Patents

Literature

546results about How to "Improve motor efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

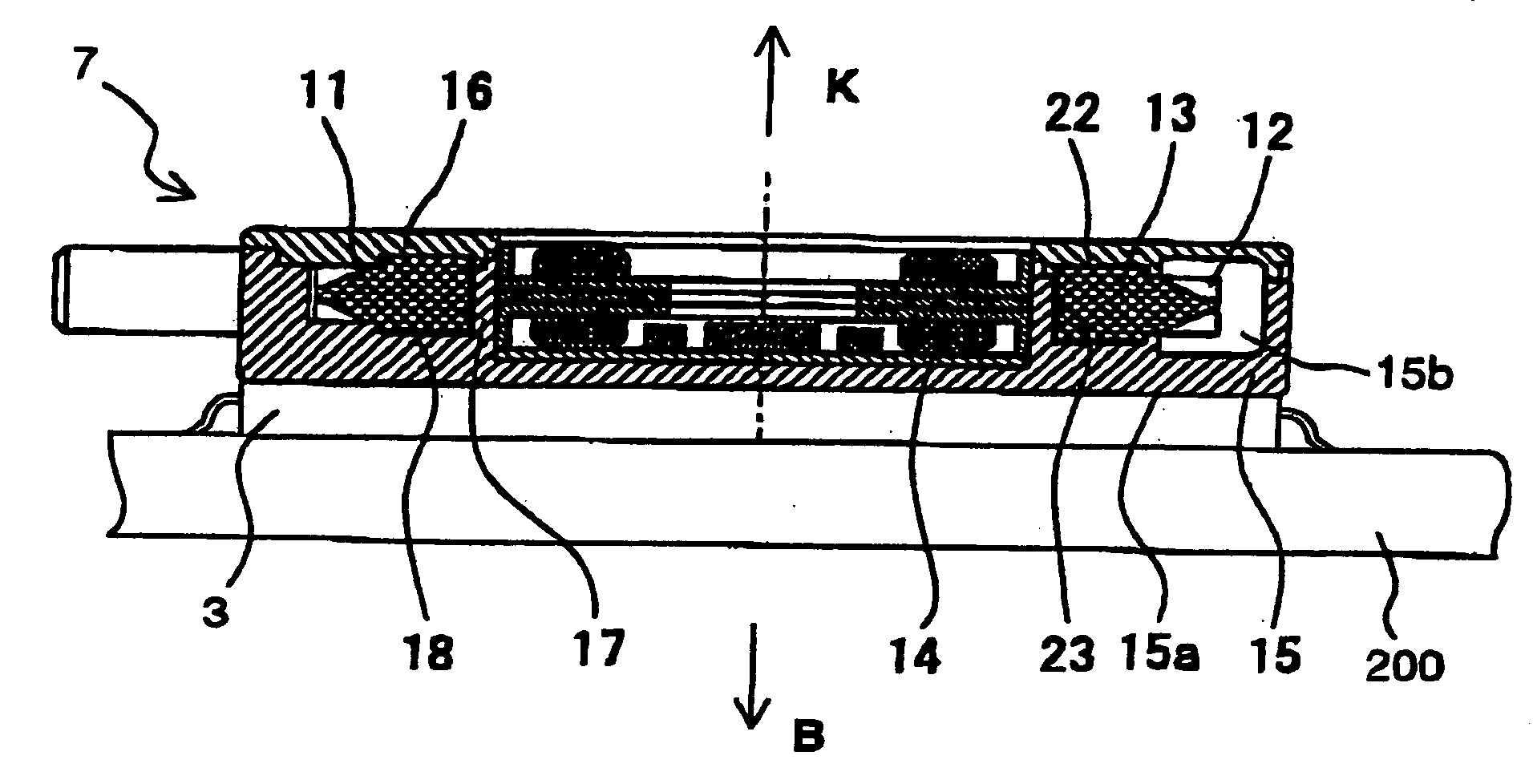

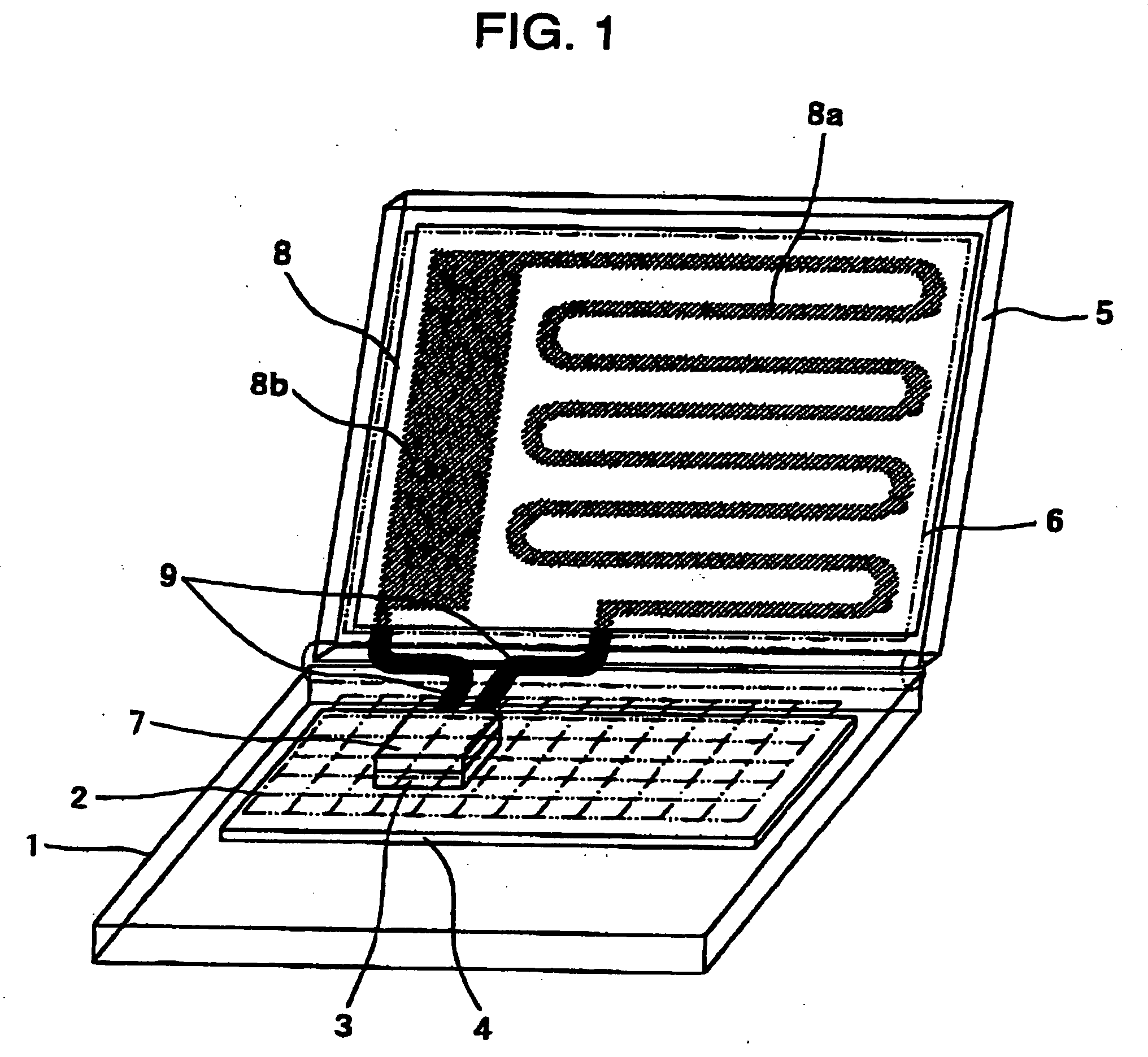

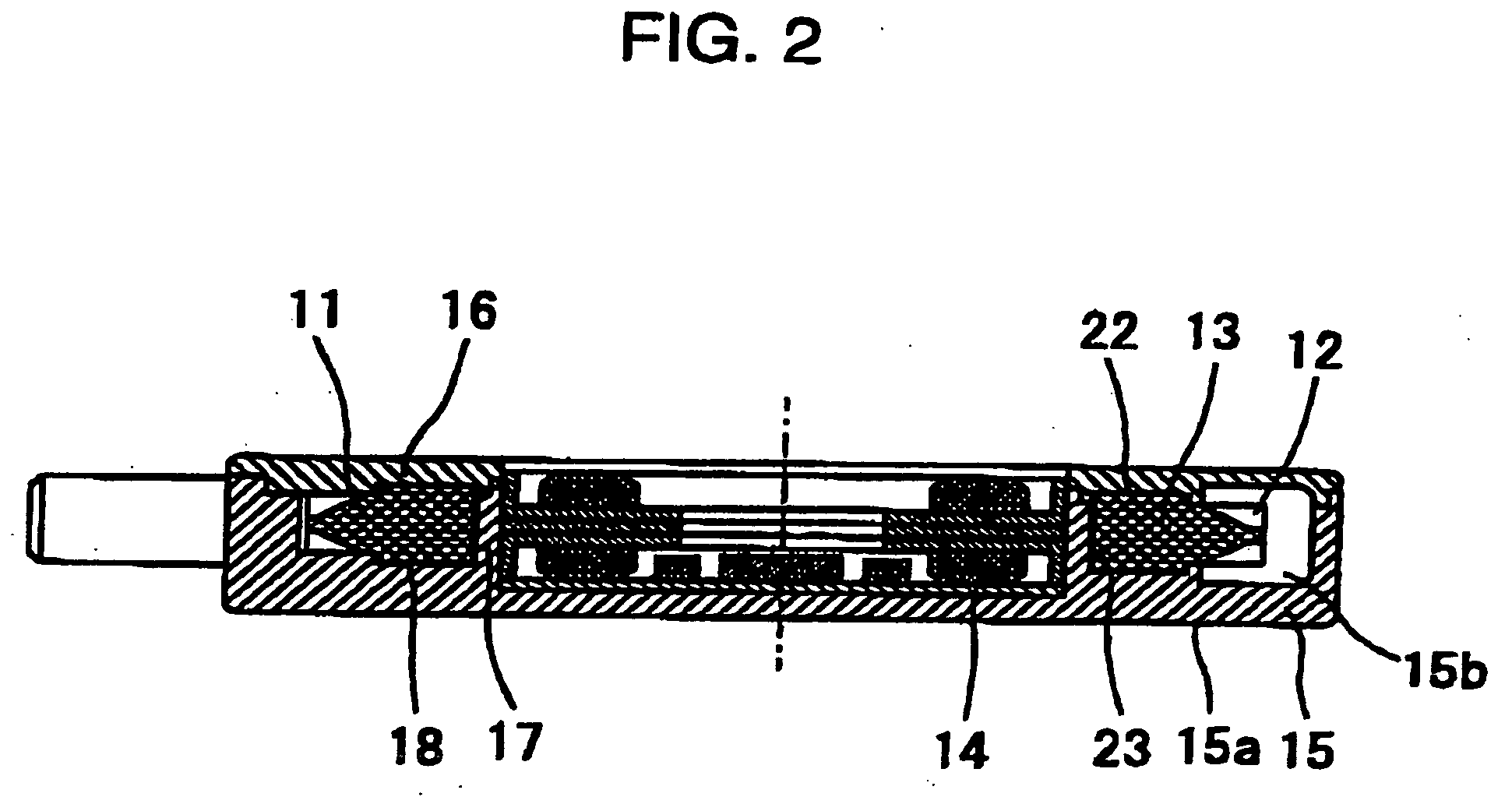

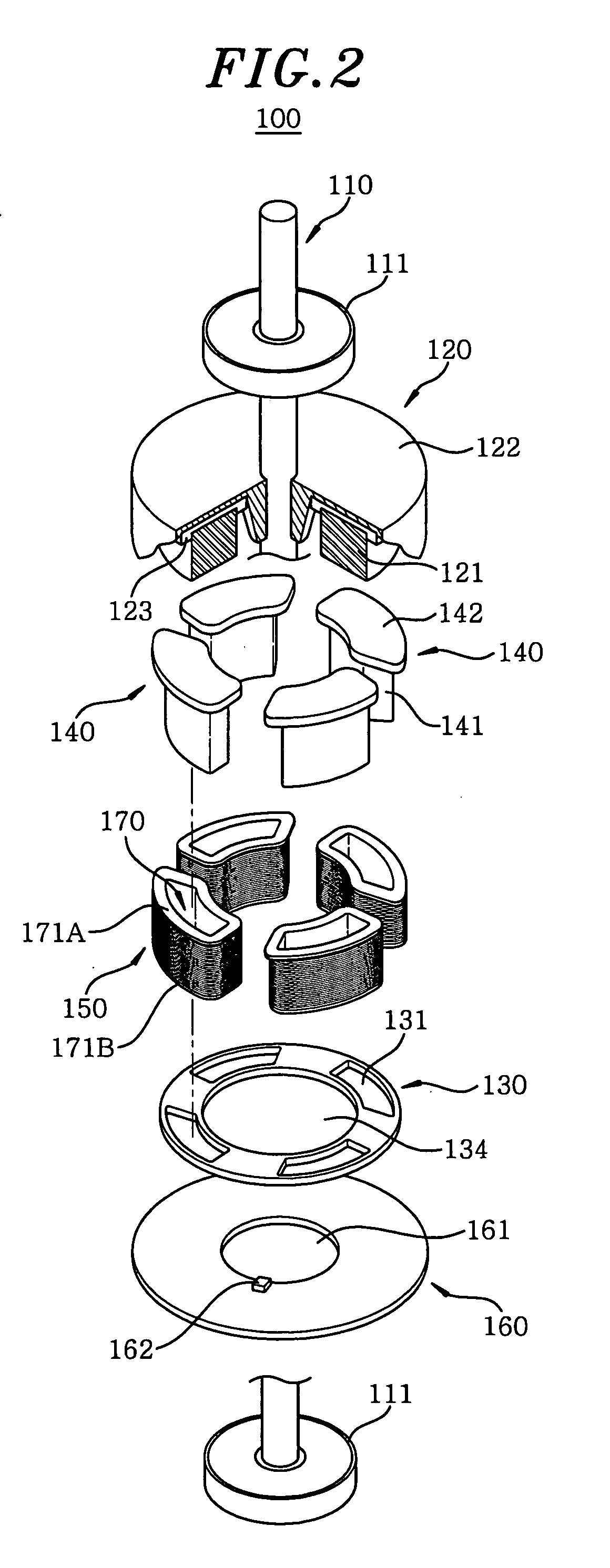

Cooling device and an electronic apparatus including the same

InactiveUS20050117298A1Improve cooling efficiencyEasy constructionDigital data processing detailsSemiconductor/solid-state device detailsCoolant flowNuclear engineering

A cooling device for cooling a heat-generating component includes a circulating passage arranged to have coolant circulate therein, a centrifugal pump including a first case made of metallic material, a second case made of resin material, and an impeller accommodated in the pump chamber, and a radiator provided at the circulating passage and being operable to release heat from the coolant. The first case has a surface arranged to contact the heat-generating component. The second case forms a pump chamber between the first case and the second case. The pump chamber stores the coolant therein. The impeller includes open-type vanes arranged to pressurize the coolant as to have the coolant flow through the circulating passage. The cooling device has a high cooling efficiency as well as a high operating efficiency of the motor while having a simple construction and a small overall size and a small thickness.

Owner:PANASONIC CORP

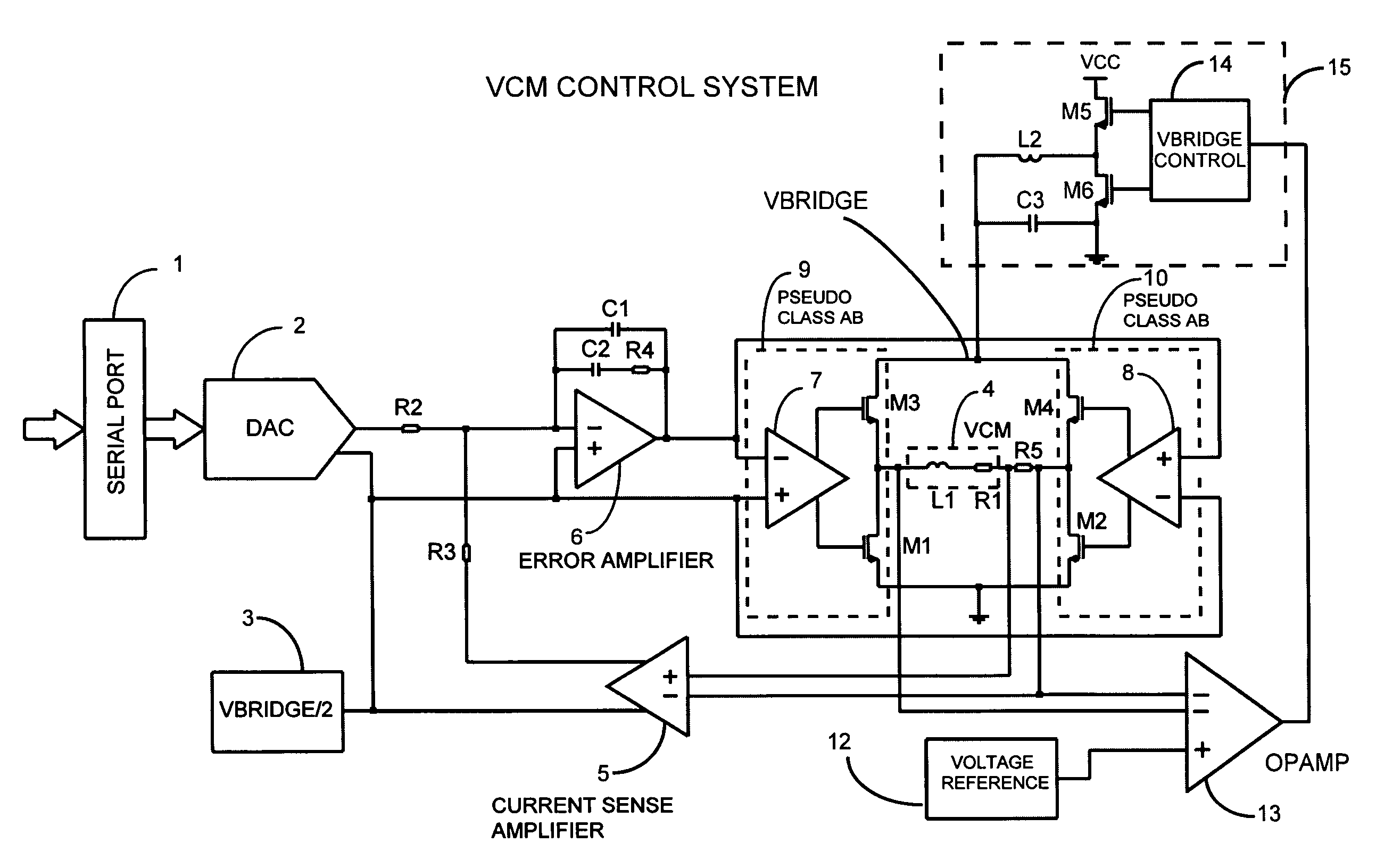

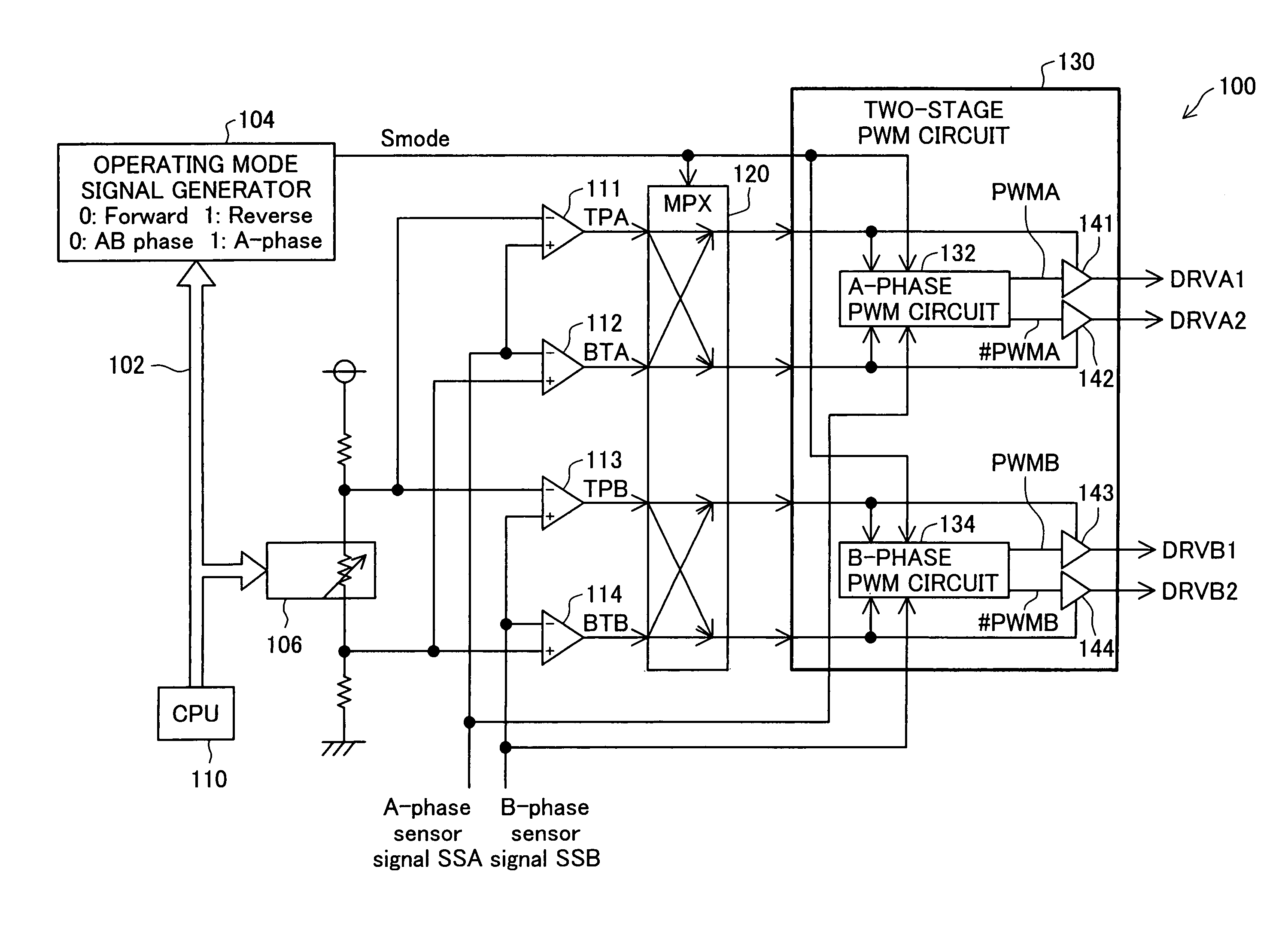

Class H Drive

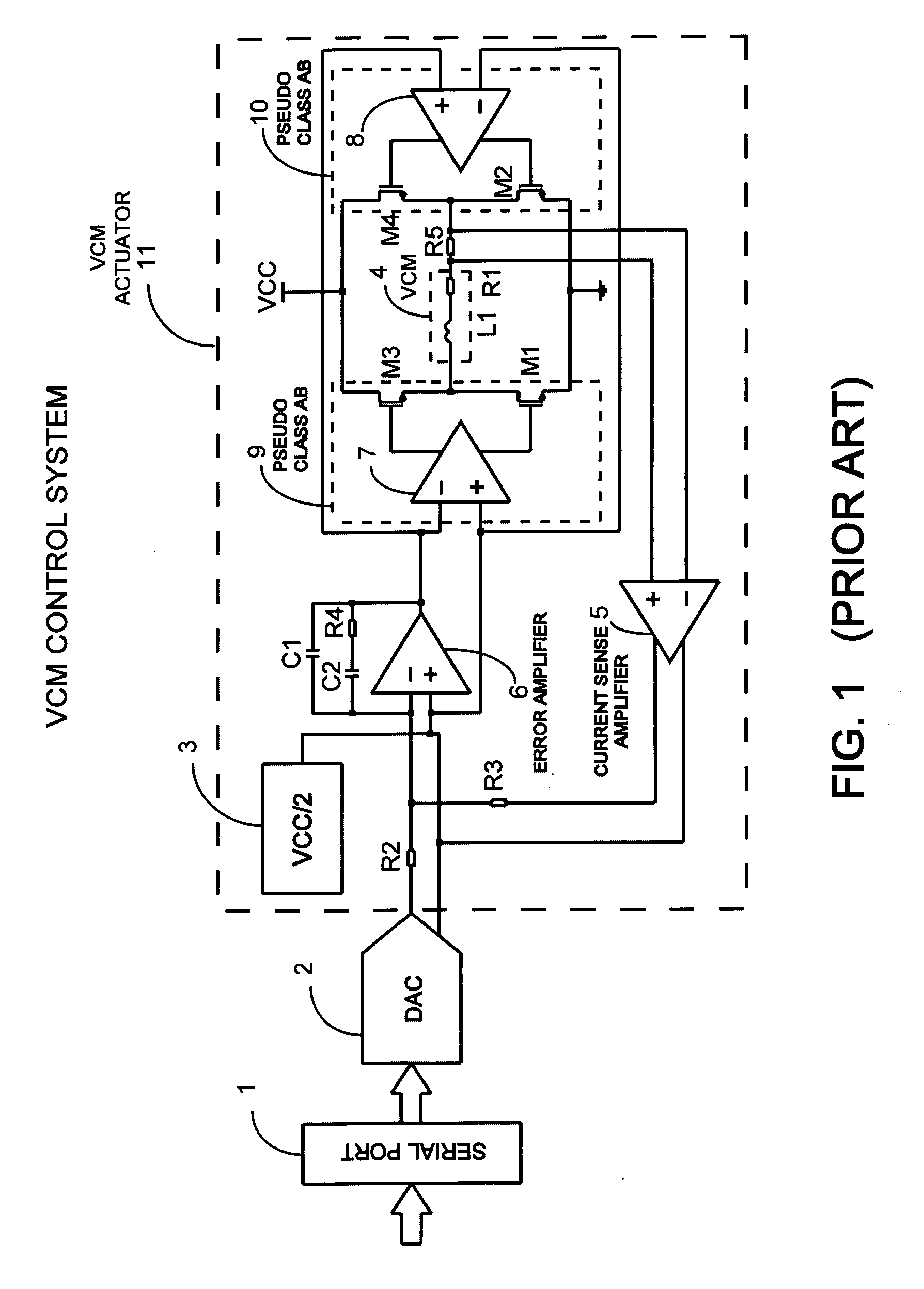

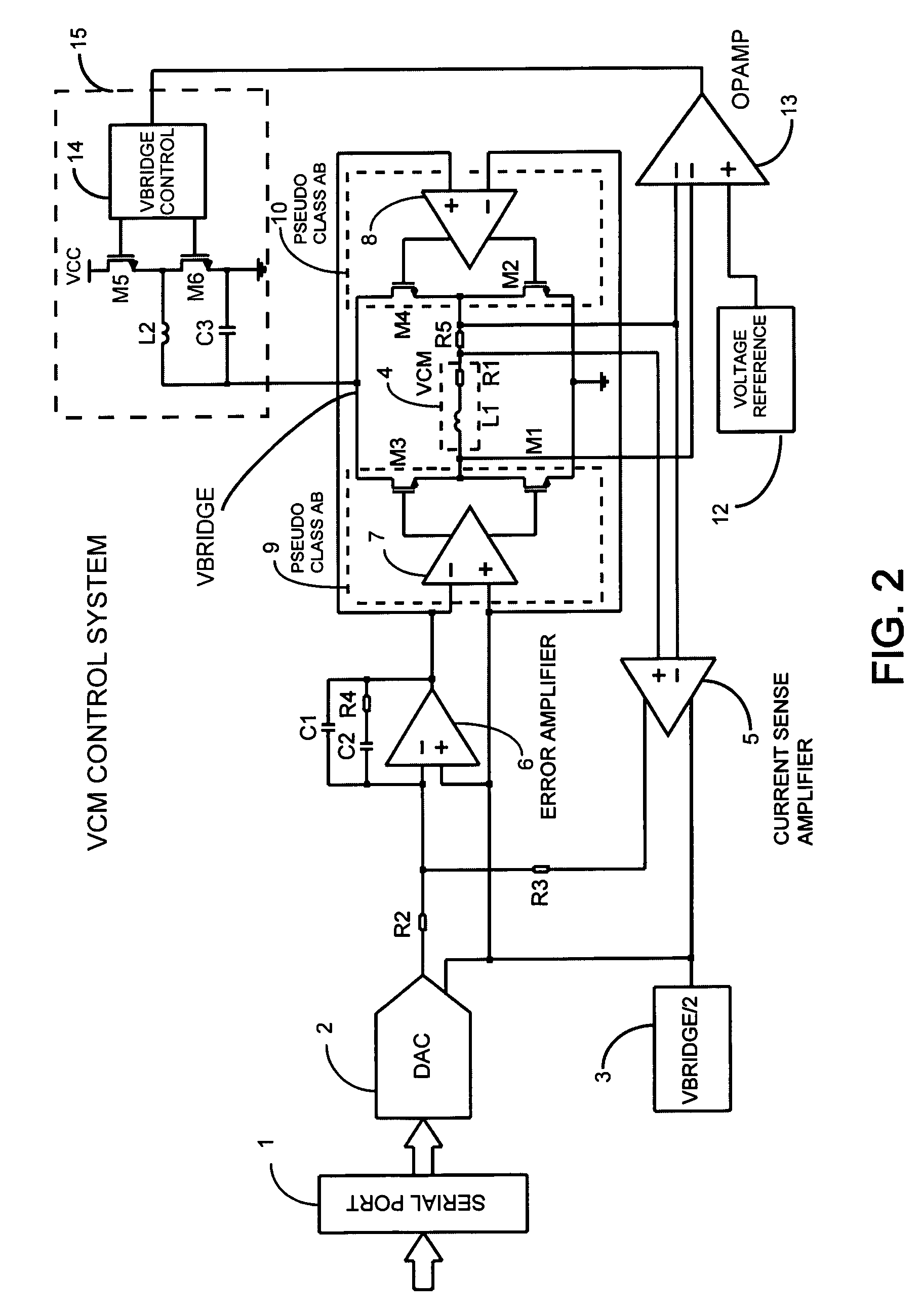

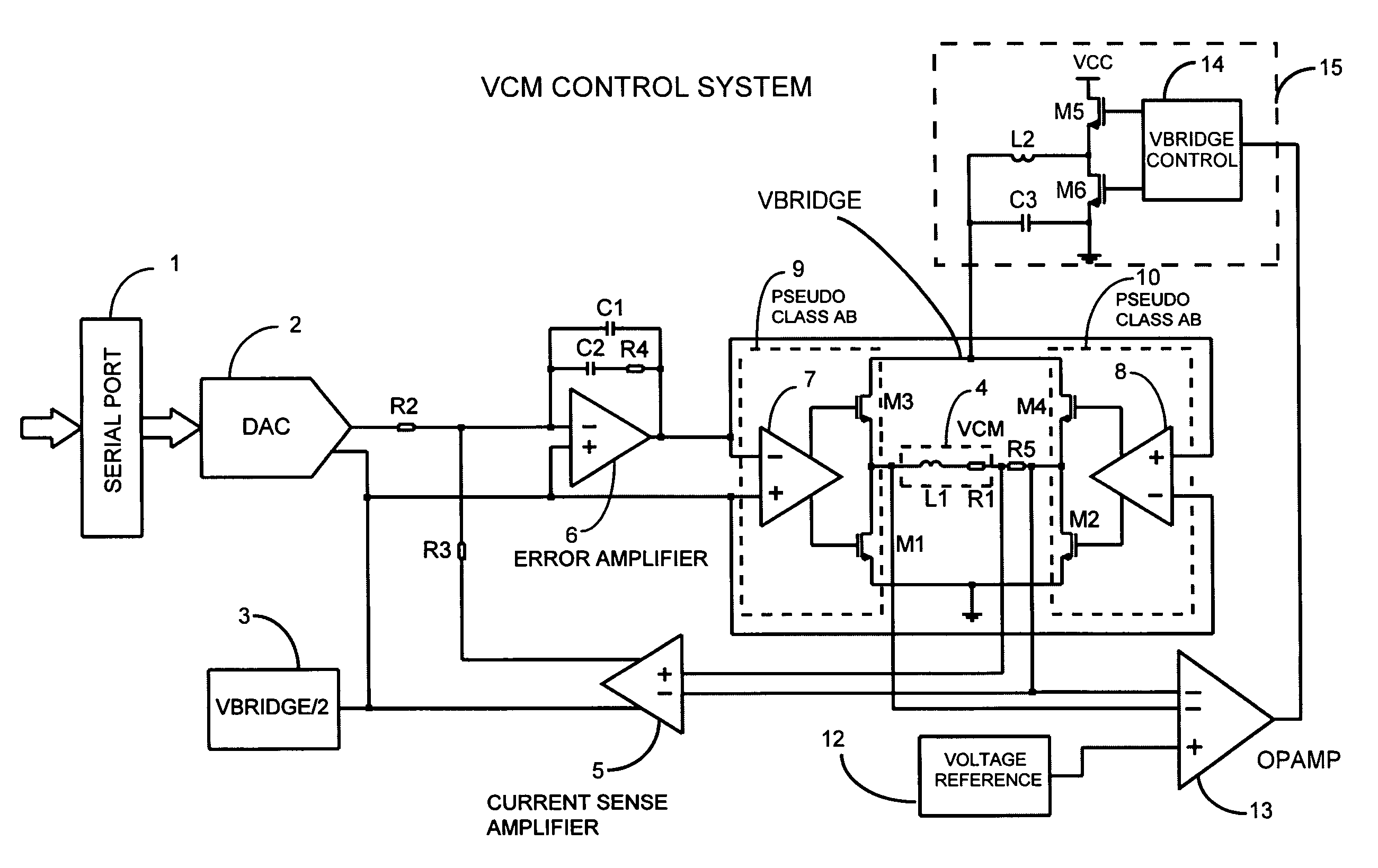

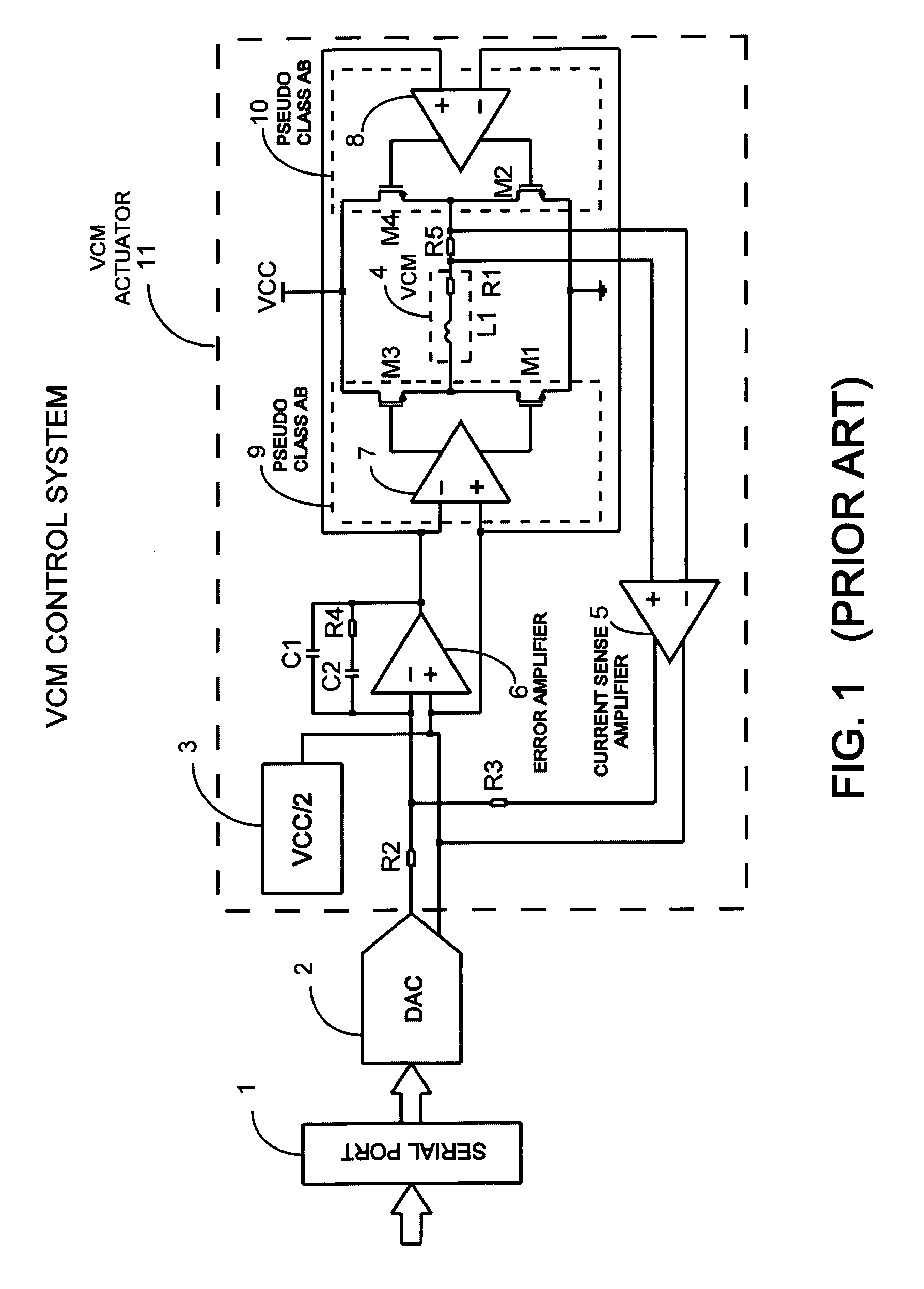

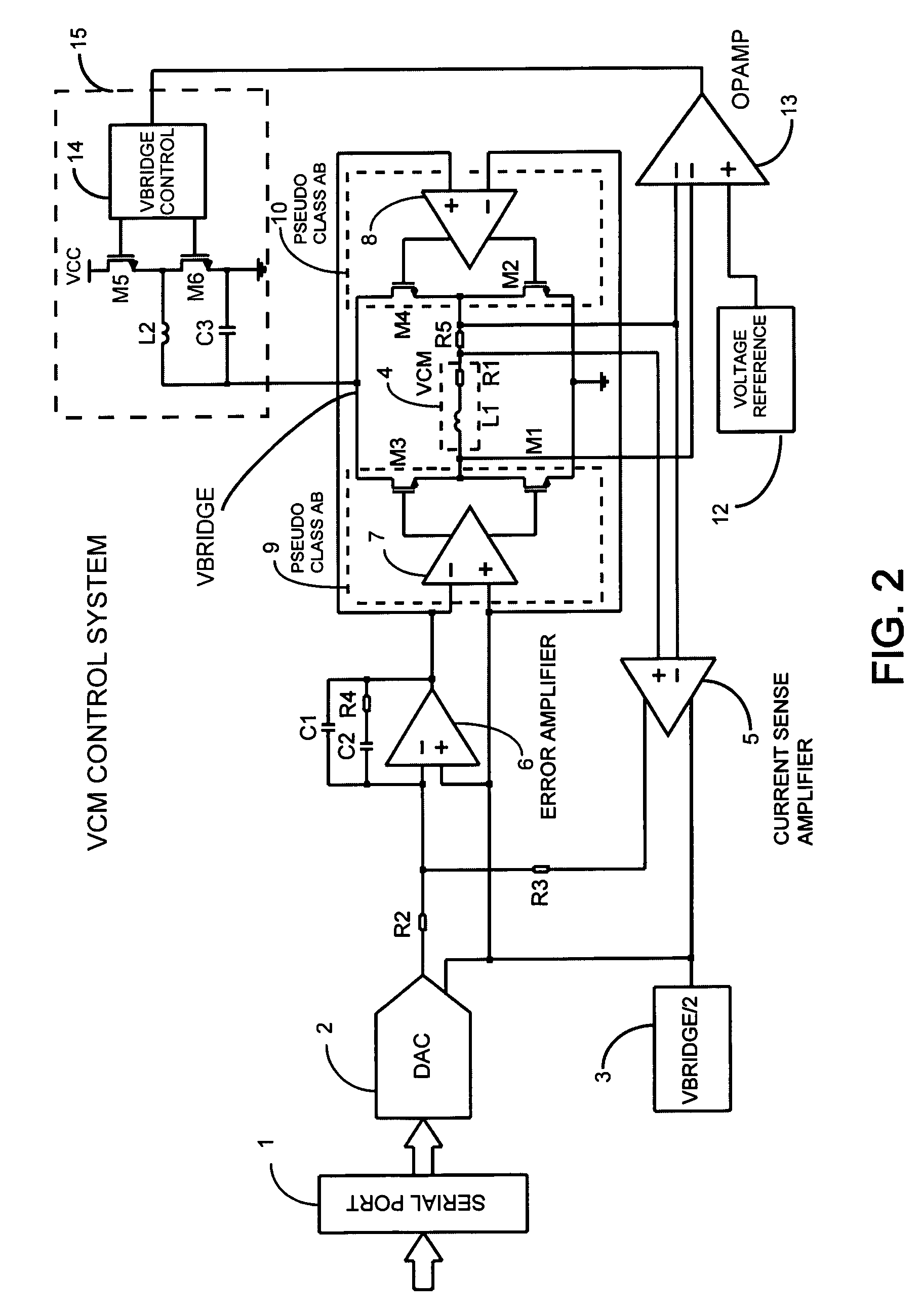

InactiveUS20080310046A1Increase the switching frequencyImprove motor efficiencySynchronous motors startersDC motor speed/torque controlAudio power amplifierDigital analog converter

A method for driving a load by using an output stage amplifier in full bridge configuration whose supply is modulated by means of a fast switching power converter, controlled in order to maintain the stage's output common mode at its minimum voltage, is presented. The modulation of the switching power converter output is obtained by a feedback control system regulating directly the voltage of the bridge output stage terminals. This bridge unipolar class H stage allows driving the load with high accuracy and improved efficiency without introducing switching noise and EMI at the load terminals typical of PWM driving. This method can be applied with the same benefits to class AB, pseudo class AB or to class A output stages. When this method is associated with an imposed current driving approach and with a current oversampling digital to analog converter the resulting advantages are very significant for accurate motor control applications.

