Robot chassis and service robot

A robot and chassis technology, applied in the field of robots, can solve problems affecting robot performance, safety, poor stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

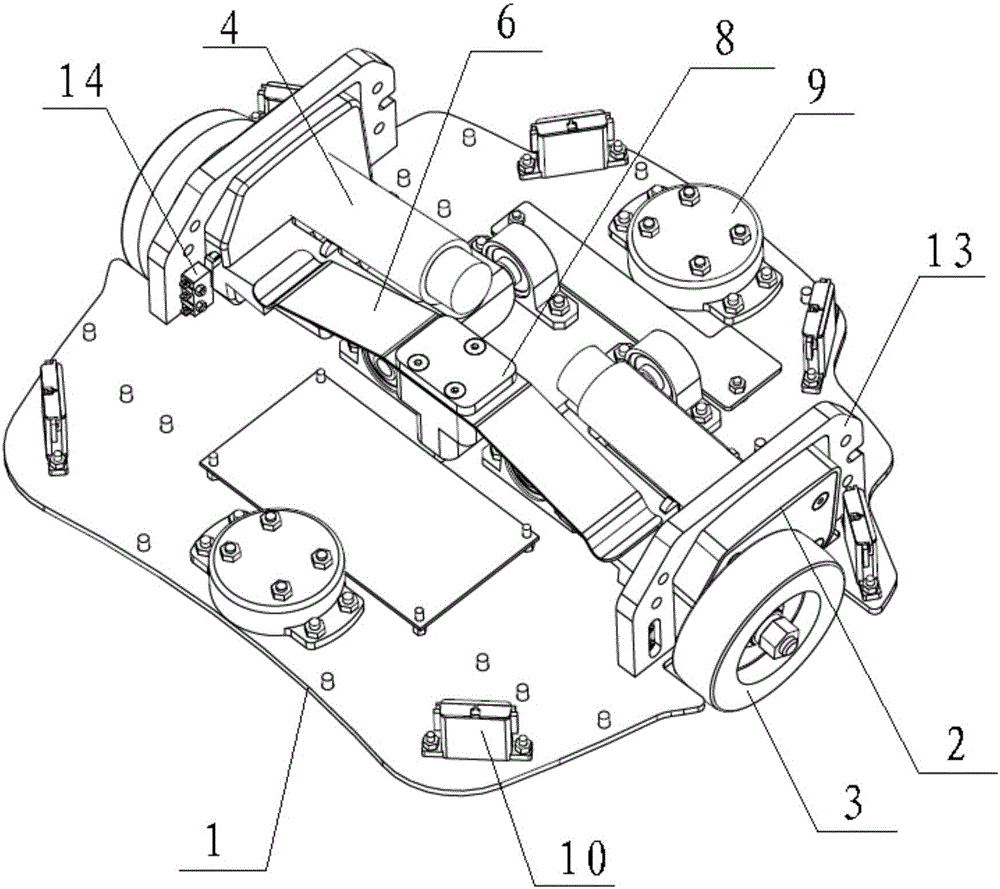

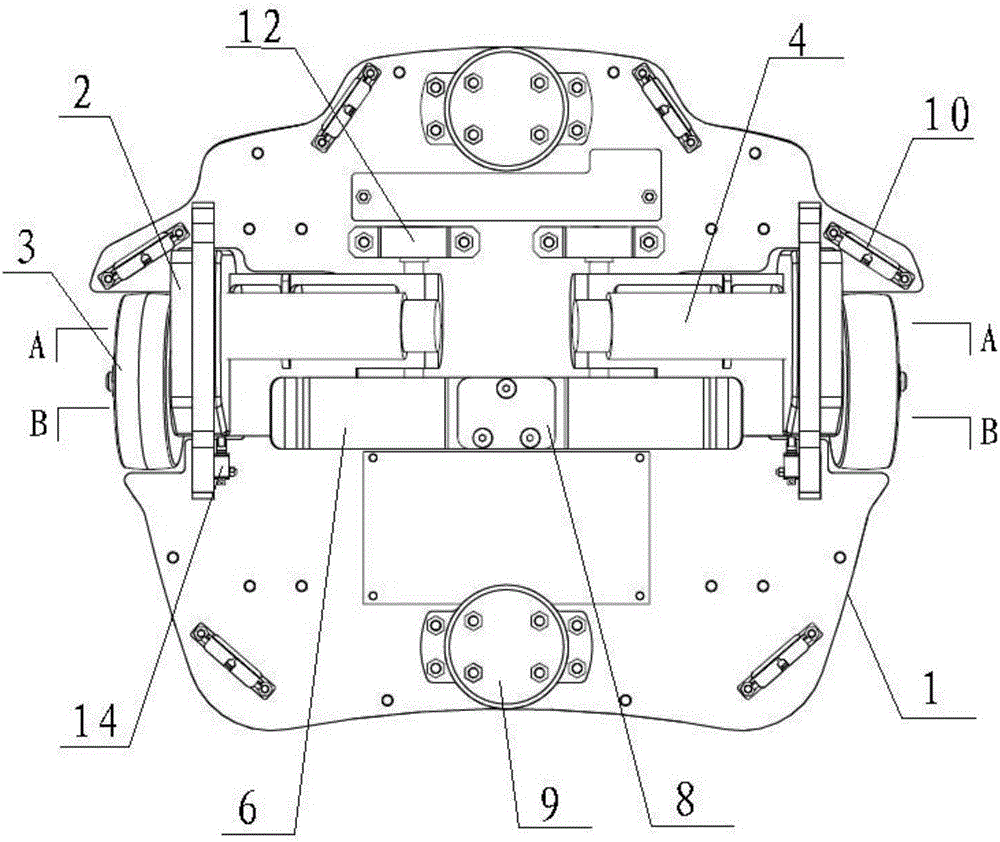

[0034] Such as Figure 1-8 As shown, a service robot chassis includes a chassis main body 1, a walking device and an anti-skid device. The chassis main body 1 is provided with at least two walking devices, and the two walking devices are respectively arranged on both sides of the chassis main body 1. Each walking device It is connected with the chassis main body 1 through an anti-skid device;

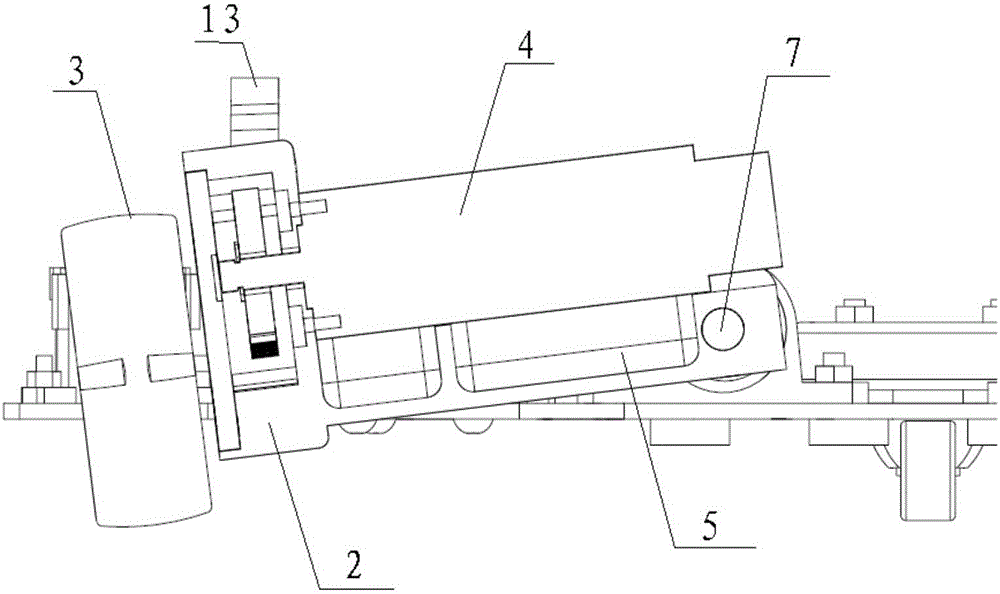

[0035] The traveling device includes a gear box 2, and the gear box 2 is connected with a traveling wheel 3 and a driving motor 4;

[0036] The anti-skid device includes a pressing plate 5 and an elastic sheet 6. One end of the pressing plate 5 is connected with the gear box 2, and the other end is connected with a rotating device. The rotating device includes a rotating shaft 7, which is connected in rotation with the pressing plate 5. The axial direction is parallel to the traveling direction of the traveling wheel 3 , one end of the elastic sheet 6 fits the pressing plate 5 , and th...

Embodiment 2

[0040] Such as Figure 1-8 As shown, a service robot chassis includes a chassis main body 1, a walking device and an anti-skid device. The chassis main body 1 is provided with at least two walking devices, and the two walking devices are respectively arranged on both sides of the chassis main body 1. Each walking device It is connected with the chassis main body 1 through an anti-skid device;

