Patents

Literature

317results about How to "Improve film application efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Automatic membrane laminating machine based on machine vision localization

InactiveCN106081223AImprove film application efficiencyReduce labor costsPackagingHuman–machine interfaceImaging processing

The invention discloses an automatic membrane laminating machine based on machine vision localization. The automatic membrane laminating machine comprises a support, a control case, a membrane taking and laminating device, a machine vision system, a dividing device and a discharge conveying device. According to the automatic membrane laminating machine, each membrane is located by the machine vision, after the membranes are sucked from a membrane outlet by a membrane laminating manipulator, fast image processing is carried out by the vision system firstly, then position data are sent to the control case, fast error compensation and movement control are carried out by a C language function module in the control case, and finally the membrane laminating process is completed. The accuracy can be effectively controlled, the membrane laminating efficiency can be improved, the human cost can be greatly reduced, and visualization and controllability of the production process can be realized by monitoring the whole process through a human-computer interface.

Owner:JIANGSU COLLEGE OF INFORMATION TECH

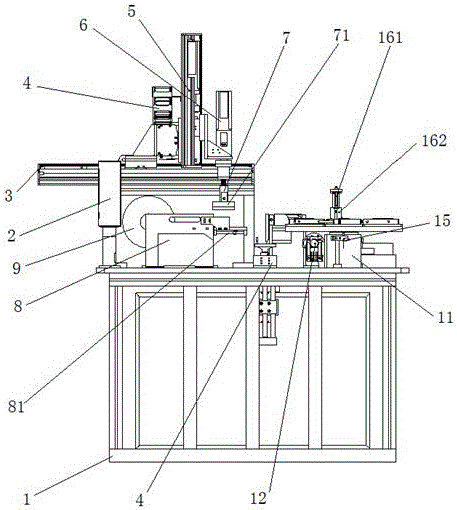

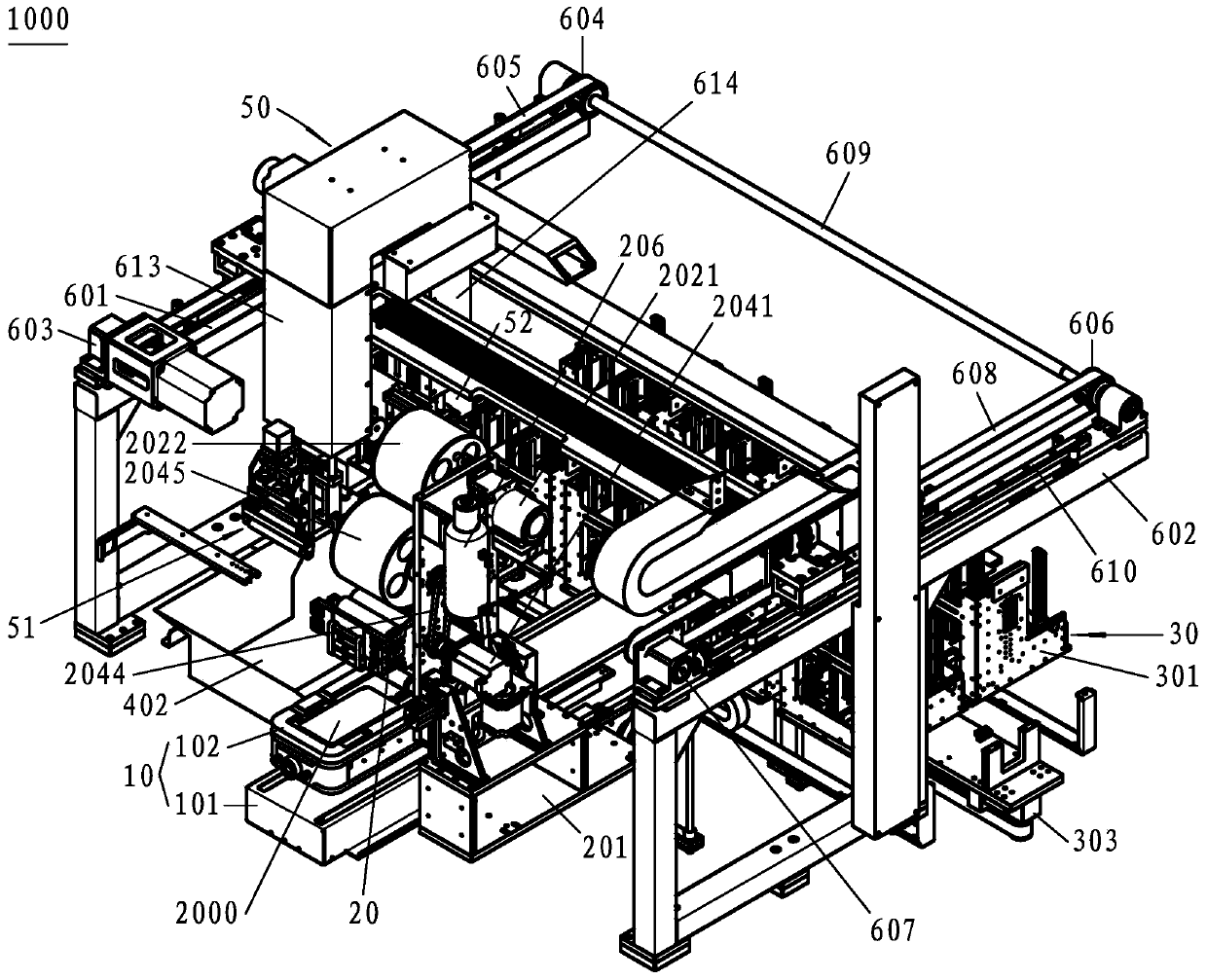

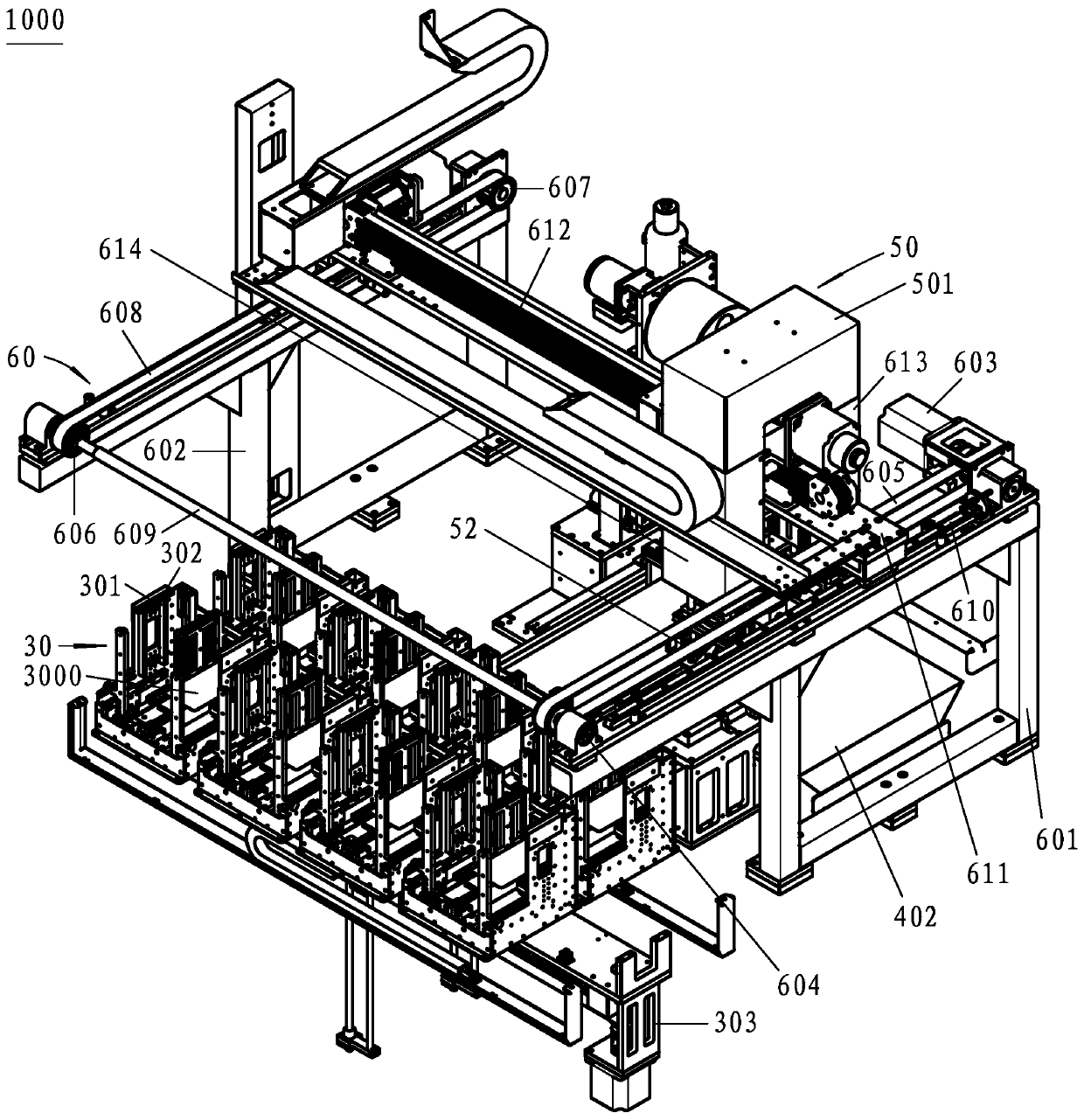

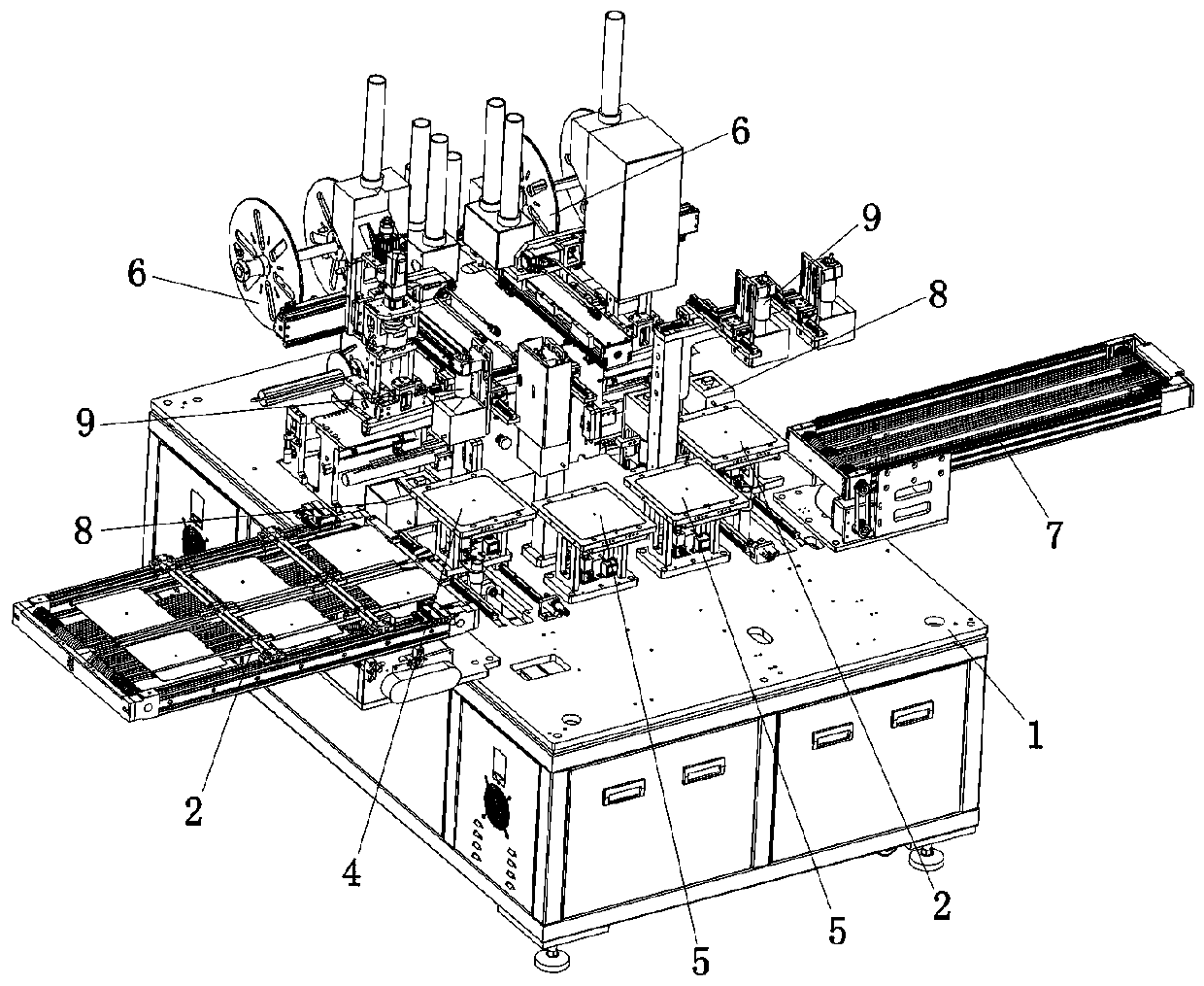

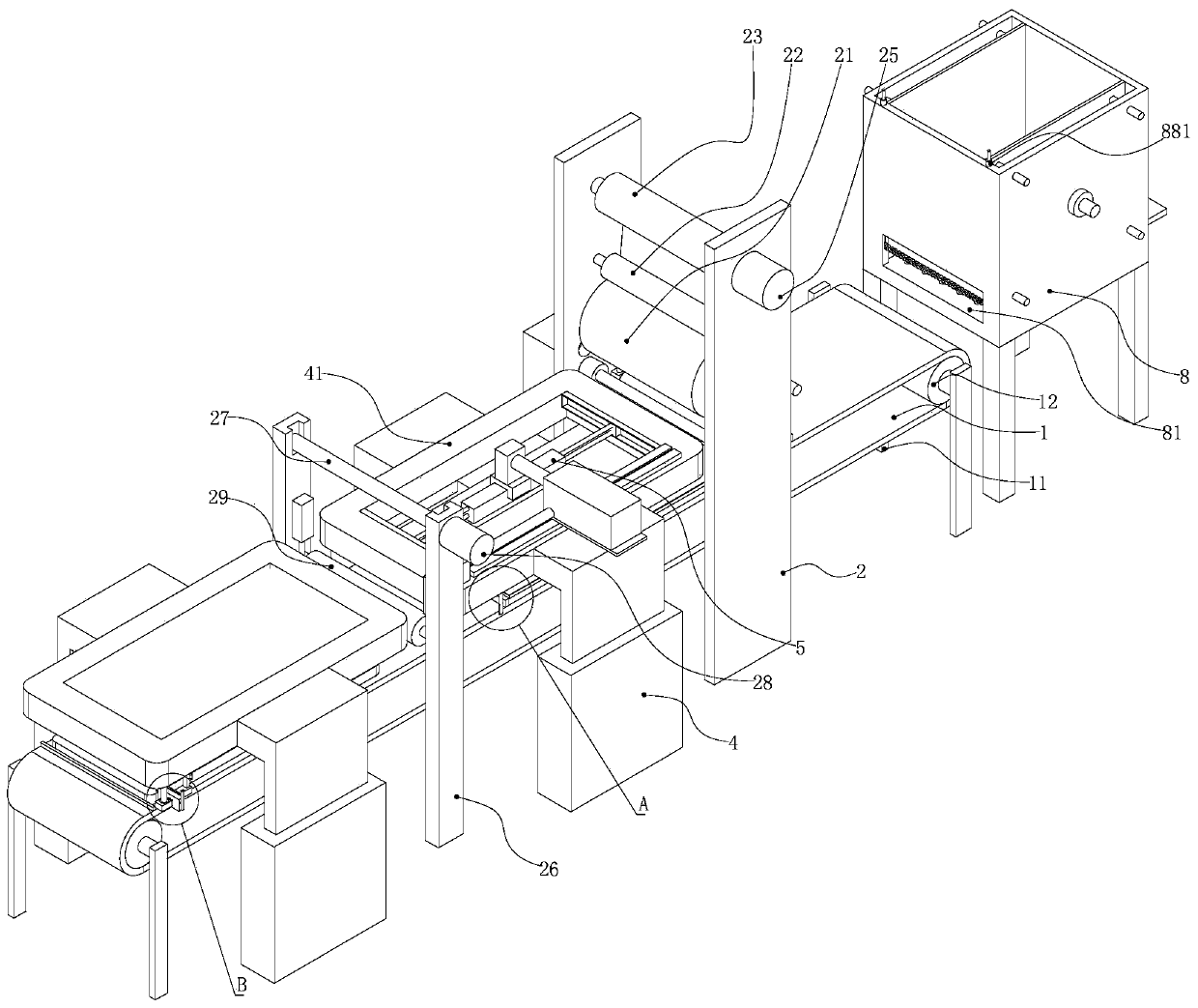

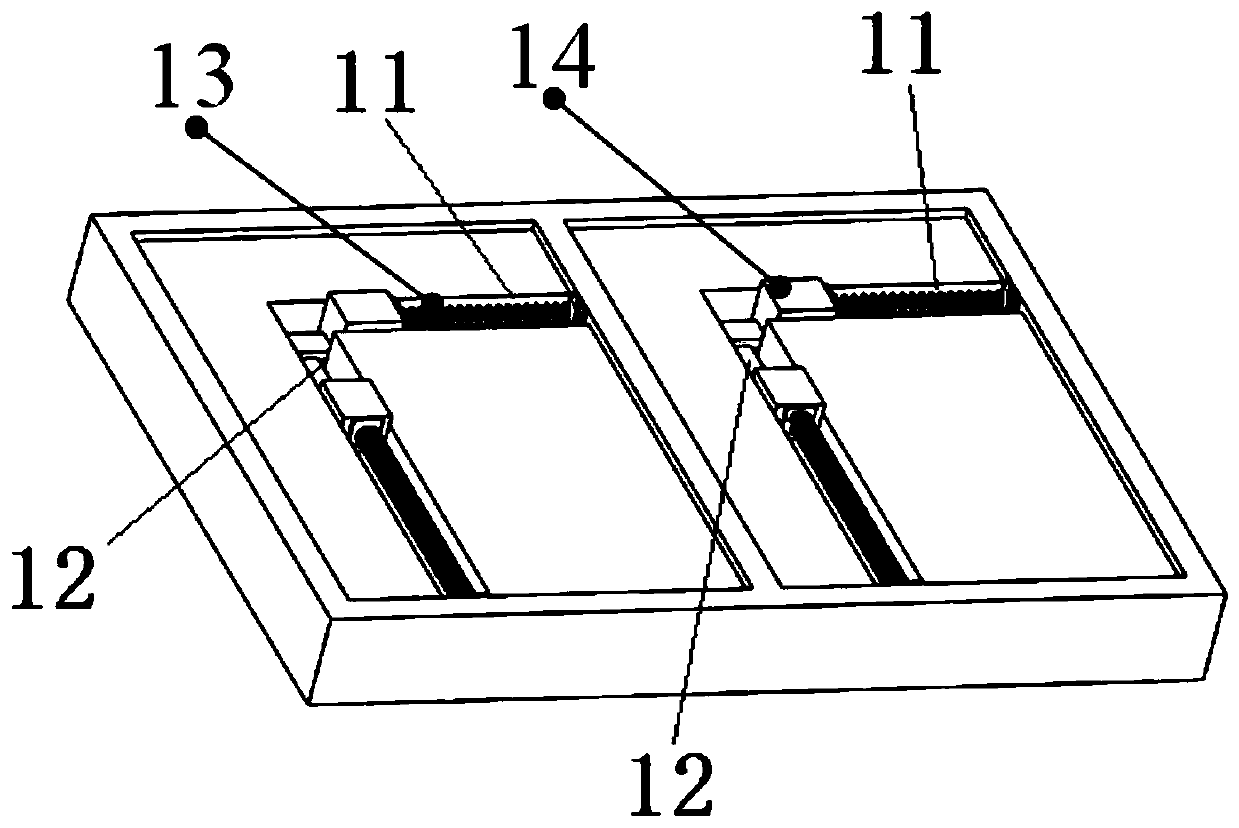

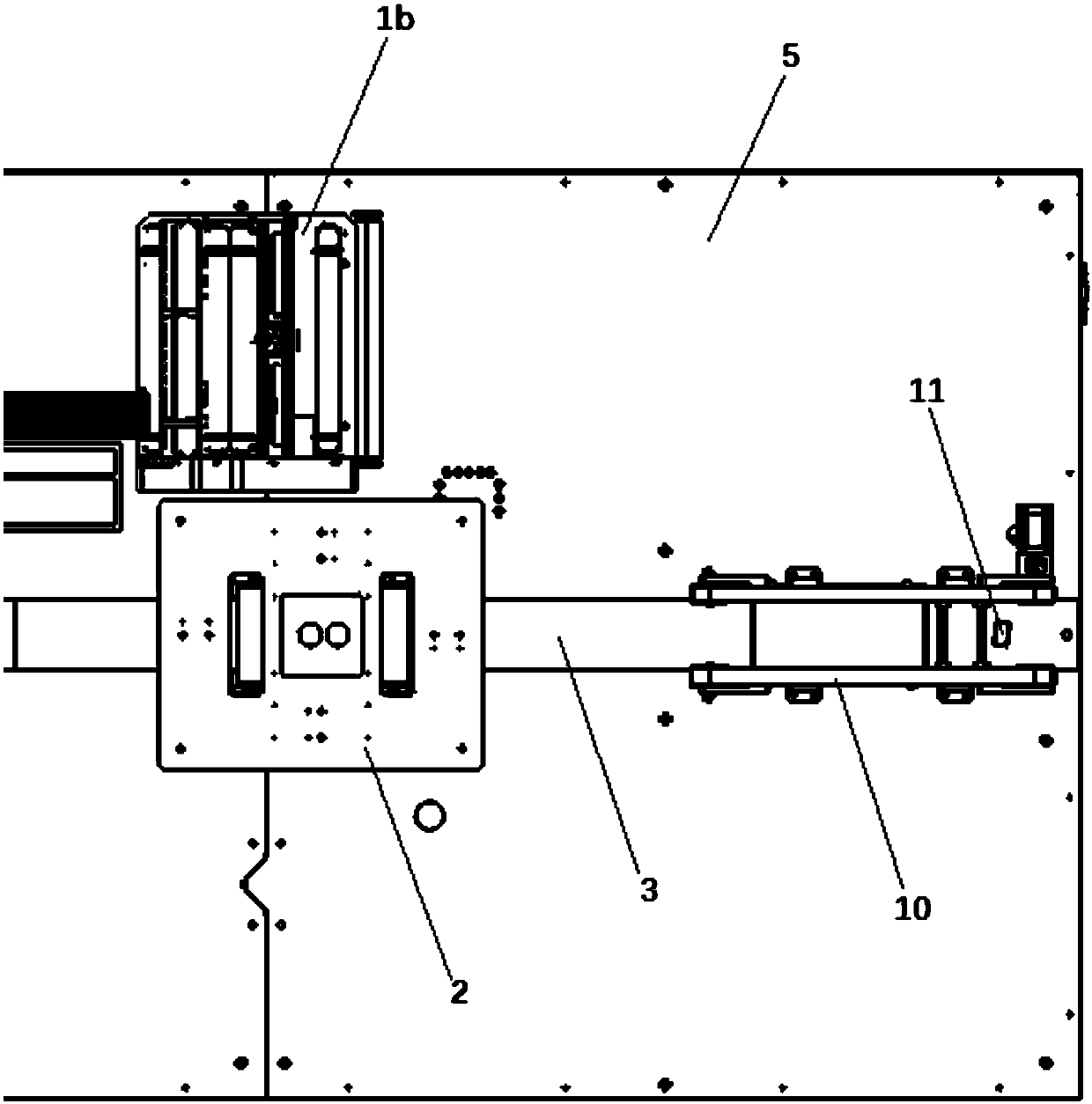

Automatic film-tearing and AOI detection integrated system for glass plates of electronic products

ActiveCN109159958AImprove film application efficiencyImprove film qualityLamination ancillary operationsMaterial analysis by optical meansTectorial membraneEngineering

The invention relates to an automatic film-tearing and AOI detection integrated system for glass plates of electronic products. The automatic film-tearing and AOI detection integrated system comprisesa product loading manipulator, a Y-directional product movement assembly, an automatic film-tearing mechanism, an automatic film-coating mechanism, a transfer manipulator and a product conveying assembly which are located on a workbench, and are sequentially arranged from left to right, wherein a PLC control equipment is arranged on the lower part of the workbench; a primary detection and sortingmechanism is arranged on the upper part of the head end of the product conveying assembly; a first material overturning device, a second material overturning device, a product front-surface and back-surface detection device and an unloading manipulator are arranged at one side of the product conveying assembly and at the right side of the primary detection and sorting mechanism, and are sequentially arranged from left to right; a plurality of bearing plates used for bearing the products are placed on the product conveying assembly; and a plurality of bearing positions are formed on each bearing plate. According to the automatic film-tearing and AOI detection integrated system, release films are fully mechanically torn, and then protective films are firmly coated onto the glass plates, sothat the manual investment is reduced, the film-tearing and film-coating efficiency for the glass plates is increased, and the film-tearing and film-coating quality for the glass plates is improved; and inferior-quality products are timely eliminated via AOI detection, so that the coating pass percentage for the glass plates of the electronic products is increased.

