Patents

Literature

149 results about "Mass reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

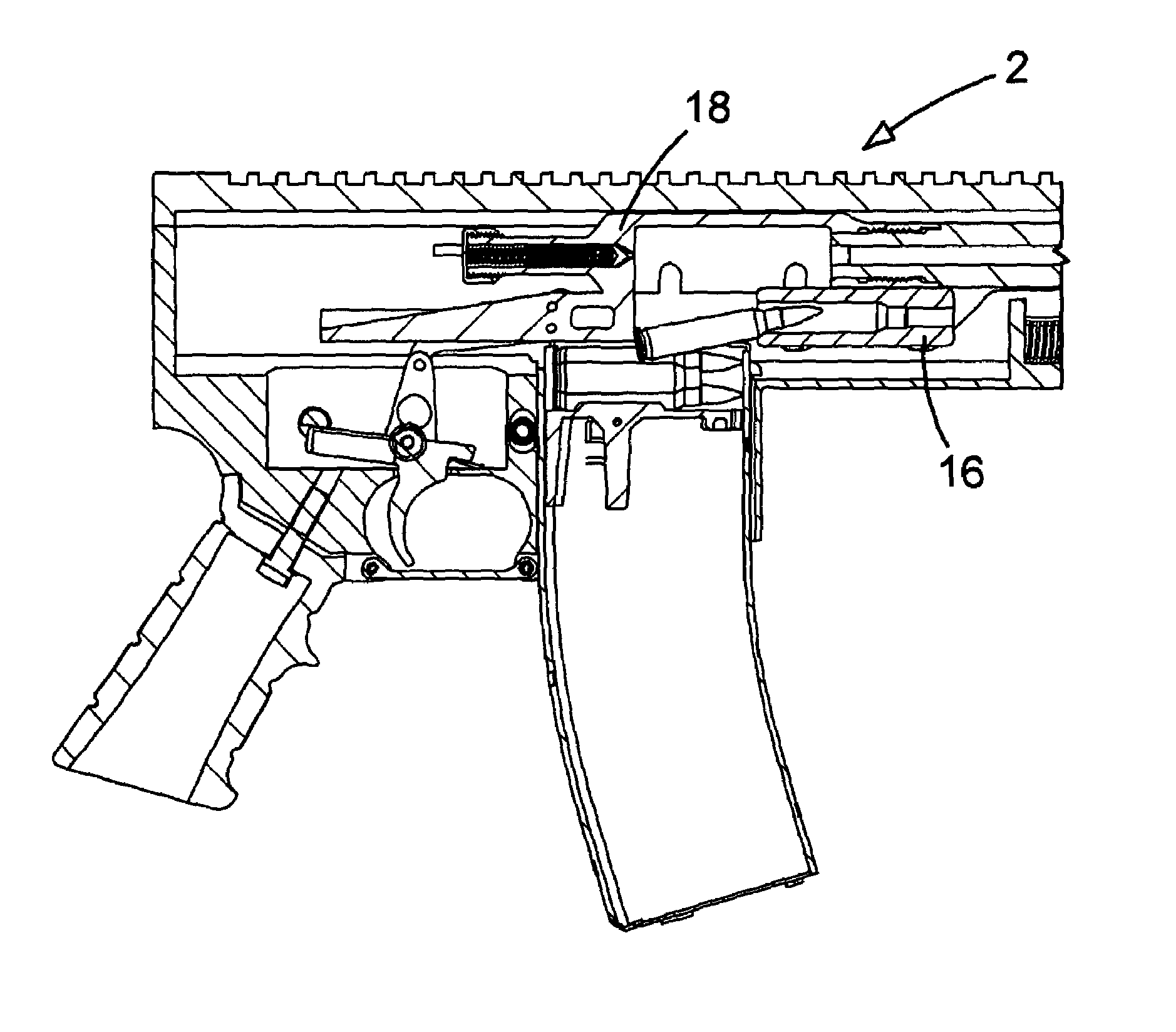

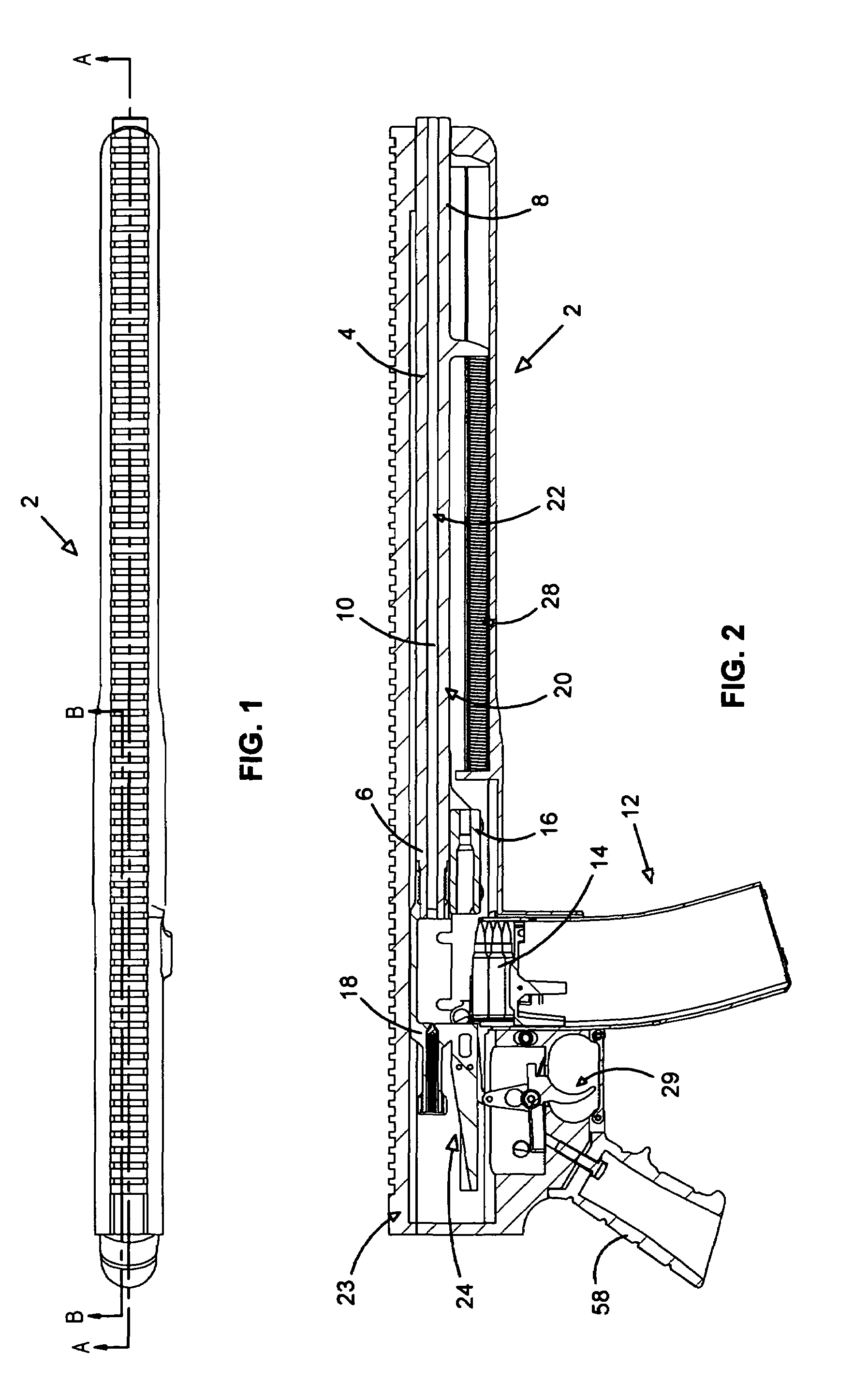

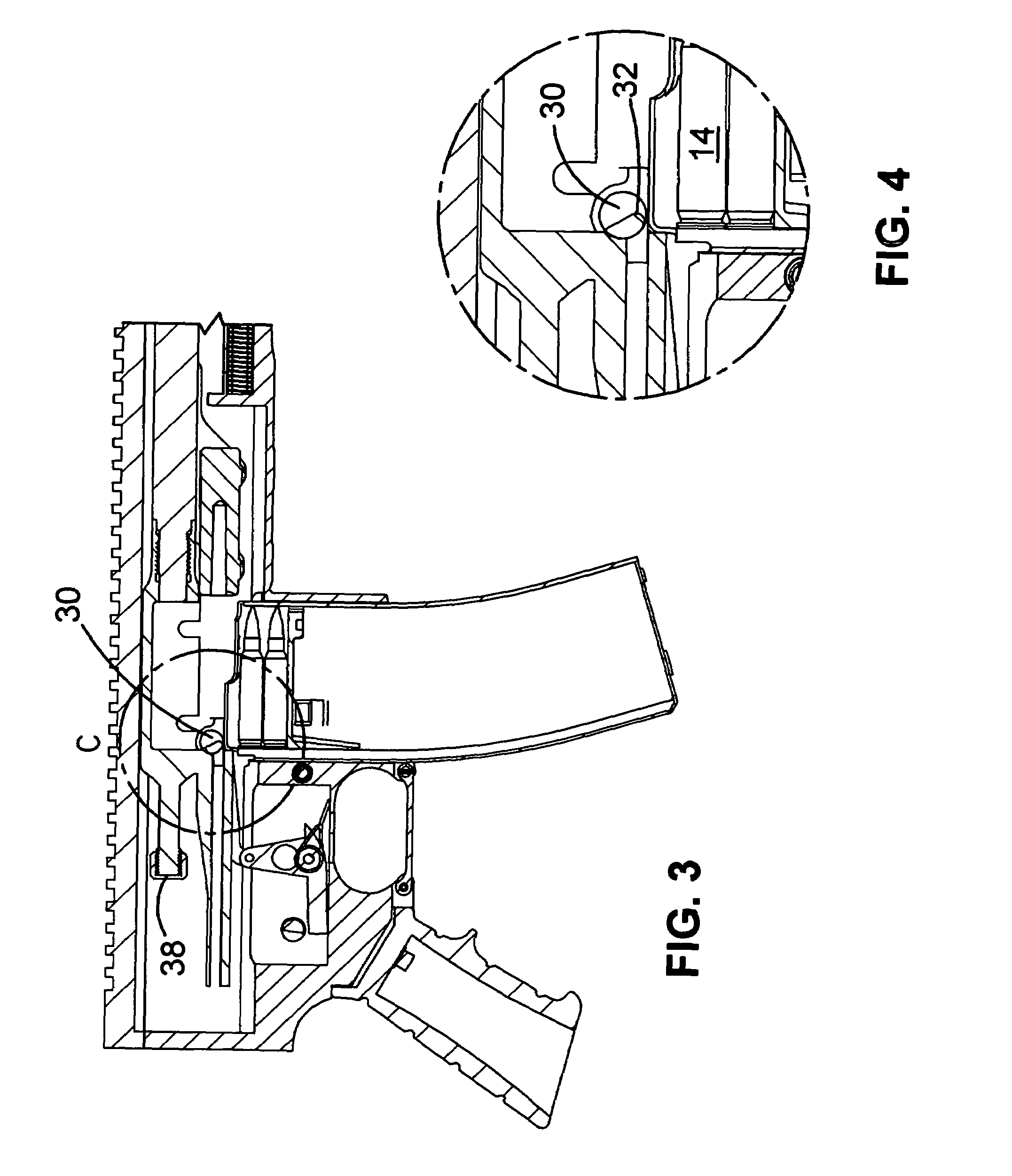

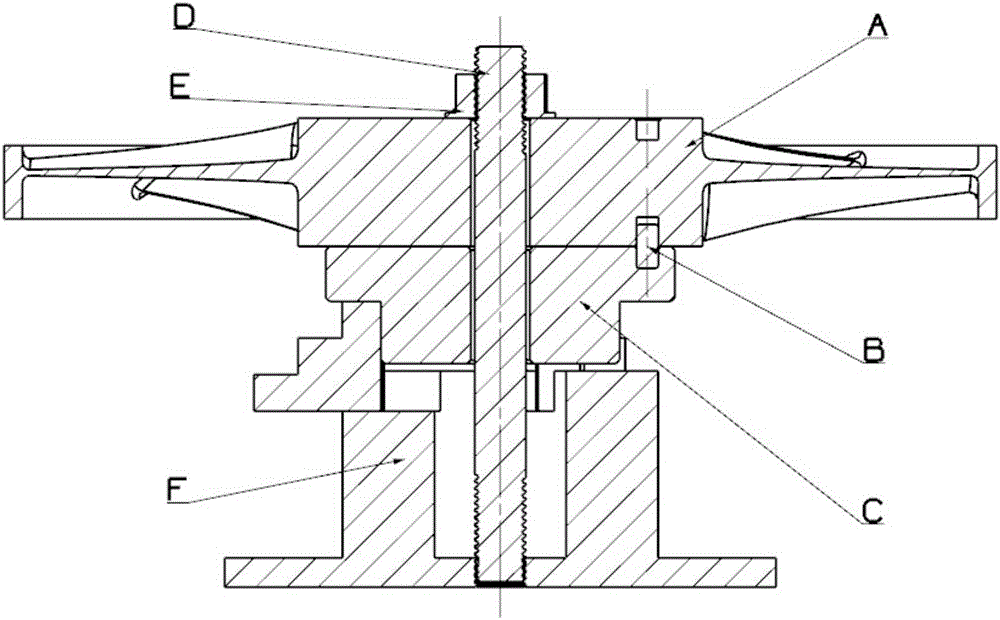

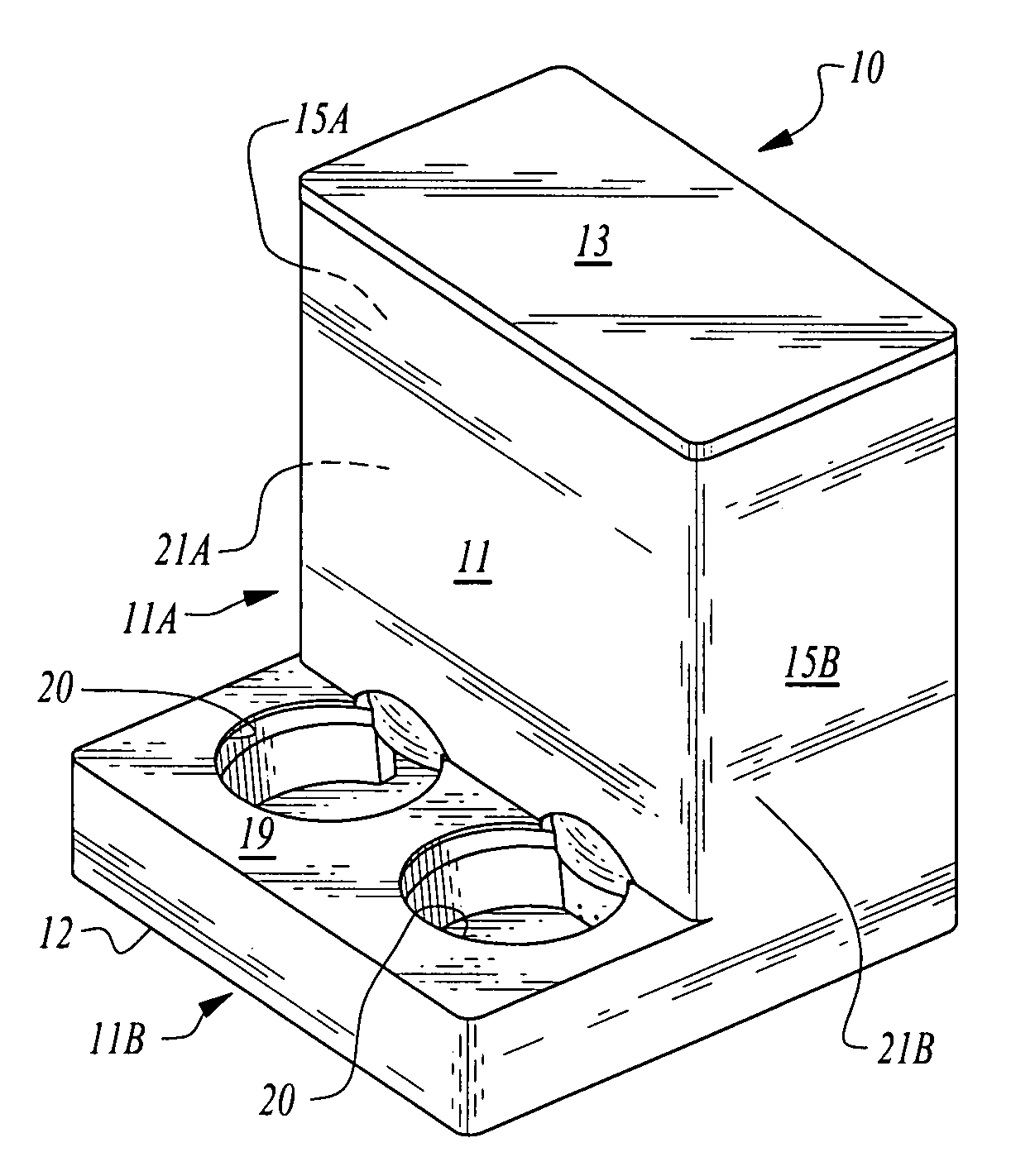

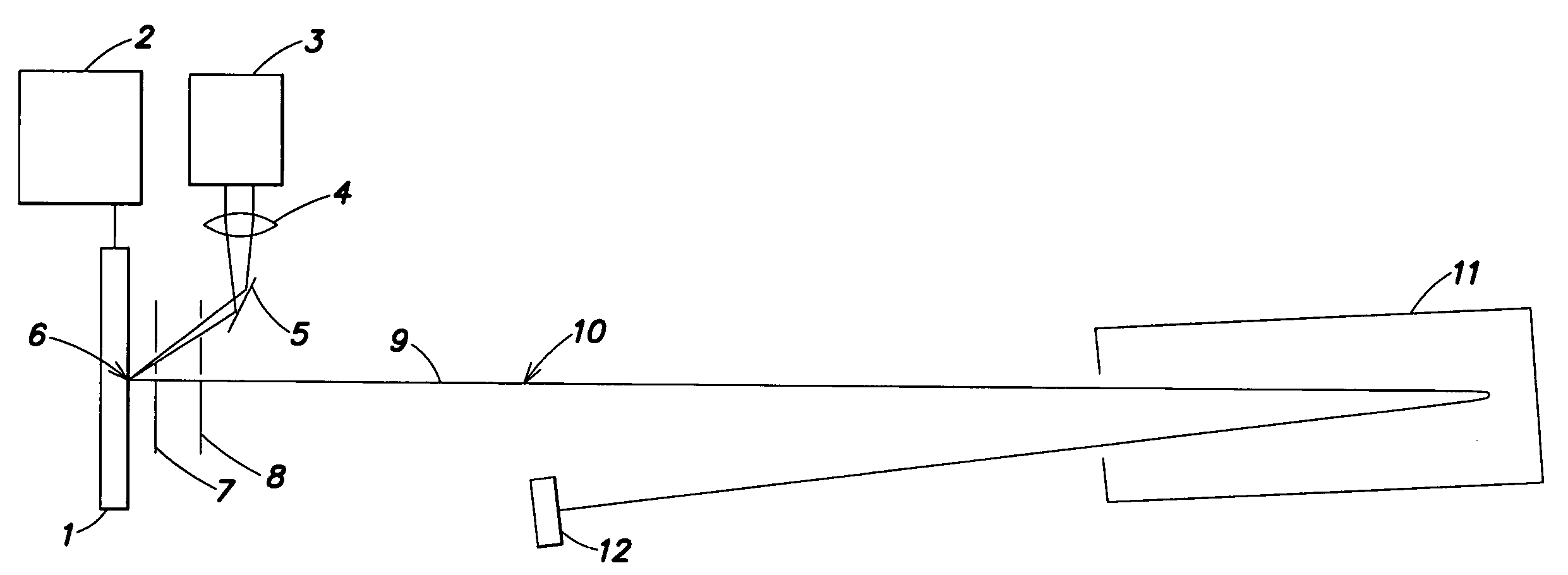

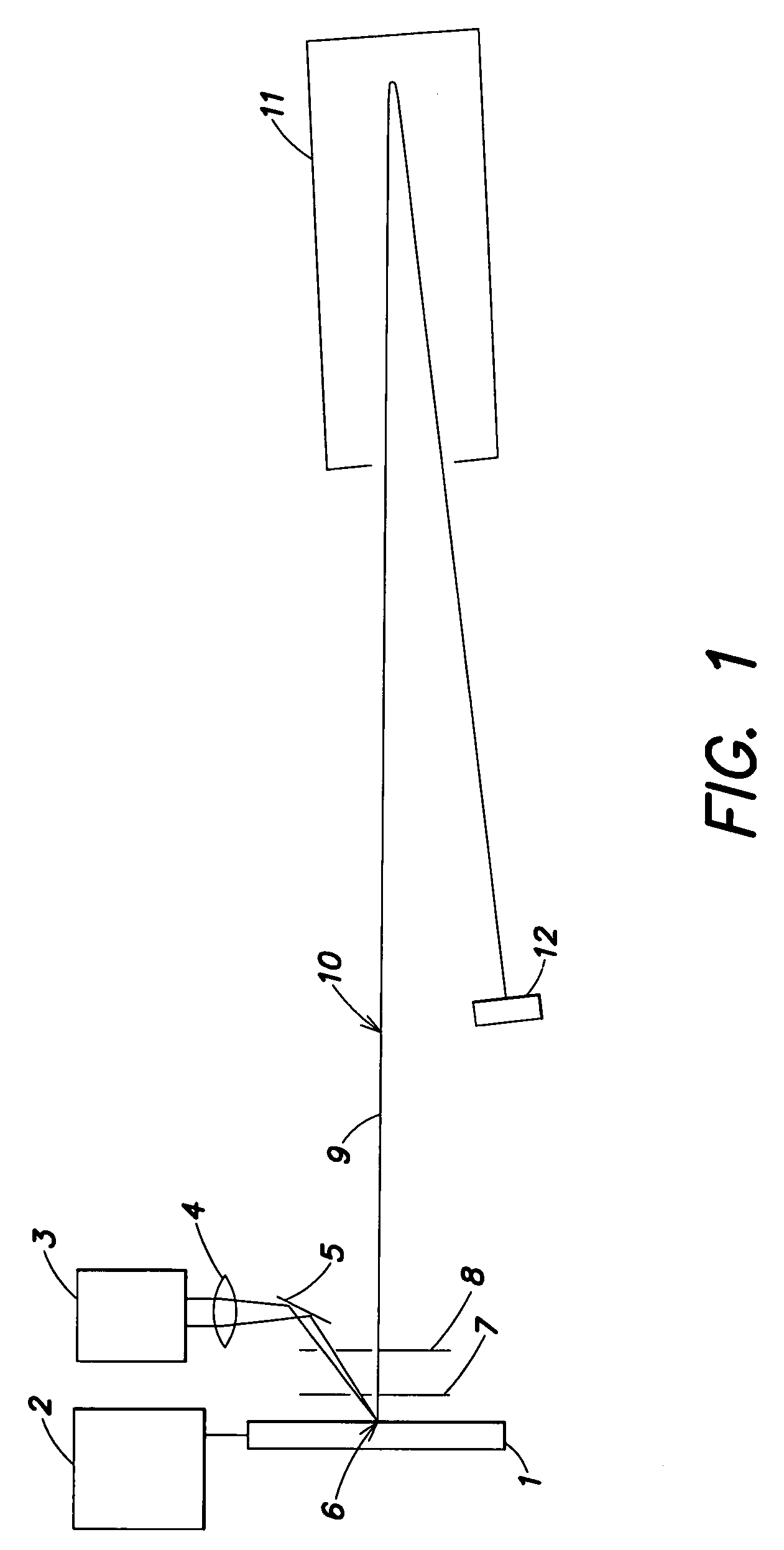

Auto-loading firearm mechanisms and methods

InactiveUS7137217B2Reduce the total massDampen the “runout” of the firearm's barrel assemblyFiring/trigger mechanismsBreech mechanismsSemi automaticEngineering

Automatic and semi-automatic firearms of remarkably reduced mass yet capable of long-range accuracy because of unique recoil reduction are characterized by (A) a temporary combination of a barrel, an integral breech and a separable chamber that in operation of the firearm is moved by a compressed spring distally before and while a chambered cartridge is fired, (B) run-out of such temporary operative combination diminishes firearm recoil, (C) recoil of the temporary operative combination recompresses the spring and (D) the separable chamber is loaded with a round while spatially separated from the breech and barrel.

