Patents

Literature

70619results about How to "Reduce labor costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

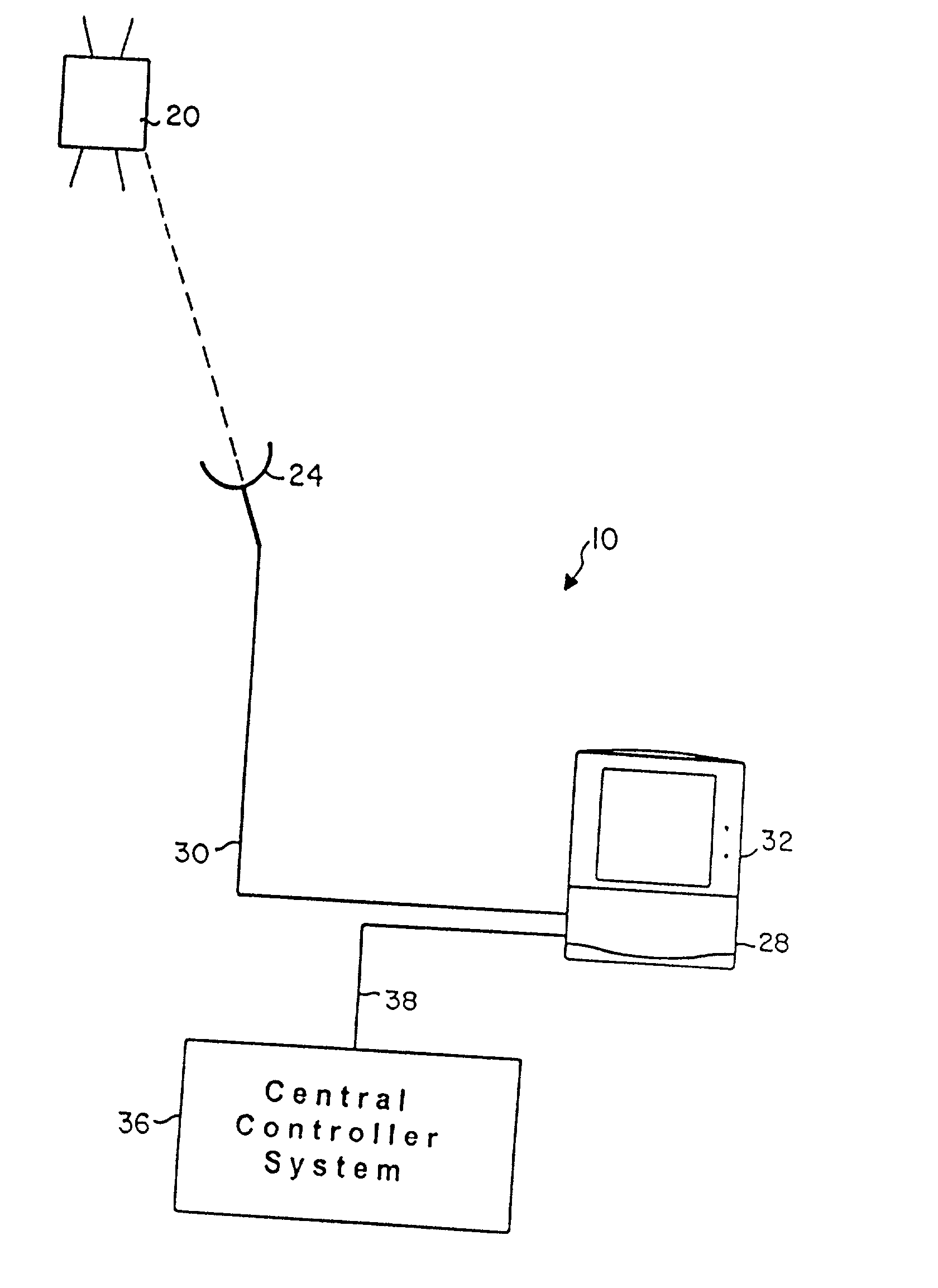

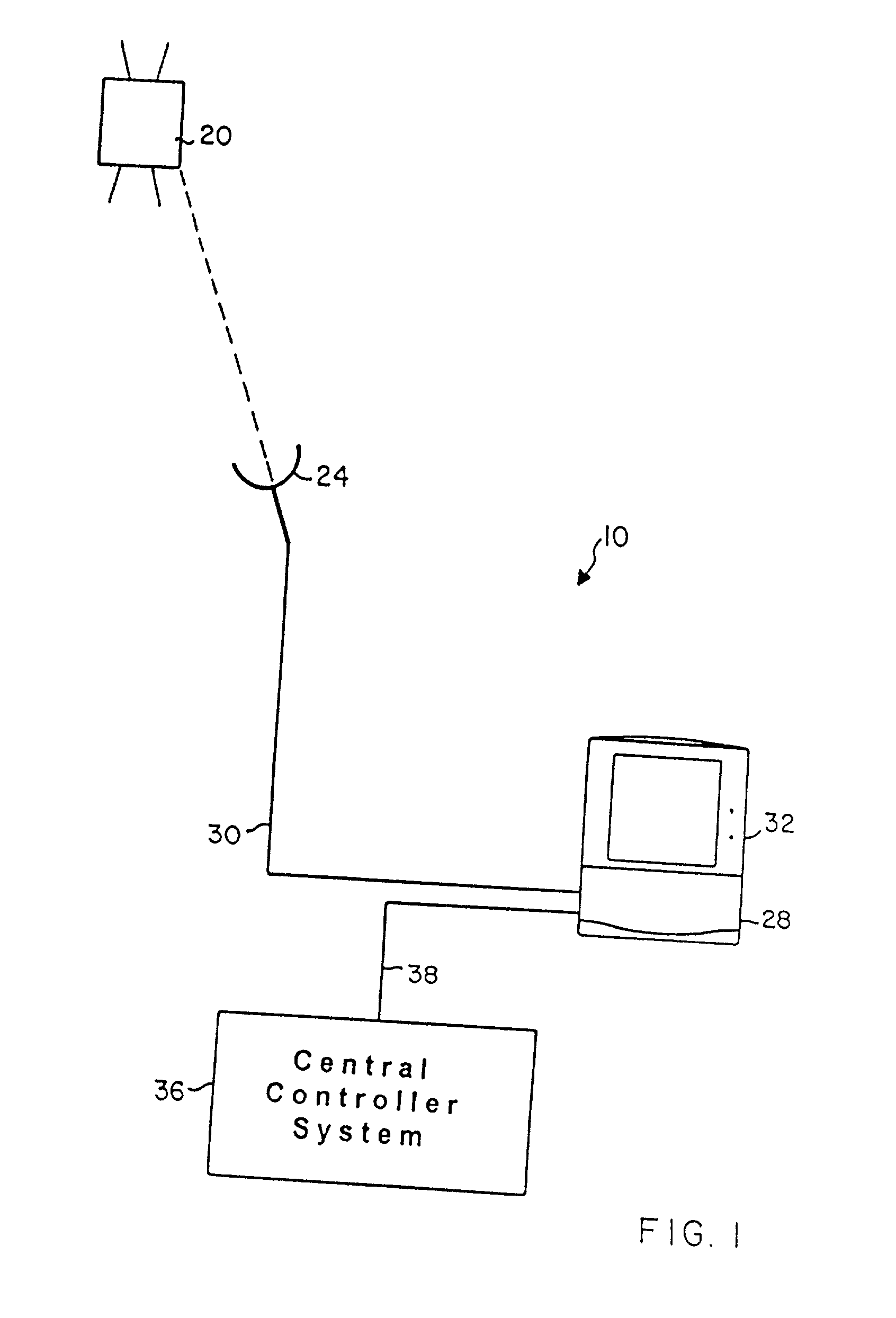

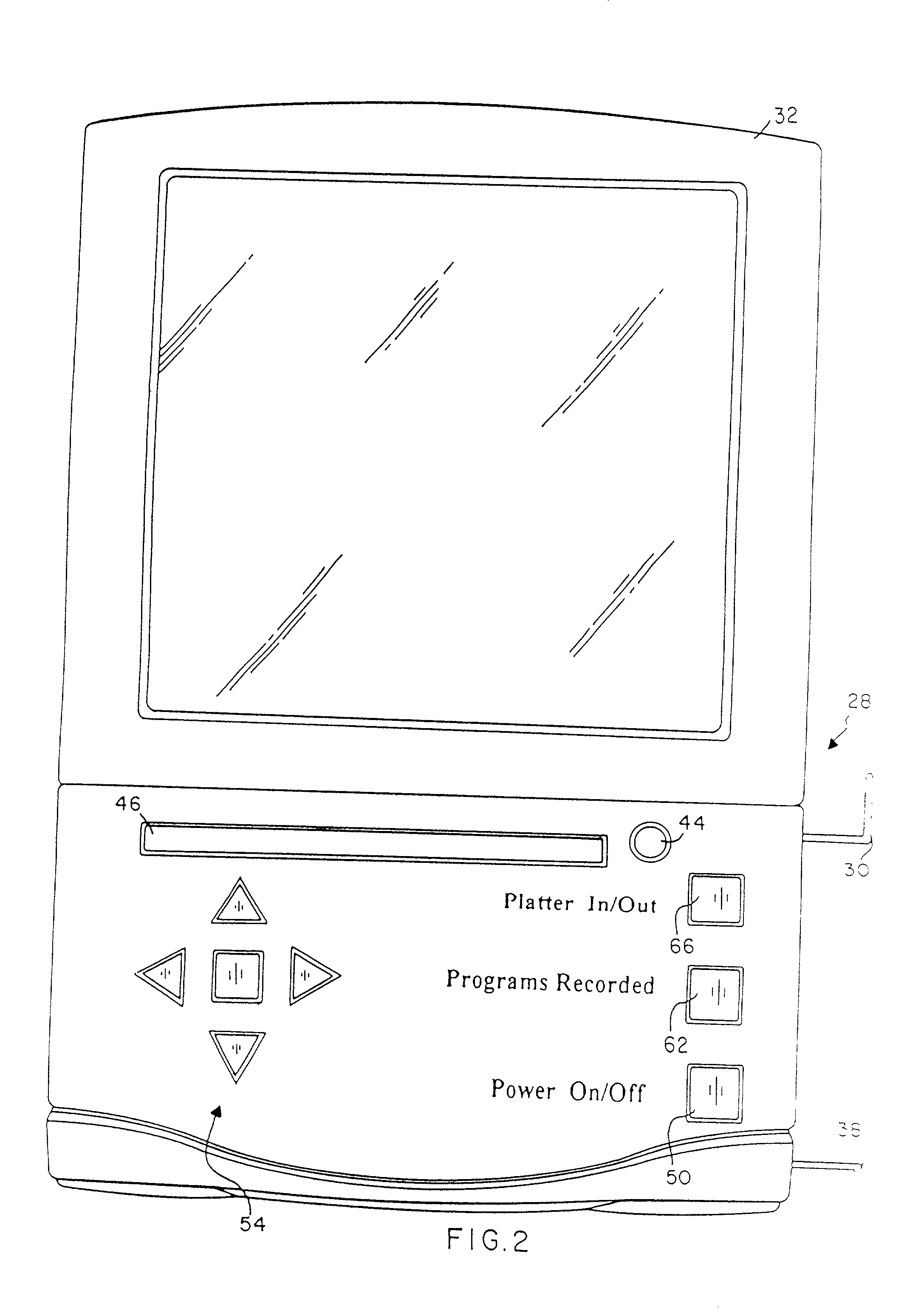

Video and music distribution system

InactiveUS20020056118A1Low costReduce labor costsTelevision system detailsRecord information storageDistribution systemAudio frequency

The invention relates to video and music distribution systems and, more particularly, to a system that blanket transmits video / audio content such as movies (for example, via satellite downlink transmission) to each customer's recording, storage and playback system. Customers may preselect from a list of available movies or other content in advance using an interactive screen selector, and pay for the video / audio content that is actually viewed.

