fracture detection device

InactiveCN105501886ASolve slippageIncrease the level of automationControl devices for conveyorsMotor controllerControl theory

The invention relates to the technical field of belt transportation, and especially relates to a belt conveyor slippage and fracture detection device. The belt conveyor slippage and fracture detection device comprises a drive roller rotating speed sensor used for detecting the rotating speed of a drive roller; and a driven roller rotating speed sensor used for detecting the rotating speed of a driven roller. The drive roller rotating speed sensor and the driven roller rotating speed sensor send detected signals to a PLC controller, the output terminal of the PLC controller is connected with a motor controller, and the motor controller controls and drives a motor to work. The belt conveyor slippage and fracture detection device is advantaged in that the device is simple in structure and convenient to install, and monitoring of belt conveyor slippage and fracture is effectively achieved.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

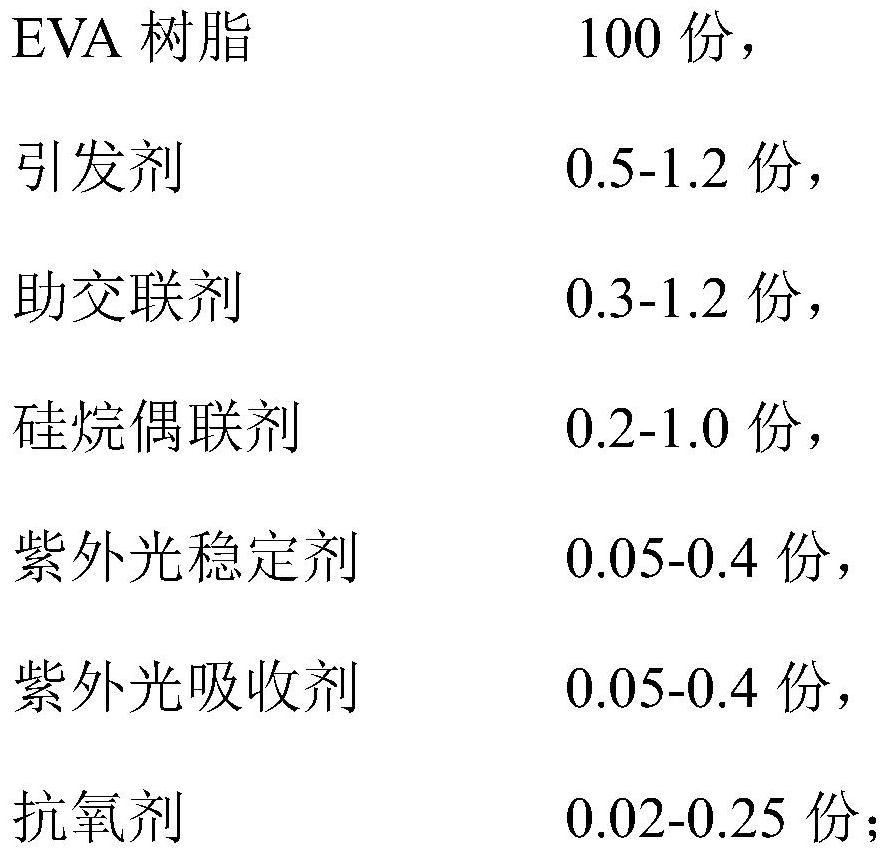

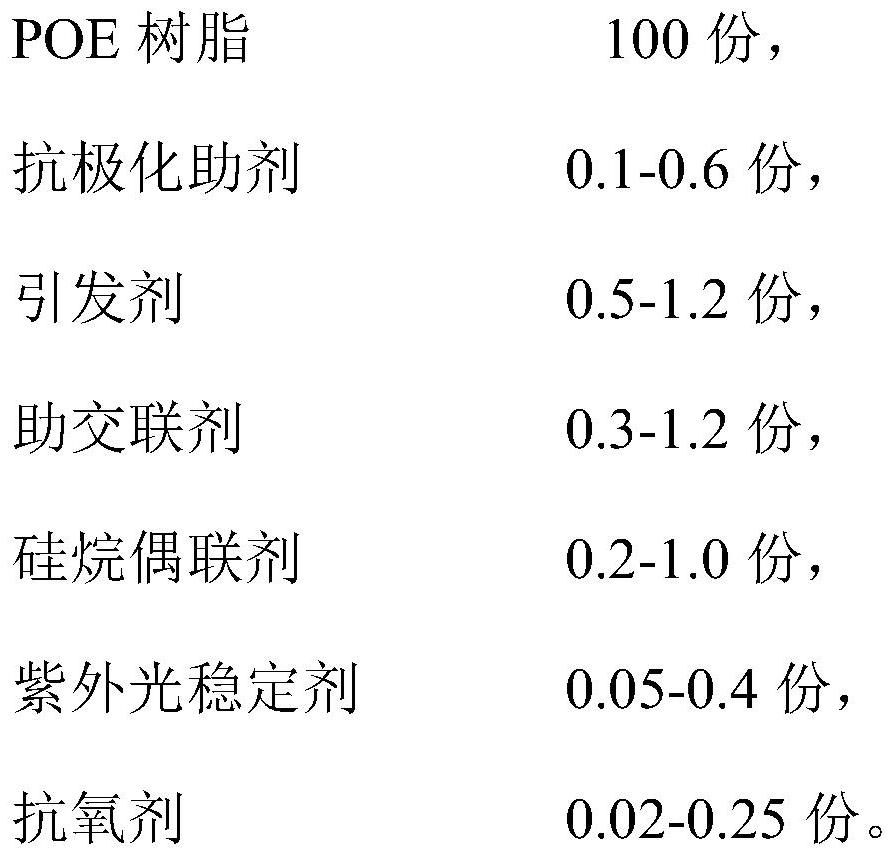

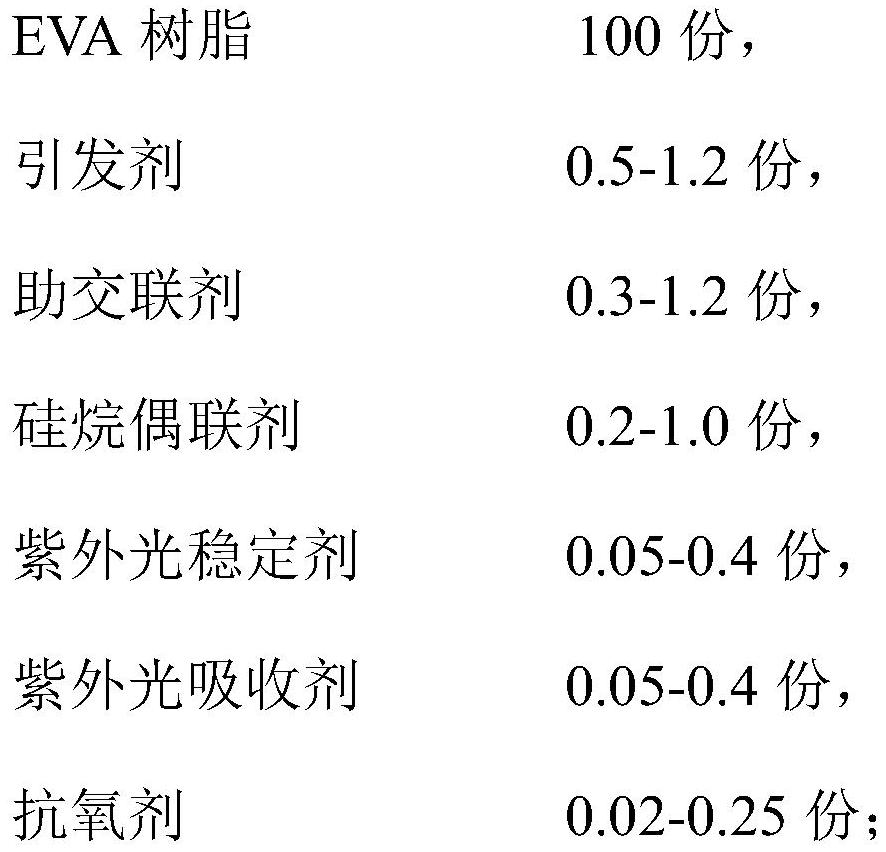

Three-layer co-extrusion composite adhesive film for packaging photovoltaic module and preparation method thereof

PendingCN111793442AGood compatibilitySolve the bubblesNon-macromolecular adhesive additivesFilm/foil adhesives without carriersPolymer scienceTransmittance

The invention relates to the technical field of photovoltaic module packaging adhesive films, in particular to a three-layer co-extrusion composite adhesive film for packaging a photovoltaic module and a preparation method thereof. The composite adhesive film comprises EVA layers, a POE anti-polarization layer and an EVA layer which are sequentially arranged from top to bottom, wherein EVA resin has a melt flow rate of 5 g / 10 min-30 g / 10 min, light transmittance of larger than 85%, volume resistivity of larger than or equal to 1.0 * 10<14>, melting temperature of 30-80 DEG C, and VA content of5-30%; POE resin has a melt flow rate of 3 g / 10 min-20 g / 10 min, light transmittance of greater than 86%, volume resistivity of greater than or equal to 1.0 * 10<15> and melting temperature of 30-80DEG C. The EVA layers are adopted on the two sides of the composite adhesive film, the compatibility of the EVA layers and polar auxiliaries is good, and the problems of bubbles, slippage and piece combining during assembly laminating can be solved.

