Patents

Literature

656 results about "Residual compressive stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

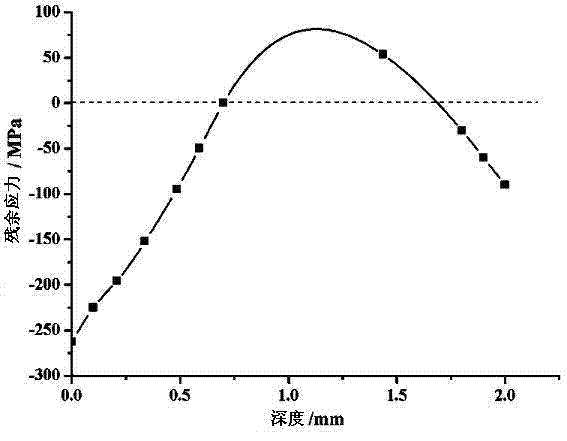

In a mathematical sense the term compressive residual stress refers to a negative residual stress condition. For example, if the residual stress condition at a particular location within a body has a value of -100 MPa, it is said to be in a state of compressive residual stress.

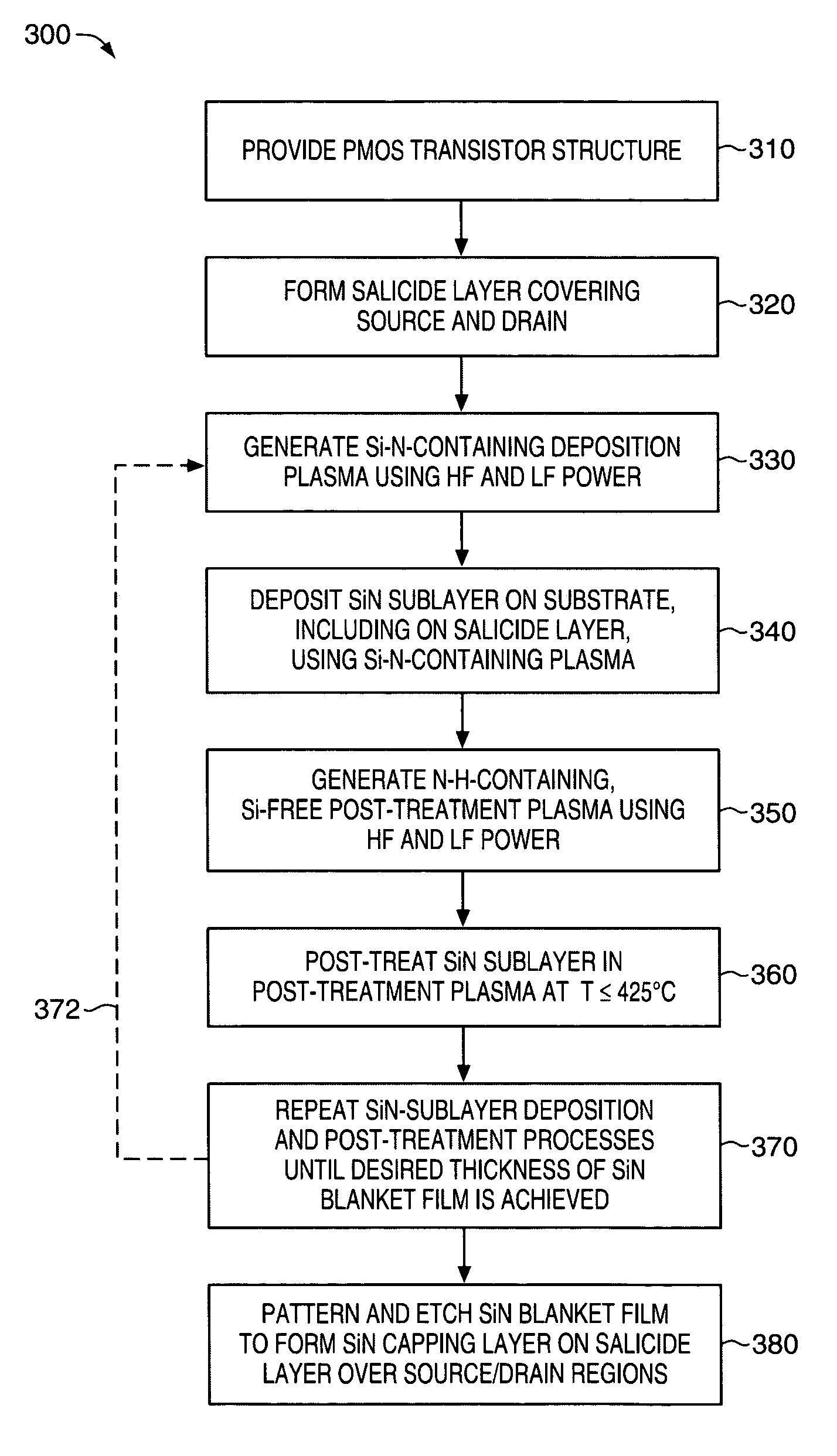

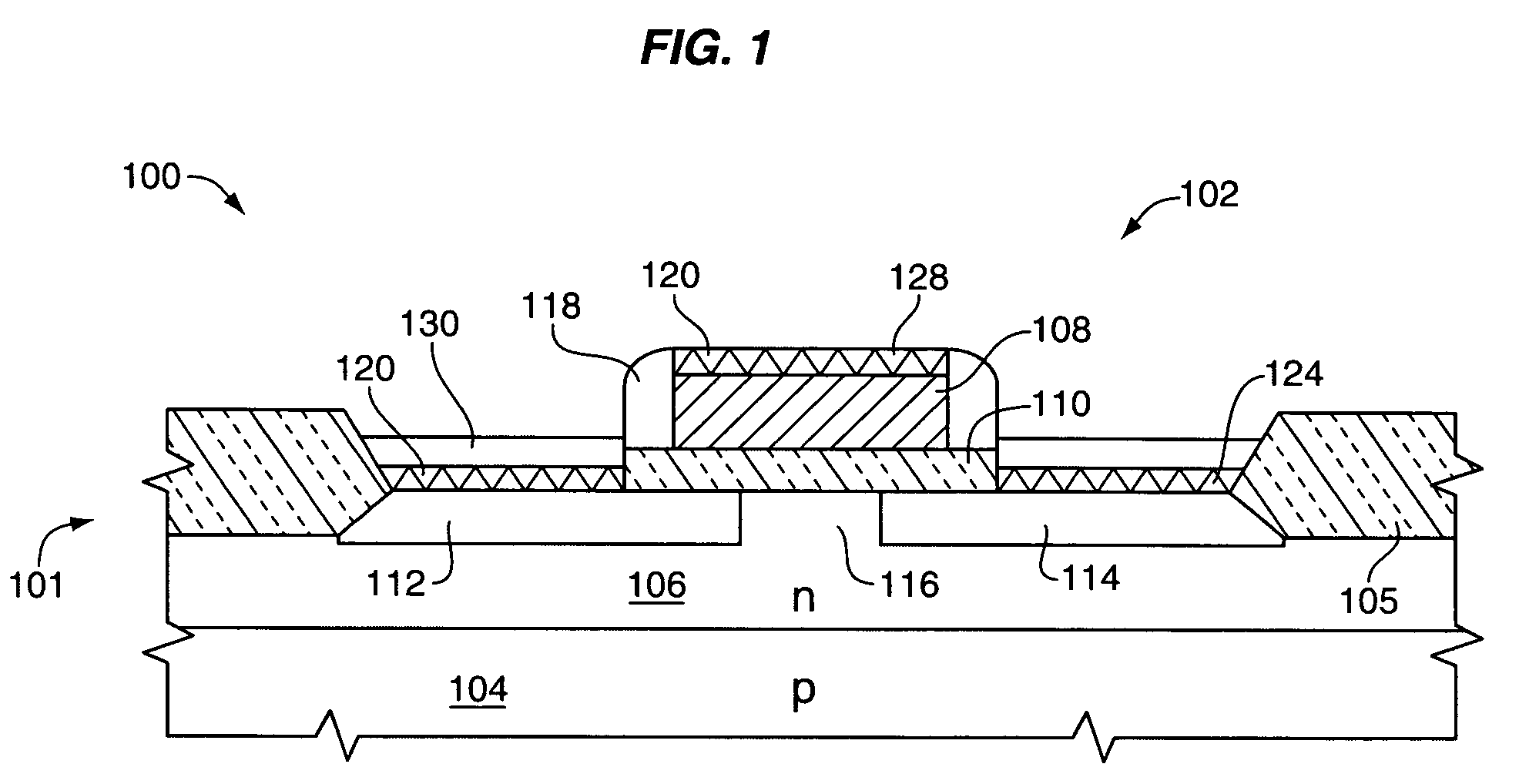

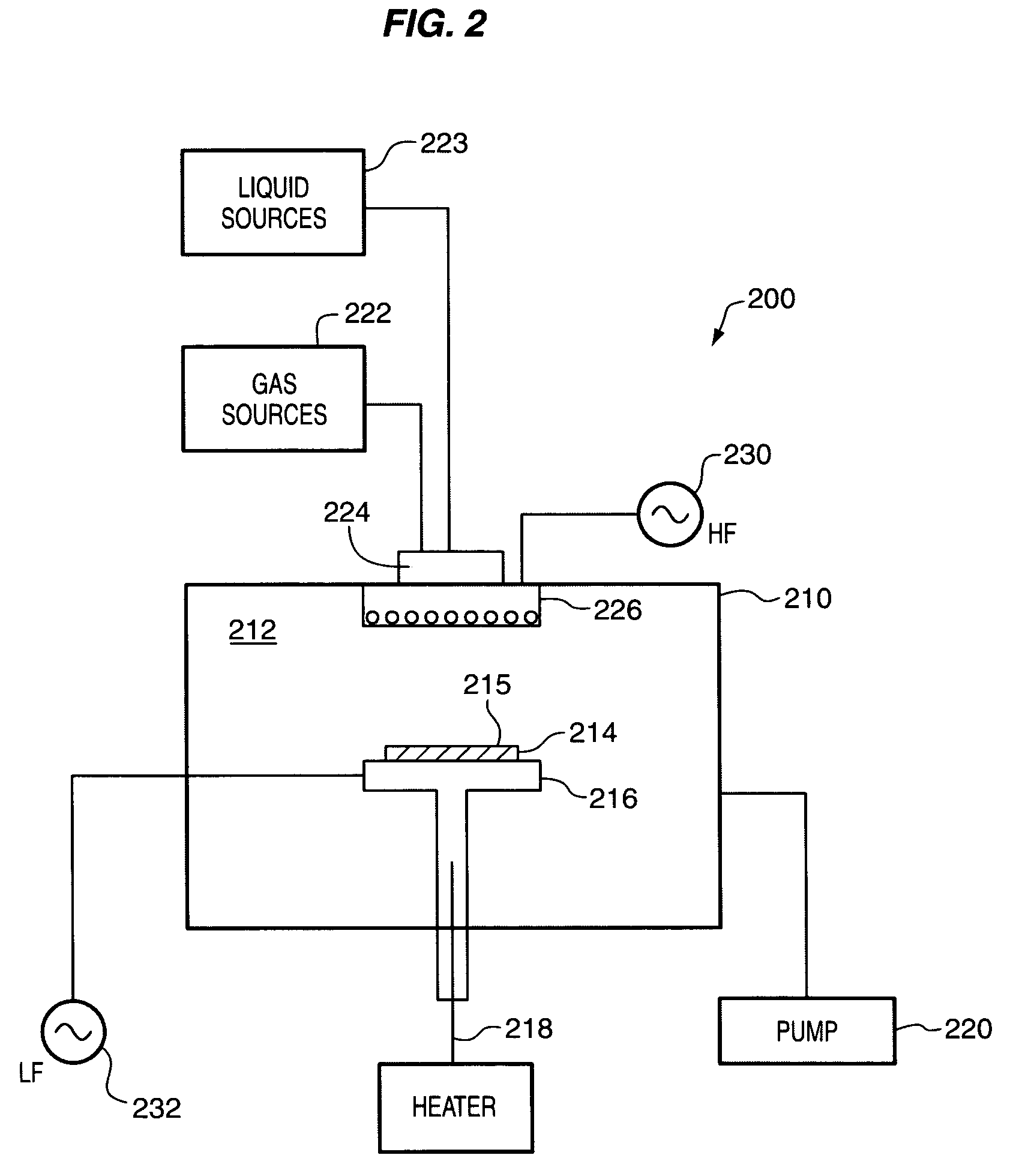

PMOS transistor with compressive dielectric capping layer

ActiveUS7214630B1Preserving material qualityImprove performanceSemiconductor/solid-state device manufacturingChemical vapor deposition coatingSalicideOxidation state

A salicide layer is deposited on the source / drain regions of a PMOS transistor. A dielectric capping layer having residual compressive stress is formed on the salicide layer by depositing a plurality of PECVD dielectric sublayers and plasma-treating each sublayer. Compressive stress from the dielectric capping layer is uniaxially transferred to the PMOS channel through the source-drain regions to create compressive strain in the PMOS channel. To form a compressive dielectric layer, a deposition reactant mixture containing A1 atoms and A2 atoms is provided in a vacuum chamber. Element A2 is more electronegative than element A1, and A1 atoms have a positive oxidation state and A2 atoms have a negative oxidation state when A1 atoms are bonded with A2 atoms. A deposition plasma is generated by applying HF and LF radio-frequency power to the deposition reactant mixture, and a sublayer of compressive dielectric material is deposited. A post-treatment plasma is generated by applying HF and LF radio-frequency power to a post-treatment gas that does not contain at least one of A1 atoms and A2 atoms. Compressive stress in the dielectric sublayer is increased by treating the sublayer in the post-treatment plasma. Processes of depositing a dielectric sublayer and post-treating the sublayer in plasma are repeated until a desired thickness is achieved. The resulting dielectric layer has residual compressive stress.

Owner:NOVELLUS SYSTEMS

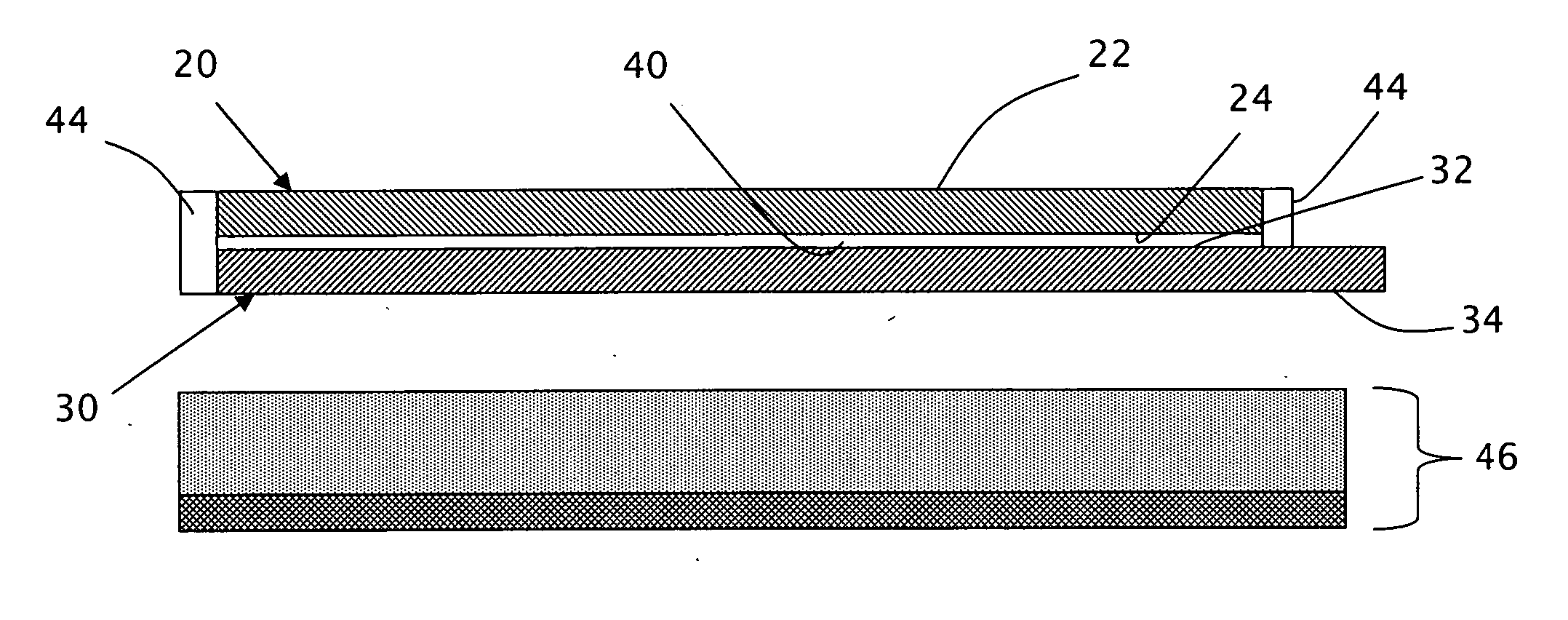

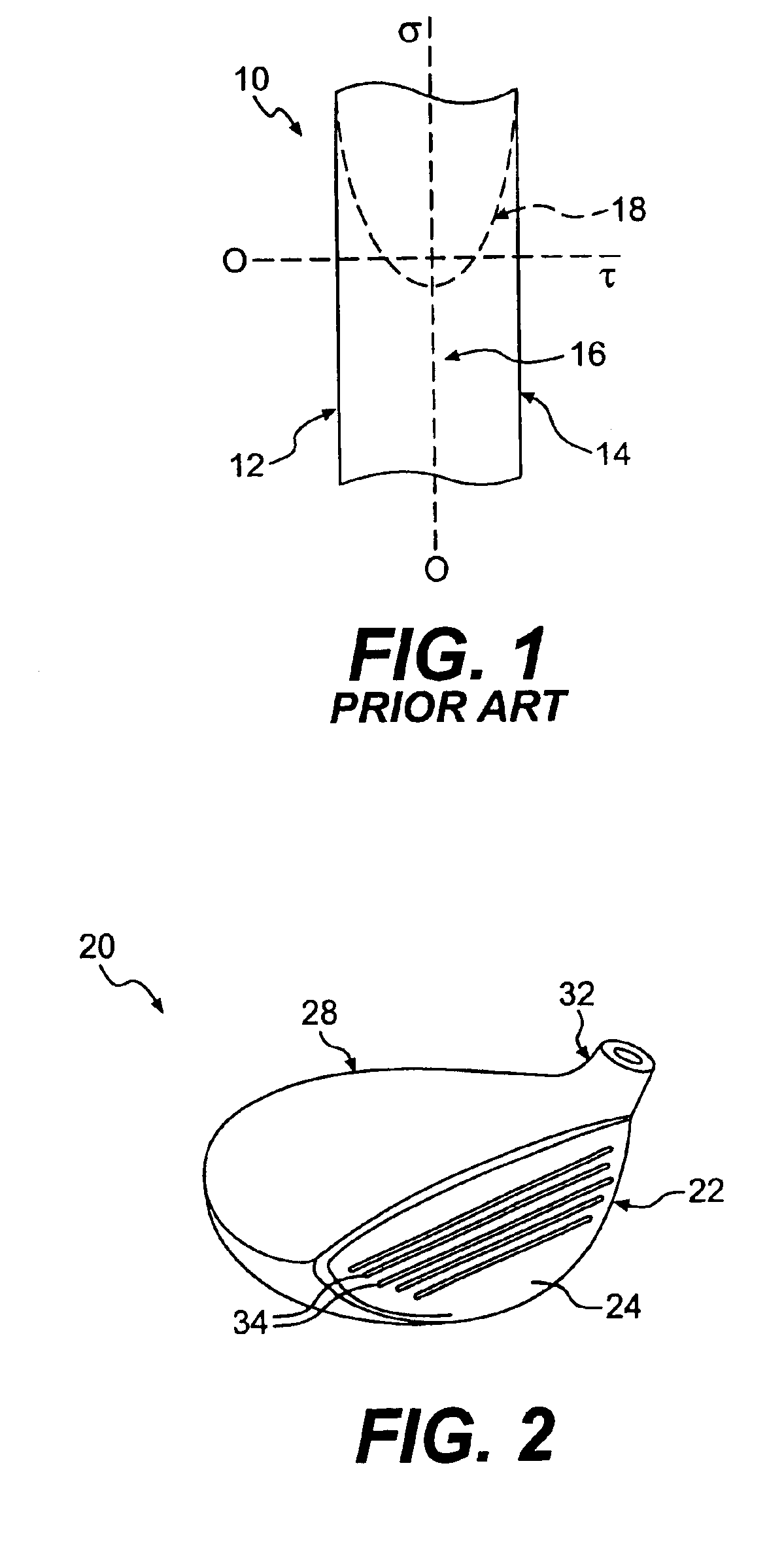

Glass laminate substrate having enhanced impact and static loading resistance

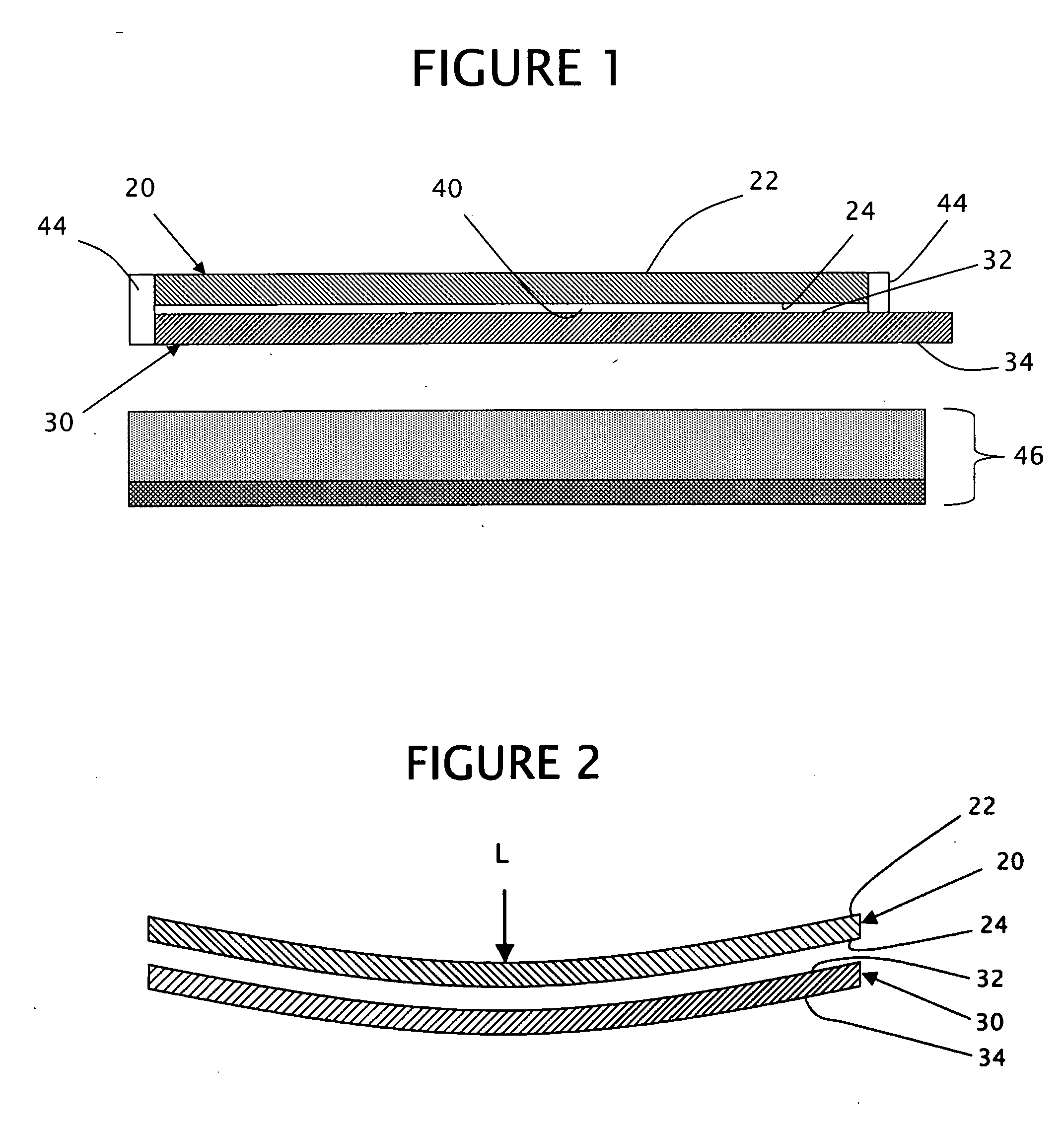

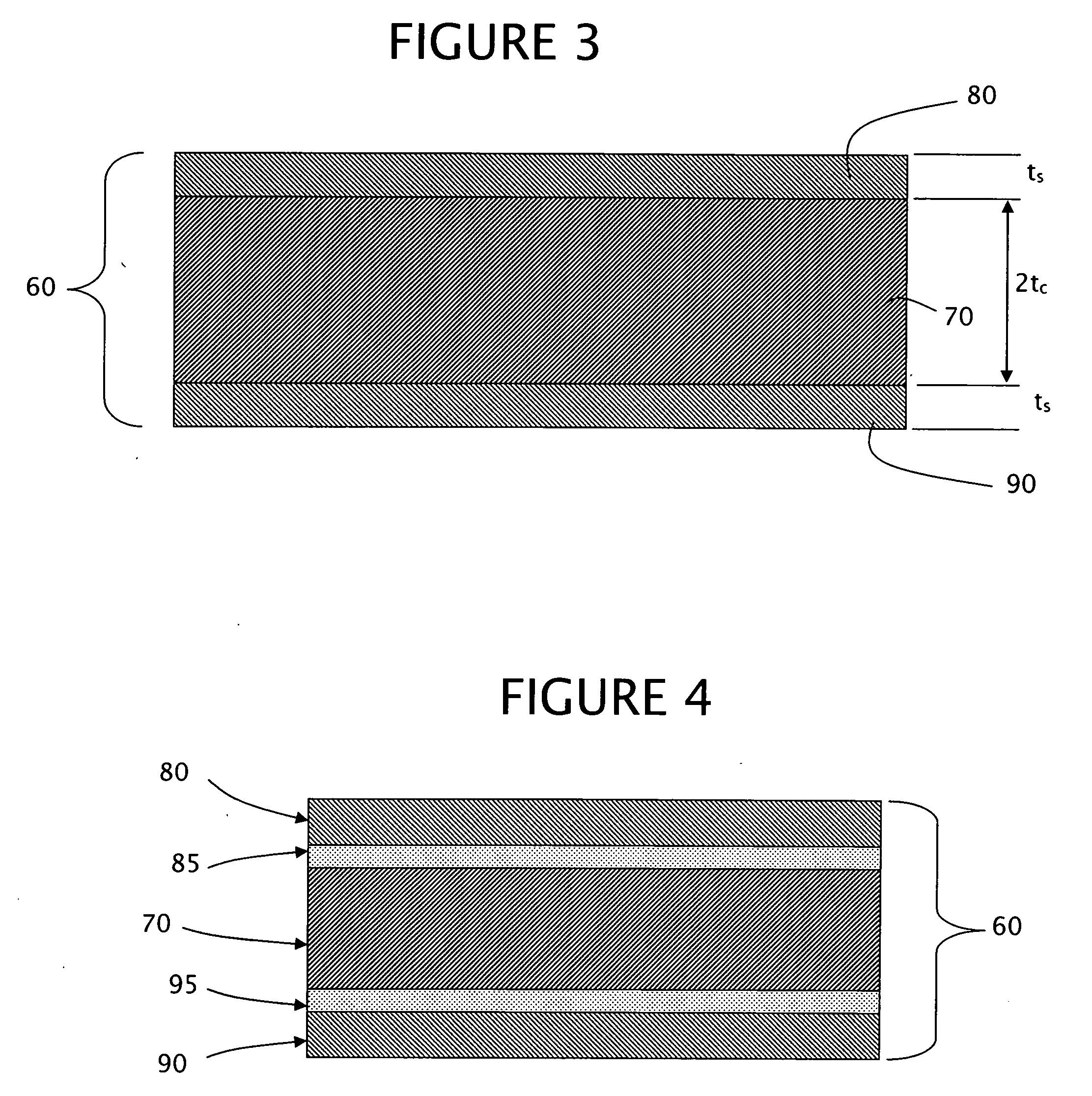

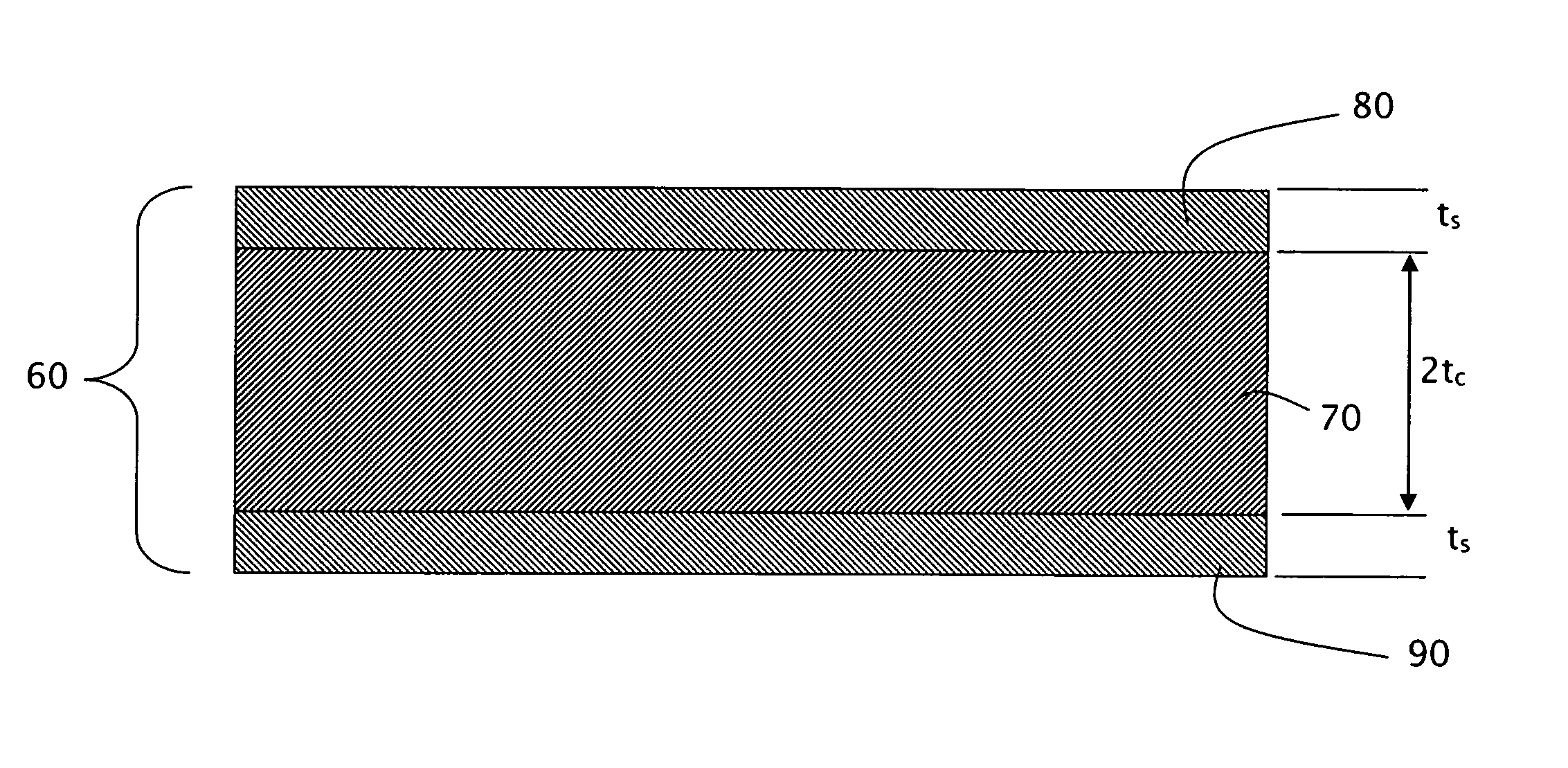

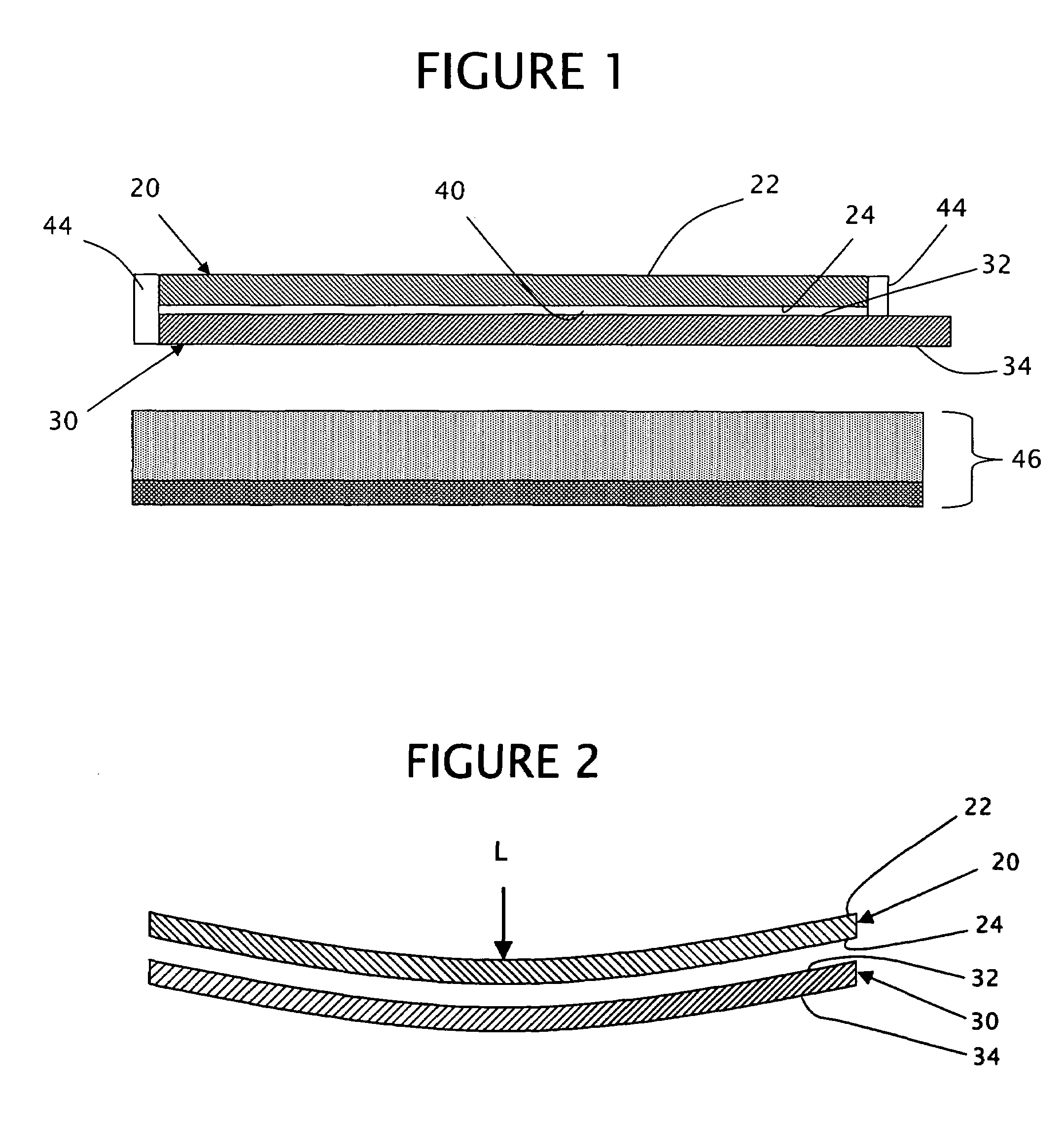

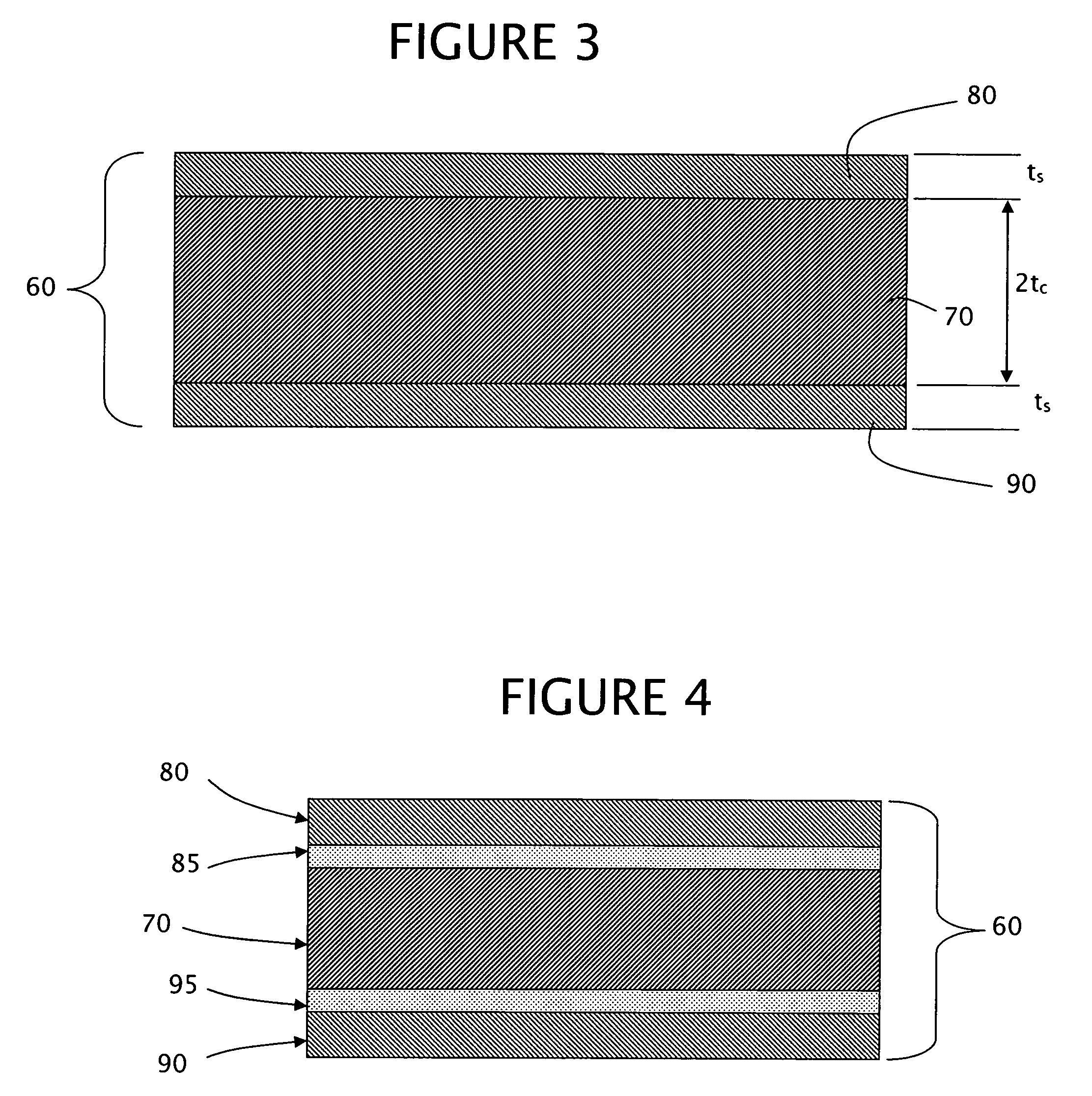

ActiveUS20060127679A1Increased resistance to impactIncrease static loadLiquid crystal compositionsGas-filled discharge tubesDisplay deviceThermal expansion

