Patents

Literature

45results about How to "Ensure fit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

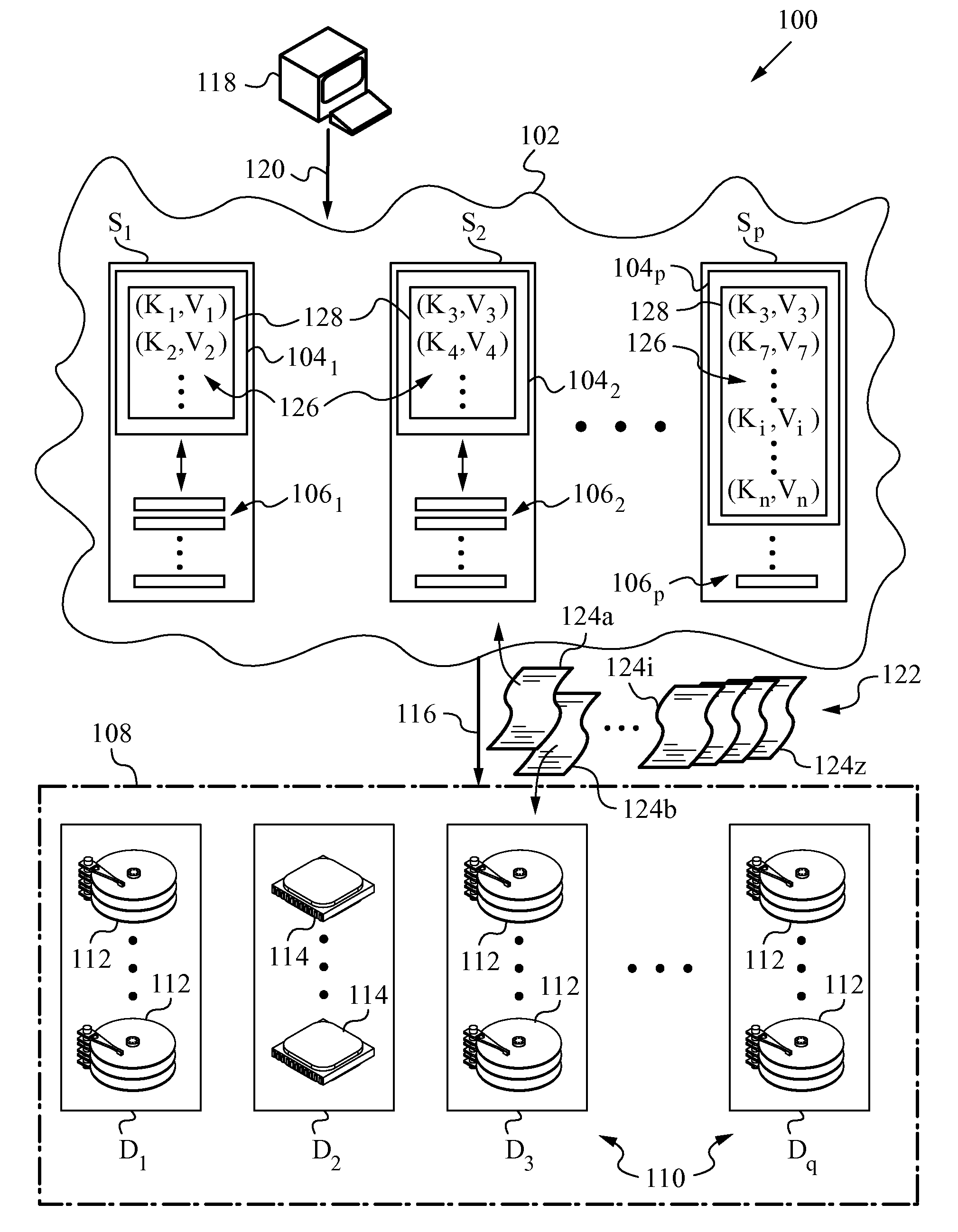

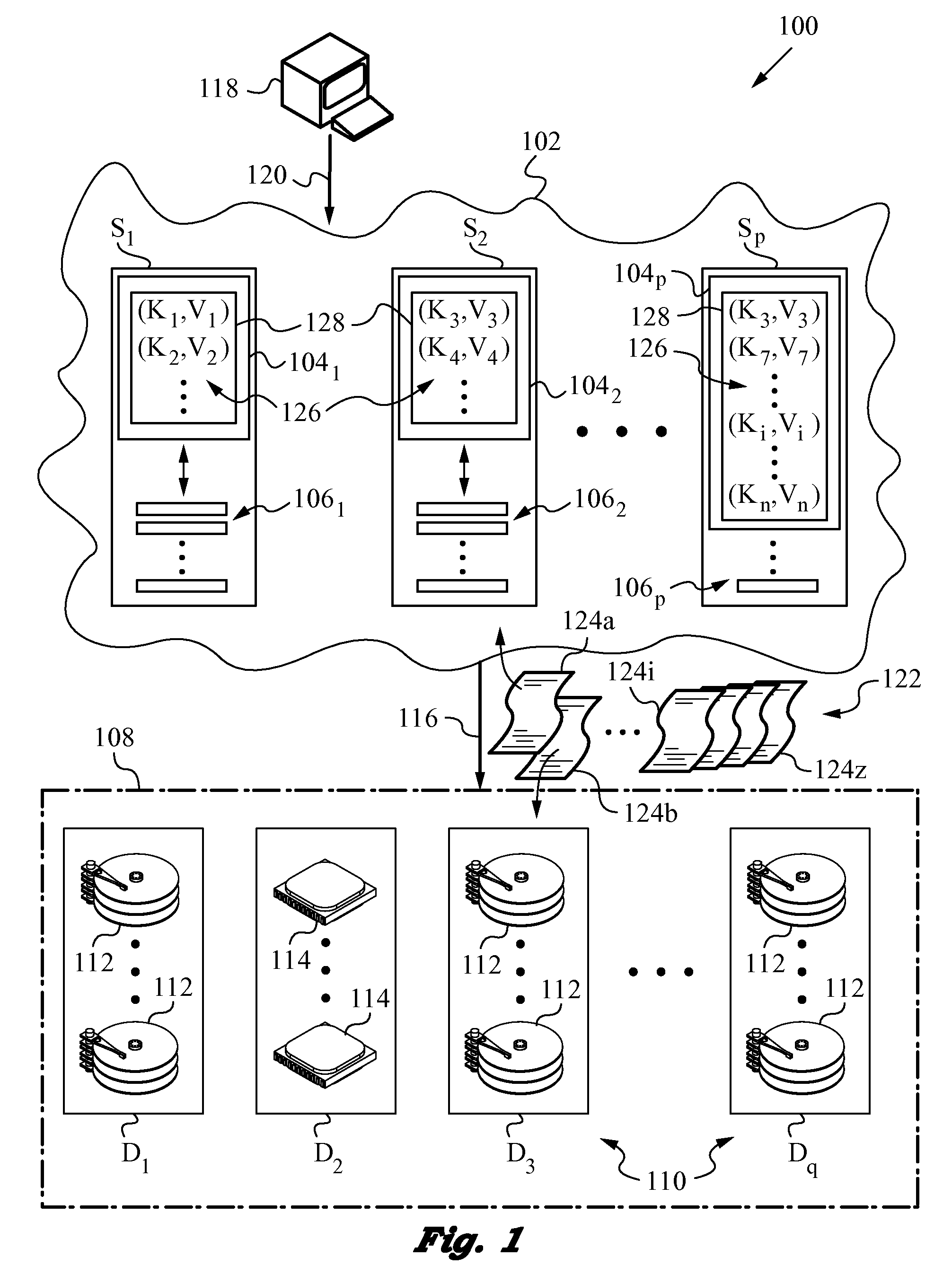

Scalable Distributed Metadata File System using Key-Value Stores

InactiveUS20120284317A1High-performance and more scalableEnsure fitFile access structuresFile metadata searchingDistributed File SystemFile system

A computer-implemented method and a distributed file system in a distributed data network in which file metadata related to data files is distributed. A unique and non-reusable mode number is assigned to each data file that belongs to the data files and a directory of that data file. A key-value store built up in rows is created for the distributed file metadata. Each of the rows has a composite row key and a row value (key-value pair) where the composite row key for each data file includes the mode number and a name of the data file. When present in the directory, the data file is treated differently depending on size. For data files below the maximum file size the entire file or portion thereof is encoded in the corresponding row value of the key-value pair. Data files above maximum file size are stored in large-scale storage.