Owner:KNIGHT'S ARMAMENT COMPANY

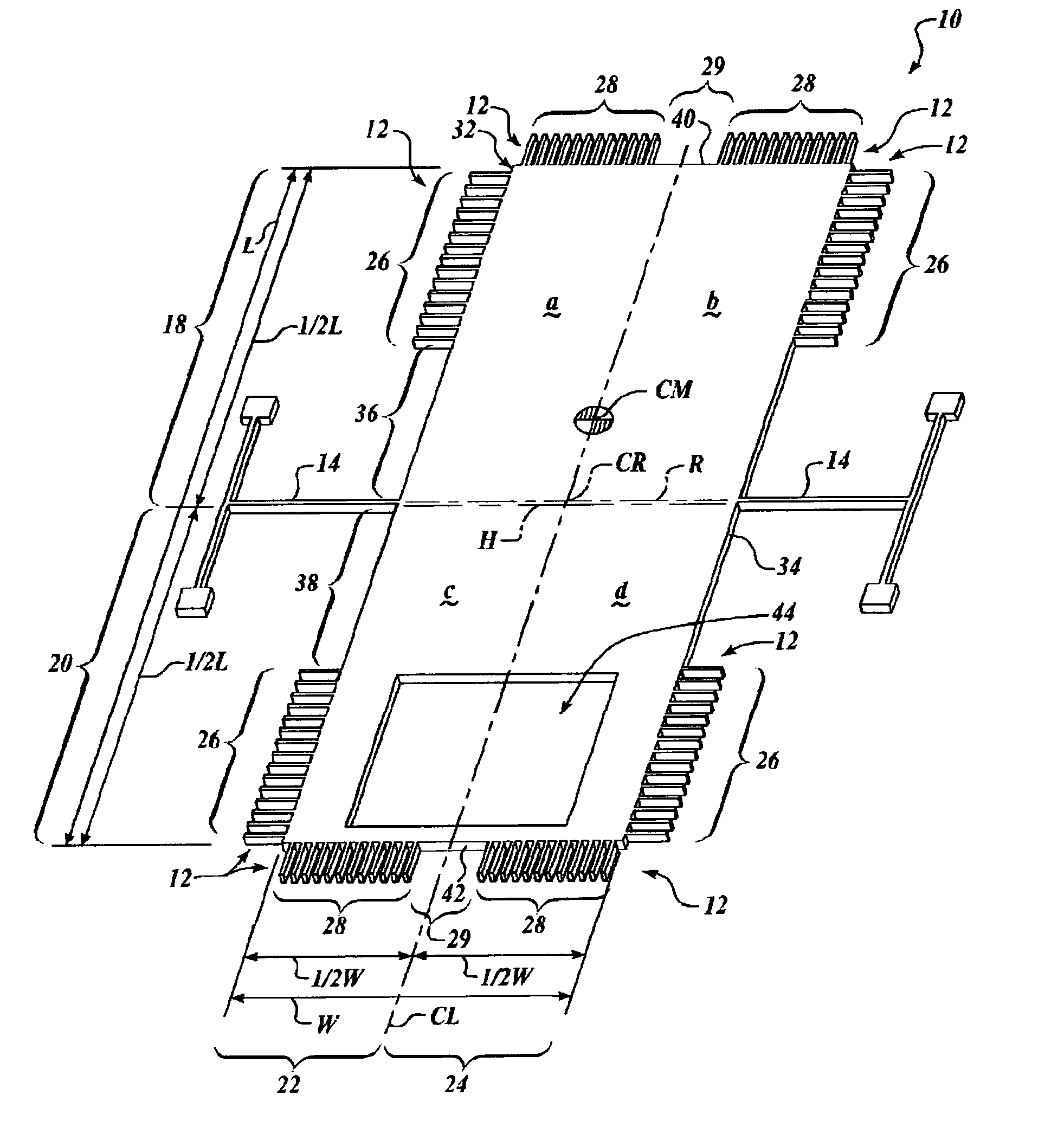

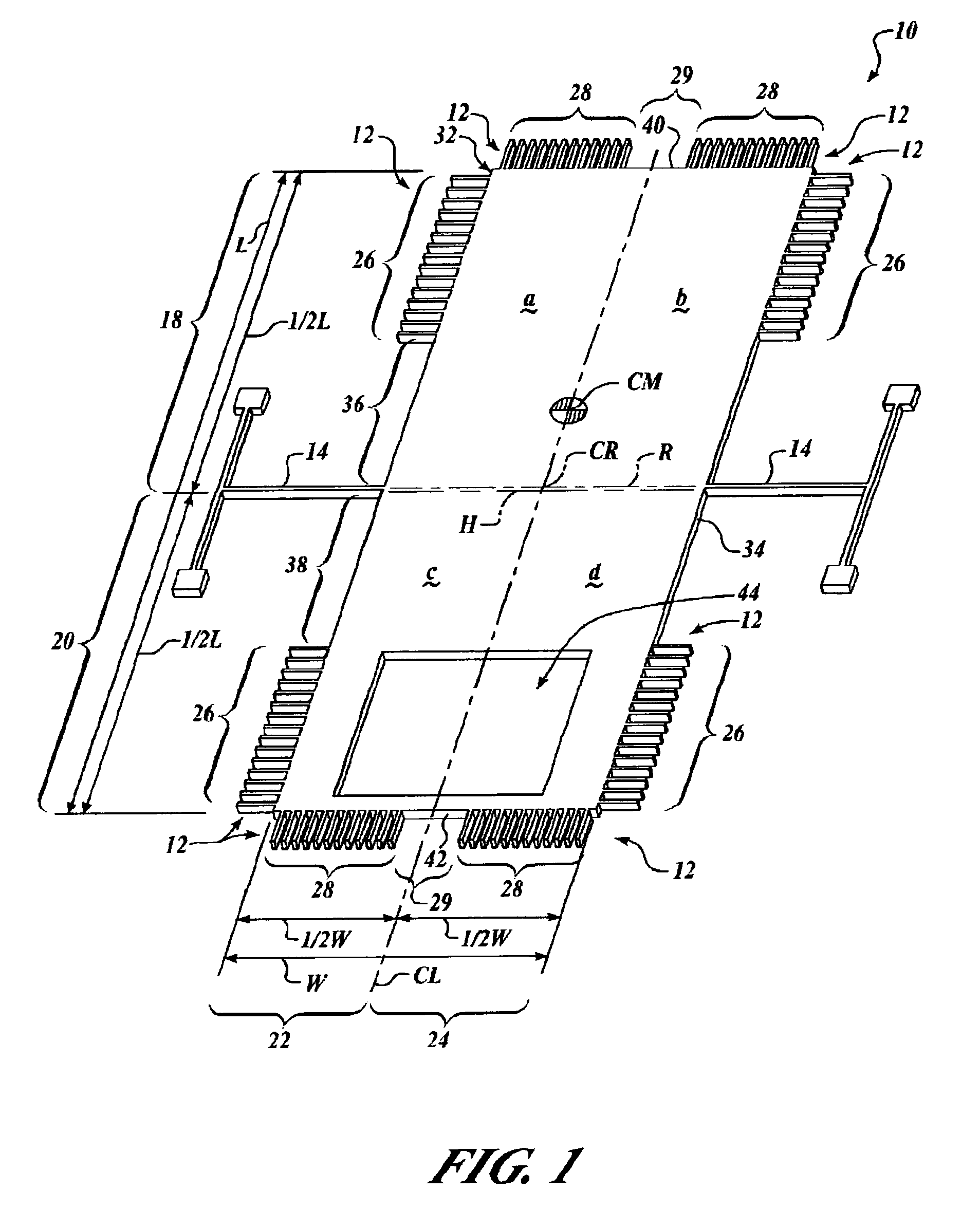

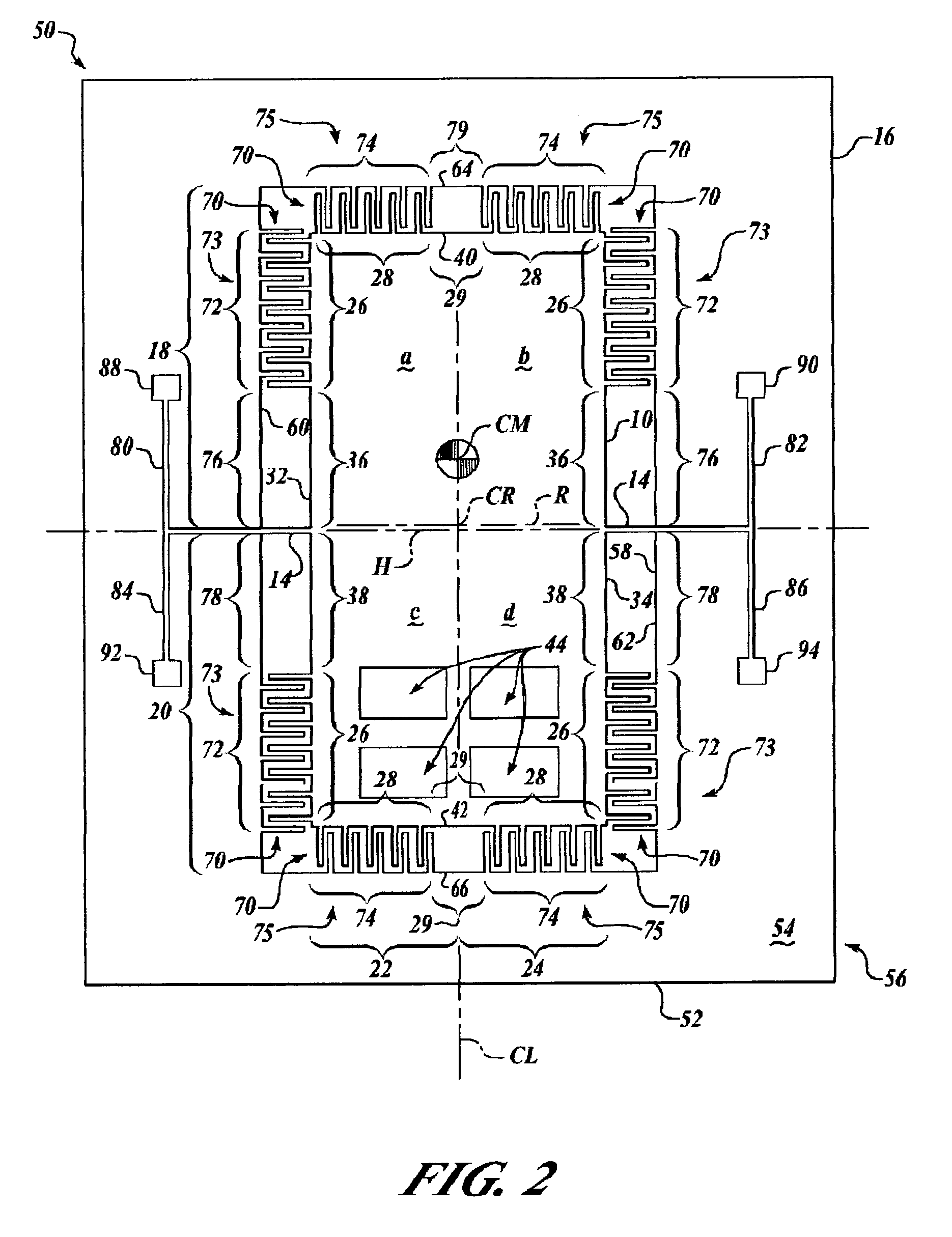

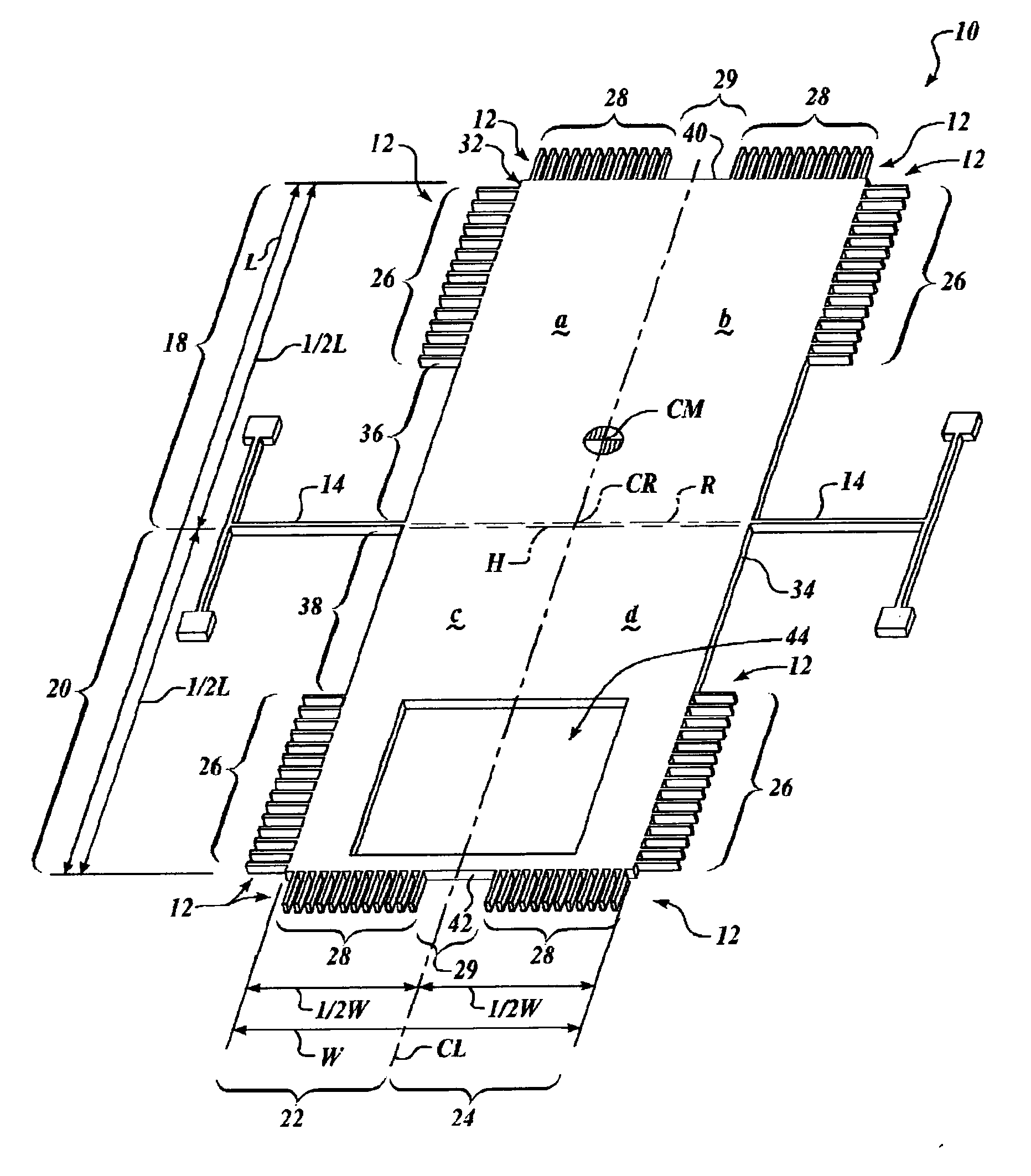

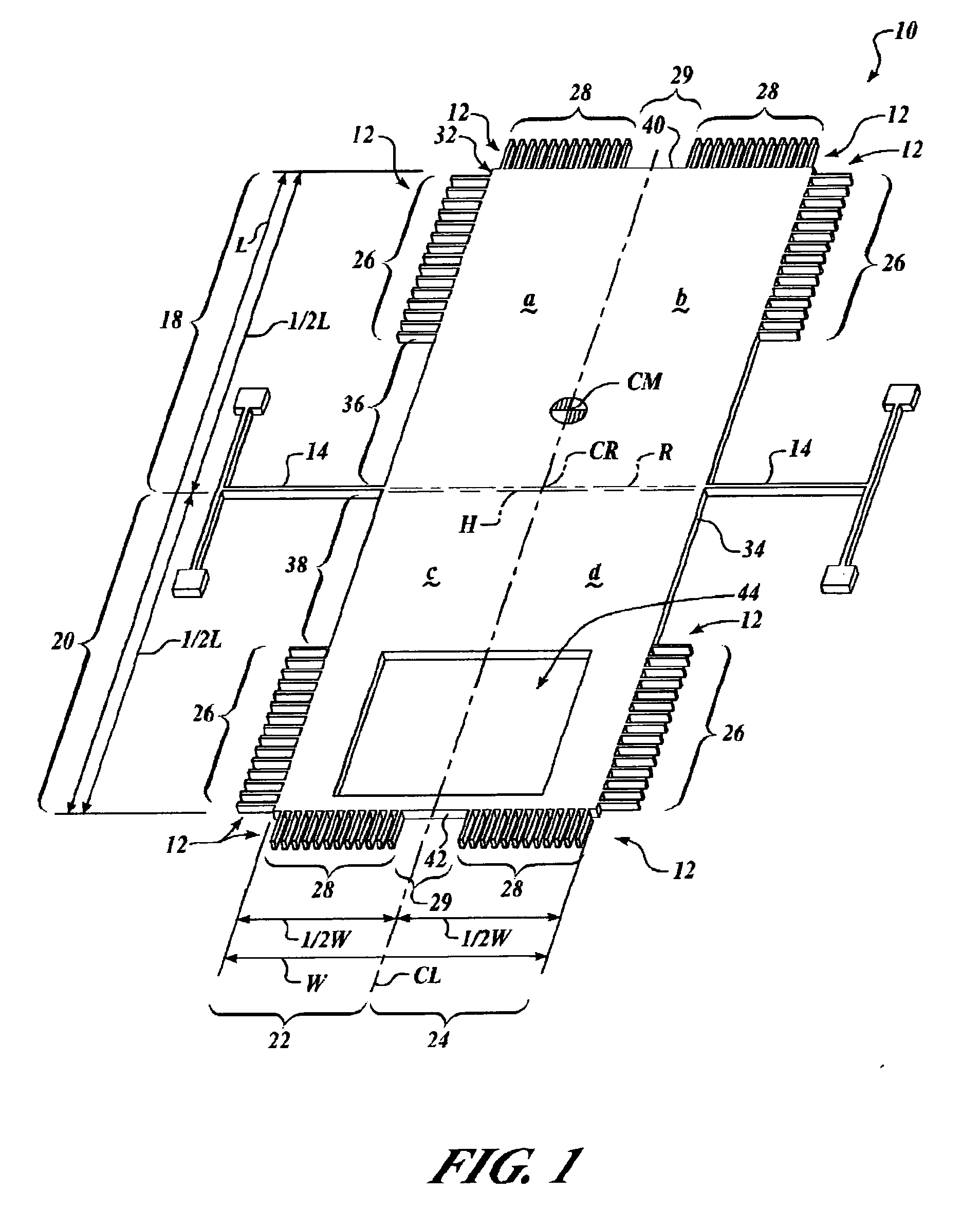

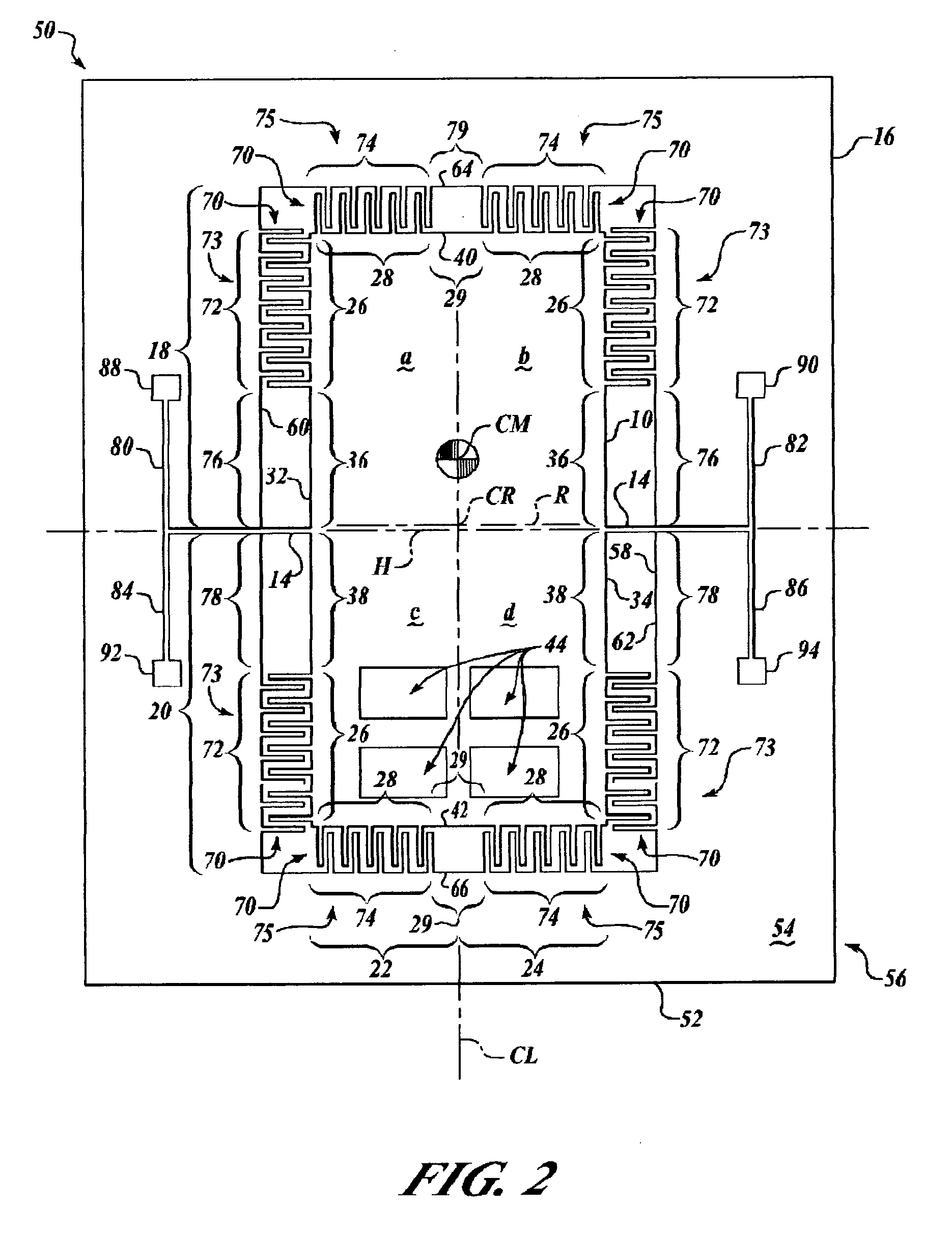

MEMS teeter-totter accelerometer having reduced non-linearty

ActiveUS7140250B2Improve accuracyLow costAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsRotational axisEngineering

An apparatus and method for force sensing device having a pendulous mechanism proof mass formed in a silicon semiconductor substrate and structured for rotation about an intermediate rotational axis, the proof mass being substantially rectangular in shape with opposing first and second lateral peripheral edges and opposing first and second endwise peripheral edges. A plurality of capacitor comb teeth are formed symmetrically along the opposing first and second endwise peripheral proof mass edges and along the opposing first and second lateral peripheral proof mass edges adjacent to the first and second endwise peripheral edges, and one or more mass reduction apertures are formed in an interior portion of the proof mass on one side of the intermediate hinge axis.

Owner:HONEYWELL INT INC

MEMS teeter-totter accelerometer having reduced non-linearty

ActiveUS20060185433A1Reduce non-linearityImprove accuracyAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsRotational axisEngineering

An apparatus and method for force sensing device having a pendulous mechanism proof mass formed in a silicon semiconductor substrate and structured for rotation about an intermediate rotational axis, the proof mass being substantially rectangular in shape with opposing first and second lateral peripheral edges and opposing first and second endwise peripheral edges. A plurality of capacitor comb teeth are formed symmetrically along the opposing first and second endwise peripheral proof mass edges and along the opposing first and second lateral peripheral proof mass edges adjacent to the first and second endwise peripheral edges, and one or more mass reduction apertures are formed in an interior portion of the proof mass on one side of the intermediate hinge axis.

Owner:HONEYWELL INT INC

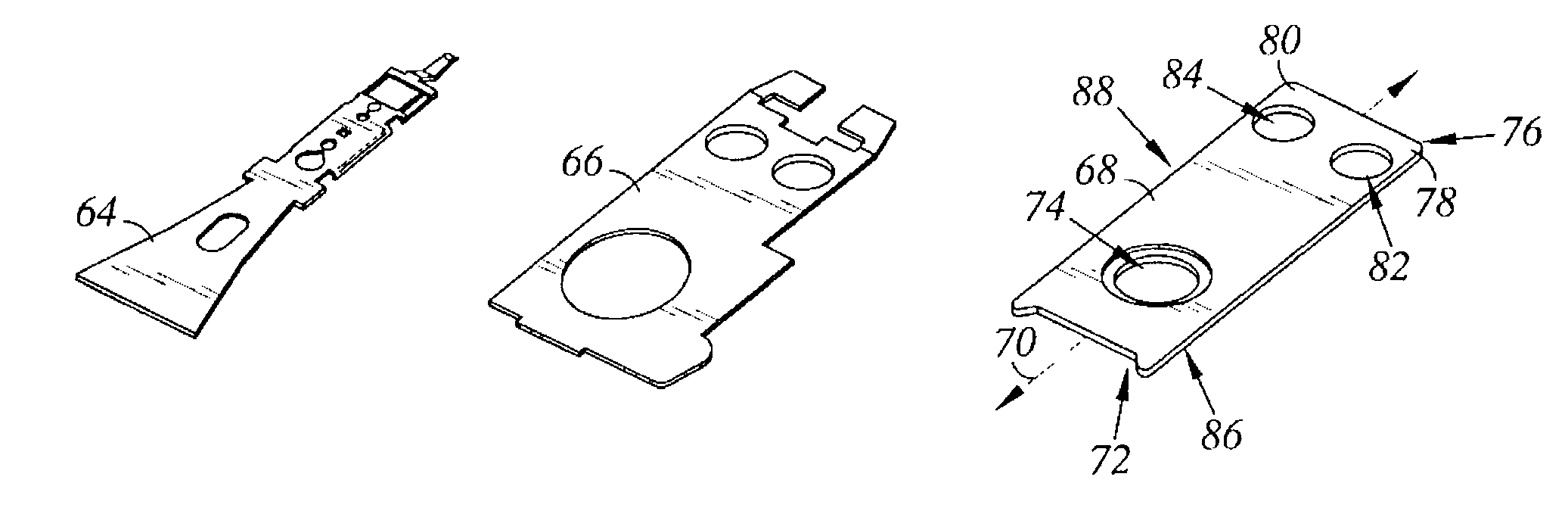

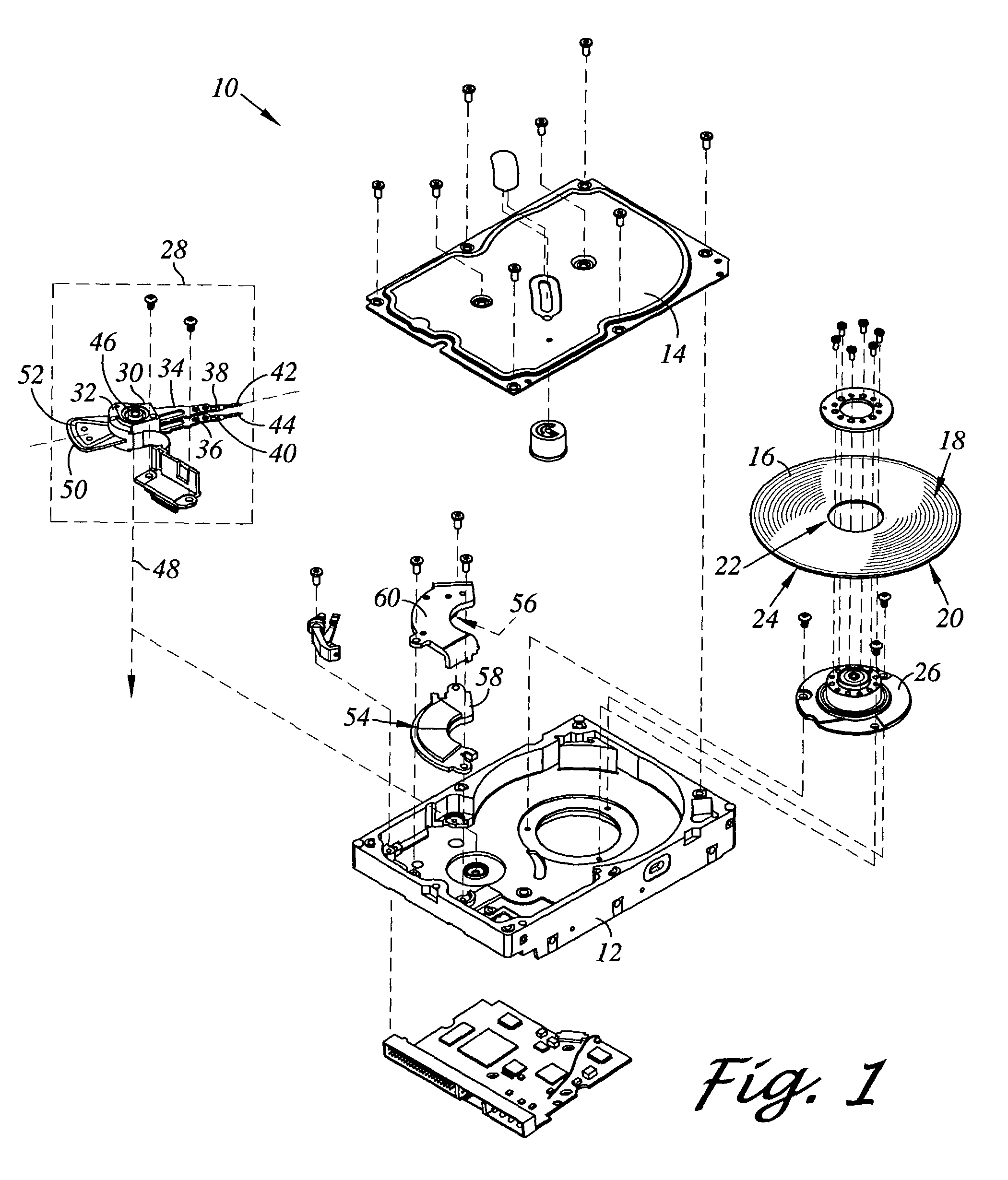

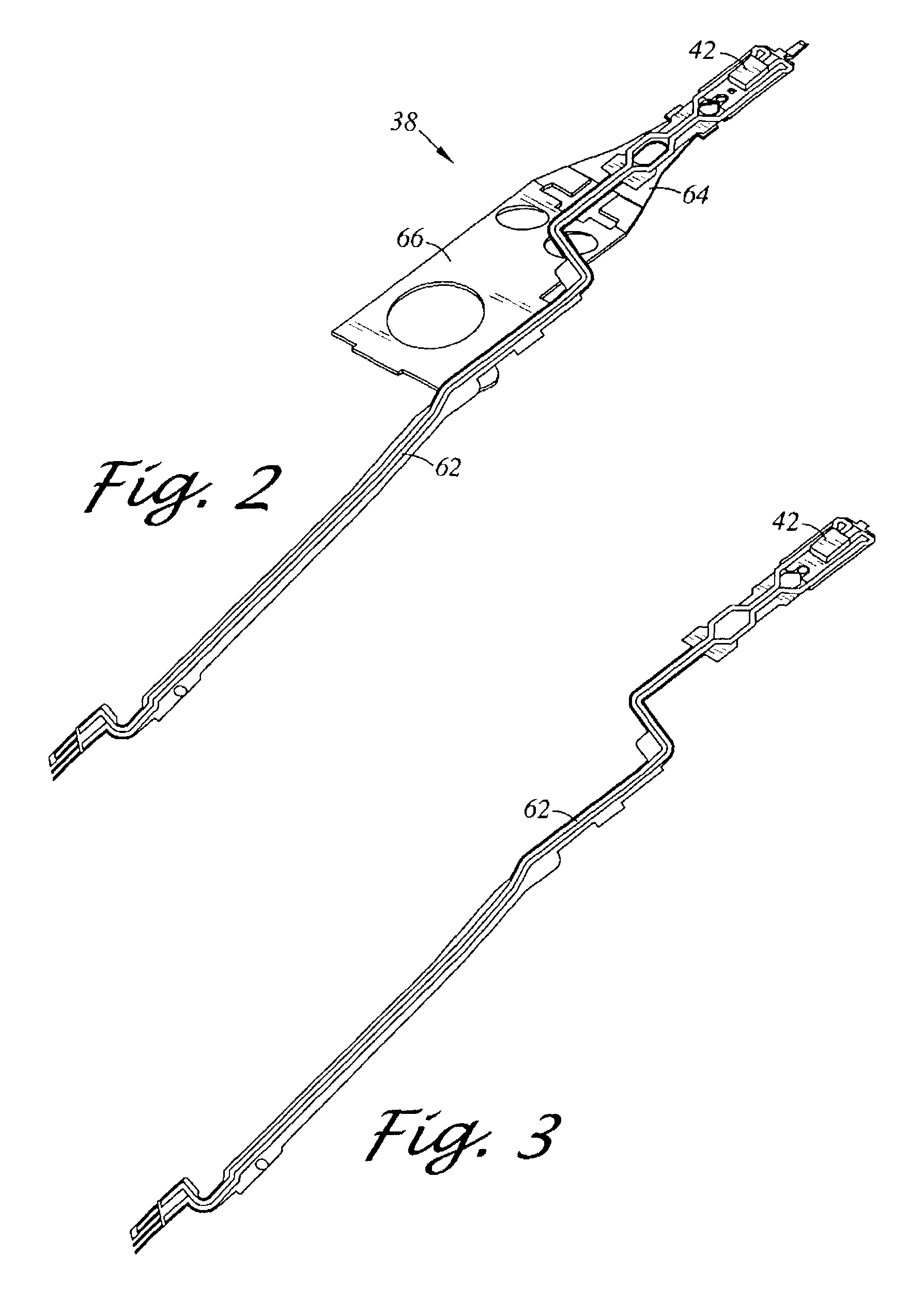

Disk drive suspension assembly including a base plate with mass reduction openings at distal corners

ActiveUS6967800B1Reduce frequencyUndesired vibrations/sounds insulation/absorptionRecord information storageMass reductionEngineering

A disk drive suspension assembly. The suspension assembly includes a load beam and a base plate with a longitudinal axis. The base plate includes an actuator arm and an opposing actuator arm end. The head gimbal end is disposed in mechanical communication with the load beam for distally supporting the load beam. The head gimbal end defines opposing first and second distal corners. The base plate includes first and second mass reduction openings formed through the base plate symmetrically about the longitudinal axis at the head gimbal end for locally reducing mass to mitigate torsional vibration mode frequency about the longitudinal axis. The first mass reduction opening is disposed at the head gimbal end between the first distal corner and the longitudinal axis. The second mass reduction opening is disposed at the head gimbal end between the second distal corner and the longitudinal axis.

Owner:WESTERN DIGITAL TECH INC

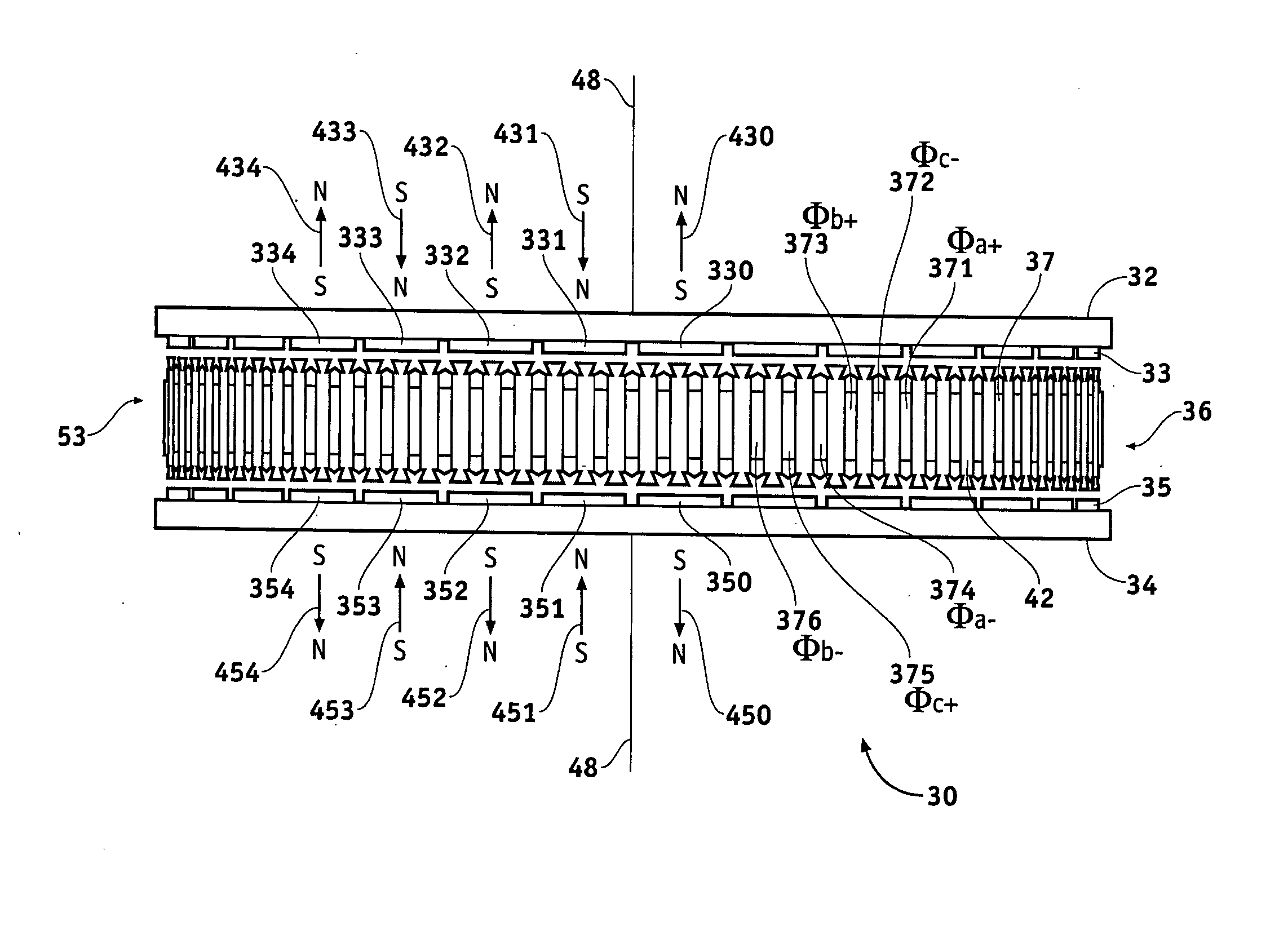

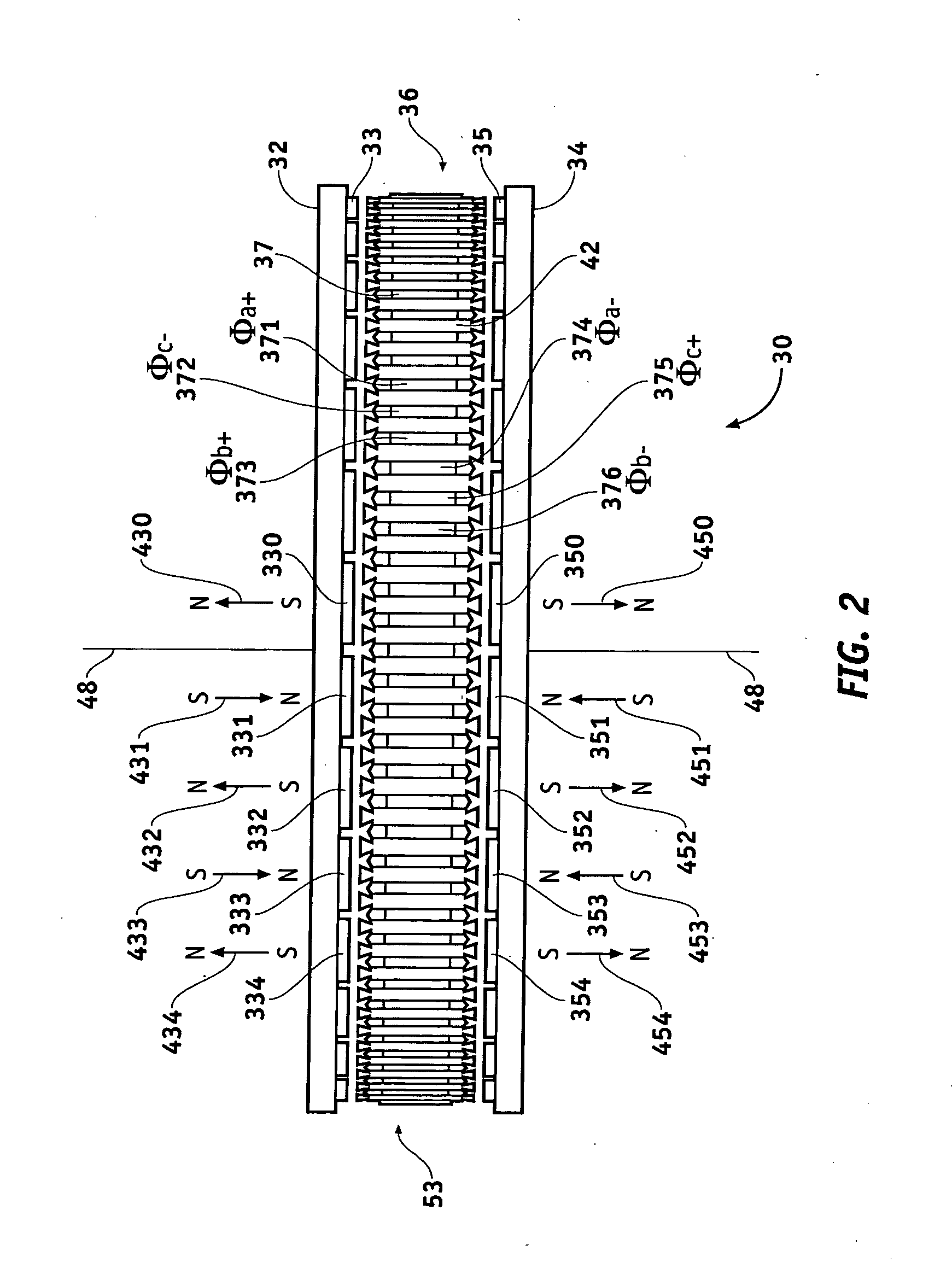

Axial flux motor mass reduction with improved cooling

InactiveUS20050035678A1Low densityReduce weightWindingsVector control systemsEngineeringNon magnetic

Methods and apparatus are provided for an axial electric motor. The apparatus comprises, a stator having coils thereon for producing a magnetic field, a rotor rotated by the magnetic field, and an output shaft coupled to the rotor. The rotor includes a magnetic and non-magnetic component. The non-magnetic component has a lower density than the magnetic component. One or both of the rotor components have apertures therein for ventilation and weight reduction. Permanent magnets are desirably mounted on the magnetic component of the rotor facing the stator and portions of the rotor behind the permanent magnets are hollowed out to be thinner than portions of the rotor between the permanent magnets. This reduces rotor weight without significantly affecting magnetic flux density in the rotor or motor torque.

