Golf club head

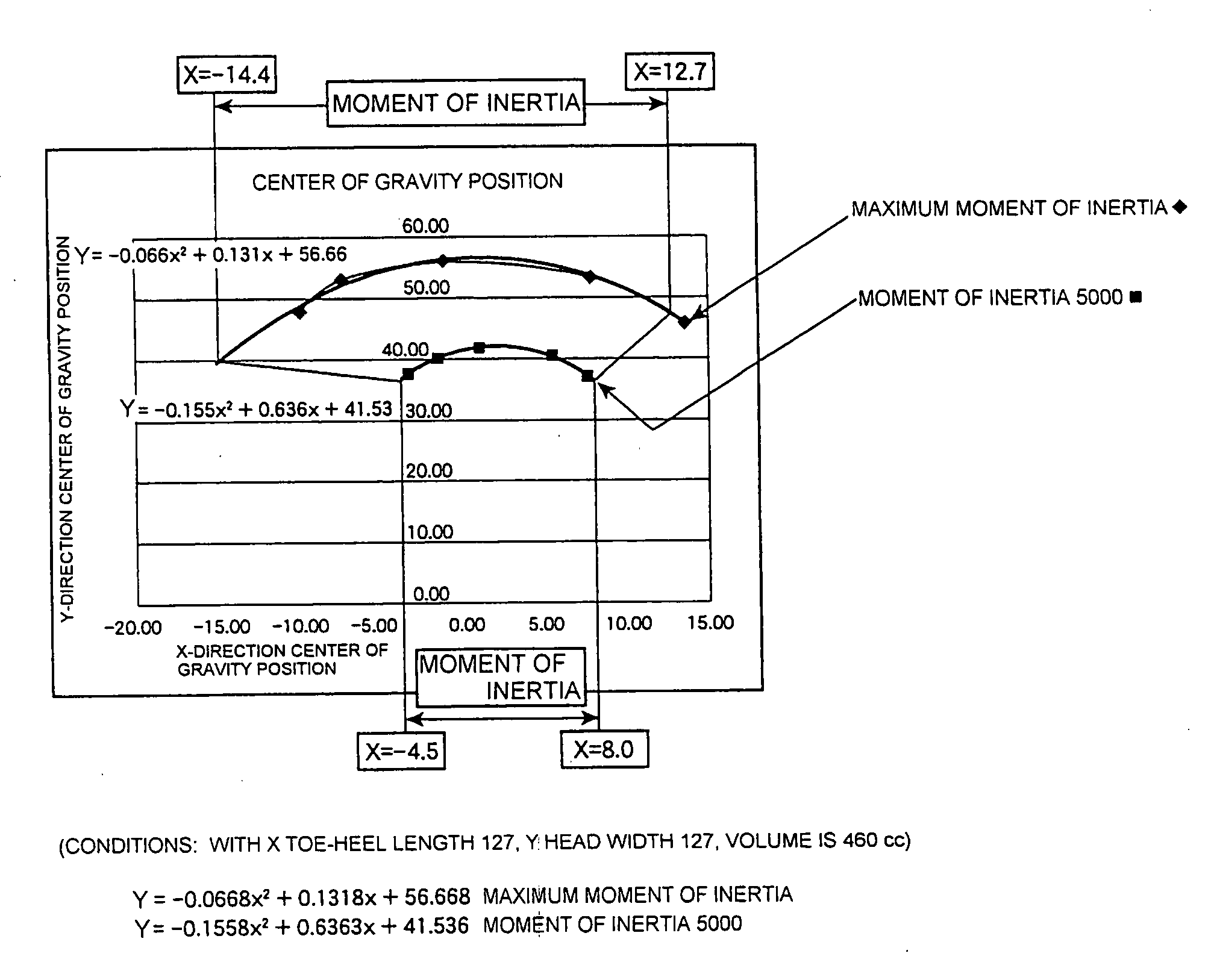

a club head and golf technology, applied in the field of golf club heads, can solve the problems of excessive mass, increased inertia, and imbalance of swing balance, and achieve the effects of improving durability, improving player's score, and improving ball-hitting sound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050]Aspect 1

[0051]Aspect 1 of the invention is explained referring to the drawings. FIG. 1 is an external view of an entire golf club of this invention, and shows the driver club head having a metal hollow golf club head. A golf club of this invention employs a metal hollow golf club head; the driver club head (hereafter also called a “head”) of Aspect 1 similarly is a metal hollow golf club head. The basic construction of a driver club head is well-known, and a detailed explanation is omitted; however, in order to facilitate understanding of the invention, a summary explanation is given as follows.