Owner:SHENZHEN HONGLICHANG MACHINERY MFG

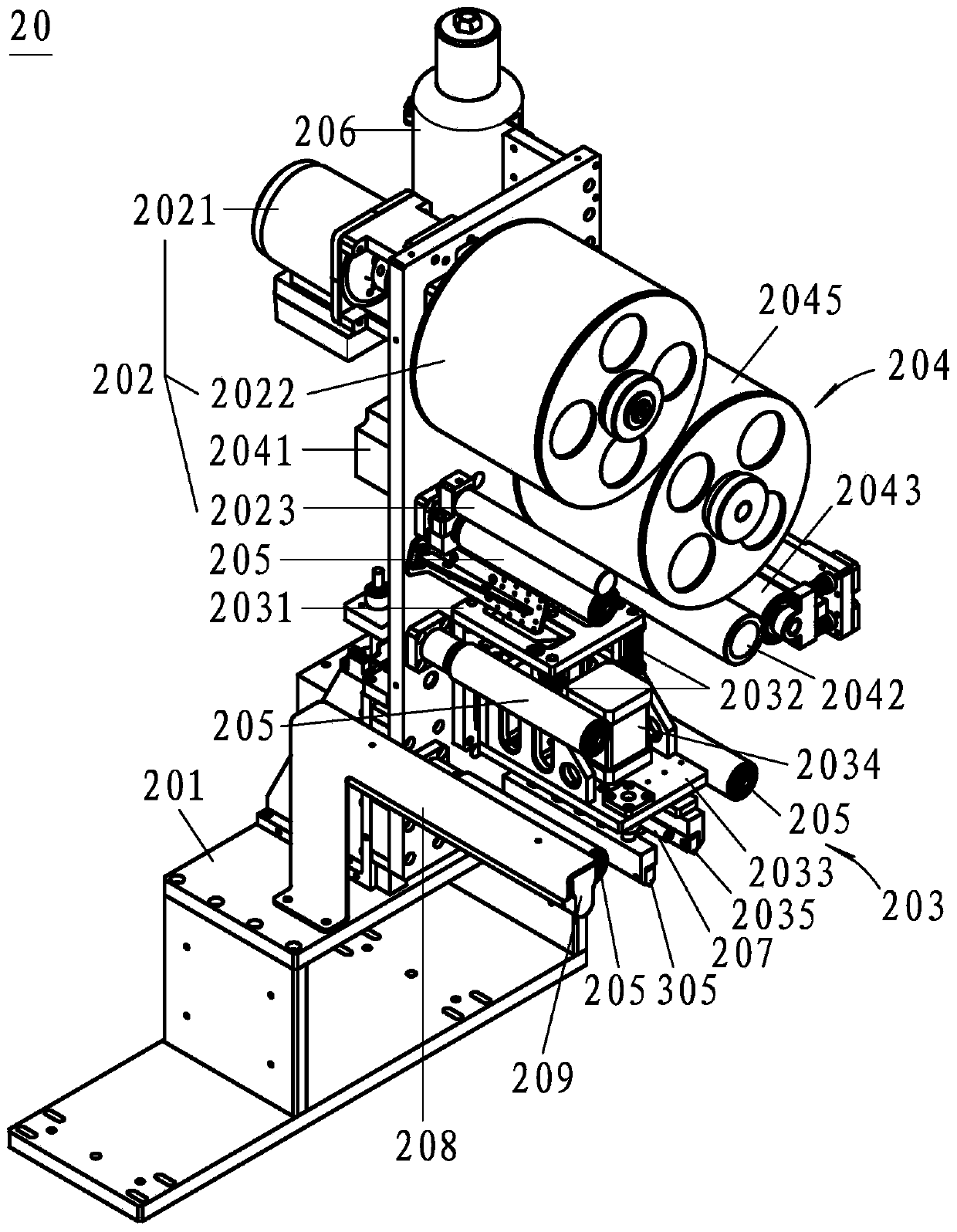

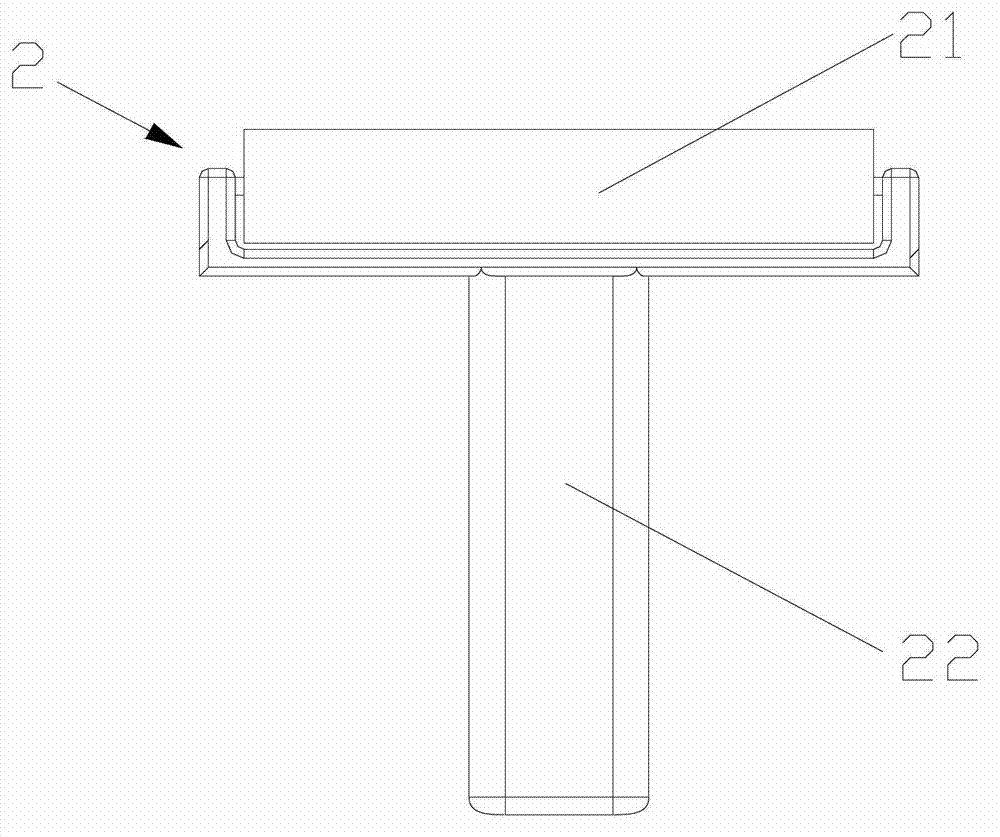

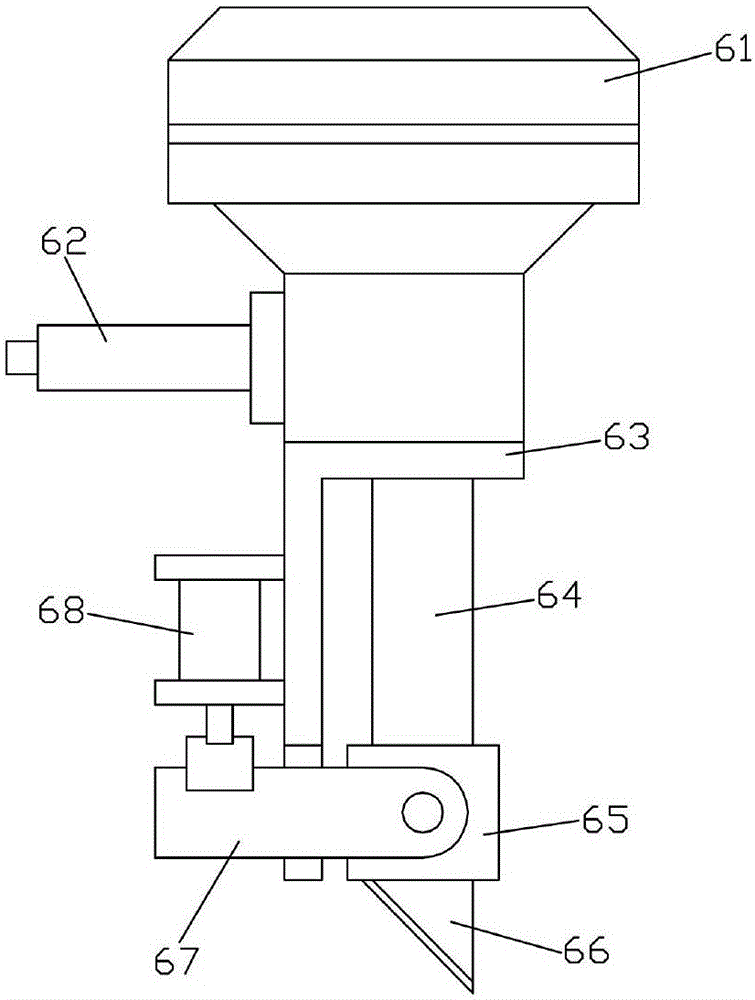

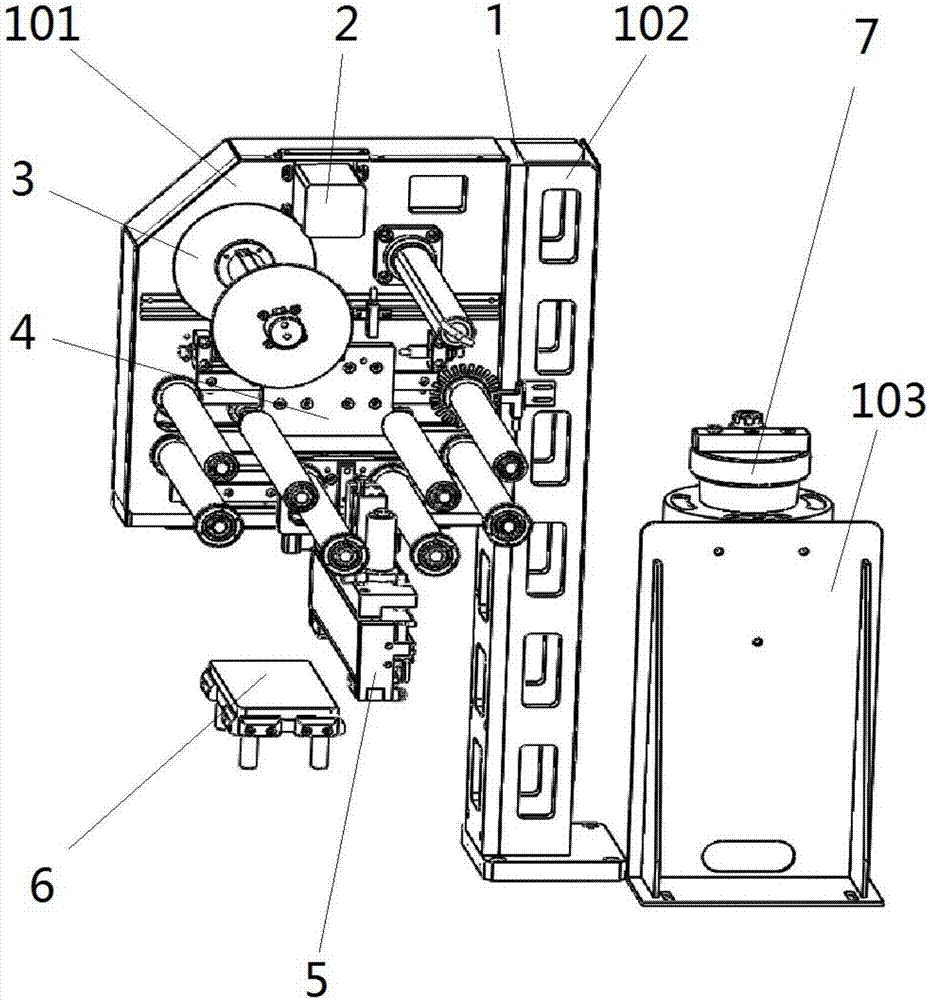

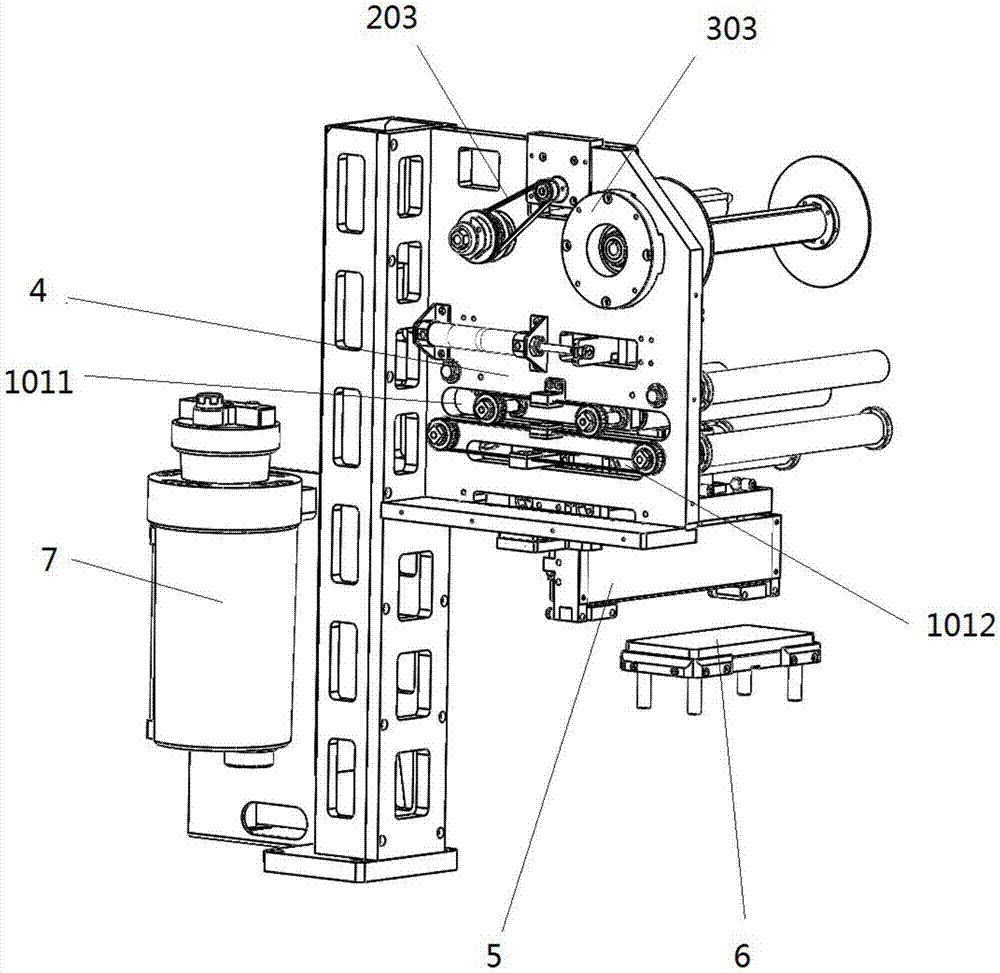

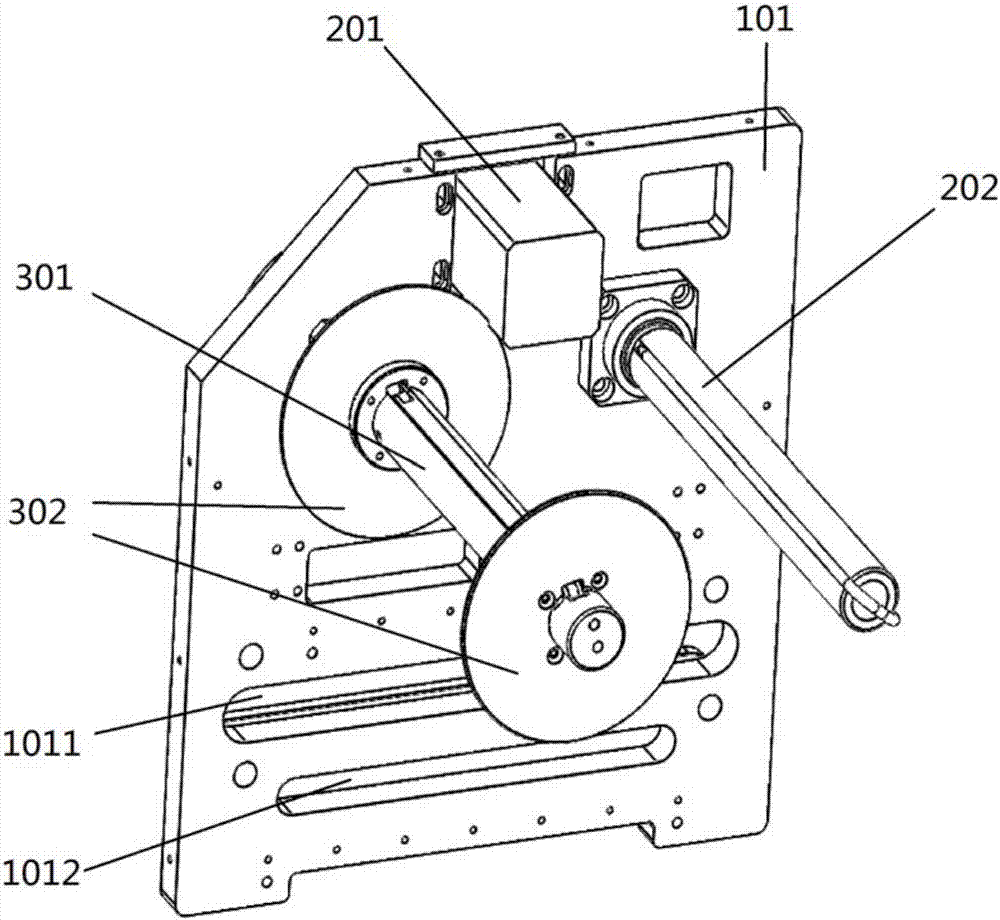

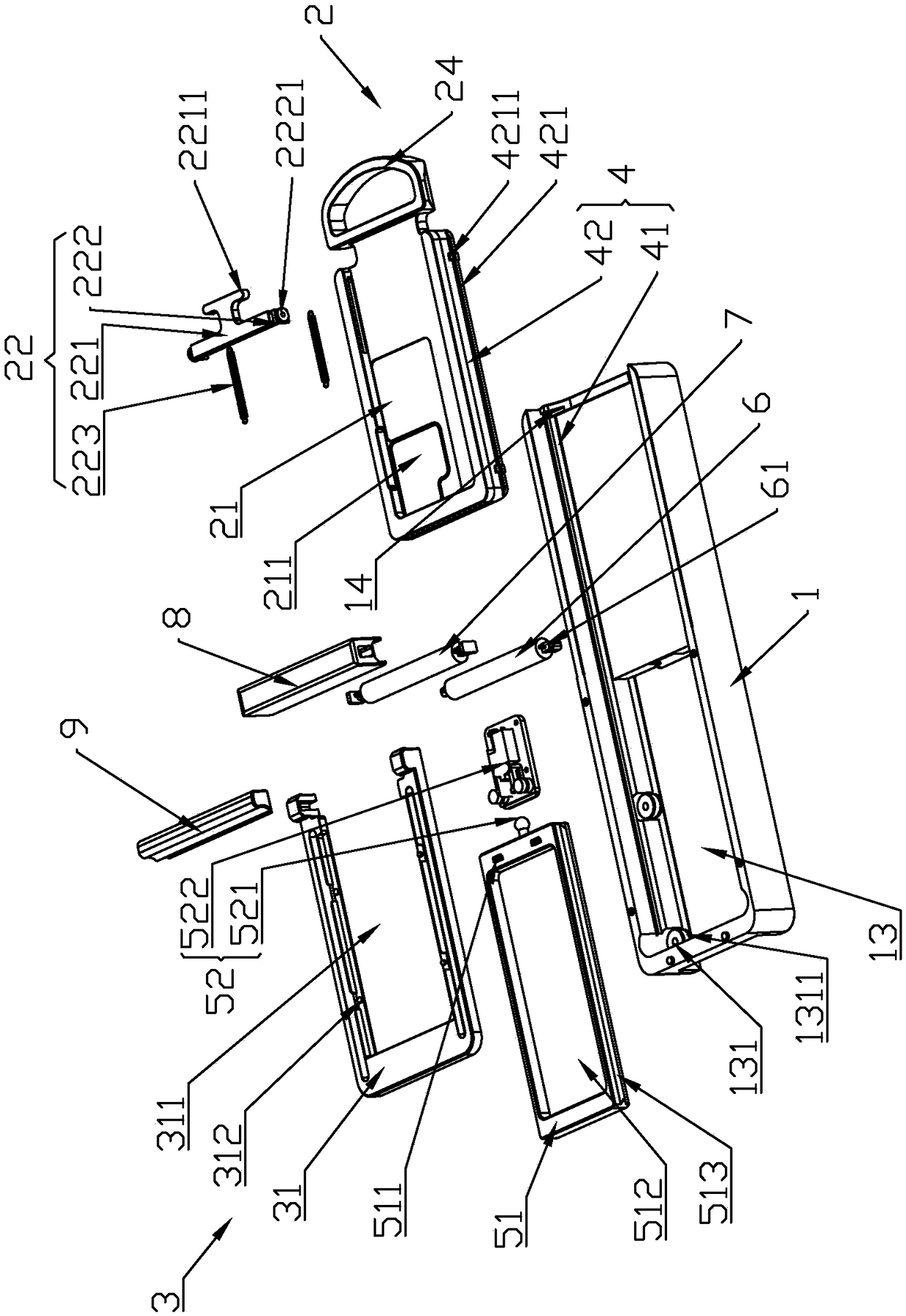

Self-service type intelligent mobile equipment laminator

ActiveCN110053247AReduce the cost of artificial filmImprove the efficiency and quality of film applicationLamination ancillary operationsControlling laminationManipulatorMaster controller

The invention discloses a self-service type intelligent mobile equipment laminator. The self-service type intelligent mobile equipment laminator comprises a case, a master controller, a mobile equipment fixing table, a mobile equipment display screen cleaning mechanism, a membrane supply mechanism, a bottom membrane stripping mechanism, a laminating mechanical hand and a three-dimensional moving mechanism for controlling the laminating mechanical hand to move front and back, left and right and up and down. The self-service type intelligent mobile equipment laminator has the beneficial effectsthat user intelligent mobile equipment can be automatically laminated, compared with traditional manual laminating, the manual laminating cost can be greatly reduced, the laminating efficiency and quality are greatly improved, the requirements that users can carry out laminating at any time can be met, and then the self-service type intelligent mobile equipment laminator is high in practicality and good in use effect.

Owner:SHENZHEN MMT TECH CO LTD

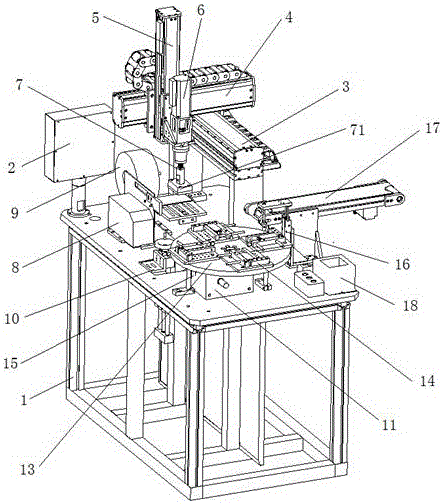

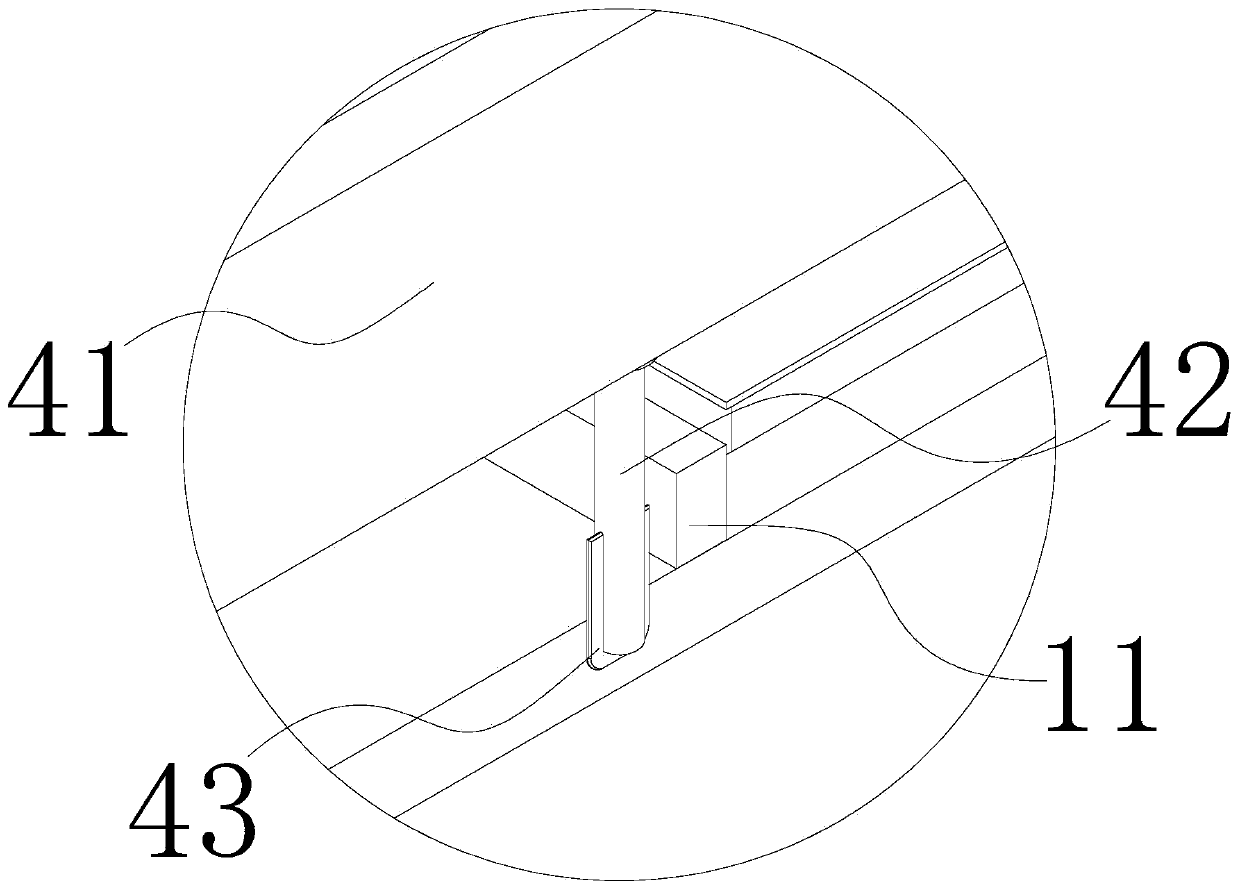

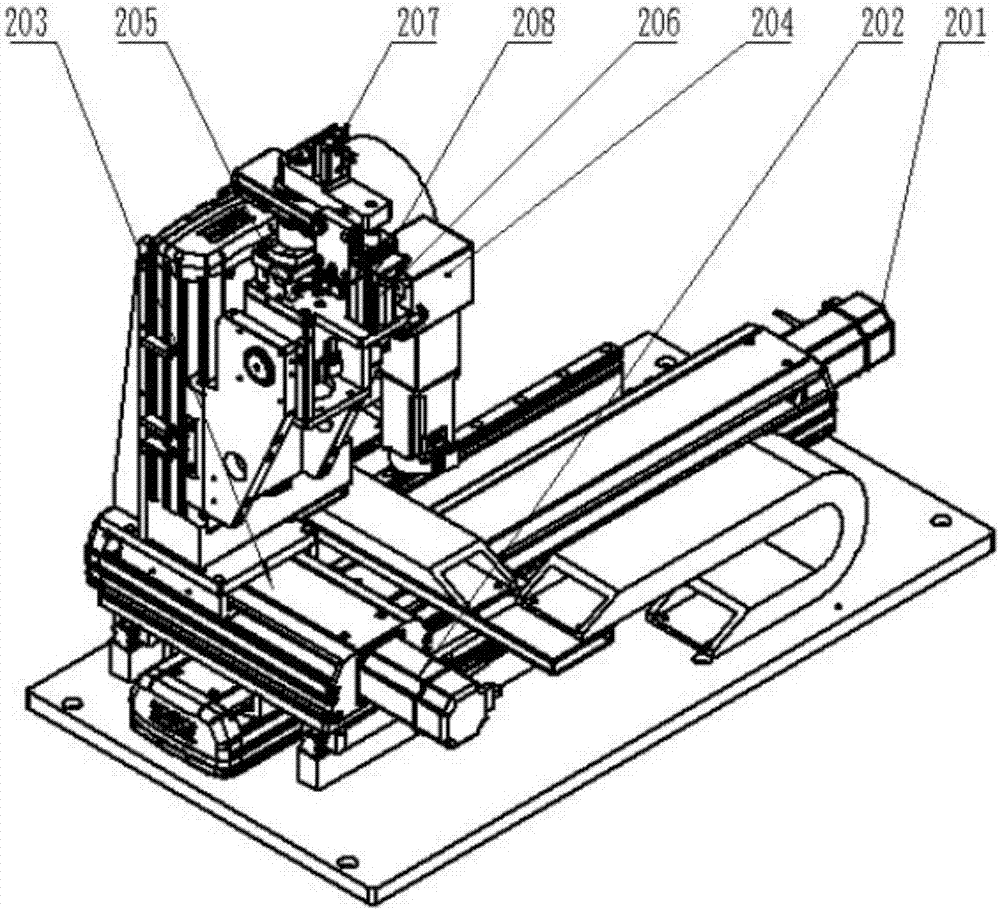

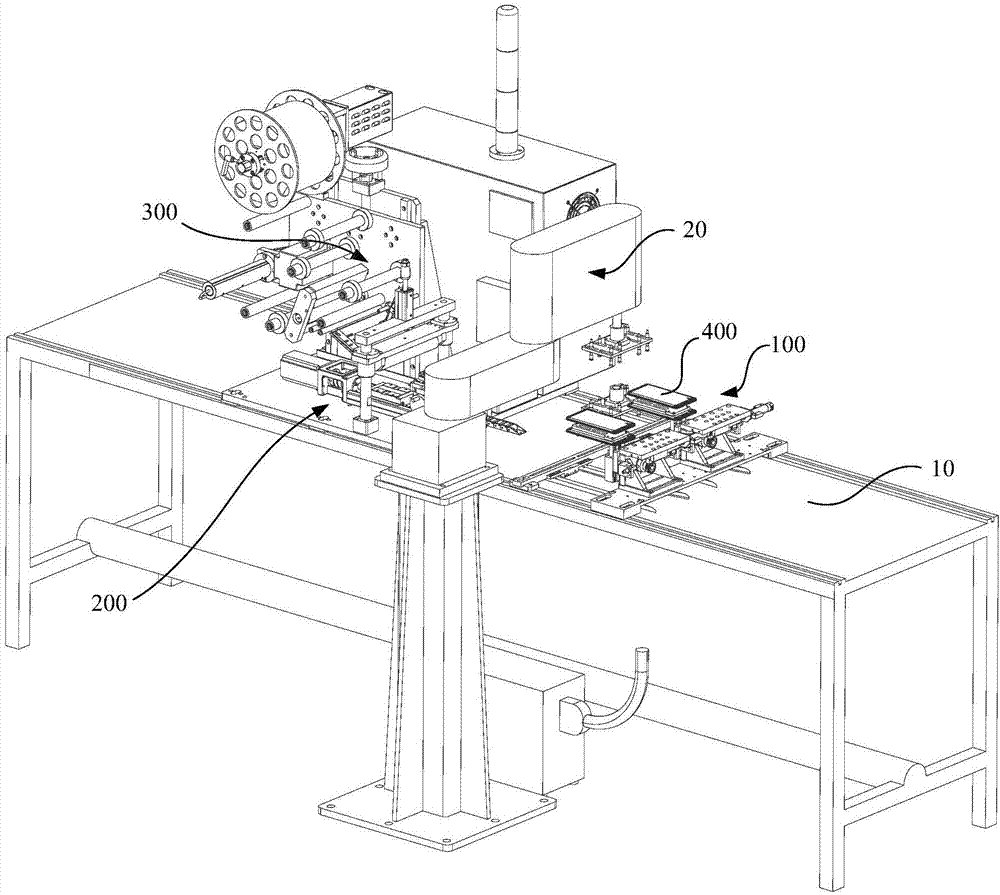

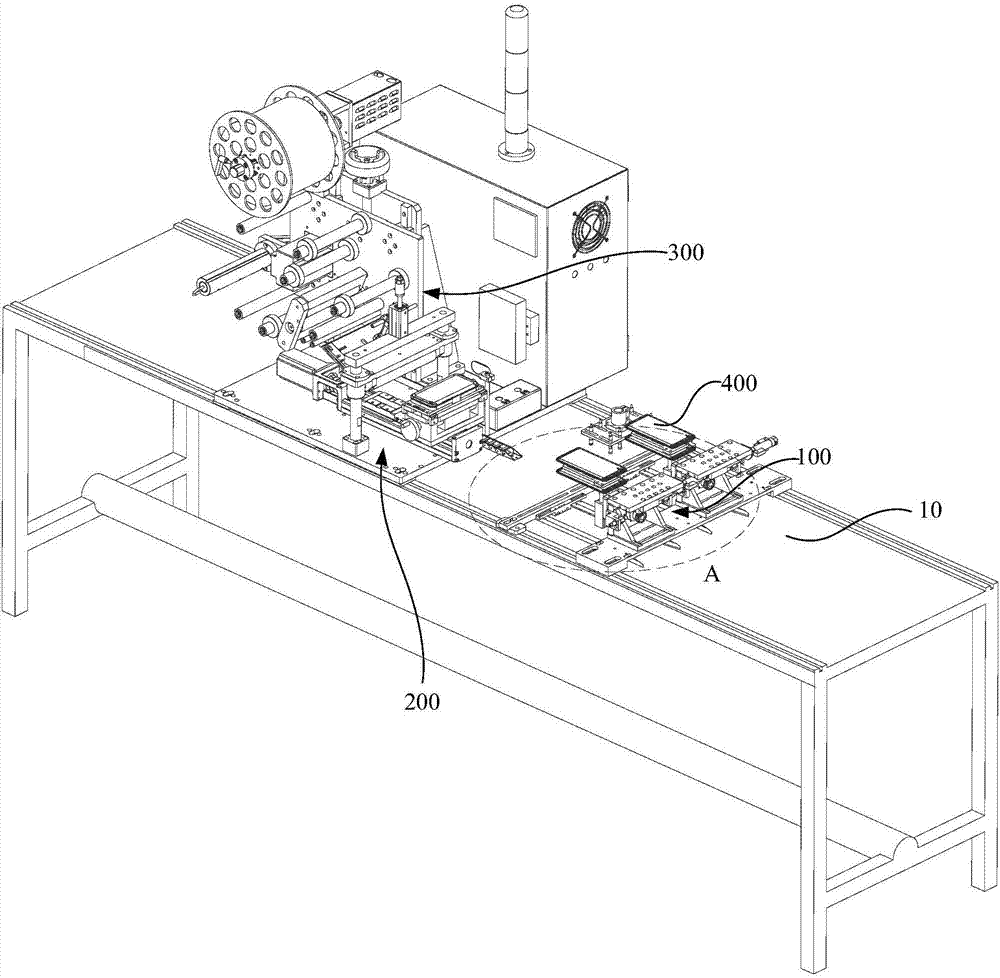

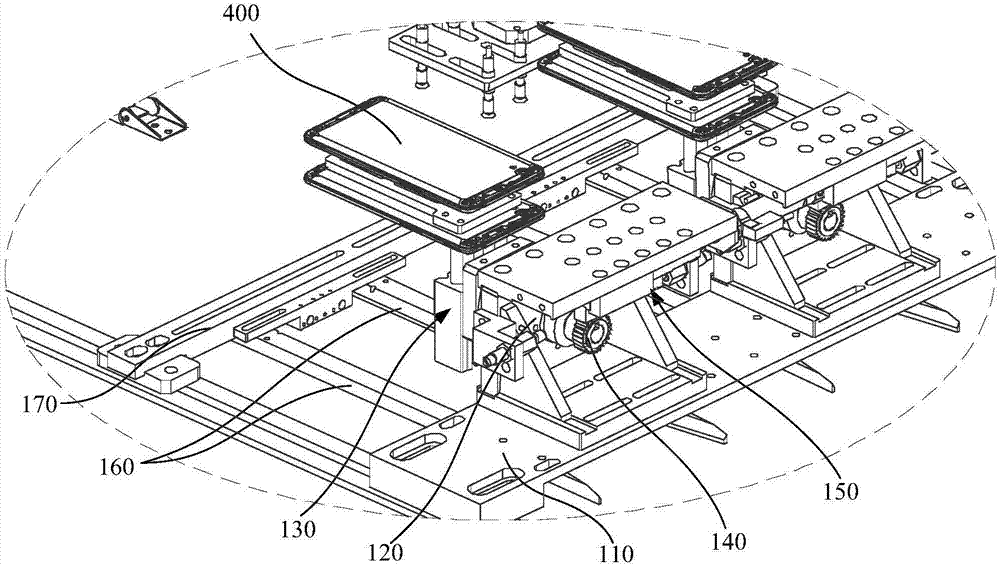

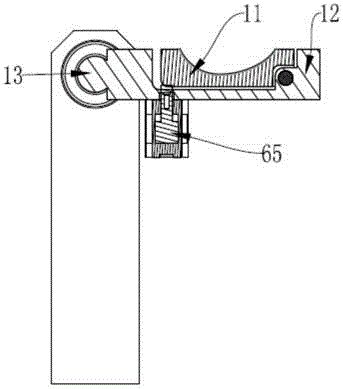

Automatic film sticking device

ActiveCN103010514AEasy to operateImprove film application efficiencyPackagingElectric machineElectrical and Electronics engineering

The invention relates to an automatic film sticking device, which comprises a base (1), a turntable (3), a chip mounting mechanism, a feeding and receiving mechanism and a control panel (4), wherein a turntable support (11) is arranged on the base (1); the turntable (3) is movably mounted at the top of the turntable support (11); the main shaft of the turntable (3) is connected with that of a servo motor (10); two bearings (18) are symmetrically fixed on the turntable (3); the chip mounting mechanism comprises a guide rail (5), a telescopic cylinder (8) and a sucker (9); the feeding and receiving mechanism comprises a feeding tray (12), a guide roller set (14), a feeding cylinder (7), a receiving tray (16) and a receiving motor (15); and the control panel (4) is connected with the telescopic cylinder (8), the receiving motor (16), the feeding cylinder (7) and the servo motor (10) respectively. The automatic film sticking device has the advantages of simplicity and convenience in operation, high film sticking accuracy, stability and reliability, low maintenance cost, time and labor conservation, and high film sticking efficiency.

