Patents

Literature

1576results about "Rotary/oscillating piston combinations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

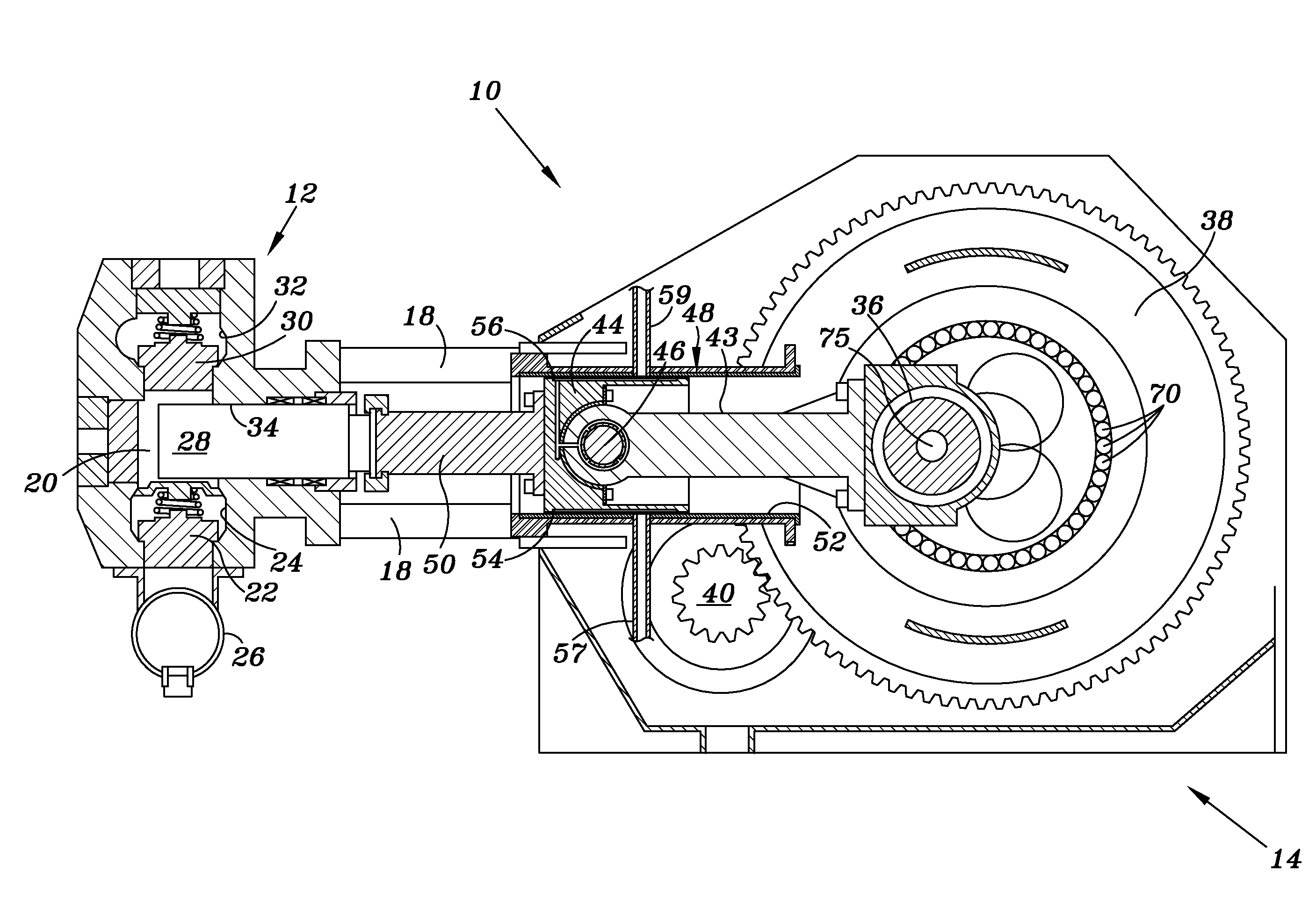

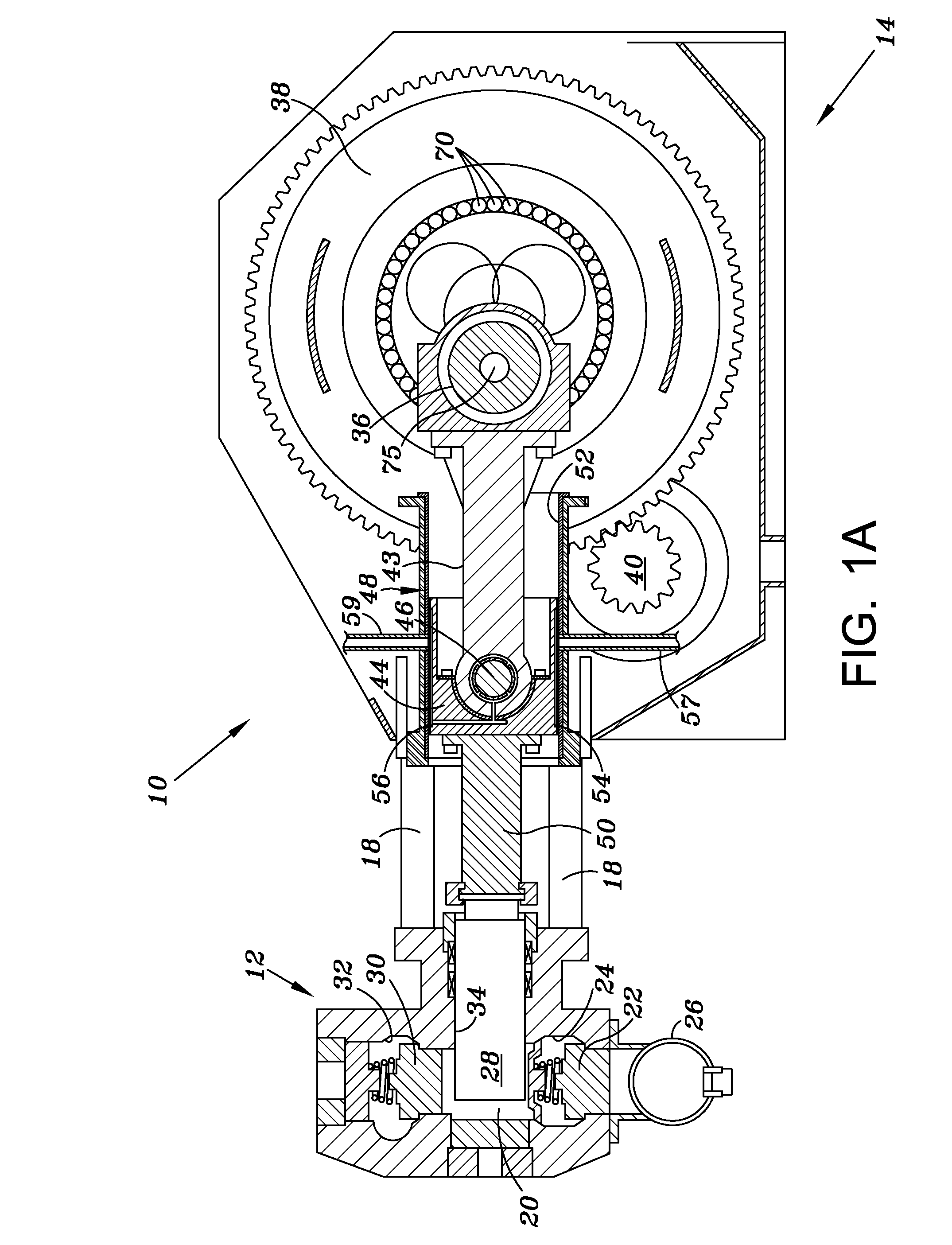

Reciprocating pump with dual circuit power end lubrication system

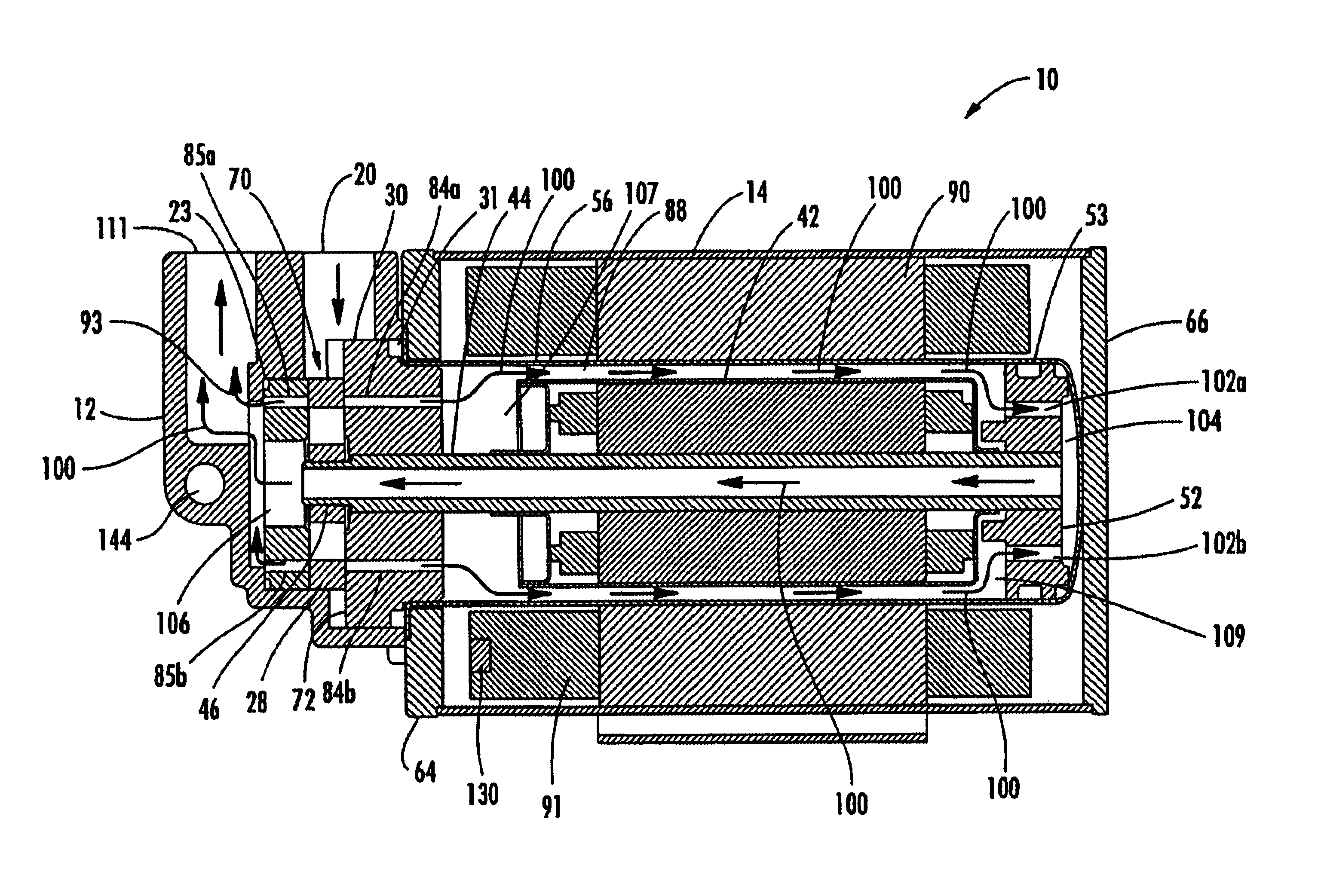

ActiveUS20190277279A1Positive displacement pump componentsRotary/oscillating piston combinationsHigh pressureLubrication

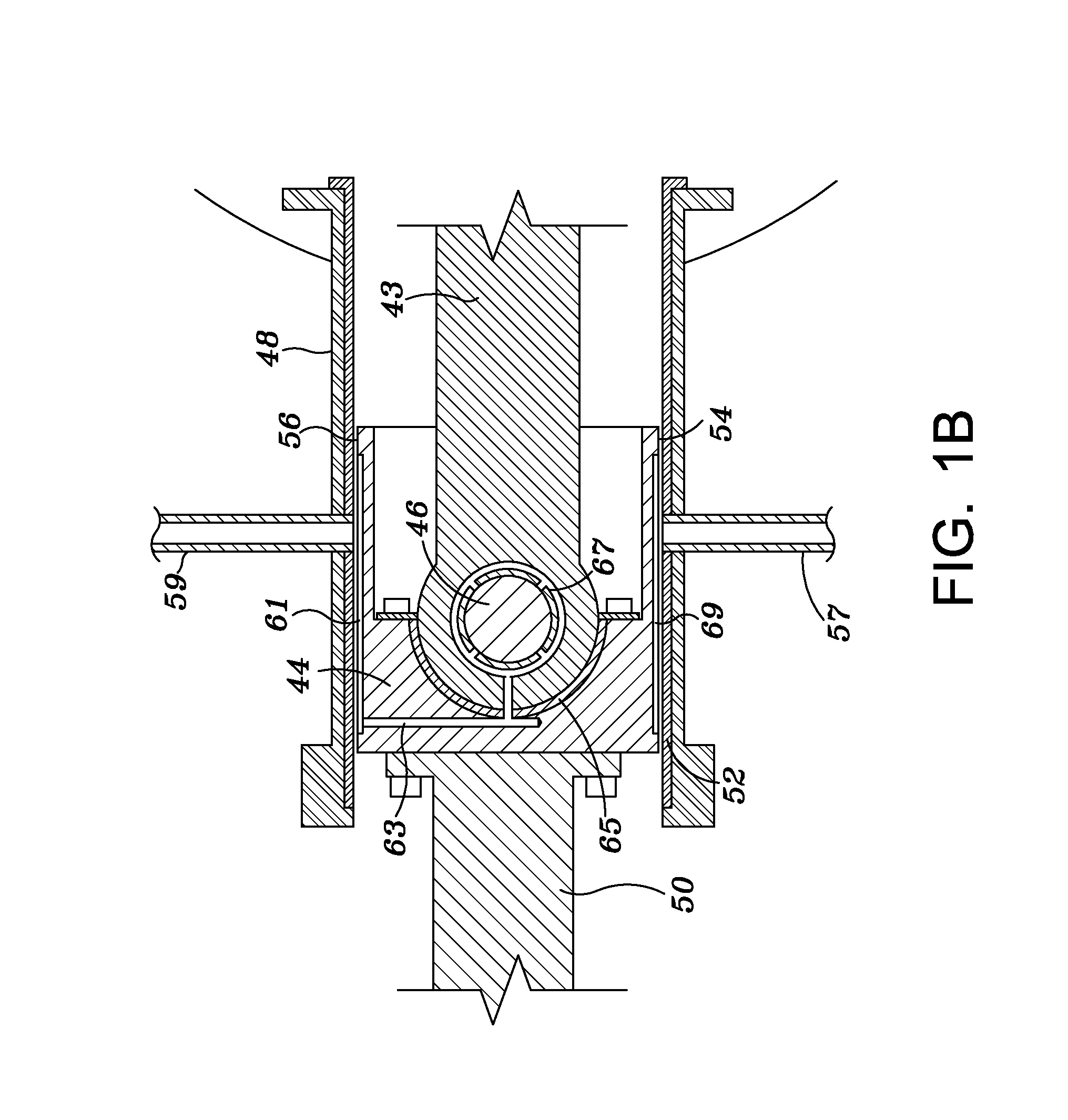

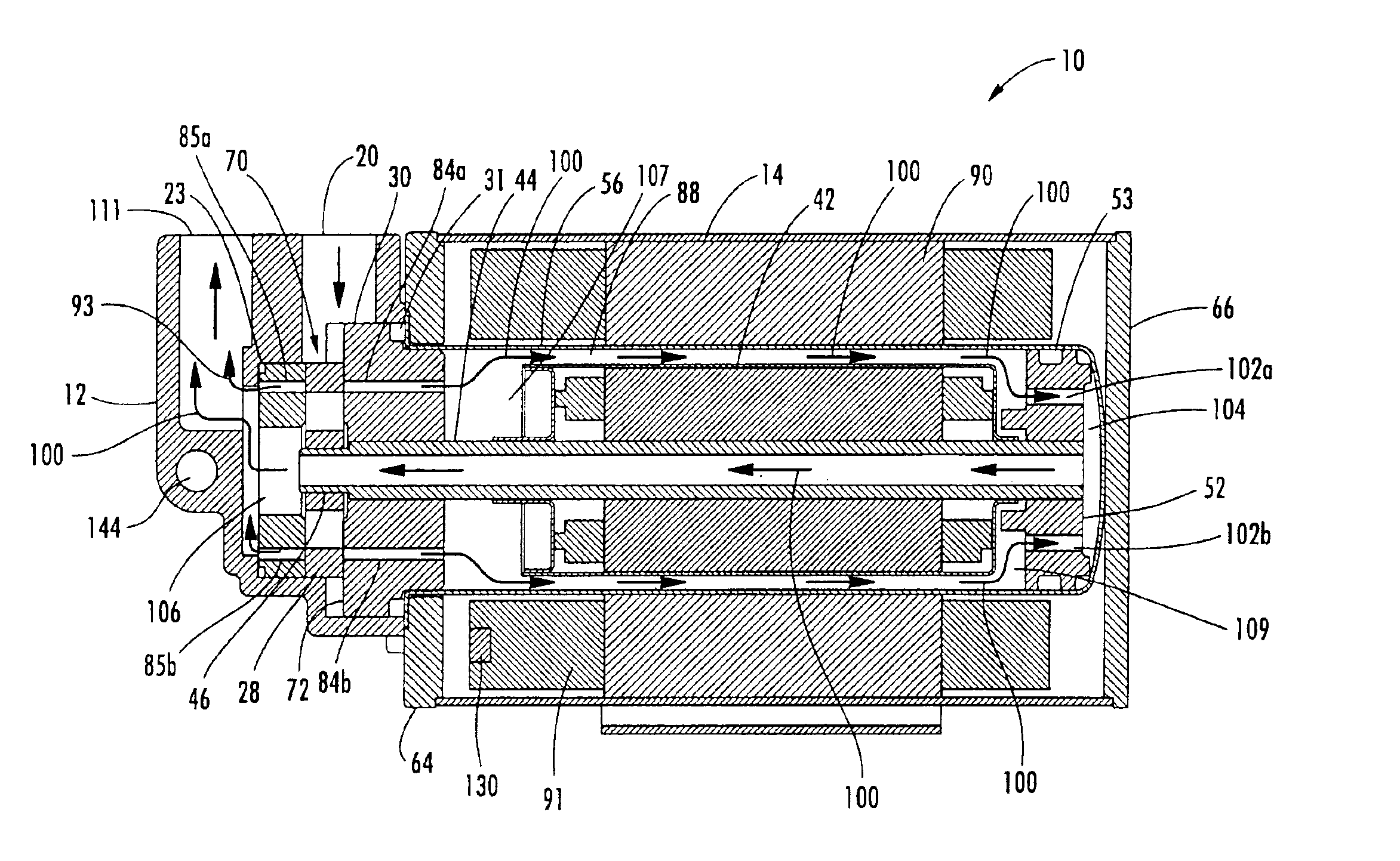

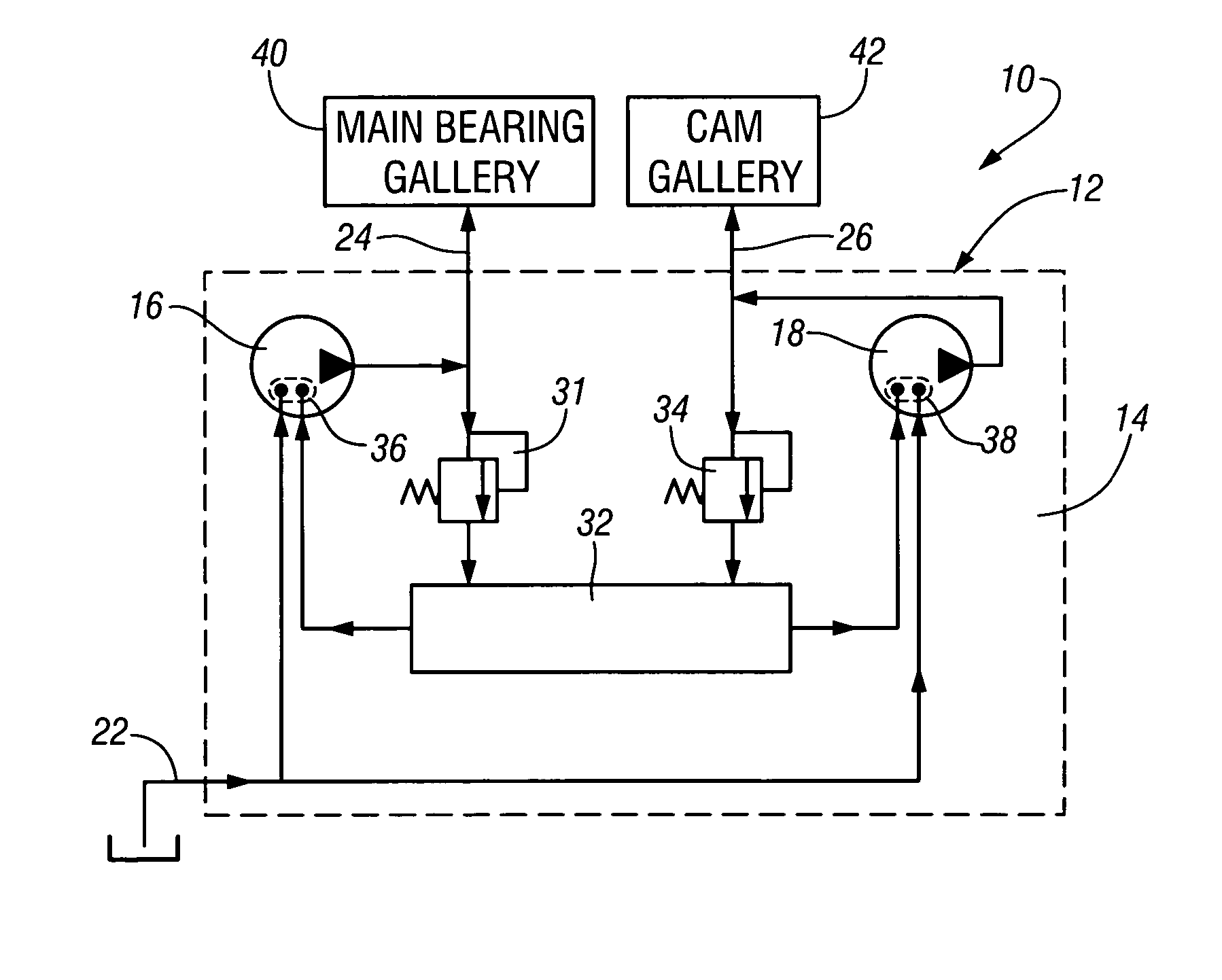

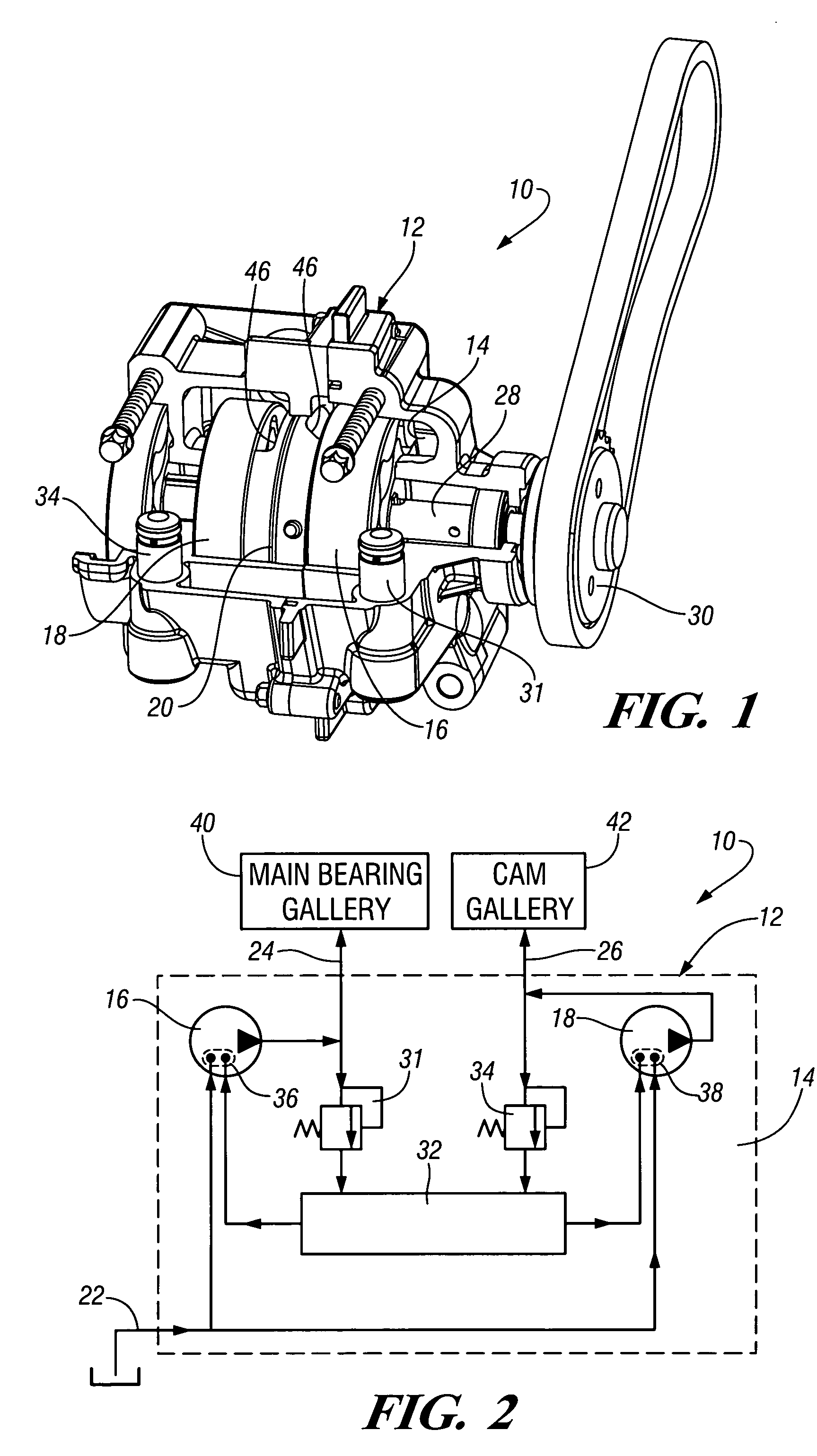

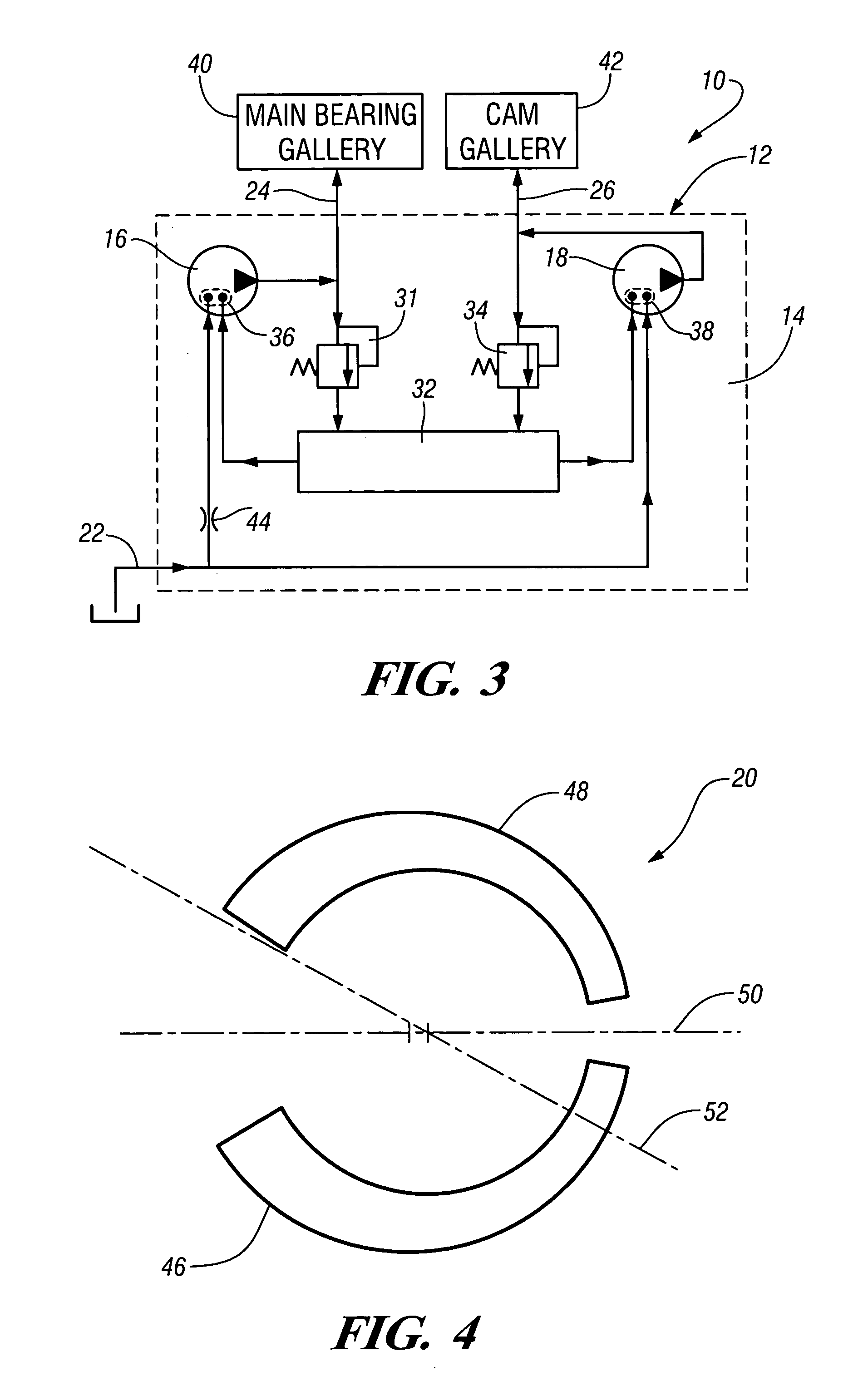

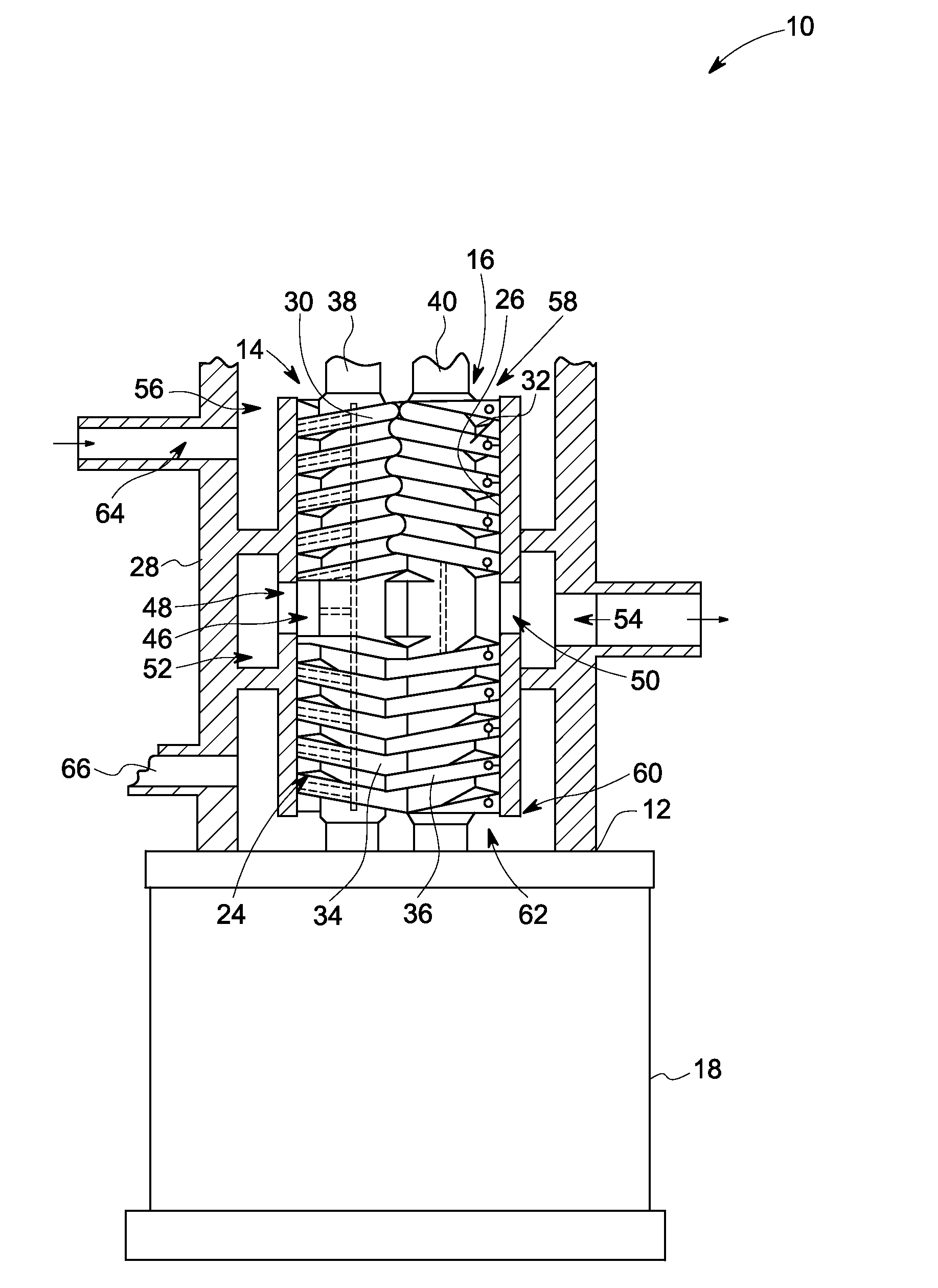

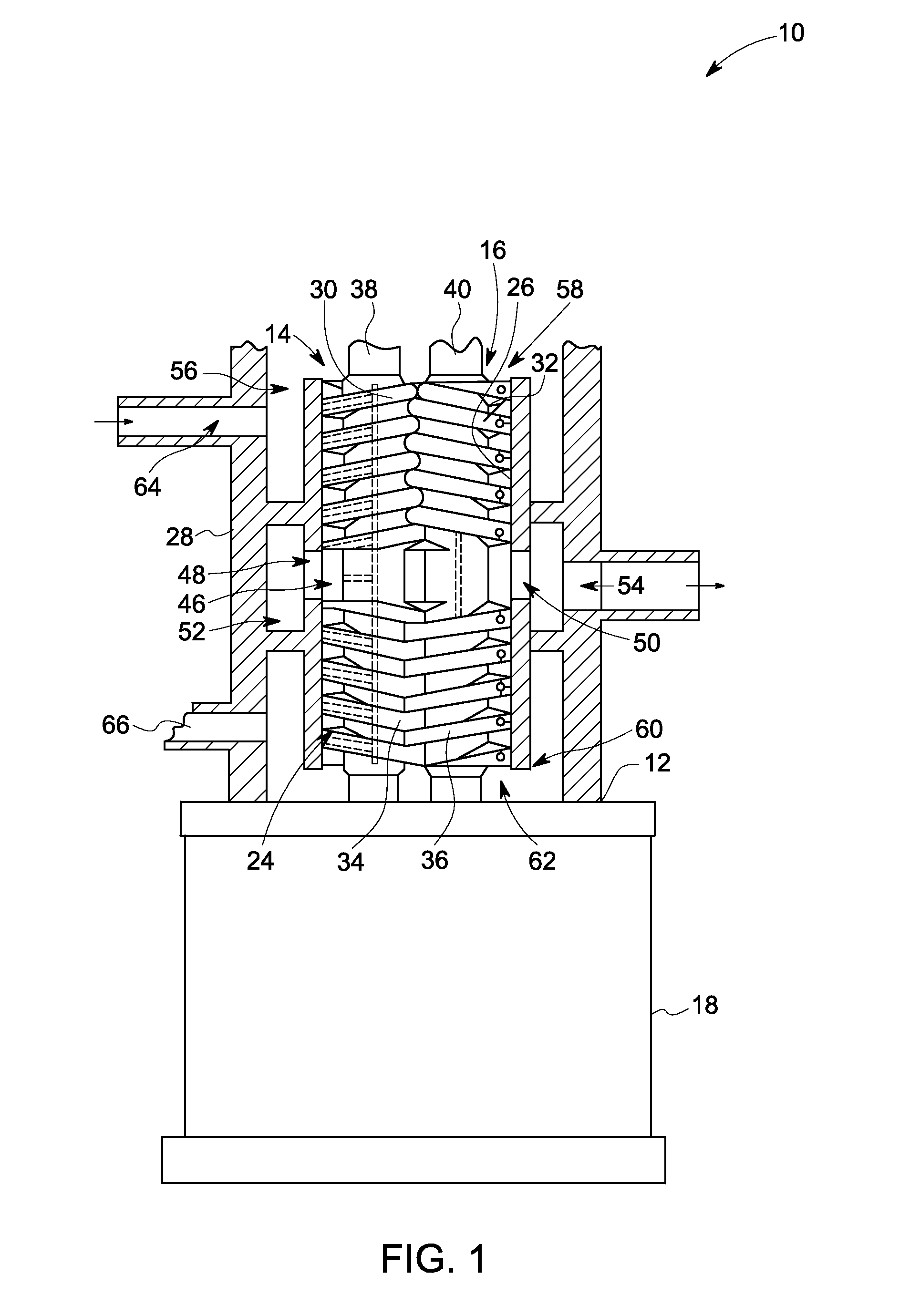

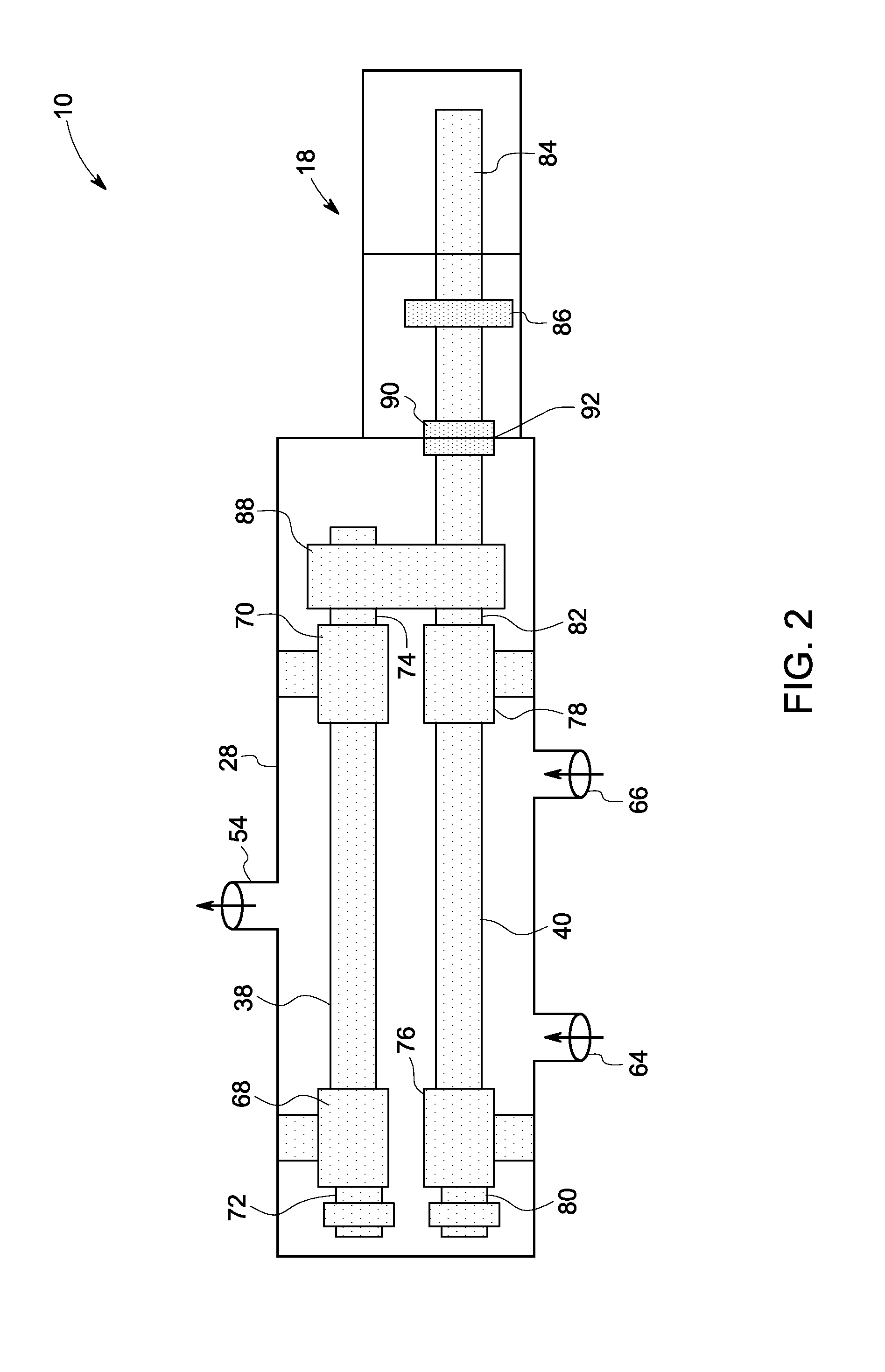

A dual circuit lubrication system for a power end of a reciprocating pump that includes a lubrication pump that supplies lubrication fluid to a high pressure lubrication circuit and a low pressure lubrication circuit. The high pressure lubrication circuit is fluidly coupled to a crankshaft to supply lubrication fluid to journal surfaces associated with the crankshaft at a first lubrication fluid pressure. The crankshaft drives a crosshead coupled to a plunger to displace fluid from a fluid end of the reciprocating pump. The low pressure lubrication circuit is fluidly coupled to supply the lubrication fluid to a plurality of roller bearing surfaces associated with the crankshaft at a second lubrication fluid pressure. The first lubrication fluid pressure is greater than the second lubrication fluid pressure.

