Forming process of large-diameter piston plug, step shaft or oil cylinder and processing equipment thereof

A forming process and step shaft technology, applied in the field of metal forging processing, can solve the problems of inability to meet the processing needs of large-diameter piston plugs or stepped shafts, complex processing technology, high cost, etc., and achieve simple demolding and product quality. Stable, fully deformed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

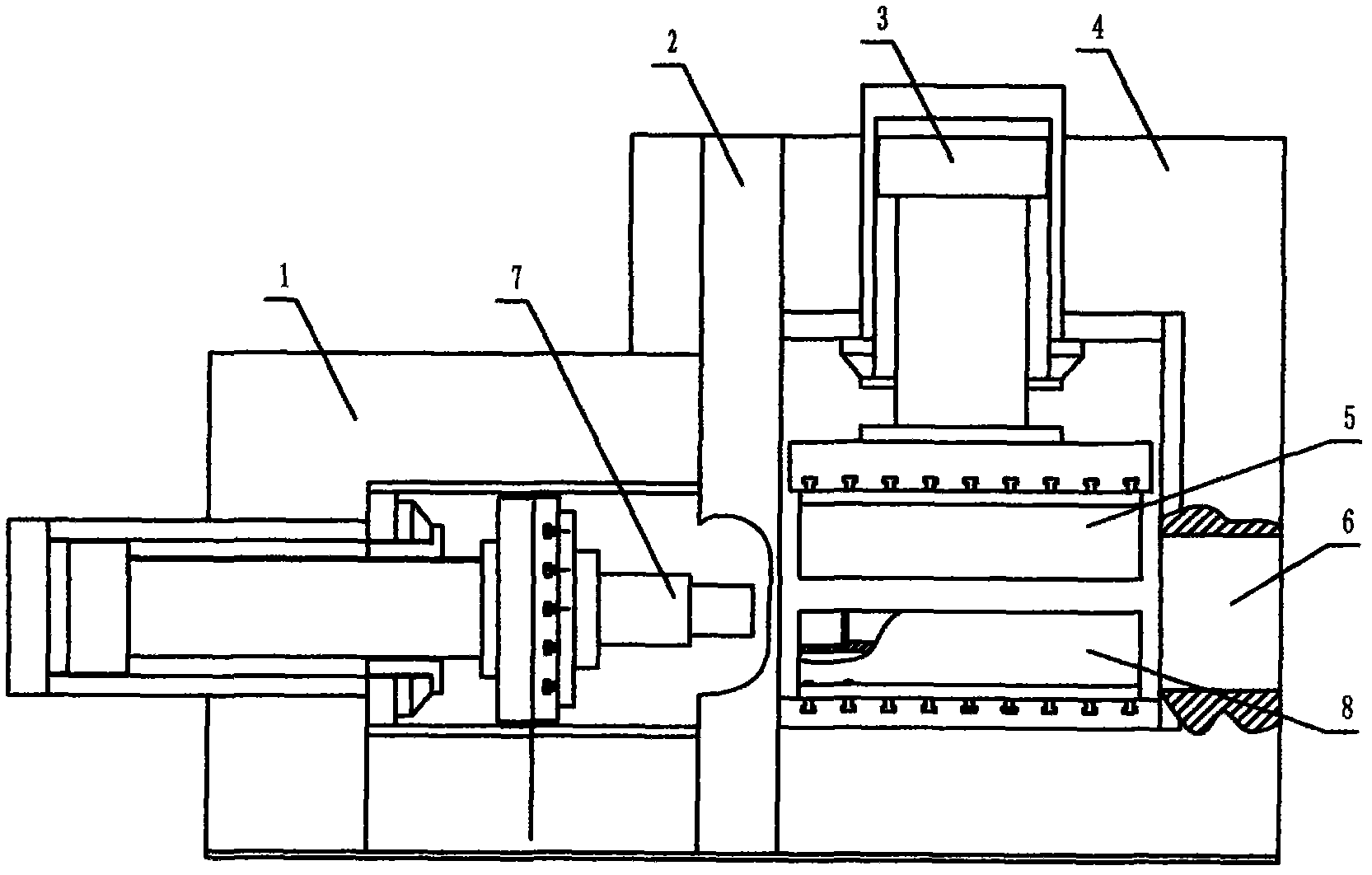

Image

Examples

Embodiment Construction

[0025] Taking the hot-extruded hydraulic press processing piston plug head of the 'back'-shaped vertical frame as an example, a further description is made of a large-diameter piston plug head, step shaft or oil cylinder forming process according to the present invention:

[0026] Step 1. Pretreatment of the piston plug head

[0027] First, use the first intermediate frequency heating furnace in the parallel intermediate frequency double furnace body to locally heat the piston to be processed. The local heating position is located at 1 / 2 the length of the piston plug head processing deformation zone and the transition zone length of one diameter. The heating temperature Control at 600-700°C; then, put all the parts of the piston that need to be heated into the second intermediate frequency heating furnace for overall heating, and make the heating temperature reach the initial forging temperature, thereby forming a gradient temperature, that is, the temperature of the deformatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com