Owner:CHANGZHOU SVECK PHOTOVOLTAIC NEW MATERIAL

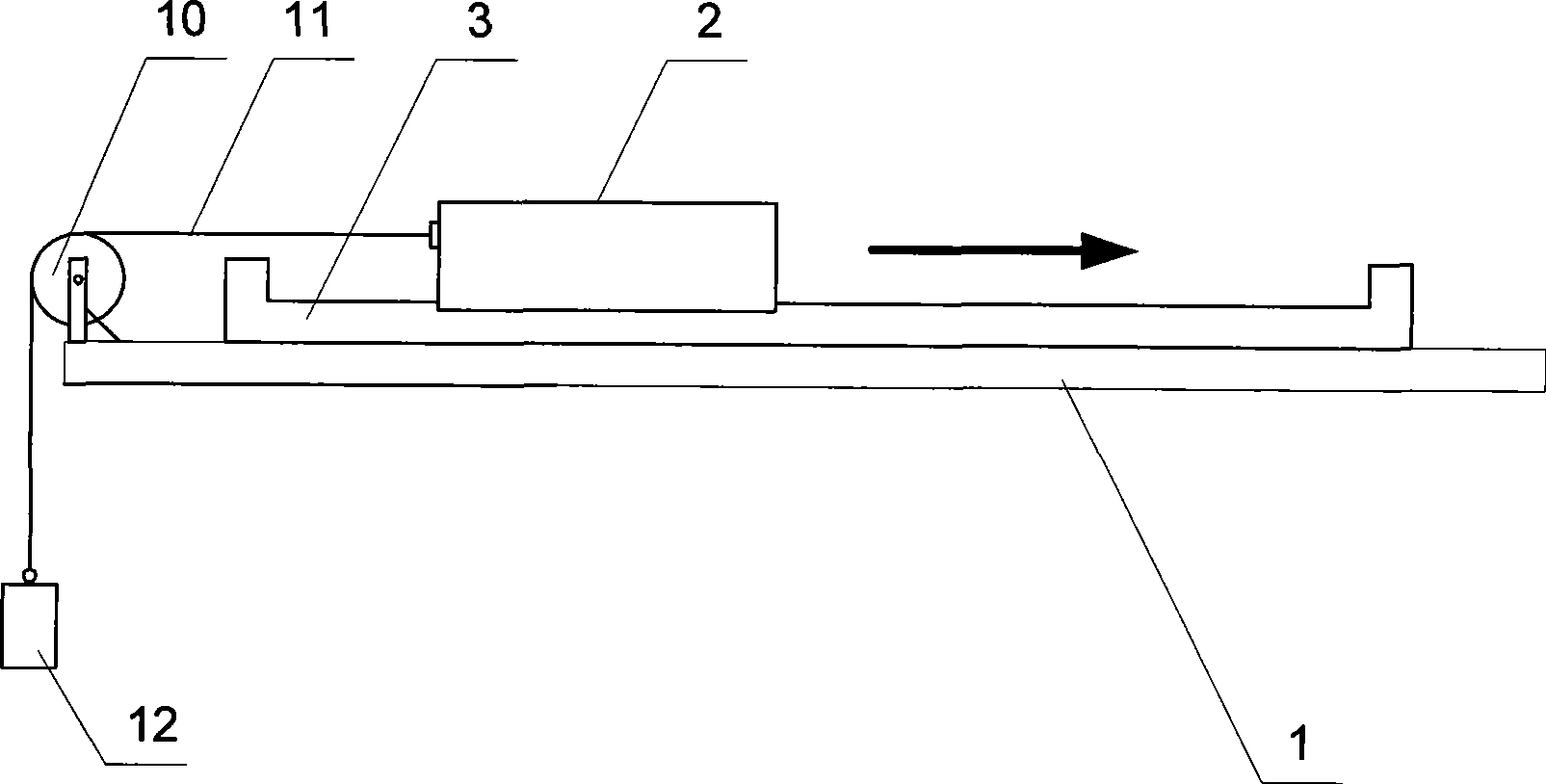

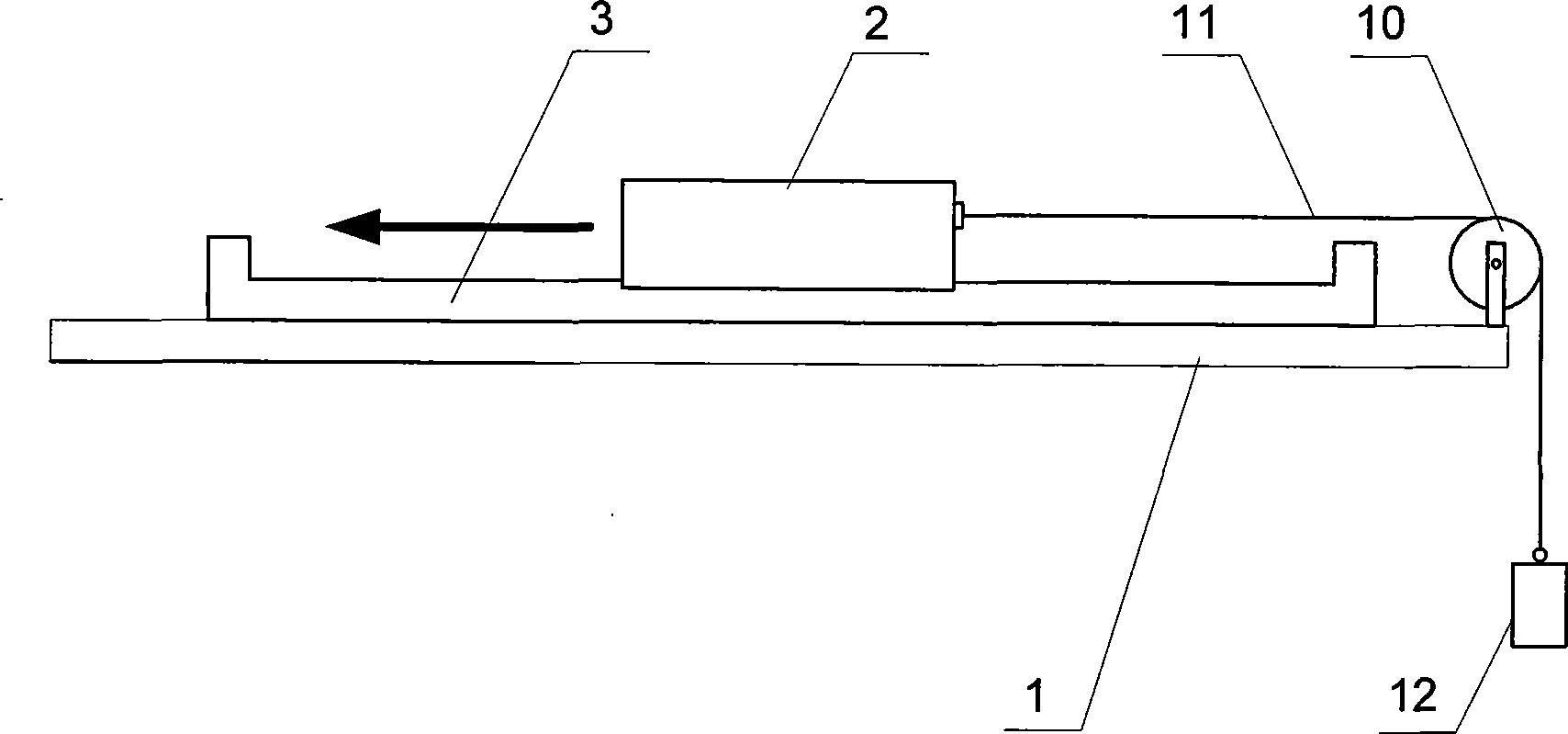

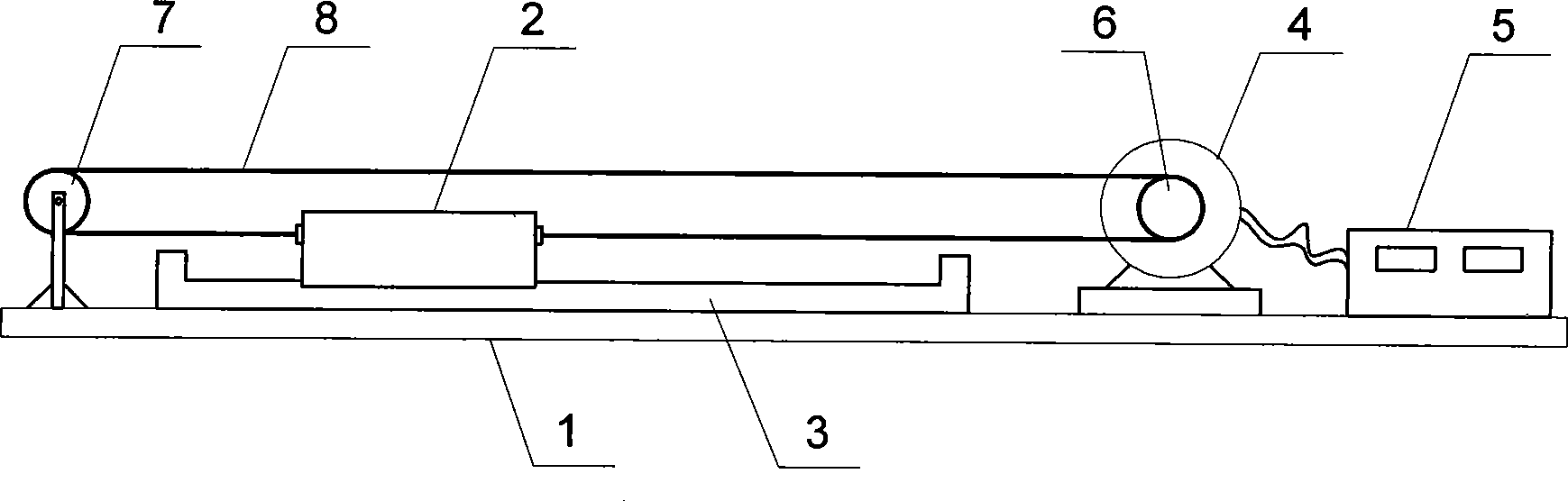

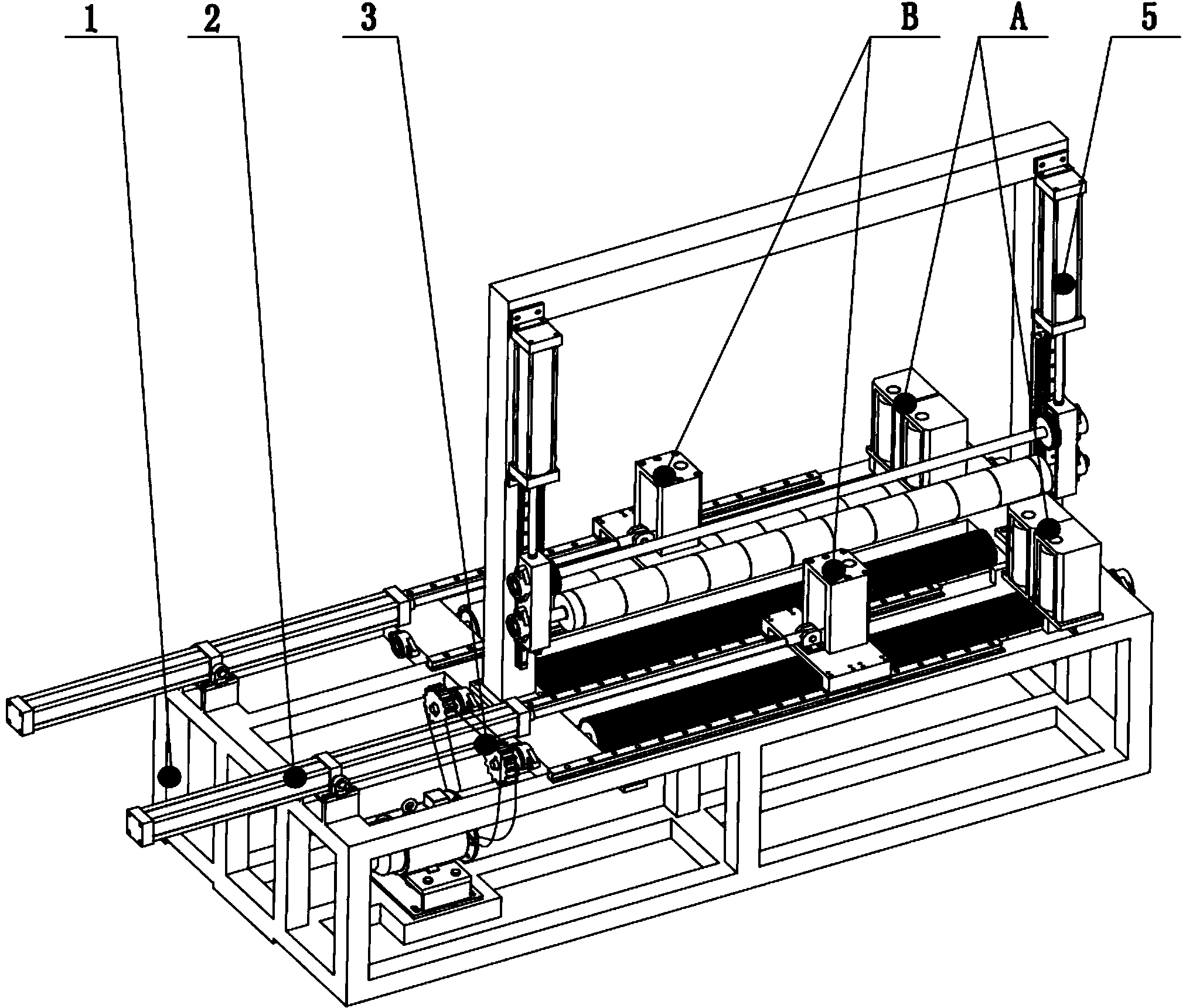

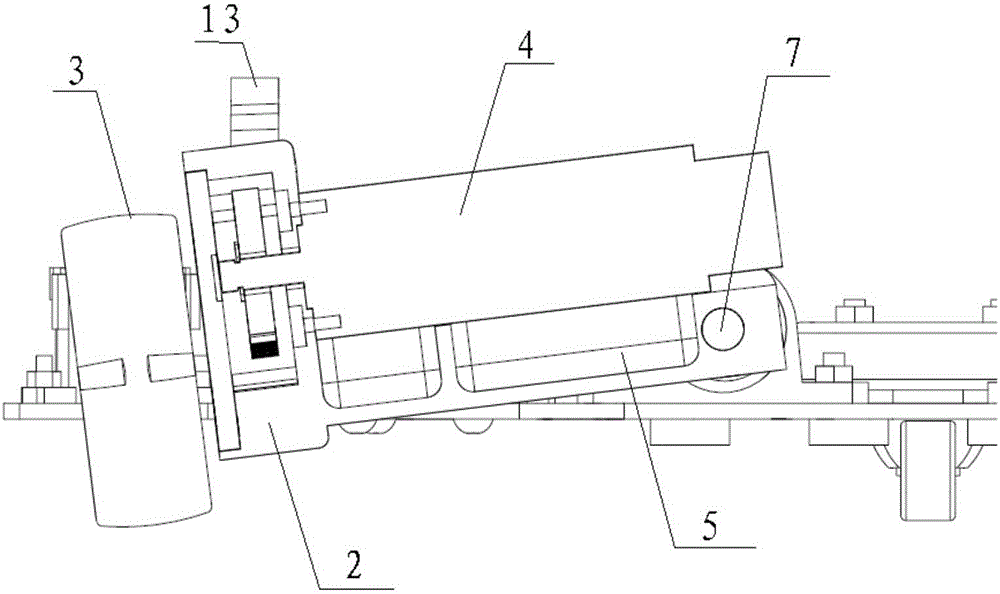

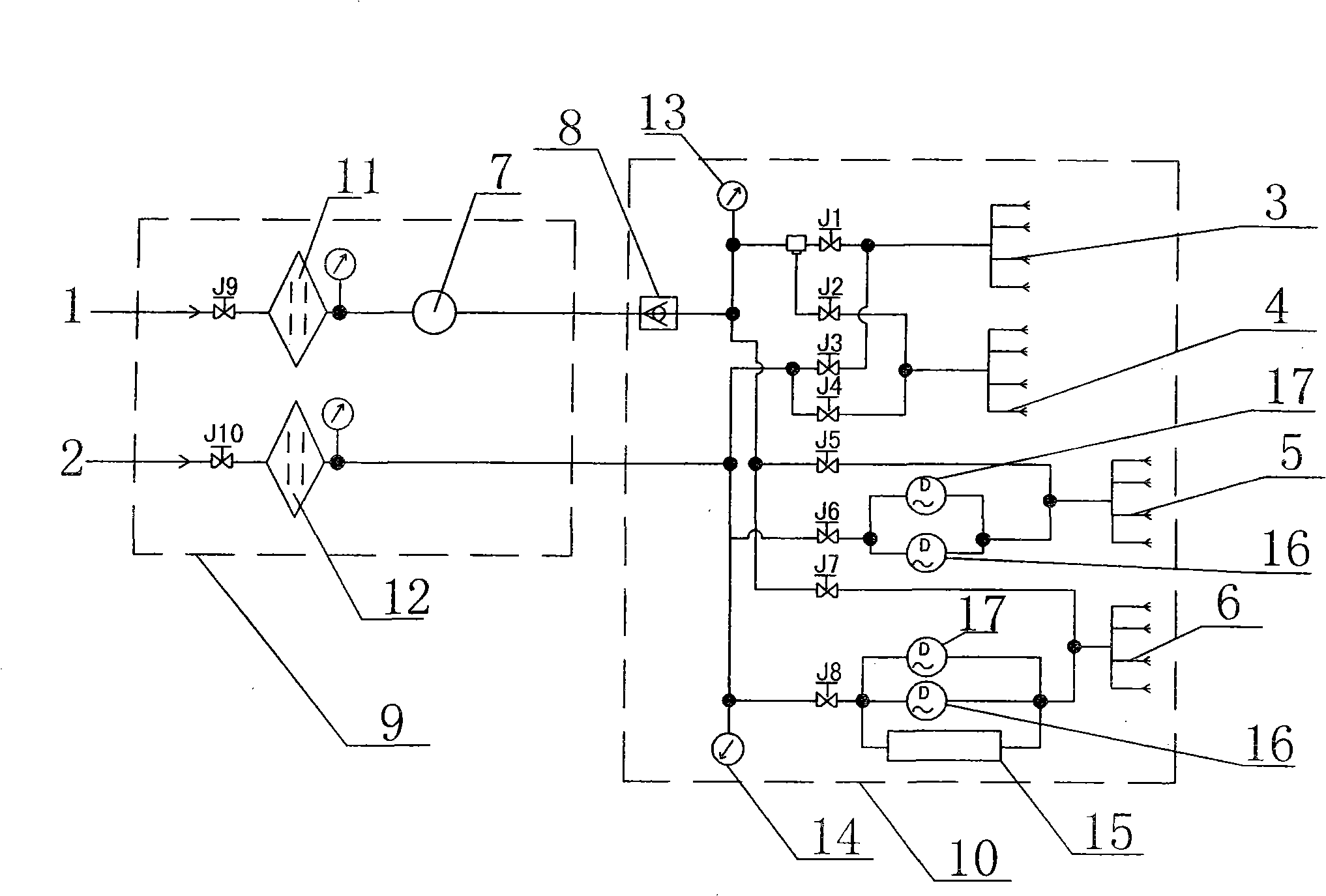

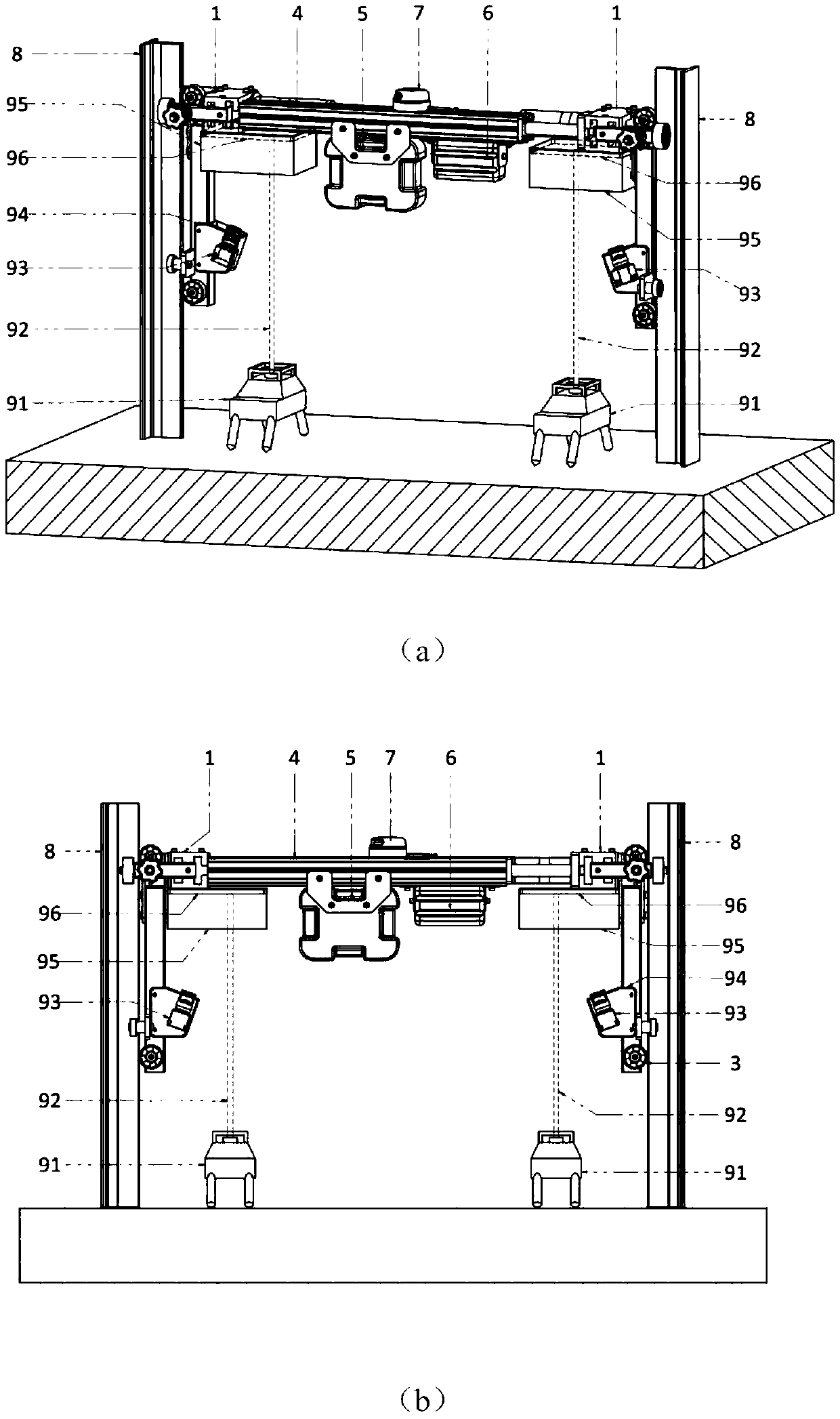

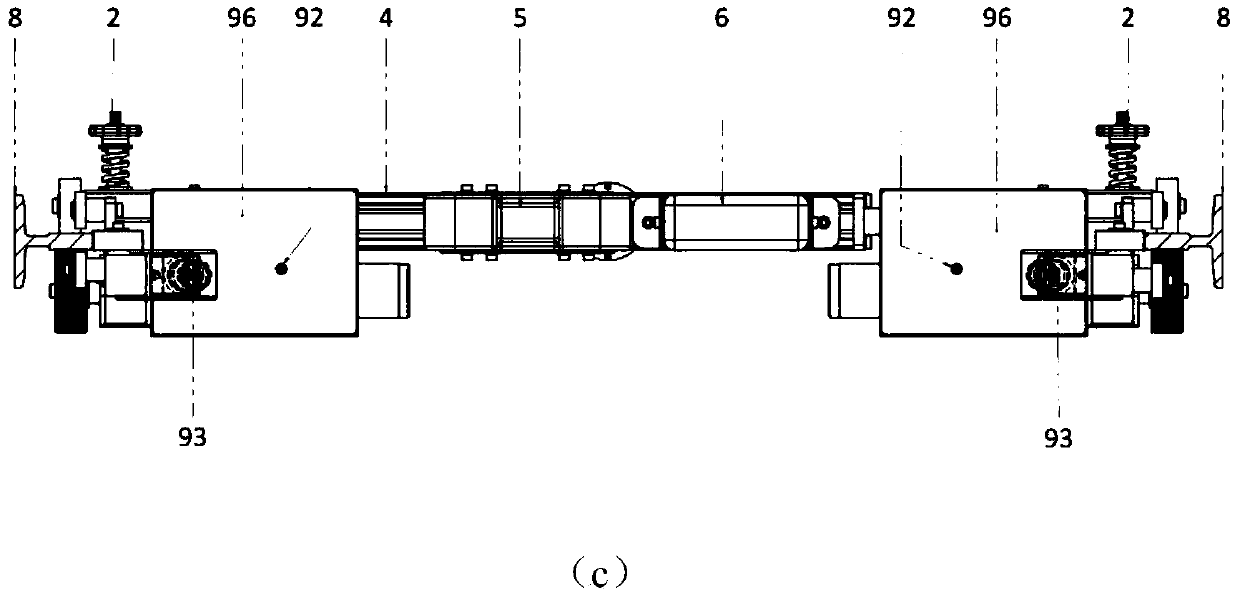

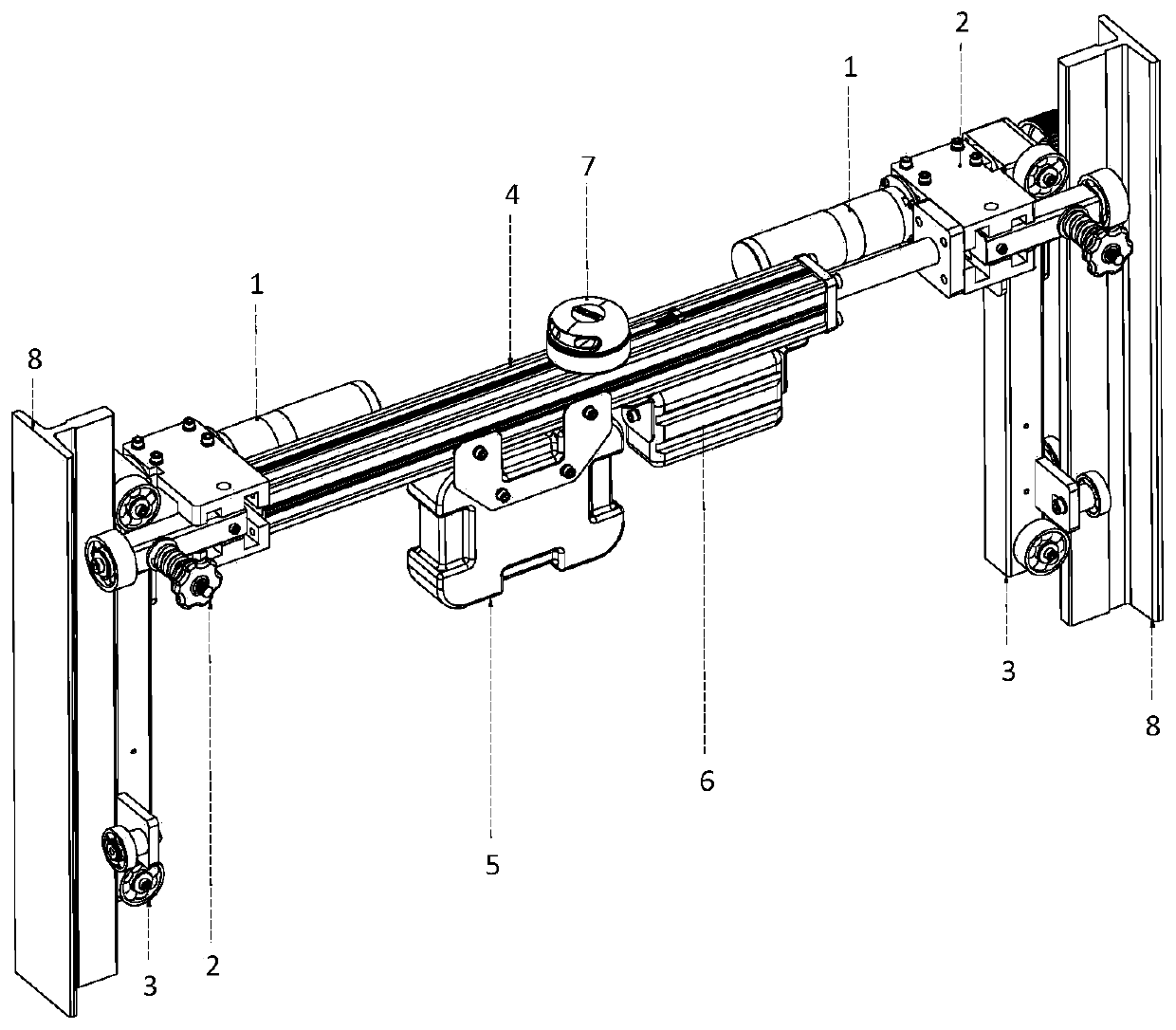

Device for testing constant thrust load of continuous linear motor

InactiveCN101520353AImplement two-way testingEfficient deliveryApparatus for force/torque/work measurementElectric machineLinear motor

The invention relates to a device for testing the constant thrust load of a continuous linear motor, belonging to the field of motor test and aiming to solve the problems of one-way measurement, complicated measuring process and poor precision of a tester which adopts loaded weights to test the constant thrust of the linear motor. The device for testing the constant thrust load of the continuous linear motor comprises a test platform, the linear motor, a magnetic powder brake, a direct current supply, a first synchronizing wheel, a second synchronizing wheel and a synchronizing belt, wherein the linear motor comprises a linear motor mover and a linear motor rotor and is arranged on the test platform and between the first synchronizing wheel and the second synchronizing wheel; one end of the test platform is provided with the magnetic powder brake, and an output shaft of the magnetic powder brake is fixedly connected with the first synchronizing wheel; both ends of the synchronizing belt are respectively connected with both ends of the mover of the linear motor, the mover of the linear motor drives the first synchronizing wheel and the second synchronizing wheel to rotate by the synchronizing belt, and the direct current supply provides the magnetic powder brake with direct current. The tester is used for measuring the constant thrust of the linear motor.

