Patents

Literature

170results about How to "Improve the film effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

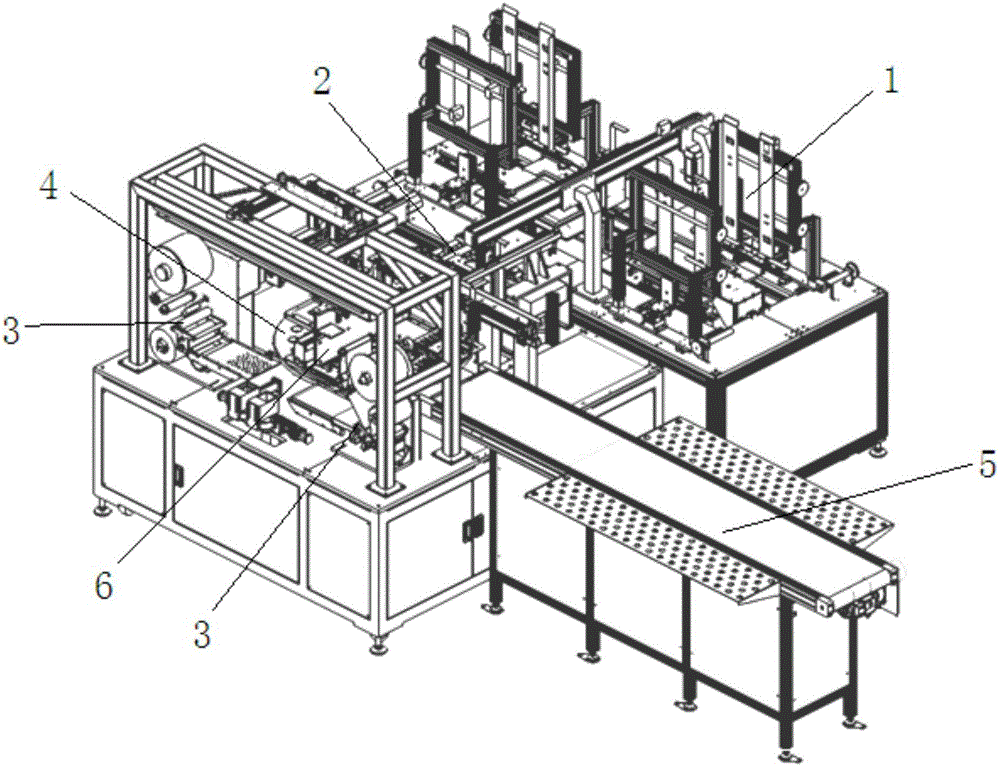

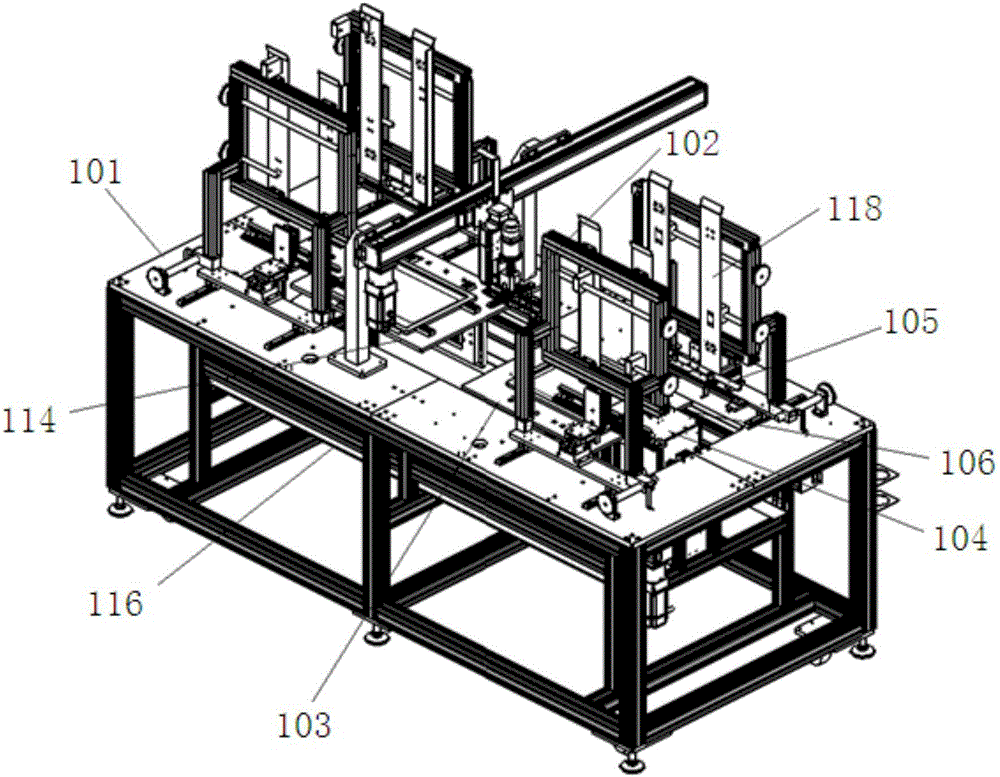

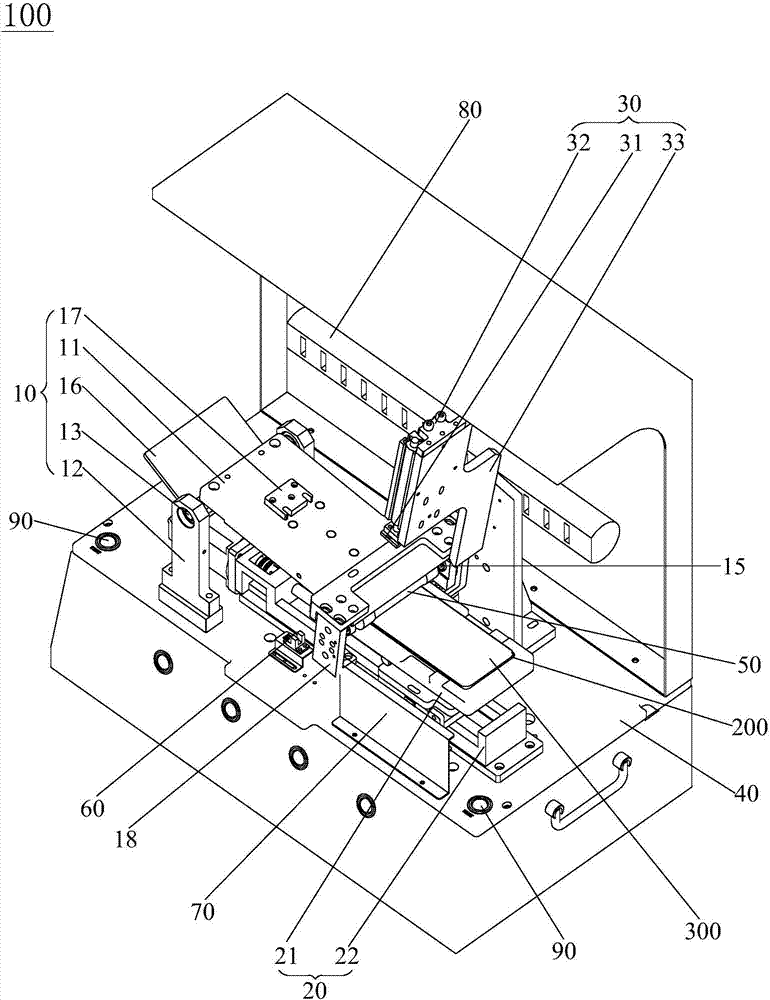

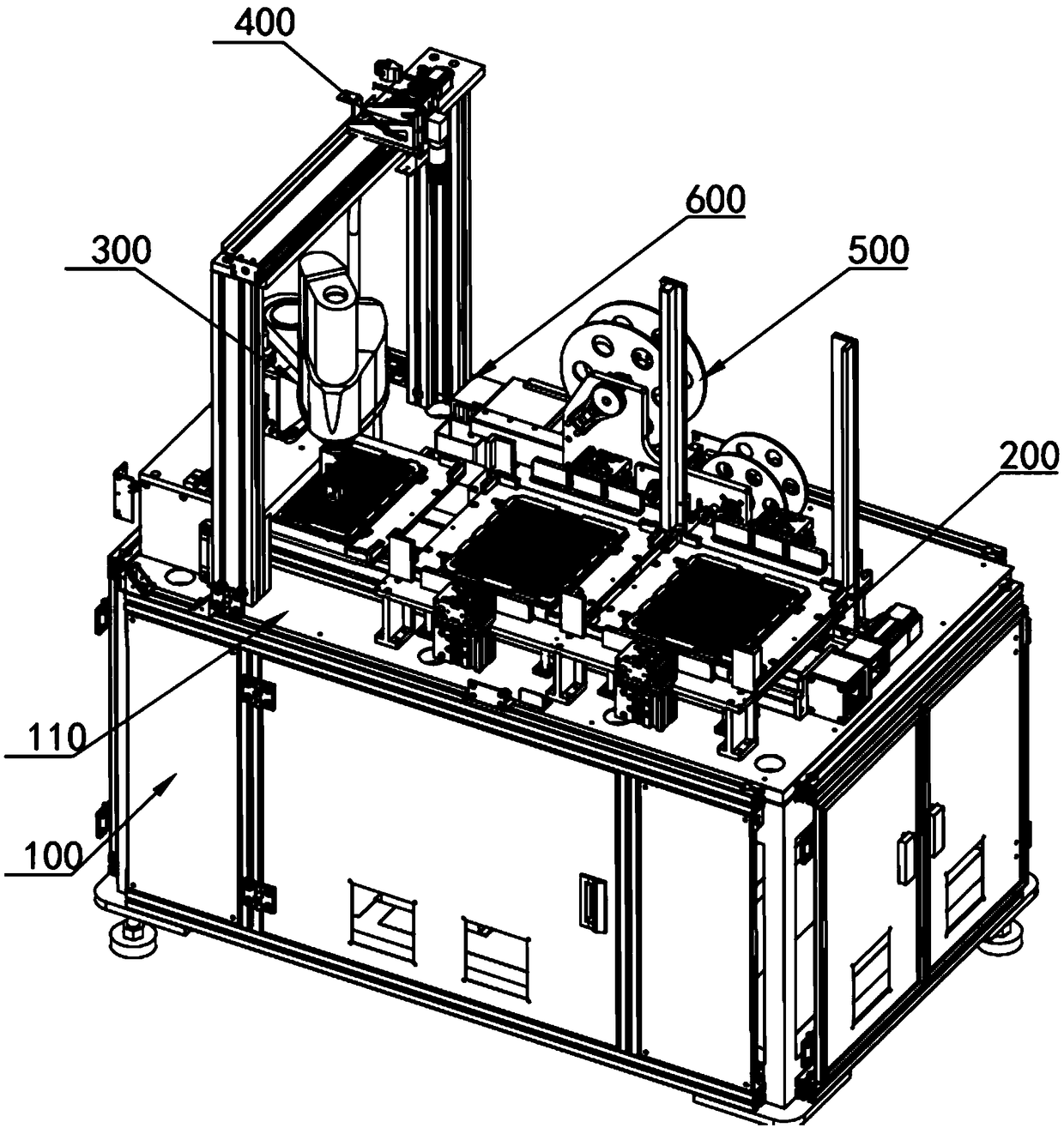

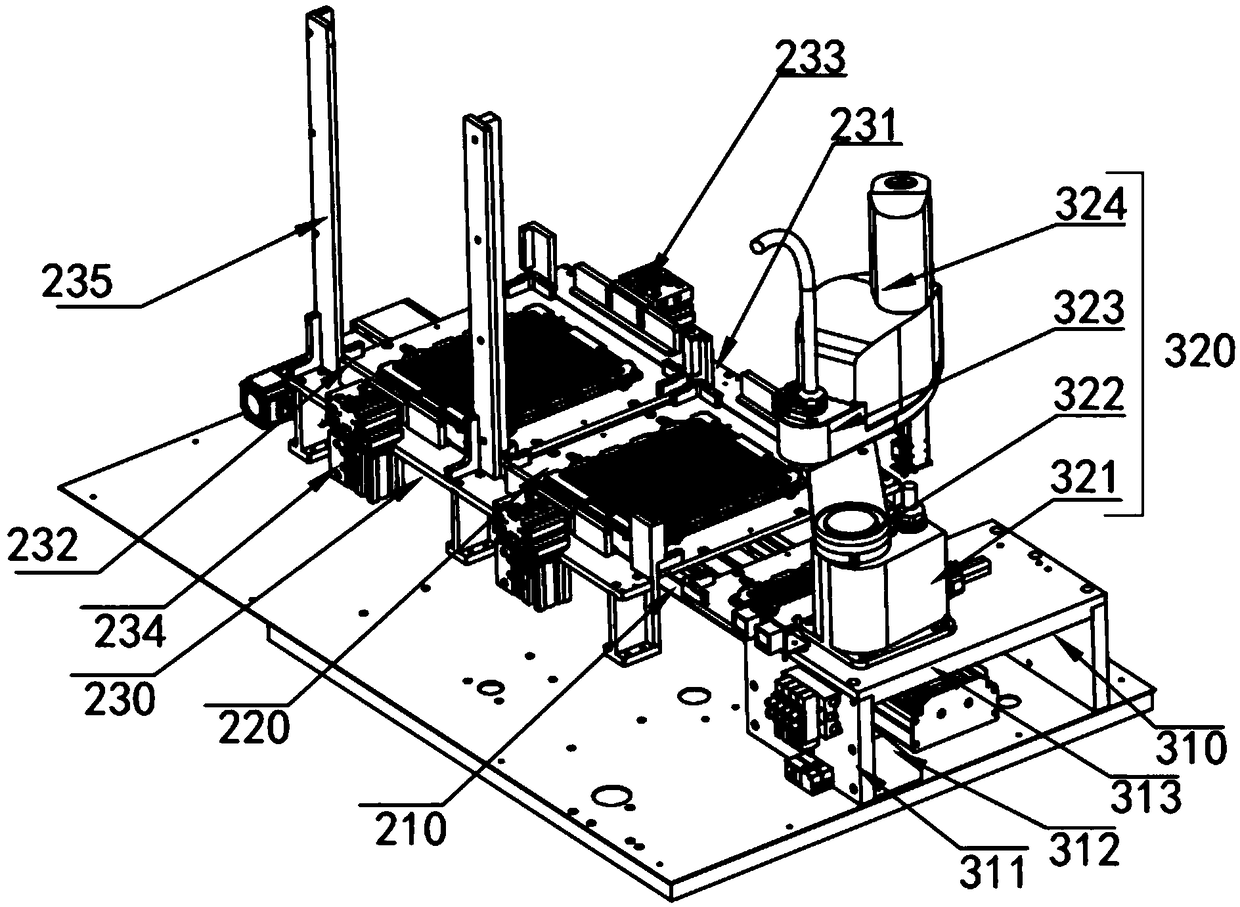

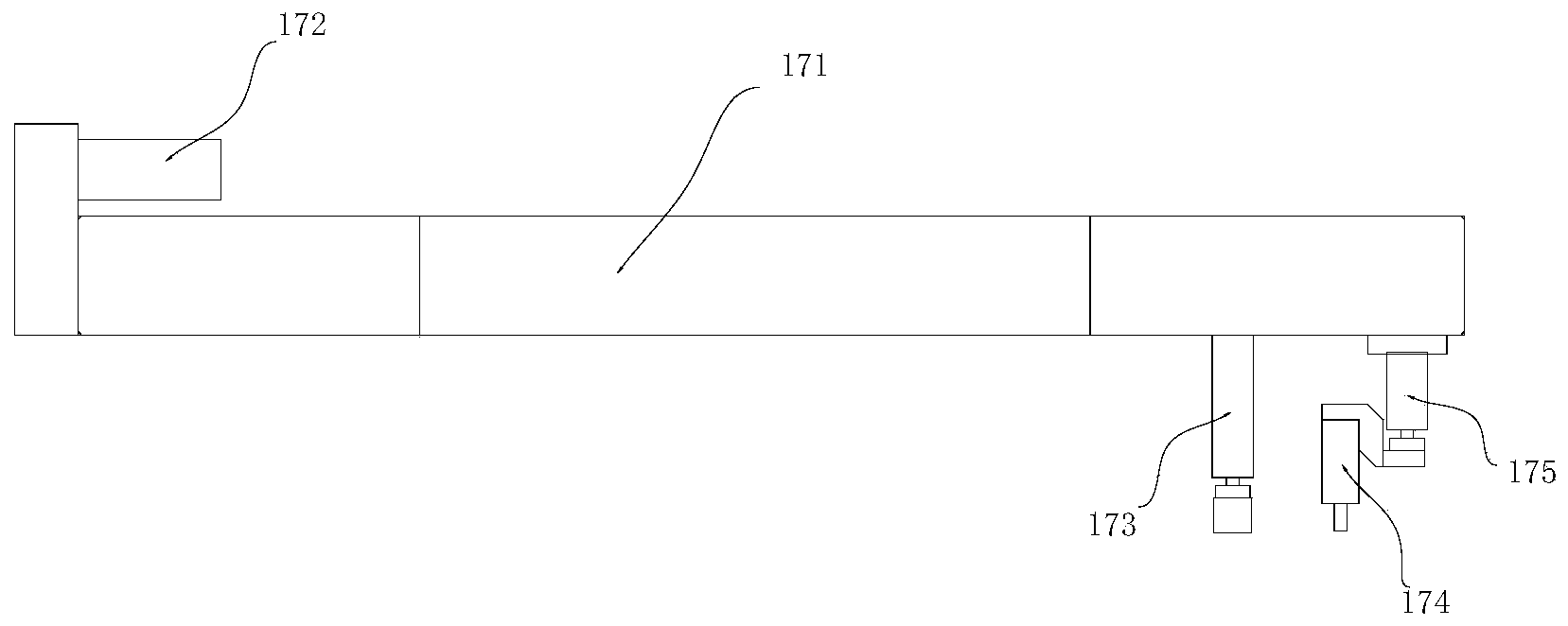

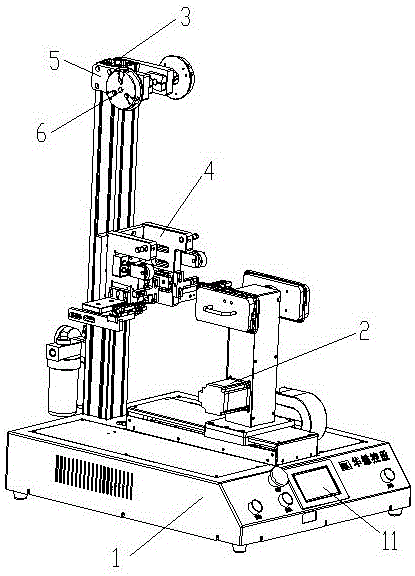

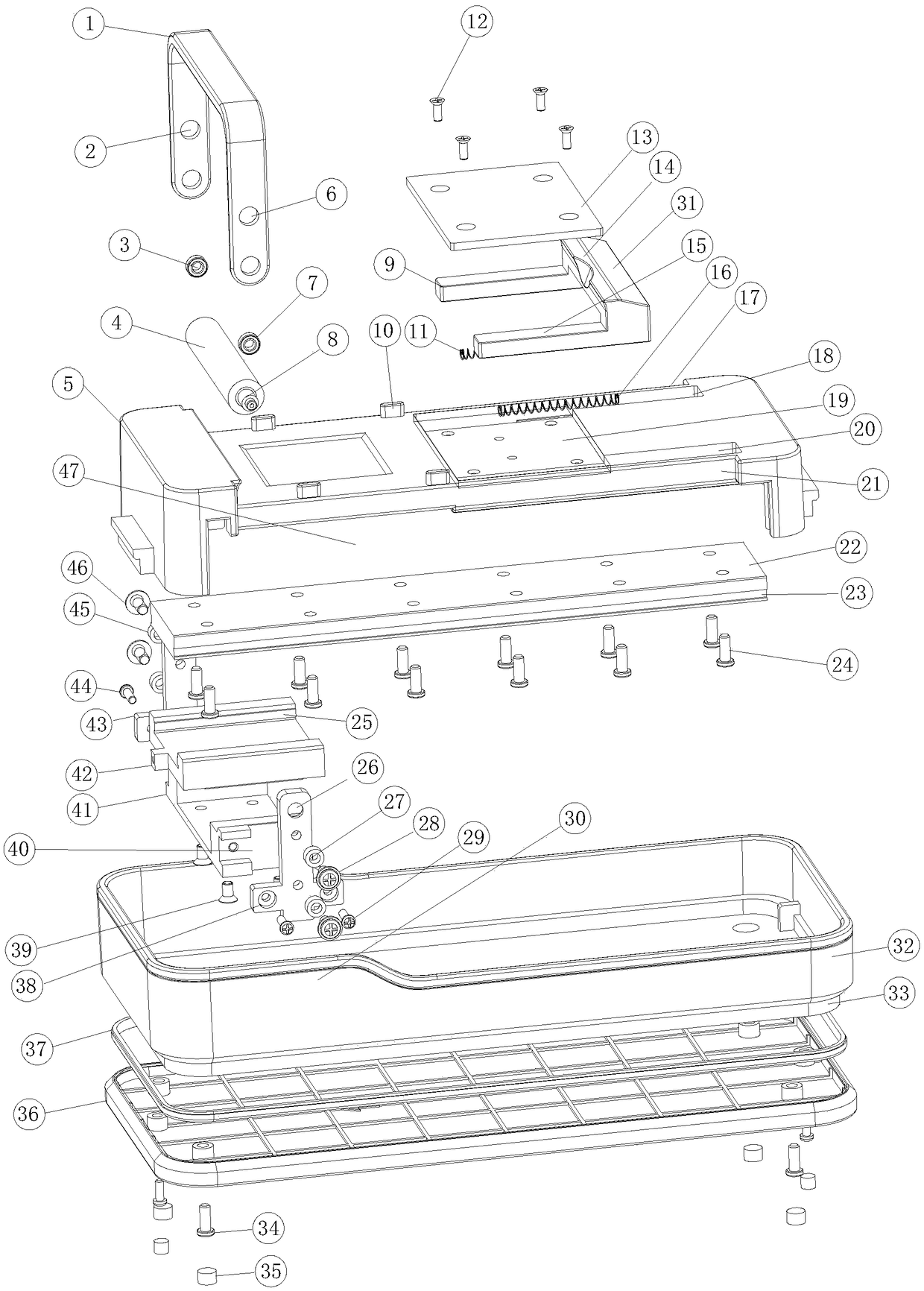

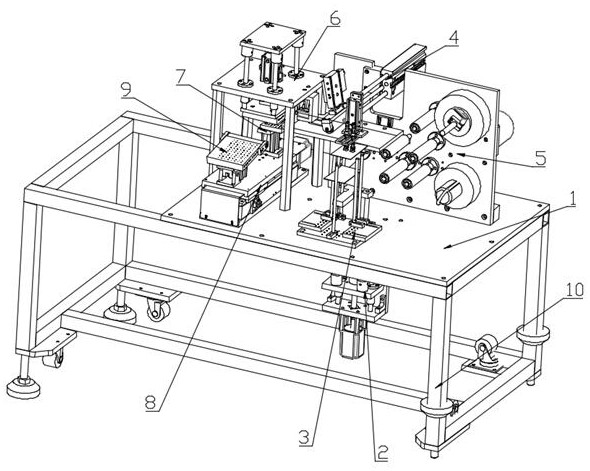

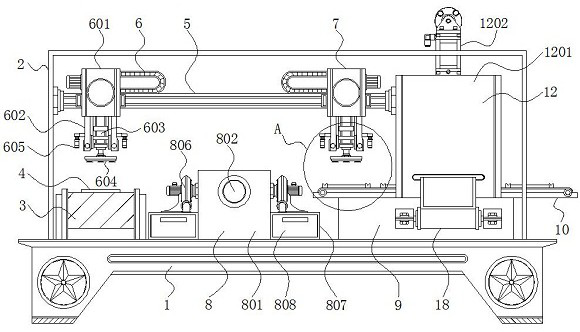

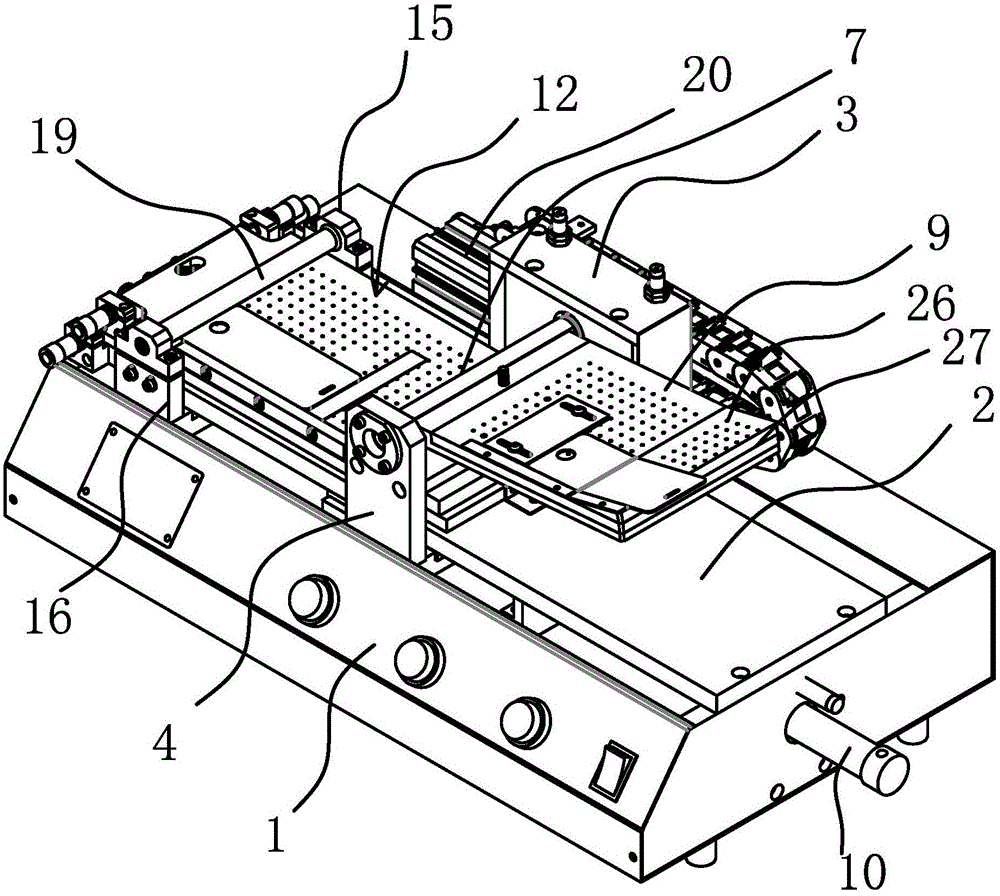

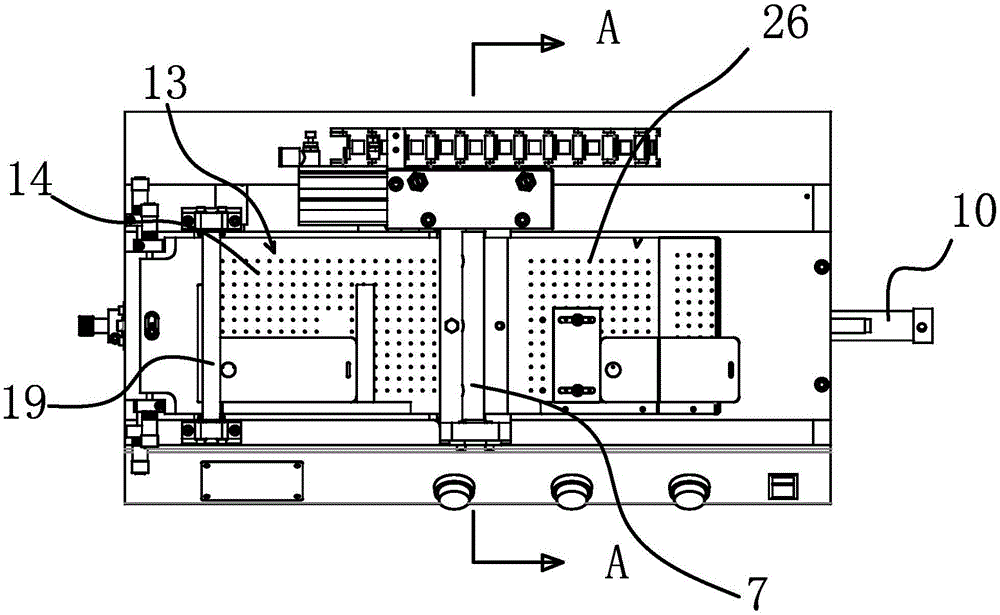

Automatic film sticking machine

ActiveCN106428746AFast and effective film applicationImprove the efficiency of automatic film applicationPackagingEngineeringElectrical and Electronics engineering

The invention discloses an automatic film sticking machine. The machine comprises an automatic feeding mechanism, a pre-positioning mechanism, a film sticking automatic stripping mechanism, a film sticking station conversion mechanism, an automatic film sticking mechanism and a finished product output mechanism; according to the automatic feeding mechanism, an element to be subject to film sticking is taken out and conveyed to the pre-positioning mechanism, the pre-positioning mechanism carries out position pre-adjustment on the element to be subject to film sticking, the element to be subject to film sticking and position pre-adjustment is placed on the film sticking station conversion mechanism, the automatic film sticking mechanism enables a sticking film stripped from the film sticking automatic stripping mechanism to be pasted and covered on the element to be subject to film sticking on the film sticking station conversion mechanism, and the element subject to film sticking is output through the finished product output mechanism for quality inspection. The automatic film sticking machine can be suitable for single-layer or multi-layer rapid effective film sticking, full-automatic feeding, cleaning, sticking film stripping, sticking film absorbing and film sticking are achieved, time and labor are saved, the automatic film sticking efficiency is improved, the film sticking yield is high, and the good application prospect is achieved.

Owner:JIANGSU BVM INTELLIGENT TECH

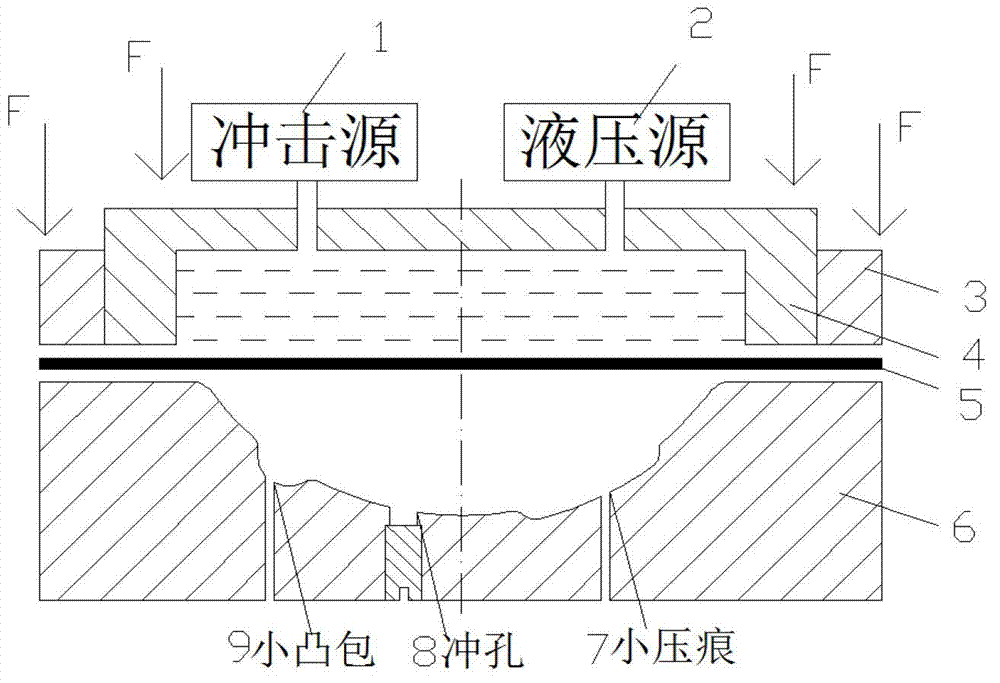

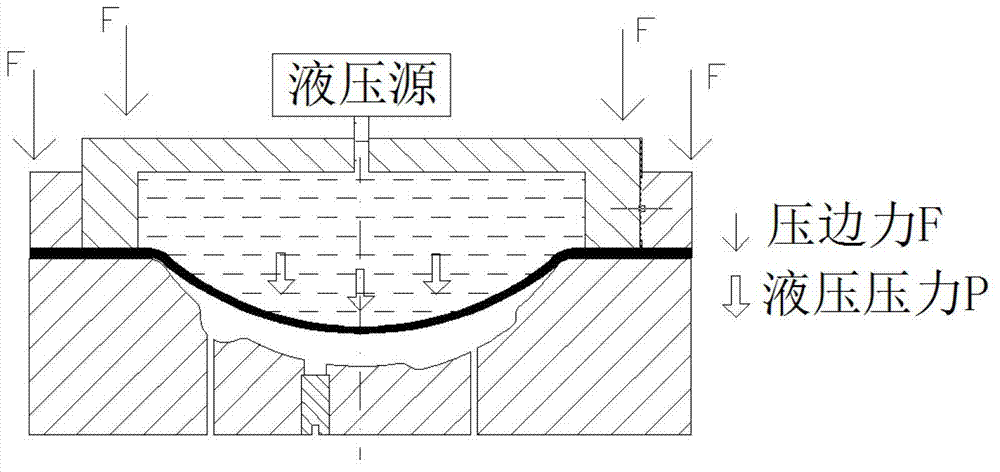

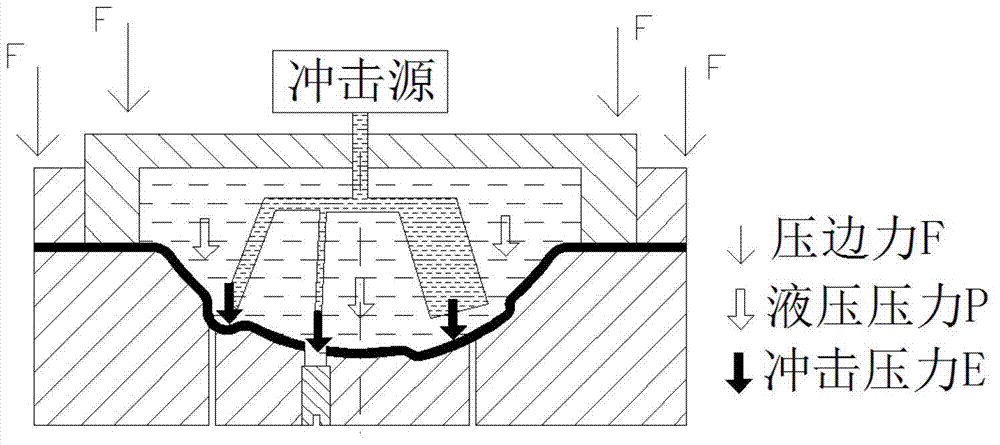

Shock hydraulic composite forming process for small feature part of complex part

InactiveCN102873165AGuarantee the overall forming quality and precisionBroad application prospectsShock waveHigh energy

