Patents

Literature

60results about How to "Dimensional accuracy is easy to control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

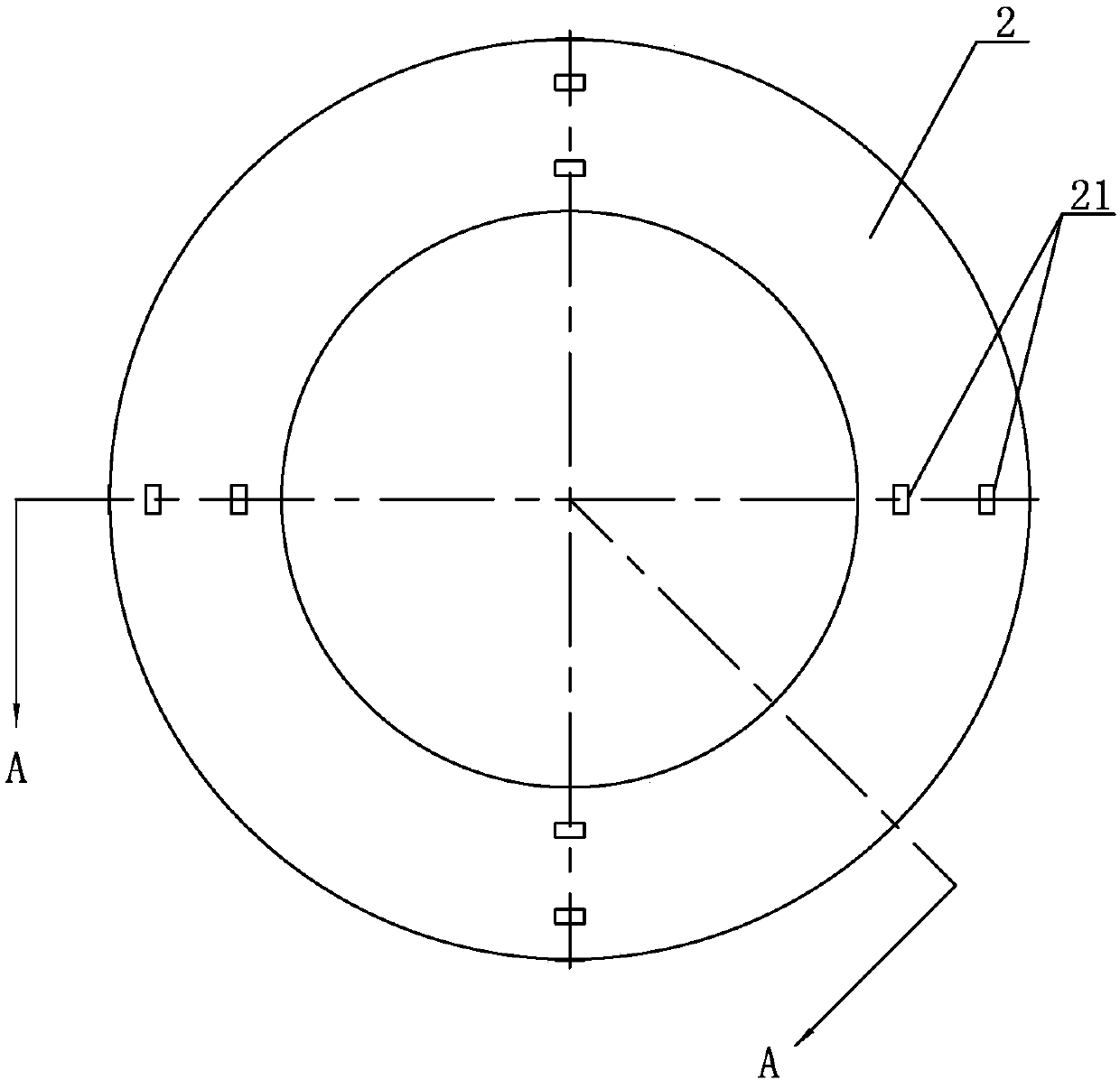

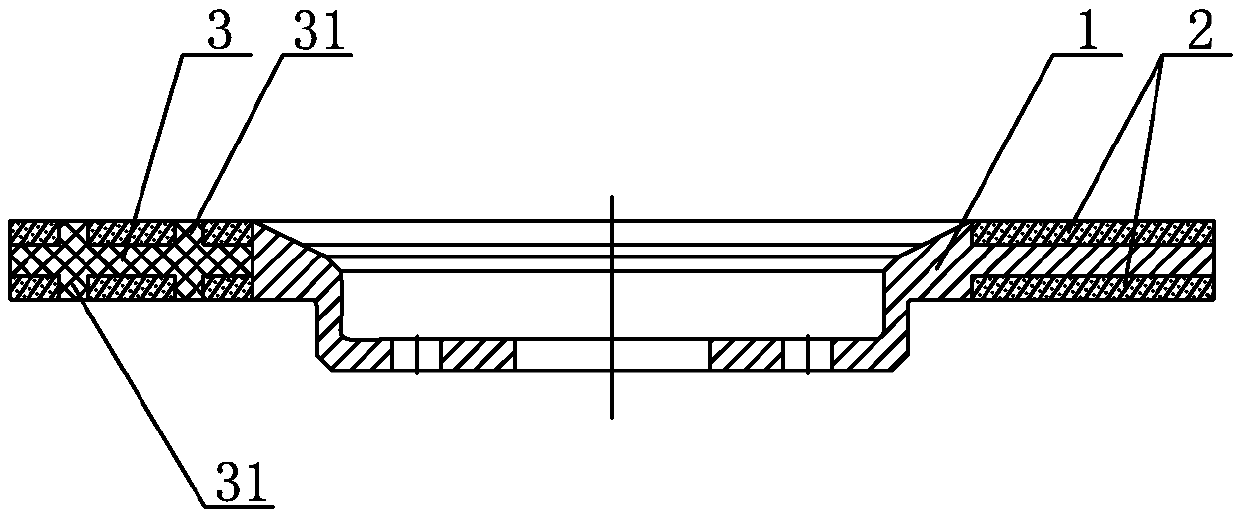

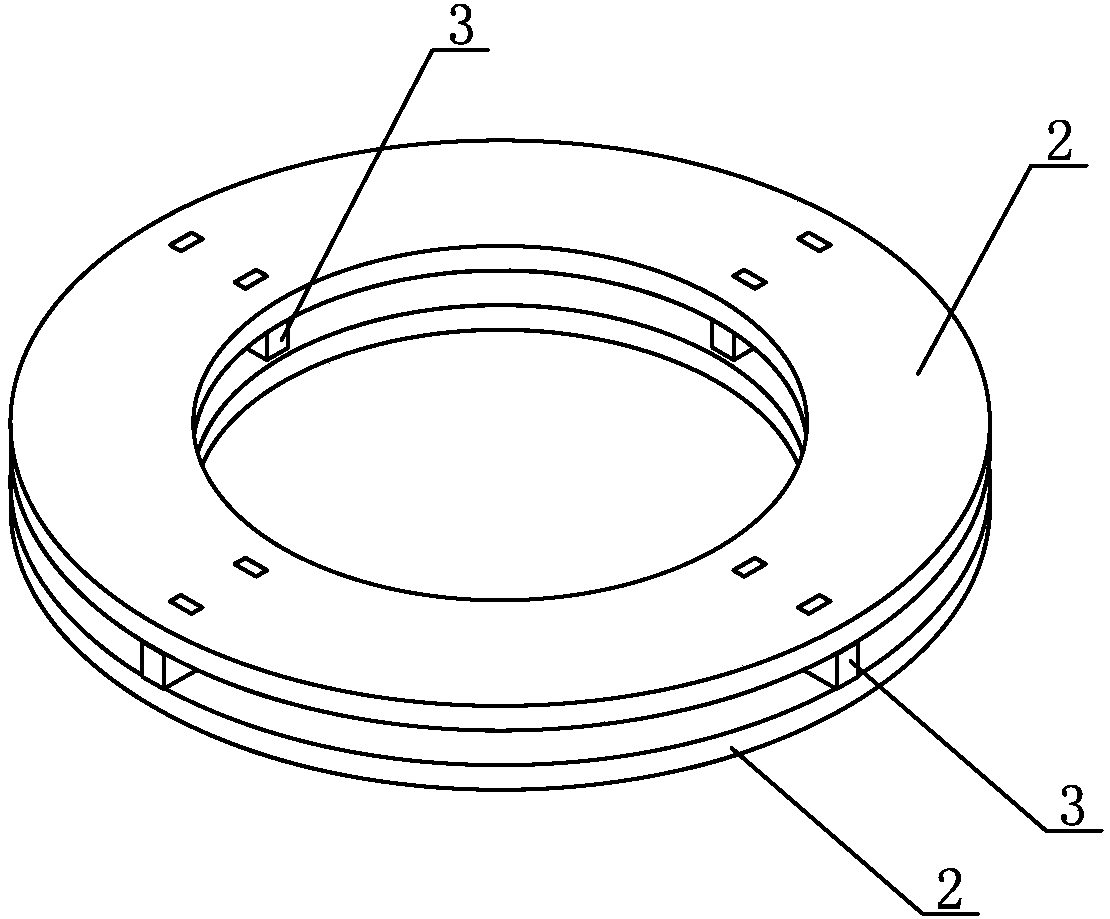

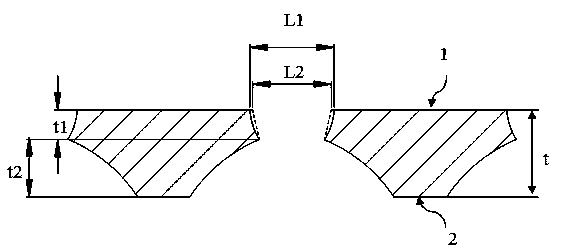

Brake disc and preparation method thereof

The invention discloses a brake disc. The brake disc is used for a brake system of a motor vehicle, rail traffic and an aircraft. The brake disc comprises a brake disc body; the brake disc body is analuminium alloy brake disc body; a wear resistant layer is compounded on each of the two working surfaces of the aluminium alloy brake disc body; the wear resistant layers are ceramic-high temperatureresistant metal composite reinforcement material wear resistant layers; the ceramic-high temperature resistant metal composite reinforcement material wear resistant layers are metallurgical combinedwith the aluminium alloy brake disc body through an extruding casting process; the brake disc disclosed by the invention is light in weight, high in strength, good in wear resistance, good in radiating property and long in service life; the weight and the service life of the brake disc are close that those of a carbon-ceramic brake disc; the machining cost and the maintenance cost are low; the service life is over three hundred thousand kilometres; the using cost is close to ductile iron brake disc; the passage capacity of the motor vehicle, the rail traffic and the aircraft can be improved, and the brake distance can be shortened; the safety is improved; and the brake disc is suitable for large-batch production.

Owner:NINGBO HIGHRISE NEW MATERIAL CO LTD

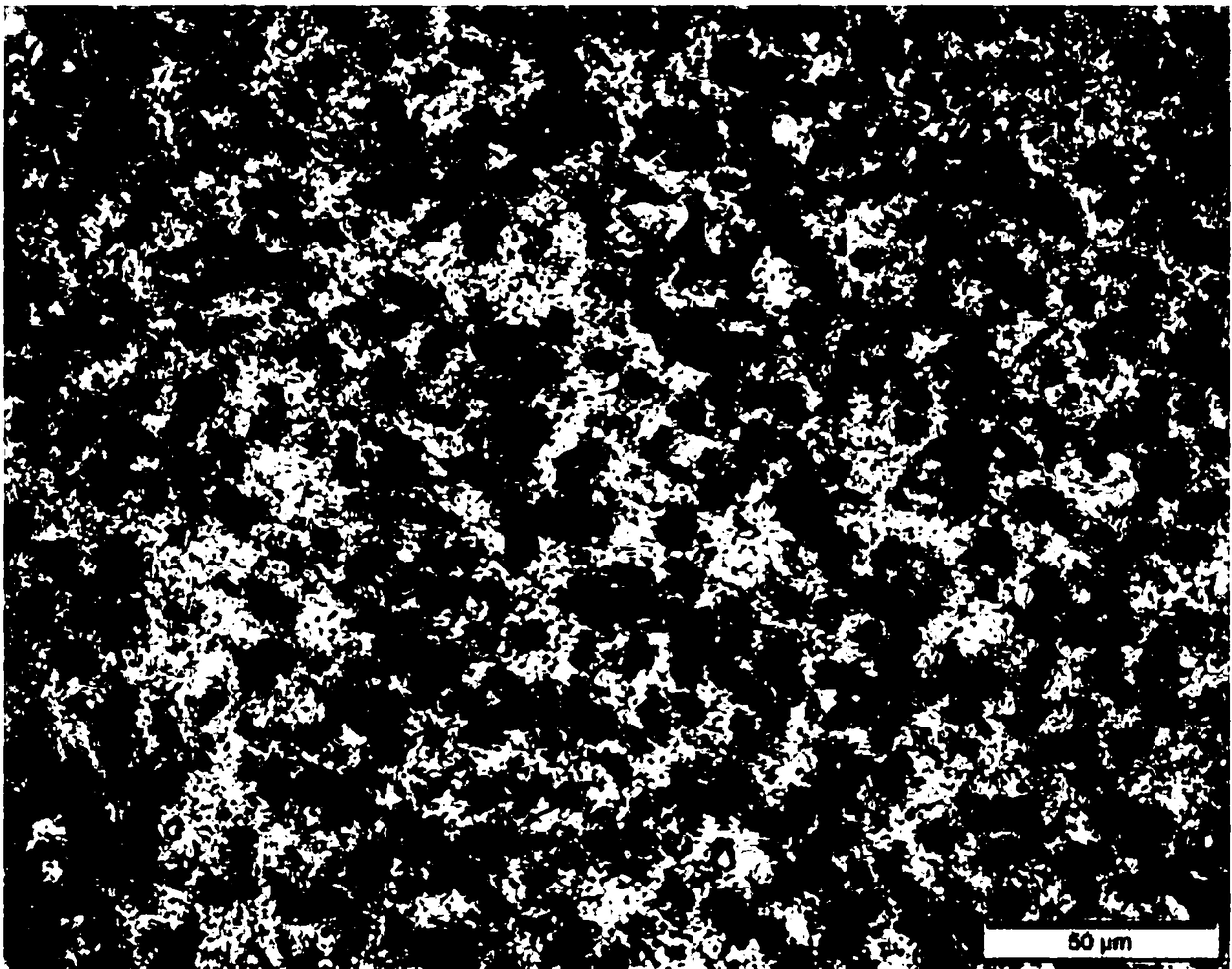

Neutron absorbing material rapid semi-solid state temperature zone forming method

The invention relates to a neutron absorbing material rapid semi-solid state temperature zone forming method, and belongs to the technical field of semi-solid state forming. The method is suitable forsemi-solid state forming plate blanks of particle (nano and micro scale) reinforced metal base composites. The method comprises the steps that a ball milling technology is adopted to prepare boron carbide and aluminum alloy mixed powder, and through isostatic cool pressing, a green body is obtained; technologies of hot pressing sintering, hot isostatic pressing and the like are carried out on solid and liquid two-phase semi-solid state temperature zone of an aluminum alloy, a high-compactness composite with ceramic particles evenly dispersed and distributed in an aluminum alloy base body isobtained, hot forging pressing, hot extrusion or hot rolling treatment is carried out on the aluminum alloy base body deformation temperature zone, heat treatment is carried out, and a high-compactness aluminum-based boron carbide neutron absorbing material with the uniform structure is made. Non-metallic materials are easily added, the preparing time is short, the material compactness is high, micrograph morphology is good, and production cost is low.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