Owner:WORLD THEATRE INC +1

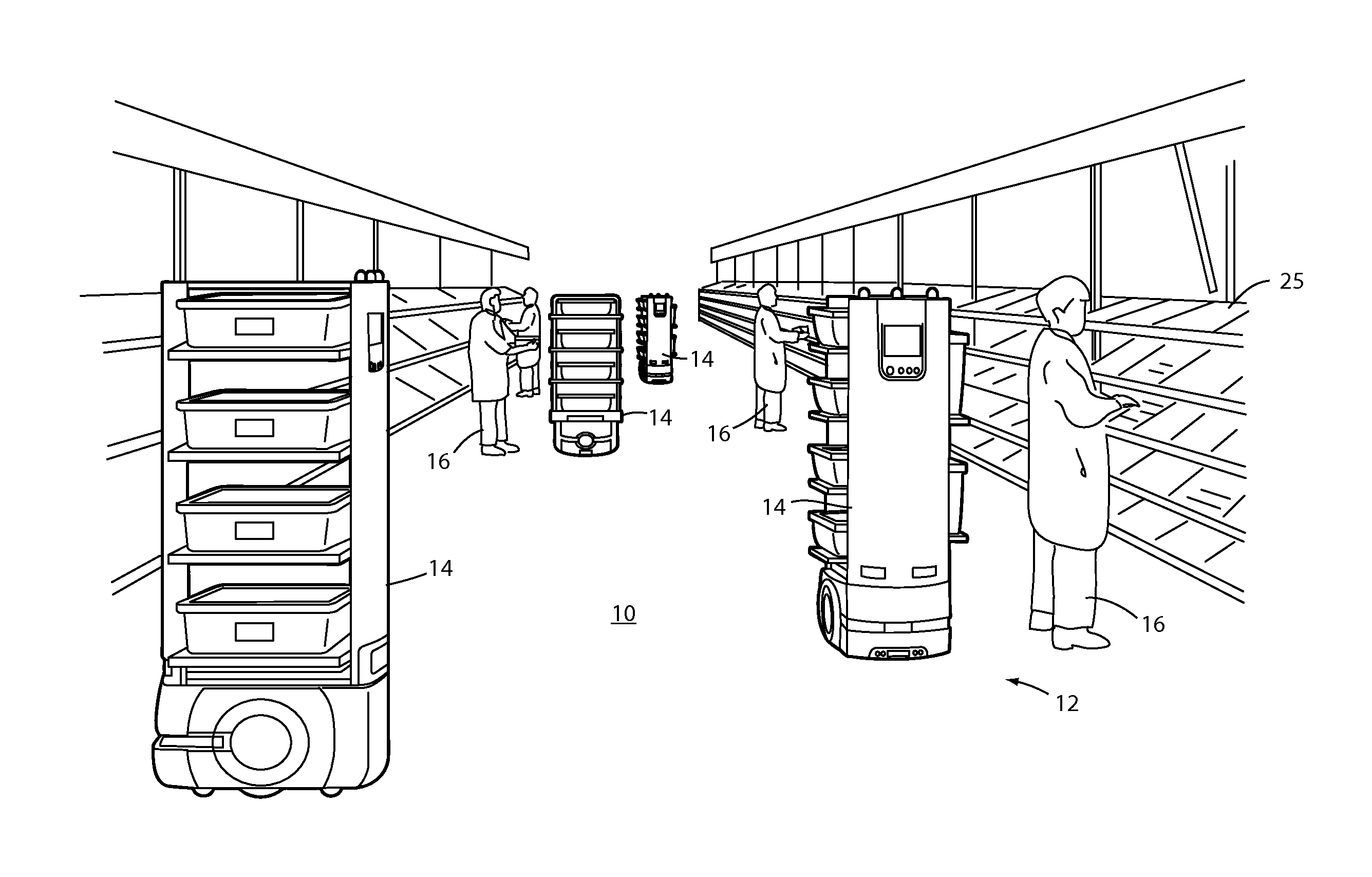

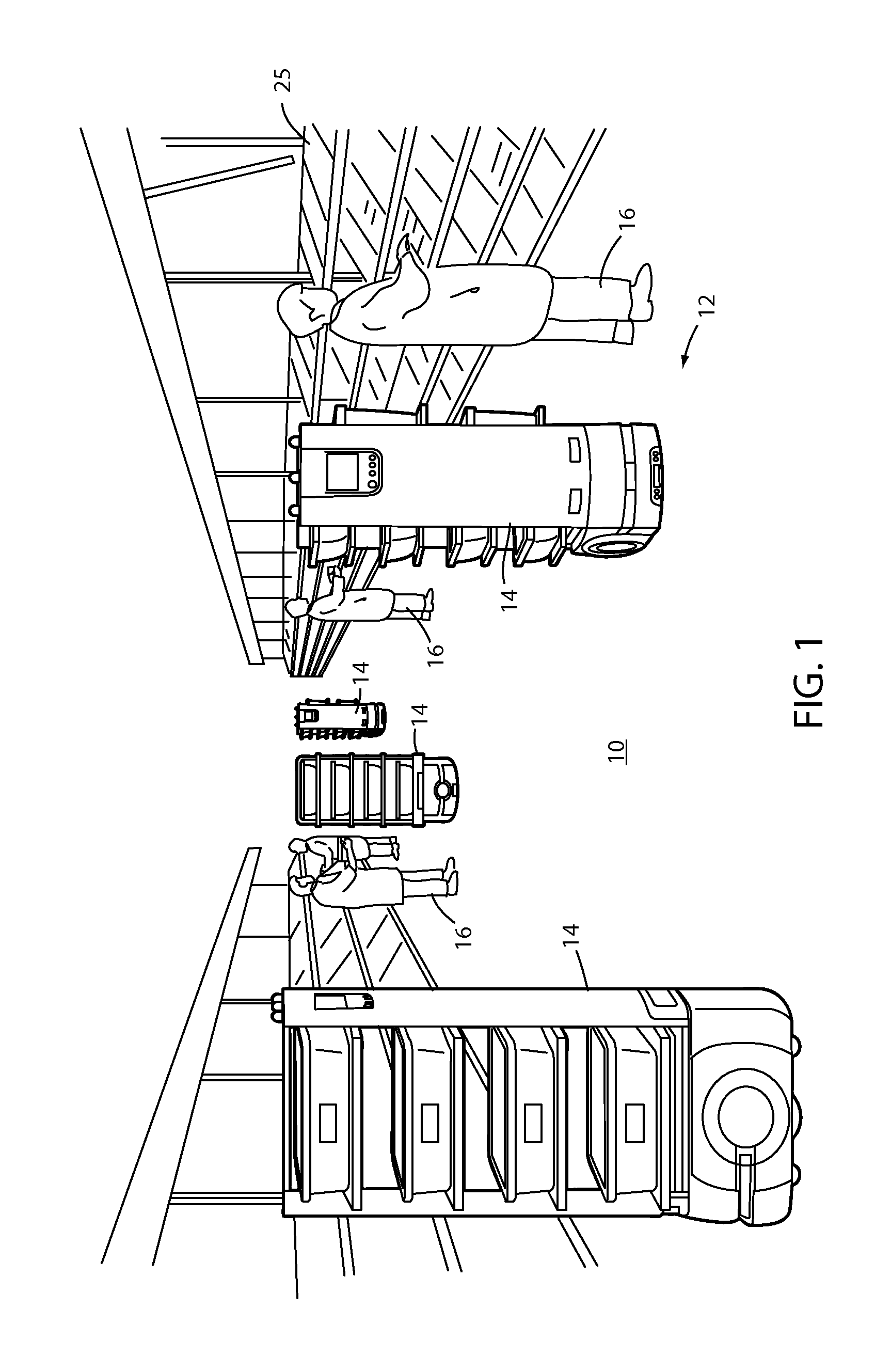

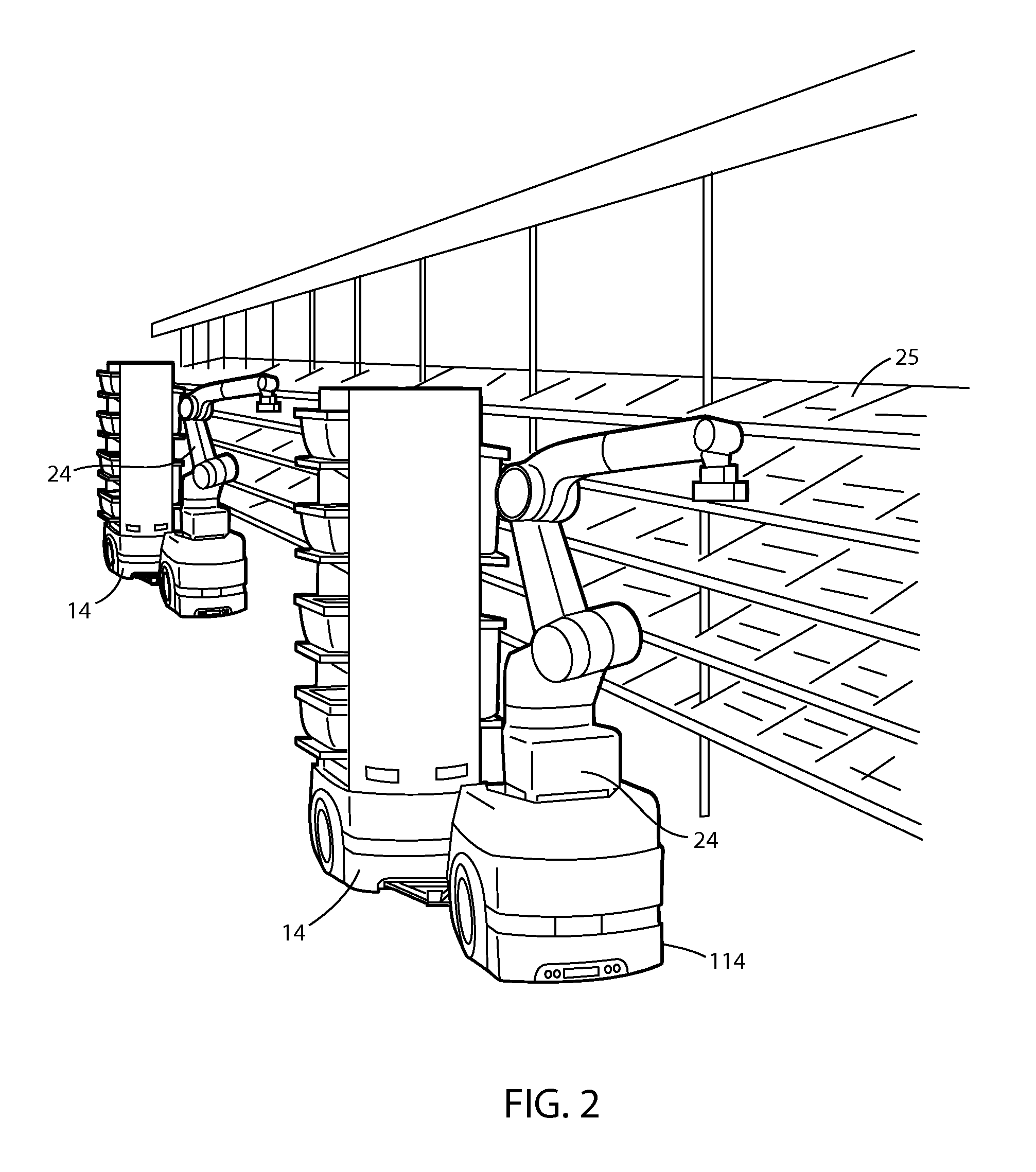

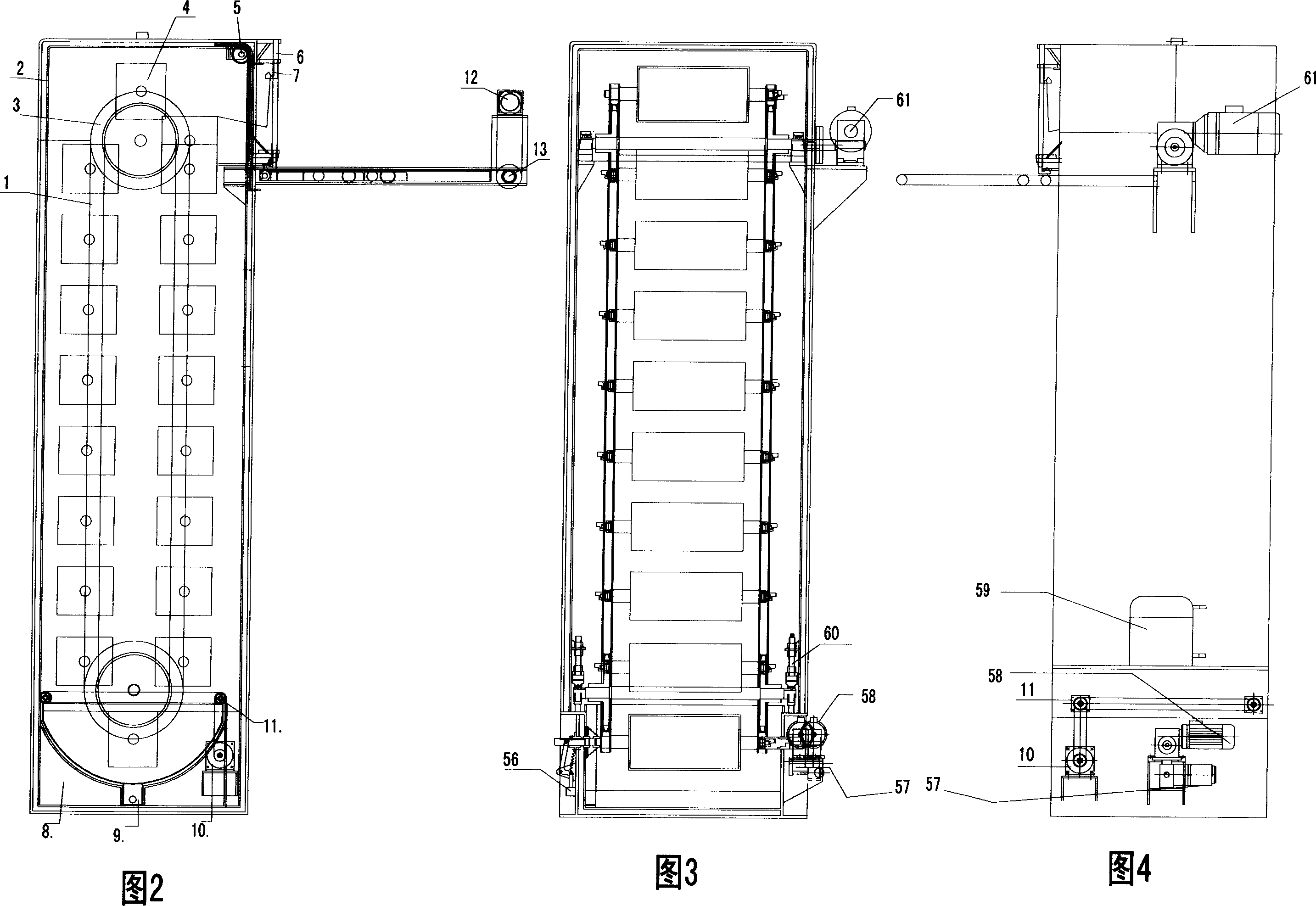

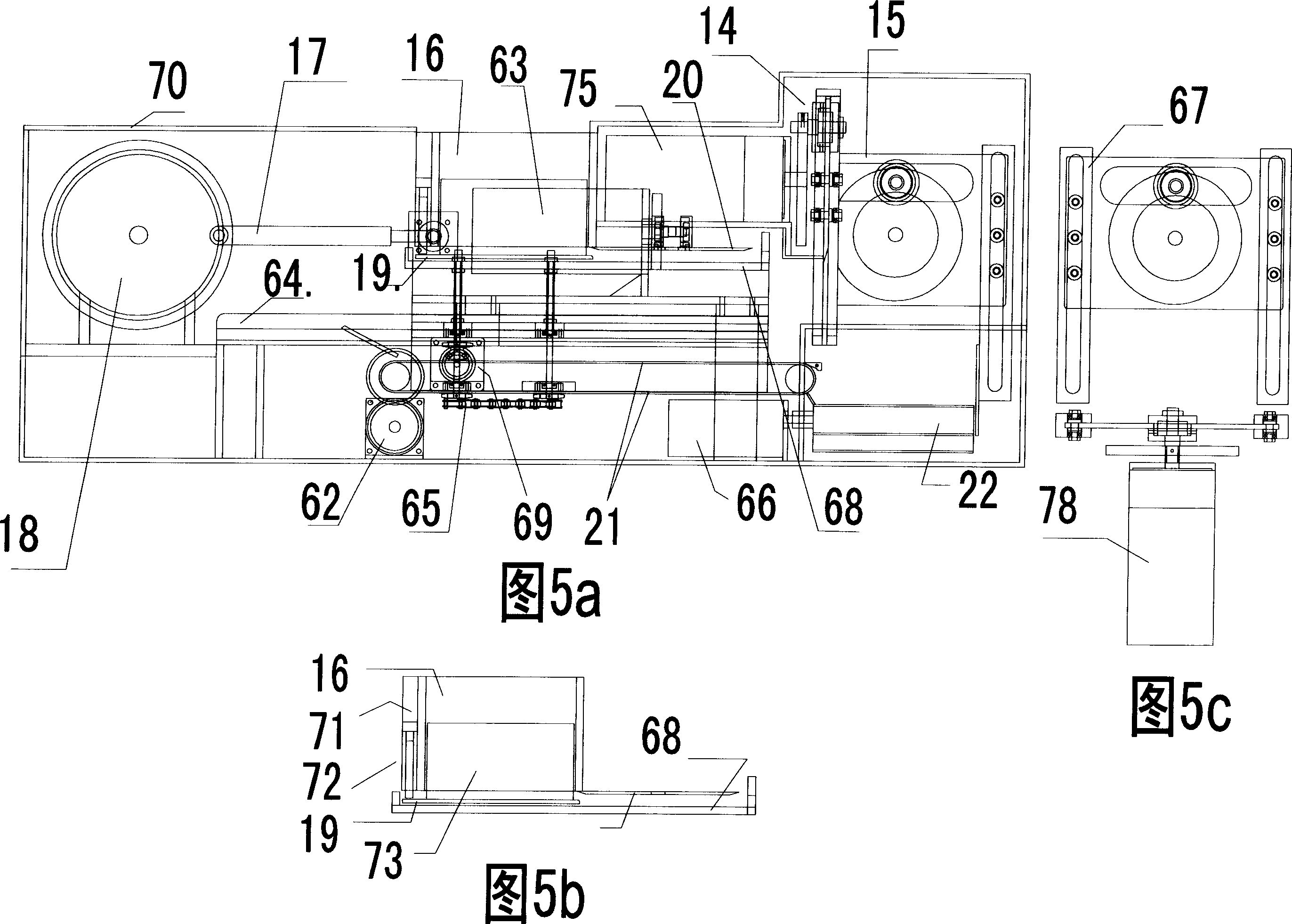

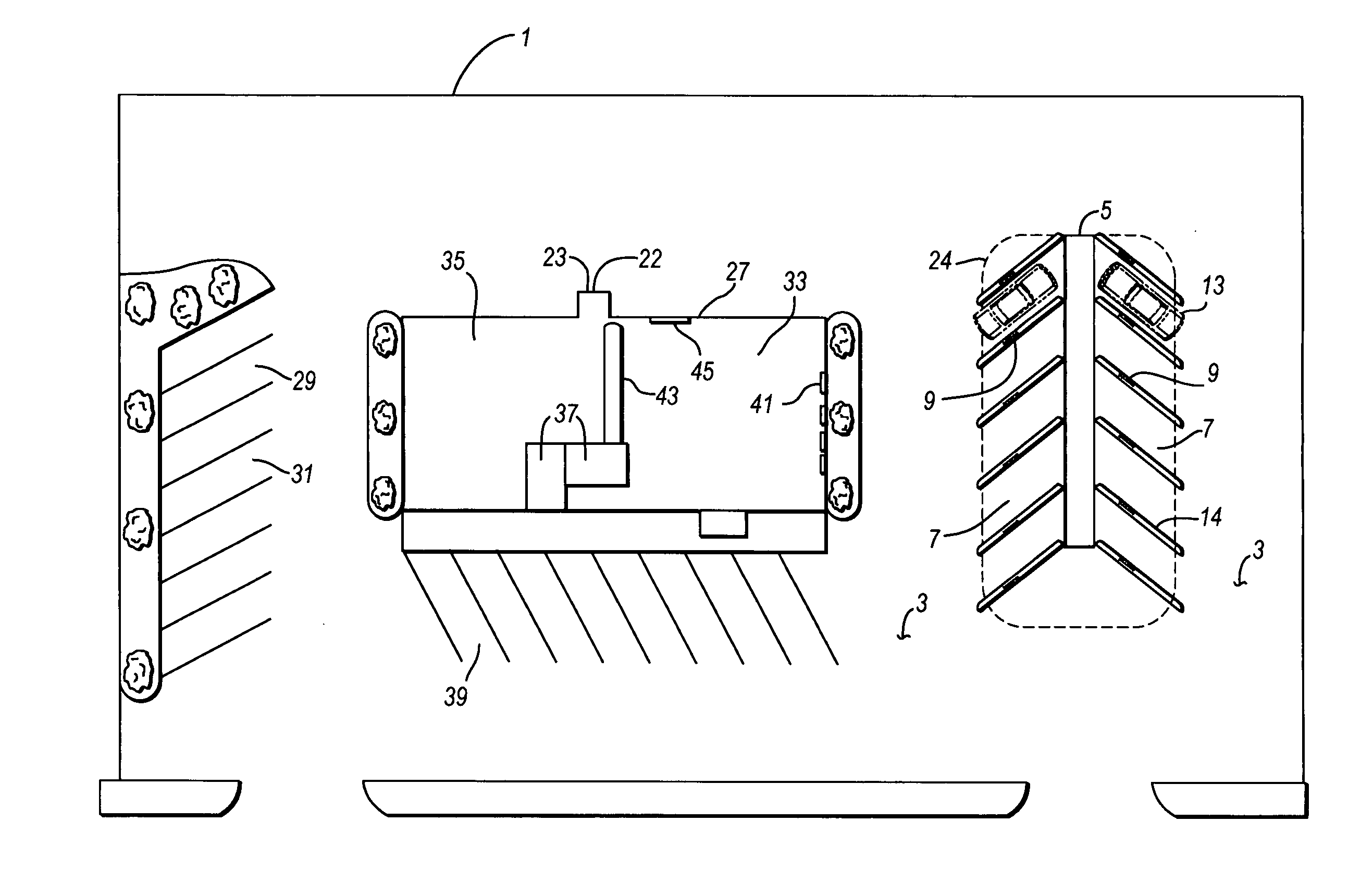

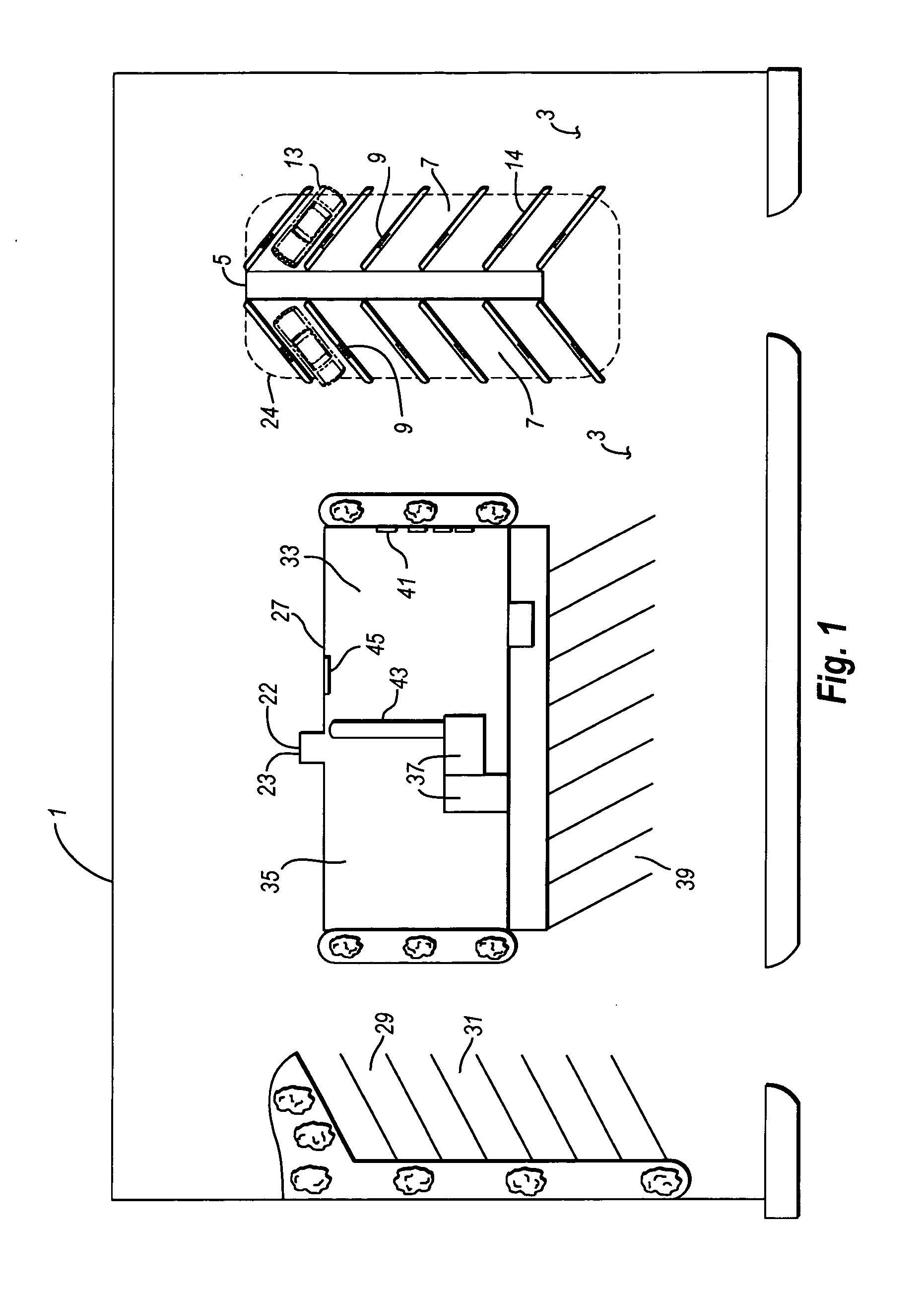

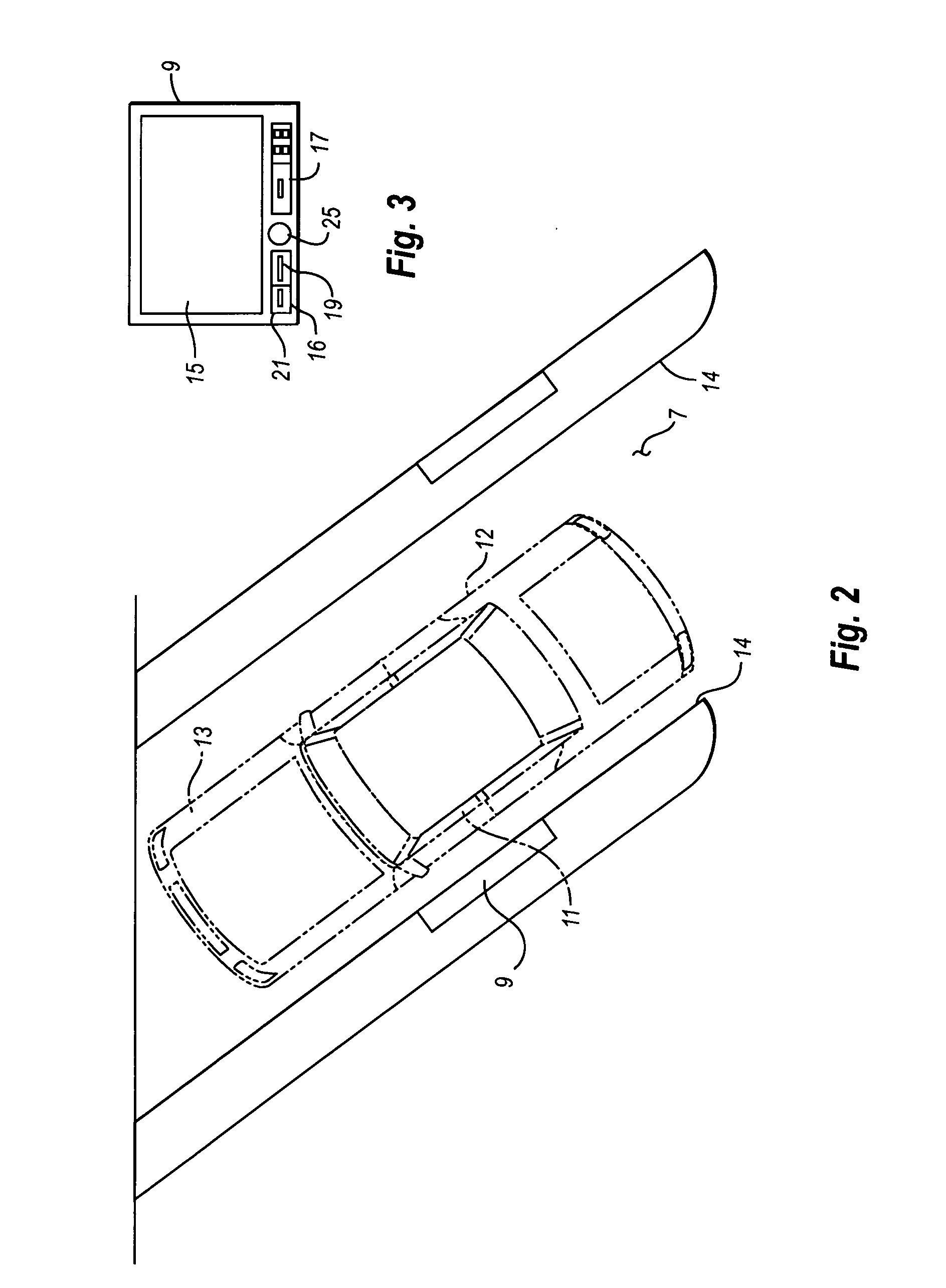

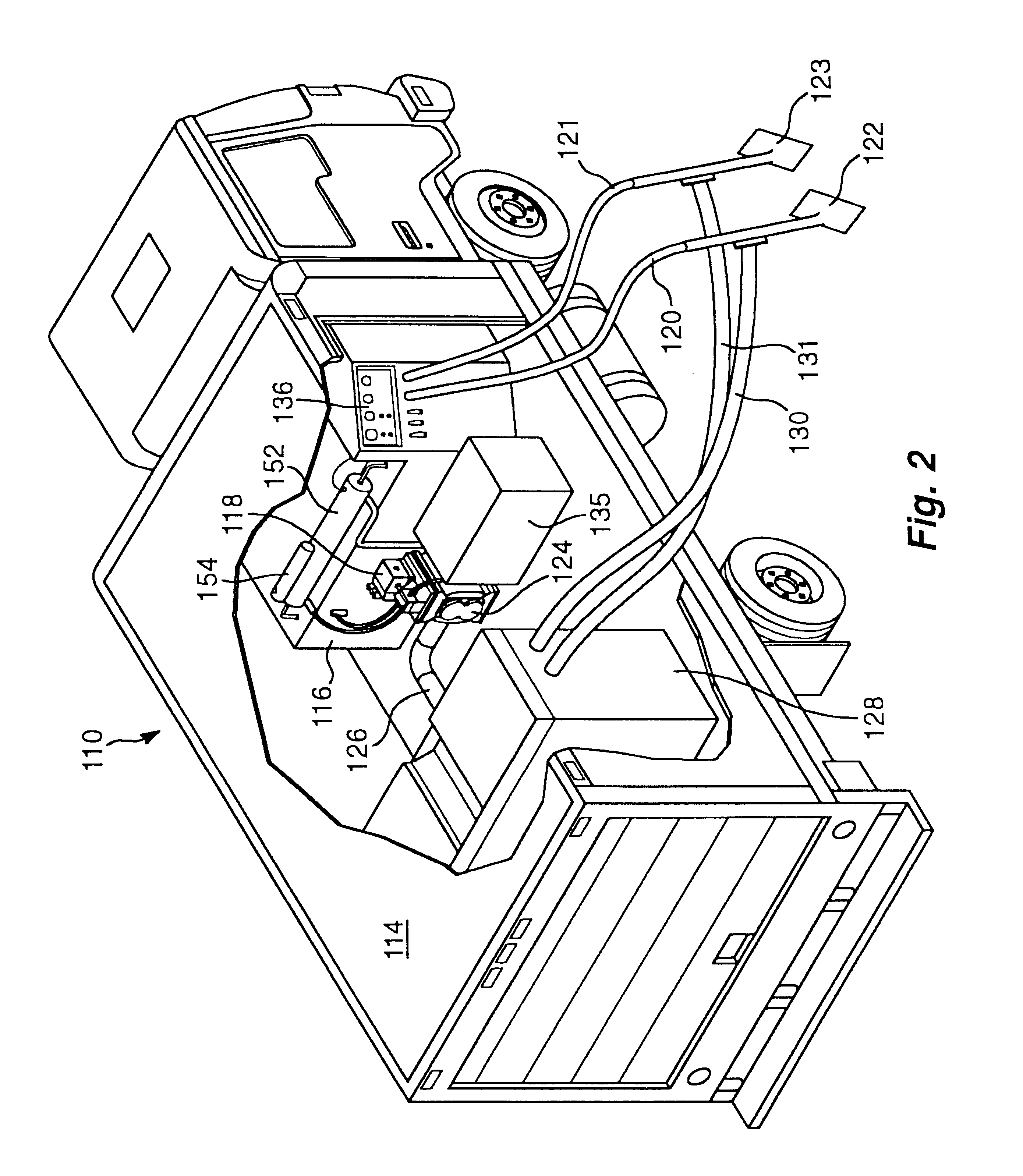

Autonomous mobile picking

ActiveUS20150073589A1Reduce labor costsFacilitates picking articleProgramme-controlled manipulatorData processing applicationsMobile vehicleOrder fulfillment

An order-picking method includes autonomously routing a plurality of mobile robotic units in an order fulfillment facility and picking articles to or putting articles from the robotic units in the order fulfillment facility. A material-handling robotic unit that is adapted for use in an order fulfillment facility includes an autonomous mobile vehicle base and a plurality of article receptacles positioned on the base. A visual indicator associated with the receptacle facilitates picking articles to or putting articles from the robotic unit.

Owner:DEMATIC

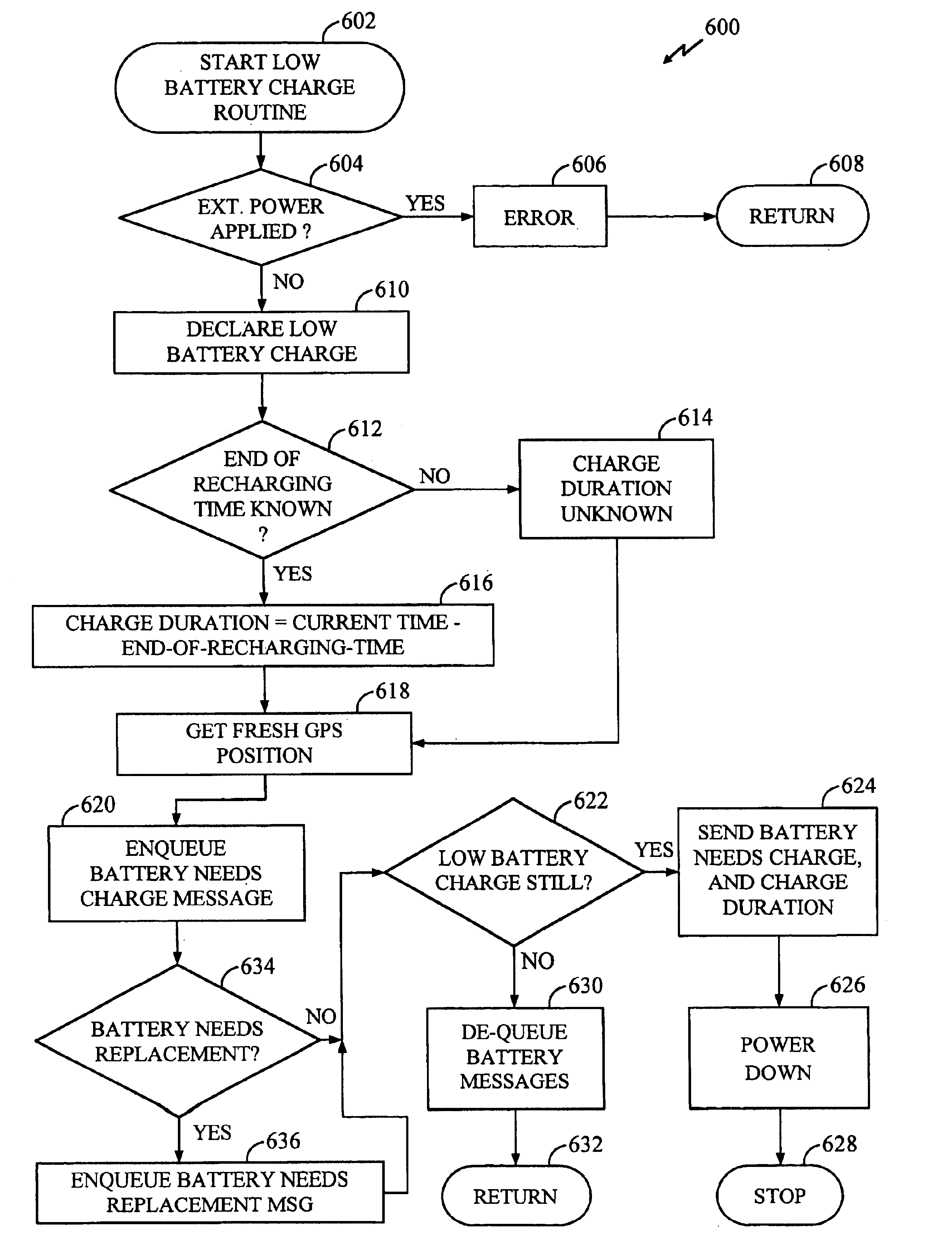

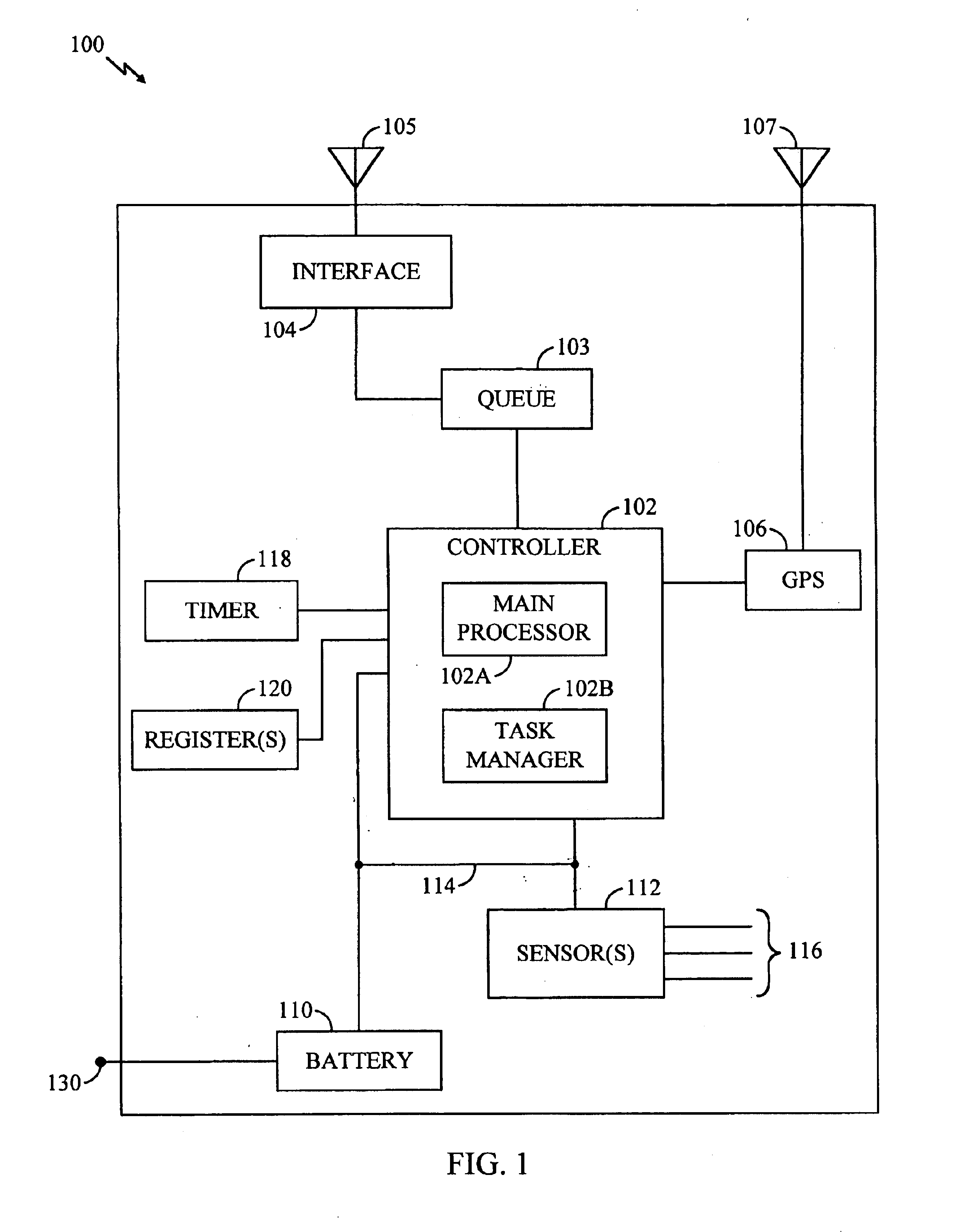

Battery monitoring system with low power and end-of-life messaging and shutdown

InactiveUS7024321B1Improve abilitiesLow costCircuit monitoring/indicationDifferent batteries chargingBattery state of chargeBattery charge

A battery monitoring apparatus that senses battery conditions such as low battery charge, end of battery capacity, and end of battery life, and responds by taking actions such as sending messages to a remote site and / or powering down. A rechargeable battery is coupled to one or more power-consuming electrical components, including battery monitoring equipment. The battery monitoring equipment senses battery charge. In response to a low-battery-charge condition, the battery monitoring equipment transmits a battery status message to a remote site and powers-down some of the electrical components. Whenever the battery nears the end of its capacity, the monitoring equipment powers down all electronic components and awaits the application of external power. The invention also tracks the time required for the battery charge to deplete. Charge duration decreases over time, and whenever it reaches a predetermined minimum, the battery monitoring equipment transmits a representative status message to the remote site.

Owner:OMNITRACS

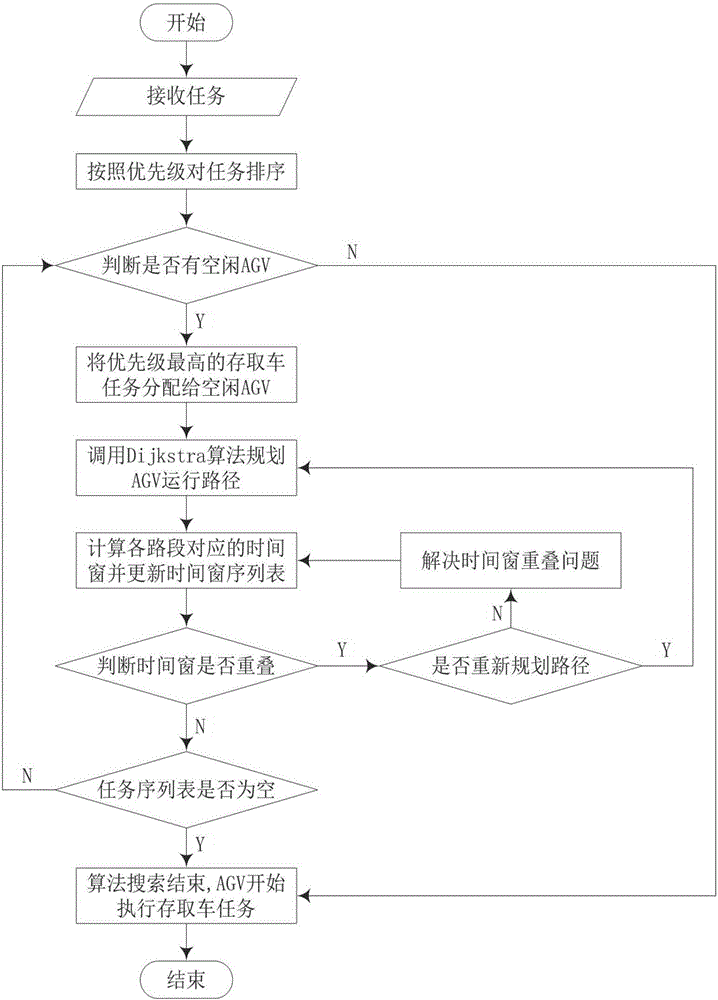

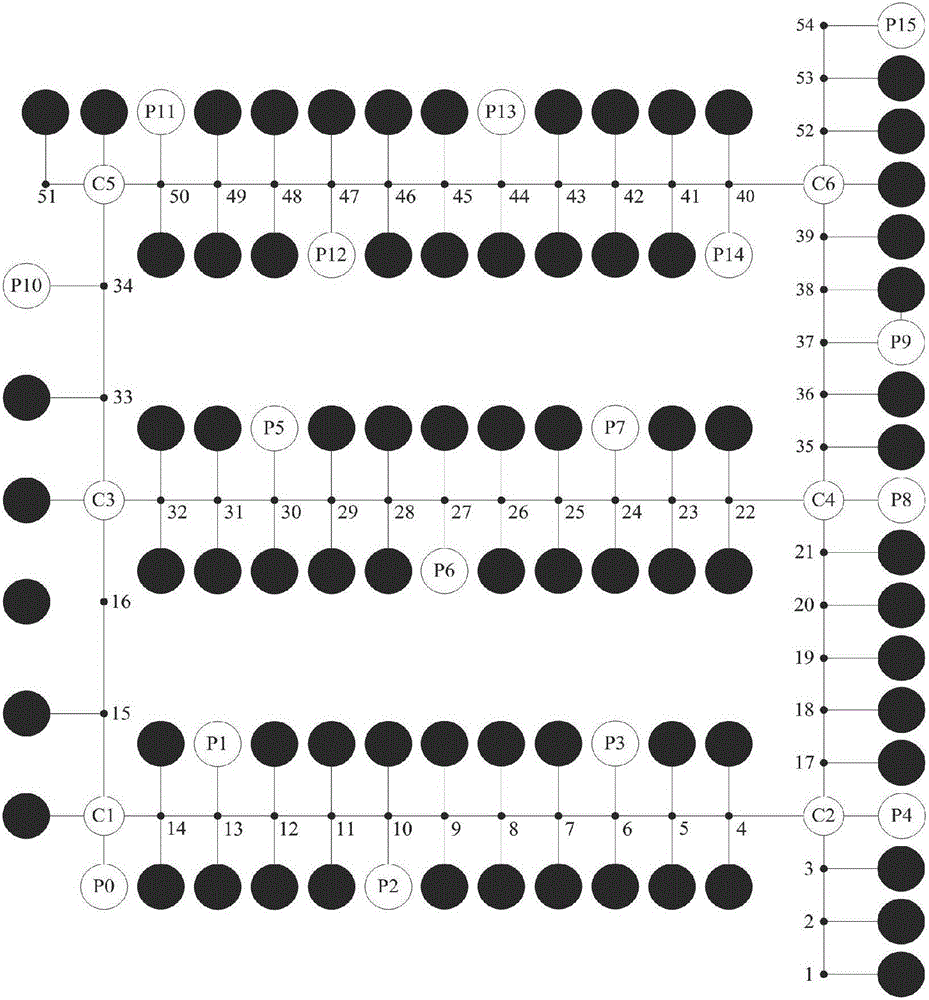

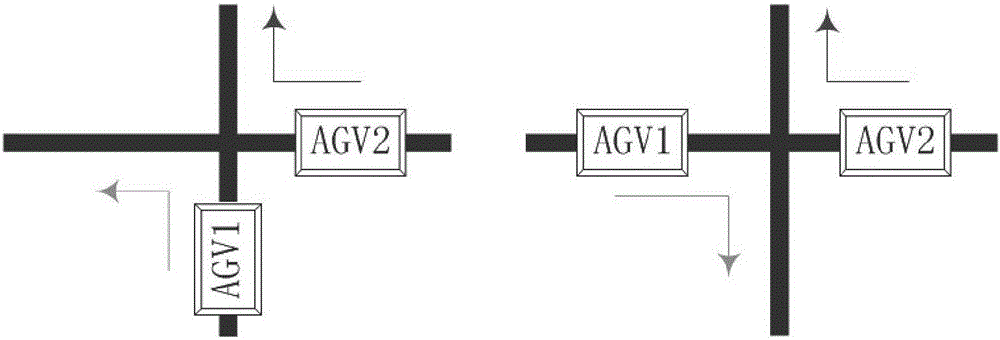

Parking system path planning method based on dynamic time windows

The invention discloses a parking system path planning method based on dynamic time windows, and belongs to the technical field of path planning. The method is characterized by comprising the following steps: S1, building a work environment model of AGVs in an intelligent garage in a topological method; S2, setting priority for each AGV and each car parking / picking task according to different evaluation criteria; S3, using a Dijkstra algorithm to plan a shortest possible path for an AGV accepting a task; S4, arranging feasible path time windows; S5, designing conflict resolution strategies according to different types of conflicts; and S6, planning a conflict-free optimal path for the AGV using a parking system path planning algorithm based on dynamic time windows. A time-sharing use strategy is used, and the Dijkstra algorithm and a time window method are combined effectively, so that the problem that the existing multi-AGV path planning is of poor flexibility and is prone to deadlock or collision conflict is solved effectively, and a shortest conflict-free optimal path can be planned for an AGV accepting a task. In addition, the overall operation efficiency of an intelligent three-dimensional parking system can be improved effectively, and the car parking / picking waiting time can be reduced for social members.

Owner:JIANGSU MARITIME INST

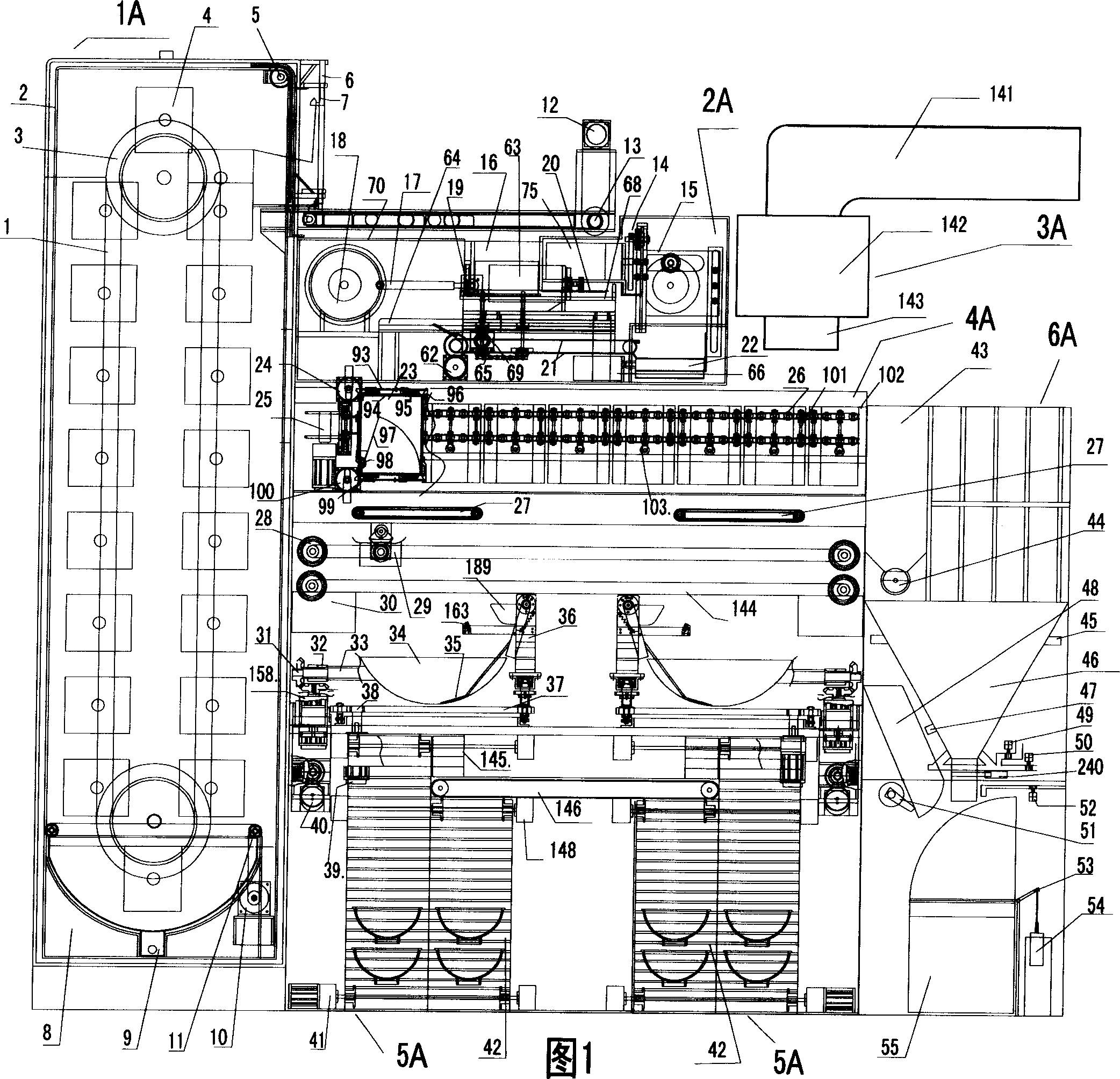

Full automatic cooking robot system

ActiveCN101006833AShorten the timeSave social resourcesFood preparationRobotic systemsLogistics management

This invention relates to a robot system capable of completing different kinds of kitcheneering affairs automatically by timing. the robot system comprise automatic multifunctional intellectualized subsystem integrated with washing vegetable, dishes, sterilization, storage and perservation; automatic multifunctional vegetable cutter subsystem; automatic intellectualized cooking and compounding subsystem and oil fume pumping system; automatic cooking subsystem; automatic rice cooking subsystem; intellectualized automatic cooking digital menu software controls subsystem. The system establishes an only recognition coding, specifically to a robot system applicable for common household kitchen, restaurant kitchen, logistics kitchen, and automatic snack service. The invention can save time spent on cooking affairs, reduce labor cost, save a great deal of social resource and money spent on cooking affair.