Owner:MENEGOLI PAOLO +1

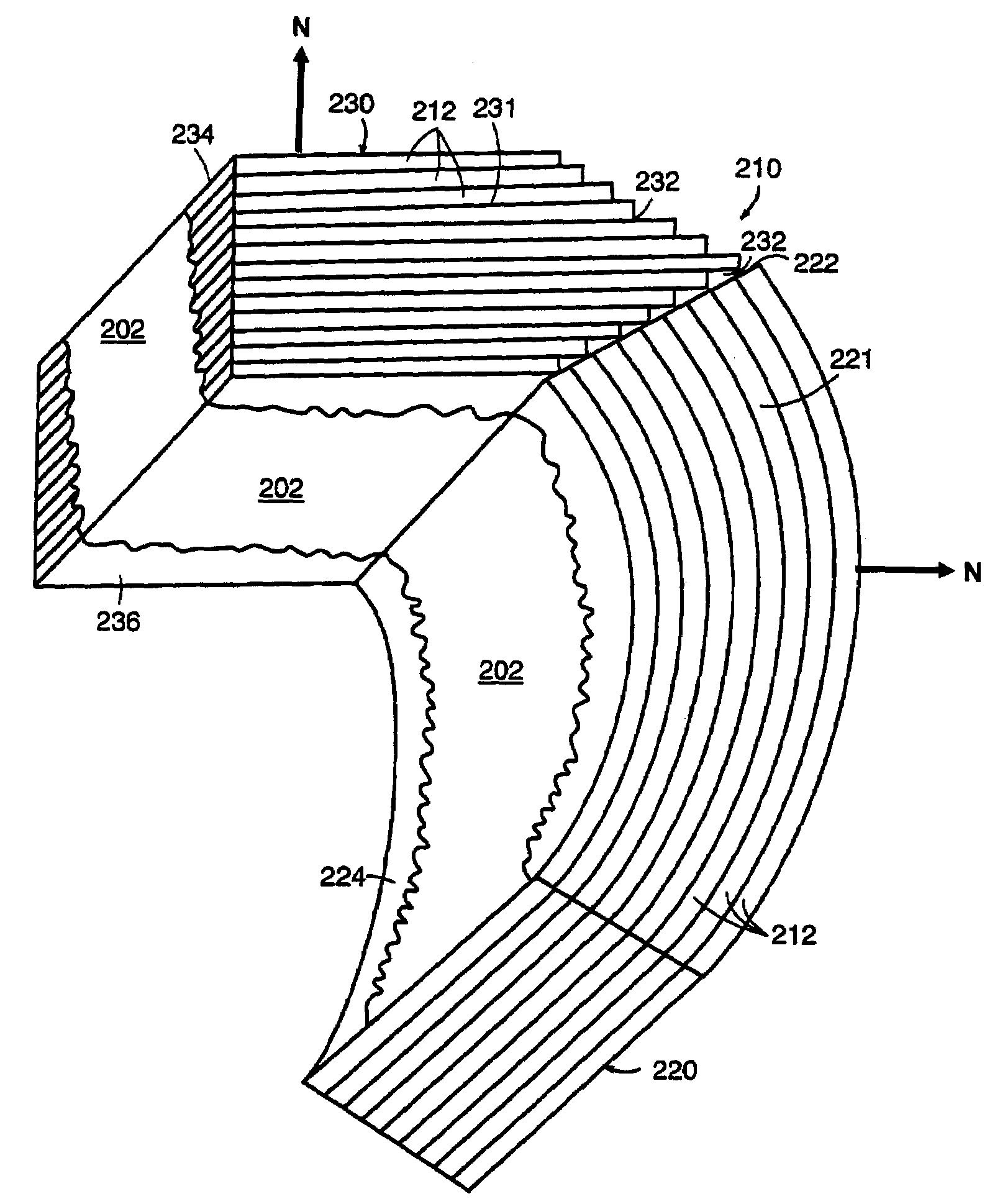

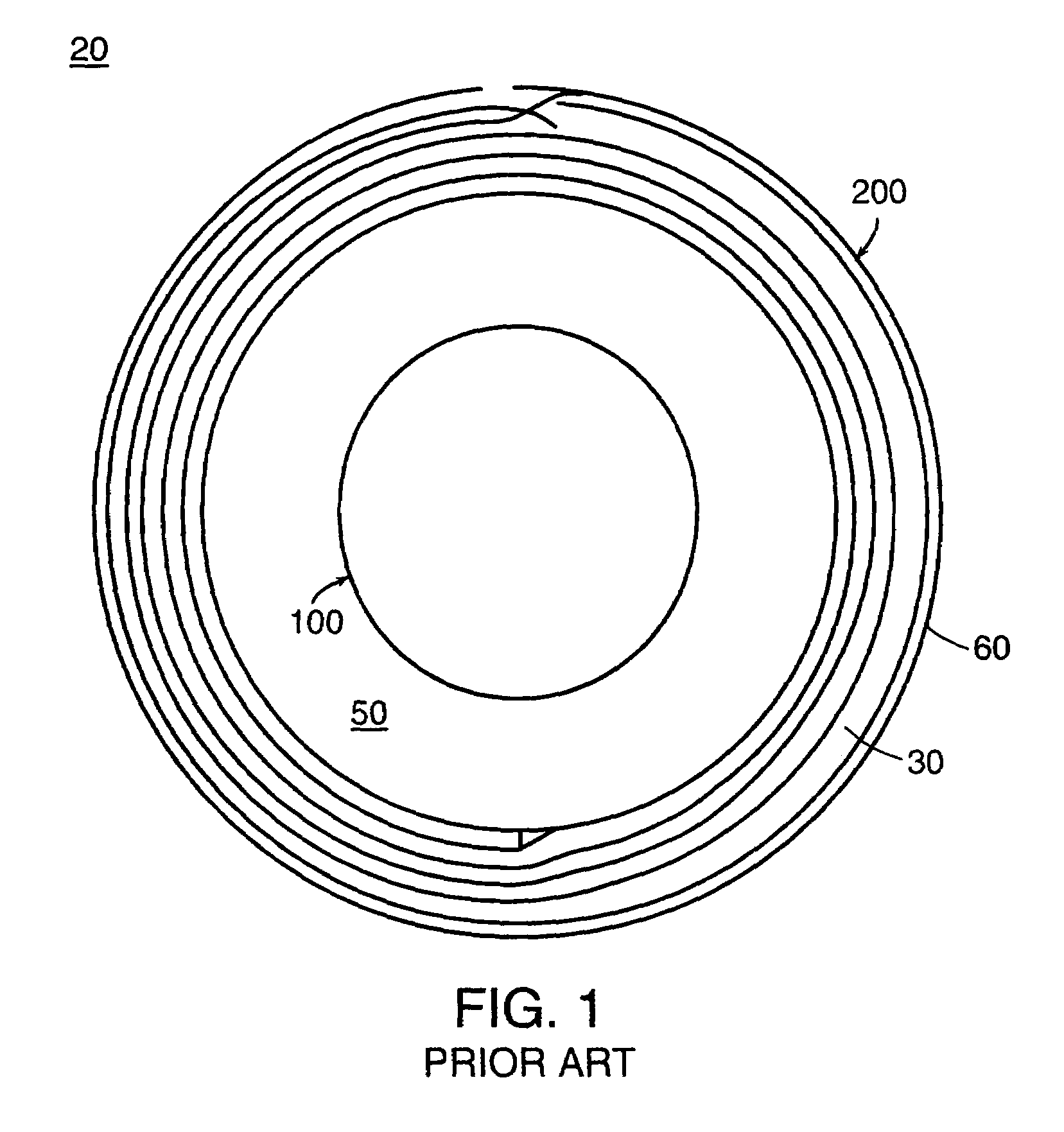

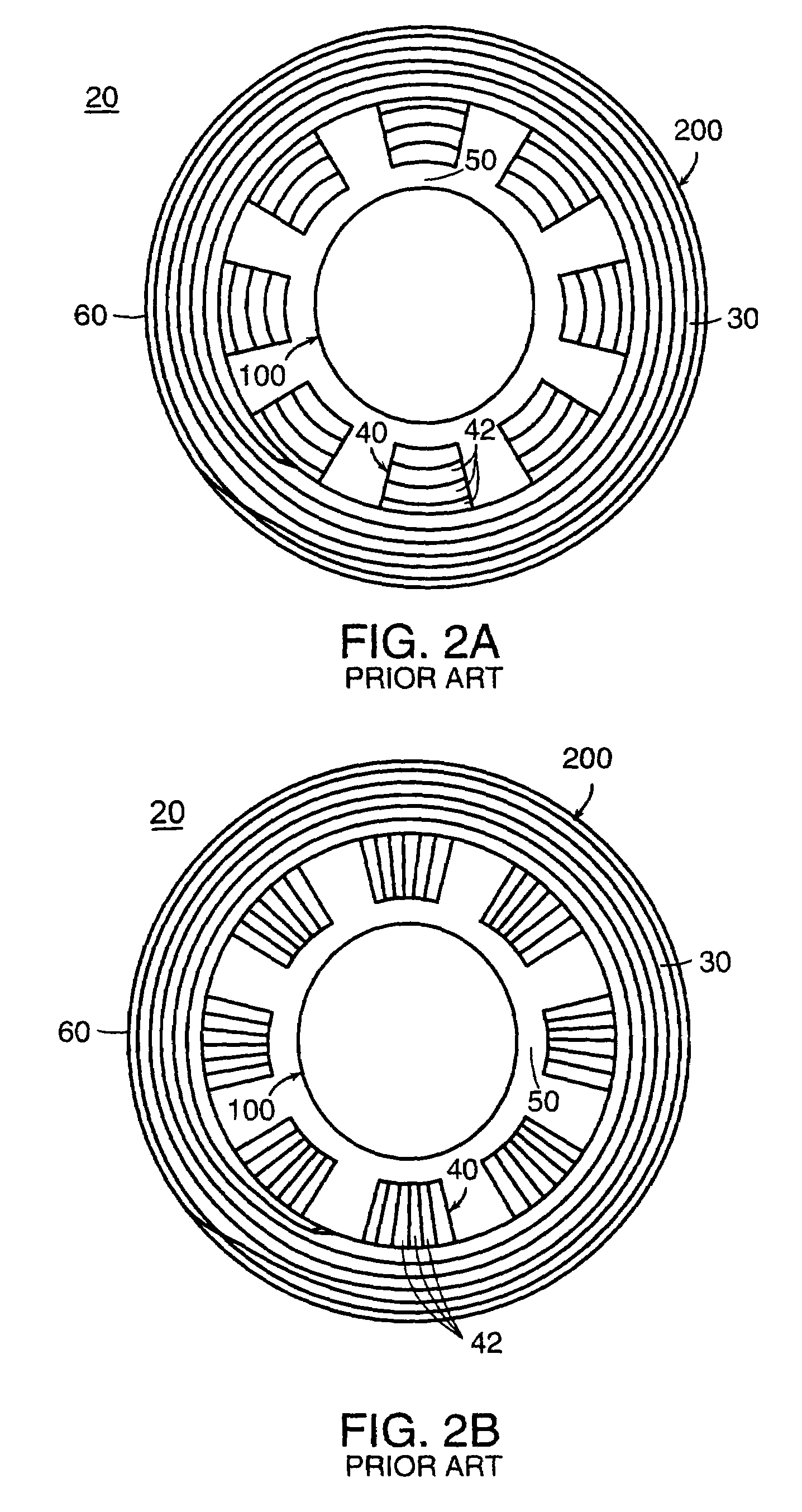

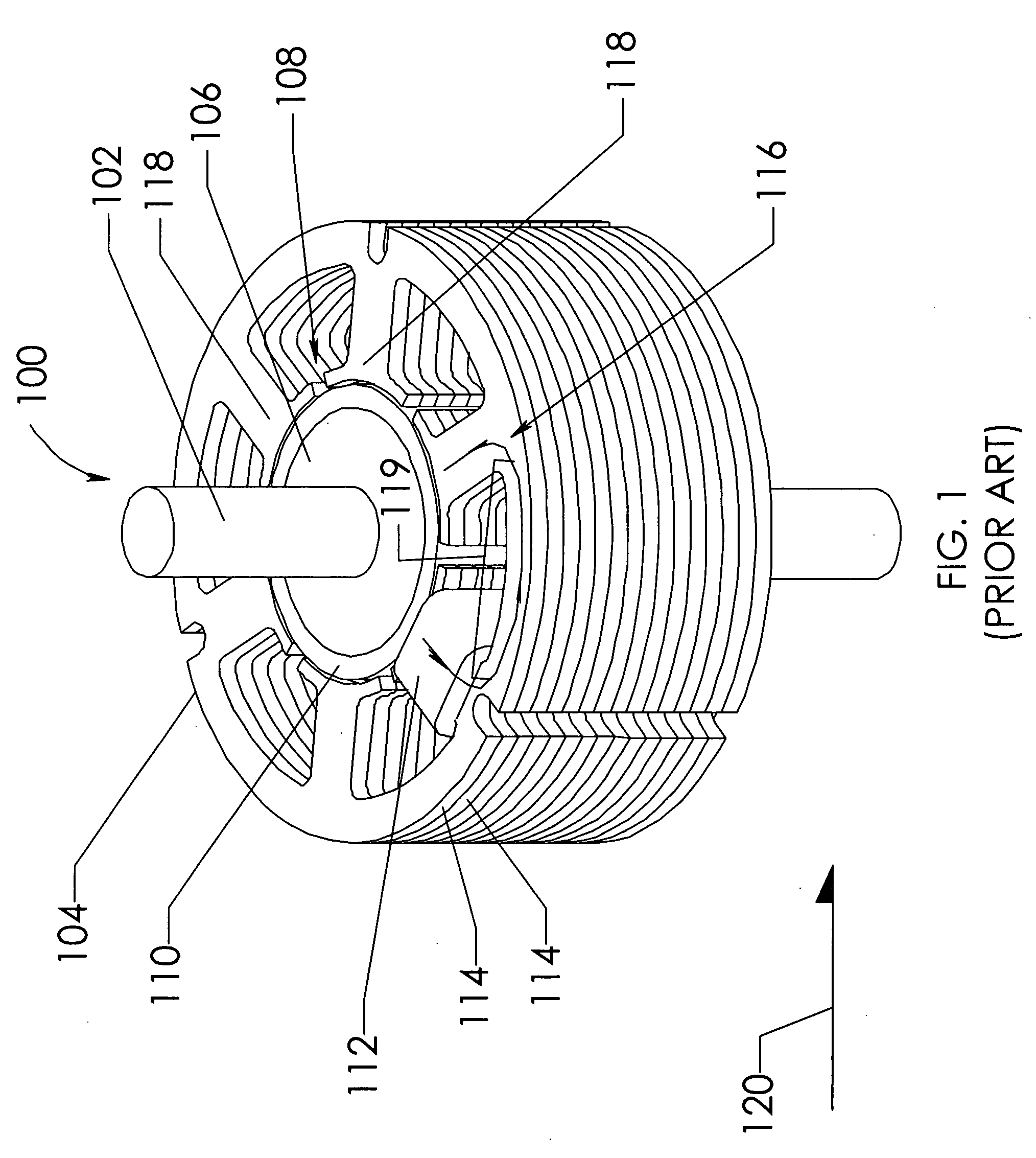

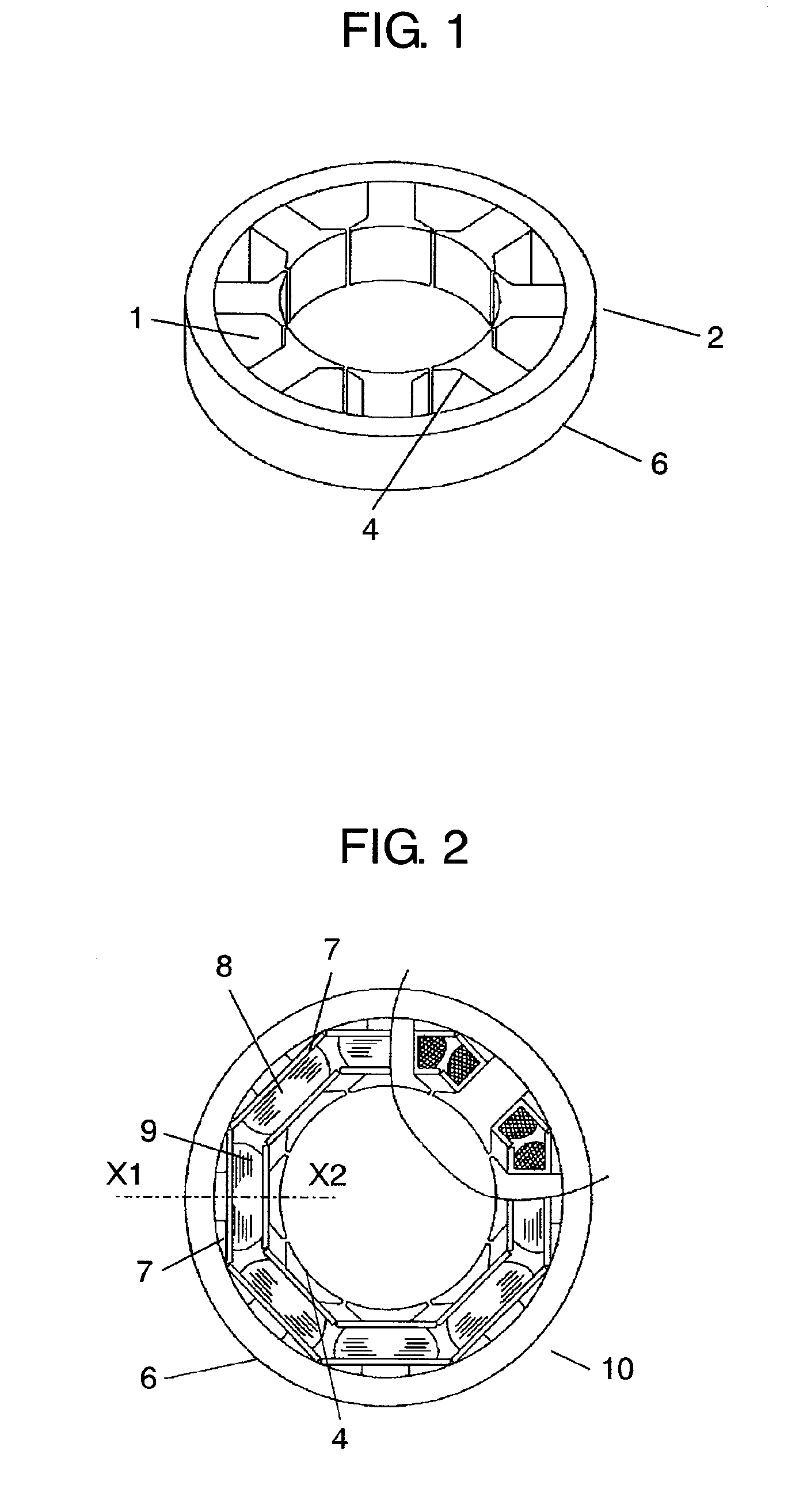

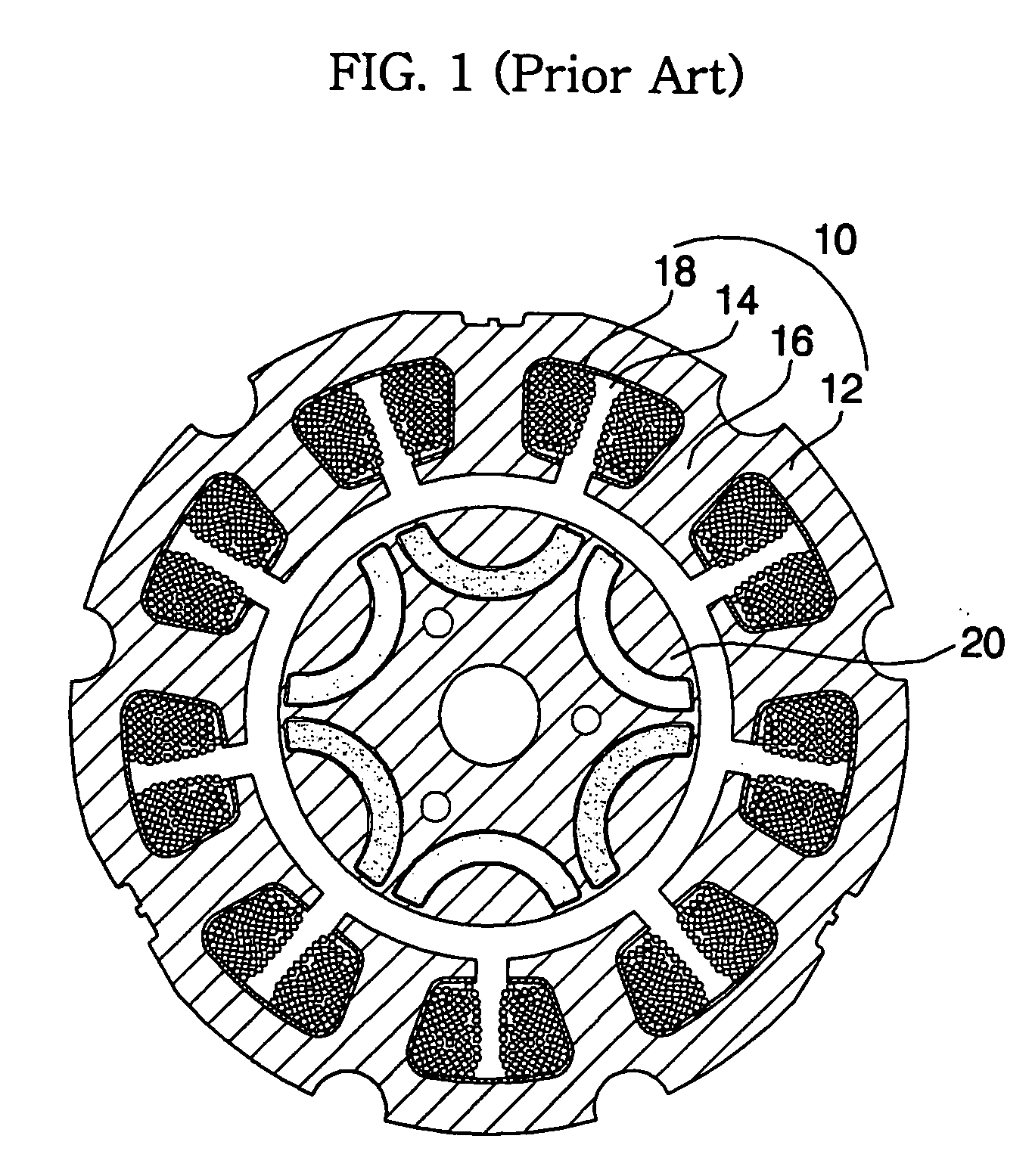

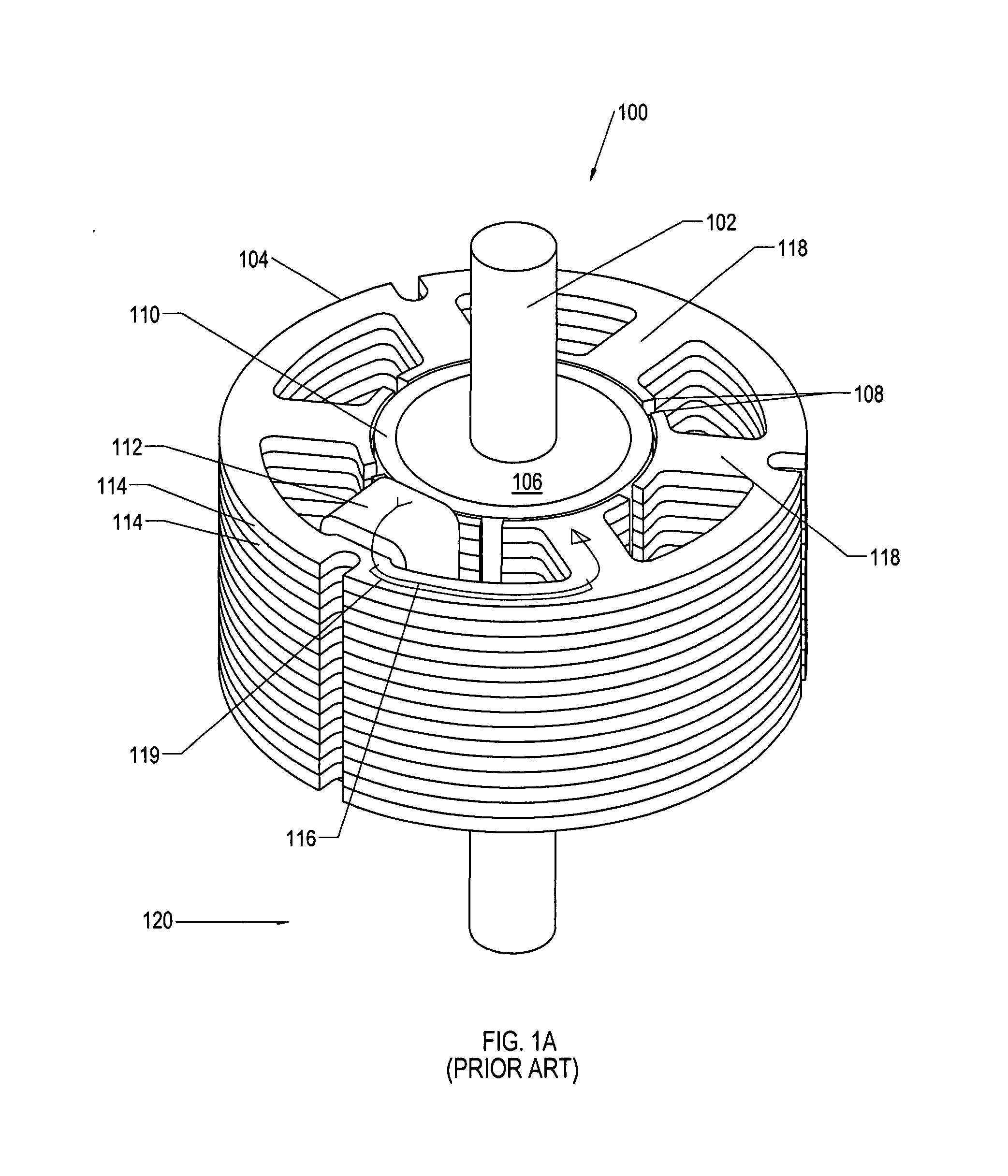

Amorphous metal stator for a radial-flux electric motor

InactiveUS6960860B1Improve motor efficiencyLow core lossMagnetic circuit rotating partsMagnetic circuit stationary partsMagnetic polesEngineering

An amorphous metal stator for a high efficiency radial-flux electric motor has a plurality of segments, each of which includes a plurality of layers of amorphous metal strips. The plural segments are arranged to form a generally cylindrical stator having a plurality of teeth sections or poles protruding radially inward from the inner surface of the stator. In a first embodiment, the stator back-iron and teeth are constructed such that radial flux passing through the stator crosses just one air gap when traversing each segment of the stator. In a second embodiment, the stator back-iron and teeth are constructed such that radial flux passing through the stator traverses each segment without crossing an air gap.

Owner:METGLAS INC

Class H drive

InactiveUS7863841B2Improve motor efficiencyHigh frequency switching noiseAC motor controlDC motor speed/torque controlAudio power amplifierControl system

A method for driving a load by using an output stage amplifier in full bridge configuration whose supply is modulated by means of a fast switching power converter, controlled in order to maintain the stage's output common mode at its minimum voltage, is presented. The modulation of the switching power converter output is obtained by a feedback control system regulating directly the voltage of the bridge output stage terminals. This bridge unipolar class H stage allows driving the load with high accuracy and improved efficiency without introducing switching noise and EMI at the load terminals typical of PWM driving. This method can be applied with the same benefits to class AB, pseudo class AB or to class A output stages. When this method is associated with an imposed current driving approach and with a current oversampling digital to analog converter the resulting advantages are very significant for accurate motor control applications.

Owner:MENEGOLI PAOLO +1

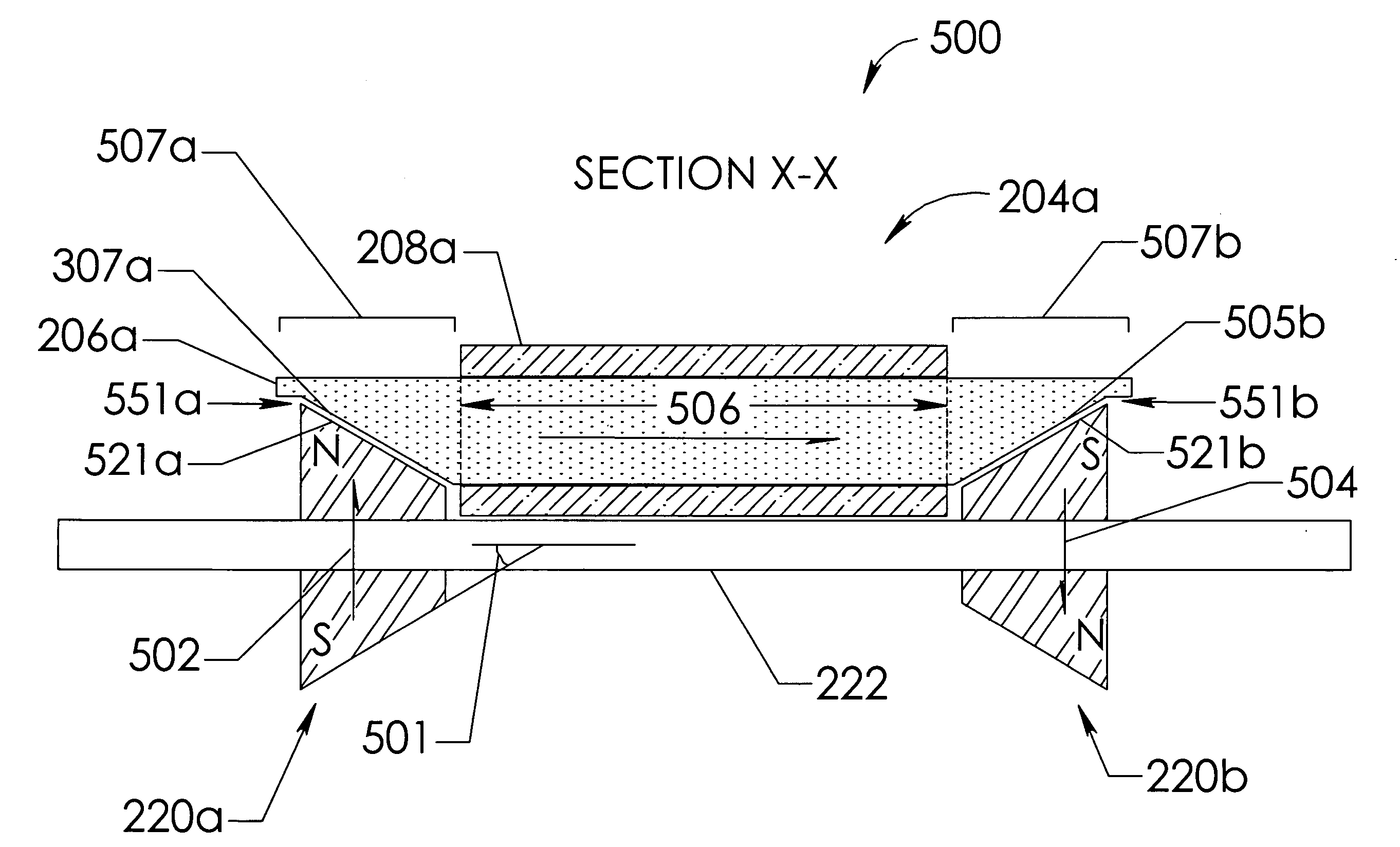

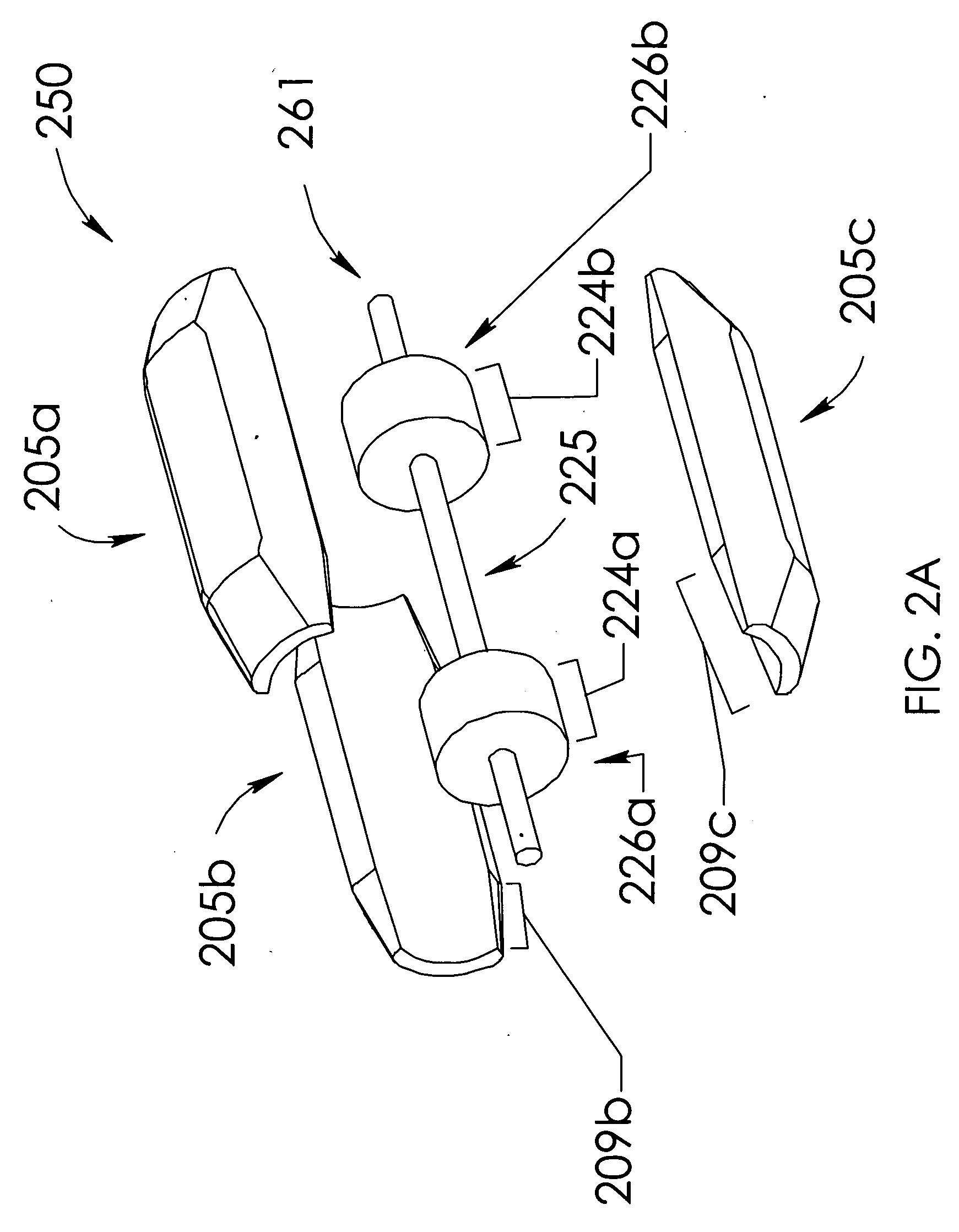

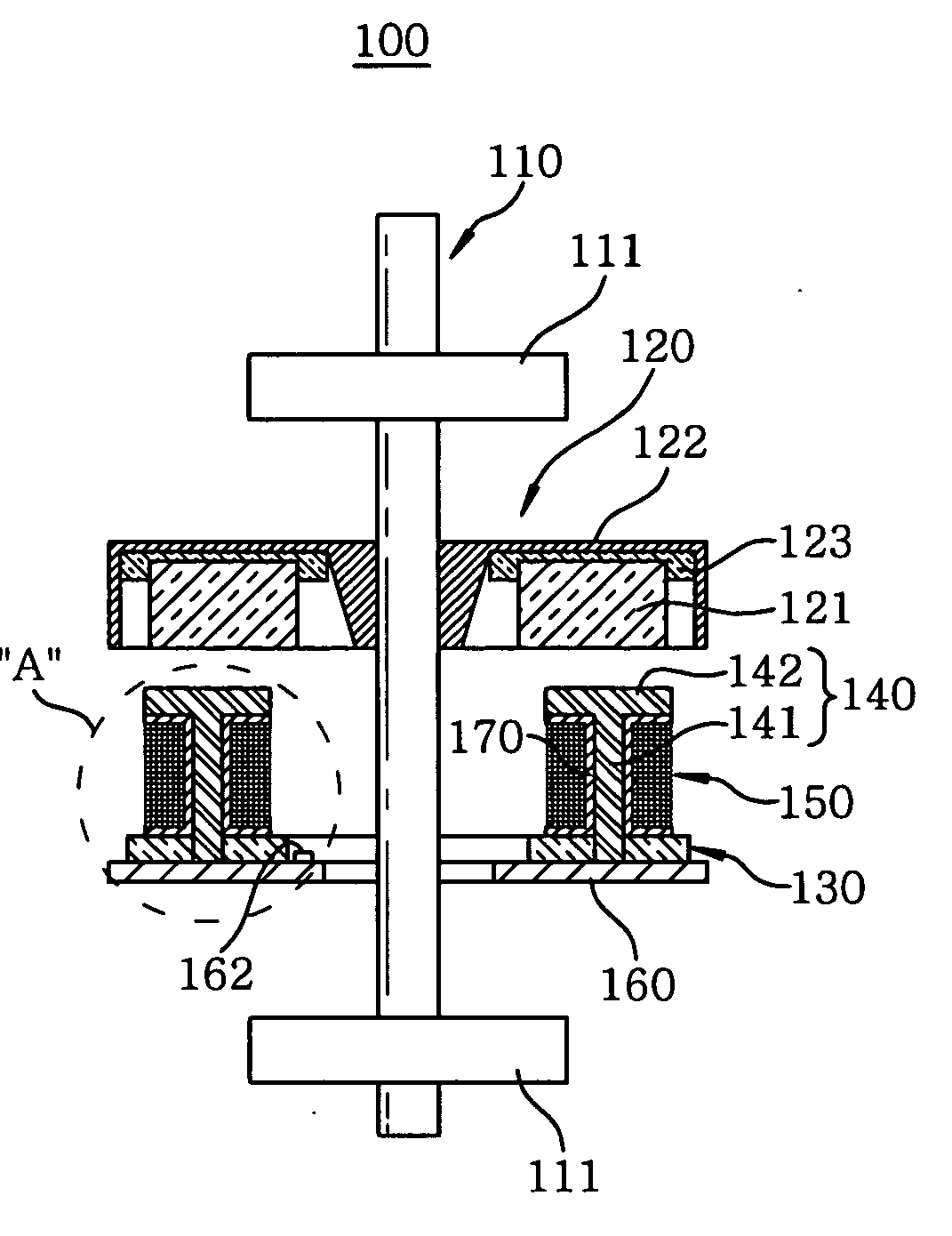

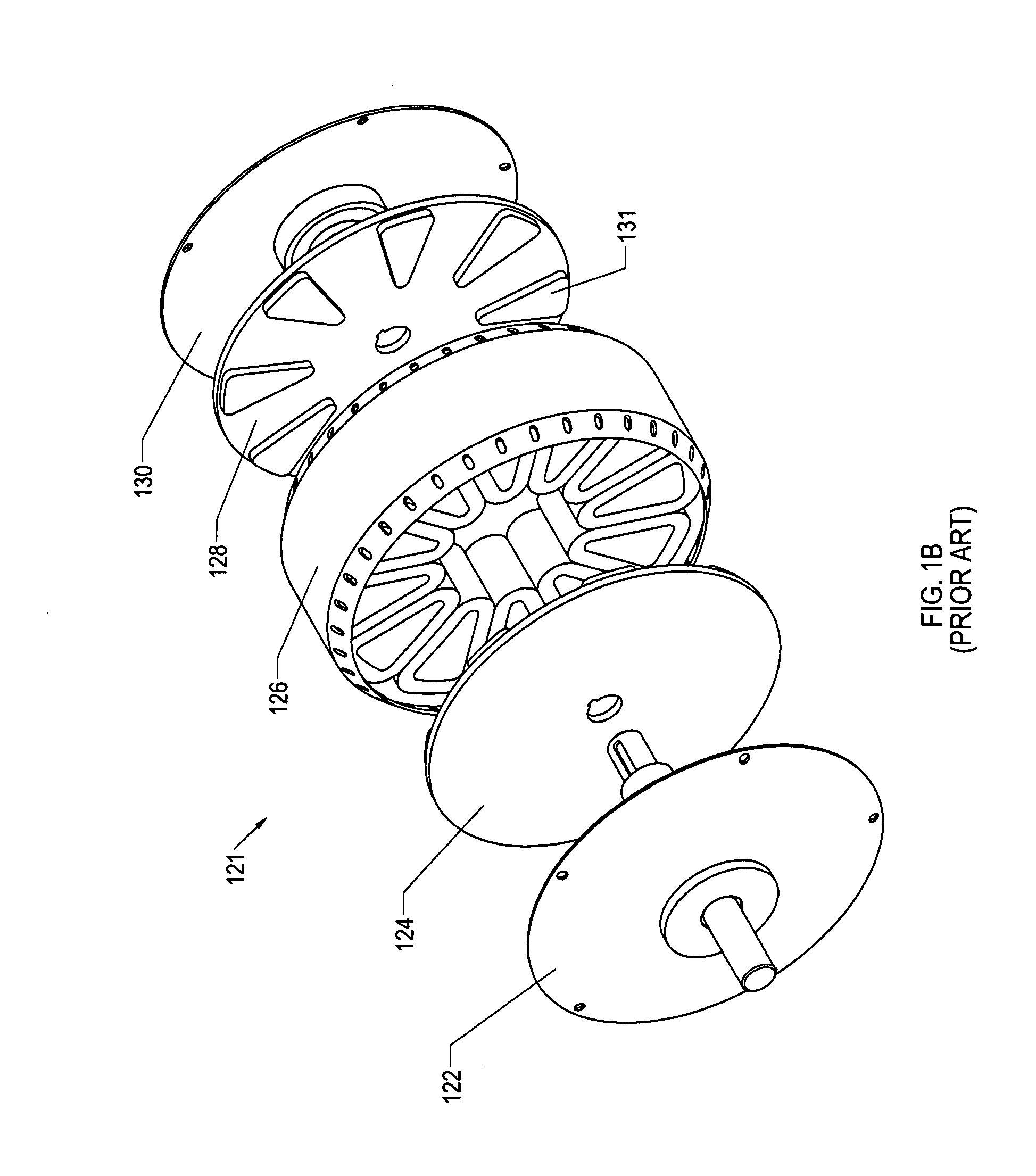

Rotor-stator structure for electrodynamic machines

ActiveUS20060087186A1More output torqueShorter and straighter magnetic pathMagnetic circuit rotating partsMagnetic circuit stationary partsManufacturing cost reductionPath length

A rotor-stator structure for electrodynamic machinery is disclosed to, among other things, minimize magnetic flux path lengths and to eliminate back-iron for increasing torque and / or efficiency per unit size (or unit weight) and for reducing manufacturing costs. In one embodiment, an exemplary rotor-stator structure can comprise a shaft defining an axis of rotation, and a rotor on which at least two magnets are mounted on the shaft. The two magnets can be cylindrical or conical magnets having magnetic surfaces that confront air gaps. In some embodiments, substantially straight field pole members can be arranged coaxially and have flux interaction surfaces formed at both ends of those field poles. Those surfaces are located adjacent to the confronting magnetic surfaces to define functioning air gaps, which are generally curved in shape.

