Patents

Literature

479 results about "Process improvement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

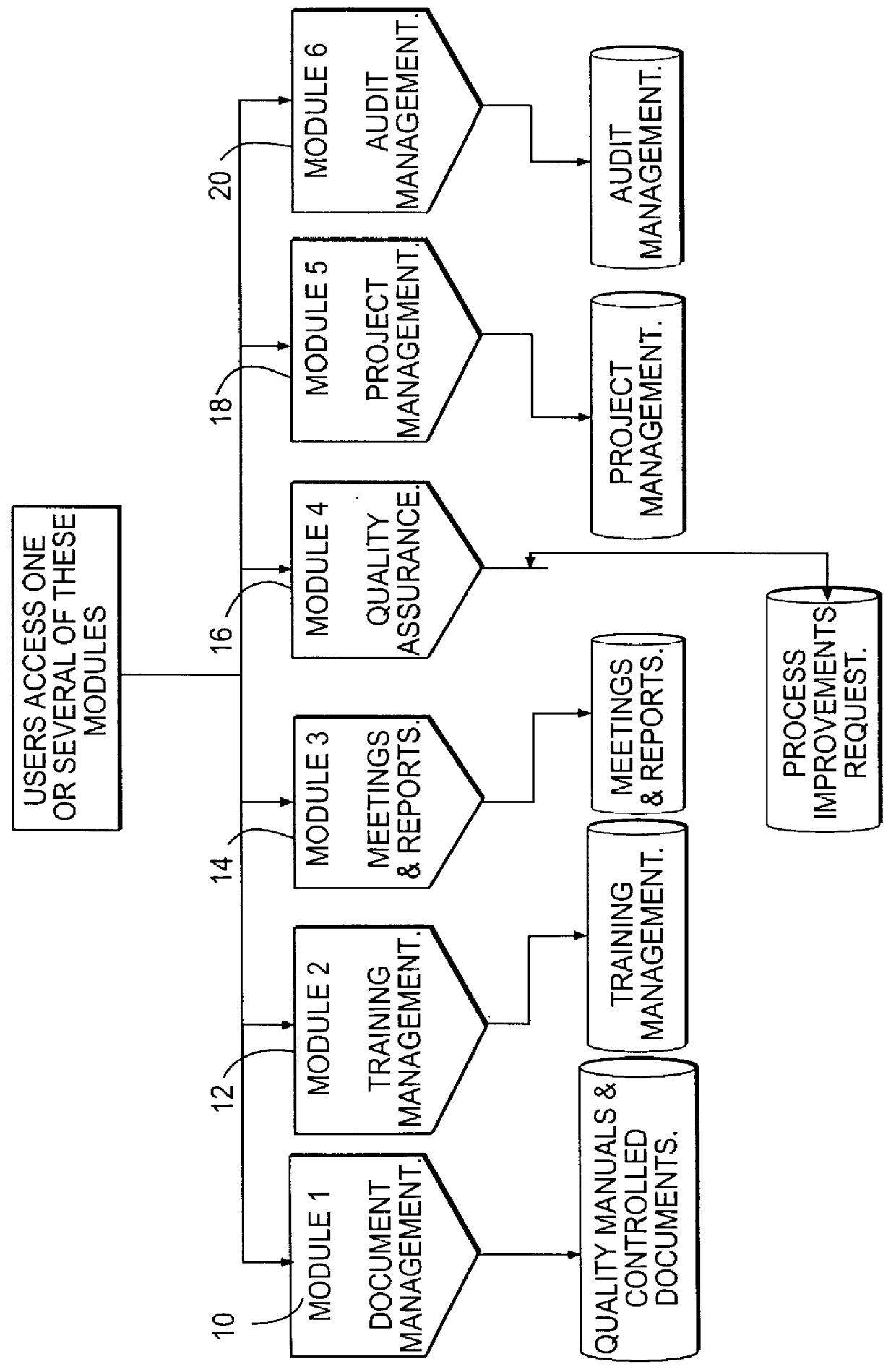

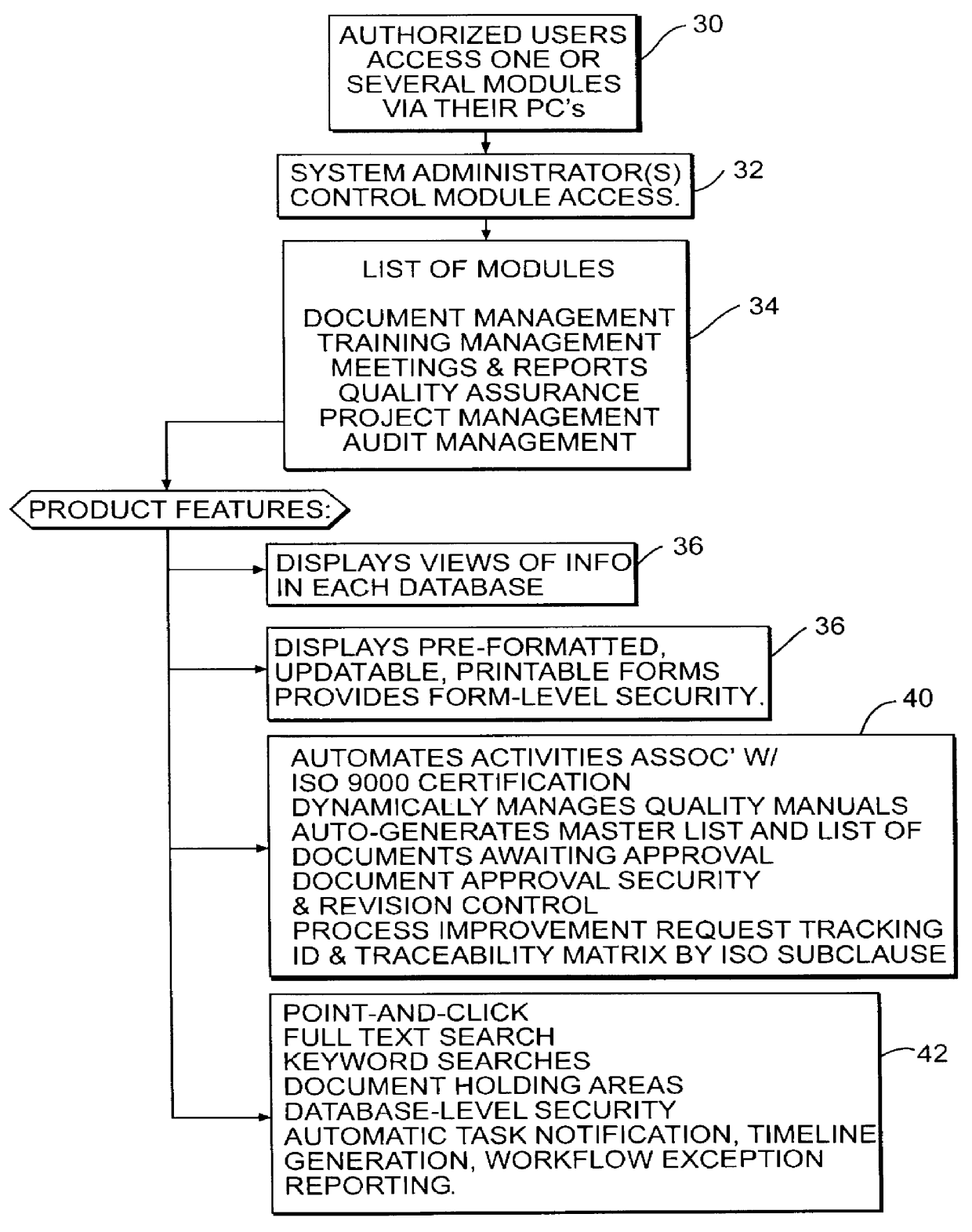

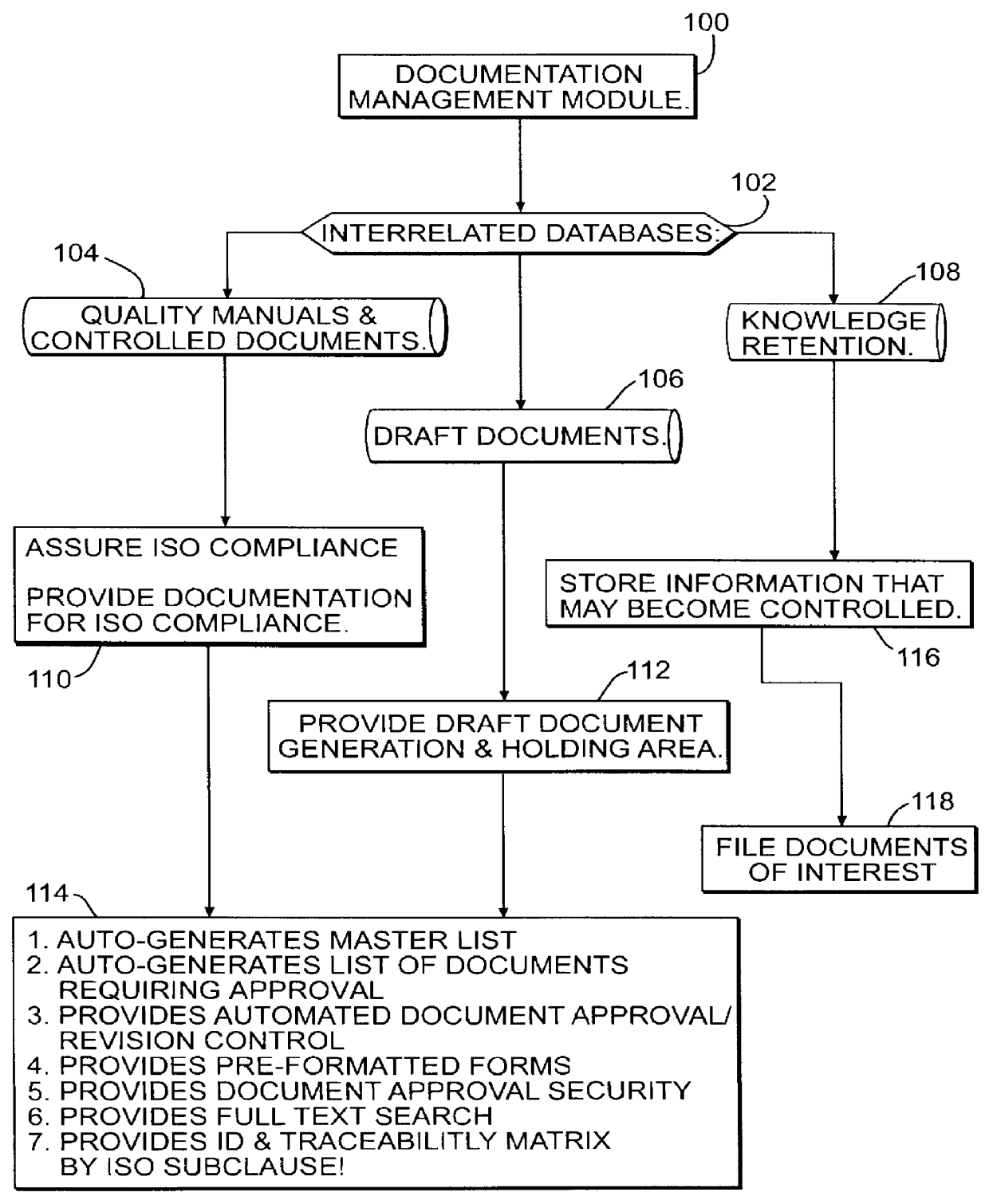

Document management system and method for business quality modeling

InactiveUS6154753AOffice automationSpecial data processing applicationsDocumentation procedureProject management

A computer implemented system and method and a computer readable medium for complying with the requirements of a quality standard known as ISO 9000. The areas covered include controlled documentation, training management, meetings and reports, process improvement requests, project management, and audit management. All controlled documents have a security and revision control portion that controls the access and approval capabilities of the documents. The system is form controlled. Certain individual fields of the forms require the entry of data, and field's control are controlled by certain fields of other forms, with the fields being updated by other fields in the system, operator entry of data, and a combination of control by both the system and operator entry. The system includes an ISO matrix relating each document to an ISO clause. The system has a controlling document for each delineated activity, and all other documents relating to such activity are linked as a child of the controlling document. An audit trail is created by storing and making available previous iterations of current documents as child documents, insuring that the first issue, subsequent changes to content, movement to draft status, reprieval, and reissue are available for auditing the activities of the business.

Owner:CABLE & WIRELESS INC +1

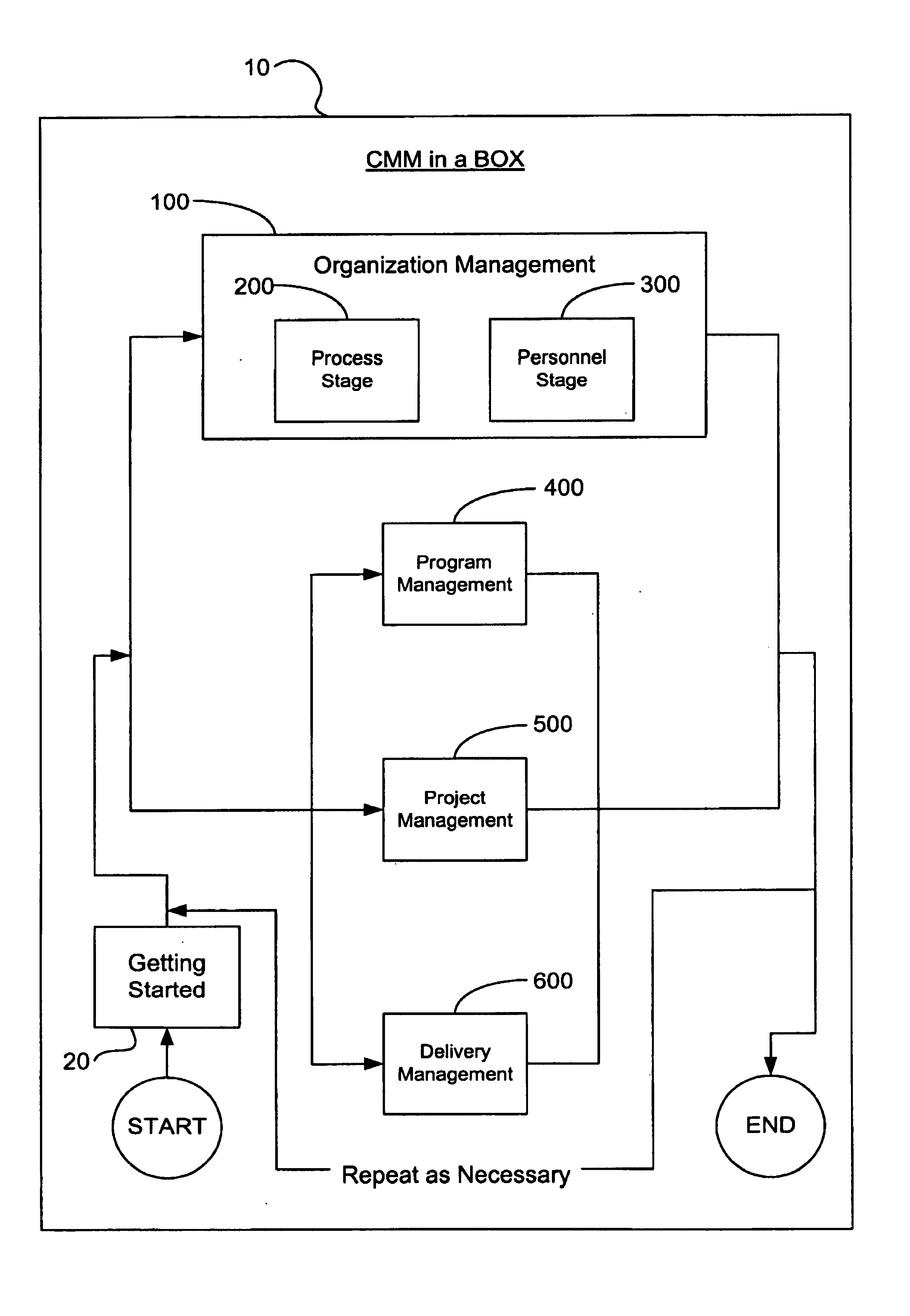

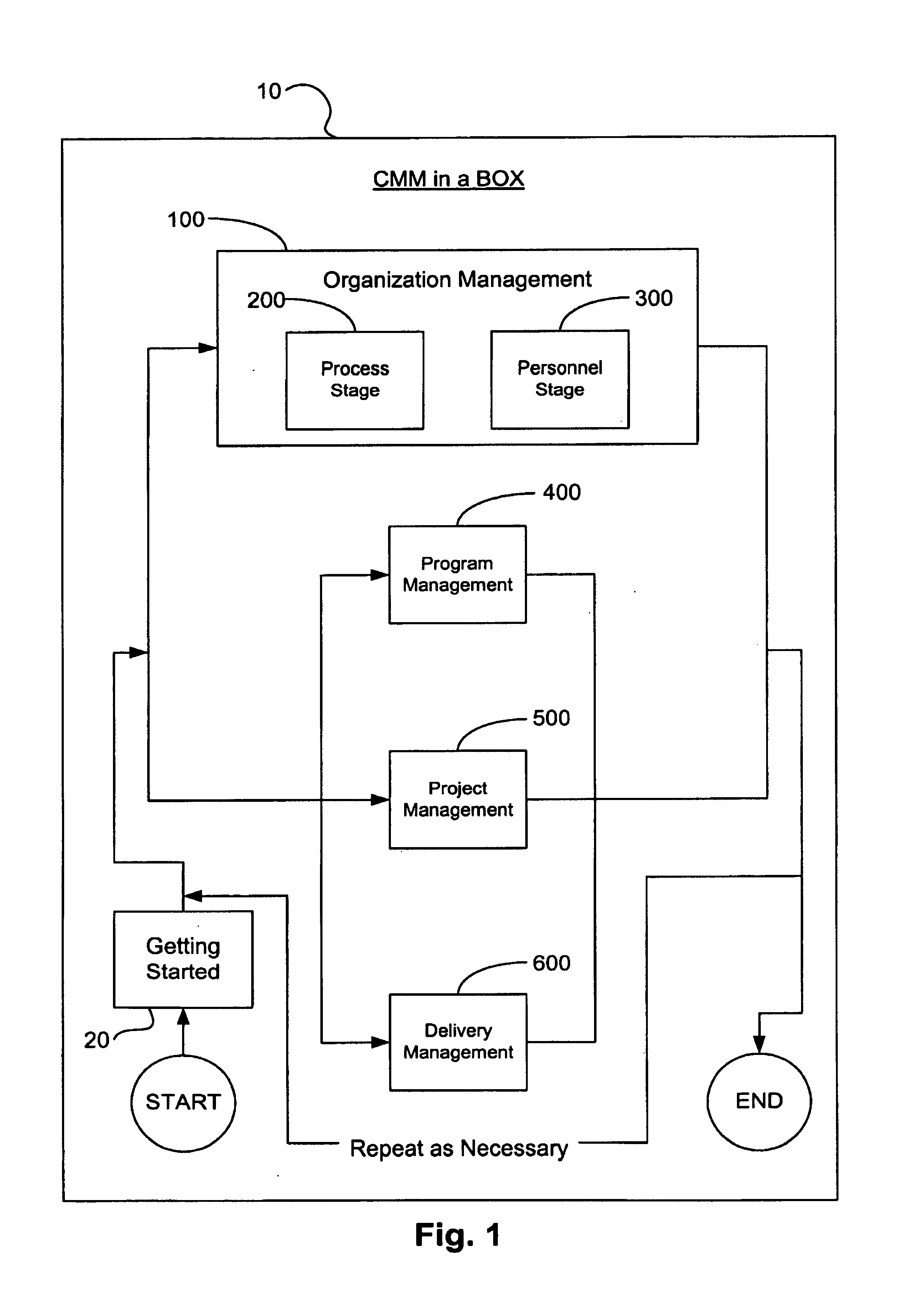

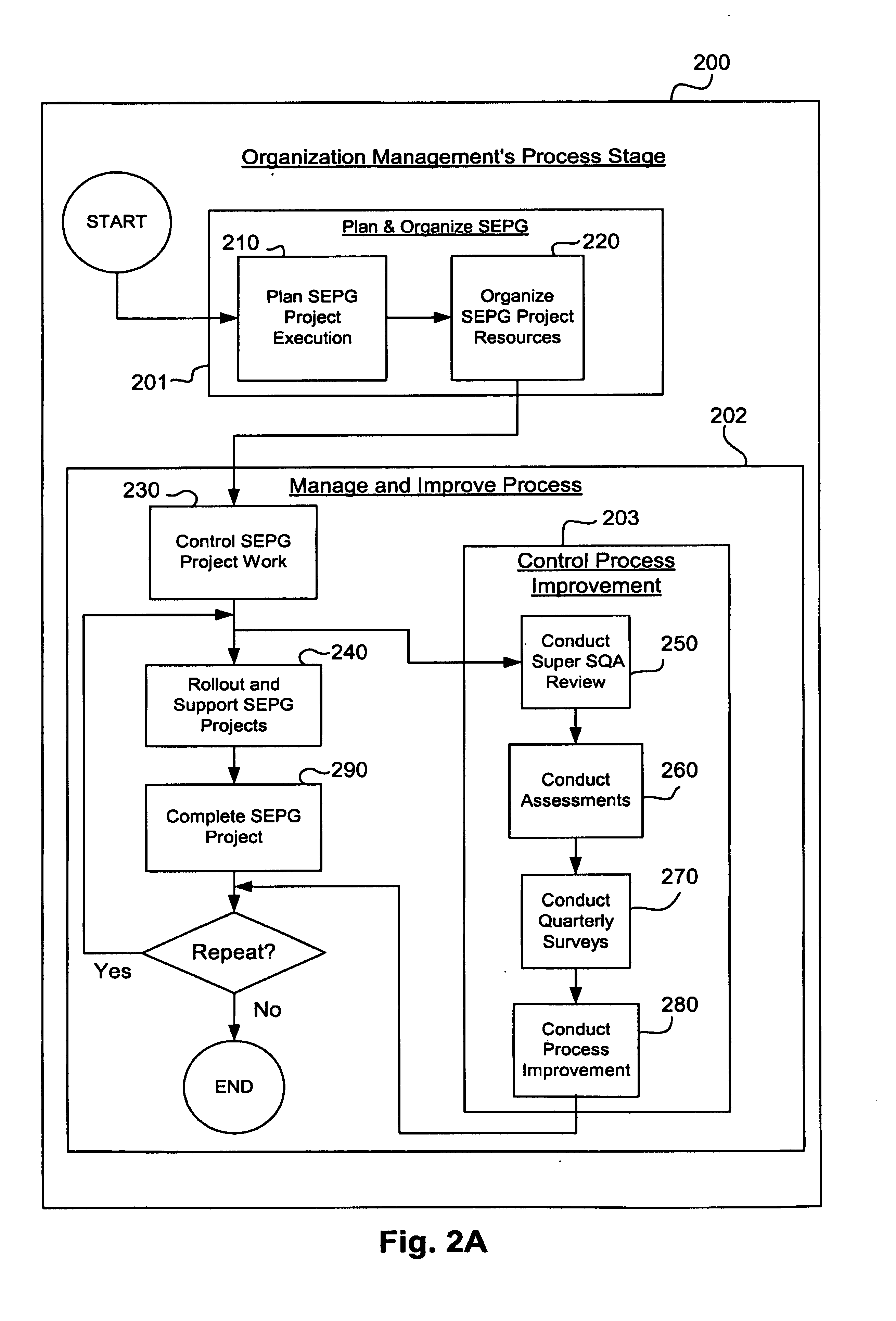

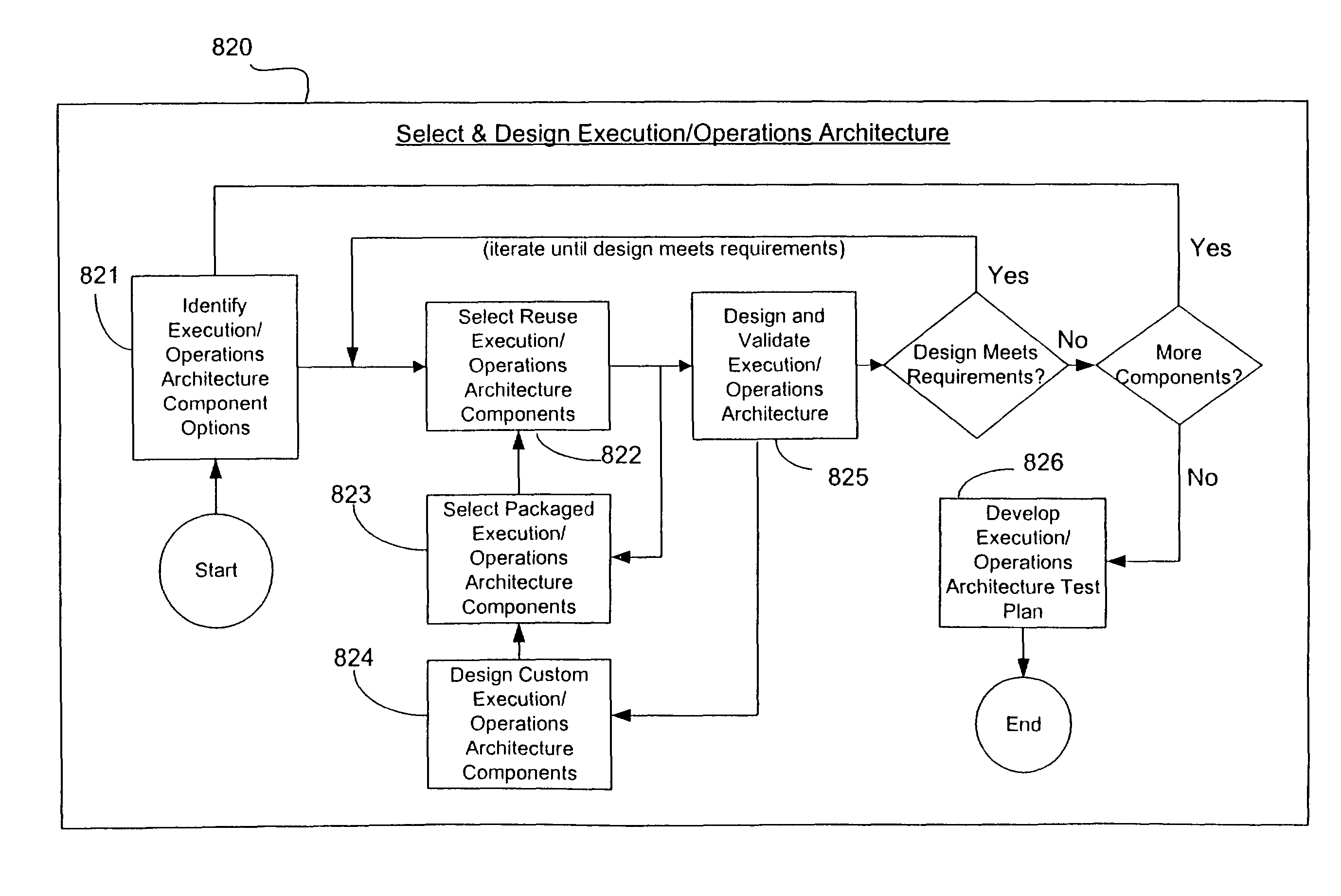

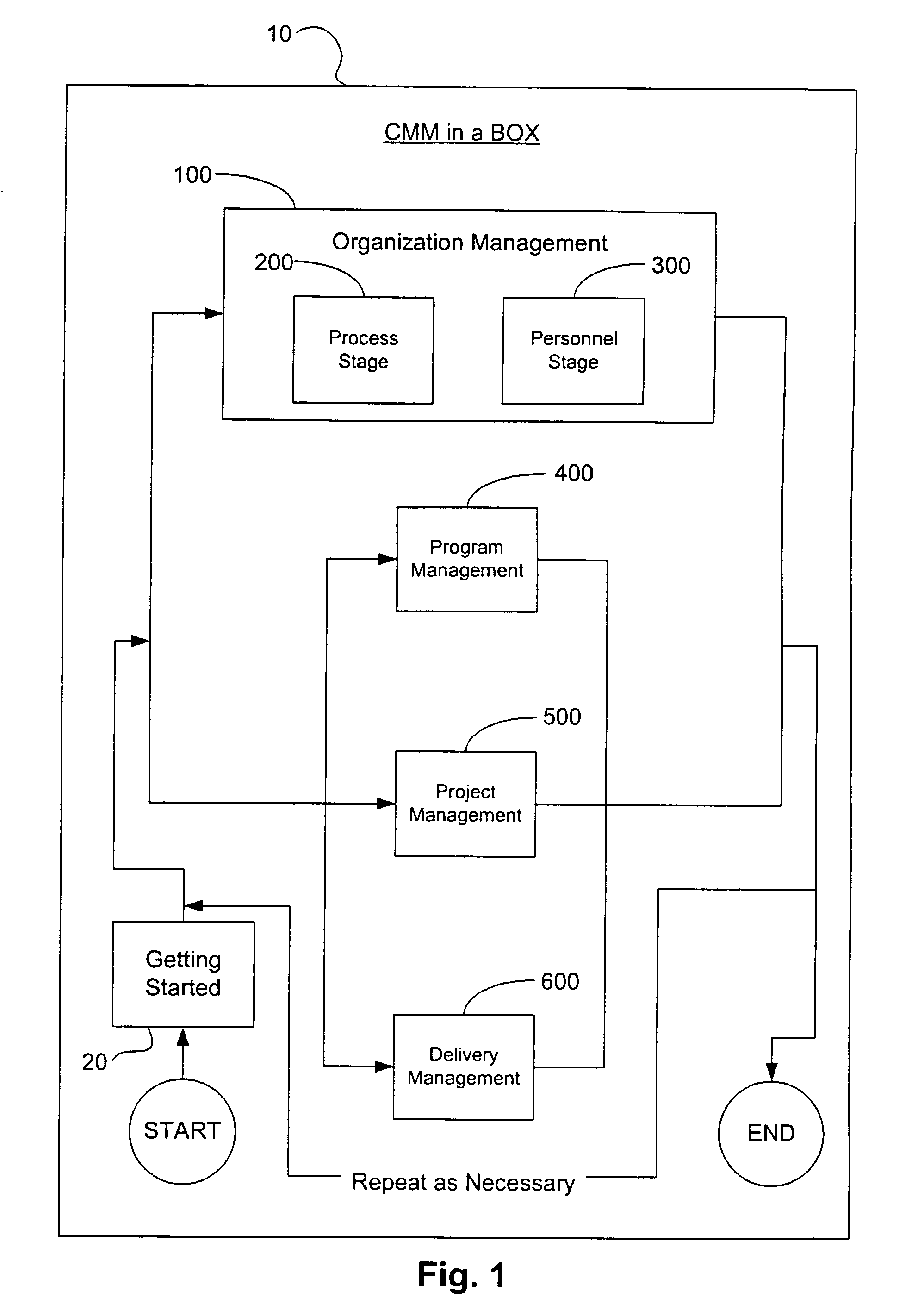

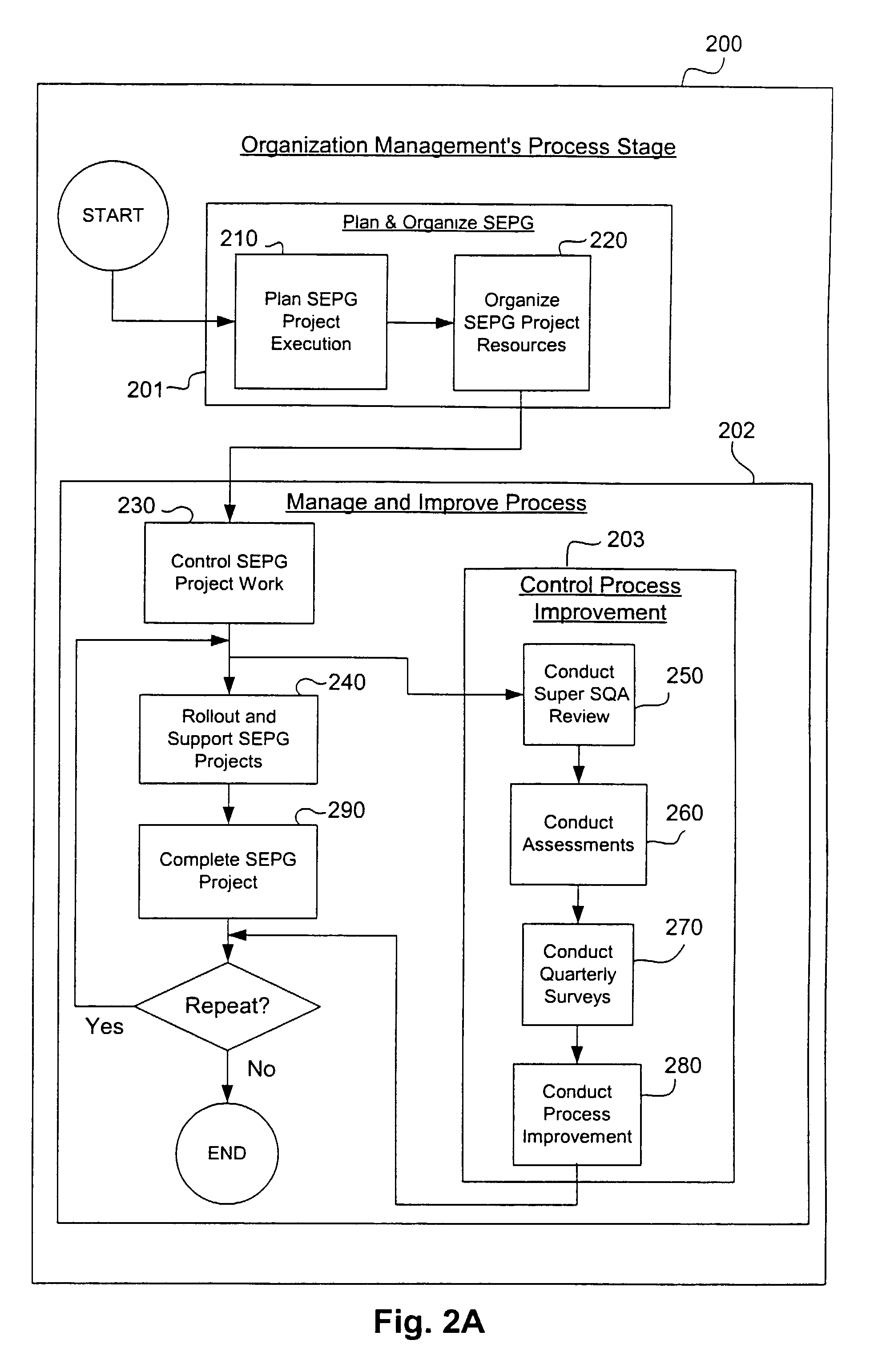

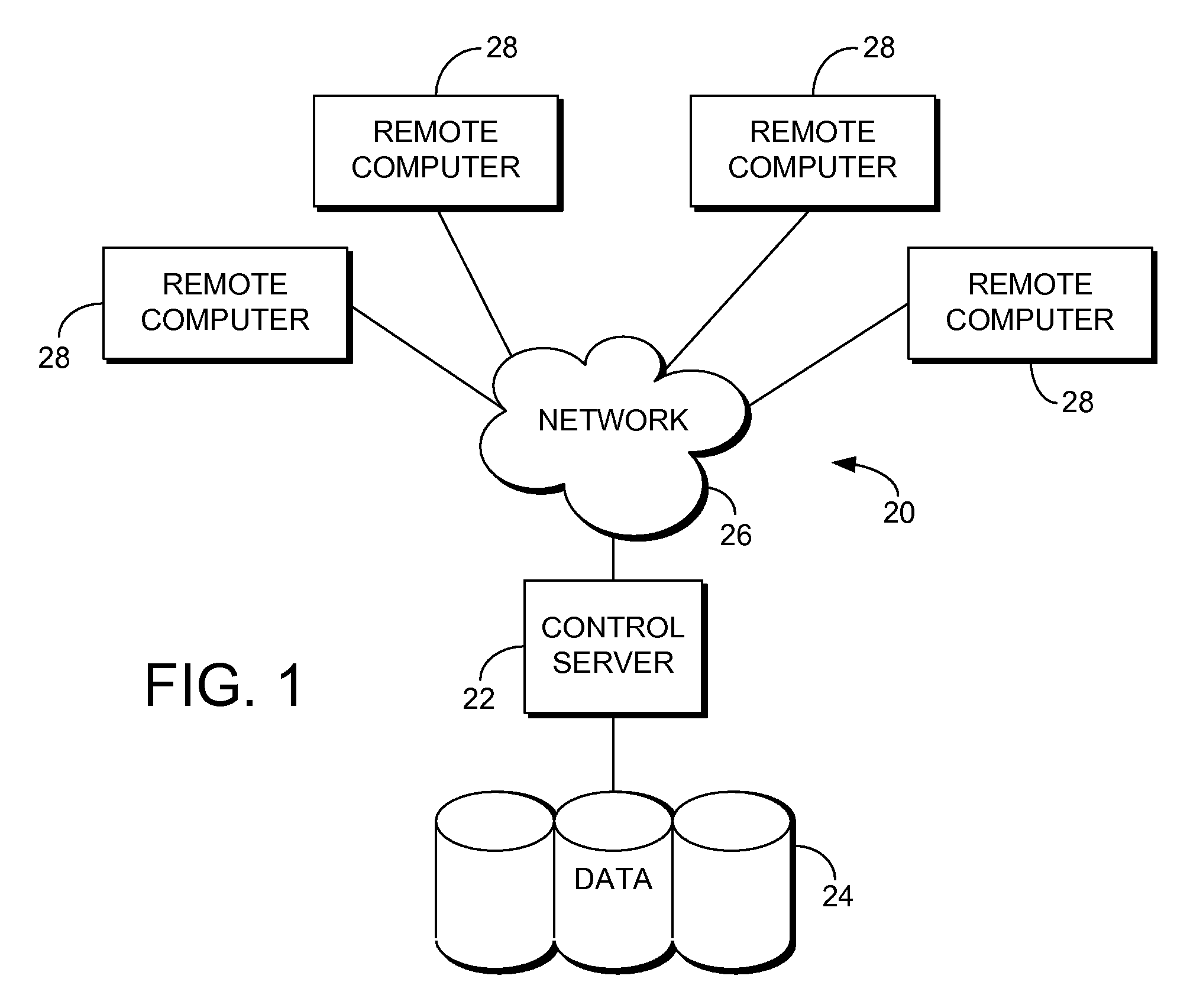

Accelerated process improvement framework

InactiveUS7035809B2Computer controlSimulator controlElectronic hardwareOrganizational behavior management

The present invention relates to a method and related system for assisting and expediting an organization's development of a more mature product. A preferred embodiment of the method comprises the managing of an organization developing the product, whereby the organizational management comprises managing personnel of the organization and implementing a product improvement process. The method may further comprise managing a project for developing the product and managing the delivery of the product. Furthermore, actions undertaken during the organizational management affects implementation of the project and delivery managements, and the actions undertaken during the project and delivery managements likewise affect implementation of the organizational management. This method may be implemented using a combination of both electronic hardware and software and may be implemented locally or over a network such as an intranet or the Internet.