A glass laminate substrate for electronic substrates, such as flat panel displays, includes a transparent glass core bounded by transparent glass skin layers, wherein the coefficient of thermal expansion of the core is greater than the coefficient of thermal expansion of the skin layers thereby forming a residual compressive stress in the skin layers and a residual tensile stress in the core. The relative thickness of the skin layers can be selected to enhance the strength of the glass laminate substrate while maintaining a sufficiently low residual tensile stress in the core to allow scribing and separating of the substrate to size. Interlayers can be located between the core and the skin layers, wherein the interlayers include a residual compressive stress, and produce a reduced residual tensile stress in the core.

Owner:CORNING INC

Glass laminate substrate having enhanced impact and static loading resistance

ActiveUS7201965B2Increased resistance to impact and static loadingImprove load resistanceLiquid crystal compositionsGas-filled discharge tubesThermal expansionFlat panel display

A glass laminate substrate for electronic substrates, such as flat panel displays, includes a transparent glass core bounded by transparent glass skin layers, wherein the coefficient of thermal expansion of the core is greater than the coefficient of thermal expansion of the skin layers thereby forming a residual compressive stress in the skin layers and a residual tensile stress in the core. The relative thickness of the skin layers can be selected to enhance the strength of the glass laminate substrate while maintaining a sufficiently low residual tensile stress in the core to allow scribing and separating of the substrate to size. Interlayers can be located between the core and the skin layers, wherein the interlayers include a residual compressive stress, and produce a reduced residual tensile stress in the core.

Owner:CORNING INC

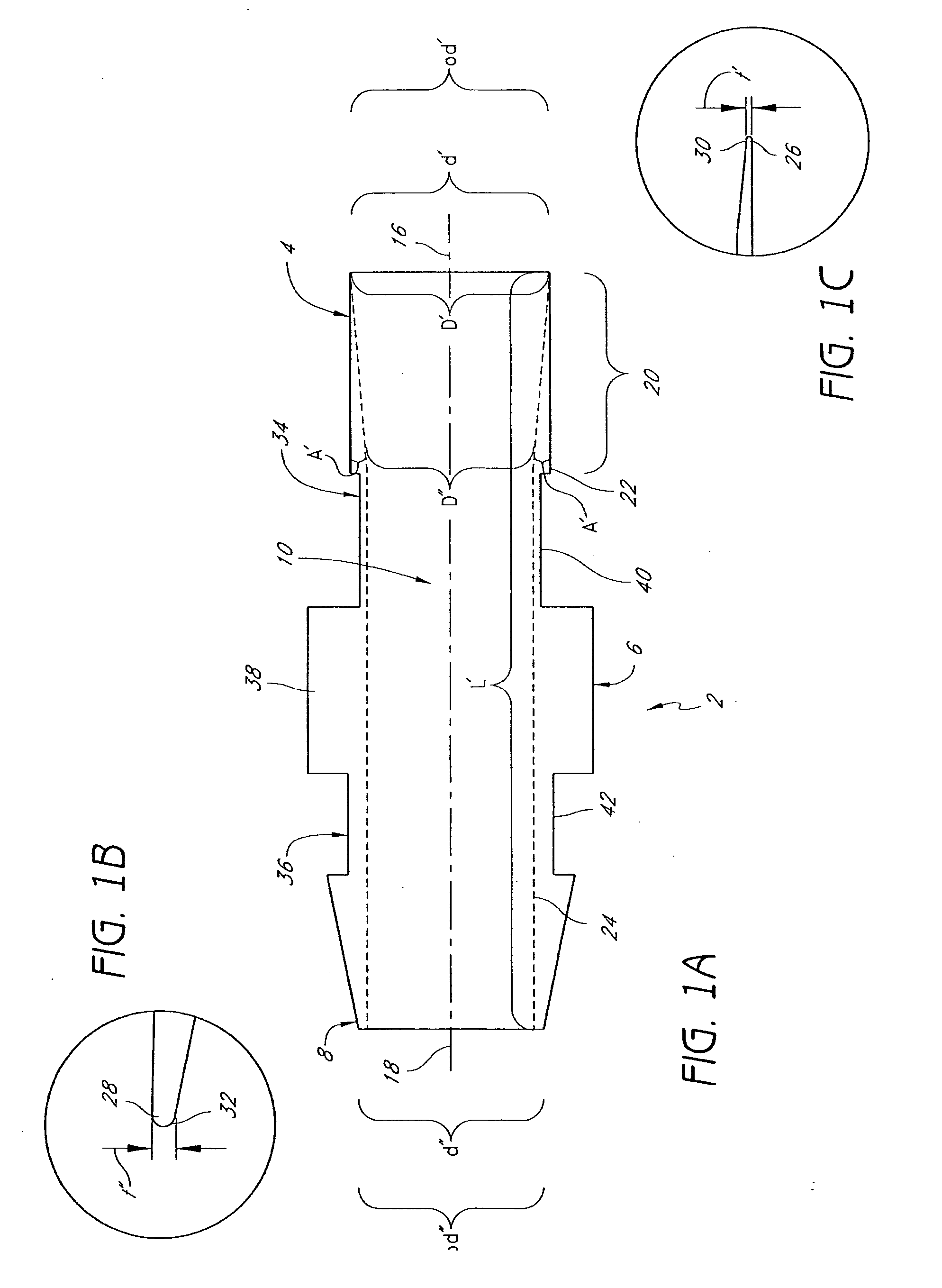

Self-sealing residual compressive stress graft for dialysis

InactiveUS20070167901A1Easy accessInhibit swellingMedical devicesBlood vesselsVeinHaemodialysis machine

Vascular access systems for performing hemodialysis are disclosed. Some embodiments relate to vascular access grafts comprising an instant access or self-sealing material reinforced with expanded PTFE to resist stretching of the instant access material and thereby resist leakage associated with stretching or bending. The graft may comprise two end segments comprising ePTFE without the instant access material to allow easier anastomosis of the graft to veins and arteries. The graft may have a unibody design or have modular components that may be joined together to create a graft with customized length or other features. One or more sections of the graft may also be cut or trimmed to a custom length.

Owner:HEMOSPHERE

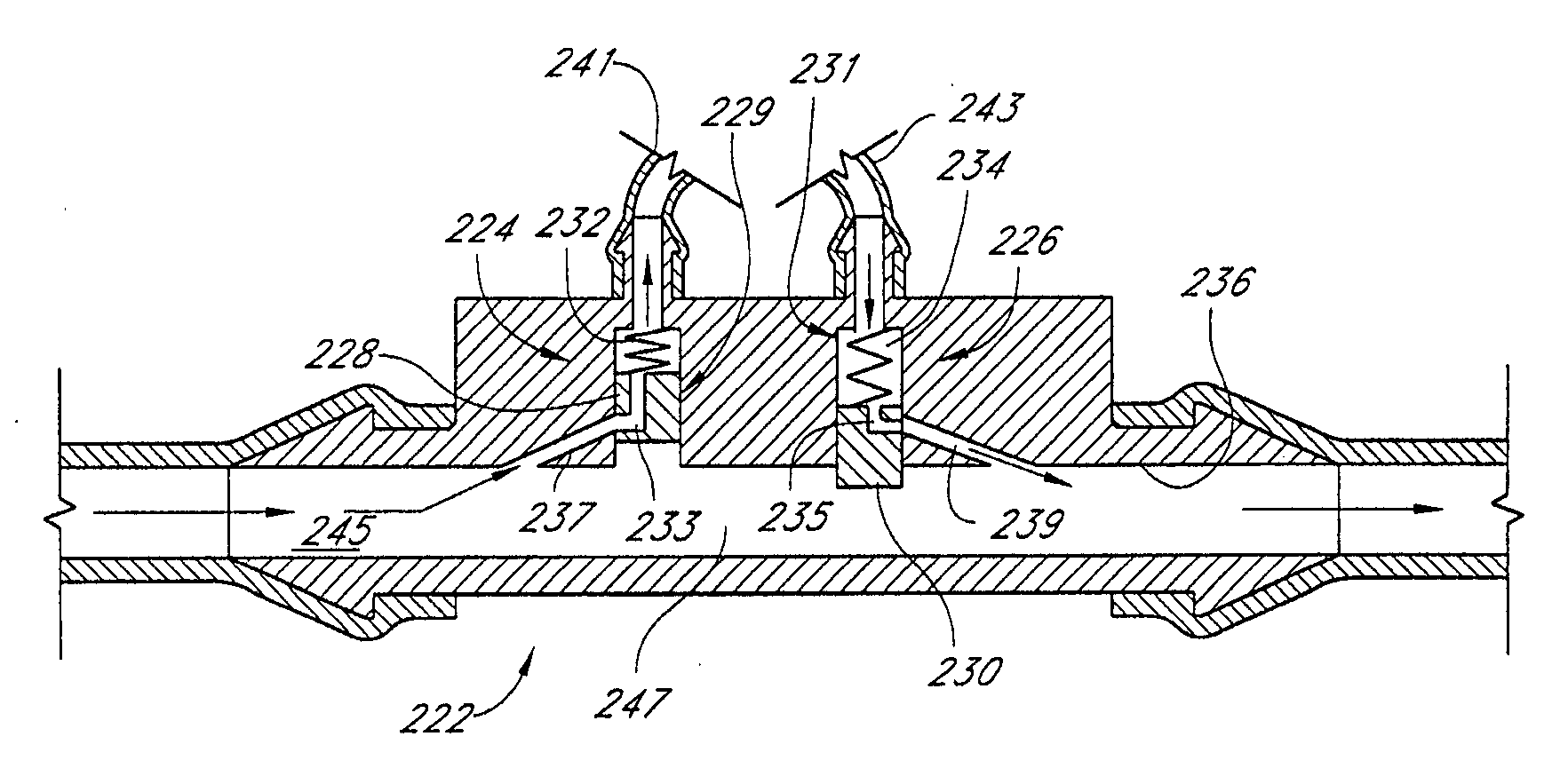

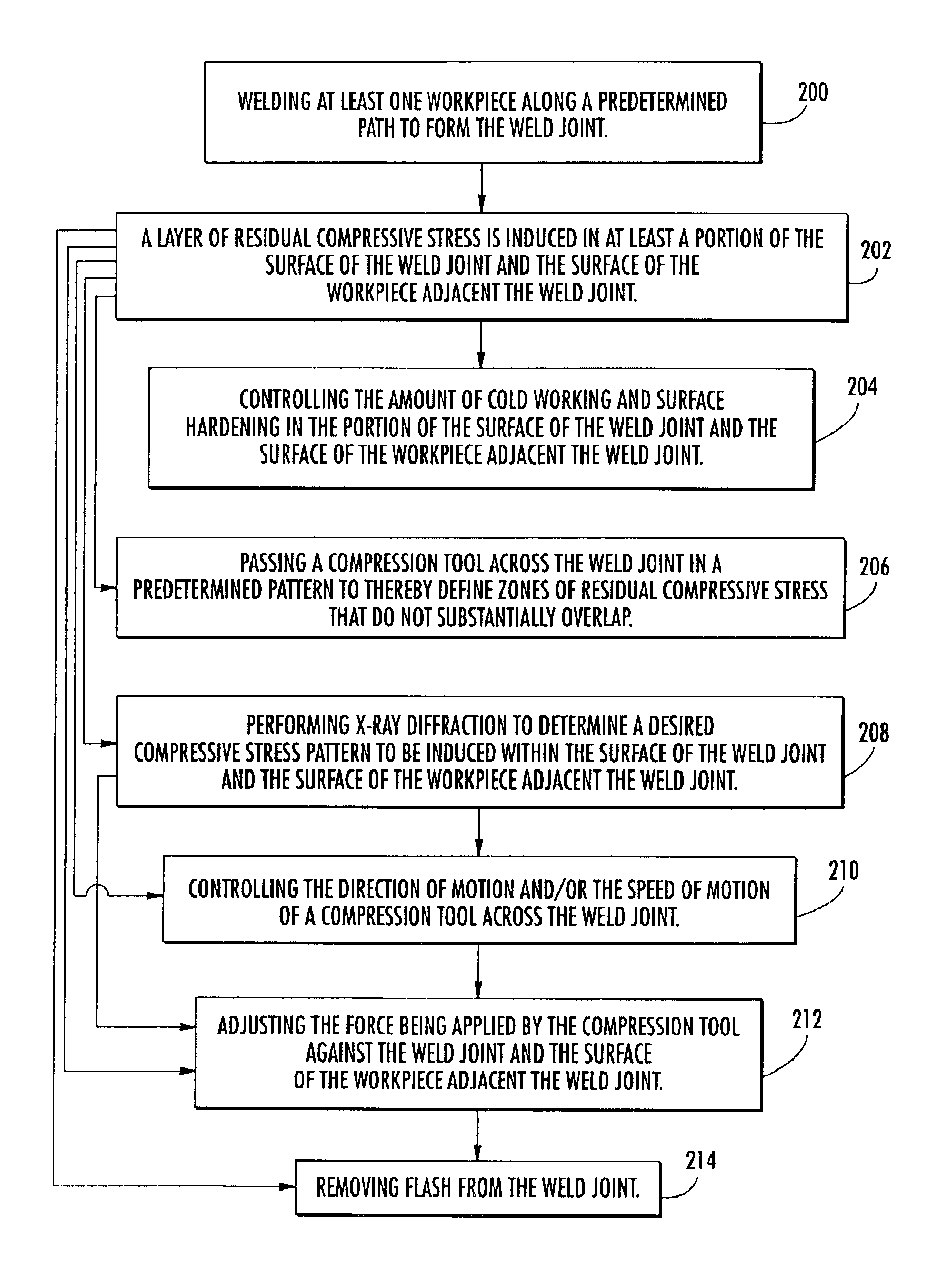

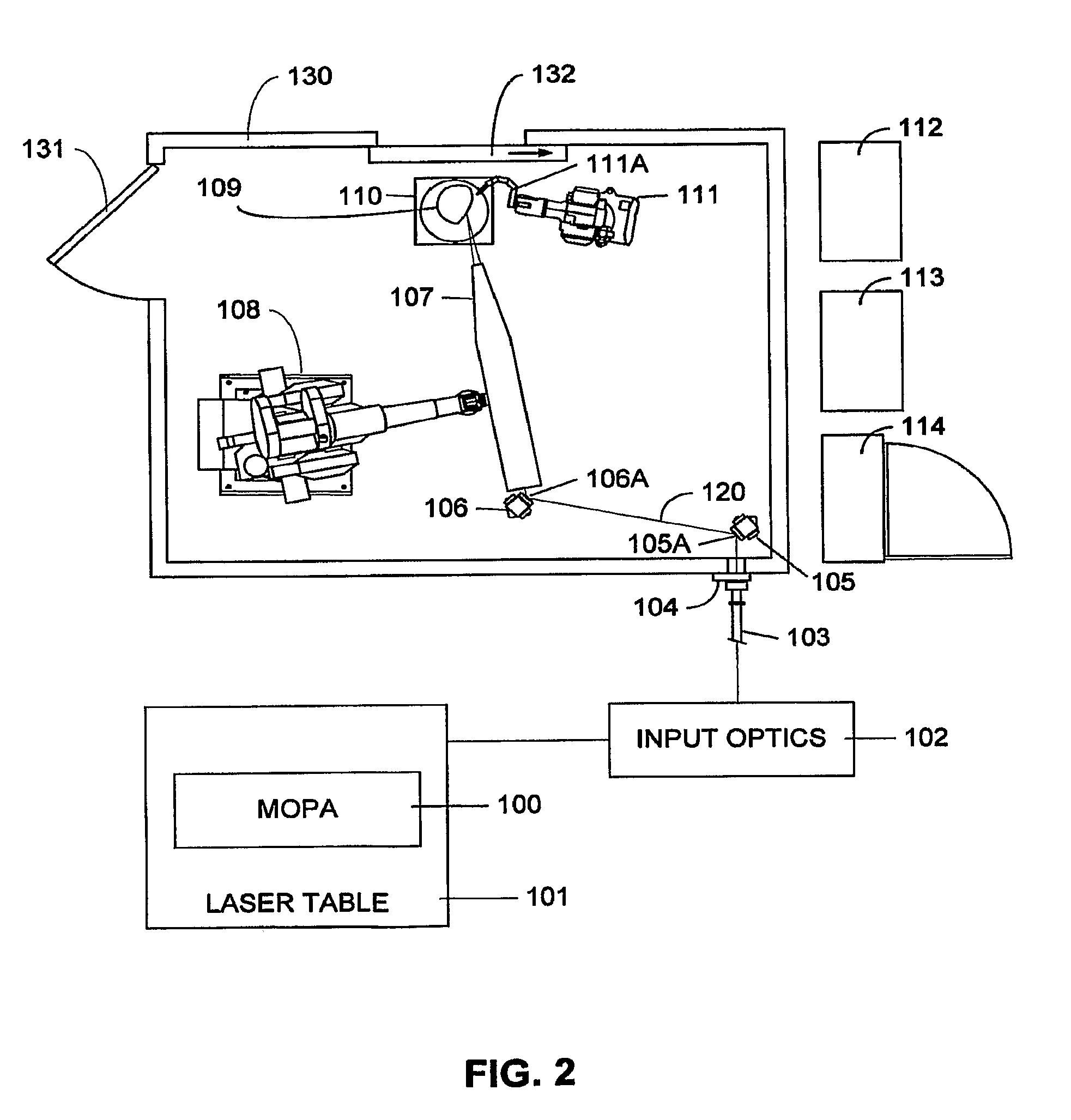

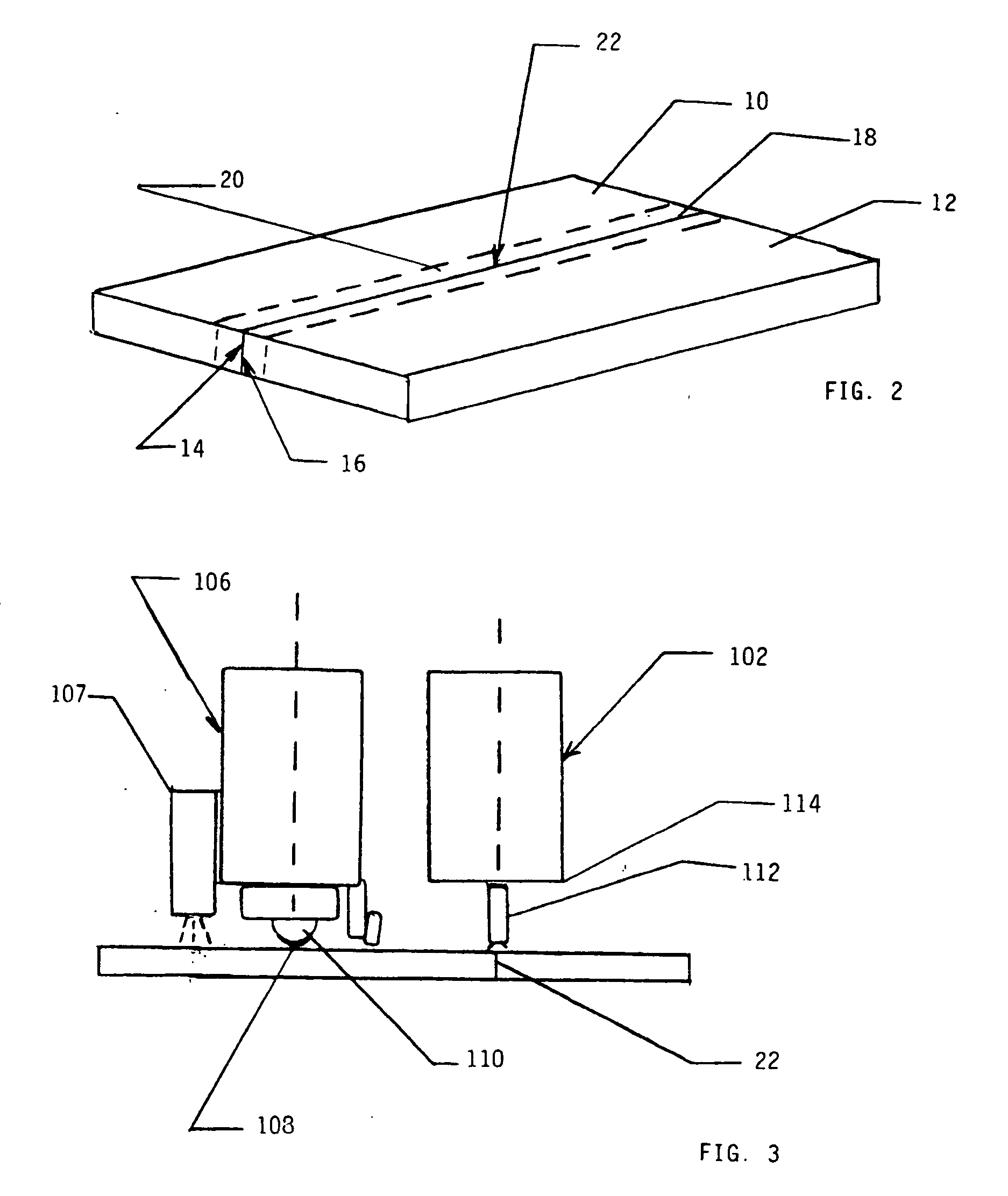

Apparatus and method for forming weld joints having compressive residual stress patterns

InactiveUS6926970B2Improve material propertiesHigh surface finishWelding/cutting auxillary devicesBurnishing machinesUltimate tensile strengthMechanical engineering

The welding apparatus and associated method are provided. The welding apparatus includes a welding tool for forming a weld joint along the surface of at least one workpiece. The welding apparatus also includes a compression tool for selectively inducing a layer of residual compressive stress in at least a portion of the surface of the weld joint and the surface of the at least one workpiece to thereby improve the material properties of the workpiece, including corrosion resistance and fatigue strength.