Owner:REGAL BELOIT AMERICA

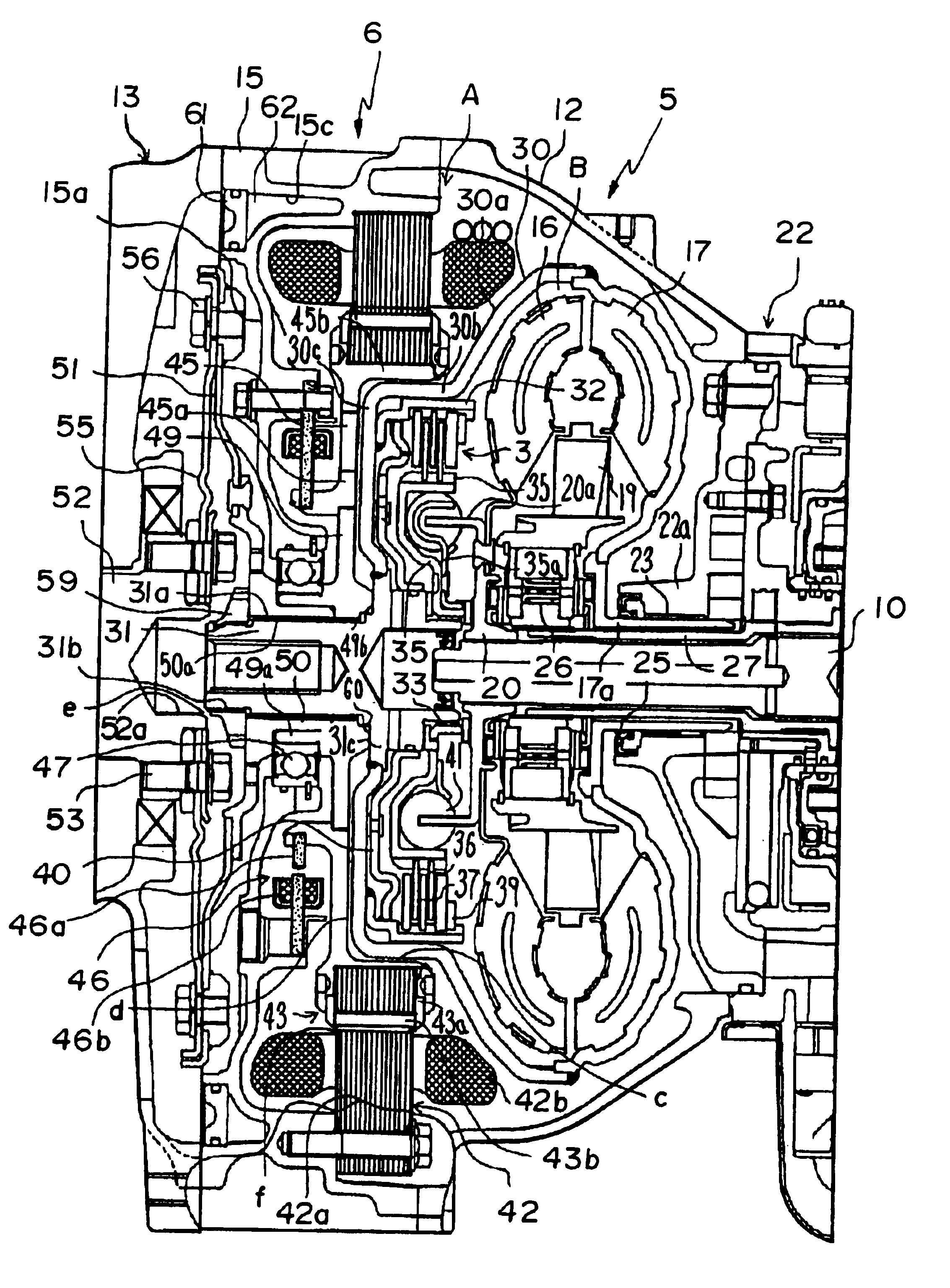

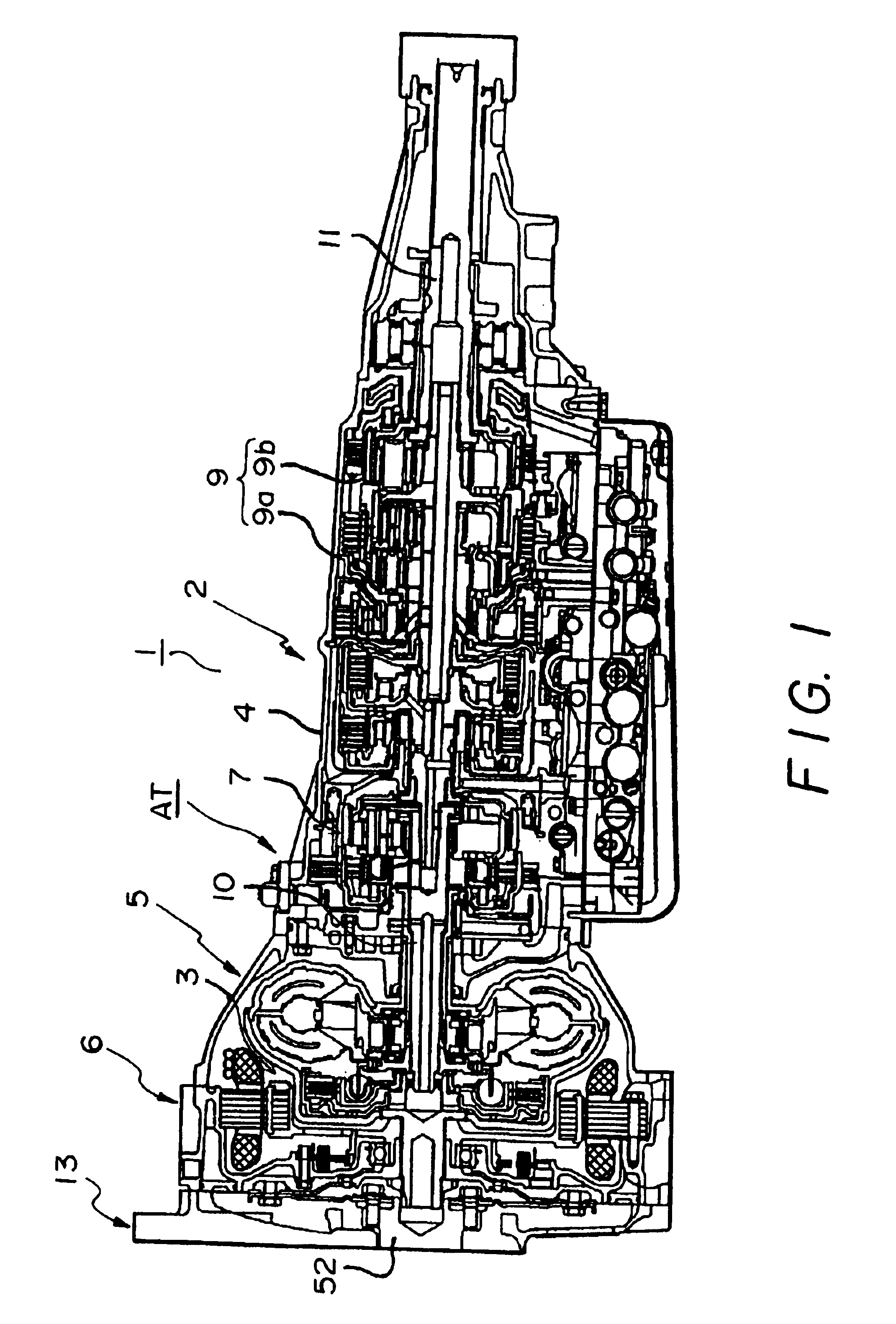

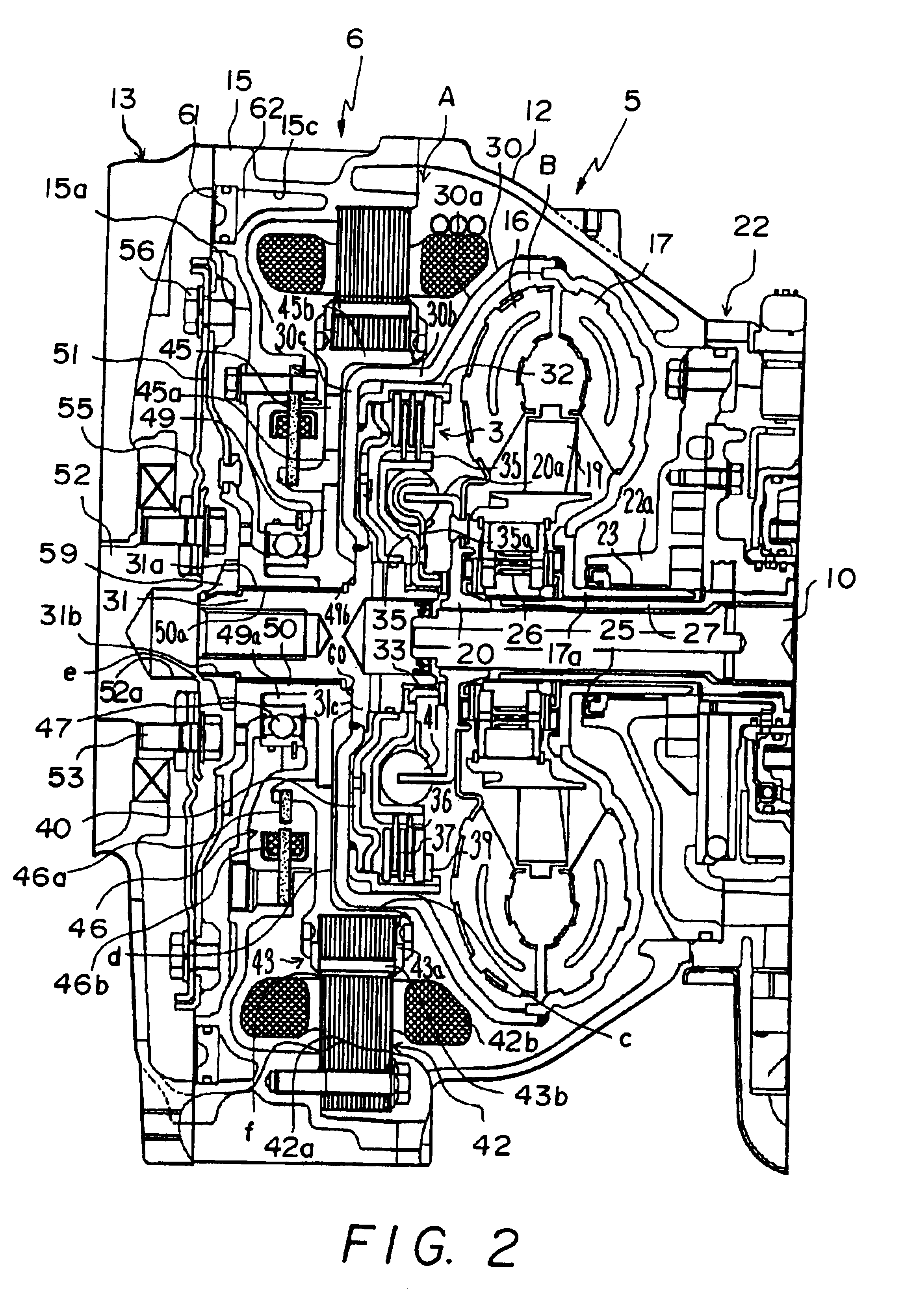

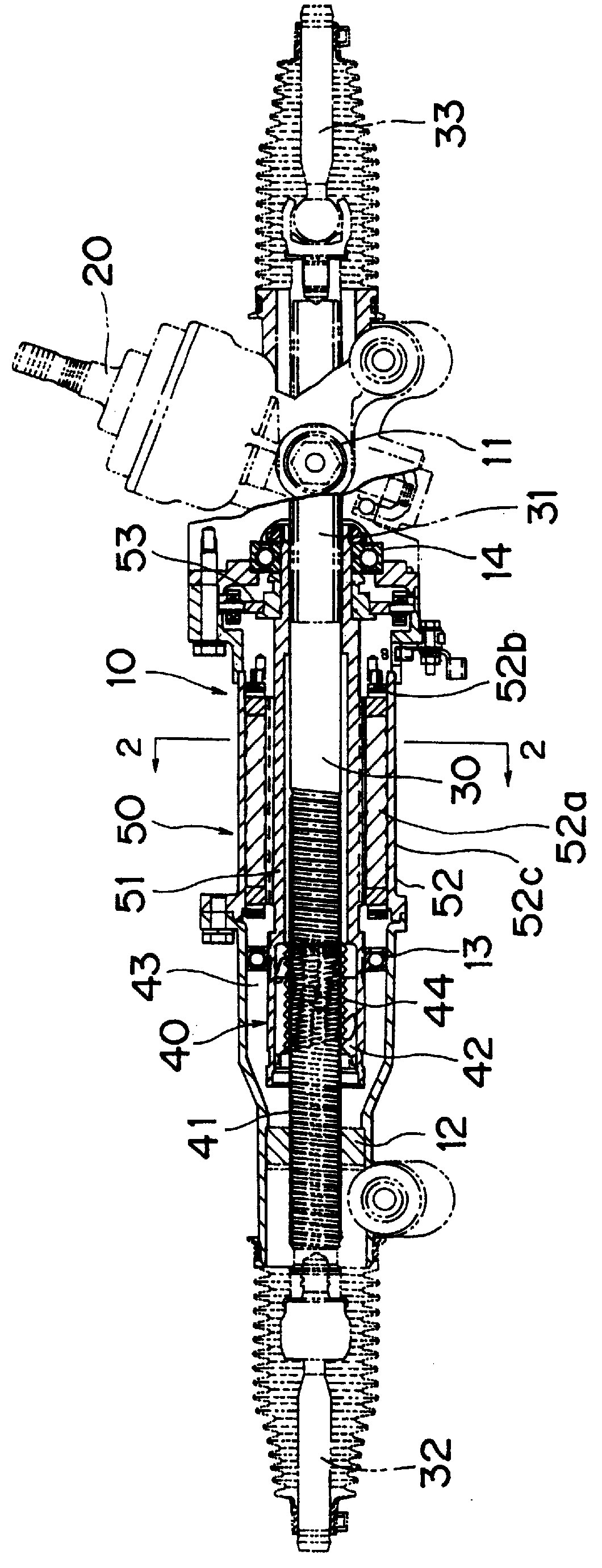

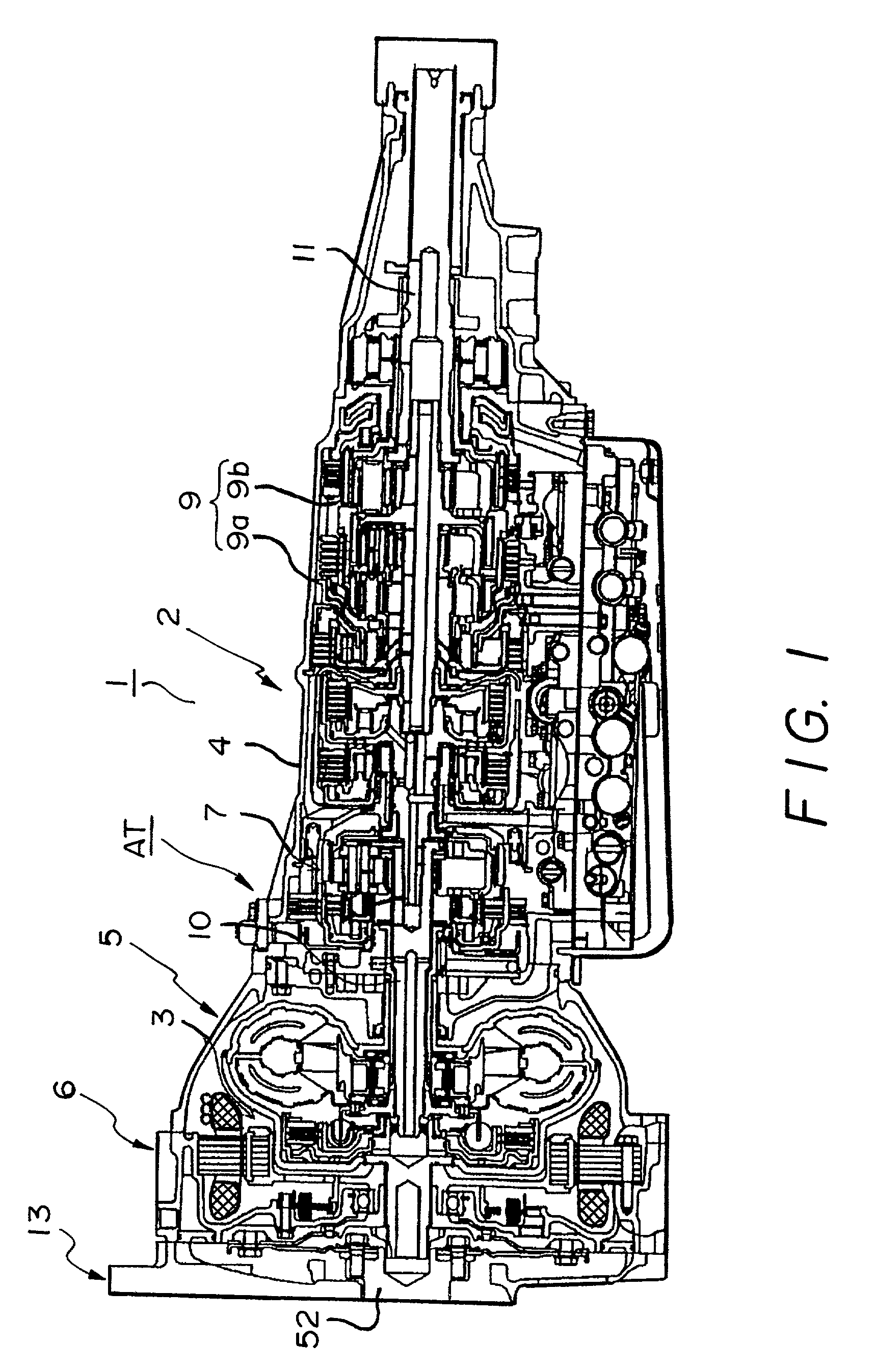

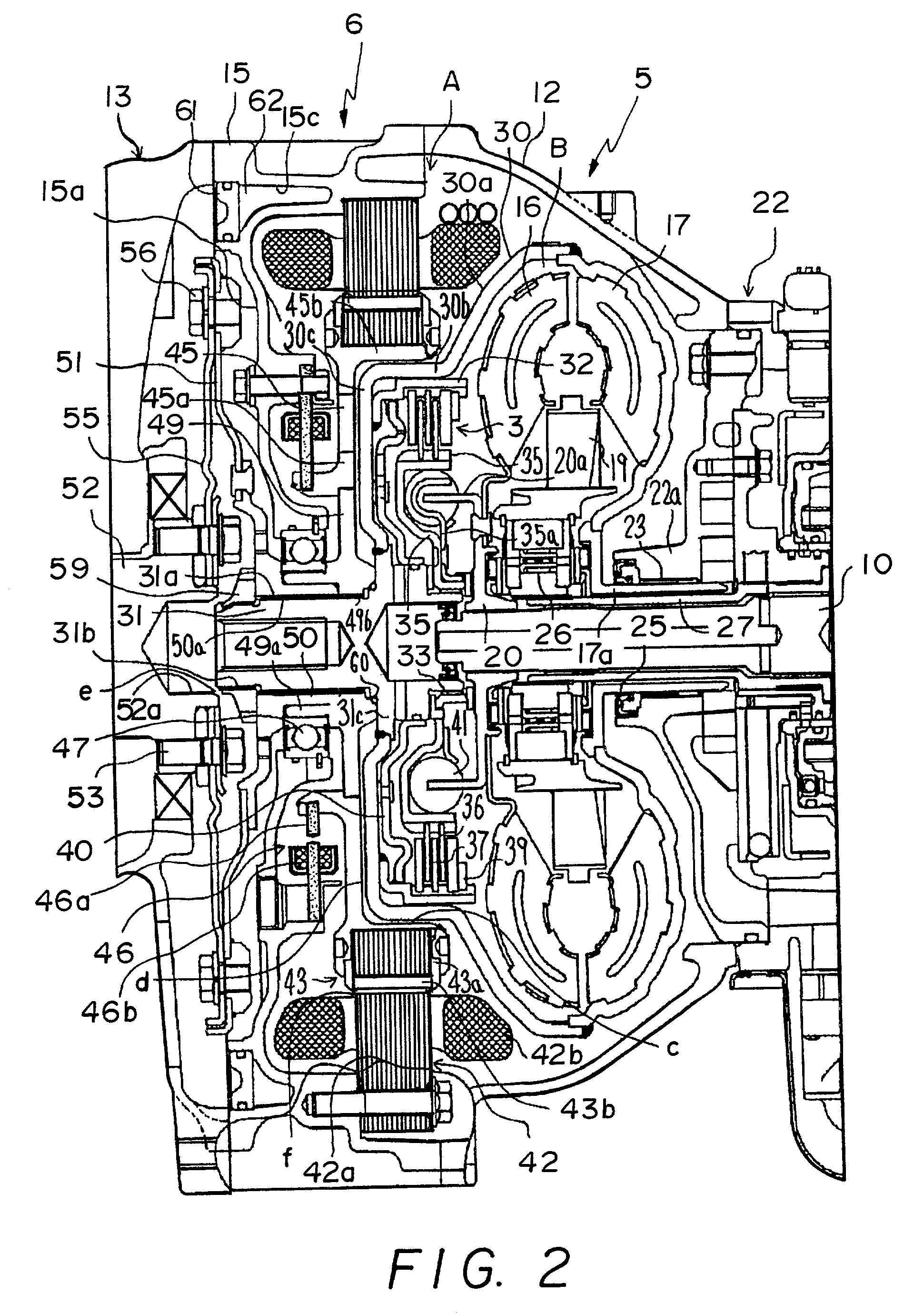

Hybrid-vehicle drive unit

InactiveUS6777837B2Improve accuracyImprove motor efficiencyReciprocating combination enginesDynamo-electric brakes/clutchesInternal combustion engineHybrid vehicle

A hybrid-vehicle drive unit supports a motor-generator with high precision, improving the efficiency of the motor-generator, and reducing the size of the motor-generator, independent of any influence of centering precision of the crank shaft and of deformation of the torque converter. According to the invention, a motor housing is disposed between a converter housing and an internal combustion engine, and a bearing is fitted to a lateral wall provided in a front portion of the motor housing. Rotor supporting members are independently supported by the bearing. Eccentric rotation of the crank shaft resulting from explosive vibrations of the engine is counteracted by two flex plates. Owing to a predetermined clearance, one of the rotor supporting members as a separate component is free from the influence of deformation of the torque converter.

Owner:AISIN AW CO LTD +1

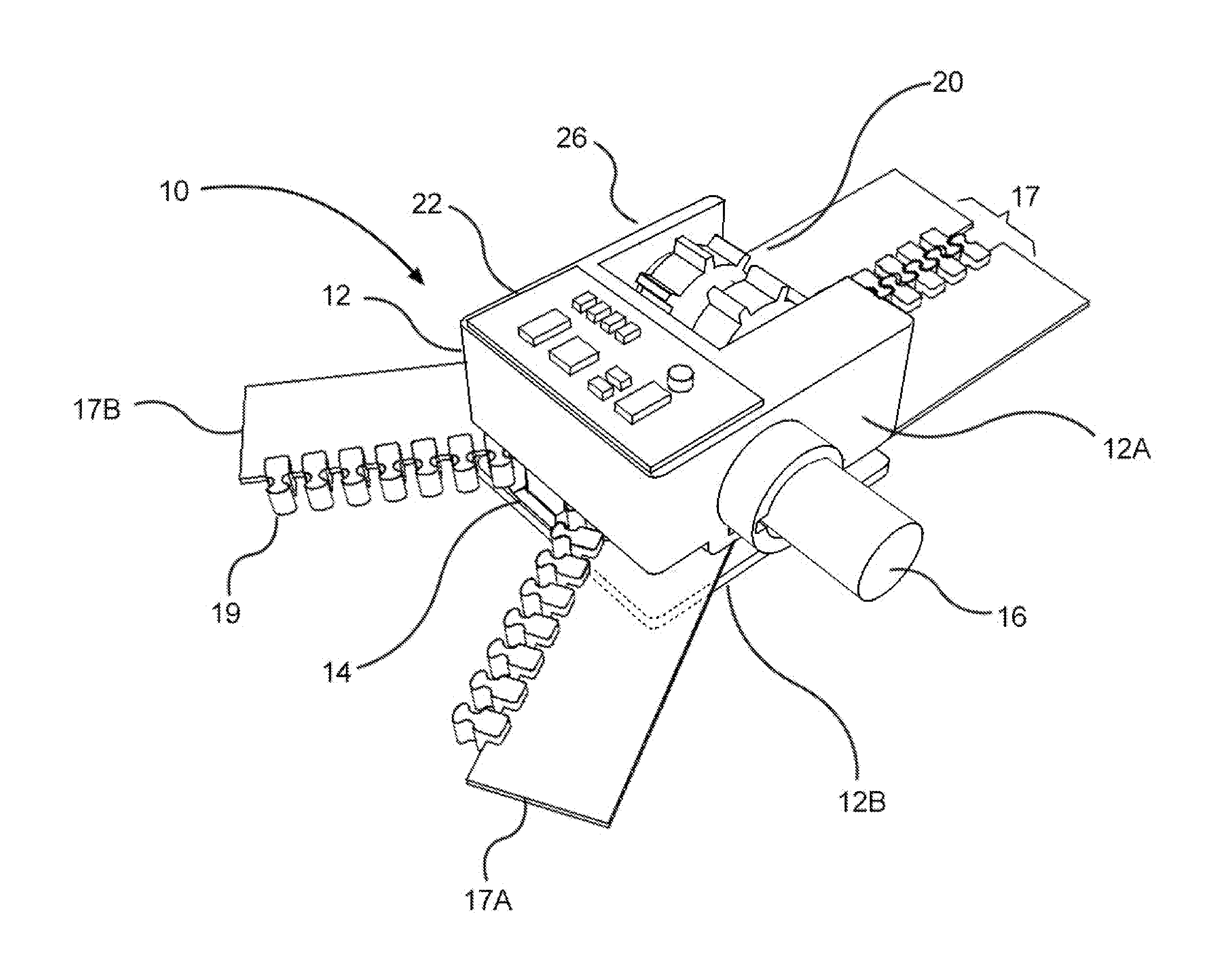

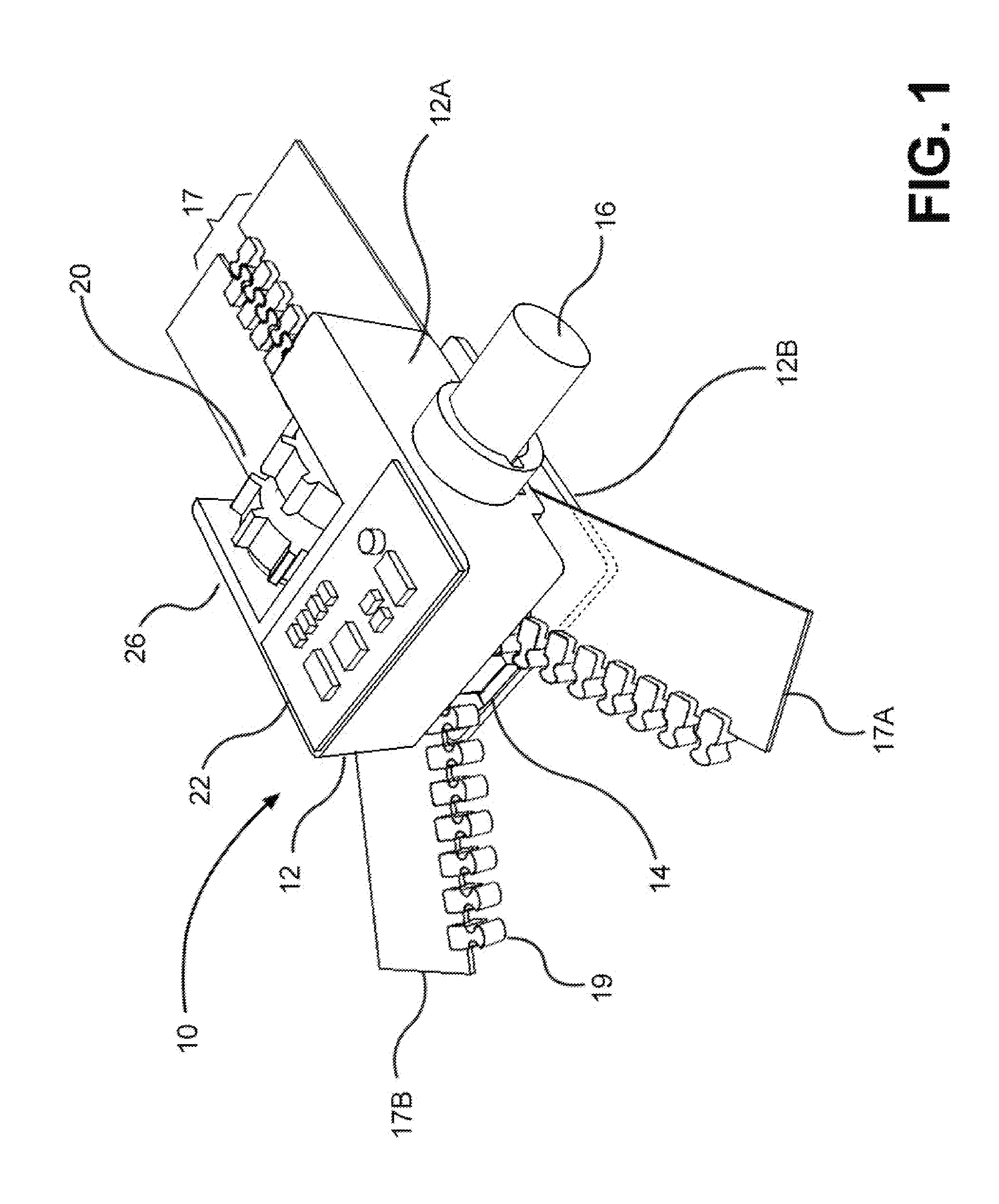

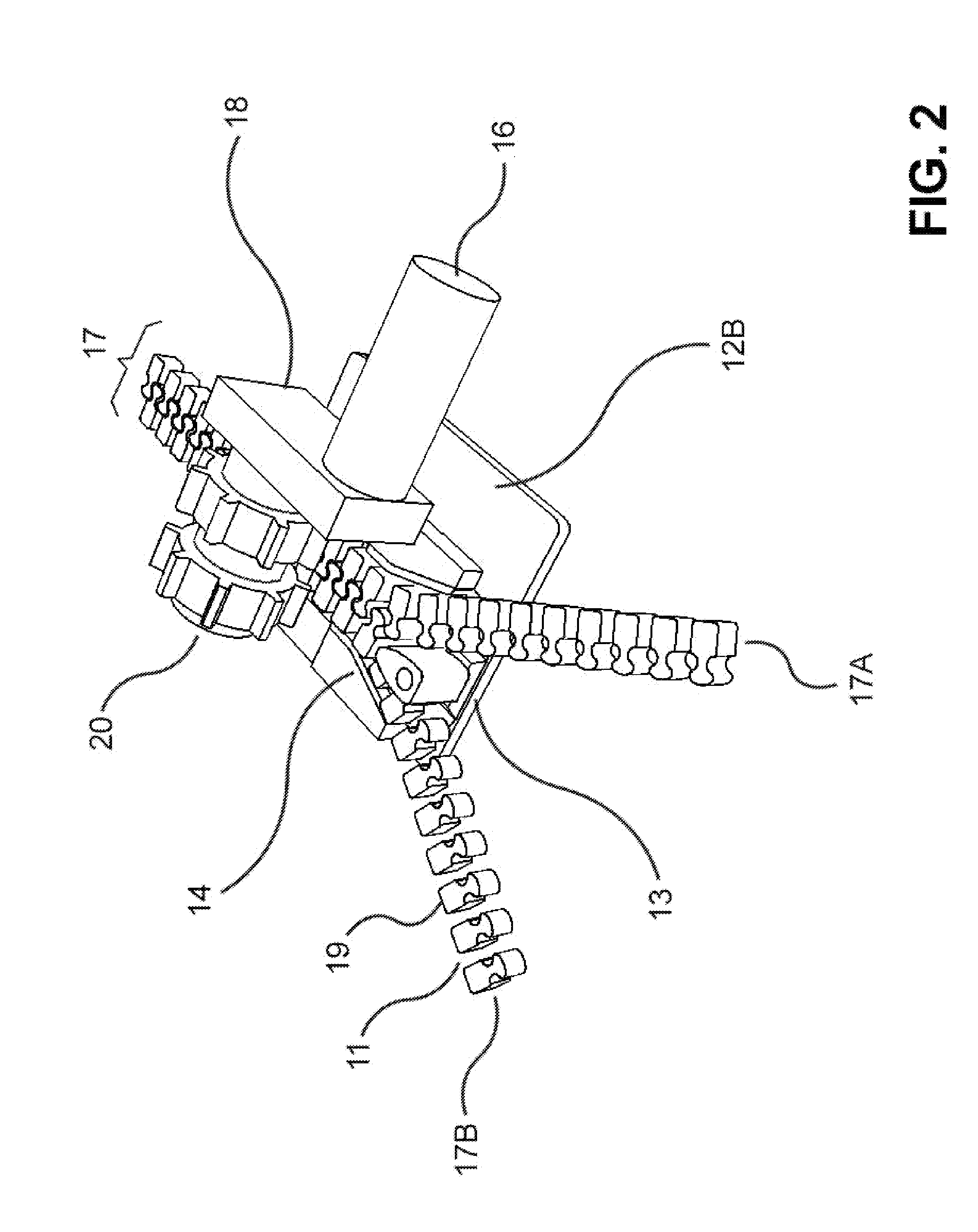

Methods and Apparatus for Robotic Zipper

ActiveUS20150082582A1Improve reliabilityImprove motor efficiencySnap fastenersSlide fastenersGear systemEngineering

A robotic zipper system for joining and separating zipper halves of a zipper tape. A chassis retains an actuator that drives a zipper slide geometry along the zipper tape to join or separate the zipper tape. A sensor can determine zipper slide position, and a control module can provide an electrical signal to the motor to move in forward or reverse. The actuator can have a motor that drives a gear system that mechanically engages zipper teeth. Teeth of the gear system can be out of phase to mesh with alternating gaps between the zipper teeth. The actuator can be removable relative to a zipper slide. Zipper slide geometry could be integrated into the chassis, such as in the form of a channel, potentially with a central post. A sensor could be positioned to detect the presence or absence of zipper teeth through an opening in a base plate.

Owner:MASSACHUSETTS INST OF TECH

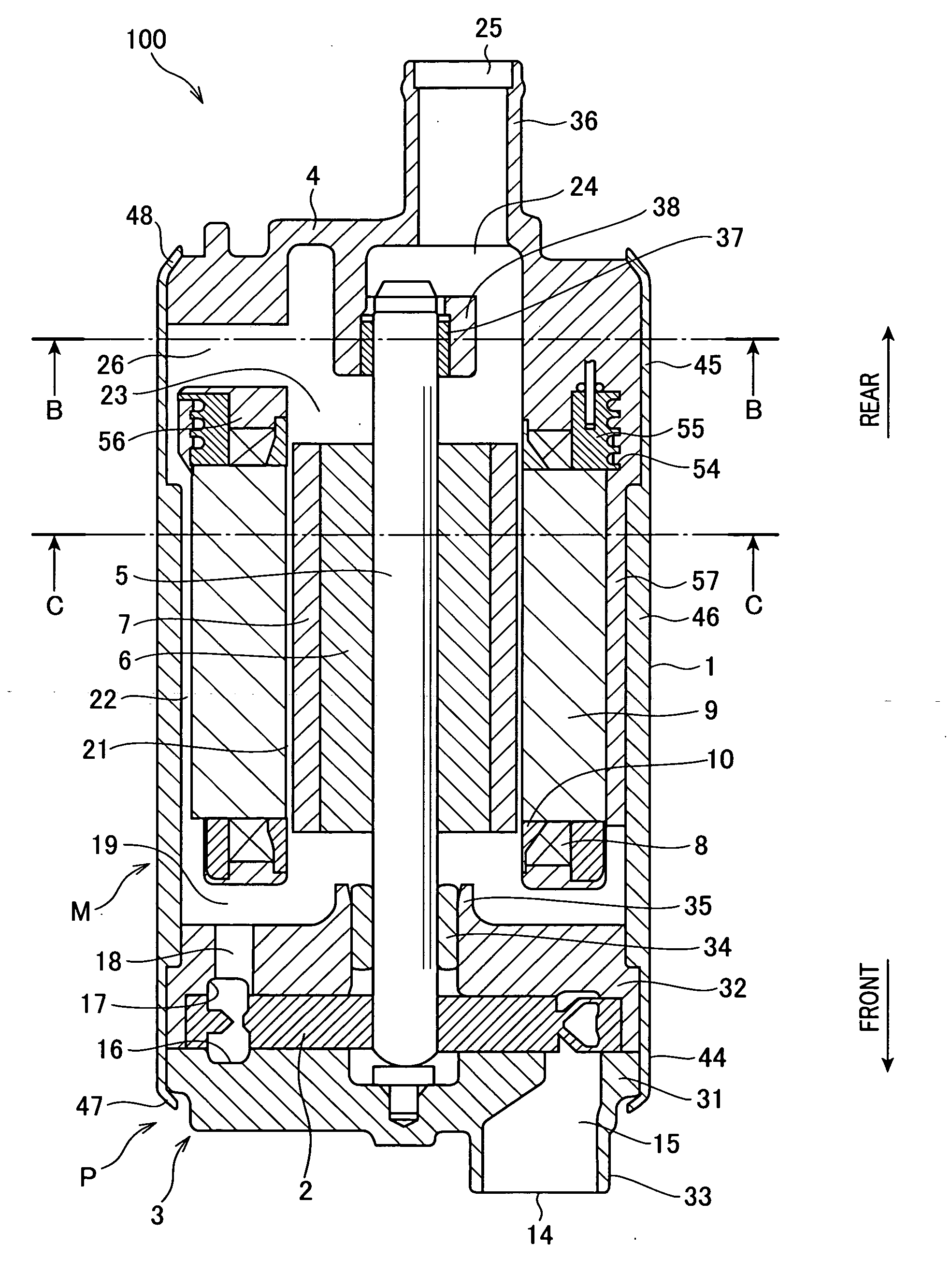

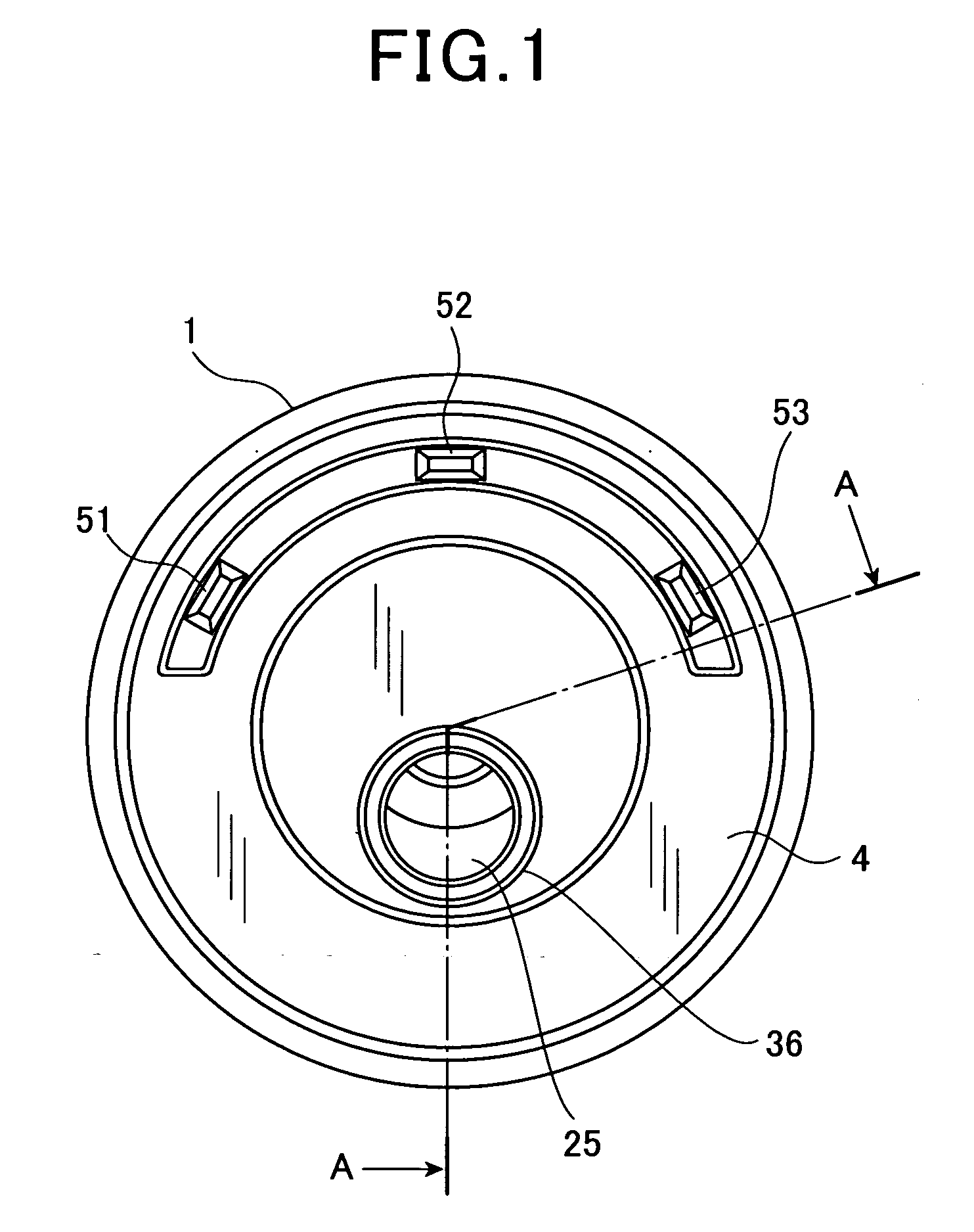

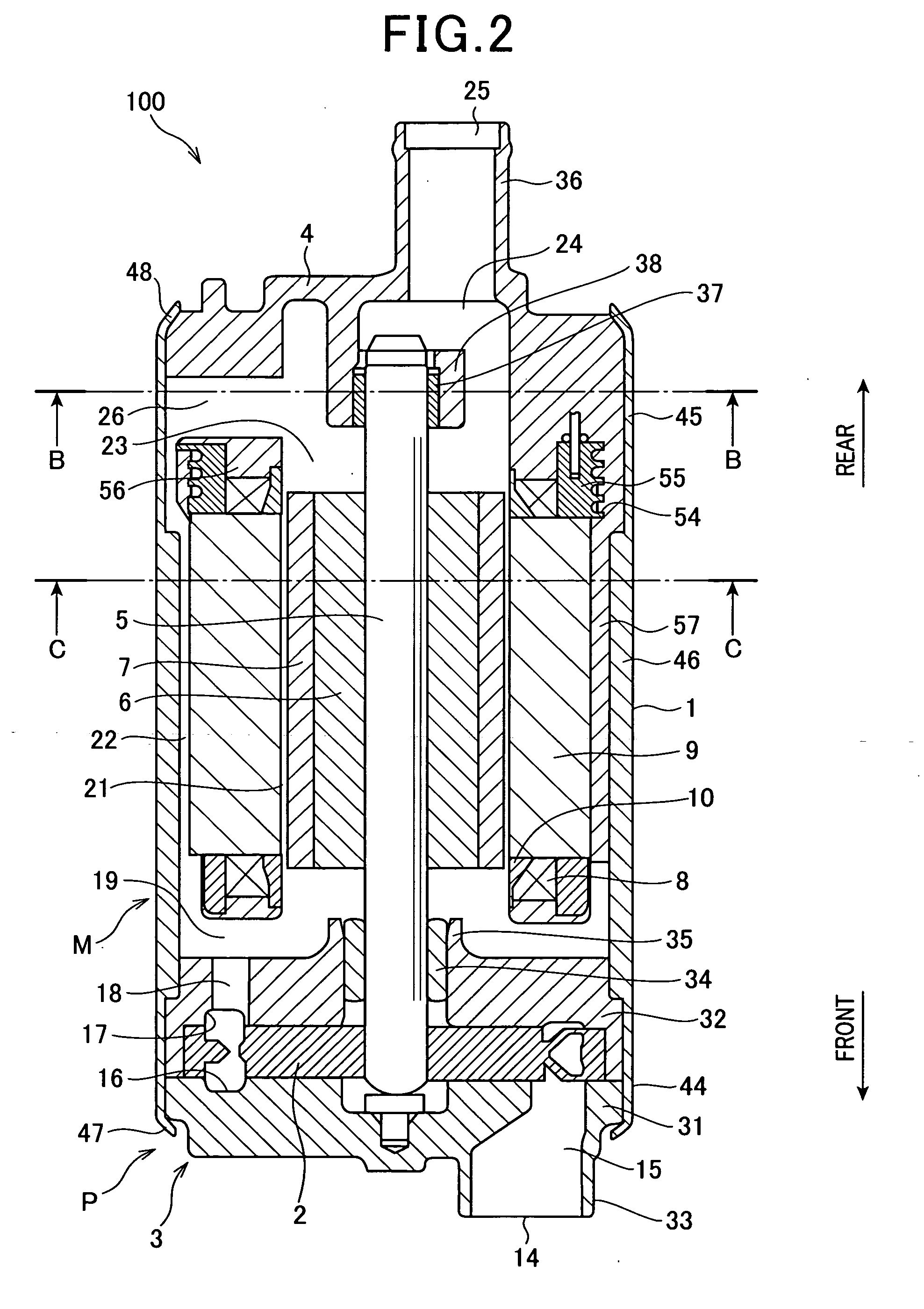

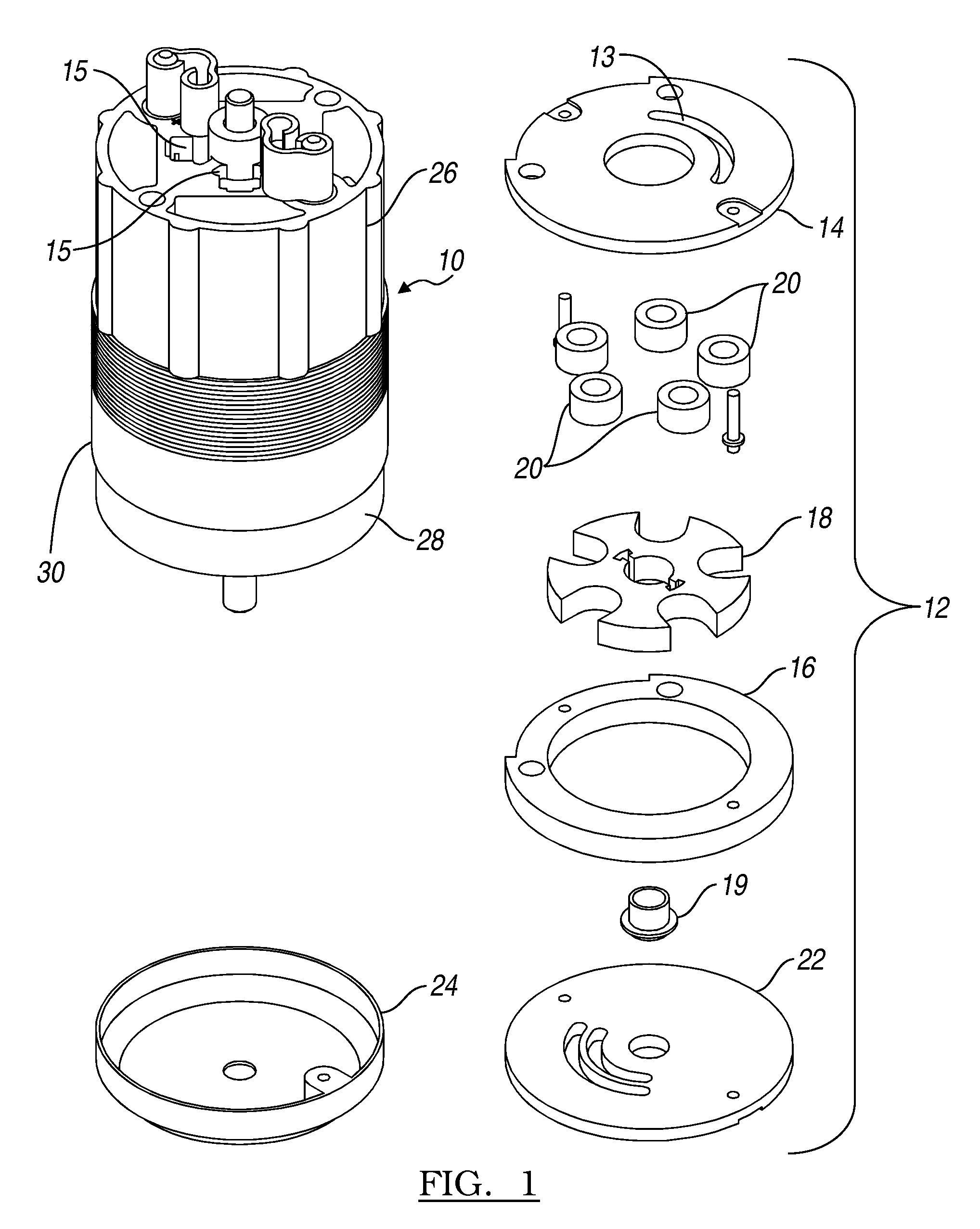

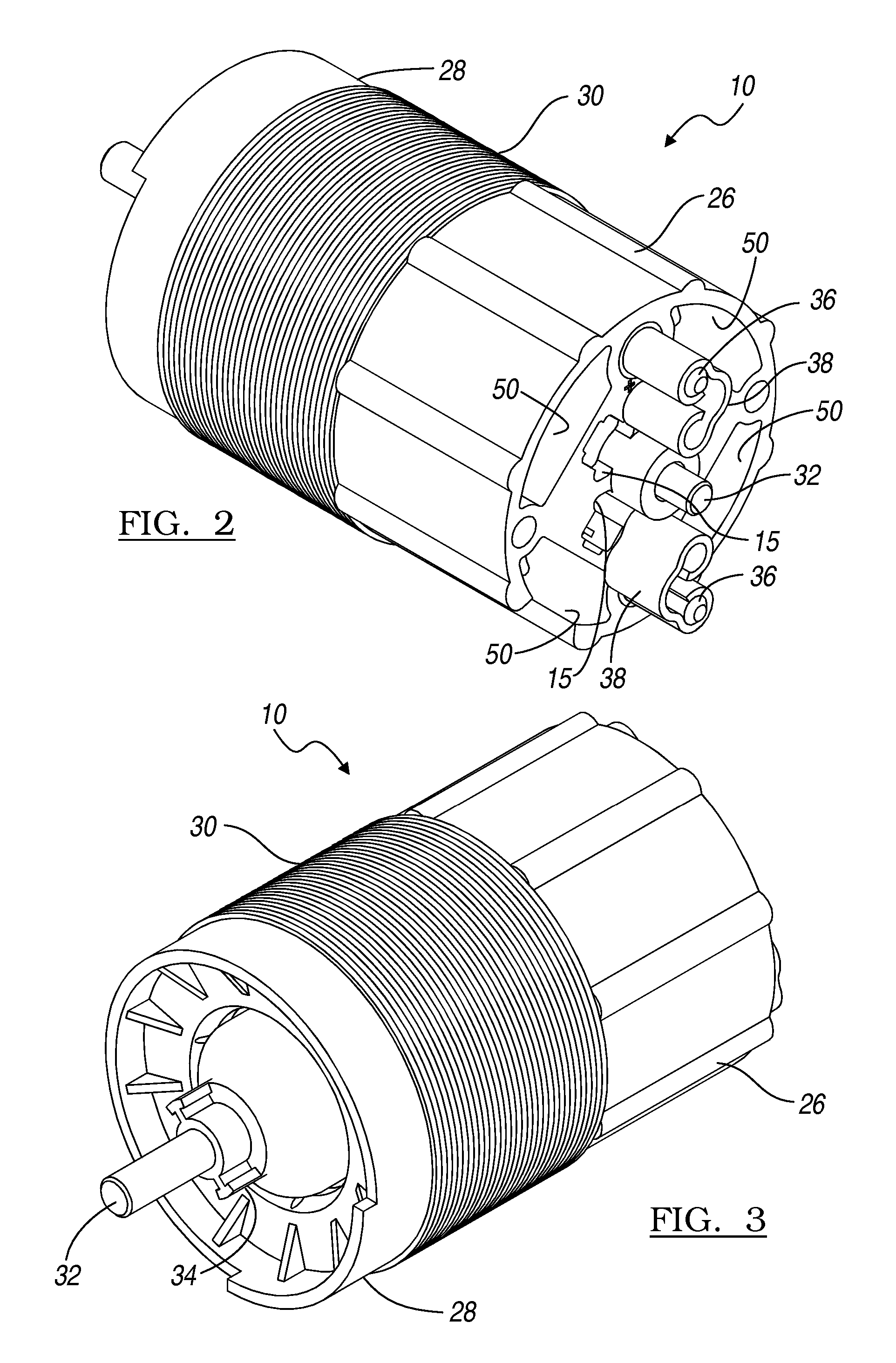

Electric fuel pump capable of supplying fuel at high flow rate

ActiveUS20100034674A1Increase flow rateReduce gapPositive displacement pump componentsMagnetic circuitEngineeringFuel pump