Owner:GM GLOBAL TECH OPERATIONS LLC

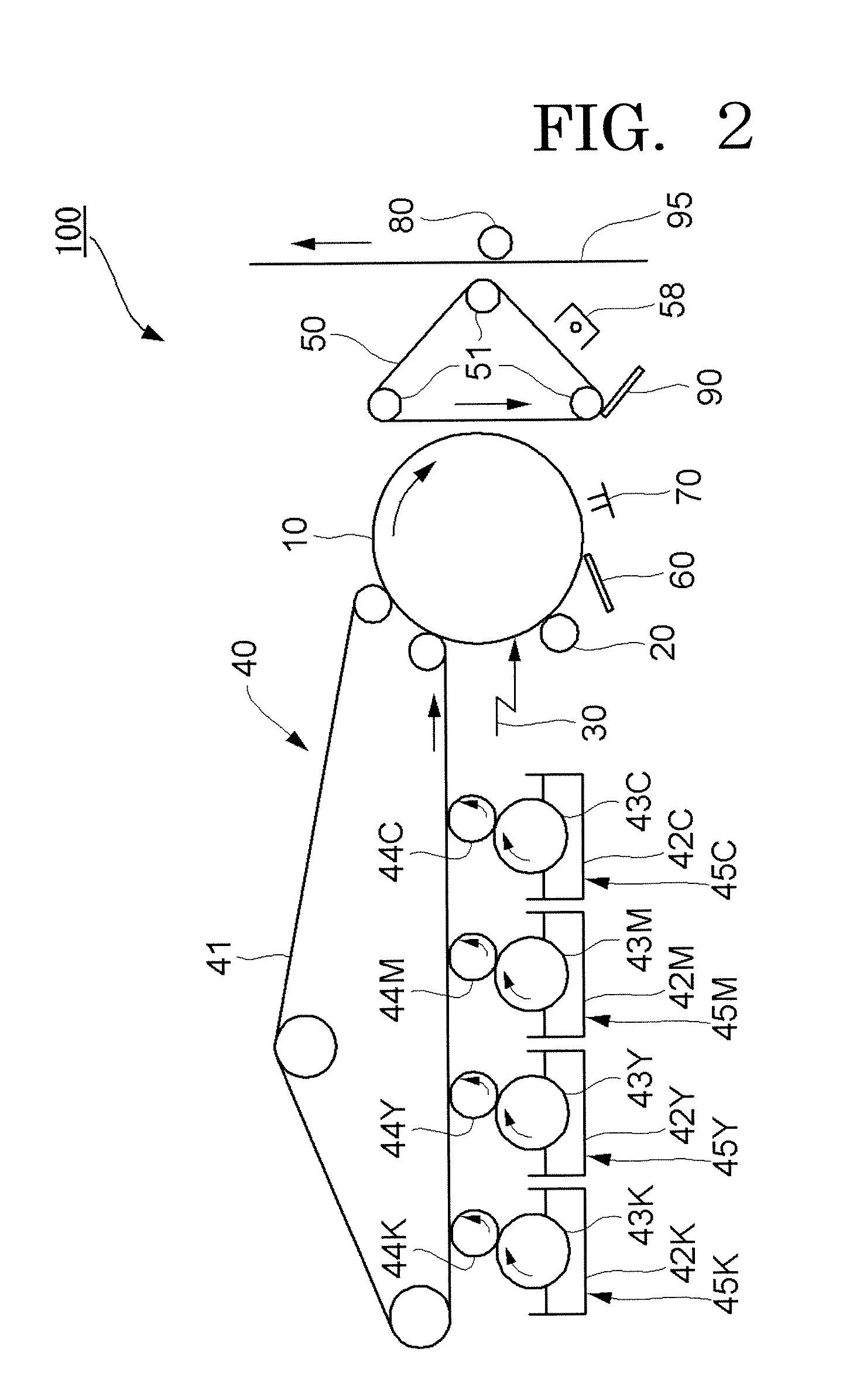

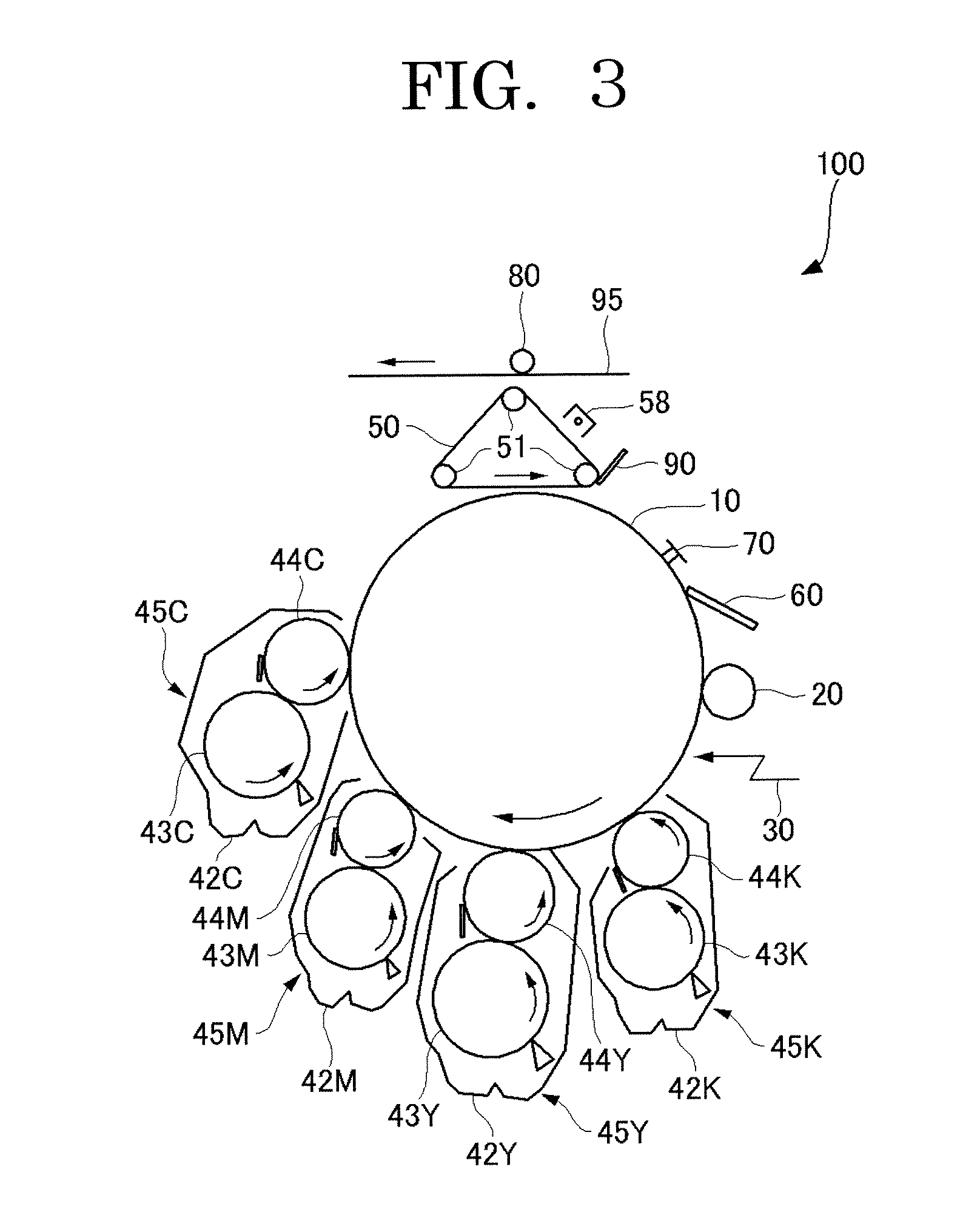

Toner as well as developer and image forming method using the same

ActiveUS20070218387A1Improve abilitiesImprove image qualityDevelopersElectrographic processes using charge patternSilica particleImaging quality

A toner which combines excellent cleaning ability, image quality and durability, as well as a developer and an image forming method using the toner are provided. A toner comprising a toner base particle which comprises at least a binding resin and a colorant, and an external additive, wherein an external additive is a non-spherical amorphous silica particle and a major axis of the silica particle is 40 nm to 180 nm. An aspect wherein the non-spherical amorphous silica particle has a true specific gravity of 1.8 to 2.3 and the silica particle is hydrophobilized and a hydrophobilization degree is 40 or more, and an aspect wherein the non-spherical amorphous silica particle is produced by a dry system and a mass reduction rate is 5% by mass or less when the silica particle is heated from 30° C. up to 250° C. are preferable.

Owner:RICOH KK

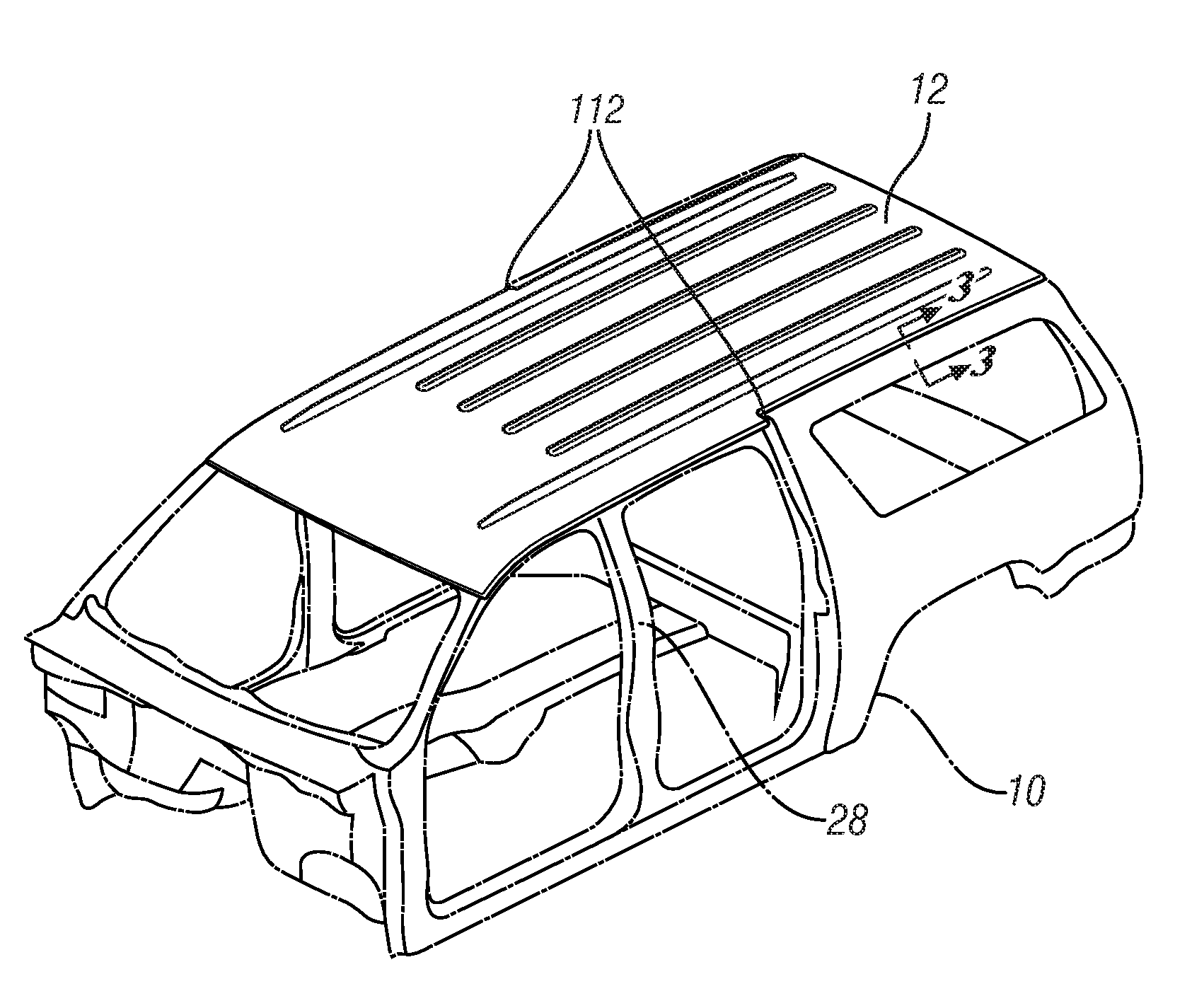

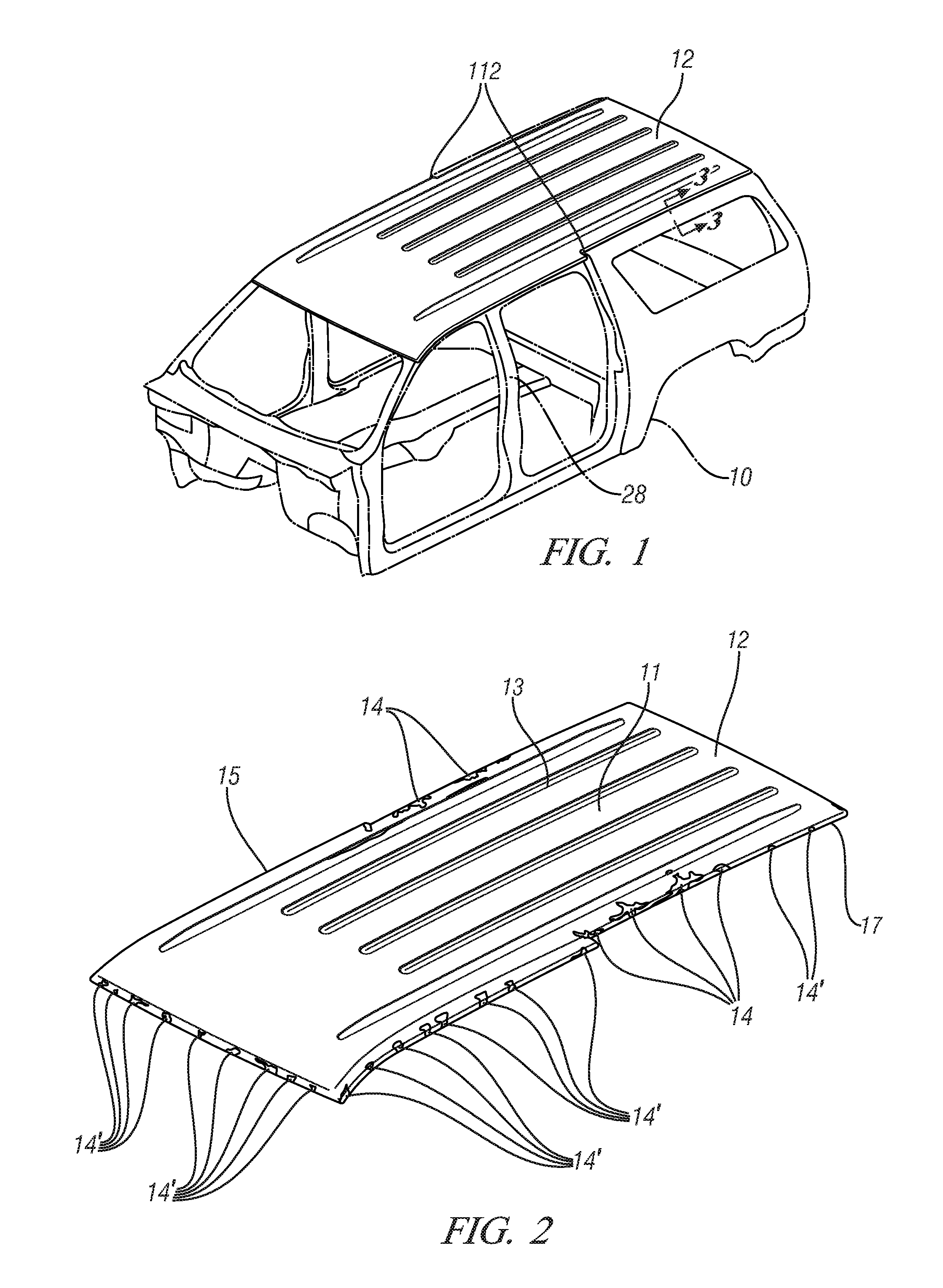

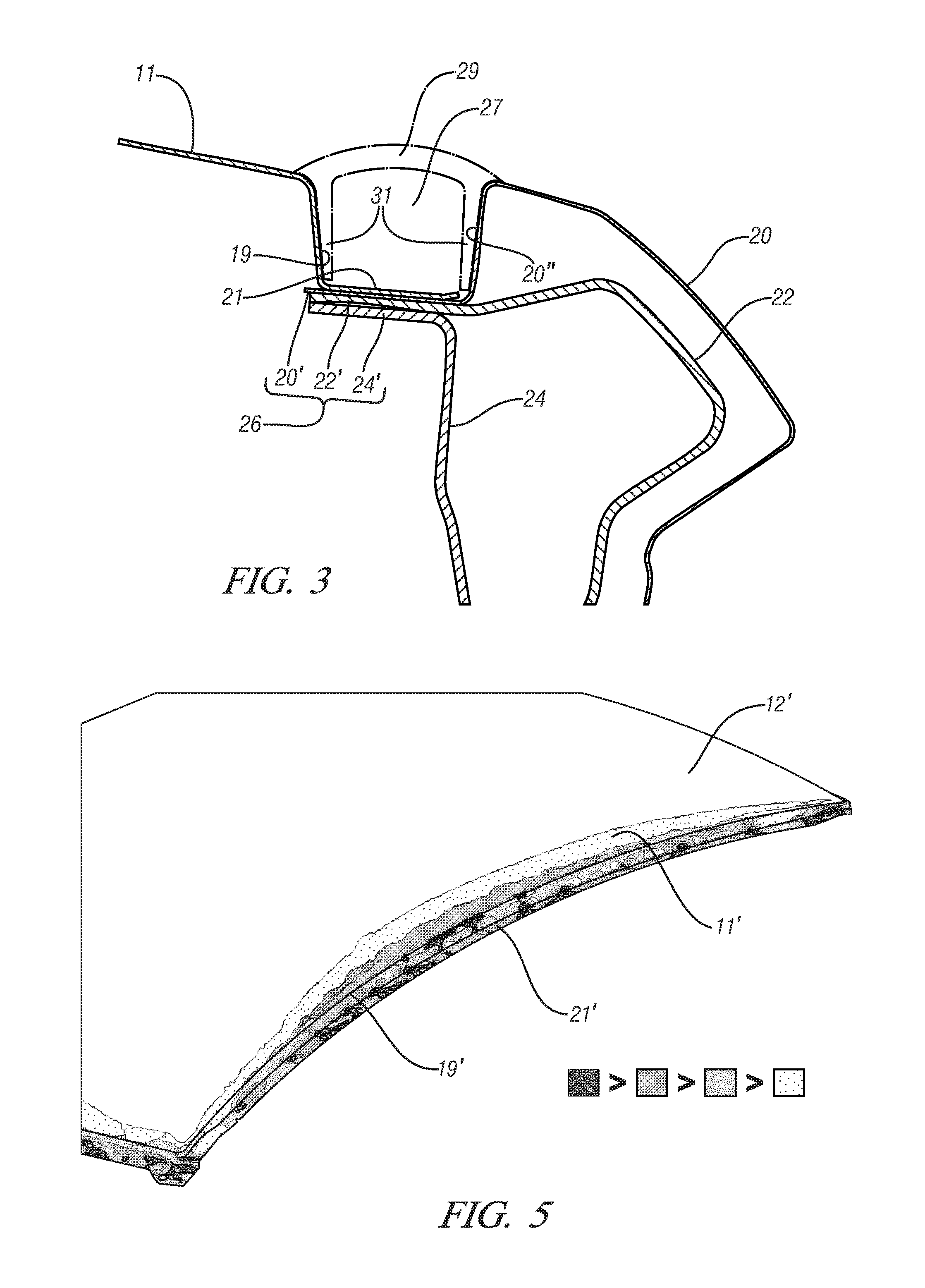

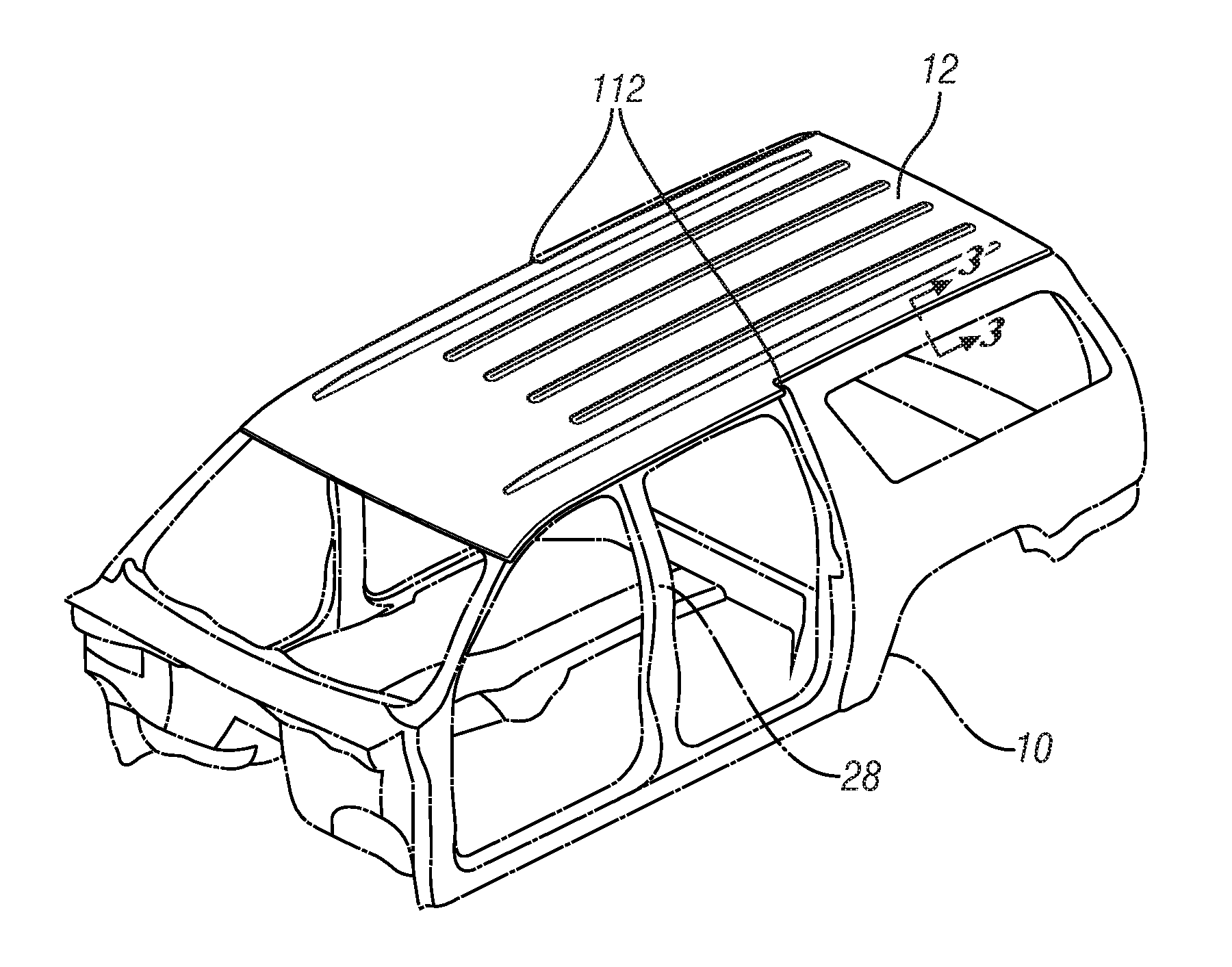

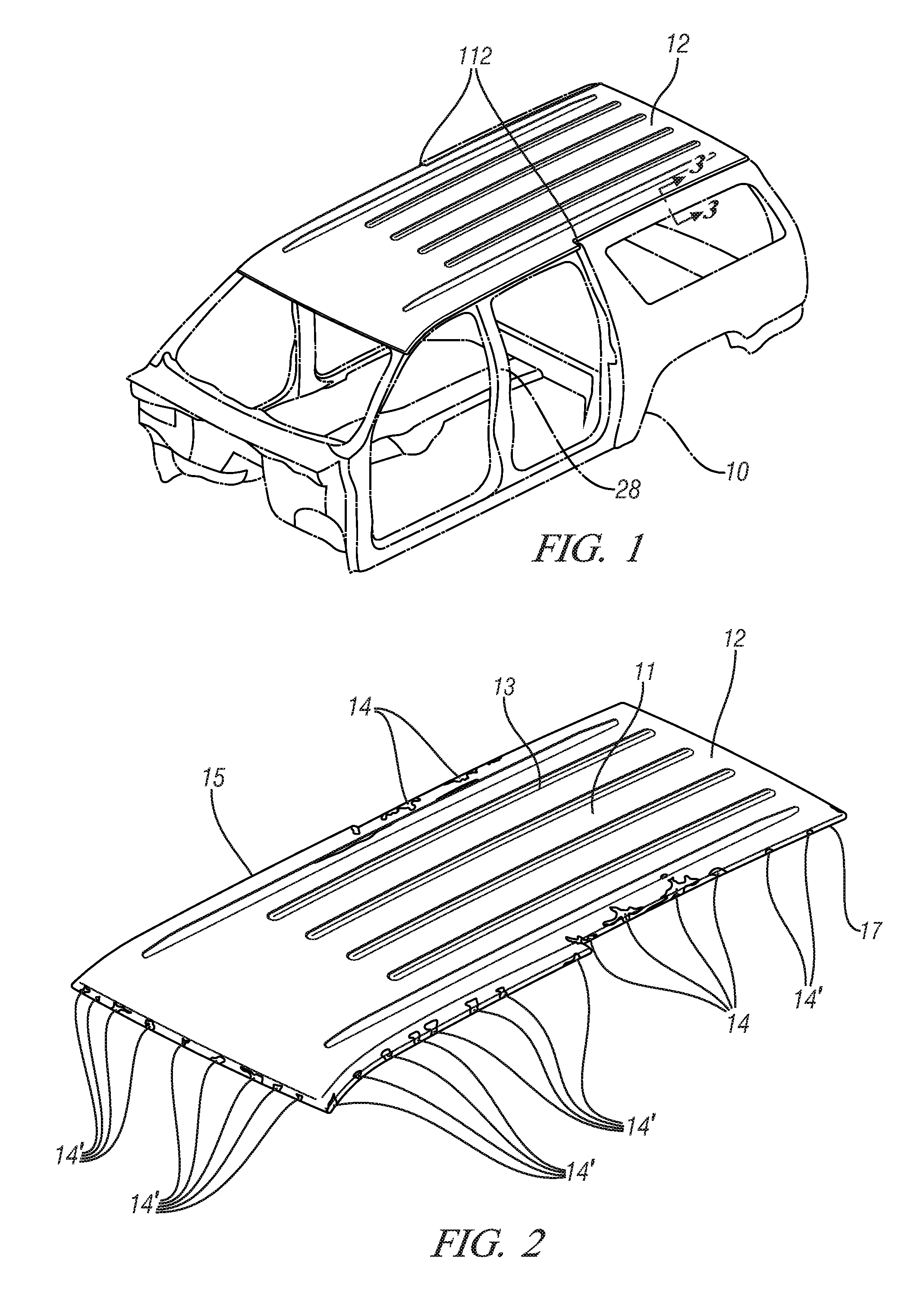

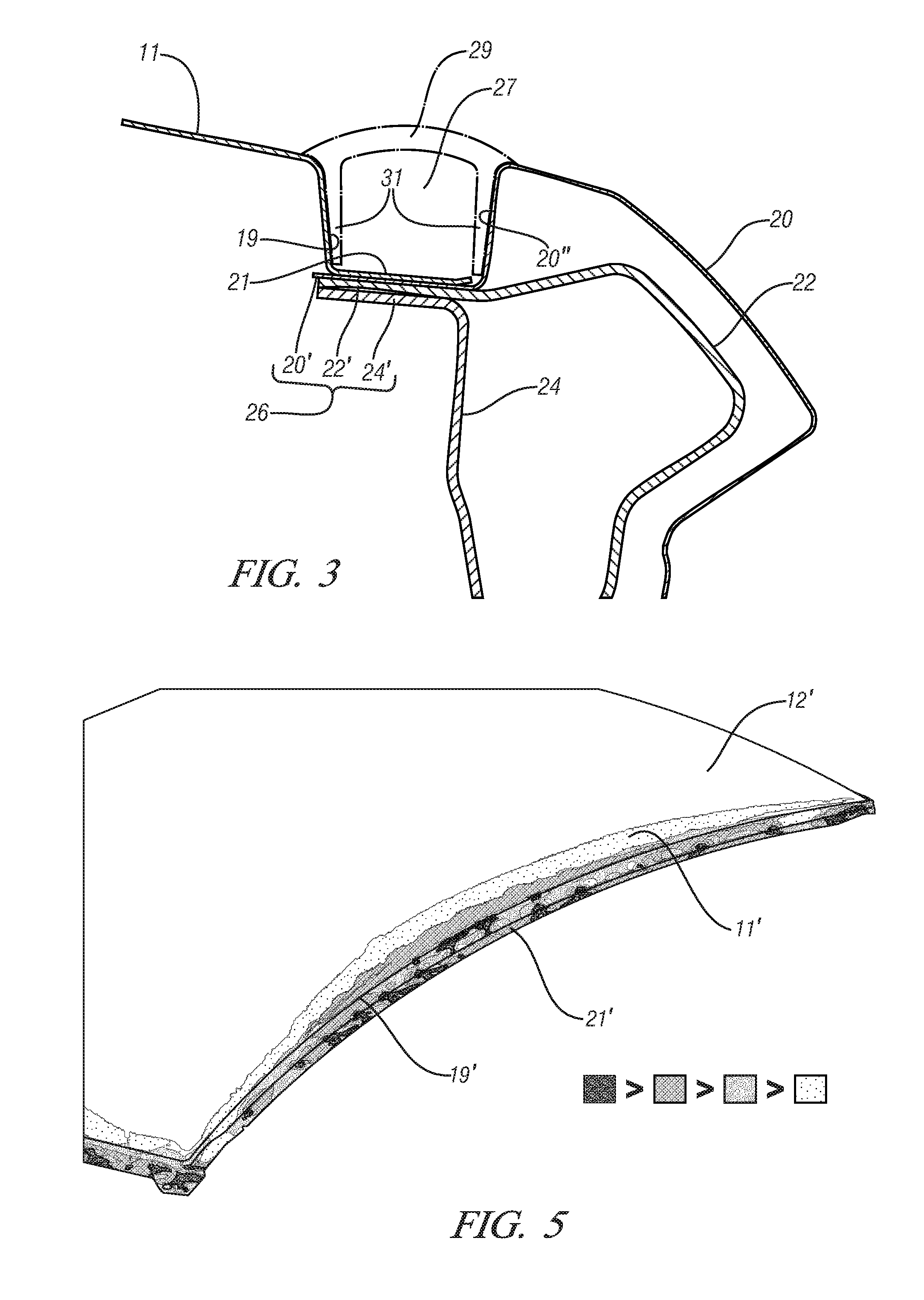

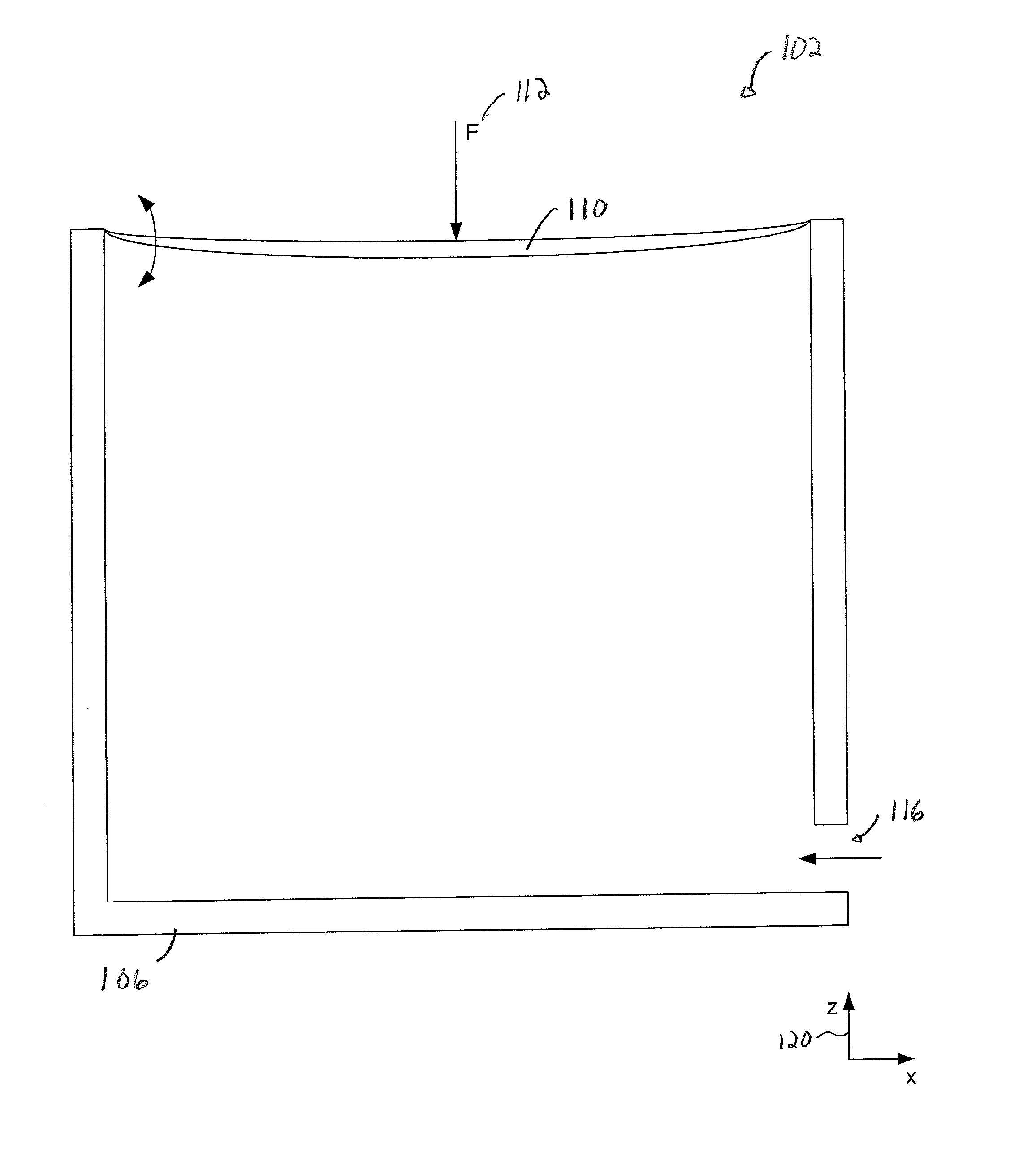

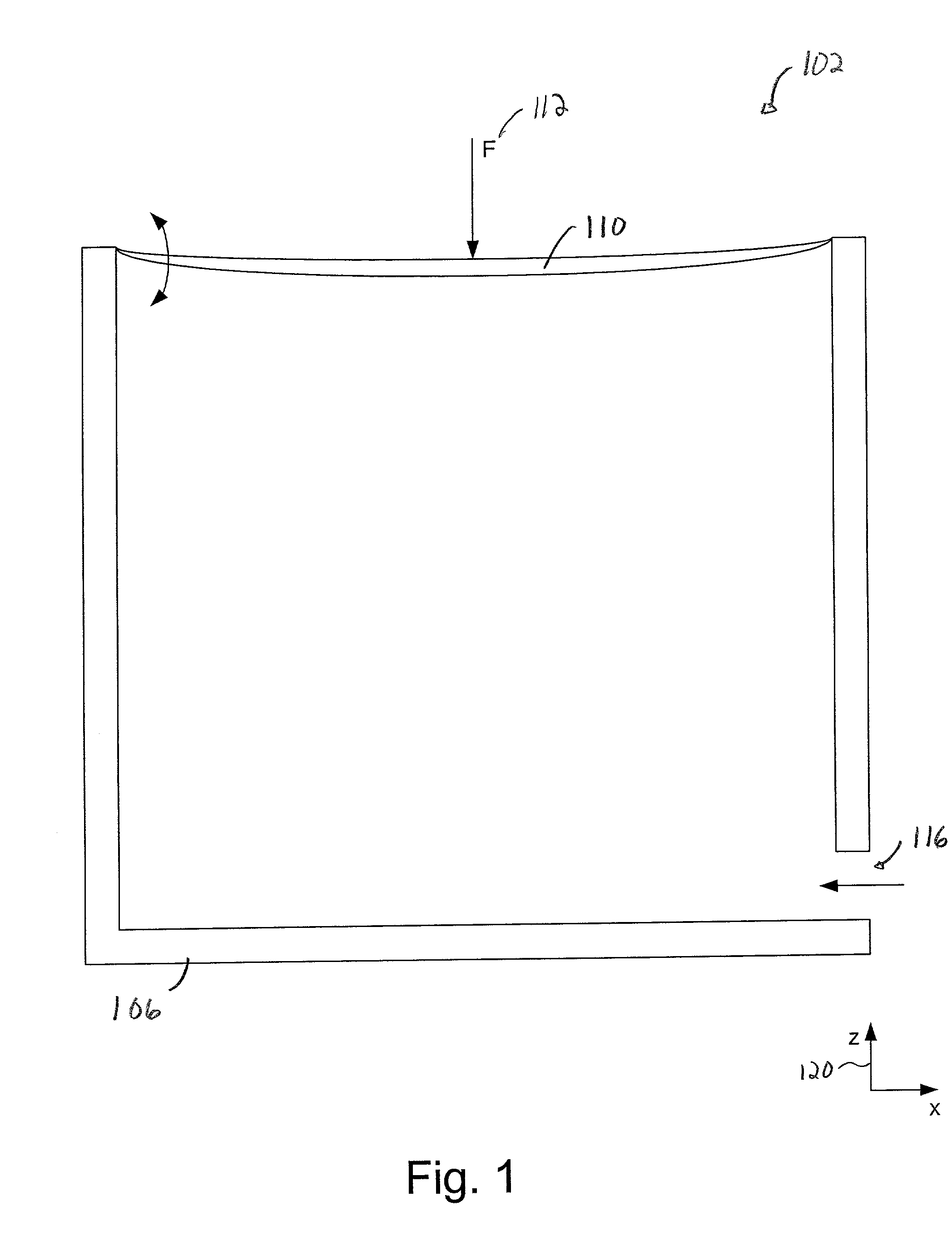

Aluminum roof panel for attachment to supporting steel vehicle body members

ActiveUS20120061998A1Reduce and eliminate distortionMaximized strengthVehicle seatsSuperstructure subunitsCarbon steelFlange

The substitution of aluminum alloy roof panels for the low carbon steel roof panels most commonly used in motor vehicles is an attractive option for vehicle mass reduction. Often, however, the remainder of the vehicle body structure continues to be fabricated of steel. The combination of the aluminum alloy roof attached to the steel body may create compressive stresses in the aluminum roof when the body is subjected to elevated temperatures such as those required to cure or bake the paint applied to the body. These stresses may lead to unacceptable appearance features in the visible segment of the roof. By modifying the roof stamping to introduce a tabbed flange for attachment to the body and / or modifying the generally-vertical wall joining the flange to the roof interior, the stresses may be minimized and relocated to segments of the roof not normally visible.