Owner:SURFACE TECH HLDG +1

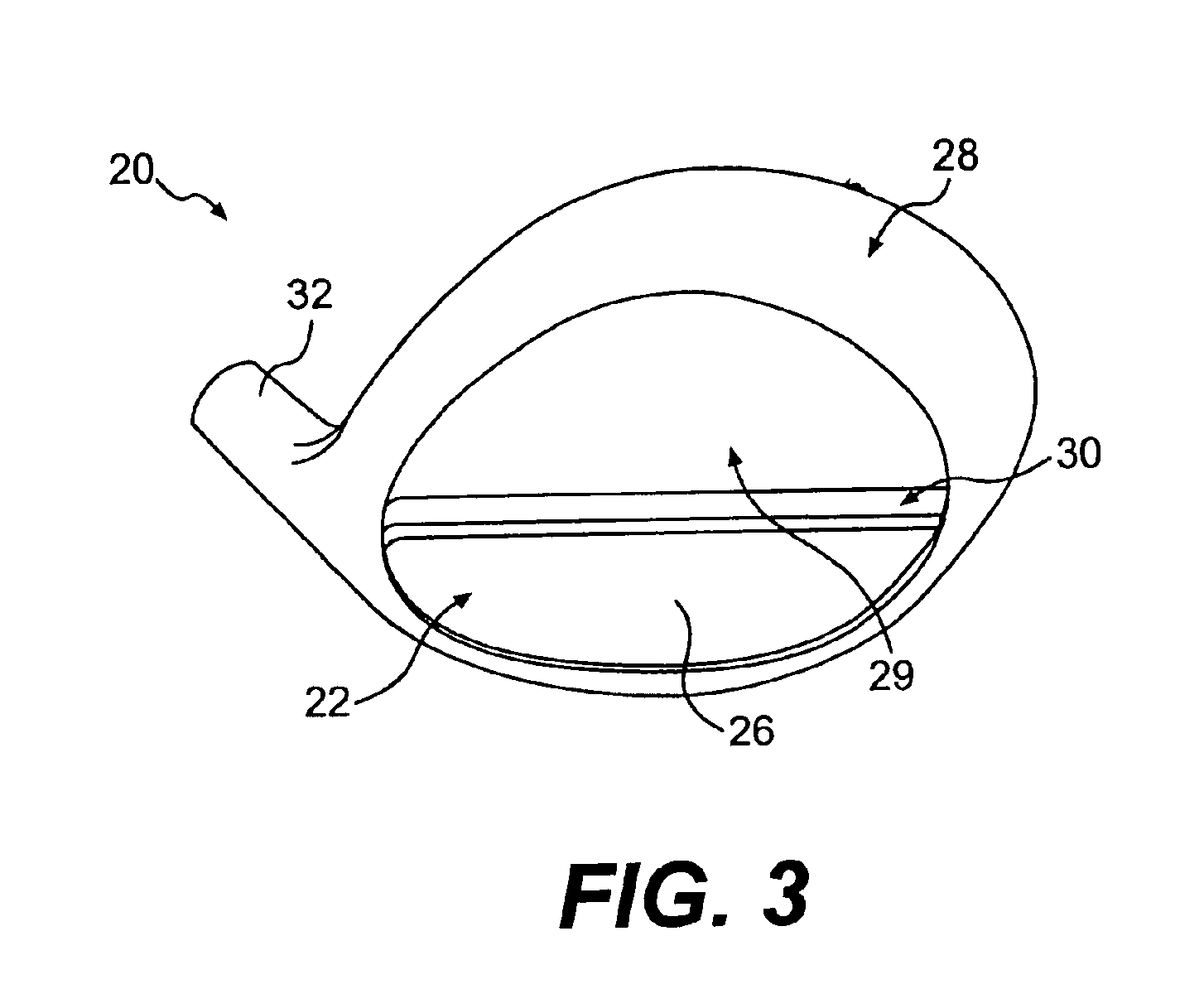

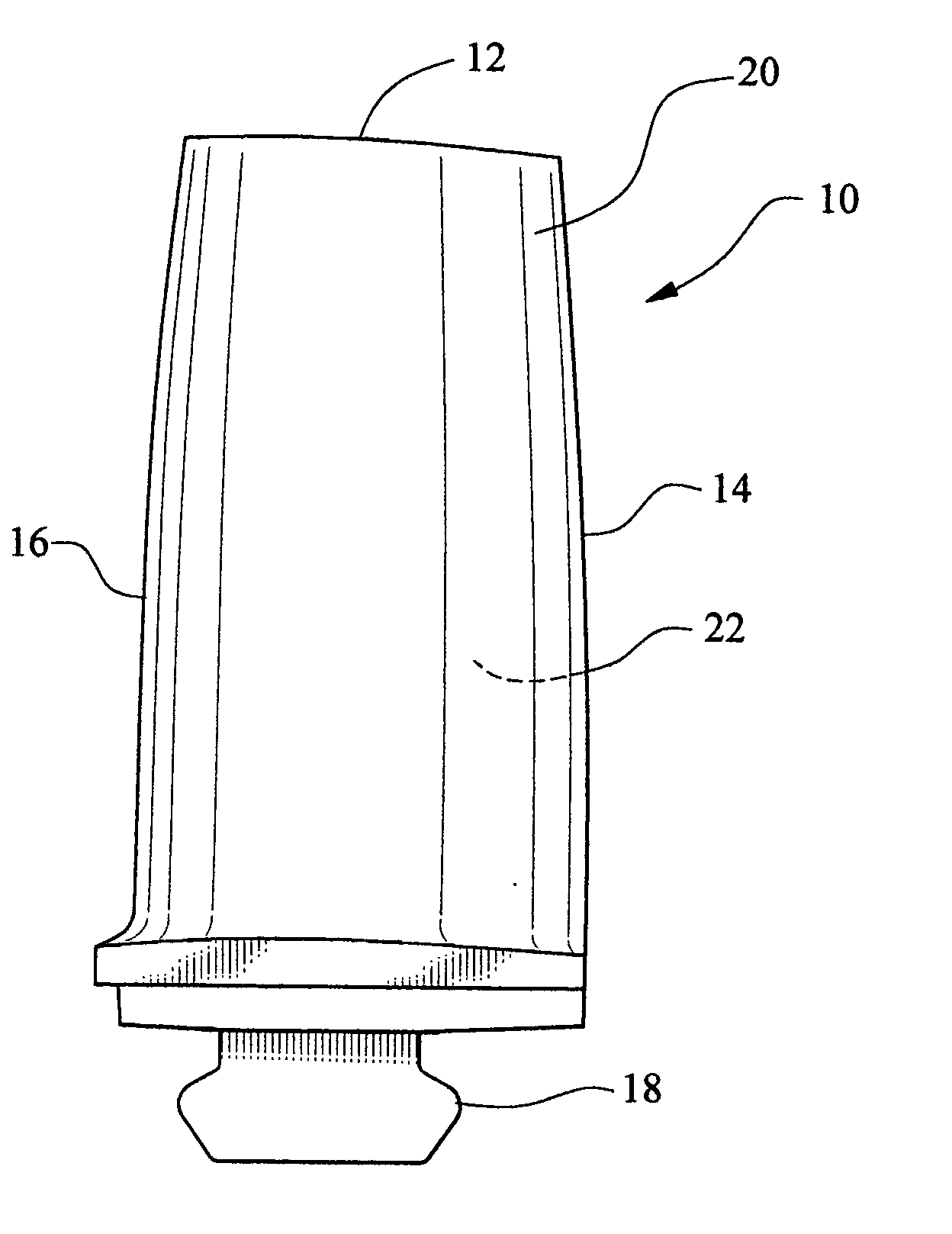

Peen conditioning of titanium metal wood golf club heads

Owner:ACUSHNET CO

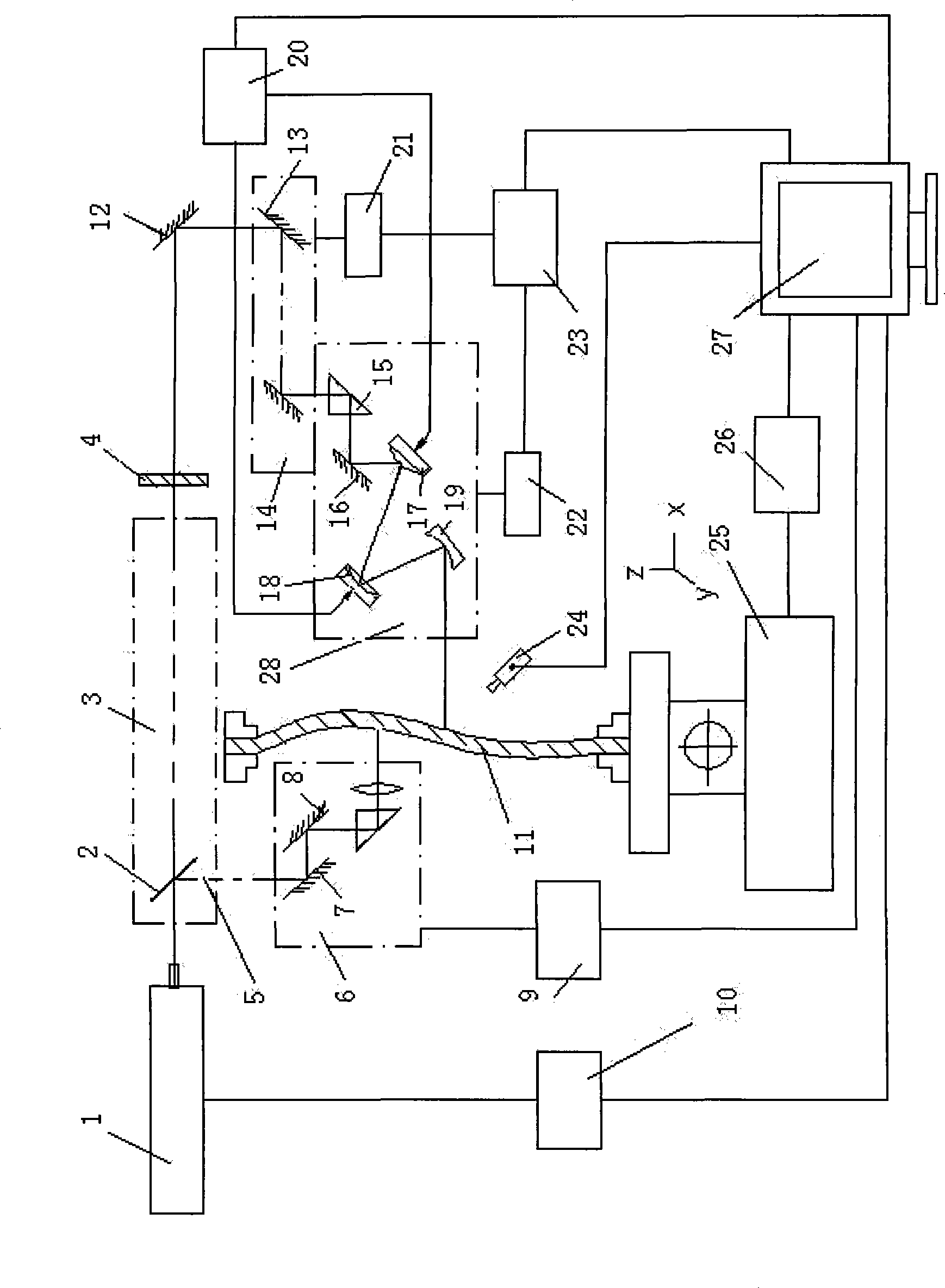

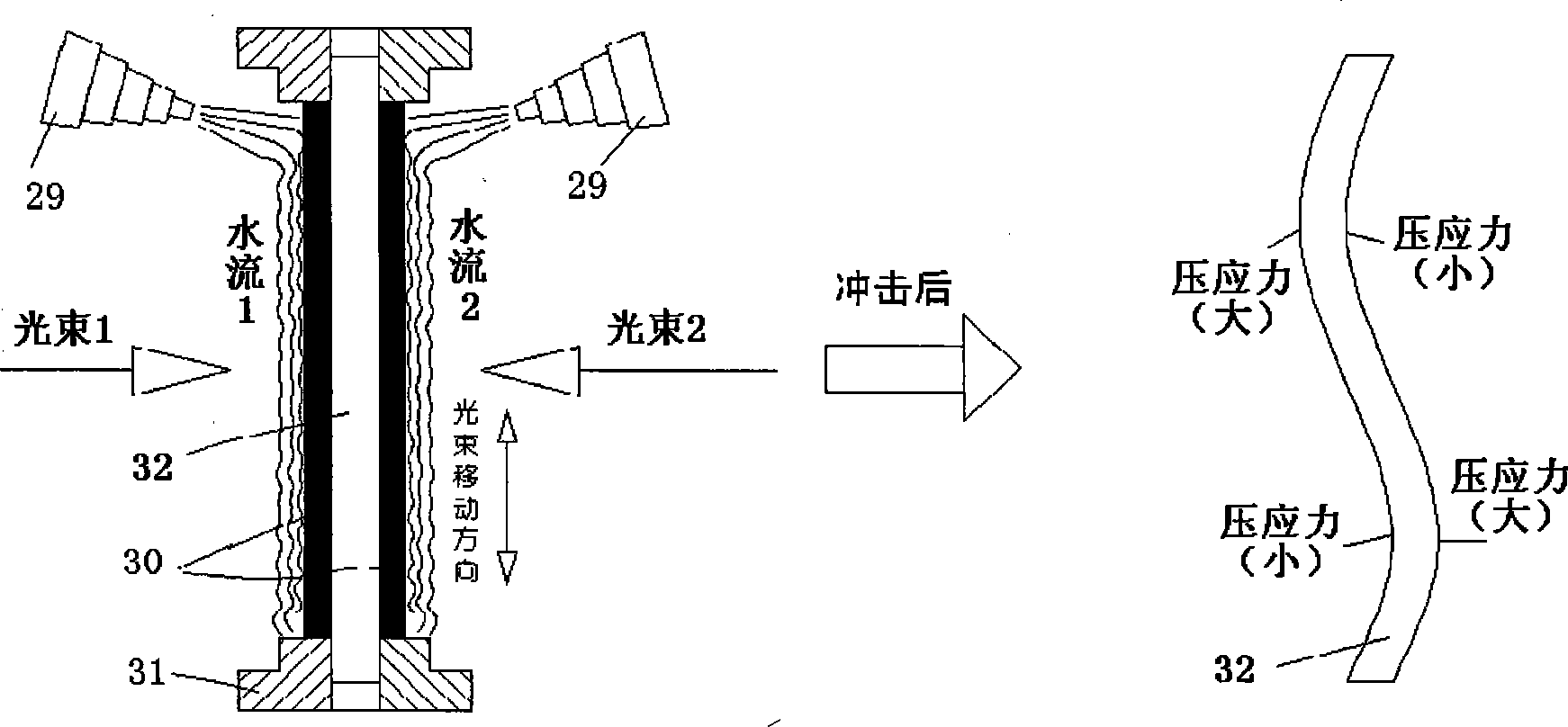

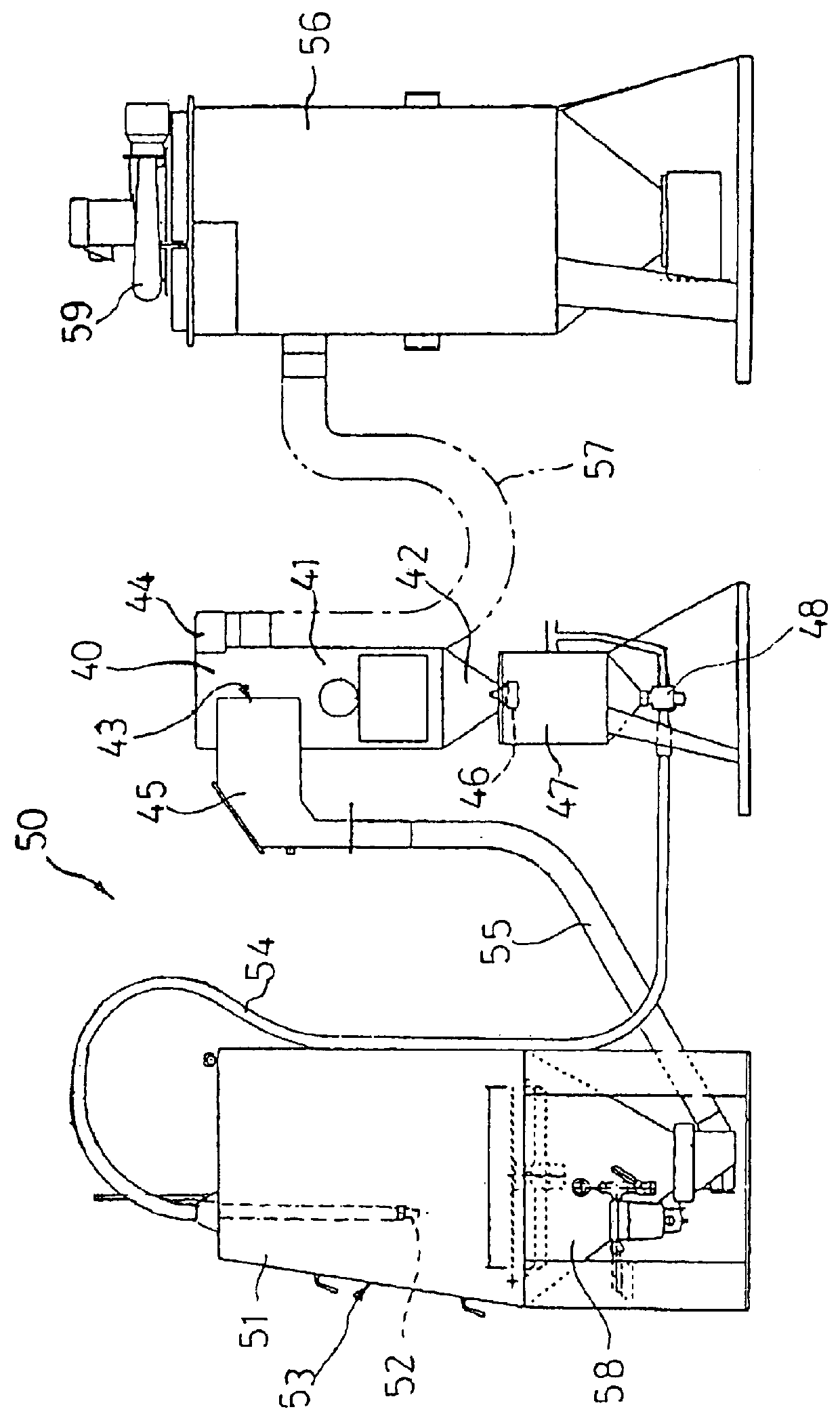

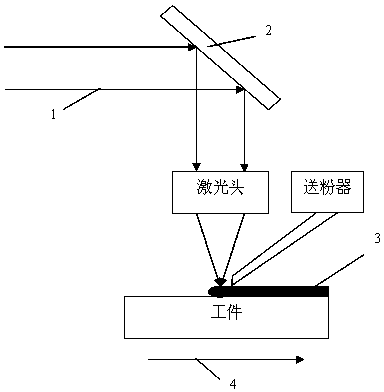

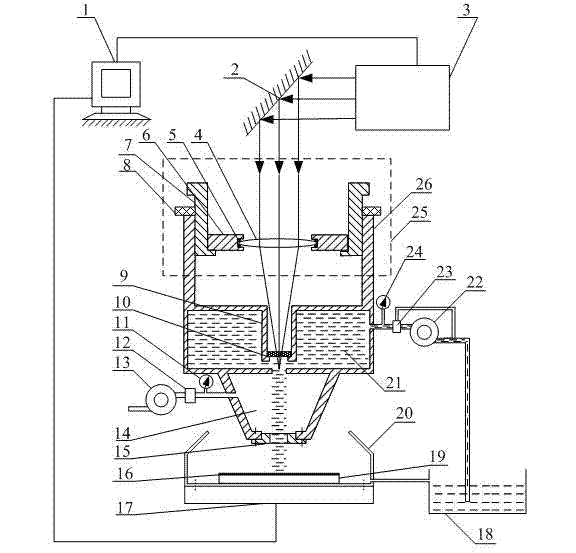

Sheet material double face precise forming method and apparatus based on laser blast wave effect

InactiveCN101249588AImprove surface propertiesPrecise workpiece contourLaser beam welding apparatusEnergy absorptionOptical processing

The invention relates to the field of laser processing manufacture, in particular to a laser shock precision forming method and a device. The device comprises a laser, an outer light path system, a laser shock head system A, a flying optical processing system with a laser shock head system B, a test sample system, a detection feedback system, a multi-axis link machine tool and a tool fixture system, a central control processor and a control system. A laser beam emitted by the laser is split by the outer light path system and are respectively transmitted to the front and the rear surfaces of a workpiece to subject the front and the rear surfaces of the double-sided workpiece with an energy absorption layer and a confinement layer to laser-induced shock wave. According to the requirements of the shape and the formation rule of a plate material, the double-sided laser shock head can execute simultaneous and non-simultaneous shock, counter shock, staggered shock, shocks with same and different energy, etc., so that the plate material is formed by generating a certain plastic deformation and a stress field distribution and that a certain residual stress is formed on the surface of the plate material. The method can achieve accurate quantitative formation, good repeatability and high forming efficiency, and can easily achieve automatic production.

Owner:JIANGSU UNIV

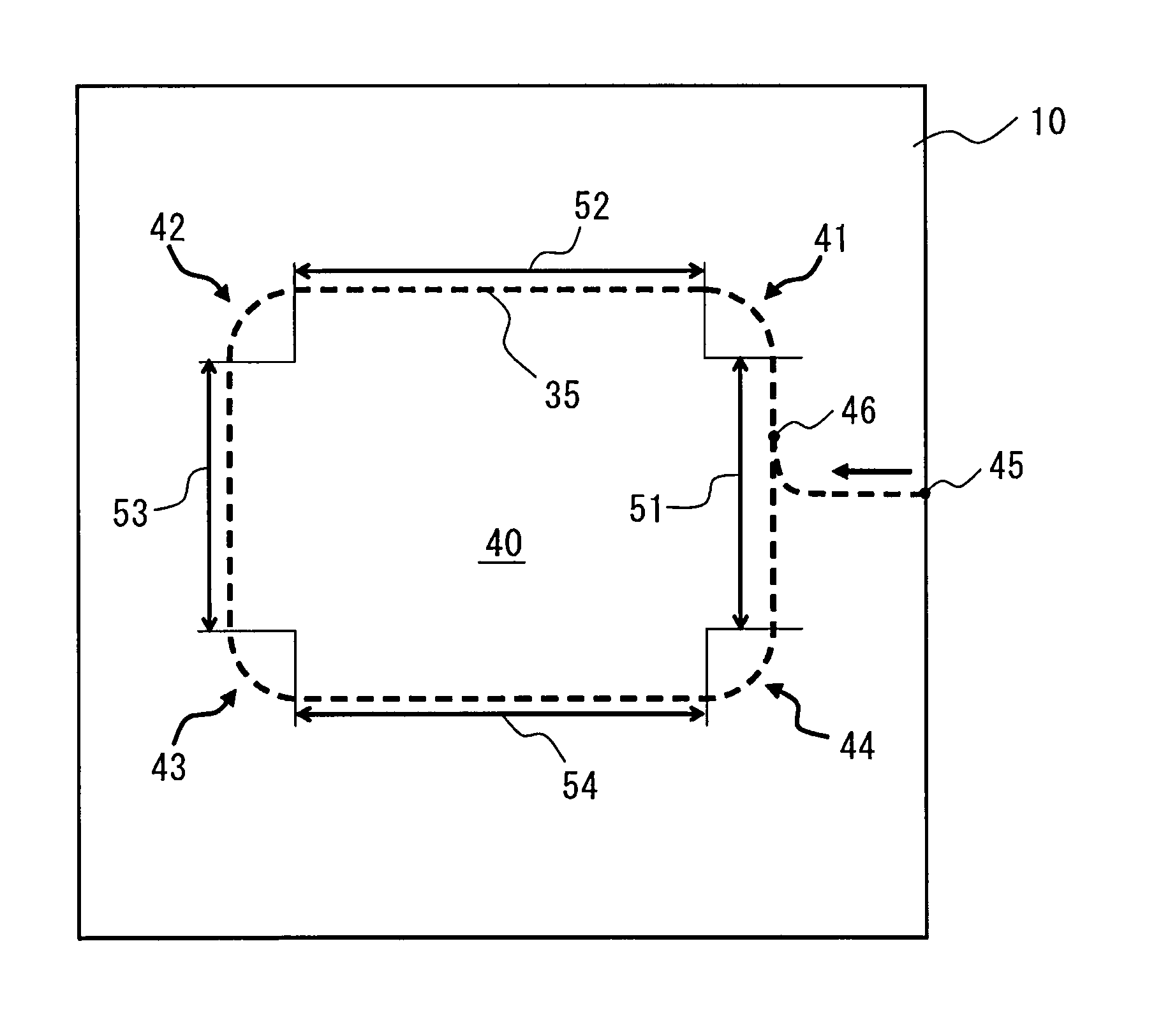

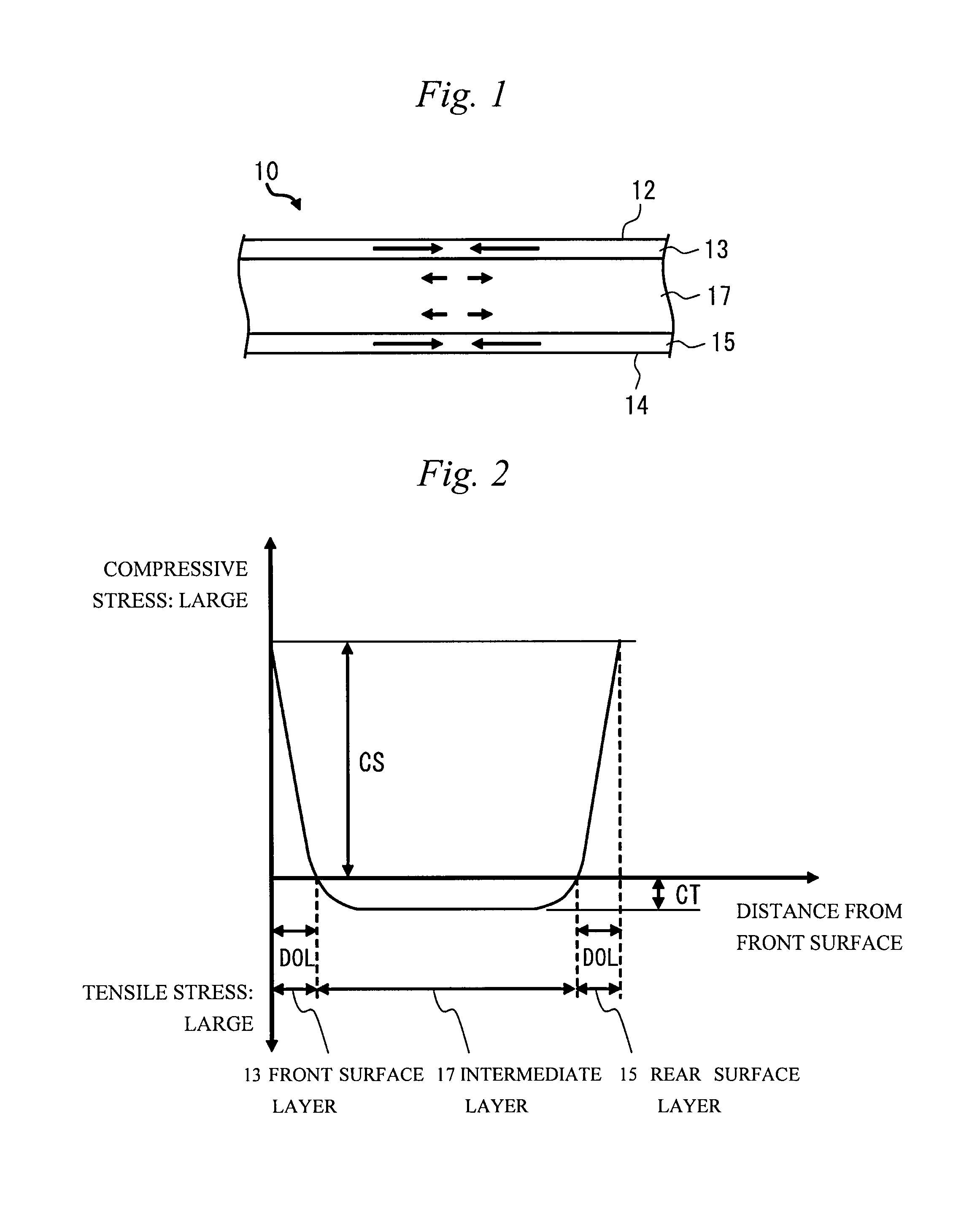

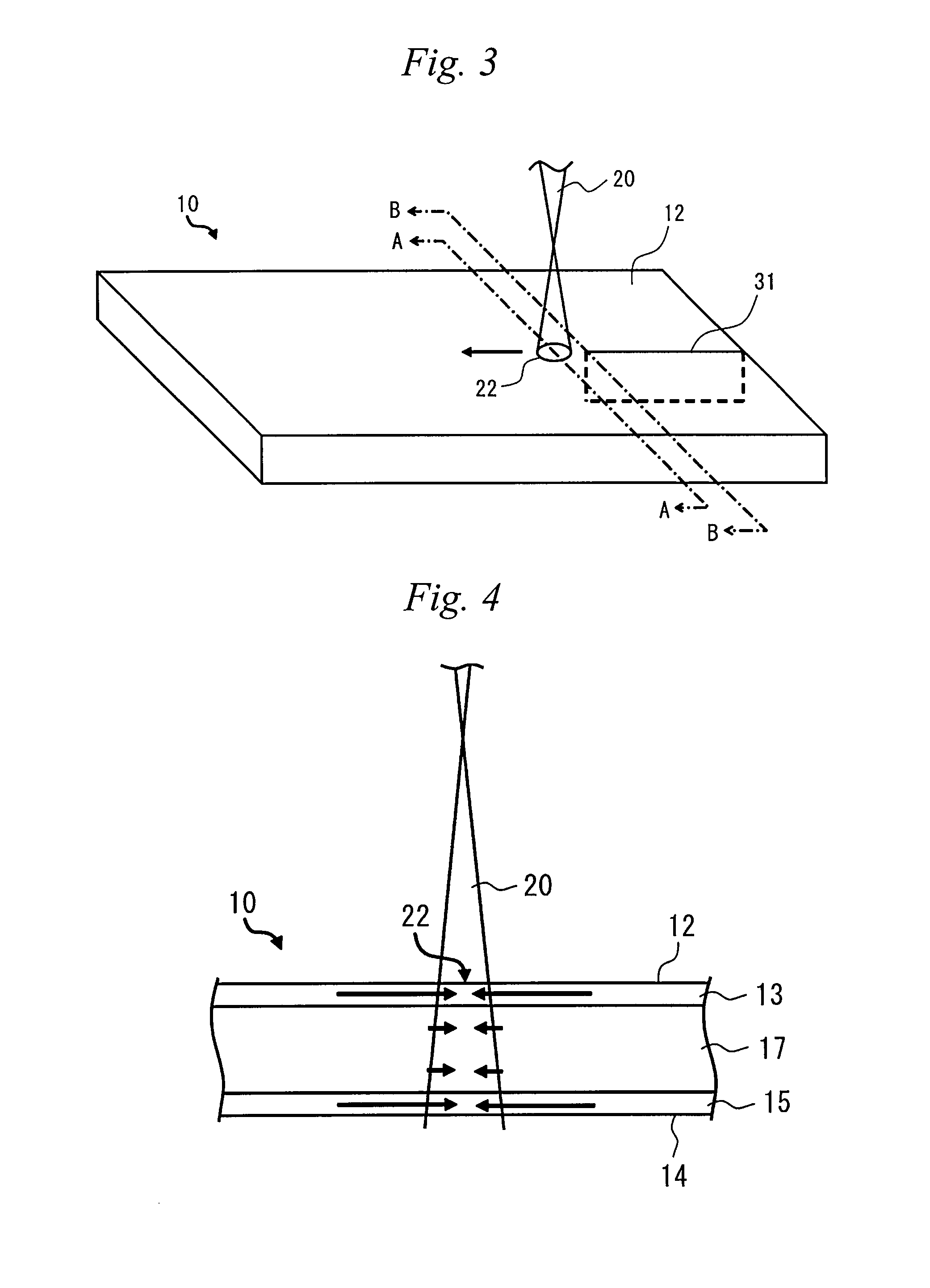

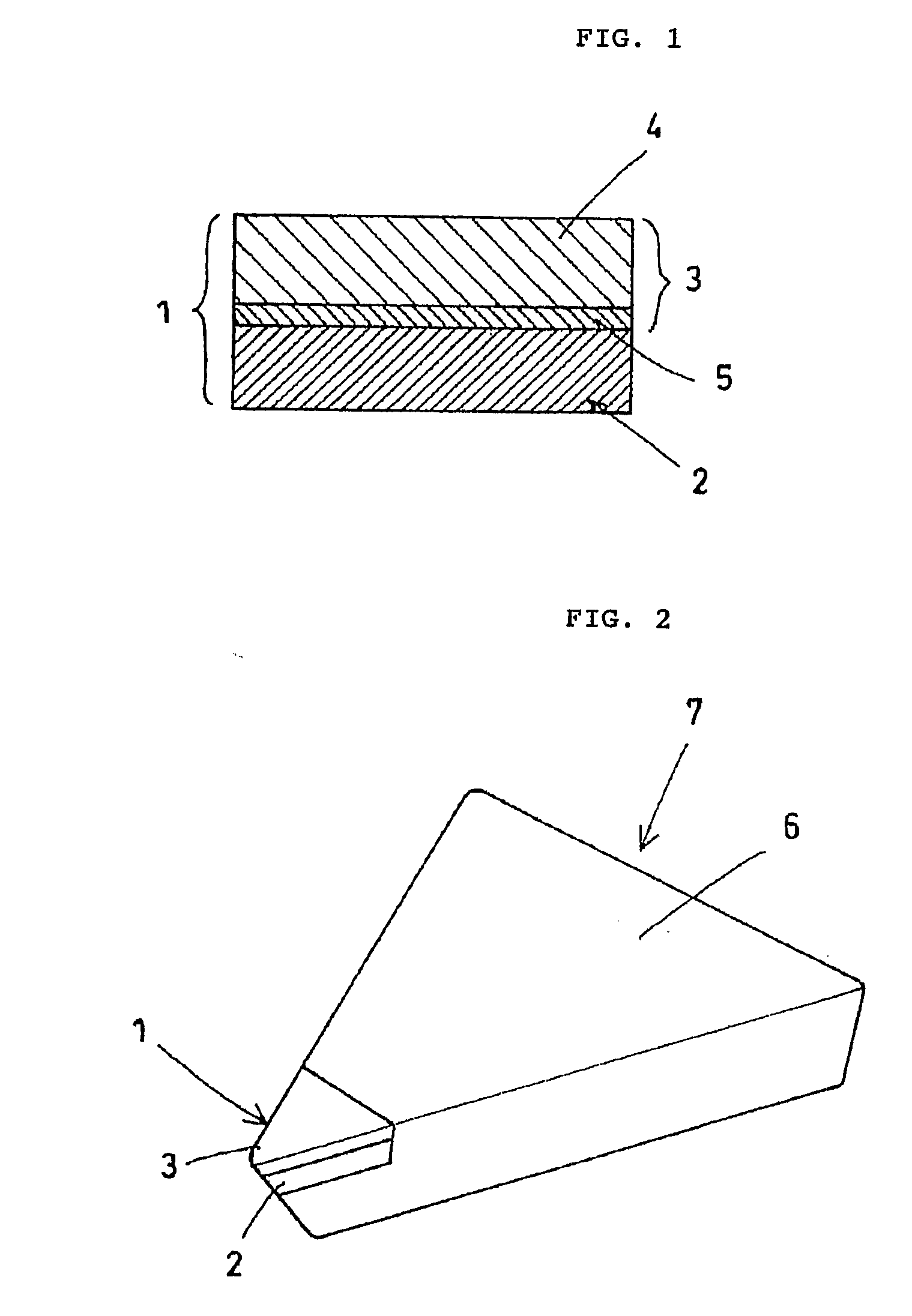

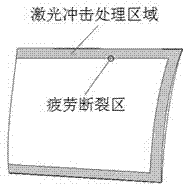

Cutting method for reinforced glass plate and reinforced glass plate cutting device

InactiveUS20140165652A1Quality improvementBlowing machine gearingsGlass reforming apparatusSurface layerOptoelectronics

The invention relates to a method for cutting a strengthened glass sheet in which, when a strengthened glass sheet 10 including a front surface layer 13 and a rear surface layer 15 which have a residual compressive stress, and an intermediate layer 17 which has an inside residual tensile stress, is cut by moving an irradiation region 22 of a laser beam so as to have a predetermined curvature radius, an irradiation energy per unit irradiation area of a laser beam 20 to be irradiated on the strengthened glass sheet 10 is increased as a curvature radius decreases. Thereby, it is possible to cut a strengthened glass sheet using a laser beam without causing a deterioration of quality.

Owner:ASAHI GLASS CO LTD

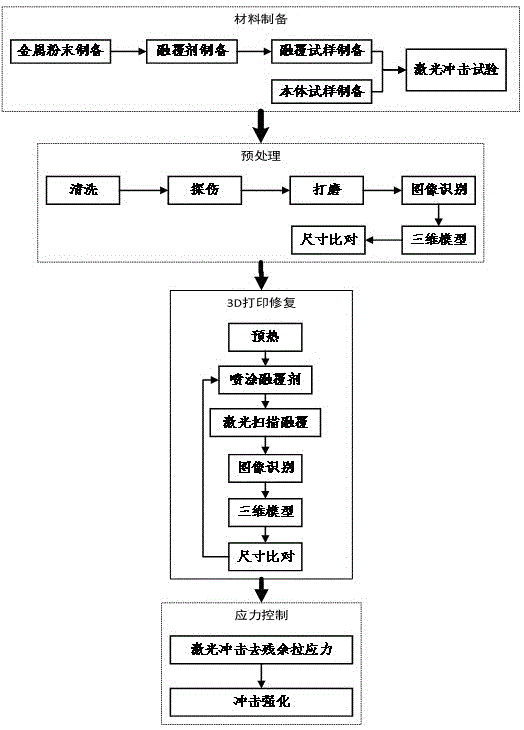

Metal part remanufacturing method adopting stress control and 3D printing

InactiveCN105154870ALarge deformationDimensional accuracy is easy to controlAdditive manufacturing apparatusMetallic material coating processesUltimate tensile strength3d printer

The invention discloses a metal part remanufacturing method adopting stress control and 3D printing. The metal part remanufacturing method comprises steps as follows: firstly, a body sample and a cladding sample of a metal part are prepared, and laser parameters required by the same residual compressive stress are acquired through laser shock; secondly, a to-be-repaired metal part is preprocessed, a repairing area and a repairing allowance of the part are determined with an image recognition method; the metal part is subjected to cladding repair layer by layer by the aid of a laser 3D printer, and the size of a repaired part reaches the originally designed size of the part; finally, residual tensile stress is eliminated through the laser shock, and then a residual compressive stress layer is formed on the working surface of the metal part with a laser shock processing method. According to the metal part remanufacturing method, the part repairing is performed by adopting laser 3D printing, the overall deformation of the part is not large, further, the repairing size precision is easy to control, and follow-up processing is not required; the repaired parts acquire equal overall strength, a value of residual compressive stress of a part surface strengthening layer after the laser shock processing keeps balance, and the service life of the remanufactured part is prolonged.