The invention discloses a shock hydraulic composite forming process for a small feature part of a complex part. The shock hydraulic composite forming process is a new forming process which intersects with a shock forming technology and a hydroforming technology and extends and develops from both of the two technologies, having advantages of both of hydro plastic forming and shock energy forming. The shock hydraulic composite forming process is defined as follows: performing the shock forming after the hydroforming is finished, utilizing momentarily released high energy of a shock source to compress high pressure liquid in a forming liquid room to obtain a surged pressure value which is transmitted to formed blanks in form of shock waves, so as to perform the new manufacturing process of elasticoplastic deformation of the part. Due to one-step installation, processing procedure is reduced, which helps to realize monolithic forming of a complex large curved surface part and guarantees positional accuracy of complex parts with various sizes. Meanwhile, the shock time is very short, which reduces requirements in terms of intensity and tightness of the device. The shock hydraulic composite forming process has a wide application prospect in fields such as aeronautics and astronautics, and automobile in aspects of forming, reforming and the like of large complex components with small feature sizes such as small convex hull, small pressing mark, and small holes.

Owner:BEIHANG UNIV

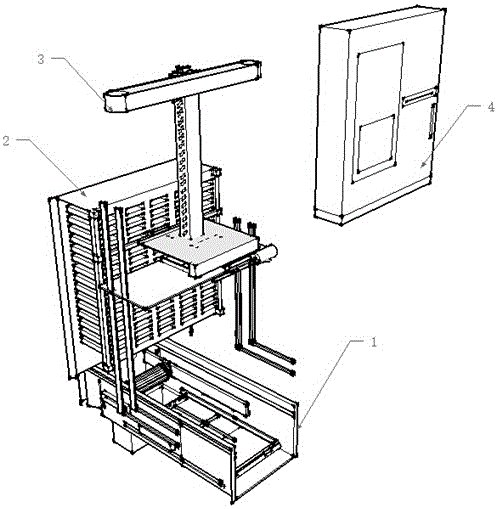

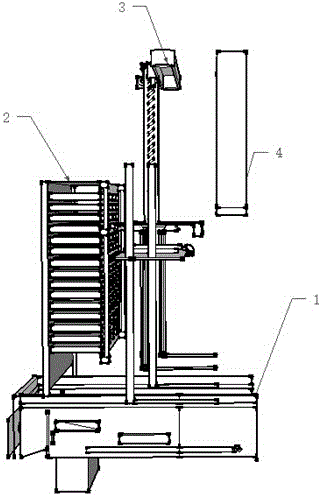

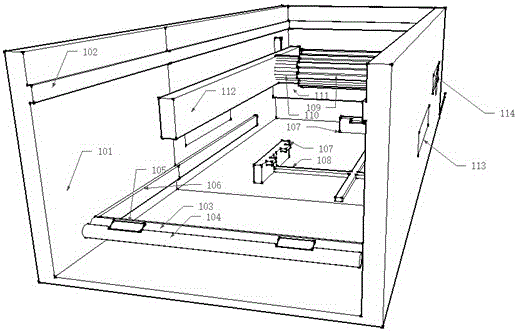

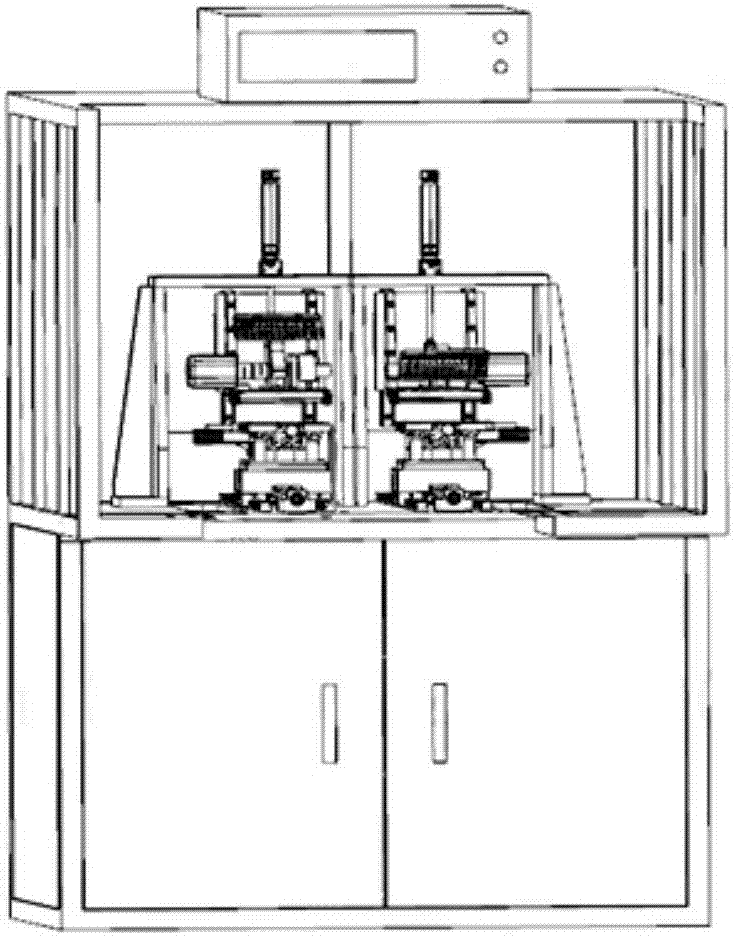

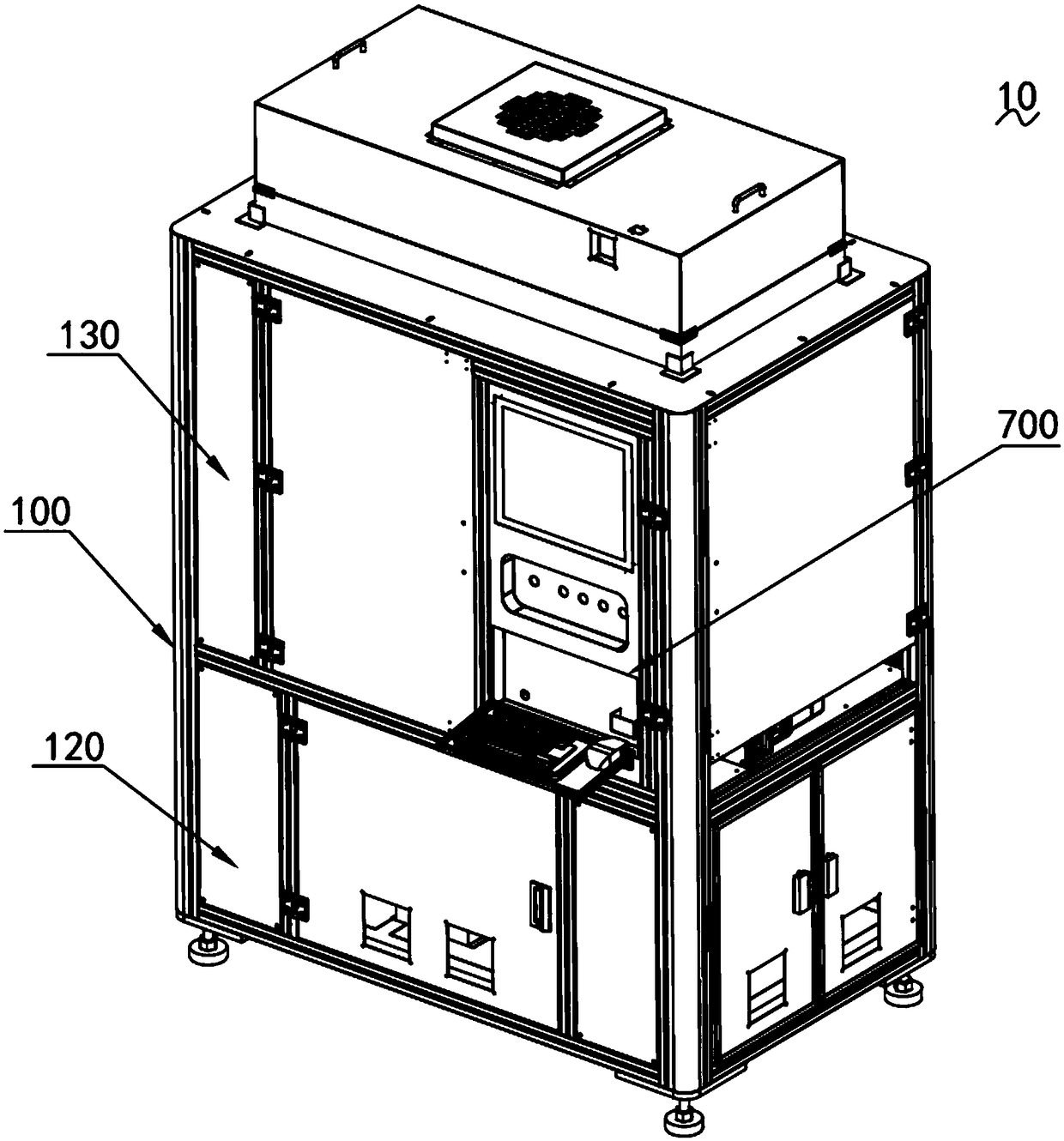

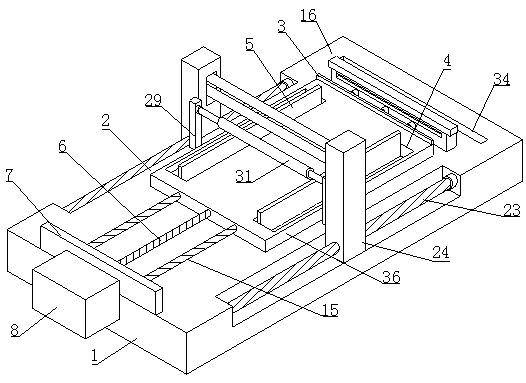

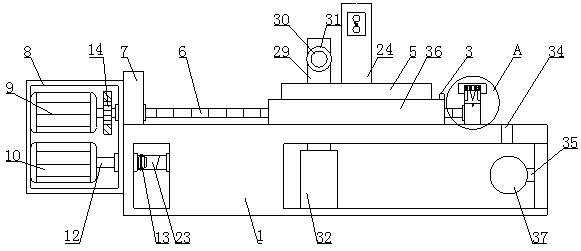

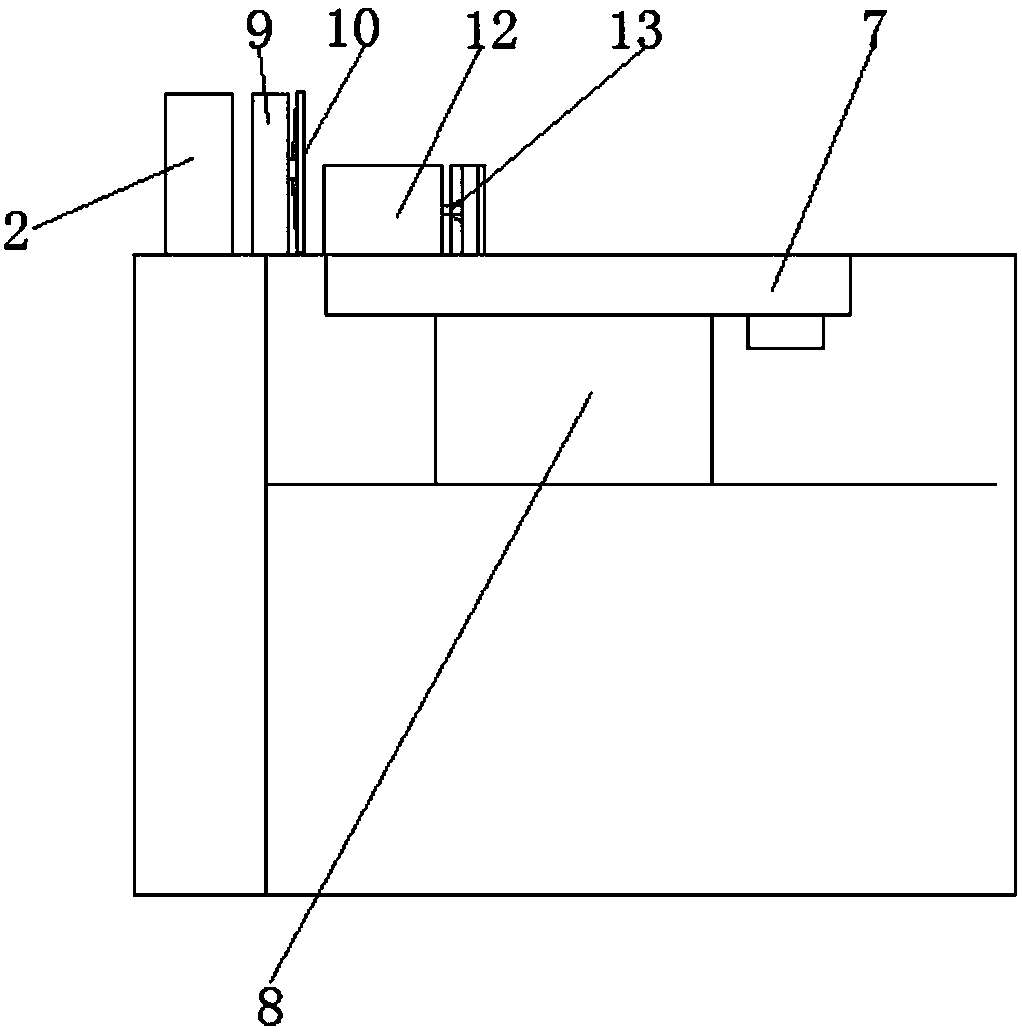

Full-automatic mobile phone film pasting cabinet

ActiveCN105083618AReduce work intensityImprove the film effectPackage sterilisationMobile phoneElectrical and Electronics engineering

The invention provides a full-automatic mobile phone film pasting cabinet which comprises a film pasting chamber, a film storage chamber, a flat plate, a mechanical movement structure and a control box. The control box is connected with the film pasting chamber, the film storage chamber, the flat plate and the mechanical movement structure through connection lines. The full-automatic mobile phone film pasting cabinet can be used for achieving full-automatic film pasting according to actual conditions of mobile phones, the whole film pasting process is conducted full automatically in a dust-free space, and the film pasting effect is good, and full-automatic film pasting can be achieved under an unmanned condition. Accordingly, film pasting quality can be guaranteed, and the labor intensity of film pasting work is lowered.