Owner:SPM OIL & GAS INC

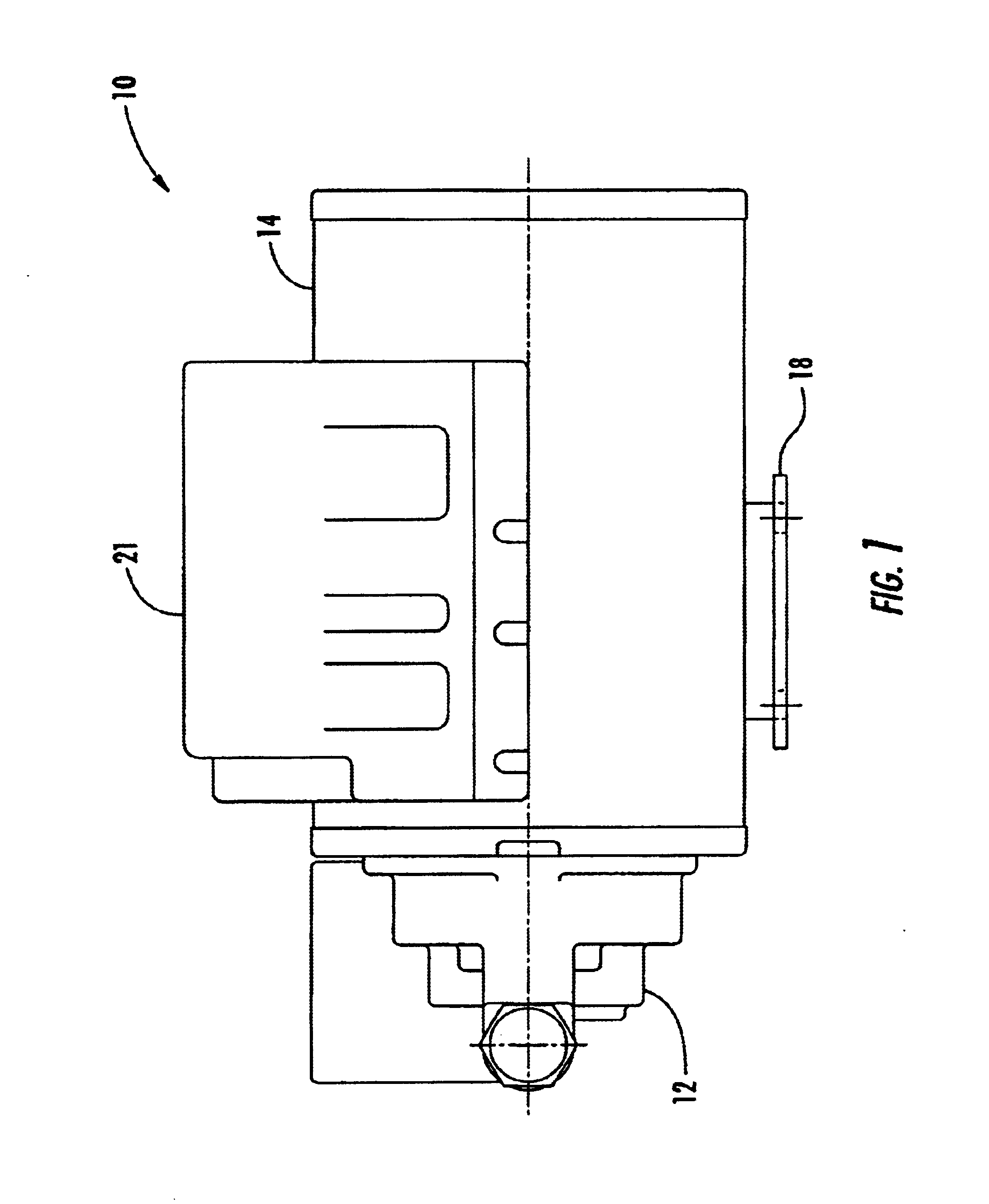

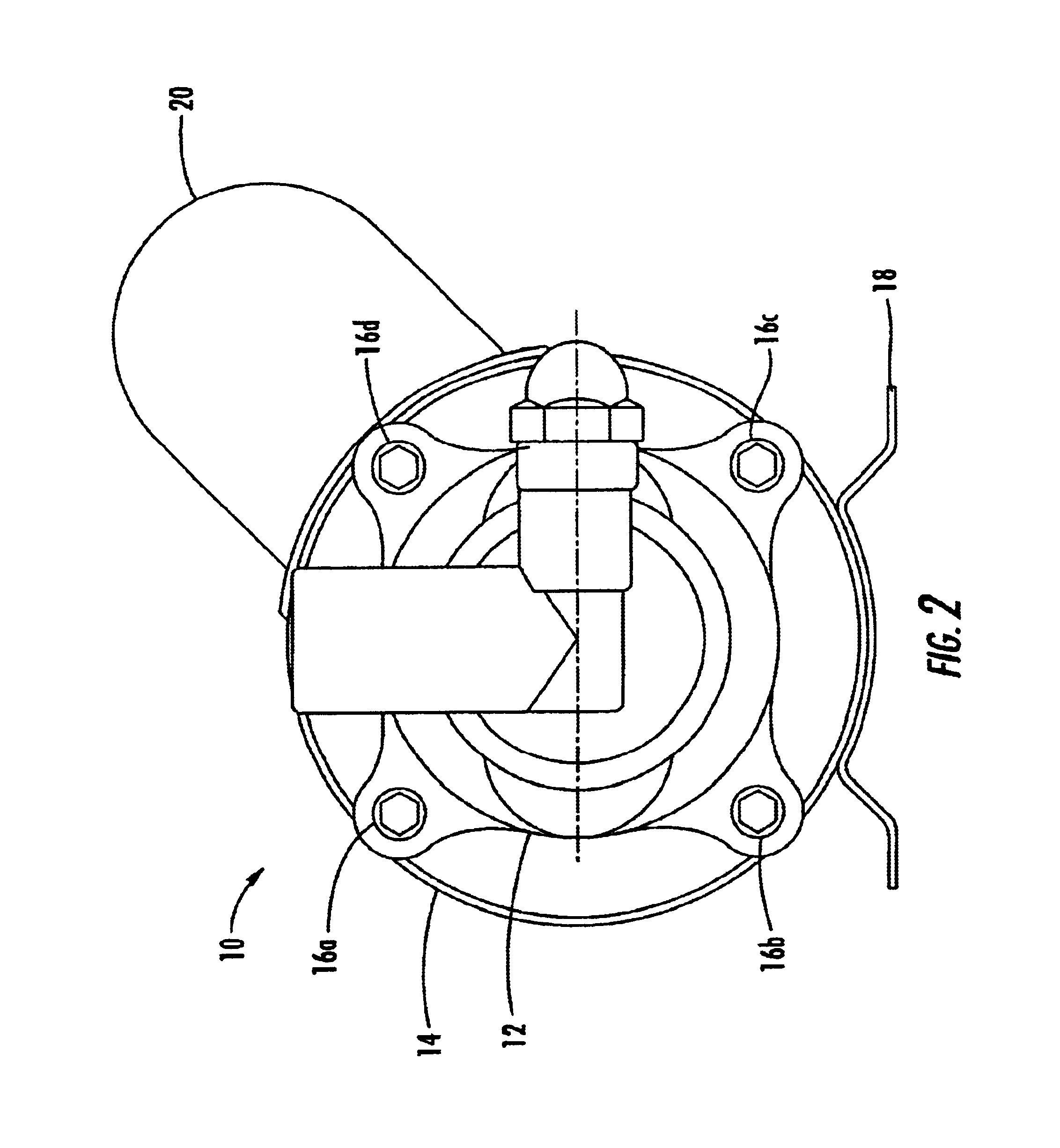

Overheat protection for fluid pump

InactiveUS6837688B2Avoid damageReduce stepsRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsPump headThreshold temperature

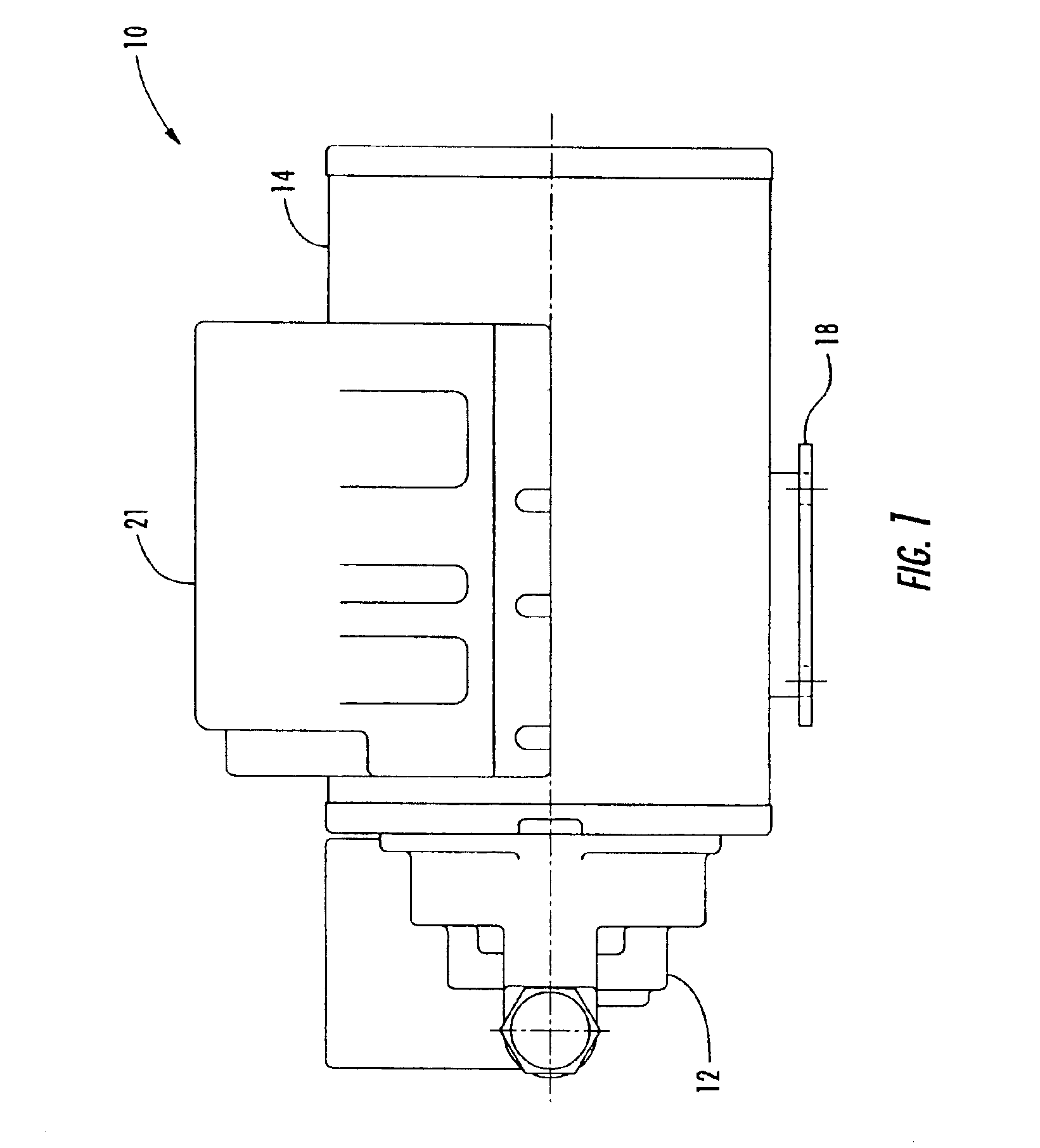

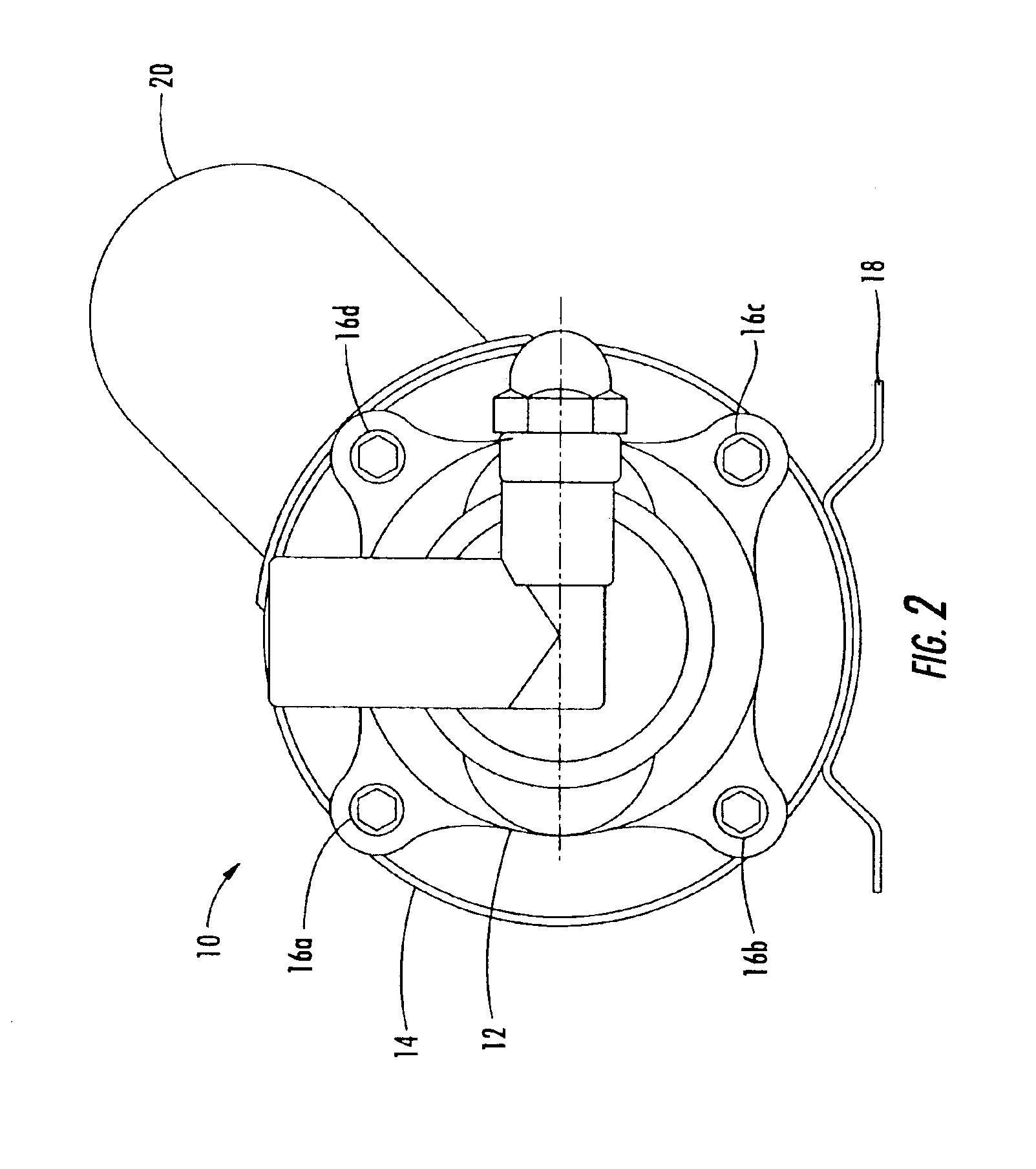

An apparatus for detecting the presence of an overheat condition in a fluid pump includes a pump head for receiving a fluid at a first pressure and outputting the fluid at a second pressure that is greater than the first pressure. A motor is positioned adjacent the pump head to drive the pump head to pressurize the fluid. A single overheat sensor senses an overheat condition in the pump head and an overheat condition in the motor. When a threshold temperature is sensed by the overheat sensor, a switch is activated to prevent operation of the motor. In one embodiment, the overheat sensor and switch are integral and may, for example, take the form of a bi-metal switch formed in the stator windings of the motor. In alternate embodiments, the overheat sensor and switch are separate.

Owner:STANDEX INT CORP

Reciprocating pump with dual circuit power end lubrication system

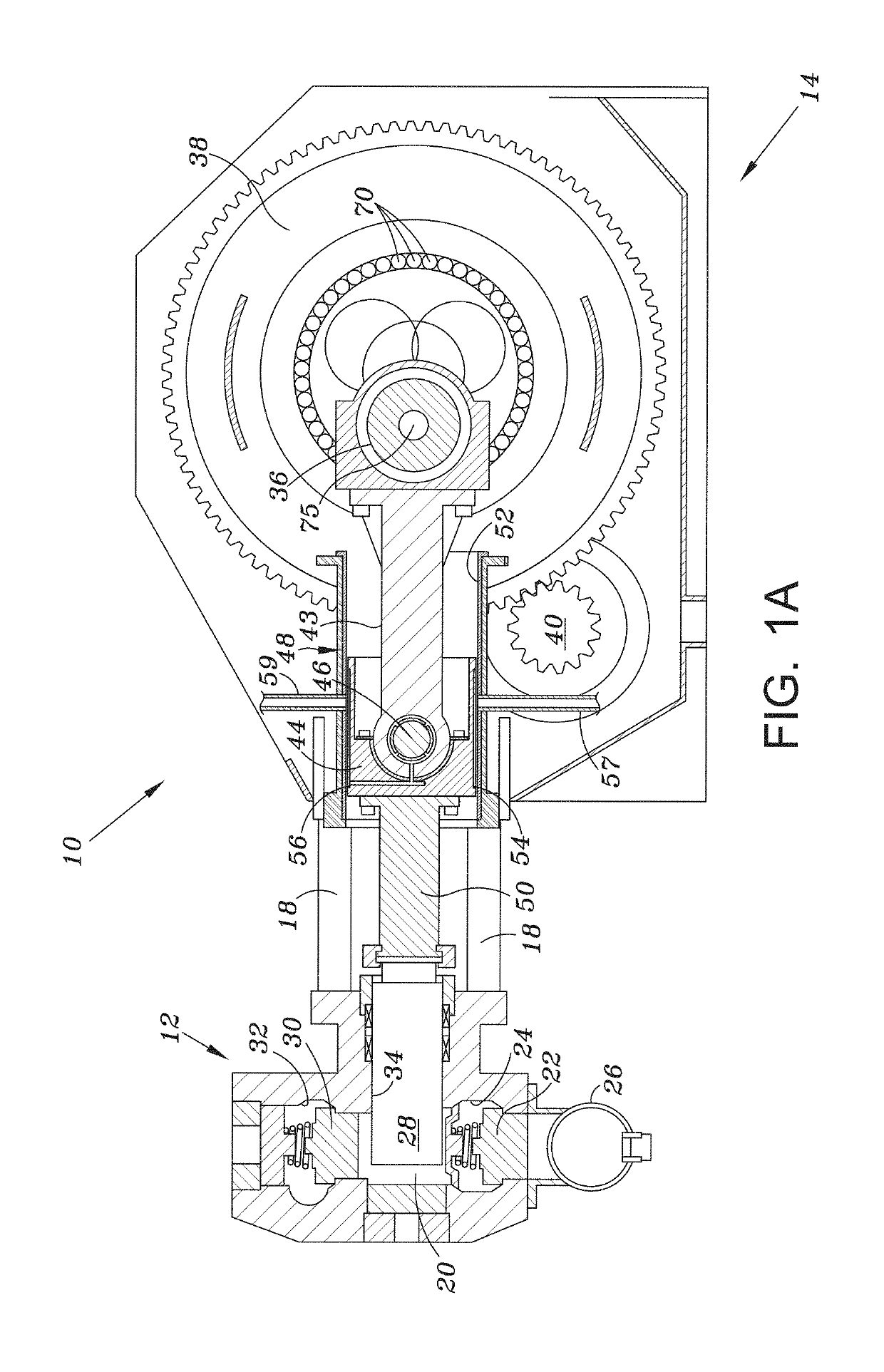

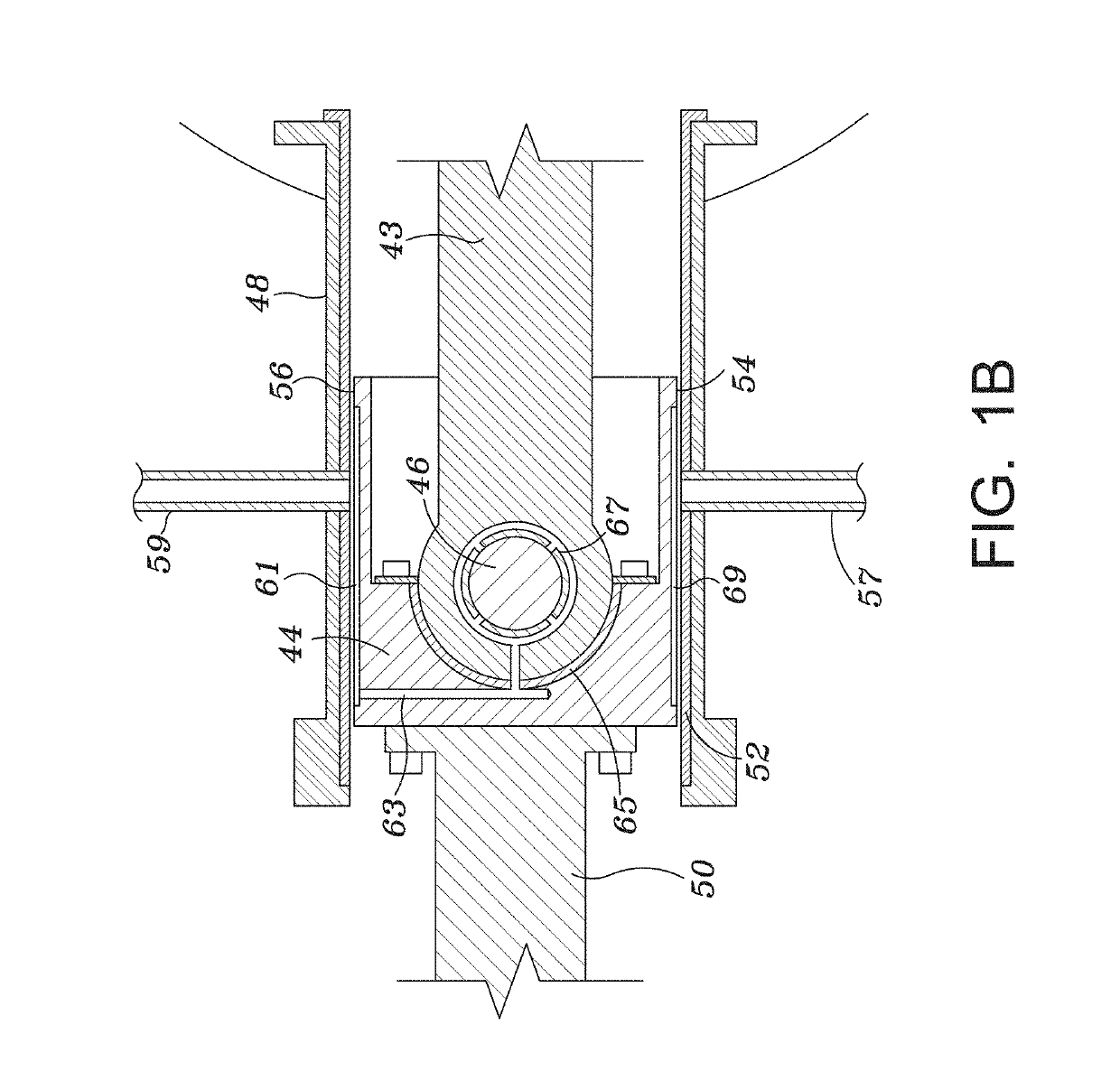

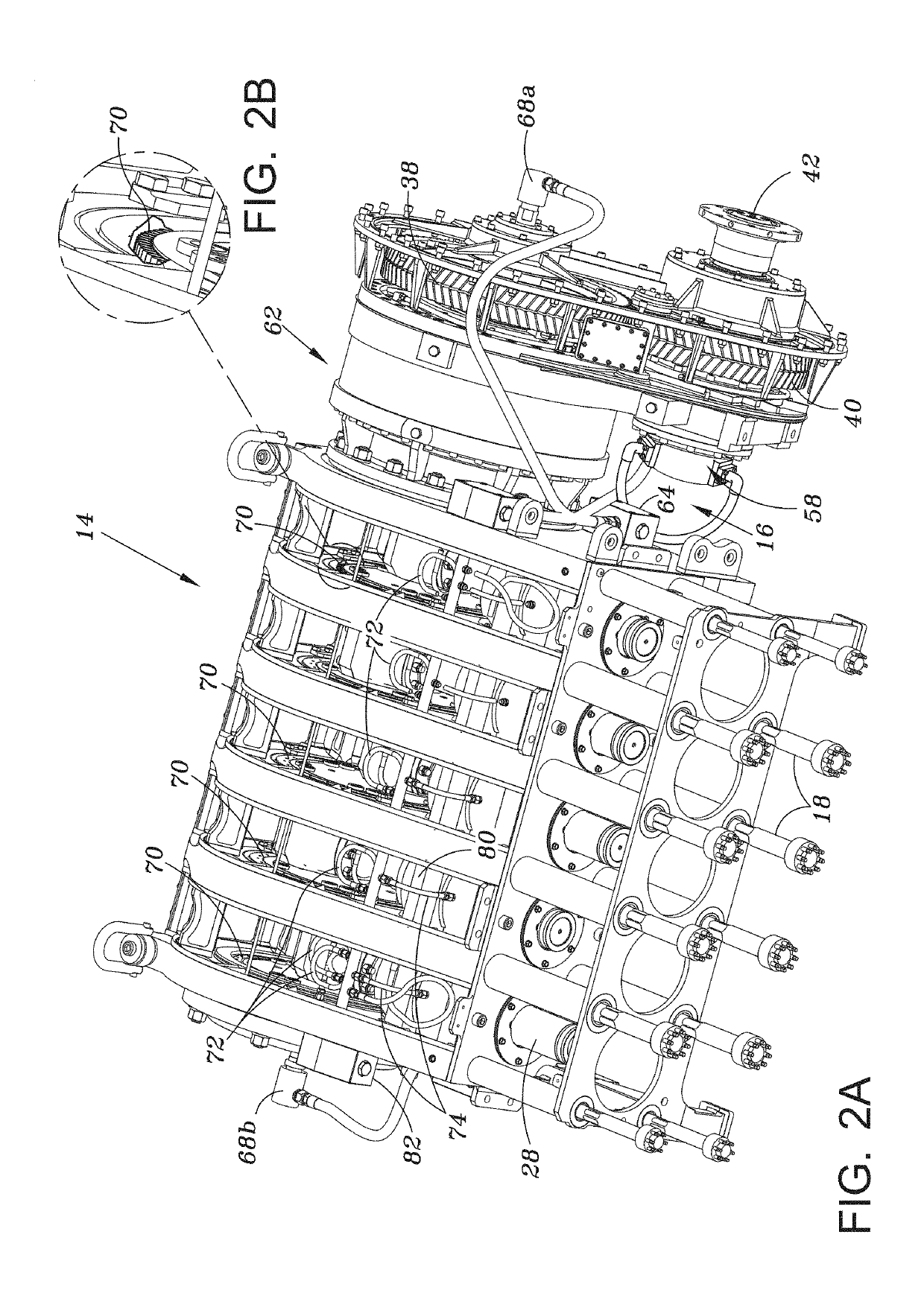

ActiveUS20160177945A1Positive displacement pump componentsRotary/oscillating piston combinationsEngineeringHigh pressure

A dual circuit lubrication system for a power end of a reciprocating pump that includes a lubrication pump that supplies lubrication fluid to a high pressure lubrication circuit and a low pressure lubrication circuit. The high pressure lubrication circuit is fluidly coupled to a crankshaft to supply lubrication fluid to sliding surfaces associated with the crankshaft at a first lubrication fluid pressure. The crankshaft drives a crosshead coupled to a plunger to displace fluid from a fluid end of the reciprocating pump. The low pressure lubrication circuit is fluidly coupled to supply the lubrication fluid to a plurality of rolling surfaces associated with the crankshaft at a second lubrication fluid pressure. The first lubrication fluid pressure is greater than the second lubrication fluid pressure.