[0041] The traveling device includes a gear box 2, and the gear box 2 is connected with a traveling wheel 3 and a drive motor 4;

[0042] The anti-skid device includes a pressing plate 5 and an elastic sheet 6. One end of the pressing plate 5 is connected with the gear box 2, and the other end is connected with a rotating device. The rotating device includes a rotating shaft 7, which is connected in rotation with the pressing plate 5. The axial direction is parallel to the traveling direction of the traveling wheel 3 , one end of the elastic sheet 6 fits the pressing plate 5 , and the ...

Embodiment 3

[0061] Such as Figure 1-8 As shown, a service robot includes a robot main body, and a robot chassis is connected to the bottom of the robot main body.

[0062] When the robot is in use, the load of the robot itself presses down on the chassis main body 1, wherein multiple traveling devices can be arranged on the chassis main body 1, and the traveling devices can be arranged symmetrically or asymmetrically, and each traveling device is connected with an anti-skid device , Therefore, it is possible to effectively control each traveling wheel 3 to always have a good contact with the ground.

[0063] In addition, the universal wheel 9 is arranged on the front end and the rear end of the chassis main body 1. During the traveling process, the traveling wheel 3 adjusts the direction to control the advancing direction of the robot, and drives the universal wheel 9 to rotate passively. The control system of the robot is pre-programmed according to The signal sent by the detection sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com