Owner:李卫红

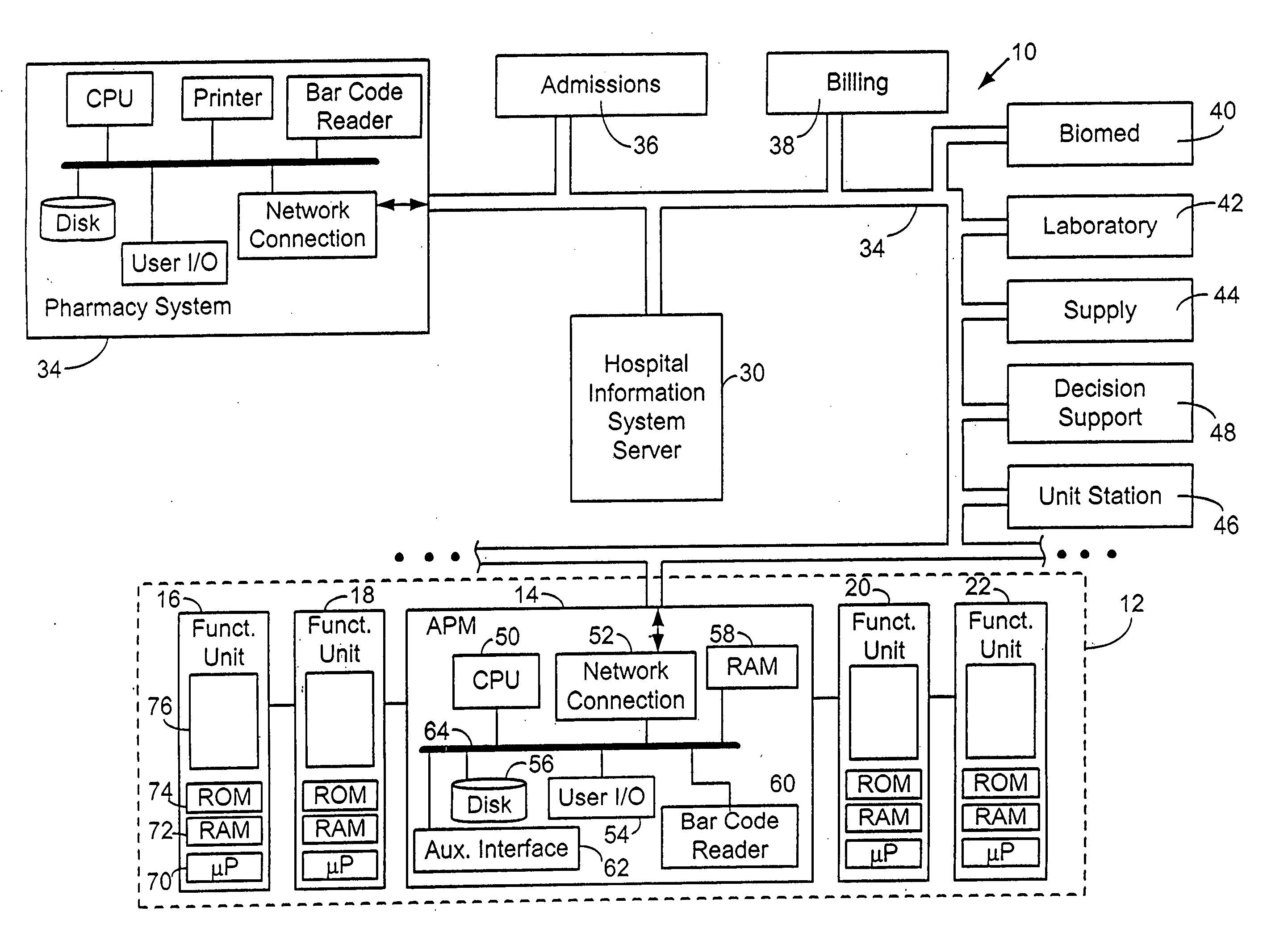

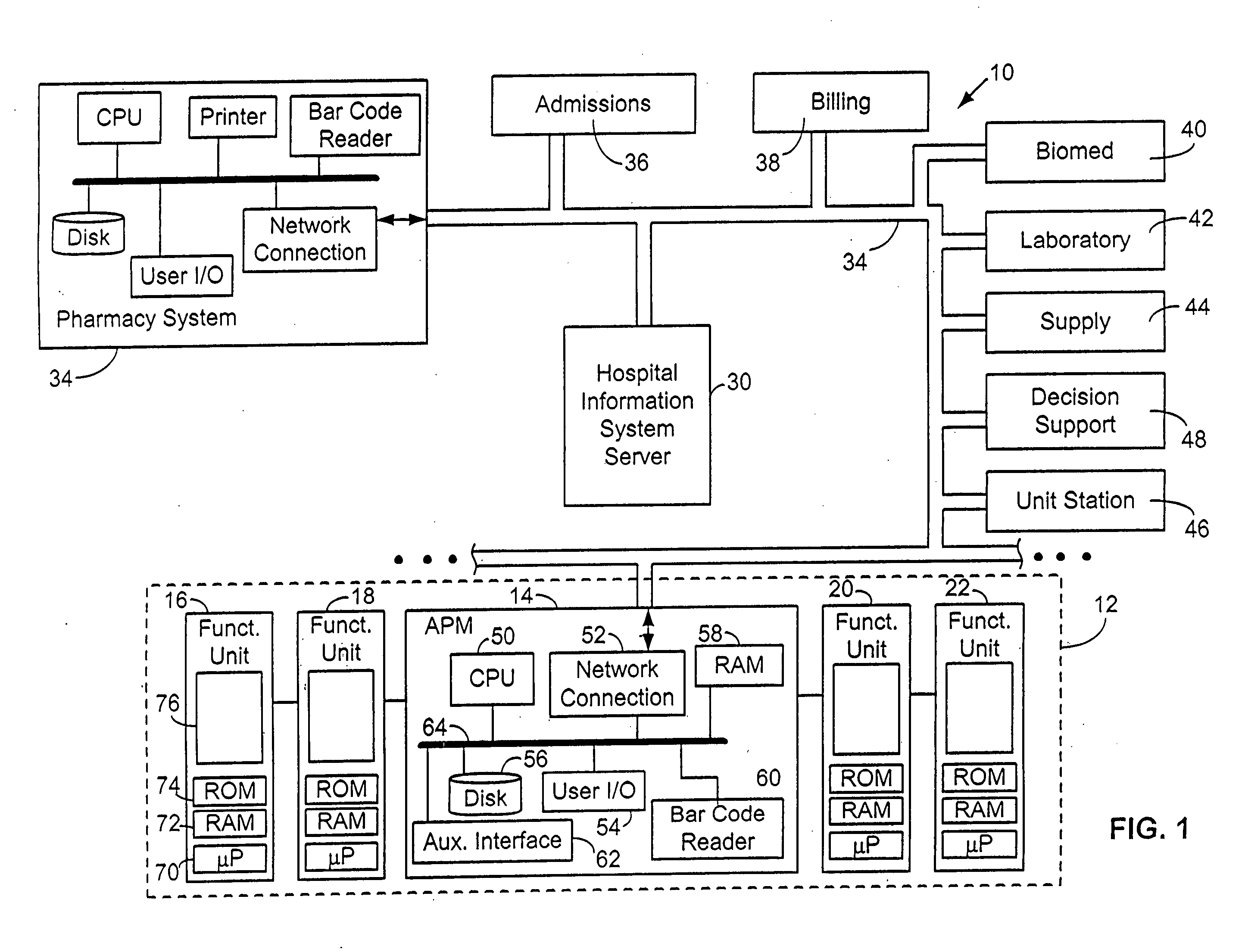

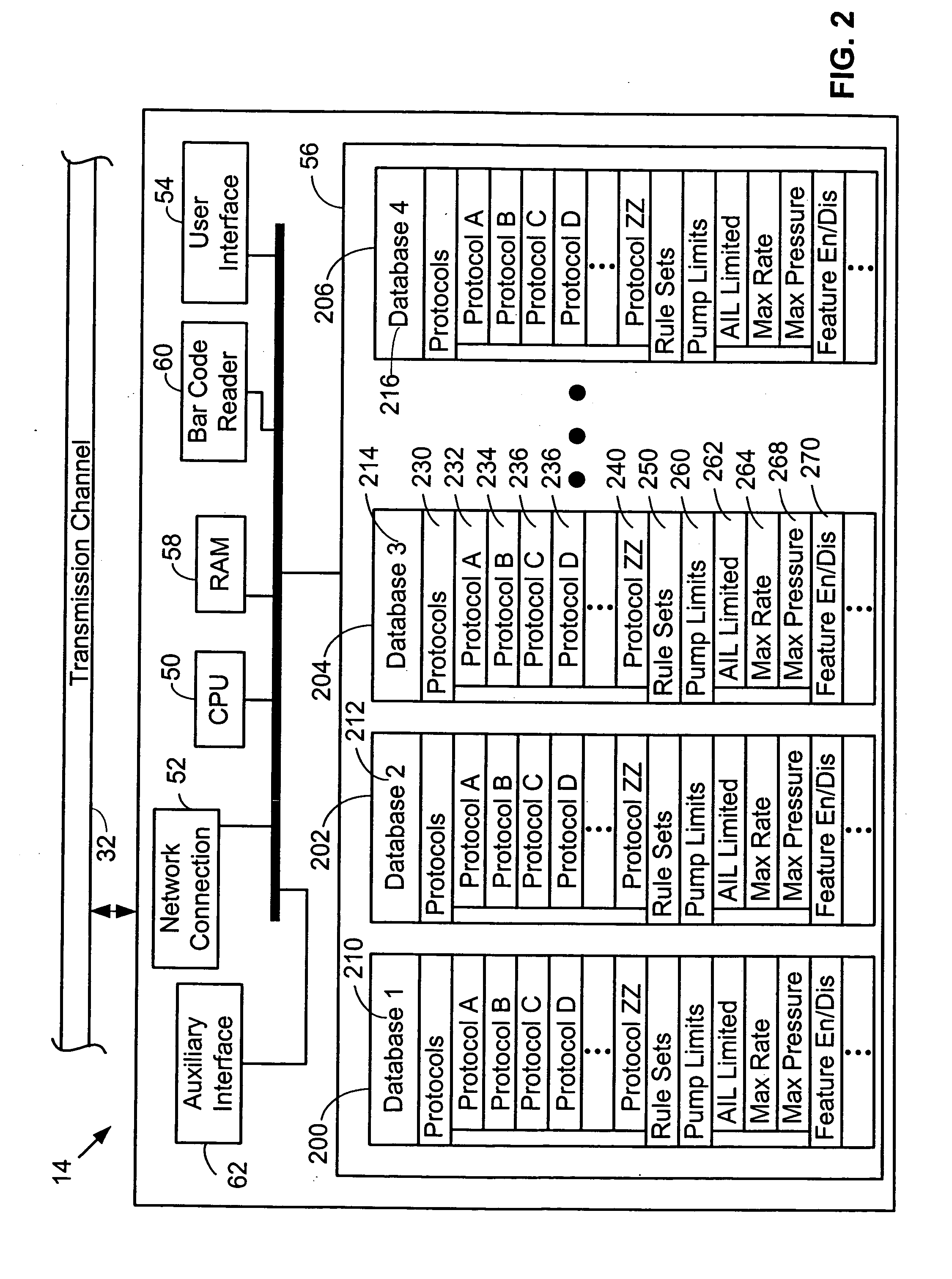

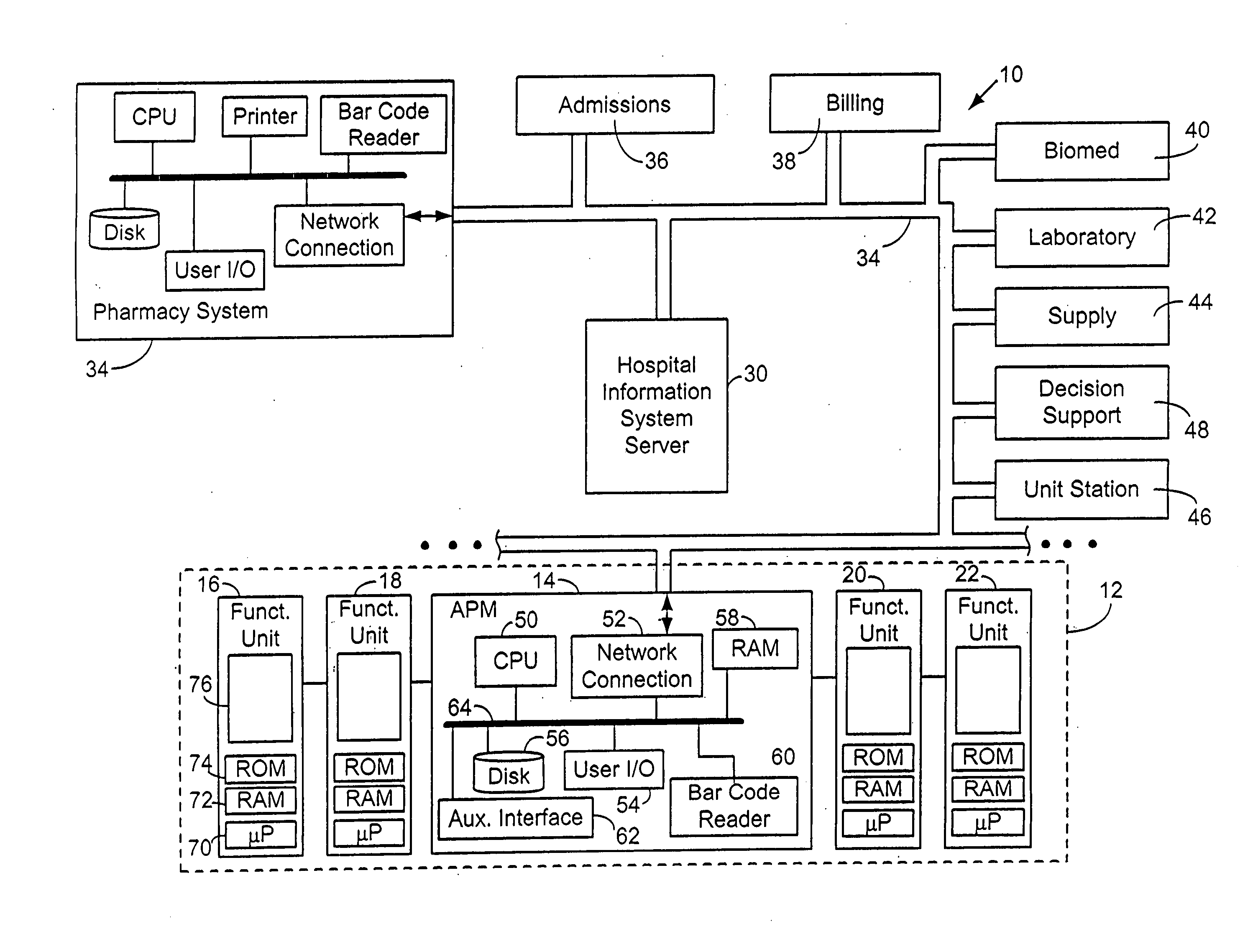

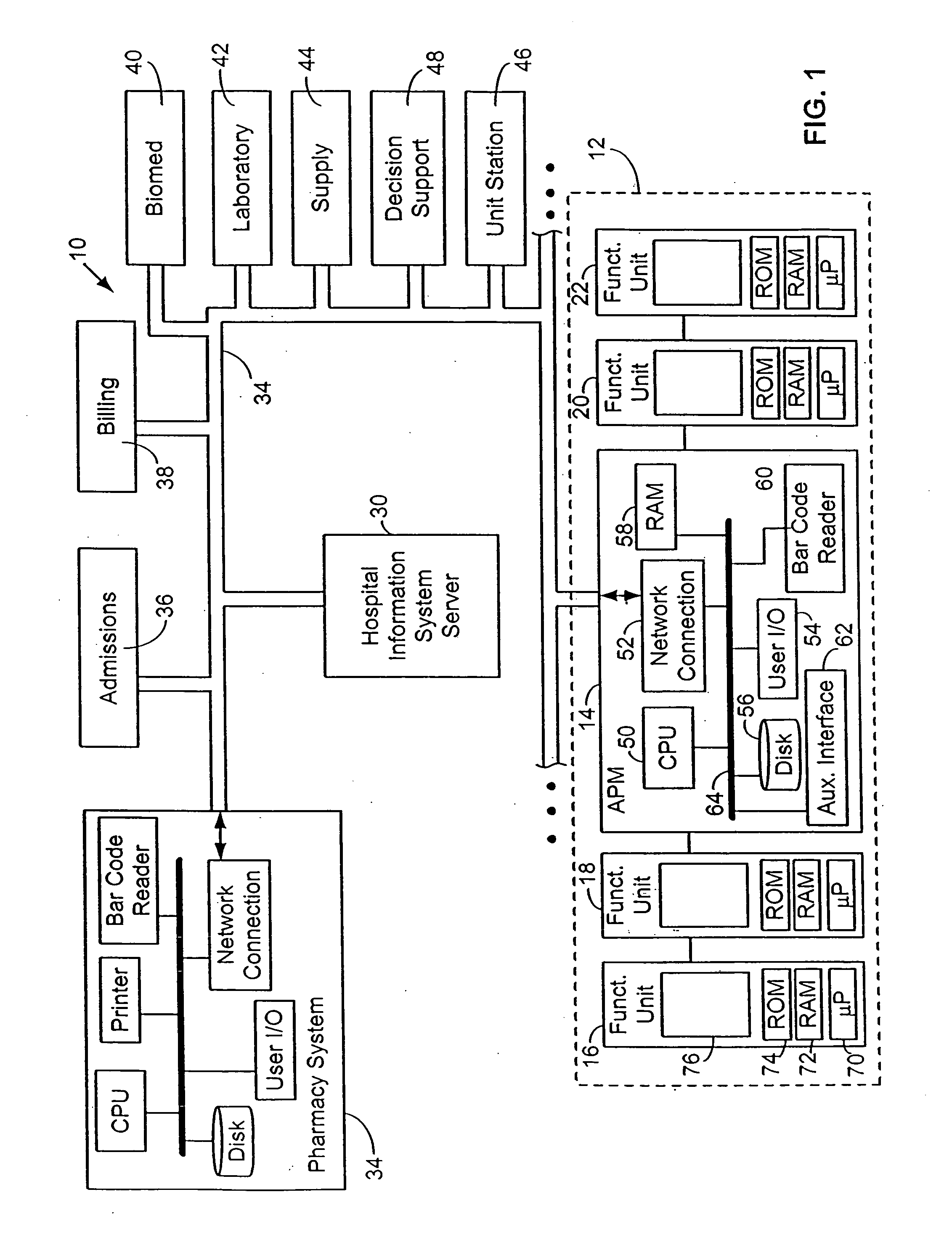

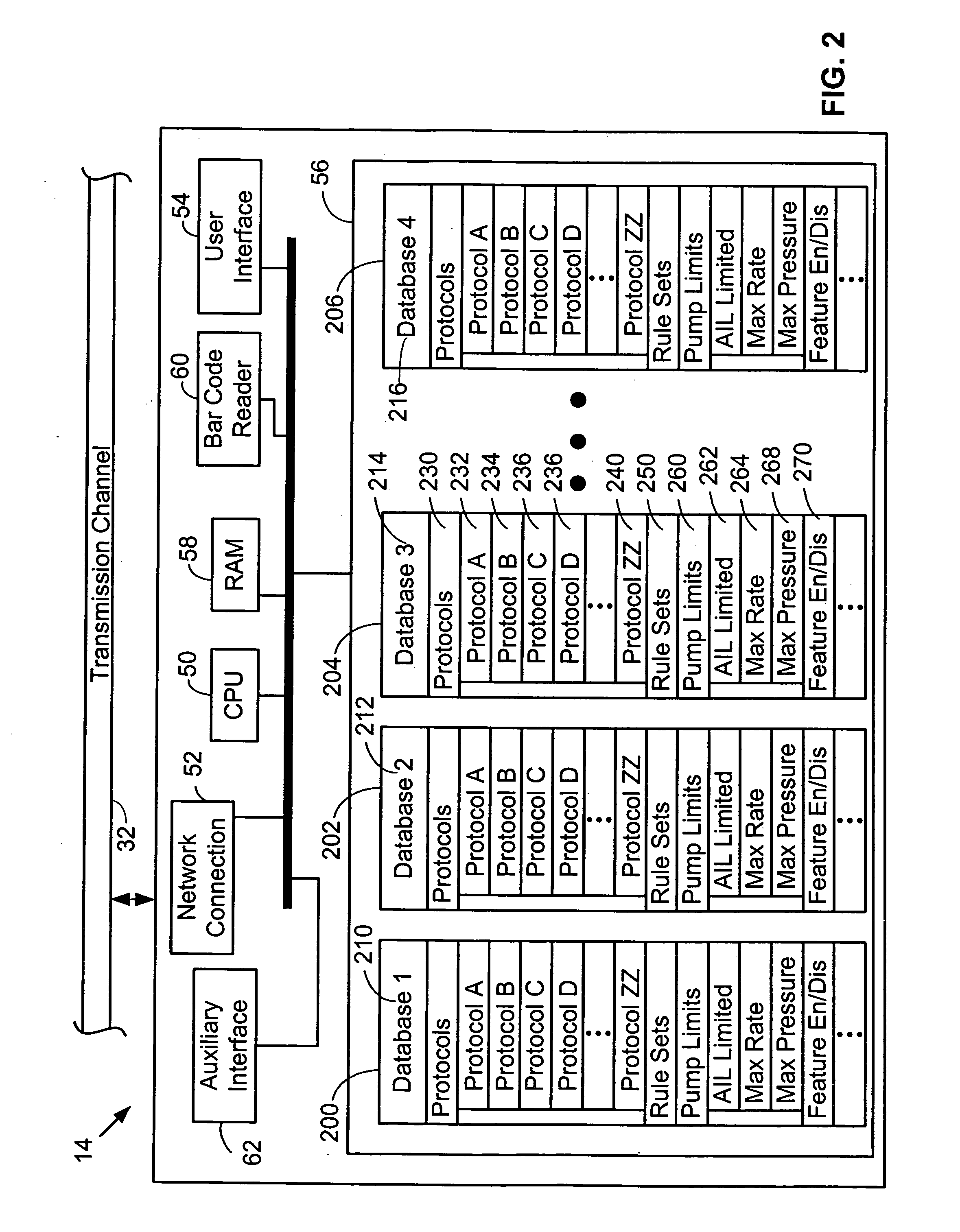

Method for programming a patient care device

InactiveUS20060106649A1Improve quality of careReduce labor costsCoupling device connectionsDrug and medicationsDrugs labelHospital network

The present invention is directed to a system and method for providing care to a patient, comprising a patient care device having a number of configuration databases stored in a memory in the device. Each configuration database preferably includes protocols, operating limits, rule sets and / or operating features that collectively define an operating environment, or personality, of the device. Selection of a specific configuration database preferably is based at least in part upon patient-specific information obtained from any location in a distributed hospital network. Examples of such patient-specific information include patient age or size, patient medical characteristics, a location of the patient or a location of the care device. In a preferred embodiment, programming a patient care device to deliver a drug to a patient entails activating a configuration database and scanning a machine-readable drug label identifying a particular protocol stored in the activated database. The selected protocol includes default parameters for delivering the drug, and the label optionally includes instructions for deviating from the default protocol.

Owner:CAREFUSION 303 INC

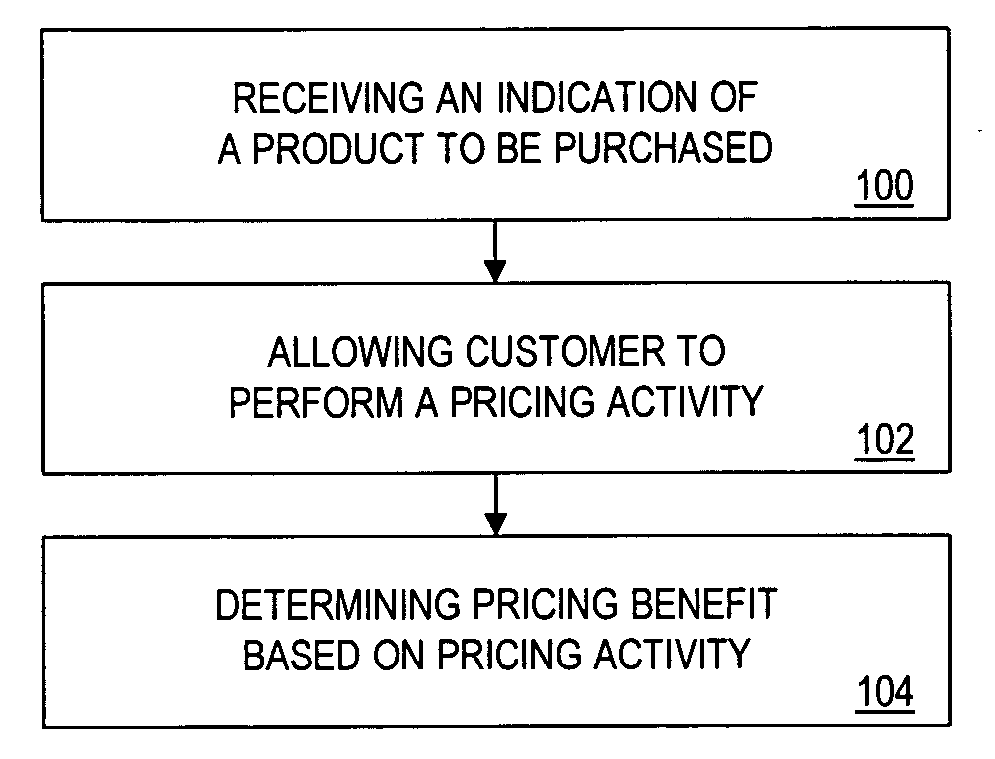

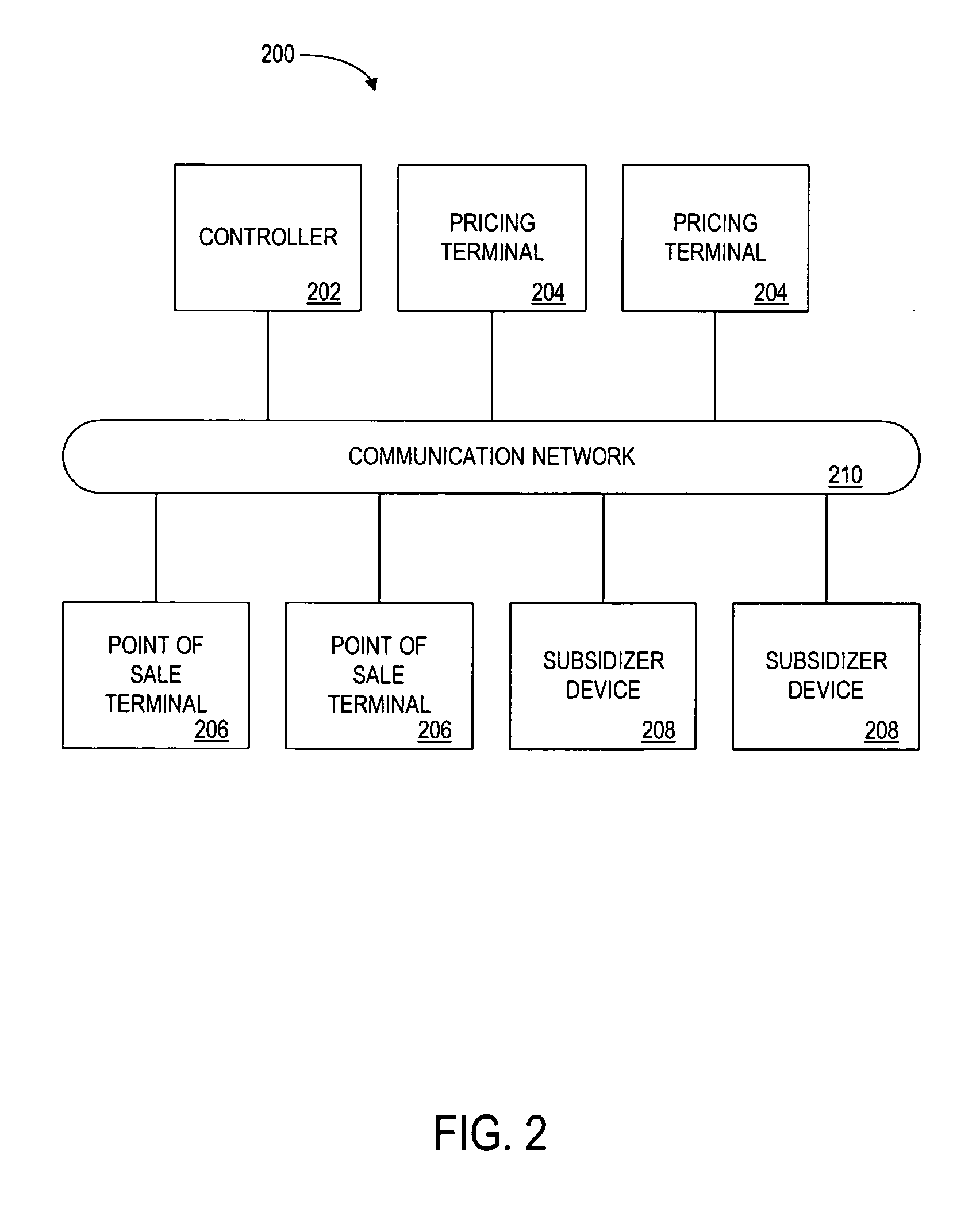

Method for allowing a customer to obtain a discounted price for a transaction and terminal for performing the method

InactiveUS20050043994A1Increase business volumeThe process is convenient and fastLottery apparatusApparatus with change-givingThird partySimulation

A pricing terminal is installed at a retail store. The pricing terminal includes an enclosure that allows a customer to be seated therein, a display screen mounted in the enclosure, a keyboard and a processor operatively connected to the display screen and the keyboard. The processor is programmed to control the display screen, receive input via the keyboard and guide the customer to perform a pricing activity. The pricing activity may include viewing an advertisement, answering survey questions, or agreeing to enter into a transaction with a third party. The customer is rewarded for performing the pricing activity by receiving a discount on a purchase transaction or another benefit.

Owner:PAYPAL INC

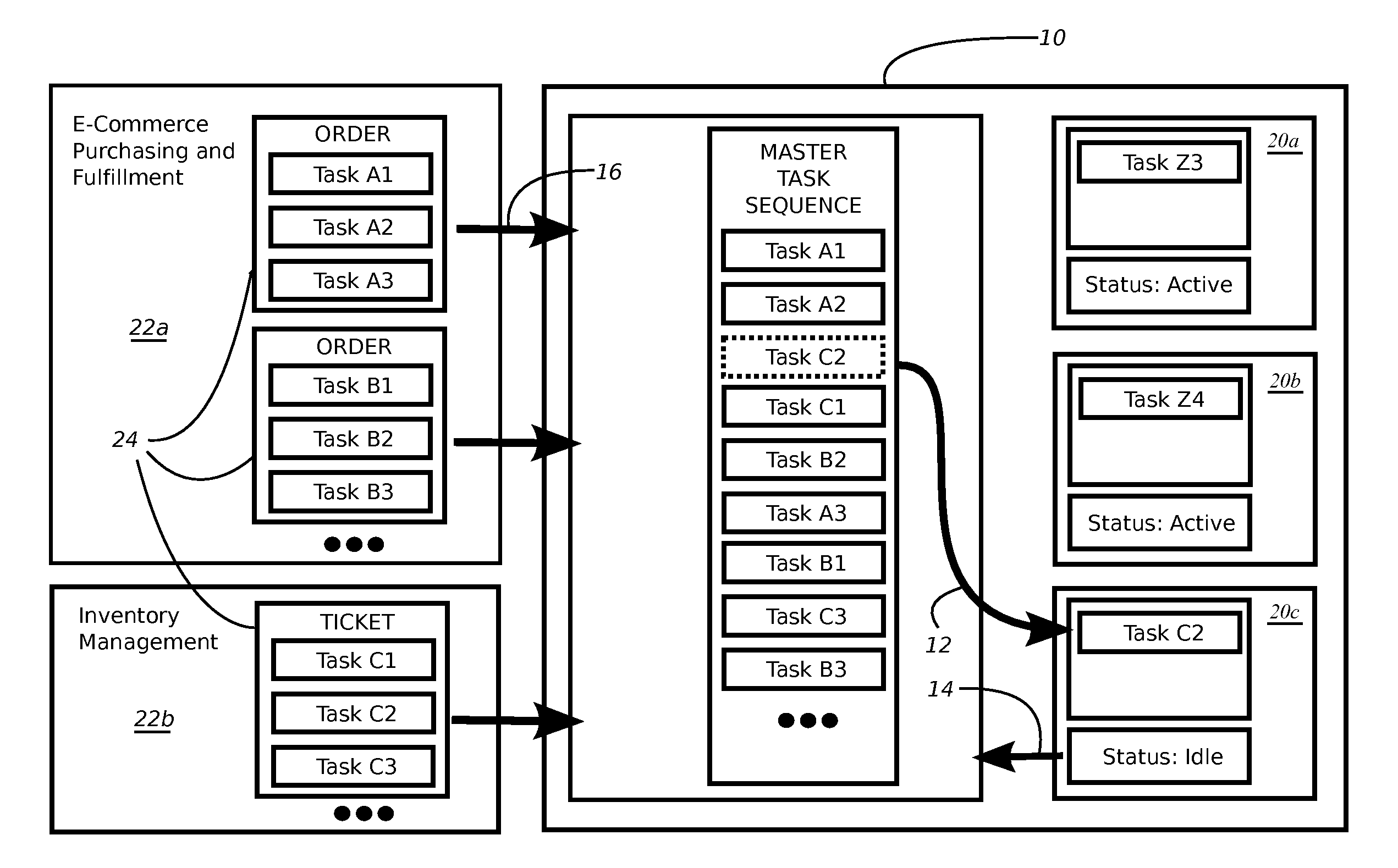

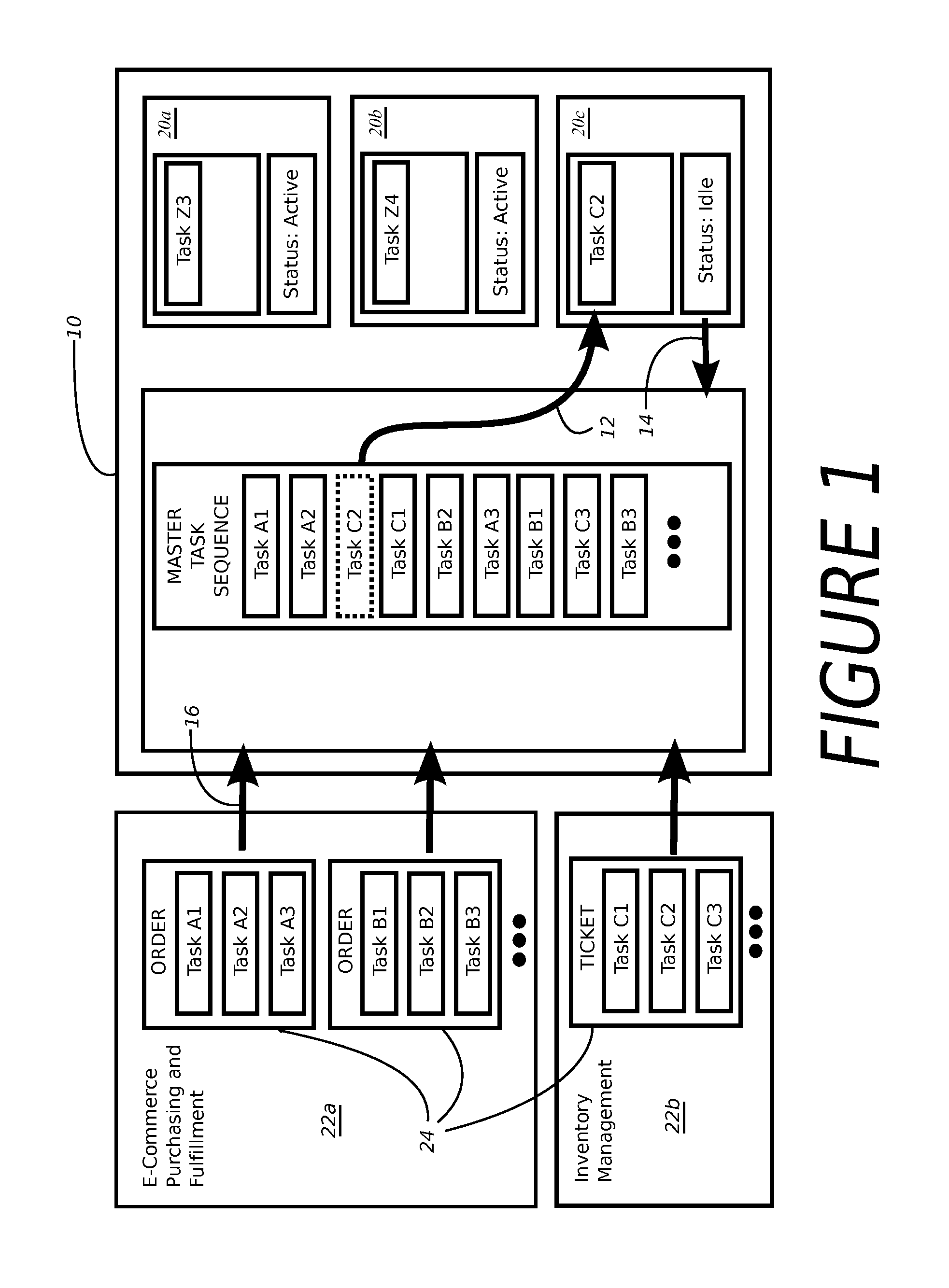

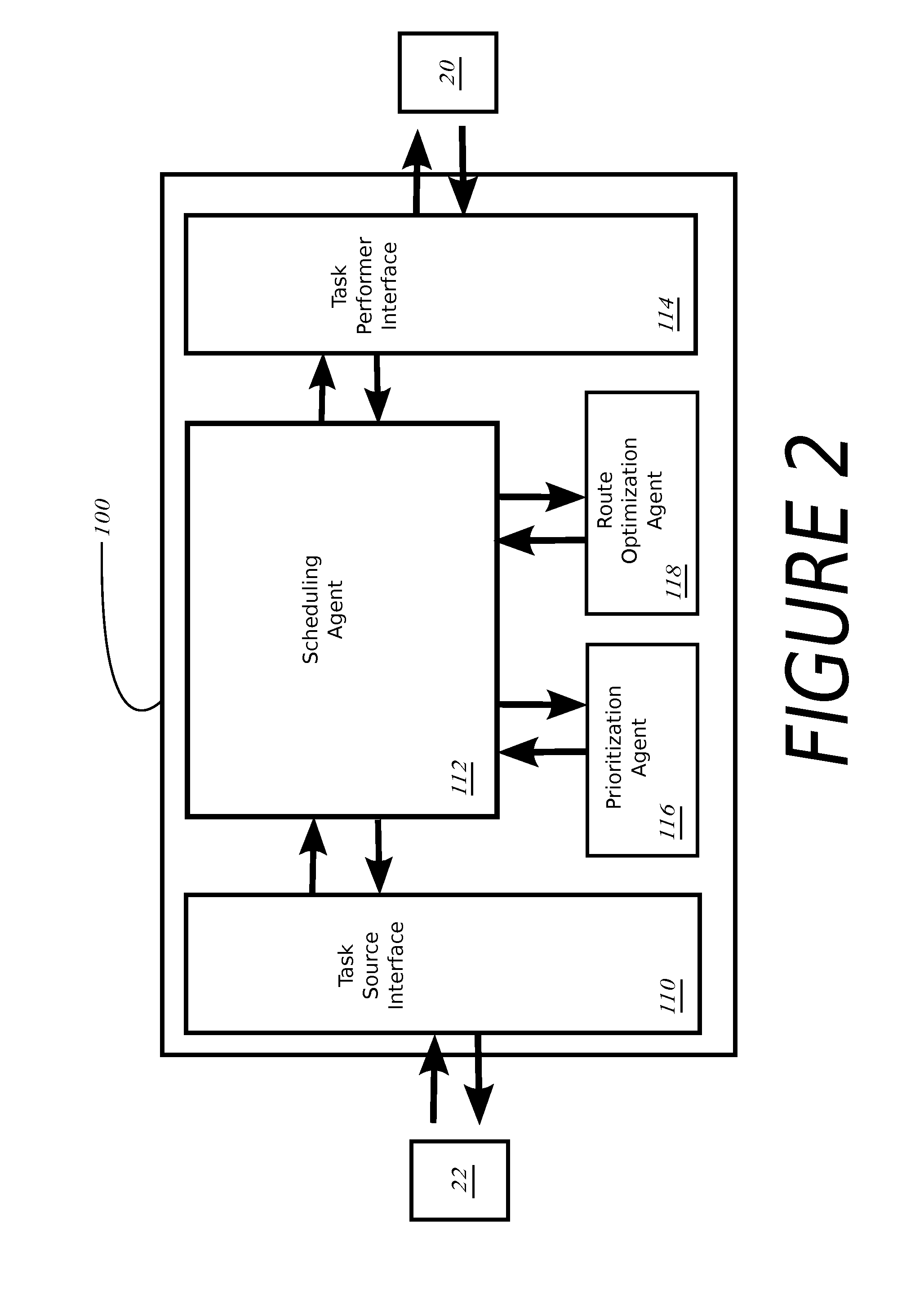

Dynamic Task Management

InactiveUS20140136255A1Labor cost be lowerSimplify processResourcesOrder fulfillmentReal-time computing

Dynamic task management processes and systems are provided, whereby tasks are assigned to workers discretely, in response to worker-originated requests, on a real-time basis. Tasks are extracted from an aggregate thereof, scheduled into one or more queues, then “pulled” by workers for execution. Comprehensive data for performing each task are monitored, as are worker skills and availability. Each task is matched to an appropriate worker, the assignment being adjusted or modified automatically, to the extent required, to satisfy certain predefined temporal and / or spatial criteria. When a worker signals completion of an assigned task, the next discrete task in the queue matching the worker's skills and / or availability is pulled from the queue and assigned. The invention is useful for managing warehouse and inventory operations, and specifically, the scheduling and assignment of pick tasks among warehouse pickers, for example, in connection with e-commerce order fulfillment.

Owner:WALMART APOLLO LLC

Enhanced fast food restaurant and method of operation

InactiveUS20060218039A1Reduce total transaction timeReduce labor costMarketingItem selectionDisplay device

A fast food restaurant and method of operating a fast food restaurant, the restaurant having an order and staging station for drive through customers. The order and staging station has a plurality of order stalls for customer vehicles, each order stall having an order panel with a menu display and a touch screen or voice or speech activator for self-service menu item selection and order placement. The order panel also has a payment acceptor and an order status reporter. The customer vehicle remains in the order stall until the customer is notified that the order is ready for pickup at a delivery station.