Owner:SPM OIL & GAS INC

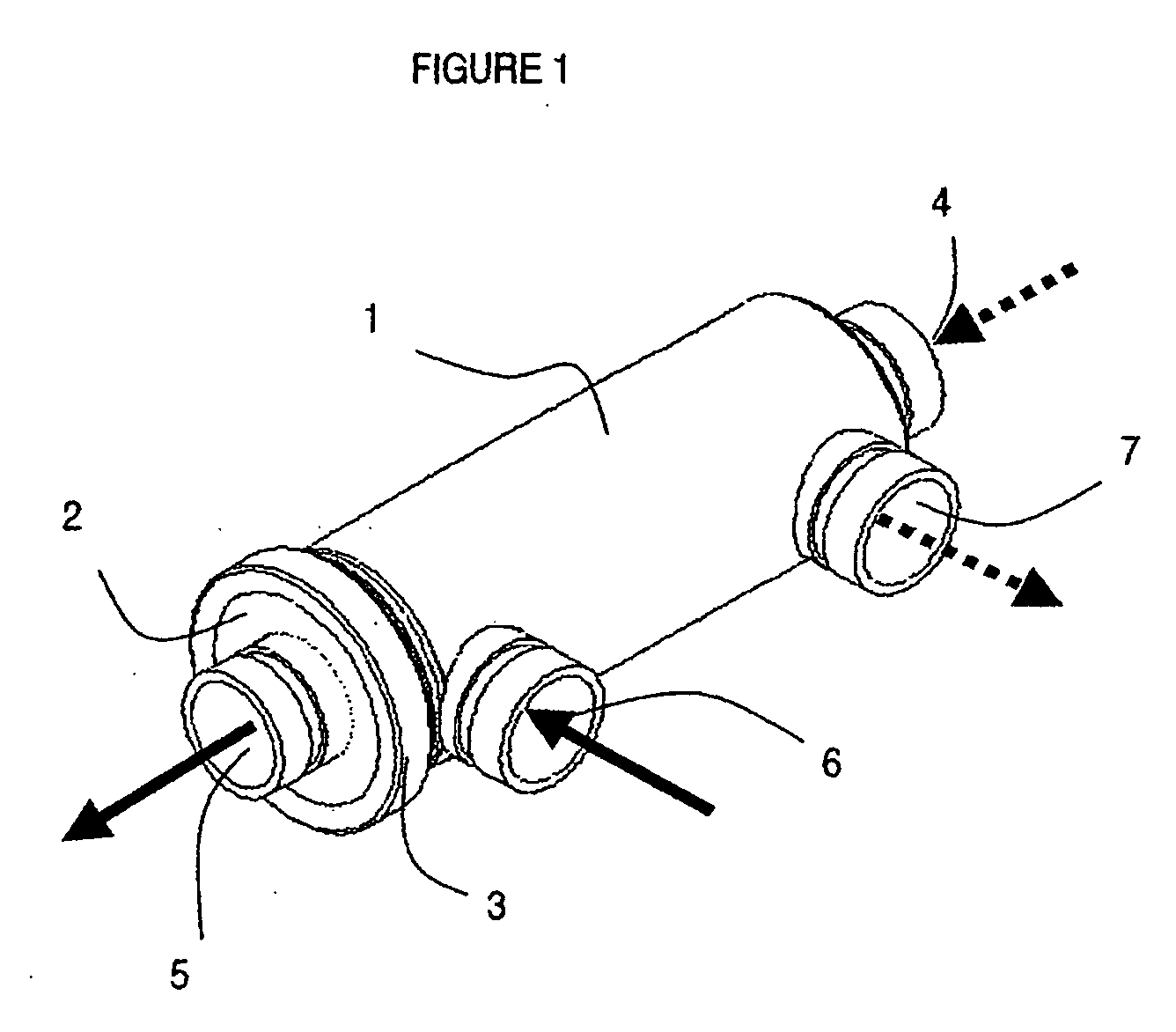

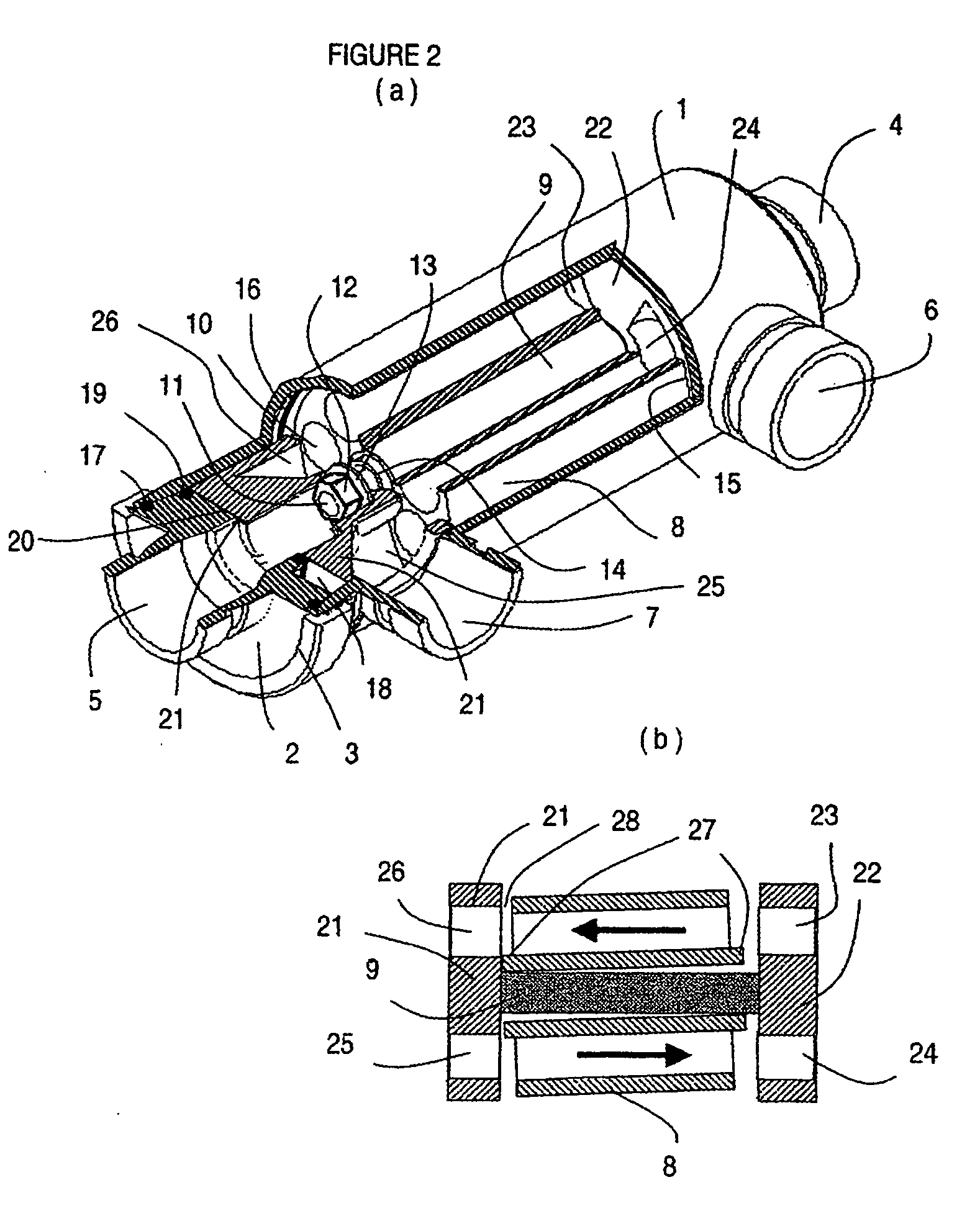

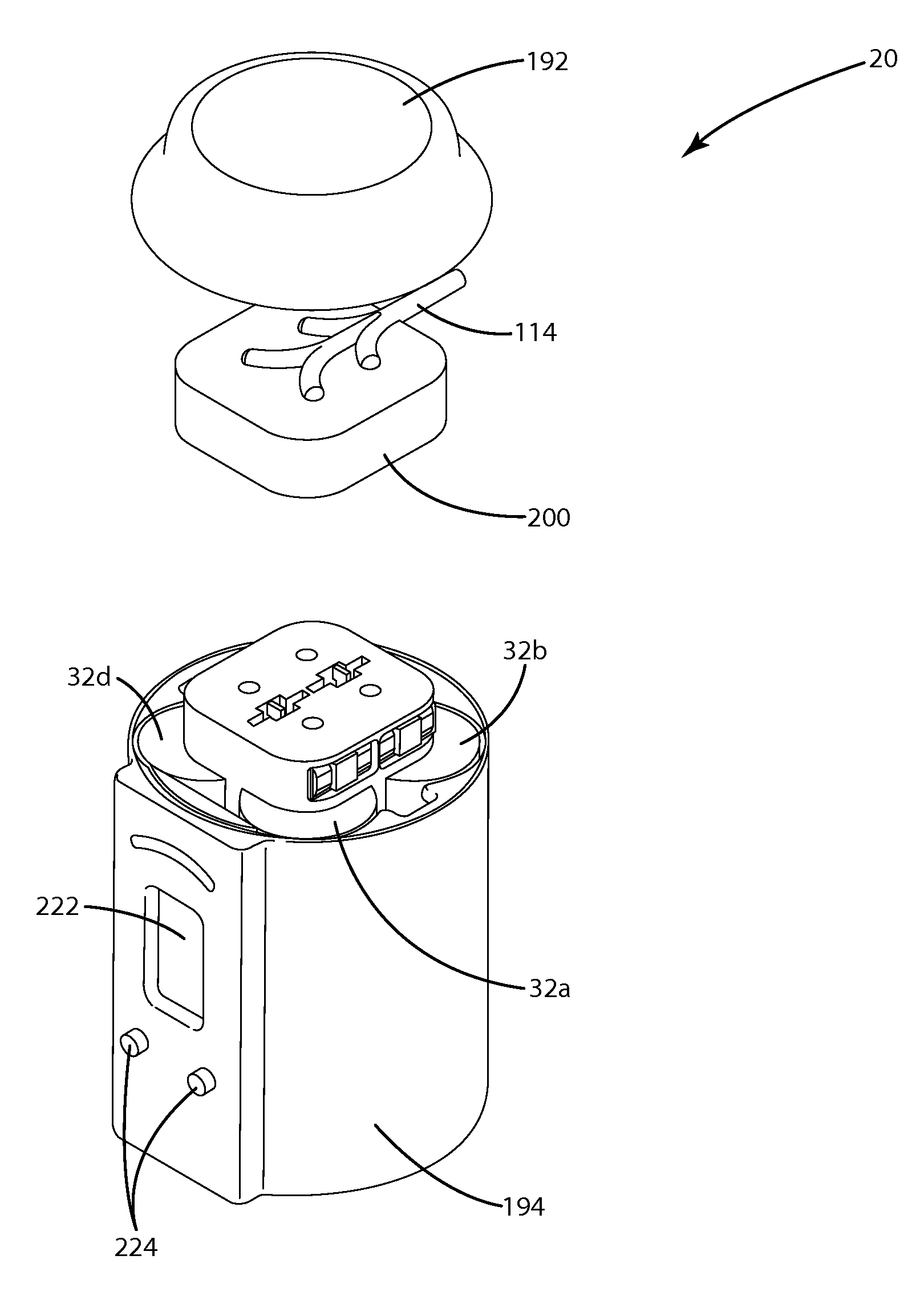

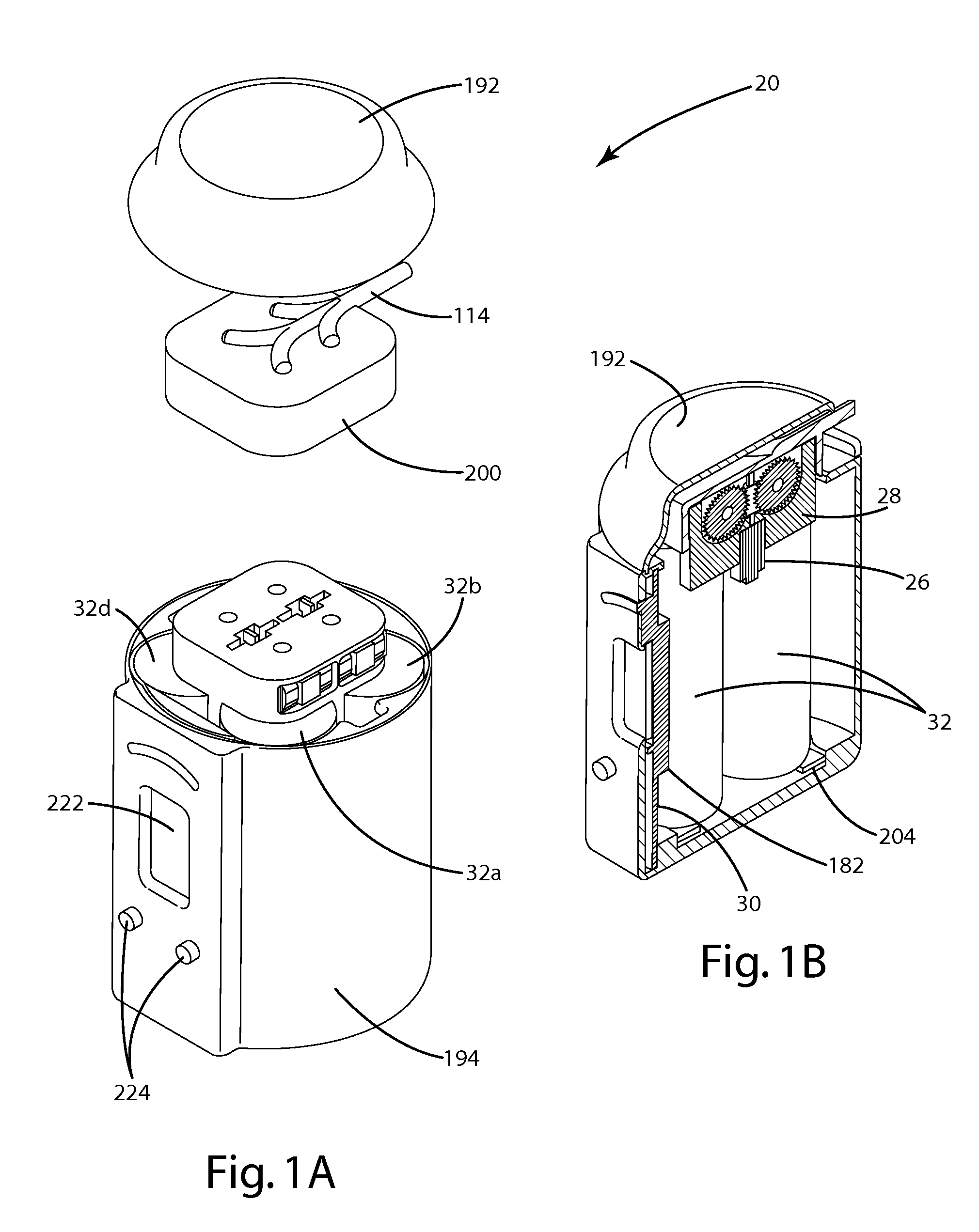

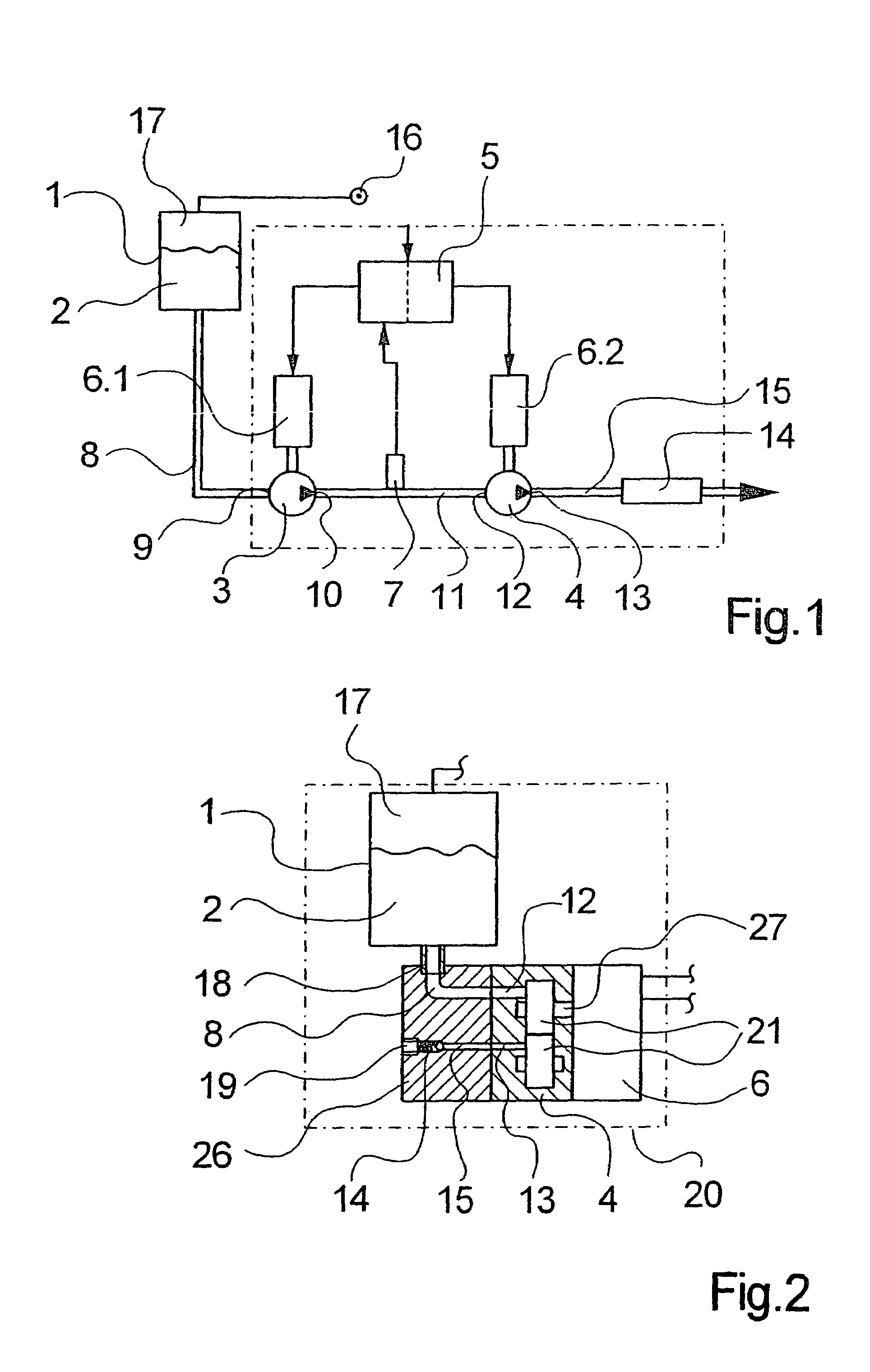

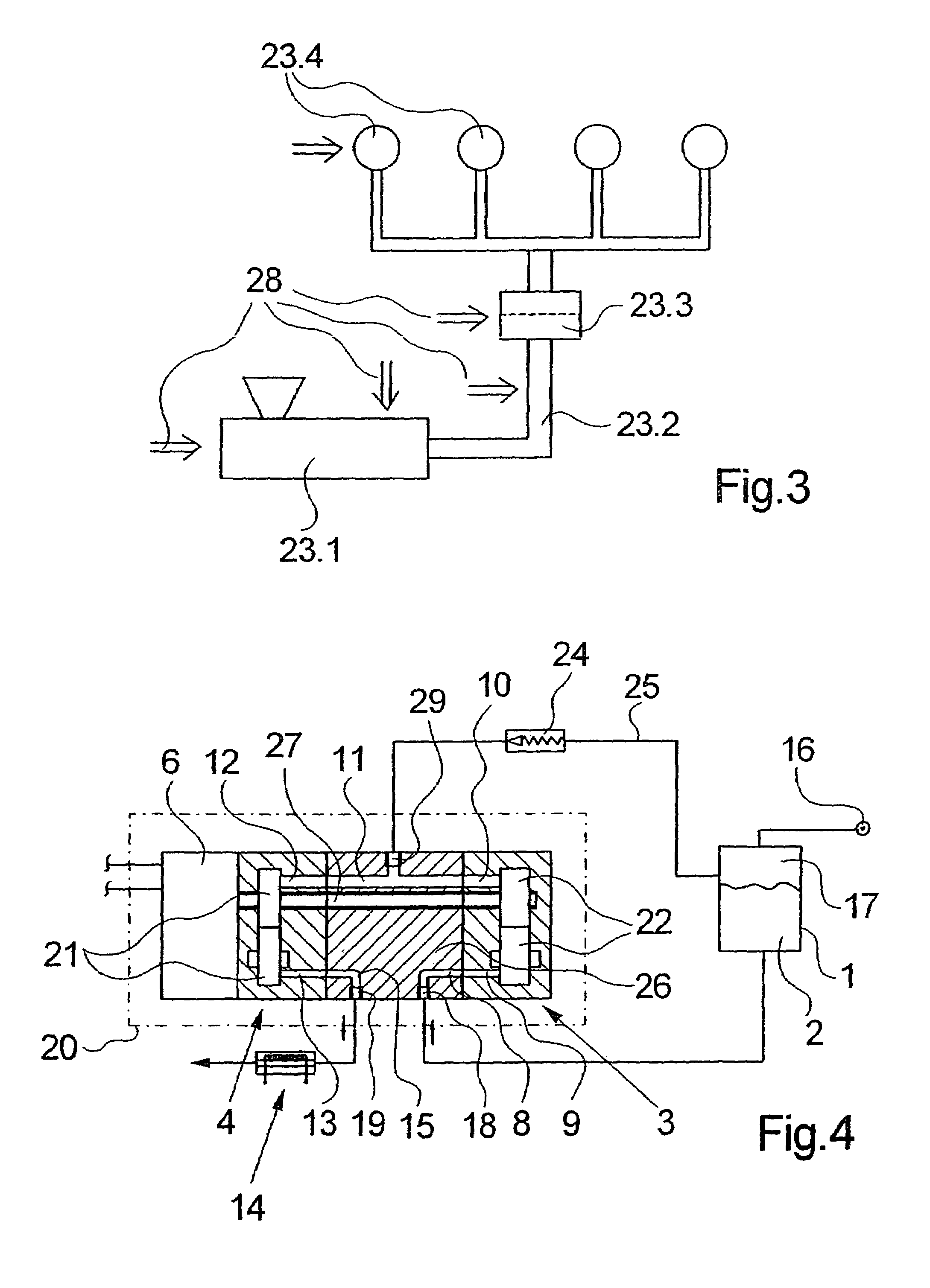

Method and apparatus for dispensing fluid compositions

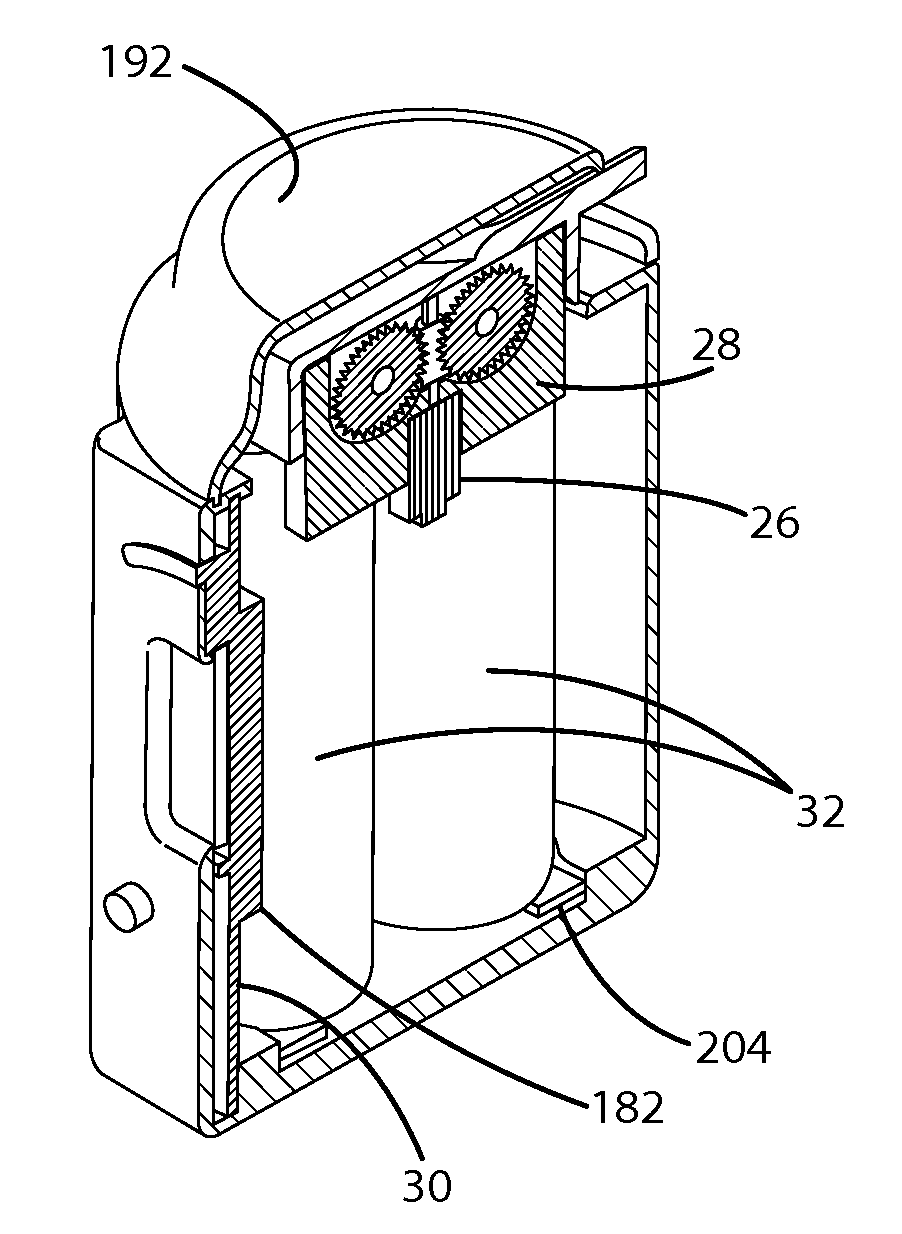

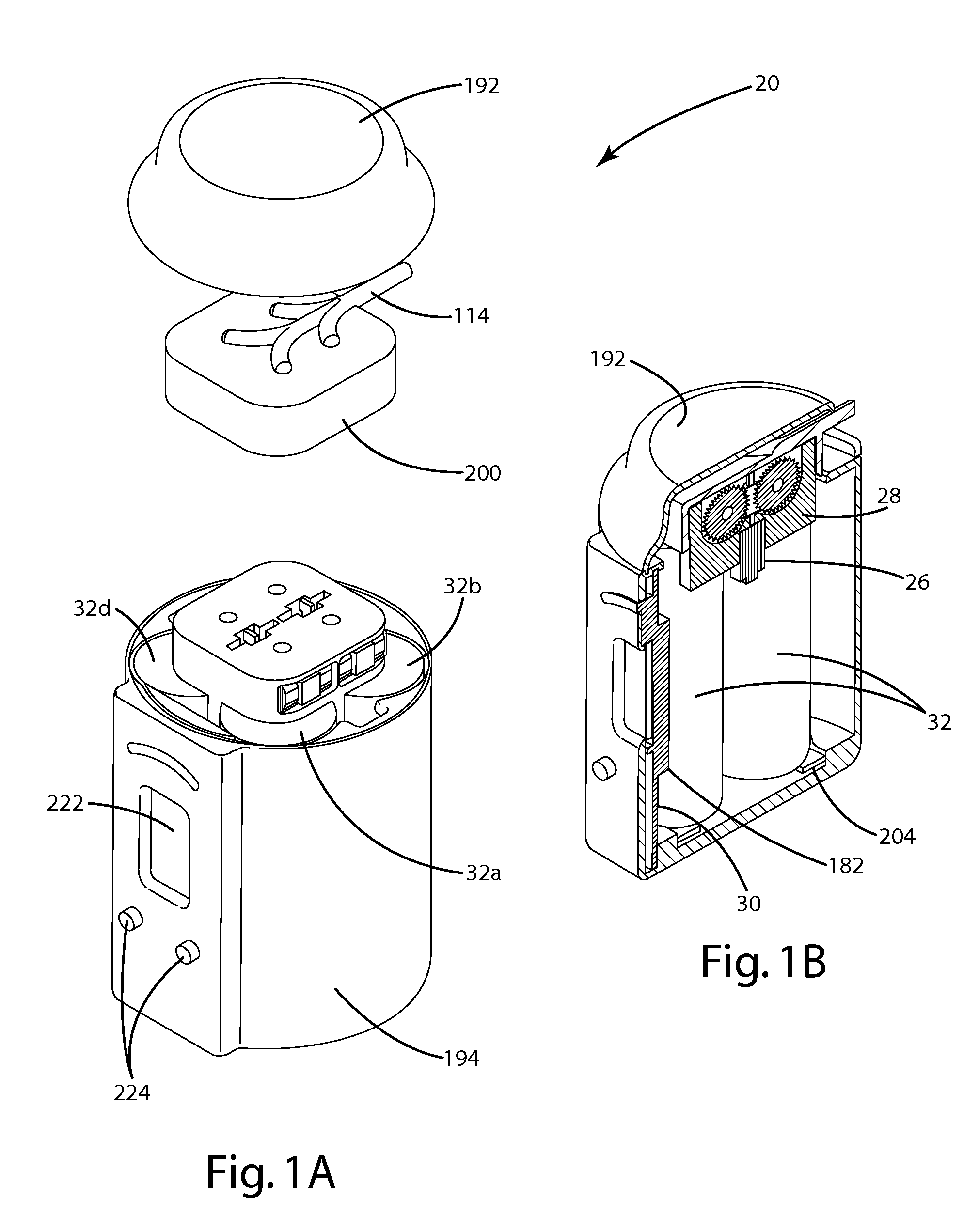

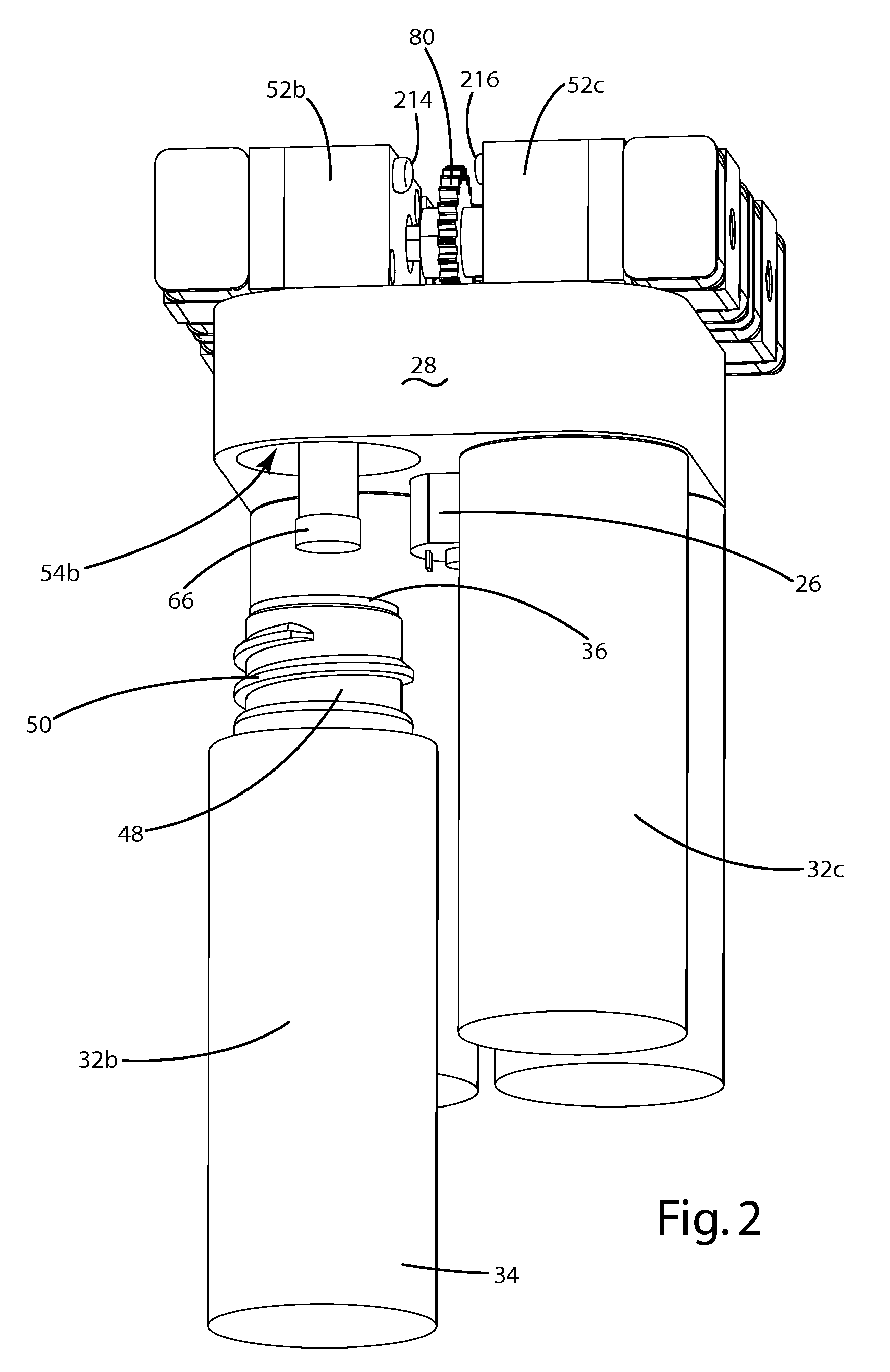

ActiveUS20100185322A1Combine accuratelySmall sizePump componentsMixer accessoriesRegimenControl system

A miniaturized fluid dispensing system for dispensing customized fluids. The dispenser may include first and second reservoirs containing constituent fluids; a drive motor; at least two pump assemblies commonly driven by the drive motor and in communication with the first and second reservoirs; first and second valve assembly in communication with the first and second pump assemblies; and a control system for selectively controlling the valve assemblies to blend and discharge a composition from the constituent fluids. The system may include a dispensing header to house the valves and to define ‘discharge’ and ‘recirculation’ flow paths for each constituent fluid. The present invention also provides a method for dispensing a fluid regimen (e.g. a plurality of compositions) by periodically blending and discharging varying compositions over time.

Owner:ACCESS BUSINESS GRP INT LLC

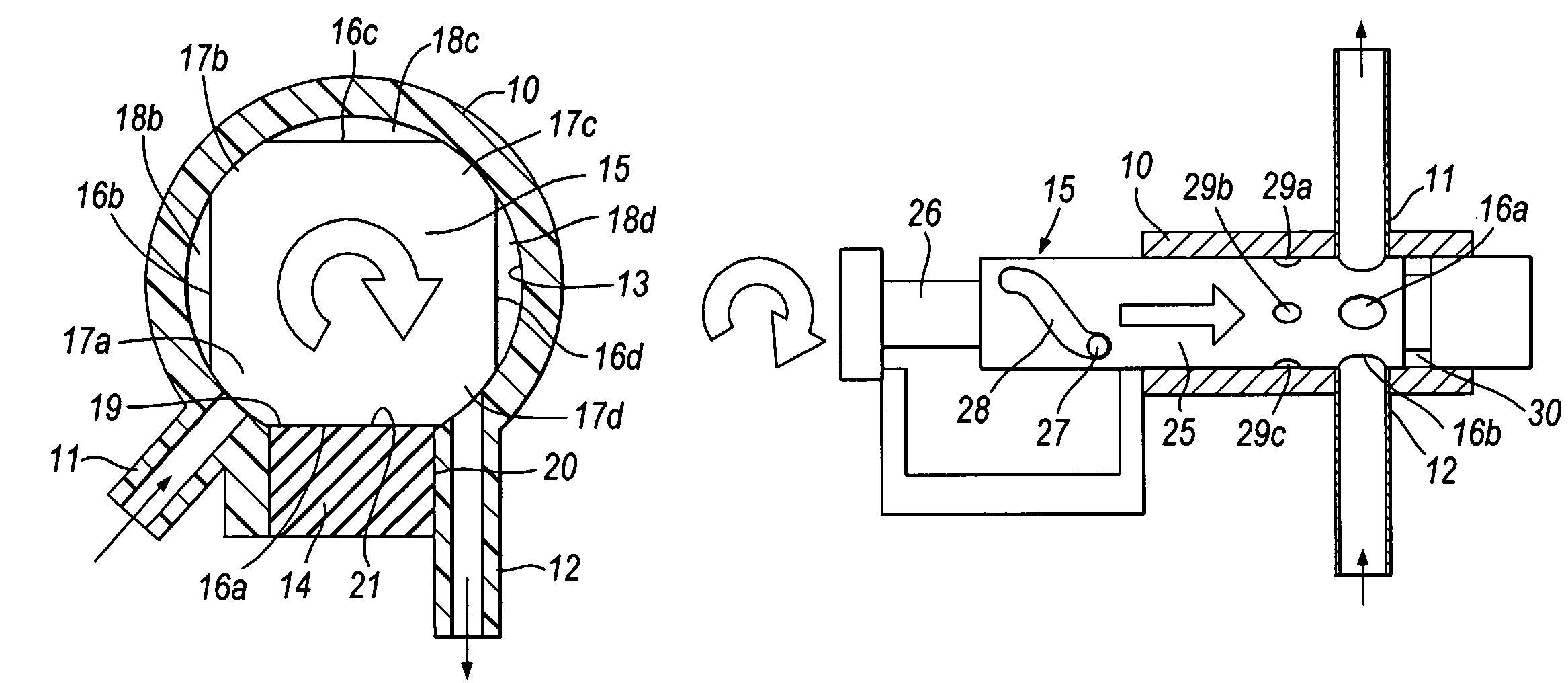

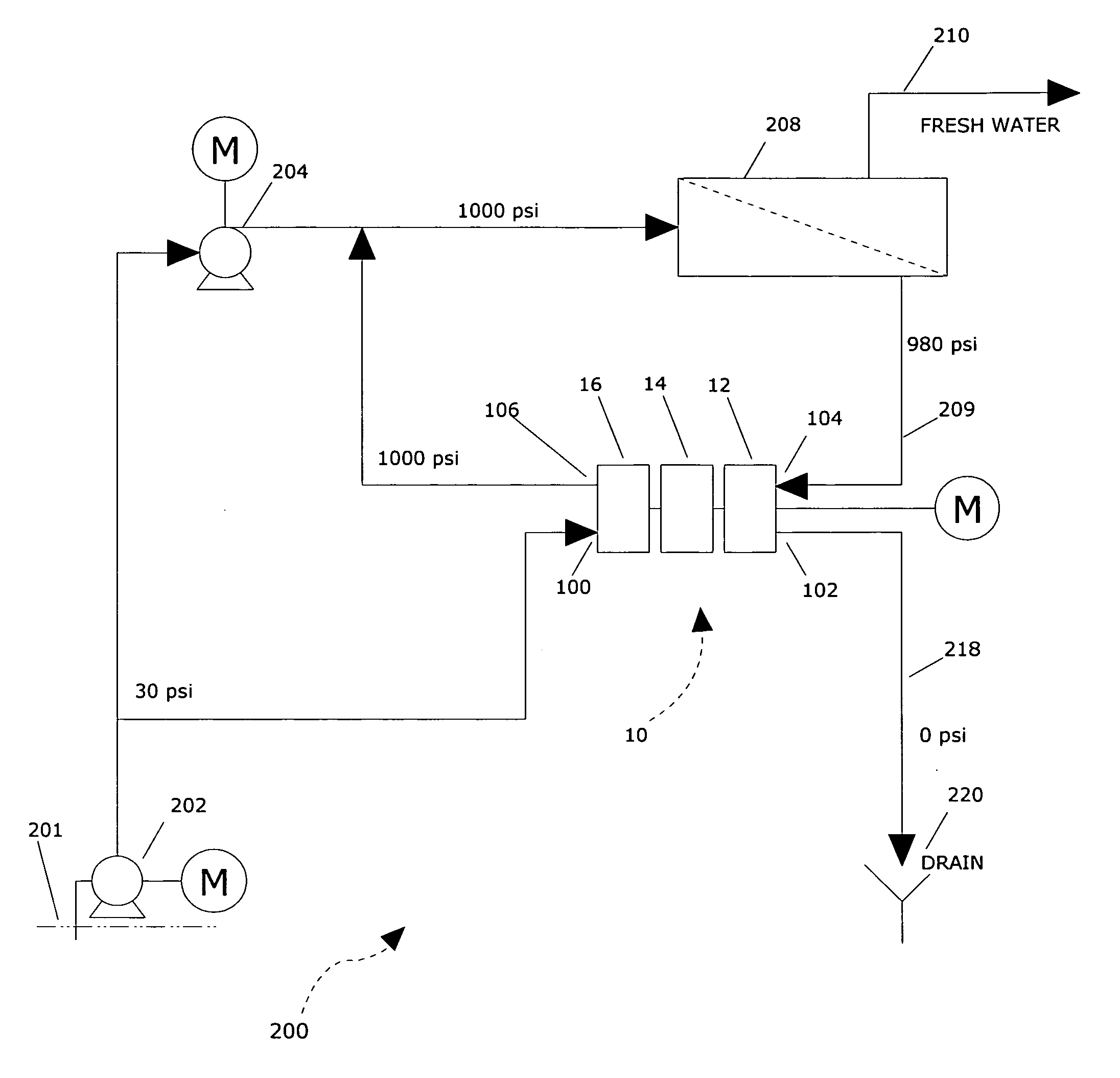

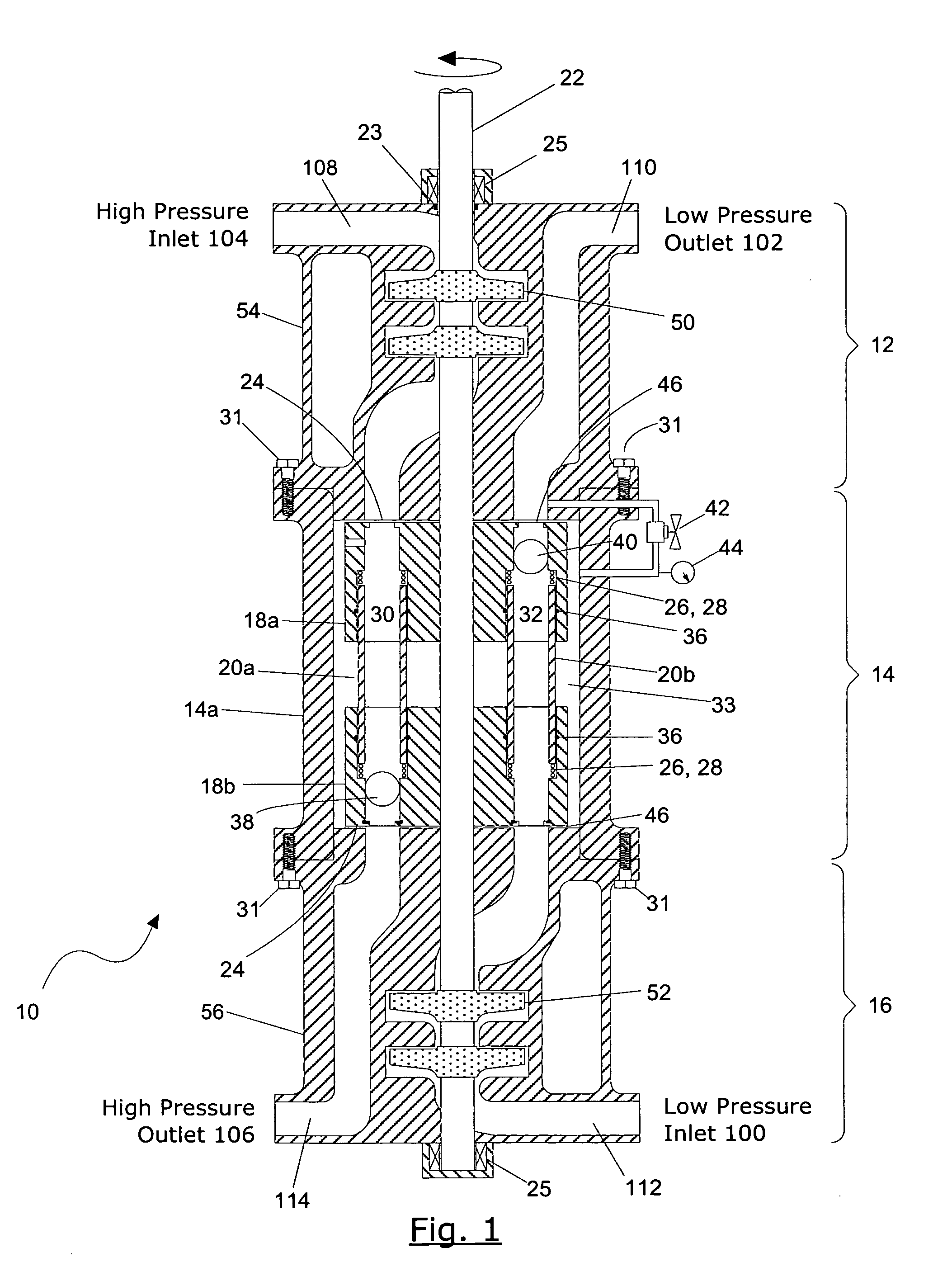

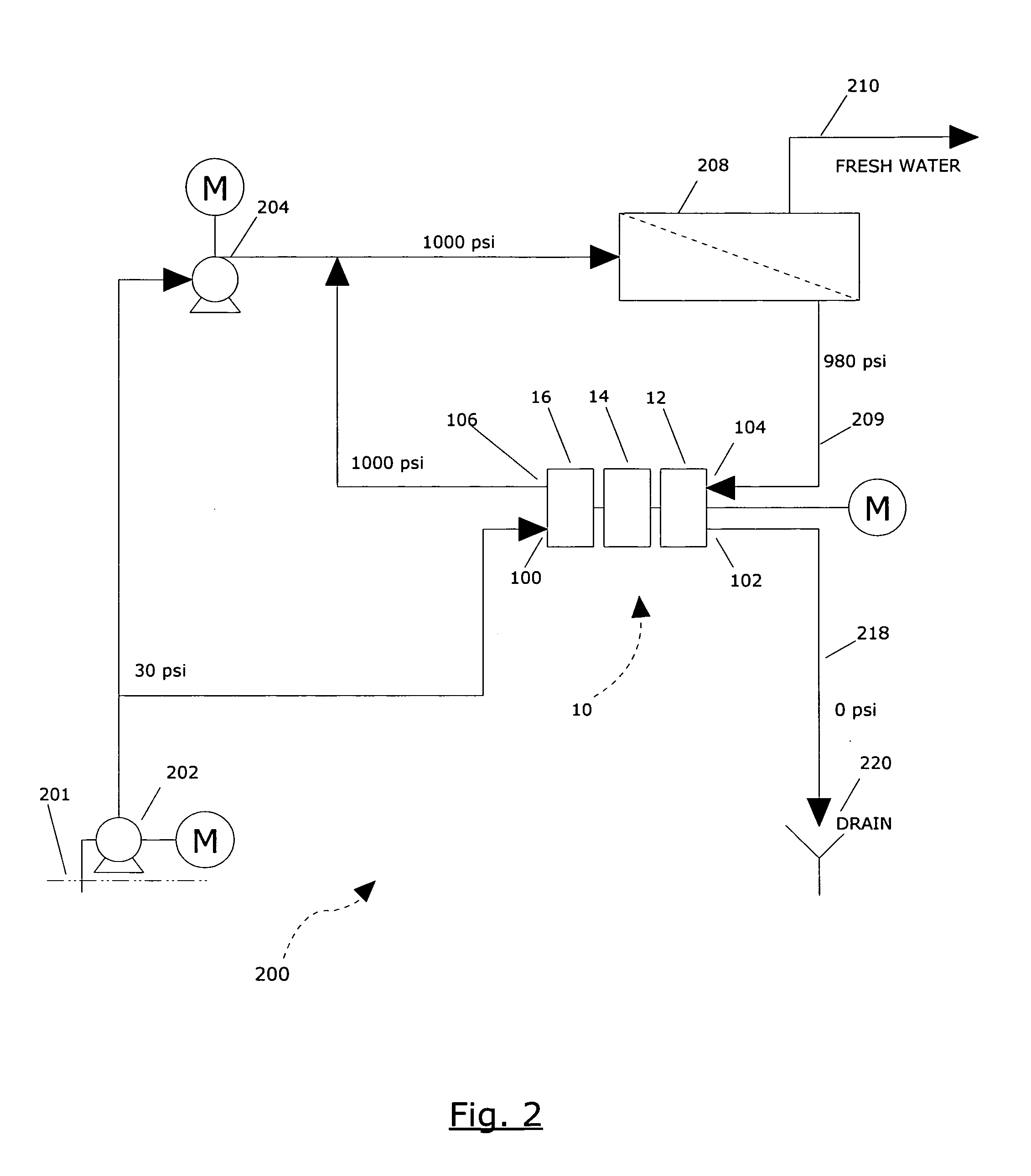

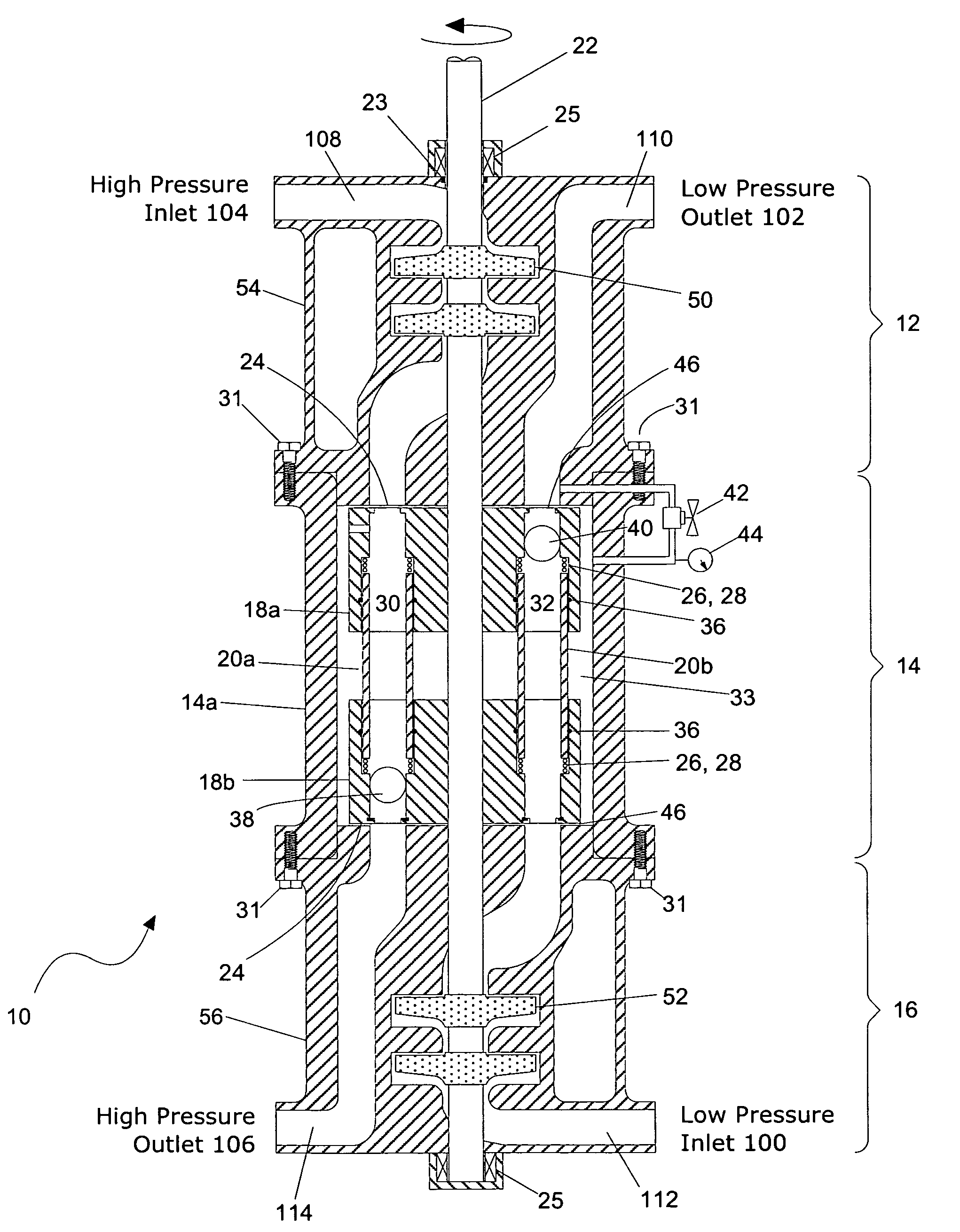

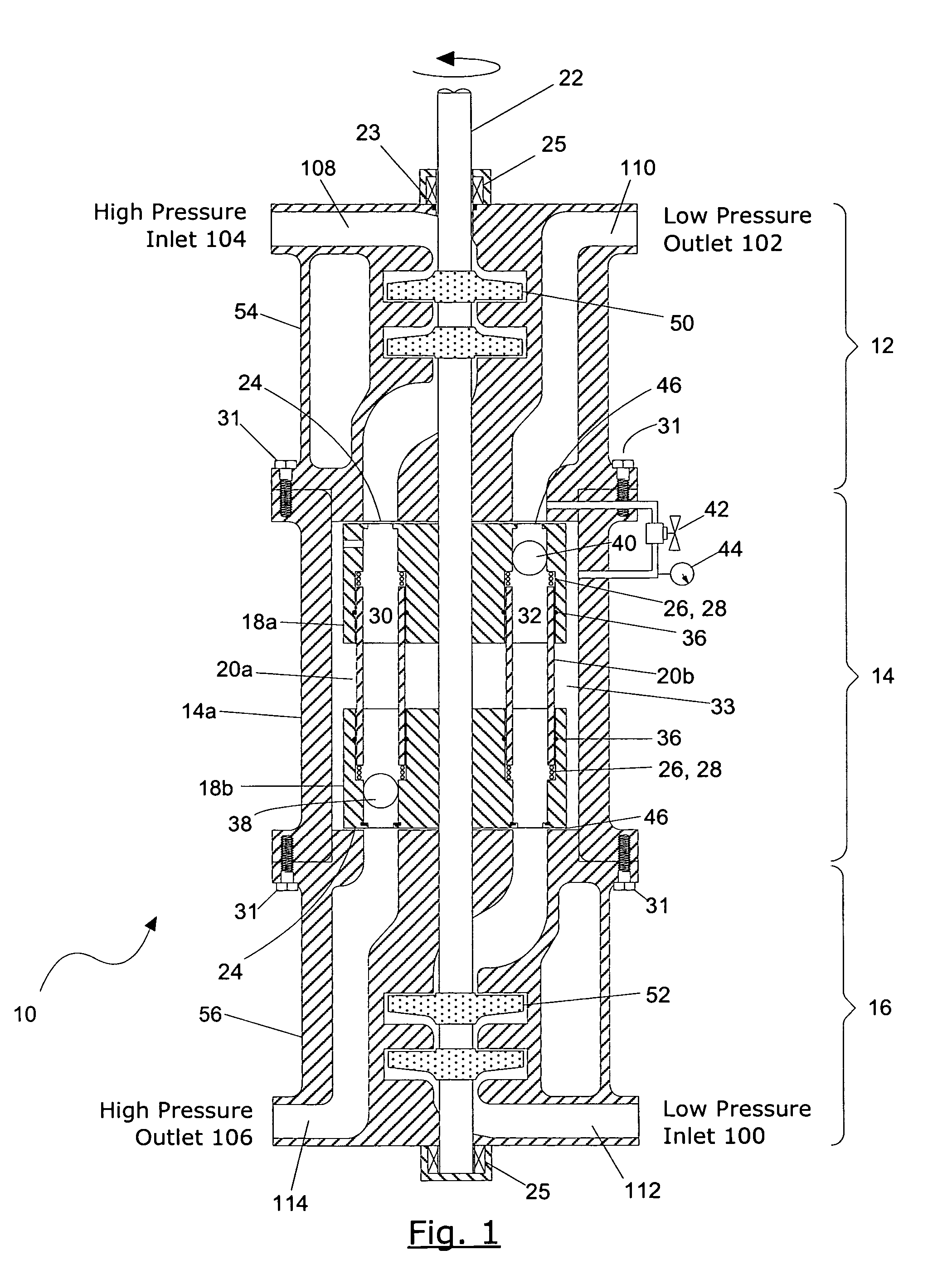

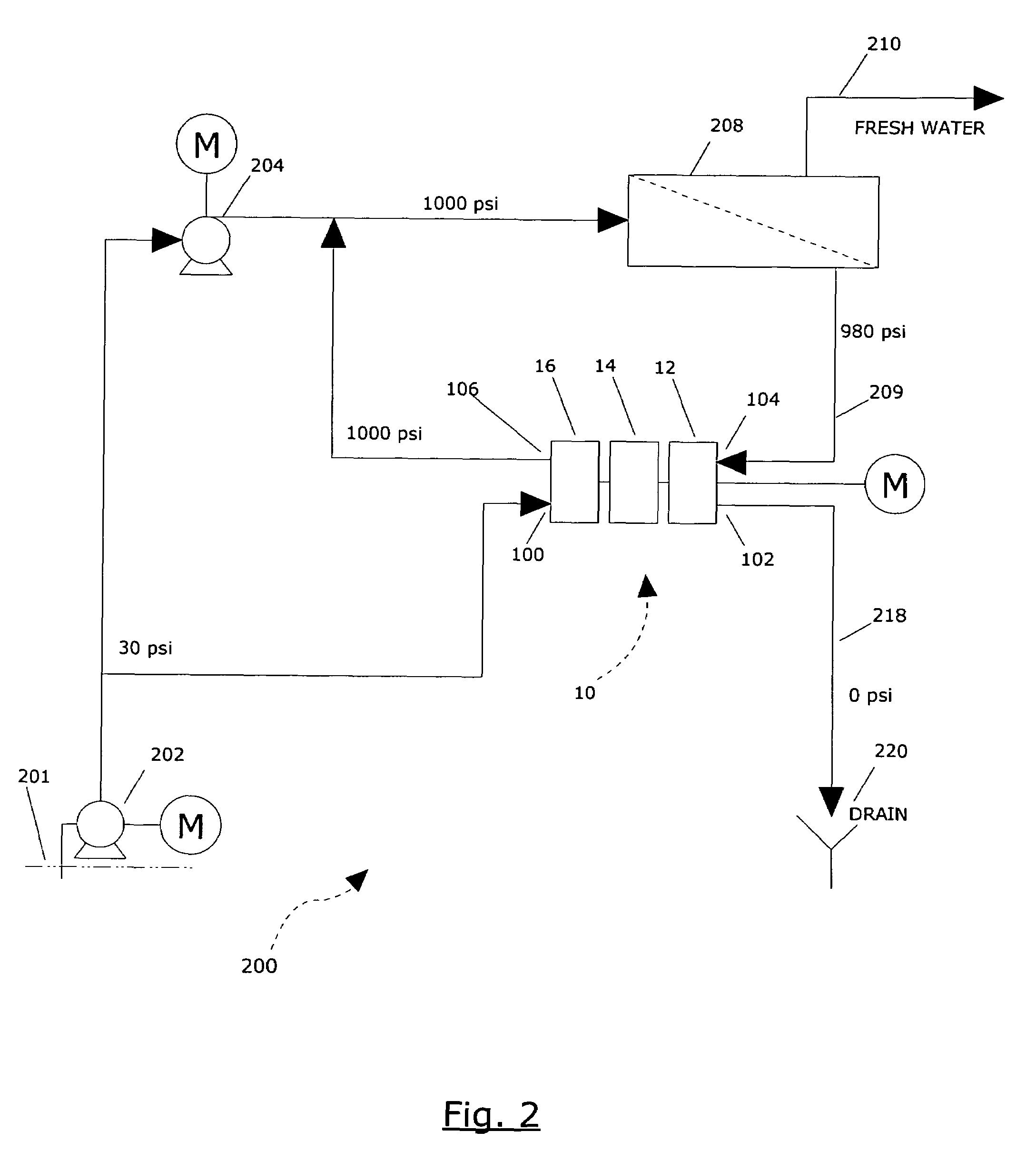

Pressure exchanger

ActiveUS7306437B2Increase capacityIncrease momentumRotary/oscillating piston combinations for elastic fluidsGeneral water supply conservationCavitationMomentum