Owner:徐州博创建设发展集团有限公司

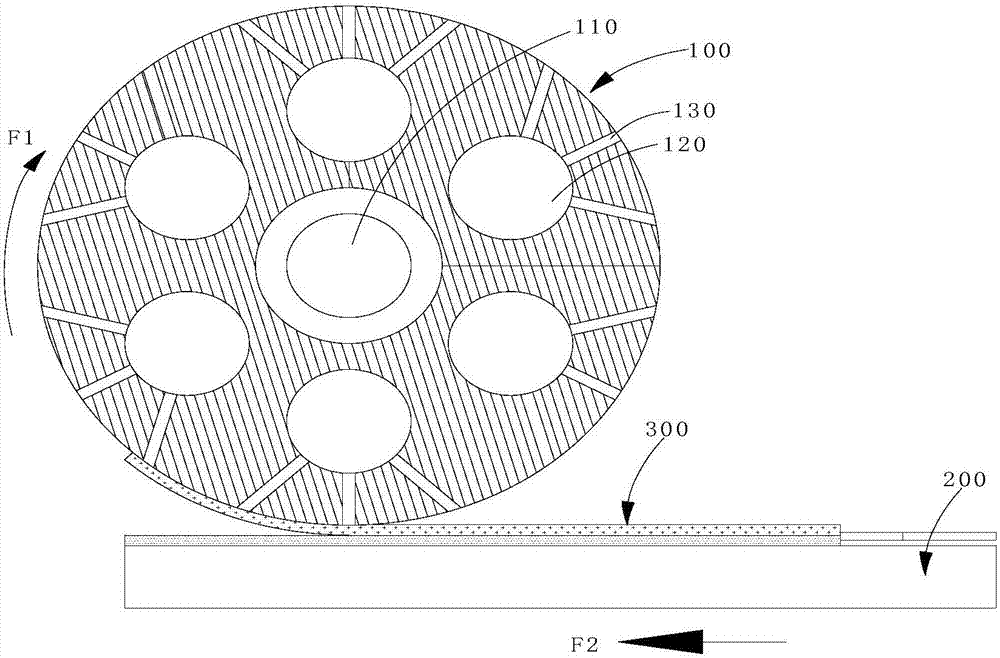

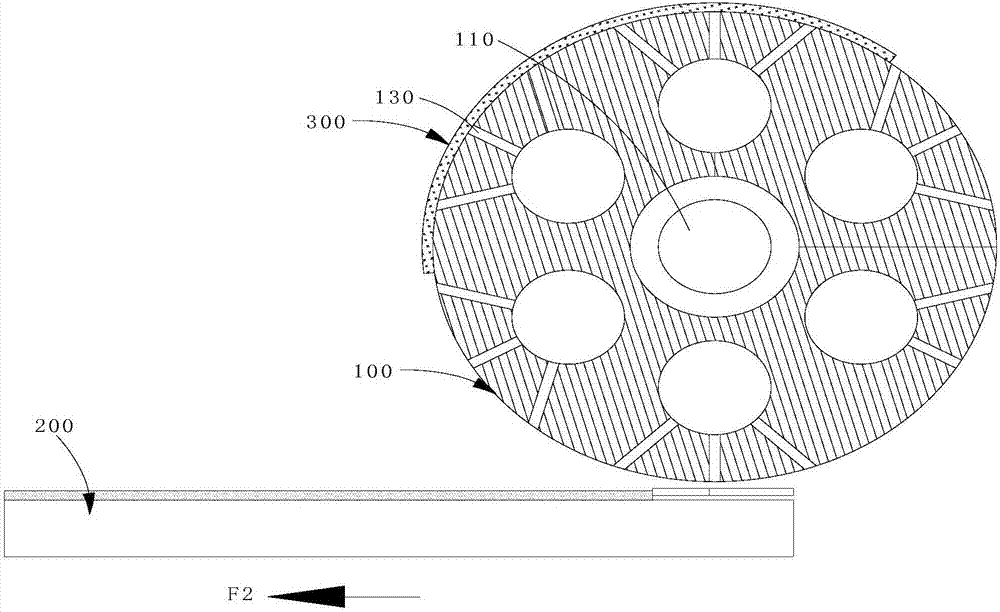

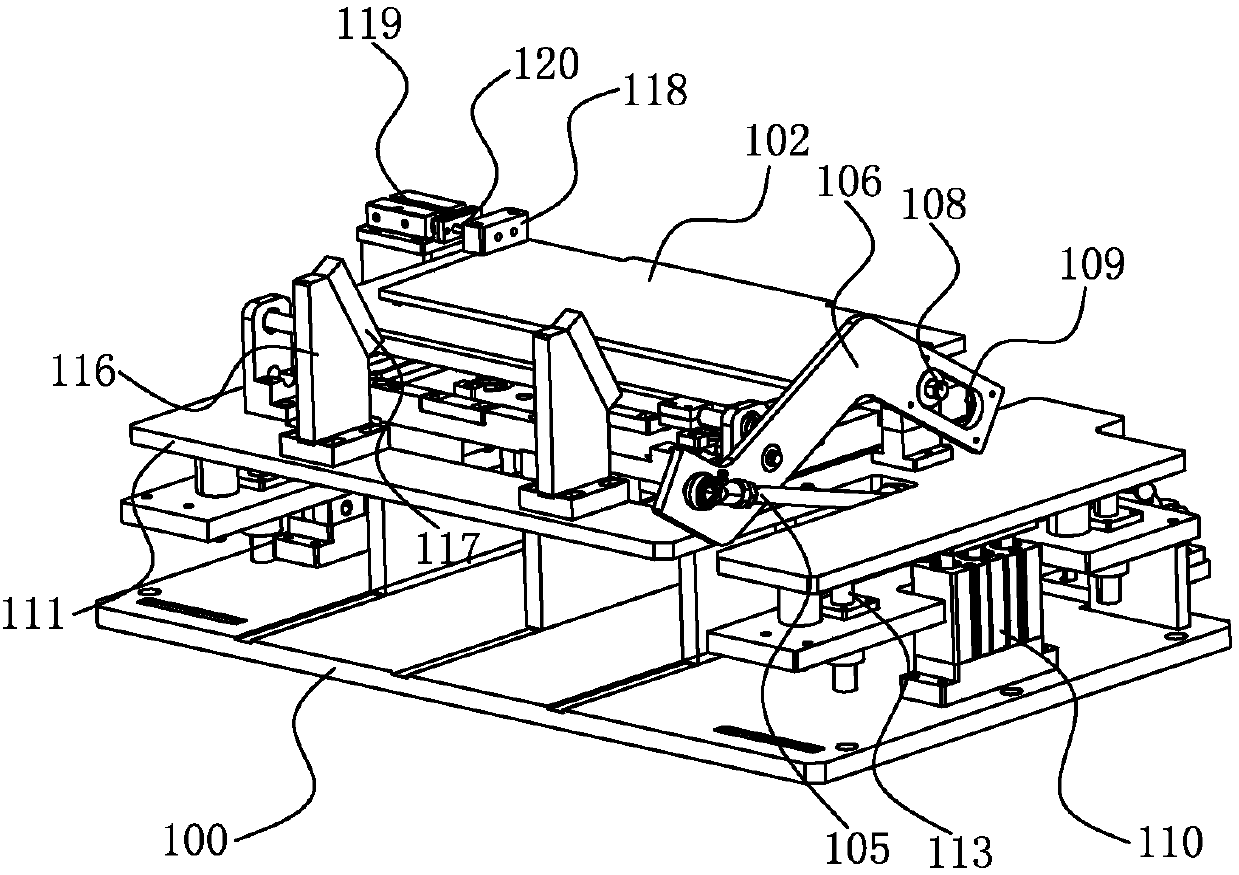

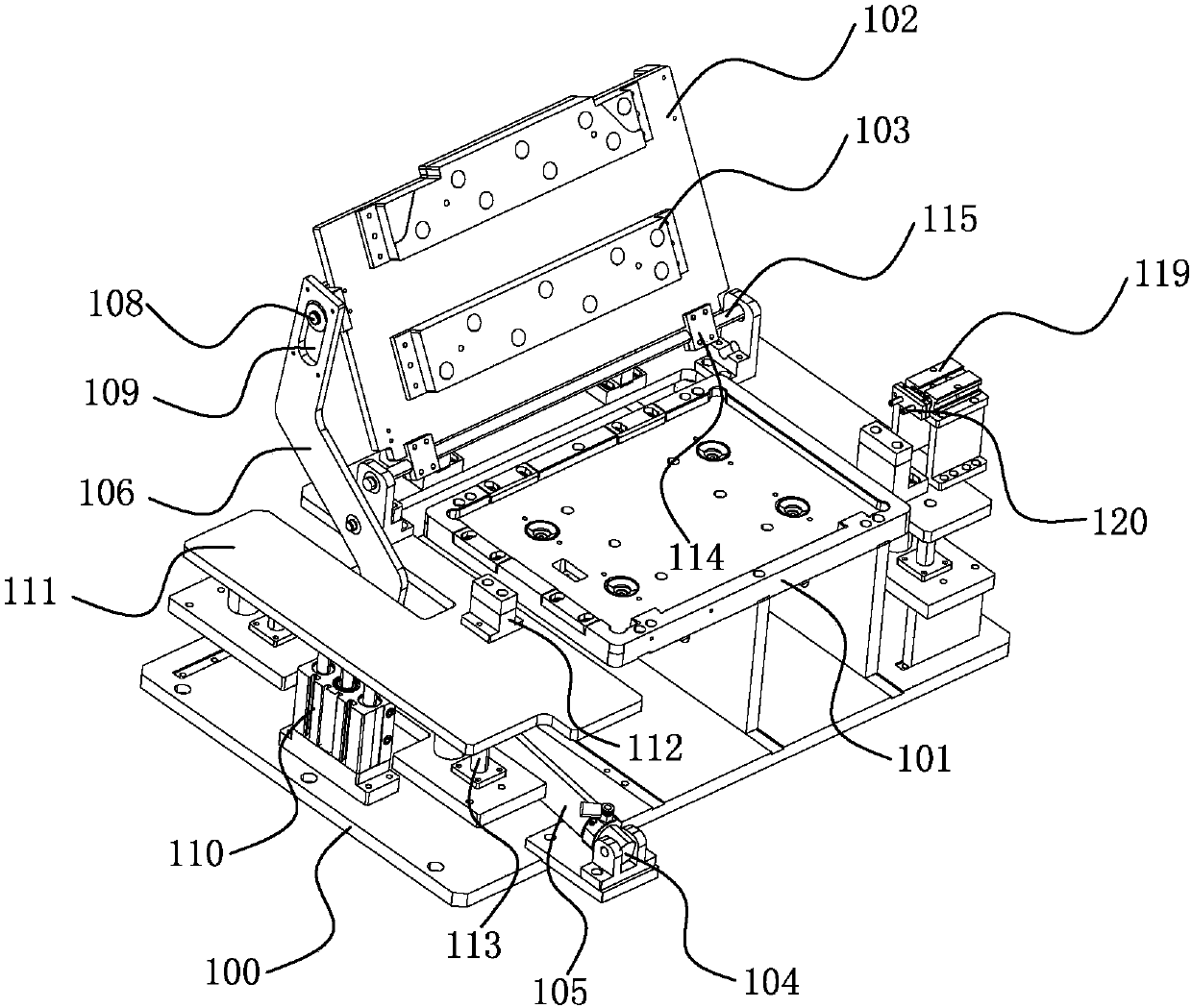

Automatic film pasting device

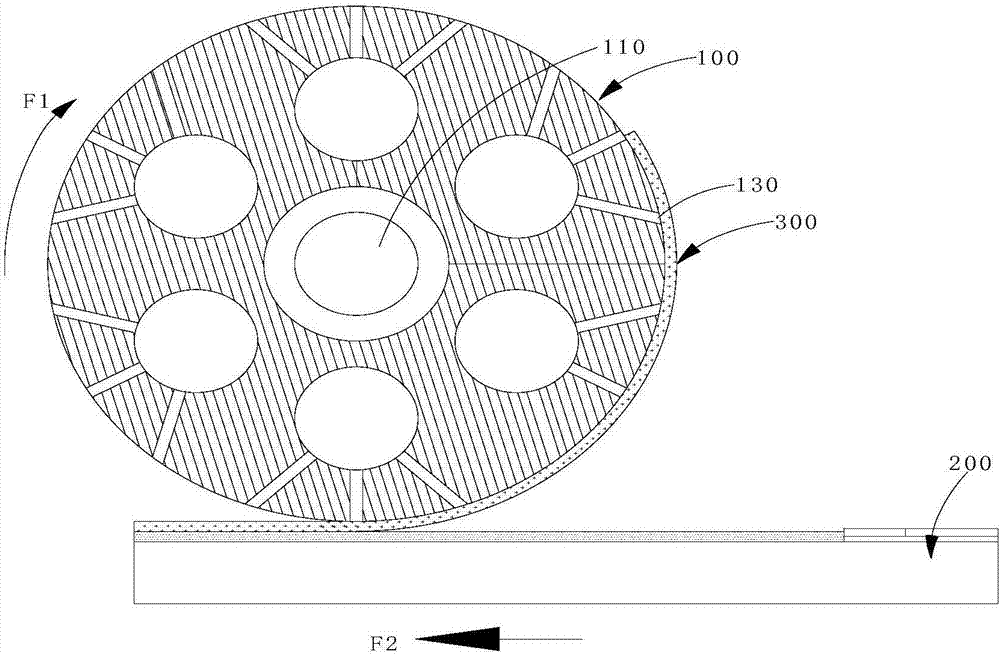

The invention discloses an automatic film pasting device used for pasting of a protection film on a screen. The automatic film pasting device comprises a first carrier carrying the protection film, a second carrier carrying the screen, and a press-fit mechanism. The first carrier is provided with a press roller. The film pressing face of the press roller and the film pasting face of the screen are matched in shape. The first carrier can rotate relative to the second carrier so that the attaching initial ends of the protection film and the screen can be connected, and the included angle of an acute angle is formed between the to-be-attached faces of the protection film and the screen. The second carrier can do the linear movement relative to the first carrier, the moving second carrier is matched with the press-fit mechanism, the press roller rolls closely attached to the screen, and the protection film located between the press roller and the screen is attached to the screen. The automatic film pasting device is simple in structure and convenient to operate, the film pasting efficiency is effectively improved, plane and hook face screens can be subjected to film pasting, and adaptability is high.

Owner:DONGGUAN WORLD PRECISION MACHINERY

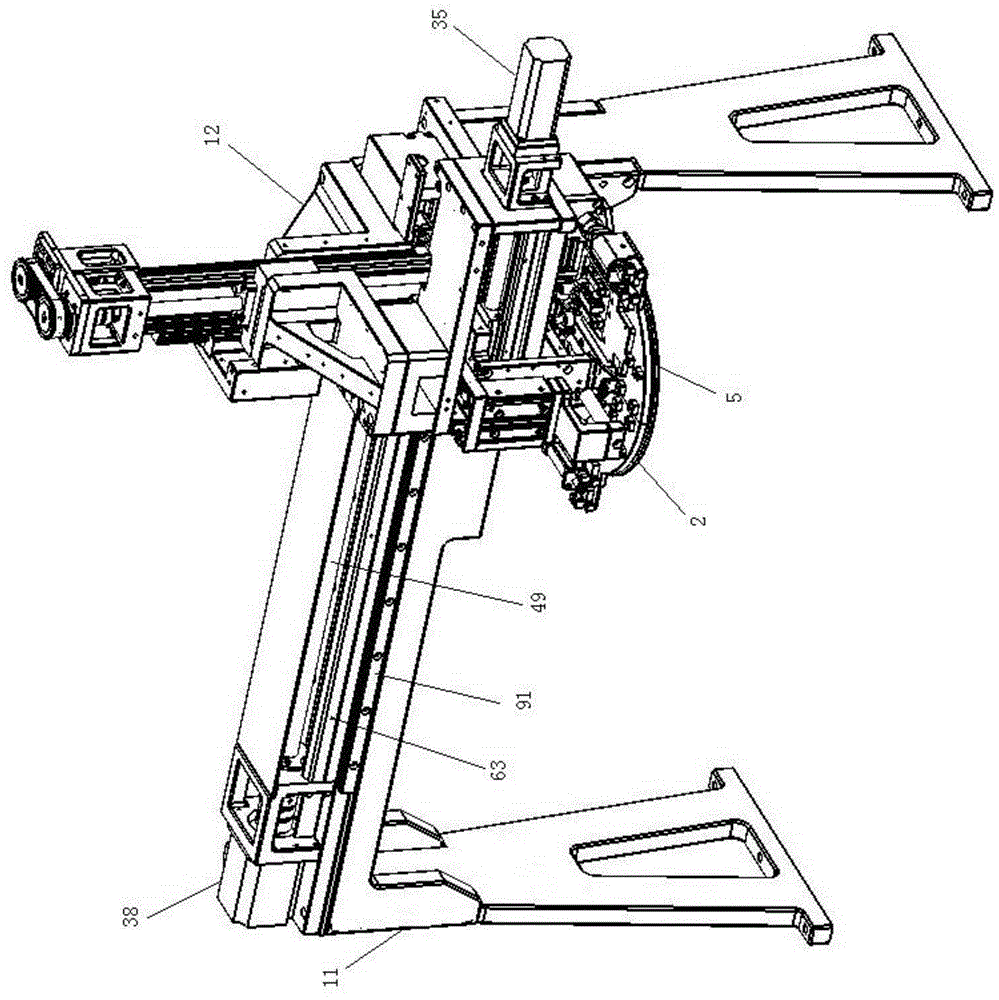

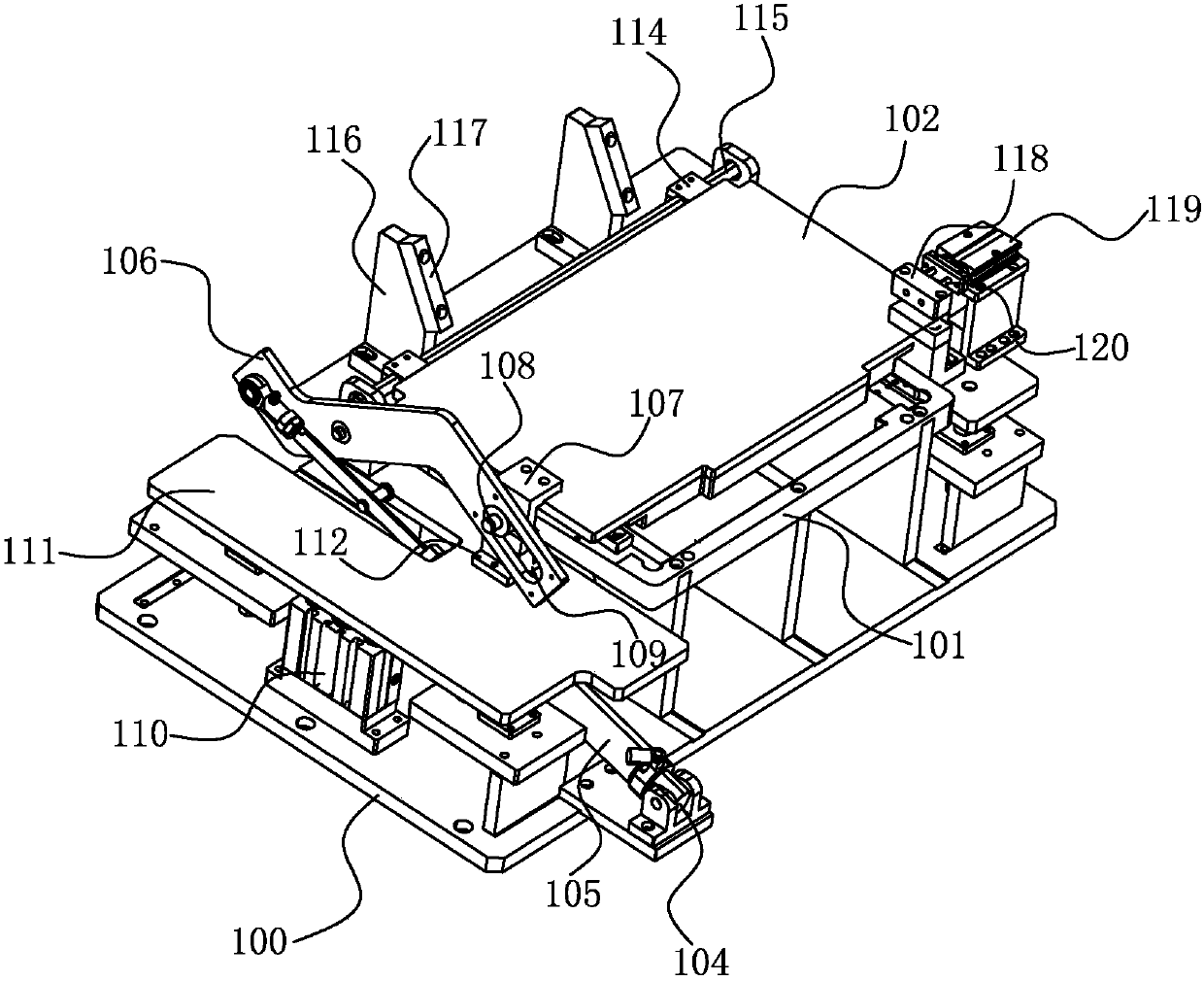

Film pasting device for 3D glass with two opposite edges as curved edges and film pasting method

ActiveCN107323726AGuaranteed non-interferenceEasy accessPackagingGlass productionEngineeringMechanical engineering