Owner:GUANGDONG UNIV OF TECH

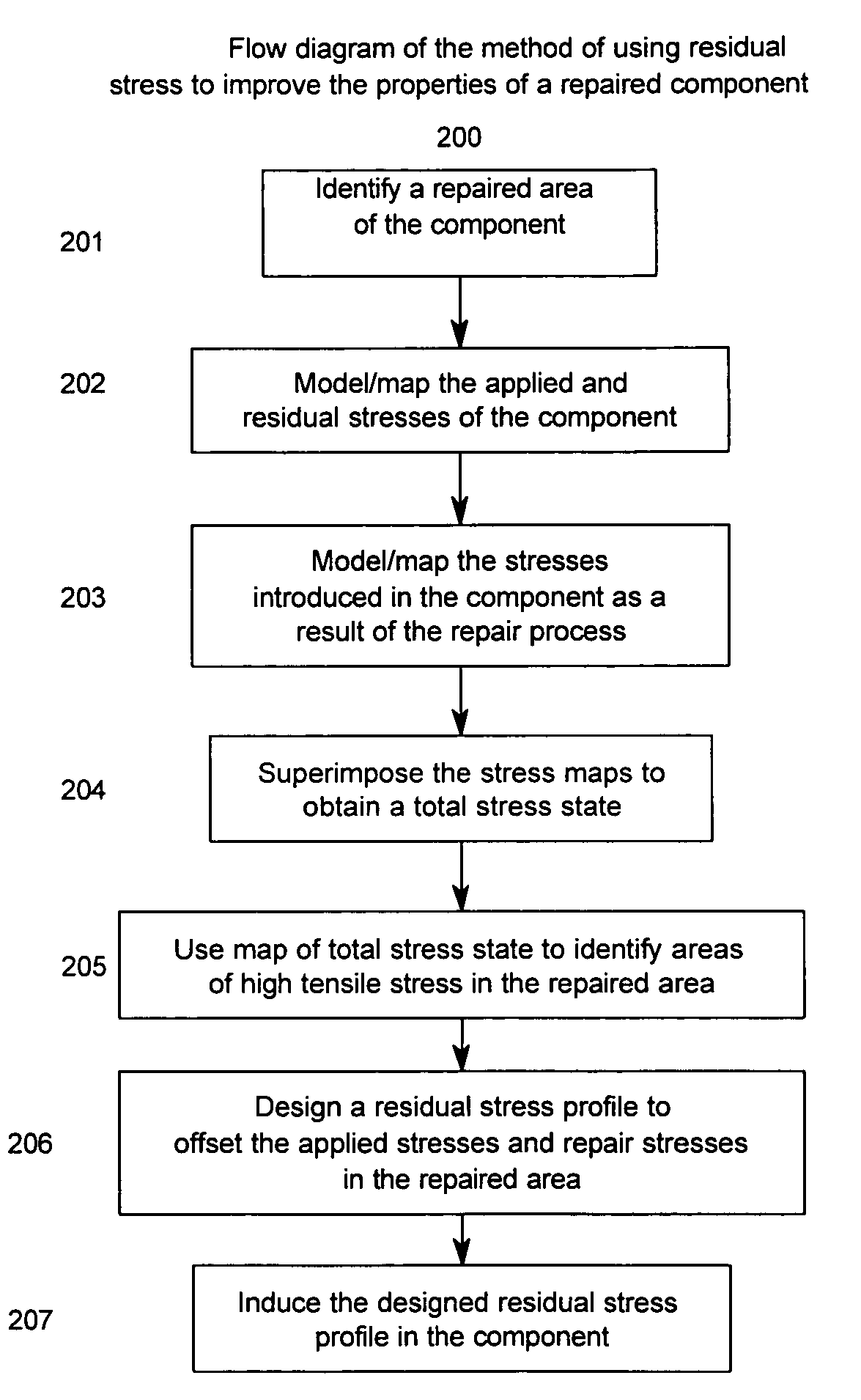

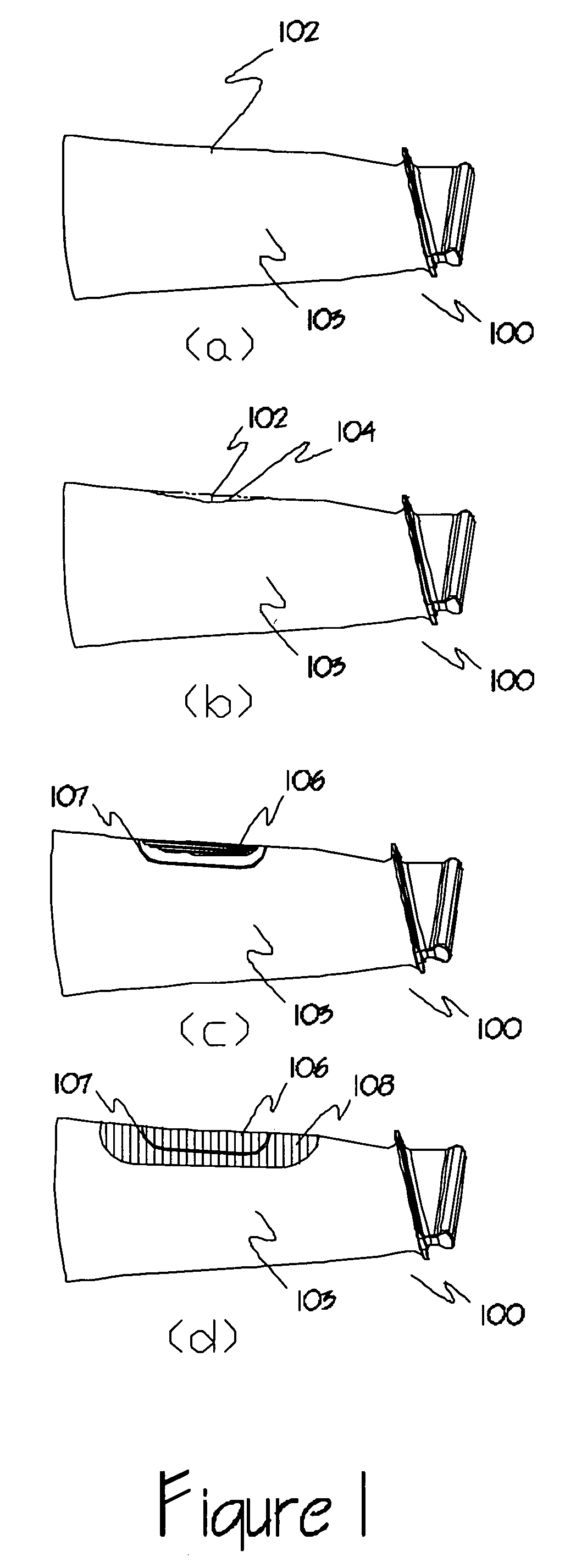

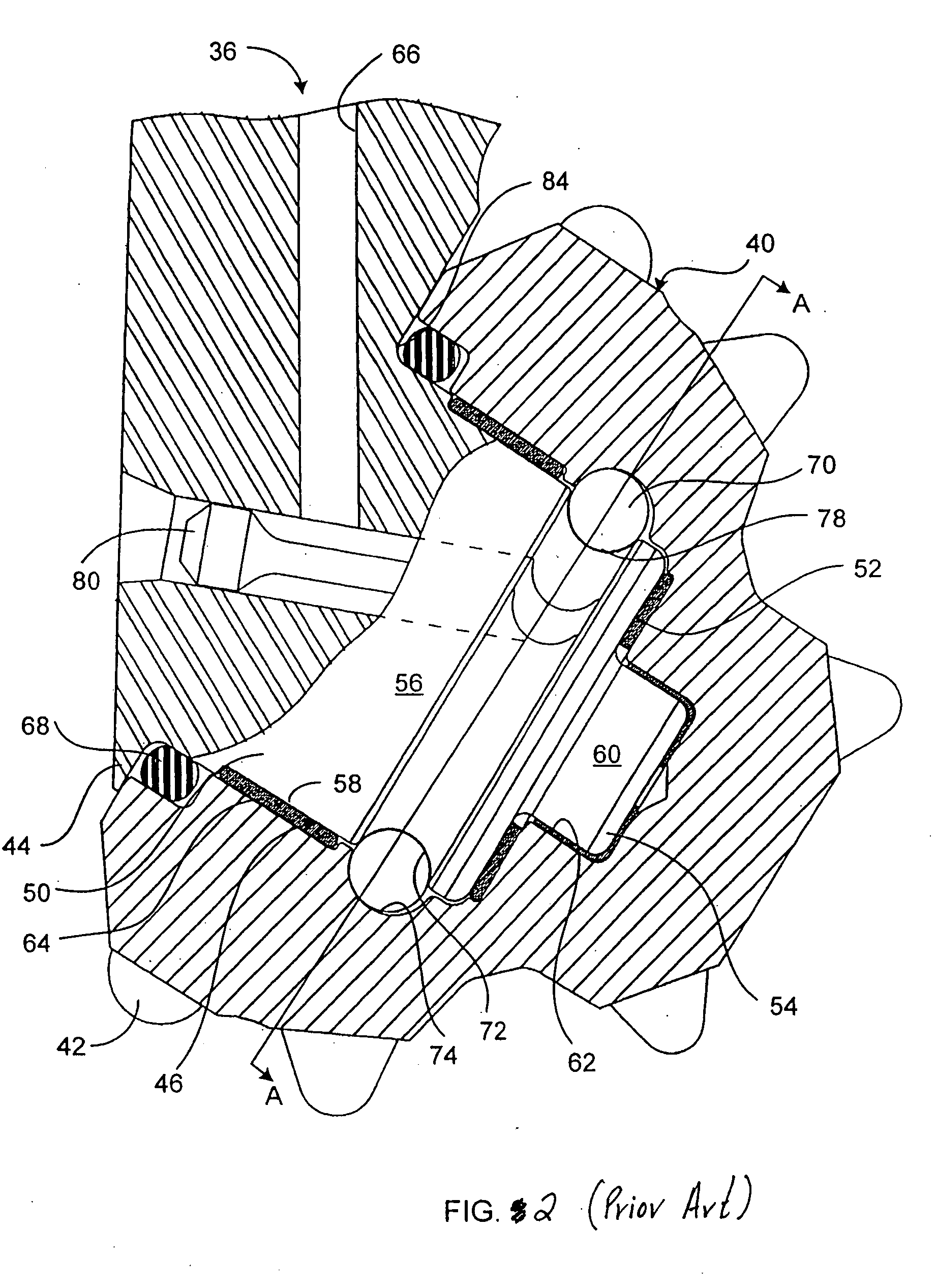

Method of improving the properties of a repaired component and a component improved thereby

InactiveUS20070157447A1Improved material and mechanical propertySimple materialBlade accessoriesEfficient propulsion technologiesForeign matterForeign object damage

A repaired component with improved material and mechanical properties and a method of improving the properties of a repaired component are provided. The repaired component comprises a body, a repaired area integral with the body, and an area of compressive residual stress wherein the area of compressive residual stress comprises at least a portion of the repaired area. One method for improving the fatigue performance, foreign object damage tolerance, and resistance to stress related failure mechanisms of a repaired component includes inducing a designed residual compressive stress distribution with a controlled amount of cold work in the repaired area to offset high-applied tensile stresses and stresses introduced as a result of the repair procedure as well as to improve the properties of the material added to the component during the repair.

Owner:PREVEY PAUL S

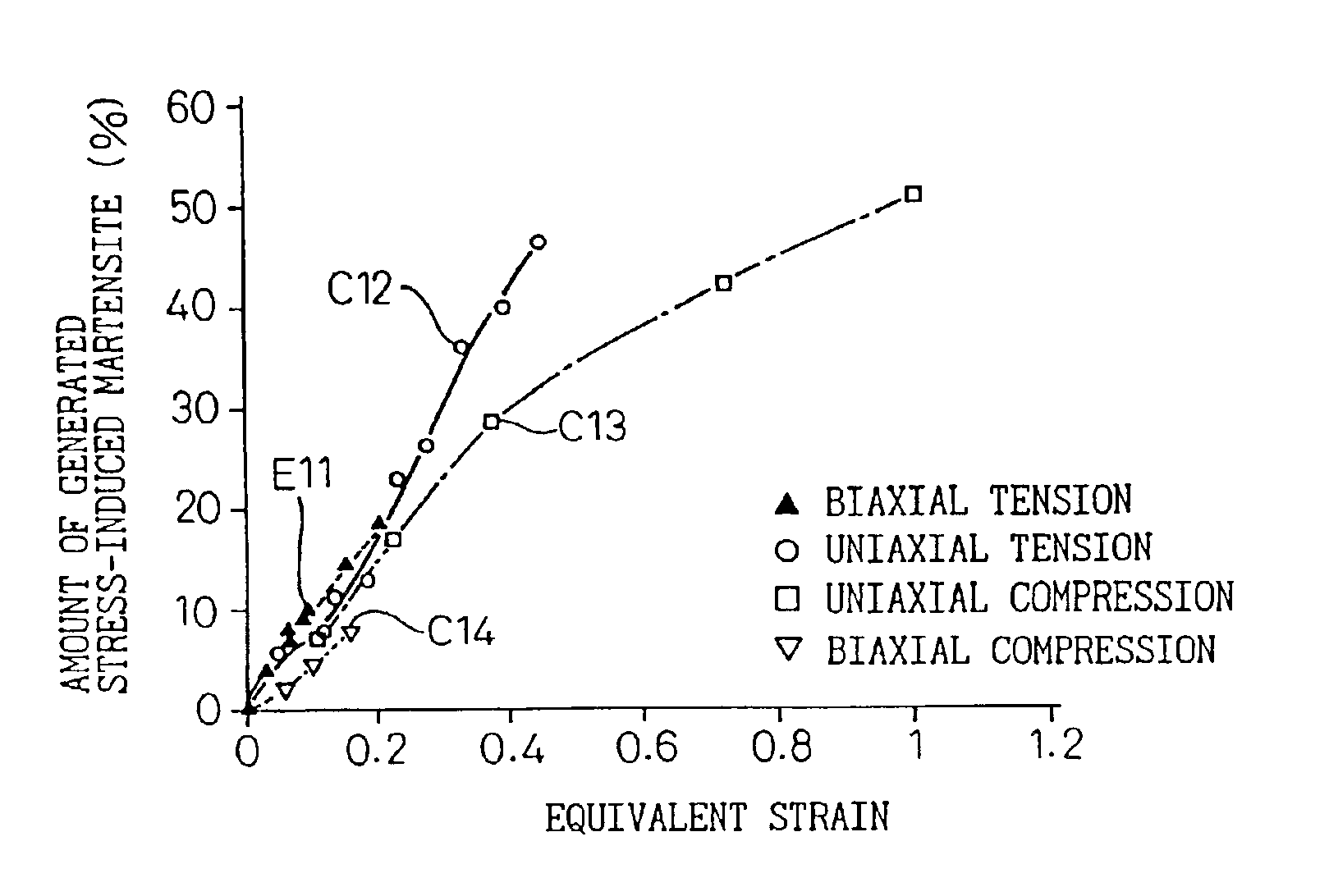

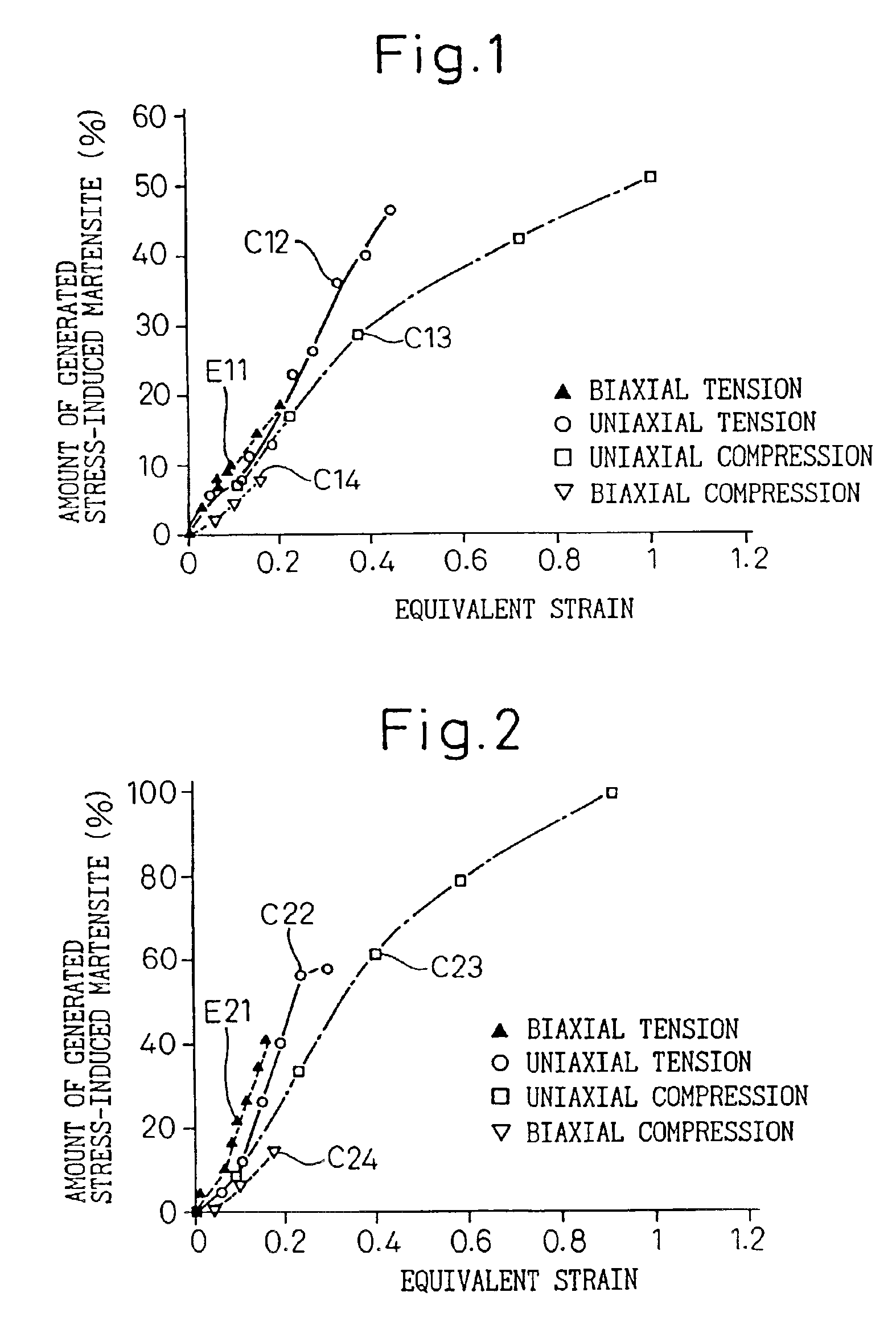

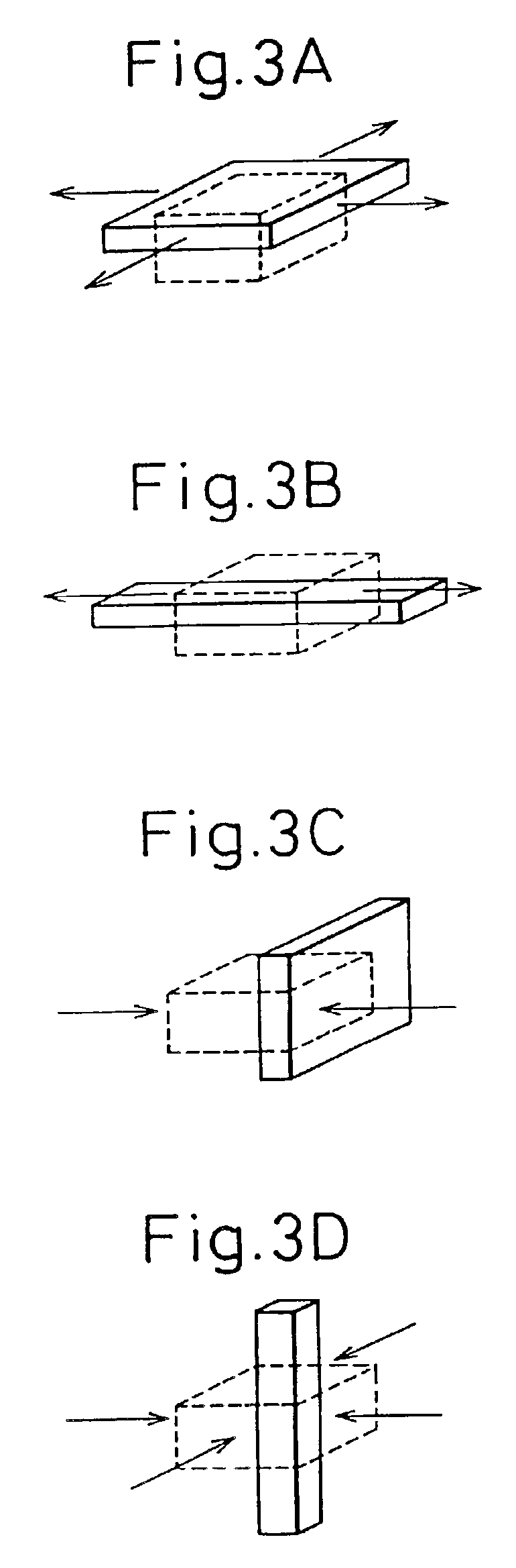

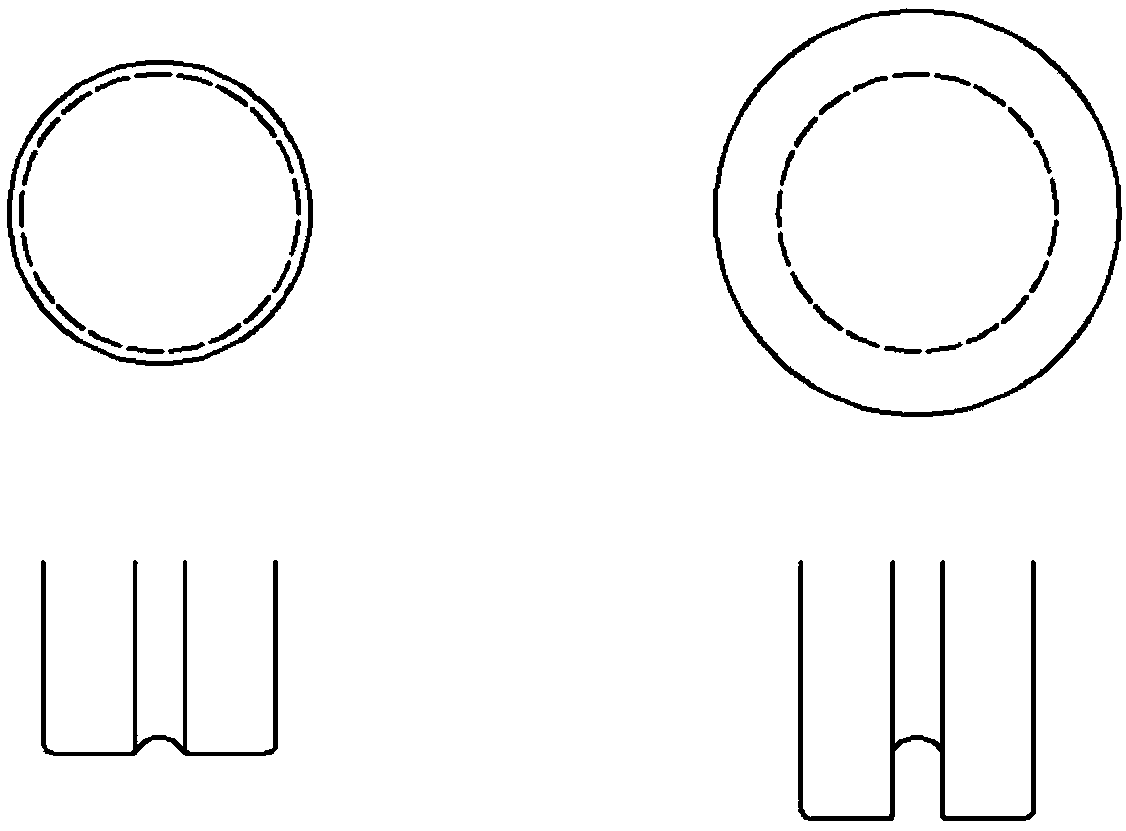

Method of stress inducing transformation of austenite stainless steel and method of producing composite magnetic members

InactiveUS6949148B2Increase generation ratioEasy to mass produceInorganic material magnetismStress inducedMetallurgy

A method of stress inducing transformation from the austenite phase to the martensite phase by conducting cold working on material of austenite stainless steel in the temperature range from the point Ms to the point Md. The above cold working is a biaxial tensing. An intermediately formed hollow body is made, which includes a ferromagnetic portion and a non-magnetic portion contracting inward. Then, the intermediately formed body is subjected to a stress removing process in which residual tensile stress is removed from an intermediately formed body. In the stress removing process, it is preferable that a punch is press-fitted into the intermediately formed body so as to expand a non-magnetic portion and then the intermediately formed body is drawn with ironing while the punch is inserted so that the residual tensile stress can be changed into the residual compressive stress in the non-magnetic portion.

Owner:DENSO CORP

Method for a surface treatment of metallic product

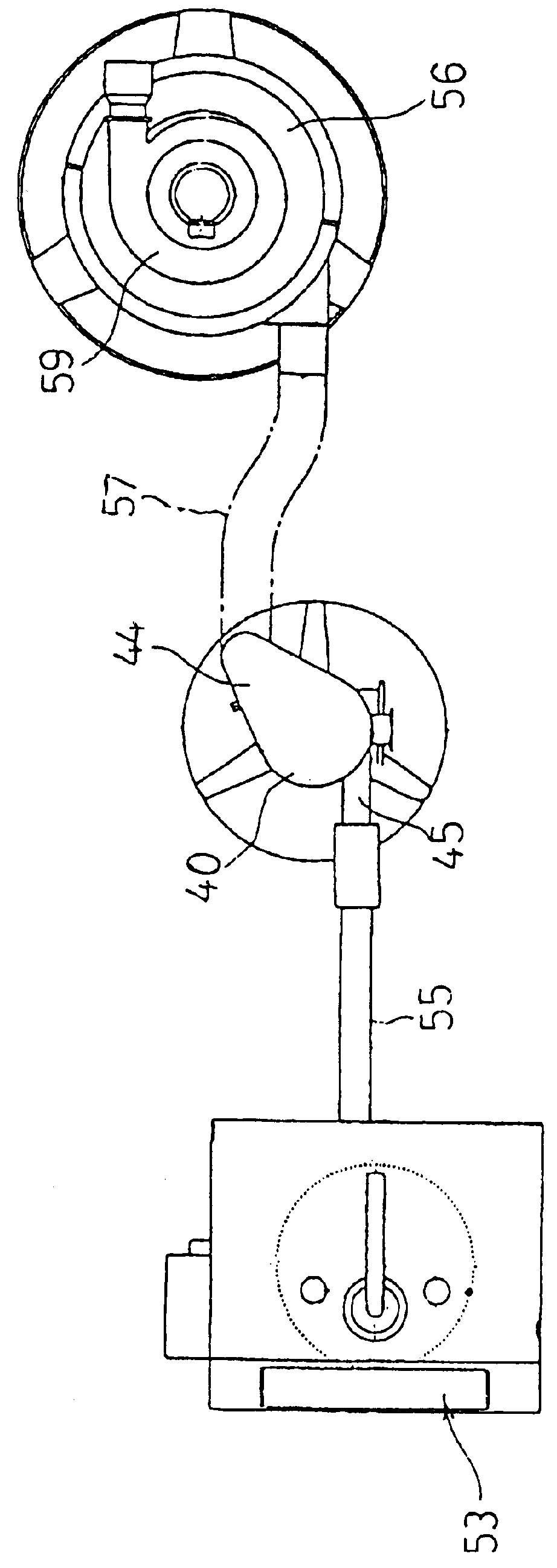

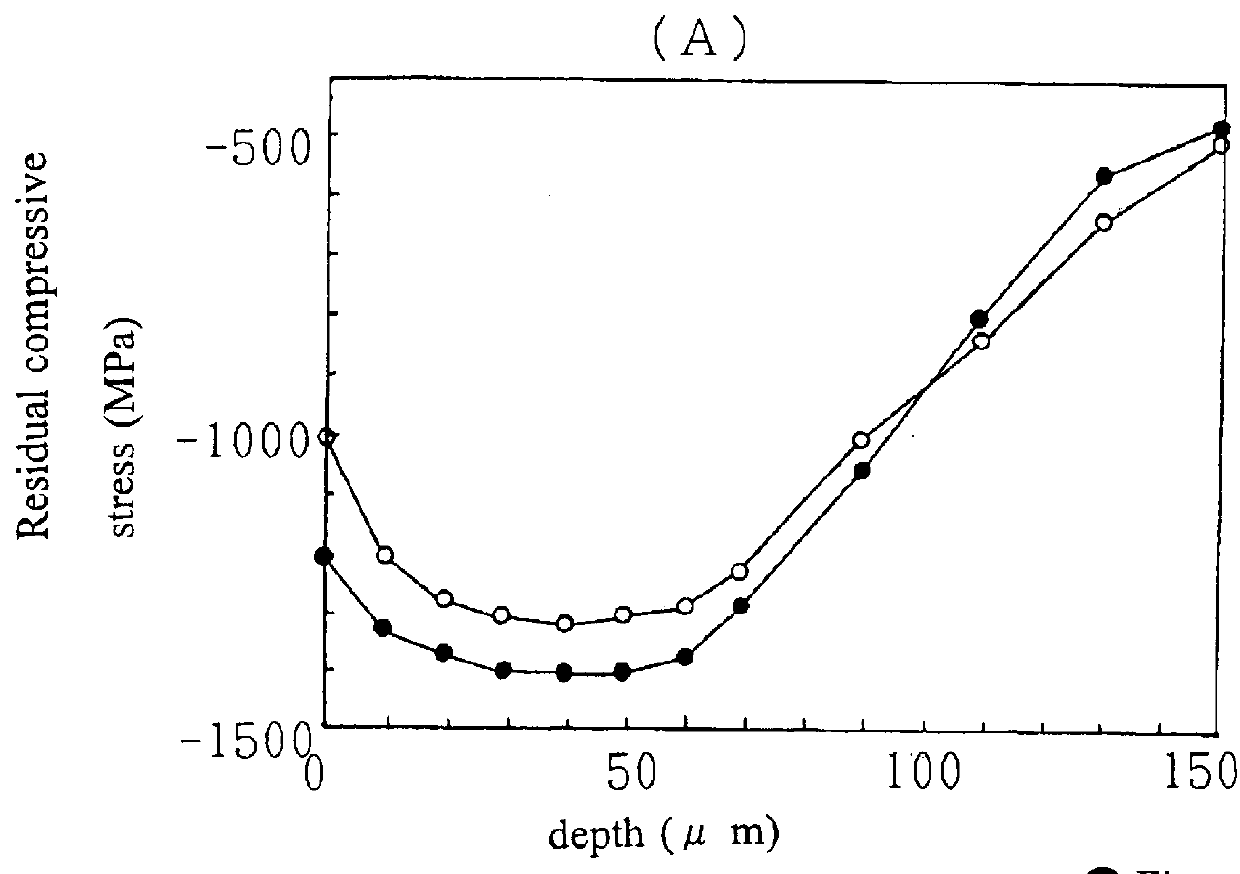

The present invention relates to a method for a surface treatment of a metallic product. In this method, by conducting one step of injecting mixture shots including at least two types of shots comprised of different or same materials consisting of high hardness metal or metallic component and having different shot diameters between 0.6 and 0.03 mm onto the surface of a metallic product at an injection pressure of not less than 0.29 MPa or not less than 50 m / sec, the residual compressive stress of the surface of the metallic product and that of a lower surface layer are made at least -1200 MPa and that of a portion having a depth of about 50 mu m below the surface of the metallic product is made -1300 MPa or higher.

Owner:FUJI KIHAN CO LTD

Combined treatment method for prolonging life of oversized shearing equipment tool

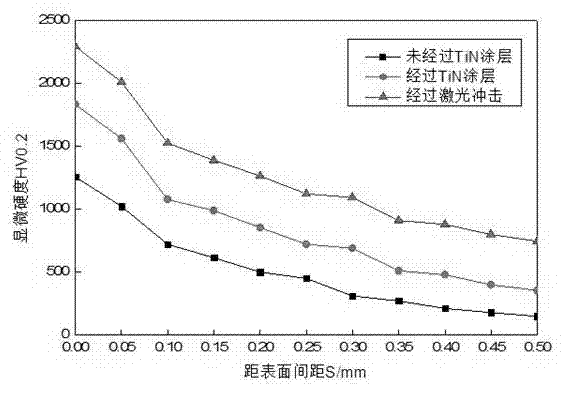

InactiveCN103668171AHigh hardnessImprove wear resistanceHeat inorganic powder coatingHardnessWear resistance

The invention discloses a combined treatment method for prolonging the life of an oversized shearing equipment tool, and relates to the technical field of application of machine manufacturing and material treatment processing. According to the invention, a TiN surface coating is utilized to improve the hardness, abrasive resistance and high-temperature resistance of the oversized shearing equipment tool, and the high-amplitude residual compressive stress layer generated by laser shock is utilized to effectively improve the mechanical property of the oversized shearing equipment tool, and particularly the fatigue life of the material is greatly increased.

Owner:JIANGSU WANLI MACHINERY +1

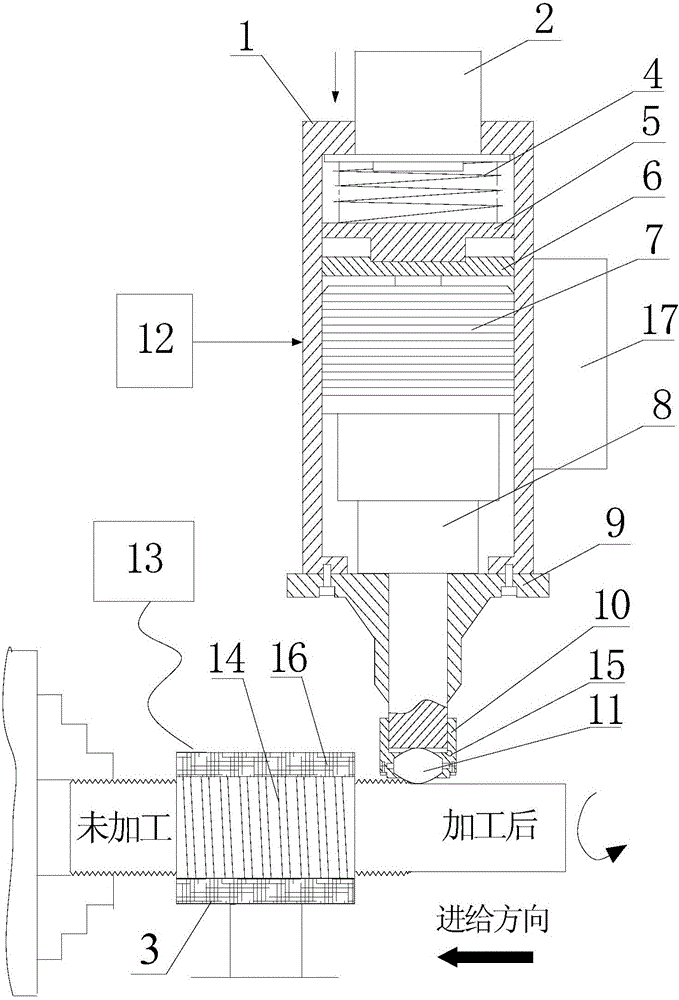

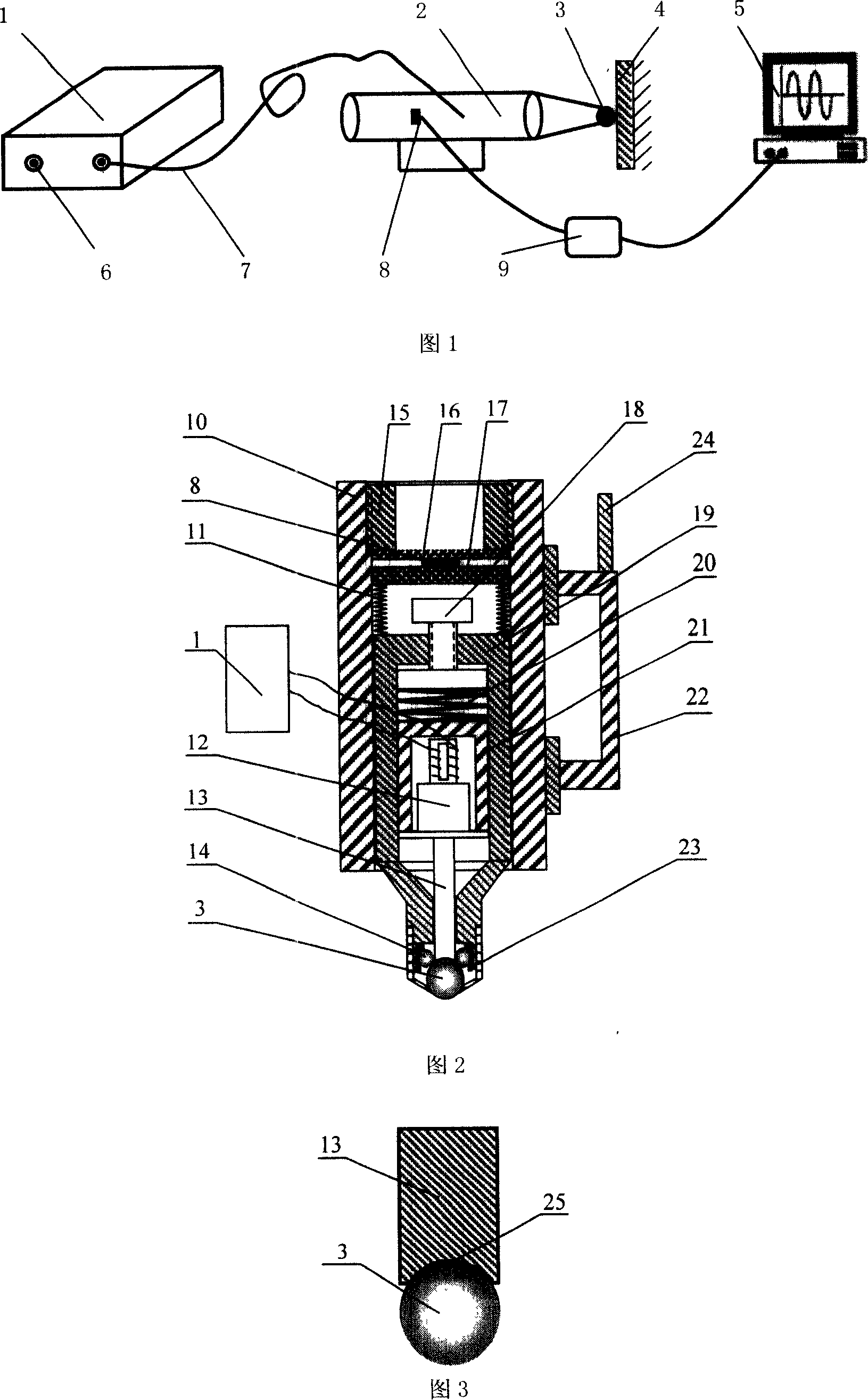

Low-temperature assisted ultrasonic surface rolling intensifying device and processing method

The invention discloses a low-temperature assisted ultrasonic surface rolling intensifying device and a processing method. The device consists of a surface rolling member, a loading member and a heating member, wherein a clamping handle is arranged on the surface rolling member; the loading member is arranged at the tail end of the surface rolling member; a spring, a pressure sensor, a baffle, a transducer and an amplitude-change pole are sequentially arranged on the end face of the loading member; the amplitude-change pole is provided with a rolling head of which the front end is provided with a roller through a guide sleeve; the outer side of the surface rolling member is connected with an ultrasonic generator; and the heating member is provided with a temperature controller and heating wires connected and controlled by the temperature controller According to the processing method disclosed by the invention, an ultrasonic rolling technology and low-temperature heating treatment are combined; on the basis of softening materials by using low temperature heating, an ultrasonic frequency electrical signal is converted into ultrasonic mechanical vibration by using the transducer; and after the ultrasonic mechanical vibration is amplified by the amplitude-change pole, vibration with a certain amplitude is outputted and transmitted to the rolling head, and high-speed vibration between the rolling head and workpieces in the rolling process is realized, thereby better refining material grains on the surface layers of the workpieces, and generating greater residual compressive stress and high surface hardness.