An electric fuel pump is disclosed which includes a pump portion, a motor portion, a housing, and a fuel passage. The pump portion pressurizes fuel. The motor portion drives the pump portion. The motor portion includes a rotor with a rotating shaft and a stator that surrounds an outer periphery of the rotor. The housing surrounds, at least, an outer periphery of the stator of the motor portion. The fuel passage, through which the fuel pressurized by the pump portion passes the motor portion, is made up of a clearance between the outer periphery of the stator of the motor portion and an inner periphery of the housing. The clearance extends, at least, in the axial direction of the rotating shaft of the rotor of the motor portion.

Owner:AISAN IND CO LTD

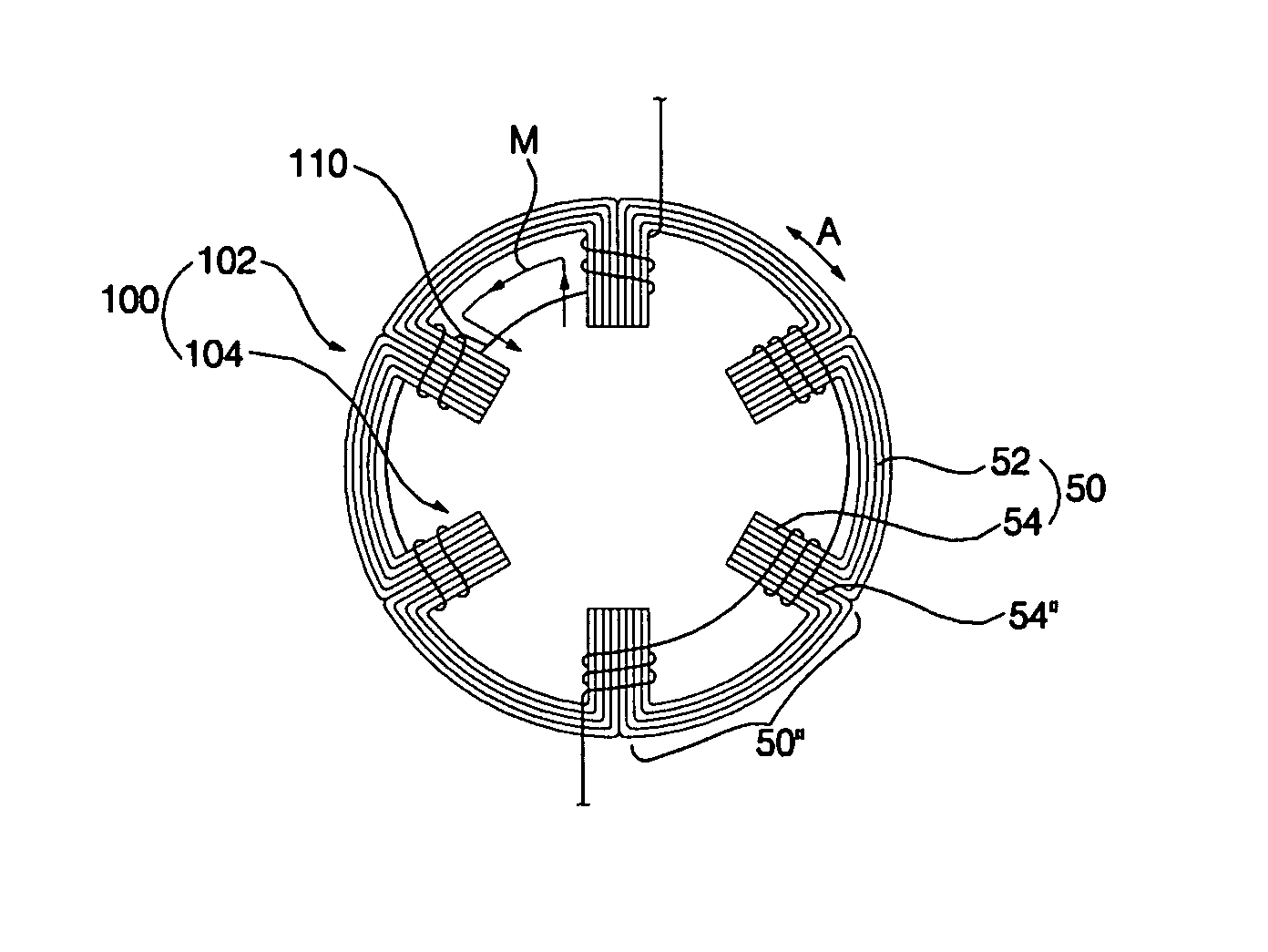

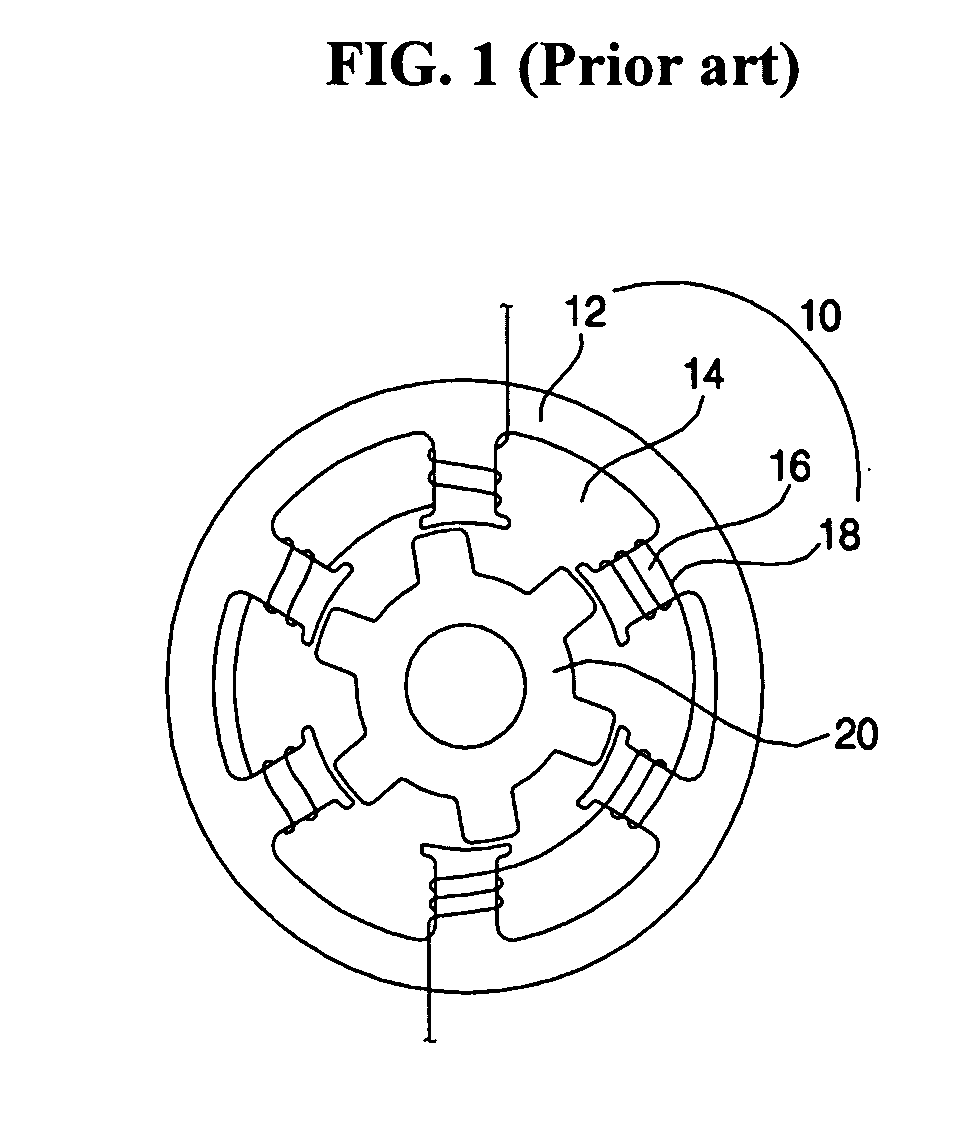

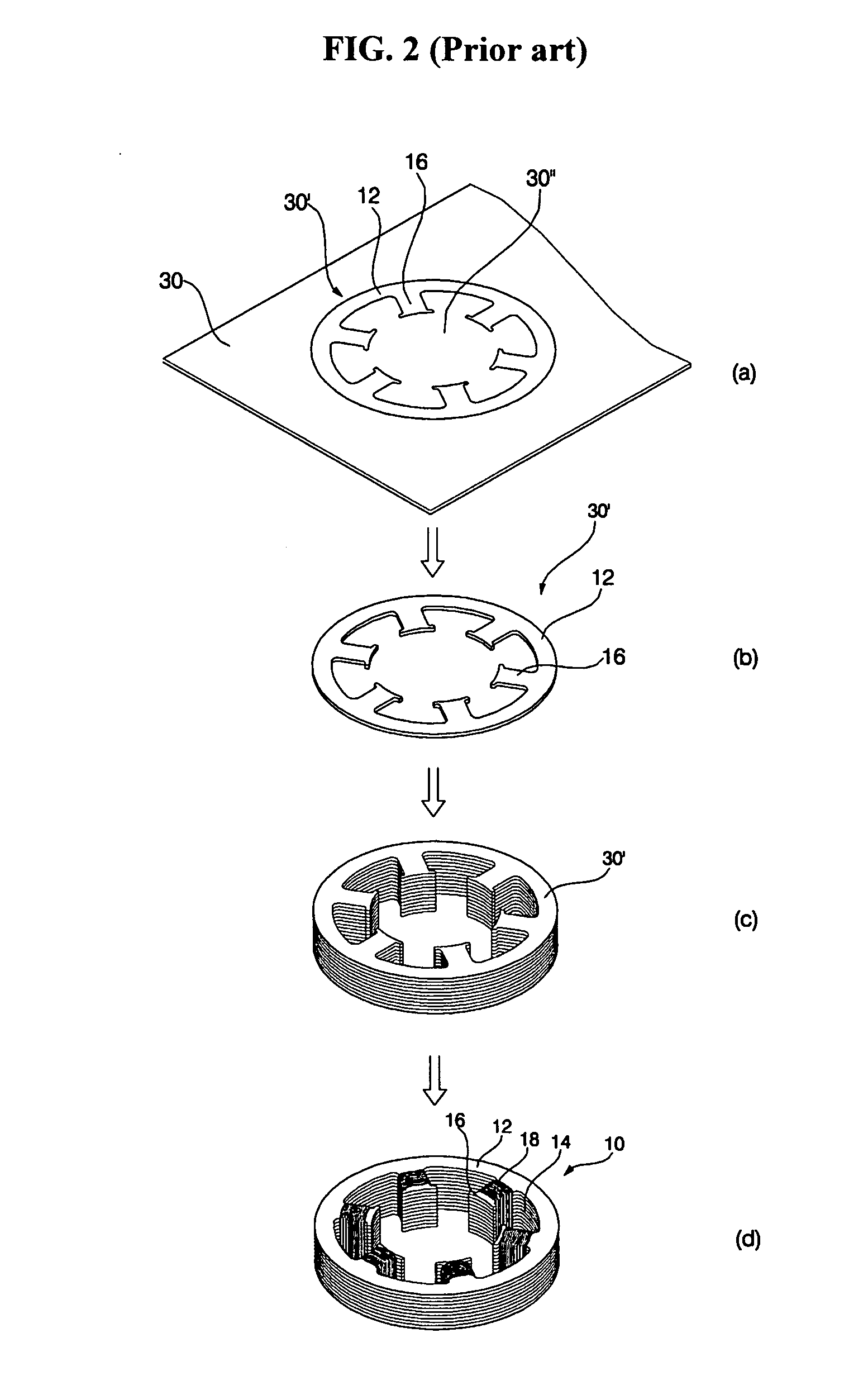

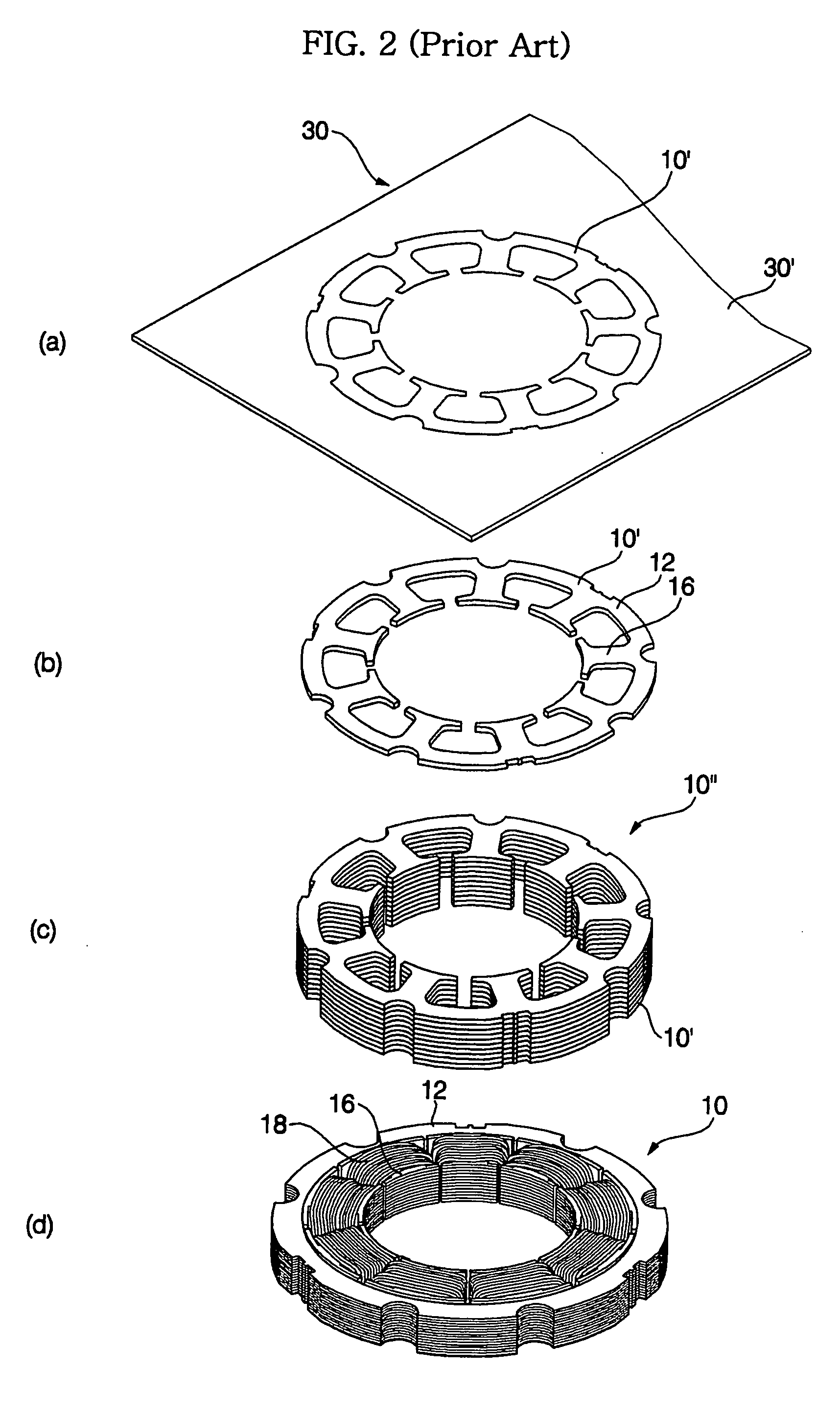

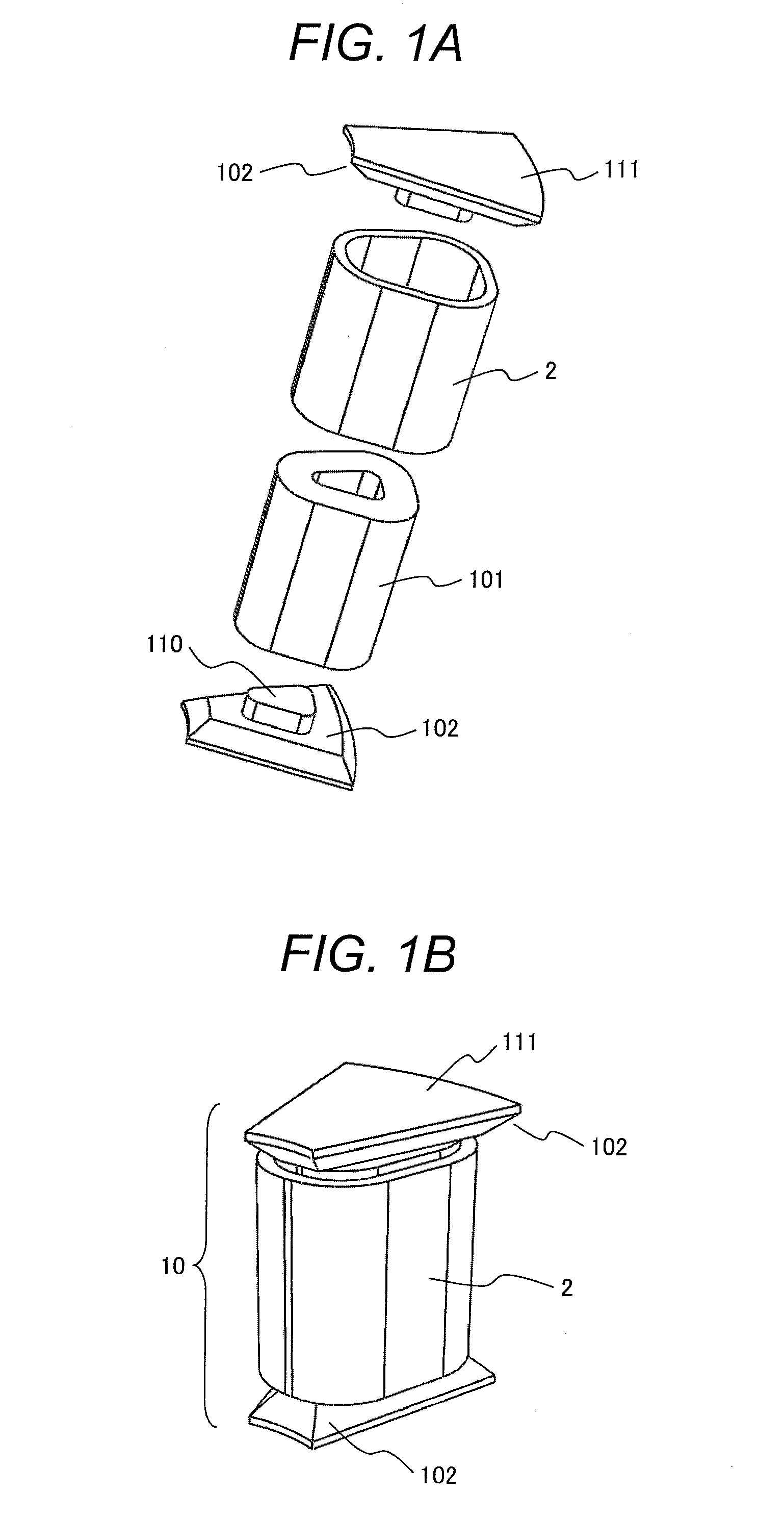

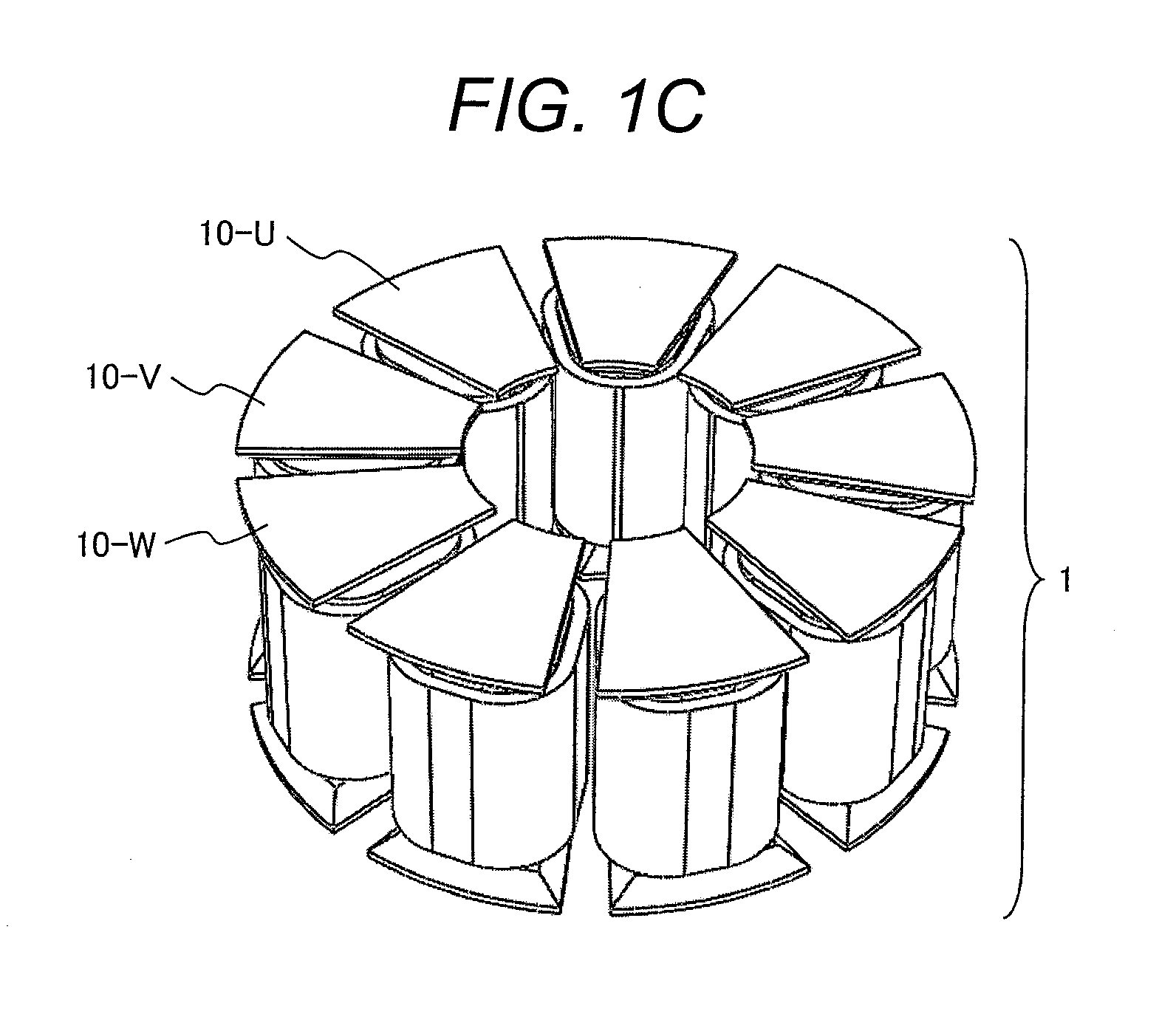

Stator of motor and method of manufacturing the same

InactiveUS20060055274A1Easy to manufactureReduce manufacturing costWindingsMagnetic circuit stationary partsElectrical steelDie preparation

A method of manufacturing a stator of a motor comprises the steps of bending at least one end of an electrical steel sheet to prepare a core sheet comprising a yoke part and at least one pole part bent from the yoke part, stacking a plurality of core sheets to prepare a unit core having a predetermined thickness, arranging a plurality of unit cores in line to prepare a core band, winding coils on the core band, and connecting both ends of the core band. In this way, the stator is manufactured. Consequently, no scrap is formed from the electrical steel sheet according to the present invention.

Owner:LG ELECTRONICS INC

Electric motor and electric power steering apparatus employing the electric motor

InactiveUS6140728AMagnetic fluxIncrease contact areaWindings insulation shape/form/constructionMagnetic circuit rotating partsElectric power steeringEngineering

An electric motor has a rotor for rotation in a stator and a plurality of permanent magnets arranged on an outer peripheral surface of the rotor. A radially inner side surface of each permanent magnet is a curved to generally be convex in a radially inward direction. The outer peripheral surface of the rotor has curved recess surfaces, each of which contacts the radially inner side curved surface of a corresponding permanent magnet so that magnetic flux between adjacent permanent magnets is considerably prevented from locally concentrating within the rotor.

Owner:TOYOTA JIDOSHA KK

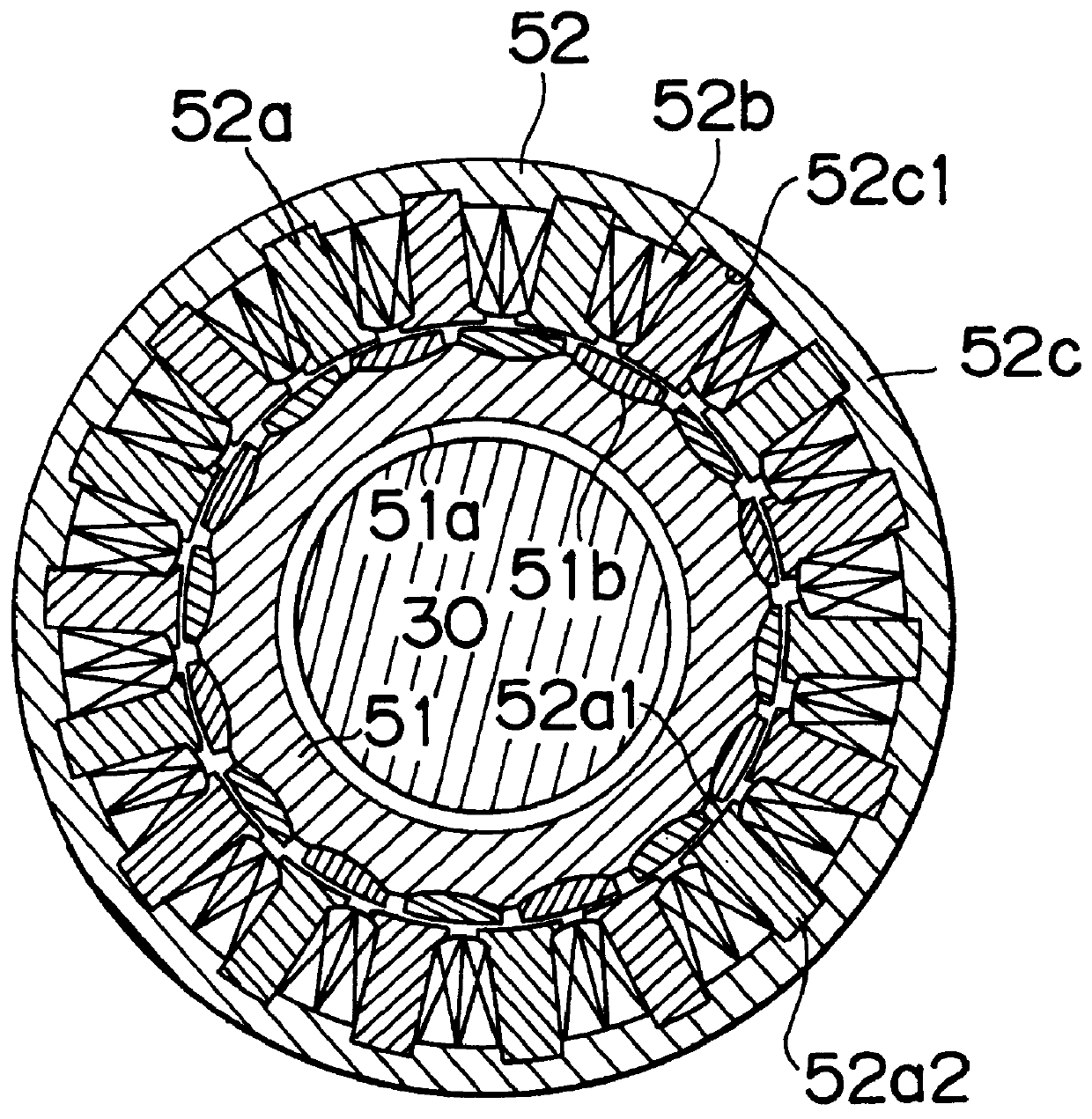

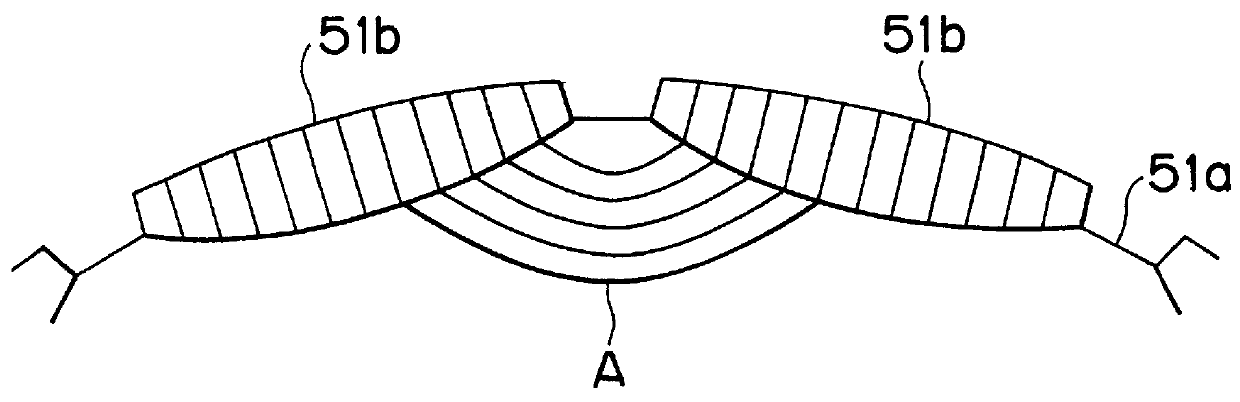

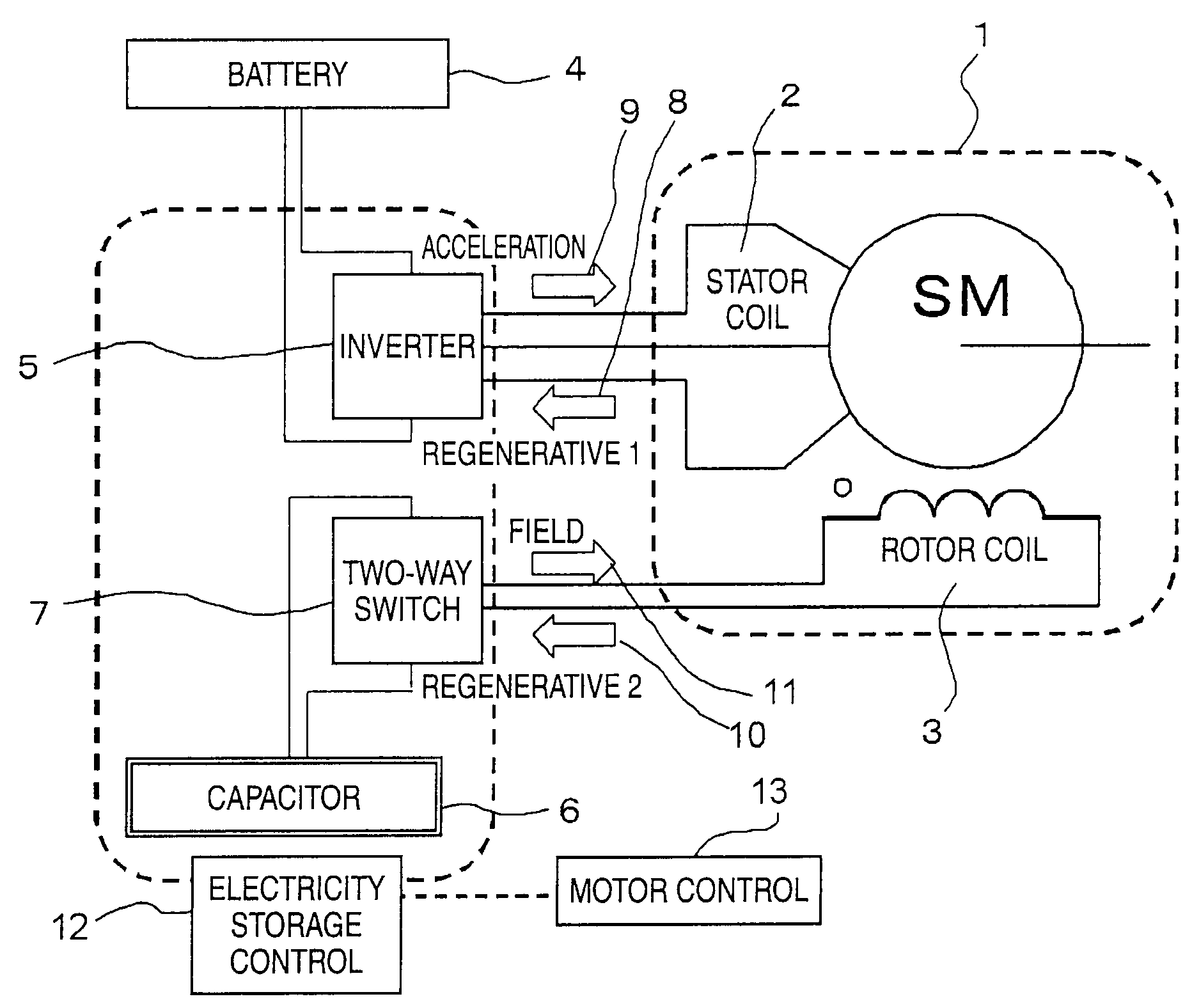

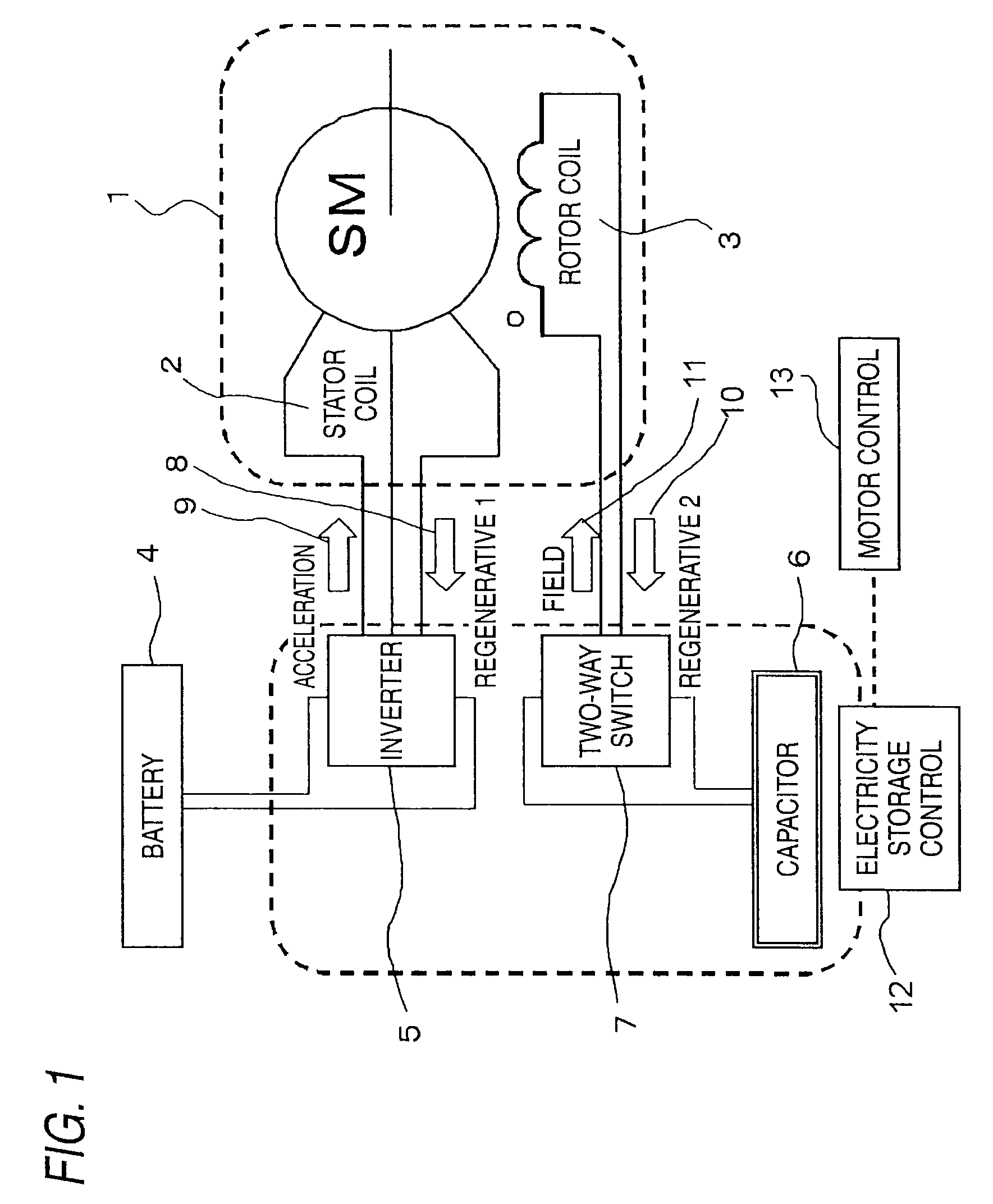

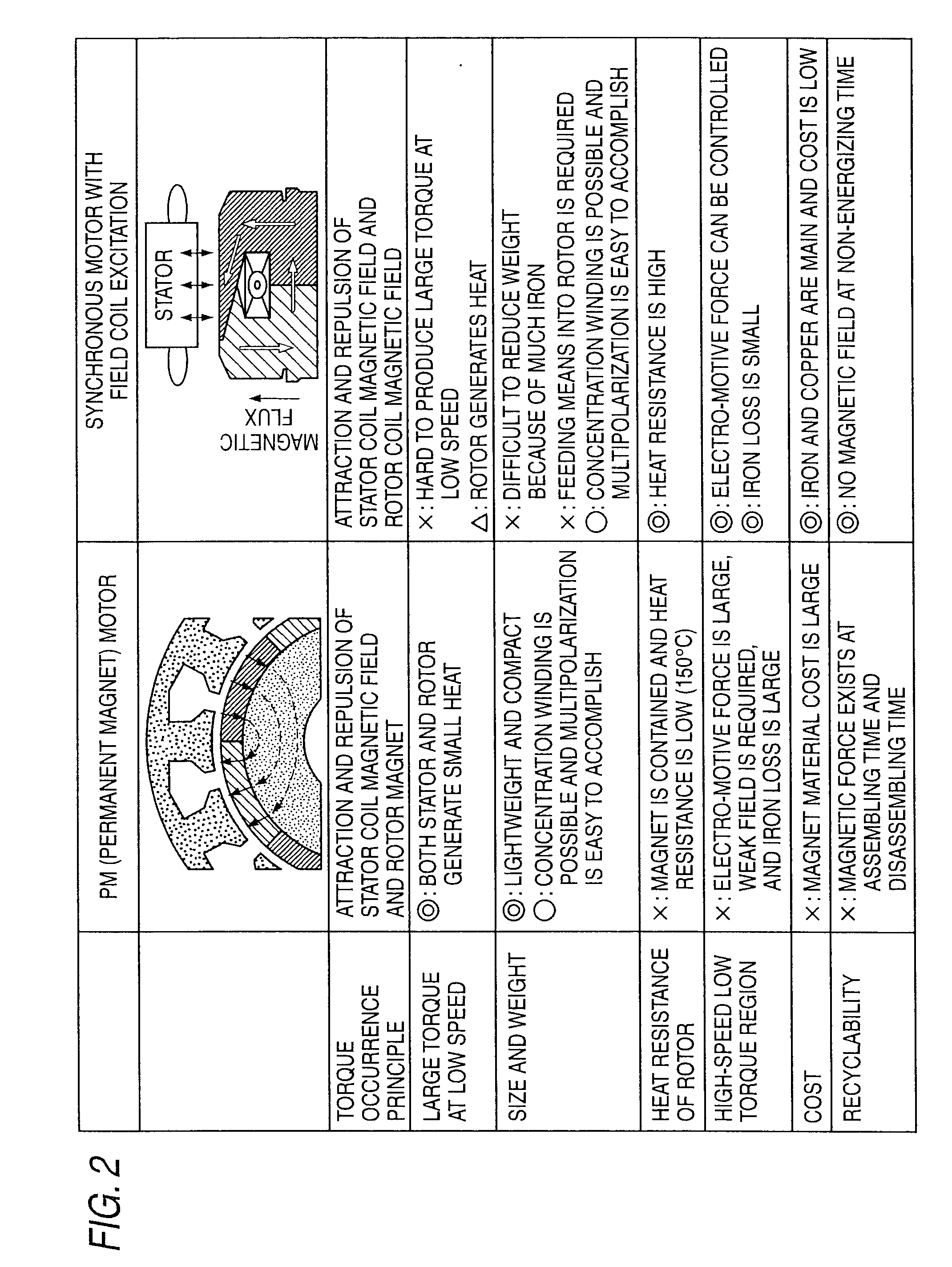

Regenerating braking system including synchronous motor with field excitation and control method thereof

ActiveUS20090302788A1Current efficiencyDecrease regenerative braking currentHybrid vehiclesAC motor controlSynchronous motorRegenerative brake

A regenerating braking system is provided, which includes: a synchronous motor with field coil excitation including a cylindrical stator coil, an inverter electrically connected to the stator coil, a battery electrically connected to the inverter, a rotor coil provided in an internal space of the stator coil, a two-way switch electrically connected to the rotor coil, and a capacitor electrically connected to the two-way switch; and a controller, wherein when the first differential calculus of acceleration of a load on the synchronous motor becomes negative, the controller stores regenerative power regenerated in the rotor coil from the stator coil, in the capacitor through the two-way switch, and wherein the controller supplies the regenerative power stored in the capacitor to the rotor coil through the two-way switch.