Owner:ISOBARIC STRATEGIES INC

Pump with conveying chamber formed in outer rotor surface

ActiveUS7674100B2Avoid flowEngine of arcuate-engagement typeRotary piston pumpsMechanical engineeringMedical treatment

Owner:QUANTEX ARC LTD

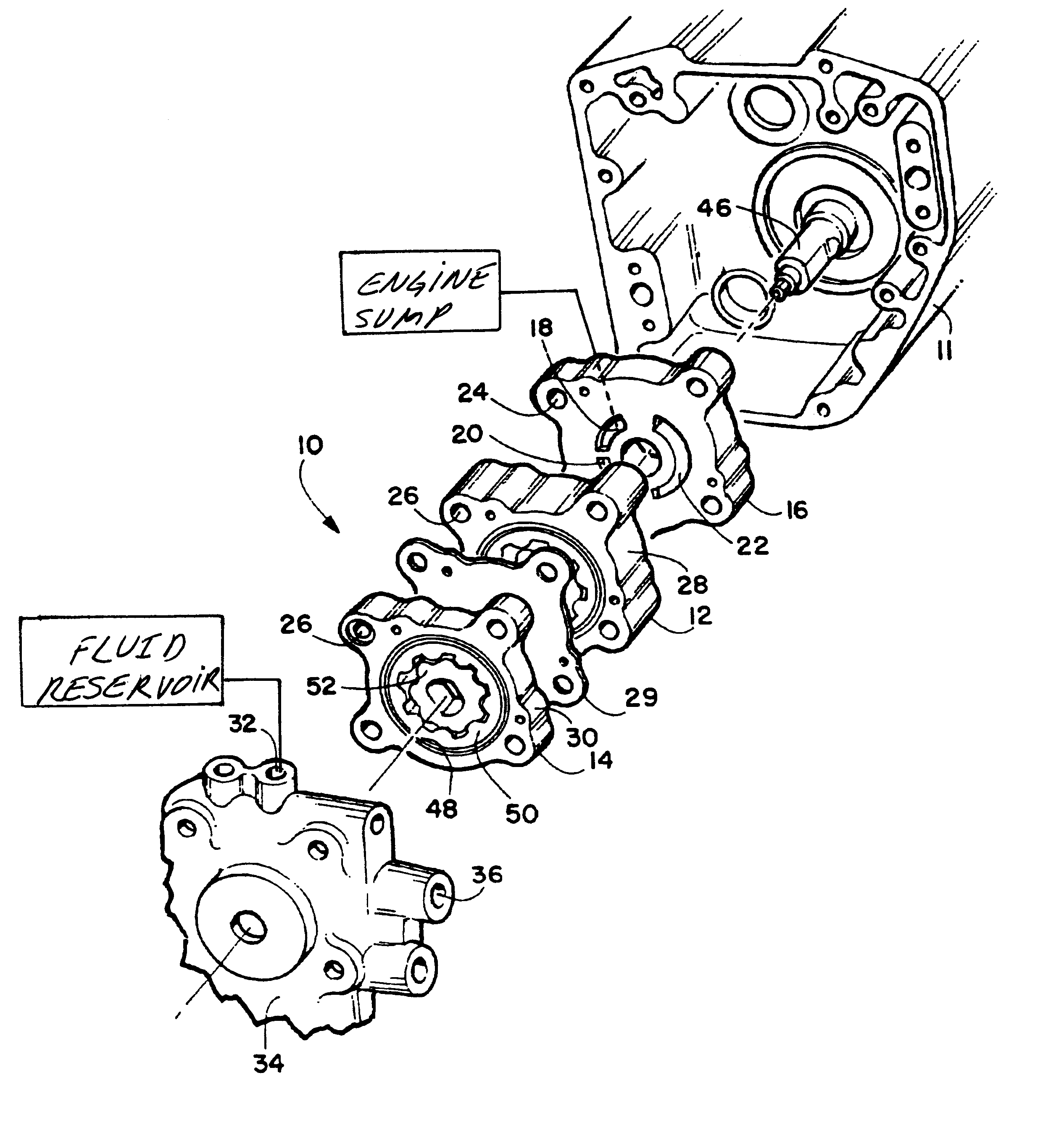

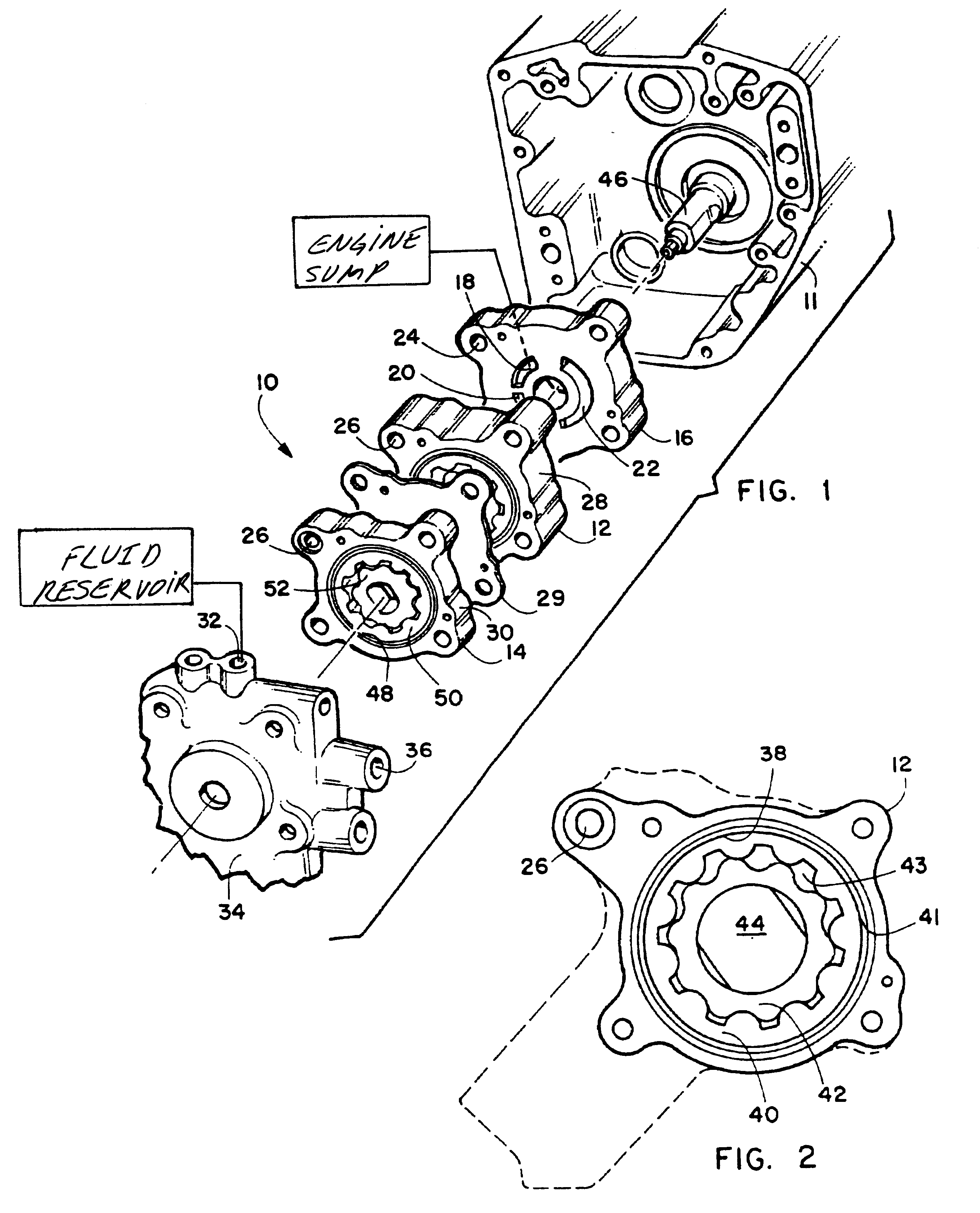

Oil pump

InactiveUS6679692B1Easy to replacePromote repairRotary/oscillating piston combinations for elastic fluidsOscillating piston enginesFuel tankEngineering

A modular oil pump for use in combination with an internal combustion engine having a dry sump lubrication system. The device features a first gerotor pump having an intake port engageable in communication with at least one engine sump and having an discharge port engageable in sealed communication with a fluid reservoir for the dry sump system. A second gerotor pump, engageable in sealed communication with the fluid reservoir has a discharge port fluidly engageable with the engine lubrication system oil supply conduit. Both the first pump and second pump are assembled from separate housings, and cooperatively engaged inner and outer gears sized for rotation and in line mounting on the engine crankshaft inside a cavity in the housings. The volume pumping capacity of the first pump at a ratio to efficiently drain fluid and gas from the engine sumps and supply the reservoir with a constant supply of lubrication fluid. The device may be assembled from a kit having a plurality of different sized components to adjust the ratio of the pumping volume of the first pump to the second pump.

Owner:FEULING JAMES J

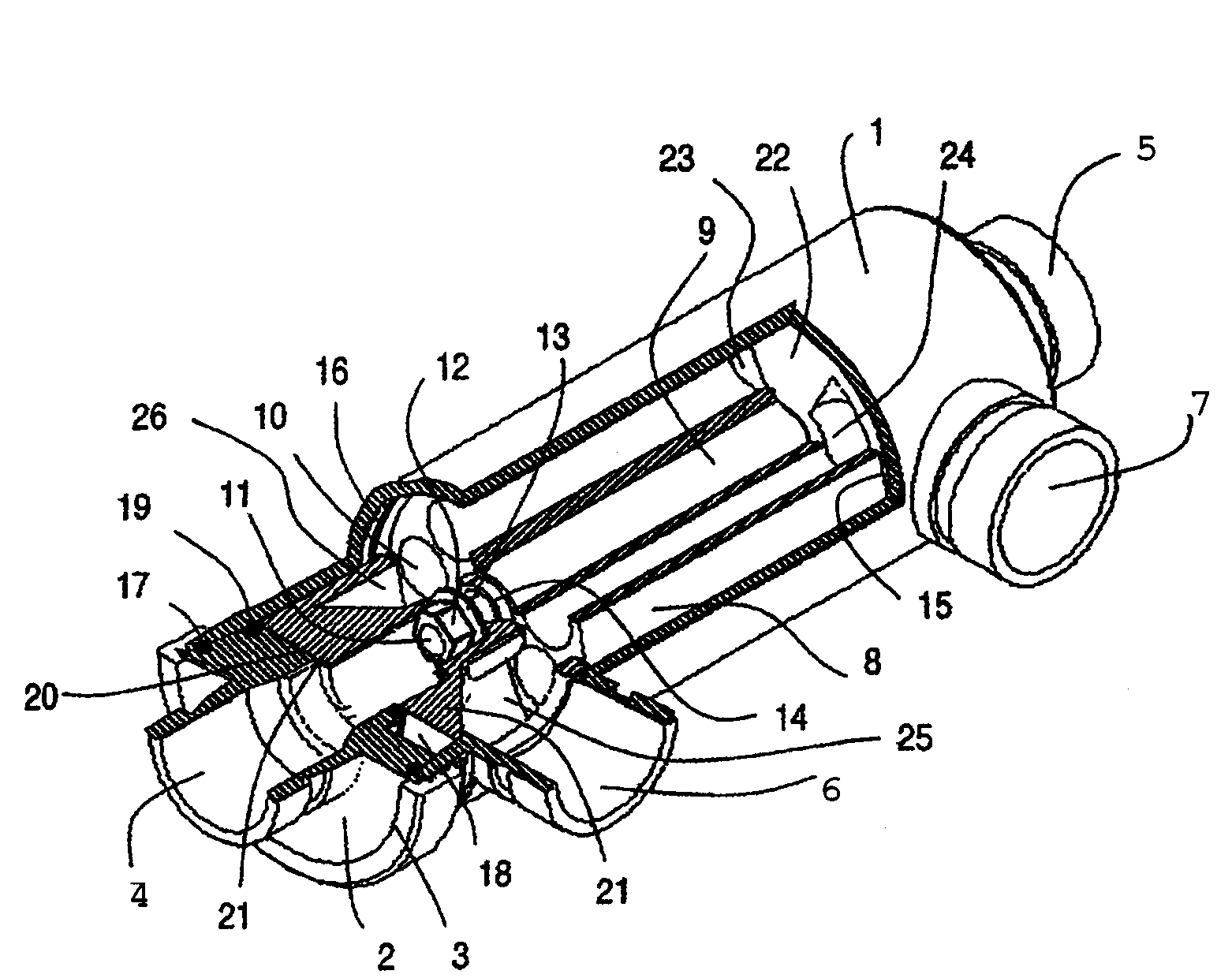

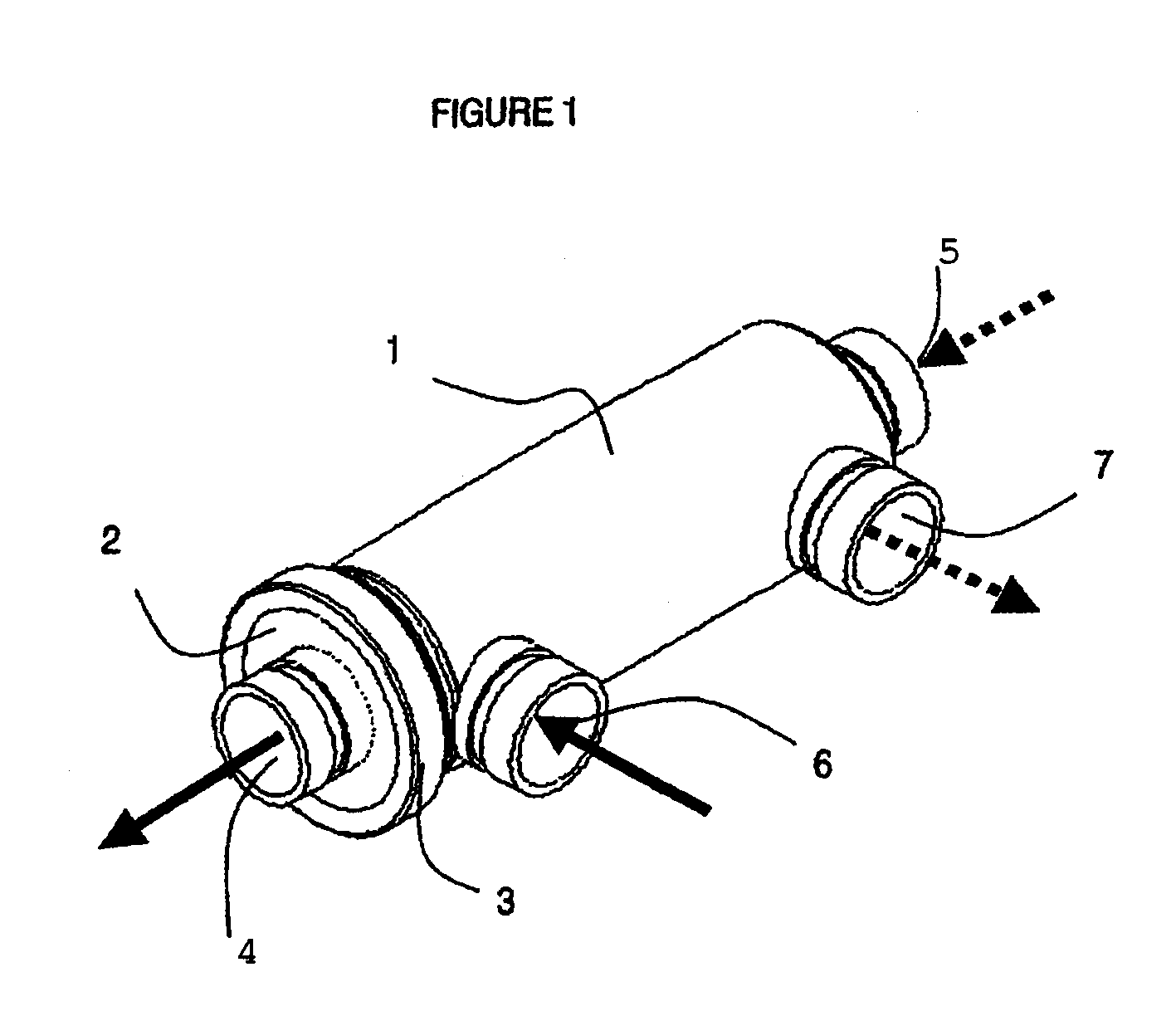

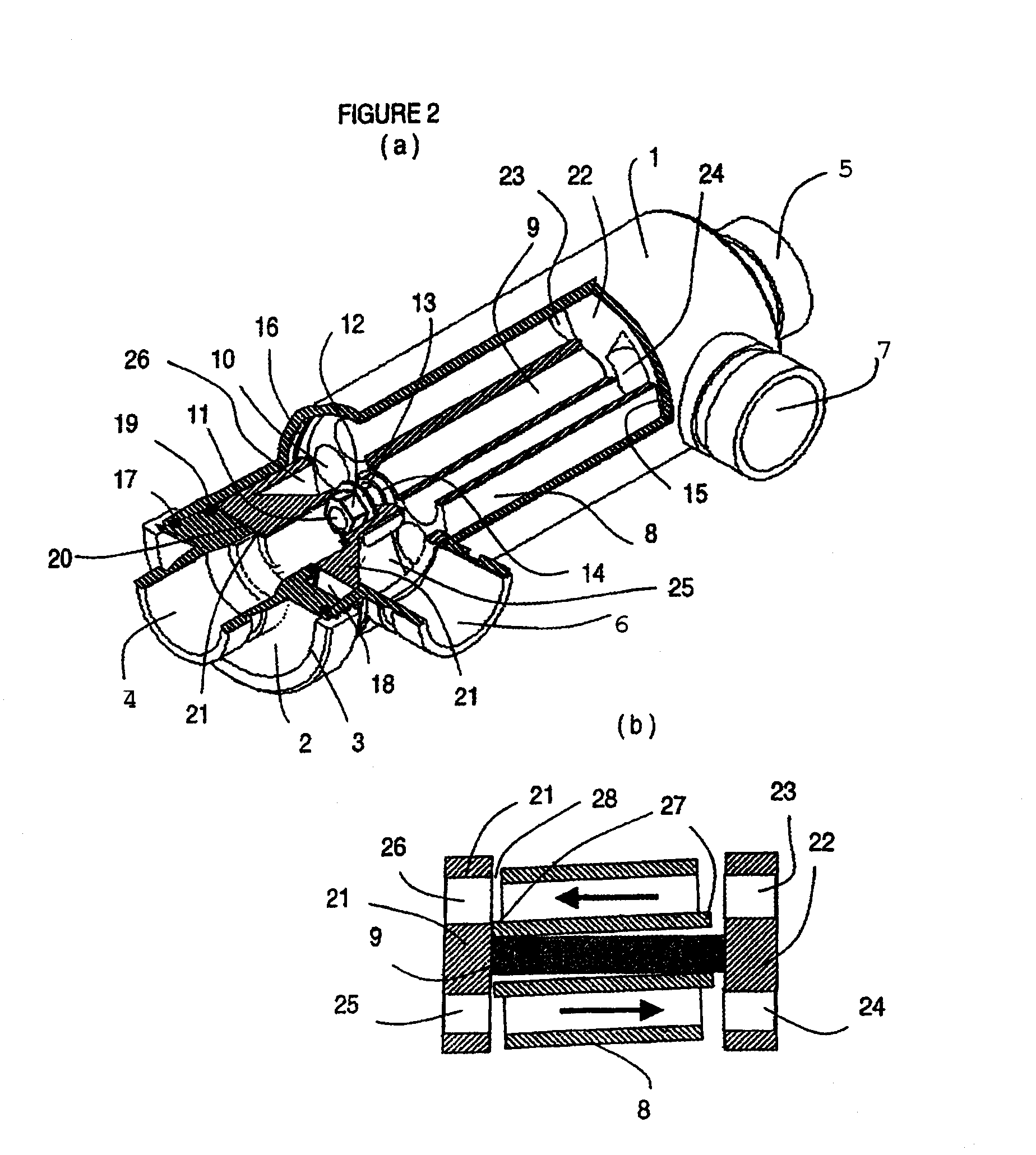

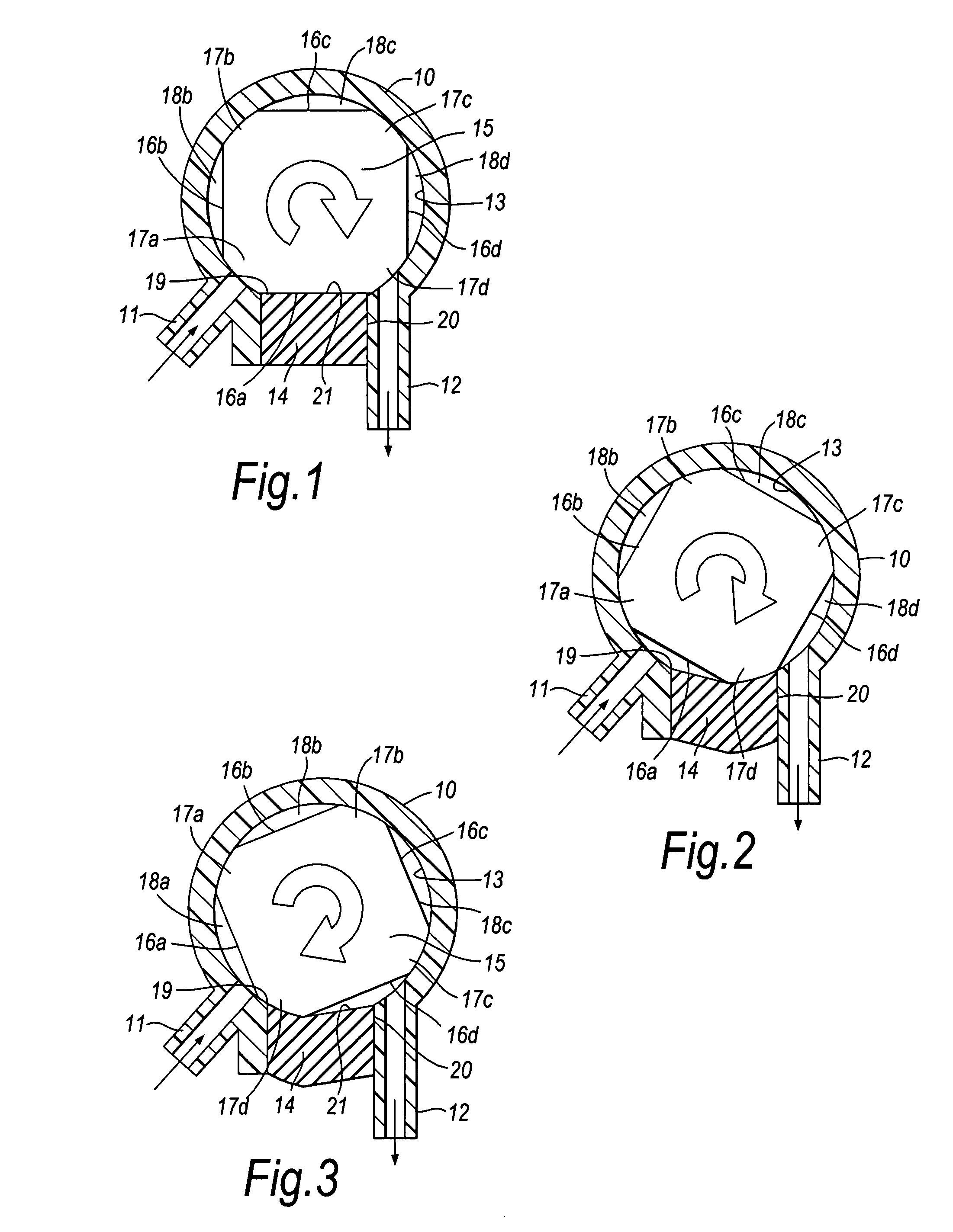

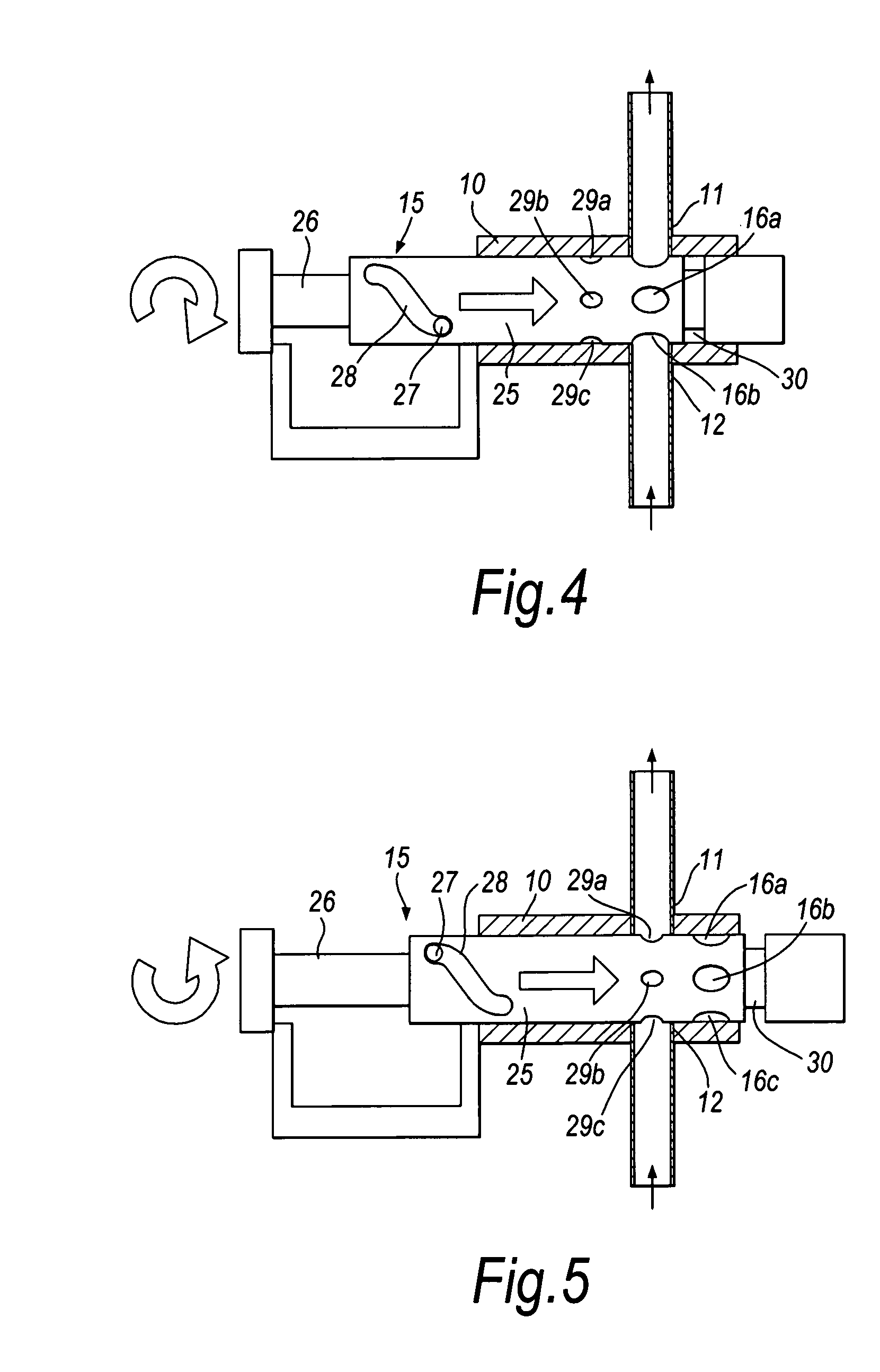

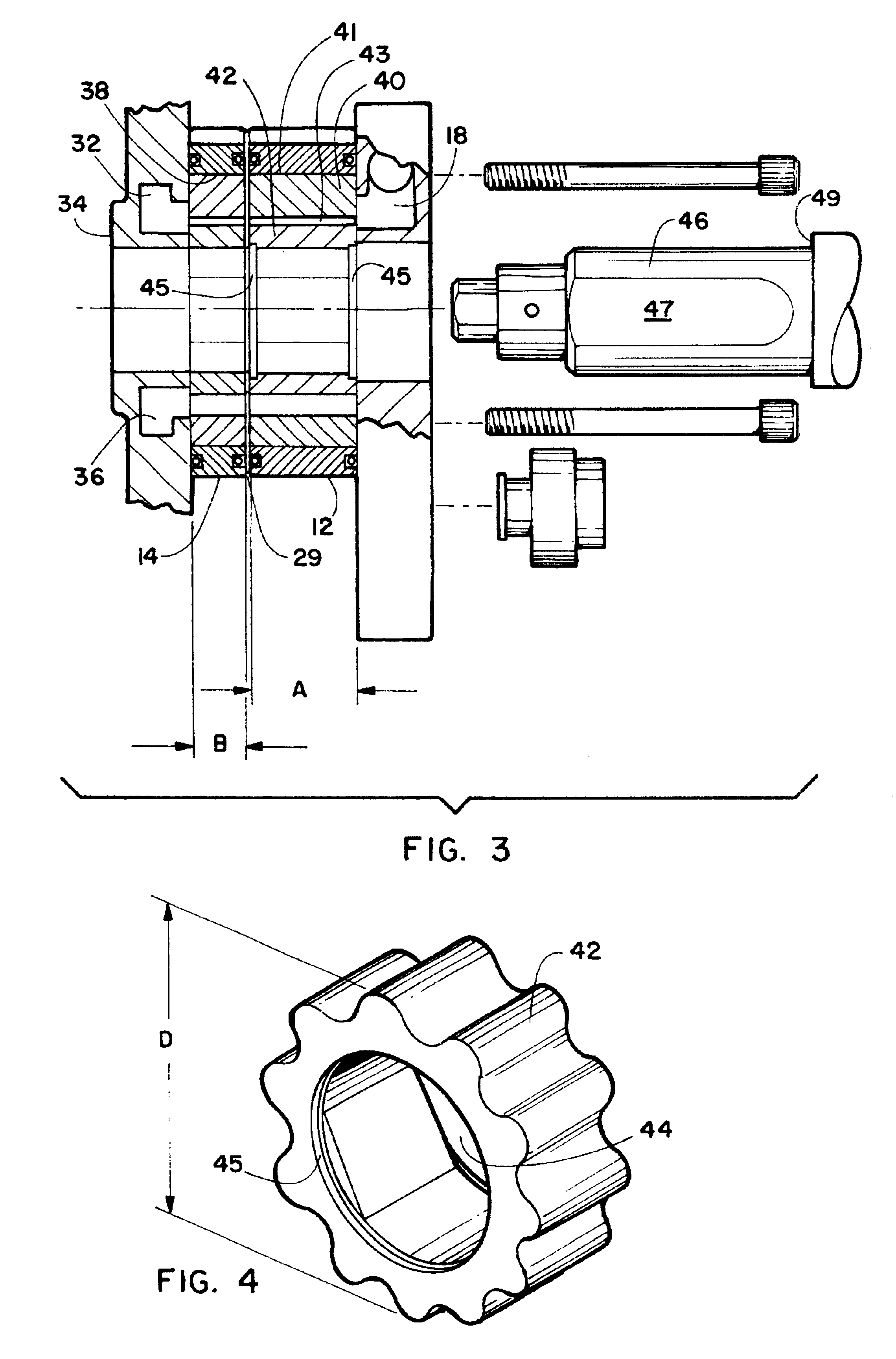

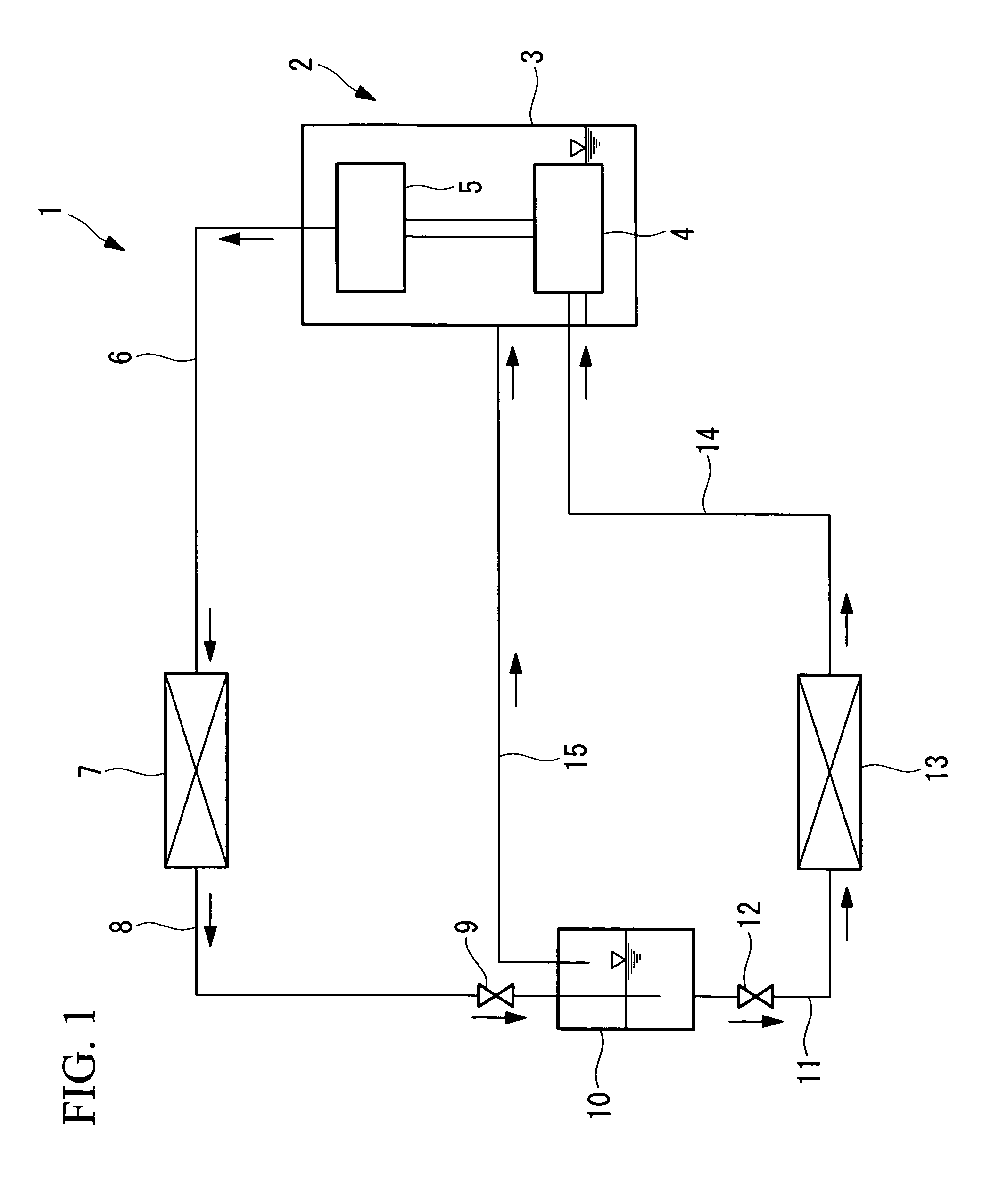

Pressure exchange apparatus with integral pump

InactiveUS20060037895A1Increase pressureRotary/oscillating piston combinations for elastic fluidsPump componentsEngineeringMechanical engineering

A pressure exchange device is provided that utilizes an integral high pressure boost pump that is in fluid communication with a pressure exchange unit. An optional low pressure boost pump unit may also be provided. The pressure exchange unit comprises a rotating rotor assembly inside a housing to transfer the pressure of a fluid from one high pressure fluid to another low pressure fluid.

Owner:SHUMWAY SCOTT

Fluid circulation path for motor pump

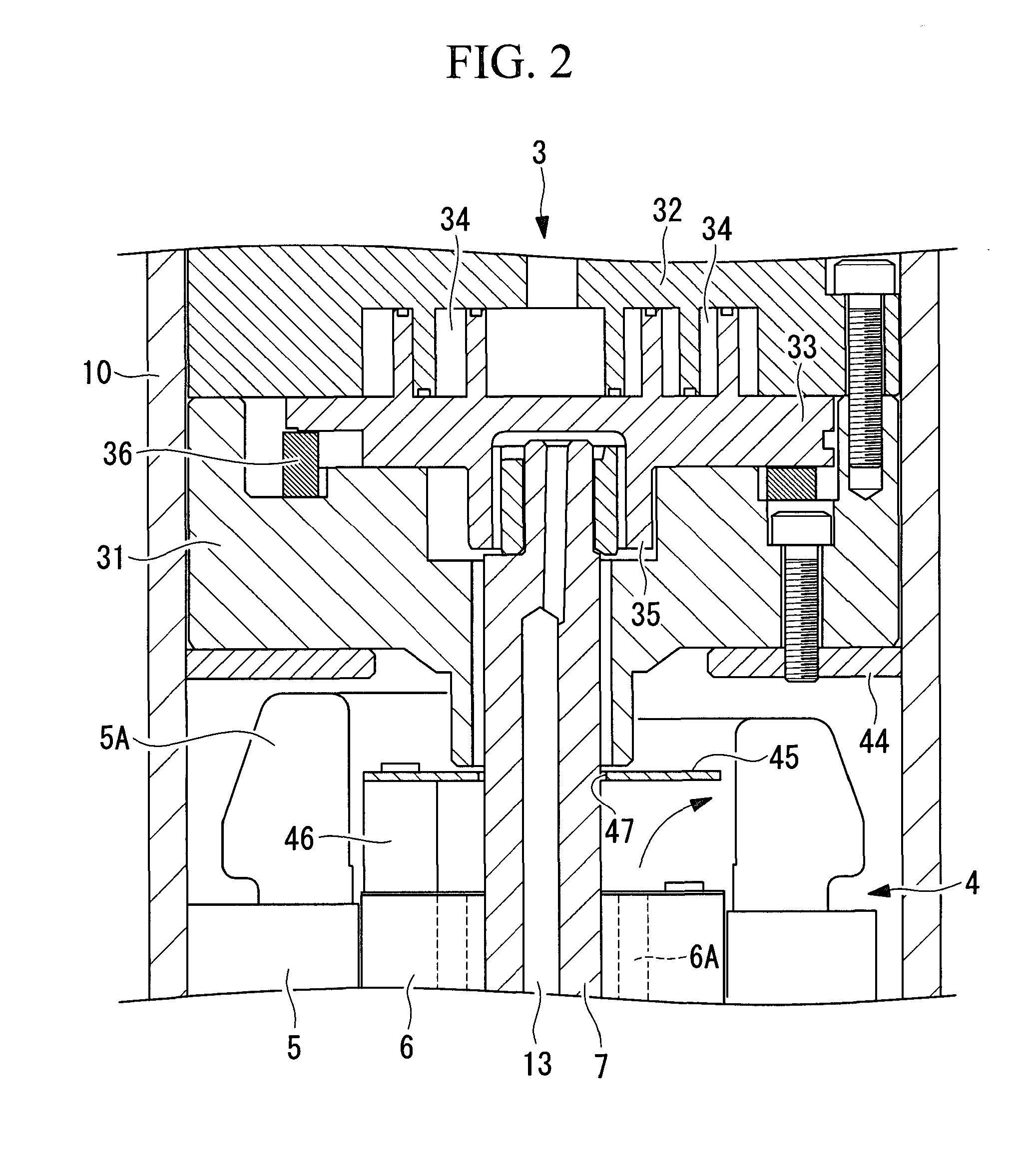

InactiveUS6884043B2Rotary/oscillating piston combinations for elastic fluidsRotary piston pumpsEngineeringPump head

A fluid pump includes a pump head having an inlet for receiving fluid at a first pressure and an outlet for outputting fluid at a second pressure greater than the first pressure. Pressurized fluid is directed through a first passage to the outlet without the pressurized fluid leaving the pump head prior to reaching the outlet. A second passage directs pressurized fluid to a fluid circulation path which is at least partially external to the pump head with the fluid circulation path terminating adjacent the outlet. Pressurized fluid passing through the first and second passages is directed to the outlet without being re-pressurized by the pump head. The first and second passages are in opposed relation to one another to provide balancing of thrust produced by the flow of pressurized fluid through the passages. An electric motor drives the pump head. The fluid circulation path may include portions of the electric motor.

Owner:STANDEX INT CORP

Pressure exchanger

ActiveUS20060032808A1Improve flow capacityIncrease momentumRotary/oscillating piston combinations for elastic fluidsGeneral water supply conservationCavitationMomentum

A pressure exchanger for transferring pressure energy from a relatively high-pressure fluid stream to another relatively low-pressure fluid stream is provided. A ducted rotor is positioned on a central axle between two end covers inside a pressure vessel with a coaxial inlet and outlet pair that is in communication with a pair of low pressure ports having inclination forming an inlet tangential velocity vector in the direction of rotor rotation and an outlet tangential velocity vector in opposite direction imparting a rotational momentum on rotor. A pair of high-pressure ports is adapted for flow without inclination and imparts no momentum to rotor and flow can be varied without impacting the rotor's RPM. The end covers have a sloped surface following a flat sealing area that increases the clearance in the direction of rotation causing increased outflow during depressurization and lower duct pressure before duct is exposed to low pressure port and furthermore causing increased inflow during the pressurization phase before duct is exposed to the high pressure port, which will dissipate pressure energy as opposed to producing cavitation or pressure waves with result wear and noise.