Owner:GM GLOBAL TECH OPERATIONS LLC

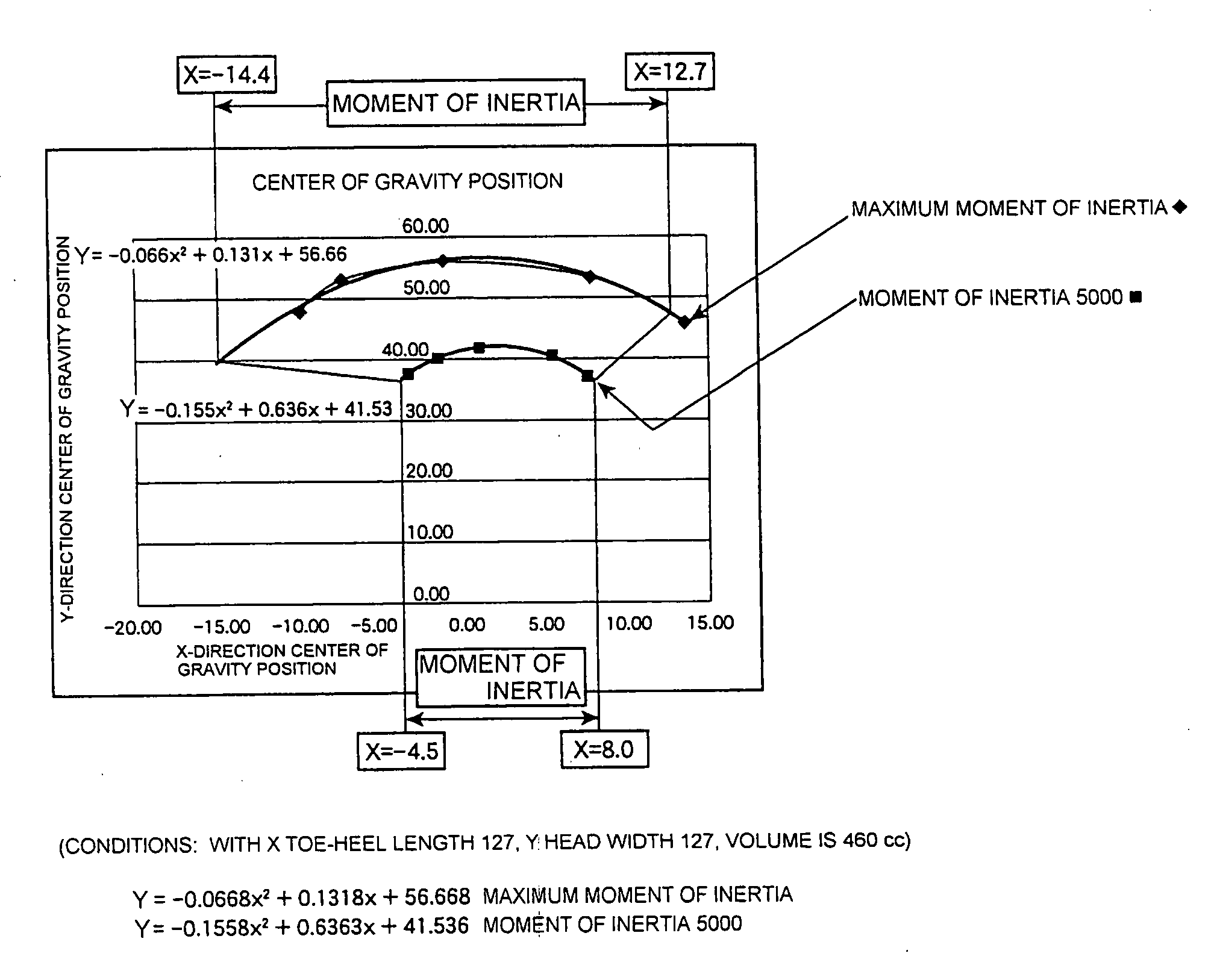

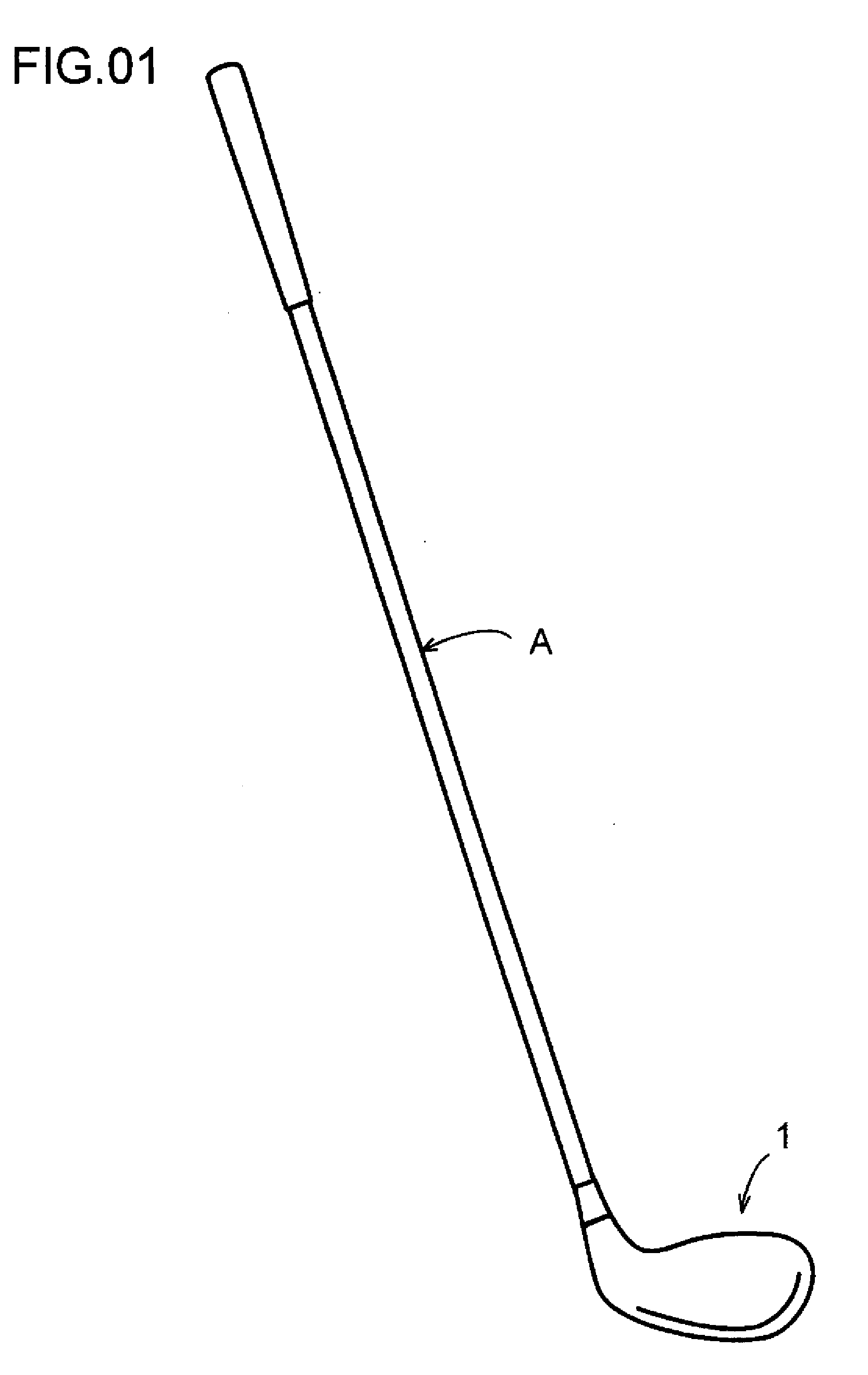

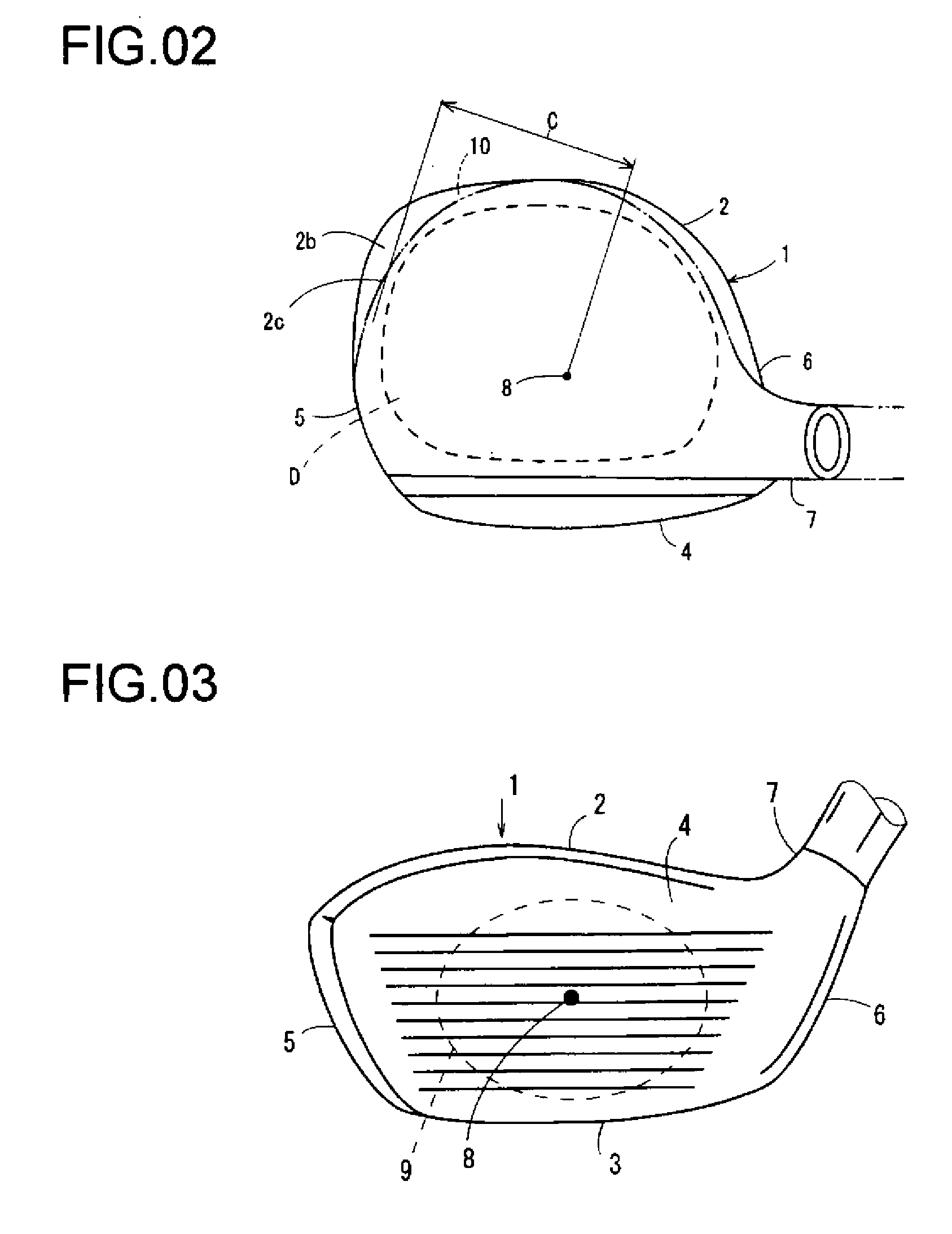

Golf club head

InactiveUS20080113825A1Stable strikingSatisfactory performanceGolf clubsRacket sportsEtchingMoment of inertia

A golf club having an increased moment of inertia and improved ball-hitting directionality is provided. A metal hollow golf club head comprises: a face portion; a crown portion; and a sole portion, and when the golf club has a lie angle of 60° with its club head volume being within 470 cm3, a moment of inertia about the axial line centered on the plumb line passing through the golf club head center of gravity is 5000 to 6000 g-cm2. In order to increase the moment of inertia, the thickness of the center portion of the crown portion is reduced by chemical etching, and a mass, including the portion of mass reduction, is positioned in the sole portion on the side of the toe portion; moreover, the separation distance from the center of gravity to the mass is increased.

Owner:ENDO MFG COMPANY

Aluminum roof panel for attachment to supporting steel vehicle body members

ActiveUS8424961B2Maximized strengthReduce and eliminate distortionVehicle seatsSuperstructure subunitsMobile vehicleCarbon steel

The substitution of aluminum alloy roof panels for the low carbon steel roof panels most commonly used in motor vehicles is an attractive option for vehicle mass reduction. Often, however, the remainder of the vehicle body structure continues to be fabricated of steel. The combination of the aluminum alloy roof attached to the steel body may create compressive stresses in the aluminum roof when the body is subjected to elevated temperatures such as those required to cure or bake the paint applied to the body. These stresses may lead to unacceptable appearance features in the visible segment of the roof. By modifying the roof stamping to introduce a tabbed flange for attachment to the body and / or modifying the generally-vertical wall joining the flange to the roof interior, the stresses may be minimized and relocated to segments of the roof not normally visible.

Owner:GM GLOBAL TECH OPERATIONS LLC

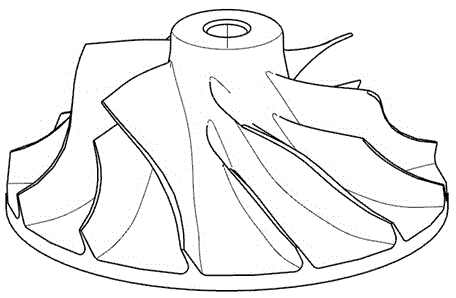

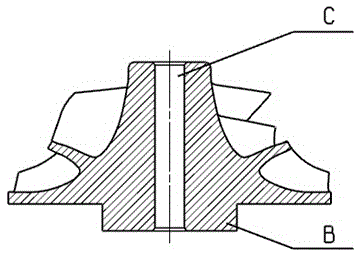

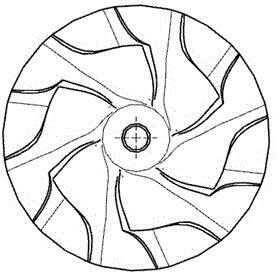

Process method for improving manufacturing accuracy of aluminum-alloy open-type integral impeller

The invention relates to a process method for improving the manufacturing accuracy of an aluminum-alloy open-type integral impeller. The method comprises the concrete steps of preparing materials, carrying out rough-turning on impeller blank shape, carrying out rough-turning on a process gripping head, carrying out heat treatment, carrying out artificial aging, carrying out semi-fine-turning on the process gripping head, carrying out semi-fine-turning on impeller shape, carrying out low-temperature treatment, carrying out five-axis-linkage-machining rough-milling, carrying out natural aging, carrying out five-axis-linkage-machining fine-milling, gripping, carrying out fine-turning on an axle hole, carrying out fine-turning on an impeller, gripping and carrying out dynamic balance. The impeller manufactured by adopting the process method provided by the invention has the characteristics that the shape is complete, the curved face is smooth and unhindered, blade curved faces and flow passage curved faces are low in deformation, and shown by the results of a fluorescent flaw detection, blade surfaces and front edges of the blades are flawless; during the dynamic balance of the integral impeller, mass reduction is relatively low, the qualified rate is high, and the qualified rate of excess-revolution tests of the integral impeller is greatly increased; the improvement of process for the series of integral impeller parts is realized, and good product quality, performance and design requirements are guaranteed; meanwhile, the stability of production quality is improved, and the reliability of products is improved.

Owner:SHANGHAI INST OF TECH

Manufacturing process of ultra-long blade complex curved surface integral impeller made of aluminum alloy material

InactiveCN105904169AManufacturing process improvements and enhancementsComplete shapeOther manufacturing equipments/toolsNumerical controlCold treatment

The invention relates to a manufacturing process of an ultra-long blade complex curved surface integral impeller made of an aluminum alloy material. The manufacturing process includes the specific steps of preparing materials, conducting rough machining on the profile of an impeller workblank, conducting heat treatment, conducting artificial aging, conducting semifinishing on the profile of the impeller, conducting ice-cold treatment, drilling a positioning hole, conducting five-axis linkage rough machining, conducting natural aging, conducting five-axis linkage finish machining, conducting clamp treatment, conducting numerical control turning, conducting linear cutting, conducting clamp treatment and conducting dynamic balancing. By the adoption of the process technology method, the ultra-long blade complex curved surface integral impeller made of the aluminum alloy material is manufactured, the blade shape of the ultra-long blade complex curved surface integral impeller made of the aluminum alloy material is complete, deformation is small, the blade lines of the blade faces of blades are smooth, mass reduction in dynamic balancing is small, and the yield is high; and process improvement in the integral impeller part of the structure is achieved, product quality is guaranteed effectively, the design requirement is met effectively, the stability of production quality is improved, and the reliability of products is guaranteed.

Owner:SHANGHAI INST OF TECH

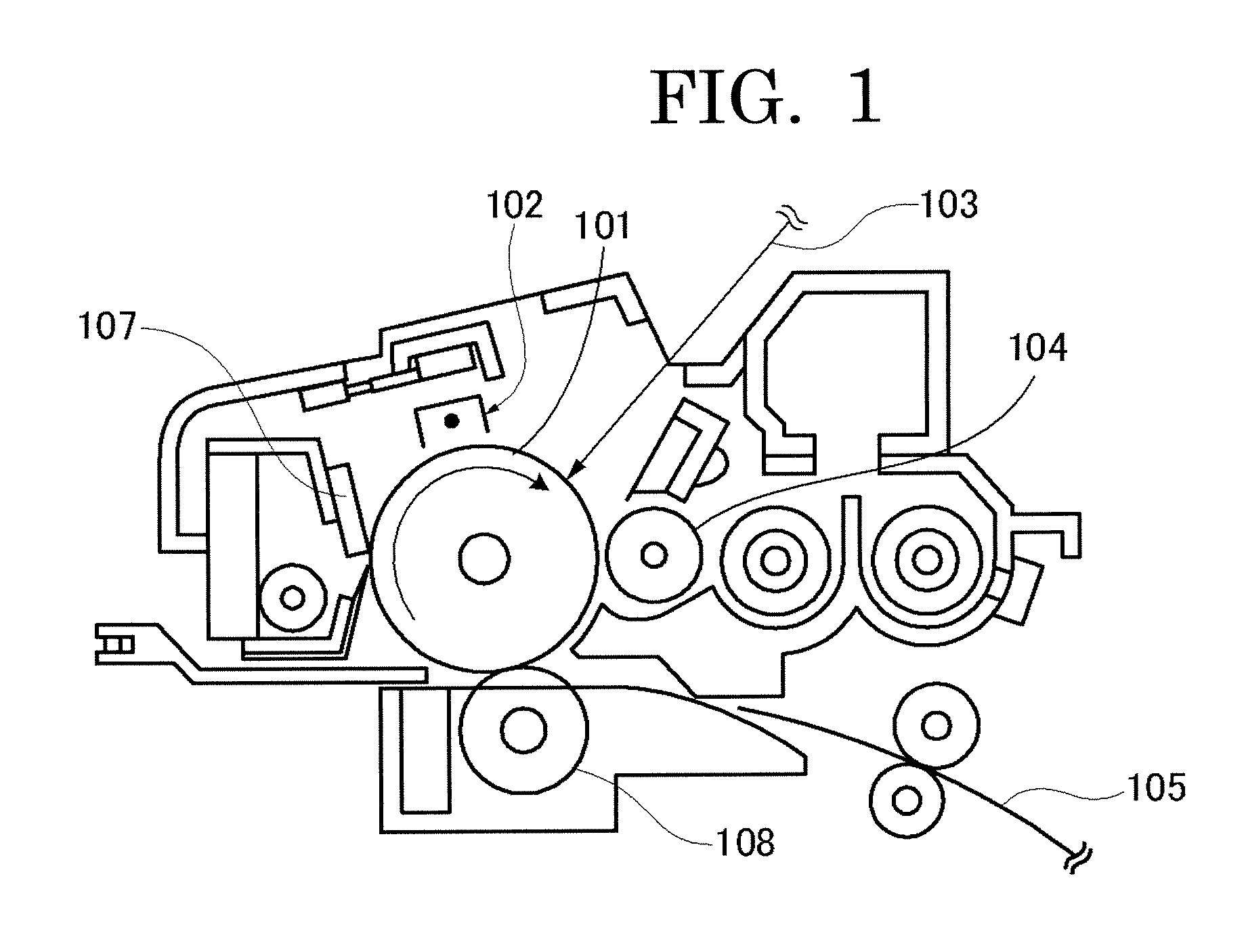

Toner, method for producing the same, and process cartridge

A toner containing a binder, a colorant, and a wax having a molecular chain consisting of C—H bond and C—C bond, wherein the mass reduction of the wax at 165° C. is 10% by mass or less, and the total amount of the wax in the toner measured by a DSC method is 1% by mass to 8% by mass, wherein a ratio, Sbet / SF, of a BET specific surface area (Sbet) of the toner to an average circularity (SF) of the toner is 1.0 m2 / g or more to less than 3.6 m2 / g, wherein the toner is obtained through a process which contains at least emulsifying or dispersing a toner material liquid in an aqueous medium containing a surfactant, and wherein the toner material liquid is a liquid containing toner-forming materials which contains at least the binder, the colorant and the wax.

