Patents

Literature

705 results about "Crosshead" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A crosshead is a mechanism used as part of the slider-crank linkages of long reciprocating engines and reciprocating compressors to eliminate sideways pressure on the piston. Also, the crosshead enables the connecting rod to freely move outside the cylinder. Because of the very small bore-to-stroke ratio on such engines, the connecting rod would hit the cylinder walls and block the engine from rotating if the piston was attached directly to the connecting rod like on trunk engines. Therefore, the longitudinal dimension of the crosshead must be matched to the stroke of the engine.

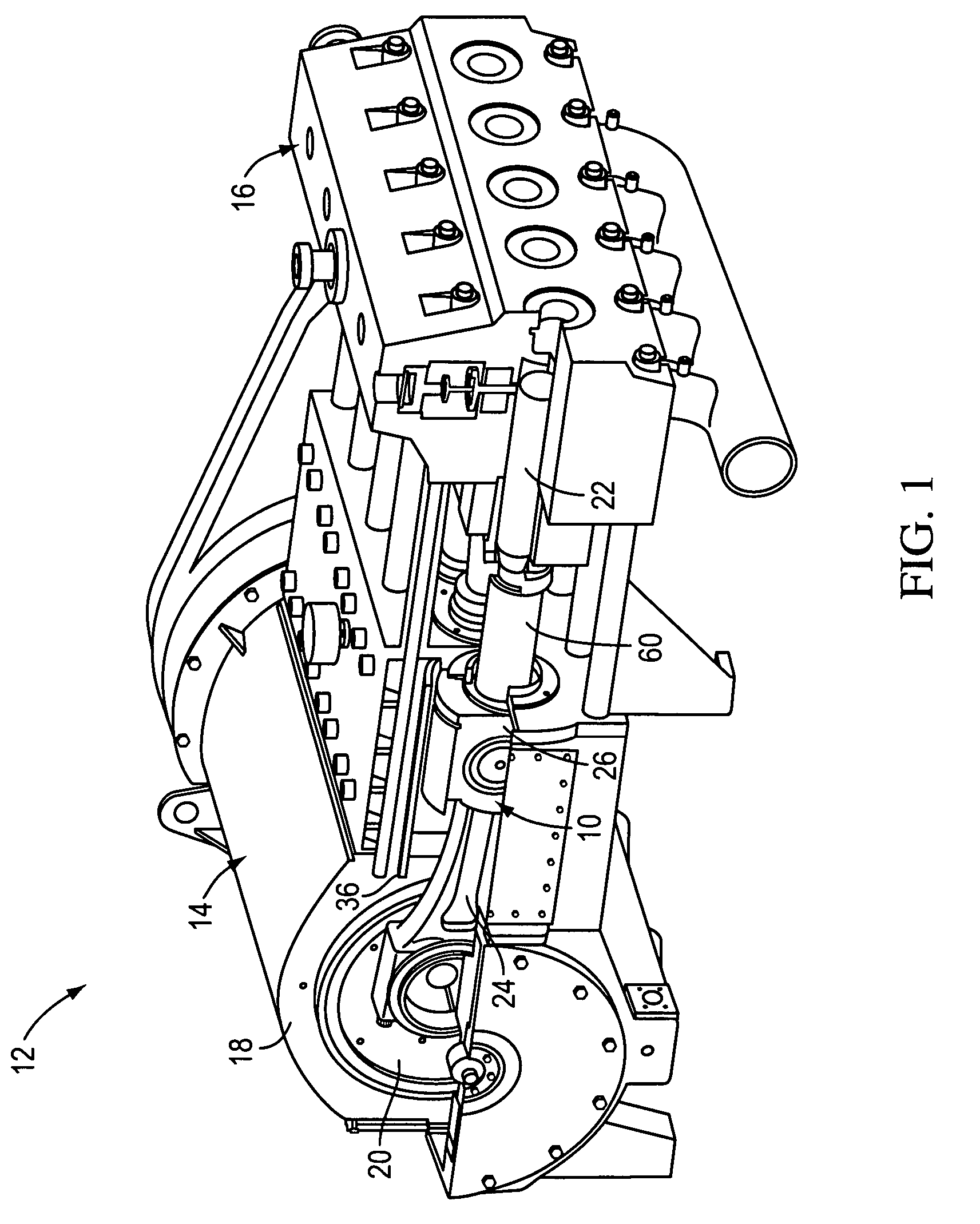

Reciprocating pump assembly

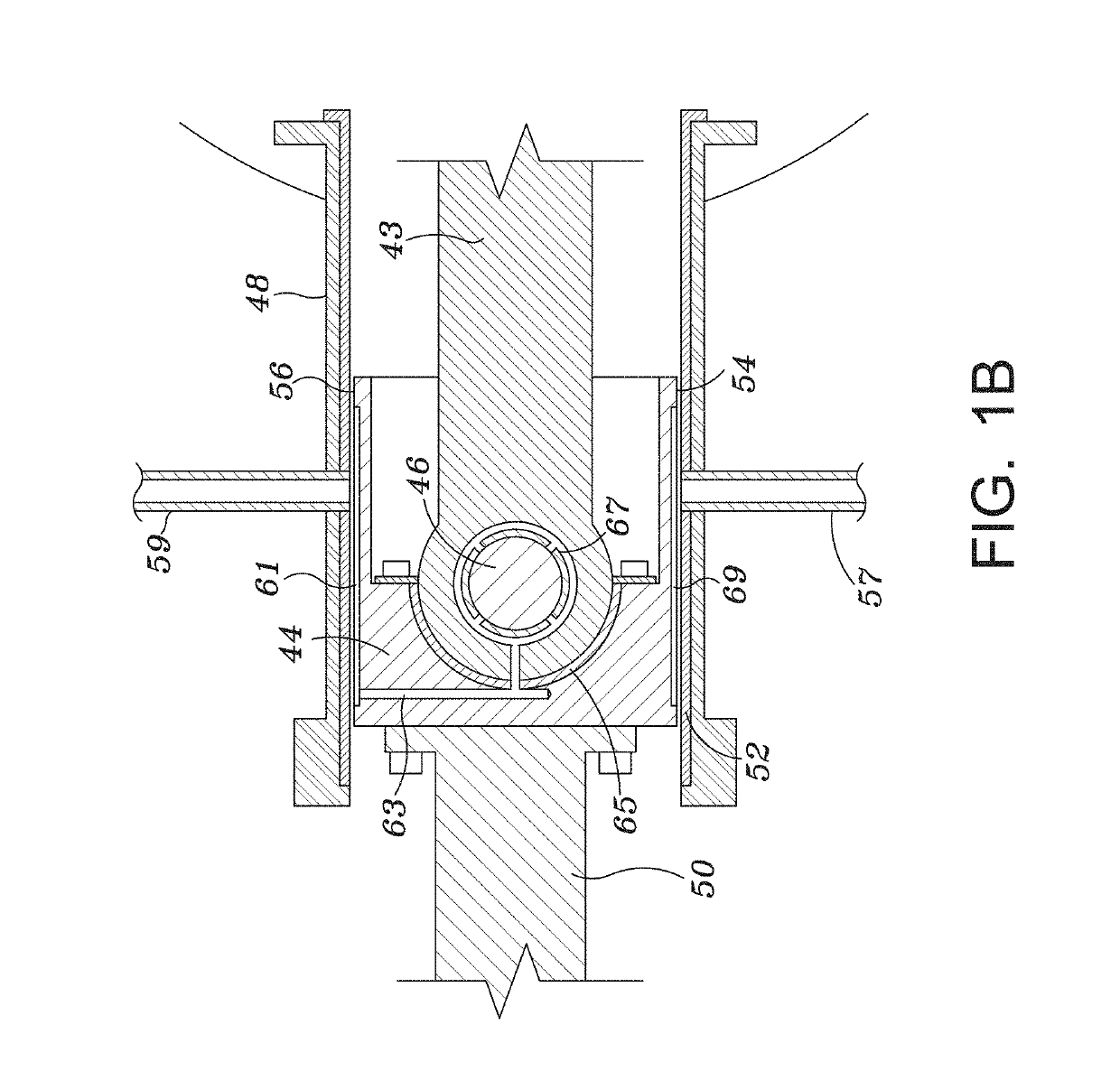

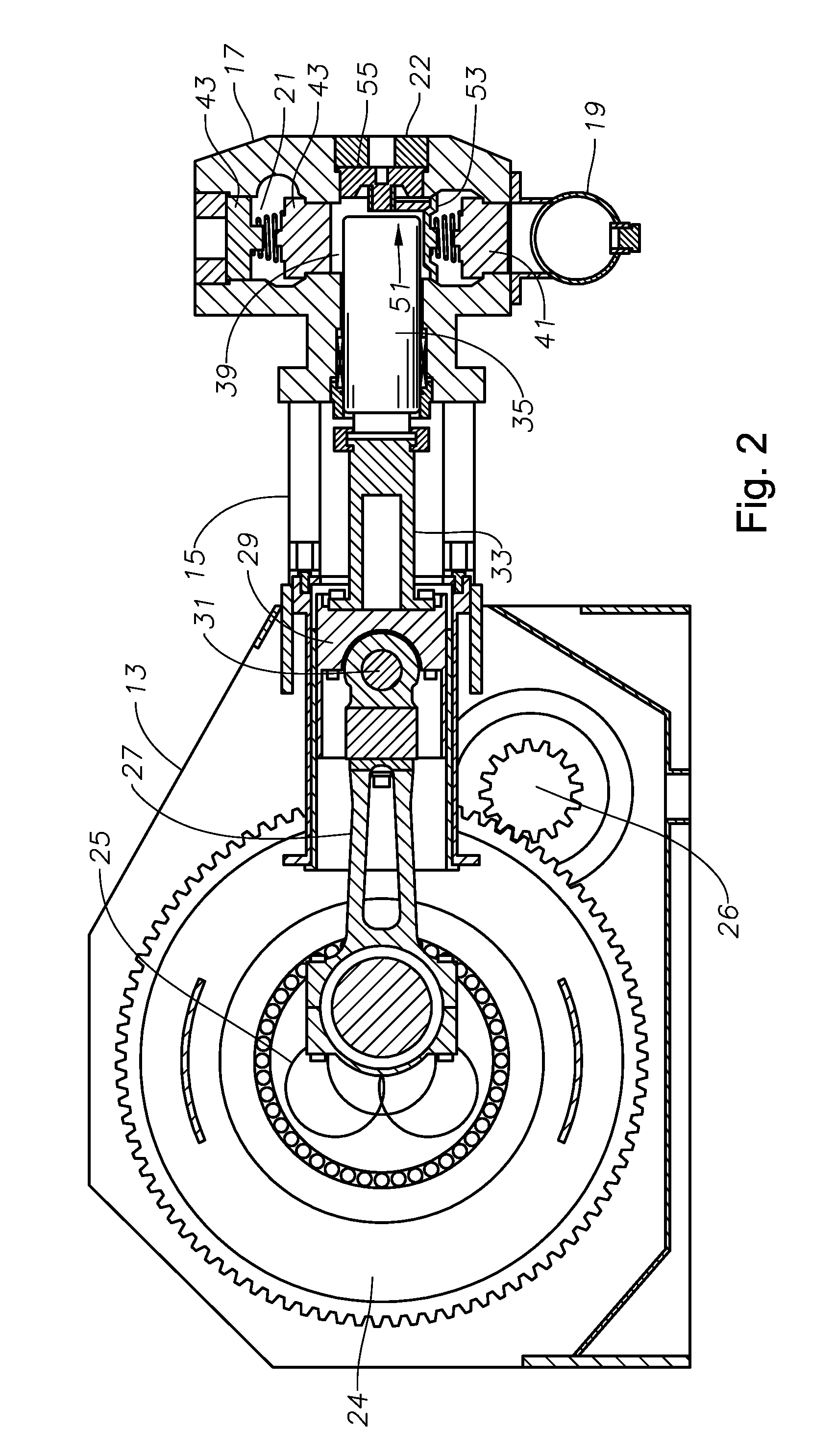

ActiveUS8707853B1Easy to fixEngine sealsPositive displacement pump componentsReciprocating motionPlunger

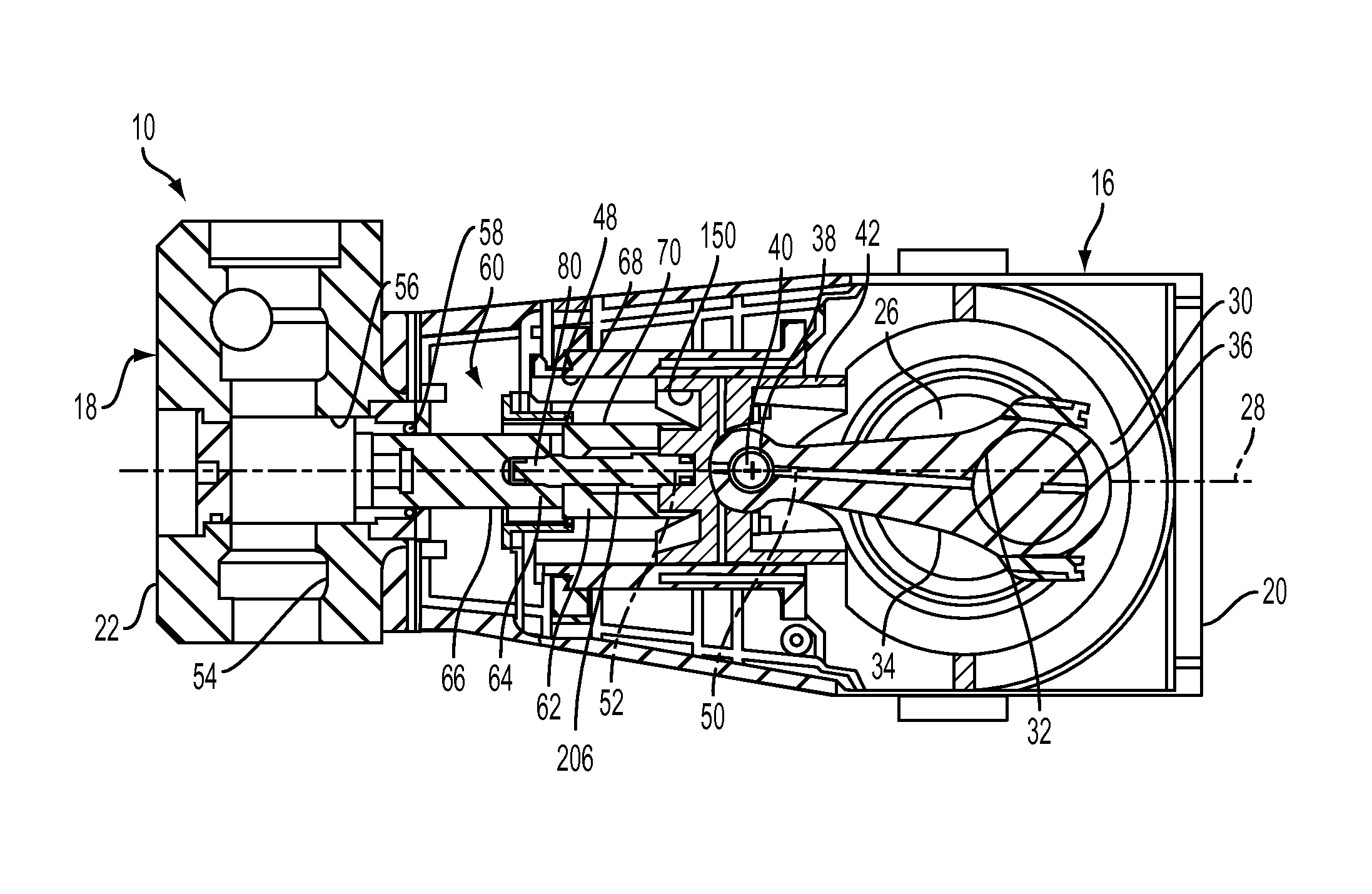

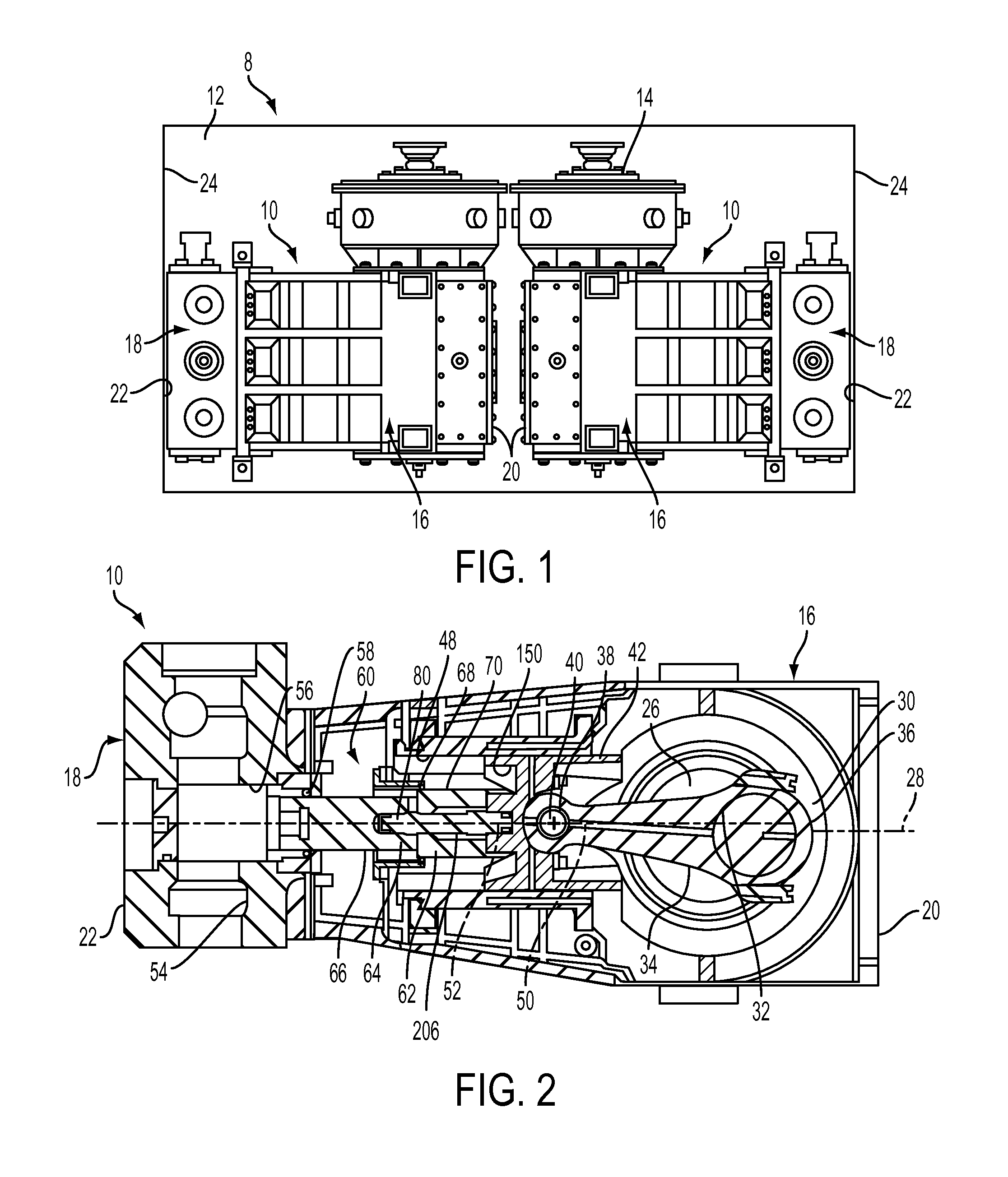

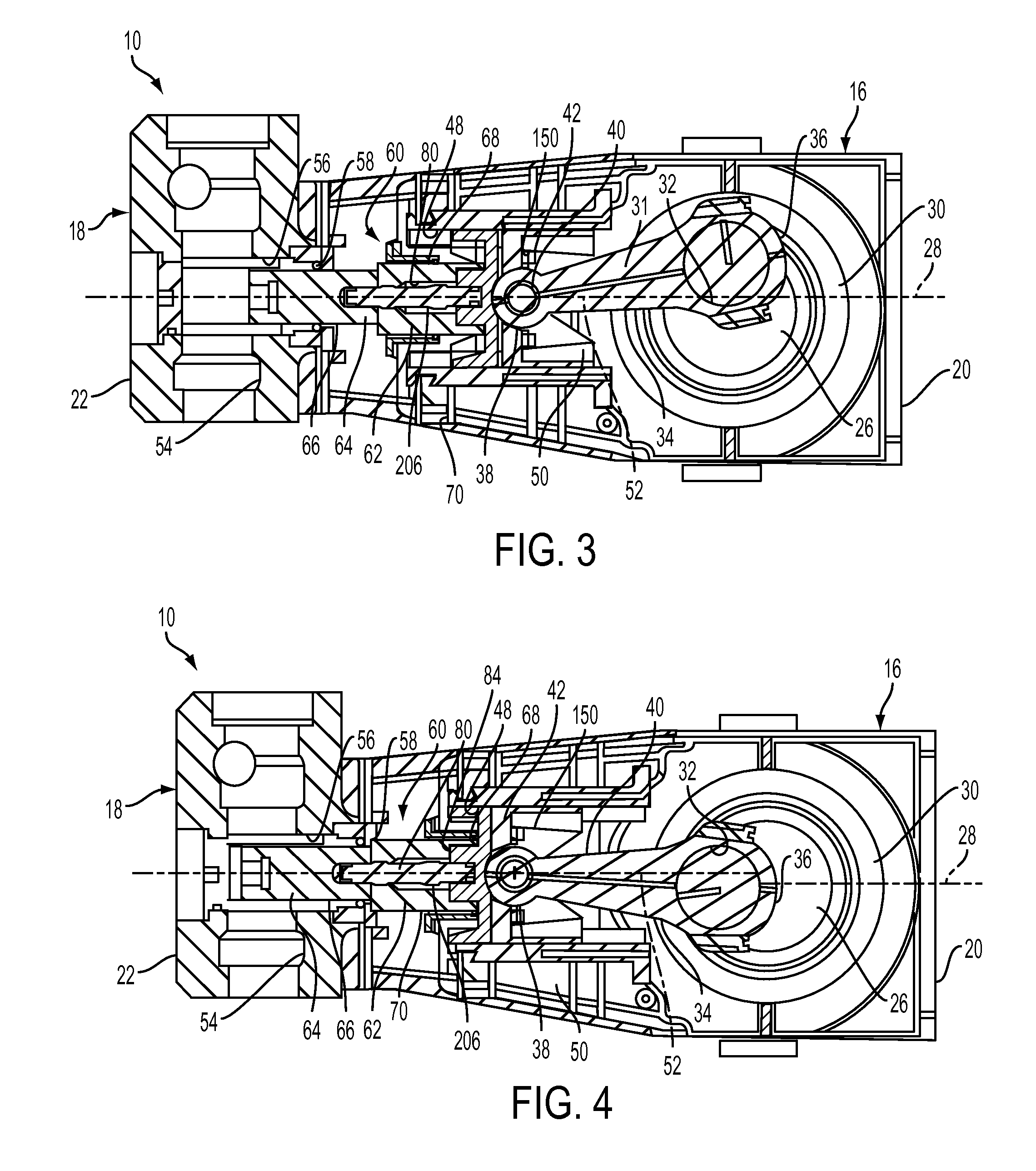

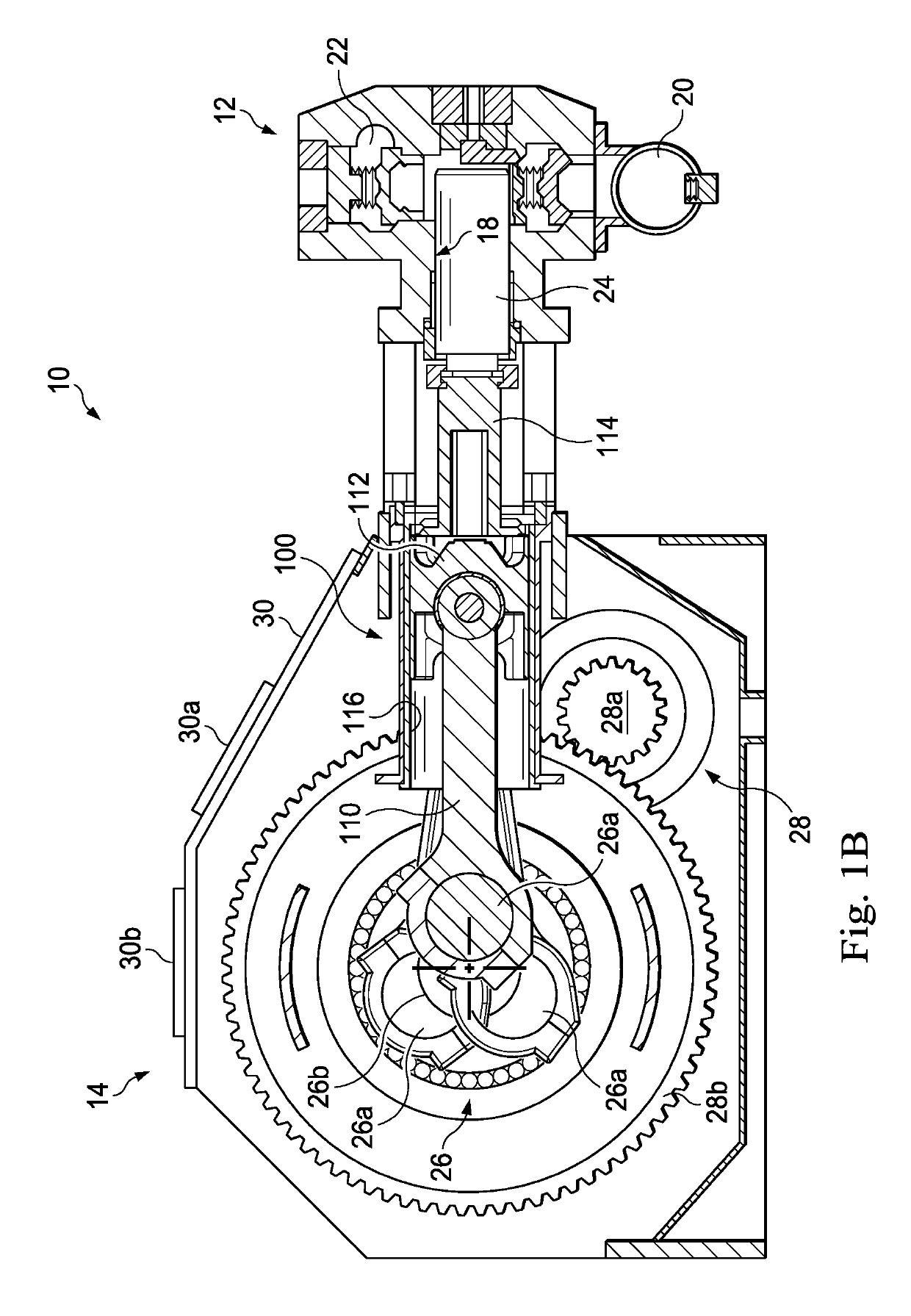

A reciprocating pump assembly having a power end housing and a fluid end housing and a cylinder having at least a portion within the power end. A plunger assembly reciprocates between the power end housing and the fluid end housing of the pump assembly, the plunger assembly having a crosshead, a first section limited to movement within the power end and a second section moveable within the fluid end housing. The pump assembly also includes a seal housing disposed within the cylinder, the seal housing having a proximal end adjacent an entrance to the cylinder, and a distal end disposed within the cylinder. A power end seal is secured to the seal housing proximate the distal end and a fluid end seal is disposed within the fluid end housing. The power end seal sealingly engages an outer surface of the first section and the fluid end seal sealingly engages an outer surface of the second section such that during the reciprocating movement of the plunger assembly, fluid end proppant is deterred from contaminating the outer surface of the first section and thus, contaminating the power end seal.

Owner:SPM OIL & GAS INC

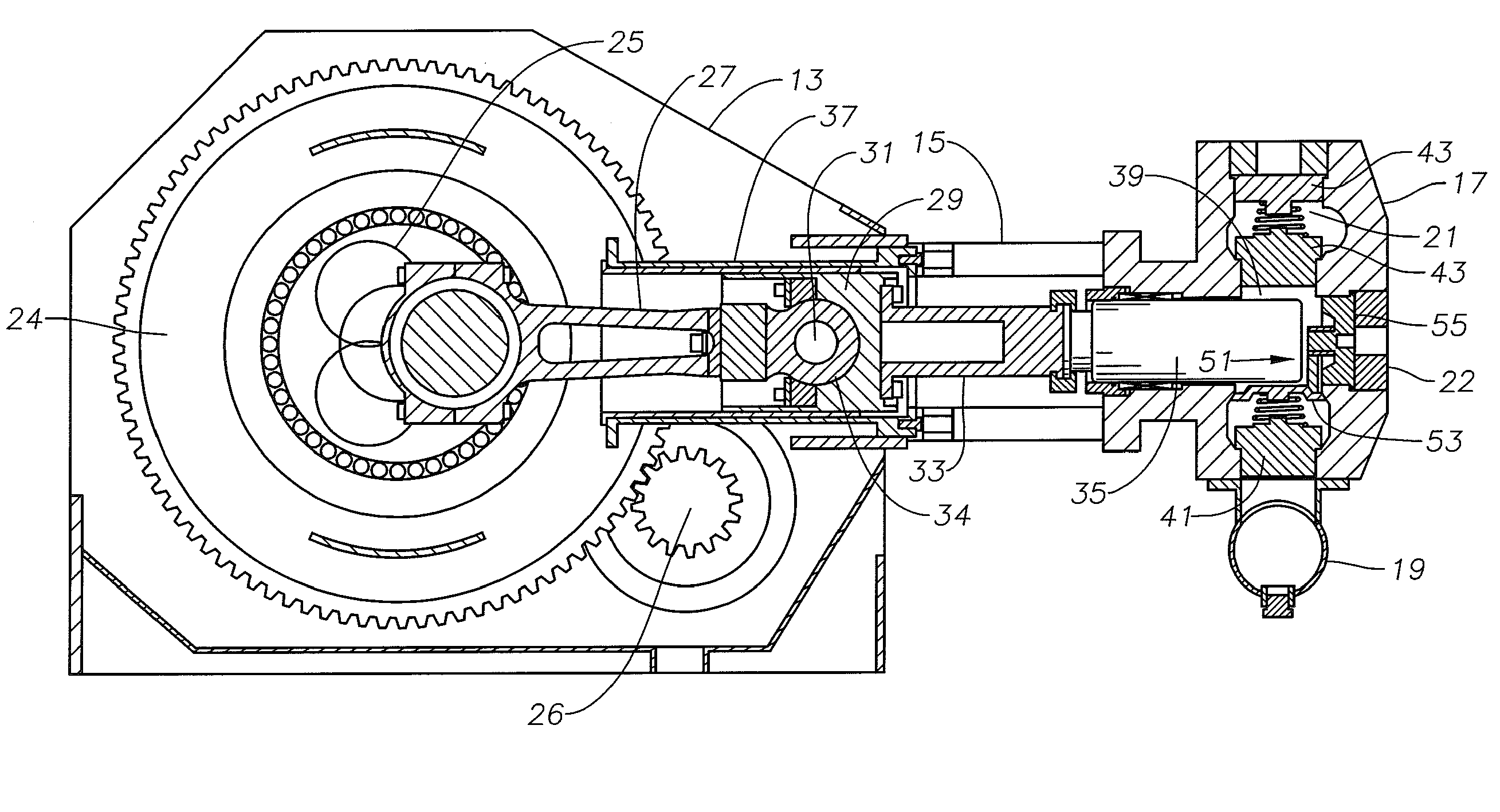

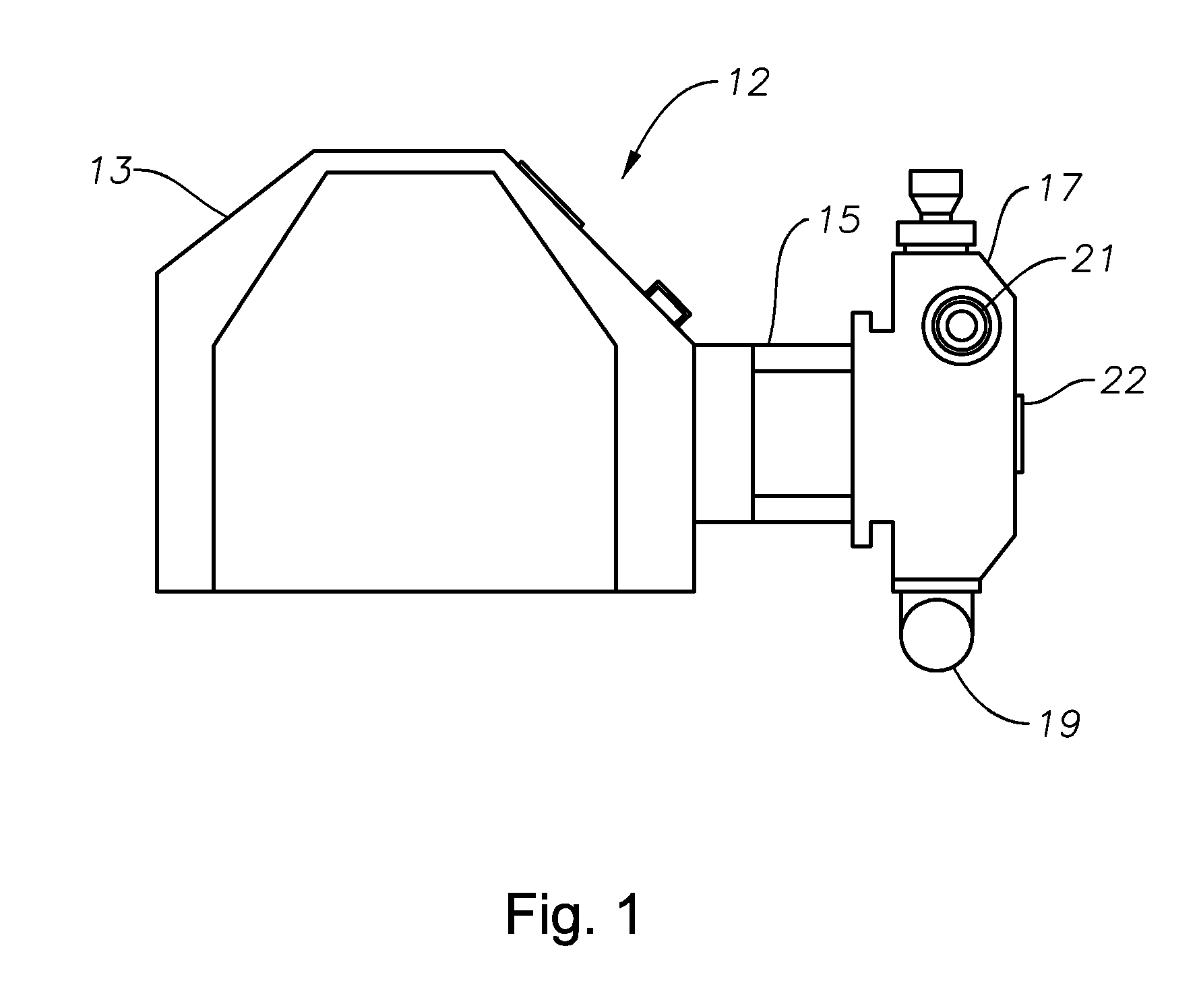

Reciprocating pump with dual circuit power end lubrication system

ActiveUS20190277279A1Positive displacement pump componentsRotary/oscillating piston combinationsHigh pressureLubrication

A dual circuit lubrication system for a power end of a reciprocating pump that includes a lubrication pump that supplies lubrication fluid to a high pressure lubrication circuit and a low pressure lubrication circuit. The high pressure lubrication circuit is fluidly coupled to a crankshaft to supply lubrication fluid to journal surfaces associated with the crankshaft at a first lubrication fluid pressure. The crankshaft drives a crosshead coupled to a plunger to displace fluid from a fluid end of the reciprocating pump. The low pressure lubrication circuit is fluidly coupled to supply the lubrication fluid to a plurality of roller bearing surfaces associated with the crankshaft at a second lubrication fluid pressure. The first lubrication fluid pressure is greater than the second lubrication fluid pressure.

