Automatic attaching structure

A sticking and automatic technology, applied in packaging and other directions, can solve the problems of high labor cost, low efficiency, poor manual sticking effect, etc., and achieve the effect of high work efficiency, labor cost saving, and good film effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

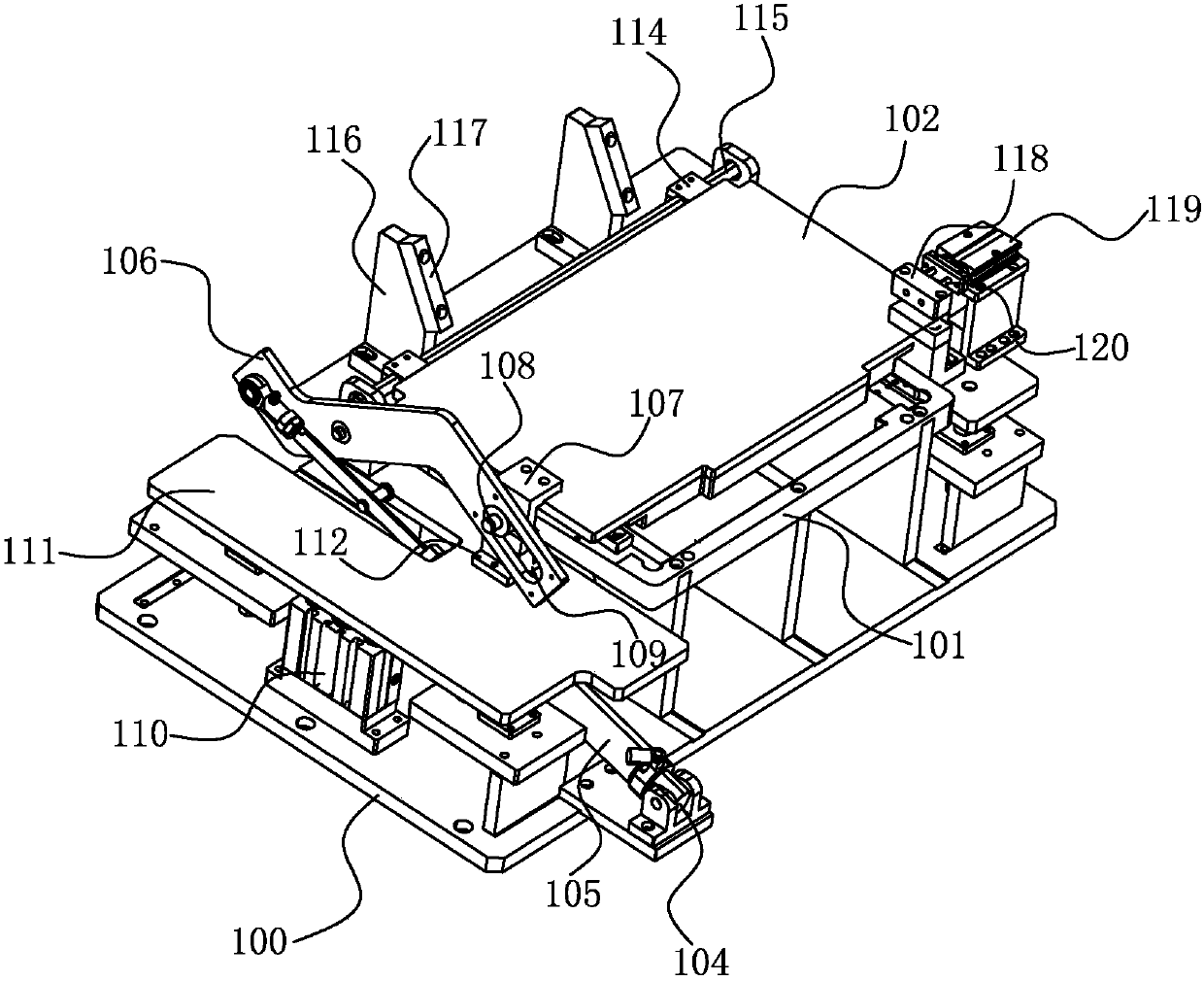

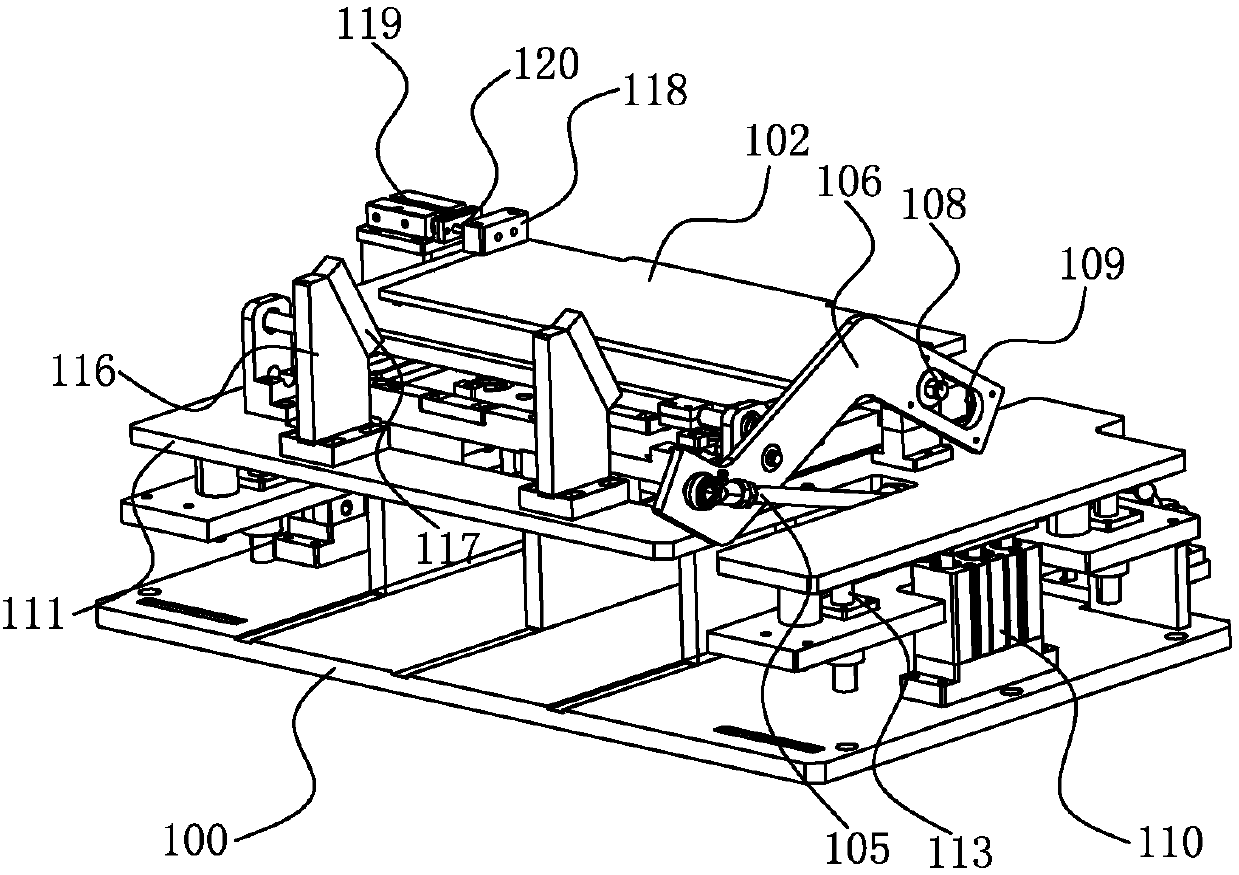

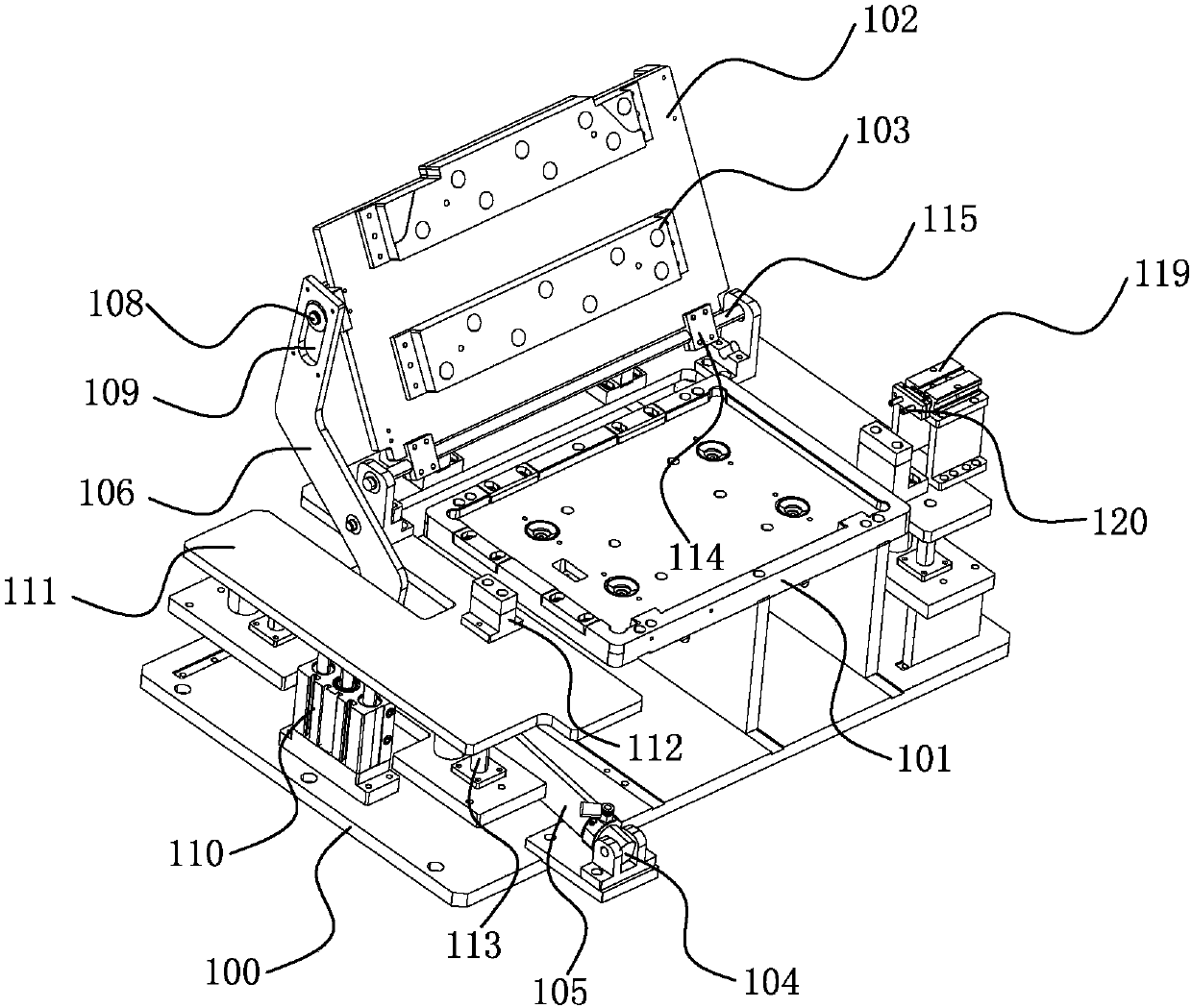

[0027] see figure 1 and figure 2 shown, where figure 1 A schematic diagram of an angle of the first working state of the automatic film sticking structure of the present invention is depicted, figure 2 A schematic diagram of another angle of the first working state of the automatic film sticking structure of the present invention is shown.

[0028] In this embodiment, the automatic attachment structure of the present invention is used to cooperate with a manipulator (not shown) to attach a protective film 10. The protective film 10 can be a sheet product such as aluminum foil. The automatic attachment structure includes :

[0029] Substrate 100;

[0030] The positioning jig 101 is set on the substrate 100, and the product 20 is placed on the positioning jig 101;

[0031] Adsorption and pressing fixture 102, cooperate with positioning fixture 101 to press and press product 20 and protective film 10, adsorption and pressing fixture 102 has adsorption structure 103 on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com