Owner:SOUTH CHINA UNIV OF TECH

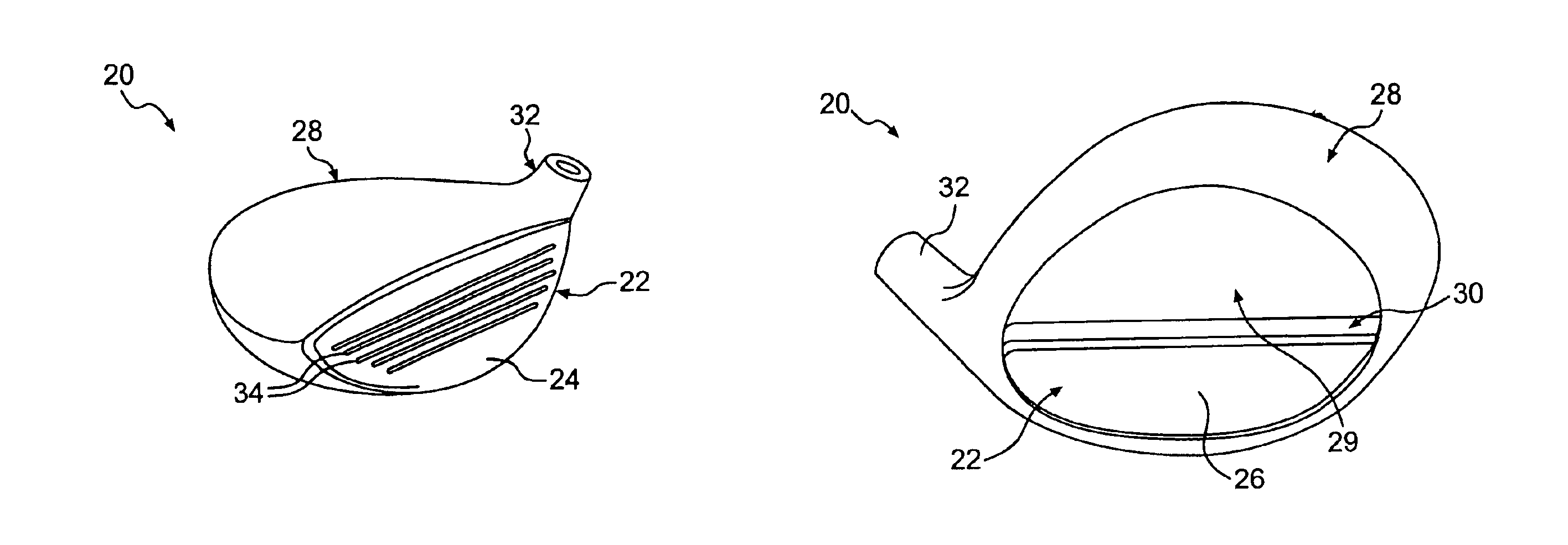

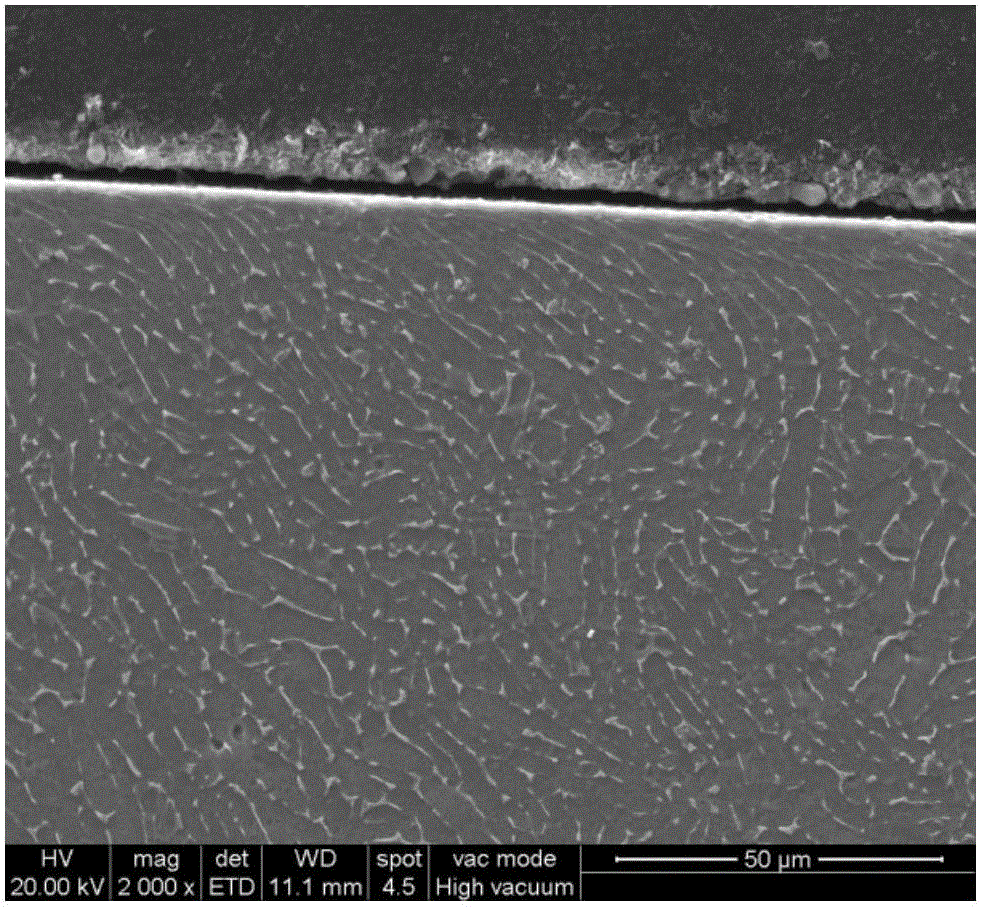

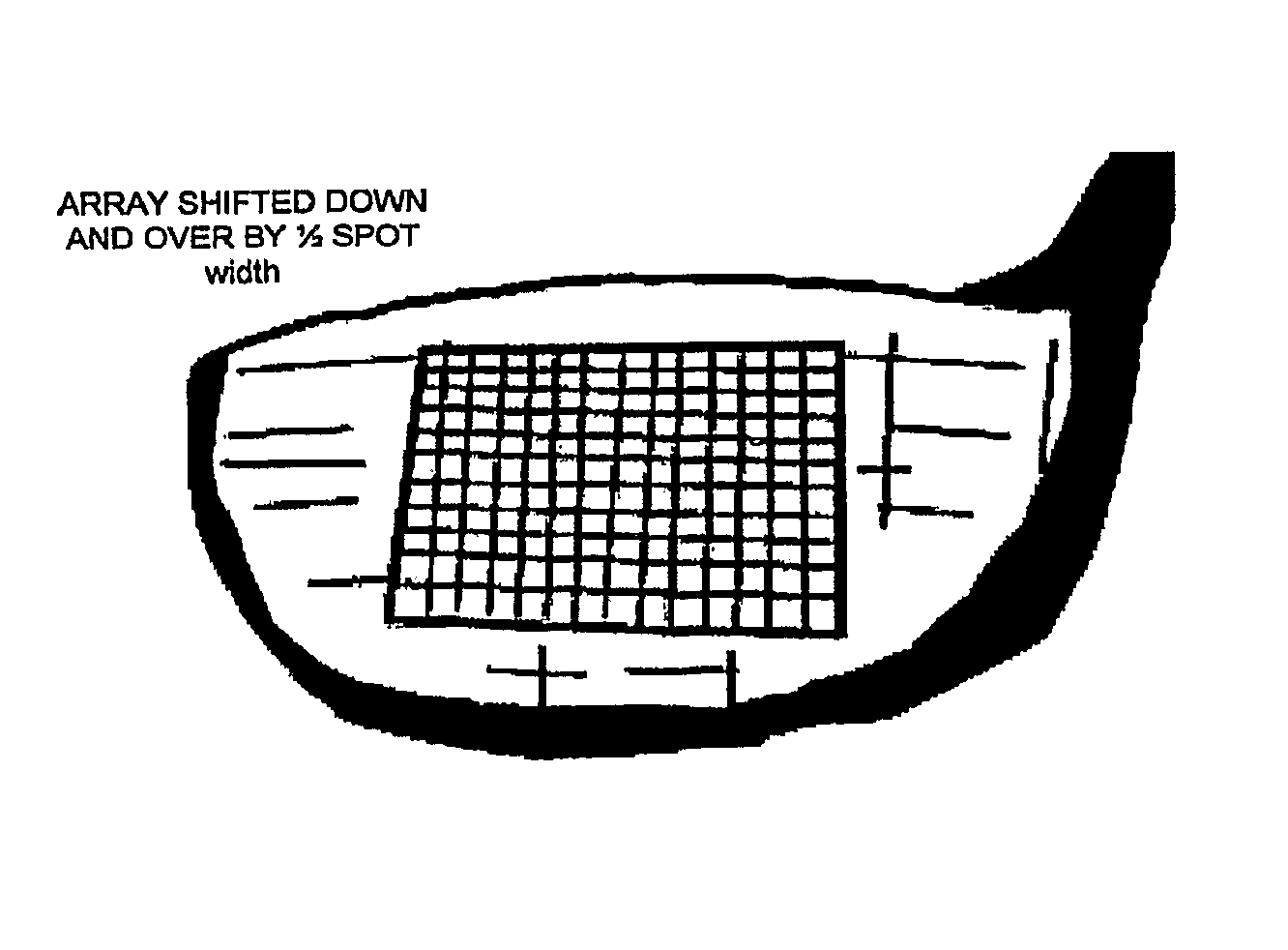

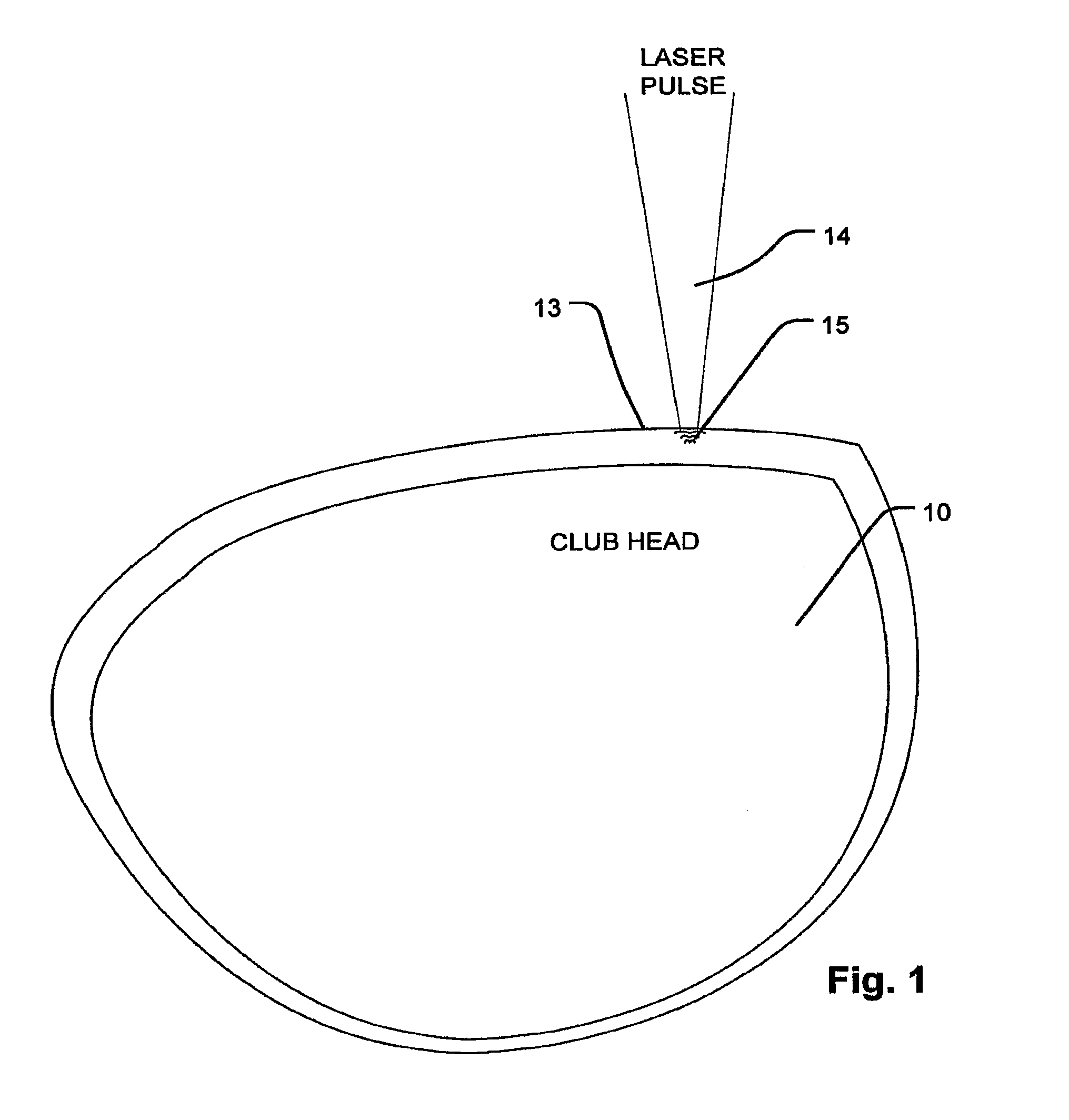

Engineered residual stress in golf clubs

InactiveUS8608590B2Surprising and improved result in performanceShorten the timeGolf clubsLaser beam welding apparatusHigh intensityGolf Ball

A method of manufacturing a driver, or other types of golf club, includes inducing residual compressive stress by high intensity laser shock peening to form an array of laser shock peened impact zones on the club face. Laser pulses having irradiance greater than 4 GW / cm2, with spot size greater than 4 mm2 are used, including a pulse with on the order of 16 ns, with spot size greater than 9 mm2. Residual compressive stress of more than 400 MPa penetrating with a depth of more than 0.2 mm are imparted, without increased hardening in or damage to the face of the club. Laser shock peening a pattern that covers an interior area leaves the perimeter unpeened, inducing a stress gradient between interior area and the perimeter of the club face. Multiple layers of arrays of laser shock impact zones are applied on the club. The technology is readily applied to assembled club heads.

Owner:METAL IMPROVEMENT CO INC

Method for prolonging life of pump shells and blades by carrying out laser strengthening micro-cracks

InactiveCN103409758AExtended service lifeImprove fatigue strengthMetallic material coating processesHeat-affected zoneLaser processing

The invention discloses a method for prolonging life of pump shells and blades by carrying out laser strengthening, which relates to the technical fields of machinery manufacturing and laser processing application. The method adequately combines the characteristics of laser cladding with laser shock strengthening, i.e., the method comprises the steps of performing laser cladding repair on micro-cracks at first, and then performing laser shock strengthening treatment on a cladding layer, thus effectively solving the problem that the pump shells and blades are easy to generate internal defects such as cracks and air holes in the laser cladding repair process, and avoiding the problems of welding deformation, large heat influence area, easy generation of heat cracks and the like in a conventional processing method; the method disclosed by the invention is capable of generating a high-amplitude residual compressive stress on the surface of a material, effectively improving the fretting fatigue resistance of the material, comprehensively improving the mechanical properties of the material, and greatly prolonging the fatigue life of the material, thus achieving the purposes of prolonging the life and improving the reliability and safety.

Owner:JIANGSU UNIV

Method for protecting new/used engine parts

InactiveUS20050158460A1Reduce erosionLower requirementLayered productsBlade accessoriesProcess engineeringStress corrosion cracking

New and used parts of gas and steam turbine engines are protected by imparting a controlled residual compressive stress to given portions of the part and then coated by a CVD or PVD process at low temperatures with layers of TiN or alloys thereof at alternate selective hard and less hardened levels. The protective treatment is particularly efficacious for airfoils of compressor blades / vanes of gas turbine engines and airfoils of airfoils and certain components of steam turbine engines. This method is targeted to reduce erosion, corrosion and stress-corrosion cracking in these parts.