Owner:SPM OIL & GAS INC

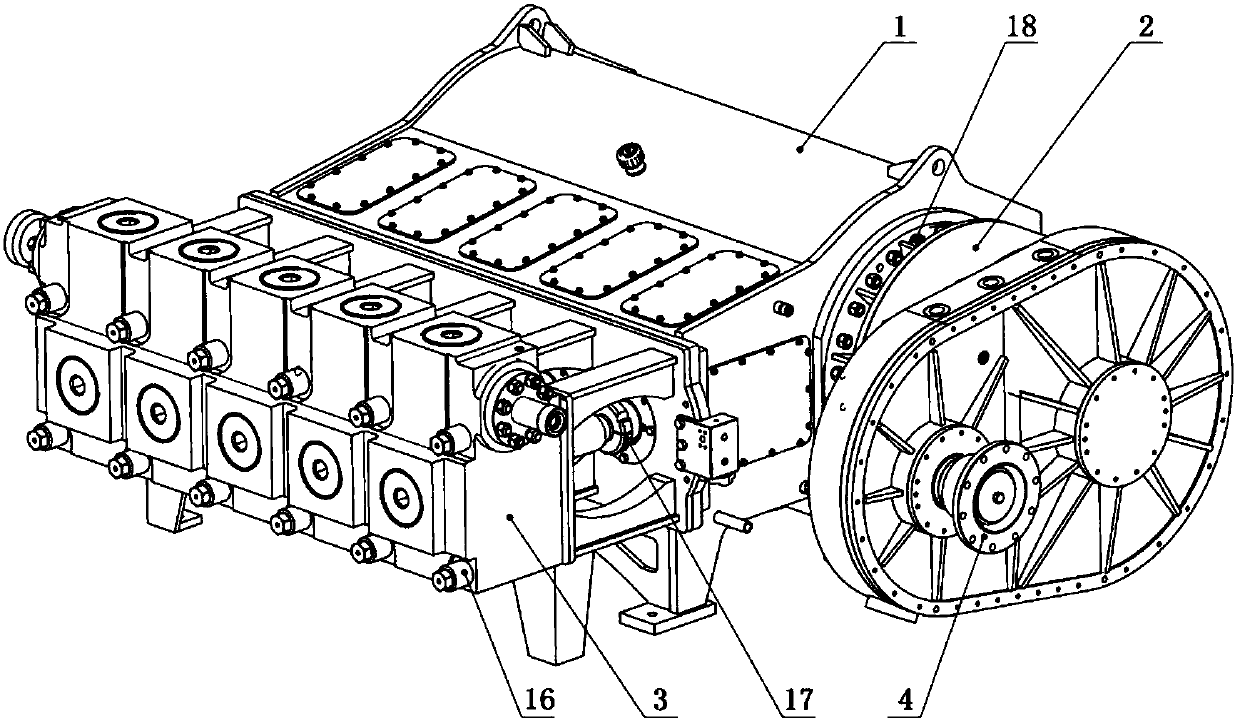

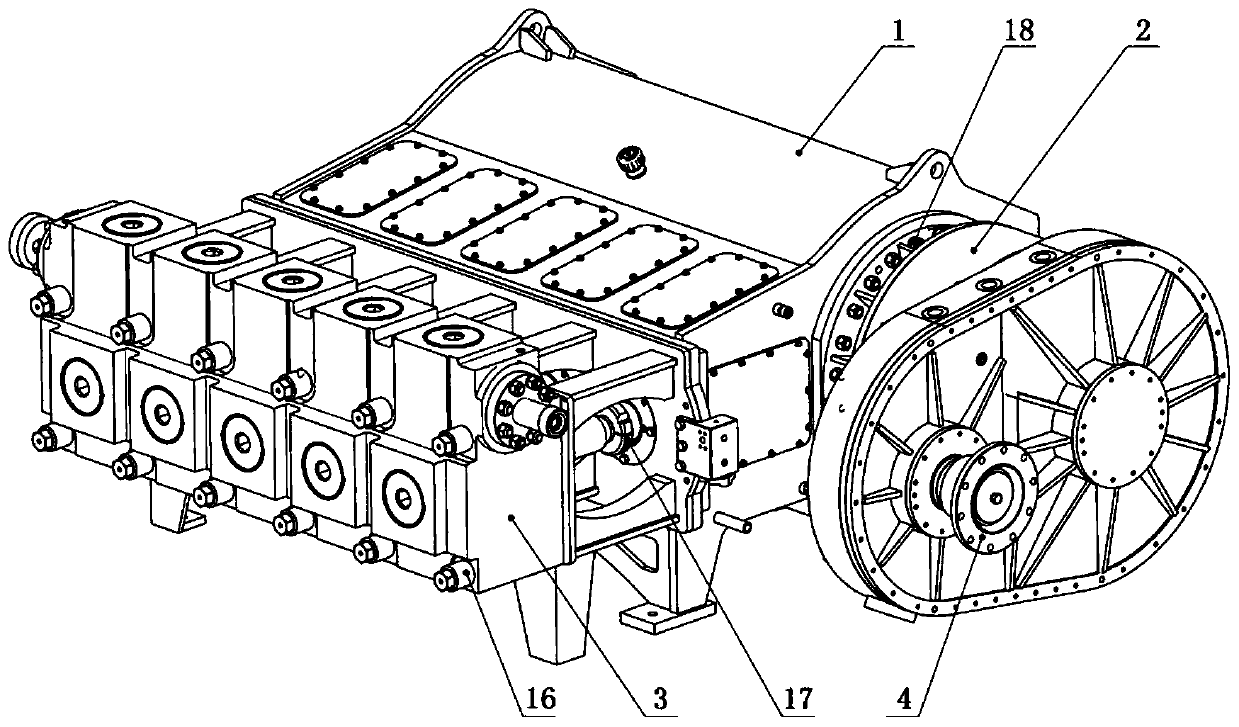

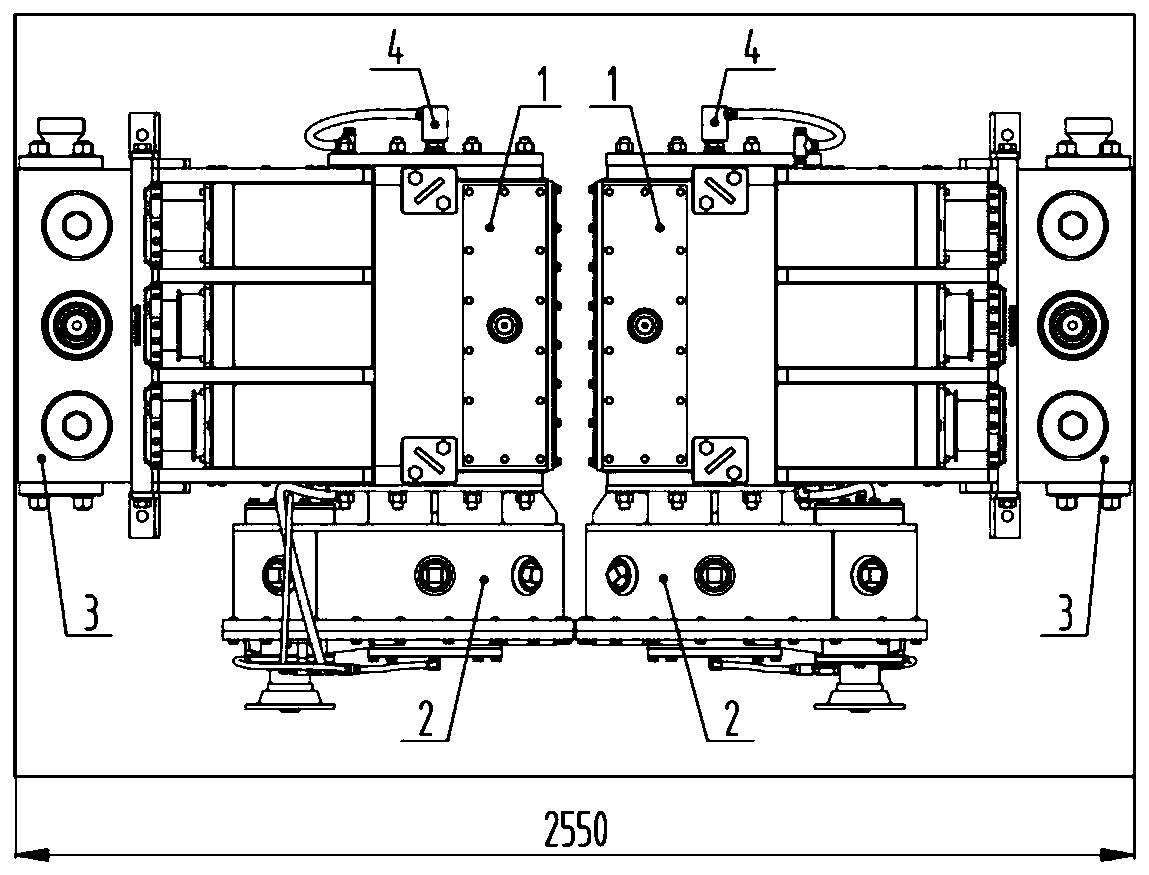

High-power five-cylinder plunger pump

PendingCN110617187AIncrease the carrying areaOptimize layoutPositive displacement pump componentsFluid removalEngineeringMechanical engineering

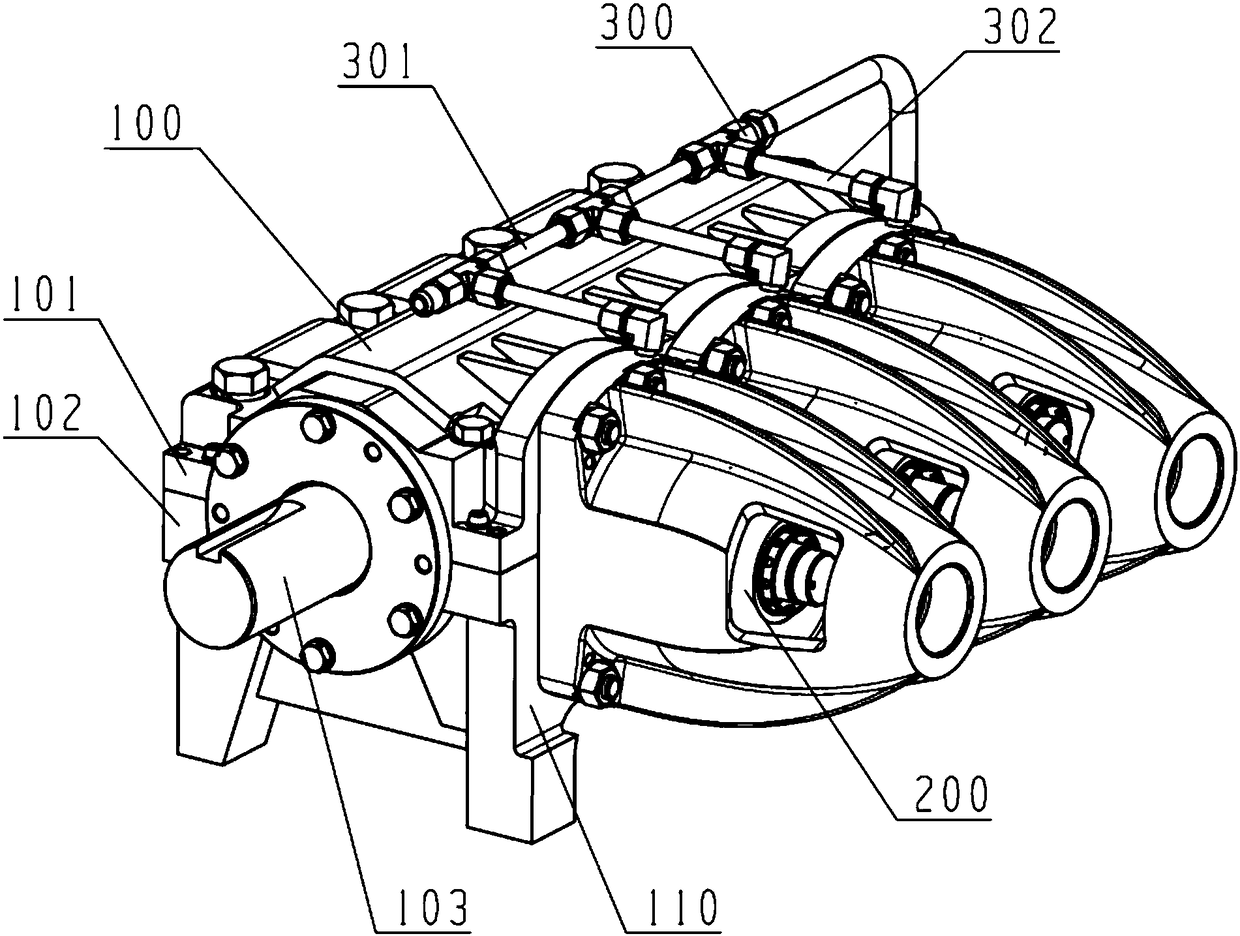

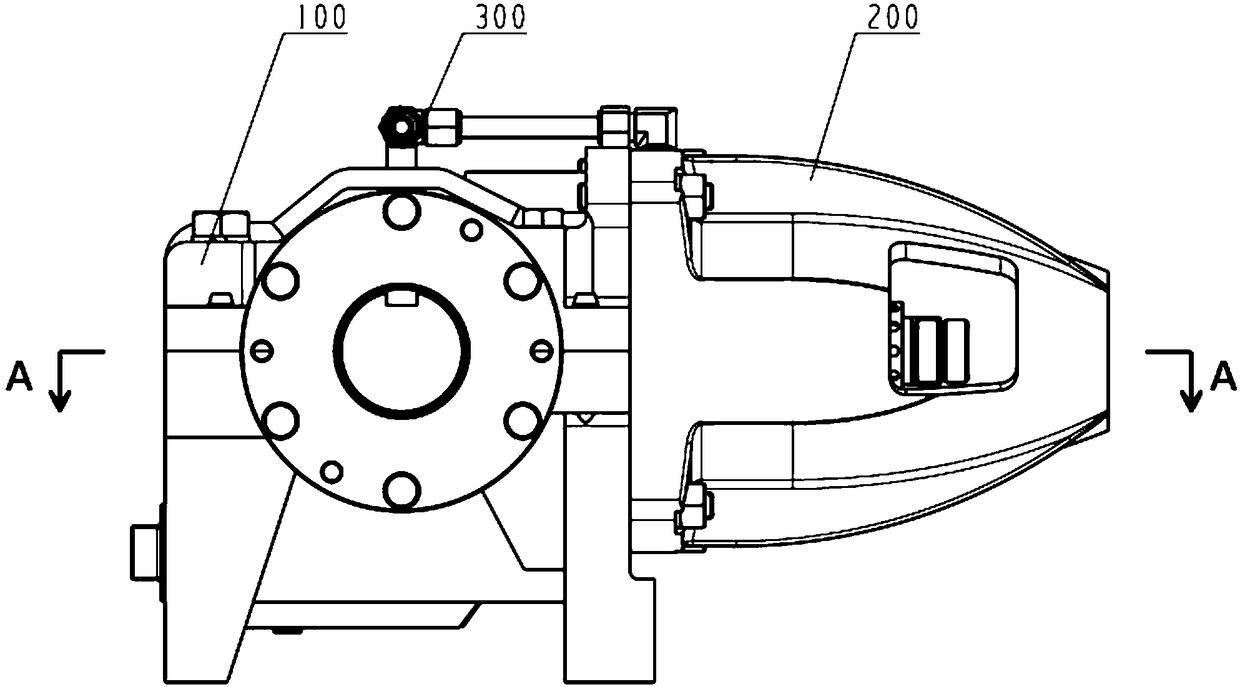

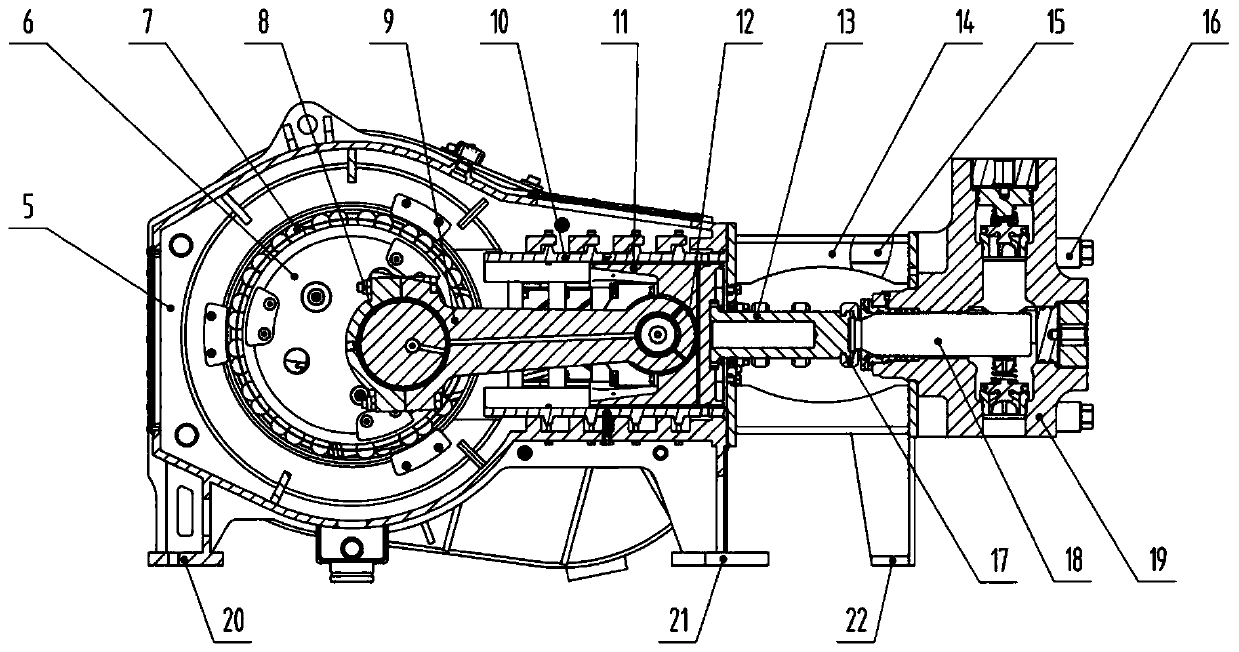

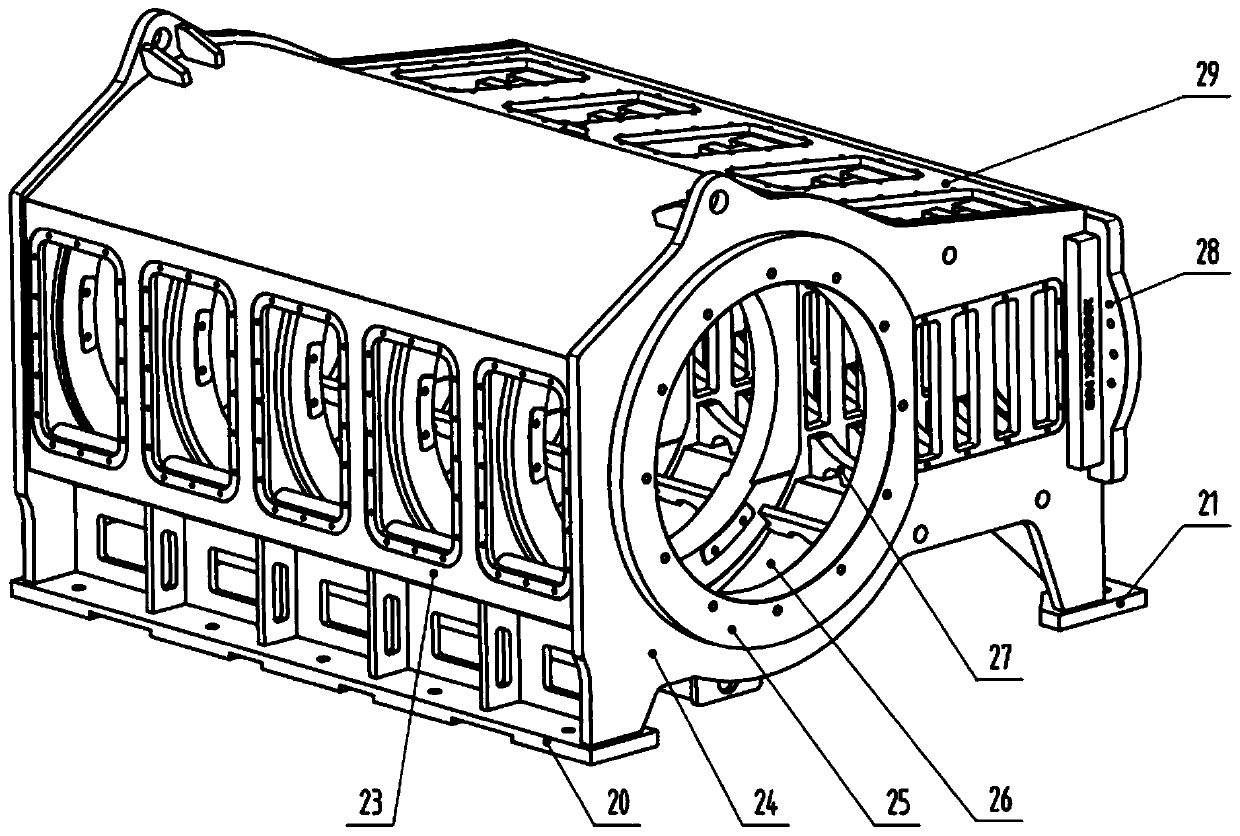

The invention discloses a high-power five-cylinder plunger pump. The plunger pump comprises a power end assembly, a hydraulic end assembly and a reduction gearbox assembly, wherein the power end assembly comprises a crankshaft box body, a crosshead box body and a spacer frame; the crankshaft box body, the crosshead box body and the spacer frame are sequentially connected; the hydraulic end assembly is fixed on the spacer frame; the reduction gearbox assembly is fixed on the crankshaft box body; and the cylinder spacing of the five-cylinder plunger pump is 13-14 inches, so that a guarantee is provided for the output of high power of the five-cylinder plunger pump. According to the high-power five-cylinder plunger pump, the problems that the area of a shale gas fracturing well site is narrowand the number of required fracturing equipment is relatively large are effectively solved, thus reducing the use of equipment, and facilitating the arrangement of the well site.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

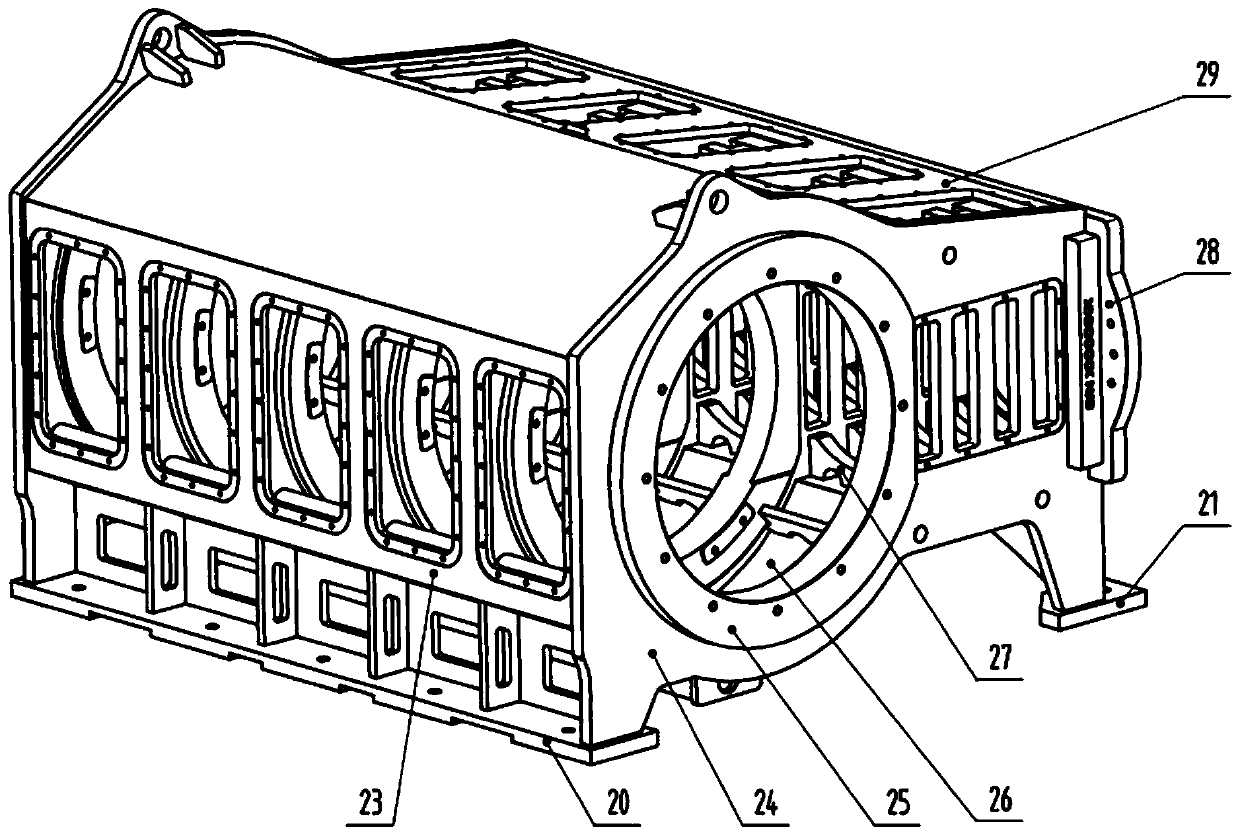

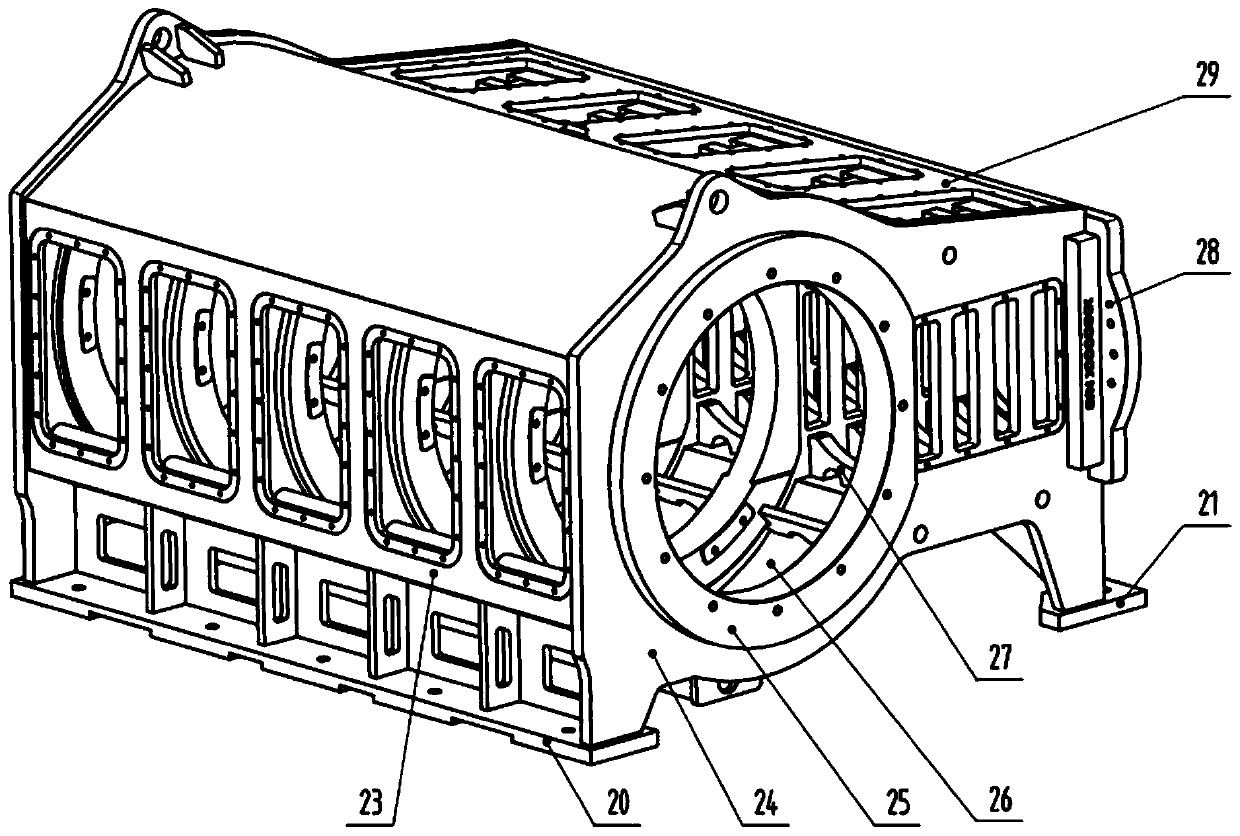

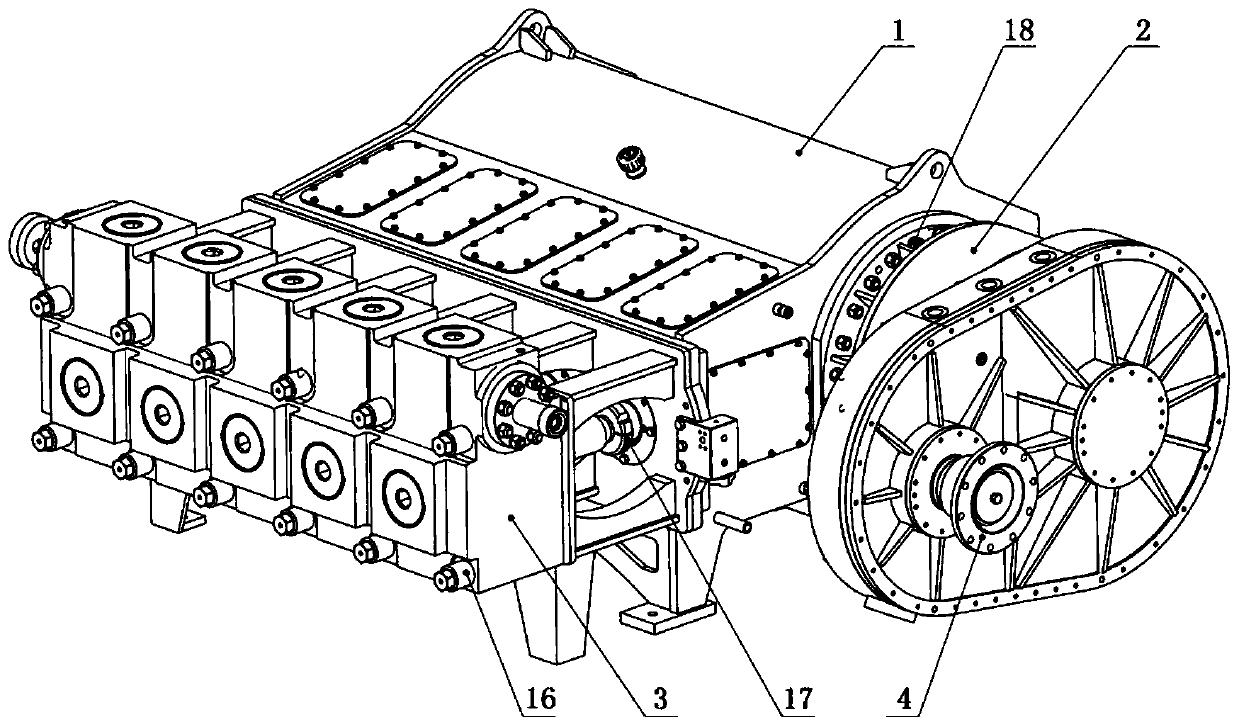

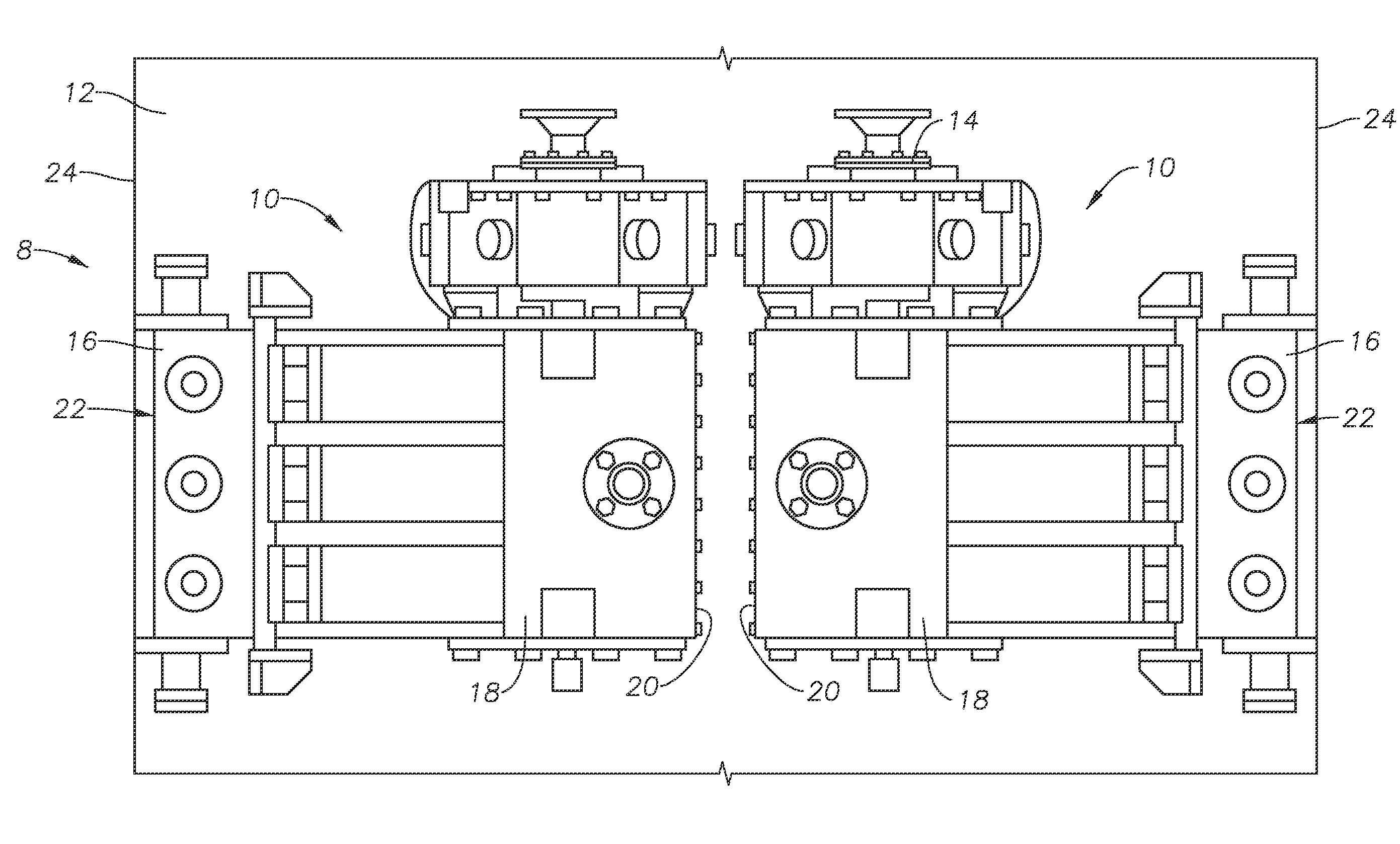

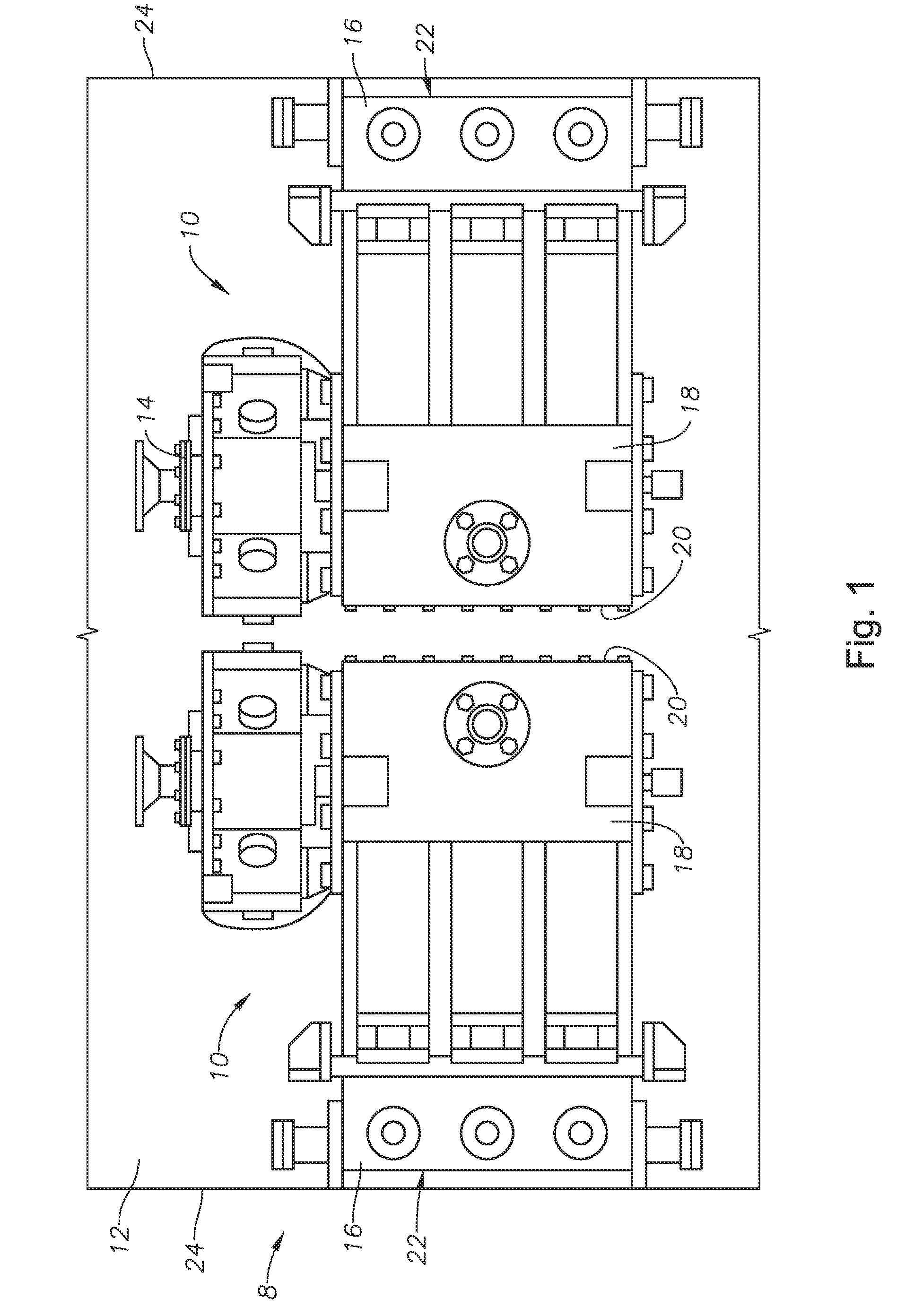

Five-cylinder plunger pump with integral power end structure

PendingCN110617318AExtended service lifeLow strokeCrankshaftsConnecting rod bearingsCrankcaseHigh load

The invention discloses a five-cylinder plunger pump with an integral power end structure. According to the five-cylinder plunger pump, an integral welding structure is adopted for a crankshaft box body and a crosshead box body in a five-cylinder plunger pump power end assembly, so that the structural strength of the power end assembly is higher, the supporting stability is better, and the whole pump vibration can be reduced; the cylinder spacing is 13-14 inches, the bearing area of connecting rods, crossheads and bearing bushes is increased, a guarantee is provided for the output of the high-power of the five-cylinder plunger pump, the high-power five-cylinder plunger pump can effectively solve the problem that the shale gas fracturing well site area is narrow and the required fracturingequipment is relatively large, the use of equipment can be reduced, and the wellsite arrangement is facilitated; the 11-inches long-stroke design can better realize large-displacement operation requirements and improve the operation efficiency; and according to the multi-point supporting design of crankcase bodies, crosshead box bodies and the hydraulic end assembly, the supporting strength of thefive-cylinder plunger pump can be improved, the vibration is reduced, the high-load operation is better guaranteed, and the operation is more stable.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