Owner:HARBIN INST OF TECH

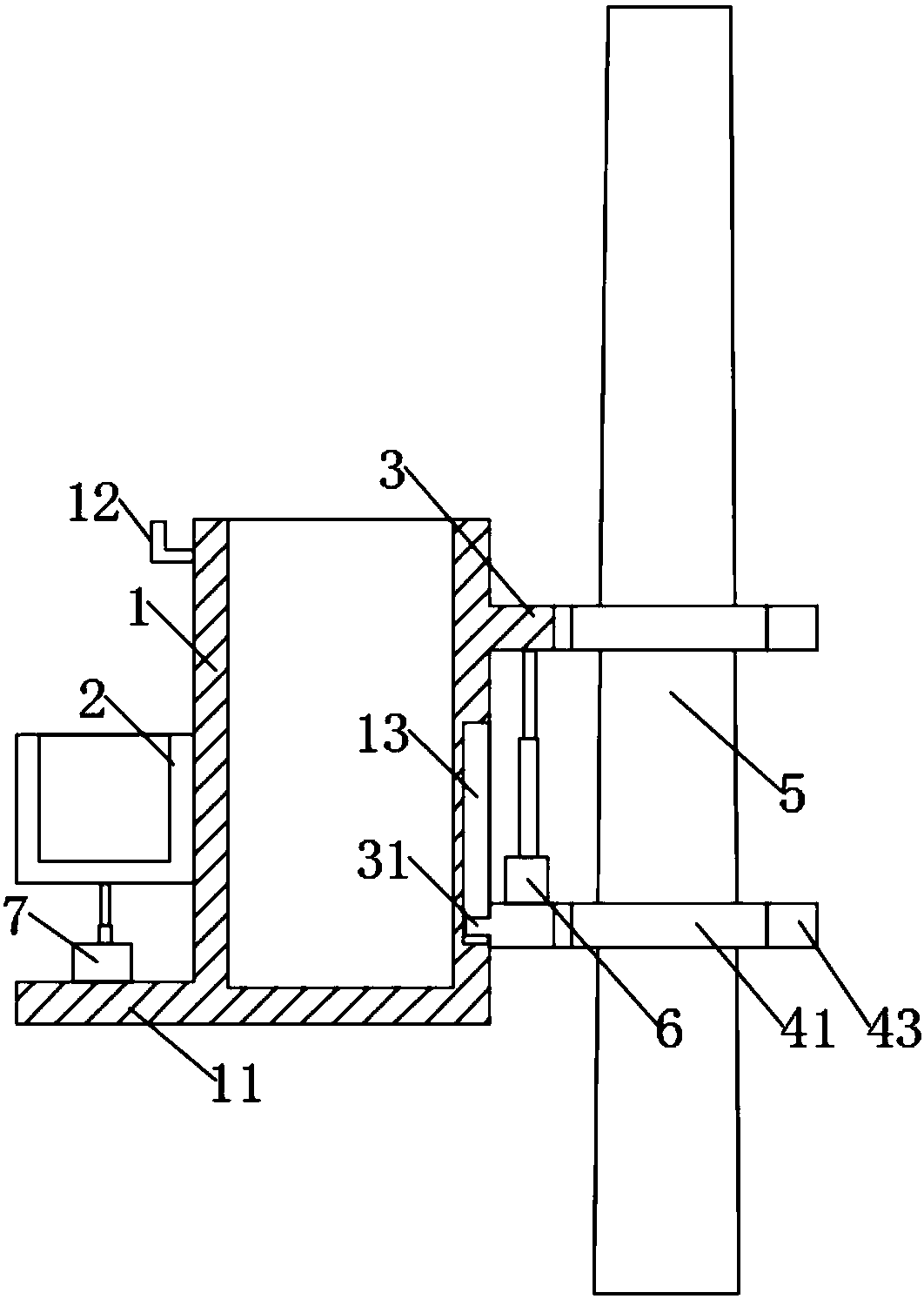

Power maintenance climbing box

ActiveCN108462112ASolve slippageFix security issuesApparatus for overhead lines/cablesEngineeringElectric power

The invention discloses a power maintenance climbing box. The power maintenance climbing box comprises a climbing box body, a tool kit, fixing rods and fixing rings; a fixing plate is arranged at thelower end of the climbing box body; an air cylinder II for driving the tool kit to ascend and descend is arranged on the fixing plate; the upper end of the air cylinder II is connected to the tool kit; the fixing rings at least comprise an upper fixing ring and a lower fixing ring which sleeve a telegraph pole and are connected to the climbing box body through the fixing rods; the at least two fixing rods comprise an upper fixing rod and an lower fixing rod, wherein the upper fixing rod is fixedly arranged at the upper end of the side surface of the climbing box body, and the lower fixing rodis arranged at the lower end of the climbing box body in a sliding mode along the side surface of the climbing box body; and an air cylinder I connected to the upper fixing rod is arranged on the lower fixing rod. The power maintenance climbing box has the advantages that the potential safety hazard that people slide off and are insecure when climbing the telegraph pole through a foot-operated auxiliary device can be eliminated, the problems that the cost is high, and the space is limited due to the fact that maintenance personnel are lifted to a high place to maintain equipment by using a crane can be solved, and the safety performance is higher.

Owner:NINGBO LONGER LIGHTING

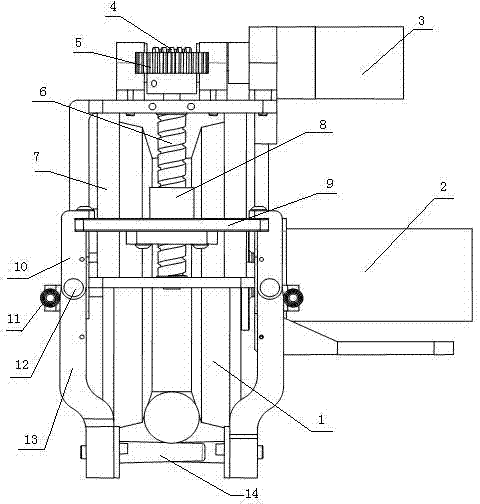

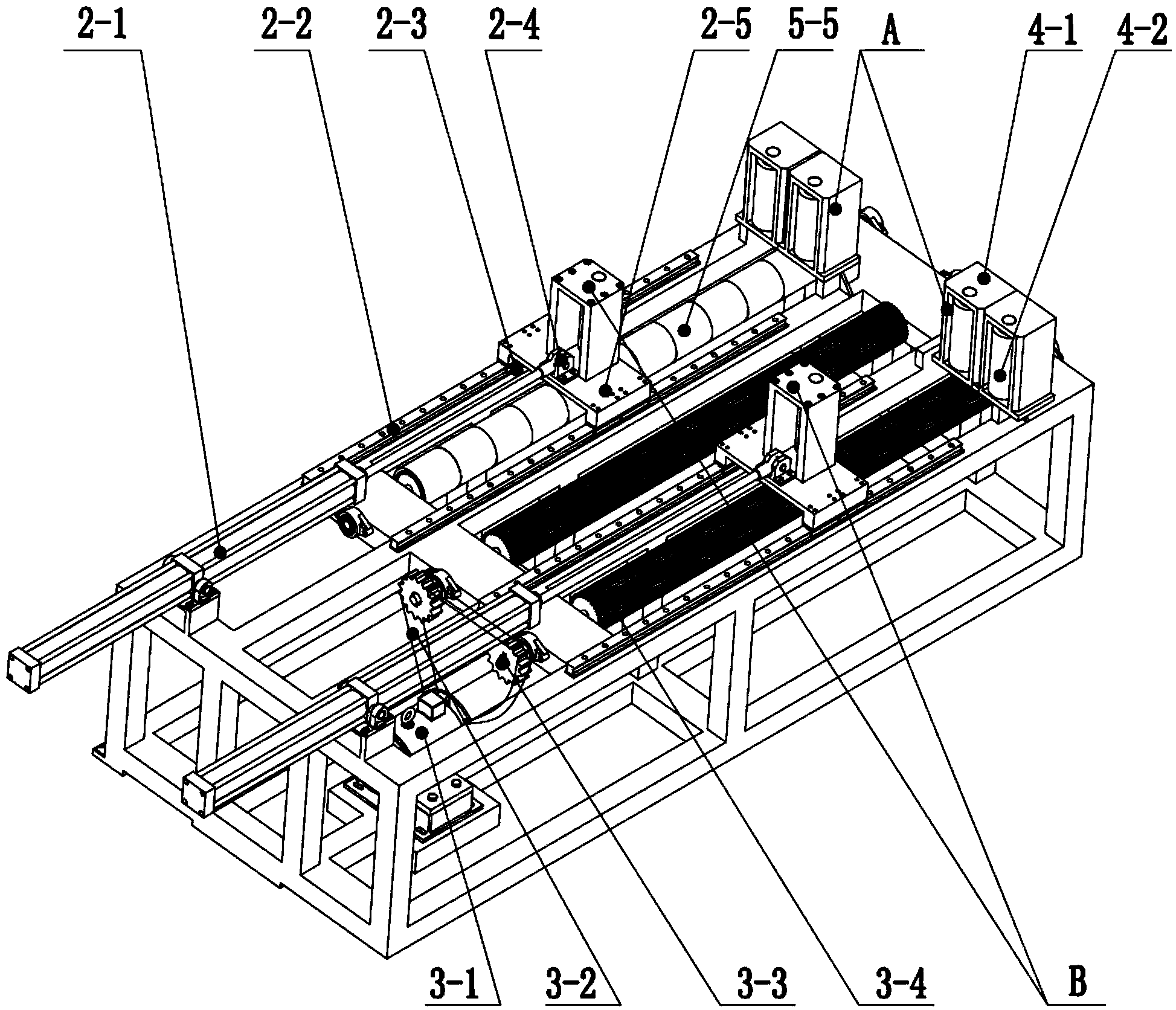

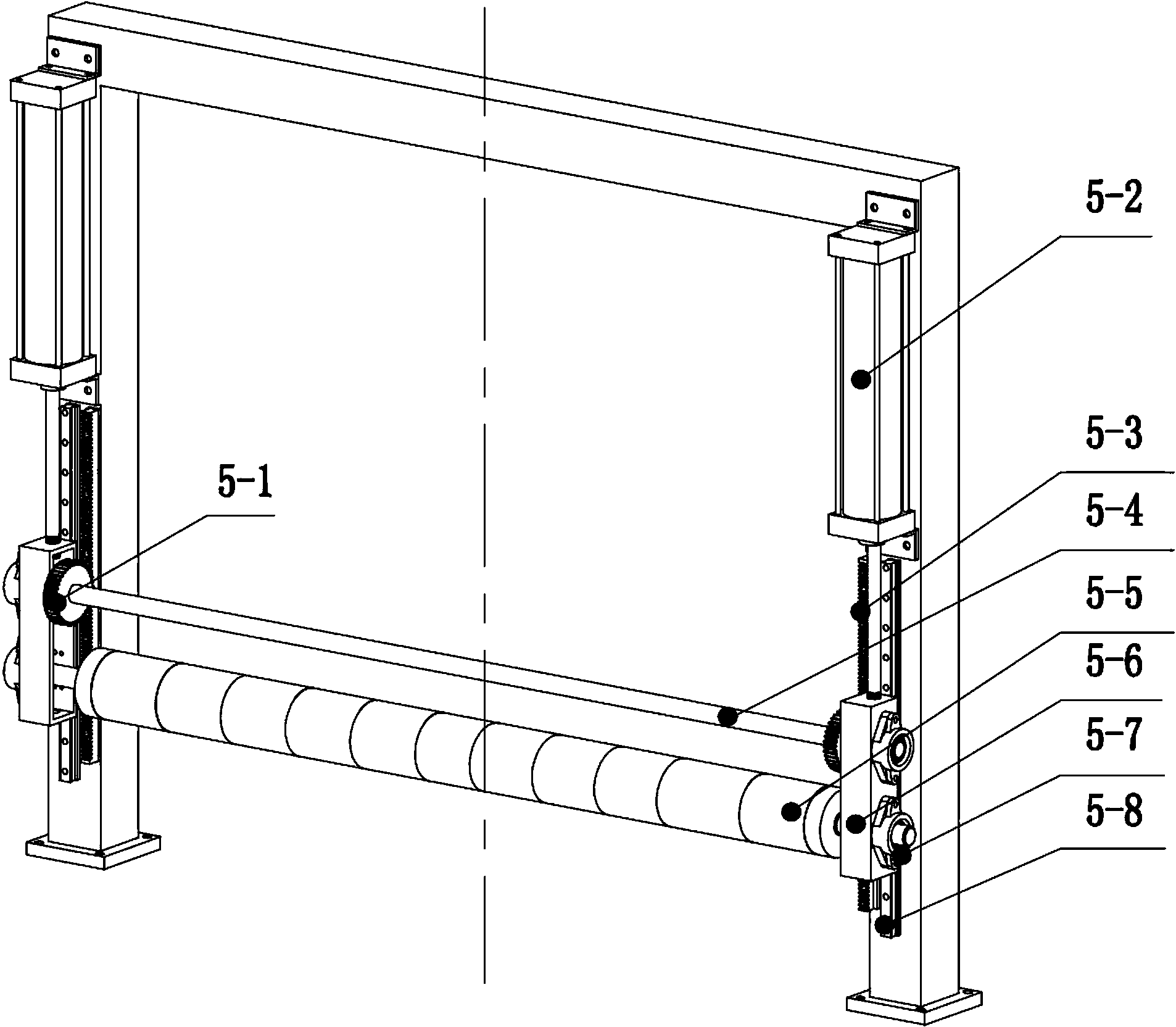

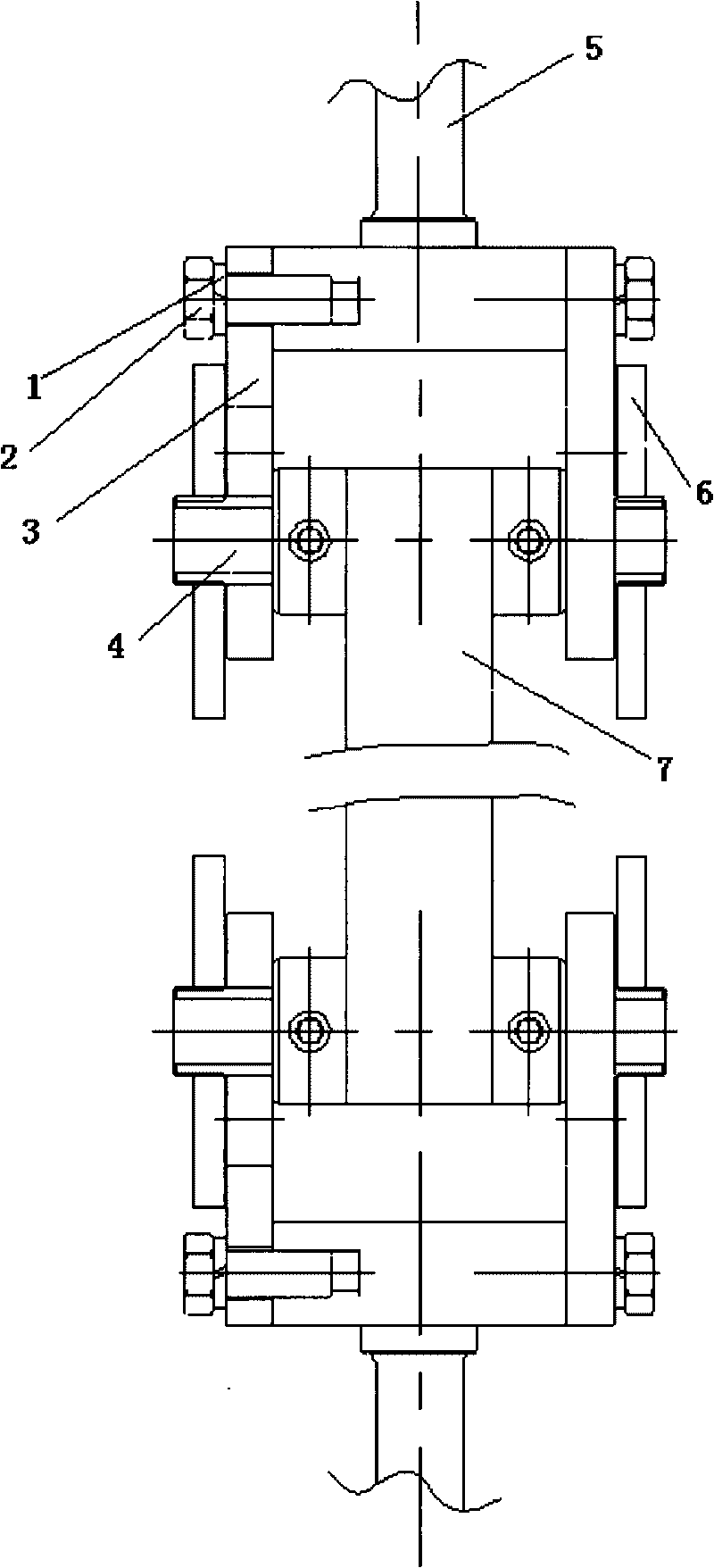

Stable clamping driving device used for H-shaped steel

InactiveCN103521963AGuaranteed stabilityGuaranteed uptimeWelding/cutting auxillary devicesAuxillary welding devicesMechanical equipmentEngineering

The invention discloses a stable clamping driving device used for H-shaped steel, and belongs to the technical field of mechanical equipment. The stable clamping driving device used for the H-shaped steel comprises a machine frame, a driving rail, a horizontal clamping device and a vertical down-pressing device. The surface of a driving roll shaft of the driving rail is provided with coarsened tooth patterns. Two movable clamping roll sets of the horizontal clamping device are provided with independent pushing devices respectively and respectively move relative to fixed clamping roll sets so as to conduct horizontal clamping on the H-shaped steel between the movable clamping roll sets and the fixed clamping roll sets. The vertical down-pressing device is of a portal structure and is composed of drive mechanisms and a down-pressing abrasion-resistant sleeve roll. The two sets of drive mechanisms are symmetrically and vertically arranged between two side pillars of a portal, the down-pressing abrasion-resistant sleeve roll is located above the H-shaped steel and horizontally arranged between the two side pillars of the portal, the down-pressing abrasion-resistant sleeve roll is driven to move up and down along a slide rail through the drive mechanisms so as to conduct vertical compressing on the H-shaped steel below the down-pressing abrasion-resistant sleeve roll according to set compression force, therefore, stable driving conveying of the H-shaped steel on a driving roll shaft is guaranteed comprehensively and the quality of H-shaped steel online relative machining is guaranteed.