Owner:ACCENTURE GLOBAL SERVICES LTD

Manufacture of composite roofing products with matrix formulated microbiocide

InactiveUS6245381B1Good dispersionEliminate the problemBiocideLiquid surface applicatorsAsphalt shingleBlue green algae

This invention discloses improved residential roofing products with durable active protection against algae discoloration. Versatile organometallic salts and chelates for this purpose are incorporated in manufacture of composite concrete tile and asphalt shingle products via integrated process modifications. These chemically stable non-volatile microbiocides, with exceptional effectiveness against both green and blue green algae, are tailored for specific matrix compatibility. By virtue of their composition and surface activity they serve a dual function in process improvement and product performance. The control of microbiocide activity, long term, significantly advances the state-of-the-art protection against algae and the service life of these products.

Owner:TAMKO BUILDING PRODS

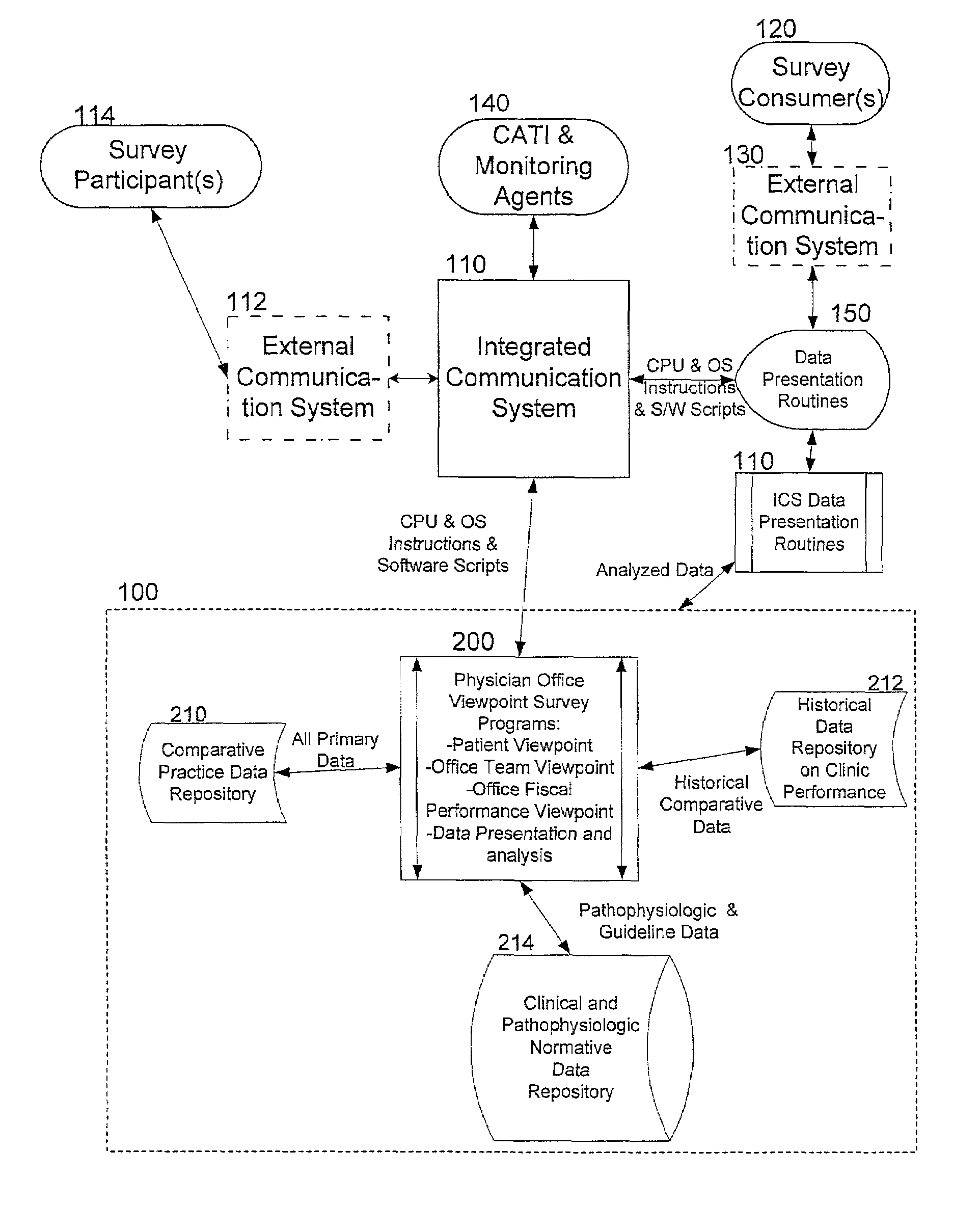

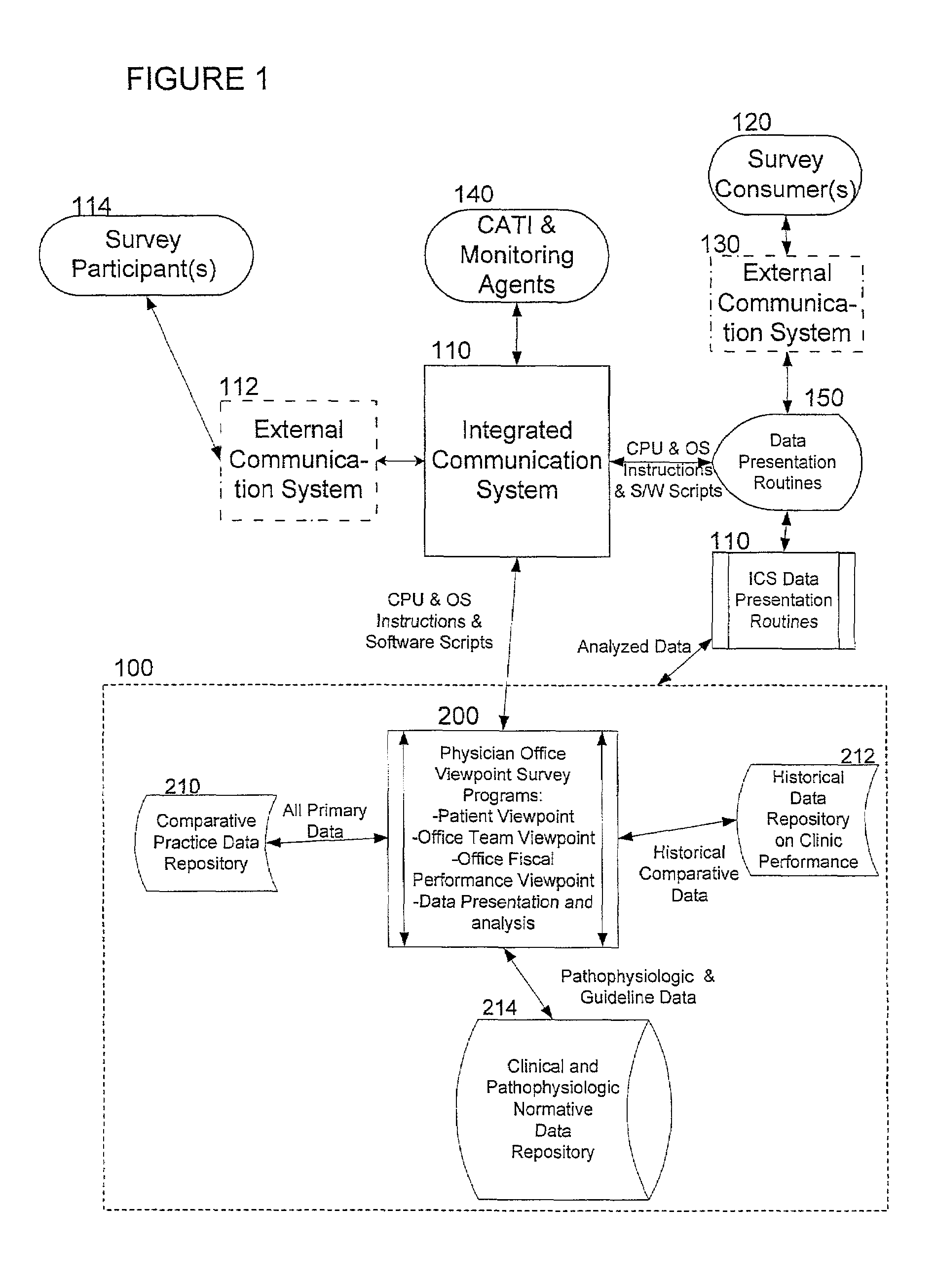

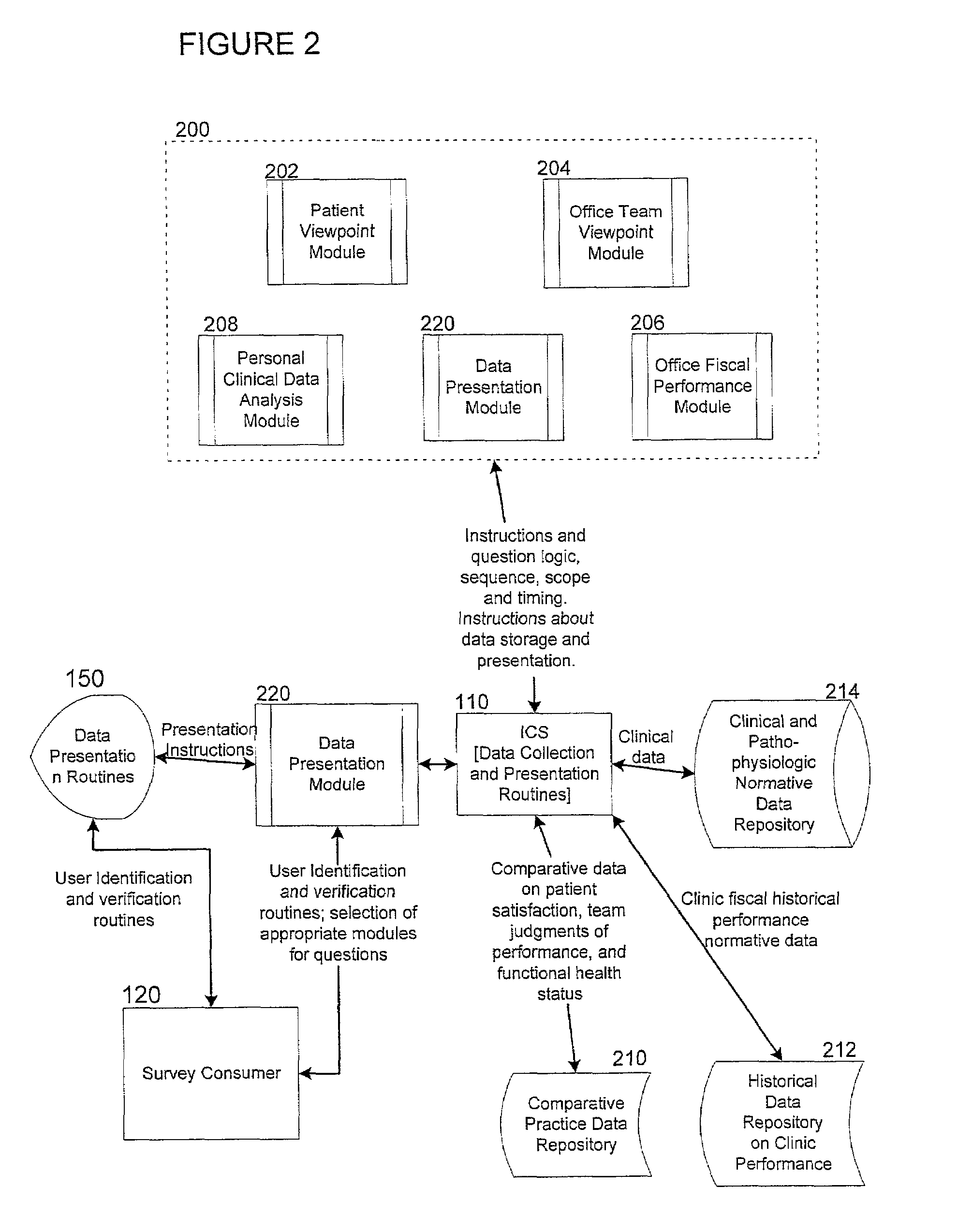

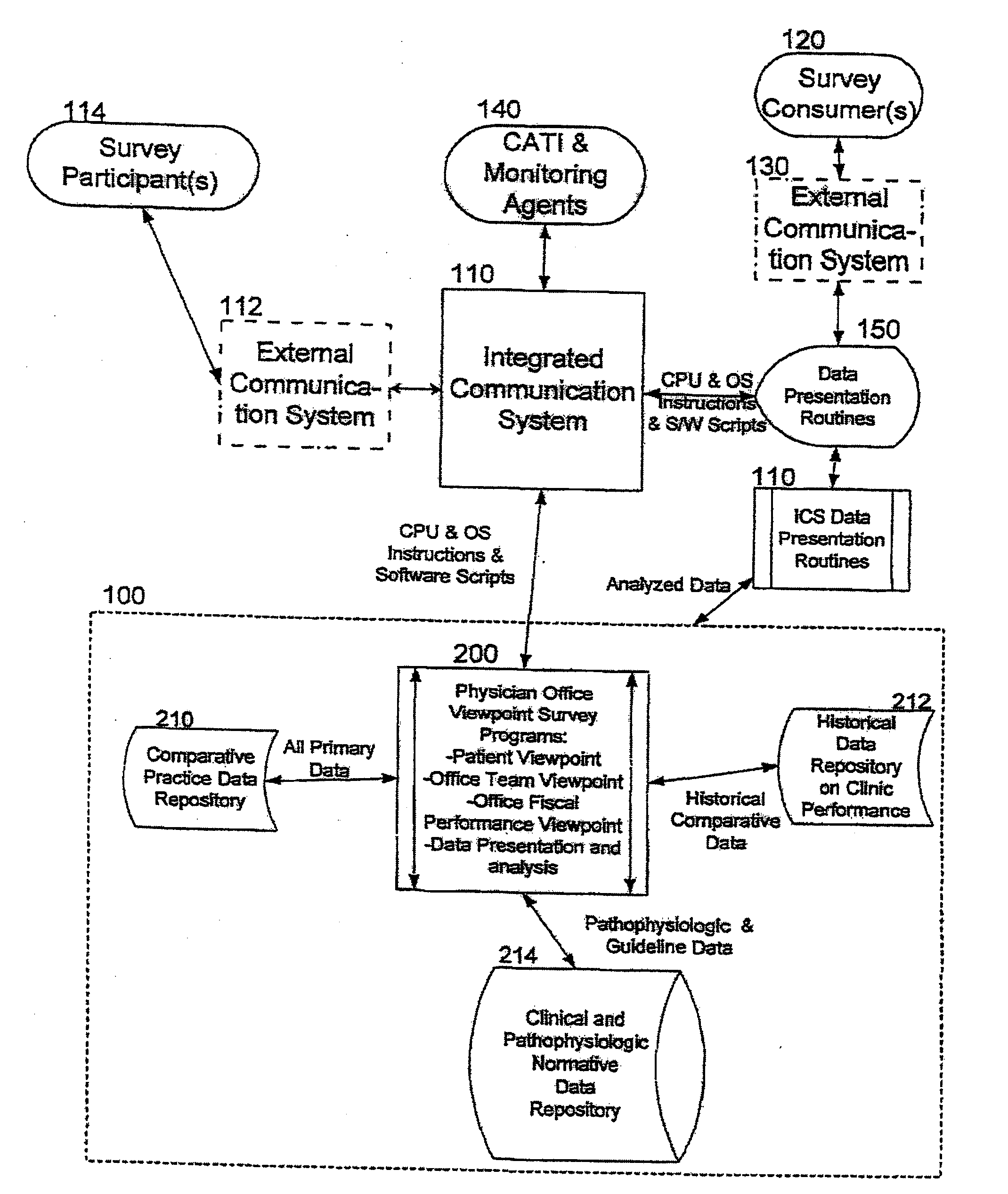

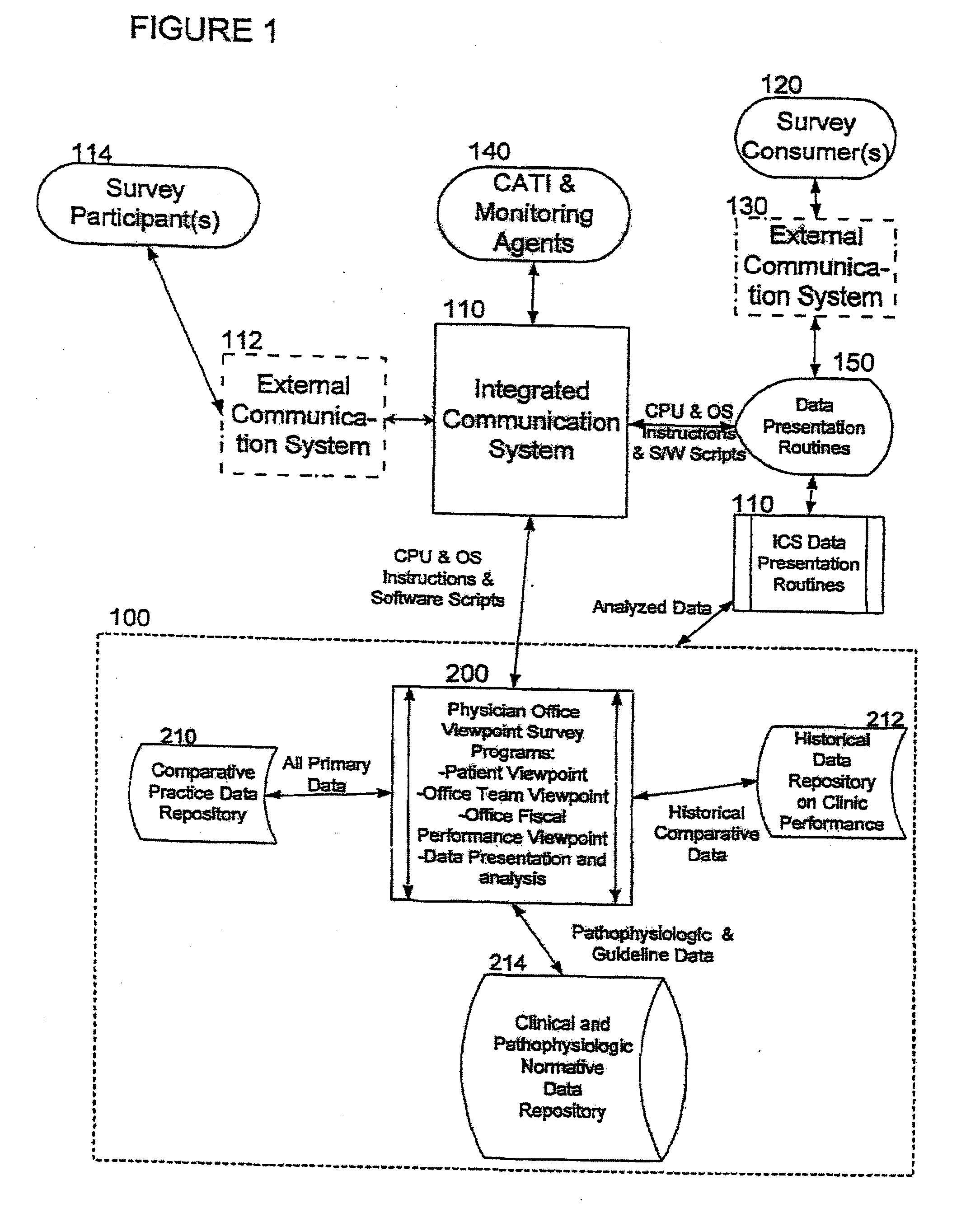

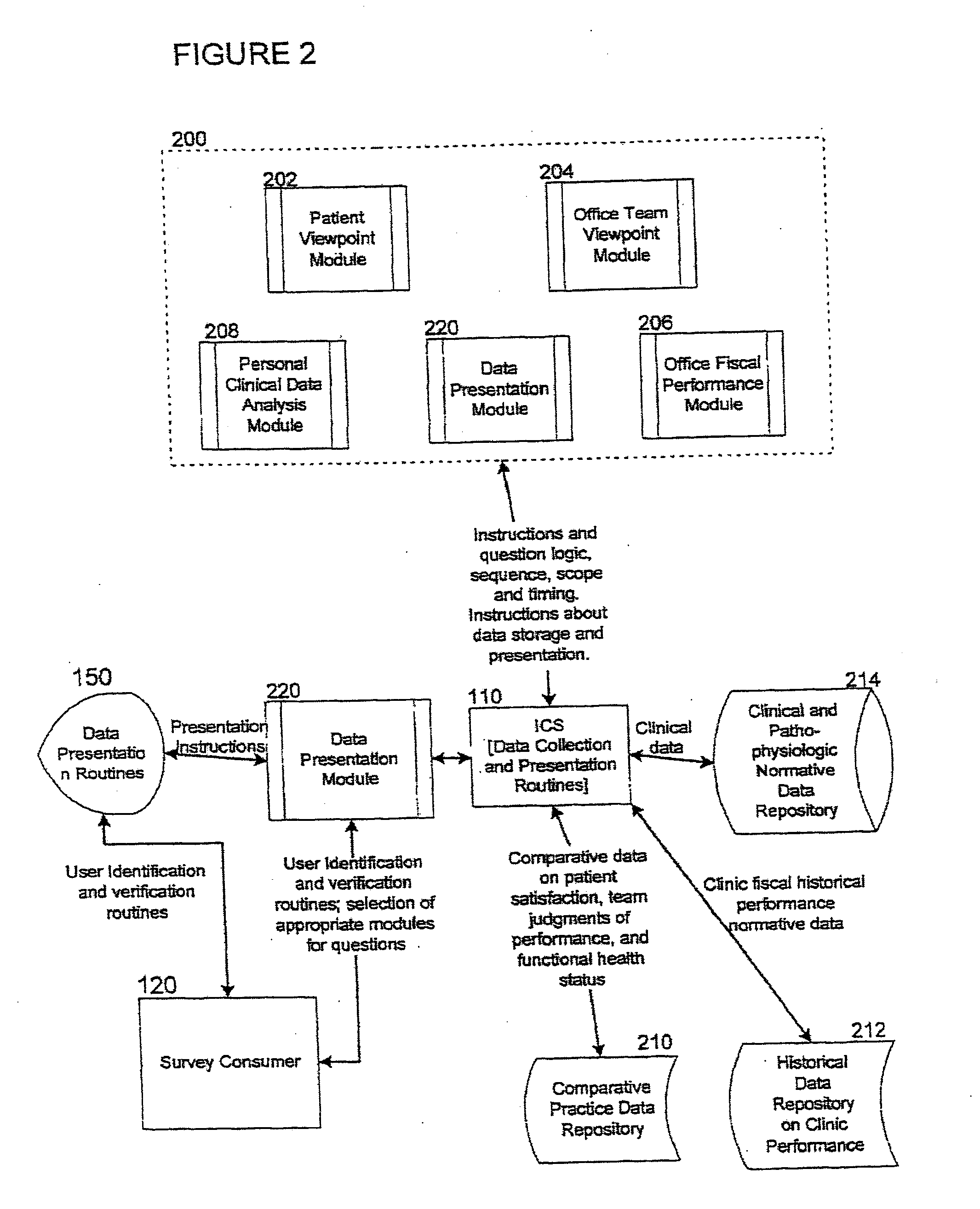

Physician office viewpoint survey system and method

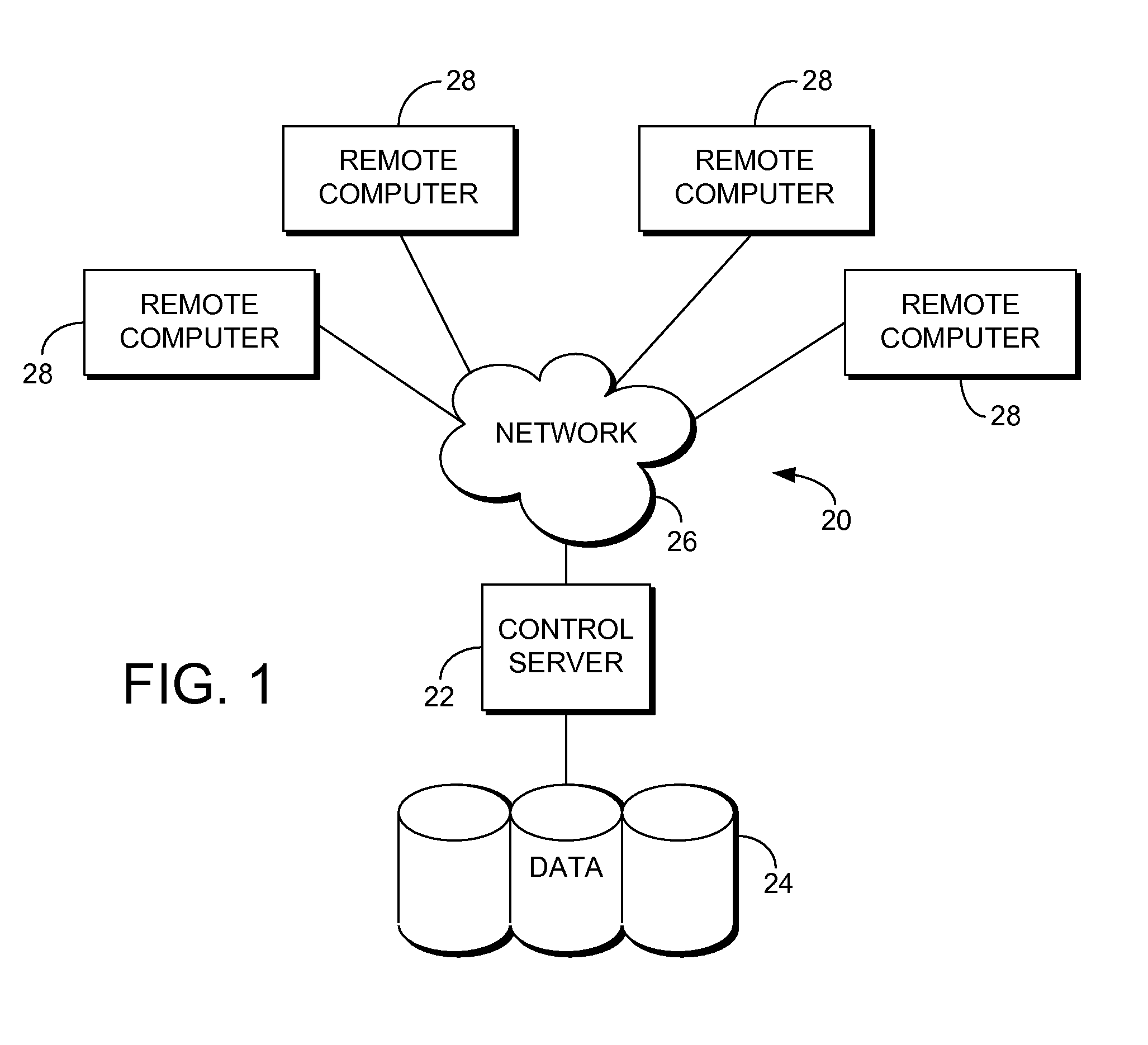

A system and method for conducting surveys, and, more particularly, an at least partially automated and efficient system and method for collecting, processing, and displaying customer satisfaction survey information that enables a product or service provider to evaluate the quality of goods and / or services received based on ratings and reports obtained by performing surveys of customers, employees, and / or staff. The system utilizes an execution platform using a clinical process improvement methodology. The system provides the execution platform with software scripts implementing the clinical improvement process, using drill-down questioning techniques and verbatim comments tailored to the survey participants comments and / or status information to gain insights into the participants' reasons for their opinions. The system obtains raw survey data and processes that data into useful survey information, such as graphs and charts, for presenting to survey consumers (i.e., system users) who may be remotely located. In this way the system and method can be utilized in a quality improvement program for any service or product provider.