Owner:N P JOHNSON FAMILY PARTNERSHIP

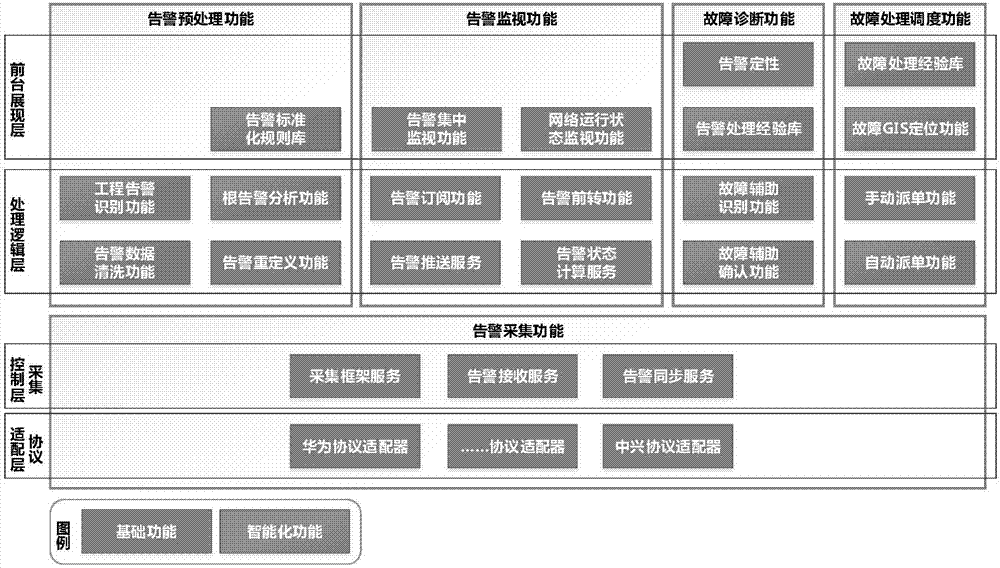

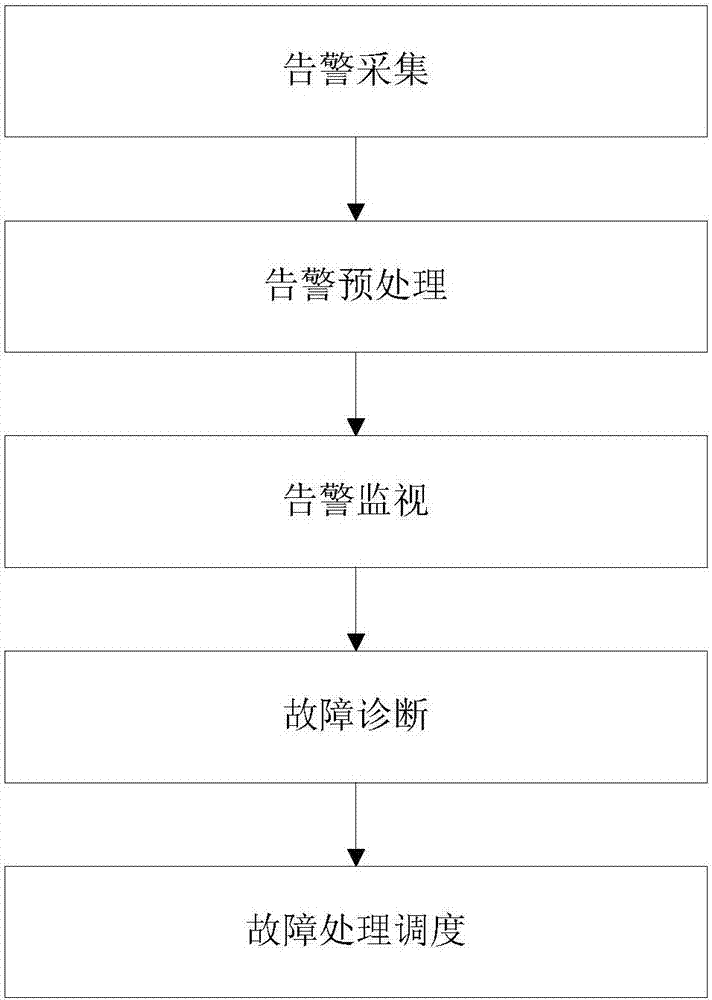

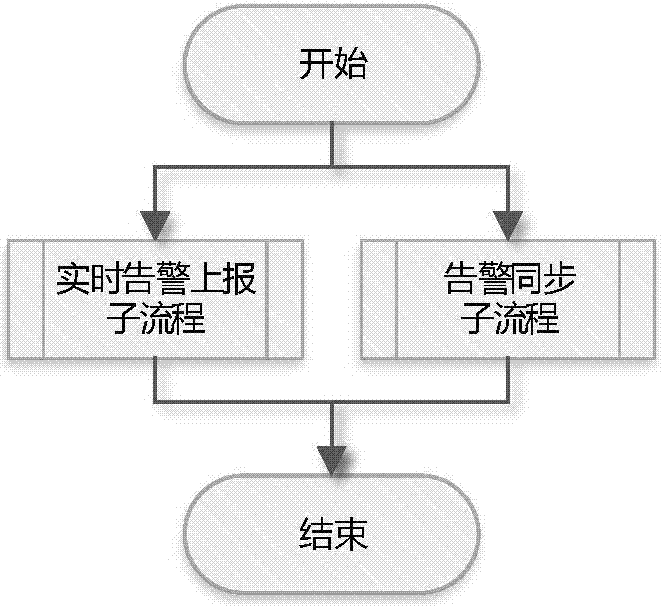

Centralized alarm monitoring system and method of power system terminal communication access network

ActiveCN107196804AImprove operation and maintenance management levelStable supportData switching networksAccess networkAlarm message

The invention discloses a centralized alarm monitoring system and method of a power system terminal communication access network. The method comprises the following steps: alarm collection: receiving real-time alarm messages reported by device network management systems, synchronizing the real-time alarm messages of the device network management systems to an alarm processor module to provide alarm and processing data sources for alarm; alarm preprocessing: performing normalized processing and classified compression on the collected alarm messages; alarm monitoring: displaying all kinds of preprocessed alarm messages on an alarm operating floor and a network topology diagram in real time, and forwarding important alarm to operation and maintenance personnel through short messages, emails and in station message means for important focus; fault diagnosis: performing analysis, diagnosis and qualitative diagnosis on the alarm according to the experience in an alarm processing experience library, and identifying all kinds of possible fault reasons inducing the alarm; and fault processing scheduling: locating the geographic position of a fault point according to the fault diagnosis result and the operation and maintenance group in charge, processing a work order, and scheduling the corresponding operation and maintenance group to remove the fault.

Owner:INFORMATION COMM COMPANY STATE GRID SHANDONG ELECTRIC POWER +1

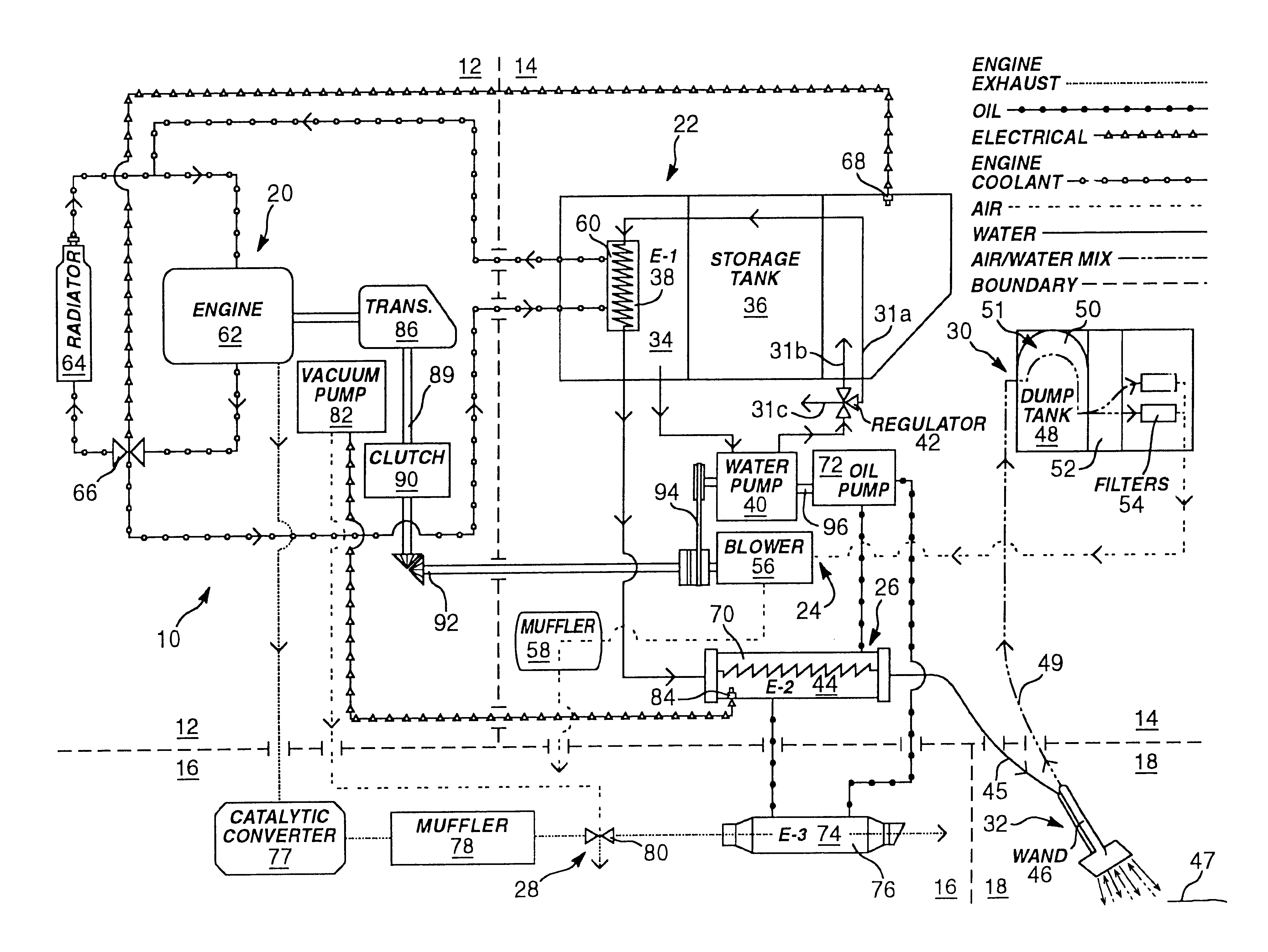

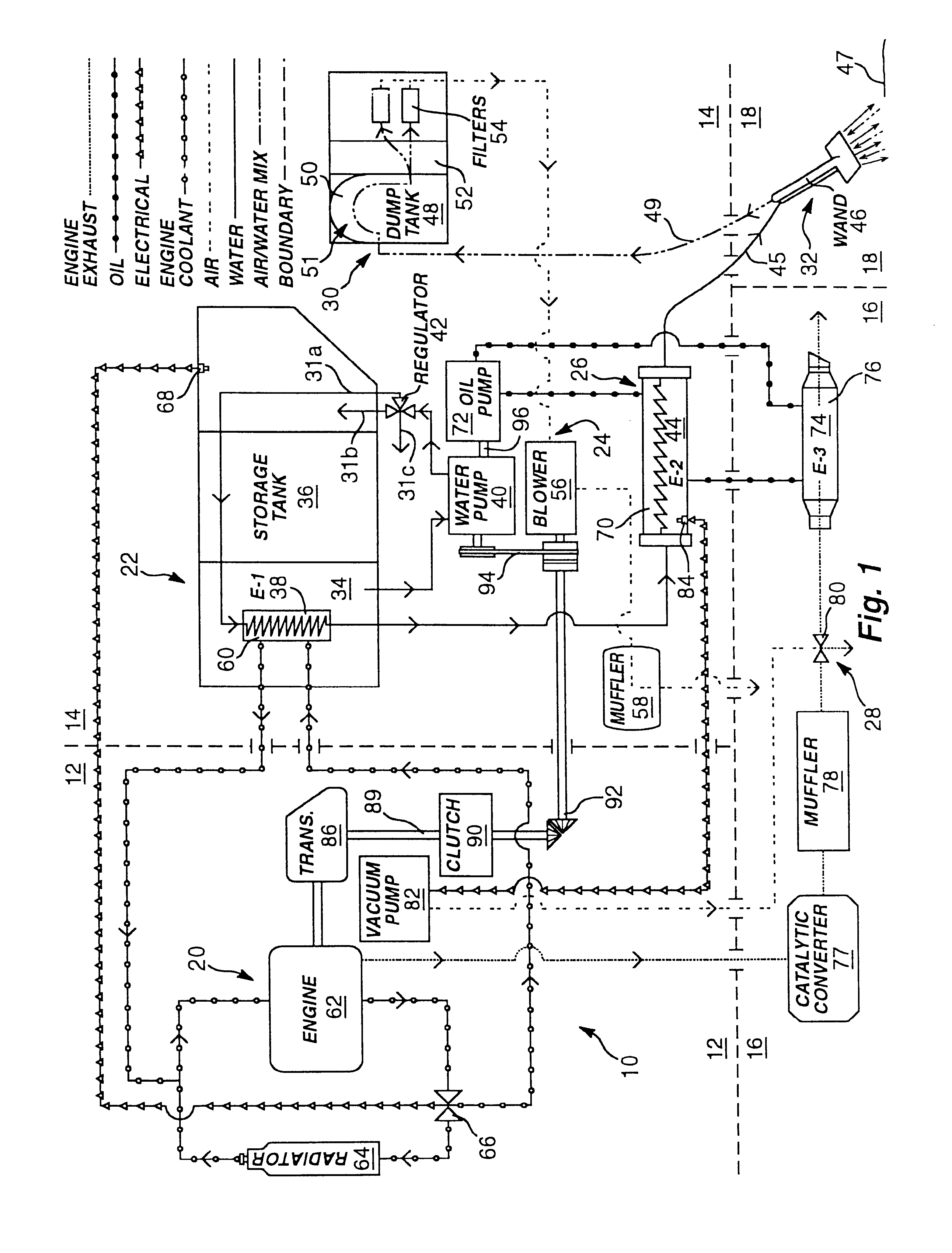

Portable high-temperature, high-pressure washing plant

InactiveUS6675437B1Reliable outputIncrease temperatureInternal combustion piston enginesRecuperative heat exchangersProcess engineeringThermal contact

A washing system for high temperature cleaning applications, such as carpet-cleaning, is disclosed that provides a consistent cleaning fluid temperature. The washing system utilizes multiple heat exchangers and multiple heat paths. The heating and power source is provided by a medium duty, diesel cycle engine. Multi-stage heating involves heat transfer from the engine's coolant to the cleaning fluid and heat transfer from the exhaust of the engine to the cleaning fluid via an intermediate medium. The system also includes a fluid clutch used to engage a power takeoff from the engine to operate the pump and blower of the washing plant. A failsafe source cutoff diverts the exhaust flow from thermal contact with an intermediate heat transfer oil.

Owner:BLUE LINE EQUIP

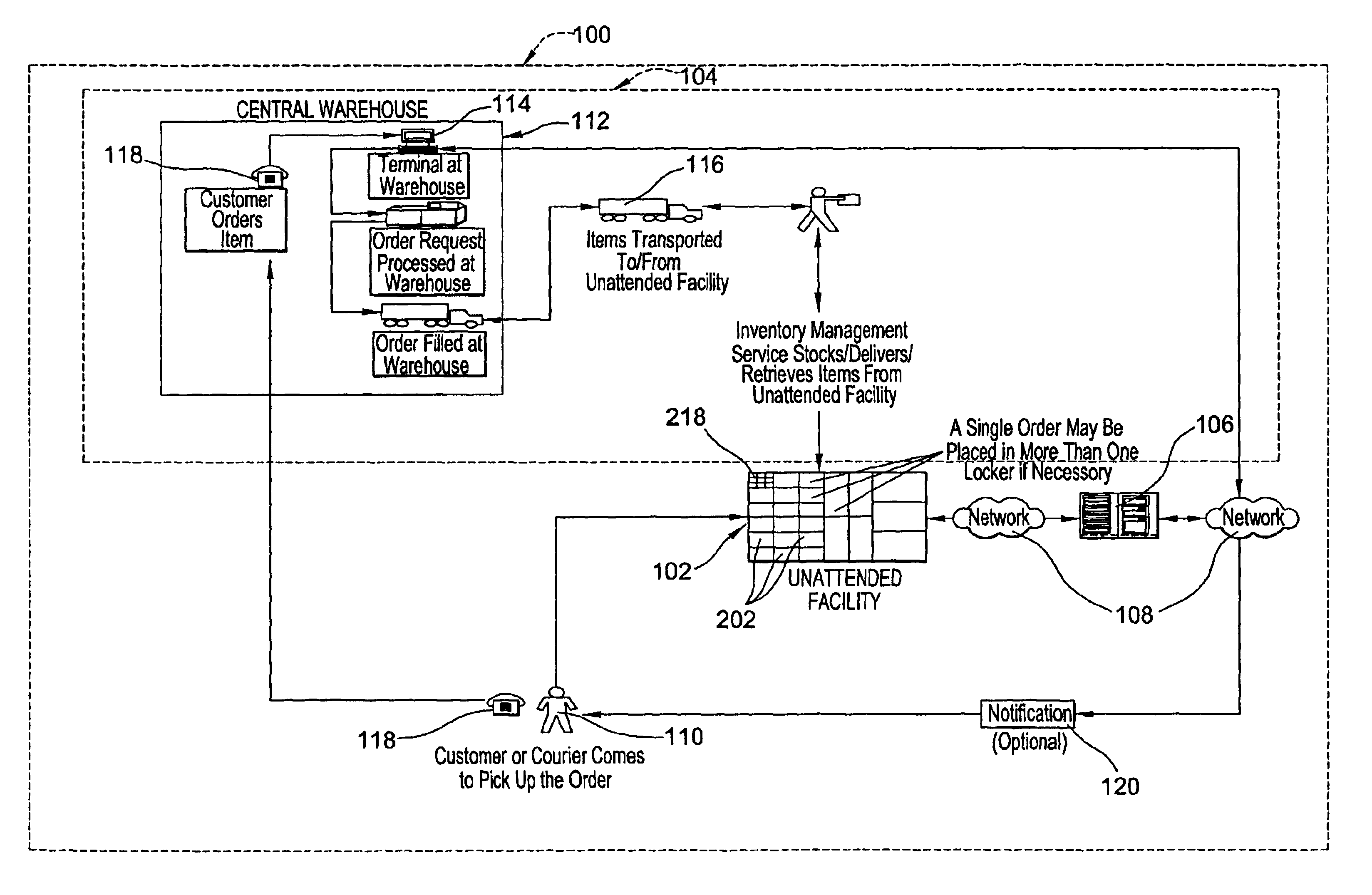

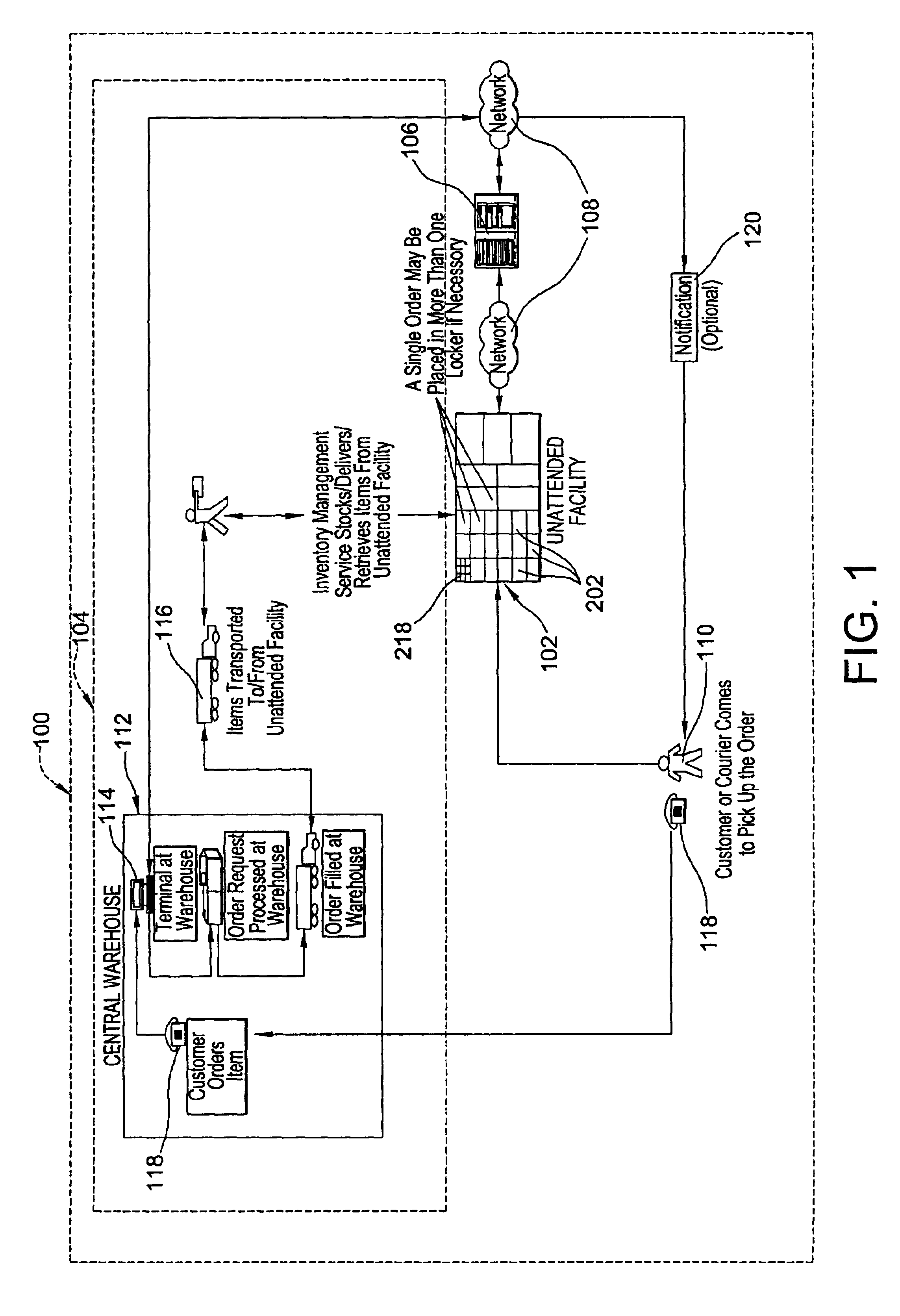

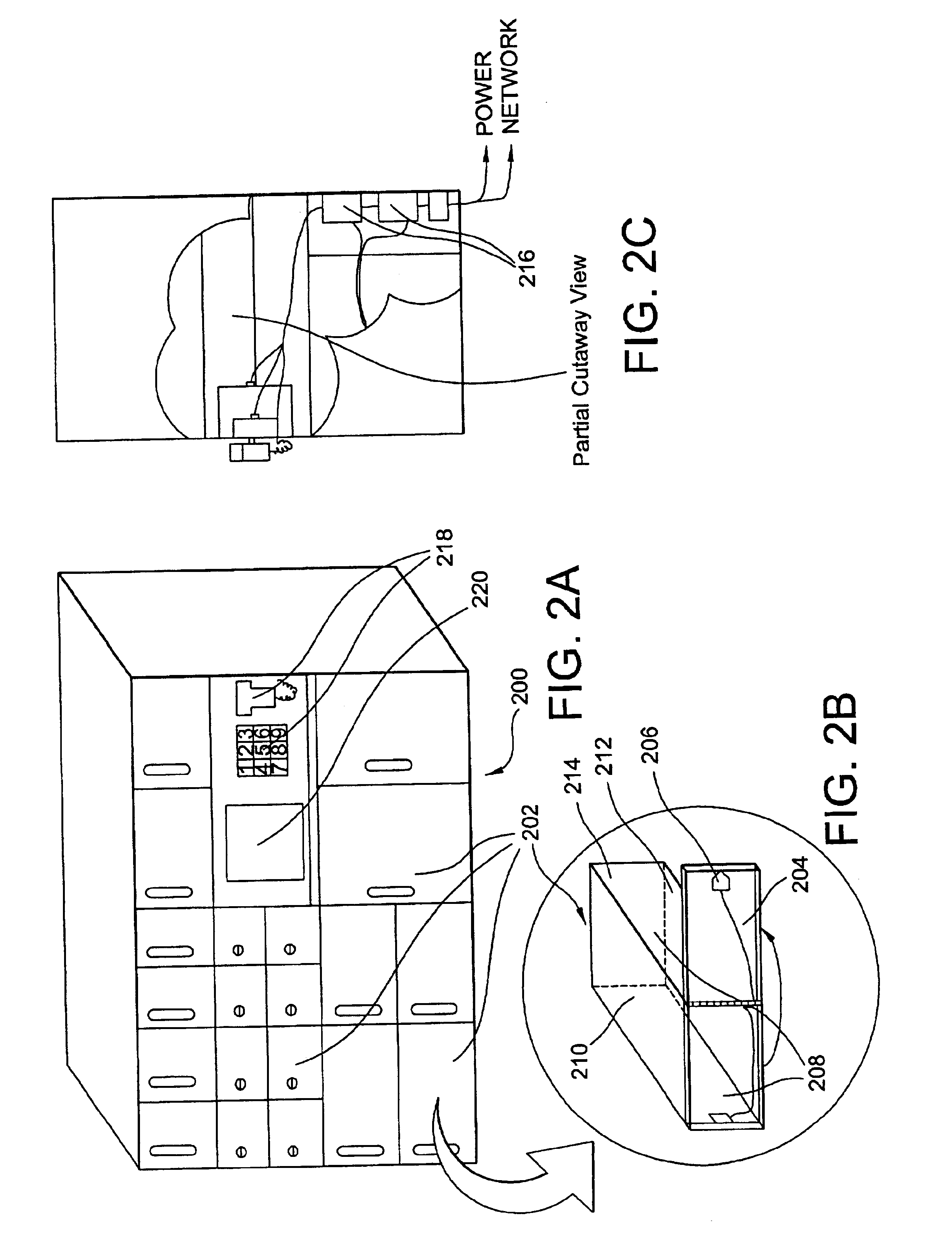

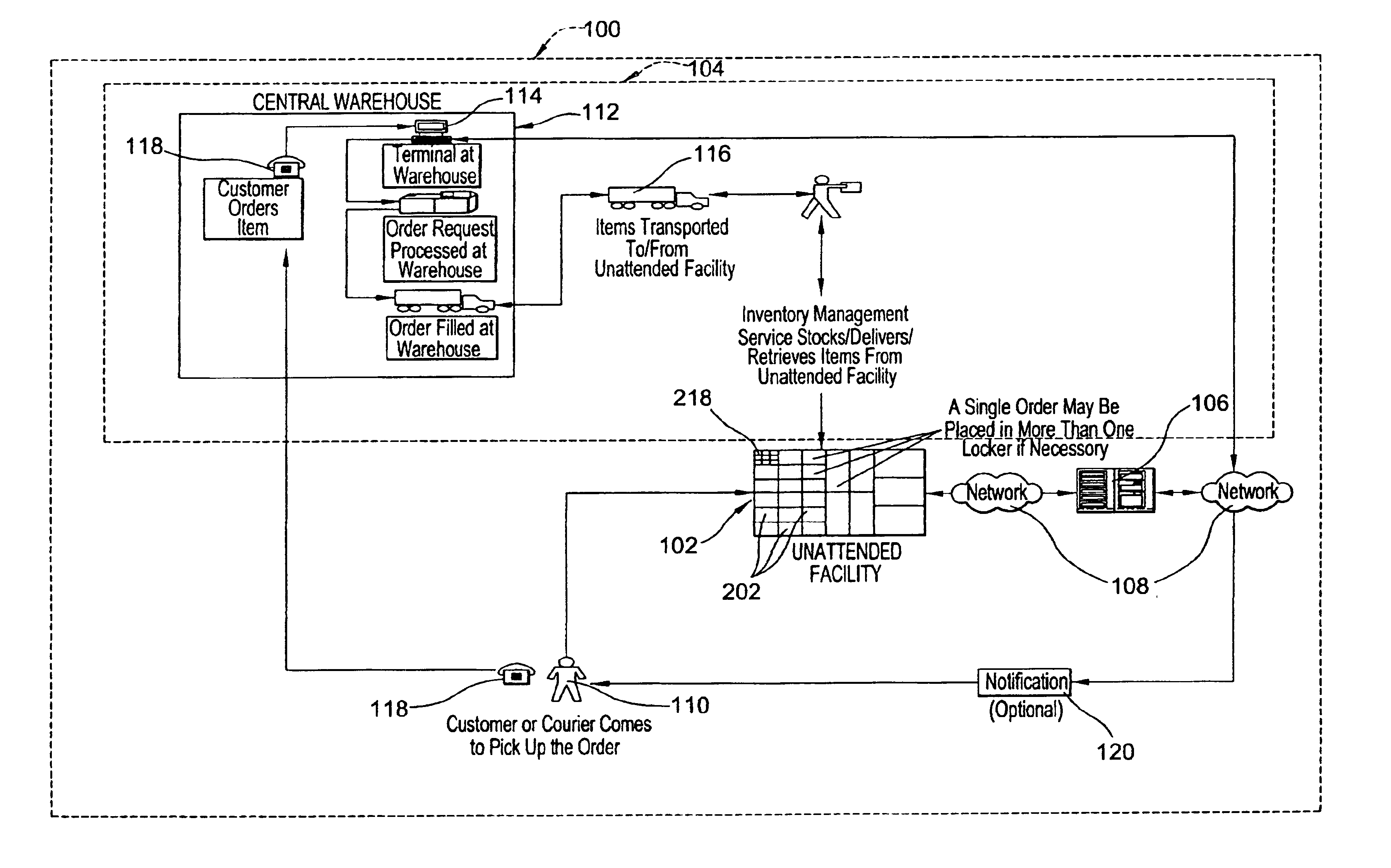

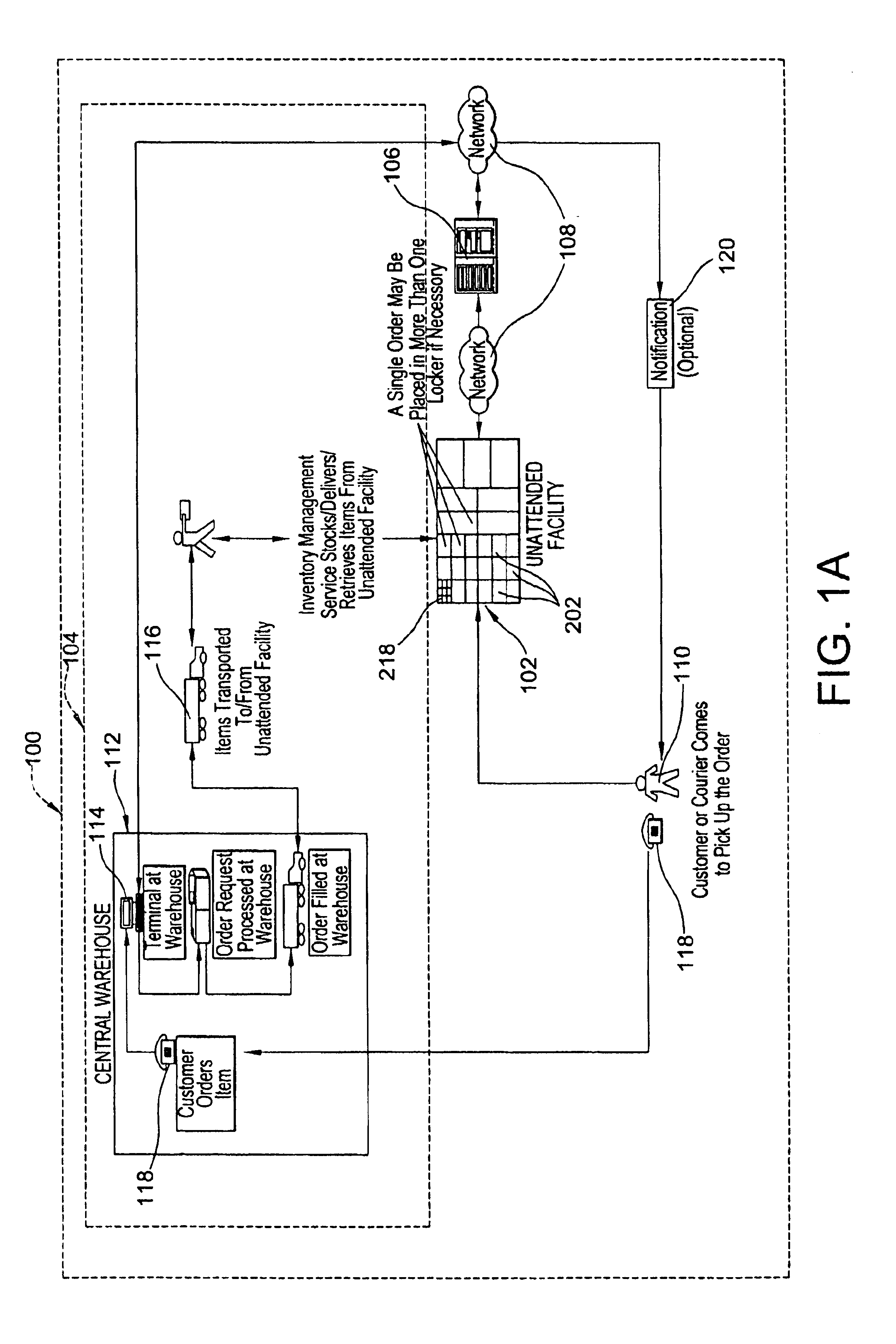

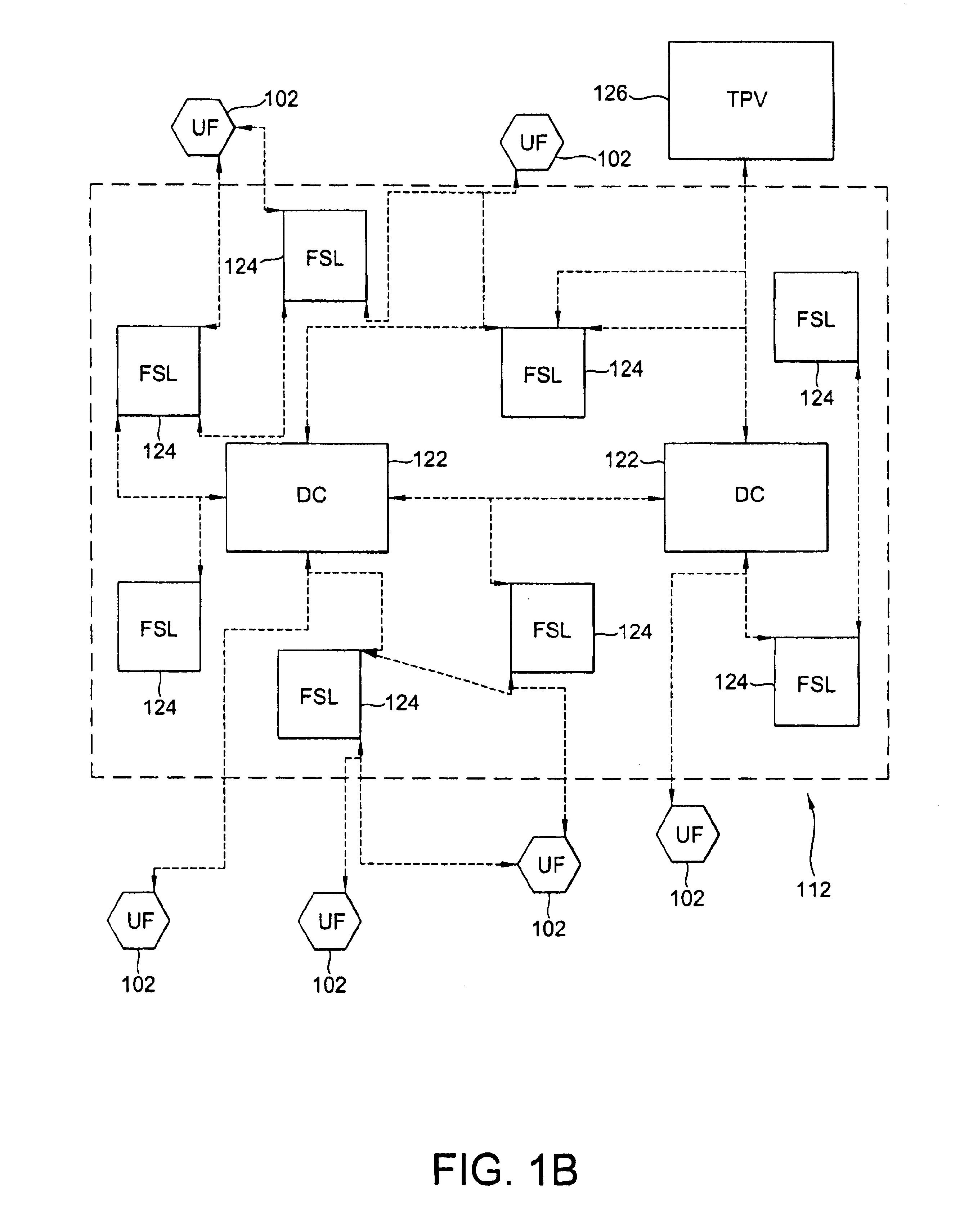

Systems and methods of inventory management utilizing unattended facilities

InactiveUS6866195B2Speed up the processLow costApparatus for meter-controlled dispensingVisual presentationLogistics managementSecure Shell

An inventory management system utilizes unattended facilities remote from a central warehouse for service parts logistics. Items are placed in inventory in secure enclosures at the unattended facilities by the inventory management service. The unattended facilities may be located near one or more customers to reduce a service technician's travel time and customers' inventory costs. A service technician utilizes a passcode to retrieve needed items. The service technician may order items that are not kept in the inventory of the unattended facility in which case the items may be delivered to the unattended facility and the service technician may receive a notification related to all the items that comprise an order that the order is ready for pick up at an unattended facility. Unused, used or damaged parts may be returned by a technician to a remote secure enclosure where such returned parts may be retrieved and disposed of, repaired or placed back into inventory if not damaged or after repair, and the processing of such returned parts begins by information entered into a data entry device at the remote secure enclosure location. Return items that are not damaged may be included in the inventory of an unattended facility.