Owner:ZETTASET

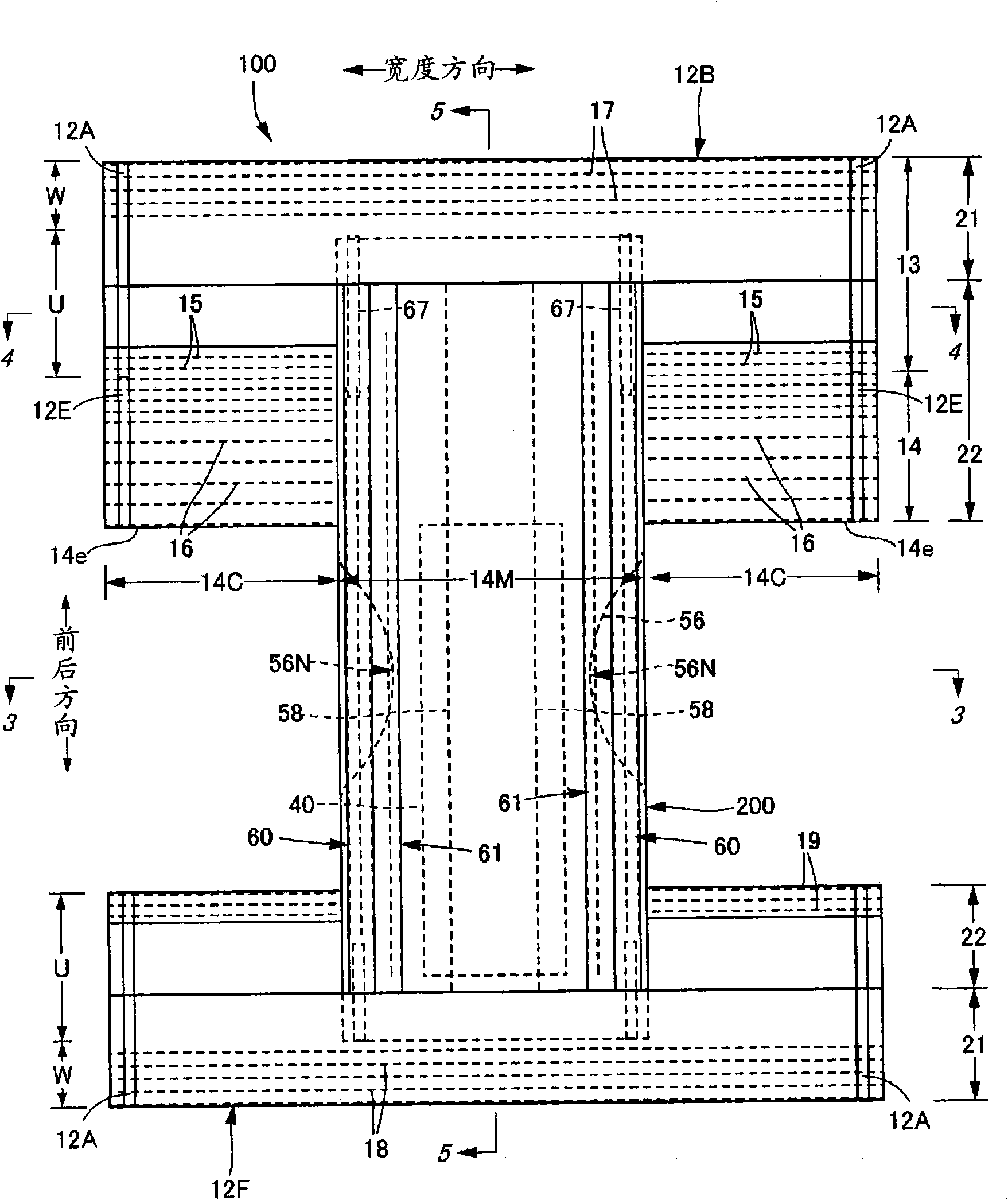

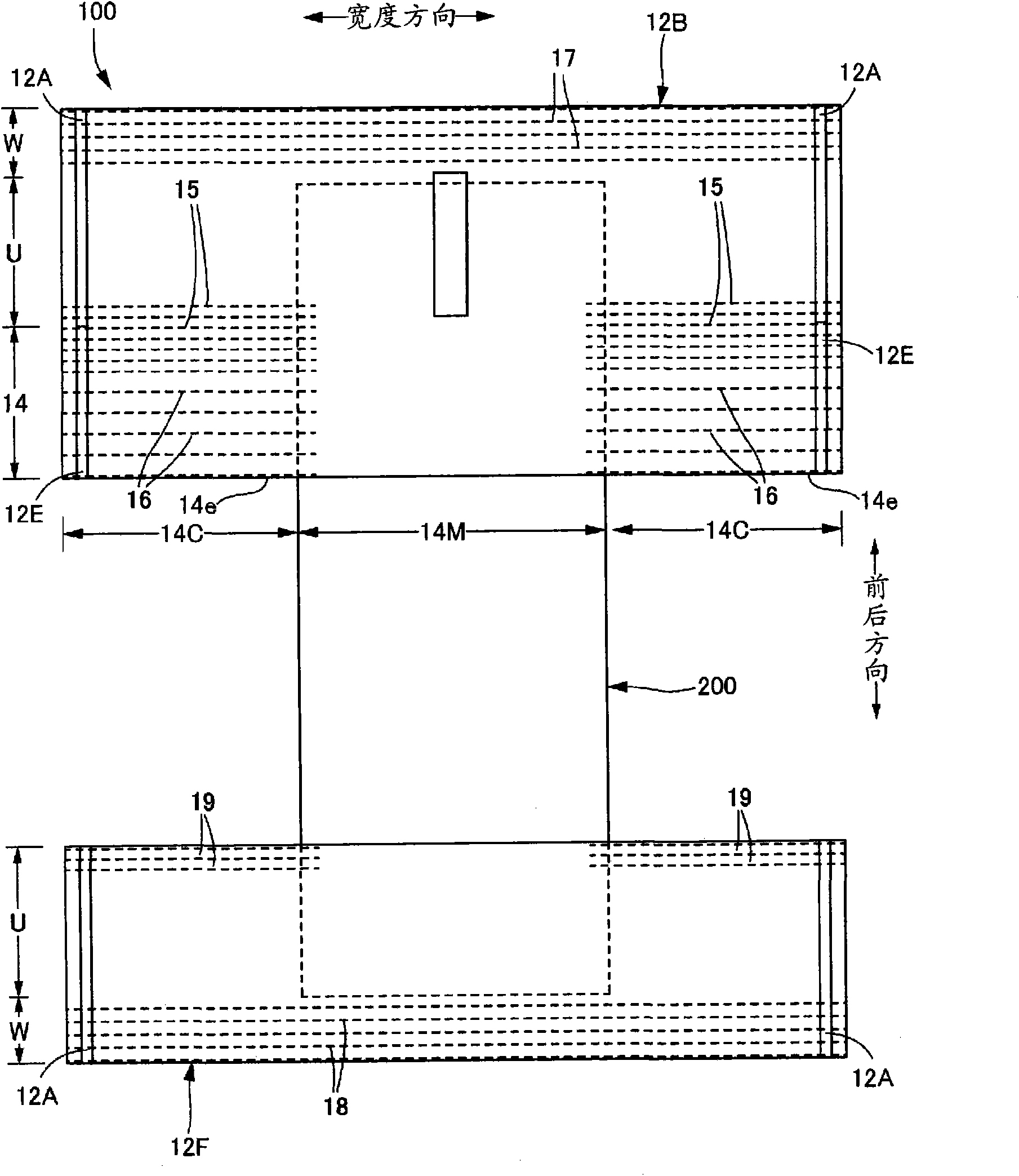

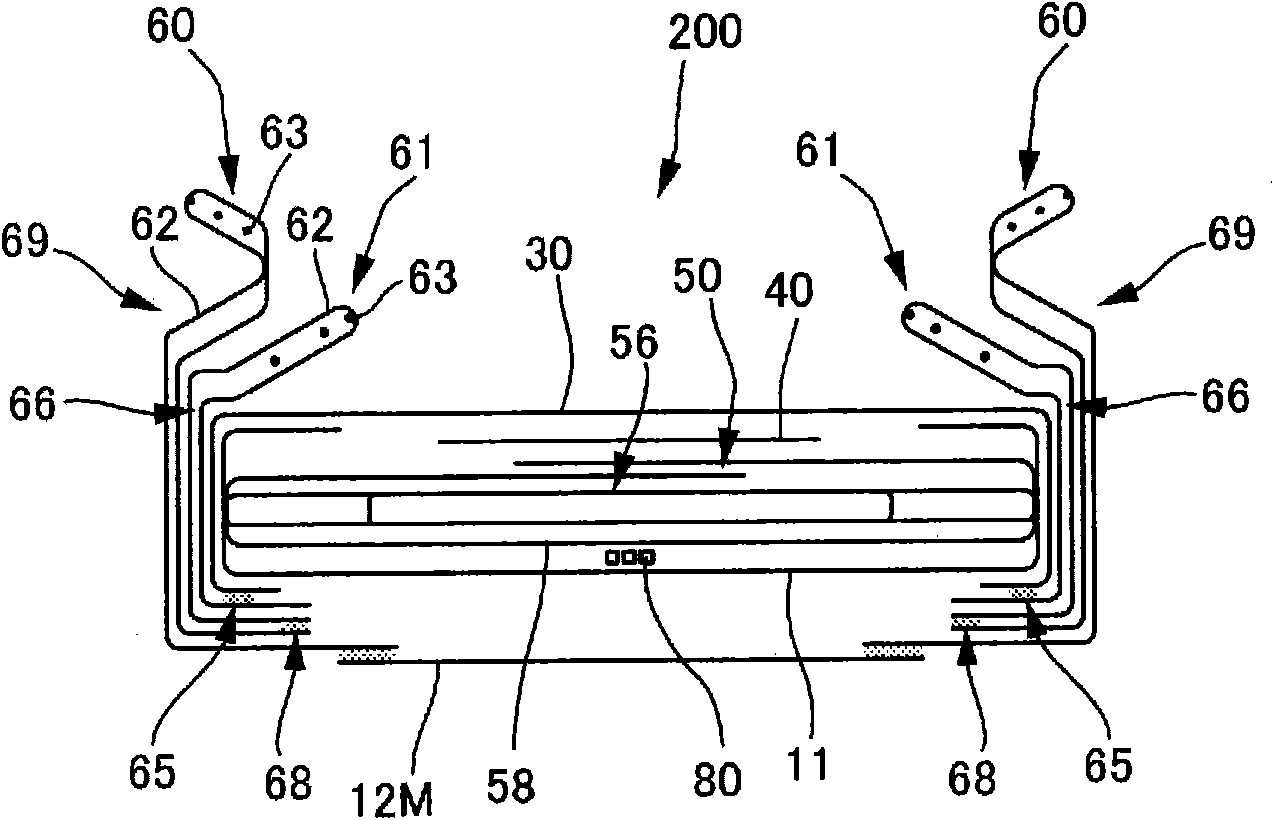

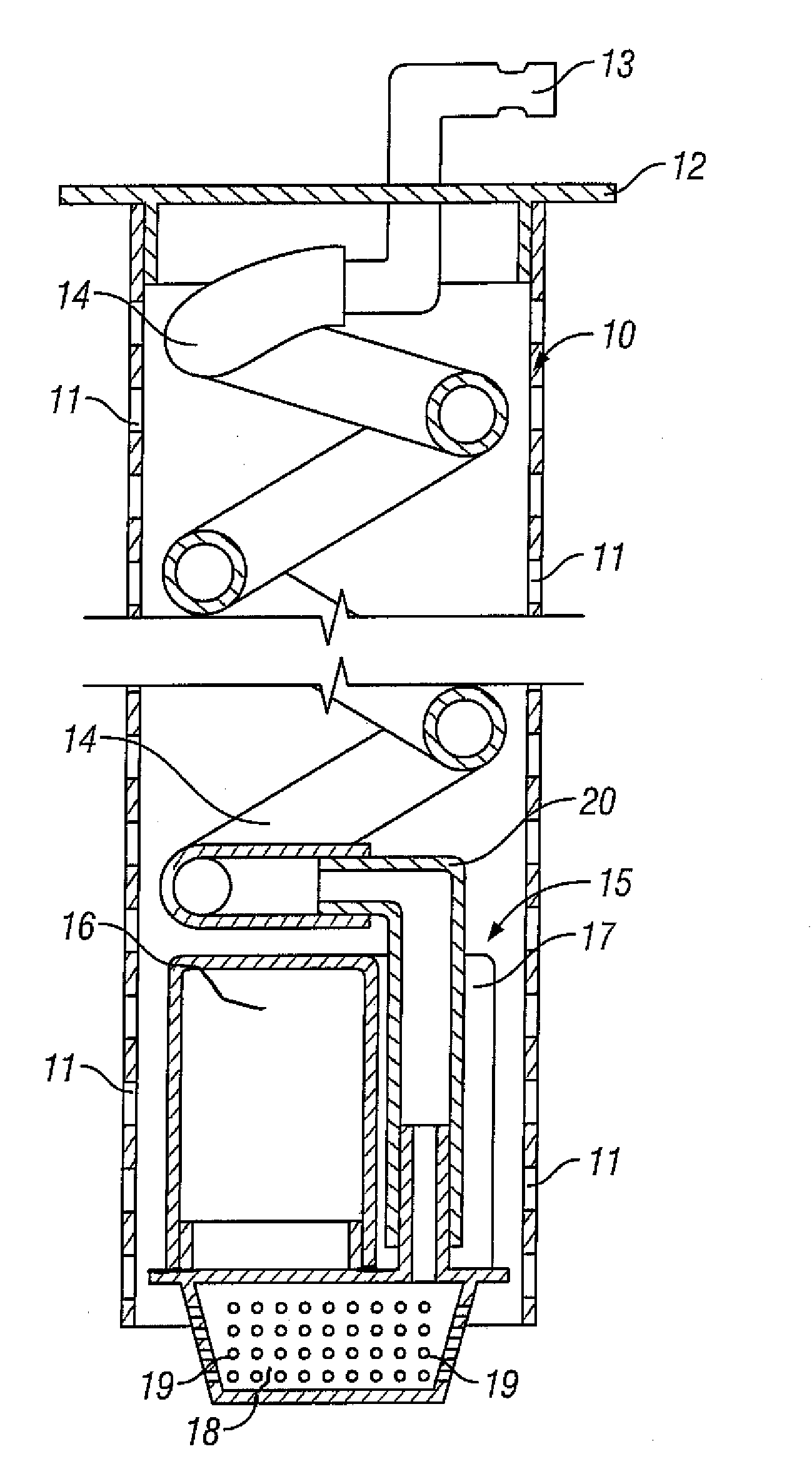

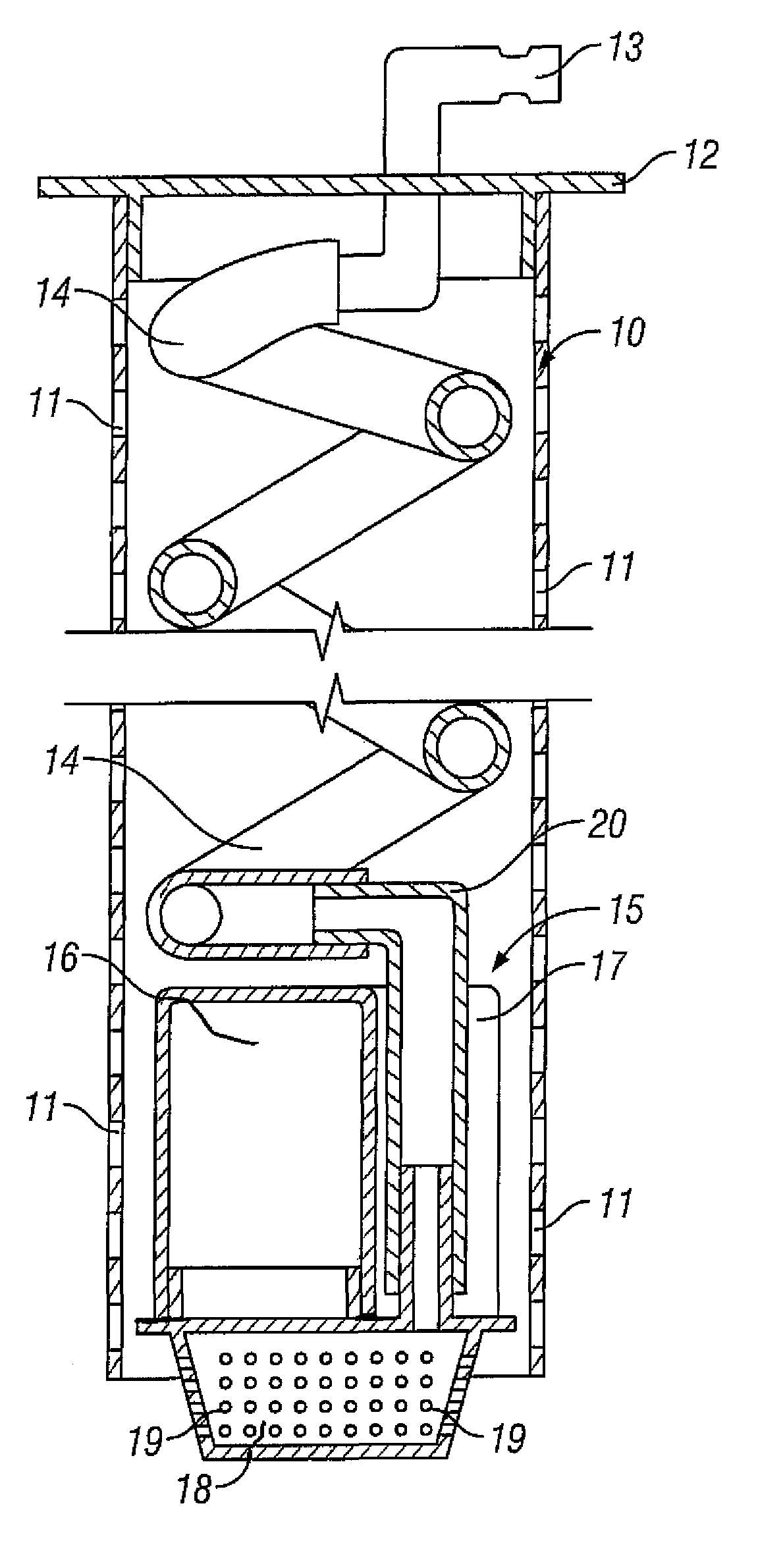

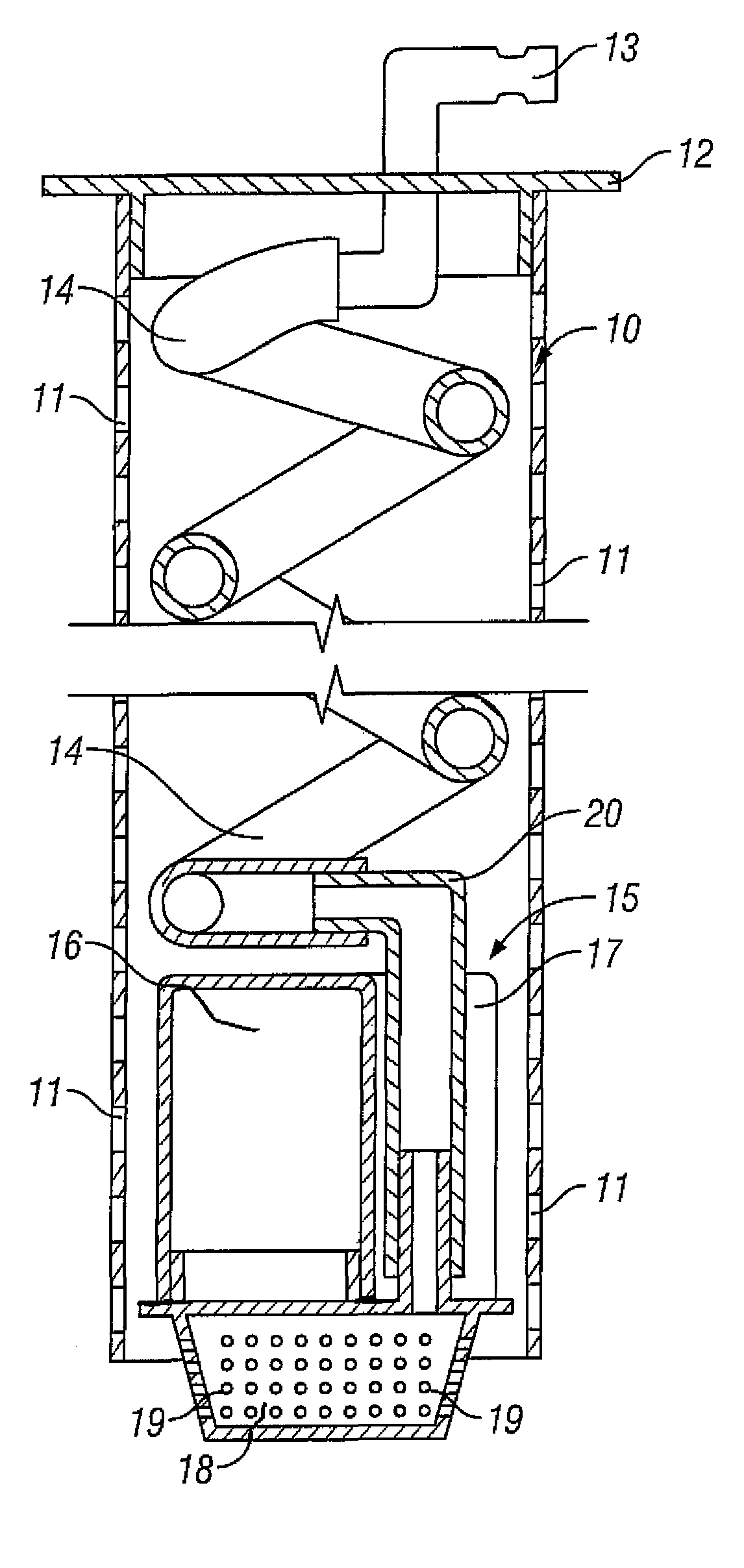

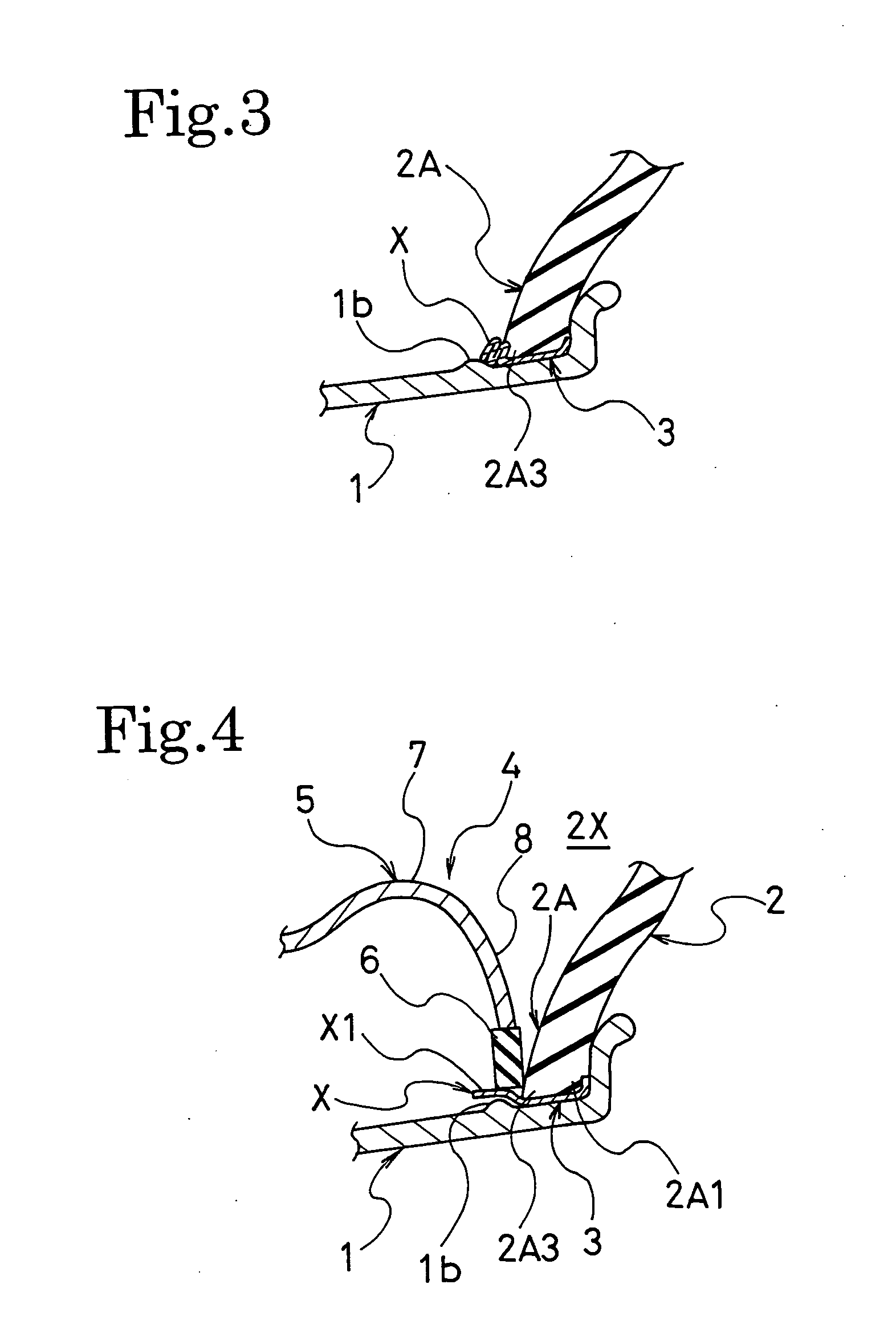

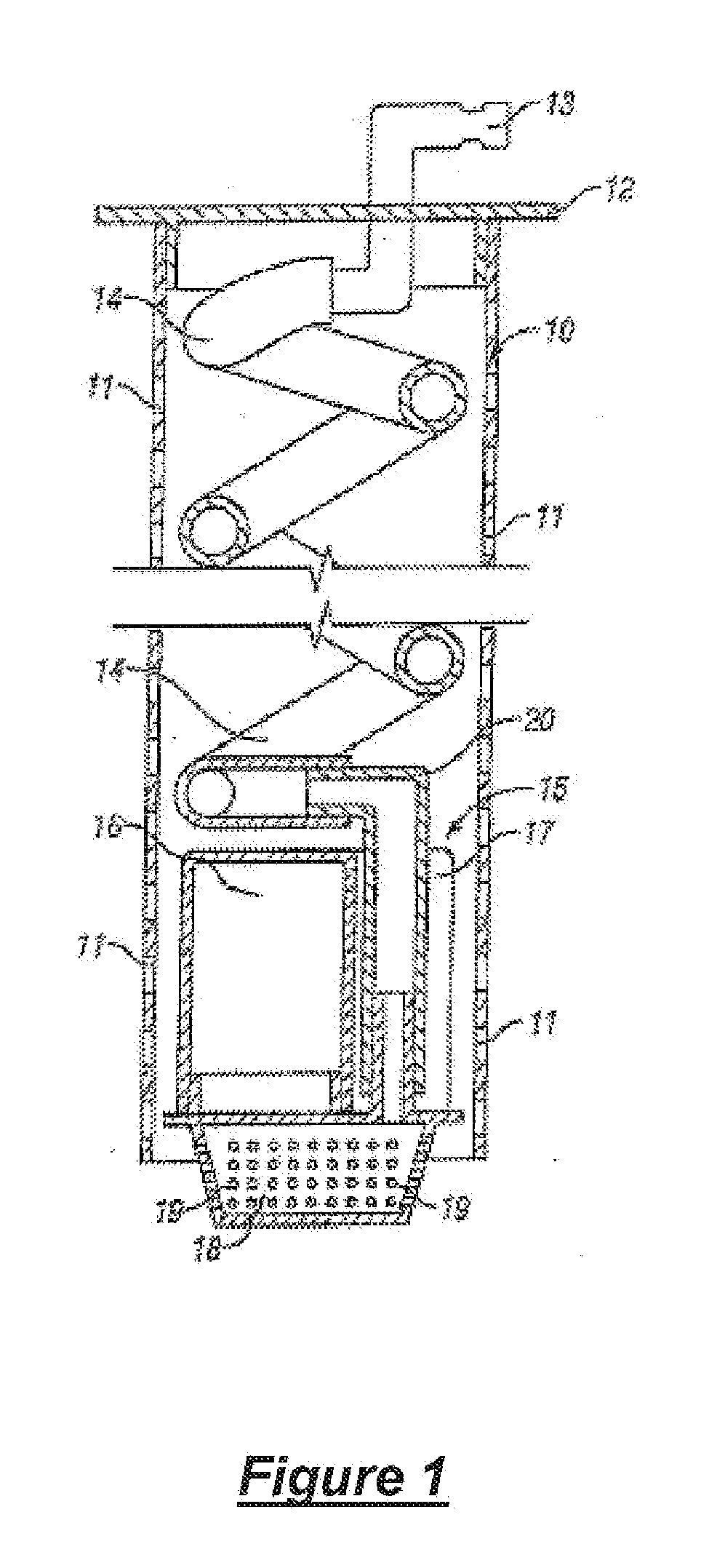

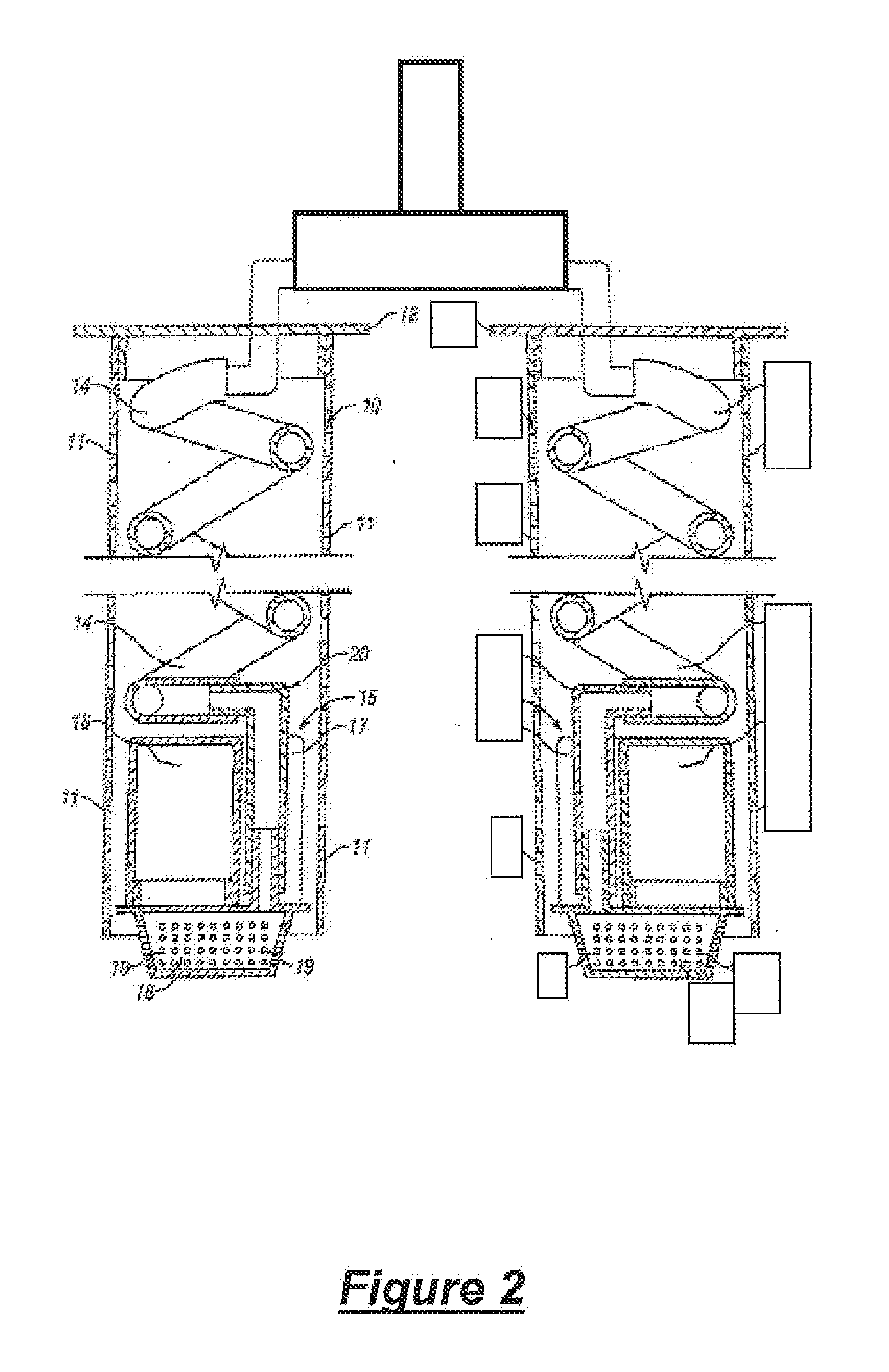

Pants type disposable diaper

ActiveCN101909568AExcellent breathability and flexibilityEnsure fitBandagesDisposable diaperEngineering

A pants type disposable diaper in which side seal sections simultaneously achieve both sufficient seal strength and ease of separation. In the pants type disposable diaper, a belly-side exterior sheet (12F) and a rear-side exterior sheet (12B) are separated from each other without being connected to each other on the crotch side. The exterior sheets (12F, 12B) have a waist-side folded back portion (21) and a crotch-side folded back portion (22). The crotch-side edge of the waist-side folded back portion (21) and the waist-side edge of the crotch-side folded back portion (22) agree with each other. The number of plies in that portion of a sheet-like air permeable material (12) which is at a waist-side end and the number of plies in that portion of the sheet-like air permeable material (12)which is at a crotch-side end are the same. Further, the number of plies in that portion of the sheet-like air permeable material (12) which is at an intermediate section between the waist-side end and the crotch-side end is the same as or less than the number of plies in those portions of the sheet-like air permeable material (12) which are at the waist-side end and the crotch-side end.

Owner:DAIO PAPER CORP

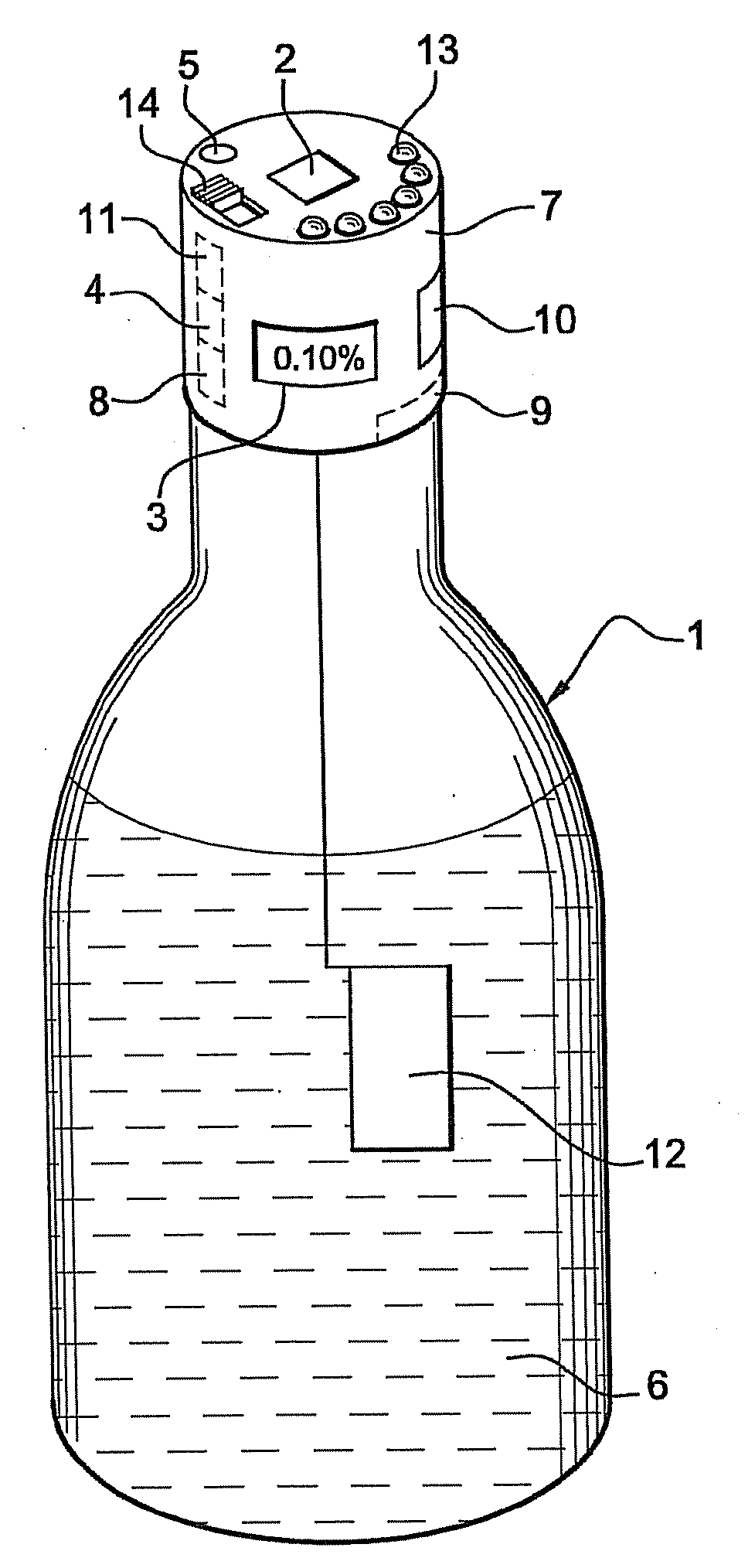

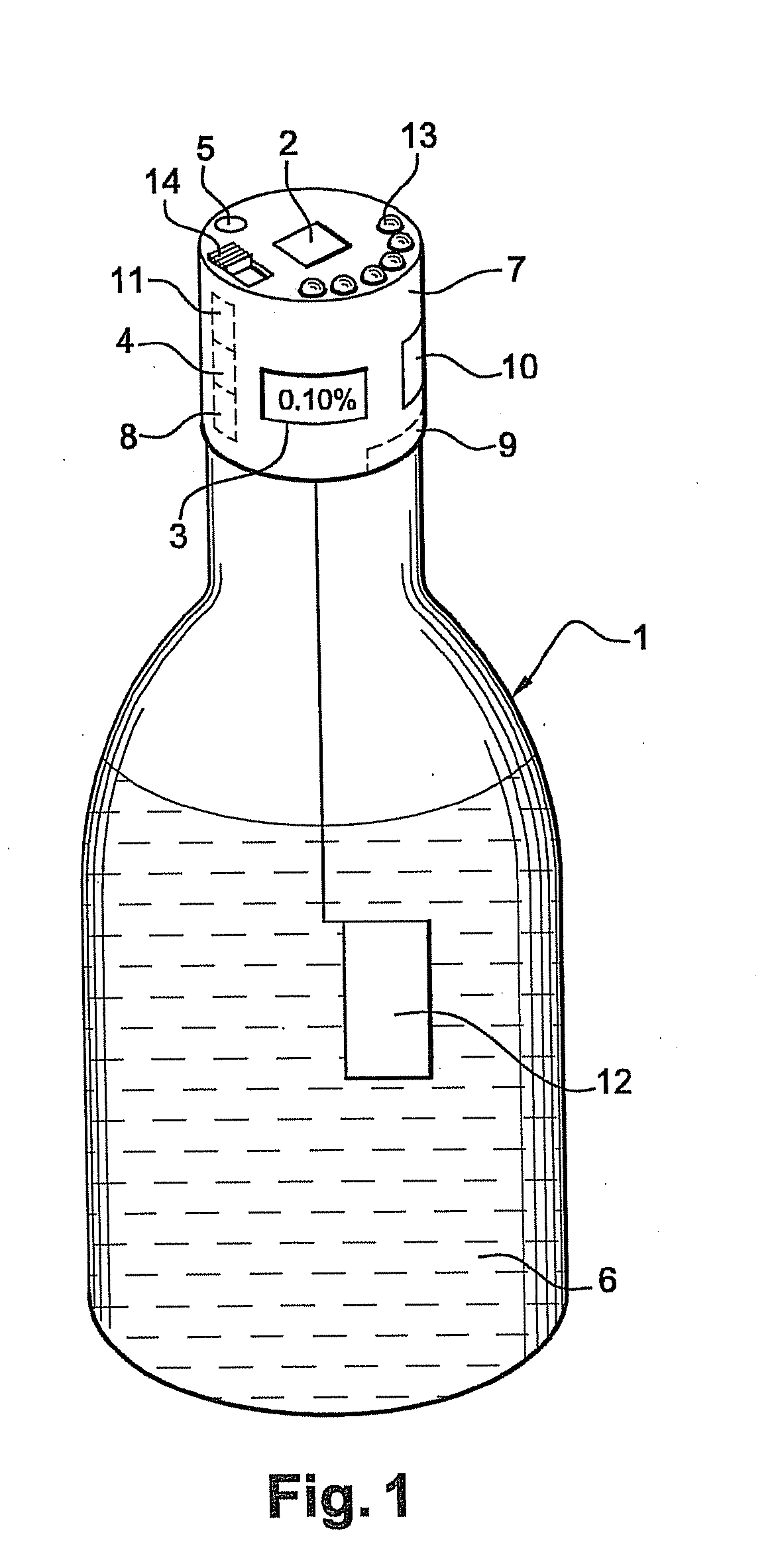

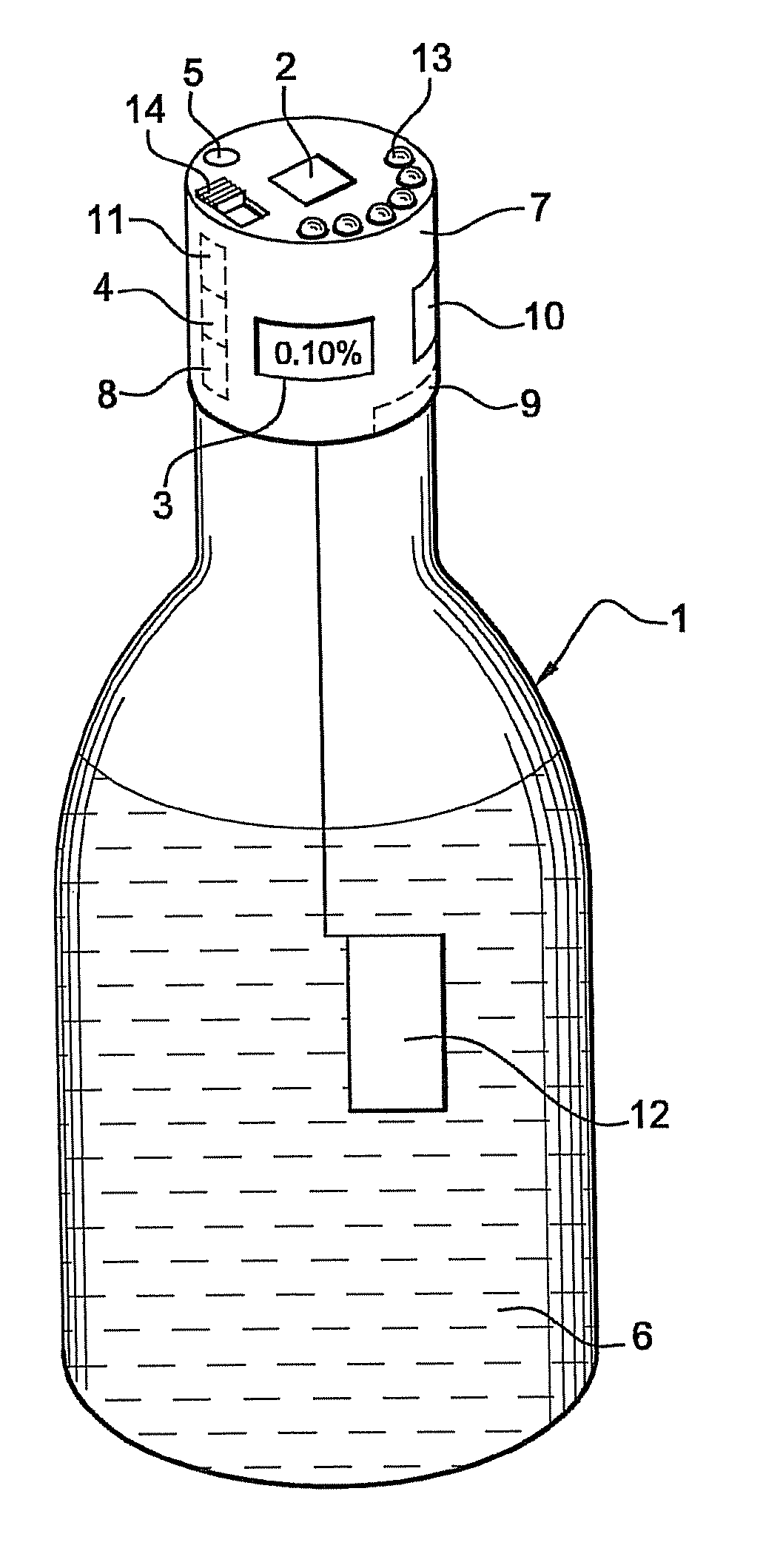

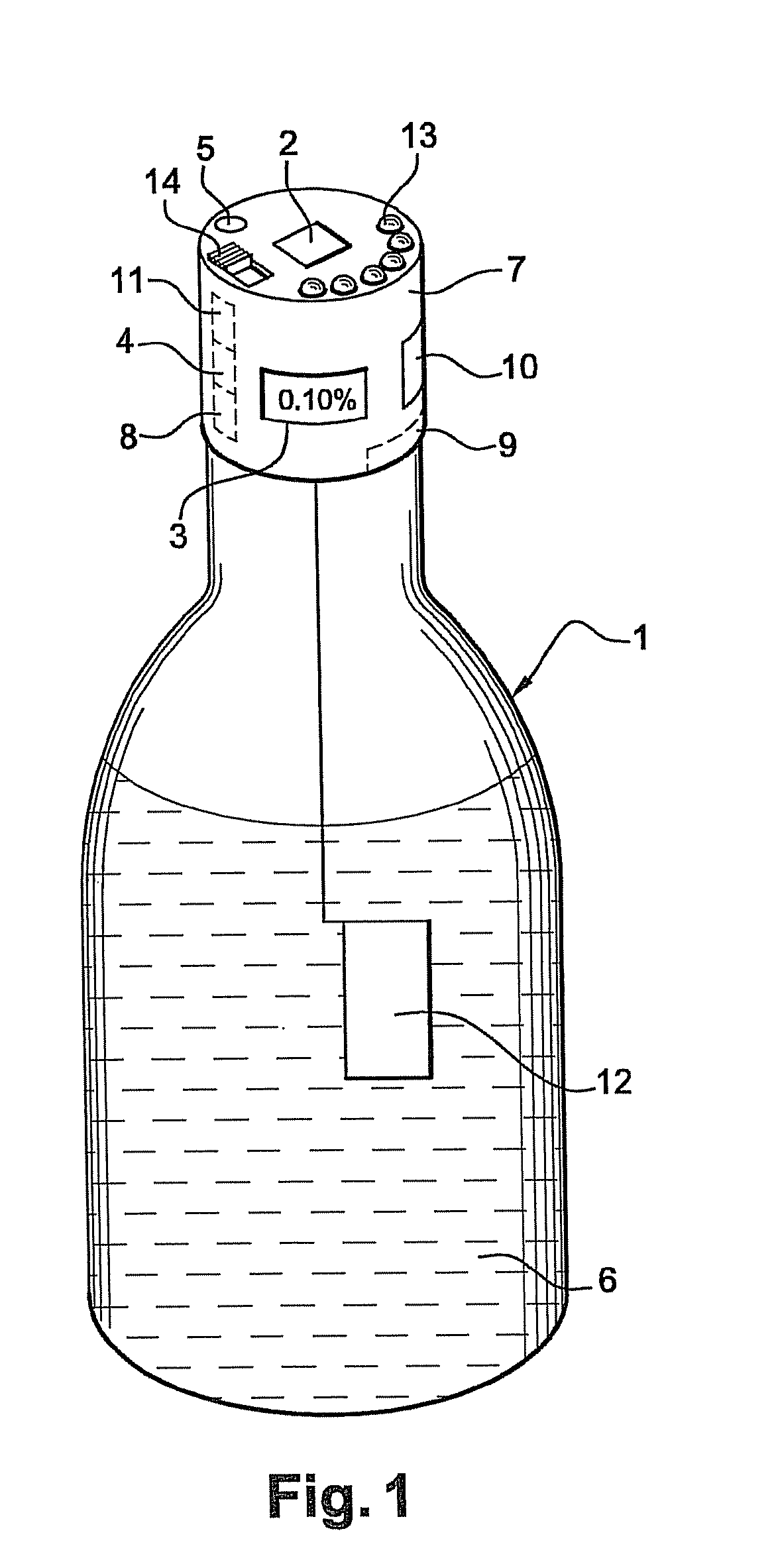

Packaging Comprising Intergrated Sensor

ActiveUS20080296191A1Easy to handleAvoid separationClosuresOther accessoriesElectric powerBiomedical engineering

“Packaging for receiving a substance having chemical properties which may change between a time when the substance is introduced for the first time into the packaging and a later time when the substance is used, the packaging includinga main body;a closure member;a first sensor arranged in the main body and suitable for delivering a signal representing a measurement of a physicochemical property of the substance contained in the packaging;a display member for generating visual information representing the measurement;a processing unit for conditioning the signal delivered by the first sensor and for displaying the visual information by means of the display member;an electric power source for supplying the first sensor, the display member and the processing unit.

Owner:INTUISKIN

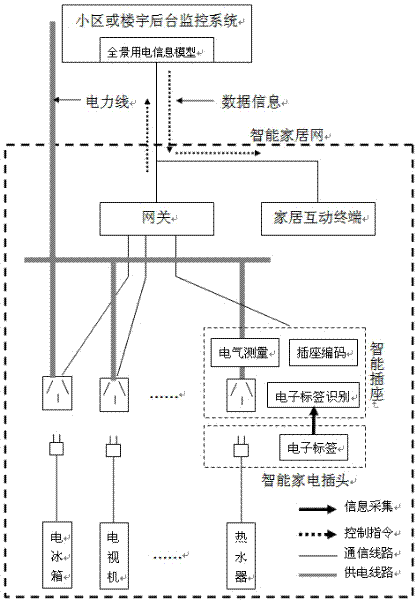

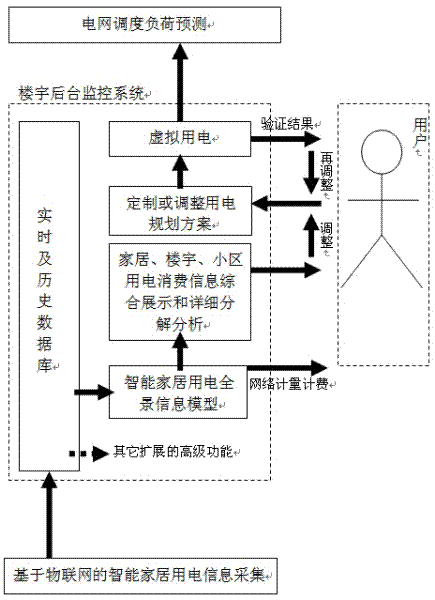

Networked comprehensive management method for panoramic electricity consumption information of smart home

ActiveCN102307125AEnsure fitImprove Load Forecasting AccuracyData switching by path configurationData platformData source

The invention relates to a networked comprehensive management method for the panoramic electricity consumption information of smart home. A unified smart home electricity consumption data platform can be constructed, kinds of advanced software application can be flexibly developed and expanded under the support of a unified data source, and a conventional electric energy meter can be replaced by networked metering and charging; a user can comprehensively learn about and analyze own electricity consumption process and way from all directions, define the structure of own energy charge and analyze the rationality and potential optimized trend of the structure; and the user autonomously plans and regulates an electricity consumption scheme by a home interaction terminal, so the pertinency of the electricity consumption scheme and the personality needs of the user can be ensured, and the simulation of 'virtual electricity consumption' can make the user clearly learn about the actual effects of a certain electricity consumption scheme.