Owner:QUALITY DATA MANAGEMENT

Accelerated process improvement framework

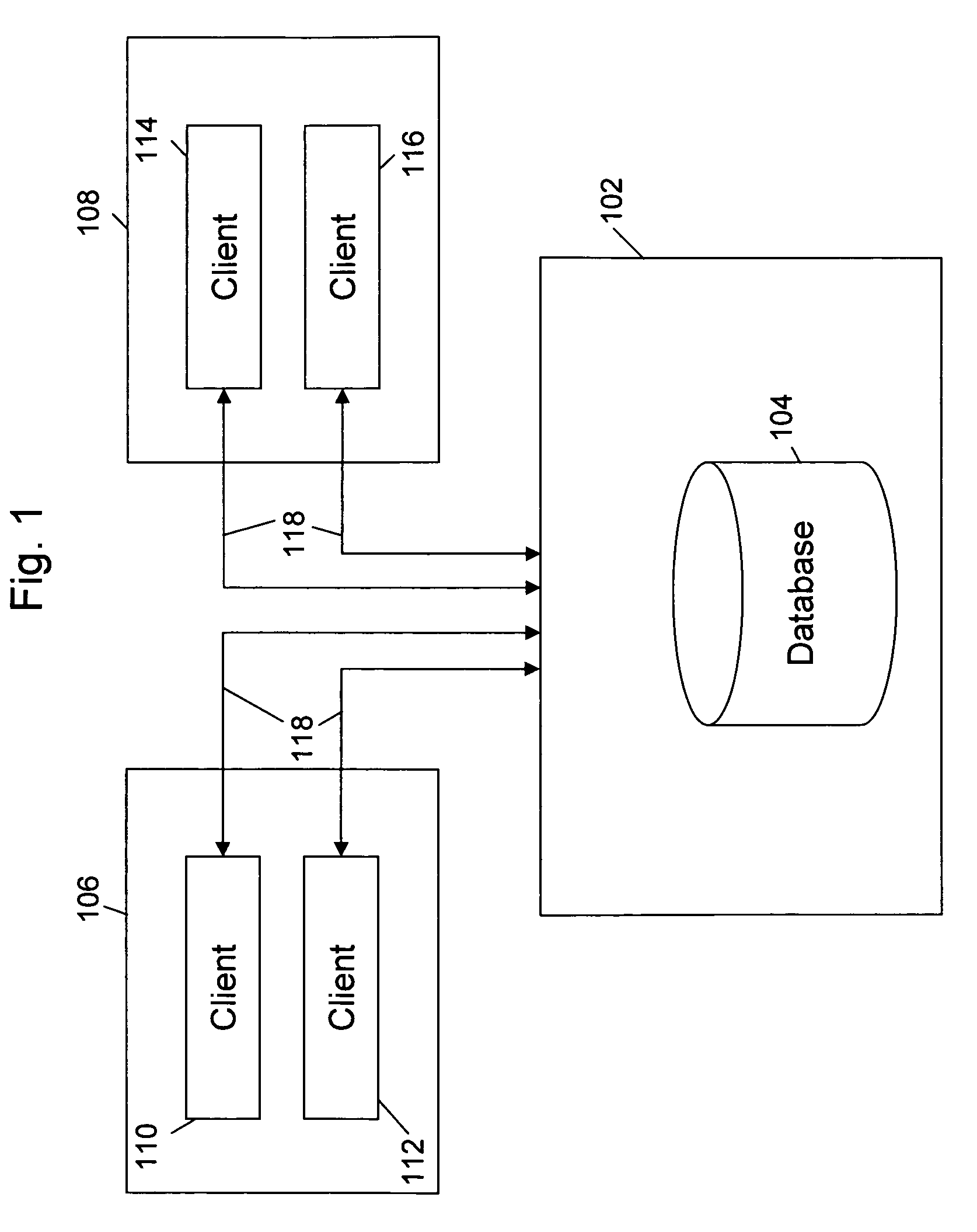

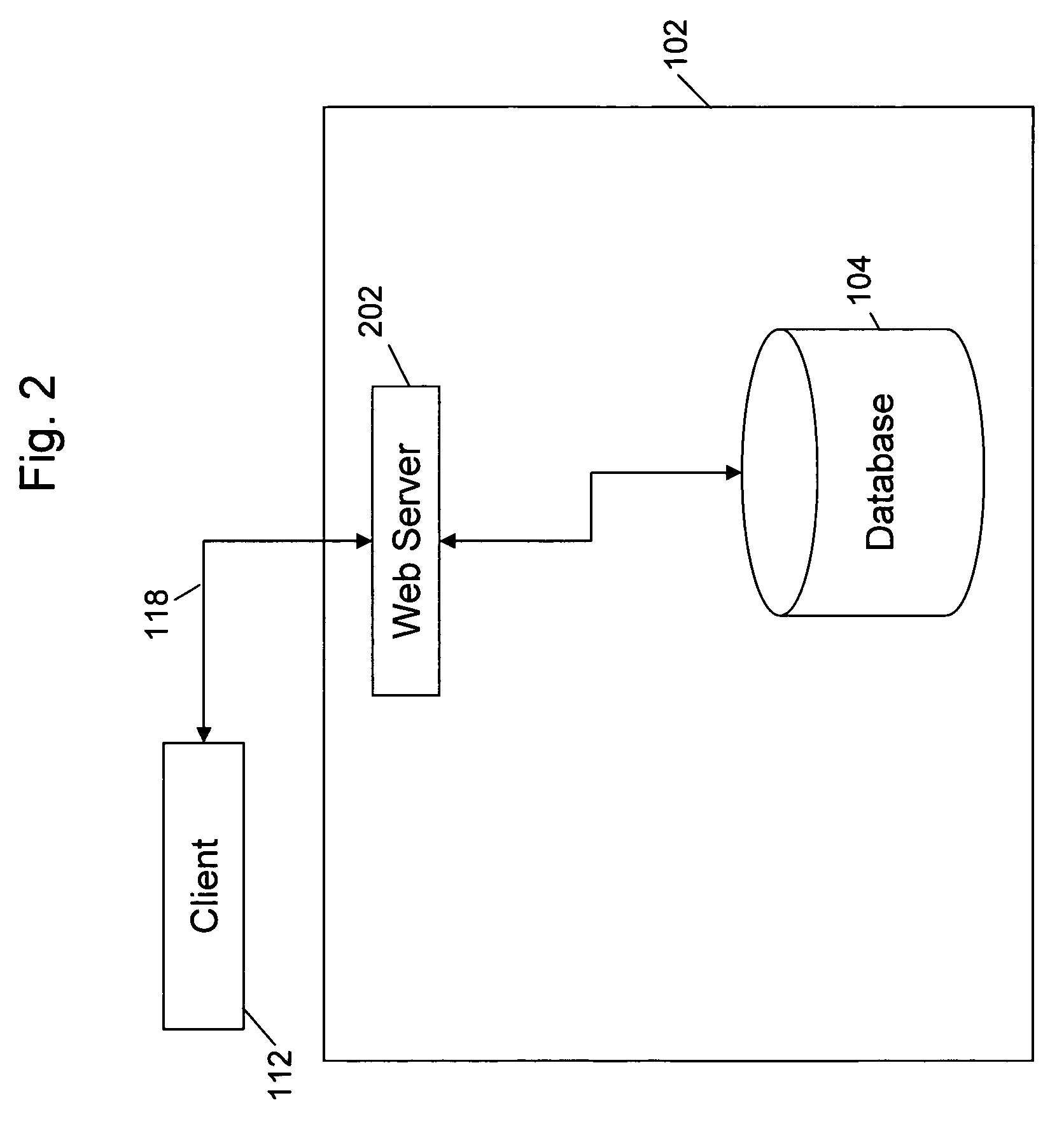

The present invention relates to a method and related system for assisting and expediting an organization production of a more mature product. The method and system may include implementation of processes using a combination of both electronic hardware and software and implementation locally or over a network such as an intranet or the Internet. In another embodiment, the method may be implemented using a document management system to administer files related to the steps in the method. These files may assist a user in the creation of required documentation. A document management tool may be integrated with the document management system to associate documentation with steps in the method. A navigator tool may be employed to create a graphical display of the steps in the method using data contained in the files. Another embodiment of the present invention uses WebDAV-based communication to coordinate access to multiple document repositories.

Owner:ACCENTURE GLOBAL SERVICES LTD

Physician office viewpoint survey system and method

Owner:QUALITY DATA MANAGEMENT

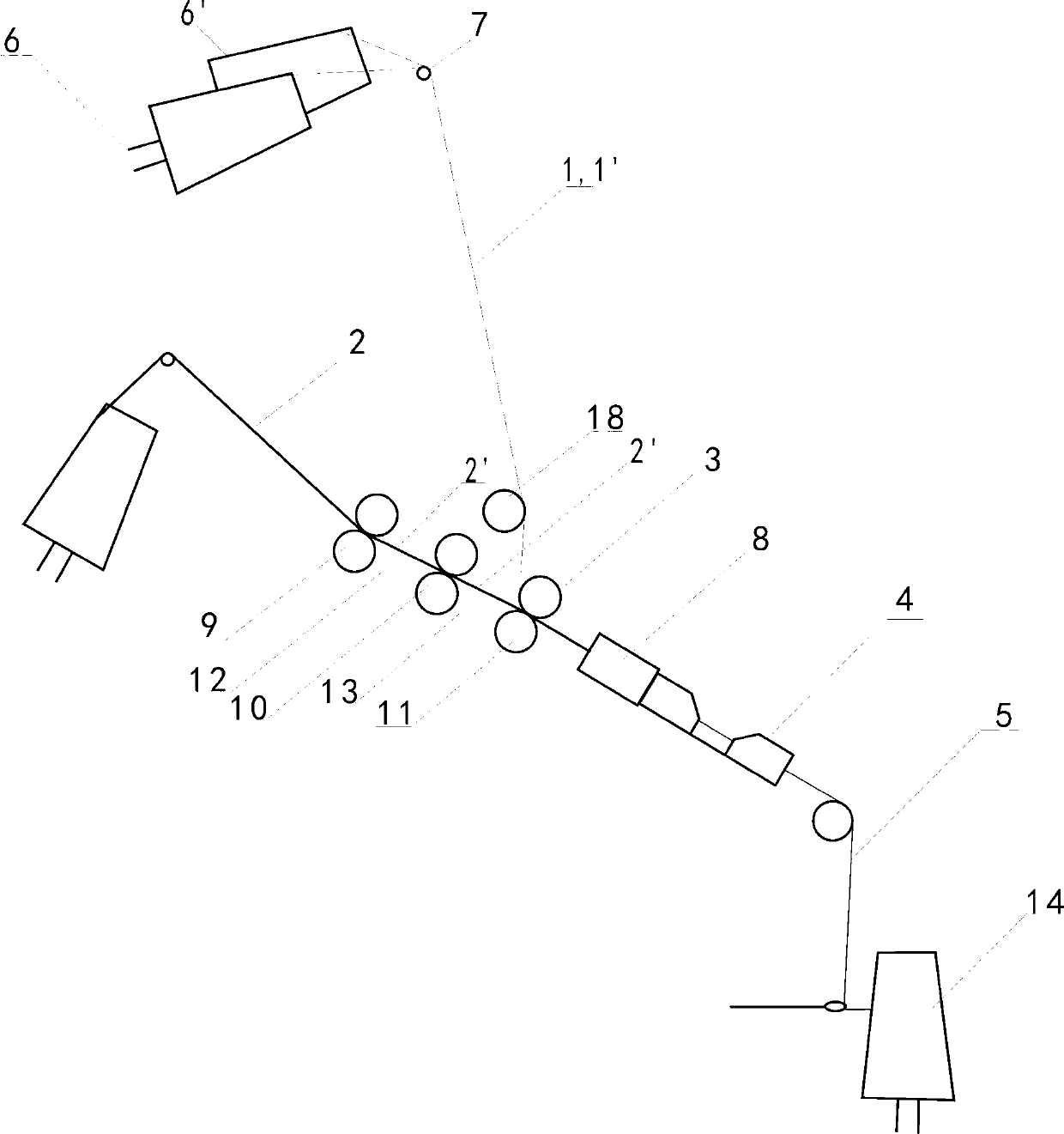

Processing method of double-component elastic spandex core-spun yarn

The invention discloses a processing method of a double-component elastic spandex core-spun yarn, comprising raw materials, production steps and production process improvement thereof, wherein the raw materials include a first elastic spandex filament, a second elastic spandex filament and wrapping yarn; the second elastic spandex filament is half of the first elastic spandex filament in diameter, and the two elastic spandex filaments differ in traction multiple; and the wrapping yarn is a short fiber; the production steps include: rolling the comparatively thick wrapping yarn into the form of a flat strip; before entering into a spinning room, guiding both the elastic spandex filaments as double cores to the middle of the flat-strip shaped wrapping yarn; folding the flat-strip shaped wrapping yarn by taking the double cores as a fold line, and covering the double cores on the fold line in the flat-strip shaped wrapping yarn; feeding the double cores and the folded flat-strip-shaped wrapping yarn into the spinning room, and stretching and twisting in an 8-shaped form to form the double-component elastic spandex core-spun yarn. The product is elastic and free from the feeling of being too tight on the body, and overcomes the shortcoming of being insufficient in elasticity or too tight.

Owner:徐州时代纺织有限公司

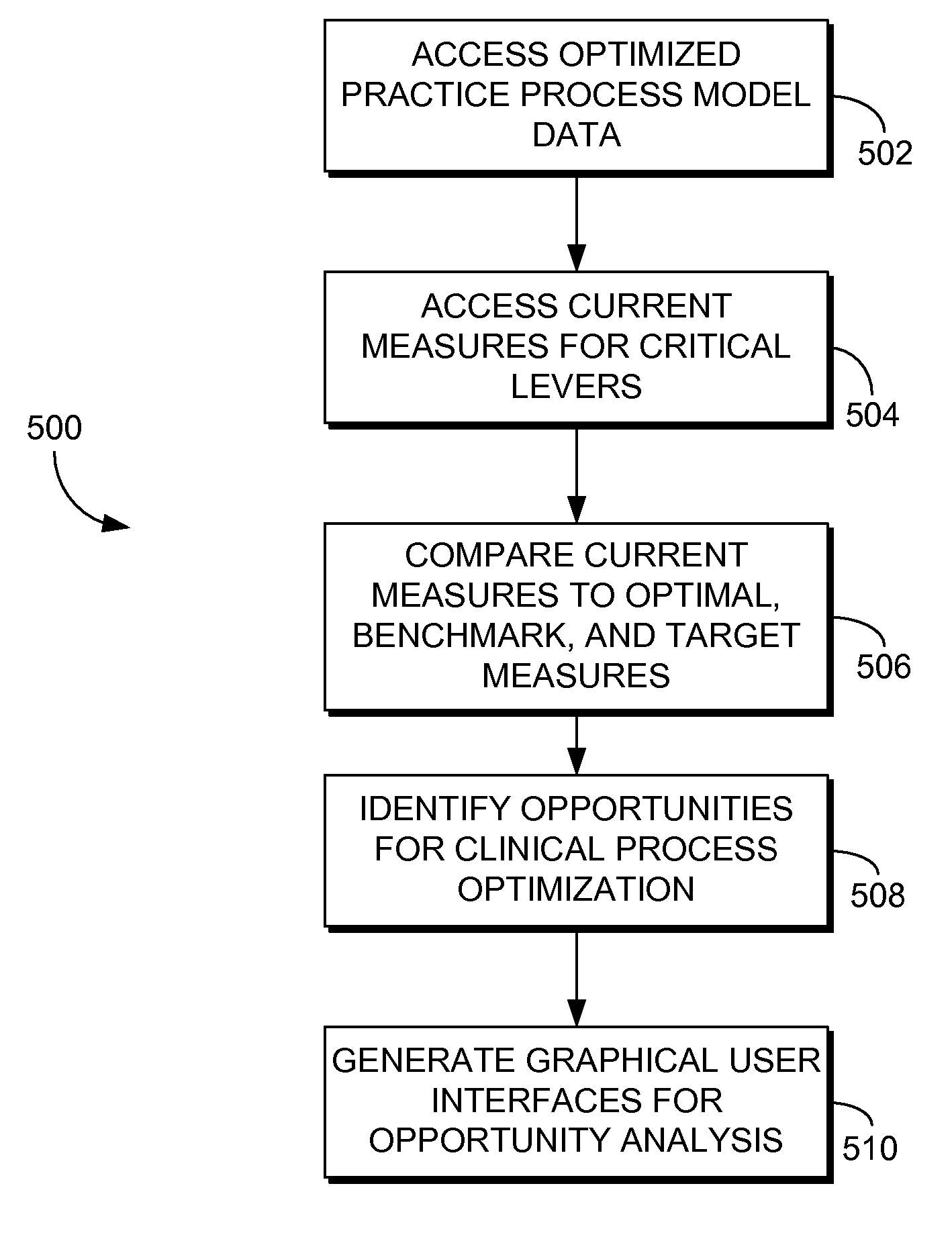

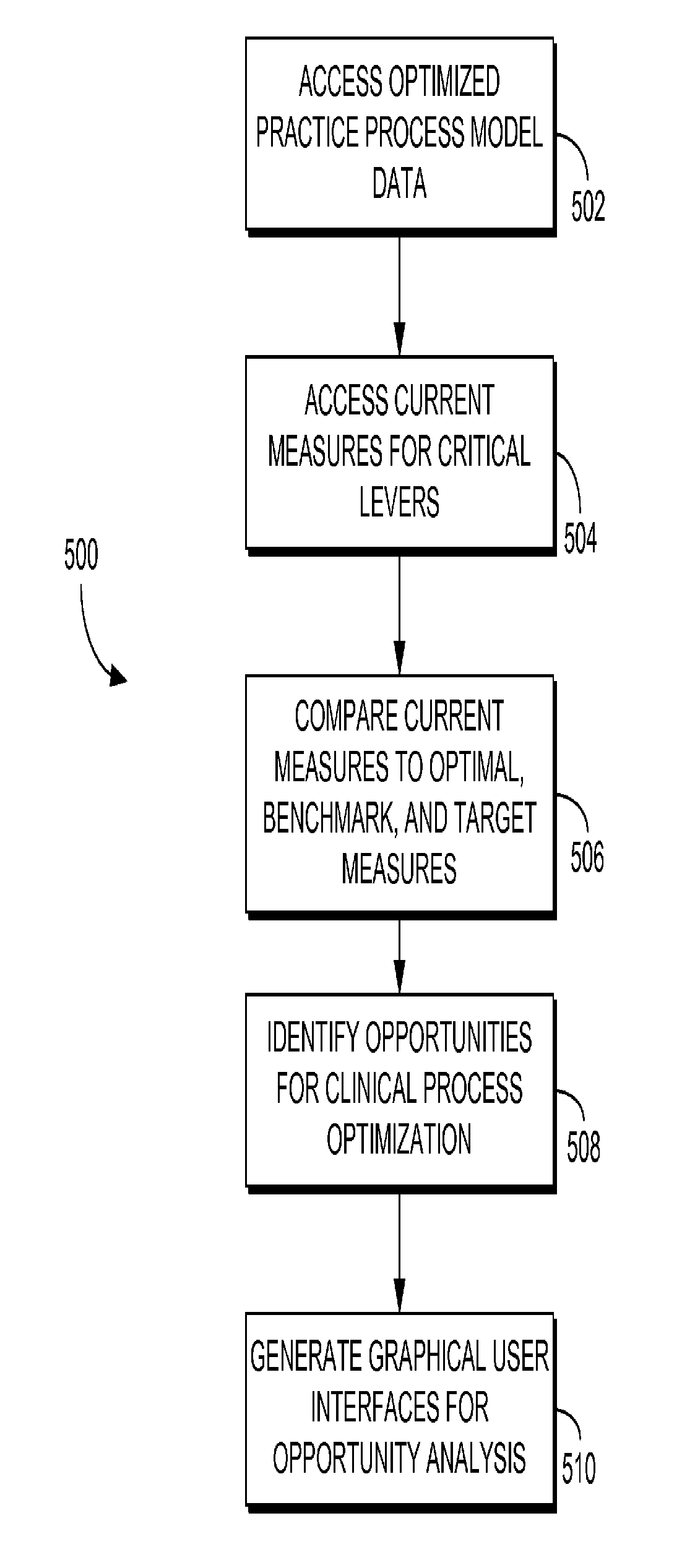

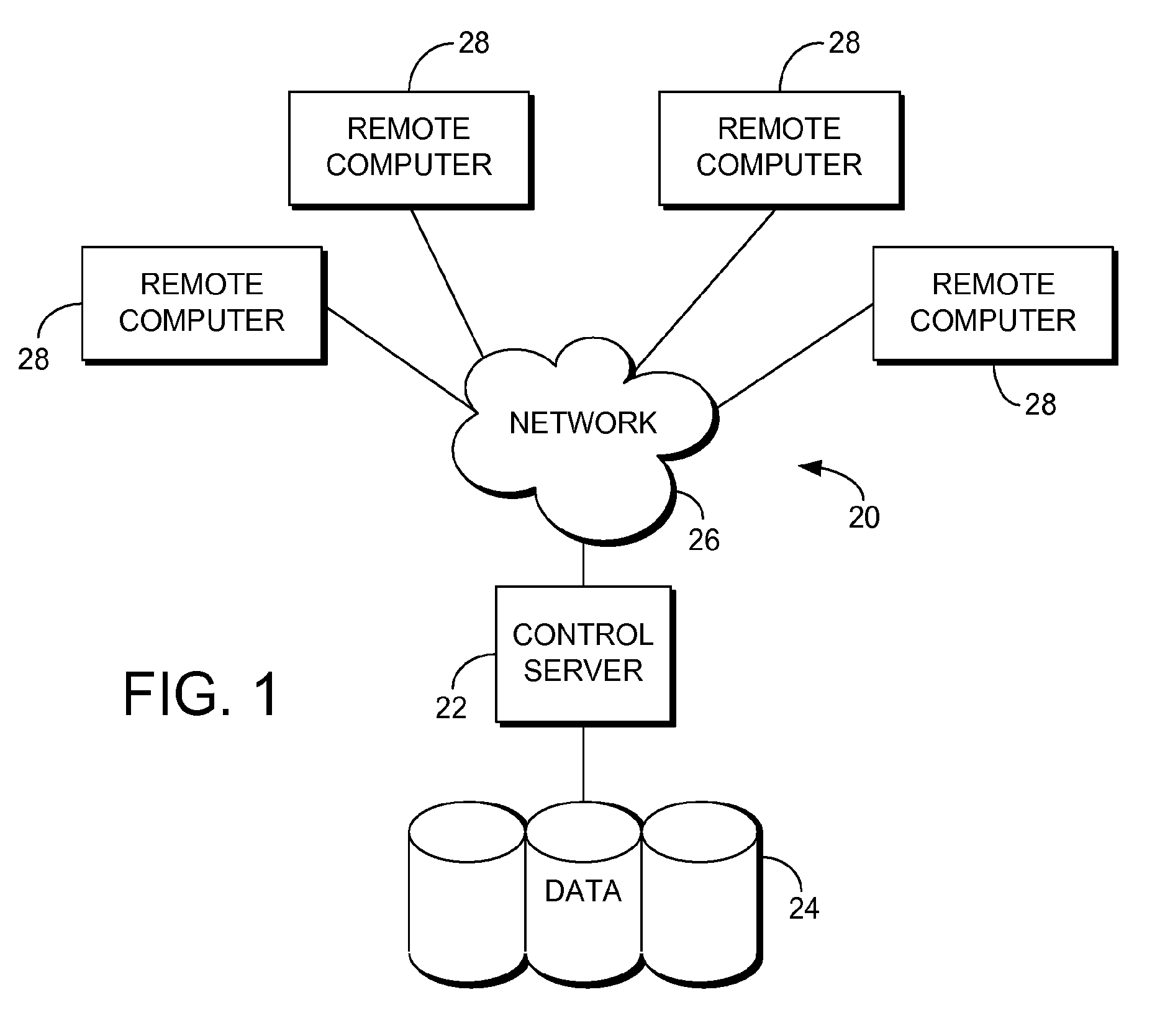

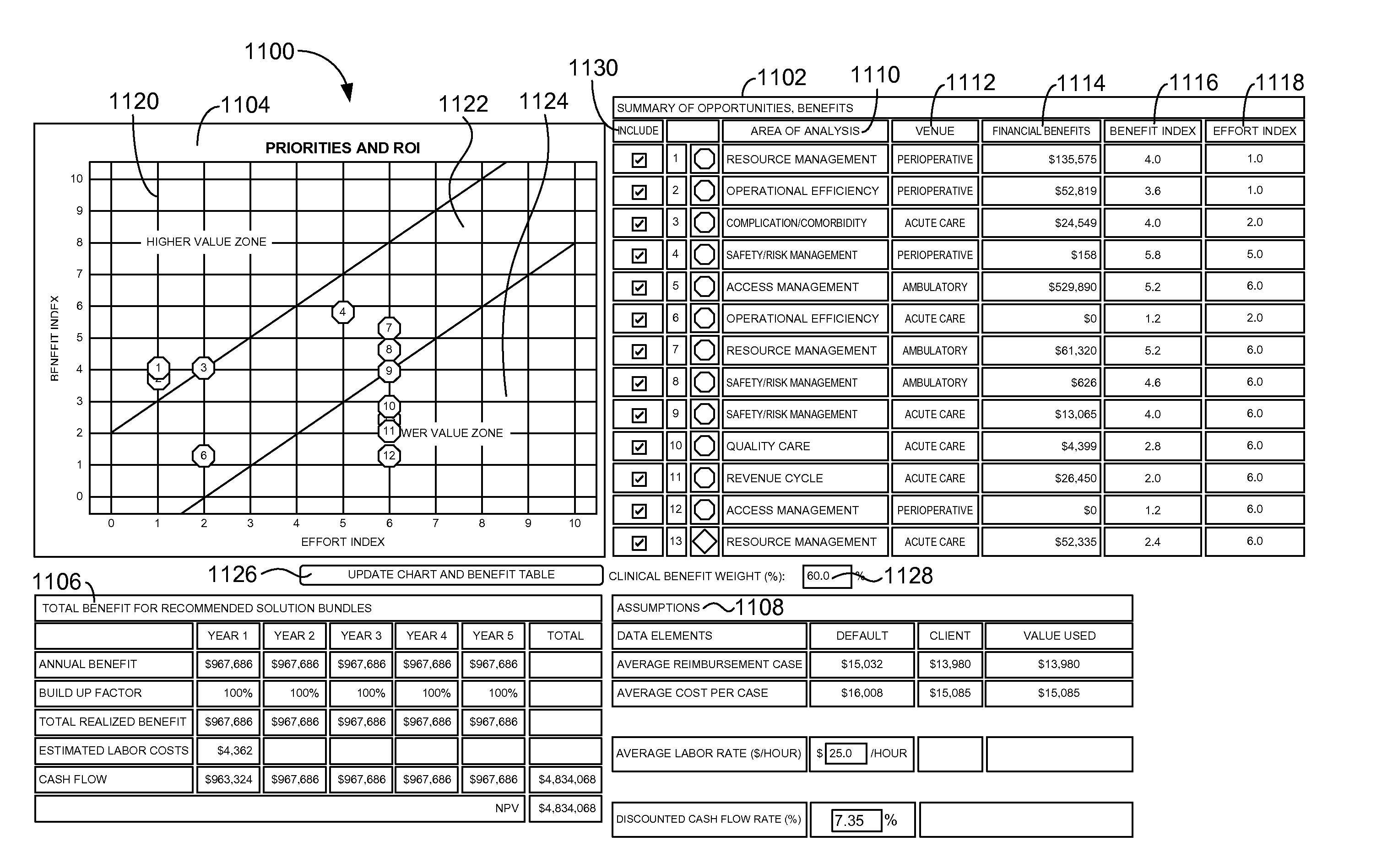

User Interface for Prioritizing Opportunities for Clinical Process Improvement

ActiveUS20070083389A1Efficient analysisContinuous monitoringTherapiesFinanceProcess optimizationComputer science

Methods and user interfaces are provided for prioritizing opportunities for optimizing clinical processes within clinical facilities. An optimized practice process model may be defined for a particular clinical procedure, setting forth an optimal clinical process. In addition, critical levers may be identified within the optimal clinical process, representing the activities that have the greatest impact on outcomes. Clinical facilities may collect current measures for the critical levers, and the current measures may be compared against an optimal, benchmark, and / or target measure. Based on the comparison, opportunities for clinical process optimization may be identified. User interfaces are provided for prioritizing the opportunities, for example, based on benefit indexes and effort indexes determined for each opportunity.

Owner:CERNER INNOVATION

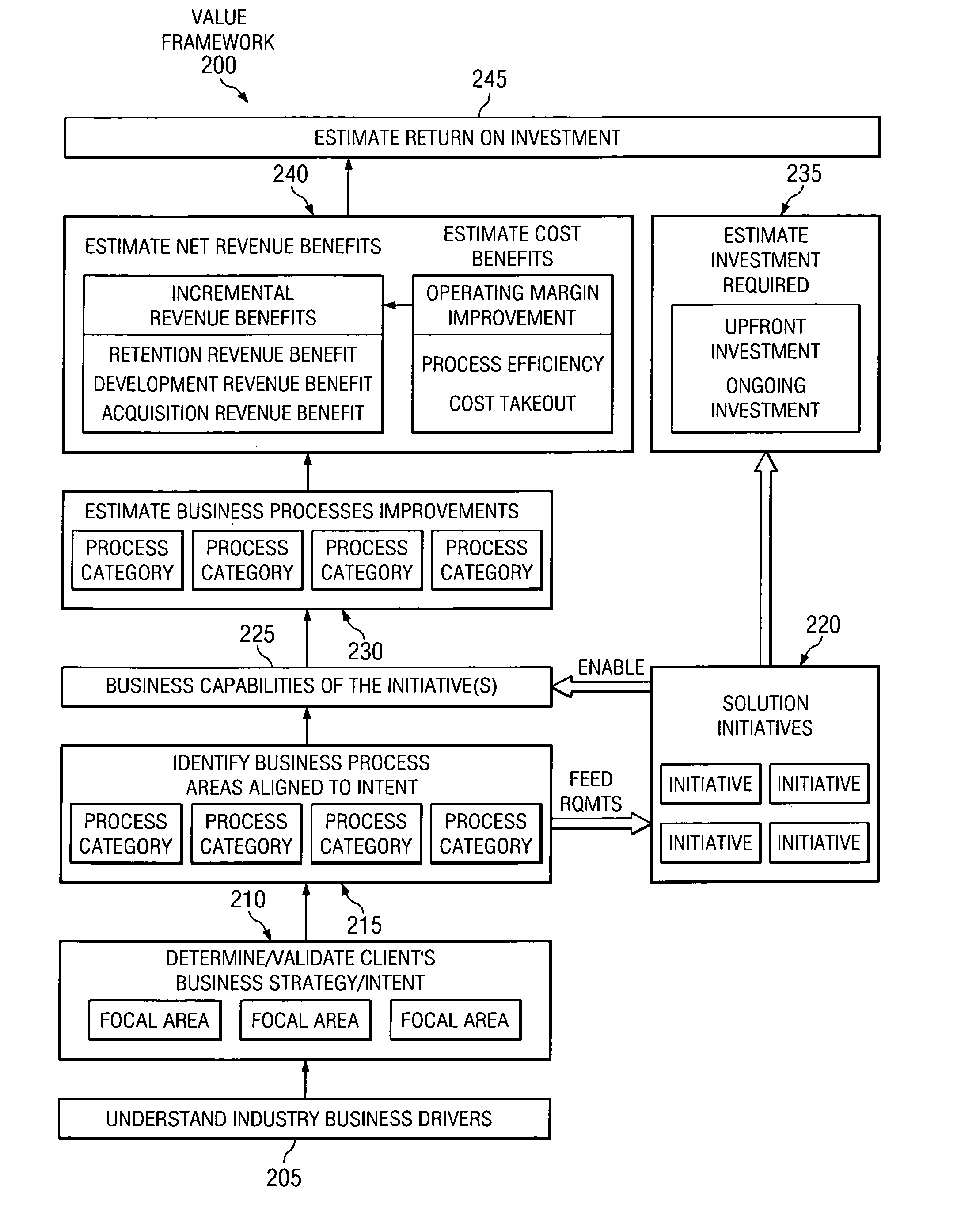

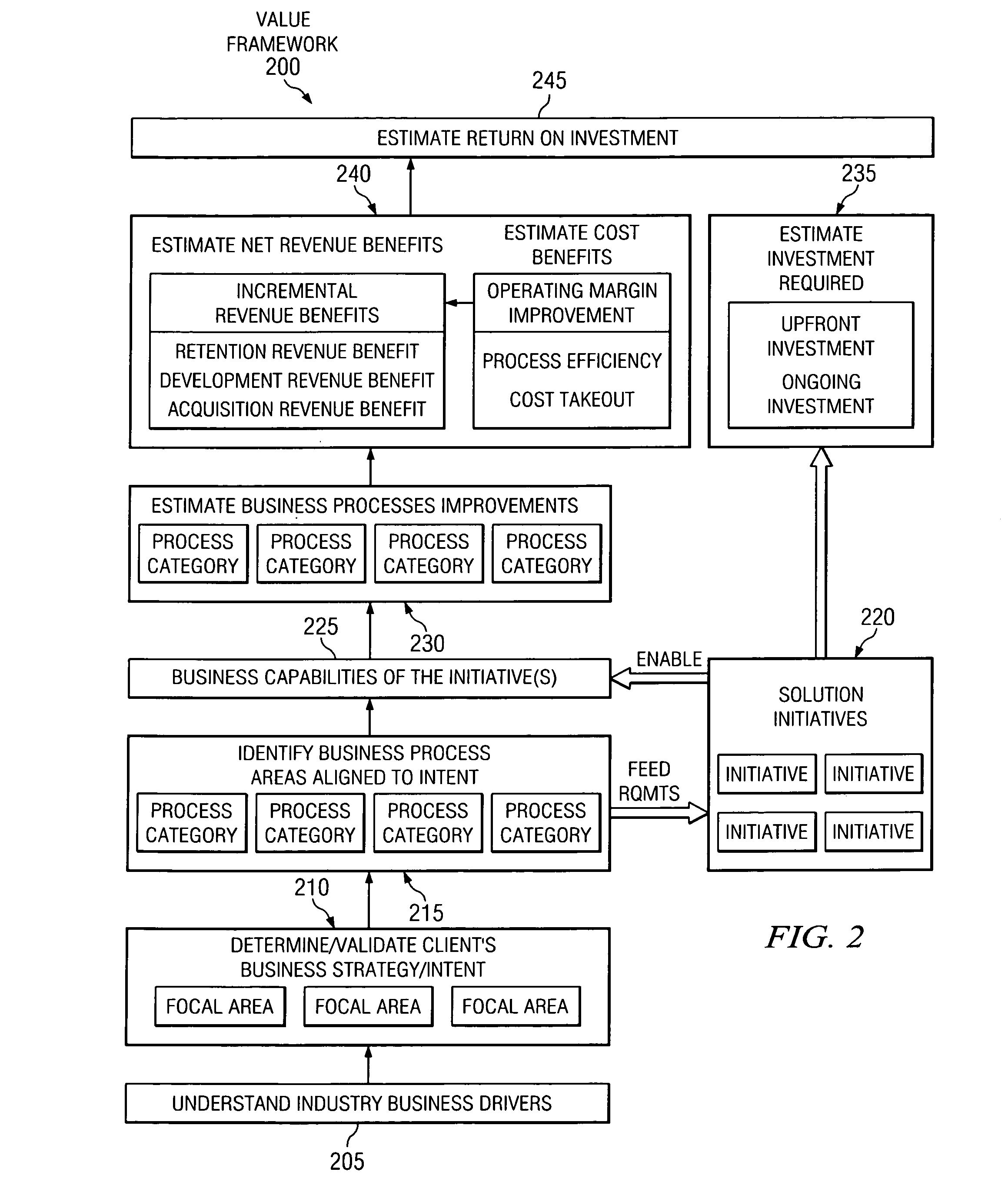

Method and apparatus for a value framework and return on investment model

InactiveUS20050137950A1Quickly and accurately estimateFinanceForecastingEnterprise architectureFinancial impact

A method and system for calculating the return-on-investments (ROI) for an enterprise architecture. The present invention discloses a unique set of metrics which provides improved accuracy for the economic and architecture for the construction of future systems. A preferred embodiment of the present invention focuses on developing process improvement assumptions associated with estimating the impact of the proposed capabilities. It includes the following components: an understanding of the client's strategic drivers, an understanding of the key business process areas, an identification of the business capabilities that a solution can offer the client, an estimation of the business processes improvements, and an estimation of the financial impact the proposed solution will have on the client. The value framework and ROI model of the present invention incorporates a client's strategic position and key processes before the benefits of a proposed solution or initiative can be estimated.