Owner:UNITED PARCEL SERVICE OF AMERICAN INC

Systems and methods of inventory management utilizing unattended facilities

InactiveUS6845909B2Reduce inventory costsQuickly and inexpensively relocatedVisual presentationBuying/selling/leasing transactionsLogistics managementSecure Shell

An inventory management system utilizes unattended facilities remote from a central warehouse for service parts logistics. Items are placed in inventory in secure enclosures at the unattended facilities by the inventory management service or are delivered directly to the unattended facility. The unattended facilities may be located near one or more customers to reduce a service technician's travel time and customers' inventory costs. A service technician utilizes a passcode to retrieve needed items. The service technician may order items that are not kept in the inventory of the unattended facility in which case the items may be delivered to the unattended facility and the service technician may receive a notification related to all the items that comprise an order that the order is ready for pick up at an unattended facility. Unused, used or damaged parts may be returned by a technician to a remote secure enclosure where such returned parts may be retrieved and disposed of, repaired or placed back into inventory if not damaged or after repair, and the processing of such returned parts begins by information entered into a data entry device at the remote secure enclosure location. Return items that are not damaged may be included in the inventory of an unattended facility.

Owner:UNITED PARCEL SERVICE OF AMERICAN INC

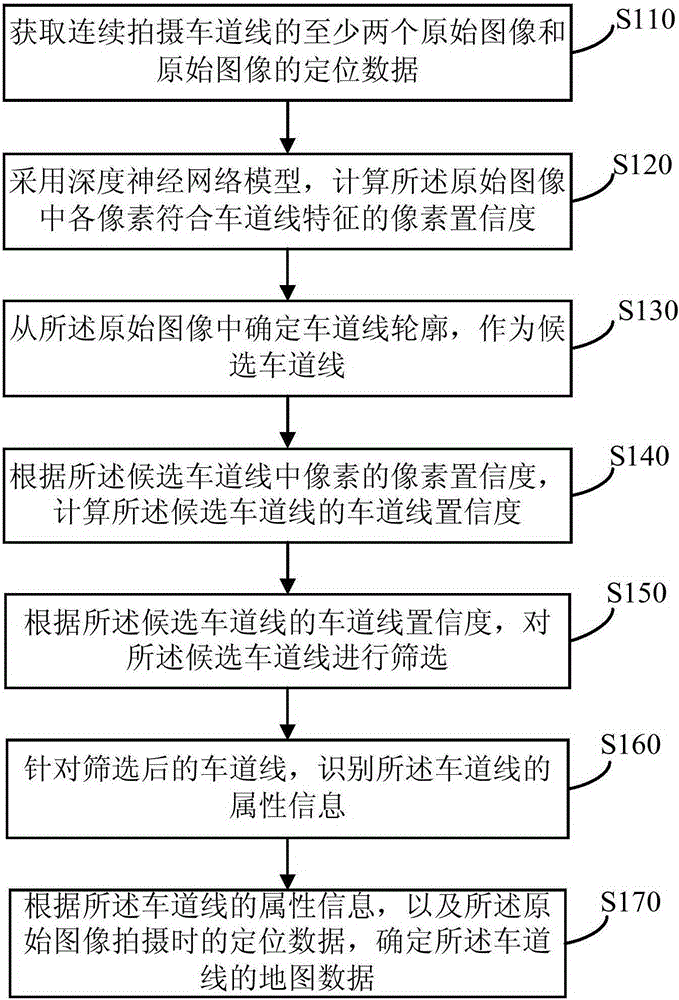

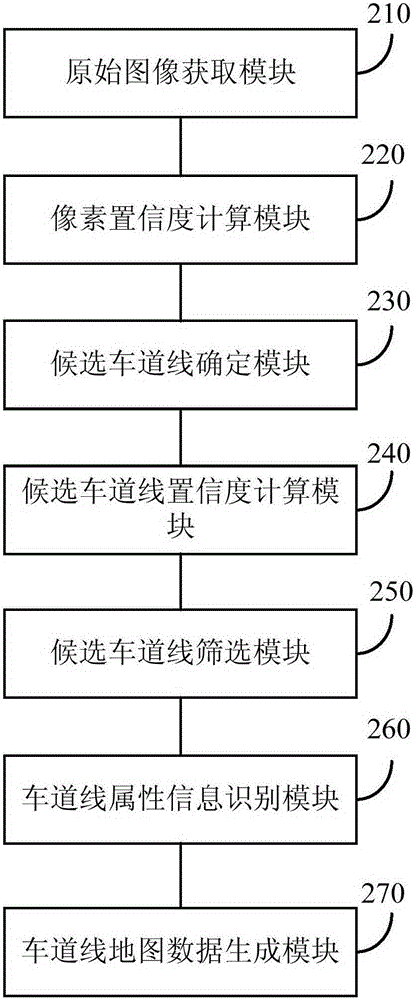

Lane line data processing method and lane line data processing device

ActiveCN105260699AEfficient determinationAccurately determineBiological neural network modelsCharacter and pattern recognitionAlgorithmNetwork model

The embodiment of the invention discloses a lane line data processing method and a lane line data processing device. The method comprises the following steps of: obtaining an original image and positioning data of the original image; using a deep neural network model for calculating the pixel confidence degree of each pixel, conforming to lane line features, in the original image; determining the lane line outlines from the original image, and using the lane line outlines as candidate lane line; calculating the lane line confidence degree of the candidate lane lines; screening the candidate lane lines according to the lane line confidence degree of the candidate lane lines; recognizing the attribute information of the lane line by aiming at the screened lane line; and determining map data of the lane line according to the attribute information of the lane line and positioning data during the original image shooting. The lane line data processing method and the lane line data processing device provided by the embodiment have the advantages that the lane line data can be efficiently and precisely determined; the labor cost in high-precision map production is greatly reduced; and the large-scale high-precision map production can be realized.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

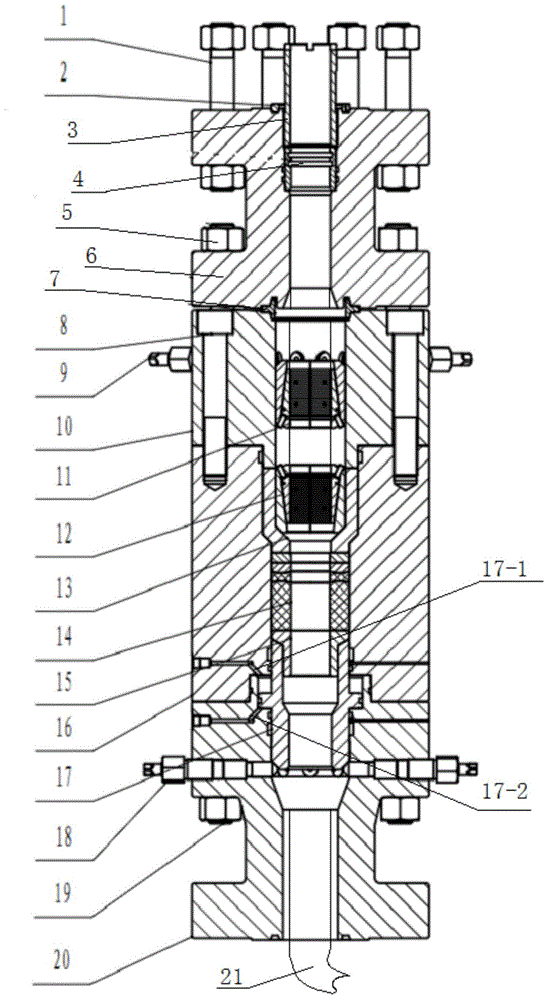

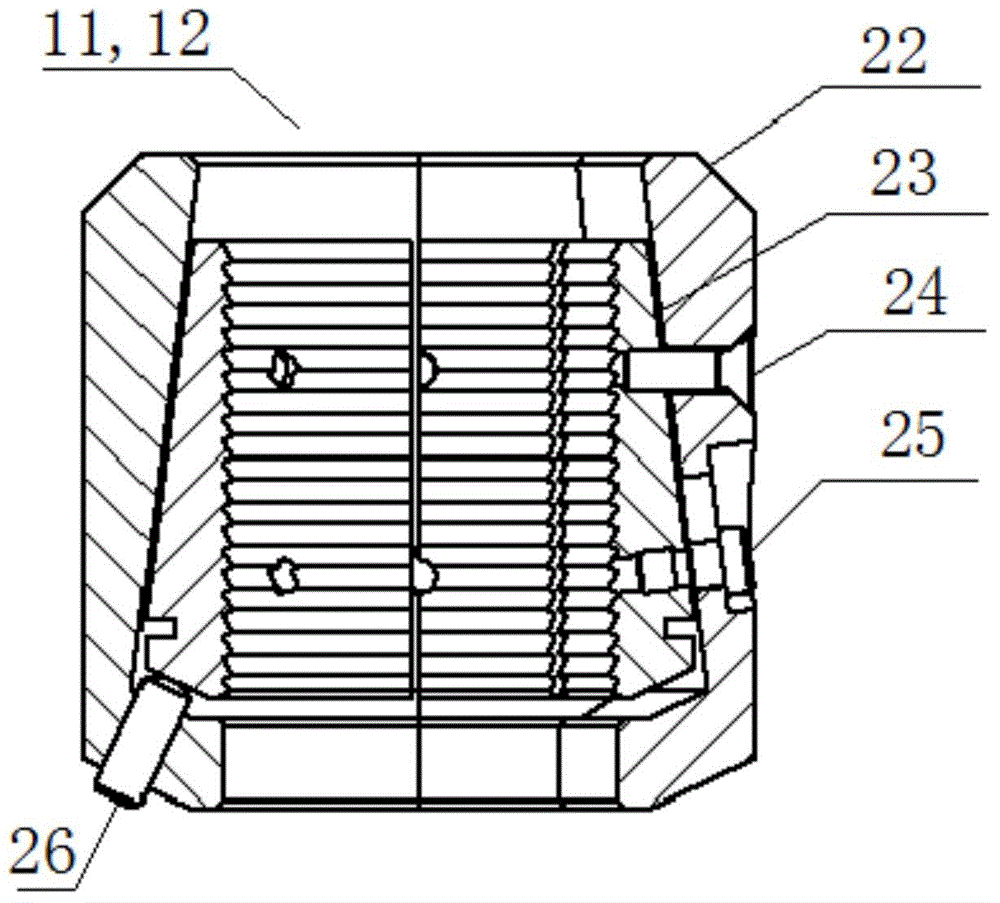

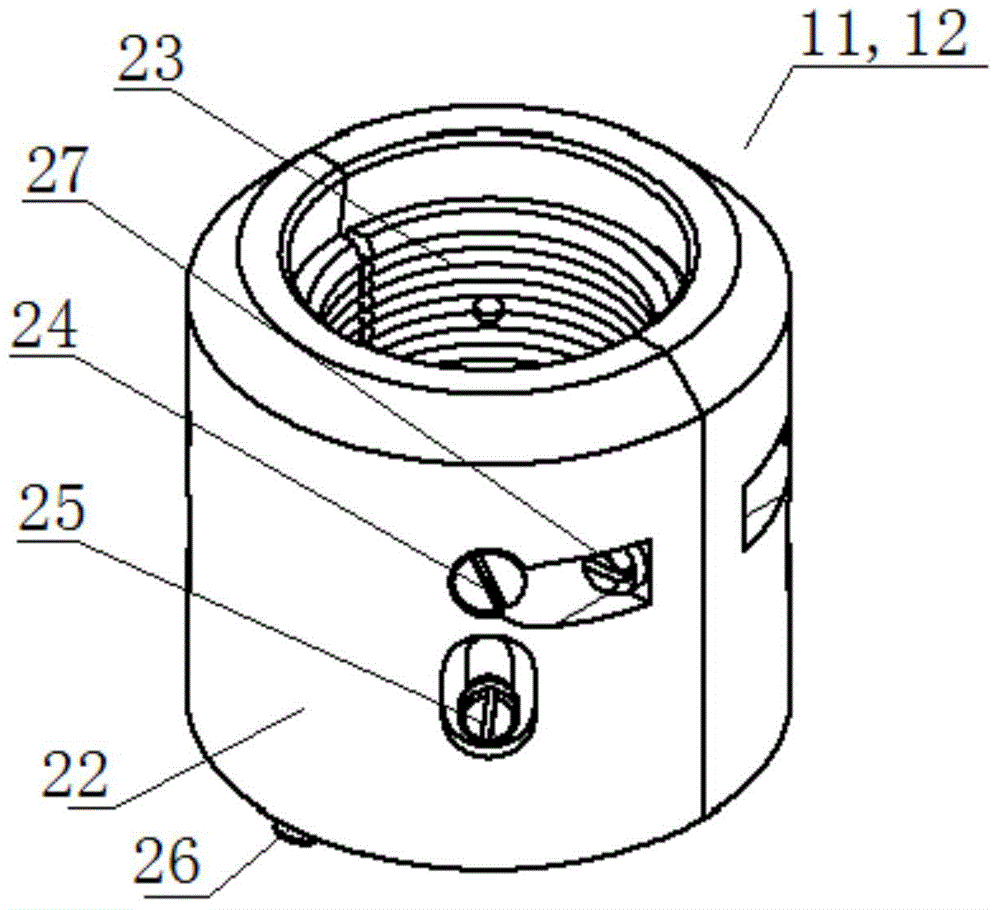

Continuous oil pipe hanger for velocity tubular column

ActiveCN104358536AGuaranteed sealing performanceFix the leakBorehole/well accessoriesCoiled tubingEngineering

The invention relates to a continuous oil pipe hanger for a velocity tubular column. The continuous oil pipe hanger comprises a continuous oil pipe, an I-shaped flange, an upper slip assembly, a lower slip assembly, an upper shell, a middle shell and a lower shell, wherein vertically penetrating central holes are formed in the upper shell, the middle shell and the lower shell; the I-shaped flange is fixedly arranged at the top of the upper shell; the continuous oil pipe passes through the I-shaped flange and the central holes of the upper shell, the middle shell and the lower shell in turn; the upper slip assembly is clamped on an inner wall of the central hole of the upper shell; the lower slip assembly is located in the central hole of the middle shell; a connecting pipe sealing set is fixedly arranged on an inner wall of the central hole of the middle shell and the lower side of a hanging supporting sleeve; at least one pair of driving pistons is arranged on the inner walls of the central holes of the middle shell and the lower shell and under the connecting pipe sealing set; an upper oil port and a lower oil port respectively communicated with the driving pistons are arranged on the side walls of the middle shell and the lower shell. The continuous oil pipe hanger has the beneficial effect of capability of hanging the continuous oil pipe.

Owner:JEREH ENERGY SERVICES

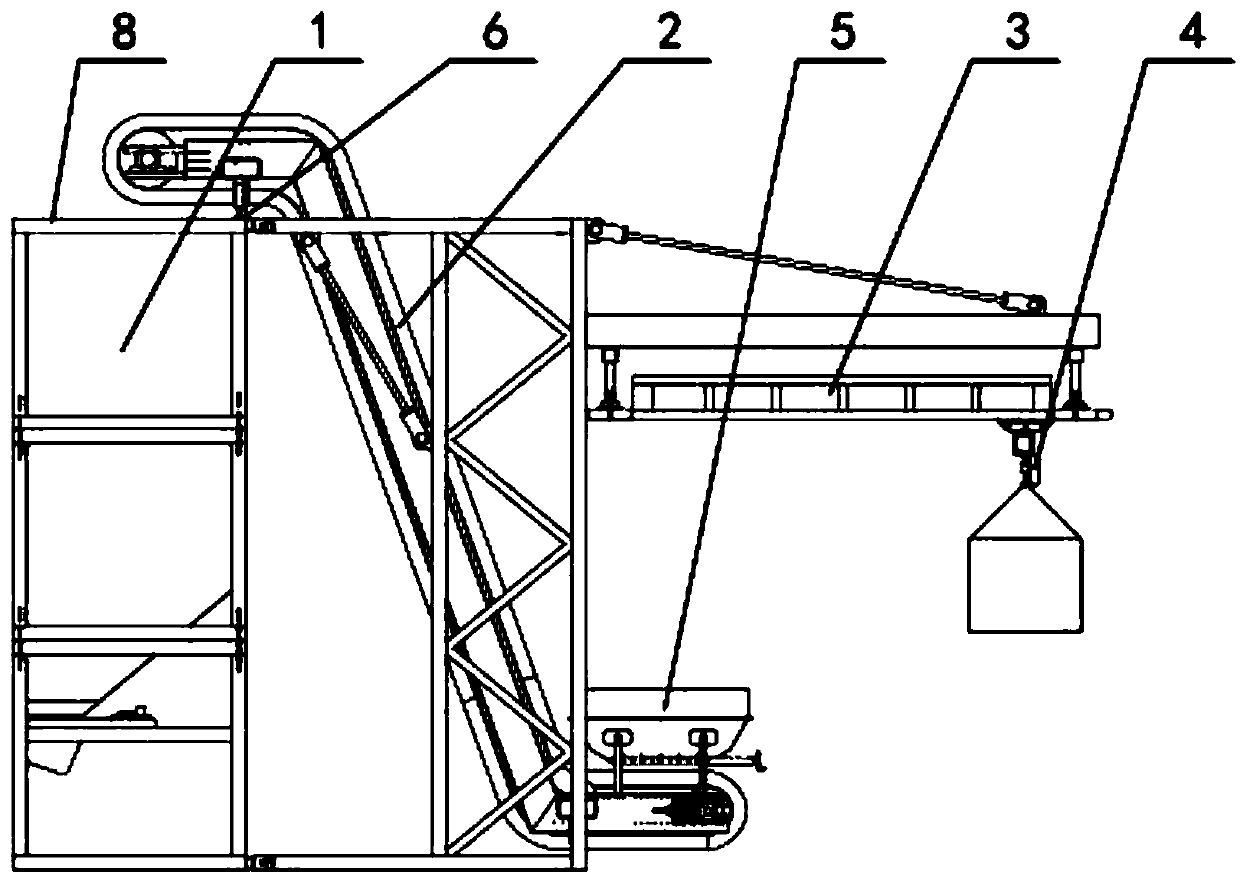

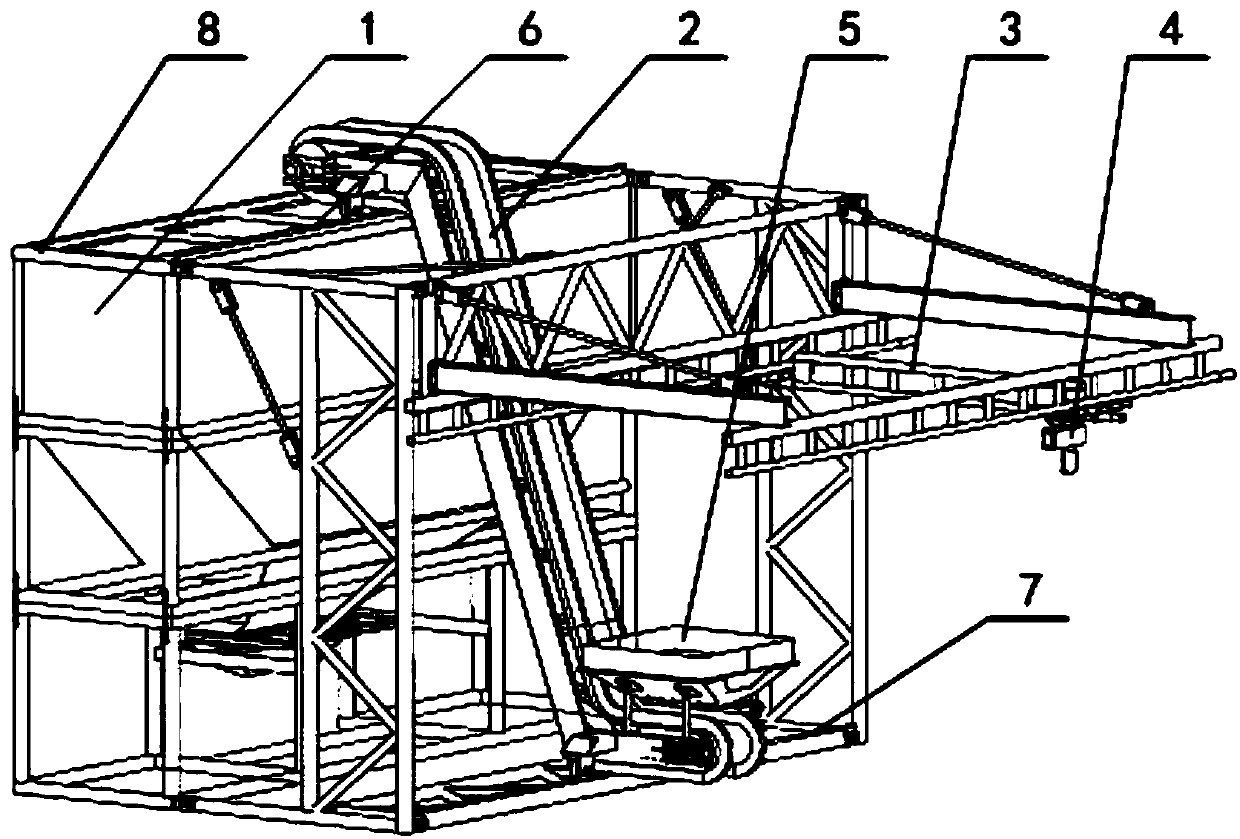

Material hoisting and transportation device

PendingCN107902427ASave on high costsEliminate potential safety hazardsStorage devicesEngineeringOrbit

The invention relates to the oil gas industry, particularly to a material hoisting and transportation device utilized in oil and gas field fracturing operation. The material hoisting and transportation device is characterized in that a material storage tank is mounted on the left of a frame body; an upper orbit is mounted at the upper part of the frame body; a lower orbit is mounted at the right end of the lower part of the frame body; a belt conveying device is mounted on the upper orbit and the lower orbit; a feeding hopper is mounted at the bottom of the belt conveying device; a hoisting device is mounted at the right end of the upper part of the frame body; the hoisting device is mounted in an operation orbit; a hook is mounted on the hoisting device; during operation, the belt conveying device can longitudinally move on the upper orbit and the lower orbit; and during operation, the hoisting device can longitudinally and transversely move in a horizontal plane. The material hoisting and transportation device has a one-key locating function, and automatic operation and locating of the belt conveying device and the hoisting device can be achieved through the function.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

Method of providing care to a patient

InactiveUS20060122867A1Improve quality of careReduce labor costsCoupling device connectionsDrug and medicationsDrugs labelHospital network

Owner:CAREFUSION 303 INC

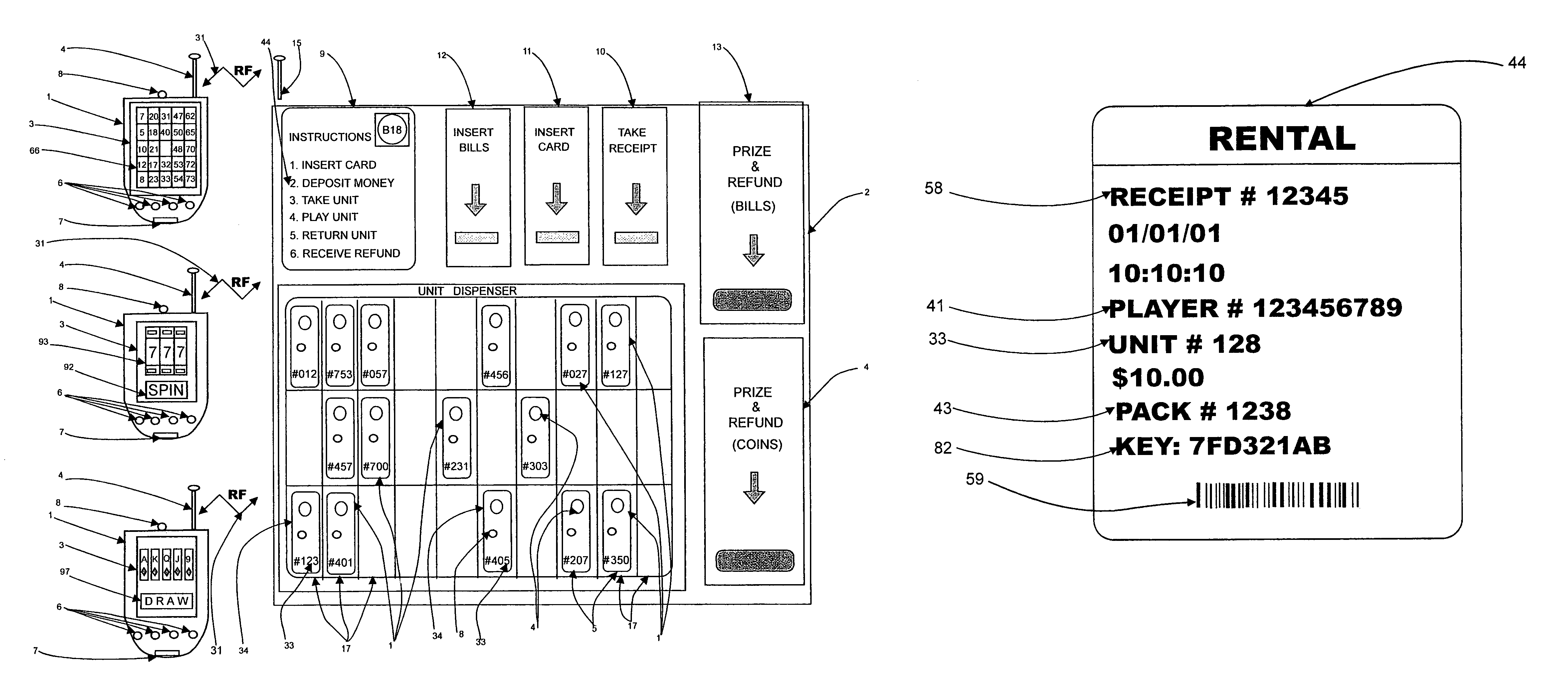

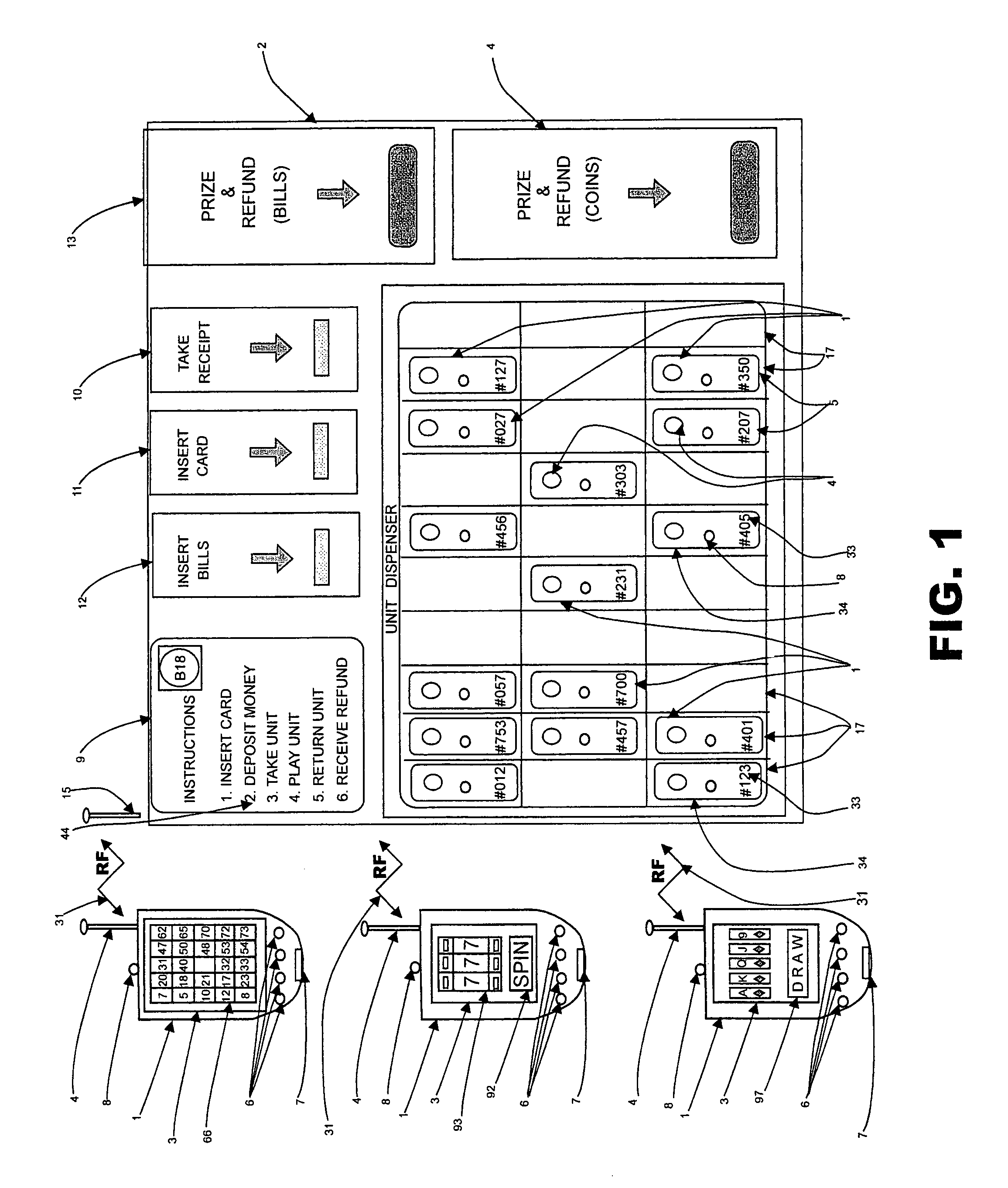

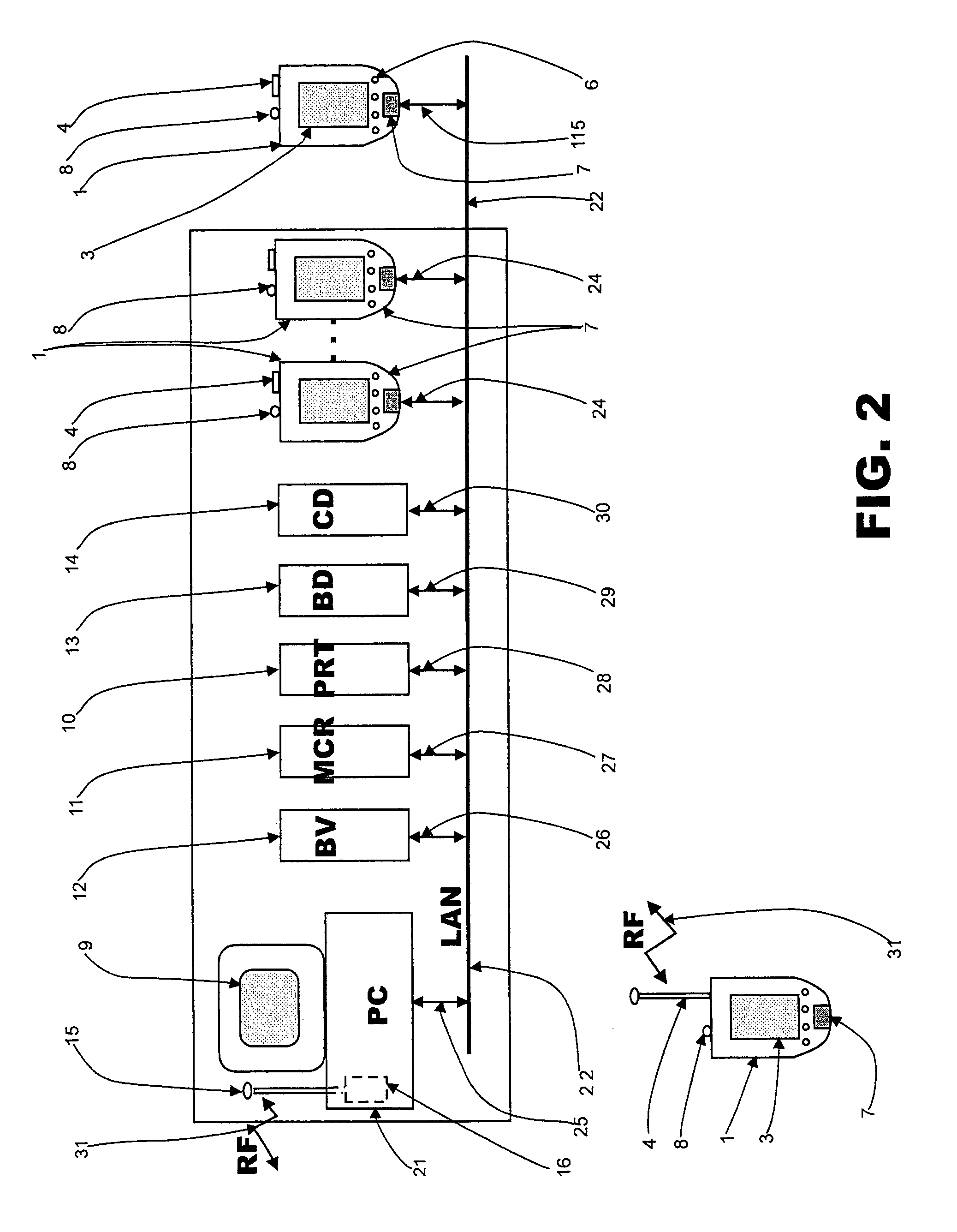

Wireless wagering system

InactiveUS7611407B1Automate processingReduce labor costsBoard gamesCard gamesWired communicationRadio channel

A casino game is implemented on the basis of a wireless mobile player unit adapted to play poker, slots, bingo and other casino games. The unit obtains random game outcomes from a central computer over a radio channel utilizing a data encryption technique relying on an authentication key. The authentication key is downloaded into the unit from the central computer via a secure wired communication channel while the unit is stored, recharged and locked in a dispensing kiosk controlled by the central computer. A player rents the unit from the kiosk, plays it throughout the casino and returns the unit to the kiosk to obtain prizes and / or bonus points earned. The central computer tracks the inventory of the units in the kiosk and on the casino floor.