Owner:BEIJING XJ ELECTRIC +2

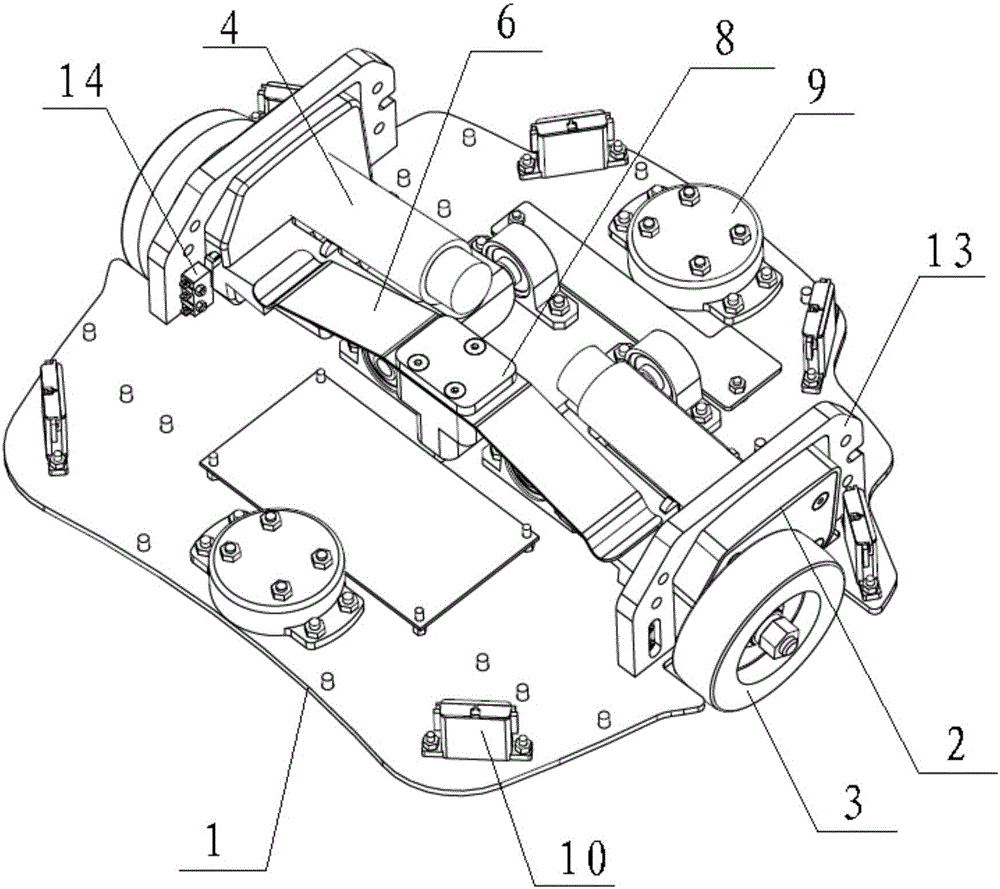

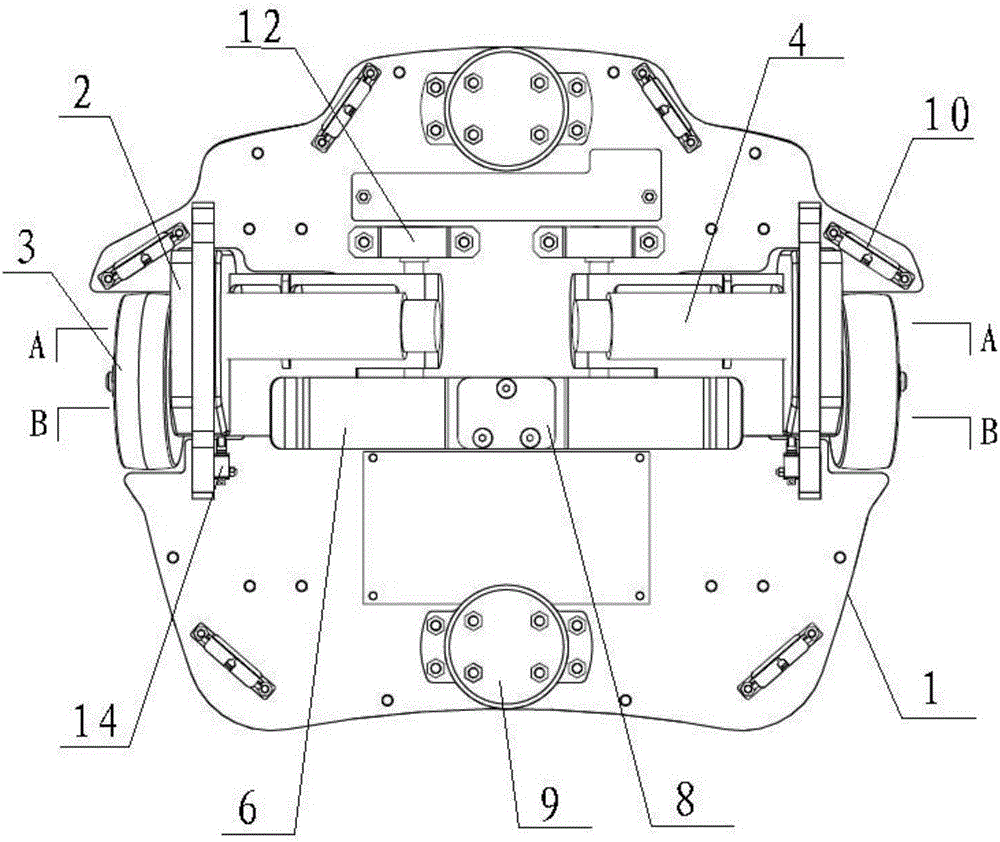

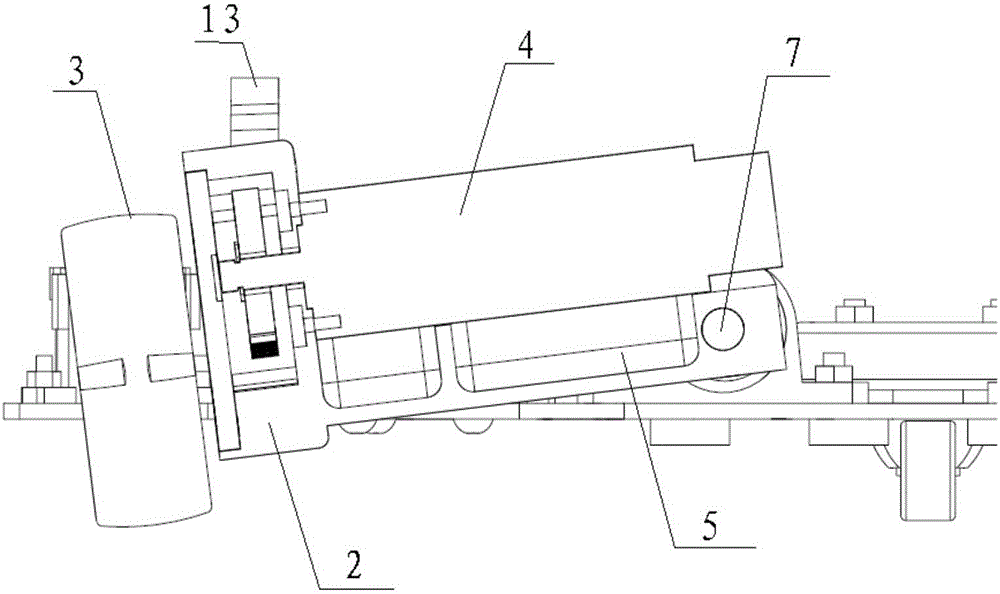

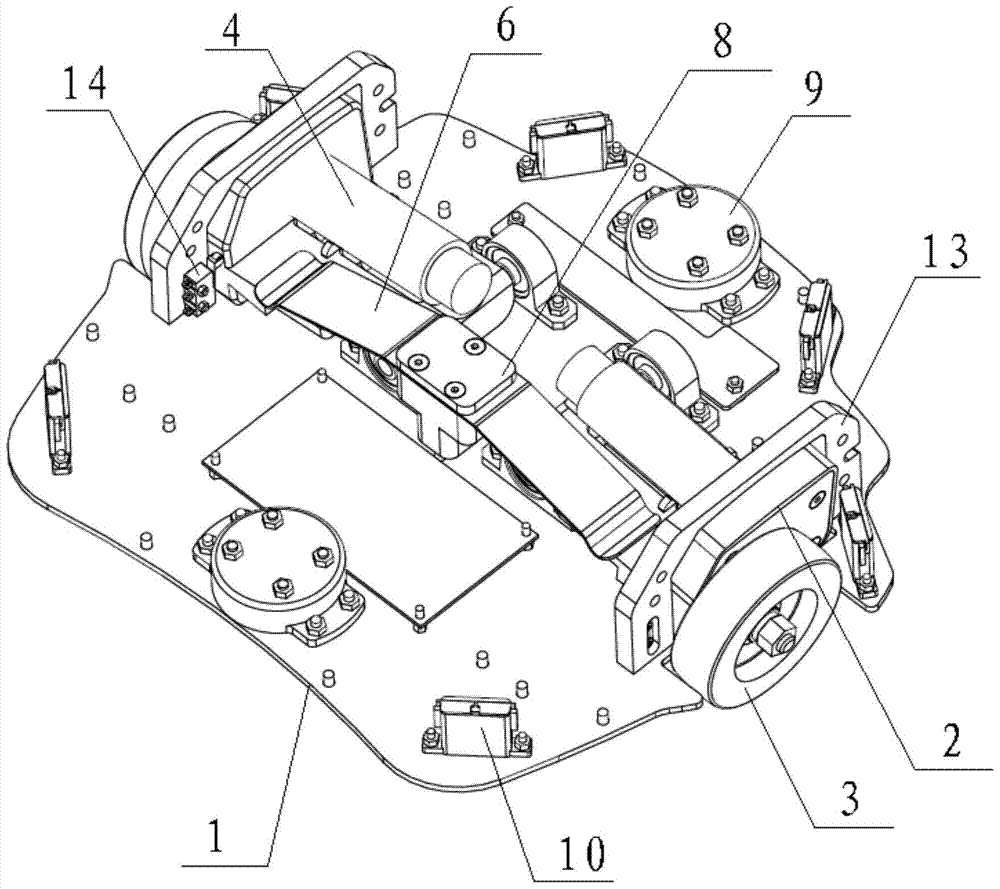

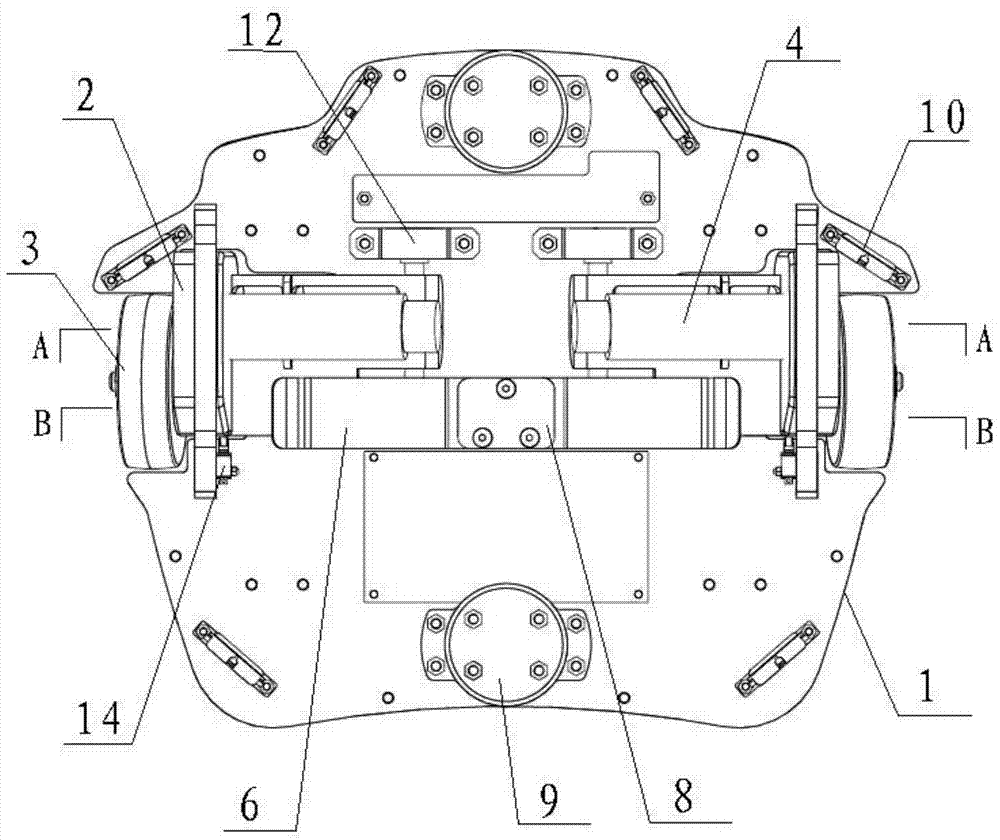

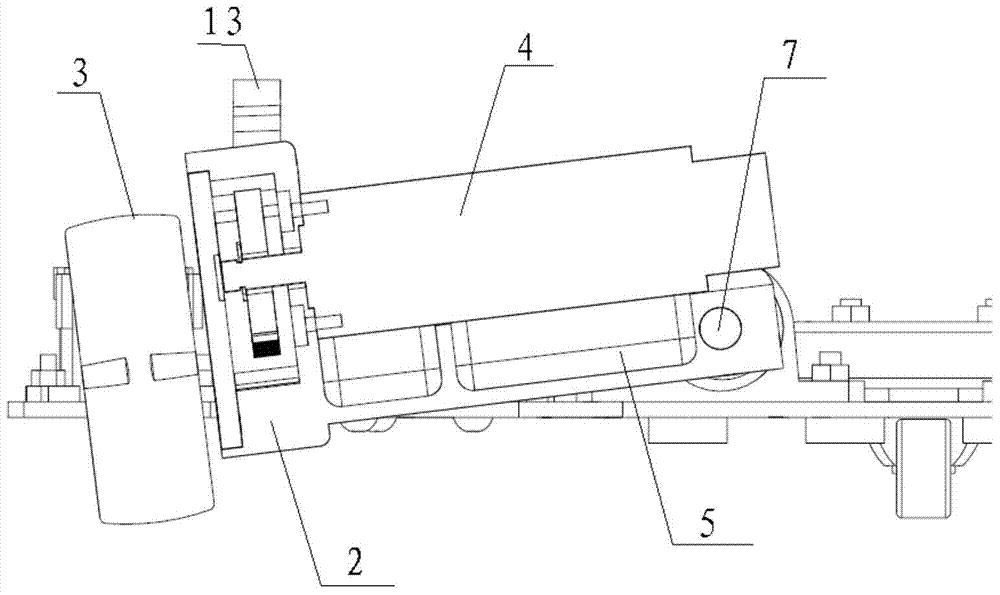

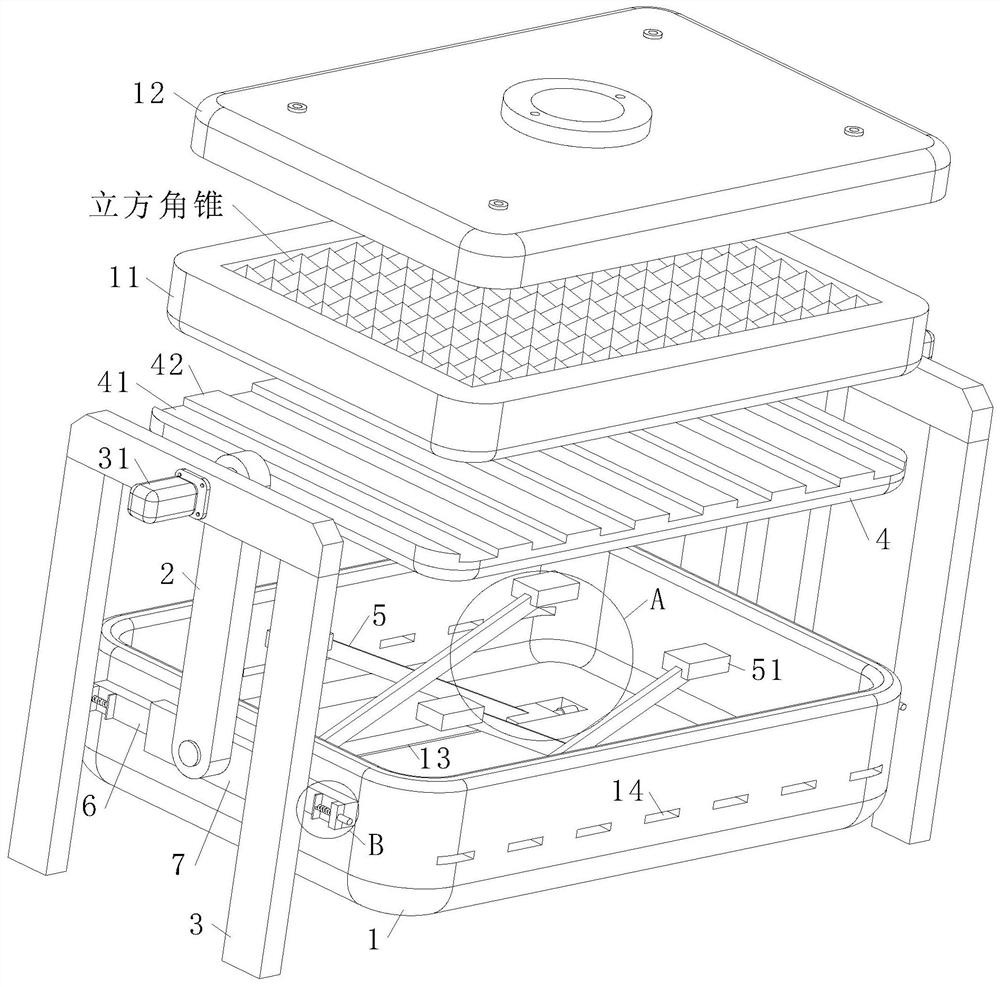

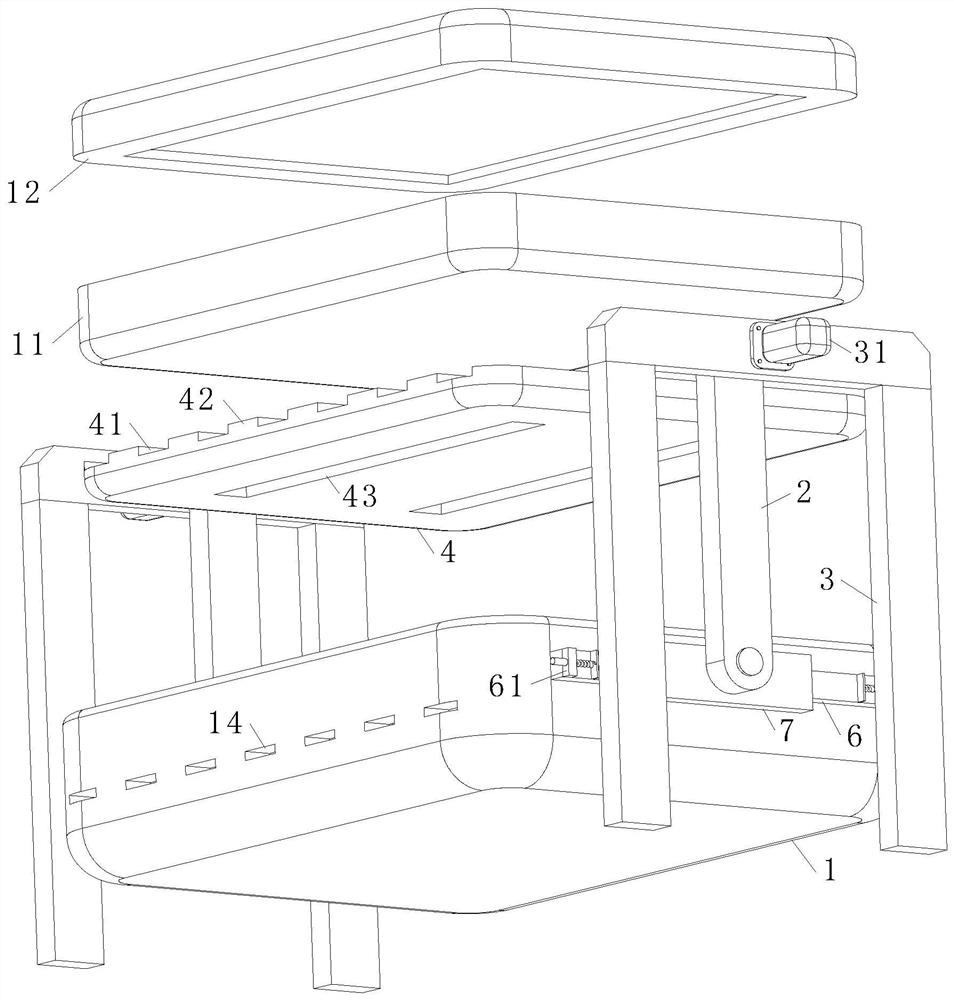

Robot chassis and service robot

InactiveCN105128978AEnsure fitAvoid the phenomenon of idling and slippingVehiclesDrive motorEngineering

The invention discloses a robot chassis and a service robot. The robot chassis comprises a chassis main body, a walking device and an anti-sliding device. The walking device comprises a gearbox, the gearbox is connected with an advancing wheel and a driving motor, the anti-sliding device comprises a pressing plate and an elastic piece, one end of the pressing plate is connected with the gearbox, the other end of the pressing plate is connected with a rotating device, the rotating device comprises a rotating shaft, the rotating shaft is rotatably connected with the pressing plate, the axial direction of the rotating shaft is parallel to the advancing direction of the advancing wheel, one end of the elastic piece adheres to the pressing plate, the other end of the elastic piece is connected with a fixed seat, and the fixed seat is arranged on the chassis main body. According to the robot chassis and the service robot, the advancing wheel can maintain a good state of adhering to the ground, and accordingly the advancing wheel can still advance normally on some special sections, the safe reliability is high, and the problem that due to the fact that the ground is smooth or the robot makes a turn at a high speed, slippage or suspension of the advancing wheel caused by drifting occurs is effectively solved.

Owner:SHANGHAI XPARTNER ROBOTICS +1

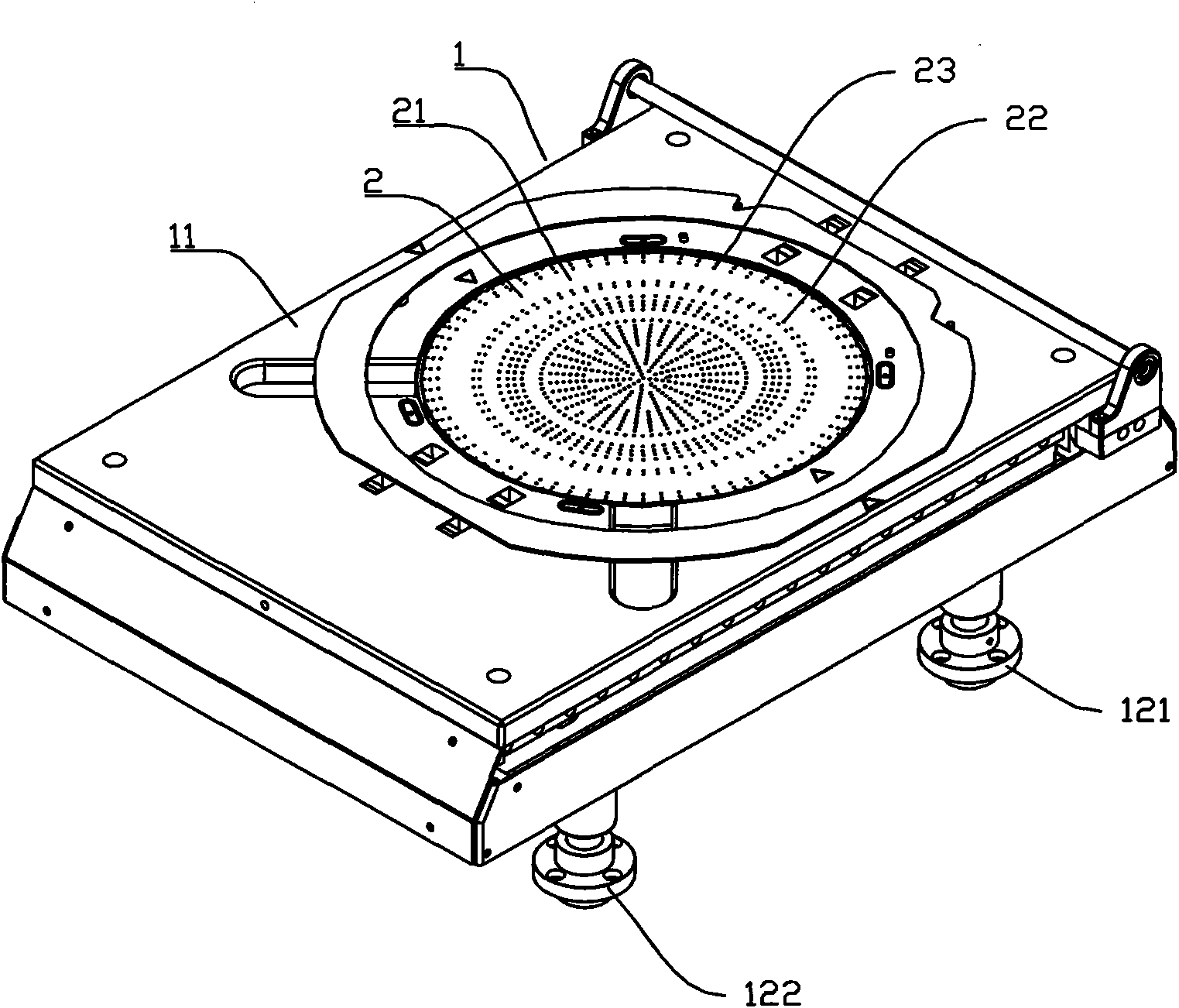

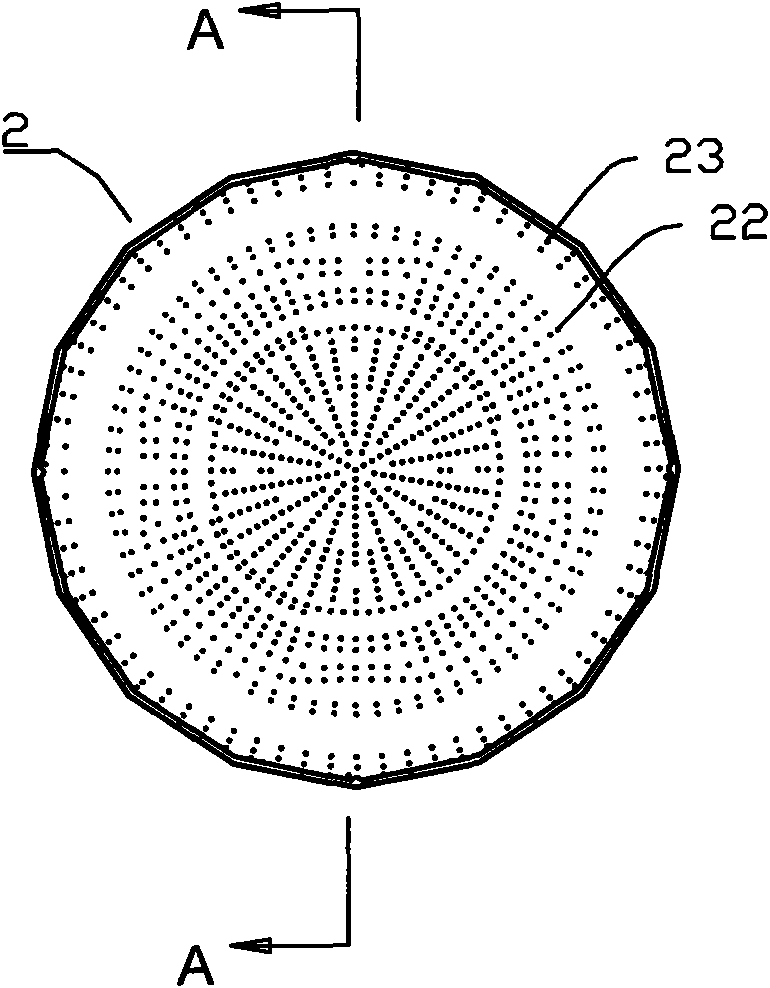

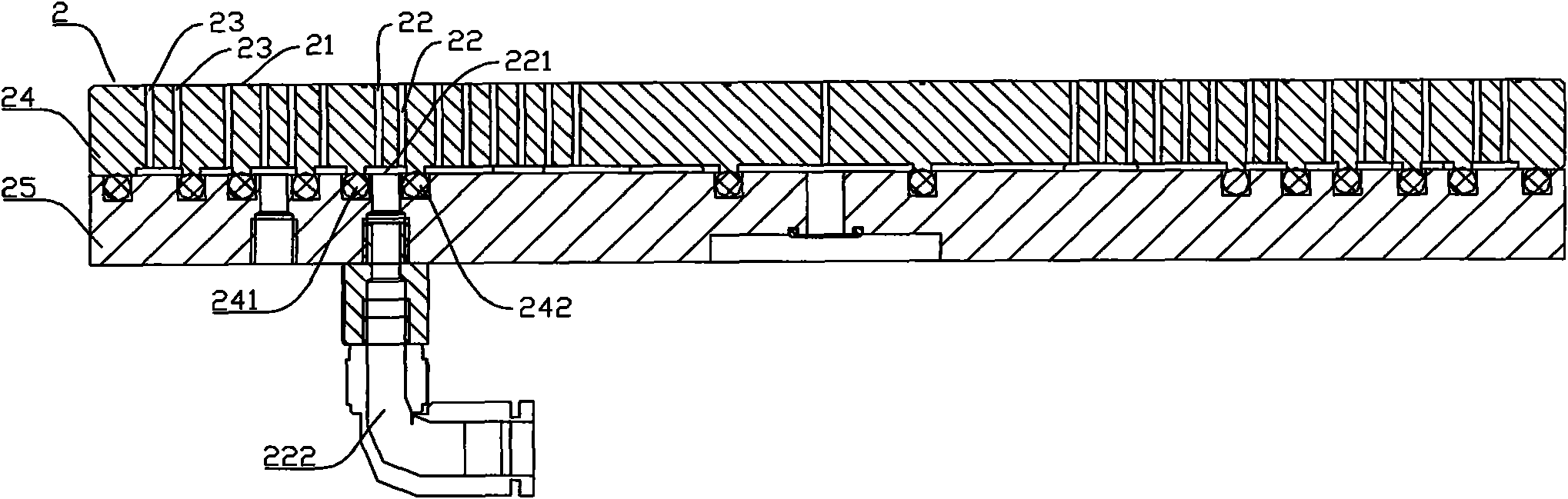

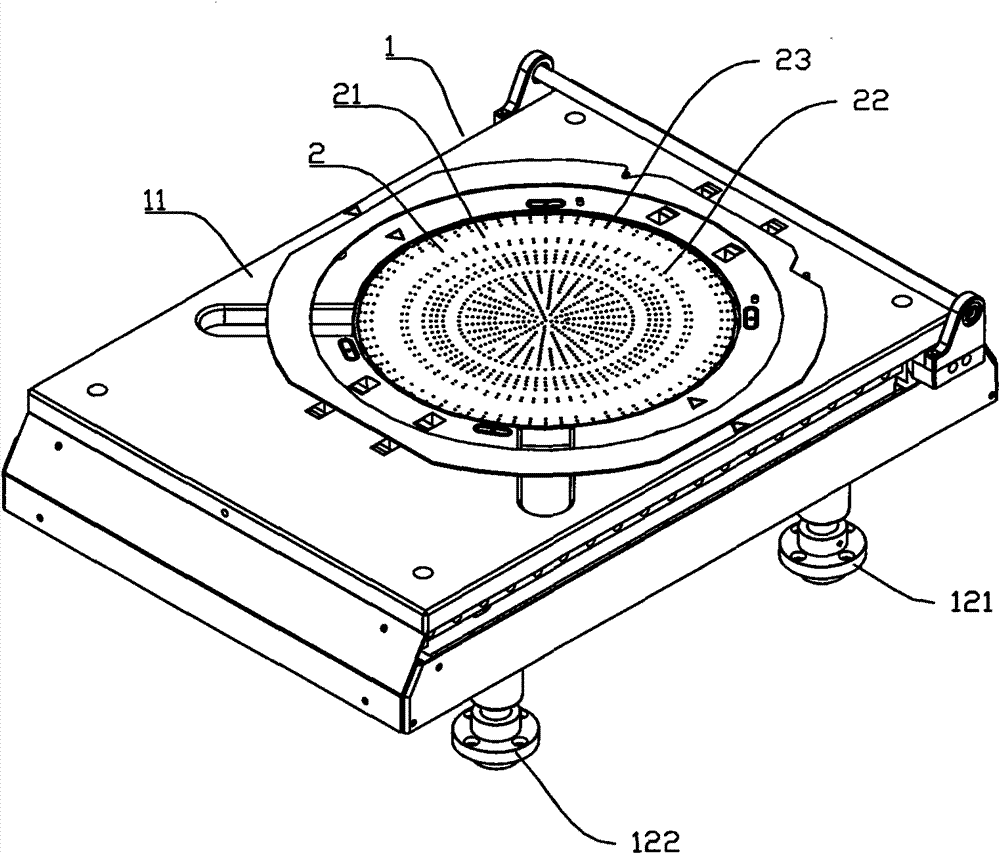

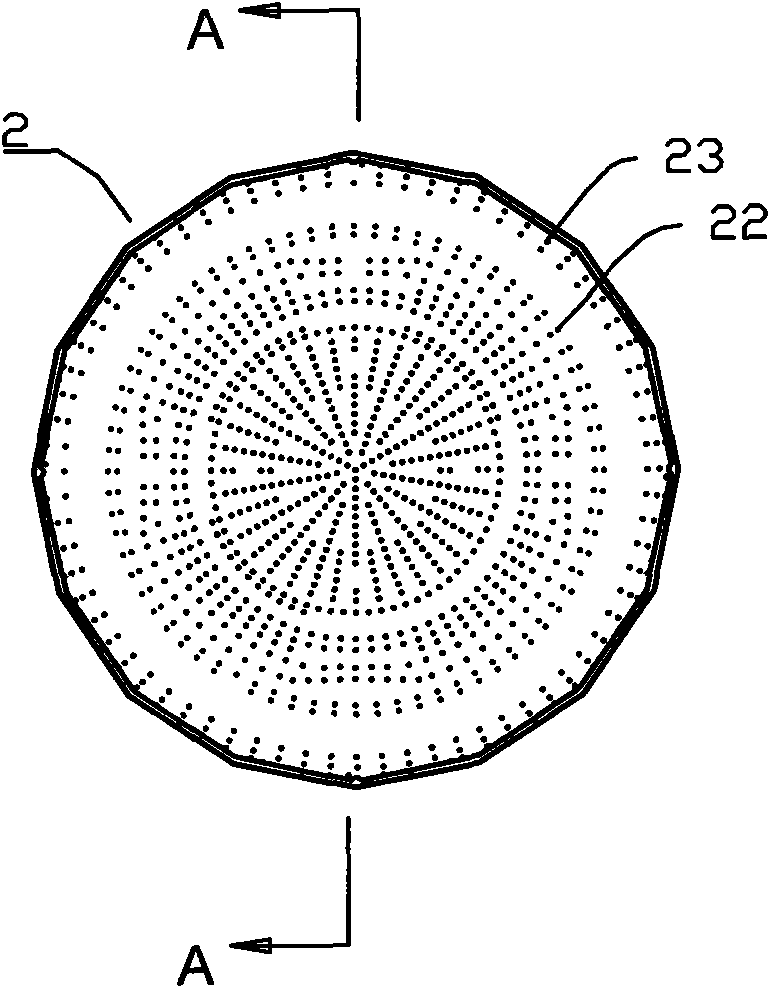

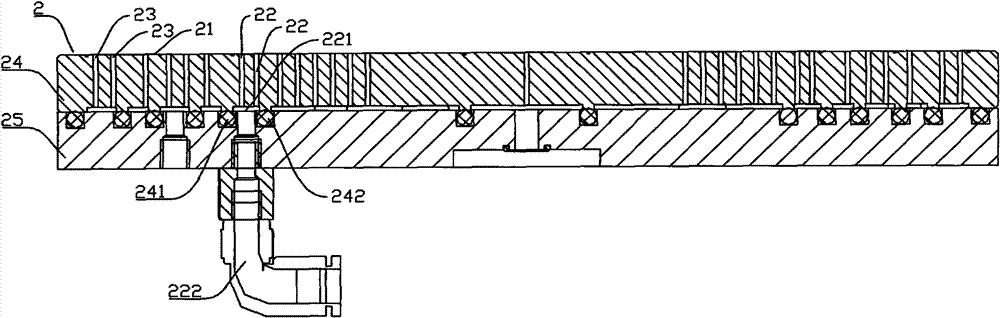

Film adhering method and device of wafer

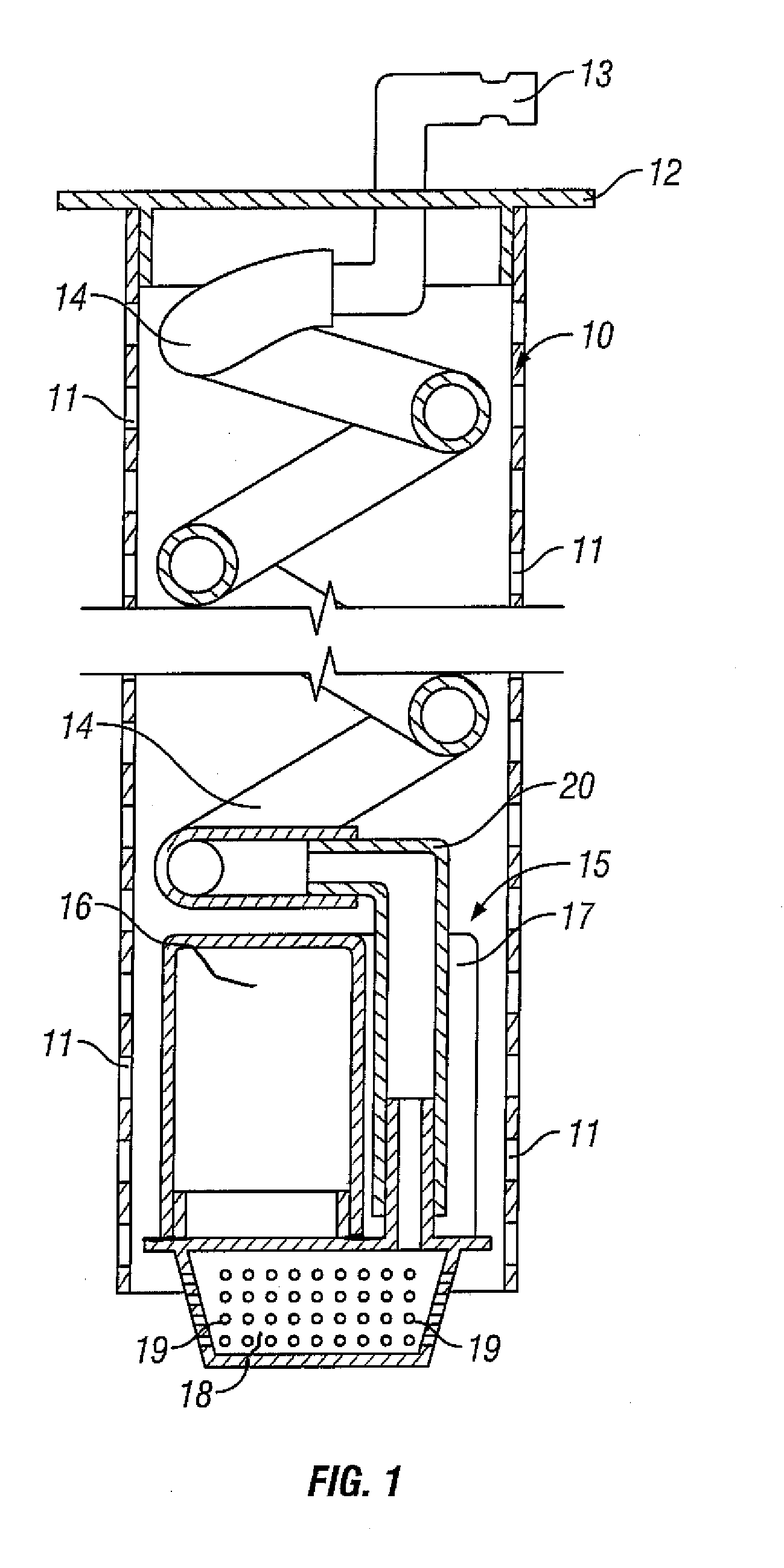

InactiveCN102103987AQuality is not affectedWon't break easilySemiconductor/solid-state device manufacturingWaferMaterials science

The invention discloses a film adhering method of a wafer. The film adhering method of the wafer is characterized by comprising the following steps of: blowing a gas between the wafer and a table disc; supporting the wafer by utilizing the blown gas; and then adhering a film on the surface of the wafer. By using the film adhering method and device of the wafer, the non-contact film adhesion can be realized and the danger of front surface damage of the wafer can be reduced; in addition, because the wafer can be supported by utilizing the gas during the pressing of a roller wheel, the pressure of the roller wheel can be offset, and the roller wheel can not be easy to press the wafer to be broken or crushed, therefore when the film adhering method and device are used for carrying out the non-contact film adhesion, the minimum thickness of the wafer which can be adhered with the film is 50 micrometers and 200 micrometers far less than that of the water adhered with the film in the prior art.

