Patents

Literature

66 results about "Die preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Die preparation is a step of semiconductor device fabrication during which a wafer is prepared for IC packaging and IC testing. The process of die preparation typically consists of two steps: wafer mounting and wafer dicing.

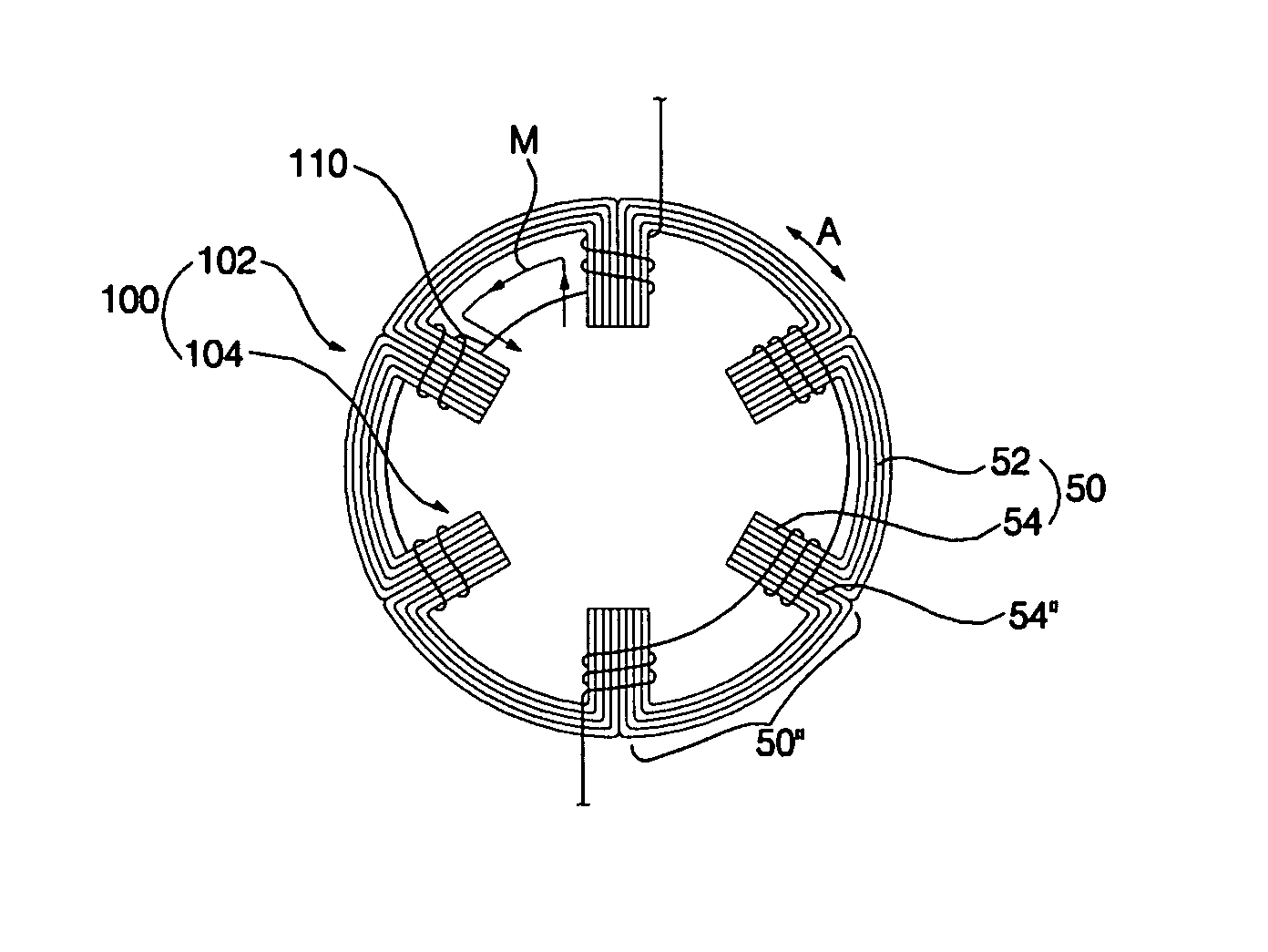

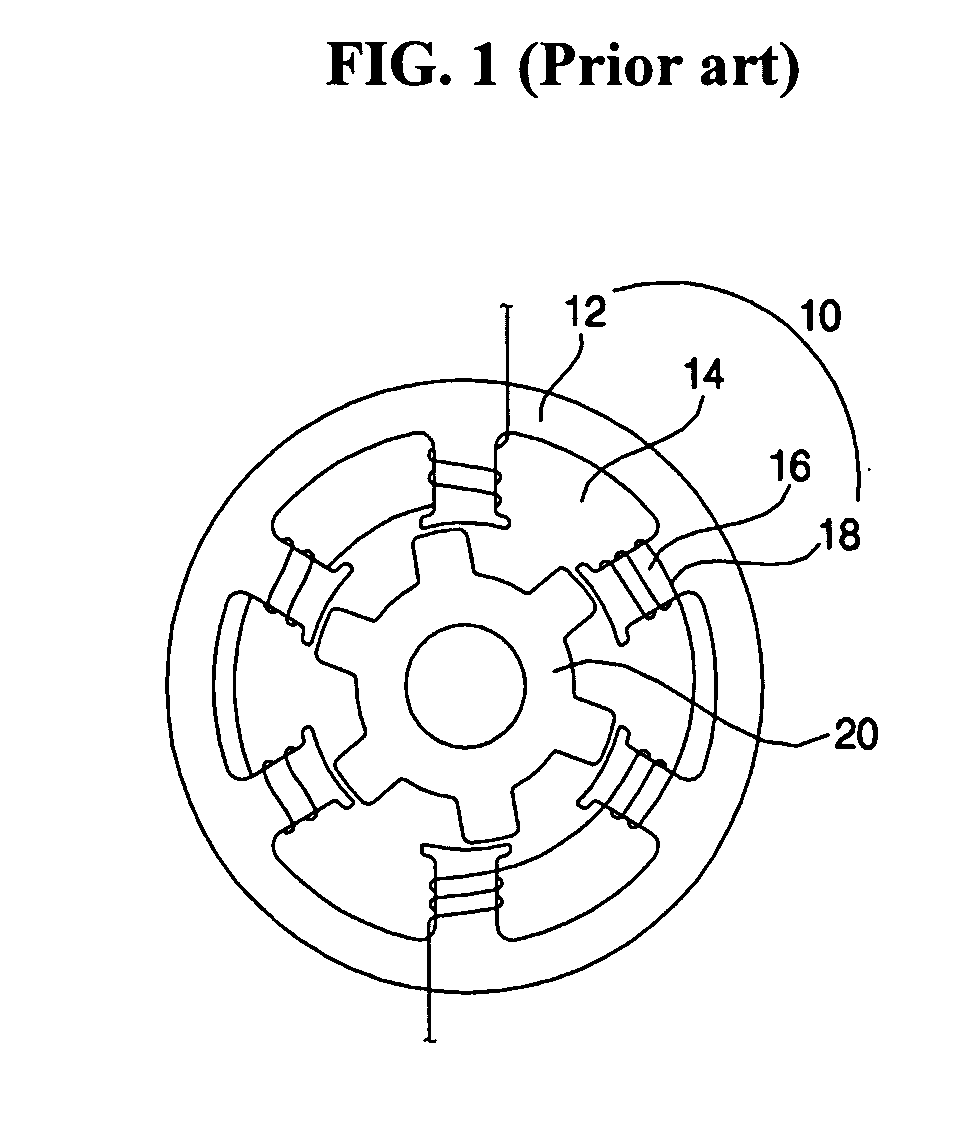

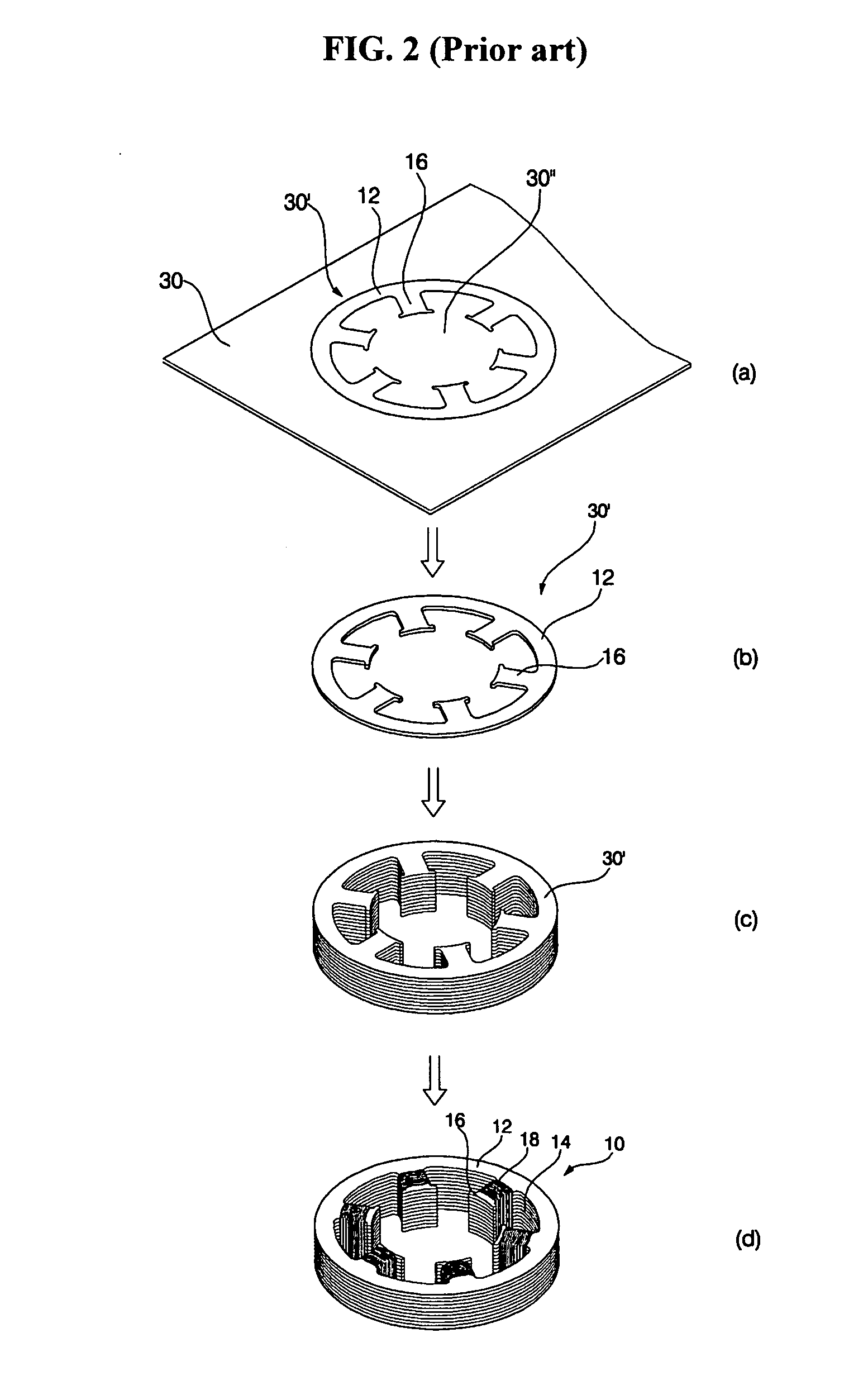

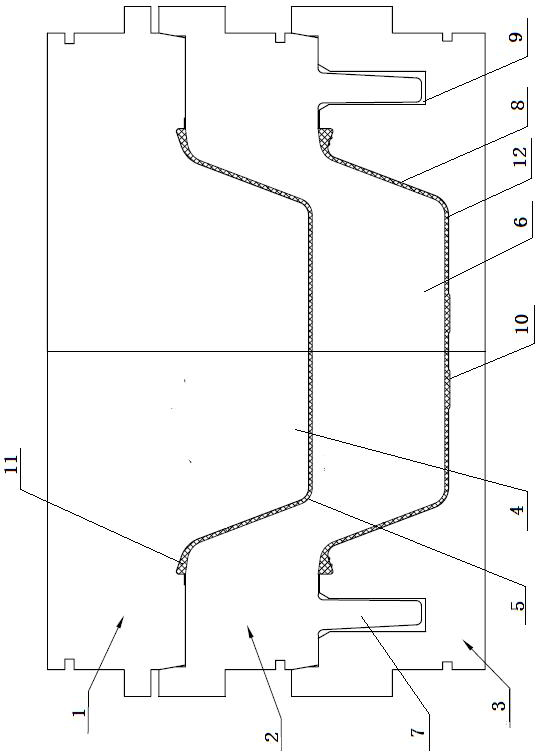

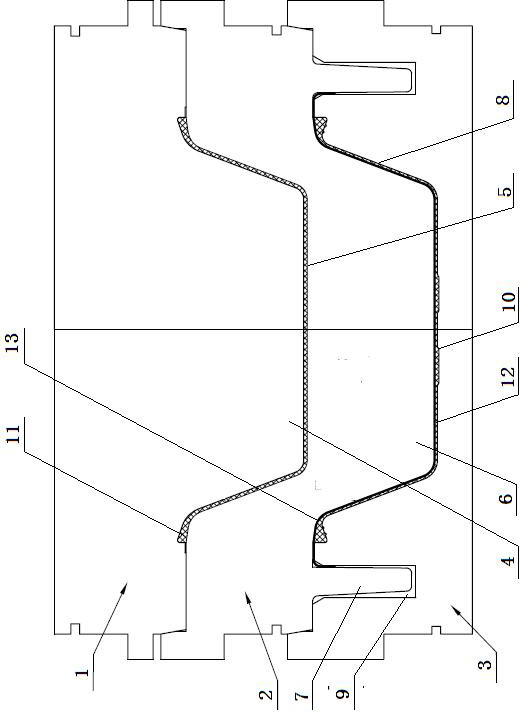

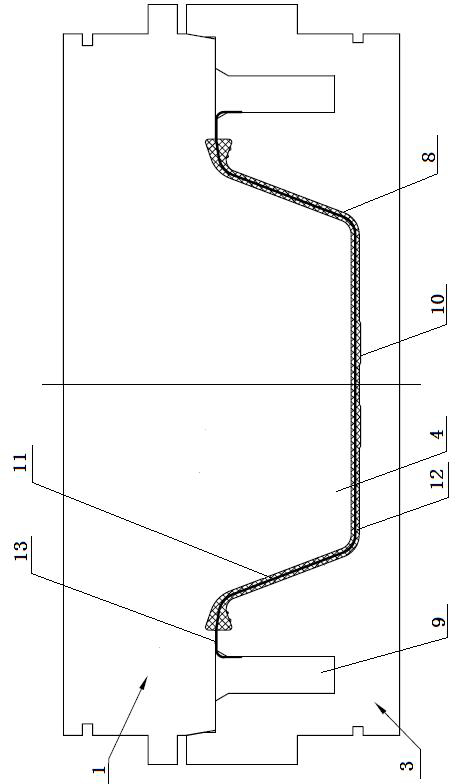

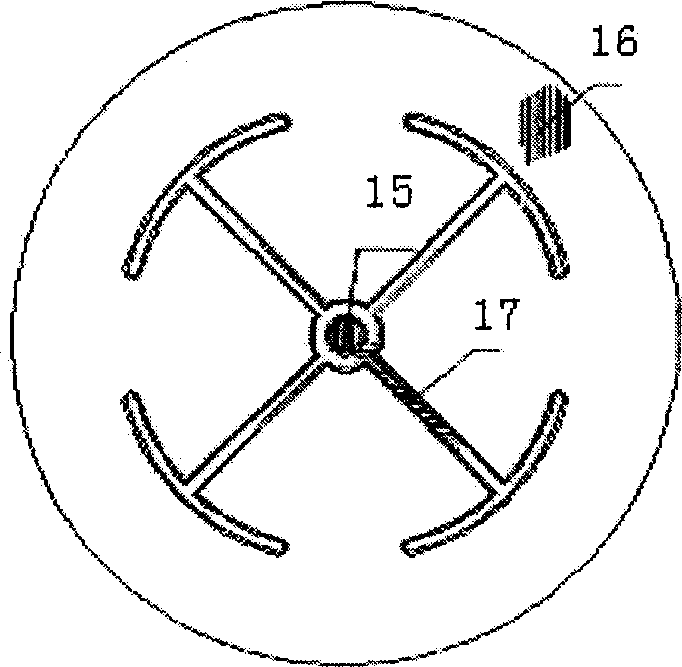

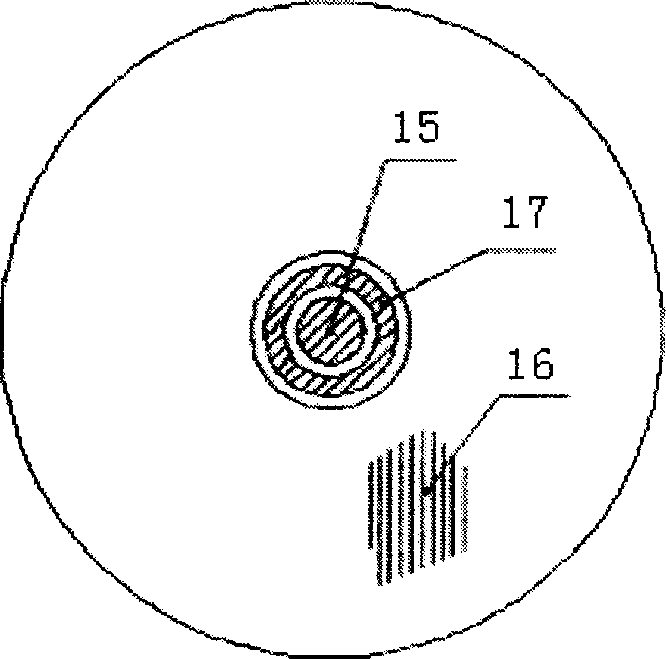

Stator of motor and method of manufacturing the same

InactiveUS20060055274A1Easy to manufactureReduce manufacturing costWindingsMagnetic circuit stationary partsElectrical steelDie preparation

A method of manufacturing a stator of a motor comprises the steps of bending at least one end of an electrical steel sheet to prepare a core sheet comprising a yoke part and at least one pole part bent from the yoke part, stacking a plurality of core sheets to prepare a unit core having a predetermined thickness, arranging a plurality of unit cores in line to prepare a core band, winding coils on the core band, and connecting both ends of the core band. In this way, the stator is manufactured. Consequently, no scrap is formed from the electrical steel sheet according to the present invention.