Owner:CHENGDU HOMIN TECH

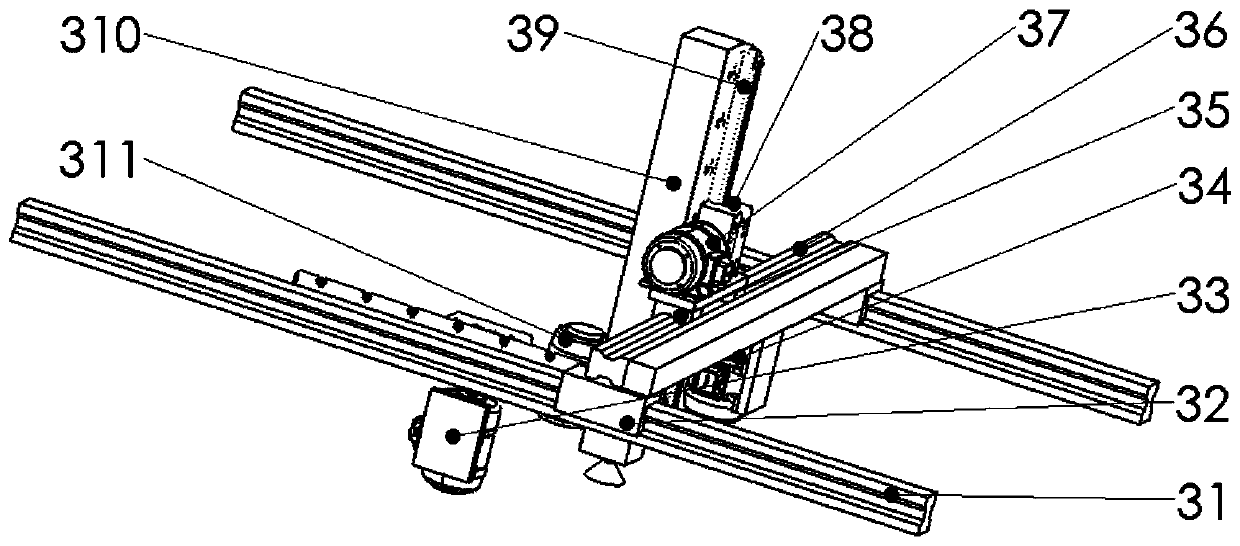

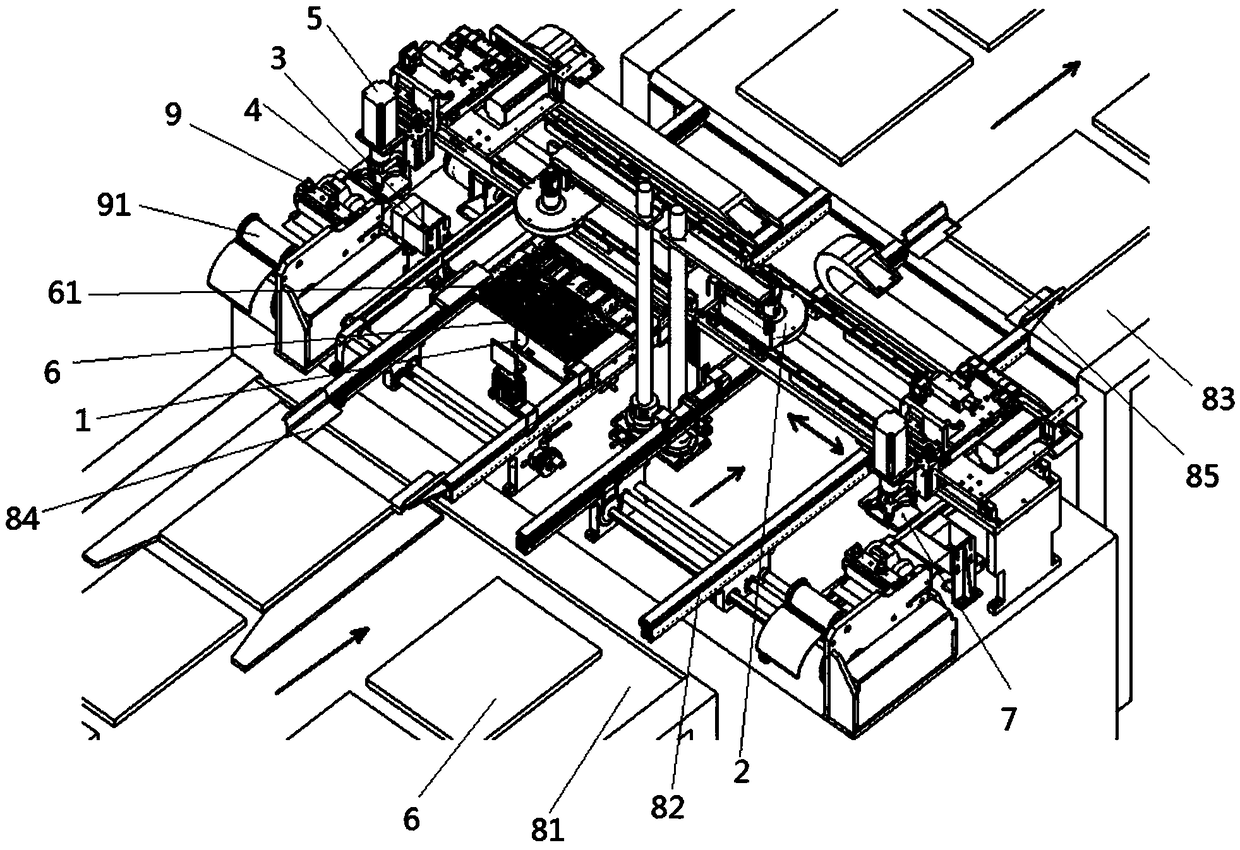

Two-in-one linkage film sticking production line and production process thereof

ActiveCN109533455AImprove film application efficiencyReduces fit bubblesPackagingProduction lineAgricultural engineering

The invention discloses a two-in-one linkage film sticking production line and a production process thereof. The two-in-one linkage film sticking production line comprises a feeding belt, a linkage carrying manipulator, a film sticking platform, a transfer platform film taking and sticking mechanism and a discharging belt, wherein the feeding belt and the discharging belt are respectively arrangedat the left end and the right end of a rack; the film sticking platform comprises two platforms; the transfer platform comprises two platforms; the linkage carrying manipulator is arranged at the front sides of the film sticking platform and the transfer platform along the left-right direction, and three sets of suction components are arranged on the linkage carrying manipulator; the film takingand film sticking mechanism comprises two sets, and the two sets of film taking and film sticking mechanisms are respectively arranged at the rear sides of the two film sticking platforms. According to the two-in-one linkage film sticking production line, the single film sheet is peeled off the peeling plate by pulling the discharge belt, the film pressing component is used for tearing off the film sheet from the mounting plate, meanwhile, the torn-off film sheet is roll-pressed on the glass plate to achieve the line contact type film sticking, the sticking air bubbles are effectively reduced,and through carrying the three sets of suction assemblies of the linkage carrying manipulator, the three groups of glass plates can be taken out and discharged, doubling the efficiency of the single-machine film sticking.

Owner:SHENZHEN NUOFENG OPTOELECTRONICS EQUIP

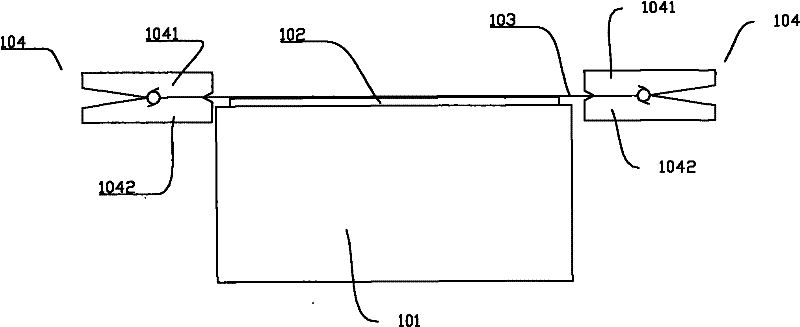

Film sticking method and equipment

InactiveCN102173316AReduce tensionReduce distortionSemiconductor/solid-state device manufacturingPackagingEngineering

The invention discloses a film sticking method which is characterized in that an adhesive film roll is driven by an idler wheel for rolling an adhesive film to rotate. By using the film sticking method disclosed by the invention, the adhesive film only needs to overcome the viscous force among the layers of the adhesive film without the need of overcoming the rotating resistance of a roller in the film sticking process, and the viscous force is extremely small, thus compared with the tradition method, through the film sticking method and the film sticking equipment disclosed by the invention,the tensile force to the adhesive film is greatly reduced, the deformation of the adhesive film in the length direction is extremely small, and the tensile force after sticking is also extremely small.

Owner:上海技美科技股份有限公司

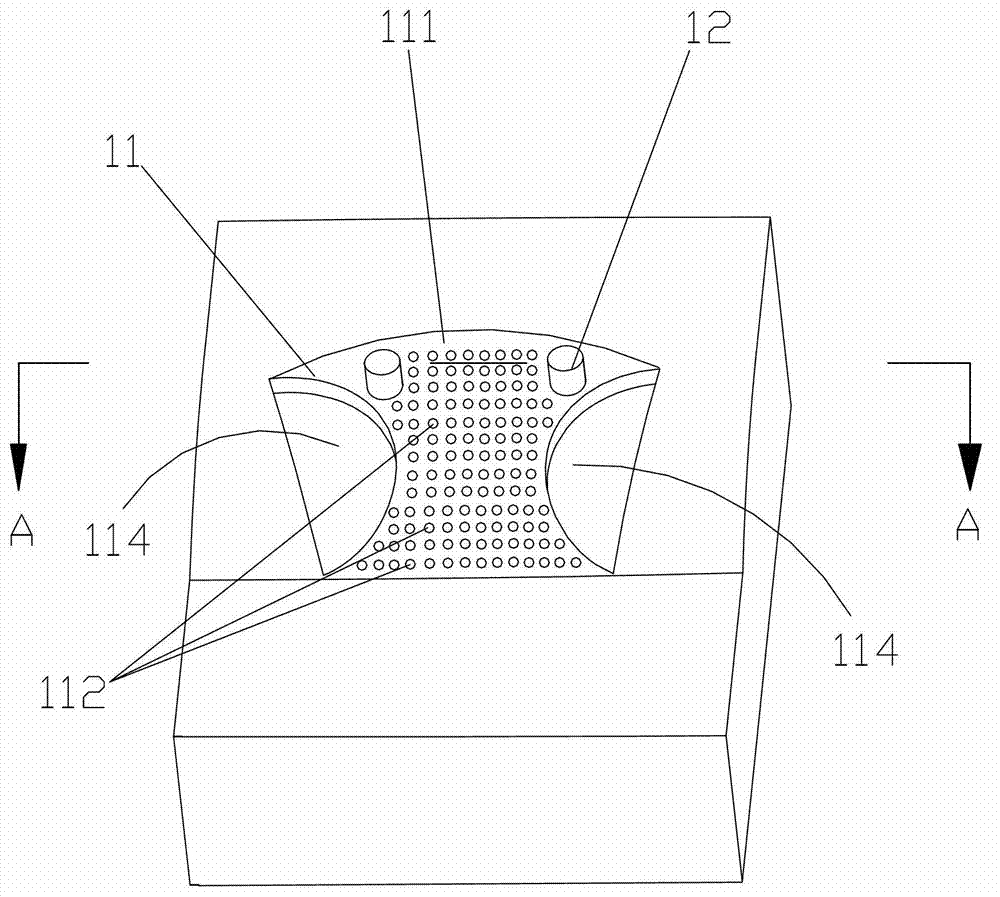

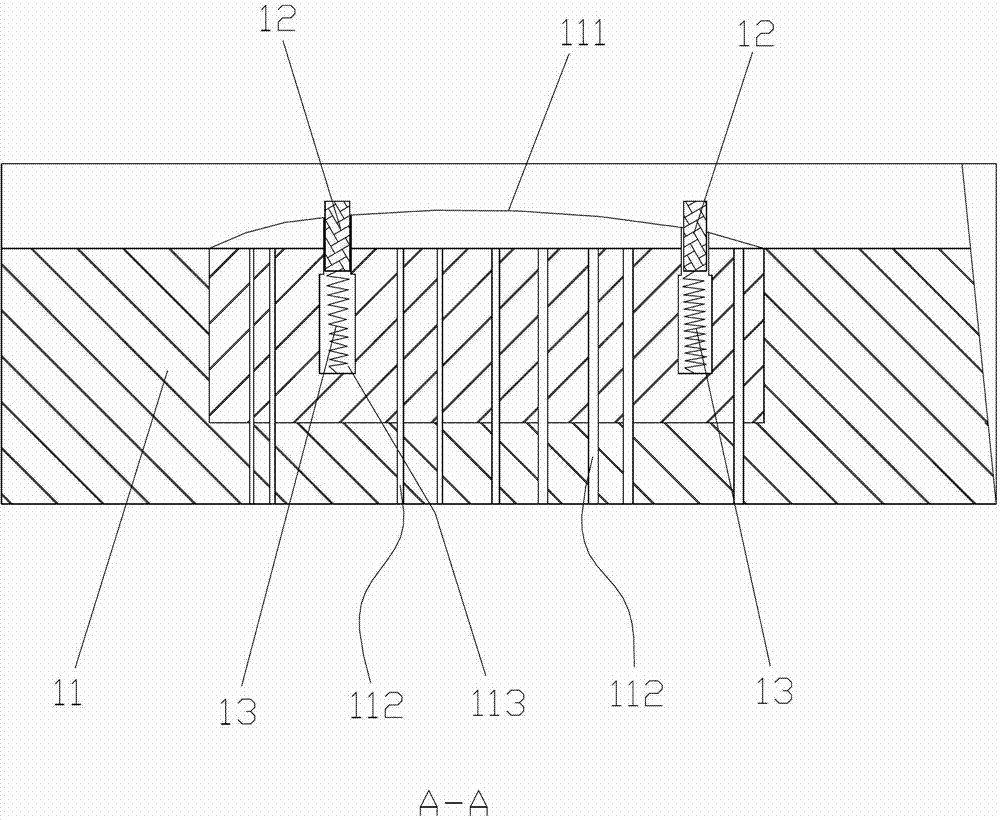

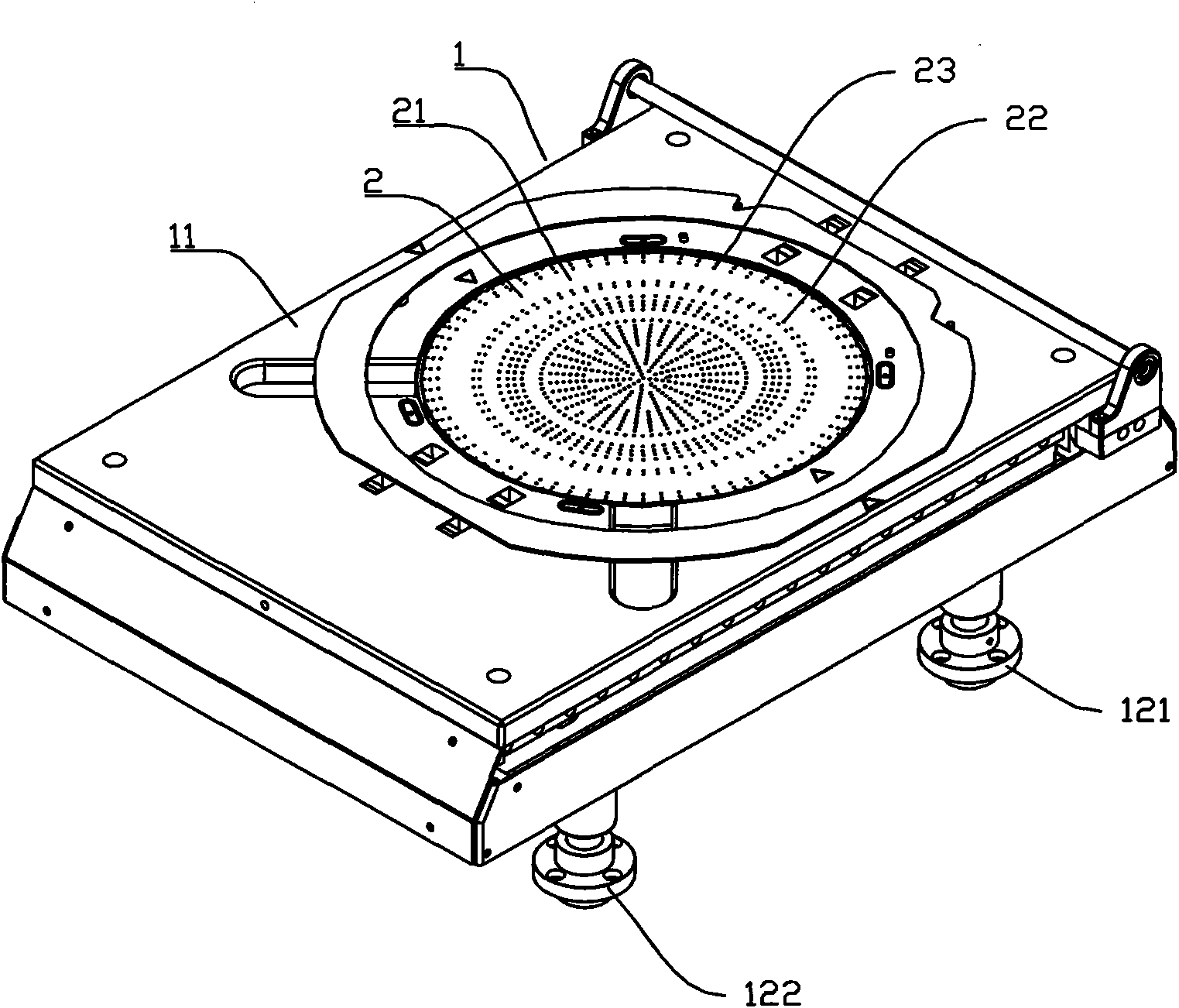

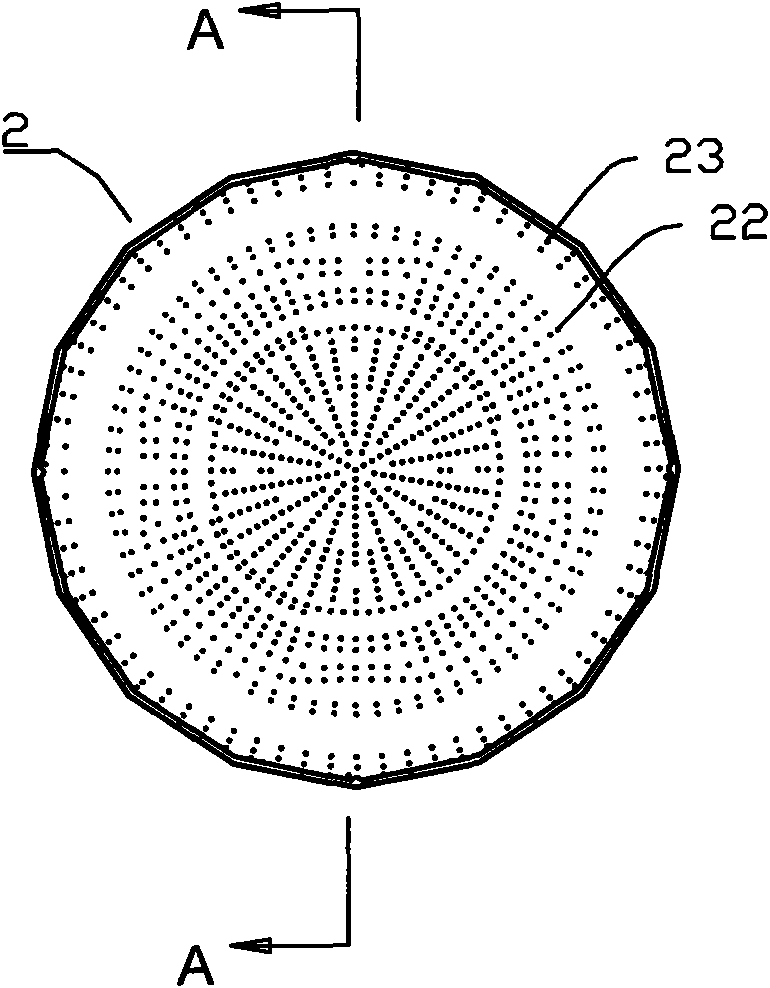

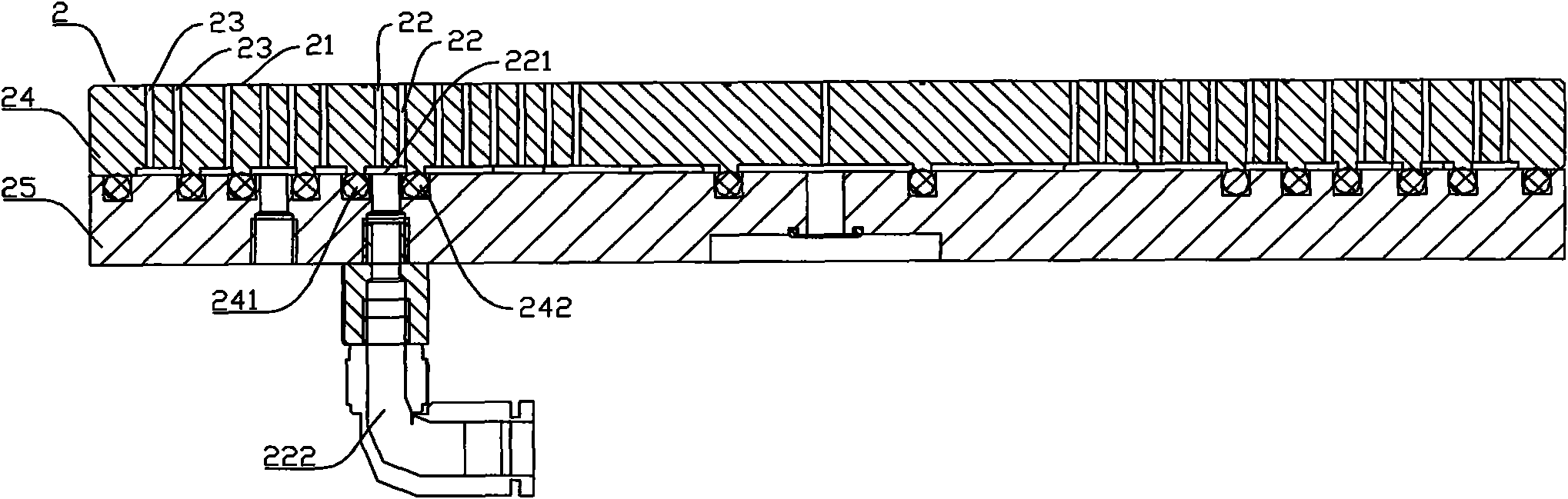

Coating device of automotive interior part

InactiveCN103042809AQuality improvementDischarge in timeLamination ancillary operationsLaminationCoated surfaceEngineering

The invention discloses a coating device of an automotive interior part. The coating device of the automotive interior part is characterized by comprising a bottom die subassembly, wherein the bottom die subassembly comprises a base on which a membrane and the automotive interior part are placed; and air holes penetrate through the surface of the base. The coating device of the automotive interior part can smoothly coat the membrane on the automotive interior part by the effect of pressure acting on the automotive interior part by coating the membrane on the base which is arranged according to the shape of the automotive interior part, and then coating the to-be-coated surface of the automotive interior part on the membrane, and thus the production efficiency is improved; and gas between the membrane and the automotive interior part can be timely discharged through the air holes in the surface of the base, so that air bubbles between the surface of the coated interior part and the membrane are greatly reduced, and the coating quality is improved.

Owner:SHANGHAI TONGLING AUTOMOTIVE TECH INC

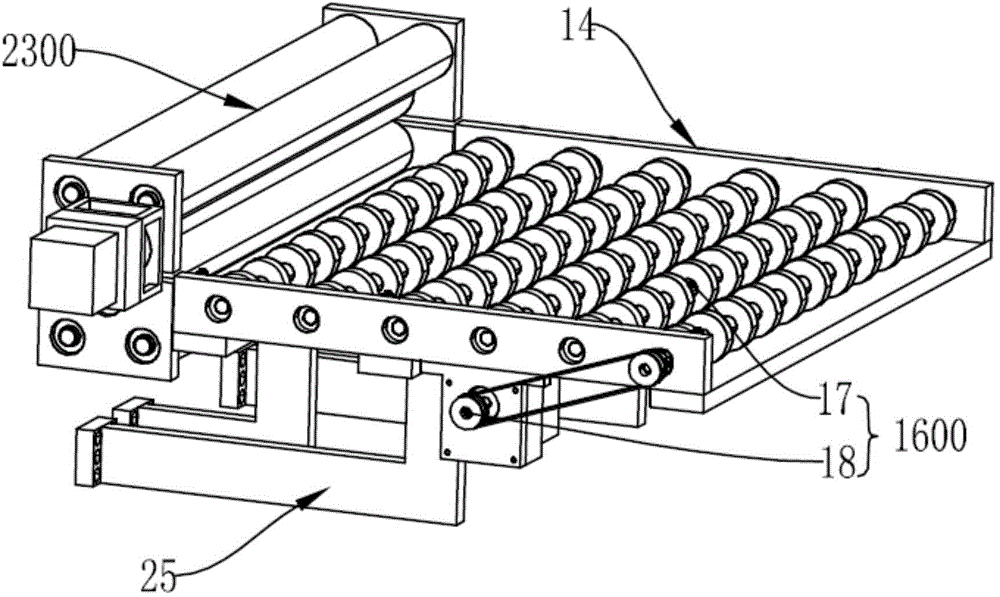

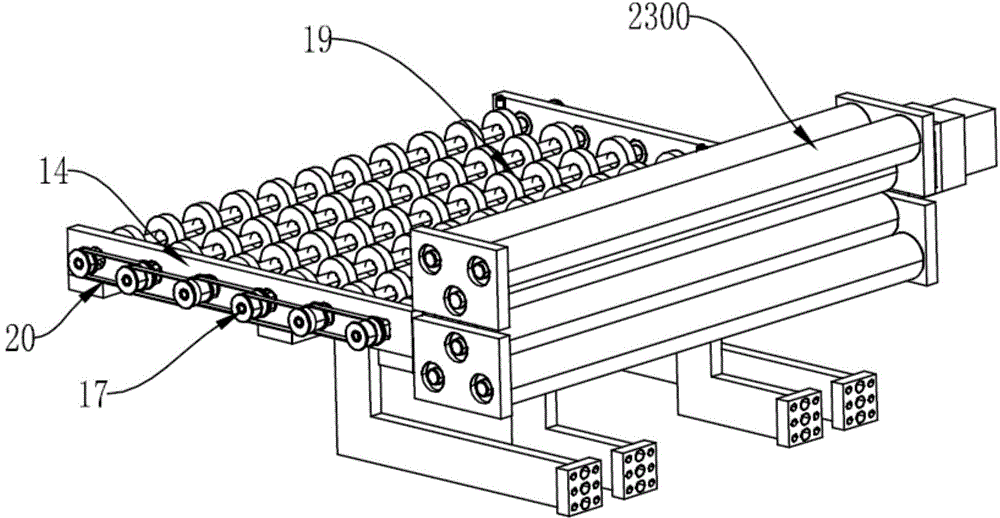

Automatic furniture plate feeding and film pasting system with high machining efficiency

InactiveCN111572165AReduce generationGood removal effectLamination ancillary operationsLaminationThin membraneStructural engineering

Owner:杭州友邻电子有限公司

Adsorbing type film sticking mechanism

InactiveCN106428745AImprove the film effectImprove pass rateWrapping material feeding apparatusTectorial membraneEngineering

The invention discloses an adsorbing type film sticking mechanism. The adsorbing type film sticking mechanism comprises a horizontal rotating angle adjusting assembly, a fixing base plate and an adsorbing film pressing base plate, wherein the fixing base plate is horizontally arranged below the horizontal rotating angle adjusting assembly, and the horizontal rotating angle adjusting assembly is used for driving the fixing base plate to horizontally rotate; the adsorbing film pressing base plate is arranged below the fixing base plate through an inclination angle adjusting assembly; the lower surface of the adsorbing film pressing base plate is a protecting film adsorbing surface; an included angle between the adsorbing film pressing base plate and the level can be adjusted through the inclination angle adjusting assembly during film sticking. The adsorbing type film sticking mechanism is applicable to the sticking of one or a plurality of layers of protecting films; no bubble is generated between the protecting film and an element to be stuck, and the film sticking position accuracy is high, so that the film sticking effect and qualification rate can be improved; the adsorbing type film sticking mechanism has a good application prospect.

Owner:JIANGSU BVM INTELLIGENT TECH

Adsorption-type quick film sticking device

InactiveCN106965970AThe film pulling process is stableFilm PreciseWrapping material feeding apparatusEngineeringSheet material

The invention relates to an adsorption type fast film sticking device, which comprises a film unwinding part for conveying the film backward; a film pulling part for driving one end of the film to move backward to make the film unroll in a horizontal direction; a feeding part, the The feeding part is used to intermittently supply the sheet material to the film pulling part to make the sheet fit with the unfolded film; the film pulling part includes a rotating mechanism and several groups of supporting cutters which are arranged on the rotating mechanism and perform rotating motion under the driving of the rotating mechanism. A cutting mechanism and a negative pressure supply mechanism arranged on one side of the rotary mechanism; the feeding part includes a clamping mechanism for supporting the sheet material and a blanking material for controlling the sheet material in the clamping mechanism to fall intermittently with the rotation of the rotary mechanism Mechanism; the invention overcomes the problems of unstable film unfolding during the film sticking process, easy occurrence of wrinkles and inability to achieve continuous and efficient film sticking and complete film cutting while sticking the film.