Owner:上海技美科技股份有限公司

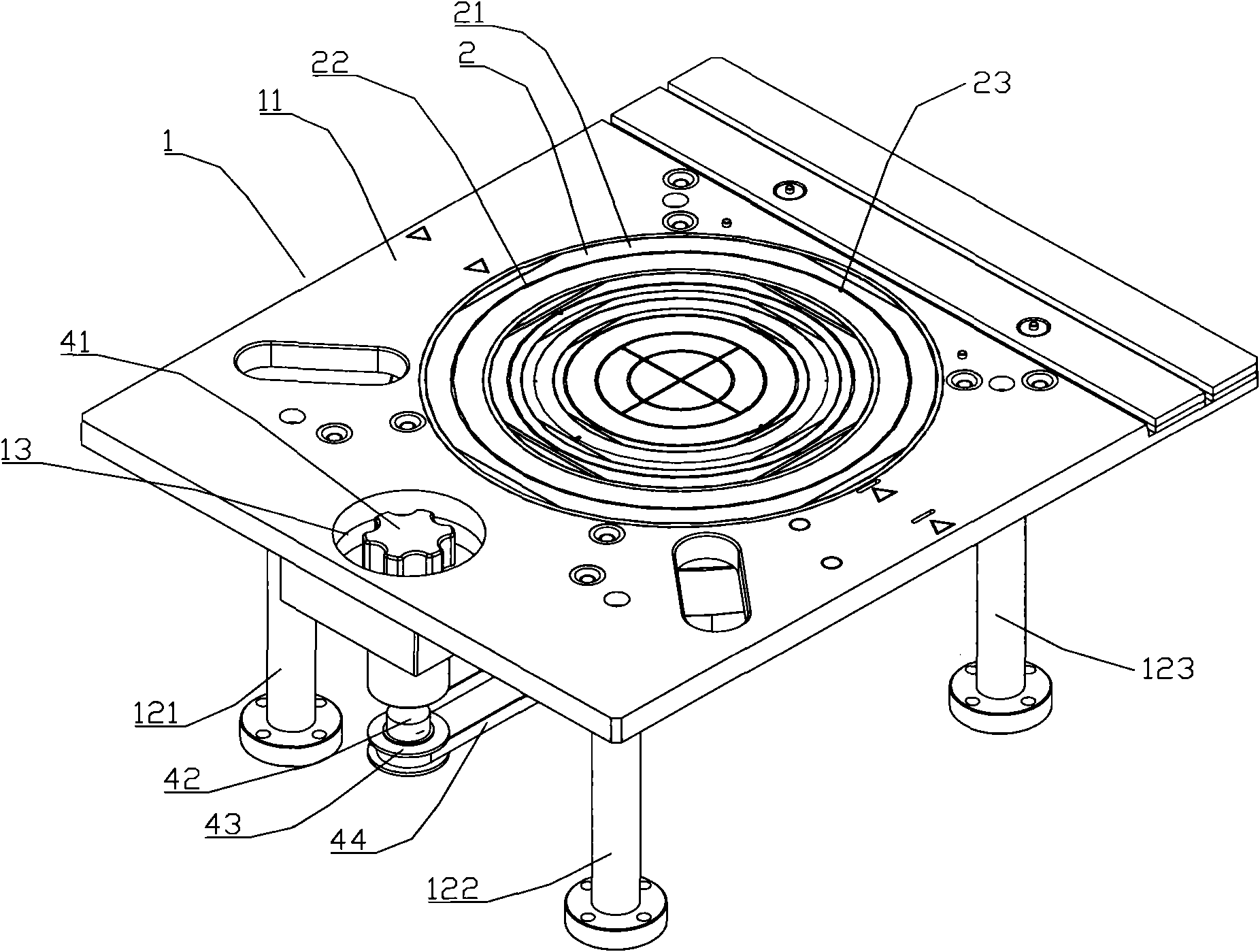

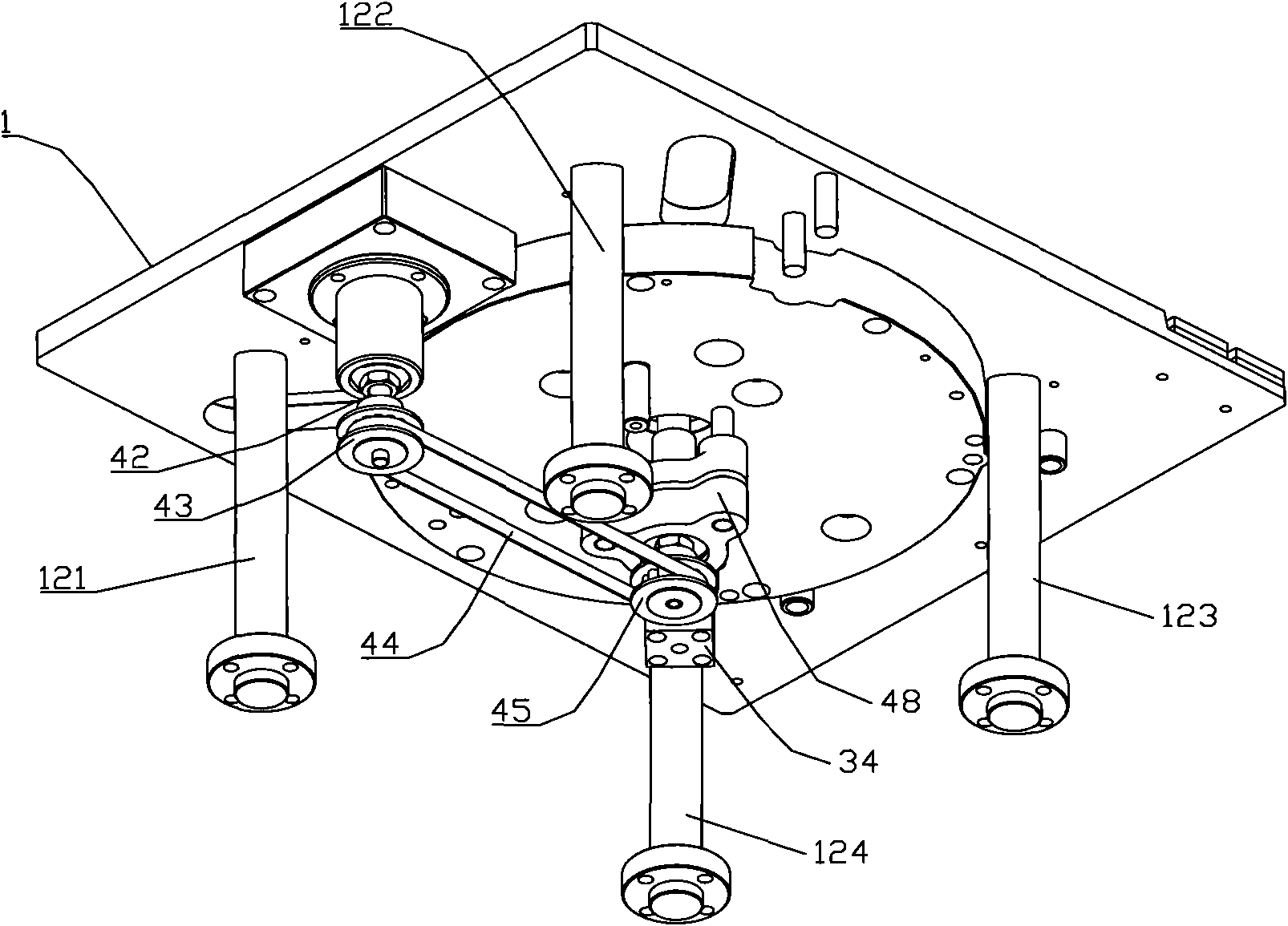

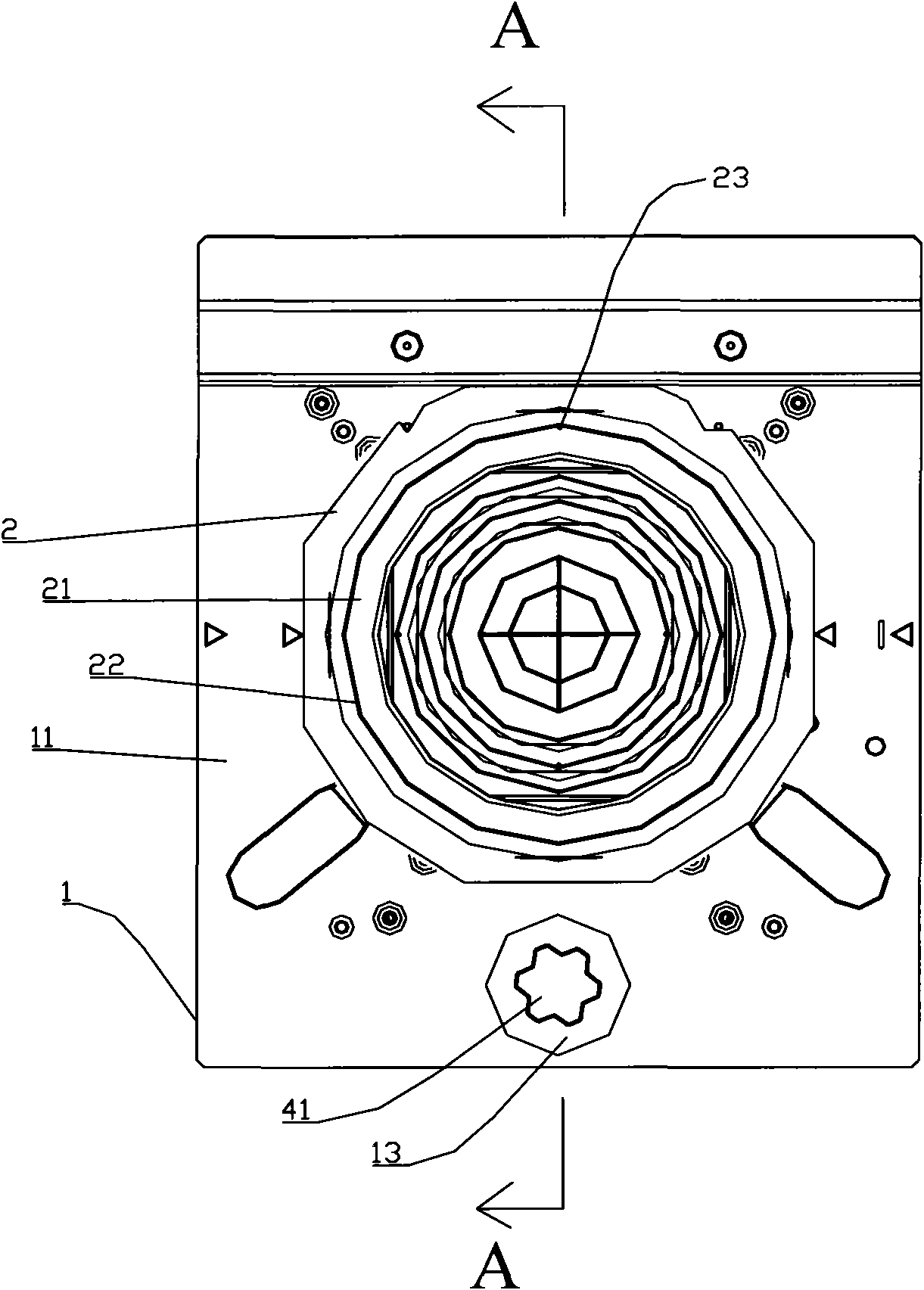

Wafer carrying device

InactiveCN101916739AHeight adjustableEasy to adjustSemiconductor/solid-state device manufacturingMechanical engineeringCoating

The invention discloses a wafer carrying device which is characterized by comprising a base and a first height adjusting device, wherein a first groove is arranged on the upper surface of the base; a movable first table disc is installed in the first groove; the first height adjusting device can adjust the relative height between the upper surface of the first table disc and the upper surface of the base; and the first height adjusting device is connected with the first table disc. The wafer carrying device of the invention can be used for coating cutting films for wafers of different sizes. When wafers of different sizes are coated with the cutting films, the table disc does not need to be changed, and the carrying device can be suitable for coating cutting films of different sizes only by simple adjustment. The adjustment and switching are convenient and quick with short time and high efficiency. The height of the table disc is adjustable, so the table disc can be suitable for coating wafers of different thickness more conveniently, thereby widening the usable range of the table disc and ensuring that the coating effect meets the requirements.

Owner:上海技美科技股份有限公司

Packaging comprising integrated sensor

ActiveUS8094014B2Guaranteed validityGuaranteed lifeClosuresOther accessoriesEngineeringVisual perception

Owner:INTUISKIN

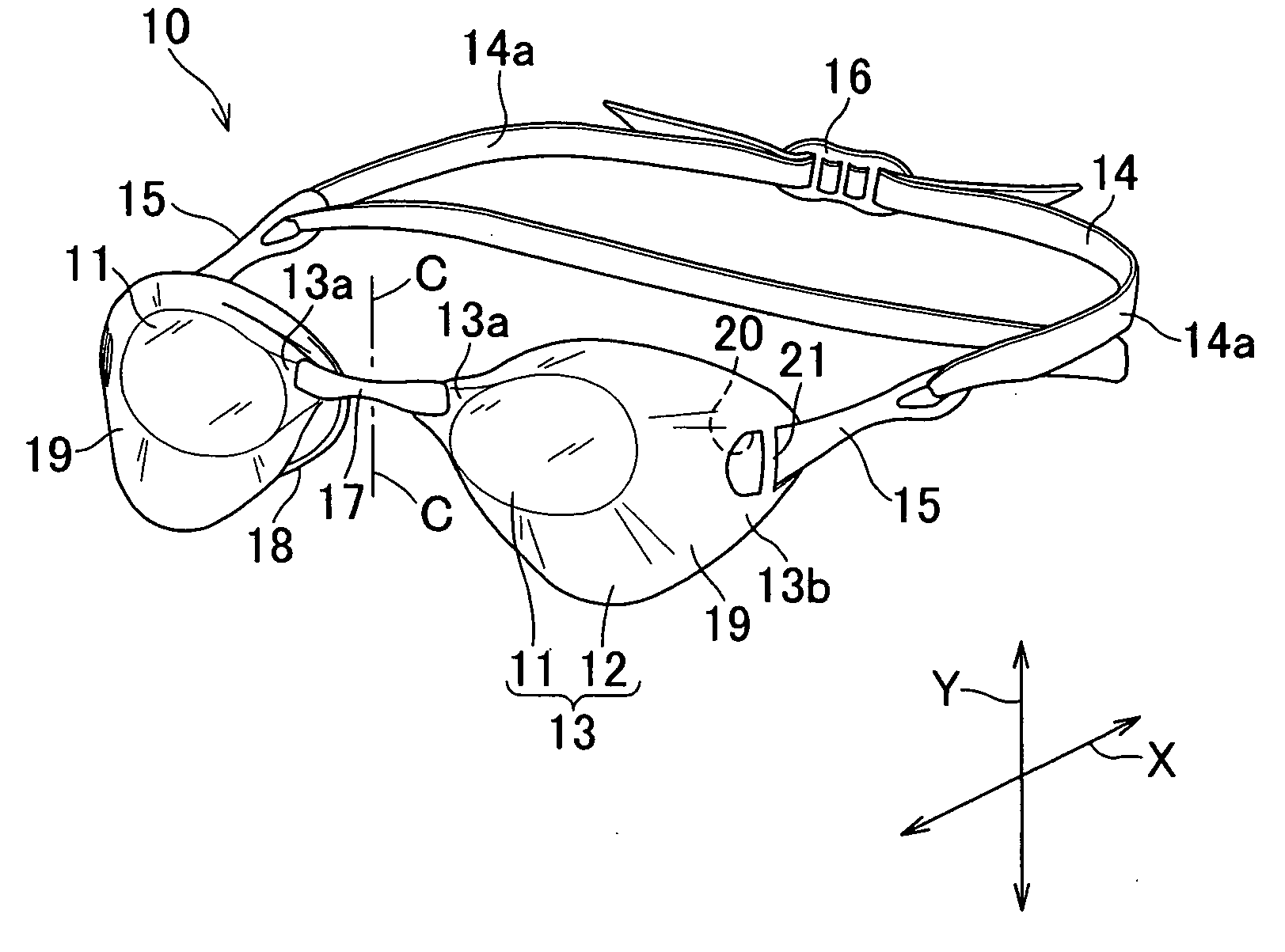

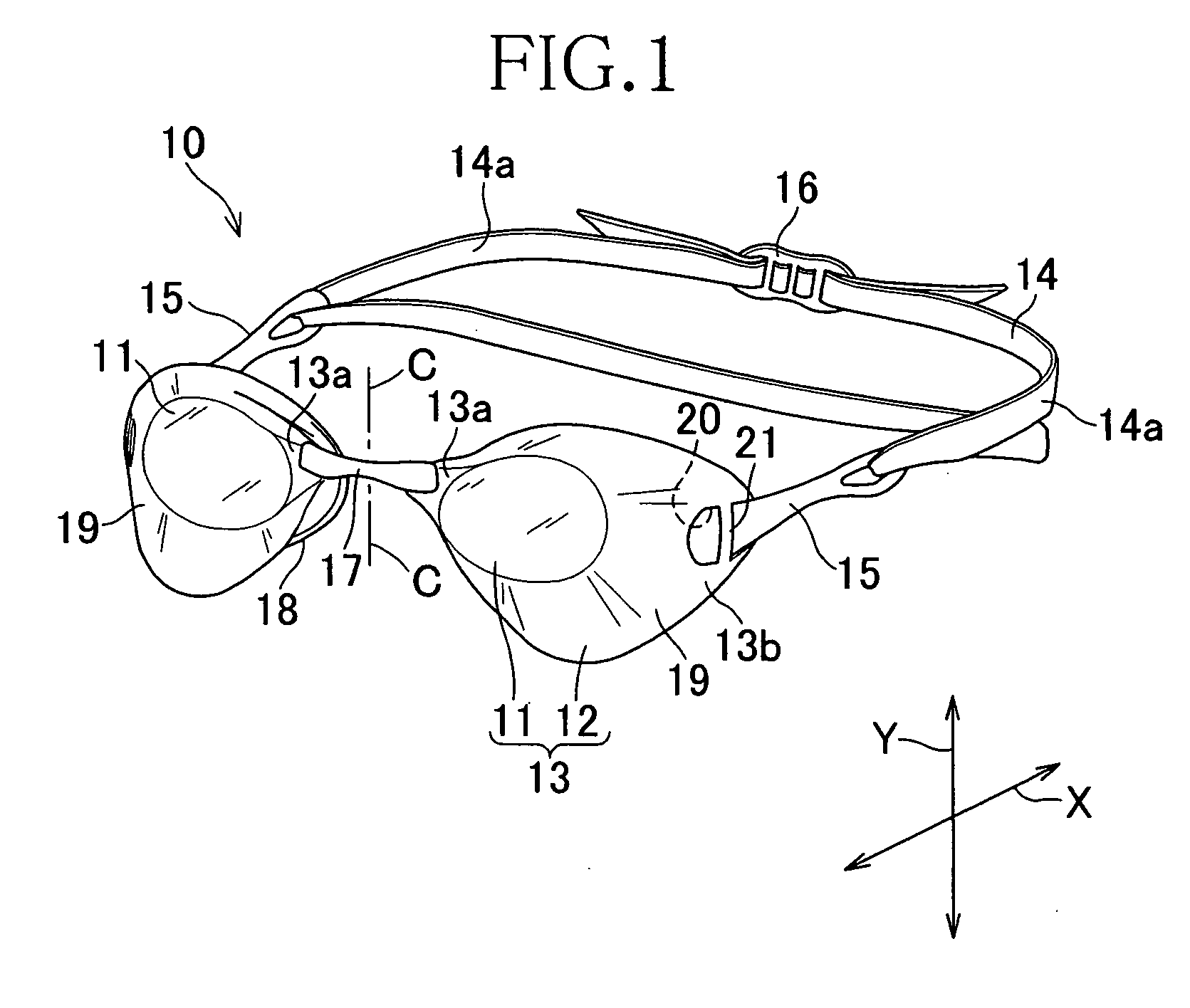

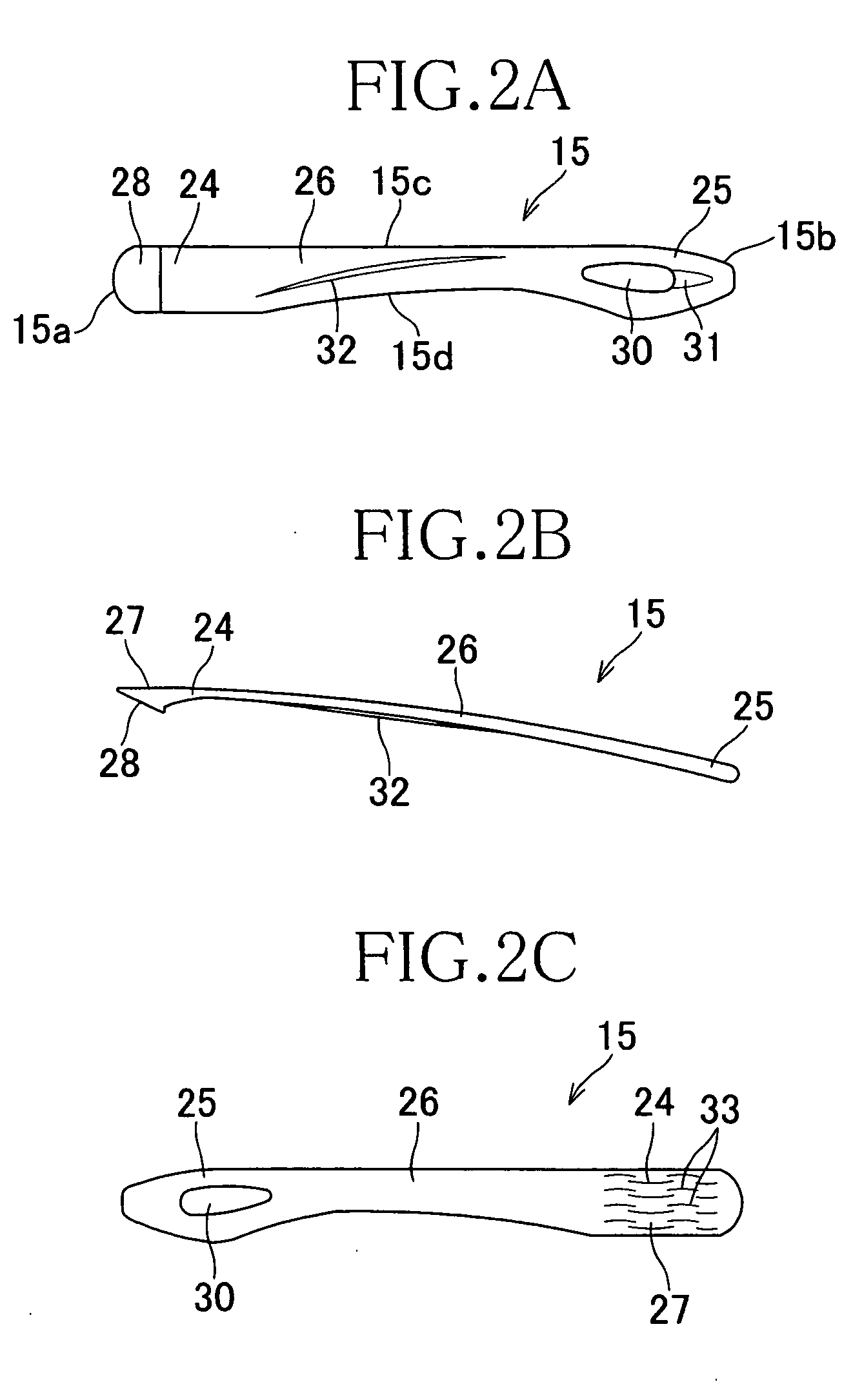

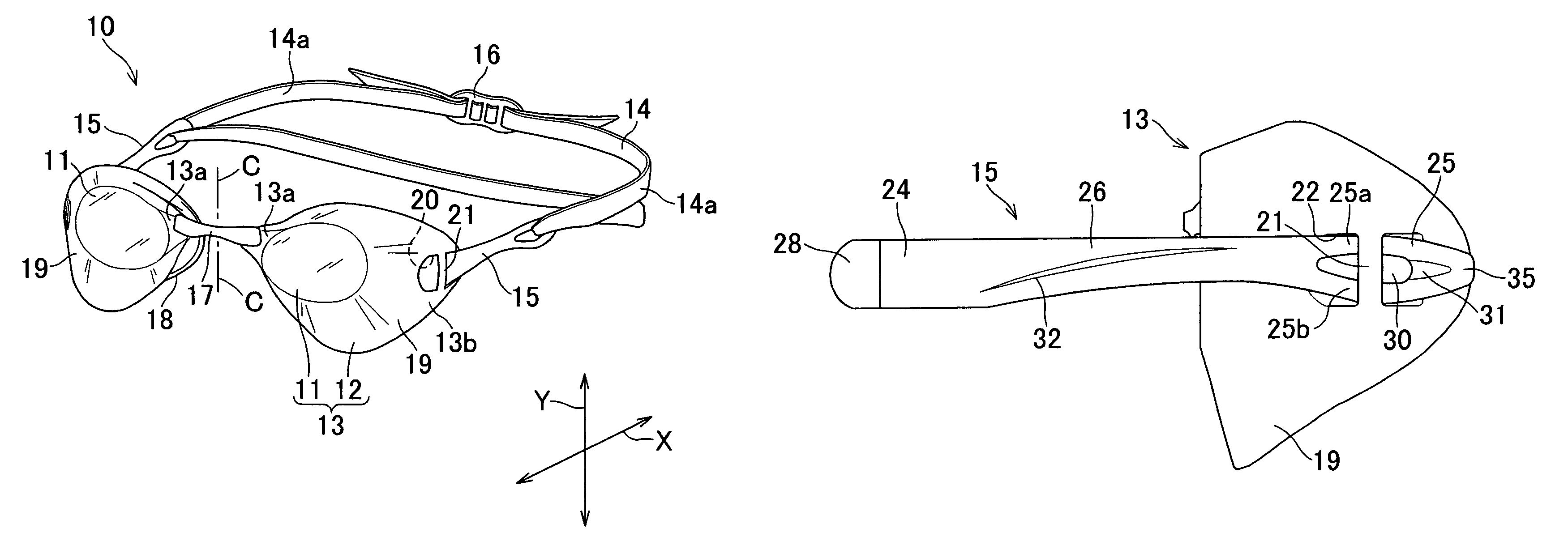

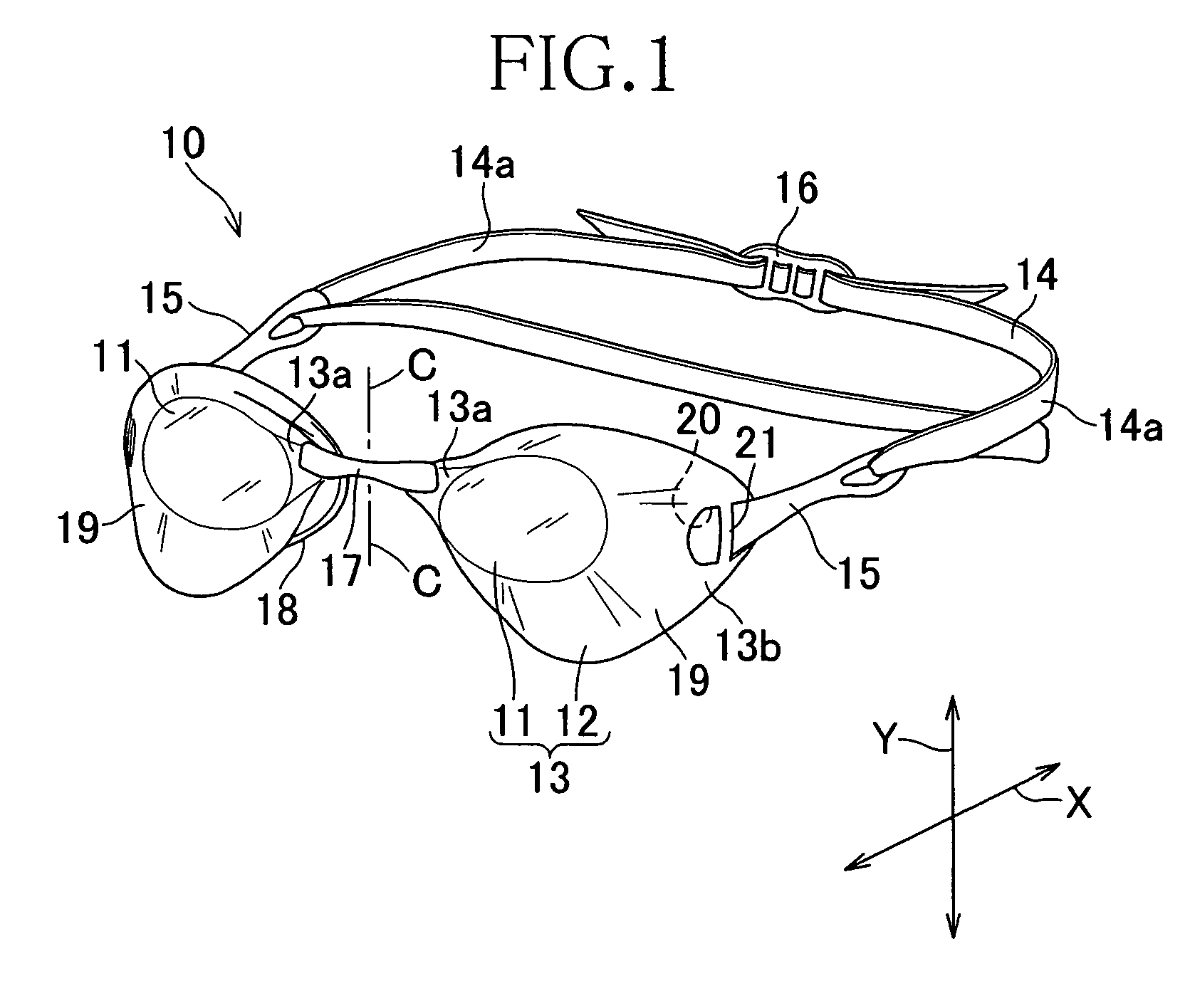

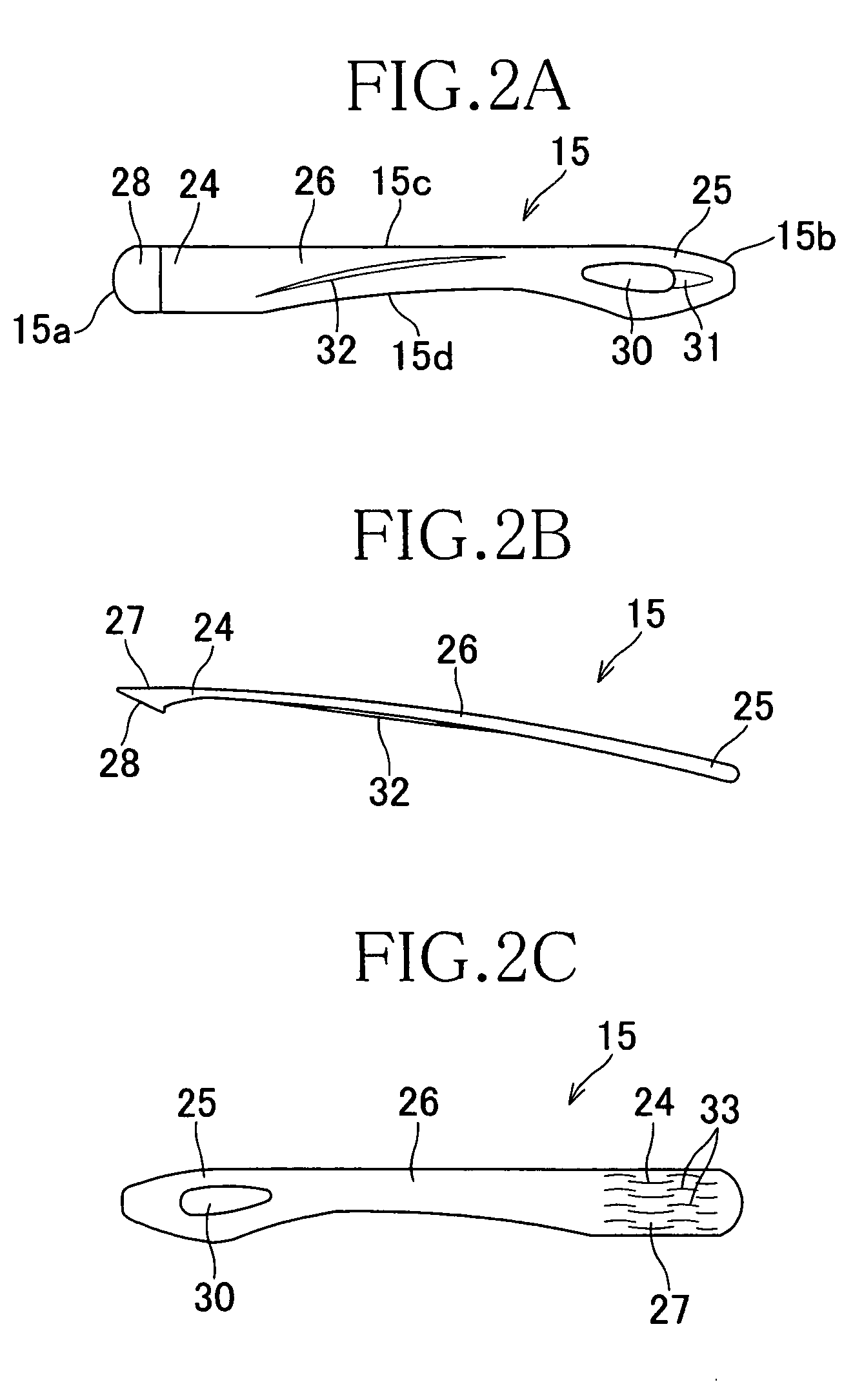

Swimming goggle

A swimming goggle having connector members which are formed by a material which is flexible, elastically deformable and has rigidity as well as hardness higher than those of the head strap where each of the eye cups is formed on its laterally outer portion with a sloped guide depression and a stopper extending in the vertical direction so as to straddle the guide depression, and the connector member has a front end segment adapted to be connected the eye cup and a rear end segment adapted to be connected with the head strap wherein the front end segment is formed with a latching detent adapted to be engaged with the stopper while the rear end segment is formed with an insertion hole through which the head strap is inserted so that the connector member is inserted with its rear end segment ahead into a gap between the guide depression and the stopper until the latching detent is engaged with the stopper to connect the connector member to the eye cup in a detachable manner.