Owner:MITSUBISHI ELECTRIC CORP

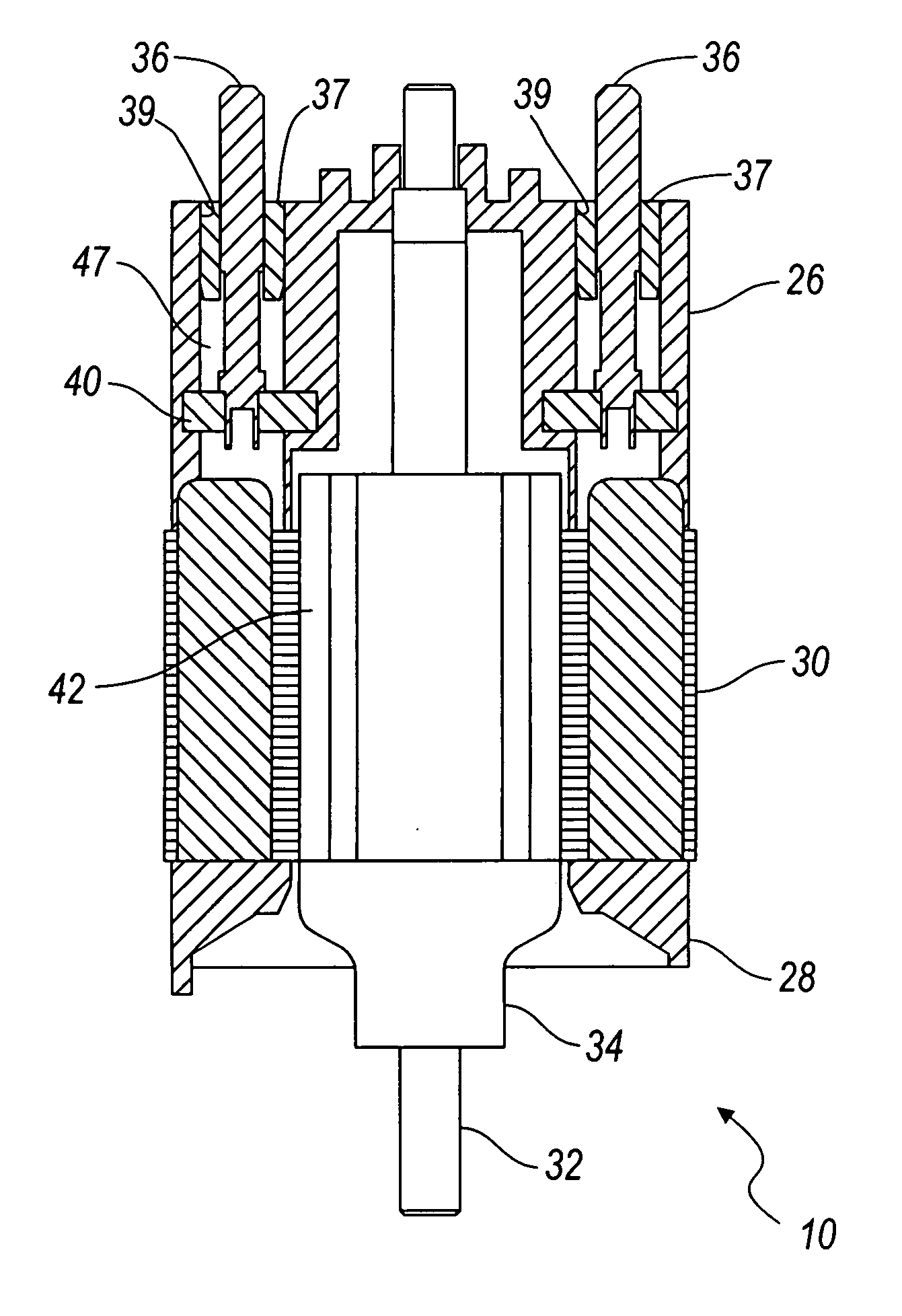

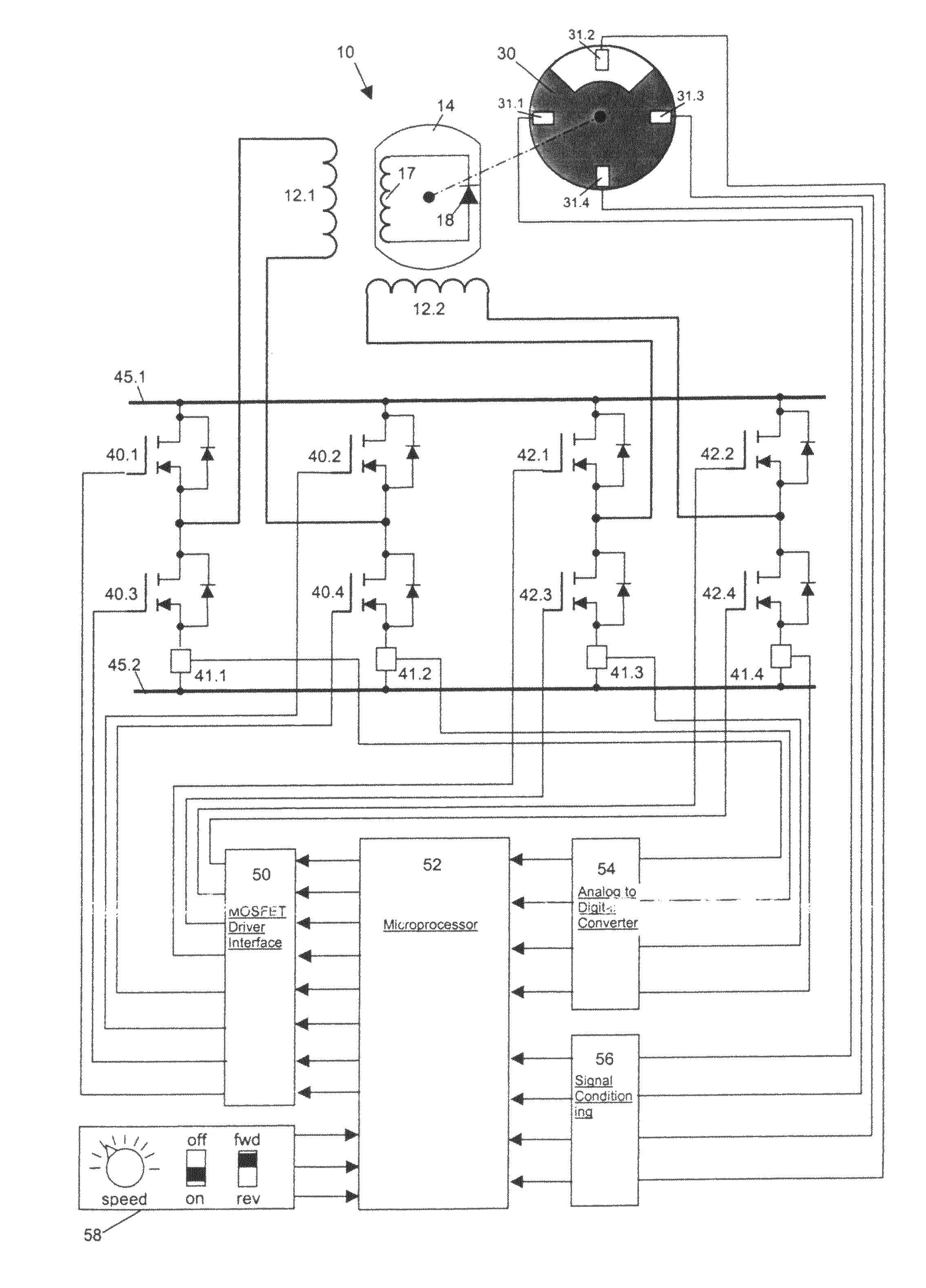

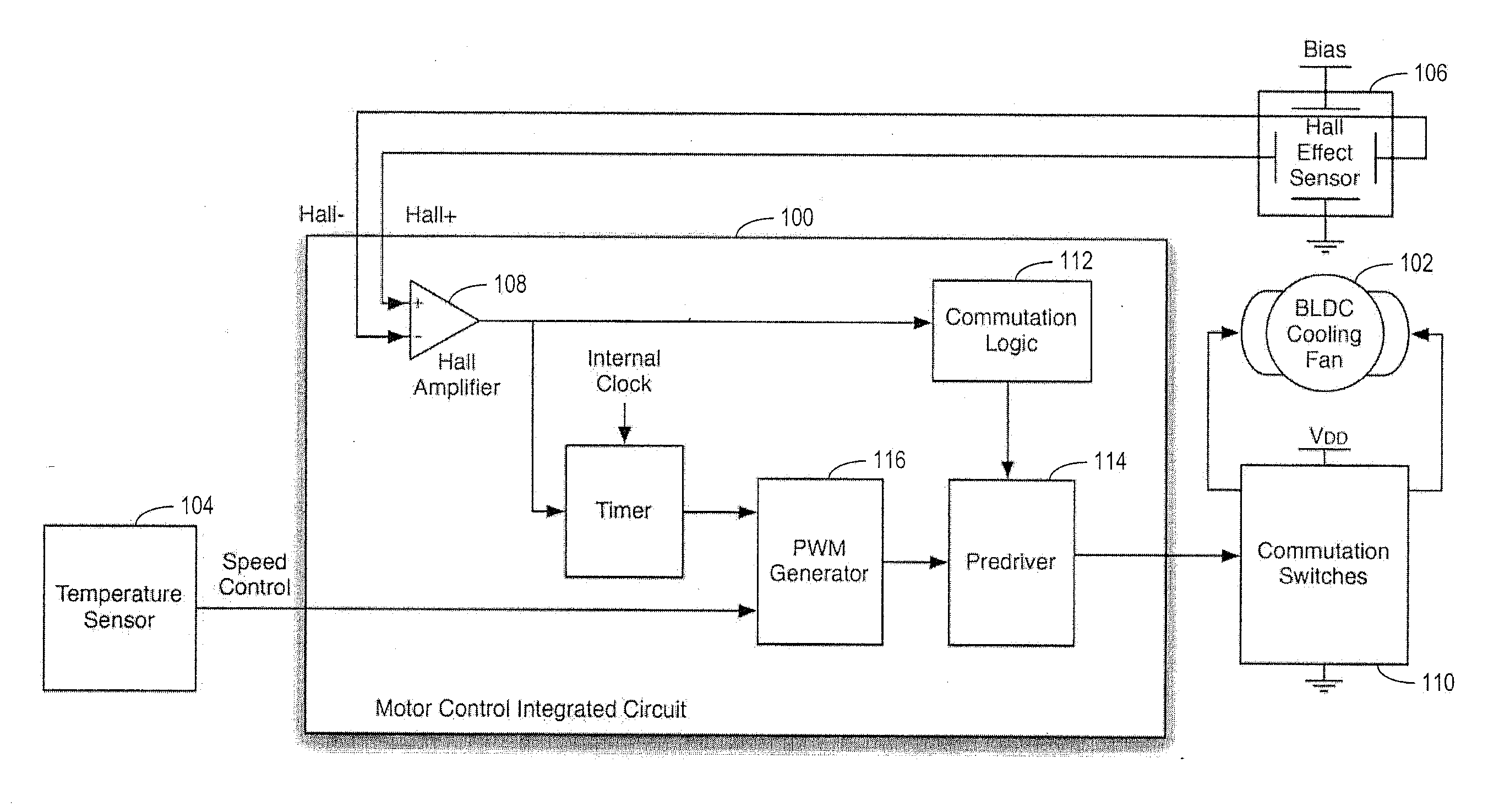

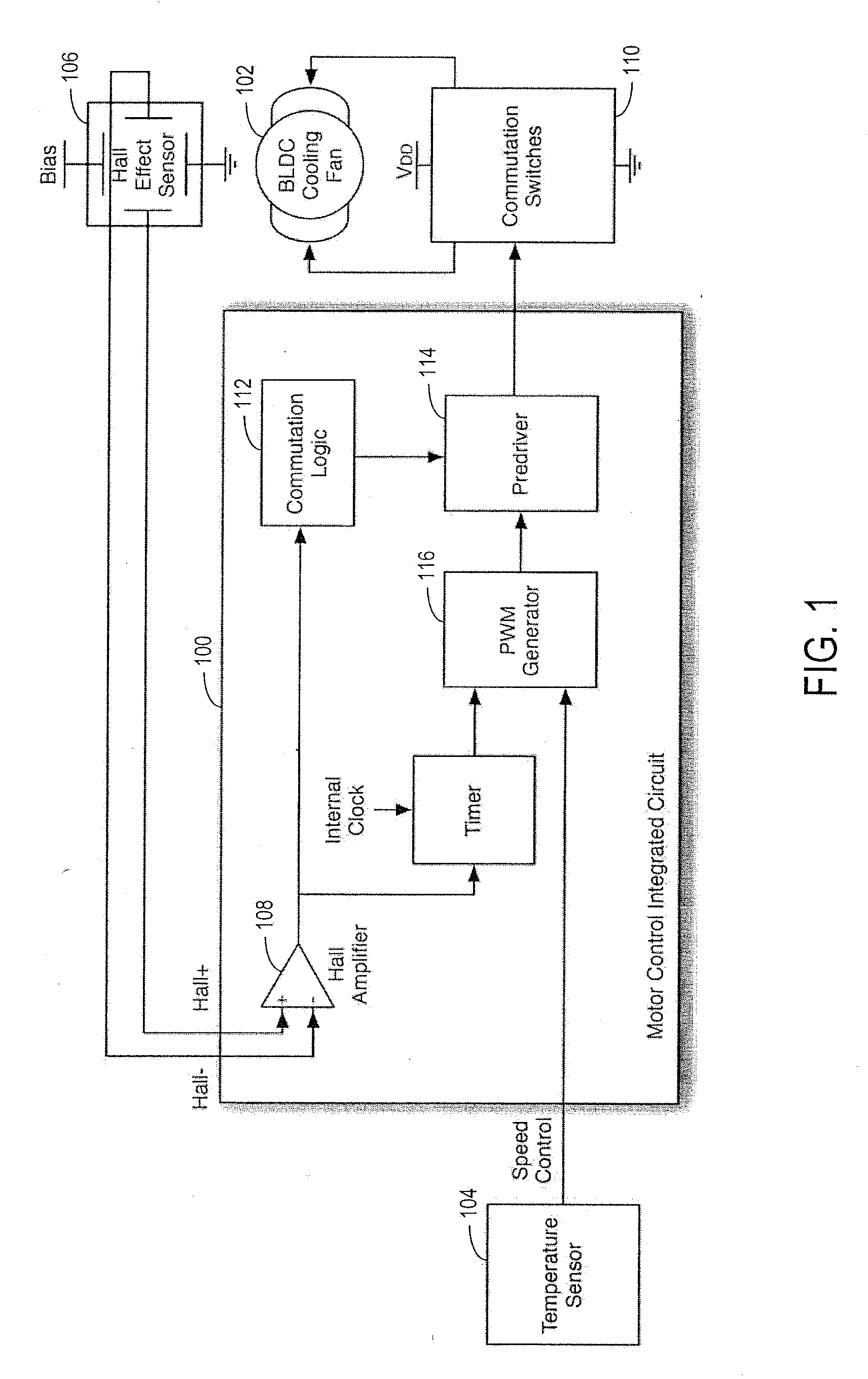

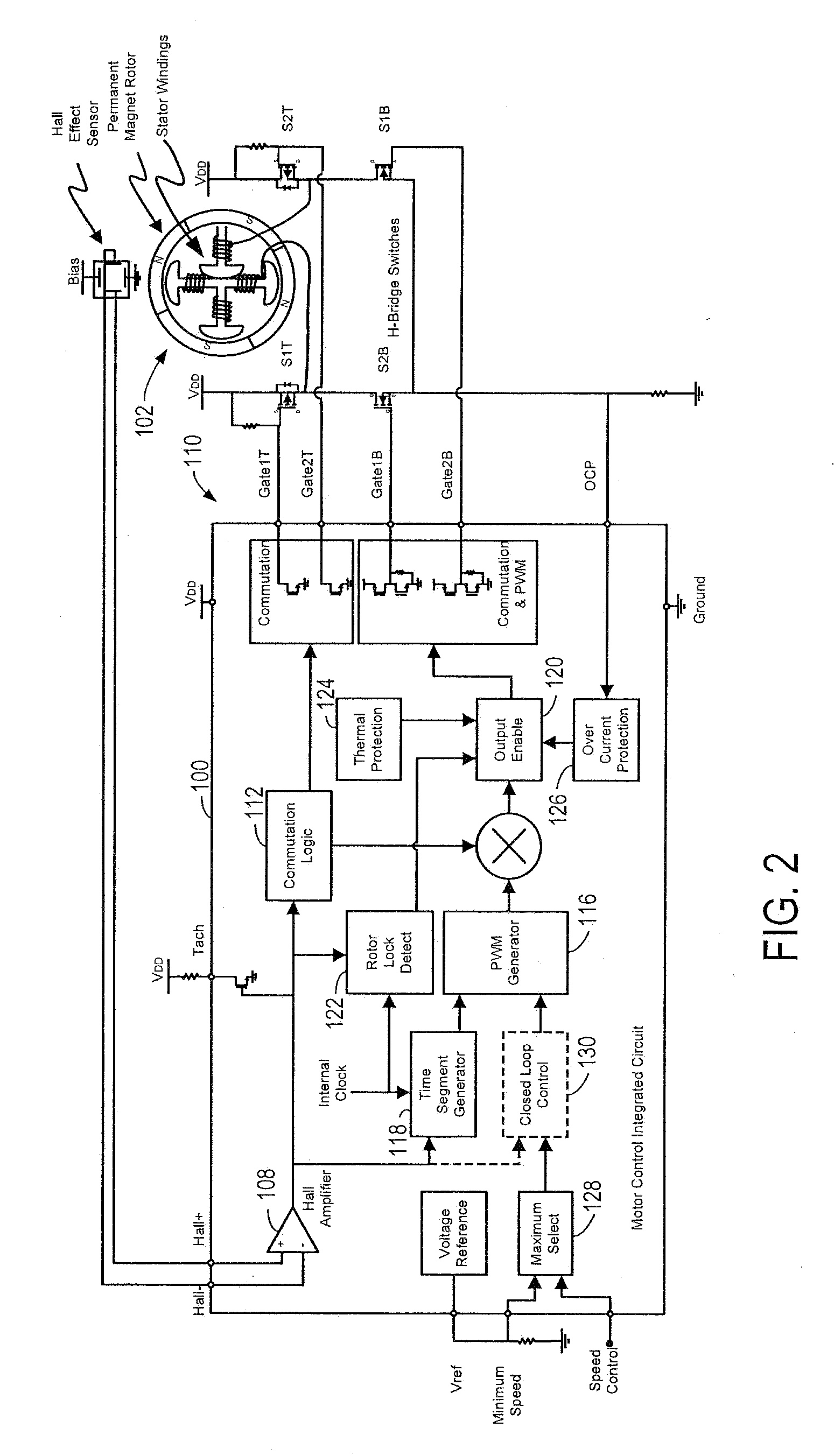

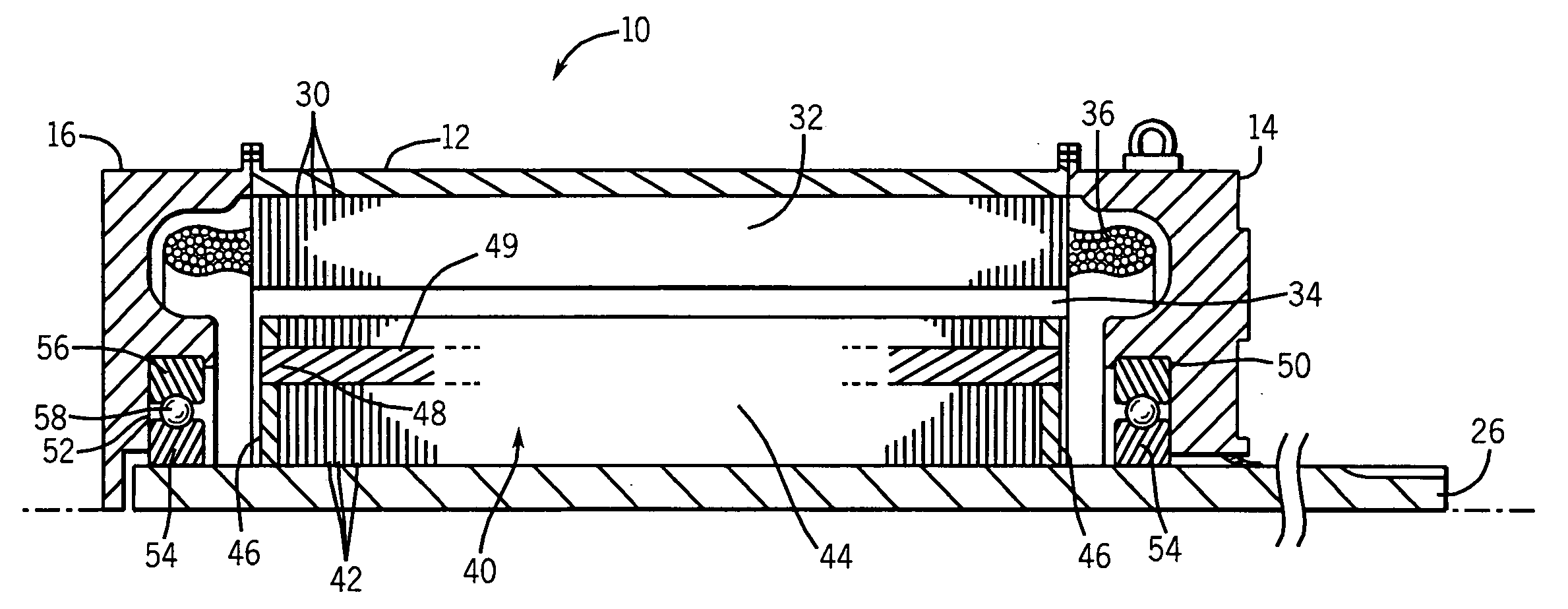

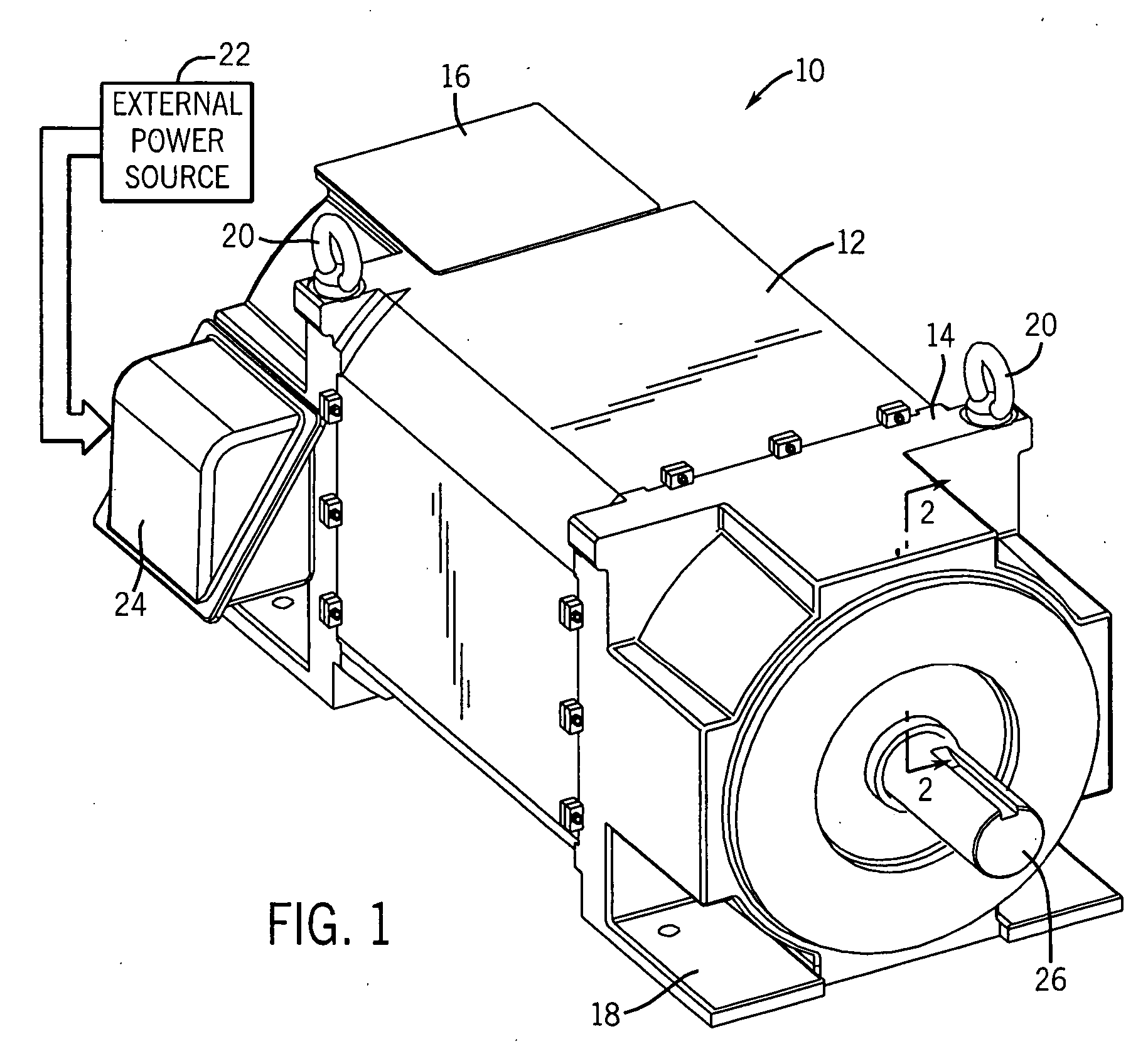

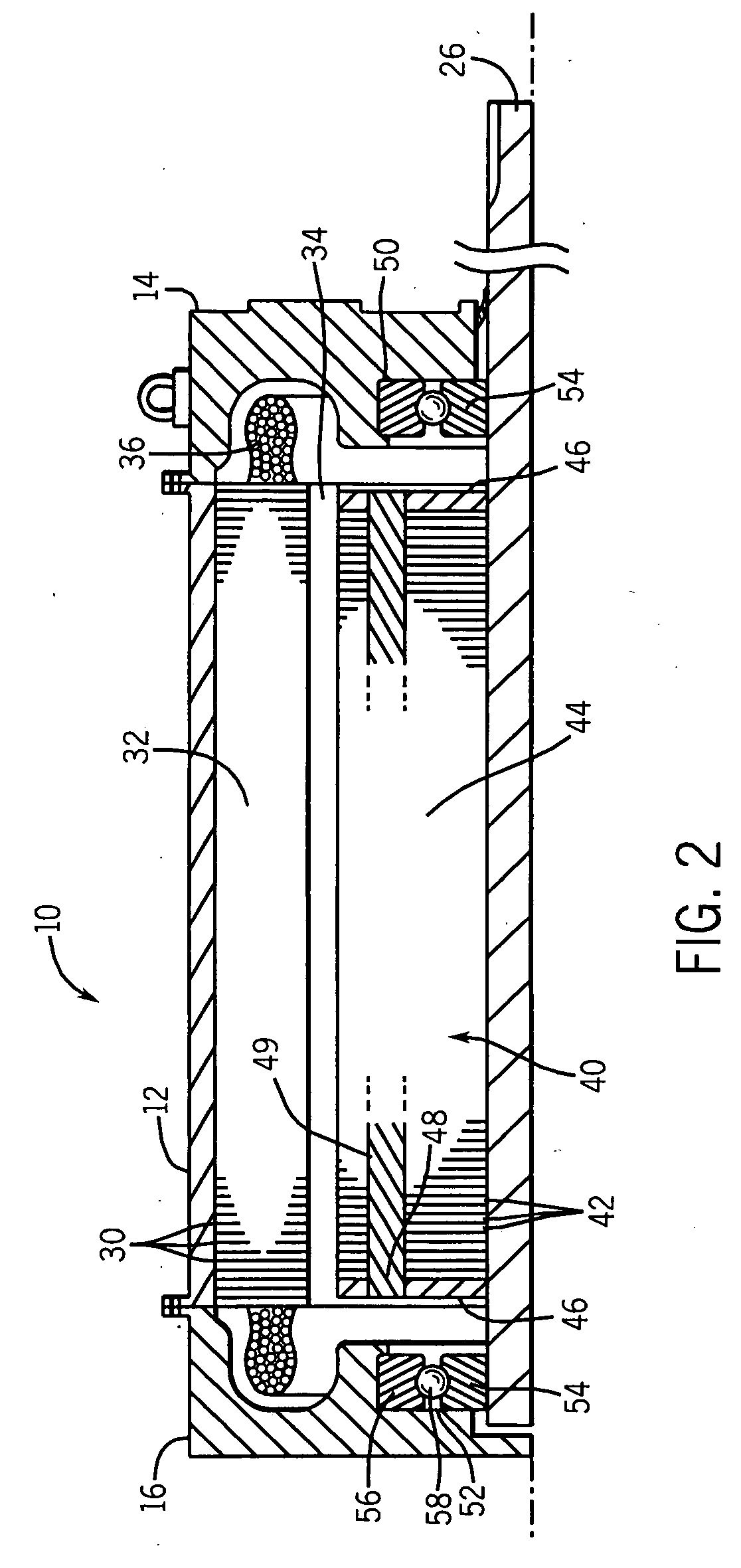

BLDC motor and pump assembly with encapsulated circuit board

ActiveUS20060279162A1Increased Design FreedomImprove motor efficiencyAssociation with control/drive circuitsRotary current collectorElectrical devicesEngineering

A BLDC motor assembly and method for manufacturing same is disclosed. The motor has a housing, a shaft supported for rotation within the housing, a stator disposed within the housing for generating an electro-magnetic field, a rotor operatively coupled to the shaft and disposed for powered rotation within the stator in response to the electro-magnetic field, at least one temperature sensitive electronic device (TSED) disposed within the housing and electrically connected to the stator for controlling or measuring an aspect of the electro-magnetic field, and a fuel resistant and electrically insulated polymeric material encapsulating the TSED so that the TSED is protected from adverse temperature and chemical agents without the need for a separate internal container or a pre-potting operating. The TSED, which may be carried on a printed circuit board within the housing, is thus overmolded with polymeric material so that the polymeric material fills, or substantially fills, a space within the housing. Not only is the cost and weight associated with a prior art dedicated container for the electronics eliminated, but this invention allows greater design freedom in the location or placement of the various electrical devices within the housing for better motor efficiency and / or protection.

Owner:CARTER FUEL SYST

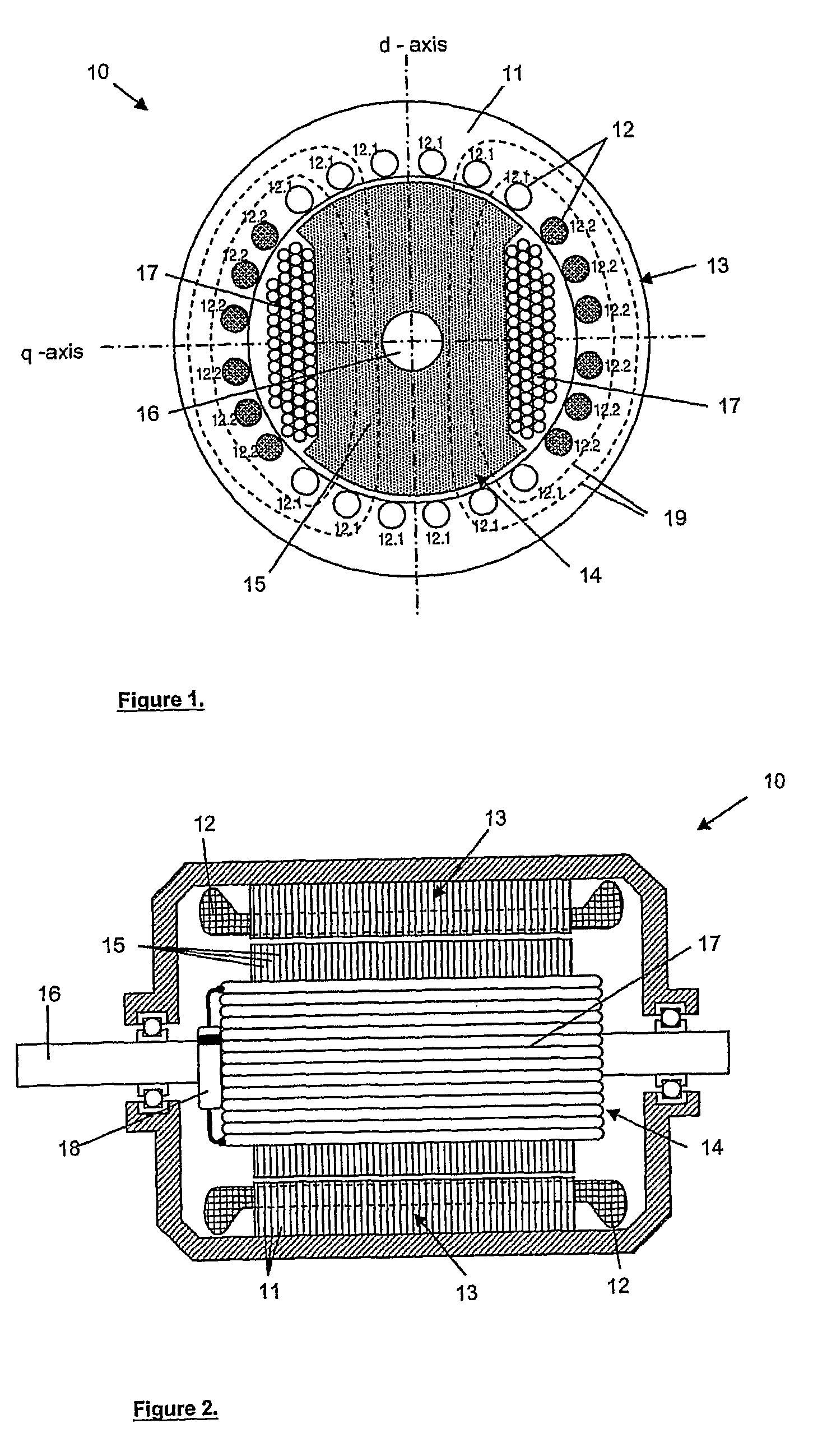

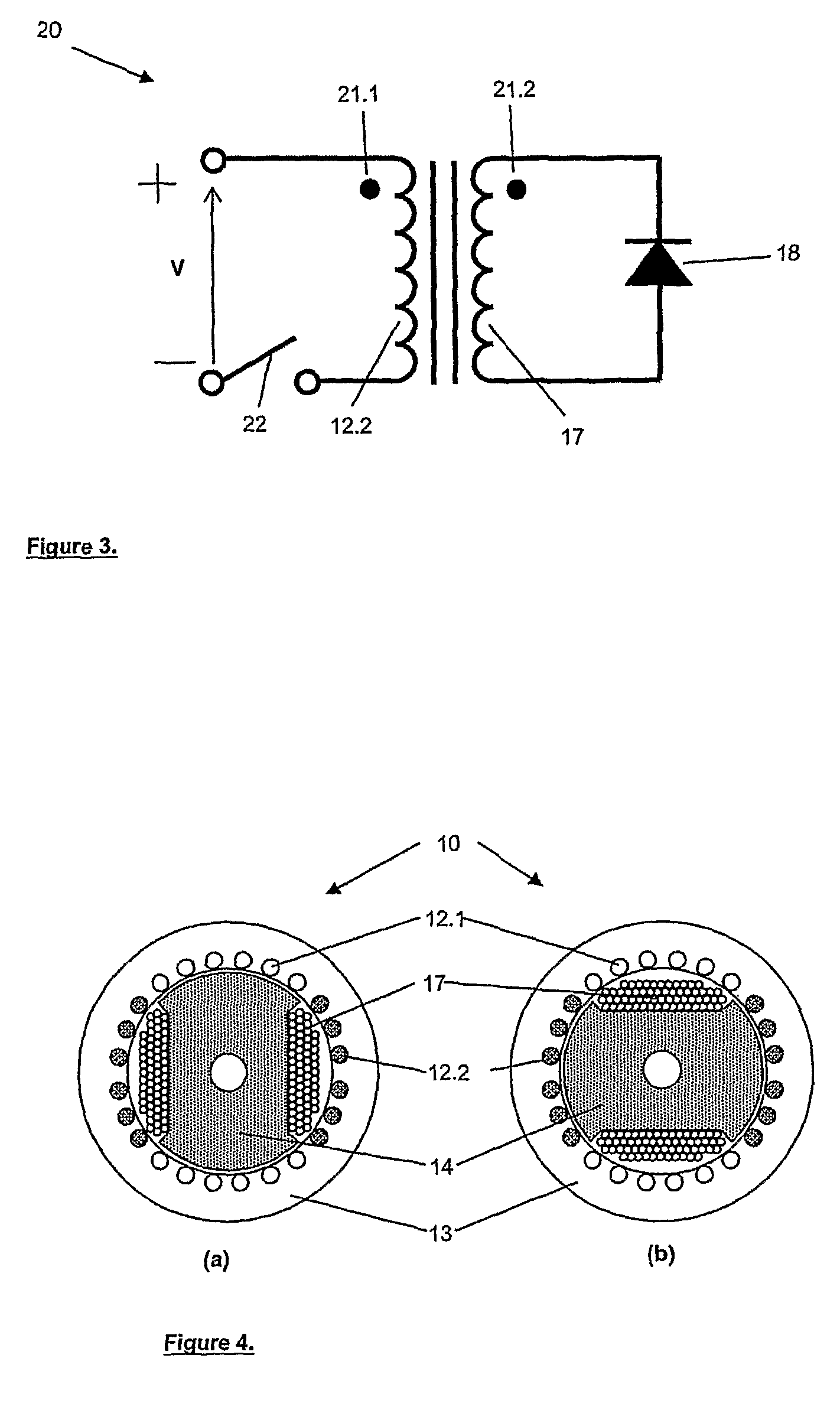

Electric motor

InactiveUS7795830B2Improve motor efficiencyEfficient captureAssociation with control/drive circuitsMotor/generator/converter stoppersConductor CoilElectric motor

An electric motor (10) which includes an armature (11) with at least two armature phase pair windings (12) and salient pole rotor arrangement (15) having field windings (17) terminating in a selective electrical switch which determines the electrical continuity of said field windings (17). Also included is control means which is configured to regulate the magnetizing of the field winding (17) so that, at any given moment, one armature phase pair is usable for magnetizing the field winding while the other pair is responsible for torque production.

Owner:ELCKON

Capacitor motor and process for producing the same

InactiveUS20100141059A1Improve efficiencyAvoid areaManufacturing dynamo-electric machinesMagnetic circuit characterised by magnetic materialsEngineeringConductor Coil

A capacitor motor is formed of a stator including a stator iron core and windings, and a rotor including a rotor iron core. The stator iron core is divided into a plurality of first divided iron-core units having tooth sections and a second divided iron-core unit forming a magnetic path of the first divided iron-core units. The windings are mounted to the tooth sections and accommodated in a plurality of slots formed by the first iron-core units and the second one. The first divided iron-core units are formed by punching electromagnetic steel plates and layering the plates punched out. The second divided iron-core unit is formed by molding magnetic powder into a given shape. The first divided iron-core units and the second one are jointed together by a given means such that the tooth sections can be arranged radially on outer wall of the rotor iron core.