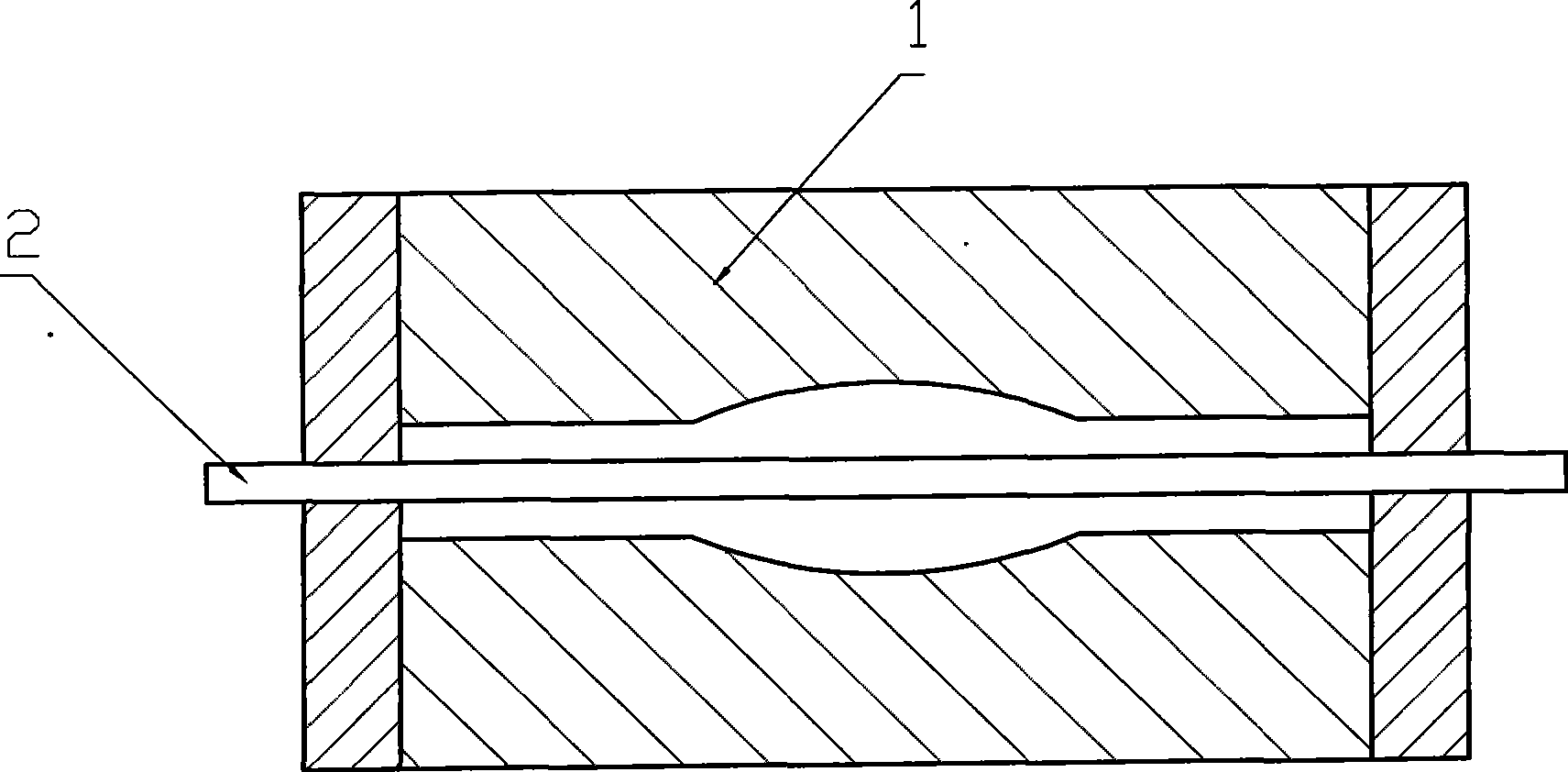

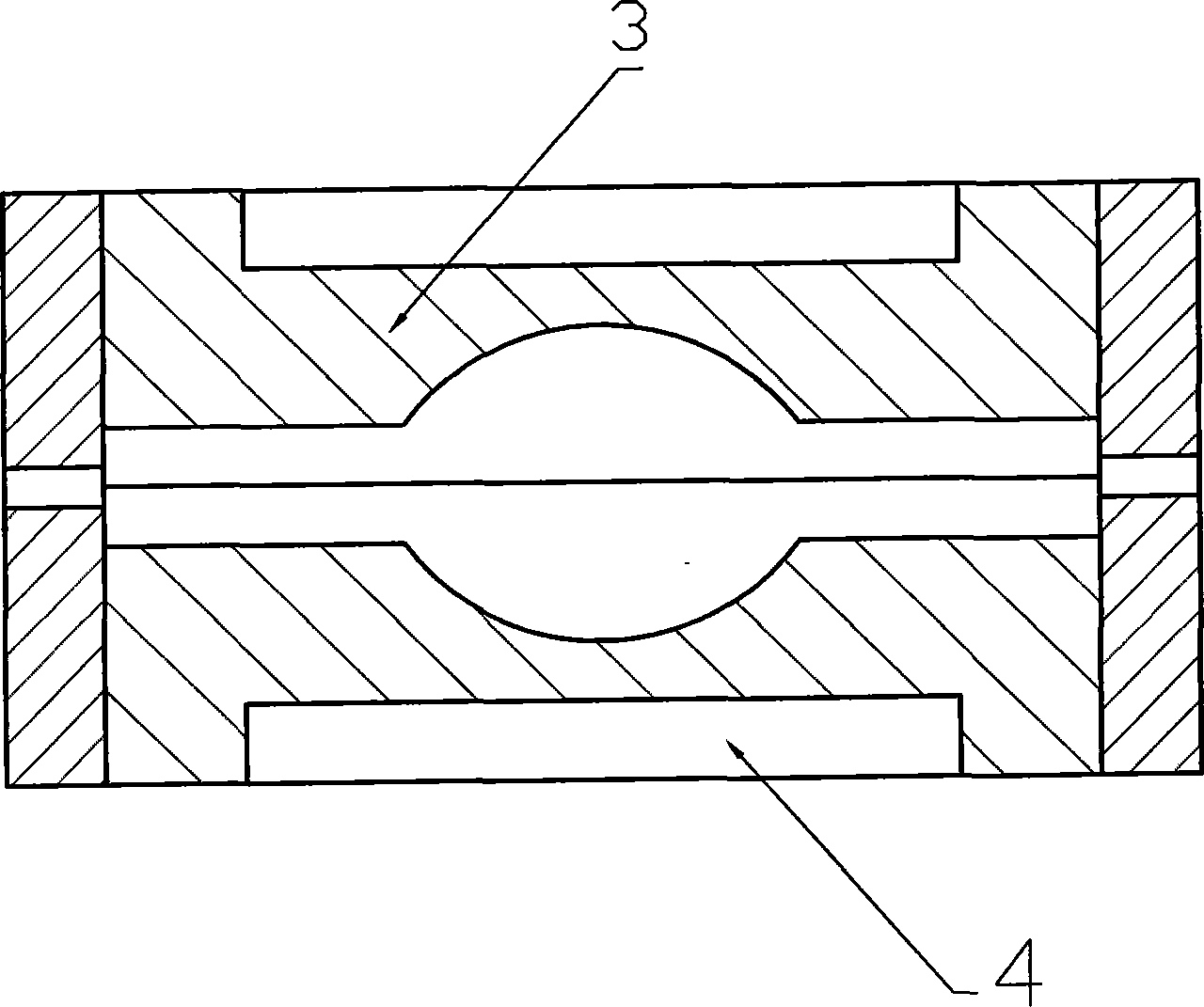

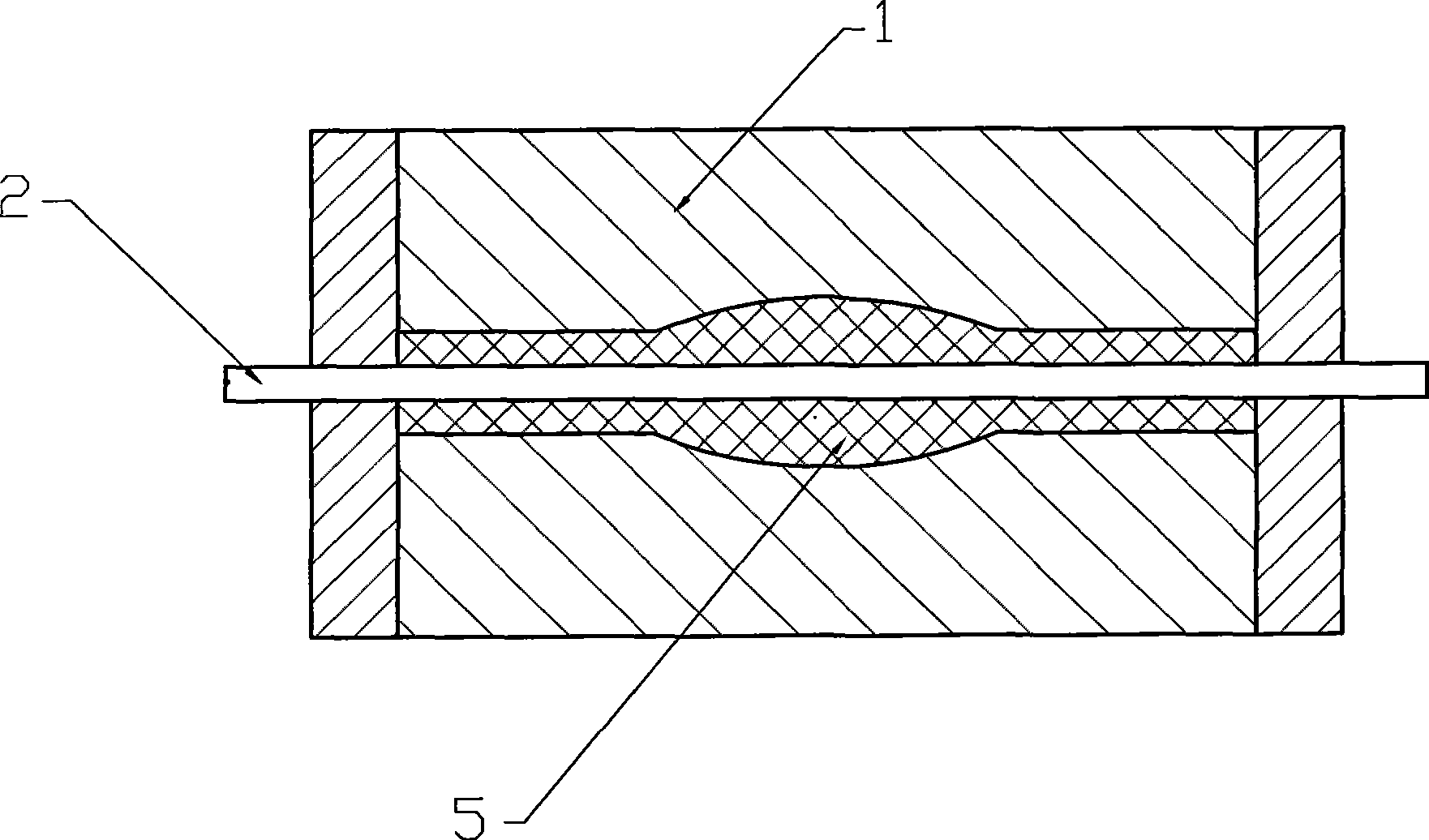

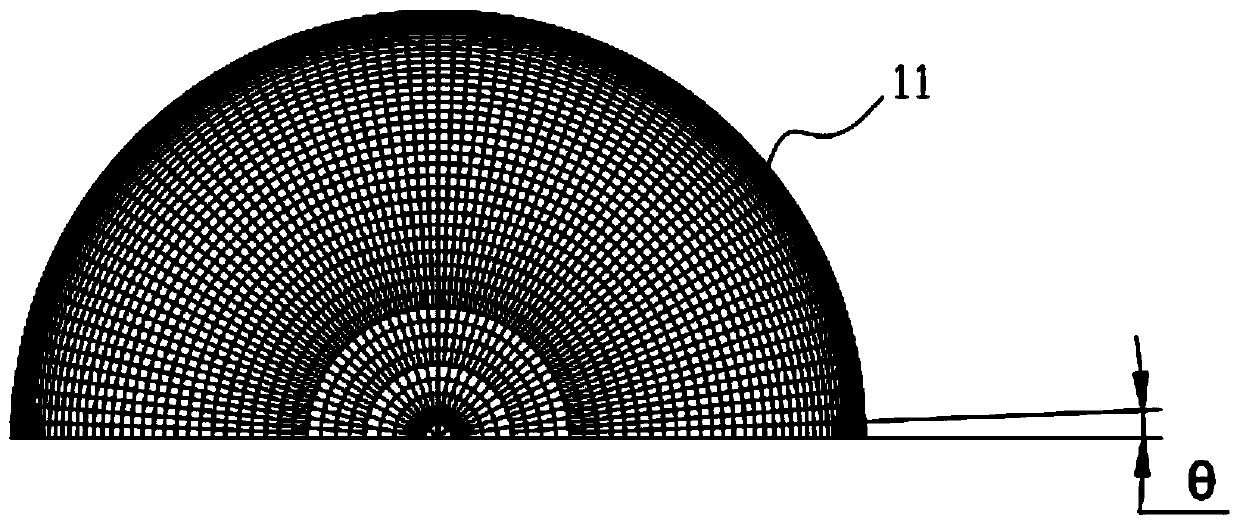

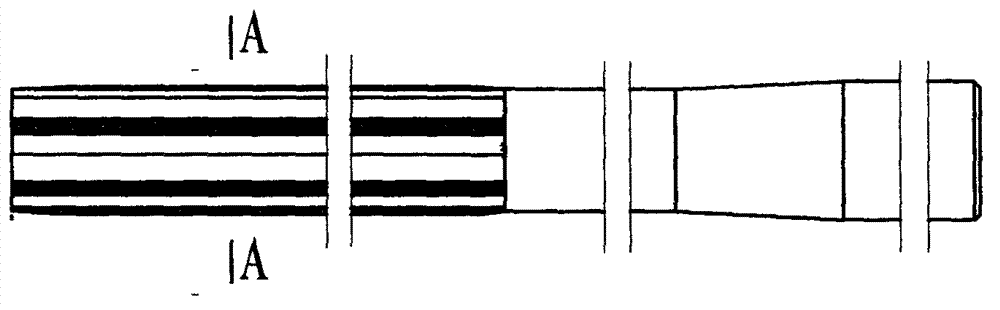

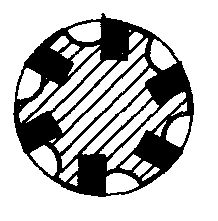

Drawing forming process of aluminum alloy deep paraboloid cylindrical part

ActiveCN110802153AQuality improvementDimensional accuracy is easy to controlShaping toolsOther manufacturing equipments/toolsStress pointForming processes

The invention relates to the technical field of drawing forming processes, in particular to a drawing forming process of an aluminum alloy deep paraboloid cylindrical part. The process is used for solving the problems of low drawing efficiency, poor product consistency and difficult control of part surface quality and dimensional accuracy in the prior art. The process comprises the steps of calculating and determining the diameter D of a blank; drawing the blank into a stepped cylindrical semi-finished product with an inclined flange edge at the large end, and calculating and determining the drawing frequency, drawing process sizes and drawing process diagrams; taking the inclined flange edge at the large end as a stress point, and drawing and expanding the deep paraboloid through a drawing die; straightening the inclined flange edge at the large end into a cylindrical shape equal to the diameter of the cylinder of the deep paraboloid; shaping the deep paraboloid and a large cylinder by using a shaping die; and obtaining the qualified part by turning the large end face. Accordingly, the quality of the surface of the part can be improved, the dimensional accuracy of the surface of the part is easier to control, the drawing efficiency is higher, and the product consistency is better.

Owner:SICHUAN AEROSPACE ZHONGTIAN POWER EQUIP CO LTD

Process method for assembling and welding pile leg of ocean platform

InactiveCN105057857AWelding quality is easy to controlDimensional accuracy is easy to controlArc welding apparatusProduction lineEngineering

The invention discloses a process method for assembling and welding a pile leg of an ocean platform. According to the method, the production speed is high, and the percent of pass of products is high. A pile leg assembly is composed of a rack and two semicircular pipes. Coming cargo examination should be carried out on the rack and the semicircular pipes carefully, and the rack and the semicircular pipes are installed through a tool. The rack is turned over through a turnover device. The assembled pile leg examined to be qualified is lifted to an electric heating furnace stage trolley, conveyed into a furnace and heated, wherein the temperature ranges from 150 DEG C to 200 DEG C. The temperature in a hearth should be kept even. The heated pile leg is placed on the ground. Two welding joints are in the horizontal state. Manual welding rods are used for backing welding. Welding is performed on the pile leg by four welding workers from the middle position. The two sides are simultaneously and symmetrically welded. After welding is finished, the pile leg is turned over and welded continuously. After the welding joints are backed for 1 to 2 layers, the pile leg is lifted to roller carriers on a submerged arc welding production line and then formally welded. The welded pile leg is conveyed into a thermal treatment furnace, the heating temperature ranges from 200 DEG C to 280 DEG C and maintained for 2 to 3 hours, and then the pile leg is delivered out of the thermal treatment furnace.

Owner:张家港润通海洋工程科技有限公司

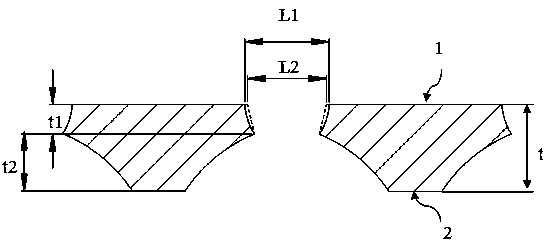

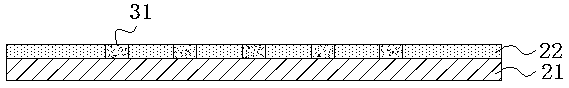

Manufacture technology of mask plate

InactiveCN104164647AControl thicknessIncreasing the thicknessVacuum evaporation coatingSputtering coatingManufacturing technologyMetal

The invention discloses a manufacture technology of a mask plate. The technology comprises the following steps: forming an electroforming layer through an electroforming technology, and etching an etched groove with a certain depth on the electroforming layer on the side near the opening of the electroforming layer, wherein the electroforming technology comprises the steps of film pasting (1), exposing (1), developing (1), and electroforming; and the etching technology comprises the steps of film pasting (2), exposing (2), developing (2), etching, and film removing. The effective deposition opening precision of the mask plate, which is prepared by the provided technology, is easy to control, thus the opening precision can be improved, and the hole wall of the opening formed by electroforming is smooth and convenient for mould removing. The etched groove prepared by the etching technology of the opening forms a bowl shaped hole wall which is matched with the opening prepared by the electroforming, the bowl shaped hole wall has a large conical angle, so that the hole wall will not shield the vapor plating material during the vapor plating process, and thus the film forming rate of vapor plating is increased.

Owner:KUN SHAN POWER STENCIL

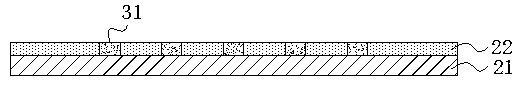

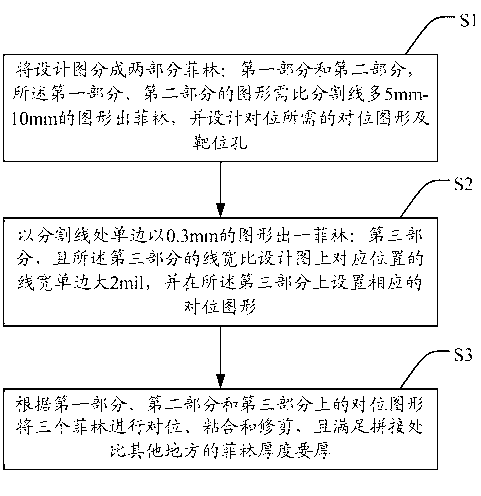

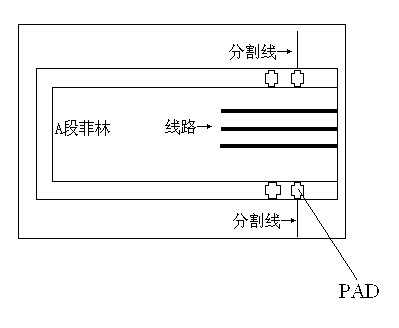

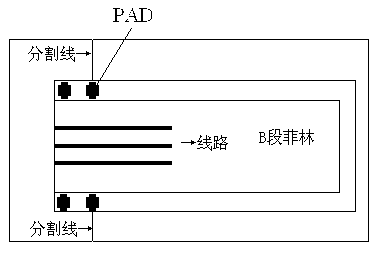

Aluminum substrate film splicing manufacture method

ActiveCN103152983ASolve Exposure Quality IssuesAvoid affecting graphics transfer accuracyPrinted circuit manufactureSplit linesMaterial resources

The invention discloses an aluminum substrate film splicing manufacture method which is used for pattern transfer of a 1250mm of aluminum substrate. Firstly, a designed drawing is divided into two parts of films: a first part and a second part; secondly, a film with a pattern and with a single edge of 0.3 mm is produced in a parting line portion as a third part; and finally, according to alignment patterns of the first part, the second part and the third part, the three films are aligned, adhered and pruned. Waste of manpower and material resources and influence on pattern transfer accuracy due to multiple times of exposure are avoided, production cost is reduced and production efficiency and quality are improved. Process capability is further improved. Extensible property of the manufactured film is better than a silver salt sheet with even larger size in the future due to the fact that the larger the size becomes, the larger the extensible property is. The film is divided into two parts so that the size of each film is easier to control. The extensible values of the two films can be compensated mutually so that size accuracy control is relatively easier.