Owner:LG ELECTRONICS INC

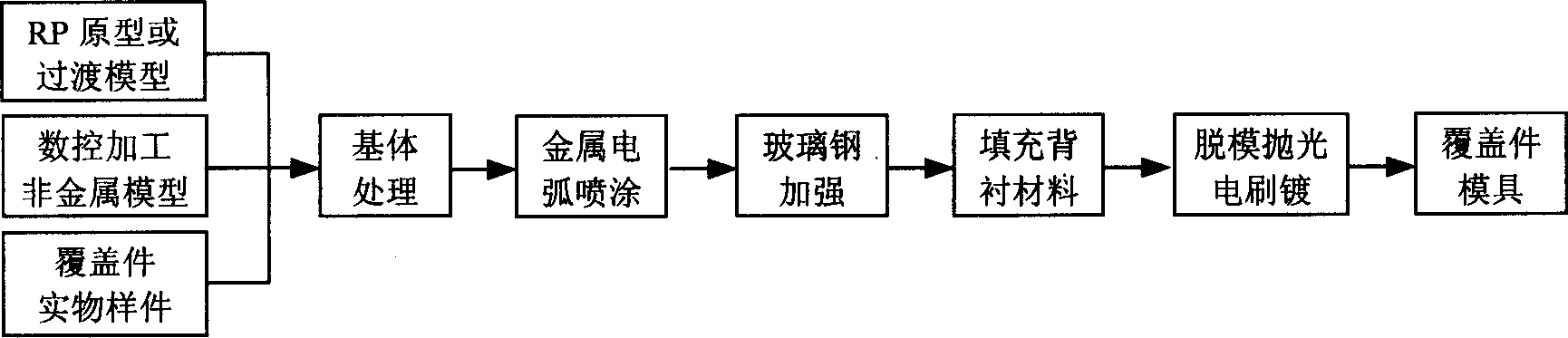

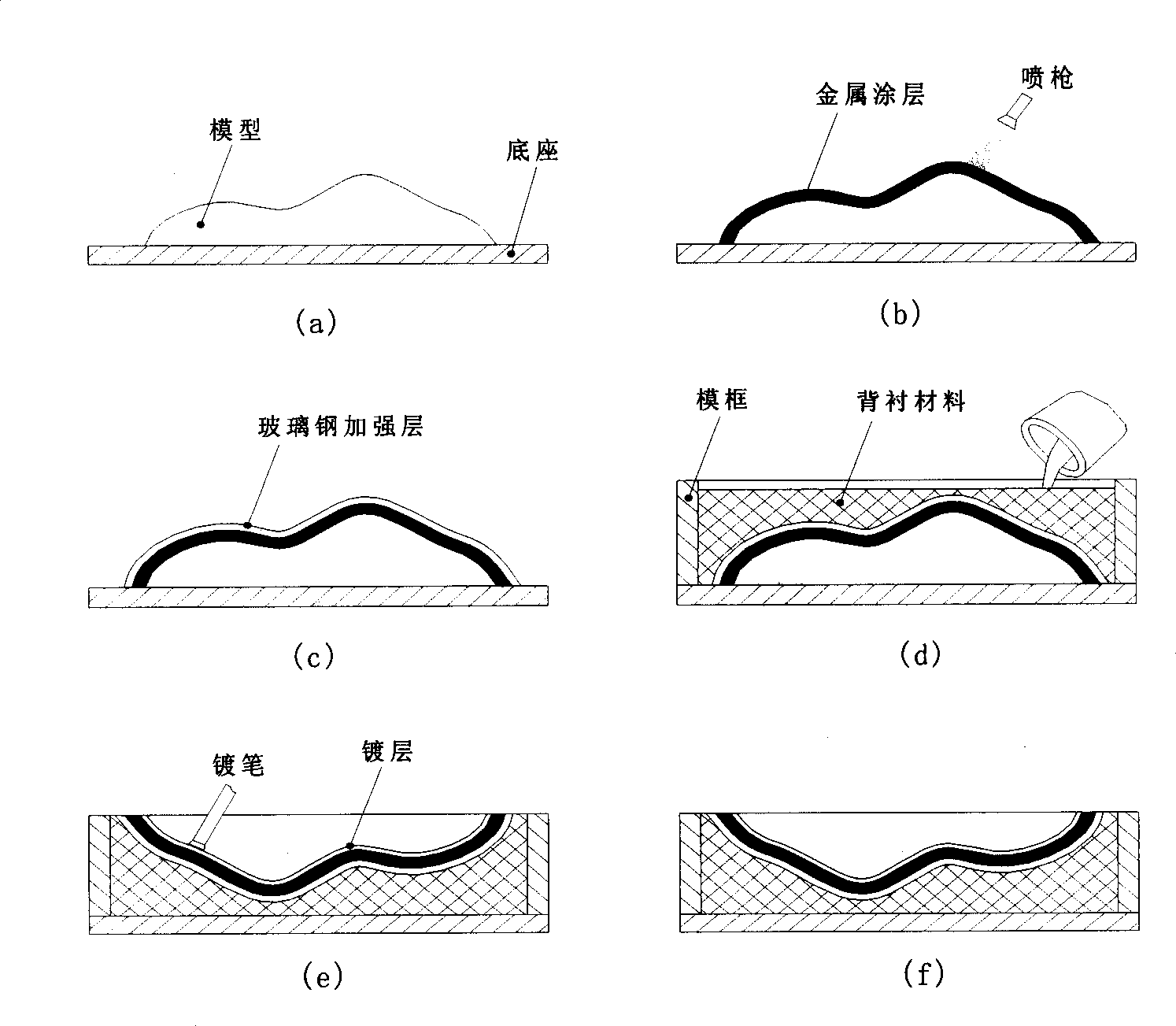

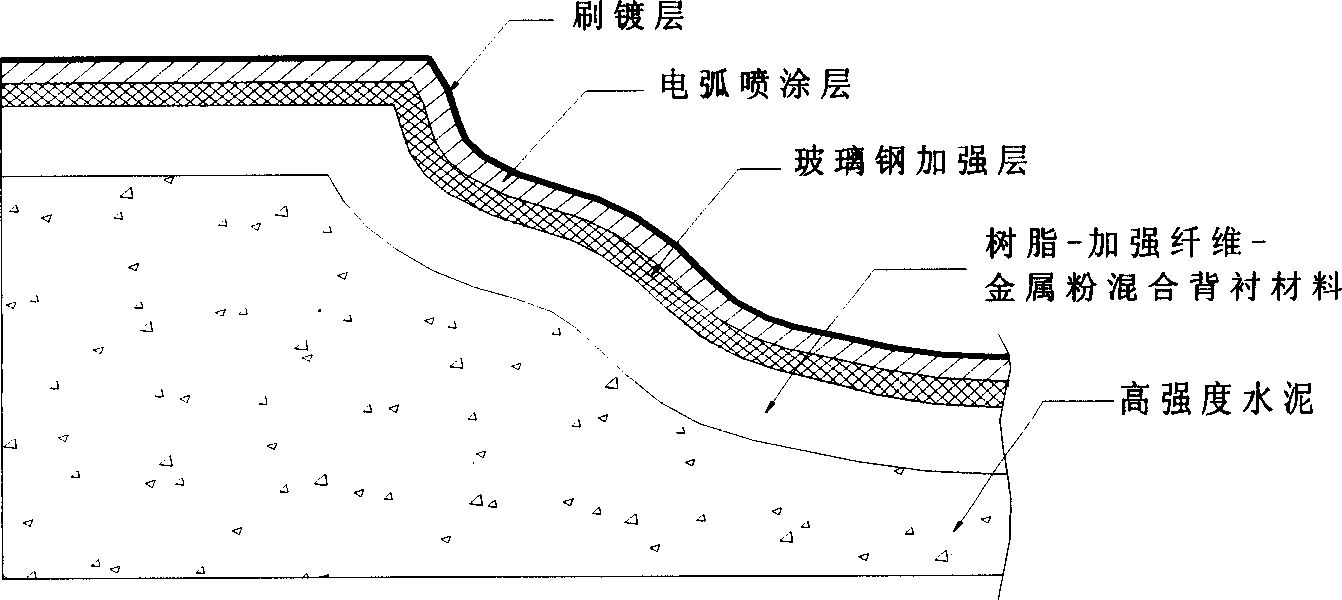

Method of rapid manufacture of stamping die for arc spraying covering-piece for automobile

The invention discloses a fast manufacturing method for punching die of metal arc painting car covers. The invention mainly uses metal arc paint technology, combines with glass steel forming, epoxy forming, electrical brush plating. The method includes: paint mother die preparation, basic process, metal arc paint, back materials filling, electrical brush plaiting. The final die is grad layer structure, each layer has different mechanism performance, easy to display material speciality. The invention simplifies the craft and reduces the cost.

Owner:XI AN JIAOTONG UNIV

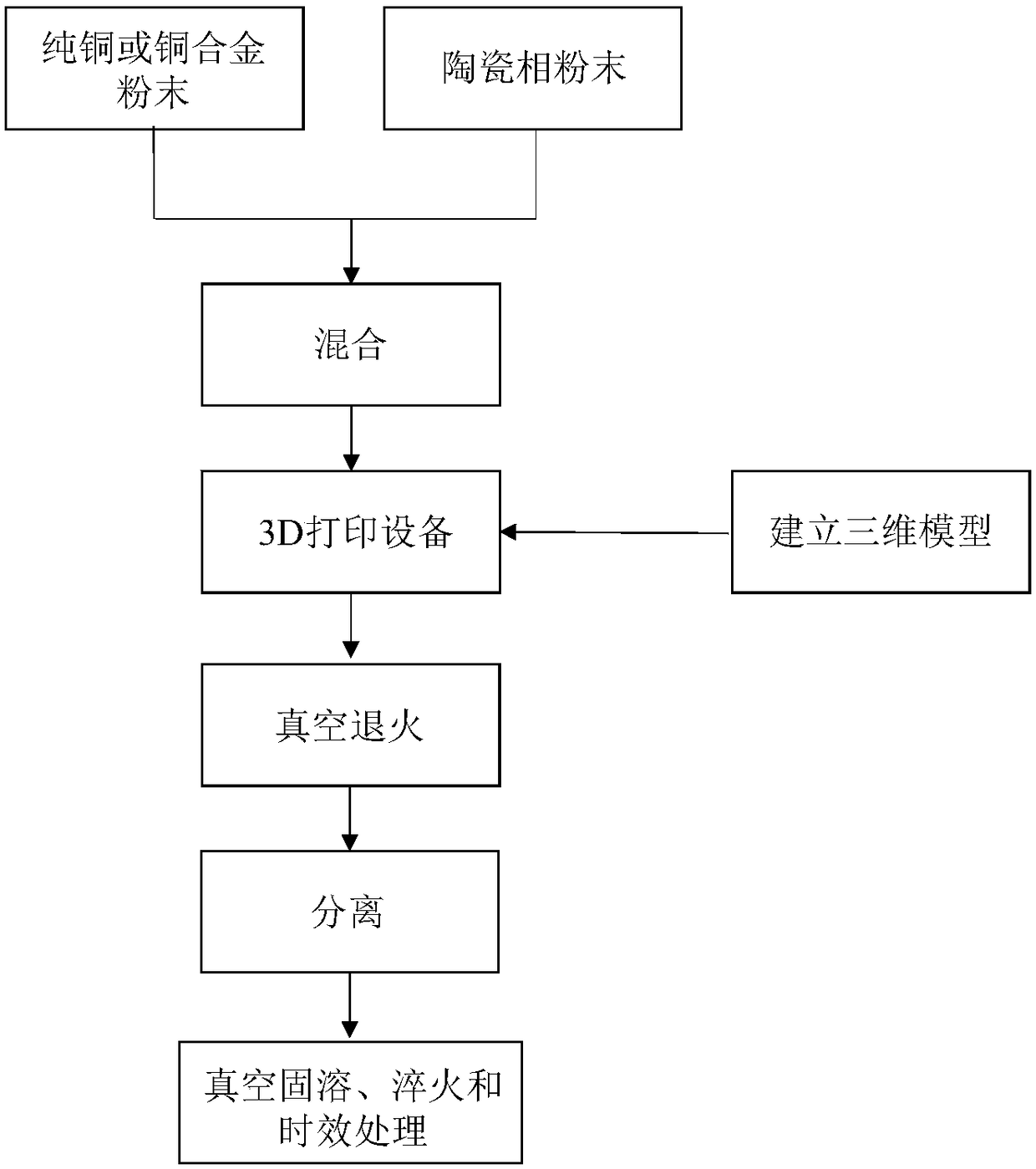

Rapid manufacturing method of enhancement type conformal cooling die copper

ActiveCN108179295AShorten the manufacturing cycleHigh forming precisionAdditive manufacturing apparatusIncreasing energy efficiencySolution treatmentHardness

The invention belongs to the related technical field of metal die preparation, and discloses a rapid manufacturing method of enhancement type conformal cooling die copper. The method comprises the steps that a die three-dimensional geometrical model is built and input into 3D printing equipment, and a two-dimensional section contour scanning model is generated; copper base powder and ceramic enhancement phase powder are mixed to be uniform; the mixed powder is dried and subjected to 3D printing to form a forming die, and annealing and separation are carried out; and the forming die is subjected to solution treatment, quenching treatment and aging treatment, and therefore the needed enhancement type conformal cooling die copper product is obtained. By means of the method, the uniform distribution characteristic of the ceramic enhancement phase in a copper substrate can be remarkably improved, the dispersion strengthening effect is achieved, meanwhile, the ceramic phase can be used as anucleating agent to increase nucleation to refine grains, and therefore copper die rigidity, hardness, wear resistance and the like are improved.

Owner:HUAZHONG UNIV OF SCI & TECH

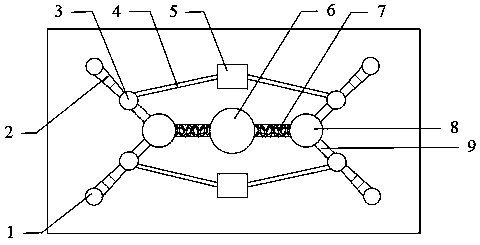

Method for using paper-based micro-fluidic chip for multi-channel detection

PendingCN109100525AFlexible operationPrecise shuntMaterial analysis by observing effect on chemical indicatorWater contaminantsPaper basedComputer science

The invention provides a method for using a paper-based micro-fluidic chip for multi-channel detection, wherein the using method comprises the following steps: chip preparation: according to the typeand quantity of heavy metal ions to be tested, detecting one metal ion, simultaneously detecting at least two samples, using two standard samples as a control group, and selecting chips having four ormore chrominance cell specifications; then adding a sample solution to be tested; adding a reagent; and finally performing the colorimetric comparison test. The method for using a paper-based micro-fluidic chip for multi-channel detection has the beneficial effects that the chip selection and the chip operation are flexible and adaptable, which is suitable for the determination of various heavy metal ions in different situations, and is capable of realizing continuous, real-time and rapid experimental requirements for on-site measurement.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

Negative-pressure airflow expendable pattern based energy-saving and effect-enhancing casting process

InactiveCN103042173AImprove product qualityQuality improvementFoundry mouldsFoundry coresHigh volume manufacturingProcess engineering

The invention discloses a negative-pressure airflow expendable pattern based energy-saving and effect-enhancing casting process, which relates to the technical field of casting. The casting process comprises the main steps of die preparation, automatic pouring, molding sand processing, and the like. Casting products produced by using the casting process disclosed by the invention are good in quality and low in cost; the size precision is high, the surface is smooth, the cleaning is reduced, and the machining amount is saved; internal defects are greatly reduced, and the texture is compact; and an effect of large-scale and high-volume production can be achieved. Due to the environmental-friendly automated flow line production, the operating environment can be greatly improved, the labor intensity can be reduced, and the energy consumption can be reduced.

Owner:渠县金城合金铸业有限公司

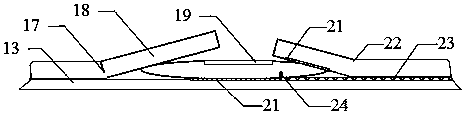

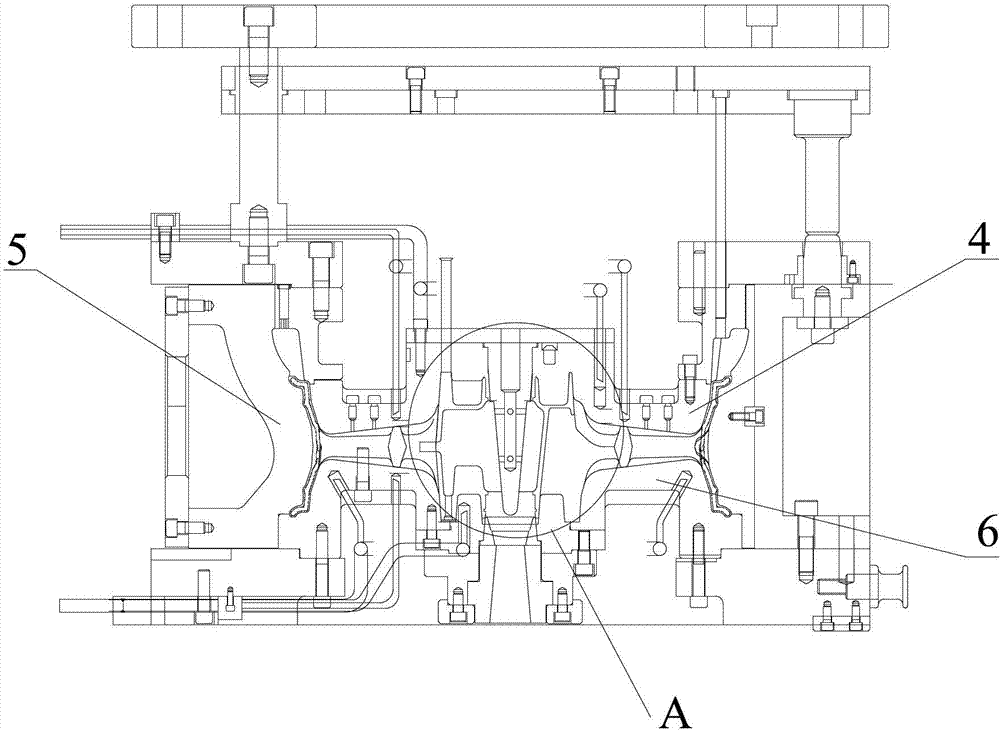

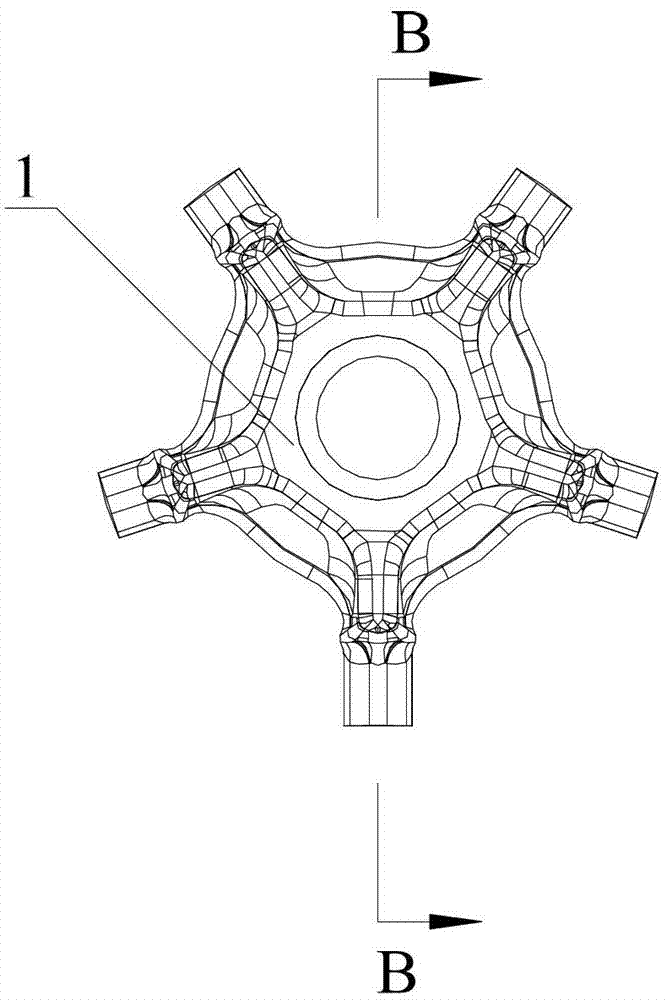

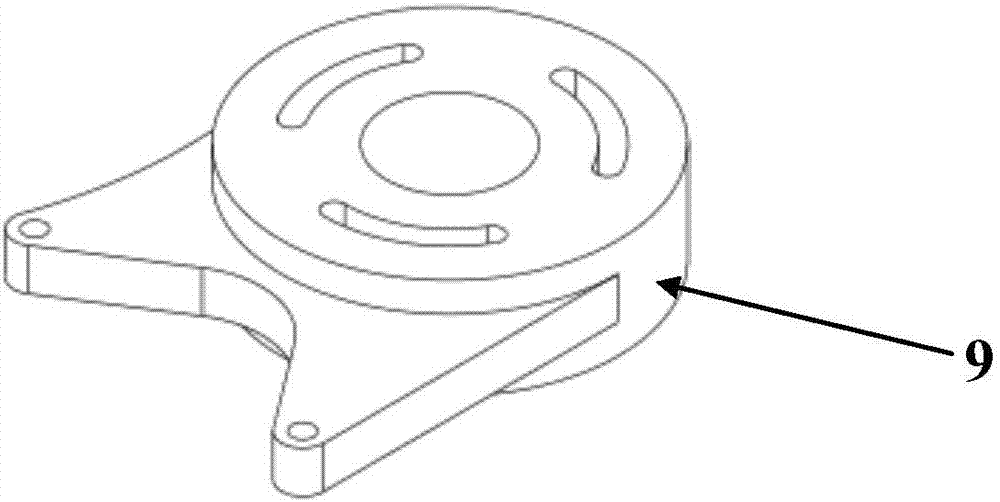

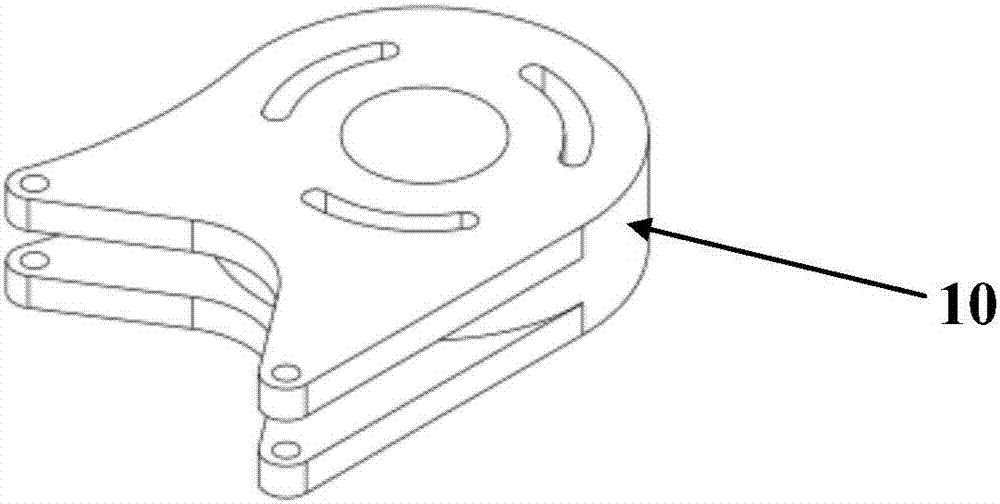

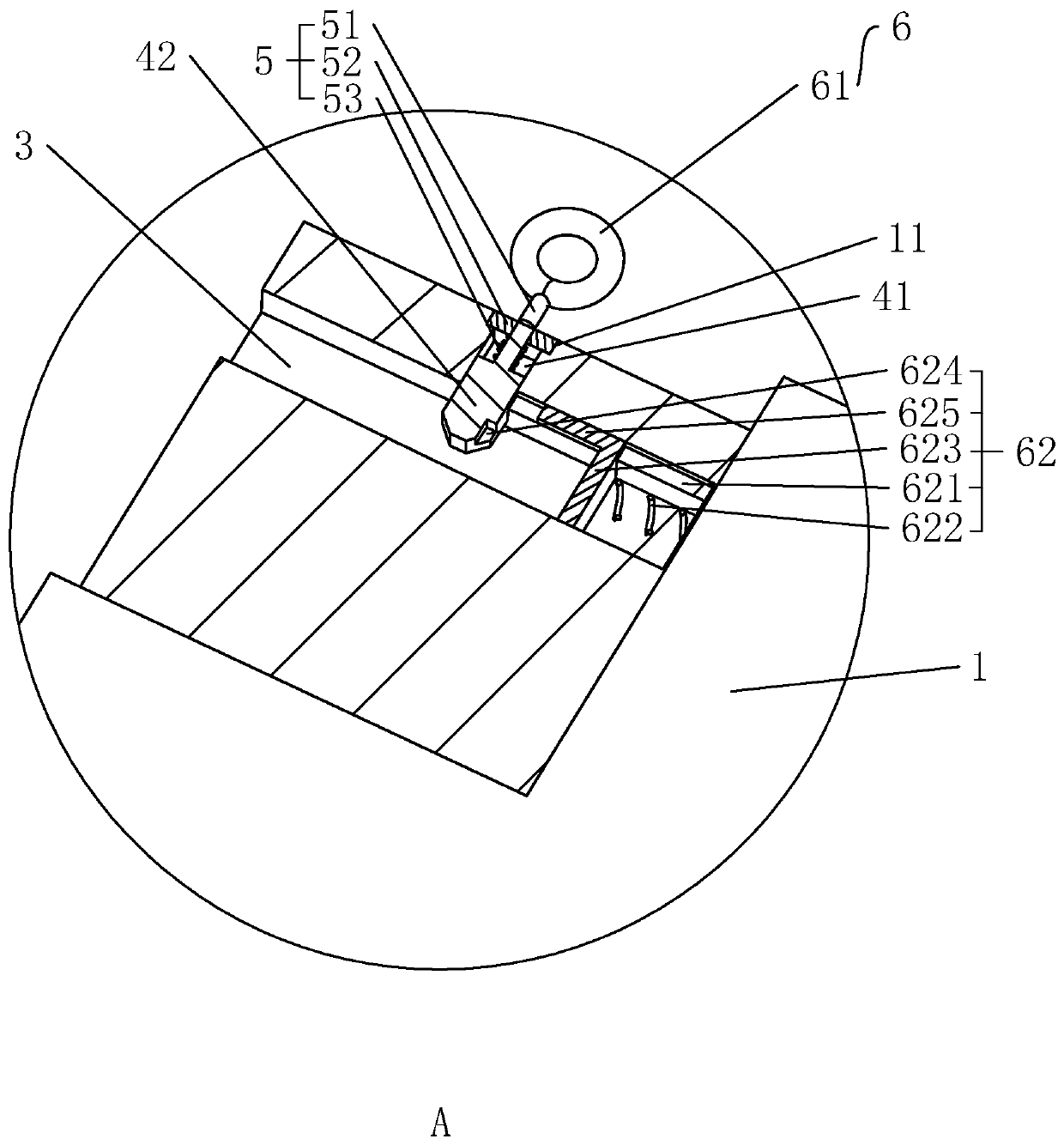

Hub sand core and low-pressure casting hub die

ActiveCN103042193AReduce volumeTo achieve the diversion purposeFoundry mouldsFoundry coresMaterials scienceBlind hole

The invention provides a hub sand core and a low-pressure casting hub die. The hub sand core comprises a sand core body (1), a tapered protrusion (11) is arranged at one end of the sand core body (1), a blind hole (12) is reserved at the other end of the sand core body (1), and an annular boss (13) is arranged at one end, with the blind hole (12), of the sand core body (1). In the technical scheme of the hub sand core, the sand core body is no longer of a through hole structure, the top of the sand core body is designed into the shape of the top of a distributing cone, an original distributing cone top is replaced by a shaped conical protrusion of the sand core to realize distribution of molten aluminum; the distributing cone no longer directly contacts with the molten aluminum, even if small amount of molten aluminum permeating through a matching surface of the distributing cone and the sand core body can flow to the bottom of a conical hole of the sand core body, so that a venting plug is prevented from being blocked, producing efficiency is improved, and die preparation cost is lowered.