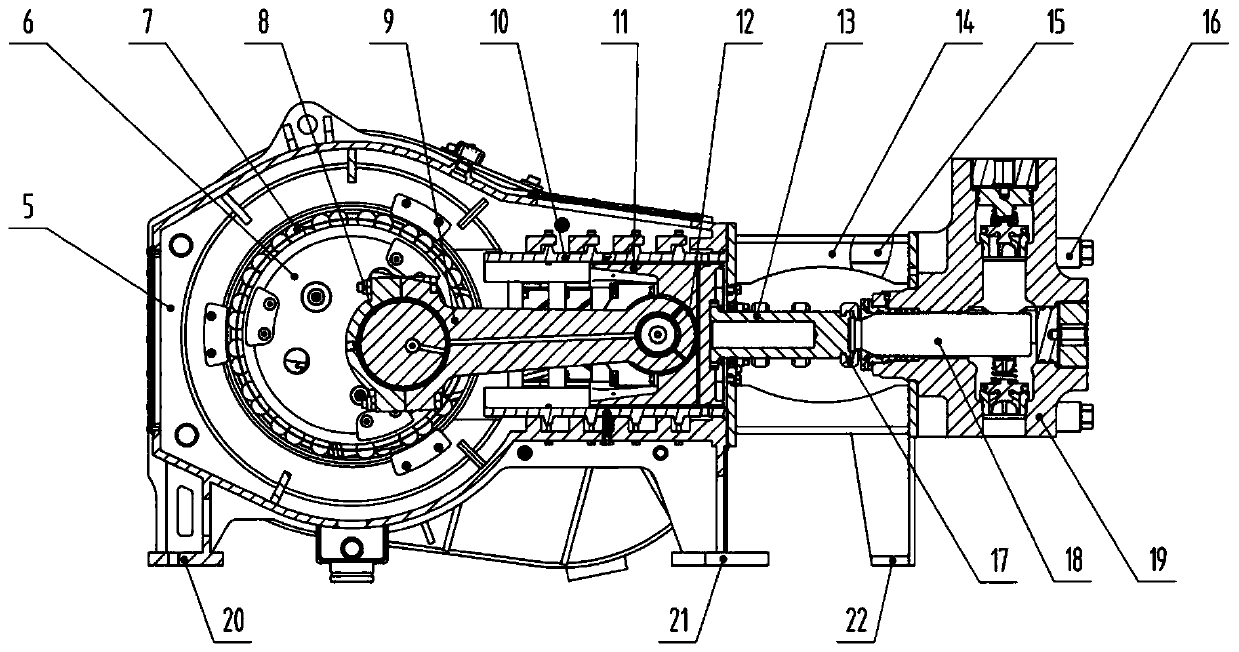

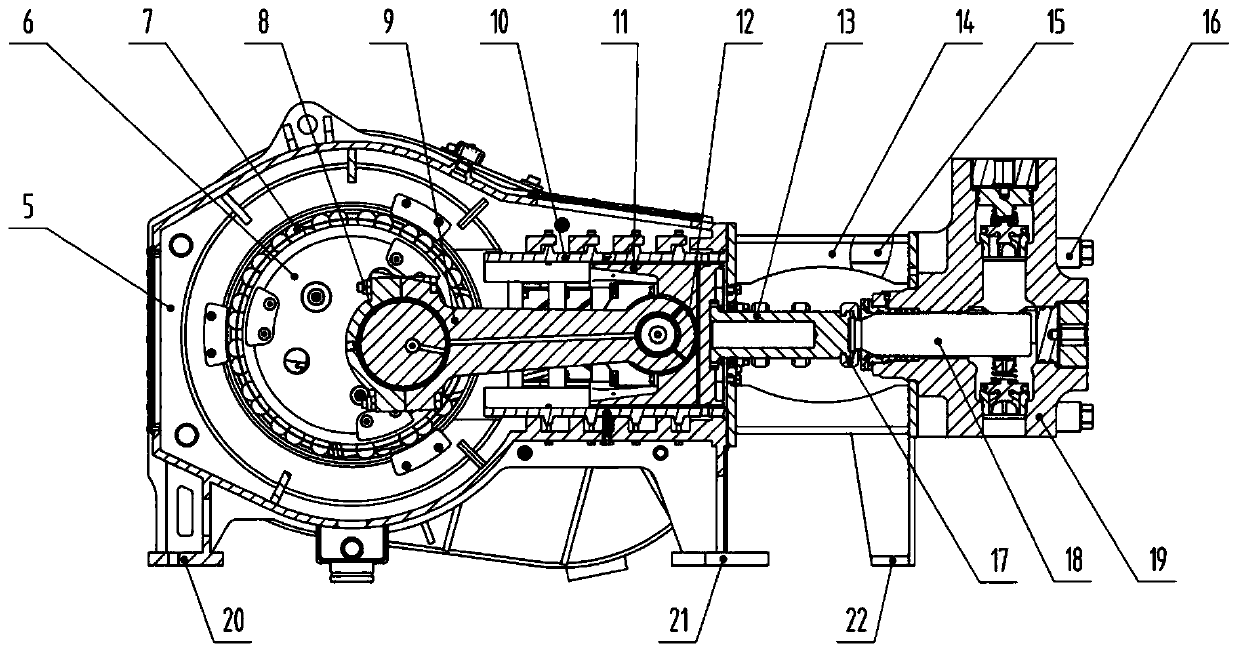

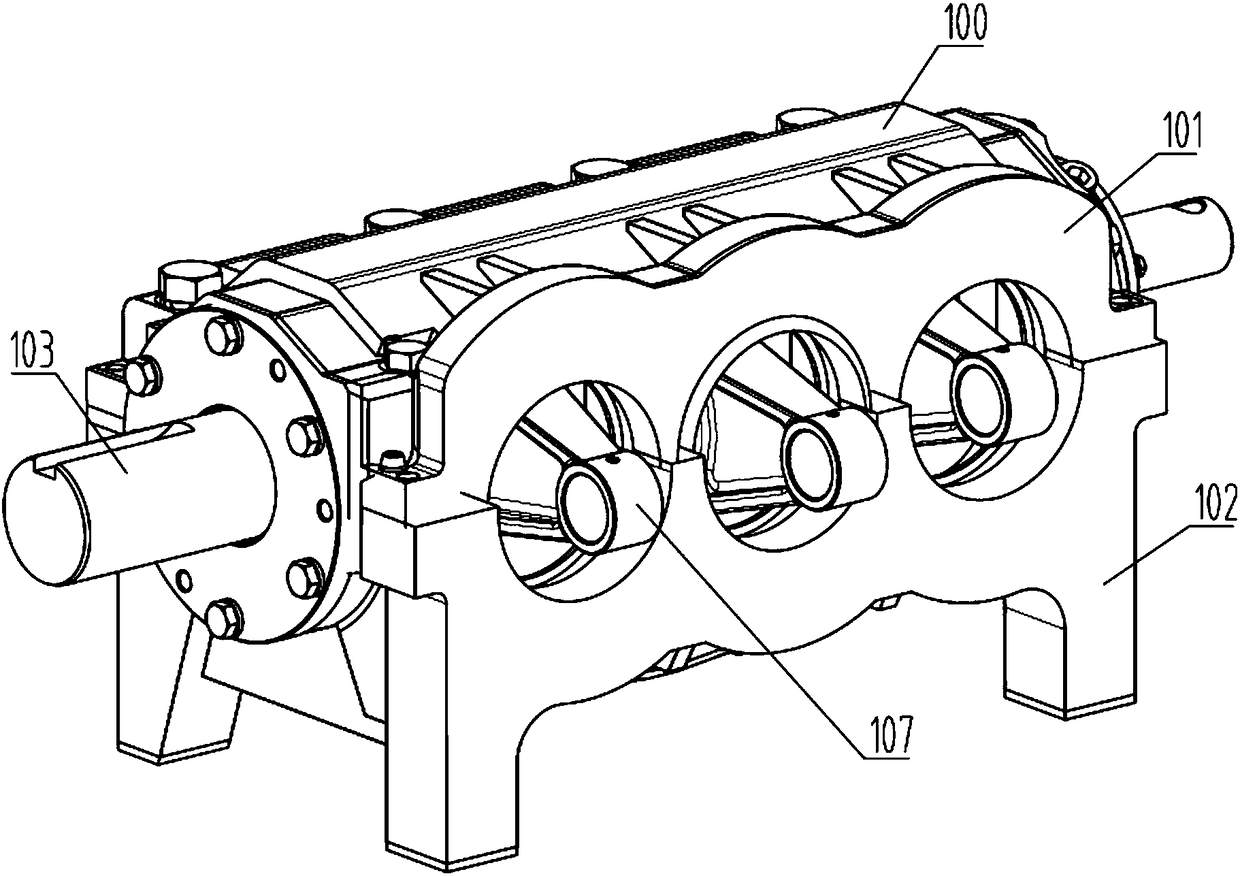

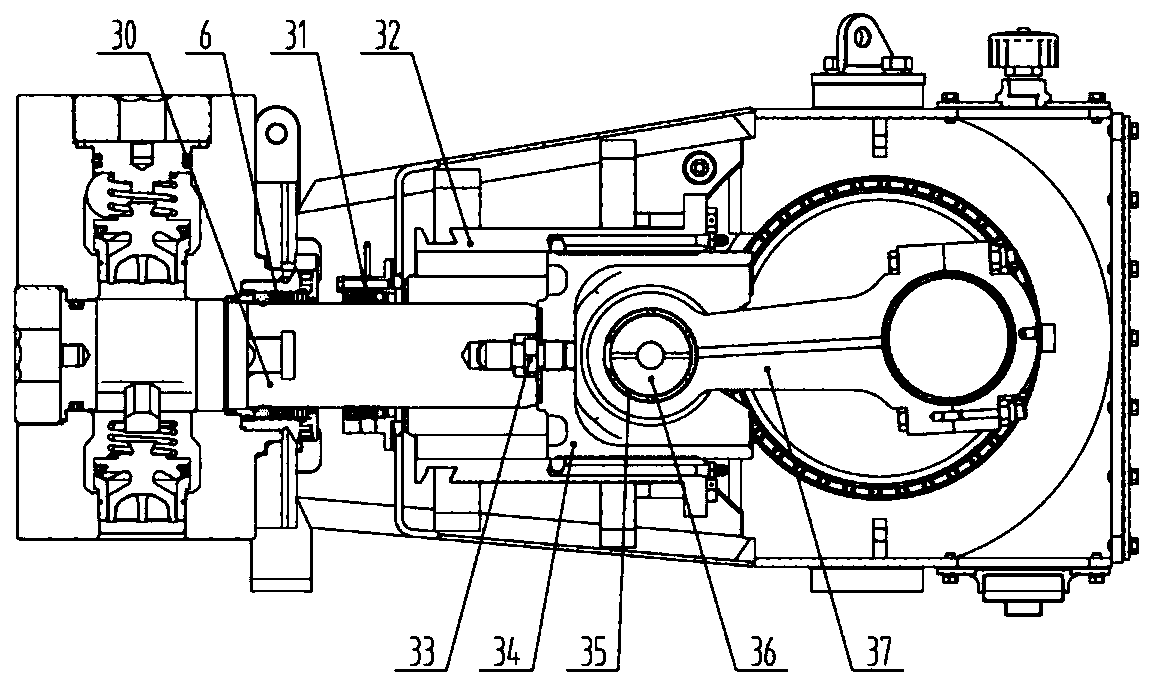

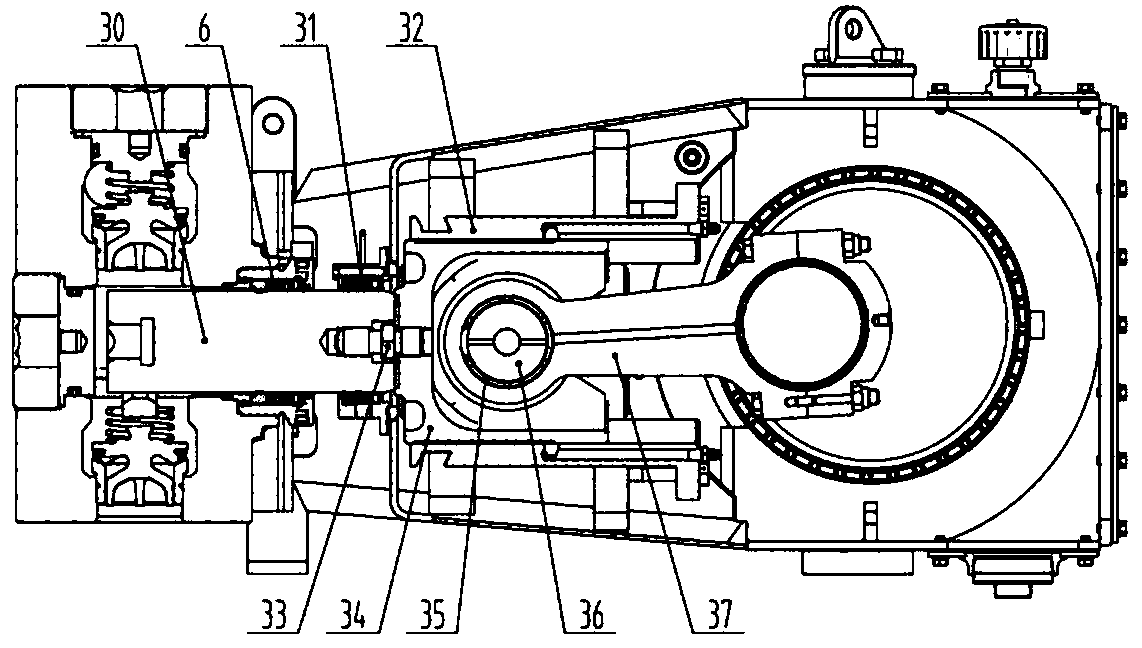

Liquid nitrogen pump power end assembly

PendingCN108547766ACompact structureEasy to processPositive displacement pump componentsPumpsTransmitted powerJackscrew

The invention provides a liquid nitrogen pump power end assembly. The liquid nitrogen pump power end assembly comprises a crankshaft box assembly. The crankshaft box assembly is correspondingly connected with crosshead shell assemblies. Lubricating systems are correspondingly arranged between the crankshaft box assembly and the crosshead shell assemblies. The liquid nitrogen pump power end assembly adopts split type module combination of the crankshaft box assembly and the crosshead shell assemblies to be assembled, a crankshaft box is designed into a welding type, crosshead shells are designed into a casting type, compared with inblock casting or overall welding, the structure is simple and compact, existing machining manners are considered, machining, manufacturing, assembling, repairingand maintaining are facilitated, crossheads are provided with threads for connection and can be connected with fluid ends with different specifications on the market to play a role in transmitting power, a crankshaft adopts a split type structure that a straight shaft and multiple eccentric wheels are connected through flat keys, the crankshaft overall machining difficulty is lowered, crosshead hinge pins are provided with jackscrew holes, by means of jackscrew fixing, axial floating of hinge pins can be eliminated, the lubricating system can protect movement members, and the service life ofeach movement member is prolonged.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

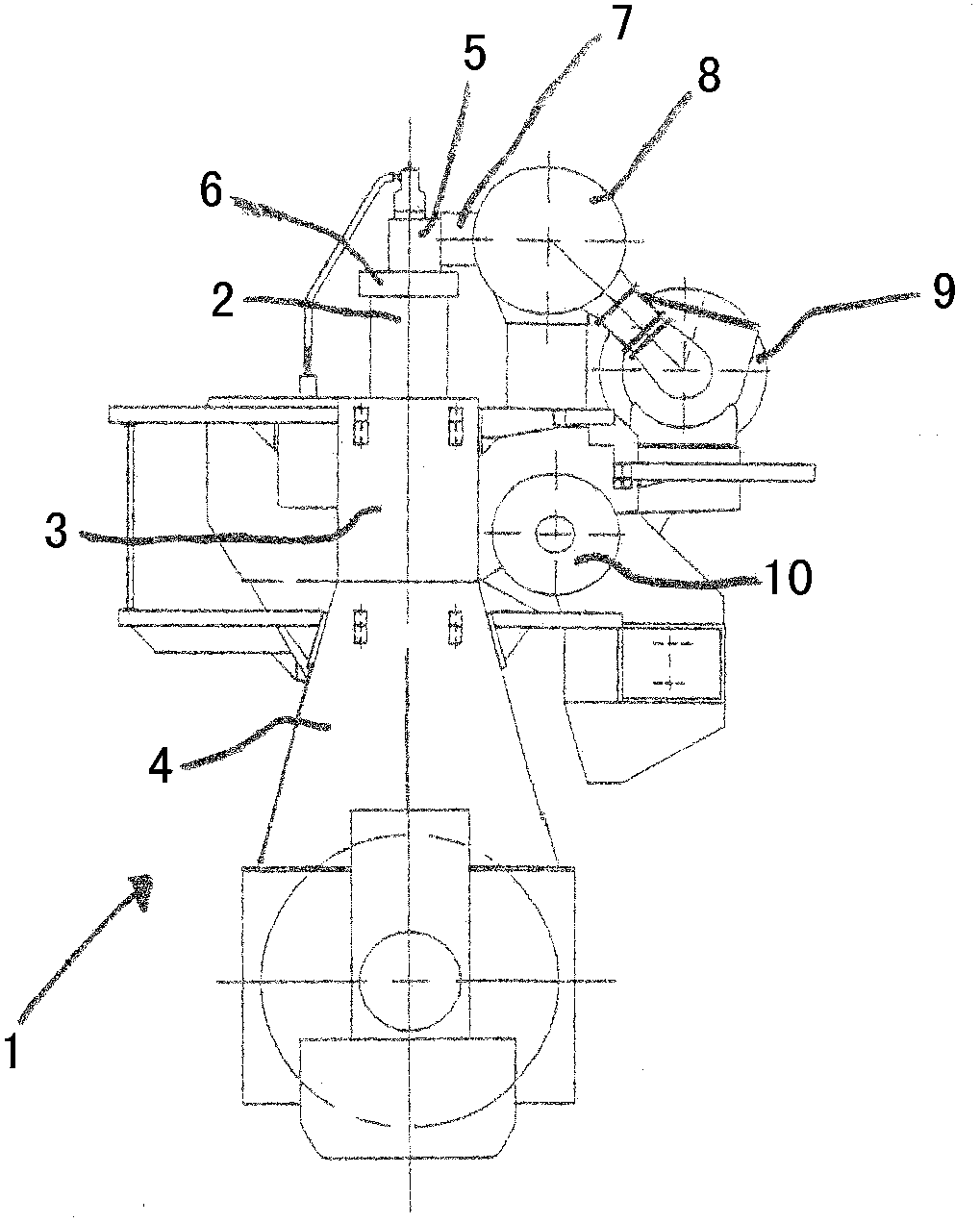

Multi-point-support five-cylinder plunger pump

PendingCN110617188AImprove structural strengthImprove support strengthPositive displacement pump componentsPiston pumpsSoftware engineeringHigh load

The invention discloses a multi-point-support five-cylinder plunger pump. The multi-point-support five-cylinder plunger pump comprises a power end assembly, a hydraulic end assembly and a speed reduction box assembly, wherein the power end assembly comprises a crankshaft box body, a crosshead box body and a space rack, and the crankshaft box body, the crosshead box body and the space rack are connected in sequence; the hydraulic end assembly is fixed on the space rack, the speed reduction box assembly is fixed to the crankshaft box body, the bottom of the crankshaft box body is provided with acrankshaft supporting body, and the crankshaft supporting body is used for supporting the crankshaft supporting box body; the bottom of the crosshead box body is provided with a crosshead supportingbody, the crosshead supporting body is used for supporting the crosshead box body, the bottom of the space rack is provided with a hydraulic supporting body, and the hydraulic supporting body is usedfor supporting the hydraulic end assembly. The multi-point-support five-cylinder plunger pump has the advantages that through the multi-point-support design on the crankshaft box body, the crosshead box body and the hydraulic end assembly, the support strength of the plunger pump can be improved, vibration is reduced, high-load work is better guaranteed, and the plunger pump runs more stably.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH

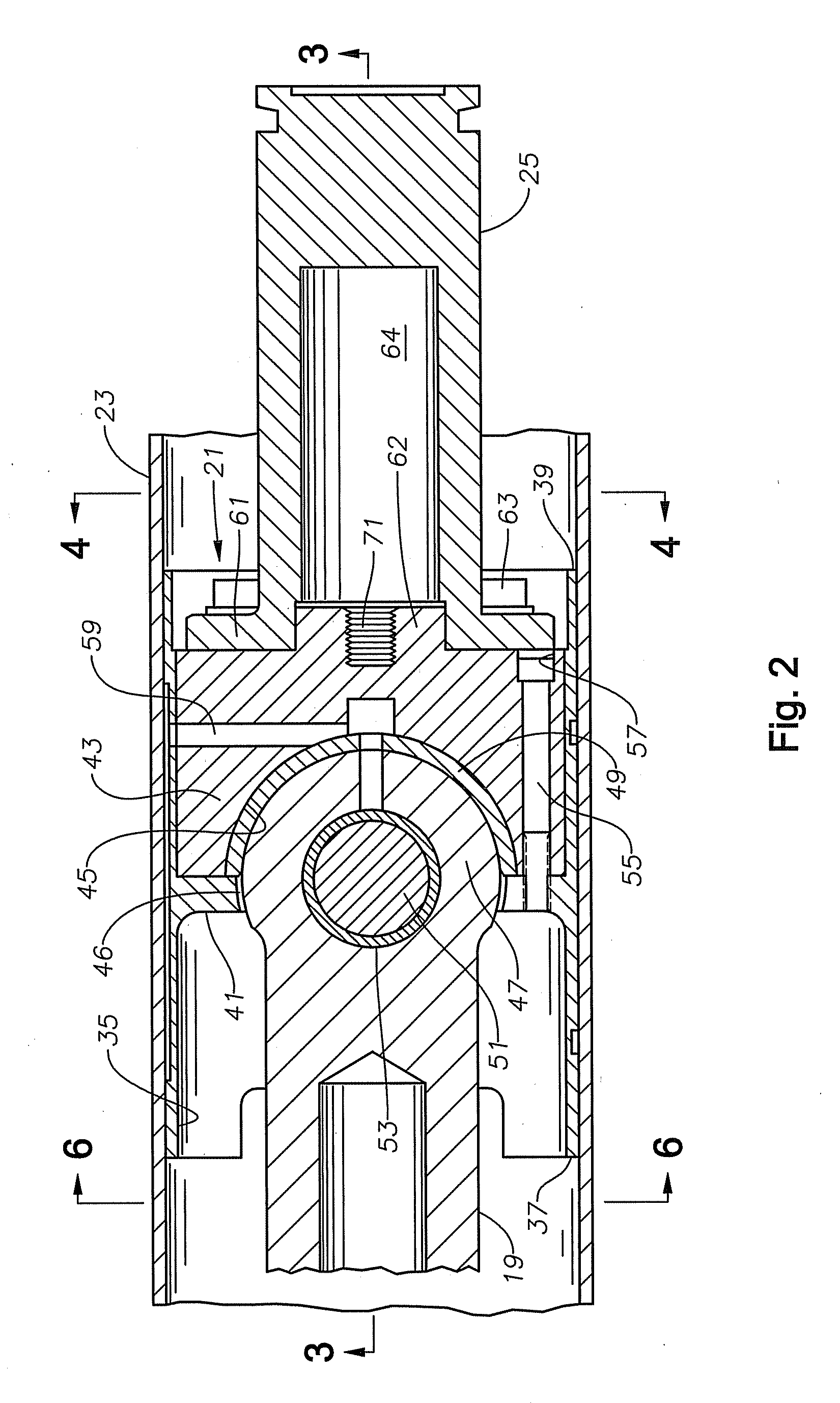

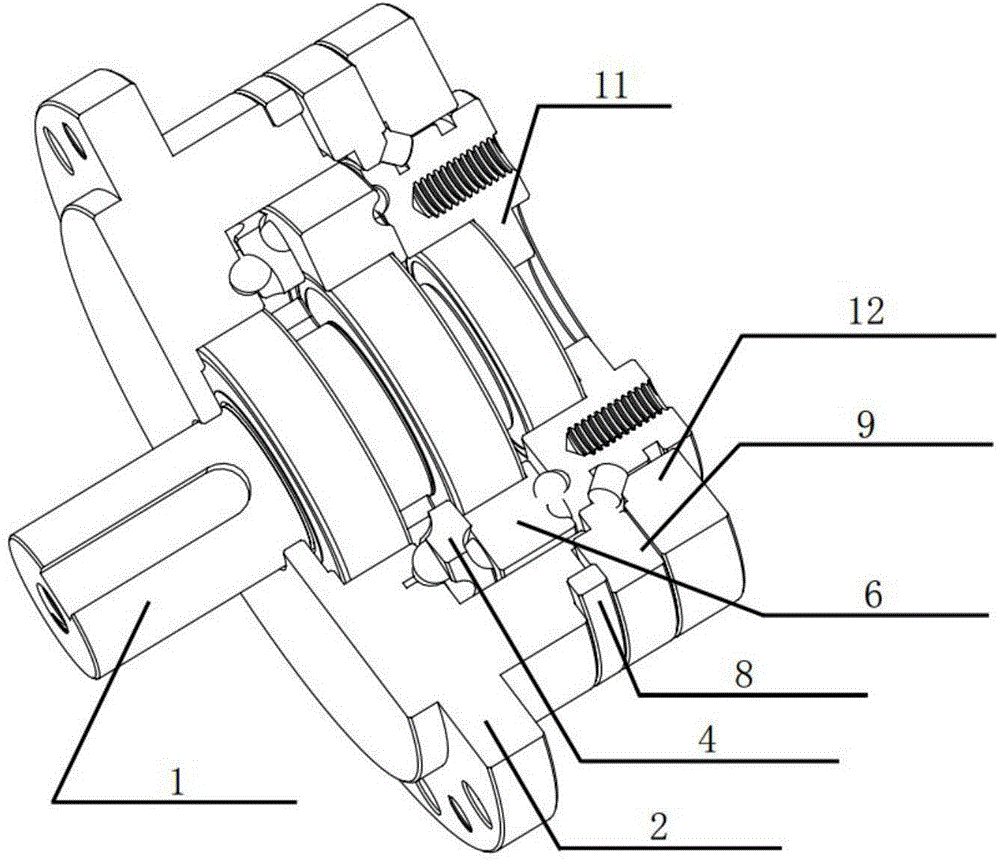

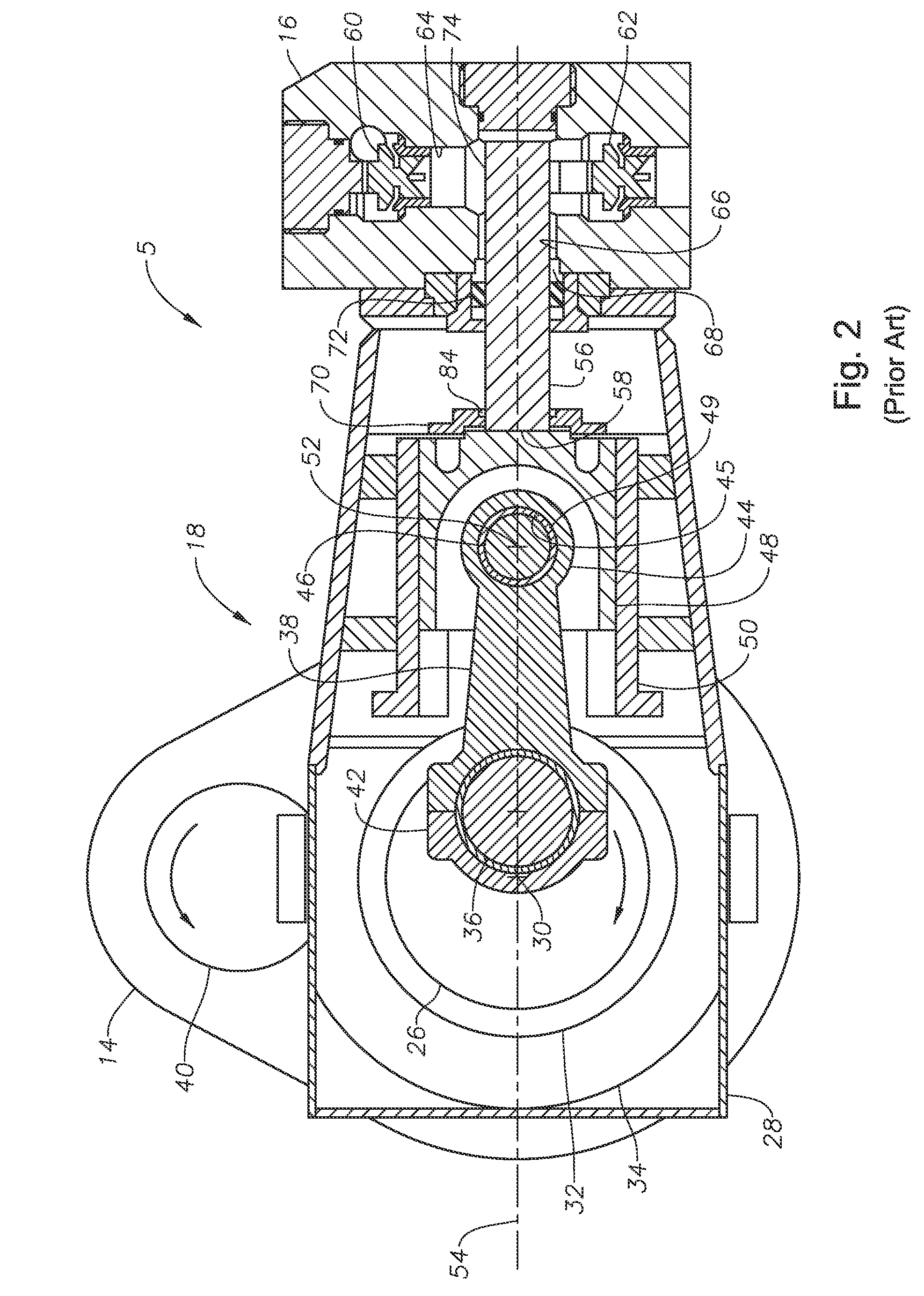

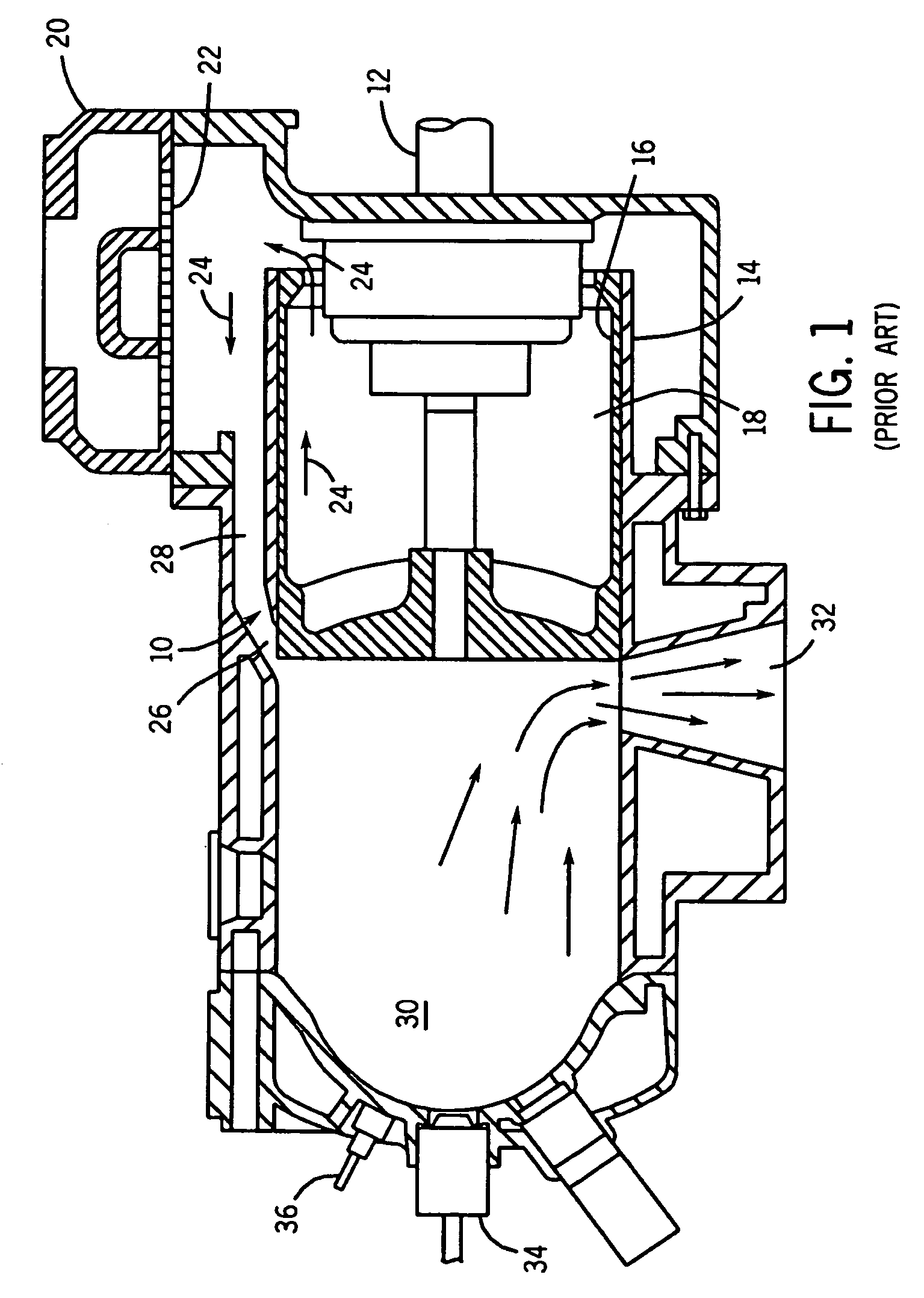

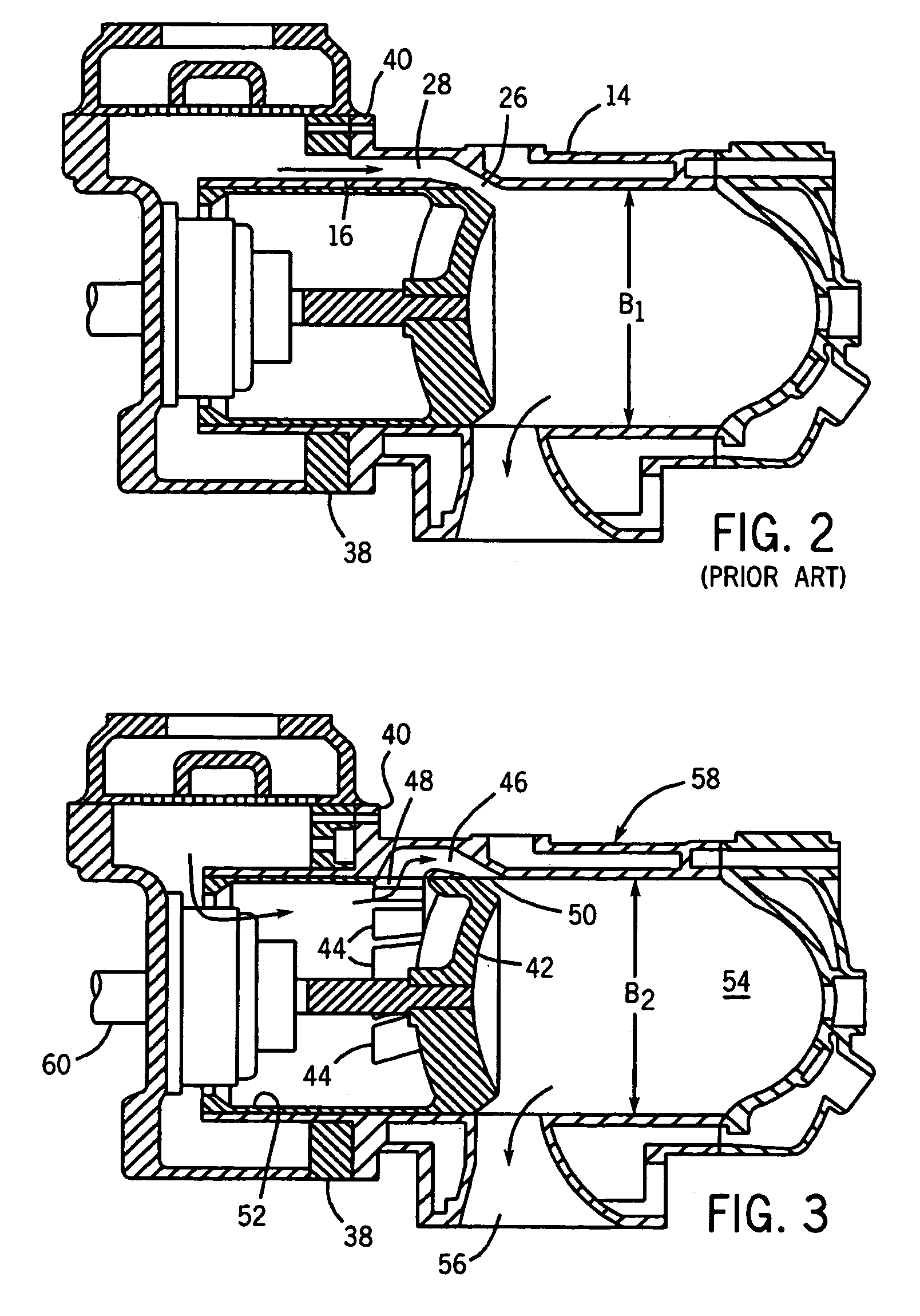

Readily Removable Pump Crosshead

InactiveUS20100322802A1Positive displacement pump componentsSuction devicesEngineeringMechanical engineering

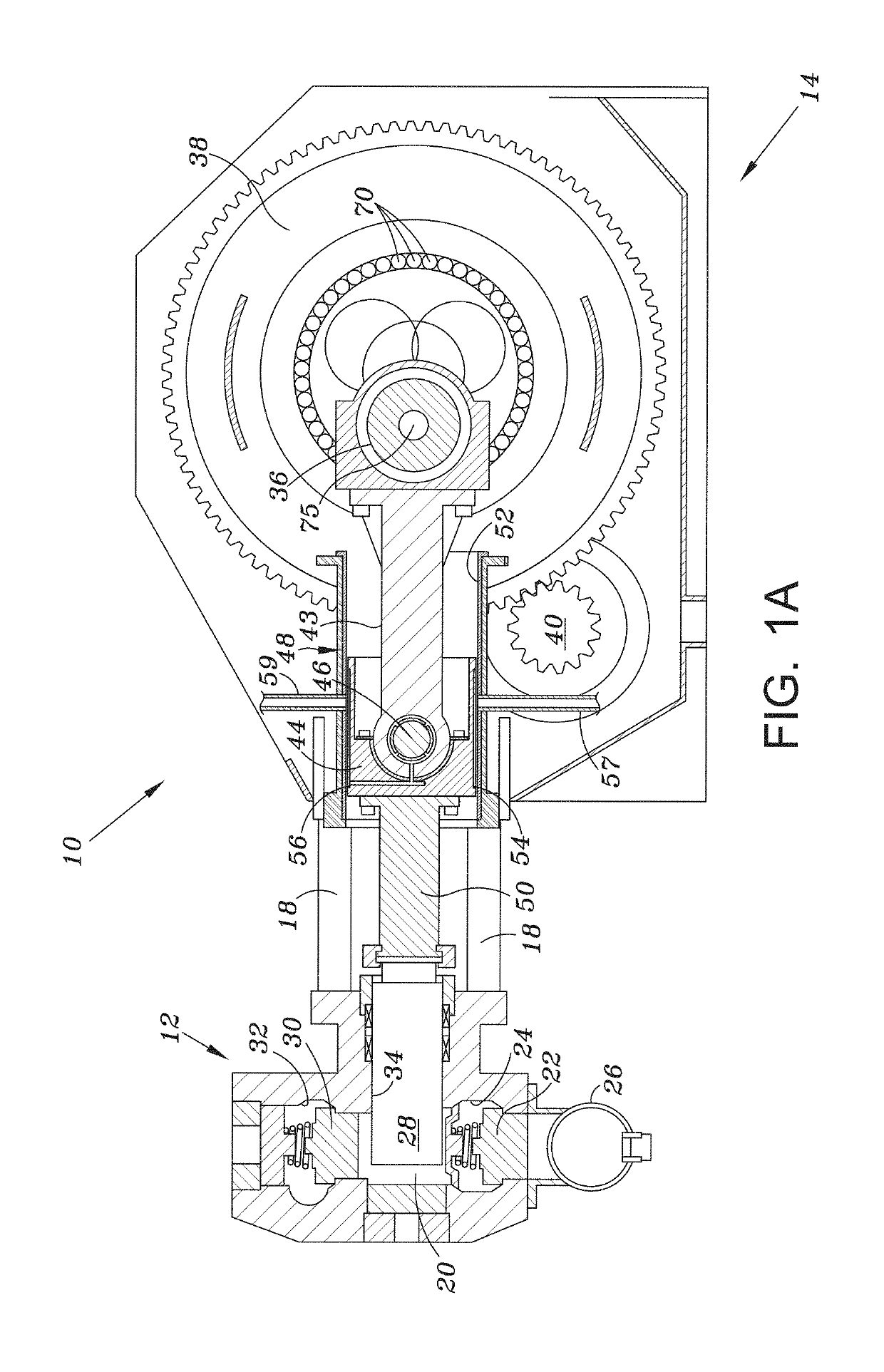

A reciprocating pump has a driven crankshaft and a connecting rod having an aft end rotatably mounted to the crankshaft. The pump has a stationarily mounted crosshead case in which a crosshead assembly strokes. The crosshead assembly has first and second crosshead members. A retainer pivotally joins the forward end of the connecting rod to the first crosshead member. The second crosshead member has a partially cylindrical recess containing a bushing. The forward end of the connecting rod is in pivotal engagement with the bushing. The second crosshead member is releasably secured to the first crosshead member to allow removal of the second crosshead member and the bushing from the crosshead case without detaching the forward end of the connecting rod from the first crosshead member.

Owner:WEIR SPM

Reciprocating type three-cylinder plunger pump for oil and gas field

PendingCN109882372AExtend your lifeFully lubricatedPositive displacement pump componentsPositive-displacement liquid enginesEngineeringLubrication

The invention provides a reciprocating type three-cylinder plunger pump for an oil and gas field. The reciprocating type three-cylinder plunger pump comprises a gear box assembly, a power end assemblyand a hydraulic end assembly which are transmitted in sequence; and the hydraulic end assembly comprises a disc root and a plunger, the power end assembly comprises a crankshaft, a connecting rod, asliding rail and a crosshead, power is transmitted from the crosshead to the plunger, a pull rod and a fender are arranged between the plunger and the crosshead, the pull rod is fixed on the cross head, the plunger is fixed to the pull rod, the fender is located between the pull rod and the plunger and fixed with the plunger, and the outer diameter of the fender is larger than that of the plungerand the pull rod. The reciprocating type three-cylinder plunger pump can solve the problems that a working medium in a hydraulic end assembly in the prior art is poured into a power end assembly alongthe plunger, a packing is inconvenient to replace, and a connecting rod large-head bearing bush is insufficient in lubrication and the like.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH

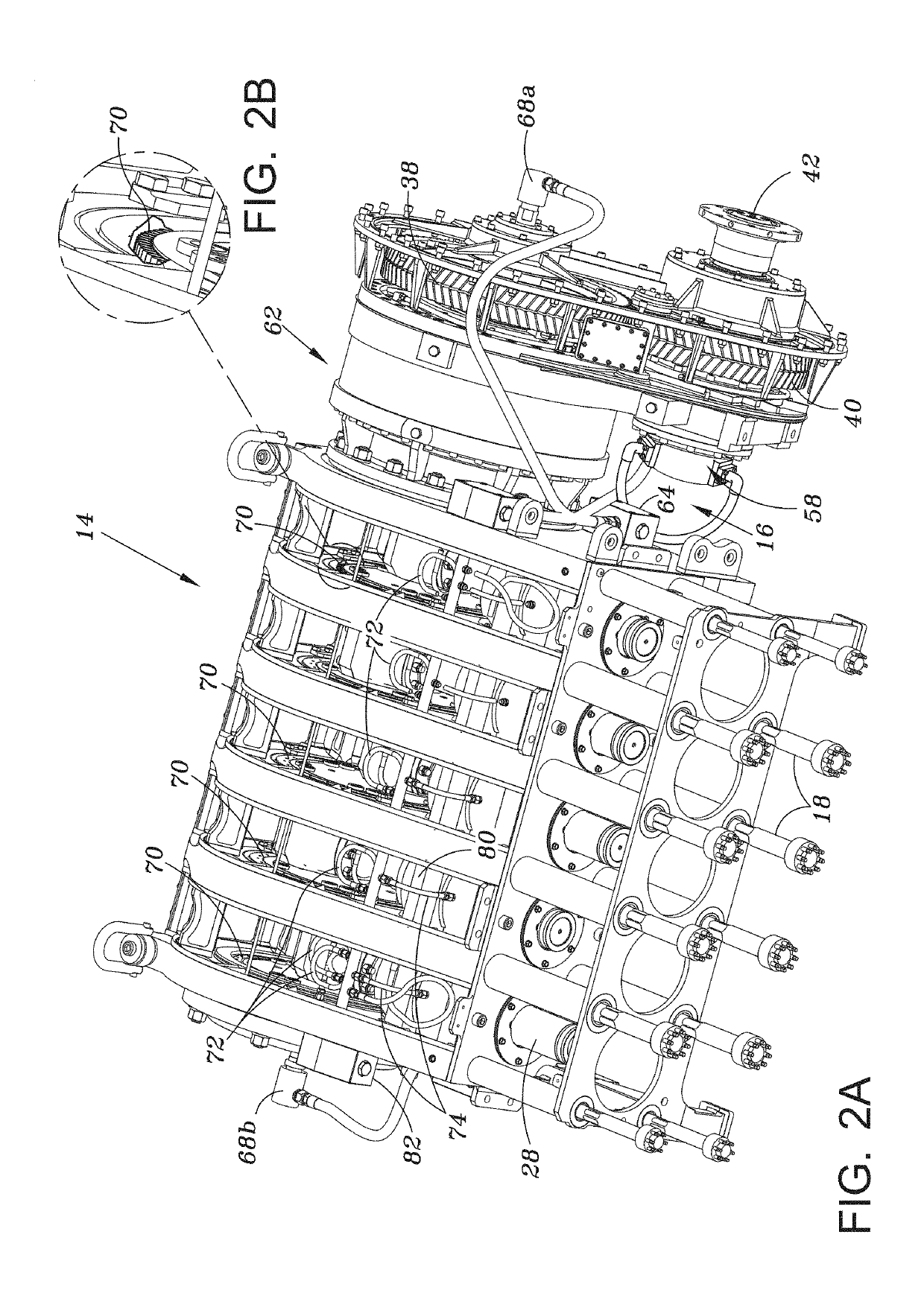

Reciprocating pump with dual circuit power end lubrication system

ActiveUS20160177945A1Positive displacement pump componentsRotary/oscillating piston combinationsEngineeringHigh pressure

A dual circuit lubrication system for a power end of a reciprocating pump that includes a lubrication pump that supplies lubrication fluid to a high pressure lubrication circuit and a low pressure lubrication circuit. The high pressure lubrication circuit is fluidly coupled to a crankshaft to supply lubrication fluid to sliding surfaces associated with the crankshaft at a first lubrication fluid pressure. The crankshaft drives a crosshead coupled to a plunger to displace fluid from a fluid end of the reciprocating pump. The low pressure lubrication circuit is fluidly coupled to supply the lubrication fluid to a plurality of rolling surfaces associated with the crankshaft at a second lubrication fluid pressure. The first lubrication fluid pressure is greater than the second lubrication fluid pressure.