Owner:KINWONG ELECTRONICS TECH LONGCHUAN

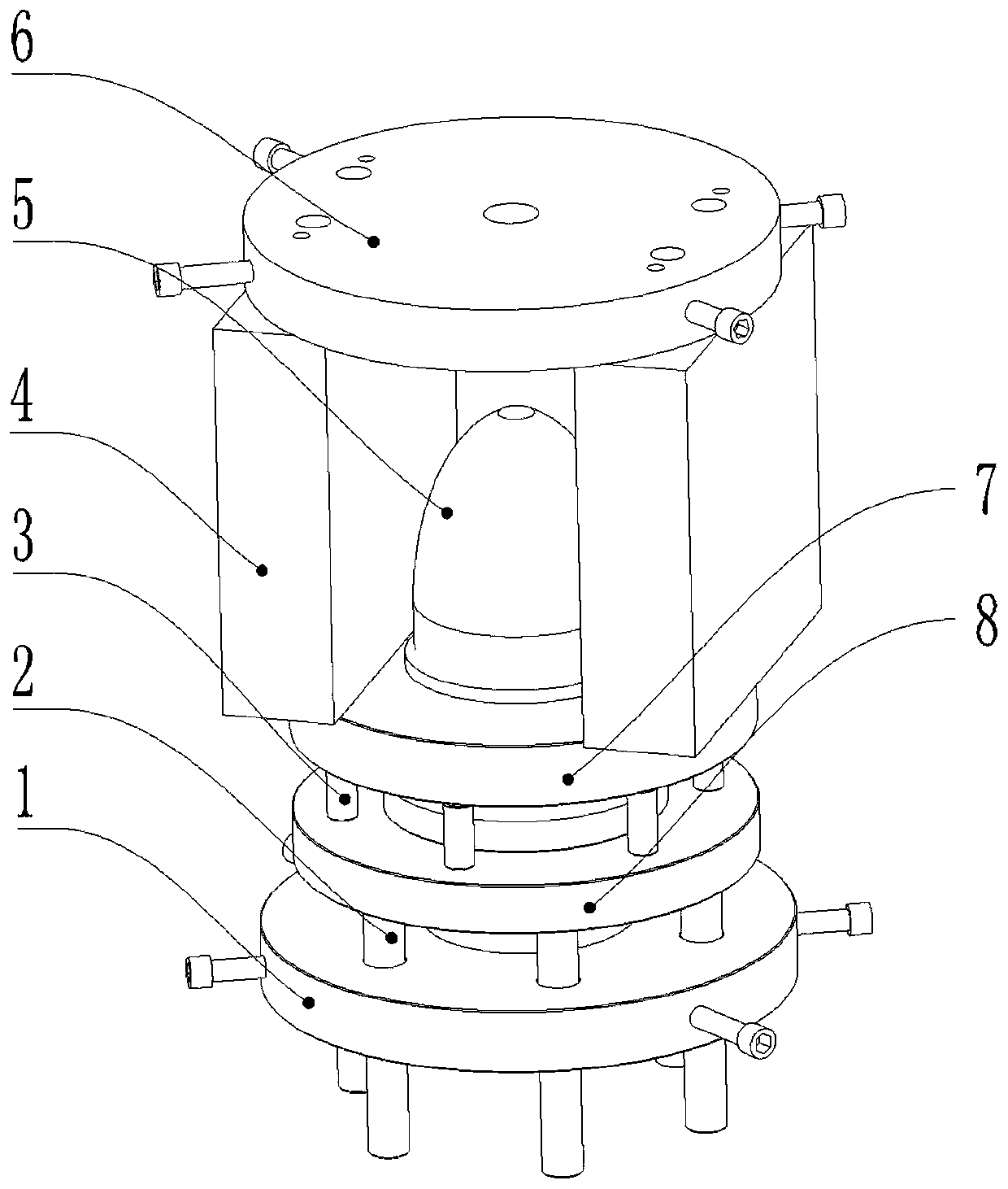

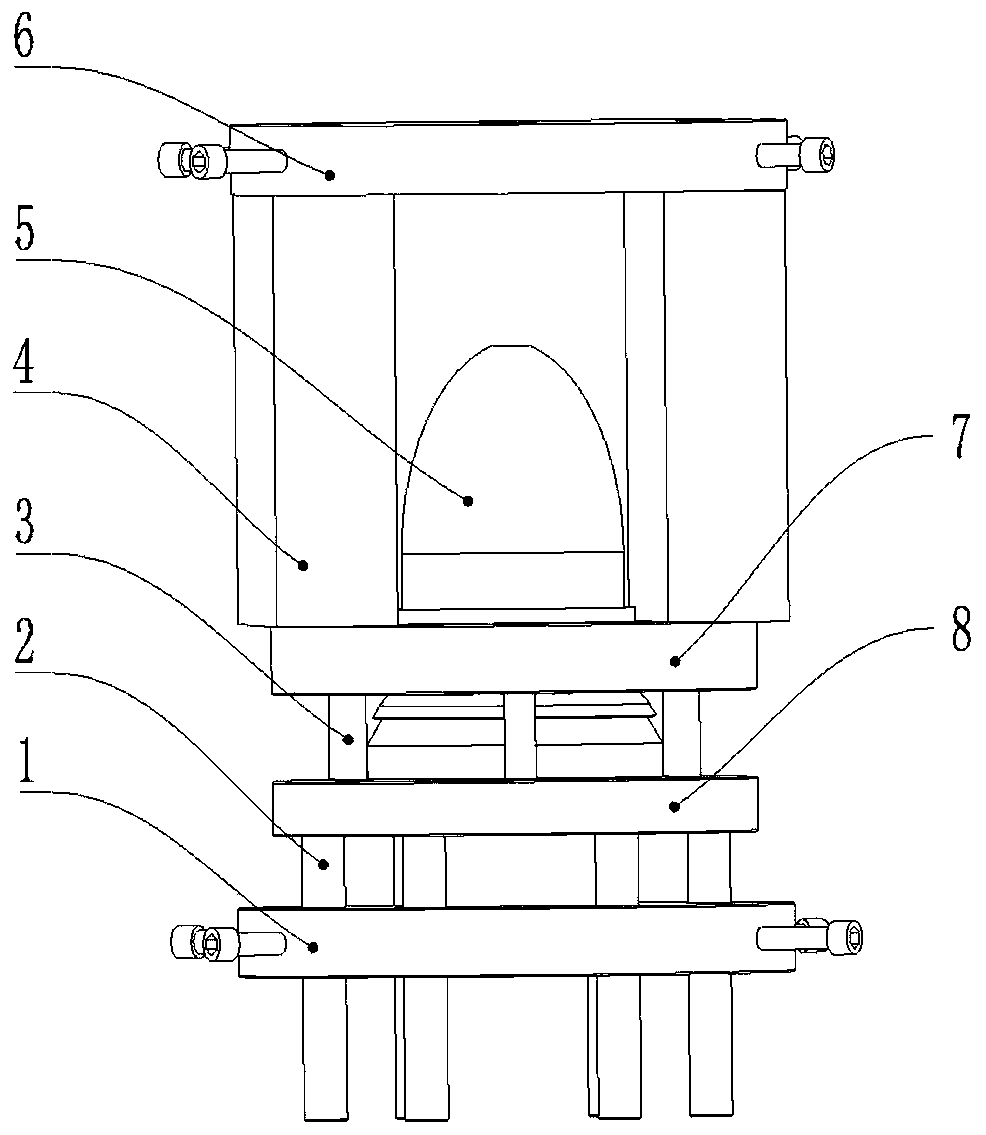

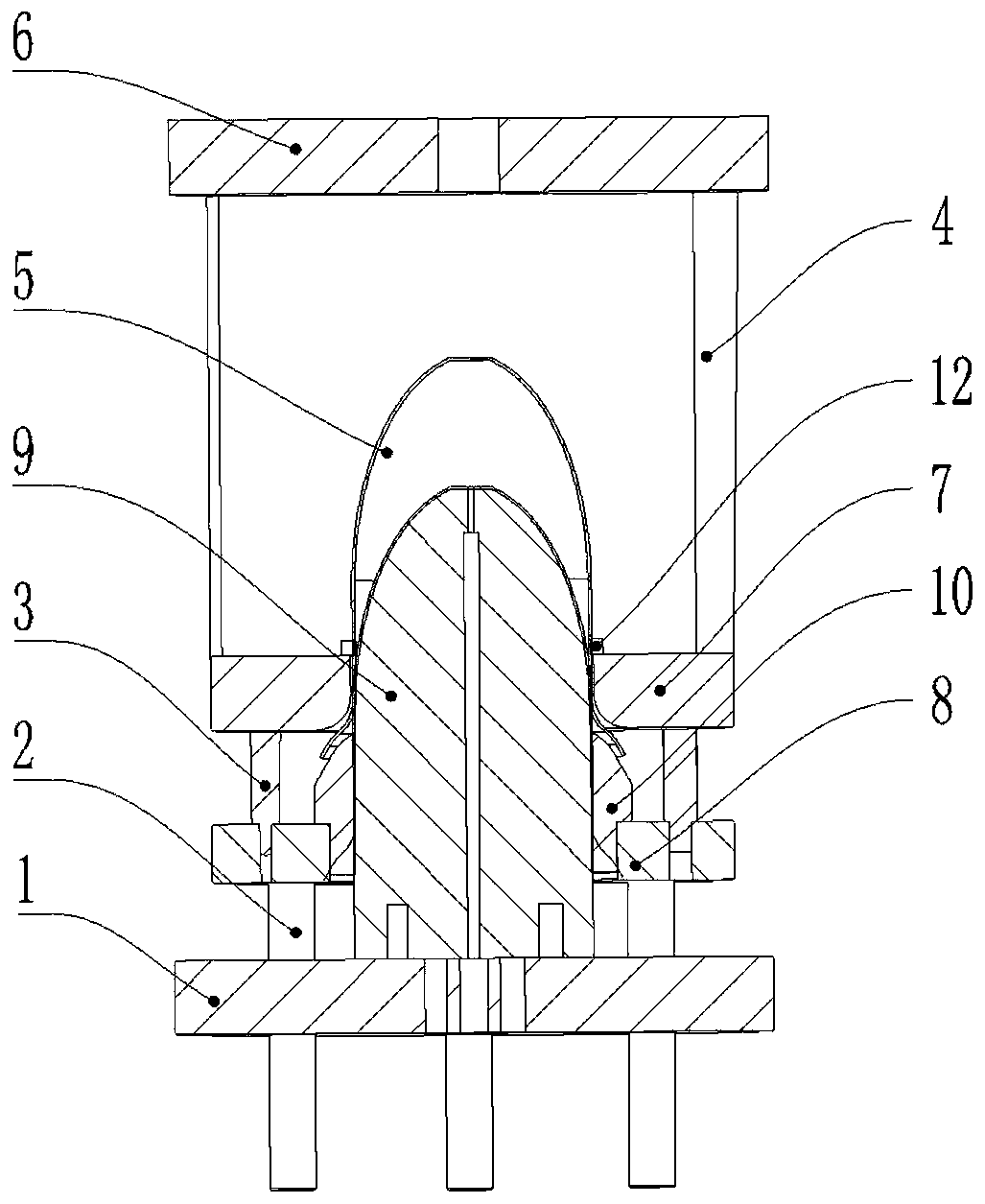

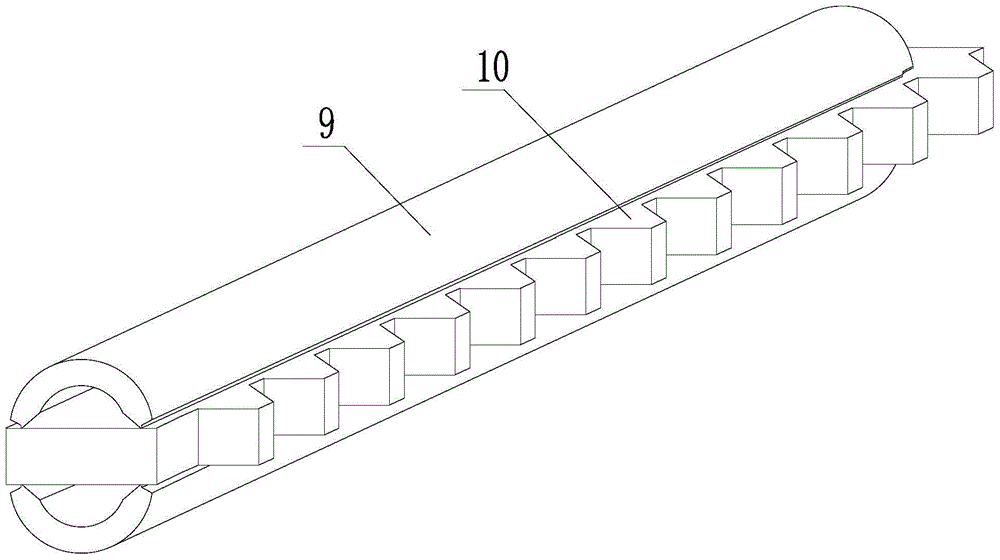

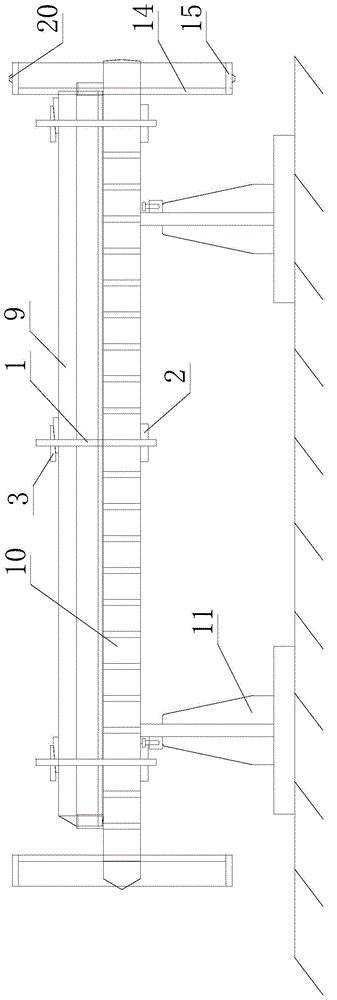

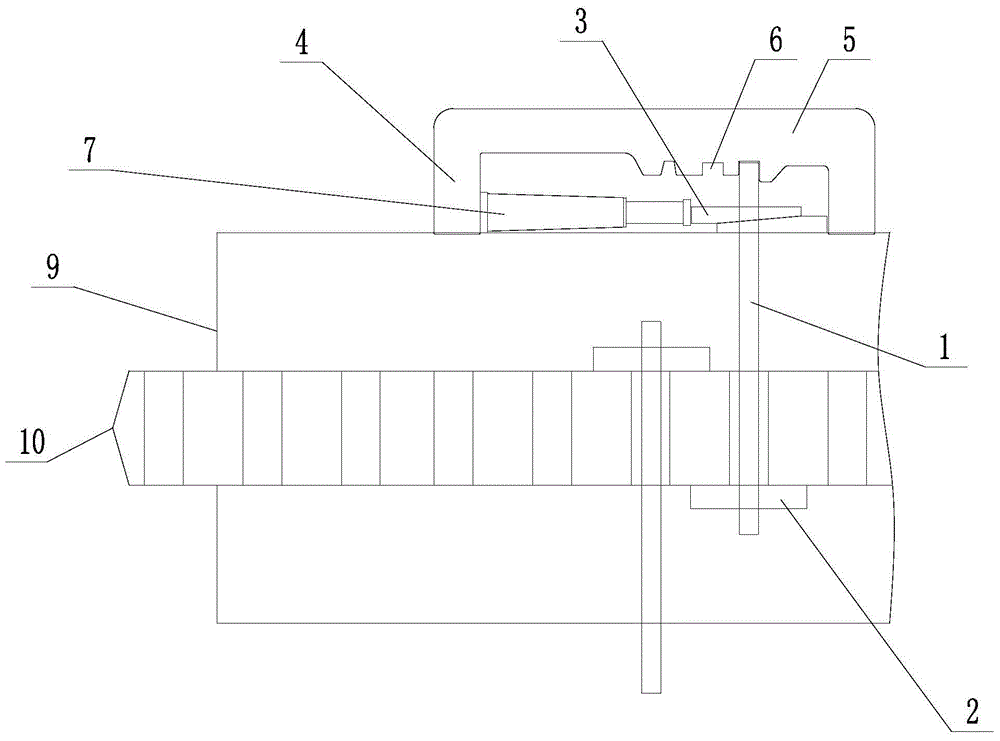

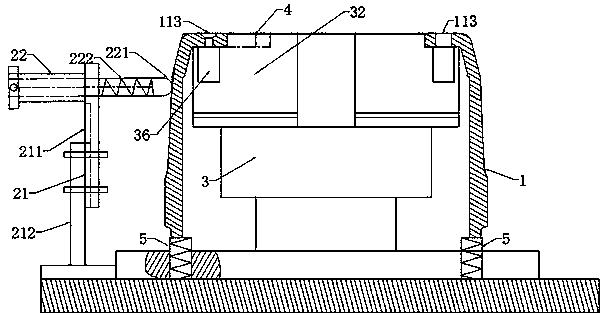

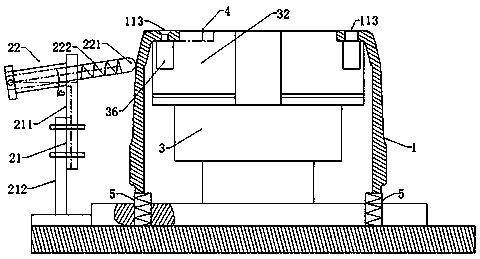

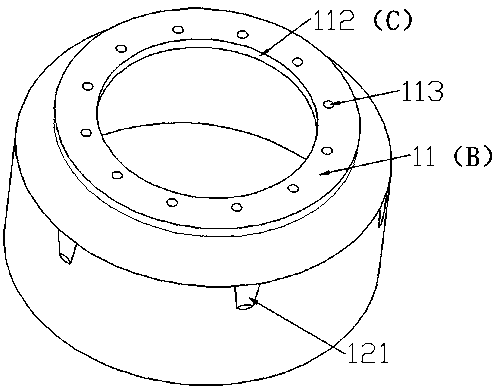

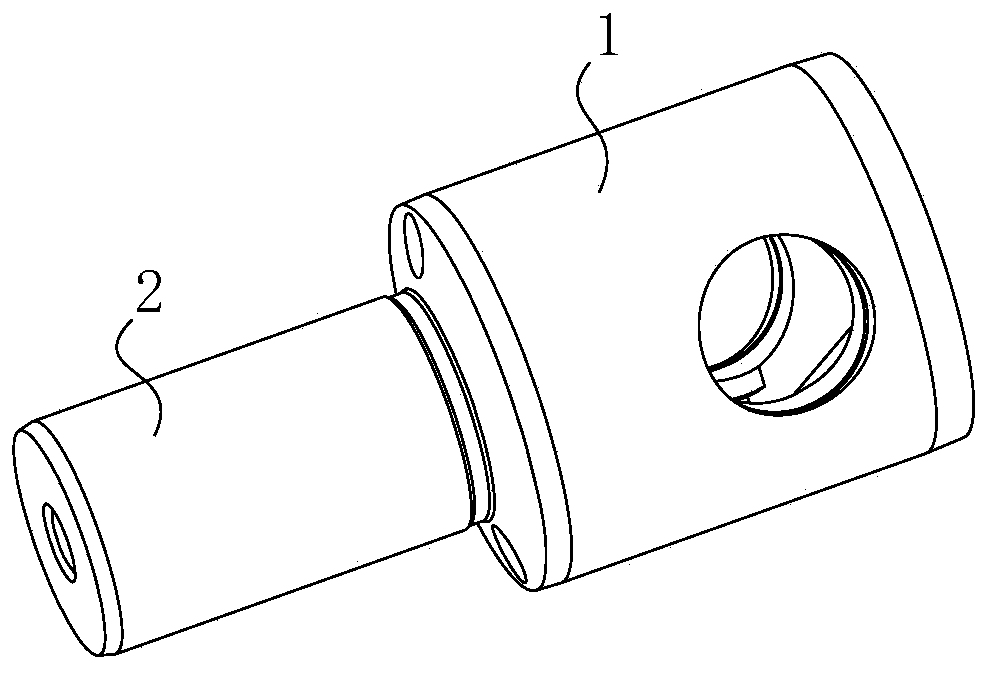

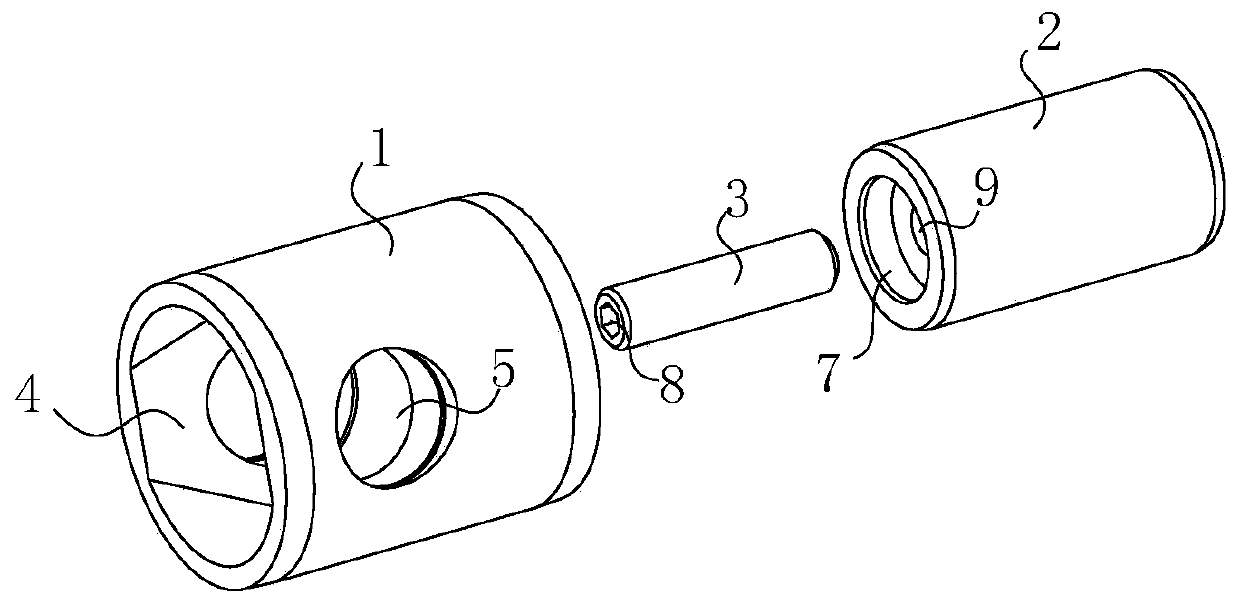

Drilling processing and fixing device and method for brake drum

InactiveCN108406352AEasy to fixAccurate drilling positioningChucksPositioning apparatusBiomedical engineering

The invention belongs to the field of automobile part processing and discloses a drilling processing and fixing device and method for a brake drum. The device comprises a chuck and a tool of an internal positioning device and comprises an upright post and an ejector rod of an external positioning device. The drilling processing and fixing device and method are accurate in positioning and drillingposition, high in dimensional accuracy, firm in fixing effect and wide in applicability.

Owner:JIANGXI JIUWANG AUTO PARTS MFG CO LTD

Preparation technology for mask plate

InactiveCN104213071AControl thicknessAvoid occlusionVacuum evaporation coatingSputtering coatingEvaporationMaterials science

A disclosed preparation technology for a mask plate comprises: firstly electroforming an electroformed layer through an electroforming technology, and then etching an etched groove with certain depth at the opening side of the electroformed layer through an etching technology, wherein the electroforming technology comprises first film pasting, first exposuring, first developing, electroforming and first film removing, and the etching technology comprises secondary film pasting, secondary exposuring, secondary developing, etching, and secondary film removing. The mask plate prepared by employing the provided technology has the opening formed by combining of an electroforming opening and the etched groove, the electroforming opening has smooth sidewall and is easy for demolding, the effective deposition opening precision is easily controlled, and the opening precision is improved; and the etched groove prepared by using the etching technology on the basis of an electroformed opening forms a bowl-shaped hole wall and is combined with the electroformed opening, due to the fact that the bowl-shaped hole wall has a large conicity, shielding of the hole wall to an evaporation material during evaporation is avoided, and the evaporation film-forming rate is improved.