Owner:PERFORMANCE TURBINE COMPONENTS T AMOR

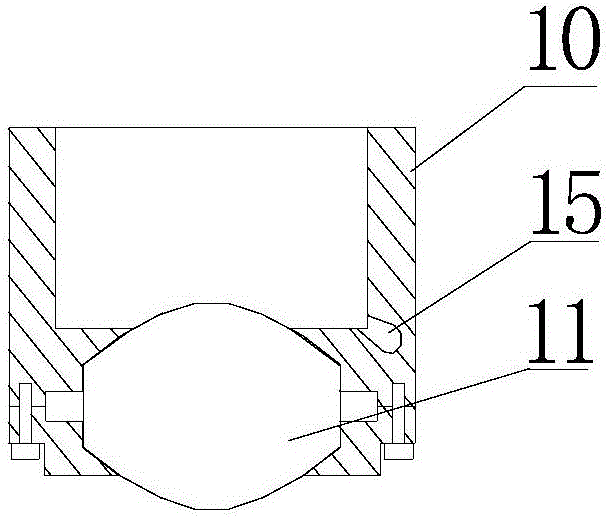

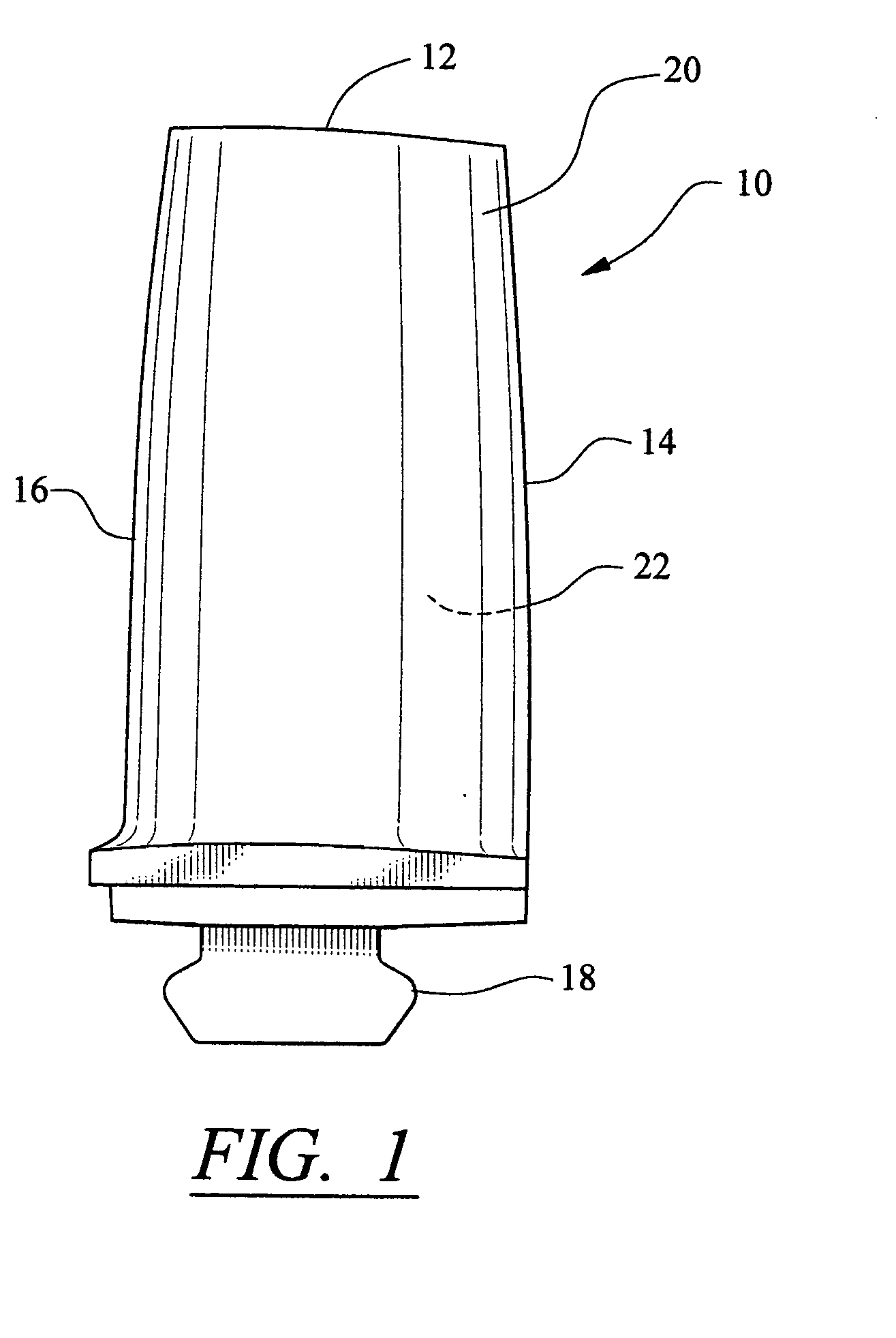

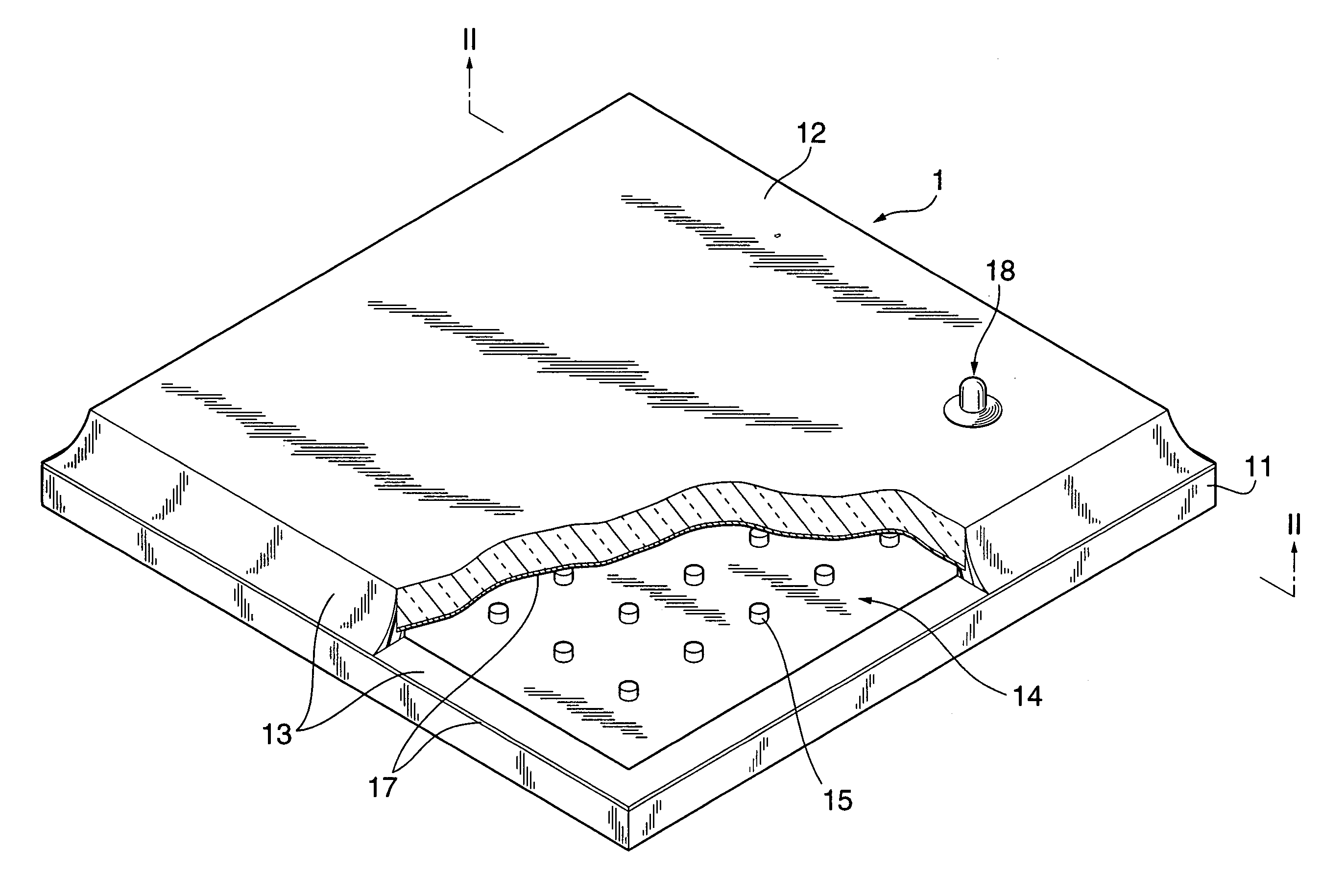

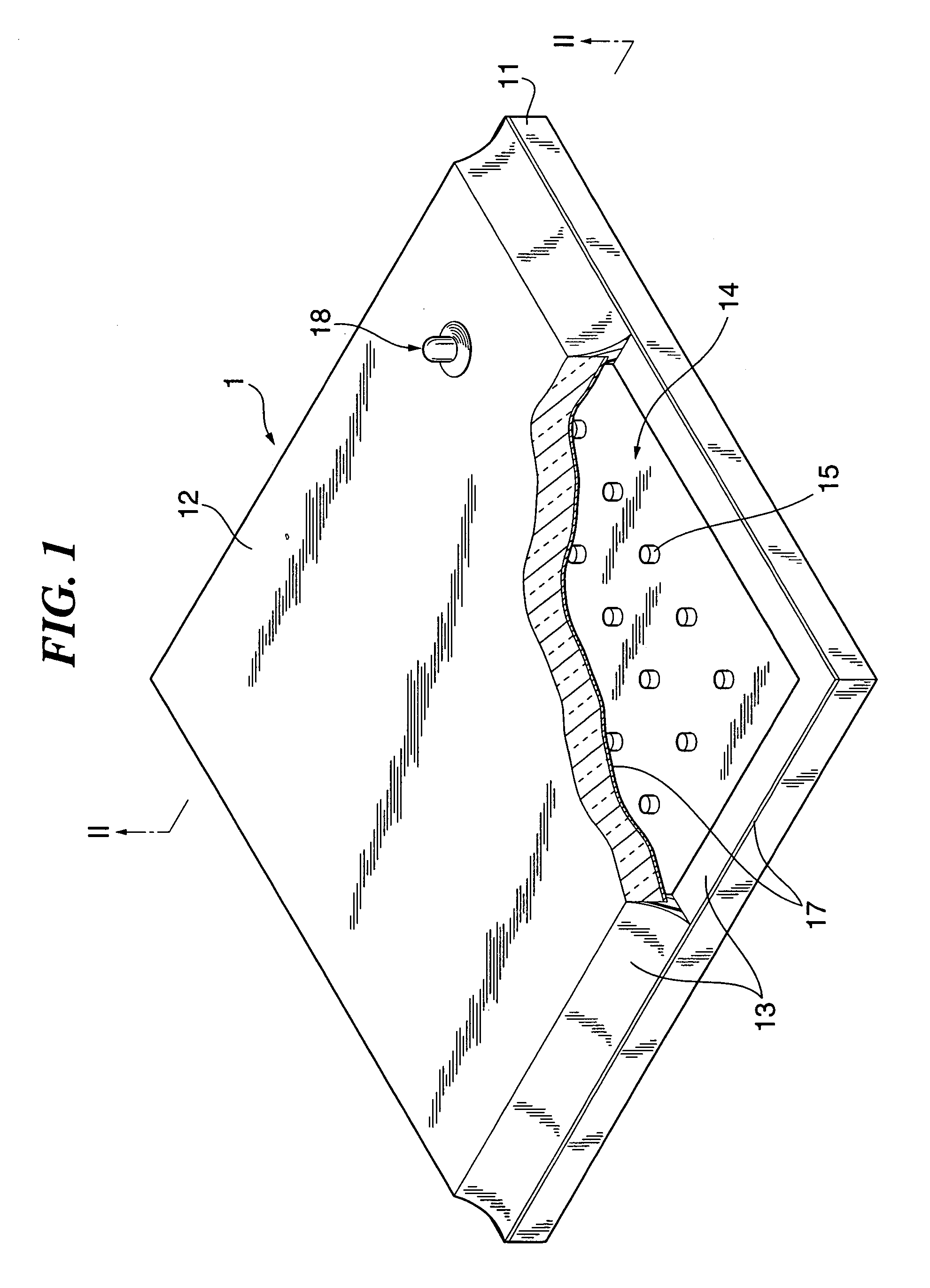

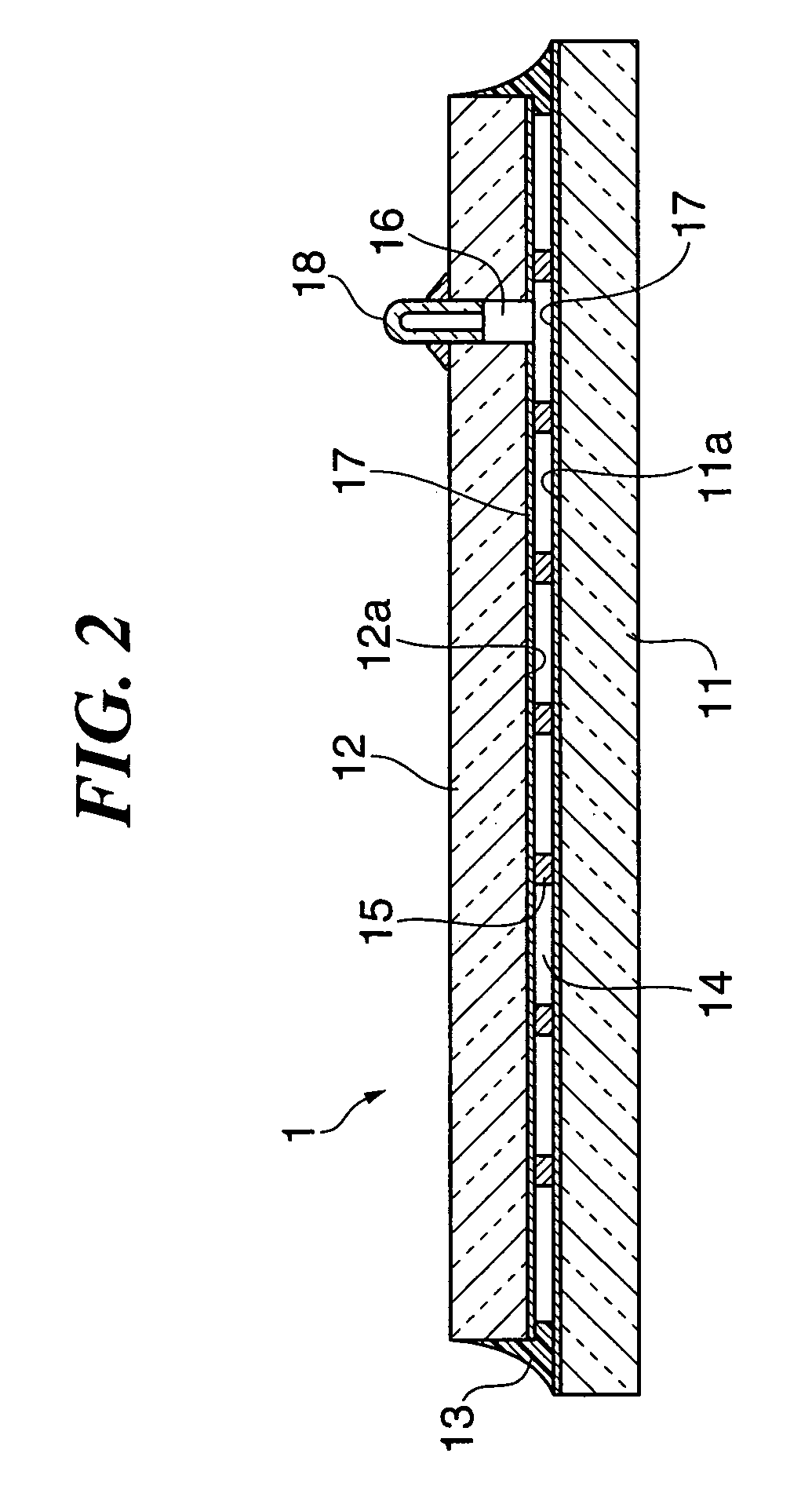

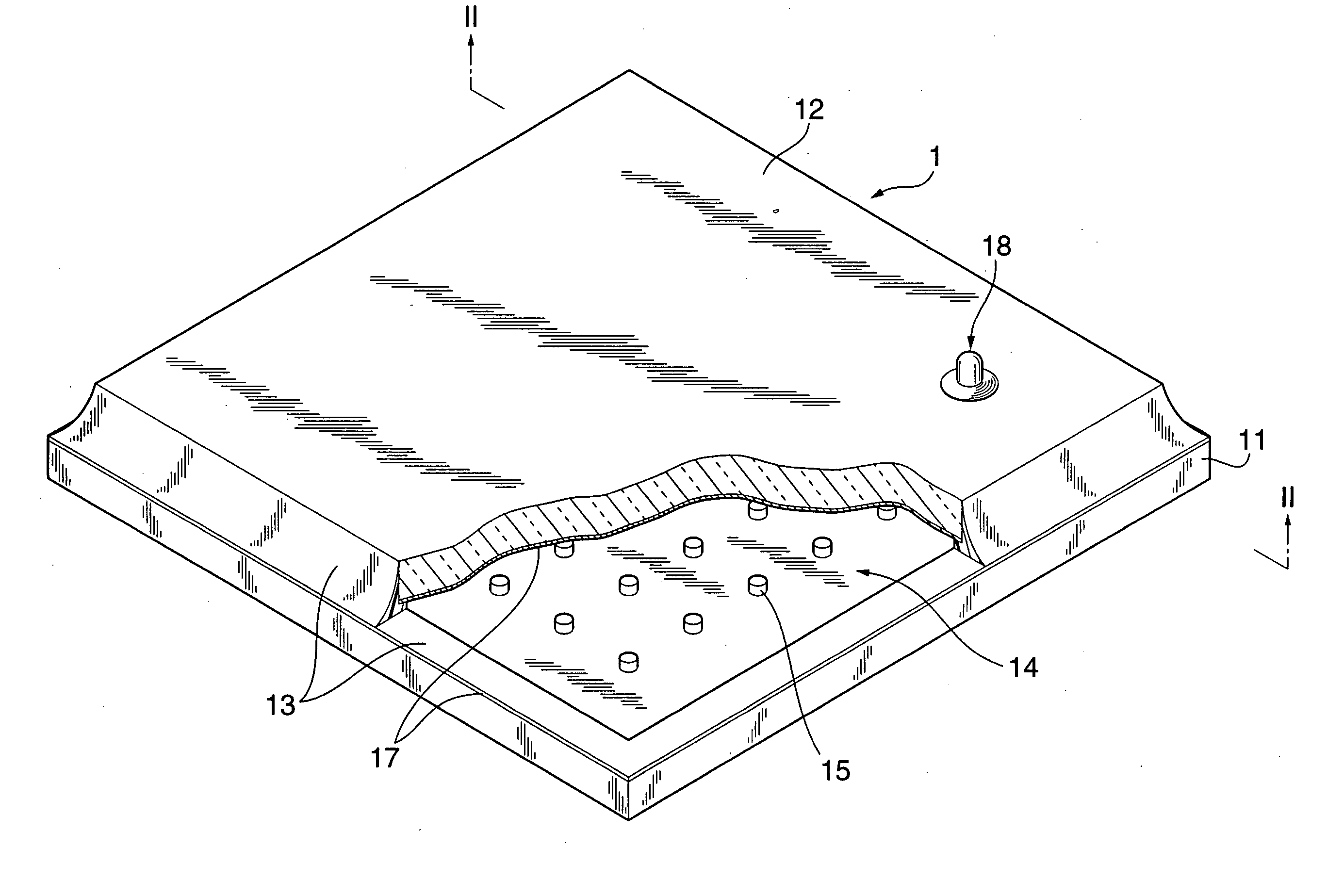

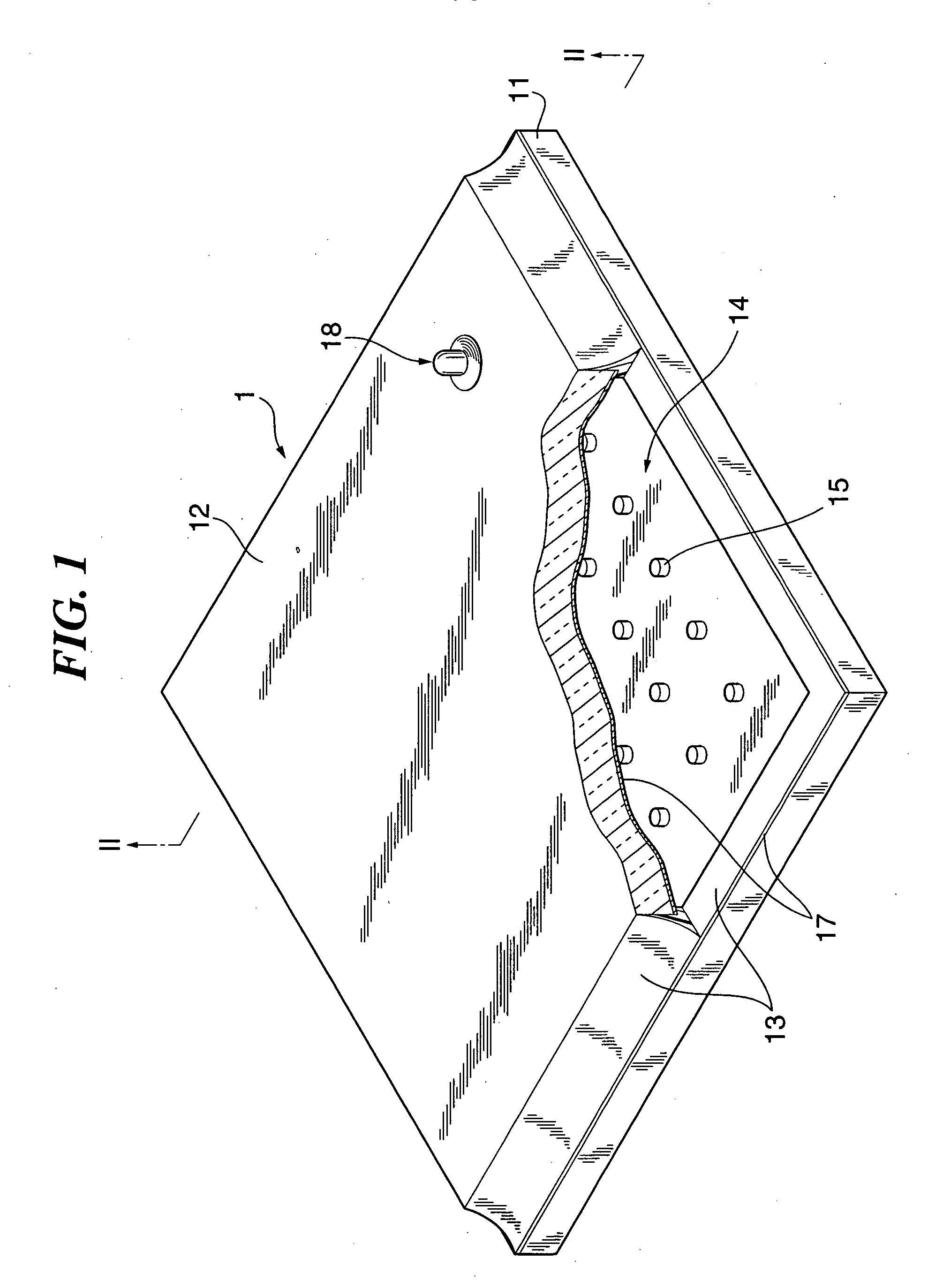

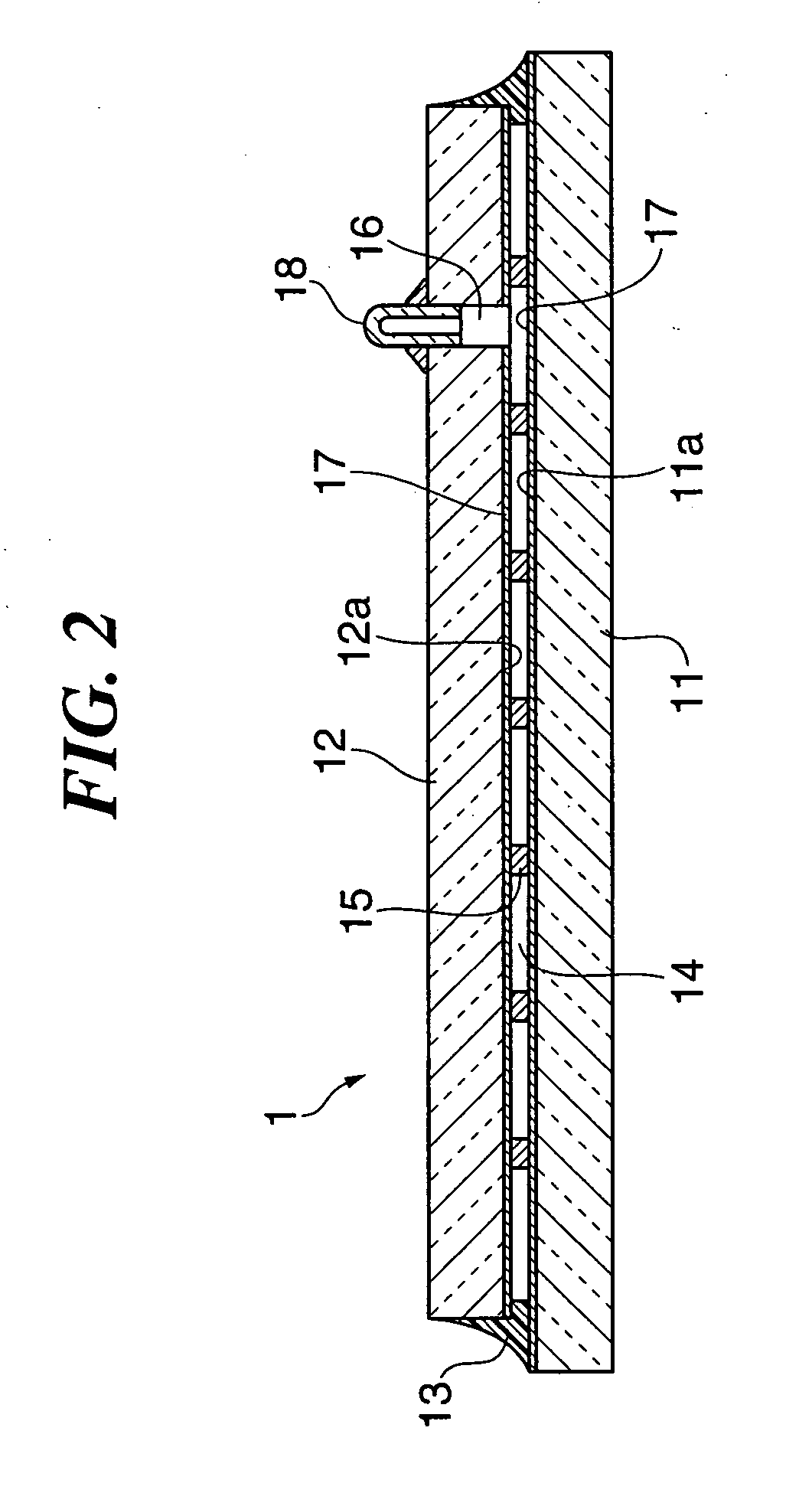

Light-transmitting glass panel

InactiveUS6955026B2Improve insulation effectClimate change adaptationWindows/door improvementEngineeringAtmospheric pressure

The light-transmitting glass panel 1 is comprised of a pair of glass plates 11 and 12 that are hermetically joined together with one surface of each thereof facing one another, the joining being via a sealing frame 13 that is provided at an outer peripheral portion of the glass plates 11 and 12 and fluidizes at low temperature, and the glass plates 11 and 12 having a hollow layer 14 formed therebetween, and pillars 15 that are substantially cylindrical spacers that are inserted into the hollow layer 14 as atmospheric pressure supporting members and determine the gap between the glass plate 11 and the glass plate 12. The pillars 15 are arranged in the hollow layer 14 in a matrix shape with a predetermined spacing, and taking the surface residual compressive stress of the glass plates 11 and 12 in MPa to be S, and the thickness of the glass plates 11 and 12 in mm to be d, the average spacing D in mm of the pillars 15 arranged in the hollow layer 14 satisfies the relationship D≦5.2d+5.5+(0.8d+0.08)·√S.

Owner:NIPPON SHEET GLASS CO LTD

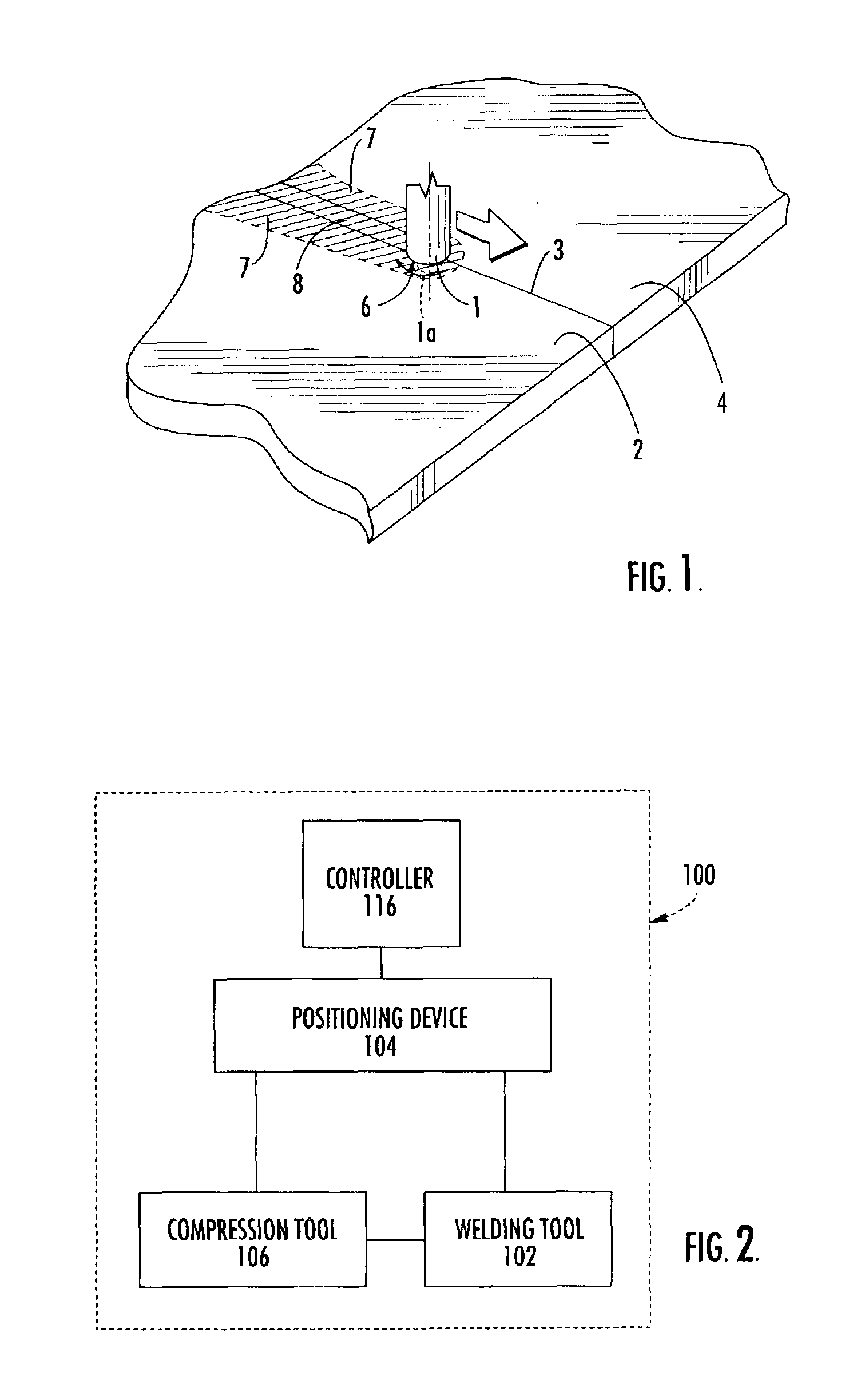

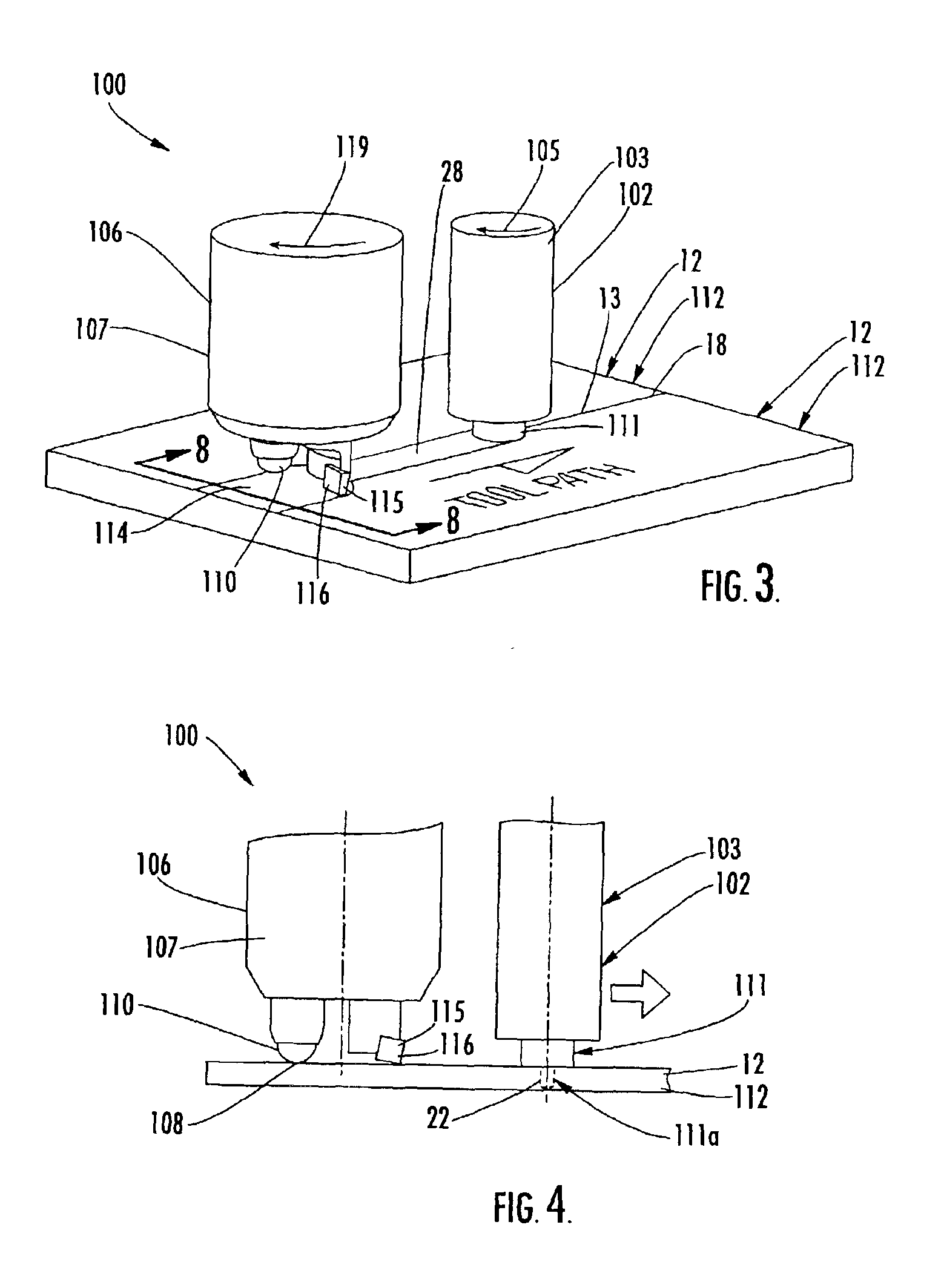

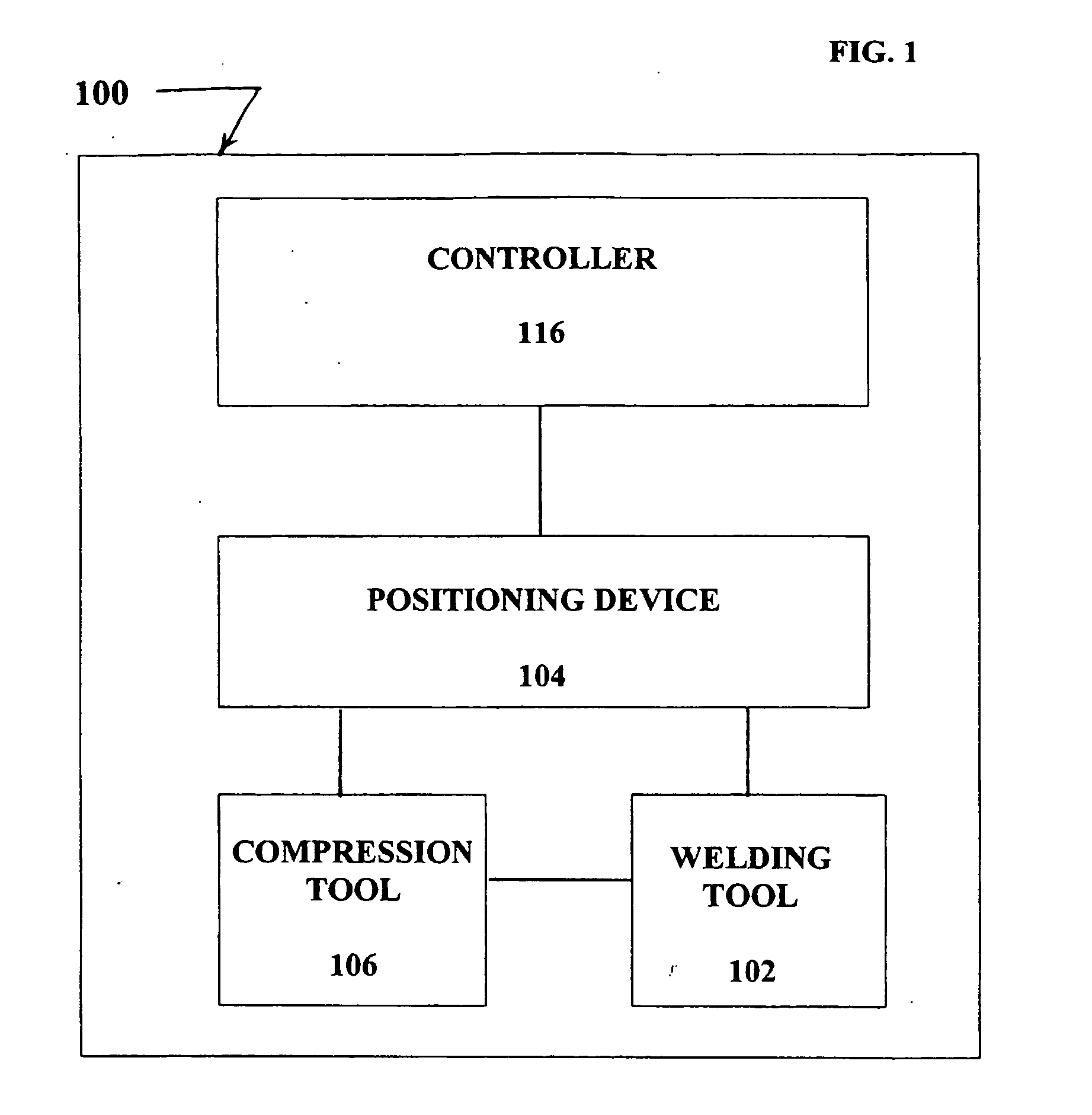

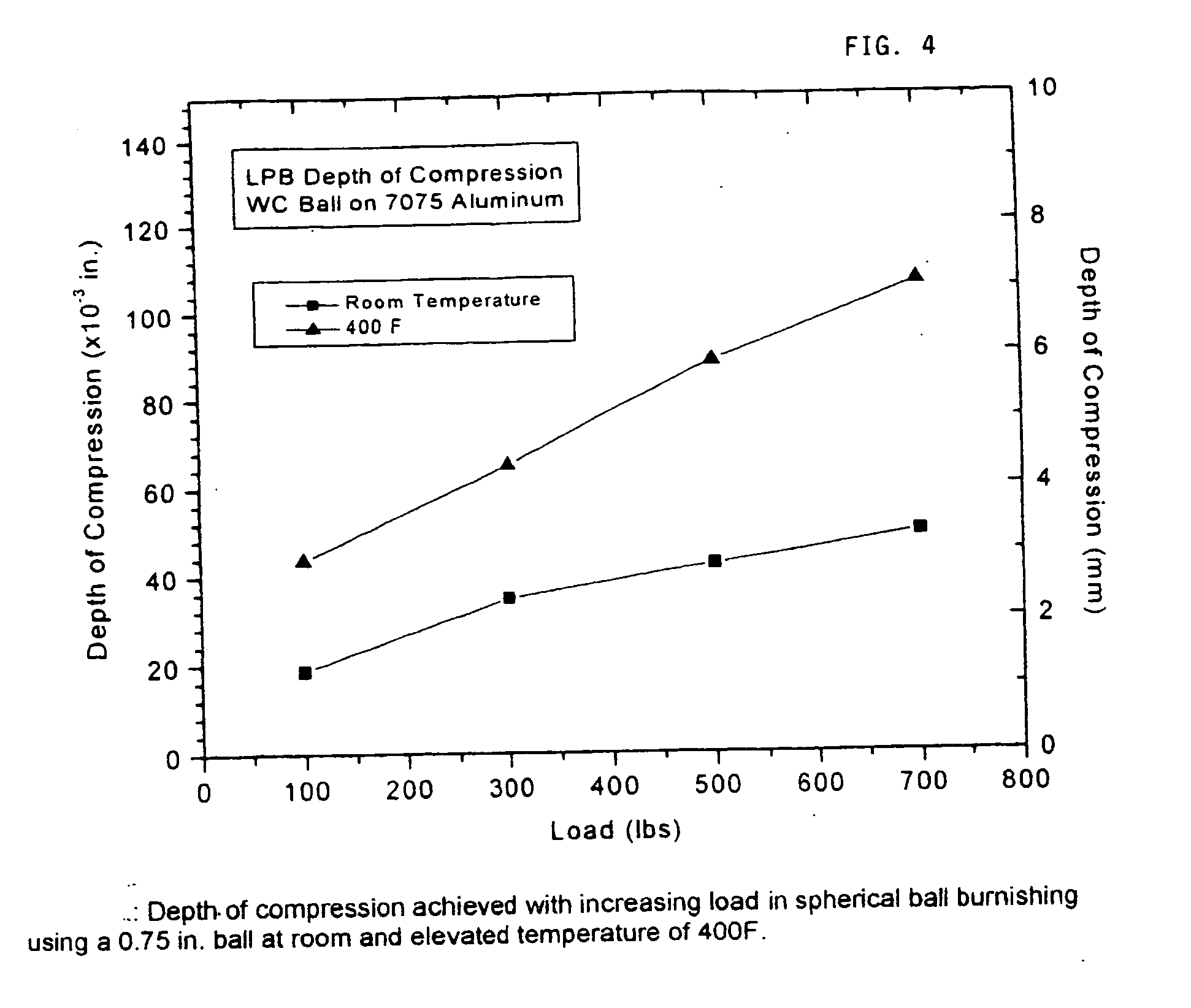

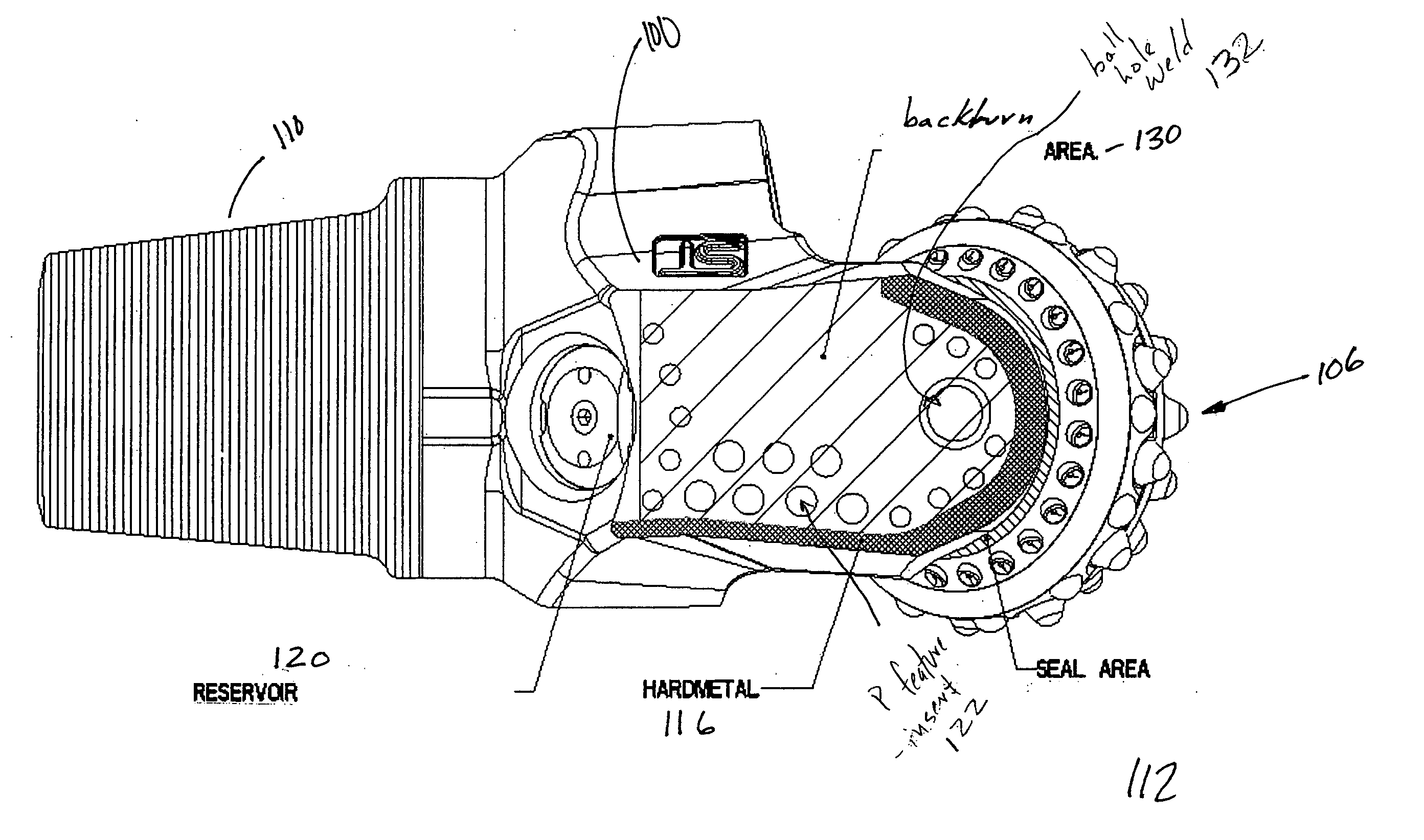

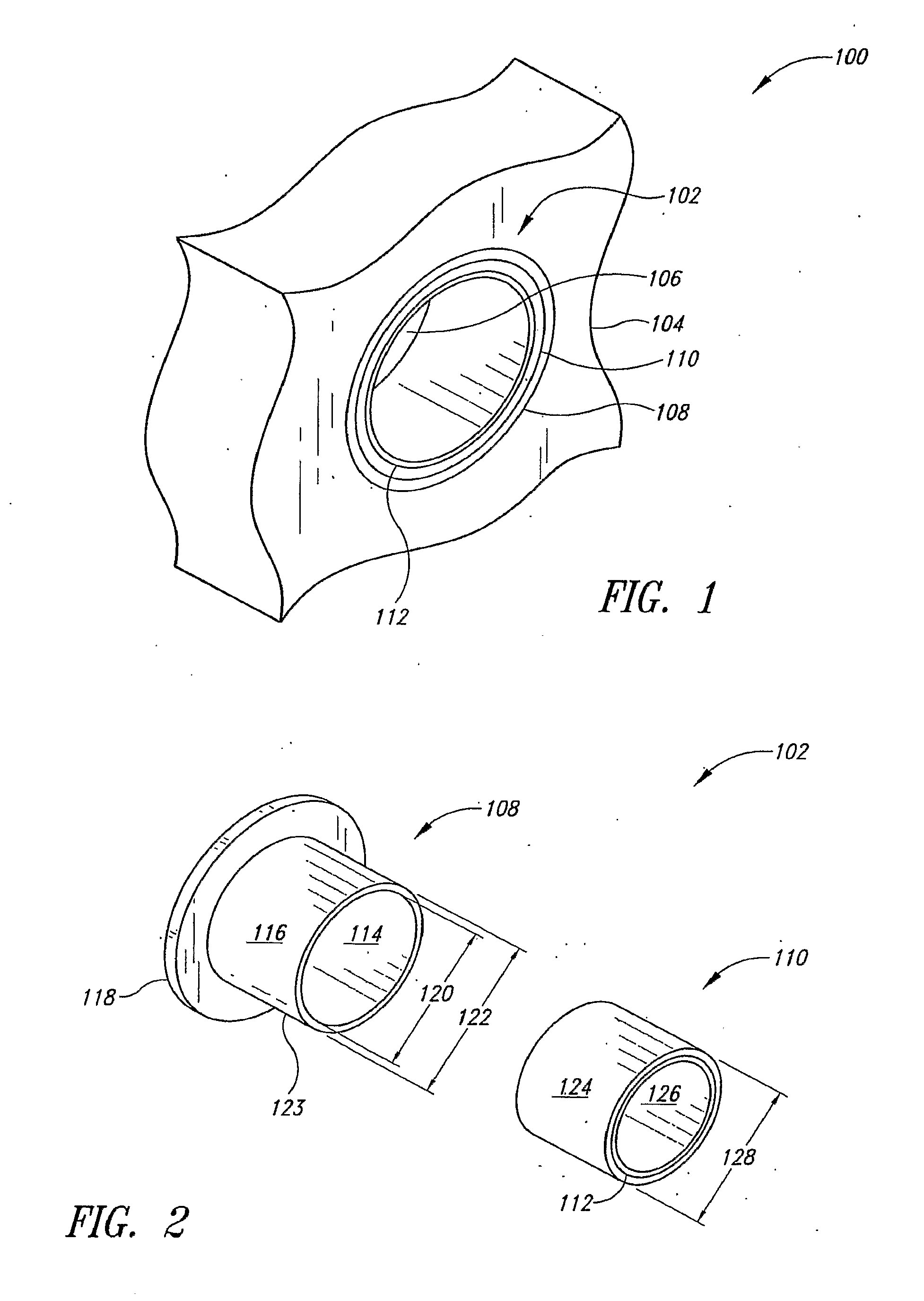

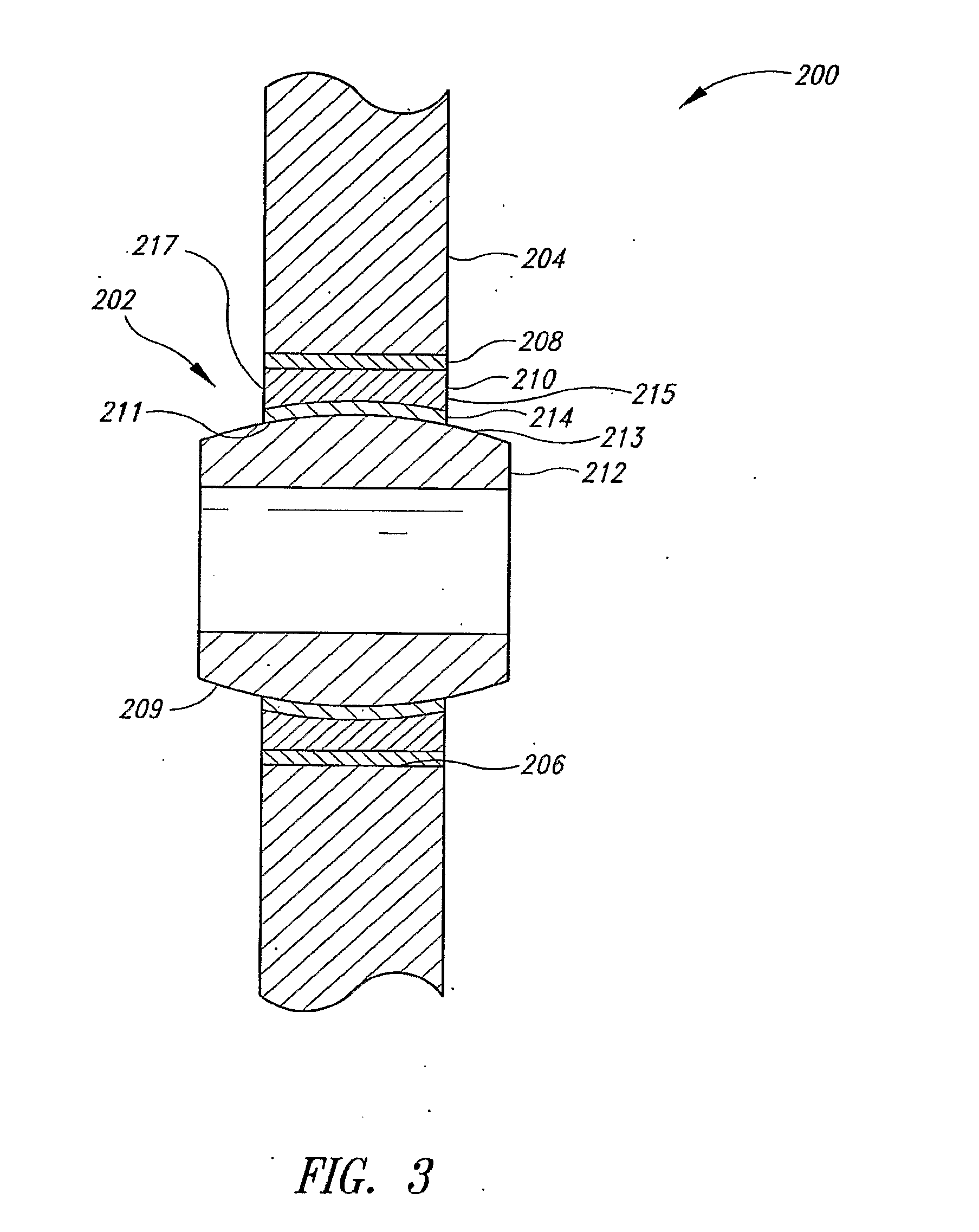

Apparatus and method for forming a weld joint having improved physical properties

InactiveUS20050224562A1Improve material performanceDeep compressionArc welding apparatusFurnace typesHeat-affected zoneEngineering

The method and apparatus for performing the method of forming a weld joint of the present invention utilizes welding apparatus (100) having welded tool (102) and a compression tool (106) for inducing a layer of residual compressive stress along the surface of the weld line (18) and any heat affected regions with a controlled amount of cold working and surface hardening. In a preferred embodiment of the invention the compression tool (106) utilizes a single-point burnishing process to provide deep compression within the weld joint (20) with a minimal amount of cold working and surface hardening.