Owner:LENS TECH CHANGSHA

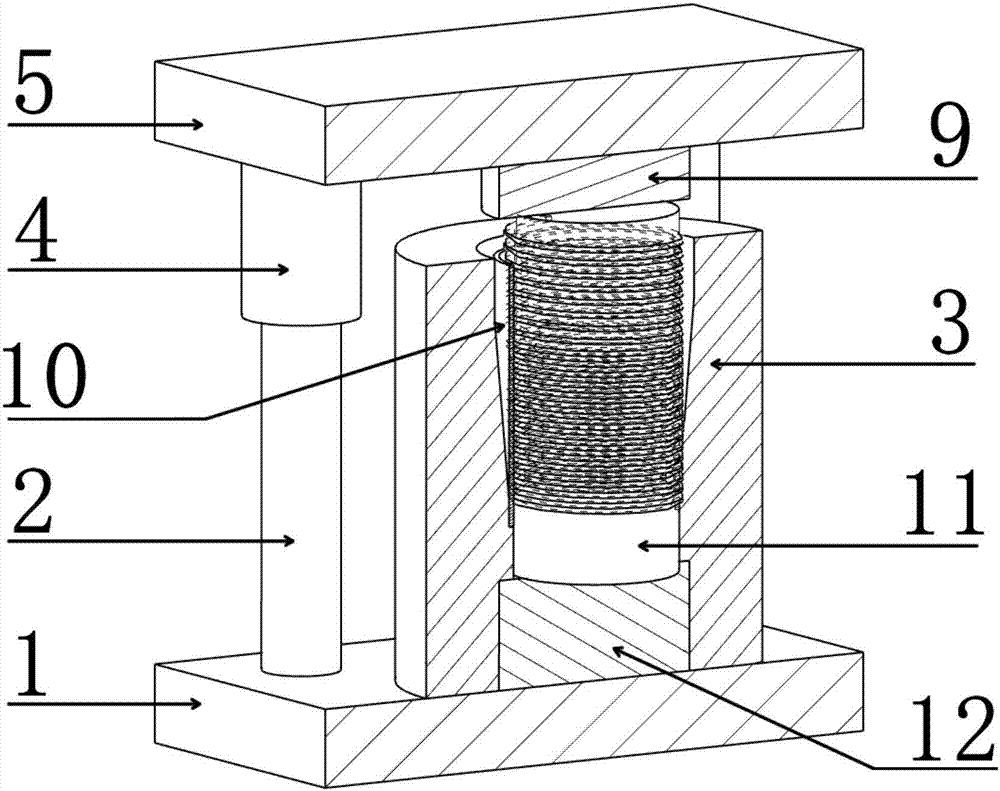

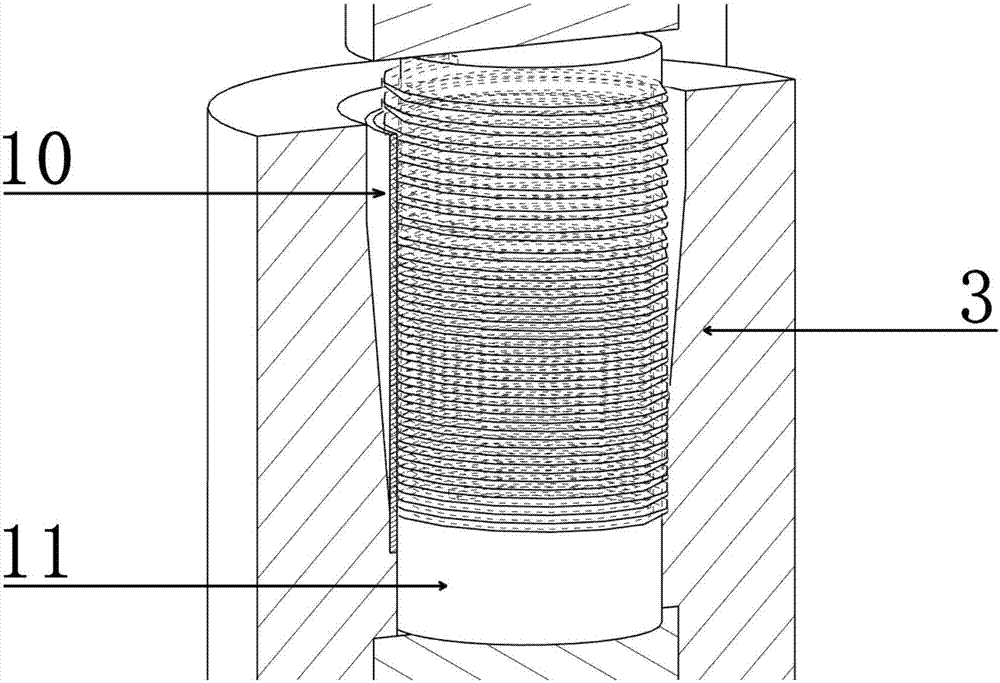

Tubular product electromagnetic bulging forming device and method

ActiveCN107413916AReasonable distribution of electromagnetic force fieldSmall field strengthShaping toolsMetallic materialsEngineering

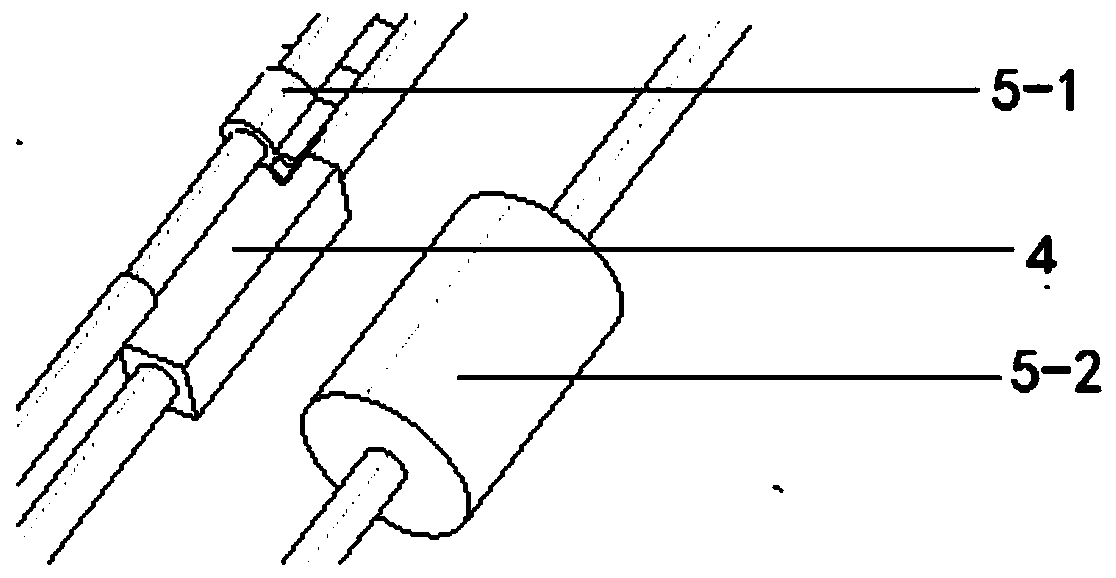

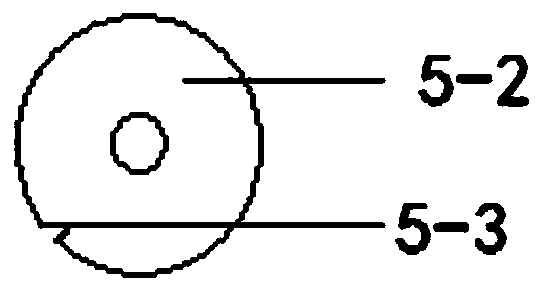

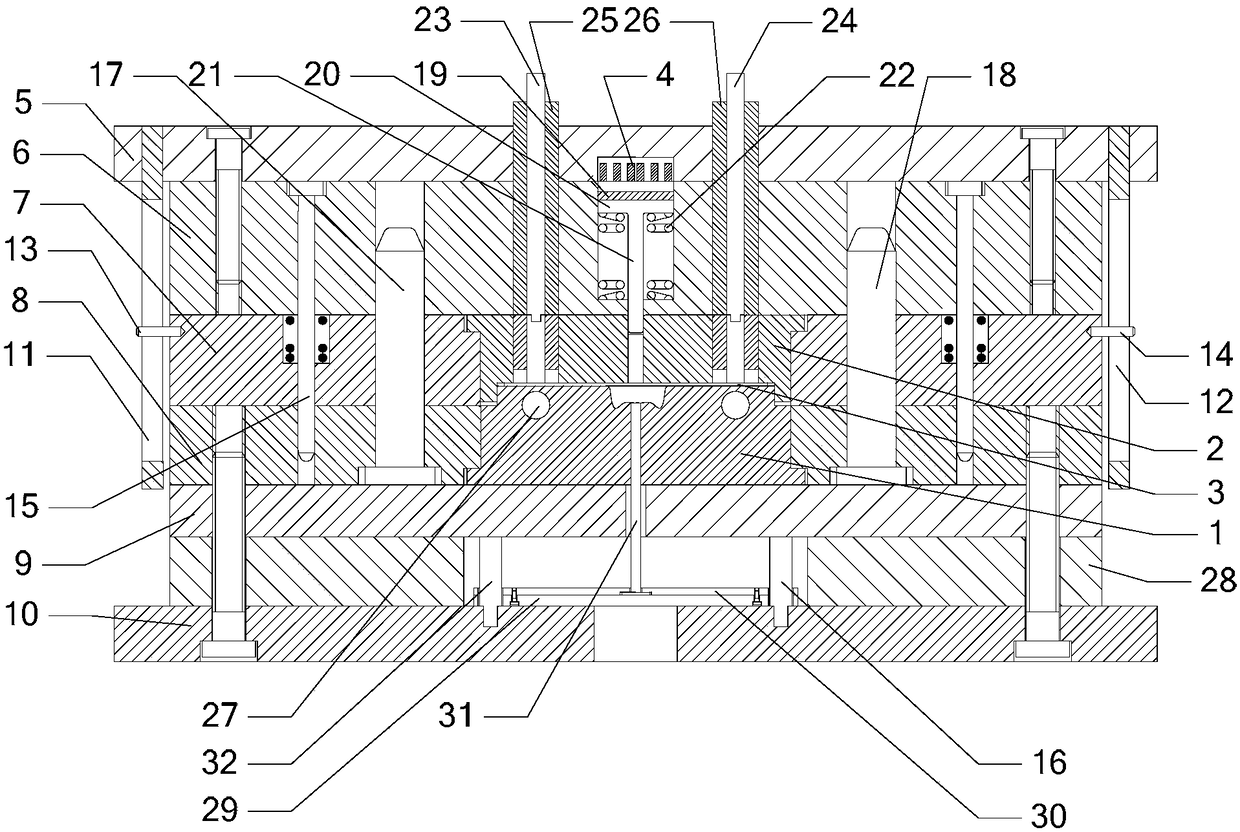

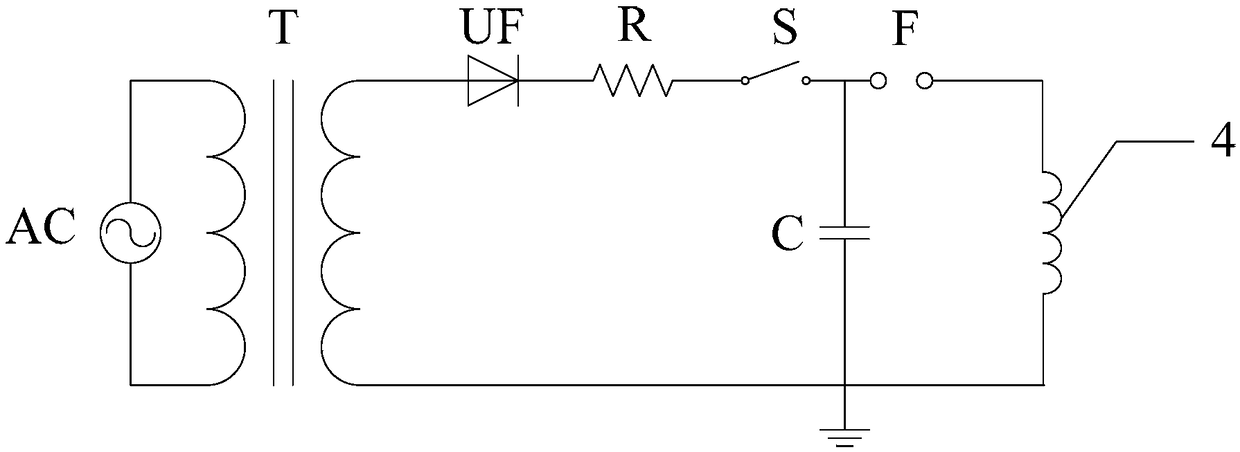

The invention belongs to the field of metallic material plastic processing and discloses a tubular product electromagnetic bulging forming device which comprises a pulse discharging circuit, a die assembly and a helix tube coil with unequal turn spaces, wherein the helix tube coil is connected with the pulse discharging circuit; the die assembly comprises a forming die; the forming die is provided with a forming inner hole; the forming inner hole is provided with a large end and a small end; the helix tube coil is placed in the forming inner hole of the forming die and comprises a forming coil; the end, close to the small end of the forming inner hole, of the forming coil is a wire close winding part, and the other end of the forming coil is a wire sparse winding part; and the turn space of the wire close winding part is smaller than that of the wire sparse winding part. According to the tubular product electromagnetic bulging forming device, a material is sequentially formed from bottom up through electromagnetic bulging and the combined action of inertia traction and die constraint; therefore, the demand of the forming force field is consistent with the distribution rule of the electromagnetic force field of the helix tube coil.