Owner:RICOH KK

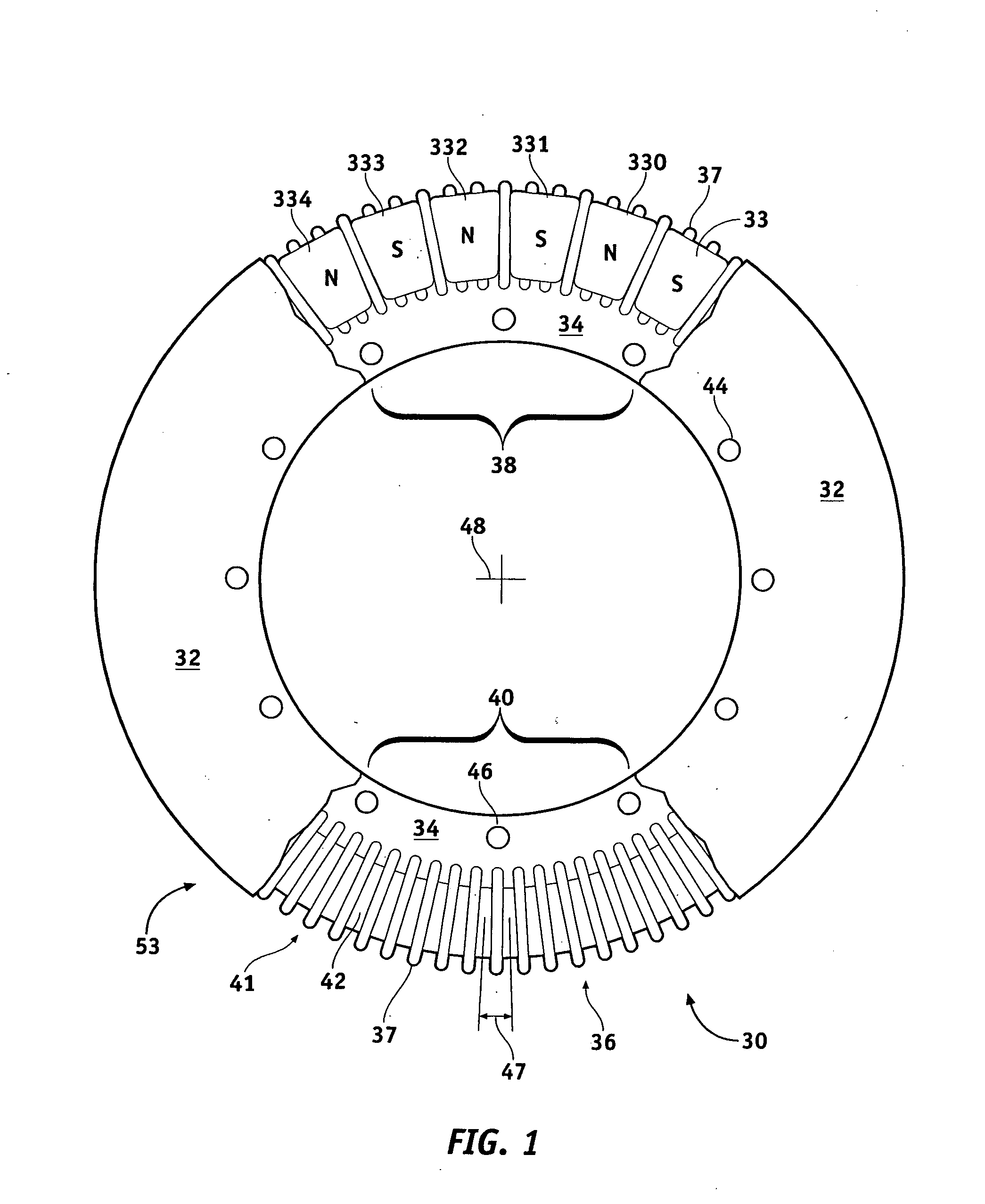

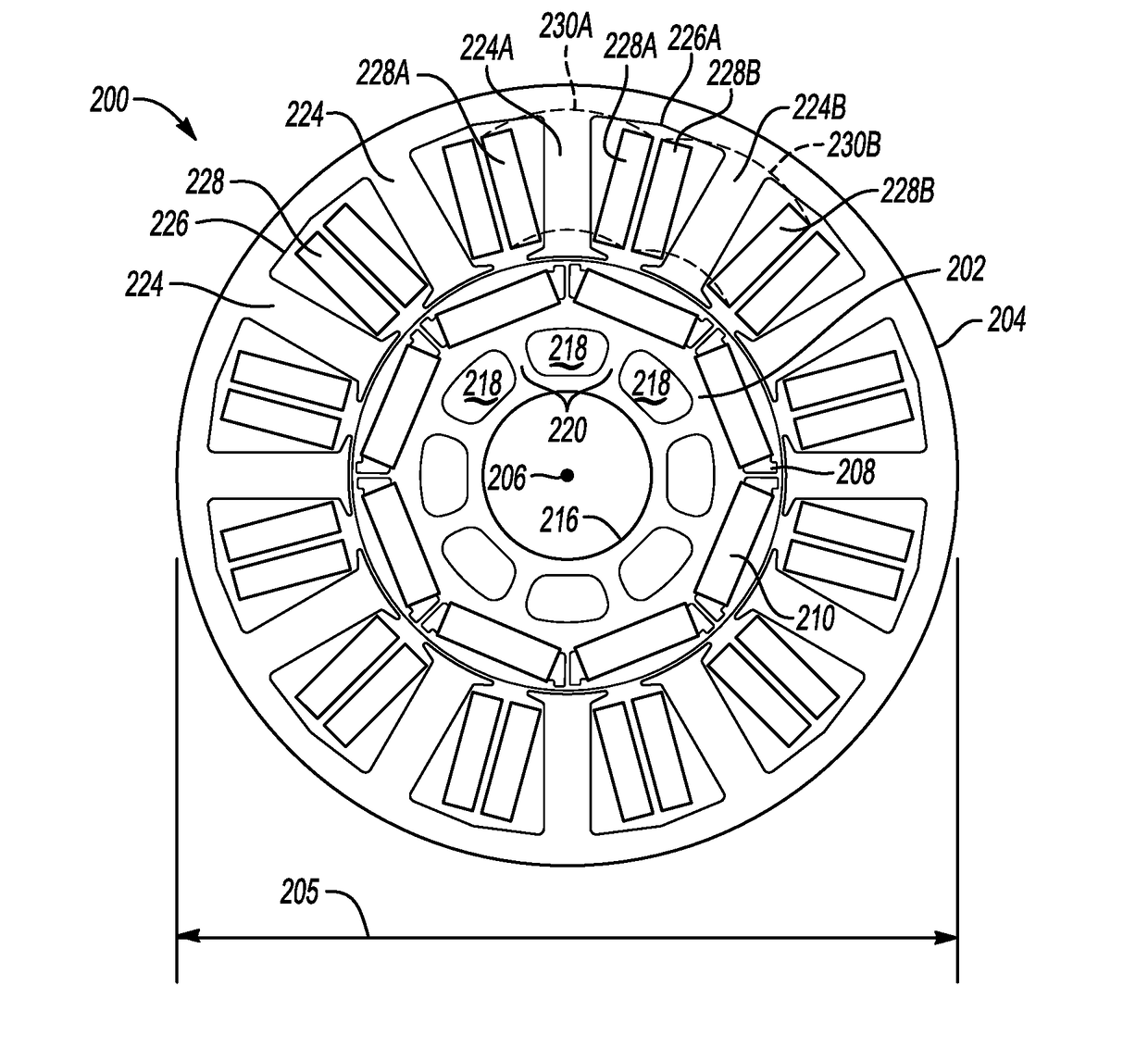

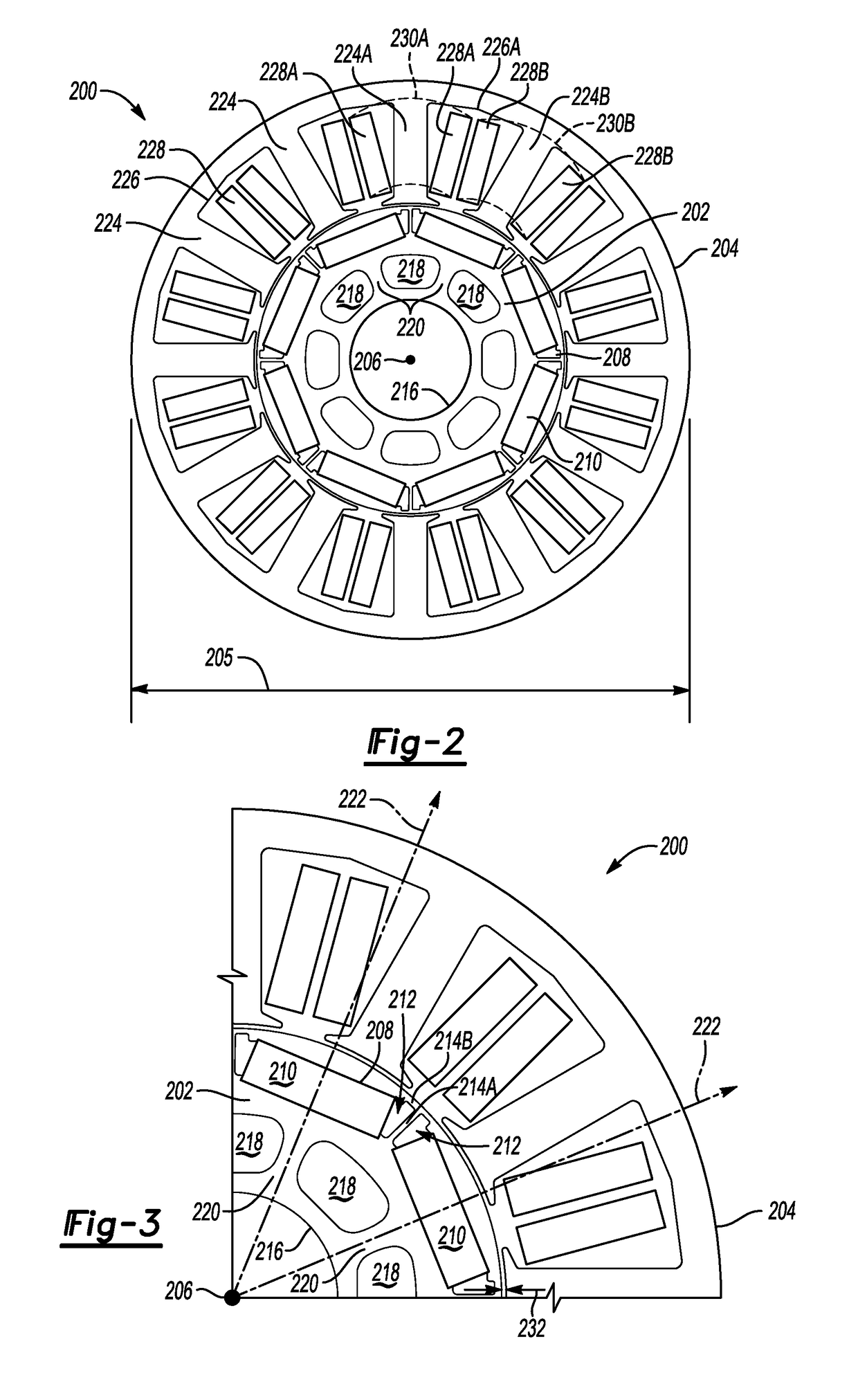

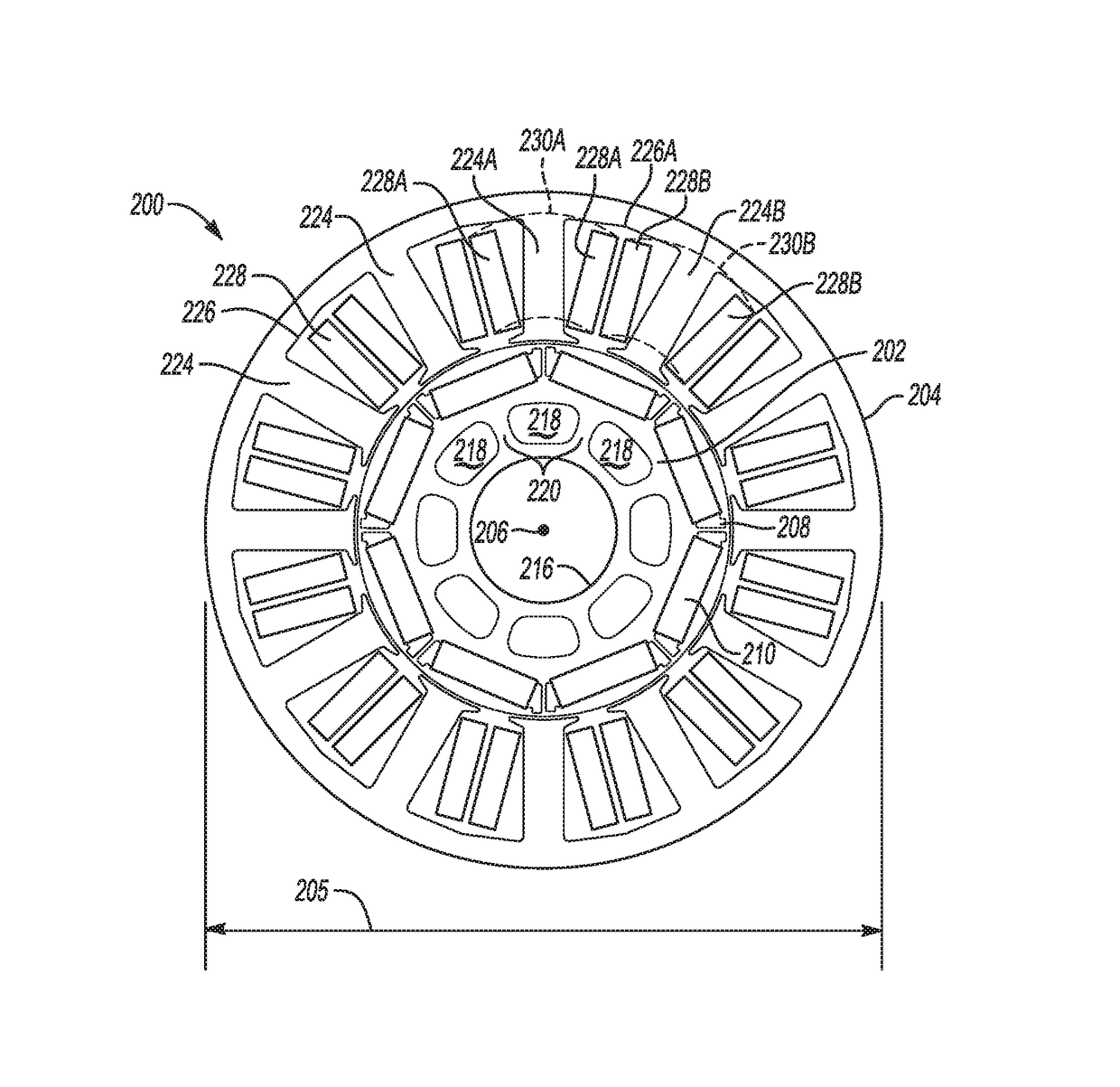

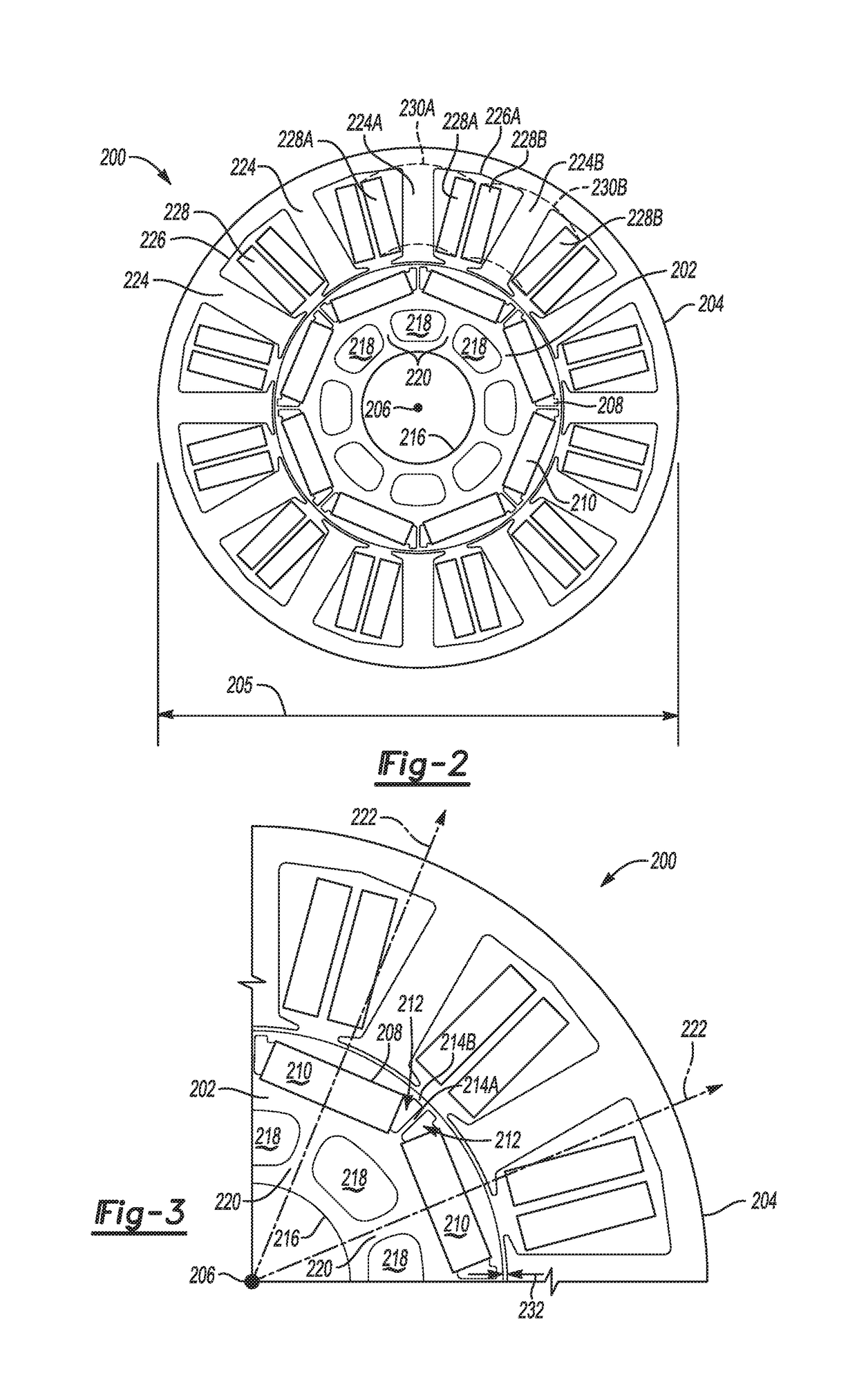

Permanent Magnet Electric Machine

An interior permanent magnet electric machine includes a stator having a plurality of teeth disposed around a circumference oriented radially towards a center defining slots interposed between each of the teeth, and a conductive winding wrapped around each of the teeth of the stator to receive an electrical current. The electric machine also includes a rotor which is rotatable relative to the stator. The rotor defines a plurality of openings to receive permanent magnets near an outer portion of the rotor and a number of spokes interposed between mass reduction cutouts located closer to the center relative to the permanent magnets. Each of the permanent magnets defines a magnetic pole and each of the spokes is circumferentially aligned with one of the magnetic poles.

Owner:GM GLOBAL TECH OPERATIONS LLC

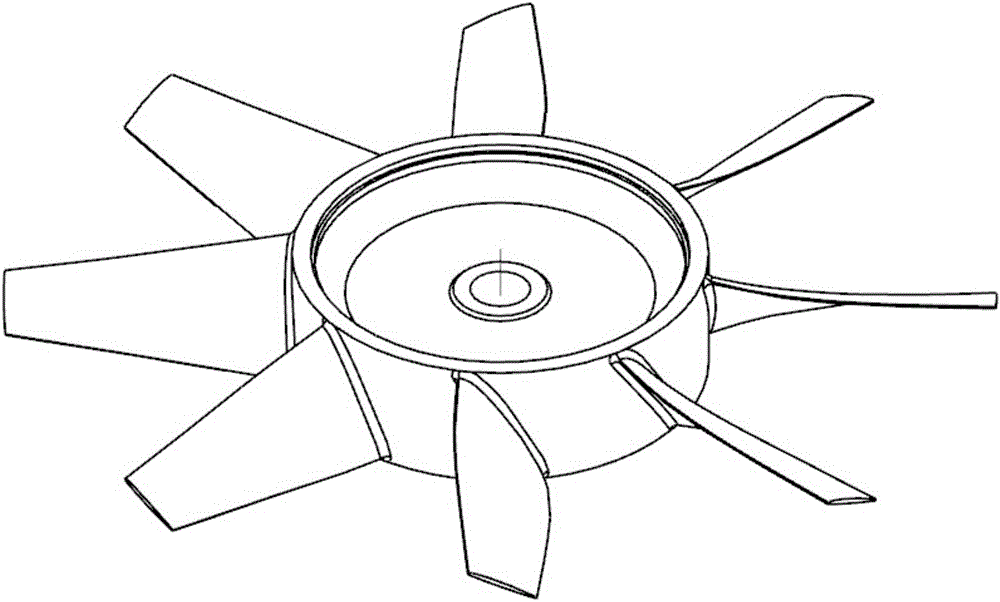

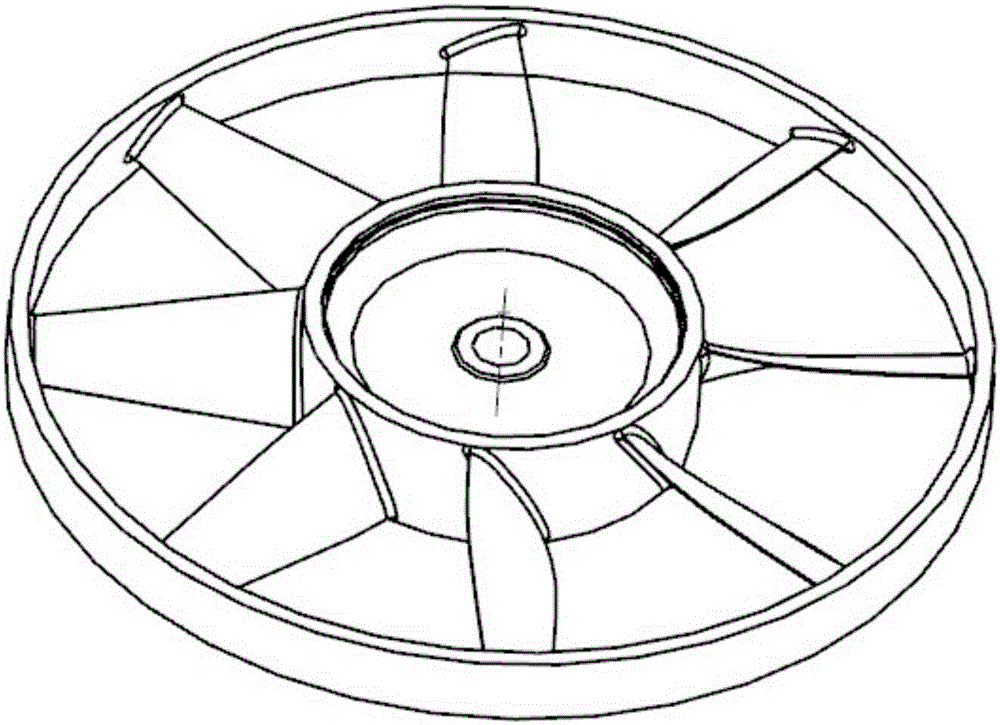

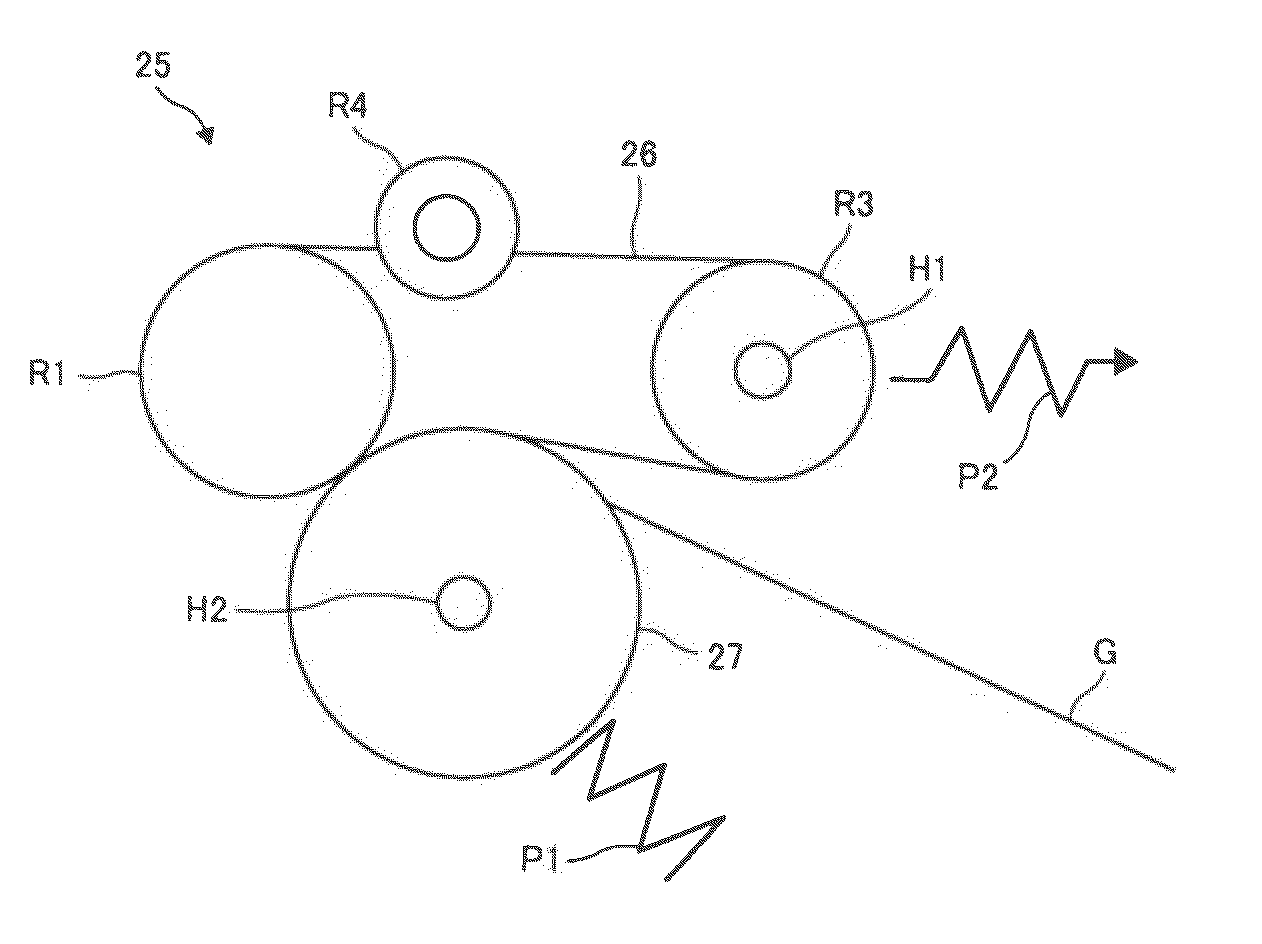

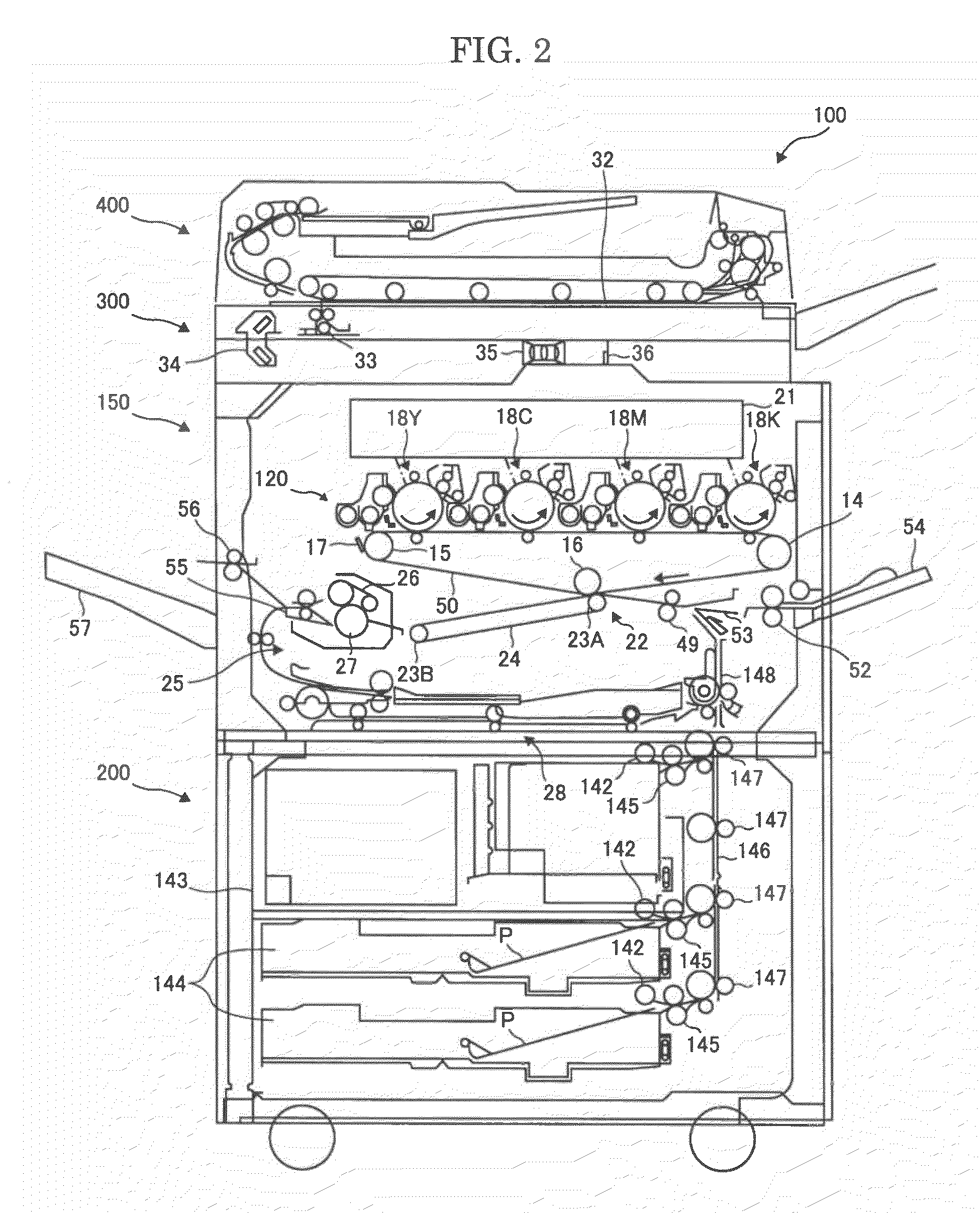

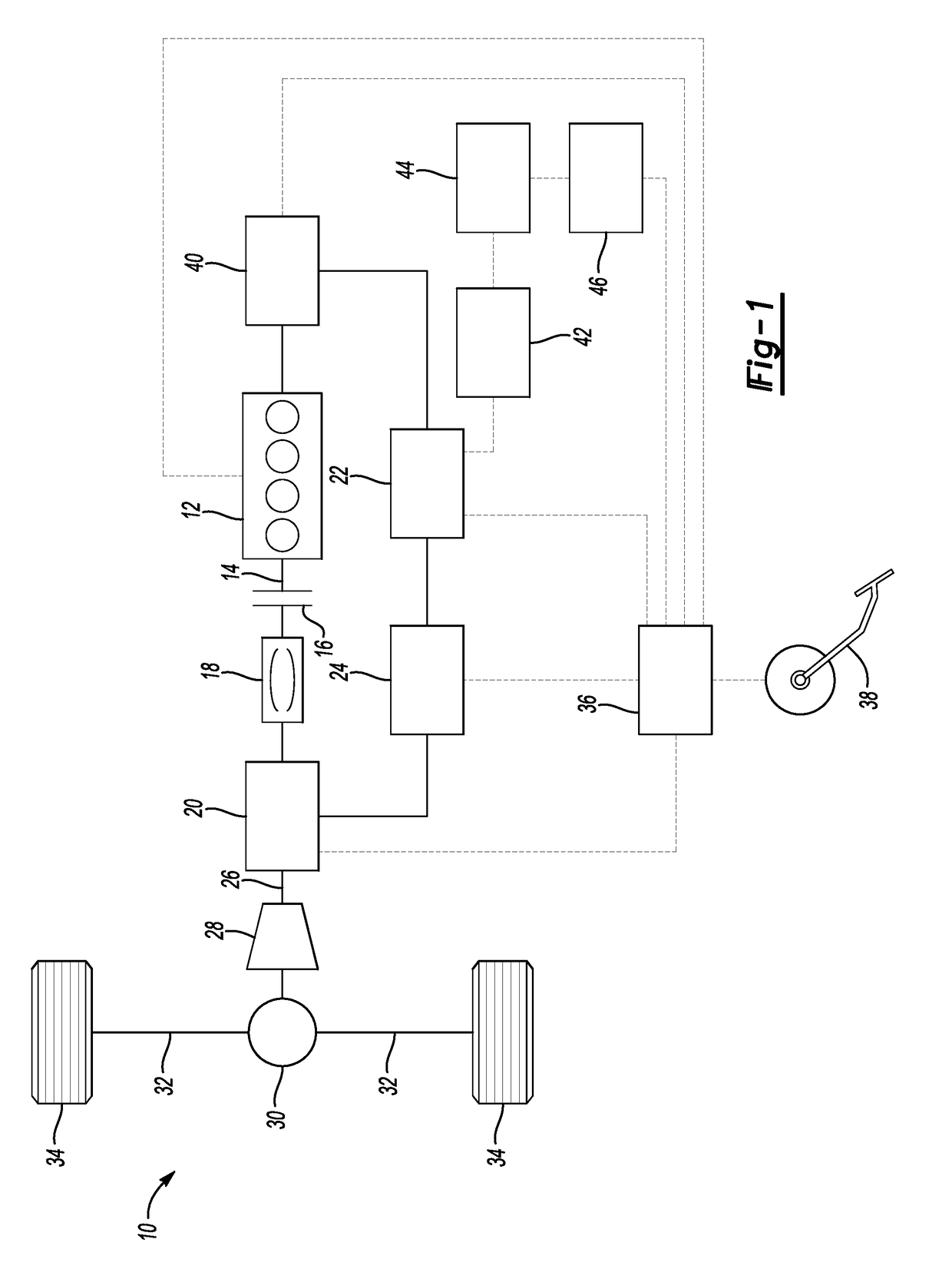

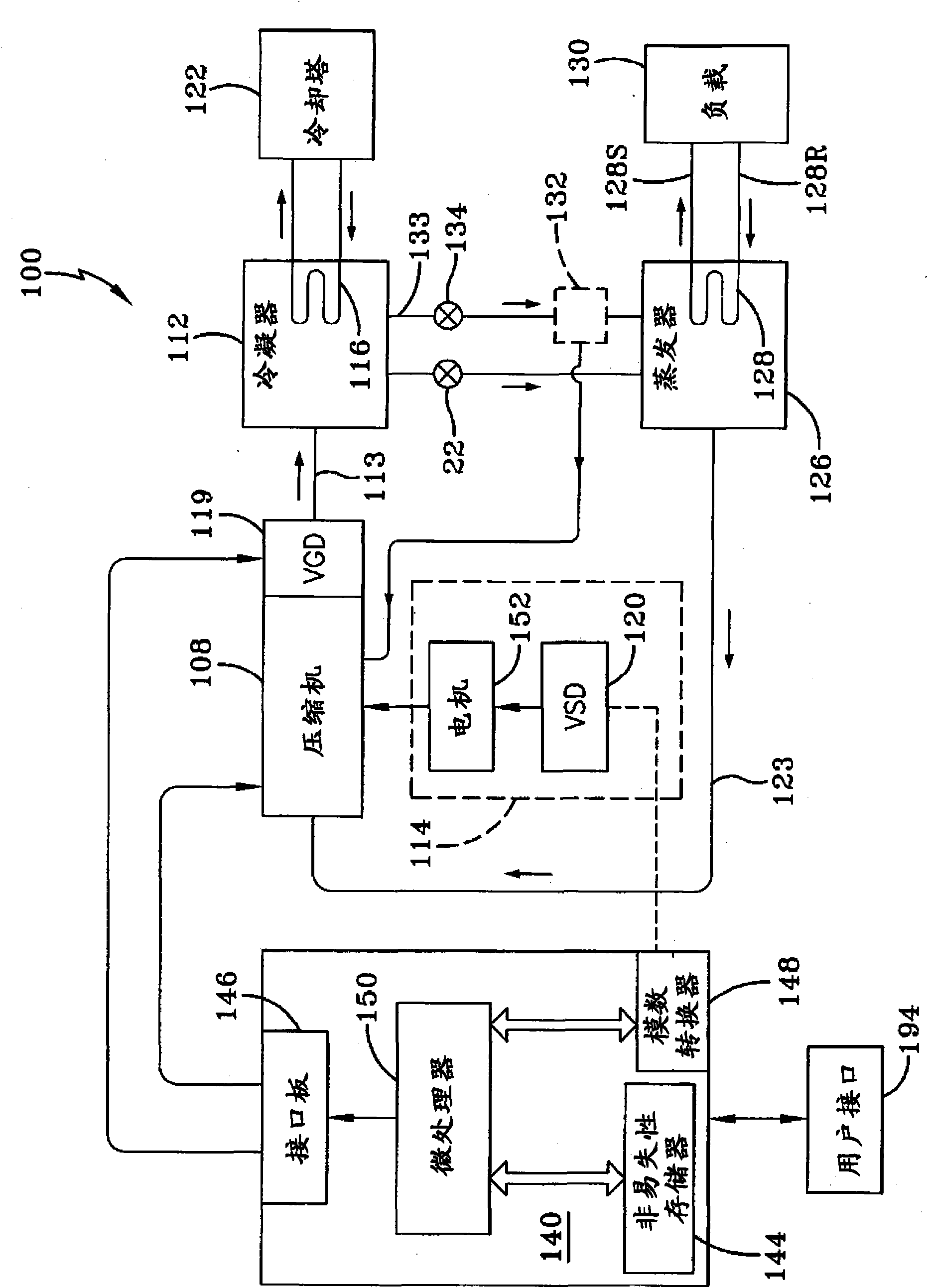

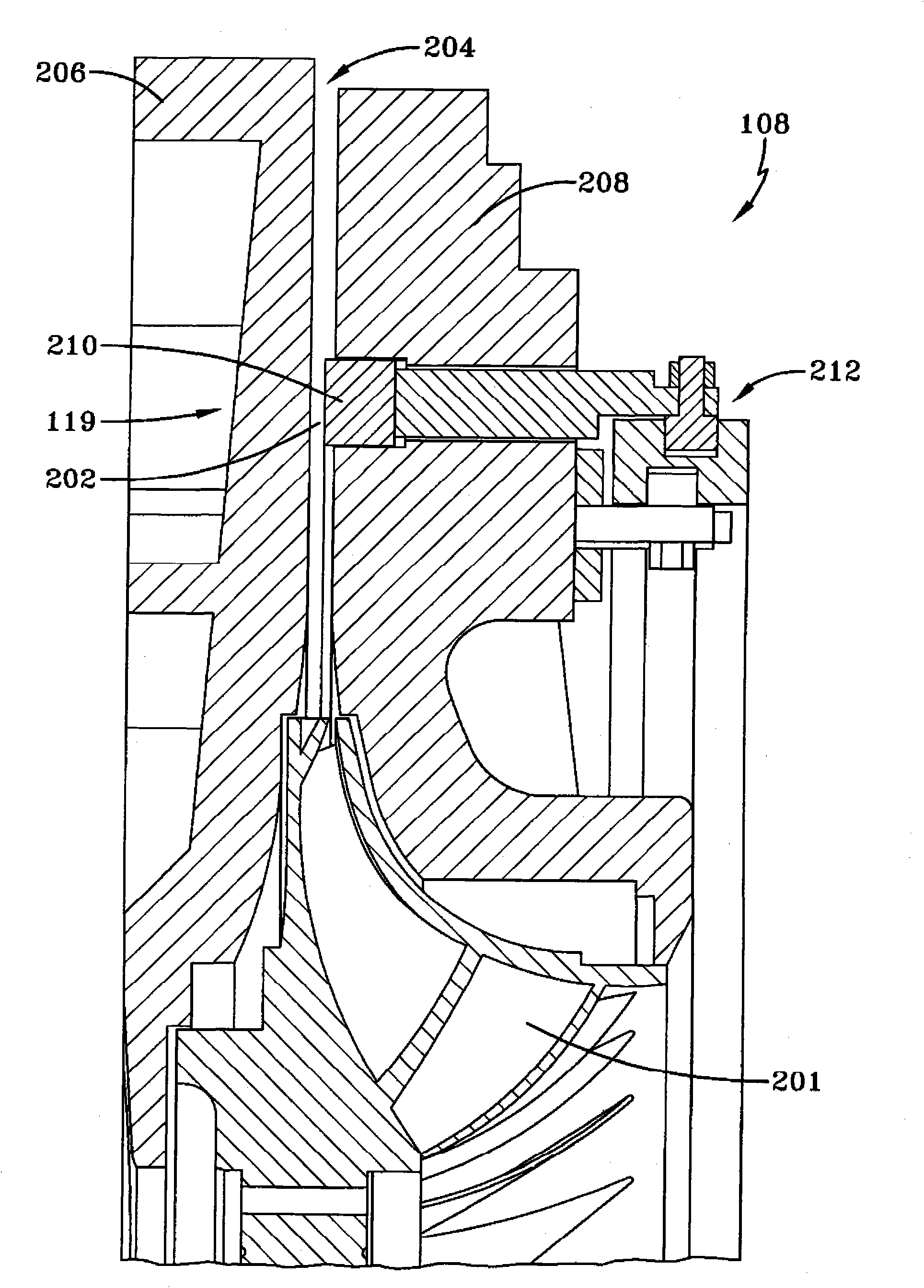

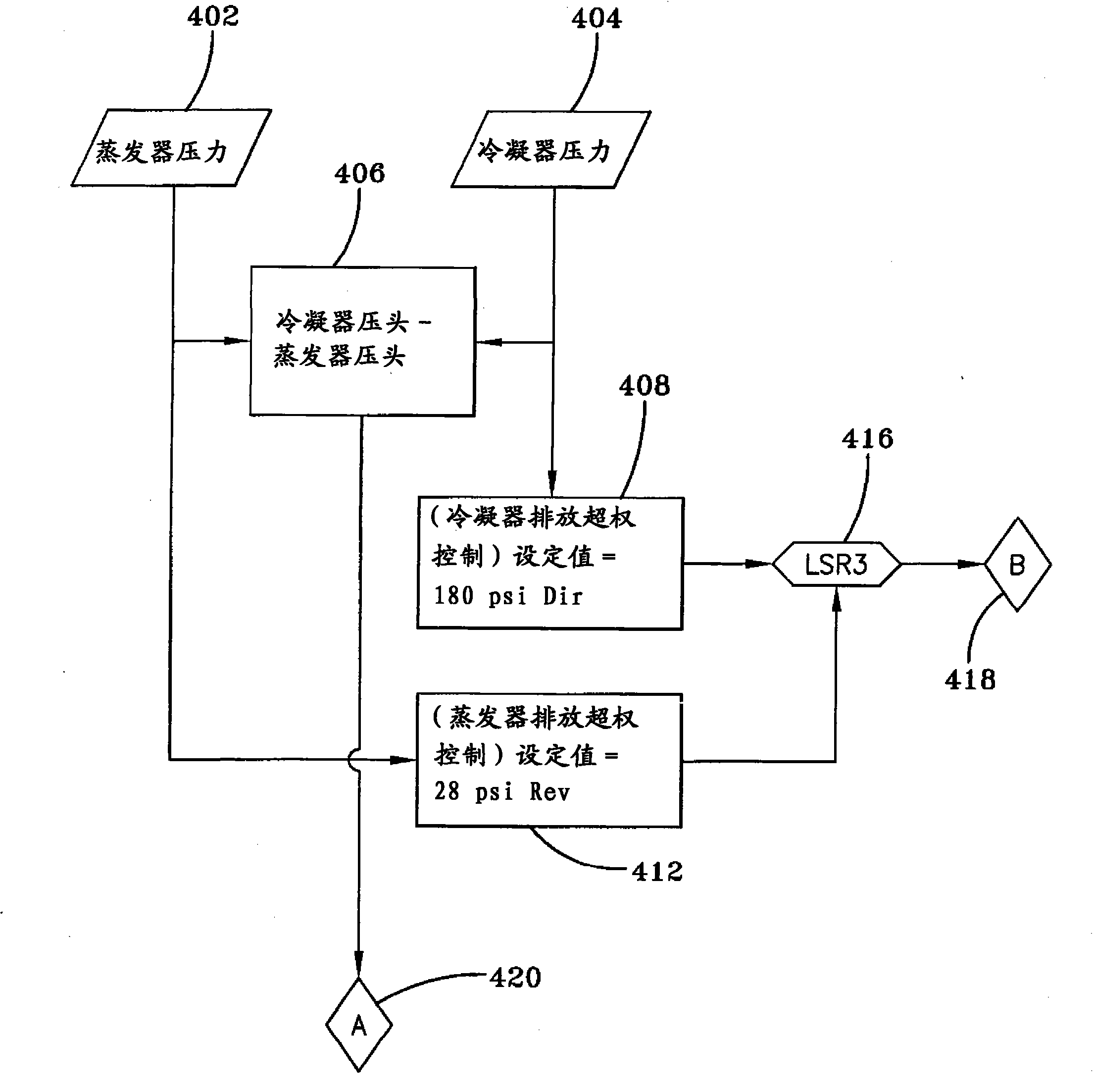

Control system

ActiveCN101842599AReduce complexityReduce operating capacityEngine manufacturePump componentsAutomatic controlStreamflow

A system for controlling a centrifugal gas compressor (108) in an HVAC, refrigeration or liquid chiller system (100) in which flow of gas through the compressor is automatically controlled to maintain desired parameters within predetermined ranges so as to prevent stall and surge conditions within the system. A variable geometry diffuser (119) in the compressor controls the refrigerant gas flow at the discharge of the compressor impeller wheel (201). This arrangement reduces mass flow, decrease / eliminate flow-reducing stall, and increases the operating efficiency of the compressor at partial load conditions. The variable geometry diffuser control in combination with a variable speed drive (VSD) (120) increases the efficiency of the compressor at partial system loads, and eliminates the need for pre-rotation vanes at the inlet of the centrifugal compressor.