Owner:ZHEJIANG JINFEI KAIDA WHEEL

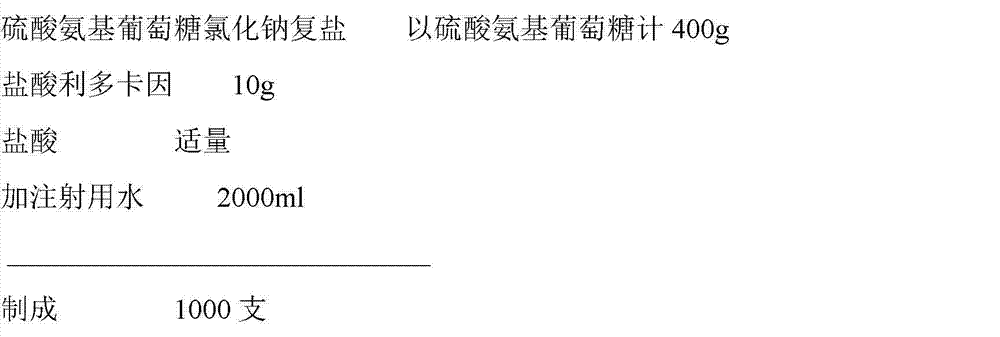

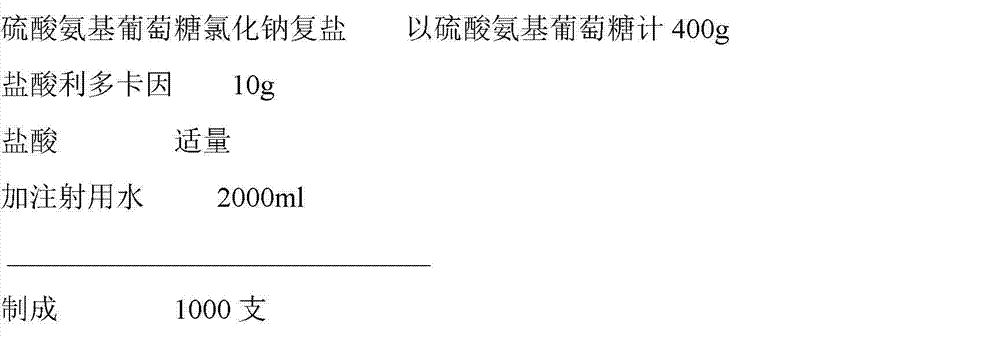

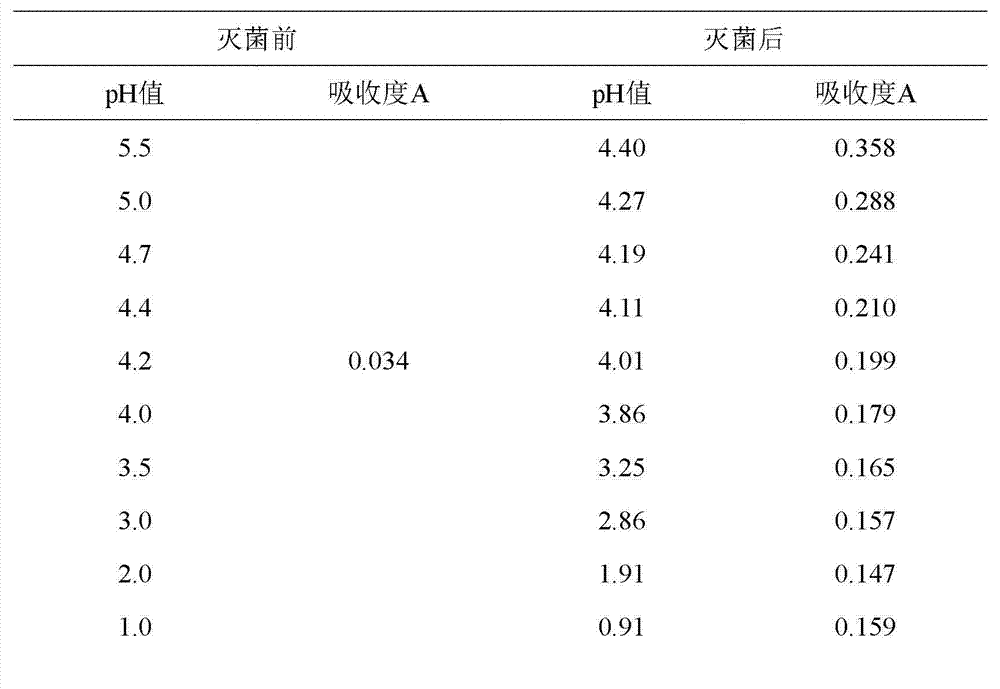

Composition containing glucosamine as well as preparation method and detection method thereof

ActiveCN102961389AMeet safety requirementsMeet stability requirementsOrganic active ingredientsAntipyreticSolubilitySide effect

The invention relates to a composition containing glucosamine. The active ingredients of the composition are glucosamine or pharmaceutically acceptable salt thereof and lidocaine or pharmaceutically acceptable salt thereof, and the composition provided by the invention can be prepared into an injection, preferably a parenteral solution, more preferably a small-volume injection. The parenteral solution further comprises an antioxidant, a pH regulator and an alkaline solvent. The composition containing glucosamine provided by the invention can be used for overcoming the defects that freeze-drying preparation of glucosamine is long in freeze-drying time, high in energy consumption and not beneficial to production in the prior art and free-dying preparations in the same batch are different in the shape and solubility. Control on the stability of the parenteral solution and related substances is realized, and the side effect caused by degradation products is reduced, so that the safety and stability requirements of the parenteral solution are met. Therefore, the glucosamine parenteral solution provided by the invention can meet industrial production and can be safely and reliably applied to the field of medicine.

Owner:任金山 +1

Production process of rubber diaphragm of automobile brake chamber

The invention discloses a production process of a rubber diaphragm of an automobile brake chamber, and aims to solve the defects that in the prior art, a product has low yield and easiness in exposed and deflected arrangement, so that the service life and the service performance of the product are influenced, and the production cost is high. The production process has the main steps of die preparation, rubber material formation, framework formation, production formation, and three times of vulcanization, so as to obtain the product. Under the premise of not influencing the production efficiency of the product, the product yield and the product properties are improved and the production cost is low, so that the deflection and the exposed arrangement of the diaphragm cloth can be radically solved.

Owner:NINGBO FENGMAO FAR EAST RUBBER

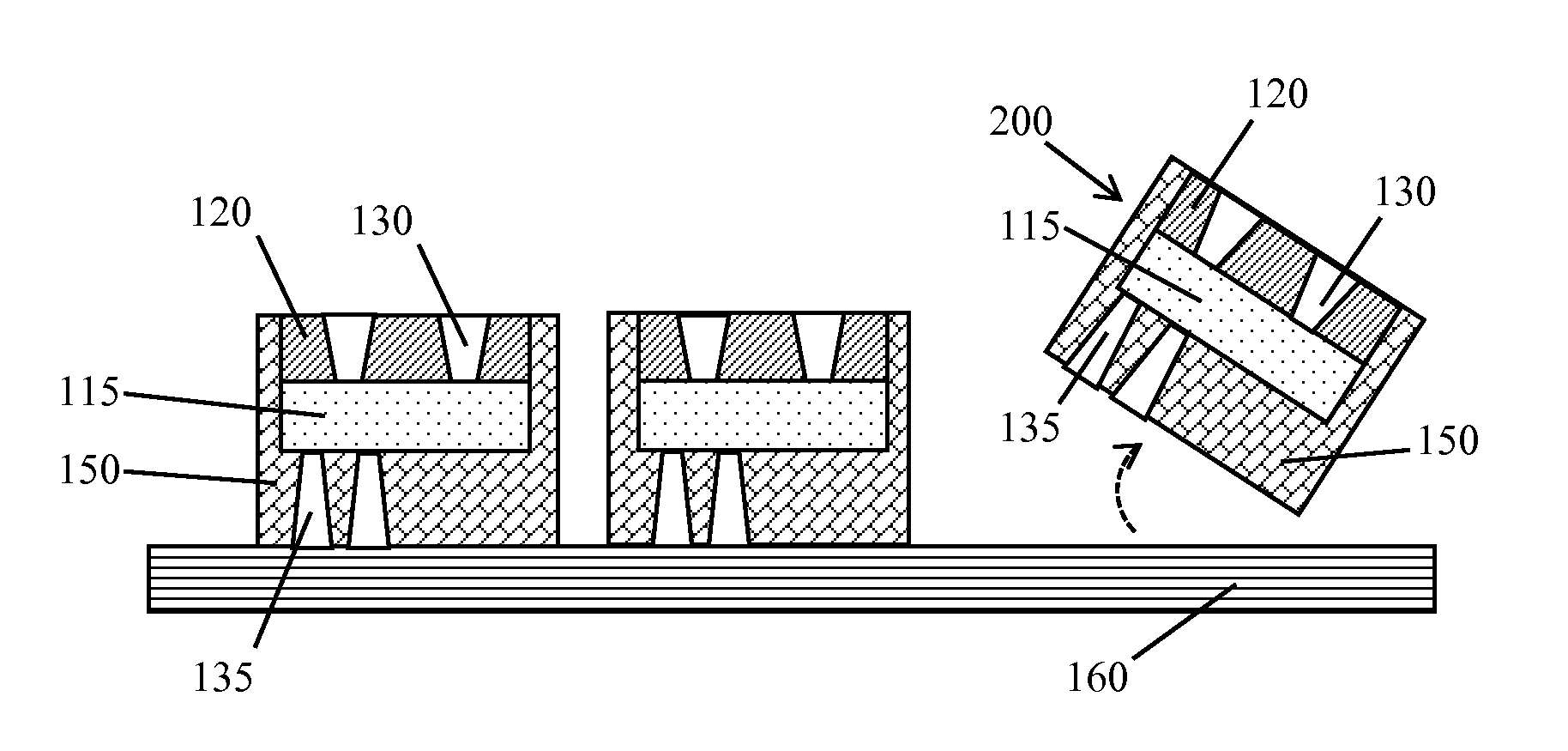

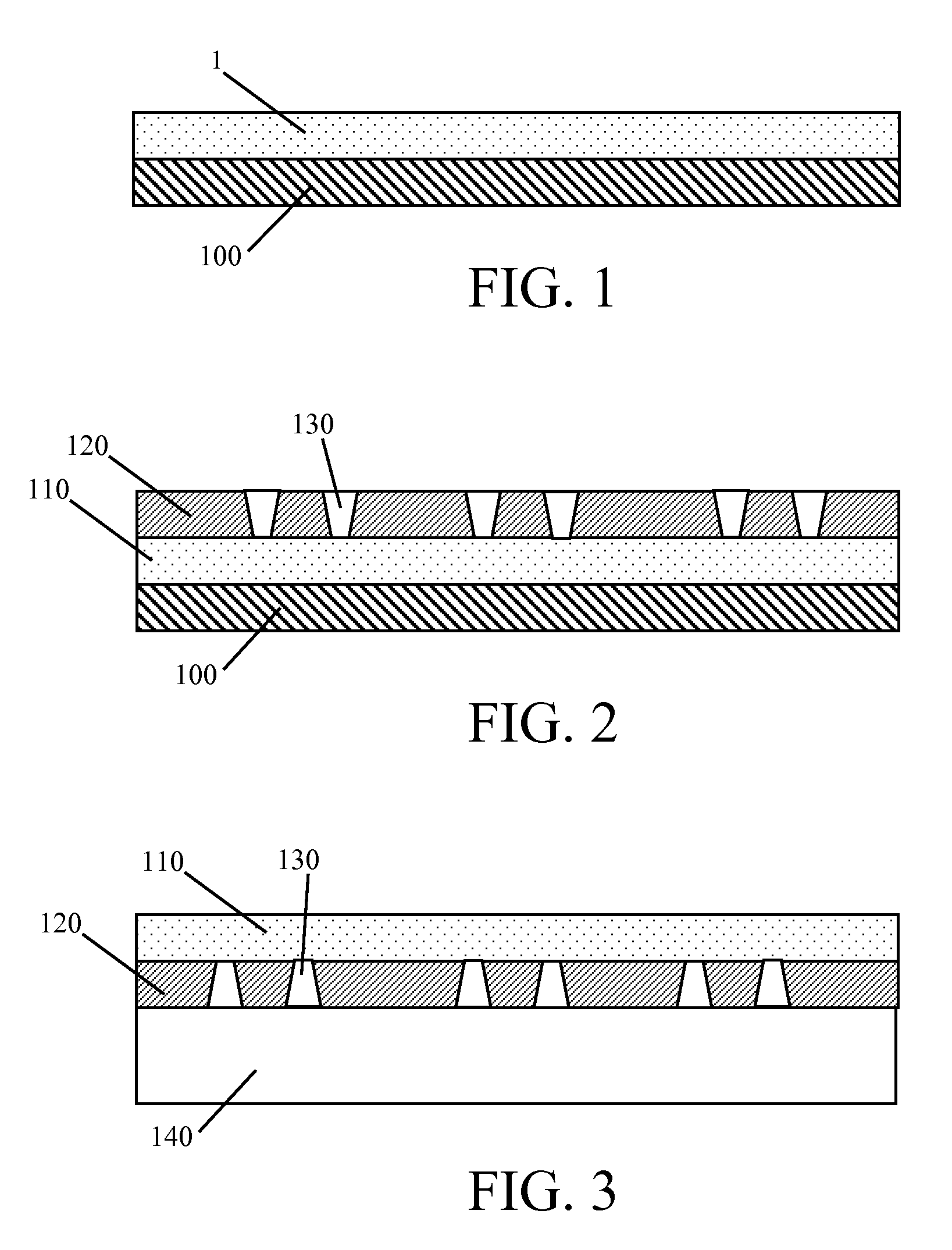

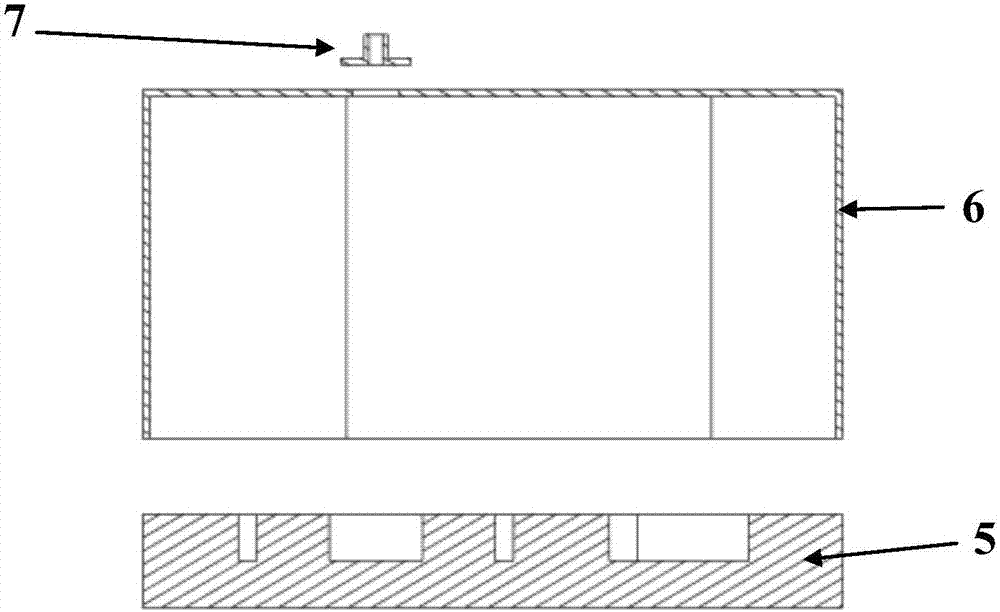

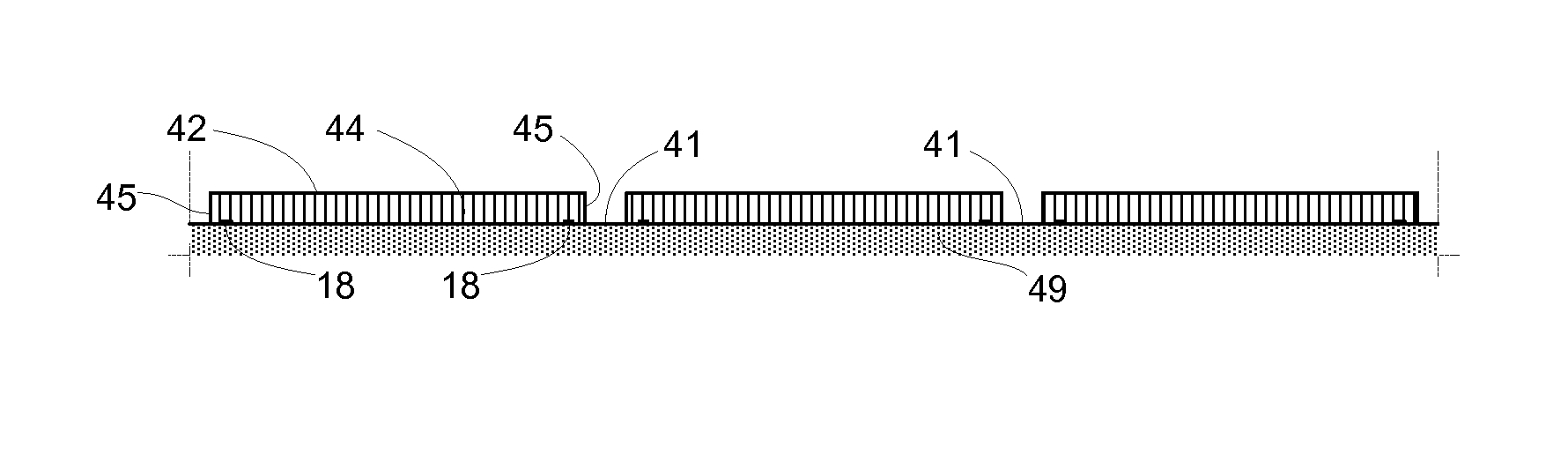

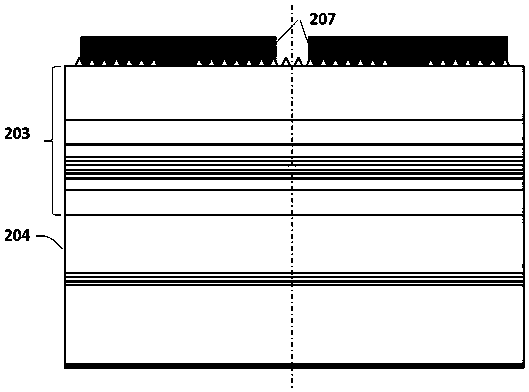

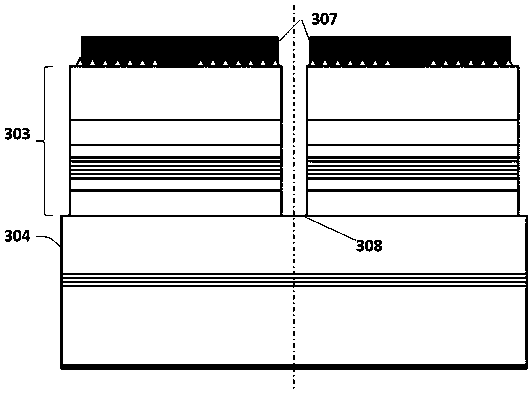

Method of producing encapsulated IC devices on a wafer

This method of waferscale packaging produces finished integrated circuits (ICs) individually completely encapsulated with environmentally protective packaging material while still in the wafer format. Following conventional semiconductor fabrication of chips at the wafer level and prior to their separation, a first polymer is applied to the front surface of the wafer with allowance for contact holes. A carrier wafer is attached to the exposed polymer. The original substrate is removed and the devices are separated by cutting through the semiconductor layer and the first polymer. A second polymer is applied to cover the exposed backside of the devices and to fill the cut spaces between them, thereby sealing the remaining five surfaces of the chips. The second polymer layer may also include contact holes for access to the back side of the device chips. A second singulation cutting leaves the chips on the wafer prepared for a pick-and-place operation.