Owner:KUN SHAN POWER STENCIL

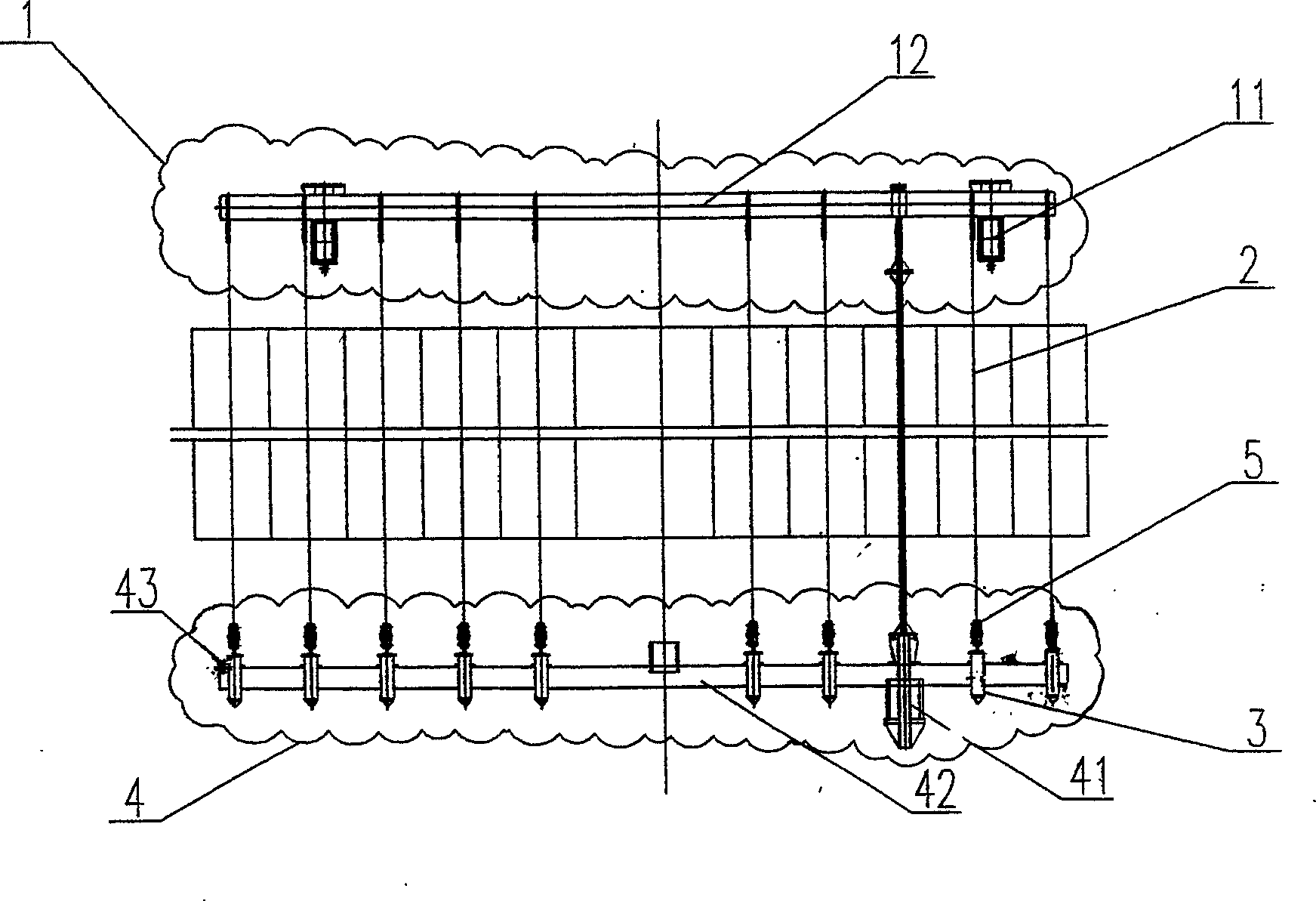

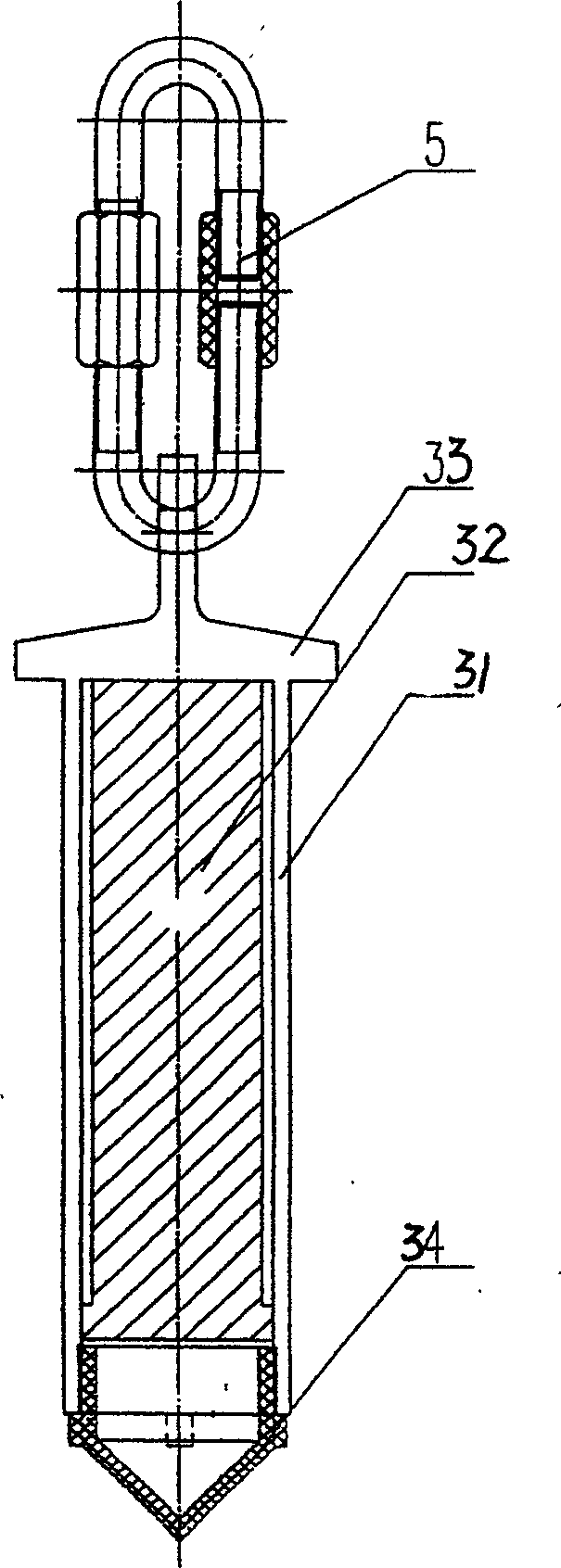

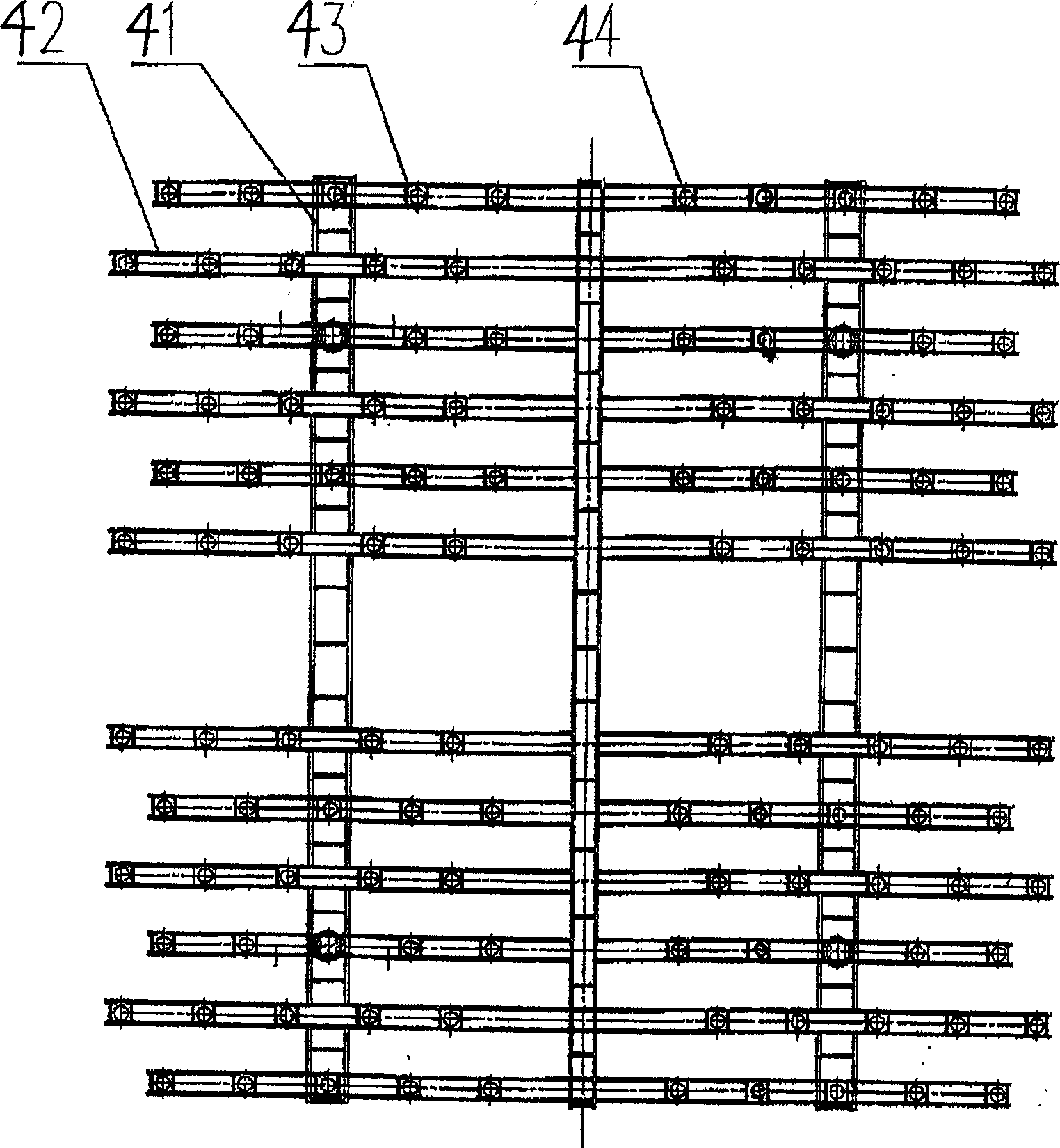

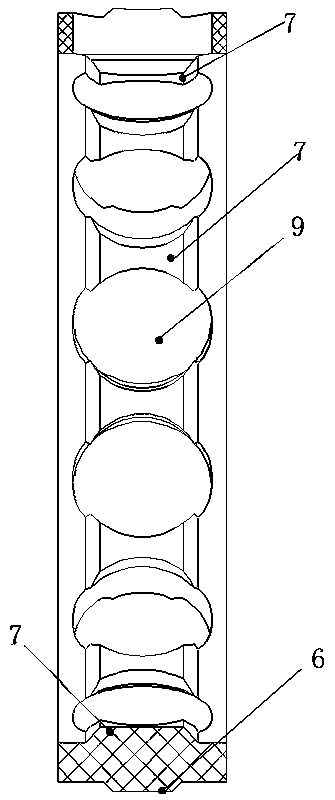

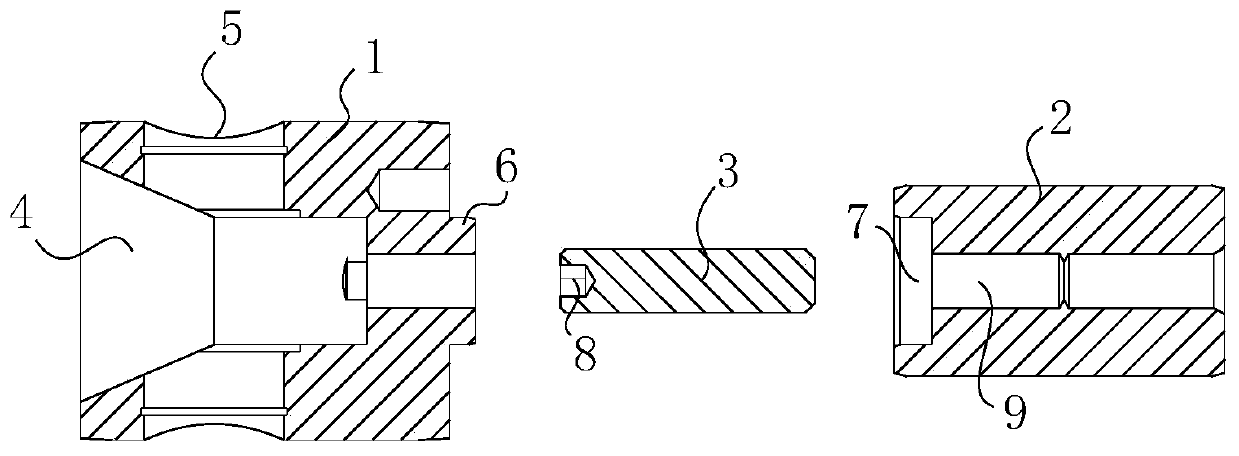

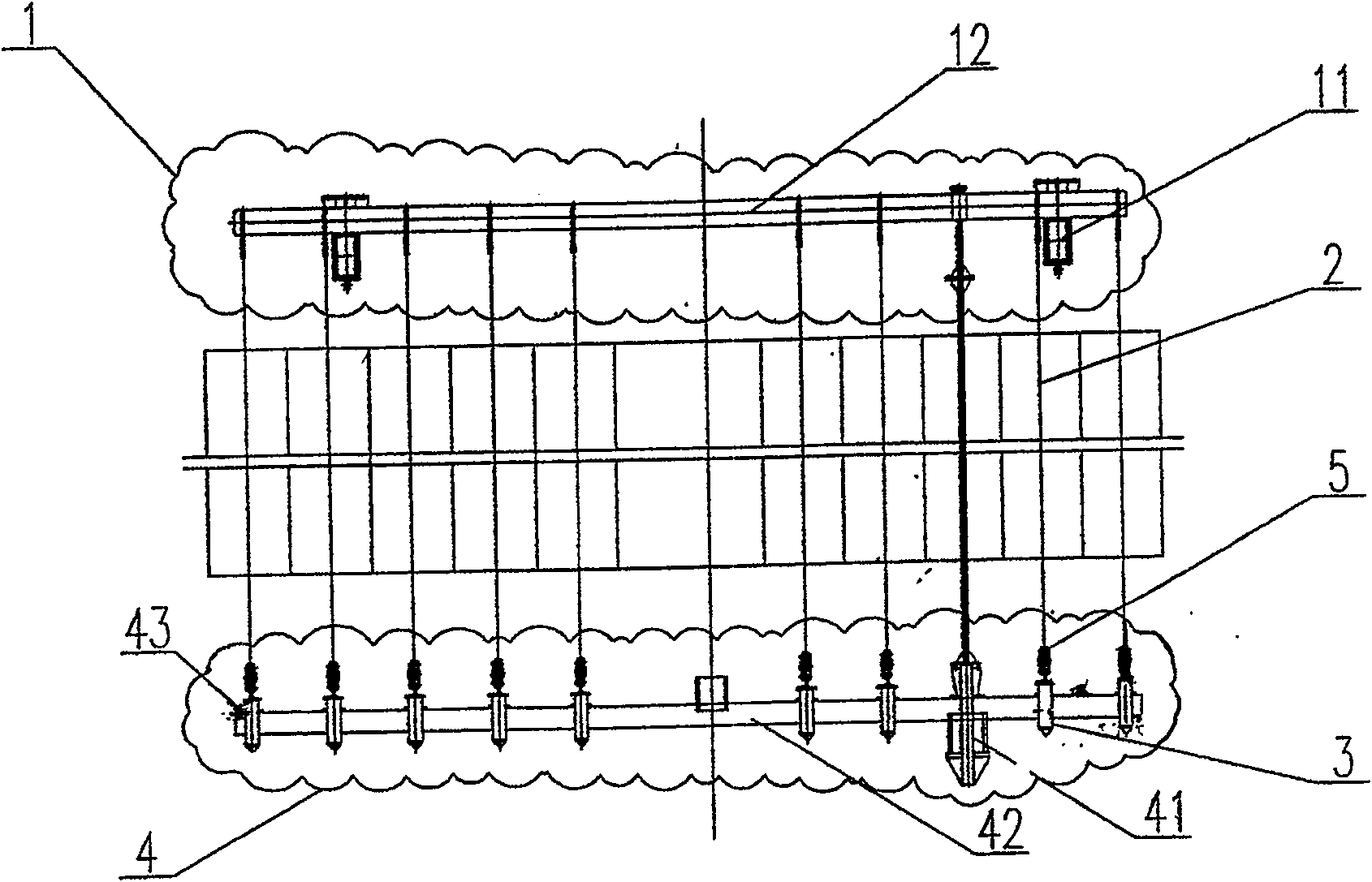

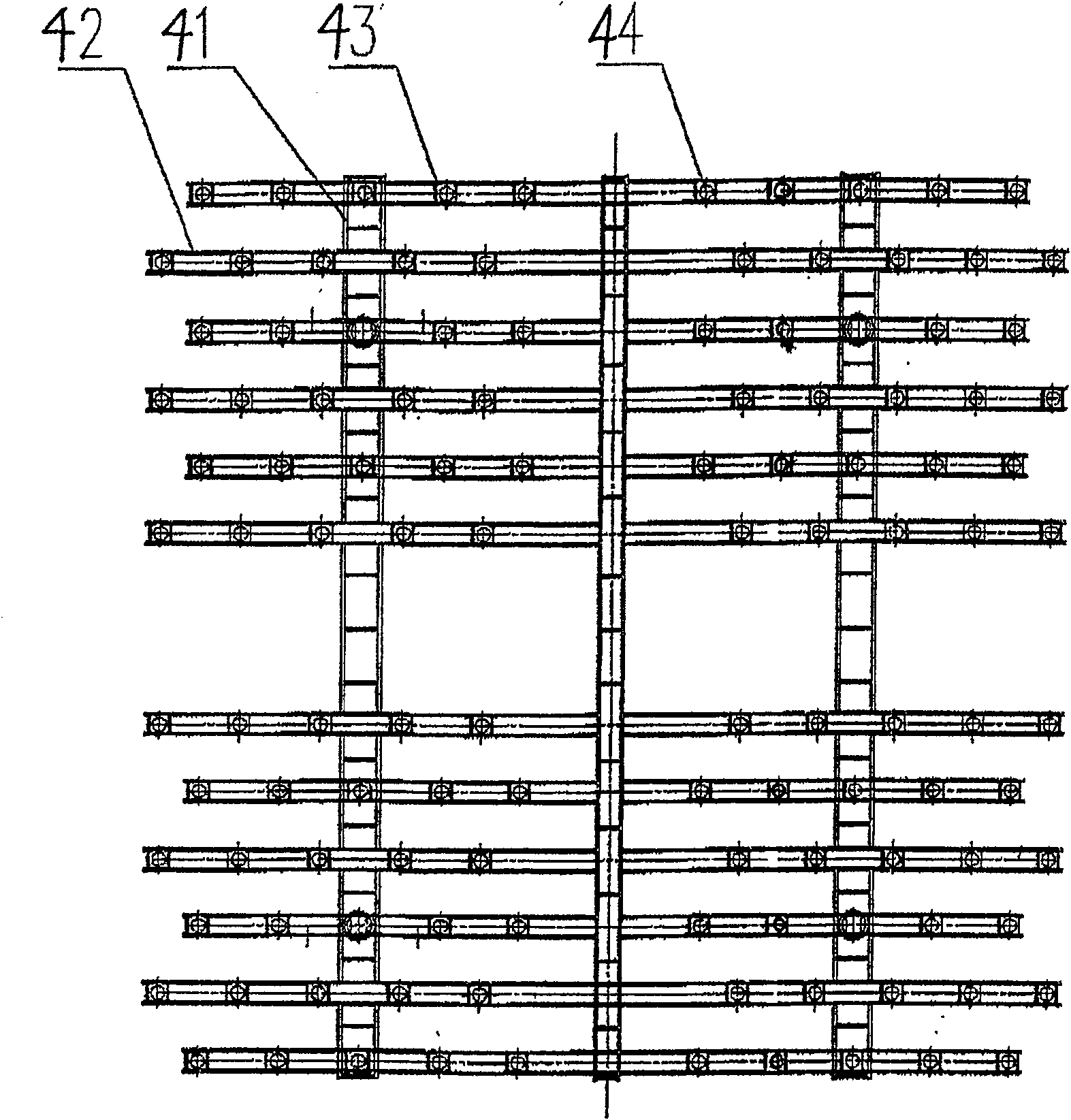

Cathode system for electric demisting device with conductive fiberglass reinforced plastic

ActiveCN1827224AAvoid Galvanic CorrosionFirmly connectedElectrode constructionsCompound (substance)Electrochemistry

The cathode system of conductive glass steel electric defroster can be used in the device for removing acid mist in the process that purifying the mercurial smoke in acid industry, belonging to the electric defroster area. The invention is formed by a cathode support beam, a cathode wire, a weight, and a lower cathode frame; wherein, the upper end of cathode wire is hanged on the cathode support beam, which is characterized in that the weight that connecting the lower end of cathode wire is formed by a sealed plastic outer cylinder and a inner lead weight; the lower cathode frame is formed by main beam and branch beam that made from plastic or glass steel; the branch beam has a hole adjusting plate; the weight outer cylinder is through the hole of said adjusting plate. In said system, lead weight inside the weight and the cathode wire are separated to effectively avoid the electric chemical erosion between them, and prolong the service life of cathode wire; the lower cathode frame has simple structure, high strength, and its hole adjusting plate make the position and distance adjustment of cathode wire easy; each cathode wire can be independently adjusted according to the shape of anode tube, with controllable size accuracy, lower weight, and easy installment; the electric field inside the conductive glass steel electric defroster is stable, with long service life, high defrosting efficiency and the acid mist outlet is not more than 3mg / NM3.

Owner:双盾环境科技有限公司

Manufacturing method for integrated liner of alumina ceramic metal halogen lamp

InactiveCN101483125ASolution to short lifeImprove overall lifespanVessels or leading-in conductors manufactureMetallic materialsLight source

The present invention relates to an inorganic non-metallic material and a ceramic tube for light source lighting, specifically to a method for preparation of alumina ceramic metallic halogen lamp integral liner, which includes the following three steps: 1) adopting an injection method to inject the thermoplastic material in an injecting molding die to form a blank; 2) adding the blank in an air pressure molding external mold for heating to soften, aerating the blank through a core tube center hole to dilate the blank, to form a blank half-finished product whose external shape satisfies the requirements; 3) performing unglazed pottery to the half-finished product, passing through an appearance surface sanding reconditioning process, and then performing high temperature sintering to obtain the alumina ceramic metallic halogen lamp integral liner. The method has beneficial effects of no need of adopting volatile inner core, regular liner shape, controlled size precision, simple process, low production costs, high reliability and application in various shapes production and the bulk production; the special-shaped integral alumina ceramic metallic halogen lamp liner manufactured by the method has high strength, long service life, good heat resistance and corrosion resistance performances.

Owner:谢灿生

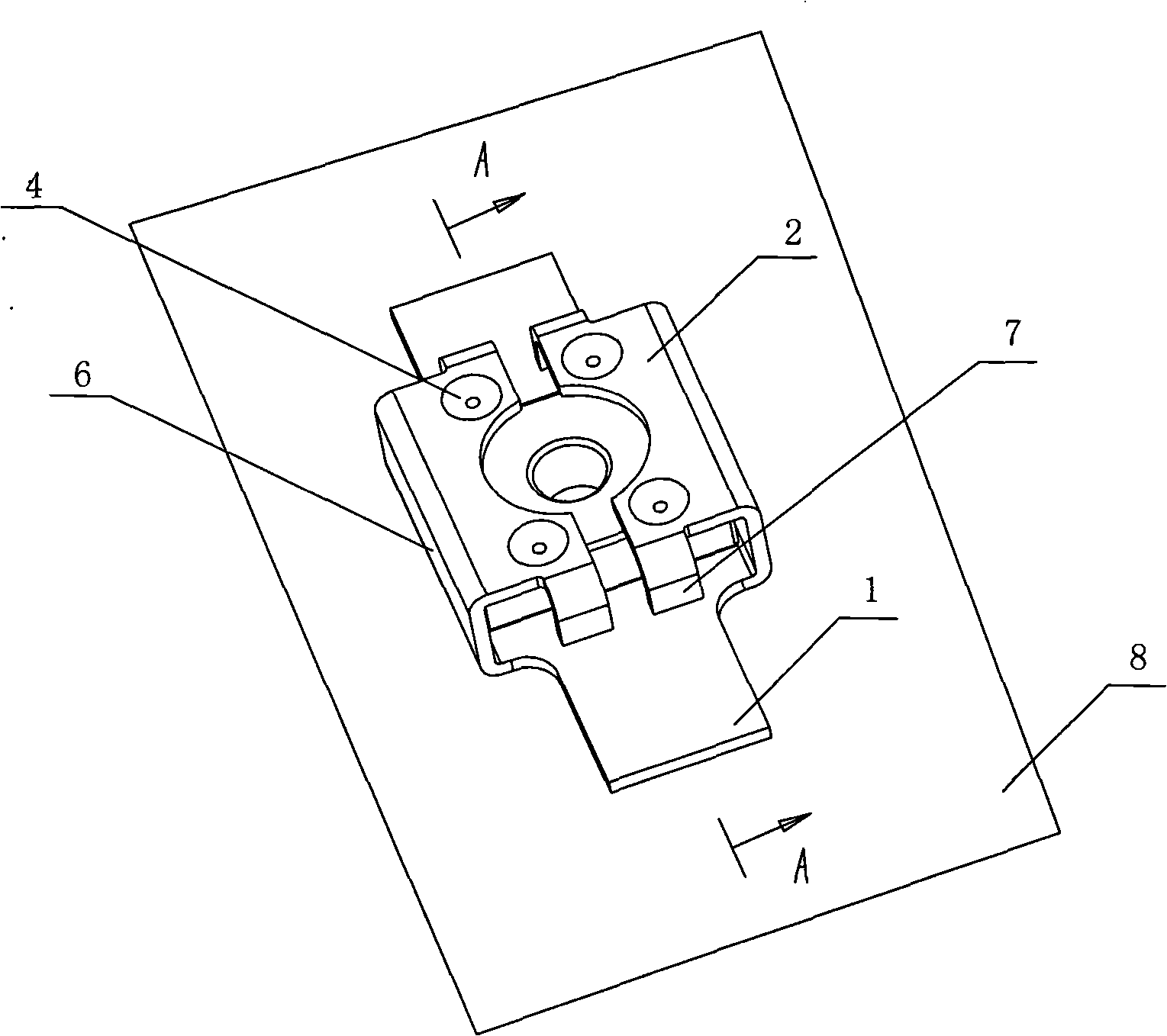

Adjustable nut mounting piece

InactiveCN101338775ASimple structureGuaranteed adjustable rangeNutsEngineeringMechanical engineering

The present invention relates to an adjustable nut installing part, which comprises a base plate, a top plate and a nut-containing cavity formed by a rectangular lateral frame; the position of a nut arranged in the nut-containing cavity is radially limited in the rectangular lateral frame; downward convex points, which are arranged on the top plate, serve as the axial limit mechanism of the nut; the top and the base plates are provided with throughholes along the axial direction of the nut. The adjustable nut installing part, which adopts standard nuts, has a simple structure and a certain radial adjustable amount and is particularly favorable for mass production.