Owner:TABATA

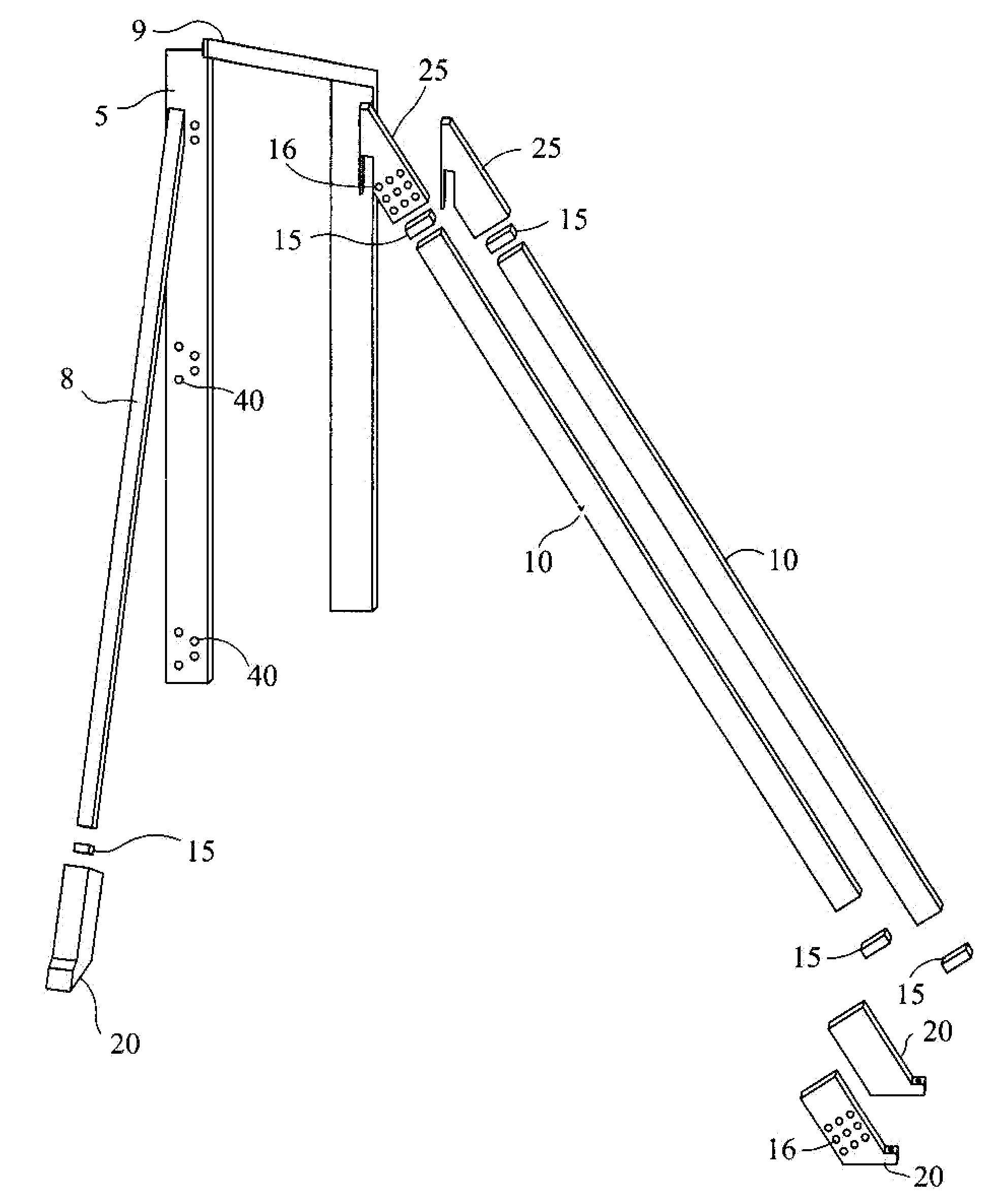

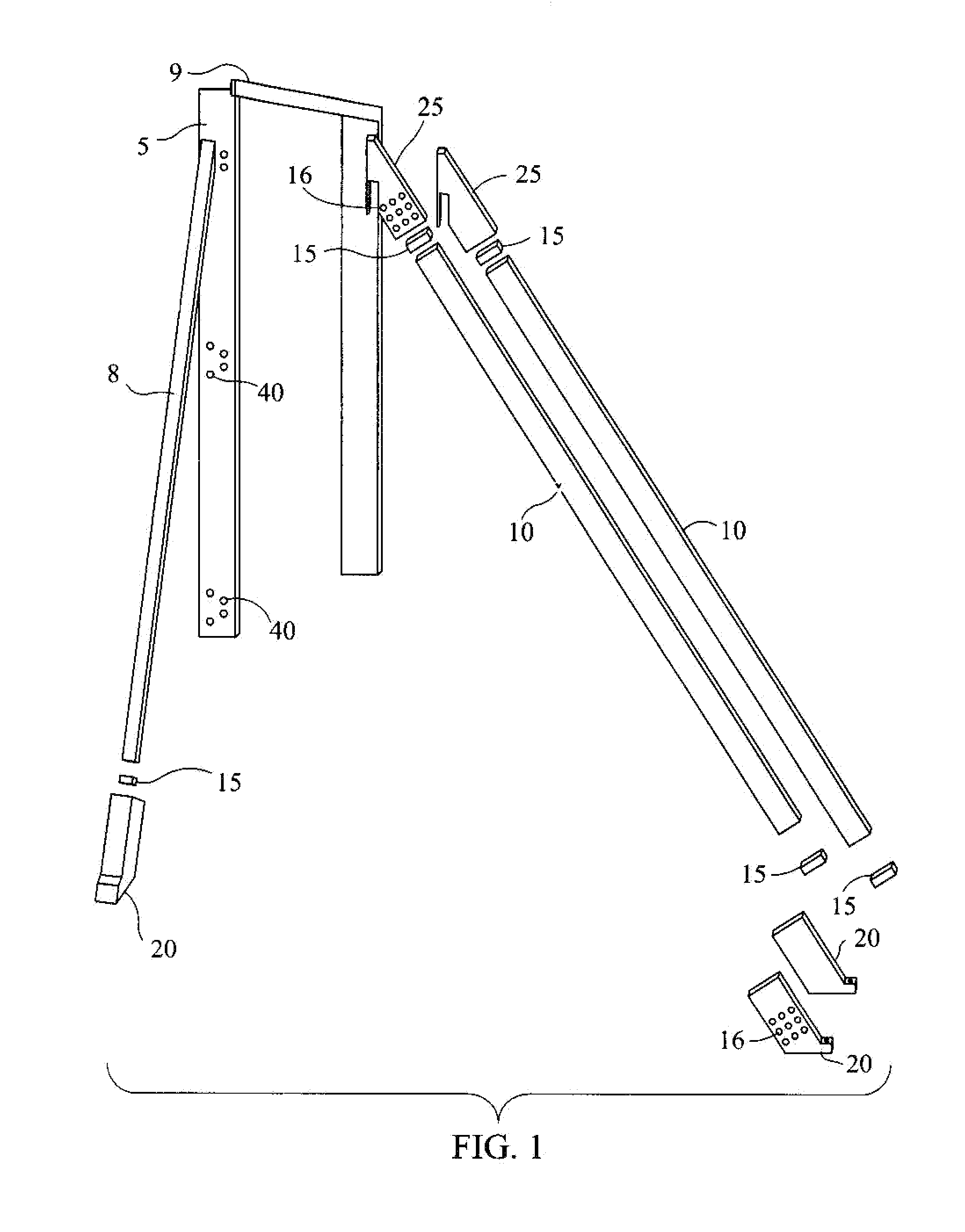

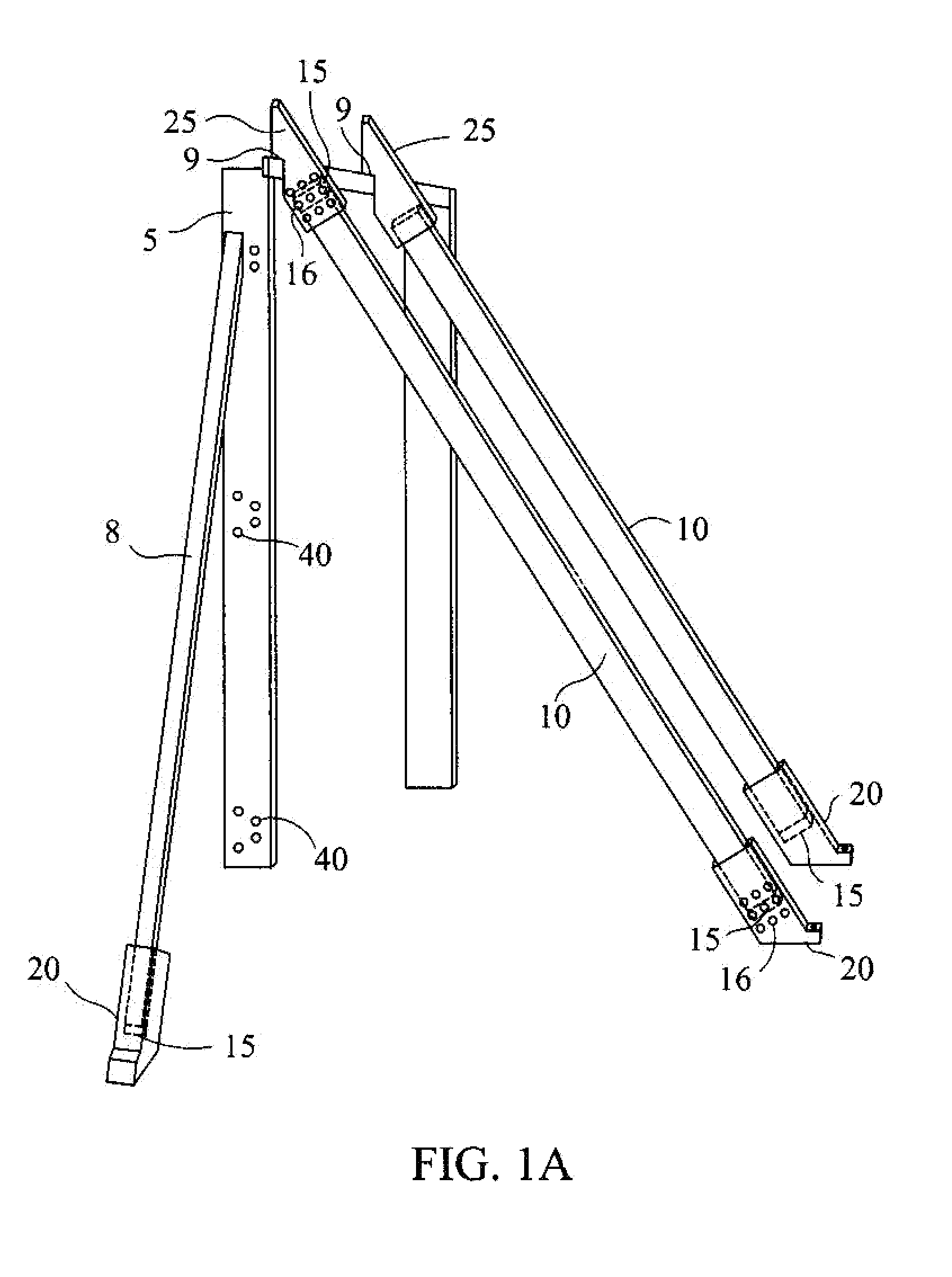

Door frame apparatus and method for installing a door frame

InactiveUS7434361B1Prevent slippingUniform placementWorkpiece holdersBuilding repairsMechanical engineeringEngineering

In order to correctly align a door in a doorway structure, this device has been contemplated. It will be comprised of several identically shaped members that extend from the top of the door jamb to another separate member that is secured to the floor. The use of dual members that extend from the door jamb to the floor aligns the door in one dimension in the doorway but in order to align the door from the side a separate side member will be used.

Owner:TAYLOR ROBERT

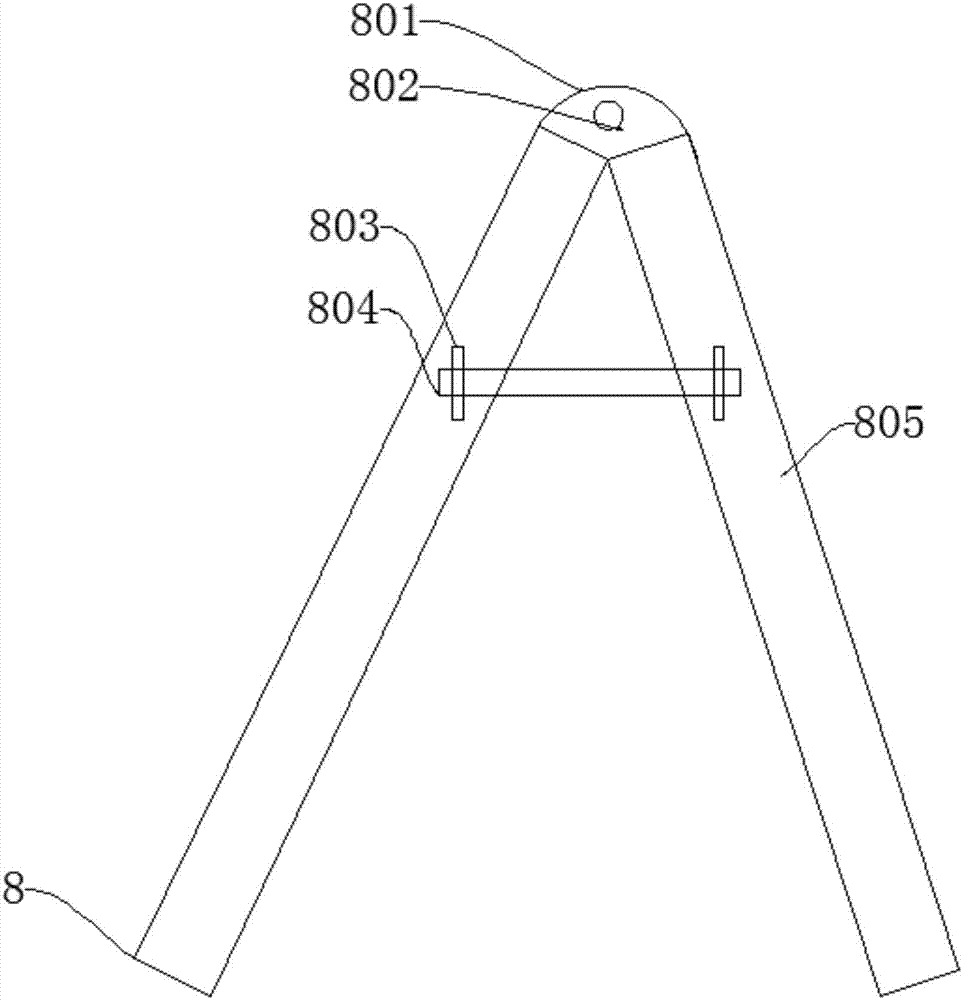

A robot chassis and service robot

InactiveCN105128978BEnsure fitAvoid the phenomenon of idling and slippingVehiclesEffective solutionRotational axis

The invention discloses a robot chassis and a service robot, which include a chassis main body, a walking device and an anti-skid device; the walking device includes a gear box connected with a traveling wheel and a driving motor; One end is connected to the gear box, and the other end is connected to a rotating device. The rotating device includes a rotating shaft, which is connected to the pressing plate in rotation. The axial direction of the rotating shaft is parallel to the traveling direction of the traveling wheel, and one end of the elastic sheet fits the pressing plate. , the other end is connected with a fixed seat, and the fixed seat is arranged on the chassis main body. The robot chassis and the service robot provided by the present invention can keep the traveling wheels in good contact with the ground. Therefore, in some special road sections, they can still travel normally, with high safety and reliability. When turning at high speed, the traveling wheel slips or hangs in the air due to drift.

Owner:SHANGHAI XPARTNER ROBOTICS +1

Float Device

ActiveUS20100163117A1Ensure fitOperating means/releasing devices for valvesFluid-delivery valvesWaste managementBuilding construction