Owner:SPM OIL & GAS INC

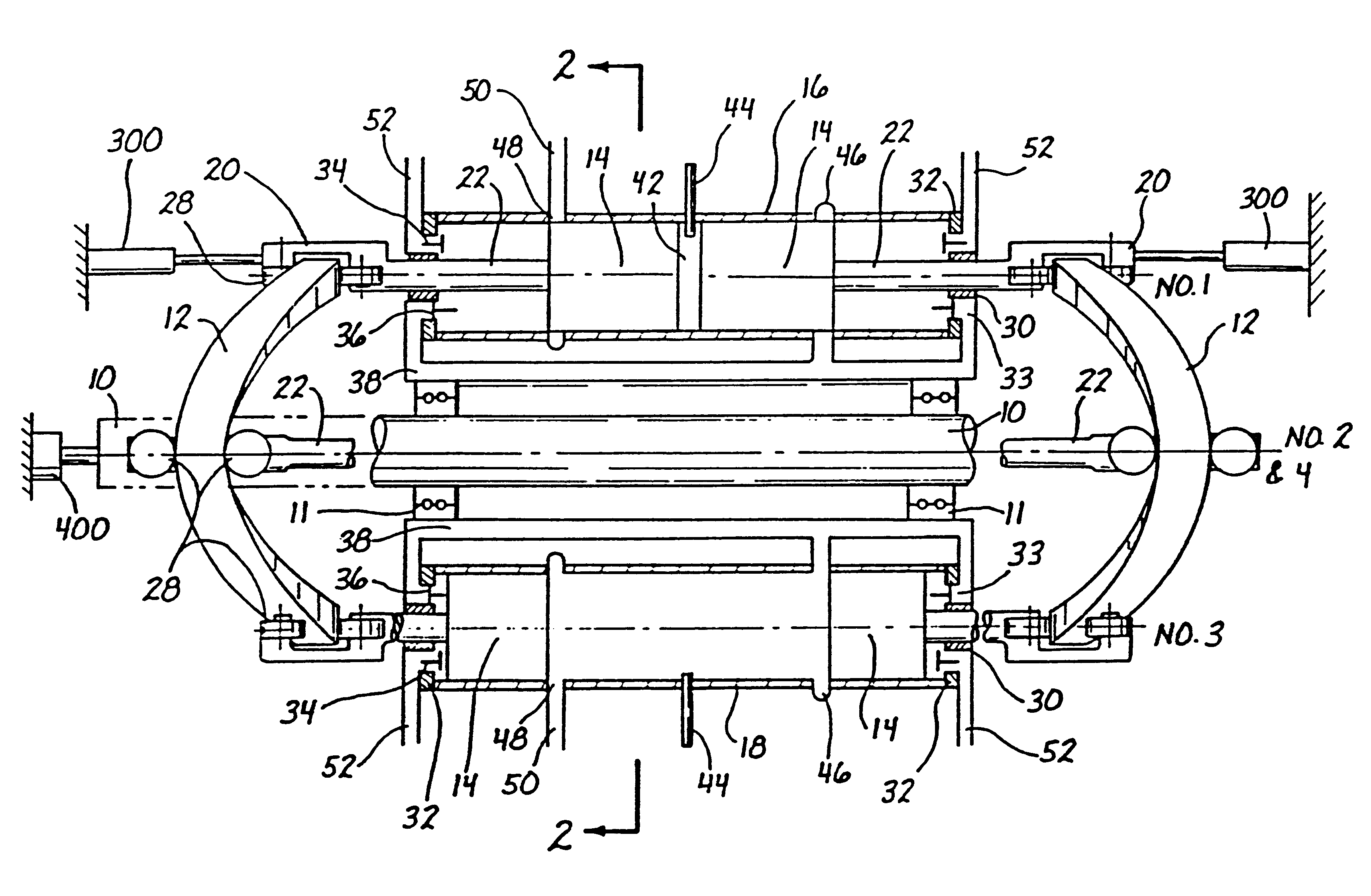

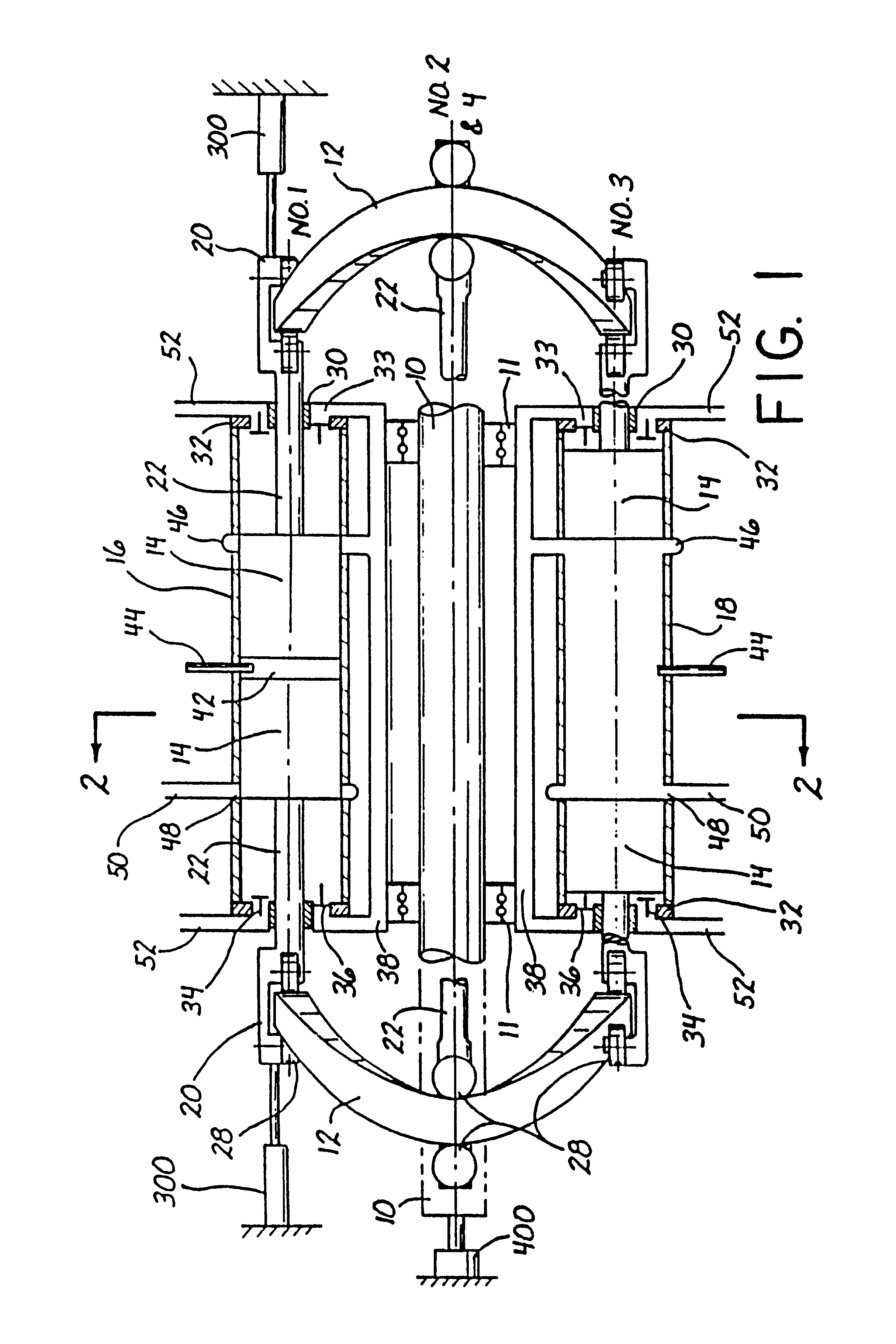

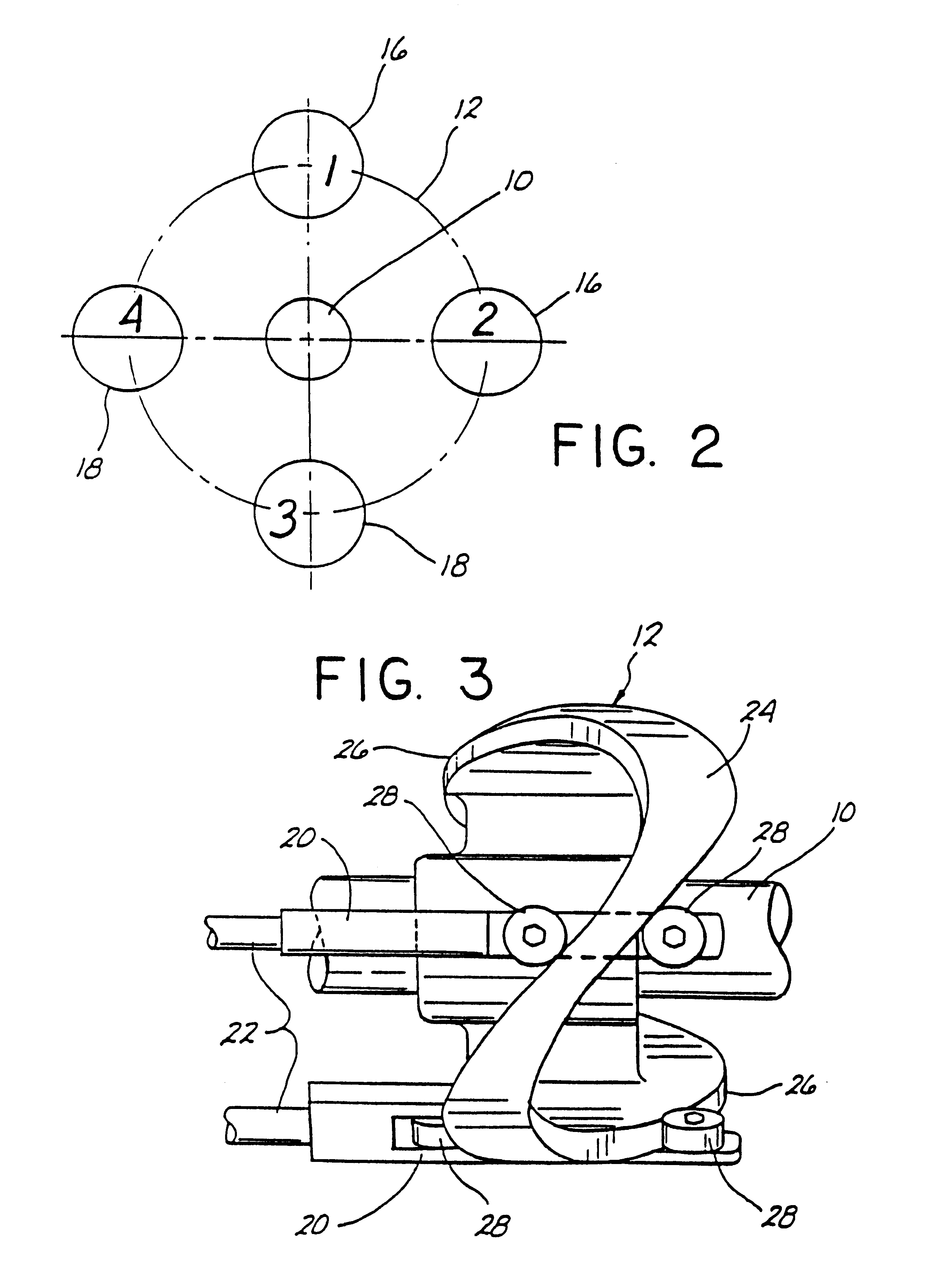

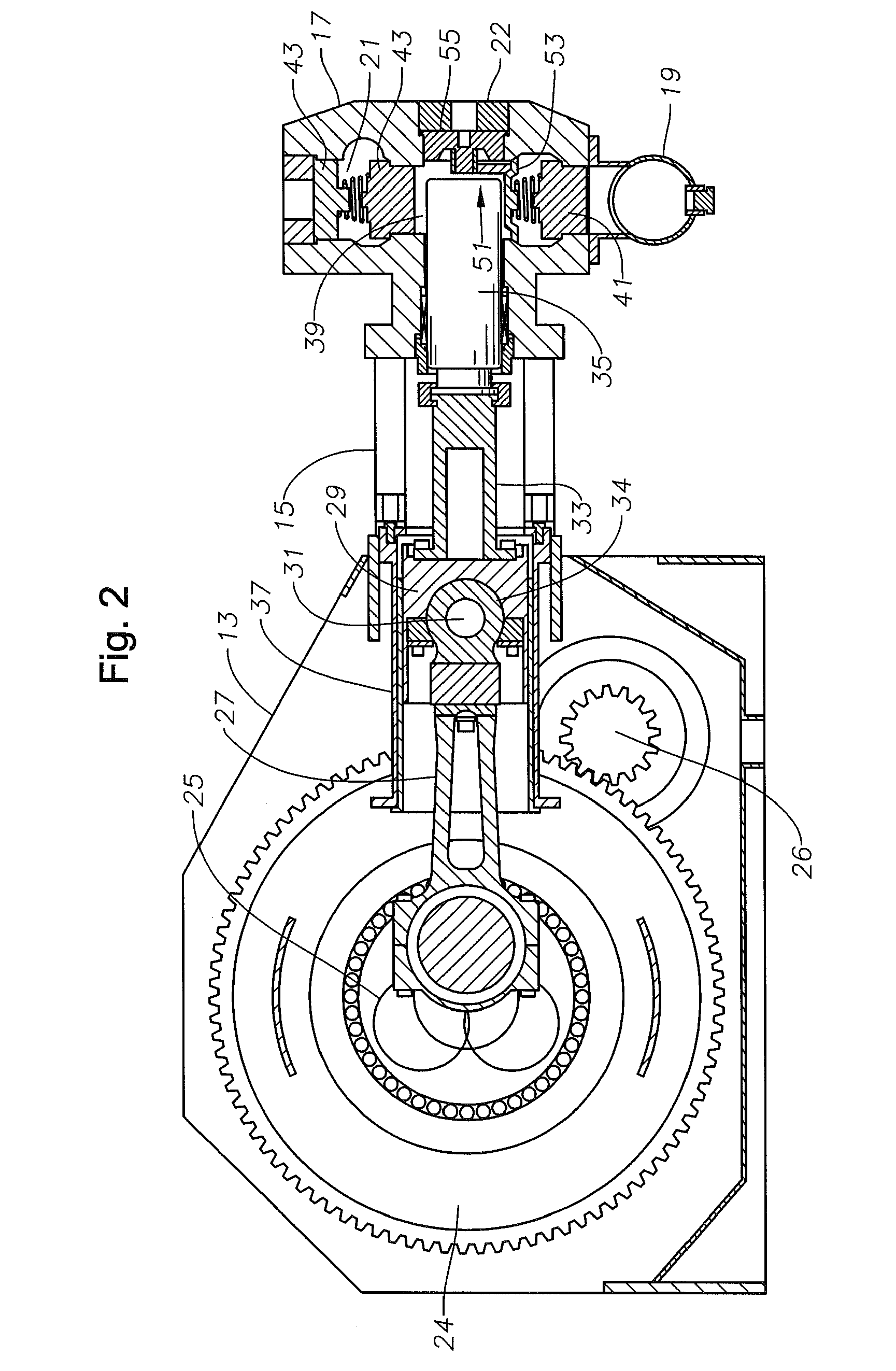

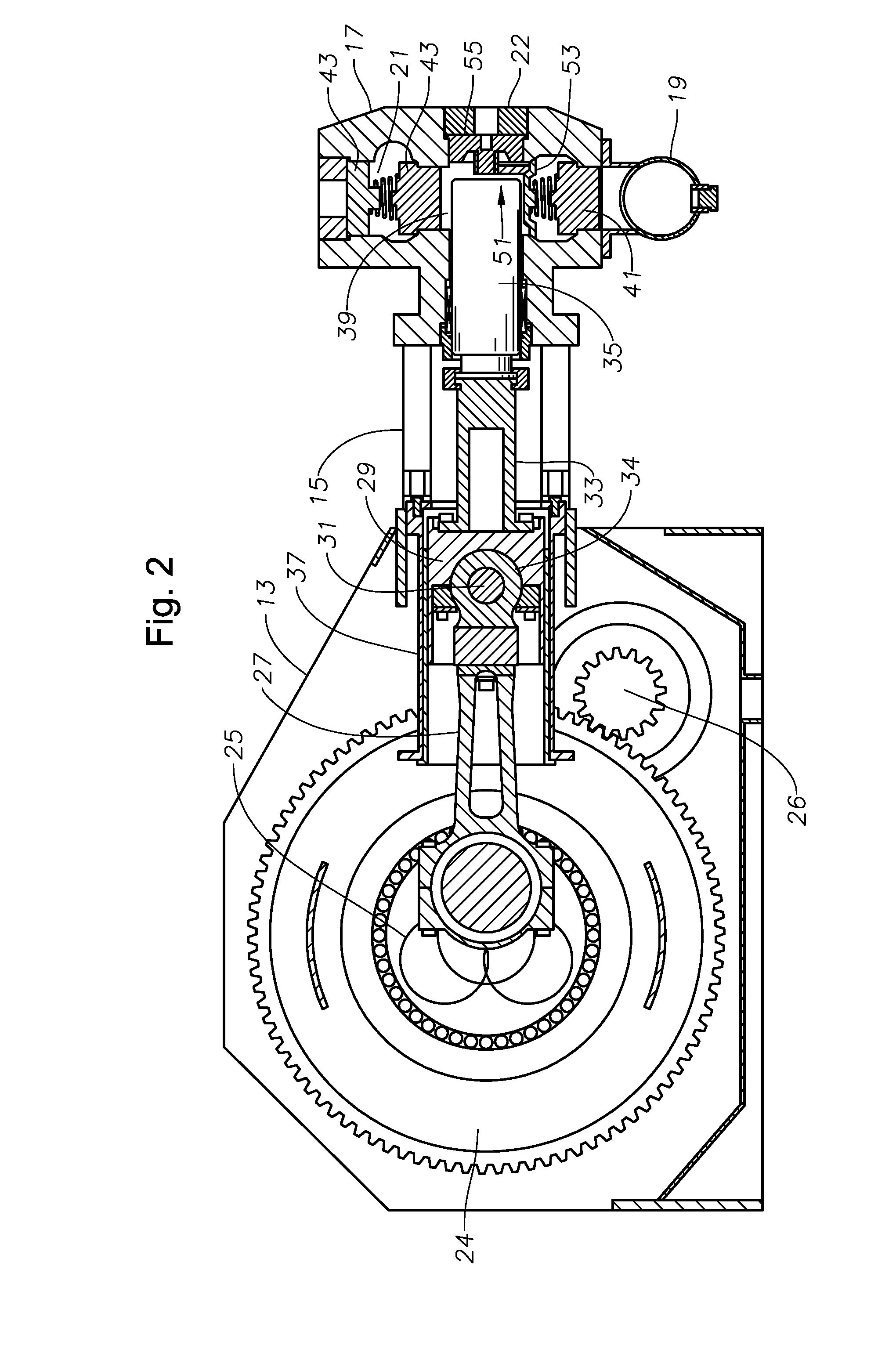

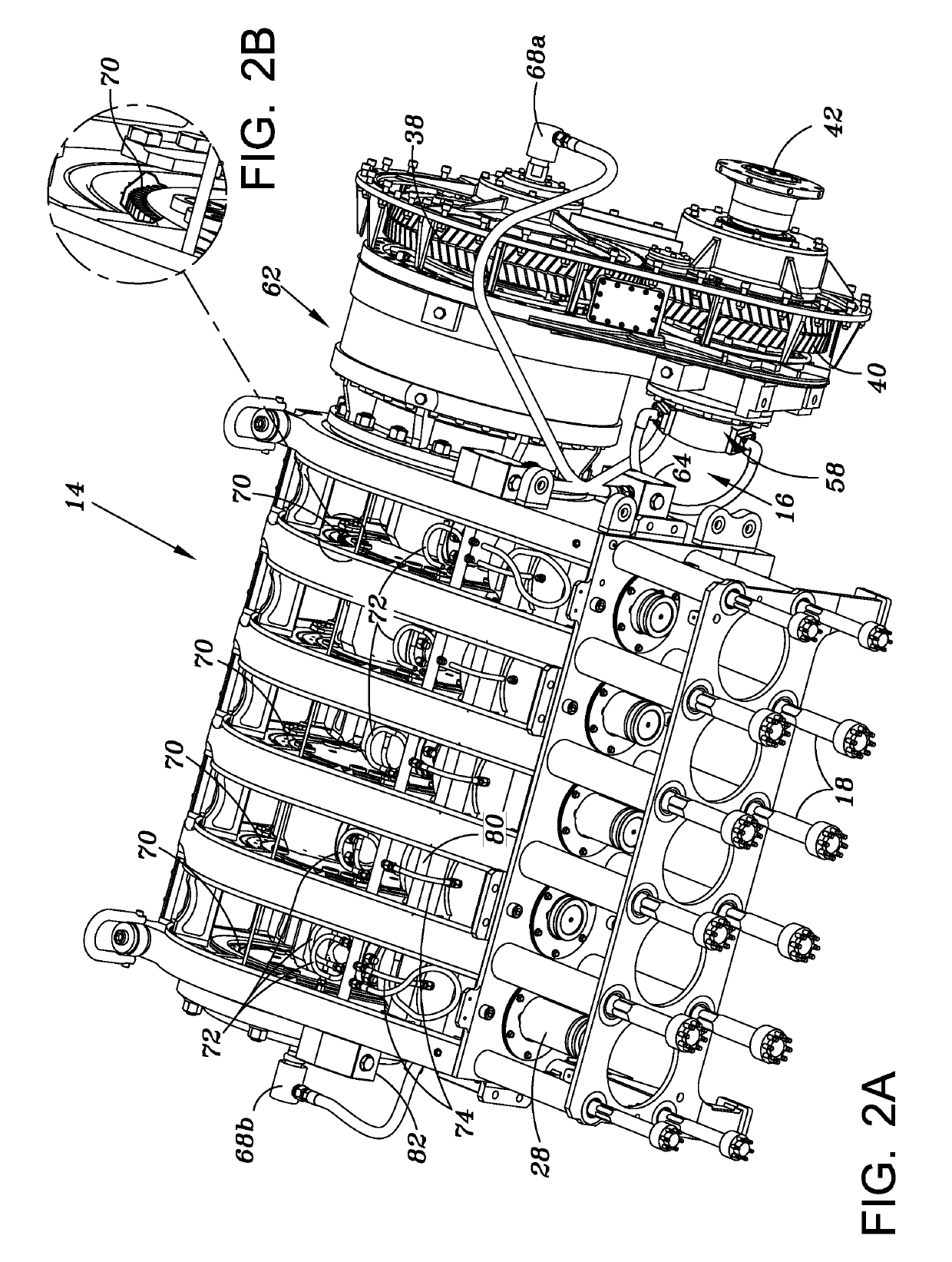

Adiabatic, two-stroke cycle engine having novel scavenge compressor arrangement

InactiveUS6279520B1Improve thermal efficiencyReduce heat lossReciprocating piston enginesAir compressionExhaust valve

An engine structure and mechanism that operates on various combustion processes in a two-stroke-cycle without supplemental cooling or lubrication comprises an axial assembly of cylindrical modules and twin, double-harmonic cams that operate with opposed pistons in each cylinder through fully captured rolling contact bearings. The opposed pistons are double-acting, performing a two-stroke engine power cycle on facing ends and induction and scavenge air compression on their outside ends, all within the same cylinder bore. The engine includes a novel compressor arrangement having an intake valve comprising a V-shaped double reed valve with an apex pointing toward the intake port and an exhaust valve having a V-shaped double reed valve with an apex pointing away from the exhaust port. The compressor arrangement may further include rectangular intake and exhaust ports, a rectangular piston rod and rectangular crosshead bearings.

Owner:LOWI JR ALVIN

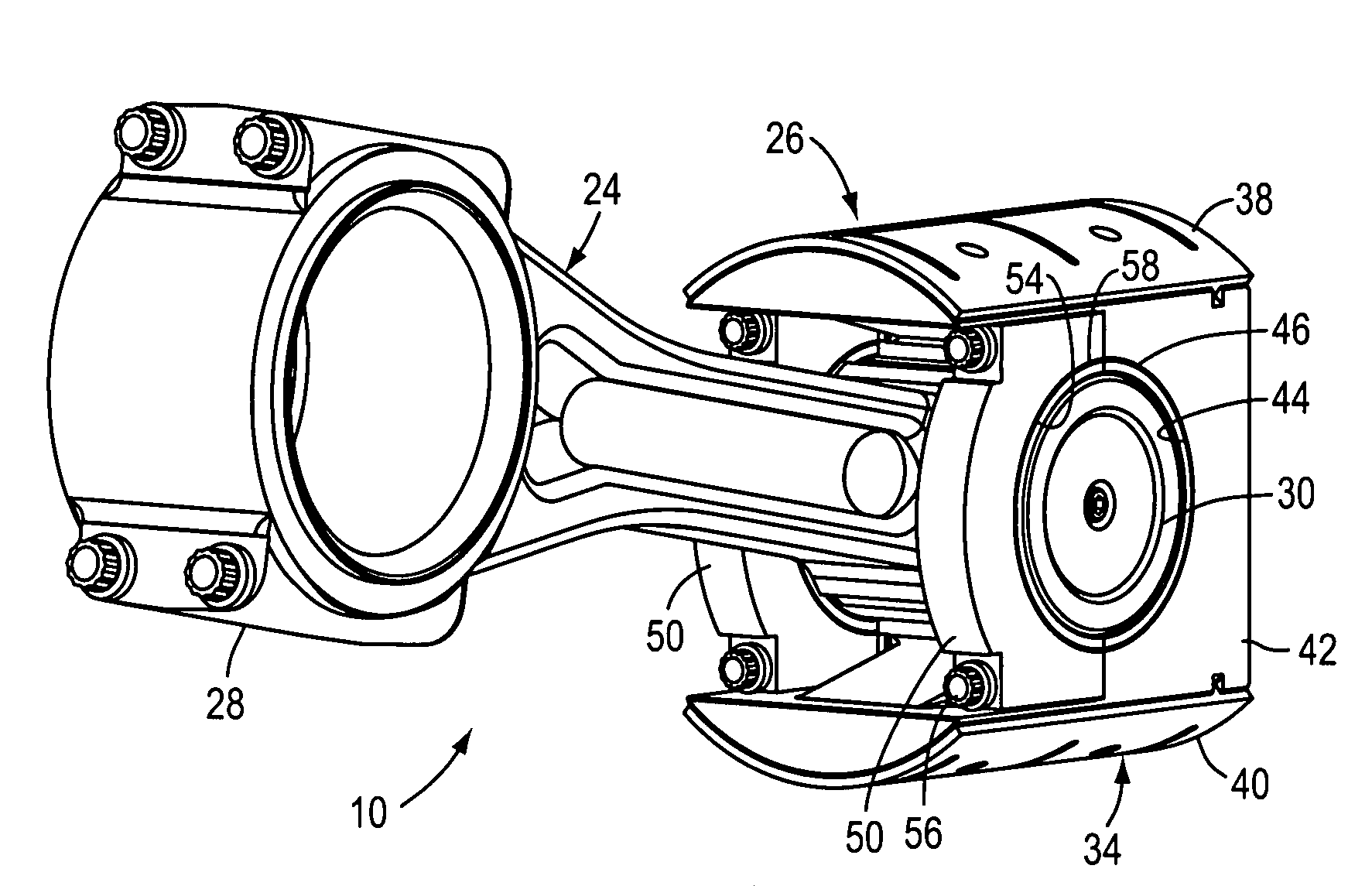

Connecting rod without wrist pin

InactiveUS8376723B2Reduce weightEliminate needConnecting rod bearingsPositive displacement pump componentsEngineeringCrankshaft

Owner:WEIR SPM

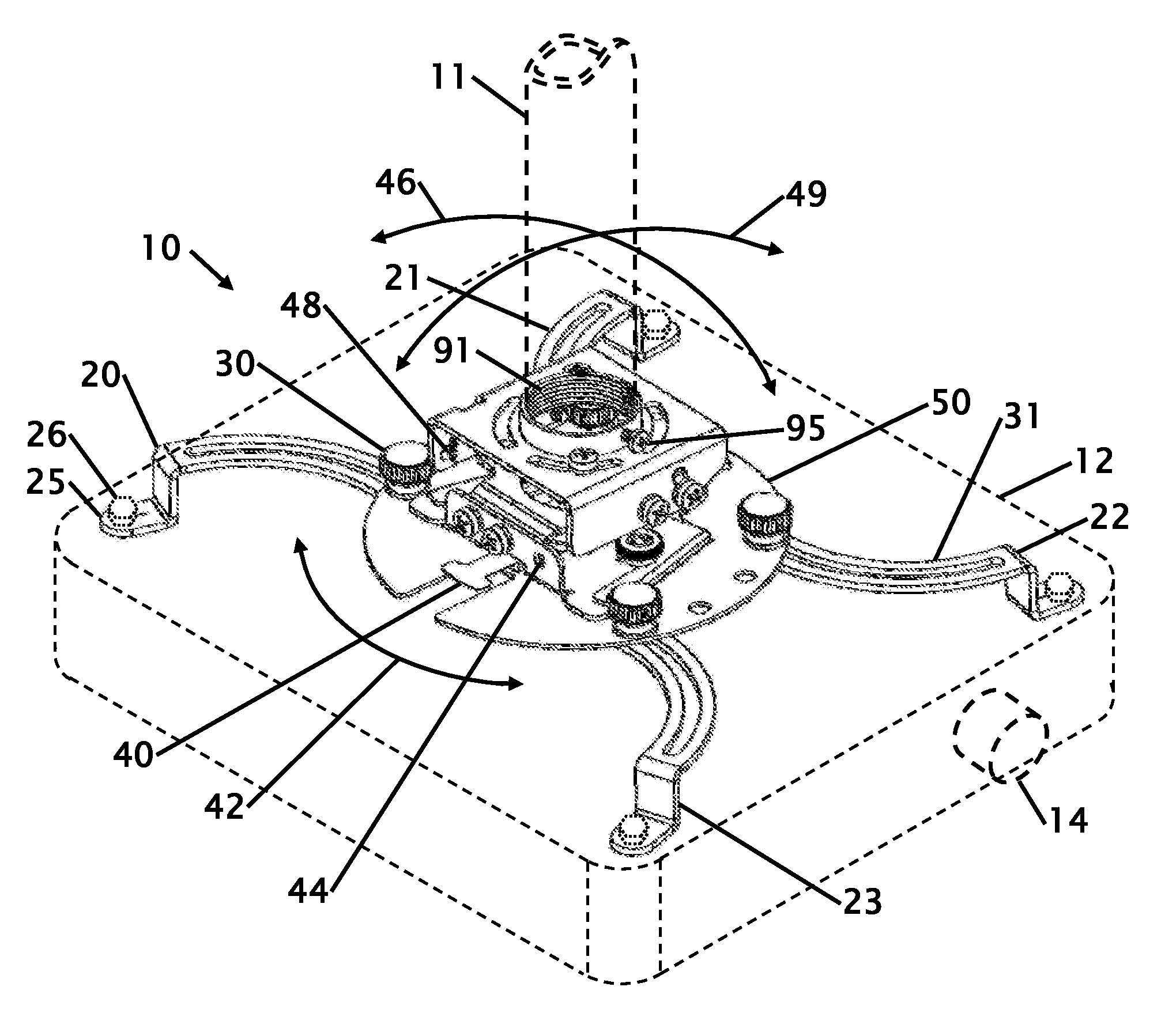

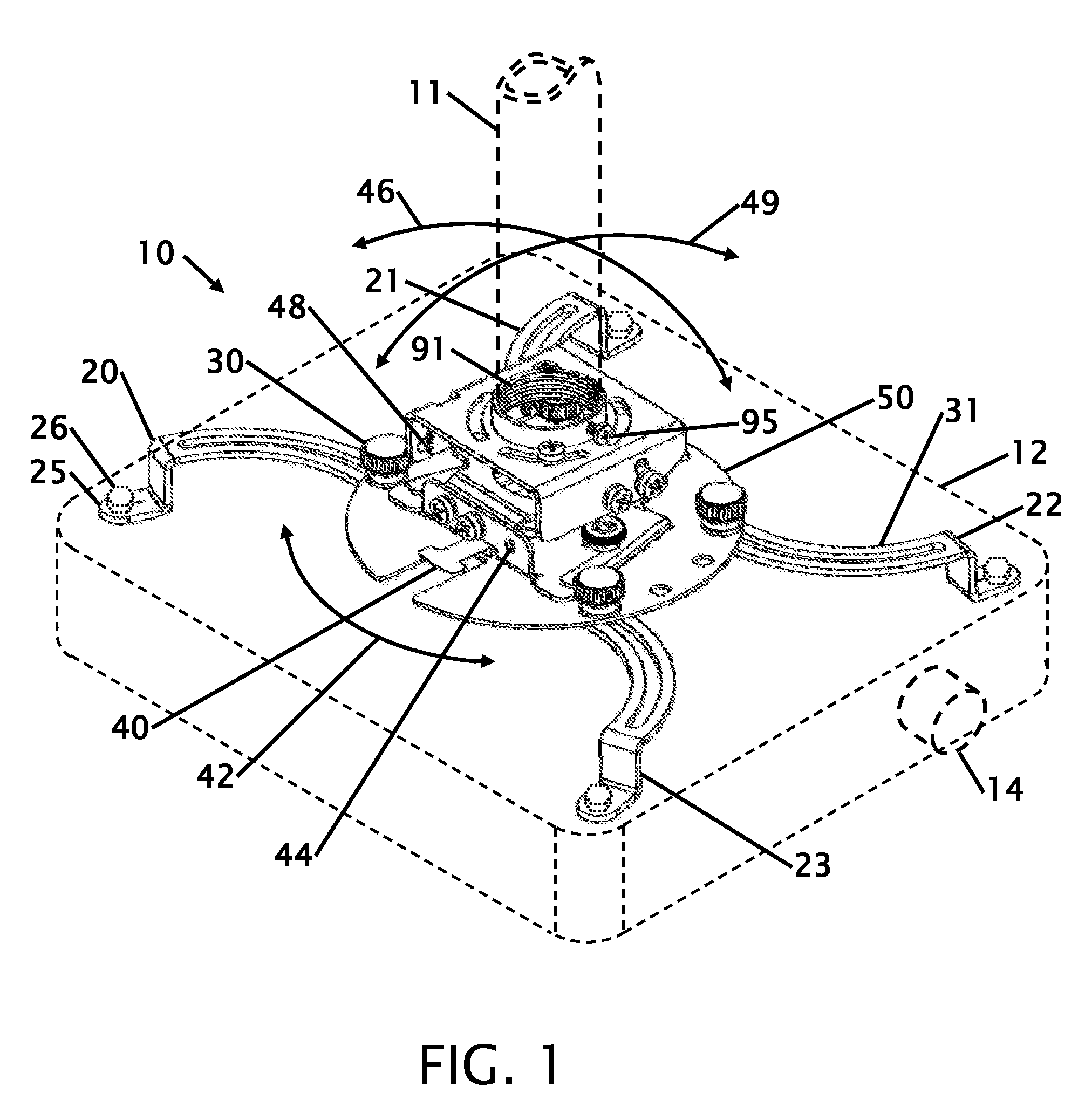

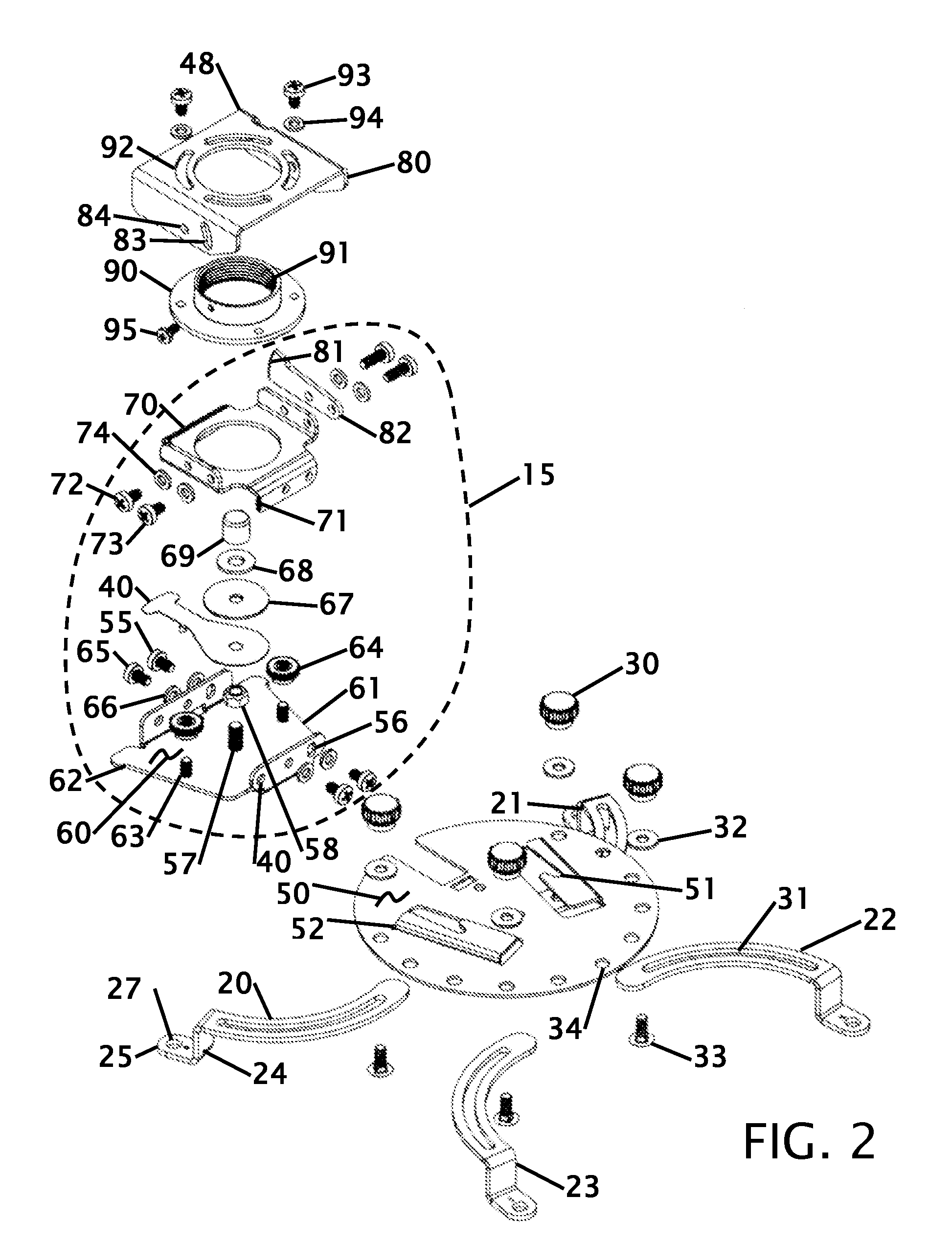

Projector mount with phillips screw driver angle adjustment

InactiveUS20090294619A1Low costReduce manufacturing costPortable framesCandle holdersRotational axisGear wheel

Improvements in a mount for attaching a television of projector to an overhead or ground structure is disclosed. The mount allows for spin, side to side and front to back angle adjustment. The adjustment components are formed from the present projector mount uses metal component having a rack comprising a plurality of formed teeth that are engageable in the recessed side of a crosshead screwdriver that is trademarked as a Phillips screwdriver. The recesses of the crosshead screwdriver act as a pinion gear in the rack to adjust the mounted angle of a projector on the projector mount. This configuration reduces parts count, size and cost without compromising functionality. The axis of rotation of both the side-to-side and front-to-back pass through the projector mount.

Owner:SPECIALTY FINANCE

Rotatable head for forming spiral extrusions

InactiveUS20050260408A1Increase sealing forceAvoid pollutionConfectioneryFilament/thread formingEngineeringCounterbore

A polymer extrusion crosshead assembly for forming a spirally-striped extrusion. The assembly includes conventional components for admitting, turning, and accelerating primary molten polymer toward a novel rotating die sub-assembly. A body element includes an axial counterbore for receiving a manifold supply block in communication with a source of secondary striping polymer. A wear plate is attached to the manifold block. The die sub-assembly includes a striping die having an annular passage for conveying the primary polymer to form an extruded tube or a core material coating. The die is loaded against the wear plate by a Belleville washer. The die includes one or more striping nozzles in communication with the manifold block for injecting secondary striping polymer into the annular stream of primary polymer flowing through the die, creating a longitudinal stripe of striping polymer. Rotating the die while extruding both polymers yields a helically striped (spiral) extrusion.