Owner:JOHNSON CONTROLS TYCO IP HLDG LLP

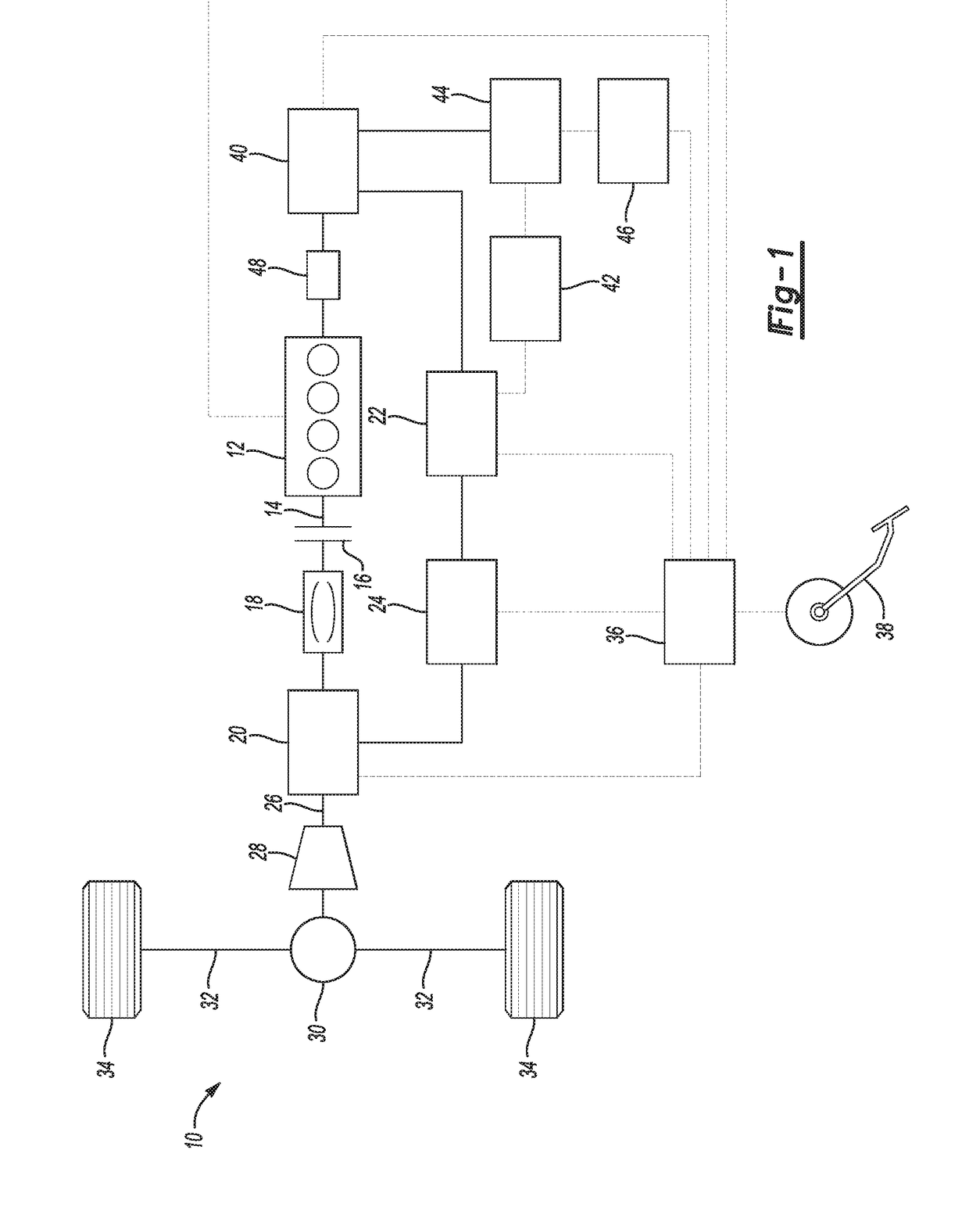

Permanent magnet electric machine

ActiveUS20170338706A1Magnetic circuit rotating partsElectric motor startersElectric machineMagnetic poles

An interior permanent magnet electric machine includes a stator having a plurality of teeth disposed around a circumference oriented radially towards a center defining slots interposed between each of the teeth, and a conductive winding wrapped around at least one of the teeth of the stator to receive an electrical current. The electric machine also includes a rotor which is rotatable relative to the stator. The rotor defines a plurality of openings configured to hold permanent magnets near an outer portion of the rotor and a number of spokes interposed between mass reduction cutouts located closer to a center of the rotor relative to the permanent magnets. Each of the permanent magnets defines a magnetic pole and each of the spokes is circumferentially aligned with one of the magnetic poles.

Owner:GM GLOBAL TECH OPERATIONS LLC

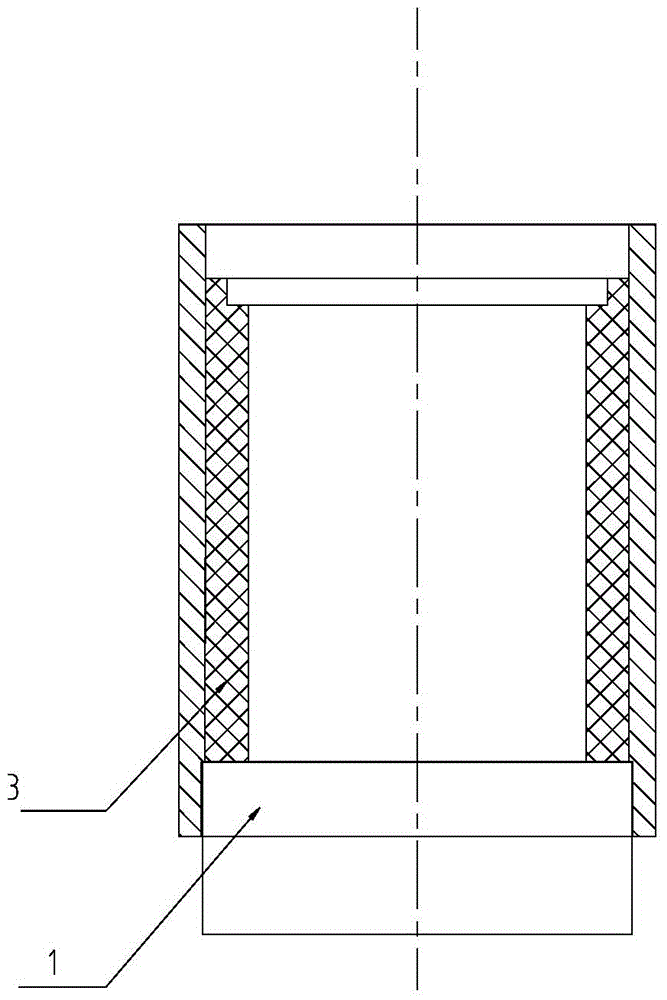

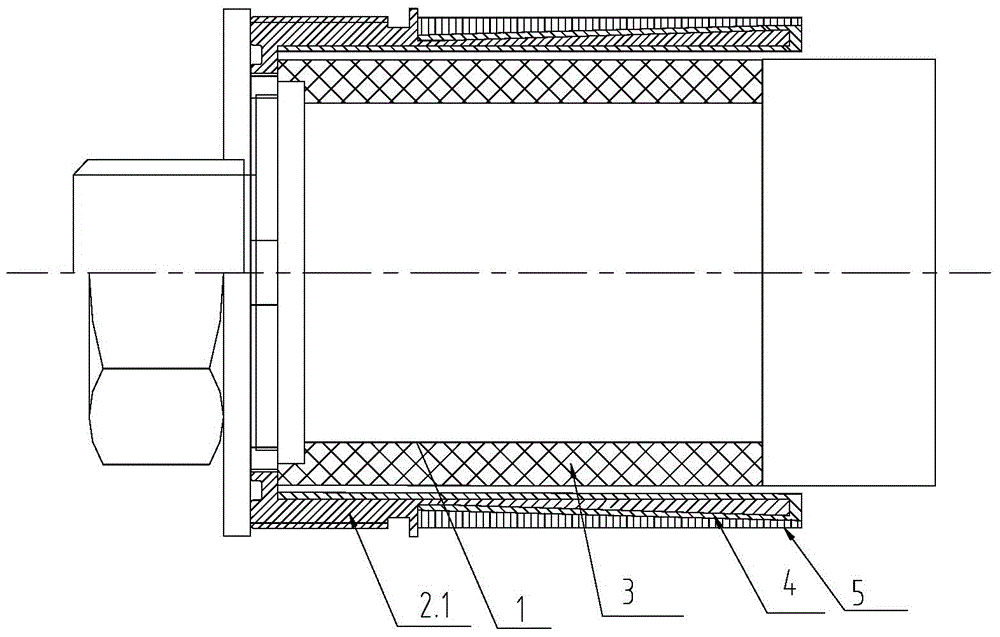

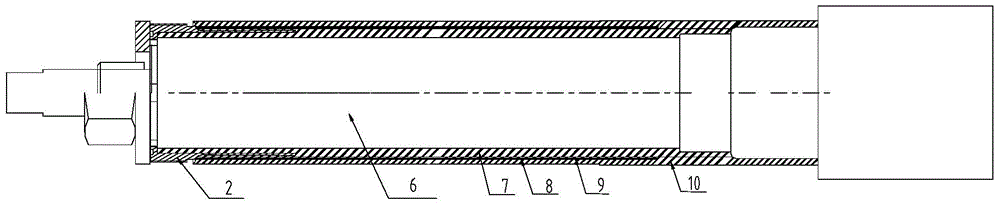

A moulding method for a long-dimension separator sleeve of a pulse motor

A moulding method for a long-dimension separator sleeve of a pulse motor is disclosed. The method includes: according to product structure characteristics and function characteristic requirements, determining the thickness of a thermal insulation layer and the thickness of a fiber composite layer and preparing a pouring mould and a metal connecting part for sleeve moulding; preparing a connector comprising the metal connecting part; installing the connector to a moulding mandrel; manually pasting the surface of the moulding mandrel, which is not covered with the connector, with a thermal insulation material; winding the surface of the manual pasting layer with fiber dry yarn; vulcanizing to obtain a base layer of the thermal insulation layer; fully dipping carbon fiber in an epoxy resin solution; winding the surface of a carbon fiber cloth with carbon fiber in a wet manner to obtain a fiber composite layer; manually pasting the surface of the composite layer with the thermal insulation material continuously; and vulcanizing to obtain the long-dimension separator sleeve of the pulse motor. The method is suitable for moulding of the separator sleeve reinforced by a resin-based composite material. The separator sleeve mainly comprises a nonmetal material, is small in product total weight, and facilitates passive mass reduction of motor shells.

Owner:湖北三江航天江北机械工程有限公司

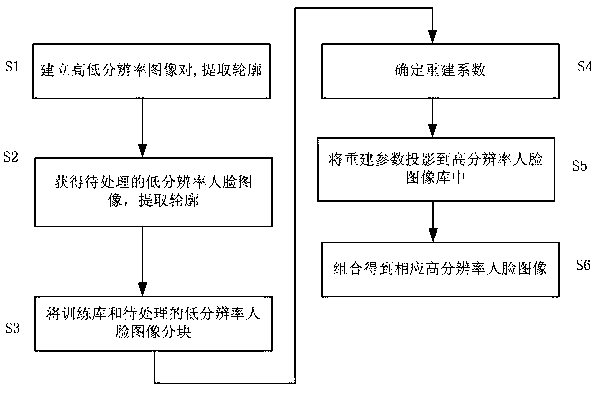

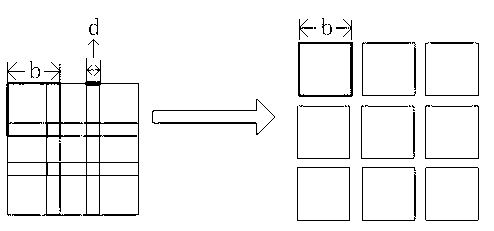

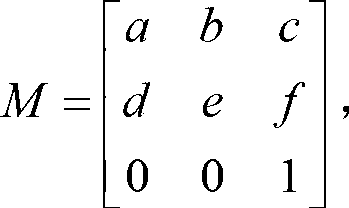

Robustness face super-resolution processing method based on contour inspection

InactiveCN102982520AImprove subjective qualityPromote recoveryImage enhancementGeometric image transformationResolution recoveryPattern recognition

The invention provides a robustness face super-resolution processing method based on contour inspection, which comprises the following steps: on the basis of a traditional face super-resolution method based on manifold, simultaneously selecting two types of image features for mass reduction process robustness and simultaneously taking as a criterion of image similarity in the algorithm process through coupling the two types of image features into an (Locally embedding) algorithm. The robustness face super-resolution processing method solves the problem incapable of being better solved by a traditional method that serious noise and fuzziness are lack of reality to a super-resolution recovery effect of a single frame face image in the monitoring and imaging process.

Owner:WUHAN UNIV

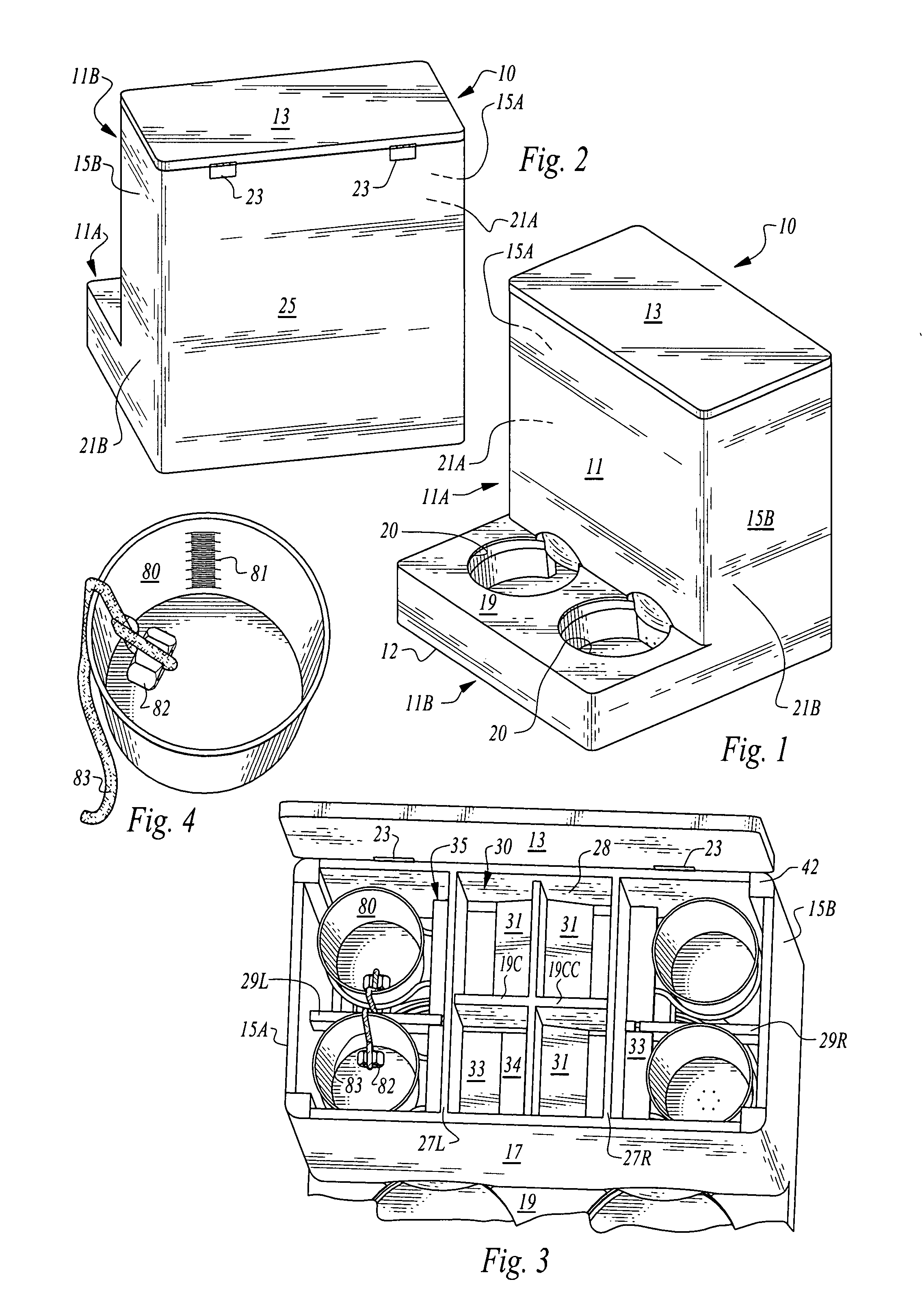

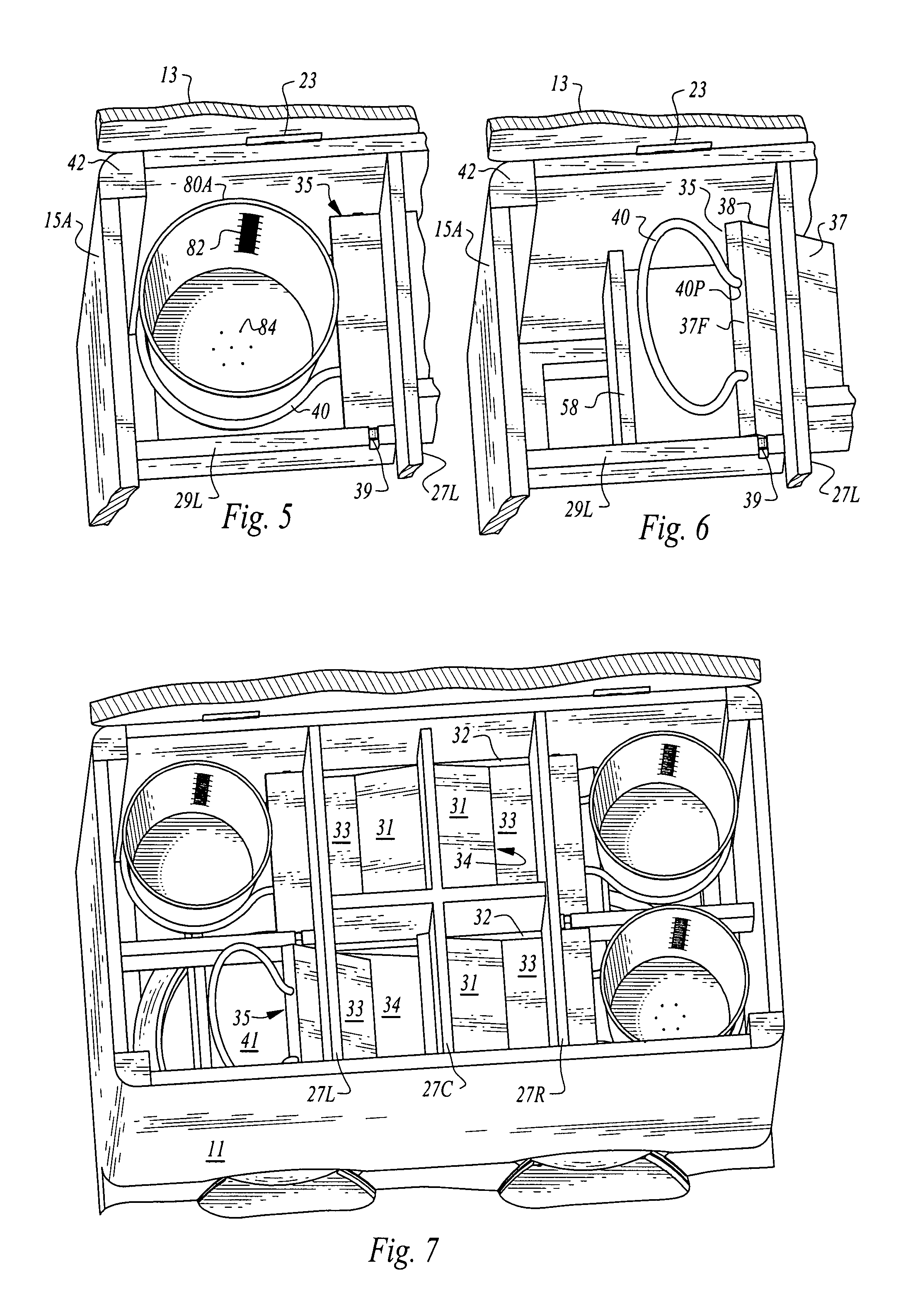

Extended time low-tech animal feeder

A plural day gravity fed animal feeding and watering apparatus. The non-electric apparatus has compartments for food and water. A timer that uses the principle of wicking action permits food and water to enter respective dishes. Alternatively, mass reduction via disposition of water in a bored container can deliver water to the water bowl. The mass of water disposed in a container is to be reduced by the wicking action to reduce fluid mass. For food delivery, the mass of water holds an impact plate upward but when the mass is reduced by the wicking action, the weight will discontinue hold up the impact plate and a gap opens thereby allowing food to exit through the apparatus into the food dish. Selection of wicks controls the time period before the gap opens. Each distinct areas for dispensing food or drink can be controlled separately by the proper choice of wick.

Owner:OR MICHAEL

Method and apparatus for predetermining natural ageing performance for hot-rolled steel products

InactiveCN1641052AEliminate stockpilingControl Alloy CompositionStrength propertiesPerformance indexHeating furnace

The present invention is especially the performance test of hot rolled steel after simulating natural ageing. The present invention features the artificial ageing for fast treatment and sample detection. The hot rolled steel with performance slightly higher than the specified indexes is sampled to form the re-tested sample; the sample is heated at constant temperature inside stove or furnace and tested for the precise performance indexes after natural ageing; and the re-tested steel is judged and processed based on the detected data. The present invention is favorable to ensuring the product quality, reducing stocks and lowering the production cost.

Owner:MAANSHAN IRON & STEEL CO LTD

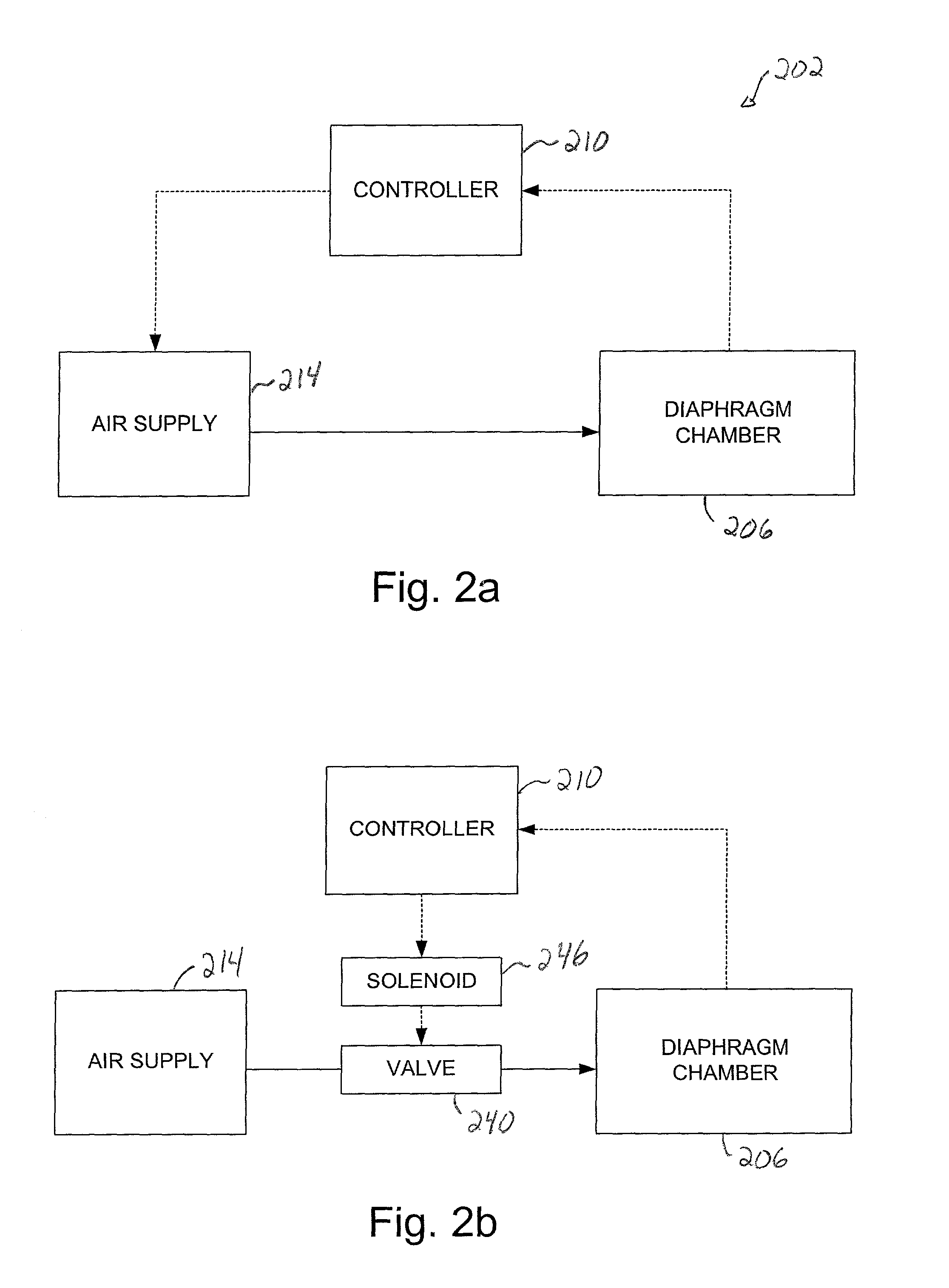

Method and apparatus for increasing flow capacity associated with a valve

InactiveUS20030008532A1Valve arrangementsSemiconductor/solid-state device manufacturingControl signalDevice Monitor

Methods and apparatus for efficiently compensating for pressure changes in a active vibration isolation system are disclosed. According to one aspect of the present system, system that reduces the vibrations experienced by a mass includes a chamber that supports the mass, a control device, a valve mechanism, and a bypass mechanism. The control device monitors a pressure level within the chamber. The valve mechanism includes a first flow path that is in fluid communication with the chamber. The valve mechanism also alters a capacity of the first flow path in response to a control signal generated by the controller. Finally, the bypass mechanism defines a second flow path that enables fluid to flows through the second flow path into the chamber. The second flow path is parallel to the first flow path to enable parallel fluid flow to occur.

Owner:NIKON CORP

Method for removing griseofulvin in biological medicine waste residues

ActiveCN106110562AHigh removal rateIncrease production capacityChemical protectionSlurrySolid content

The invention relates to a method for removing griseofulvin in biological medicine waste residues. The method for removing the griseofulvin in the biological medicine waste residues specifically comprises the following steps of (1) a pretreatment process including the sub-steps that (1-1) the to-be-treated biological medicine waste residues containing the griseofulvin is mixed with water, and waste residue slurry with the solid content being 5%-45% is prepared through slurry mixing and dispersing, and (1-2) the waste residue slurry is sterilized; and (2) a catalytic and oxidative degradation process, specifically, catalytic and oxidative degradation is conducted by adding an oxidative and catalytic agent into the sterilized waste residue slurry, and then filtering separation and drying are conducted. Compared with the prior art, a wet catalytic and oxidative treatment integrated technique is used for removing the griseofulvin left in the waste residues, the removal rate is high, secondary pollutants are avoided, and harmless treatment is achieved; the concentration of the griseofulvin left in the waste residues can be rapidly decreased to 0-50 ppm from the original 1000-5000 ppm, the mass reduction rate of the biological medicine waste residues is smaller than 10%, and the method has extremely good application prospects.