Owner:IBM CORP

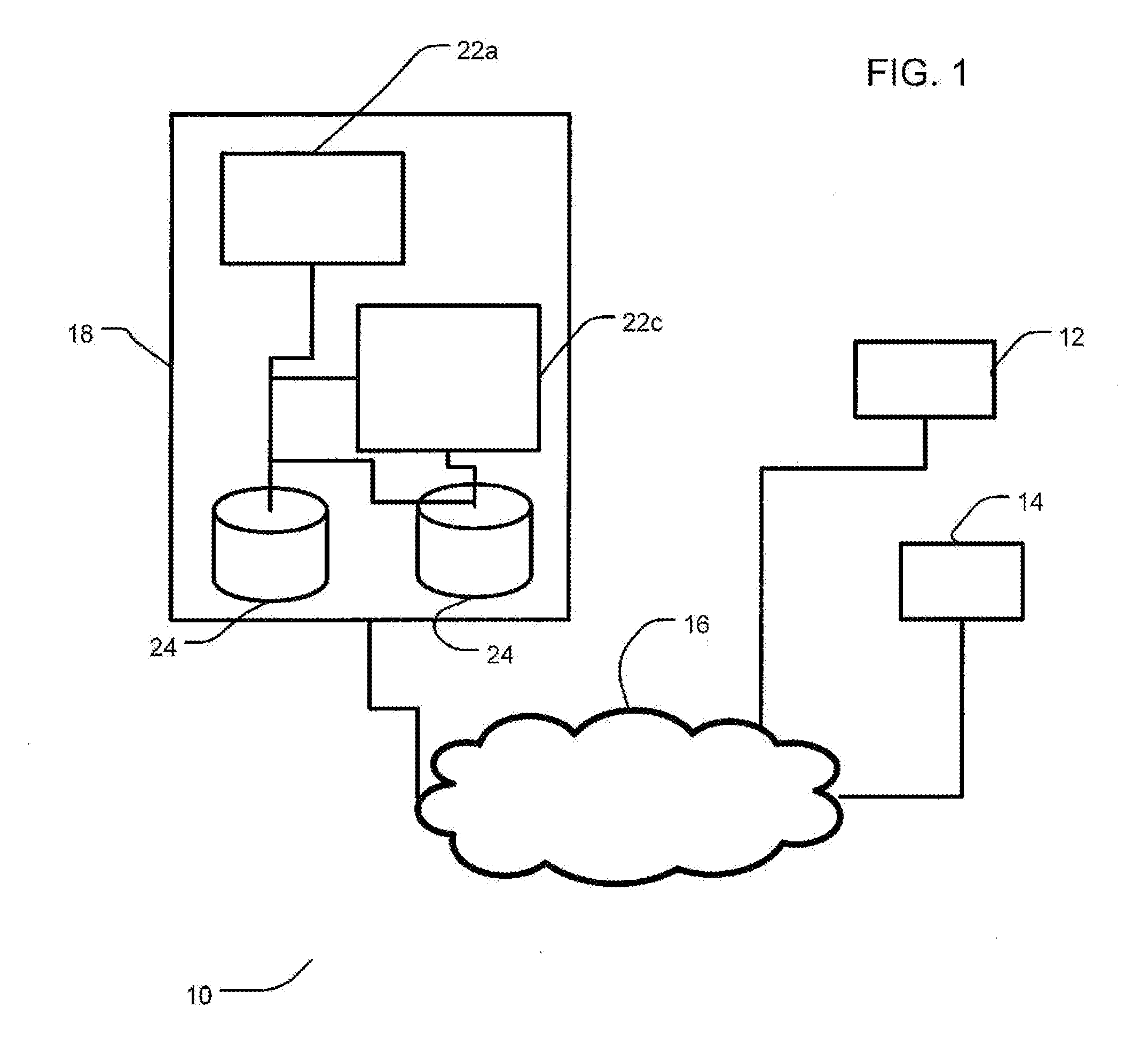

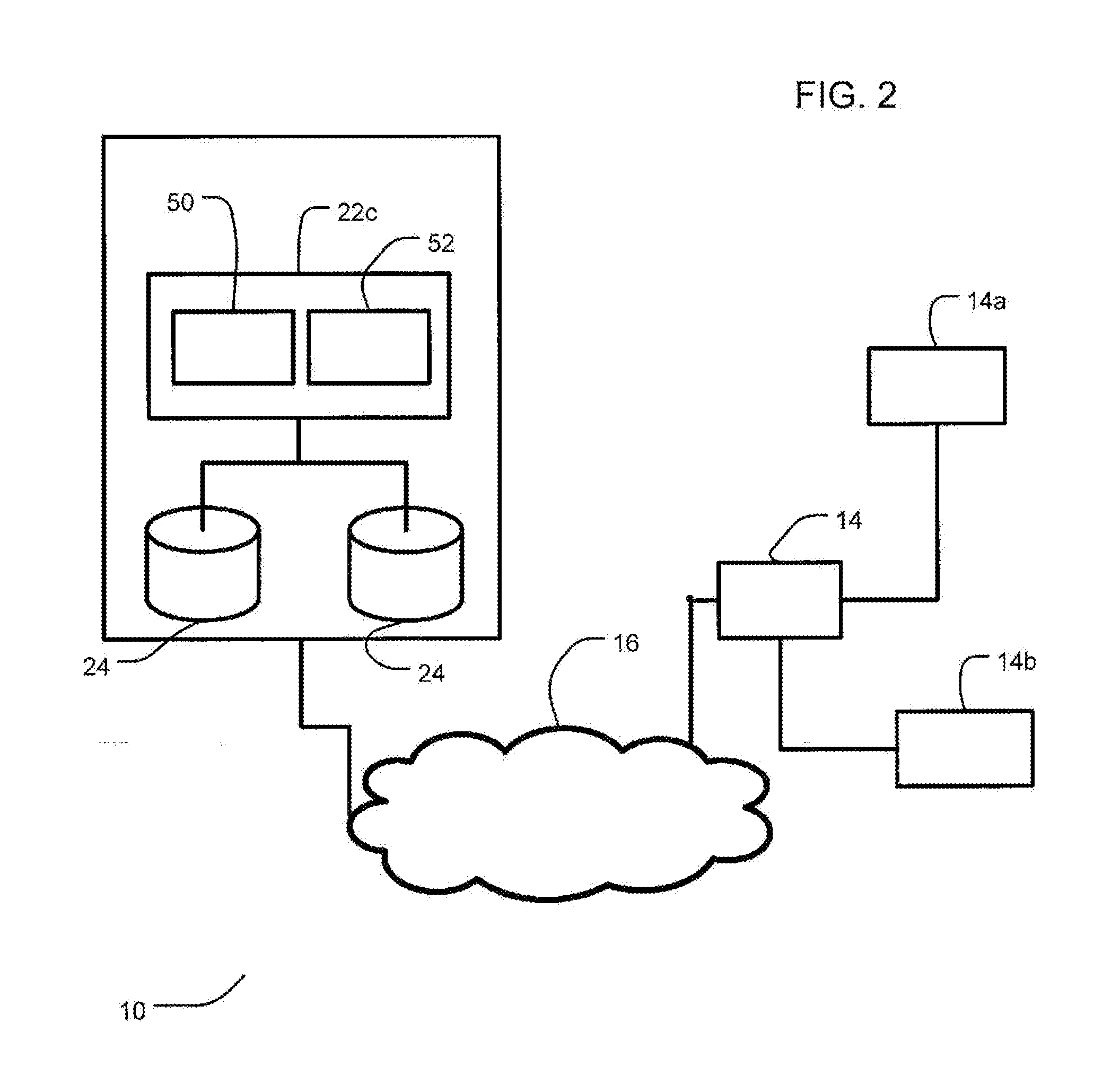

System, method, and computer program for manufacturing estimation production assembly and inventory management

The present invention relates to novel systems and methods for manufacturing estimation, production assembly and inventory management. In an embodiment, a system is provided to create and respond to RFPs, perform capacity planning for an eventual production line, efficiently implement the production line in software, and track detailed warehouse data, including transaction data. Such tracking may allow process improvement, report generation, and market research analysis. In an embodiment, one or more systems may be used to implement one or more aspects of the present invention.

Owner:NULOGY CORP

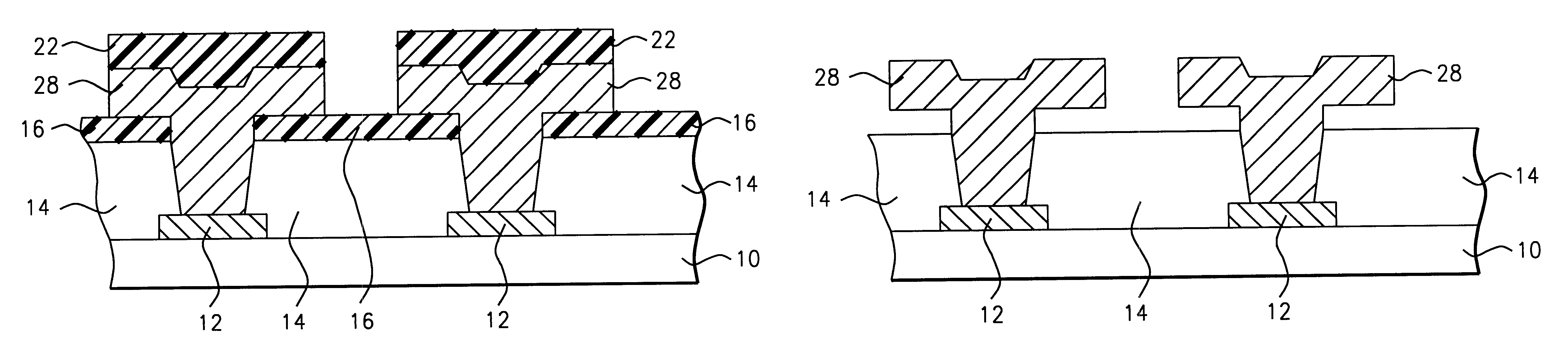

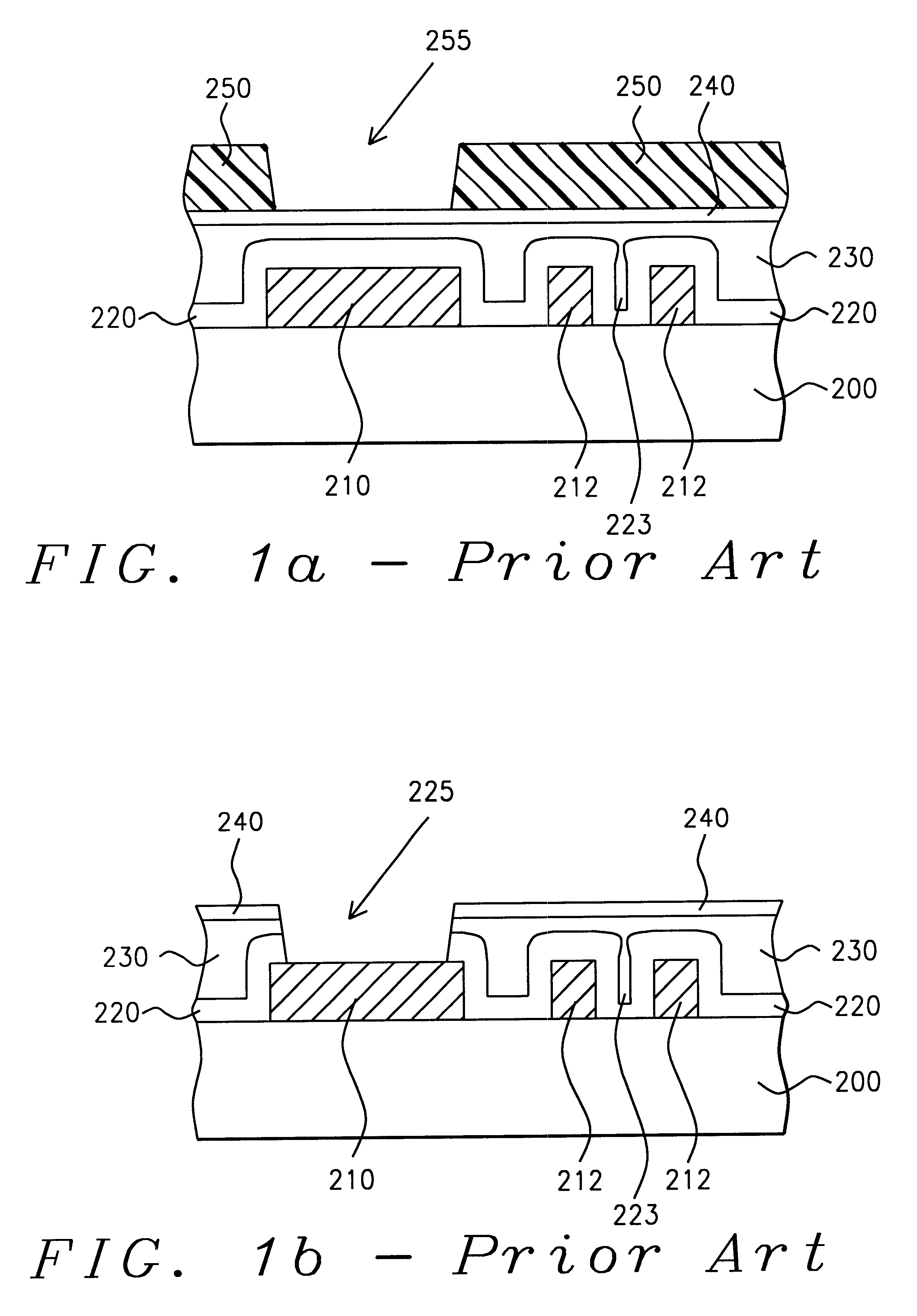

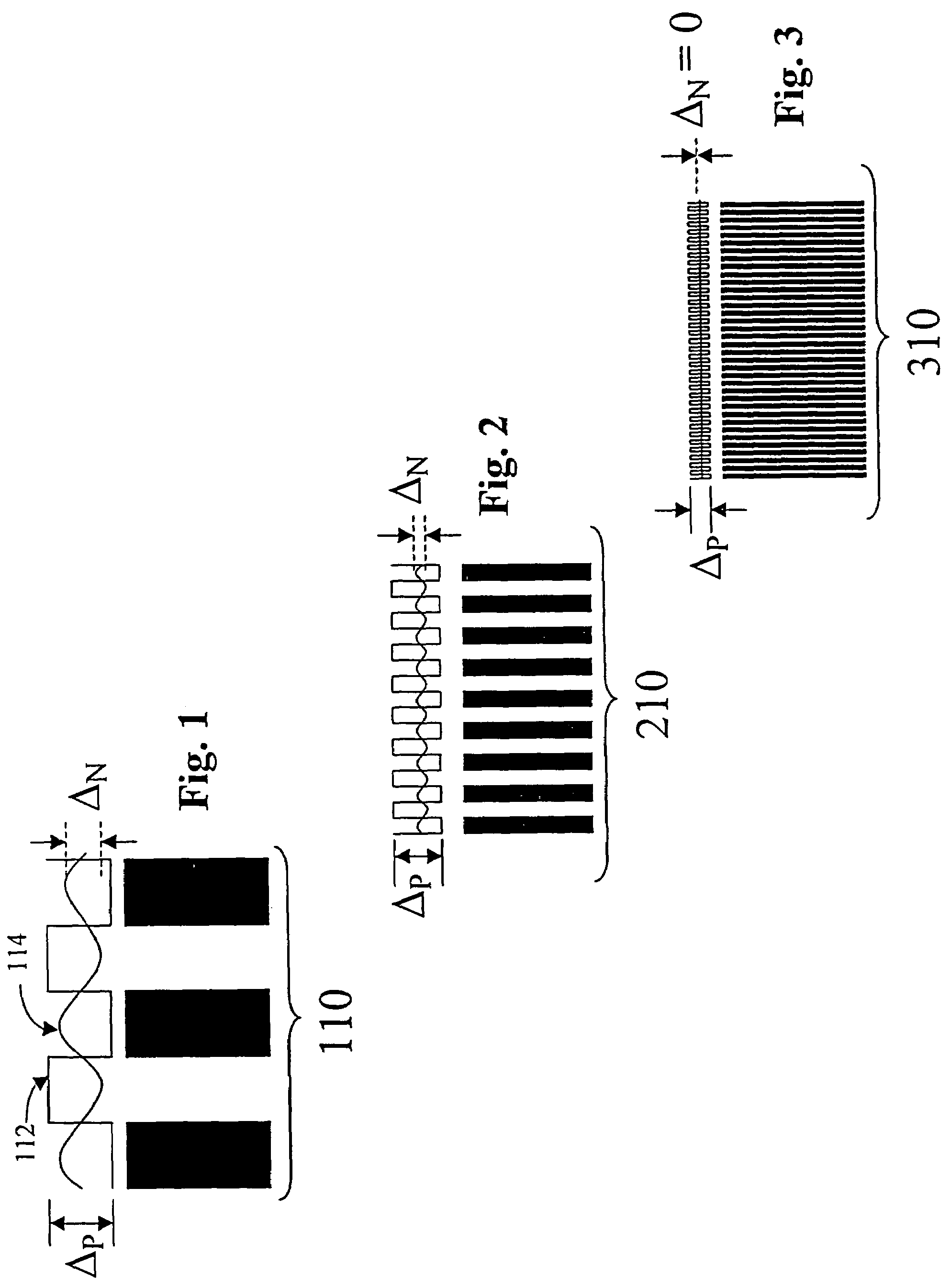

Process improvement for the creation of aluminum contact bumps

InactiveUS6479376B1Semiconductor/solid-state device detailsSolid-state devicesSputter depositionPhotoresist

A new method is provided for the creation of an aluminum bump on a surface of a semiconductor device. A patterned layer of aluminum overlying a substrate is created, the patterned layer of aluminum is the layer of aluminum over which a contact bump is to be created. A layer of passivation is deposited, a first layer of photoresist is deposited for the creation of an opening in the layer of passivation that partially exposed the surface of the patterned layer of aluminum. This patterned first layer of photoresist remains in place, a layer of aluminum is sputter deposited, a second layer of photoresist is deposited which is patterned and etched for the creation of the aluminum bump overlying the patterned layer of aluminum. The aluminum solder bump is created by etching the deposited layer of aluminum. After the solder bump has been created, the patterned first and the second layers of photoresist are removed in one processing step, leaving in place the solder bump.

Owner:TAIWAN SEMICON MFG CO LTD

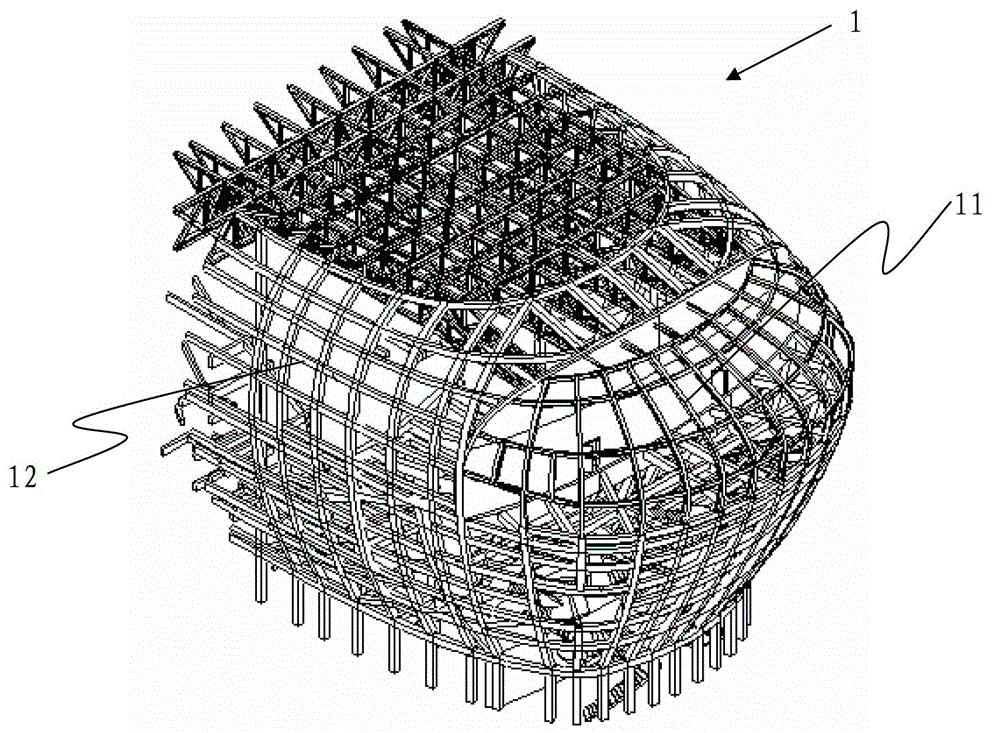

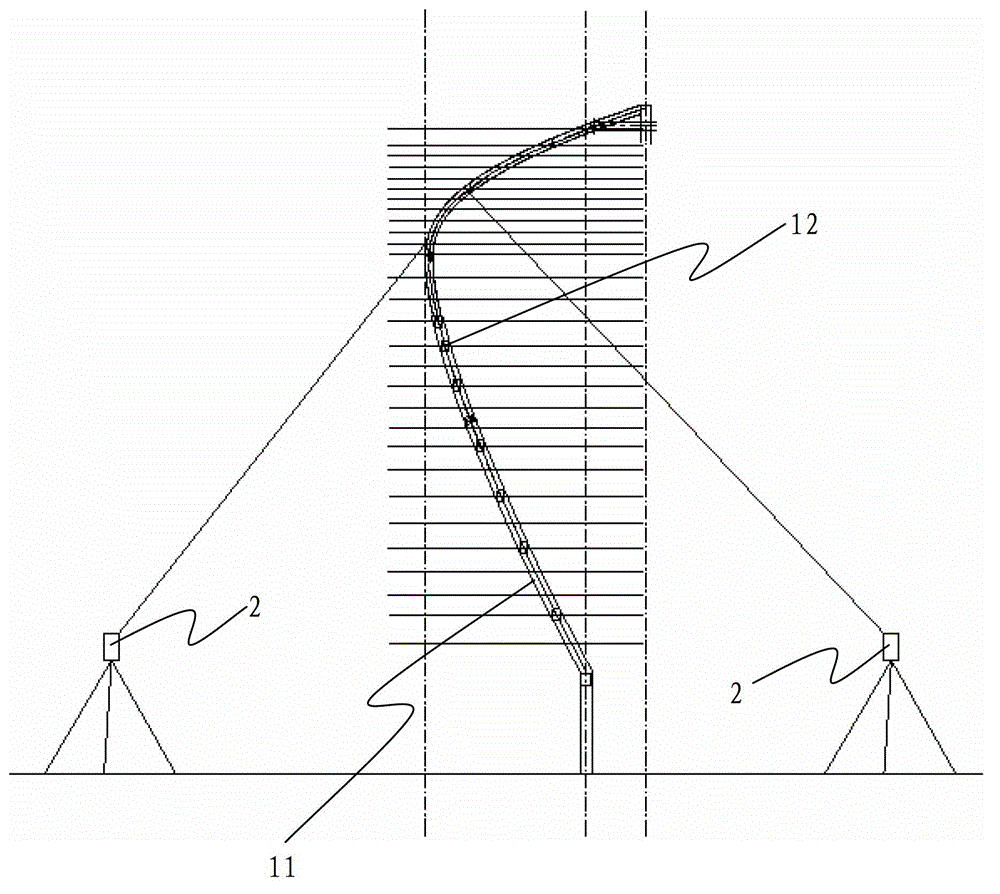

Construction method of large-sized arc-shaped wall

The invention discloses a construction method of a large-sized arc-shaped wall. The method mainly comprises the following steps of: measuring and positioning; erecting a scaffold; mounting an arc-shaped in-column section steel column; binding a steel bar on the periphery of the section steel column; measuring and positioning, mounting an arc-shaped annular beam inner steel bar on the section steel column, and binding and fixing; mounting and fixing an arc-shaped column and an arc-shaped annular beam template on the steel bar; pouring concrete to form the arc-shaped column and an arc-shaped annular beam; measuring and manufacturing an arc-shaped plate; and mounting and fixing the arc-shaped plate on the arc-shaped column and the arc-shaped annular beam. According to the construction method of the large-sized arc-shaped wall, vertical sectioned construction is adopted, inner section steel and a steel bar structure of the arc-shaped column and the arc-shaped annular beam are erected layer by layer; the template is bound and is poured and molded; the poured arc-shaped column and the arc-shaped annular beam are continually provided with the upper-layer arc-shaped column and the arc-shaped annular beam; and finally, the arc-shaped plate which is designed and manufactured outside a field is mounted on the arc-shaped column and the arc-shaped annular beam, and process improvement can be carried out according to implementation effects.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

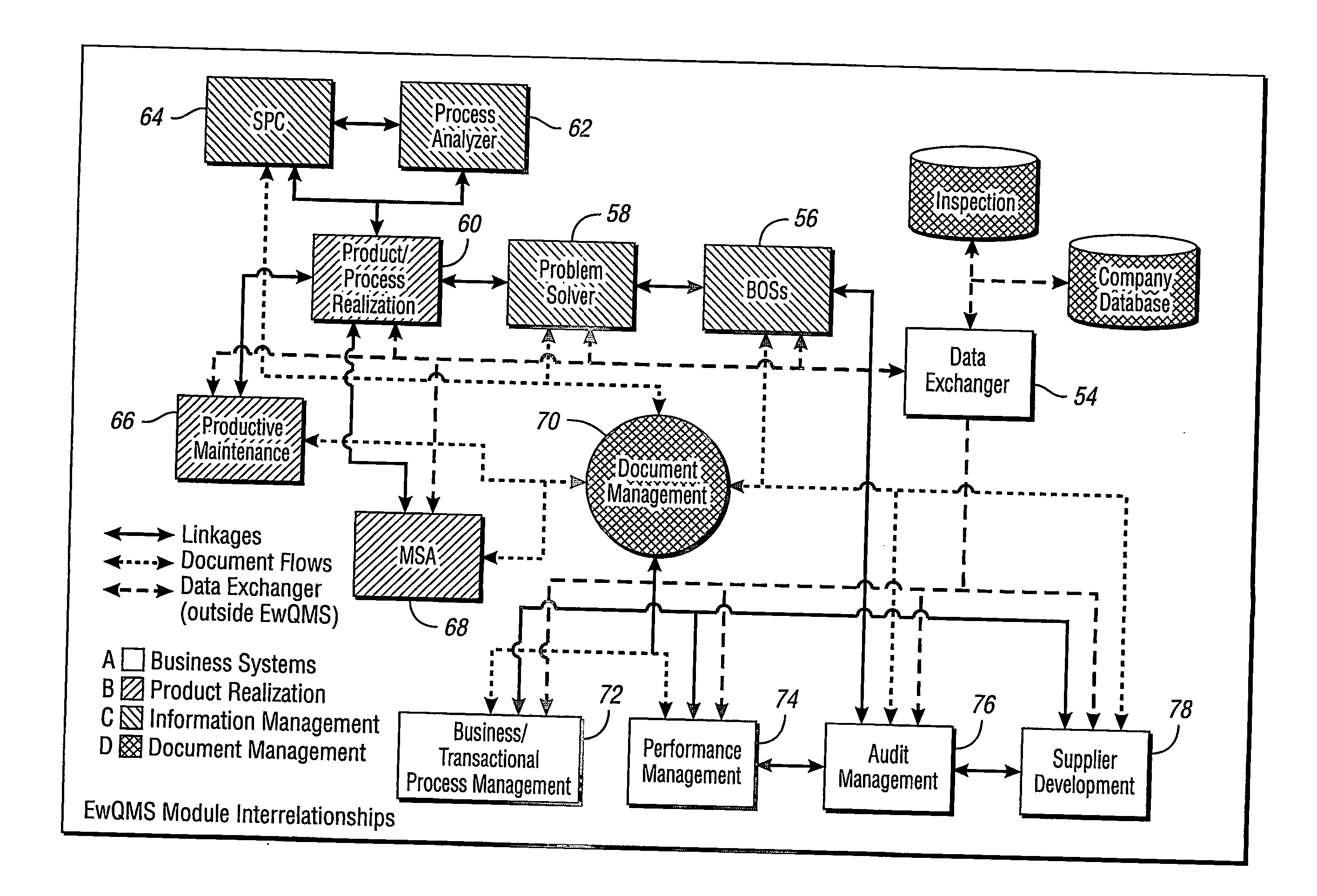

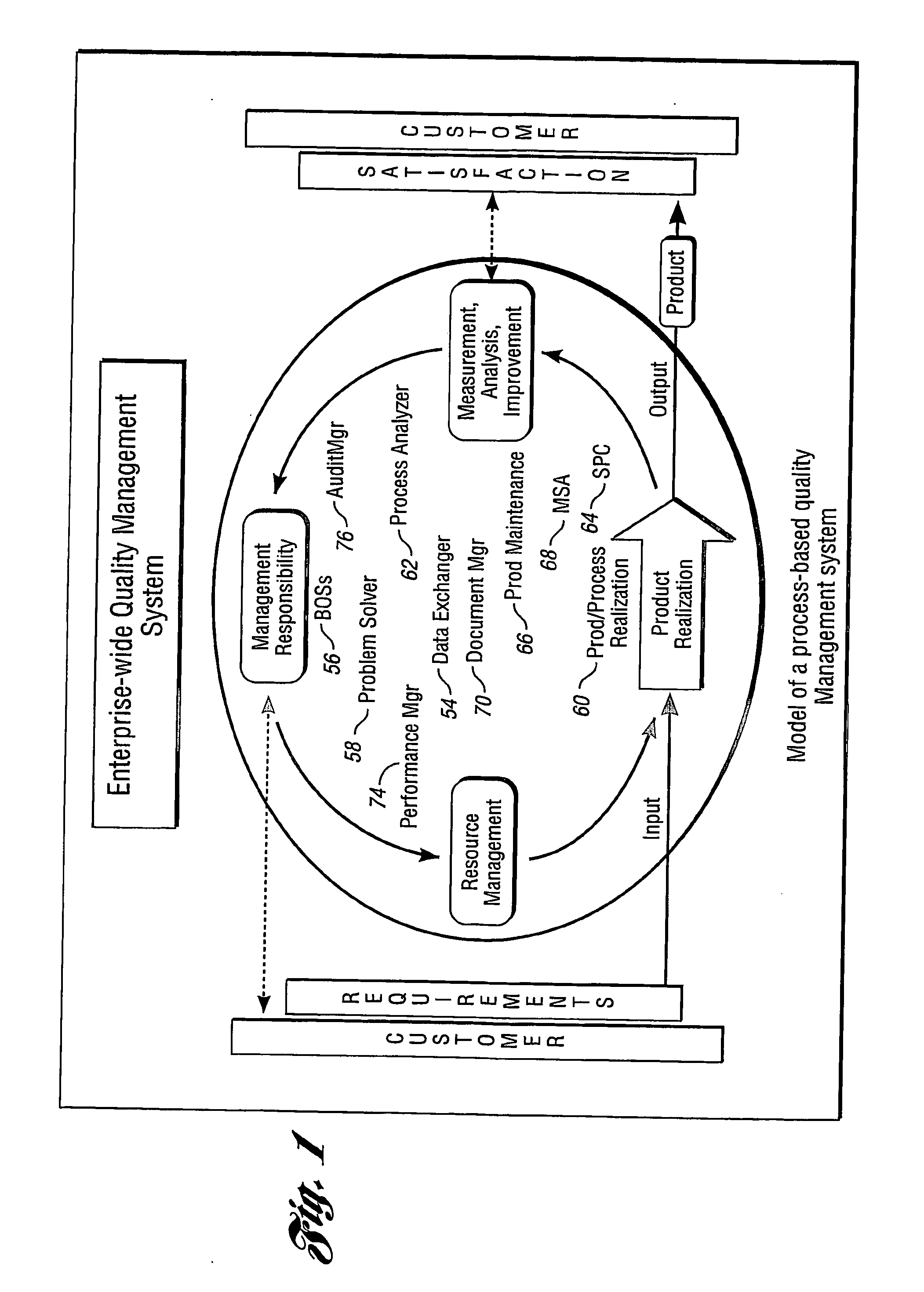

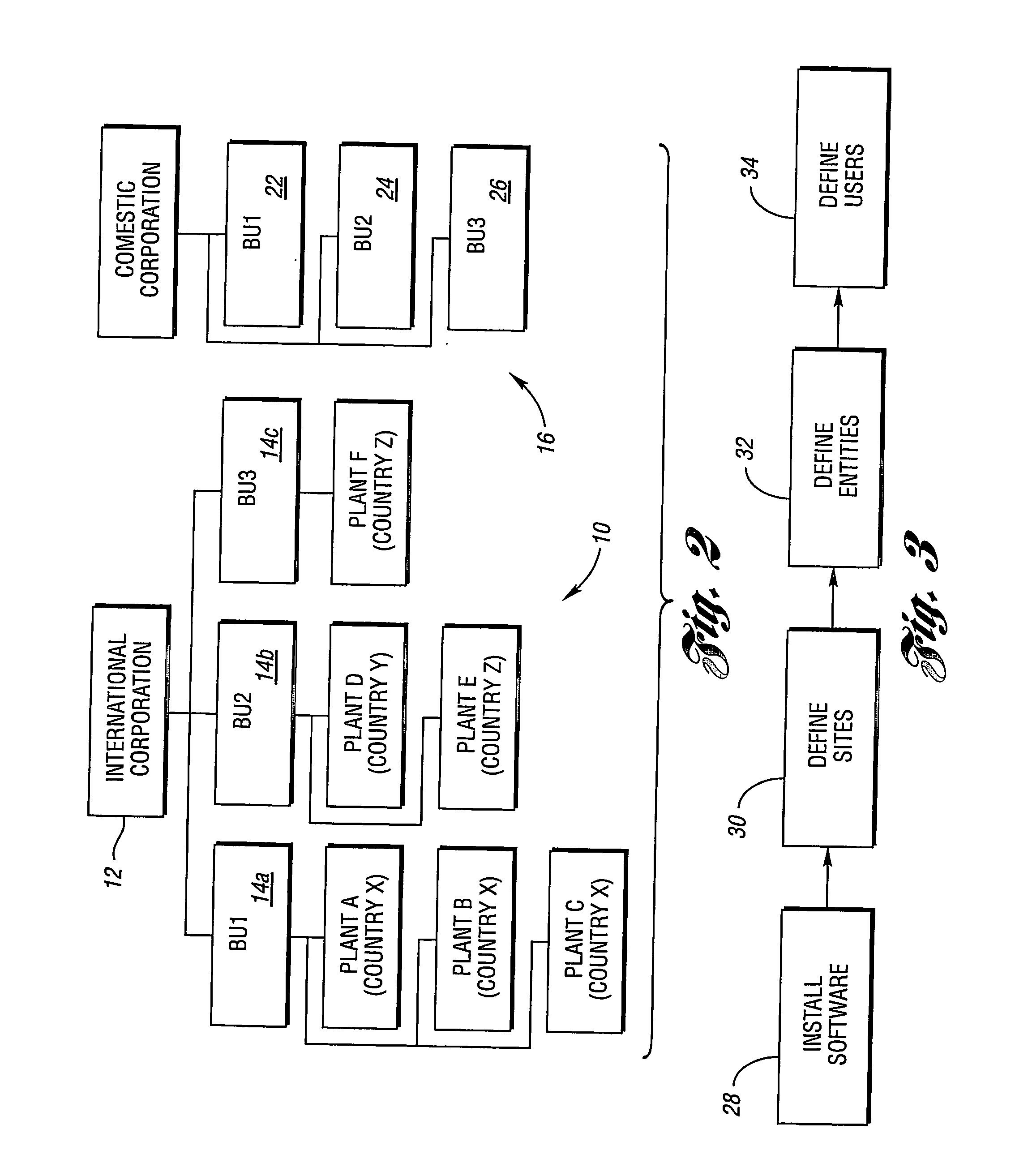

Quality information management system

ActiveUS20060253289A1ForecastingNatural language data processingDocumentation procedurePaper document

Computer system for controlled creation, processing, administration and display of quality information within an enterprise. Linkages may be defined among enterprise entities, process / product development attributes, strategies, goals, process improvement opportunities, etc. Visual analysis of data associated with the linkages is provided in an interactive fashion. Linkages may also be defined among online quality-related documentation throughout an enterprise such that information is automatically propagated / reconciled through the enterprise in a controlled and efficient fashion. The creation of process documentation for new products is facilitated based on a concept of content / document inheritance.