Owner:HUBEI HONGYI STEEL CONSTR ENG

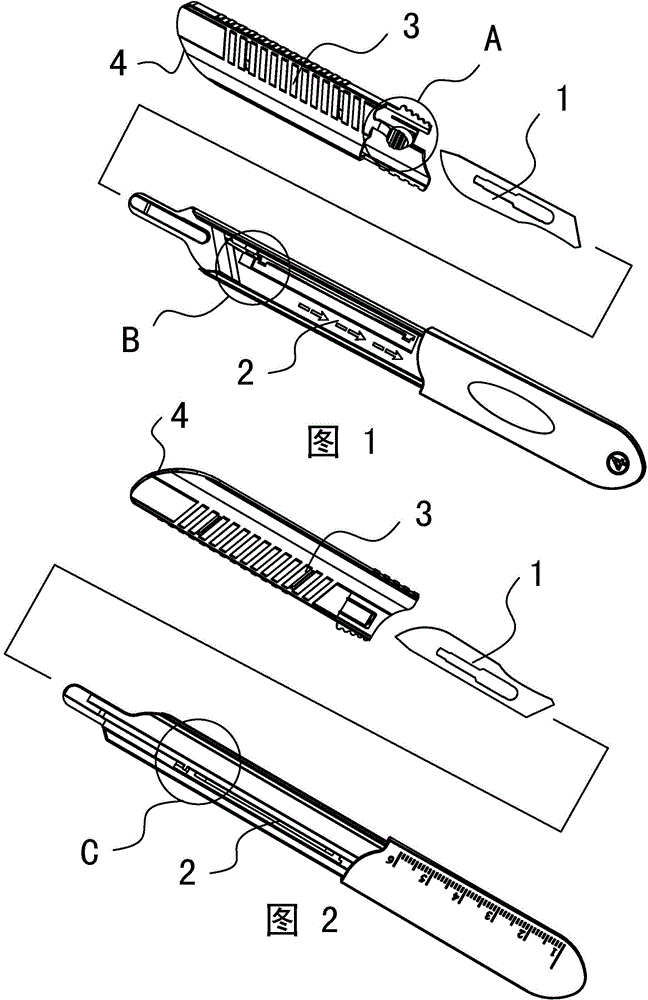

Disposable safety scalpel

ActiveCN103976776ASolve slippageImprove convenienceIncision instrumentsEngineeringMechanical engineering

The invention relates to a disposable safety scalpel. The disposable safety scalpel comprises a blade, a handle and a sleeve. When the sleeve slides front and back relative to the handle and is located, the blade presents a stretching state and a retraction state from the sleeve. The disposable safety scalpel is characterized in that a first lock opening is formed in the front of a scalpel protection lock opening in the back of the handle, and the scalpel protection lock opening and the first lock opening are in inclined face or cambered face transition. A second lock opening and a stopping block are arranged in the front of a handle front through groove. When a button is in a press state and the sleeve is pushed forwards, an impact head is stopped by the stopping block, so that the impact head slides into the second lock opening from the front end of the through groove, and the condition that the scalpel is pushed into the lock state without being used is effectively prevented. Besides, by the front and back simultaneous lock state, slipping due to overlarge space between the sleeve and the handle and deformation is prevented, and the lock state stability is well guaranteed.

Owner:STERILANCE MEDICAL SUZHOU

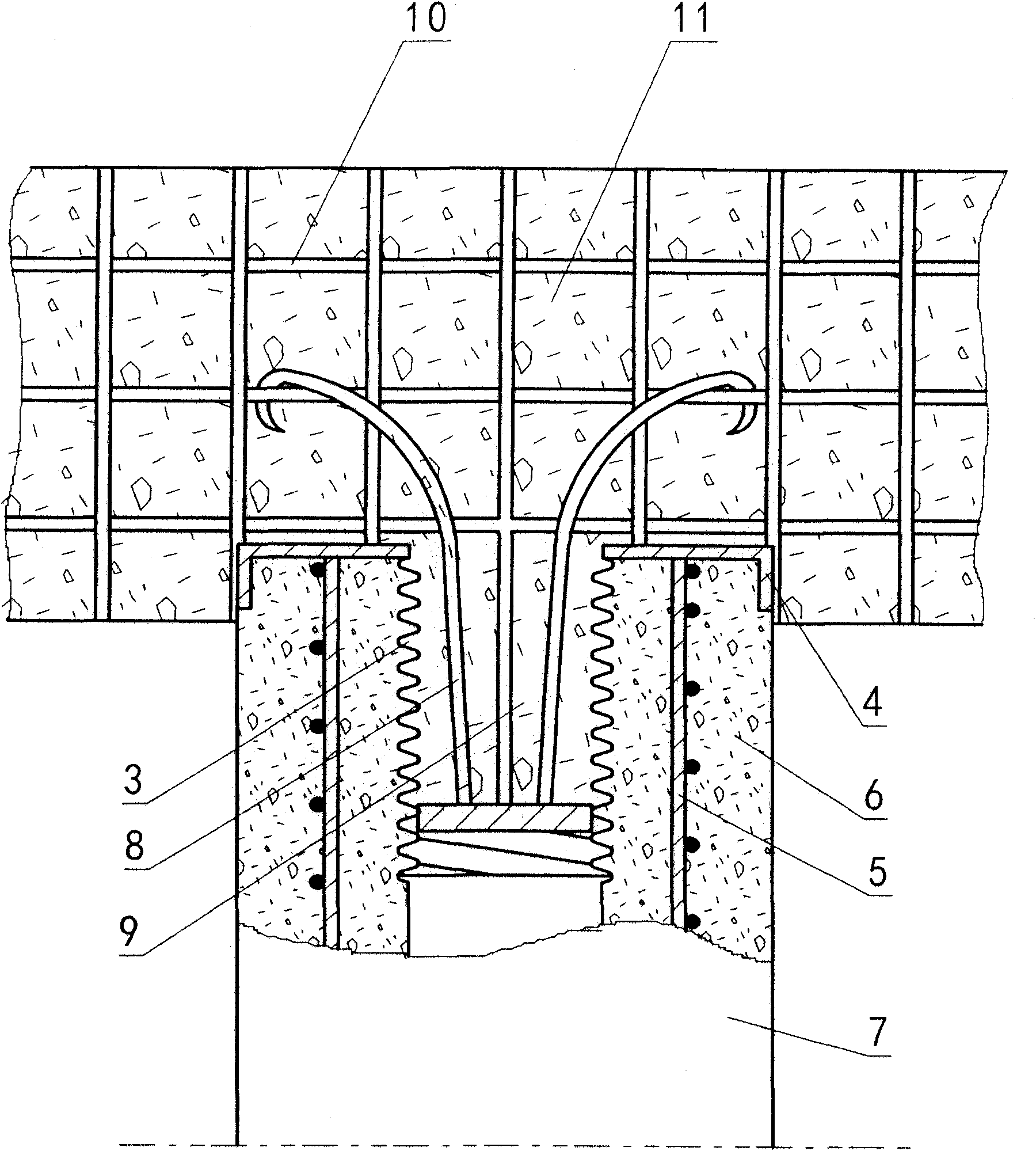

Prefabricated steel sleeve guided rock-socketed system and application method thereof

The invention relates to a prefabricated steel sleeve guided rock-socketed system and an application method of the prefabricated steel sleeve guided rock-socketed system. The application method comprises the following steps: (1) manufacturing and assembling a guided rock-socketed system; (2) putting a prefabricated steel sleeve system in the hole of a cast-in-situ bored pile; (3) stabilizing a steel sleeve guide system in a guide wall plane position; (4) cutting out the parts, higher than the guide wall plane position of an underground diaphragm wall, of the guide steel sleeve and a hoisting anchor ring; (5) inserting a rock-socketed drill stem in the guide steel sleeve and correcting the vertical degree of the guide steel sleeve system any time; (6) drilling to a designed depth after the drill bit of the rock-socketed drill stem goes into oblique bed rock; (7) carrying out rock-socketed drilling circularly one by one; and (8) carrying out the construction of the cast-in-situ bored pile of the underground diaphragm wall. Due to the limiting actions of a limiting plate and the guide steel sleeve, the rock-socketed drill stem is freely inserted in the guide steel sleeve to drill the oblique bed rock and directional drilling of the bed rock is realized, and therefore, the technical problems of pile toe slippage and difficult hole forming in hard oblique rock face drilling construction are effectively solved, the cost is saved and the working efficiency is improved.

Owner:POWERCHINA MUNICIPAL CONSTR GRP CO LTD

Compound polyurethane sleeper pad and preparation method thereof

PendingCN108660867ASolve the problem of piercingSolve the problem of fast pulverizationBallastwayNonwoven fabricBallast

The invention discloses a compound polyurethane sleeper pad and a preparation method thereof. The sleeper pad comprises a polyurethane foam layer; a plurality of reinforced fibers are embedded in thepolyurethane foam layer; and a non-woven cloth layer for preventing being pierced by ballast gravel is fixedly arranged on the bottom end face of the polyurethane foam layer. The preparation method comprises the steps that a non-woven cloth is laid on a plane worktable with side blocking parts; polyurethane composite materials and the reinforced fibers are evenly poured through a pouring machine with fiber cutting and adding functions, so that poured materials are formed; the poured materials are poured on the plane worktable with the laid non-woven cloth and naturally level; and meanwhile, afoaming reaction is conducted, a fiber compound polyurethane layer with a micropore structure is formed by solidifying, and the fiber compound polyurethane layer and the non-woven cloth on the bottomlayer are pasted closely to form a whole so as to form the compound polyurethane sleeper pad. According to the compound polyurethane sleeper pad and the preparation method thereof, the problem that the sleeper pad is pierced by the ballast gravel can be solved on the basis of solving the problem that the ballast gravel is pulverized quickly, thus the ballast gravel tamping period and the ballast bed hardening time are prolonged, and the railway maintenance cost is reduced.

Owner:铁科腾跃科技有限公司

Robot foot end structure

The invention discloses a robot foot end structure and aims to solve the problem that the foot-end stress area of an existing foot-type robot is small, the robot possibly produces a slippery phenomenon and difficultly stably walks on a non-structural road surface, normal work of the robot is affected, but a large foot-type robot walks unstably due to excessive self weight, great impact is producedto the robot and the service life of the robot is affected. The robot foot end structure adopts a spring structure and mutual cooperation of parts to achieve the functions of contact area increase and buffering damping. According to the robot foot end structure, on one hand, the contact range of foot end toes is widened and a robot body is kept stable through spring compression, on the other hand, a buffering damping effect is played, and thus the service life of the robot is prolonged. The robot foot end structure is reasonable in design, ingenious in concept, simple in structure, convenientto operate, low in production and maintenance cost and easy to use, has a higher application value and has remarkable progressive significance in development of multi-legged robots.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY +2

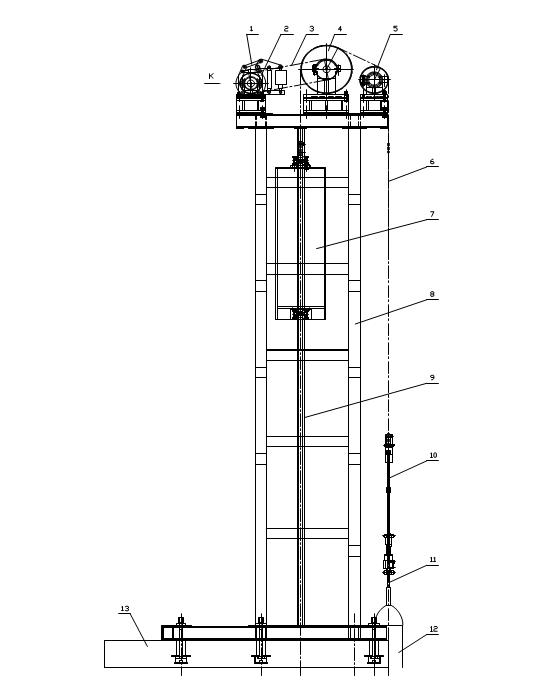

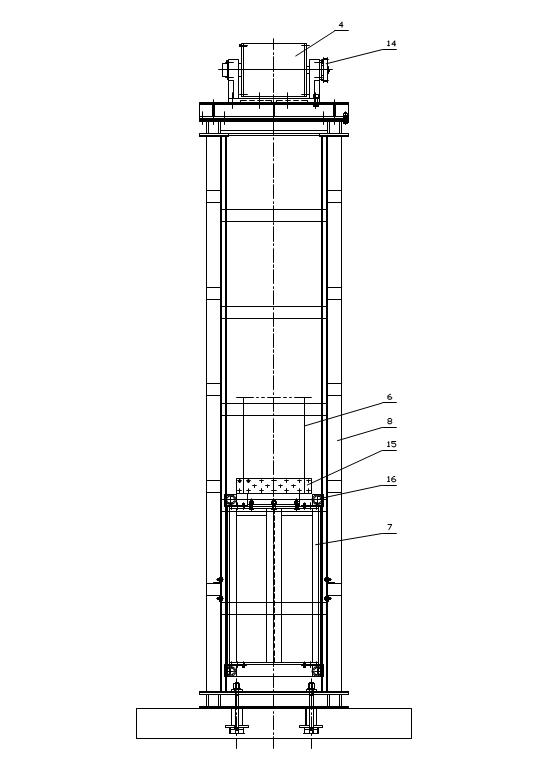

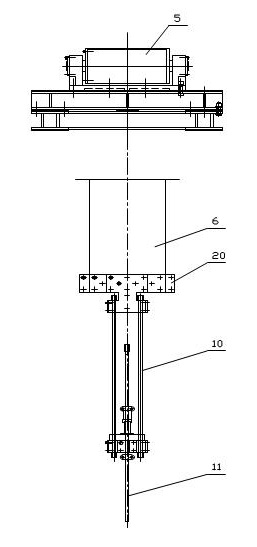

Double-roller tower type oil-pumping unit device

The invention discloses a double-roller tower type oil-pumping unit device. A roller type speed reducer drives a driven roller to rotate through an opening belt, one end of the opening belt is connected with a weight box, the other end of the opening belt is connected with a suspension assembly, the other end of the suspension assembly is connected with one end of a belt clip, the other end of the belt clip is connected with one end of an oil pumping rod, the other end of the oil pumping rod is movably connected with an oil pumping unit, and a brake is connected with a coupler assembly; an output shaft of an electric motor is connected with a belt wheel shaft through the coupler assembly, a driving synchronous belt wheel is installed on the belt wheel shaft, a driven synchronous belt wheel is installed on an input shaft of the roller type speed reducer, and synchronous belts sequentially are wounded the driving synchronous belt wheel and the driven synchronous belt wheel and then are rotationally driven to connect; and guide wheels are installed on both sides of the weight box, a guide rail is fixed on a rack, and the rack is fixed on a concrete foundation by bolts. The double-roller tower type oil-pumping unit device has the characteristics of simple structure, good stability, non-skid performance of the belts, long stroke, low stroke frequency and long fatigue service life, is convenient to use, is easy to regulate strokes and stroke frequencies and is widely used for the oil extraction industry.

Owner:周生祥

Municipal asphalt concrete road and construction method

InactiveCN110396887ASpeed up meltingSolve vehicle skidPhotovoltaic supportsBatteries circuit arrangementsElectric heatingStructural engineering

The invention relates to a municipal asphalt concrete road and a construction method and belongs to the technical field of municipal roads. The key point of the technical scheme is that the municipalasphalt concrete road comprises a road base course, a waterproof course and an asphalt concrete course, wherein the waterproof layer is arranged on the road base course; the asphalt concrete course isarranged on the waterproof course; a horizontal passage is formed between the waterproof course and the asphalt concrete course; an electric heating wire connected with a power supply is placed in the horizontal passage in the extending direction of the horizontal passage; a water drainage device used for removing pavement accumulated water is arranged in the asphalt concrete course; an air exhaust pipe led to the pavement is connected to the horizontal passage; and an air exhaust device is arranged in the horizontal passage. According to the municipal asphalt concrete road, during using, ices and snows covering turns or downhill parts of roads can be very conveniently removed; and therefore, the vehicle running safety performance can be effectively improved, and unnecessary loss can be reduced.