Owner:CHERY AUTOMOBILE CO LTD

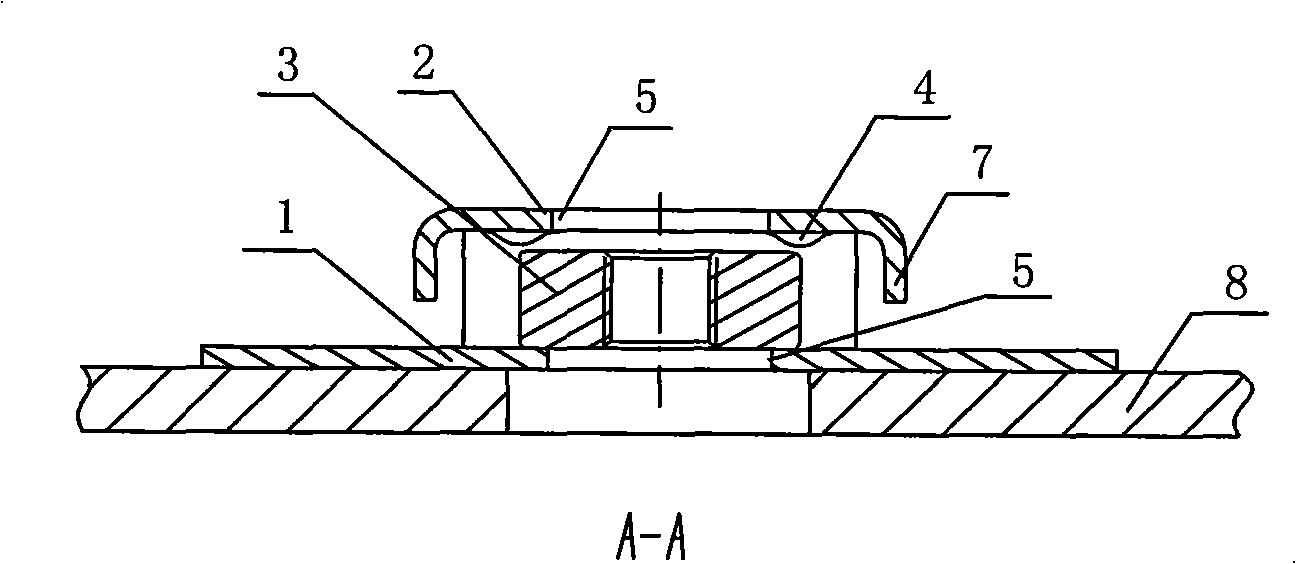

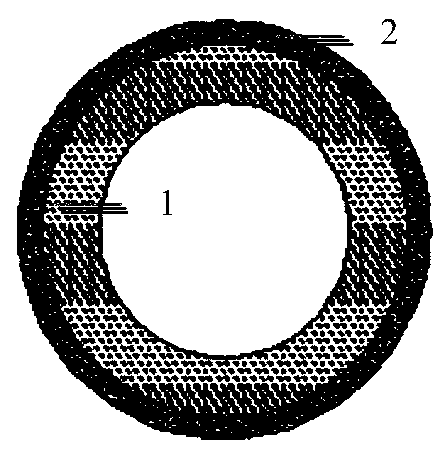

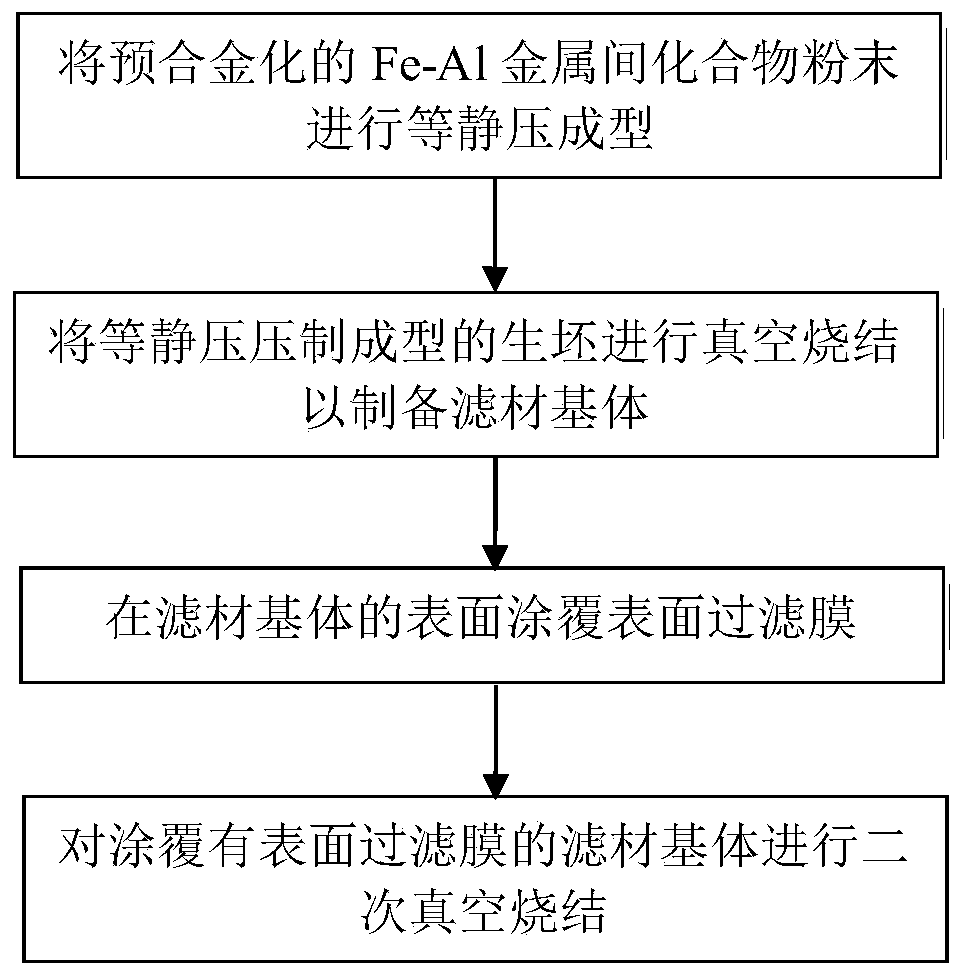

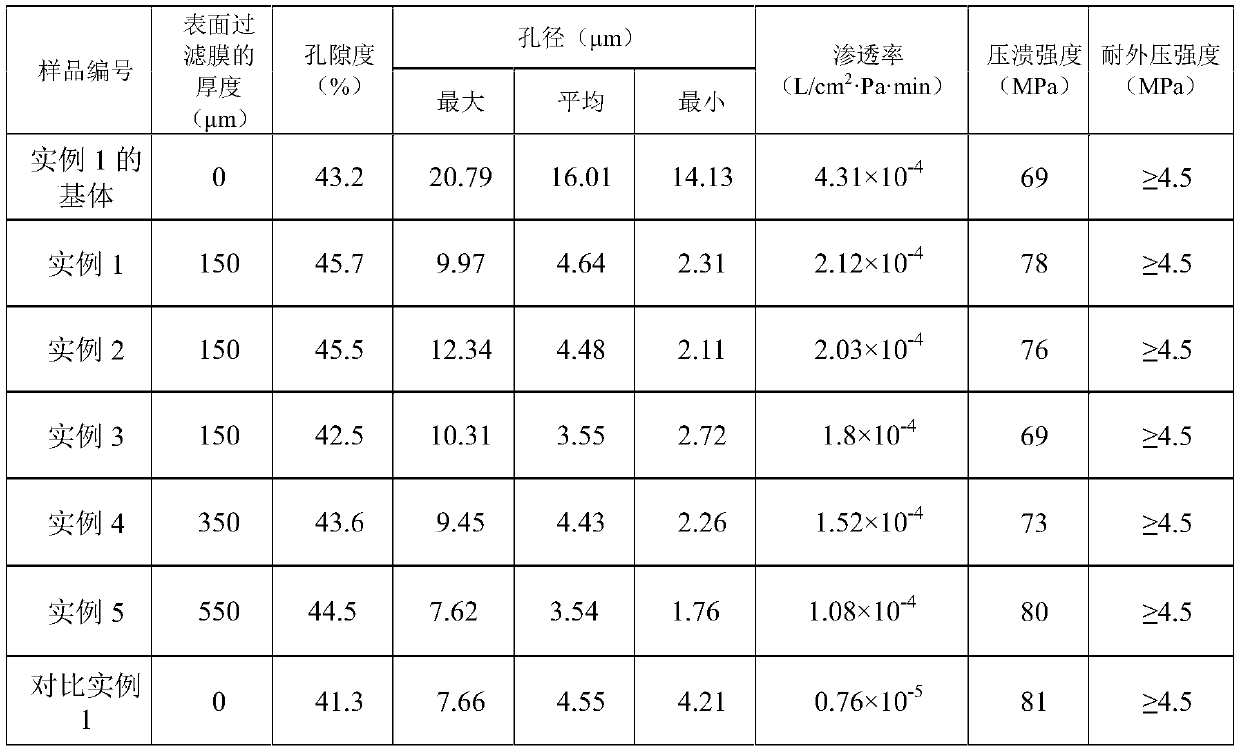

Gradient composite Fe-Al intermetallic compound microporous filter material and preparation method thereof

PendingCN111069590AHigh strengthImprove toughnessSemi-permeable membranesMembranesIntermetallicHigh-temperature corrosion

The invention discloses a gradient composite Fe-Al intermetallic compound microporous filter material and a preparation method thereof, and relates to the field of powder metallurgy preparation. Aiming at the problem that a Fe-Al filter material with high temperature corrosion resistance is difficult to prepare due to process limitation in the prior art, the invention provides the gradient composite Fe-Al intermetallic compound microporous filter material. The gradient composite Fe-Al intermetallic compound microporous filter material is characterized by comprising a matrix framework and a surface filter membrane outside the matrix framework, wherein the matrix framework is pressed and sintered prealloyed Fe-Al intermetallic compound powder; and the surface filter membrane is a mixture ofa binder, water and the prealloyed Fe-Al intermetallic compound powder which are coated on the outer surface of the matrix framework and then sintered for the second time. Therefore, the gradient composite Fe-Al intermetallic compound microporous filter material with high precision, large flux, low resistance drop, good back flushing regeneration characteristic, high strength and high temperaturecorrosion resistance is realized.

Owner:AT&M ENVIRONMENTAL ENG TECH CO LTD

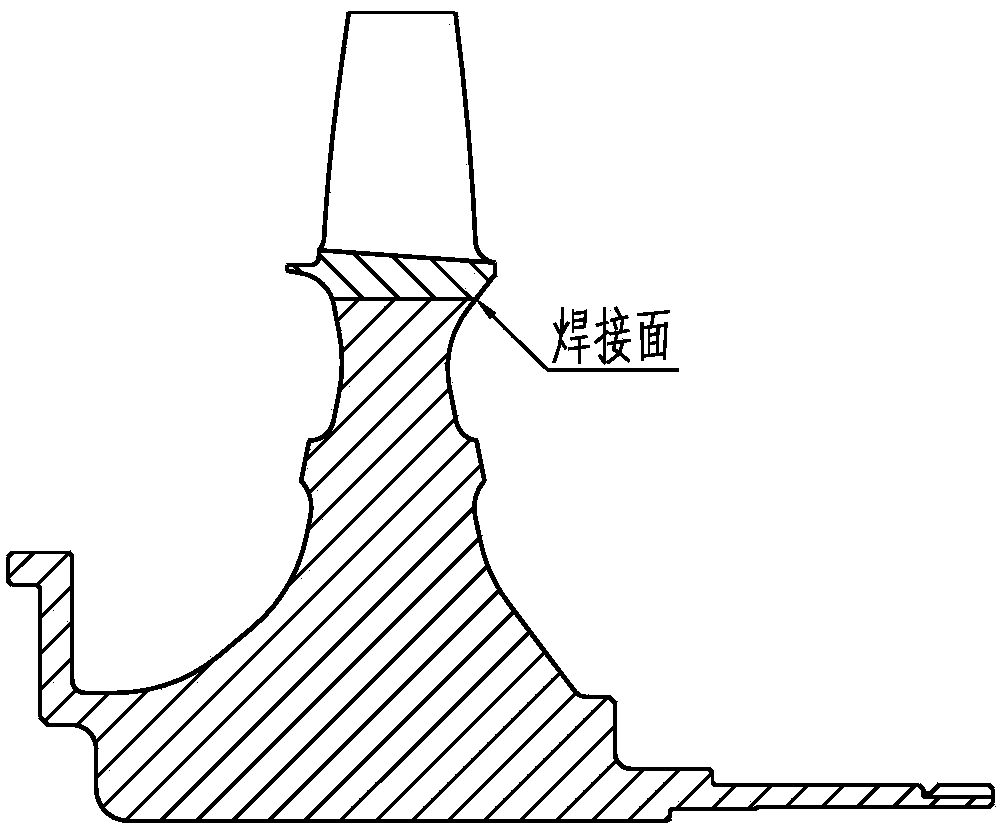

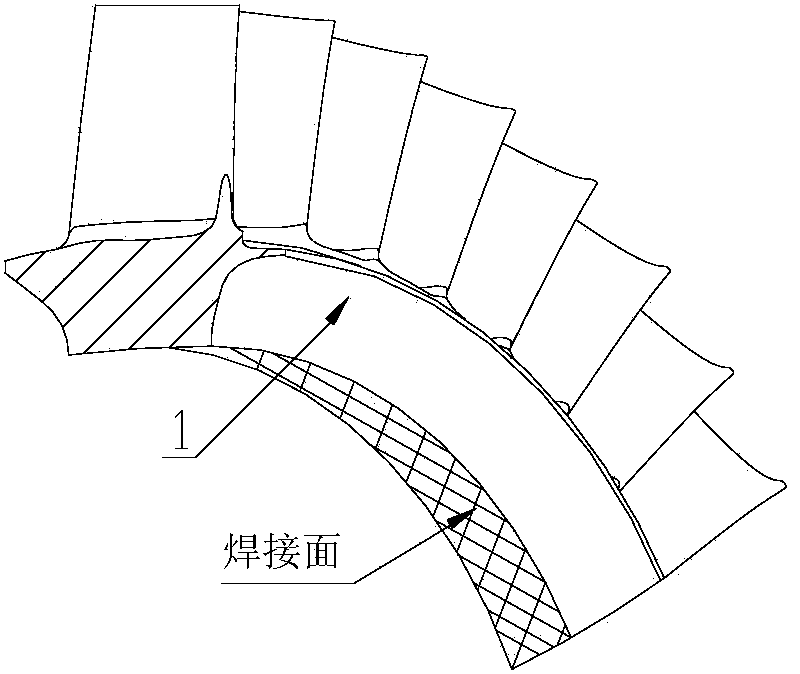

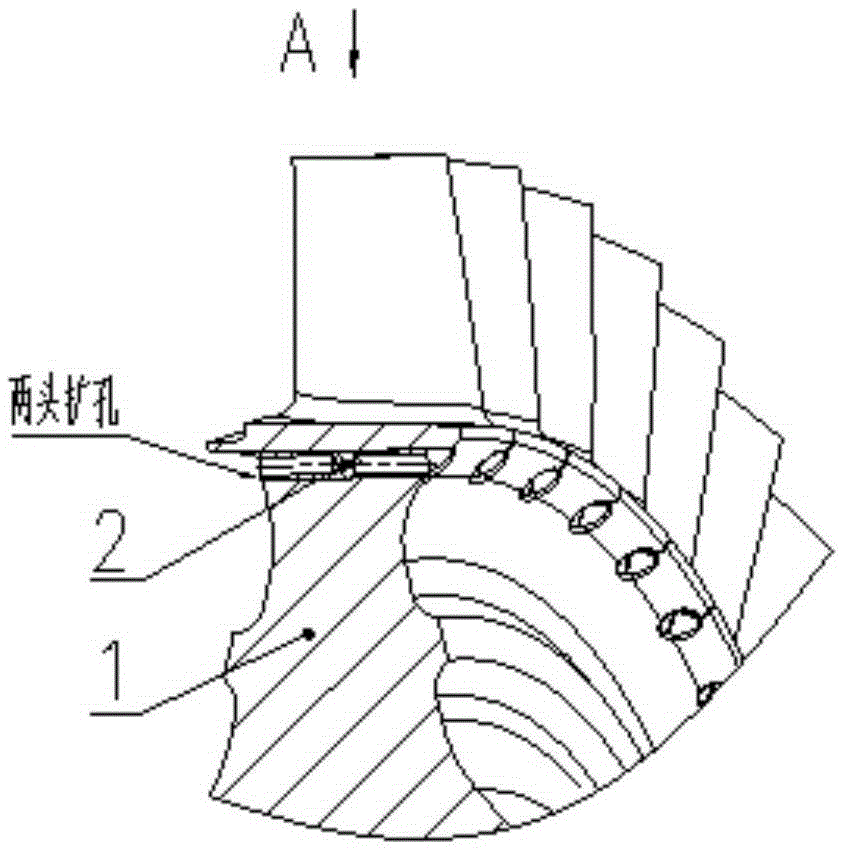

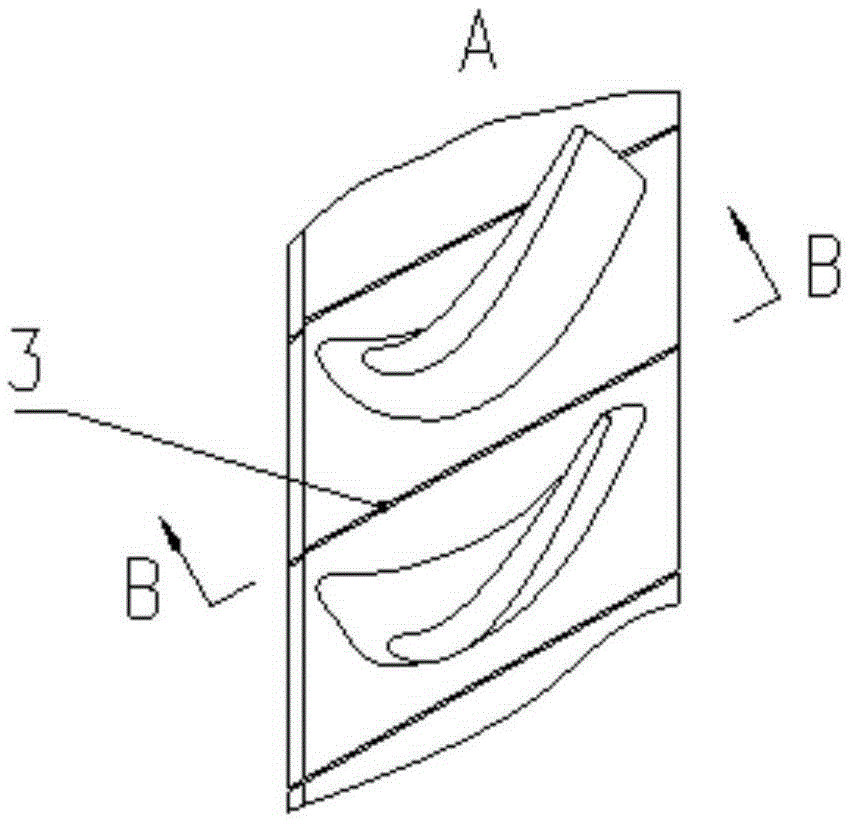

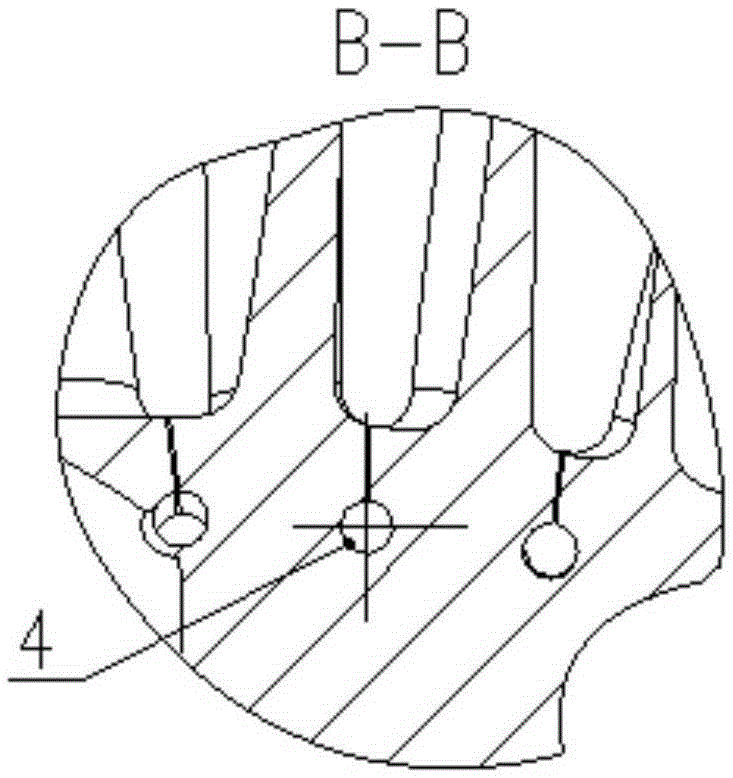

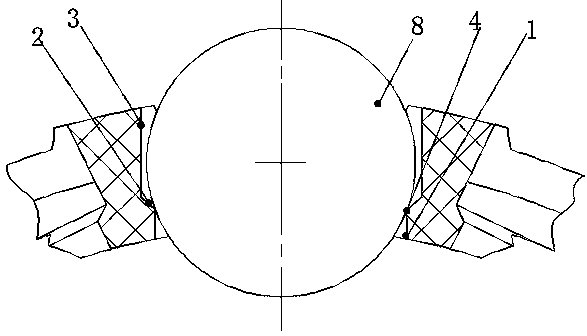

Anti-vibration type dual-alloy turbine blisk and manufacturing method thereof

InactiveCN104191184AHigh temperature durable creep performanceChange the stiffnessBlade accessoriesMachines/enginesTurbinePrecision casting

The invention belongs to turbine blisk technologies, and relates to an anti-vibration type dual-alloy turbine blisk and a manufacturing method thereof. The anti-vibration type dual-alloy turbine blisk is formed by welding a precision cast blade ring component and a sintered alloy blisk body in a diffusion mode through hot isostatic pressure, cut joints are formed between blade channels of the blisk, damping holes communicated with the cut joints are formed in the lower portion of the rim of the blisk, and friction dampers are arranged in the damping holes. The anti-vibration type dual-alloy turbine blisk is formed by welding the precision cast blade ring component and the sintered alloy blisk body in the diffusion mode through hot isostatic pressure, flexible selection and best usability matching of turbine disks and blades are achieved, meanwhile, the friction dampers are arranged on the blisk, the damping and vibration reducing effect is improved, the purposes of improving anti-fatigue ability of the blades and reducing vibration stress of the blades are achieved, and the anti-vibration type dual-alloy turbine blisk has great practical use value.