Owner:ISOBARIC STRATEGIES INC

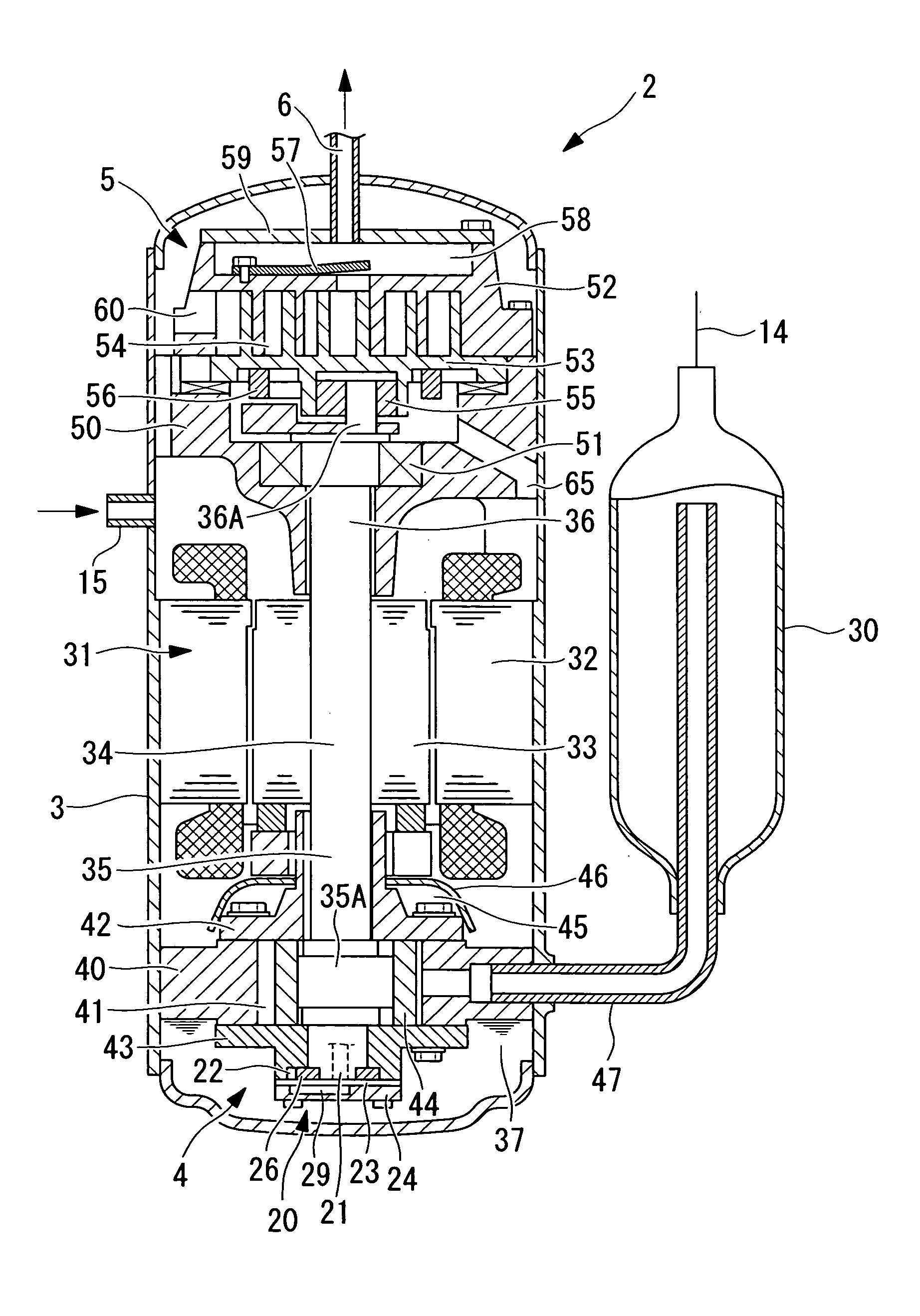

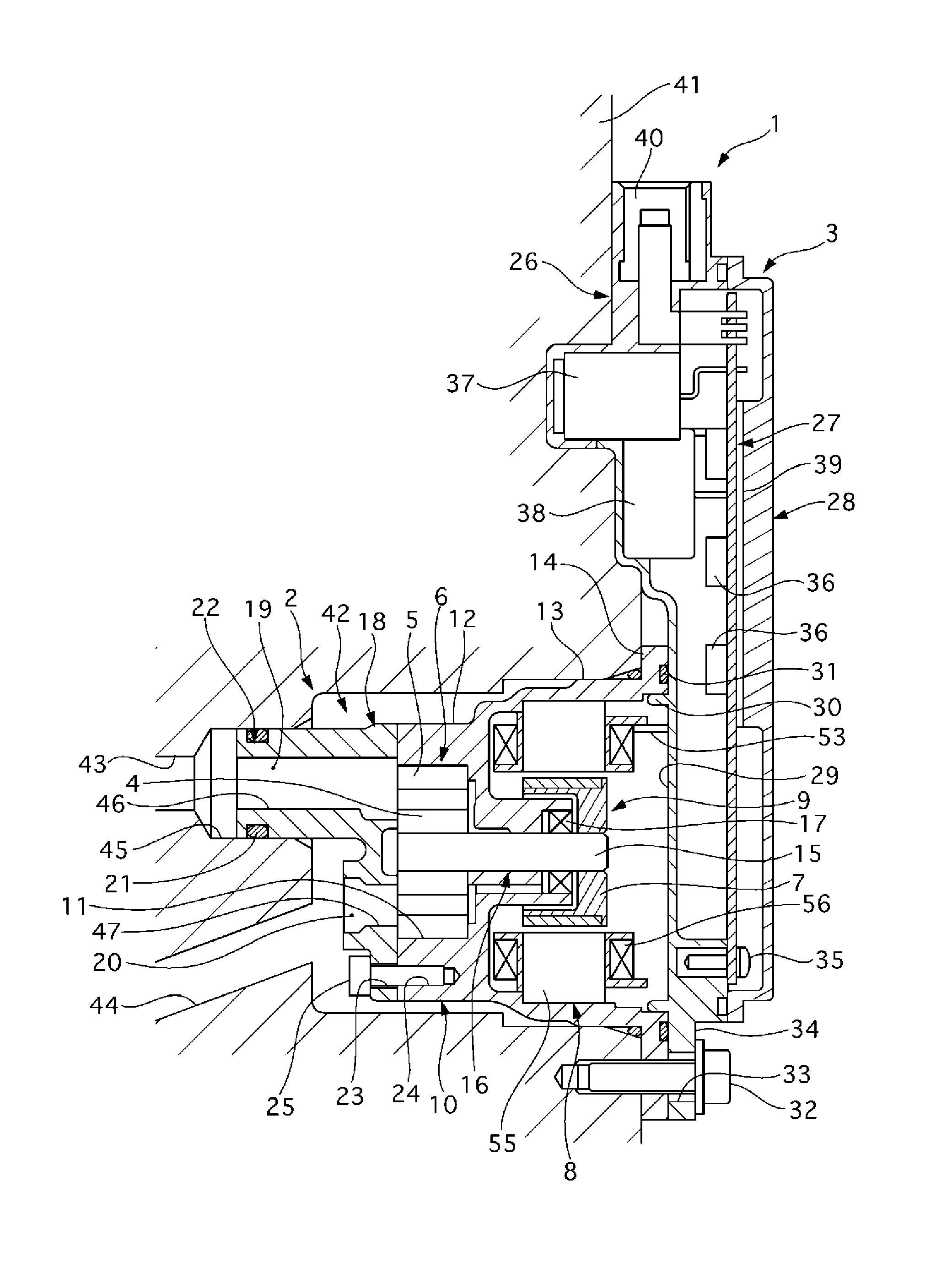

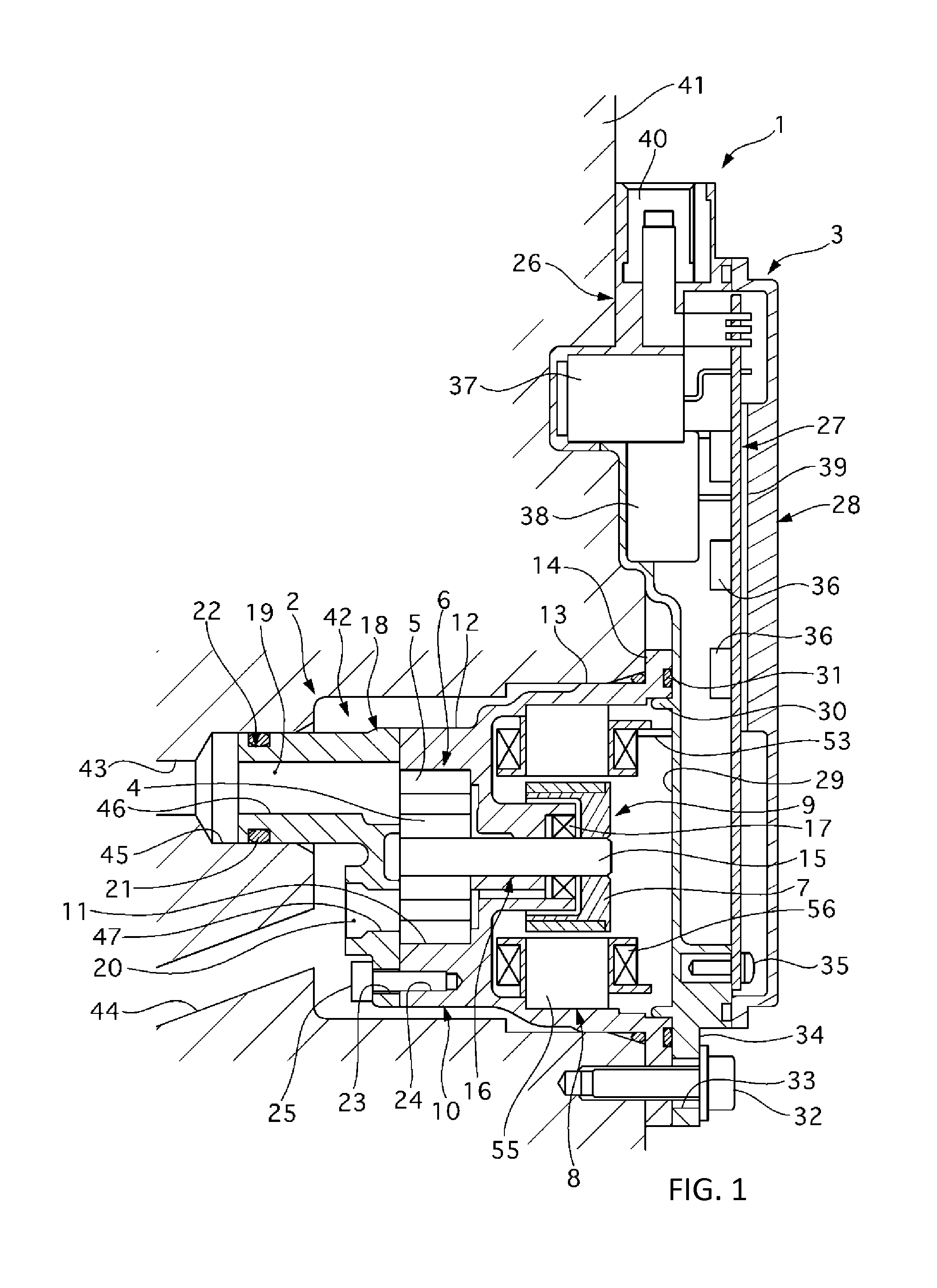

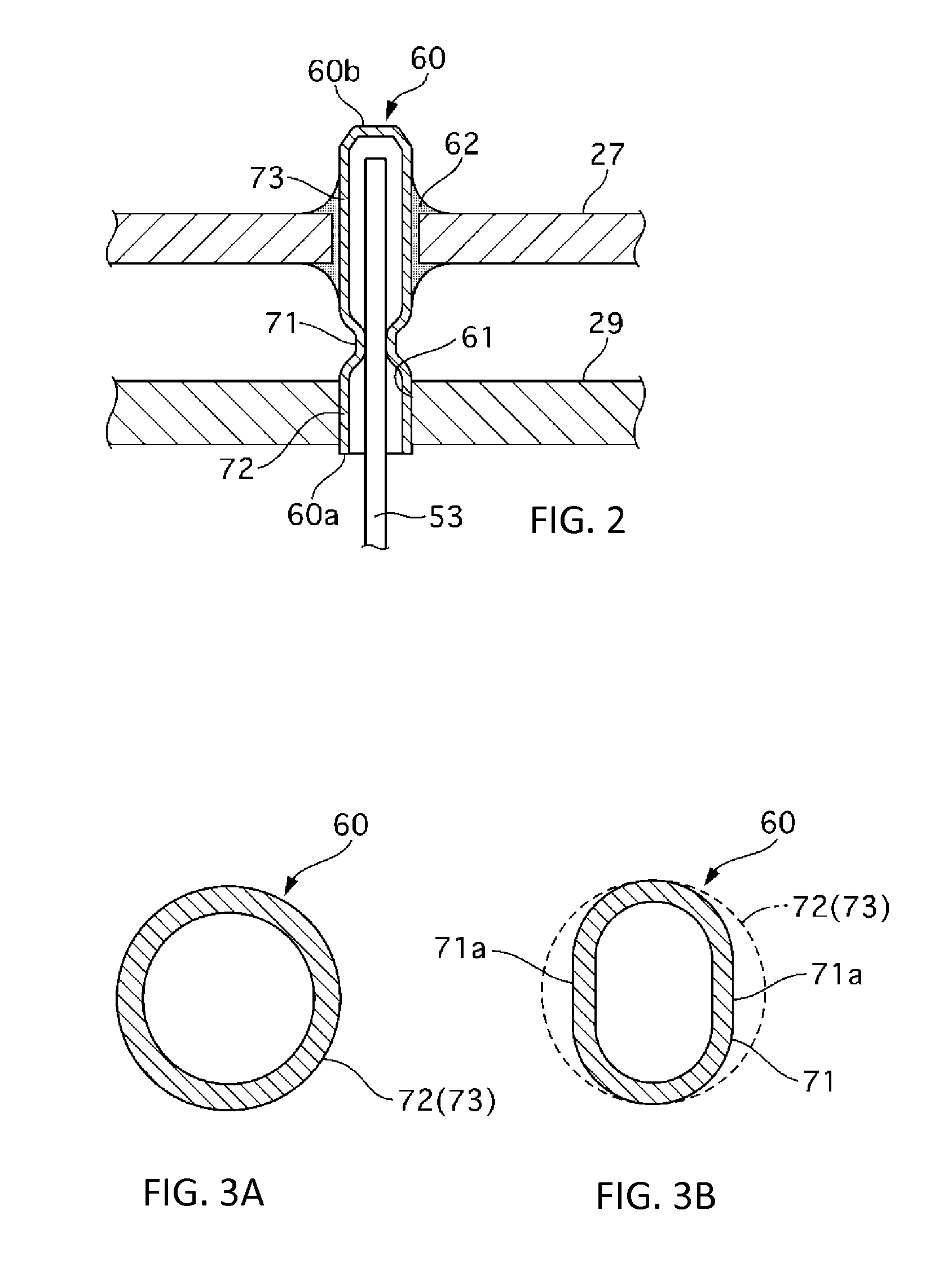

Electric pump

InactiveUS20110135516A1Pump componentsRotary piston pumpsMechanical engineeringRotating magnetic field

An electric pump includes a stator, a rotor, a shaft, a bearing part, and a pump unit. The stator has a magnetic part, and the stator forms a rotation magnetic field when a coil of the stator is energized. The bearing part has a longitudinal central position that is positioned on an imaginary plane perpendicular to a rotation axis of the rotor. The imaginary plane is positioned within an inner range defined between longitudinal end portions of the magnetic part of the stator.

Owner:DENSO CORP

Method and apparatus for dispensing fluid compositions

ActiveUS8224481B2Combine accuratelySmall sizePump componentsRotary piston pumpsRegimenControl system

A miniaturized fluid dispensing system for dispensing customized fluids. The dispenser may include first and second reservoirs containing constituent fluids; a drive motor; at least two pump assemblies commonly driven by the drive motor and in communication with the first and second reservoirs; first and second valve assembly in communication with the first and second pump assemblies; and a control system for selectively controlling the valve assemblies to blend and discharge a composition from the constituent fluids. The system may include a dispensing header to house the valves and to define ‘discharge’ and ‘recirculation’ flow paths for each constituent fluid. The present invention also provides a method for dispensing a fluid regimen (e.g. a plurality of compositions) by periodically blending and discharging varying compositions over time.

Owner:ACCESS BUSINESS GRP INT LLC

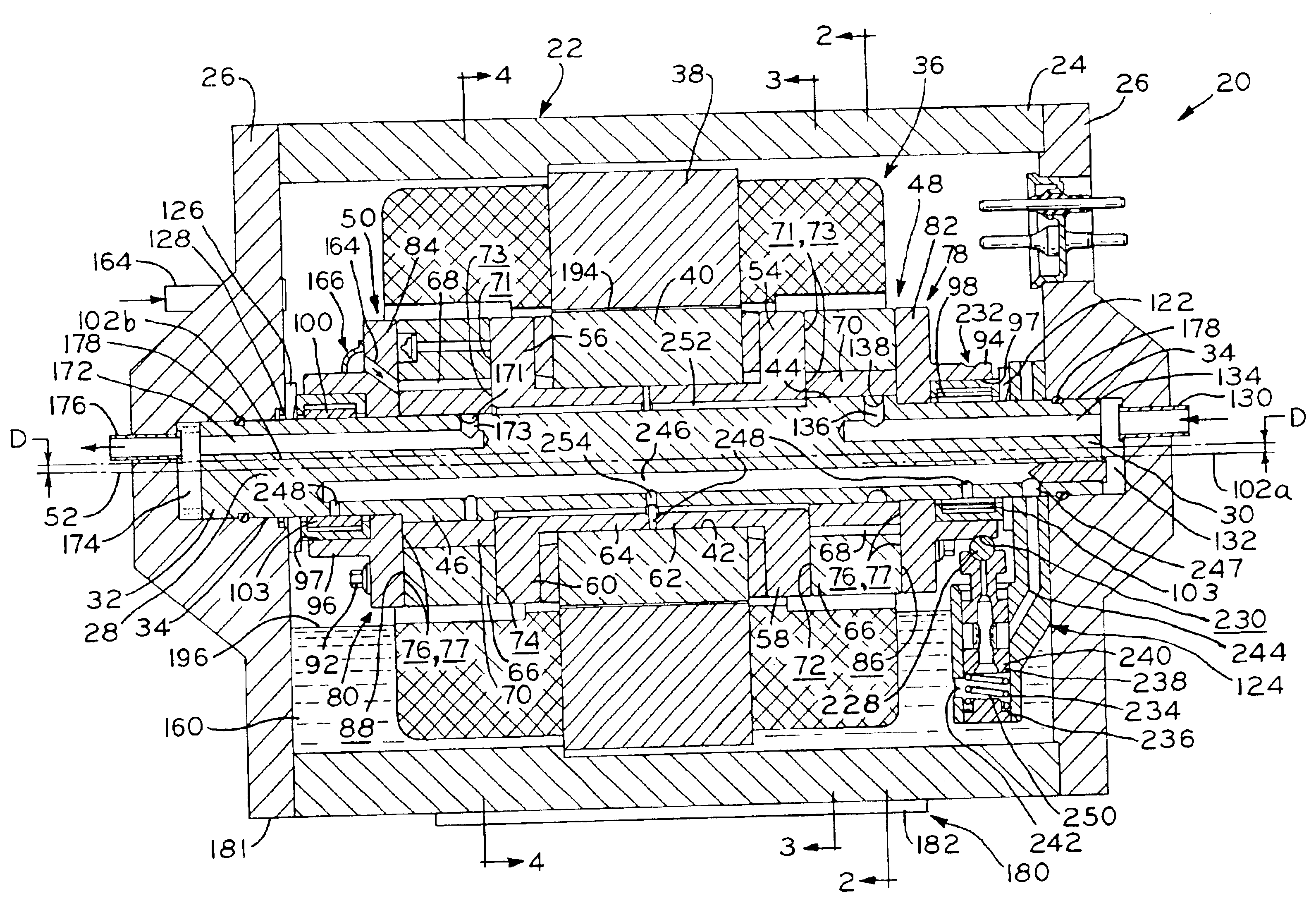

Dual oil supply pump

InactiveUS20050180870A1Maximizing packing efficiencyReduces flow pulsationPositive displacement pump componentsRotary piston pumpsCavitationEngineering

An automotive engine oil pump assembly having first and second pump mechanisms contained within a common housing. A shaft rotatably supported in the housing drives the pump mechanisms in a conventional manner. The pump mechanisms are offset in phase to reduce flow pulsations through the housing and limit pump noise and vibration. The first pump mechanism communicates with a common inlet and first outlet of the housing. The second pump mechanism communicates with the common inlet and second outlet of the housing. A common reservoir connected to inlets of the first and second oil pump mechanisms provides a supplemental oil source to balance oil pressures at the pump inlets to prevent pump cavitation and further reduce pump noise and vibration.

Owner:GM GLOBAL TECH OPERATIONS LLC

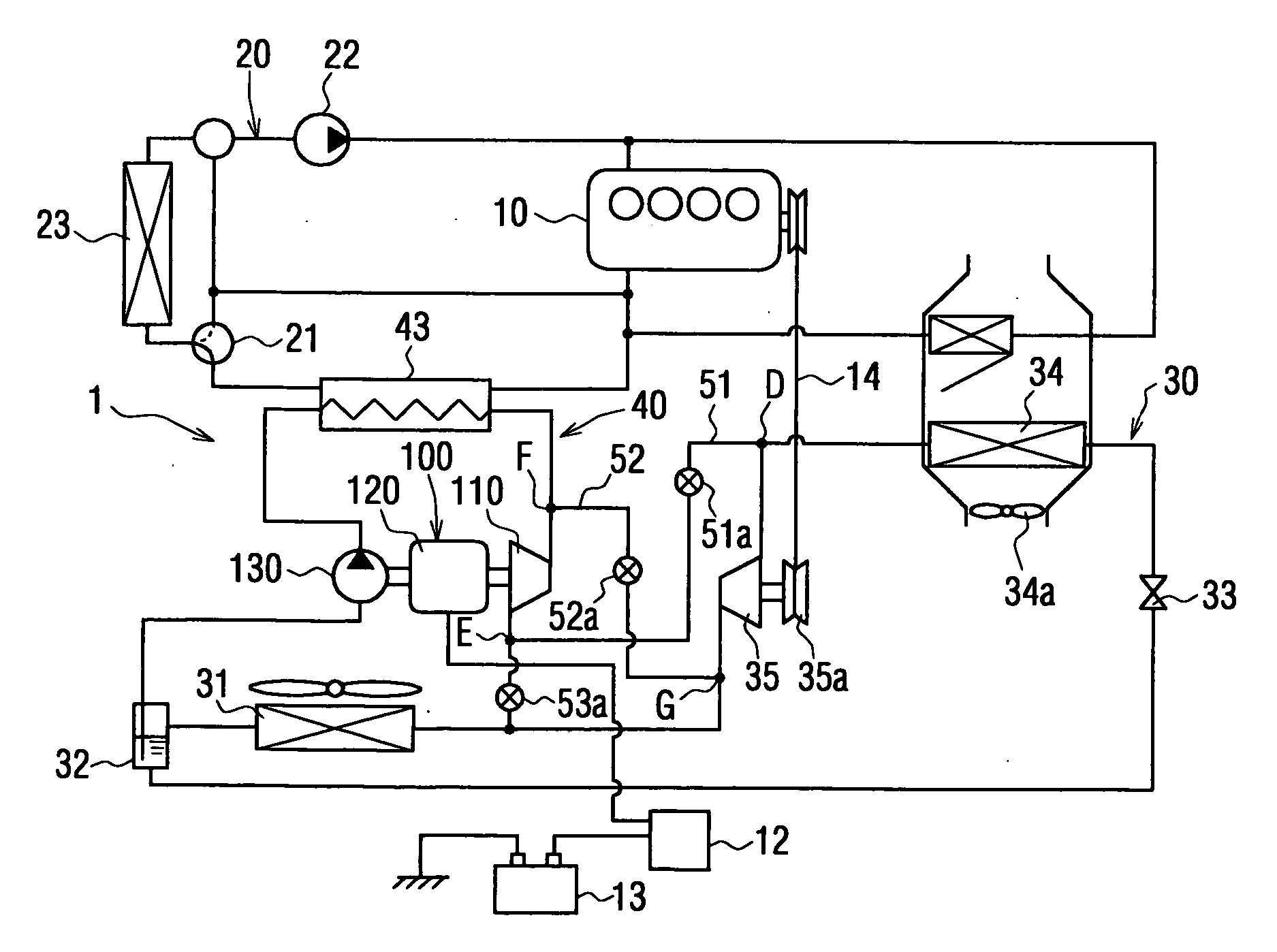

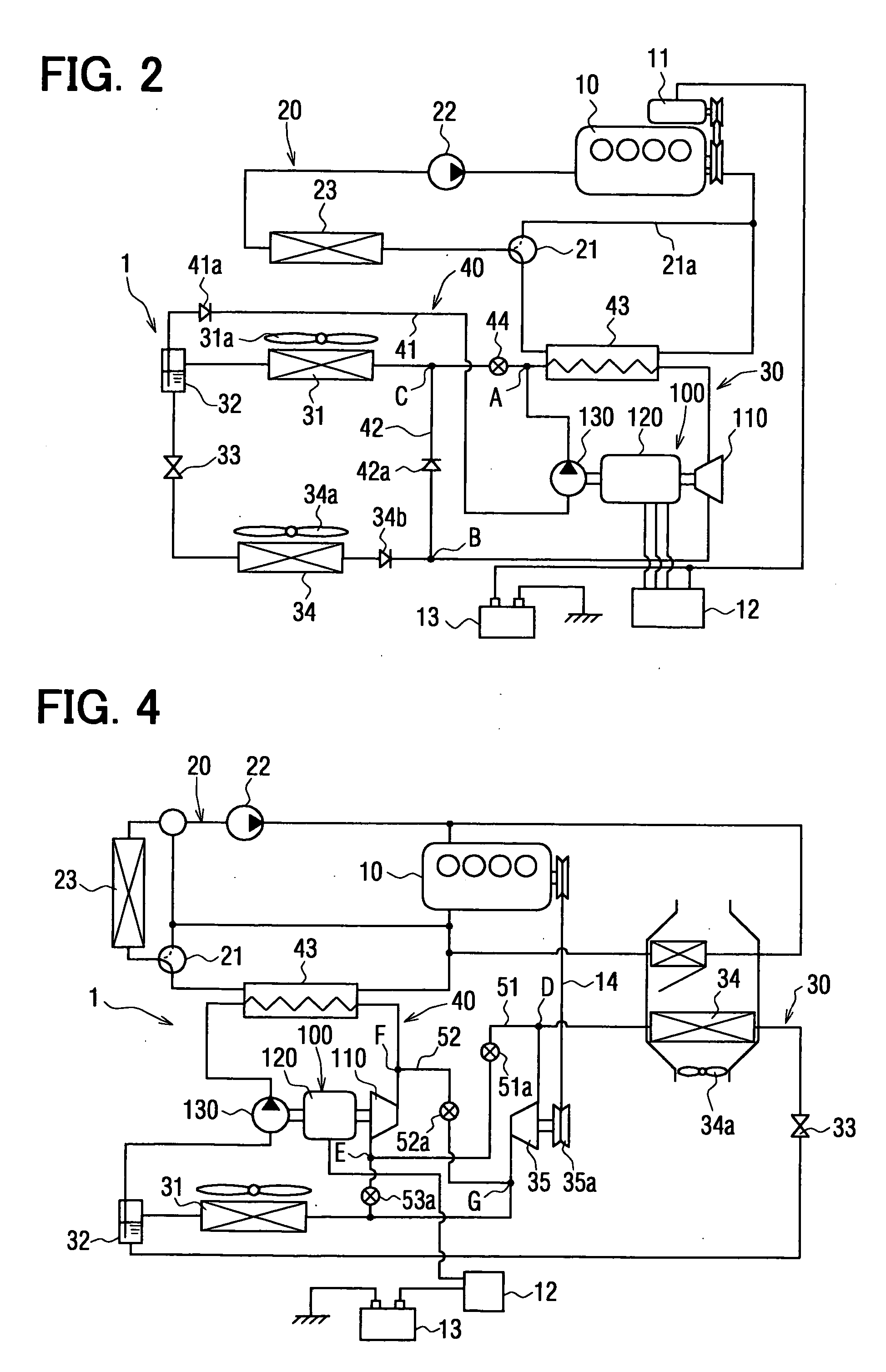

Refrigerating apparatus and fluid machine therefor

InactiveUS20060107681A1Efficient collectionEfficient comprehensive utilizationPump componentsDomestic cooling apparatusEngineeringElectric generator

A complex fluid machine has an expansion-compressor device, a pump, and a motor generator, wherein the expansion-compressor device, the pump, and the motor generator are operatively connected and arranged in series, and a power transmitting device for disconnecting the pump from the motor generator, when the expansion-compressor device is driven by the motor generator so as to be operated as a compressor device.

Owner:DENSO CORP +1

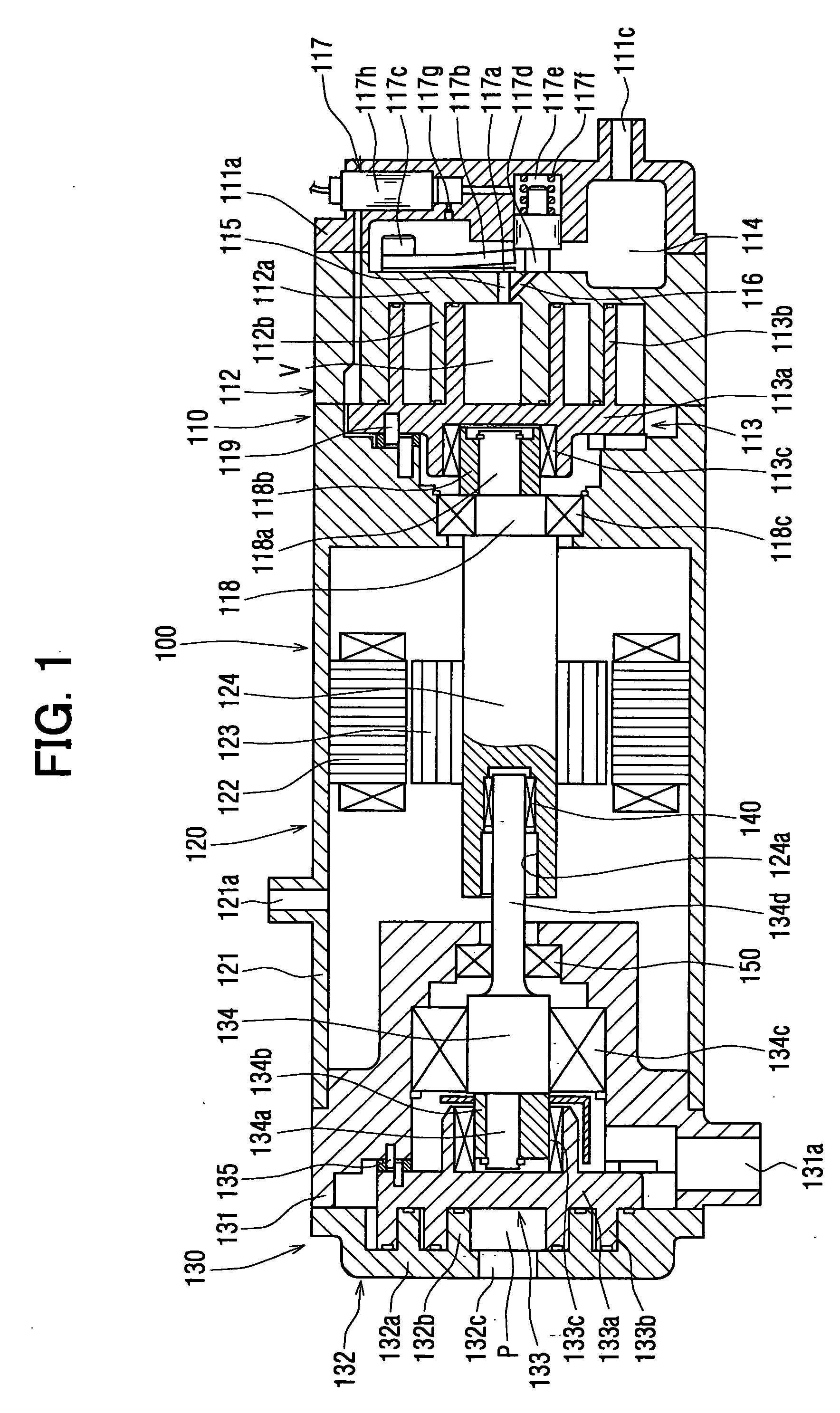

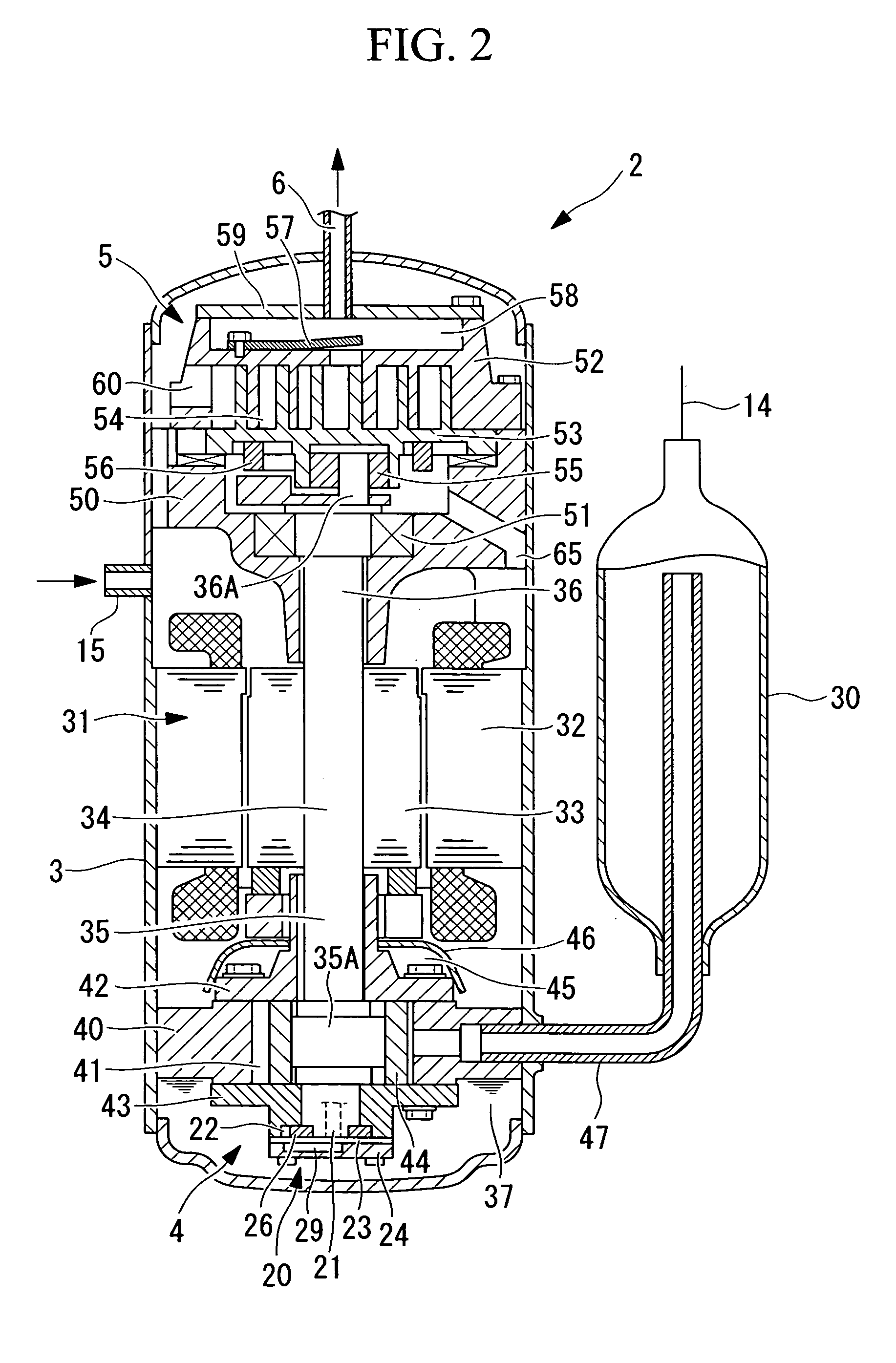

Multistage Compressor

ActiveUS20100143172A1Improve motor efficiencyImprove performanceRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeEngineeringRefrigerant

A multistage compressor employing a gas injection system for CO2 cycle that attains enhancements of compression efficiency and compression performance. The multistage compressor is multistage compressor (2) for CO2 cycle (1) adapted to carry out two-stage compression involving emitting the CO2 refrigerant gas compressed by inferior-stage side rotary compression means (4) into sealed housing (3) and having the intermediate-pressure refrigerant gas within the sealed housing (3) suctioned by superior-stage side scroll compression means (5), wherein to the sealed housing (3), there is connected gas injection circuit (15) capable of injection of intermediate-pressure CO2 refrigerant gas extracted from a refrigerant circuit into the sealed housing (3), and wherein the inferior-stage side rotary compression means (4) and the superior-stage side scroll compression means (5) are approximately identical with each other in pressure ratio and approximately equivalent with each other in displacement ratio.

Owner:MITSUBISHI HEAVY IND LTD

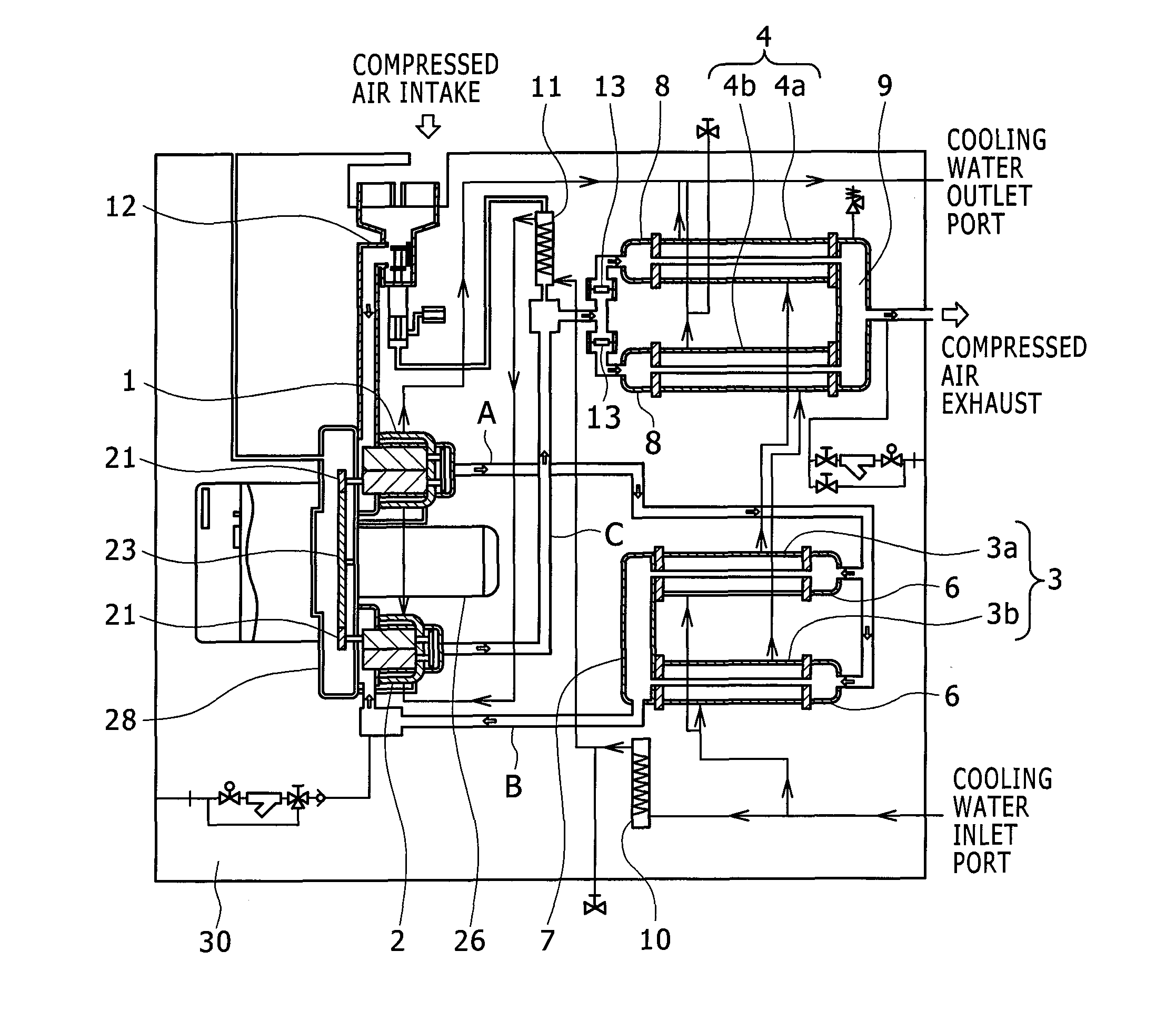

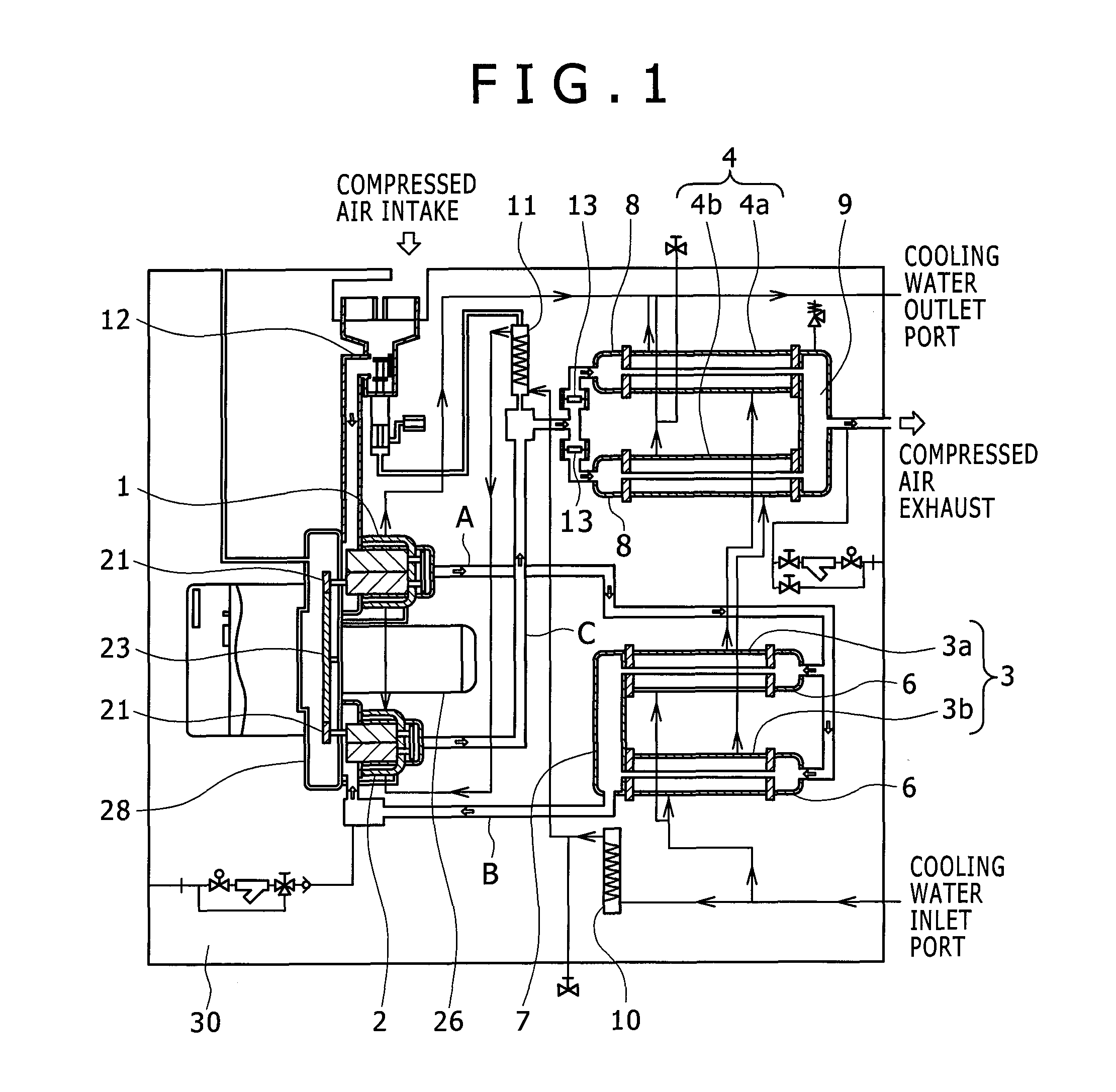

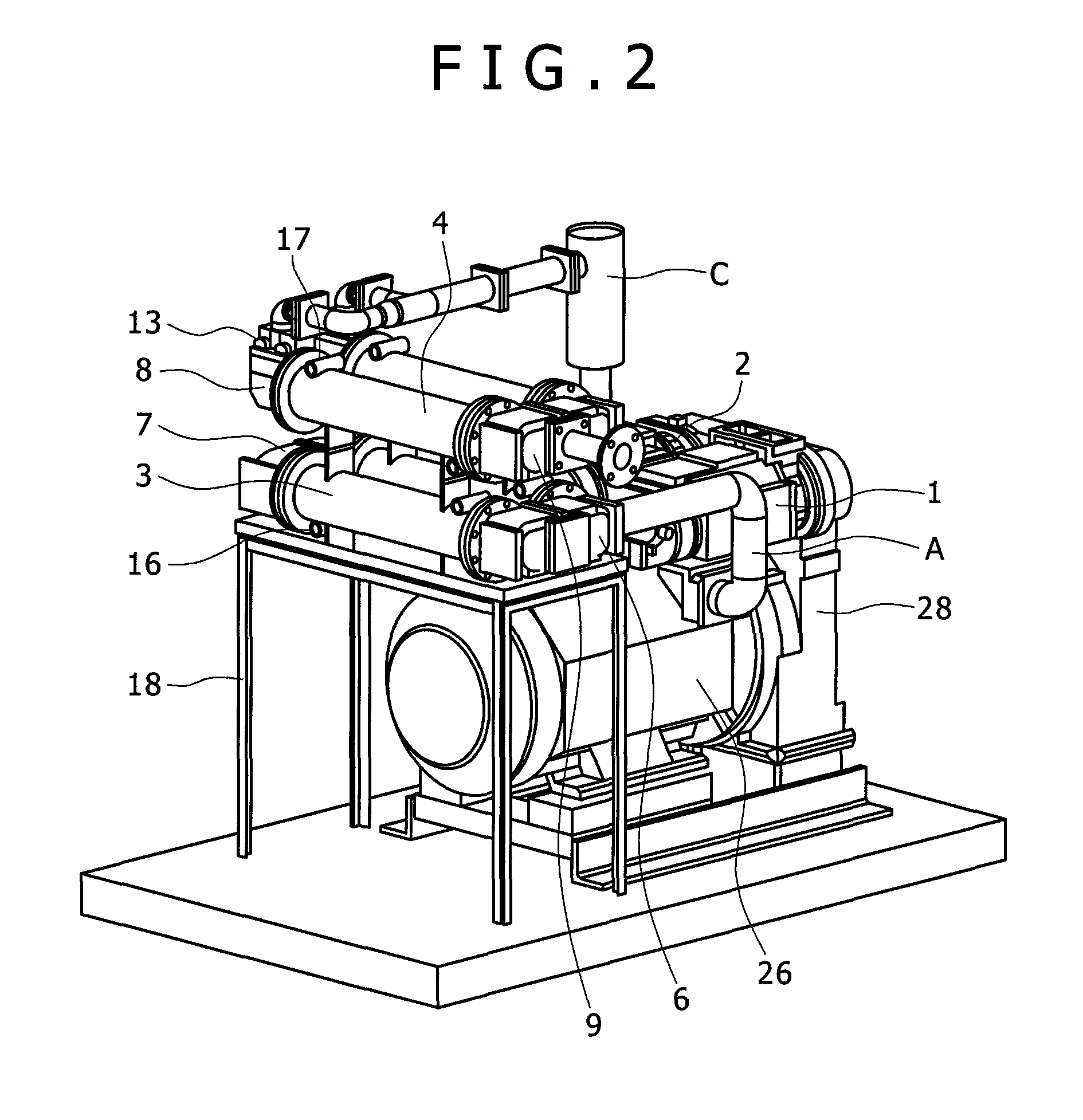

Water-Cooled Oil-Free Air Compressor

InactiveUS20100303658A1Increase productivityImprove maintainabilityRotary/oscillating piston combinations for elastic fluidsPositive displacement pump componentsProduction rateOil free

A water-cooled oil-free air compressor which features compactness and ensures improved productivity and maintainability. The compressor is an oil-free screw compressor which includes a low pressure stage compressor body, an intercooler for water-cooling the compressed air discharged from the low pressure stage compressor body, a high pressure stage compressor body for further compressing the compressed air cooled by the intercooler, and an aftercooler for water-cooling the air discharged from the high pressure stage compressor body. The intercooler and aftercooler each have a plurality of units, all of which are almost equal in shape. A cooler header on each or either of the inlet and outlet sides for compressed air is shared by the units of each cooler.