Owner:SURFACE TECH HLDG

Light-transmitting glass panel

InactiveUS20050138892A1Climate change adaptationWindows/door improvementThermal insulationEngineering

A light-transmitting glass panel having high thermal insulation performance with thermal conductance sufficiently reduced. The light-transmitting glass panel 1 is comprised of a pair of glass plates 11 and 12 that are hermetically joined together with one surface of each thereof facing one another, the joining being via a sealing frame 13 that is provided at an outer peripheral portion of the glass plates 11 and 12 and fluidizes at low temperature, and the glass plates 11 and 12 having a hollow layer 14 formed therebetween, and pillars 15 that are substantially cylindrical spacers that are inserted into the hollow layer 14 as atmospheric pressure supporting members and determine the gap between the glass plate 11 and the glass plate 12. The pillars 15 are arranged in the hollow layer 14 in a matrix shape with a predetermined spacing, and taking the surface residual compressive stress of the glass plates 11 and 12 in MPa to be S, and the thickness of the glass plates 11 and 12 in mm to be d, the average spacing D in mm of the pillars 15 arranged in the hollow layer 14 satisfies the relationship D≦5.2d+5.5+(0.8d+0.08)·{square root}S.

Owner:NIPPON SHEET GLASS CO LTD

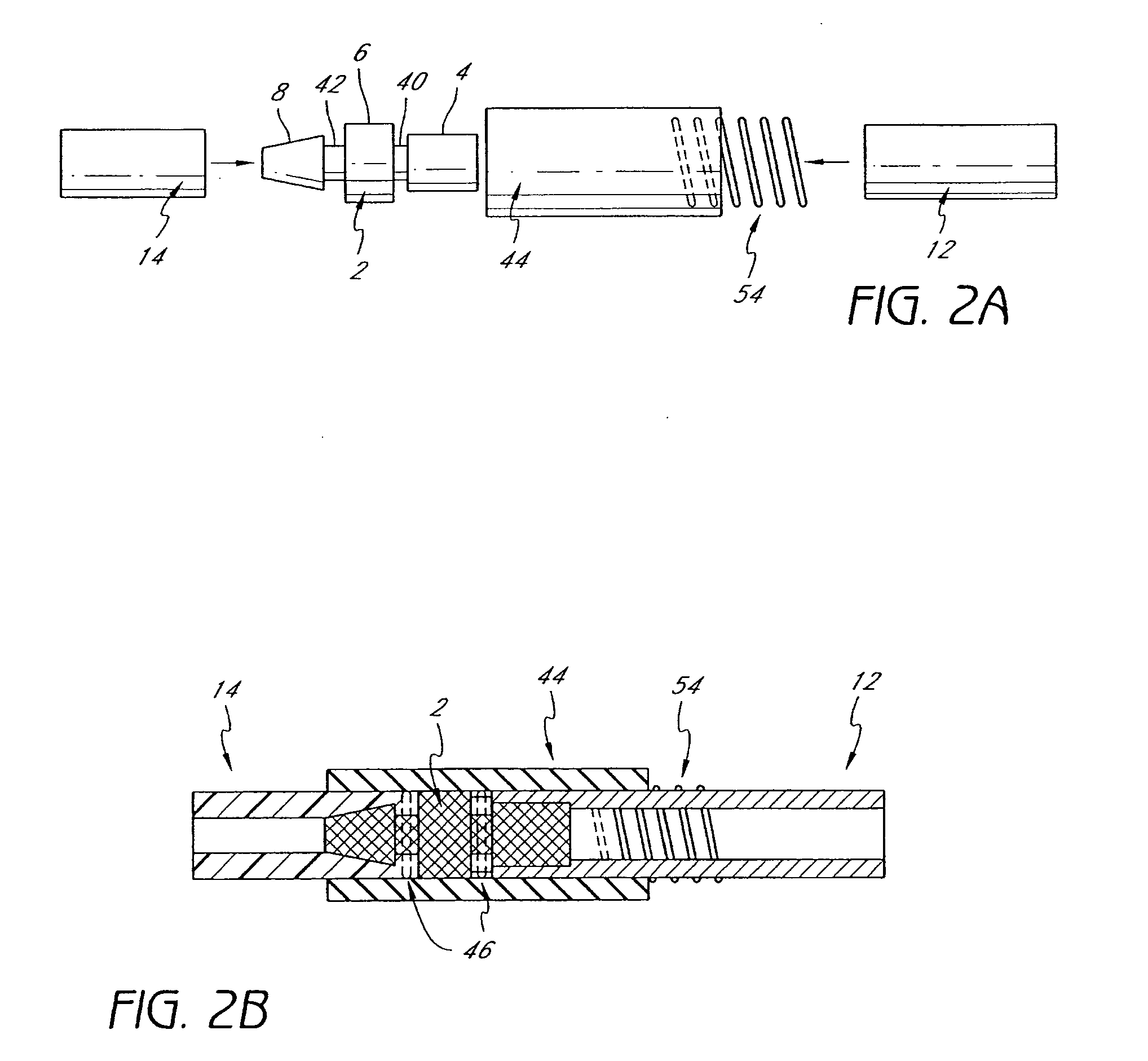

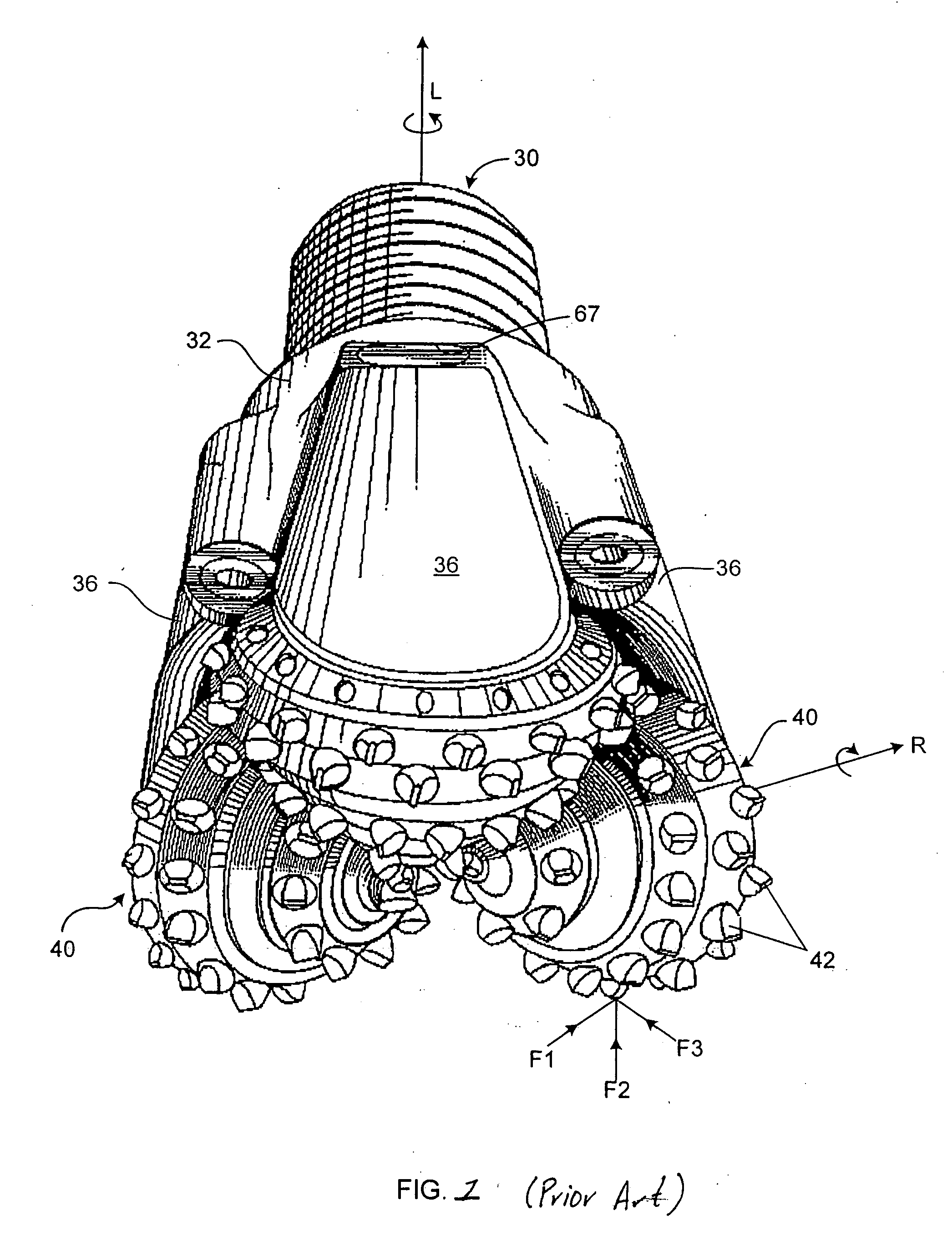

Drill bit having increased resistance to fatigue cracking and method of producing same

The present invention relates to a roller cone drill bit that includes a bit body adapted to be rotated about a longitudinal axis, where the bit body has at least one leg depending therefrom, wherein the leg comprises a treated portion that provides a residual compressive stress, and a roller cone rotatably mounted on a journal. The treated portion treatment may comprise one selected from shot peening, laser-shock peening, and hammer peening. Further, the present invention relates to a method of manufacturing a roller cone drill bit that includes inducing a compressive stress, through plastic deformation, in at least a portion of at least one leg depending from a bit body. The inducing a compressive stress may comprise one selected from shot peening, laser-shock peening, and hammer peening.

Owner:SMITH INT INC

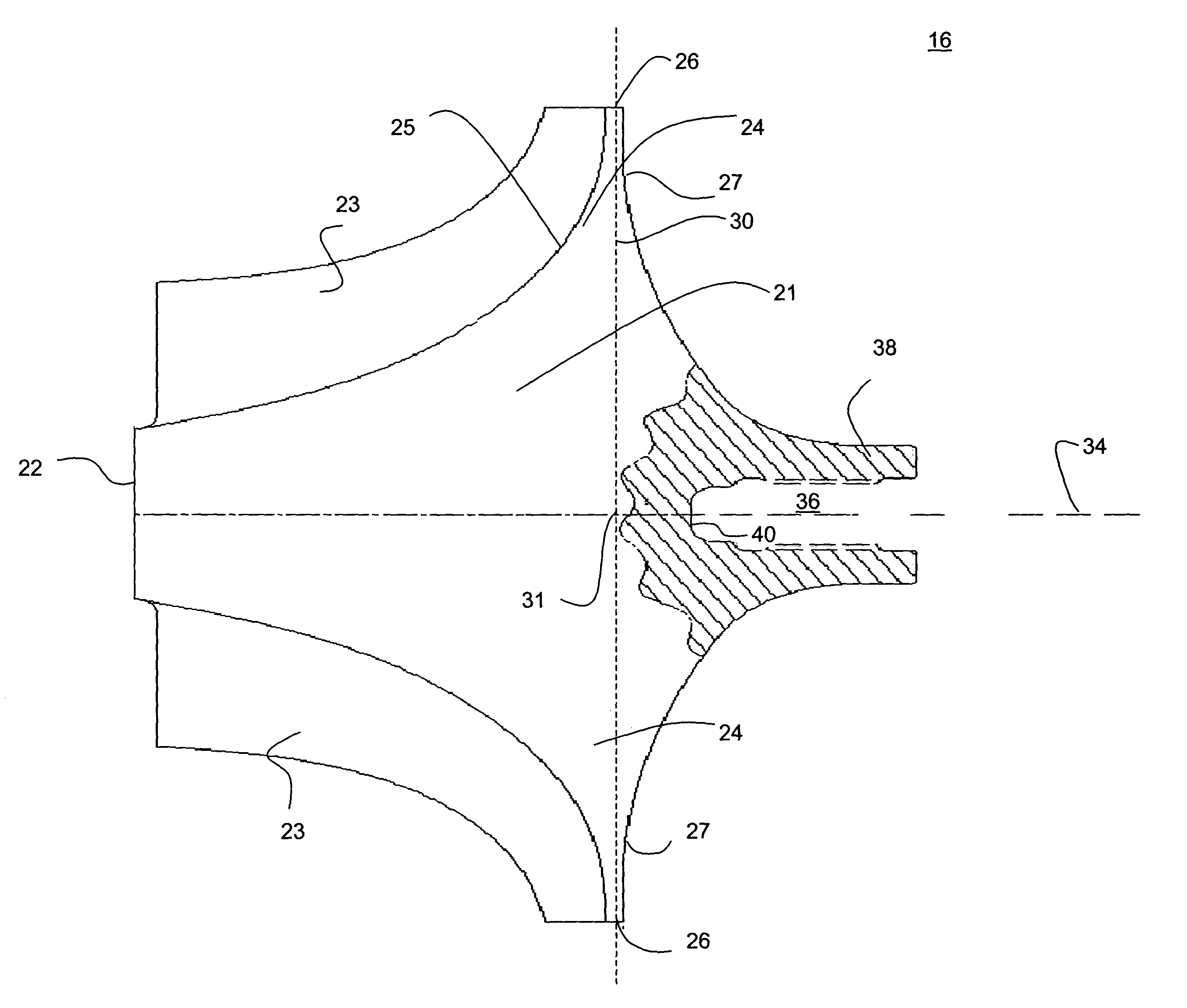

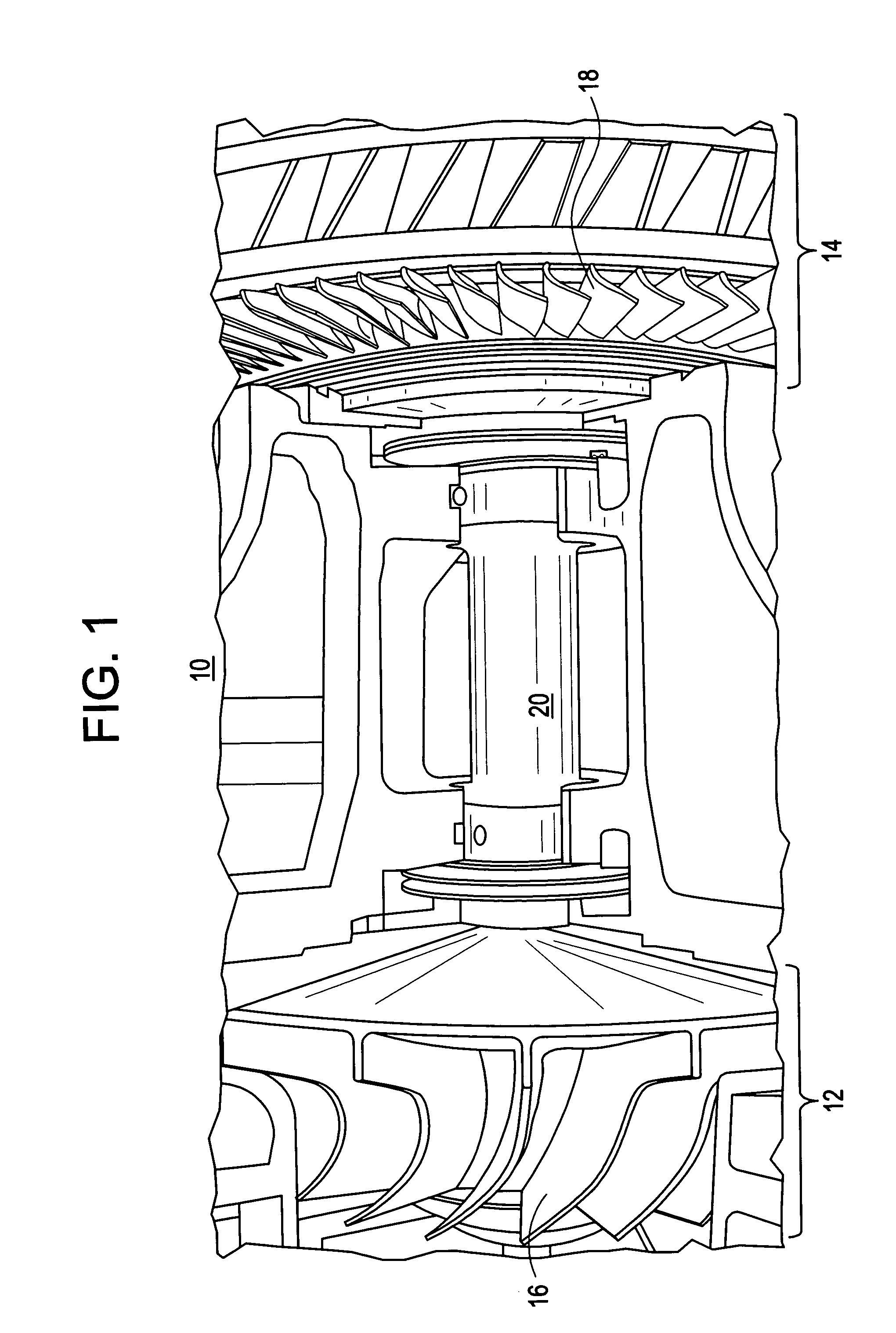

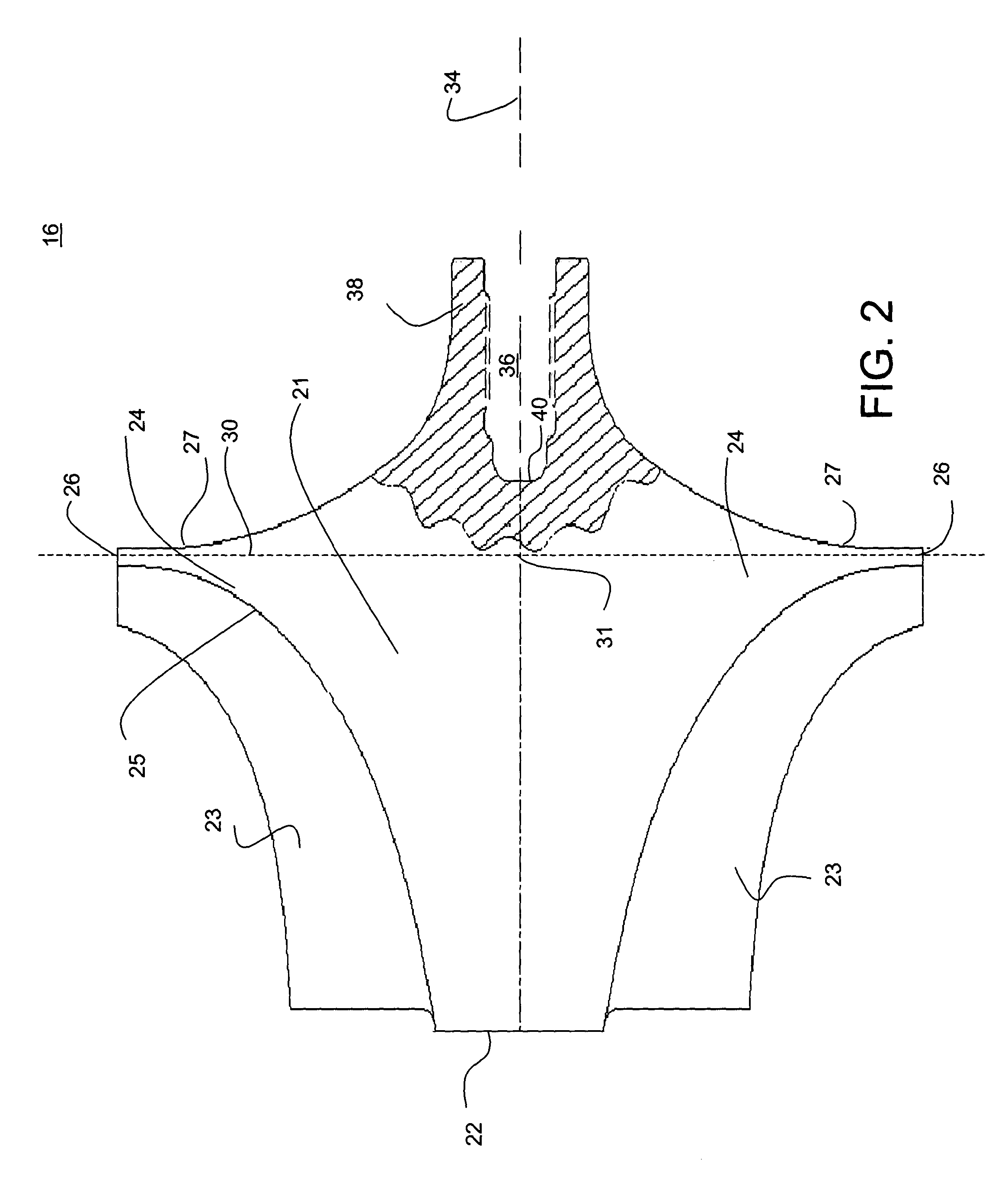

Turbocharger compressor wheel having a counterbore treated for enhanced endurance to stress-induced fatigue and configurable to provide a compact axial length

InactiveUS6994526B2Avoiding and reducing overhangProlong lifePropellersPump componentsImpellerStress induced

Owner:GENERAL ELECTRIC CO

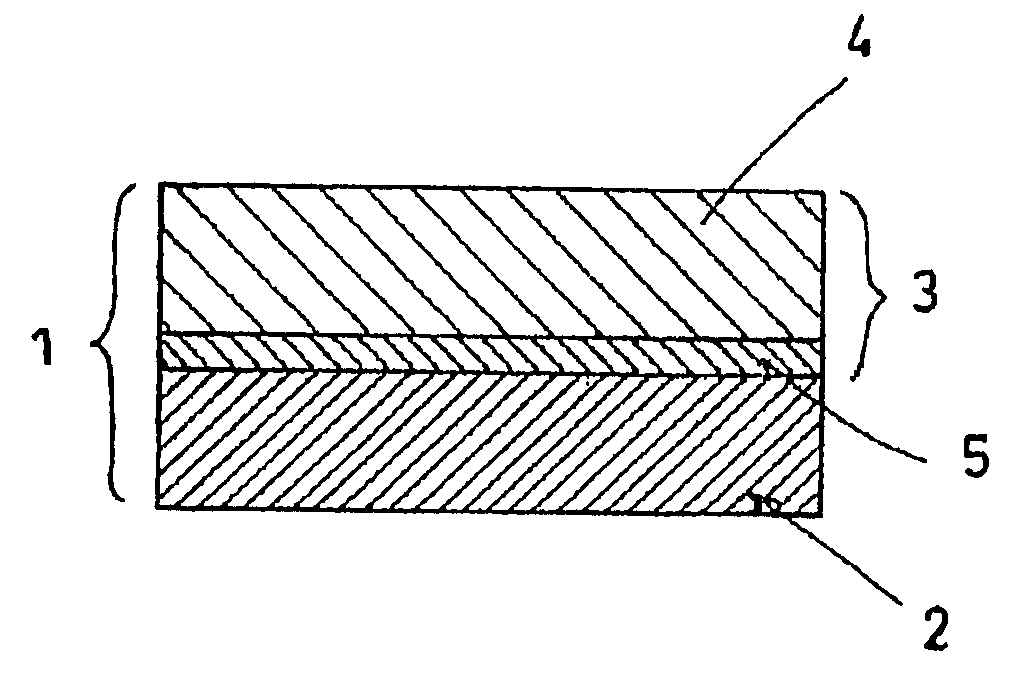

Diamond Sintered Compact

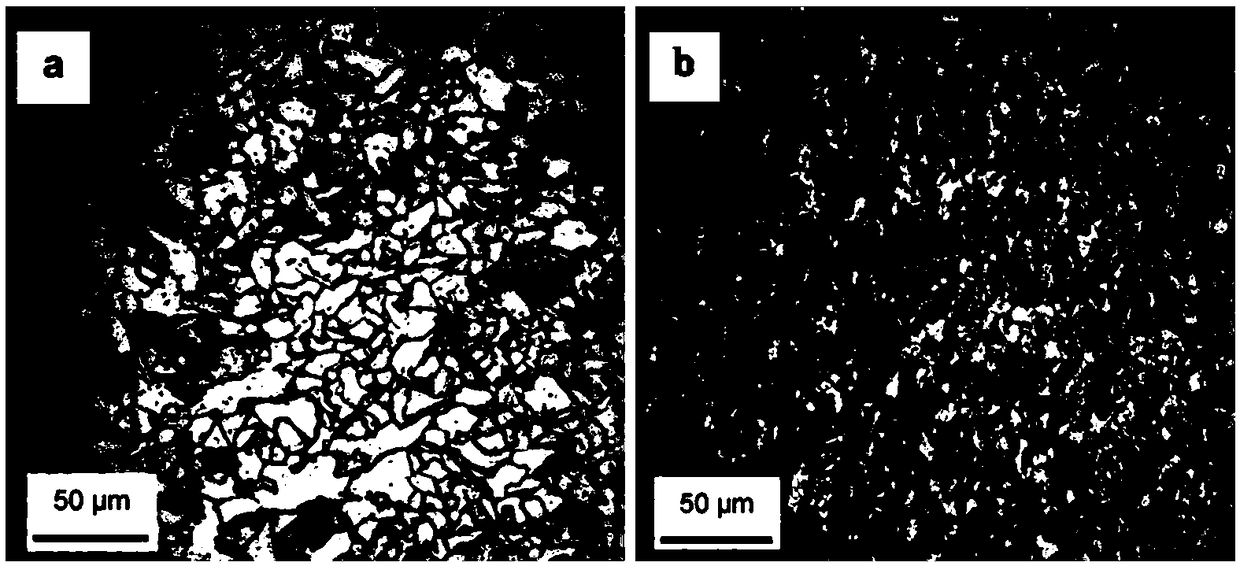

ActiveUS20090208301A1High bonding strengthReduce resistancePigmenting treatmentCutting insertsCemented carbideWear resistance

An object is to raise both the wear resistance and chipping resistance of diamond sintered compacts while taking advantage of the characteristics of highly chipping-resistant microfine-grain diamond sintered compacts. A sintered diamond layer 3 is formed by sintering diamond grains and a binder on a cemented carbide substrate 2. This sintered diamond layer 3 comprises a main diamond layer 4 and a Co-rich diamond layer 5 that is present between the main diamond layer 4 and the cemented carbide substrate 2 and that has a Co content larger than that of the main diamond layer 4; the main diamond layer has a residual compressive stress of 1.5 GPa to 3 GPa.

Owner:SUMITOMO ELECTRIC HARDMETAL CORP

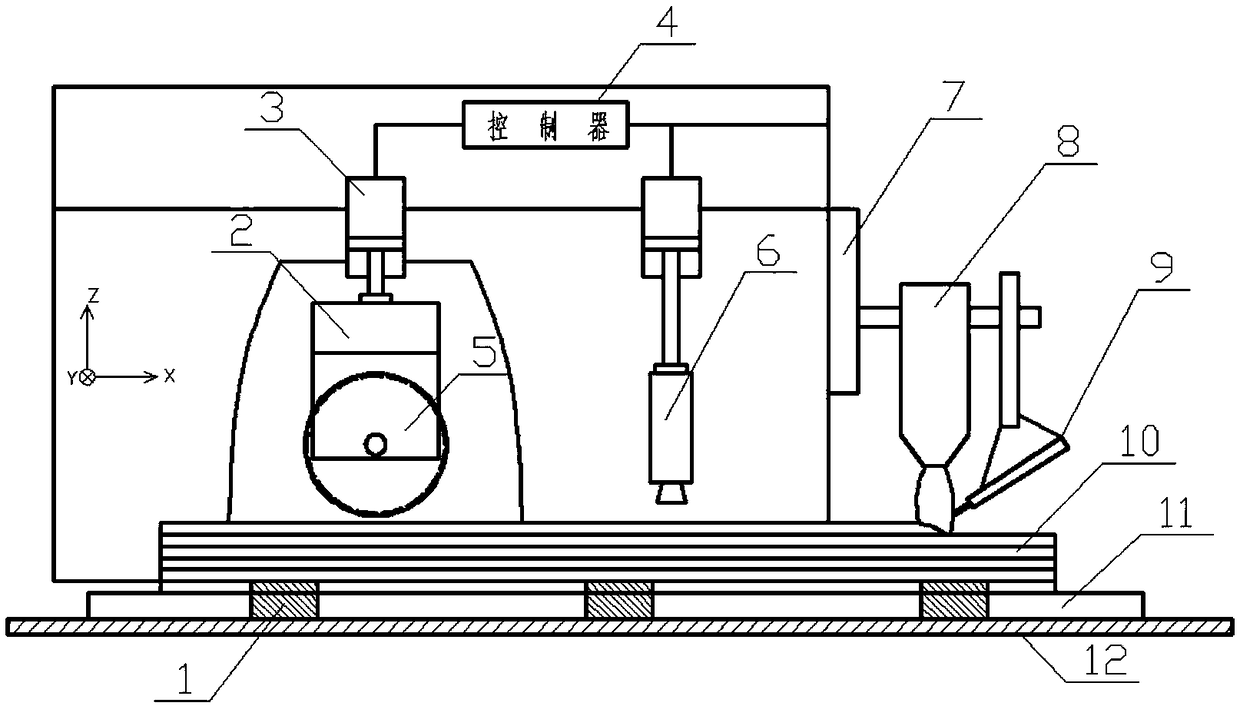

Electric arc wire filling and rolling combined material additive manufacturing method and device

InactiveCN108637504AImprove wear resistanceImprove corrosion resistanceWelding apparatusSurface roughnessEngineering

The invention relates to a material additive manufacturing method and device, in particular to an electric arc wire filling and rolling combined material additive manufacturing method and device. During operation of the device, a substrate is fixed to a welding platform; a welding gun is controlled to move in cooperation with a wire feeding mechanism to conduct electric arc wire filling to form aweld layer; meanwhile, the temperature of the weld layer is collected through a temperature sensor; collected data are transmitted to a controller; the controller controls a rolling wheel to conduct synchronous rolling strengthening on the surface of the weld layer. In the workpiece manufacturing process, metal grains are refined. A residual compressive stress layer is introduced to reduce the surface roughness. The wear resistance, corrosion resistance and compatibility of the surface of a workpiece are improved. The internal defects such as pores, non-fusion and shrinkage porosity possibly occurring to metal parts manufactured through a common electric arc material additive manufacturing method are avoided. Meanwhile, the comprehensive mechanical properties of metal workpieces are improved.