Owner:AMERICAN SEMICON

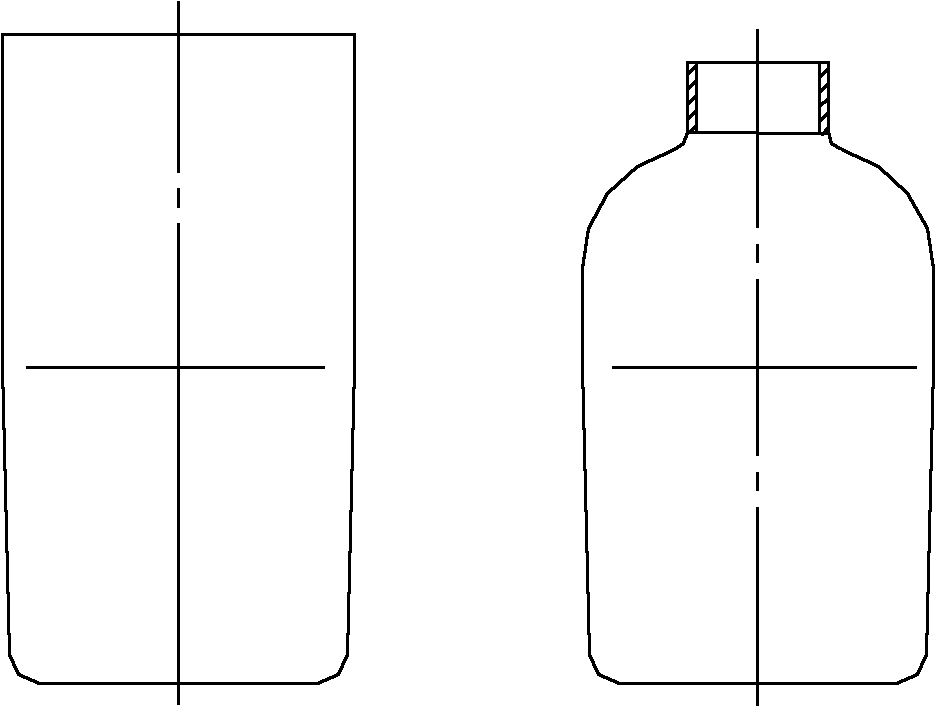

Method for manufacturing thin-wall cylindrical member necking die

ActiveCN101954418AIncrease productivityQuality improvementShaping toolsMaterial selectionThin walled

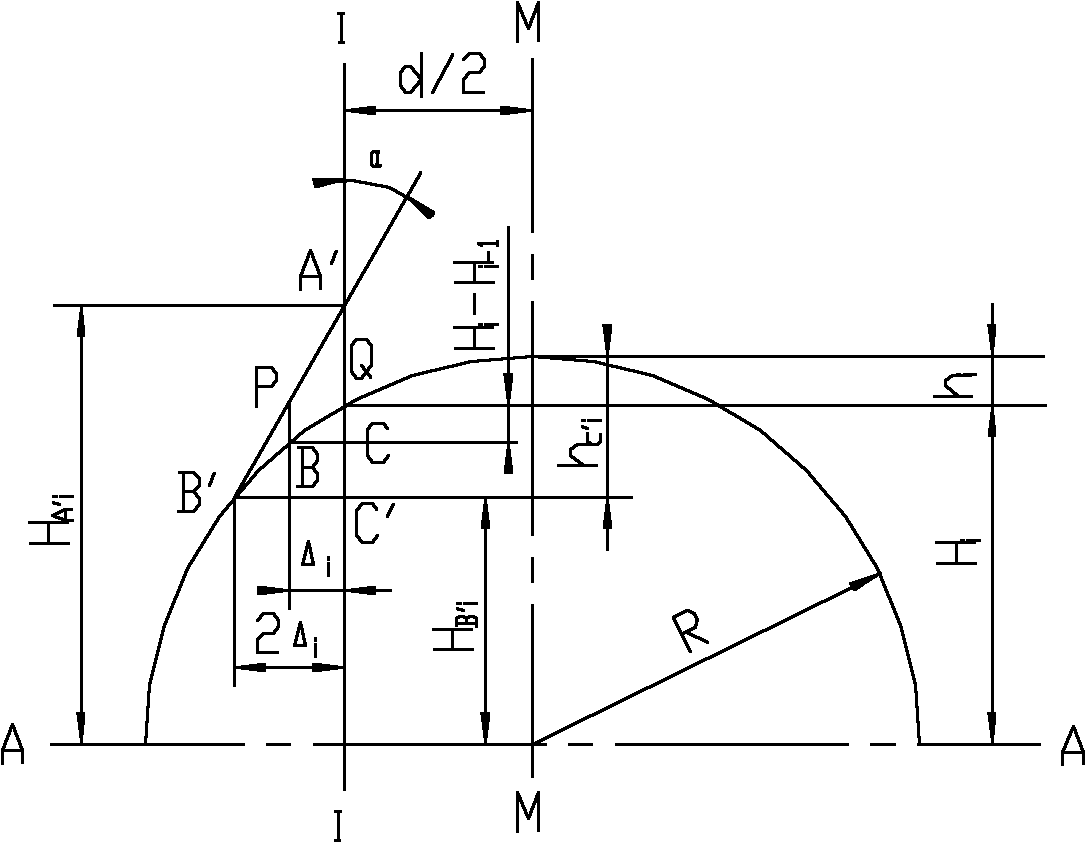

The invention relates to a method for manufacturing a thin-wall cylindrical member necking die, which comprises the following steps of: 1. precisely calculating and confirming reasonable necking coefficients and necking passes, wherein the step 1 has the key of well distributing the necking coefficients of all passes, to be used as a theoretical basis of necking die preparation; 2. scientifically and reasonably designing a multipass necking die structure to ensure easy material selection and processing manufacture; 3. establishing a feasible processing manufacture process to ensure the manufacture precision of the necking die; and 4. designing an installation structure of the die on an automatic necking press to ensure the positioning precision of the die. The die of the invention has the advantages of simple manufacture method, scientific and reasonable design, convenient installation and use and durability, and the invention can effectively ensure the quality of a thin-wall heterogenic cylindrical member during multipass necking, and is a novel method for manufacturing the multipass necking die and particularly suitable for various thin-wall cylindrical members during necking.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME +1

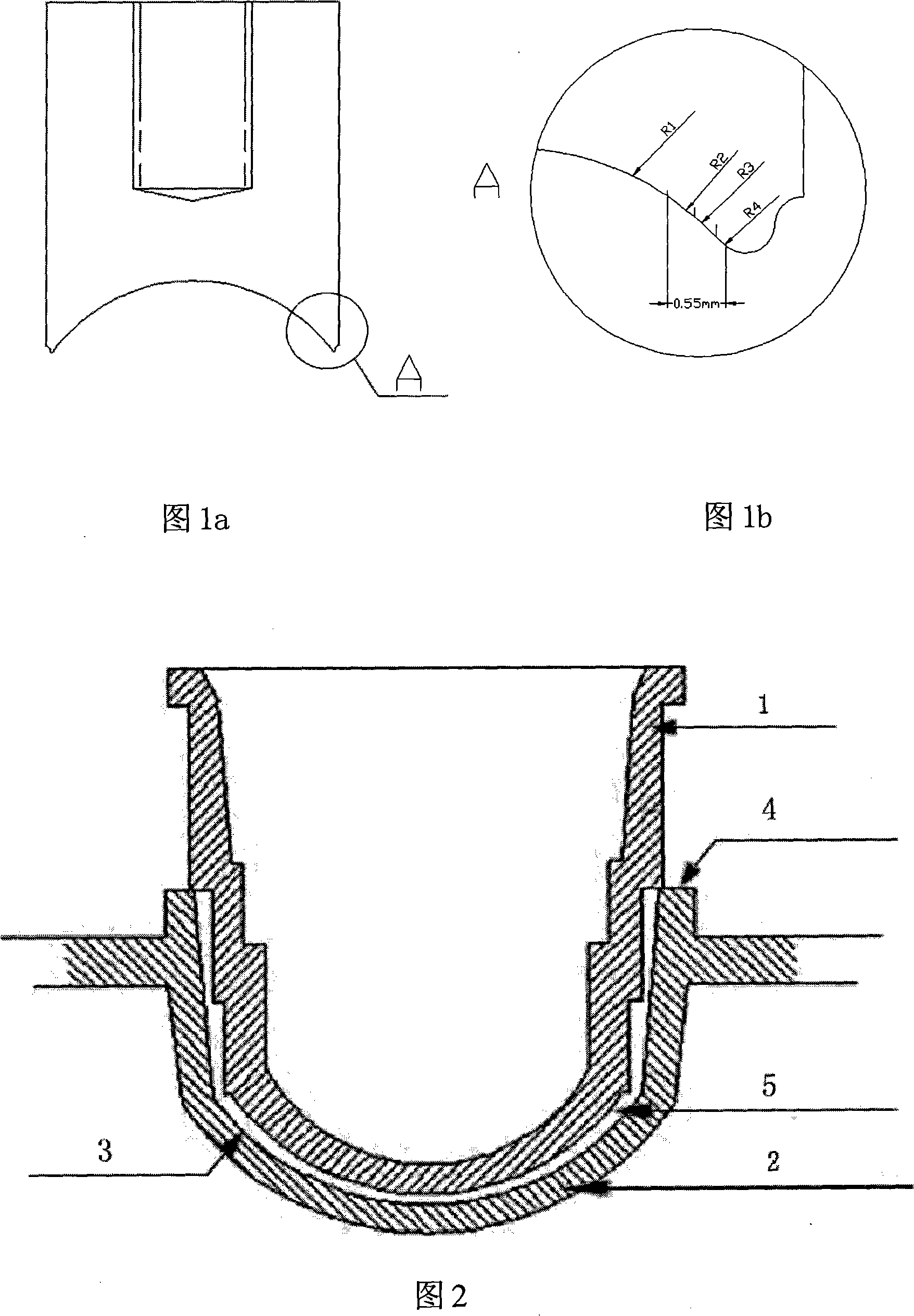

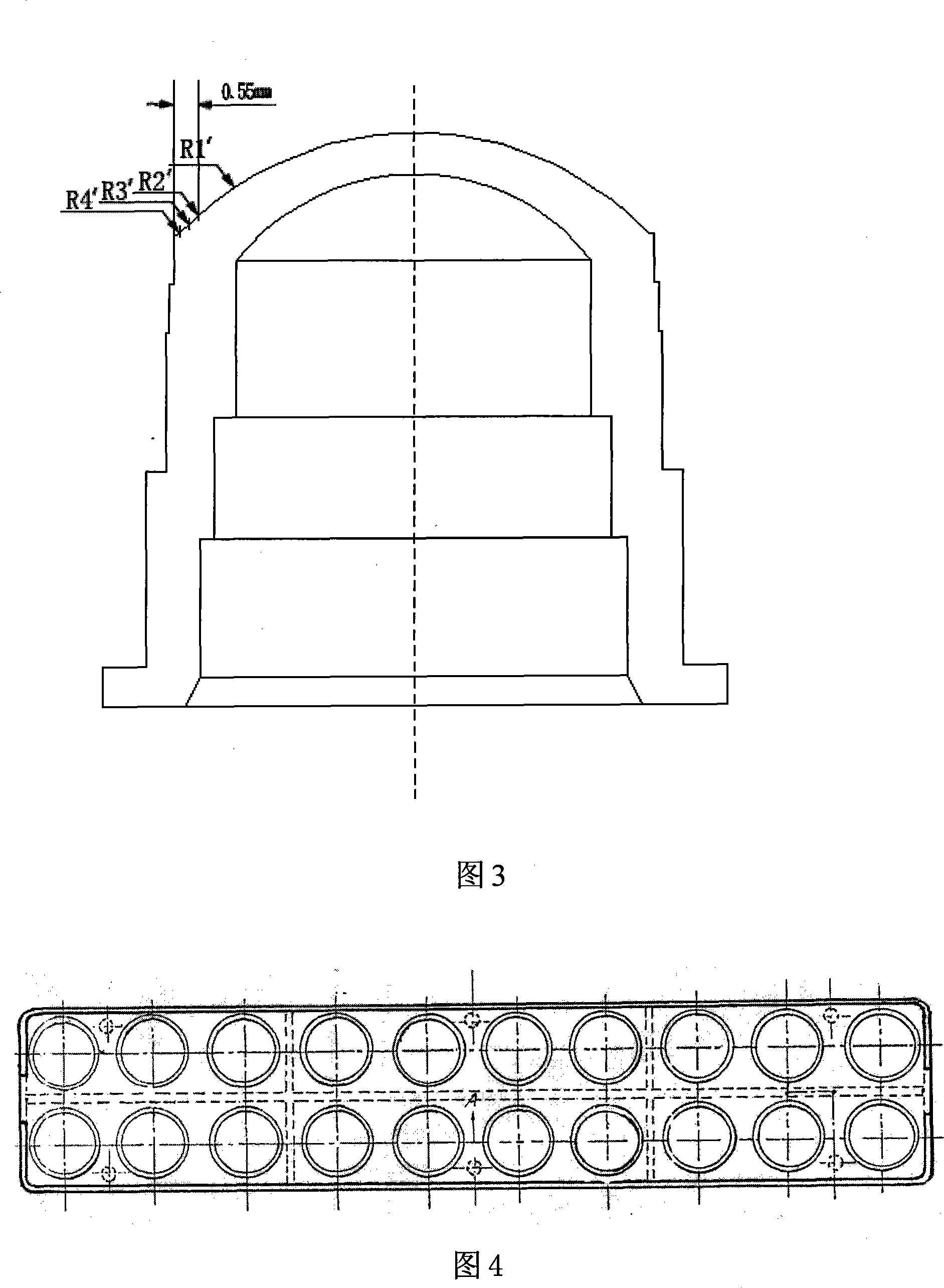

Contact lenses plastics mould used for semi-lathe production and manufacturing method thereof

The invention discloses a plastic mould for contact lens manufactured by a half turning method and a preparation method thereof. The method comprises five processes: a male die metal die kernel, an injection die preparation, a feed preparation, an extrusion palletizing, a male die injection and a female die injection. The feed preparation is counted by the mass portion. 70 portions of PBT and 30 portions of PC are mixed and then are placed in a baking oven and are carried out a drying process at the temperature of 100-140 DEC C for more than 4 hours; 25-35 portions of coupling agent and 65-75 portions of inorganic additives are carried out a surface process and are manufactured into a filling master batch; the temperature of the male die injection is 170-245 DEG C, and the injection pressure is 700-1000bar and the holding time is 15-25sec. The manufactured male die has the advantages of hydrophilicity and a high surface energy. The manufactured female die has the advantages of a hydrophobicity and low surface energy. The invention, through a reasonable selection to the male and female die plastic, causes that the unqualified rate of separating the contact lens roughcast and the male die is not less than 2 percent and the deformation unqualified rate of the contact is less than 5 percent.

Owner:GUANGZHOU BAOSHINING OPTICAL PROD

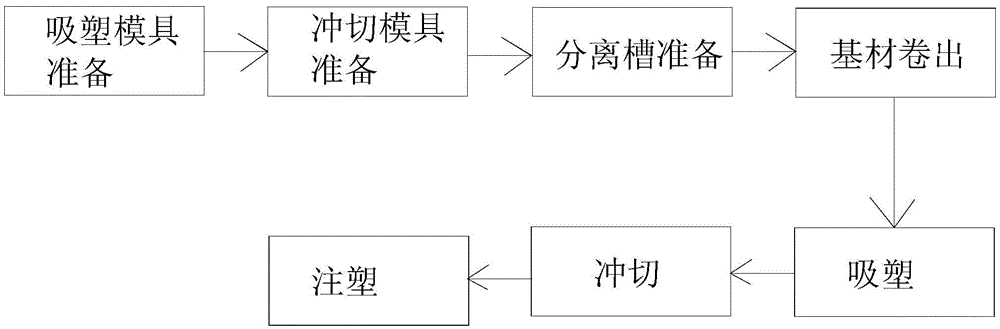

Double-mold-embedment production process of instrument panel

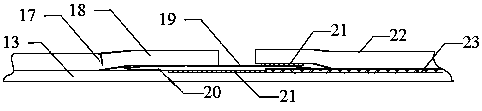

ActiveCN105479764AEliminate the steps of manual assemblyReduce manufacturing costLaser beam welding apparatusPunchingEngineering

The invention provides a double-mold-embedment production process of an instrument panel. The process flow of the double-mold-embedment production process includes the steps of plastic absorption mold preparation, punching die preparation, separation groove preparation, base material roll-out, plastic absorption, punching and injection molding. Double-mold-embedment injection molding of an electroplating strip and a plastic membrane is conducted through a separation groove during injection molding, and the step of manually splicing the electroplating strip and the plastic membrane in a traditional instrument panel can be omitted; the traditional production concept is totally subverted, and the deformation problem of the large-area electroplating strip in the production process cannot happen any more; the number of devices required for the technological process is smaller, and the production cost is greatly saved; and styles of instrument panels which can be produced are complex, and the problem whether instrument panels with complex styles can be produced or not needs to be considered during design of a traditional panel and does not need to be considered in the double-mold-embedment production process.