Owner:HITACHI IND EQUIP SYST CO LTD

Multiphase screw pump

InactiveUS20090098003A1Engine of intermeshing engagement typeRotary piston pumpsLiquid mediumEngineering

A twin screw pump includes a pair of rotors disposed inside a casing having an inlet and an outlet. Each rotor includes a set of threads disposed on a portion of an outer surface of a shaft. A first bearing is coupled at a first end of the shaft and a second bearing is coupled at a second end of the shaft. The first and second bearings are not separated by one or more seals. The first and second bearings are configured for being lubricated by the liquid medium of the process fluid when the twin screw pump is in an operational mode.

Owner:GENERAL ELECTRIC CO

Liquid-cooled electromotor

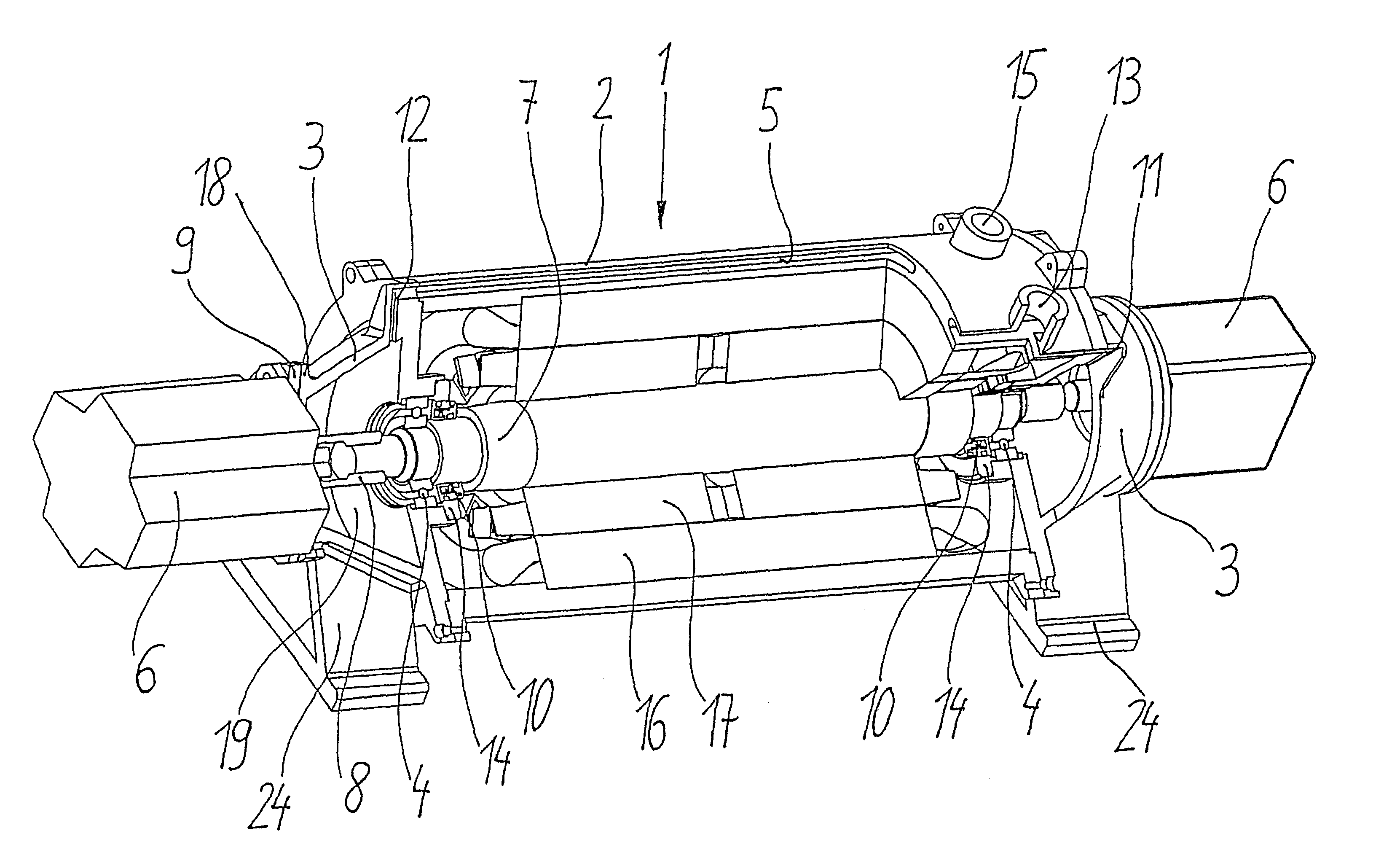

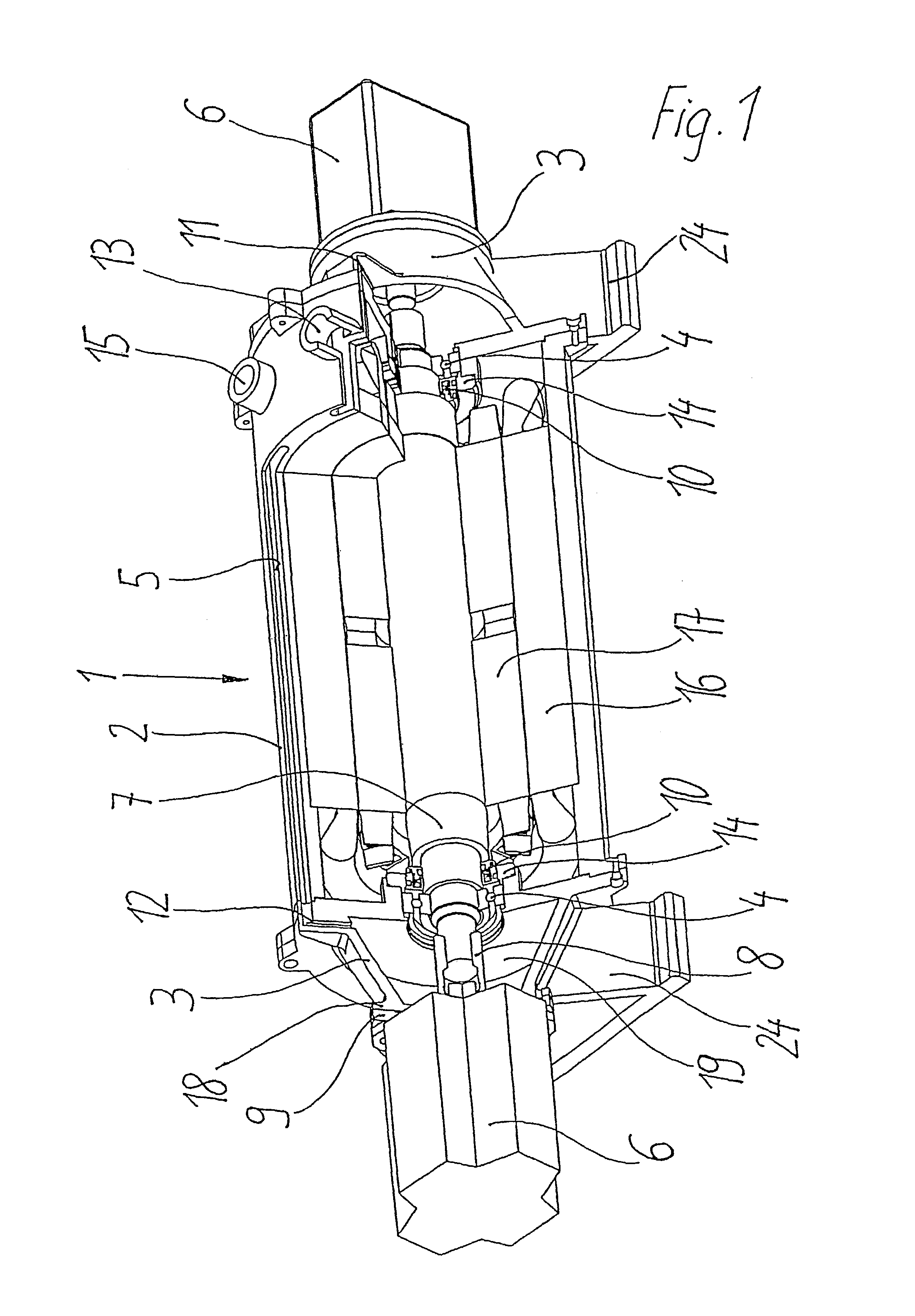

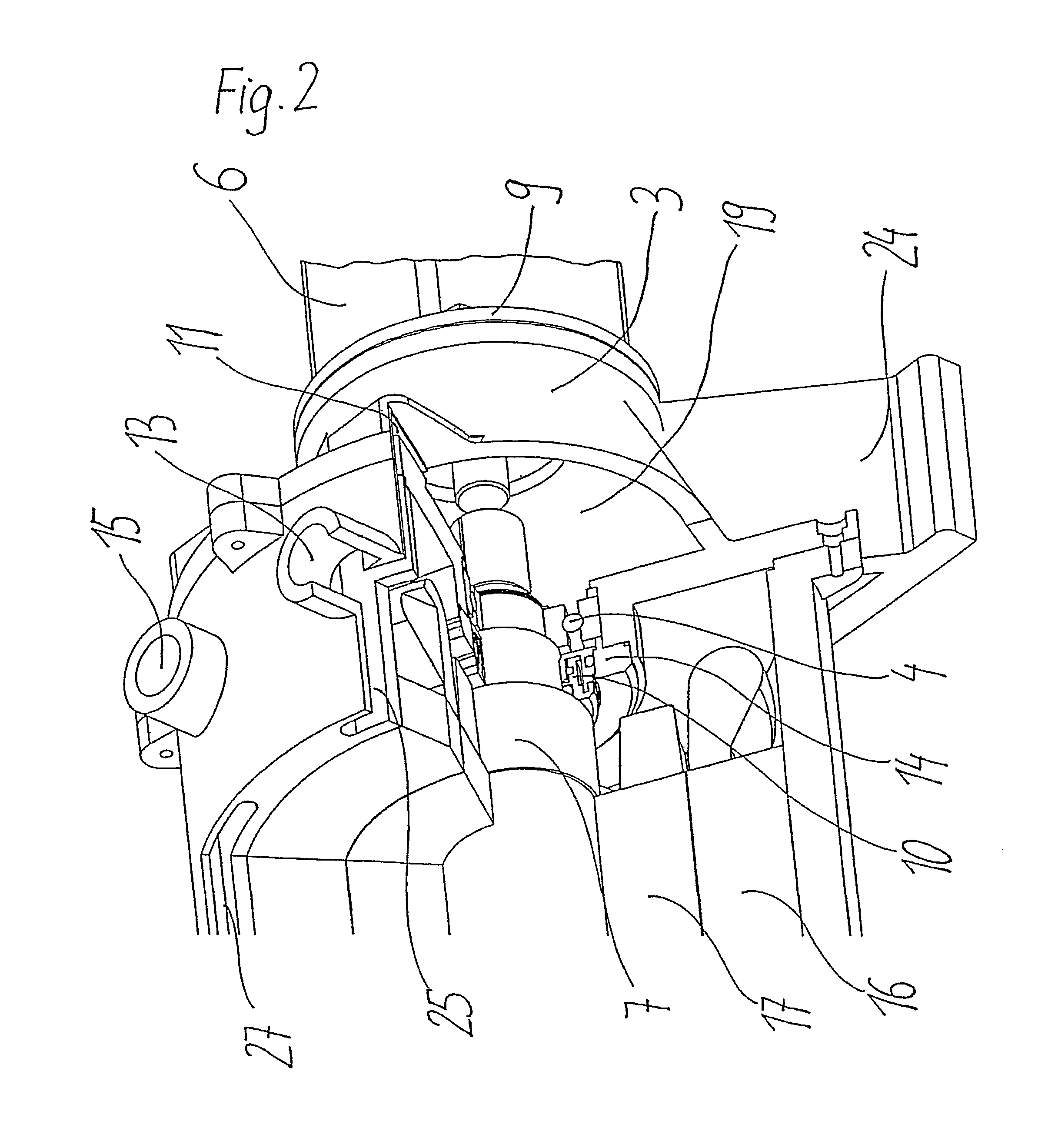

InactiveUS7005765B1Improve cooling effectGuaranteed cooling effectMagnetic circuit rotating partsPositive displacement pump componentsDrive shaftCoupling

A liquid-cooled electric motor with a motor shaft, with two bearing plates which are mounted on the end faces of the motor housing and which carry on each side at least one bearing, the motor shaft being mounted rotatably in the bearings, and with at least one rotating hydraulic pump, the drive shaft of which is connected to the motor shaft by way of a coupling and which is driven by the electric motor. The casing of the motor housing receives a cooling liquid, has an at least partially hollow design and forms a casing cavity. At least one connecting duct for the supply of cooling liquid from the casing cavity to the bearings for cooling and lubrication of the bearings is provided in each of the bearing plates and in that said flanged-on hydraulic pump is sealed off in a liquid-tight manner with respect to the bearing plate interiors.

Owner:ELIN EBG MOTOREN

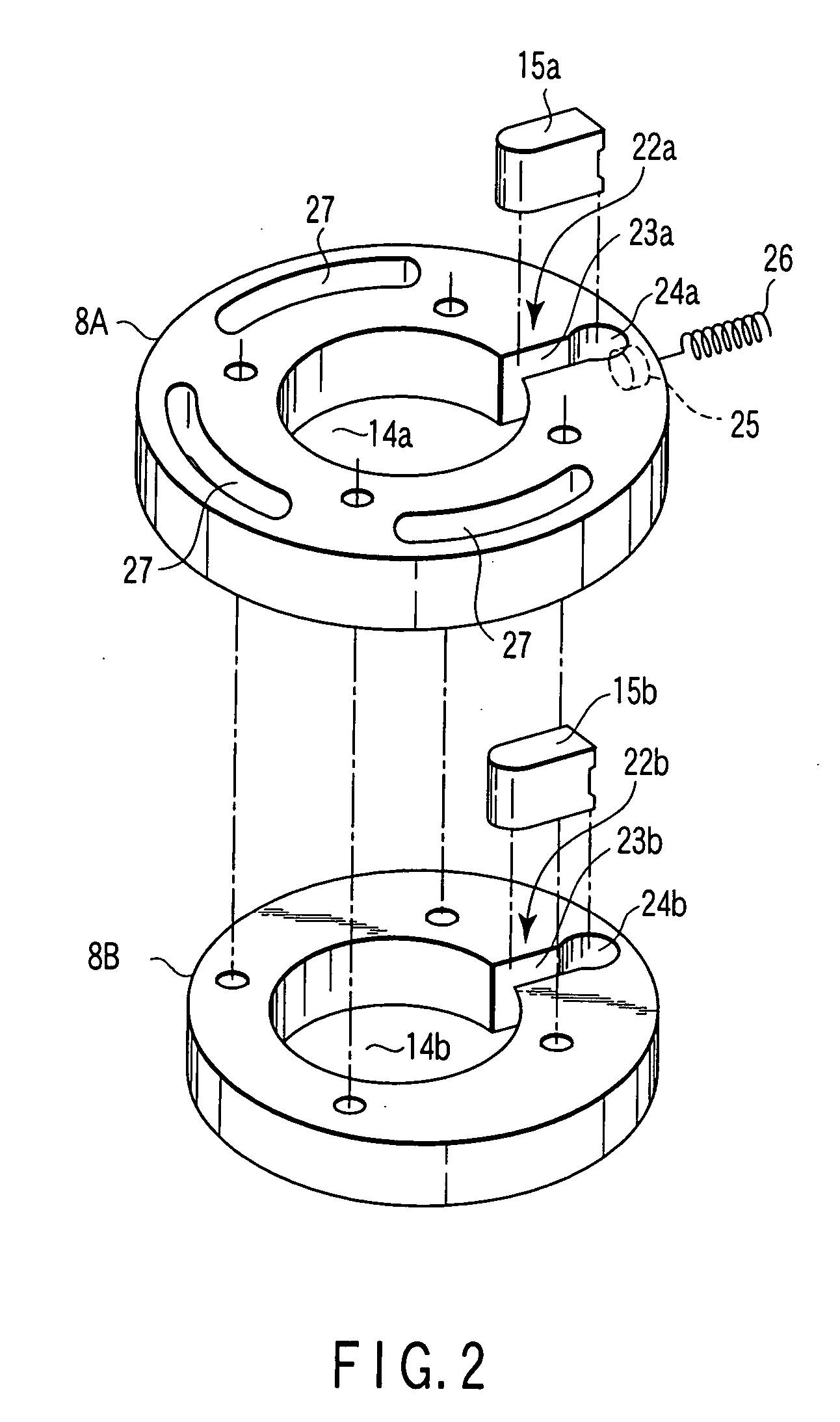

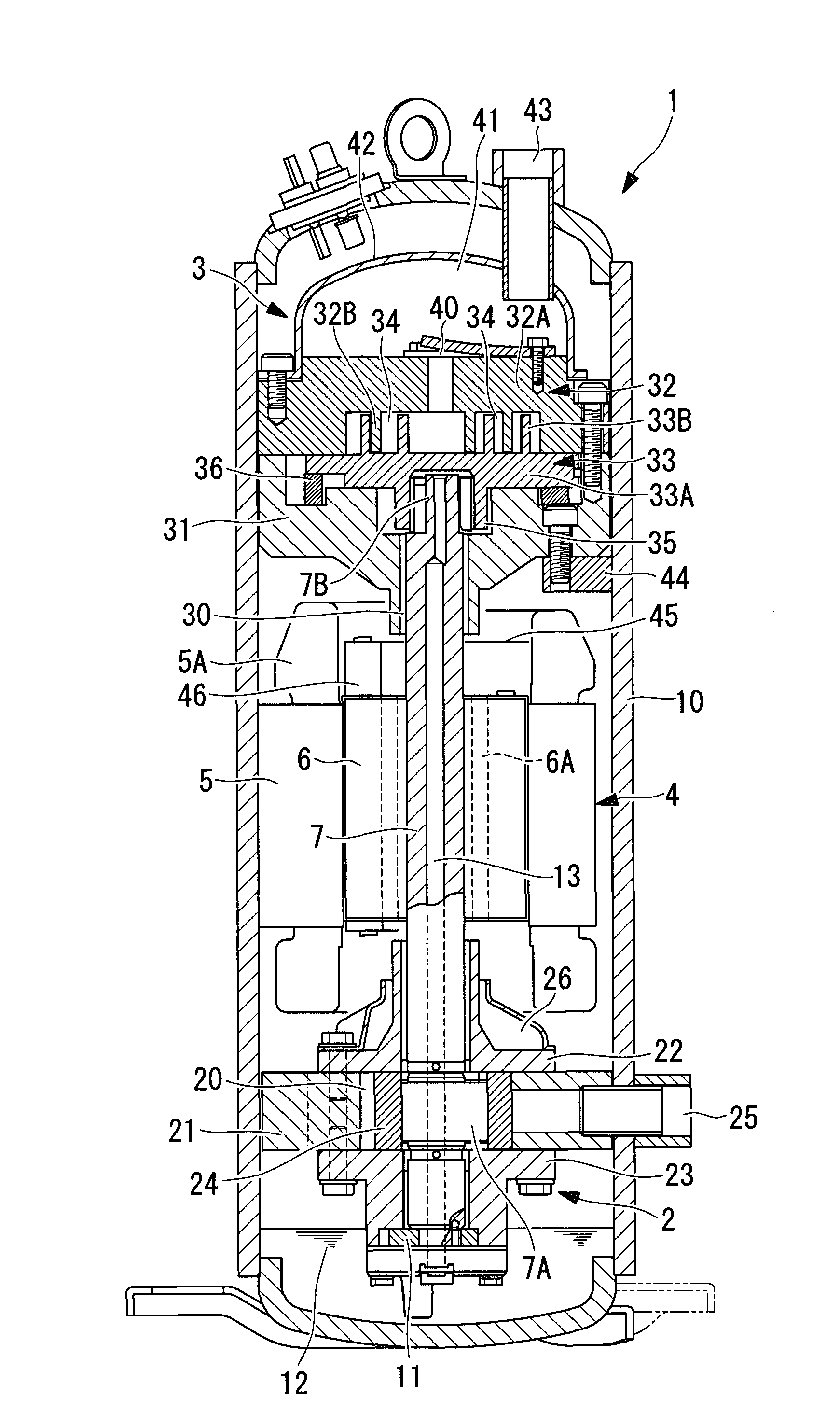

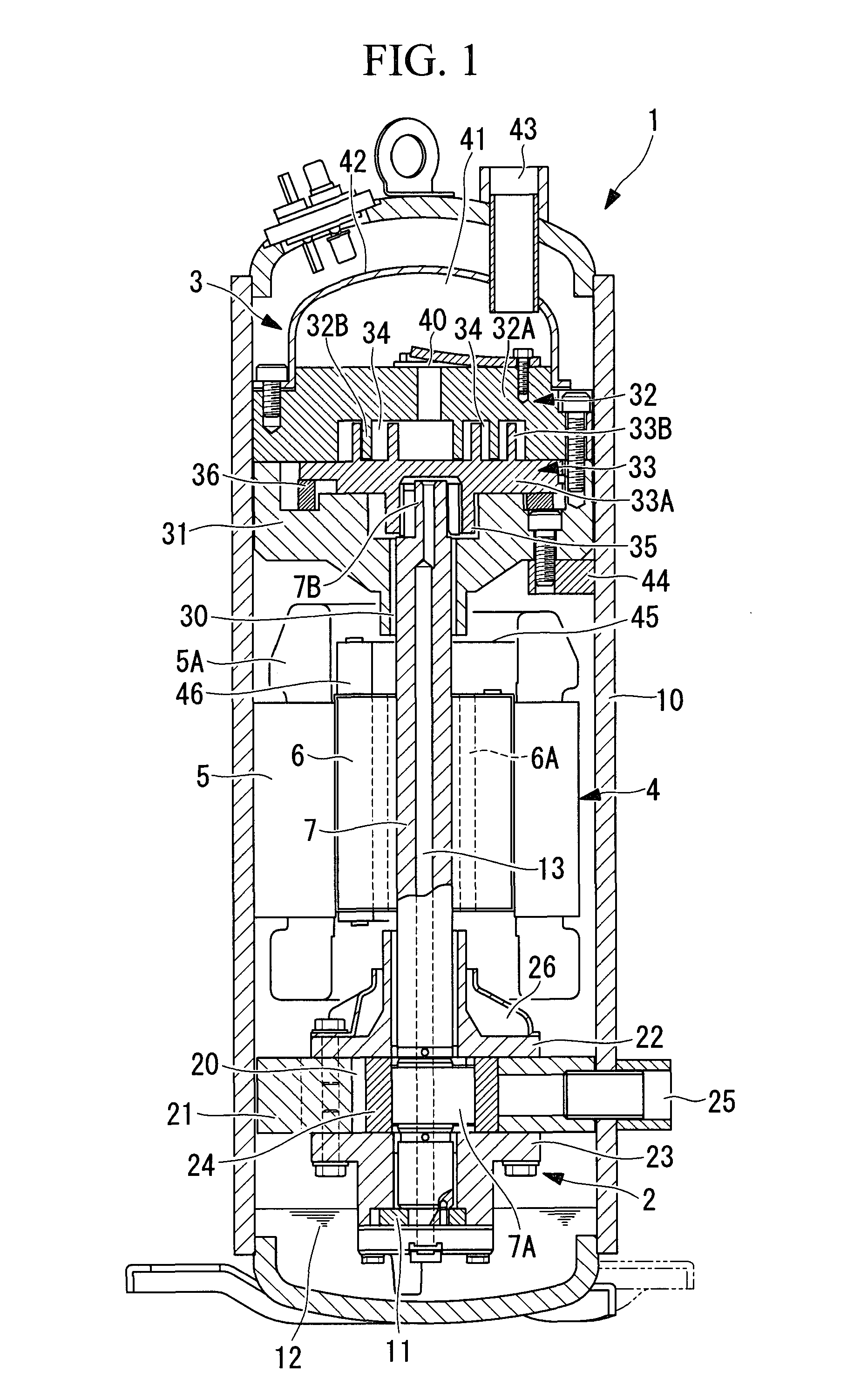

Rotary closed type compressor and refrigerating cycle apparatus

ActiveUS20060002809A1Improve reliabilitySimple structureRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeInternal pressureEngineering

A rotary closed type compressor is configured such that an inside of a case becomes high pressure, and the rotary closed type compressor comprises a first cylinder and a second cylinder having cylinder chambers in which eccentric rollers are housed, respectively, vanes which divide the cylinder chamber into two sections, respectively, and vane chambers in which back-face side end portions of the vanes are housed, respectively. The vane on the first cylinder side is pressed and biased by a spring member provided in the vane chamber, and the vane on the second cylinder side is pressed and biased according to pressure difference between case internal pressure introduced to the vane chamber and suction pressure or discharge pressure introduced to the cylinder chamber.

Owner:TOSHIBA CARRIER CORP

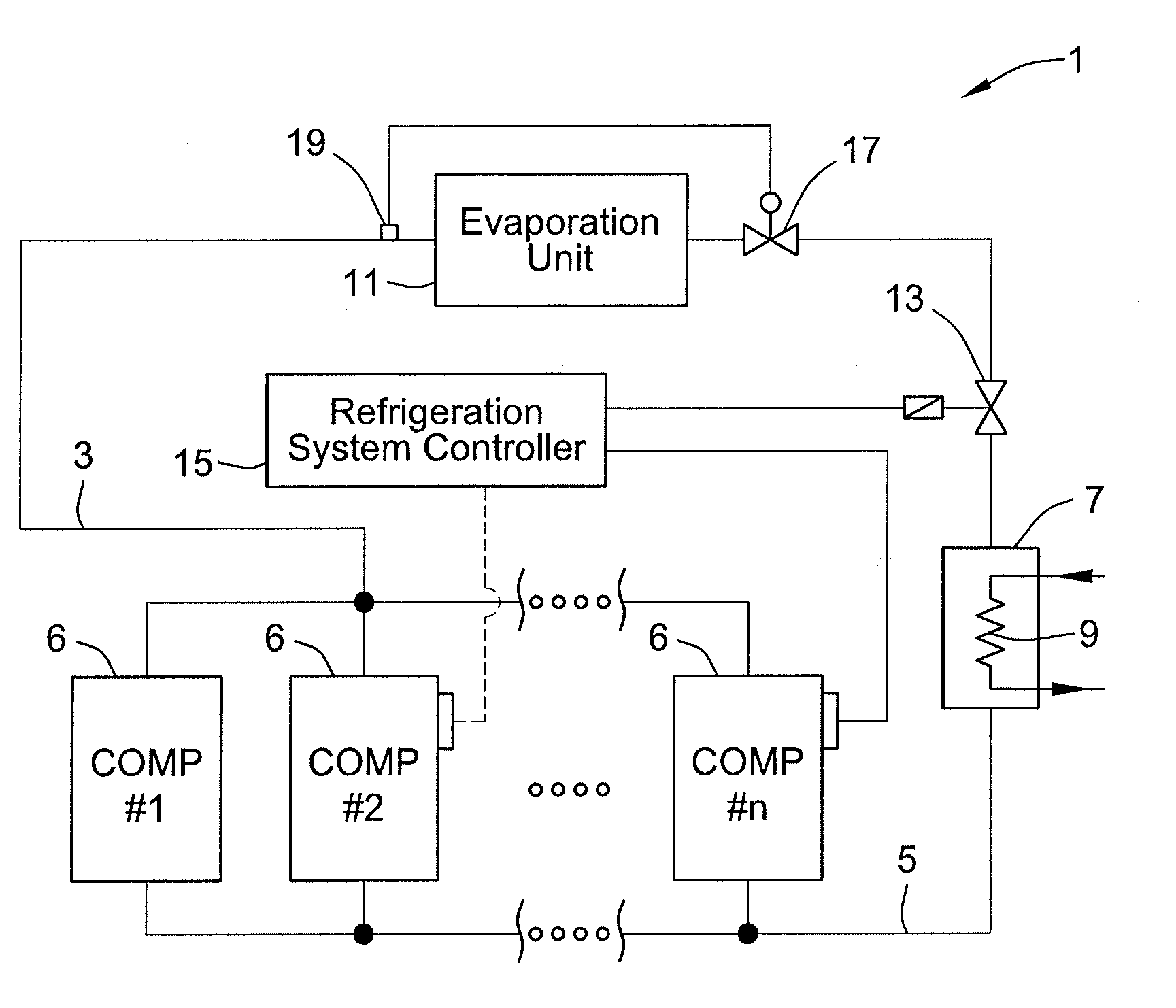

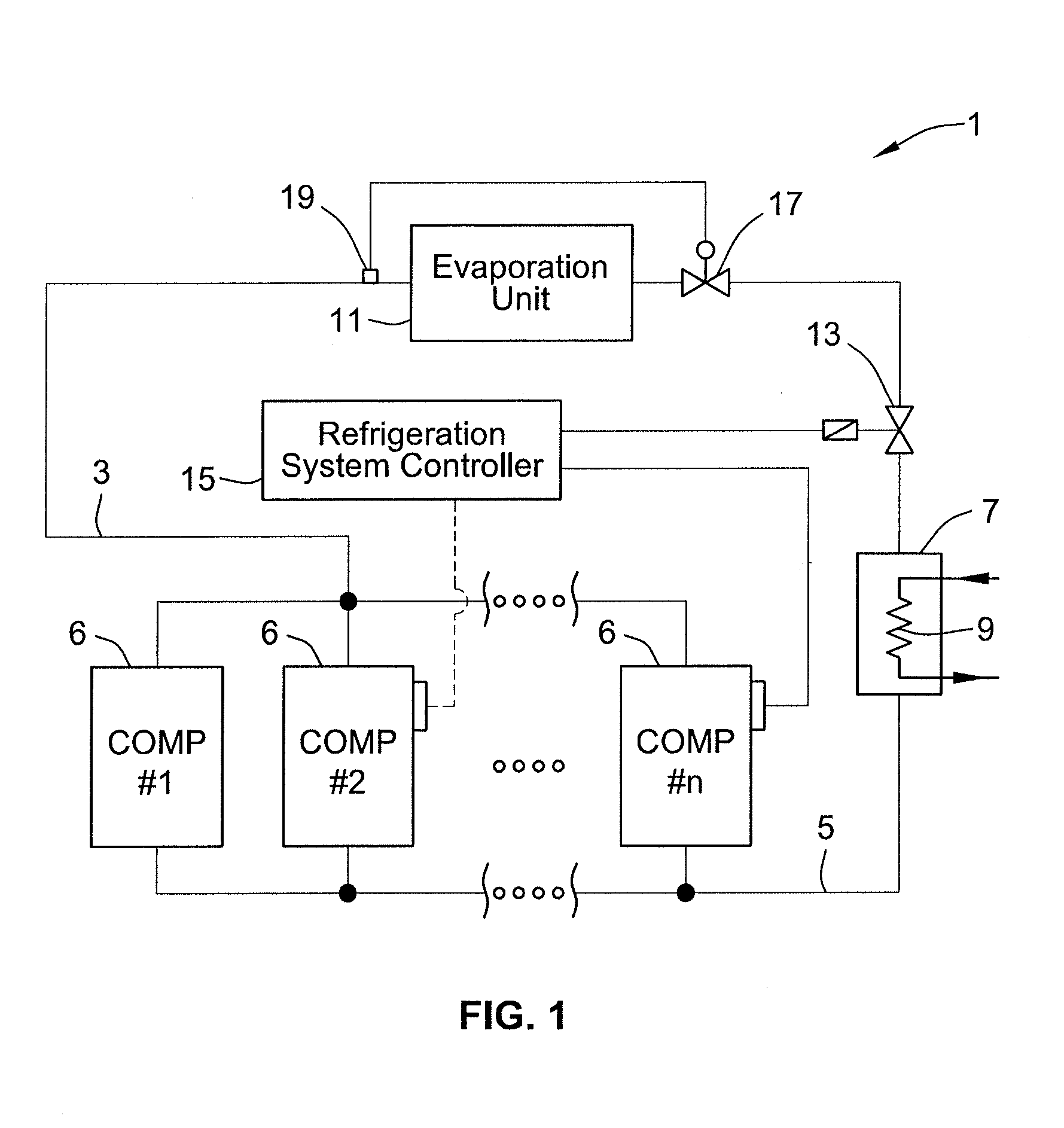

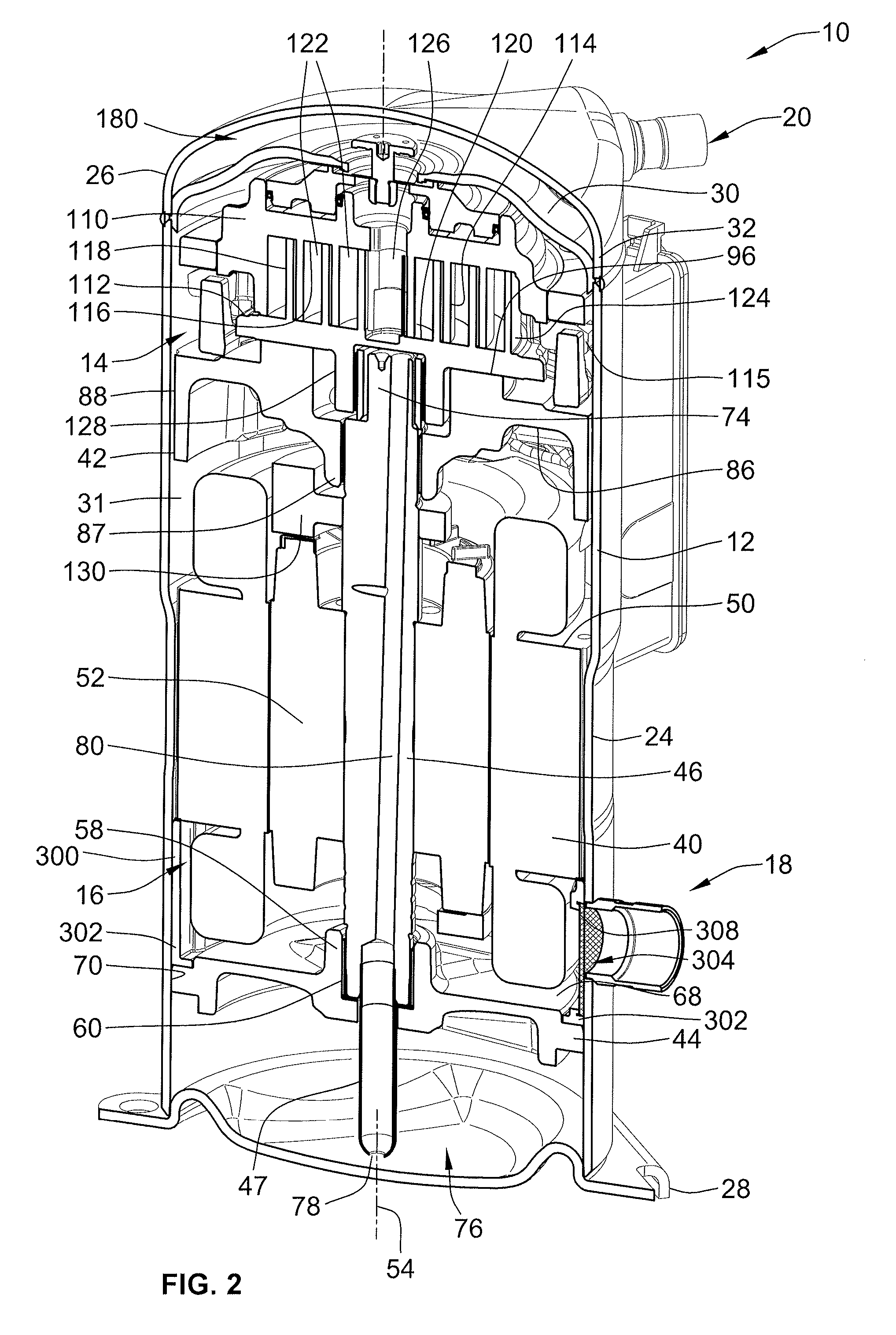

Apparatus and Method for Oil Equalization in Multiple-Compressor Systems

ActiveUS20140241926A1Promote sportsRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeEngineeringEqualization

A method of operating a refrigeration system, that includes providing a plurality of compressors connected in parallel. The plurality of compressors includes a plurality of scroll compressors. The method further includes returning circulated refrigerant to the plurality of compressors, the circulated refrigerant having oil entrained therein. Returning circulated refrigerant to the plurality of compressors includes returning more oil to one of the plurality of compressors than to another of the plurality of compressors. The method also includes supplying oil from one of the plurality of compressors to at least one other of the plurality of compressors. Supplying oil from one of the plurality of compressors includes supplying oil from the one of the plurality of compressors having an opening in its housing. A fitting is assembled into the opening. The fitting protrudes through the housing into an interior portion of the housing.

Owner:BITZER KUEHLMASCHINENBAU GMBH

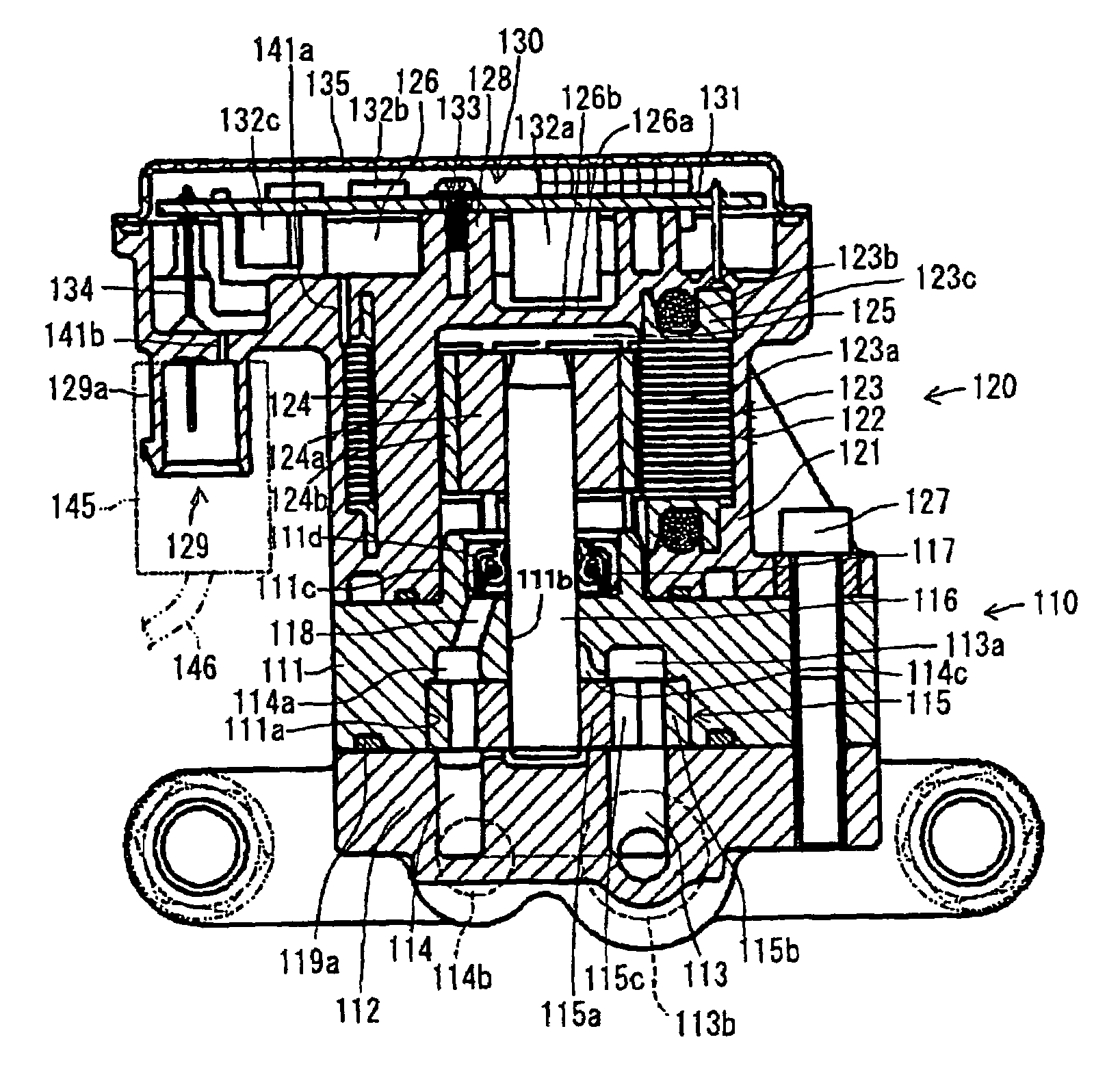

Electric powered pump

An electric powered pump includes a pump body having a suction chamber, a discharge chamber and an accommodation concave portion for accommodating a pump rotor, a rotational shaft rotatably supported by the pump body, the pump rotor is fixed at a first end of the rotational shaft, a motor having a rotor including a magnet, an annular stator including a core and a coil, the rotor is fixed at a second end of the rotational shaft which is opposite to the first end of the rotational shaft, a motor housing having a hole shaped cylindrical space inside of the stator formed with the motor housing, the motor housing is fixed at the pump body to be positioned in the cylindrical space having a predetermined clearance relative to the rotor, a driver portion for driving the motor, a accommodation space formed at an end surface of the motor housing provided at a side of the second end of the rotational shaft, the accommodation space is configured to accommodate the driver portion, and a cover for covering the accommodation space.