Owner:深圳港湾建设有限公司

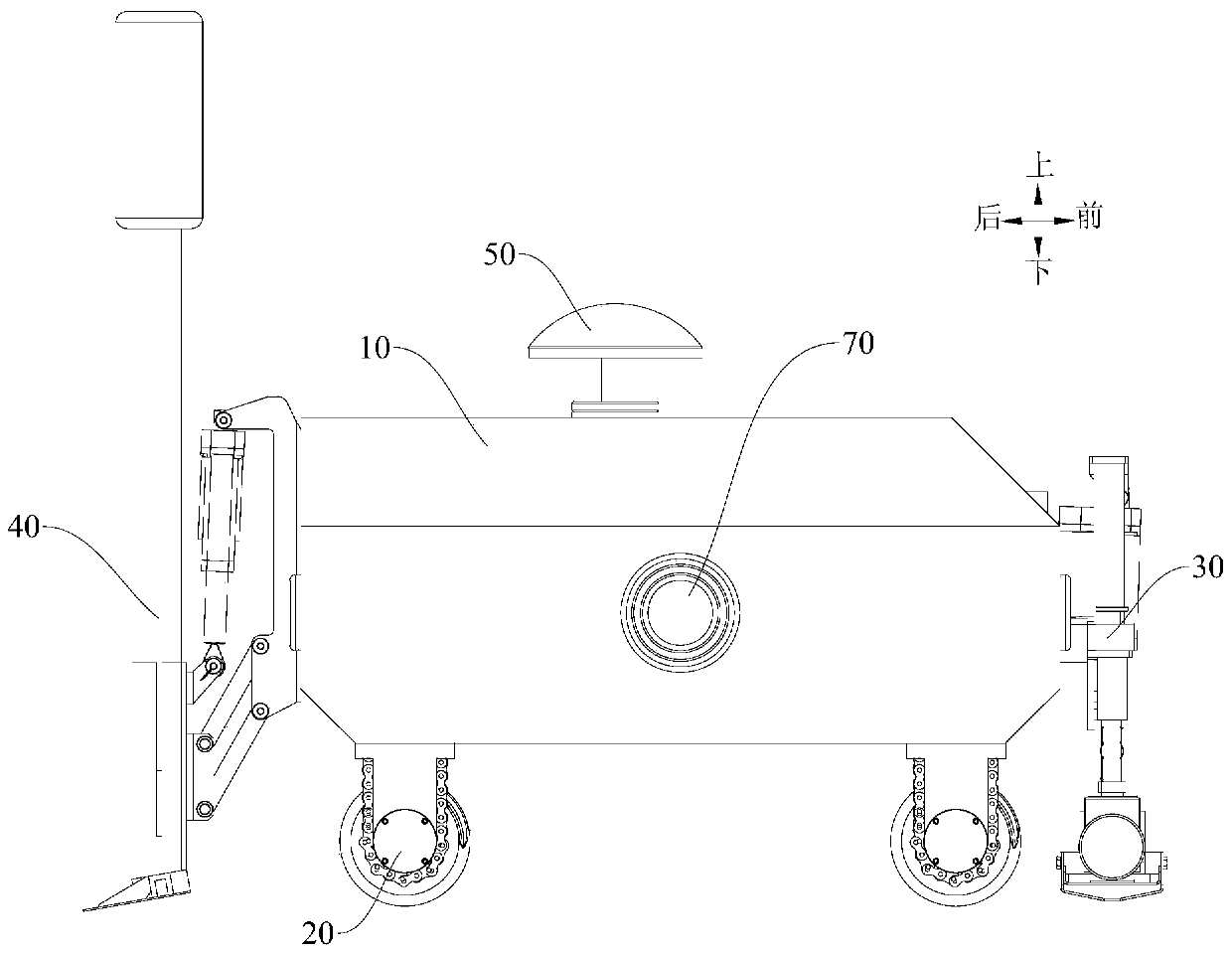

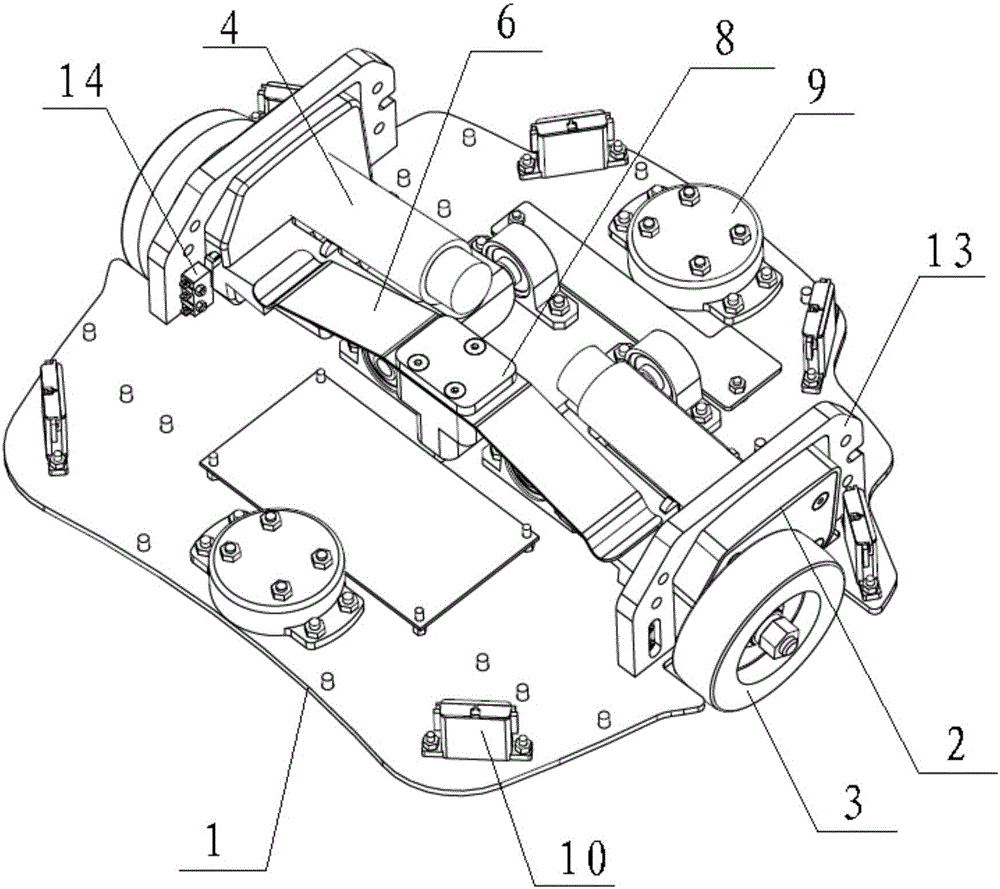

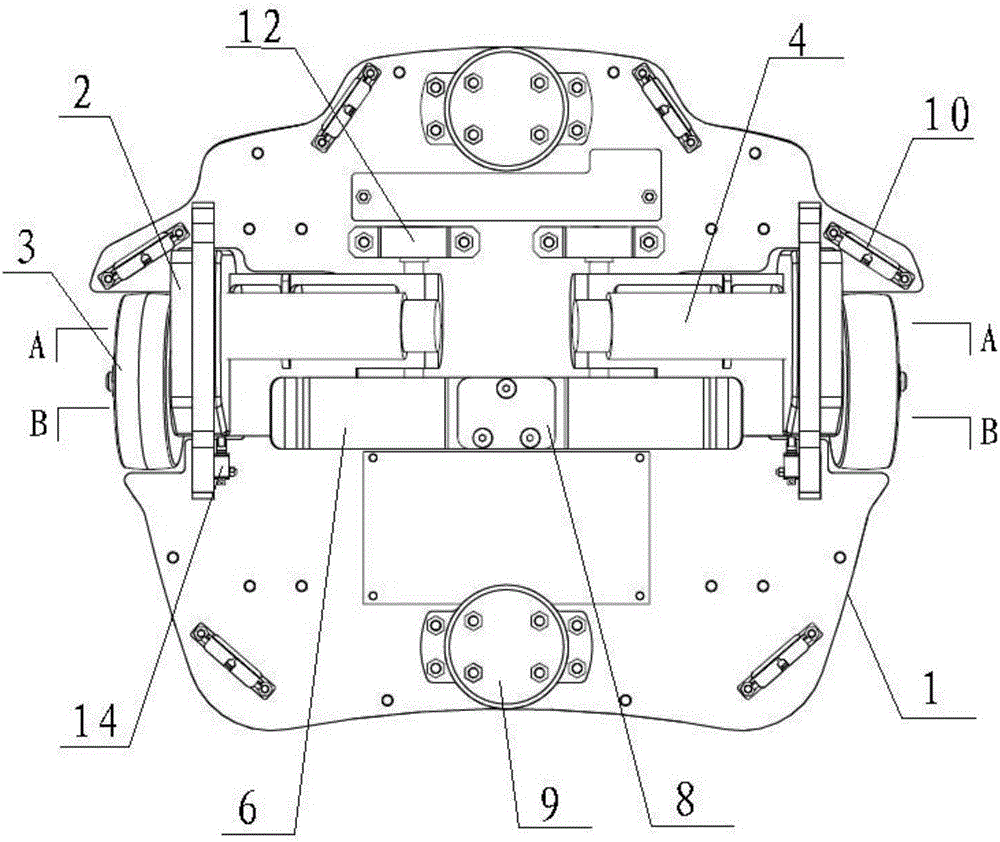

Robot chassis and service robot

InactiveCN105128978AEnsure fitAvoid the phenomenon of idling and slippingVehiclesDrive motorEngineering

The invention discloses a robot chassis and a service robot. The robot chassis comprises a chassis main body, a walking device and an anti-sliding device. The walking device comprises a gearbox, the gearbox is connected with an advancing wheel and a driving motor, the anti-sliding device comprises a pressing plate and an elastic piece, one end of the pressing plate is connected with the gearbox, the other end of the pressing plate is connected with a rotating device, the rotating device comprises a rotating shaft, the rotating shaft is rotatably connected with the pressing plate, the axial direction of the rotating shaft is parallel to the advancing direction of the advancing wheel, one end of the elastic piece adheres to the pressing plate, the other end of the elastic piece is connected with a fixed seat, and the fixed seat is arranged on the chassis main body. According to the robot chassis and the service robot, the advancing wheel can maintain a good state of adhering to the ground, and accordingly the advancing wheel can still advance normally on some special sections, the safe reliability is high, and the problem that due to the fact that the ground is smooth or the robot makes a turn at a high speed, slippage or suspension of the advancing wheel caused by drifting occurs is effectively solved.

Owner:SHANGHAI XPARTNER ROBOTICS +1

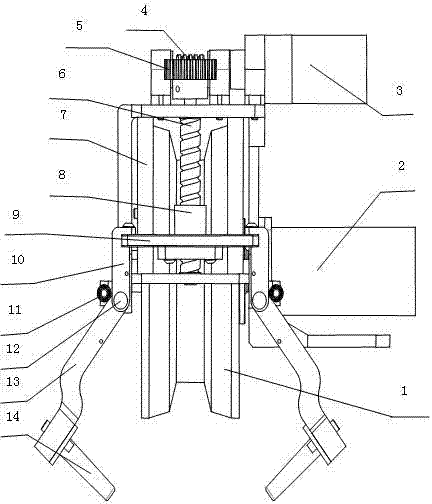

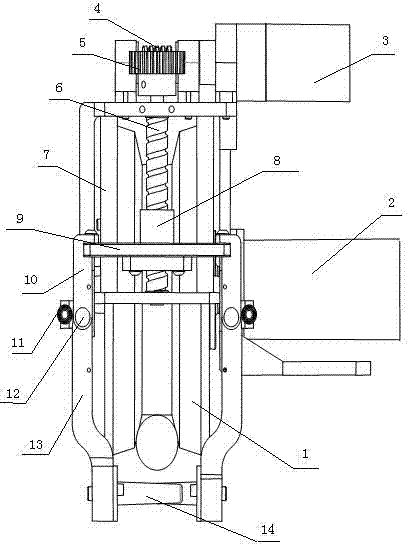

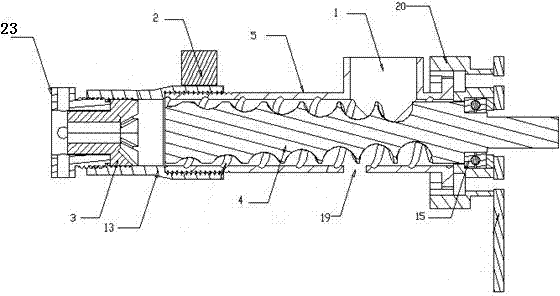

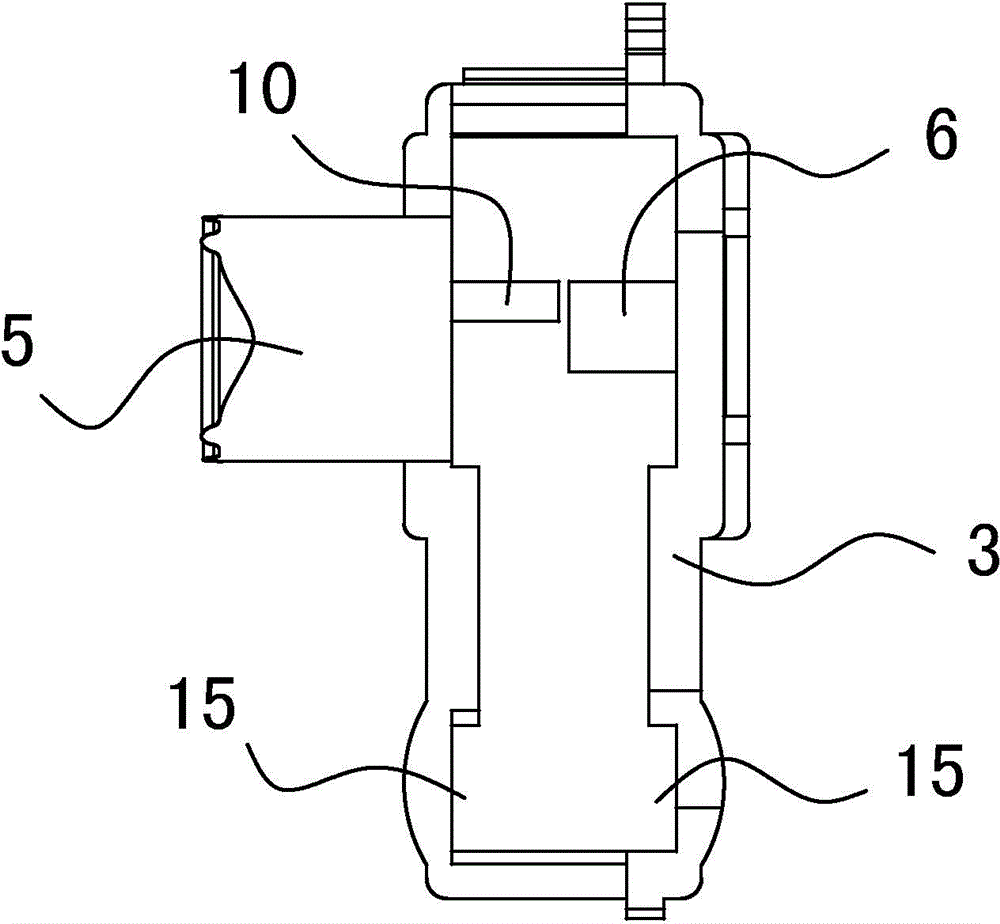

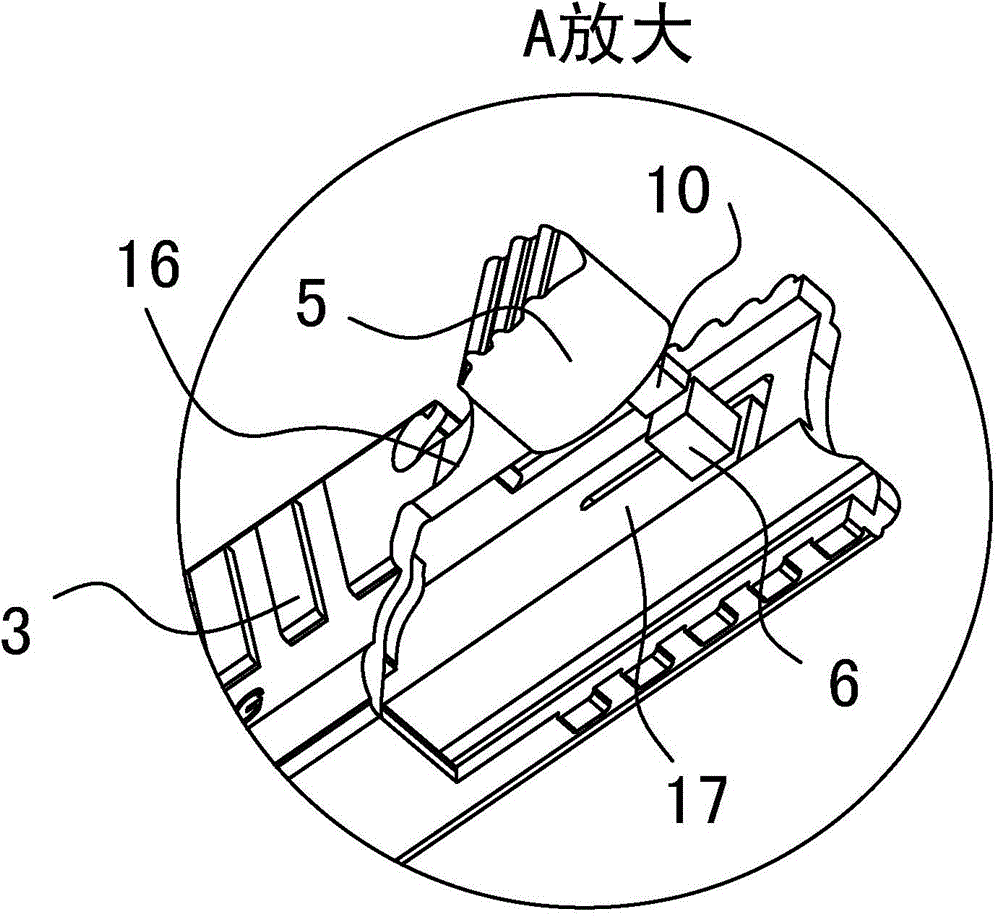

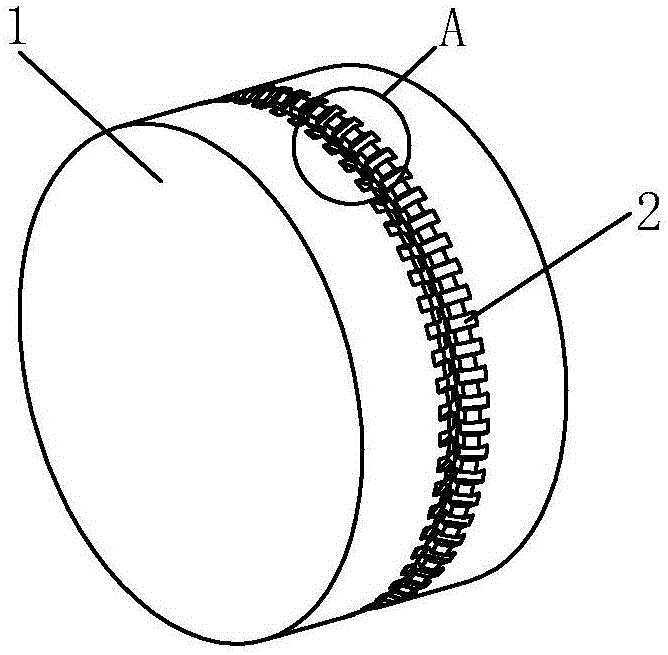

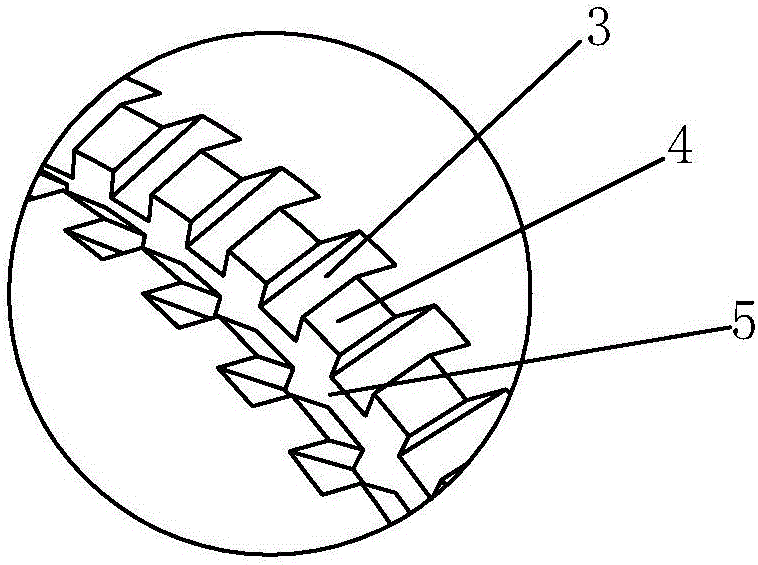

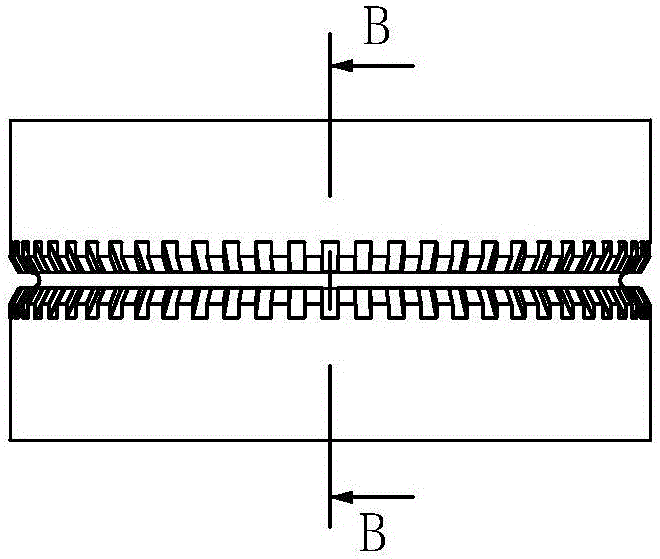

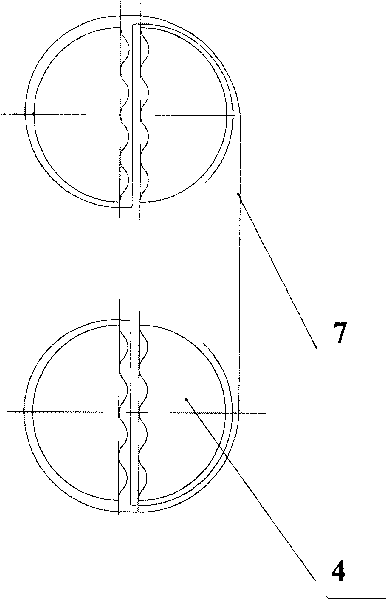

3D printing wire feeding, clamping and guiding device

InactiveCN105690771AImprove clamping bite forceIncrease frictionAdditive manufacturing apparatusEngineeringGuide wires

The invention discloses a 3D printing wire feeding, clamping and guiding device, and relates to the technical field of quick molding of 3D printing. The 3D printing wire feeding, clamping and guiding device comprises a guide wheel I and a guide wheel II; the guide wheel I and the guide wheel II are arranged side by side; a lap of V-shaped tooth grooves I, inwards recessed, is formed in the peripheral surface of the guide wheel I; a lap of V-shaped tooth grooves II, inwards recessed, is formed in the peripheral surface of the guide wheel II; the V-shaped tooth grooves I in the guide wheel I and the V-shaped tooth grooves II in the guide wheel II are opposite in position; when the guide wheel I and the guide wheel II are arranged side by side, the V-shaped tooth grooves I and the V-shaped tooth grooves II surround guide grooves for clamping and guiding wires; waste grooves I communicated with the V-shaped tooth grooves I are inwards recessed in the inner sides of the V-shaped tooth grooves I; and waste grooves II communicated with the V-shaped tooth grooves II are inwards recessed in the inner sides of the V-shaped tooth grooves II. The 3D printing wire feeding, clamping and guiding device can improve the wire surface clamping engagement force and friction force to prevent the wire slip or deviation in the feeding process.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

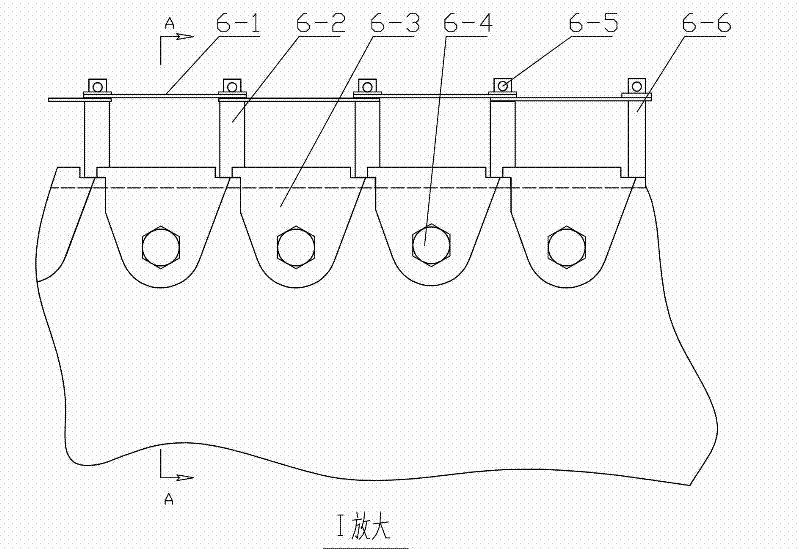

Locking nut

The invention discloses a locking nut, comprising a hexagon nut body, an annular boss, a nylon ring, a flange gasket, anti-loosening elastic pieces and adjusting screws, wherein the upper end surfaceof the hexagon nut body is provided with the annular boss, the annular boss is provided with a mounting ring groove, the nylon ring is embedded in the mounting ring groove, the center line of the hexagon nut body is provided with a central threaded hole, the lower end face of the hexagon nut body is connected with the flange gasket, the lower end face of the flange gasket is provided with a plurality of containing grooves, the anti-loosening elastic pieces are arranged in the containing grooves, and the adjusting screws are installed on the side wall of the hexagon nut body. The adjusting screws cooperate with the anti-loosening elastic pieces, the multiple adjustable anti-loosening elastic pieces are arranged under the flange gasket, so that the locking reliability is ensured, and the locking nut is especially suitable for the uneven fastening situation of the fastening end face, and the resilience force to the bolt is generated by extruding deformation of the threads of the bolt to the nylon ring, so that the problems of loosening and slipping off under the condition of vibration can be effectively solved.