Owner:ATRA PLASTICS SHANGHAI

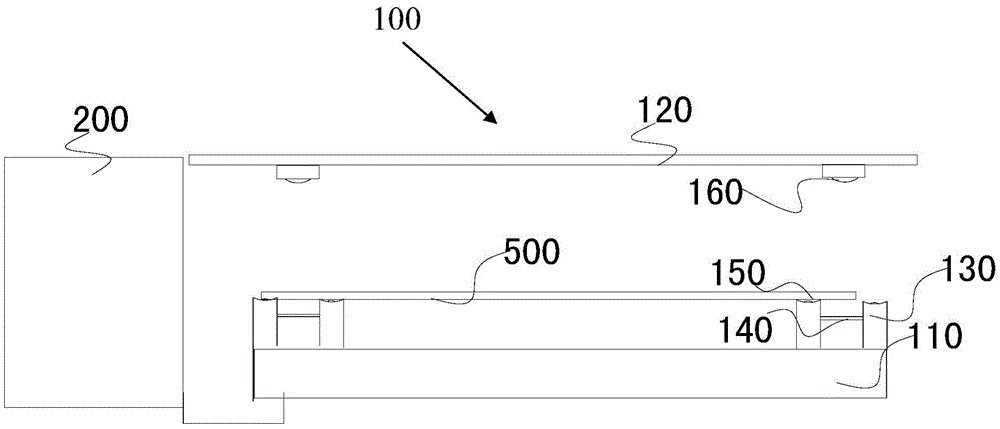

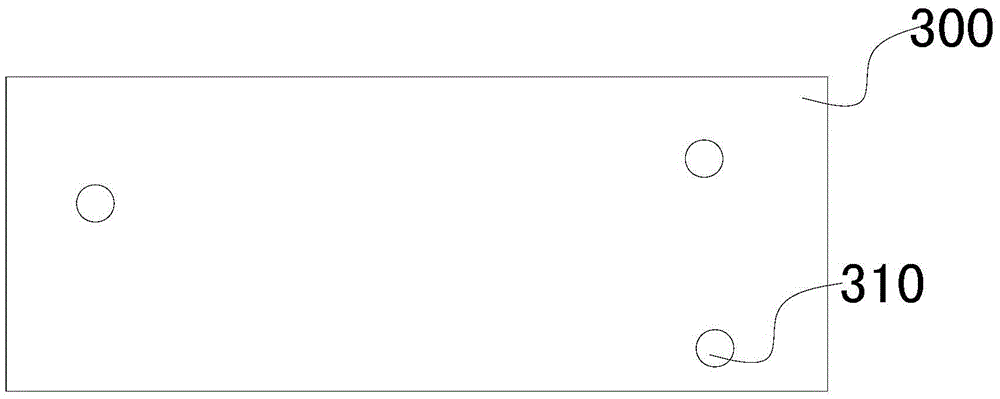

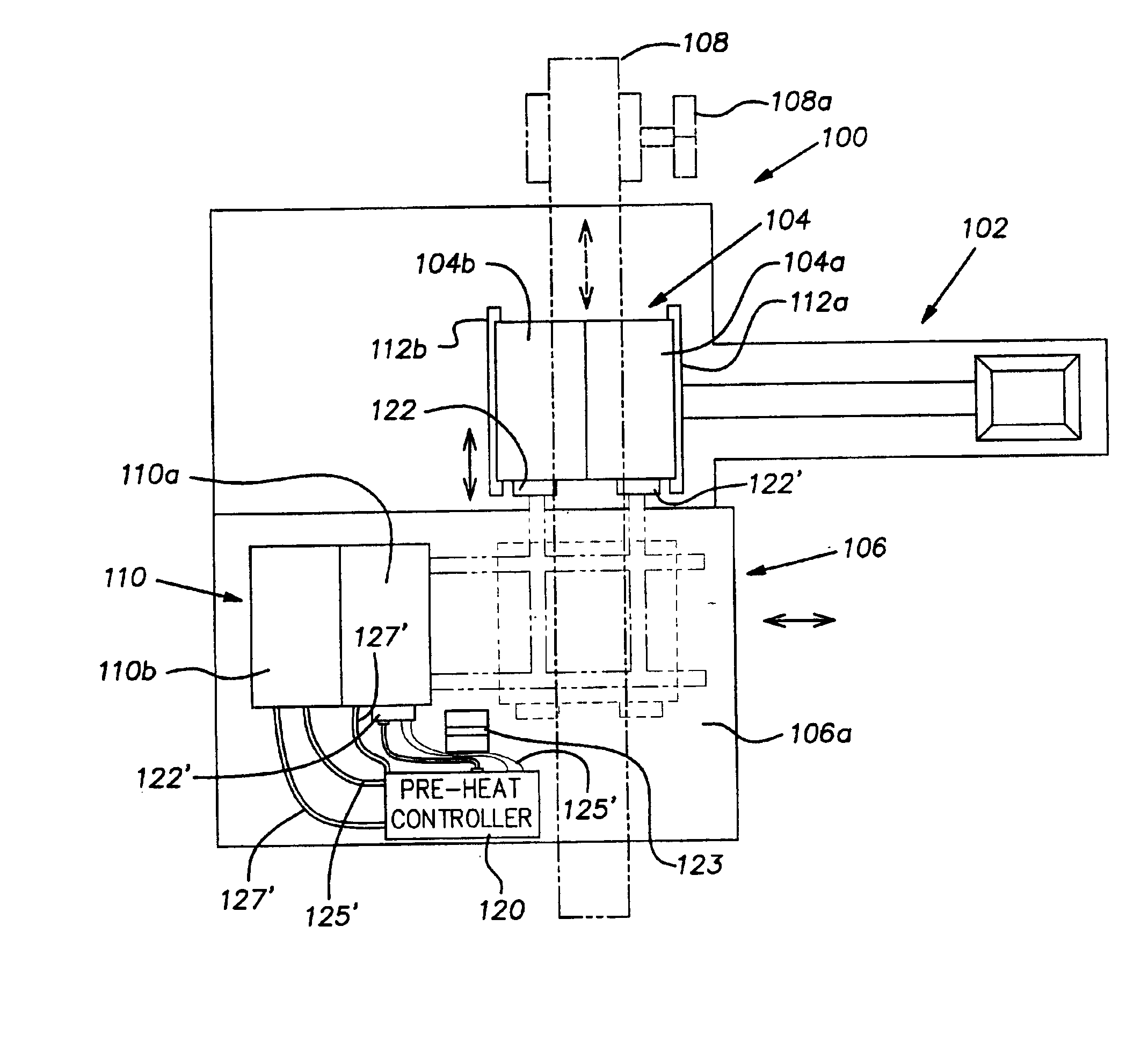

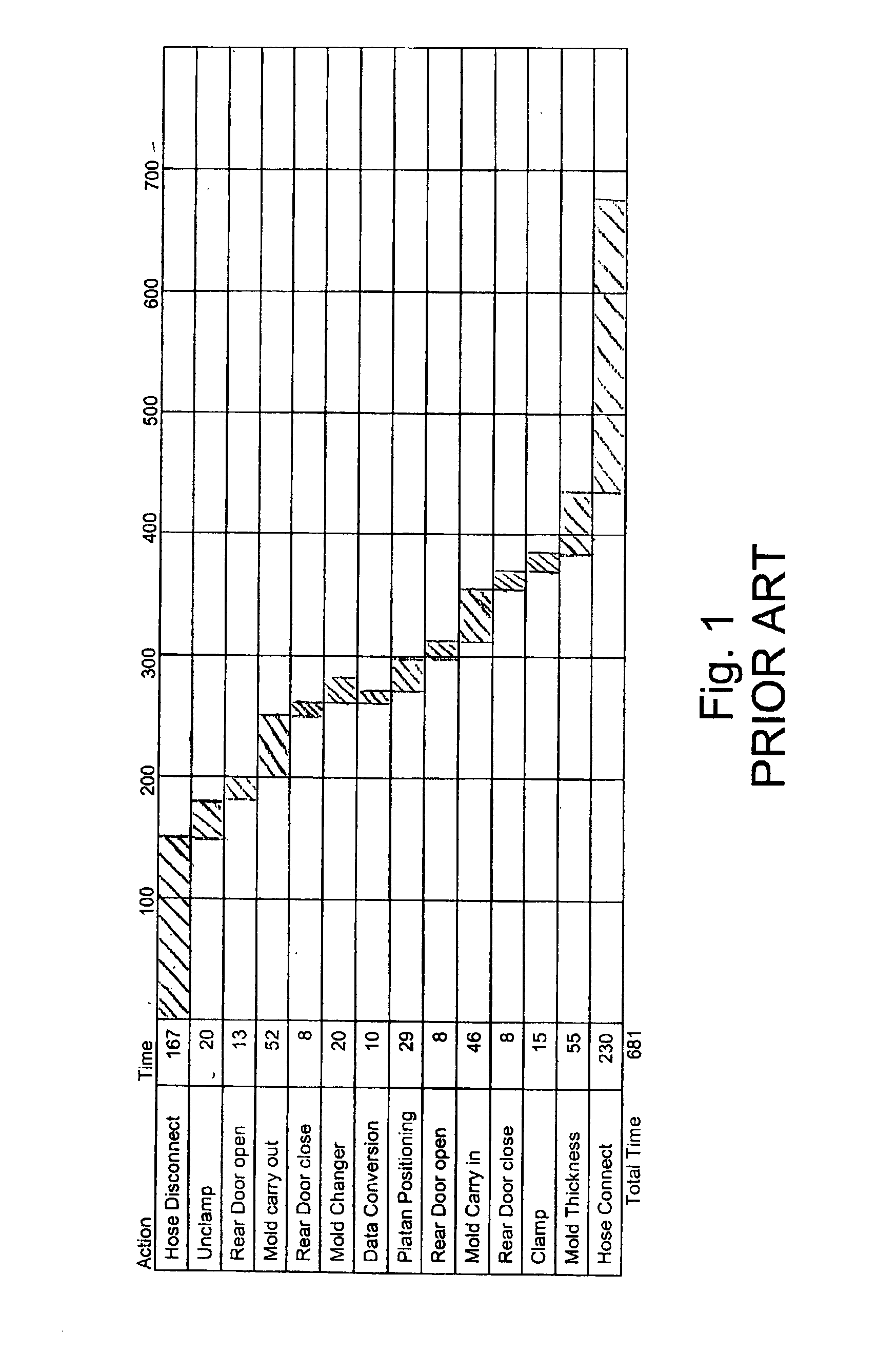

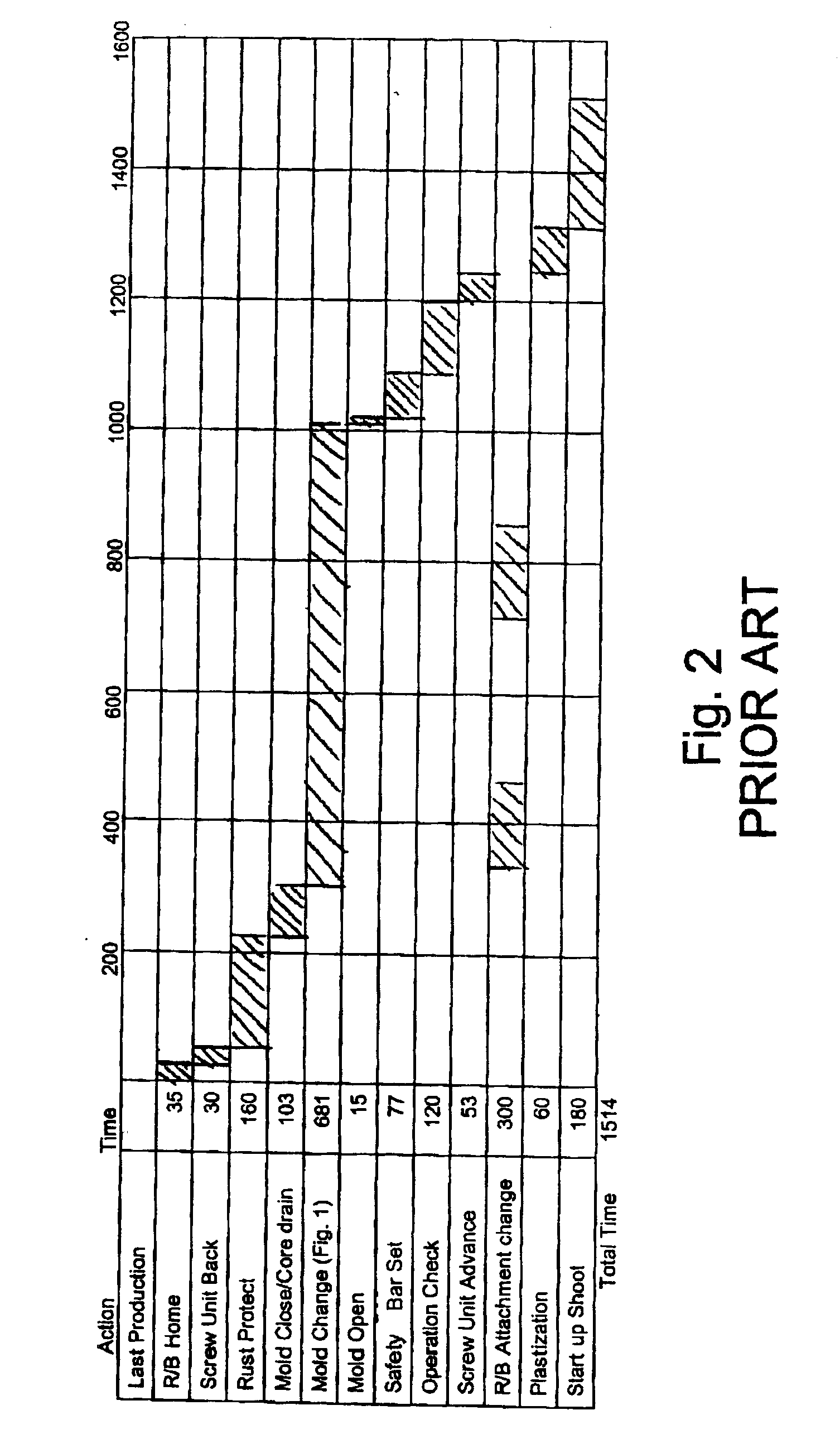

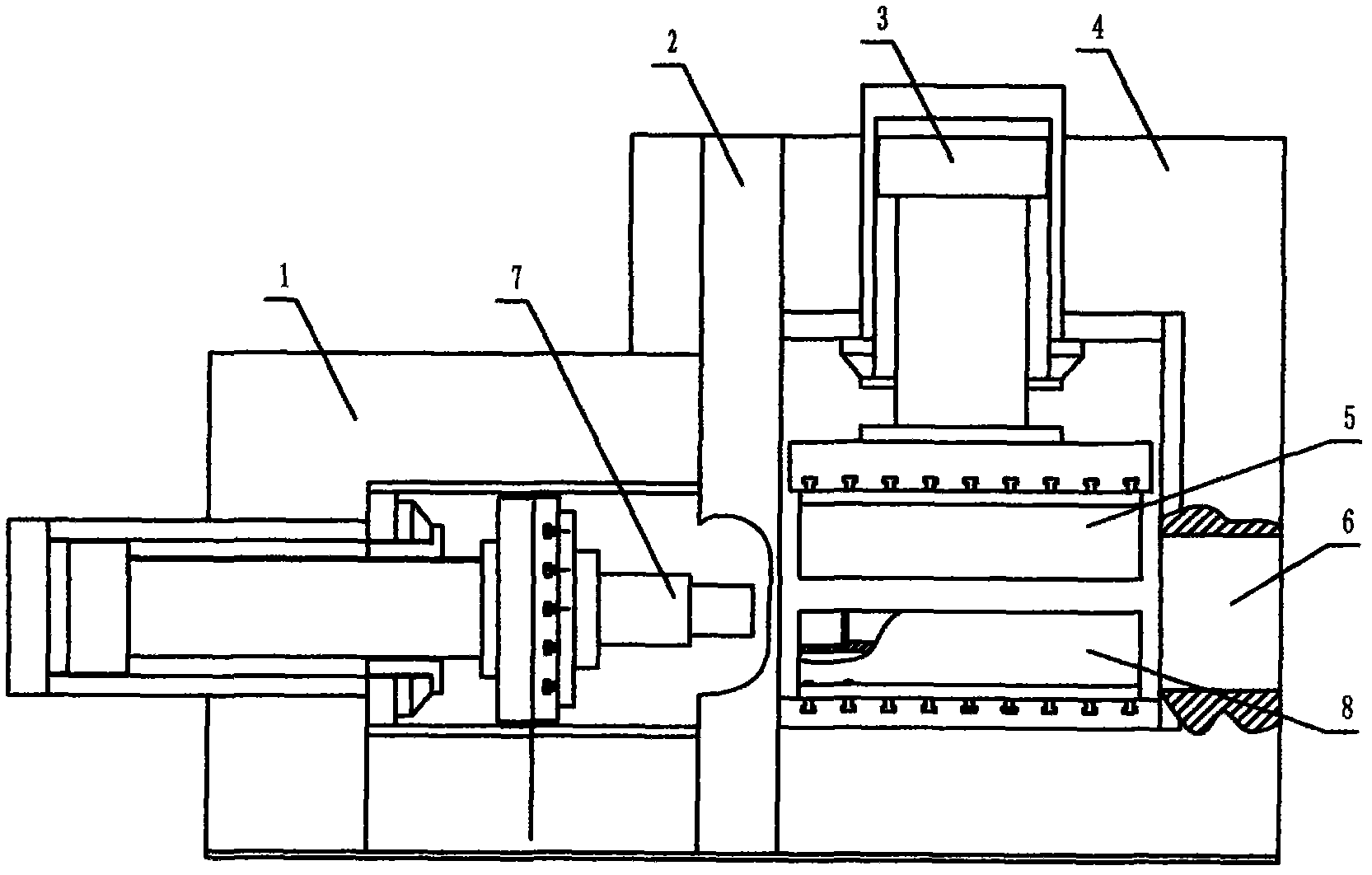

Injection mold machine with reduced mold change downtime

A die preparation and exchange method wherein dies to be inserted into an injection molding machine are electrically and fluidly heated prior to insertion so as to prepare the dies to make parts more quickly. The die exchange sequence wherein a first set of dies are removed from the machine and are replaced by a second set of dies has been changed from a generally serial sequence to a sequence wherein most steps are performed in parallel or simultaneously, greatly reducing the downtime associated with mold change.

Owner:HONDA MOTOR CO LTD

Pressure gel forming method for multi-winding current transformer

ActiveCN104299766AReduce labor intensityIncrease productivityTransformersInductances/transformers/magnets manufactureInjection pressureContraction rate

The invention discloses a pressure gel forming method for a multi-winding current transformer, and belongs to the technical field of electric manufacturing and electric equipment. According to the method, the traditional method that multiple windings are shielded respectively in a device correcting process is improved, the windings are combined and wrapped as a whole, and exhaust dead corners generated in the pouring process of the multi-winding current transformer are effectively avoided. In a transformer die preparation process, temperatures of different parts of a die are set, so that it is guaranteed that the curing process of gel materials which are injected firstly and the curing process of gel materials which are injected later basically keep consistent, and cracks generated due to an inconsistent curing contraction rate in the transformer are avoided. In the pressure gel forming process, viscosity of mixed materials is large, a certain period of time is needed when gas is exhausted from the inside of a product, and accordingly a staged material injection method is adopted. Besides, staged pressure maintaining can effectively avoid the situation that iron core magnetic permeability is reduced because of excessively large material injection pressure and accordingly error tests are not qualified, and therefore product quality and the pass percent are guaranteed.

Owner:STATE GRID CORP OF CHINA +1

Using method of multilayered micro-fluidic chip for detection

ActiveCN108704684AComplete specificationsEasy to assembleMaterial analysis by observing effect on chemical indicatorLaboratory glasswaresExperimental methodsEngineering

The invention provides a using method of a multilayered micro-fluidic chip for detection. The using method of the multilayered micro-fluidic chip for detection is characterized by comprising the following steps: first step, selecting the specification of the chip; second step, preparing the chip; third step, assembling and closing; fourth step, adding samples and detecting; and fifth step, disassembling and cleaning. The using method of the multilayered micro-fluidic chip for detection has the beneficial effects that the specifications of chips are numerous, requirements for simultaneous detection of multiple heavy metals can be met, the chip is assembled conveniently, and an experimental method is simple; and the chip is disassembled easily, a filter device and the like can be convenientto clean and change, and field detection is facilitated.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

Titanium alloy cylinder lock type folding system hot isostatic pressure forming method

The invention provides a titanium alloy cylinder lock type folding system hot isostatic pressure forming method. The method comprises the steps of die preparation, coating sleeve preparation and spherical powder selection, hot isostatic pressure pretreatment, hot isostatic pressure process control, aftertreatment and the like. According to the titanium alloy cylinder lock type folding system hot isostatic pressure forming method, when the hot isostatic pressure technology is adopted for solidifying and forming titanium alloy powder, the characteristics of a titanium alloy part are formed by adopting the way of matching an inner die and an external mold core, accordingly, characteristic forming can be completed, the part forming efficiency is improved, inner surface treatment in the later period is reduced, and the machining period is shortened.

Owner:BEIHANG UNIV

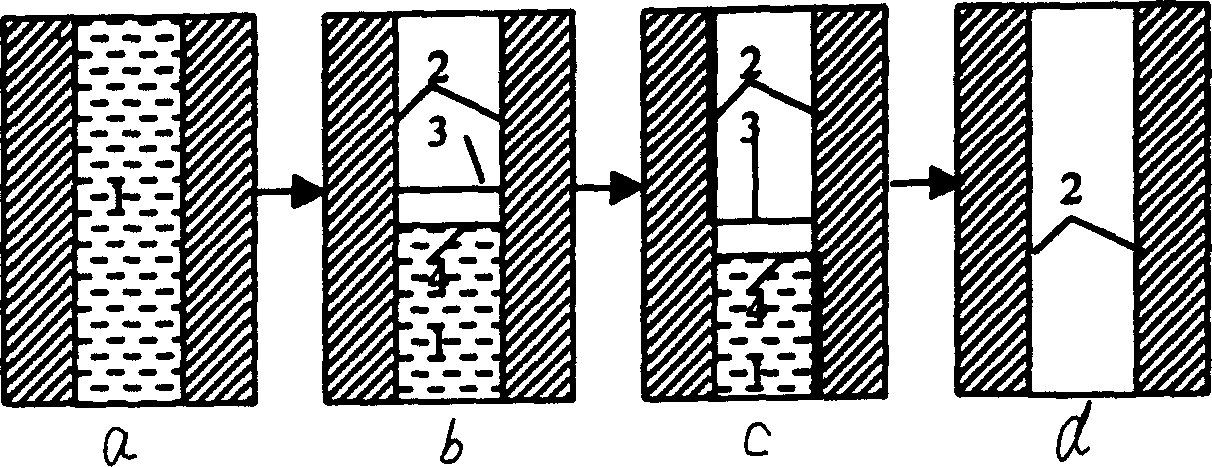

Preparation of ceramic coat die by static self-spreading method for ferrous metal semi-solid processing

InactiveCN1762618AHigh bonding strengthImprove thermal shock performanceFoundry mouldsFoundry coresCeramic coatingSemi solid

This invention relates to a static self contagious method to preparing ceramic coating die, which comprises the following steps: a, mixing the reaction raw material AL and Fe 203 powder; fill the die with the mixed powder, fixing the cavity die, skirt and duct together and cover the cap of the skirt and duct; b, preheating the die in the heater, taking the die out and setting vertical, moving the cap out; c, igniting the mixed powder, Al and Fe 203 will create thermite reaction, the product Fe and Al 203 will be in liquor condition, Al203 liquid phantom will adhere to the inner wall of the cavity die and crystallization, forming continuous coating lever in the inner wall; d, Fe liquor will curing at last, removing the Fe solid in the duct tube, cooling and removing the skirt and duct, getting the rough cavity die; e, abrasive machining the ceramic coating in the inner wall of the rough cavity die.

Owner:JIANGSU FASTEN TECH DEV CENT

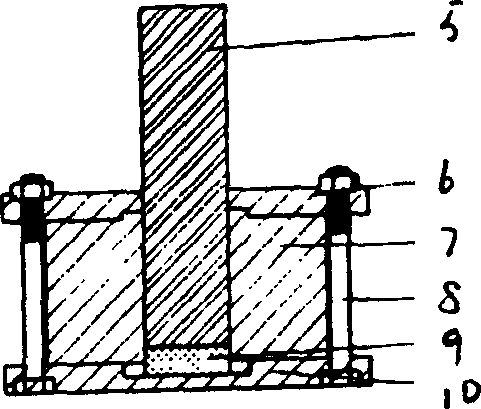

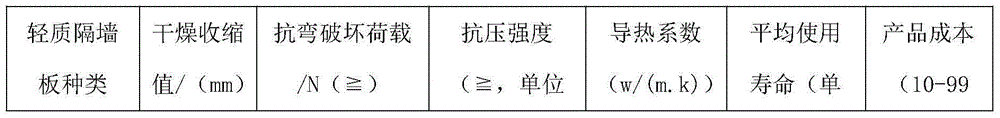

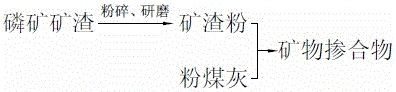

Light partition board and preparation method thereof

InactiveCN105062111AMeet lightweight requirementsImprove stress resistanceConstruction materialSlagSlurry

The invention discloses a light partition board, which is prepared from the following raw materials by mass: 10-12 parts of glass fiber, 55-60 parts of iron slag powder, 20-24 parts of fly ash, 30-35 parts of quartz sand, 180-200 parts of magnesium oxide, 12-15 parts of calcium carbonate, 15-20 parts of sodium carbonate, 2-3 parts of ferrous sulfate, and 30-35 parts of modified sawdust powder. The preparation method includes making of modified sawdust powder, making of slurry, die preparation, molding curing and die release. The invention aims to provide a foamed light partition board and a preparation method thereof. The light partition board has the advantages of high strength, low cost, and long service life. The preparation method selects conventional equipment, is simple and easy to operate, and can be exclusively used in processing of the light partition board provided by the invention.