Owner:SHANGHAI RES INST OF CHEM IND

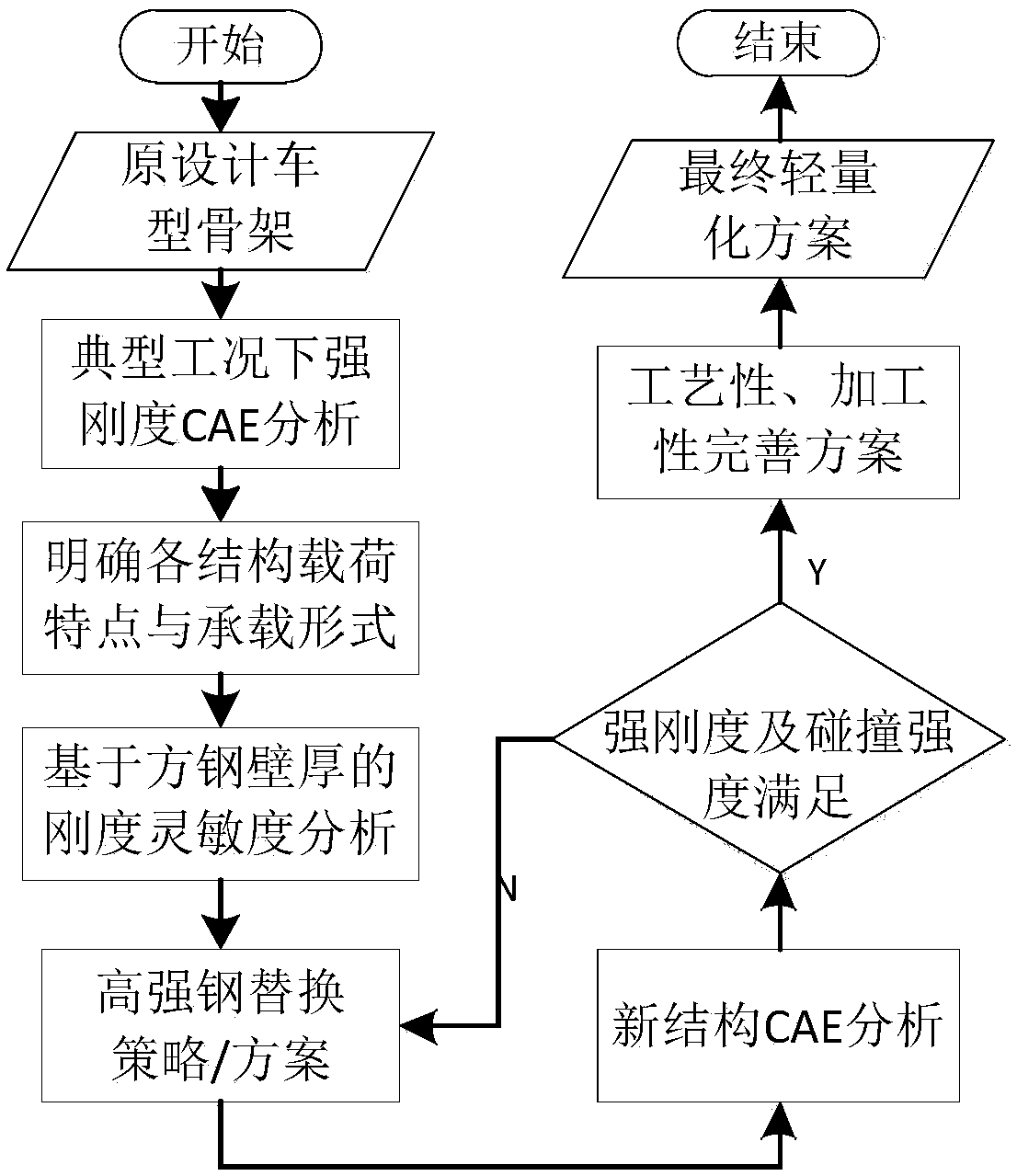

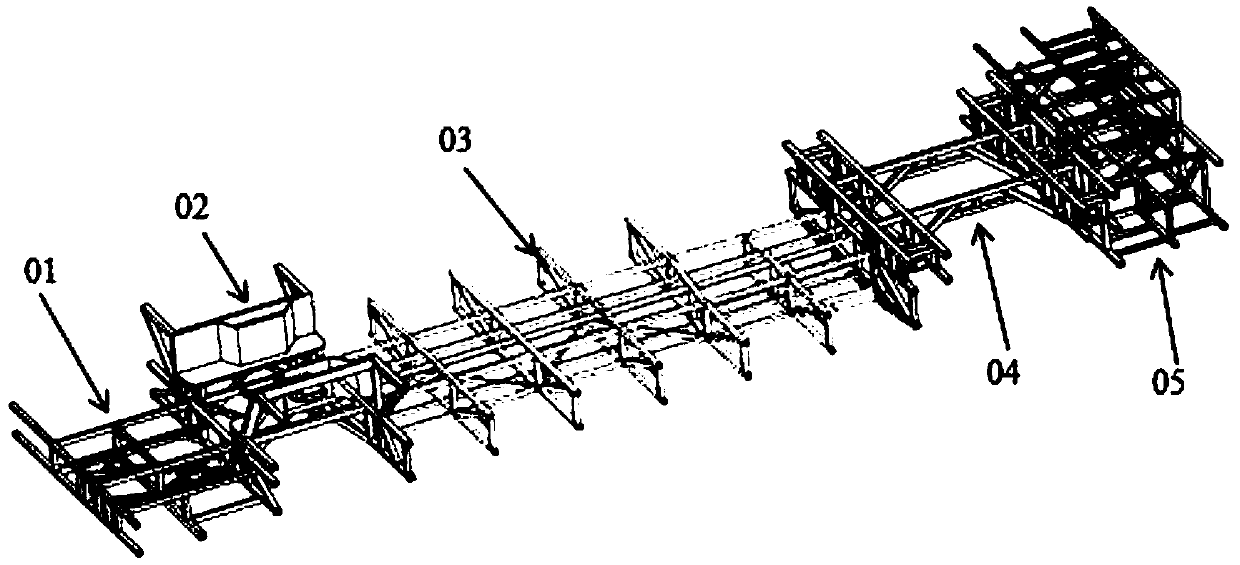

Full-load-bearing passenger car frame weight lightening method based on high-strength steel

InactiveCN109533041AHigh yield strengthIncrease mileageGeometric CADDesign optimisation/simulationVehicle frameEngineering

The invention discloses a full-load-bearing passenger car frame weight lightening method based on high-strength steel. By the use of 700MPa high-strength steel products, combining a reasonable wall thickness replacement formula with a finite element simulation method, the yielding strength of the structure is effectively improved, frame mass reduction is achieved by thinning the wall thickness ofsquare pipes, the energy consumption of a whole vehicle is reduced, and the driving range of the whole vehicle is increased. Only the wall thickness of the square steel is changed, the size of the outer cross section of the square steel is not changed, the original structural design change is small, the method almost has no effect, the universality of steel structure is better, and the method is beneficial to mass production. Compared with aluminum alloy, the high-strength steel has better price and better processability, and the method is beneficial to reduce the cost of an adjusting production process. By means of simulation calculation of the stiffness sensitivity based on the wall thickness of the square steel, the weight is lightened in a targeted manner on the premise that the rigidity performance of the frame is ensured.

Owner:开沃新能源汽车集团股份有限公司

Device and Method For Tuning Mechanical and Electromagnetic Natural Frequencies of an Energy Harvester

InactiveUS20150229243A1Wave amplification devicesPiezoelectric/electrostriction/magnetostriction machinesEnergy harvesterEngineering

The present invention is an energy harvester having a mechanical natural frequency that can be mechanically tuned to the natural frequency of the vibrating environment without having to add or subtract mass to seismic / proof mass, change the mass of the mechanical spring or change the physical dimensions of the mechanical spring of the energy harvester. In another embodiment, the electromagnetic natural frequency of the energy harvester is electronically tuned by adding a tuning circuit comprising a variable dissipative element without changing the mechanical natural resonant frequencies of the energy harvester.

Owner:CHIMAMKPAM EMMANUEL F C

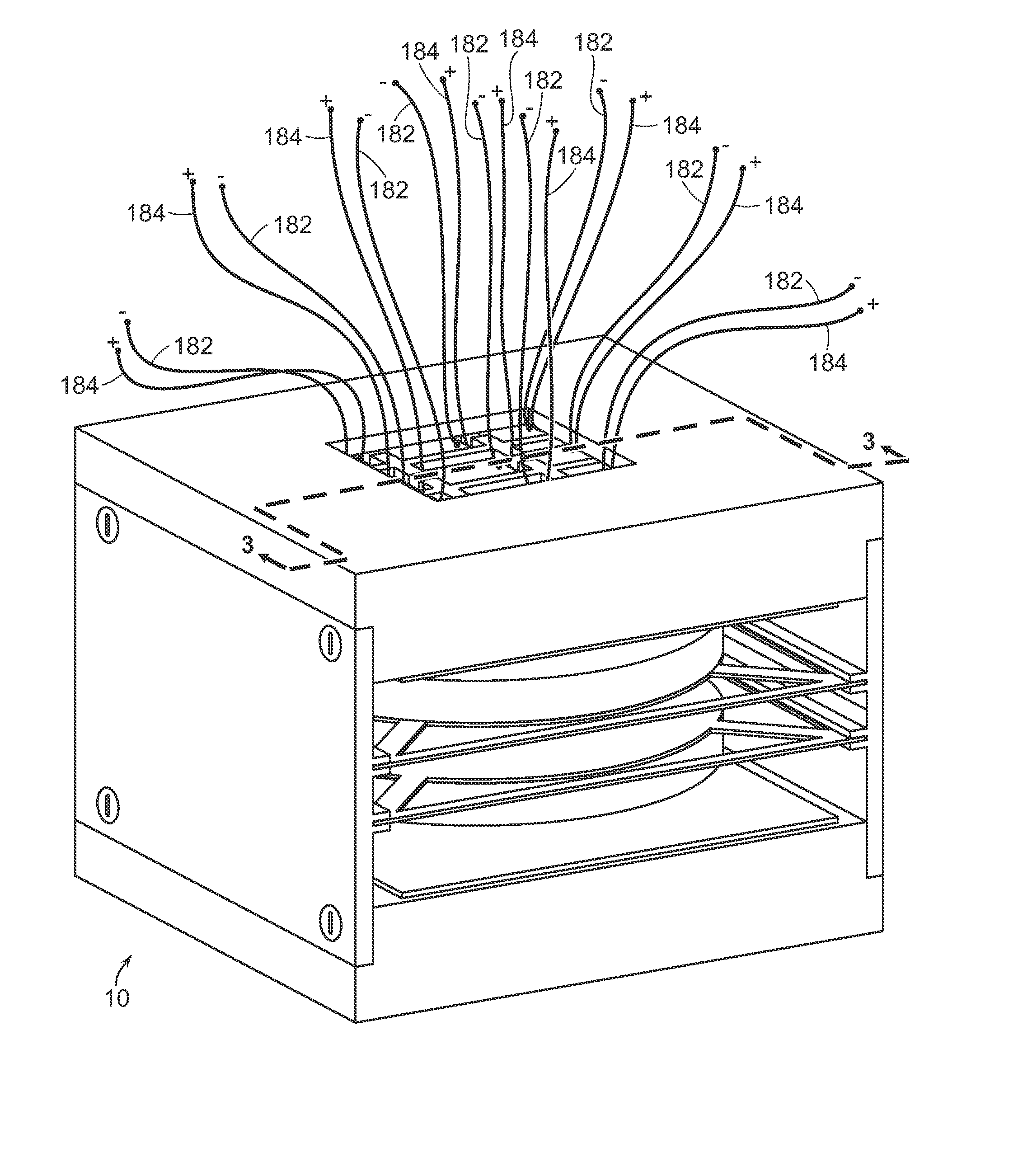

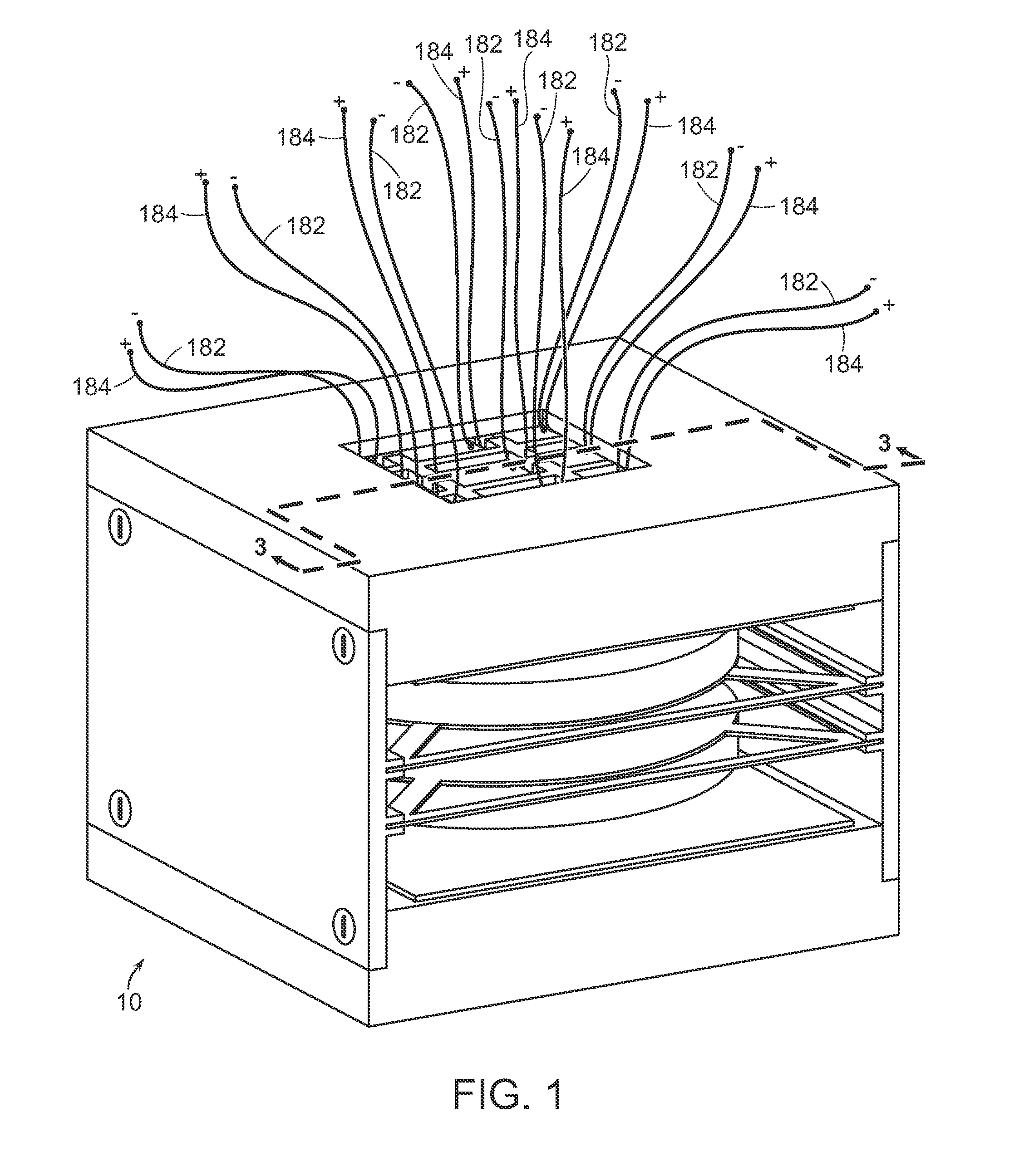

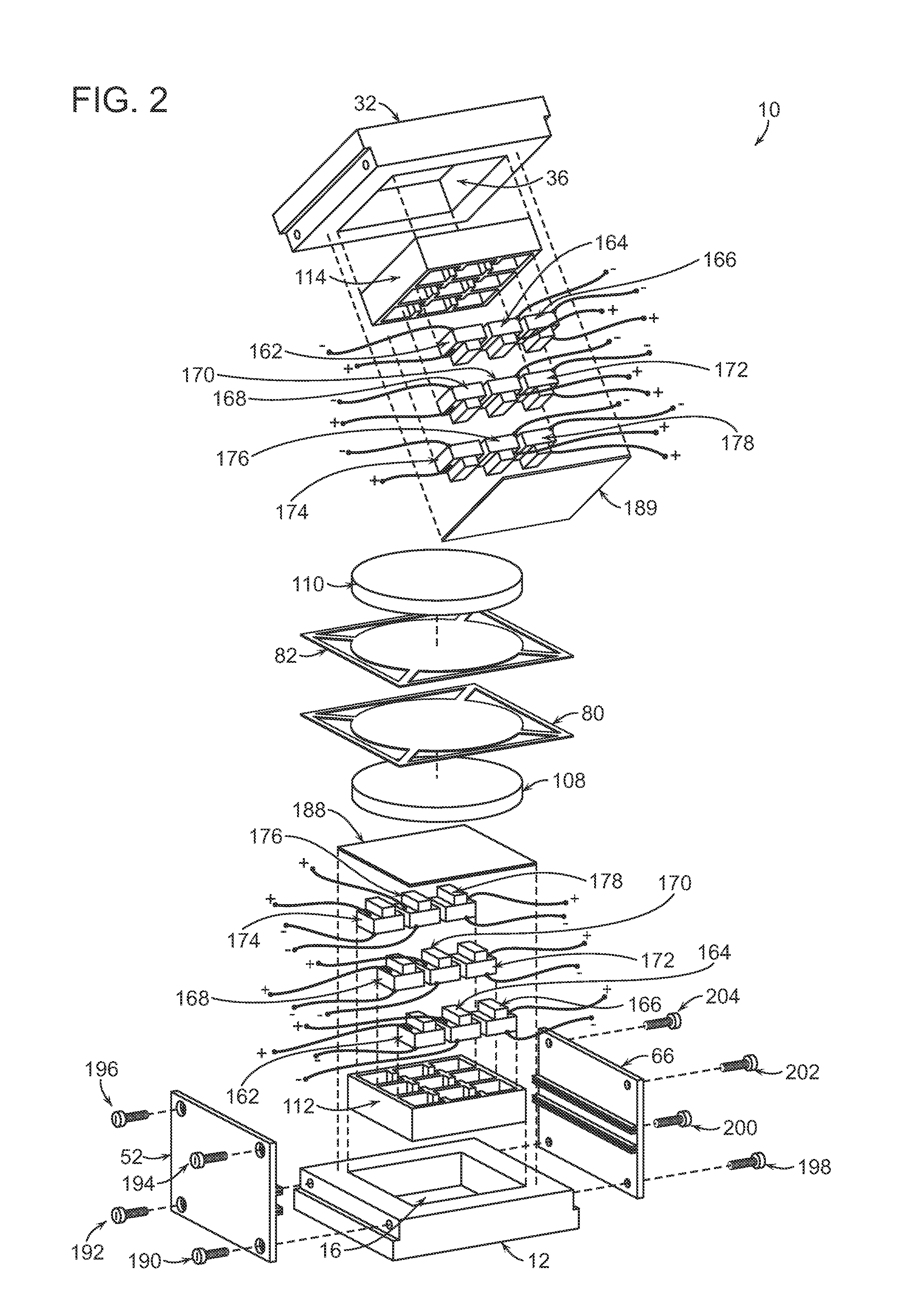

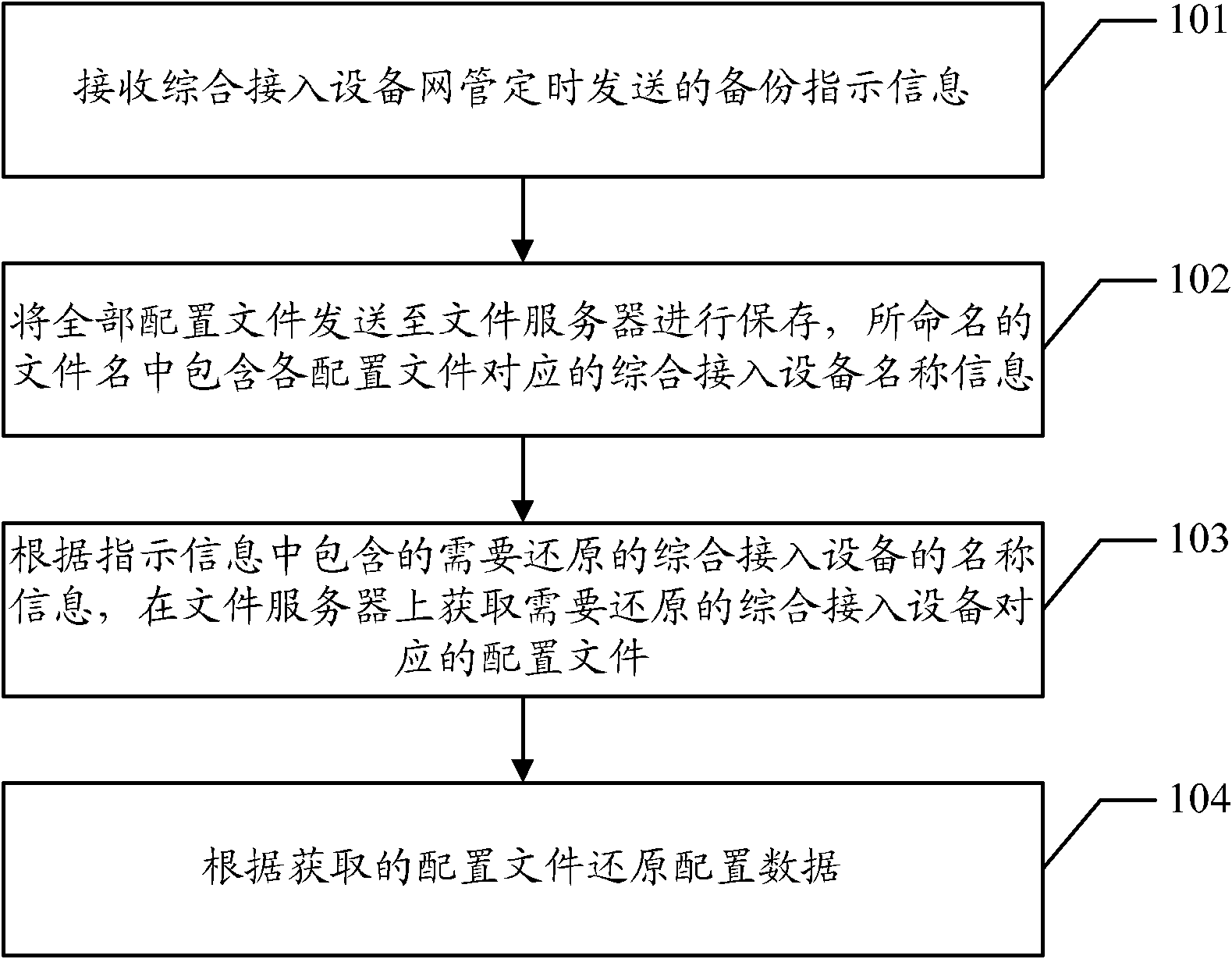

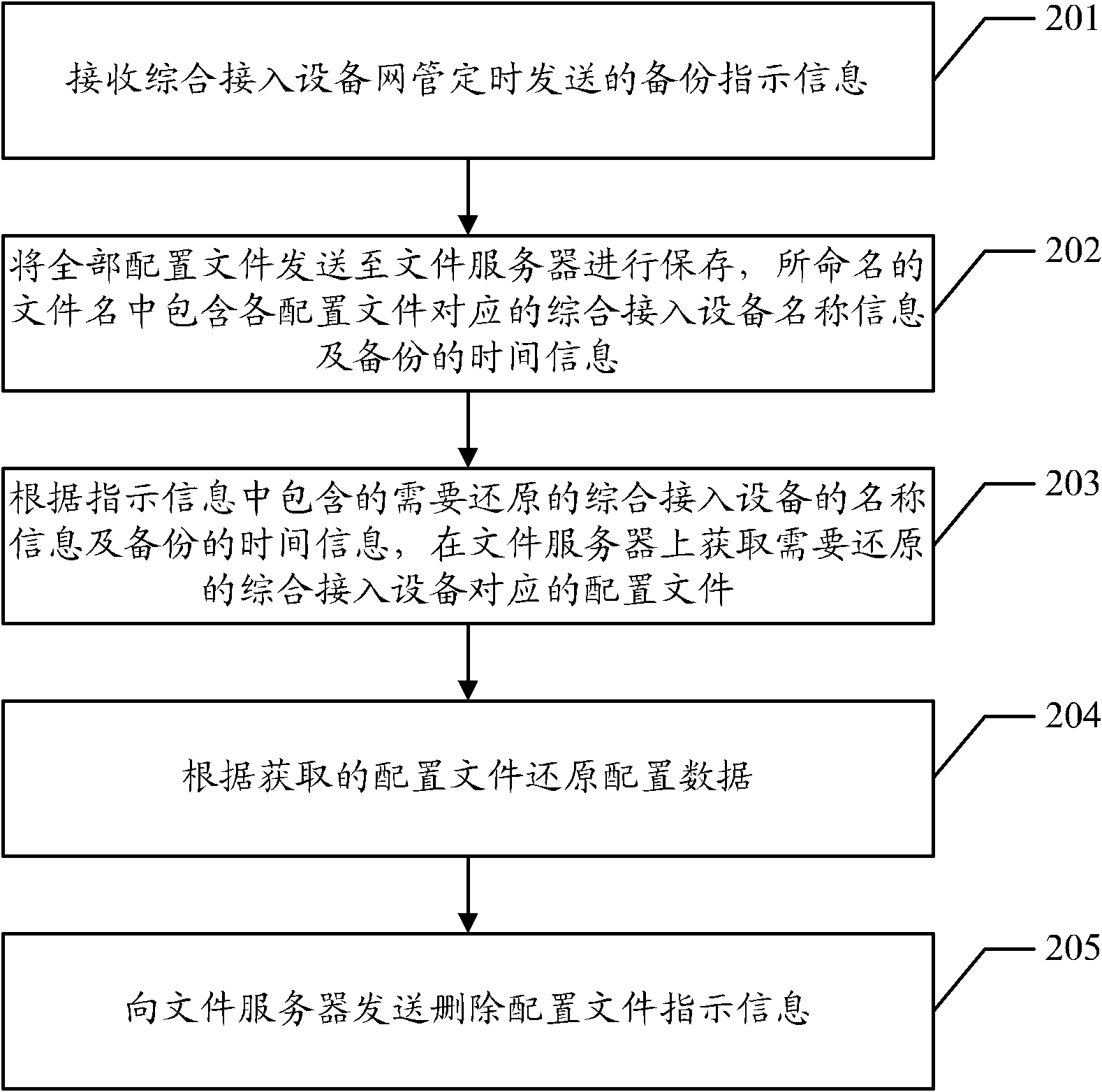

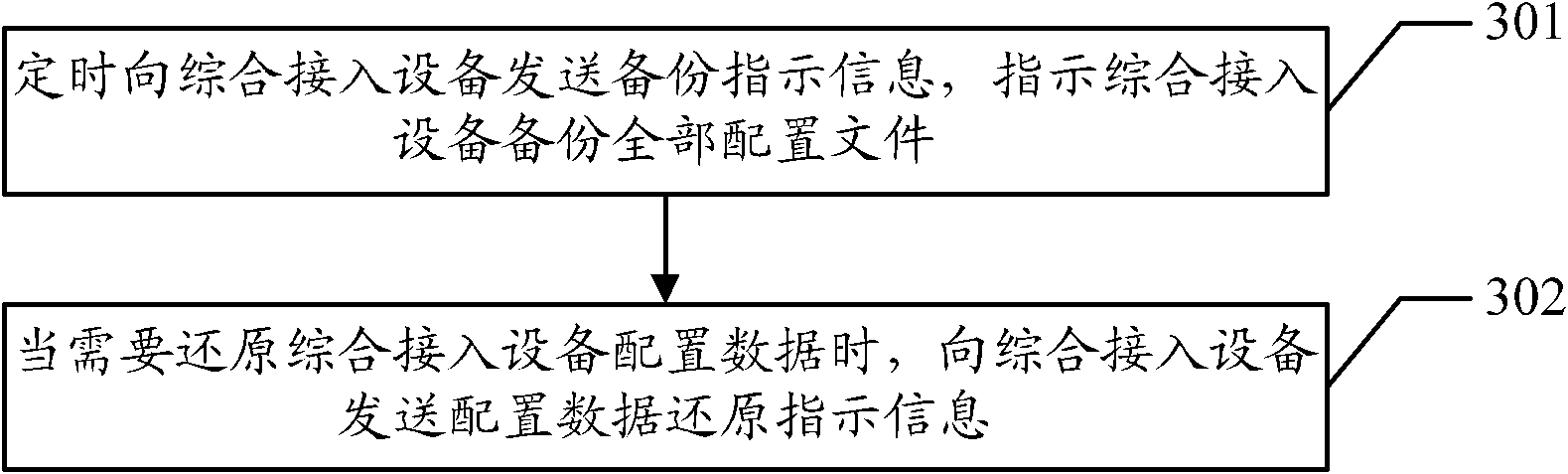

Method, device and system for data backup of integrated access device

ActiveCN102136941AImprove efficiencyData switching networksNetwork managementIntegrated access device

The embodiment of the invention discloses a method, device and system for data backup of an integrated access device, aiming at mass reduction of configuration data of the IAD (Integrated Access Device) when the IAD is needed to be replaced, and improvement of backup and reduction efficiency of the configuration data of the IAD. The method provided by the embodiment of the invention comprises the following steps: an IAD network management system is added; the IAD network management system sends backup indication information at regular intervals and indicates the IAD to back up all configuration documents, wherein a configuration document name named during storage includes name information of the corresponding IAD; and when configuration data reduction indication information sent by the IAD network management system is received, a configuration document required to be reduced, corresponding to the IAD is acquired from a document server according to the IAD information required to be reduced and included in the configuration data reduction indication information, and the configuration data is reduced according to the acquired configuration document.

Owner:HUAWEI TECH CO LTD

Calibration curves for time-of-flight mass spectrometers

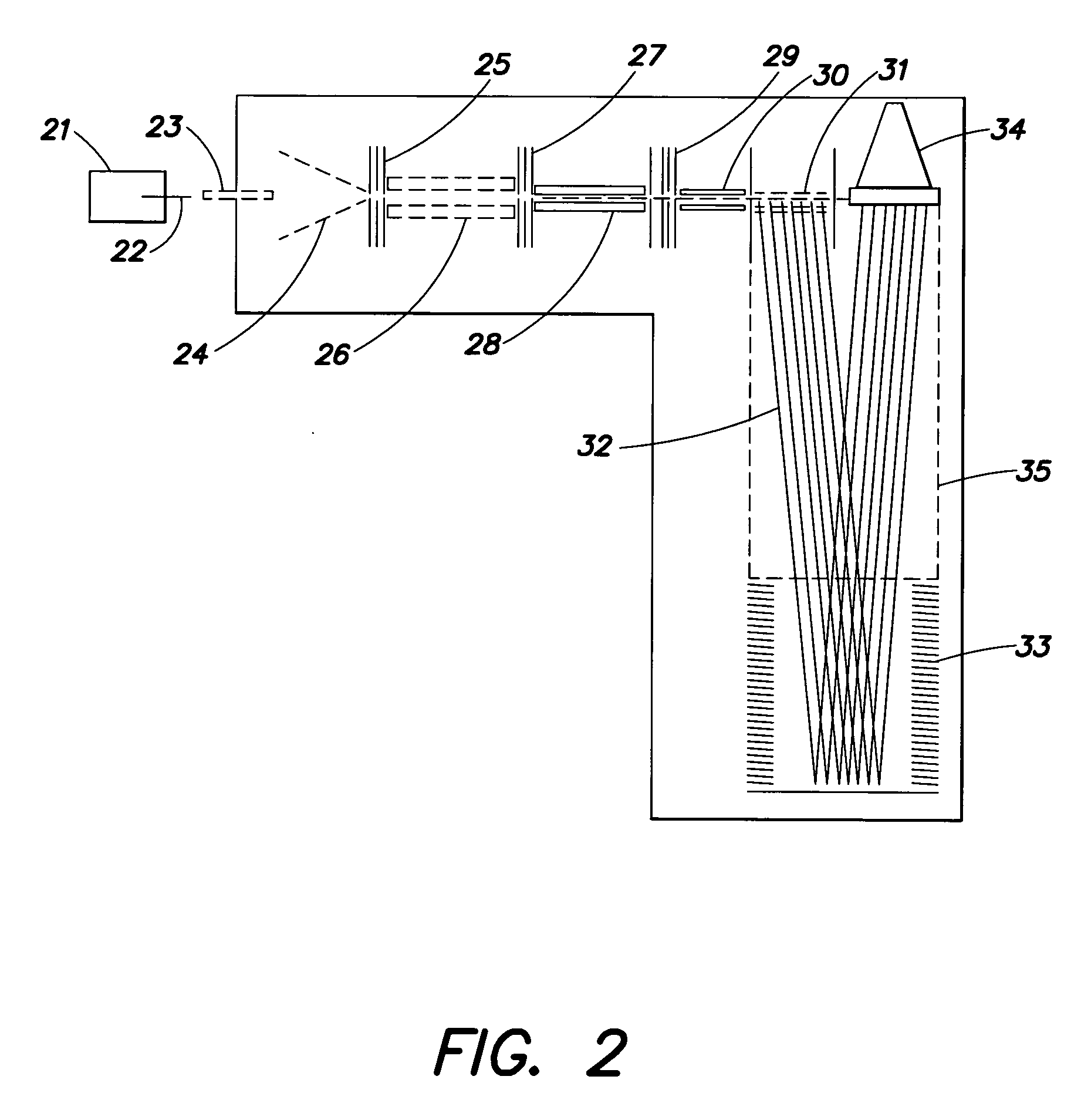

ActiveUS20080308724A1Time-of-flight spectrometersIsotope separationTime-of-flight mass spectrometryMass analyzer

The invention relates to determining the masses from the time-of-flight values of ions in time-of-flight mass spectrometers where the accelerating voltage for the ions is not applied permanently, but is switched on at a certain time, resulting in a temporally changing acceleration for a short time after the voltage has been switched on. An aspect of the invention includes formally describing the effect of the temporally changing acceleration on the calibration curve—an effect which cannot be subjected to a strict mathematical-analytical calculation—by introducing a “reduced mass” m—m0 instead of the mass m. The mass reduction factor m0 does not describe a real mass difference, but a mass-dependent shortfall in the final kinetic energy after the ions have passed through the acceleration, a shortfall which can be observed with the temporally changing acceleration. This surprisingly simple formalism makes it possible to calculate the mass of the ions over a wide mass range and with an accuracy of approximately one part per million of the mass, using a calibration curve containing only four to six calibrated coefficients.