Owner:HAIYAN HUASHENG AUTO PARTS

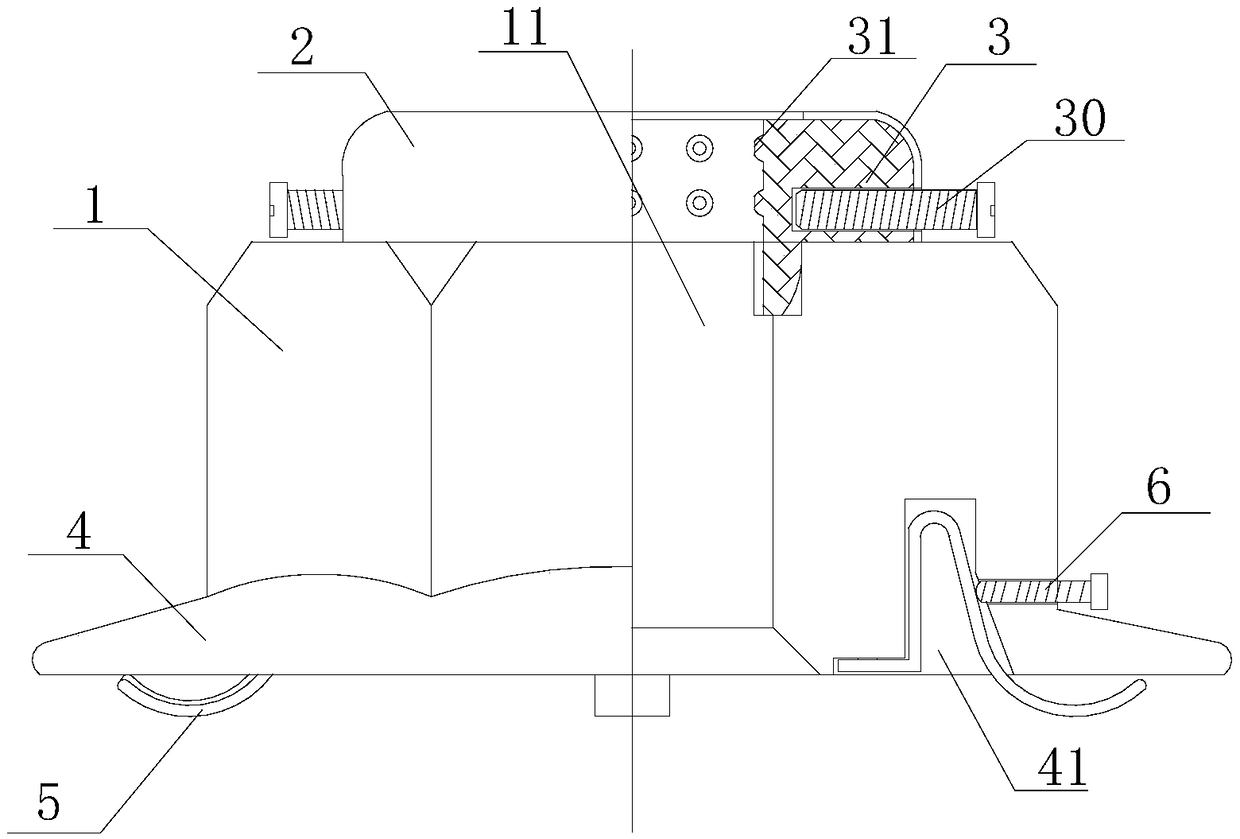

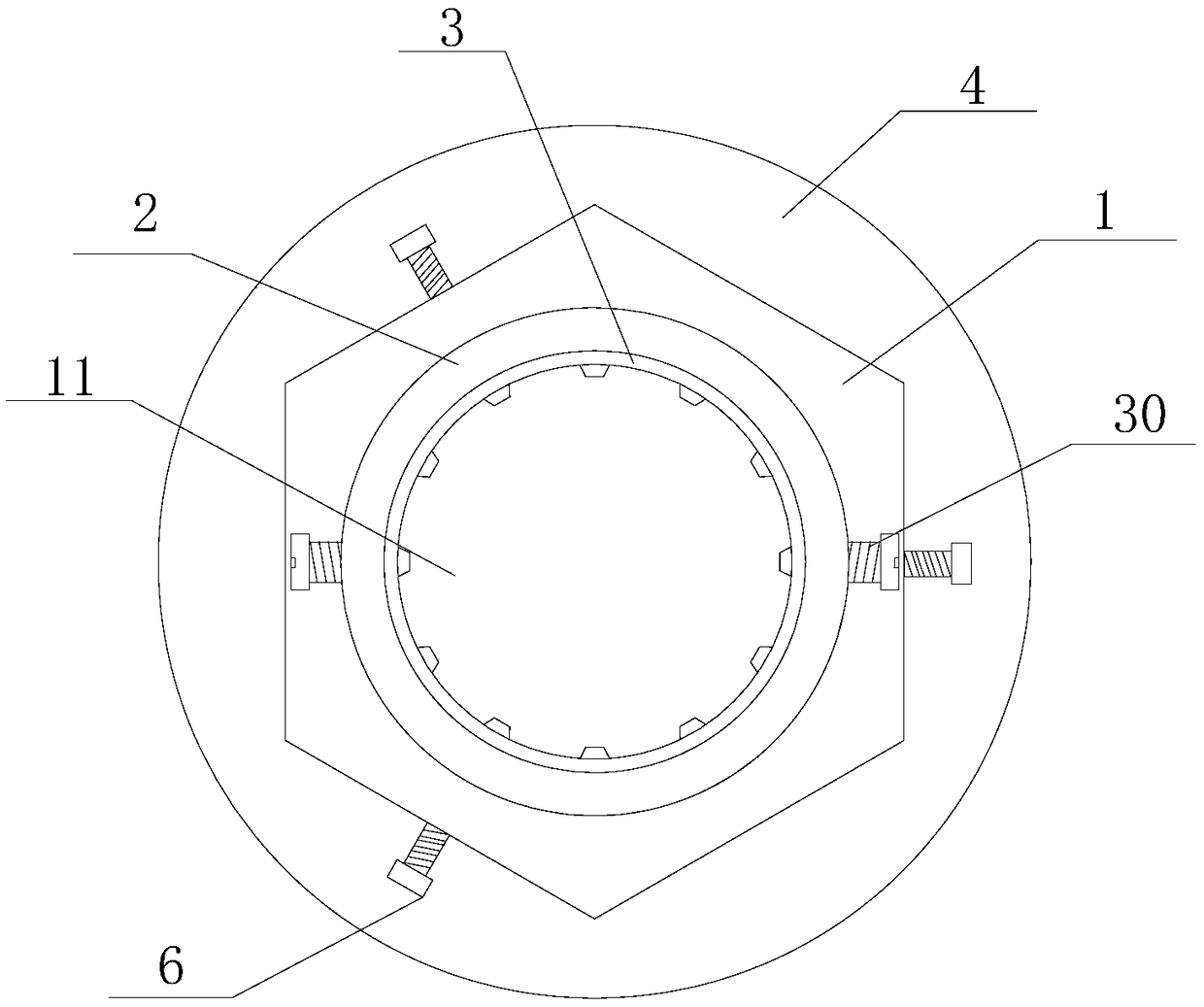

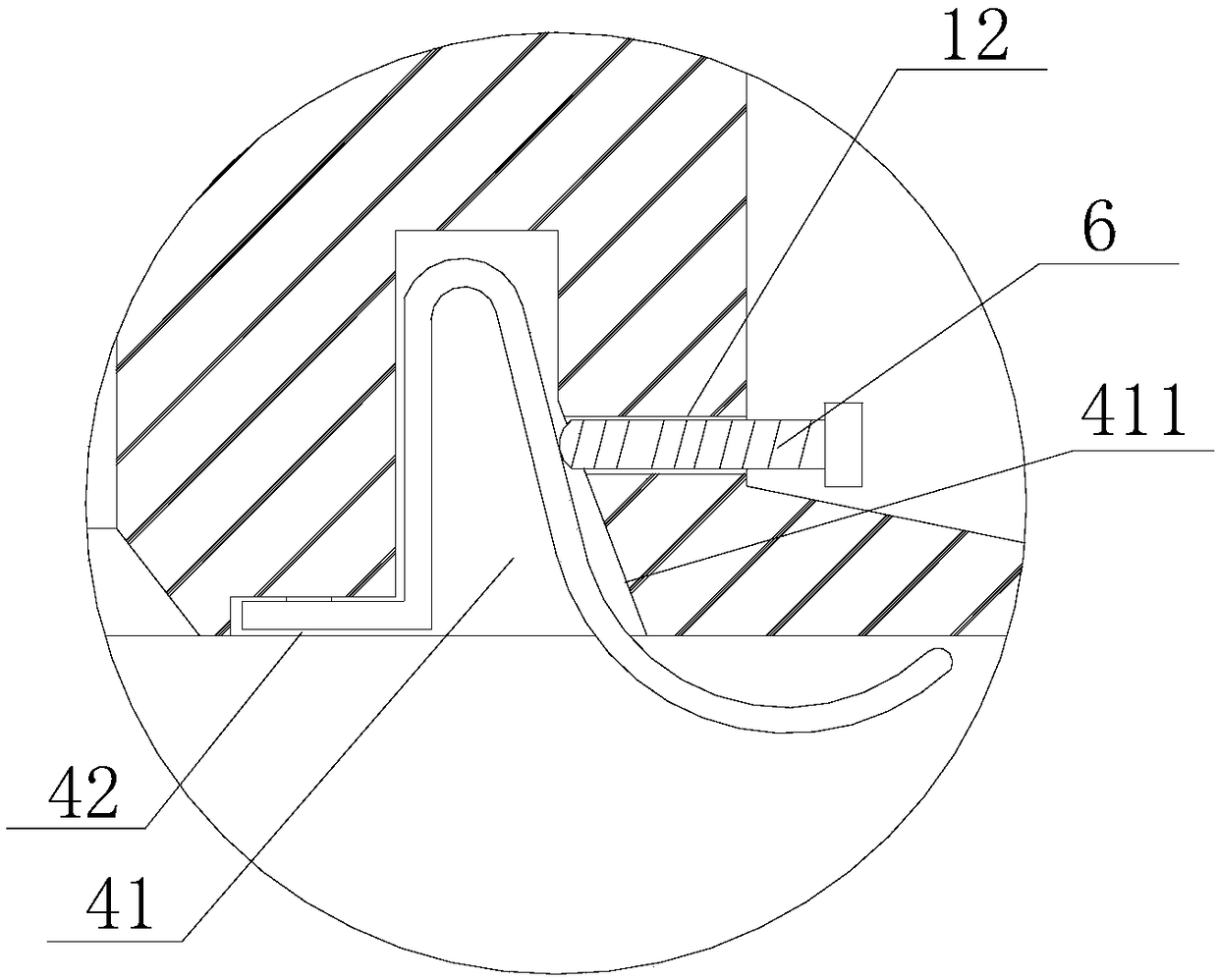

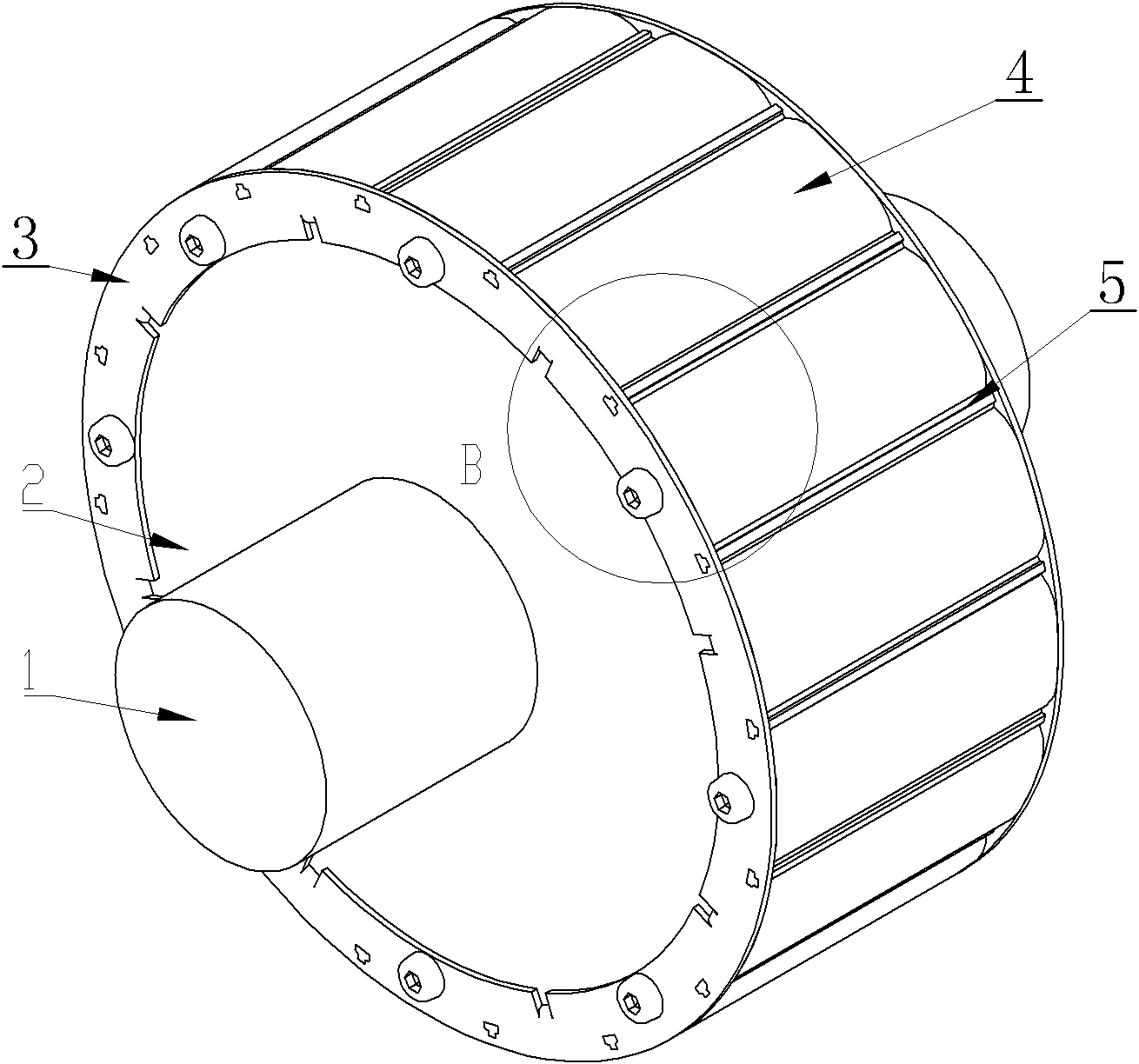

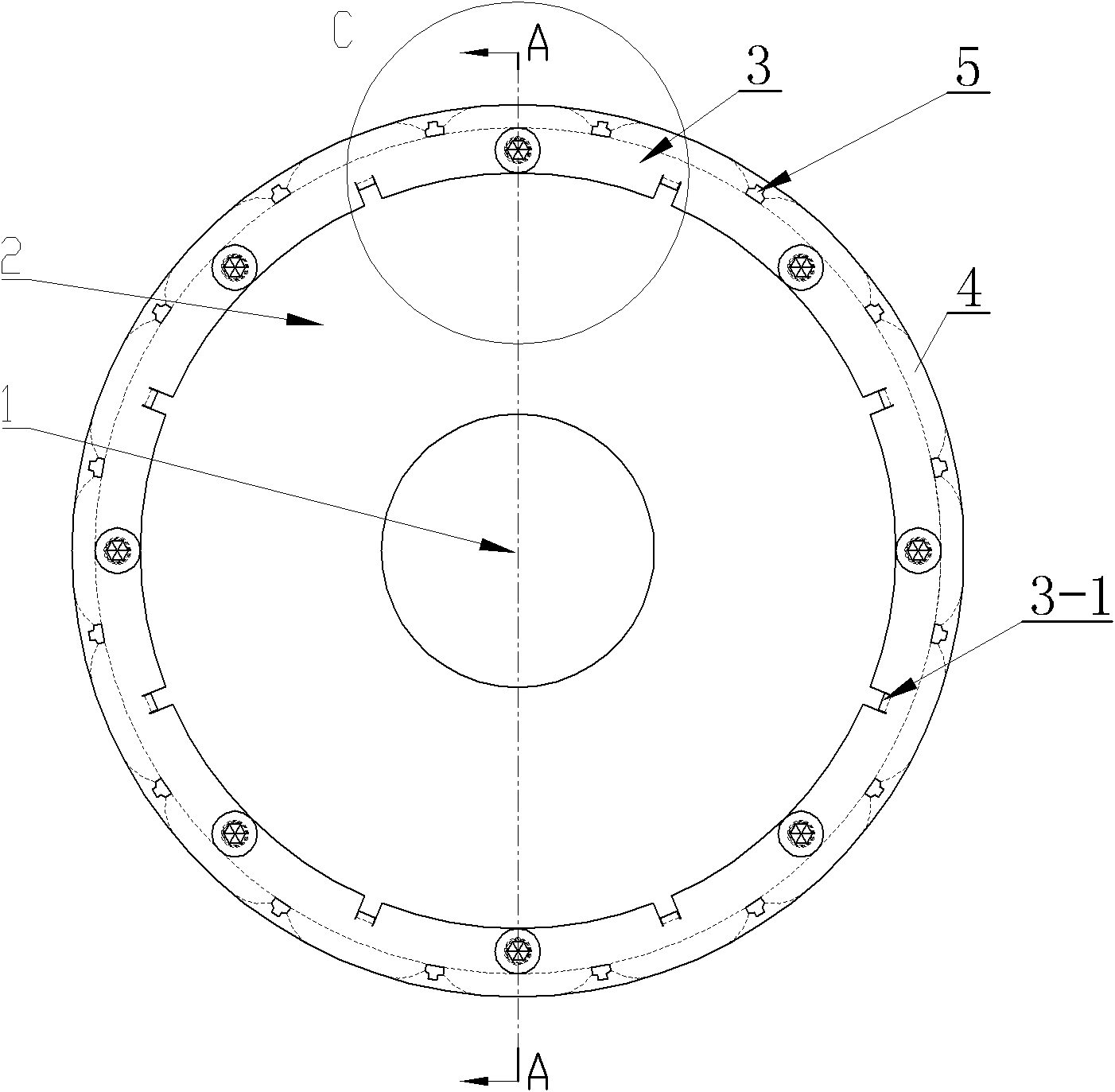

Structure for fixing magnetic poles of permanent magnet motor

ActiveCN102097878AAddress reliabilitySolve the cumbersome installationMagnetic circuit rotating partsPermanent magnet synchronous motorMagnetic poles