Owner:FUEL ACTIVE LTD

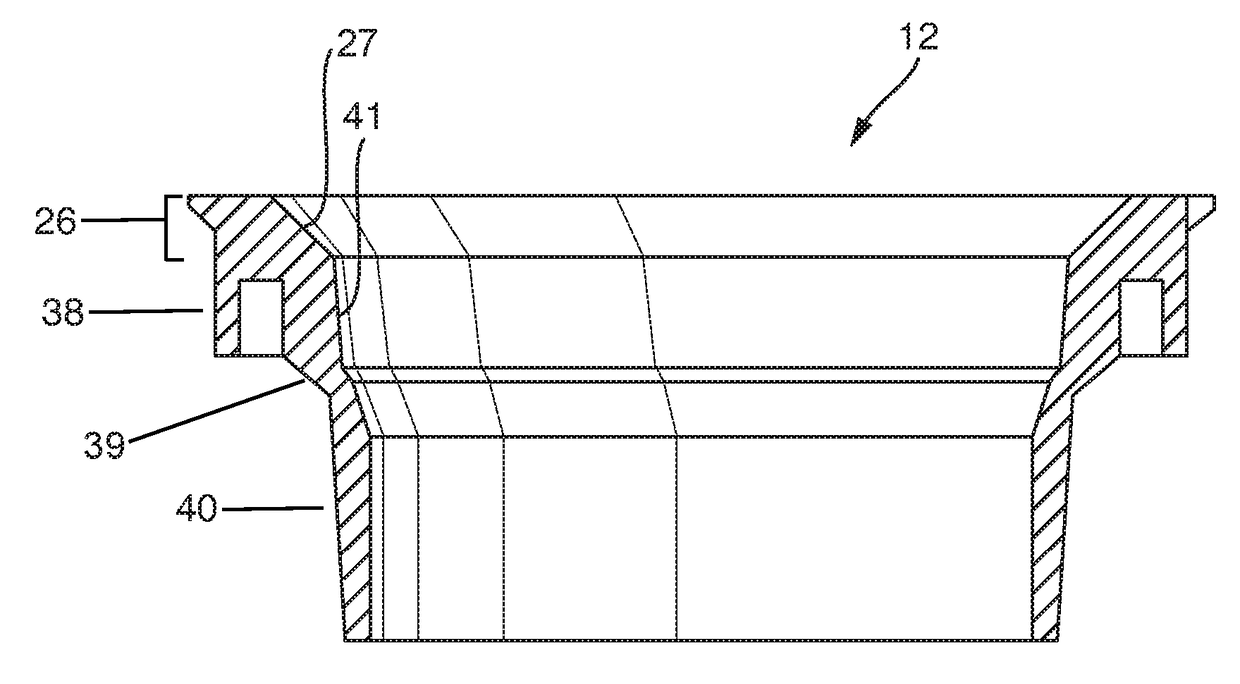

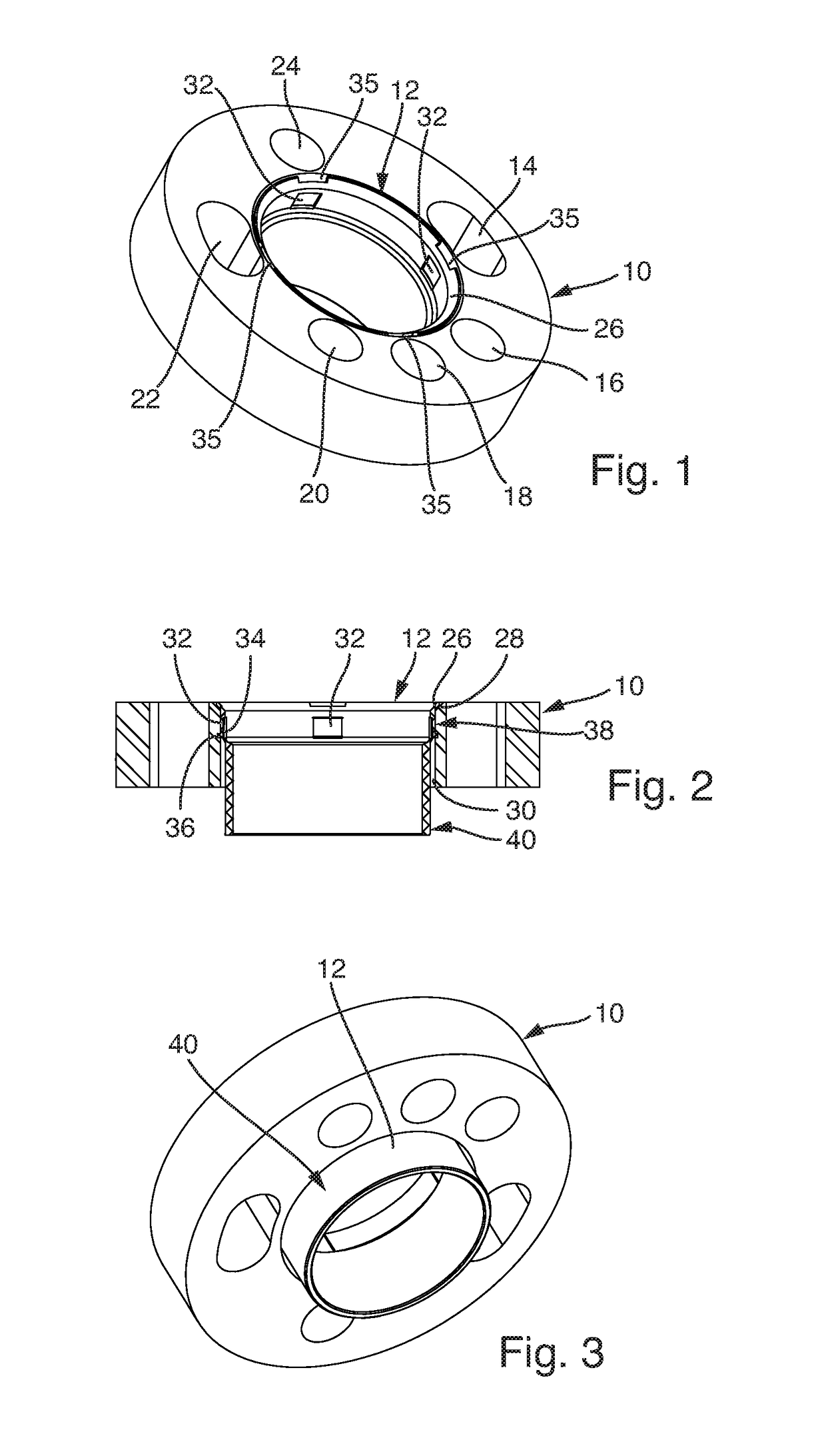

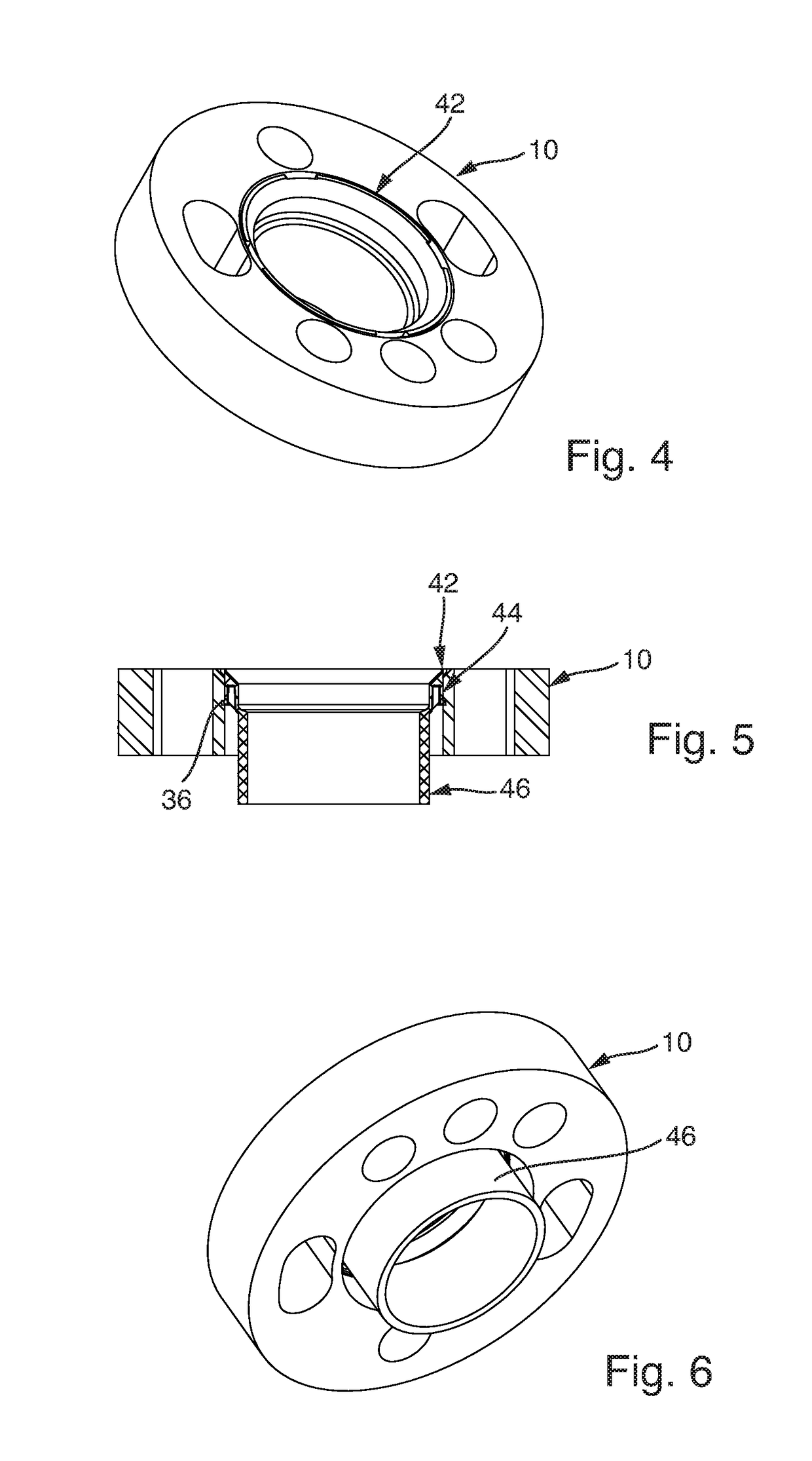

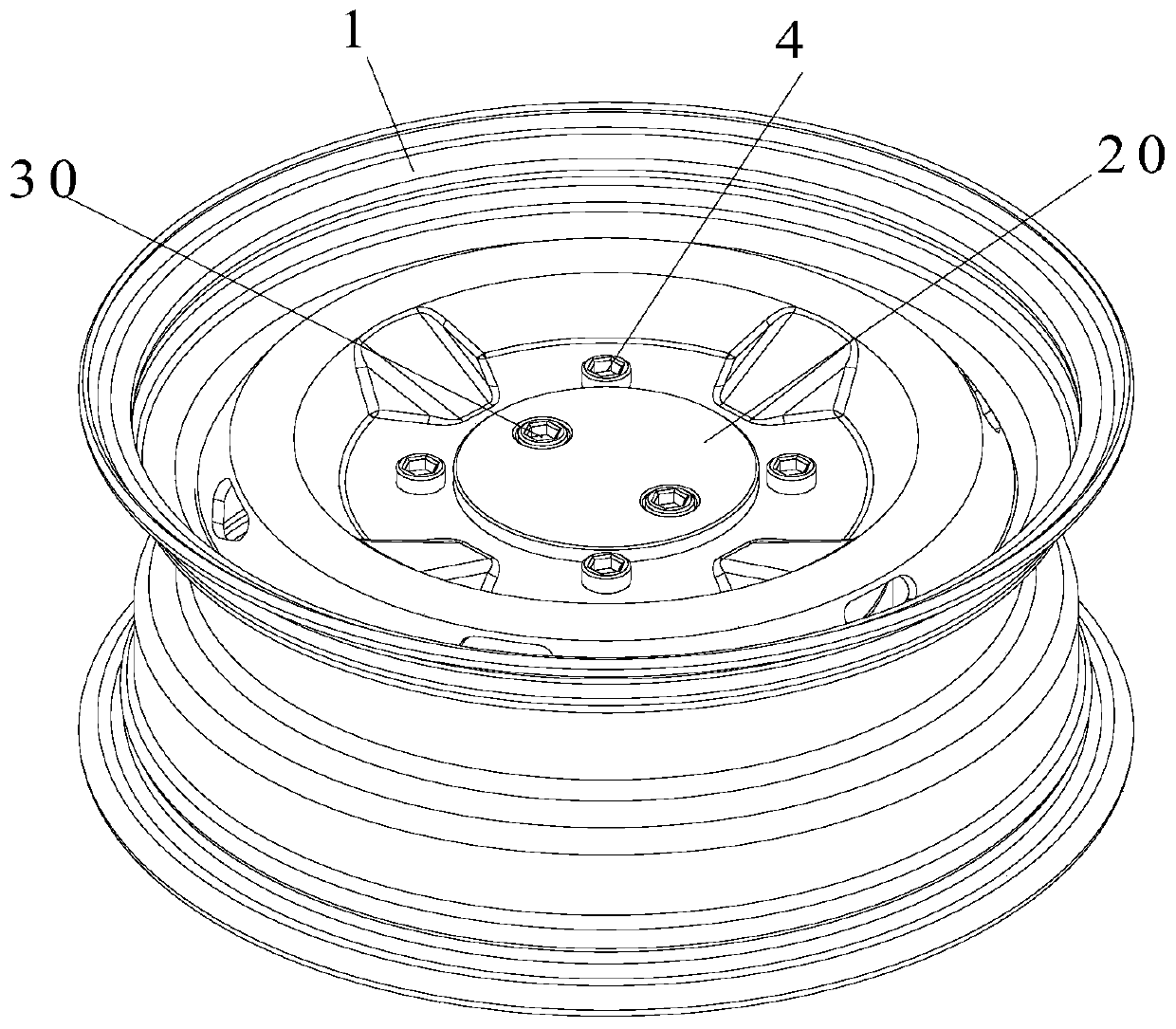

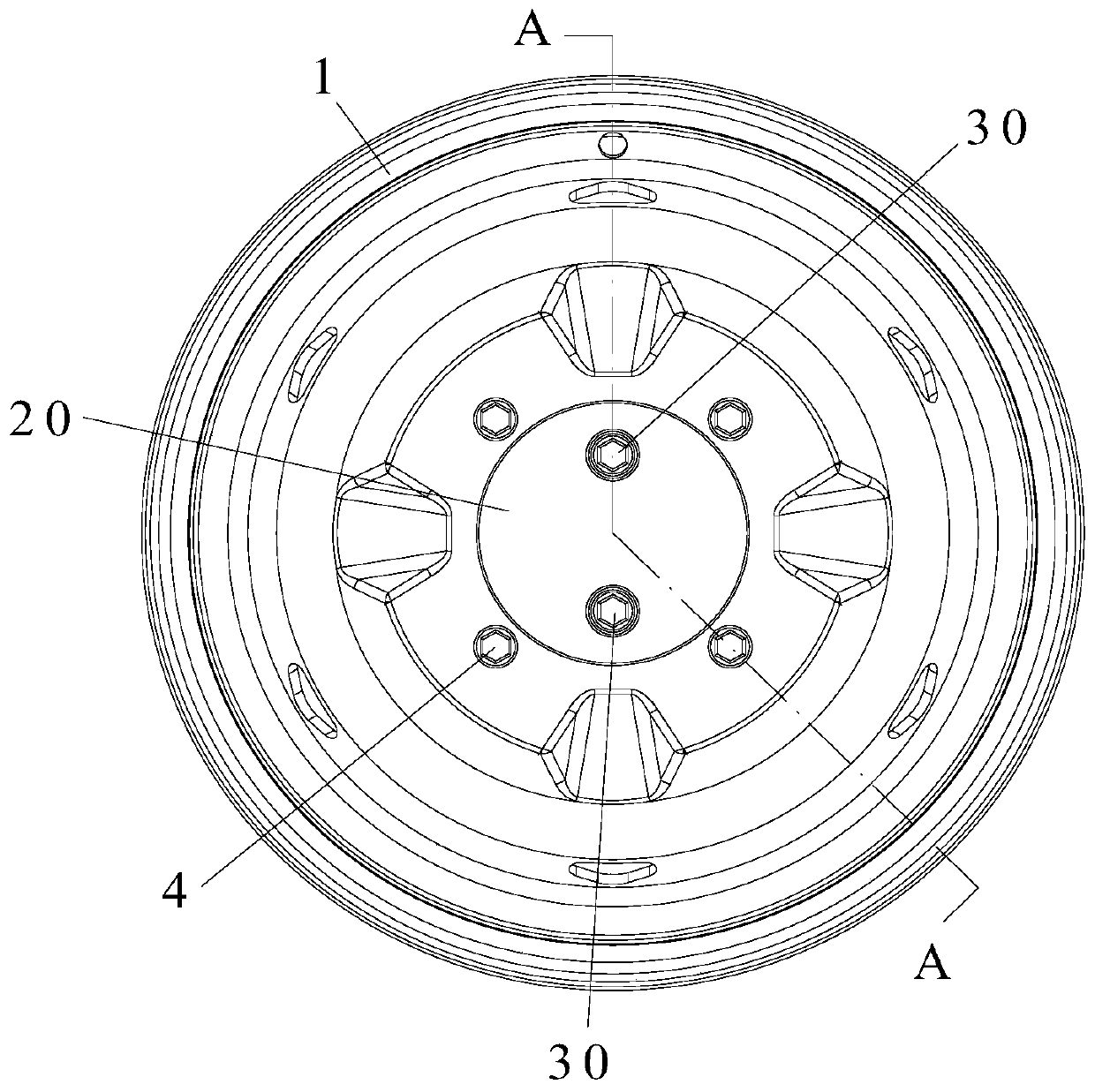

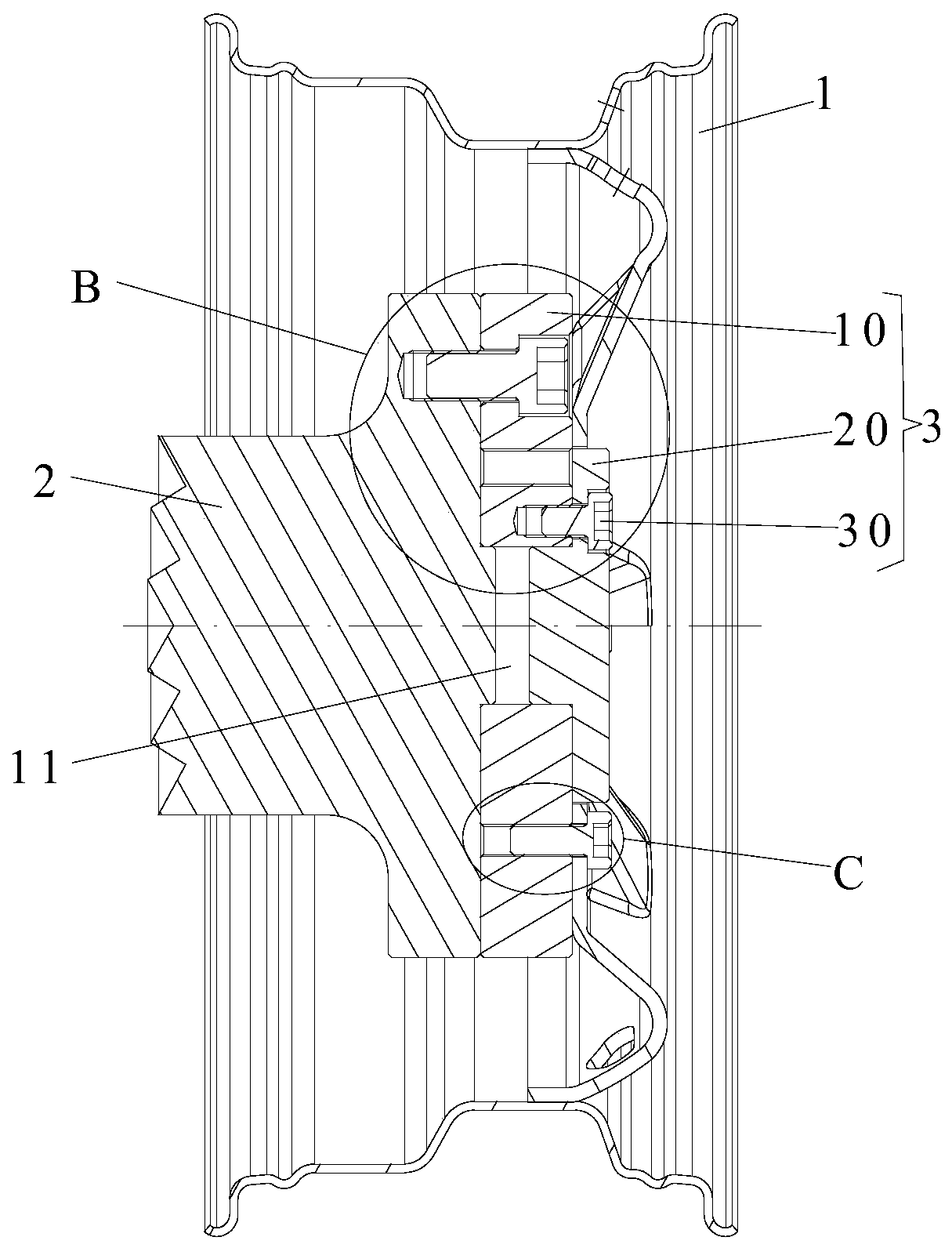

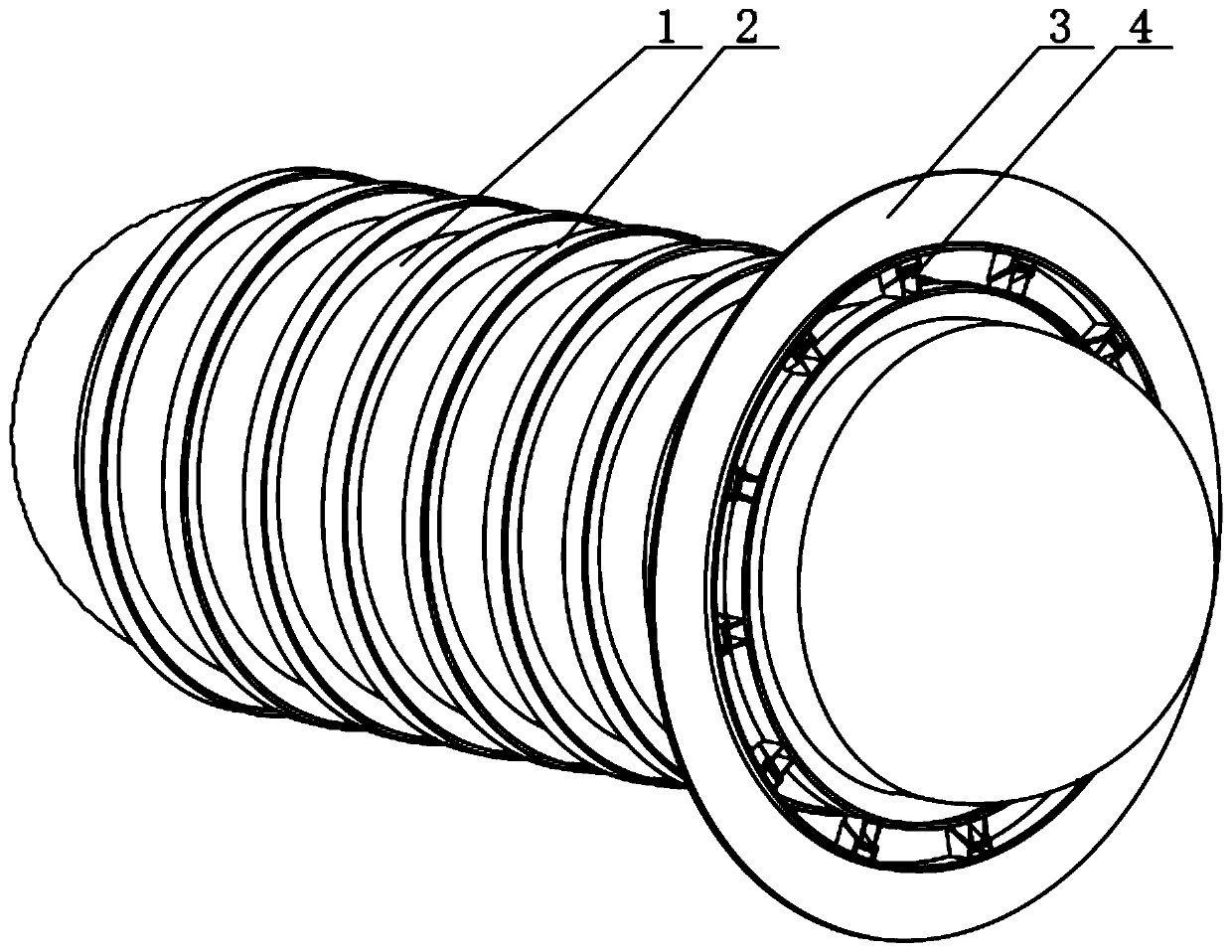

Track Widening System for Motor Vehicles

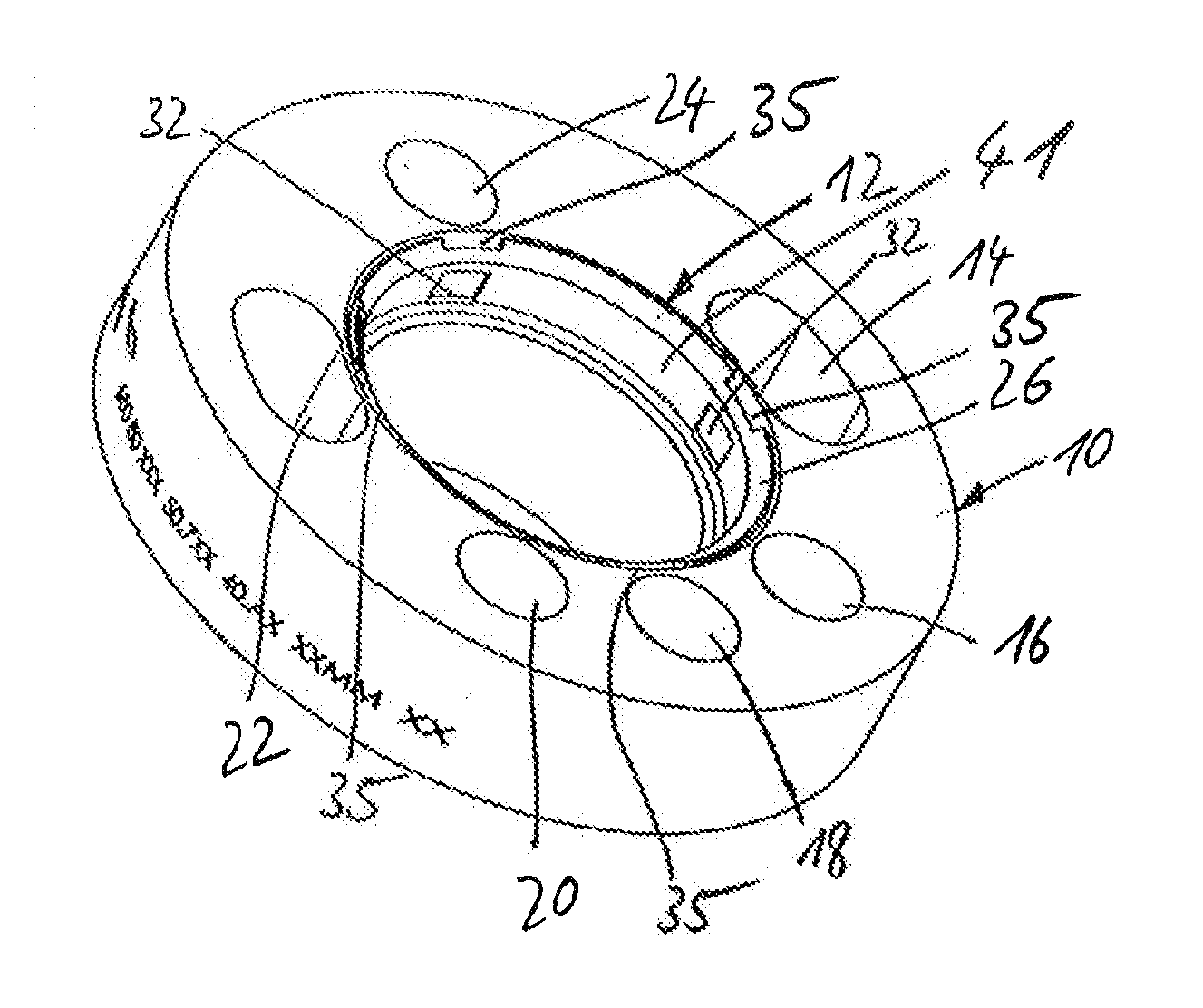

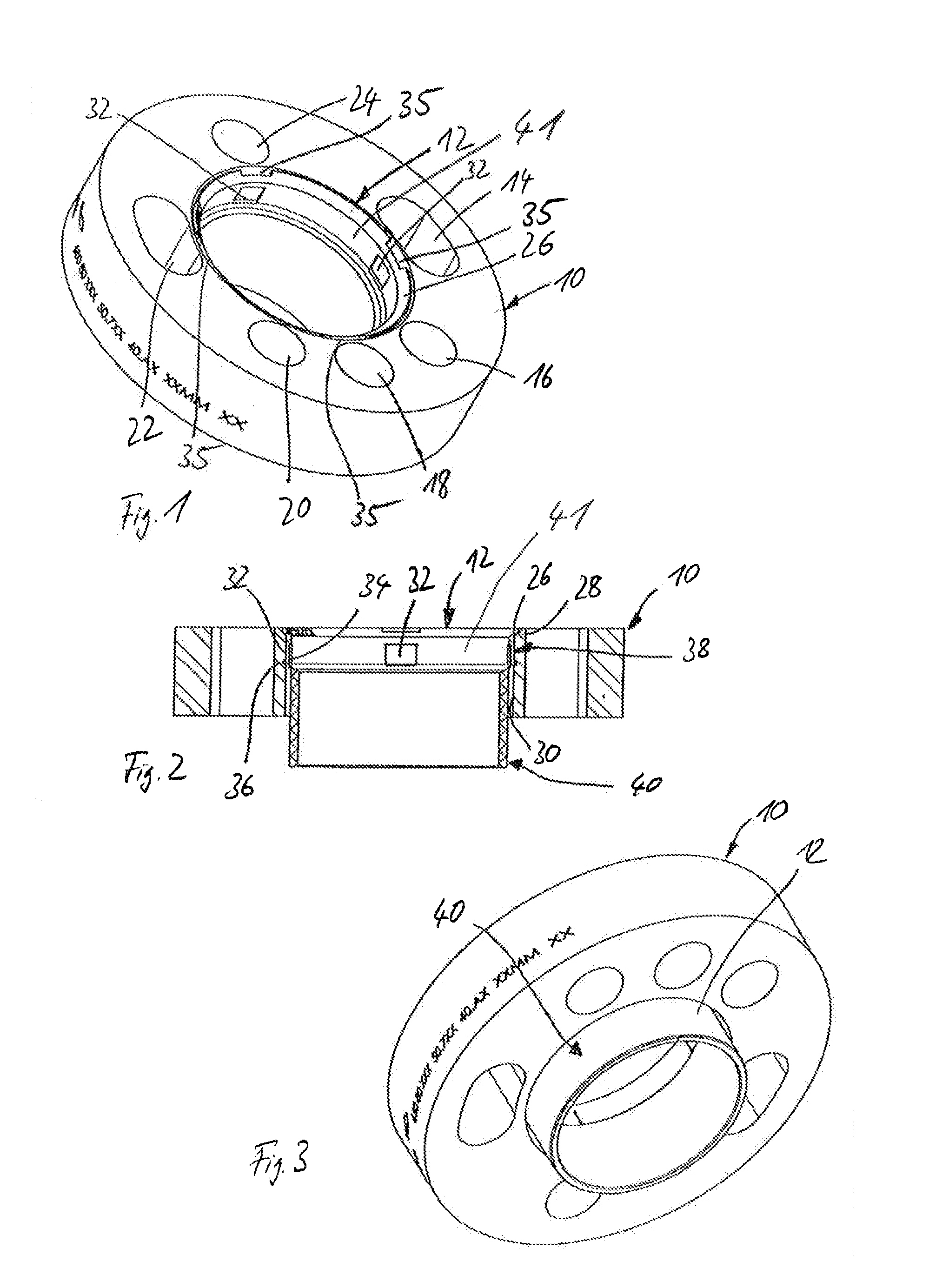

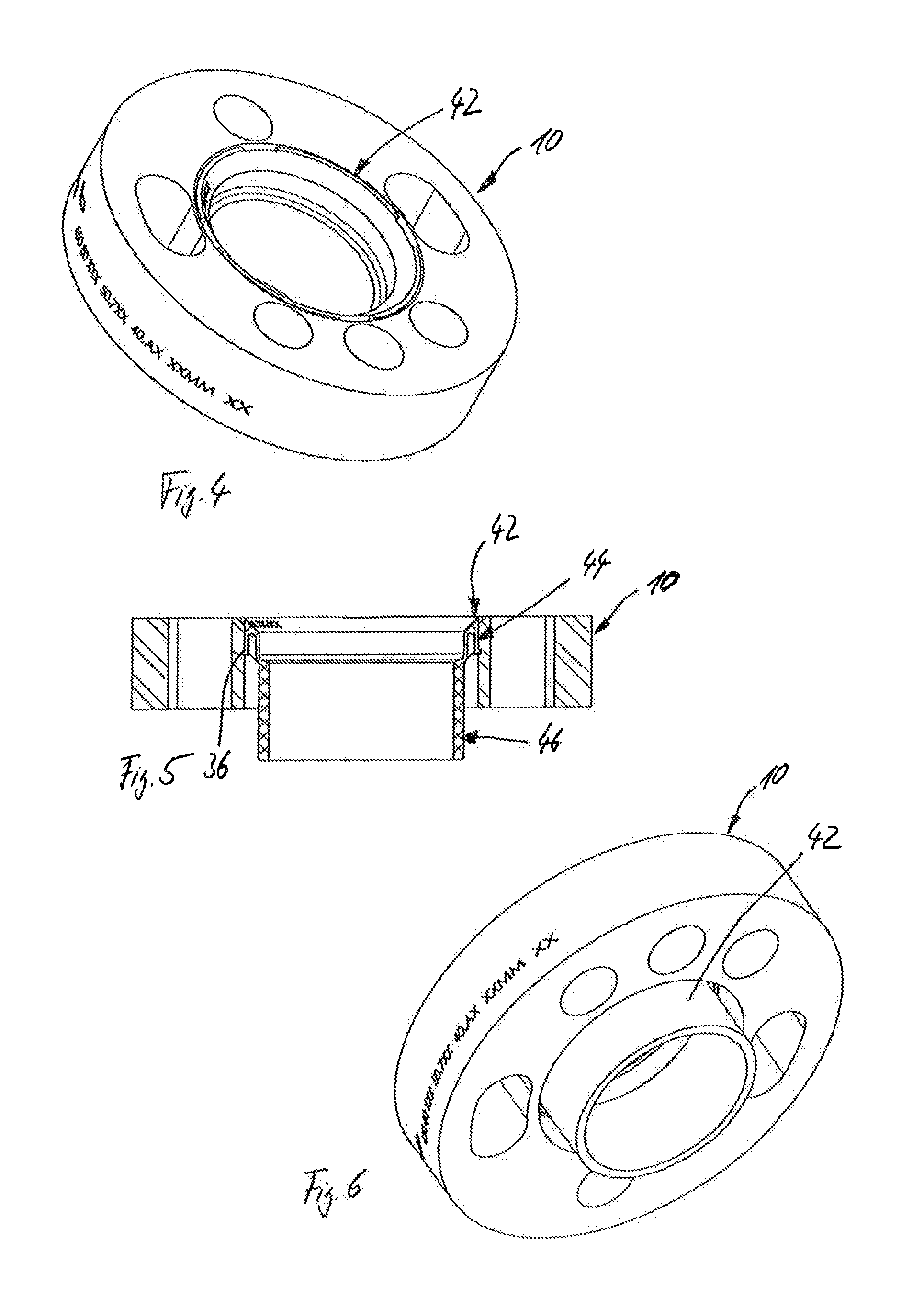

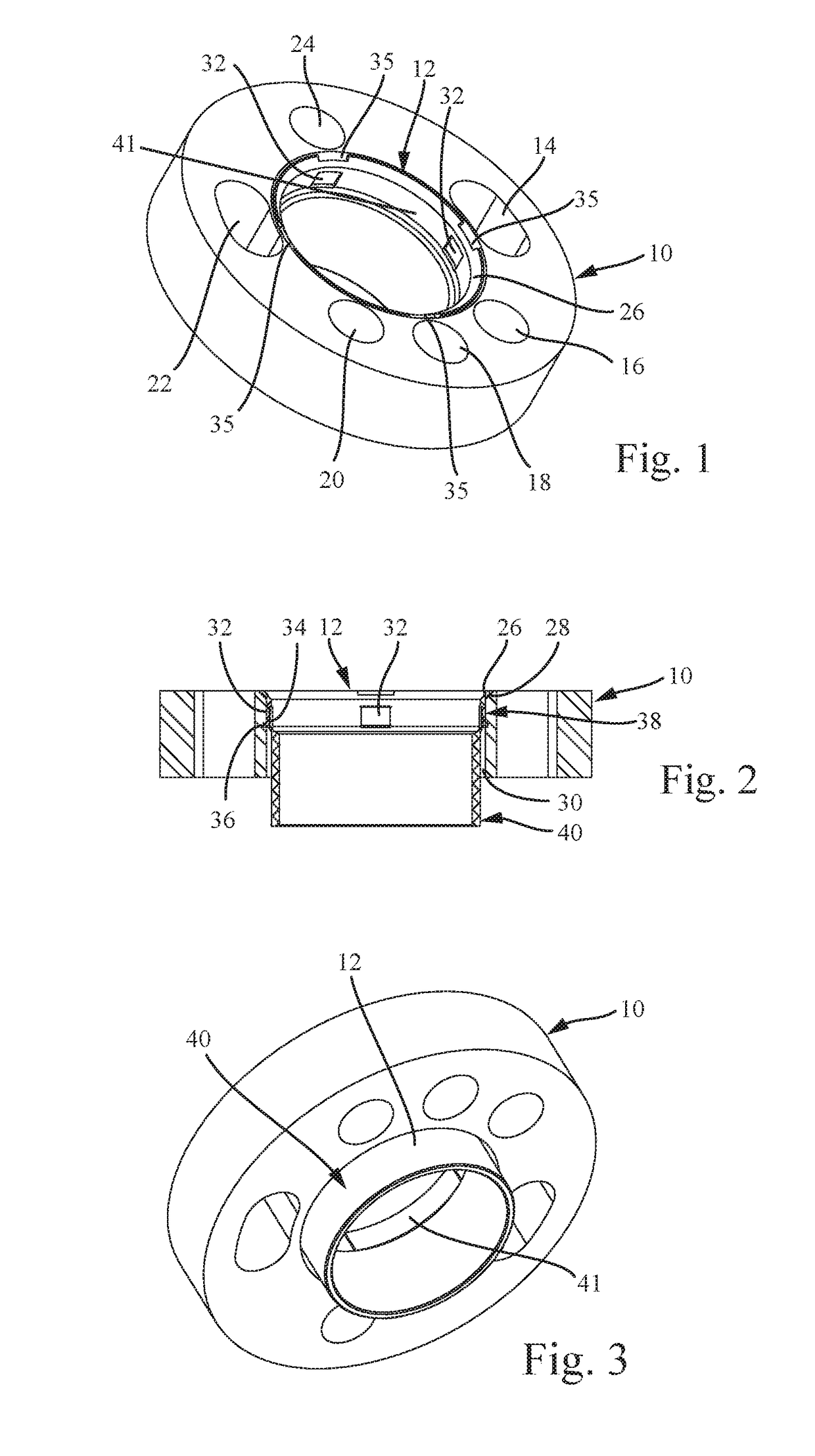

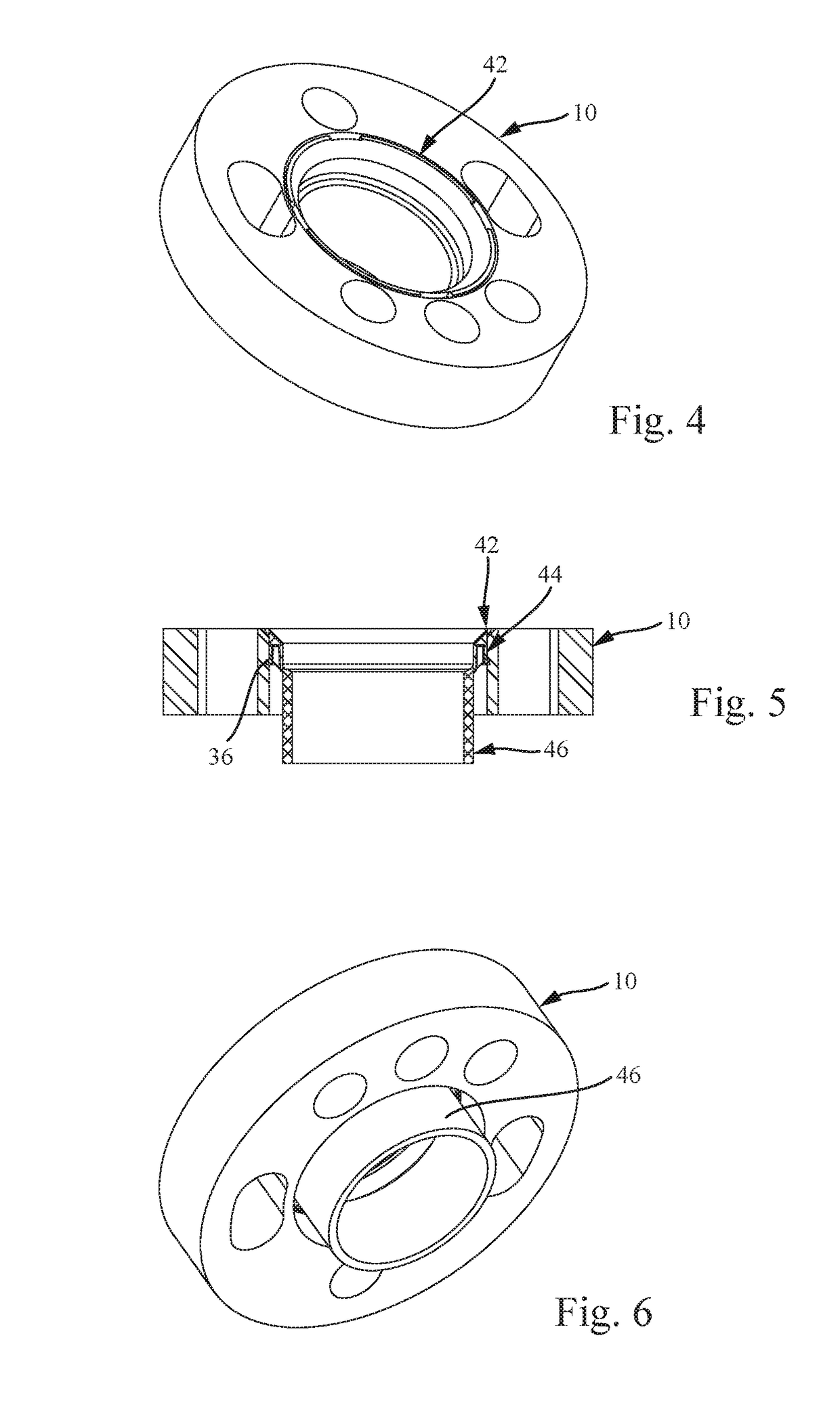

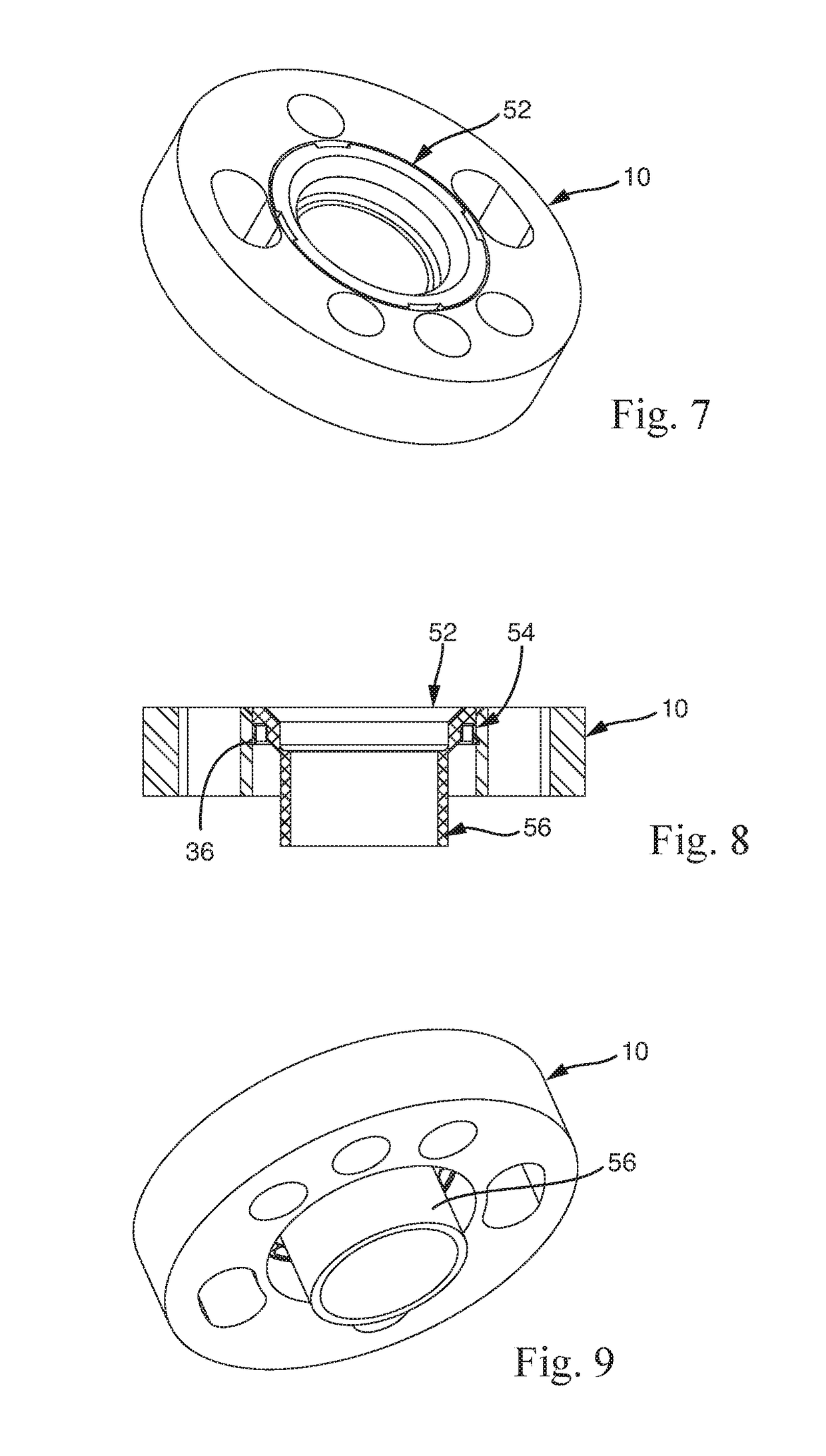

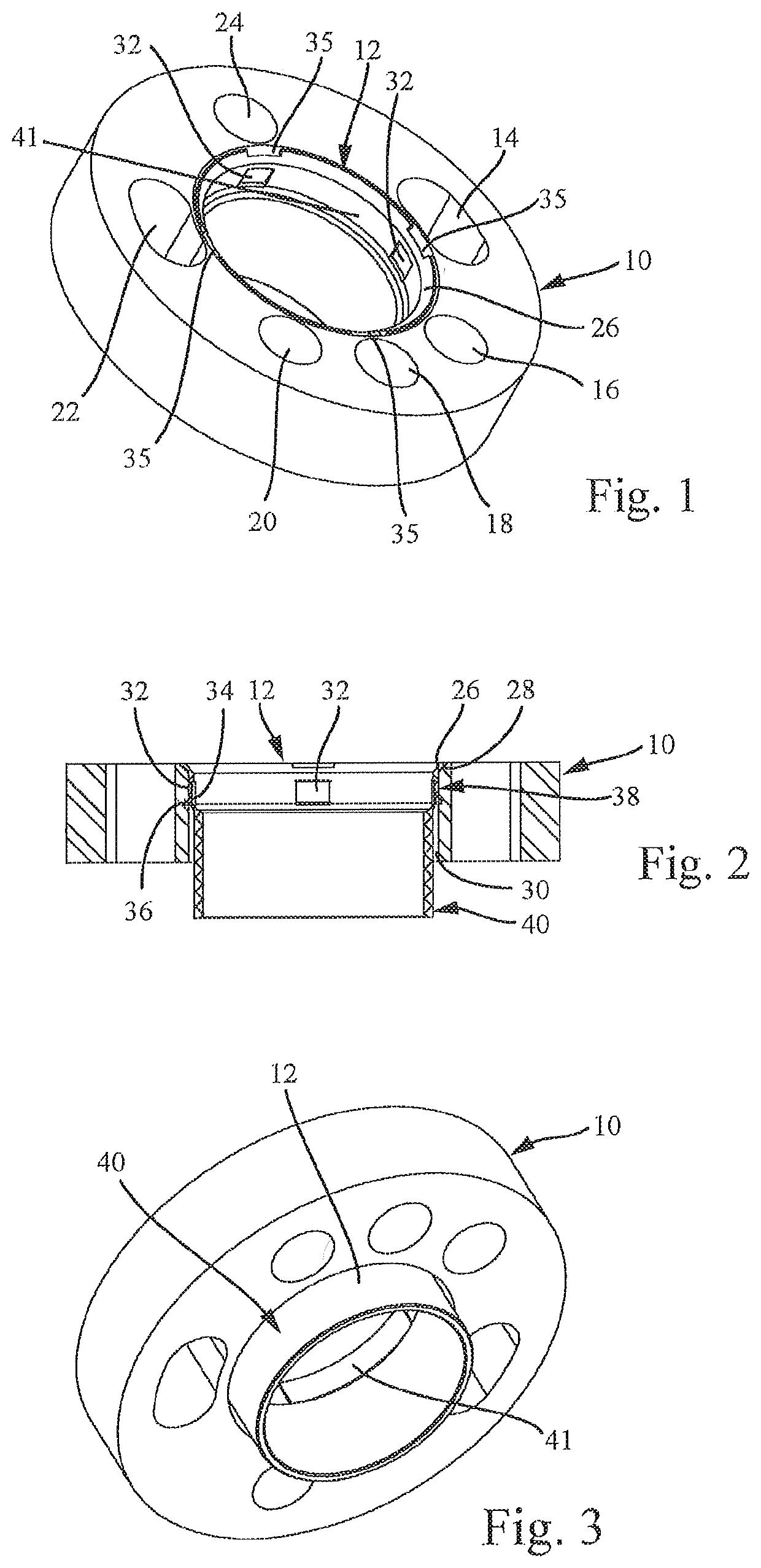

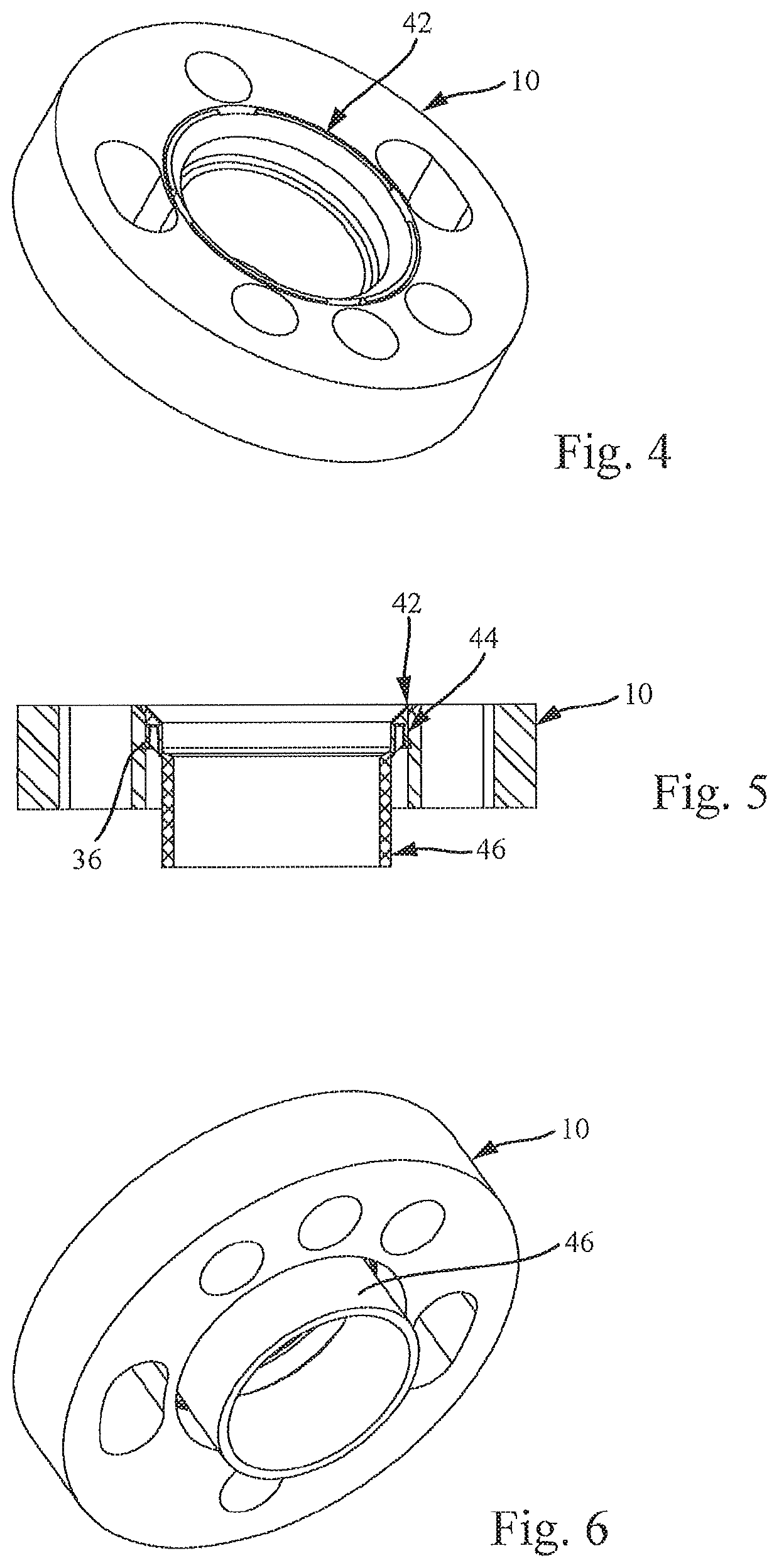

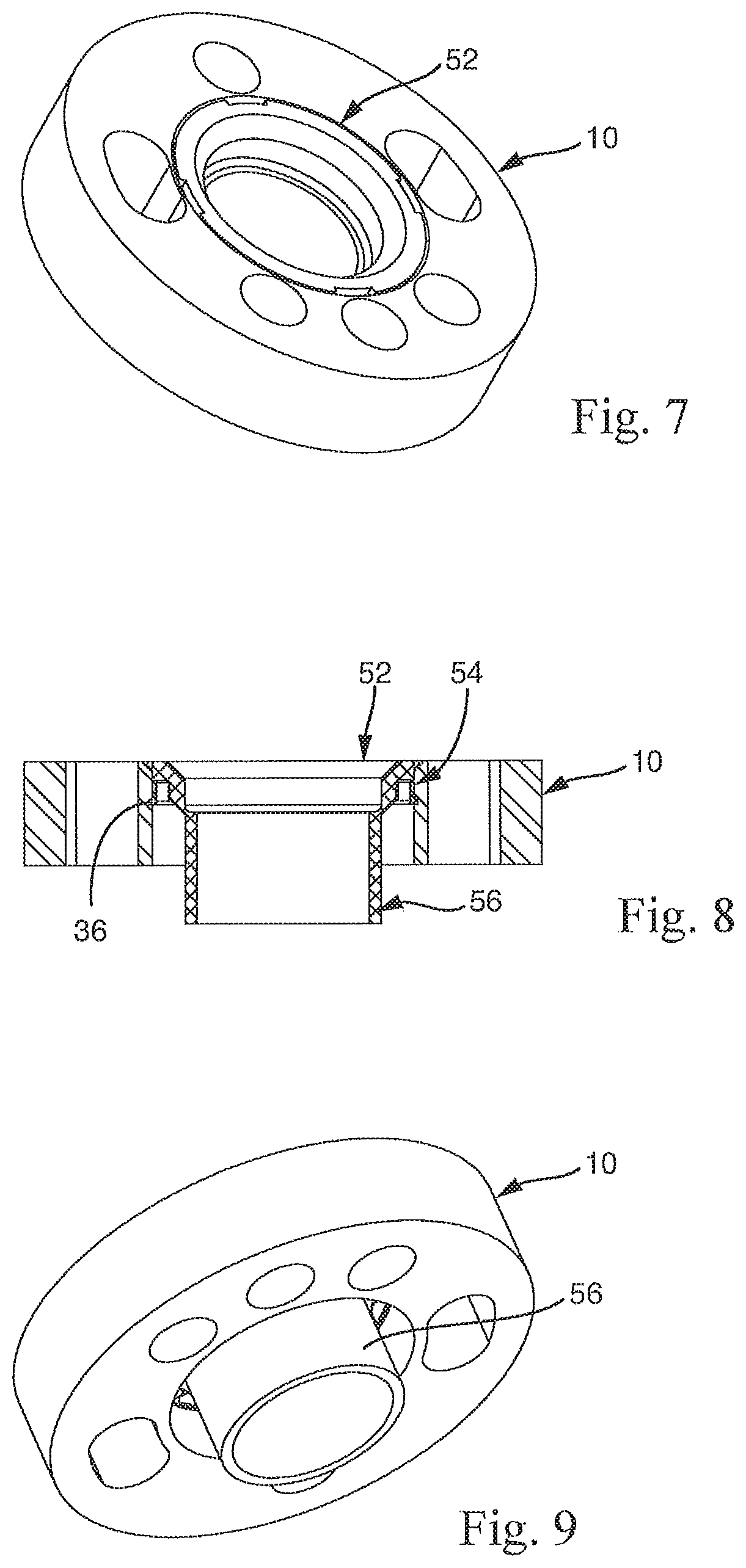

The invention relates to a track widening system for motor vehicles, having at least one track widening disc and at least one centering ring which is inserted into a central opening of the track widening disc, wherein the centering ring has at least one first catch device which is arranged at the free end of a resilient arm and wherein the track widening disc has a corresponding second catch device. The centering ring may comprise plastic, and may be fiber-reinforced. One or more centering rings may have different colors.

Owner:WOHLFARTH KLAUS

Track widening system for motor vehicles

ActiveUS10086644B2Adapted flexiblyEasy to producePassengers carsWheel manufactureMobile vehicleEngineering

A track widening system for motor vehicles, having at least one track widening disc and at least one centering ring, which is inserted into a central opening of the track widening disc, wherein the centering ring has at least one catch device which is arranged at the free end of a resilient arm and wherein the track widening disc has at least one corresponding catch device. The centering ring may be plastic, and may be fiber-reinforced. One or more centering rings may have different colors.

Owner:WOHLFARTH KLAUS

Float device

ActiveUS8707991B2Ensure fitOperating means/releasing devices for valvesWater cleaningWaste management

Owner:FUEL ACTIVE LTD

Swimming goggle

A swimming goggle having connector members which are formed by a material which is flexible, elastically deformable and has rigidity as well as hardness higher than those of the head strap where each of the eye cups is formed on its laterally outer portion with a sloped guide depression and a stopper extending in the vertical direction so as to straddle the guide depression, and the connector member has a front end segment adapted to be connected the eye cup and a rear end segment adapted to be connected with the head strap wherein the front end segment is formed with a latching detent adapted to be engaged with the stopper while the rear end segment is formed with an insertion hole through which the head strap is inserted so that the connector member is inserted with its rear end segment ahead into a gap between the guide depression and the stopper until the latching detent is engaged with the stopper to connect the connector member to the eye cup in a detachable manner.

Owner:TABATA

Track Widening System for Motor Vehicles

The invention relates to a track widening system for motor vehicles, having at least one track widening disc and at least one centering ring which is inserted into a central opening of the track widening disc, wherein the centering ring has at least one first catch device which is arranged at the free end of a resilient arm and wherein the track widening disc has a corresponding second catch device. The centering ring may comprise plastic, and may be fiber-reinforced. One or more centering rings may have different colors. One or more protrusions may extend from a hub centering portion of a centering ring.