Owner:浙江班萘特复合材料股份有限公司

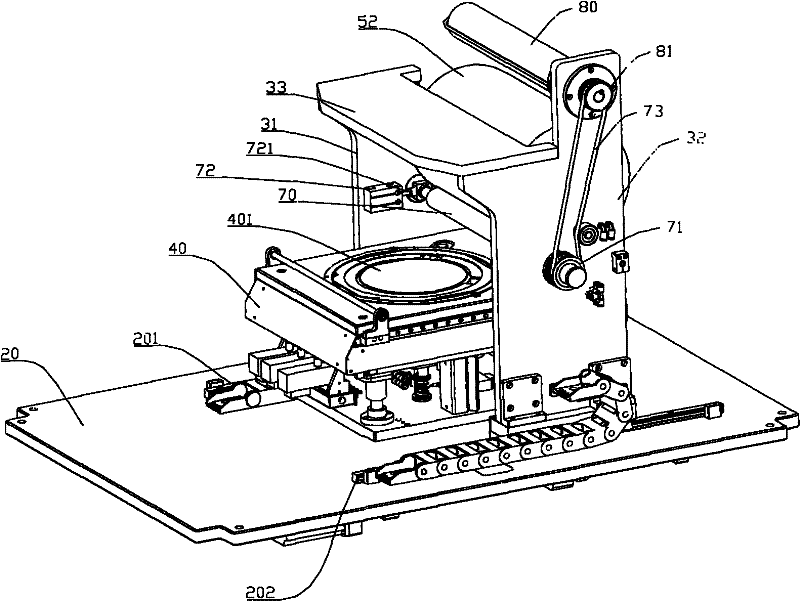

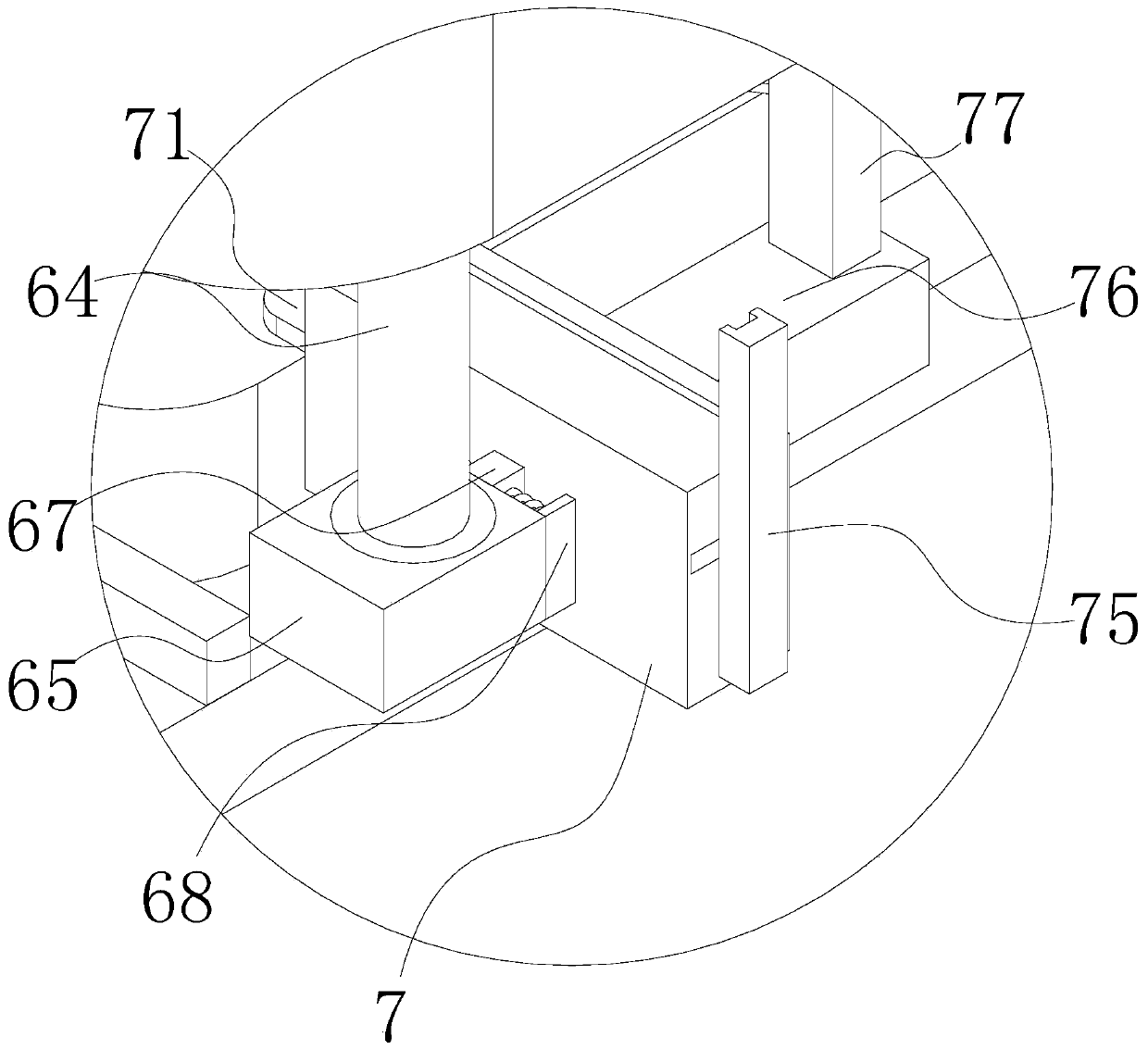

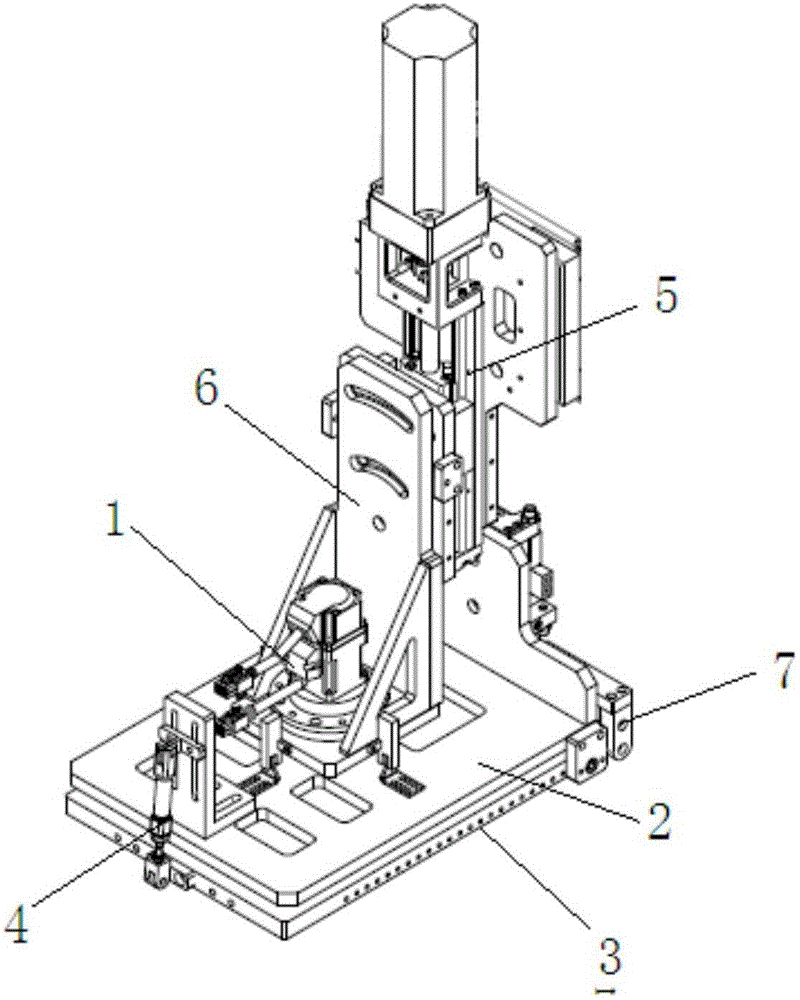

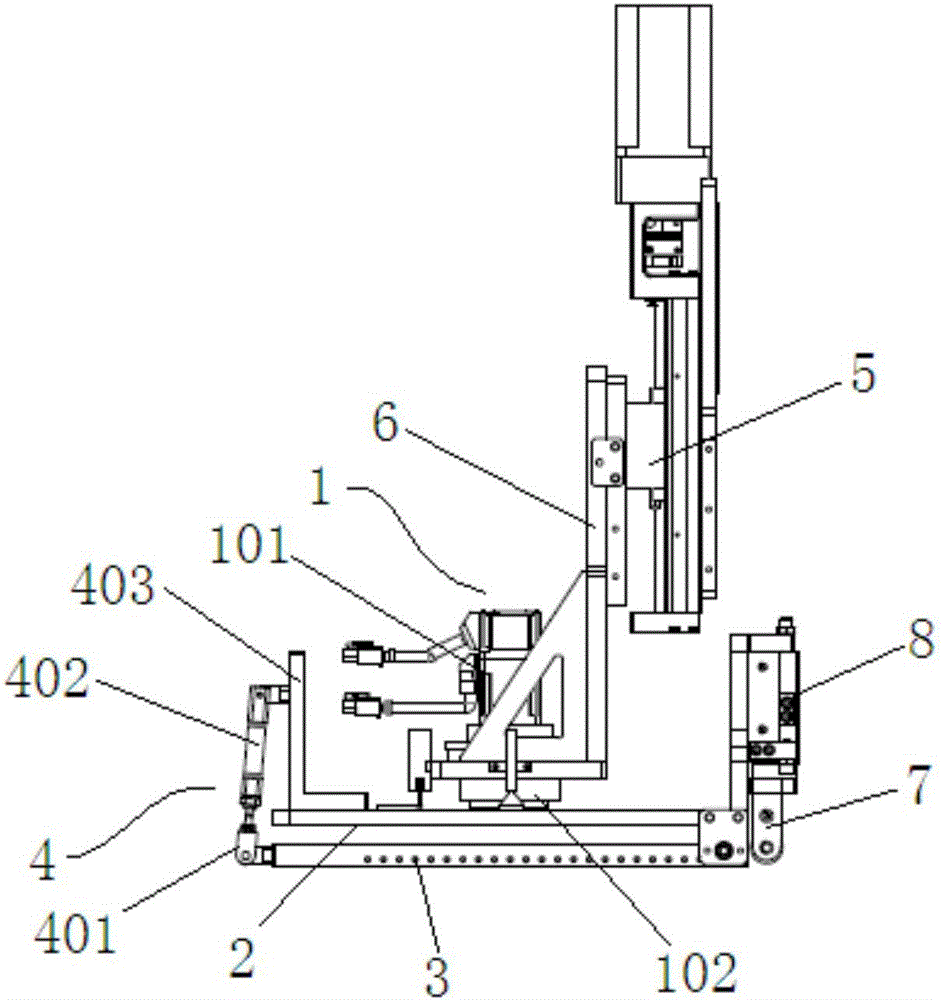

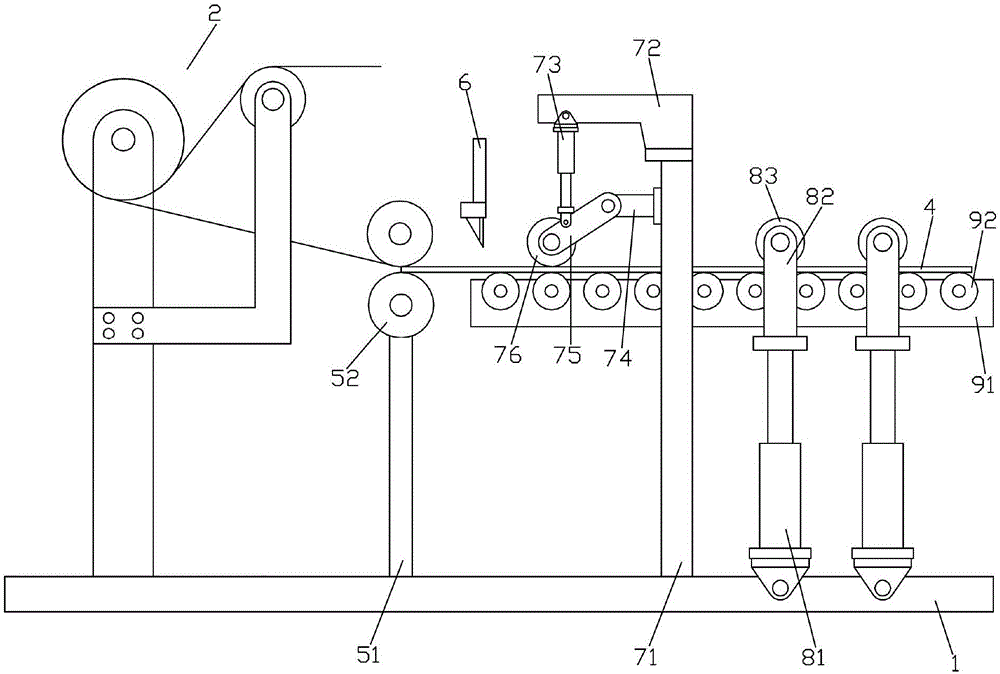

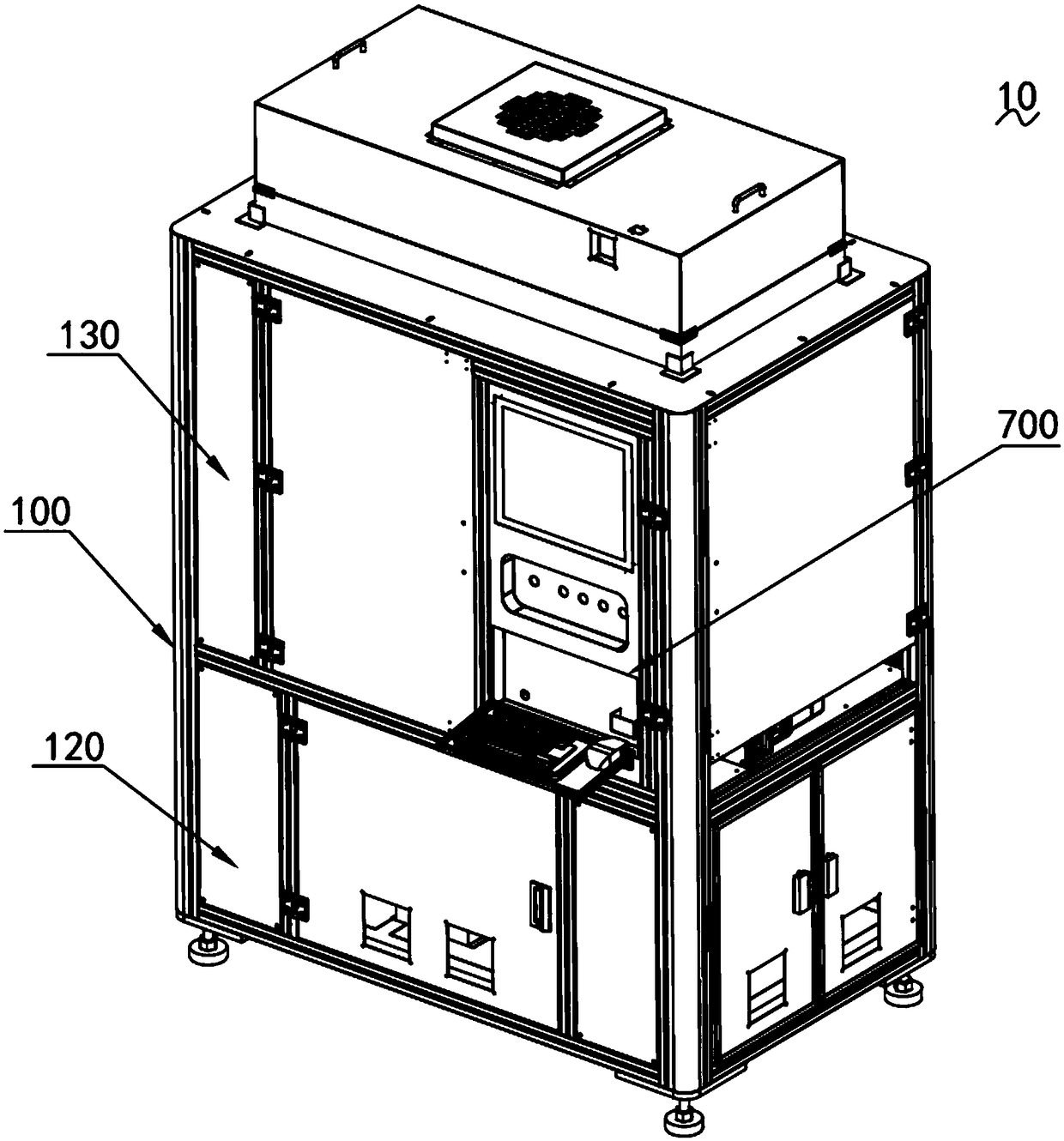

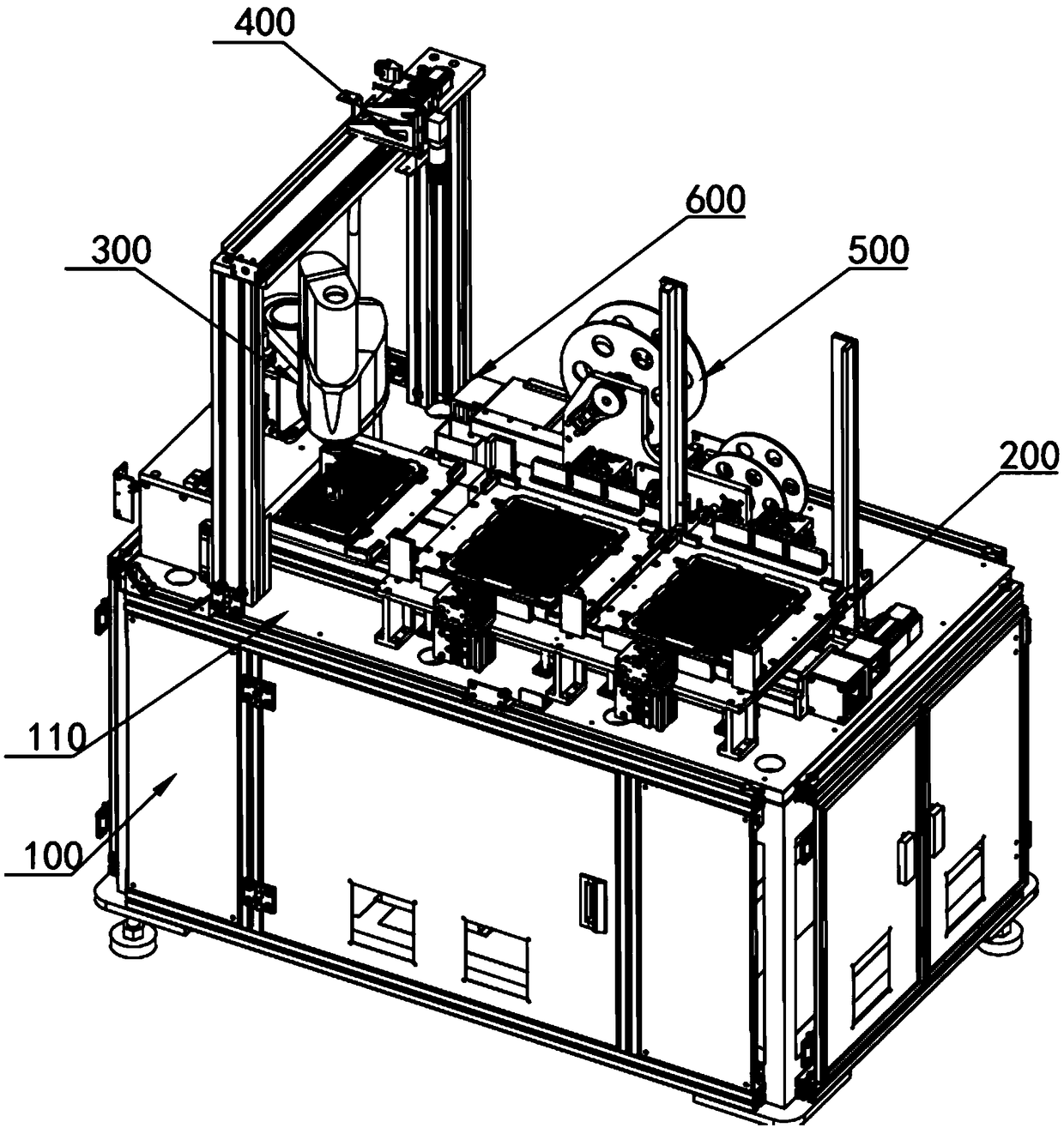

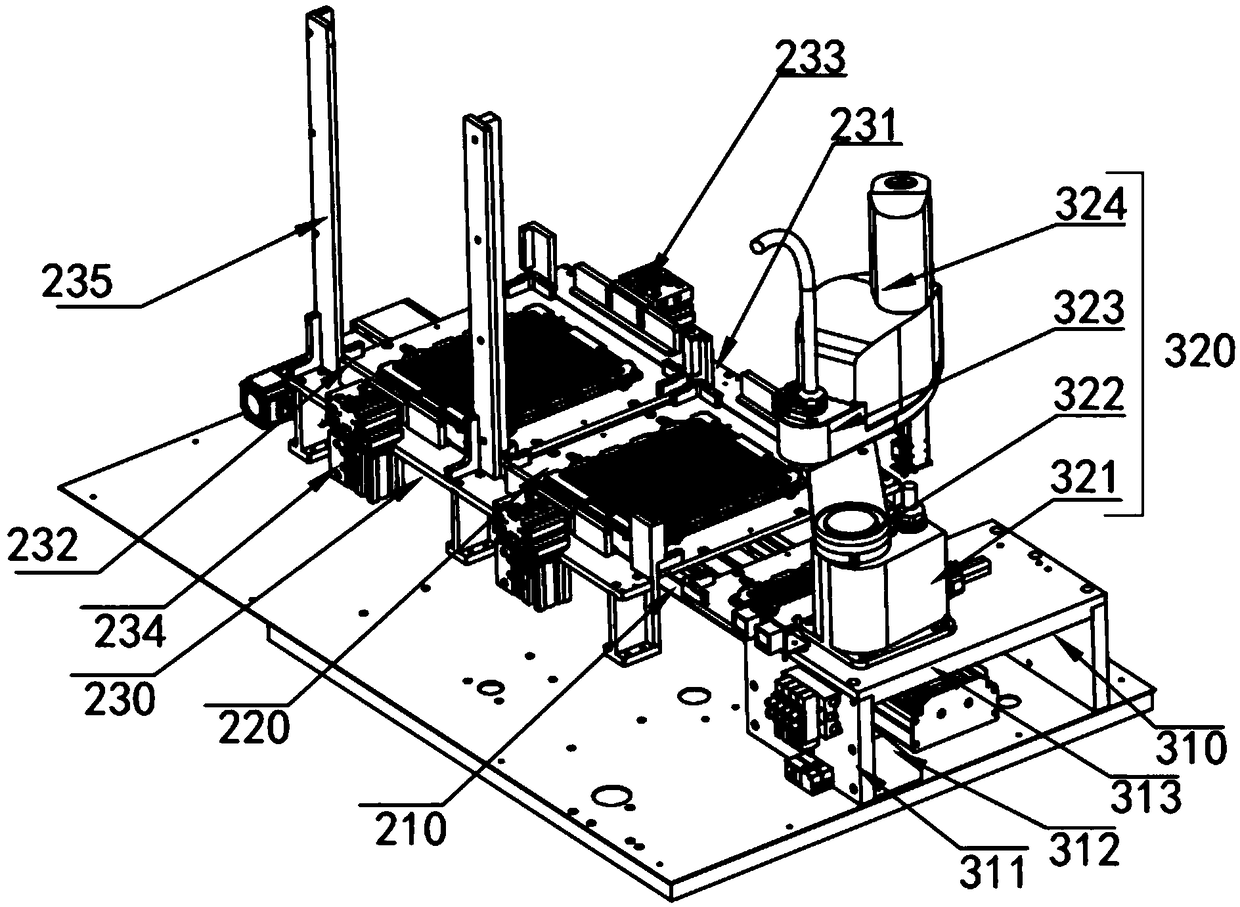

Automatic film sticking machine and film sticking method based on automatic film sticking machine

ActiveCN109968650AImprove the accuracy of film applicationImprove film application efficiencyCleaning using toolsCleaning using liquidsEngineeringMechanical engineering

The invention belongs to the technical field of film sticking machines, and particularly discloses an automatic film sticking machine and a film sticking method based on the automatic film sticking machine. The automatic film sticking machine comprises a controlling unit and an executing mechanism, wherein the executing mechanism comprises a machine frame, a worktable, a wiping mechanism and a mechanical arm; the worktable is used for clamping electronic products and tempered-glass films, and positioning the tempered-glass films; the wiping mechanism is used for wiping screens of the electronic products; the mechanical arm is used for sucking the tempered-glass films and moving the tempered-glass films to the electronic products; and through the cooperation of the worktable, the wiping mechanism and the mechanical arm, the cleaning work before sticking the tempered-glass films is completed jointly, and then the tempered-glass films are stuck, so that the film sticking precision of theelectronic products is enhanced, the film sticking efficiency of the electronic products is improved, and humans are replaced during sticking films and the working fatigue of the humans is relieved.

Owner:NINGXIA UNIVERSITY

Film sticking device for automotive glass

ActiveCN106476399ASimple structureHigh degree of automationLamination plant layoutLaminationEngineeringAutomation

The invention discloses a film sticking device for automotive glass. The film sticking device comprises a base, a film sticking assembly, a film conveying assembly, a cutting knife and a control assembly, wherein the film conveying assembly is located at the left side of the film sticking assembly, the cutting knife is located between the film conveying assembly and the film sticking assembly, the control assembly is electrically connected with the film sticking assembly, the film conveying assembly and the cutting knife, and both the film sticking assembly and the film conveying assembly are arranged at the upper part of the base; and the film sticking assembly comprises a glass conveying part, multiple groups of uniformly-arranged rollers are arranged on the glass conveying part, the automotive glass is located at the upper parts of the rollers, a main rack is arranged on the glass conveying part close to the left side of the glass conveying part, the upper part of the main rack is connected with a transverse plate, a cross arm is vertically arranged at the upper part of the main rack, the tail end of the cross arm is connected with a swing arm, the tail end of the swing arm is hinged to a main pressing roller, and a swing cylinder is connected between the lower part of the transverse plate and the swing arm. According to the film sticking device for the automotive glass, the structure is simple, the degree of automation is high, the quality of film sticking is improved, the efficiency of film sticking is increased, and the intermittence and discontinuity of a film sticking process are avoided.

Owner:九江力达科技股份有限公司

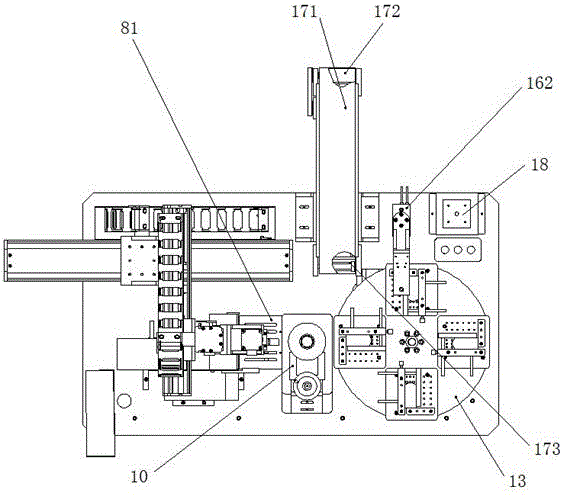

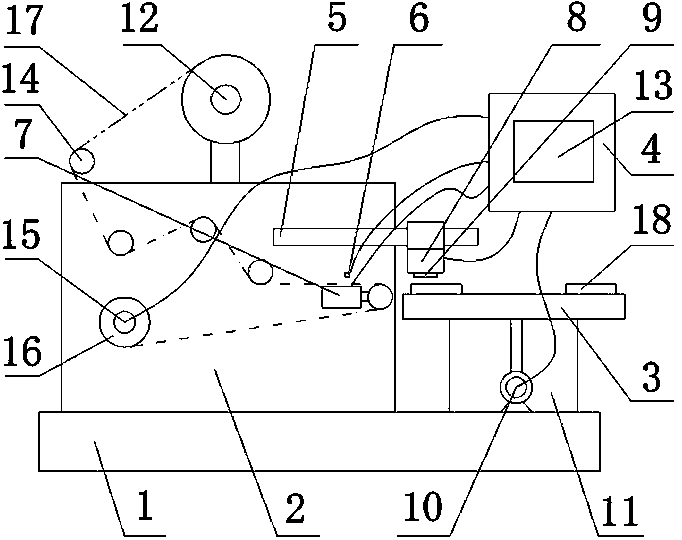

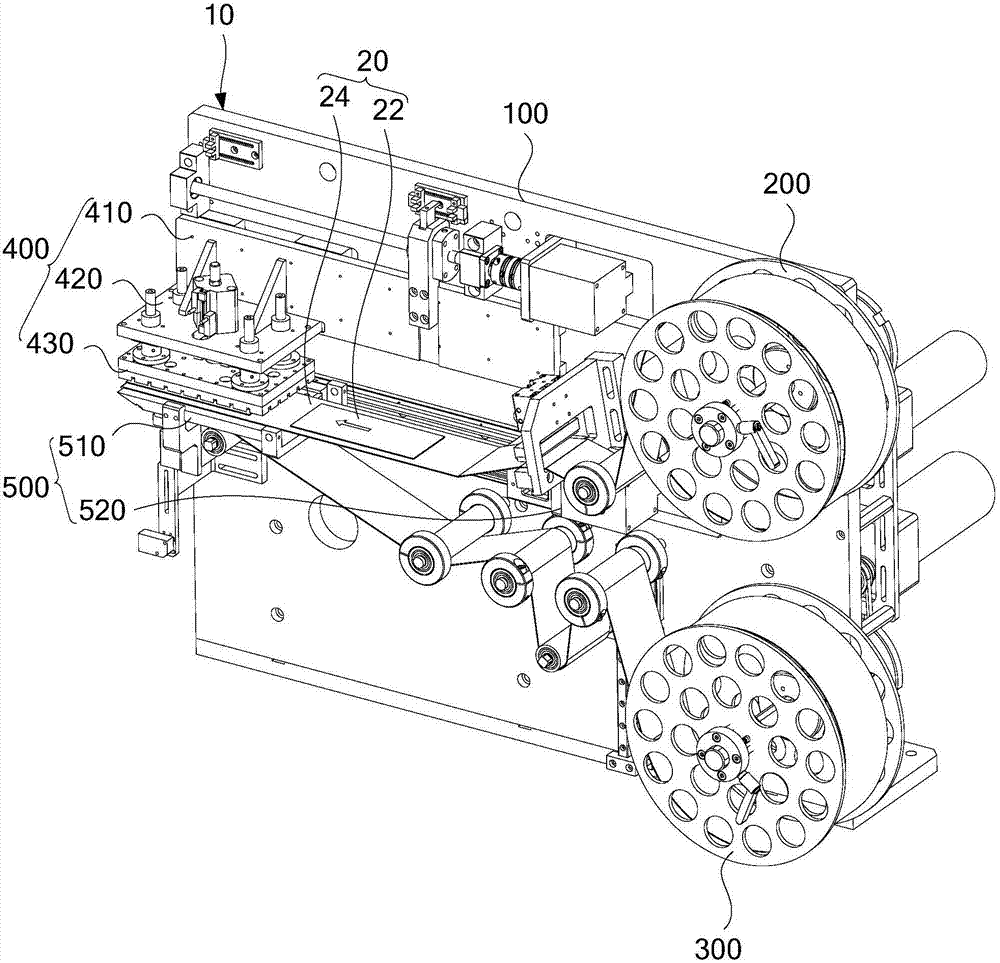

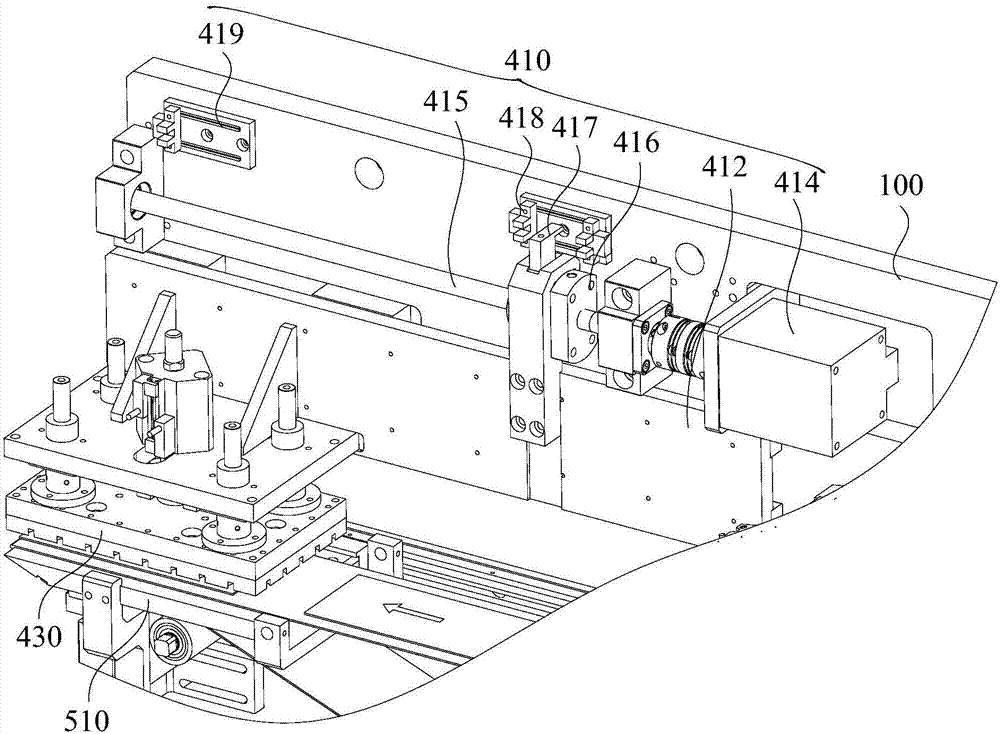

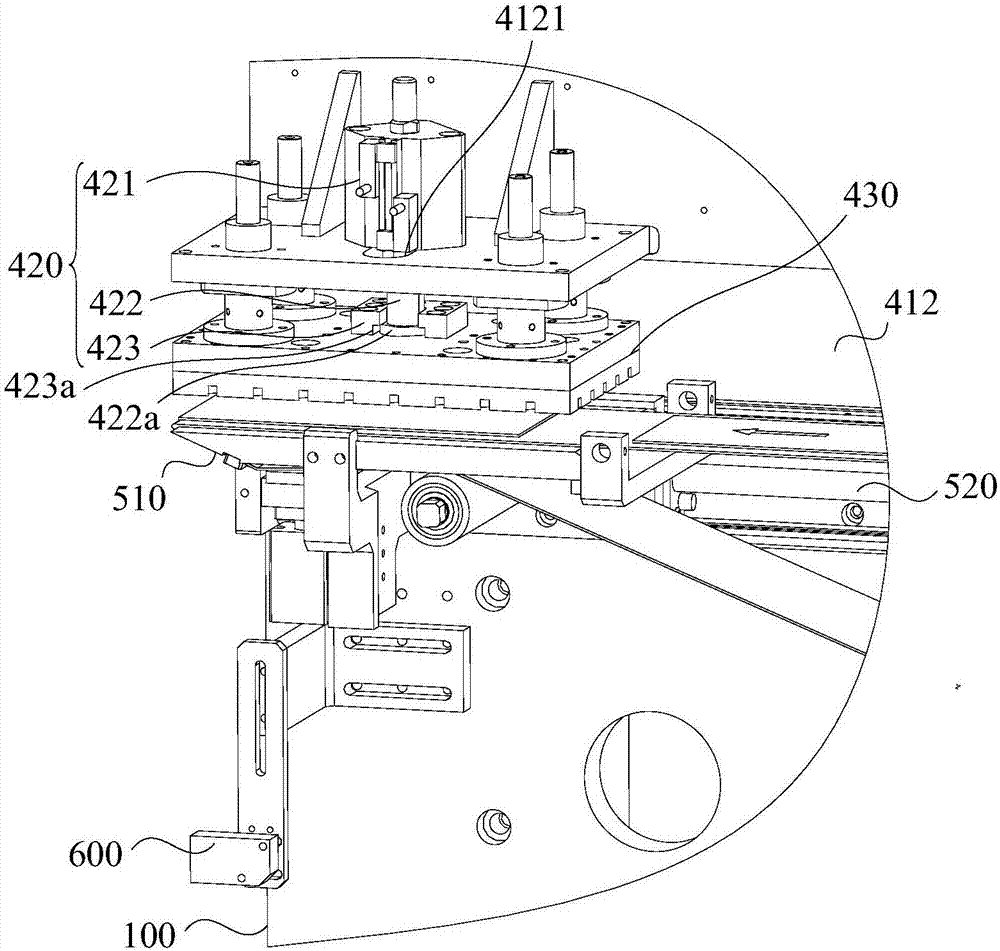

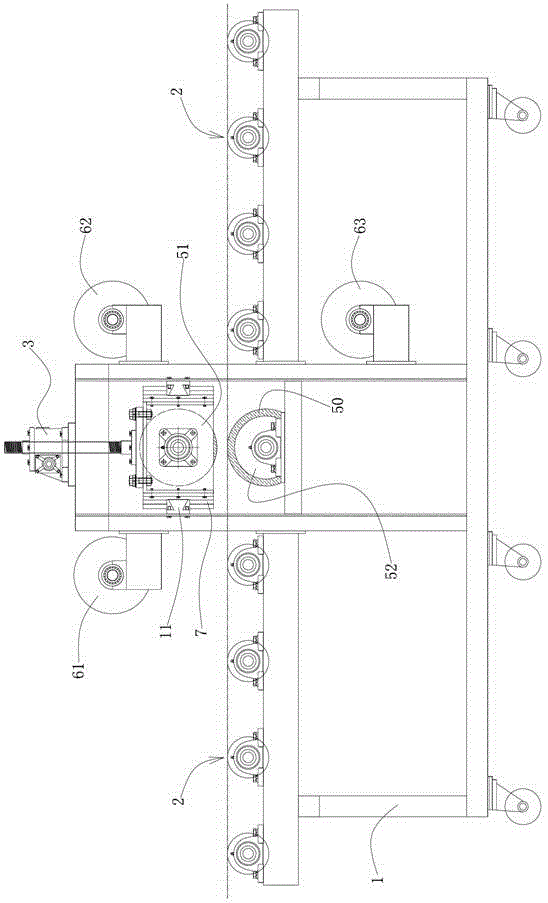

Film-pasting device

The invention relates to a film-pasting device. The film-pasting device comprises a base plate, an unwinding mechanism, a paper-collecting mechanism, a carrying mechanism and a film-pulling mechanism. The unwinding mechanism is arranged on the base plate and used for loosing and releasing film materials. The paper-collecting mechanism is arranged on the base plate and used for collecting and rolling a release paper of the film materials. The carrying mechanism comprises a moving assembly, a lifting assembly and a film-absorbing part. The moving assembly is arranged on the base plate. The lifting assembly is arranged at the power outputting end of the moving assembly. The film-absorbing part is arranged at the power outputting end of the lifting assembly and used for absorbing a film slice of the film materials which are in adhesive bonding with the release paper. The film-pulling mechanism comprises a film-pulling plate and a film-pulling driving assembly. The film-pulling plate is slidably connected with the base plate. The film-pulling driving assembly is arranged on the base plate and drives the film-pulling plate to slide relative to the base plate. The film-pulling plate is parallel to the film-absorbing part. The film-pulling plate is used for pulling the release paper and connected with one side, away from the film slice, of the release paper in an abutting mode. According to the film-pasting device, the problem of the low efficiency of film-pasting operation is solved through the continuous circulating operation.