Owner:HUAZHONG UNIV OF SCI & TECH

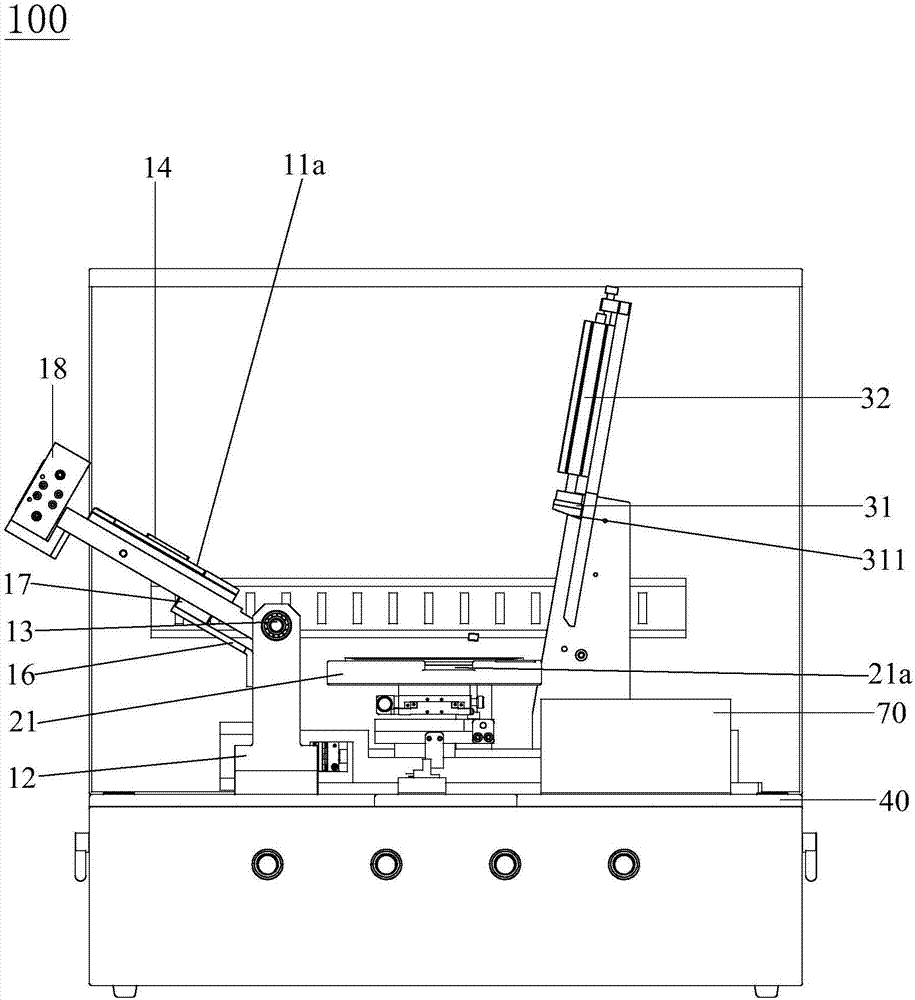

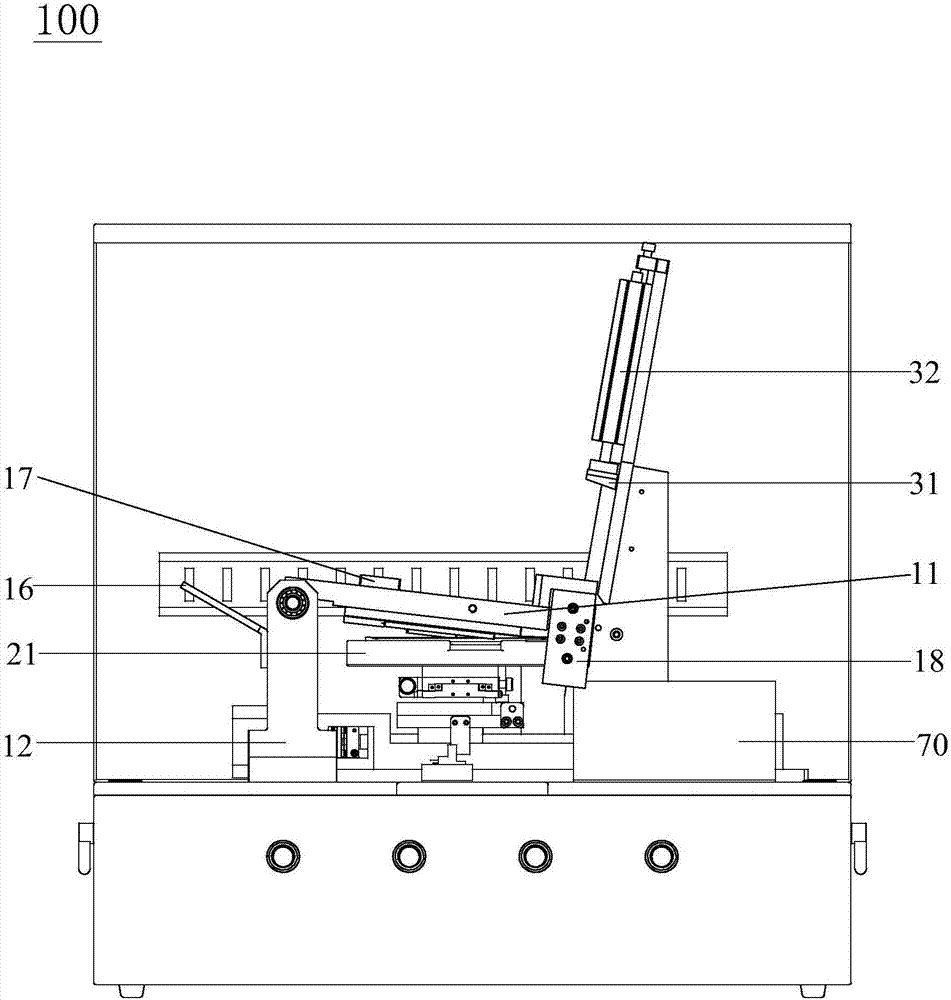

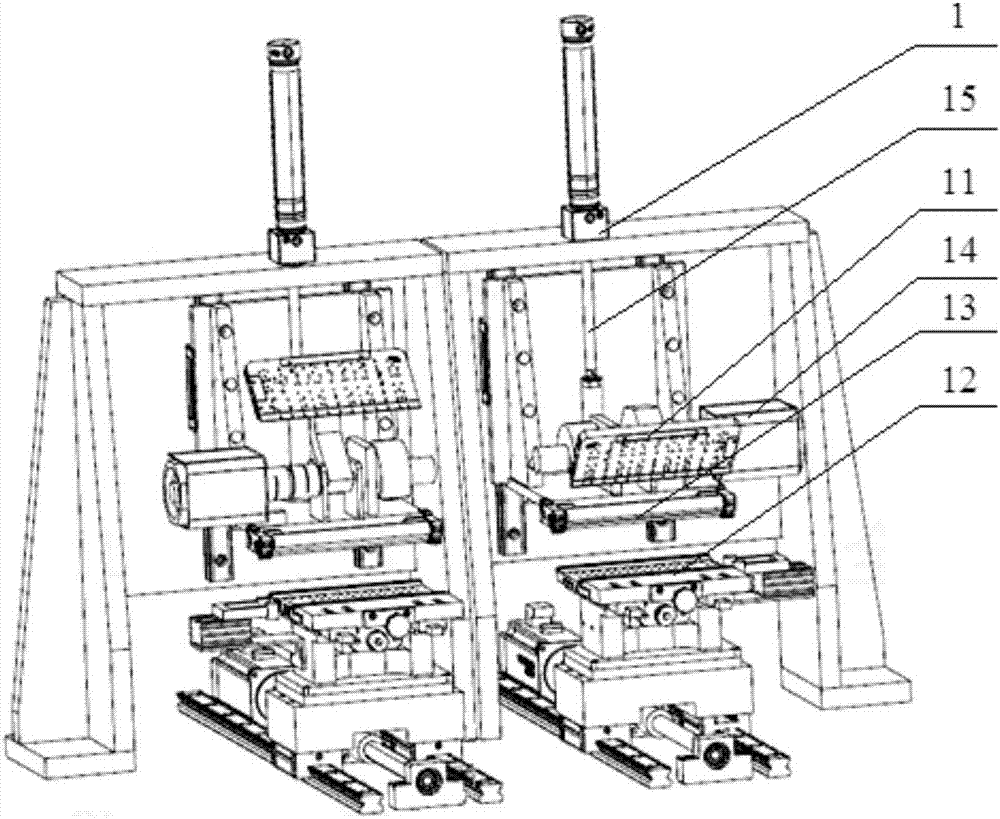

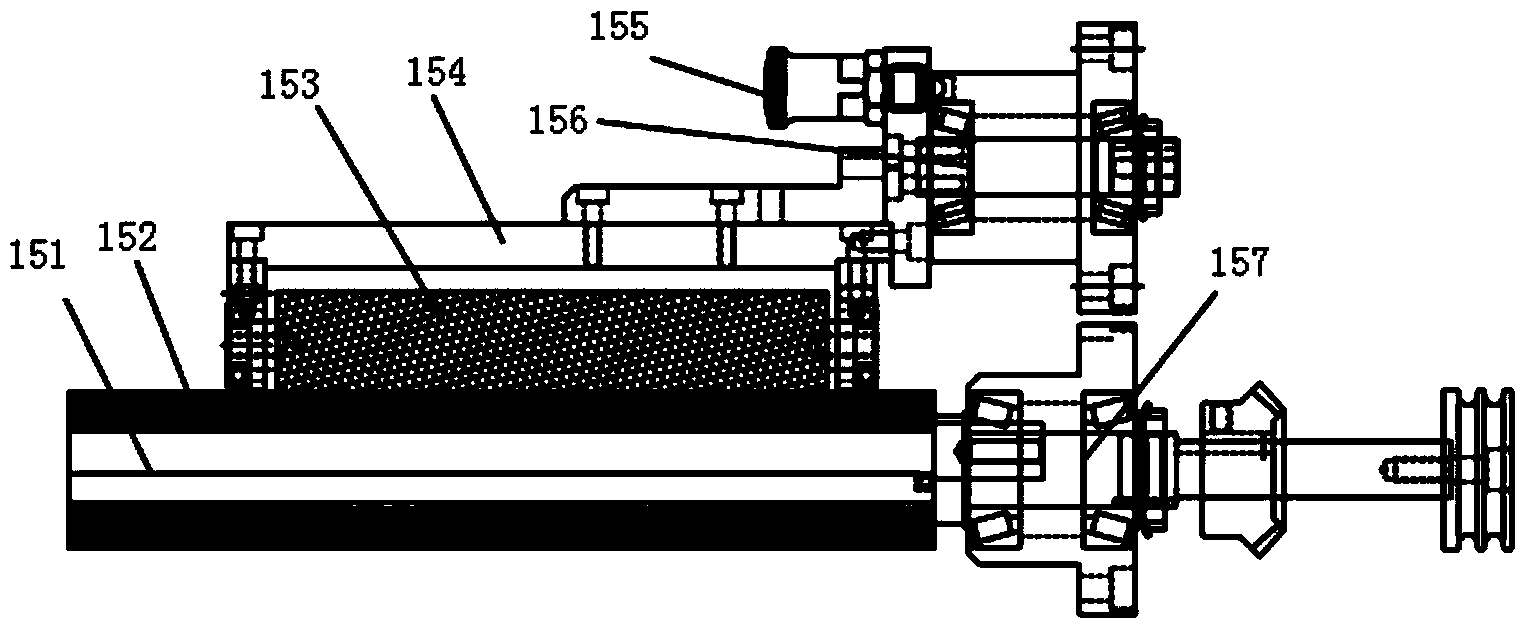

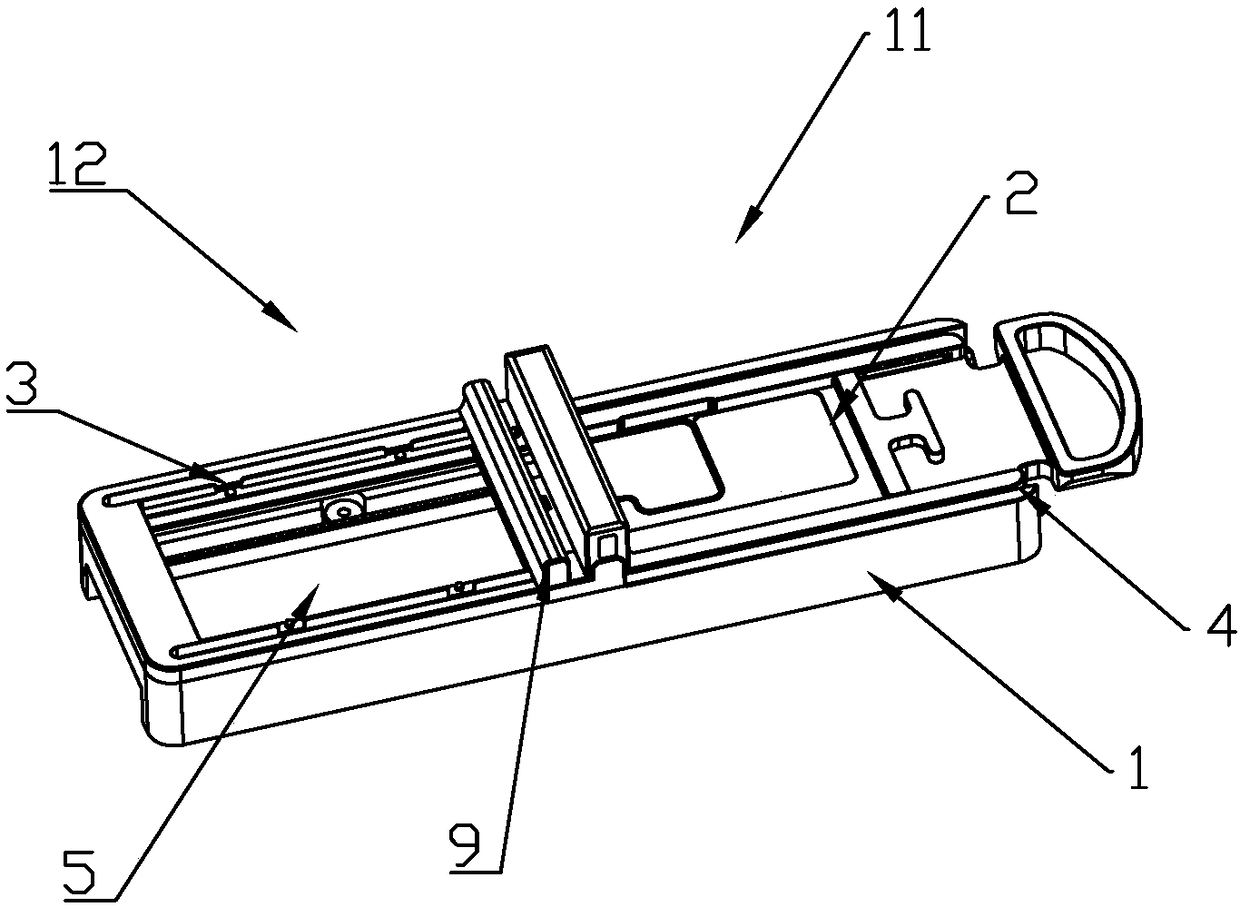

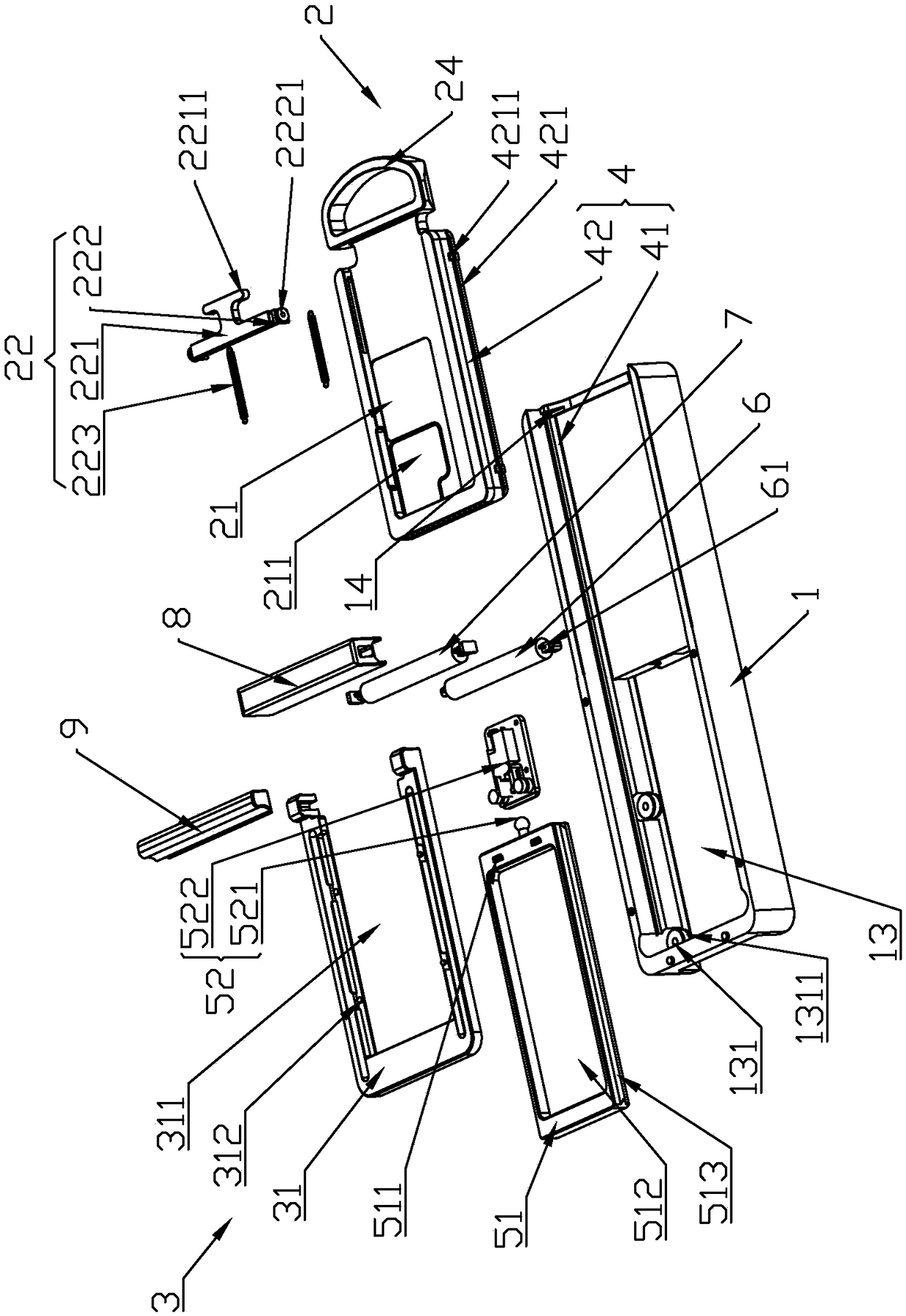

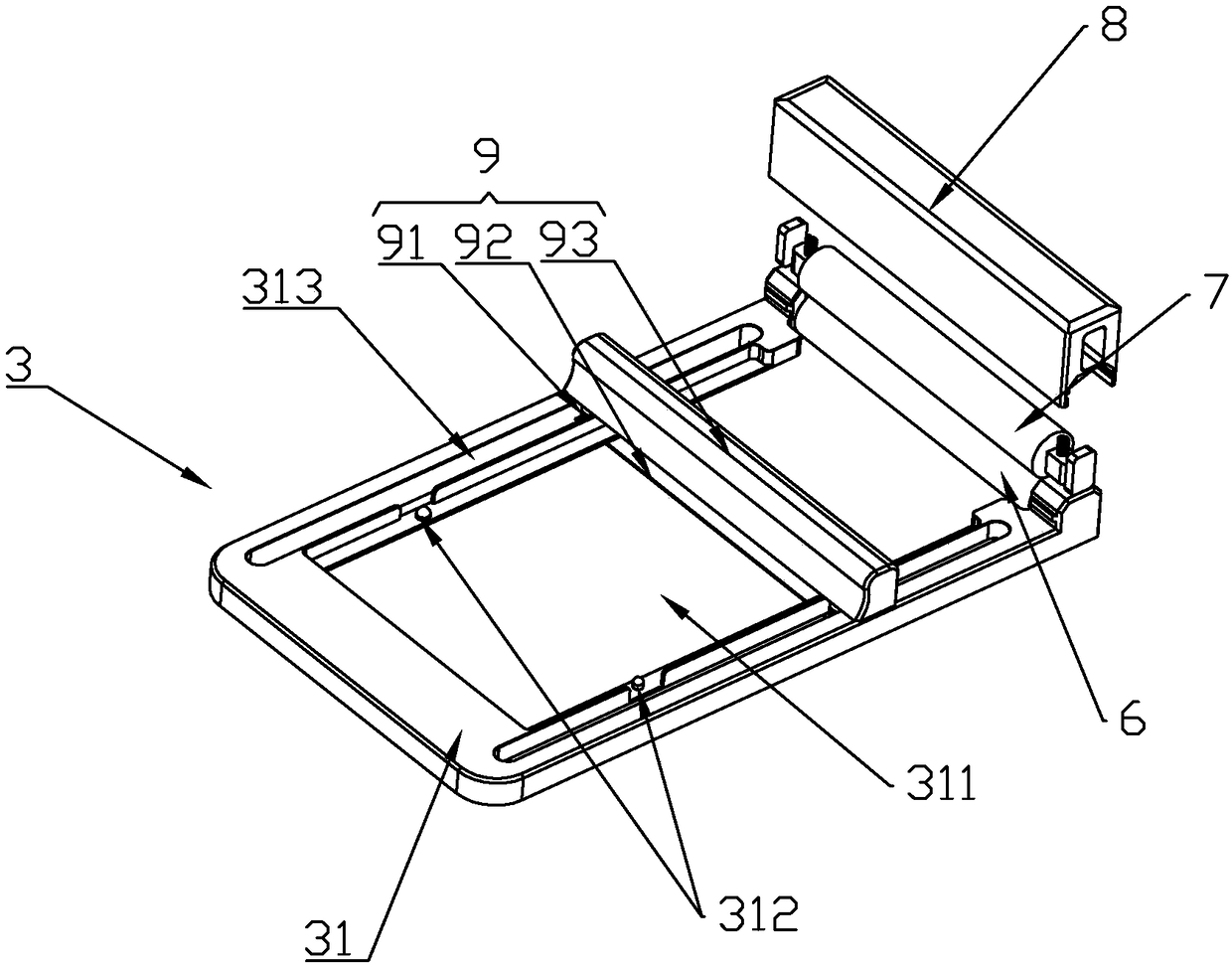

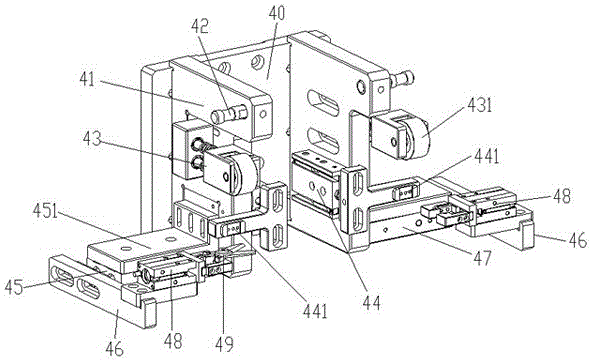

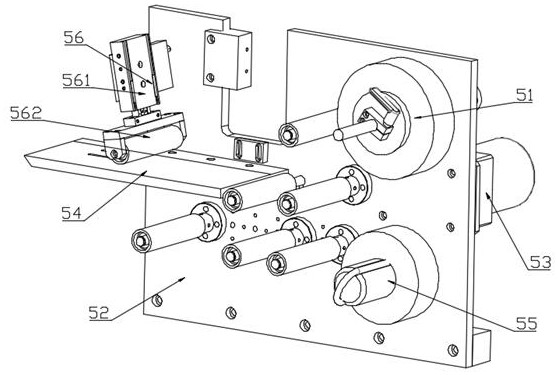

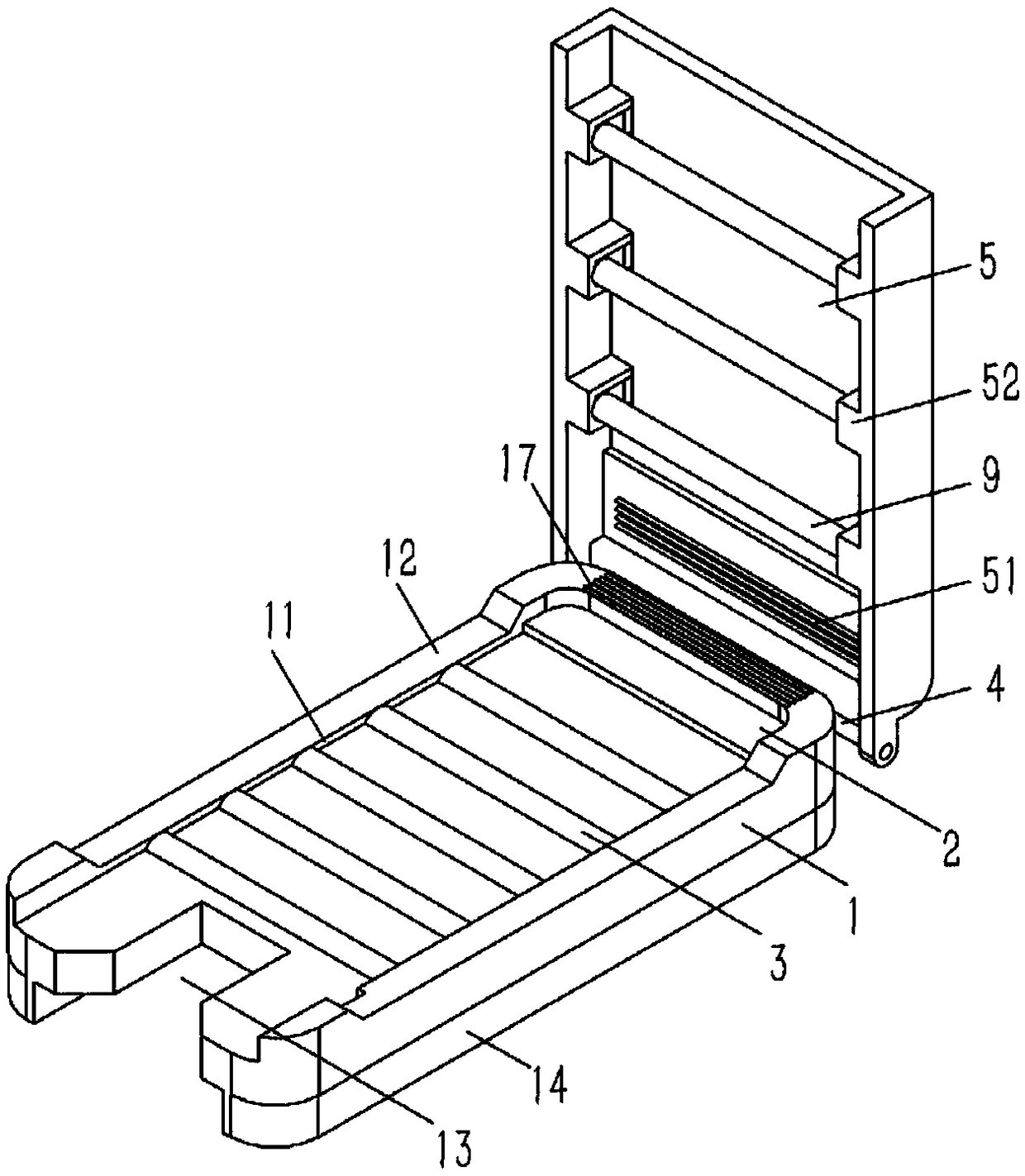

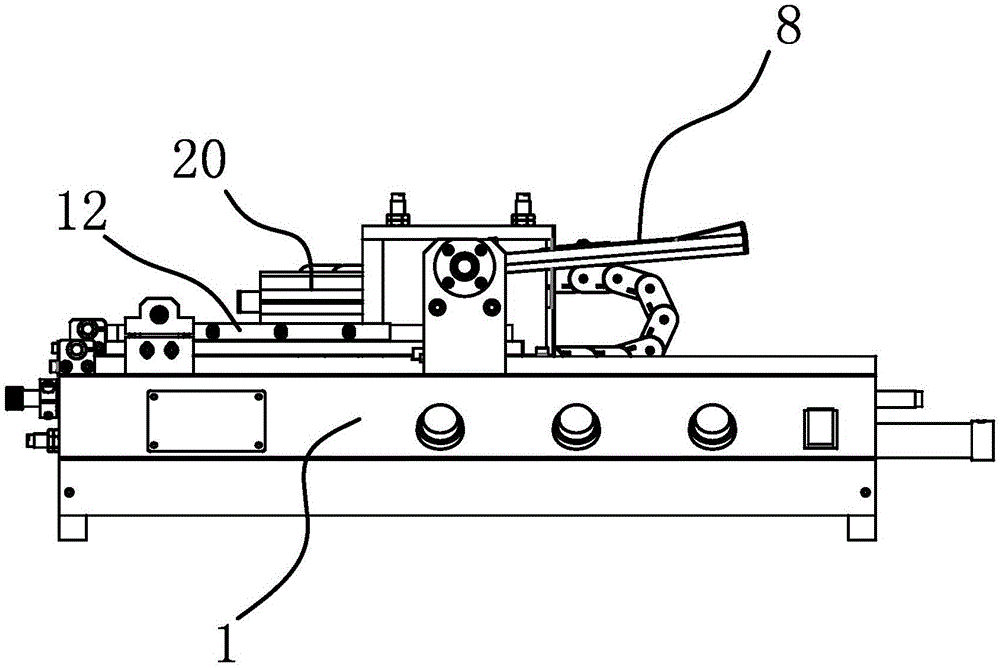

Adsorbing type film sticking mechanism

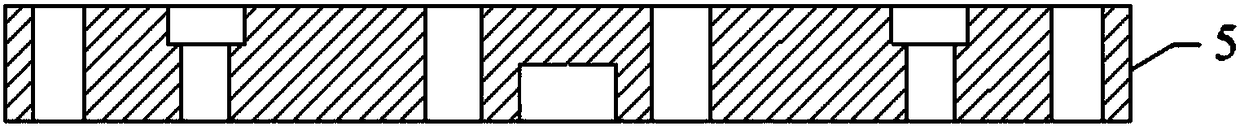

InactiveCN106428745AImprove the film effectImprove pass rateWrapping material feeding apparatusTectorial membraneEngineering

The invention discloses an adsorbing type film sticking mechanism. The adsorbing type film sticking mechanism comprises a horizontal rotating angle adjusting assembly, a fixing base plate and an adsorbing film pressing base plate, wherein the fixing base plate is horizontally arranged below the horizontal rotating angle adjusting assembly, and the horizontal rotating angle adjusting assembly is used for driving the fixing base plate to horizontally rotate; the adsorbing film pressing base plate is arranged below the fixing base plate through an inclination angle adjusting assembly; the lower surface of the adsorbing film pressing base plate is a protecting film adsorbing surface; an included angle between the adsorbing film pressing base plate and the level can be adjusted through the inclination angle adjusting assembly during film sticking. The adsorbing type film sticking mechanism is applicable to the sticking of one or a plurality of layers of protecting films; no bubble is generated between the protecting film and an element to be stuck, and the film sticking position accuracy is high, so that the film sticking effect and qualification rate can be improved; the adsorbing type film sticking mechanism has a good application prospect.