Owner:HARBIN INST OF TECH

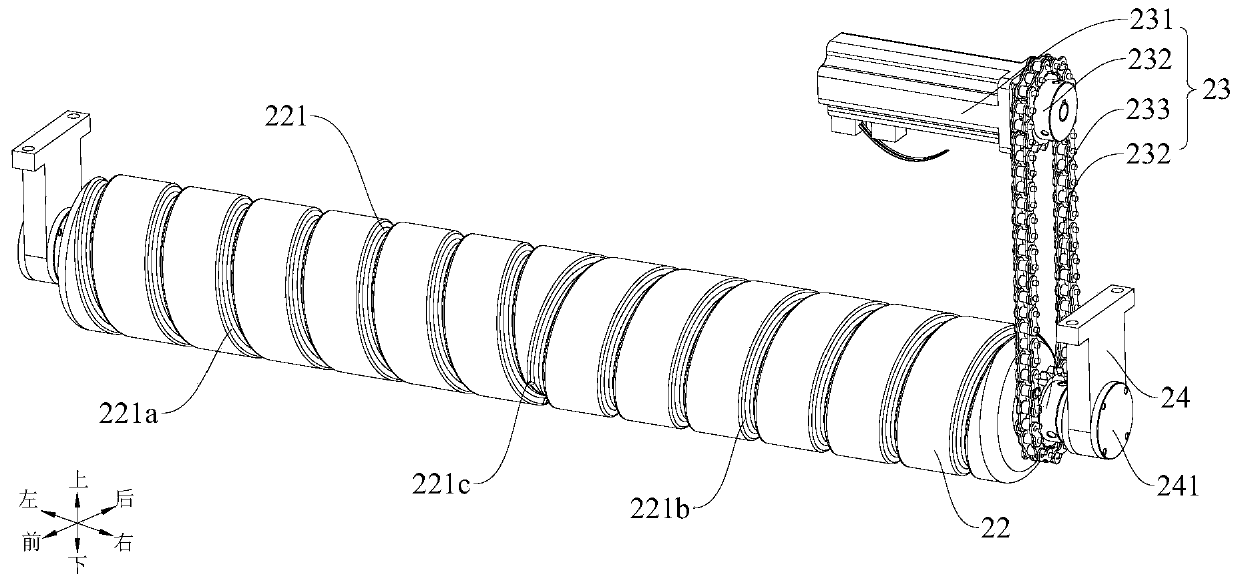

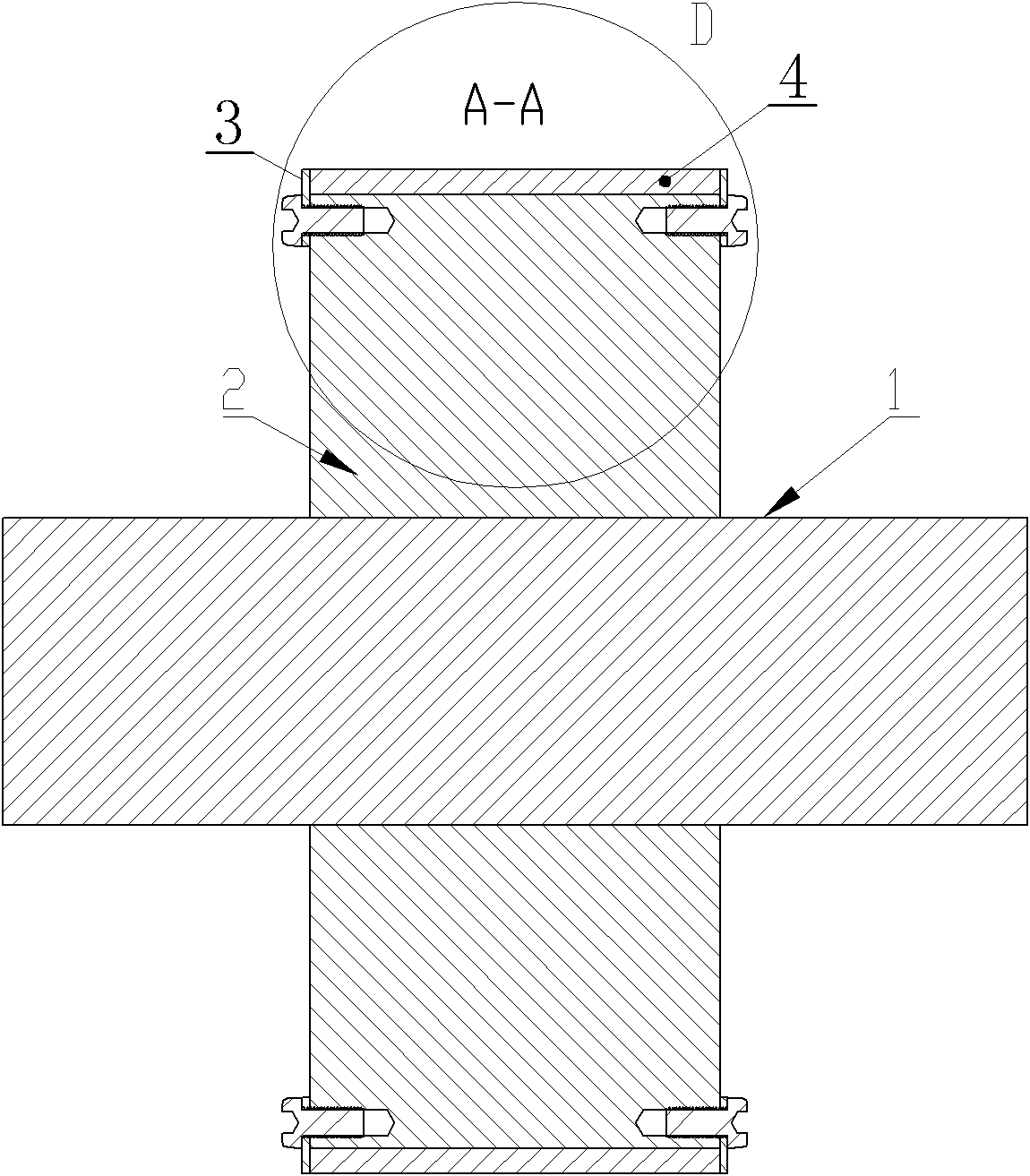

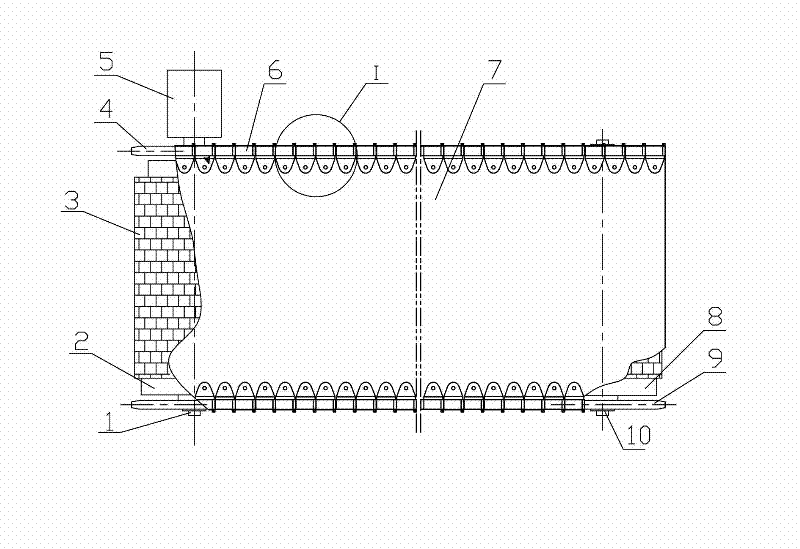

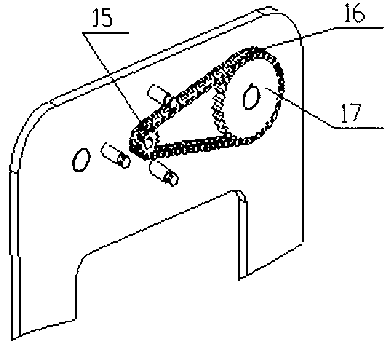

Chain-transmission belt conveyer

ActiveCN102219107ASolve slippageSolve the phenomenon of material accumulation, etc.ConveyorsRollersTransmission beltDrive shaft

The invention belongs to the technical field of belt conveyers, and particularly relates to a chain-transmission belt conveyer, which comprises a machine frame, a driving device, a driving shaft, a driving roller, a rotating shaft, a rotating roller, a group of belt carrier rollers and a conveying belt, wherein two ends of the driving shaft are connected with driving chain wheels respectively; two ends of the rotating shaft are connected with rotating chain wheels respectively; the rotating chain wheels and the driving chain wheels are both in meshed connection with an annularly-closed chain; the lateral edge of the conveying belt is connected with the chain; anti-skidding rubber layers are arranged on outer surfaces of the driving roller and the rotating roller; the chain consists of chain links which are connected mutually, and each chain link consists of a dual-lug chain plate, a chain sleeve, a chain shaft, a flat chain plate, a limit pin shaft and a fastening assembly; and a group of bosses are distributed on the anti-skidding rubber layers uniformly. The invention has the advantages that: the conveying belt does not have the phenomena of slipping, off-slipping, material accumulation and the like, and the chain-transmission belt conveyer is simple in a structure, low in transformation cost and convenient to install and is suitable to be popularized in mine enterprises energetically.

Owner:ANSTEEL GRP MINING CO LTD

Fracture strength testing device and method of ribbon for automobile safety belt

InactiveCN101718654ASolve slippageEasy to useMaterial strength using tensile/compressive forcesEngineeringAutomobile safety

The invention relates to facture strength testing device and method of a ribbon for an automobile safety belt, wherein a power part is a universal testing machine usually used in a testing laboratory, the testing device takes two components as a group, a connecting end of each component is connected with the universal testing machine and manufactured according to an interface of the universal testing machine, and the facture strength testing device mainly comprises a bearing frame and a locking part which plays a role of locking the ribbon. A lock catch chucking table plays the functions of transferring a load as well as supporting and locking a lock catch, and the lock catch comprises a concave part and a concave part which have wavy contact surfaces and plays the roles of locking the ribbon. The ribbon is wound on the lock catch in a specific mode so as to ensure not to skid during the testing process. The fracture strength value is finished through the universal testing machine.

Owner:CHERY AUTOMOBILE CO LTD

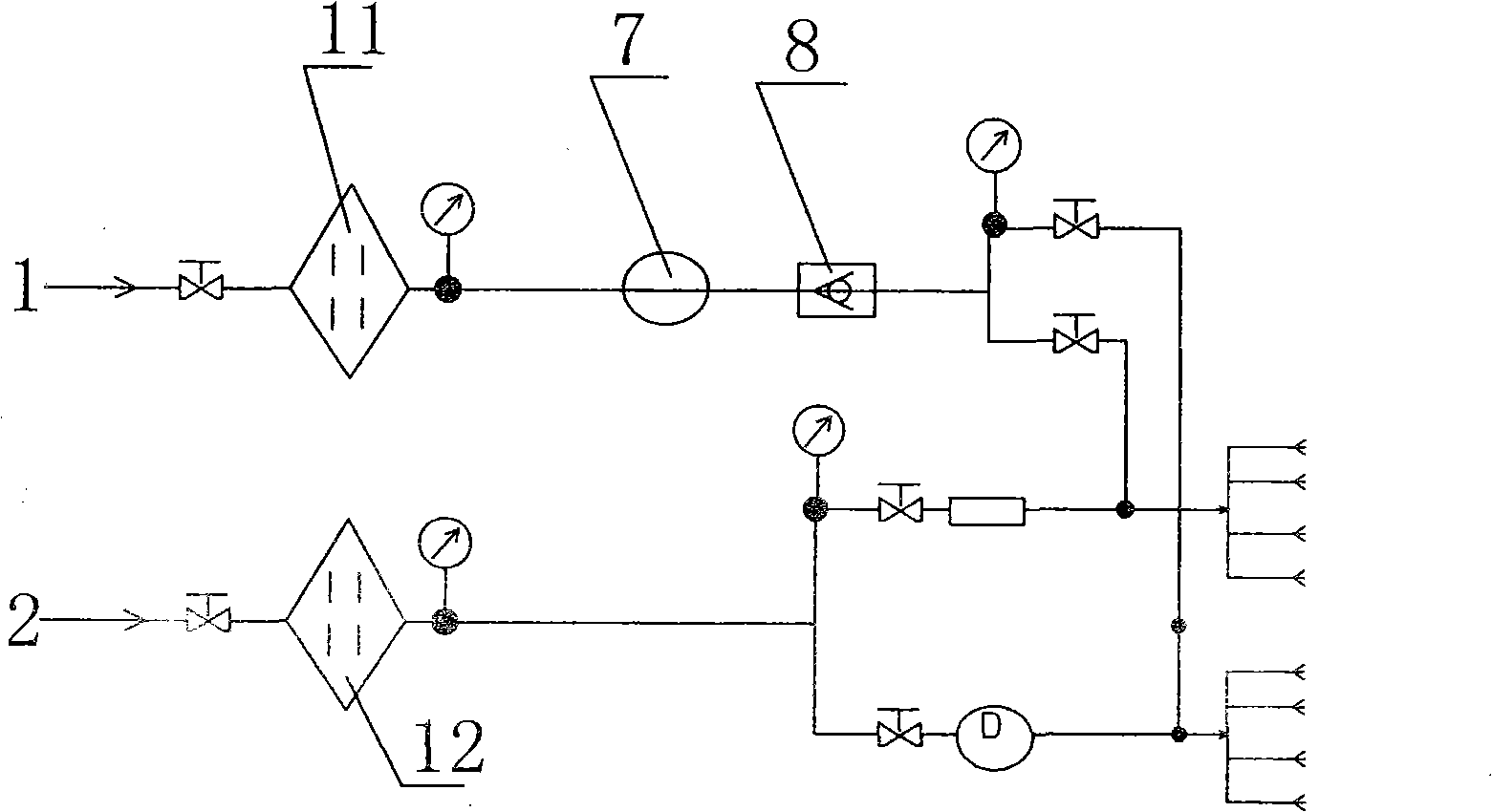

Wind water mixed atomizing method for down-hole coal cutter fully-mechanized coal winning machine

InactiveCN101307691AEfficient captureSolve slippageDust removalFire preventionWater sourceWater vapor

The invention belongs to a wind-water mixing spray technology which can be applied in underground comprehensive mining, comprehensive digging and in places requiring settling dust so as to improve safe production of a coal mine. The invention is characterized in that the technology is realized through the steps as follows: a wind source pipeline which is connected from a ground forcing fan to an extraction working surface with a selectable wind pressure of between 0.5 and 0.7MPa is in parallel connection with a water source pipeline which has certain pressure with a selectable hydraulic pressure of between 3 and 5MPa, and the volume ratio of the mixed wind and water is between 100-135 to 1; the wind source pipeline and the water source pipeline are both connected to nozzles of internal spraying and external spraying of a coal mining machine and a mechanical boring machine, so that wind-water mixing atomized water vapor is sprayed with a flow rate of between 15 and 20M<3> / minute; and the atomized water vapor captures coal dust, and disperses local gas generated during cutting a coal body. The invention aims to solve the problems caused by the local gas which is generated during settling dust and cutting coal and can not be dispersed in time, such as safety threat in production, water resource waste, affected coal quality, slipping belt, slipping goods, bin blockage or other problems.