Owner:CANGEN HLDG

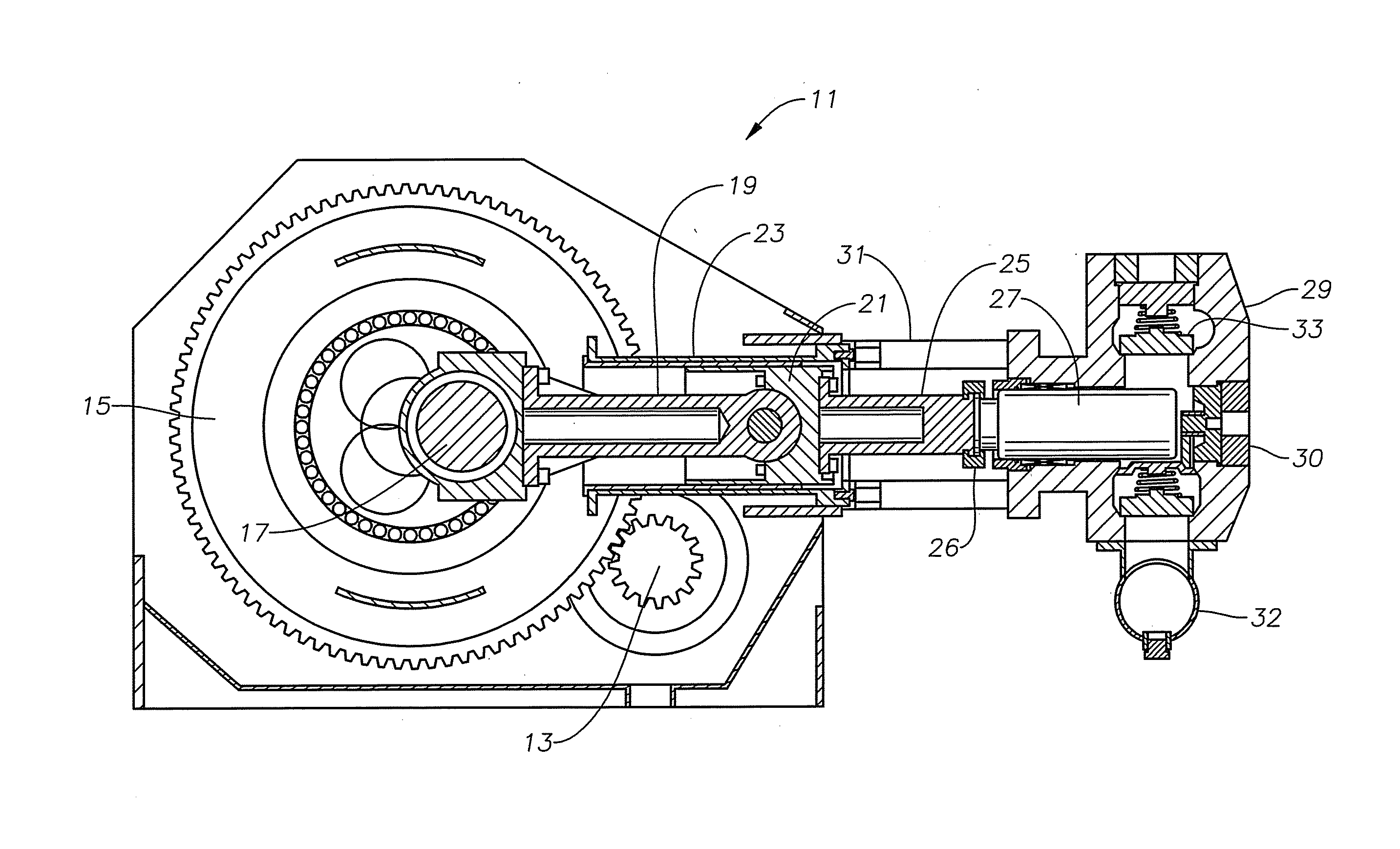

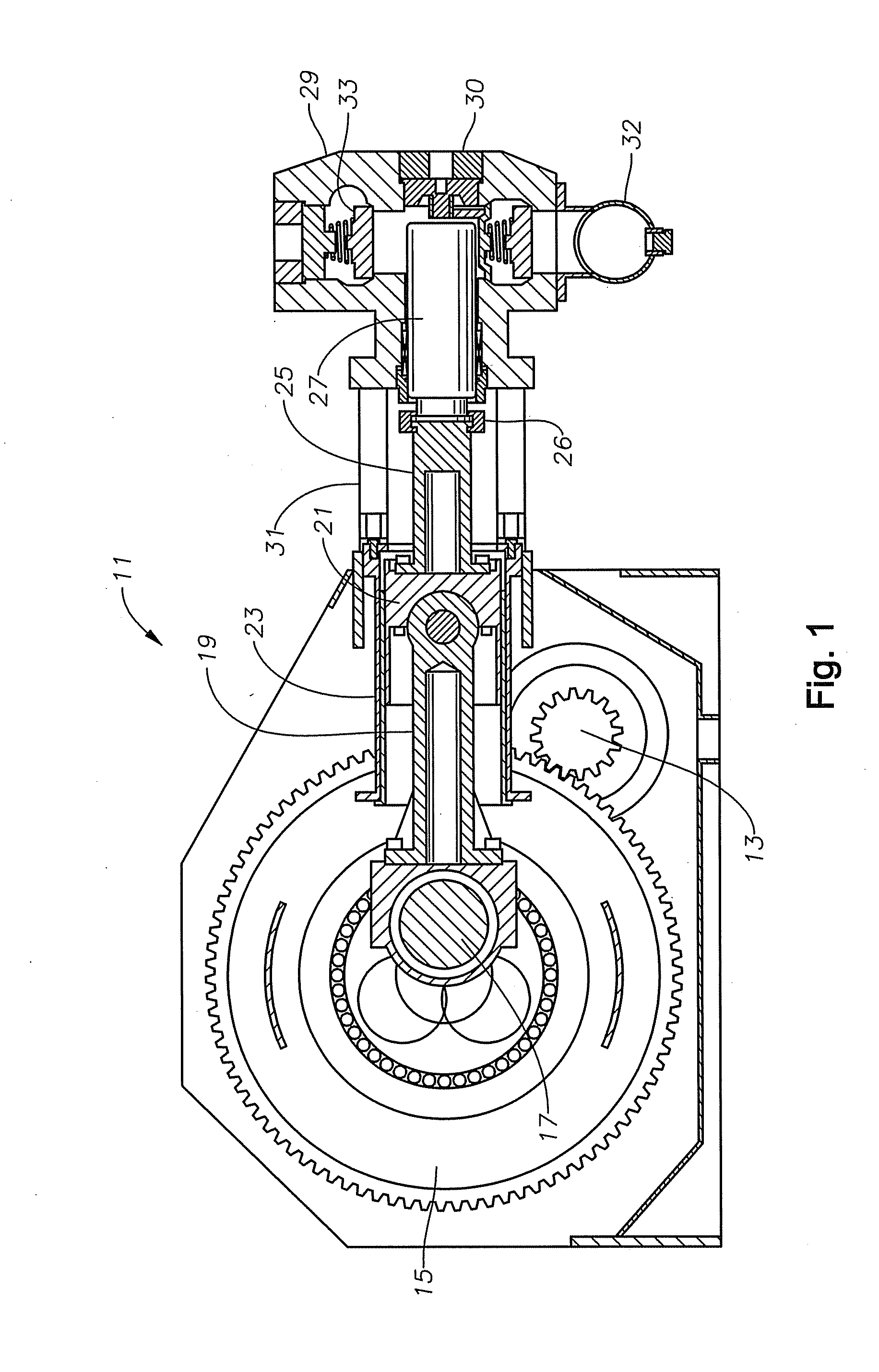

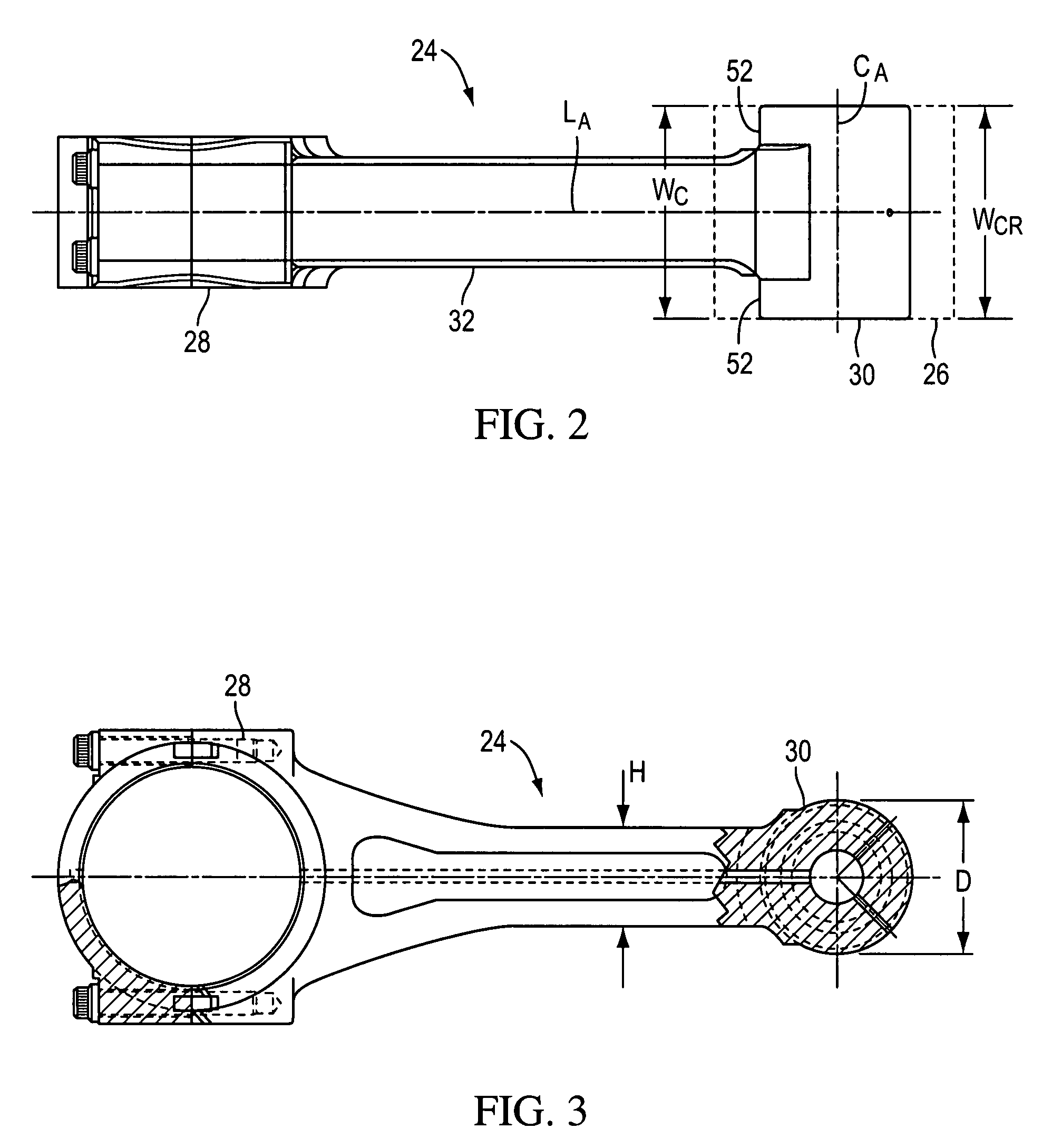

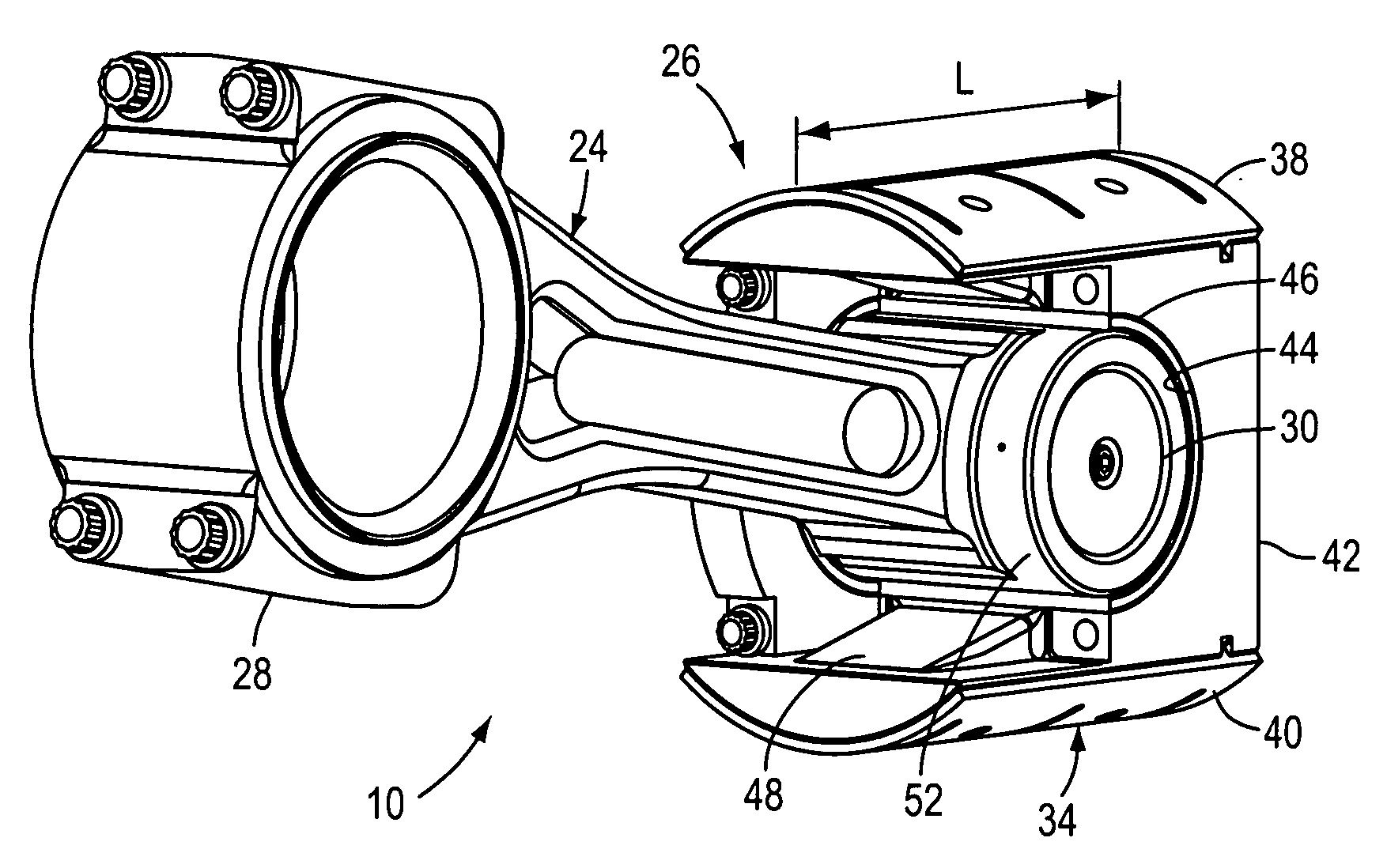

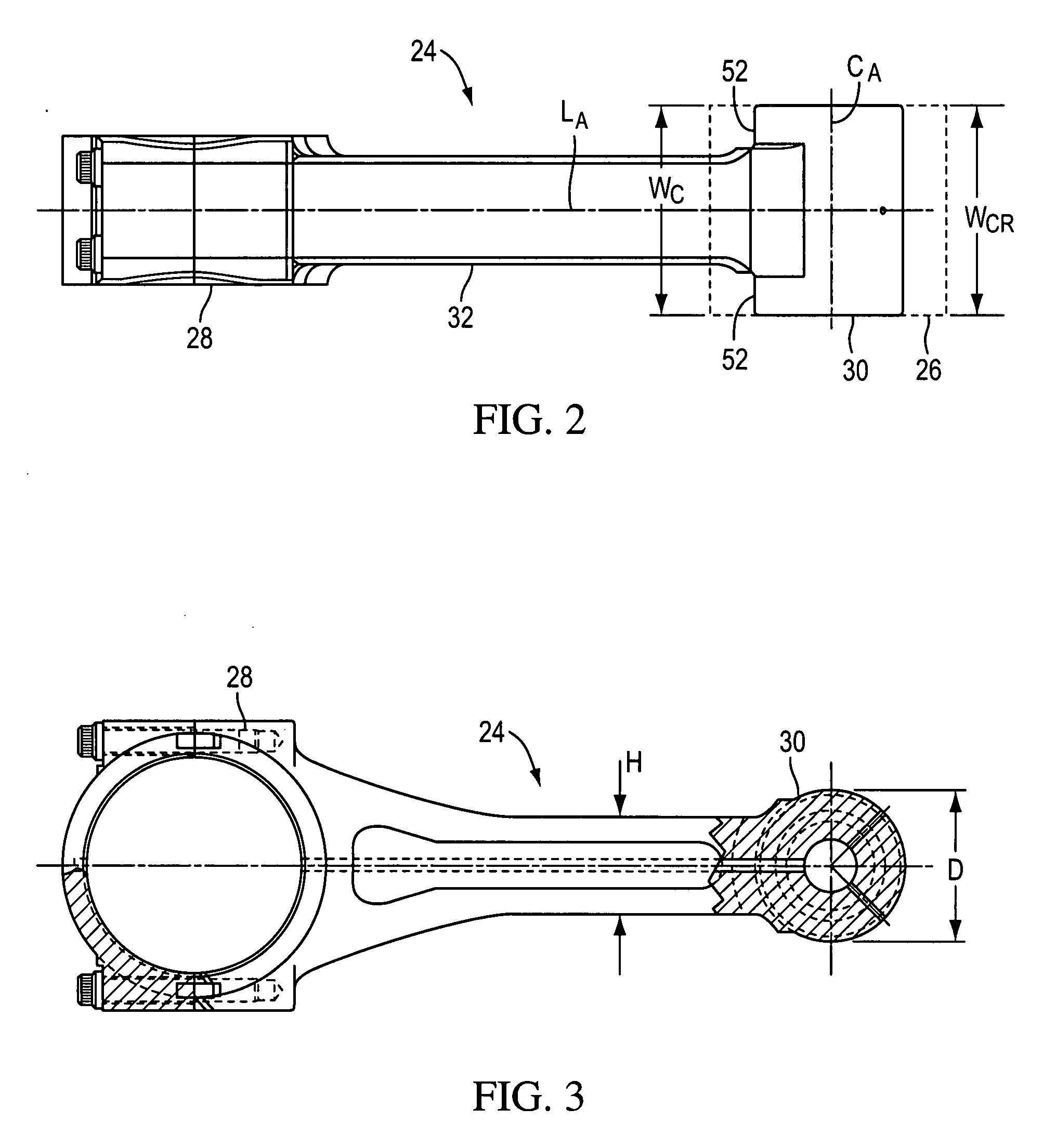

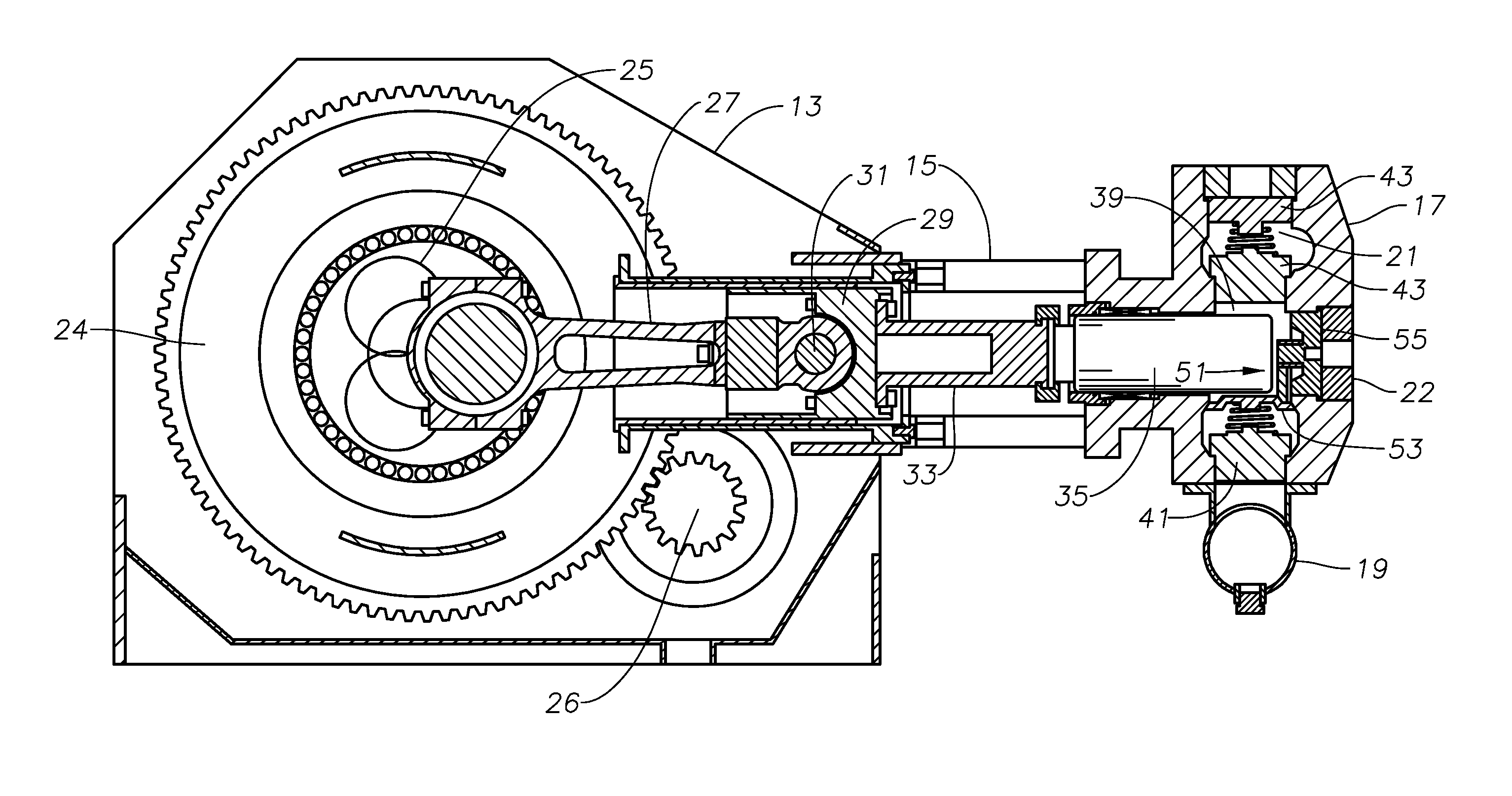

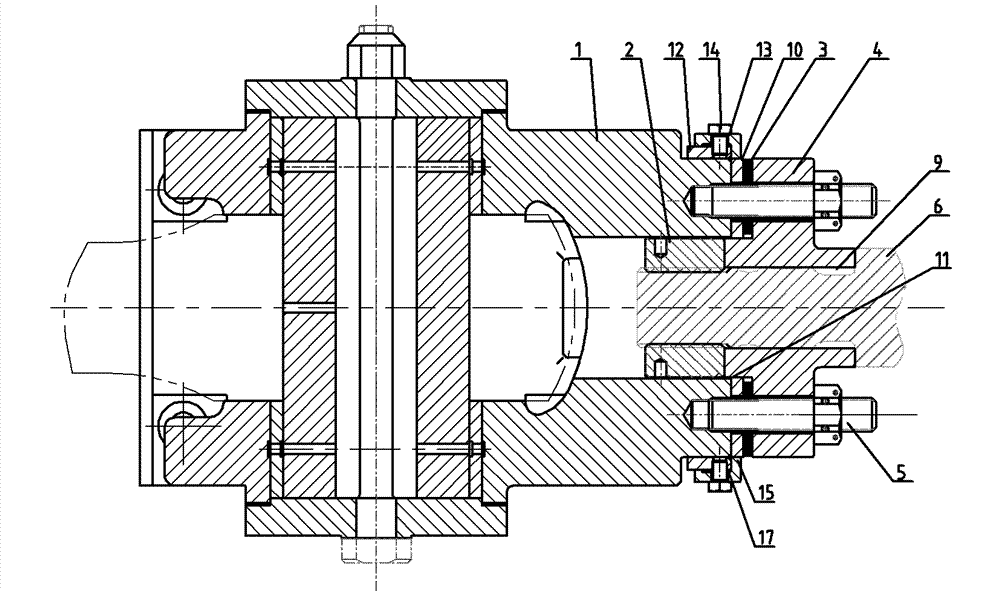

Pump crosshead and connecting rod assembly

ActiveUS7610847B2Increase surface areaBearing stressConnecting rodsPositive displacement pump componentsEngineeringMechanical engineering

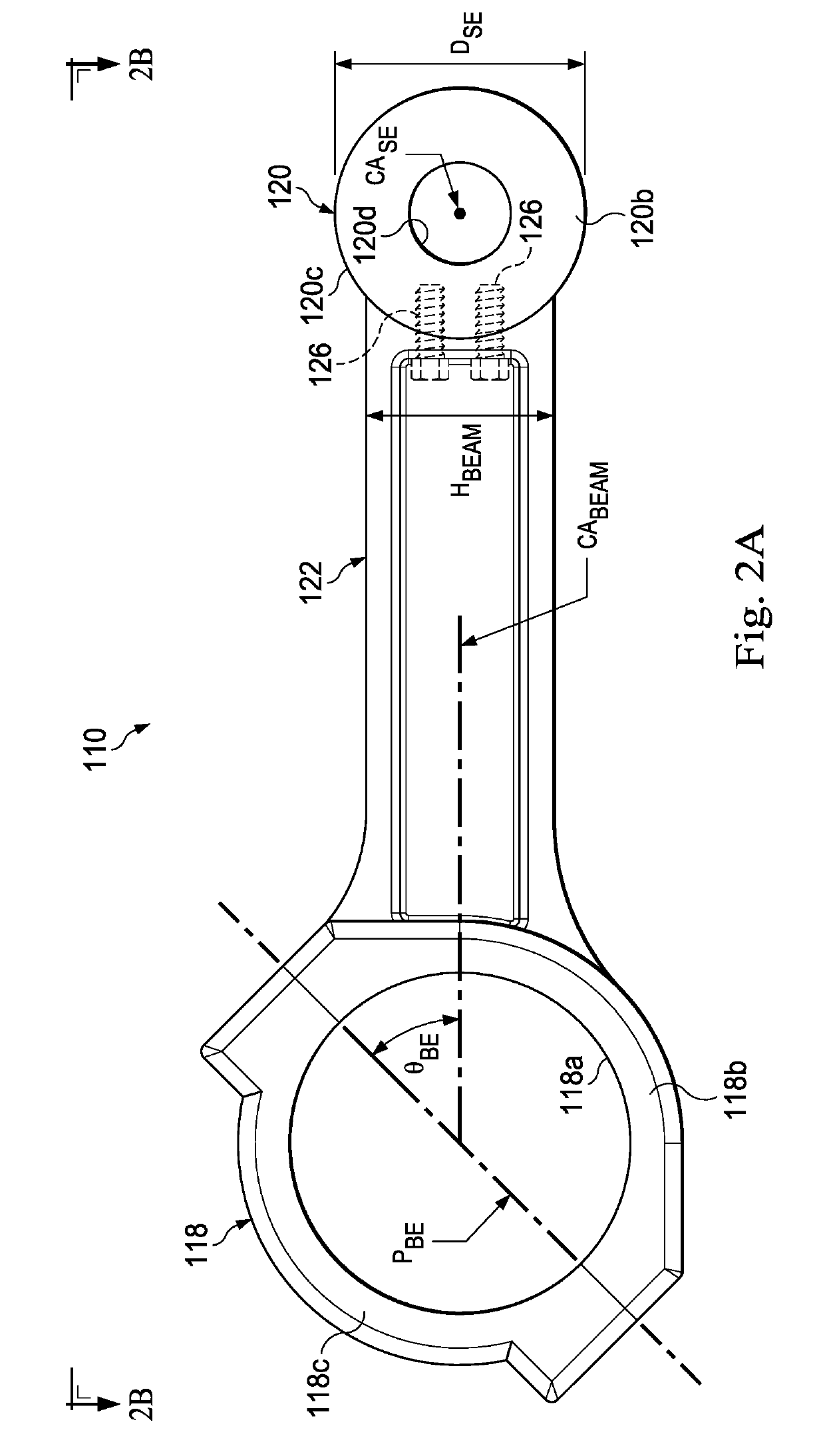

A crosshead and connecting rod assembly for a pump comprises a connecting rod which includes a first end that is rotatably connected to the crankshaft of the pump, a second end that comprises a generally cylindrical configuration, and a shaft that extends between the first and second ends. The second end comprises at least one annular shoulder adjacent to the shaft, and the crosshead and connecting rod assembly further comprises a crosshead which includes a body that comprises a generally semi-cylindrical socket within which the second end is rotatably received and at least one trunnion that comprises a generally semi-cylindrical recess which aligns with the socket and within which the shoulder is rotatably received when the trunnion is connected to the body.

Owner:FMC TECH INC

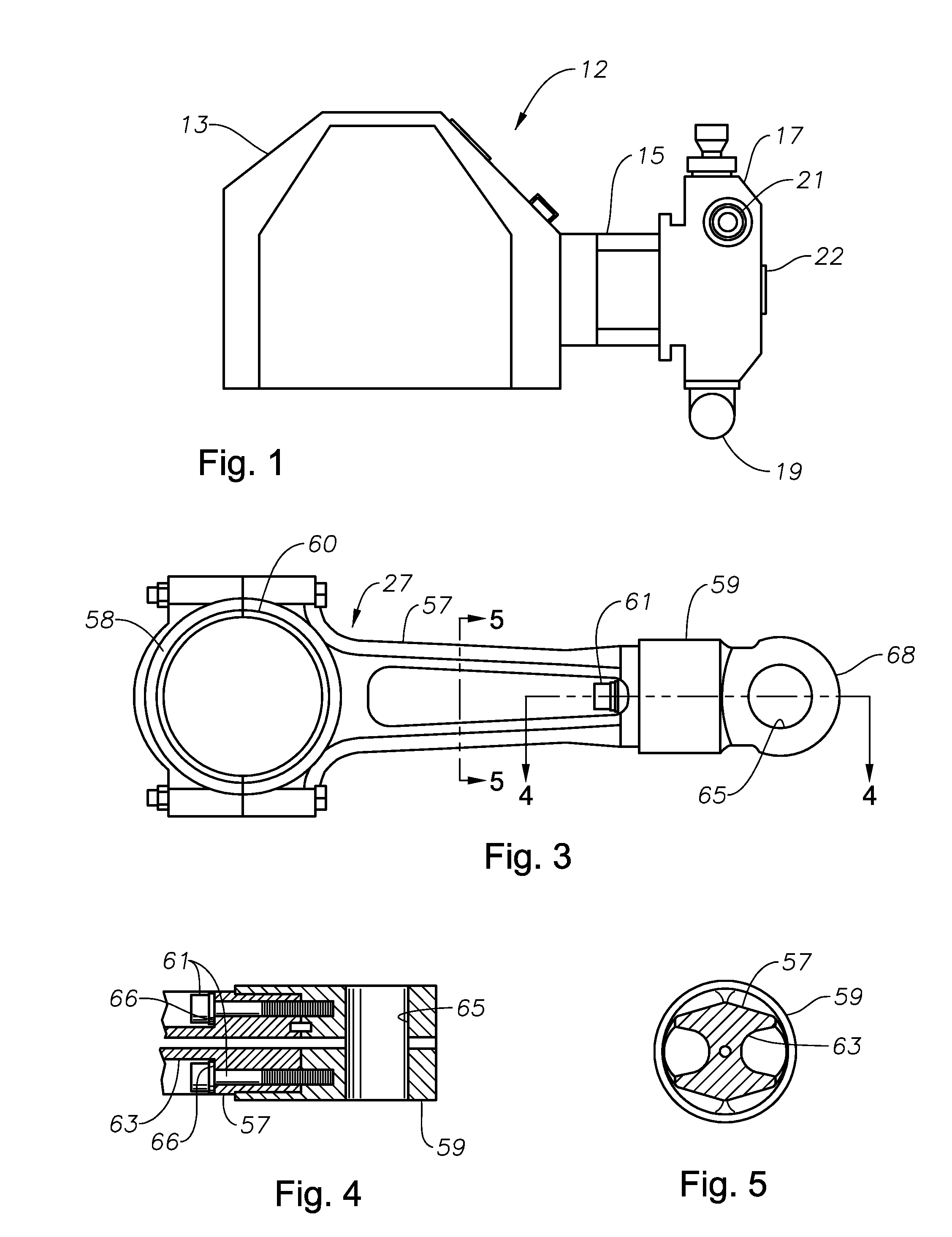

Connecting rod without wrist pin

InactiveUS20100172778A1Reduce weightEliminate needConnecting rod bearingsPositive displacement pump componentsLinear motionEngineering

A reciprocating pump assembly has a pump within a housing. The pump has a crankshaft that rotates and a crosshead that is connected to a plunger via a pony rod. The plunger pumps fluid through cylinders in the pump. A connecting rod connects at one end to the crankshaft and at another end to the crosshead to translate the crankshaft's rotational movement into linear movement of the crosshead and thereby the plunger. The end connected to the crosshead is secured to the crosshead by a bushing located within the crosshead that allows the connecting rod end to pivot during operation. The bushing extends more than 180 degrees, retaining the connecting rod with the crosshead without the need for a wrist pin. The end secured by the bushing can be retained within the bushing by a lock plate, and retainers without the need for a wrist pin.

Owner:WEIR SPM

Pump crosshead and connecting rod assembly

ActiveUS20080006148A1Increase surface areaBearing stressConnecting rodsPositive displacement pump componentsEngineeringMechanical engineering

A crosshead and connecting rod assembly for a pump comprises a connecting rod which includes a first end that is rotatably connected to the crankshaft of the pump, a second end that comprises a generally cylindrical configuration, and a shaft that extends between the first and second ends. The second end comprises at least one annular shoulder adjacent to the shaft, and the crosshead and connecting rod assembly further comprises a crosshead which includes a body that comprises a generally semi-cylindrical socket within which the second end is rotatably received and at least one trunnion that comprises a generally semi-cylindrical recess which aligns with the socket and within which the shoulder is rotatably received when the trunnion is connected to the body.