Owner:JIANGSU BVM INTELLIGENT TECH

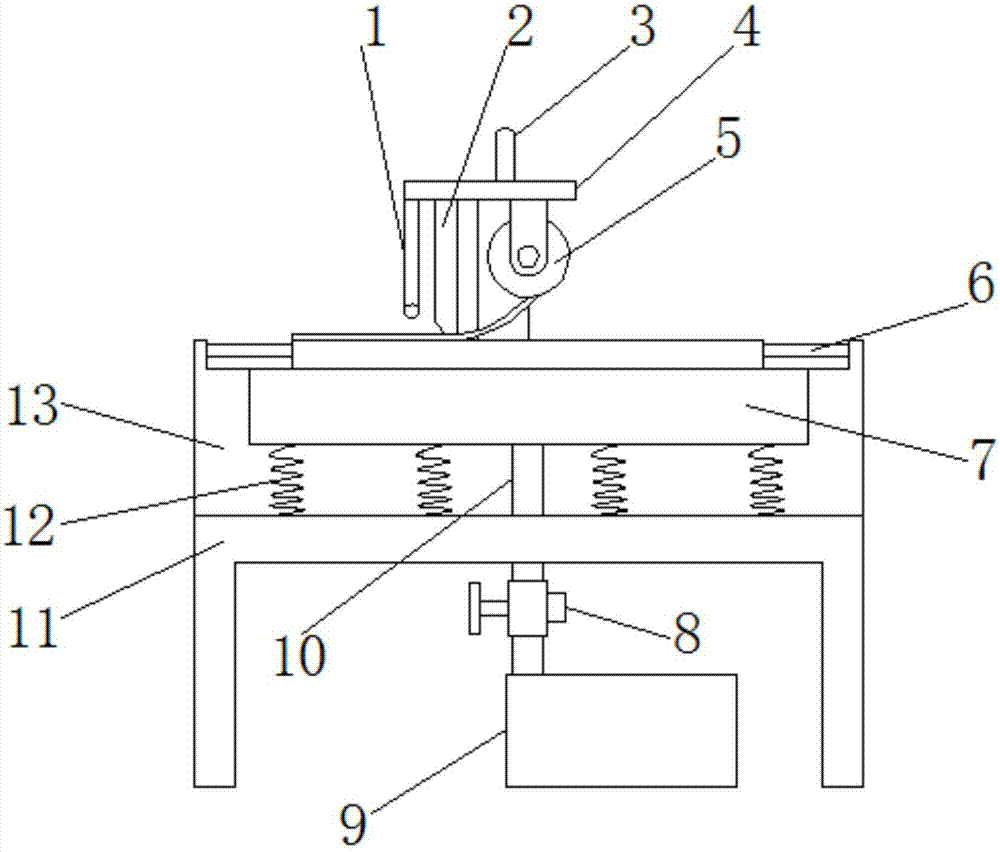

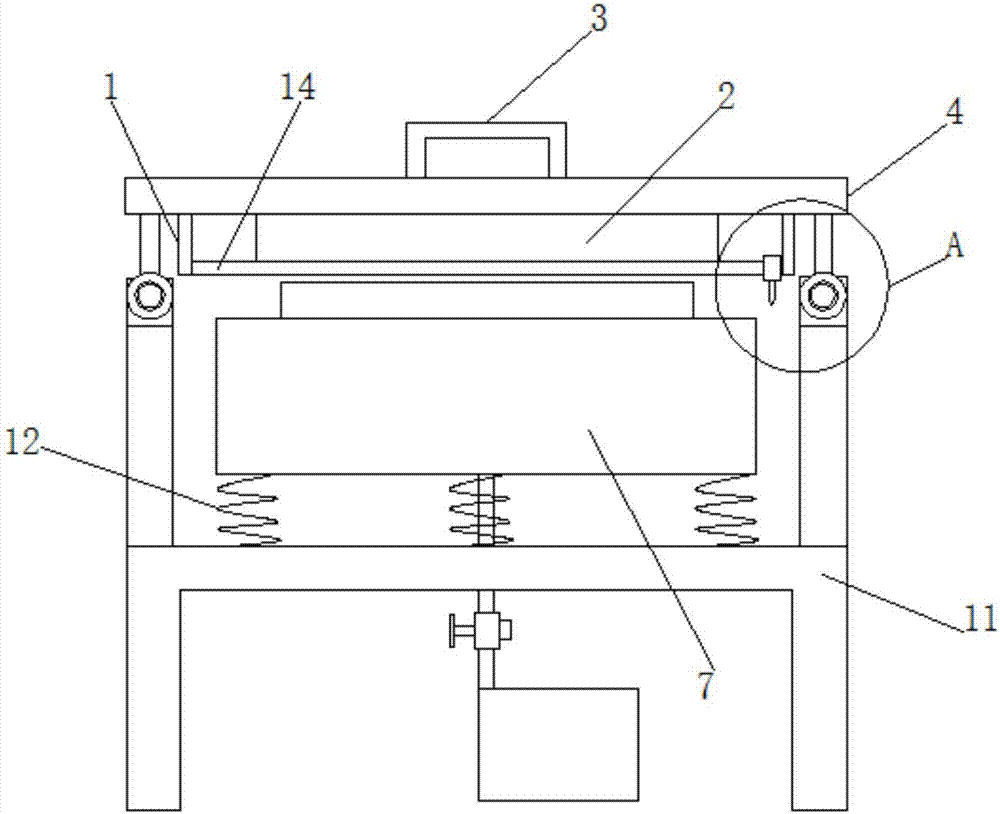

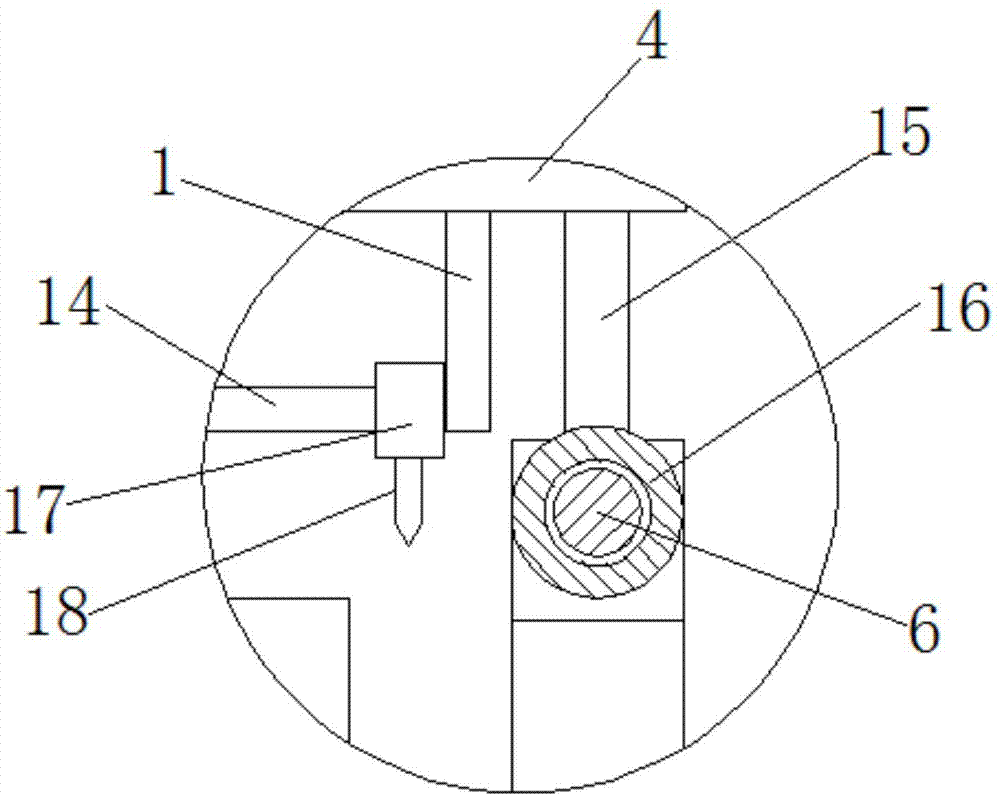

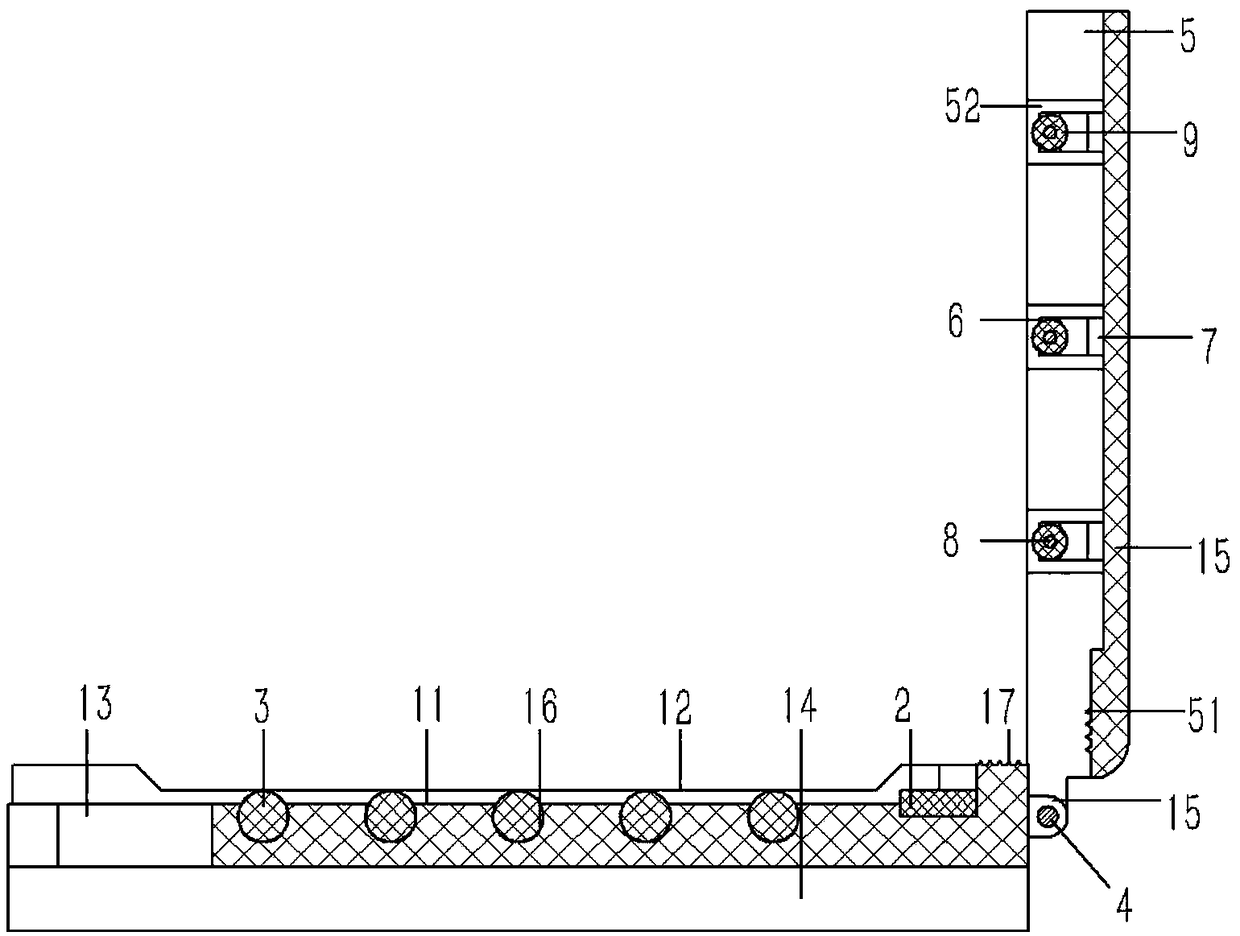

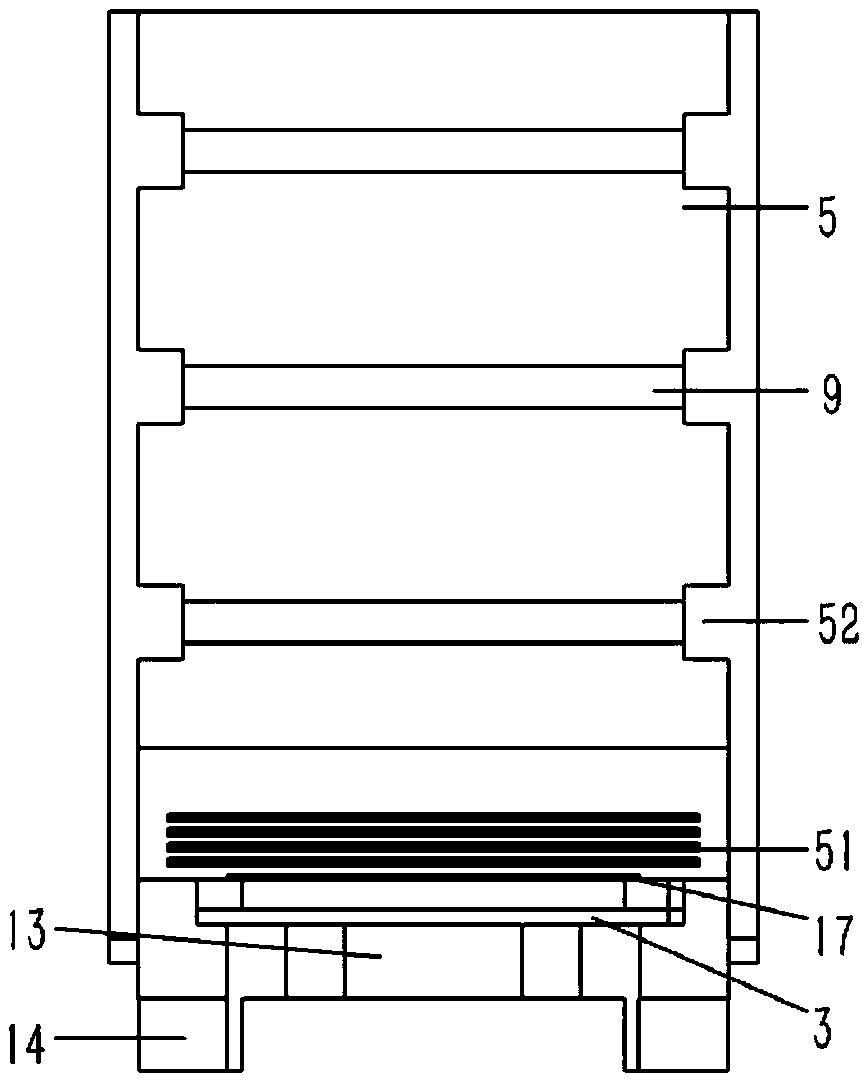

LCD panel film pasting auxiliary mechanism

InactiveCN107379720AAvoid offsetStable intervalLamination ancillary operationsLaminationEngineeringVacuum pump

The invention discloses an LCD panel film pasting auxiliary mechanism. The LCD panel film pasting auxiliary mechanism comprises a fixing platform and a frame. The frame is fixedly connected to the lower surface of the fixing platform through a spring. The bottom of the fixing platform is connected to a vacuum pump through a pipe. Two sides of the frame are respectively welded and fixed to the bottoms of side plates. First sliding rods are slidingly connected to first sliding sleeves. The tops of the first sliding sleeves are welded and fixed at the bottoms of ejector rods. The top ends of the ejector rods are welded and fixed on the two ends of an ejector plate. The lower surface of the ejector plate is orderly provided with a fixing rod, a scraper plate and a discharge roller. A LCD suction plate is adsorbed and fixed by negative pressure so that LCD plate shift in film pasting is prevented. The ejector plate is pushed manually to drive the scraper plate so that the film is automatically pasted. The LCD panel film pasting auxiliary mechanism has a fast film pasting rate. The spring can ensure load balance of the LCD plate so that film pasting effects are improved and bubbles are effectively avoided. The mechanism can fast cut a film, is easy to operate and improves film pasting quality and efficiency.

Owner:成都预细科技有限公司

High-accuracy full-automatic film adhering equipment

The invention relates to the technical field of automatic film adhering equipment, and particularly relates to high-accuracy full-automatic film adhering equipment. The high-accuracy full-automatic film adhering equipment comprises a rack, a working table, a loading and unloading mechanism, an automatic film adhering manipulator, a detection mechanism, a discharging mechanism, a stripping mechanism and a control mechanism, wherein the working table is arranged at the upper part of the rack; the loading and unloading mechanism is arranged on the working table and used for loading and unloadinga product; the automatic film adhering manipulator is arranged on the working table, positioned at one end of the loading and unloading mechanism and used for automatically taking a material to adherea film; the detection mechanism is arranged on the working table, positioned above the manipulator and used for detecting and correcting a film material; the discharging mechanism is arranged on theworking table, positioned at one side of the loading and unloading mechanism and used for discharging and rolling up the film material; the stripping mechanism is positioned at one side of the discharging mechanism and used for stripping off the film material; the control mechanism is arranged on the rack and used for controlling the film adhering equipment to work. The high-accuracy full-automatic film adhering equipment integrally adopts full-automatic setting, so that both human and material resources are saved; a protective film is adhered after being corrected in the film adhering process, so that film adhering accuracy and film adhering efficiency are greatly improved, and integral reliability is high.

Owner:东莞市威耐科智能装备有限公司

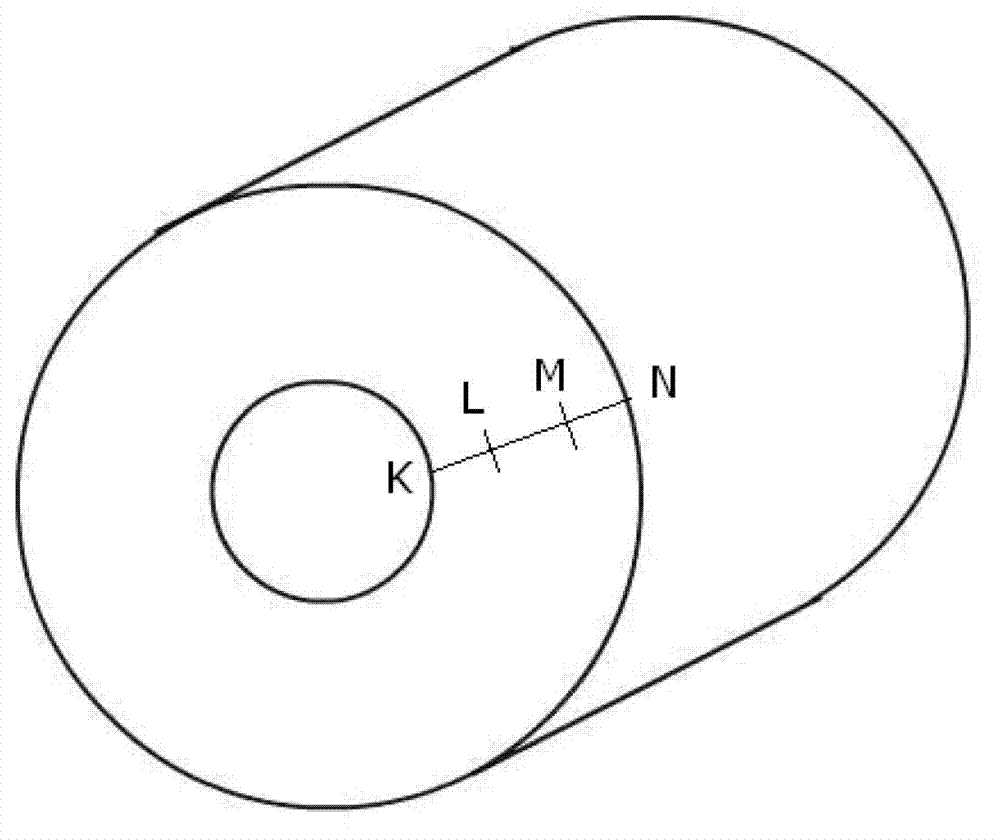

Membrane tearing and pasting device and membrane tearing and pasting method

InactiveCN107283986AEasy to operateEasy to tear filmLamination ancillary operationsLaminationTectorial membraneEngineering

The invention relates to a tearing film sticking device and a tearing film sticking method, the tearing film sticking device is used for tearing off a protective film from a screen surface and for attaching the torn off protective film to the screen, The tearing film sticking device includes: a roller, the roller has a chamber inside, the circumferential surface of the roller is provided with a plurality of through holes communicating with the chamber, the axial ends of the roller Respectively connected with a rotating shaft; a vacuum mechanism, communicated with the chamber to vacuumize the through hole when tearing off the film and sticking the film, and is used to make the protective film pasted on the screen be adsorbed on the circumference of the roller surface and stick the protective film adsorbed on the peripheral surface of the roller to the screen; a driving mechanism, the driving mechanism is connected with the rotating shaft to drive the roller to rotate around the rotating shaft. The above film tearing and sticking device is simple to operate, can effectively realize the operation of tearing and sticking the film, and has high efficiency and good effect.