Owner:FORTUNET

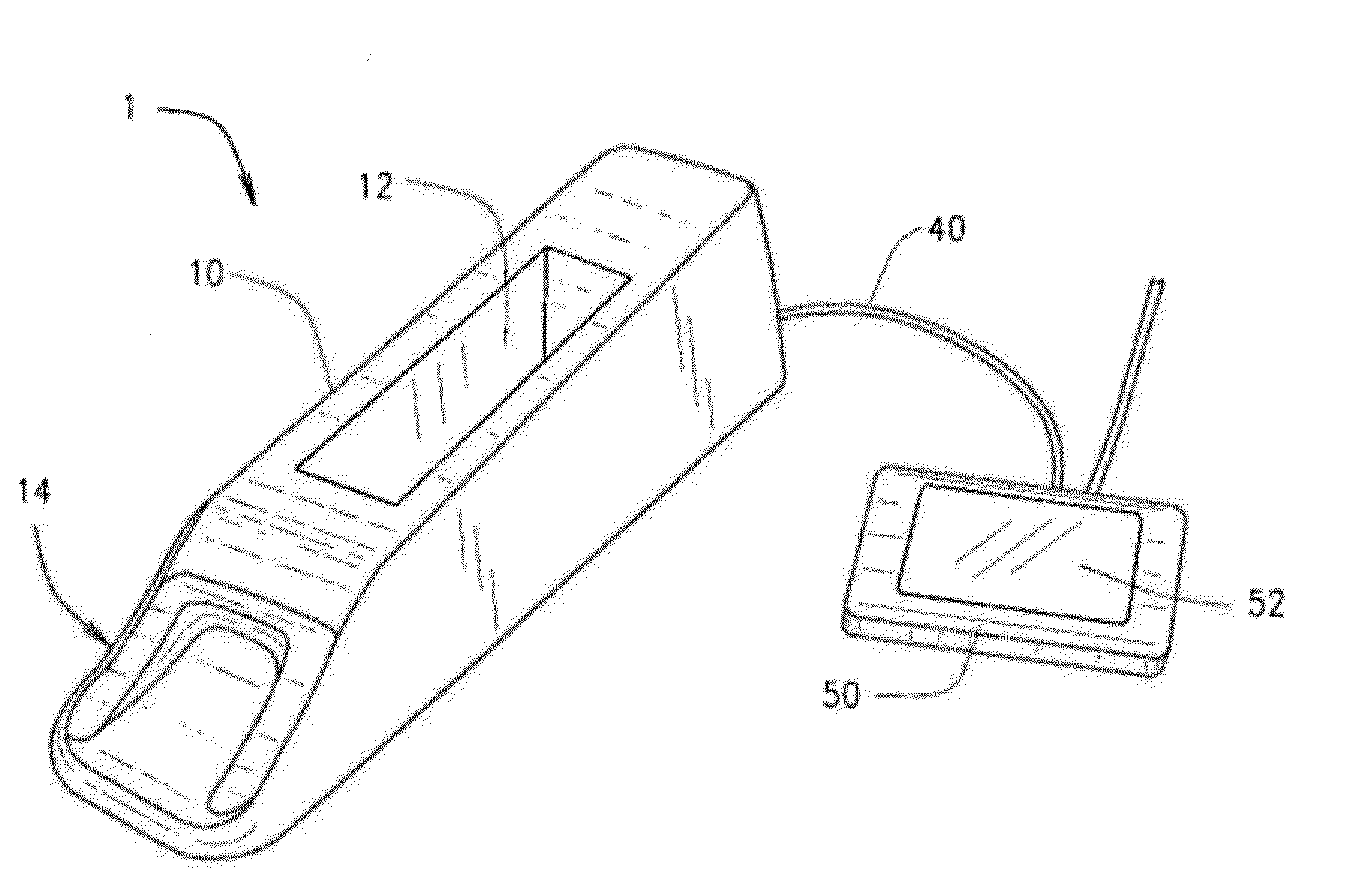

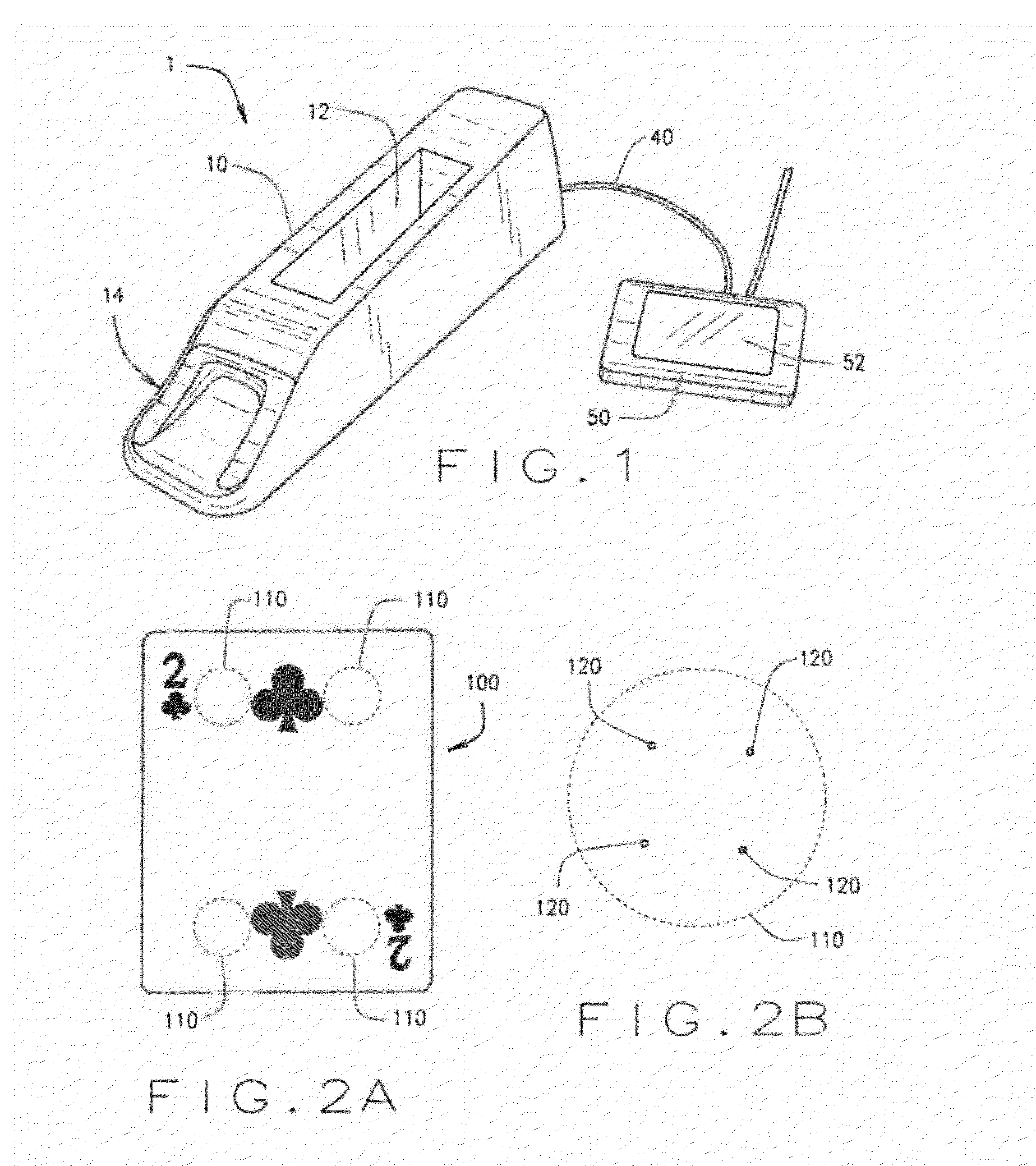

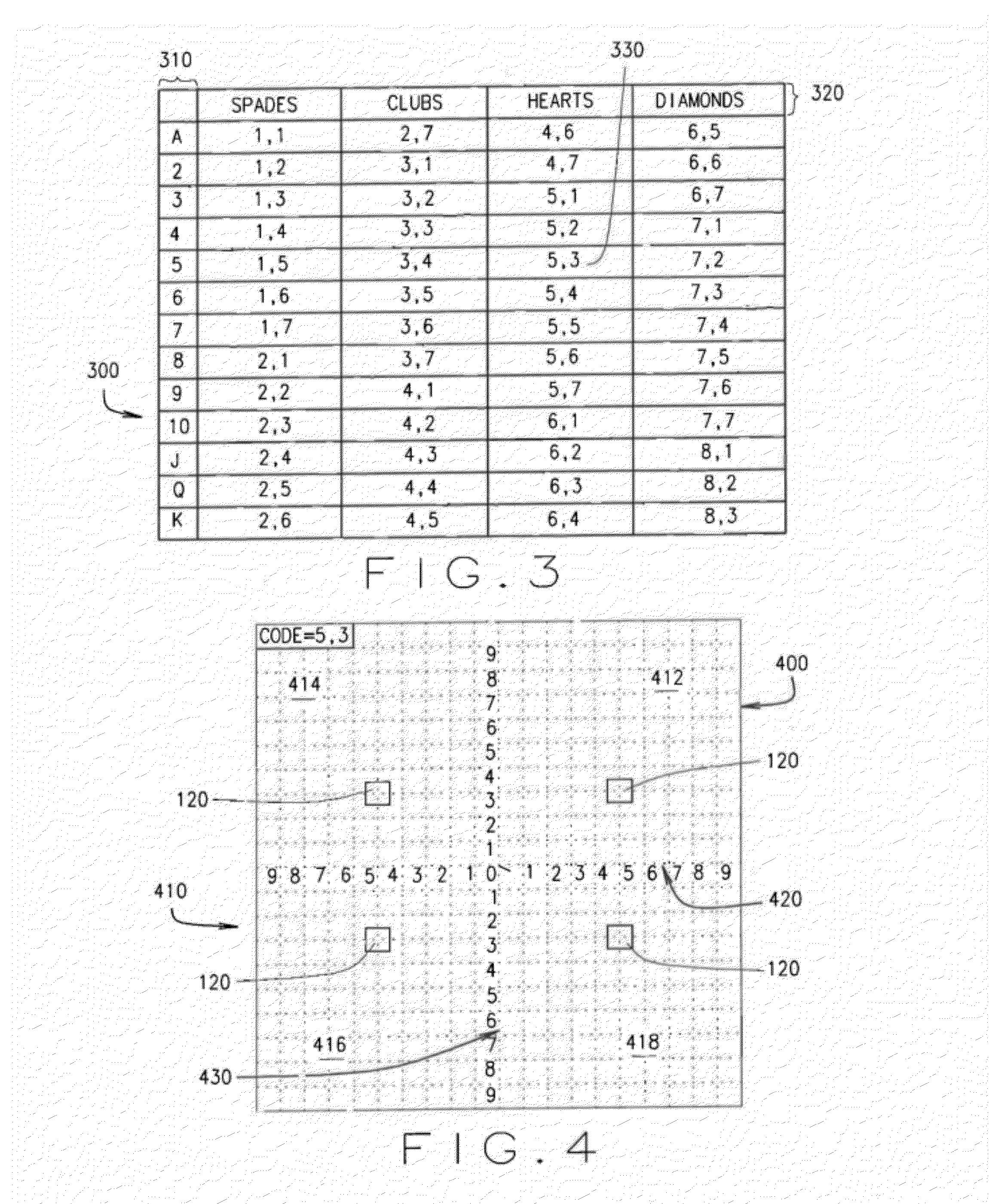

Intelligent table game system

A card dealing system incorporating playing cards with rank and suit information encoded thereon via micro-dots, and a shoe capable of reading such micro dots as a playing card is drawn from the shoe. A game controller unit determines the location of the micro-dots on the playing card, and determines the rank and suit information therefrom. The game controller thereby monitors the progress and status of a card game.

Owner:THE US PLAYING CARD

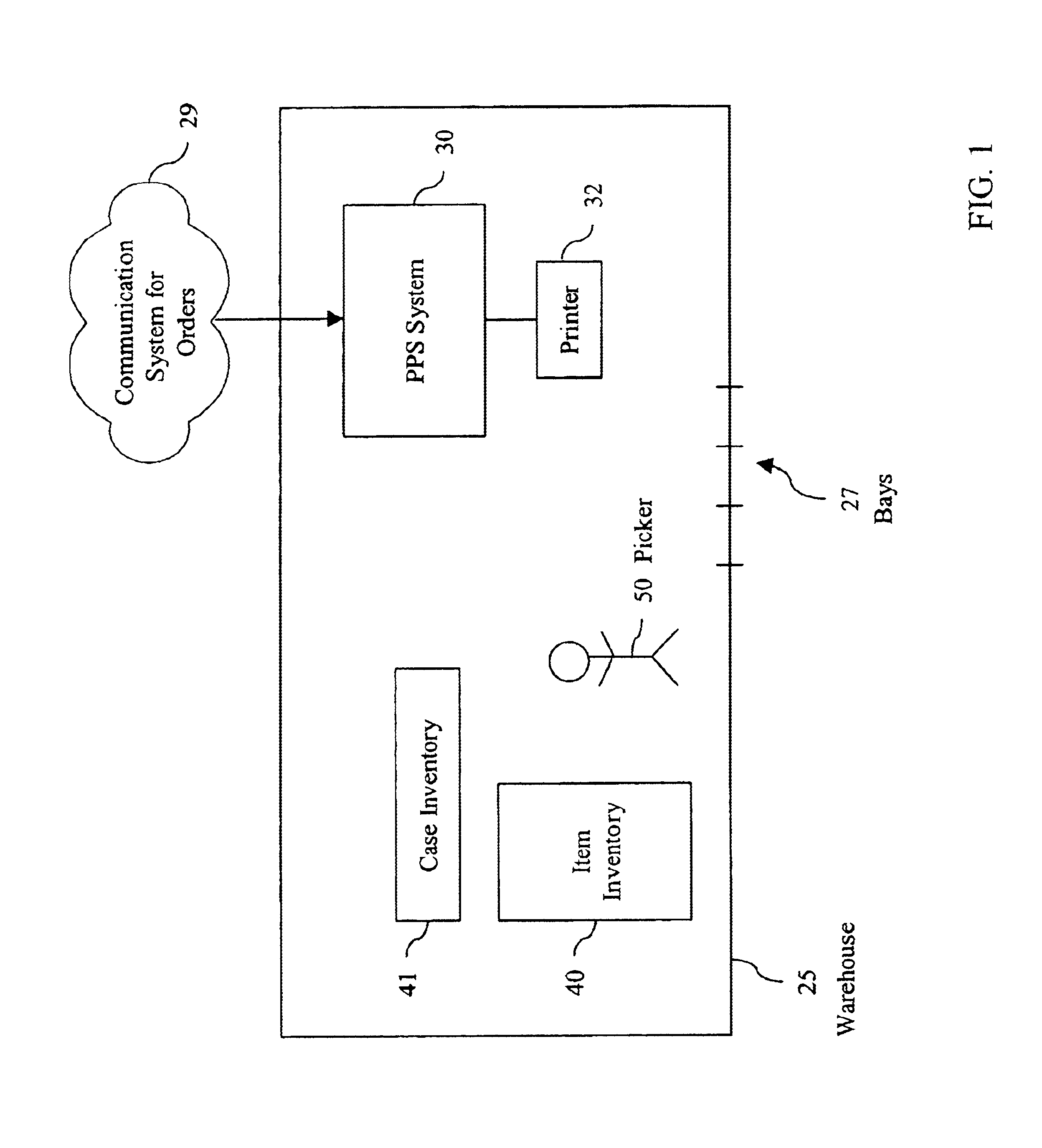

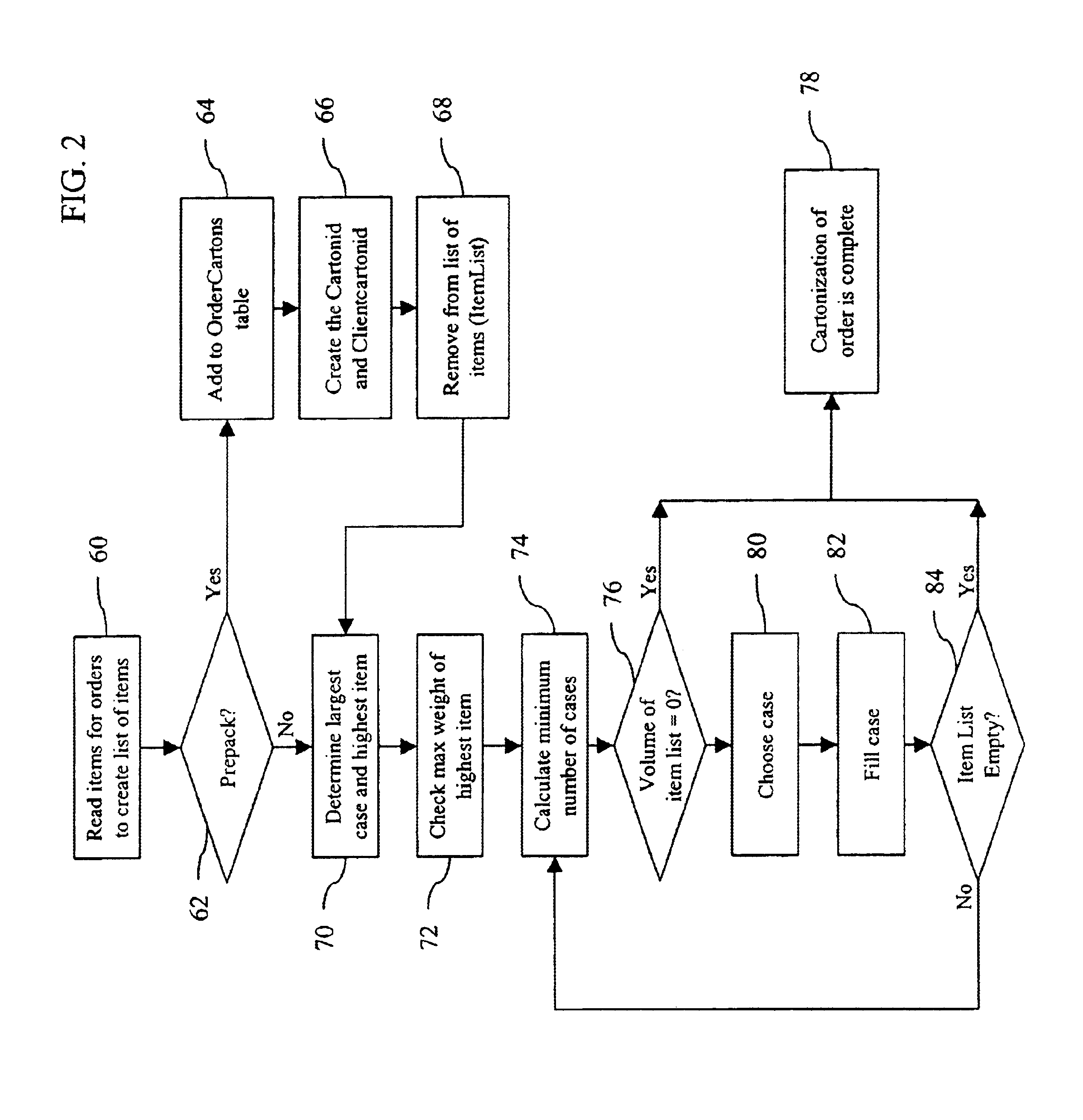

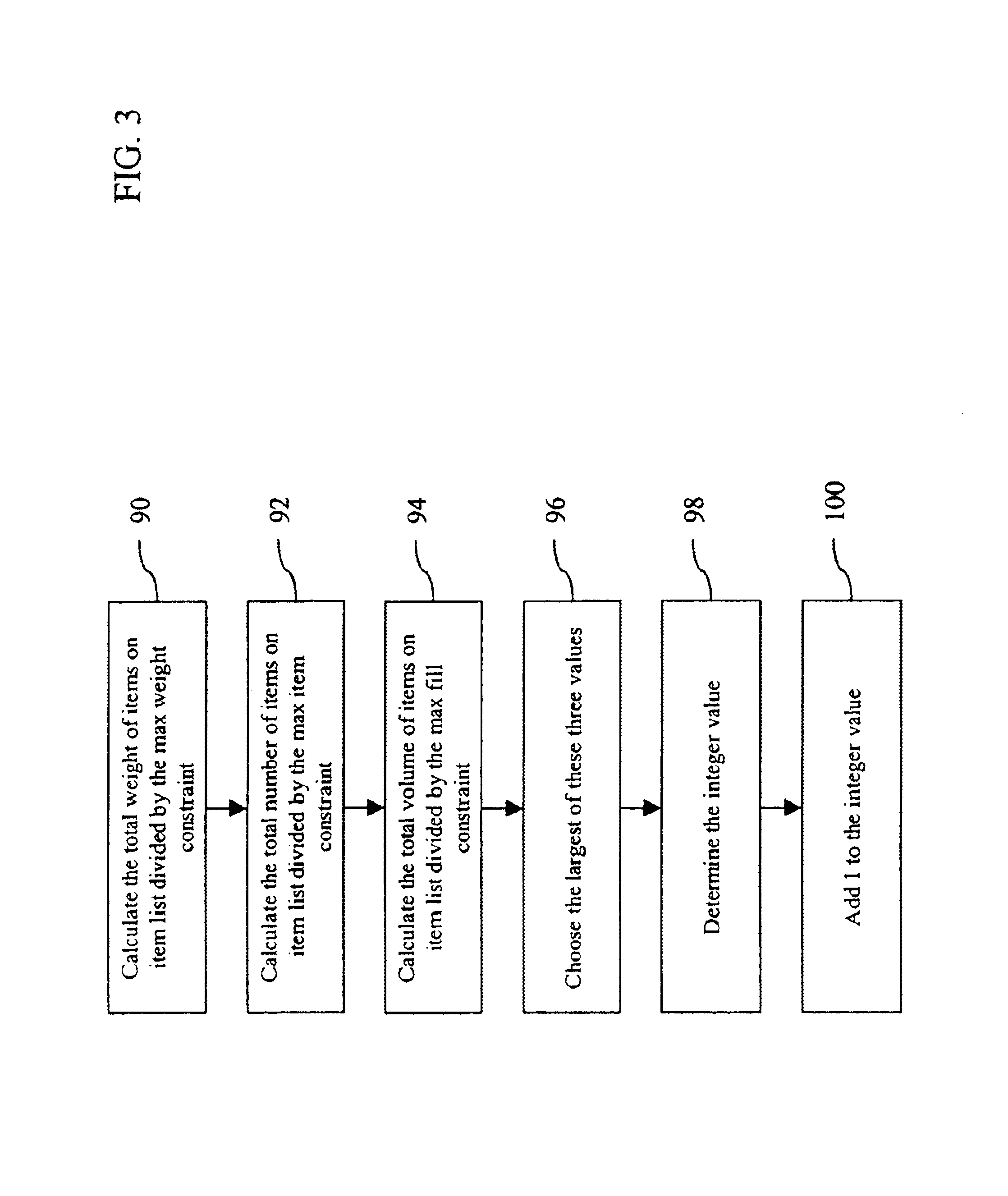

Method and system of optimized sequencing and configuring of items for packing in a bounded region

The present invention includes methods of selecting cases in which to pack items in an item order and selecting the sequence and configuration of placement of items into the selected cases. One such method includes examining an order comprising a list of items to be packed, determining the cases available for packing, determining the minimum number of cases required for packing the items in the list of items to be packed, selecting a case to be packed with one or more of the items in the list of items to be packed, wherein said selecting a case comprises determining a desired average volume per case and selecting the smallest of the cases available to be packed that comprises a volume in excess of the average volume per case, and determining the configuration of placement in the case to be packed of items in the list of items to be packed. Such steps may be repeated until all items in the item list are selected and configured for packing.

Owner:NEW BREED

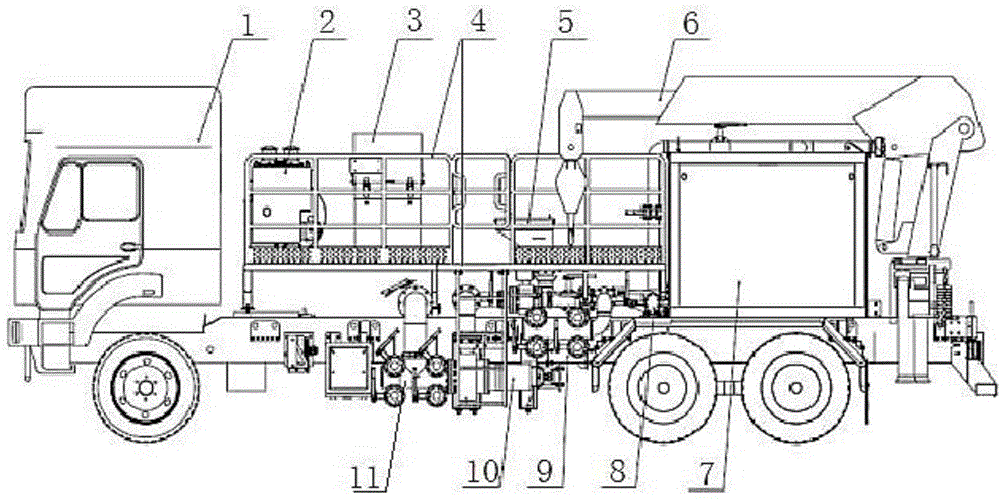

Multifunctional blending and liquid supplying vehicle

InactiveCN104057864AReduce labor costsAchieve mixingFluid removalItem transportation vehiclesControl systemElectrical control

The invention relates to a multifunctional blending and liquid supplying vehicle, which comprises a chassis, wherein an operation platform, a hydraulic oil tank, a dry powder feeder, an operation box for an electrical control system, a lorry-mounted crane and a liquid adding tank are fixedly arranged above the main beam of the chassis, wherein a centrifugal pump, an exhaust manifold and a suction manifold are arranged on each of two sides of the middle part of the main beam of the chassis, the exhaust manifold is communicated with the water outlet of the centrifugal pump, and the suction manifold is communicated with the water inlet of the centrifugal pump; the liquid adding pump is fixedly arranged on the side wall of the liquid adding tank, the water inlet of the liquid adding pump is communicated with the liquid adding tank, and the water outlet of the liquid adding tank is communicated with the exhaust manifold; a discharge opening in the lower end of the dry powder feeder is communicated with the exhaust manifold; the engine of the chassis is connected with a hydraulic pump, and the hydraulic pump is connected with the centrifugal pump, the lorry-mounted crane, the liquid adding tank and the liquid adding pump through a hydraulic multiway valve; the electrical control system is connected with the engine of the chassis, the hydraulic pump and the hydraulic multiway valve. The multifunctional blending and liquid supplying vehicle provided by the invention is low in cost, high in working efficiency, and can achieve various oil field operation functions.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

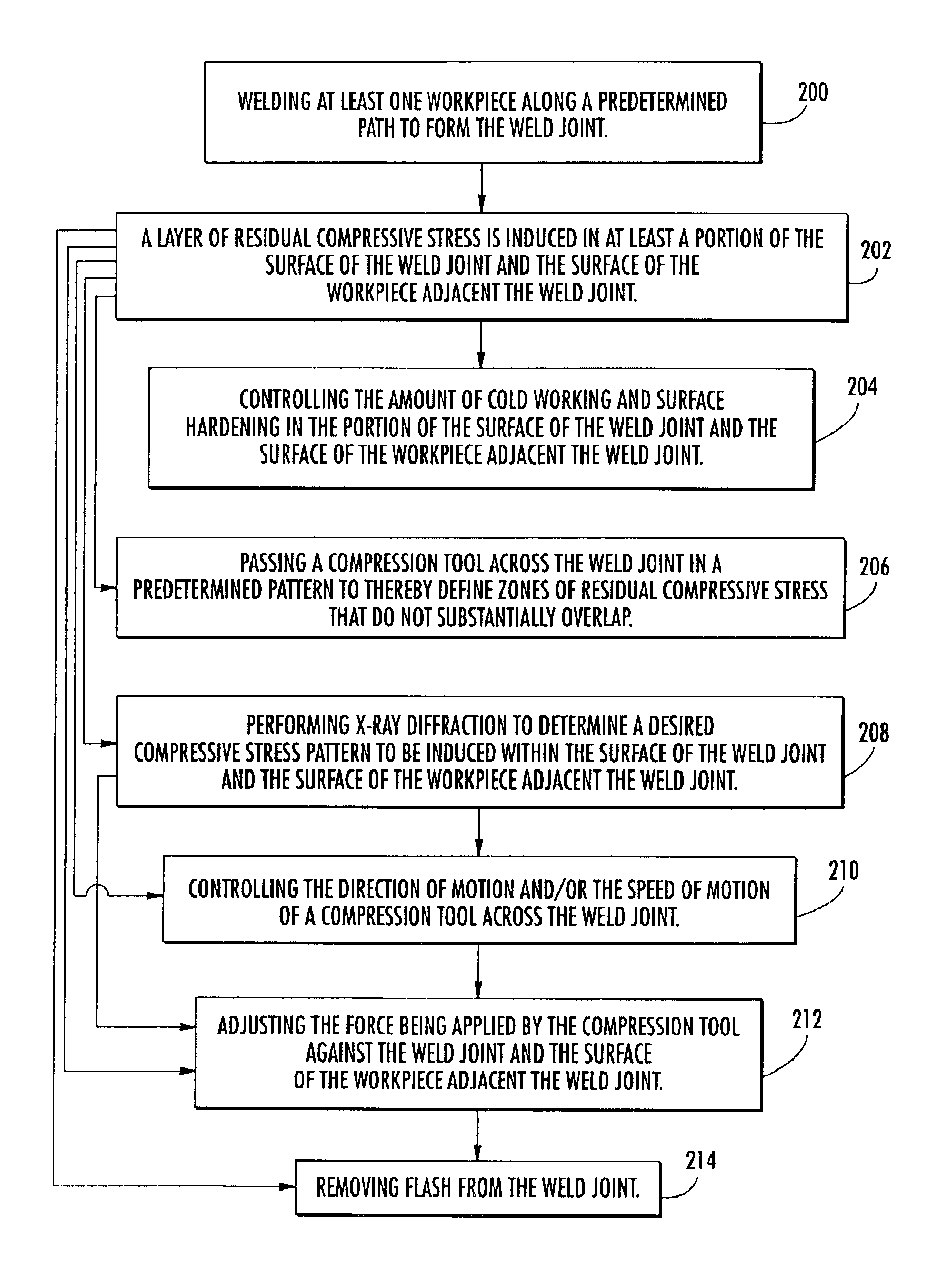

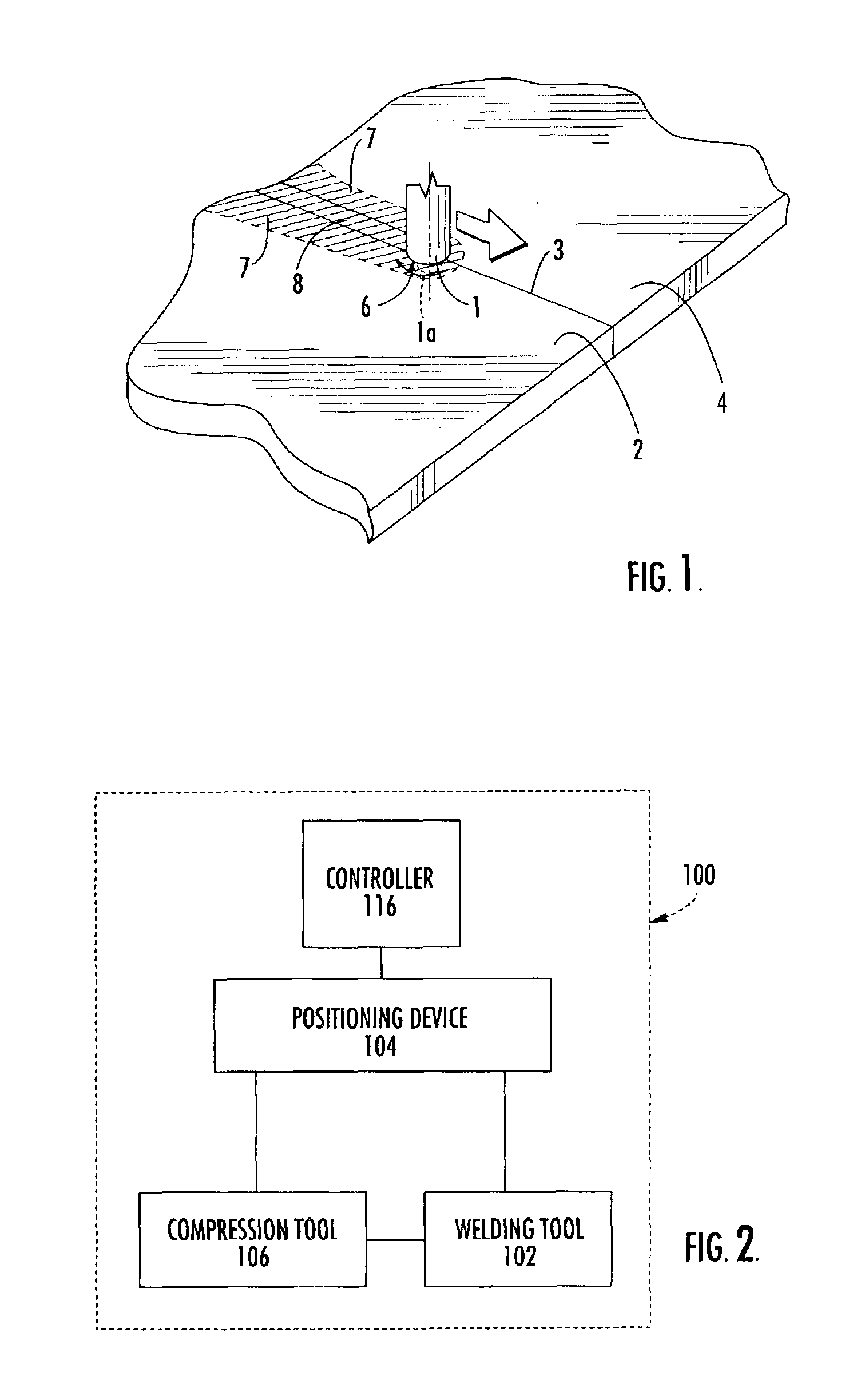

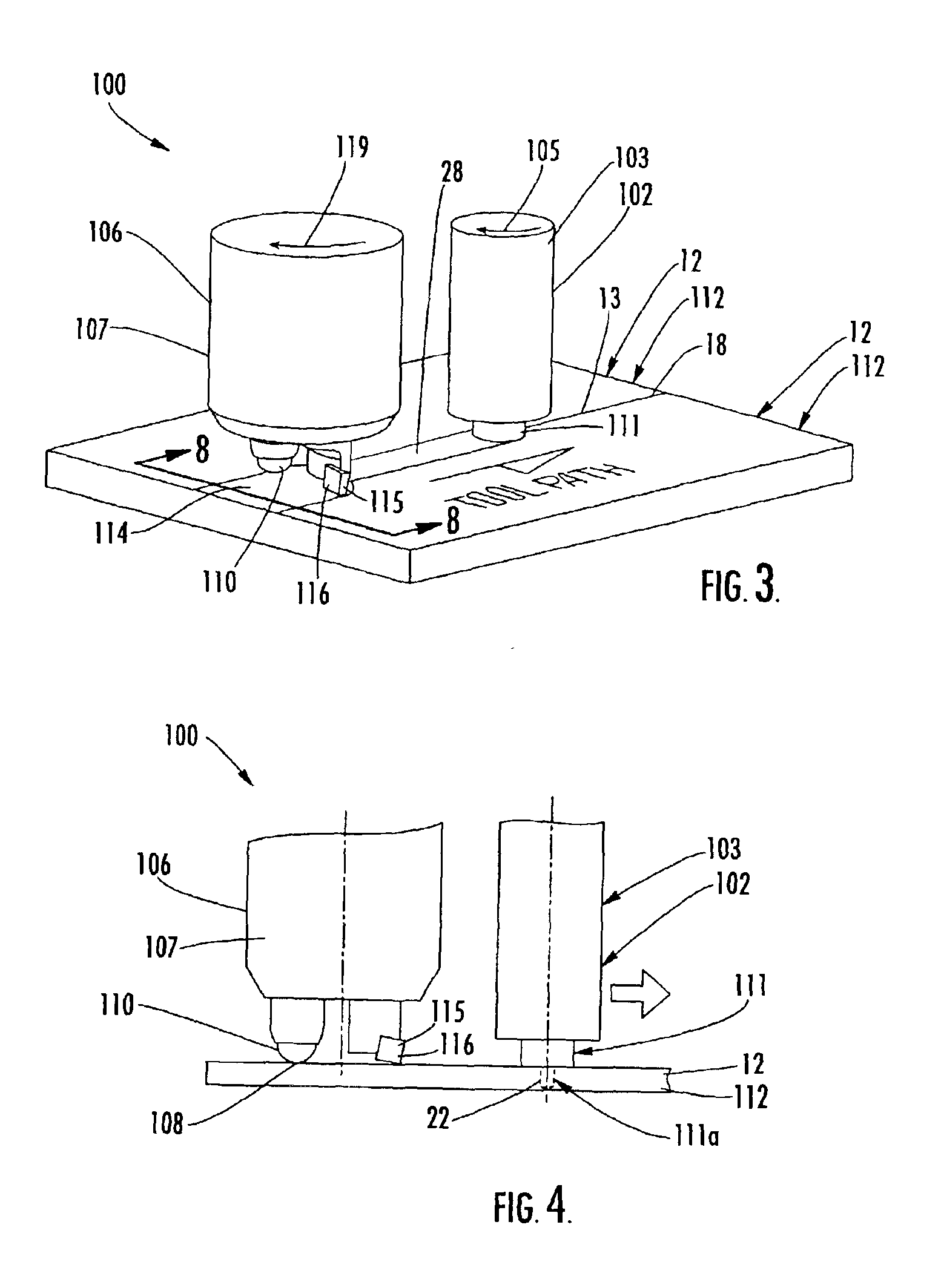

Apparatus and method for forming weld joints having compressive residual stress patterns

InactiveUS6926970B2Improve material propertiesHigh surface finishWelding/cutting auxillary devicesBurnishing machinesUltimate tensile strengthMechanical engineering

The welding apparatus and associated method are provided. The welding apparatus includes a welding tool for forming a weld joint along the surface of at least one workpiece. The welding apparatus also includes a compression tool for selectively inducing a layer of residual compressive stress in at least a portion of the surface of the weld joint and the surface of the at least one workpiece to thereby improve the material properties of the workpiece, including corrosion resistance and fatigue strength.

