Manufacturing process of ultra-long blade complex curved surface integral impeller made of aluminum alloy material

A technology of aluminum alloy material and integral impeller, which is applied in the direction of manufacturing tools and other manufacturing equipment/tools, etc., to achieve the effects of improving stability, ensuring reliability, and complete shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

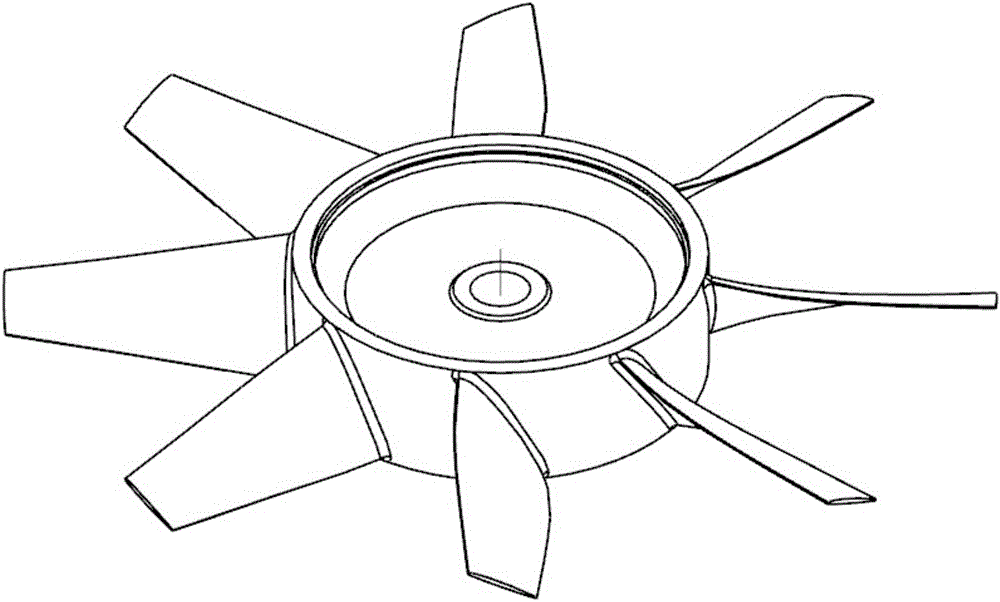

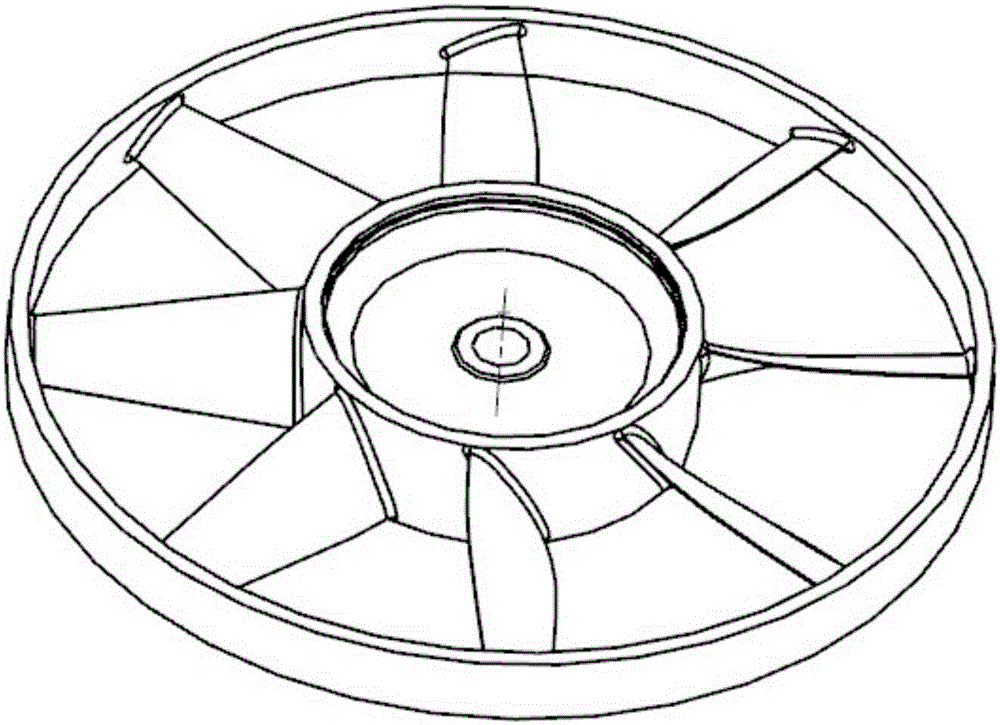

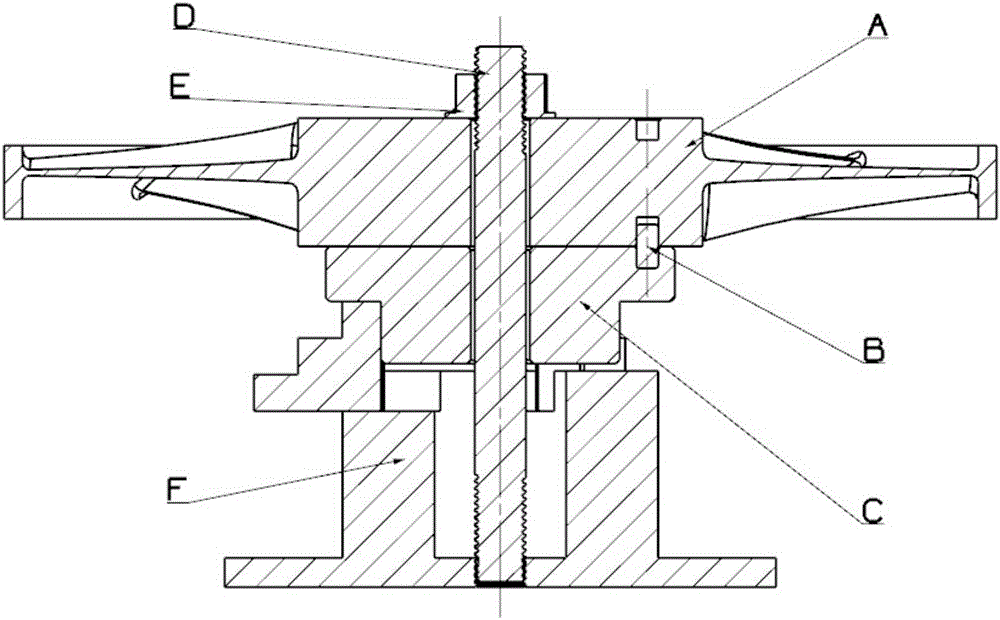

[0051] This example is manufactured as attached figure 1 The complex curved integral impeller with extra-long blades shown has a part diameter of 261.9mm, a hub diameter of 108mm, a height of 38mm, a maximum thickness of the blade crown of 1.36mm, and a thinnest part of 0.39mm. The number of blades distributed around the blade circumference is Z=8. The working conditions need to meet the requirements of high speed, large thrust-to-weight ratio, high performance, high surface profile and good dynamic balance performance.

[0052] The manufacturing process technology method of the aluminum alloy material super long blade complex curved surface integral impeller of this embodiment mainly includes the following steps:

[0053] Step 1: Prepare materials:

[0054] Prepare Φ310mm×50mm aluminum alloy forging material.

[0055] Step 2: Rough machining impeller blank shape:

[0056] Roughly cut the shape of the impeller blank, reserve 25mm margin in the radial direction, and reserve ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com