Owner:CHINA GAS TURBINE ESTAB

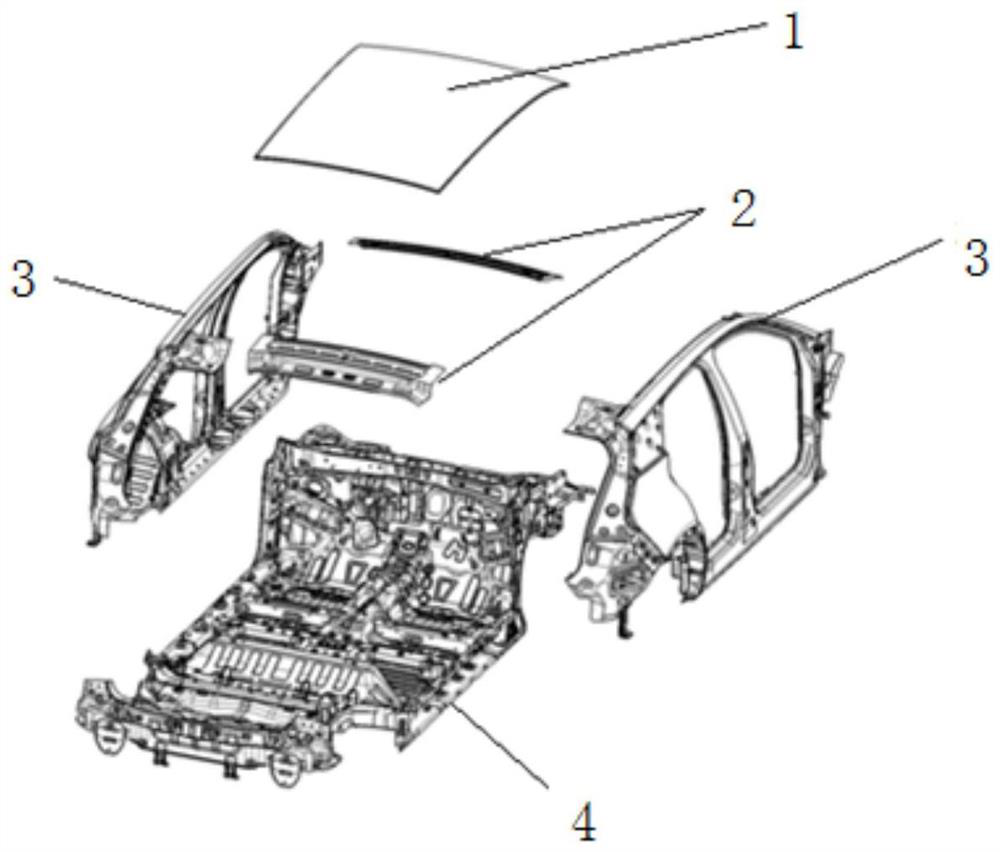

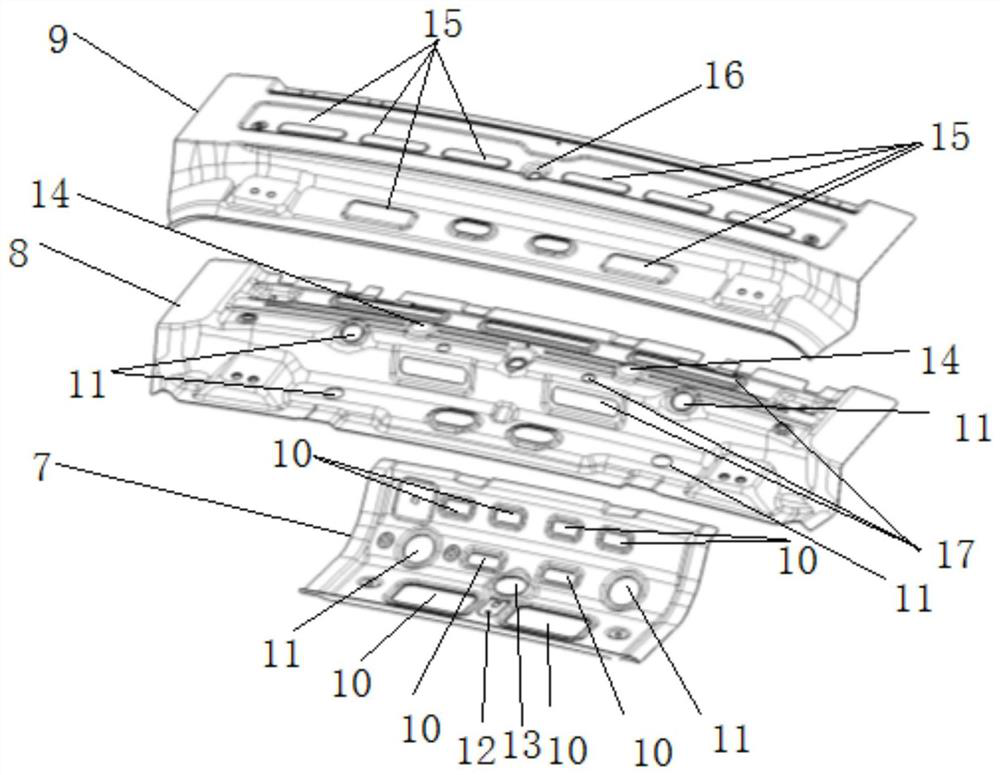

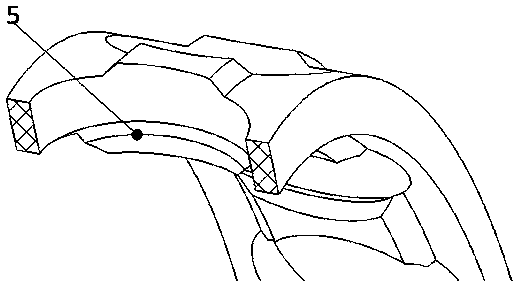

Panoramic backdrop automobile roof rear assembly

The invention discloses a brand-new panoramic backdrop automobile roof rear assembly structure which comprises a rear cross beam lower plate, a rear cross beam upper plate and a rear cross beam outerplate. The rear cross beam lower plate is concave, the rear cross beam upper plate is step-shaped, a first cavity is formed between the rear cross beam lower plate and the rear cross beam upper plate,and a second cavity is formed between the rear cross beam outer plate and the rear cross beam upper plate; and a backdrop glass fixing structure is arranged on the top surface of the rear cross beamouter plate. According to the scheme, the rear assembly structure is used for installing film-coated panoramic backdrop tempered glass, parts such as sunshade curtains, stiffening beams and ceilings can be omitted, the weight of an automobile body is reduced, the rigidity of an automobile roof is improved, the concave resistance of a top cover is improved, the space in the automobile is larger, transparent, open and bright, the view field is wide, lighting is good, and the ergonomics is improved.

Owner:BAIC MOTOR CORP LTD

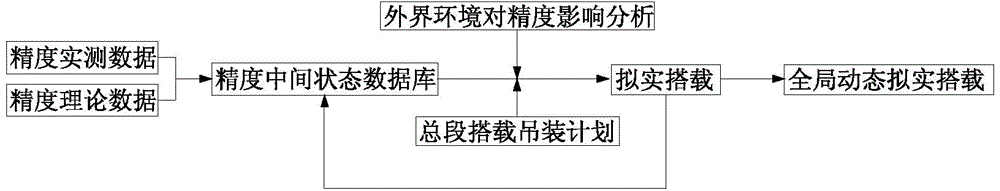

Global dynamic virtual reality carrying method based on precision database

InactiveCN104973215AHigh retention rateControllable accuracy of main dimensionsVessel partsIntermediate stateParallel computing

The invention discloses a global dynamic virtual reality carrying method based on a precision database. The method includes the steps that according to the number of blocks, and after precision measured data and precision theory data of one block are compared according to a sequence, the data are stored in a precision intermediate state database; outside environments are introduced for virtual reality simulation carrying of precision influence analysis and block carrying and hoisting plans, and obtained simulated results are stored in the precision intermediate state database; two blocks subjected to simulation twice are adjacent blocks, two simulation results serve as intermediate states and then simulation carrying is carried out again, and accordingly carrying precision states of the two blocks are obtained; the steps are repeated till virtual reality carrying of all the blocks of a whole spaceship is completed. The method enables main size precision of the whole spaceship to be controllable, and virtual reality carrying efficiency of the blocks of the whole spaceship is improved.

Owner:SHANGHAI WAIGAOQIAO SHIP BUILDING CO LTD

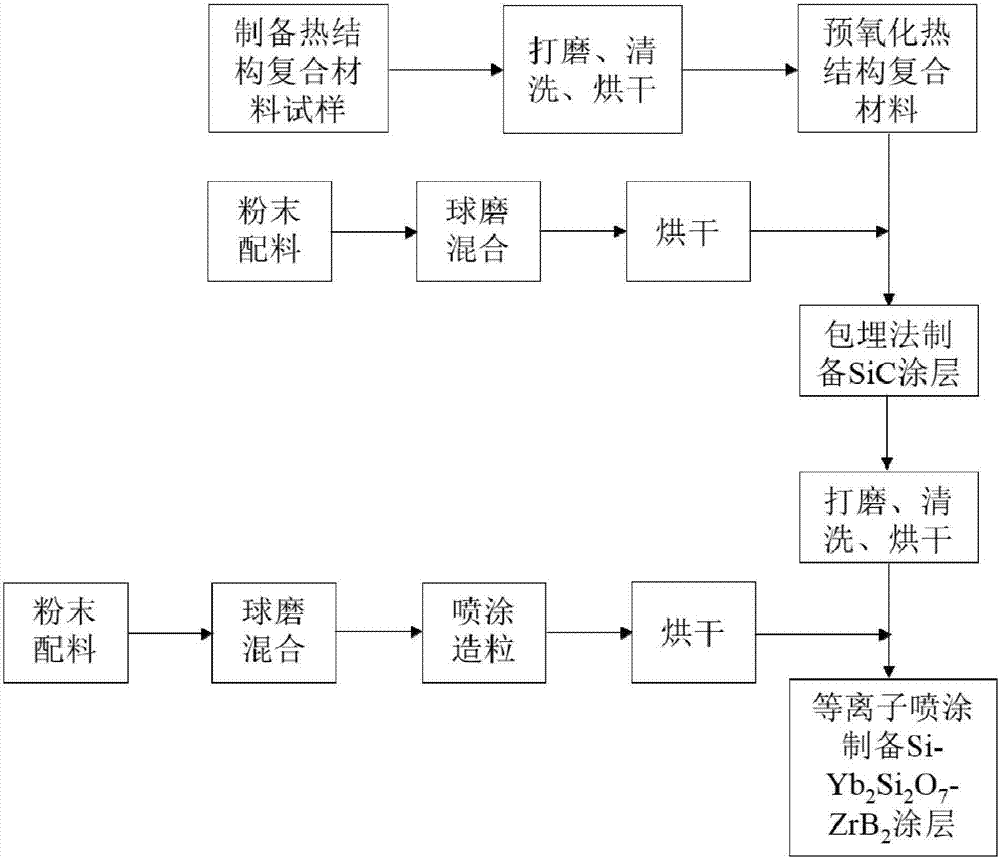

Thermal structure composite material high-temperature anti-oxidation composite coating and preparation method thereof

ActiveCN106966764AImprove antioxidant capacitySimple preparation processPower flowThermal insulation

The present invention relates to a thermal structure composite material high-temperature anti-oxidation composite coating and a preparation method thereof. The preparation method comprises: carrying out thermal insulation on a thermal structure composite material for a first preset time at a first preset temperature, carrying out pre-oxidation, and naturally cooling the thermal structure composite material to a room temperature; under a protection atmosphere, embedding the thermal structure composite material into an embedding powder material, and carrying out thermal insulation for a second preset time at a second preset temperature to obtain a thermal structure composite material having a SiC coating; and spraying a spraying powder material onto the thermal structure composite material having the SiC coating under a preset voltage and a preset current by using a plasma spraying method to obtain the Si-Yb2Si2O7-ZrB2 coating. According to the present invention, the preparation method has advantages of simple preparation process, convenient operation, easily available raw material, and low preparation cost.

Owner:BEIHANG UNIV

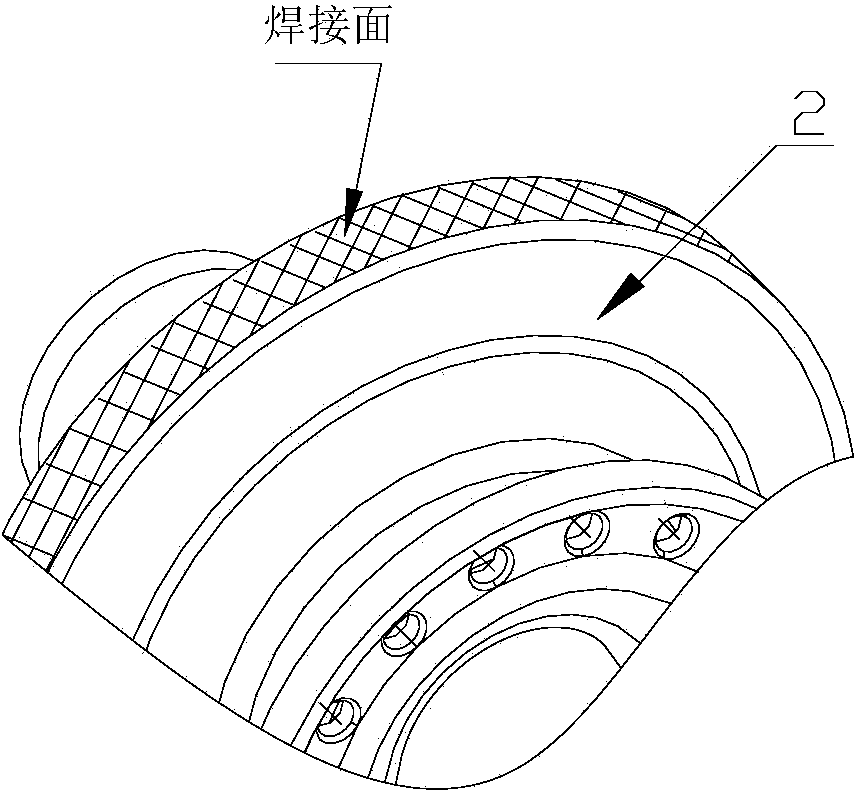

A structure and method for adjusting the natural frequency of a turbine integral blisk blade

ActiveCN104314619BLower natural frequencyChange the stiffnessBlade accessoriesMachines/enginesStress distributionTurbine blade

The invention belongs to the overall blade disk technology of turbines and relates to an adjustment structure and method for the inherent frequencies of blades of the overall blade disk of a turbine. Firstly, the initial inherent frequencies of the blades of the overall blade disk of the turbine are measured; then, according to the measured frequencies, the excitation frequency of periodic pulsation of airflow or the result of dynamic stress measurement is combined and the blade frequency needing to be adjusted is calculated, so that the inherent frequency of each stage of the blades can have safe resonance frequency margin; then, according to the blade frequency needing to be adjusted, the space between every two blades of the overall blade disk is slotted, and the radial depth of each slot is determined according to the requirements of adjusting the frequency; a stop hole is formed in each slot bottom, and a pin is mounted in each stop hole. The structure and the method effectively reduce the inherent frequencies of the blades and change the stiffness, modes of vibration and vibration stress distribution of the blades, and the blades do not resonate or the important mode of vibration of resonance of the blades is tuned out the range of working speed. The structure and the method are simple and easy to operate and significant in frequency modulation effect, are easy to control size precision, and can meet actual requirements.

Owner:AECC SICHUAN GAS TURBINE RES INST

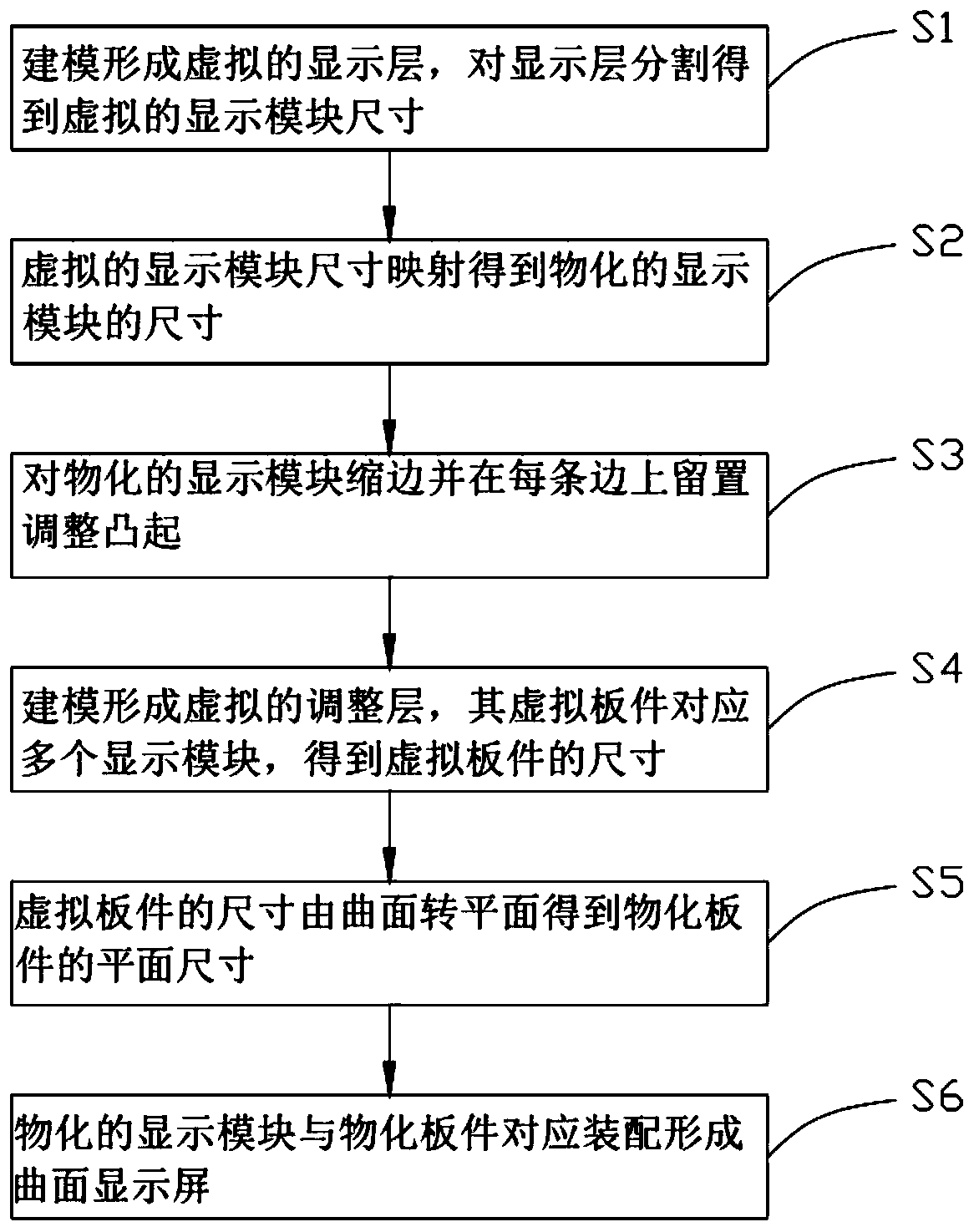

Curved-surface display screen, and bearing framework and forming method thereof

PendingCN111261058AEasy to processDimensional accuracy is easy to controlStatic indicating devicesStands/trestlesSurface displayEngineering

The invention relates to the technical field of LED screen display, in particular to a curved-surface display screen, and a bearing framework and a forming method thereof. According to the curved-surface display screen forming method, the size of a virtual display module is mapped to the size of a materialized display module; the sizes of all the virtual display modules are scaled up or down to the plan view size of the materialized display modules in equal proportion; that is to say, the display modules for actual splicing are of a surface plate structure, the display modules of the surface plate structure are easy to machine, and the dimensional precision is easy to control; furthermore, the display modules are subjected to edge shrinking, correspondingly, an adjusting space is reservedfor two adjacent display modules, adjusting protrusions are further reserved on each edge, gaps can be prevented from being formed in the splicing process of the display modules under the condition that the machining precision is not high, adjusting bosses of the display modules with the large size are machined when the problem of over-tight installation occurs, the splicing precision can be ensured, the installation precision is effectively improved, and accumulated errors are eliminated.