Owner:AISIN SEIKI KK

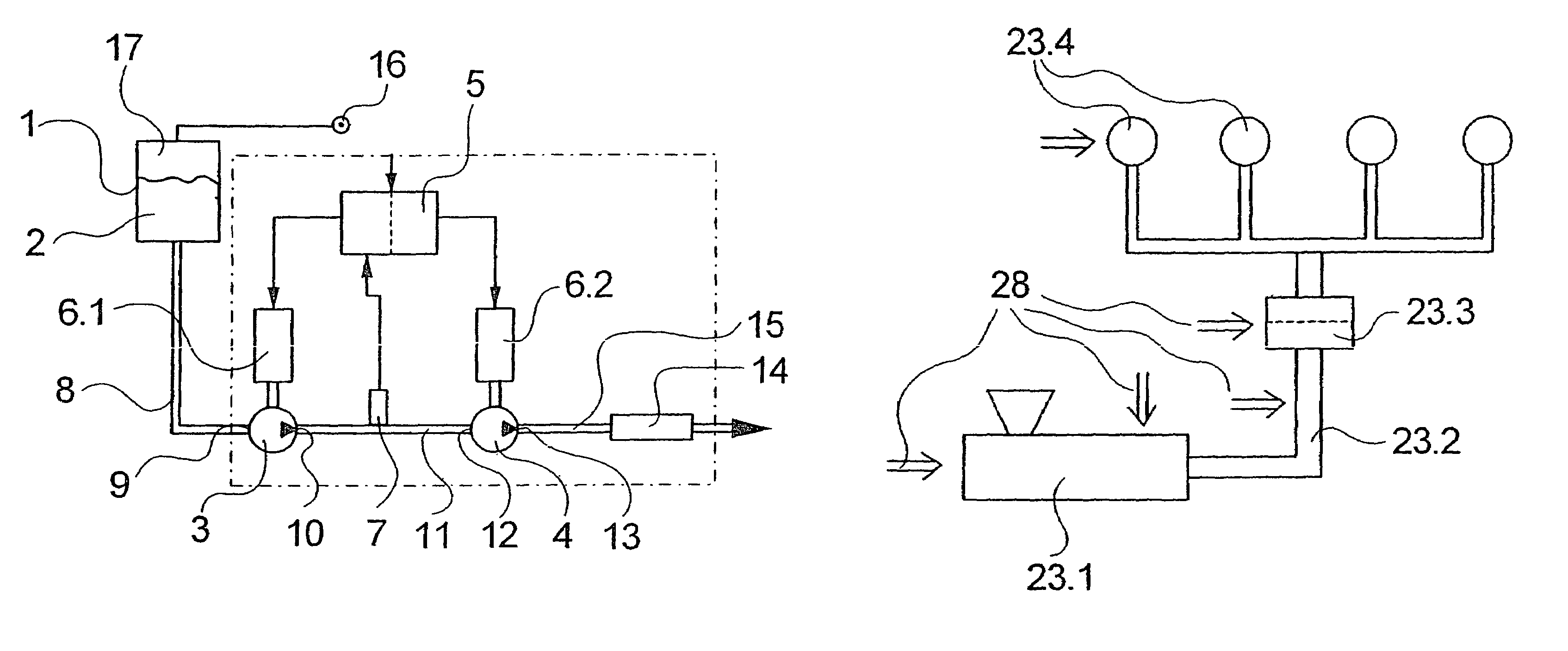

Apparatus and method for injecting a liquid dye into a polymer melt

InactiveUS7278776B2Easy to addImprove accuracyPump componentsSpinning head liquid feederInjection pressureFuel tank

An apparatus and a method for injecting a liquid dye into a polymer melt, which includes a metering pump with a metering inlet and a metering outlet. The metering inlet connects to a dye tank and the metering outlet connects to a polymer melt carrying component. To add the liquid dye to the polymer melt in the melt carrying component in a quantity that is as uniform and accurate as possible, the invention provides for connecting the metering inlet of the metering pump to a feed outlet of a feed pump, which connects with its feed inlet to the tank. With that, it is possible to generate a feed pressure at the metering inlet of the metering pump, which can be adapted to an injection pressure at the metering outlet of the metering pump.

Owner:SAURER GMBH & CO KG

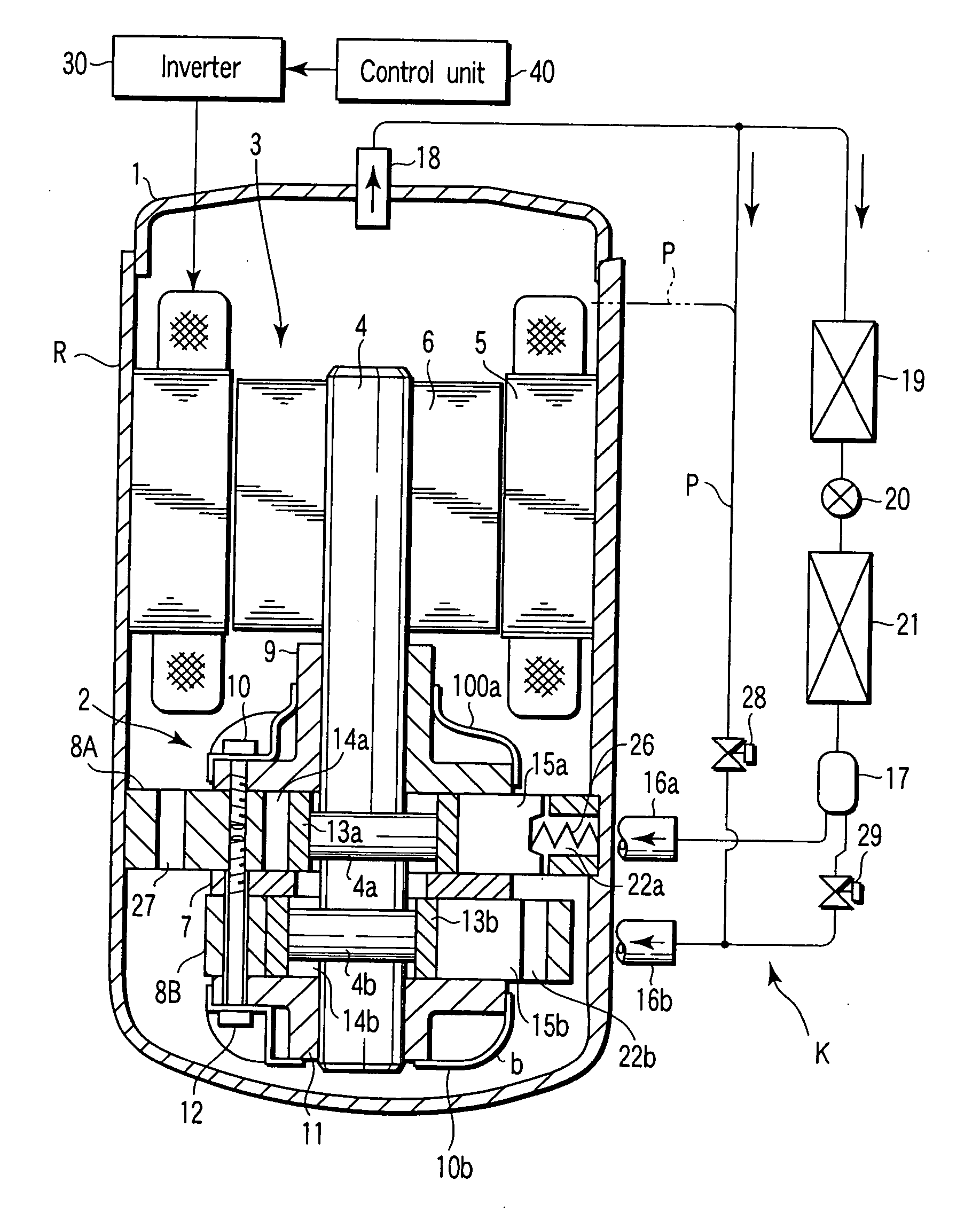

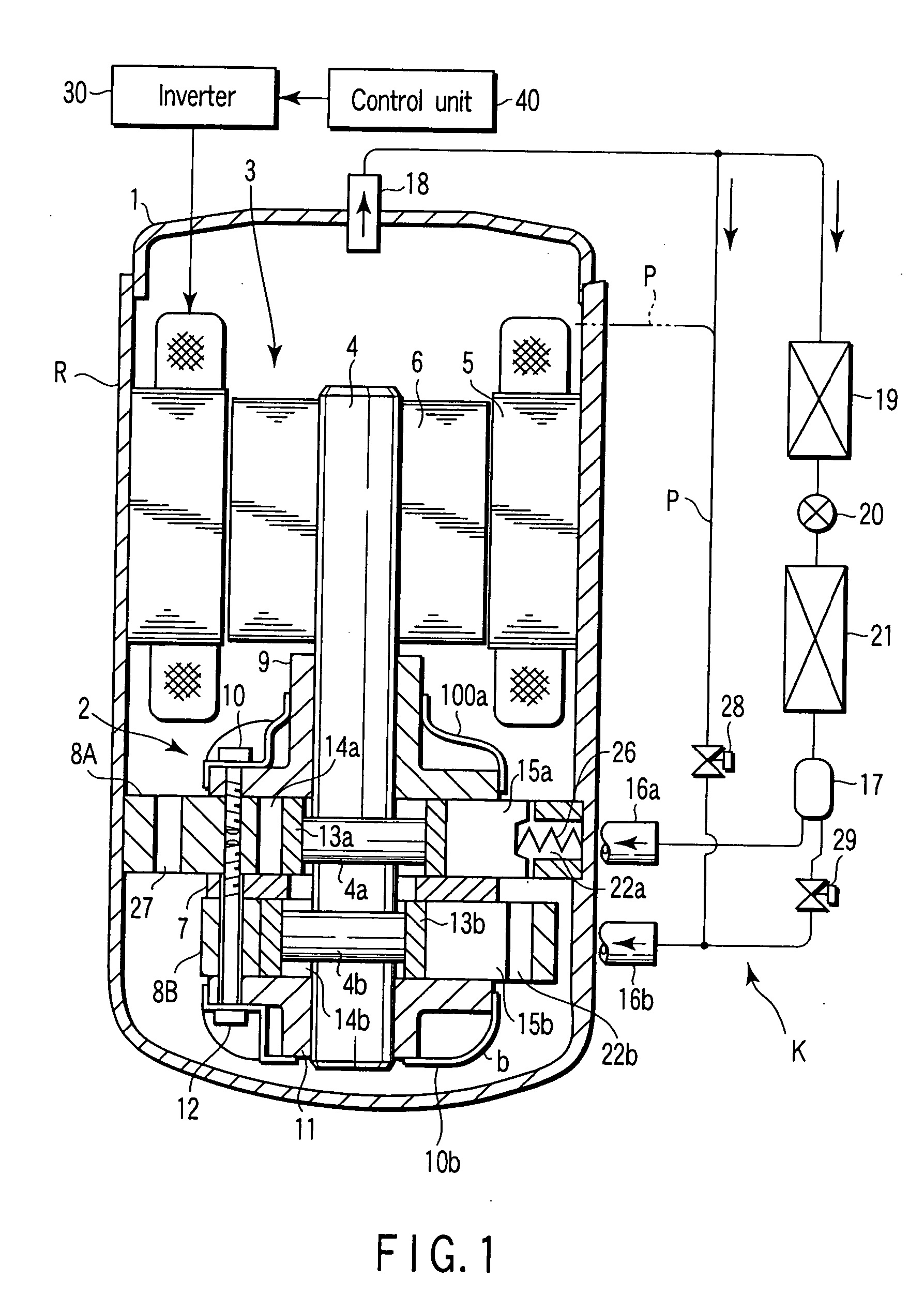

Multistage compressor

ActiveUS20100083690A1Improve system efficiencyReduce oil circulationRotary/oscillating piston combinations for elastic fluidsCombination enginesProduct gasEngineering

A multistage compressor is provided, which can reduce an oil circulation ratio by reducing the amount of lubricating oil to be taken in by a high-stage compression mechanism to improve the system efficiency and prevent a shortage of lubricating oil. A low-stage compression mechanism and a high-stage compression mechanism are disposed below and above to flank an electric motor, respectively, intermediate-pressure refrigerant gas compressed by the low-stage compression mechanism is discharged into a sealed housing, and the intermediate-pressure refrigerant gas is taken in by the high-stage compression mechanism so as to be compressed in two stages, an oil separator plate that centrifugally separates lubricating oil contained in the intermediate-pressure refrigerant gas, which is taken in by the high-stage compression mechanism after passing through the electric motor, is provided at one end of a rotor of the electric motor such that a rotary shaft extends through the oil separator plate.

Owner:MITSUBISHI HEAVY IND LTD

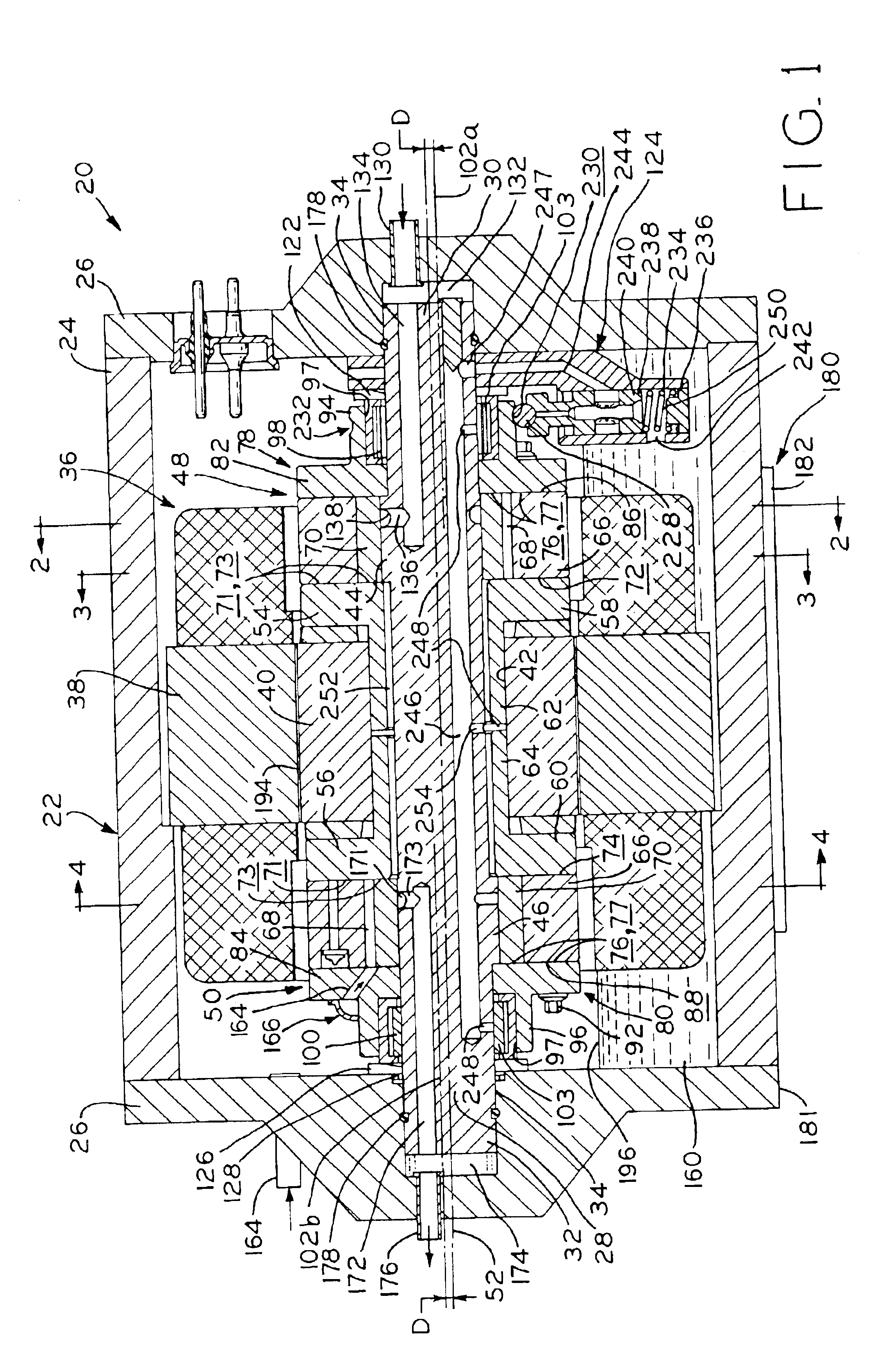

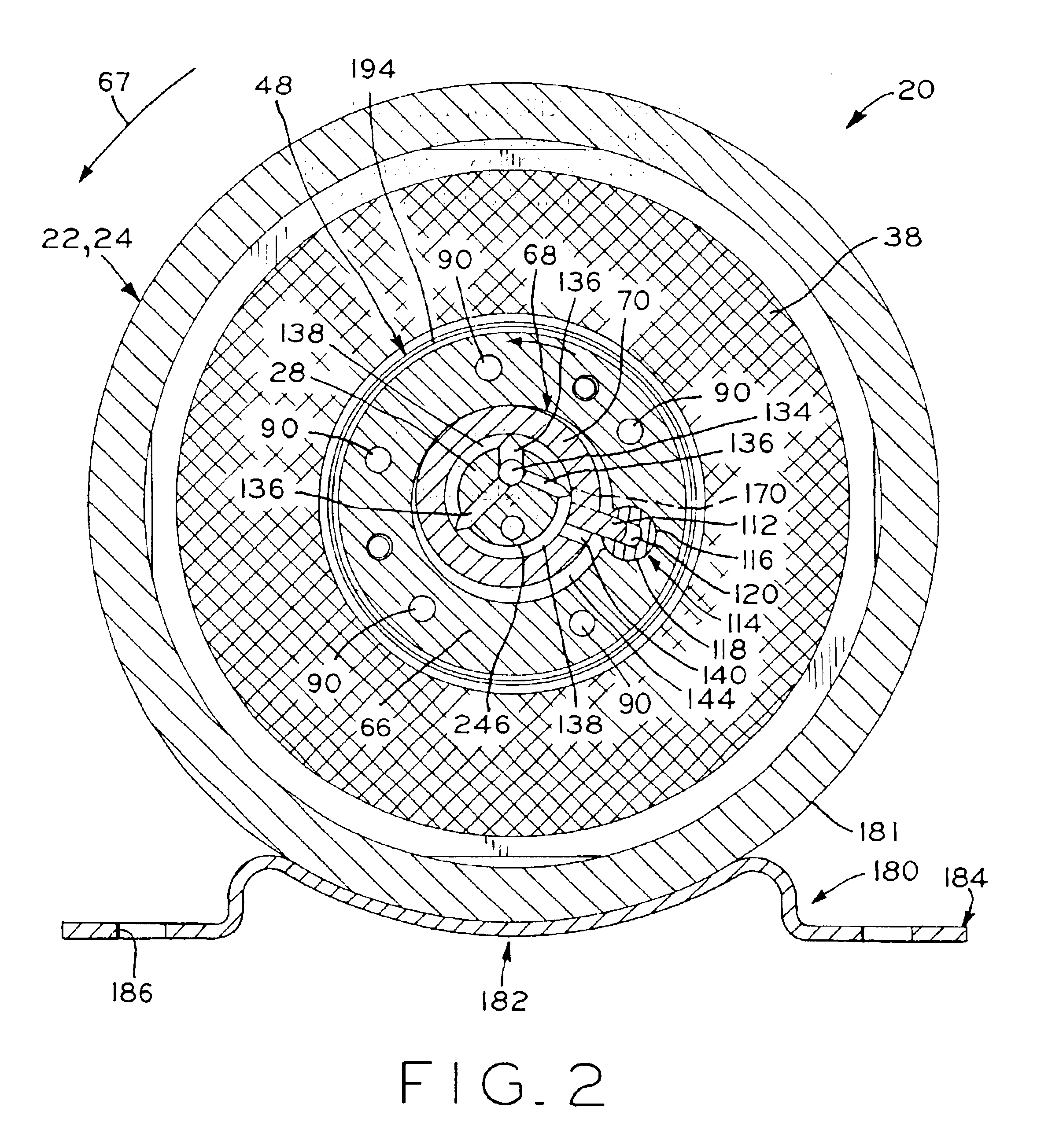

Horizontal two stage rotary compressor

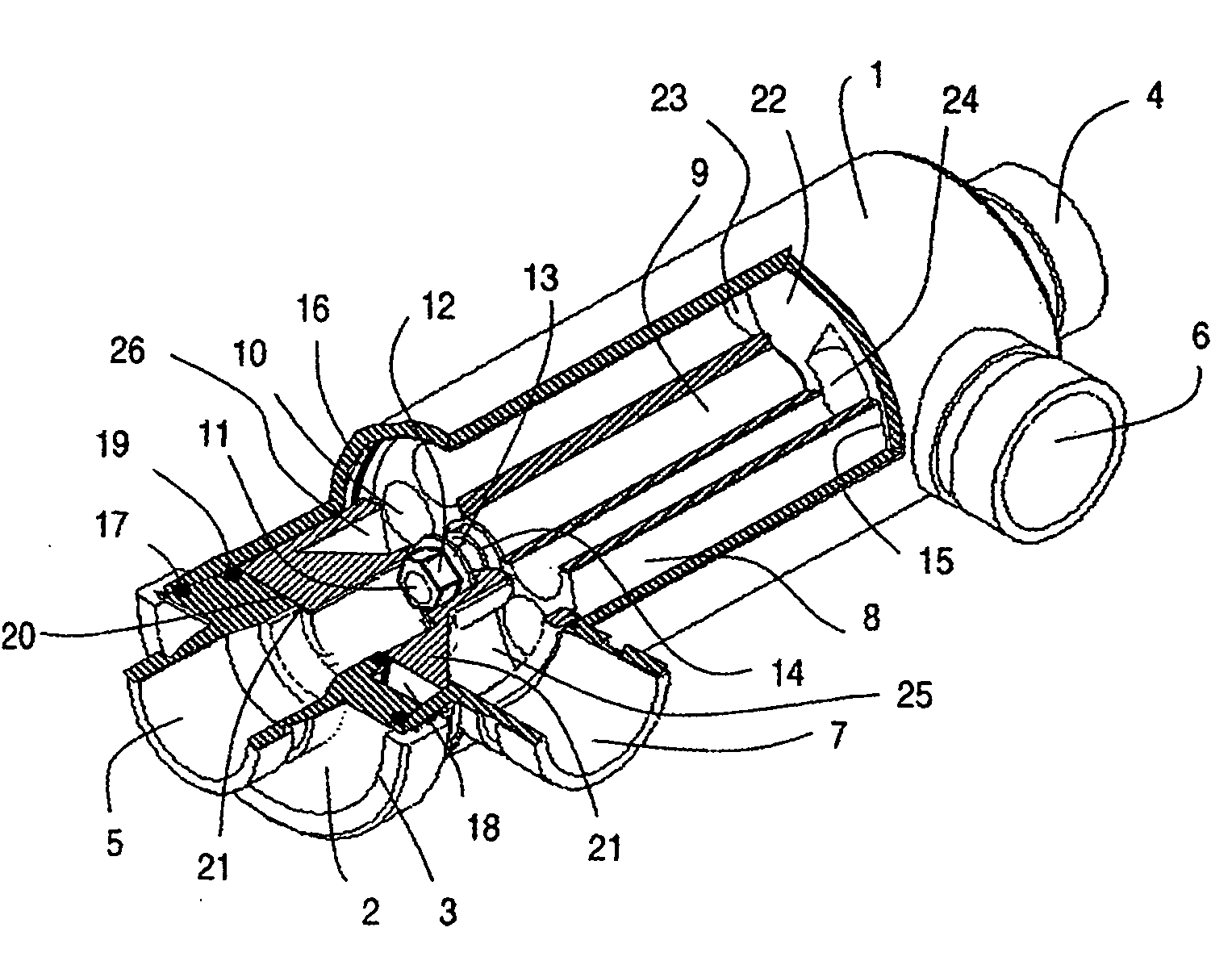

InactiveUS6929455B2Reduce loadEliminate needRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeEngineeringSump

A hermetic two stage rotary compressor having a housing with a stationary shaft fixedly mounted in the housing. A motor having a rotor and a stator is mounted in the housing with the rotor being rotatably mounted on the shaft. A pair of compression mechanisms are rotatably mounted on the shaft with one compression mechanism being located adjacent a first end of the rotor, and one compression mechanism being located adjacent a second end of the rotor. The compression mechanisms are operatively associated with the rotor such that rotation of the rotor drives the compression mechanisms. A fluid flow path is defined in the compressor including a plurality of longitudinal bores formed in the stationary shaft. A mounting assembly is attached to the housing so as to mount the compressor in either a substantially horizontal or vertical orientation. The pump is positioned so as to be at least partially immersed in an oil sump in the housing when the compressor in either orientation.

Owner:TECUMSEH PROD CO

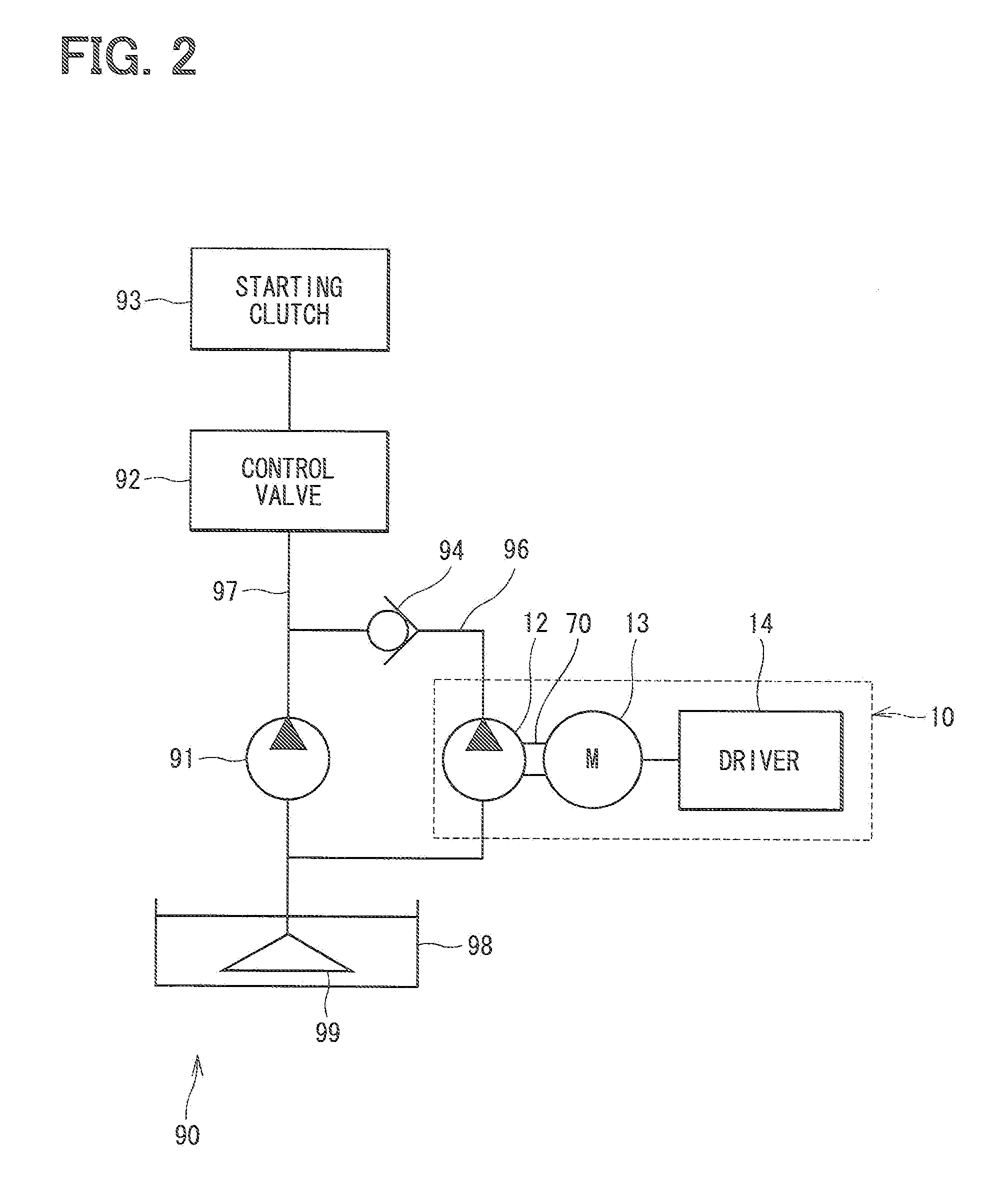

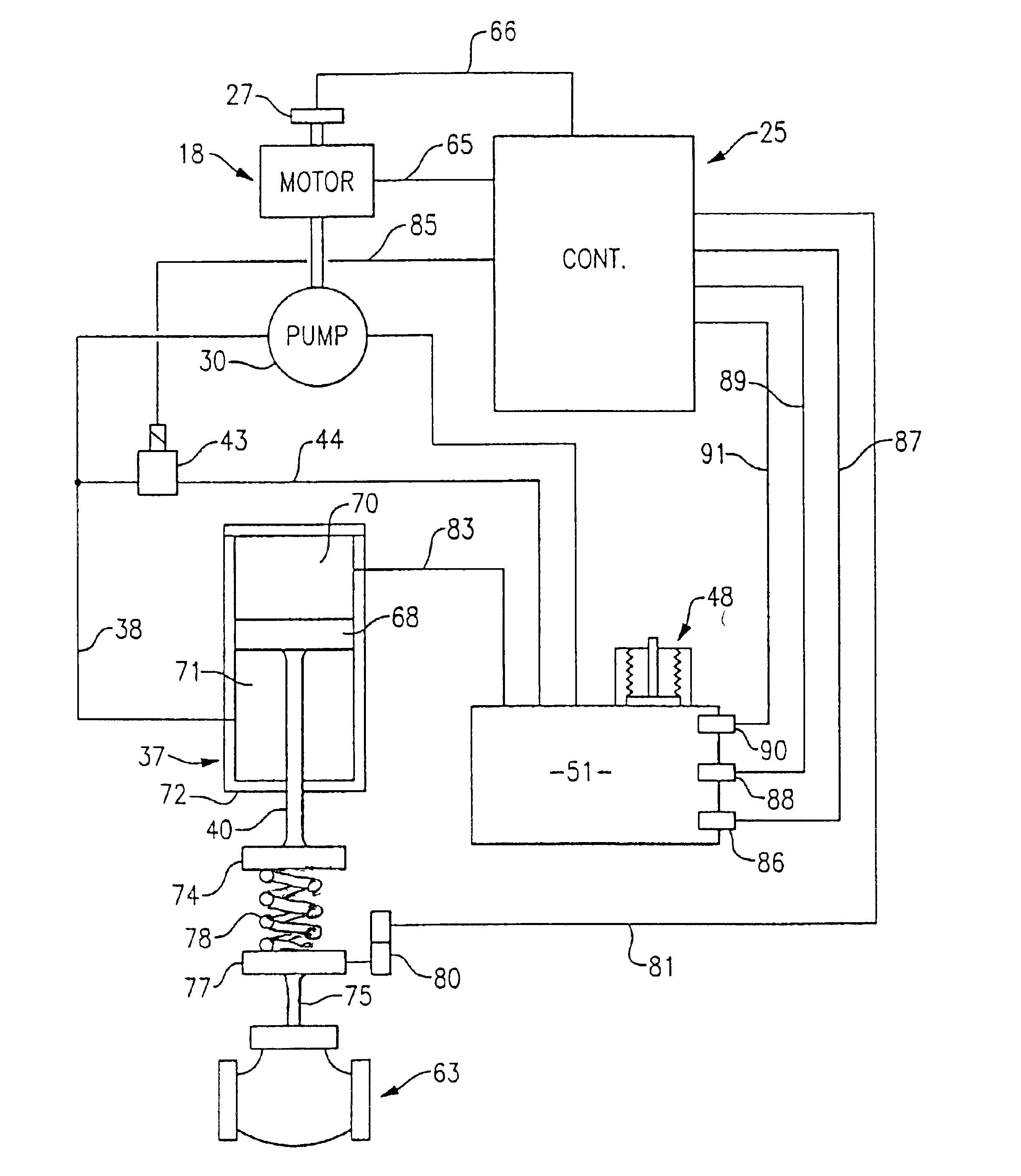

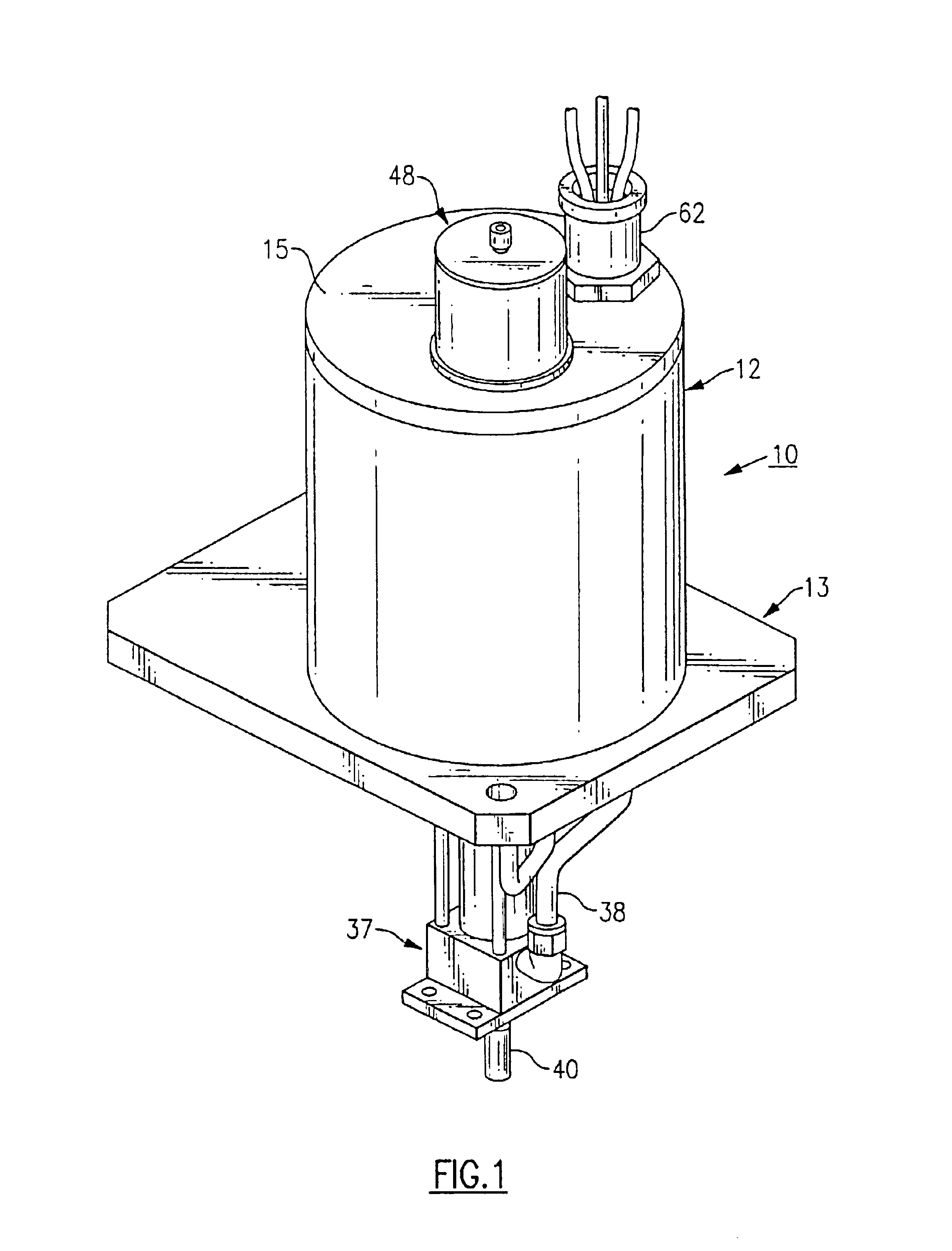

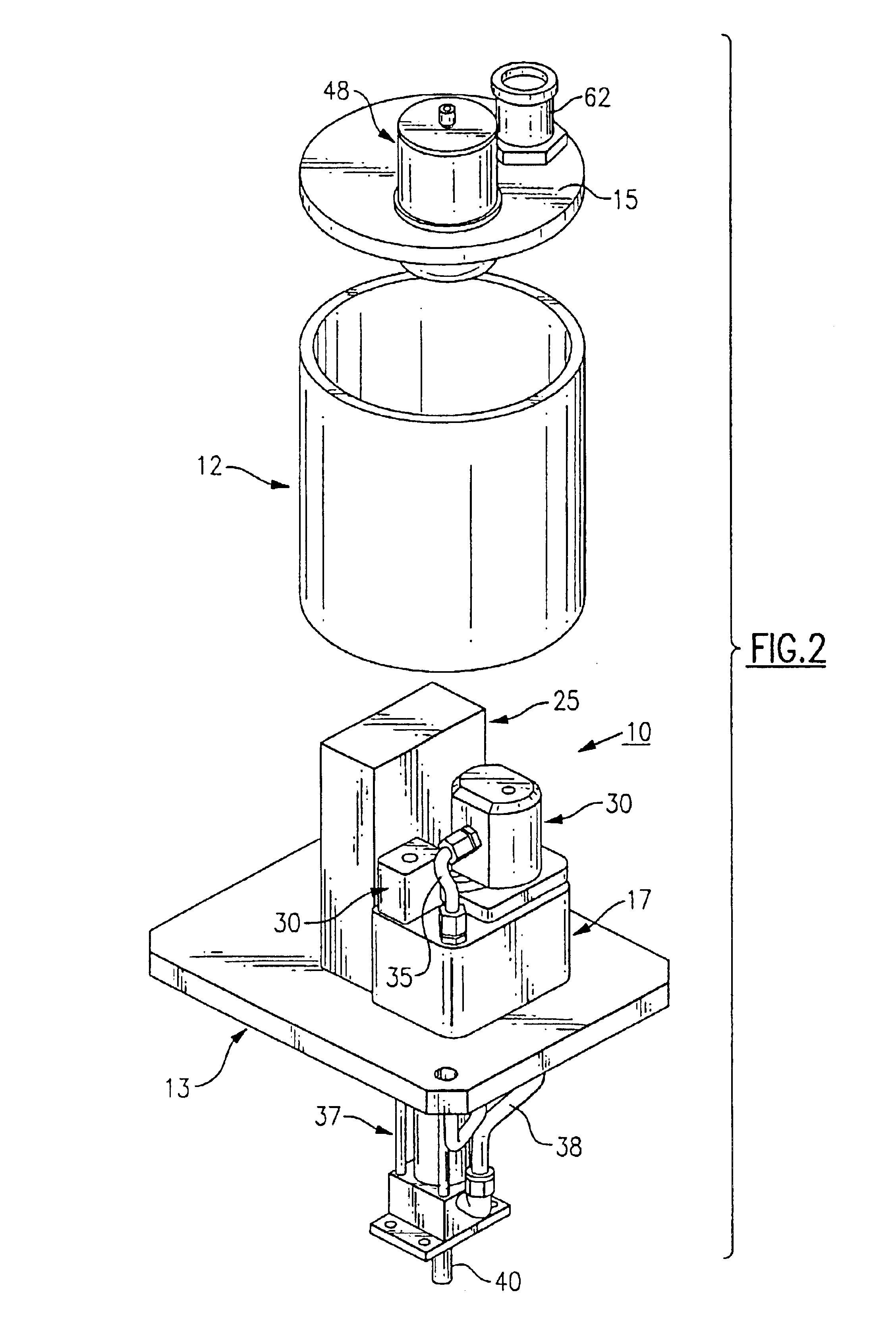

Electro-hydrostatic actuator

InactiveUS6974115B2Reduce transmission lossOperating means/releasing devices for valvesFluid couplingsHydraulic cylinderMotor drive

An electro-hydrostatic actuator having a sealed housing filled with a dielectric fluid. A motor driven pump and electronics for controlling the pump are all immersed in the fluid. The pump is arranged to deliver fluid from the housing to a hydraulic cylinder to control the positioning of the piston rod. A solenoid operated valve is integrated as a bypass or tip valve for quick fail safe position. The actuator is ideally suited to control various types of plunger valves. In one embodiment of the invention, the hydraulic cylinder is located outside of the housing and in another embodiment the cylinder is located inside of the housing.