Owner:SURFACE TECH HLDG +1

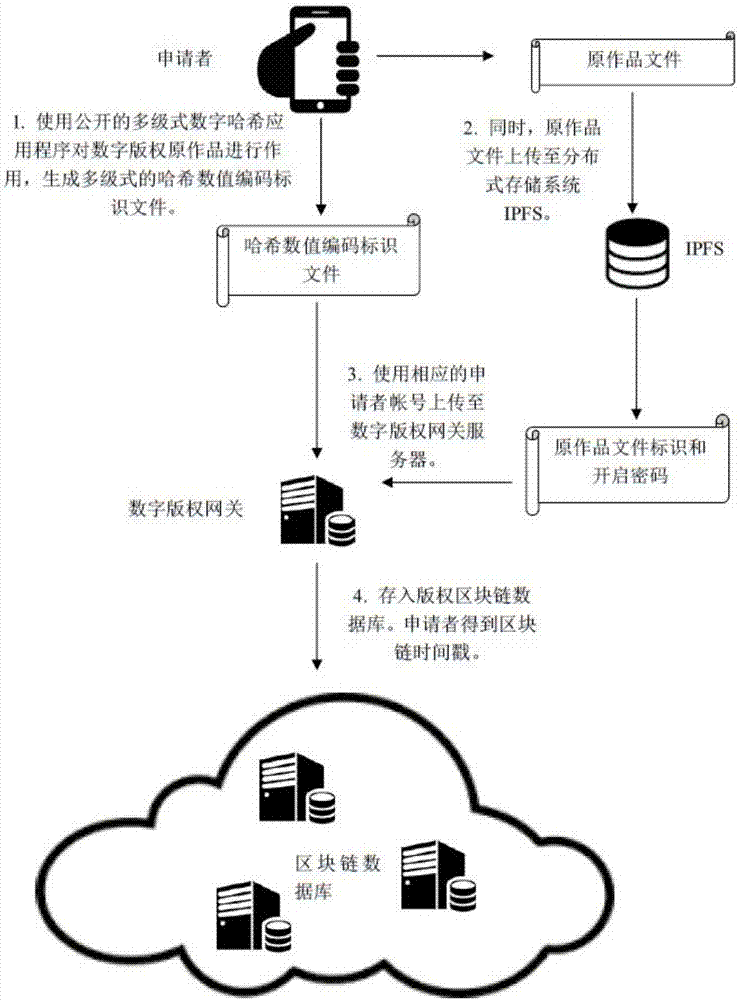

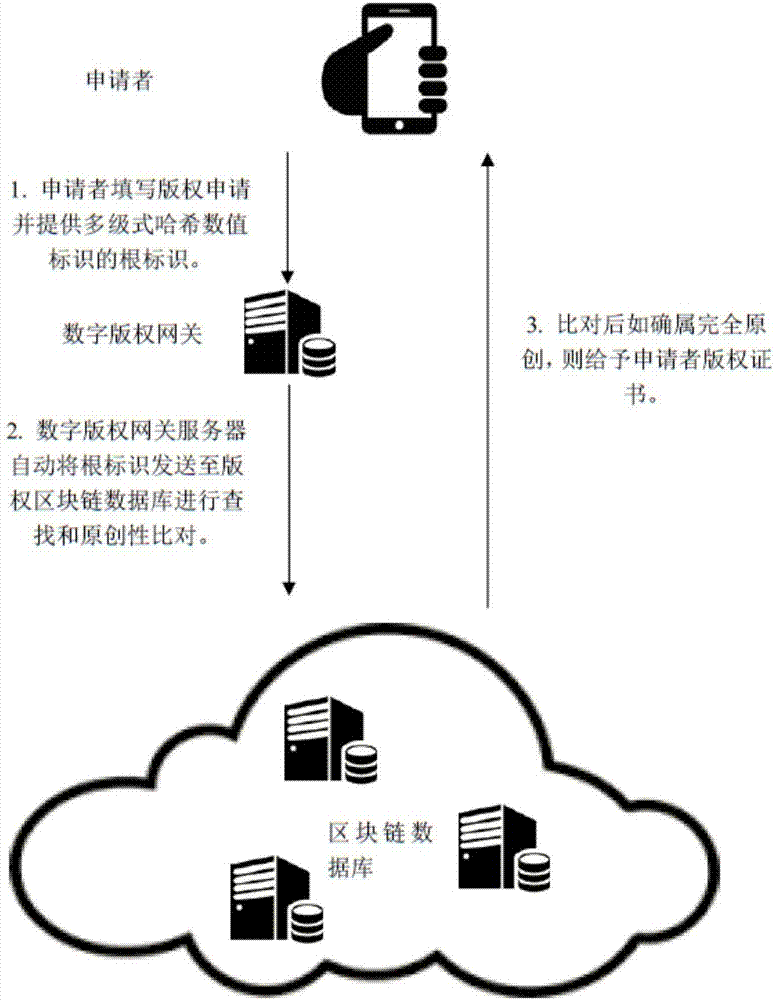

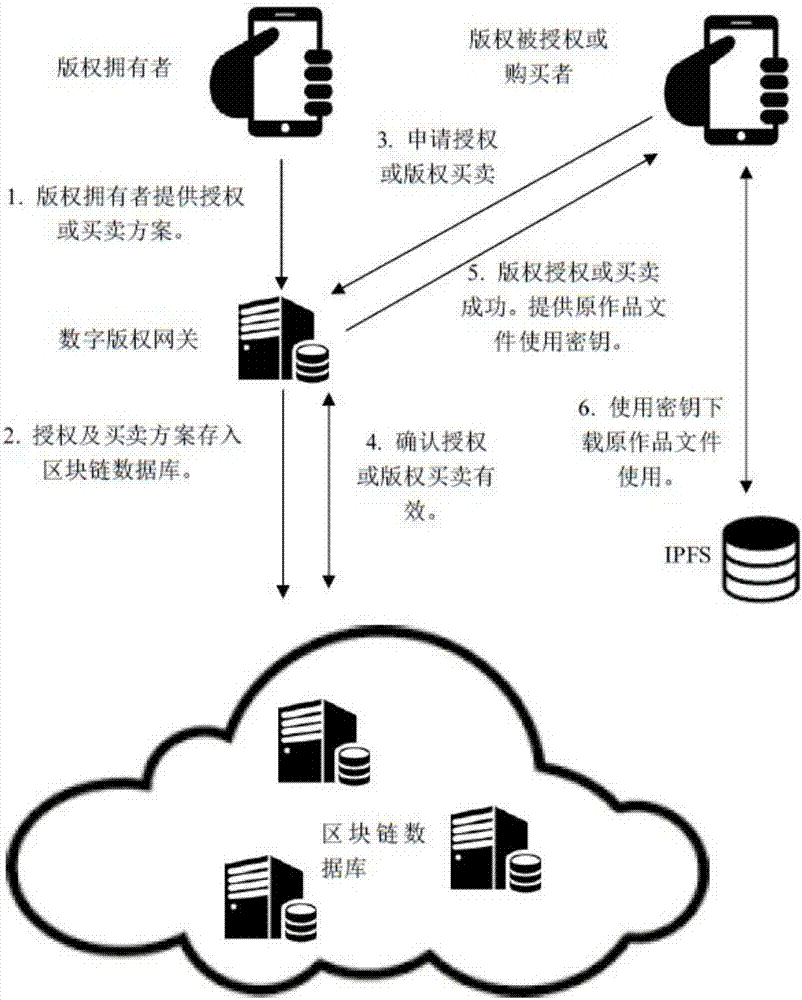

Copyright authorization method based on block chain

InactiveCN107086920AGuaranteed confidentialityShorten the overall cycleUser identity/authority verificationAuthorization certificateFinancial transaction

The invention discloses a copyright authorization method based on a block chain. The method comprises steps of: 1, uploading a work to a client so as to enable the work to become a multi-level hash value code identification document; 2, generating a self identity identifier in a copyright block chain database; 3, enabling a digital copyright gateway server to store the generated multi-level hash value code identification document uploaded by an applicant in self identity into a copyright block chain database; 4, enabling the applicant to fill in a copyright application agreement in detail through a digital copyright application website; 5, enabling the digital copyright application website system to search the duplicate records of various levels of digital identification codes in the block chain database, and to give a copyright authorization conclusion; 6, determining the ownership of copyright according to the copyright authorization conclusion, and sending to the applicant a copyright authorization certificate or an electronic copyright authorization certificate; and 7, enabling two copyright traders to apply for authorization and an authorization transaction at the digital copyright application website system. The method solves the shortcomings of conventional copyright authorization and ensures the high security and reliability of the copyright.

Owner:无锡井通网络科技有限公司

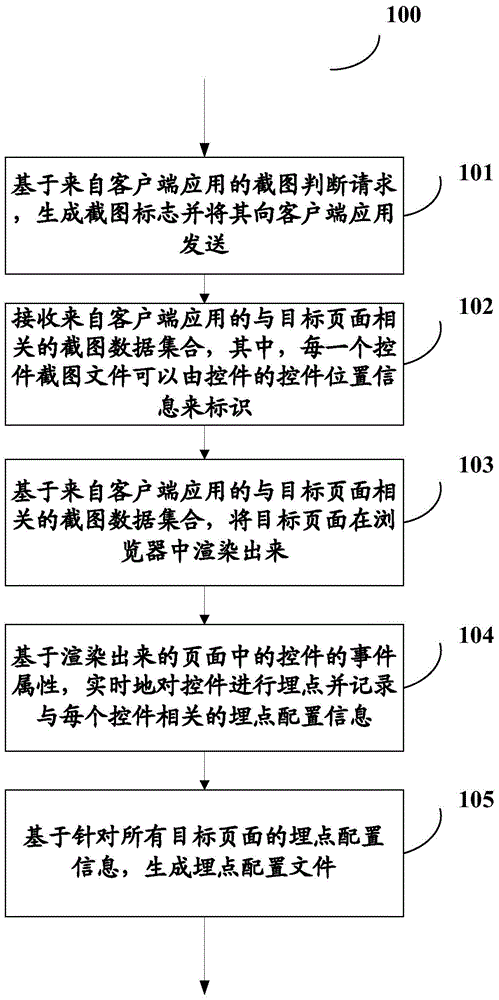

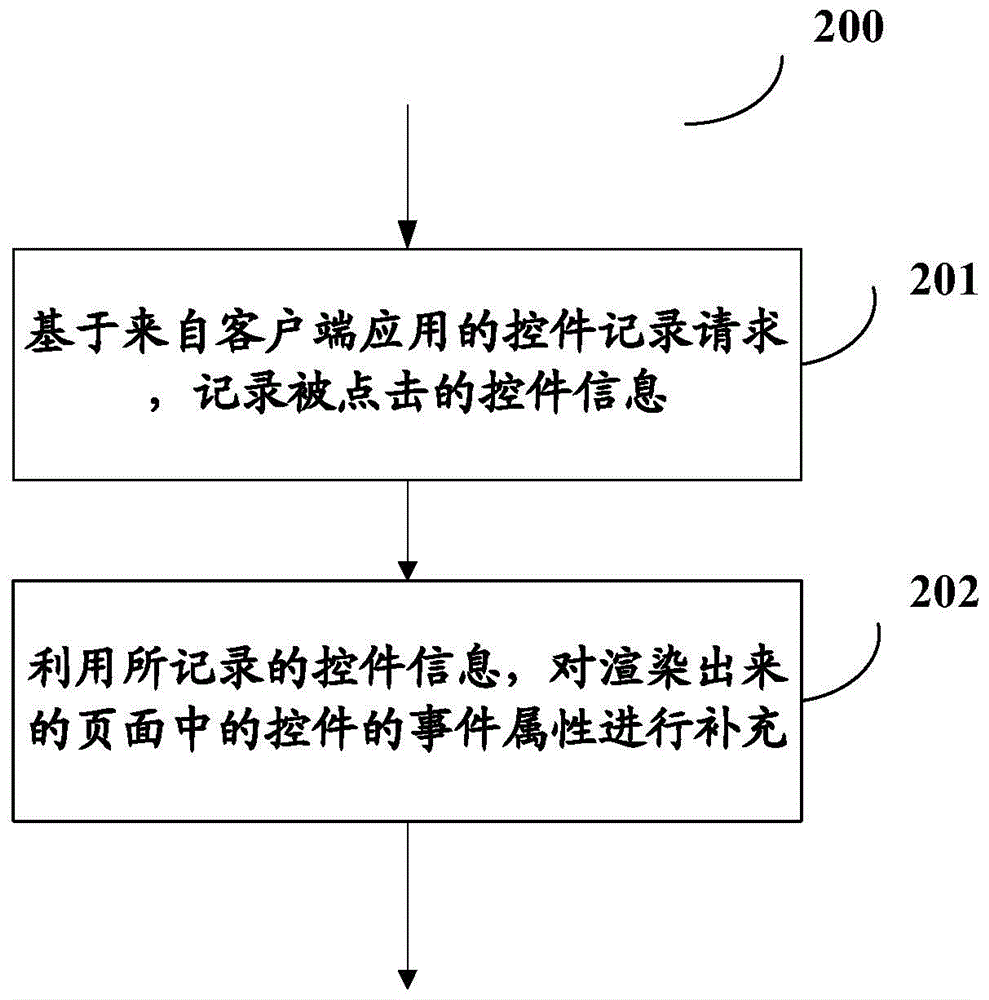

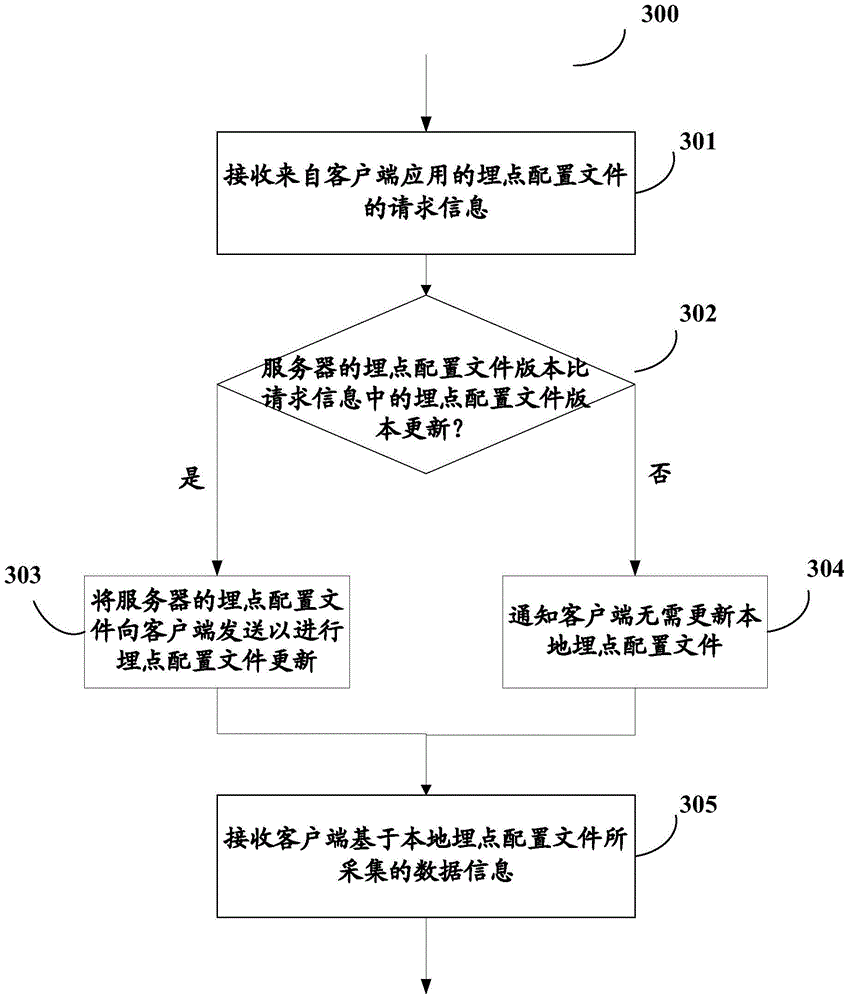

Method and device for embedding points for controls of client application in real time

ActiveCN104572043AReduce labor costsTransmissionSpecific program execution arrangementsData setTheoretical computer science

The application provides a method and device for embedding points for controls of a client application in real time. The method comprises the following steps: judging a request on the basis of screenshots from the client application, generating screenshot marks, and sending the screenshot marks to the client applications; receiving a screenshot data set which is from the client application and is relevant to target pages, wherein the screenshot data set comprises control screenshot files, page screenshot files and page structure information, and each control screenshot file is identified by the control position information of each control; rendering the target pages in the browser on the basis of the screenshot data set which is from the client application and is relevant to the target pages; embedding points for the controls in real time and recording the configuration information of the embedded points on the basis of the rendered event attributes of the controls in the pages. Through the adoption of the method disclosed by the invention, the problem that the points are manually embedded for the controls of the client application in the out-dated prior art is solved, and the automatic embedding of the points for the controls of the client application is realized.

Owner:ADVANCED NEW TECH CO LTD

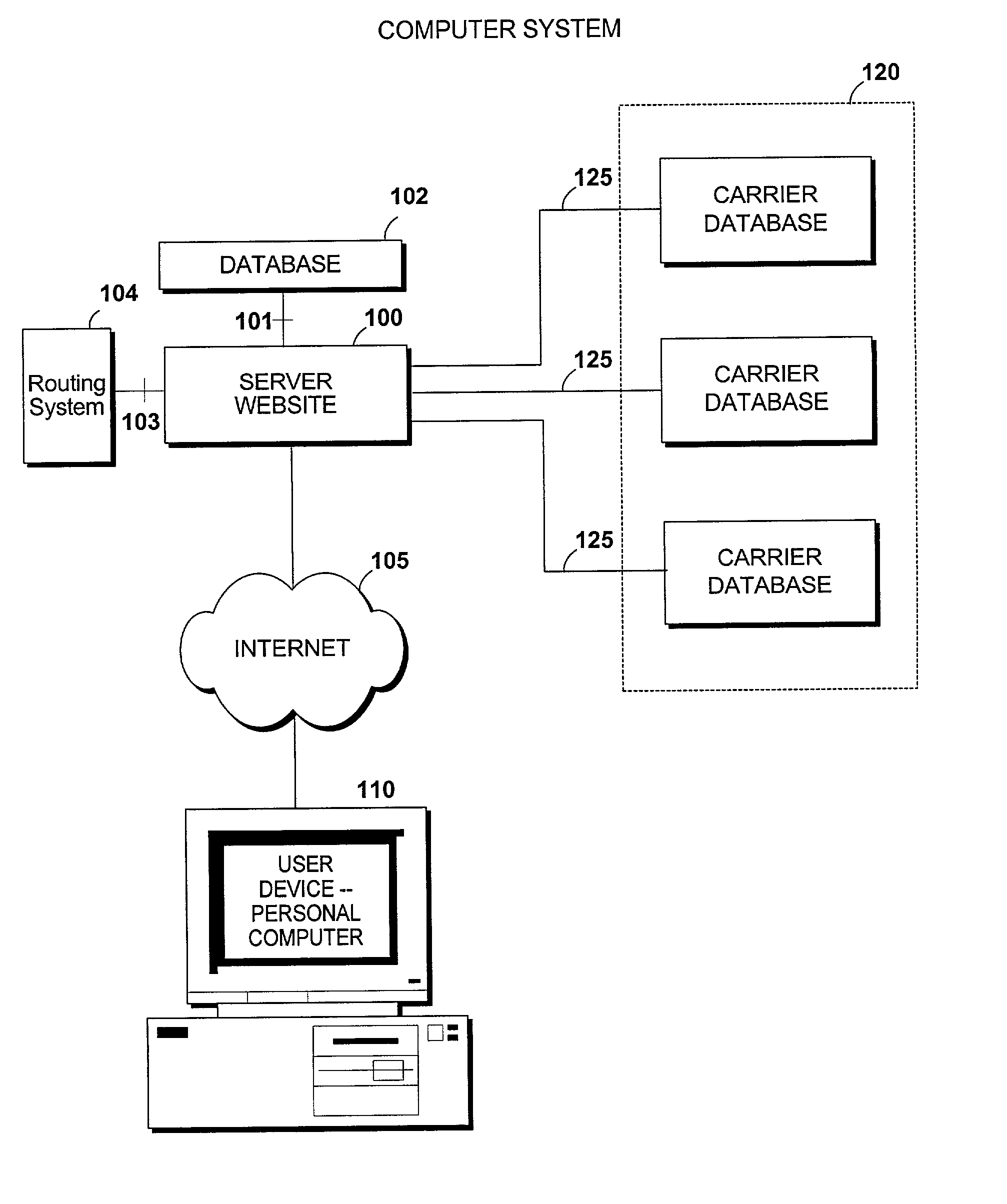

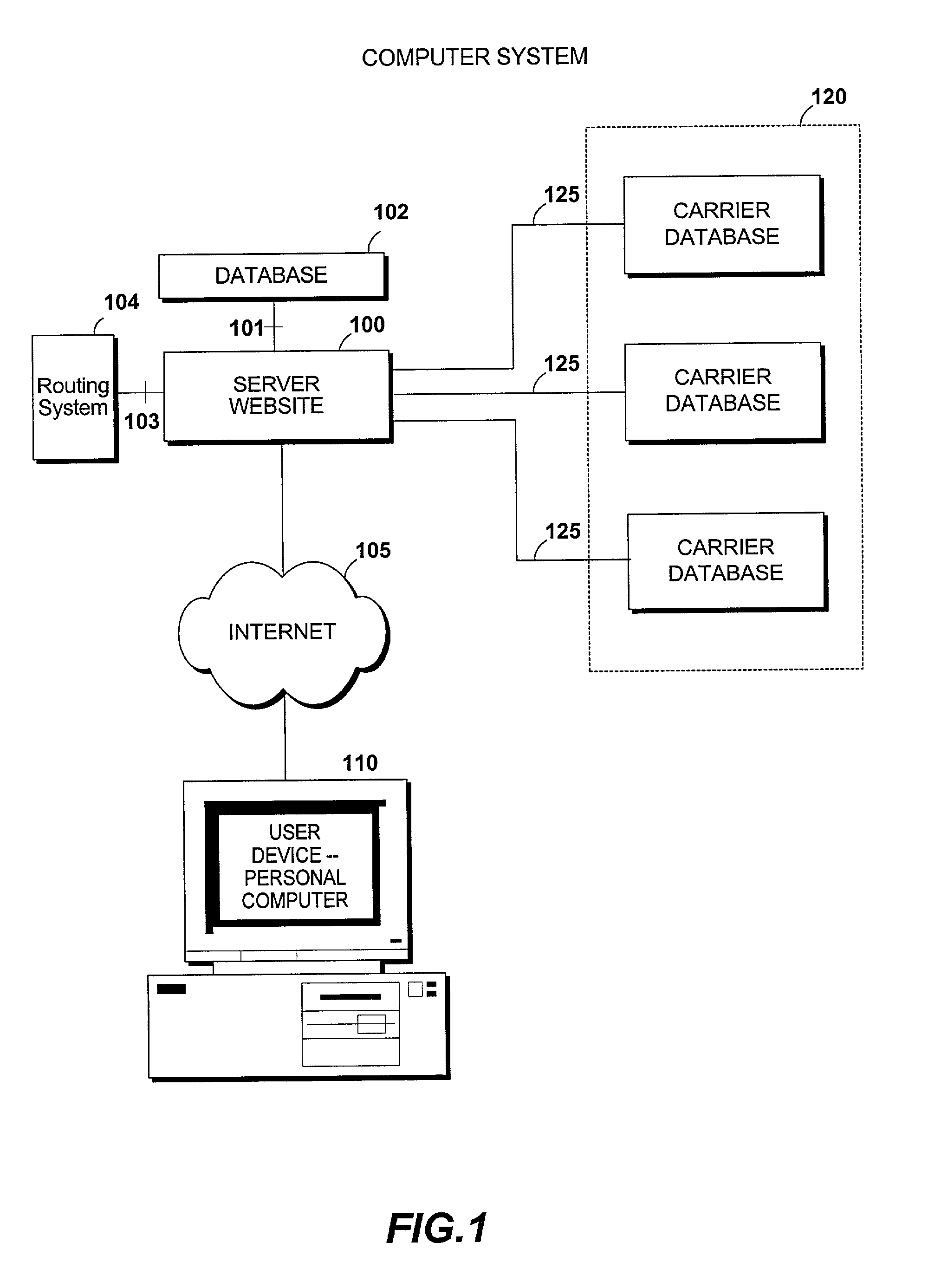

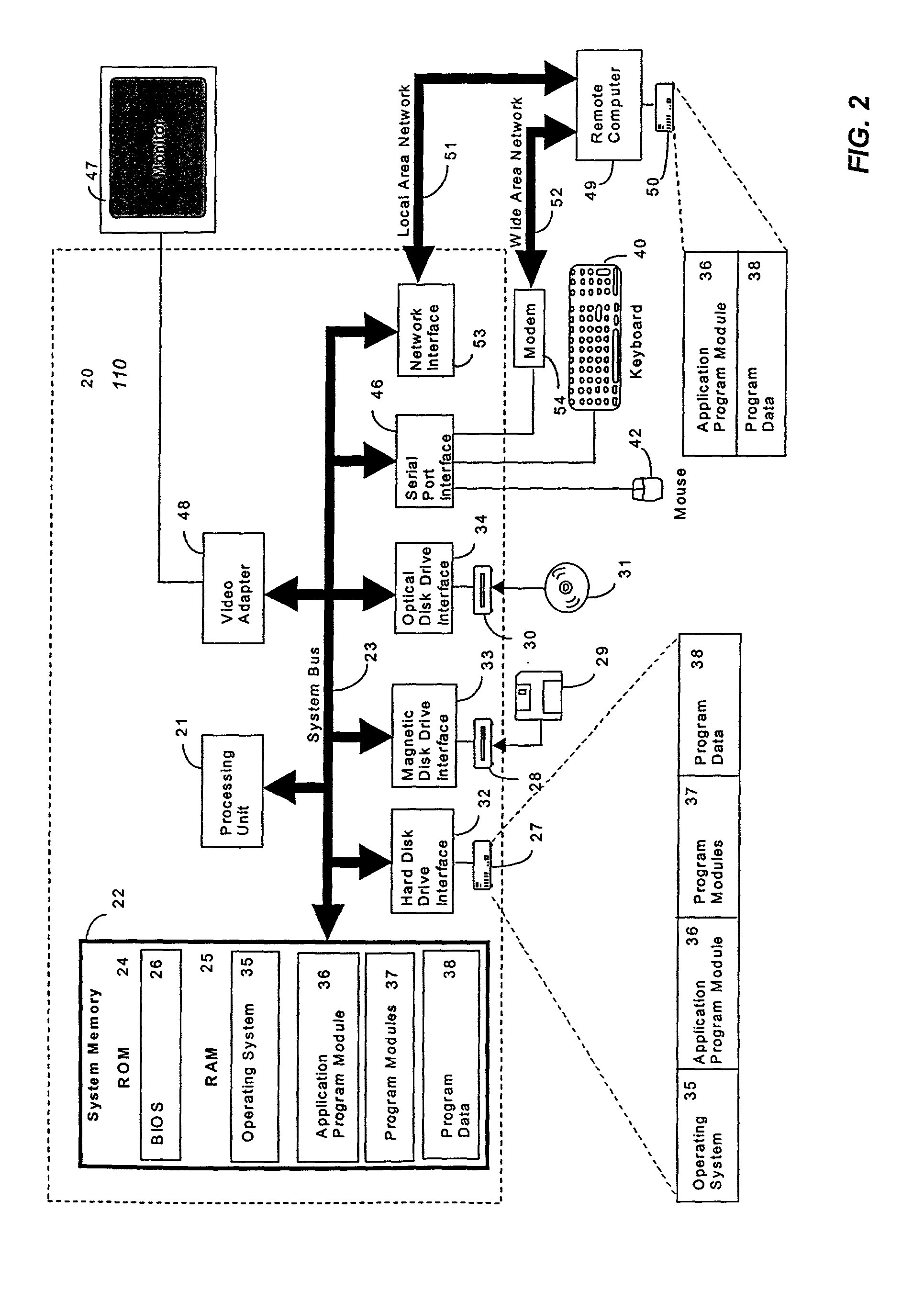

Method and computer system for generating historical claims loss data reports

InactiveUS20020049618A1Reduce labor costsFinanceSpecial data processing applicationsComputerized systemThe Internet

A method and computer system for generating historical claims loss data reports is disclosed. A method and computer system allows a user, via the Internet and facsimile authorization procedures, to obtain electronic historical claims loss data reports. A server Website, after obtaining the proper information from the user, queries insurance carriers databases, generates the reports, and distributes the reports. The reports are comprehensive; they provide summary reports which combine loss run data from a plurality of insurance carriers and they provide detail reports which disclose the details of each claim for each line of business..

Owner:LOSSRUNS

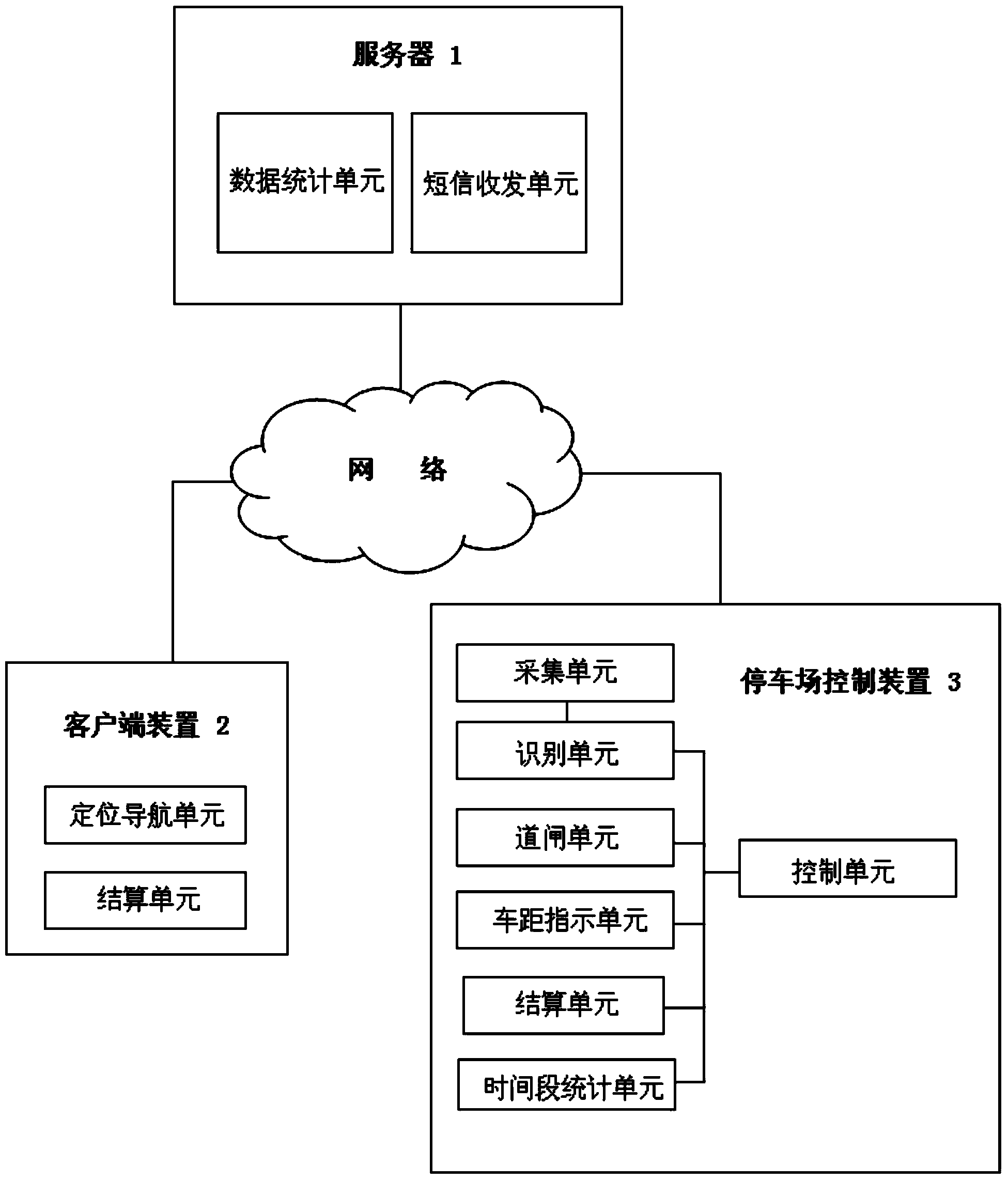

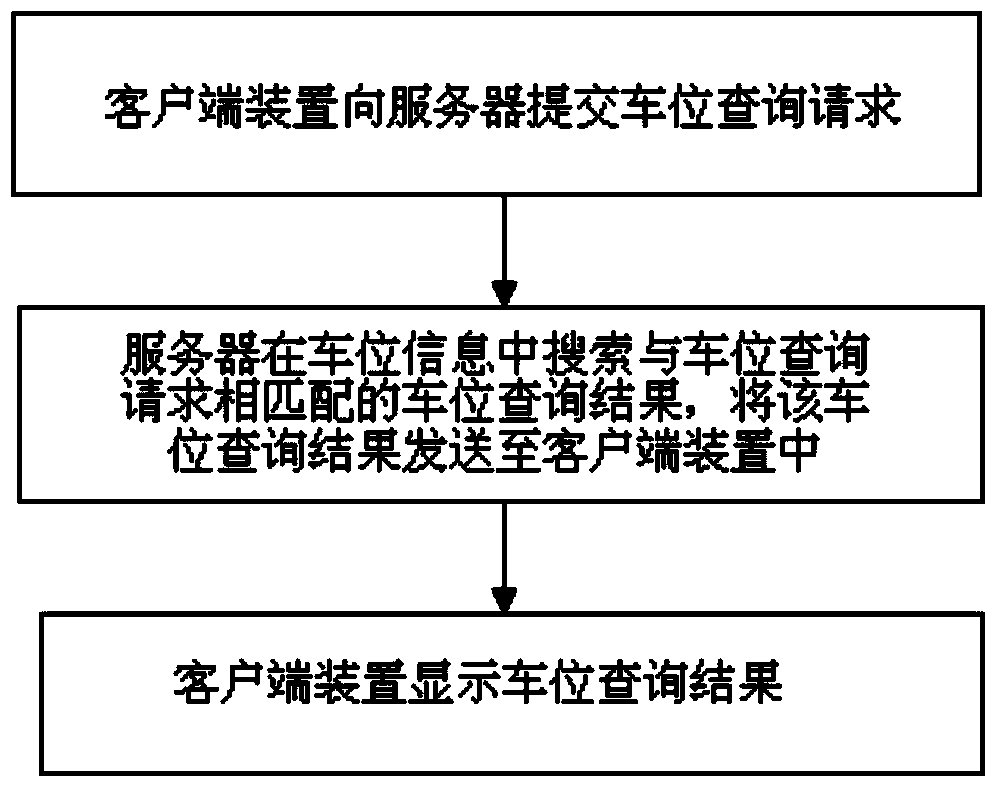

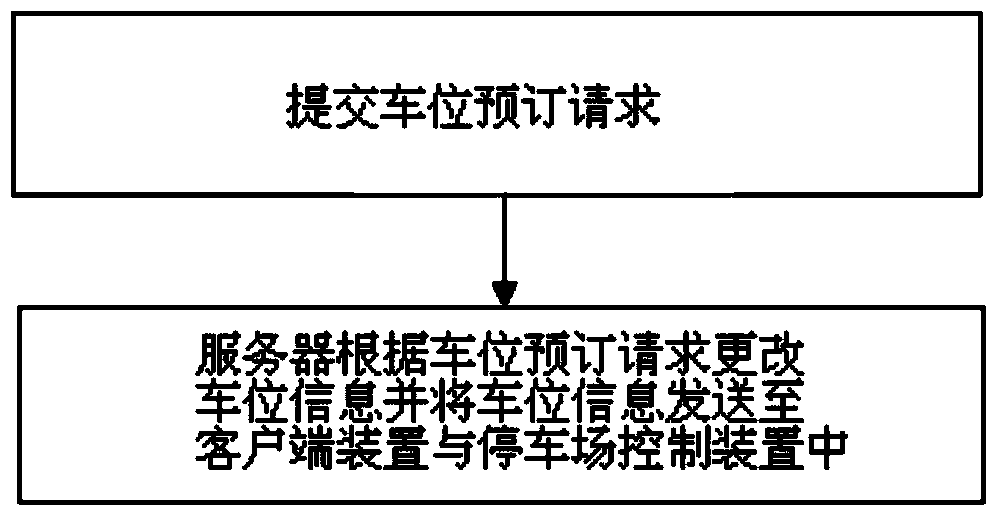

Parking space management system and management method thereof

InactiveCN103942977AReduce labor costsLow costIndication of parksing free spacesClient-sideParking space

The invention discloses a parking space management system which comprises a server, a client side device and a parking lot control device. The server, the client side device and the parking lot control device are connected through a network. The parking lot control device updates parking space information in real time according to the using condition of parking spaces in parking lots, and sends the updated parking space information to the server in real time. The real-time updated parking space information of the parking lots is stored in the server. The client side device is used for sending a parking space query request to the server, and the parking space query request comprises a destination or the parking rate. The server searches for the parking space information according to the parking space query request to obtain a parking space query result matched with the parking space query request, and the parking space query result is sent to the client side device. According to the parking space management system, management and information distribution of the parking spaces of the parking lots are achieved, a user can remotely search for the parking spaces around the destination and book the parking spaces, automatic navigation and automatic settlement can be achieved, and the parking spaces can be managed intelligently. The invention further discloses a parking space management method.

