Pump split type crosshead

A crosshead, split-type technology, applied to pump components, variable capacity pump components, liquid fuel engines, etc., can solve the problems of crosshead cavity demoulding difficulties, reduce material utilization, increase machining hours, etc., to achieve The effect of reducing maintenance costs, reducing costs, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

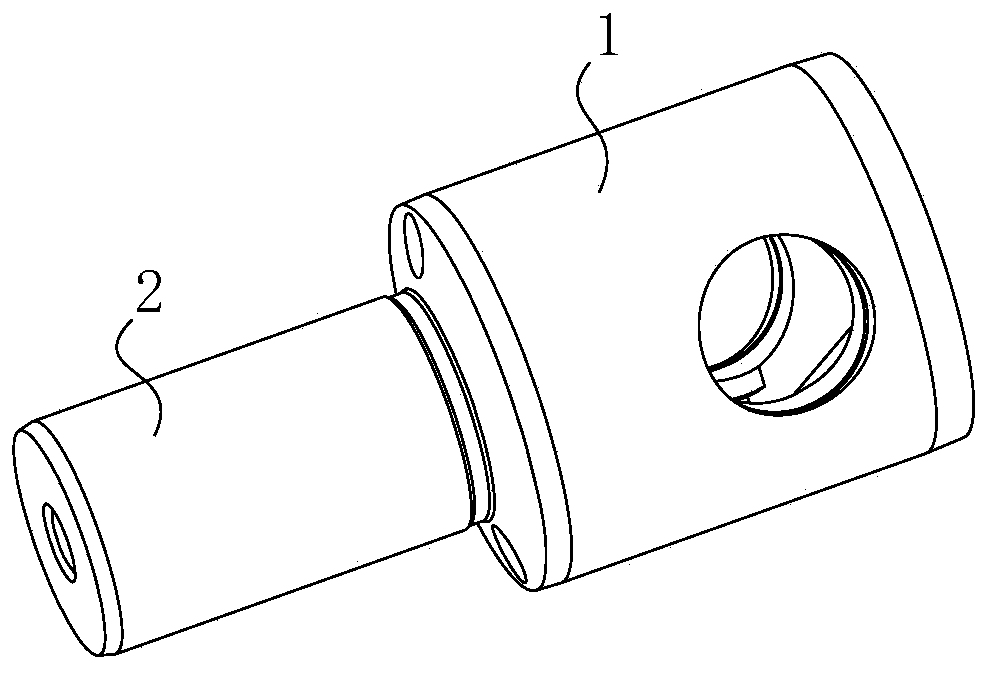

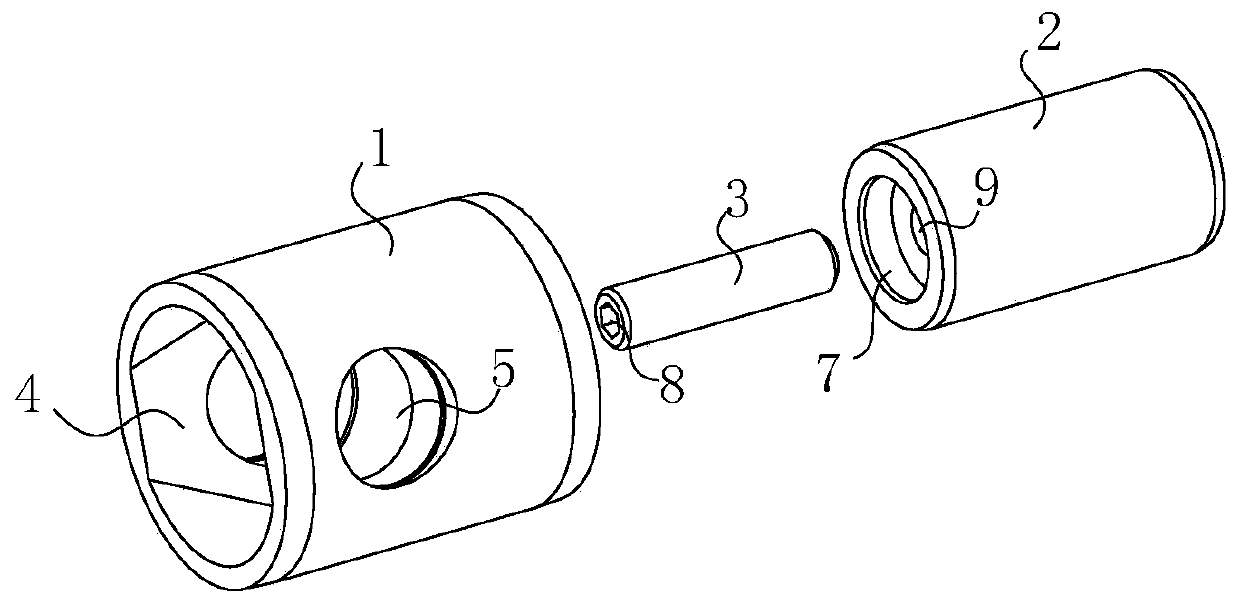

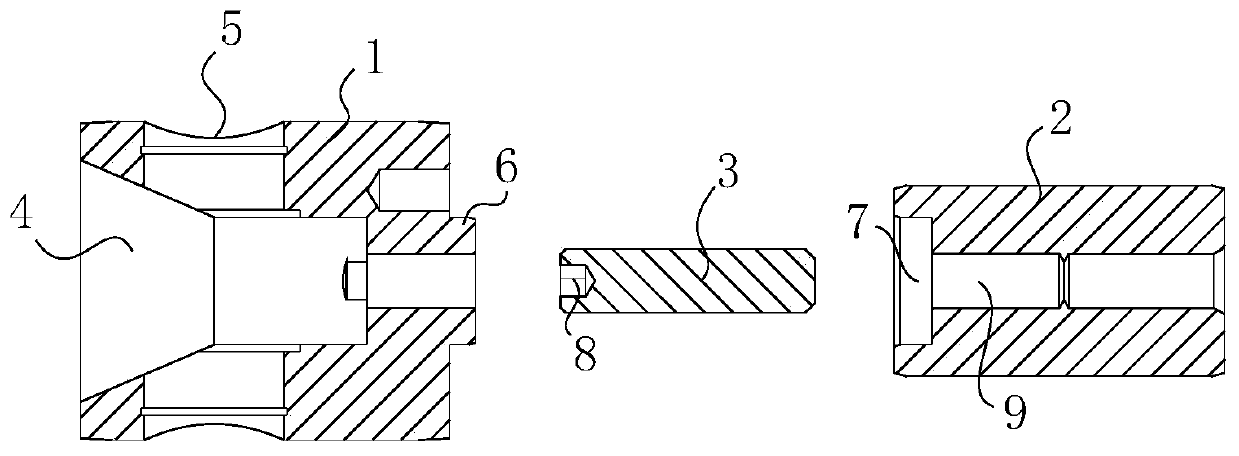

[0023] As shown in the figure, the present invention provides a split crosshead for pumps, which includes a split crosshead main body 1, crosshead extension 2 and locking parts 3, the crosshead main body 1 and crosshead extension 2 are cylindrical structure, and the diameter of the crosshead extension 2 is smaller than that of the crosshead main body 1. In the later actual use process, the wear degree of the crosshead extension 2 is much smaller than that of the crosshead main body 1, so the staff can only replace the crosshead main body 1, thereby reducing the later stage The maintenance cost is reduced to reduce the cost. The left side of the crosshead main body 1 is provided with an inner cavity 4 for inserting one end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com