An internal combustion engine with control of fuel gas injection pressure

A fuel gas and internal combustion engine technology, applied in fuel injection control, electrical control, internal combustion piston engine, etc., can solve the problems of low maximum combustion pressure, damage, wear, etc., and achieve the effect of saving maintenance costs, reducing damage risks, and optimizing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

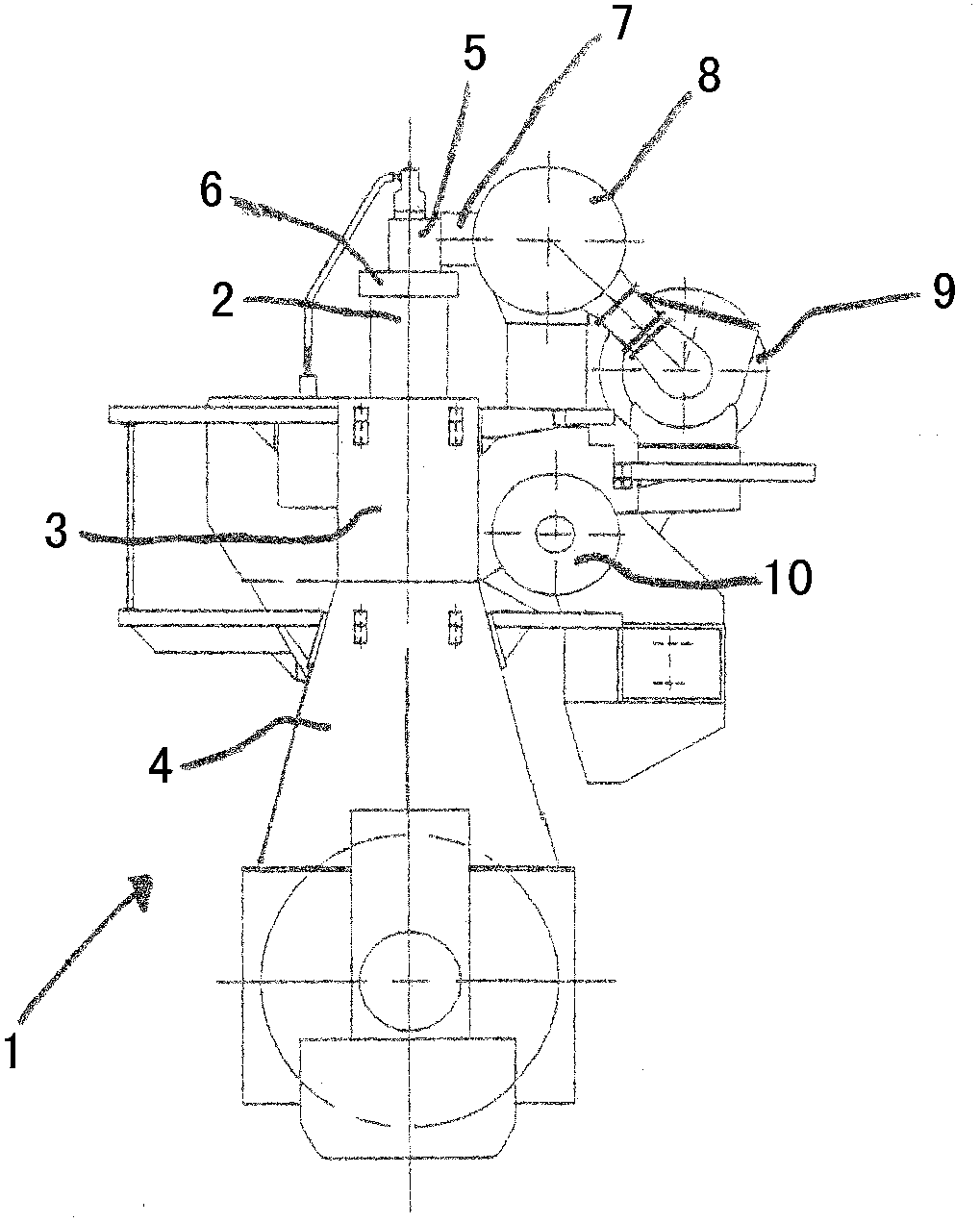

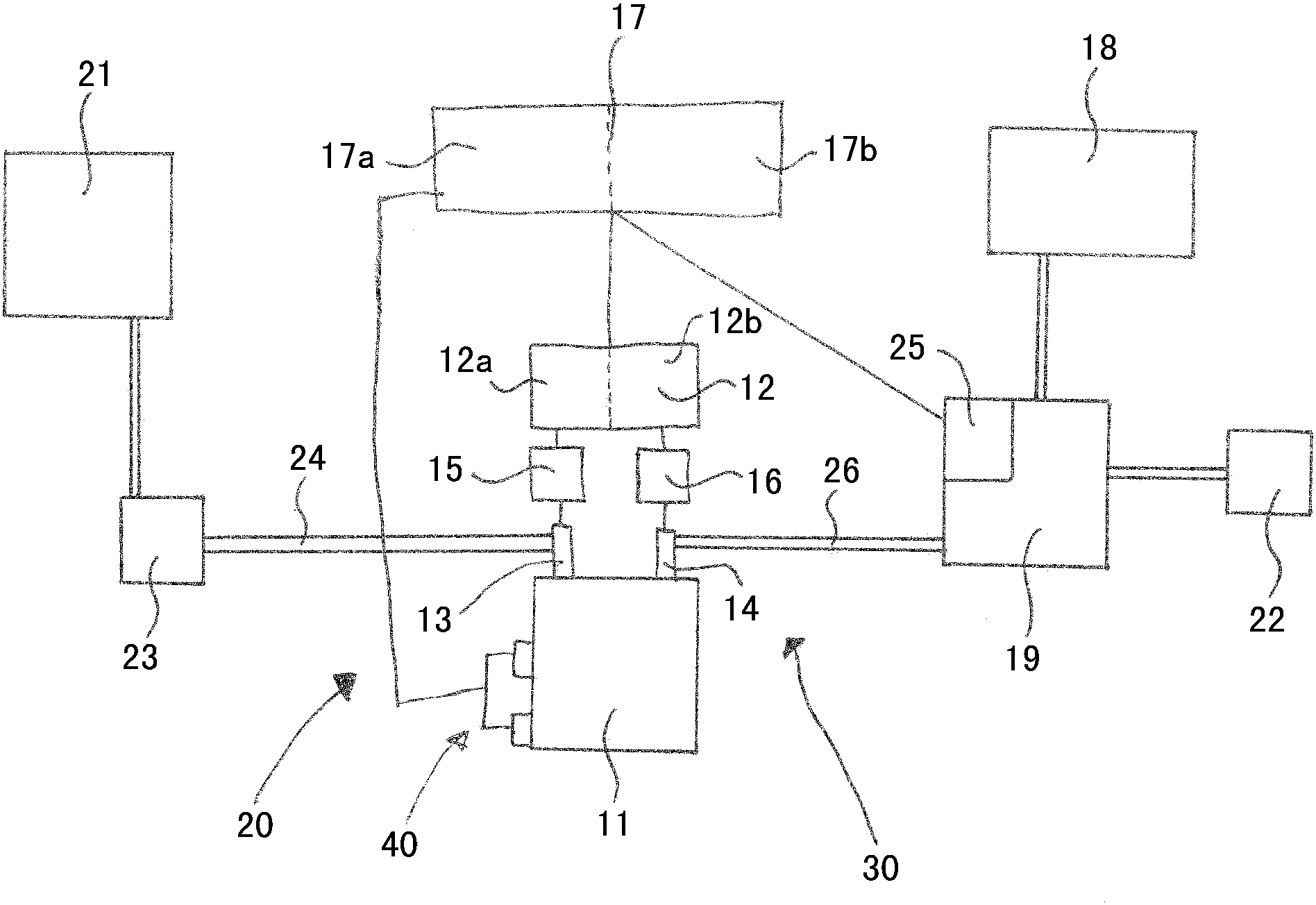

[0026] The internal combustion engine 1 according to a preferred embodiment of the present invention may be a two-stroke crosshead diesel engine, such as figure 1 shown in . This engine 1 can be brand MAN Diesel and type MC or ME, or brand Model Sulzer RT-flex or Sulzer RTA, or brand Mitsubishi Heavy Industries (Mitsubishi Heavy Industries). Engines of this type are large engines that are typically used as the main engine in a ship or as a stationary engine in a power plant. The cylinder may for example have a cylinder bore in the range of 25 cm to 120 cm and the engine may for example have a power in the range of from 3000 kW to 120000 kW. Engine speed typically ranges from 40 rpm to 250 rpm. Compression ignition internal combustion engines according to the invention are typically capable of using heavy fuel oil as the primary fuel.

[0027] figure 1 The engine 1 has a plurality of cylinders, and the cylinder liner 2 is installed in the cylinder portion 3 of the engine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com