Owner:WOHLFARTH KLAUS

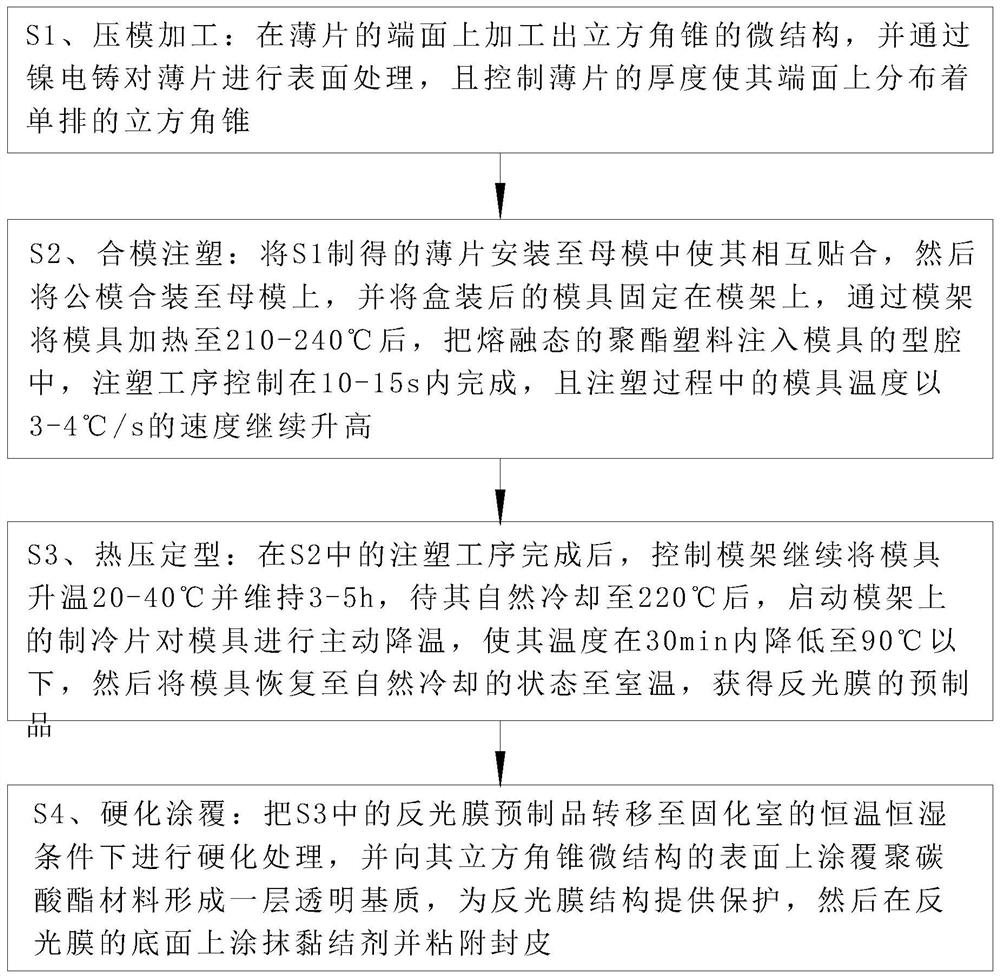

Manufacturing process of directional reflective film

InactiveCN112248359AQuality assuranceSmall shapeOptical articlesFlat articlesPolyesterInjection molding process

The invention relates to the technical field of reflective materials, in particular to a manufacturing process of a directional reflective film. The manufacturing process of the directional reflectivefilm comprises the steps of mold pressing processing, mold closing injection molding, hot-pressing shaping and hardening coating, and a mold frame adopted by the manufacturing process of the directional reflective film comprises a supporting shell, a swing rod and a controller. Due to the mutual contact state between cubic pyramid surfaces formed by combining the thin sheets, the precision of thecubic pyramid surfaces is influenced, the temperature change of a mold in the injection molding process needs to be accurately controlled, and otherwise, the quality of the reflective film formed through injection molding can be reduced. Therefore, according to the manufacturing process of the directional reflective film, the working procedure process of the reflective film injection mold is controlled through the arranged mold frame; the supporting shell is driven to vibrate through the swing rod to balance the distribution state of polyester plastic in a mold cavity, so that the overall planeness of the cubic pyramid combined by the thin sheets is kept; by utilizing the wrapping state of the supporting shell on the mold, the temperature state is accurately controlled under the action ofa supporting plate at the bottom of the mold, so that the temperature adjusting requirement in the reflective film manufacturing process is met; and therefore, the operation effect of the manufacturing process of the directional reflective film is improved.

Owner:YESHILI NEW MATERIALS (XIANJU) CO LTD

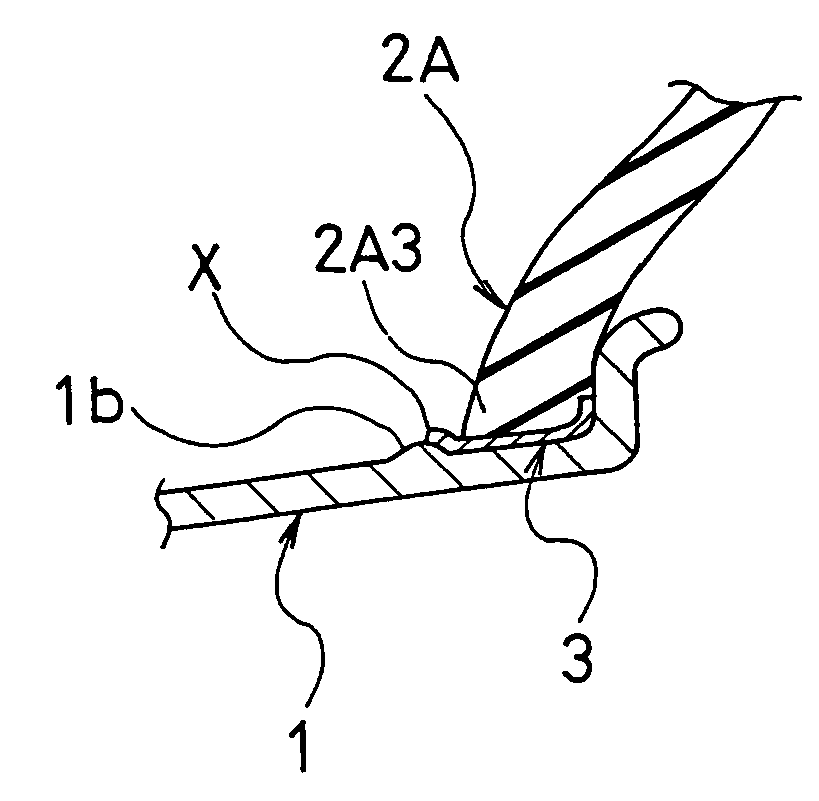

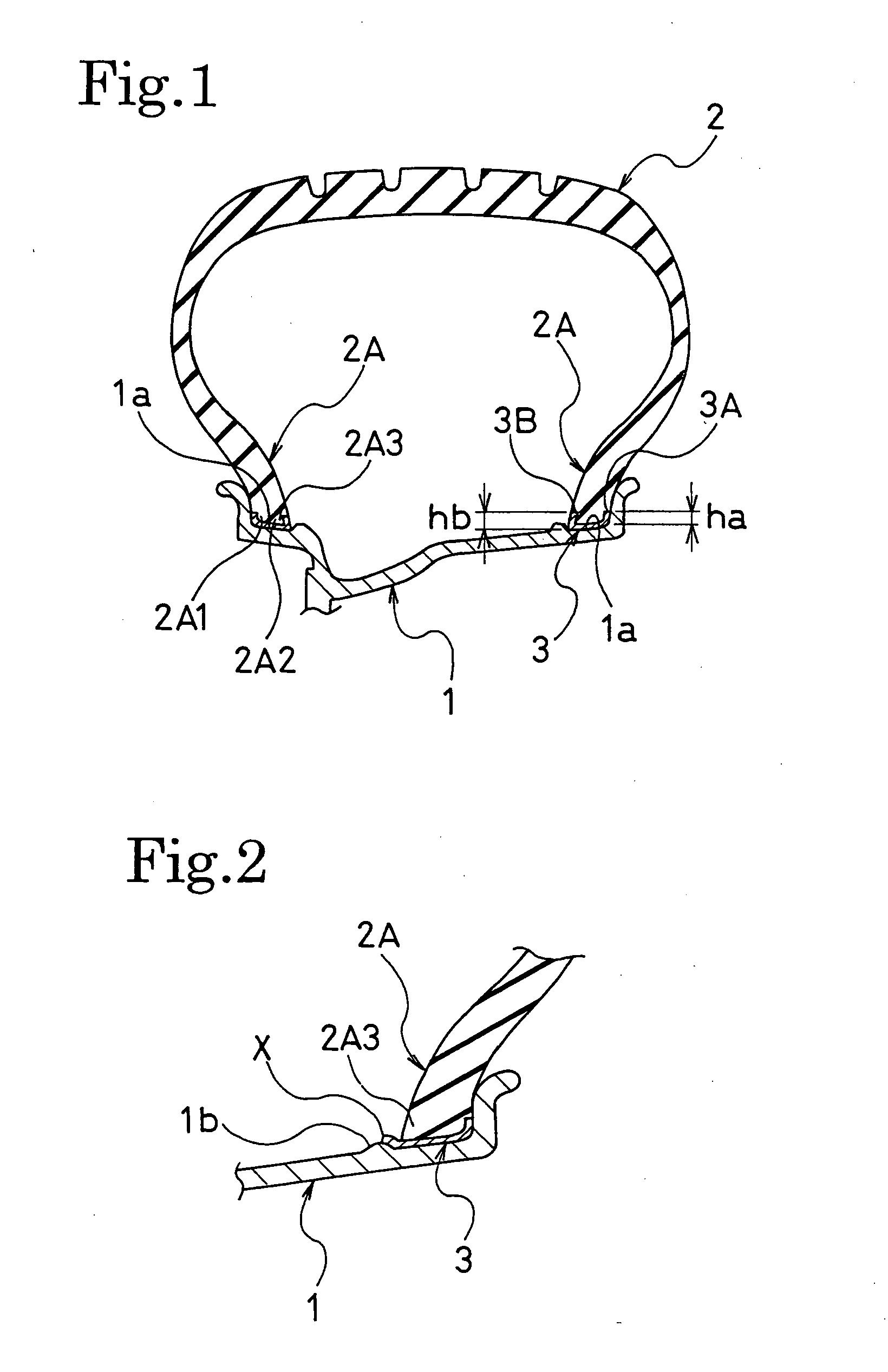

Tire/wheel assembly and pneumatic tire

InactiveUS20070017621A1Increase rigidityFit ability of to be improveWithout separate inflatable insertsRimsEngineeringMechanical engineering

An auxiliary member, made of metal or synthetic resin, is disposed between each rim seat of the rim of a wheel and at least a bead base portion of each of the beads of a pneumatic tire fitted to the rim seats.

Owner:YOKOHAMA RUBBER CO LTD

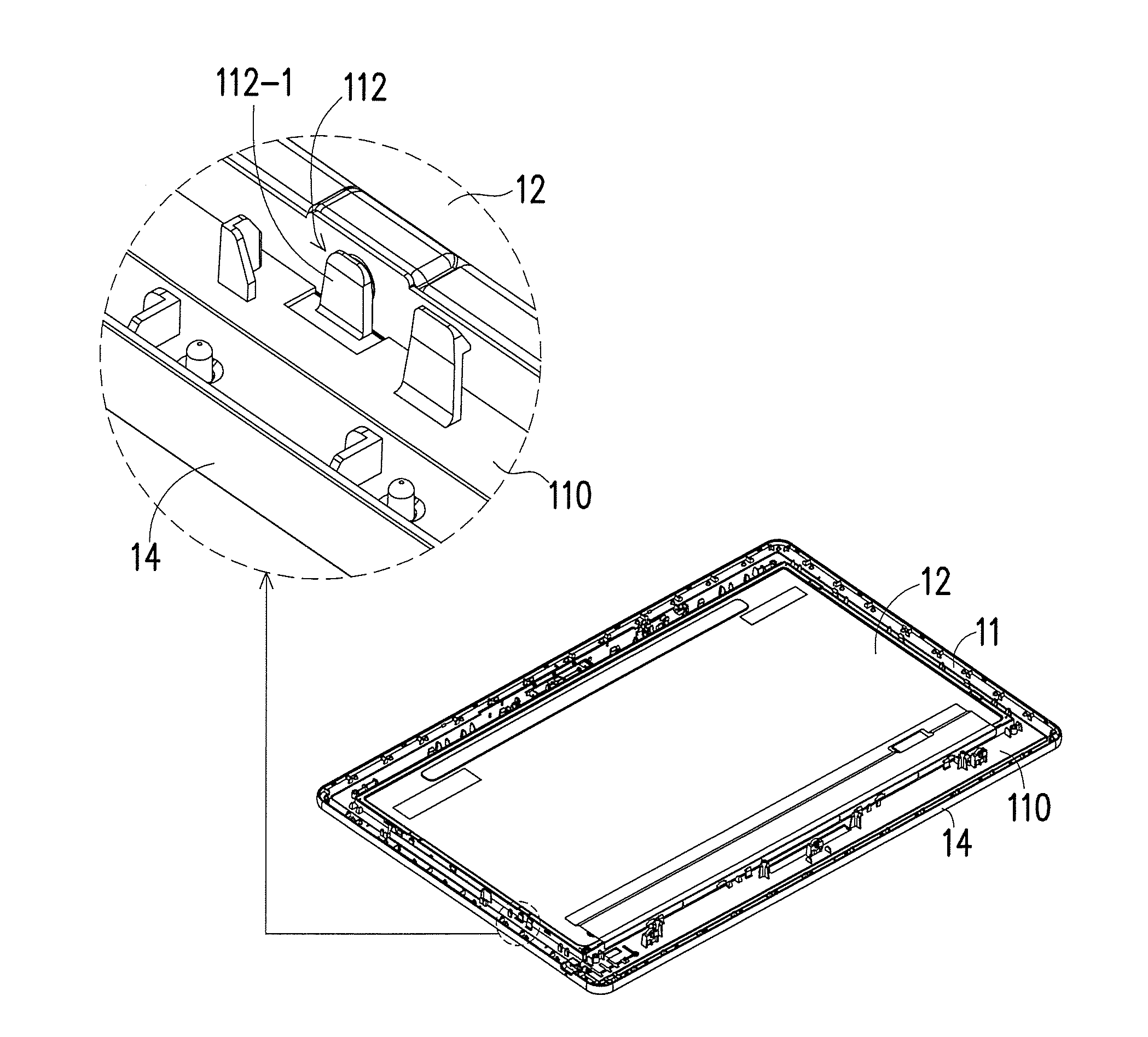

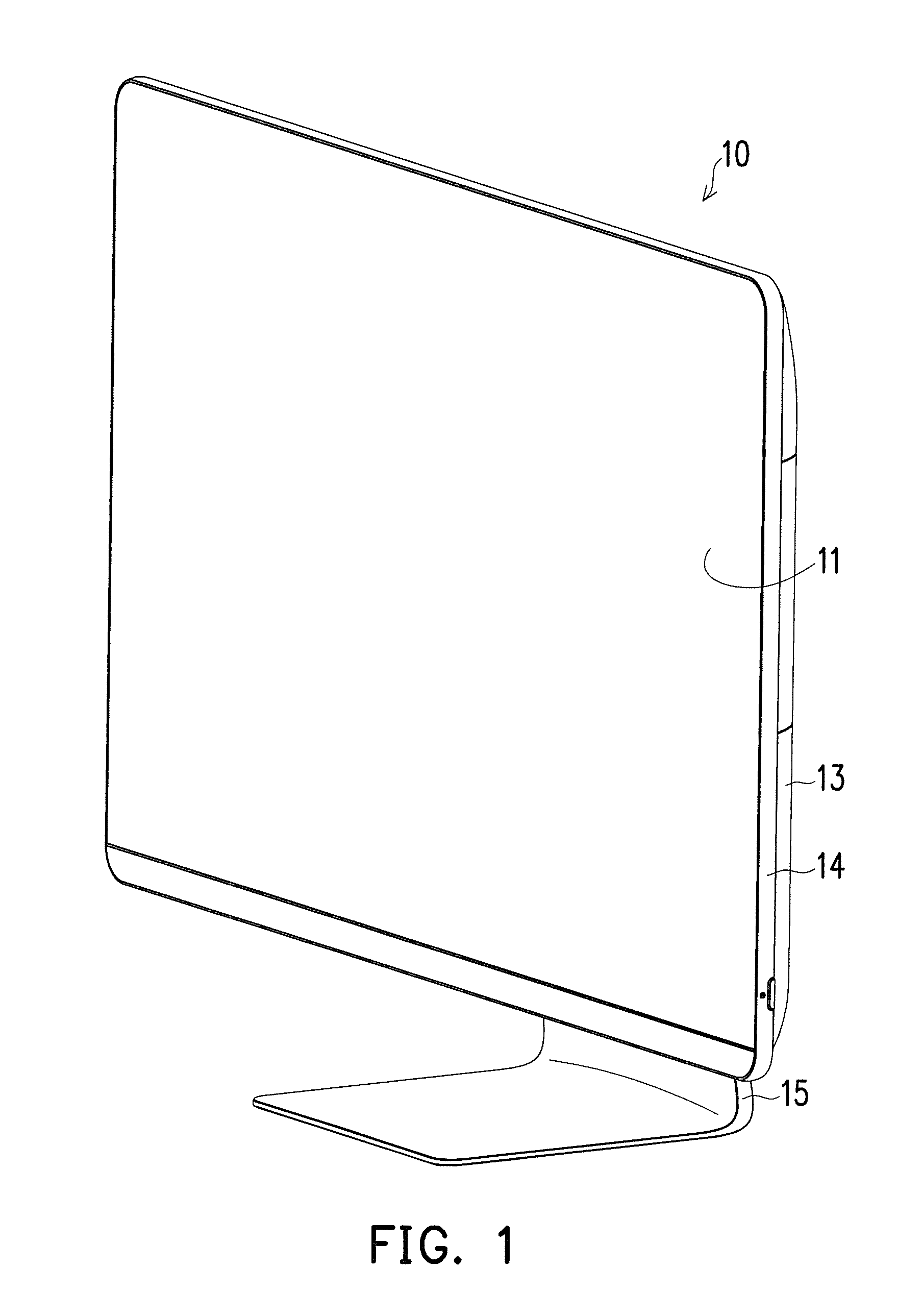

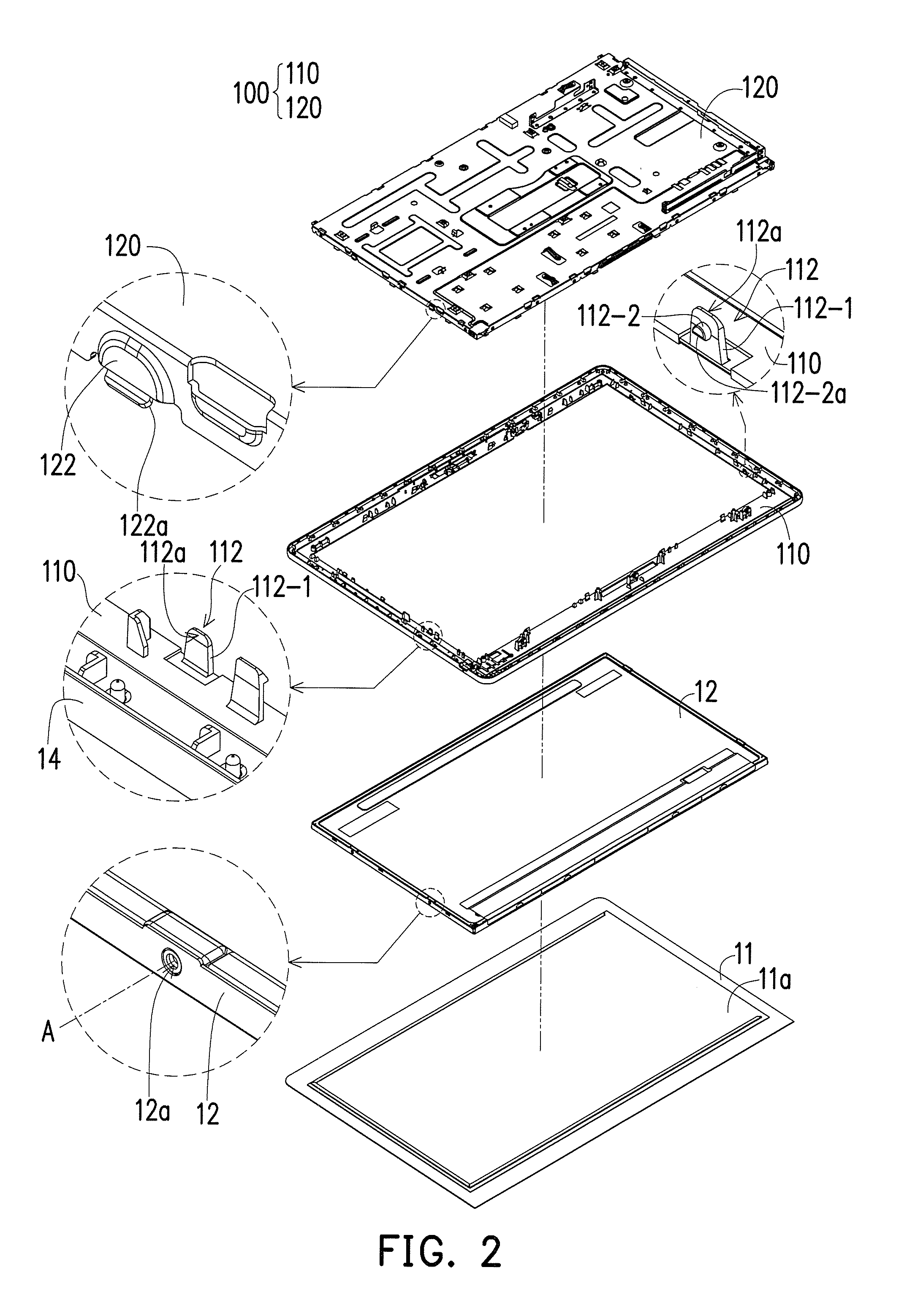

Fixing structure, electronic device and method for assembling an electronic device

ActiveUS20170013727A1Reduces manufacturing time and costPromote repairMachine supportsCasings with display/control unitsEngineeringElectron device