Owner:OMNEX SYST

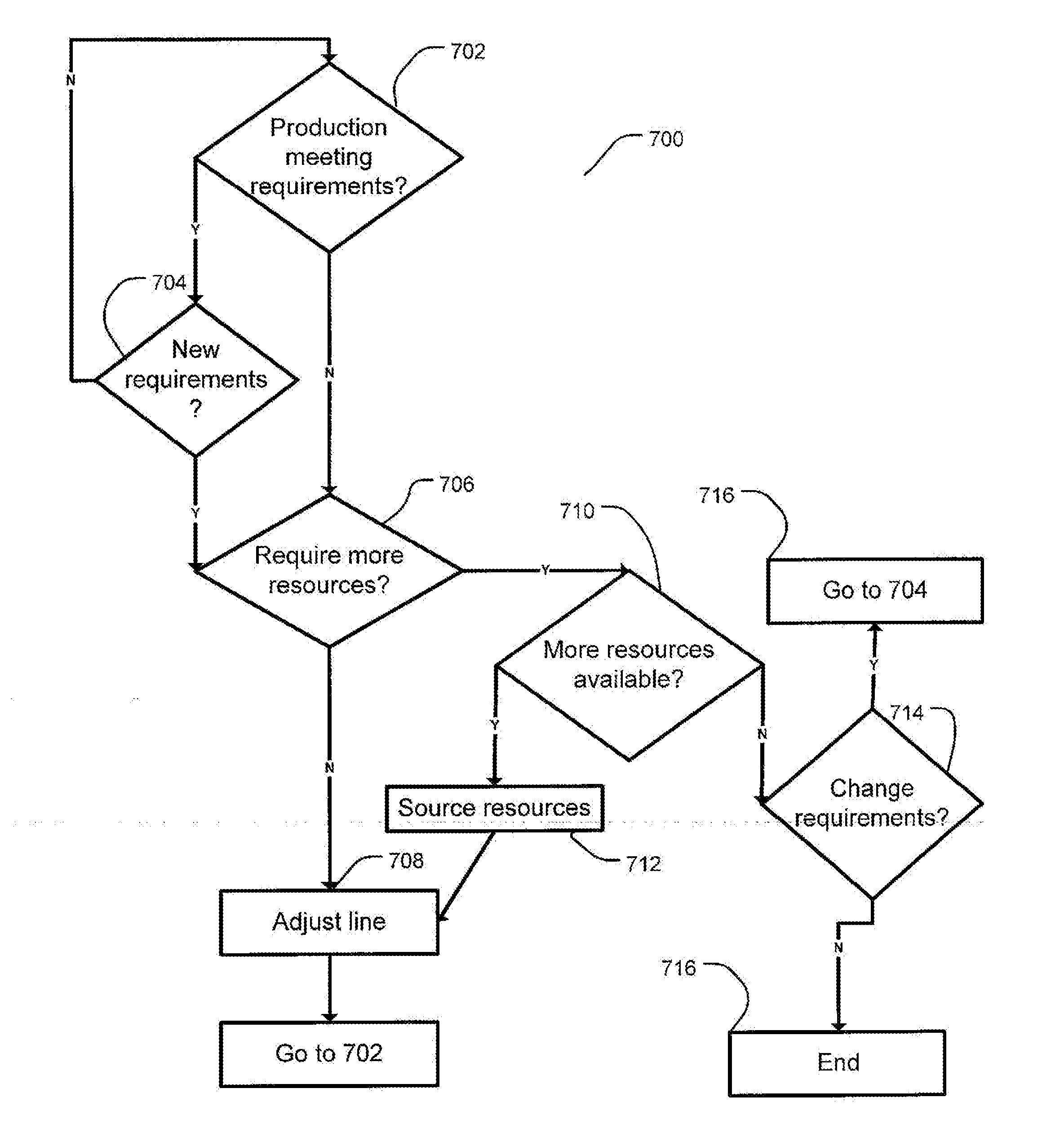

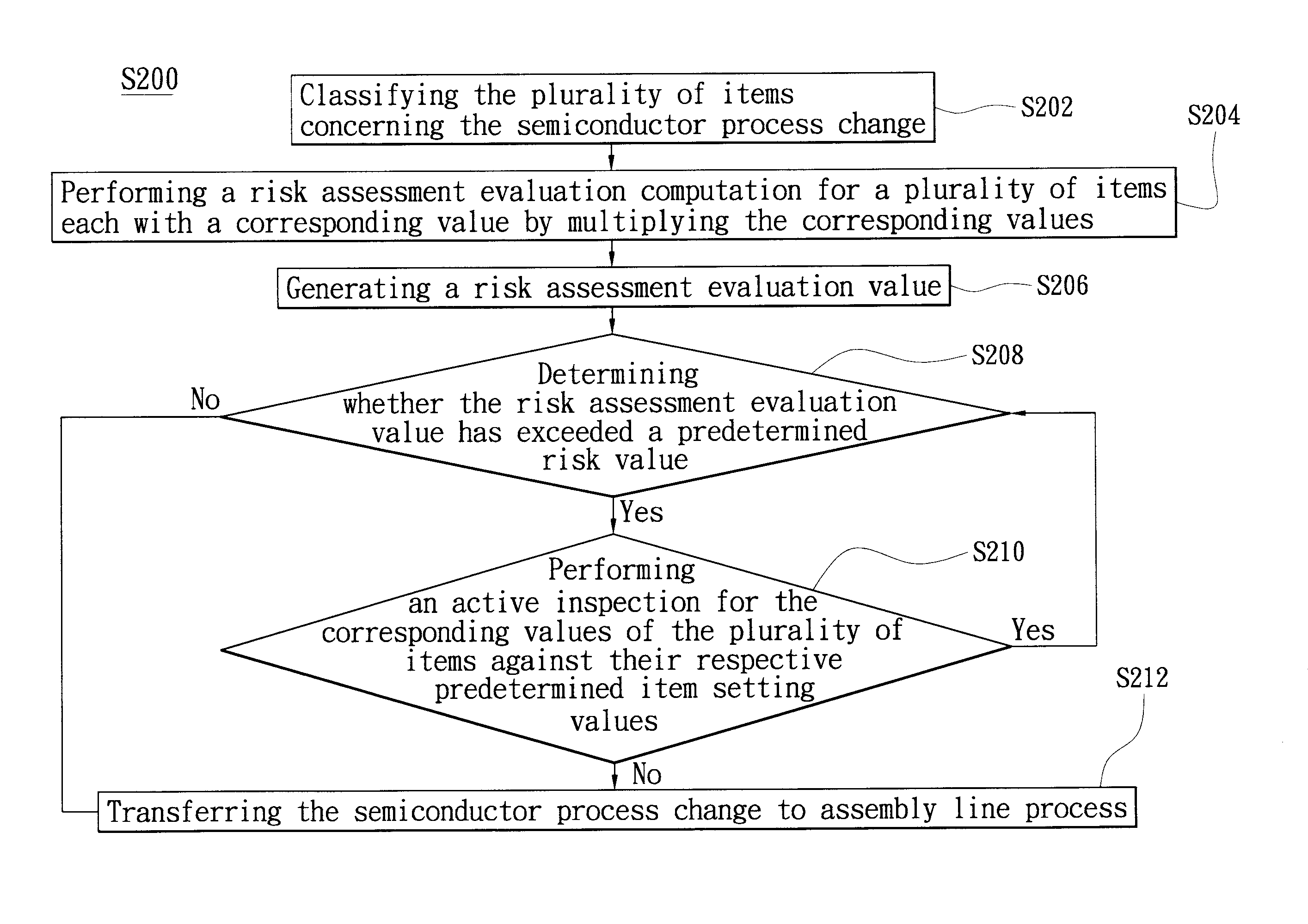

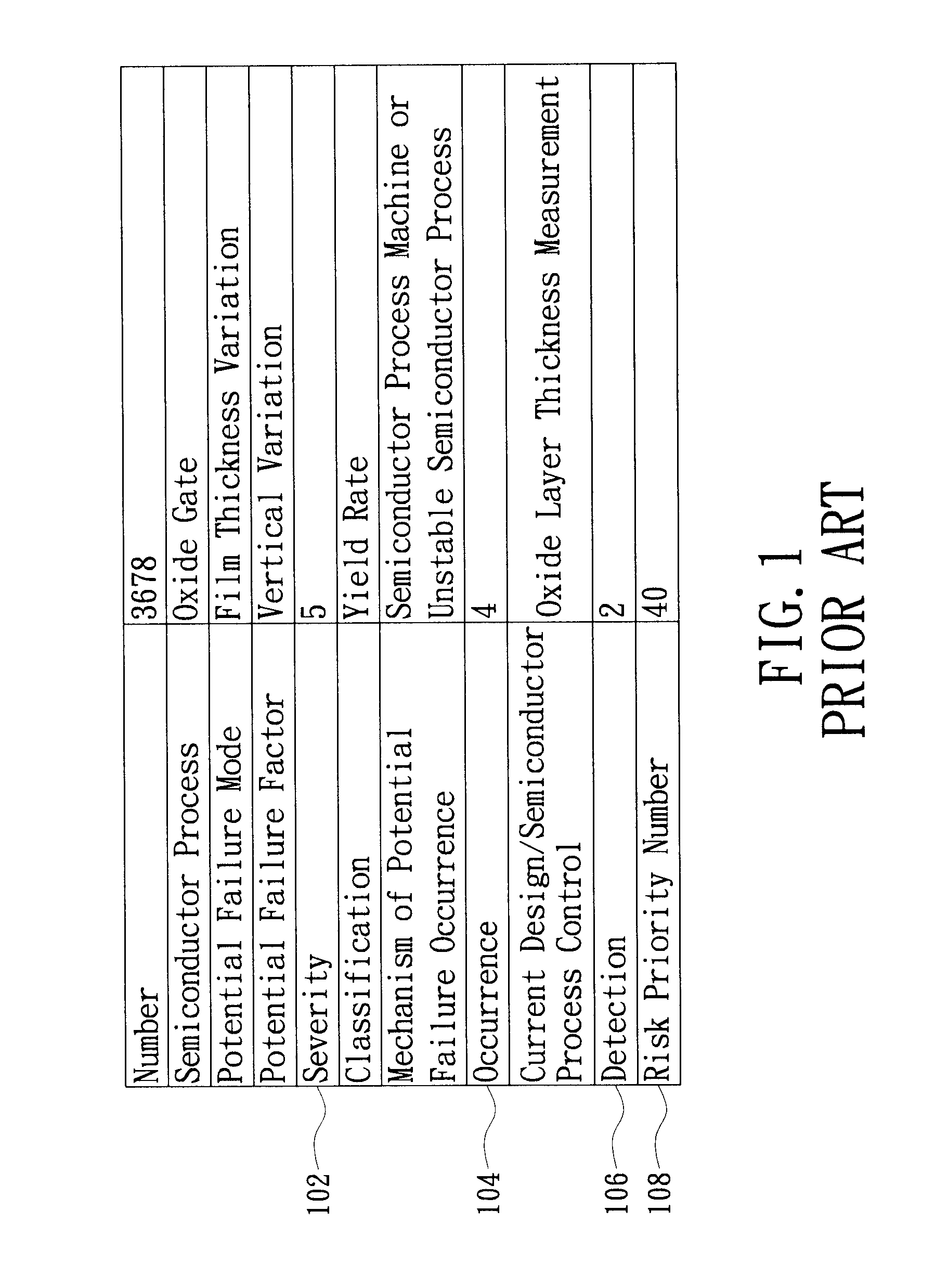

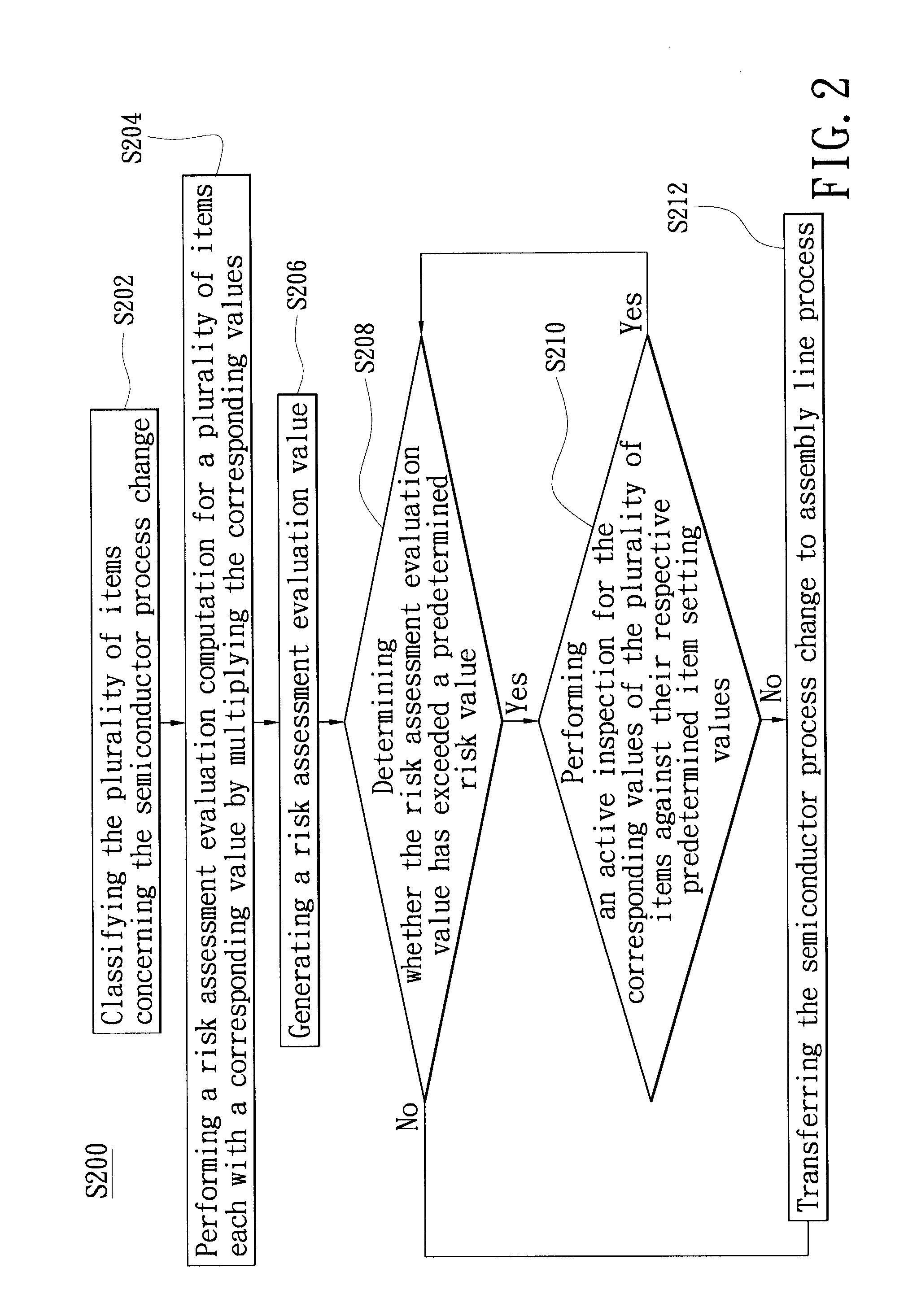

Assessment method for process improvement decisions

InactiveUS20090276261A1Reduce learning cycleLessen process change costFinanceResourcesAssessment methodsProcess improvement

A risk assessment method for process improvement decisions applying for semiconductor process change comprises: performing a risk assessment evaluation to compute a polarity (plurality?) of items corresponding to their values, generating a risk assessment evaluation value to determine if the risk assessment evaluation value is in a risk setting value, go to next two steps; not, go to next step; performing an active inspect for the polarity (plurality?) of items corresponding to their item setting values, if not satisfied with the active inspect, repeat the above step; if not, transferring the semiconductor process change to online process.

Owner:INOTERA MEMORIES INC

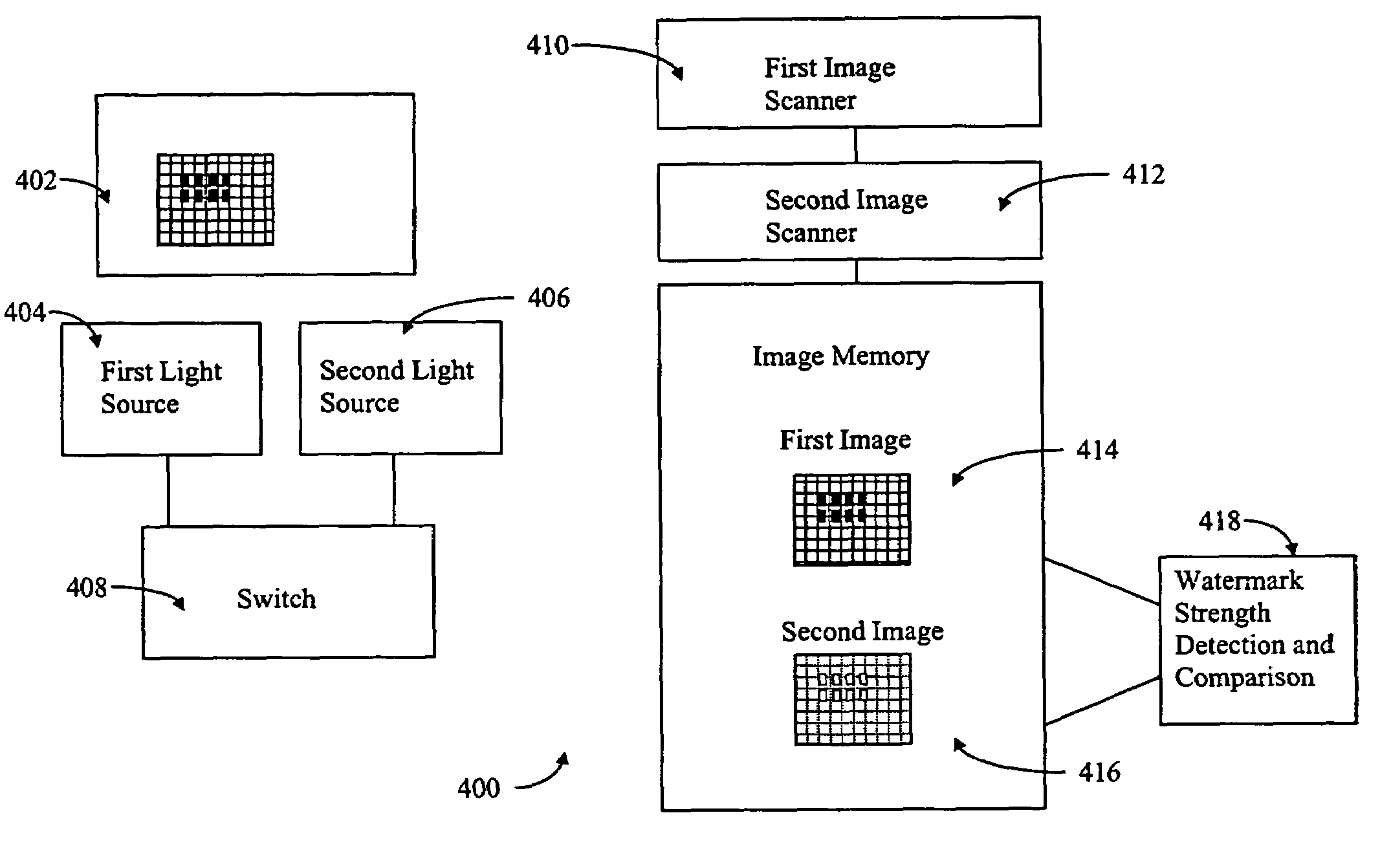

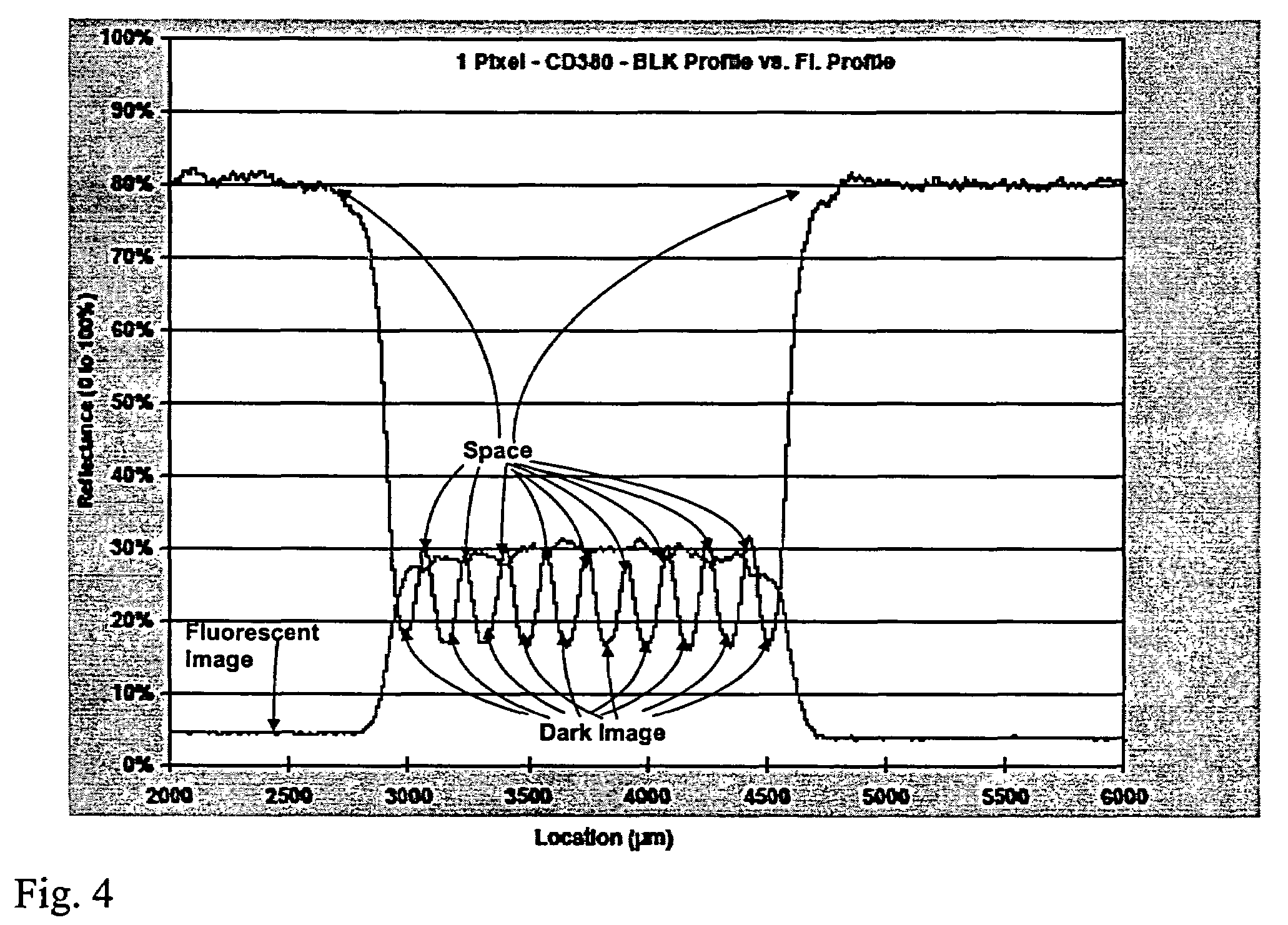

Fragile water mark printed with two component inks and process

InactiveUS7114657B2Reduce complexityRecord carriers used with machinesSensing by electromagnetic radiationFluorescenceUltraviolet lights

Improvements are provided in processing of documents to increase their security and / or decrease the complexity of testing for authenticity. Methods for printing documents with security markings and methods and apparatus for authenticating documents are described. In one aspect a document is printed with a security marking comprised of an image printed in at least two image segments. The image can be printed with an ink capable of forming images which are visible both to viewing under white light and as fluorescent images when irradiated with ultraviolet light, the segments having features of different sizes. The relative sizes of the two image segments will provide a detectable difference in fluorescent image sharpness. The apparatus provides means, all of which are simple and easily available for carrying out the methods.

Owner:PITNEY BOWES INC

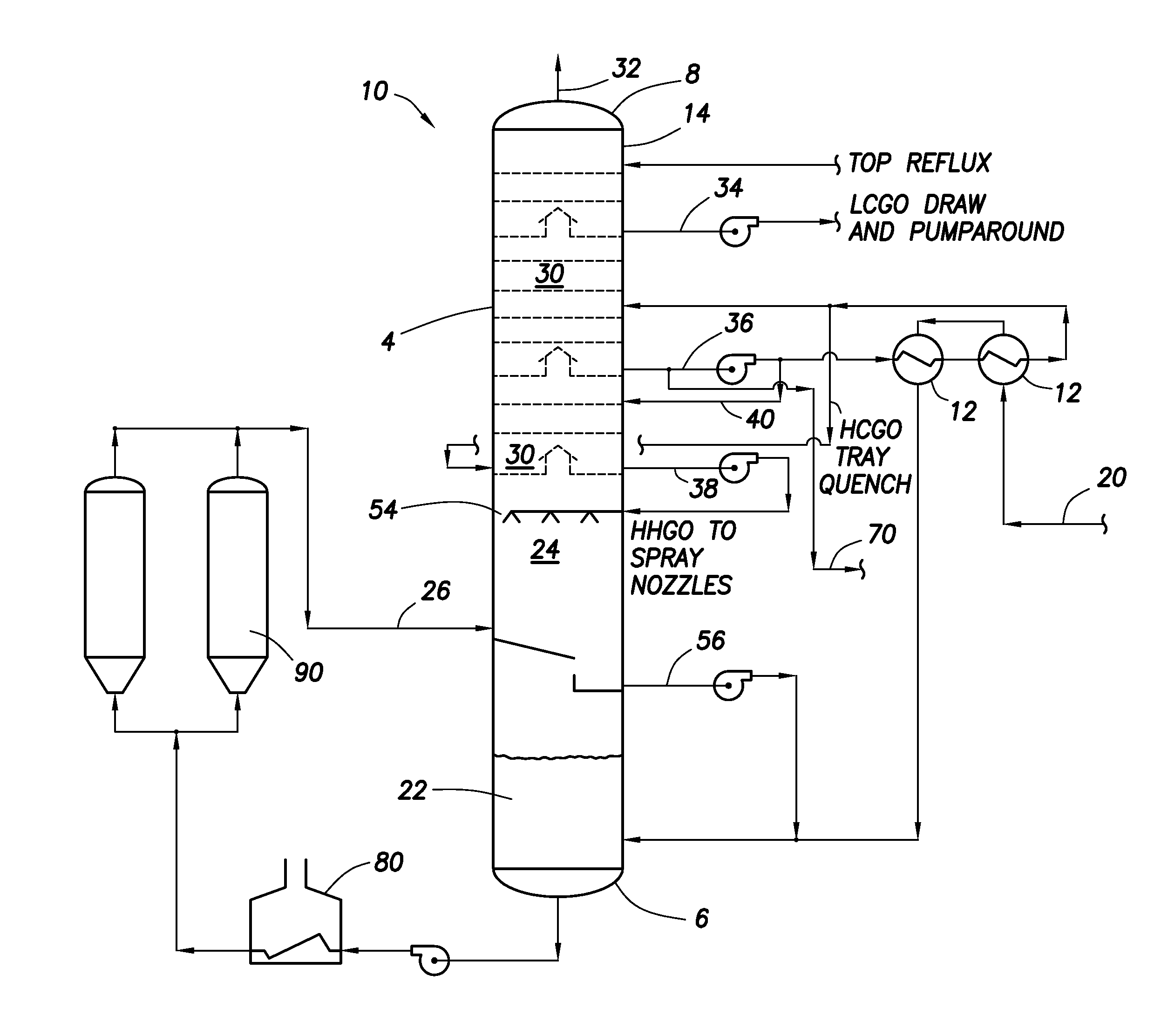

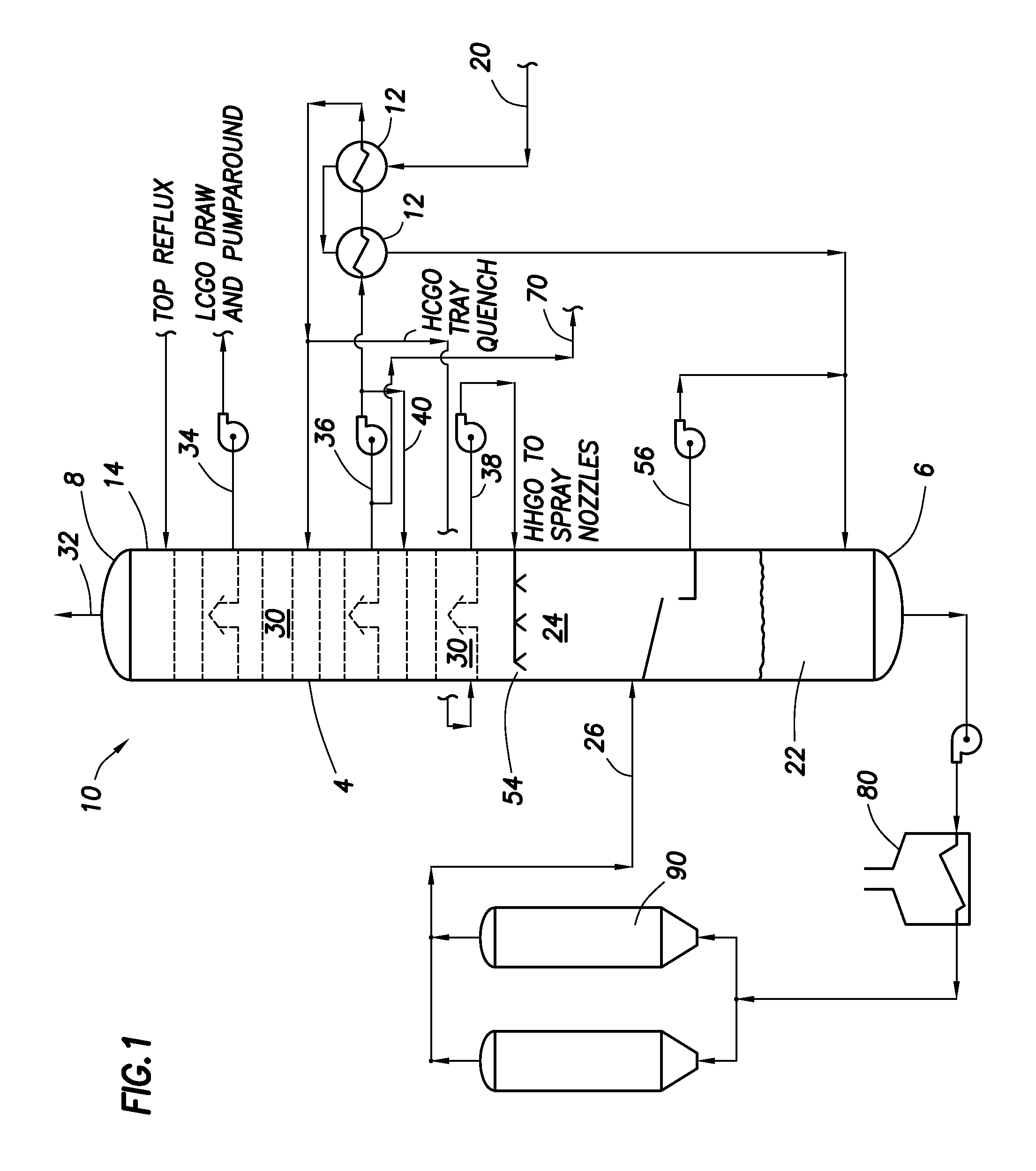

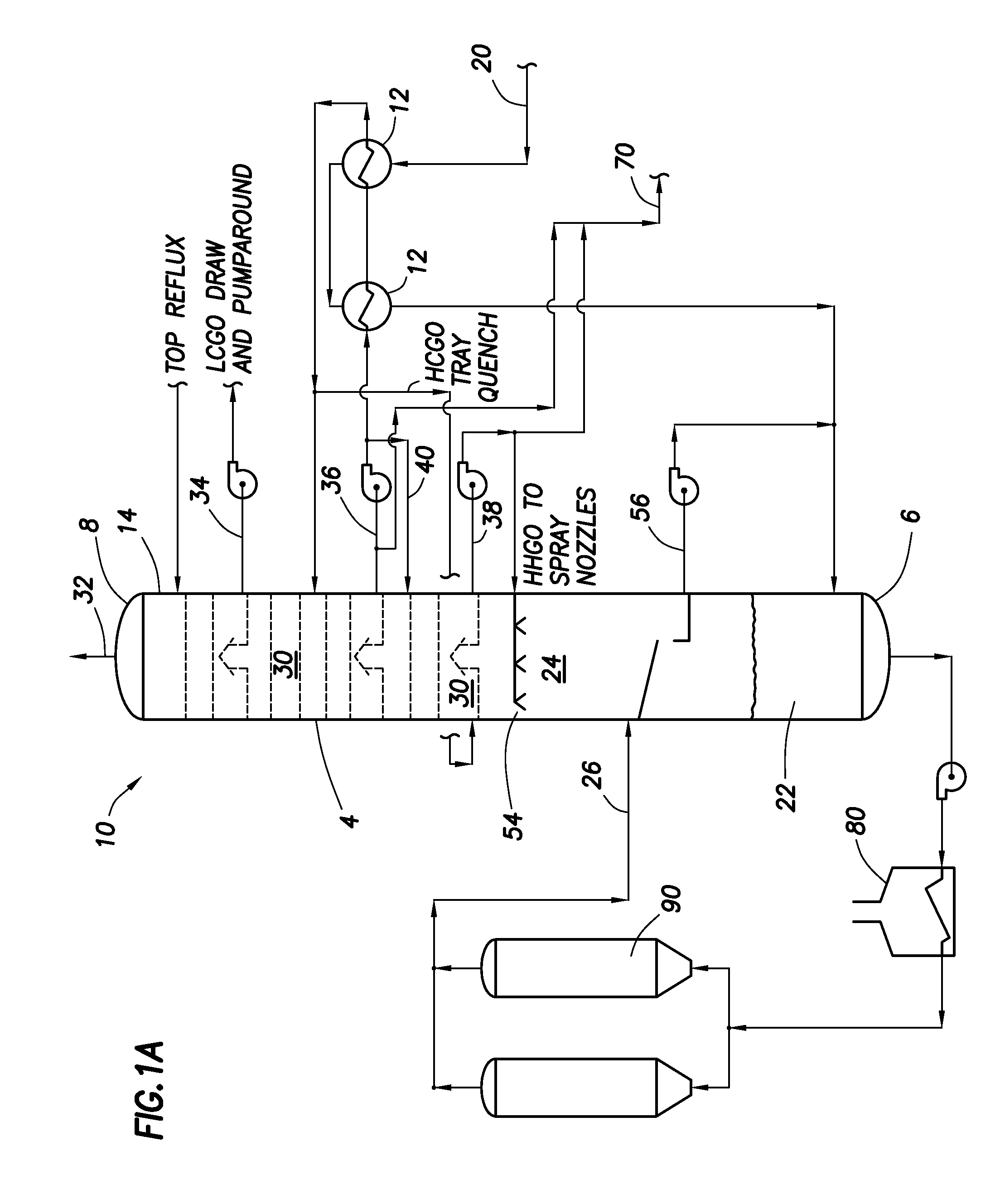

Efficient method for improved coker gas oil quality

ActiveUS20100270208A1Thermal non-catalytic crackingCombustible gas coke oven heatingEngineeringOil quality

An efficient delayed coking process improvement for producing heavy coker gas oil of sufficient quality to be used as hydrocracker feedstock.