Owner:NANJING LUOPU TECH CO LTD

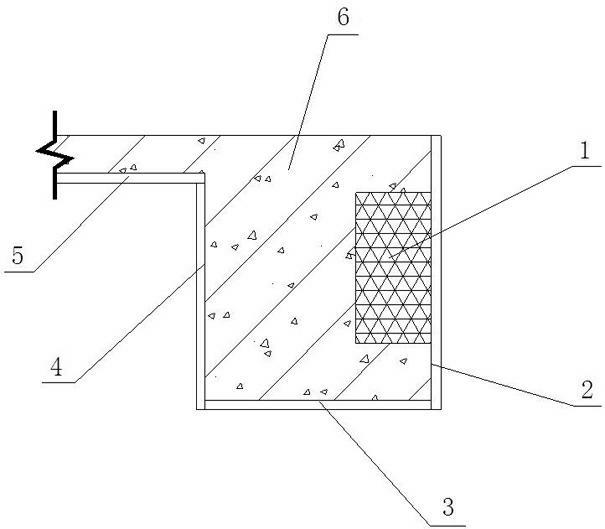

Processing technology of boron carbideagglomerate for radiation shield assembly

The invention relates to a processing technology of a boron carbideagglomerate for a radiation shieldassembly, and relates to the technical field of radiation shield assembly material processing. Theprocessing technology comprises the following processing steps of adding weighed and compounded powder into a blender mixer, adding 0 to 25 percent of deionized water for mixing 2 to 6h, and preparingto obtain powder or an emulsion distributed uniformly; adding the uniformly mixed powder or emulsion and a binder and the deionized water with a certain mass fraction into a high-speed stirrer, uniformly stirring, and preparing to obtain an emulsion with a certain solid content for standby use; carrying out spray palletization; pressing; finishing a pressed blank; dewatering and degumming; sintering; packaging. Traditional filling boron carbide powder or a boron silicon resinshielding material is replaced with a whole boron carbideagglomerate or a boron carbideagglomerate assembly block for filling, so that on the basis of meeting the radiation shield performance, the preparation process is simplified, the production cost is reduced, volume production of the boron carbideagglomerates withhigh-precision specifications is realized, and the practicability is higher.

Owner:ANHUI YINGLIU JIUYUAN NUCLEAR ENERGY NEW MATERIAL TECH CO LTD

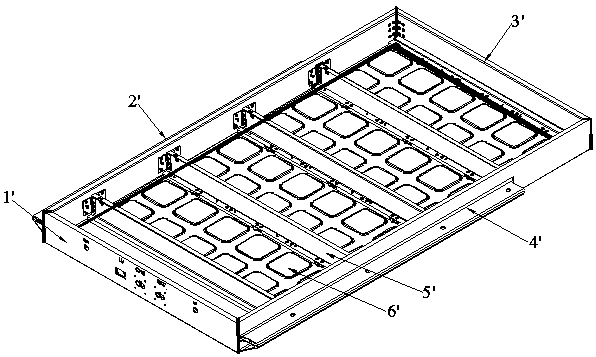

Weldless lightweight battery box body and manufacturing process thereof

PendingCN111261818AImprove efficiency and costDimensional accuracy is easy to controlCell component detailsFusion weldingAdhesive

The invention discloses a weldless lightweight battery box body and a manufacturing process thereof. The weldless lightweight battery box body comprises frame profiles, frame corner connectors, crossbeams and a bottom plate, wherein the frame profiles are assembled together through the frame corner connectors to form a frame set, the cross beams are transversely installed in the frame set and locked with the left side and the right side of the frame set, and the bottom plate is connected to the frame set in a buckled mode and locked and fixed with the frame set; the frame set is sequentiallysubjected to the steps of coating the frame corner connectors with adhesive, inserting the frame corner connectors into one frame, inserting the frame corner connectors into the other frame, clamping,screw assembling, adhesive supplementing or smearing and curing; the cross beams are sequentially subjected to pre-fixing, structural adhesive coating, assembling and curing; and the bottom plate issequentially subjected to adhesive coating, adhering and FDS riveting. According to the weldless lightweight battery box and the manufacturing process thereof, large-area fusion welding and stirring welding can be removed, the cost and the efficiency are greatly improved, the size precision is easy to control, the deformation is avoided, the equipment cost is reduced, the adhesive coating processand the FDS process are used together, and high feasibility of an automatic production line is guaranteed.

Owner:纽维科精密制造江苏有限公司

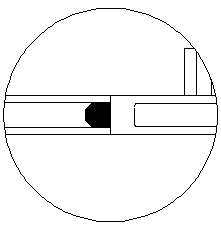

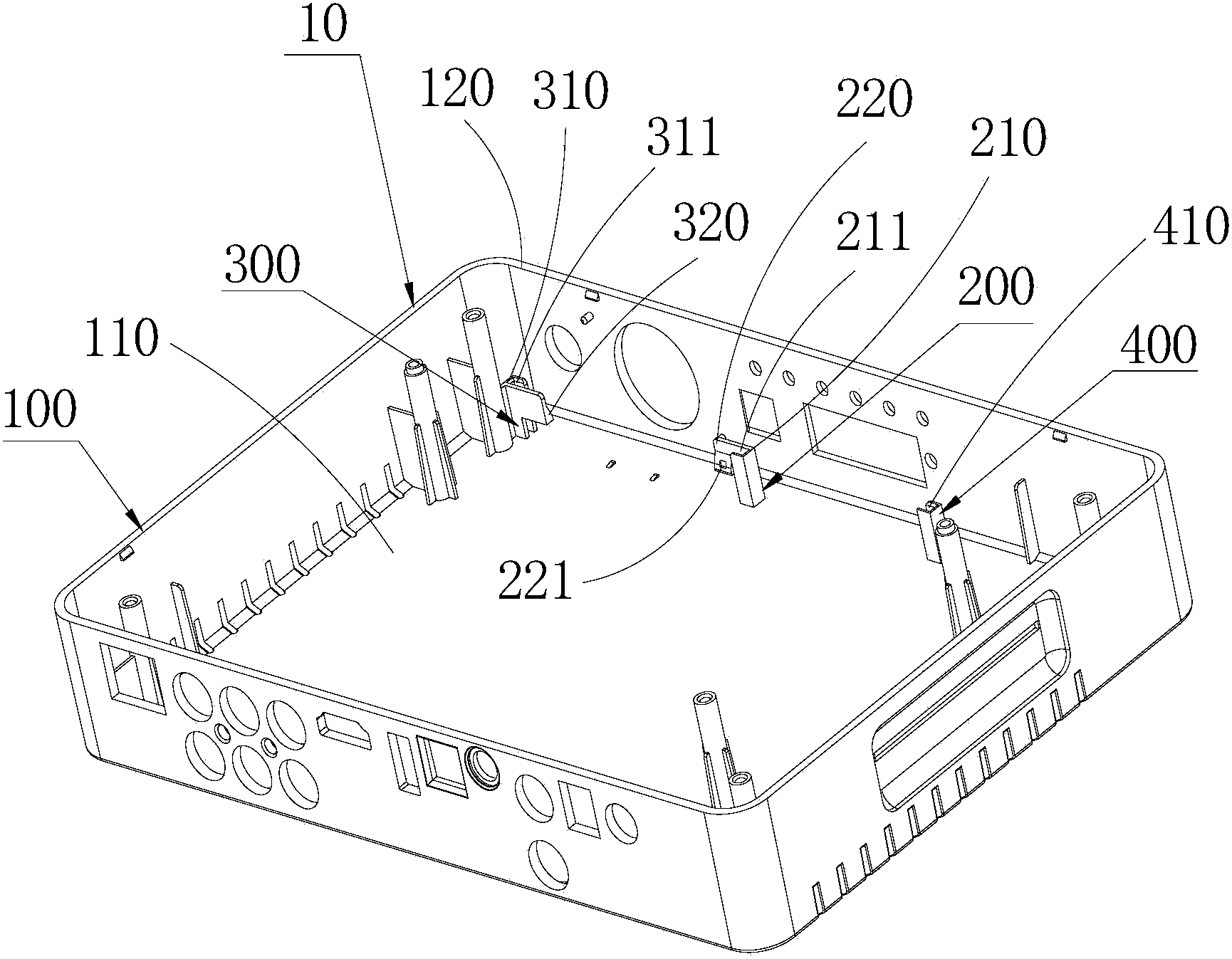

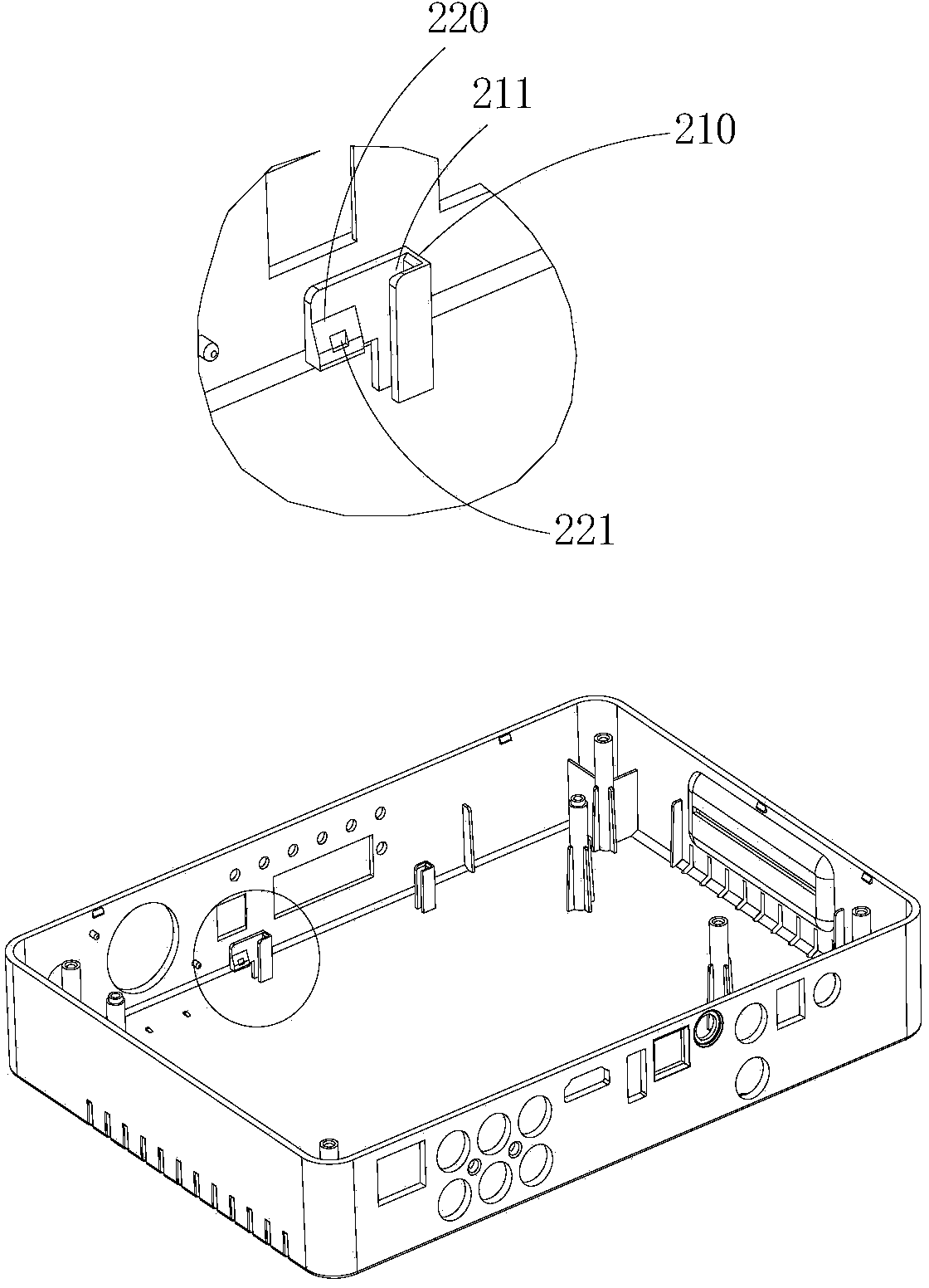

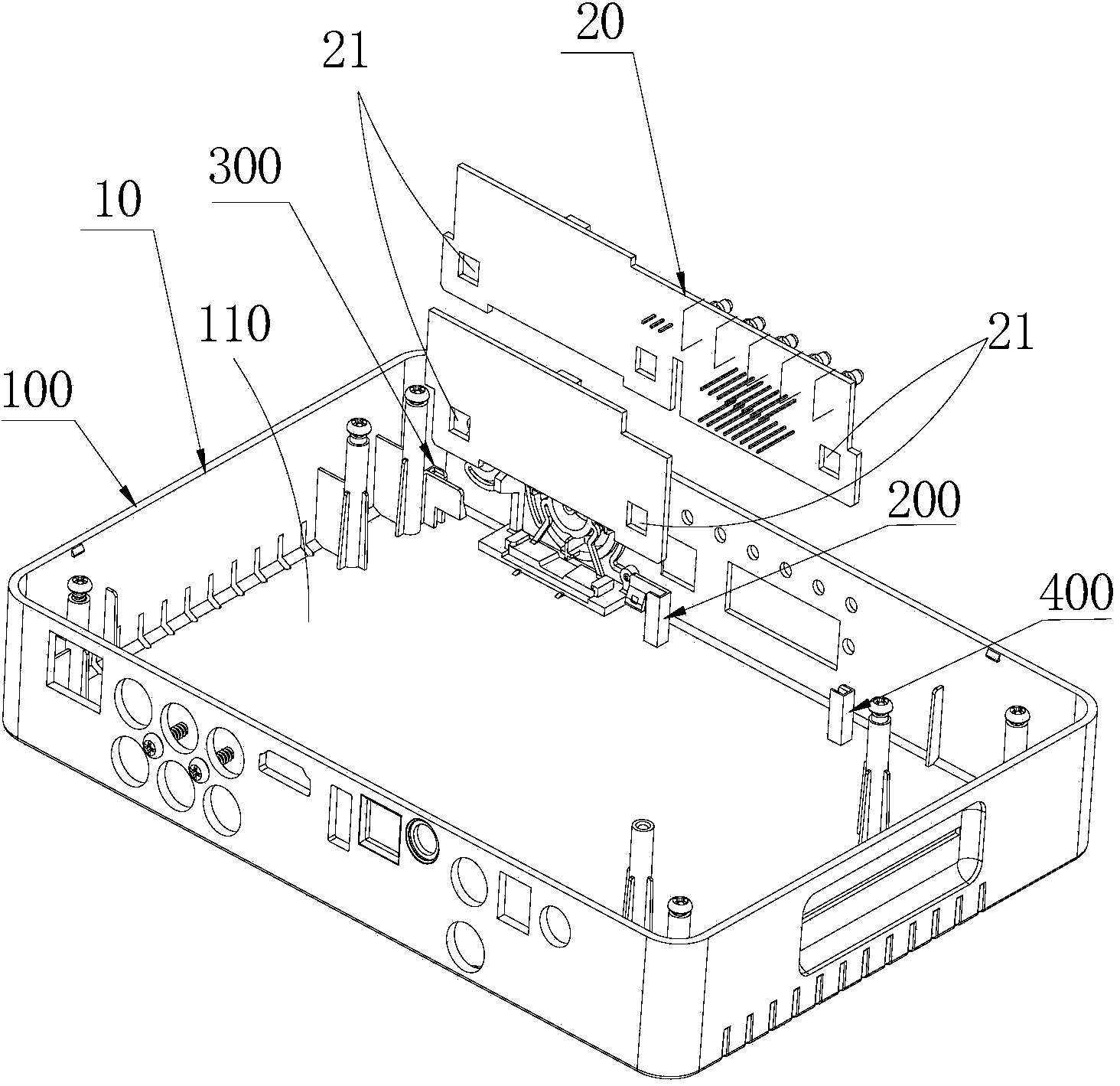

Fixing structure of front control board of set top box and set top box

The invention relates to a fixing structure of a front control board of a set top box and the set top box. The fixing structure of the front control board of the set top box comprises a shell, a first fixing part and a second fixing part. The first fixing part comprises a first limiting part and a first buckle, the second fixing part comprises a second limiting part and a second buckle, and when the first buckle and the second buckle are buckled to the front control board and installed in a first limiting groove and a second limiting groove respectively, the first buckle and the second buckle penetrate through two buckle holes formed in the front control board in advance respectively to be buckled. Because the fixing structure is provided with two fixing parts, the two fixing parts respectively comprise one limiting groove and one buckle, the front panel is fixed through the two oppositely arranged limiting grooves and two buckle structures hung upside down, the front control board can be stably fixed just by being installed in the two limiting grooves and buckled to the two buckles, no structure needs to be arranged on the front side wall, no screw needs to be used for fixation, the implementation difficulty of a mold is greatly reduced, the precision is very high, the difficulty in fixing the front control board is reduced, and the cost of the set top box is effectively reduced.

Owner:SHENZHEN JIUZHOU ELECTRIC

Riding edge internal lock type retainer

PendingCN110886780AGuaranteed StrengthGuaranteed drawing effectBearing componentsNew energyEngineering

The invention belongs to the technical field of bearings, is applied to a bearing of a new energy photovoltaic silicon wafer cutting machine, in particular to a riding edge internal lock type retainer; a first cylindrical section, a conical section and a second cylindrical section are arranged in a pocket of the retainer from inside to outside; the diameter of the cross section of the first cylindrical section is less than that of the cross section of the second cylindrical section; the conical section expands from the first cylindrical section to the second cylindrical section; and the position of an internal lock of the retainer is at the joining edge of the first cylindrical section and the conical section. The bearing mounted with the retainer operates flexibly. The retainer ensures high speed and high precision of the bearing and also can lower the noise of the bearing.

Owner:WAFANGDIAN BEARING GRP STATE BEARING ENG TECH RES CENT CO LTD

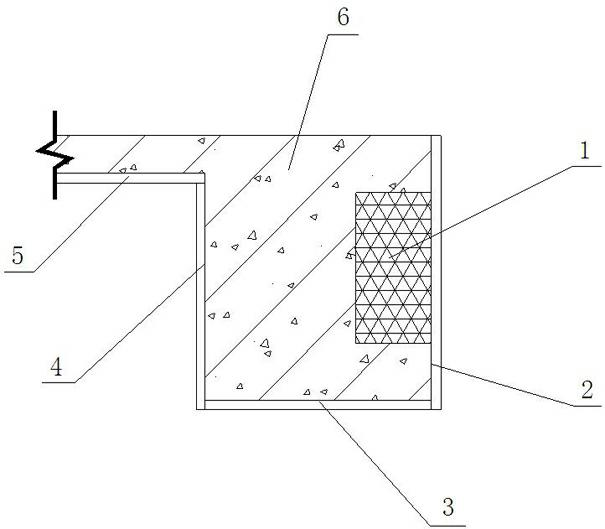

Construction method for grooving and punching on concrete

InactiveCN102367707ADimensional accuracy is easy to controlReduce supportBuilding material handlingWork periodMaterials science

The invention discloses a construction method for grooving and punching on concrete, relating to the technical field of construction engineering, in particular to an engineering technology for grooving and punching on concrete. The method comprises the following steps of: manufacturing a foam bar of which the size is same as that of a groove or a hole, fixing the foam bar on one side of a template, and enclosing the template and other templates into a concrete pouring cavity; and pouring concrete mortar into the cavity, detaching the template after the concrete mortar is cured, and removing the foam bar. Due to the adoption of the method, the erection of at least three templates is reduced, the shaping size accuracy of the foam bar is easy to control, and the foam bar is convenient to fix with the template, and is more convenient to remove after molding. According to the method, convenience is brought to manufacturing, the labor force and work period are saved, and the quality accuracy is high.