Owner:YOUNG & FRANKLIN

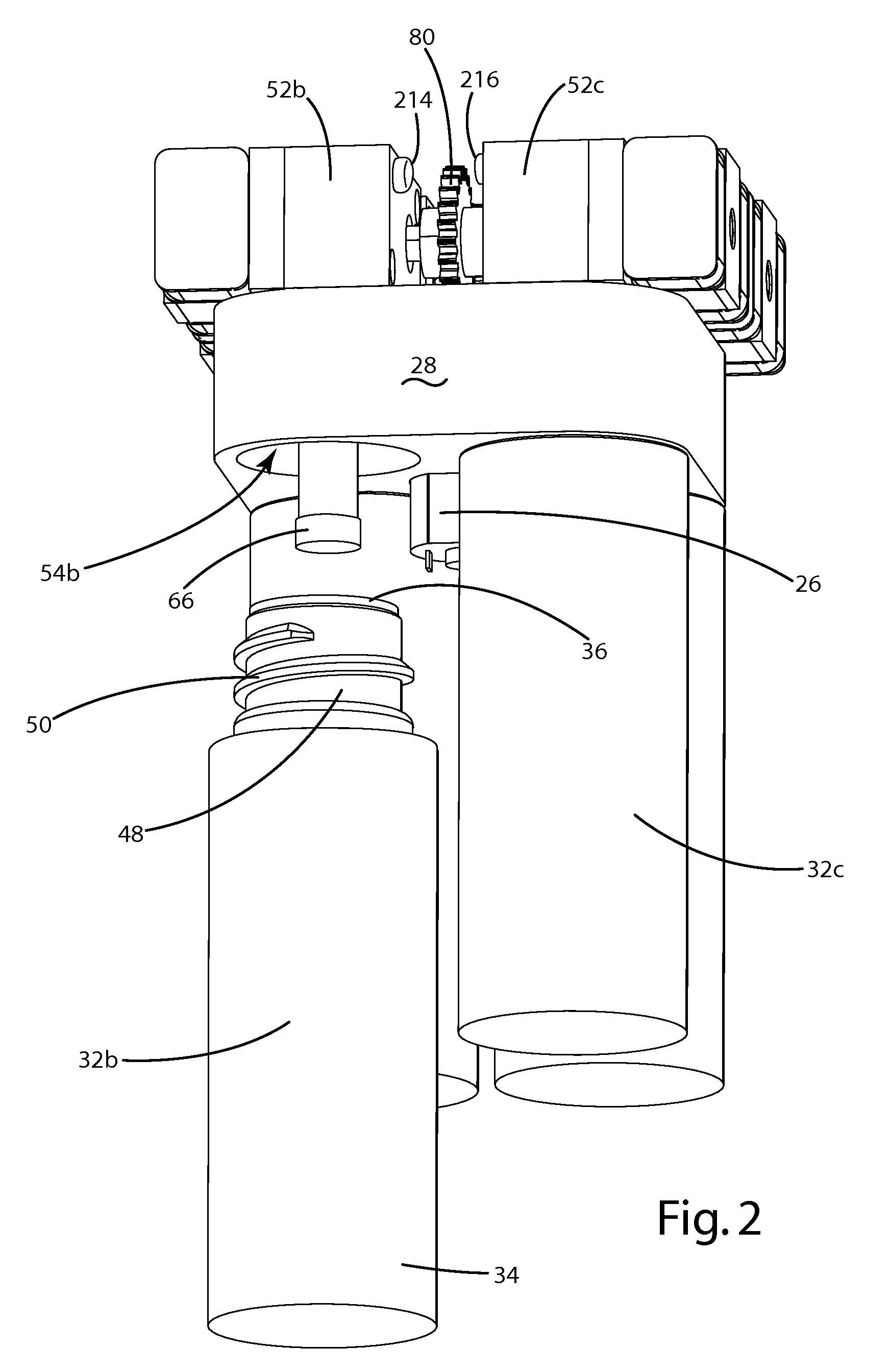

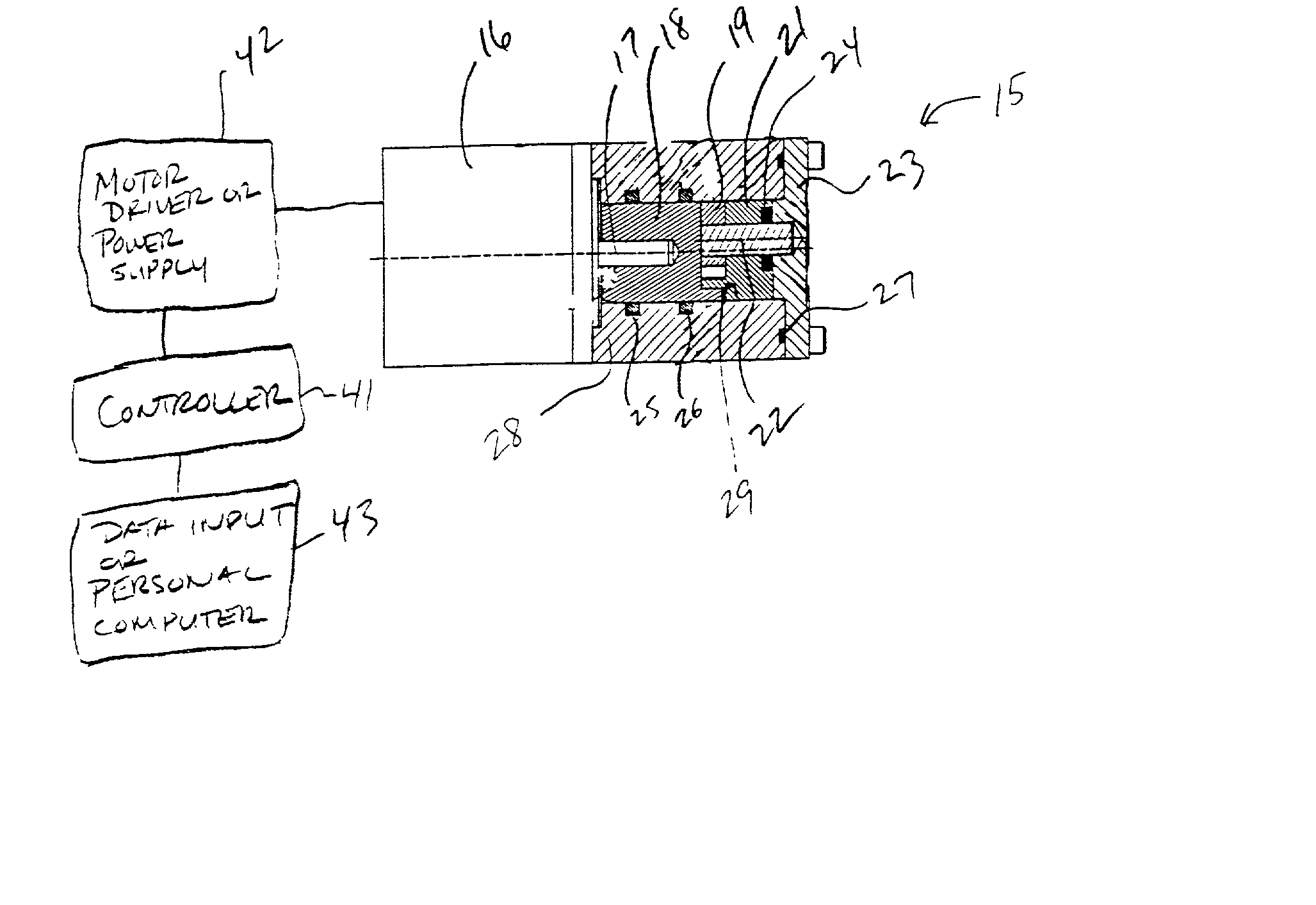

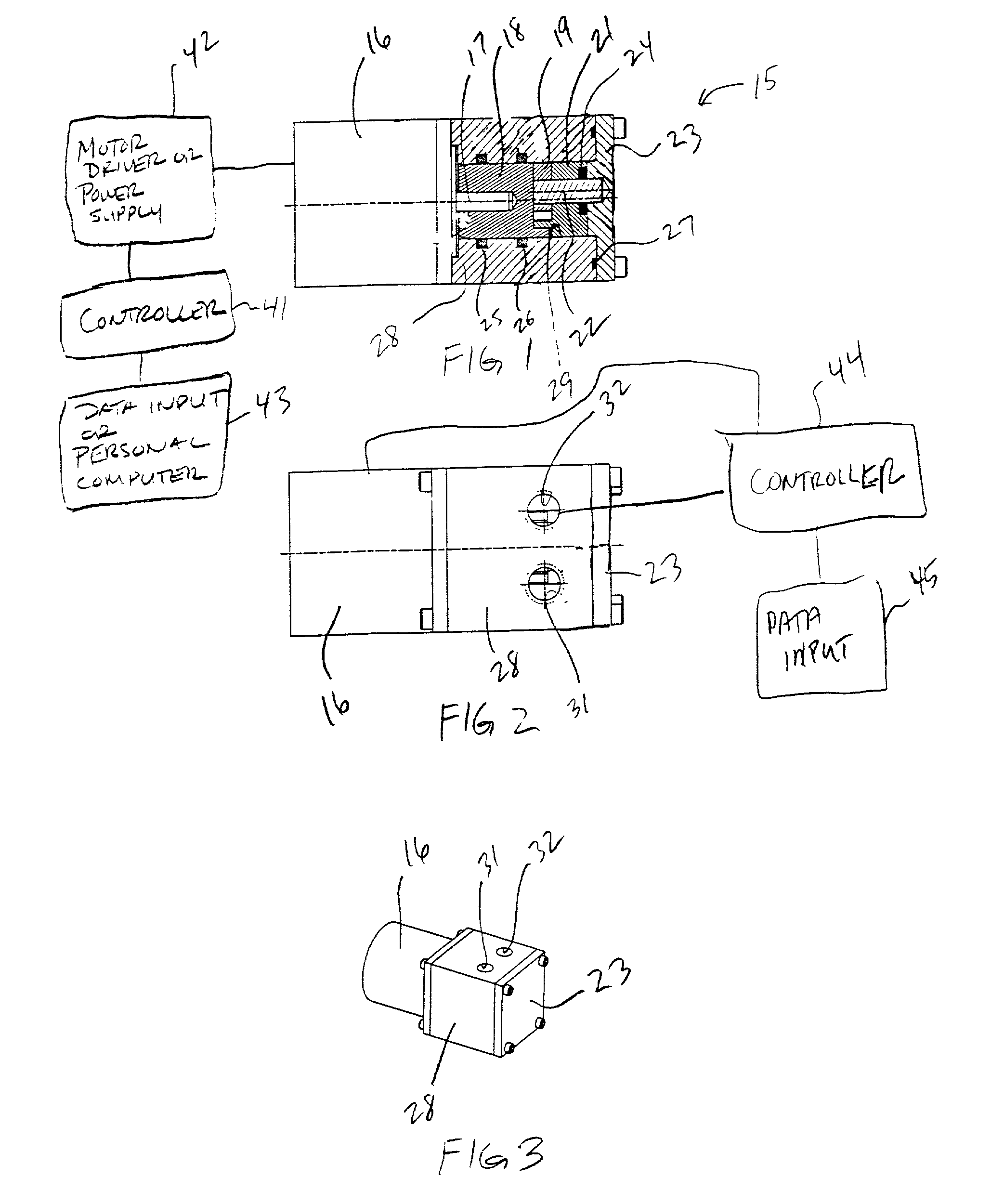

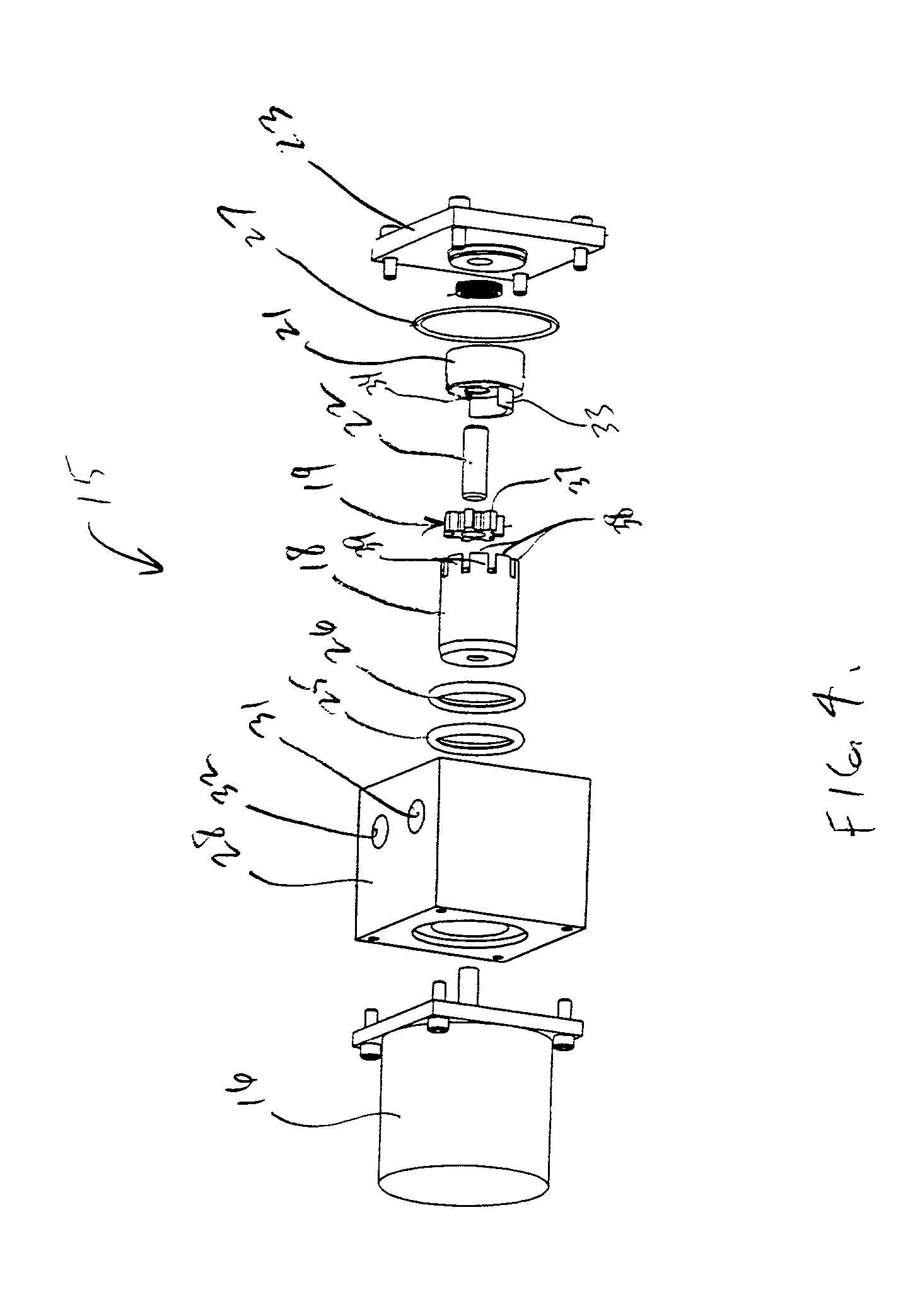

Liquid dispensing pump system

An internal gear pump including a stepper motor coupled to a drive shaft that is coupled to a rotor and meshed with an idler is disclosed. A controller is linked to the stepper motor. The stepper motor imparts a stepped rotational movement to the drive shaft wherein a single 360° rotation of the drive shaft comprises a plurality of steps. The controller sends a signal to the stepper motor to rotate the drive shaft a predetermined number of steps, based upon an inputted dispense amount. The signal causes the stepper motor to rotate the drive shaft a predetermined number of steps. The controller calculates the predetermined number of steps based upon the inputted dispense amount using an algorithm that is derived experimentally that defines a relationship between dispense amount and the number of steps required for each dispense amount. The algorithm is unique for each fluid to be pumped. A head surface area that is planar with the exception of an aperture for receiving the idler pin and a crescent is provided for increased accuracy.

Owner:FLUID MANAGEMENT LLC

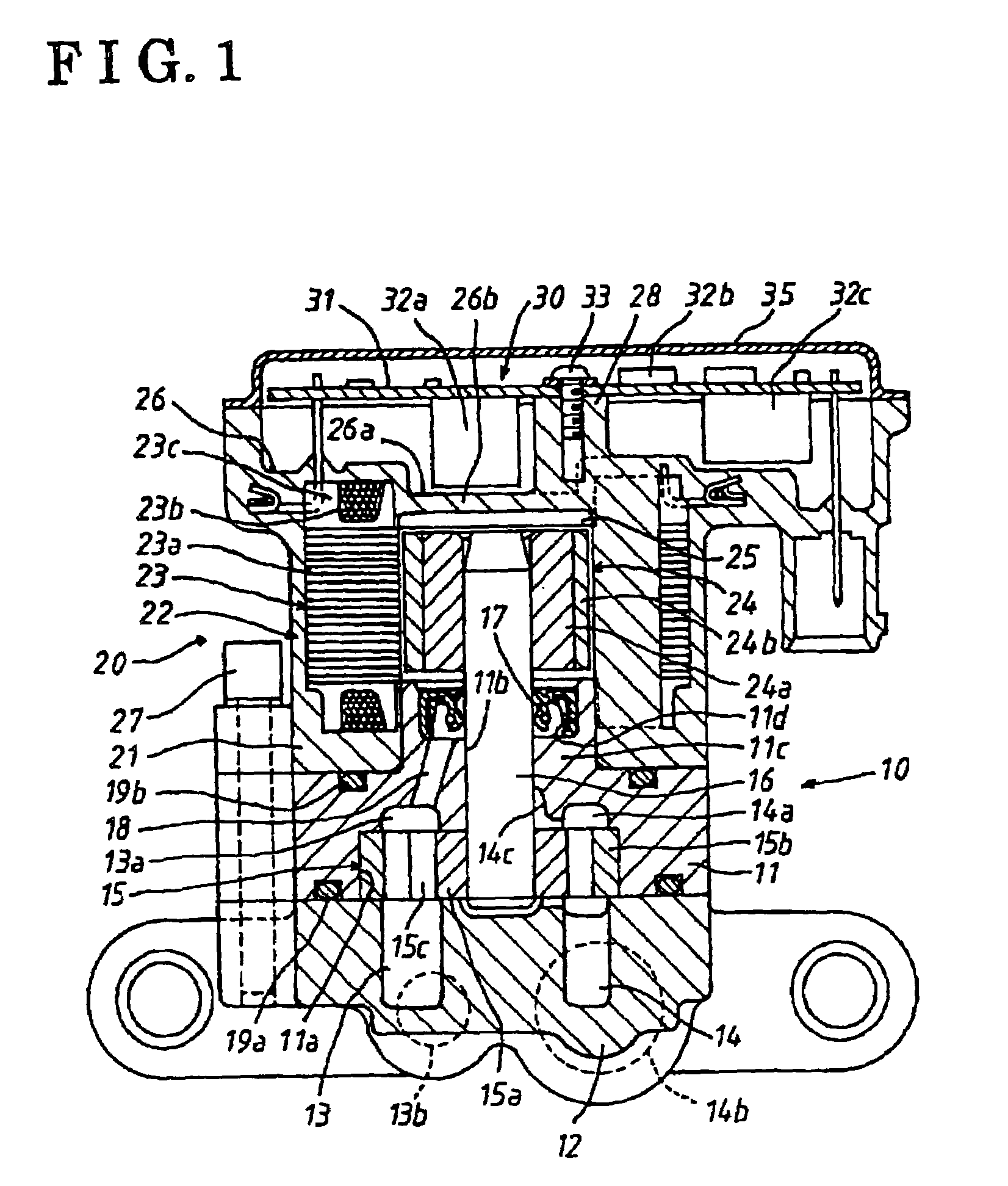

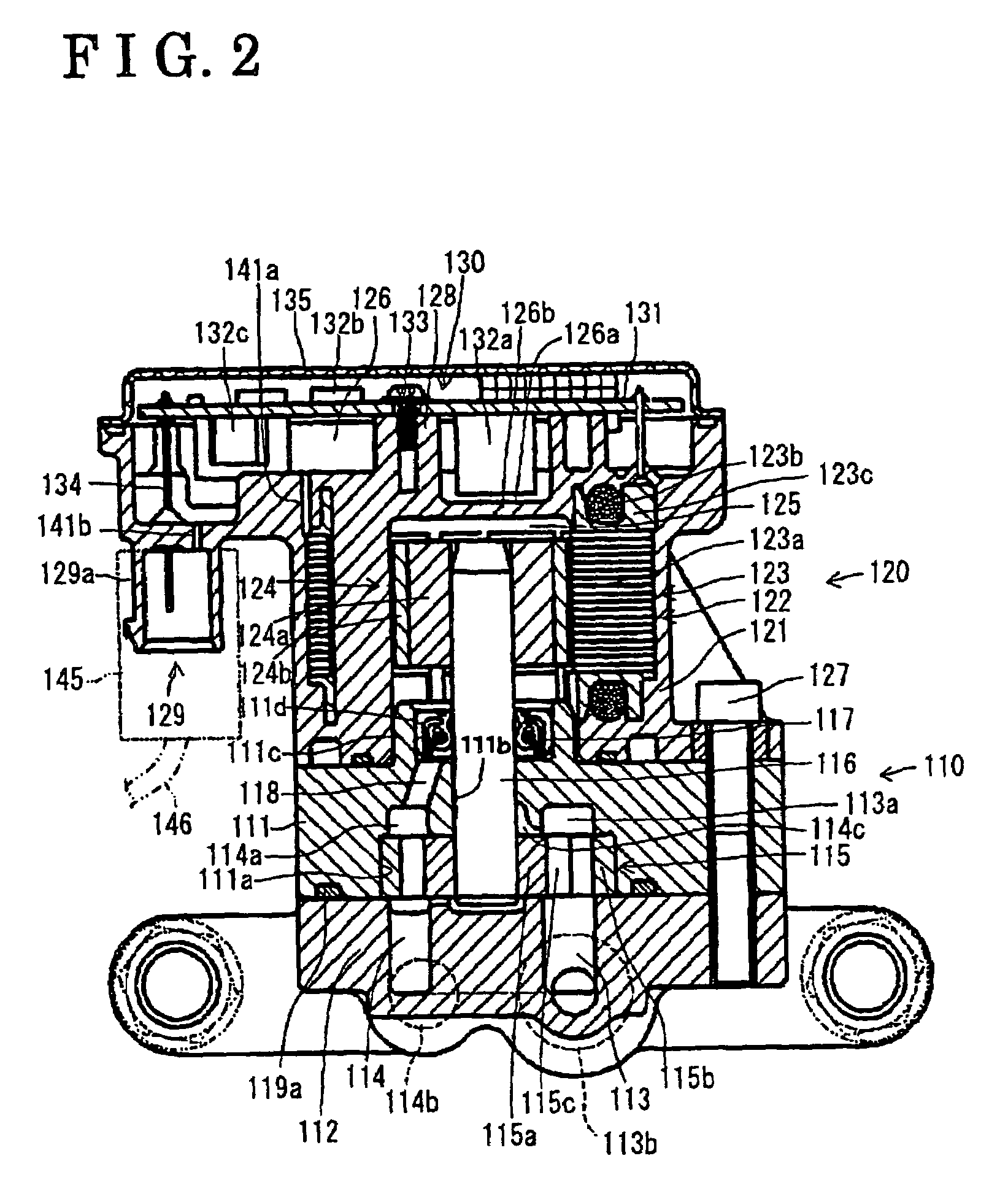

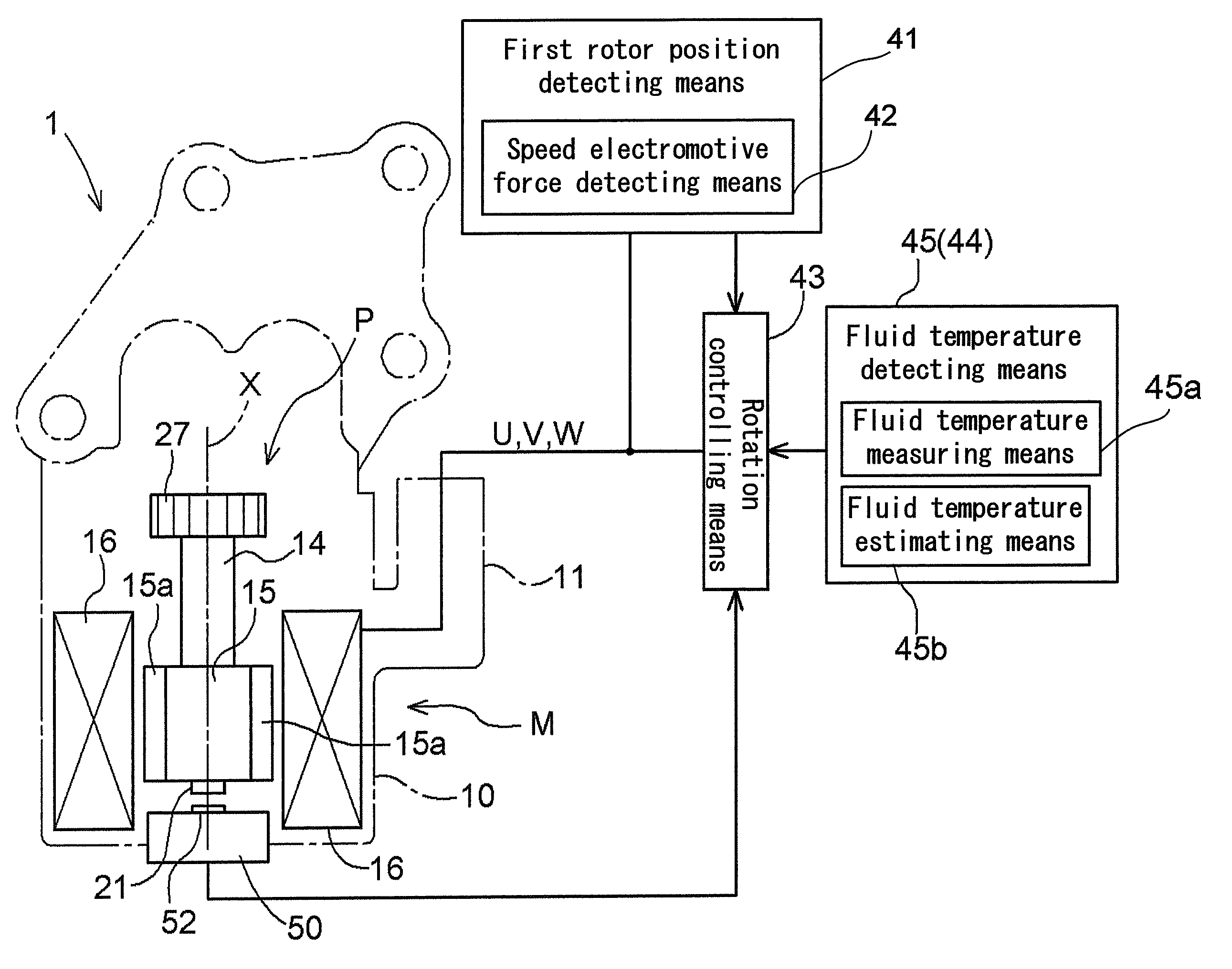

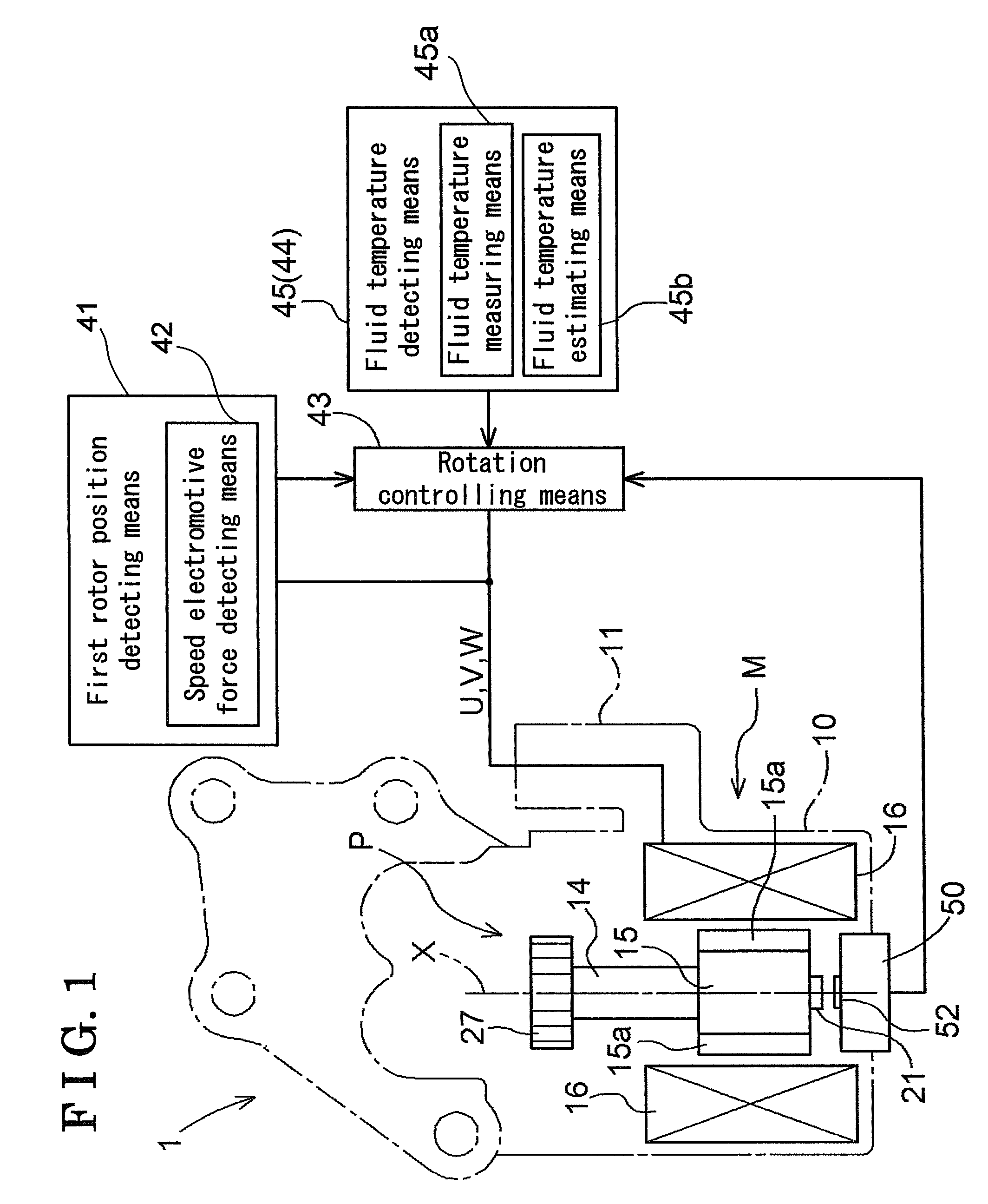

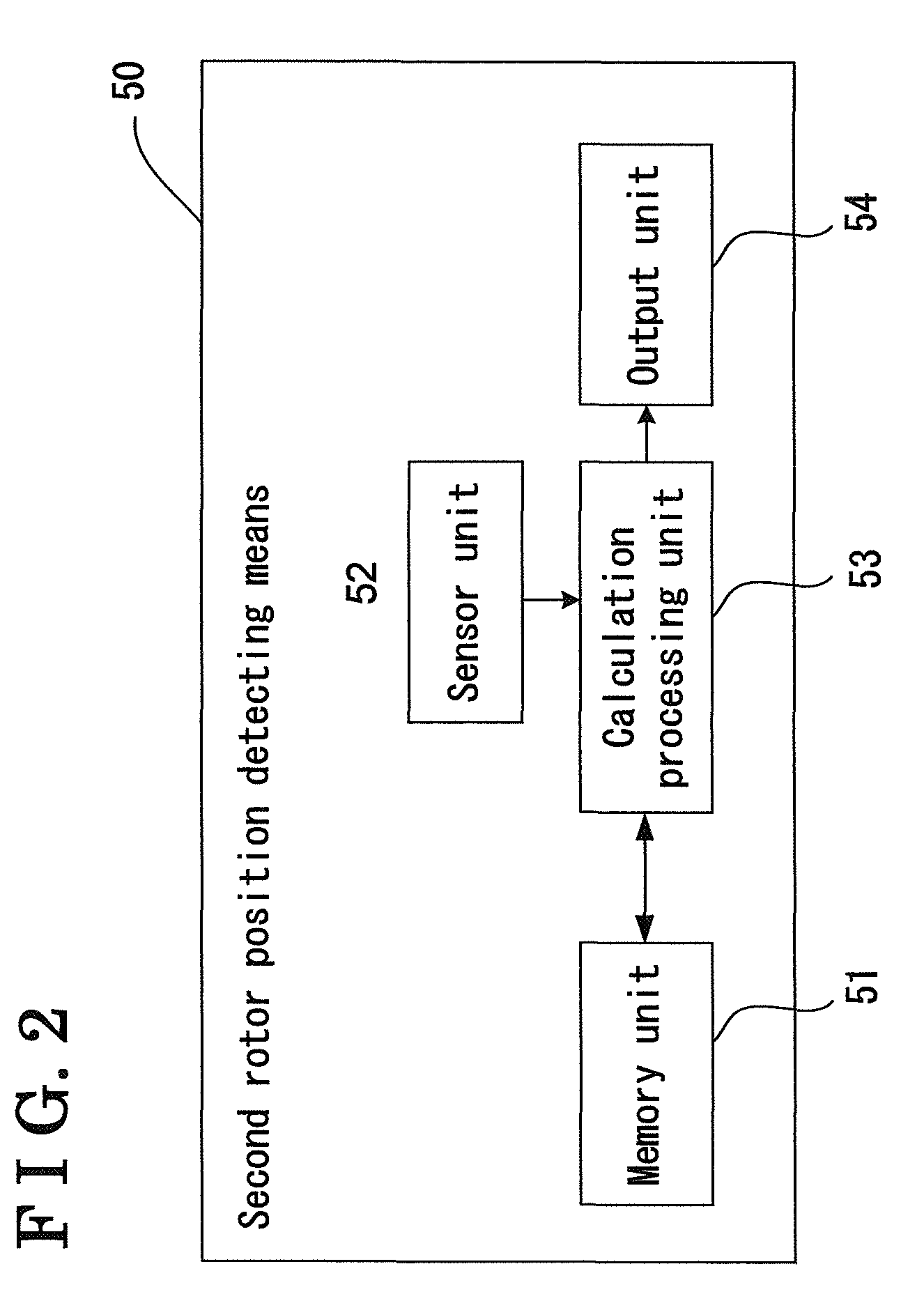

Electrically operated hydraulic pump

An electrically operated hydraulic pump having a pump portion and a motor portion includes rotation controlling means controlling rotation of a rotor, first rotor position detecting means detecting rotational position of the rotor on the basis of speed electromotive force induced by exciting coils, second rotor position detecting means detecting the rotational position of the rotor on the basis of magnetic field of a magnet provided at the motor portion, and motor operating condition detecting means detecting operating condition of the motor portion. The rotation controlling means switches a first rotation controlling based on the rotational position of the rotor detected by the first rotor position detecting means, and a second rotation controlling based on the rotational position of the rotor detected by the second rotor position detecting means, on the basis of a result detected by the motor operating condition detecting means.

Owner:AISIN SEIKI KK

Pressure exchange apparatus with dynamic sealing mechanism

InactiveUS20060037907A1Good sealing contactGeneral water supply conservationSeawater treatmentEngineeringHigh pressure

A pressure exchange device is provided that utilizes a rotor assembly inside a housing to transfer the pressure of a fluid from one high pressure fluid to another low pressure fluid. The housing may comprise a pressurized fluid contained therein to provide a sealing force to reduce fluid leakage between the spinning rotors and the housing. The sealing force and wear characteristics may be controlled to reduce leakage and wear of the pressure exchange device. The rotor assembly may be driven in either direction and the high pressure ports may be switched with the low pressure ports if desired.

Owner:SHUMWAY SCOTT

Pressure exchange apparatus with integral pump

InactiveUS7214315B2Rotary/oscillating piston combinations for elastic fluidsPump componentsEngineeringHigh pressure

A pressure exchange device is provided that utilizes an integral high pressure boost pump that is in fluid communication with a pressure exchange unit. An optional low pressure boost pump unit may also be provided. The pressure exchange unit comprises a rotating rotor assembly inside a housing to transfer the pressure of a fluid from one high pressure fluid to another low pressure fluid.

Owner:SHUMWAY SCOTT

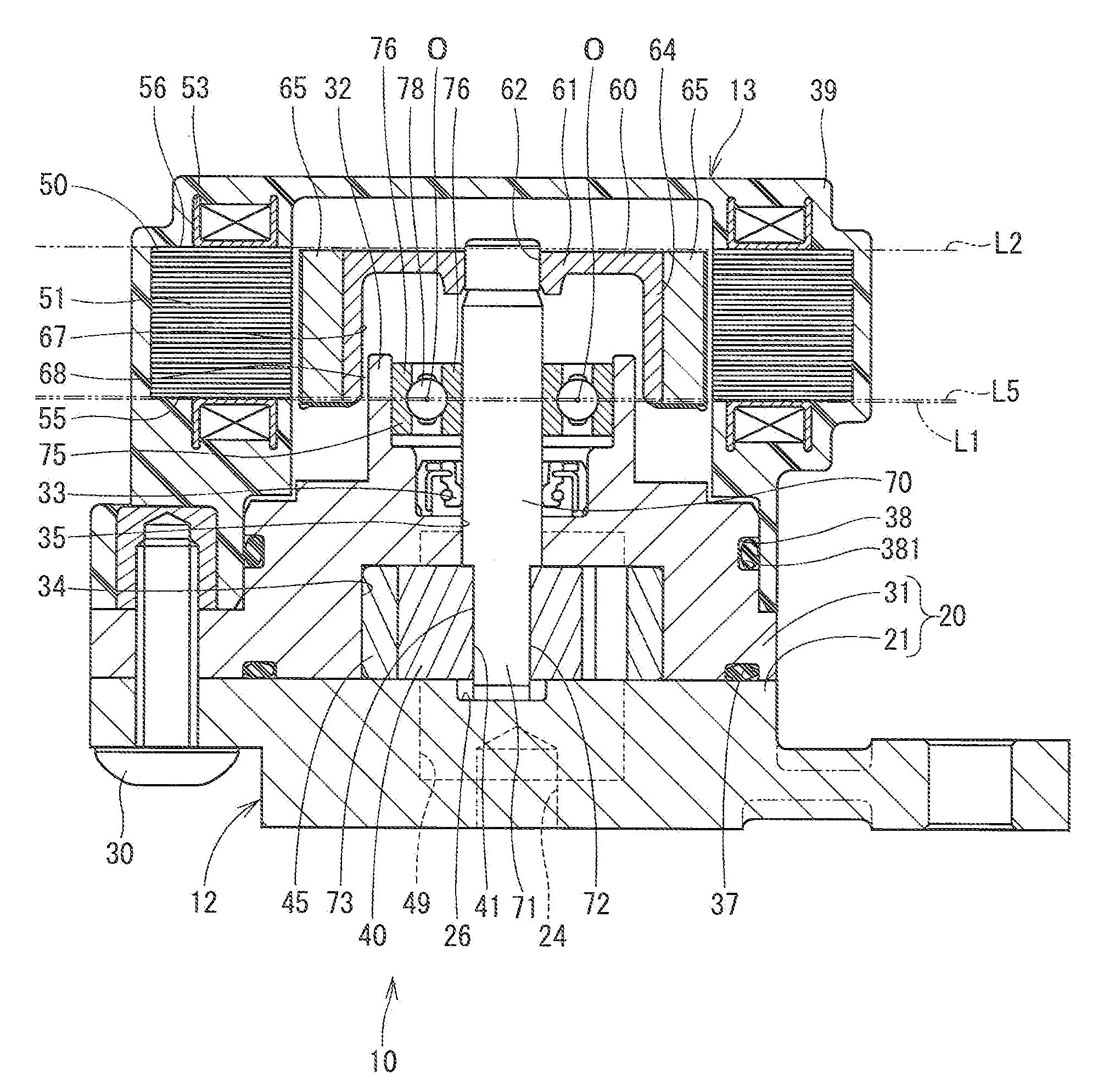

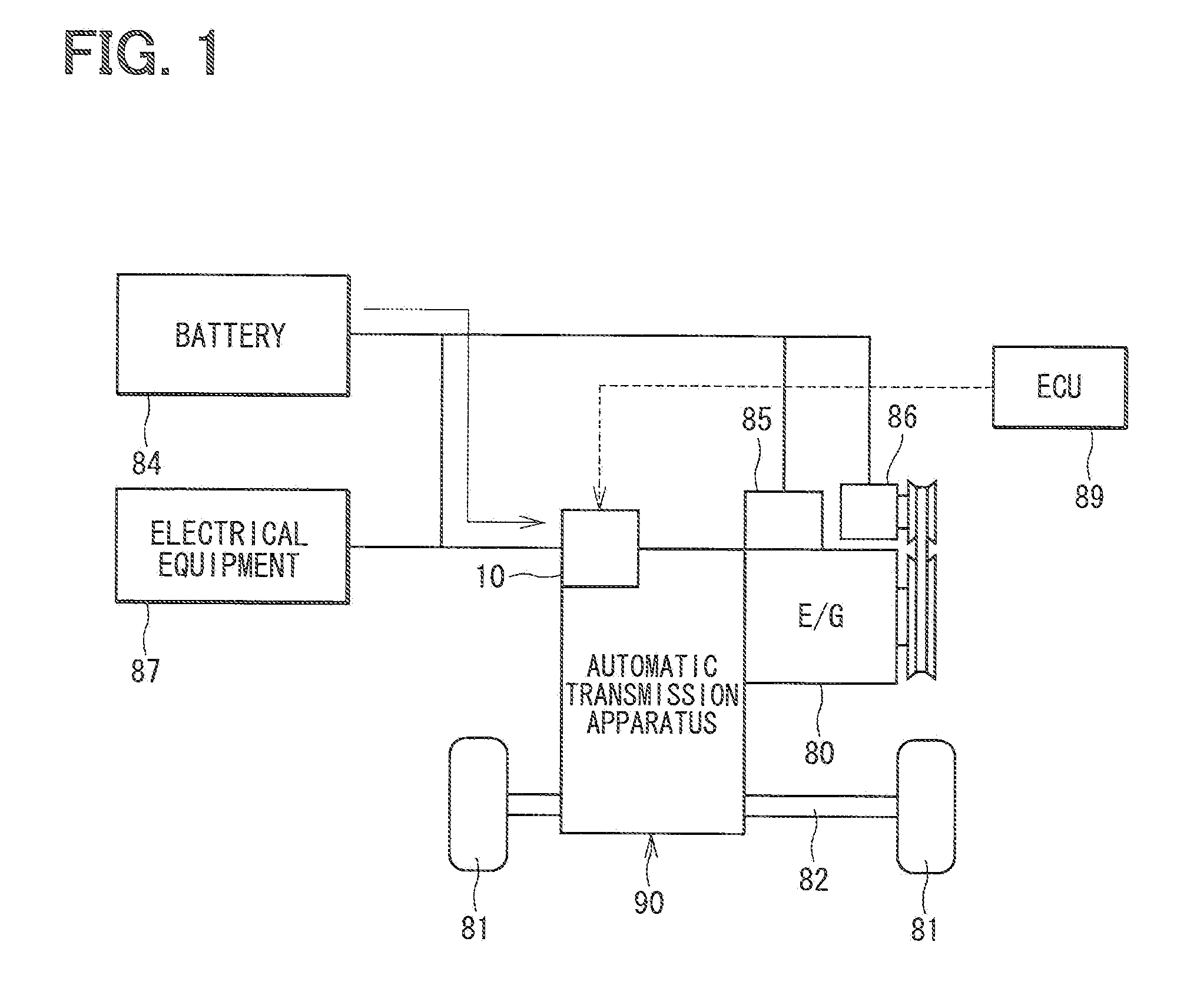

Mechanical and Electrical-Integrated Drive Unit

InactiveUS20140054991A1Improve layout flexibilityMinimize impactAssociation with control/drive circuitsRotary piston pumpsEngineeringElectronic component

A mechanical and electrical-integrated drive unit is provided that is configured to be able to protect a control circuit board from thermal stress, a contaminant, or operating fluid from a motor housing chamber and that can improve the flexibility of layout of electronic components mounted on the control circuit board. The drive unit includes a motor, a control circuit board for controlling energization of the motor, the circuit board installed integrally with the motor, an obstruction portion isolating the motor from the circuit board, and an inverter housing for the circuit board. A coil wire of the motor is covered at its end by a conductive thin-walled narrow tube so as to be joined to the tube. The tube is fixedly inserted into a through-hole formed in the obstruction portion so that at least the leading end portion of the tube is projected into the inverter housing.

Owner:HITACHI AUTOMOTIVE SYST LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com