Owner:重庆市泰日建材有限公司

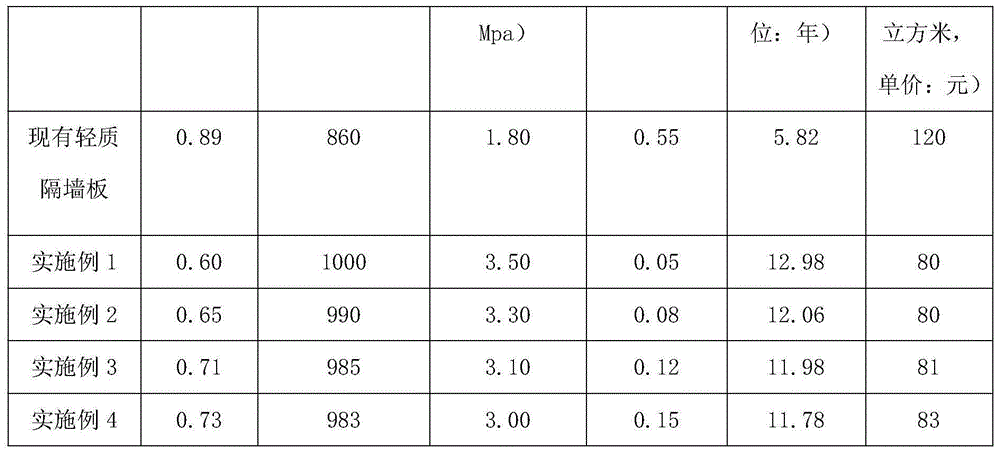

Method for manufacturing thyratron transistor door-pole and cathode isolation

InactiveCN1828847AAvoid damageImprove reliabilitySemiconductor/solid-state device manufacturingThyratronVaporization

The present invention discloses a thyristor gate polar and cathode isolative manufacturing method. It contains thyristor chip preparation, testing and packaging, making mask block piece and packaging gasket, installing mask block piece, installing chip by alignment of mask graphic, first vaporization, taking off mask block piece and chip, installing chip once more, a second time vaporization, general technology annealing, etching, floor molding and protecting, and installing package gasket to prevent electromigration before packaging. Said invention adopts mask, vaporization and photetch combined technique without sticking cathode conducting strip to realize gate polar, amplification gate polar and cathodal isolation, effectively preventing device damage in thereafter testing packaging process.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD

Forming process of large-diameter piston plug, step shaft or oil cylinder and processing equipment thereof

The invention discloses a forming process of a large-diameter piston plug, a step shaft or an oil cylinder and processing equipment thereof. The forming process comprises the following steps of adopting gradient pretreatment, split die preparation, die applying, heat extrusion and die opening, applying horizontal heat extrusion on a to-be-processed workpiece in the premise of radial load, and completing the heat extrusion heading process of the to-be-processed workpiece. The forming process and the processing equipment have the advantages that the deformation of the workpiece is sufficient and accurate, one part of a transition area has the complete metal flow line, and the processing quality is stable and reliable; meanwhile, the layout of a horizontal loading hydraulic machine and a vertical loading hydraulic machine which are supported by a gantry framework is reasonable, the structure is stable, the convenience in use is realized, and the flat-pushing heat extrusion process under the condition of large load is effectively ensured; and the forming process and the processing equipment are particularly suitable for the heat extrusion heading of the large-diameter piston plug, the step shaft or the oil cylinder.

Owner:雷中坤

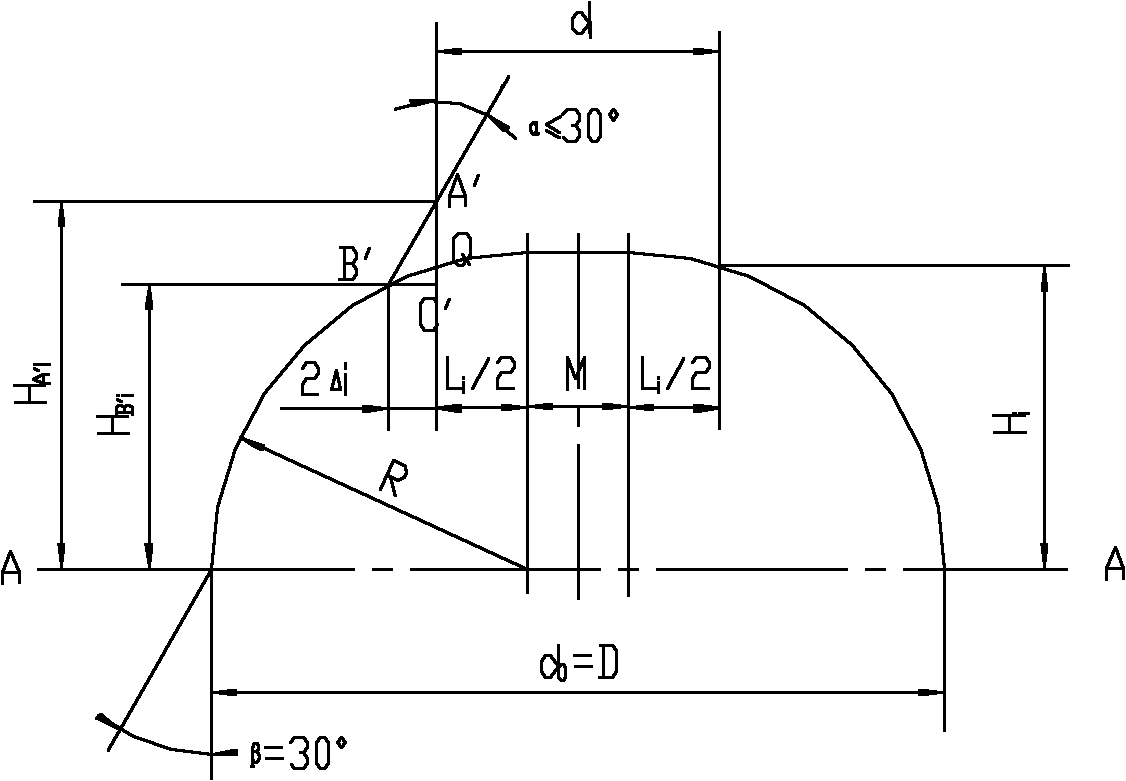

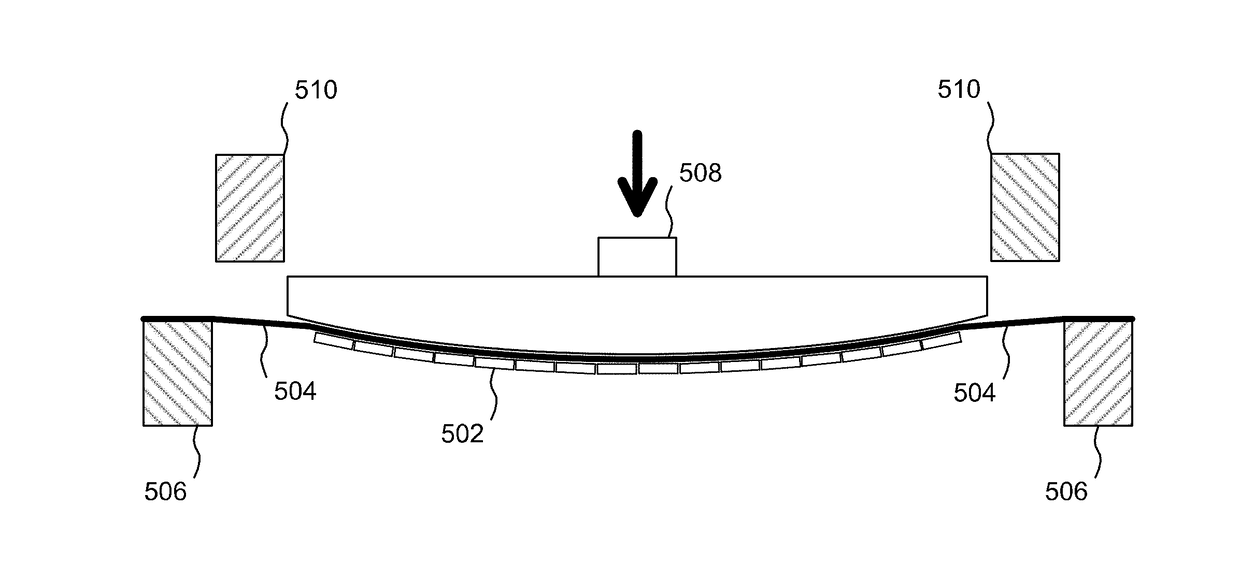

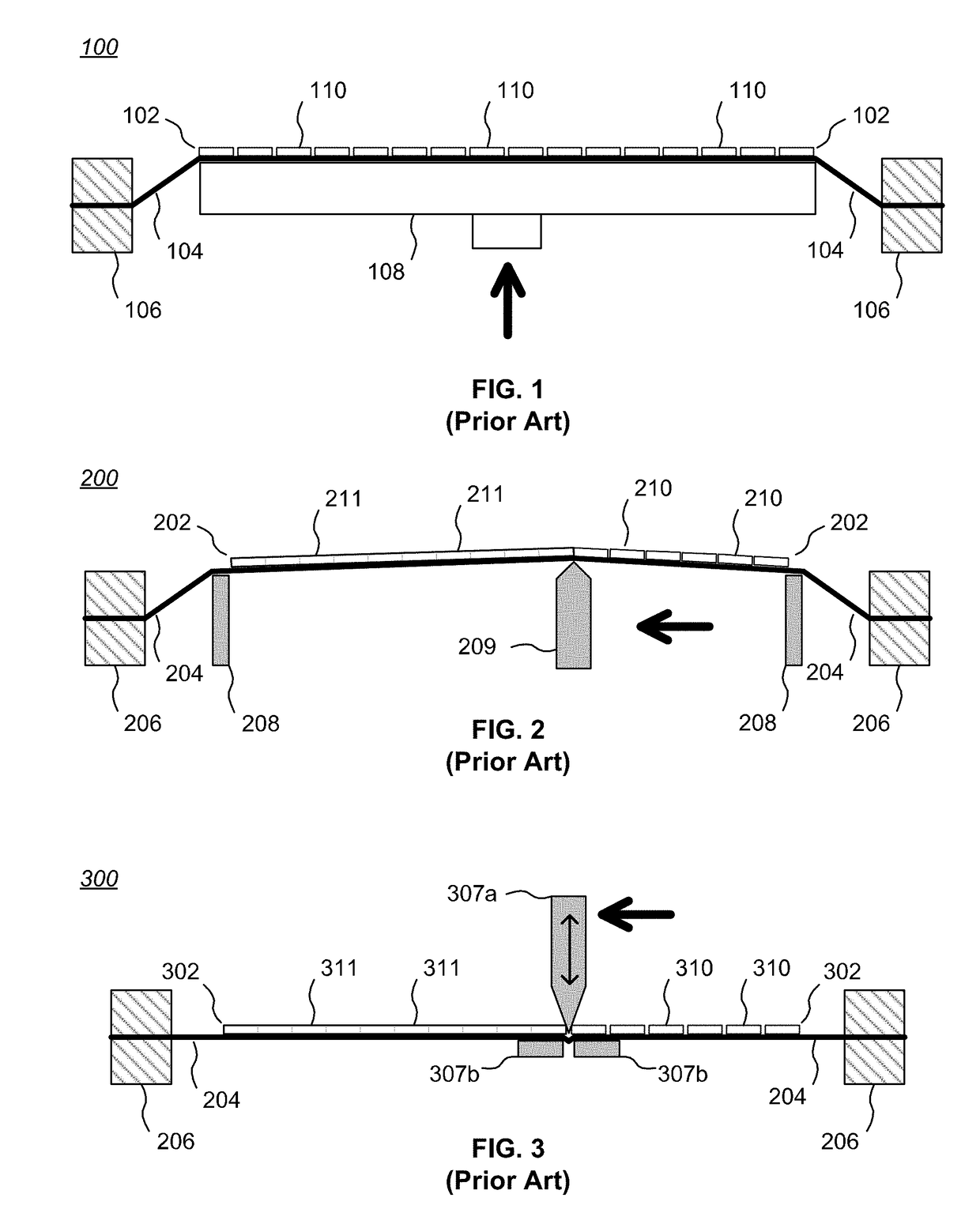

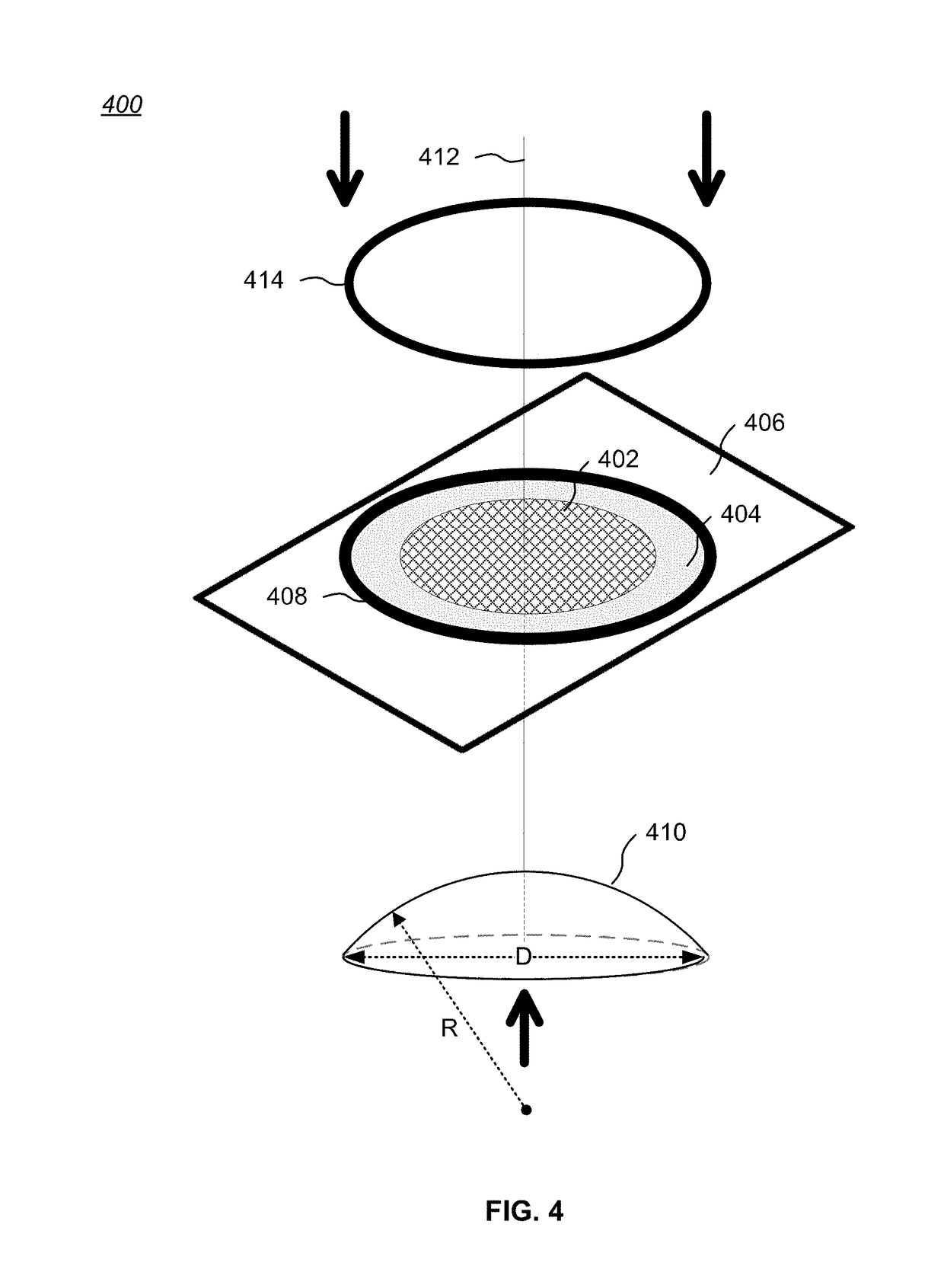

Simultaneous Break and Expansion System for Integrated Circuit Wafers

InactiveUS20180323105A1Reduce and eliminate die collisionConvenience to workSolid-state devicesSemiconductor/solid-state device manufacturingDicing tapeEngineering

Improved methods and apparatuses for singulating integrated circuit (IC) dies that reduce or eliminate die collisions and work well with very small dies. Embodiments simultaneously separate dies in two dimensions by utilizing a break and expansion system that avoids die collisions by maintaining IC die separation after singulation. Singulation is achieved by placing the joined dies of the wafer substrate on a dicing tape, scoring the wafer substrate between the joined dies, and imposing a bending action by pressing a curved surface against the scored wafer substrate, which also expands the wafer substrate by stretching the dicing tape. After breaking, an inner expansion grip ring is pressed into an outer expansion grip ring in a nested configuration so as to maintain the stretched state of the dicing tape after the curved surface is fully removed, thereby maintaining the dicing tape in tension and the singulated die in spaced apart relation.