Owner:BECHTEL ENERGY TECH & SOLUTIONS INC

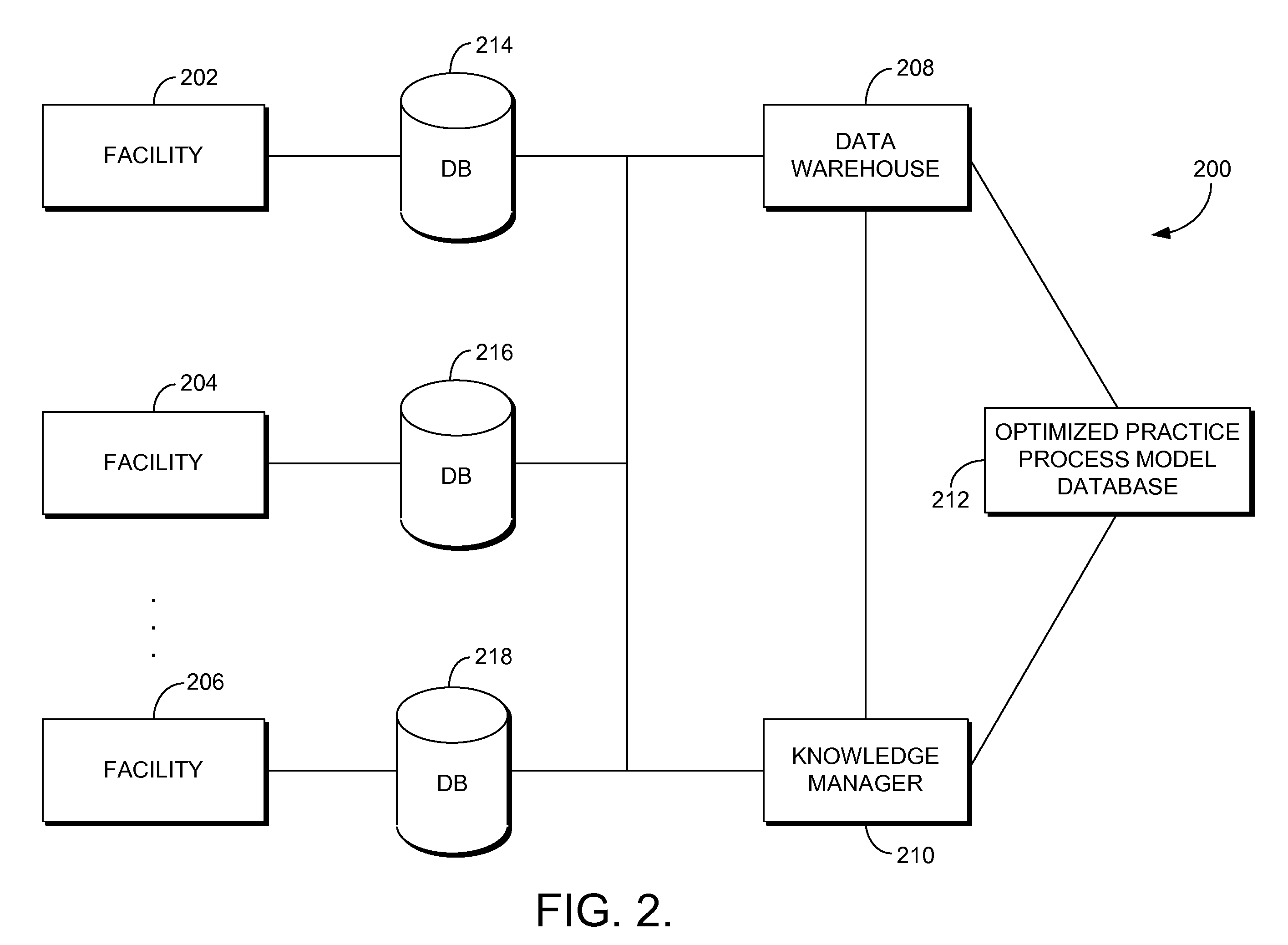

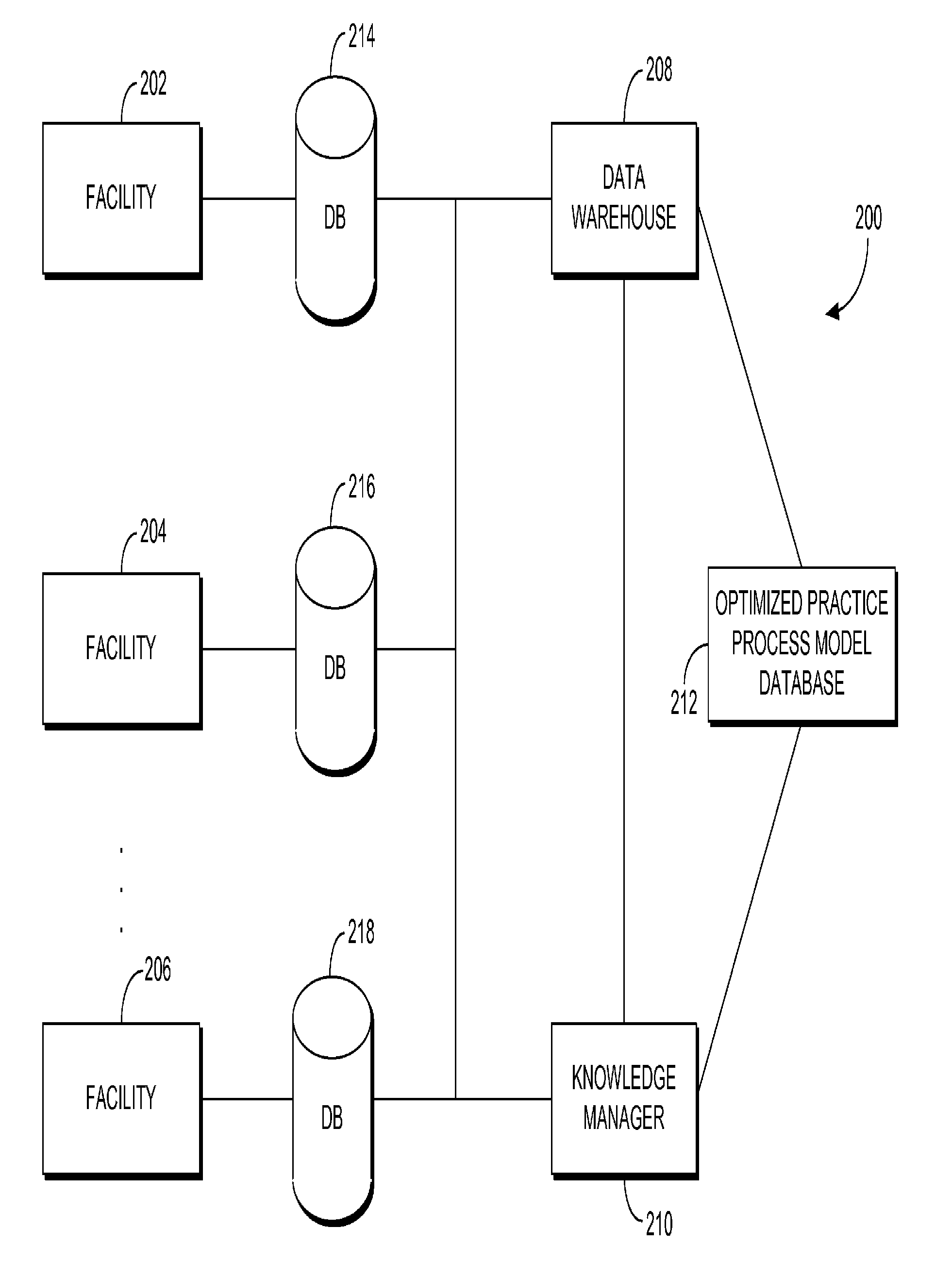

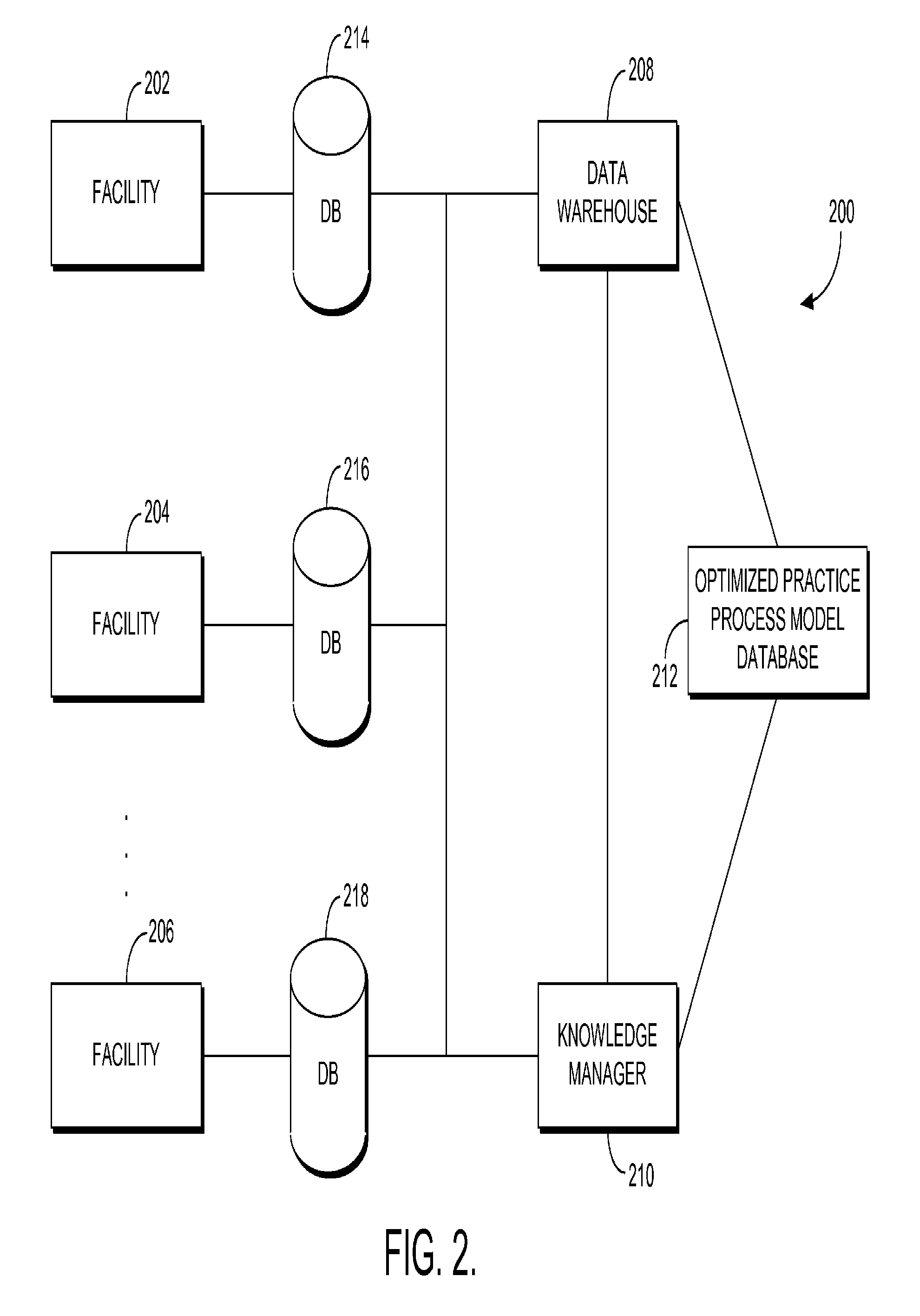

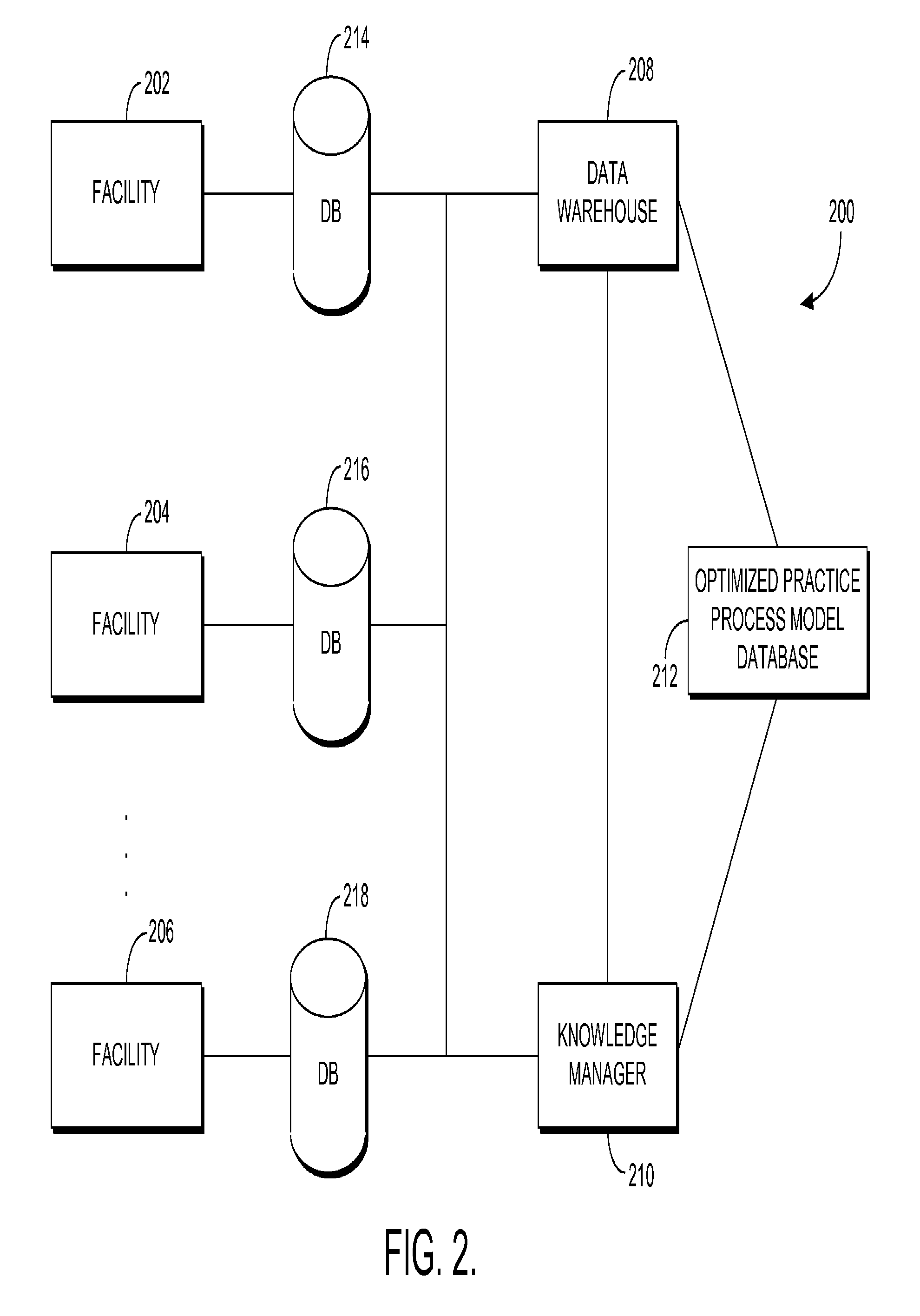

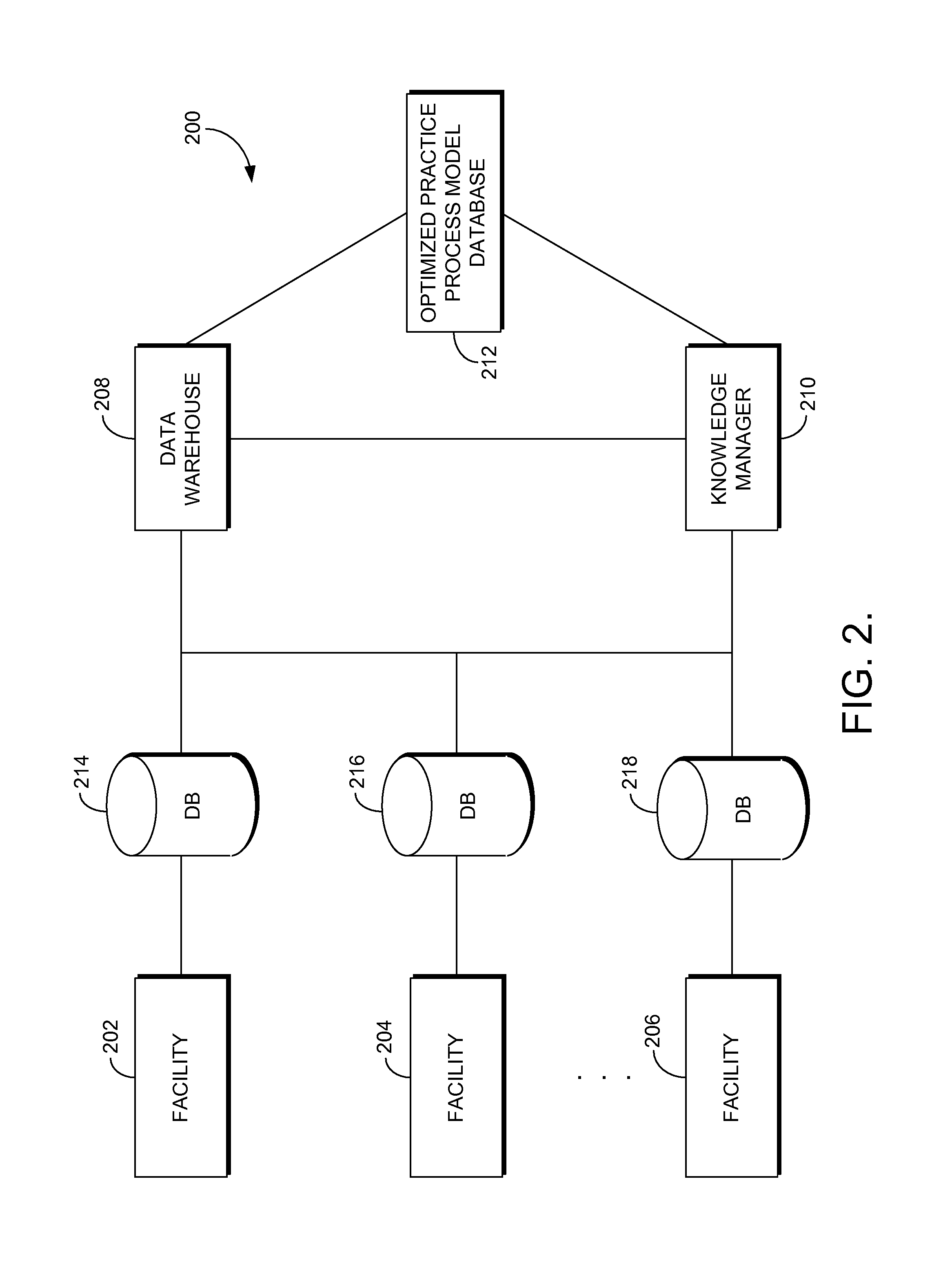

Optimized Practice Process Model for Clinical Process Improvement

ActiveUS20070083385A1Continuous monitoringIncrease opportunitiesDigital computer detailsDiagnostic recording/measuringProcess optimizationGraphics

Systems, methods, and graphical user interfaces are provided for identifying, analyzing, and adopting opportunities for optimizing clinical processes within clinical facilities. An optimized practice process model may be defined for a particular clinical procedure, setting forth an optimal clinical process. In addition, critical levers may be identified within the optimal clinical process, representing the activities that have the greatest impact on outcomes. Clinical facilities may collect current measures for the critical levers, and the current measures may be compared against an optimal, benchmark, and / or target measure. Based on the comparison, opportunities for clinical process optimization may be identified. Those opportunities may then be analyzed and prioritized for adoption into a facility's current practice. Clinical processes within healthcare facilities may be further improved by continuously monitoring facility data and identifying further opportunities of optimization. Further, collected data may be used to refine the optimized practice process model, allowing for further optimization.

Owner:CERNER INNOVATION

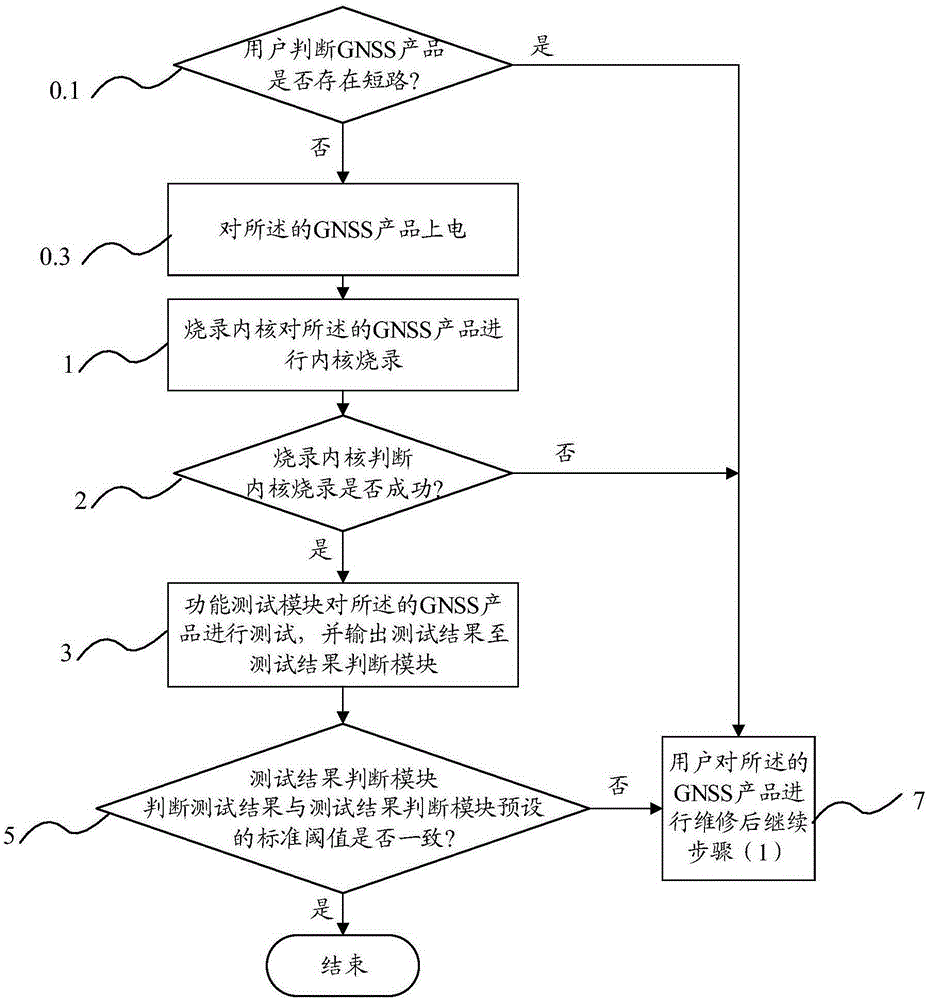

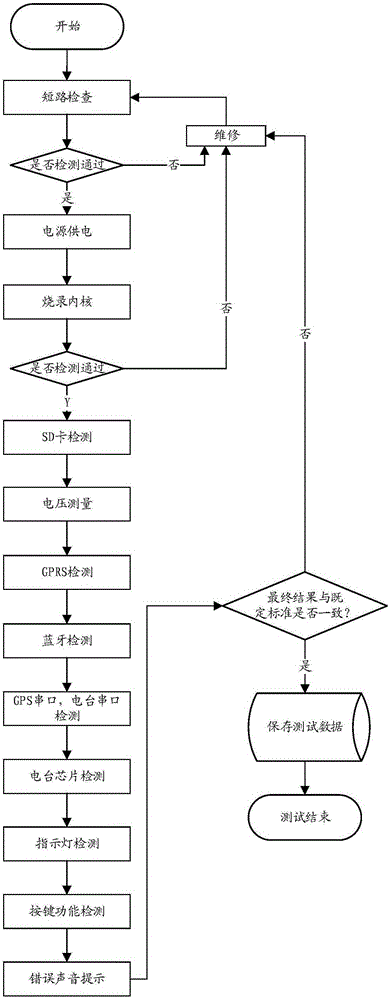

GNSS product automatic test method based on function test

InactiveCN105182371AReduce quality inspection costsSimplify the commissioning processSatellite radio beaconingTest efficiencyFunctional testing

The invention relates to a GNSS (Global Navigation Satellite System) product automatic test method based on function test. A function test module is in connection with a detected GNSS product through a test point, controls the on-off of power-on, burning and detection switches, and successively completes function model test of the GNSS product so as to detect whether each function module of the GNSS product is normal. According to the invention, after the surface mount of the GNSS product, a common operator of a supplier can directly complete mainboard debugging and aging work, requiring no professional debugging personnel to perform test, thereby simplifying a whole debugging process, minimizing manual operation, improving test efficiency and accuracy, meanwhile reducing surface mount quality costs, promoting the surface mount process improvement of the supplier, and realizing win-win.

Owner:SHANGHAI HUACE NAVIGATION TECH

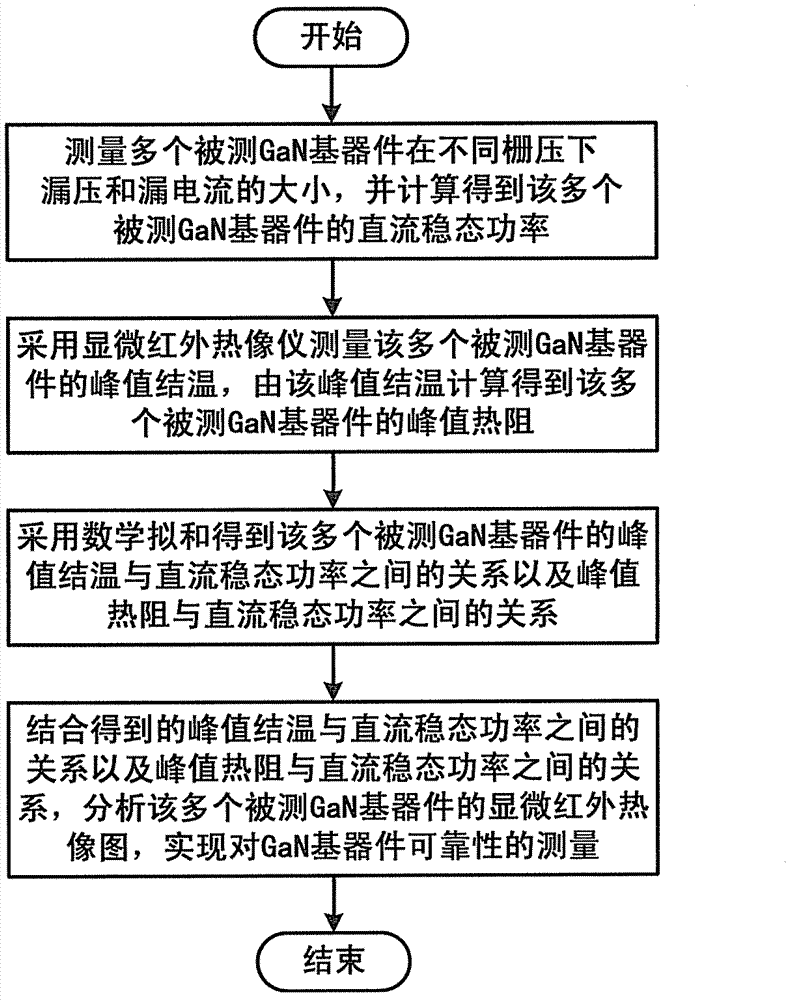

Method for measuring thermal reliability of GaN-based devices

InactiveCN102955113AAdvantages and disadvantages of structureAchieve initial assessmentRadiation pyrometryIndividual semiconductor device testingJunction temperaturePeak value

The invention discloses a method for measuring thermal reliability of GaN-based devices. The method includes: measuring magnitudes of drain voltage and drain current of multiple tested GaN-based devices under different gate voltages, and calculating to obtain direct-current steady-state power of the multiple tested GaN-based devices; using a microscopic thermal infrared imager to measure peak junction temperature of the multiple tested GaN-based devices, and calculating to obtain peak thermal resistance of the multiple tested GaN-based devices according to the peak junction temperature; obtaining the relation between the peak junction temperature of the multiple tested GaN-based devices and the direct-current steady-state power and the relation between the peak thermal resistance and the direct-current steady-state power by means of mathematic fitting; and analyzing microscopic thermal infrared images of the multiple tested GaN-based devices according to the obtained elation between the peak junction temperature and the direct-current steady-state power and the relation between the peak thermal resistance and the direct-current steady-state power to realize measurement of thermal reliability of the GaN-based devices. The method realizes effective evaluation on thermal reliability of the GaN-based HEMT (high electron mobility transistor) devices and has important guidance significances to structural optimization and process improvement of the devices.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

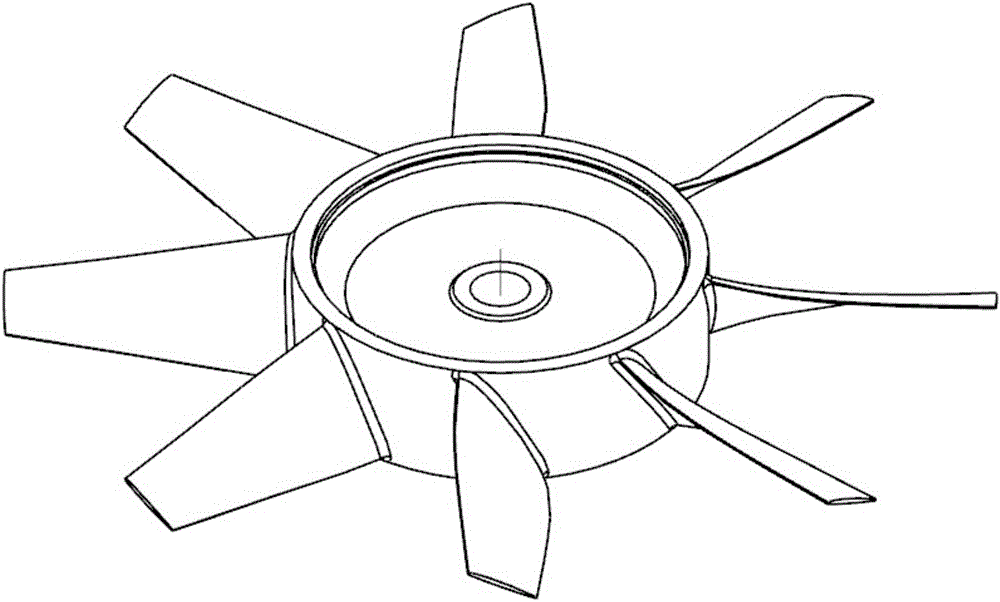

Manufacturing process of ultra-long blade complex curved surface integral impeller made of aluminum alloy material

InactiveCN105904169AManufacturing process improvements and enhancementsComplete shapeOther manufacturing equipments/toolsNumerical controlCold treatment

The invention relates to a manufacturing process of an ultra-long blade complex curved surface integral impeller made of an aluminum alloy material. The manufacturing process includes the specific steps of preparing materials, conducting rough machining on the profile of an impeller workblank, conducting heat treatment, conducting artificial aging, conducting semifinishing on the profile of the impeller, conducting ice-cold treatment, drilling a positioning hole, conducting five-axis linkage rough machining, conducting natural aging, conducting five-axis linkage finish machining, conducting clamp treatment, conducting numerical control turning, conducting linear cutting, conducting clamp treatment and conducting dynamic balancing. By the adoption of the process technology method, the ultra-long blade complex curved surface integral impeller made of the aluminum alloy material is manufactured, the blade shape of the ultra-long blade complex curved surface integral impeller made of the aluminum alloy material is complete, deformation is small, the blade lines of the blade faces of blades are smooth, mass reduction in dynamic balancing is small, and the yield is high; and process improvement in the integral impeller part of the structure is achieved, product quality is guaranteed effectively, the design requirement is met effectively, the stability of production quality is improved, and the reliability of products is guaranteed.

Owner:SHANGHAI INST OF TECH

Method for preparing bioactive protein powder through endogenous enzymolysis of marine low-value coarse fish

InactiveCN101731453AOvercome costsOvercome stabilityAnimal feeding stuffProtease preparationFood flavor

The invention discloses a method for preparing bioactive protein powder through endogenous enzymolysis of marine low-value coarse fish, which is characterized by comprising steps of raw material preparation, primary crushing, enzymolysis, small peptide liquid preparation, mixing and drying, post treatment and the like. During enzymolysis, enzymolysis process parameters are selected according to the endogenous enzyme activity measured from the raw materials; and during mixing and drying, peeled bean pulp powder is used as a carrier to prepare a bioactive protein material. The method of the invention performs process improvement based on the enzymolysis of the primary exogenous proteinase preparation, solves the difficult problems of high production cost, unstable exogenous enzyme activity and non-thorough enzymolysis in the endogenous enzymolysis process, and is more suitable for industrialized production; and the prepared bioactive protein powder has the sense, flavor and cultivation effects superior to those of the fish powder, and is a good fish powder substitute.