Owner:FMC TECH INC

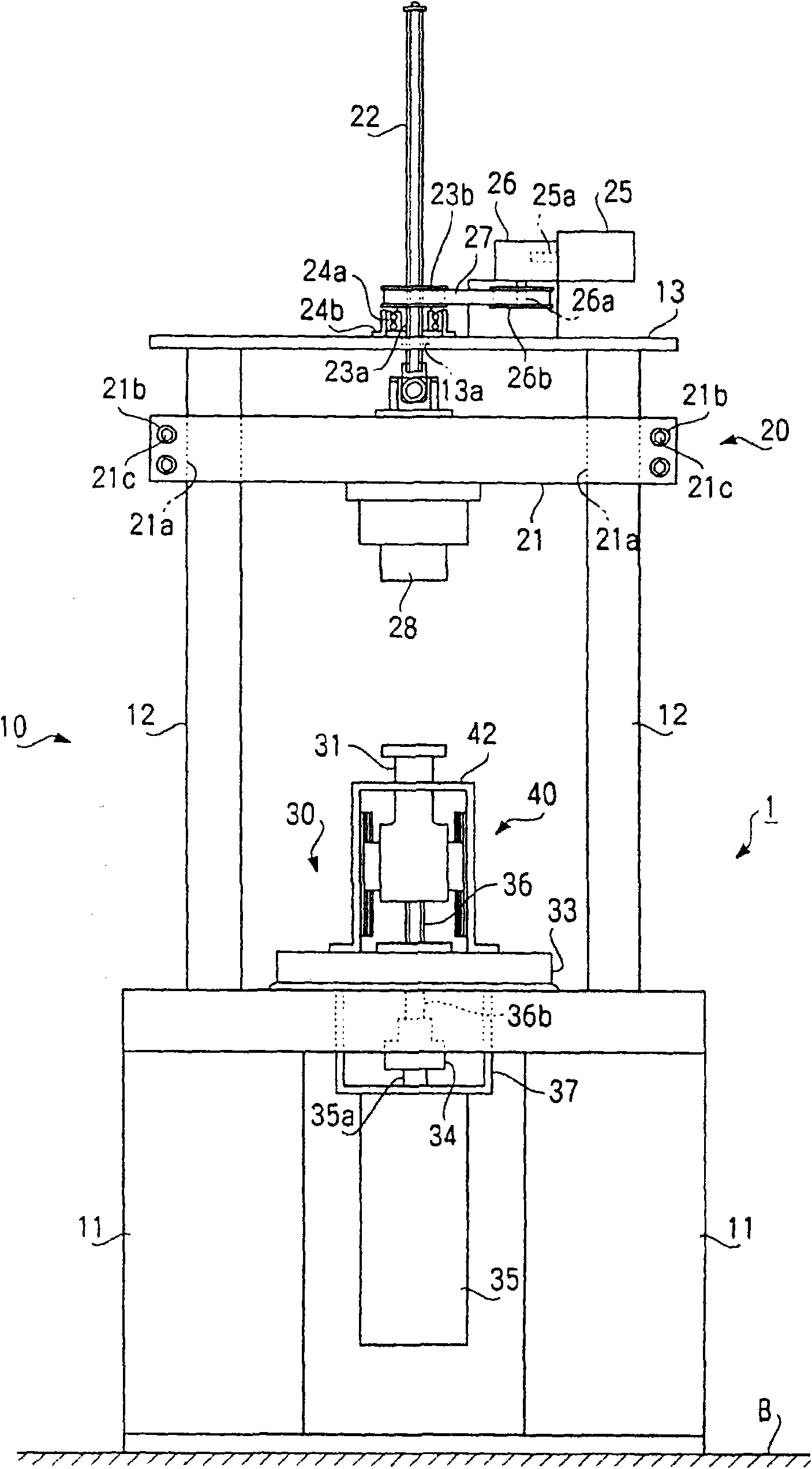

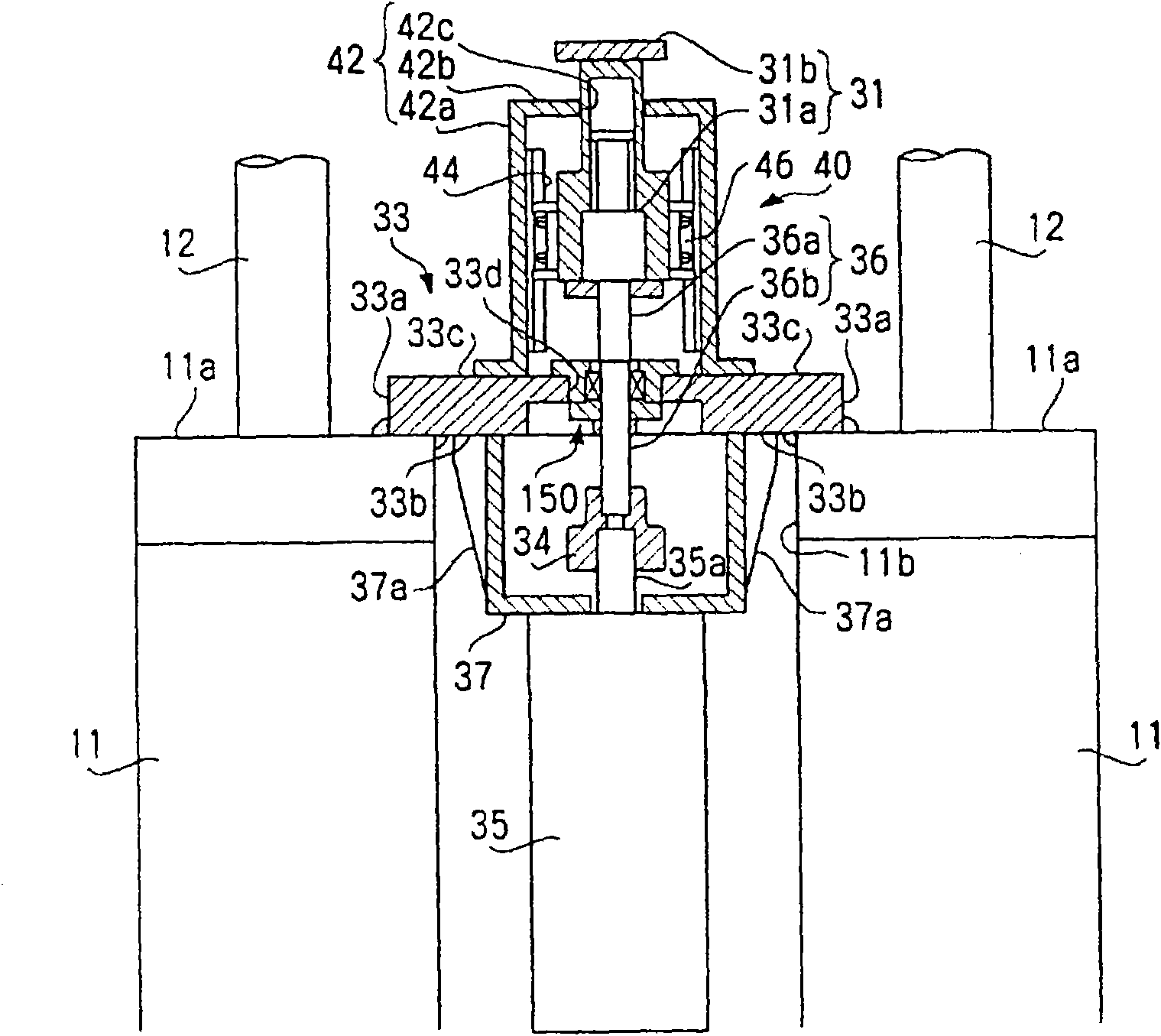

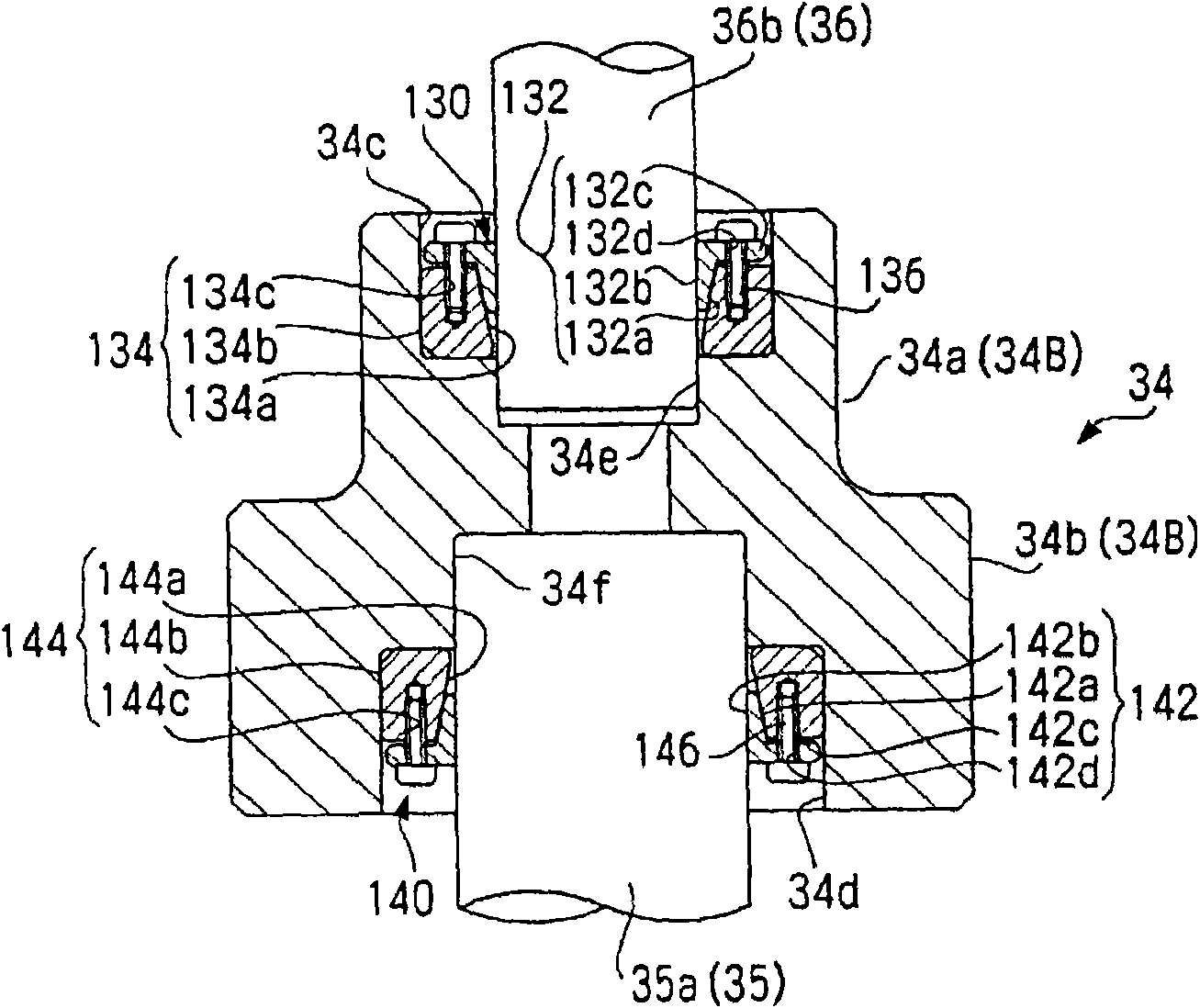

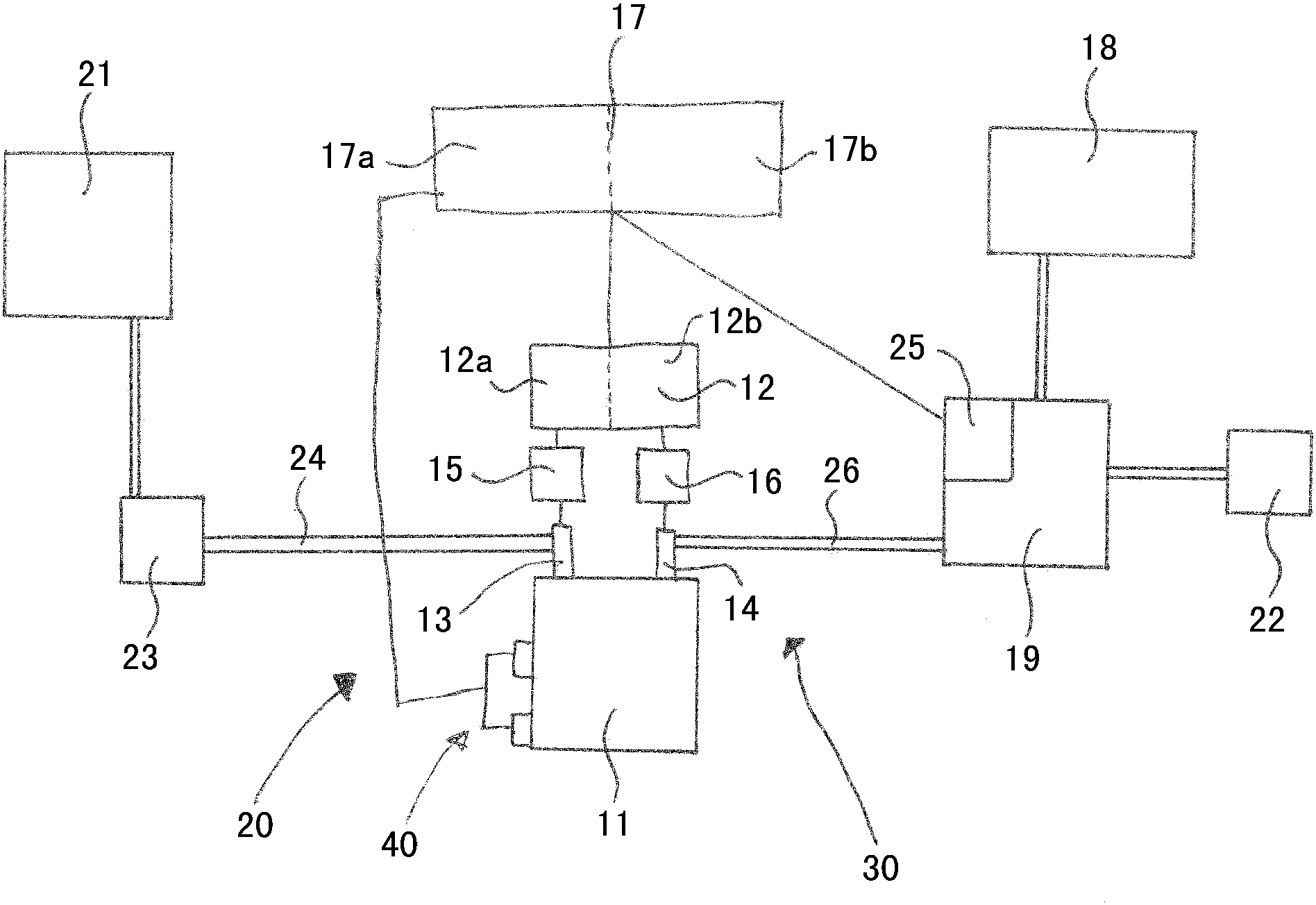

General-purpose test device, linear actuator, and twist test device

InactiveCN101680828AHigh precisionMaterial strength using tensile/compressive forcesMaterial strength using repeated/pulsating forcesLinear actuatorCrosshead

The invention provides a general-purpose test device and a linear actuator and a twist test device. In the general-purpose test device and the linear actuator which drive a cross head by a servo motorand a feed screw mechanism, the servo motor and a linear guide of the feed screw mechanism are fixed to a single support plate. It is preferable that a drive shaft of the servo motor be coupled to the feed screw by a rigid coupling or a semi-rigid coupling. Moreover, in a twist test device which applies a twist load to a test piece by the servo motor and a speed reduction mechanism, both of the servo motor and the speed reduction mechanism are fixed to a first support member as a single member. It is preferable that a drive shaft of the servo motor be coupled to an input shaft of the speed reduction mechanism by the rigid coupling or the semi-rigid coupling.

Owner:KOKUSAI KEISOKUKI KK

Crosshead shoes driving reducer for multi-joint robot

ActiveCN104964011ACompact structureReduce noiseGearing detailsFriction gearingsMechanical wearReducer

The invention relates to a crosshead shoes driving reducer for a multi-joint robot. The crosshead shoe driving reducer for the multi-joint robot comprises input shafts, output shafts, reducer bodies, crosshead shoes, transmission balls, track controllers and drive balls. The input shafts, the crosshead shoes, the track controllers and the output shaft are installed in the reducer bodies. Transmission tracks used for the installation of the transmission balls are arranged in the crosshead shoes. The transmission balls move in the transmission tracks to convey the movement of the input shafts to the track controllers. Moving track used for the installation of the drive balls are arranged on the lower surfaces of the track controllers. The track controllers adjust the output of the output shafts through the drive balls. According to the crosshead shoe driving reducer for the multi-joint robot, automatic adjustment for complete consistency of movement and eccentric magnitude of an eccentric shaft is achieved, the tracks of the transmission balls and the tracks of the track controllers of the reducer are completely consistent, the output of the reducer is stable, and the mechanical wear rate is low.

Owner:中正数据技术有限公司

An internal combustion engine with control of fuel gas injection pressure

ActiveCN103511104AReduce risk of damageReduce maintenance costsPropulsion based emission reductionElectrical controlCombustion chamberDiesel engine

An internal combustion engine, such as a two-stroke crosshead Diesel engine, comprising a fuel gas supply system and cylinders provided with fuel gas injectors for injecting fuel gas directly into combustion chambers in the cylinders, and at least one engine control unit controlling the amount of fuel gas injected into the combustion chambers according to an applied fuel index for obtaining a desired engine speed at a given engine bad, where the fuel index defines an amount of fuel gas to be injected into the cylinders per injection, and the amount of fuel gas injected is controlled by adjusting the duration of a fuel gas injection period. A sensor arrangement is provided for measuring the engine bad during operation, and the at least one engine control unit controls the injection pressure of fuel gas into the combustion chambers in response to changes in the energy density of the fuel gas, so that the applied fuel index corresponds to the reference fuel index.