Owner:PSEMI CORP

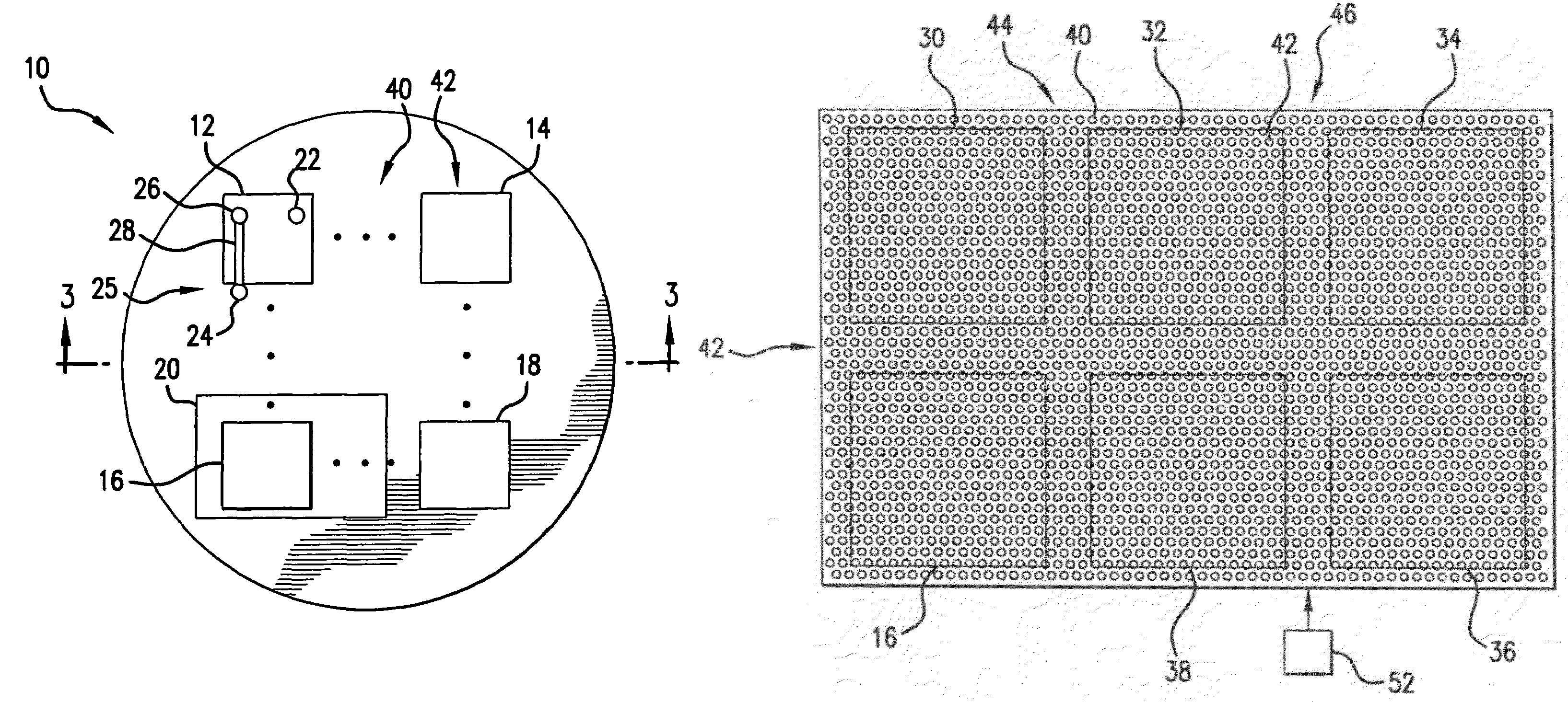

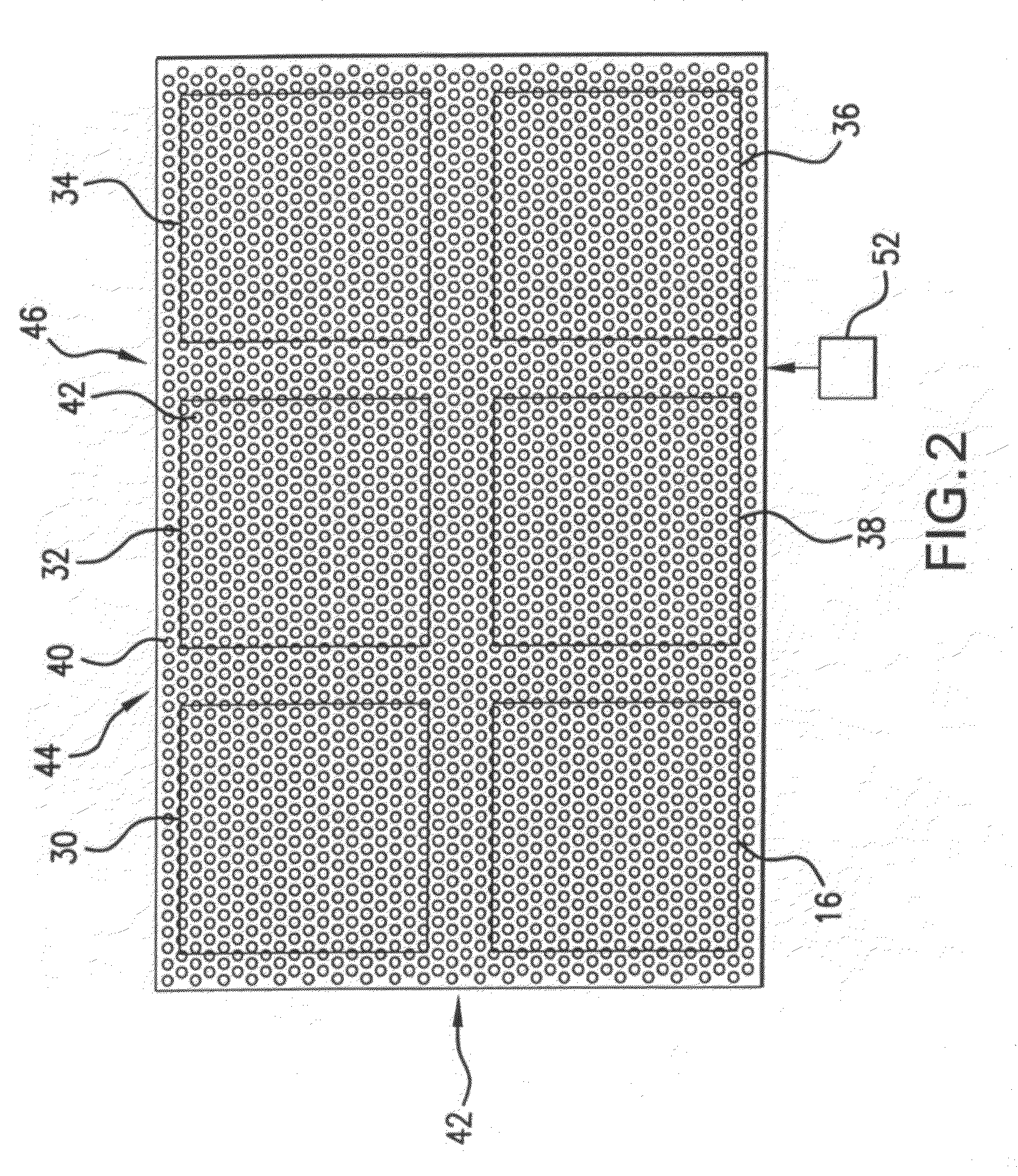

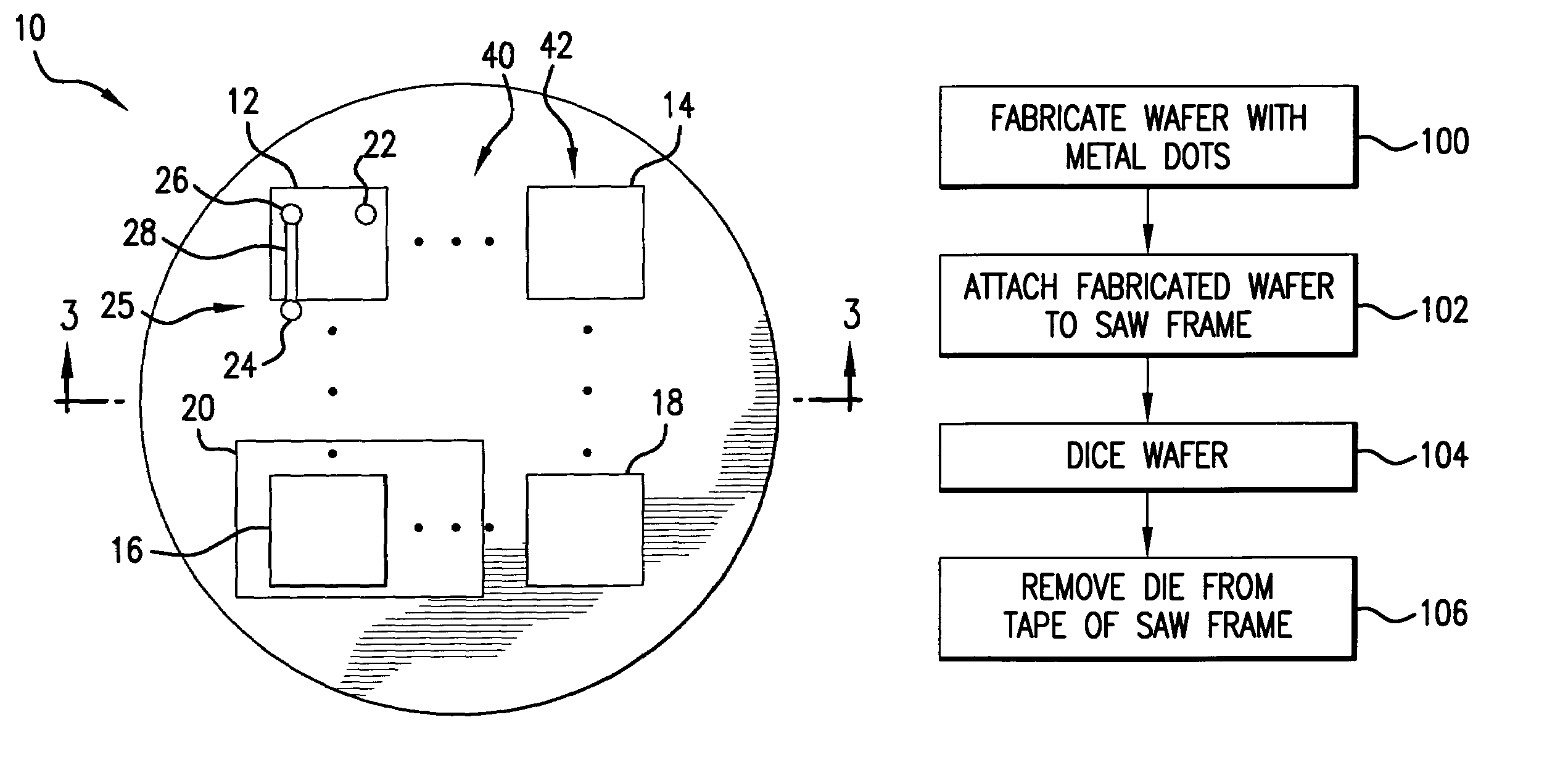

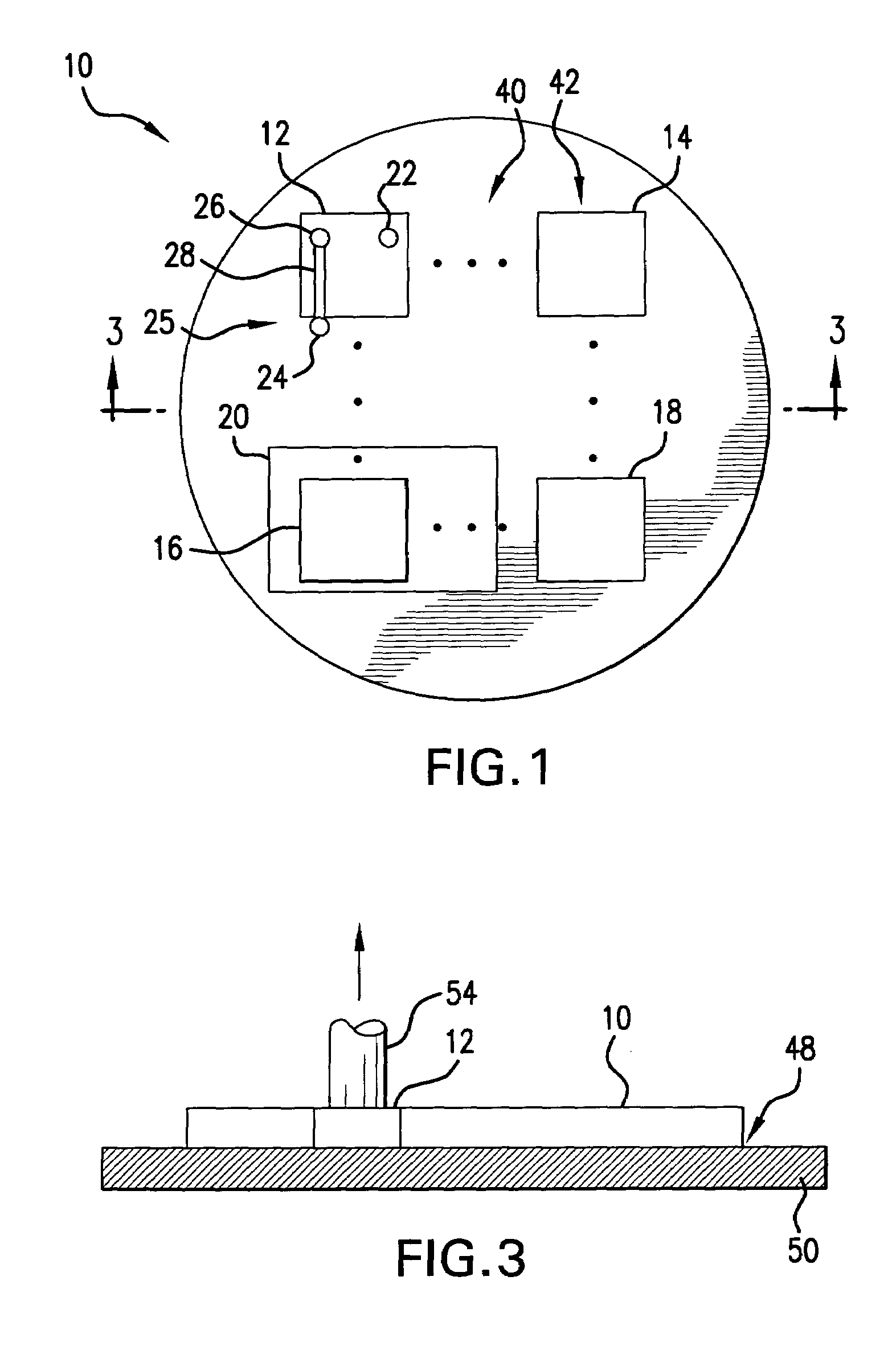

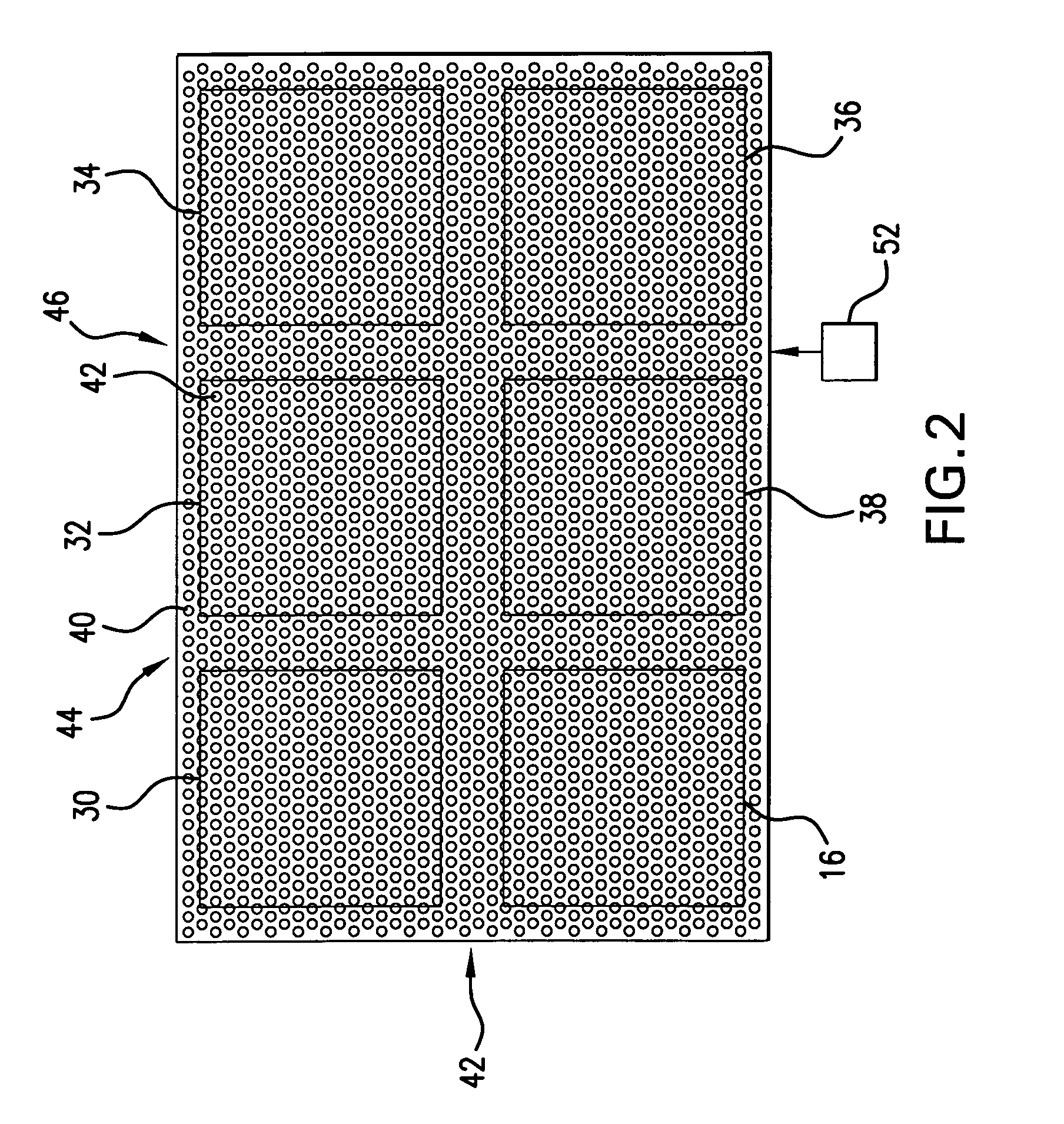

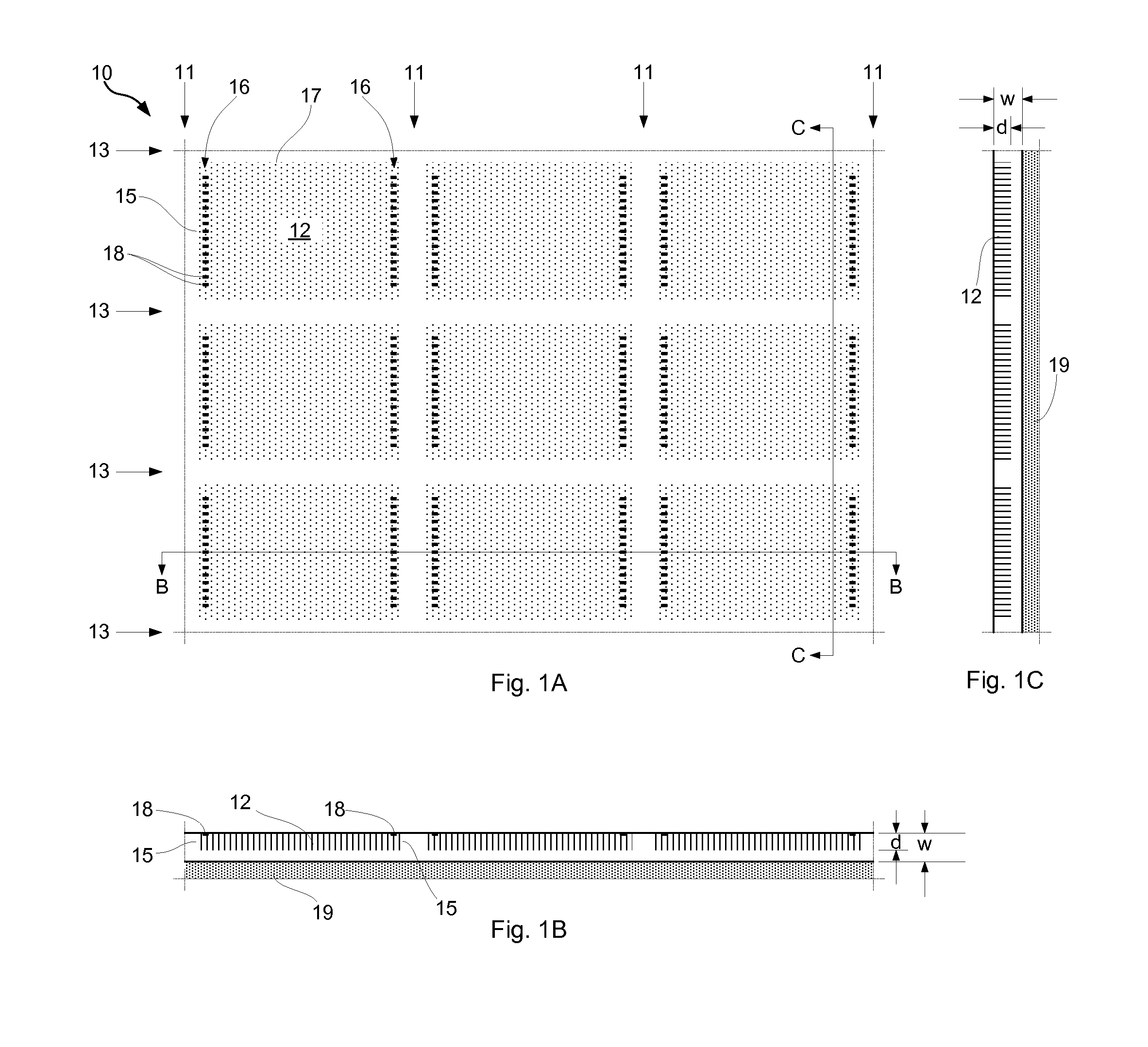

Deposition pattern for eliminating backside metal peeling during die separation in semiconductor device fabrication

A semiconductor wafer that includes a plurality of groups of active devices or circuits on a first side of the wafer and a patterned electrical contact on the backside of the wafer. Each group consisting of an active device or circuit is intended to be diced into a discrete chip. The backside of the wafer includes a metal layer patterned into discrete spaced-apart deposits that form an electrical contact to the semiconductor and the respective group of active devices. The deposits are not contiguously or laterally connected to each other and function to protect the metal layer from peeling or detaching from the wafer during dicing of the semiconductor wafer into chips.

Owner:SUMITOMO ELECTRIC DEVICE INNOVATIONS U S A

Method for eliminating backside metal peeling during die separation

ActiveUS7198988B1Avoid mechanical damageSemiconductor/solid-state device detailsSolid-state devicesElectrical connectionSemiconductor

A method of protecting metal traces and contacts on a fabricated semiconductor wafer from mechanical damage during dicing of the fabricated wafer, where the metal traces and contacts form electrical connections with an active device region of the semiconductor. The method includes the steps of providing a group of discrete metal deposits adjacent the metal traces and contacts, wherein said metal deposits are substantially not contiguously connected to each other or to any traces or contacts of the active device regions of semiconductor die, attaching the fabricated wafer to an adhesive tape used for securing the fabricated wafer during a die separation process, separating the die from the fabricated wafer while attached to the adhesive tape and removing the die from the adhesive tape.

Owner:SUMITOMO ELECTRIC DEVICE INNOVATIONS U S A

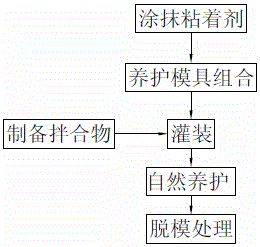

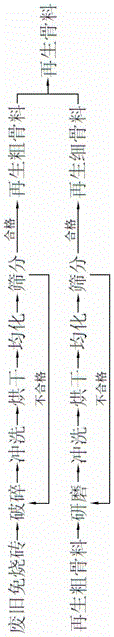

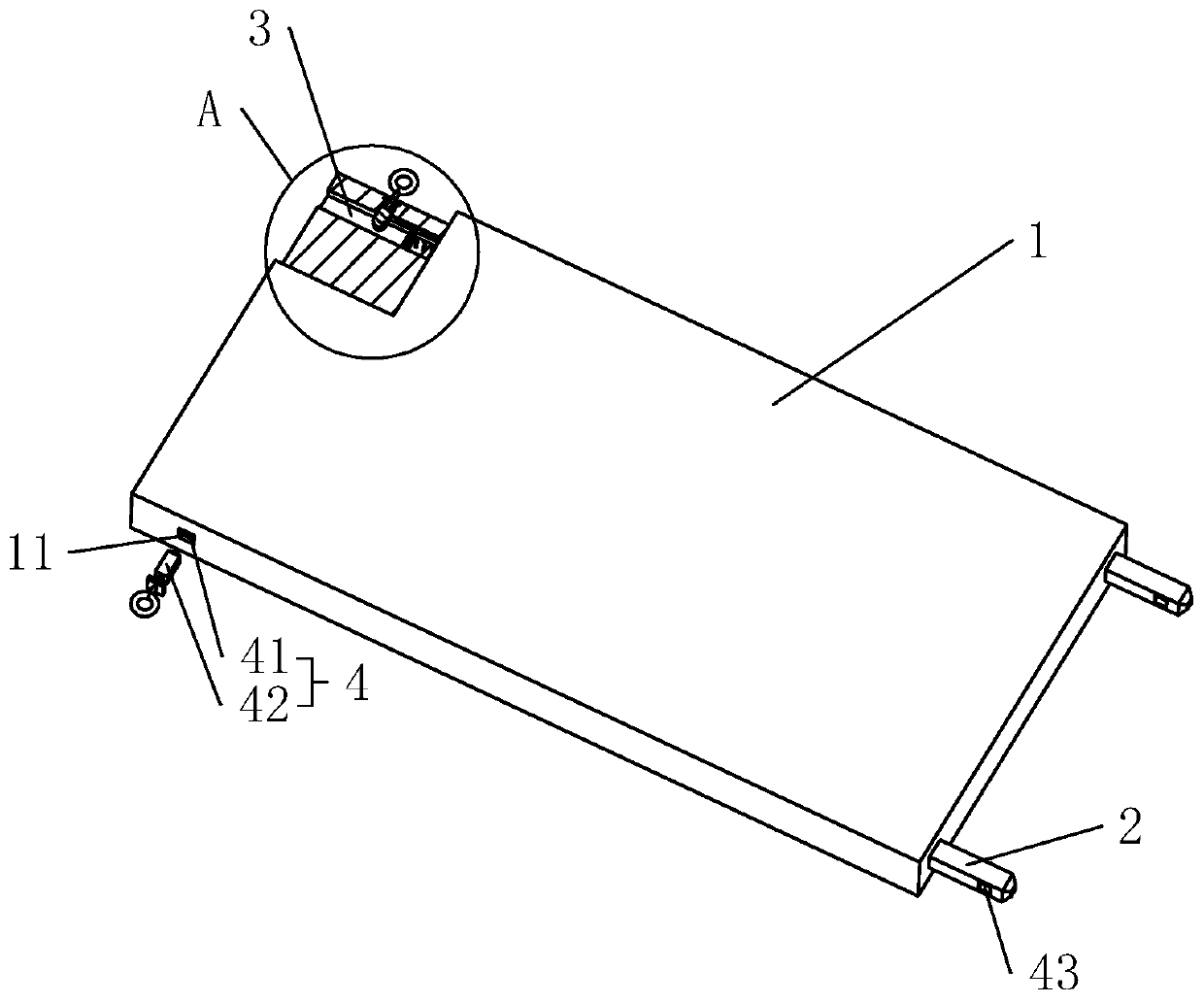

Method used for preparing test dies with recycled aggregate concrete

ActiveCN106746824AGuaranteed surface qualityReduce roughnessSolid waste managementMouldsAdhesiveConstruction aggregate

The invention belongs to the field of preparation of building test dies, and especially relates to a method used for preparing test dies with recycled aggregate concrete. According to the method, a die assembly used for preparing dies is prepared; a preparation space is arranged in the die assembly; the size of the preparation space matches that of a standard die; the standard die is used for preparing standard test blocks. The method comprises following steps: 1, smearing of an adhesive; 2, nourishing of the die assembly; 3, preparing of a mixture; 4, filling; 5, natural curing; and 6, demoulding. According to the method, recycled aggregate concrete is used in die preparation for the first time, and technical problems in direct application of common recycled aggregate concrete in die preparation, such as rough die surfaces, poor test block surface quality, and inaccurate testing results, are avoided.