Owner:WISTRON CORP

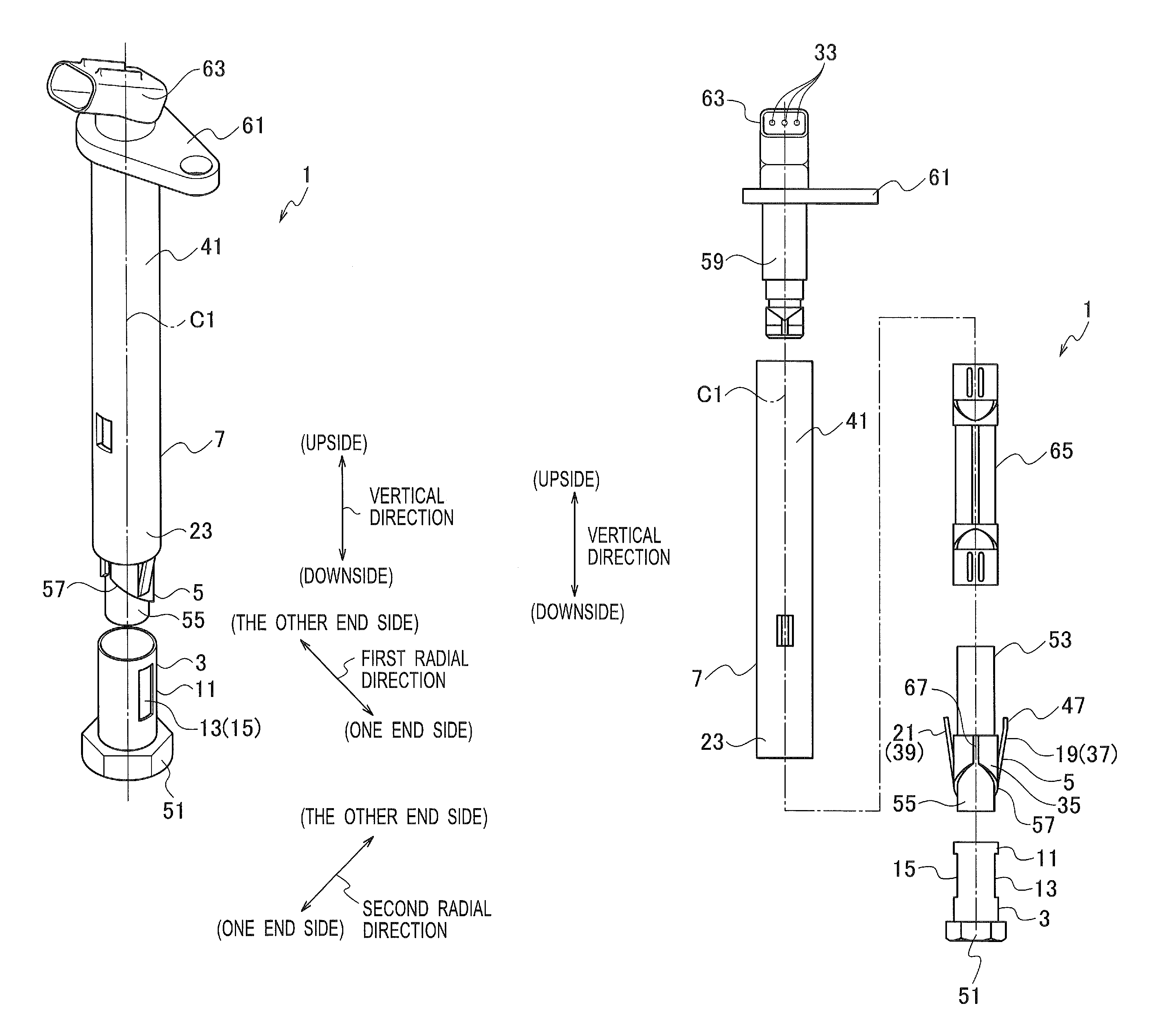

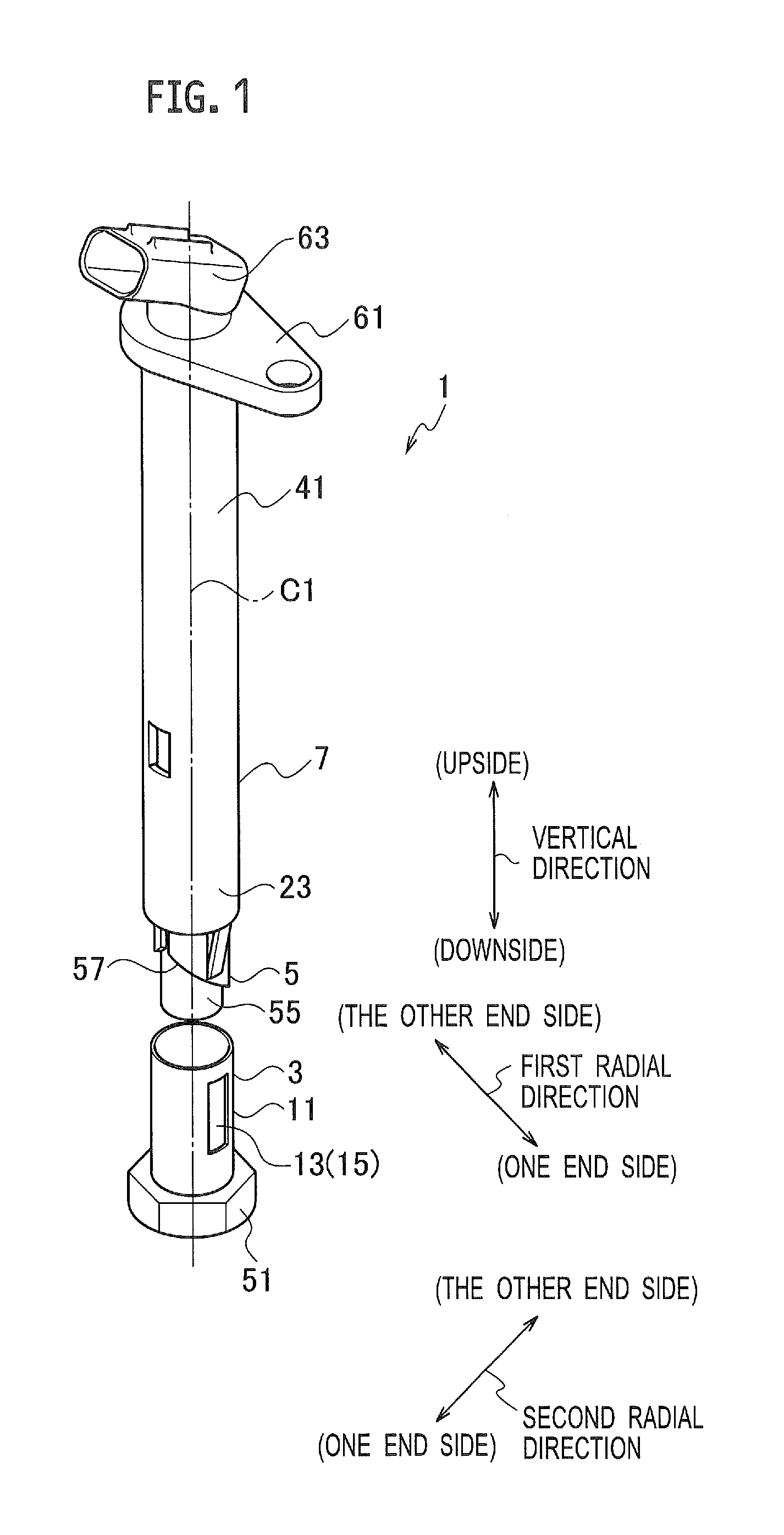

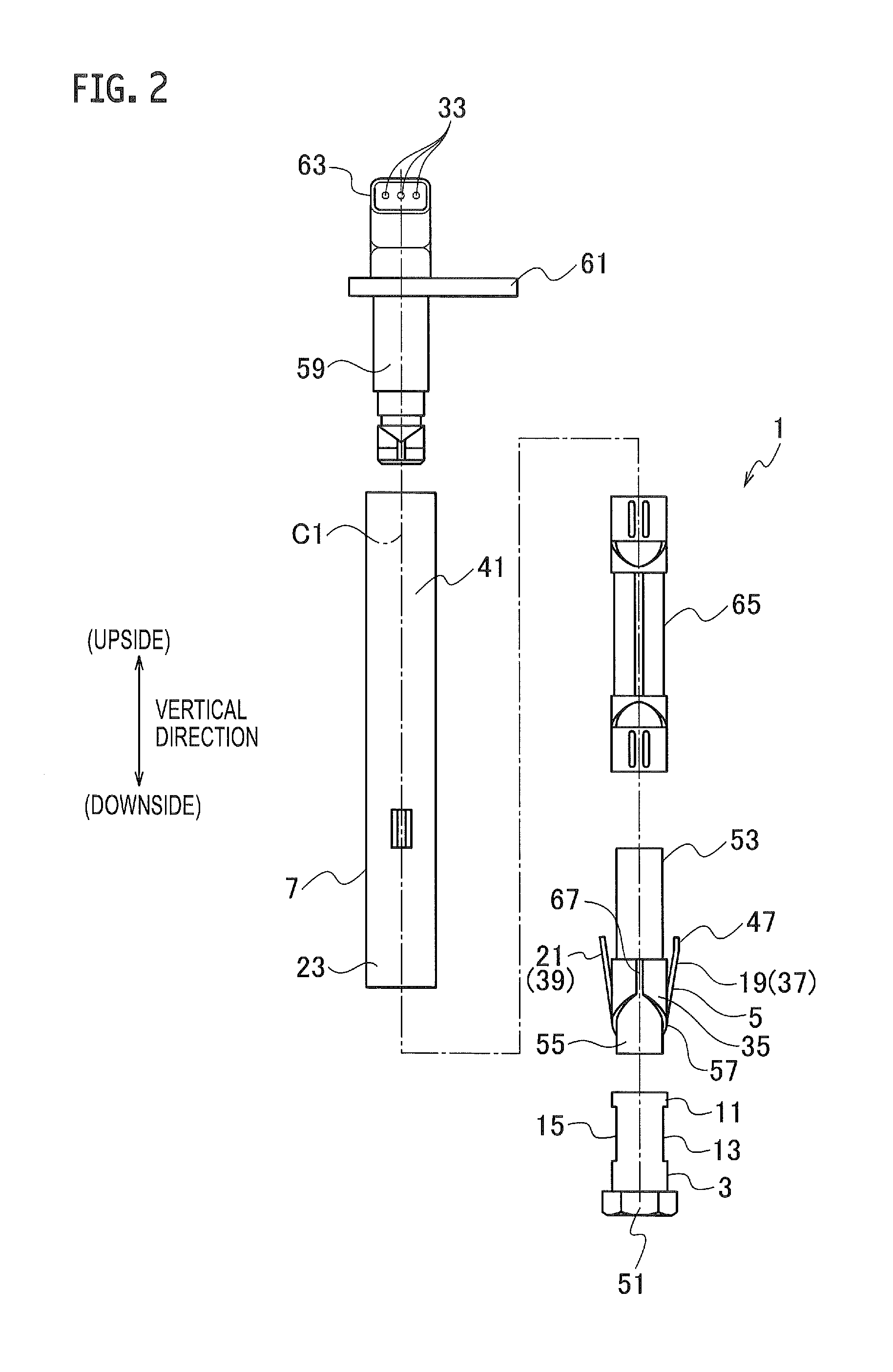

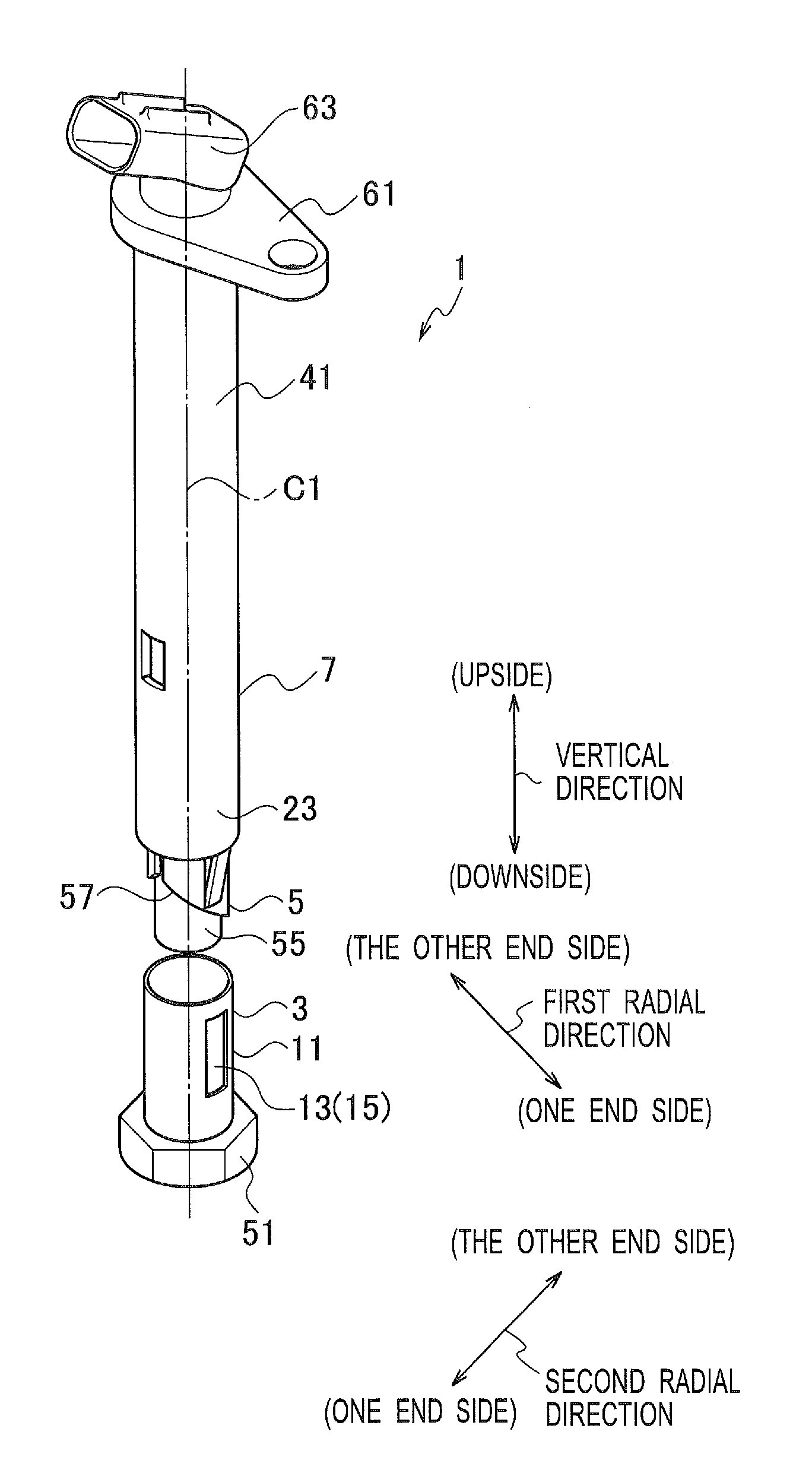

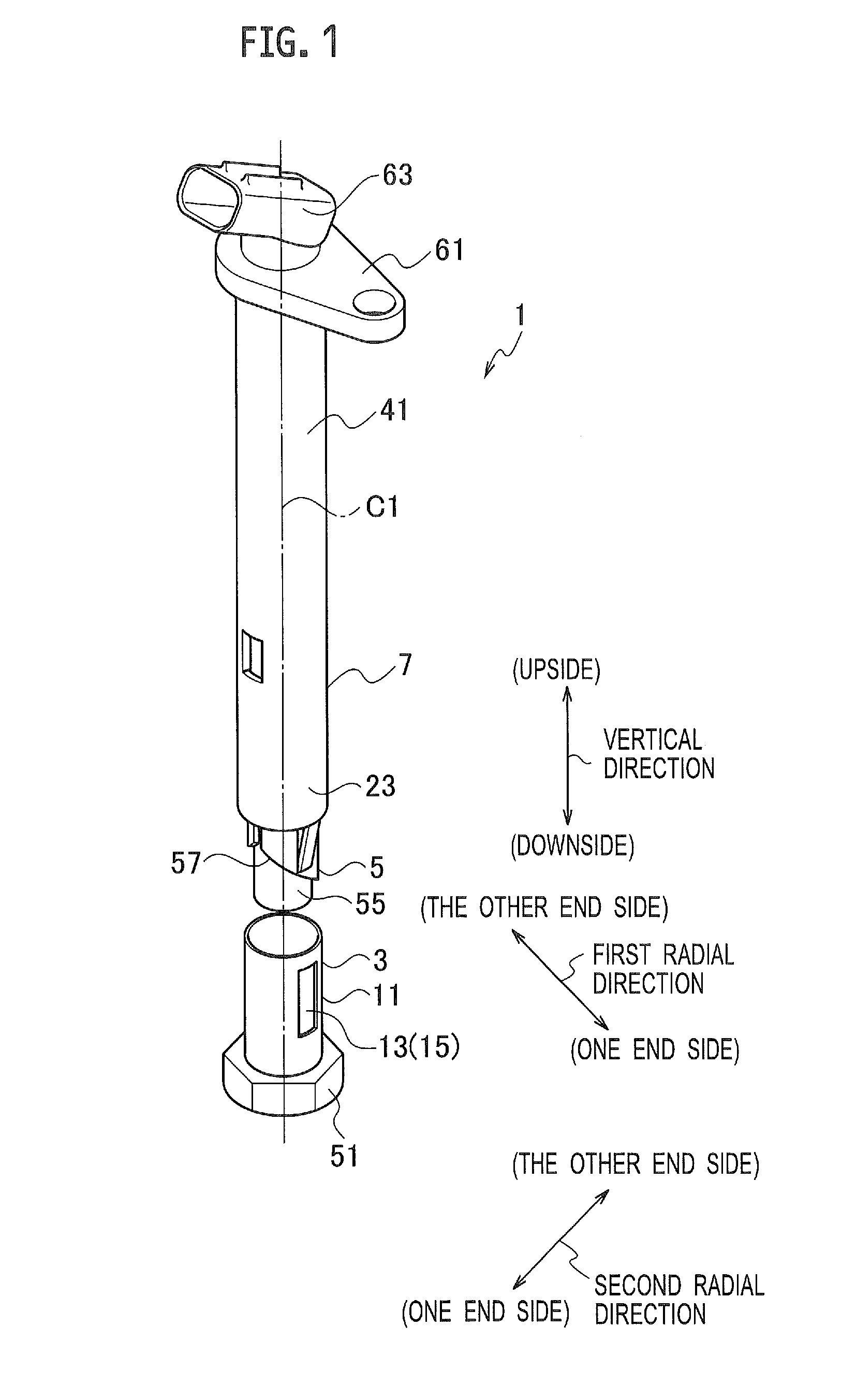

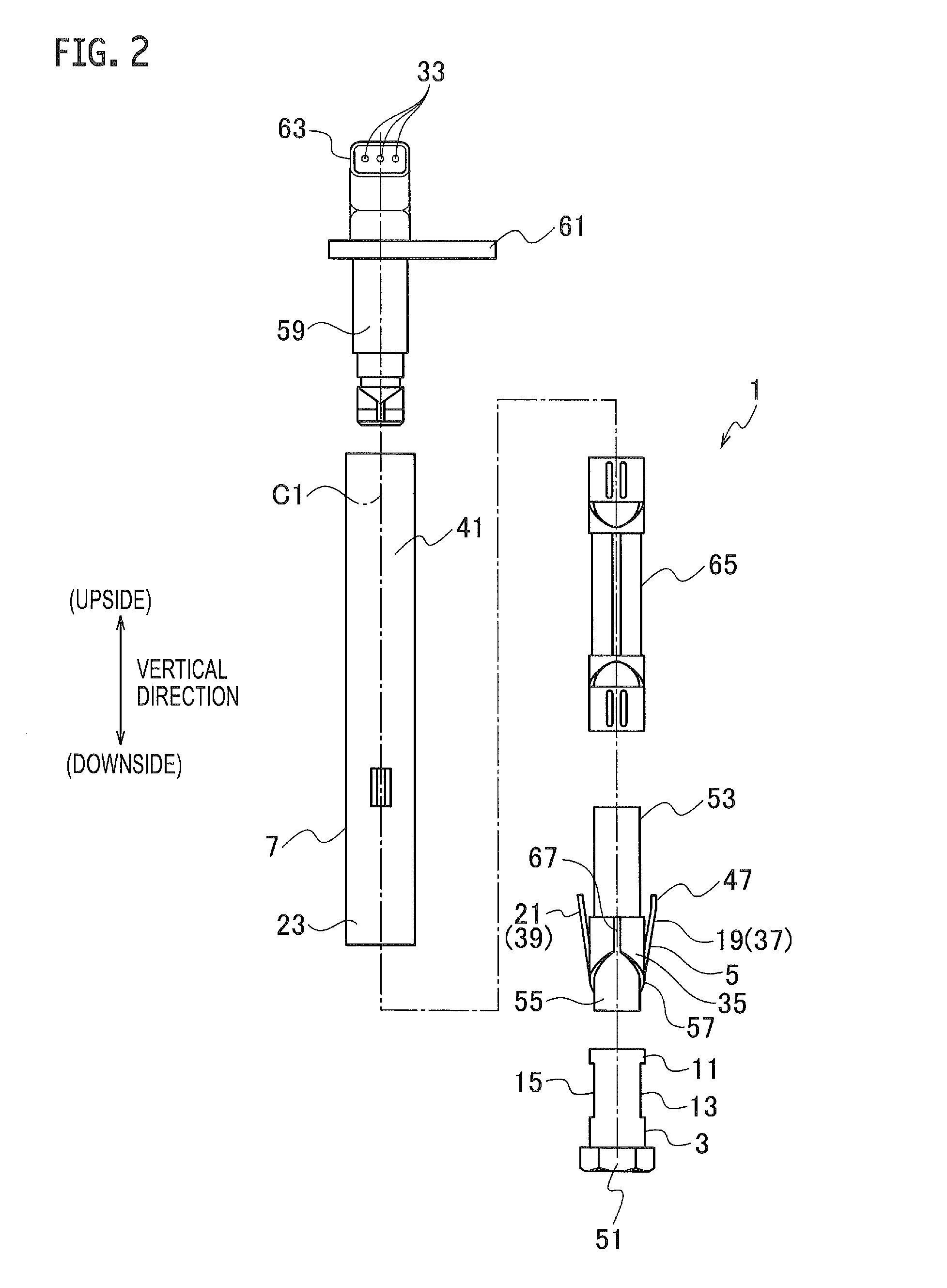

Connector

ActiveUS9490569B2Ensure fitIncorrect coupling preventionCoupling device engaging/disengagingEngineeringMechanical engineering

Owner:YAZAKI CORP

Float Device

Owner:FUEL ACTIVE LTD

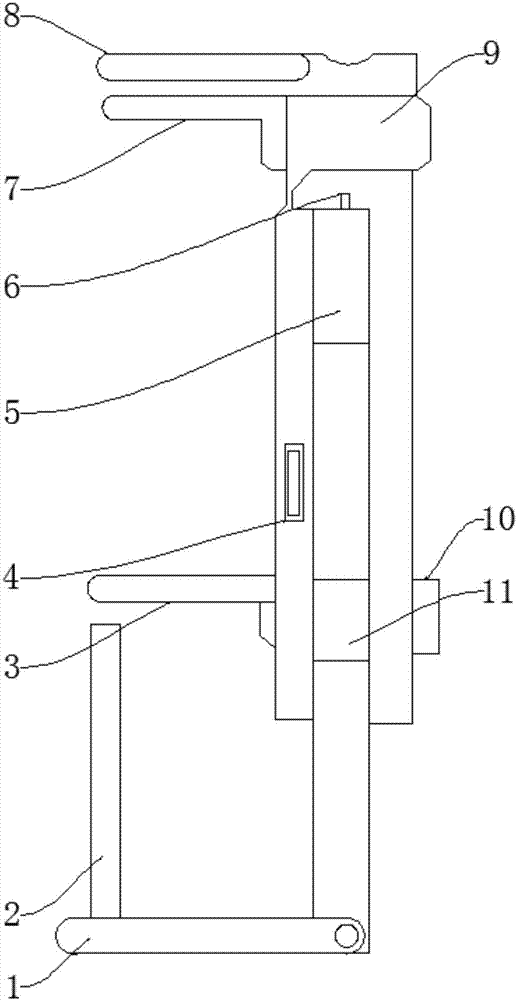

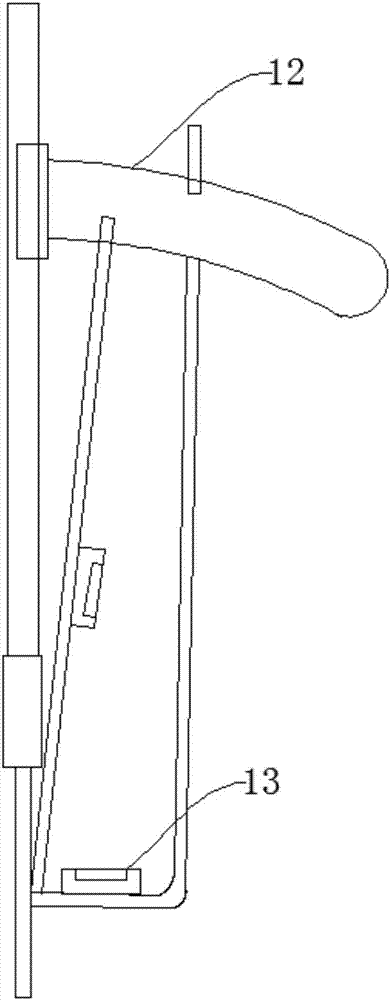

Device and method for measuring cloth length in clothing tailoring

InactiveCN107373840AAccurate measurementEnsure fitClothes making applicancesMeasurement deviceEngineering

The invention discloses a measuring device and a measuring method for measuring the length of cloth in the garment sewing process, comprising a device with a first inflection ruler, a measuring soft ruler, a cutting knife, a positioning lock, a bayonet, and a second inflection Ruler, standing bracket, arc scale is installed above the positioning locking device, the bayonet is installed above the arc scale, the second inflection ruler is installed above the bayonet, and the second inflection The standing support is installed above the ruler, the main body of the device is installed below the standing support, a sliding scale is installed below the main body of the device, a sliding ruler is installed below the sliding scale, and a radian scale moving groove is installed above the sliding ruler , a level is installed below the radian ruler moving slot. The beneficial effect lies in that the data of some special parts of the human body can be accurately measured to ensure that the clothes made fit, the structure is simple, and the clothes are convenient to carry.

Owner:广州弘雅服装科技有限公司

Track widening system for motor vehicles

ActiveUS10759218B2Adapted flexiblyEasy to produceRimsDisc wheelsStructural engineeringMotorized vehicle

A track widening system for motor vehicles, having at least one track widening disc and at least one centering ring which is inserted into a central opening of the track widening disc. The centering ring has at least one first catch device which is arranged at the free end of a resilient arm and the track widening disc has a corresponding second catch. The centering ring may include plastic, and may be fiber-reinforced. One or more centering rings may have different colors. One or more protrusions may extend from a hub centering position of a centering ring.

Owner:WOHLFARTH KLAUS

Mounting module and fatigue life test system with the same

The invention provides a mounting module and a fatigue life test system with the same. The mounting module is used for fixing a wheel on a test board and comprises a body disc and a positioning disc,the positioning disc is detachably arranged on the body disc, at least a part of the positioning disc protrudes out of an axial end face of the body disc to form a positioning boss, and the positioning boss is used for positioning and mounting the wheel on the test board. The invention solves the problems that: in the prior art, a mounting disc of the fatigue life test system has poor universality, mounting discs fitting wheels of different models need to be machined and manufactured according to the wheels of different models, and the machining and manufacturing cost of the fatigue life testsystem is increased.

Owner:ZHEJIANG JINGU CO LTD

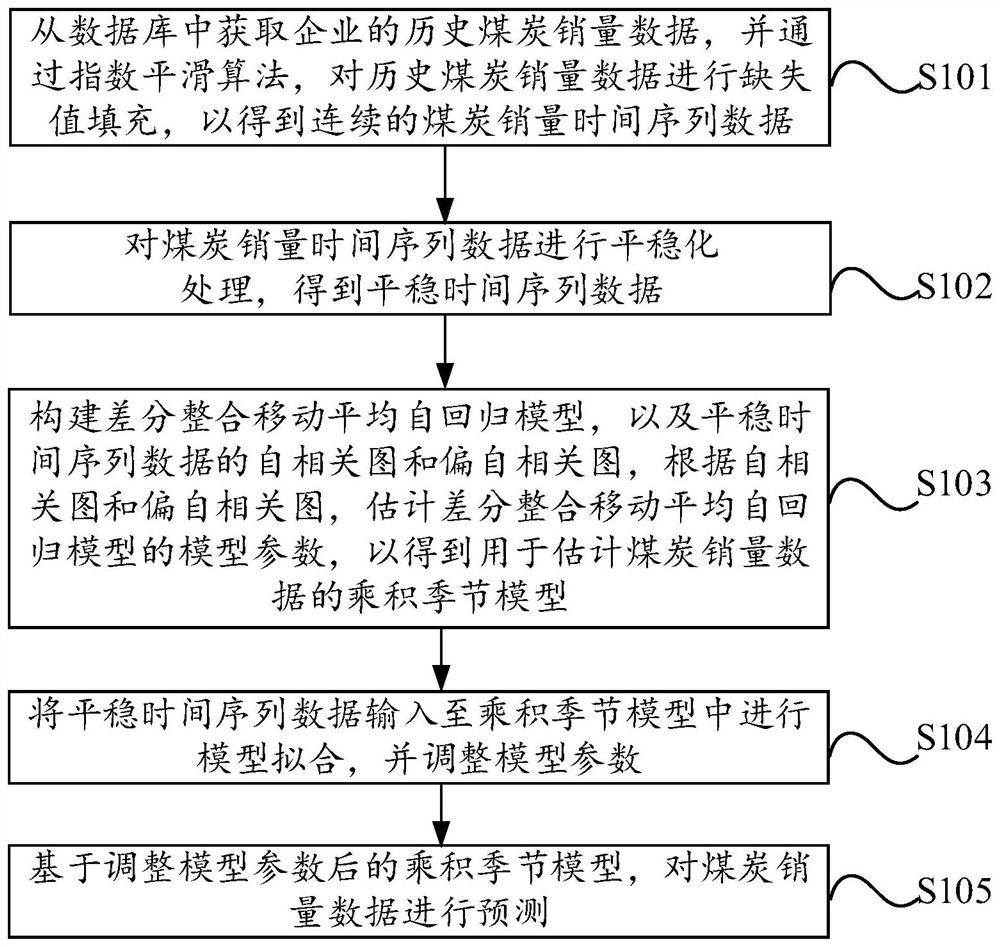

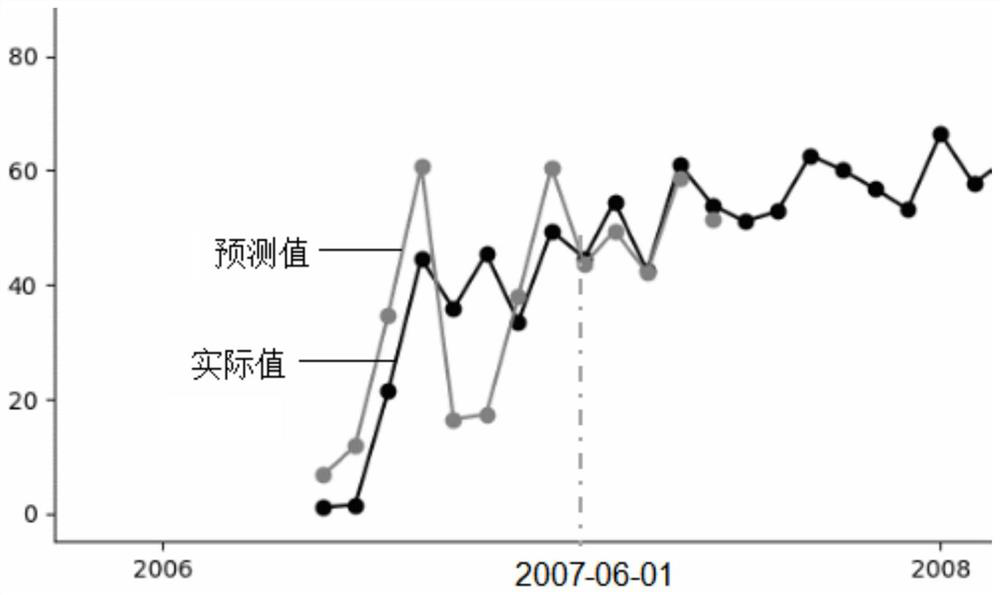

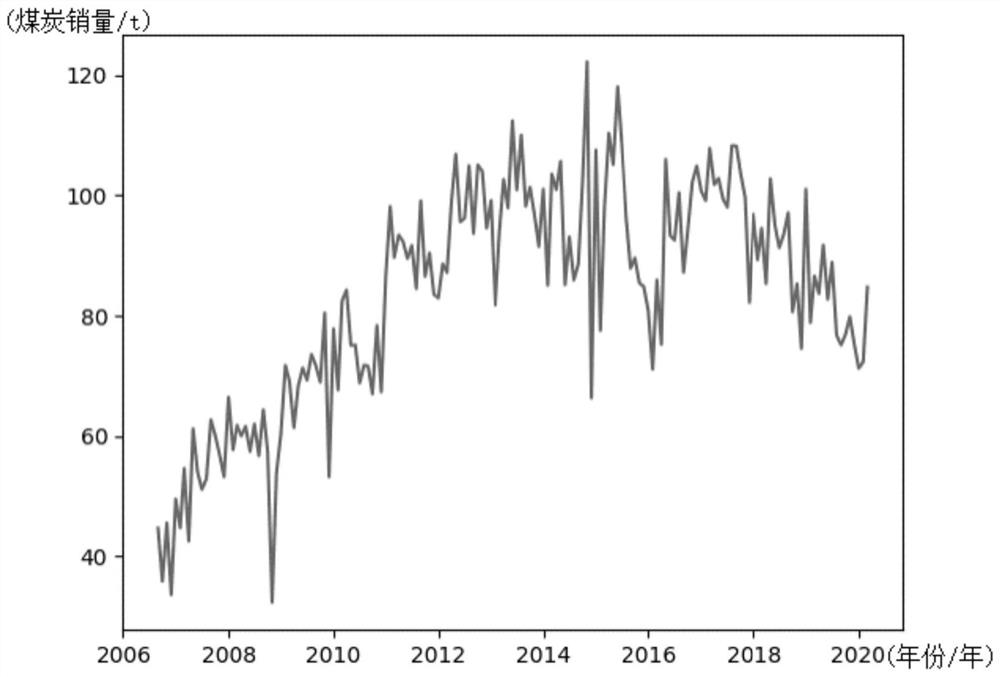

Coal sales volume data prediction method and device, and medium

PendingCN113962741AImprove efficiencyEnsure valueComplex mathematical operationsMarket data gatheringData predictionMoving average

The invention discloses a coal sales data prediction method and device and a medium, and is used for solving the technical problems that an existing prediction algorithm cannot accurately reflect seasonal periodic changes of coal sales and is not high in accuracy. The method comprises the steps of obtaining historical coal sales volume data of an enterprise from a database, and performing missing value filling on the historical coal sales volume data through an exponential smoothing algorithm to obtain continuous coal sales volume time sequence data; performing stationary processing on the coal sales time sequence data to obtain stationary time sequence data; according to an autocorrelation graph and a partial autocorrelation graph, estimating model parameters of a difference integration moving average autoregression model so as to obtain a product season model used for estimating the coal sales volume data; inputting the stationary time sequence data into the product season model for model fitting, and adjusting model parameters; and on the basis of the product season model after model parameter adjustment, predicting coal sales volume data.

Owner:浪潮卓数大数据产业发展有限公司

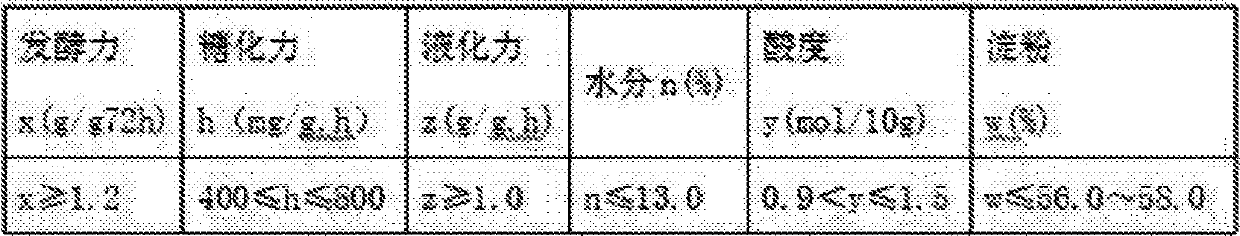

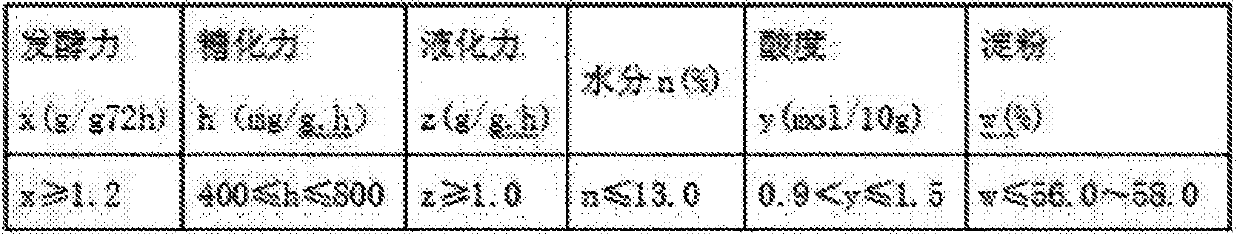

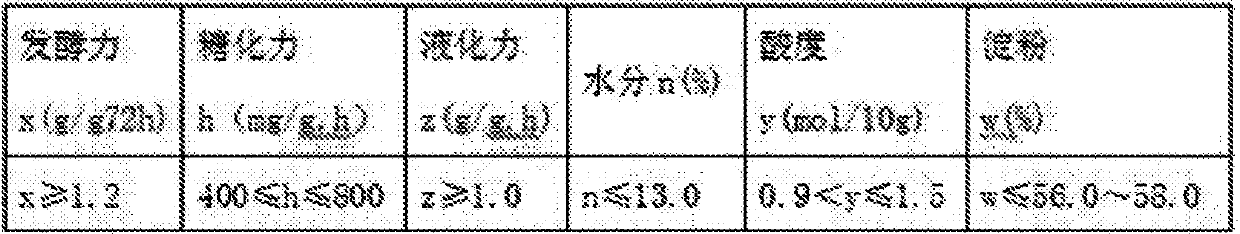

Baijiu brewing method

InactiveCN109837178AIncrease softnessGuaranteed thicknessAlcoholic beverage preparationBrewingChemistry

The invention discloses a Baijiu brewing method comprising the following steps: A, preparing high-temperature Daqu; B, preparing medium-temperature Daqu; and C, mixing the high-temperature Daqu and the medium-temperature Daqu in a certain proportion, to obtain a mixed yeast; and D, adding the mixed yeast into grains, and fermenting to obtain the product.

Owner:刘大兴

Film adhering method and device of wafer

InactiveCN102103987BQuality is not affectedRealize non-contact film applicationSemiconductor/solid-state device manufacturingWaferMaterials science

The invention discloses a film adhering method of a wafer. The film adhering method of the wafer is characterized by comprising the following steps of: blowing a gas between the wafer and a table disc; supporting the wafer by utilizing the blown gas; and then adhering a film on the surface of the wafer. By using the film adhering method and device of the wafer, the non-contact film adhesion can be realized and the danger of front surface damage of the wafer can be reduced; in addition, because the wafer can be supported by utilizing the gas during the pressing of a roller wheel, the pressure of the roller wheel can be offset, and the roller wheel can not be easy to press the wafer to be broken or crushed, therefore when the film adhering method and device are used for carrying out the non-contact film adhesion, the minimum thickness of the wafer which can be adhered with the film is 50 micrometers and 200 micrometers far less than that of the water adhered with the film in the prior art.

Owner:上海技美科技股份有限公司

Connector

ActiveUS20160028180A1Ensure fitElectric discharge tubesIncorrect coupling preventionEngineeringMechanical engineering

A connector includes: a first connector constituent including a first terminal and a cylindrical part provided with a first locking part and a second locking part; a second connector constituent provided with a second terminal, a first locked part, and a second locked part; and a connector cover body including a first cylindrical part provided with a first abutment part, and a second cylindrical part provided with a second abutment part, the second cylindrical part constituting a locked-part holding part. When the connector cover body is moved closer to the first connector constituent from a state in which the second connector constituent is installed in the connector cover body, the second connector constituent is joined to the first connector constituent.

Owner:YAZAKI CORP

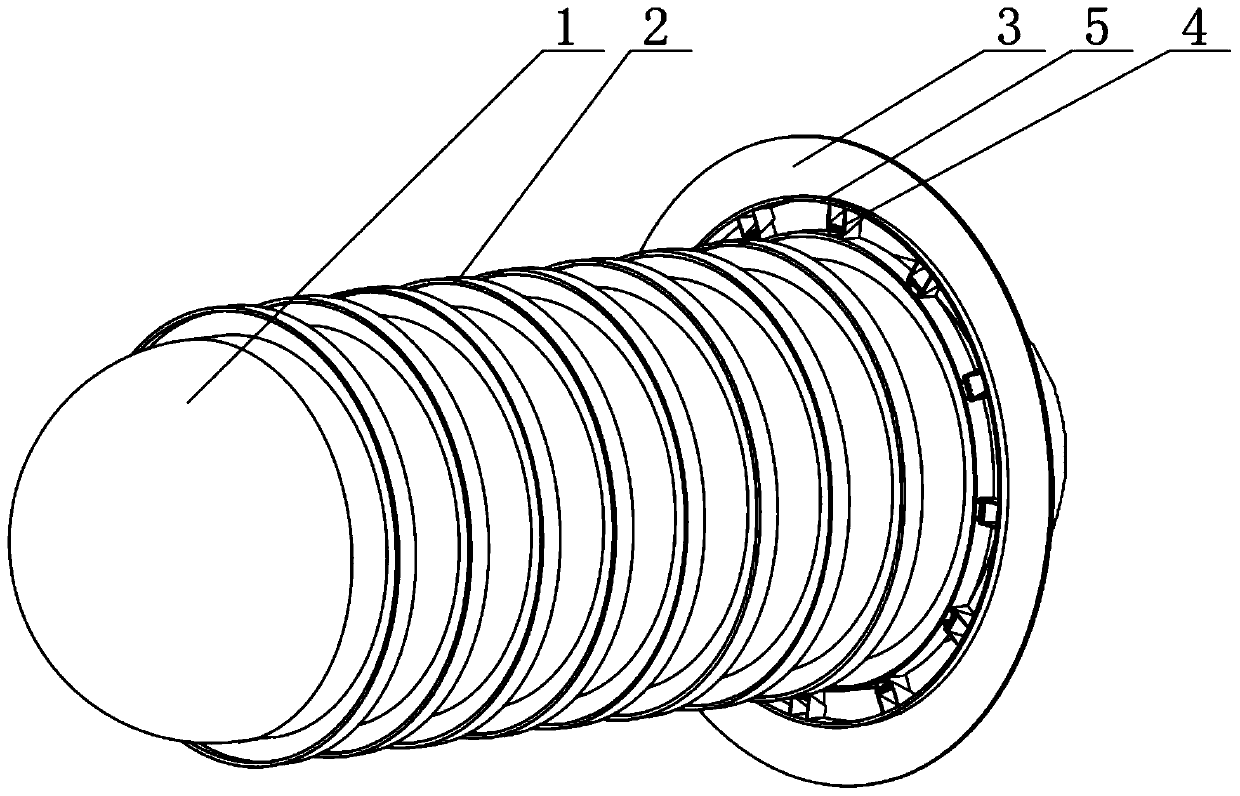

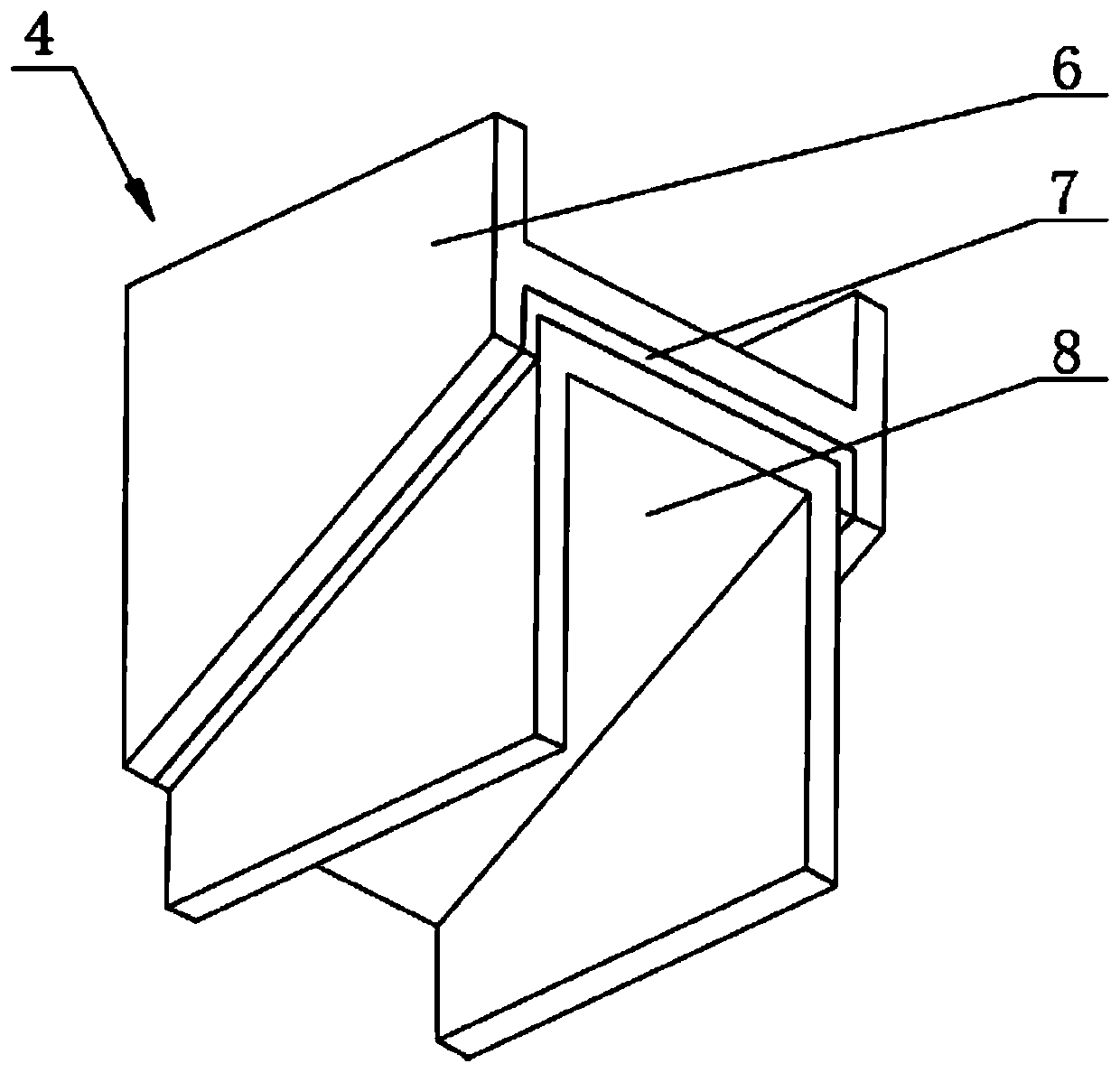

Pressure-resistant body limit and shrinkage deformation compensation device of deep-sea submersible and installation method thereof

ActiveCN110271639BAvoid intensityAvoid stabilityUnderwater vesselsUnderwater equipmentMarine engineeringUltimate tensile strength

A deep-sea submersible pressure body limit and shrinkage deformation compensation device and installation method thereof, comprising a pressure body, outer rib panels arranged in parallel at intervals on the outer circumference of the pressure body, spaced from one of the outer rib panels A non-pressure-resistant structure is nested, and the bottom of the non-pressure-resistant structure is extended with an inner panel perpendicular to it. The inner panel and the outer rib panel are arranged in parallel and at intervals, and multiple compensations are welded between the inner panel and the outer rib panel. device, a plurality of compensation devices are evenly spaced and distributed in the circumferential space between the inner panel and the outer rib panel. The compensation device is between the pressure-resistant body and the non-pressure-resistant structure, which can replace the traditional direct welding connection method between the non-pressure-resistant structure and the pressure-resistant body of the submersible, and can decouple the non-pressure-resistant structure and the pressure-resistant body on the connection boundary , so that the non-pressure-resistant structure is free from the strength and stability problems caused by the implicated deformation of the pressure-resistant body, and it can also avoid the strength problem caused by the non-uniform deformation of the pressure-resistant body due to the restraint of the non-pressure-resistant structure.

Owner:CHINA SHIP SCIENTIFIC RESEARCH CENTER (THE 702 INSTITUTE OF CHINA SHIPBUILDING INDUSTRY CORPORATION)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com