Owner:上海思亮信息技术股份有限公司 +1

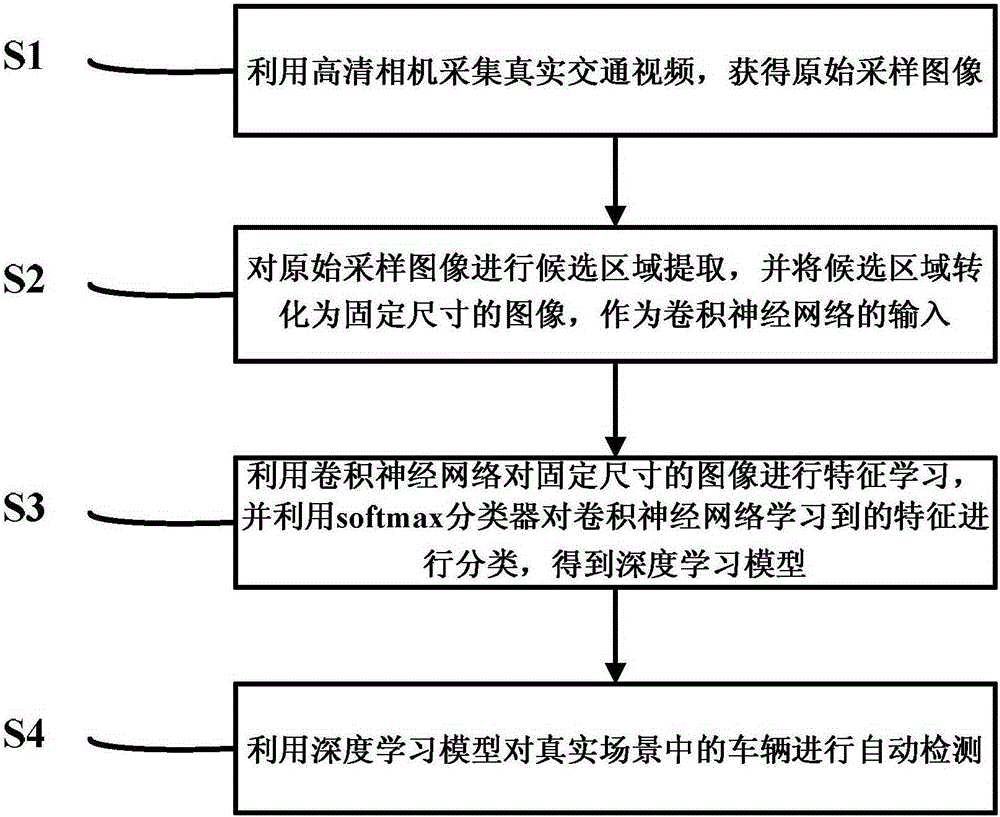

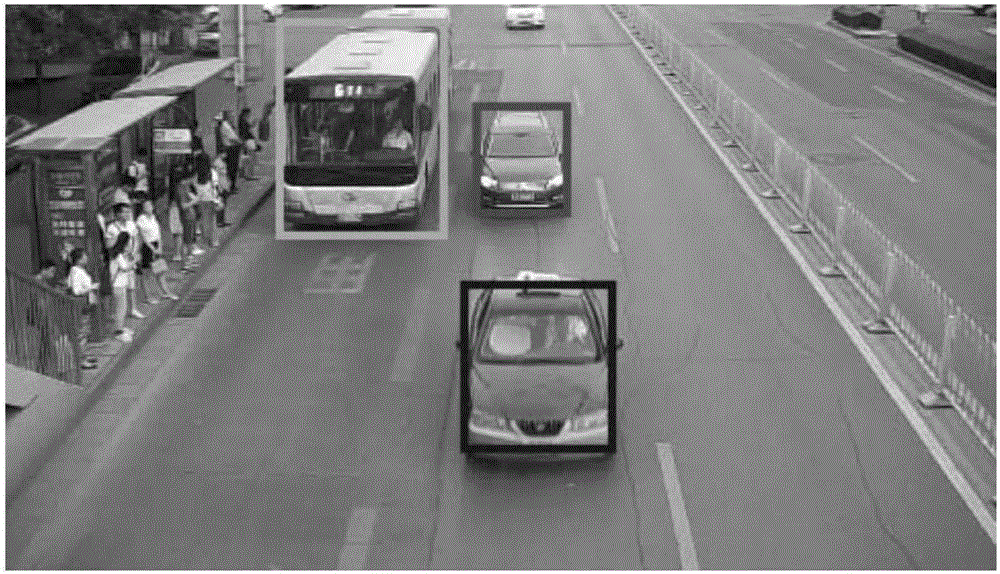

Automatic vehicle detection method based on deep learning

InactiveCN105184271AReduce workloadReduce labor costsCharacter and pattern recognitionVideo monitoringVehicle detection

The invention provides an automatic vehicle detection method based on deep learning. The automatic vehicle detection method based on deep learning can utilize a convolution neural network to automatically extract the vehicle characteristics in the traffic environment so as to eventually realize automatic detection and identification of a vehicle target. The automatic vehicle detection method based on deep learning can be applied to different environments, different illumination intensities and different weather situations, and can guarantee higher accuracy for detection for a vehicle in a complicated traffic environment, and provides a new real-time reliable preprocessing step for identifying and tracking the vehicle target for the subsequent video monitoring.

Owner:SUZHOU PAIRUI LEIER INTELLIGENT TECH CO LTD +3

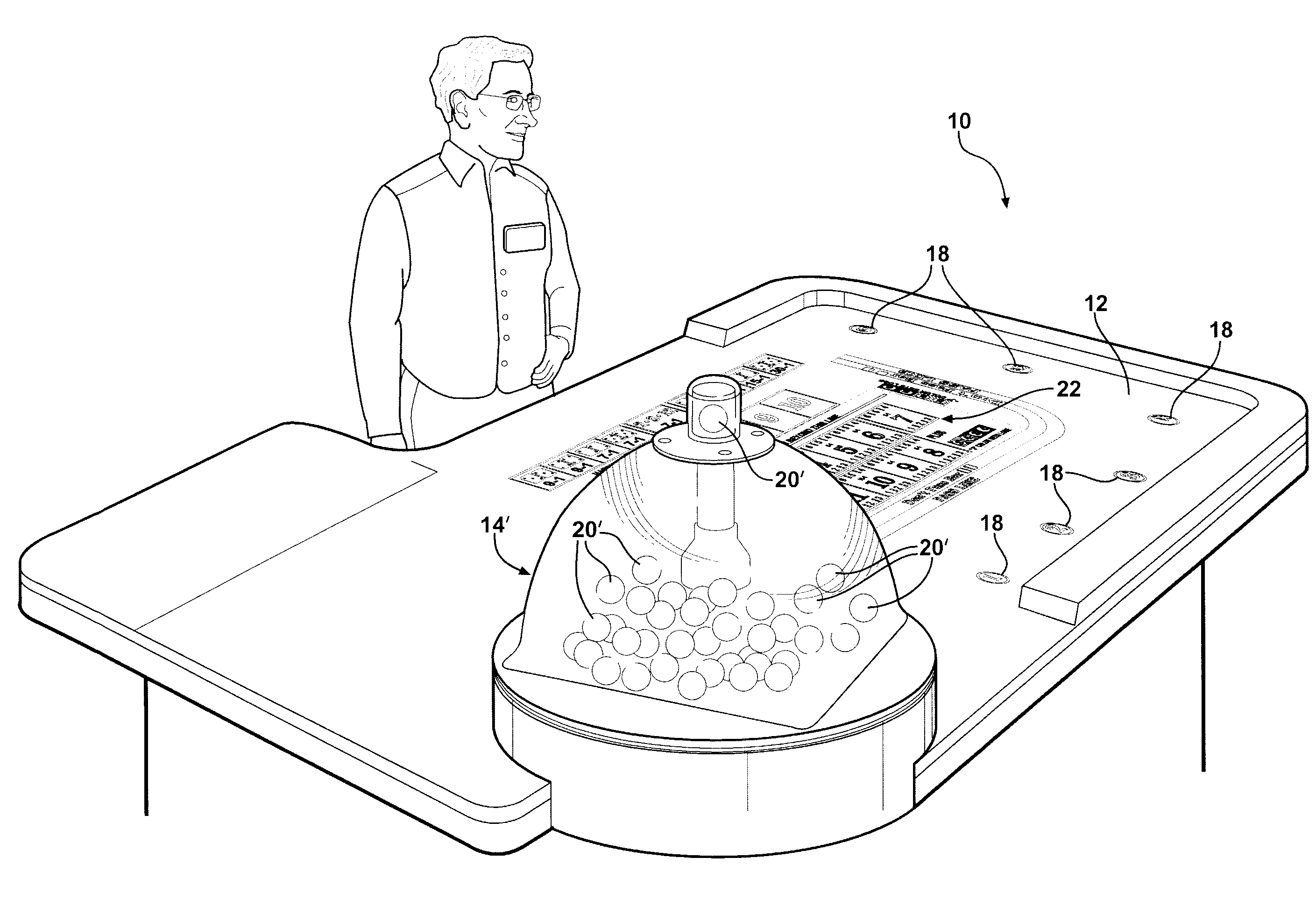

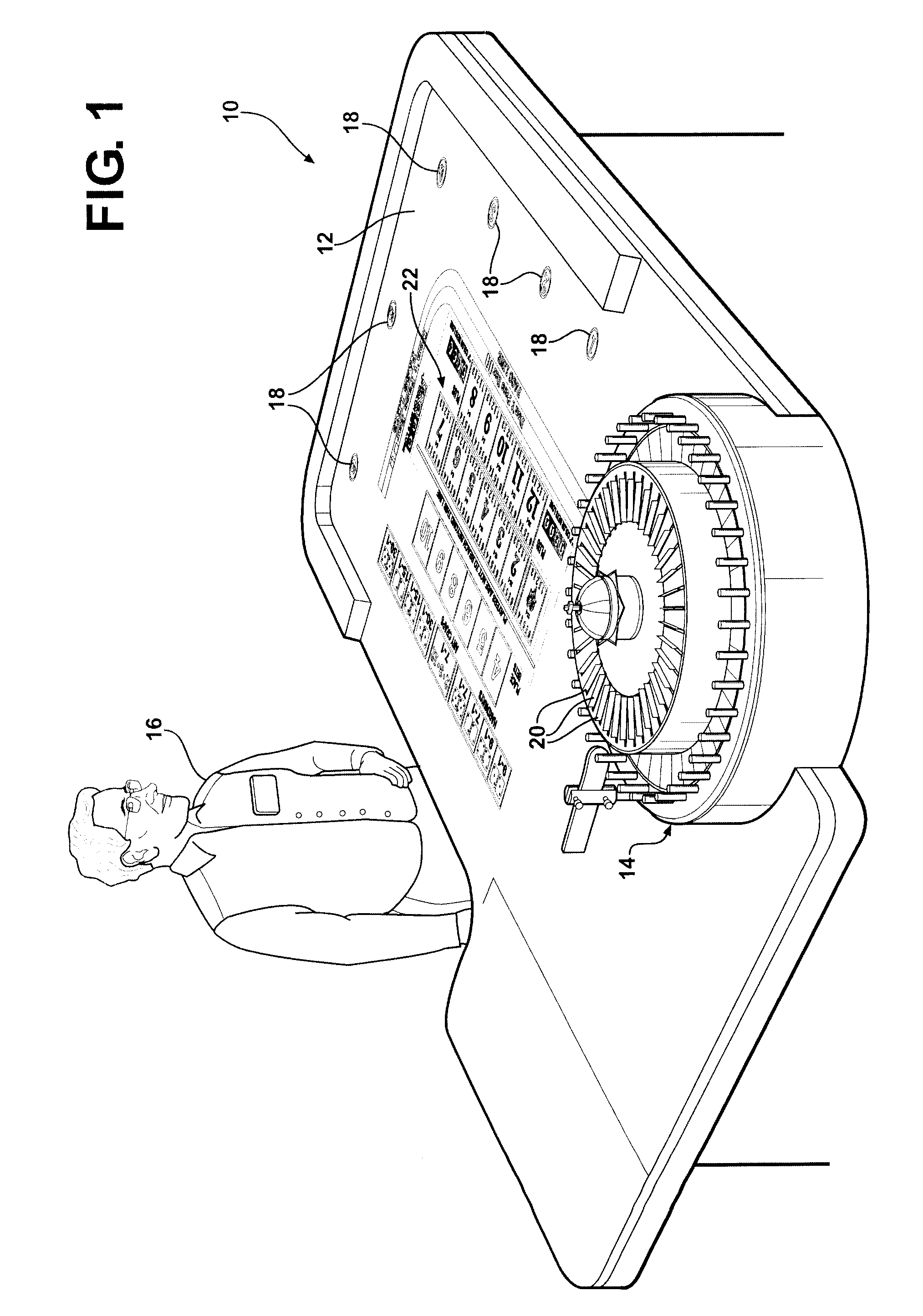

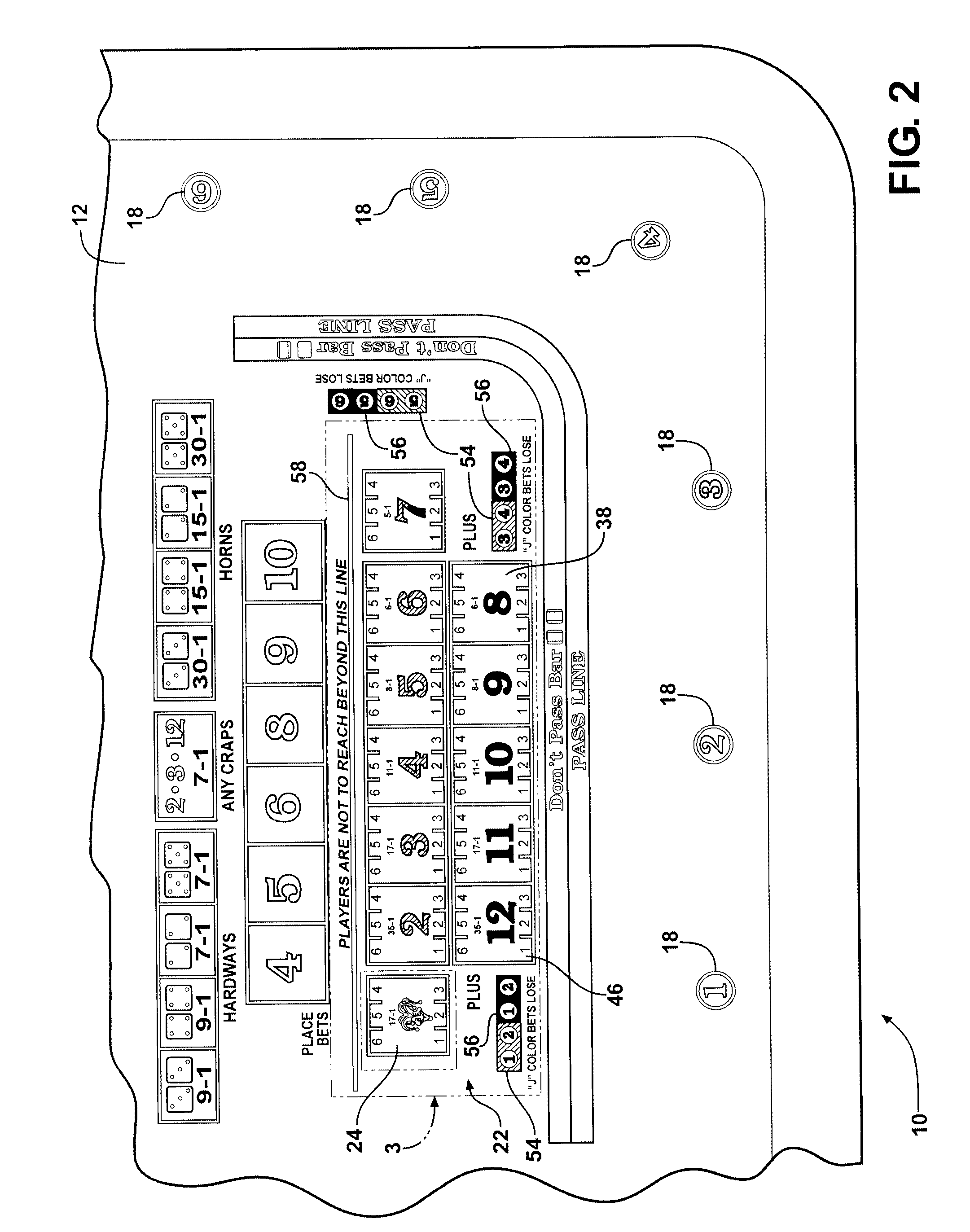

Method for playing a game similar to craps

A method for playing a multi-player table game similar to craps includes use of a point generation device capable of randomly selecting one outcome from a group consisting of thirty-seven or thirty-eight possible outcomes. Betting locations similar to the game of craps are provided on a betting surface (12). Twelve common betting locations (22) allow proposition bets based on the sum of two six-sided dice, together with an additional possible outcome comprised of a wild non-die depiction. Player positions (18) are designated about the betting surface (12), with replicas (48) of each player position (18) affixed within each of the twelve common betting locations (22), as well as at respective first (54) and second (56) color bet locations distributed about the betting surface (12). Game play enables a dealer to handle only value cheques. The game method can utilize a variety of point generation devices (14, 14′) thereby making the game suitable for many jurisdictions and interesting for players.

Owner:MARK HAMILTON JONES & SHERYLE LYNN JONES FAMILY TRUST DATED NOVEMBER 7 2013

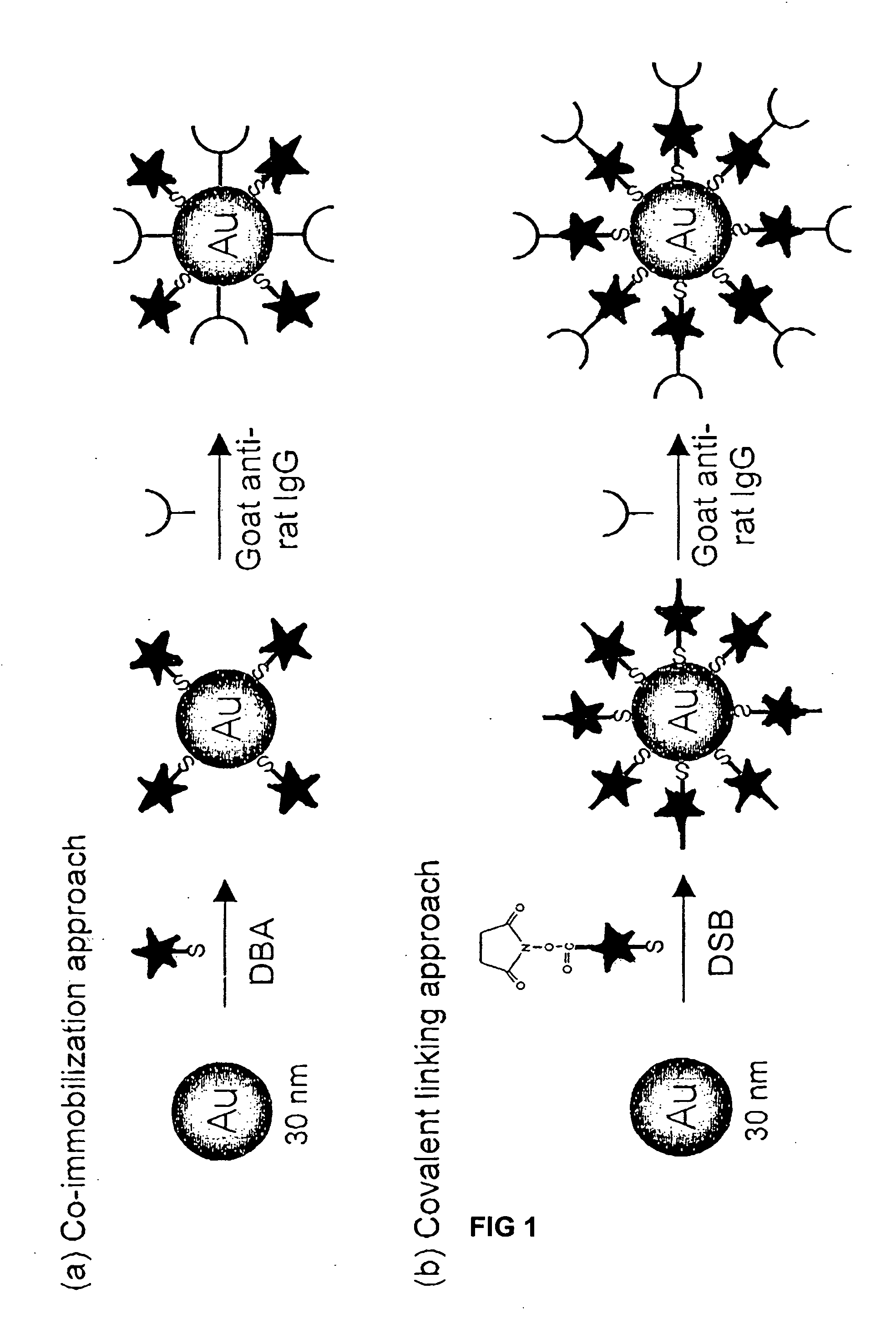

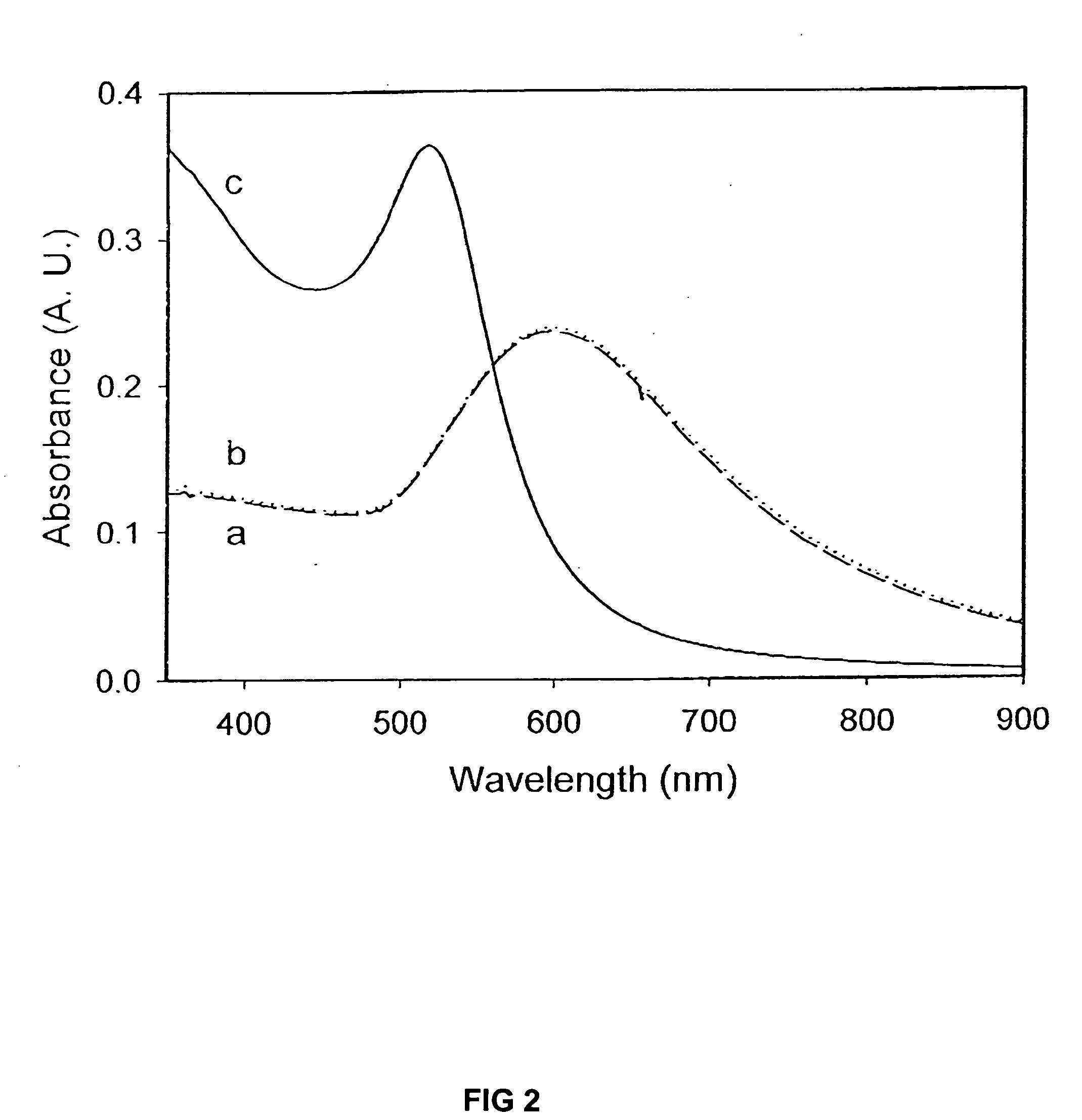

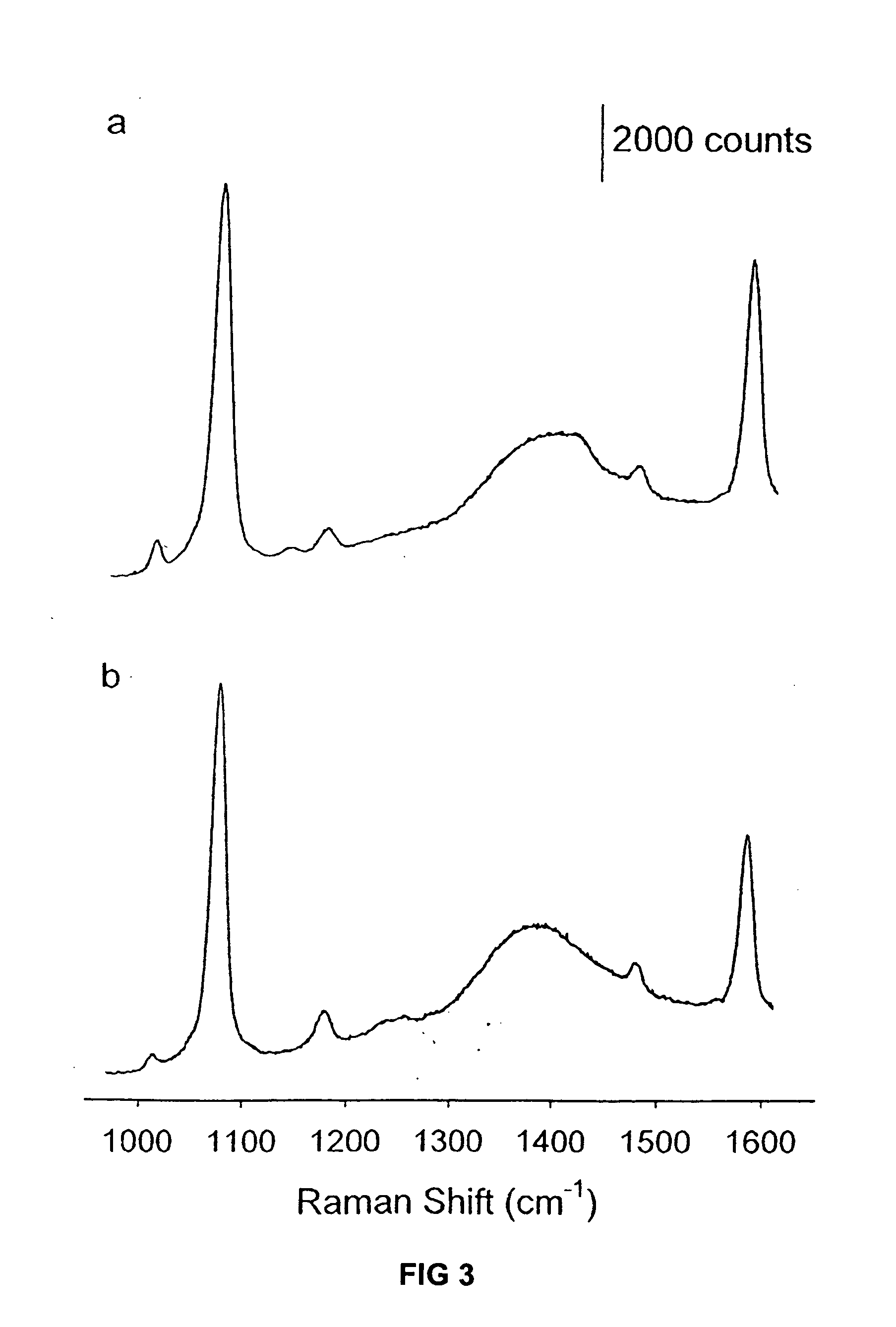

Raman-active reagents and the use thereof

InactiveUS20050089901A1Minimizes separationMaximizing numberHybrid immunoglobulinsSugar derivativesAntigenBiological materials

The present invention provides a new class of Raman-active reagents for use in biological and other applications, as well as methods and kits for their use and manufacture. Each reagent includes a Raman-active reporter molecule, a binding molecule, and a surface enhancing particle capable of causing surface enhanced Raman scattering (SERS). The Raman-active reporter molecule and the binding molecule are affixed to the particle to give both a strong SERS signal and to provide biological functionality, i.e. antigen or drug recognition. The Raman-active reagents can function as an alternative to fluorescence-labeled reagents, with advantages in detection including signal stability, sensitivity, and the ability to simultaneously detect several biological materials. The Raman-active reagents also have a wide range of applications, especially in clinical fields (e.g., immunoassays, imaging, and drug screening).

Owner:PORTER MARC D

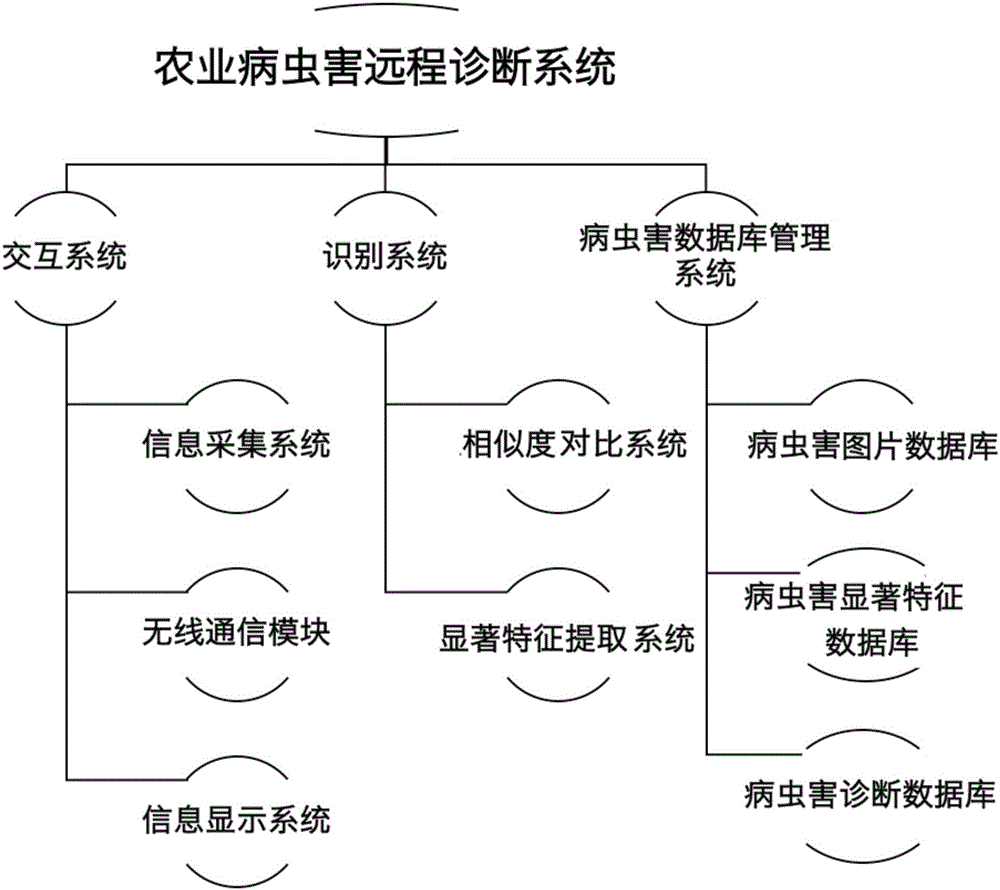

Smart agricultural insect disease remote automatic diagnosis system

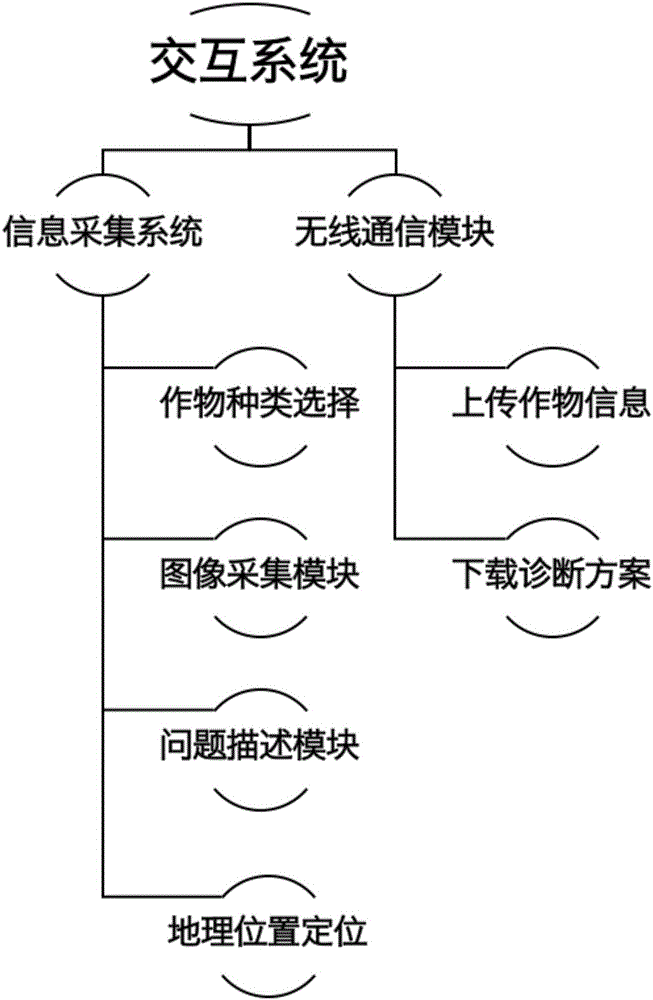

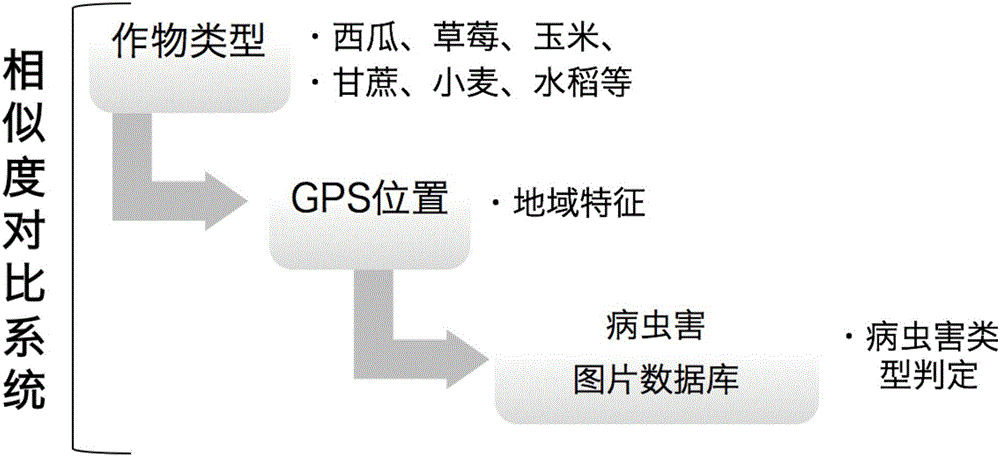

InactiveCN105787446AImprove accuracyComprehensive responseData processing applicationsCharacter and pattern recognitionInteraction systemsBiotechnology

The invention relates to a smart agricultural insect disease remote automatic diagnosis system. The system comprises an interaction system, an identification system and an insect disease database management system. The interaction system comprises an information acquisition system, a wireless communication system and an information display system; the identification system comprises a similarity comparison system and a remarkable feature extraction system; and the inset disease database management system comprises an insect disease picture database, an insect disease remarkable feature database and an insect disease diagnosis database. The smart agricultural insect disease remote automatic diagnosis system, based on images of crop growth conditions, through intersection operation of the image similarity and remarkable feature extraction comparison system and a machine learning algorithm of the identification system, can effectively improve the identification accuracy of an insect disease type. According to the insect disease type, the system provides an omni-directional diagnosis scheme so as to improve the survival rate and the quality of crops.

Owner:上海劲牛信息技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com