Owner:BRUKER DALTONIK GMBH & CO KG

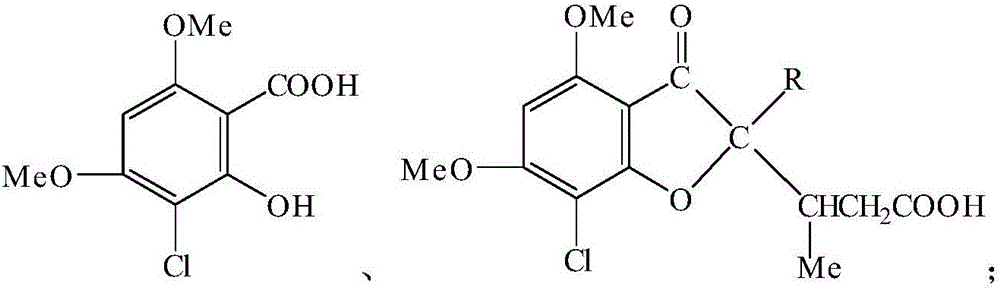

Modified metal complex and use thereof

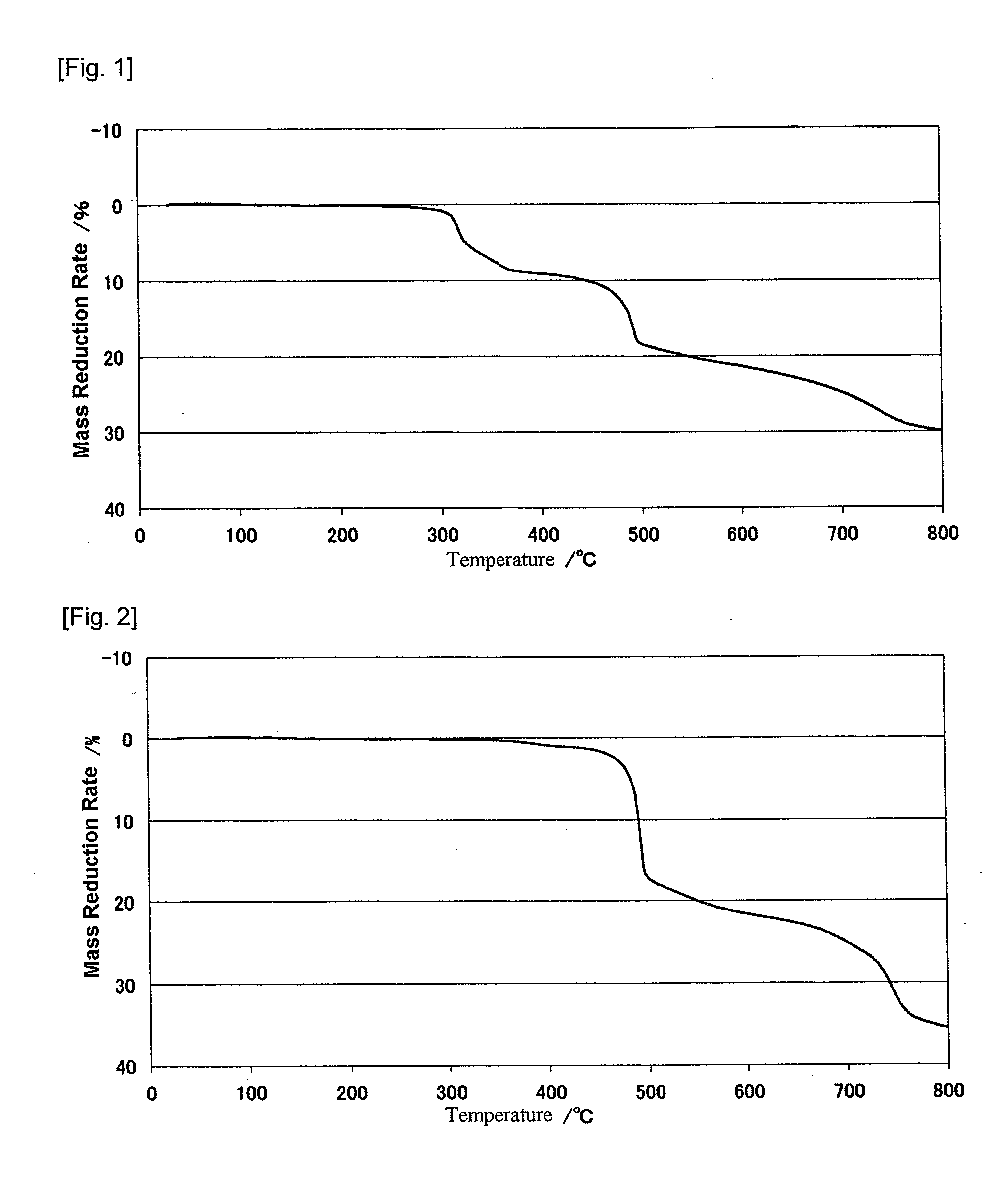

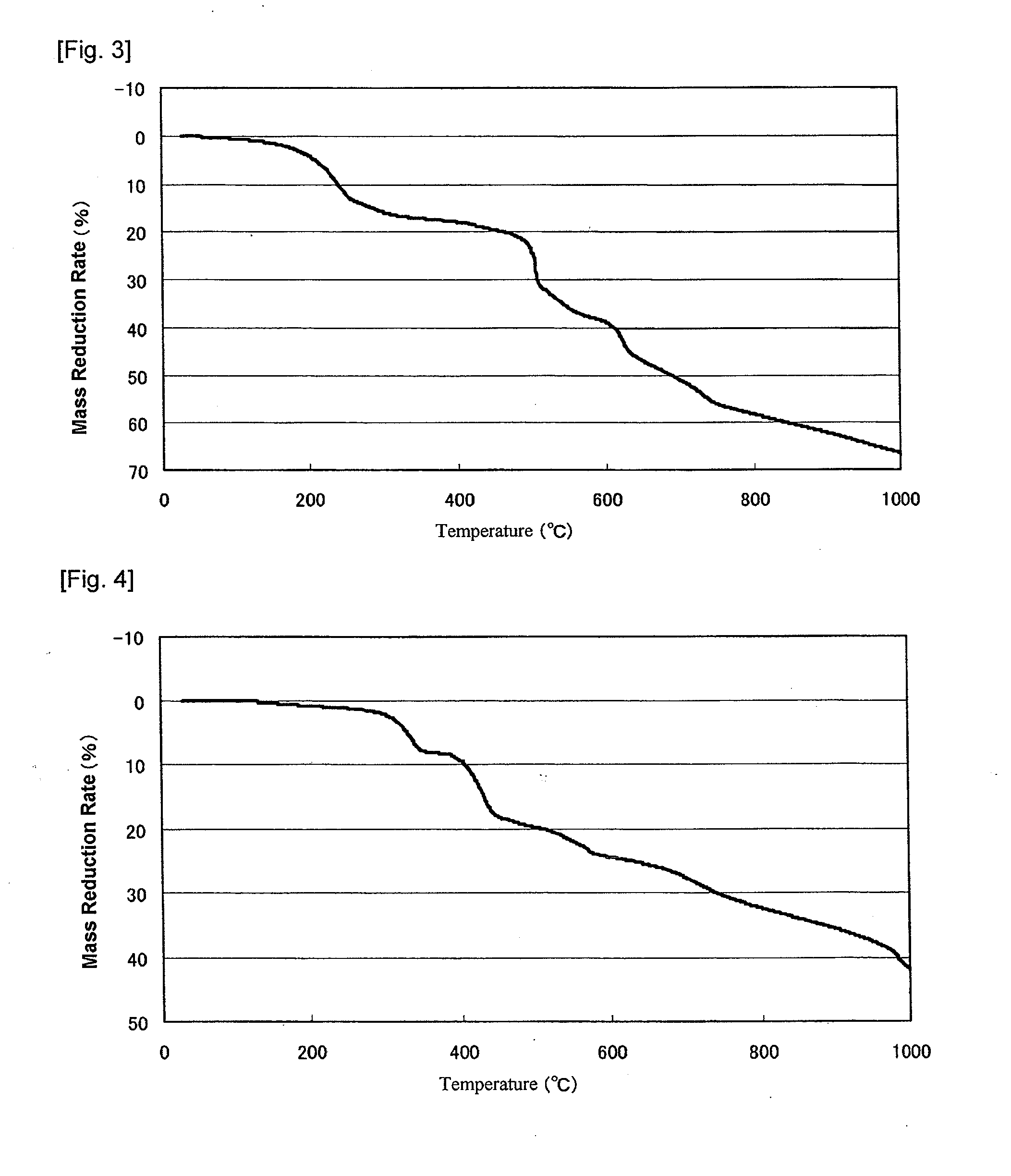

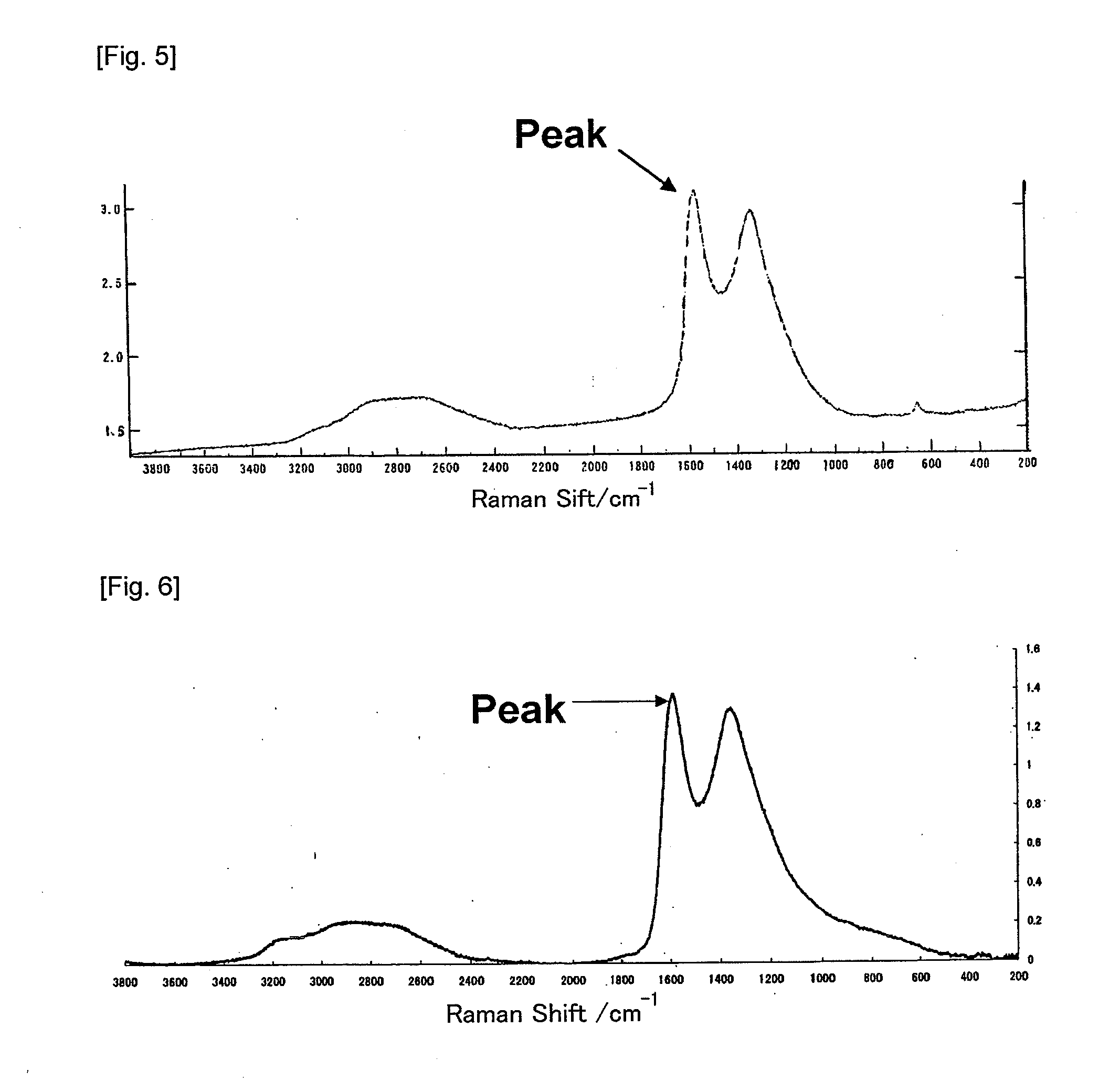

ActiveUS20100105909A1Improve thermal stabilityHigh reactivityOrganic-compounds/hydrides/coordination-complexes catalystsIron organic compoundsSimple Organic CompoundsNitrogen

A modified metal complex obtained by subjecting a metal complex containing an organic compound having one nitrogen-containing aromatic heterocycle and four or more structures of a phenol, thiophenol, aniline or nitrogen-containing aromatic heterocyclic ring or an organic compound having two or more phenol rings and three or more nitrogen-containing aromatic heterocycles, in its molecule as a ligand, to a heating, radiation irradiation or discharge treatment until a mass reduction rate after the treatment becomes from 1 to 90 mass %, thereby the complex shows a carbon content after the treatment of 5 mass % or more.

Owner:SUMITOMO CHEM CO LTD

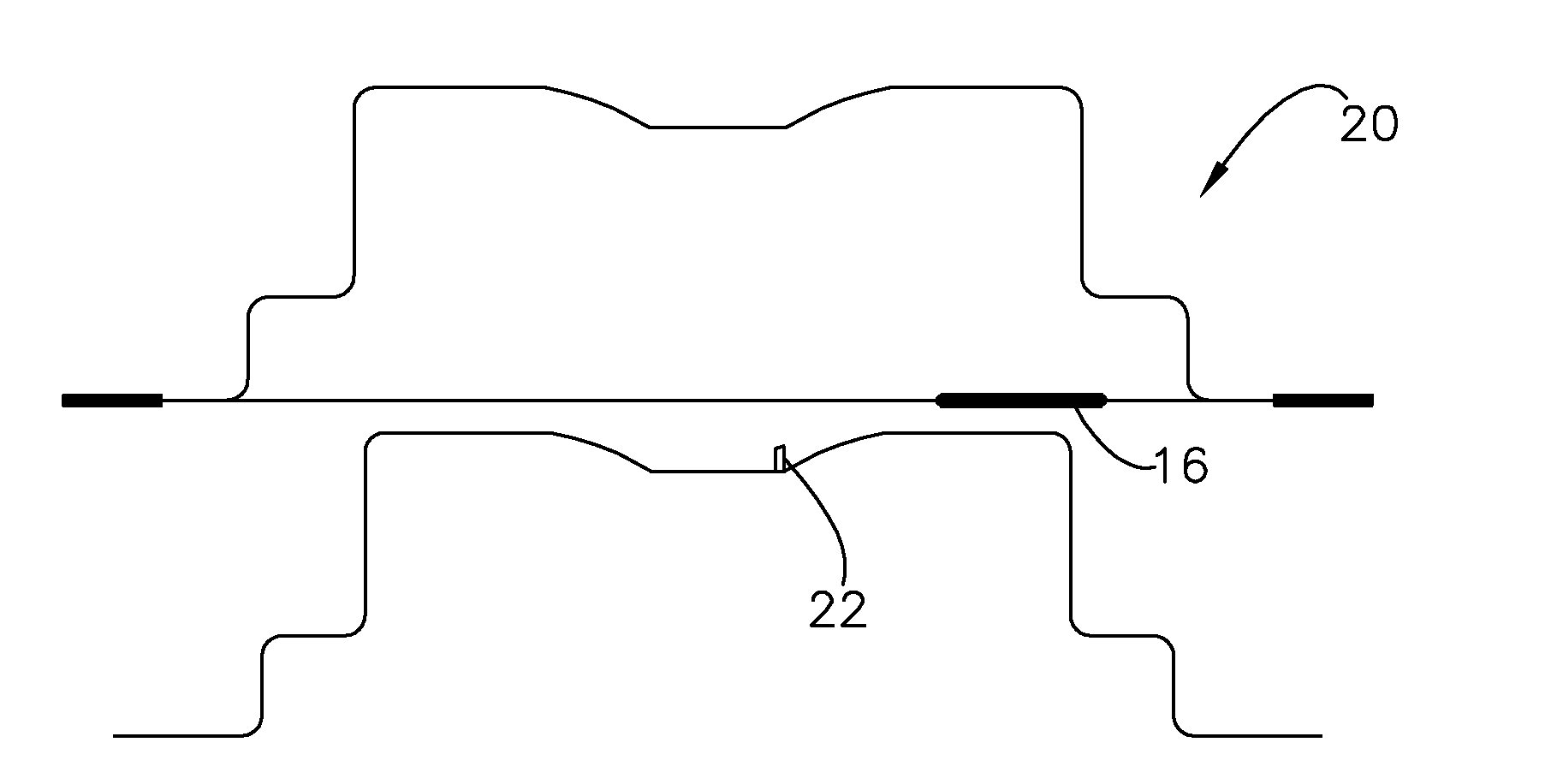

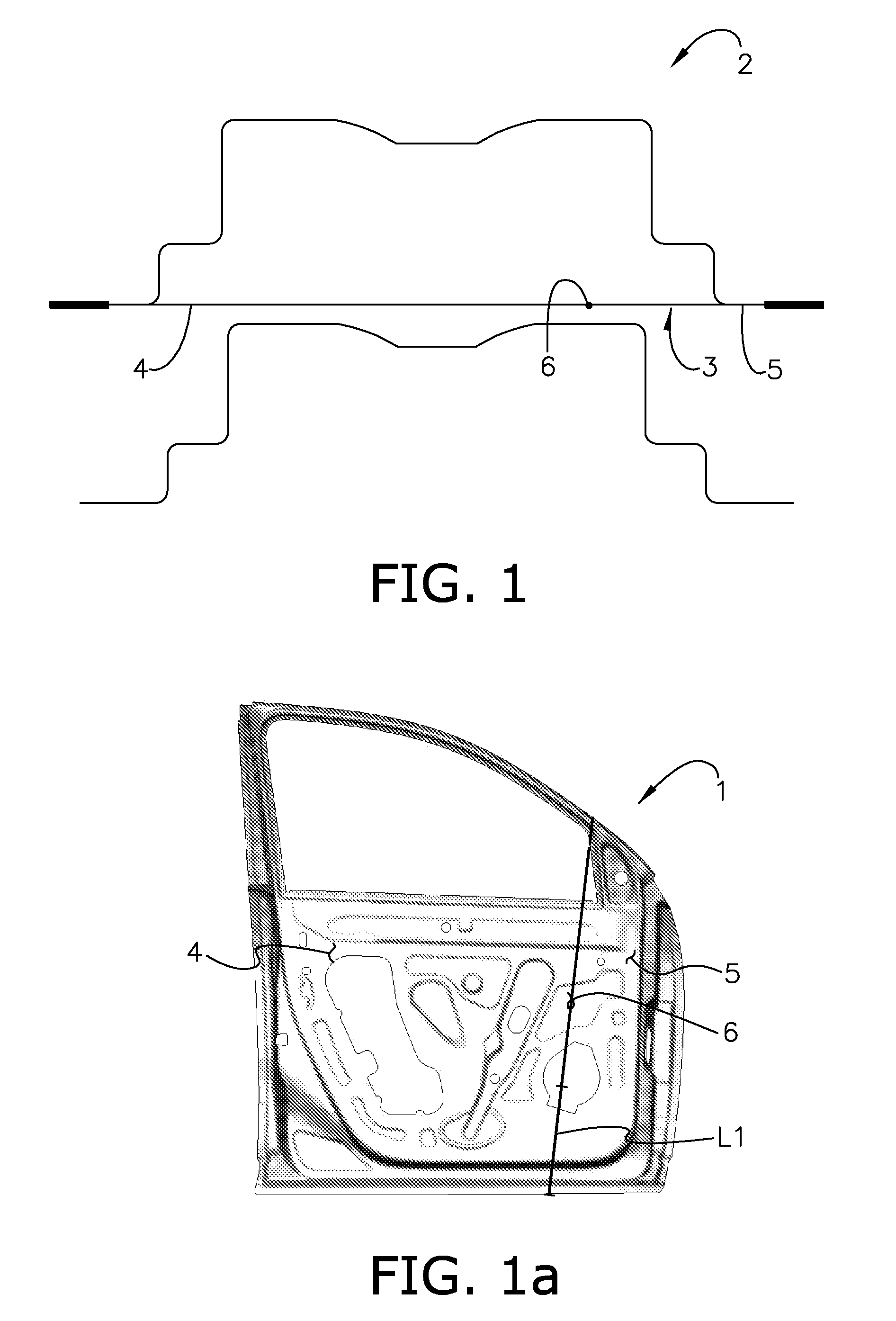

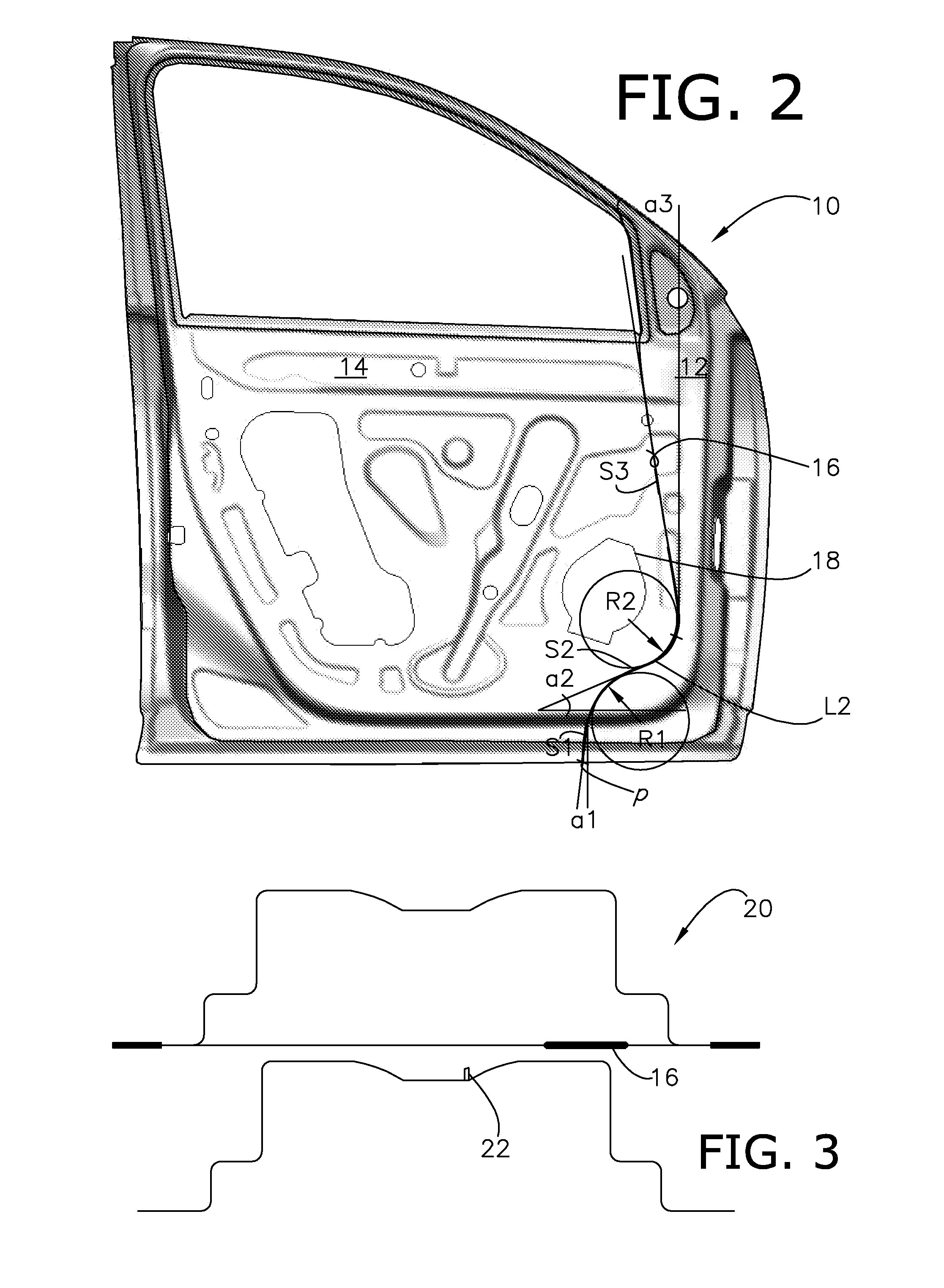

Non-linear welded blank and method of reducing mass

InactiveUS20100055488A1Reduce the total massImprove fuel economyLayered productsSemiconductor/solid-state device detailsEngineeringLoudspeaker

A structural inner, such as a vehicular door inner, formed from an engineered non-linearly welded blank comprising blank sections of differing thickness, a method of reducing the mass of the blank and redistributing the stresses experienced thereby during a drawing process, and a modified three-piece draw die having a control split device adapted for stamping the blank and localizing, minimizing and redirecting a blank failure to a predetermined location, such as the speaker hole of the door, during the process.

Owner:GM GLOBAL TECH OPERATIONS LLC

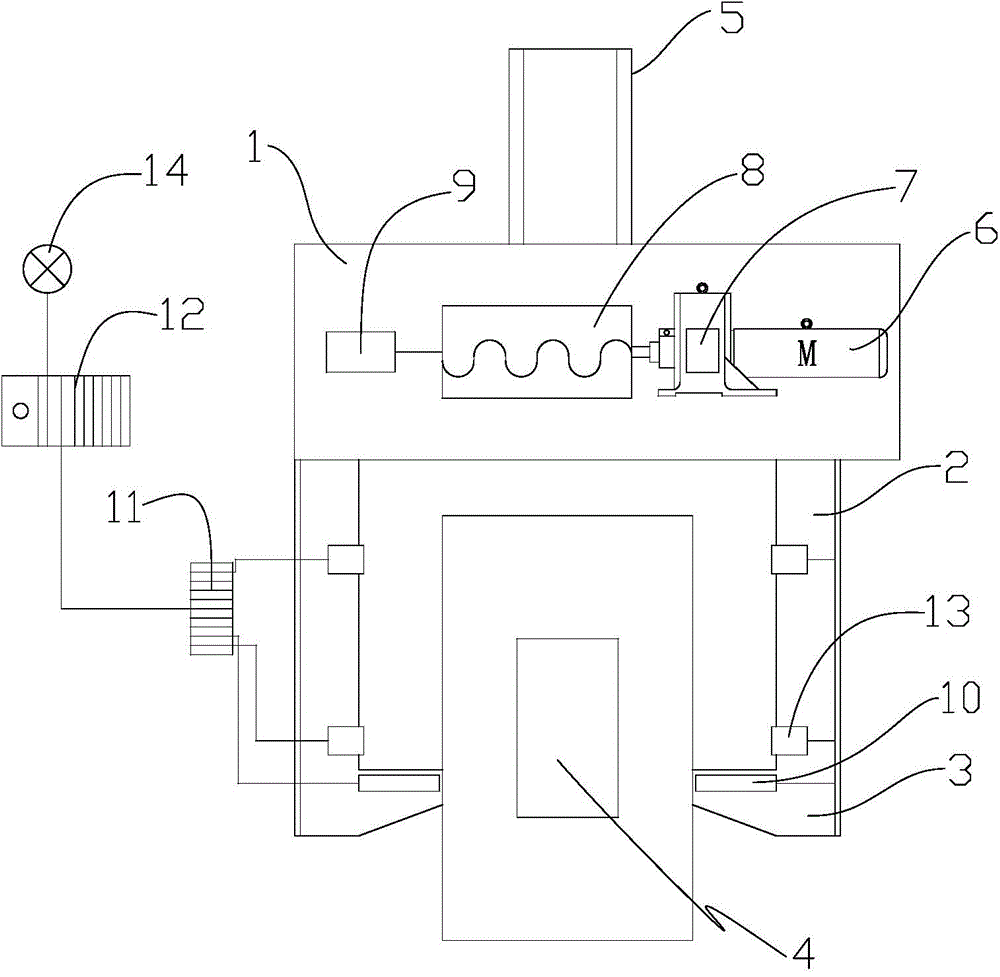

Horizontal steel coil clamp

ActiveCN104787670AOvercome the pinchOvercome scratchesGear lubrication/coolingSafety gearEngineeringDrive motor

The invention discloses a horizontal steel coil clamp. The horizontal steel coil clamp is characterized by comprising a beam, a hanging bracket, a clamping arm and a pothook, wherein a driving motor, a reduction gear, a gear transmission system and a lubrication system are arranged in the beam; a photoelectric switch is arranged on the pothook and connected to a PLC controller through an intermediate terminal strip; a steel coil detector is arranged on the clamping arm and comprises a range sensor and an indicator lamp. The steel coil detector can monitor closing of the clamp in real time, ensures in-time monitoring of the steel coil position in the coil fetching process, ensures the safe clamping situation of the steel coil, and avoids the problem that the steel coil end surface is damaged by clamping and scratched due to over shrinkage of the clamp, so as to reduce quality loss; the horizontal steel coil clamp can effectively control the clearance between the hoisted steel coil and the clamp, reduces the influence of the manual operating skill factor on the hoisting quality, increases the automation control level of the clamp in the steel coil clamping and hoisting process, and is safe and reliable.

Owner:SHANDONG IRON & STEEL CO LTD

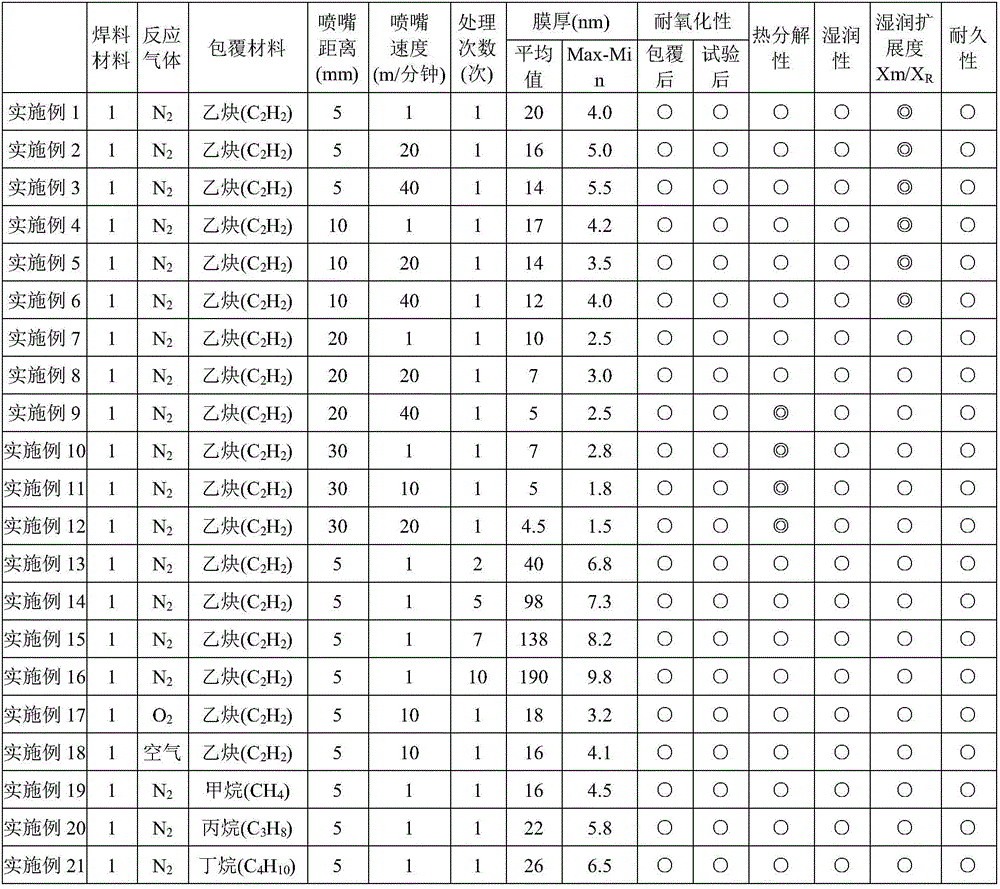

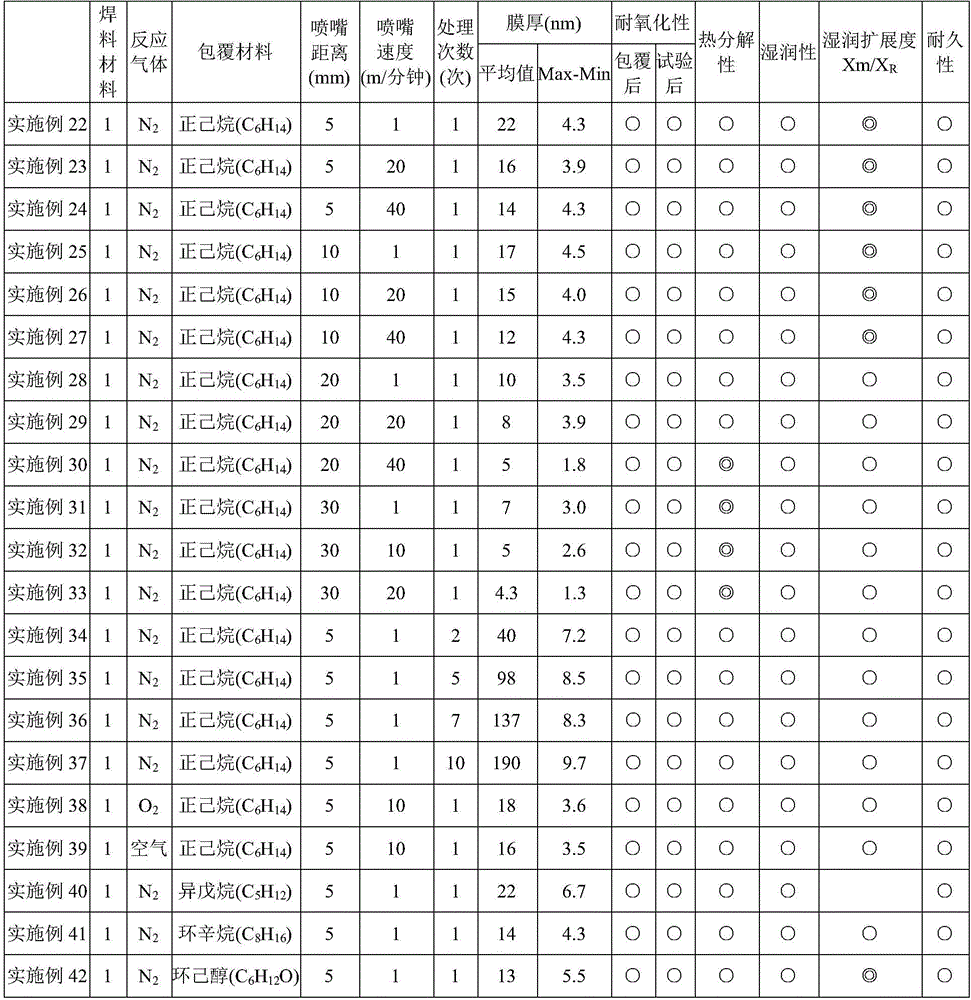

Coated solder material and method for producing same

InactiveCN106211763AEfficient preparationPrevent surface oxidationWelding/cutting media/materialsChemical vapor deposition coatingSimple Organic CompoundsAtmospheric pressure

The present invention provides a coated solder material, with which the progression of oxidation of a surface can be prevented during long-term storage and during melting, which has superior wet spreading and bondability, and with which no gaps will occur at bonding sections, as well as a method for producing the same. This coated solder material is characterized in that: a coated film has been formed on the surface of a solder material; the thickness is 4 to 200 nm; and the mass reduction rate in a case of being heated at 150 DEG C to 300 DEG C and melted is 60% or higher; the coated film is composed of a carbon compound formed by introducing a C8 or lower organic compound along with a carrier gas into a reaction gas that has been converted into plasma under atmospheric pressure, radicalizing the organic compound to form a radical organic compound, and thereafter having the radical organic compound react to a metal of the surface of the solder material.

Owner:SUMITOMO METAL MINING CO LTD

Manufacturing method of carbon fiber bundle

The invention discloses a manufacturing method of a carbon fiber bundle. After non-sized carbon fibers are soaked in a thermoplastic sizing agent bath with the concentration of 1.0-5.0%, the carbon fibers are subjected to drying and heat treatment at the temperature of 200-240 DEG C, in the drying and heat treatment process, the mass reduction rate of the thermoplastic sizing agent is within 30%-70%, and finally the carbon fiber bundle containing 0.3-2.5% of the thermoplastic sizing agent is obtained. The manufacturing method has the advantages that in the molding and compounding process, thethermoplastic sizing agent is attached to the surface layers of the fibers, then by means of specific heat treatment, the fibers show excellent dispersion performance in water, meanwhile, the affinityof the fibers and a thermoplastic resin matrix is also greatly improved, the abrasion resistance and the splitting performance of the fibers are good, the fibers and resin have excellent affinity, ahigh-performance carbon fiber reinforced thermoplastic resin material can be prepared, and the manufacturing method is especially suitable for the fields such as automobile manufacturing and electronic product shells.

Owner:ZHENJIANG COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com