Owner:MAN DIESEL & TURBO FILIAL AF MAN DIESEL & TURBO SE TYSKLAND

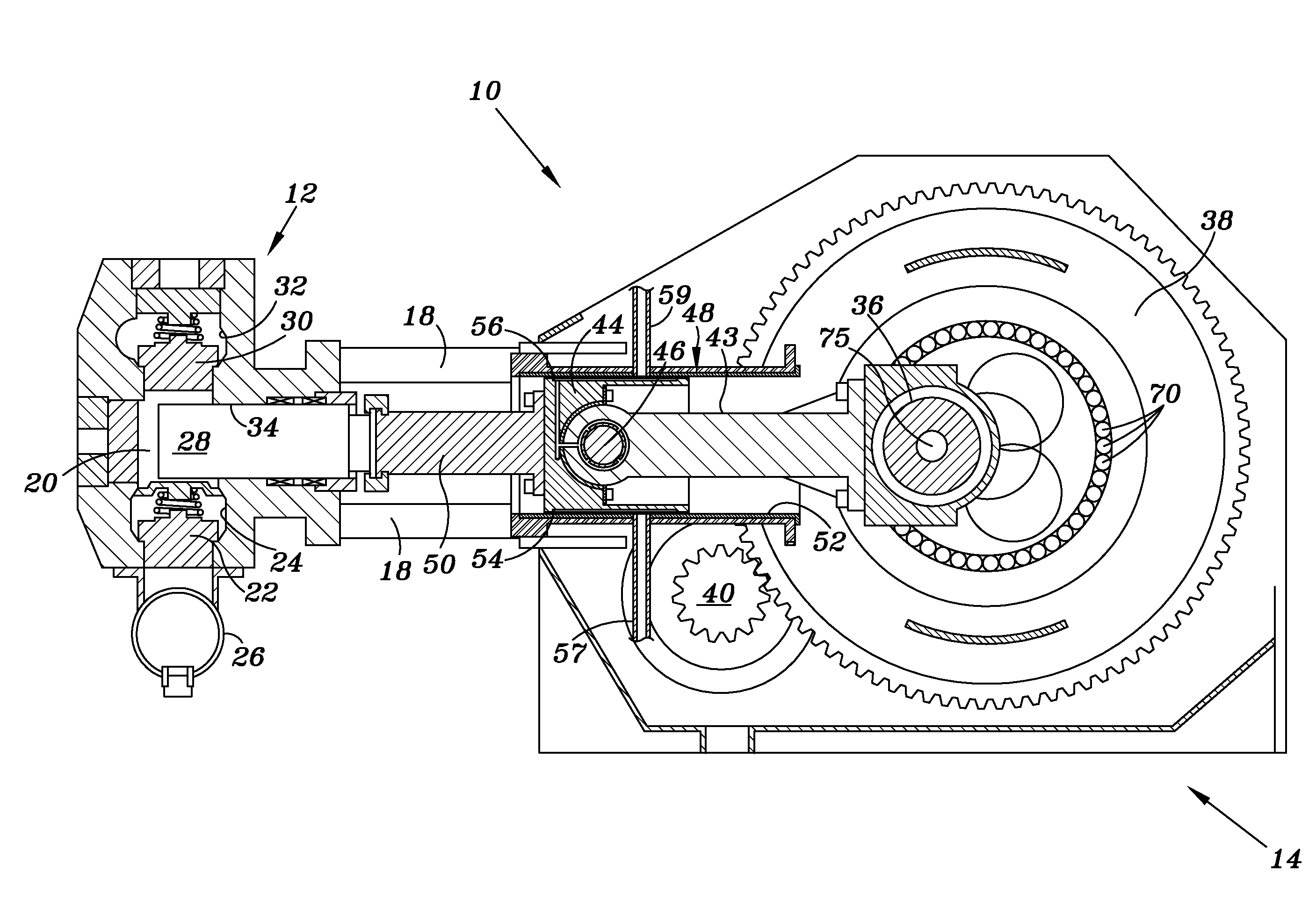

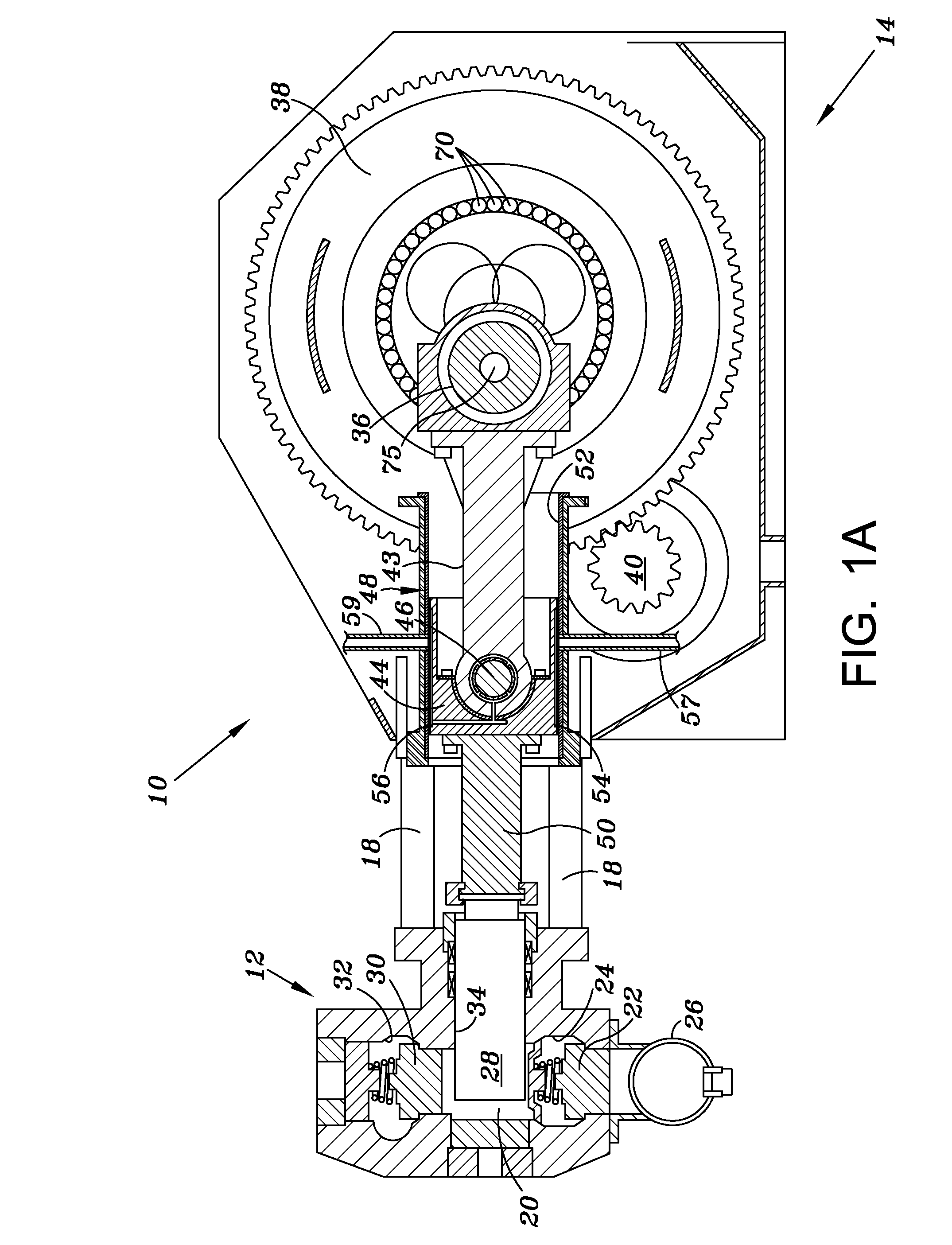

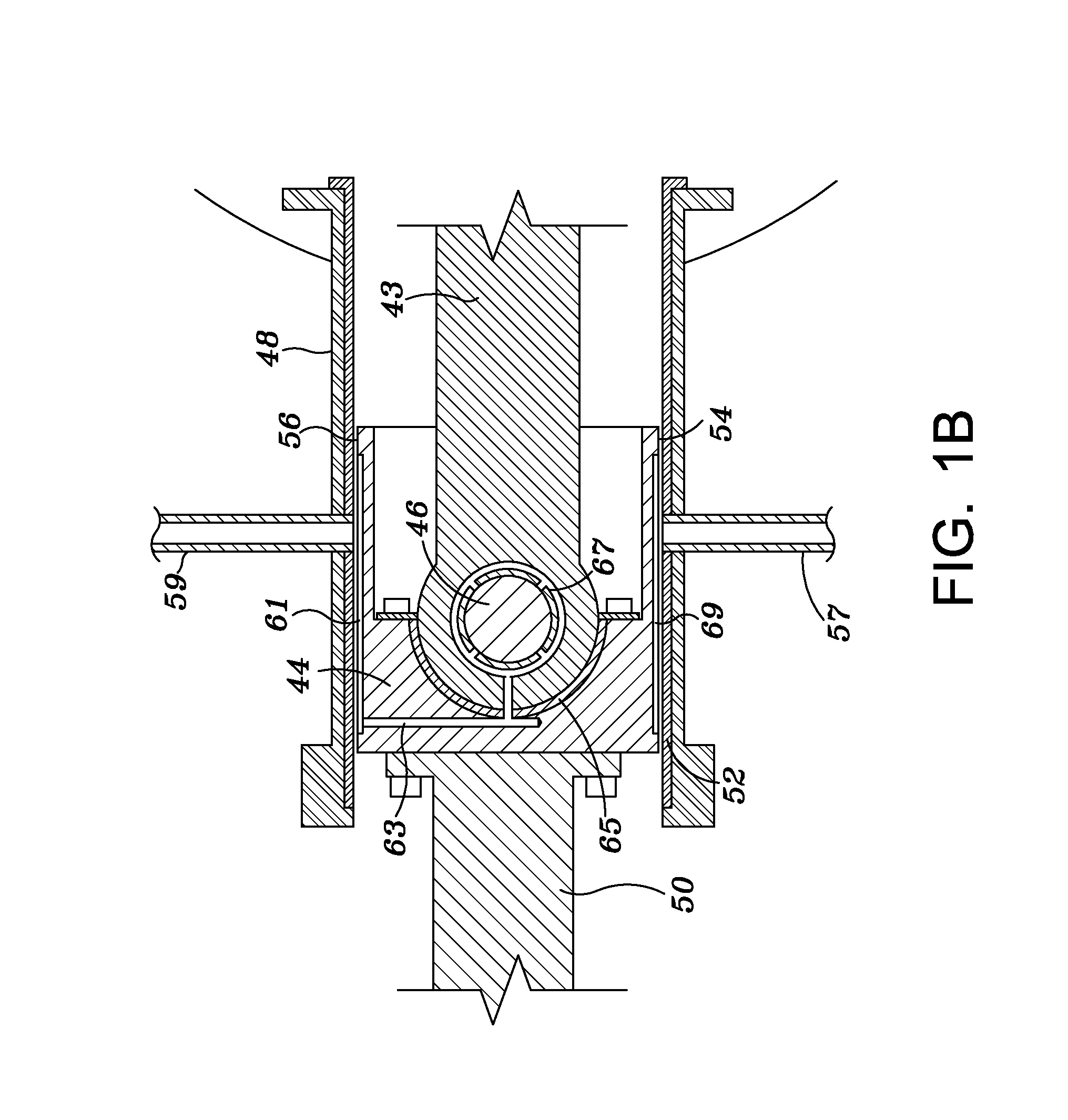

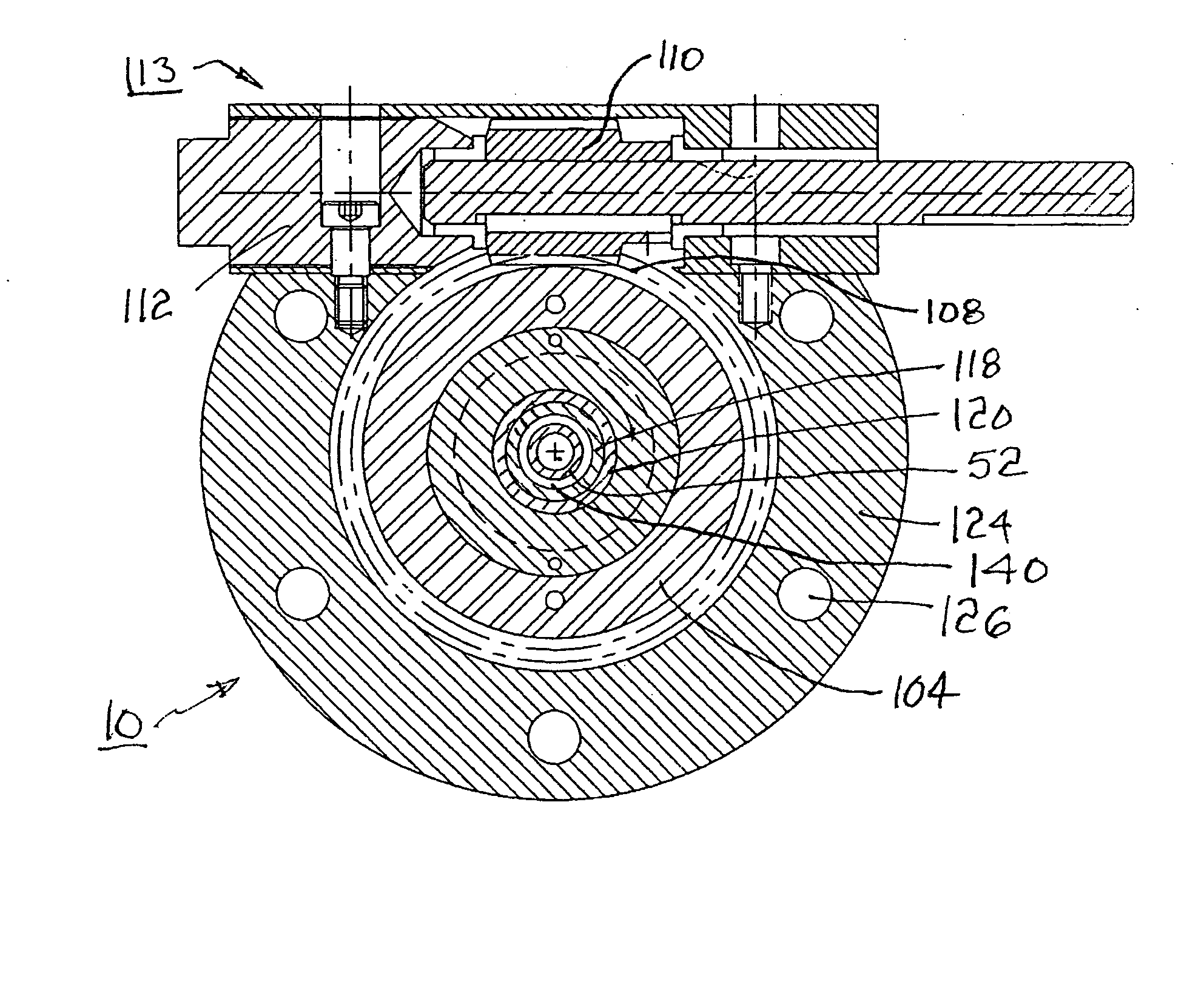

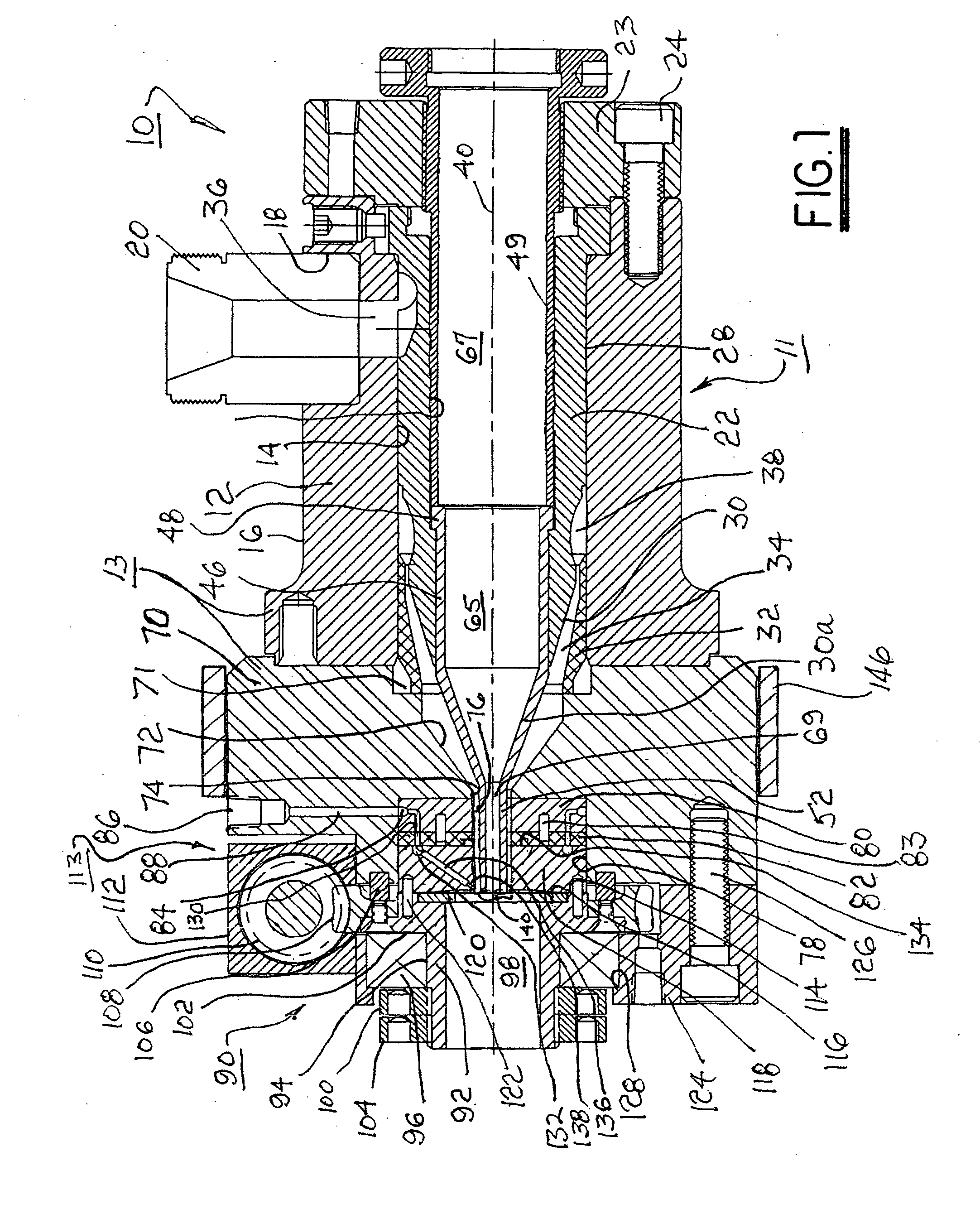

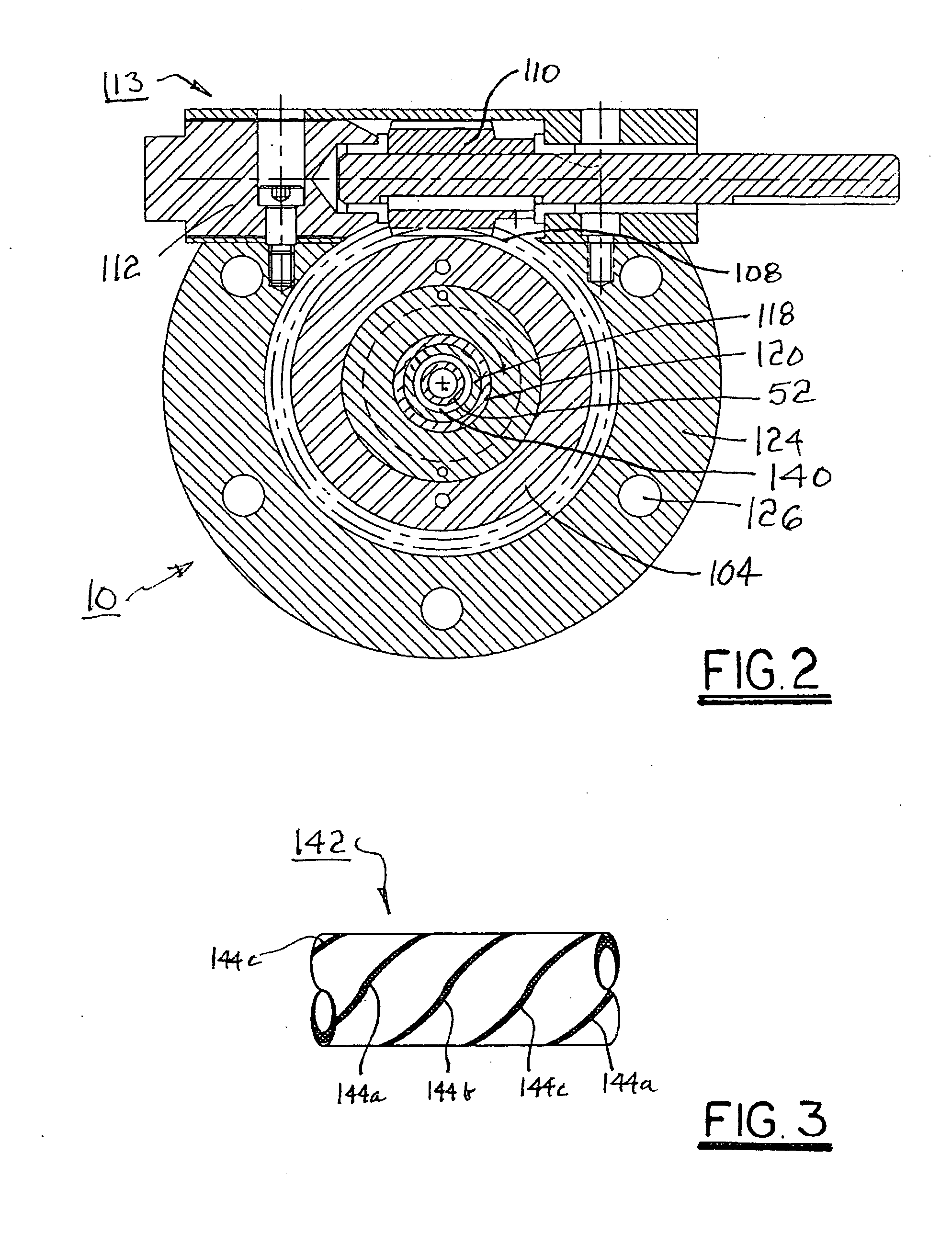

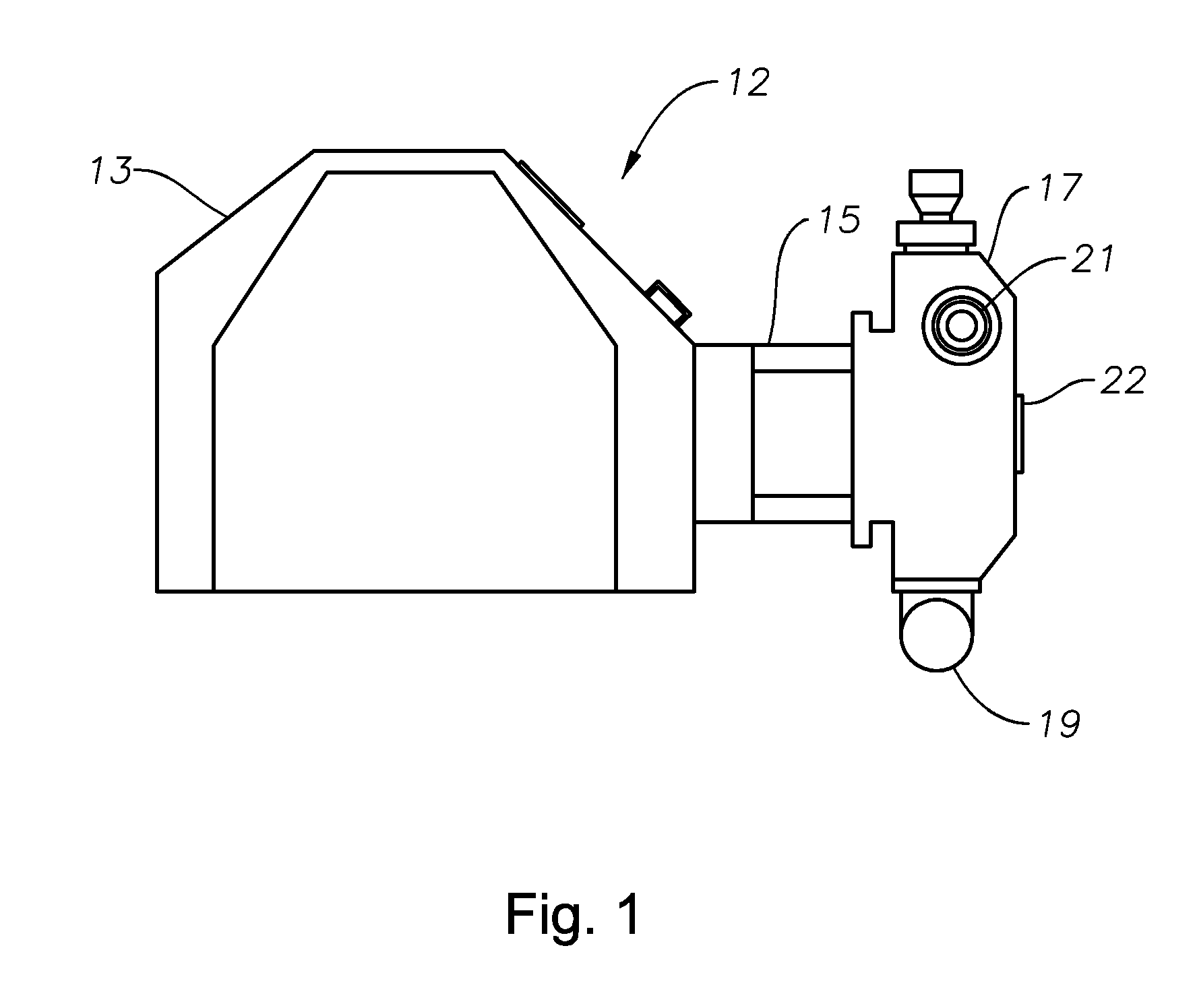

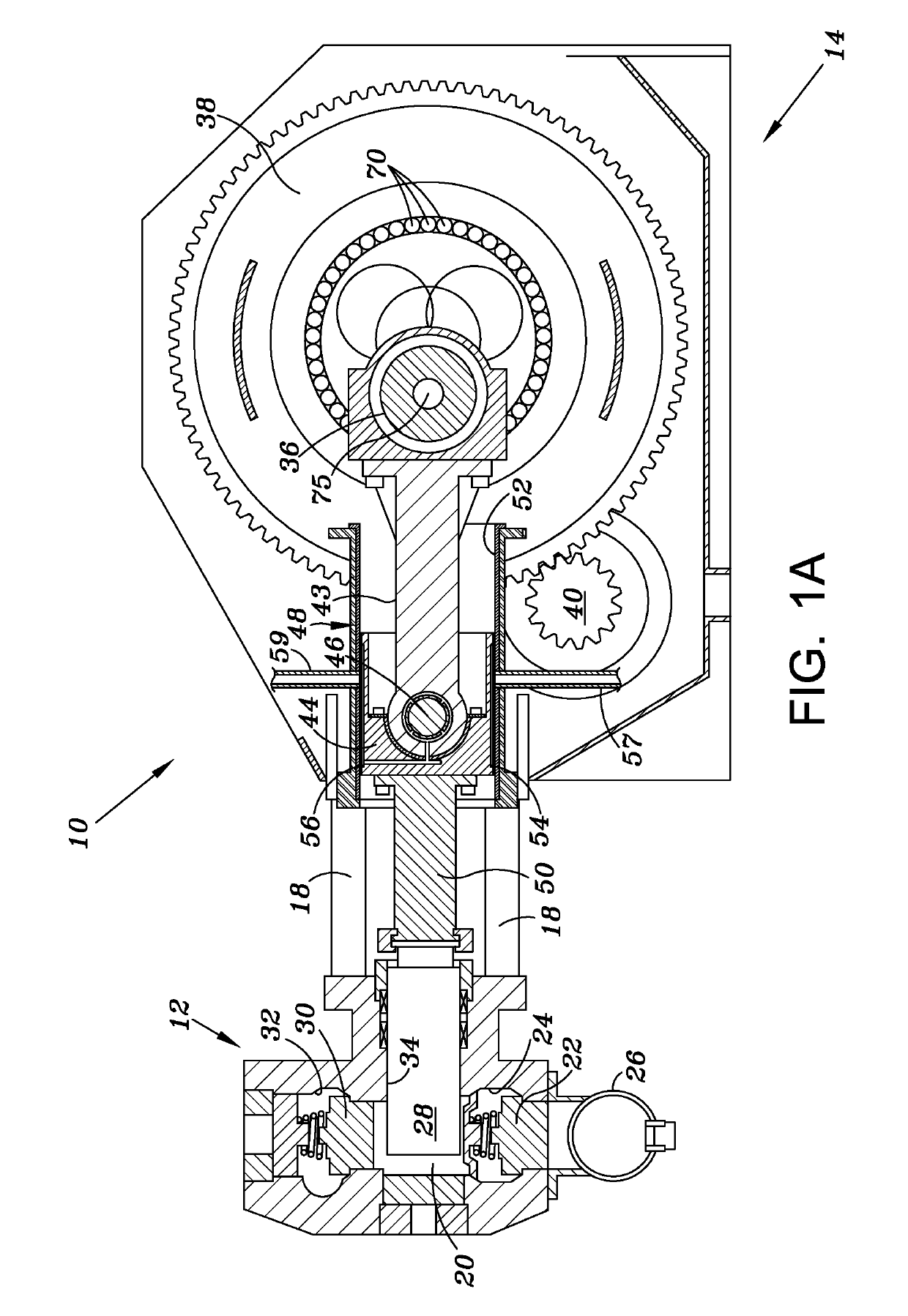

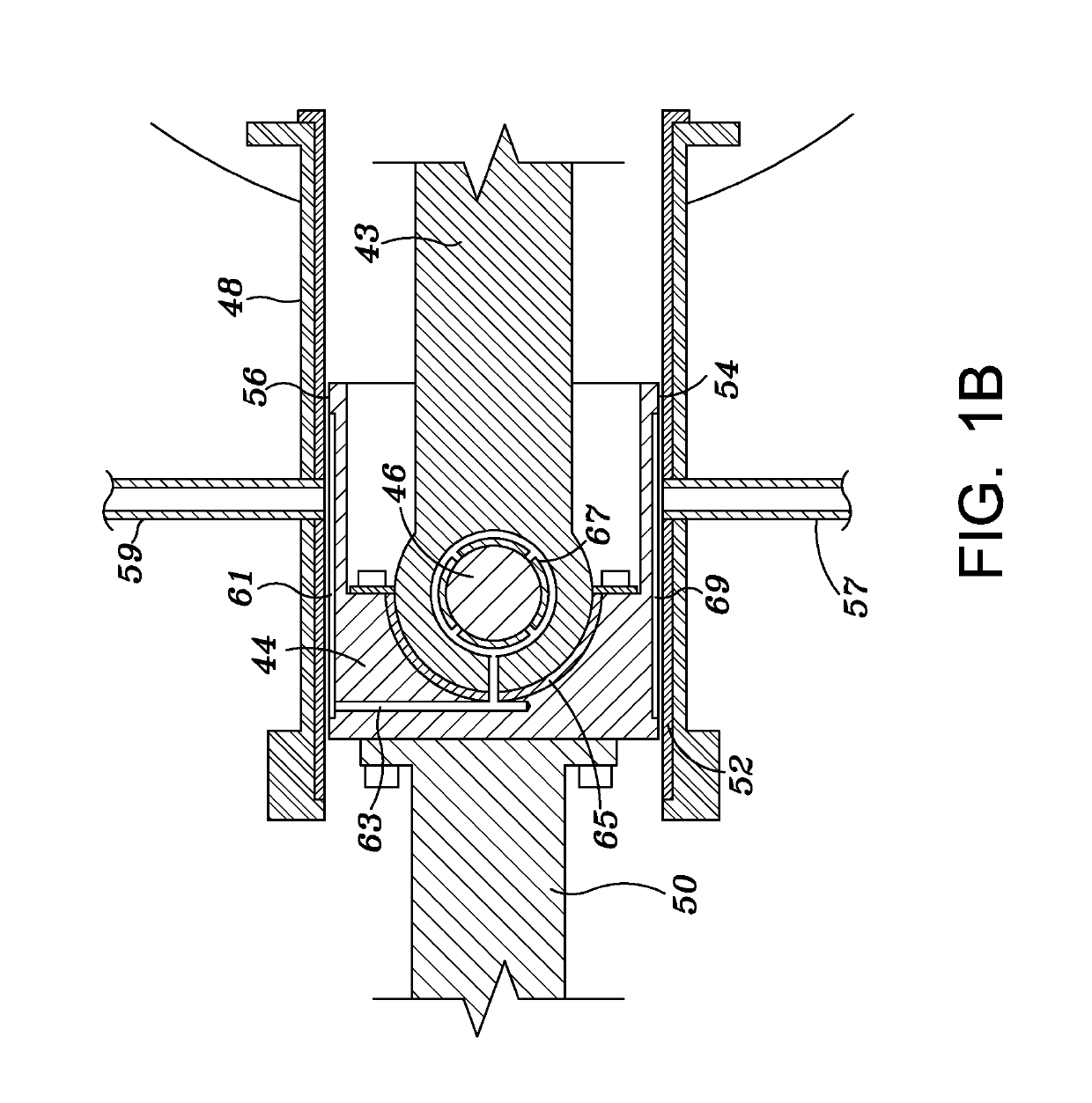

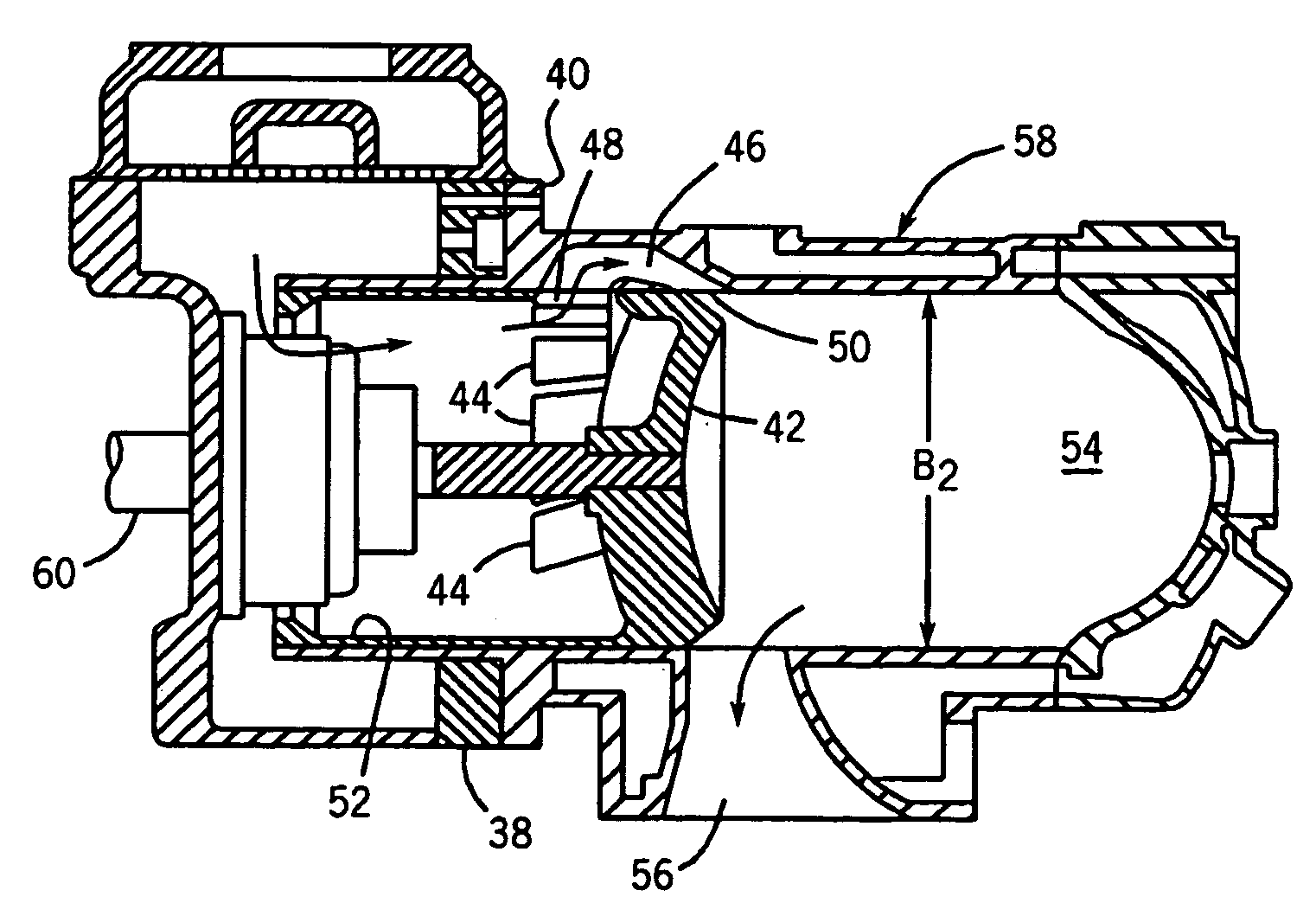

Short Length Pump Having Brine Resistant Seal and Rotating Wrist Pin and Related Methods

InactiveUS20120167759A1Improve deflection problemEasy to keepPositive displacement pump componentsPlungersLateral extensionEngineering

Pumps and plunger assemblies are provided. An exemplary pump can have or contain a cylinder mounted in a pump housing, a plunger assembly including a crosshead, a plunger, a stationary bushing having substantial portions fixedly mounted within a laterally extending bore of the crosshead, and a non-stationary pivotally rotating wrist pin mounted within the bushing. The pump can also include a power end seal assembly including a seal housing extending at least partially through an aperture in the sealed fluid end-facing side of the power end of the pump, a power end seal disposed therein in sealing contact with the power end section of the plunger and a splashguard assembly.

Owner:S P M FLOW CONTROL

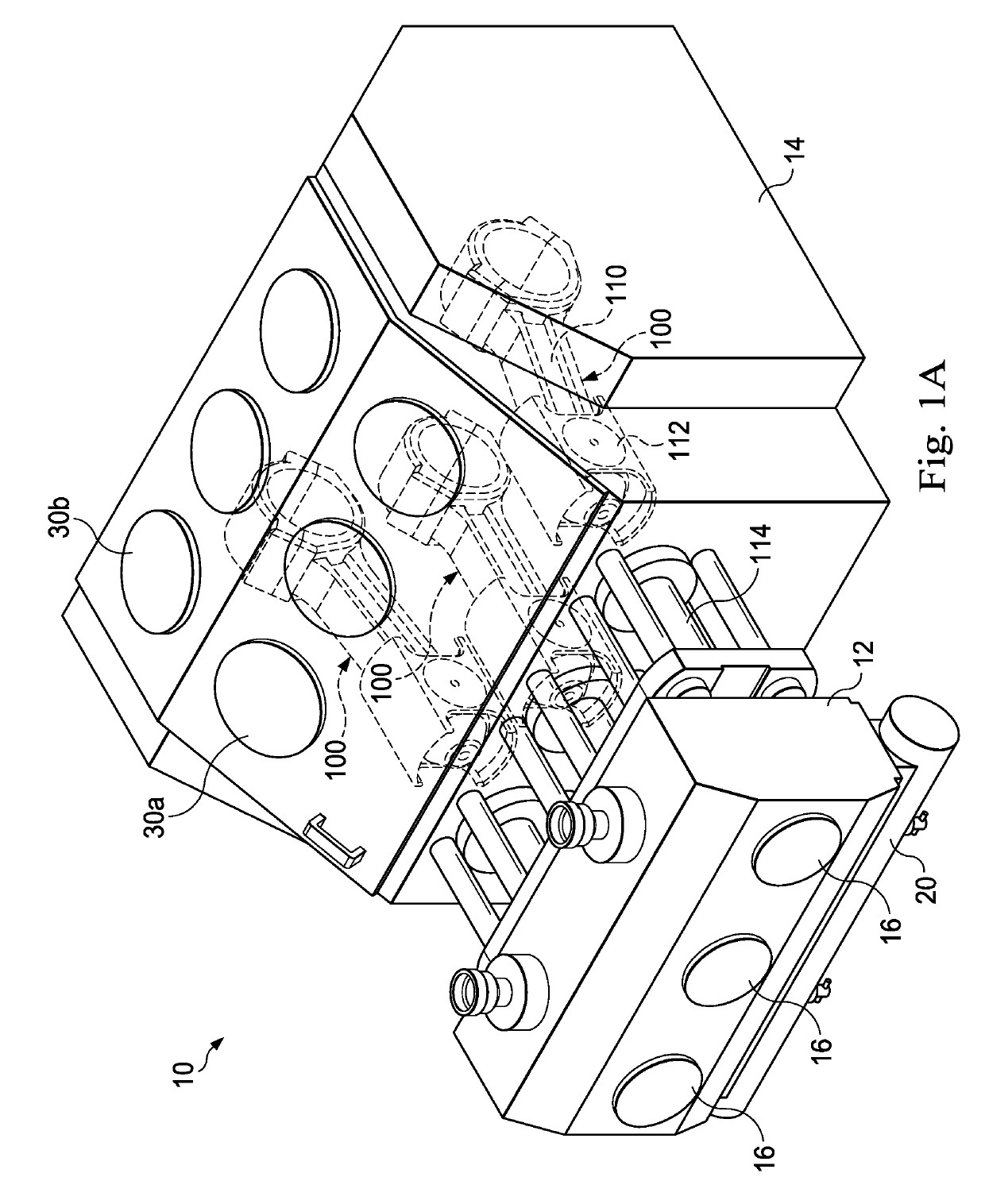

Reciprocating pump with dual circuit power end lubrication system

ActiveUS10352321B2Positive displacement pump componentsRotary/oscillating piston combinationsEngineeringHigh pressure

A dual circuit lubrication system for a power end of a reciprocating pump that includes a lubrication pump that supplies lubrication fluid to a high pressure lubrication circuit and a low pressure lubrication circuit. The high pressure lubrication circuit is fluidly coupled to a crankshaft to supply lubrication fluid to sliding surfaces associated with the crankshaft at a first lubrication fluid pressure. The crankshaft drives a crosshead coupled to a plunger to displace fluid from a fluid end of the reciprocating pump. The low pressure lubrication circuit is fluidly coupled to supply the lubrication fluid to a plurality of rolling surfaces associated with the crankshaft at a second lubrication fluid pressure. The first lubrication fluid pressure is greater than the second lubrication fluid pressure.

Owner:SPM OIL & GAS INC

Multi-piece connecting rod

InactiveUS20100260631A1Reduce weightEasy to transportConnecting rod bearingsConnecting rodsLinear motionEngineering

A reciprocating pump assembly having a pump within a housing. The pump having a crankshaft that rotates and a crosshead that is connected to a plunger via a pony rod. The plunger pumps fluid through cylinders in the pump. A connecting rod connects at one end to the crankshaft and at another end to the crosshead to translate the crankshaft's rotational movement into linear movement of the crosshead and thereby the plunger. The connecting rod is fabricated from multiple pieces, with the body of the connecting rod fabricated out of light weight aluminum and the end connected to the crosshead fabricated out of steel. The steel end of the connecting rod can withstand the stress at the crosshead. The lighter weight of the connecting rod lightens the weight of the pump and its transportation is easier and less costly.

Owner:WEIR SPM

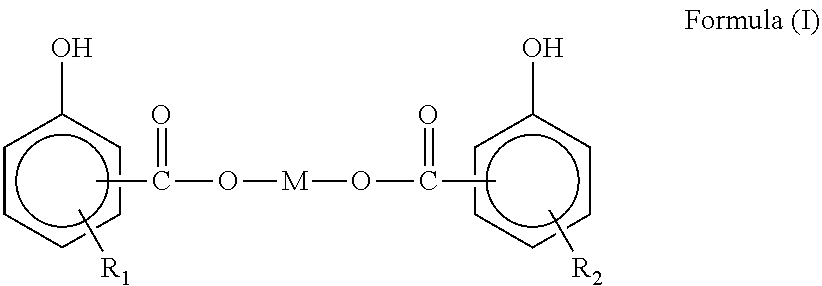

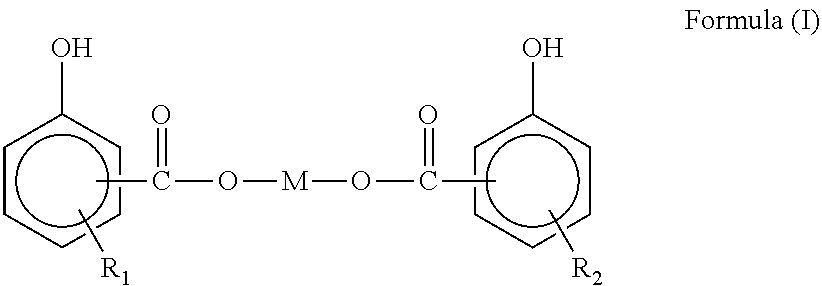

System oil formulation for marine two-stroke engines

ActiveUS20110077182A1Improve protectionEasy to controlOrganic compound preparationLiquid carbonaceous fuelsMechanical componentsCarboxylic salt

In one aspect of the present invention, a marine system oil composition is provided for lubrication of mechanical components in marine engines, for example, two-stroke, cross-head marine diesel engines and methods / additives for using the marine system oil composition in the same. In one aspect of the present invention, a marine system oil composition is provided that has salt of a carboxylate-containing detergent comprising at least one alkyl-substituted hydroxyaromatic carboxylic acid, wherein at least 50 mole % of, the alkyl groups are C20 or greater.

Owner:CHEVRON ORONITE TECH BV

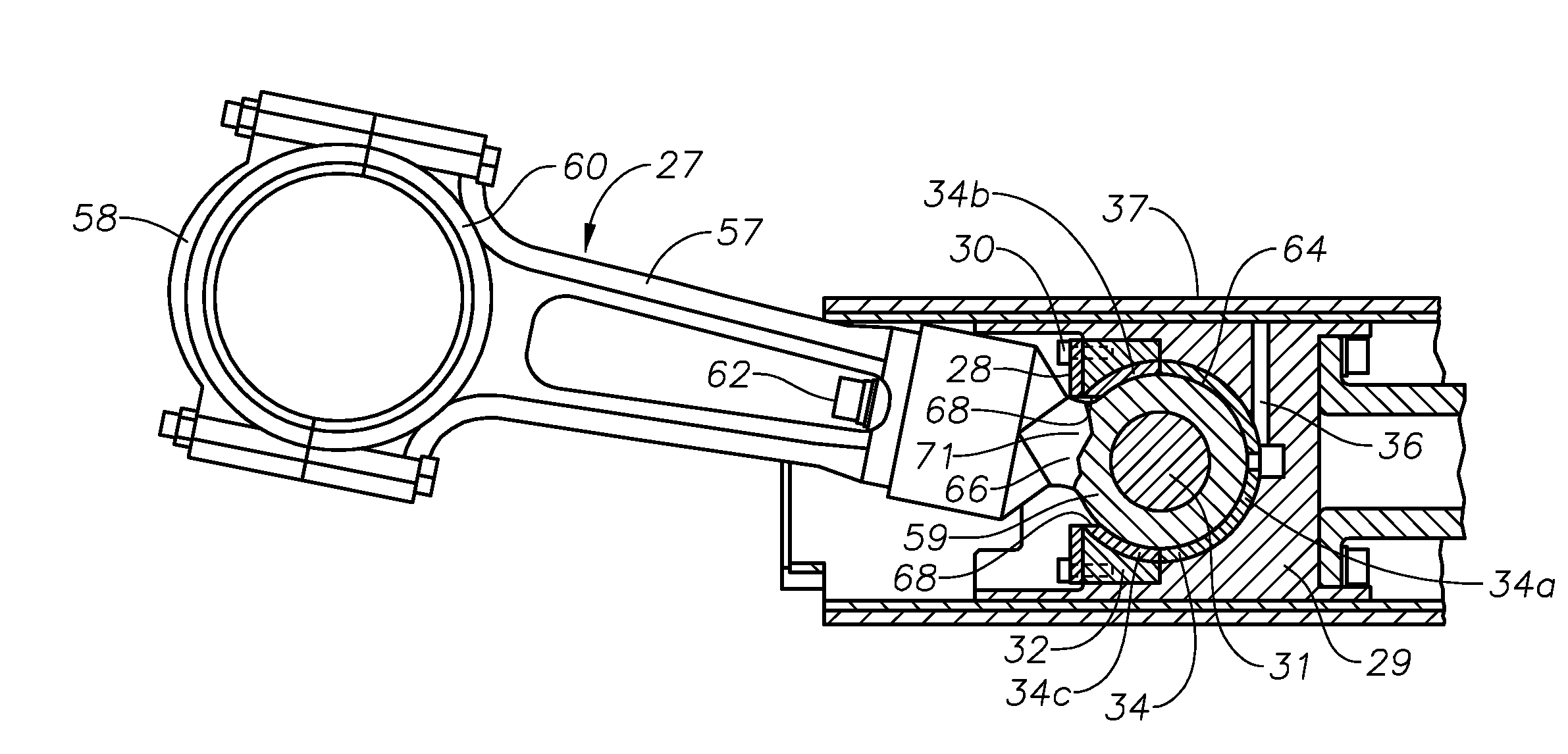

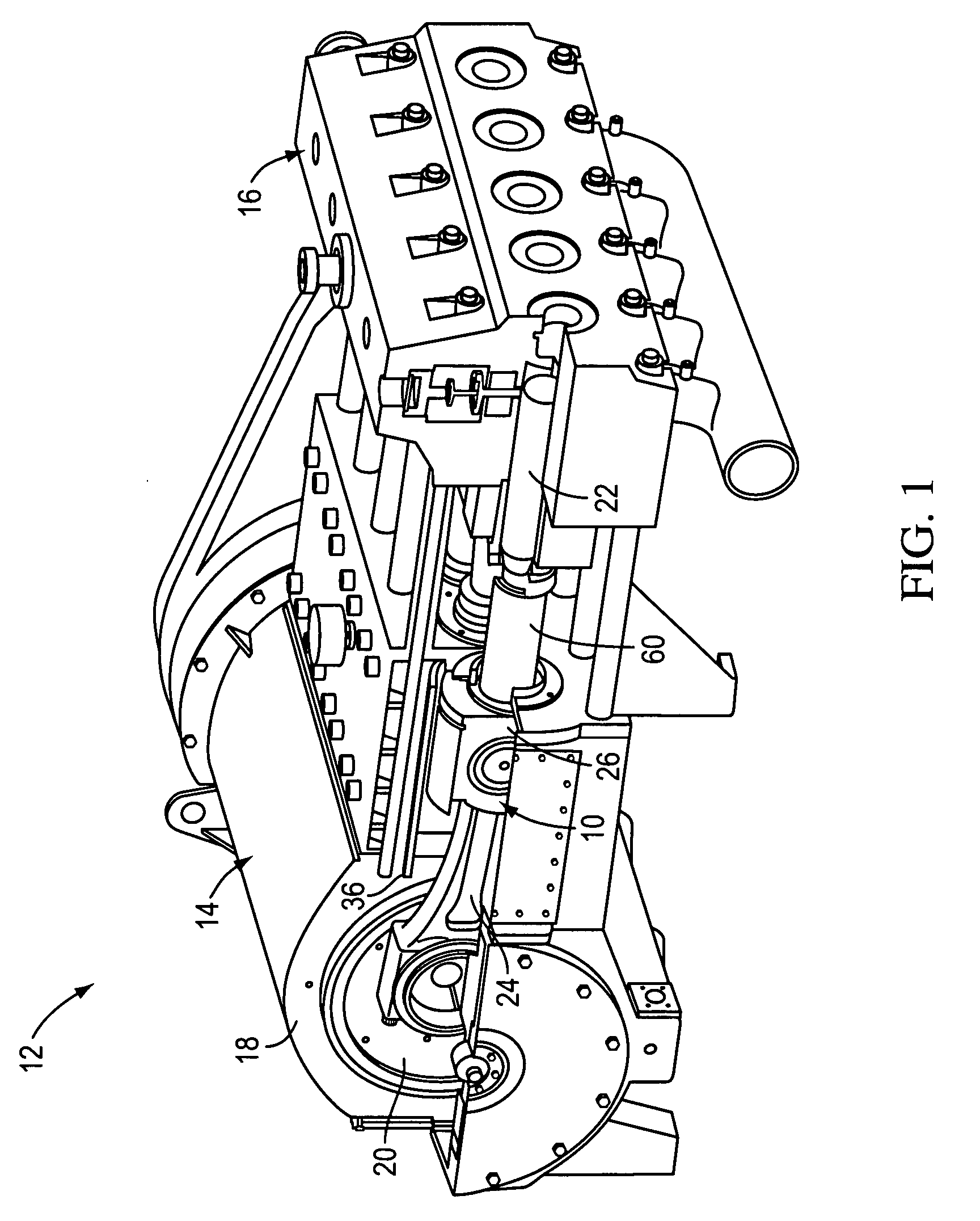

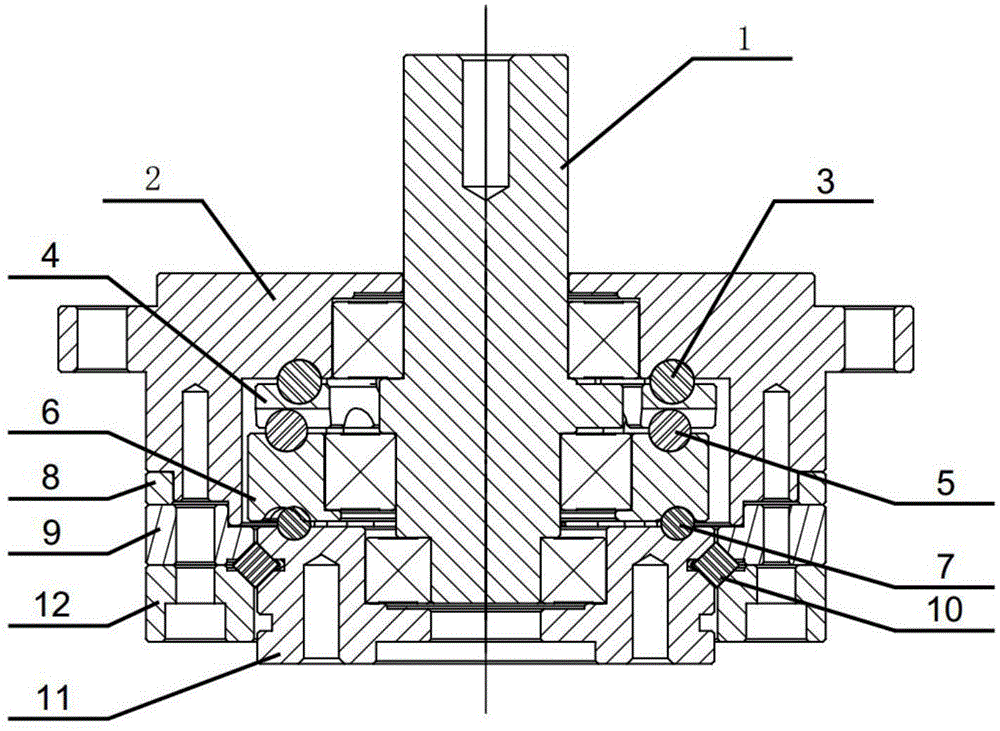

Connecting rod and crosshead assembly for enhancing the performance of a reciprocating pump

ActiveUS10393113B2Reduce displacementPositive displacement pump componentsCrossheadsAxial displacementEngineering

A method and apparatus for a reciprocating pump assembly, including a crosshead and a connecting rod. The crosshead includes a main body having a cylindrical bore formed therethrough and defining a bearing surface, and a window formed through the main body and into the cylindrical bore. The connecting rod includes a small end disposed within the cylindrical bore and a beam portion extending through the window and being connected to the small end. In an exemplary embodiment, a bearing including a tubular body and a cutout is disposed within the cylindrical bore. In another exemplary embodiment, a clamp engages both the main body of the crosshead and the respective opposing end portions of the small end, thus reducing axial displacement of the small end relative to the crosshead.

Owner:SPM OIL & GAS INC

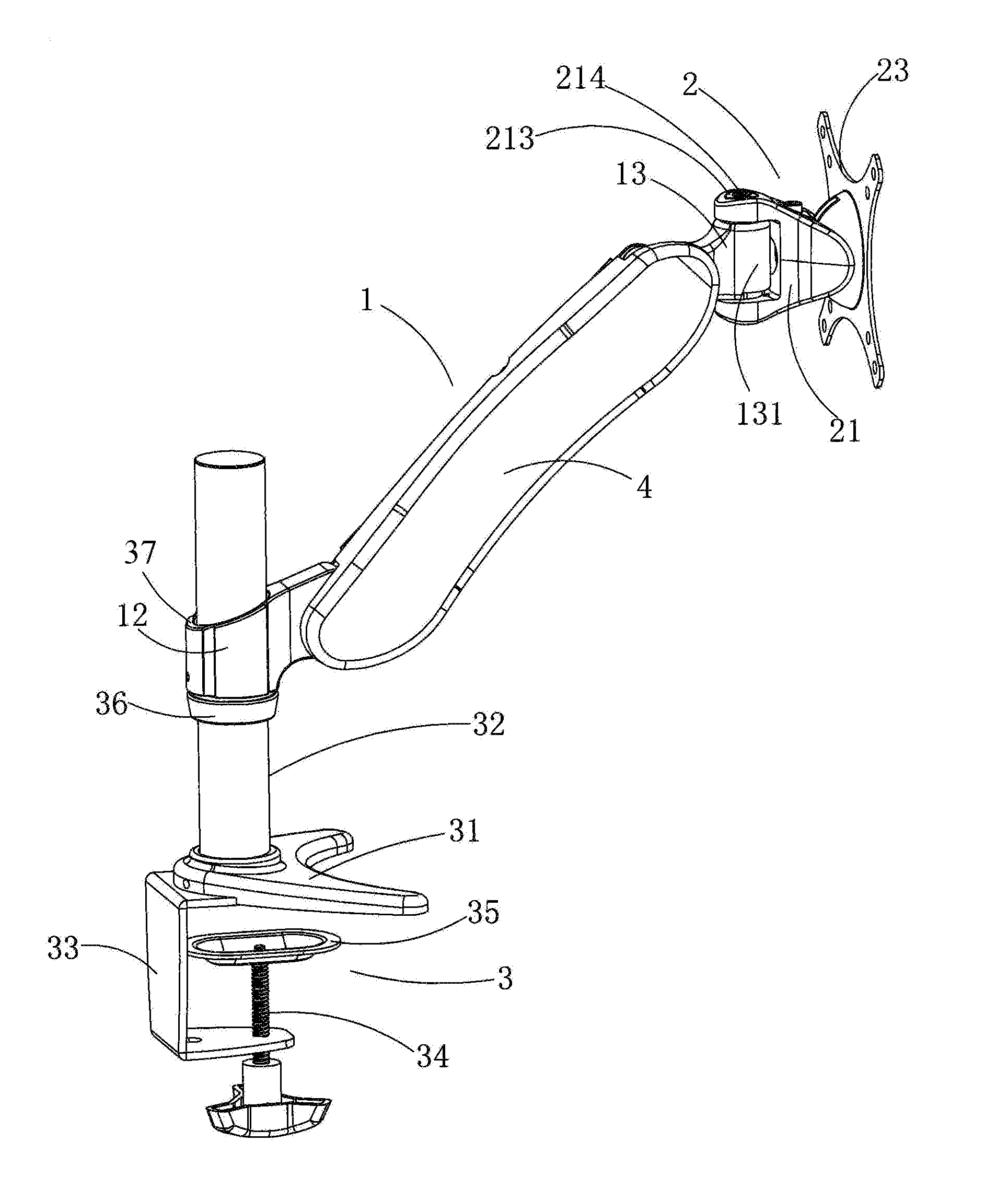

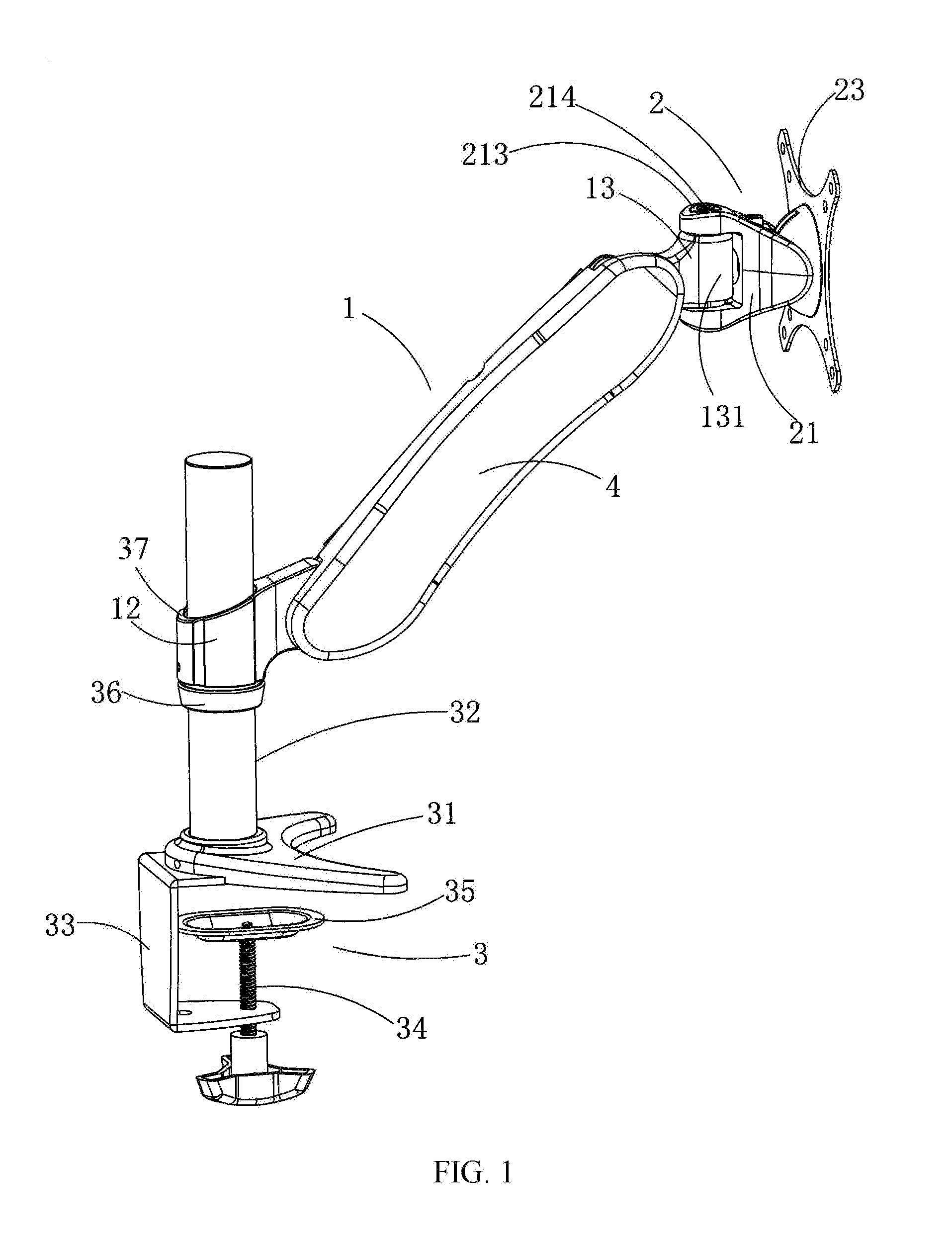

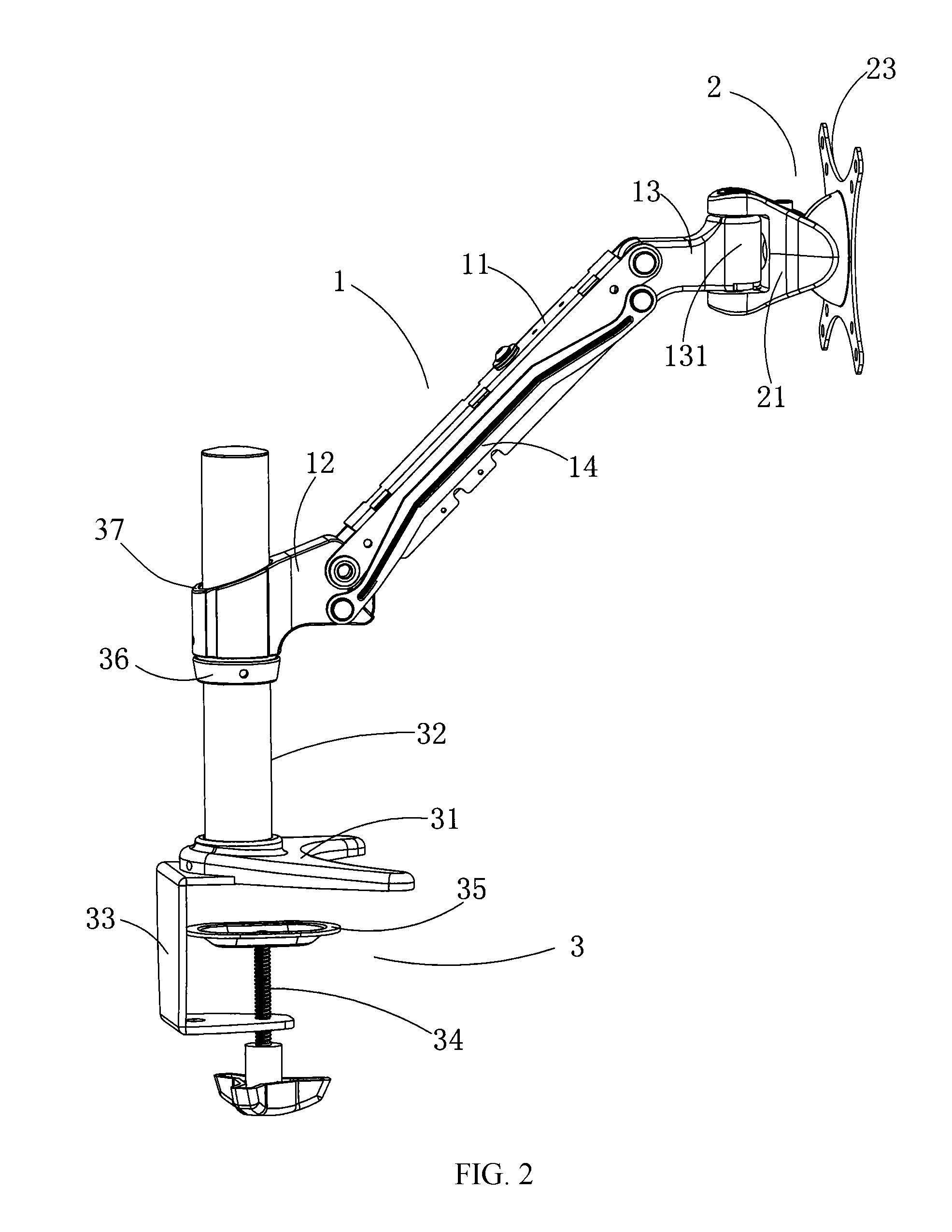

Universal Frame For Flat Panel Displays

InactiveUS20120138754A1Avoiding further fallingBeautiful appearancePipe supportsCandle holdersDisplay deviceSpring force

The present invention provides a universal flat panel display frame which includes a supporting arm system, a universal head system and a fixing pedestal system. The universal flat panel display frame applies a translation mechanism with dual connecting rod supported by a spring force, and a crosshead universal head system, so as to allow the flat panel display installed thereon to be adjusted and fixed at a desired position and a desired angle at will. Only one person could activate the flat panel display by hand, and the height, front / back incline angle and right / left incline angle of the flat panel display can be adjusted at random just by applying a little force. Therefore, the present invention is convenient for a user to adjust the flat panel display at a desired position, or to rotate the flat panel display at a desired angle to show the screen to other people.