Owner:四川明誉防水工程有限公司

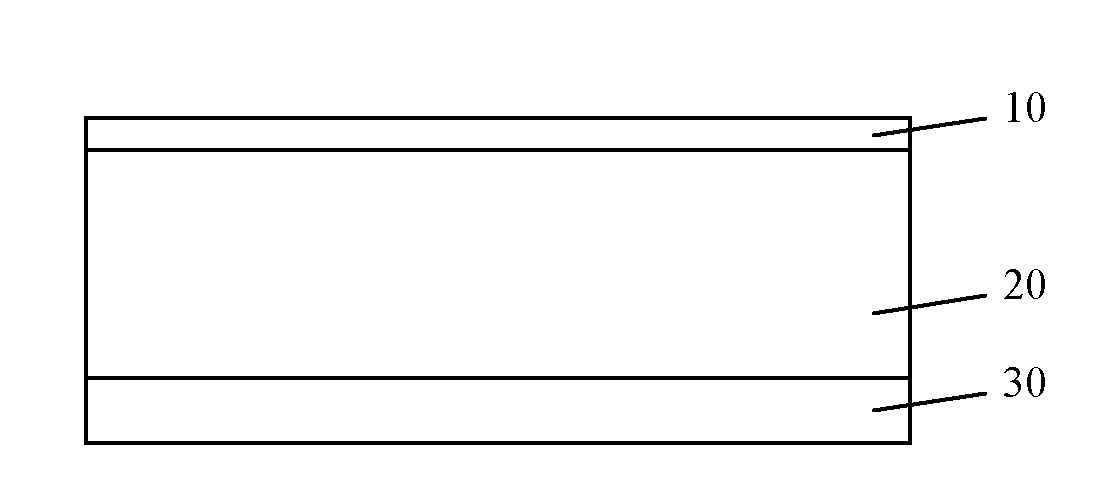

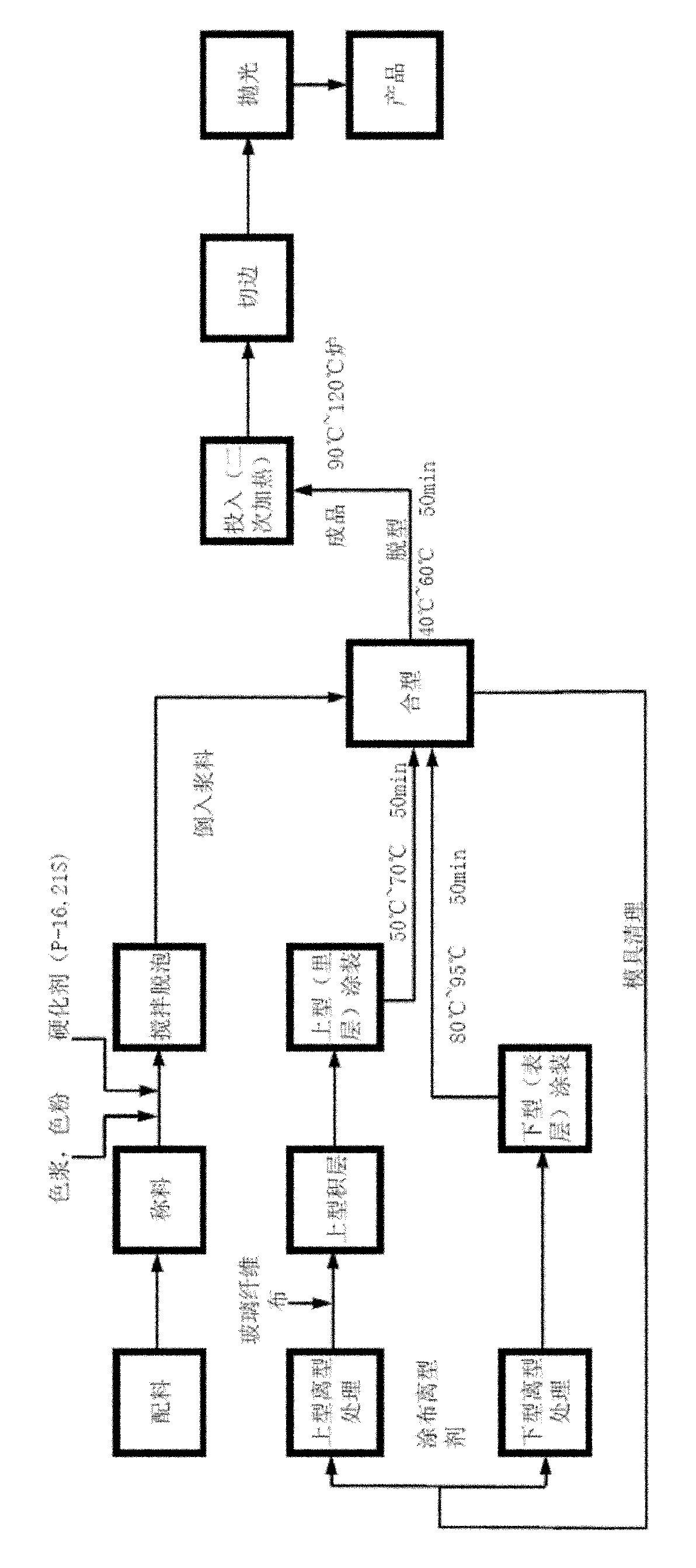

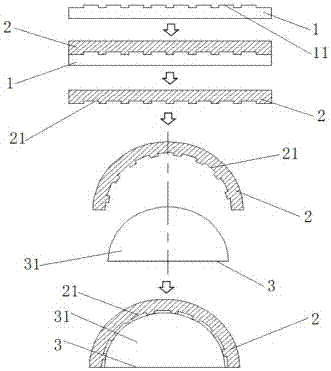

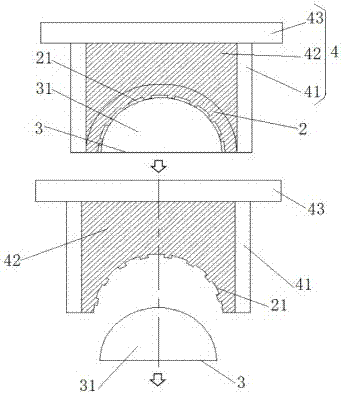

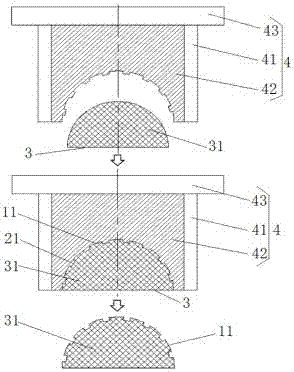

Imitation marble and method for manufacturing bathroom equipment by using same

InactiveCN101954769BTightly boundImprove waterproof performanceSynthetic resin layered productsCoatingsSurface layerBathroom Equipment

Owner:YAMAMOTO SANITARY FUJIAN

Method and device for three-dimensional curved surface nano imprinting, and die preparation method

PendingCN108008599AGraphic transfer with high precisionExtended service lifePhotomechanical apparatusMicro structureAdhesive

The invention provides a method and a device for three-dimensional curved surface nano imprinting, and a die preparation method, relating to nano imprinting. The nano imprinting device comprises a mother template, a base, a PDMS adhesive layer, and a holding mechanism, wherein a set concave-convex shape is arranged at the top of the mother template, an imprinted three-dimensional curved surface isarranged at the top of the base, the bottom surface of the PDMS adhesive layer and the top of the mother template are cured and then cover the imprinted three-dimensional curved surface, the holdingmechanism is but-jointed and cured with the PDMS adhesive layer covering the imprinted three-dimensional curved surface, so as to cure the bottom surface of the PDMS adhesive layer to obtain an imprinting die imprinting the set concave-convex shape onto the imprinted three-dimensional curved surface, so that the set concave-convex shape is imprinted onto the imprinted three-dimensional curved surface, that is, a micro-structure is imprinted onto a base of the curved surface.

Owner:GERMANLITHO CO LTD

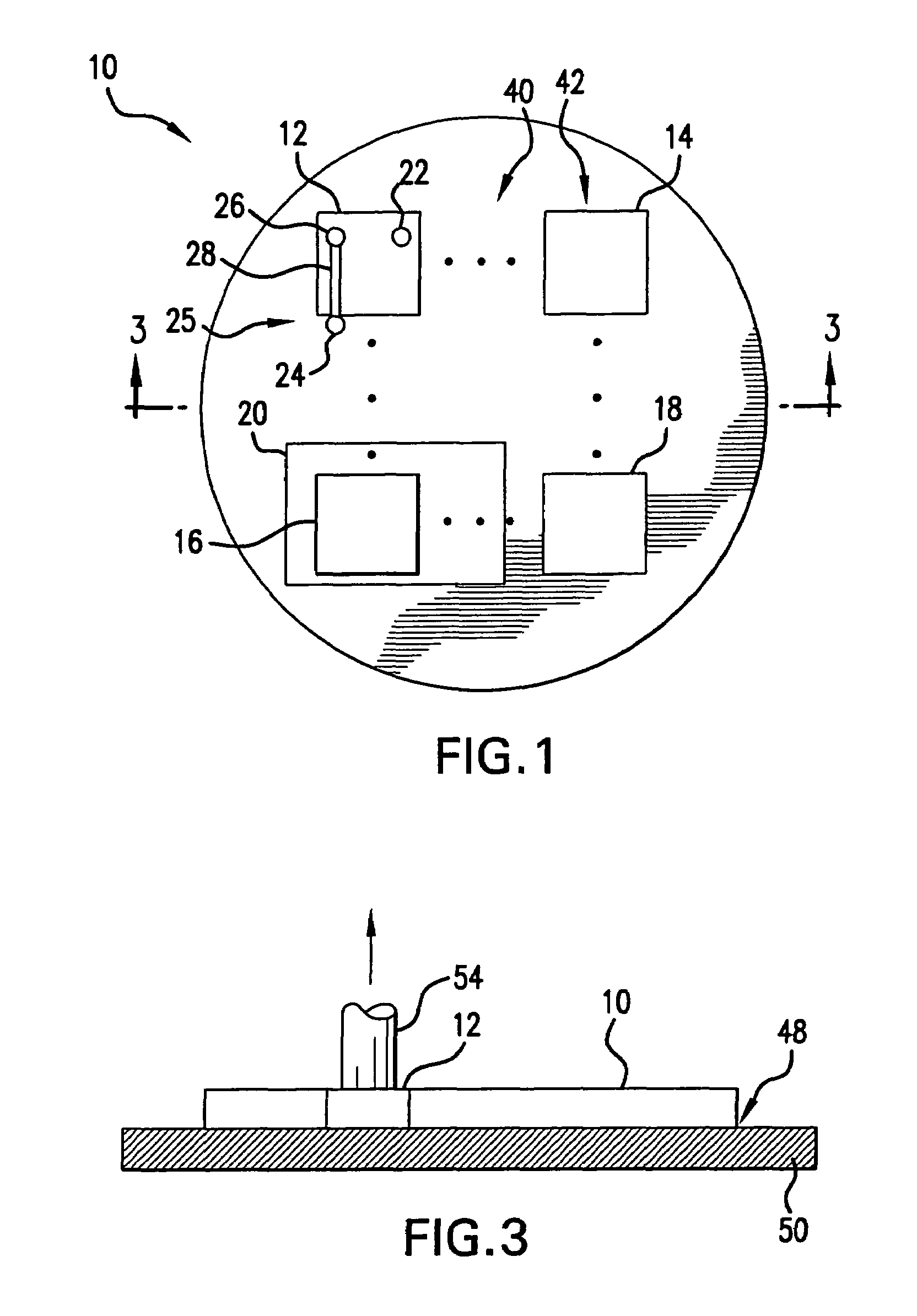

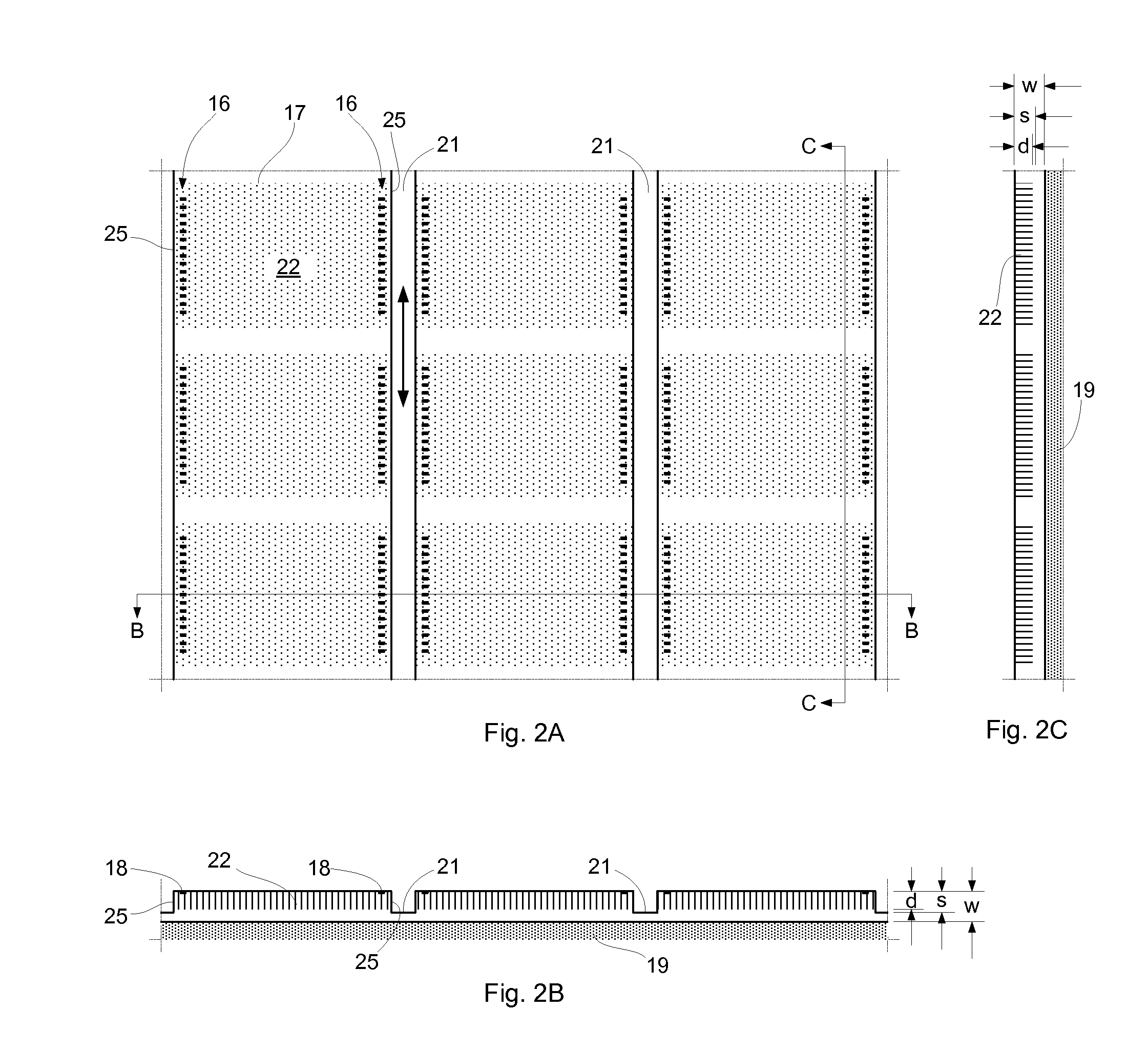

Semiconductor die array structure

ActiveUS8884403B2Die shift is reduced or substantially eliminatedSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipDie preparation

According to the invention, die shift is reduced or substantially eliminated, by cutting the wafer in two stages. In some embodiments a first wafer cutting procedure is carried out prior to thinning the wafer to the prescribed die thickness; and in other embodiments the wafer is thinned to the prescribed die thickness prior to carrying out a first wafer cutting procedure. The first wafer cutting procedure includes cutting along a first set of streets to a depth greater than the prescribed die thickness and optionally along a second set of streets to a depth less than the die thickness. The result of the first cutting procedure is an array of strips or blocks of die, each including a plurality of connected die, that are less subject to shift than are individual singulated die. In a second wafer cutting procedure the die are singulated by cutting through along the second set of streets. Subsequent to the first cutting procedure, and prior to the second cutting procedure, additional die preparation procedures that are sensitive to die shift may be carried out.

Owner:INVENSAS CORP

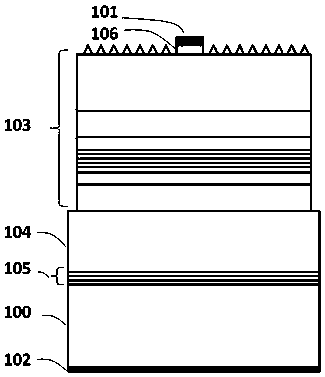

Preparation method of AlGaInP thin film LED chip dicing line

InactiveCN107731676AProtect your healthProtect environmentSemiconductor/solid-state device manufacturingSemiconductor devicesBromineEpitaxial material

The invention discloses a preparation method of an AlGaInP thin film LED chip dicing line. The method comprises the steps that an AlGaInP LED epitaxial material is prepared by a conventional MOCVD, and then the epitaxial material is transferred onto a bond substrate by using conventional die preparation processes such as metal evaporation, photoetching, corroding, bonding and alloying to prepare the AlGaInP thin film LED chip with N light-emitting sides; before the AlGaInP thin film LED chip is cut and separated, a photoetching process is used to protect the area other than a dicing line witha photoresist; the AlGaInP thin film LED chip to be cut is put into a dicing line corrosive liquid prepared from aqueous solution of iodic acid, hydrochloric acid and water to corrode the epitaxial material in the corresponding area of the dicing line to prepare the dicing line; and finally, a laser dicing machine or an abrasive wheel dicing machine is used to separate the AlGaInP thin film LED chip along the centerline of the dicing line. According to the invention, the method has good stability and consistency; and the dicing line corrosive liquid is free of highly toxic elemental bromine, which is beneficial to the health of craftsmen and environmental protection.

Owner:NANCHANG UNIV +1

Method for manufacturing die through silica gel

The invention belongs to the technical field of die preparation, and particularly relates to a method for manufacturing a die through silica gel. The method comprises the specific steps that 1, a female die is manufactured, i.e., the female die is in a basic shape of a formed tin product and is used for manufacturing a pattern die; 2, the pattern die is manufactured by printing patterns on the outer wall of the female die onto the inner wall of a die sleeve through the female die; and 3, silica gel compounds are prepared, and after a tin blank is put into the die sleeve, the interval between the tin blank and the die sleeve is filled with the silica gel compounds and the silica gel compounds are made to cover the outer wall of the tin blank, wherein the silica gel compounds comprise, by mass, 80-90 parts of the silica gel and 0.5-2.5 parts of paliurus ramosissimus. Compared with the prior art, the method for manufacturing the die through the silica gel is high in efficiency and large in production scale, the obtained tin product is smooth and clean in surface and free of parting surfaces, and neither reprocessing nor less processing is not needed.

Owner:DAYU DONGHONG TIN PROD CO LTD

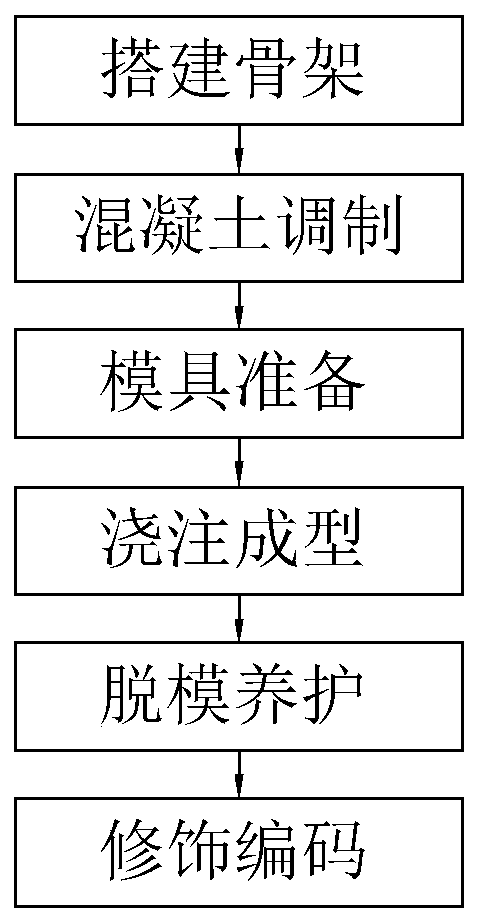

Production technology and product of prefabricated bridge slab

ActiveCN109732771AWon't breakAvoid damageCeramic shaping apparatusBridge structural detailsBrickCoal

The invention discloses a production technology and a product of a prefabricated bridge slab, and relates to building technology in order to solve the problem of damage to the environment due to adoption of bricks for construction. The production technology comprises steps as follows: building of a framework; concrete mixing; die preparation; casting formation; demoulding maintenance; modifying and coding. The production technology and the product of the prefabricated bridge slab have advantages and effects as follows: clay is not needed in the production process of the technology, damage to fields cannot be caused, a coal firing mode is also not needed for solidifying formation of the bridge slab, so that compared with clay and bricks, damage to the fields and atmosphere can be reduced, and purpose of energy conservation and emission reduction are achieved.

Owner:浙江大经住工科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com