Owner:GUANGDONG TIANJI IND INTELLIGENT SYST CO LTD

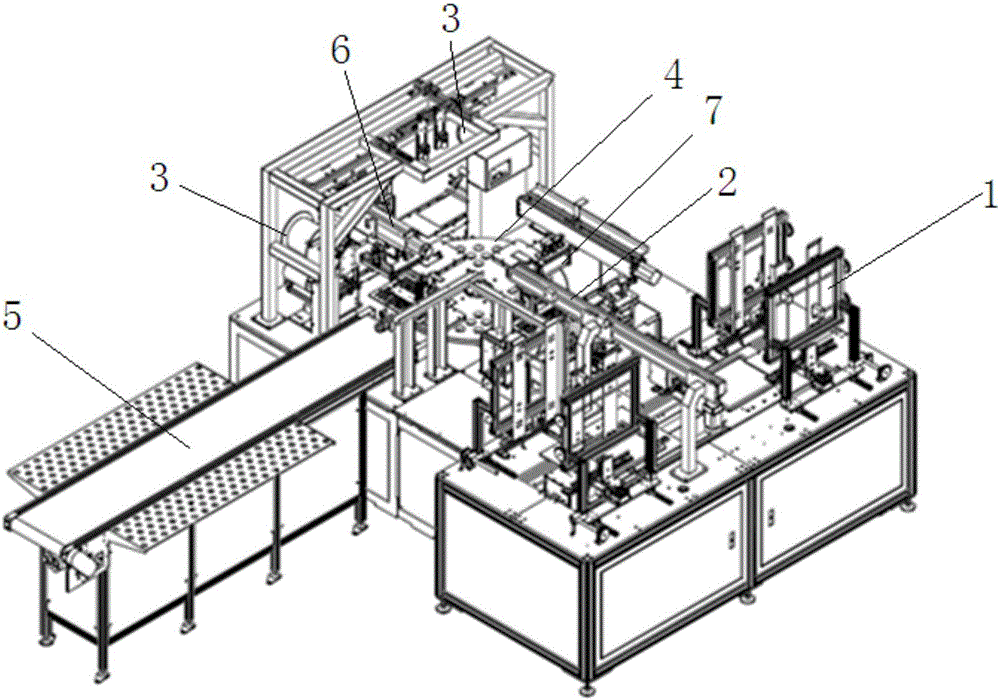

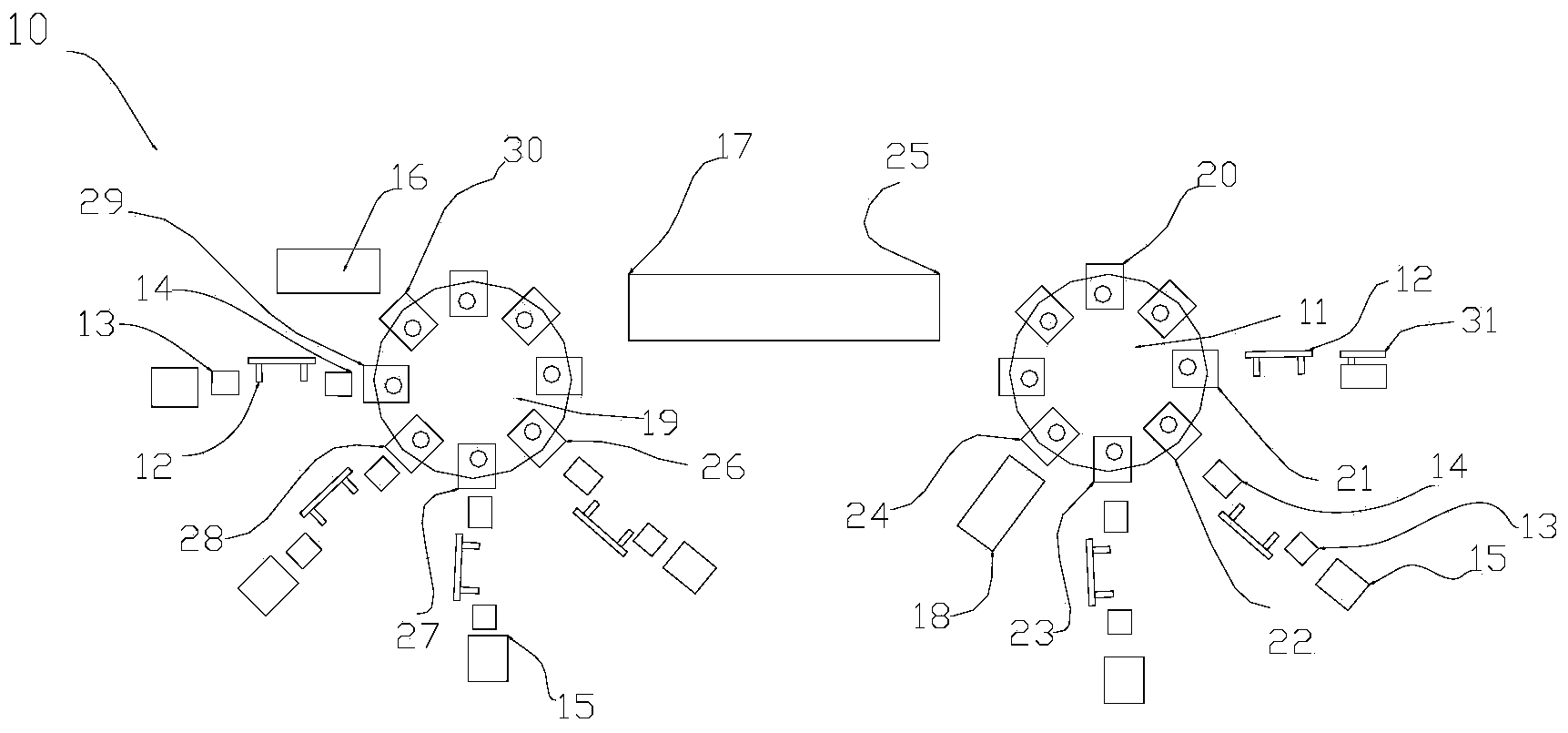

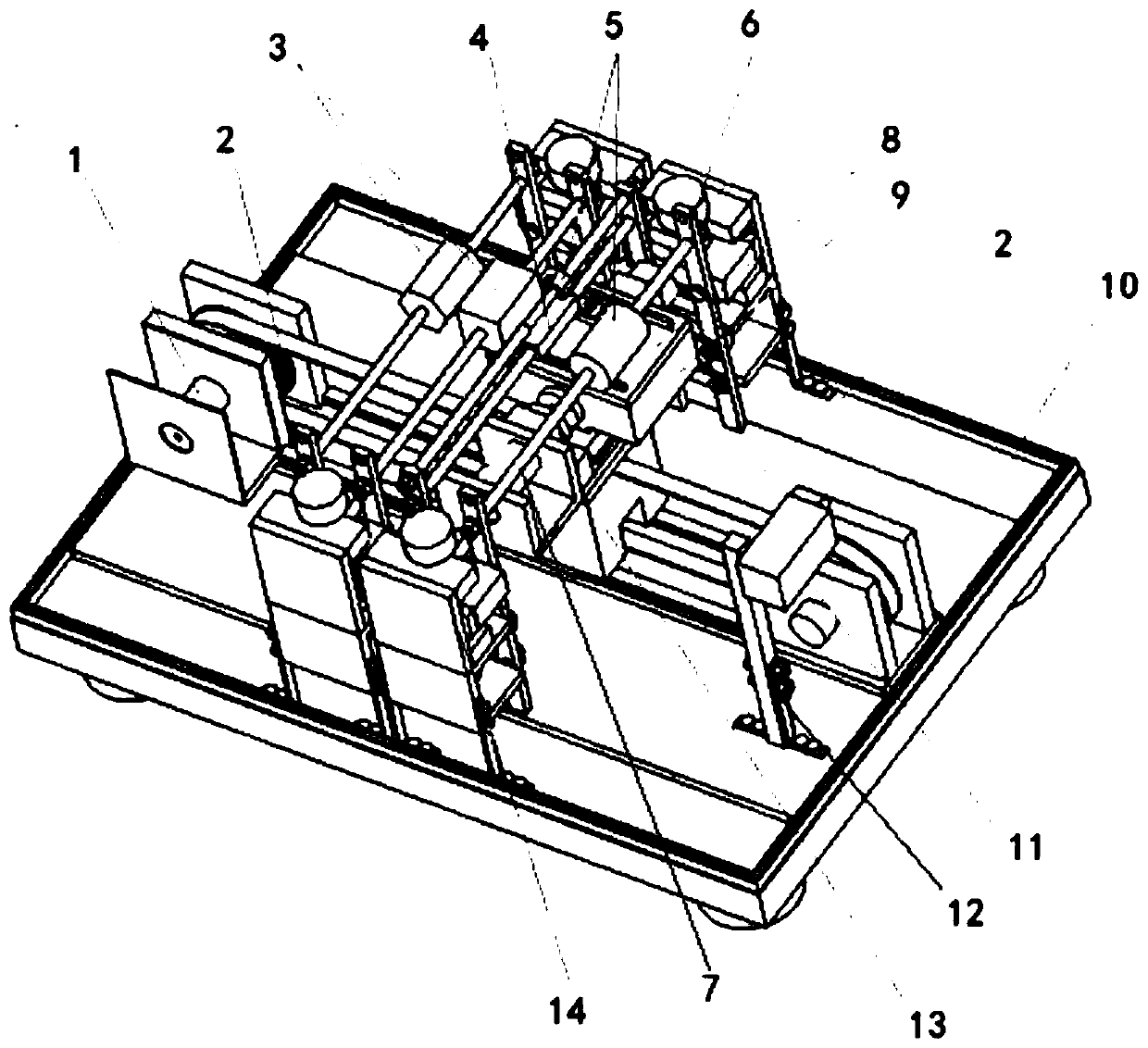

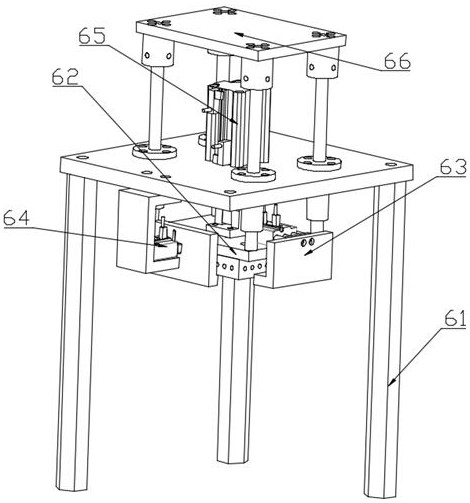

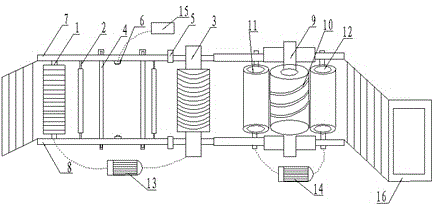

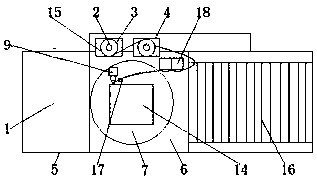

Backlight integrally assembled equipment

ActiveCN104354440AHigh precisionImprove the film effectLamination ancillary operationsLaminationLight guideEngineering

The invention discloses backlight integrally assembled equipment. The equipment comprises a first rotary work table, a second rotary work table, an FPC (flexible printed circuit) manual laying position, an automatic reversing glue frame position, a reflecting film pasting position, a light guide plate pasting position, an FPC assembly position, a diffusion barrier pasting position, a light enhancement film 1 pasting position, a light enhancement film 2 pasting position, a light shading film pasting position, a compressing discharge position and a connecting position, wherein the reflecting film pasting position, the light guide plate pasting position, the diffusion barrier pasting position, the light enhancement film 1 pasting position, the light enhancement film 2 pasting position and the light shading film pasting position respectively comprise a feeding mechanism, a stripping mechanism corresponding to the feeding mechanism, a pre-alignment mechanism, an alignment mechanism and a grabbing mechanism. The equipment is high in accuracy, saves material, has a good film pasting effect andhigh operating continuity, saves manpower and is fully automatically operated during backlight assembly, and positions of the two rotary work tables can be operated in a combined manner or the position of a single rotary work table can be operated.

Owner:SHENZHEN WEIHONGKE TECH

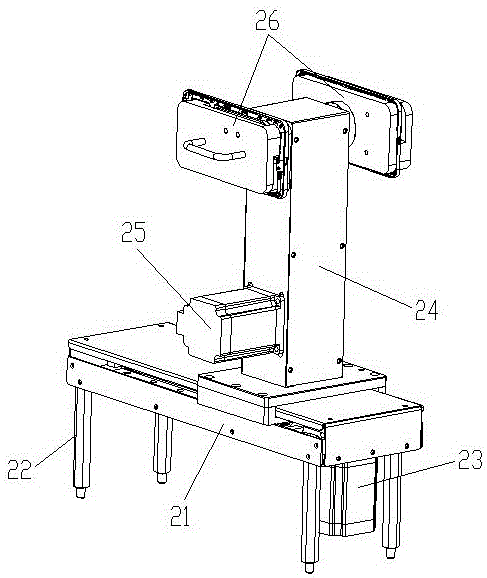

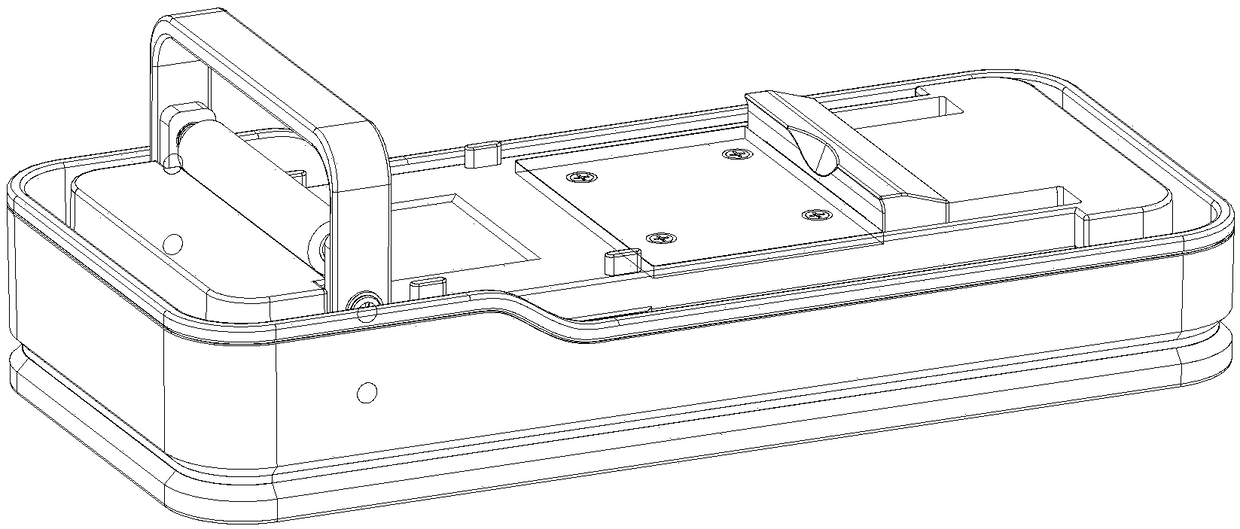

Portable film sticking machine

PendingCN108748969AEasy to operateImprove film application efficiencyDomestic articlesElectrical and Electronics engineeringElectronic equipment

The invention discloses a portable film sticking machine, and relates to the technical field of electronic equipment film sticking equipment. The portable film sticking machine comprises a base, a positioning base, a sticking film fixing base, a conveying device and a film separating device, and a positioning station and a film sticking station are arranged on the two sides of the base correspondingly; the positioning base is arranged at one end of the positioning station and used for locking the position of electronic equipment; the sticking film fixing base is arranged at one end of the filmsticking station and used for locking the position of a sticking film; the conveying device is used for enabling the positioning base to slide between the positioning station and the film sticking station in a reciprocating mode so as to enable the electronic equipment and the film to be matched with each other; and the film separating device is arranged at one end of the film sticking station and used for enabling a releasing layer and the film to be separated. According to the portable film sticking machine, the electronic equipment and the sticking film only need to be put on the positioning base and the sticking film fixing base respectively, film sticking can be completed after the conveying device slides once in a reciprocating mode, and the portable film sticking machine is easy tooperate, high in film sticking efficiency, precise in sticking film positioning and good in film sticking effect.

Owner:JIANGMEN IGUARDER ELECTRONIC CO LTD

Side edge film sticking machine

InactiveCN106347747APrecise positioningImprove efficiencyWrapping material feeding apparatusAgricultural engineeringMobile phone

The invention discloses a side edge film sticking machine. The side edge film sticking machine comprises a machine table, a control panel, a jig positioning mechanism, a tray support assembly, a film sticking mechanism, a tray mounting plate and tray mold wheels, wherein at least two rotary jigs, at least two glue coating wheels, at least two vacuum suckers and at least two pairs of pneumatic shears are arranged, loading, conveying, film roll unfolding, film tearing, film cutting, film sticking, unloading of a finished product and a series of other operations can be performed on two mobile phone shells simultaneously in a full-automatic manner by means of double stations, a series of automation operations for each mobile phone shell can be completed within two seconds, and the film sticking operation of all side edges of each mobile phone shell can be accurately completed once. Compared with a conventional machine taking at least 60 seconds only to stick films on side edges of each mobile phone, the machine has the greatly improved working efficiency, the productivity is also greatly improved, the positioning is accurate, the film sticking effect is good, the phenomena that bubbles and displacement easily happen in the film sticking process of a conventional mobile phone are prevented, and the cost is low.

Owner:DONGGUAN HUAMAO PRECISION MACHINERY TECH

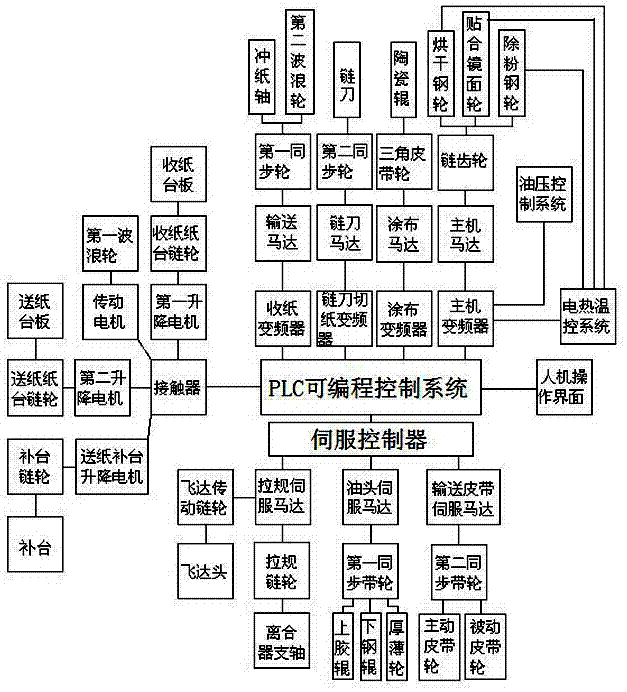

Servo control system for full-automatic laminating machine

ActiveCN107310243AAvoid driftingImprove the accuracy of film applicationLamination ancillary operationsControlling laminationFrequency changerTemperature control

The invention relates to a servo control system for a full-automatic laminating machine. The servo control system comprises a PLC programmable control system, a servo controller, a contactor, a paper-receiving frequency converter, a chain knife paper-cutting frequency converter, a coating frequency converter, a mainframe frequency converter, a man-machine operation interface, an oil head servo motor, an upper rubber roller, a lower steel roller, thick and thin wheels, a driving pulley, a driven pulley, a paper impact shaft, a chain knife, a ceramic roller, an oil pressure control system, an electric heating temperature control system, a drying steel wheel, an attaching mirror surface wheel and a powder-removing steel wheel and the like. Each frequency converter, each servo motor and the contactor are controlled through the PLC programmable control system, so that not only can operation front-rear speeds of each component of the whole machine be kept consistent, but also paper feeding, conveying, dedusting, gluing, film pasting pressurization, slitting and recycling are integrated, the paper film pasting precision is high, film pasting efficiency is high, a film pasting effect is good, and the servo control system is suitable for film pasting for paper of different specifications and different thicknesses and is convenient to use.

Owner:广东鑫佳机械科技有限公司

Mobile phone film pasting equipment and method thereof

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI +1

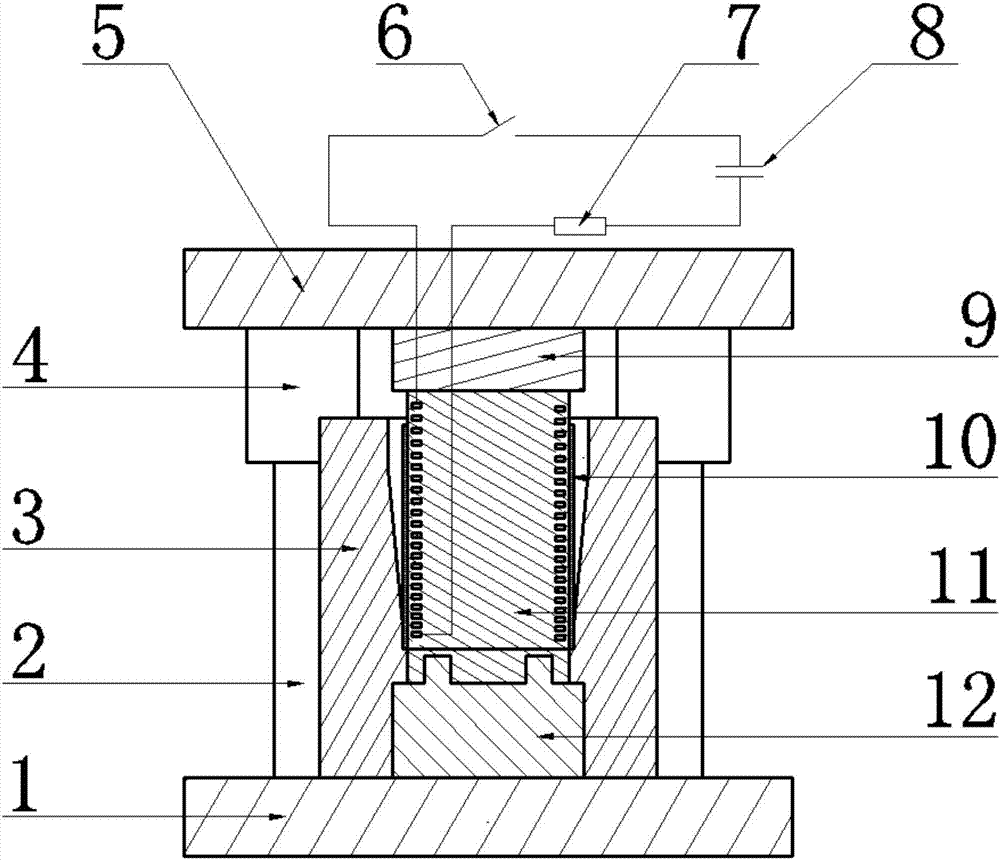

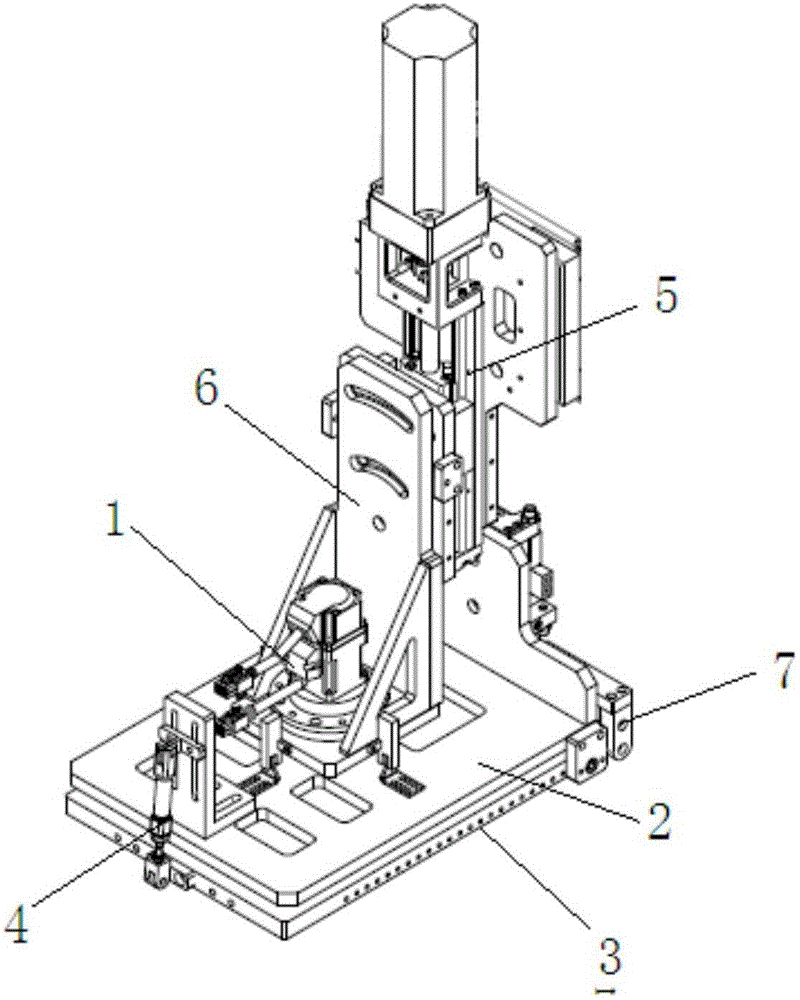

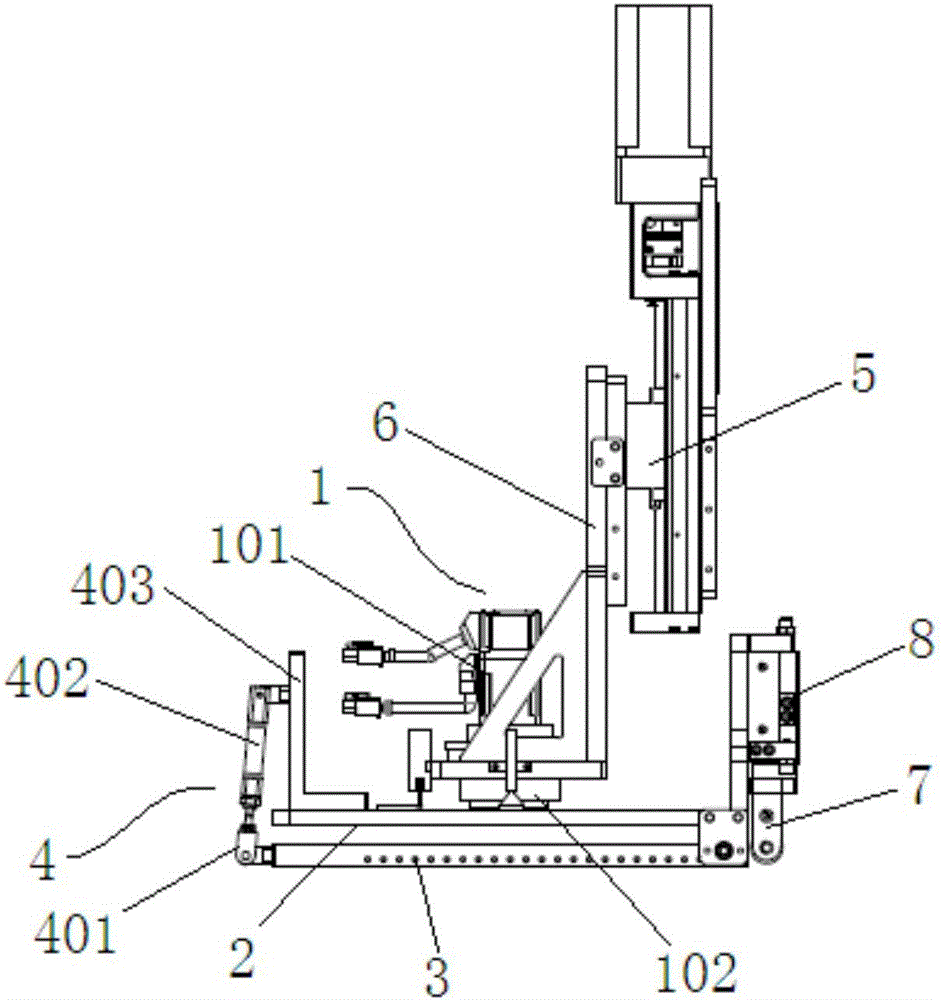

Electroplastic-effect-based elastic particle medium assisted electromagnetic forming device and forming method for light-alloy miniature complex component

ActiveCN108555110AImprove plasticityReduces the possibility of irreversible production defects such as cracksShaping toolsElectricityMetallic materials

The invention provides an electroplastic-effect-based elastic particle medium assisted electromagnetic forming device and forming method for a light-alloy miniature complex component and belongs to the field of metal material processing and forming. By means of the device and method, the problem that according to existing miniature complex component forming methods, both the workpiece quality andthe precision cannot be taken into account simultaneously is solved. According to the device, a light-alloy plate is clamped between an elastic particle medium cavity and a die, an electroplastic unitmakes the plate be subjected to the electroplastic effect, a temperature measurement unit measures the plate surface temperature, and an impact unit withstands electromagnetic force from an electromagnetic pulse generating unit and applies impact force to the plate through an elastic particle medium to make the plate be attached to a forming cavity of the die. The method comprises the steps thatthrough the electroplastic unit, the plate is subjected to the electroplastic effect, through cooperation between the electroplastic unit and the temperature measurement unit, the plate surface temperature is controlled, through the electromagnetic pulse generating unit, the electromagnetic force is applied on the impact unit, and through cooperation between the impact unit and the elastic particle medium, the plate is made to be attached to the forming cavity.

Owner:XIANGTAN UNIV

Simple film laminating machine and film laminating method thereof

The invention discloses a simple film laminating machine and a film laminating method thereof. The simple film laminating machine comprises a bracket mounting frame and a bottom shell, wherein a bracket, a guide rail mounting slot, a guide rail, a slide block, a supporting plate connector, a front rotary shaft supporting plate and a rear rotary shaft supporting plate are arranged in the bracket mounting frame; a first rotary shaft hole and a first bearing are arranged at the upper end of the front rotary shaft supporting plate; a second rotary shaft hole and a second bearing are arranged at the upper end of the rear rotary shaft supporting plate; the first bearing is connected with the second bearing through a film-pressing rotary shaft; a silica gel sleeve is arranged on the film-pressingrotary shaft in a sleeving manner; a first slide slot and a second slide slot are formed in the bracket; an U-shaped handle is arranged on the bracket; a front slide slot, a rear slide slot, a frontslide strip, a rear slide strip, a fixing plate, a first spring and a second spring are arranged on the upper end surface of the bracket; and the upper end surface of the bracket is equipped with a limiting plate. According to the simple film laminating machine disclosed by the invention, the bracket, the guide rail and the slide block are arranged in the bracket mounting frame, a mobile phone isfixed by the fixing plate, and the slide block drives movement of the film pressing rotary shaft to realize film laminating, so that the stable rolling-fitting way is uniform in stress, use of different users is convenient, and the film-laminating effect is good.