Owner:PANASONIC CORP

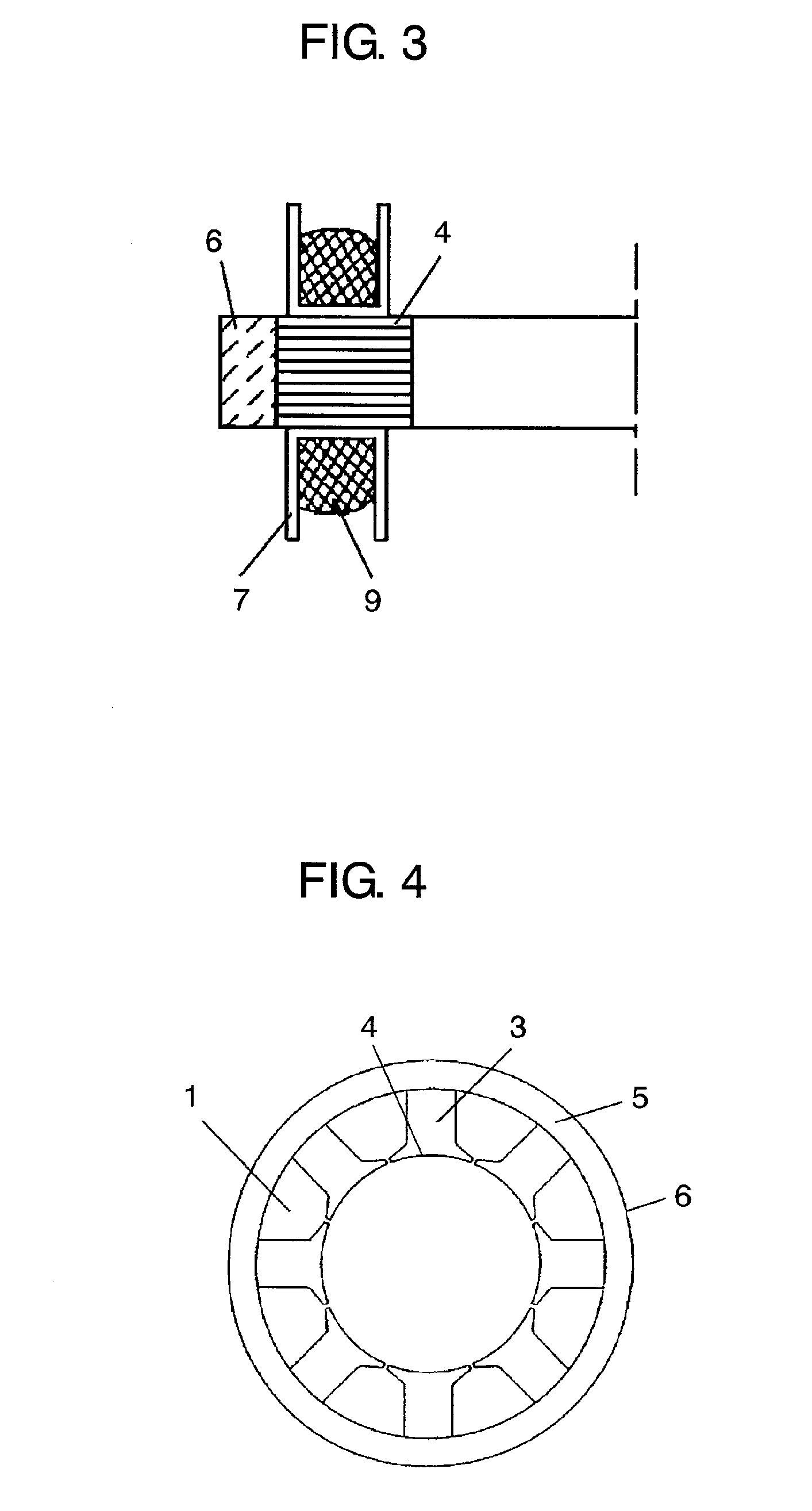

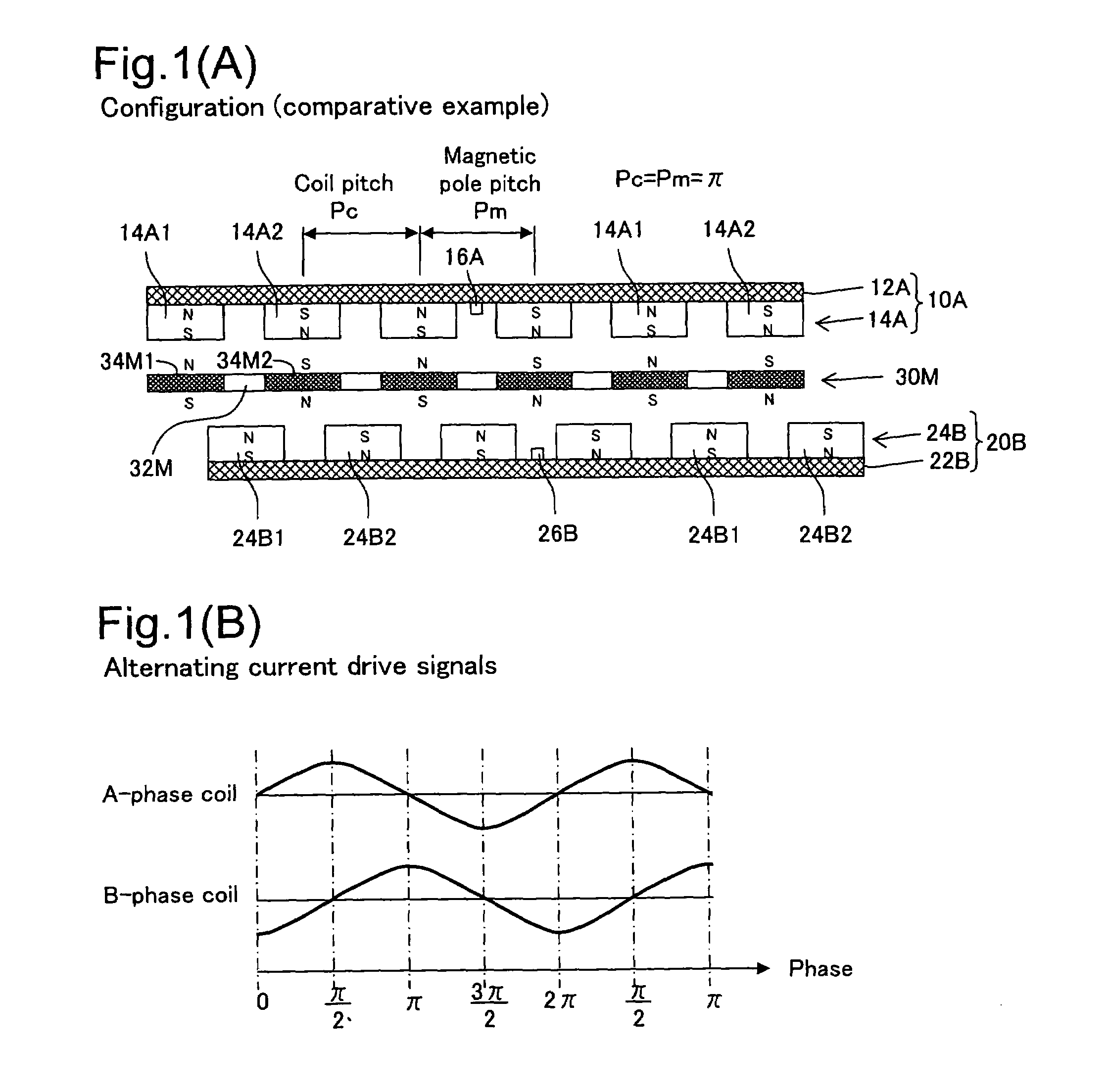

Motor

ActiveUS7126309B1Improve motor efficiencyReduce weightAC motor controlMagnetic circuit rotating partsElectric machinePhase difference

The electric machine of the present invention comprises a first coil group containing a plurality of coils and a magnet group. The first coil group is classified into M phase sub coil groups, with the coils of the sub coil groups aligned one at a time in sequence at a specified sub coil group interval Dc from the first phase sub coil group to the M-th phase sub coil group. A sub coil group interval Dc is set to a value of K / M times a magnetic pole pitch Pm (K is a positive integer excluding an integral multiple of M) where the distance corresponding to an electrical angle of π is defined as the magnetic pole pitch Pm. The adjacent sub coil groups are driven at a (K / M)π phase difference. Each coil have substantially no magnetic material core.

Owner:GK BRIDGE 1

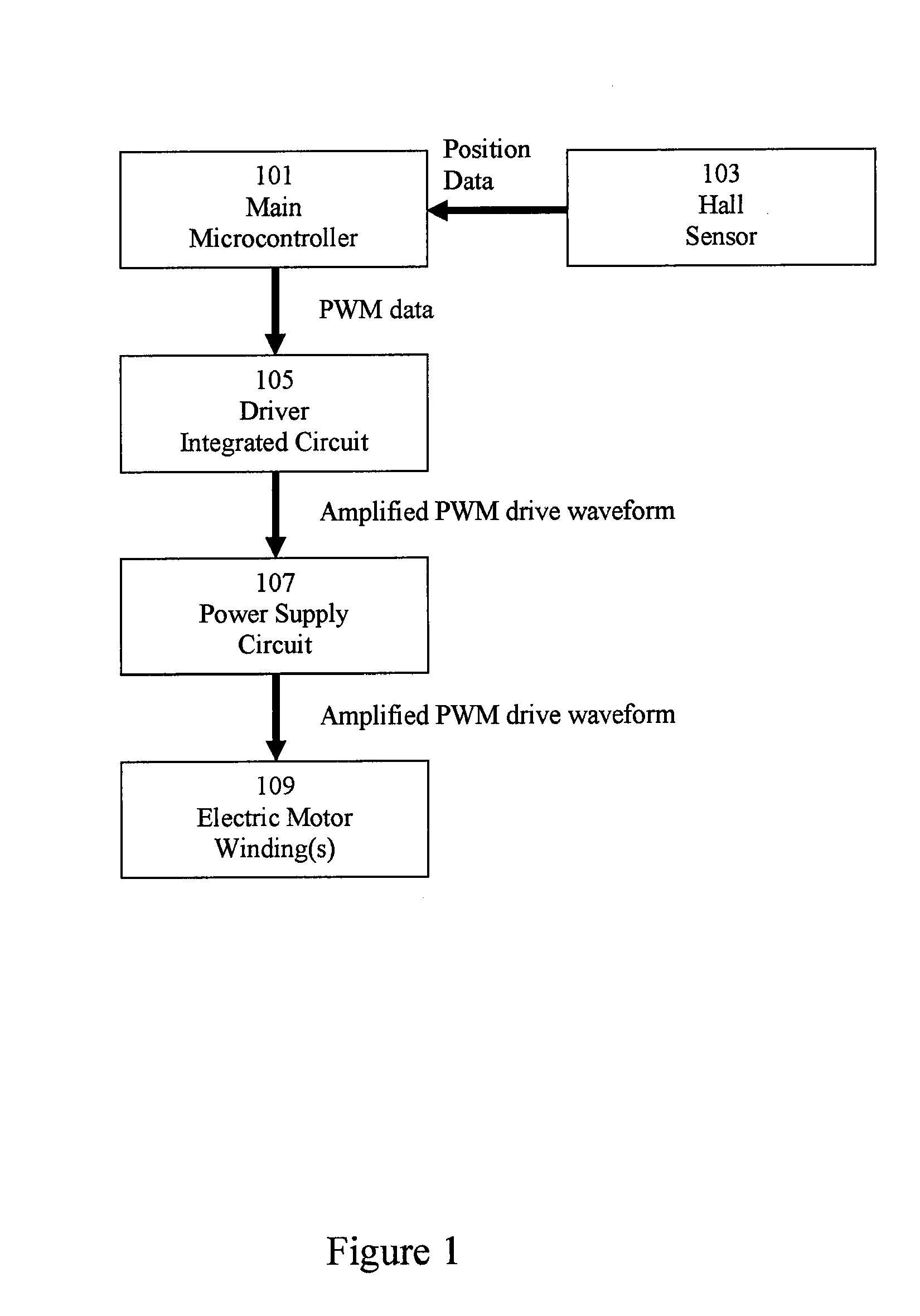

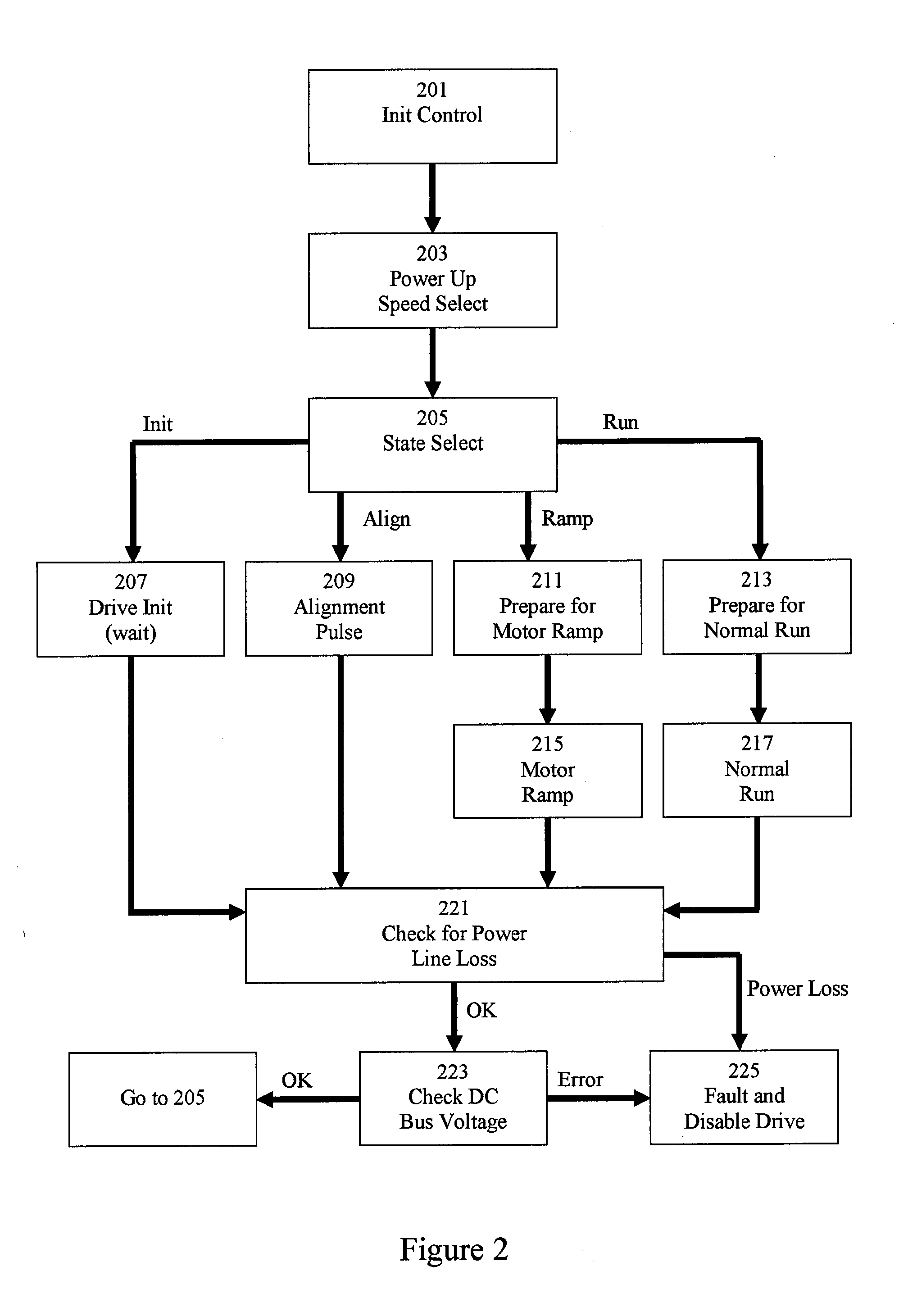

Position Corrected Pulse Width Modulation for Brushless Direct Current Motors

ActiveUS20120326643A1Increased torque outputReduce motor noiseTorque ripple controlMotor/generator/converter stoppersPosition dependentDirect current

A method of operating a brushless direct current motor is provided that generates a rotor position dependent pulse width modulation waveform. The waveform can improve motor efficiency and reduce torque variation.

Owner:AGAVE SEMICON

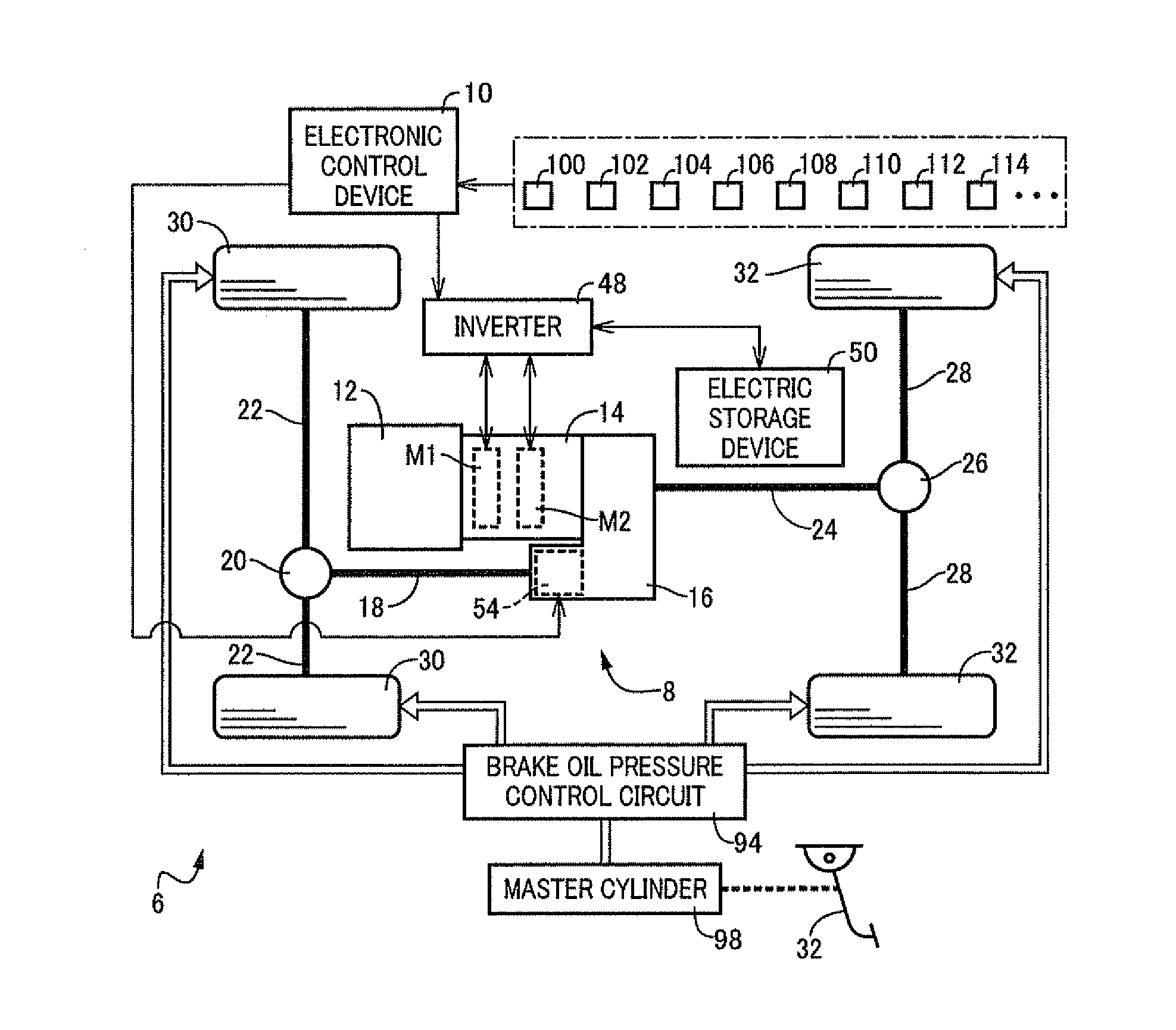

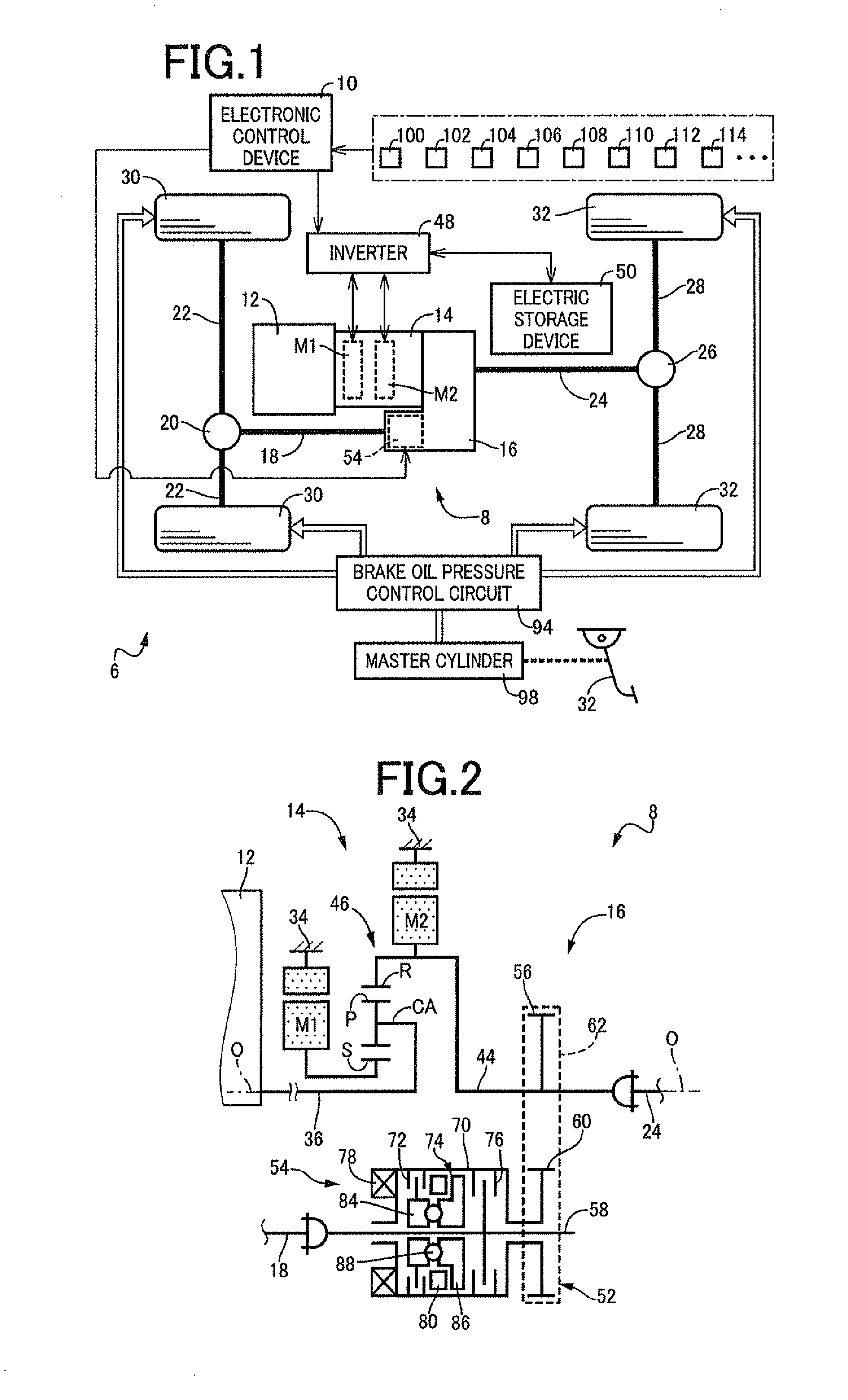

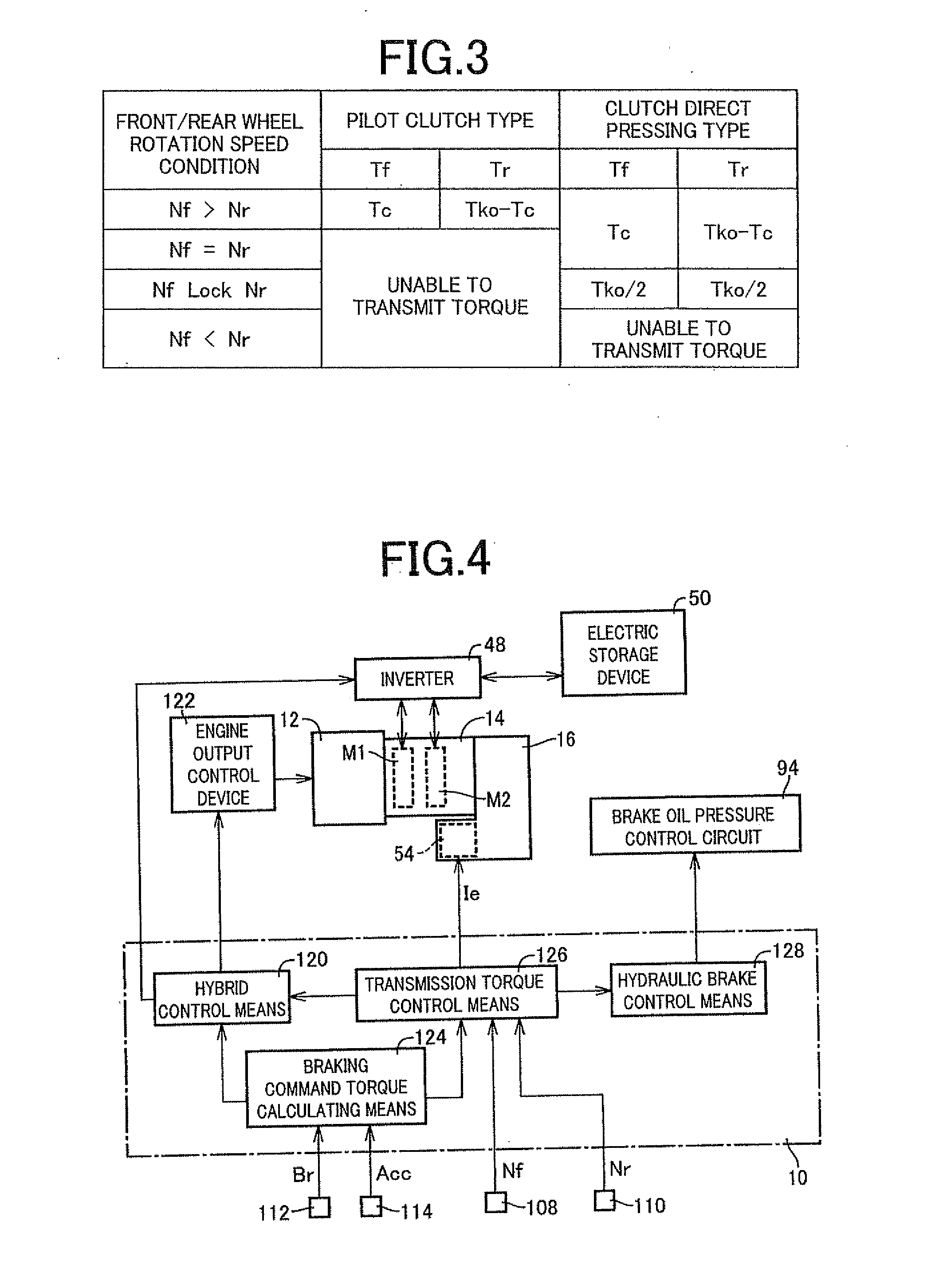

Drive control device for standby four-wheel drive vehicle

InactiveUS20120203416A1Improve fuel economyGreat power transmission lossHybrid vehiclesDigital data processing detailsBrake torqueRegenerative brake

Provided is a drive control device for a standby four-wheel drive vehicle having primary drive wheels coupled to a drive source including a motor generator that generates a regenerative braking torque and a clutch device disposed between the drive source and secondary drive wheels to switch a two-wheel drive state using the primary drive wheels and a four-wheel drive state using the primary drive wheels and the secondary drive wheels, including: a transmission torque control portion that causes the clutch device to set a transmission torque between the drive source and the secondary drive wheels to zero so as to allow only the primary drive wheels to perform regenerative braking if a request braking torque of the vehicle is equal to or lower than a predetermined primary-drive-wheel regeneration limit torque during the regenerative braking by the motor generator, the transmission torque control portion causing the clutch device to generate the transmission torque between the drive source and the secondary drive wheels so as to allow the primary drive wheels and the secondary drive wheels to perform the regenerative braking if the request braking torque exceeds the primary-drive-wheel regeneration limit torque.

Owner:TOYOTA JIDOSHA KK

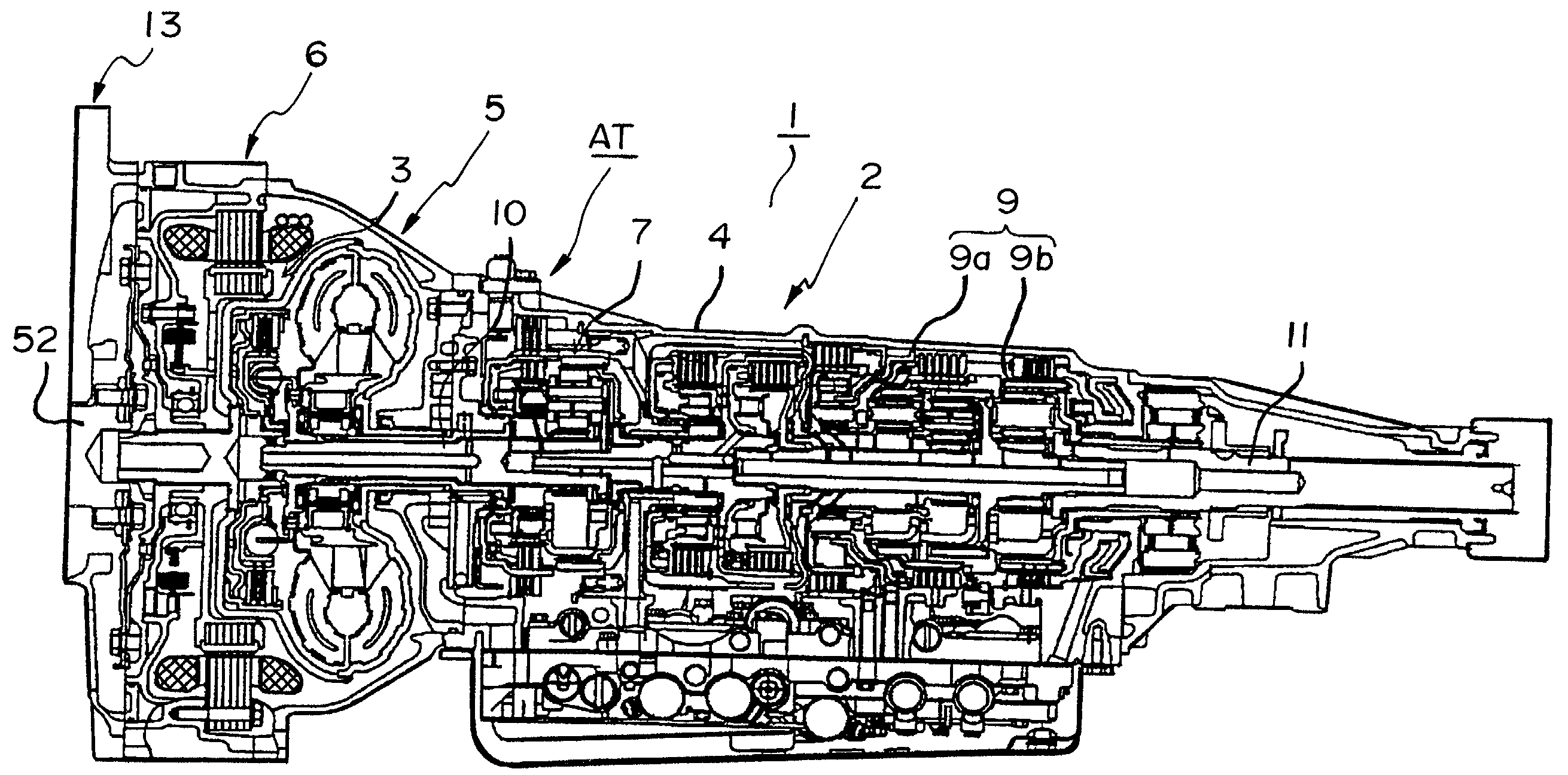

Hybrid-vehicle drive unit

InactiveUS20020036434A1Improve accuracyImprove motor efficiencyReciprocating combination enginesDynamo-electric brakes/clutchesInternal combustion engineHybrid vehicle

A hybrid-vehicle drive unit supports a motor-generator with high precision, improving the efficiency of the motor-generator, and reducing the size of the motor-generator, independent of any influence of centering precision of the crank shaft and of deformation of the torque converter. According to the invention, a motor housing is disposed between a converter housing and an internal combustion engine, and a bearing is fitted to a lateral wall provided in a front portion of the motor housing. Rotor supporting members are independently supported by the bearing. Eccentric rotation of the crank shaft resulting from explosive vibrations of the engine is counteracted by two flex plates. Owing to a predetermined clearance, one of the rotor supporting members as a separate component is free from the influence of deformation of the torque converter.

Owner:AISIN AW CO LTD +1

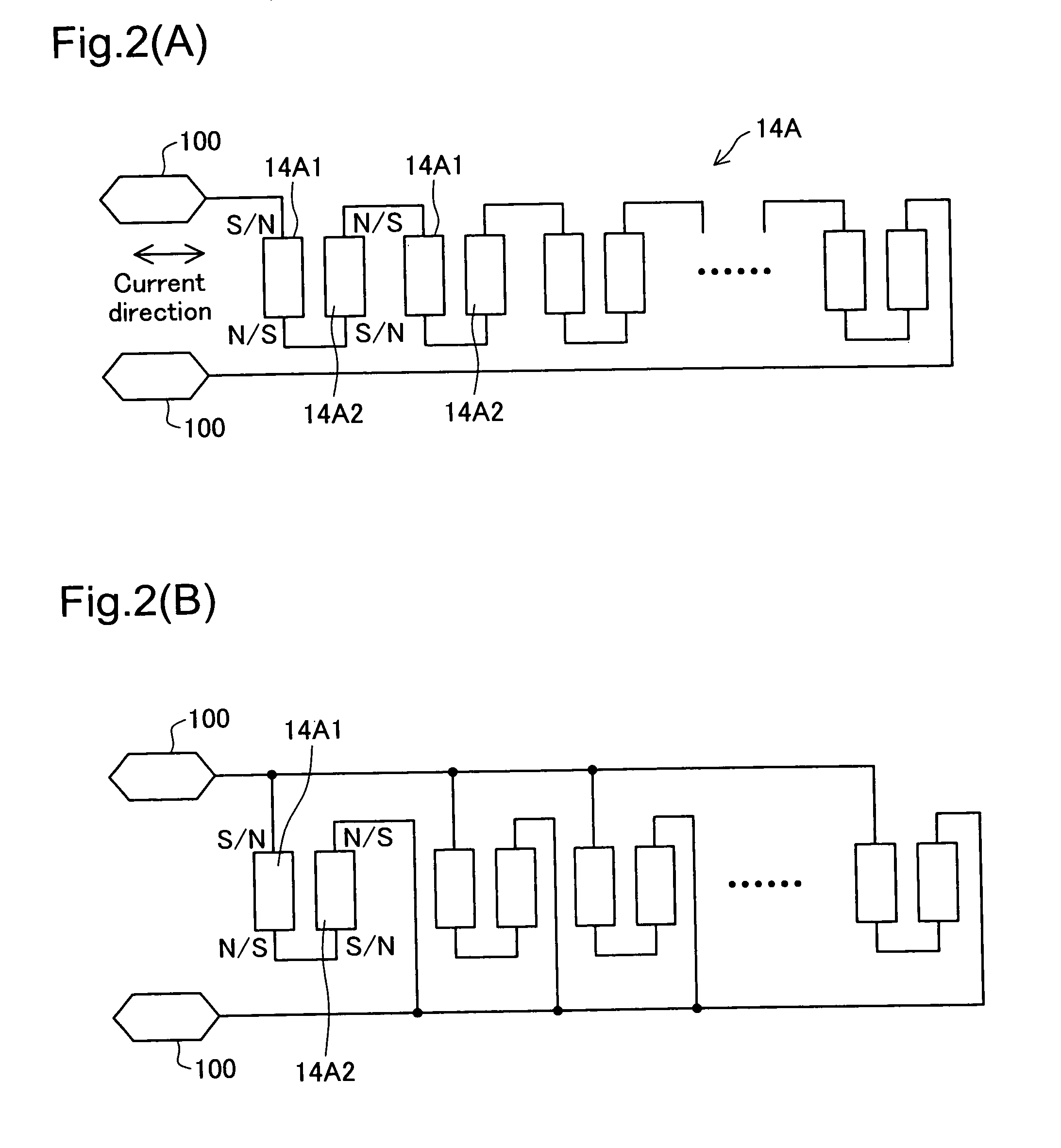

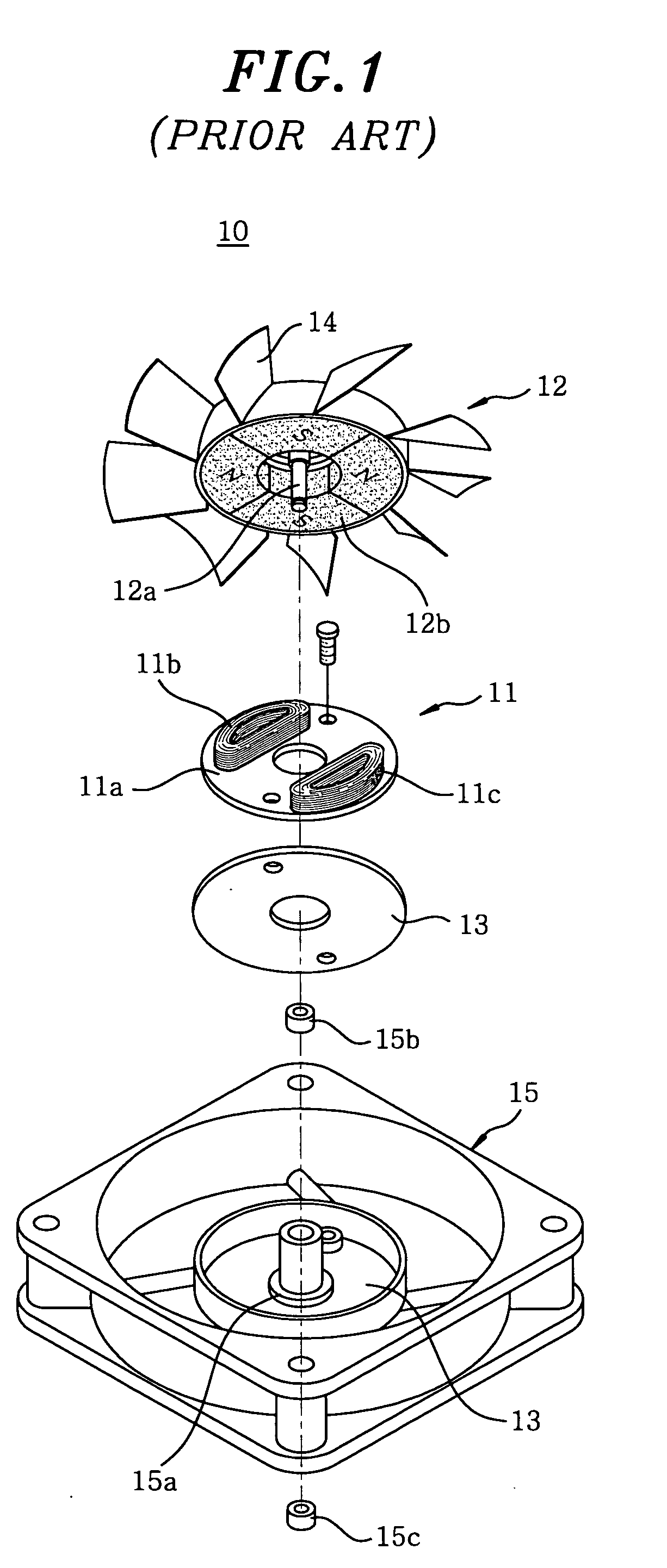

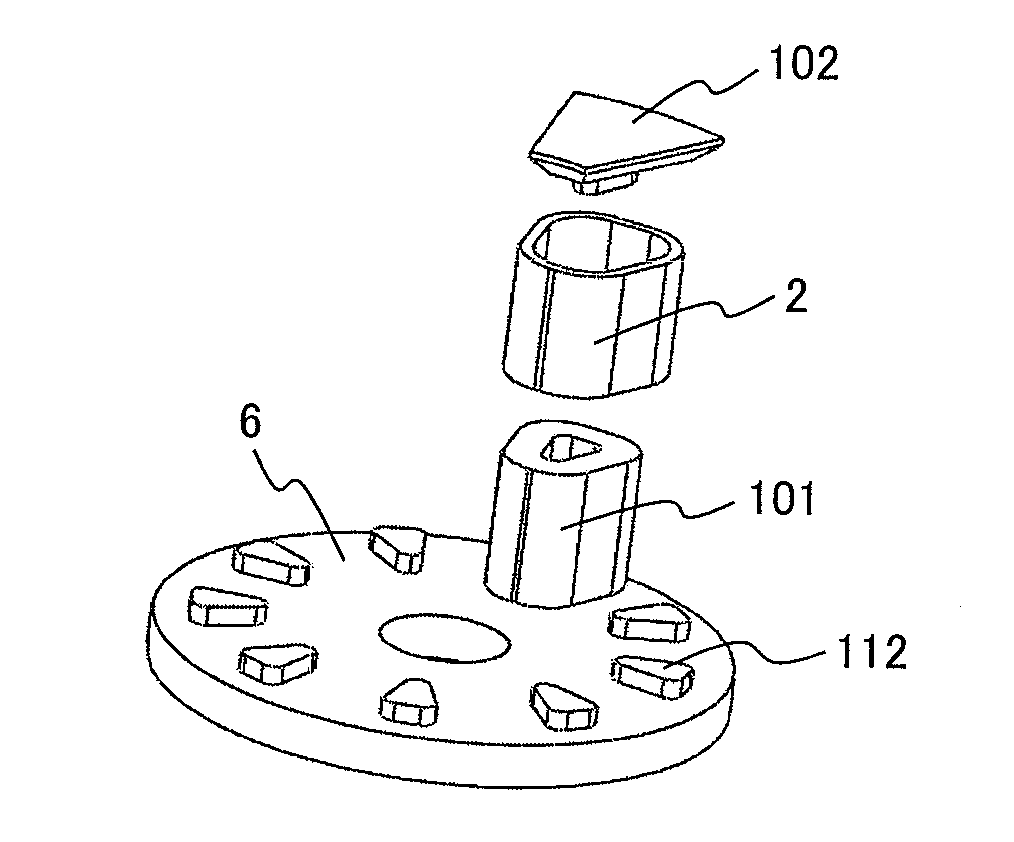

Flat-type single phase brushless DC motor

InactiveUS20070138904A1Improve motor efficiencyMinimize a loss of magnetic fieldsWindingsMagnetic circuit rotating partsDirect currentDC motor

A flat-type single phase brushless direct current (BLDC) motor includes a rotor rotatably fixed to a shaft and having a permanent magnet attached to a lower side thereof; a stator plate installed below the rotor; a plurality of stator cores installed on the stator plate to face the permanent magnet, the stator cores including soft magnetic powder and arranged to be asymmetric with respect to a rotation radial direction of the rotor so as to determine a rotational direction of the rotor; and a multiplicity of coils each being wounded around corresponding one of the stator cores to form a magnetic field toward the permanent magnet.

Owner:DAEWOO ELECTRONICS CO LTD

Electric motor having different stator lamination and rotor lamination constructions

InactiveUS20060066169A1Improve mechanical propertiesReduced core lossMagnetic circuit rotating partsSynchronous motorsElectric machineEngineering

In accordance with one exemplary embodiment, the present technique provides an electric motor having a stator core that is formed of a plurality of stator laminations and a rotor core that is formed of a plurality of rotor laminations. In the exemplary motor, the rotor laminations have mechanical and / or electrical characteristics that are different from the stator laminations. For example, the rotor laminations may have a different thickness than the stator laminations. Also, the rotor laminations may comprise a different material than the stator laminations. For example, the stator laminations may by alloyed with a certain percentage of an element, while the rotor laminations are alloyed with a different percentage of element.