Owner:陈忆凤

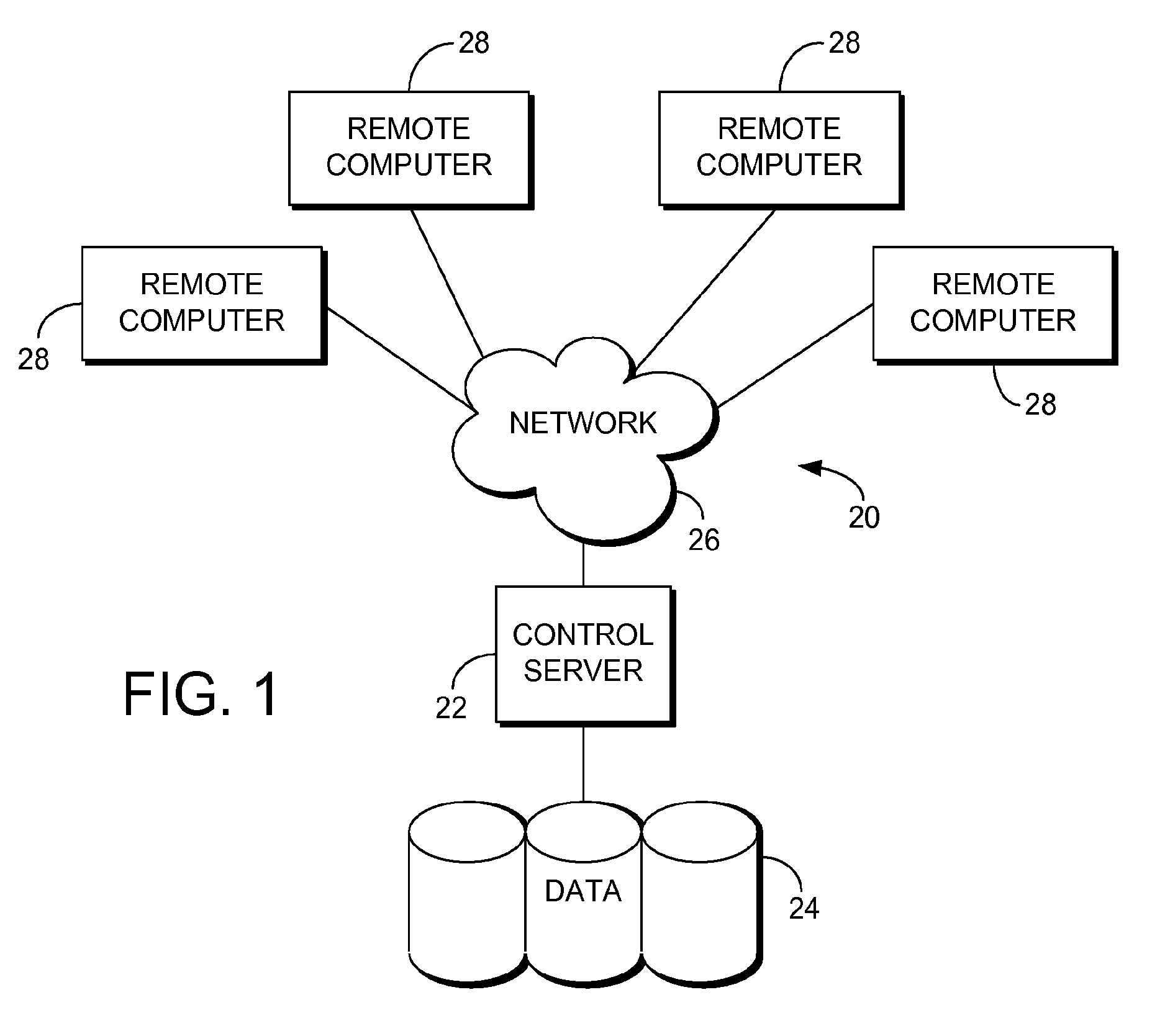

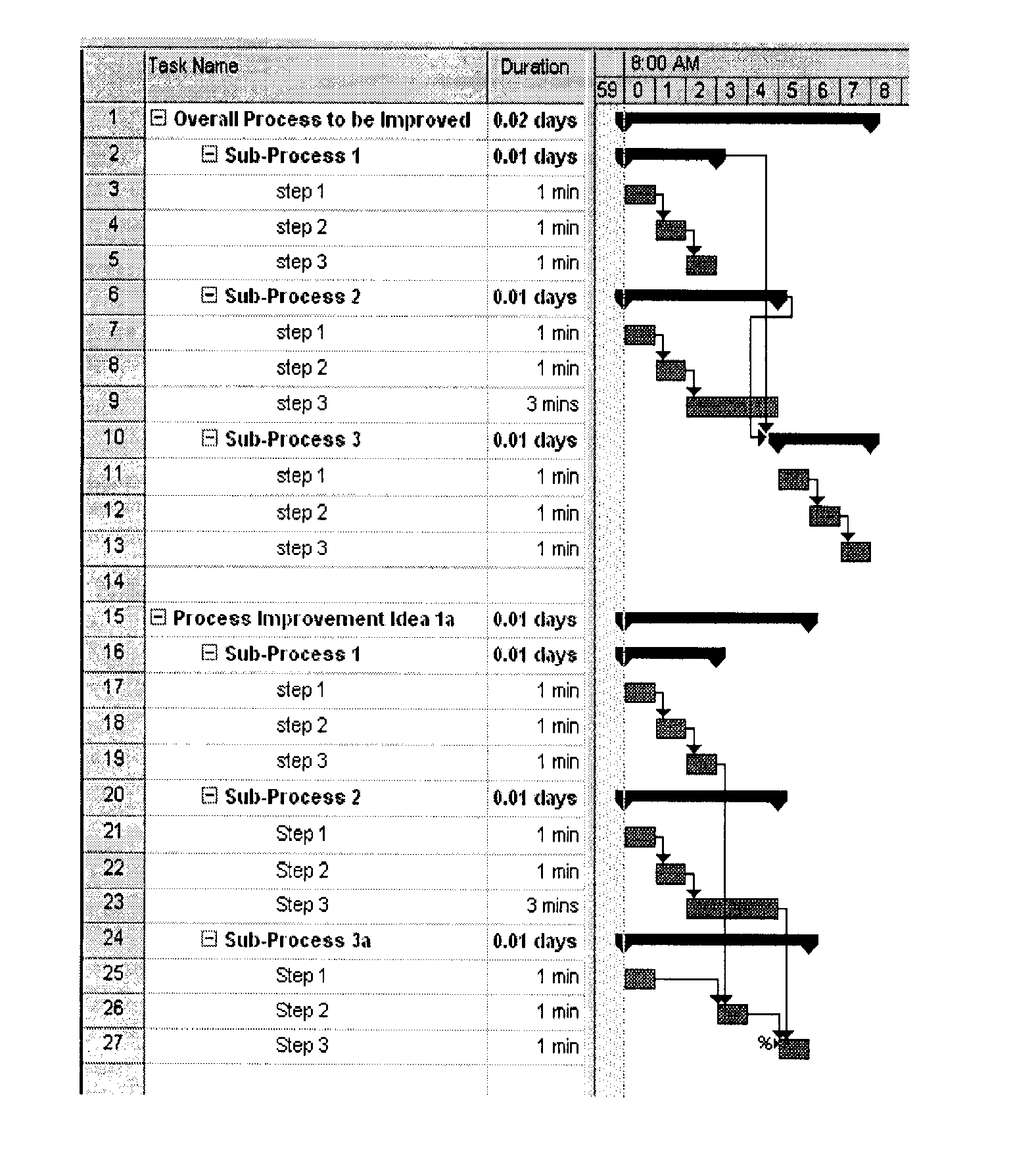

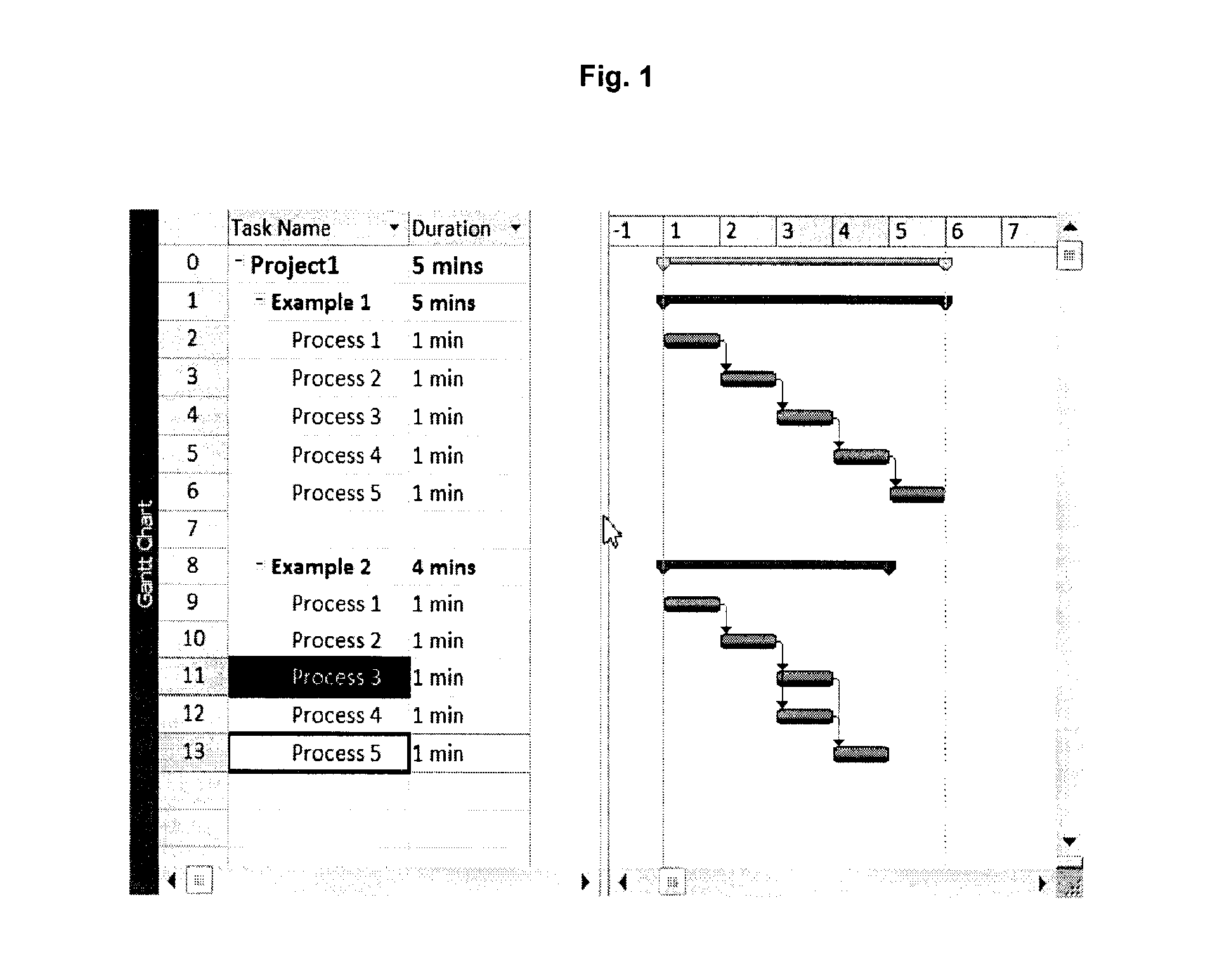

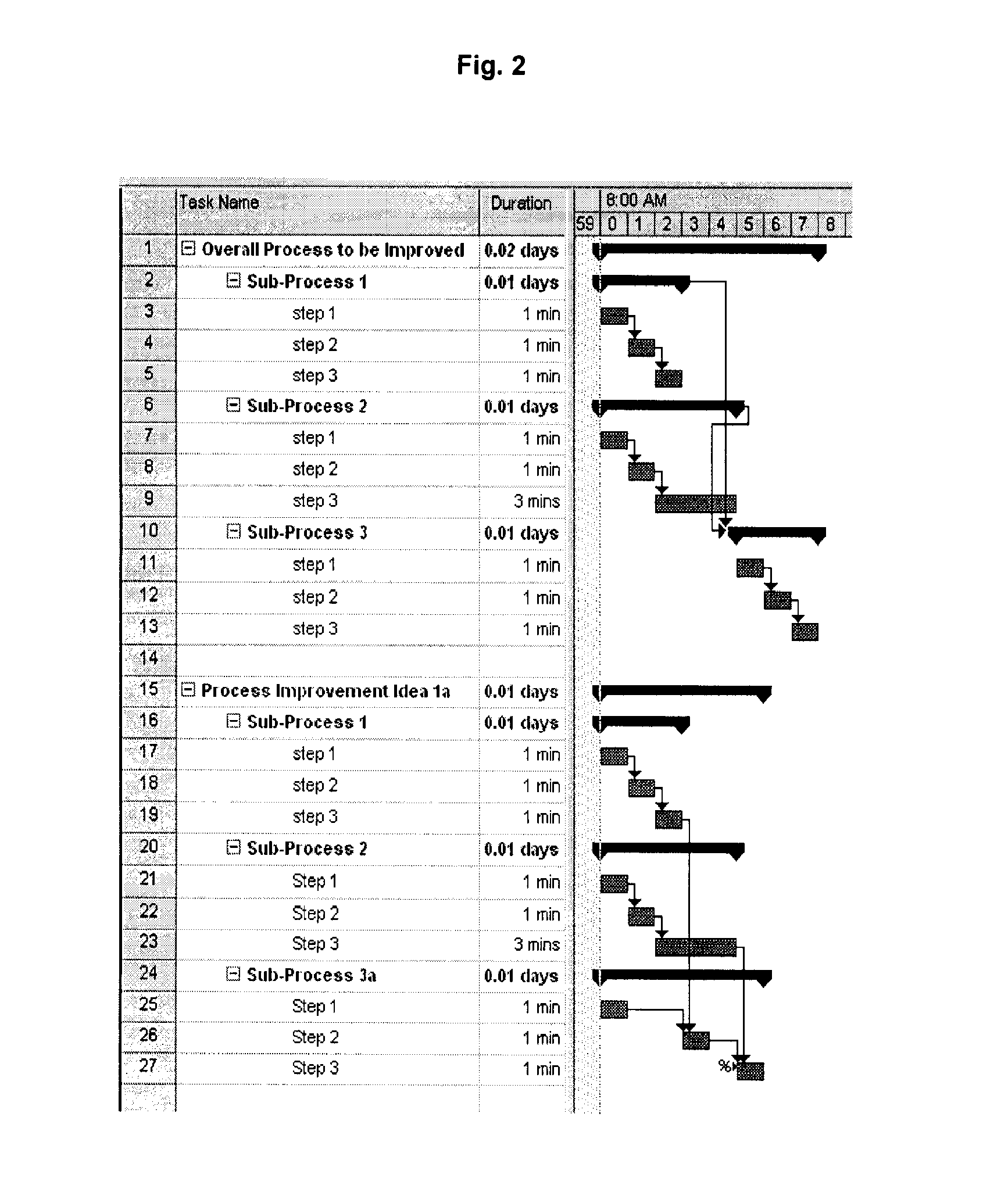

System and Method for Process Improvement and Associated Products and Services

A method for identifying opportunities in a computer environment to improve a process comprising providing a tool for measuring and manipulating inputted and collected data. The measurements are scaled in large or small increments, convertible to other scales, and provided in units that are mixable. The tool allows a user to associate objects with other objects and resources. The tool provides the ability for a user to select, view, manipulate, analyze and graph effects to resources and other objects caused by incremental changes to an object to determine an amount of improvement of the process.

Owner:ANSLEY REBECCA

Optimized practice process model for clinical process improvement

ActiveUS8214227B2Continuous monitoringEasy to analyzeDigital computer detailsDiagnostic recording/measuringGraphicsProcess optimization

Owner:CERNER INNOVATION

User interface for analyzing opportunities for clinical process improvement

ActiveUS8060381B2Continuous monitoringEasy to analyzeFinanceResourcesProcess optimizationComputer science

User interfaces are provided for analyzing opportunities for optimizing clinical processes within clinical facilities. An optimized practice process model may be defined for a particular clinical procedure, setting forth an optimal clinical process. In addition, critical levers may be identified within the optimal clinical process, representing the activities that have the greatest impact on outcomes. Clinical facilities may collect current measures for the critical levers, and the current measures may be compared against an optimal, benchmark, and / or target measure. Based on the comparison, opportunities for clinical process optimization may be identified. User interfaces are provided for analyzing the opportunities.

Owner:CERNER INNOVATION

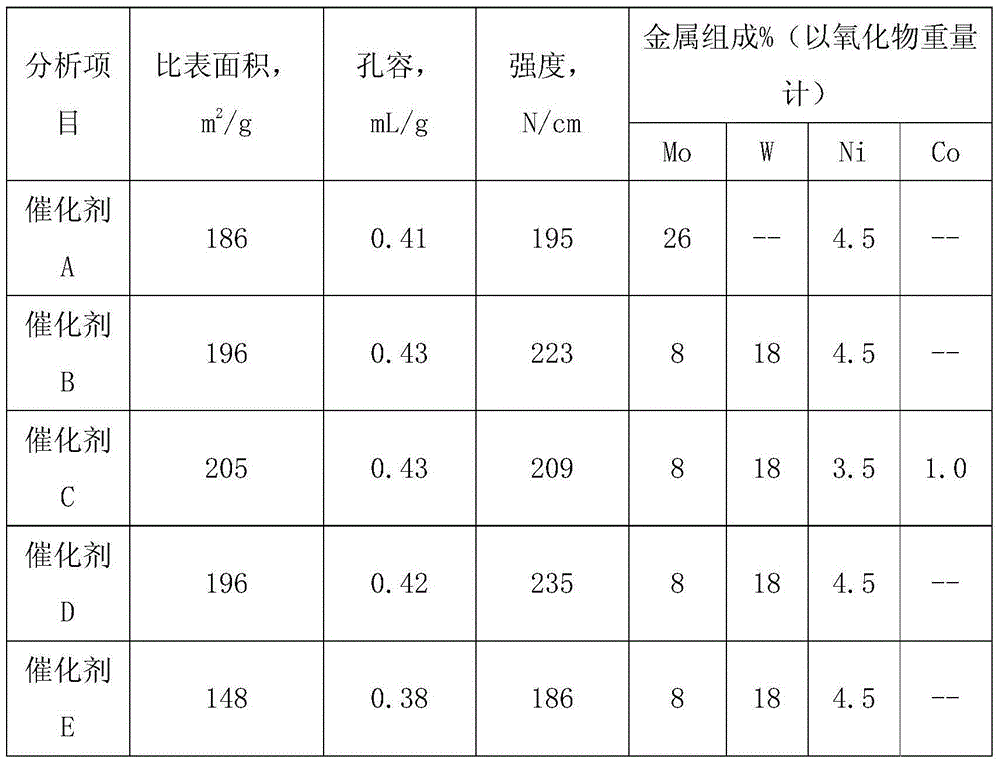

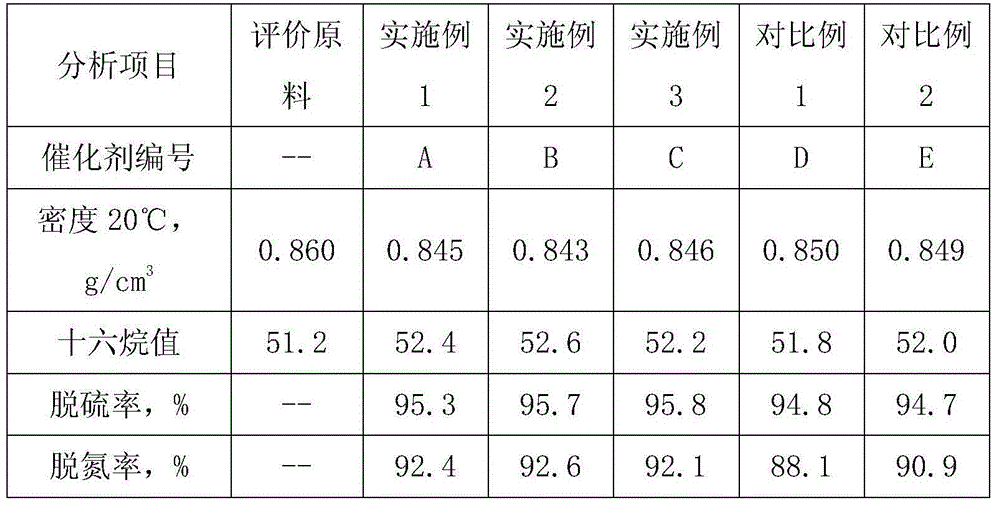

Process improvement method of vulcanized hydrogenation refining catalyst

ActiveCN104646010ALow costNo storage securityMetal/metal-oxides/metal-hydroxide catalystsIn situ crystallizationInorganic salts

The invention relates to a process improvement method of a vulcanized hydrogenation refining catalyst. The process improvement method is characterized by comprising the following steps: soaking macroporous alumina powder by adopting a dipping solution containing active metal, carrying out the in-situ crystallization, adding the binder, mixing the binder, carrying out the forming and drying, and then carrying out the roasting under the protection of inert gas to obtain the vulcanized hydrogenation refining catalyst. The method is characterized in that the dipping solution contains an inorganic salt precursor of active metal ammonium molybdate and / or ammonium tungstate and Ni and / or Co and also contains an organic vulcanizing agent, a complexing agent, a dispersing agent and the binder; the in-situ crystallization reaction is carried out in a closed vessel after the dipping solution soaks the macroporous alumina powder to prepare the vulcanized catalyst in one step. The method is simple in procedures, low in cost and uniform in dispersion of active metal.

Owner:CHINA NAT OFFSHORE OIL CORP +2

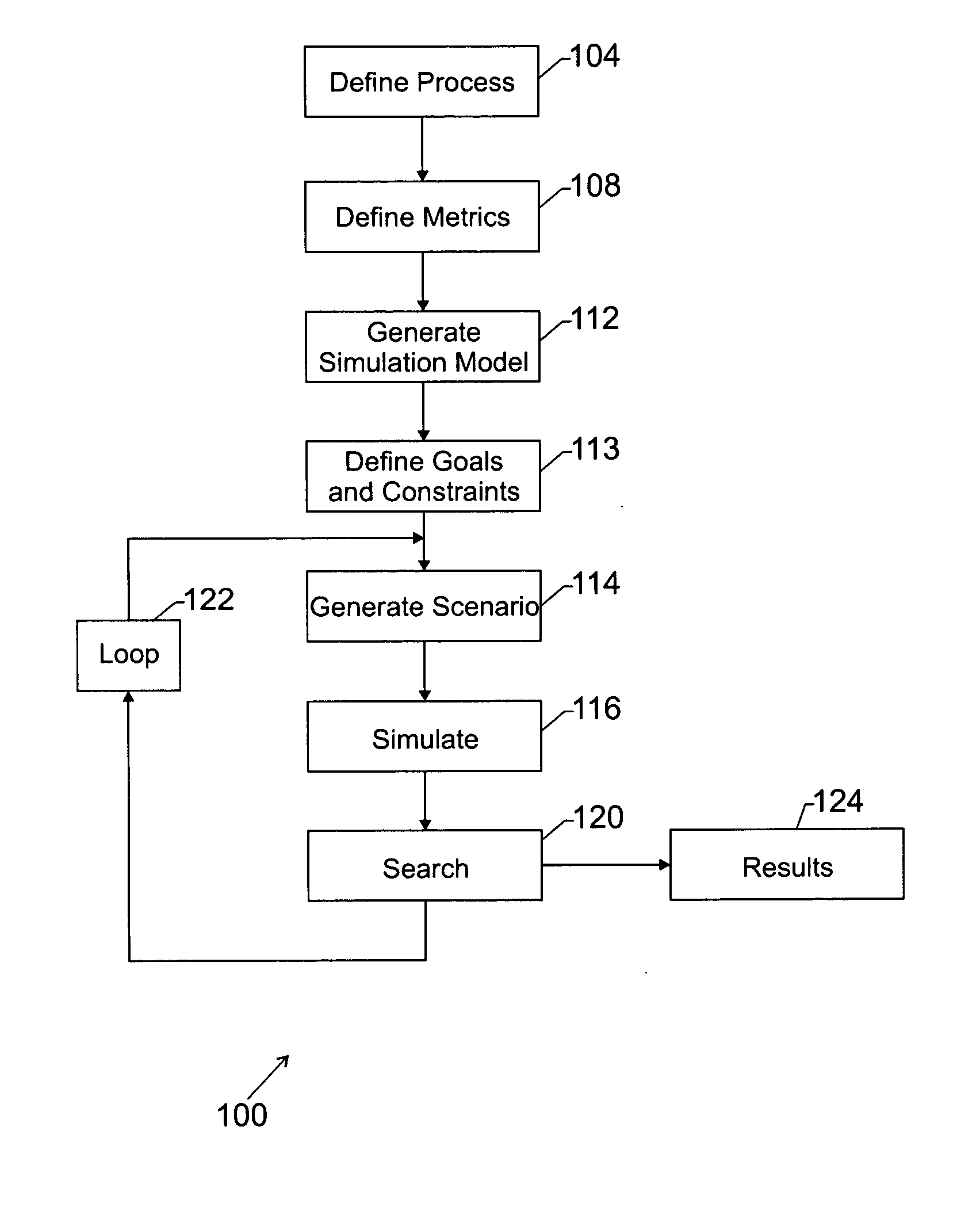

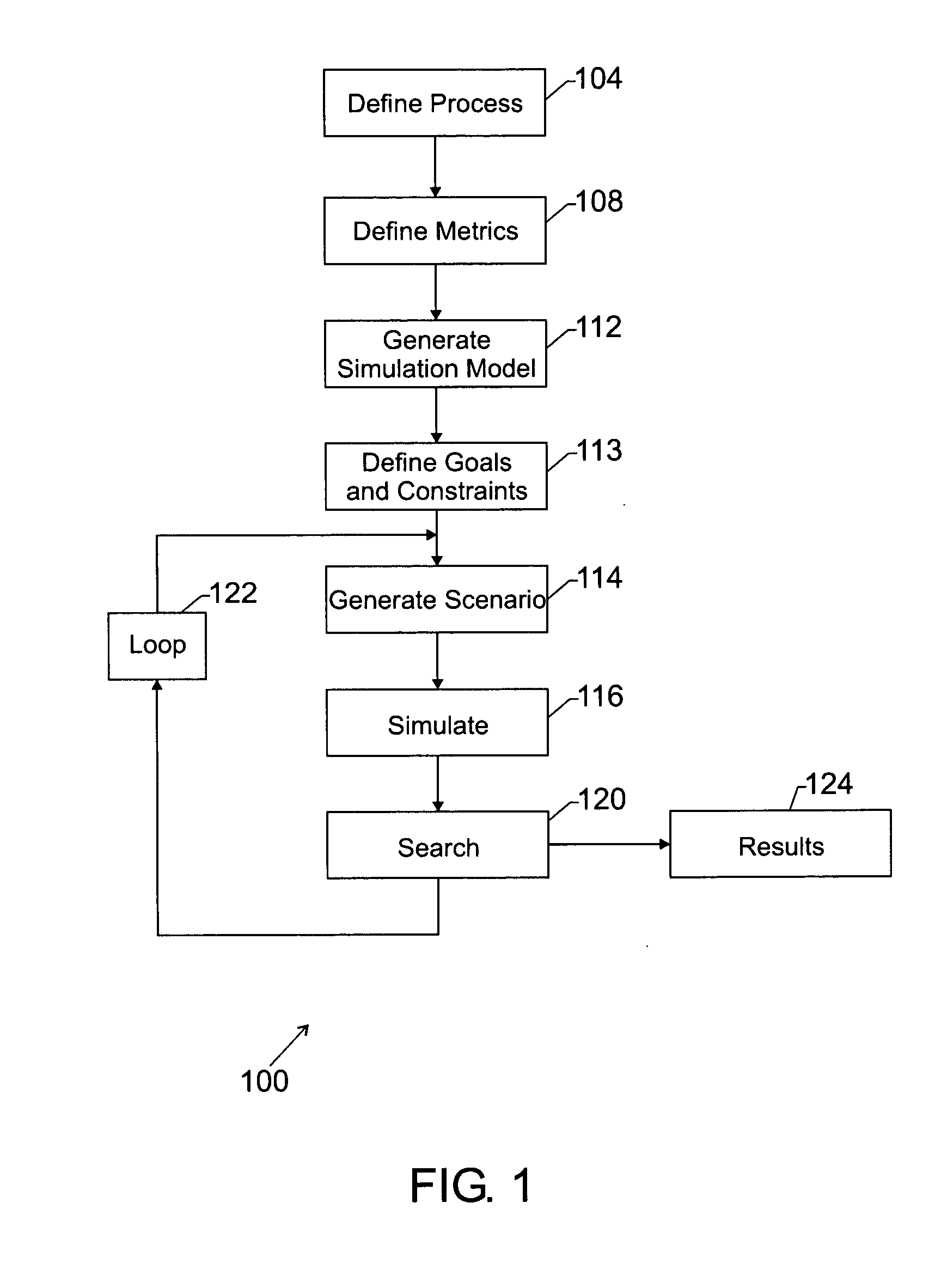

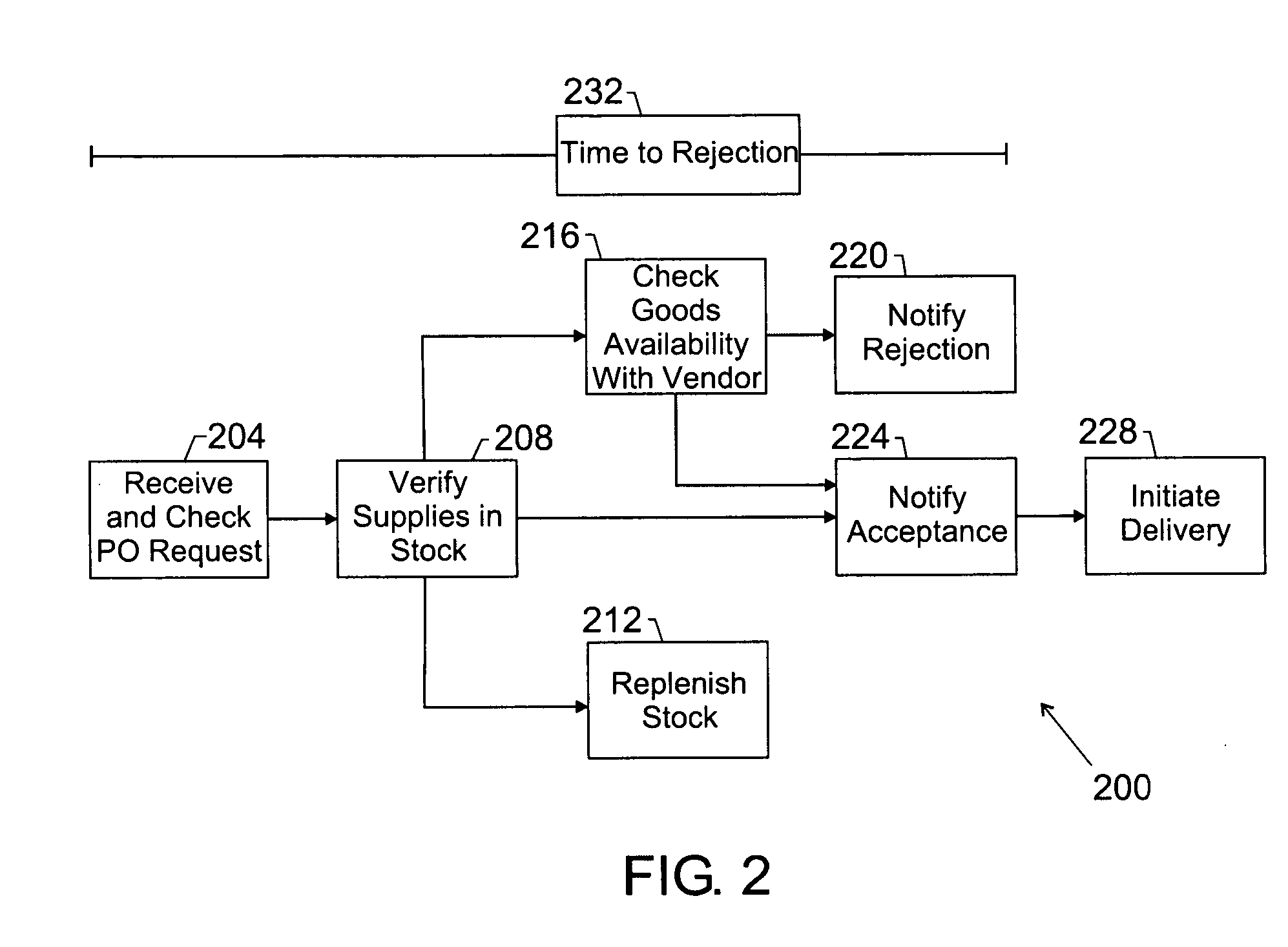

System and method for determining an optimized process configuration

InactiveUS20050278301A1Digital data processing detailsDesign optimisation/simulationExpected value of sample informationProcess configuration

The disclosed embodiments relate to a system and method for processing data. The system may involve a process-modeling tool adapted to define a process model, to define mapping from a resource to an activity in the process model, and to define a metric on the process model. Additionally, the system may have a designation module adapted to designate a goal and define constraints. Also included may be a process simulation engine adapted to employ the process model to simulate a process execution based on the process data according to different configurations and to produce process execution data that comprises an expected value for the metric. Further, a process improvement engine may be a component adapted to evaluate the process simulation data produced by the process simulation engine and to provide process improvement data indicative of changes in the expected value of the metric. A search tool may further be included that is adapted to search a configuration space that comprises the process improvement data to determine a prospective configuration that causes the expected value of the metric to approach the goal.