Owner:GUANGDONG TIANJI IND INTELLIGENT SYST CO LTD

Full-automatic efficient glass film sticking machine

The invention discloses a full-automatic efficient glass film sticking machine. The full-automatic efficient glass film sticking machine is characterized by comprising a frame, a conveying roller arranged on the frame and used for conveying the to-be-filmed glass, a film storage roller arranged on the frame and used for placing the film which is coiled to be barrel-shaped, and a film sticking roller arranged on the frame and used for dragging and sticking the film on the film storage roller to the glass surface conveyed by the conveying roller. The full-automatic efficient glass film sticking machine provided by the invention is simple in structure, compact and relatively small in volume, occupies less area and can realize full-automatic and efficient film sticking.

Owner:ZHONGSHAN YIQI HARDWARE MACHINERY MFG

High-accuracy full-automatic film adhering equipment

The invention relates to the technical field of automatic film adhering equipment, and particularly relates to high-accuracy full-automatic film adhering equipment. The high-accuracy full-automatic film adhering equipment comprises a rack, a working table, a loading and unloading mechanism, an automatic film adhering manipulator, a detection mechanism, a discharging mechanism, a stripping mechanism and a control mechanism, wherein the working table is arranged at the upper part of the rack; the loading and unloading mechanism is arranged on the working table and used for loading and unloadinga product; the automatic film adhering manipulator is arranged on the working table, positioned at one end of the loading and unloading mechanism and used for automatically taking a material to adherea film; the detection mechanism is arranged on the working table, positioned above the manipulator and used for detecting and correcting a film material; the discharging mechanism is arranged on theworking table, positioned at one side of the loading and unloading mechanism and used for discharging and rolling up the film material; the stripping mechanism is positioned at one side of the discharging mechanism and used for stripping off the film material; the control mechanism is arranged on the rack and used for controlling the film adhering equipment to work. The high-accuracy full-automatic film adhering equipment integrally adopts full-automatic setting, so that both human and material resources are saved; a protective film is adhered after being corrected in the film adhering process, so that film adhering accuracy and film adhering efficiency are greatly improved, and integral reliability is high.

Owner:东莞市威耐科智能装备有限公司

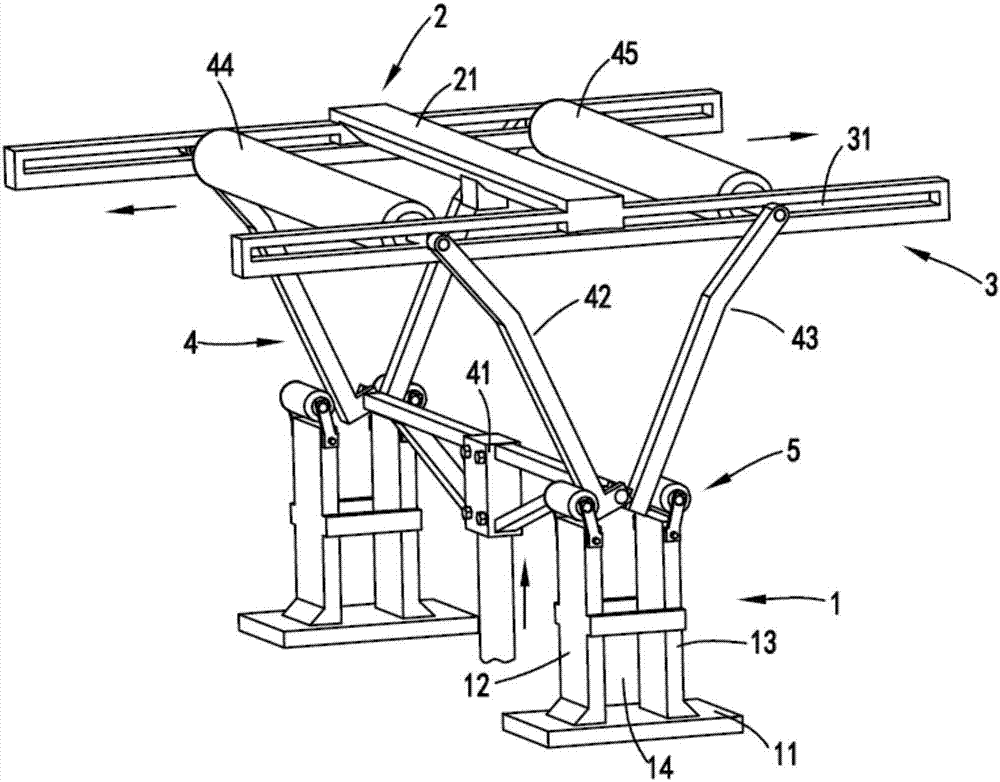

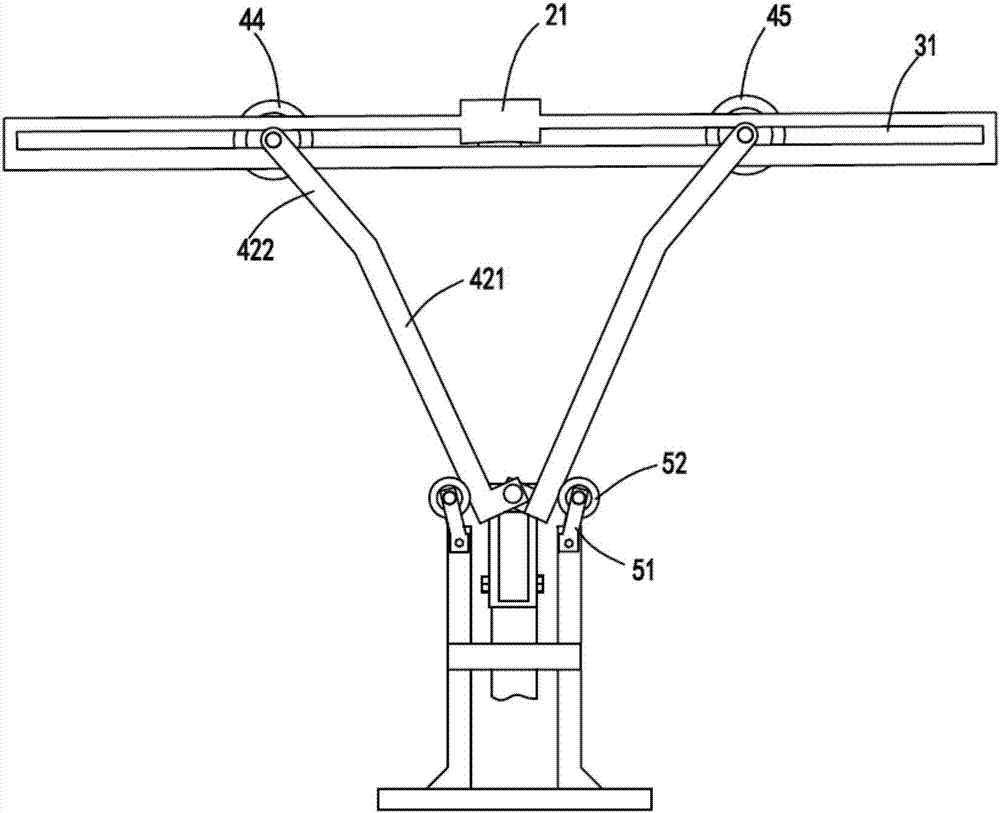

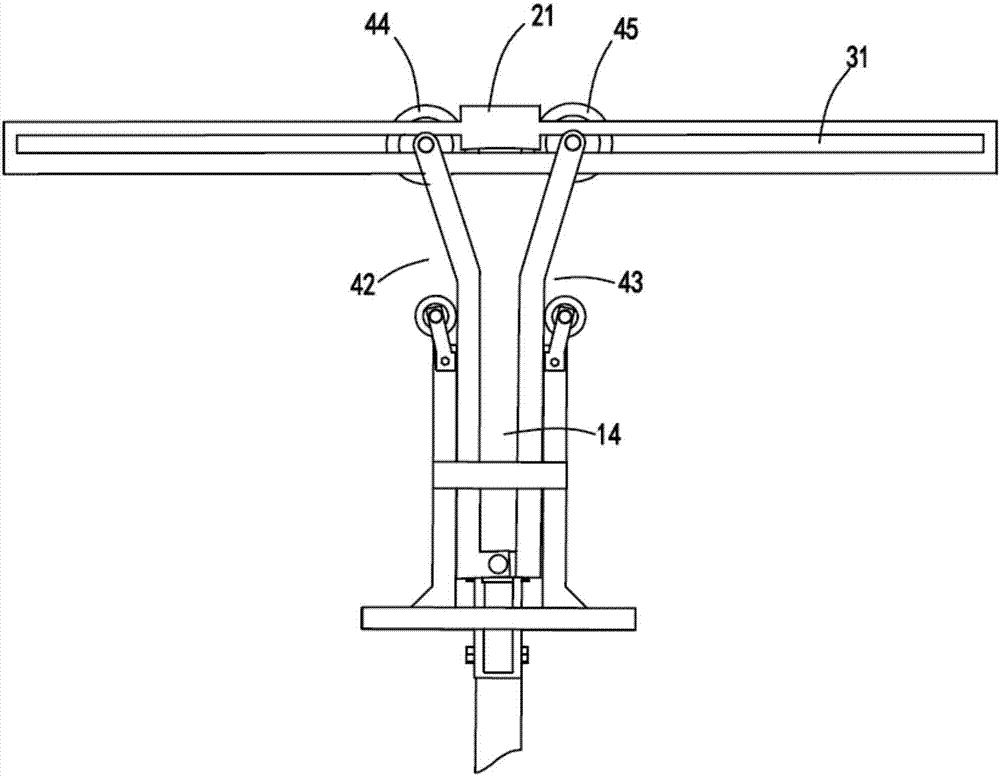

Rolling type leveling mechanism

InactiveCN107031905AImprove film application efficiencyPrevent prone toPackagingEngineeringAir bubble

The invention relates to a rolling smoothing mechanism, which includes a limit device, a support device for supporting a film, guide devices arranged on both sides of the support device, and a device for driving the guide device, the support device and the film along the support device. The limiting device moves upward to make the film contact with the workpiece to be filmed, and then moves along the guide device to both sides so that the film is completely attached to the surface of the workpiece; the invention overcomes the problems of low film sticking efficiency and many bubbles in the film sticking process.

Owner:长兴昊太机械有限公司

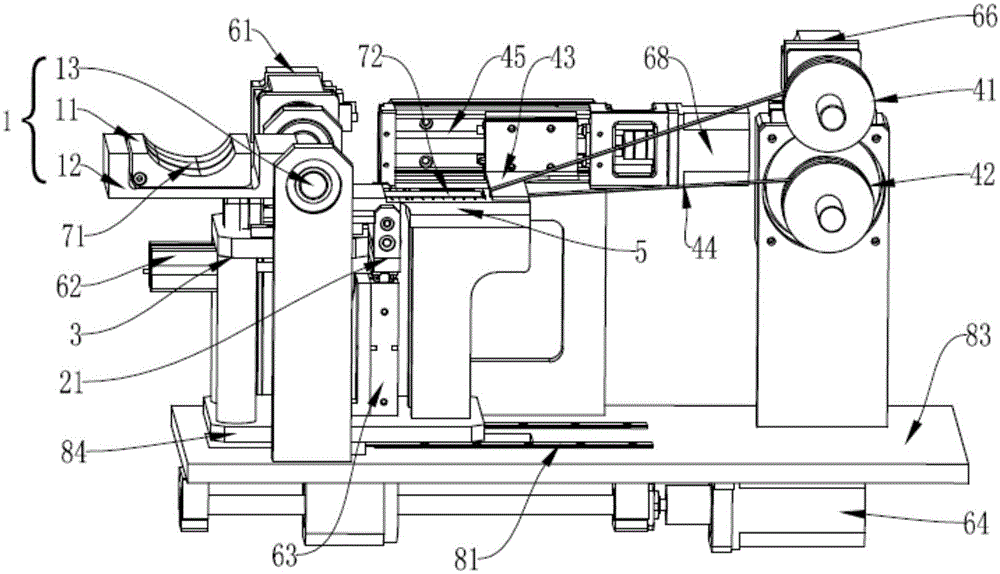

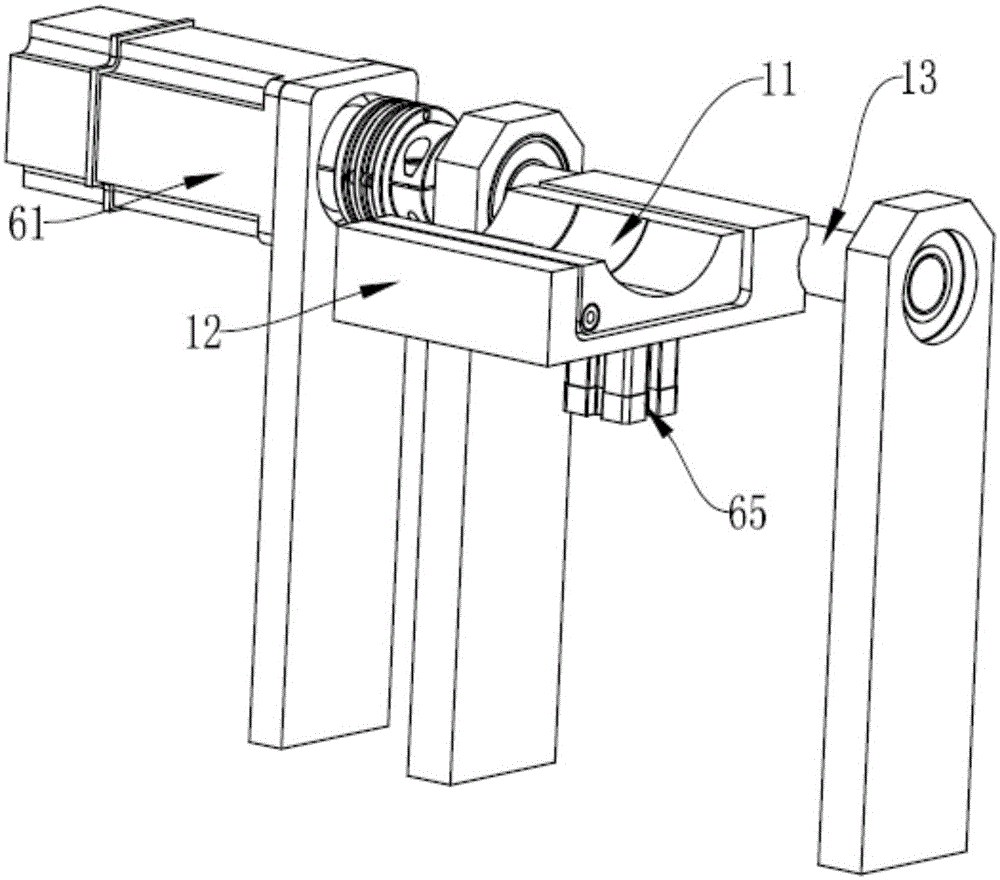

Fully-automatic laminating machine

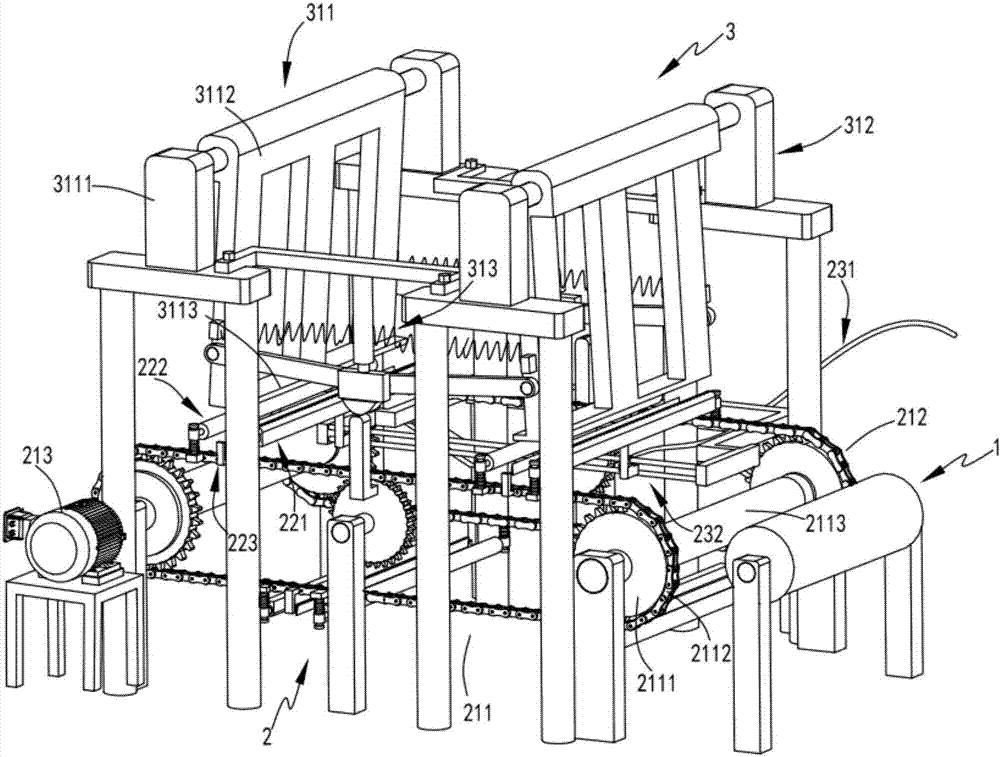

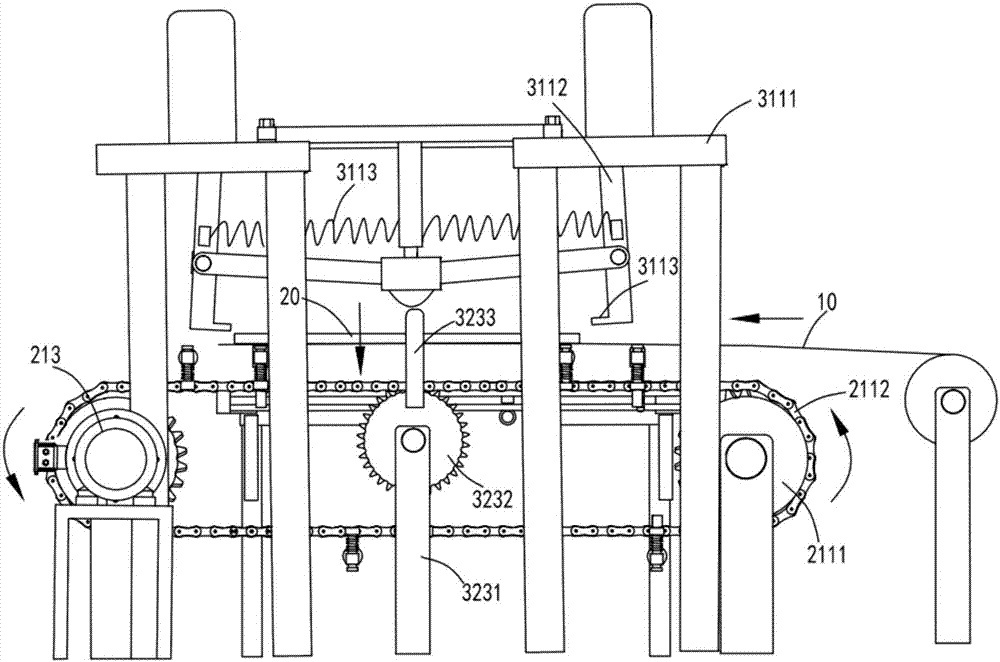

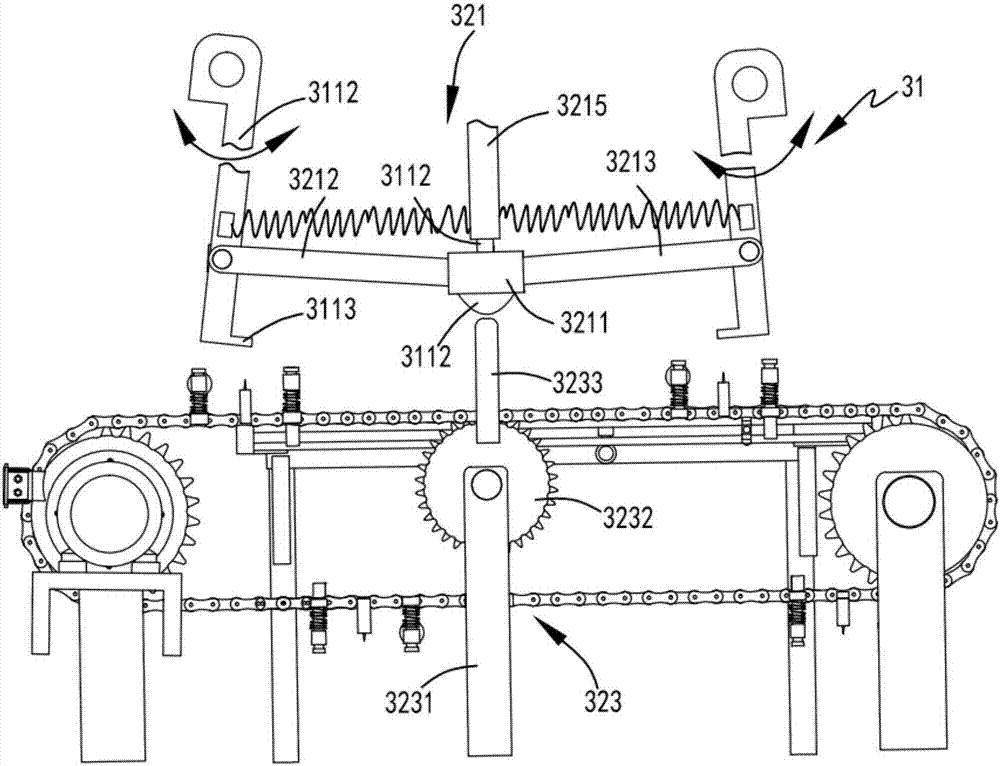

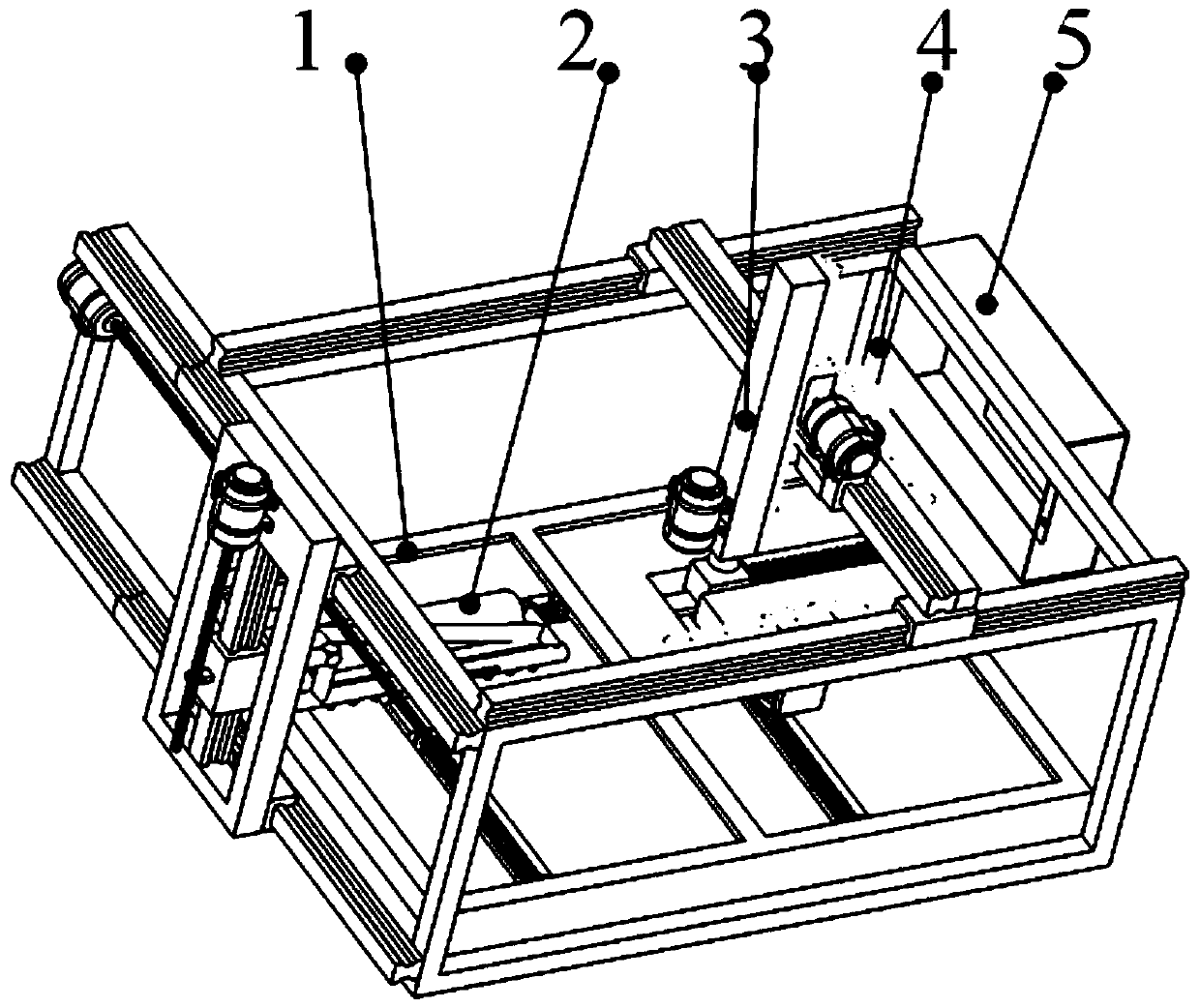

ActiveCN104691075ASimple structureSimplify the steps of applying the filmLamination ancillary operationsLaminationFully automaticComputer engineering

A fully-automatic laminating machine comprises a machine frame, wherein the machine frame is provided with a feeding device, a positioning device, a single-side laminating device, an overturning device, a positioning device and a single-side laminating device in sequence. After a part to be machined passes through the feeding device to reach the corresponding positioning device to be well positioned, single-side lamination is conducted on the corresponding single-side laminating device, the part to be machined with one side laminated is overturned through the overturning device and then is re-positioned through the other positioning device, and then lamination of the other side is conducted by means of the other single-side laminating device. By the adoption of the laminating machine, processes are simplified, and machining efficiency is improved.

Owner:SHENZHEN YANCHUANG PRECISION EQUIP MACHINERY

Automatic 3D film attaching device for mobile phone

Owner:无锡沃格自动化科技股份有限公司

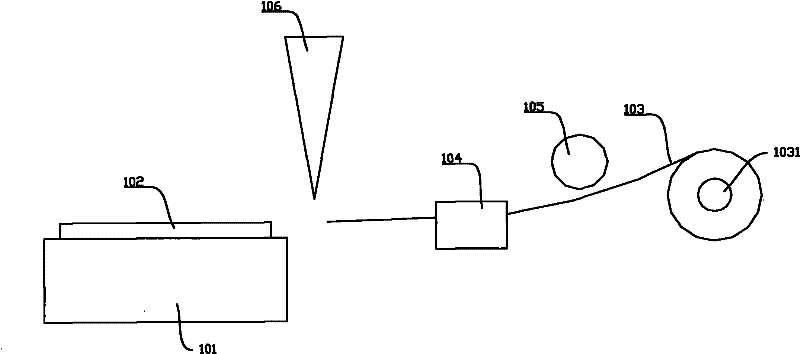

Film adhering method and device of wafer

InactiveCN102103987AQuality is not affectedWon't break easilySemiconductor/solid-state device manufacturingWaferMaterials science

The invention discloses a film adhering method of a wafer. The film adhering method of the wafer is characterized by comprising the following steps of: blowing a gas between the wafer and a table disc; supporting the wafer by utilizing the blown gas; and then adhering a film on the surface of the wafer. By using the film adhering method and device of the wafer, the non-contact film adhesion can be realized and the danger of front surface damage of the wafer can be reduced; in addition, because the wafer can be supported by utilizing the gas during the pressing of a roller wheel, the pressure of the roller wheel can be offset, and the roller wheel can not be easy to press the wafer to be broken or crushed, therefore when the film adhering method and device are used for carrying out the non-contact film adhesion, the minimum thickness of the wafer which can be adhered with the film is 50 micrometers and 200 micrometers far less than that of the water adhered with the film in the prior art.