Owner:RELIANCE ELECTRIC TECH

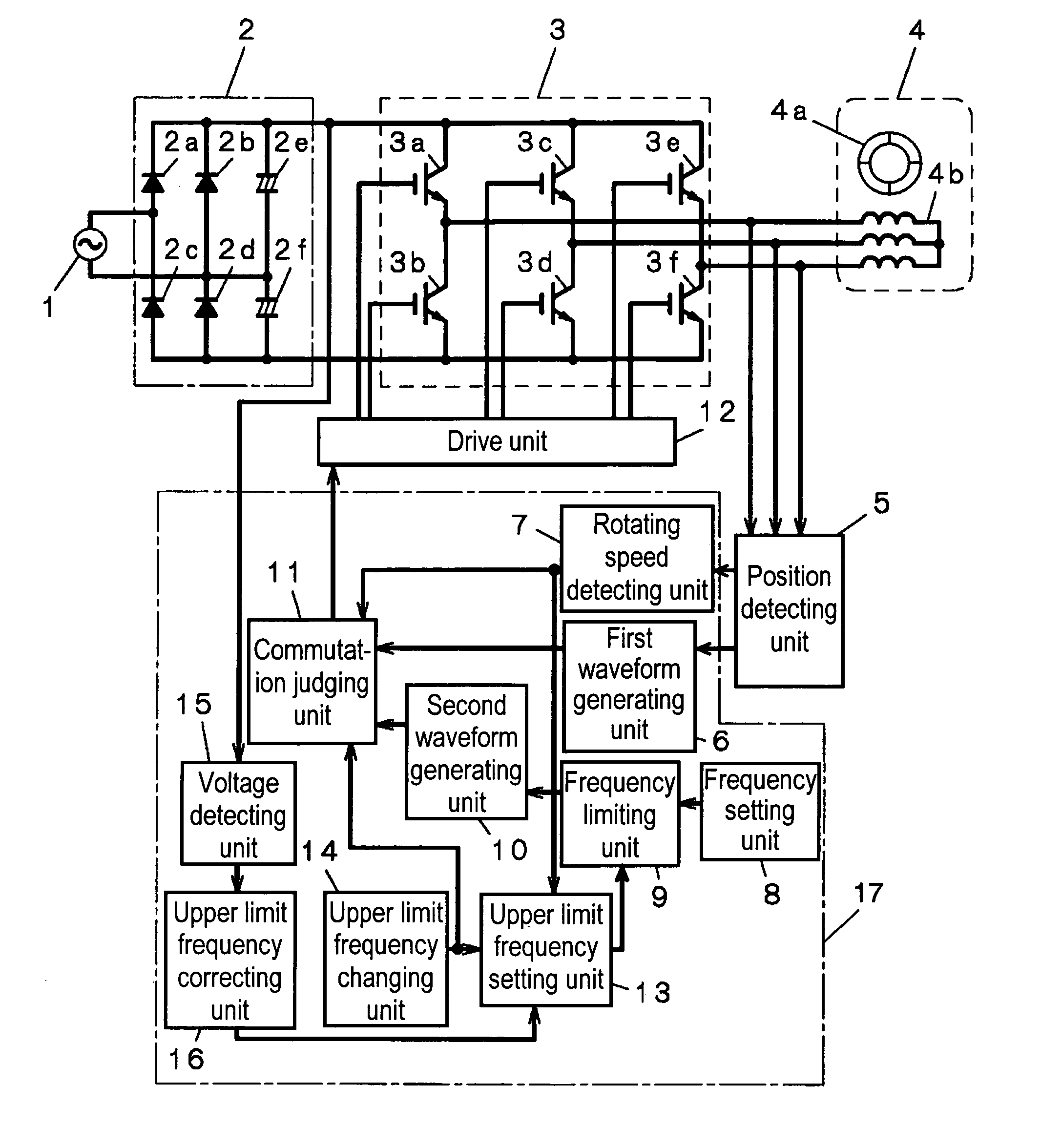

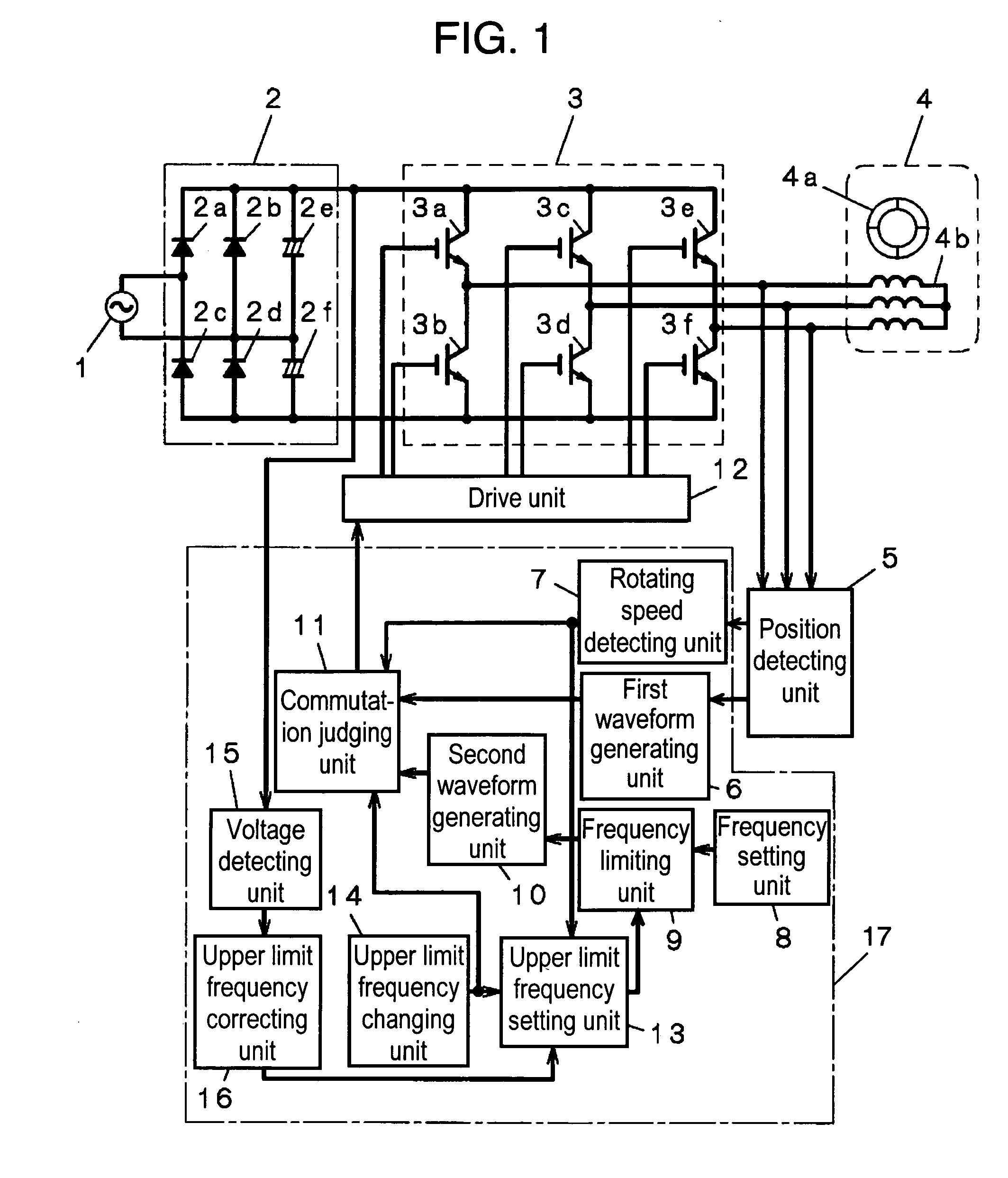

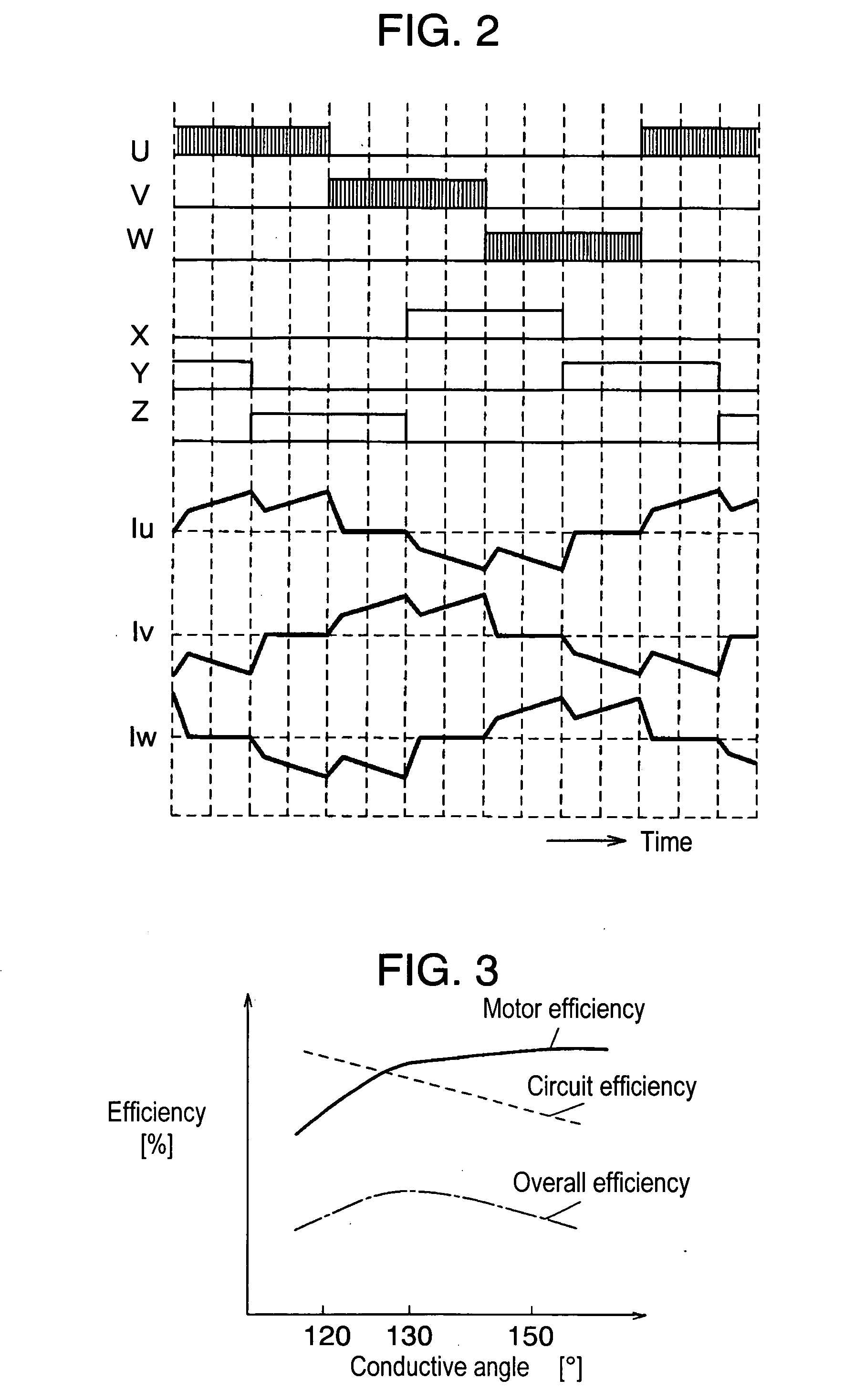

Brushless DC motor driving method and apparatus for it

ActiveUS20060082339A1Improve motor efficiencyHigh speed rotationTorque ripple controlSynchronous motors startersLow noiseLow speed

A rectangular wave or a waveform similar to the rectangular wave is output with an conductive angle no less than 120° but no more than 150° during low-speed operation, but output a rectangular wave, a sine wave or a waveform similar to them with an conductive angle no less than 130° but under 180° by changing the frequency only while maintaining the PWM duty constant at high-speed operation, making it possible to realize high-efficiency and low-noise operation at low-speed operation, secure stable high speed, and prevent peak current of effective current because the current waveform also comes closer to sine wave.

Owner:PANASONIC CORP

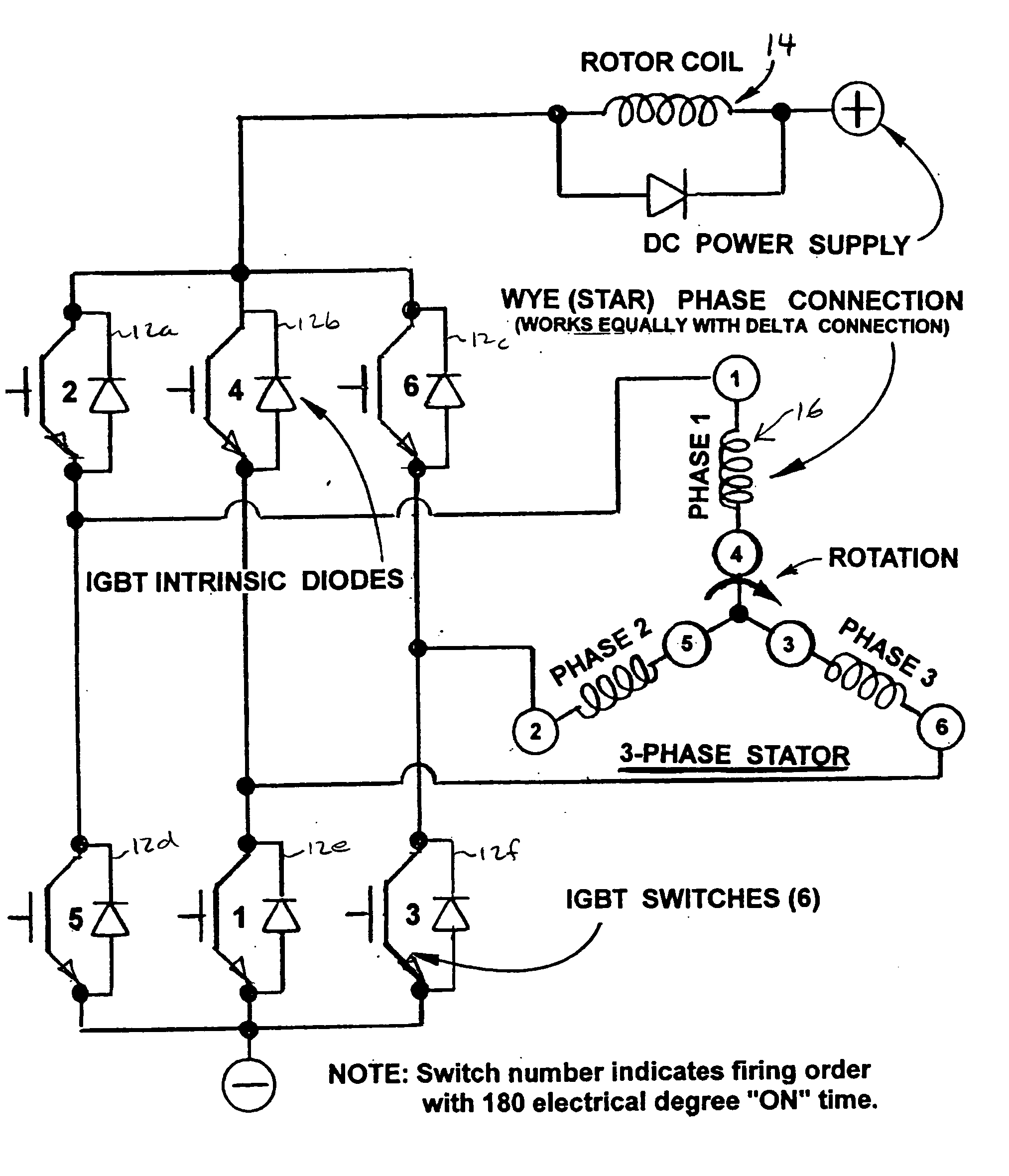

Electromagnetic motor

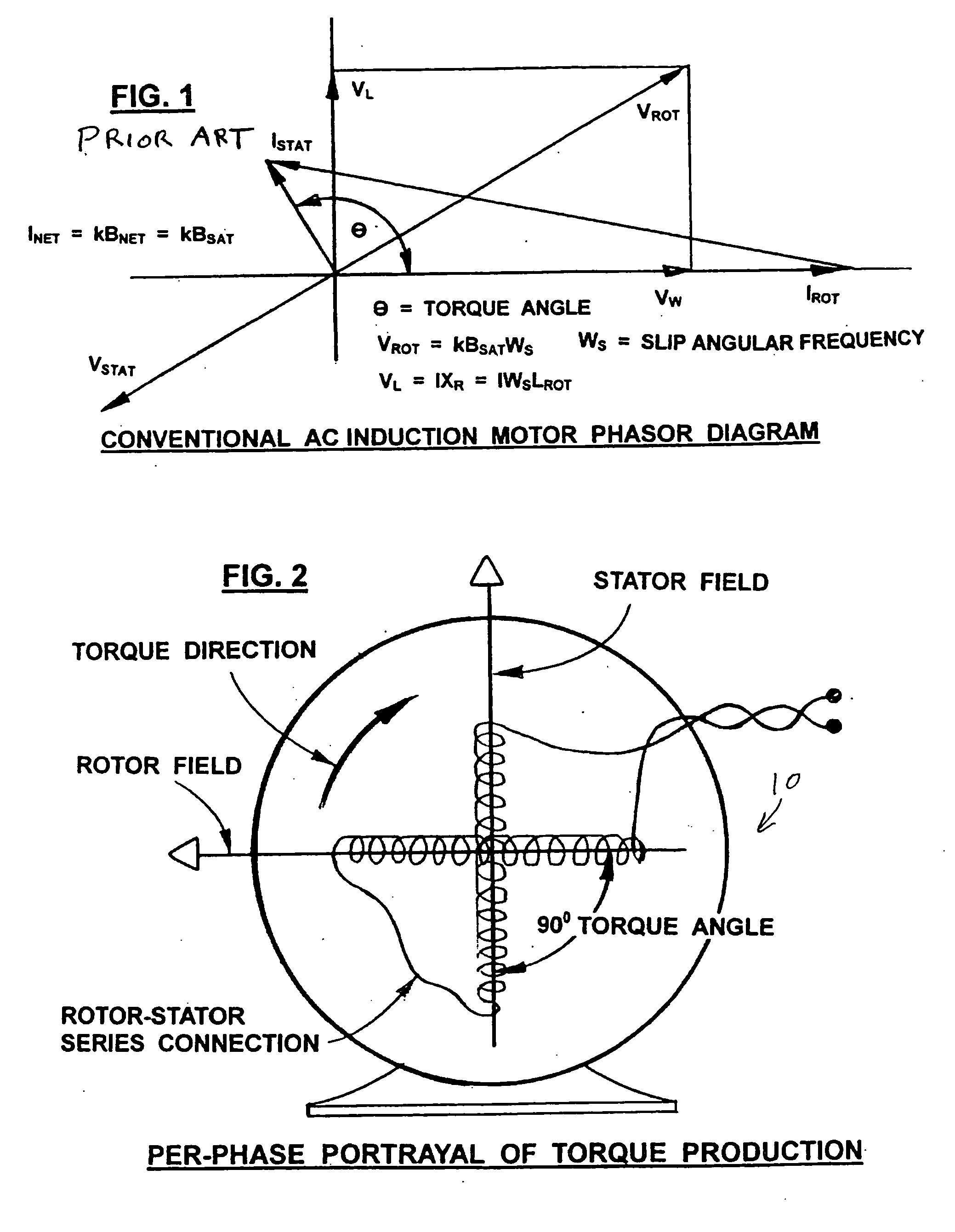

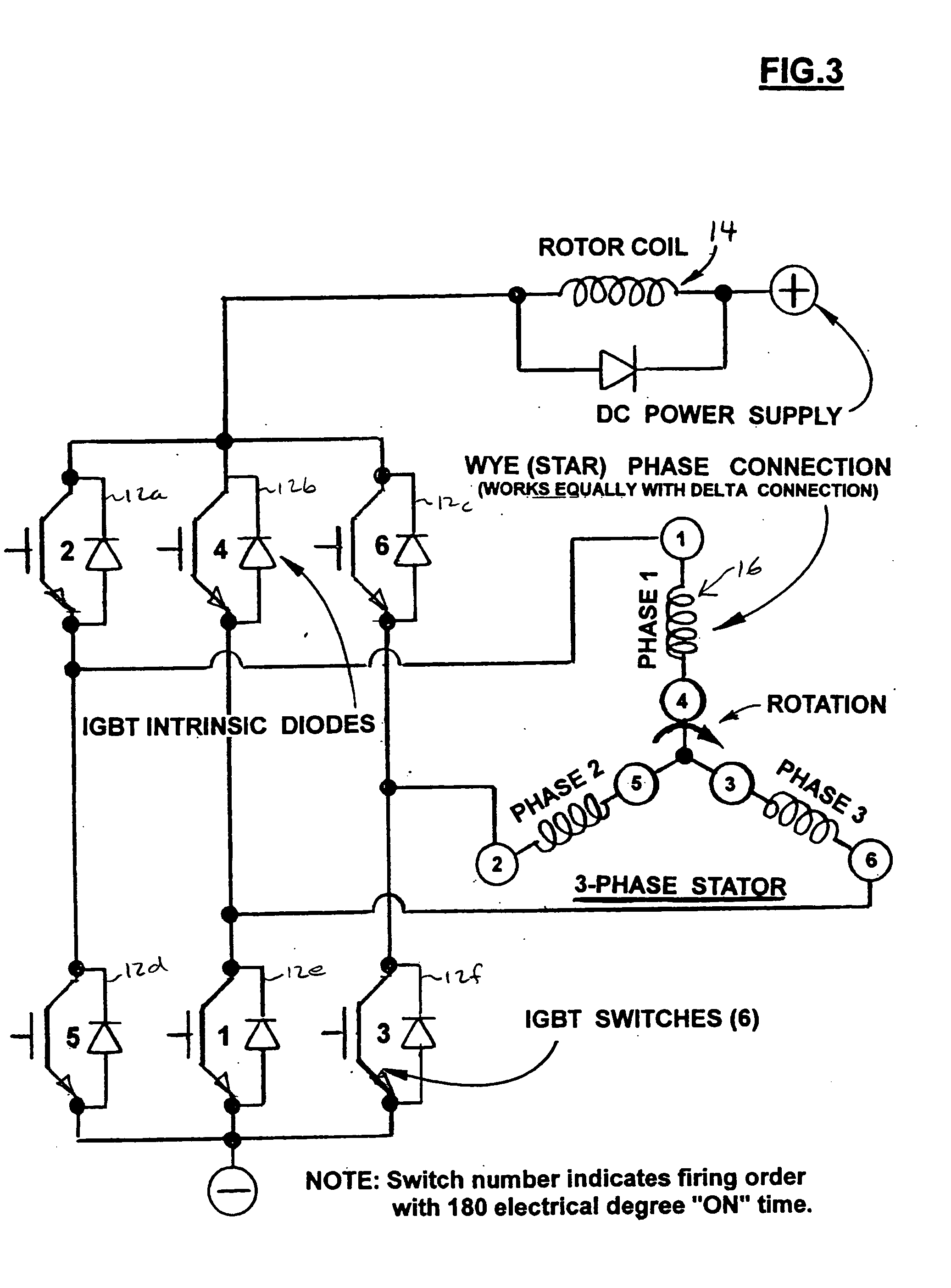

InactiveUS20050073281A1Efficient productionEffectively doubles iron utilizationSingle-phase induction motor startersAC motor controlStator coilMagnetic field

An electromagnetic motor with increased torque. The motor has a rotor coil configured to generate a magnetic field. At least two stator coils are connected in series with the rotor coil. Each of the stator coils is configured to generate a respective magnetic field. The motor further includes a plurality of switches configured to generate the magnetic field in each of the respective rotor and stator coils. The switches are configured to generate the magnetic field in the stator coils such that the rotor coil rotates in response thereto. By having the rotor and stator coils connected in series, the torque of the motor is increased.

Owner:PRATT & WHITNEY POWER SYST

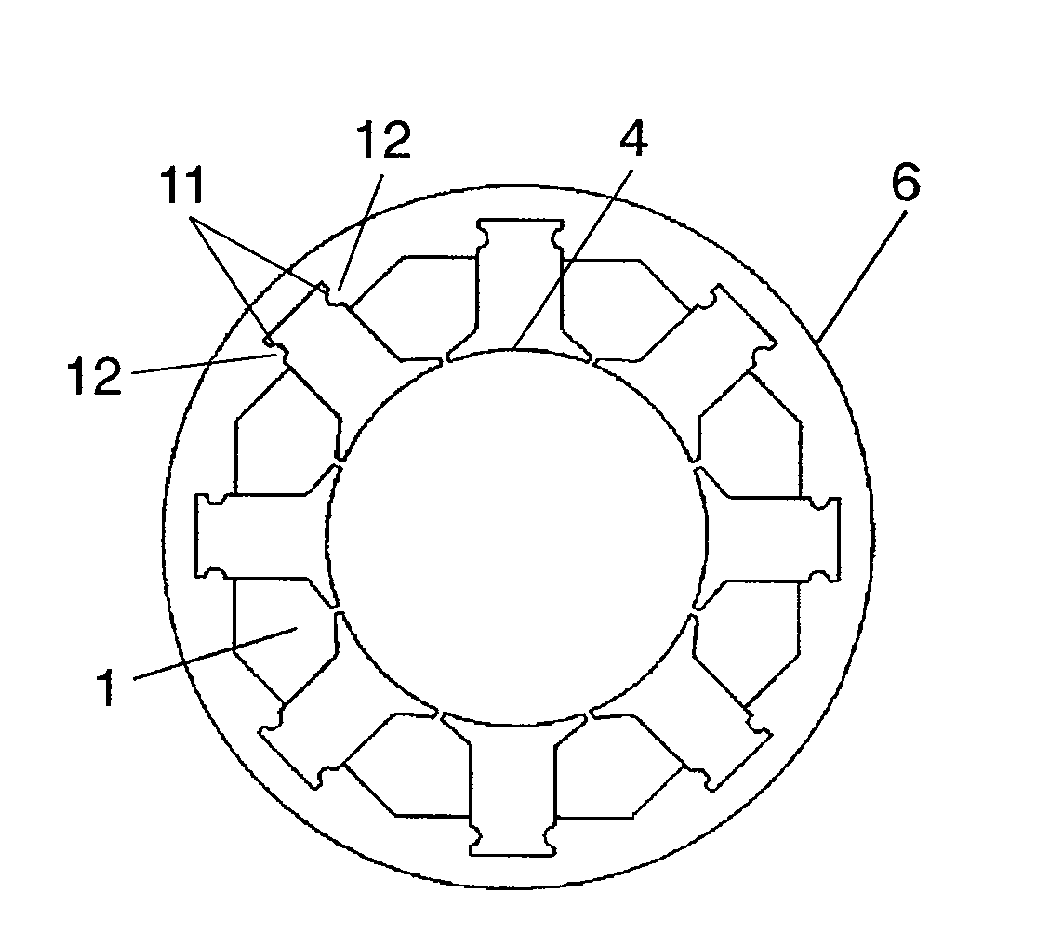

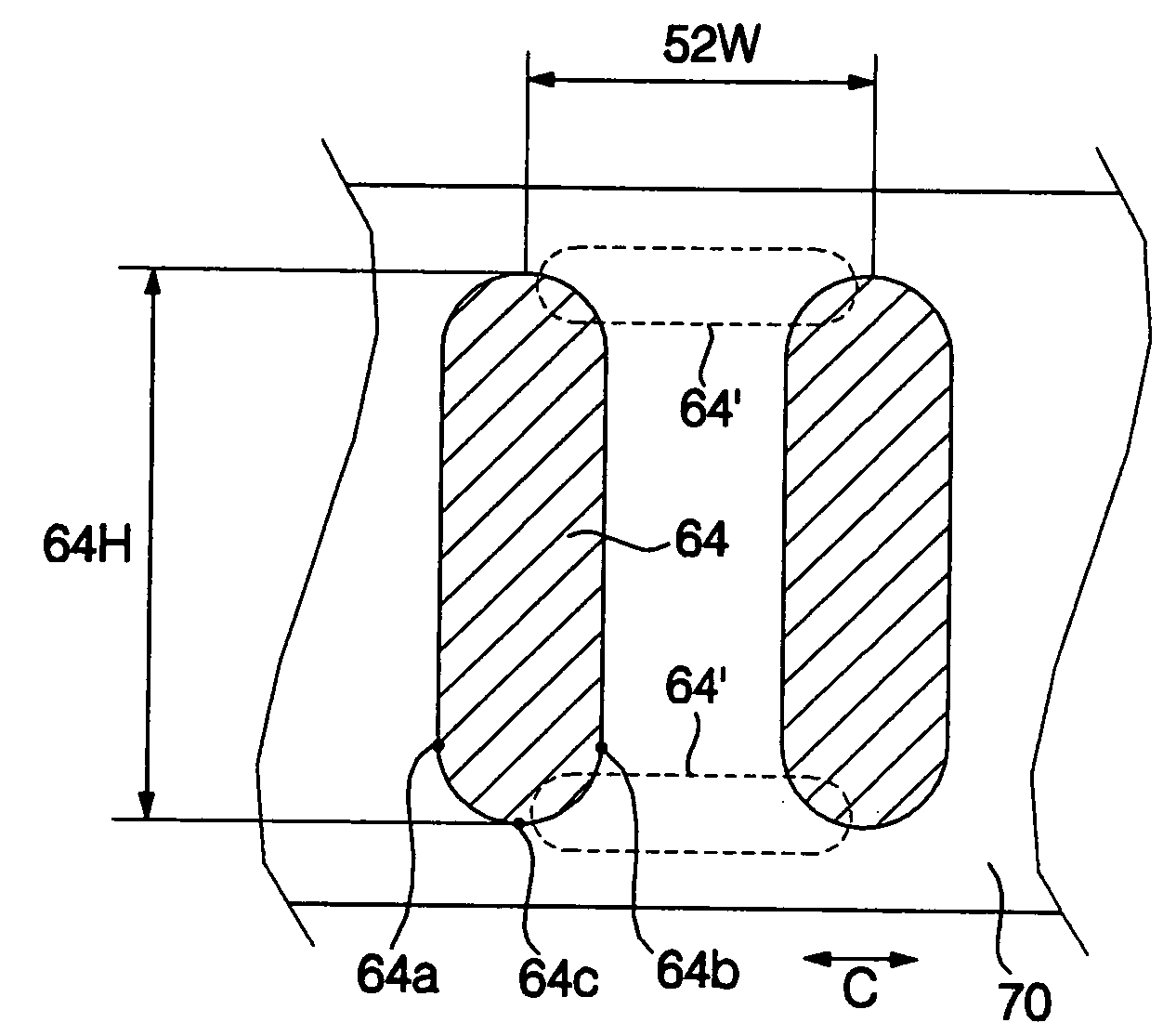

Stator of motor

ActiveUS20060055275A1Improve motor efficiencyLow costMagnetic circuit rotating partsMagnetic circuit stationary partsIron powderEngineering

A stator of a motor having various shapes and capable of minimizing the manufacturing costs. At least teeth are manufactured by the iron powder metallurgy method. In order to obtain the overhang effect, the height of a tip of each tooth is lower than the height of a rotor and the height of a yoke is higher than the height of a tip of each tooth so as to minimize the core loss of the yoke. Since, in order to minimize the end coil, the height of a neck of each tooth is gradually higher as running from the sides to the central portion in the circumferential direction, costs for manufacturing a motor can be minimized and sufficient efficiency can be obtained.

Owner:LG ELECTRONICS INC

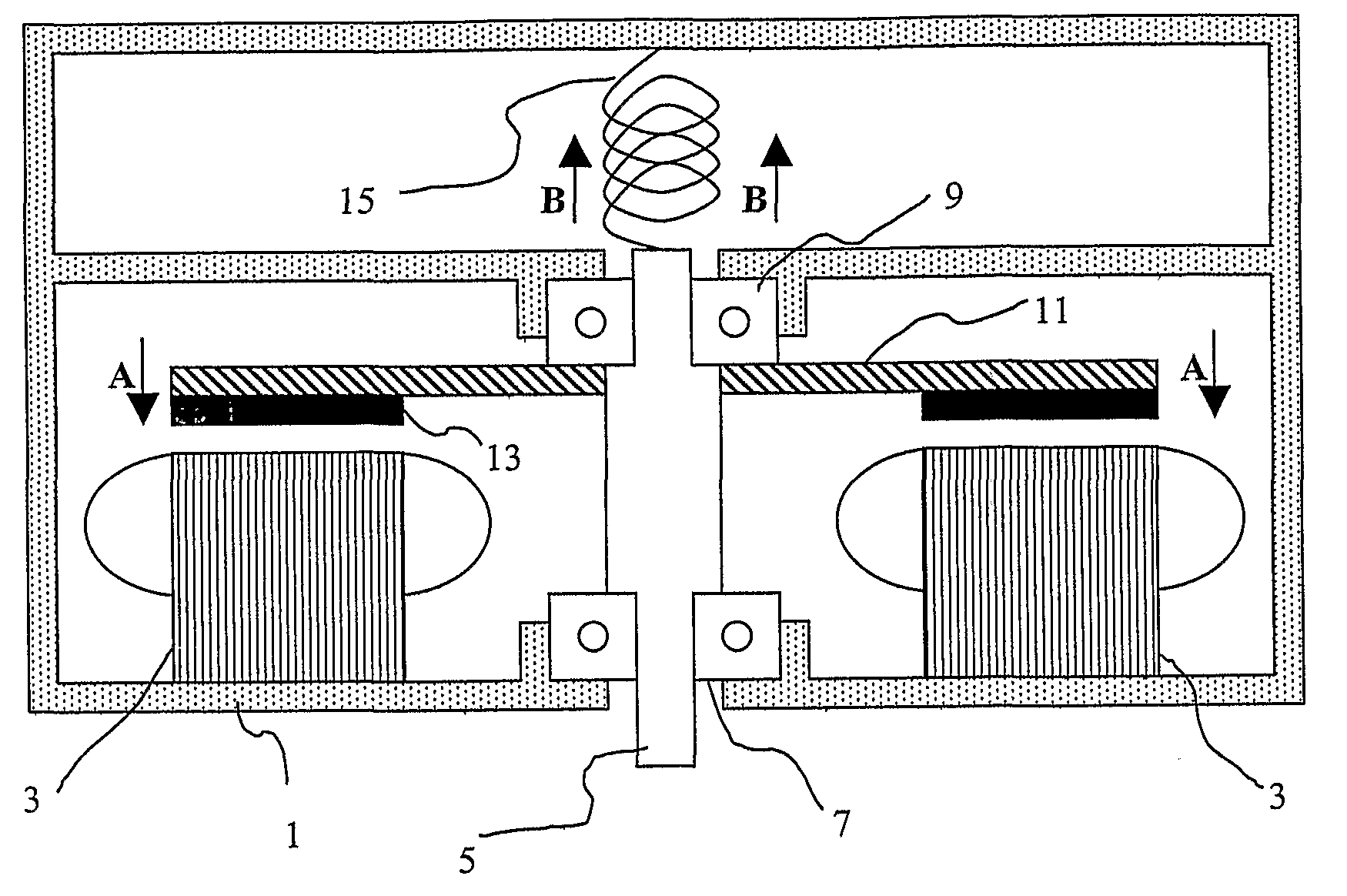

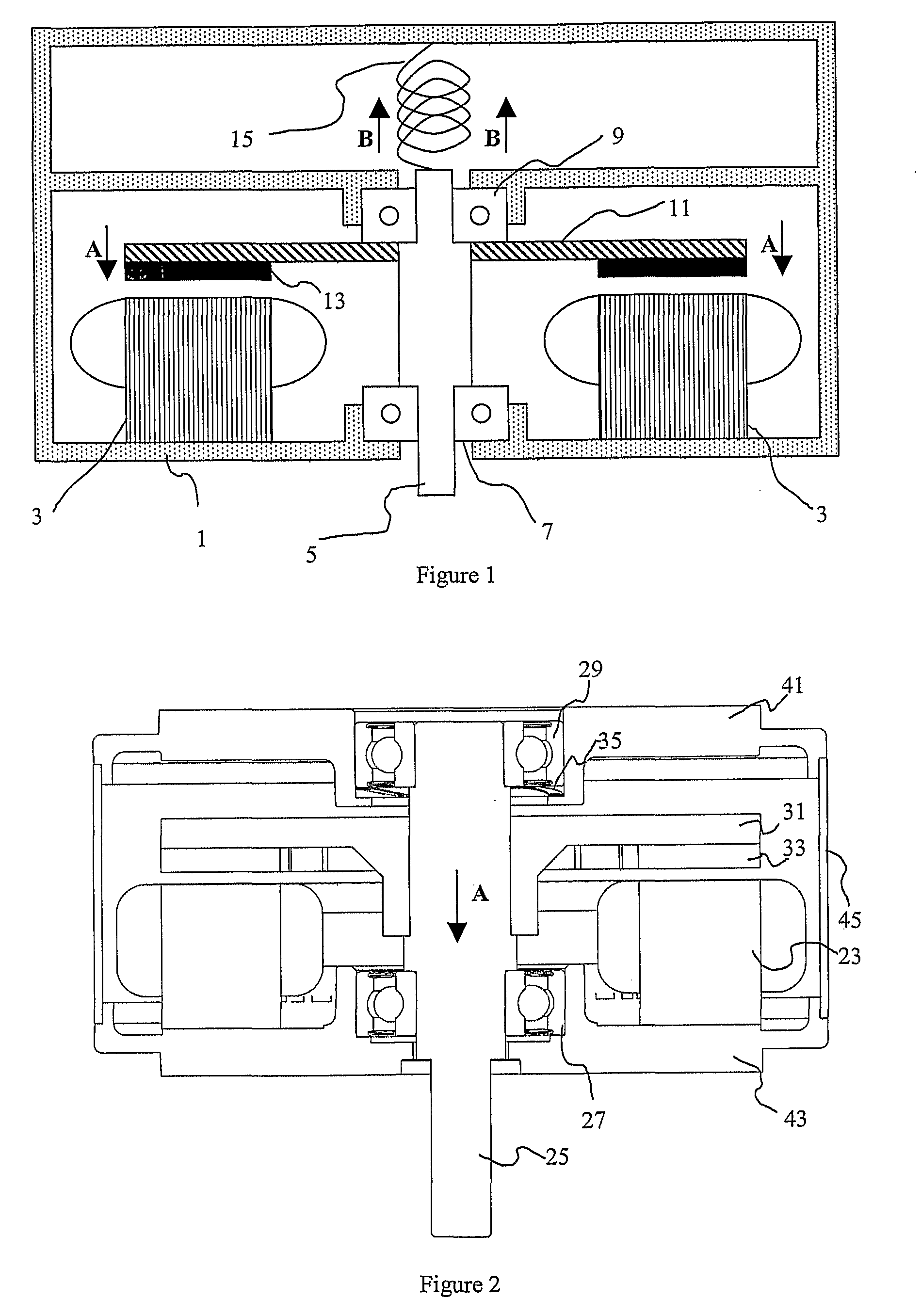

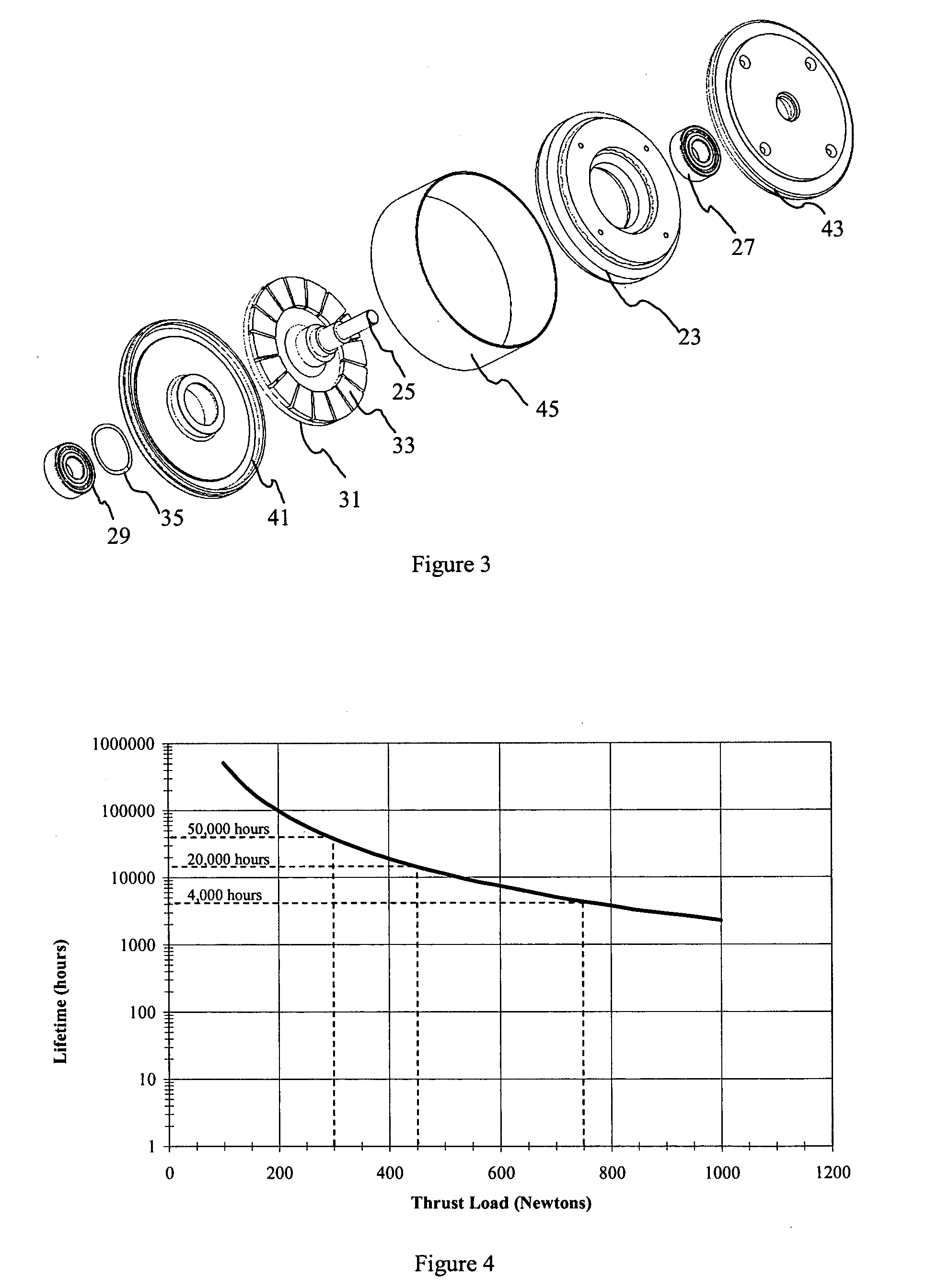

Axial flux electrical machine

ActiveUS20100164313A1Reduce loadExtended service lifeRolling contact bearingsShaftsAxial thrustAxial flux

An axial flux electrical machine including a housing, a stator located within the housing, a rotatable shaft carried by the housing by means of at least a main bearing, and a rotor fixed to the shaft within the housing. Magnetic attractive forces between the rotor and the stator produce an axial thrust on the main bearing and a biasing means (preferably in the form of a spring) is arranged to urge the shaft in a direction opposite to the axial thrust so as to reduce the net load on the main bearing. This reduction in net load on the main bearing increases bearing life and improves motor efficiency.