Owner:HEWLETT PACKARD DEV CO LP

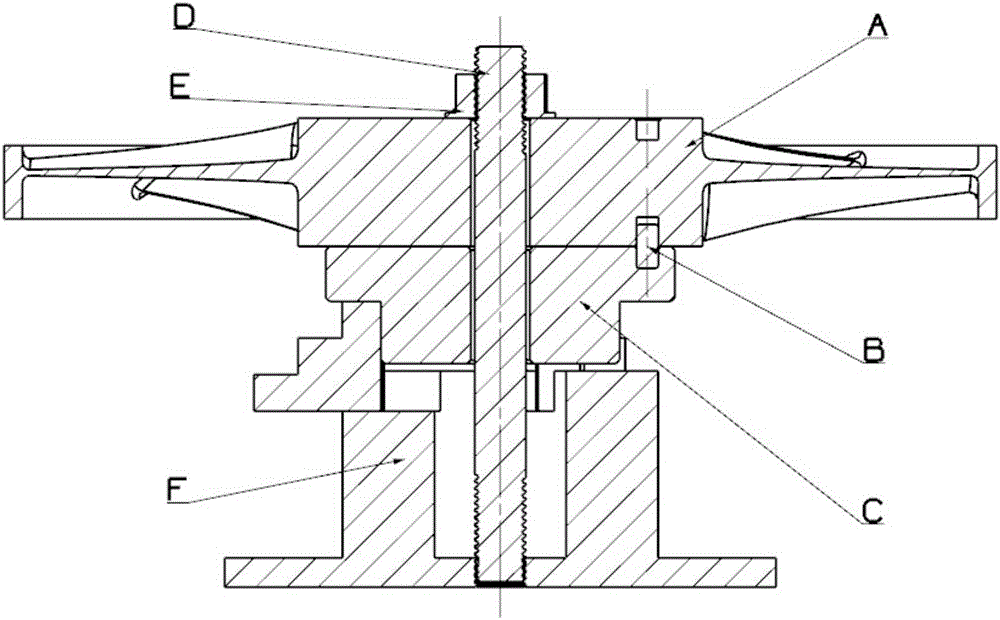

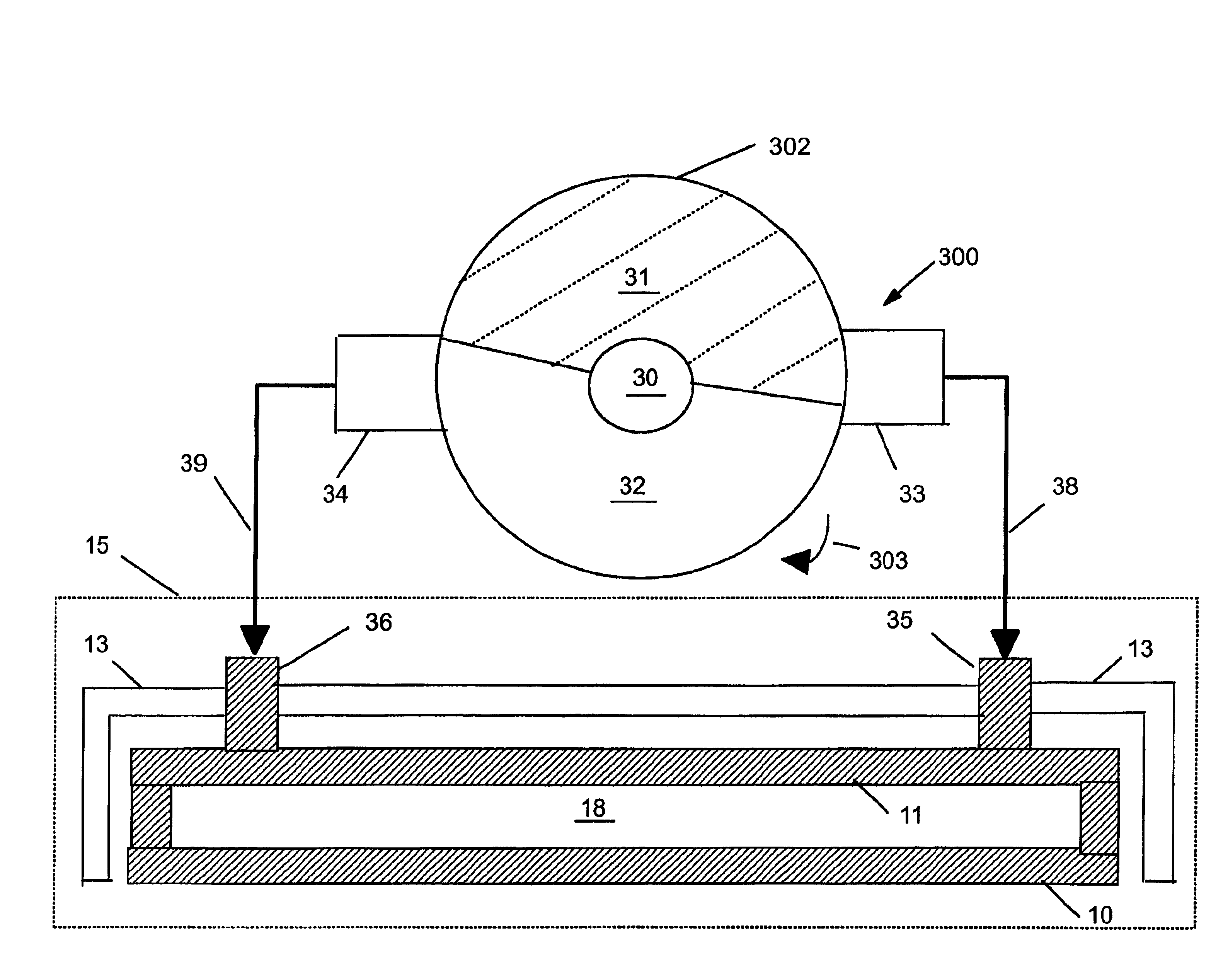

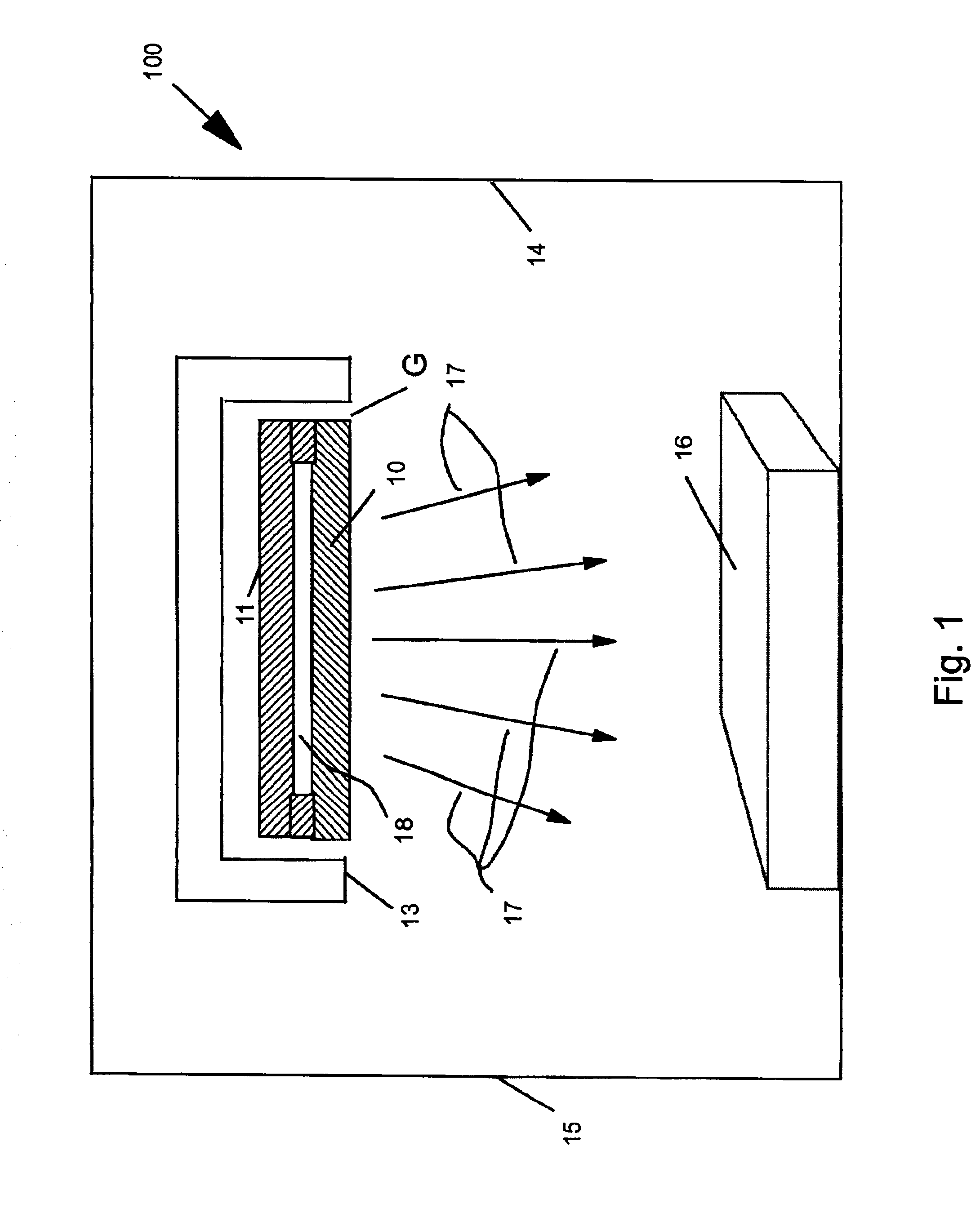

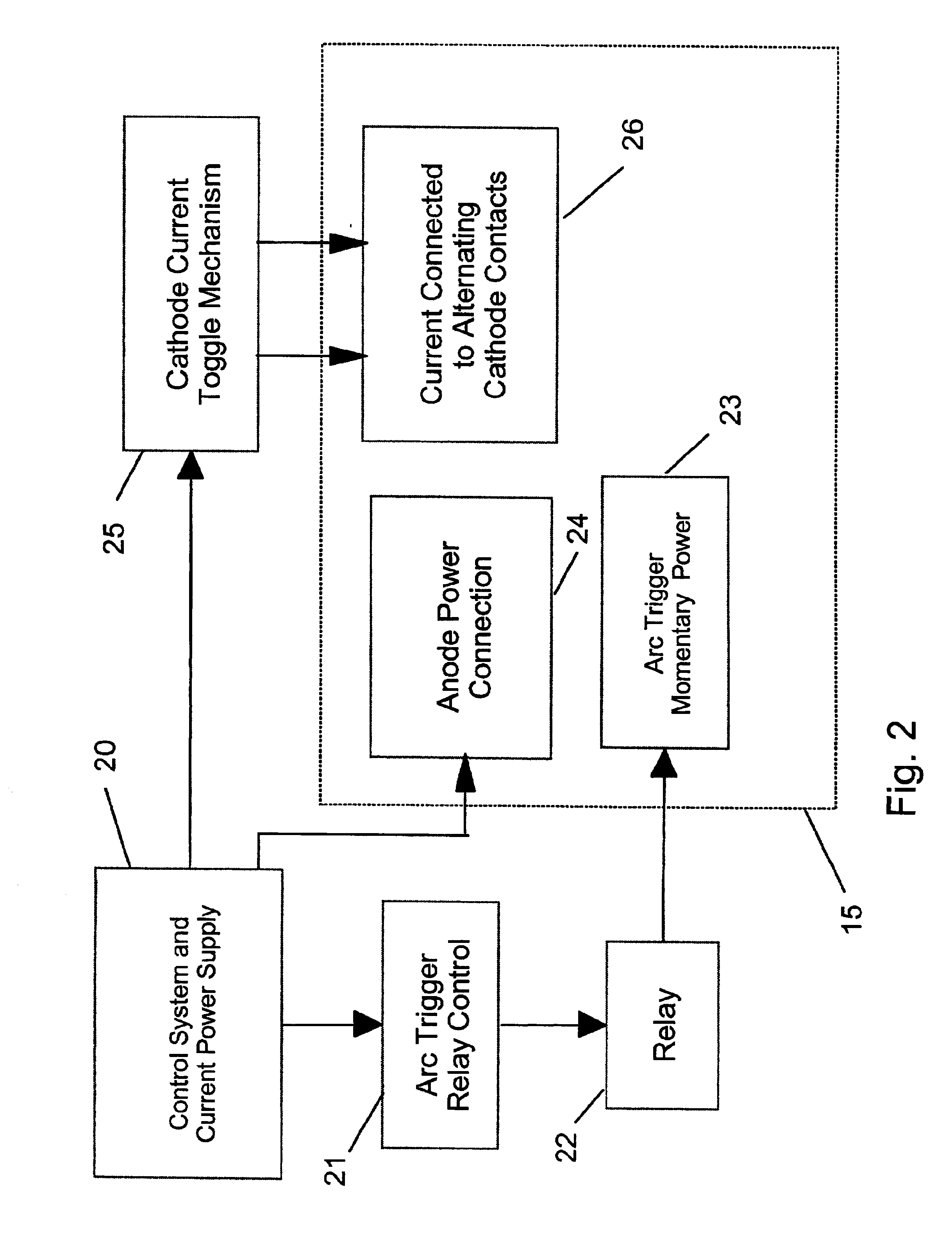

Coating method and apparatus

A method and apparatus used for the application of plating / coating in a cathodic arc process to improve coating uniformity, deposition rates, quality, cost, packaging, arc triggering, target wear and other improvements is described in the patent. The process improvements utilize a cathode with external current switching to two or more electrical cathode contacts, employment of magnets on the backside of the cathode, a non-mechanical arc initiation trigger, patterned target surfaces, adjustable cathode insulation, current modulation, and new packaging schemes.

Owner:IONEDGE CORP

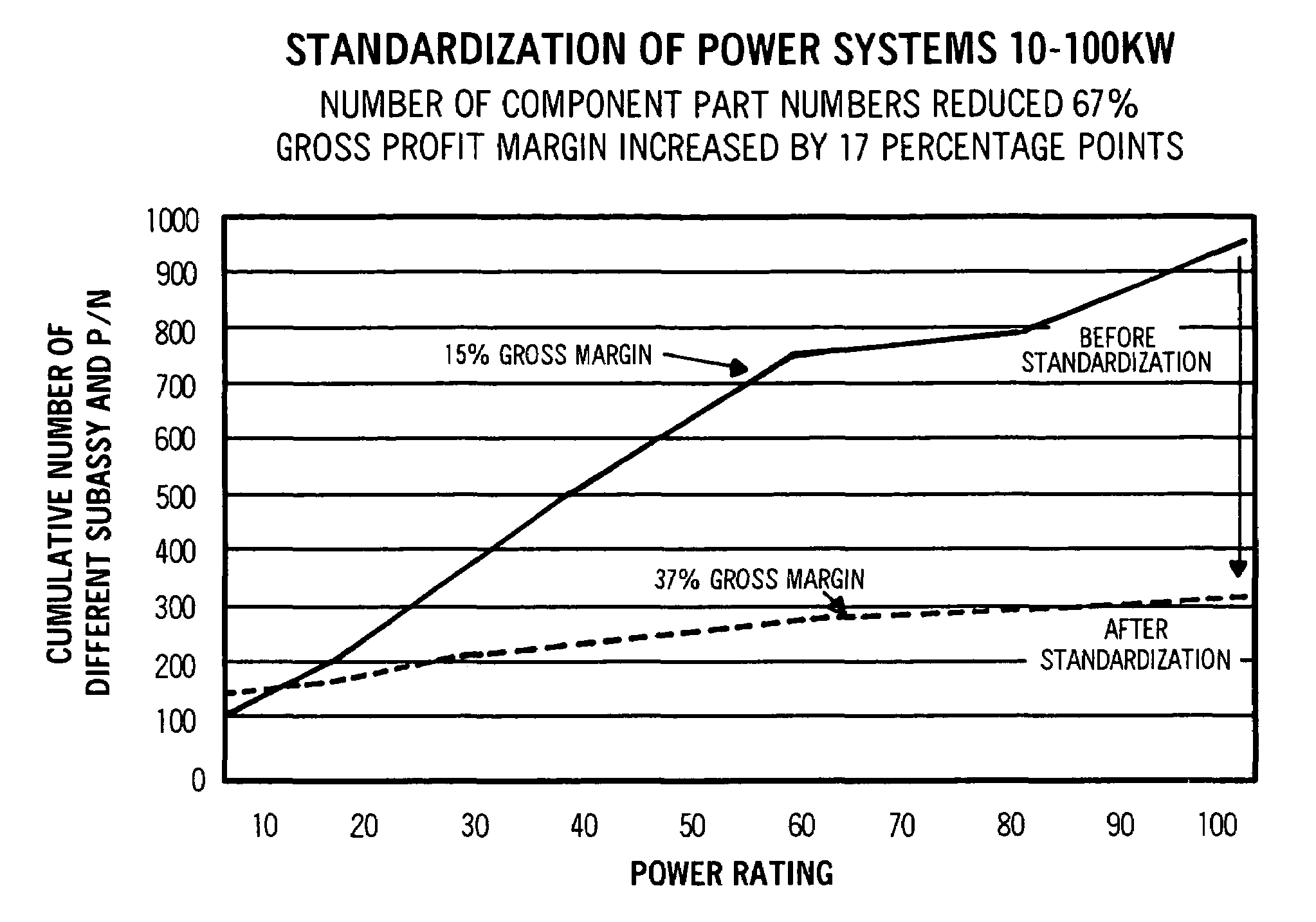

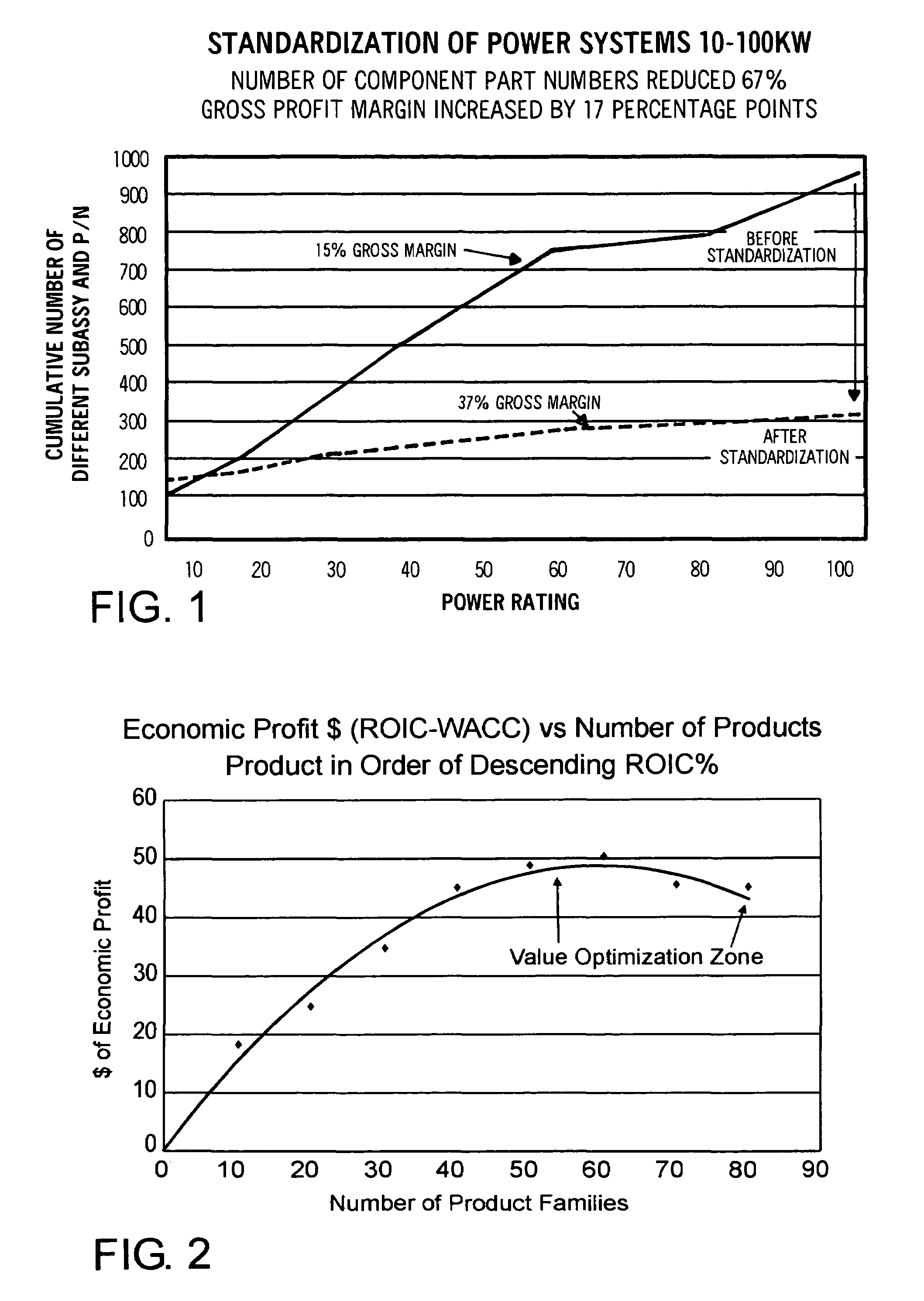

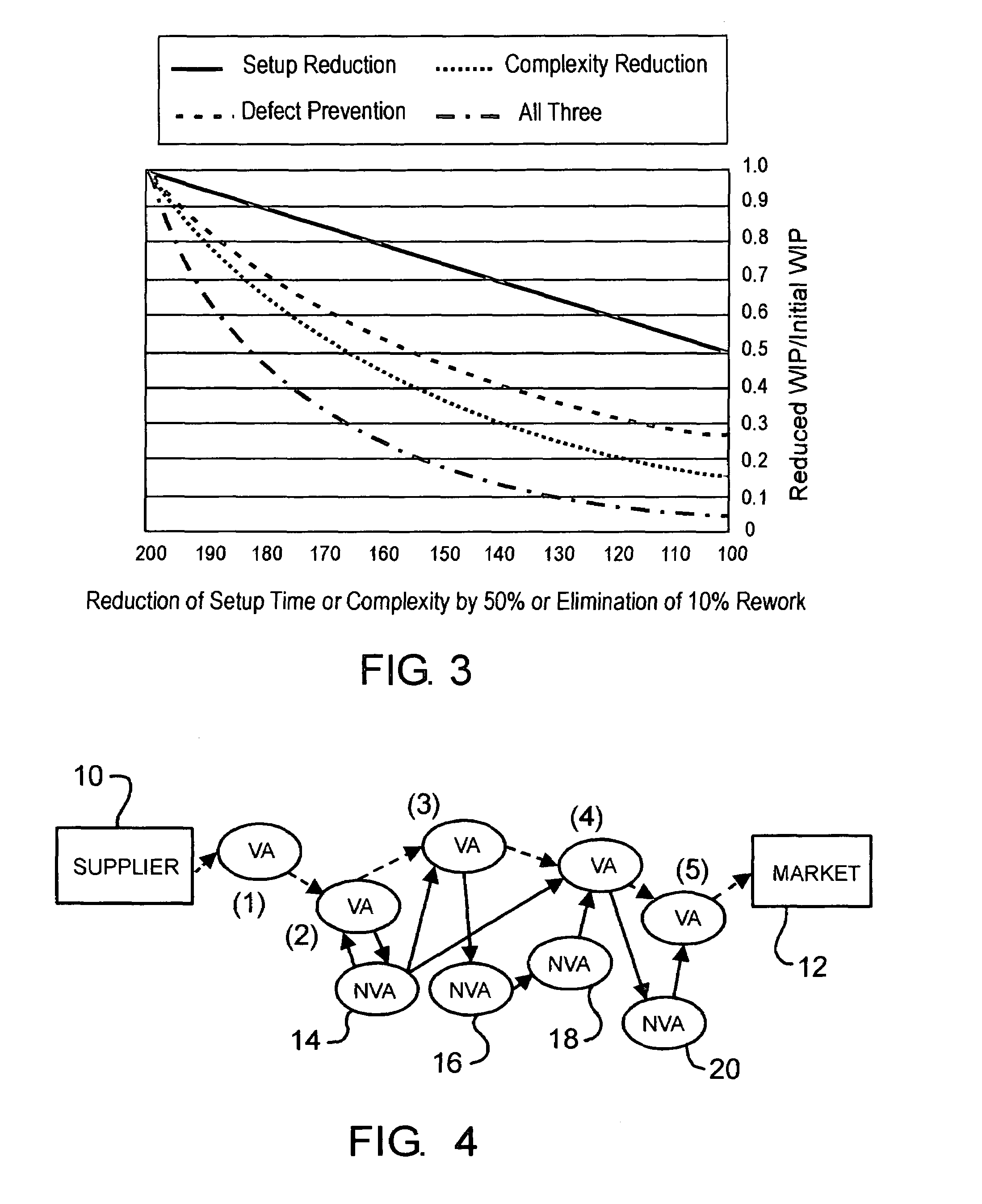

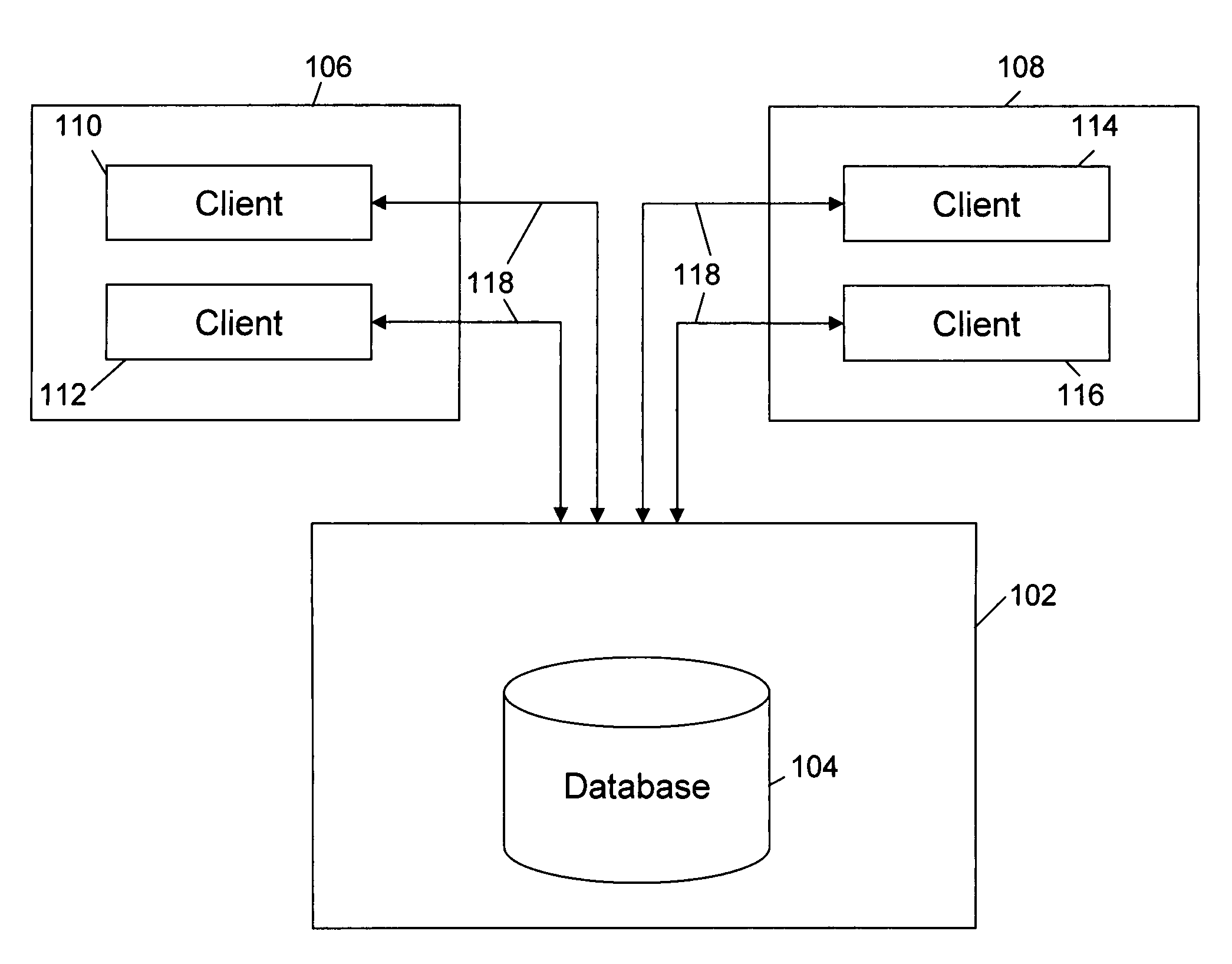

Method for determining and eliminating the drivers of non-value added cost due to product complexity and process parameters

A method for measuring and reducing the cost of complexity in producing products or providing a service by comparing selected non-value added steps in the manufacturing or service process with the number of different products or services provided, so as to provide the non-value added cost of the product or service for various selected complexities. The number of products required to be processed or held in inventory for a particular demand, or the number of different specific services required for a particular demand of the service is determined by comparing the number of different product part numbers, or service categories offered, with selected non-value added steps in the respective processes. Mathematical analyses are derived from equations of motion of process improvement including the first derivative of process velocity.

Owner:ACCENTURE GLOBAL SERVICES LTD

Method and system for auditing processes and projects for process improvement

Systems and methods for auditing knowledge-based projects or methods wherein the users participate in and contribute to generating an automatically updating community data set for obtaining information for evaluating and comparing a target project to best practices and relevant comparables from within the community data to audit likelihood of success and to predict the outcome of the knowledge-based project, and to identify components for improvement or modification to improve the outcome.

Owner:RALLY SOFTWARE DEV CORP +1

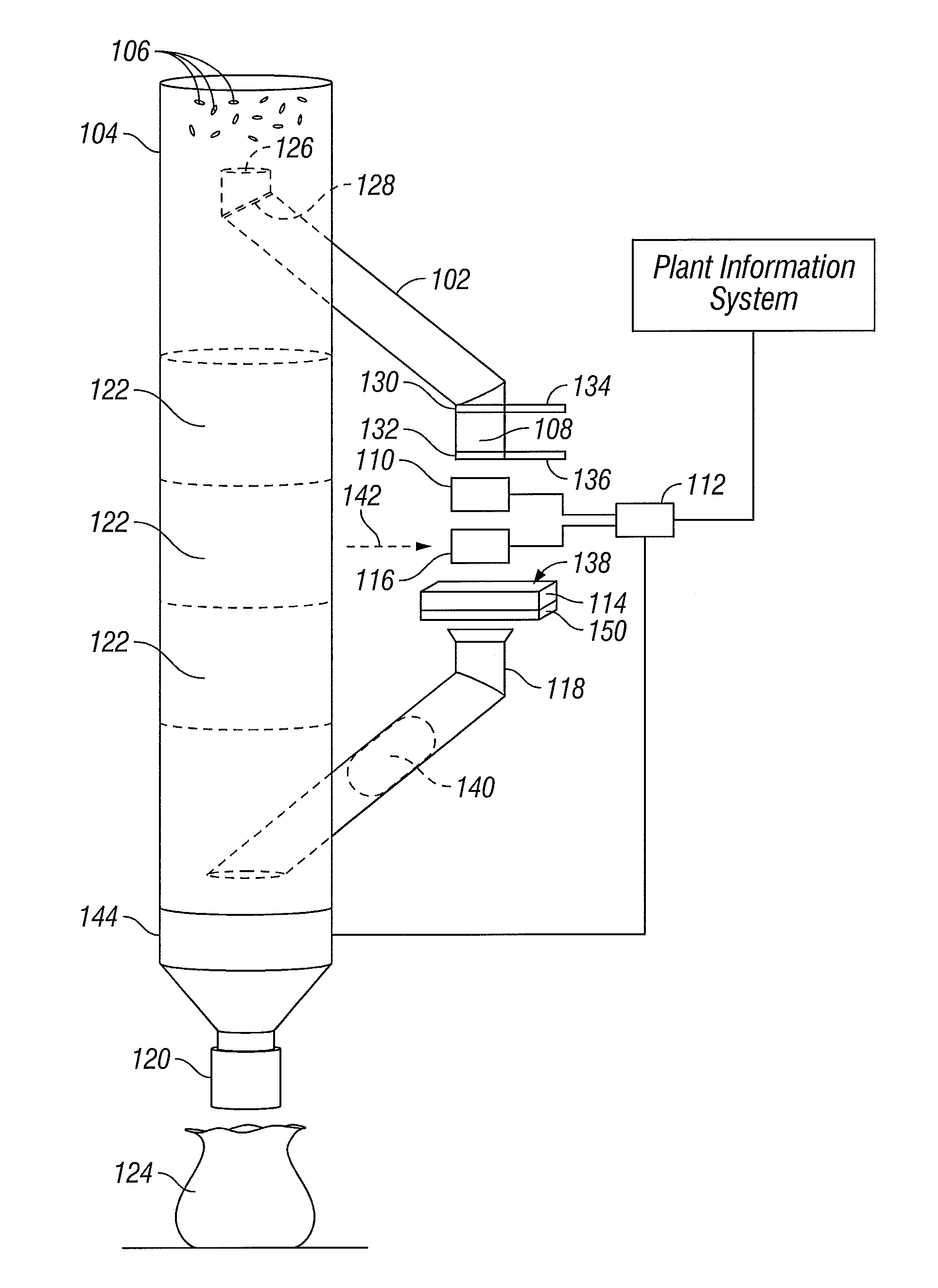

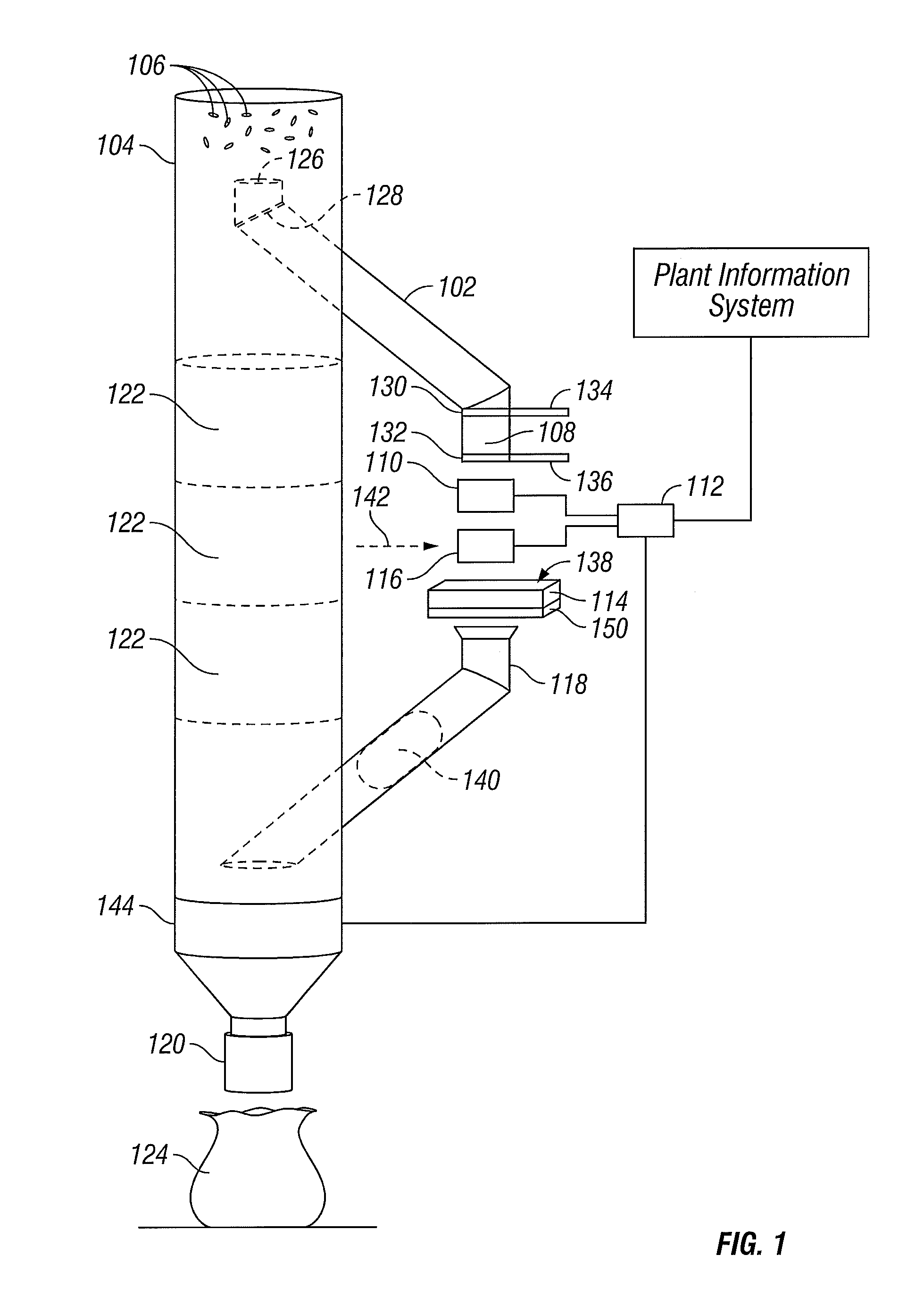

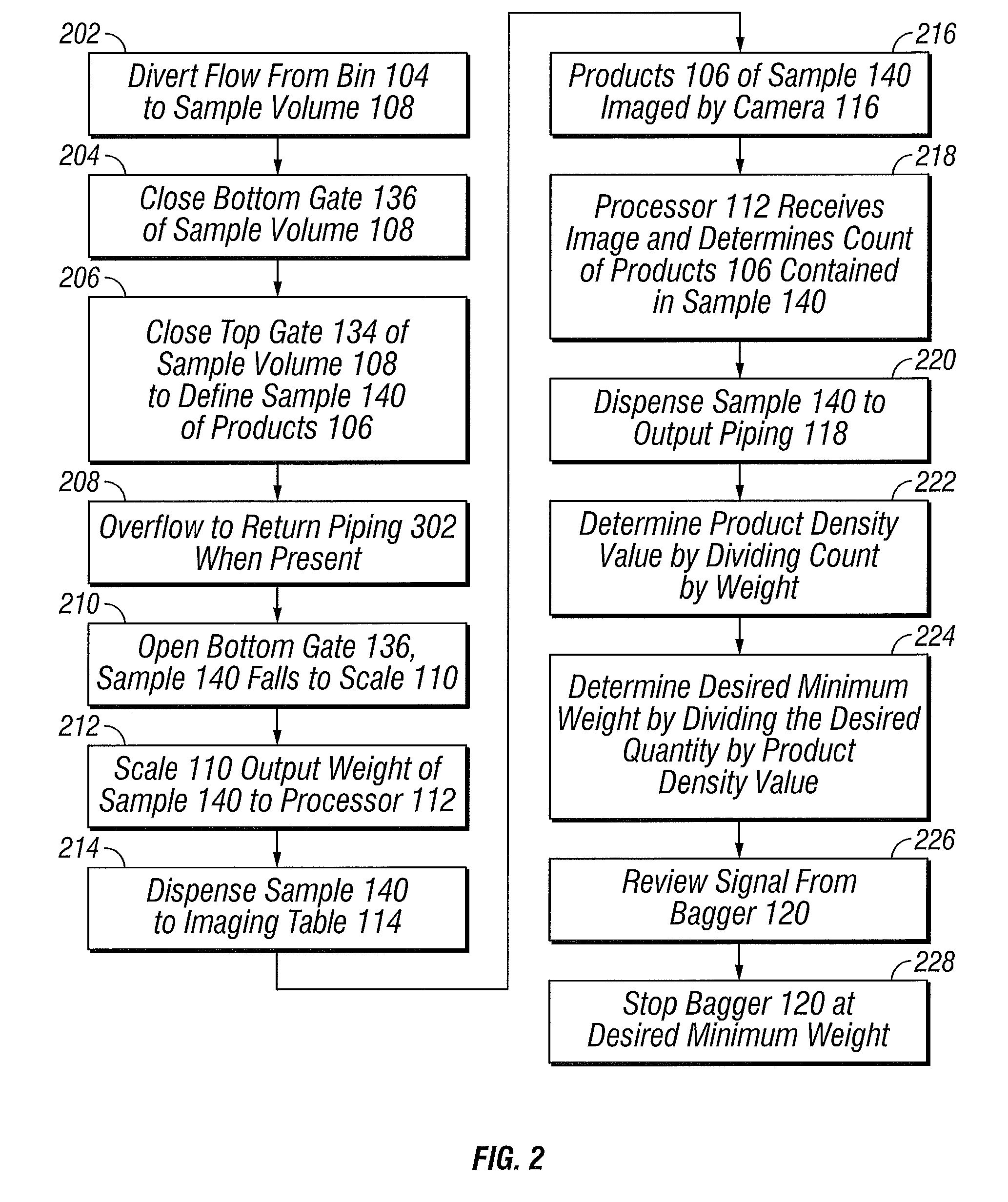

System to determine in near real-time product density in a continuous dispensing product flow

InactiveUS8175327B2Avoid huge wasteReducing line retoolingImage enhancementImage analysis16-bitProcess engineering

Owner:SATAKE USA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com