Owner:上海技美科技股份有限公司

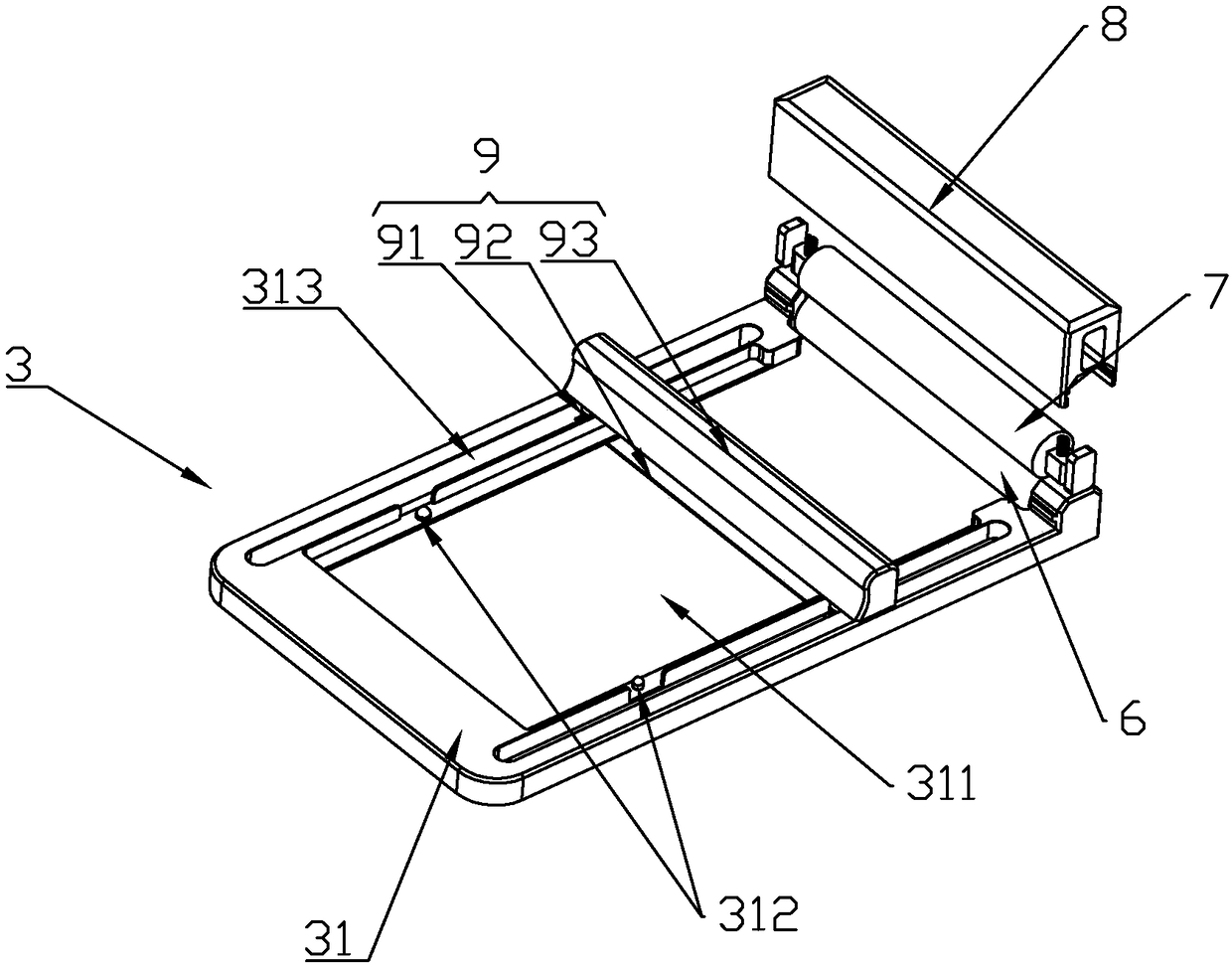

Film laminating machine

ActiveCN107380519ASimple structureImprove film application efficiencyPackagingEngineeringTransfer mechanism

The invention relates to a film laminating machine which is used for laminating protective films onto workpieces and further corresponds to a conveying belt and a material collecting mechanical arm. The film laminating machine comprises an overturning mechanism, a transfer mechanism and a film laminating mechanism. The overturning mechanism comprises a first base, a rotating shaft installed on the first base, an adsorption assembly which is connected with one end of the rotating shaft and used for adsorbing the workpieces, a gear which is connected with the other end of the rotating shaft and a first driving assembly used for driving the gear to rotate. The transfer mechanism comprises a second base, a linear guide rail installed on the second base, a carrier which is in sliding fit with the linear guide rail and used for bearing the workpieces, and a second driving assembly used for driving the carrier to slide. The adsorption assembly adsorbs the workpieces from the conveying belt, the rotating shaft drives the adsorption assembly to be overturned, a robot carries the workpieces on the adsorption assembly onto the carrier, and the workpieces with the films being laminated are taken from the carrier onto the conveying belt. The film laminating efficiency is improved on the basis that film laminating quality is guaranteed.

Owner:GUANGDONG EVERWIN PRECISION TECH

Turnover mechanism of plane piece film attachment machine

A turnover mechanism of a plane piece film attachment machine comprises a turnover shaft and a first driver for driving the turnover shaft to rotate. A glass screen is placed on a jig mechanism, the jig mechanism is arranged on the turnover shaft, and the turnover mechanism is fixed to a machine tool. The jig mechanism comprises a jig, a jig mounting piece and a fifth driver. One end of the jig mounting piece is fixed to the turnover shaft, and the jig is fixed to the jig mounting piece. The jig is a plane piece jig and is provided with an area for fixing the plane glass screen. The jig is arranged on the jig mounting piece through a rotary shaft, and the rotary shaft is located at the end, far away from the turnover shaft, of the jig. The fifth driver acts between the jig and the jig mounting piece so that the jig can rotate around the rotary shaft. According to the structure, film attachment efficiency is high, the product yield is improved, the cost is low, and dust adhesion is avoided.

Owner:广东韦达尔传媒有限公司

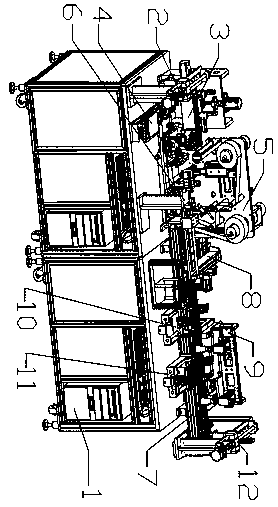

Automatic laminator

ActiveCN107792423AReduce labor intensityRealize automatic film sticking operationFinal product manufacturePackagingRobot handBarcode

The invention discloses an automatic laminator which comprises a transplant jacking mechanism, a product positioning frame, a first discharging component, a second discharging component, a third discharging component, an edge covering and laminating mechanism, a conveying mechanism, a barcode scanning gun, a short-edge material laminating mechanical-arm component, a long-edge material laminating mechanical-arm component, a short-edge material peeling mechanism, a long-edge material peeling mechanism, a short-edge material detecting device, a long-edge material detecting device, a product short-edge camera positioning component, a product long-edge camera positioning component, etc., which are arranged on an operation table. Through the mutual coordination and match of the transplant jacking mechanism, the material peeling mechanisms, the laminating mechanical-arm components, the edge covering and laminating mechanism, the conveying mechanism, etc., the automatic laminator completes theprocess of feeding, positioning, material peeling, laminating, edge covering, discharging, etc. in order. The automatic laminator realizes the automatic laminating operation of products, reduces thelabor intensity of workers, shortens the laminating time, greatly improves the laminating precision and the laminating efficiency, and reduces the production cost.