Owner:JIANGSU JIANGDU CONSTR GRP

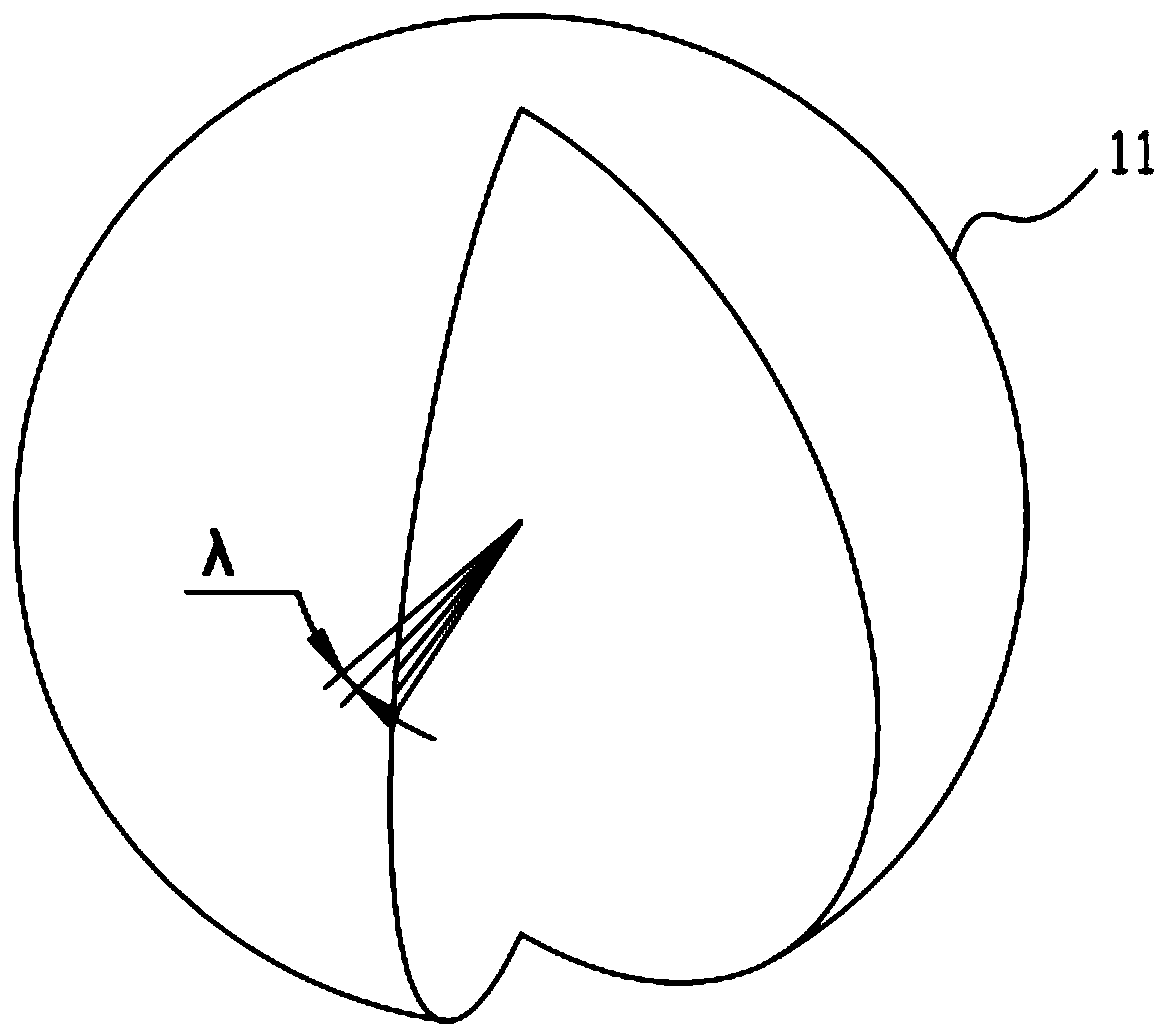

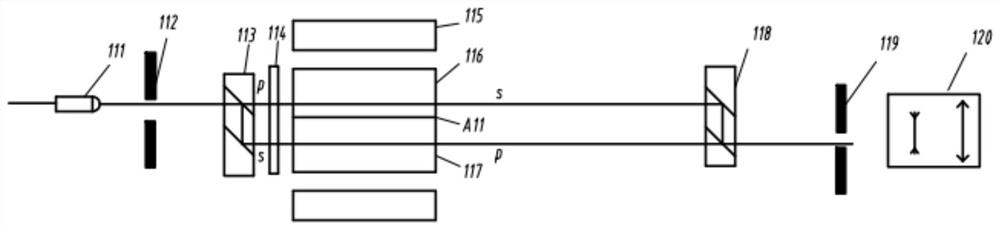

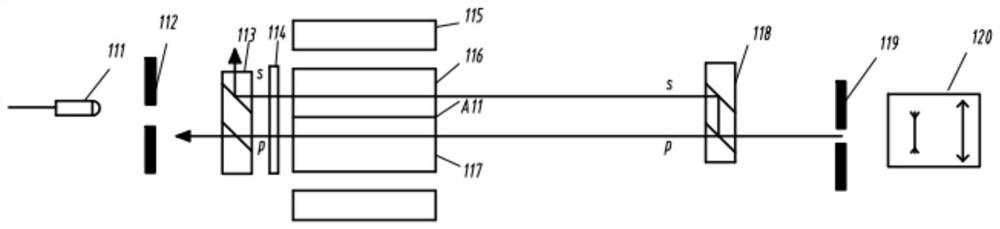

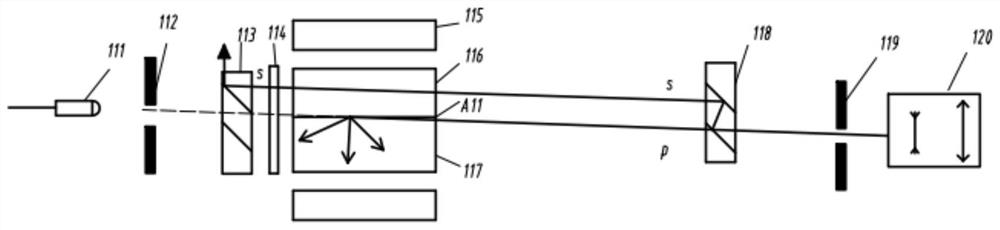

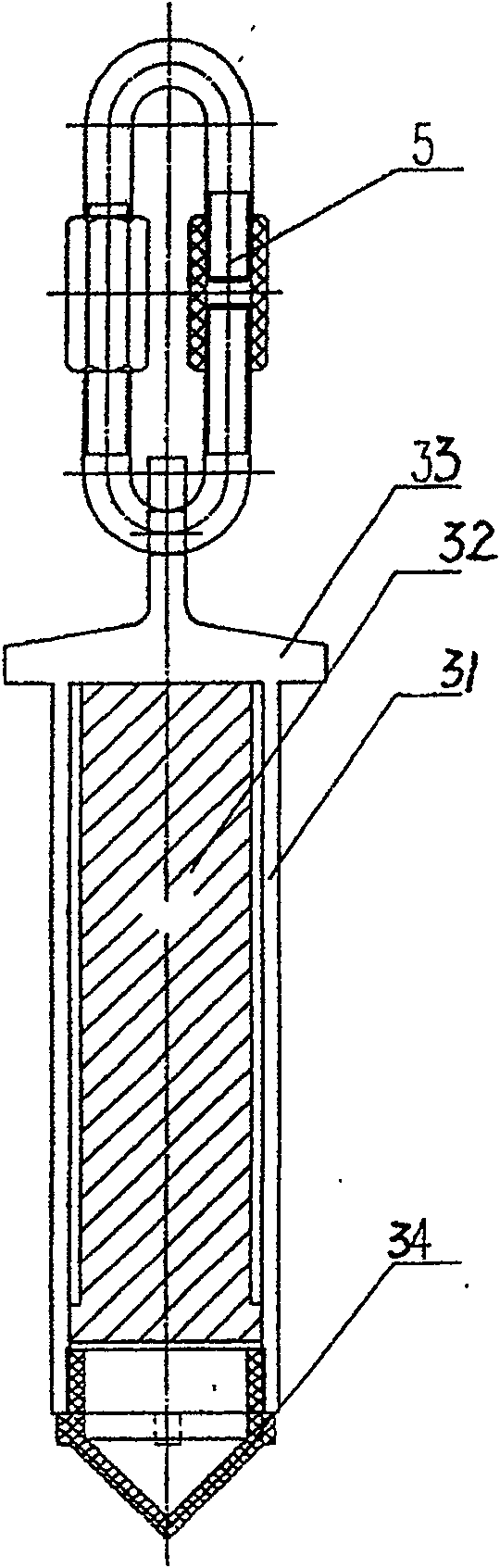

An optical isolator capable of blocking all angles

ActiveCN110488511BImprove isolationDimensional accuracy is easy to controlNon-linear opticsBeam splitterMaterials science

The invention discloses an optical isolator capable of blocking all angles, which comprises an input fiber collimator, an entrance aperture, a first beam splitter, an optical rotation plate, a magneto-optical crystal, and a second beam splitter arranged in sequence , a light exit diaphragm and a beam expander collimation output optical system, magnets are provided on the side of the magneto-optic crystal, and a blocking interface for blocking return light is provided inside the magneto-optic crystal. The blocking interface scatters or blocks the return light with a certain angle and is not blocked by the light entrance diaphragm and the light exit diaphragm without affecting the forward light transmission, so as to avoid coupling into the fiber and causing damage to the laser. Realize the effect of working from all angles. In addition, the folded optical path can also be used to remove the reflective film in the area where the return light with a certain angle and not blocked by the entrance diaphragm and the exit diaphragm passes through the folded mirror, so that this part of the light passes through the mirror without being blocked. Reflections avoid coupling into the collimator and improve isolation over the full angular range.

Owner:福建海创光电技术股份有限公司

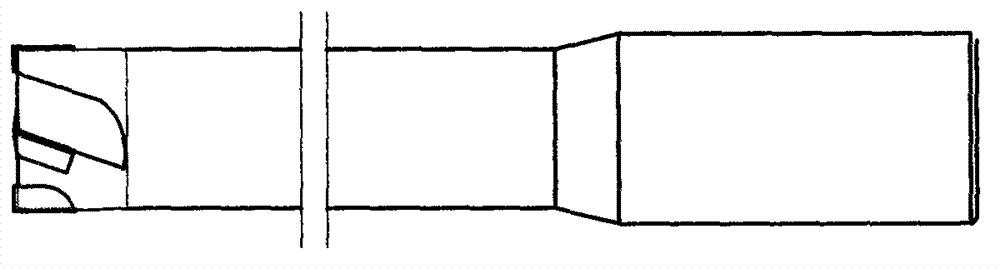

Hard alloy integral type expansion-extrusion countersink for machining deep hole

InactiveCN103691997ASimple manufacturing processEasy to processTransportation and packagingTrepanning drillsVertical planeSpiral blade

The invention provides a hard alloy integral type expansion-extrusion countersink for machining a deep hole. The countersink comprises a hard alloy circular cutter bar. The countersink is characterized in that the front half section of the hard alloy circular cutter bar is evenly provided with 4-6 twist bit-shaped spiral grooves, and the lift angle of each spiral groove is 20-25 degrees; the leading surfaces along the rotation direction of the excircle surfaces of the spiral bodies between every two adjoining spiral grooves are raised along the radial direction to have spiral blade belts, the circumferential belt width of each spiral blade belt is 0.5-1.2mm, the radial raised height of each spiral blade belt is 0.3-0.5mm, and the relief angle of each spiral blade belt is 0 degree; the front end face of each spiral body 5 is inwards concaved, the front end face of each spiral body is provided with a radial blade which is raised out of the front end face of each spiral body from the tail end of each spiral blade belt to the axial lead of the circular cutter bar, the width of each radial blade is 0.8-1.0mm, the concave inclined angle Q of the vertical plane between the front end face of each radial blade and the axial lead of the circular cutter bar 1 is 3 degrees, and the relief angle of each radial blade is 6-8 degrees. The hard alloy integral type expansion-extrusion countersink has the advantages that the countersink is good in manufacturability, and convenient to machine, the dimensional accuracy is easy and stable to control, and the expansion and the extrusion can be completed at once.

Owner:FUAN XINJIU ALUMINUM ALLOY DIE CASTING

Pump split type crosshead

PendingCN111396303AHigh strengthNo post-processing requiredPositive displacement pump componentsLiquid fuel engine componentsEngineeringMechanical engineering

The invention provides a pump split type crosshead and relates to the field of high-pressure plunger pump components. The pump split type crosshead comprises a split type crosshead main body, a crosshead stretcher and a locking component; during the later actual using process, the wear degree of the crosshead stretcher is far less than that of the crosshead main body, so that a working staff can change the crosshead main body only, the later maintaining cost is further reduced, and the cost is decreased; in addition, the crosshead main body and the crosshead stretcher can be separately manufactured, so that later treatment to the cavity and the pin hole of the crosshead is further avoided, and the production efficiency is improved; and moreover, the locking component can lock the crossheadmain body and the crosshead stretcher in the axial direction to prevent the connecting part of the crosshead main body and the crosshead stretcher from breaking, so that the overall strength of the crosshead can be effectively improved.

Owner:上海清力源流体科技有限公司

Cathode for electric demisting device with conductive fiberglass reinforced plastic

ActiveCN100560217CReduce shakingAvoid depositionElectrode constructionsEngineeringElectrochemical corrosion

The cathode system for conductive FRP electric demister is used in the acid mist removal device in the mercury-containing smelting flue gas purification process of acid engineering. It belongs to the field of electric demister and consists of cathode load beam, cathode wire, weight and lower cathode frame. , the upper end of the cathode line is hung on the cathode load beam, which is characterized in that the weight vertically connected to the lower end of the cathode line is composed of a closed plastic outer cylinder and a plumb weight inside it, and the lower cathode frame is a main beam made of plastic or glass steel It is composed of a support beam, and the support beam is correspondingly provided with an opening adjustment plate, and the outer cylinder of the weight passes through the hole of the adjustment plate. In this system, the plumb weight in the weight is isolated from the cathode line without direct contact, which effectively prevents the cathode line The electrochemical corrosion between the lead bob and the cathode wire prolongs the service life of the cathode wire. The lower cathode frame has a simple structure and high strength. The opening adjustment plate on it makes it easy to adjust the position and distance of the cathode wire. The shape of the anode tube is adjusted separately, the size accuracy is easy to control, the stability is good, the weight is light, and the installation is convenient. The electric field in the conductive FRP electric demister is stable, the operation is safe, the service life is long, the demisting efficiency is high, and the acid mist outlet is ≤3mg / NM3.

Owner:双盾环境科技有限公司

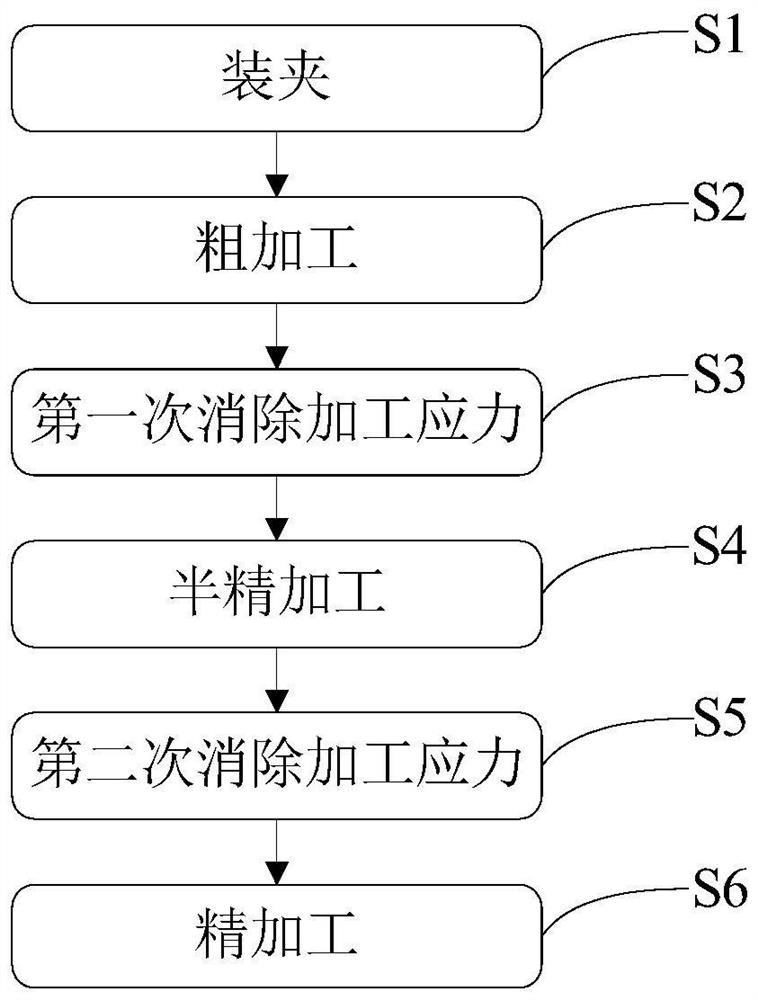

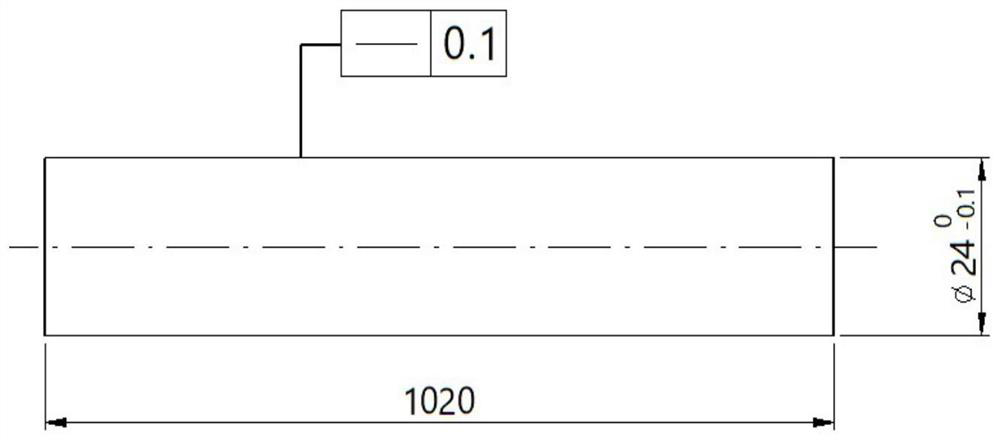

Machining process method suitable for slender iron-stainless steel rod piece

PendingCN114346603AReduce distortionImprove processing qualityMachining processDimensional precision

The invention relates to a machining process method suitable for a long and thin iron-stainless steel rod piece. According to the machining process method suitable for the slender rod piece made of the ferritic stainless steel, machining and detection are combined in real time, deformation of the slender rod piece made of the ferritic stainless steel in the machining process is effectively reduced from the angle of the machining process, so that the machining quality of the slender rod piece is improved, and it is guaranteed that the size precision and the form and position precision of the slender rod piece meet the requirements. According to the method provided by the invention, machining is carried out in a one-jacking and one-clamping manner, and the follow rest is used within the full-length machining length of the slender rod piece made of the iron and stainless steel, so that the situation that the slender rod piece made of the iron and stainless steel is laterally bent due to improper clamping force is avoided. Meanwhile, according to the method provided by the invention, the feed amount is as small as possible, the pressure generated by a cutter on the slender rod piece made of the molten iron in each machining step is reduced, and the lateral bending of the slender rod piece made of the molten iron is reduced, so that the straightness of the slender rod piece made of the molten iron is controlled; and the requirement on the surface roughness of the slender iron-stainless steel rod piece can be better met by small feeding amount.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

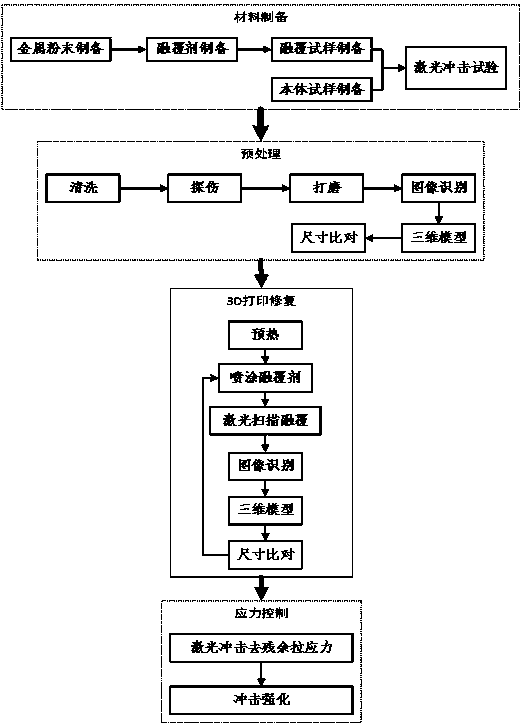

A stress-controlled 3D printing remanufacturing method for metal parts

InactiveCN105154870BSmall overall deformationDimensional accuracy is easy to controlAdditive manufacturing apparatusMetallic material coating processesPeeningLayer wise

The invention discloses a stress-controlled 3D printing remanufacturing method of a metal part. Firstly, a metal part body sample and a cladding sample are prepared, and laser parameters required for the same residual compressive stress are obtained by laser shock; processing, and use the image recognition method to determine the repair area and repair margin of the part; then use the laser 3D printer to repair the metal parts layer by layer, so that the size of the repair part reaches the original design size of the part; finally use laser shock to eliminate the residual tensile stress, and then use The laser shock strengthening method forms a residual compressive stress layer on the working surface of metal parts. The invention uses laser 3D printing to repair the parts, the overall deformation of the parts is not large, and the dimensional accuracy of the repair is easy to control, and no subsequent processing is required; the overall strength of the repaired parts is the same, and the residual compressive stress of the strengthening layer on the surface of the parts after using laser shock strengthening Values are balanced to extend the service life of parts after remanufacturing.

Owner:GUANGDONG UNIV OF TECH

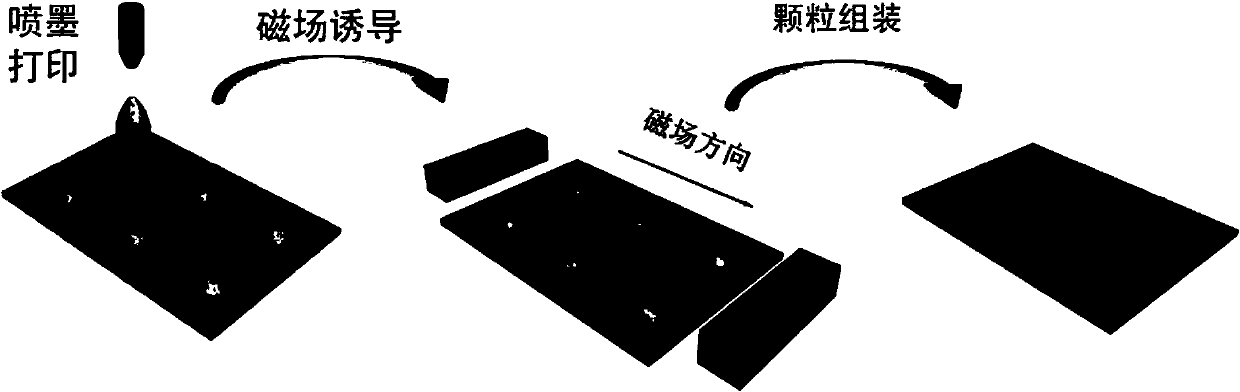

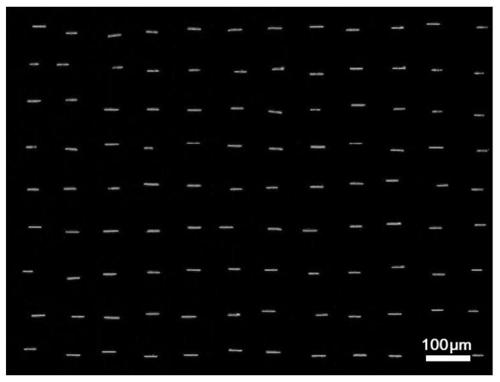

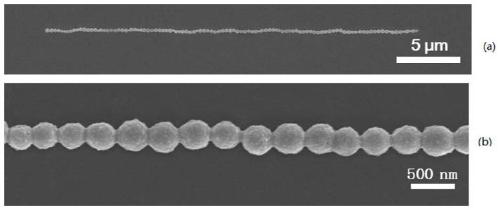

One-dimensional magnetic assembly array with single nanoparticle precision and its preparation method and application

ActiveCN109879246BDimensional accuracy is easy to controlUniform shapeNanostructure manufactureMagnetic materialsMagnetite NanoparticlesMagnetic field

The invention relates to the field of one-dimensional arrays, and discloses a single-nanoparticle-precision one-dimensional magnetic assembly array and a preparation method and application thereof. The preparation method of the single-nanoparticle-precision one-dimensional magnetic assembly array comprises the following steps: (1) spraying water-based ink containing magnetic nano-particles onto the surface of a substrate in an array form by an ink-jet printing method, wherein the retreating angle of the surface of the substrate is 3-30 degrees; and (2) drying and assembling the ink printed onthe surface of the substrate under the induction action of a magnetic field. The preparation method disclosed by the invention is simple and rapid, saves the cost, and can be used for preparing the single-nanoparticle-precision one-dimensional magnetic assembly array with controllable size and uniform morphology on a large scale.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com