Owner:GUANGZHOU XINRU PLASTIC FILM

Continuous online coating and coiling process for color-coated steel coils

ActiveCN102765503ASimple processImprove the film effectPackagingWebs handlingStrip steelAmygdalus persica

The invention relates to a continuous online coating and a coiling process for color-coated steel coils. The problems of defects such as deformations and small bubble folds in the continuous online coating process of the existing color-coated steel coils and collapsed coils or peach-heart coils easily produced in the coiling process are solved. Coating pressure and tension are effectively controlled, and different coiling unit tensions are selected at different coiling moments at the same time, so that problems can be effectively avoided. The continuous online coating and coiling process provided by the invention is simple has good coating effect, and can achieve continuous online cold coating of color-coated strip steel; problems of defects of pulled and deformed films or pulled and broken films or loosened films on the surface of the color-coated strip steel, small bubbles, various folds and the like are solved; the collapsed coils or the peach-heart coils can be avoided in the color-coated steel coils after the color-coated steel coils are coiled; and therefore horizontal type packaging and shipment standards are fully met.

Owner:武汉钢铁有限公司

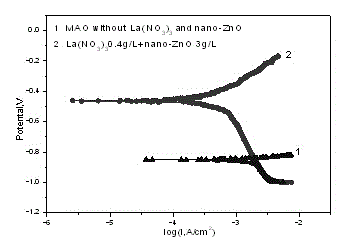

Method for improving corrosion resistance of ZL303 aluminum alloy film

InactiveCN104651903AReduce microcracksAdd thickness and hardnessAnodisationMicro arc oxidationCorrosion resistant

The invention discloses a method for improving corrosion resistance of a ZL303 aluminum alloy film. According to the method, a micro-arc oxidization electrolyte comprises 10g / L of Na2SiO3, 2g / L of Na2WO4, 2g / L of NaOH and 4ml / L of H2O2, a zinc oxide composite additive is added into the micro-arc oxidization electrolyte, and the nano concentration of the zinc oxide composite additive is 3g / L. After being added into the micro-arc oxidization electrolyte, the zinc oxide composite additive can join the micro-arc oxidization reaction and is deposited into the micro-arc oxidization ceramic layer, the microcracks on the surface of a micro-arc oxidization film can be reduced after the addition of the zinc oxide composite additive, the thickness and the hardness of the surface of the film can be increased, and the corrosion resistance of the micro-arc oxidization film can be enhanced.

Owner:罗伟

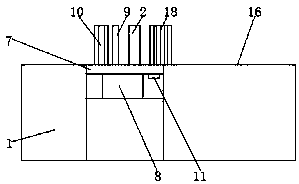

Wafer laminating device

InactiveCN104409384AAvoid crackingAvoid scratchesSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingAutomationElectrical and Electronics engineering

The invention discloses a wafer laminating device. The wafer laminating device is characterized by comprising a first fixing device, a second fixing device and a pressing device, wherein the first fixing device is arranged in such a manner that the first fixing device can move leftwards and rightwards; the second fixing device is arranged in such a manner that the second fixing device can move leftwards and rightwards; the second fixing device and the first fixing device get close to and far away from each other when either or both of the second fixing device and the first fixing device move; the first device and the second device are used together for clamping a film; the pressing device is arranged in such a manner that the pressing device can move leftwards and rightwards; and the pressing device can be used for pressing the film along with the leftward and rightward movement of the first fixing device or the second fixing device to stick the film to the wafer. Through adoption of the wafer laminating device disclosed by the invention, full automation of a laminating process can be realized; the laminating efficiency is increased greatly; the laminating stability is enhanced greatly; and the laminating effect is improved.

Owner:上海技美科技股份有限公司

Touch screen laminating equipment

ActiveCN112693664AAvoid offsetImprove film application efficiencyWrapping material feeding apparatusWebs handlingTouchscreenMechanical engineering

The invention discloses touch screen laminating equipment which comprises a rack, a bottom plate, a feeding mechanism, a feeding assisting assembly, a material taking mechanism, a film laminating and conveying mechanism, a correcting and pressing mechanism, a hot compress mechanism, a longitudinal conveying mechanism and a trowelling mechanism. The bottom plate is arranged on the upper part of the rack; the film laminating and conveying mechanism is transversely arranged on the rear side of the right end of the bottom plate; the feeding mechanism is arranged on the back of the front side of the right end of the bottom plate; the longitudinal conveying mechanism is longitudinally arranged at the left end of the bottom plate; the hot compress mechanism is arranged on the left side of the upper part of the longitudinal conveying mechanism; the trowelling mechanism is arranged on the right side of the upper part of the longitudinal conveying mechanism; and the correcting and pressing mechanism is arranged at the right end of the bottom plate. According to the touch screen laminating equipment provided by the invention, the film pasting efficiency can be improved,the film pasting position is guaranteed, film pasting position deviation is effectively avoided, the film pasting effect is good, the reject ratio is greatly reduced, consumables are saved, the production benefits are increased, and the touch screen laminating equipment has a good market application value.

Owner:深圳市汇凌信息技术有限公司

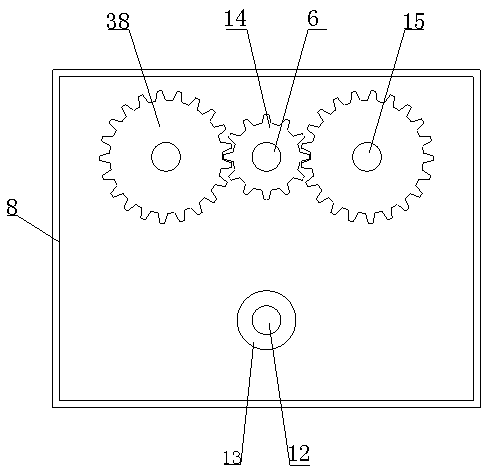

Membrane adhering device for amorphous silicon membrane manufacturing

The invention discloses a membrane adhering device for amorphous silicon membrane manufacturing. The device comprises a device body, wherein the device body is provided with a bottom plate; a positioning seat is connected to upper part of the bottom plate, and a mounting plate is connected to the front of the bottom plate; a protecting box is connected to the outer sides of the mounting plate andthe bottom plate; a first speed reduction motor which is connected to a first lead screw is mounted in the protecting box; the first lead screw is connected to a gear; second gears connected to secondlead screws are connected to the left and right of the first gear; the first lead screw and the second lead screws penetrate the protecting box and the mounting plate through a first bearing; and thefirst lead screw and the second lead screw are in thread connection with a positioning plate. According to the device, objects which are different in shapes and sizes and are to be adhered with membranes can be clamped and positioned through the positioning seats, so that the membranes can be continuously adhered in later period; the membranes can be distributed through a membrane distributing board, and the operation is simple, so that the problem that both time and force are wasted by manual membrane shearing can be avoided, and the working efficiency is improved; an upper clamping rod, a lower clamping rod and a spring are matched to clamp one end of each membrane, and thus the length of each membrane can be conveniently adjusted; a membrane pressing rod with adjustable height is arranged, so that the membrane adhering effect is good, and the design is reasonable.

Owner:中山市恒辉自动化科技有限公司

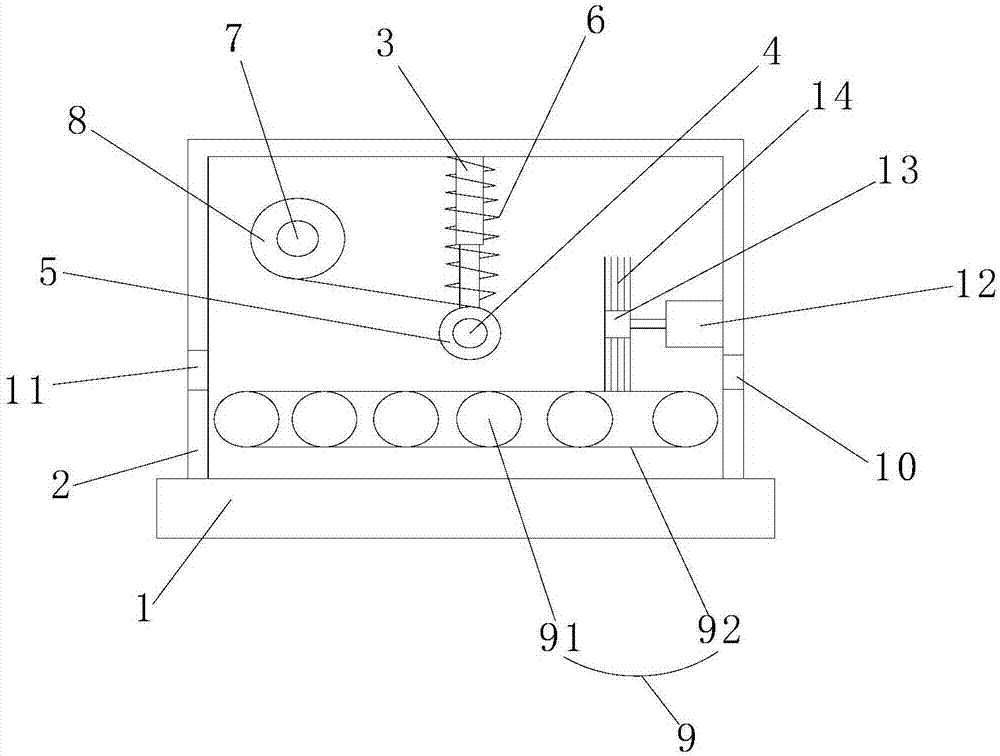

Film sticking device for PVC plates

The invention discloses a film sticking device for PVC plates. The film sticking device comprises a base, a machine frame, a telescopic rod, a traction roller, an inflatable sleeve, a spring, a film roller, a thin film, a conveying device, a feeding inlet, a discharging outlet, a motor, a turning wheel and bristles; the upper part of the base is provided with the machine frame, the telescopic rodis arranged at the bottom of the transverse part of the machine frame, and the traction roller is rotatably arranged at the lower end of the telescopic rod; the circumferential surface of the tractionroller is sleeved with the inflatable sleeve, and the spring is arranged outside the telescopic rod; the film roller is arranged at the upper right of the traction roller, and the thin film is arranged at the outer side of the film roller; the conveying device is arranged below the traction roller, the feeding inlet is arranged at the right side of the machine frame, and the feeding outlet is arranged on the left side of the machine frame; and the motor is arranged at the right side of the machine frame, the turning wheel is arranged on a rotating shaft of the motor, and the bristles are arranged on the circumferential surface of the turning wheel. Compared with the prior art, the PVC plates can be quickly and conveniently filmed by the film sticking device, the efficiency and the effectof film sticking are improved, and the PVC plate processing is facilitated.

Owner:XINCHANG LONG HAO BEARING CO LTD

Automatic attaching structure

The invention provides an automatic attaching structure used for cooperating with a manipulator to attach a protective film. The automatic attaching structure comprises a substrate, a positioning fixture, an adsorbing and pressing fixture, a turning cylinder, a turning rod and a control unit; the positioning fixture is arranged on the substrate, and a product is placed on the positioning fixture;the adsorbing and pressing fixture cooperates with the positioning fixture to press the product and the protective film, the side, facing the positioning fixture, of the adsorbing and pressing fixtureis provided with an adsorbing structure body used for adsorbing the protective film, and the manipulator is used for clamping and tearing down release paper of the protective film; the turning cylinder is arranged on the substrate and provided with a pushing rod doing telescoping motion; one end of the turning rod is connected with the pushing rod, the other end of the turning rod is connected with the adsorbing and pressing fixture, and the pushing rod moves to drive the turning rod and the adsorbing and pressing fixture to rotate; and the control unit is used for controlling actions of theturning cylinder and the manipulator. According to the automatic attaching structure, the labor cost is reduced, the working efficiency is high, the film attaching consistency is guaranteed, and the film attaching effect is good.

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

Furniture plate flow line film sticking machine

InactiveCN104554885AExtended service lifeImprove the film effectPackagingEngineeringUltimate tensile strength

The invention discloses a furniture plate flow line film sticking machine, which comprises a film sticking machine body, a transmission motor group and a flattening motor group, wherein a left support frame and a right support frame are arranged on the film sticking machine body; one end of the left support frame and one end of the right support frame are provided with a feeding roller; the feeding roller is connected with the transmission motor group through a belt, and through being driven by the transmission motor group, a furniture plate workpiece enters the left and right support frames along the feeding rollers. The furniture plate flow line film sticking machine has the advantages that the film pasting effect is good, and the furniture plate flow line film sticking machine is particularly suitable for being popularized in furniture plates and decoration industries, and the work intensity is reduced, and the work efficiency is improved.

Owner:圣鹿(苏州)环保新材料科技有限公司

Manual film pasting device for smart phone

The invention discloses a manual film pasting device for a smart phone. A rectangular base is included, and a concave table penetrating the rear end face of the base is formed on the upper end face ofthe base; a rubber cushion block is inserted and connected to the bottom face of the front end of the concave table of the base; a plurality of arc-shaped transverse grooves are formed in the bottomface of the portion, on the rear side of the rubber cushion block, of the concave table; downward pressing rollers are inserted and connected in the transverse grooves of the base; a notch is formed in the rear end of the concave table of the base; longitudinal cushion plates are formed in the lower end face, on the two sides of the notch, of the base; a plurality of transverse lower protruding strips are formed in the upper end face of the portion, on the front side of the concave table, of the base; a plurality of supporting lugs are formed on the front end face of the base; a transverse hinged shaft is hinged to the supporting lugs; and the two ends of the hinged shaft are hinged to an n-shaped groove cover. The manual film pasting device for smart phone is simple in structure, is usedas an auxiliary device for film pasting of the mobile phone to assist a person which does not master film pasting in achieving film pasting of the mobile phone, and has a good film pasting effect, andtherefore film pasting by a mobile phone owner himself / herself is achieved conveniently, and cost is saved.

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

Film laminating device with display screen cleaning function and for laminating film on computer display screen

PendingCN113247348AEasy maintenanceTo achieve the effect of flippingPackaging automatic controlSynchronous motorEngineering

The invention discloses a film laminating device with a display screen cleaning function and for laminating a film on a computer display screen, and relates to the technical field of computer display screen machining. The film laminating device comprises a base, a cleaning mechanism and a film laminating mechanism, a placement frame is arranged at the position, close to the edge, of the upper end of the base, a feeding conveying belt is arranged on the left side of the upper end of the base, and a computer display screen body is placed at the upper end of the feeding conveying belt. The computer display screen body placed in a first transfer mechanism can be clamped through clamping assemblies symmetrically distributed on the two sides of a cleaning bin, the effect that the clamping assemblies drive the computer display screen body to turn over can be achieved in cooperation with an arranged synchronous motor, dust on the surface of the computer display screen body can be cleaned through cooperation with a cleaning palm brush vertically distributed in the center of the interior of the cleaning bin, lifting and rotating of the cleaning palm brush are achieved through an air cylinder and a motor arranged at the bottom, and the effect of cleaning the dust on the surface of the computer display screen body is achieved.

Owner:深圳市凤舞科技有限公司

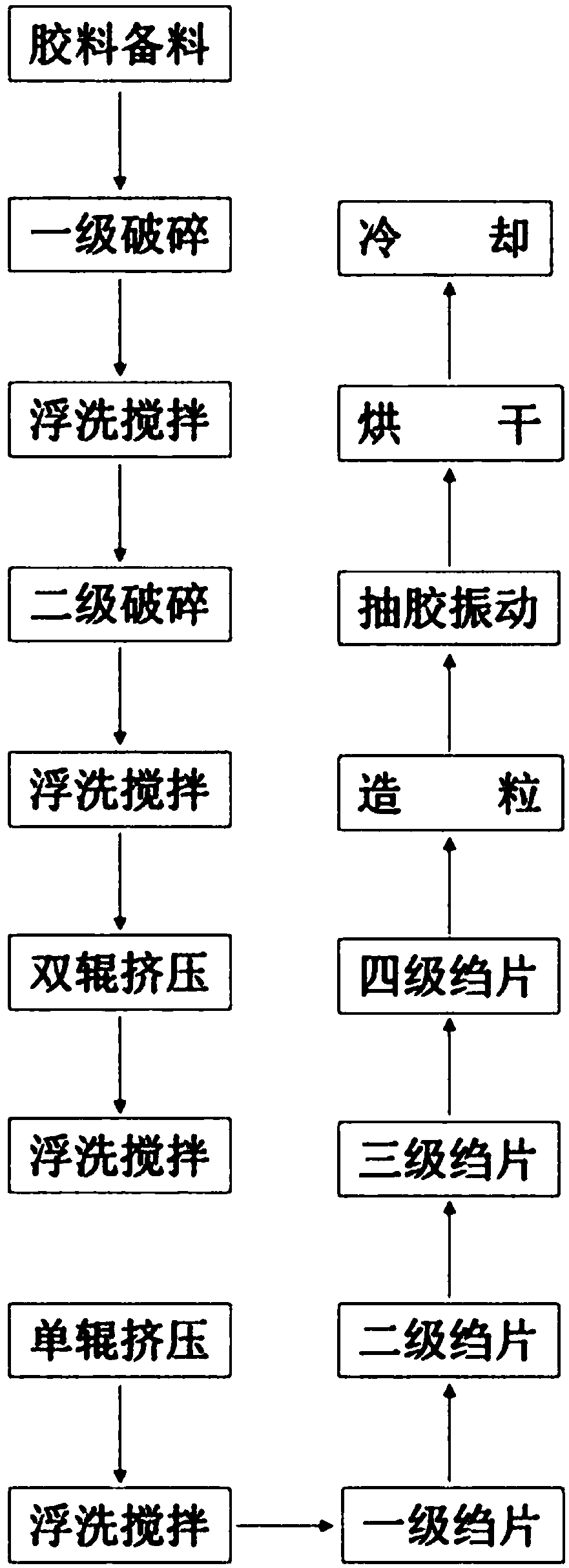

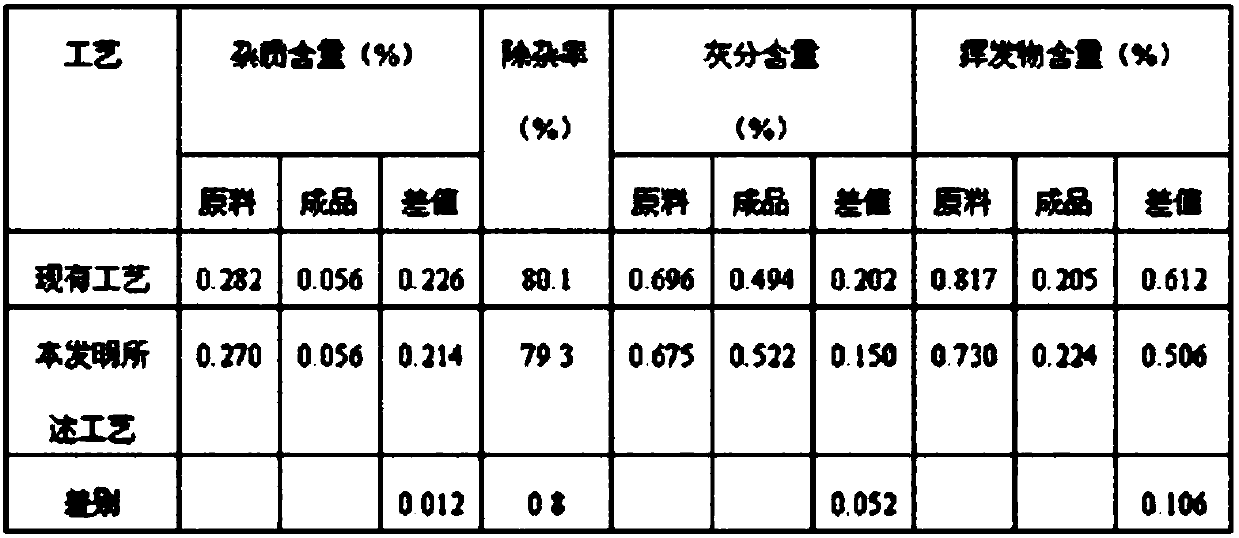

Processing technology for special rubber for radial tire

The invention discloses a processing technology of special rubber for radial tires. The process first divides the recovered rubber raw materials into two grades according to the evaluation results of the enterprise quality inspection standards, and breaks them into rubber blocks of 40cm×10cm×8cm~50cm×15cm×20cm respectively, and divides the graded rubber raw materials after removal of impurities by 1 ~3:1~3 weight ratio mixing. The mixed rubber material is crushed in the first stage, floated and stirred, and the secondary crushed, floated and stirred, the floating washing time must be ≥ 20min, and then the mixed rubber material is subjected to two-stage extrusion floating washing, and the floating washing time must be ≥ 12min, Make the rubber into a gelatinous mass. The rubber material is treated with one to four stages of creping to make the rubber material into a continuous sheet with a thickness of 6-12mm, and the creped rubber material is granulated to make rubber particles with a diameter of 6-12mm. The colloidal particles are pumped and vibrated, dried at 82-108°C according to the standard of 4-6t / h rubber material, and then cooled to room temperature. The process improves the impurity removal rate of the equipment, avoids damage to the rubber structure due to excessive processing, simplifies the equipment configuration of the production line, reduces the overall failure rate, reduces the amount of crushed rubber, and improves production efficiency.

Owner:南通通江橡胶制品有限公司

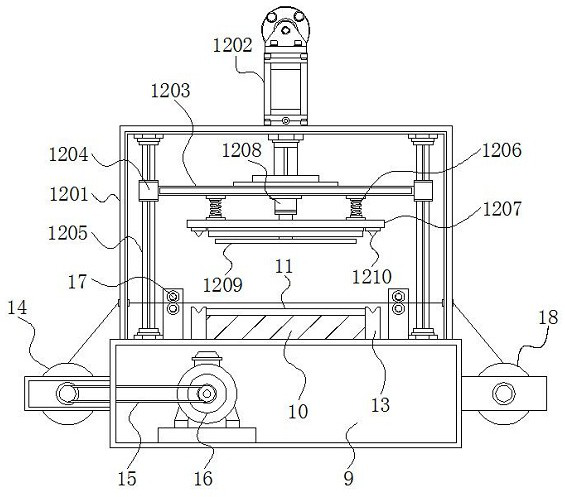

Movable film sticking device for automatic film sticking machine for mobile phone touch screen

The invention provides a movable film sticking device for an automatic film sticking machine for a mobile phone touch screen and belongs to the technical field of mobile phone touch screen film sticking equipment. The technical problem that the existing film sticking speed and efficiency are very low is solved. The movable film sticking device comprises a first sliding seat and a second sliding seat which are arranged on the two sides of a fixed plate respectively, a sliding rail in the horizontal direction is fixed on the lower surface of the fixed plate, the sliding direction of the sliding rail is consistent with the length direction of the fixed plate, the first sliding seat and the second sliding seat are opposite in position and are fixed through a first linkage plate, the first linkage plate is located below the fixed plate and slidably connected to the sliding rail, and a rotating shaft is connected between the first sliding seat and the second sliding seat. A driving mechanism of the movable film sticking device drives the rotating shaft to rotate, so that a protective film is automatically overturned and stuck to the touch screen, the automatic overturning is achieved, and the speed is improved. A driving cylinder indirectly drives an upper film sticking plate to move, the automatic movement of the protective film is achieved, and the film sticking speed is also improved.

Owner:ZHEJIANG XINGXING TECH CO LTD

Film wrapping mechanism

InactiveCN110386301AHigh degree of automationEasy to useWrapping material feeding apparatusWrapping with article rotationRotary stageCompression device

The invention discloses a film wrapping mechanism. The mechanism comprises a feeding table, a film winding roller, a film roll, a film winding motor, a conveying roller, a machine body, a film wrapping table, a rotating table, a rotating motor, a supporting compression device, a supporting compression roller, an air pump, an air cylinder, a pneumatic pushing rod and a placing groove, wherein the feeding table is arranged on the front side of the machine body, the film wrapping table is arranged on the rear side of the feeding table, the rotating table is arranged on the film wrapping table, and the rotating motor is arranged at the bottom of the rotating table. According to the film wrapping mechanism, a film winding device is arranged, so that automatic film feeding is realized, and the rotating table is arranged, so that a product is rotated; a pneumatic device is arranged, so that a film is pressed; a stretching device is arranged, so that the film is stretched; and a cutting deviceis arranged, so that the film is automatically cut off. Compared with an existing film wrapping device, the film wrapping mechanism has the advantages of being high in automation degree, convenient to use and good in film wrapping effect.

Owner:江敏

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com