Owner:苏州才哲智能科技有限公司

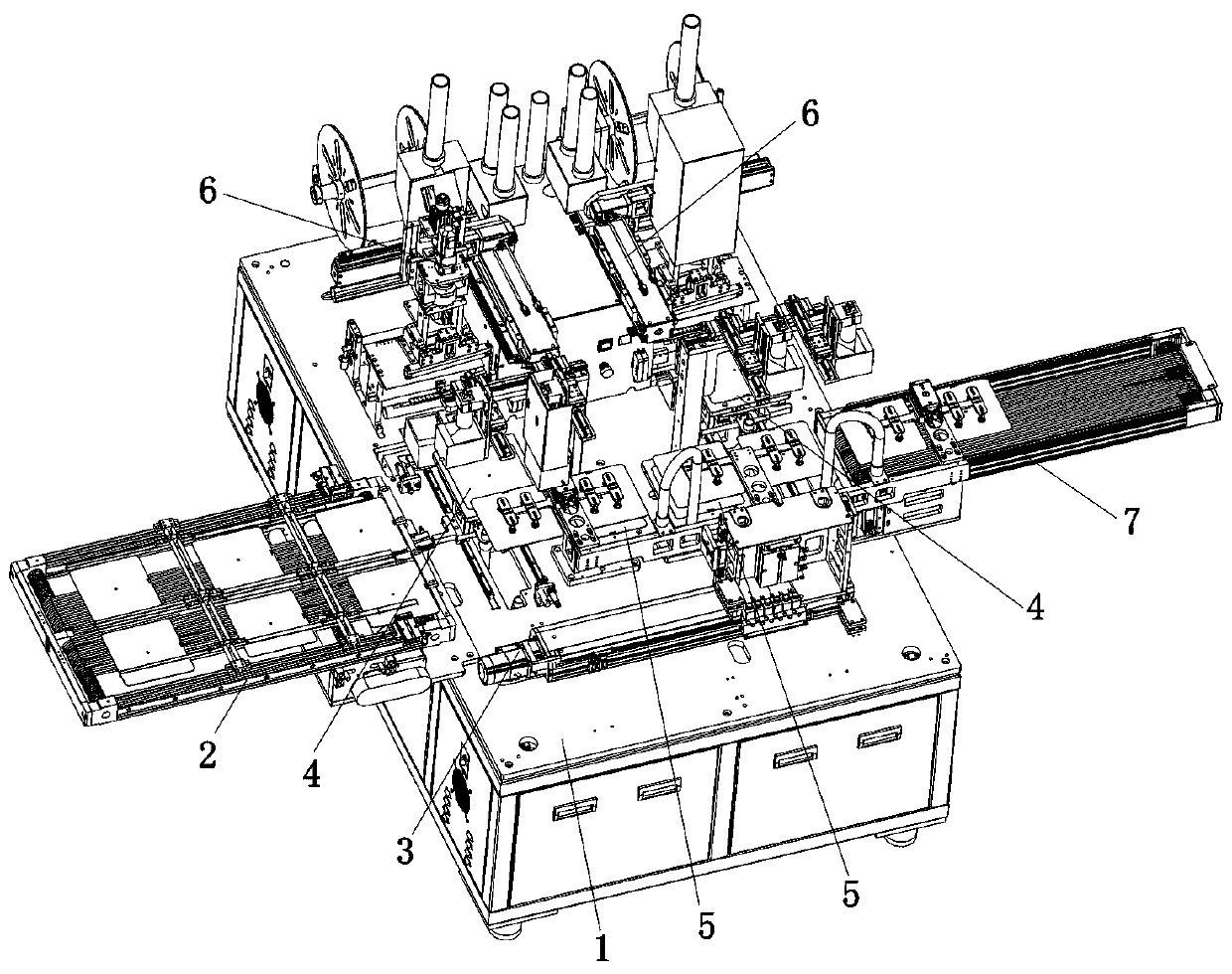

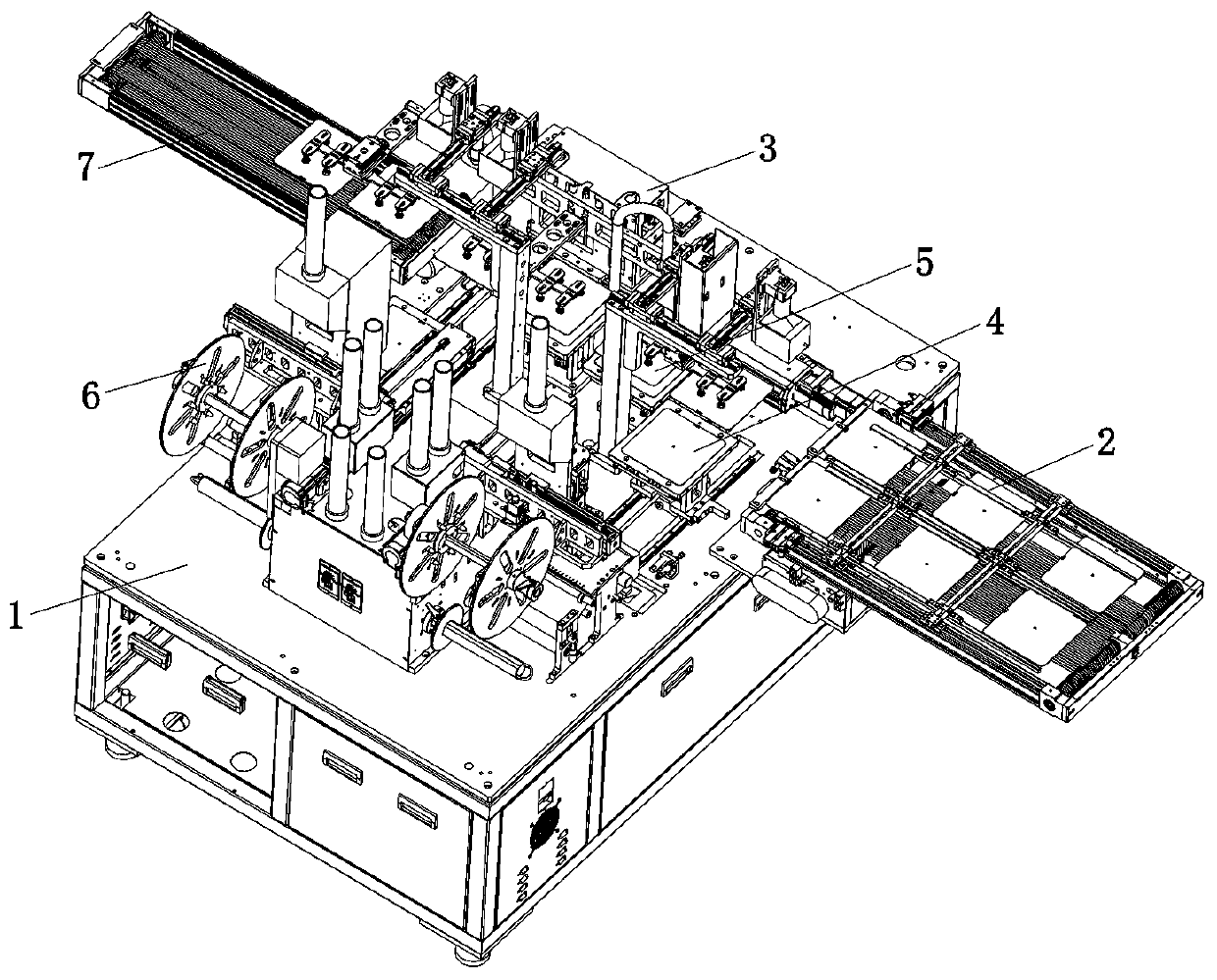

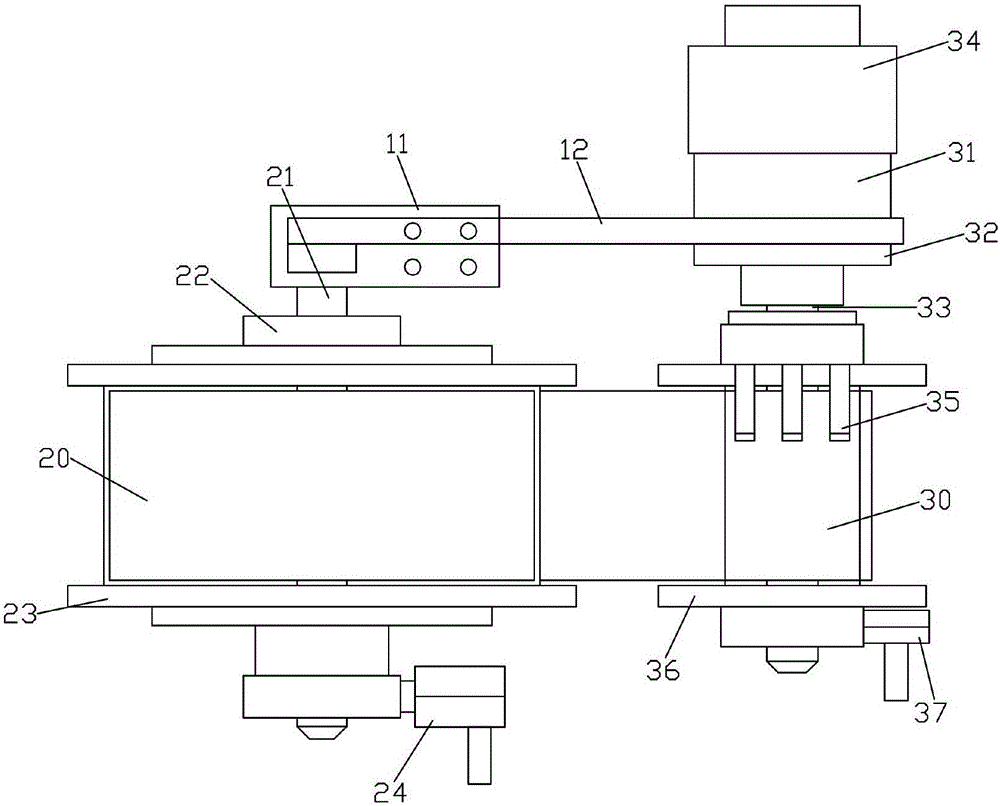

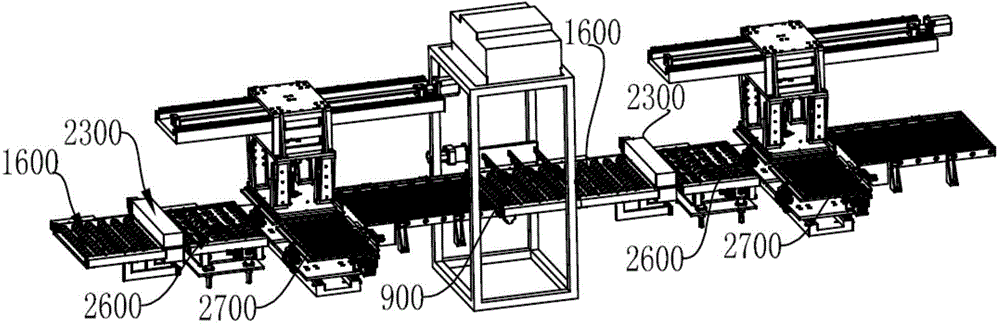

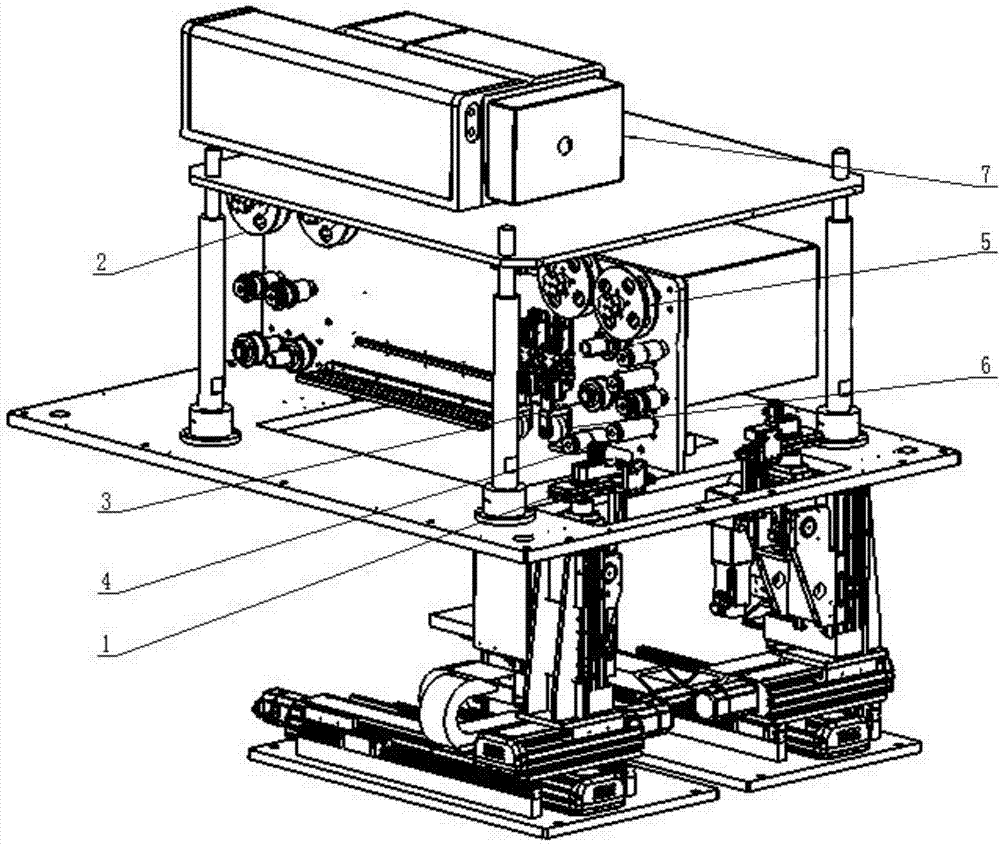

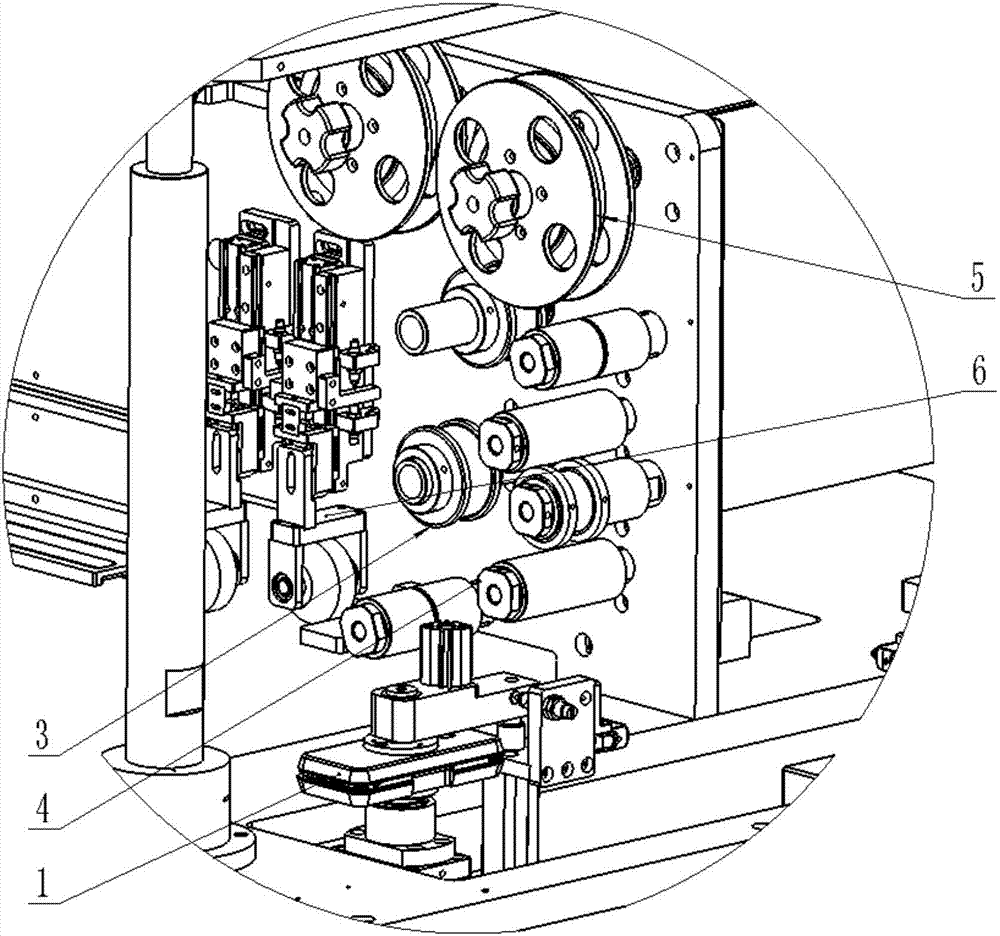

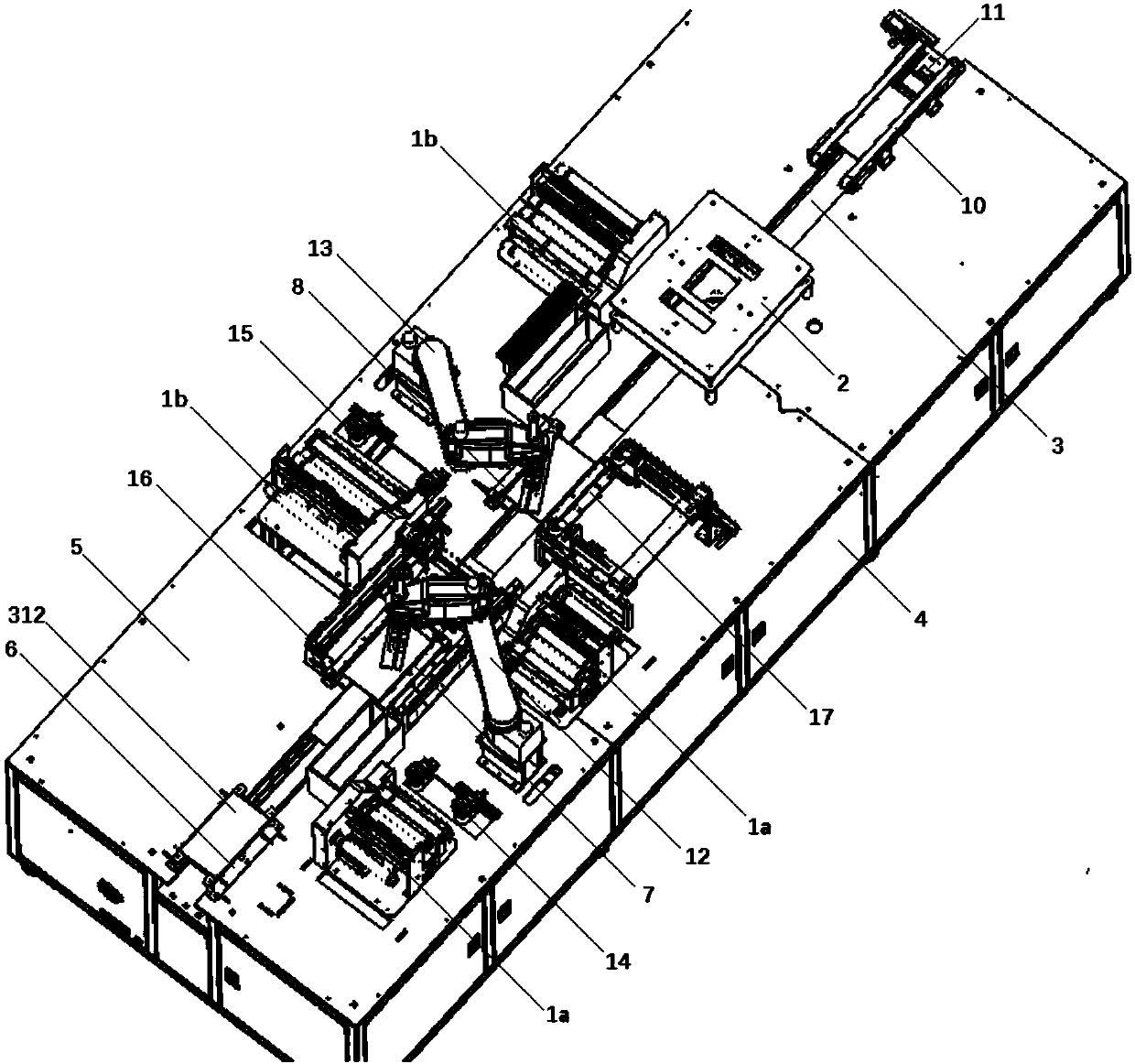

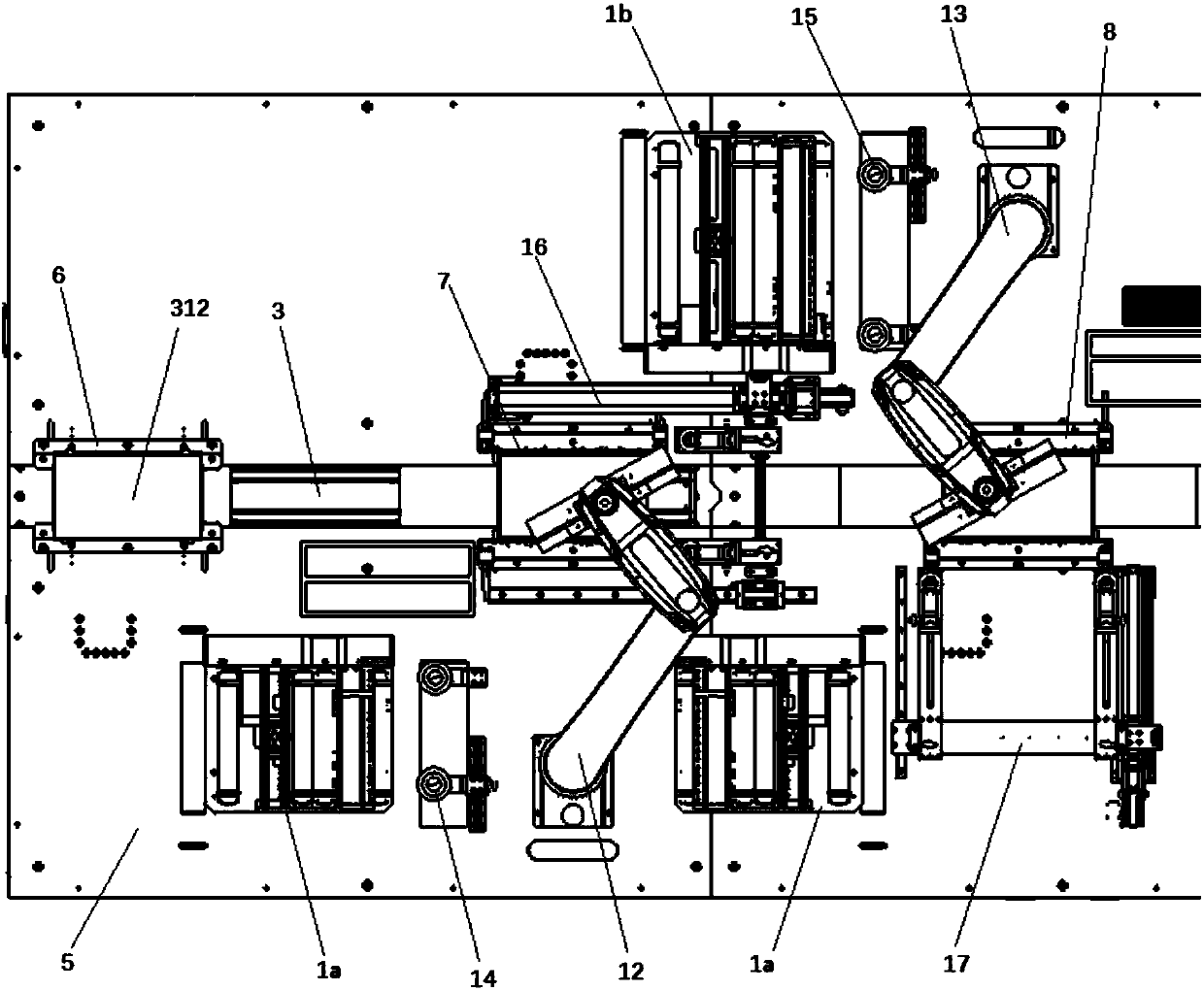

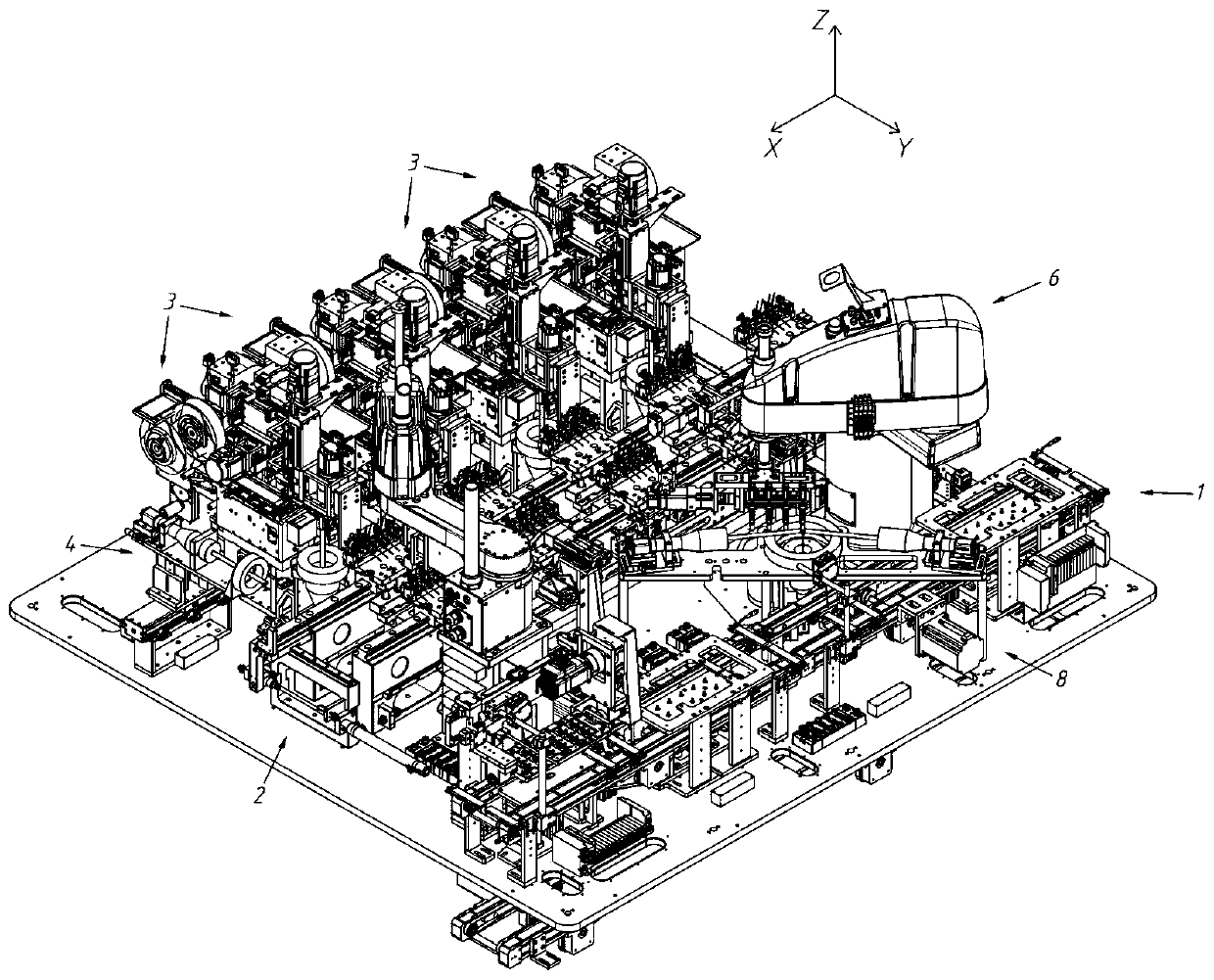

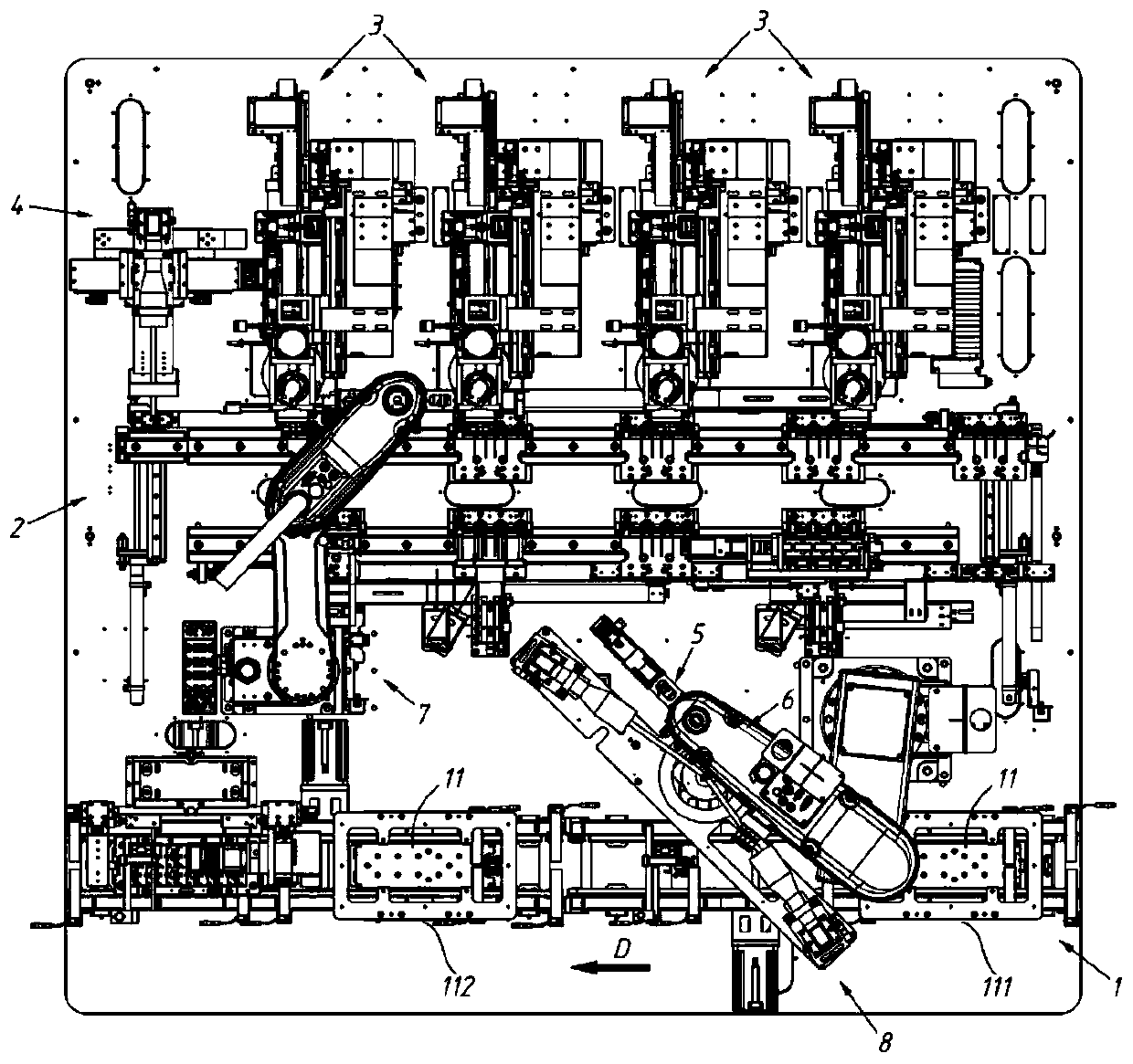

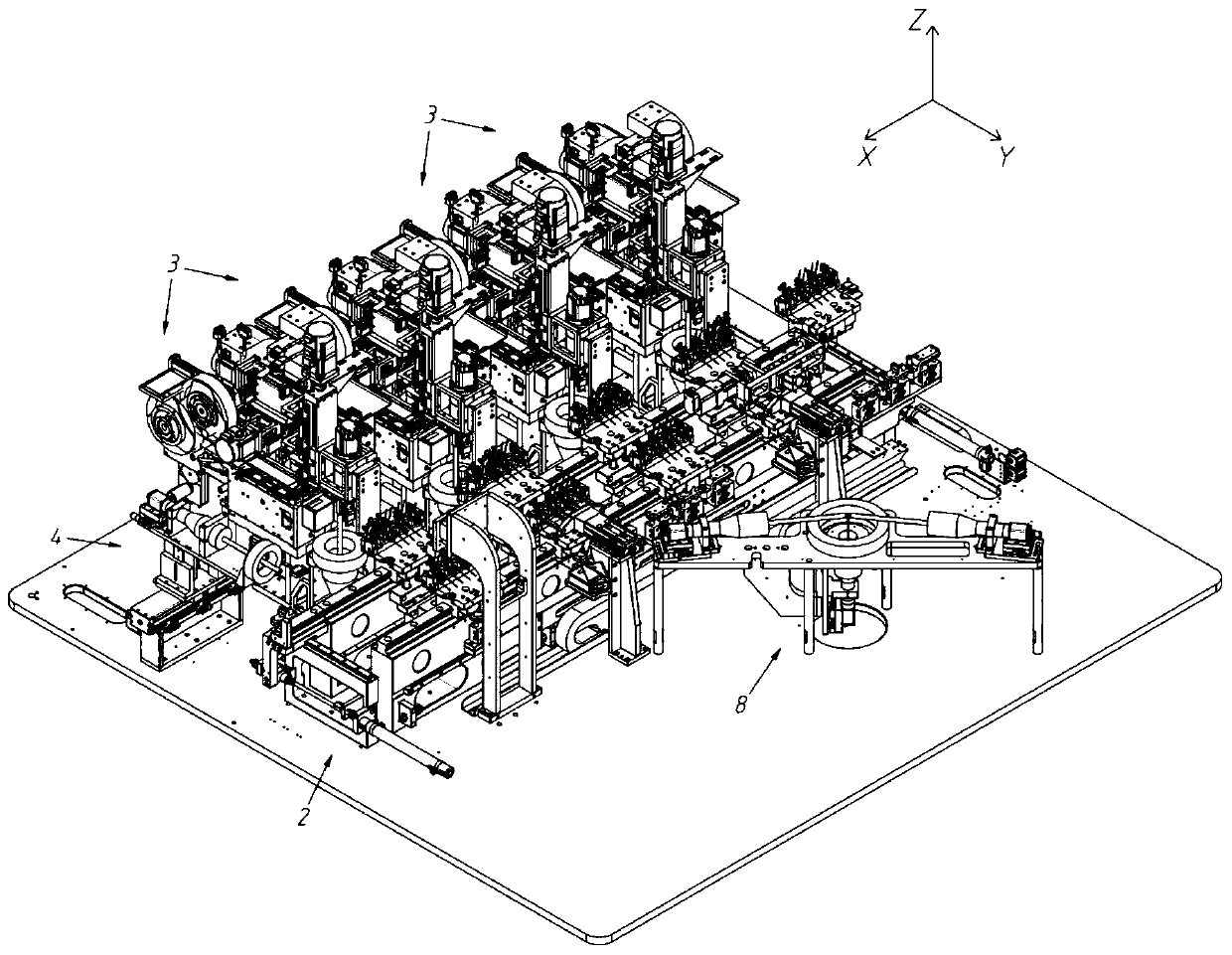

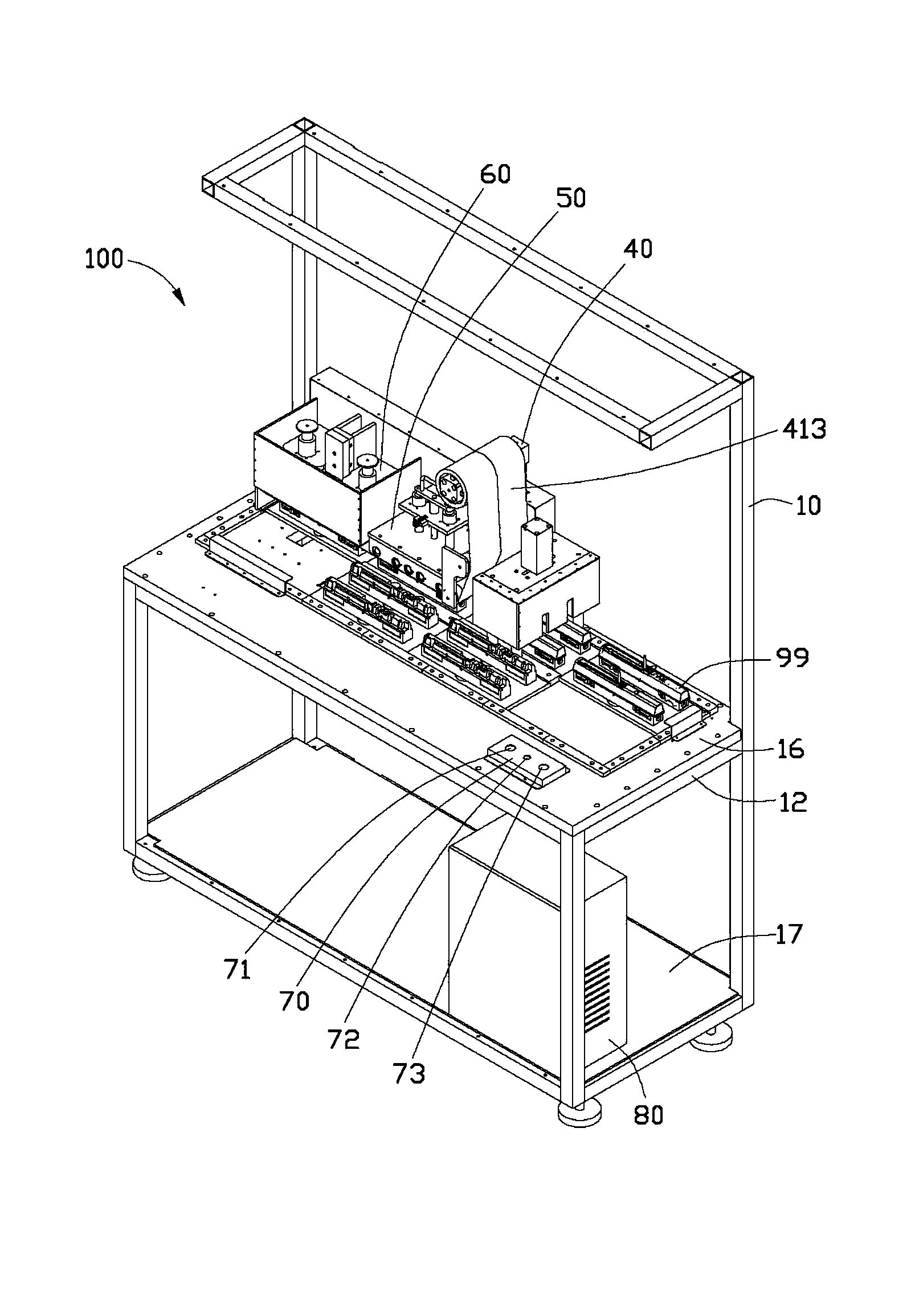

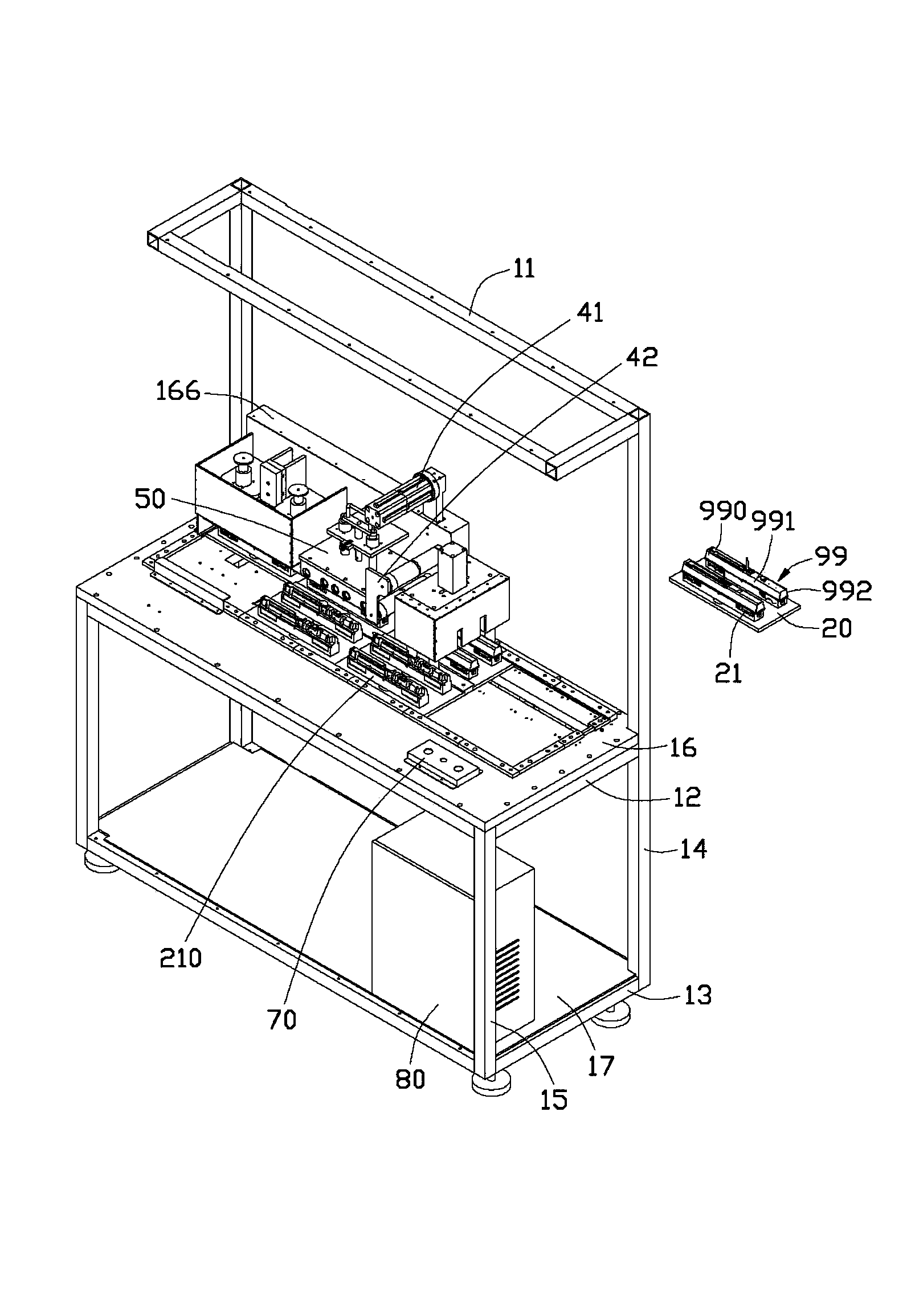

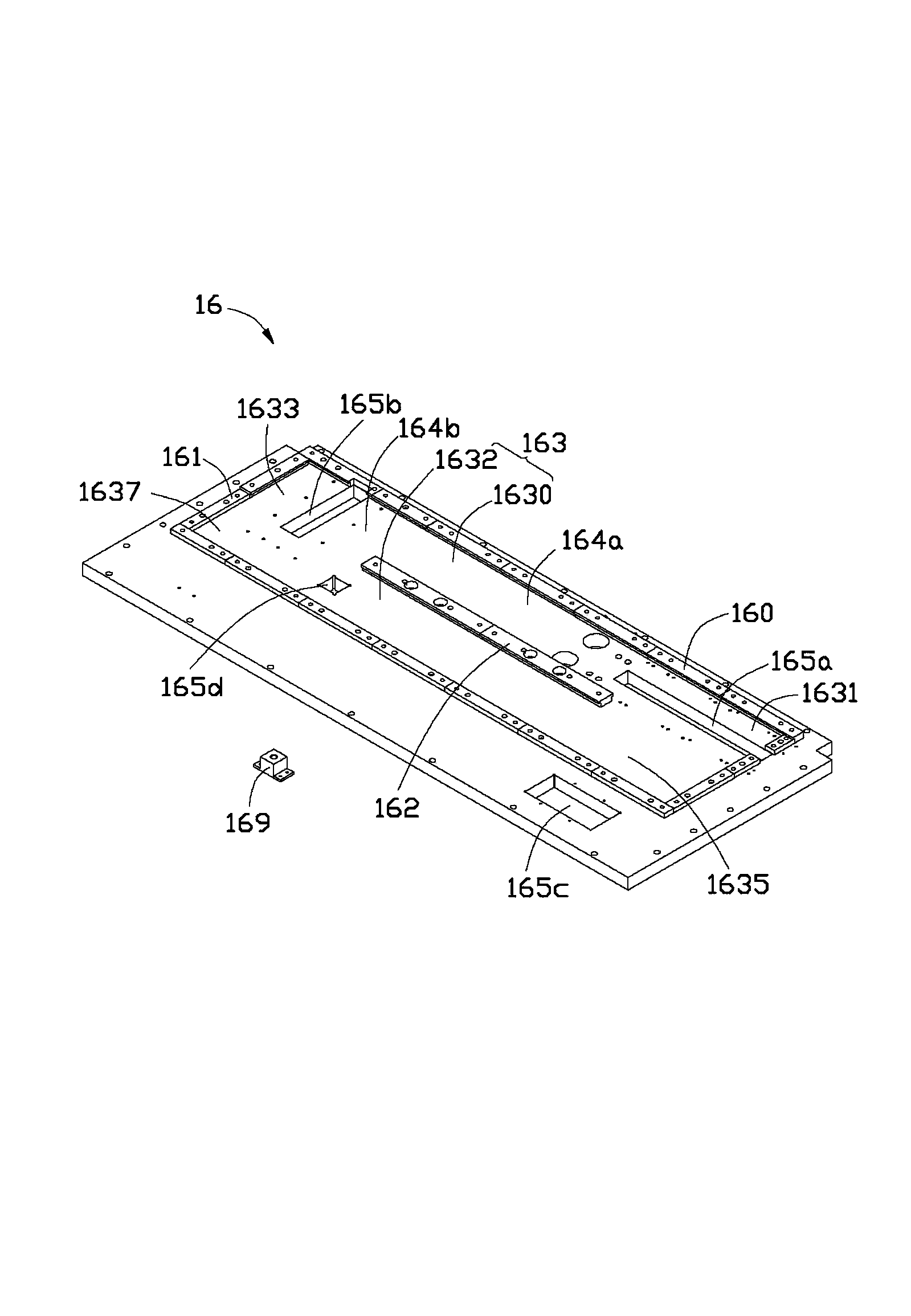

Full-automatic assembly line integrating feeding, positioning, film pasting and discharging

ActiveCN111115189AShorten the transmission strokeImprove film application efficiencyFinal product manufactureConveyor partsRobot handThin membrane

The invention discloses a full-automatic assembly line integrating feeding, positioning, film pasting and discharging. The full-automatic assembly line comprises a feeding assembly line, a film pasting assembly line, a feeding mechanical arm, a discharging mechanical arm and a visual positioning mechanism, wherein the film pasting assembly line is opposite to the feeding assembly line, the film pasting assembly line and the feeding assembly line are arranged at an interval to form a transferring space between the film pasting assembly line and the feeding assembly line; and the feeding mechanical arm, the discharging mechanical arm and the visual positioning mechanism are arranged in the transferring space. According to the full-automatic film sticking machine, material supply, positioning, feeding, thin film supply, film pasting and stacking operation are integrated on a unified assembly line for rhythmic and ordered operation through high-integration-degree design thinking, so that the transferring stroke of transferring materials back and forth among a plurality of assembly lines is greatly shortened, time waste caused in the transferring process is greatly reduced, the automation degree and the film and material supplying and stacking efficiency are remarkably improved, and the film pasting efficiency of the assembly line is greatly improved.

Owner:SUZHOU RS TECH

Automatic wiping mechanism for screen

PendingCN107999455AImprove film application efficiencyImprove film qualityCleaning using toolsCleaning using liquidsEngineeringMechanical engineering

The invention discloses an automatic wiping mechanism for a screen. The automatic wiping mechanism for the screen comprises a machine frame, a power assembly which is mounted on the machine frame, a material roll assembly, a swinging assembly, and a wiping assembly which is fixedly mounted on the swinging assembly and can move along with the swinging assembly; the material roll assembly is used for holding a wiping cloth roll and is used for leading out wiping cloth; and the wiping cloth wraps half of the wiping assembly, is dragged through the swinging assembly and the power assembly, and isgradually rolled through the power assembly, so that the half-wrapping part of the wiping assembly is replaced. The swinging assembly drives the wiping assembly to perform automatic wiping, and meanwhile, the use of a pulse sprayer is matched, so that the wiping quality is improved, and meanwhile, the use efficiency of the wiping cloth and wiping liquid is obviously improved.

Owner:深圳市利和兴股份有限公司

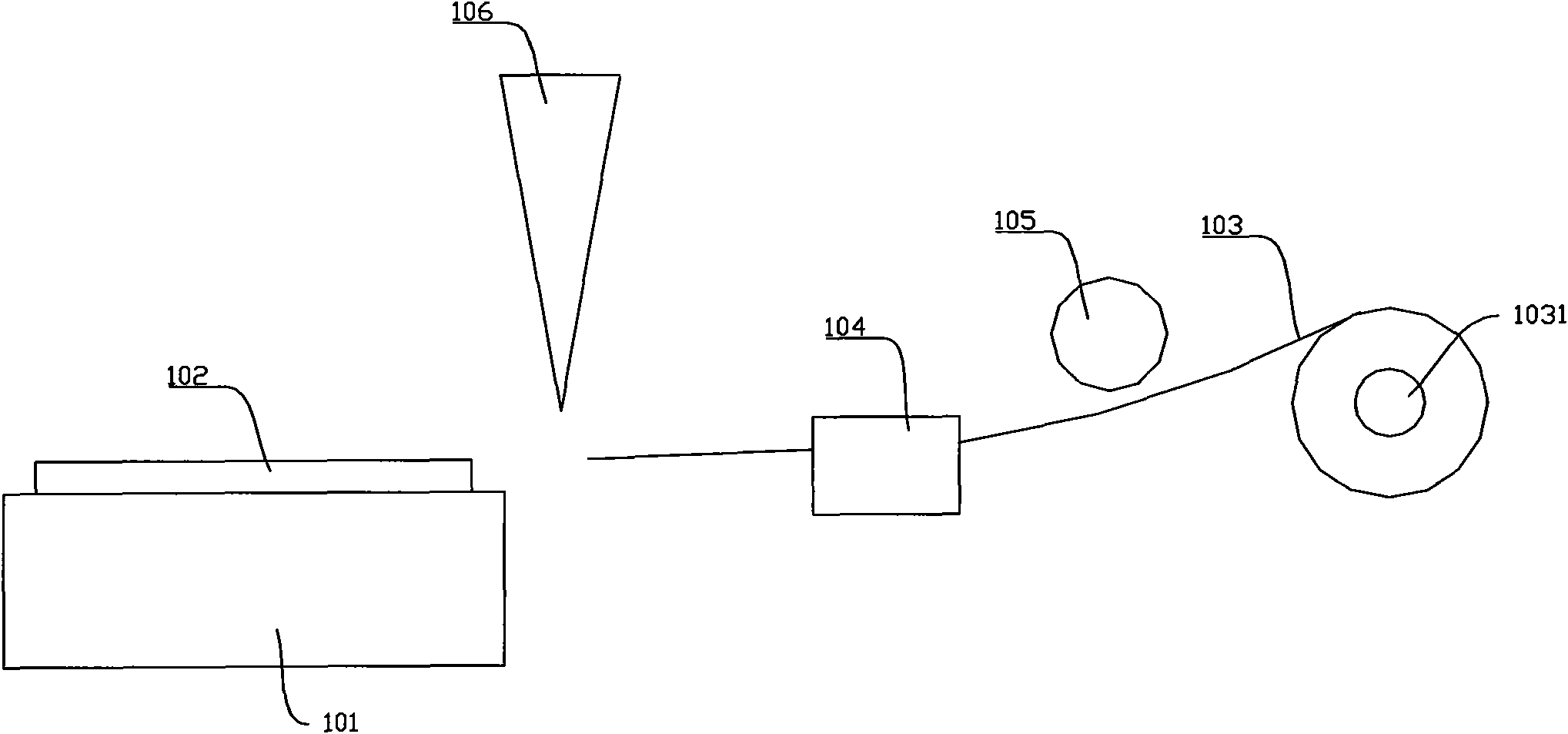

Film adhesion device for film active release

InactiveCN102148177ASolve wasteAvoid wrinklesSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

The invention discloses a film adhesion device for film active release. The device is characterized by comprising a supporting shaft and a driving device, wherein the supporting shaft is used for supporting an adhesive film roll; and the driving device drives the supporting shaft to rotate. The film adhesion device for the film active release changes the conventional mode of pulling an adhesive film by a film clamping device to drive the adhesive film roll to rotate so as to release the adhesive film into a mode of driving the adhesive film roll by the driving device to rotate so as to release the adhesive film actively. When the adhesive film is pulled by the film clamping device to cover a wafer, a pulling force applied to the adhesive film by the film clamping device can be quite small, so that the adhesive film cannot be deformed by stretching, and the quality of film adhesion is improved.