Owner:REGAL BELOIT AUSTRALIA PTY LTD

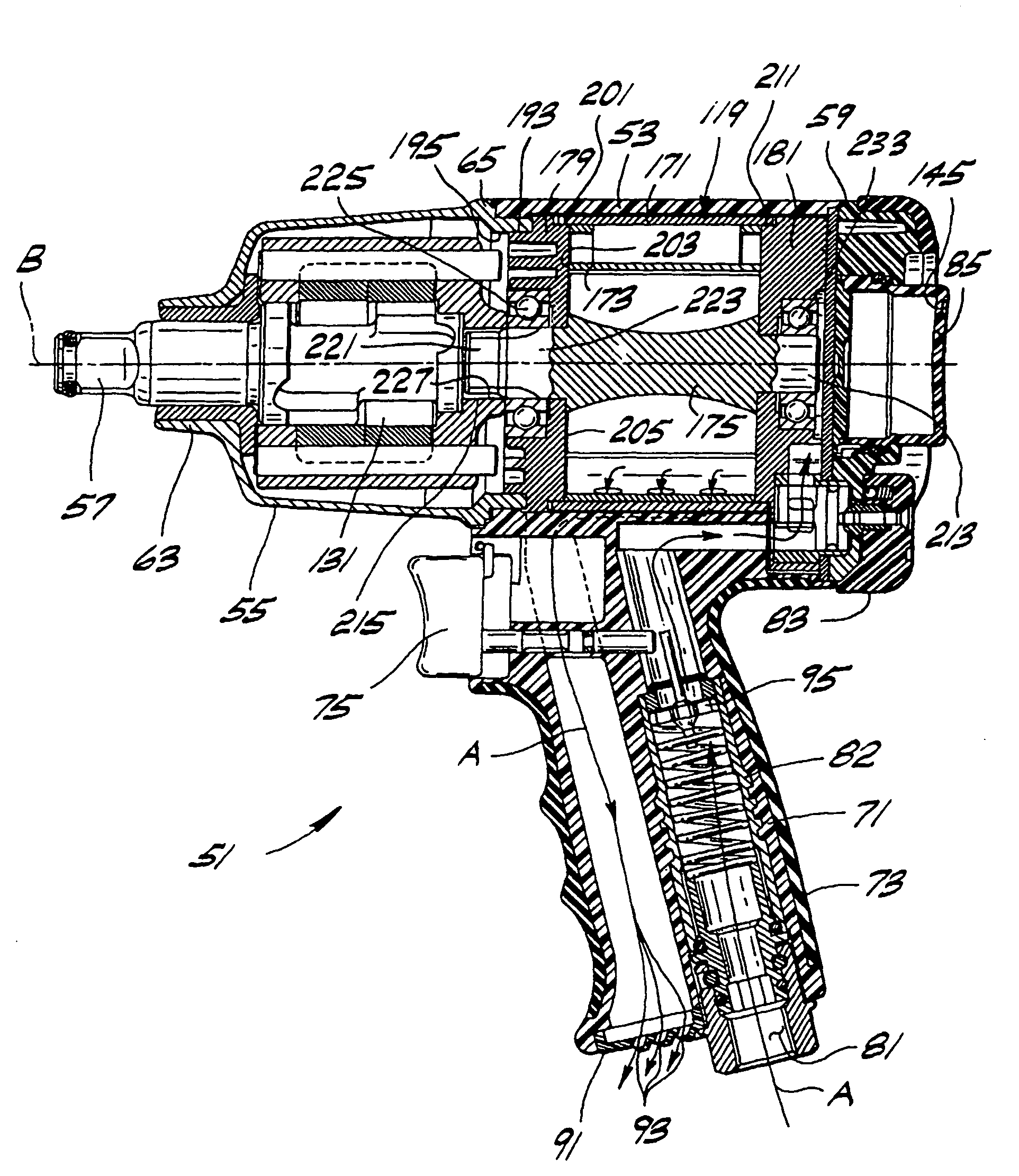

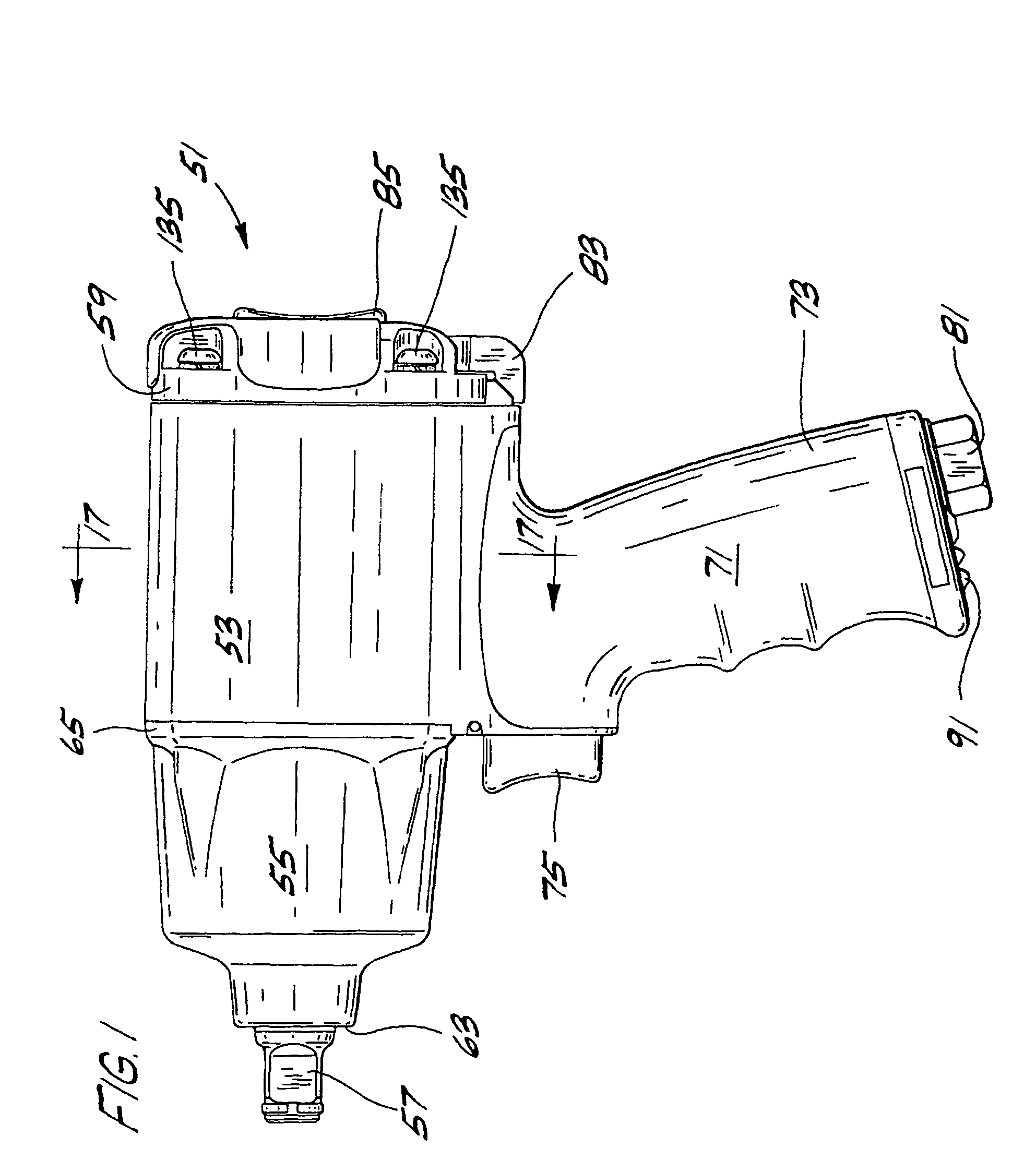

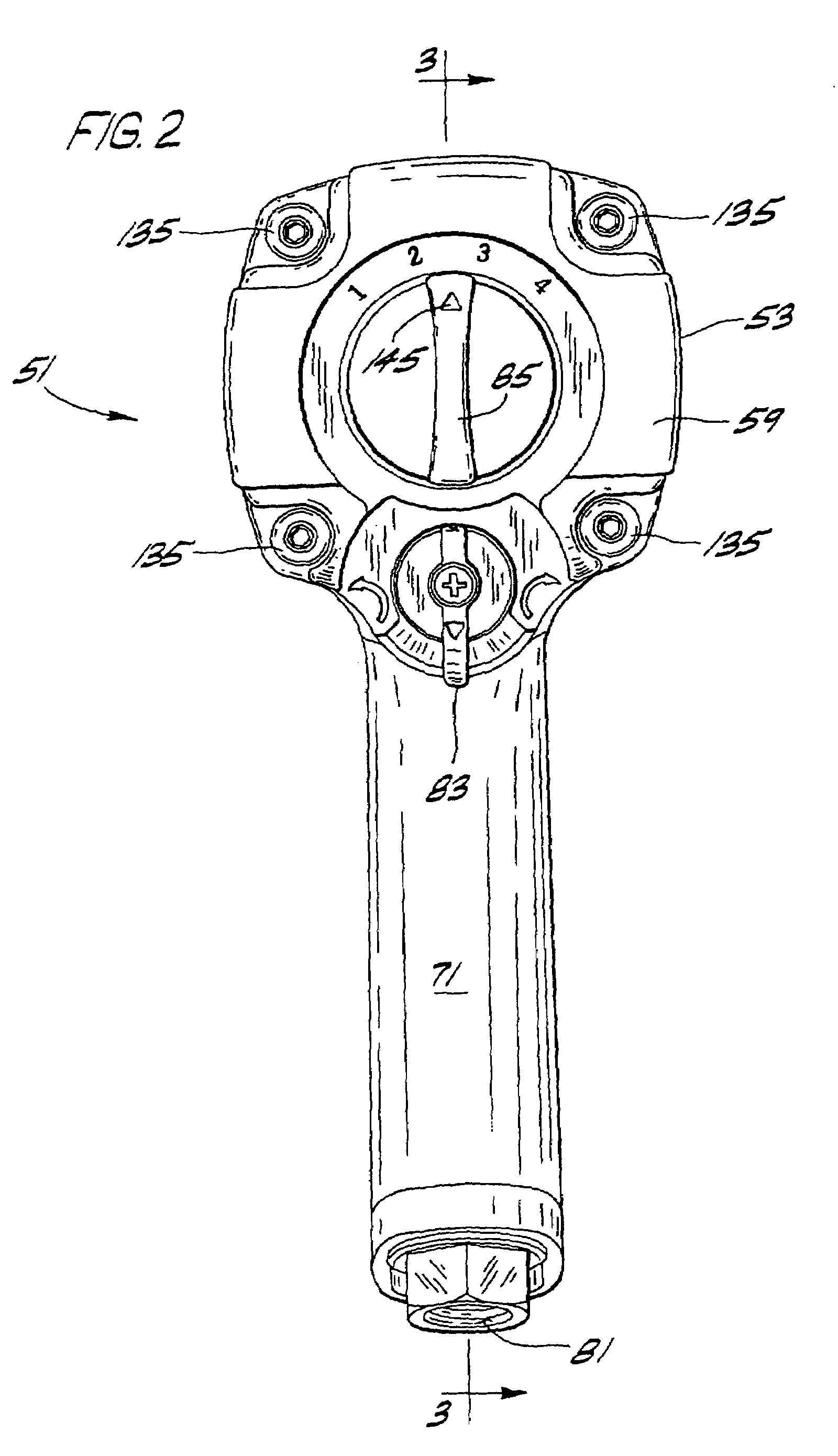

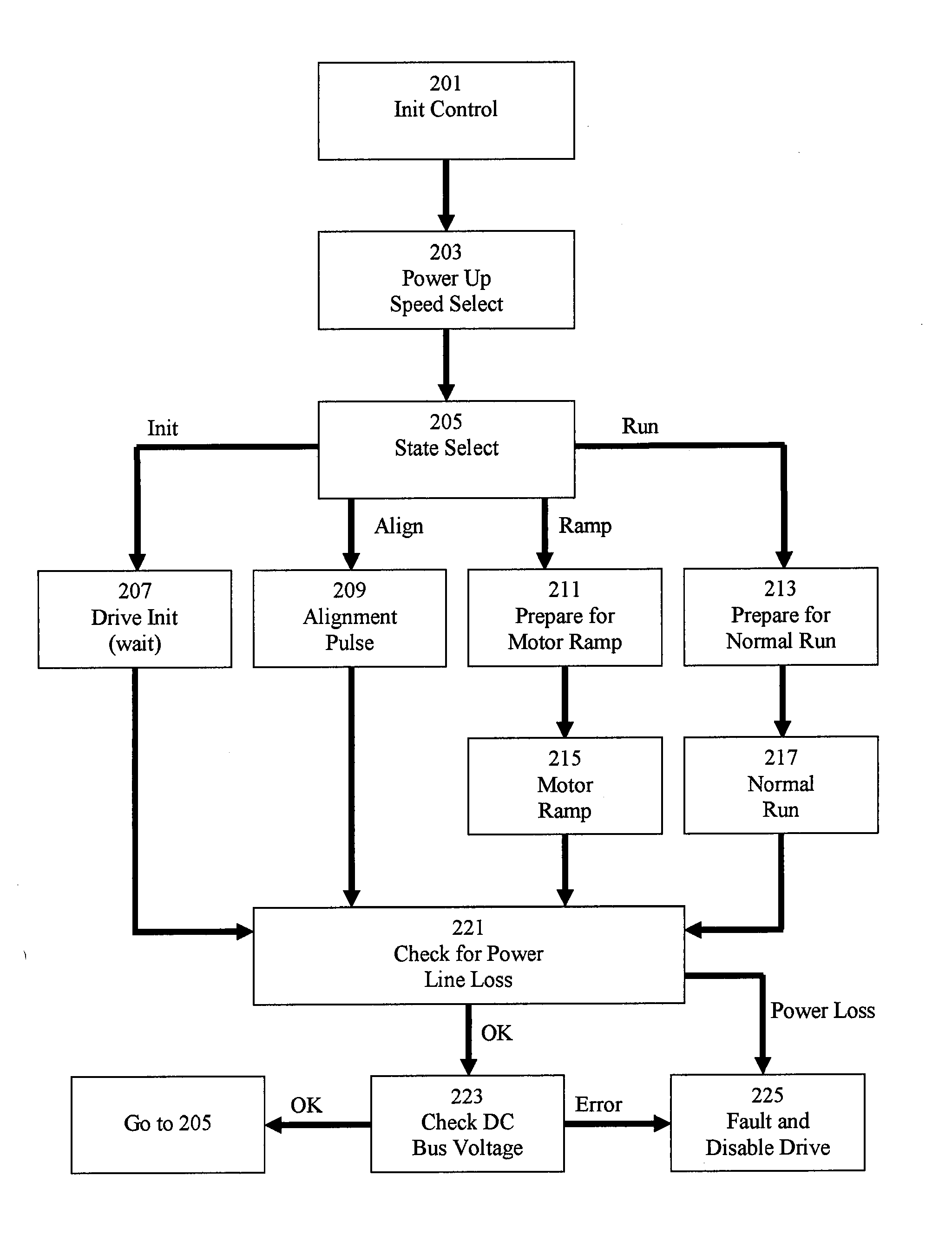

Pneumatic rotary tool

InactiveUS7404450B2Reduce back pressureLow costConstructionsReciprocating drilling machinesPneumatic toolLate stage

A pneumatic rotary tool has a housing formed primarily from plastic so that the weight and price of the tool are substantially reduced. The air motor is formed for economic assembly while permitting greater structural stability should the housing deflect under an impact. The tool includes a torque selector which controls the amount of pressurized air allowed to enter the air motor, thereby controlling the torque output of the motor. The user may adjust the torque selector to a number of set positions which correspond to discrete torque values. The tool additionally incorporates early and late stage exhaust ports, so that backpressure within the air motor does not slow motor rotation or decrease tool power.

Owner:S P AIR

Electric Motor and Motor Control

InactiveUS20120032629A1Less audible noiseIncrease costSingle-phase induction motor startersTorque ripple controlWave shapeMotor control

Various embodiments of an electric motor and electronic control for an electric motor are disclosed. An exemplary electric motor comprises a single-phase brushless permanent magnet electric motor. In exemplary embodiments, the electronic motor control is configured to commutate an electric motor at a frequency other than line frequency, perform pulse width modulation, and drive the electric motor with a drive waveform that approximates the counter-electromotive force of the motor.

Owner:NIDEC MOTOR CORP

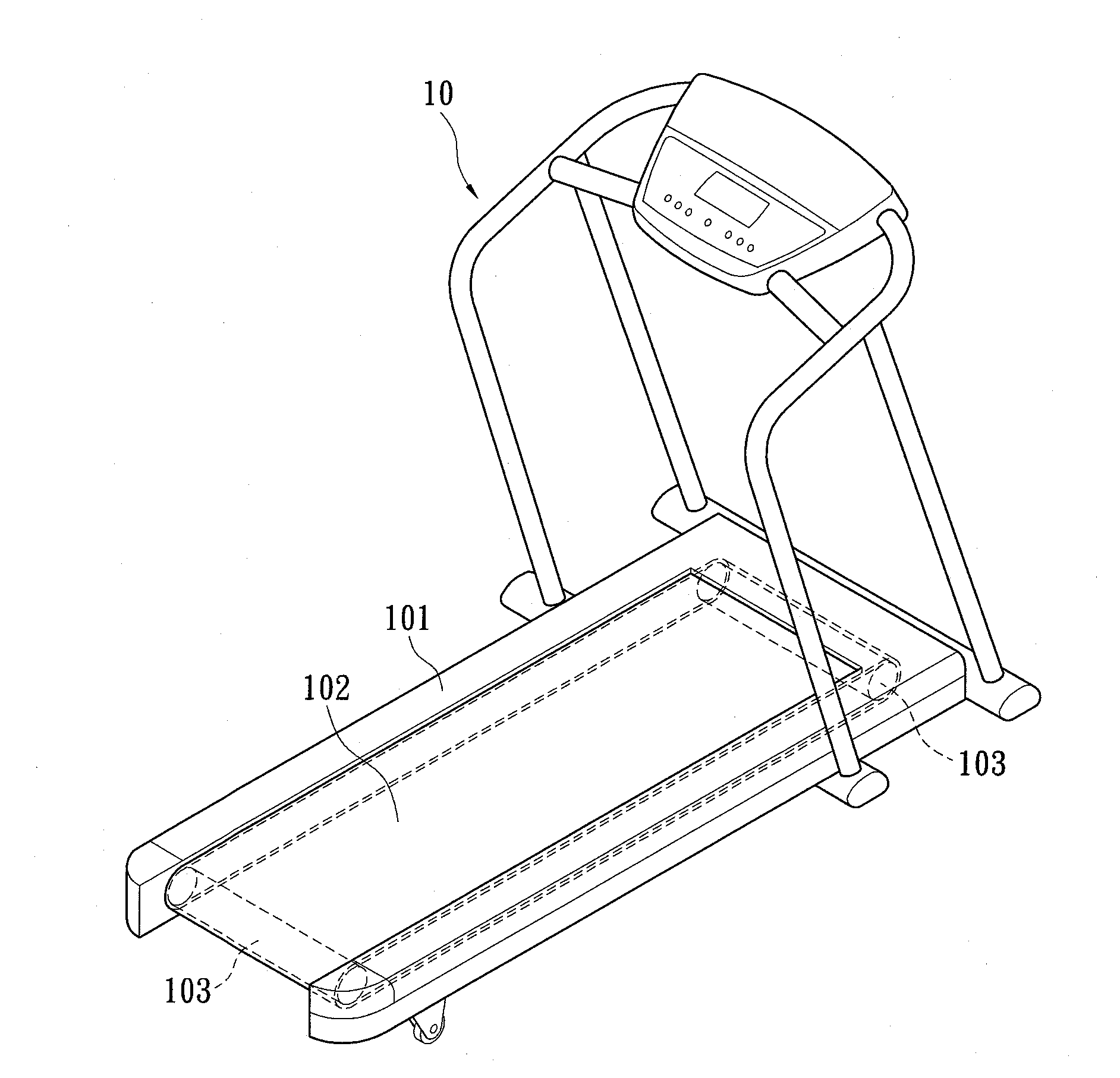

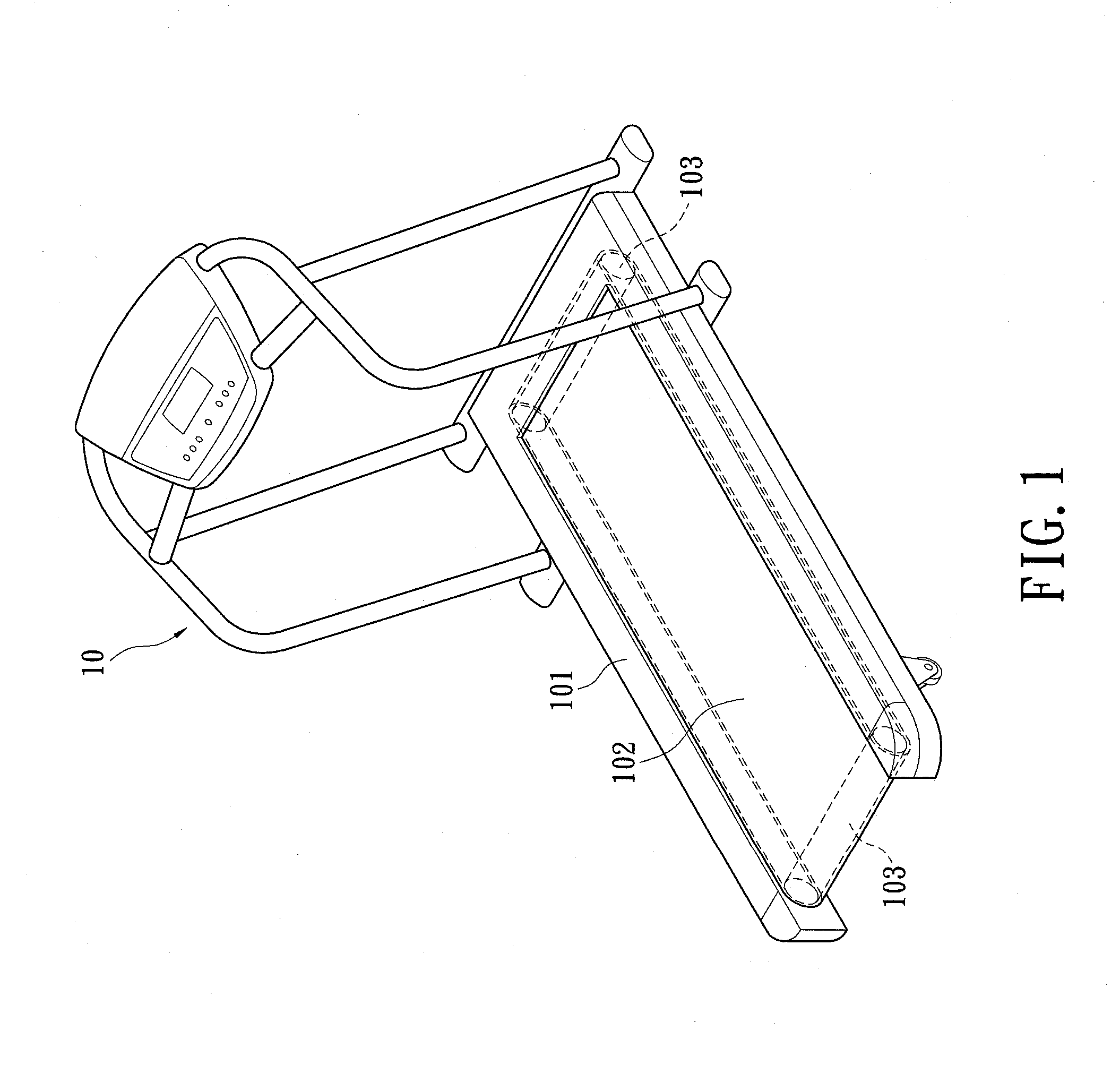

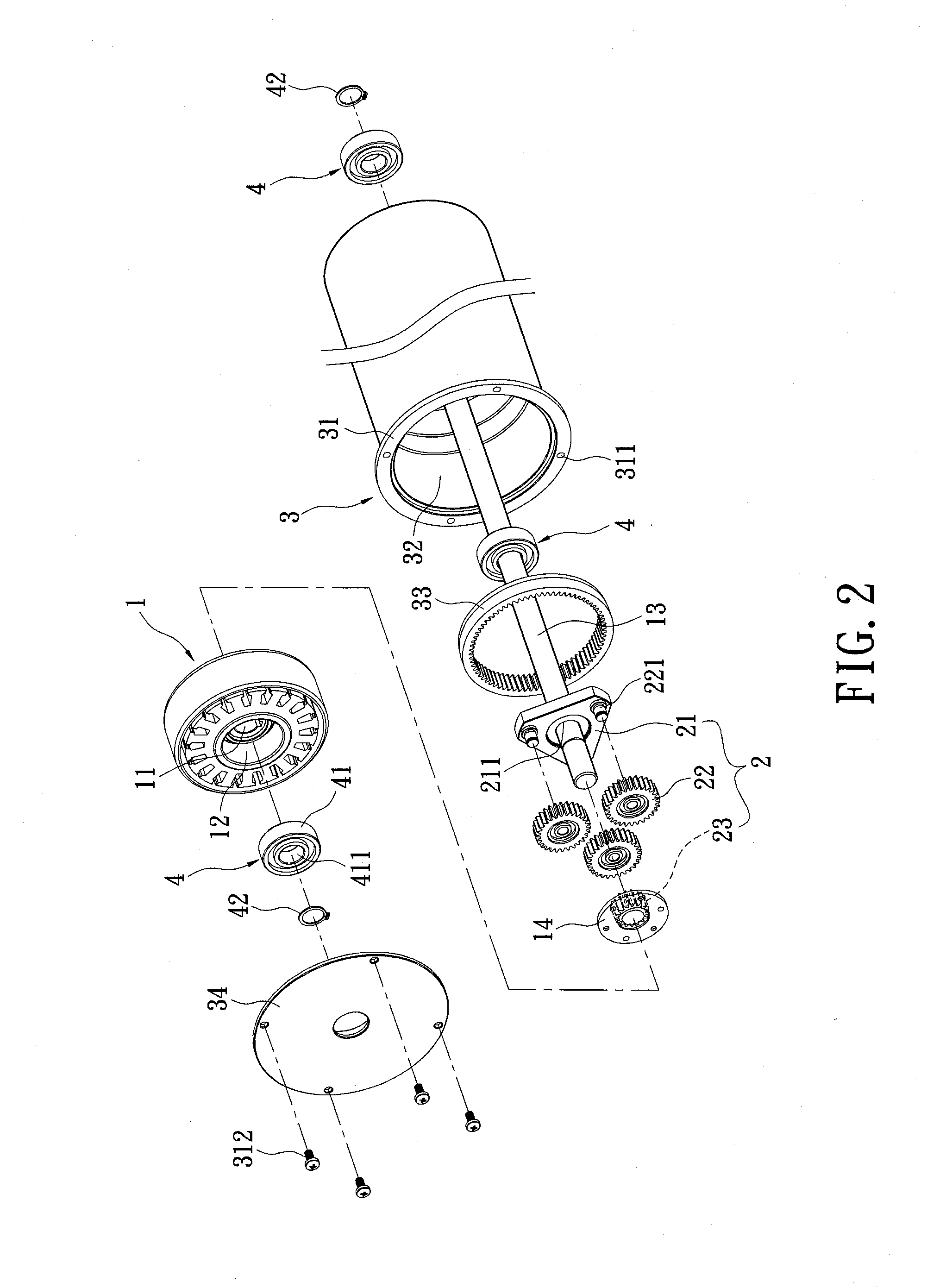

Treadmill roller structure and treadmill

InactiveUS20100331148A1Improve motor performanceImprove motor efficiencyRollersMovement coordination devicesGear wheelConveyor belt

A treadmill roller structure comprises a motor, a gear set and a case. The motor is an out-runner motor. The power output section of the motor rotates about stationary spindle. The rotary power output section is engaged to the gear set, while the gear set is in turn engaged to the case, thus allowing the case to rotate relatively to the spindle of the motor as well. The roller structure does not require a driving belt to transfer power from the motor to the roller, thus reduces the power loss due to frictional force during power transfer through belt driving, which enhances the performance of the motor and offers a space-saving feature. In addition, the instant disclosure also provides a treadmill.

Owner:YIHSUAN ENTERPRISE

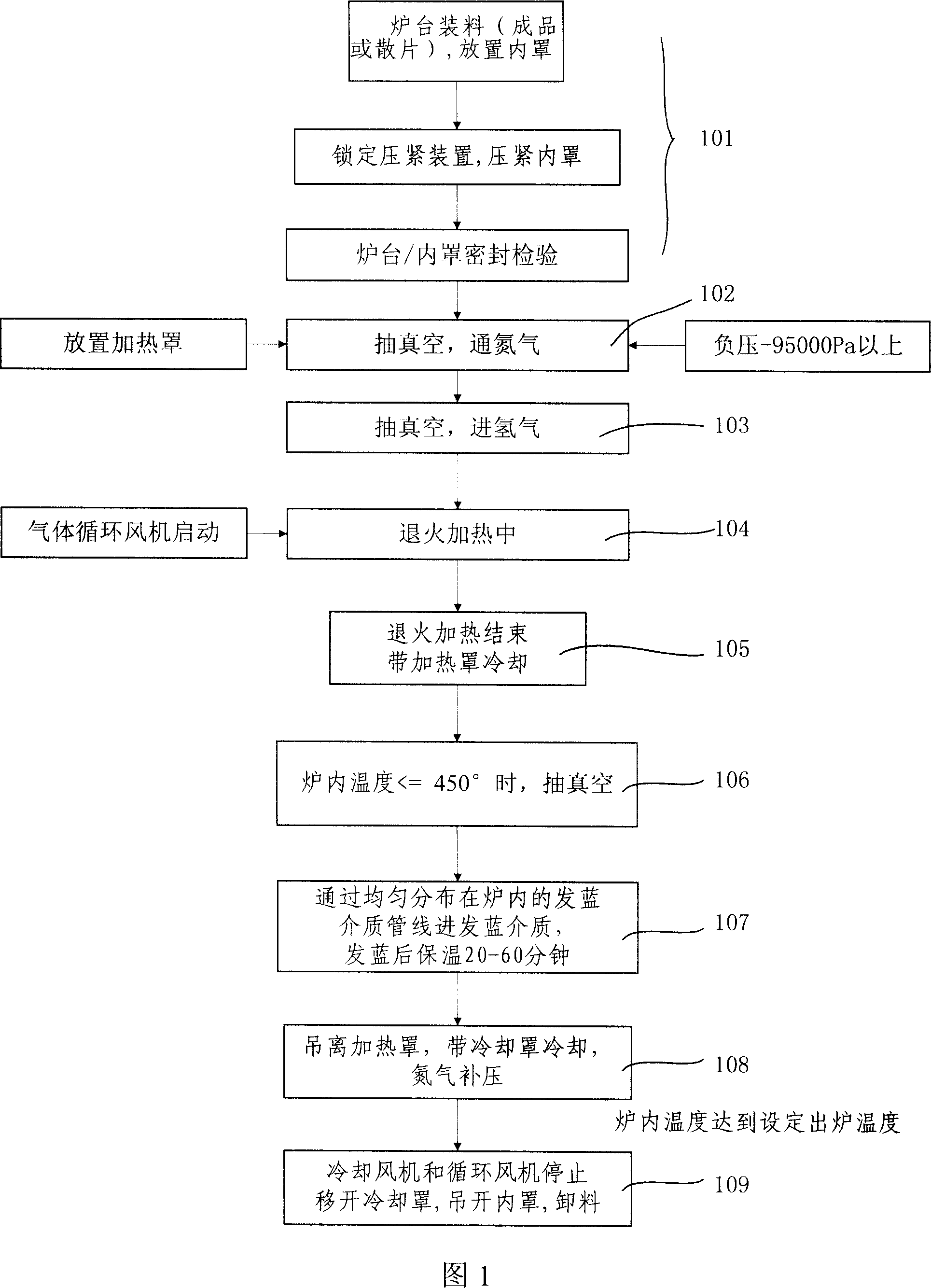

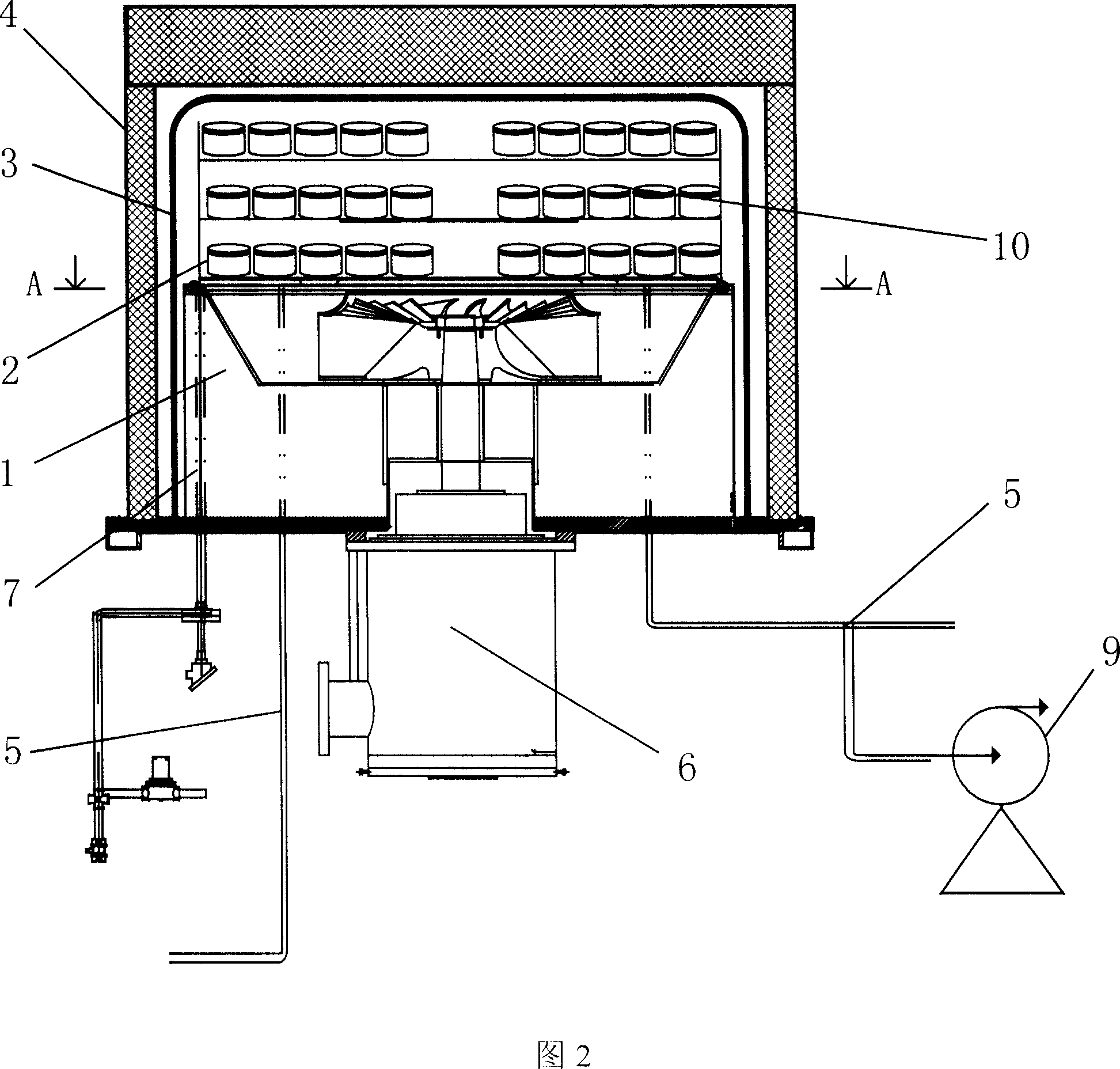

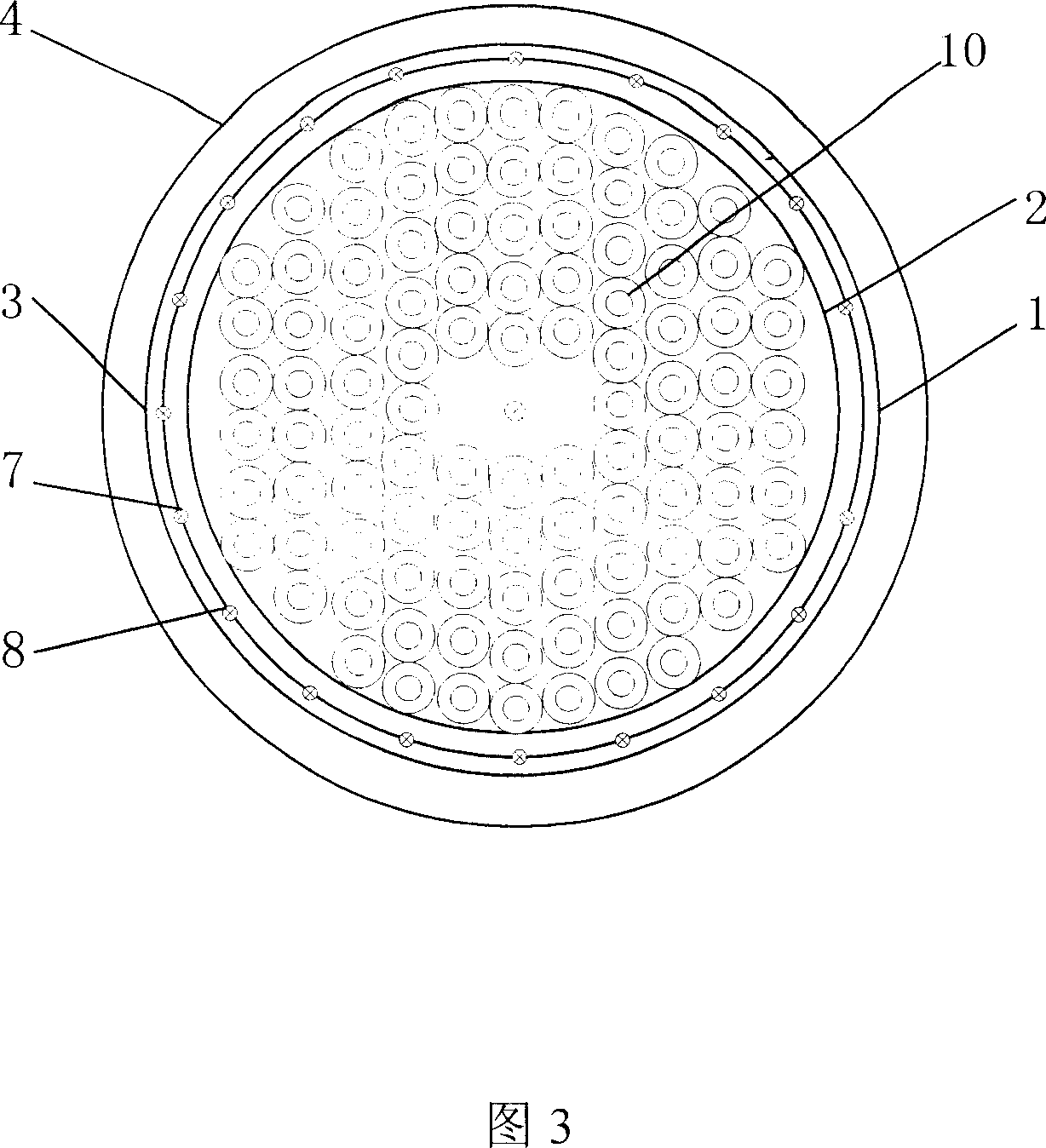

Process and device for coating-free electrical steel annealing and bluing

ActiveCN101082075AHigh magnetic inductionImprove efficiencyMetallic material coating processesHeat treatment process controlElectrical steelStress relieving

The no-coating electric steel sheet annealing and blueing process includes the following steps: 1. annealing laminated no-coating silicon steel sheets inside a bell type furnace under hydrogen atmosphere; 2. vacuumizing the bell type furnace to vacuum degree lower than 95000 Pa after the silicon steel sheets are cooled slowly to 300-450 deg.c, and leading blueing water solution to the furnace before maintaining the temperature for 20-60 min; and 3. vacuumizing for the second time, filling nitrogen for cooling and discharging in the temperature lower than 150 deg.c. The process has high annealing quality, homogeneous blueing effect, and capacity of raising the magnetic induction coefficient of silicon steel sheets and lowering their iron loss.

Owner:BAOSHAN IRON & STEEL CO LTD

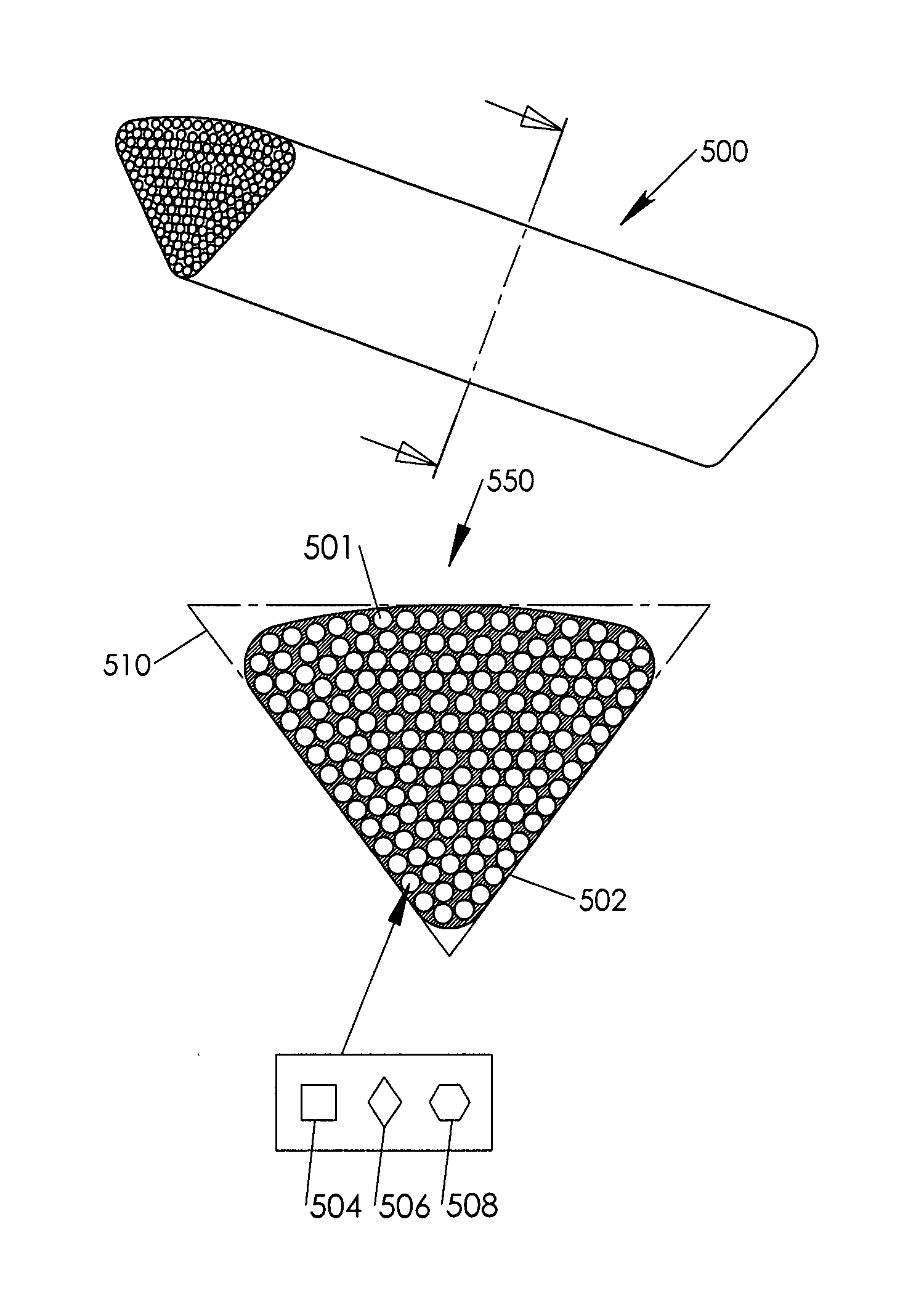

Field pole members and methods of forming same for electrodynamic machines

ActiveUS20070205675A1Increase torqueReduce manufacturing costMagnetic circuit rotating partsMagnetic circuit stationary partsUnit sizeManufacturing cost reduction

A method, apparatus, article of manufacture and system for producing a field pole member for electrodynamic machinery are disclosed to, among other things, reduce magnetic flux path lengths and to eliminate back-iron for increasing torque and / or efficiency per unit size (or unit weight) and for reducing manufacturing costs. For example, a field pole member structure can either reduce the length of magnetic flux paths or substantially straighten those paths through the field pole members, or both. In one embodiment, a method provides for the construction of field pole members for electrodynamic machines.

Owner:REGAL BELOIT AMERICA

Axial gap motor, compressor, motor system, and power generator

ActiveUS20110095628A1Improve motor efficiencyLow costMagnetic circuit stationary partsManufacturing dynamo-electric machinesStator coilDegrees of freedom

The present invention provides a low-iron-loss (high-efficiency) and low-cost axial gap motor that includes a high-quality soft magnetic material placed at an appropriate position, reduces torque pulsation, keeps induced voltage in the shape of a sine wave, and increases the degree of freedom in design. The axial gap motor includes a stator having stator teeth; and a rotor being opposed to the stator with a gap in an axial direction of the stator. Each of the stator teeth includes a stator tooth body, a stator tooth end joined to at least one axial-direction end of the stator tooth body, and a stator coil disposed around the stator tooth body. The stator tooth body includes a wound core comprised of a multi-layered amorphous foil strip winding. The stator tooth end is formed by a compact made of a powder magnetic core, and includes an opposed surface to the rotor. A cross-sectional area of the stator tooth end perpendicular to an axis of the amorphous foil strip winding is larger than a cross-sectional area of the stator tooth body perpendicular to the axis of the amorphous foil strip winding.

Owner:HITACHI METALS LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com