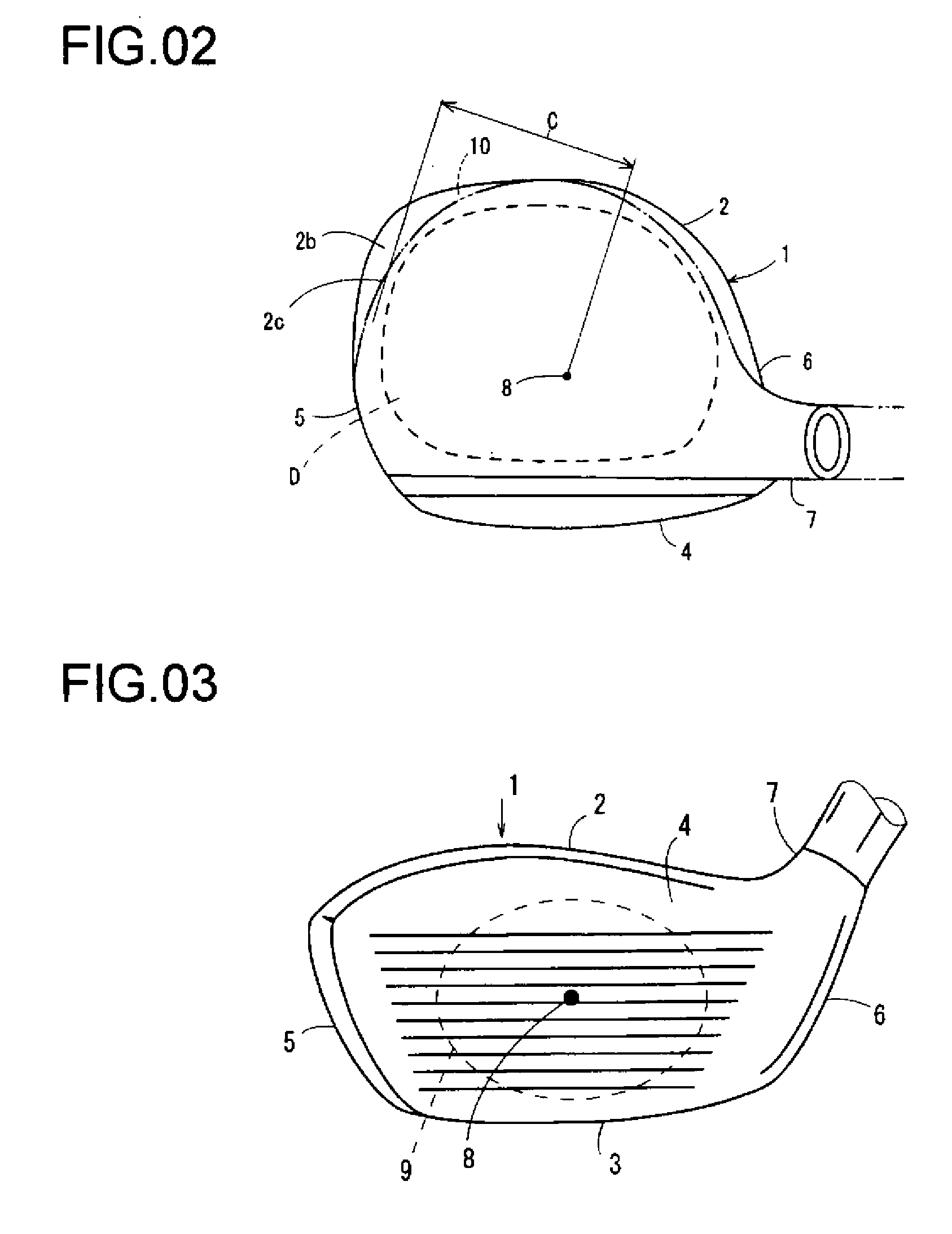

[0052]A driver club head 1 of this invention has one end of the shaft A fixed. FIG. 2 to FIG. 4 show an aspect of a driver club head 1 of a metal hollow golf club of this invention. FIG. 2 to FIG. 6 show only the head portion; the shaft A and other members are not related to the gist of this invention, and so are omitted from the drawings.

[0053]FIG. 2 is a plane view of the head 1, FIG....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com