Owner:上海技美科技股份有限公司

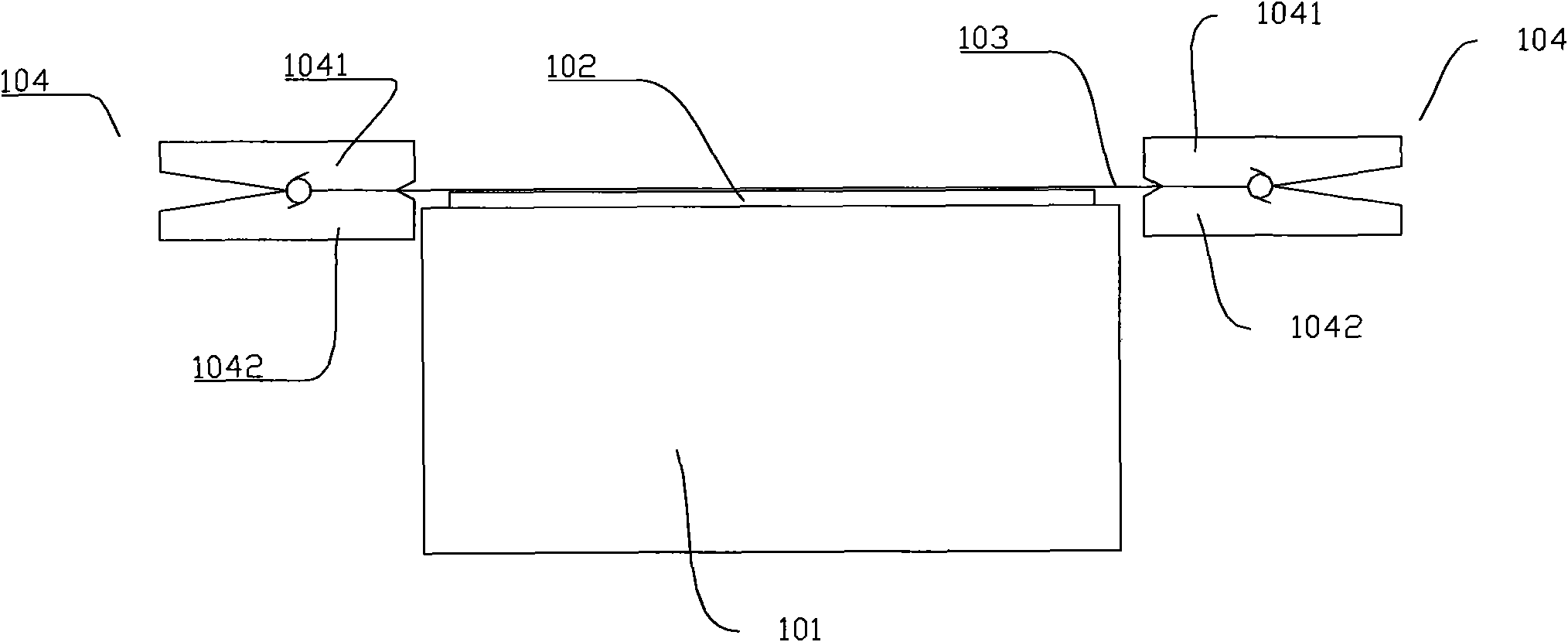

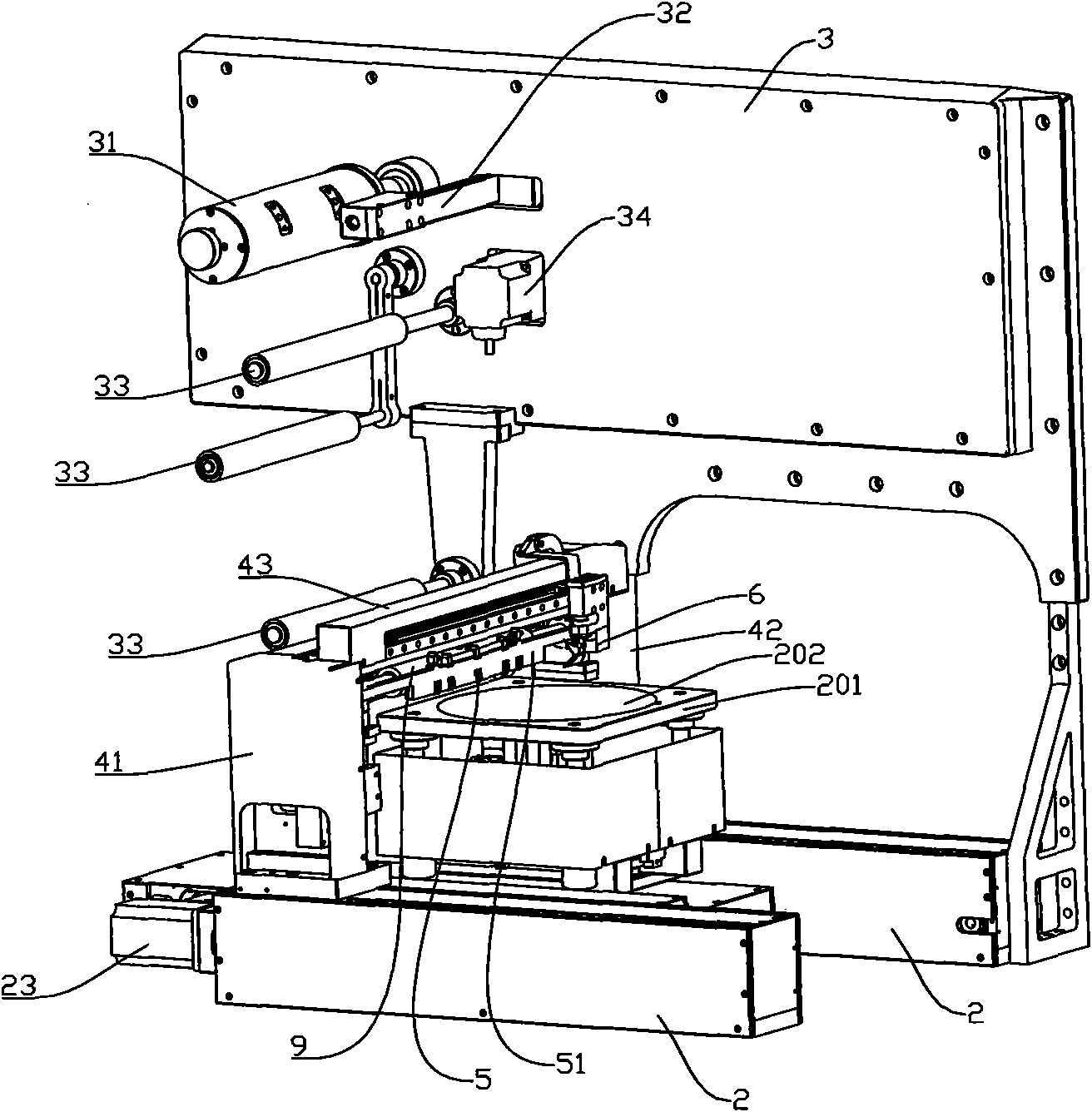

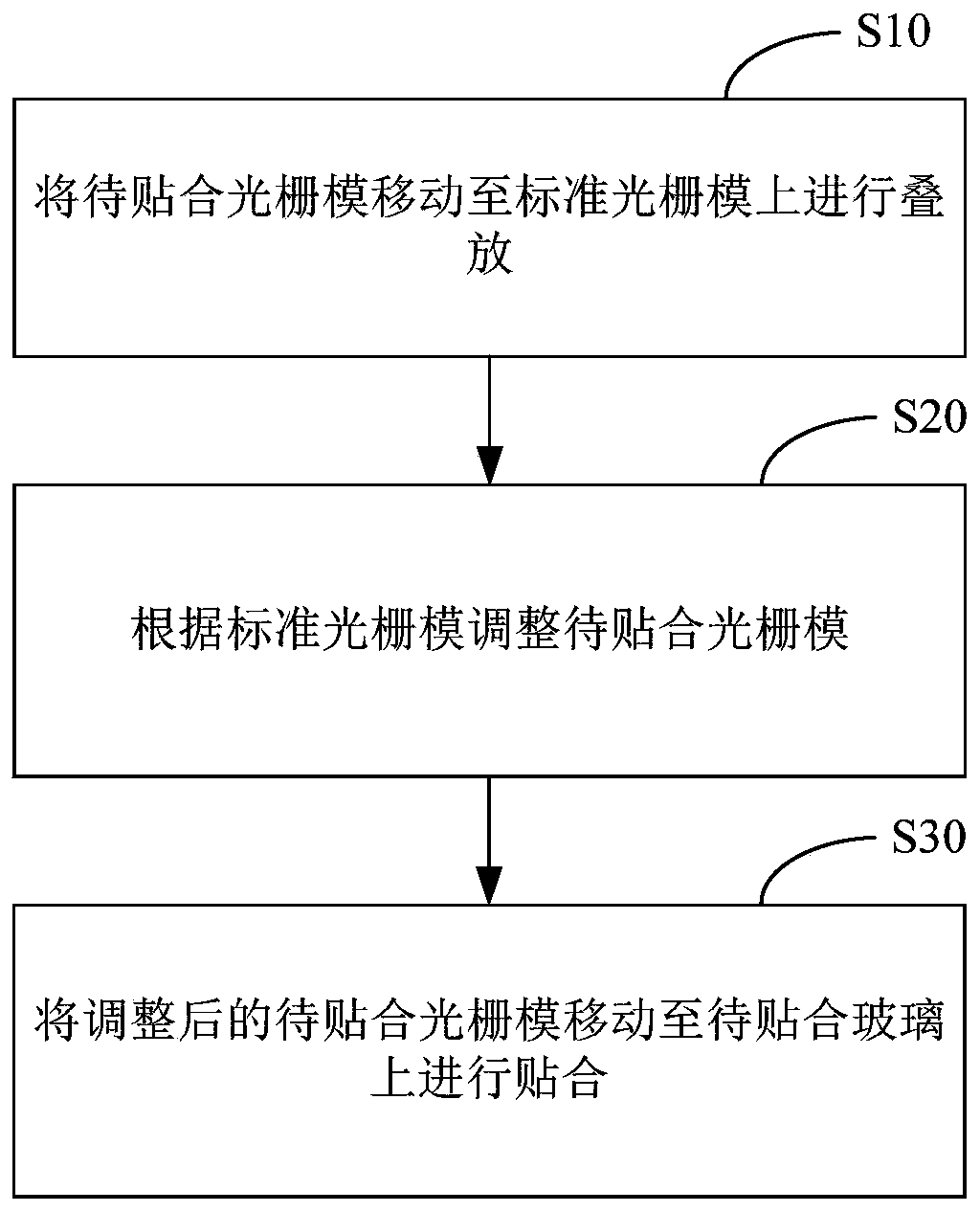

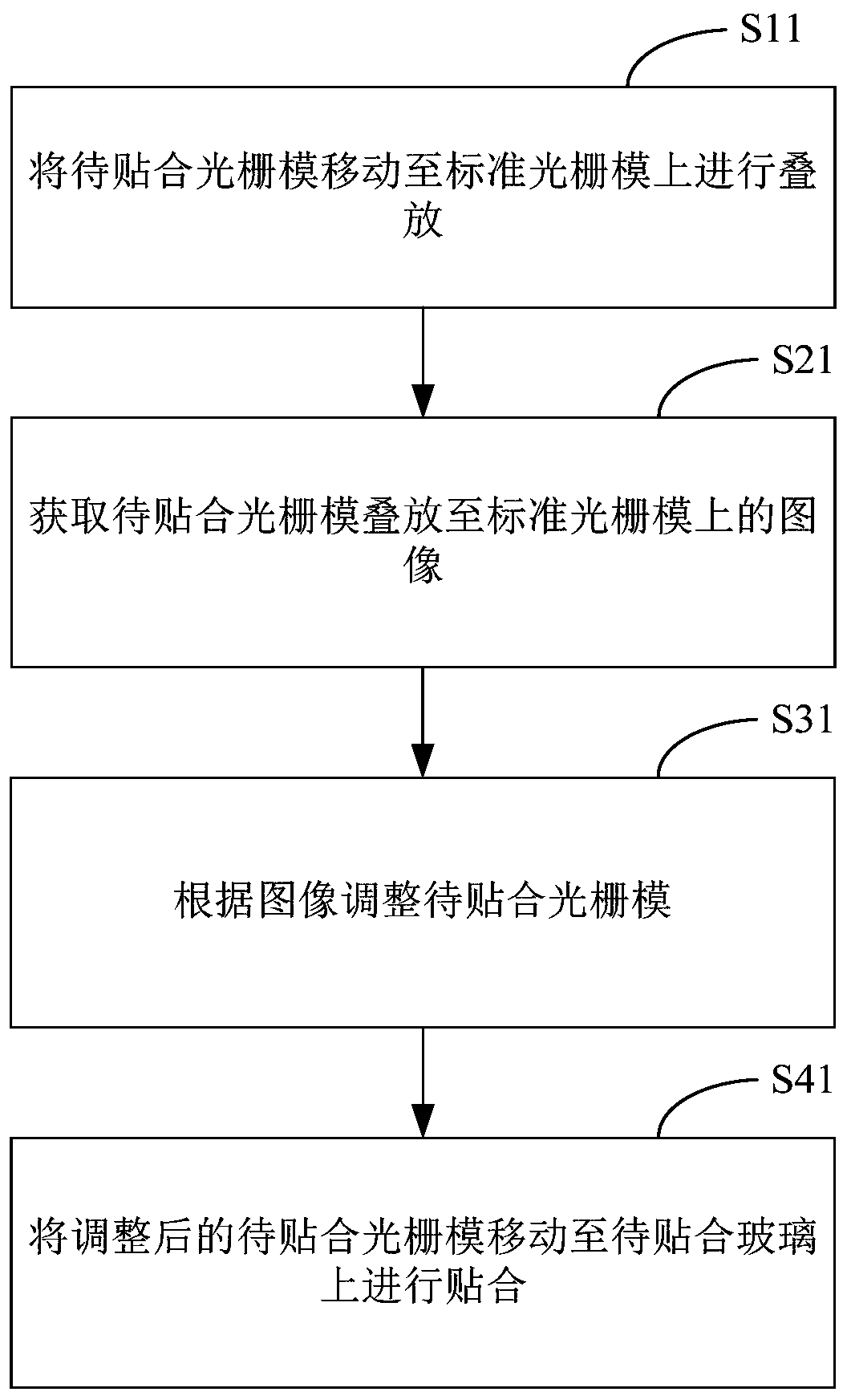

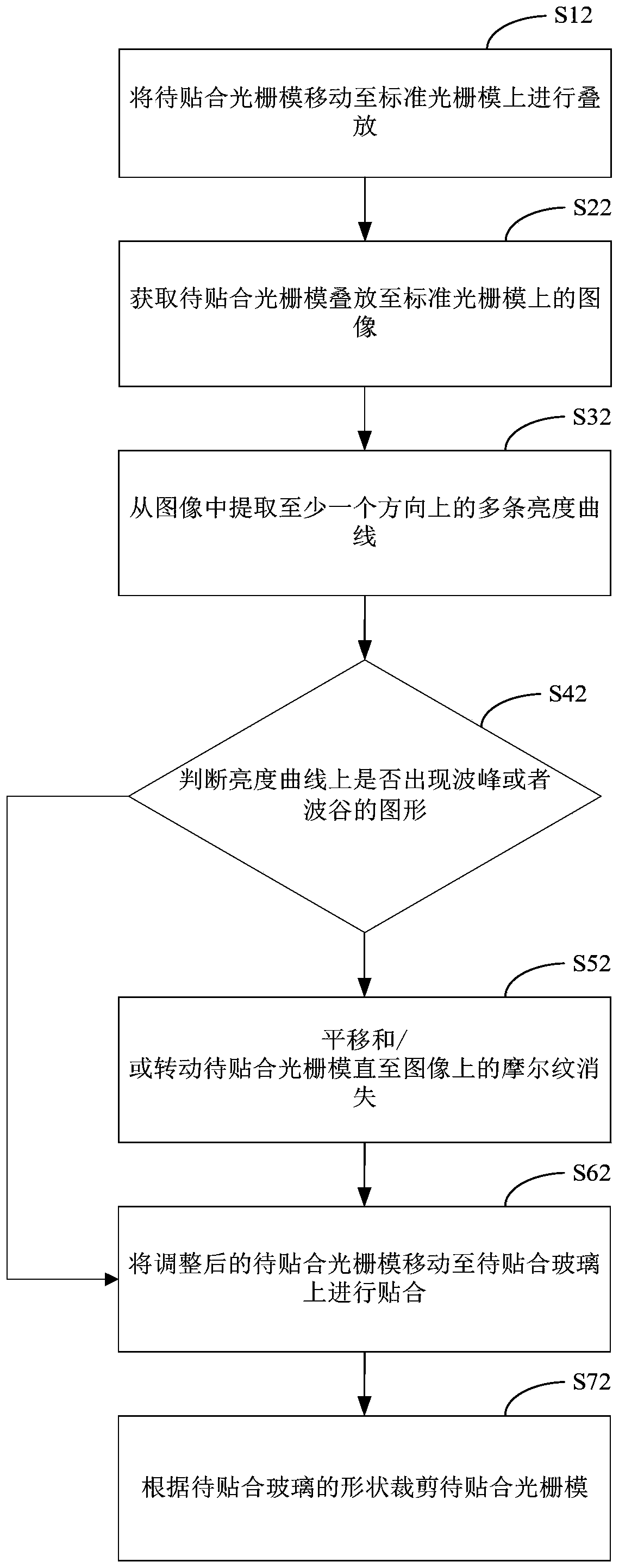

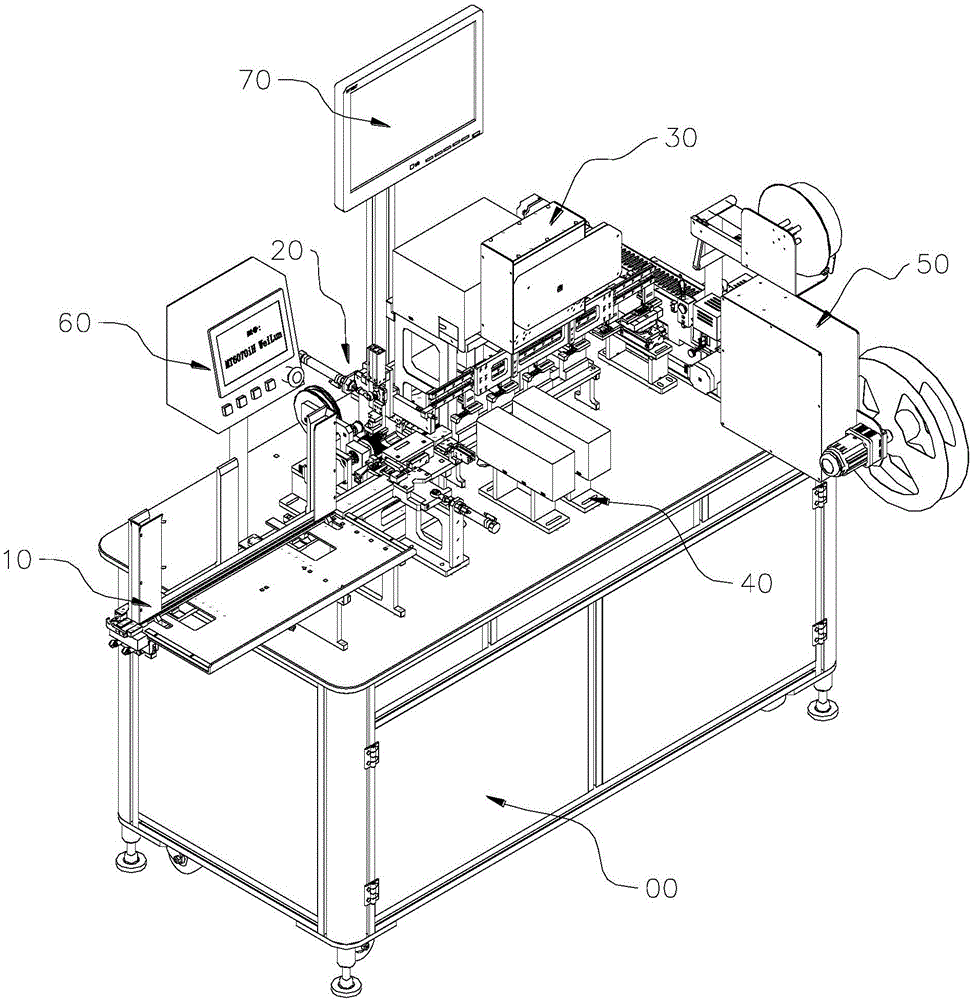

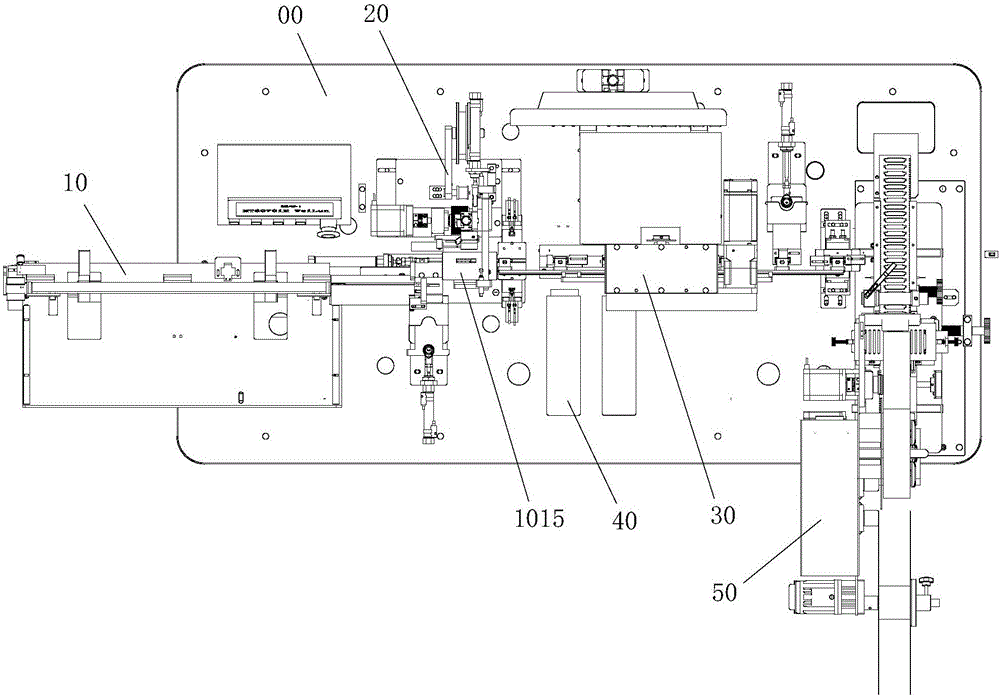

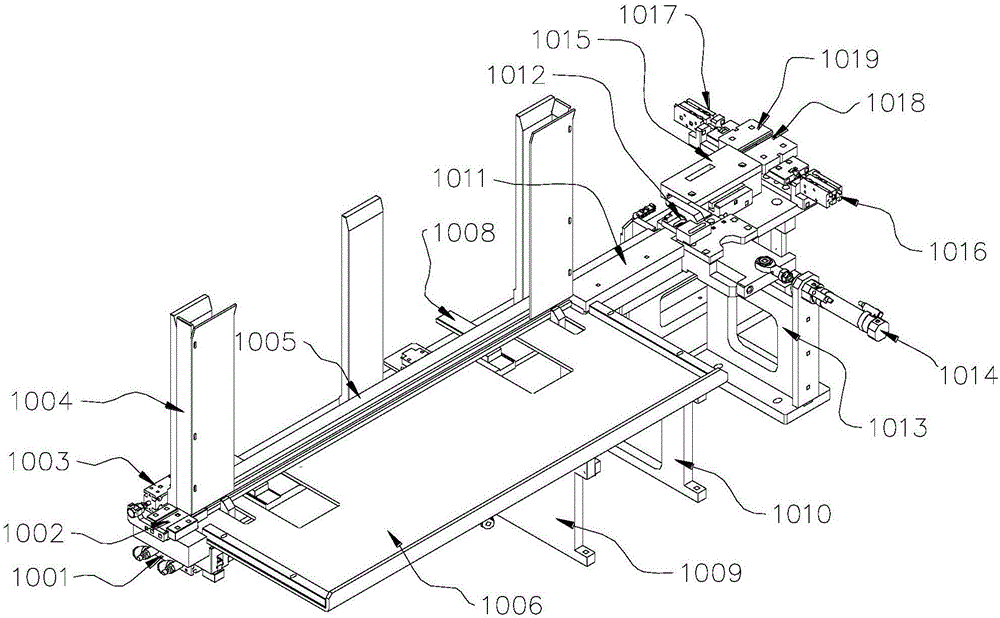

Device and method for bonding 3D grating film and glass

InactiveCN109733043AFast and accurate fit workImprove film application efficiencyControlling laminationLaminationGrating

According to the technical scheme, the invention provides a device and method for bonding a 3D grating film and glass. A to-be-bonded grating film is adjusted according to a standard grating film, then the to-be-bonded grating film is bonded onto to-be-bonded glass, so that the to-be-bonded grating film can be rapidly and accurately bonded, the film is accurate to bond, the bonding efficiency is high, and great convenience can be brought to the actual production.

Owner:SHENZHEN VISION POWER TECH

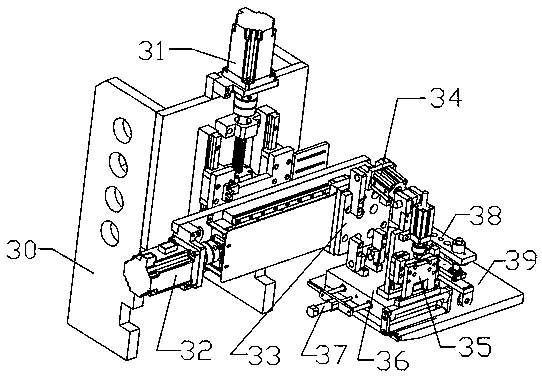

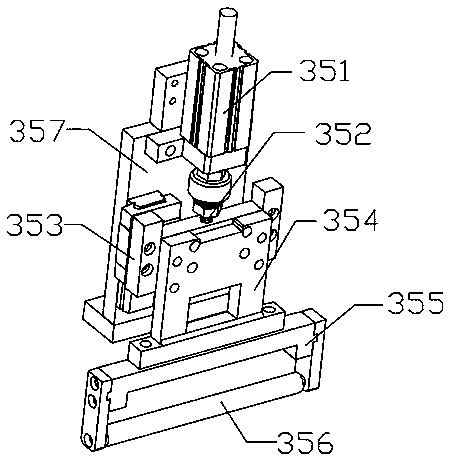

Automatic inspecting and packaging equipment for electric connectors

The invention discloses automatic inspecting and packaging equipment for electric connectors. The automatic inspecting and packaging equipment comprises a power supply mechanism, a control mechanism, a rack, a tube discharge device, an adhesive film sticking device, a CCD detection device, a material transfer device and a packaging device; the tube discharge device is located at the head end, the adhesive film sticking device is connected with the pipe discharge device in a butt-joint mode, the CCD detection device is connected with the adhesive film sticking device in a butt-joint mode, the packaging device is located at the tail end of the process, and the material transfer device is located between the adhesive film sticking device and the CCD detection device and between the CCD detection device and the packaging device. According to the automatic inspecting and packaging equipment, by means of mutual cooperation of the tube discharge device, the adhesive film sticking device, the material transfer device, the CCD detection device and the packaging device, feeding, film sticking, transferring, detecting and packaging operation of the products can be automatically completed in the whole process, the automation degree is high, the product film sticking and packaging quality is good, the film sticking, detecting and packaging efficiency can be significantly improved, the labor cost is reduced, and the false detecting rate is decreased.

Owner:DONGGUAN SIWEB CONNECTORS

Automatic film laminator

InactiveCN103569395AImprove film application efficiencyWeb rotation wrappingEngineeringMechanical engineering

A film affixing apparatus is used for affixing a film to a workpiece. The film affixing apparatus includes a stand, a film provider, and an affixing and cutting device. The stand includes a work platform. The workpiece is capable of sliding around the work platform under an external force. The film provider is mounted to the stand, and a roll of film is mounted to the film provider to dispense the film. The affixing and cutting device includes a pressing part. The pressing part presses the film onto the workpiece, and the film is cut, allowing the workpiece to slide away from the affixing and cutting device and be removed manually.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

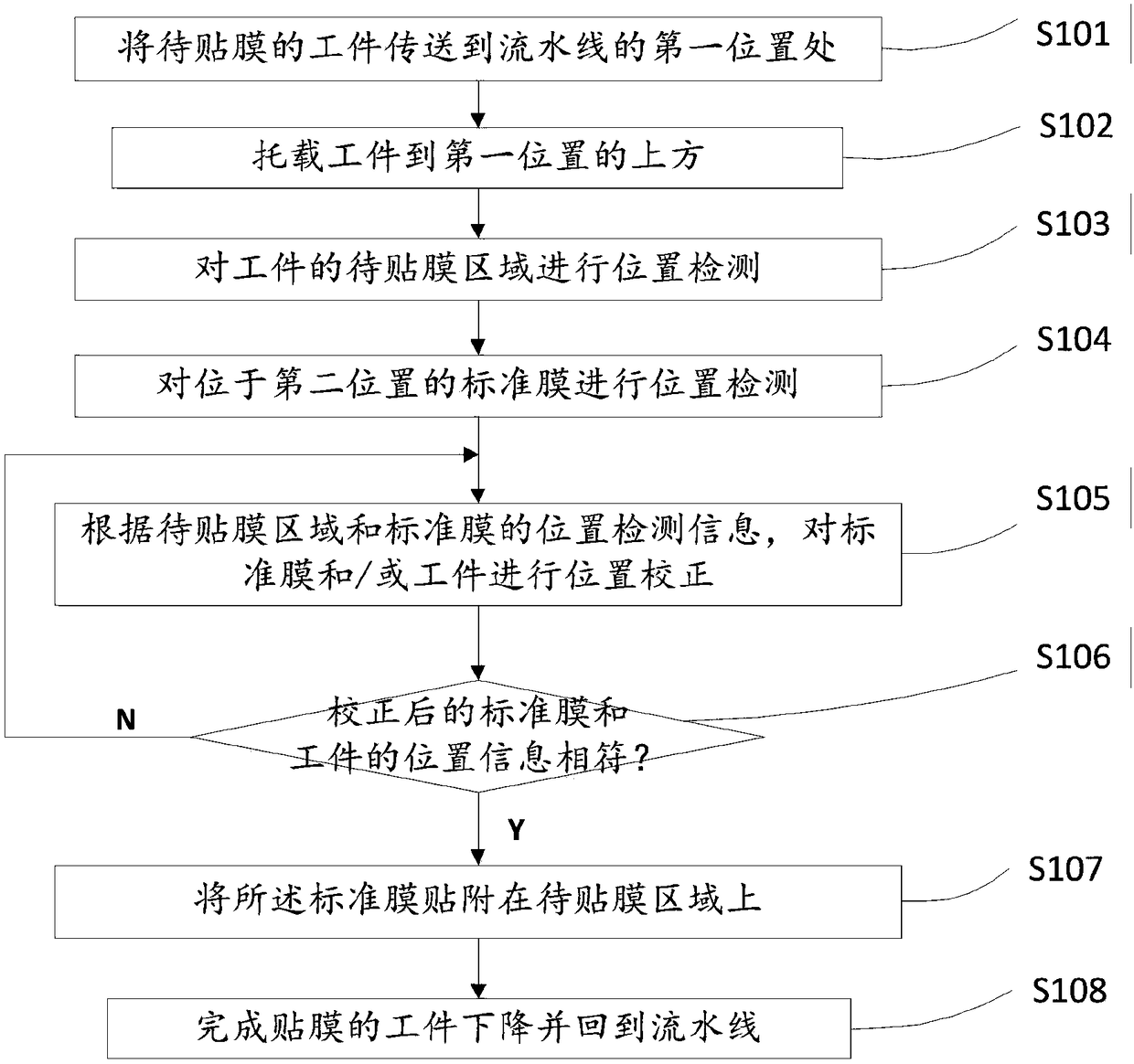

Automatic film pasting method and device applied to assembly line

PendingCN108327976ALabor savingRespond to the needs of the development of automated assembly linesLiquid surface applicatorsSpraying apparatusEngineeringAssembly line

The invention discloses an automatic film pasting method and device which are applied to an assembly line, and belongs to the field of automation. The automatic film pasting method applied to the assembly line comprises the steps that a workpiece which is conveyed to a first position and is to be subjected to film pasting on the assembly line is supported and carried and the workpiece is located above the first position; an area to be subjected to the film pasting of the workpiece is subjected to position detection, and a standard film located at a second position is subjected to the positiondetection; according to position detection information of the area to be subjected to the film pasting and the standard film, the standard film and / or the workpiece are / is subjected to position correction; whether the position information of the corrected standard film and the workpiece is consistent, and if so, the standard film is attached to the area to be subjected to the film pasting; and theworkpiece subjected to the film pasting descends and returns to the assembly line. By integrating internal information of two sensing devices, standardized automatic film pasting is realized, and thefilm pasting and the assembly line are combined seamlessly, and the film pasting efficiency is improved.

Owner:重庆铂汉塑胶有限公司

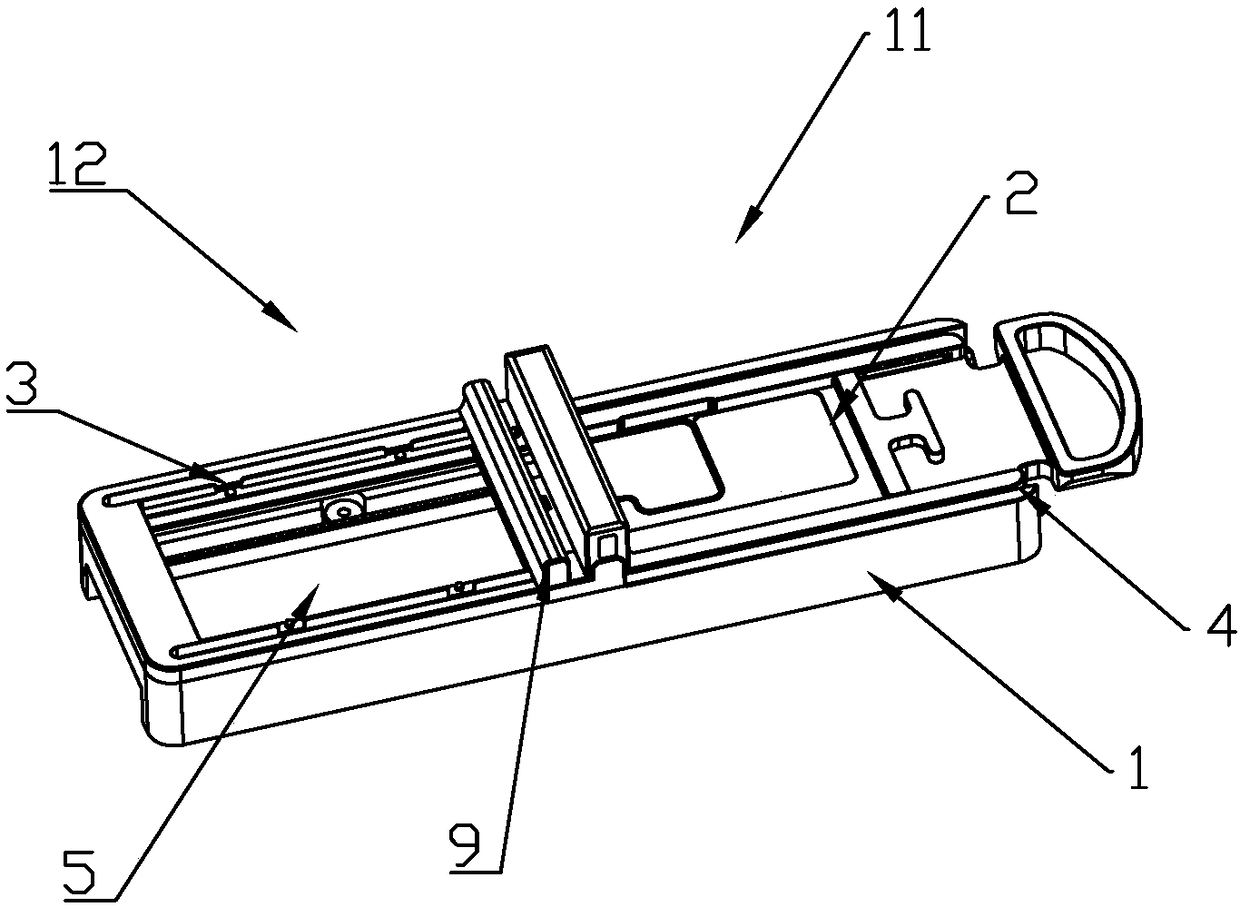

Portable film sticking machine

PendingCN108748969AEasy to operateImprove film application efficiencyDomestic articlesElectrical and Electronics engineeringElectronic equipment

The invention discloses a portable film sticking machine, and relates to the technical field of electronic equipment film sticking equipment. The portable film sticking machine comprises a base, a positioning base, a sticking film fixing base, a conveying device and a film separating device, and a positioning station and a film sticking station are arranged on the two sides of the base correspondingly; the positioning base is arranged at one end of the positioning station and used for locking the position of electronic equipment; the sticking film fixing base is arranged at one end of the filmsticking station and used for locking the position of a sticking film; the conveying device is used for enabling the positioning base to slide between the positioning station and the film sticking station in a reciprocating mode so as to enable the electronic equipment and the film to be matched with each other; and the film separating device is arranged at one end of the film sticking station and used for enabling a releasing layer and the film to be separated. According to the portable film sticking machine, the electronic equipment and the sticking film only need to be put on the positioning base and the sticking film fixing base respectively, film sticking can be completed after the conveying device slides once in a reciprocating mode, and the portable film sticking machine is easy tooperate, high in film sticking efficiency, precise in sticking film positioning and good in film sticking effect.

Owner:JIANGMEN IGUARDER ELECTRONIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com