Owner:李本学 +1

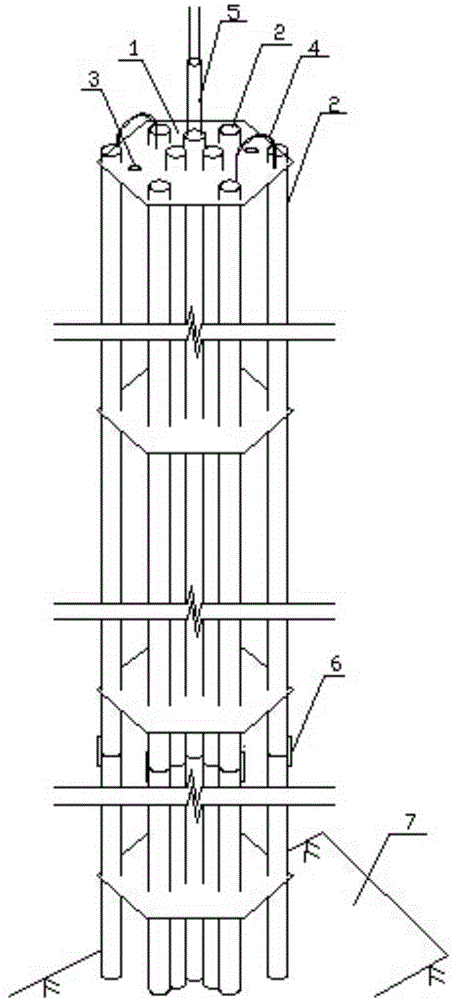

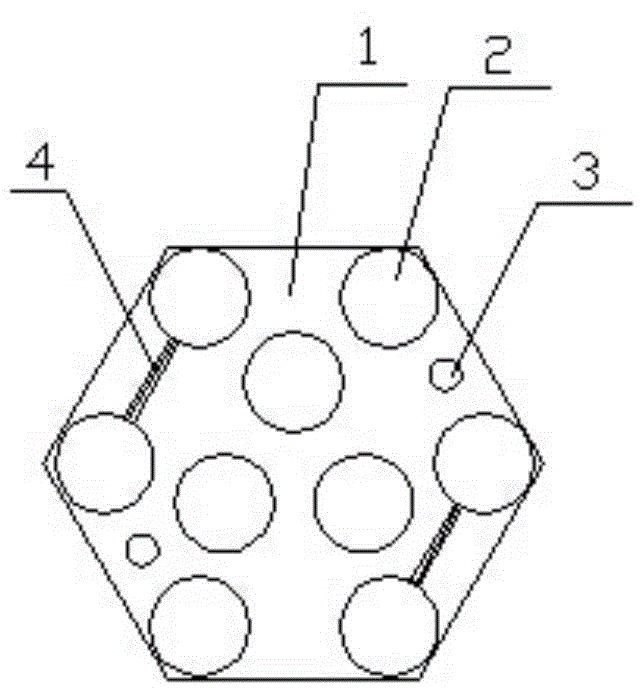

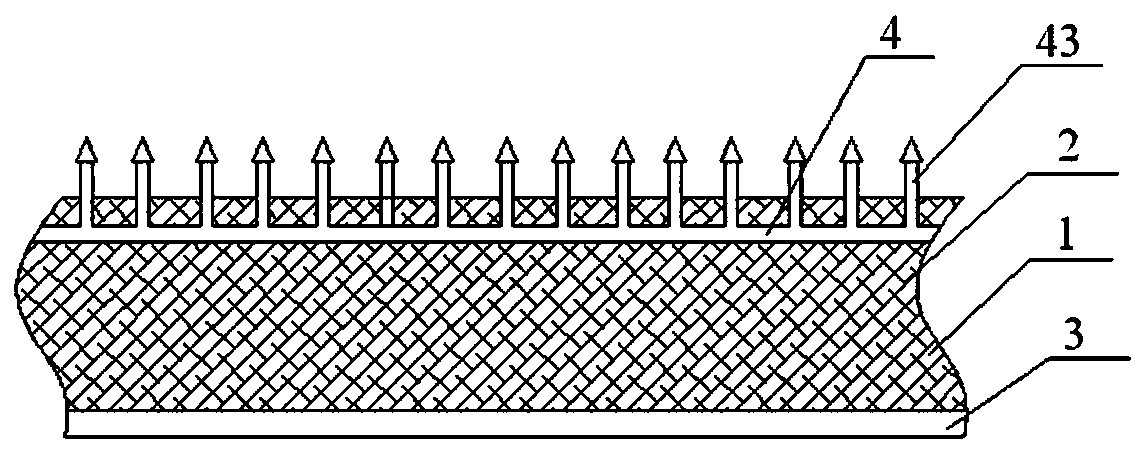

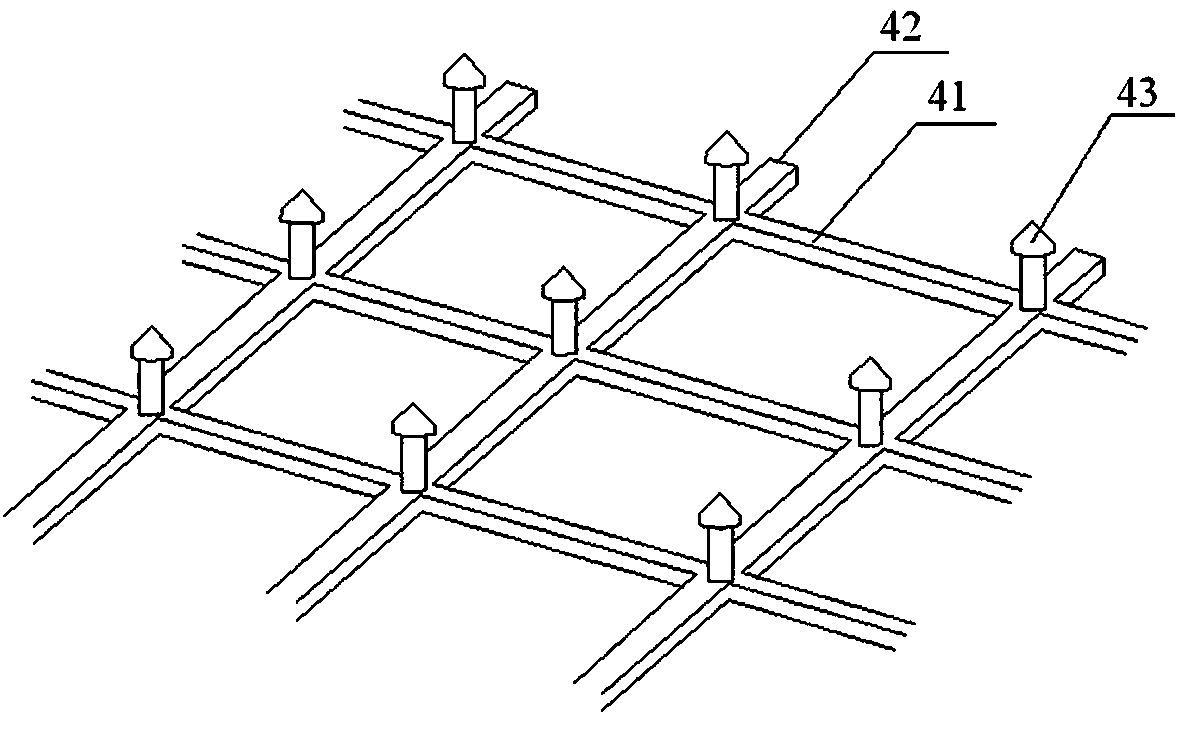

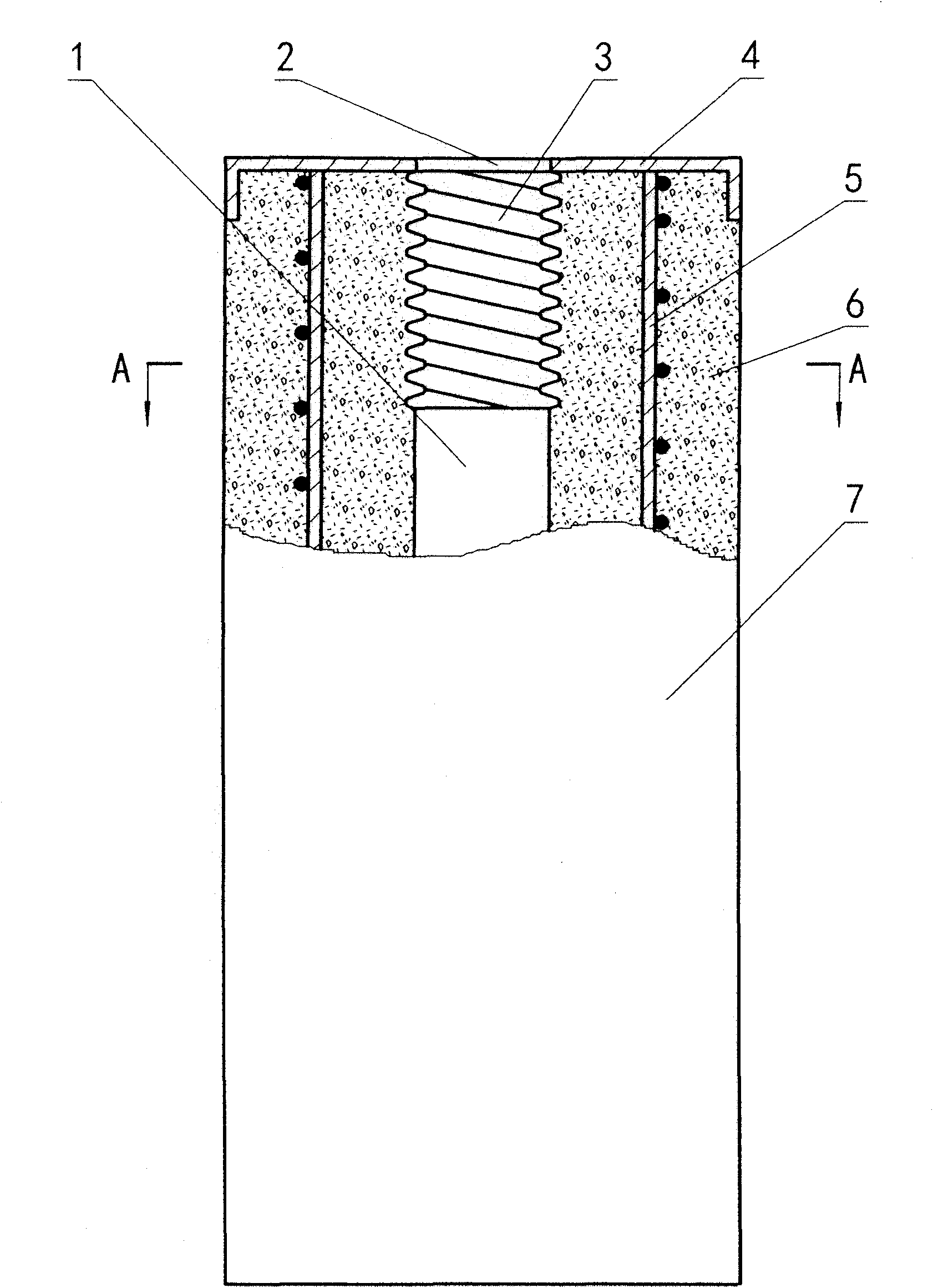

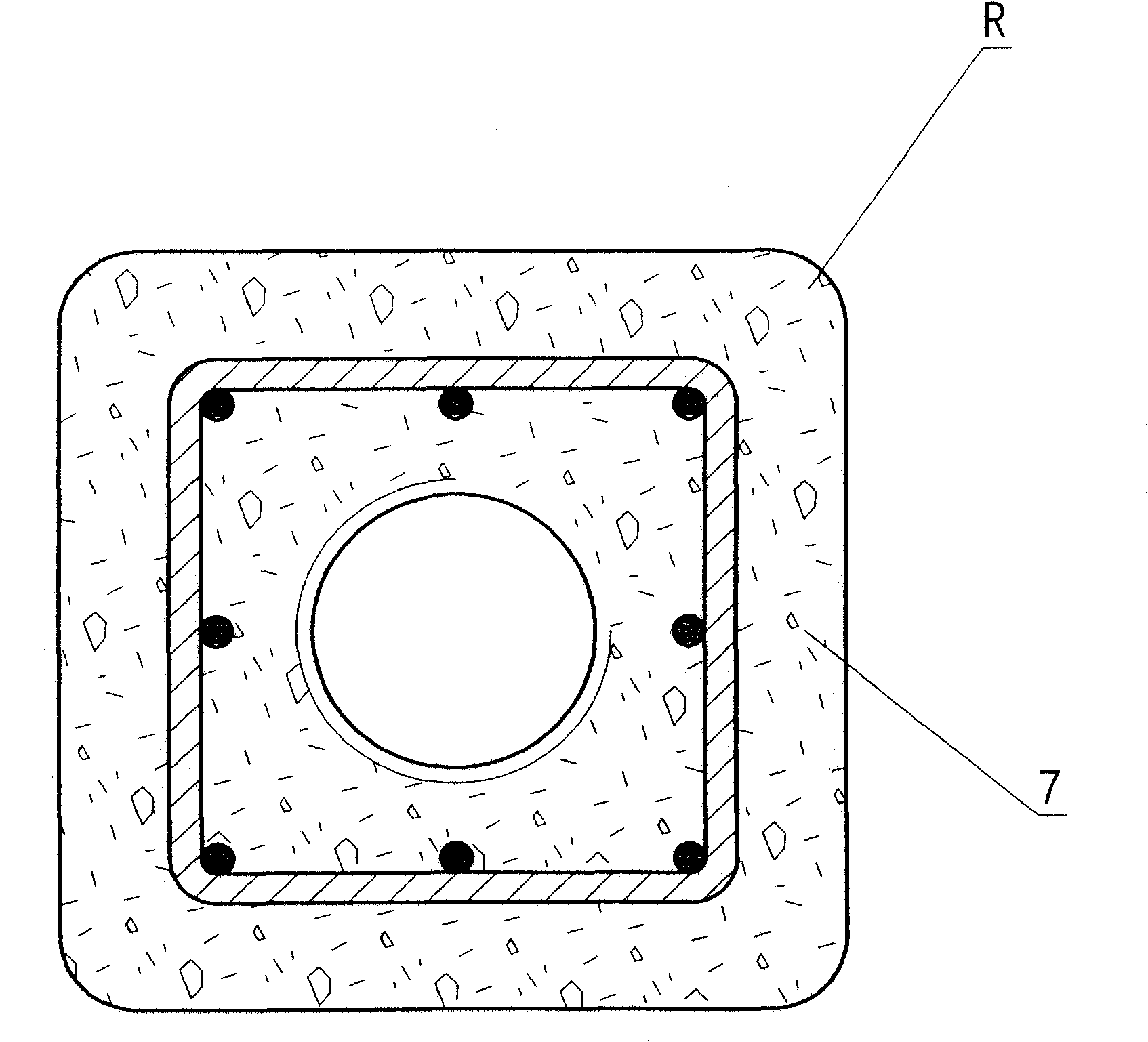

Rectangular Pre-stressed reinforced concrete hollow pile with internal thread or internal groove and method for processing hollow pile

ActiveCN102212992ASolve slippageAvoid the risk of topplingCeramic shaping apparatusBulkheads/pilesReinforced concretePre stress

The invention relates to a rectangular pre-stressed reinforced concrete hollow pile, which comprises a rectangular pile body and rectangular metal end plates. The rectangular pile body comprises a reinforcement cage and concrete and is axially provided with a through central round hole; the rectangular metal end plates are arranged at the two ends of the rectangular pile body and correspond to the central round hole of the rectangular pile body; central round holes are also formed in the rectangular mental end plates; an internal thread structure, or an internal groove structure, or a tooth-shaped bulge, or a plurality of pits, or a plurality of bumps is or are arranged on the inner wall of the central round hole of the rectangular pile body to make the bonding force between reinforce concrete of a lower-edge part of a building bearing platform and the central round holes strong, so the problem that the reinforce concrete of the lower-edge part of the building bearing platform slips off from the central round holes is effectively solved, and a building on the bearing platform is prevented from turning over due to shaking or swinging under the action of external force; therefore, the hollow pipe has good safety. The rectangular pile body is processed by the conventional method, the internal thread structure or the internal groove structure on the inner wall is processed by a cutting or extrusion mode, and the processing technology is simple, low in cost and high in efficiency.

Owner:盐城市双强管桩有限公司

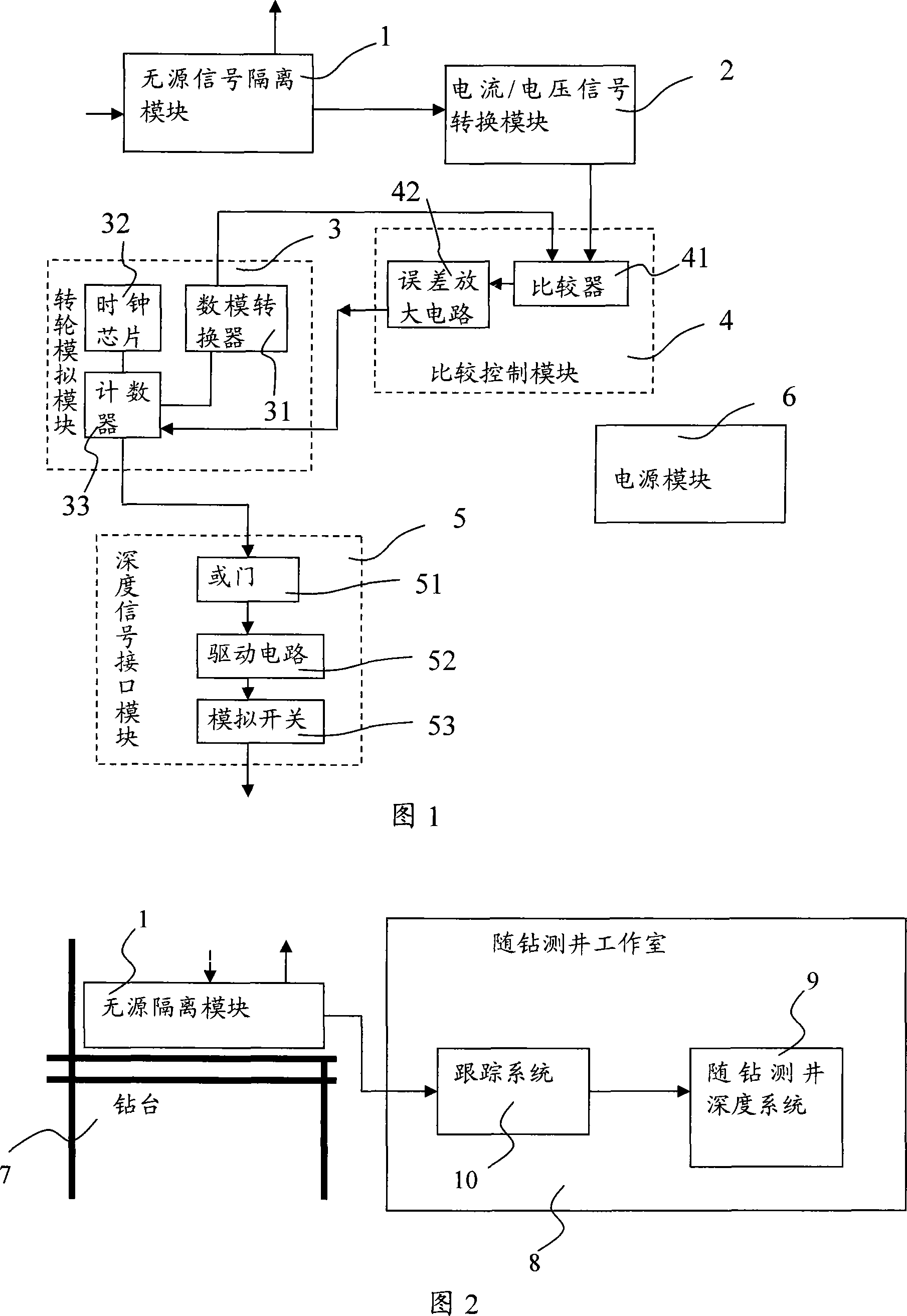

Depth tracking device for logging while drilling

A tracing device along with drilling includes current / voltage signal transfer module, motor simulation module, comparison control module, depth signal module and power source module. With this invention, it is not necessary to install a depth sensor to winch and the related mechanical transition. All signals are electronically transferred and treated.

Owner:CHINA NAT OFFSHORE OIL CORP +1

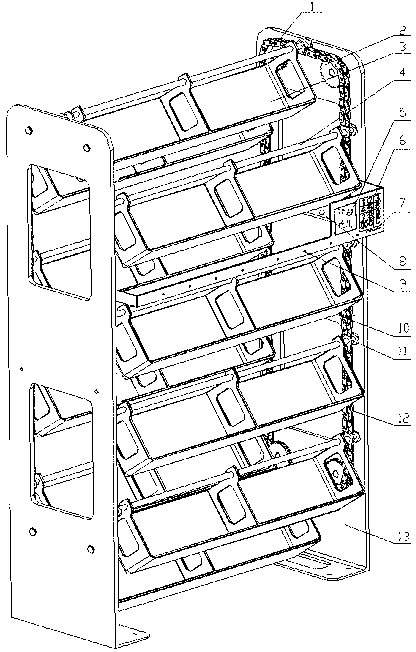

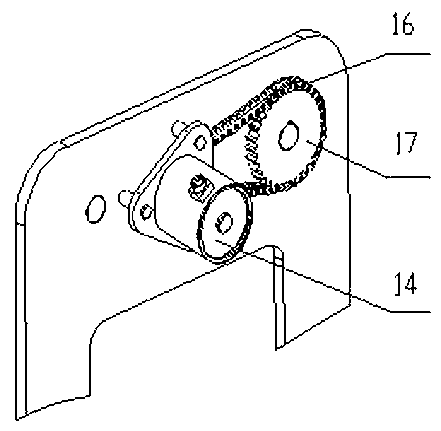

Automatic bookshelf

The invention discloses an automatic bookshelf, which aims to effectively use a space resource of a library, realize digitalization of the library and automation and quickness of book searching and effectively save time of finding books and information. A chain encircles a circle around driving chain wheels, driven chain wheels and guide chain wheels; long shafts are fixedly connected with special chain sections; book buckets are arranged on the long shafts through bearings; a position sensor is fixedly arranged on a right support of a bracket; a keyboard, a display screen and a bar-code scanner are fixedly arranged on a front panel of the bracket; indicating lamps are arranged on the front panel of the bracket; a motor is fixedly arranged on the outer side face of the right support of the bracket; and a small chain wheel is fixedly arranged on an output shaft of the motor. The automatic bookshelf can effectively utilize high-altitude spaces and current areas of libraries and document rooms, and books and documents can be quickly searched.

Owner:QINGDAO UNIV OF SCI & TECH

Elevator guide rail quality detecting device and method

ActiveCN111170121AAvoid insufficient frictionAvoid damageElevatorsElectromagnetic wave reradiationImage resolutionClassical mechanics

The invention relates to an elevator guide rail quality detecting device which comprises two plumb lasers independently fixed on the ground, a reflector and a camera. The reflector is fixed below thebottom bodies of grippers on the two sides of an elevator guide rail crawling robot; the camera is fixed on the inner side of a stabilizing arm unit; a pair of traction wheels and a pair of gripper wheels of the elevator guide rail crawling robot always cling to the elevator guide rail and crawl along the guide rail; the laser rays of the plumb lasers separately shine to the positions near to thecenter of the reflector; the camera shoots laser points generated on the reflector without stop; guide rail quality variation is directly converted into position changes of the reflector and the camera in the horizontal direction; and the straightness and other quality conditions of the elevator guide rail can be measured through treating each crawling information of the robot and the position data of the laser points. The elevator guide rail quality detecting device is convenient to use and mount and easy to operate, and has the advantages of being low in cost, high in resolution, measuring precision and efficiency and wide in building applicable range.

Owner:QINGDAO UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com