Owner:JIANGSU UNIV

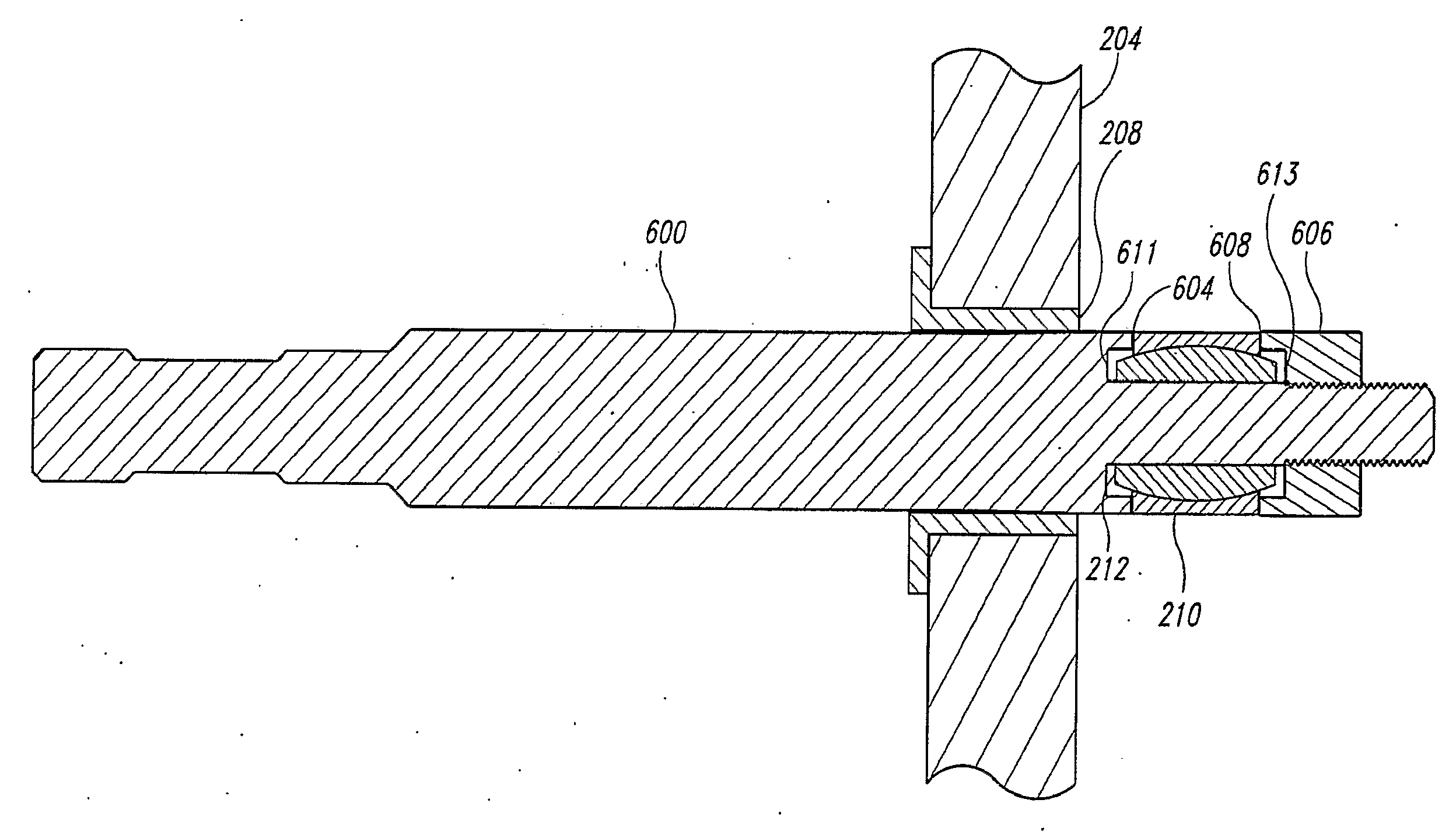

Bushing kits, bearings, and methods of installation

ActiveUS20090304315A1Rapid and consistent and controlled interferenceShrinkage connectionsBearing componentsInterference fitEngineering

At least one embodiment of the invention generally relates to a bushing kit (102) and method of installing the same with a mandrel (300) having a tapered region (304). The bushing kit comprises an inner member (110) and an outer bushing (108). The inner member may include an inner surface (126) having an engagement portion, such as a coating, plating, and / or lining, such as a self-lubricating coating. The method of installing the bushing kit (102) includes passing the tapered portion of the mandrel through the outer bushing (108) to radially expand the outer bushing into the structural workpiece (104) and possibly induce some amount of residual compressive stress in the structural workpiece (104). Contemporaneously, the inner member (110) is passed into the radially-expanded outer bushing (108) before the outer bushing is permitted to radially inwardly rebound or spring back. The outer bushing (108) is then permitted to radially contract onto the inner member to form an interference fit therewith.

Owner:FATIGUE TECH

Ultrasonic deep-rolling and tumbling integrated surface strengthening device

The present invention discloses an ultrasonic deep-rolling and tumbling integrated surface-strengthening equipment. The utilization of said equipment can implement surface-strengthening treatment by using ultrasonic deep-rolling process and tumbling process. It is mainly characterized by that it utilizes ultrasonic vibration and independent rolling ball to reduce friction force and static pressure between tool head and workpiece surface so as to prevent surface scoring and structure deformation.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

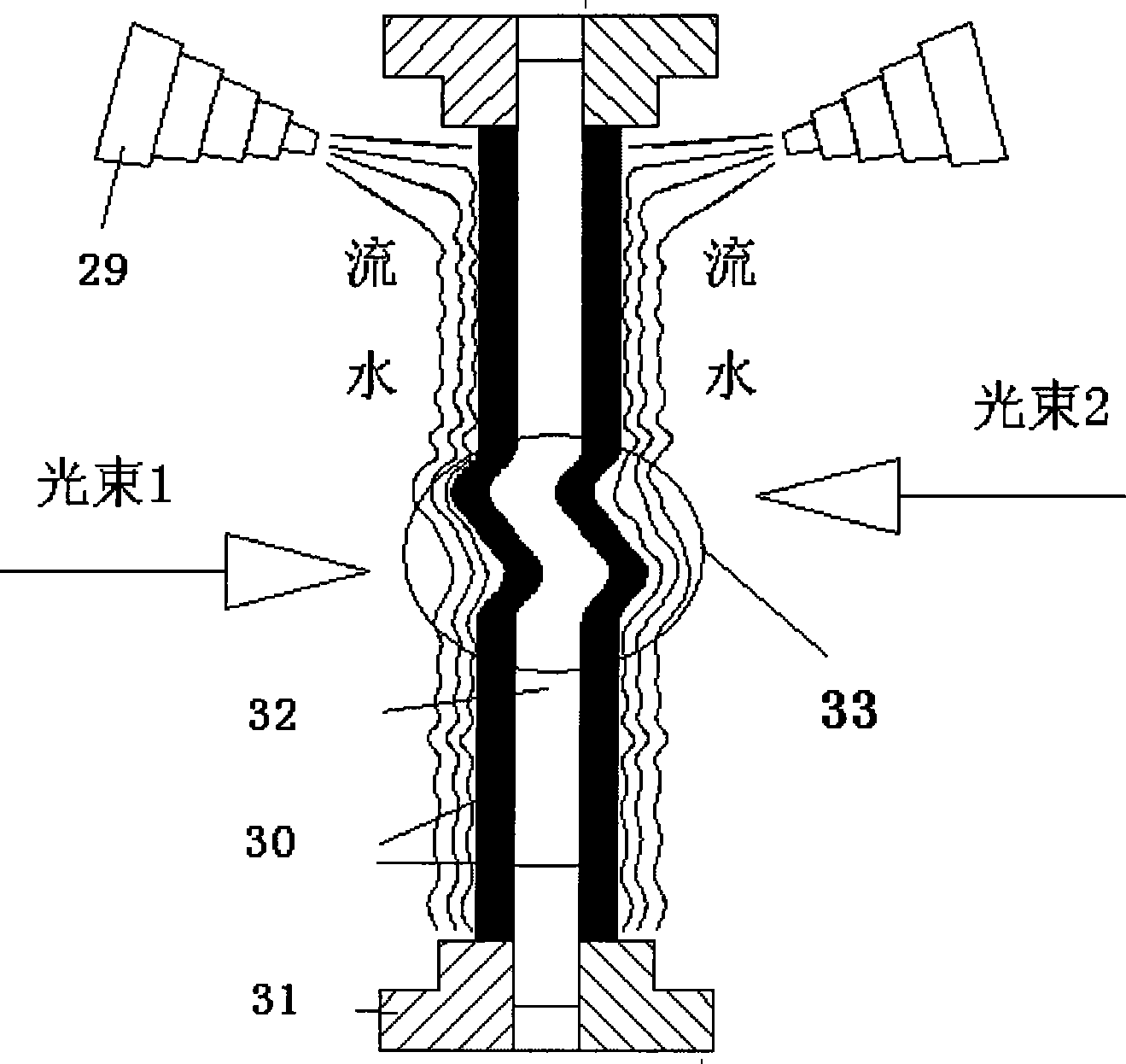

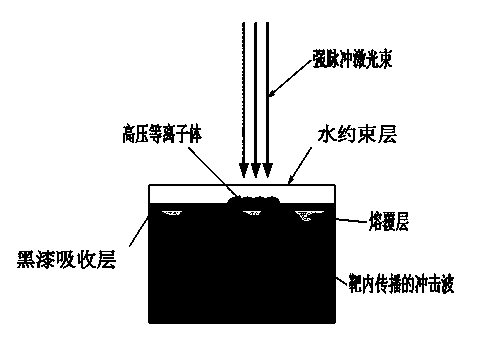

Method and device of shot peening for surface of metal component by means of light-water complex

ActiveCN102925646AImprove impact performanceLarge amplitude of residual compressive stressLaser processingHigh energy

The invention relates to the technical field of laser processing, and discloses a method and a device of shot peening for the surface of a metal component by means of a light-water complex. According to the method and the device of the shot peening for the surface of the metal component by means of the light-water complex, laser beams of high energy density and deionized water with certain pressure are utilized for coupling, and the light-water complex obtained after the coupling is utilized for the shot peening for the surface of the metal component. Through the shot peening with the light-water complex, the problem that shot peening effect is not ideal due to the fact that a water constraining layer is uneven in thickness and high in flexibility is solved, the deionized water with the certain pressure has certain momentum, the constraining effect of the deionized water can be similar to rigid constraint, and therefore the constraining effect is better. At the same time, after the shot peening, the shock pressure of the deionized water and the laser induced shock pressure are superposed, and therefore residual compressive stress amplitude generated on the surface of the material is enabled to be significantly improved, the residual compressive stress field is distributed more evenly, the surface material is high in nanocrystallization, and mechanical properties of the material are effectively improved.

Owner:JIANGSU UNIV

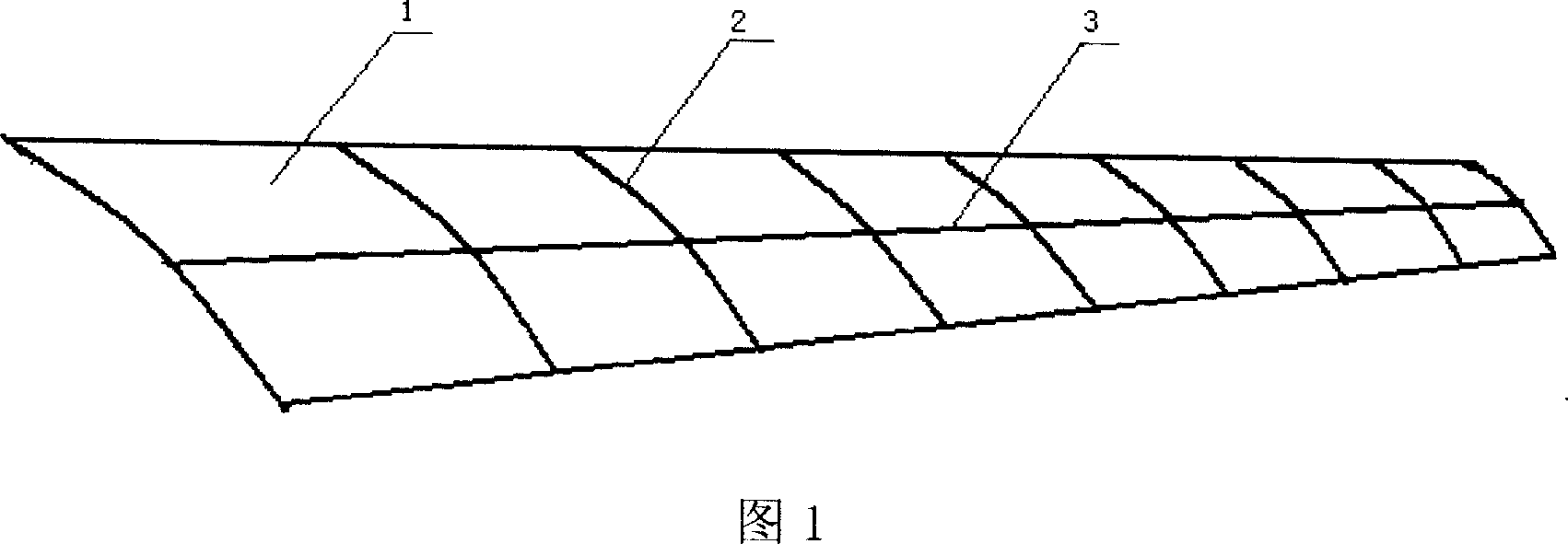

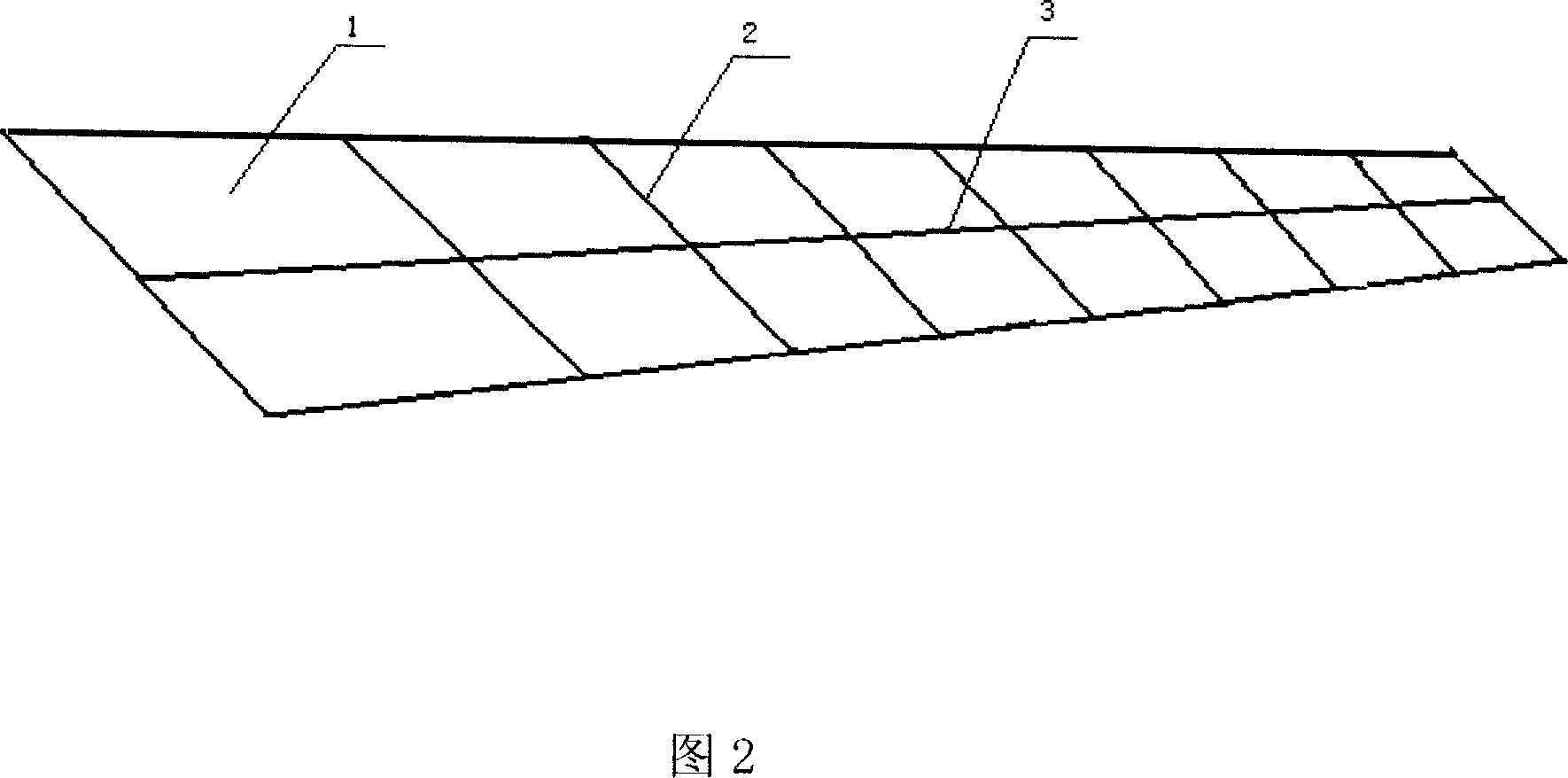

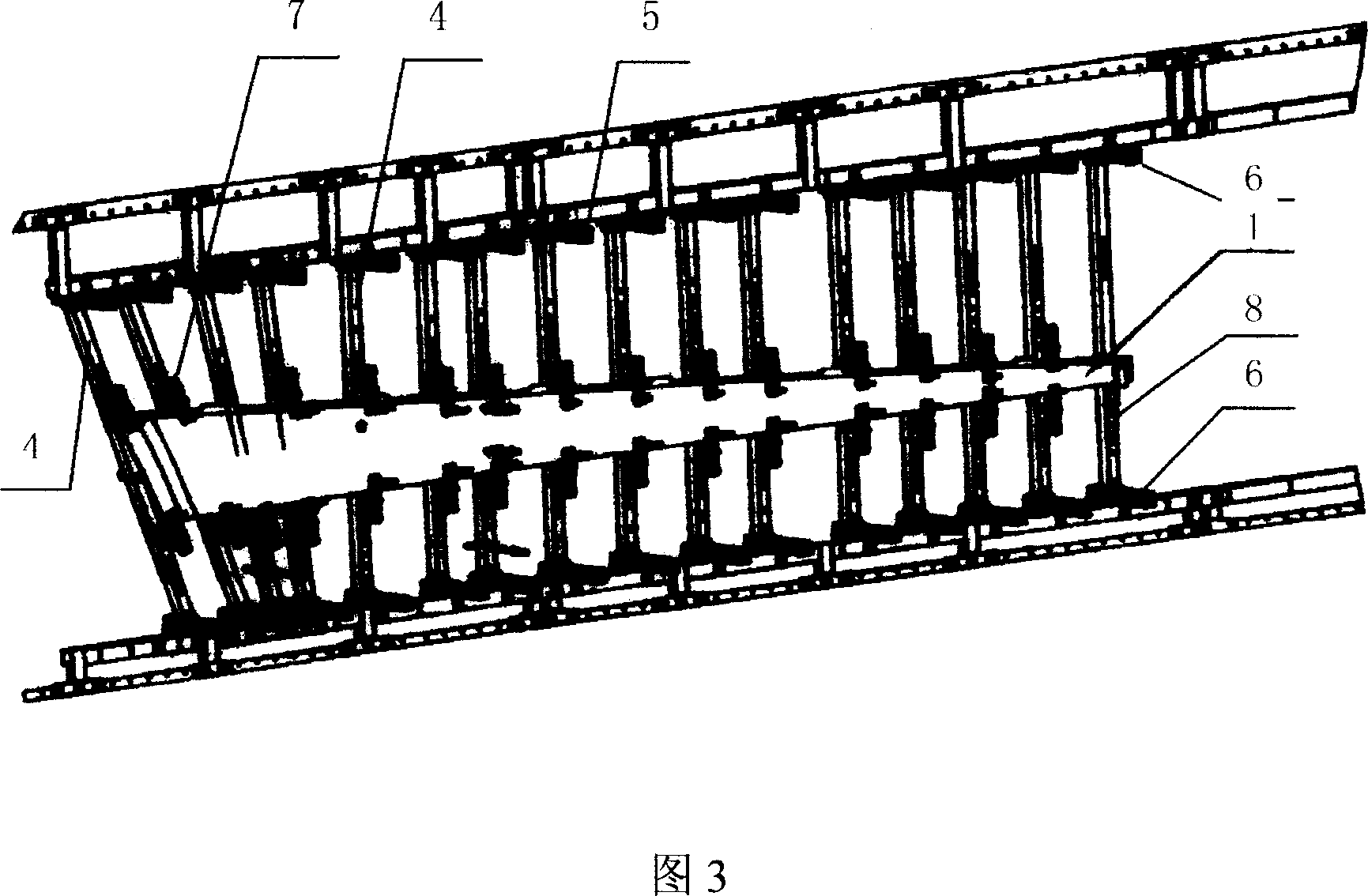

Prestressing shot-blasting formation technique for double-curved wallboard

A pre-stressing and grit-blasting technique for shaping a double-curvature plate wall used as the thick jacket of large airplane features that a pre-stressing fixture unit is used to pre-bend a plate longitudinally and transversely and fix it for applying a pre-stress to it while the grits are blasted onto said plate for obtaining a needed shape.

Owner:XIAN AIRCRAFT IND GROUP

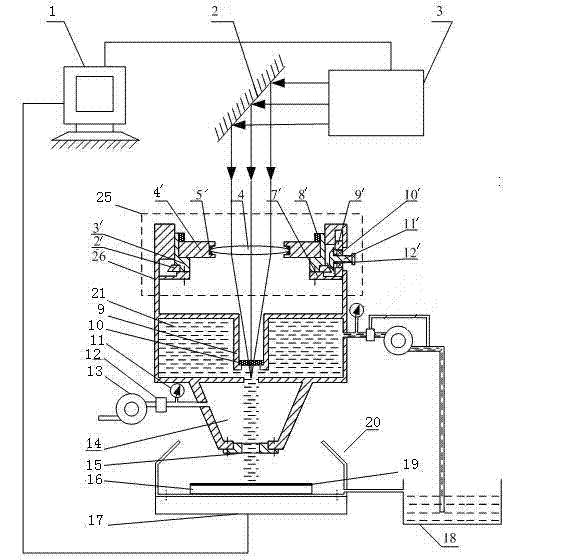

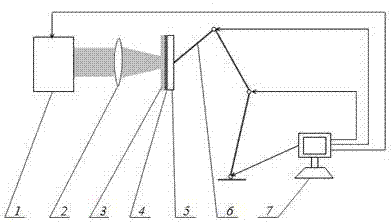

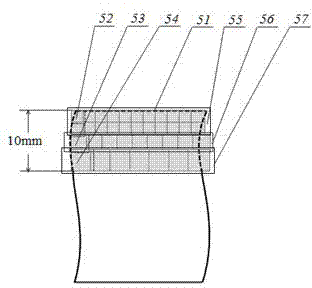

Combination method and apparatus for laser shock processing of engine blade

InactiveCN103205545AAdjustable distanceAdjustable sizeFurnace typesHeat treatment furnacesSurface layerProcess region

The invention provides a combination method and apparatus for laser shock processing of an engine blade. The invention is characterized in that a blade shock strengthening area is divided into a marginal region, a transition region I and a transition region II which are increasingly far away from the edge of the blade successively, power density of laser used in the marginal region, the transition region I and the transition region II gradually decreases while light spots in the regions gradually increase, so residual compressive stress smoothly transits from a blade marginal surface layer to an unprocessed area, thereby improving the fatigue life of the blade.

Owner:BEIJING AERONAUTICAL MFG TECH RES INST +2

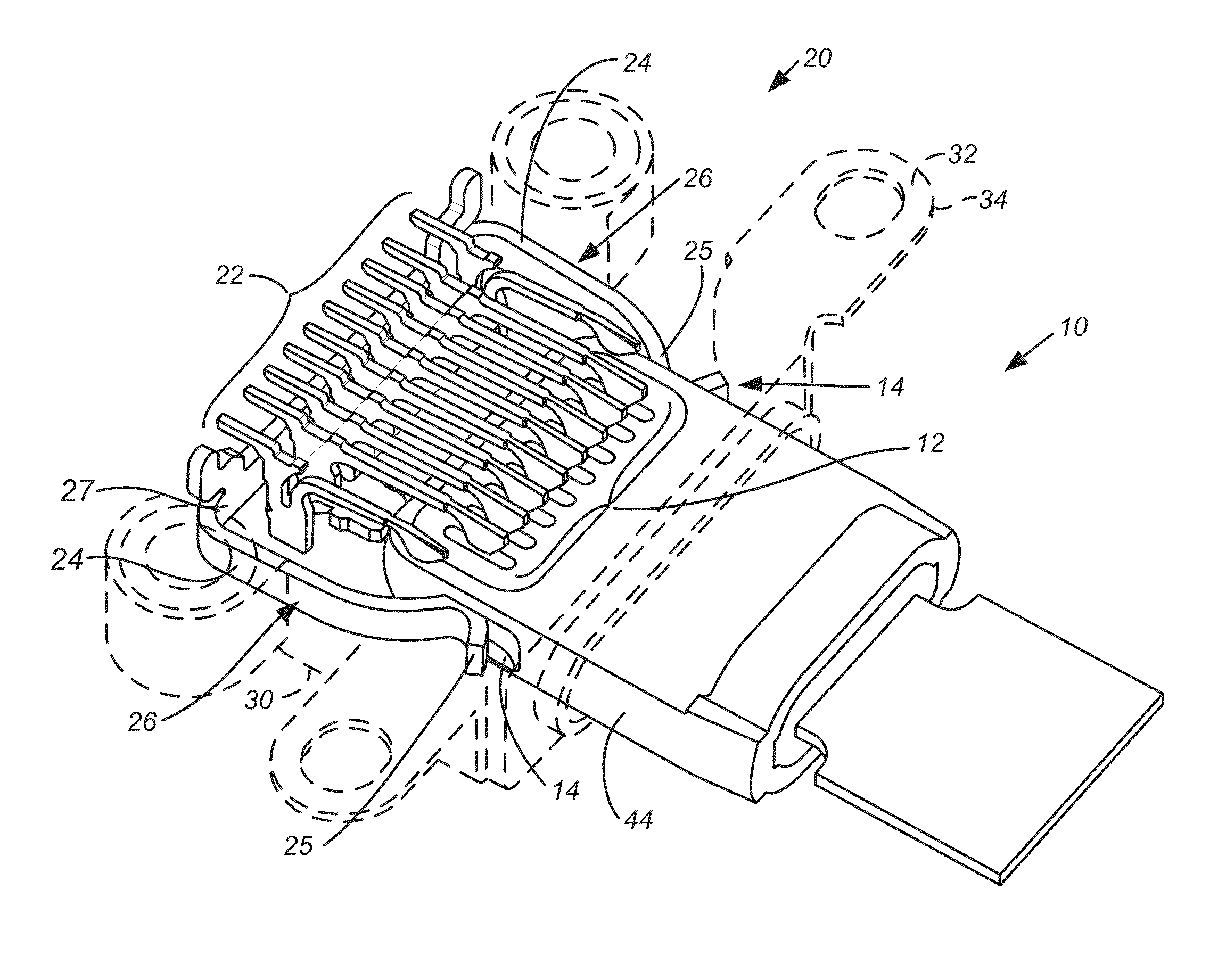

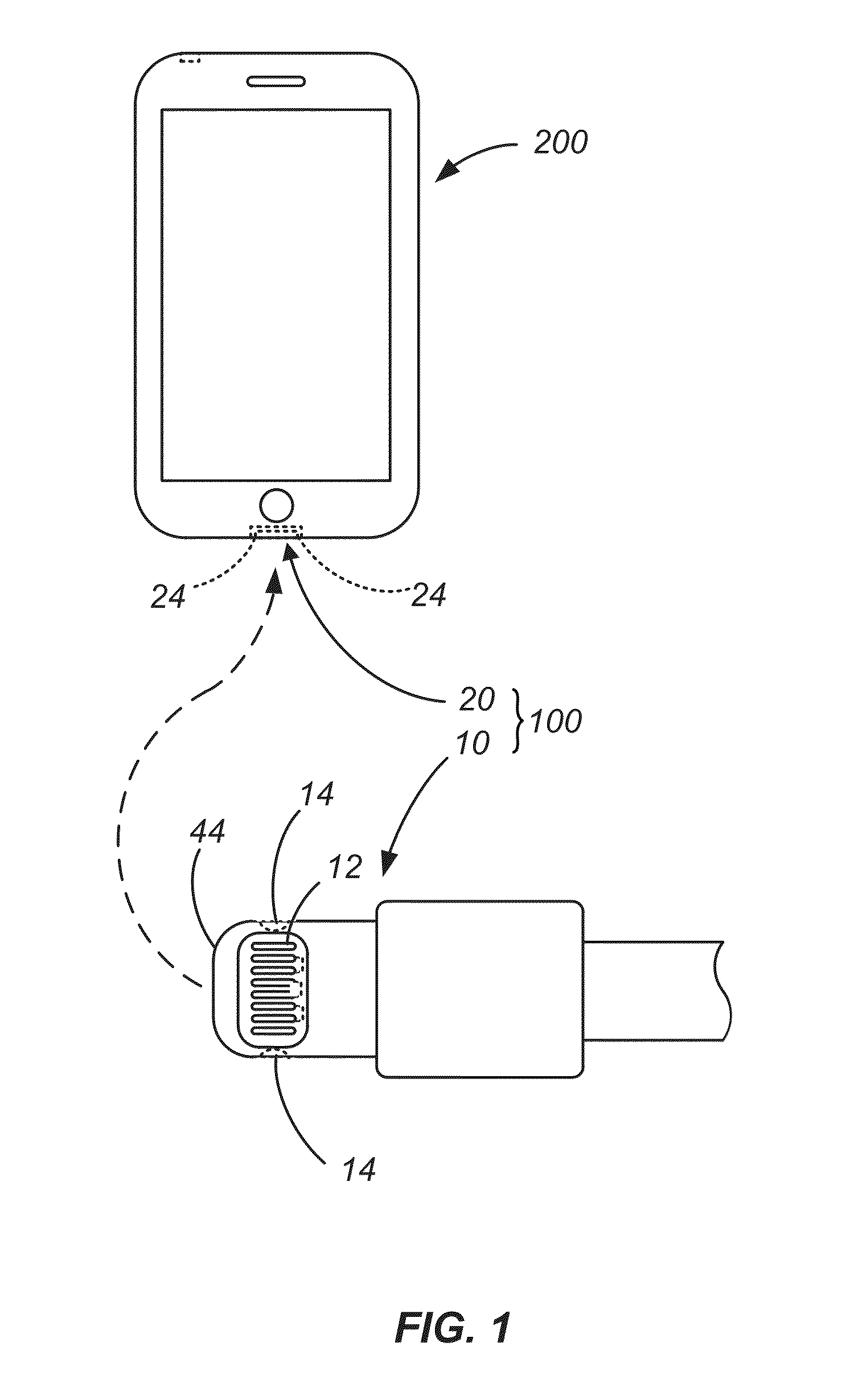

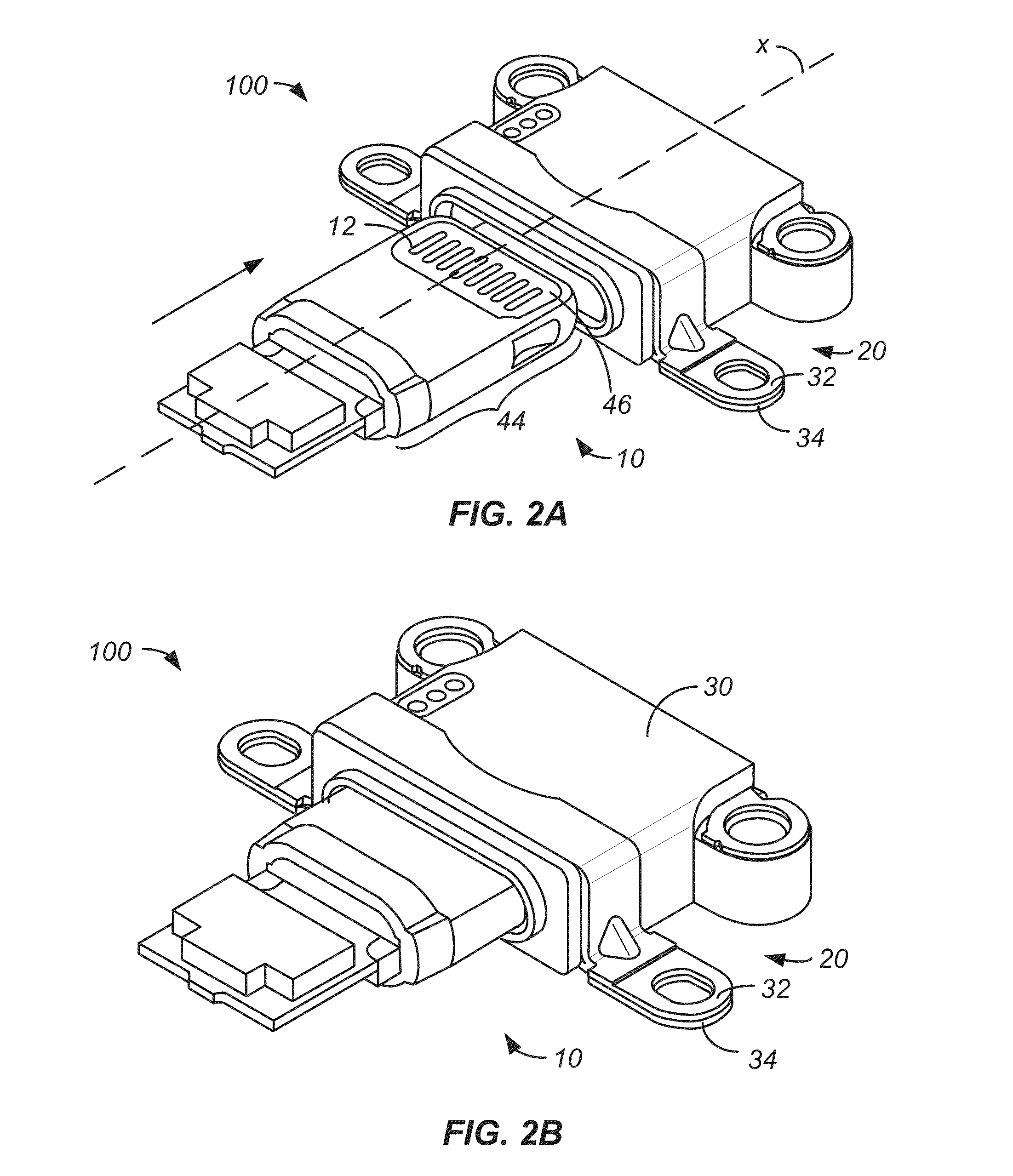

Retention mechanism having improved fatigue strength

InactiveUS20140057479A1Improved retention mechanismIncreased normal forceContact member cases/bases manufactureContact member assembly/disassemblyEngineeringUltimate tensile strength

A retention latch mechanism having a retention spring of a first connector engageable with a retention feature of a second connector. The retention spring may include a spring arm having a distal, curved retaining portion that is resiliently received within the retention feature and a reinforced portion that is proximal of the distal retaining portion. The reinforced portion includes a layer having residual compressive stress to inhibit fatigue failure during repeated cycling of the latch mechanism. The reinforced portion may be formed by a cold working method, such as shot peening a select region of the spring arm. The reinforced portion is formed to inhibit fatigue failure during repeated cycling of the latch mechanism. Methods of forming a retention mechanism having a retention spring with a reinforced portion are provided herein.

Owner:APPLE INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com