Owner:KUSN YIFENG SHEET METAL TECH

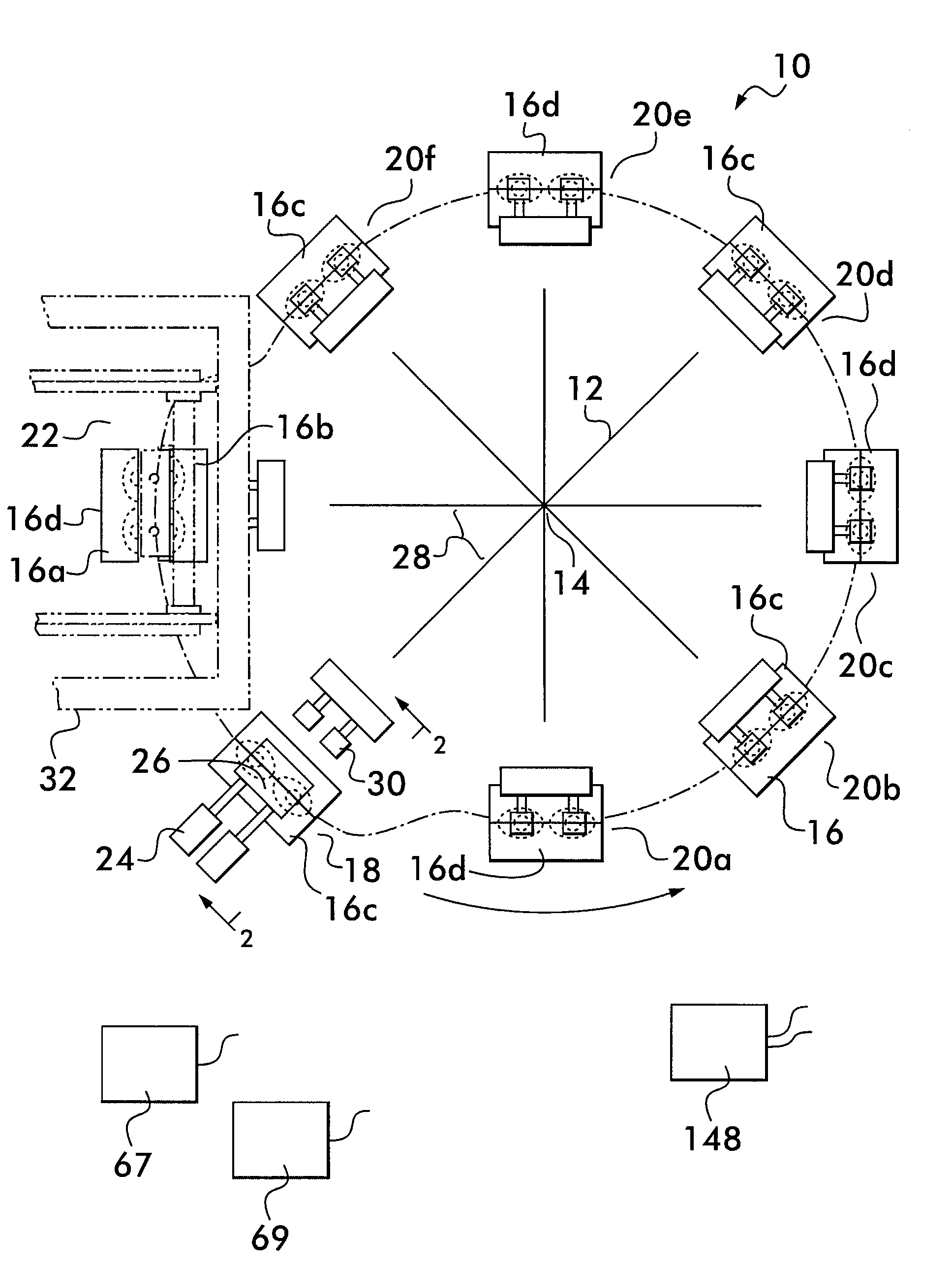

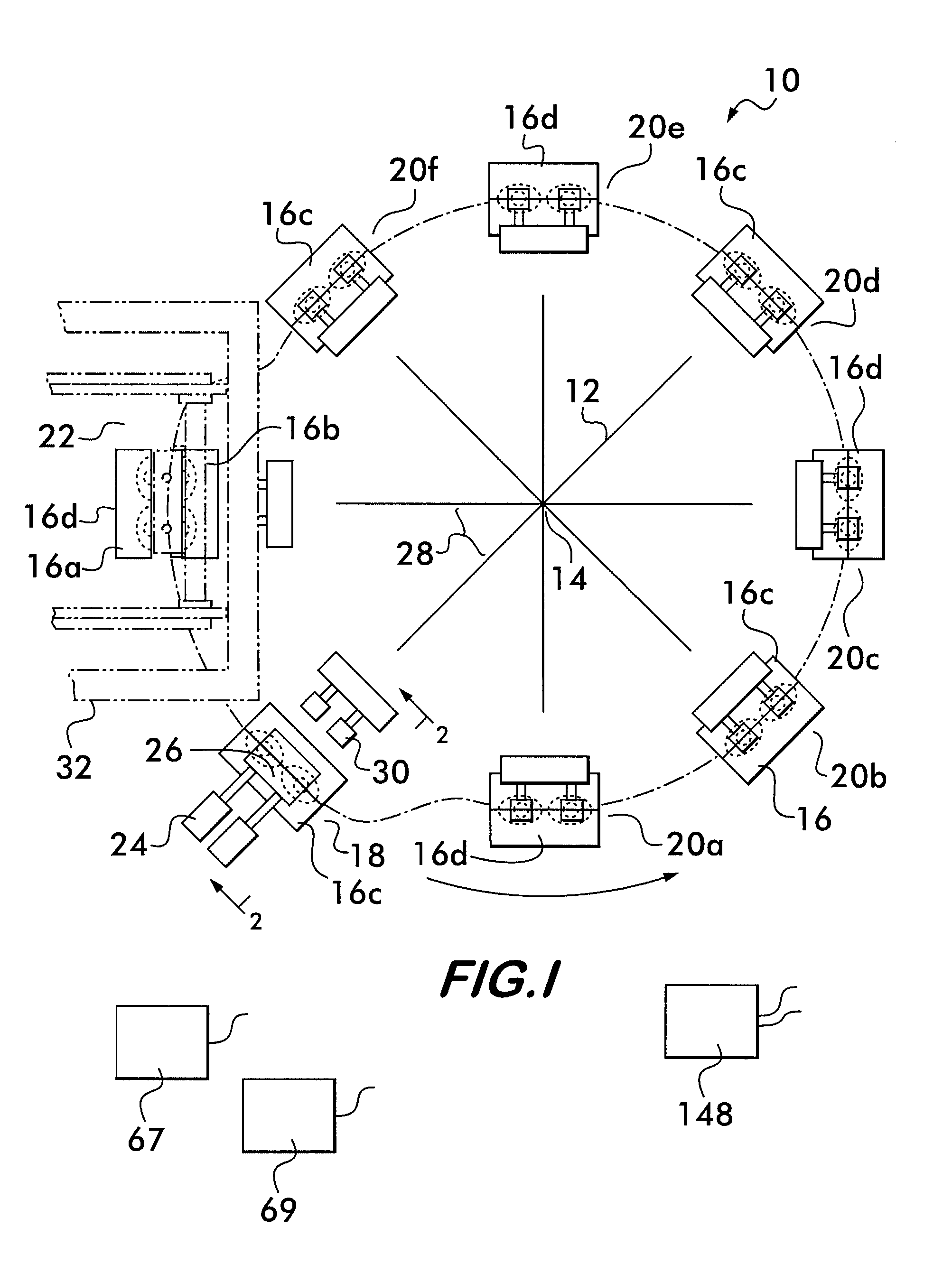

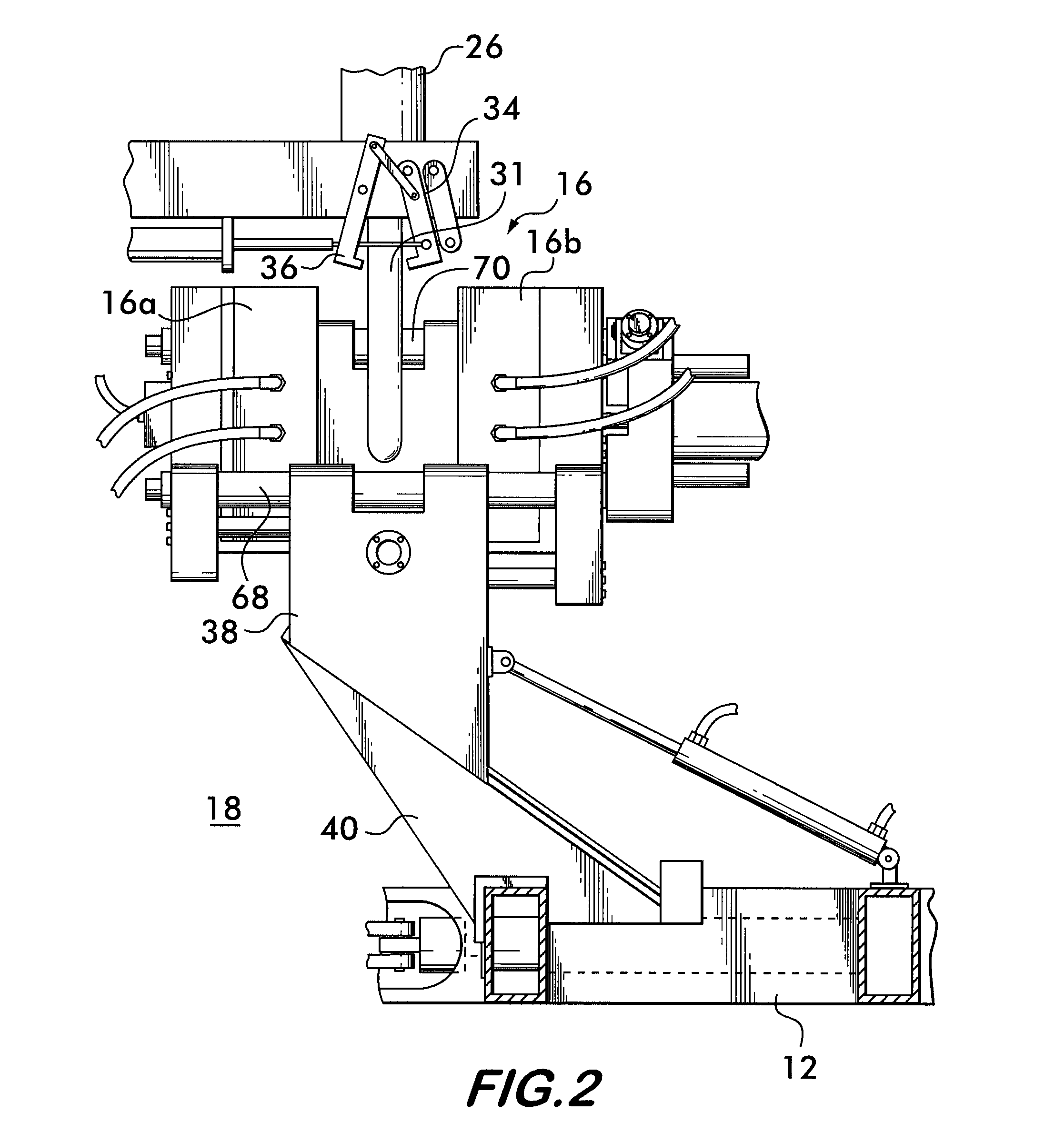

Blow molding machine and associated mechanisms

InactiveUS20100225033A1Lower potentialClose toleranceTailstocks/centresConfectioneryBlow moldingAcute angle

A machine (10) for blow molding containers (110). The machine (10) has a stationary flow head (26) located above a turntable (12) with molds (16) mounted on carriages (38). The carriages (38) are mounted on ramps (40) and are raised to remove containers (110) and are lowered from the flow head (12) using a closed loop hydraulic system actuated by a cam. A double rack-and-pinion assembly (78) guides opening and closing of the molds (16) and a locking system having locking shafts (94, 96) engaging apertures (98, 100) in a cross head (74) with pivoting locking keys (102, 104) movable into alignment with the apertures (98, 100) prevents inadvertent mold opening. A container transfer device (32) has inflatable bladders (140) which engage the interior of the containers (110) to prevent damage. Augmented cooling of the containers (110) in the mold (16) is provided by positioning the flow head (26) at an acute angle (28) to the transfer device (32). Different molds (16) may be positioned on the turntable (12) in an alternating arrangement to facilitate production changeover.

Owner:GRAHAM PACKAGING CO LP

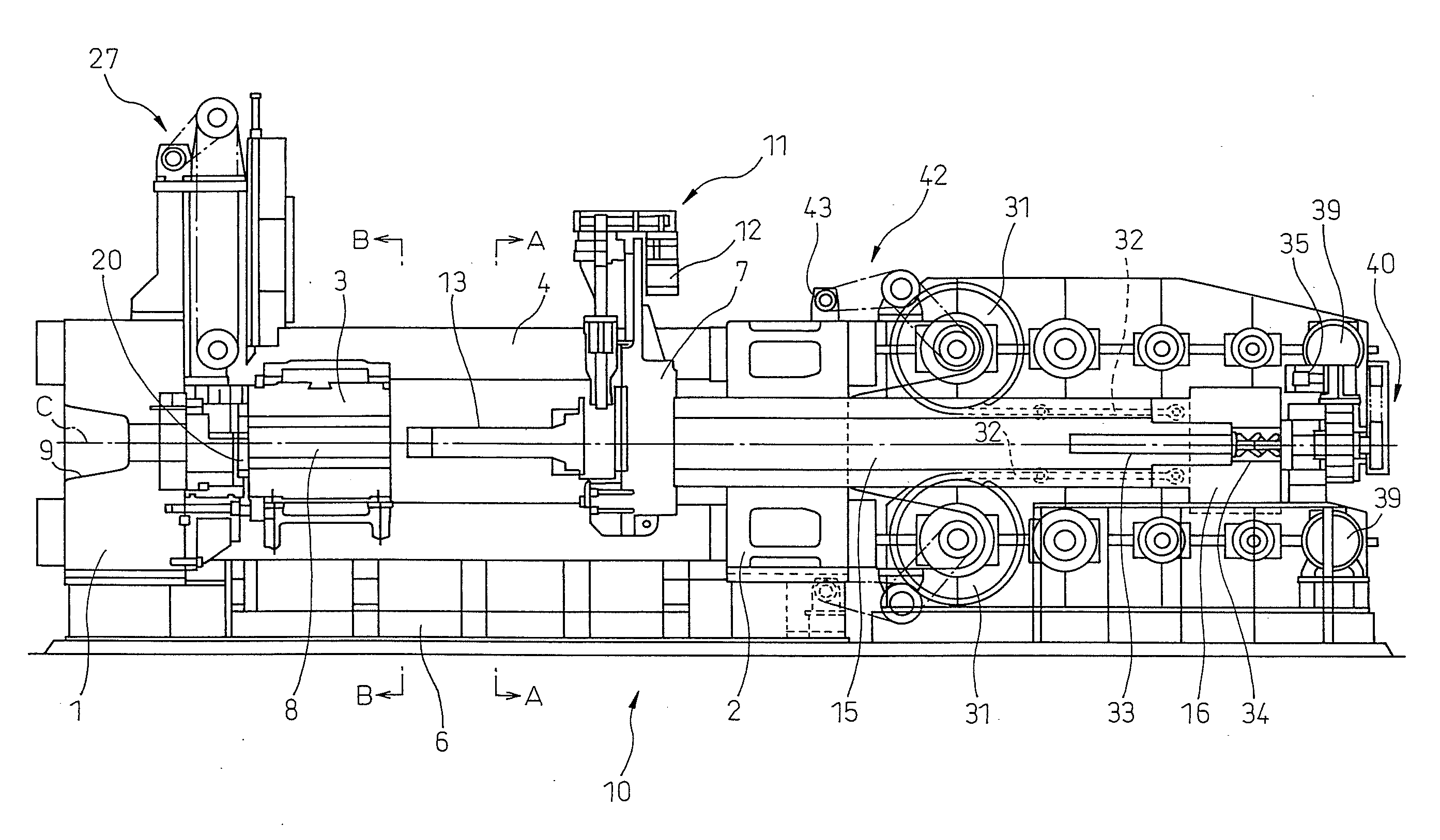

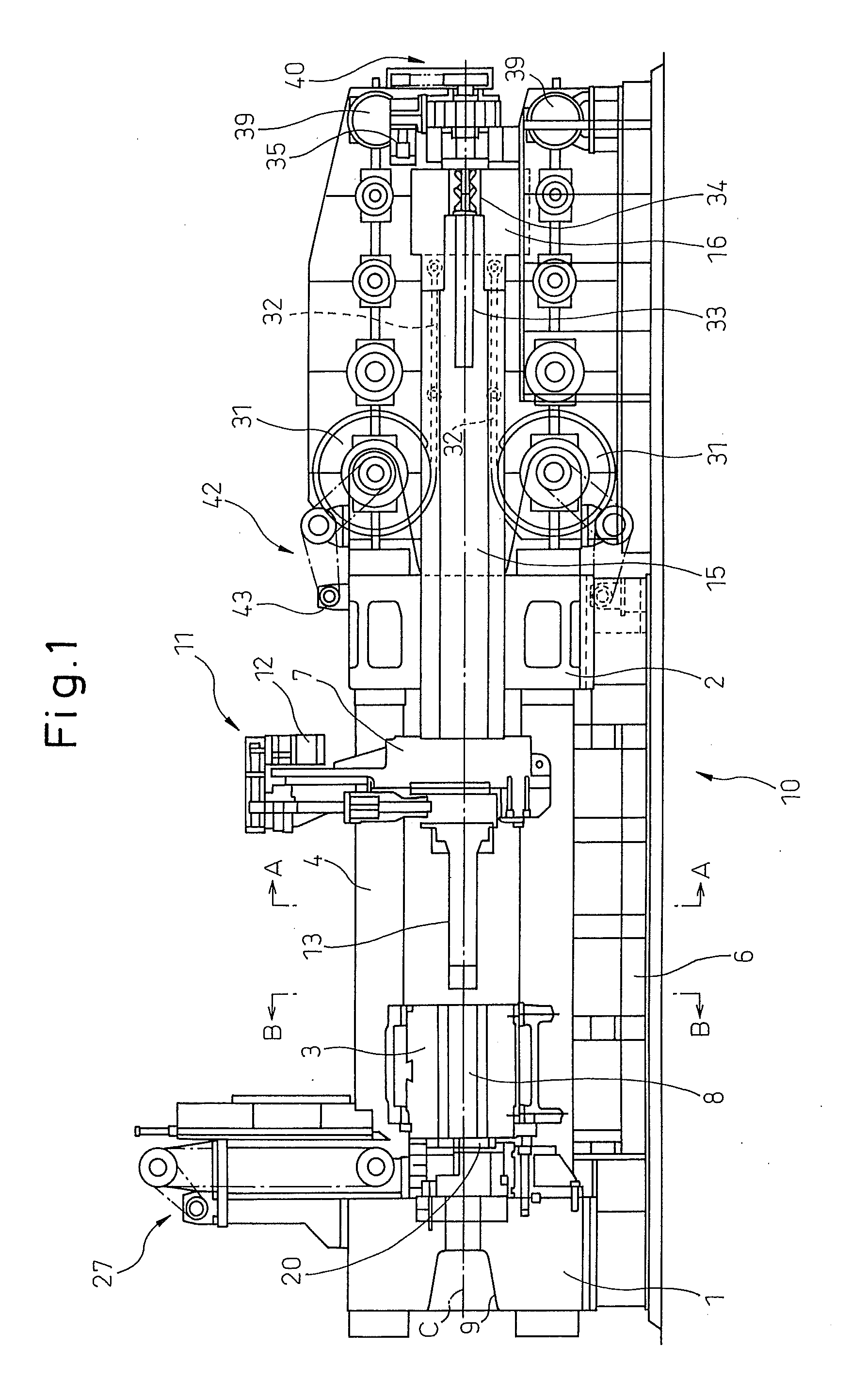

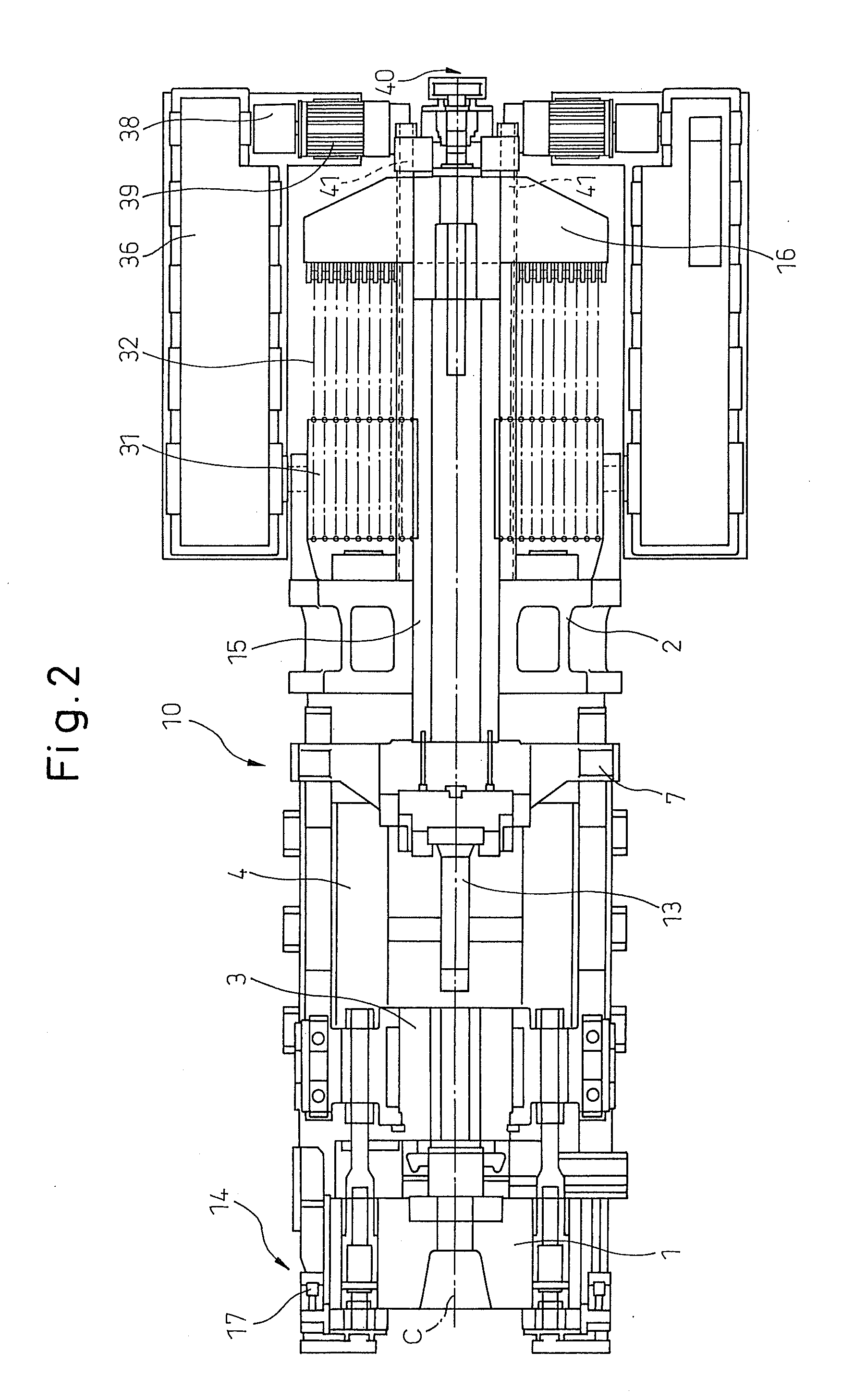

Extrusion press

InactiveUS20120244239A1Reduce the required powerCost maintenanceConfectionerySweetmeatsWire rodEngineering

To provide a fully electric extrusion press to reduce power consumption, improve maintenability and operability, and eliminate an adverse effect on the environment.An extrusion press (10) comprises an end platen (1), a fixed platen (2) arranged at the rear thereof, a tie rod (4) configured to link the end platen and the fixed platen, a die (20), a container (3) loaded with a billet (8), an extrusion stem (13) configured to press the billet, a crosshead (7) attached with the extrusion stem, and an extrusion drive configured to reciprocate the extrusion stem. The extrusion drive comprises a rotatable wire drum (31) driven by an electric extrusion main motor (39) and drives the extrusion stem to perform extrusion molding by winding the wire (30) by rotating the wire drum.

Owner:UBE MASCH CORP LTD

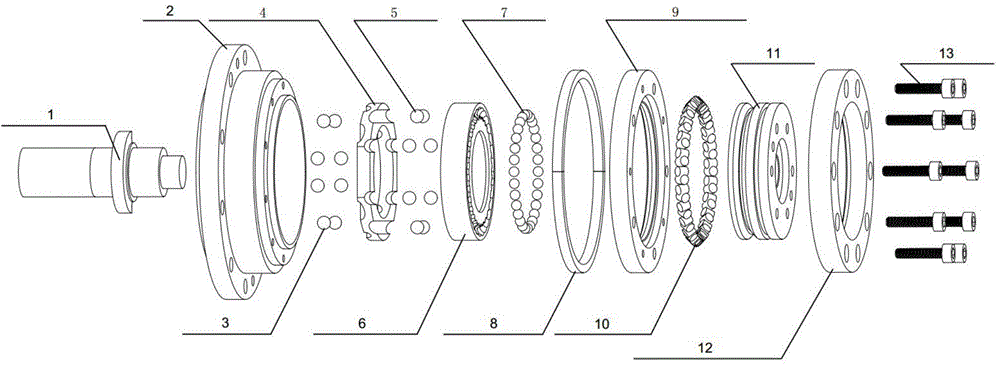

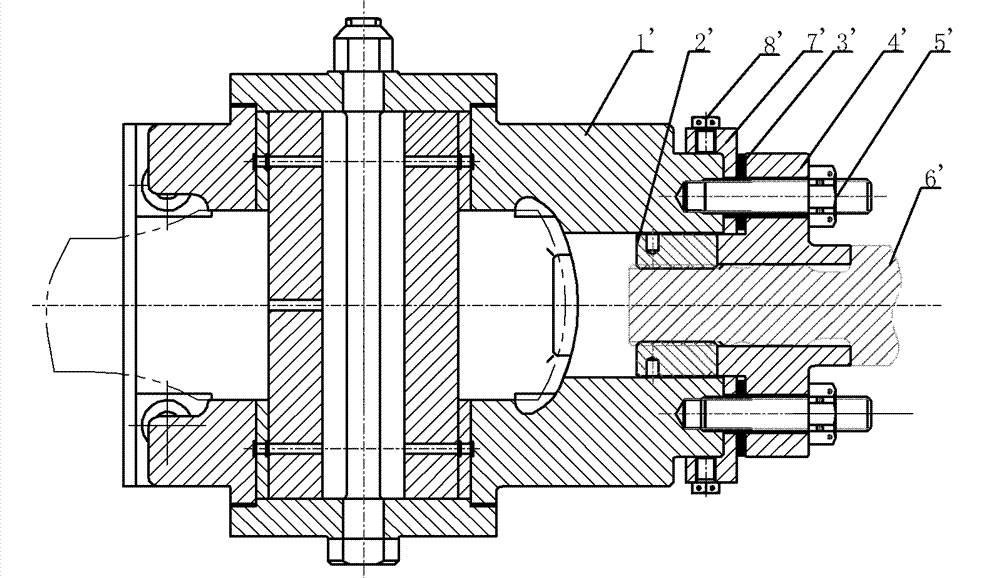

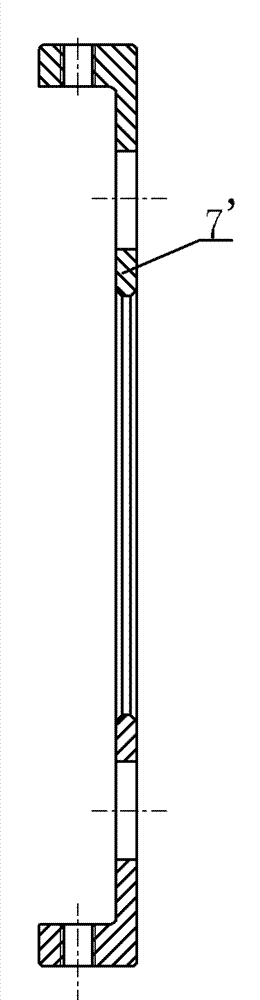

Piston rod and crosshead body connection adjusting structure

ActiveCN104121185AAdjustable processing technologySimple processing technologyPositive displacement pump componentsLiquid fuel engine componentsPiston rodFlange

The invention provides a piston rod and crosshead body connection adjusting structure. The piston rod and crosshead body connection adjusting structure has the advantages of being convenient to install, good in manufacturability, safe, attractive and the like. After the radial gap of a piston rod is adjusted, all the other parts for adjustment can be detached, potential safety hazards are avoided, the parts are good in manufacturability, and meanwhile it can be guaranteed that adjustment can be performed many times. The piston rod and crosshead body connection adjusting structure comprises a crosshead body, a hydraulic nut, the piston rod, a gasket and a flange. The hydraulic nut is arranged in an inner hole in the front end of the crosshead body, the positioning face of the flange is fastened to the axial outer end face of the crosshead body through a bolt, the piston rod penetrates through a center hole of the flange and then is positioned to the hydraulic nut, and the gasket is arranged between the axial outer end face of the crosshead body and the positioning face of the flange. The piston rod and crosshead body connection adjusting structure is characterized in that the space between the inner end face of the gasket and the axial outer end face of the crosshead body is stuffed with the adjustable gasket, the adjustable gasket is in the shape of a flange, and an inner side convex shaft of the flange is sleeved with the adjustable gasket.

Owner:WUXI COMPRESSOR CO LTD

Air intake porting for a two stroke engine

ActiveUS7258087B1High power outputReduce needCylinder headsOutput powerFour-stroke engineEngineering

A two stroke engine of a particular configuration can have its power output increased by running bigger pistons and using ports in the piston skirt through which to conduct compressed air within the skirt through short passages in the cylinder housing that conduct the air from within the skirt to above the piston. As a result a larger piston can be used for the same spacing and opening size in the block to save the need to redesign the block and the crankshaft. A position adjuster for the piston moves it axially without rotation of the piston ports out of alignment with inlet ports in the housing. The piston rod is held in the crosshead using a flat to prevent rotation while an adjuster nut that is turned creates axial movement in the piston rod with a lock nut securing the final piston position.

Owner:COOPER MASCH SERVICES LLC

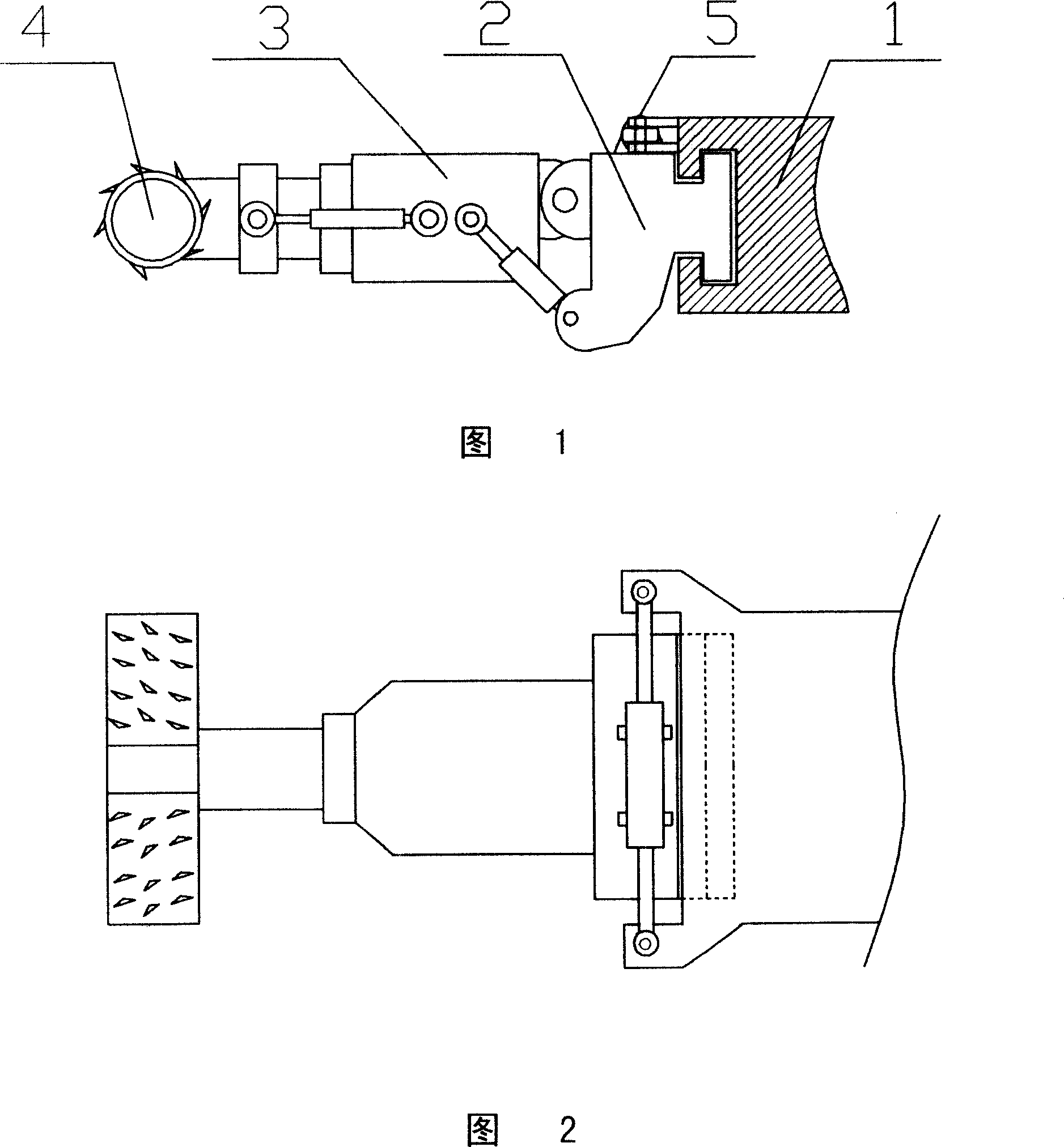

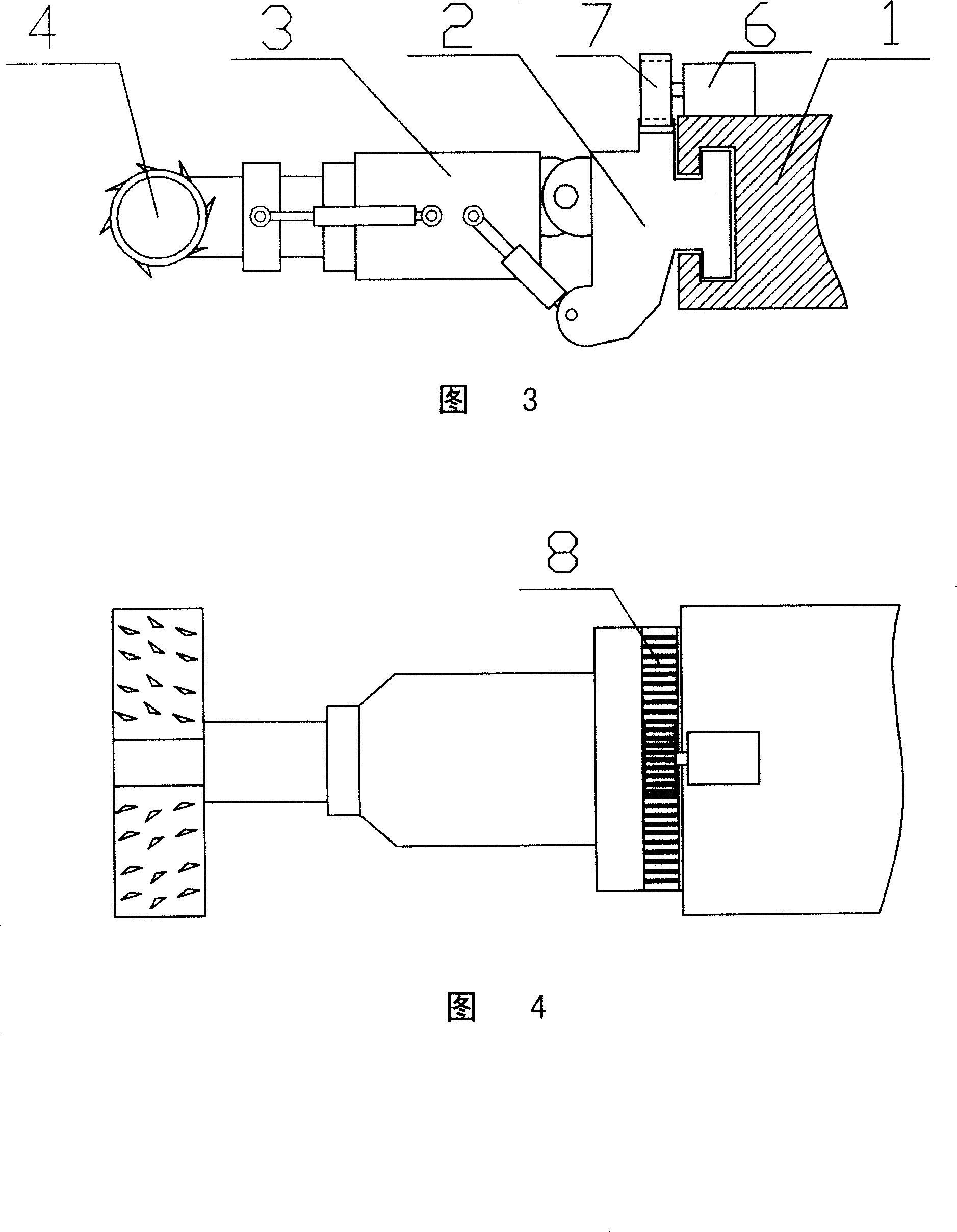

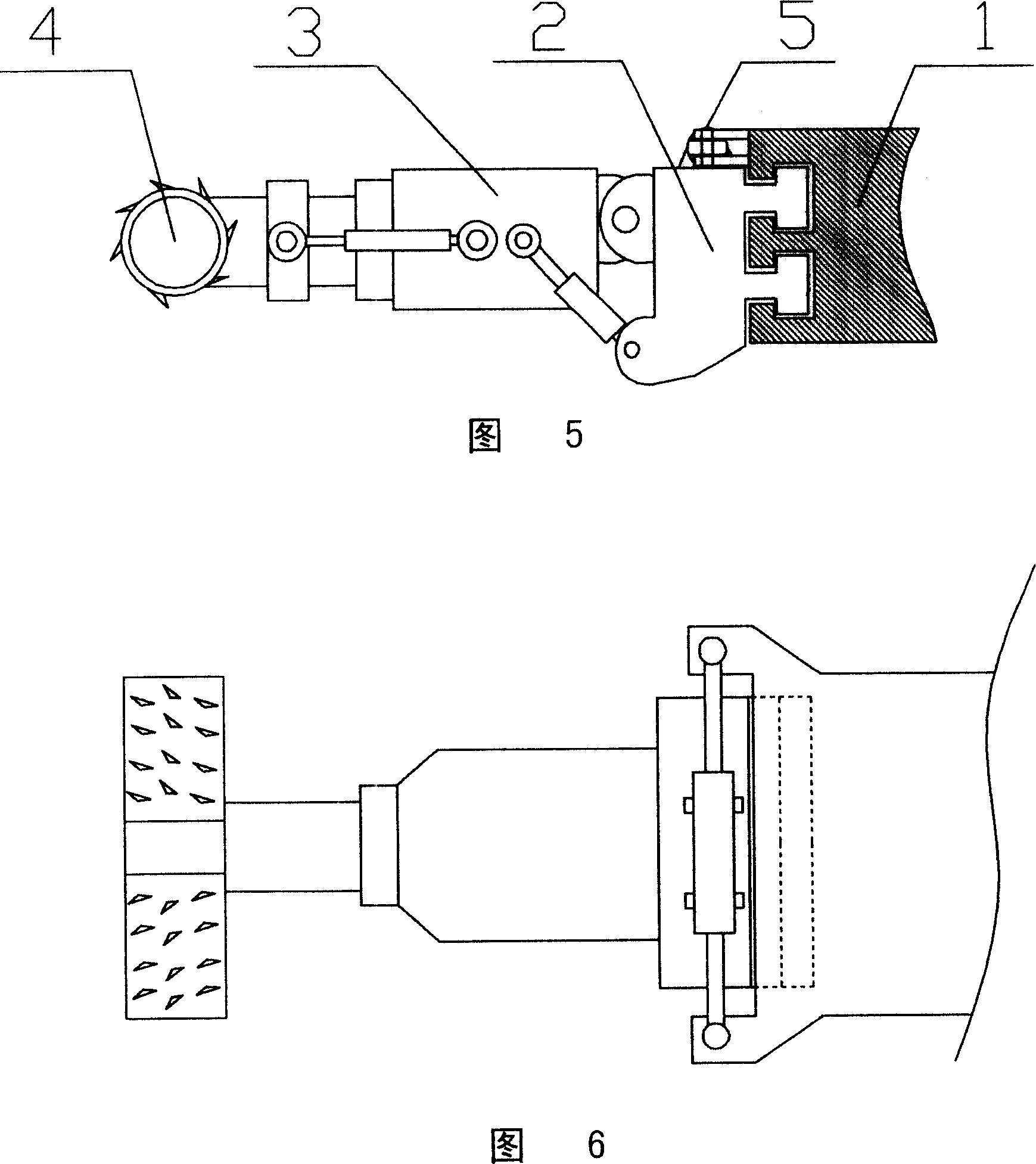

Roadheader

InactiveCN101153540AAdd supportImprove support efficiencyDriving meansCutting machinesEngineeringCantilever

A tunneling machine for tunneling gross section coal drift consists of a cutting unit, a body, a travel unit, a blade, a conveyor and a hydraulic system, etc. The cutting unit consists of a cutting head (4), a cantilever (3), a cutting motor, a cutting reduction gearbox and a telescopic part, etc. The cantilever (3) is connected with the body through a side slip guide mechanism namely a crosshead (2) is hinged onto the rear end of the cantilever (3); a guide body is arranged on the rear end of the crosshead; a guide holder (1) is fixed on the body; a guide groove is arranged on the front end of the guide holder, and the guide body is embedded in the guide groove and is in slide fit with the guide groove; or the two parts are arranged in a reverse way. A driving element or mechanism for driving the crosshead and the cantilever to make lateral movement is arranged between the guide holder and the crosshead. A cantilever tilt cylinder is hinged between the cantilever (3) and the crosshead (2). The wall of the coal drift cut by the tunneling machine is smooth, flat and easy in supporting, thereby improving supporting efficiency and effect. The cutting unit makes a large range of lateral movement, thereby realizing gross section fixed point cutting in a wider coal drift without lateral movement of the whole machine, shortening cycle time, improving tunneling speed and efficiency with great adaptability.

Owner:贾民

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com